Prefabricated vertical member

A component, vertical technology, applied in building components, building structures, columns, etc., can solve problems such as low construction efficiency, long construction period, and large amount of work at heights, to ensure worker safety, construction efficiency and construction quality improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

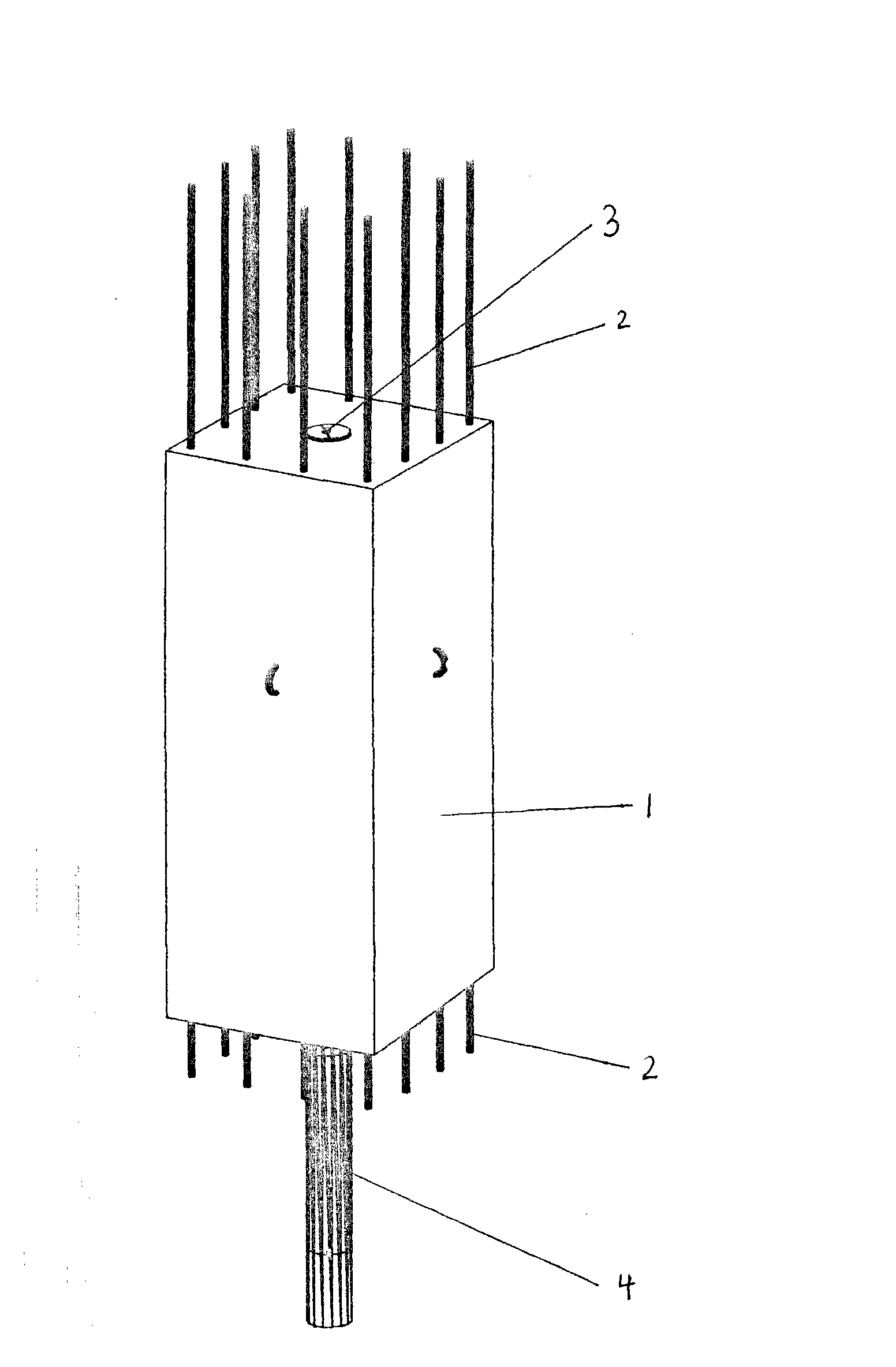

[0029] Example 1 Prefabricated column

[0030] Prefabricated columns, the structure of which is as figure 1 As shown, including the column body 1 and the pre-installed steel bars, the stressed steel bars 2 protrude from the upper and lower end surfaces of the column body, and there are 4 bars on each side. The lower end surface of the column body 1 is a slope of 15°. There is movable guide reinforcing bar 5 inside, and there is guide hole 3 coaxial with column body 1 lower end face core column 4 in the center of column shaft 1 upper end surface, and active cold extruded sleeve 6 is arranged on the stressed reinforcing bar 2 upper end.

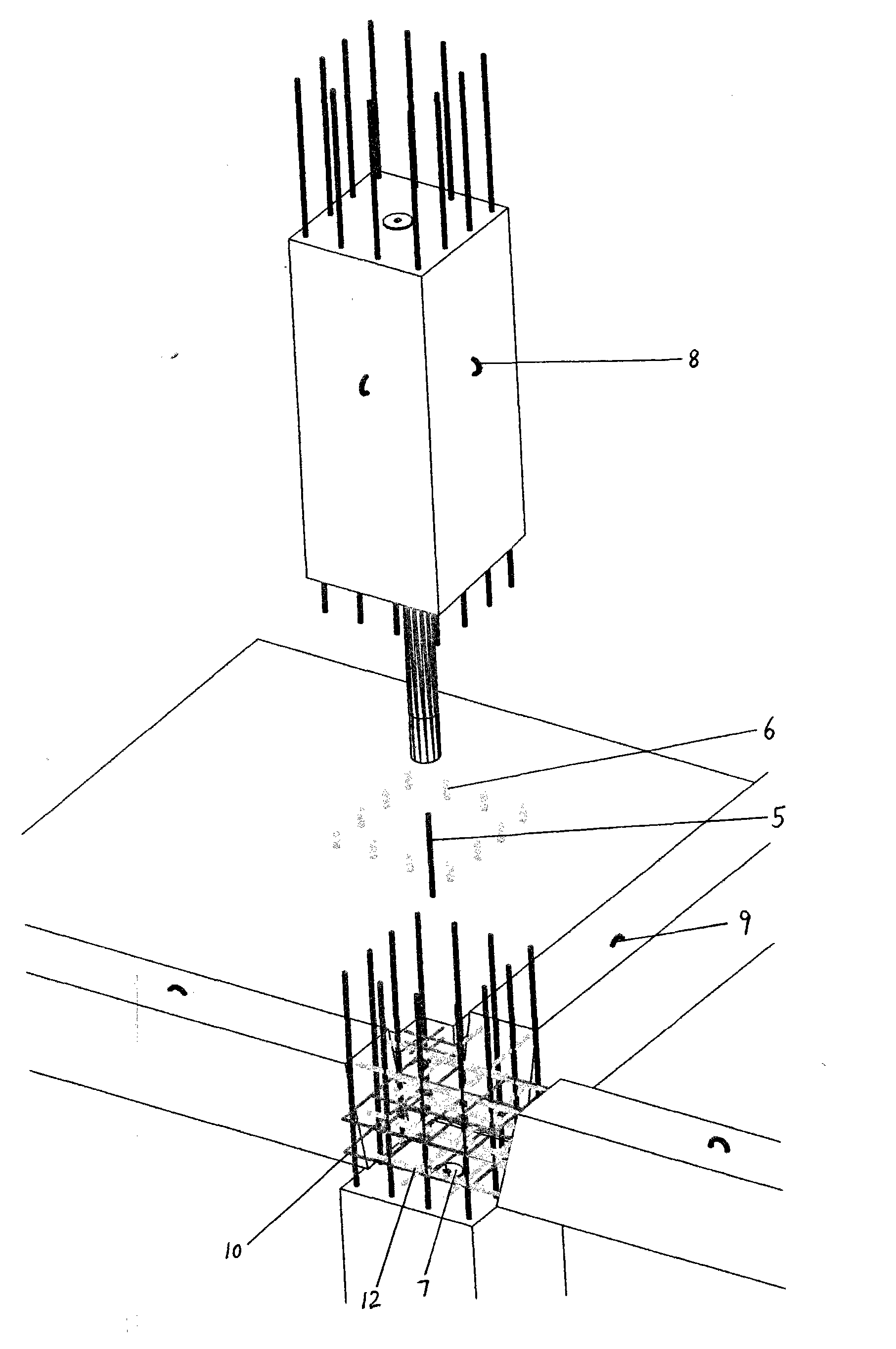

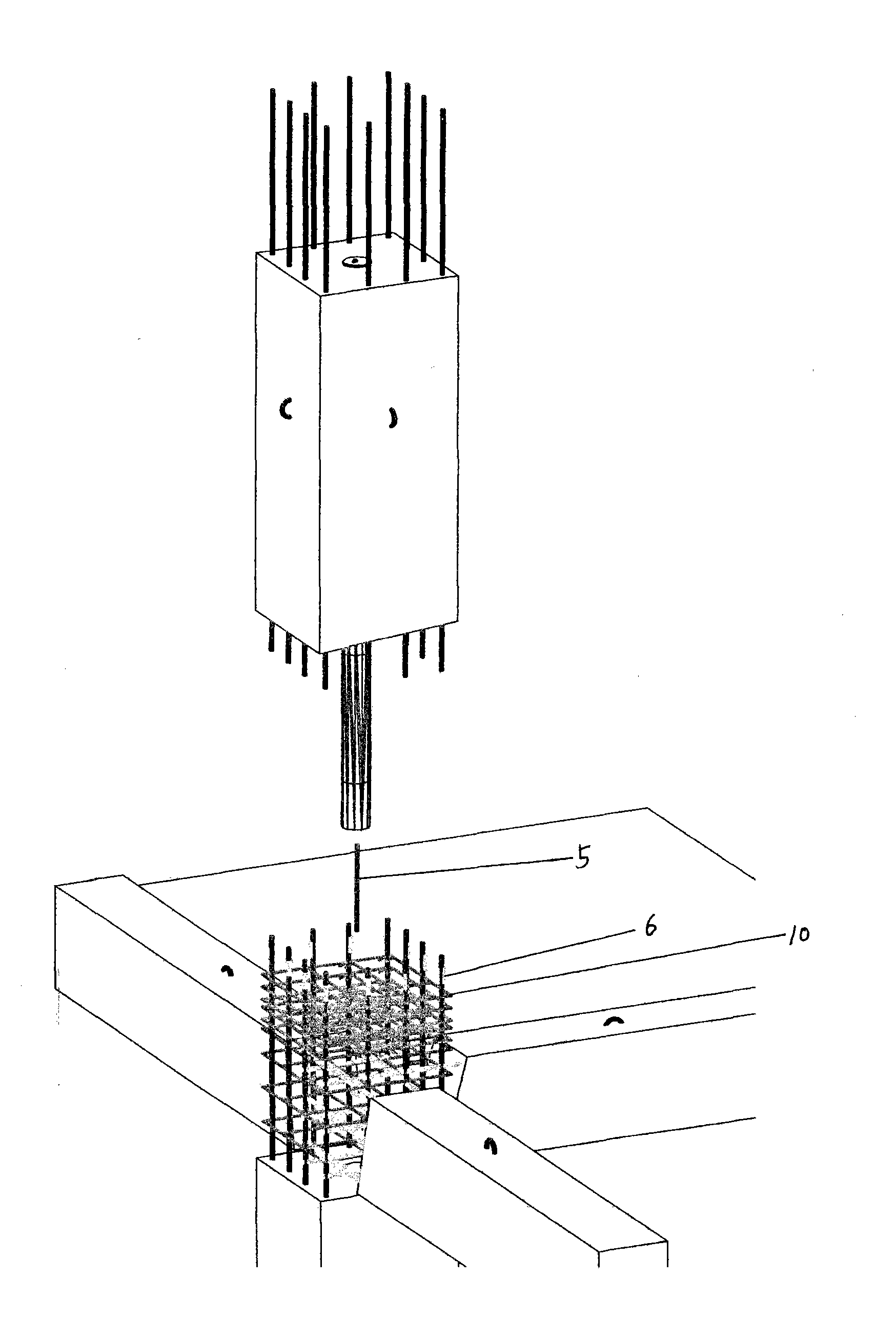

[0031] When constructing the standard layer of frame structure (such as figure 2 As shown), firstly install the prefabricated columns of the lower floor, and after the reinforcement binding or welding at the joints of the beams, slabs and columns is completed, place a number of semi-circular gaskets 7 on both sides of the guide holes of the p...

Embodiment 2

[0035] Embodiment 2 Prefabricated shear wall

[0036] Prefabricated shear walls, the structure of which is Figure 5 As shown, including the wall 1 and the pre-installed steel bars, the stressed steel bars 2 and the vertically distributed steel bars 13 protrude from the upper and lower end faces of the wall body 1, the lower end face of the wall body 1 is a slope of 15°, and there are two symmetrically distributed core columns in the middle 4. There is a guide hole 3 in the middle of the upper end of the wall 1 that is consistent with the core column 4 on the lower end of the wall 1.

[0037] When constructing the standard layer of shear wall structure (such as Figure 6 As shown), first install the prefabricated shear wall on the lower floor, and after the reinforcement binding or welding at the joints of beams, slabs and shear walls is completed, place a number of half-rings on both sides of the guide hole 3 on the upper prefabricated shear wall Gasket, the sum of its thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com