Patents

Literature

466 results about "Hooping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hooping (also called hula hooping or hoop dance) generally refers to manipulation of and artistic movement or dancing with a hoop (or hoops). Hoops can be made of metal, wood, or plastic. Hooping combines technical moves and tricks with freestyle or technical dancing. Hooping can be practiced to or performed with music. In contrast to the classic toy hula hoop, modern hoopers use heavier and larger diameter hoops, and frequently rotate the hoop around parts of the body other than the waist, including the hips, chest, neck, shoulders, thighs, knees, arms, hands, thumbs, feet, and toes. The hoop can also be manipulated and rotated off the body as well. Modern hooping has been influenced by art forms such as rhythmic gymnastics, hip-hop, freestyle dance, fire performance, twirling, poi, and other dance and movement forms.

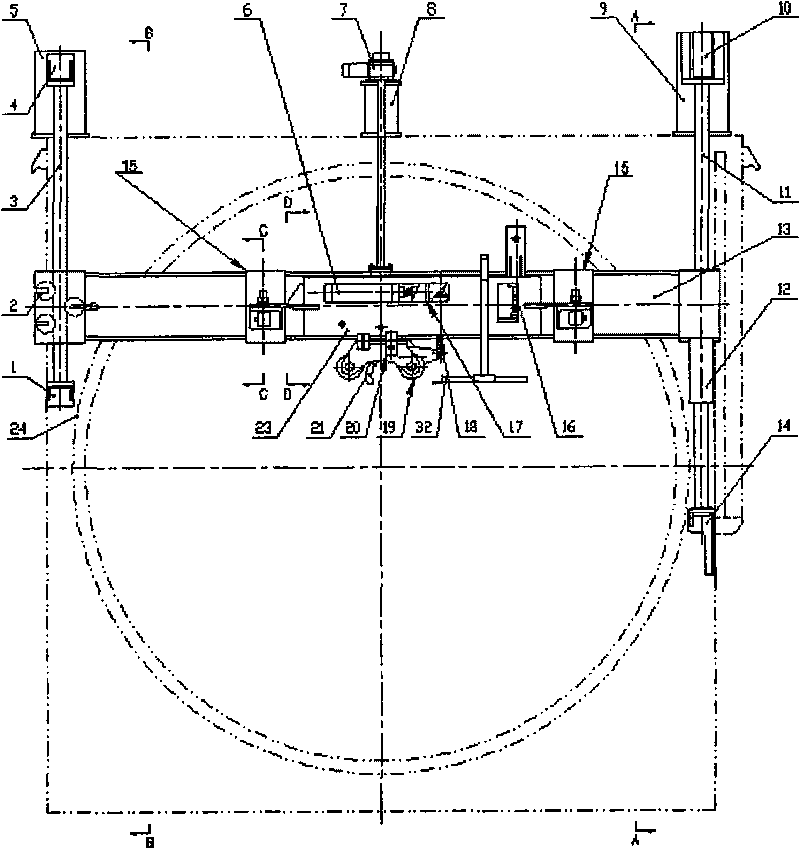

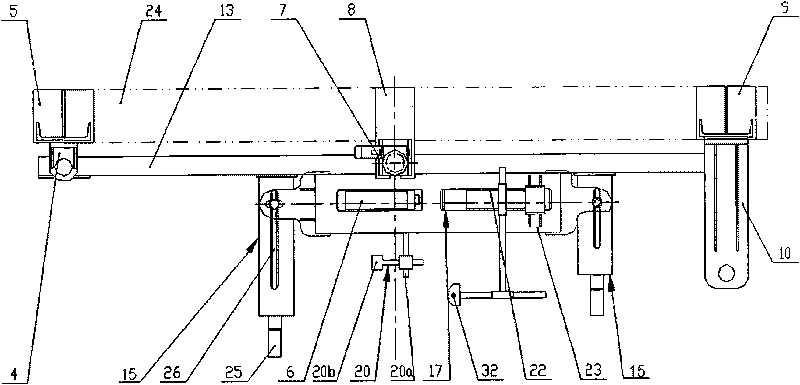

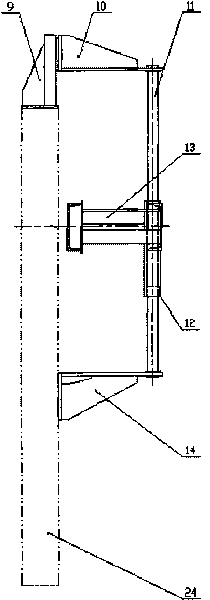

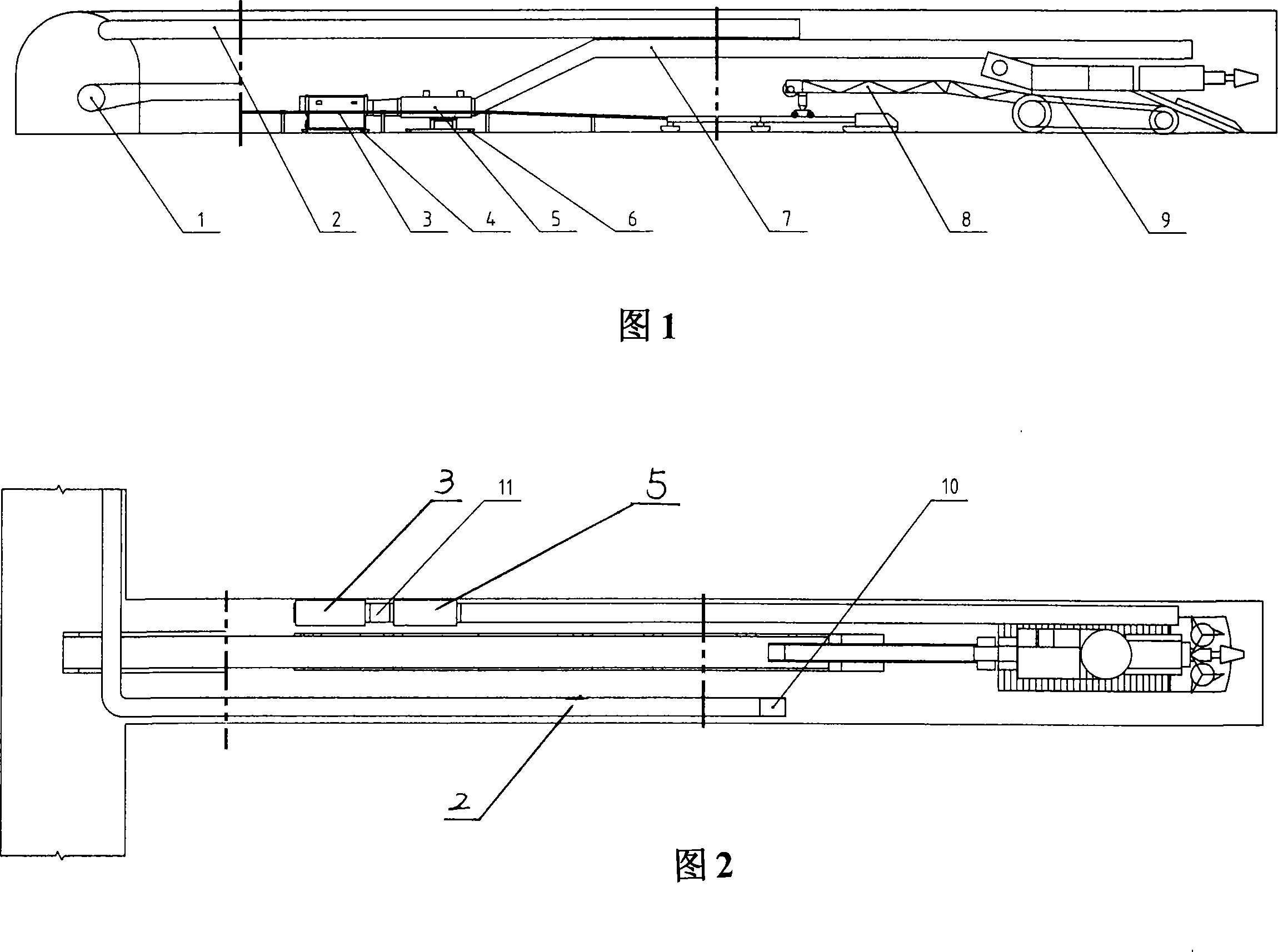

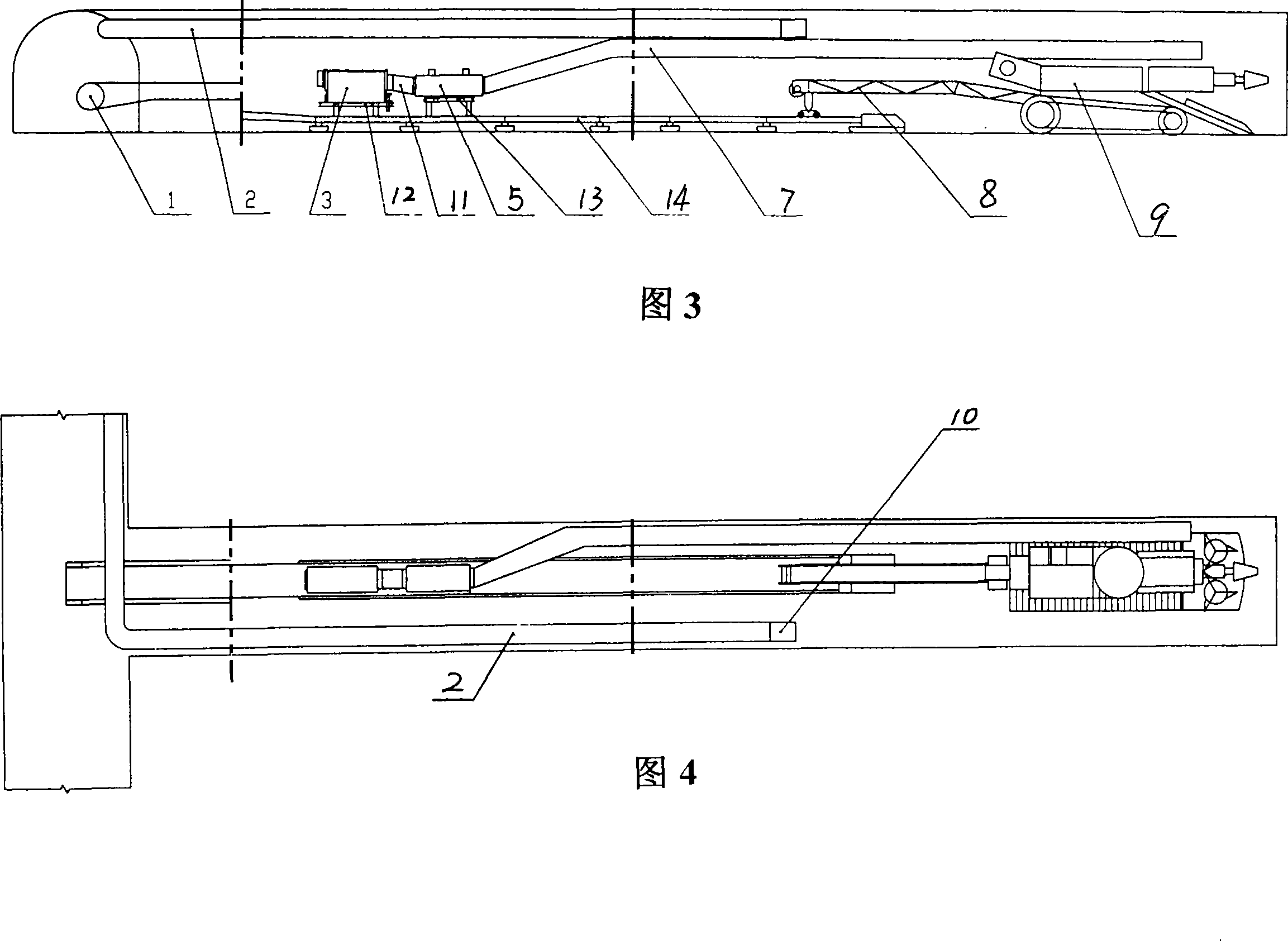

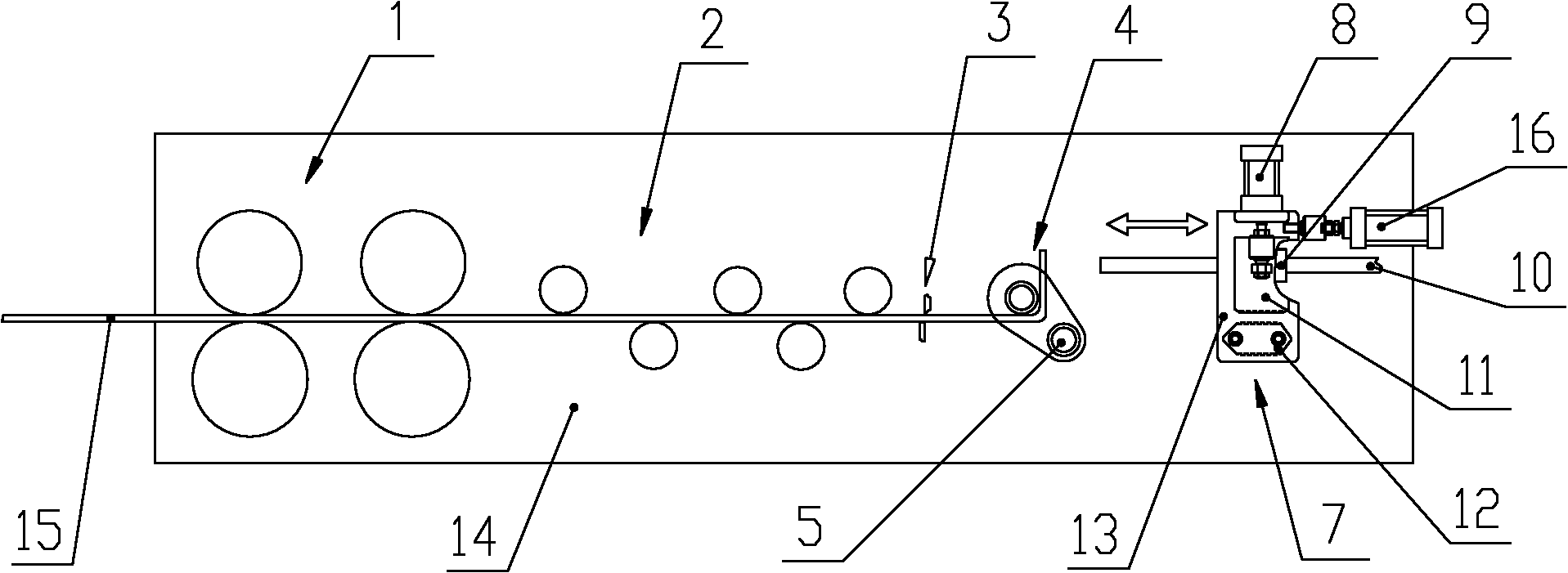

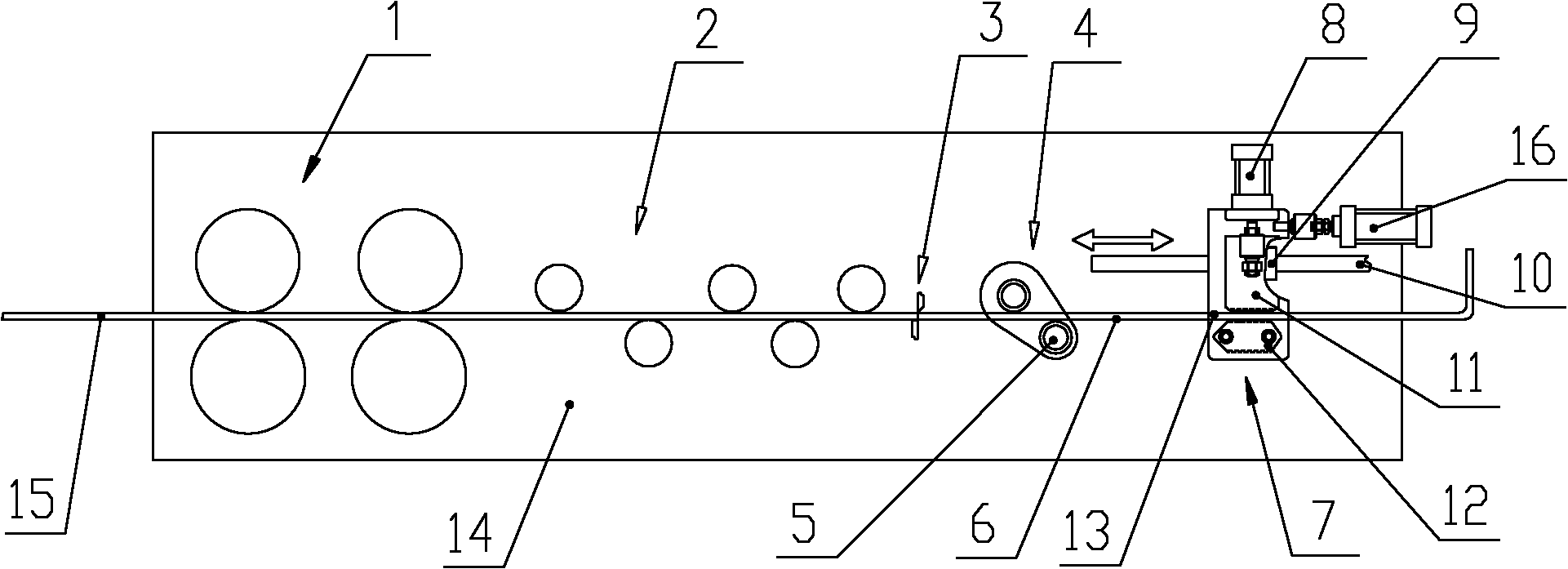

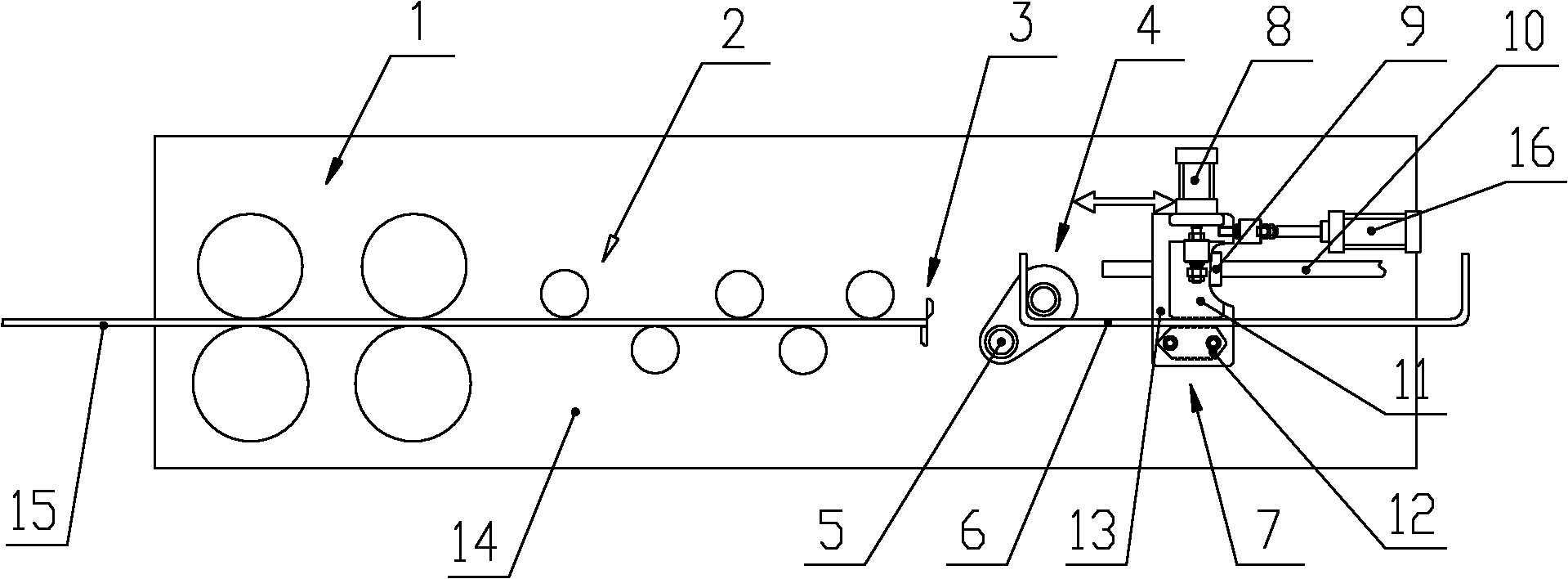

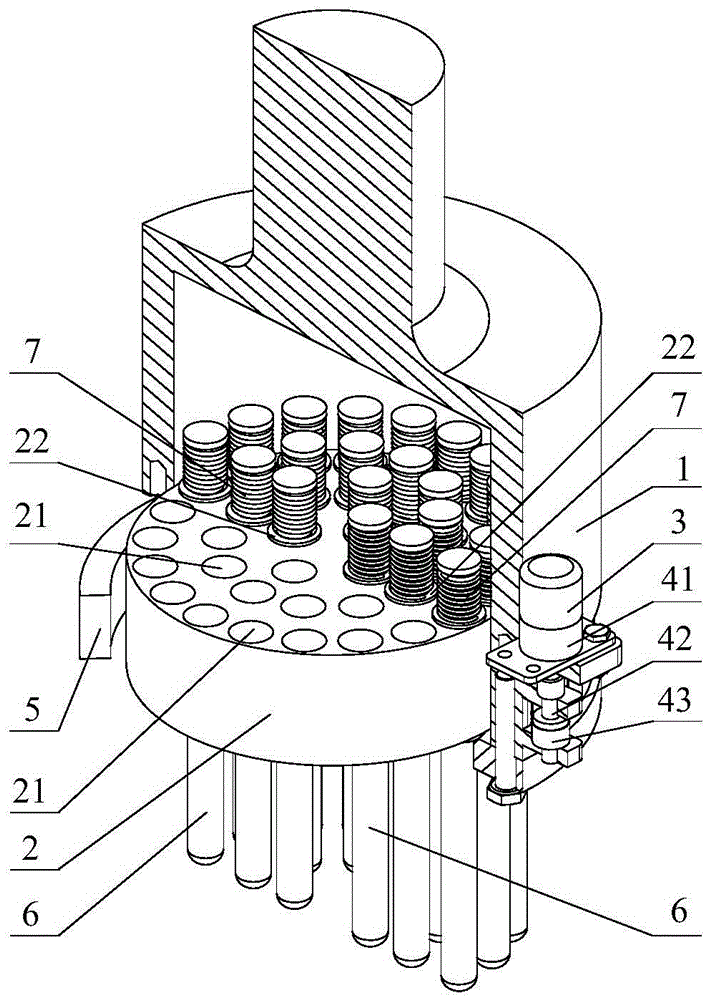

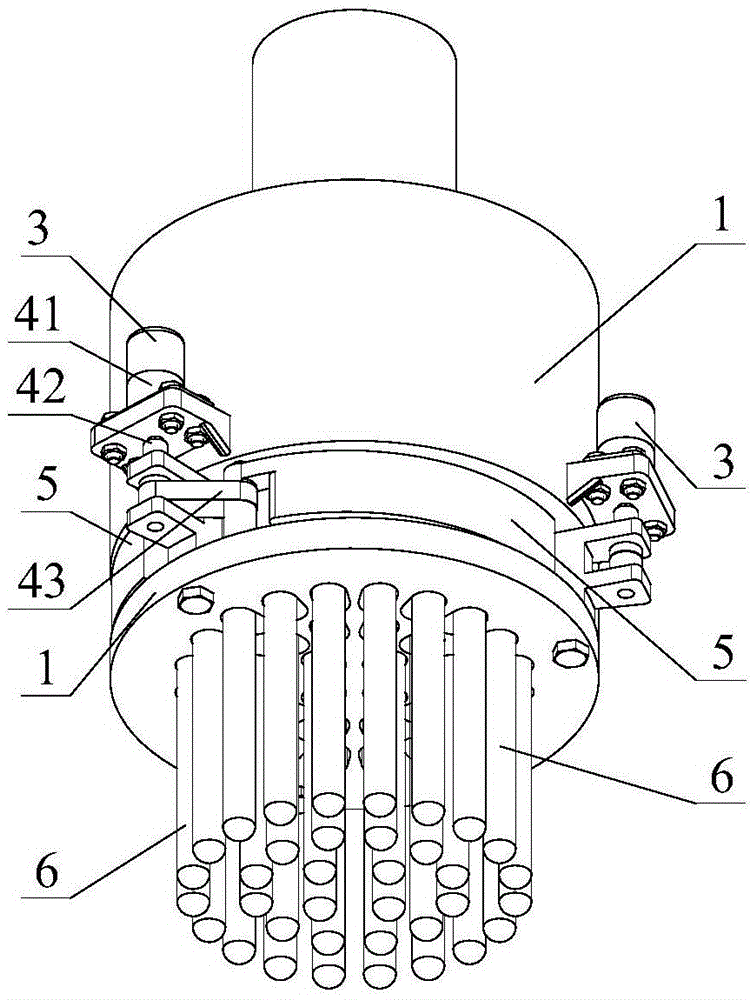

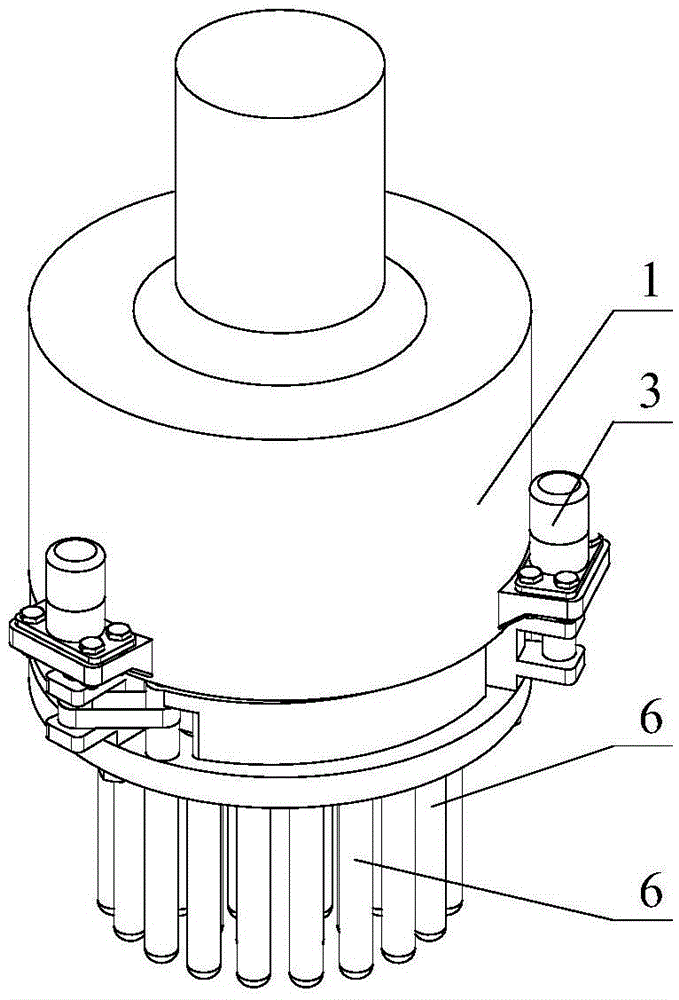

Automatic wielding mechanical device for forming machine of numerical control reinforcing cage

ActiveCN101700555AReduce labor intensityLow costMeshed-ring wire networkWelding/cutting auxillary devicesNumerical controlHooping

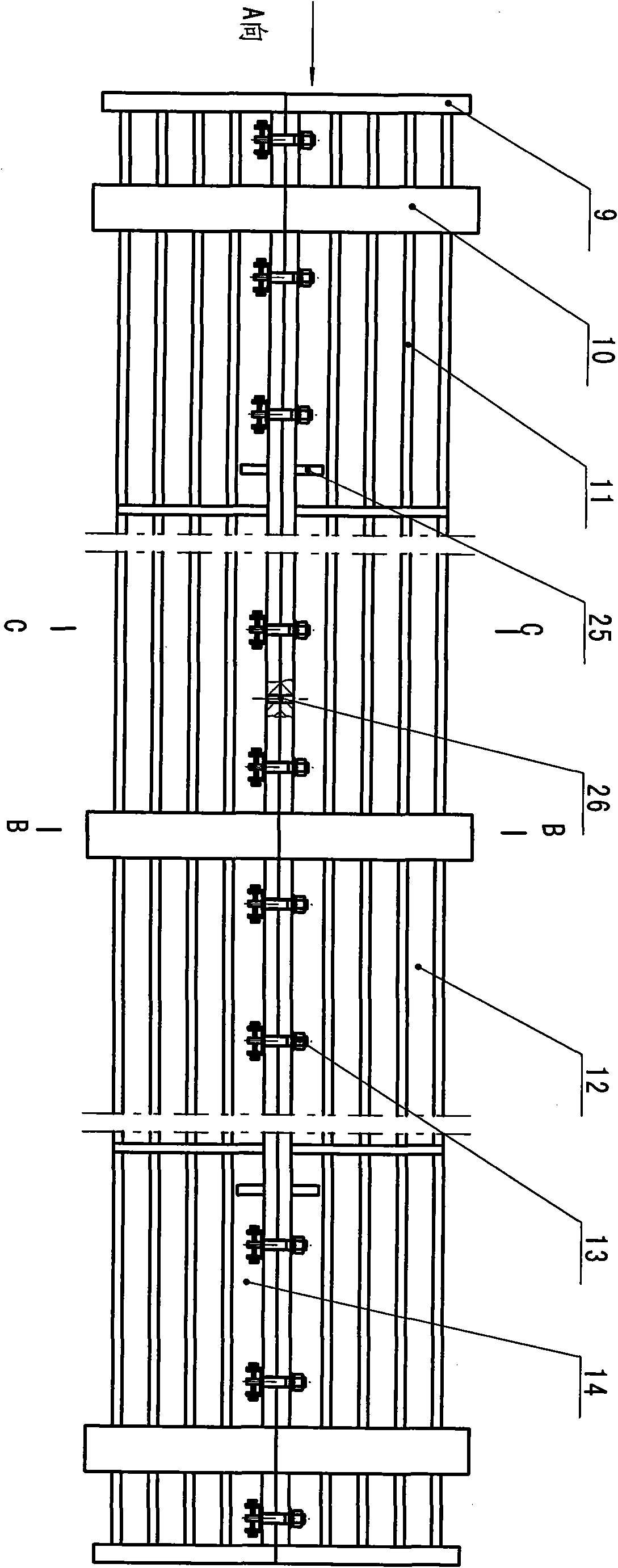

The invention discloses an automatic wielding mechanical device for a forming machine of a numerical control reinforcing cage. The structure thereof comprises a turnplate rack, a first guide post, a second guide post, a movable bracket, a hoist, a case shell, a hook, a rolling mechanism, a welding-gun supporting mechanism and a screw pitch regulating mechanism; the left side and right side of the movable bracket are mounted on the first guide post and the second guide post in a sliding way; the top of the movable bracket is provided with the hoist driving the movable bracket to move up and down; the case shell is arranged at one side of the movable bracket and provided with the hook, the rolling mechanism, the welding-gun supporting mechanism and the screw pitch regulating mechanism; and the screw pitch regulating mechanism is used for regulating the position and angle of the case shell. The invention has the beneficial effects that: the automatic wielding mechanical device can automatically and coordinately complete welding operation of the reinforcing cage under the control of a control system, the regulation of different positions and angles of the case shell can be realized; with the rotation of the reinforcing cage, the hook can automatically hook the longitudinal steel bars, the welding-gun supporting mechanism and the reinforcing cage rotate synchronously and are always aligned with the intersection point of the hooping and the main reinforcement of the reinforcing cage, so as to perform automatic wielding in replacement of man power; the labor intensity is lowered, man power is saved, production efficiency is improved, and welding quality is bettered.

Owner:TJK MACHINERY TIANJIN

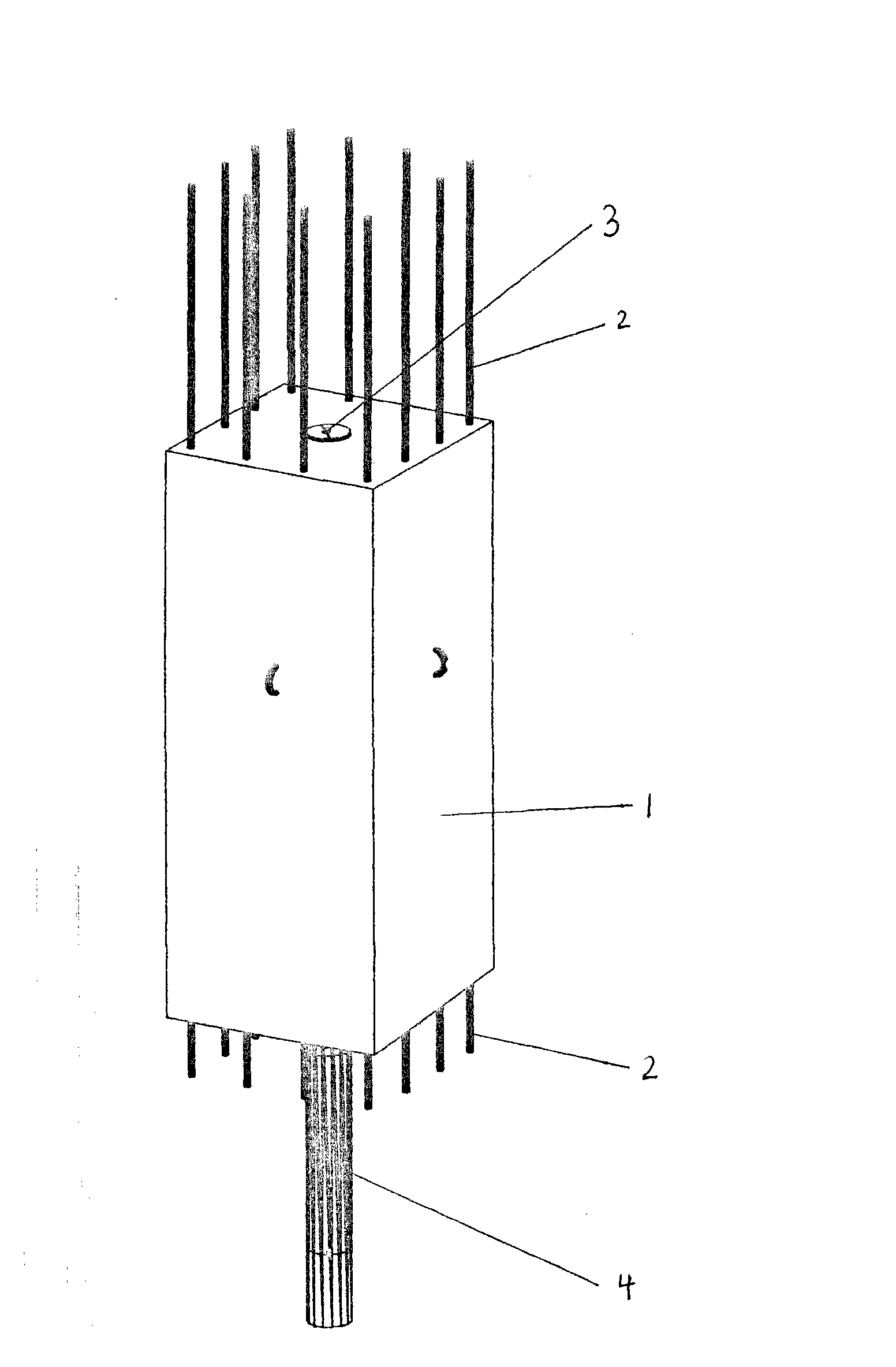

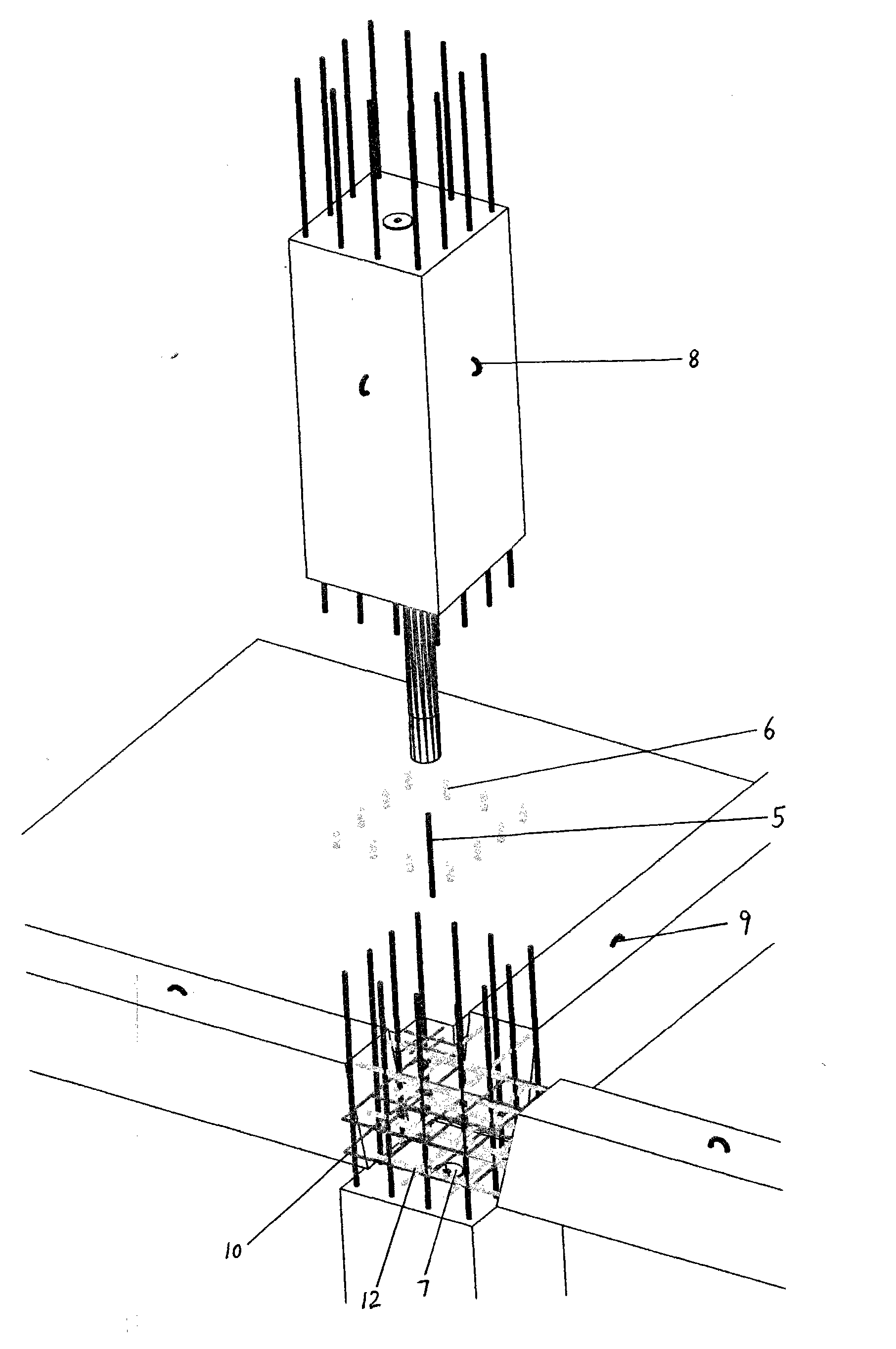

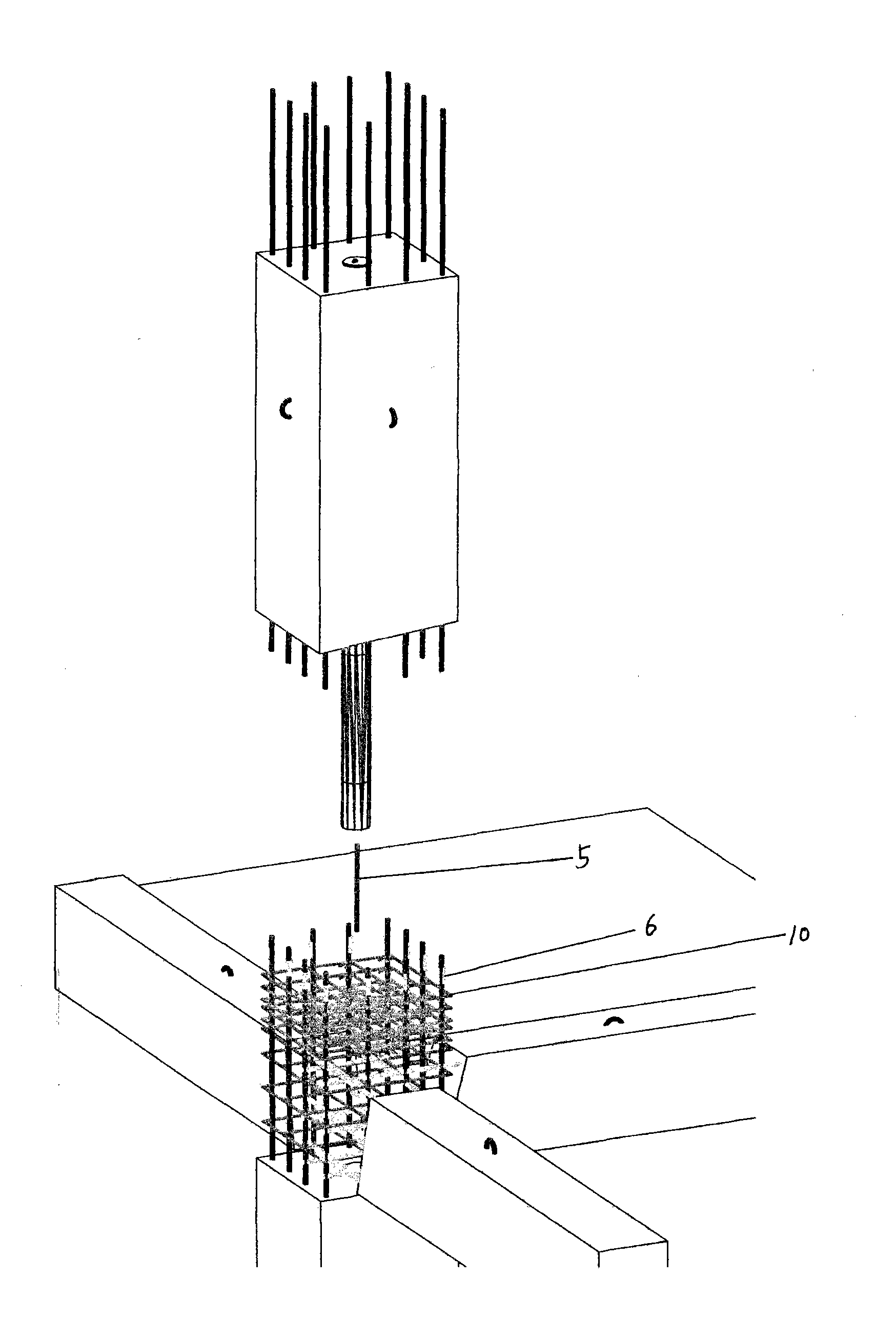

Prefabricated vertical member

The invention provides a prefabricated vertical member (including a pillar and a wall), which mainly comprises a member body and a prefabricated reinforcing bar (the reinforcing bar is the joint name of a principle bar longitudinally arranged along the member body, a vertically-distributed reinforcing bar, a hooping and a tie bar), and the principle bar or the principle bar and the vertically-distributed reinforcing bar stretch out of the upper end surface and the lower end surface of the member body. The prefabricated vertical member is characterized in that a core column is arranged in the middle of the lower end surface of the member body. The invention has the advantages that the installation of the prefabricated vertical member has no conflict with the anchoring of beam steel at a support, so as to meet the code requirement of the structure of cast-in-situ reinforced concrete; the core column is adopted for bearing load, the upper-layer construction operation can be carried out when in the joint concreting; no special design is needed; the connection of the reinforcing bar and the binding of a template are carried out at a floor slab, thereby not only ensuring the safety of workers, but also obviously improving the construction efficiency and the construction quality; the quantity of overhead work can be greatly decreased; the quantity of cast-in-situ concrete can be greatly decreased; and the operation is carried out at the floor slab, therefore, the construction speed is greatly improved.

Owner:管乃彦

Digging laneway aerating and dust removing system arrangement method

InactiveCN101169041ADisadvantages of reducing open rateSolve the problem of poor ventilation and dust removal effectDust removalFire preventionCycloneHooping

The invention provides an arrangement method of a ventilating and dust-removing system for the excavation tunnel, and includes a boring machine, a belt feeding machine, a belt transshipment device, a dust-removing device, and a ventilating device. The boring machine is connected with the belt transshipment. The transshipment device is set on the belt feeding machine, and the negative pressure wind cylinder of the ventilating device is hung on the tunnel and connected with a fan in a hooping method. Two positive pressure wind cylinders are arranged on the ventilating device, one positive pressure wind cylinder is connected with a fan and a dust catcher in the hooping method; the other positive pressure wind cylinder is connected with a cyclone in the hooping method and is hung on the tunnel. The dust catcher of the dust-removing device is set up on a dust catcher supporting device. The dust-removing device is arranged on a position 20 to 40 meters behind the boring machine, and the negative pressure wind cylinder is connected at a position 3 to 5 meters apart from and opposing the drivage face, fresh air is pressed in by the positive pressure wind cylinder, and the outlet is 15 to 35 apart from and opposing the drivage face. The ventilation arrangement of the method is rational and safe, the movement is convenient, the operation is simple, the dust removing effect is good, the water consumption is low, and the cost is low.

Owner:TANGSHAN KAILUAN GUANGHUI EQUIP MFGCO

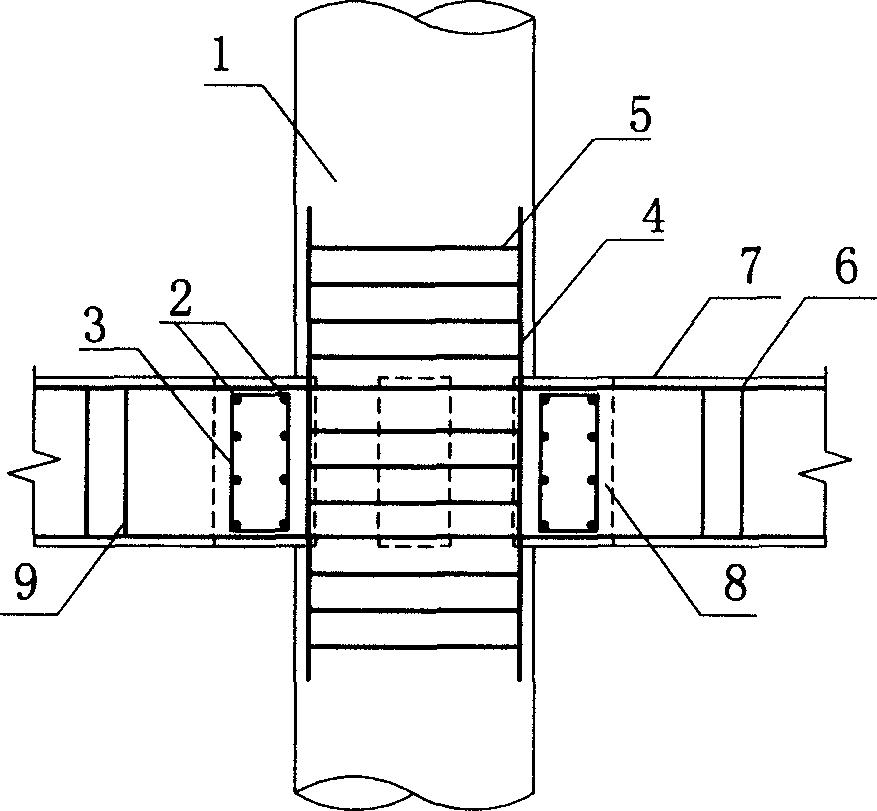

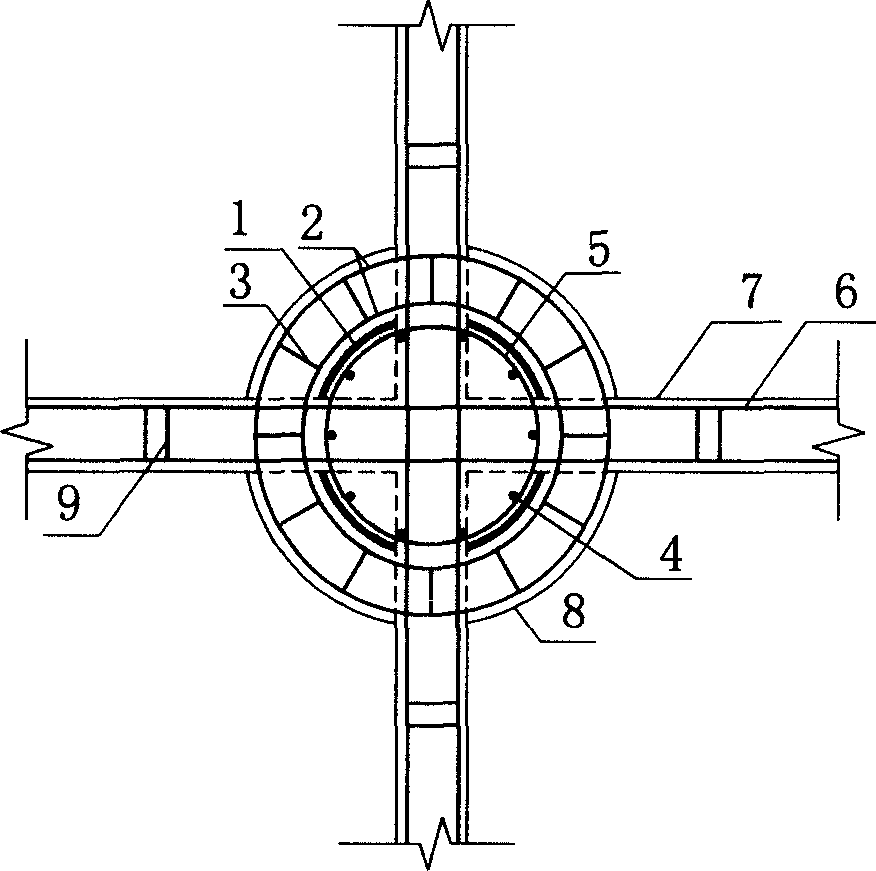

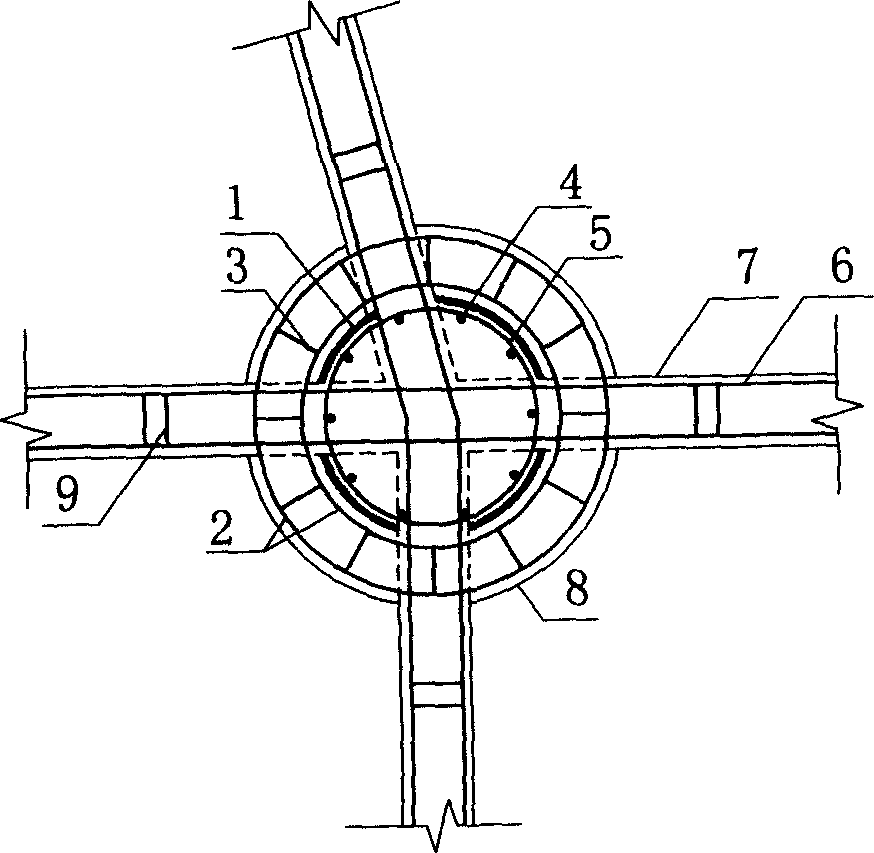

Connection structure of connection of floor beam and steel pipe concrece pole and construction method thereof

InactiveCN1560393ARigid Performance GuaranteeFirmly connectedBuilding reinforcementsHoopingConcrete beams

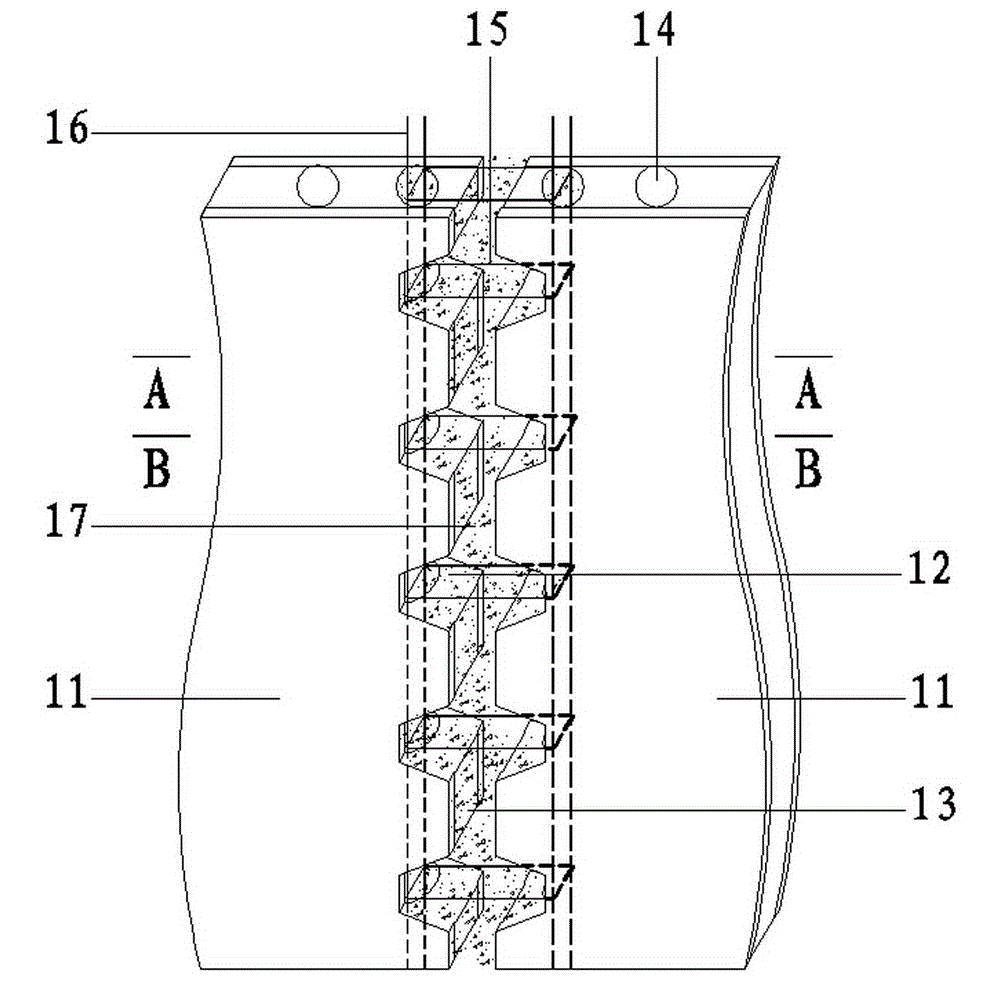

The invention discloses a joint structure at the connection part of steel pipe concrete pile and floor beam and the constructing method. The joint structure includes steel pipe concrete pile, floor beam and ring type concrete beam. The vertical component steel pile and the parallel component floor beam are connected at the joint, the steel pipe is drilled with a aperture at position correspondent to the joint on the floor, thus the beam lengthwise rib of the beam can pass through the steel pile directly; ring type concrete beams are arranged around the steel pipe in the joint area, the steel bar in the ring concrete beam includes ring type beam lengthwise rib which is concentric with the steel pipe concrete pile and radiate ring beam hooping in radius direction; a steel bar cage concentric with the steel pipe is arranged in the pile, which includes vertical pile connection lengthwise rib and parallel pile connection hooping, the anchor in the steel bar cage extension length is decided by the diameter of the steel bar.

Owner:SOUTH CHINA UNIV OF TECH

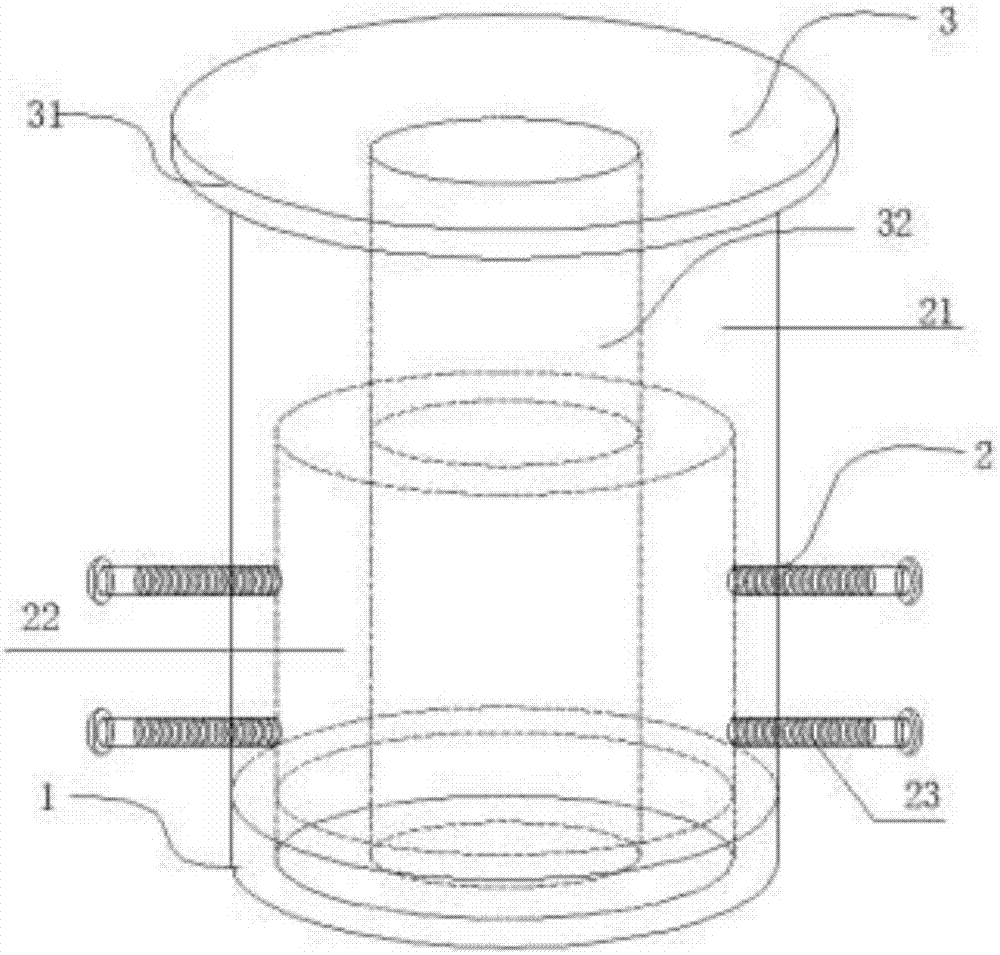

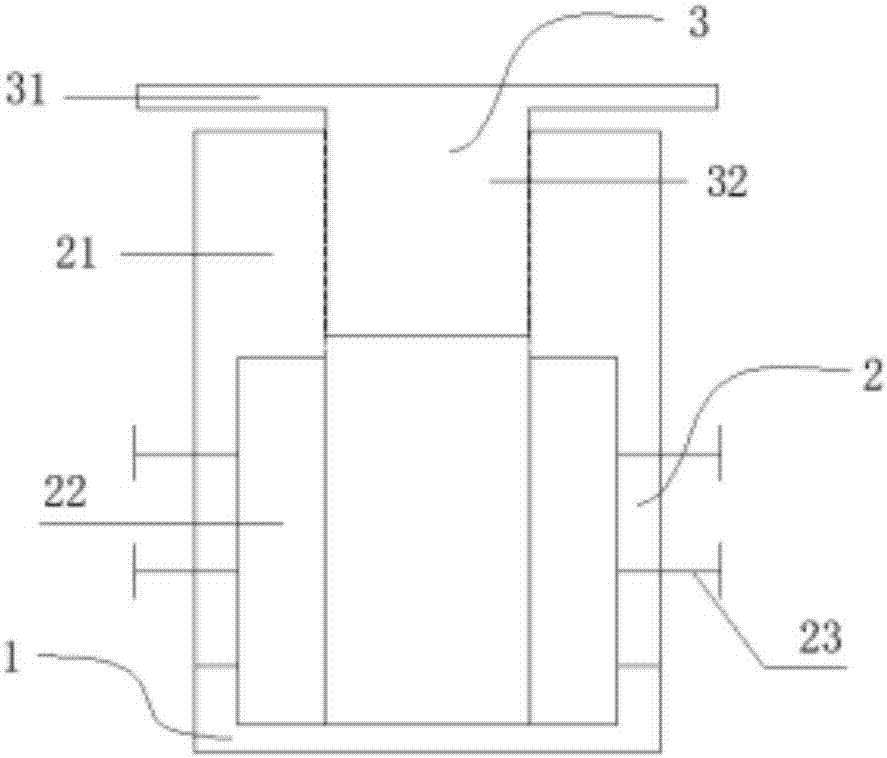

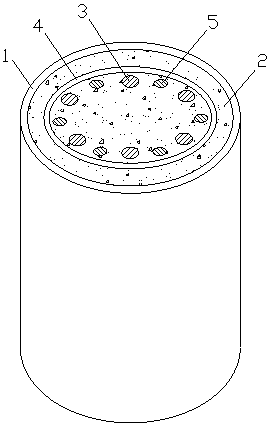

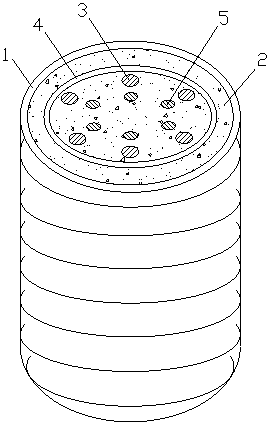

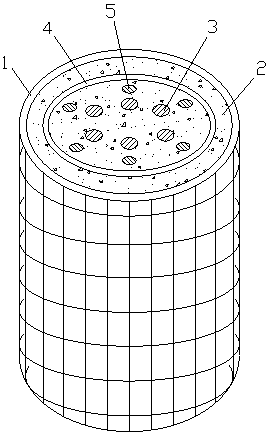

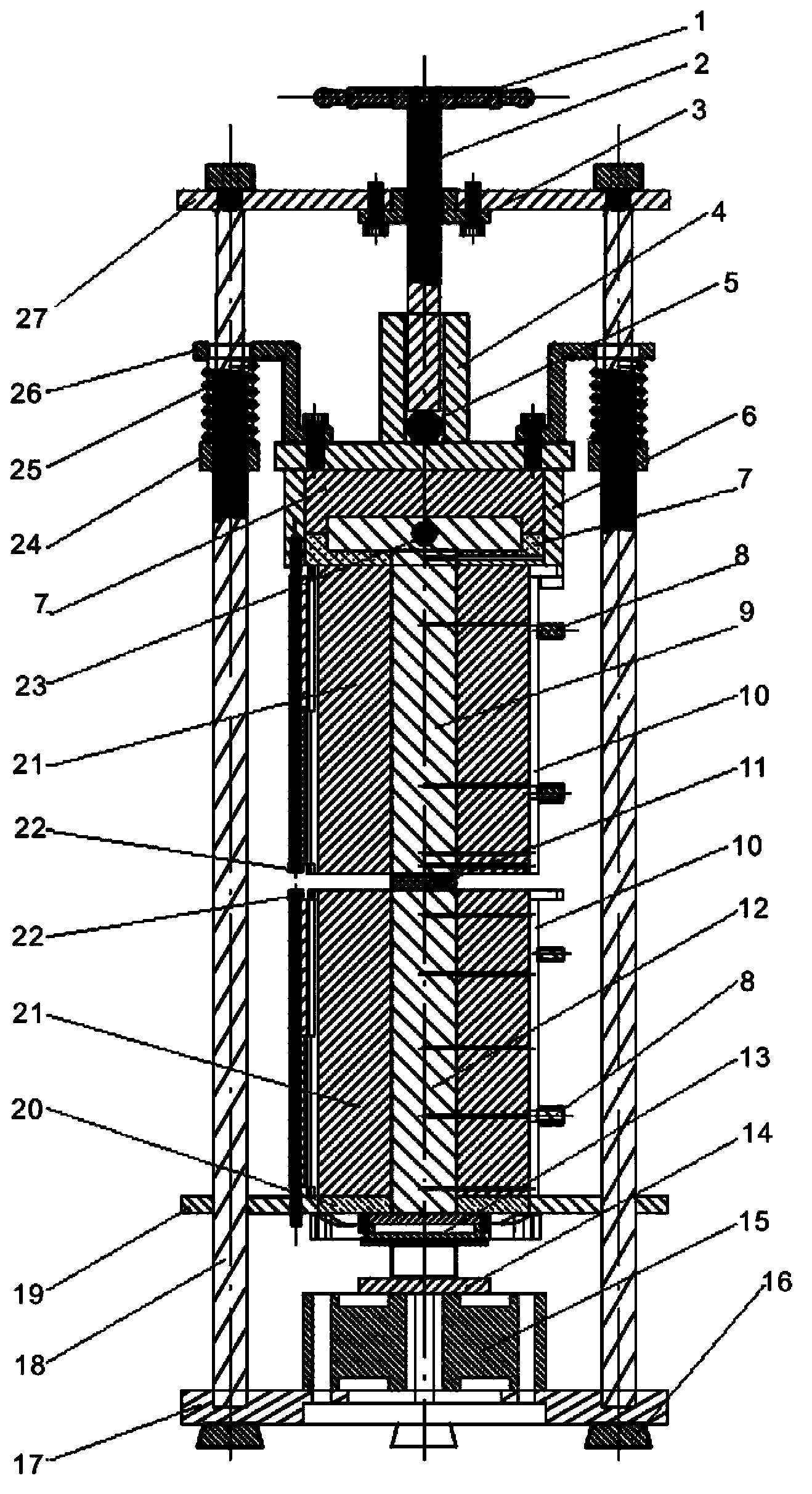

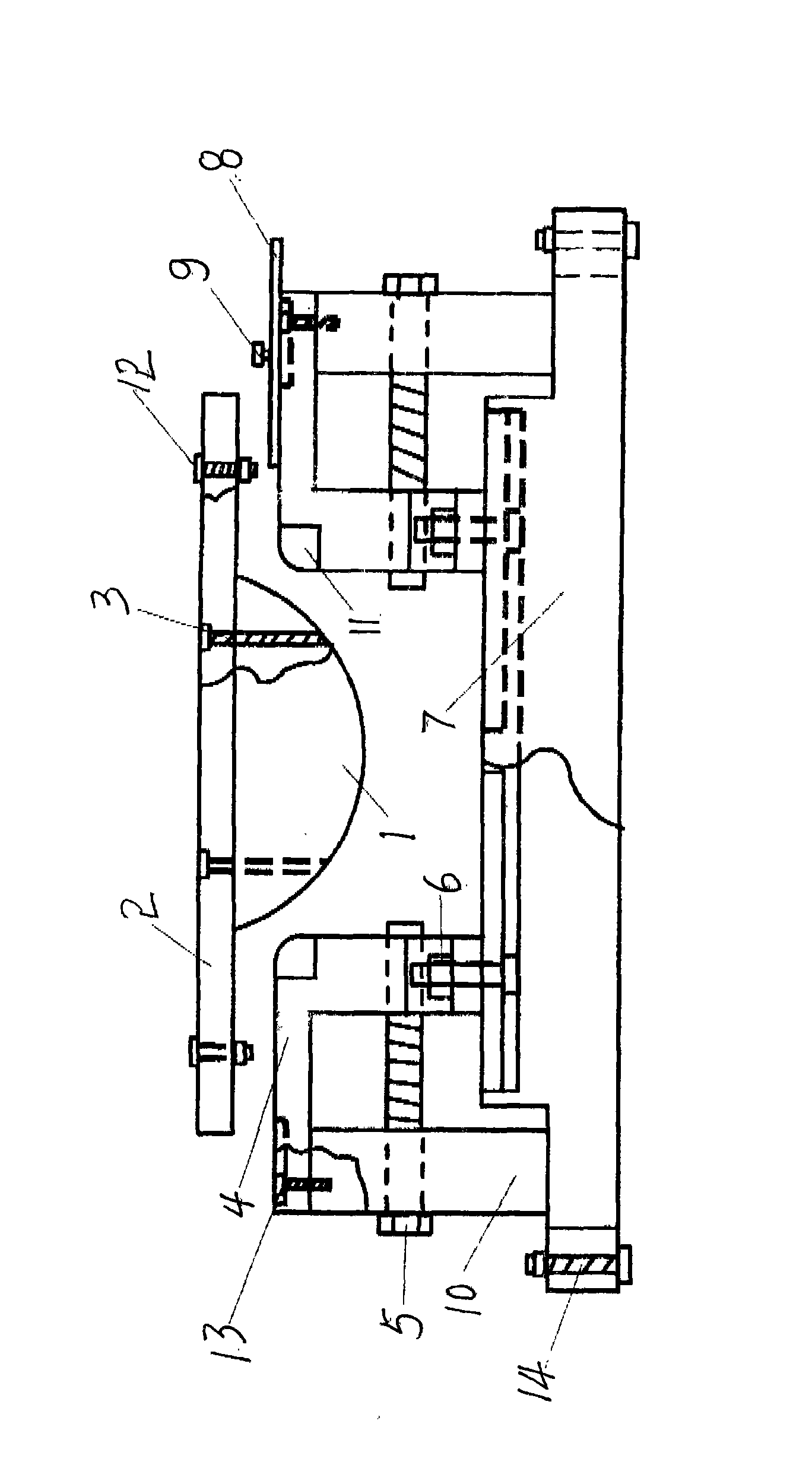

Remoulded soil stratified compaction sample preparer for indoor triaxial test and method thereof

ActiveCN107101855ASimple structureEasy to assemble and disassemblePreparing sample for investigationHoopingTriaxial shear test

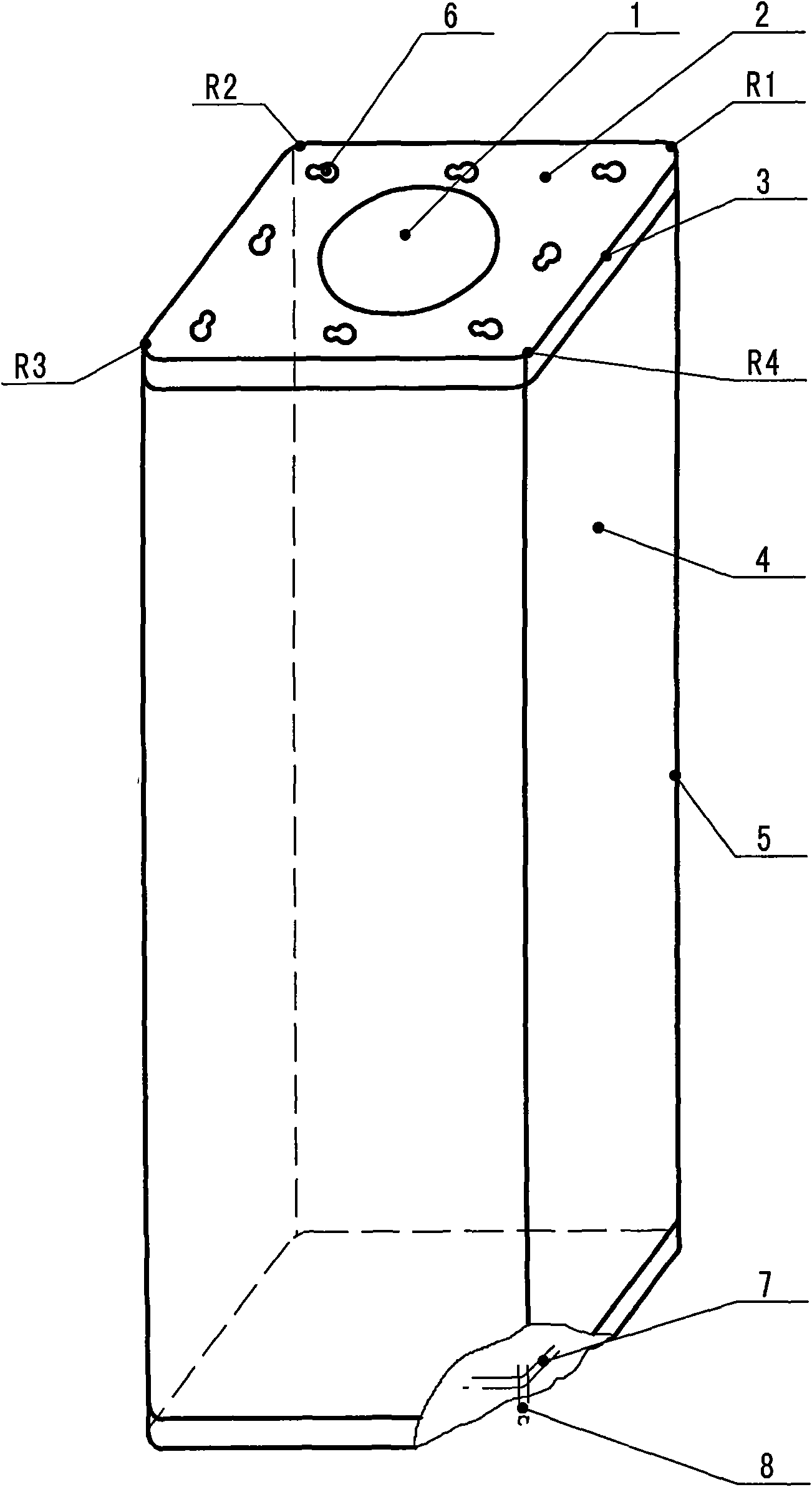

The invention discloses a remoulded soil stratified compaction sample preparer for an indoor triaxial test and a method thereof and relates to a sample preparation technology of the indoor triaxial test. The sample preparer comprises a base, a compaction barrel and a limiting compaction cover; the base, the compaction barrel and the limiting compaction cover are successively connected from bottom to top; the base is a short cylinder; the compaction barrel comprises an outer sleeve, a soil sample forming barrel and a hooping bolt; the limiting compaction cover comprises a top cover and a limiting column connected up and down. According to the sample preparer disclosed by the invention, the thicknesses of the layers of the test sample can be guaranteed uniform, and the relative density is uniform; the sample preparer can be repeatedly used, and test samples of other specifications can be manufactured by changing the structure and dimension of a part; the sample preparer is simple in structure, convenient to disassemble, simple to operate, relatively low in cost, long in service life, accurate to prepare sample, efficient and reliable and small in interference by artificial factors; the sample preparation method is easy to master, high in universality, time- and labor-saving and convenient and rapid.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

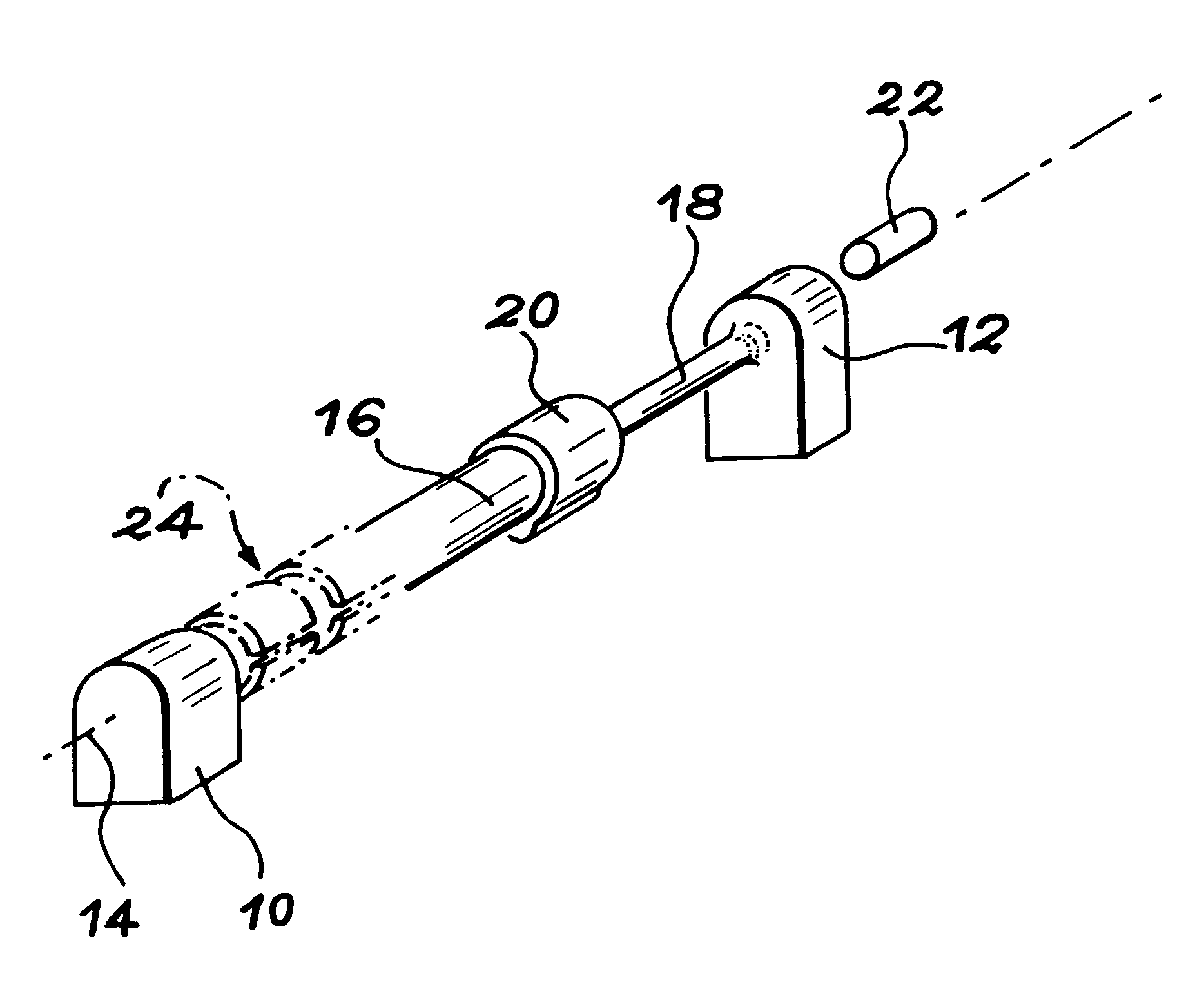

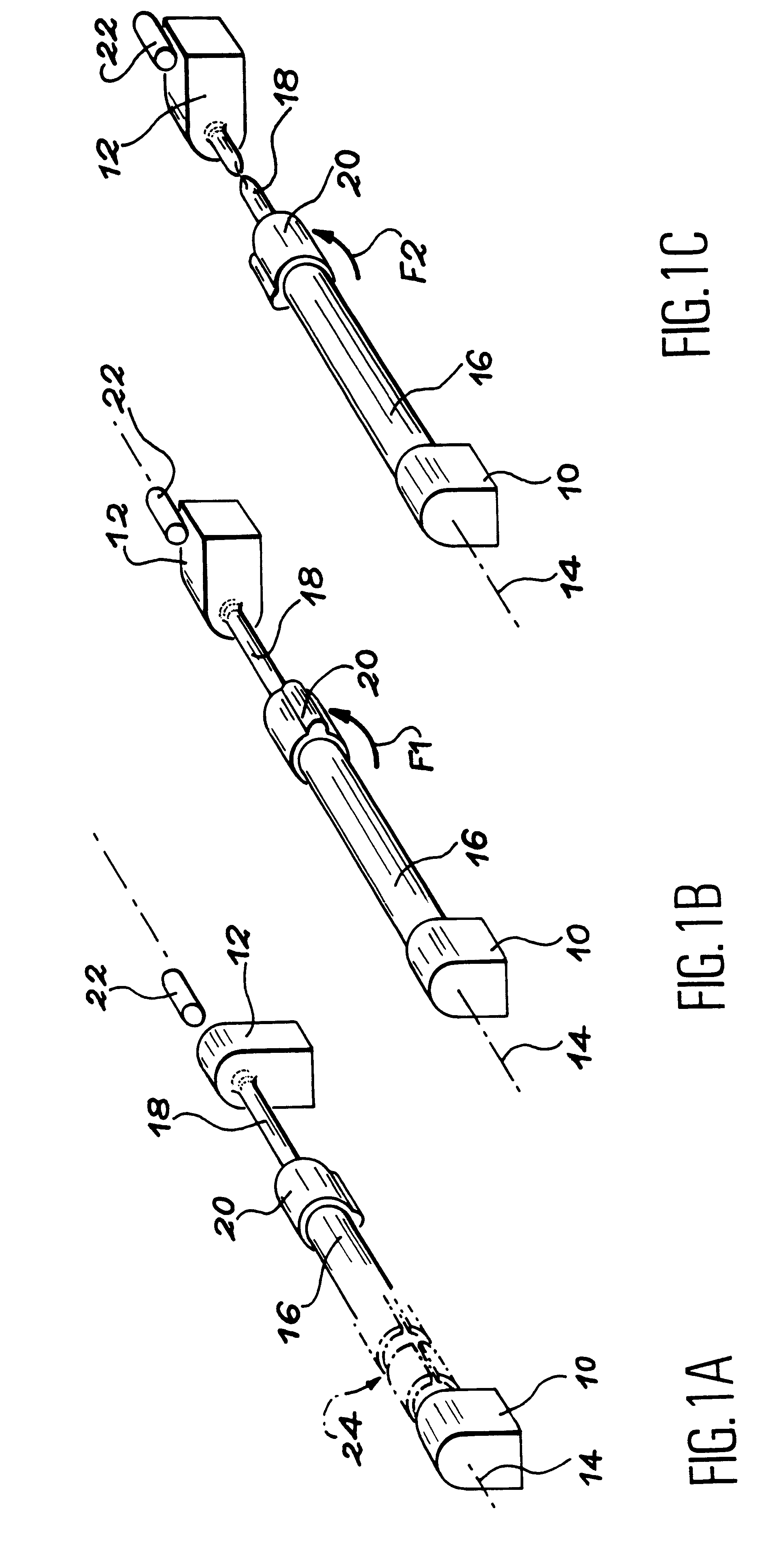

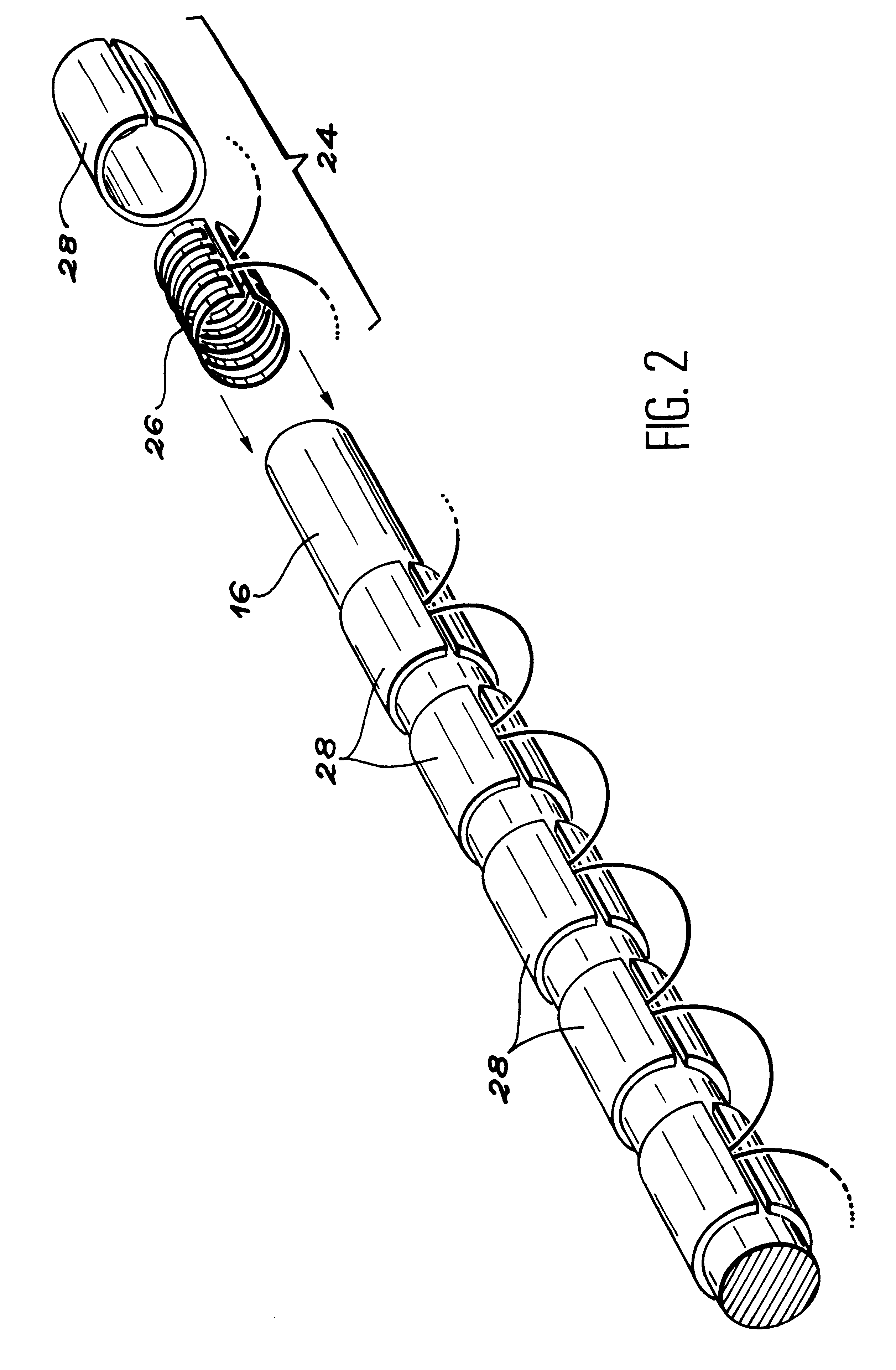

Device for controlling a relative rotation between two articulated elements and a deployable mechanical structure, particularly for a space vehicle, using at least one device of this type

InactiveUS6298662B1Improve reliabilityStraightforward to operateCosmonautic vehiclesCosmonautic power supply systemsHoopingShape-memory alloy

To control a relative rotation between two elements (10, 12), such as flaps of a deployable mechanical structure, on a space vehicle, a torsion bar (16) is used made of a bistable shape memory alloy, heated over its whole length by heaters stuck on the bar and retained by hooping rings. A stop (22) restricts pivoting to the pre-set pivoting angle to be controlled. Excess pivoting of the torsion bar (16) is applied to a mechanical fuse (18), interposed between the bar and one (12) of the elements.

Owner:ALCATEL LUCENT SAS

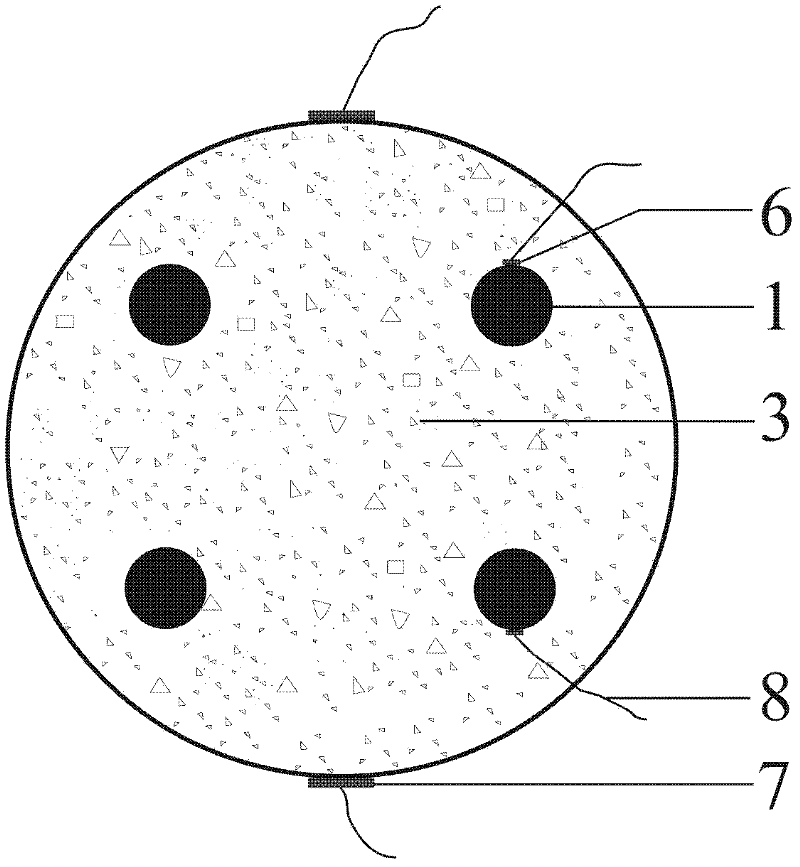

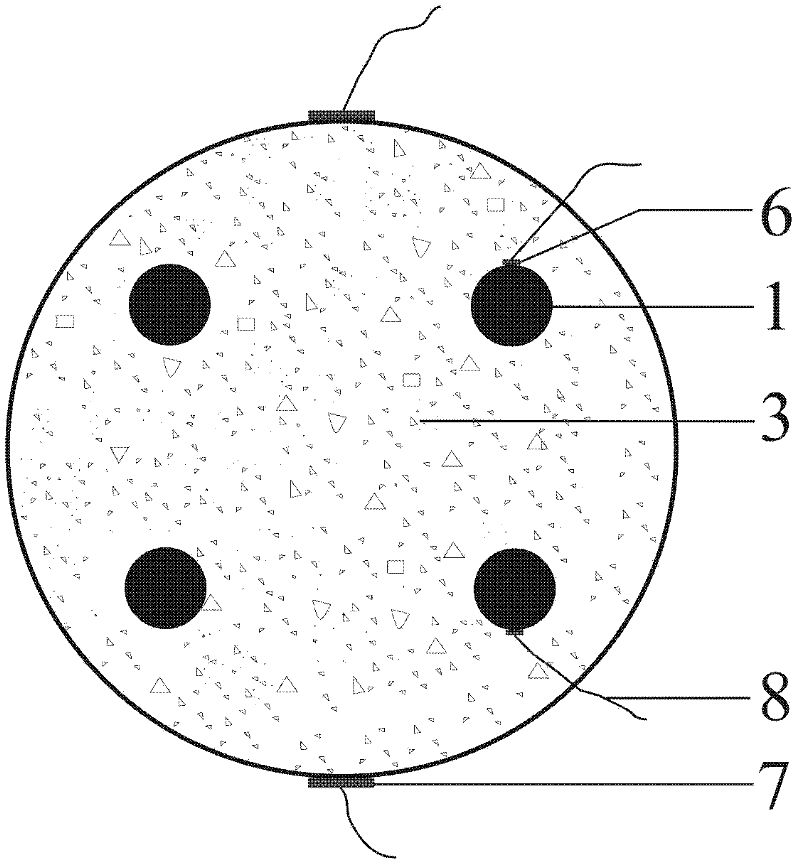

Novel reinforced-concrete combined pier column and construction method thereof

ActiveCN103074847AImprove carrying capacityImprove ductilityBridge structural detailsBridge materialsHoopingReinforced concrete

The invention relates to a novel reinforced-concrete combined pier column. The combined pier column comprises a fibre-reinforced composite material pipe, wherein a plurality of common reinforcing steel bars and a plurality of fibre bars are arranged in the fibre-reinforced composite material pipe in a distributing way along the length direction of the fibre-reinforced composite material pipe, these common reinforcing steel bars and these fibre bars are all coiled at the middle part in the fibre-reinforced composite material pipe by a plurality of hooping bars, and concrete is poured in the fibre-reinforced composite material pipe. The invention also relates to a corresponding construction method of the novel reinforced-concrete combined pier column. According to the novel reinforced-concrete combined pier column and the construction method of the novel reinforced-concrete combined pier column, the bearing capacity of a pier column structure can be enhanced; moreover, the shock resisting performance of a pier column and the recoverable performance after shock can be effectively enhanced; furthermore, the self weight of the structure is decreased; and the novel reinforced-concrete combined pier column has the characteristic of corrosion resistance under severe environments, such as ocean, humidity, saline-alkali soil and the like.

Owner:FUZHOU UNIV

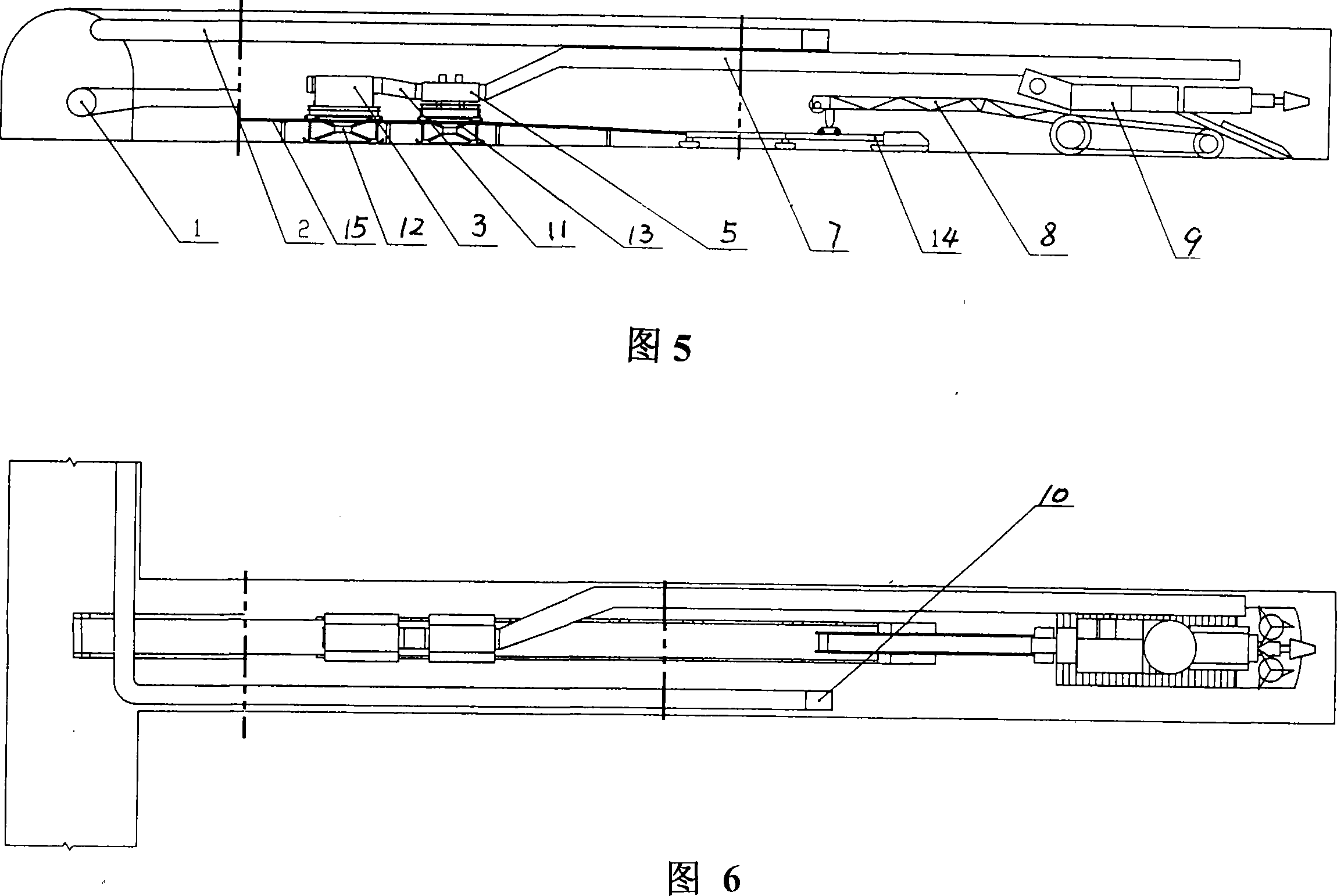

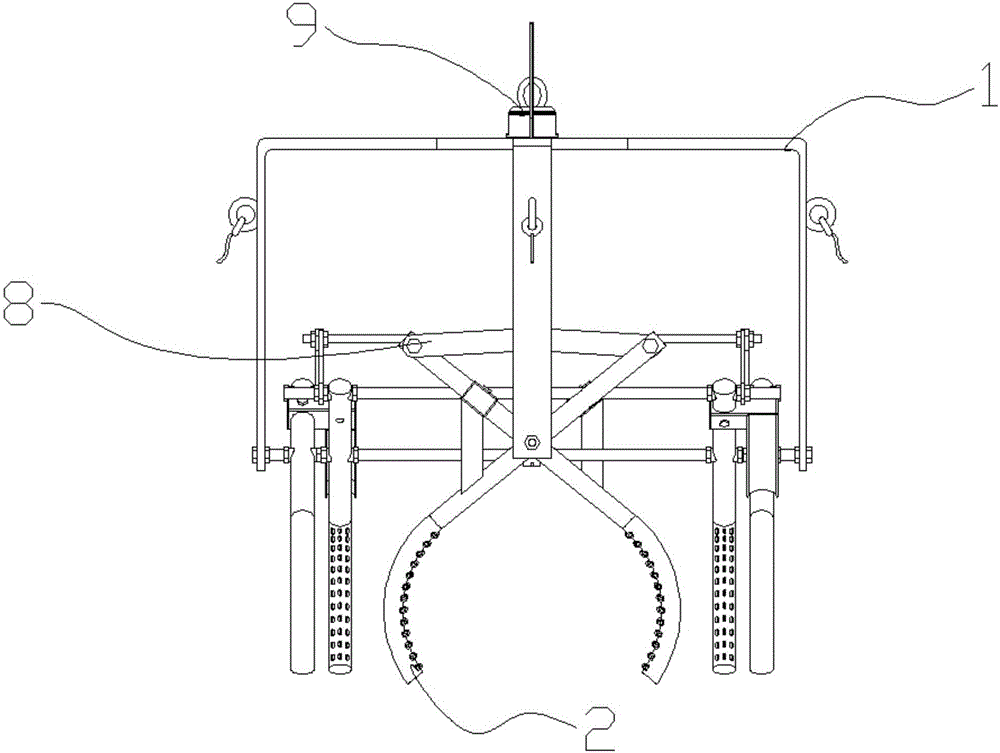

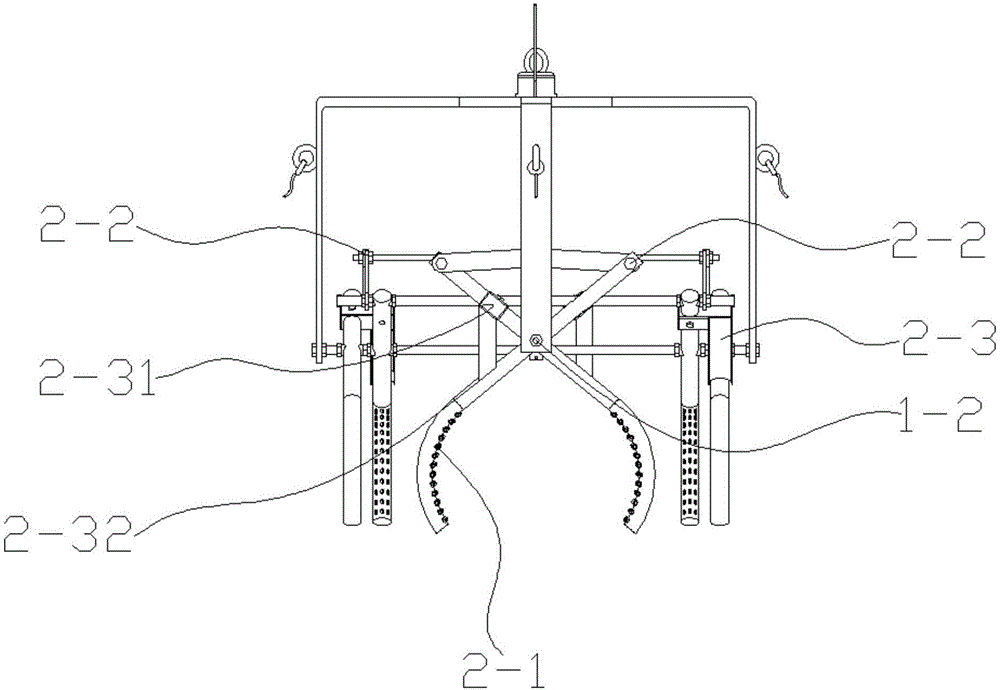

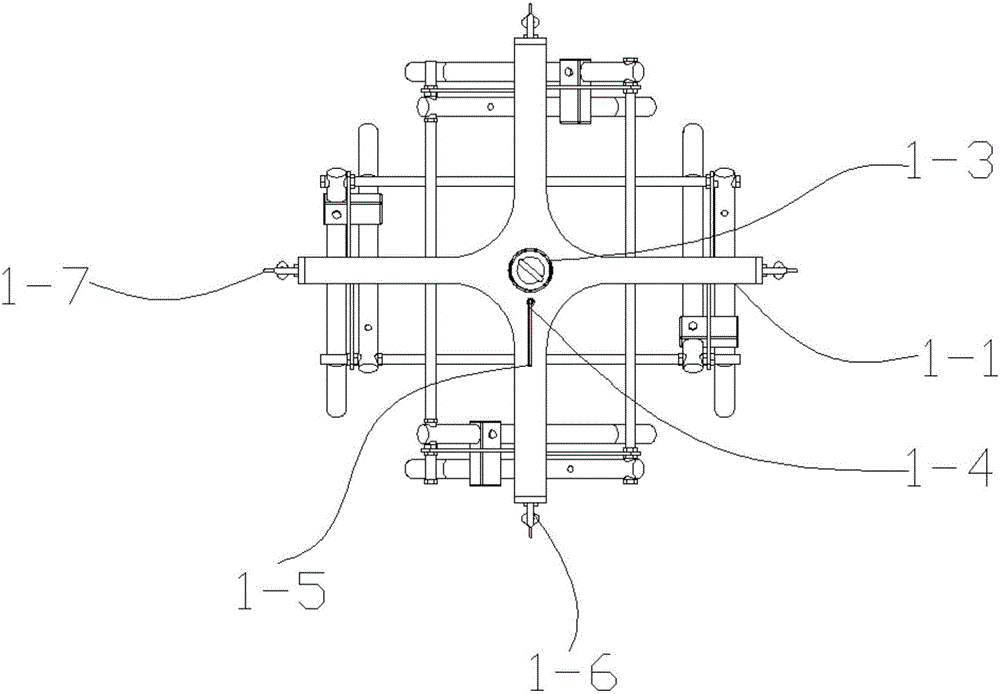

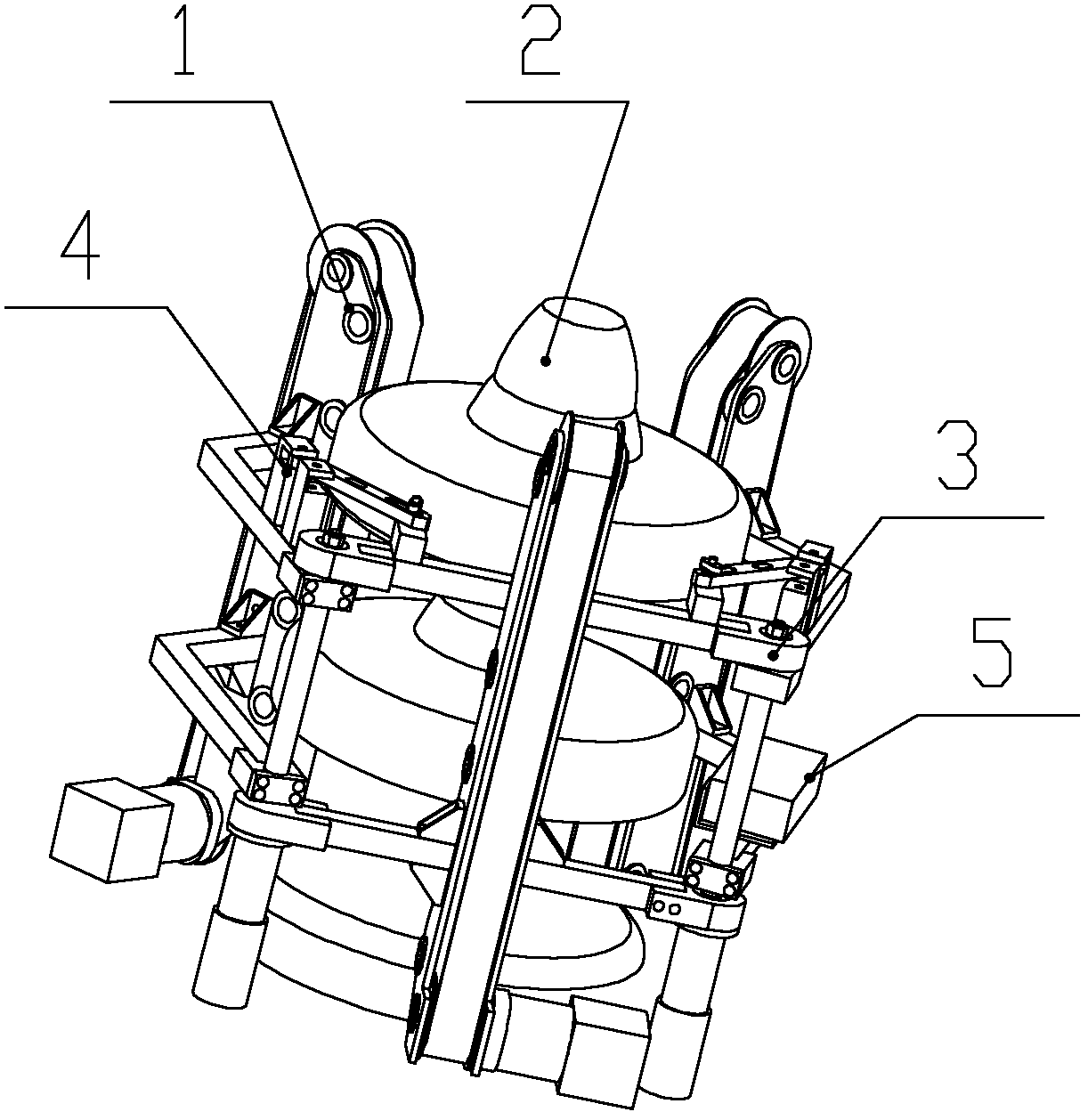

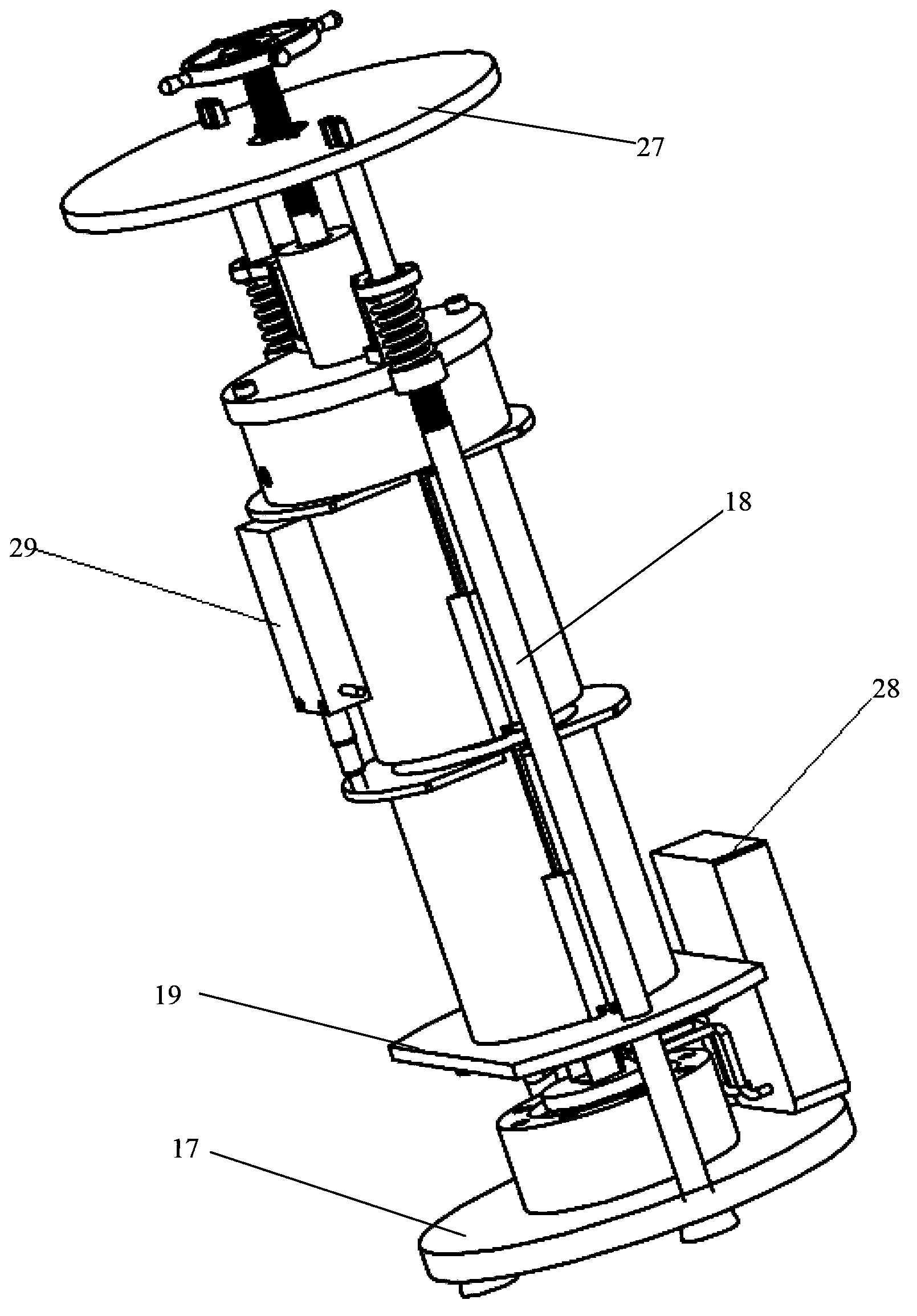

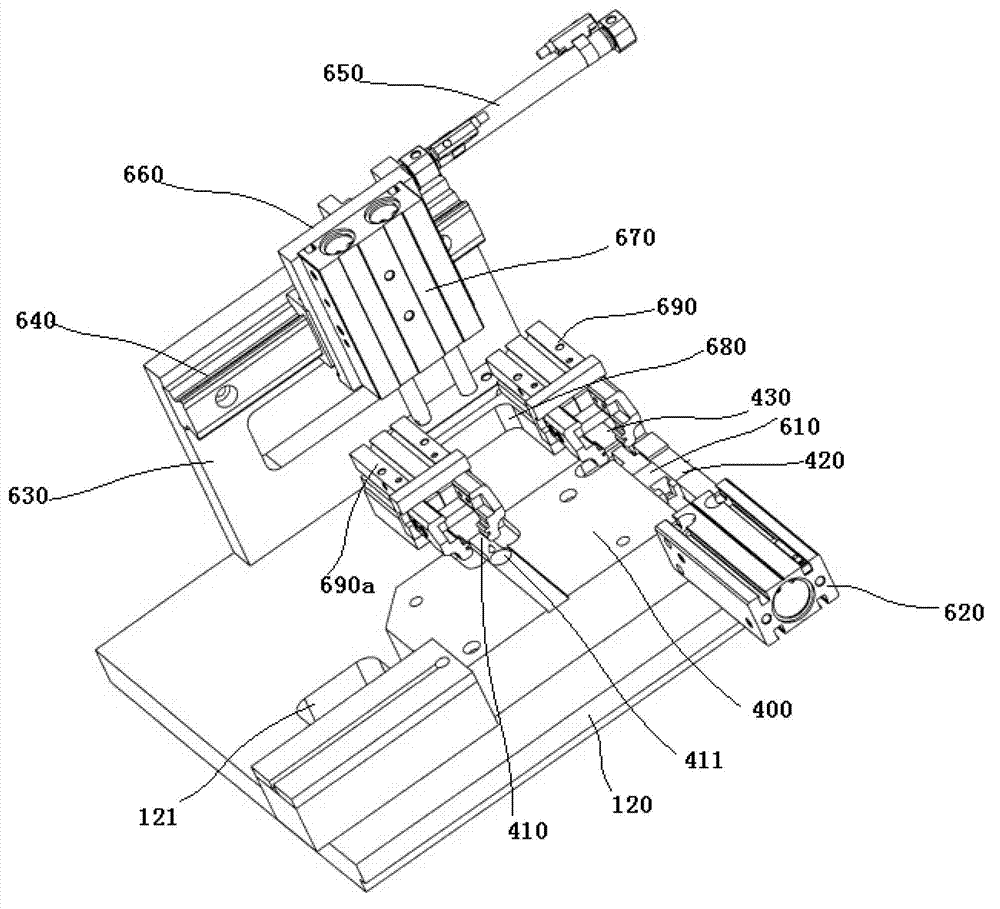

Two-dimensional omnibearing launching and retrieval device of underwater glider and launching and retrieval method

ActiveCN106275286AEasy to deployEasy to recycleCargo handling apparatusGripping headsHoopingRecovery method

The invention relates to the technical field of launching and retrieval of underwater gliders, underwater and surface aircrafts and the like, and relates to a two-dimensional omnibearing launching and retrieval device of an underwater glider and a launching and retrieval method. The corresponding pure mechanical structure comprises a main support, hooping jaw pairs, synchronous cross shafts, synchronous tensile shafts, connecting rods, a spring tensioning mechanism, a movable block stretching mechanism, jaw vice arms and a force removal swivel. The two-dimensional omnibearing launching and retrieval device fulfills the hooping and releasing functions on the underwater glider in a manner that the hooping jaw pairs are matched with the synchronous cross shafts, the synchronous tensile shafts, the connecting rods, the spring tensioning mechanism, the movable block stretching mechanism and the like, so that the underwater glider is launched and retrieved simply quickly. According to the invention, the launching and retrieval functions on the underwater glider are fulfilled through the mechanical structure, the structure is simple and ingenious, maintenance is convenient, operation is simple, the underwater glider is launched and retrieved extremely simply, the risk in the launching and retrieval processes is decreased, and the problems of high costs and high risks in the launching and retrieval processes are solved.

Owner:OCEAN UNIV OF CHINA

Prestressed spun concrete square piles and mould thereof

ActiveCN101560769AConsistent tensile stressUniform thicknessCeramic shaping apparatusBulkheads/pilesHoopingPrestressed concrete

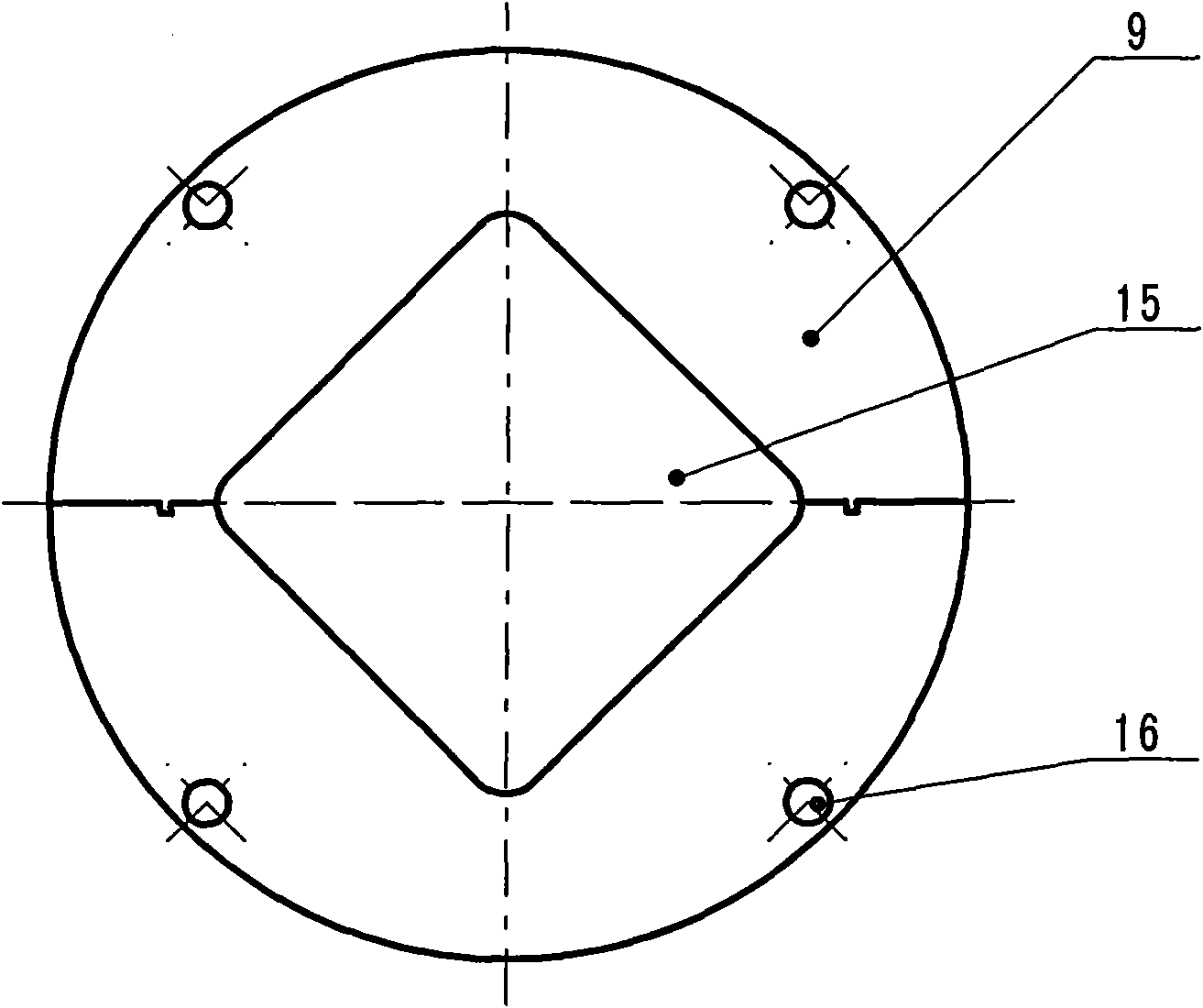

The invention relates to a prestressed spun concrete square pile, comprising a square pile and a square metal end plate, wherein, the square pile consists of a reinforcing cage and the concrete. The reinforcing cage consists of a main reinforcement and a spiral hooping which is welded on the main reinforcement. The four arms of angle of the square pile and square metal end plate are all of circular arcs with the same radius of 10 to 40mm. The mould consists of an upper mould, a lower mould, a locking device and a hanging tight bolt. After the snap-fit of the upper mould and the lower mould, the inner chamber of the mould is square, wherein, the four interior arms of angle of the square are of circular arcs with the same radius. A locating pin is positioned at the joint part of upper mould and the lower mould; the hanging tight bolt is a coarse thread bolt, with the thread pitch of 2 to 4mm. The prestressed spun concrete square piles have the characteristics that the tensile stress of the main reinforcement is consistent after moulding and tension-releasing of the pile body, the concrete protective layer enfolded on the main reinforcement is uniform, the strength of the pile body is high; the hanging tight bolt on the mould of the prestressed spun concrete square pile has the advantages of high efficiency in folding and packing, long life and low cost.

Owner:凌德祥

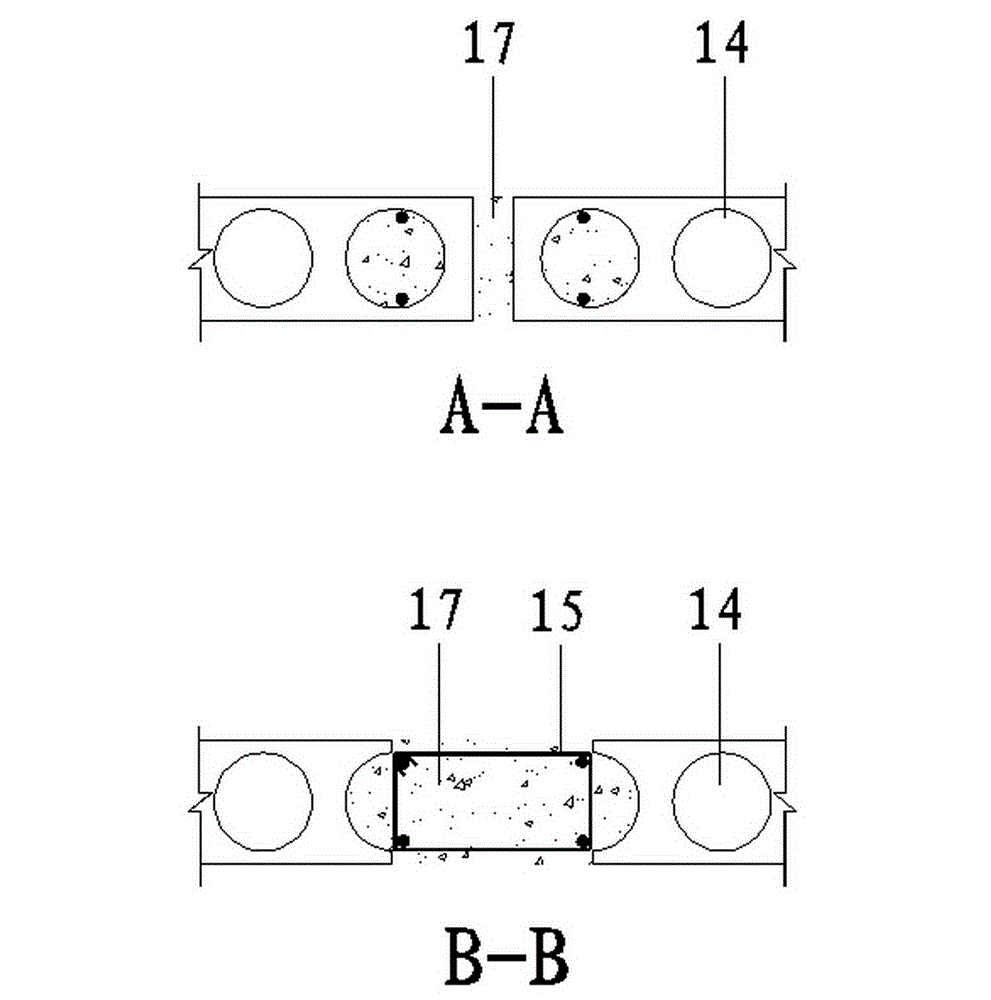

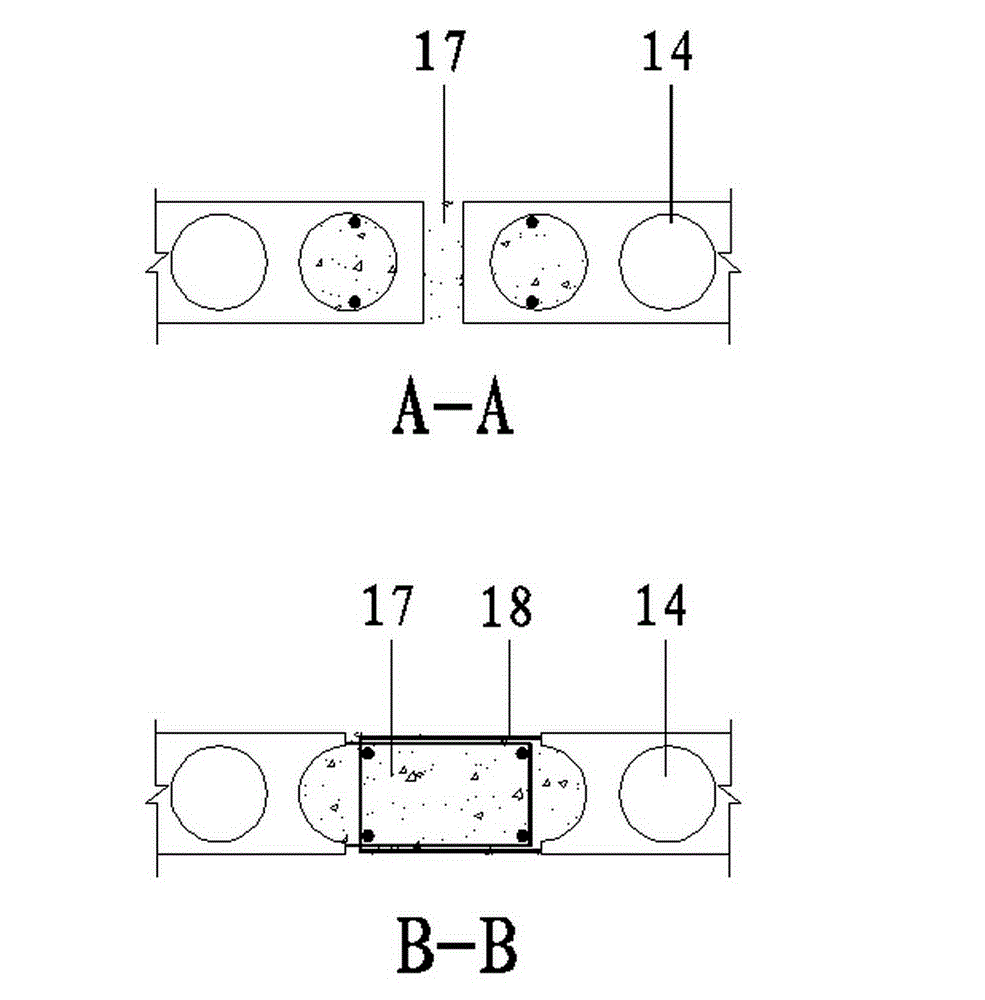

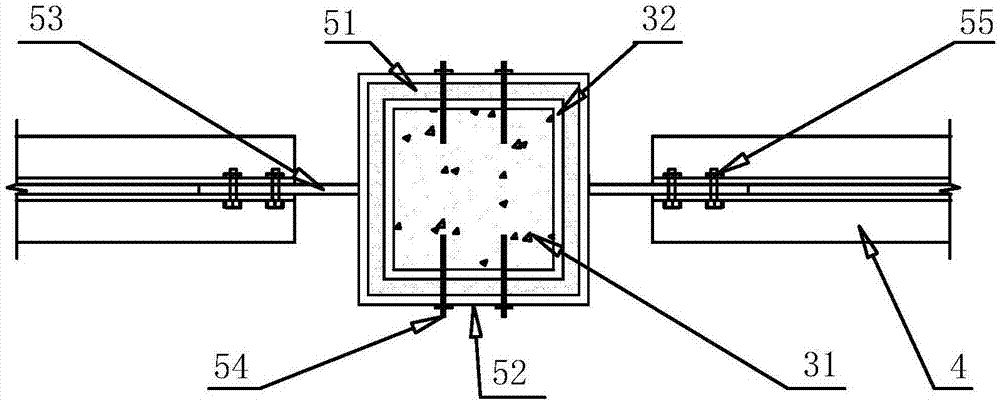

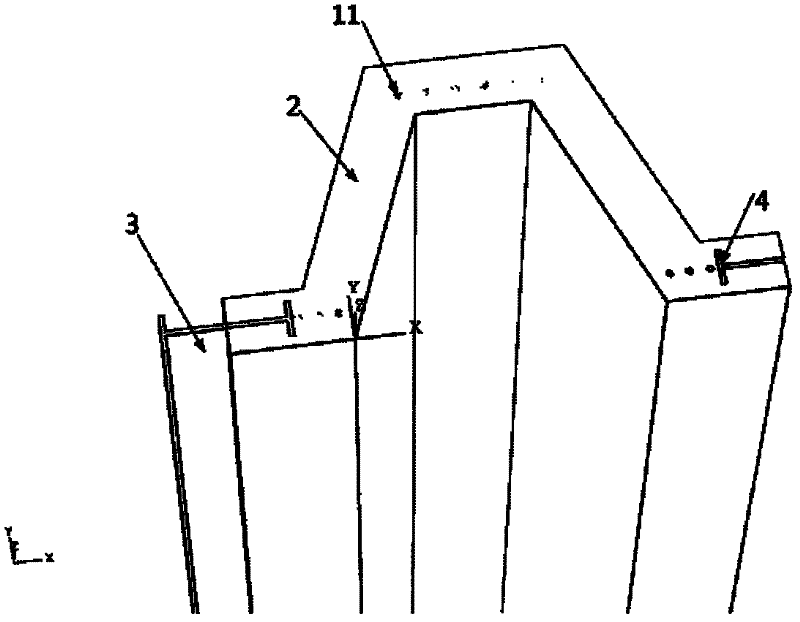

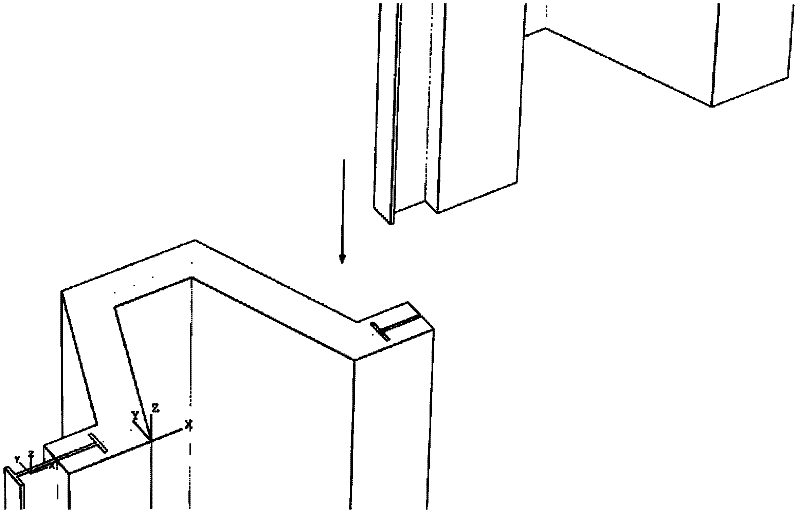

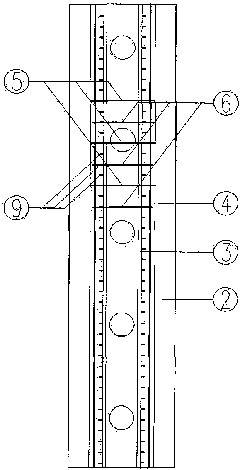

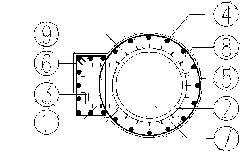

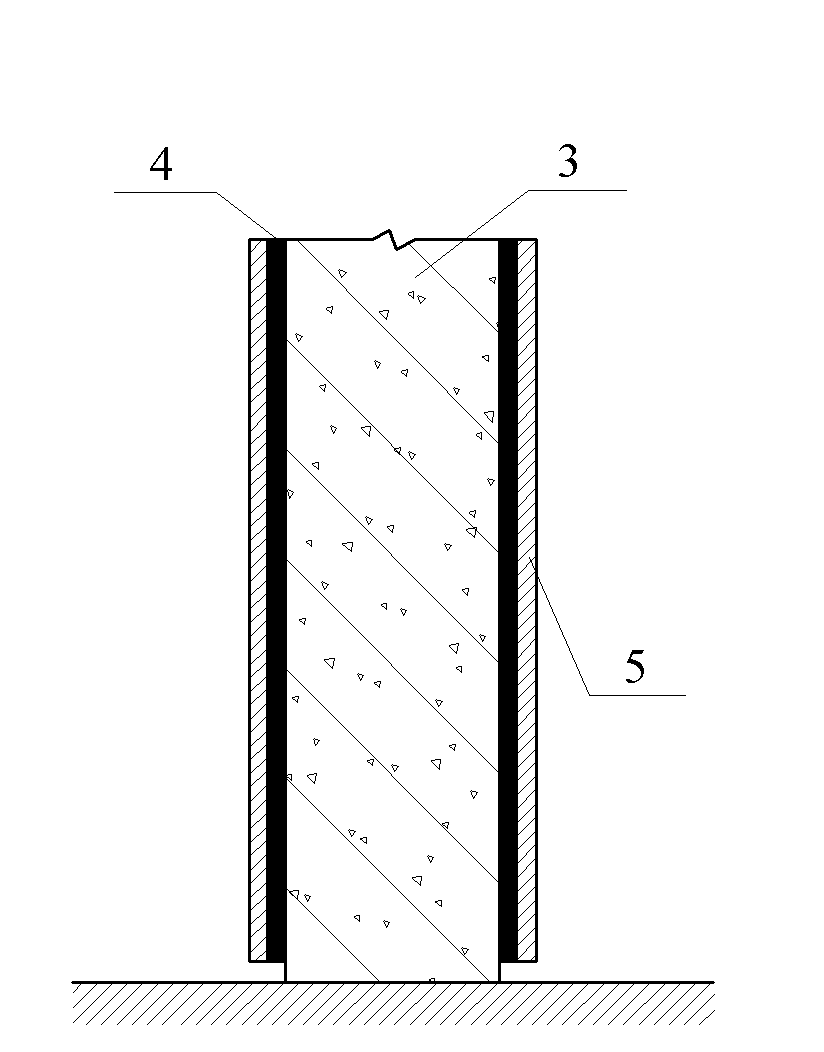

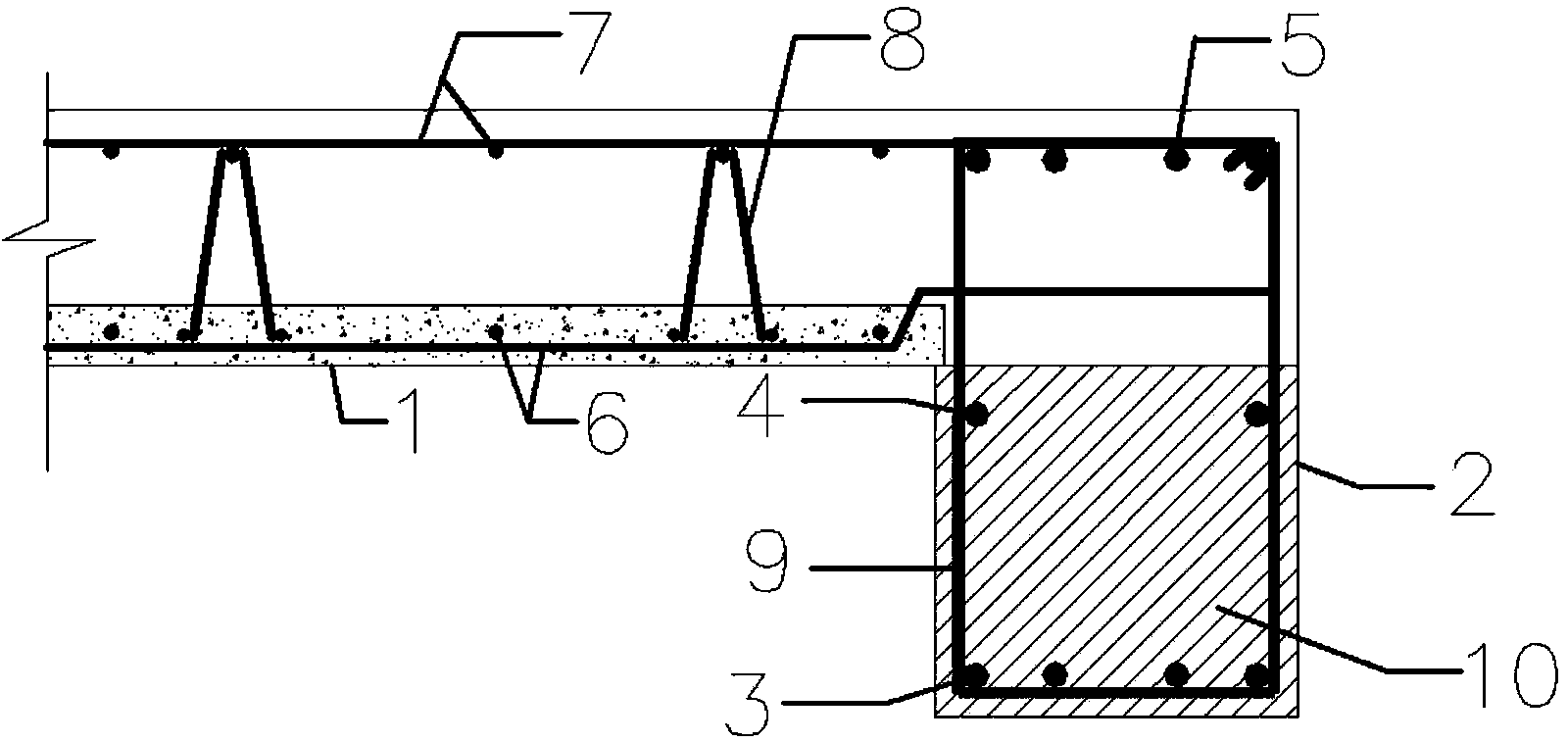

Embedded column type prefabricated part connection node and manufacturing method thereof

ActiveCN102720272ASolve the problem of weak seam connectionImprove performanceBuilding material handlingHoopingVertical edge

The invention provides an embedded column type prefabricated part connection node and a manufacturing method thereof and belongs to the technical field of a building structure. The node comprises a hooping and post-poured concrete; prefabricated concrete parts with grooves are connected to form a whole body; the prefabricated concrete parts with the grooves are provided with vertical holes which are parallel to the surface; transverse grooves which are crossed with the vertical holes at the outer sides are arranged at the vertical edges at intervals; the transverse grooves of the prefabricated parts at the two sides of the node are oppositely arranged; the hooping is arranged in a space formed by the transverse grooves at the two sides of the node; the embedded column type node is formed by pouring concrete into the transverse grooves and the vertical holes at the outer sides of the prefabricated parts; when vertical steel bars are arranged in the vertical holes at the outer sides of the prefabricated parts, a framework is formed by the vertical steel bars and the hooping; and the embedded column type node is formed by pouring the concrete into the transverse grooves and the vertical holes at the outer sides of the prefabricated parts. The manufacturing method disclosed by the invention comprises the following steps of: transporting the prefabricated concrete parts with the grooves, which are prefabricated in a factory, into a field to be mounted, so that the grooves of the adjacent prefabricated parts are oppositely arranged; arranging the hooping in the groves; and forming the embedded column type node by pouring the concrete into the transverse grooves of the prefabricated parts and the vertical holes at the outer sides. According to the invention, the integrity of assembling an integral concrete structure can be improved, the performance of a building structure is improved and the industrial development of a building is accelerated.

Owner:初明进

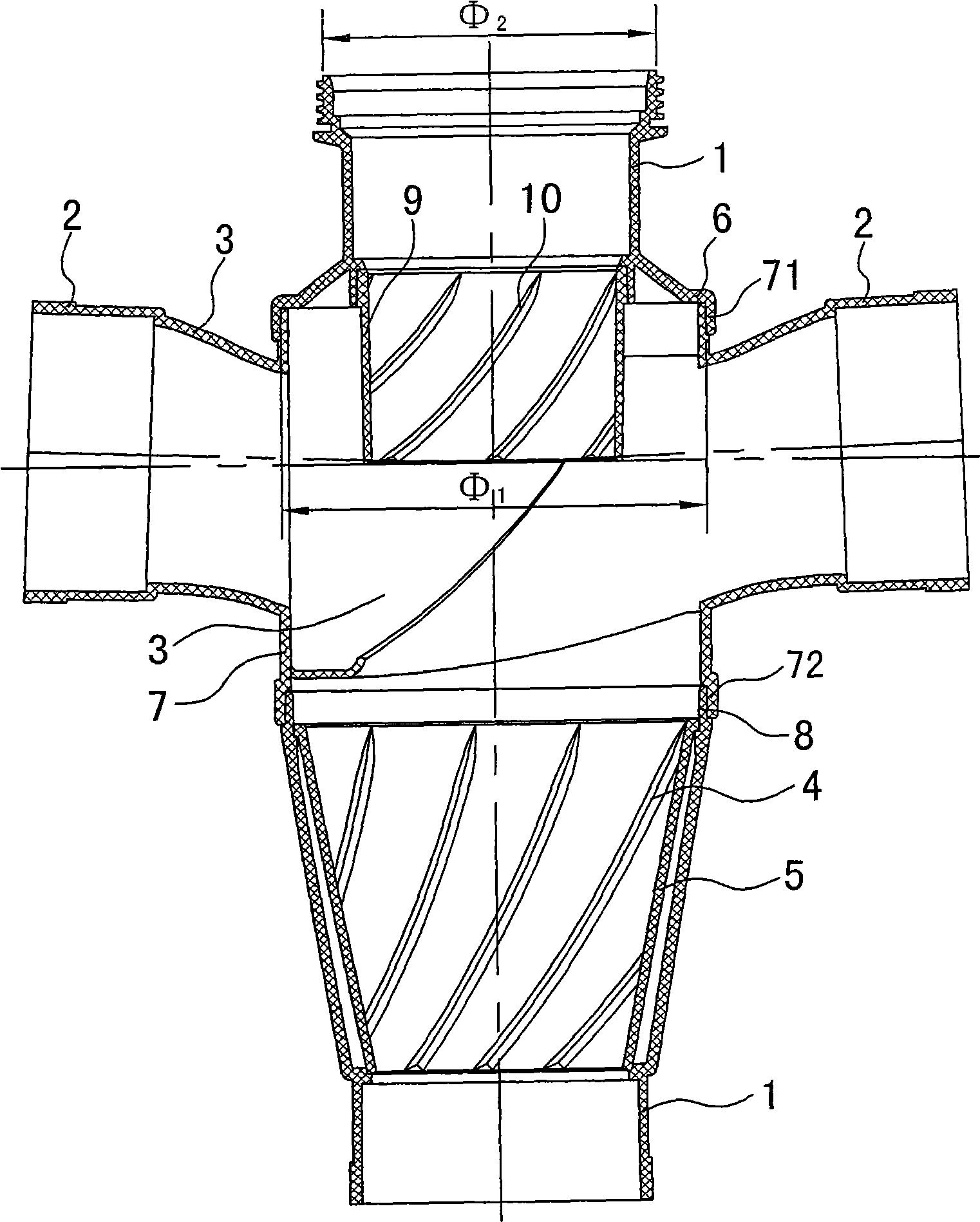

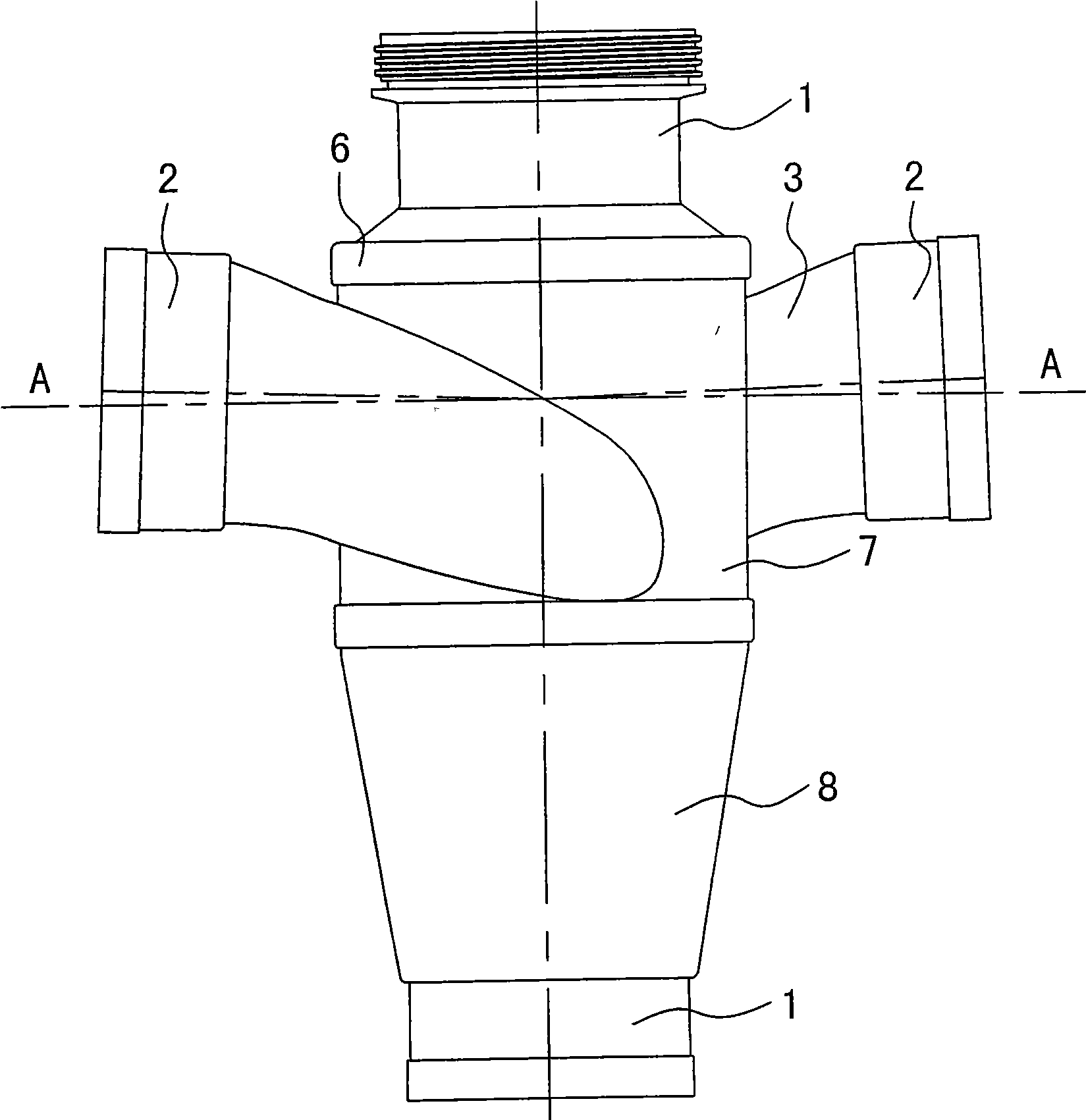

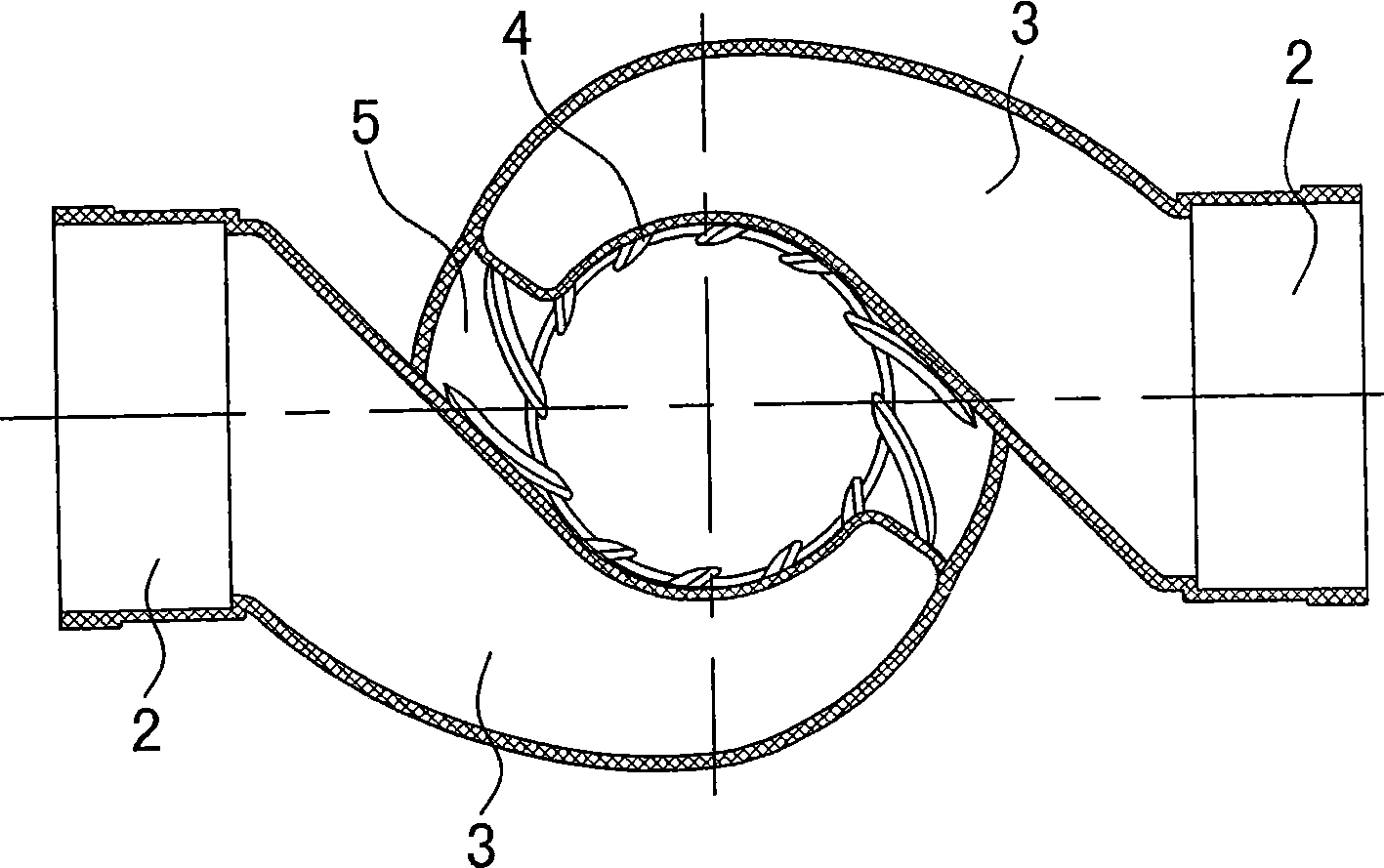

Swirling-flow noise-reduction joint used in construction drainage

The invention relates to a swirling-flow noise-reduction joint used in construction drainage, which comprises a joint main body. The main body is provided with main raiser joints respectively at the upper and the lower parts and a cross branch joint at the sides. The invention is characterized in that the joint main body comprises a cross branch connector, an upper main raiser connector and a lower raiser connector; the lower main raiser connector is in funnel type and looks like a round platform; a lower guide sleeve is arranged in the funnel-type lower main raiser connector, and the inner wall of the lower guide sleeve is provided with a spiral hooping B. The outer diameter of the cross branch connector is larger than that of the upper and the lower main raiser joints; and the cross branch joint is connected with the cross branch connector through a spiral waterway. The proposal continues the overall main raiser spiral flow; and the branch flow and the main raiser spiral flow converge through the spiral waterway and whirl and flow down along the inner walls of pipes, thereby avoiding the crash between the branch flow and the raiser flow, guaranteeing the swirling falling of the raiser flow to reduce noise; in addition, the branch flow and raiser flow also can be connected in a UPVC draining pipe with smooth inner walls to reduce noise.

Owner:浙江光华塑业有限公司

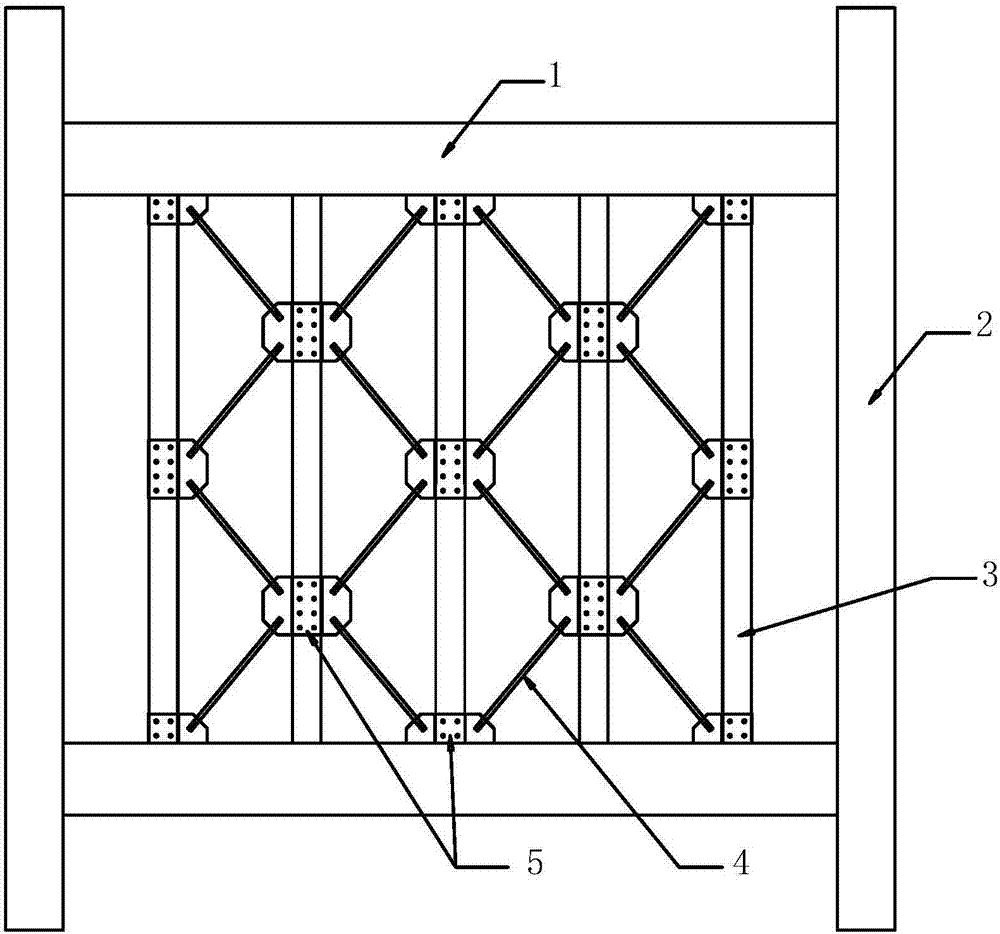

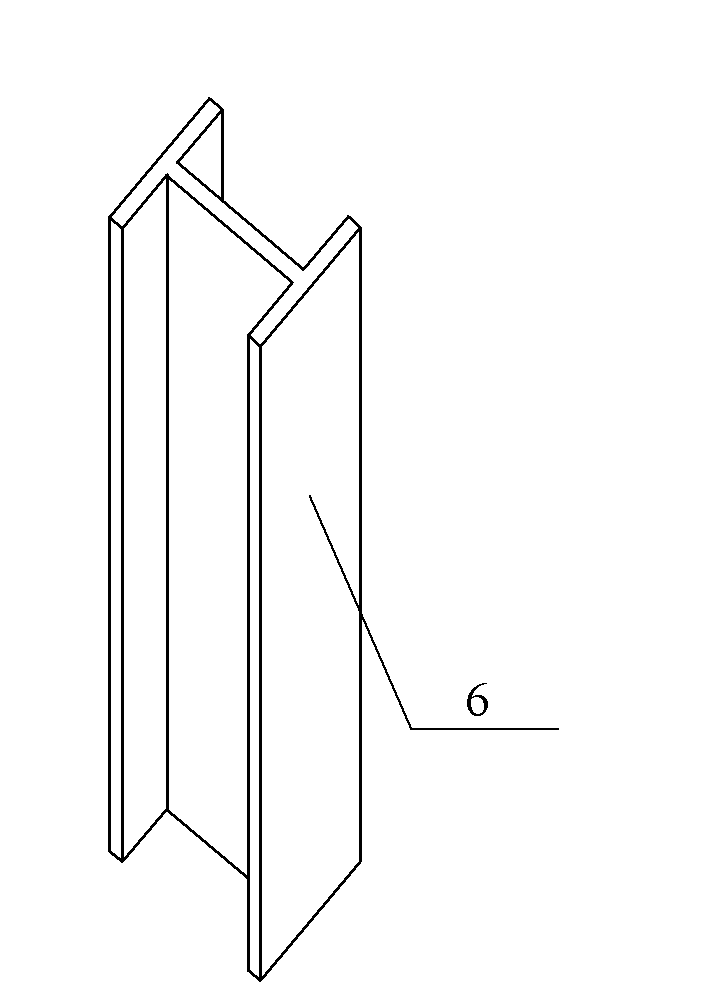

Concrete filled steel tube row column shear wall with structural steel support and manufacturing method thereof

ActiveCN106869367AGood axial compression performanceGuaranteed vertical bearing capacityWallsHoopingRebar

The invention discloses a concrete filled steel tube row column shear wall with a structural steel support and a manufacturing method thereof. The shear wall comprises prefabricated concrete filled steel tubular columns arranged at certain intervals, structural steel supporting components, sleeve connecting components for connecting structural steel and concrete filled steel tubes, concrete poured into a wall space in a filling mode, and steel bar nets which are used for preventing early cracking of the concrete and arranged on two sides of a wall body in advance. The shear wall gives full play to the good axial compressive performance of the concrete filled steel tubular columns. The rigidity of the wall body is increased due to addition of the structural steel supporting components. A rubber pad layer is arranged in each sleeve connecting component, so that partial damage at the joints of the concrete filled steel tubular columns and the supporting components is reduced to a certain extent. Bulging of steel tubes is restrained due to the hooping function of sleeves to the concrete filled steel tubes, and the three layers of defenses including the concrete, the structural steel support and the concrete filled steel tubes are formed. The combined shear wall has high bearing capacity and a good anti-seismic property, most of the components are prefabricated components and are convenient to splice after being conveyed to a construction site, and work time is saved.

Owner:TIANJIN UNIV

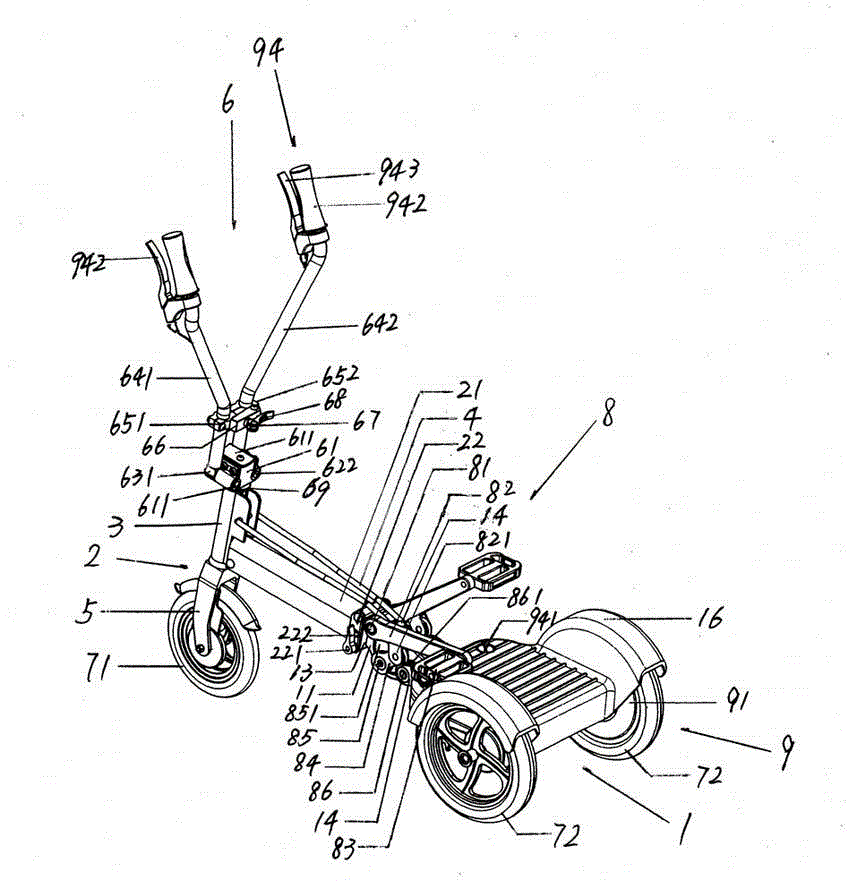

Quick foldable portable three-wheel power-driven pedal bike

The invention provides a quick foldable portable three-wheel power-driven pedal bike. The bike provided by the invention comprises a bike body back piece, a bike beam, a front pipe fitting, a support bracket, a front fork, a V-shaped foldable handle, a front wheel, a back wheel, a labor-driven mechanism and a power-driven mechanism, wherein the bike body back piece comprises a main piece, a back fork, a foldable back leaf, a fixed shaft piece, a hoop piece and a faceplate; the main piece is welded with the back fork and the foldable back leaf; the hoop piece and the main piece are connected with the support bracket in a hooping way; the bike beam is connected with the foldable back leaf and the front pipe fitting; the front pipe fitting is connected with the support bracket; the V-shaped foldable handle is connected with the front fork; the front fork is connected with the front pipe fitting; the front wheel is arranged at the front fork; a back wheel shaft and the back wheel are arranged at the back fork; the labor-driven mechanism is arranged on the main piece by a positioning shaft, a crankshaft and a front-stage gear; a foot bar is in sleeved connection with the positioning shaft; a swinging piece is connected with a connecting ear and the crankshaft; back-stage teeth are meshed and merged with the front-stage gear to be coaxial with a chain wheel; a fly wheel is arranged on the back wheel shaft; a chain is in surrounding connection with the chain wheel and the fly wheel; and the power-driven mechanism comprises a motor, a battery for the bike, a battery box, a controller and a control switch.

Owner:安徽创意达技术转移服务有限公司

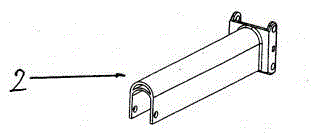

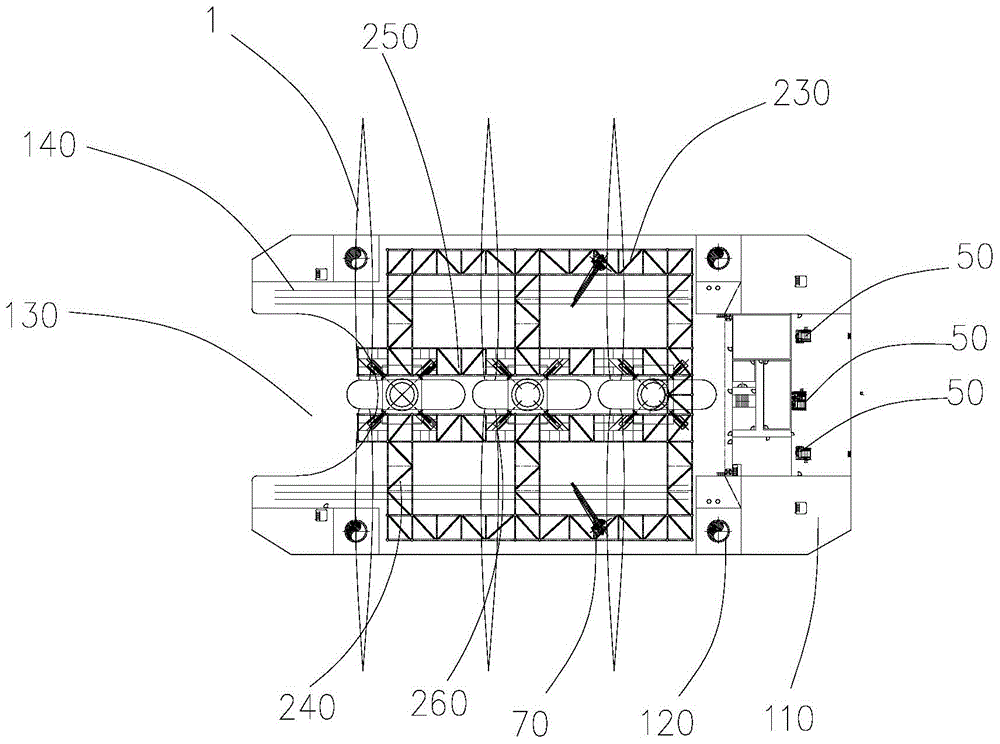

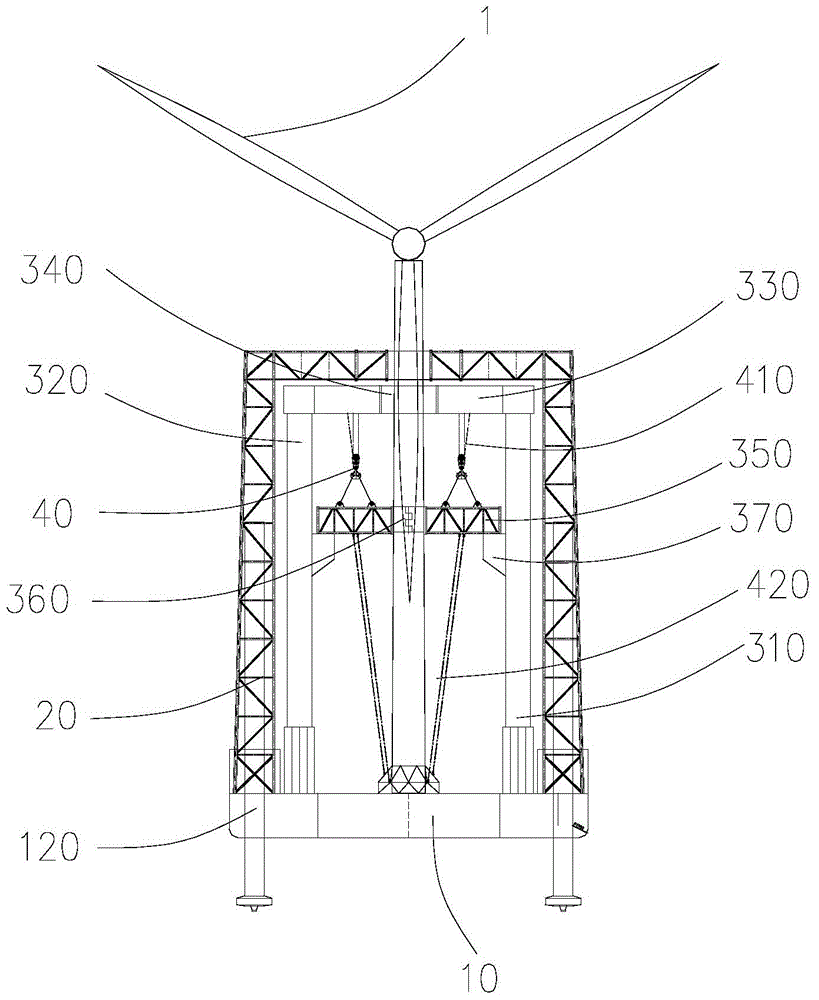

Ship special for transporting and installing whole offshore wind turbine and method

The invention discloses a ship special for transporting and installing a whole offshore wind turbine and a method. The ship special for transporting and installing the whole offshore wind turbine comprises a transporting barge, a fixed steel framework and a movable steel framework. A plurality of self-elevating piles are arranged on a main body of the transporting barge. The fixed steel framework is provided with a plurality of first wind turbine hooping mechanisms. The movable steel framework is arranged below the fixed steel framework in a sliding mode. The movable steel framework comprises a first supporting leg and a second supporting leg, wherein the first supporting leg and the second supporting leg are arranged on the two sides of the main body oppositely. Crossing supporting beams are arranged at the upper end of the first supporting leg and the upper end of the second supporting leg. A second wind turbine hooping mechanism is arranged in the middle of each supporting beam. A sliding track is arranged on the lower end face of each supporting beam and provided with a hoisting mechanism. Balance hangers are arranged below the supporting beams. Third wind turbine hooping mechanisms are arranged on the balance hangers. The hoisting mechanisms are connected with the balance hangers. A wind turbine installing notch is formed in the stern of the main body. The ship can transport and install the whole wind turbine and effectively reduce cost.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

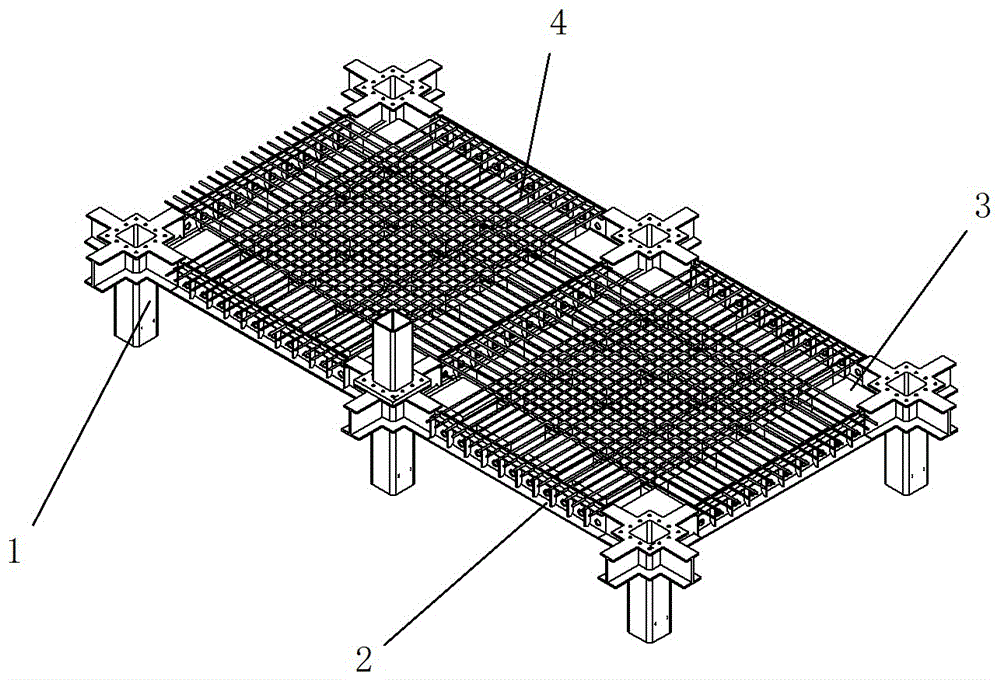

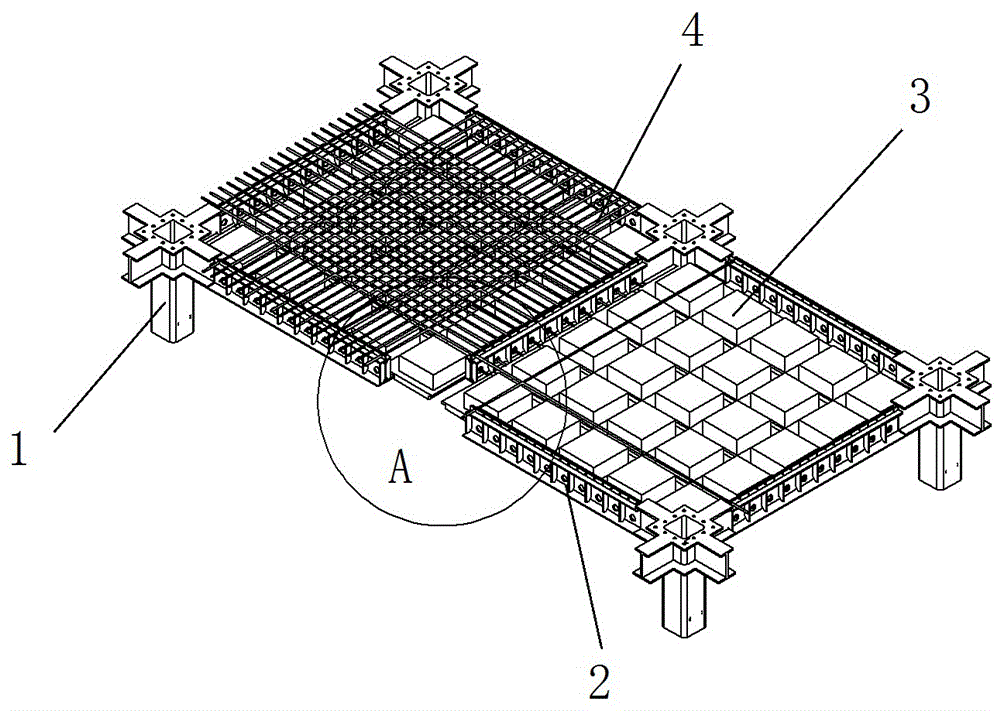

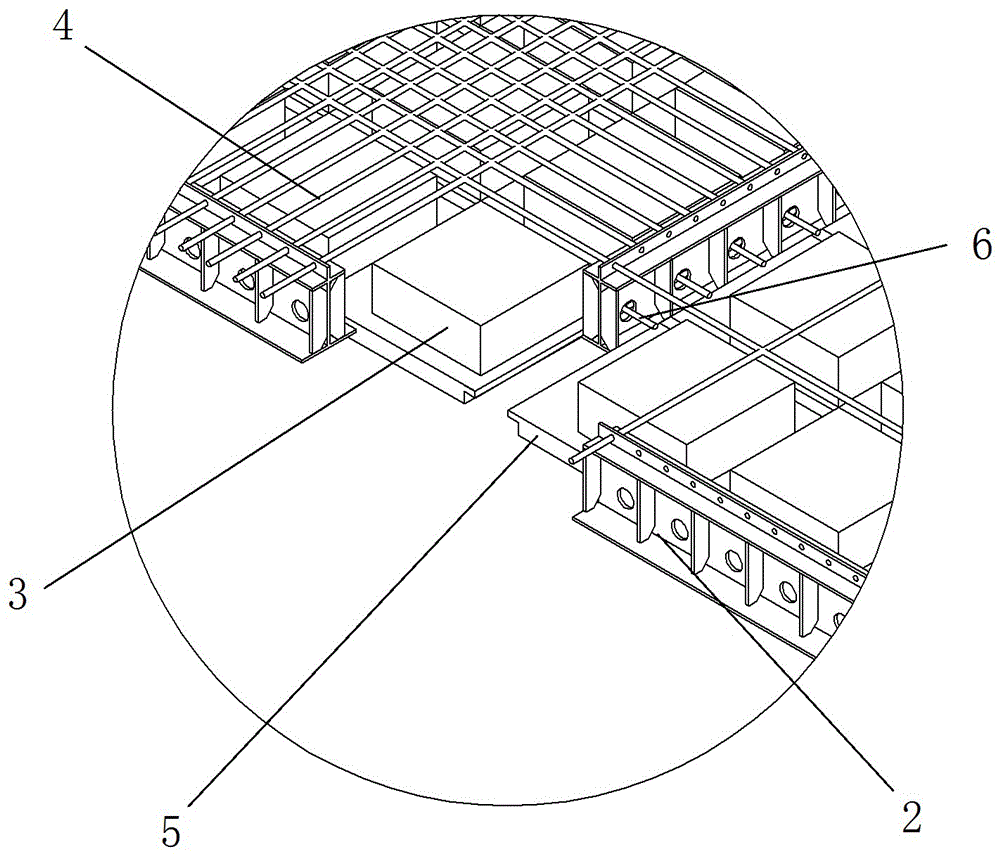

Assembly type steel structure overlapped hollow floor and construction method thereof

The invention discloses an assembly type steel structure overlapped hollow floor which comprises steel beams, prefabricated bottom slabs, ribbed beams, filling bodies and cast-in-place concrete layers. The section of each steel beam is in an H shape. Each steel beam is composed of an upper flange, a web and a lower flange, and the lower flange is wider than the upper flange. The assembly type steel structure overlapped hollow floor is good in anti-seismic performance, through the arrangement of a shear connection structure, cooperative work of the steel beams and the hollow floor can be guaranteed, due to the restriction of longitudinal ribs and hoopings in the solid areas where the steel beams intersect with the hollow floor, the effect similar to steel reinforced concrete hidden beams is achieved, and the anti-seismic performance is good.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

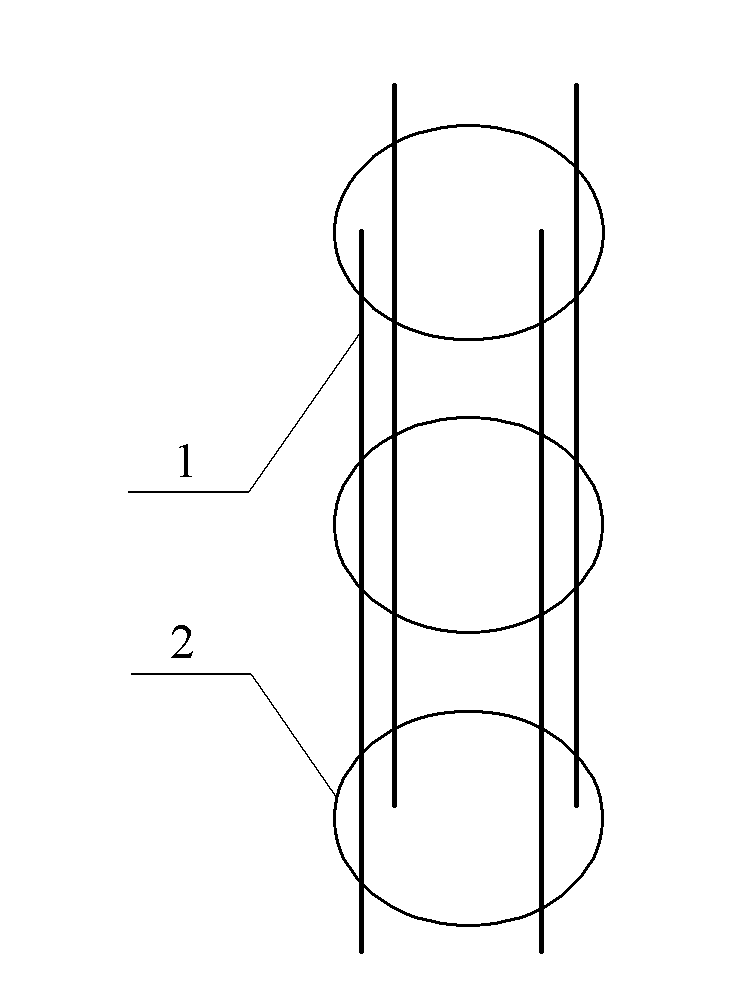

Miniature pile model used for model tests and manufacturing method thereof

InactiveCN102535530AClear deformationClarify the situationPreparing sample for investigationFoundation testingHoopingEngineering

The invention relates to a miniature pile model used for model tests and a manufacturing method thereof. The miniature pile model used for tests comprises a steel reinforcing cage and a grouting cylinder, the steel reinforcing cage comprises a plurality of longitudinal main reinforcing bars and hooping reinforcing bars, the main reinforcing bars are connected transversely through the hooping reinforcing bars, and the steel reinforcing cage is coated by the grouting cylinder, each main reinforcing bar of the steel reinforcing cage is provided with at least one strain piece, the strain pieces are provided with leads which extend out of the grouting cylinder, and at least one strain piece is arranged on the outer wall of the grouting piece. The manufacturing method of the miniature pile model includes: determining parameters of the miniature pile model, preparing the steel reinforcing cage, setting the strain pieces on the steel reinforcing cage, disposing the steel reinforcing cage into a mould, injecting grouting materials into the mould, maintaining the grouting materials to form the grouting cylinder and setting the strain pieces on the outer wall of the grouting cylinder. Internal structures of the miniature pile model and the original body are identical, and test results including failure mode and distribution law of internal force and the like of the miniature pile are more practical.

Owner:INST OF GEOMECHANICS

Intelligent detection robot system for horizontal insulator strings

ActiveCN102621430AReduce wearGuaranteed uptimeElectrical measurement instrument detailsElectrical testingHoopingControl system

The invention discloses an intelligent detection robot system for horizontal insulator strings, which comprises a plurality of crawler belt pulleys, a plurality of rotary hooping mechanisms, at least one insulator electrified detector and a plurality of falling protection mechanisms, wherein the crawler belt pulleys, the insulator electrified detectors and the falling protection mechanisms are arranged on the rotary hooping mechanisms, and the crawler belt pulleys and the rotary hooping mechanisms are connected with the control system through circuits. The crawler belt pulleys and the rotary hooping mechanisms are integrated together and surround the insulators uniformly when a robot runs by 120 degrees, the robot can detect distribution of insulator string electric field intensity automatically and identifying whether the insulators are in good conditions when running by carrying the electric-field type insulator detectors. The horizontal insulator string intelligent detection robot system is compact in structure, stable in crawling, low in abrasion to the insulators, safe and reliable in running and capable of electrically detecting horizontal insulator strings, and at most three insulators are in short circuit.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

Precast U-shaped plate pile with mixed structure of steel and concrete

The invention discloses a precast U-shaped plate pile with a mixed structure of steel and concrete. The U-shaped plate pile comprises reinforced concrete and a steel structure which is combined with the reinforced concrete; the cross section main body of a plate pile is in a U shape; a stressed steel bar of a pile body is a prestressed steel bar or a common steel bar; a hooping and a waist steel bar are arranged on the pile body; the U-shaped plate pile is characterized in that a T-shaped through slot is arranged in one side of a lower flange of the plate pile; the direction of the T-shaped through slot is along the length of the pile body; the other side of the lower flange is combined with an inverted H-shaped steel bar; half of the inverted H-shaped steel bar is left outside the pile body structure, and the other half of the inverted H-shaped steel bar is embedded in the internal part of the pile body structure. When sunken construction of plate pile is conducted, the adjacent plate piles are firstly assembled integrally through the inverted H-shaped steel bar and the T-shaped through slot, and then the piles are sunken by machines. The U-shaped precast plate pile provided by the invention has the characteristics of convenient in construction, reliable in connection, good in water sealing effect and saves construction period and the like. If the plate pile is used as a temporary structure, after the construction is completed, the inverted H-shaped steel bar can be recycled and reused.

Owner:SHANGHAI ZHONGJI PILE IND +1

Heat conductivity tester

The invention relates to a heat conductivity tester which comprises a rack, a heating module, a cooling module and a measuring module, wherein the heating module is arranged at the upper-middle part of the rack, the cooling module is arranged at the lower-middle part of the rack, a loading module is arranged at the top of the rack and is used for loading and pressing the top surface of the heating module, the measuring module comprises thermocouples embedded in the heating module and the cooling module, the heating module and the cooling module are sheathed in heat insulation devices (21) which are locked and fixed through a fastening device (10), the fastening device (10) comprises two hooping members, one sides of the two hooping members are connected through a hinge, and the other sides of the two hooping members are detachably connected. The heat conductivity tester provided by the invention is simple in structure, convenient to install and easy to maintain.

Owner:SHENZHEN KAIFA TECH

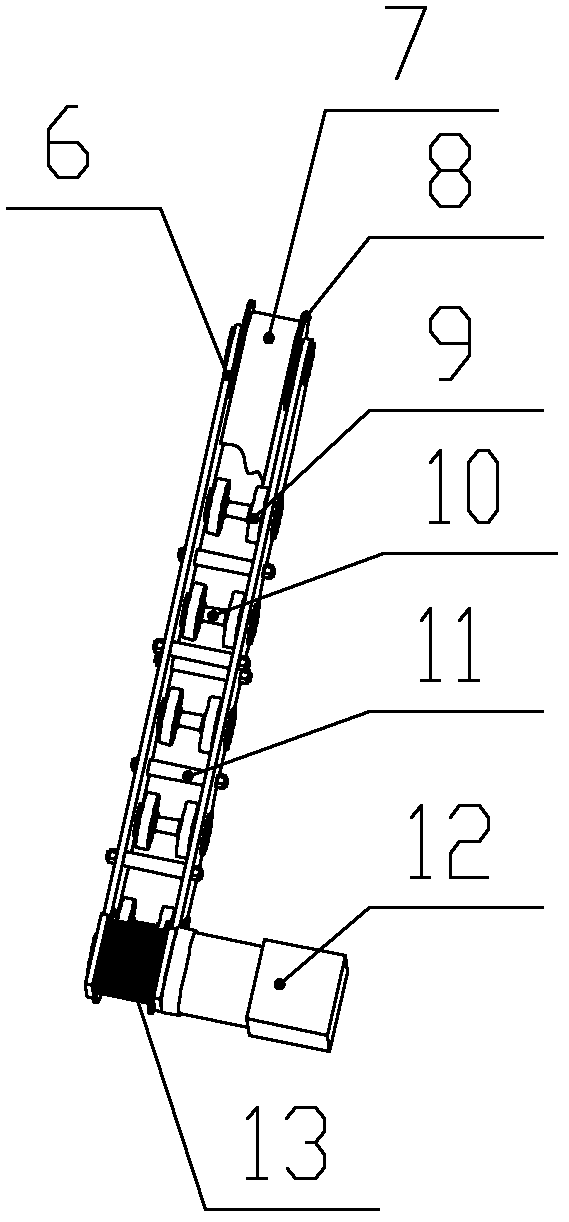

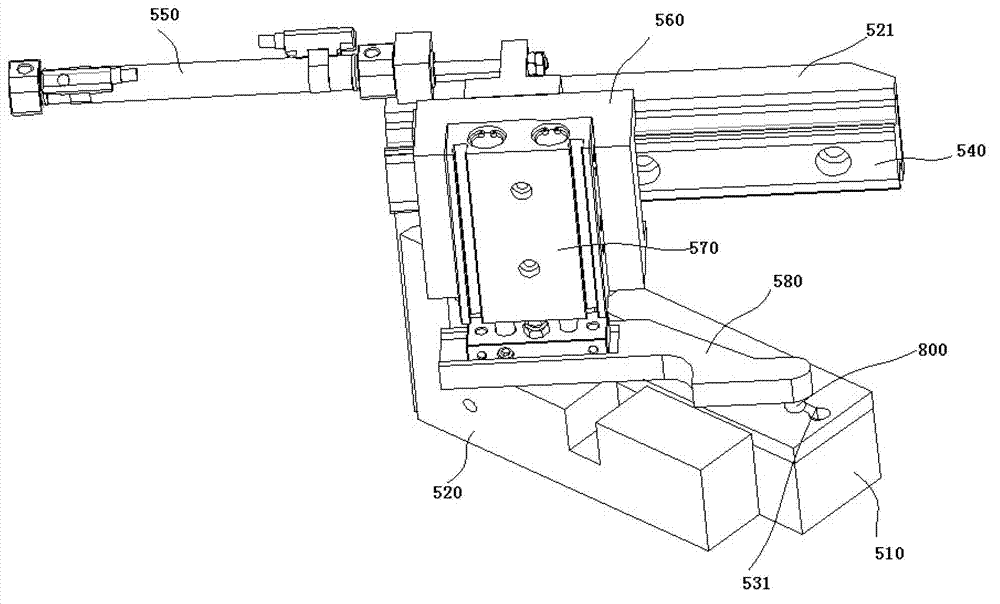

Clamping and returning bending mechanism on automatic hoop bending machine for steel bars

The invention discloses a clamping and returning bending mechanism on an automatic hoop bending machine for steel bars. The clamping and returning bending mechanism is positioned on one side of a bending mechanism on the automatic hoop bending machine for the steel bars, and comprises a guide rail and a clamping base plate, wherein the bottom of the guide rail is fixed on a frame; one side surface of the clamping base plate is arranged on the upper part of the guide rail in a sliding fit mode; a steel bar clamping mechanism is arranged on the other side surface of the clamping base plate; and the clamping base plate is connected with a reciprocation driving unit driving the clamping base plate to move. The invention has the advantages that: the other end of a steel bar sheared by a shearing mechanism is bent, namely products that two ends of the steel bar have the same shape can be rapidly bent at one time simultaneously, and the production requirement is met; the bending mechanism is simple in structure, low in cost and high in adaptability and can be matched with the automatic hoop bending machine for the steel bars and other equipment with a bending mechanism; the function of the hoop bending machine is expanded, so that a lot of hooping products can be machined by the clamping and returning bending mechanism; and the bending mechanism can bend coiled steel bars and also can rapidly bend straight steel bar-molded hooping products general for engineering.

Owner:TJK MACHINERY TIANJIN

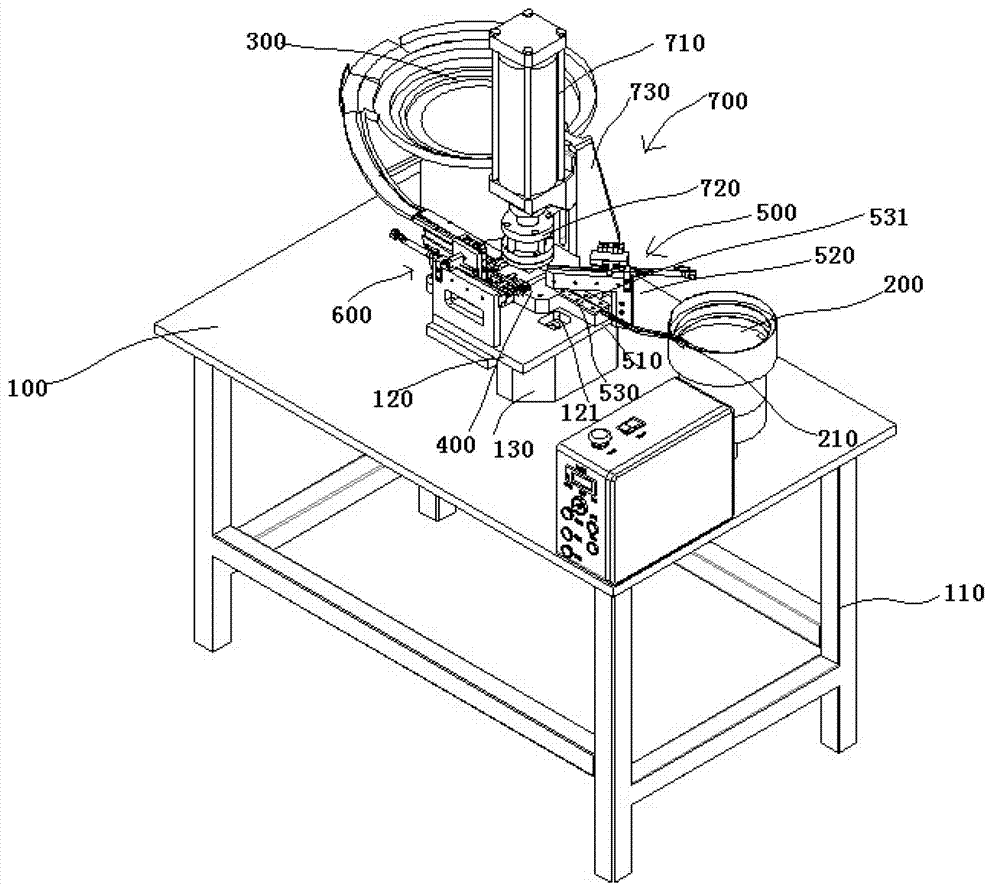

Method and device for automatically riveting static reed and contact of contactor

The invention discloses a method for automatically riveting a static reed and a contact of a contactor. The method comprises the steps of 1) sending the contact into a riveting cavity inside a riveting die in such a way that a handle head is located on the lower side; 2) sending the static reed into the riveting die, and sleeving a riveting hole on the static reed on a riveting stud of the contact; 3) exerting a first pressing force on the static reed, pre-pressing the static reed on a nail head of the contact; 4) exerting a second pressing force on the contact to rivet the riveting stud into a riveting head; and 5) discharging. According to the method, air cylinder riveting is adopted, and simultaneously, a cylinder body is moved to conduct pre-pressing, material hooping and material separating, so that the riveting firmness of the contact is high, and the consistency is good.

Owner:上海特德电气有限公司

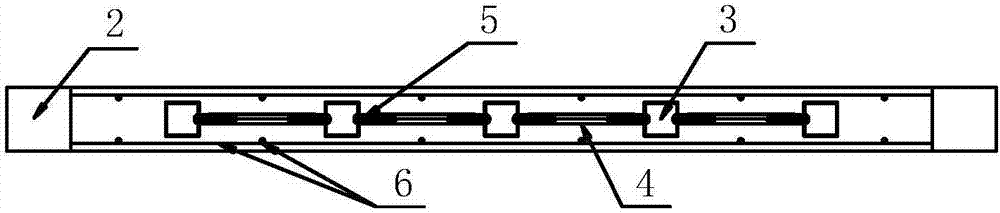

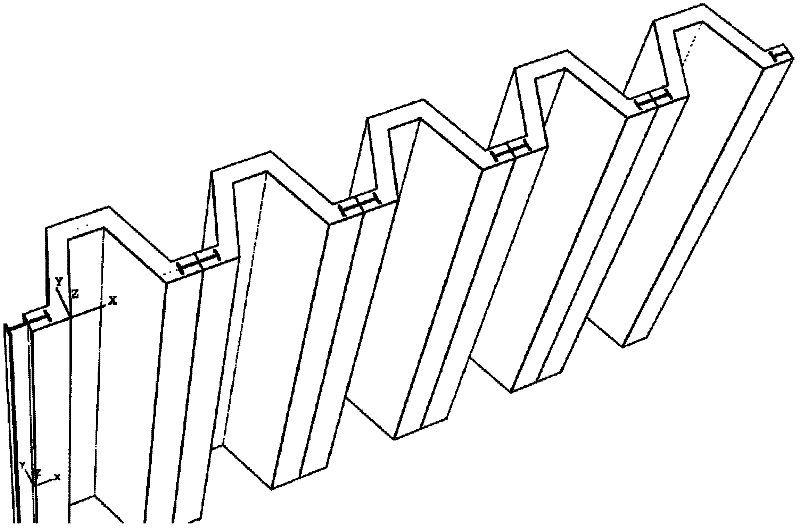

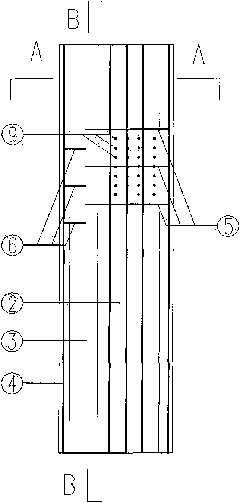

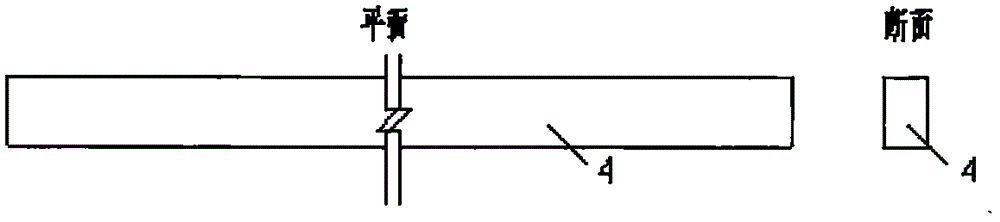

Hooping cold bending punch forming module

The invention discloses a hooping cold bending punch forming module, comprising an upper module and a lower module. The upper module has the structure that a semi-cylinder film is fixed below an upper bottom plate. The lower module has the structure that the two sides of the semi-cylinder film corresponding to the upper bottom plate on a lower bottom plate, the two edges of which are provided with concave platforms, are respectively provided with a right-angled punching mould; the concave platforms arranged at the two edges of the lower bottom plate are respectively fixedly connected with a vertical rod which is parallel with punching slide block vertical plates; the middle parts between the each vertical rod and the punching slide block vertical plates are respectively connected with screw rods; the outer side of the each punching slide block mould is respectively symmetrically provided with two strip adjusting screw holes; the each adjusting screw hole is respectively internally provided with a screw which is matched with the tightness of top screw holes; the lower step of the each punching slide block is respectively provided with a bolt which is connected with the lower bottom plate through a strip positioning hole; an arc transition special steel mould is respectively fixed on the corner of the each punching slide block; and a neck pressing positioning plate is horizontally fixed at the top end of one vertical rod. The punching equipment hoops with high work efficiency and no environment pollution.

Owner:XINXIANG POWER SUPPLY COMPANY STATE GRID HENAN ELECTRIC POWER

Multi-cavity steel tube concrete superposed column and preparation method thereof

ActiveCN101824878AImprove carrying capacityImprove stabilityStrutsBuilding reinforcementsHoopingSheet steel

The invention relates to a superposed column, particularly to a multi-cavity steel tube concrete superposed column and a preparation method thereof. The superposed column is prepared by the steps of: welding a steel plate and a steel tube, which are preprocessed with holes, vertically to obtain a multi-cavity steel tube; welding rivets on the external wall of the multi-cavity steel tube; binding a steel mesh formed by longitudinal steel bars and hoops on the outside of the multi-cavity steel tube; and supporting a template and pouring concrete to form the multi-cavity steel tube concrete superposed column, the inside of which is a multi-cavity steel tube concrete column and the outside of which is reinforced concrete. The superposed column solves the disadvantage that the hooping effect is reduced due to an oversize steel tube in a large-sized steel tube concrete superposed column. Moreover, compared with the traditional superposed column, the superposed column has much more flexible and diverse section forms, and thus the functions of a building can be fully utilized and the usable floor area is increased without lowering the carrying capacity of the superposed column.

Owner:BEIJING UNIV OF TECH

Bridge jacking counter-force device suitable for narrow and small space between beam bottom and cover beam

InactiveCN105735149AAvoid secondary damageSpeed up the installation processBridge erection/assemblyBridge strengtheningHoopingMaterial resources

The invention discloses a bridge jacking reaction force device suitable for the narrow space between the bottom of the beam and the cover beam. The platform structure on the side, the high-strength bolt hoop used to connect the load-bearing beam and the platform structure, and the clamping device used to fix the entire device and the cover beam. The two load-bearing beams cross the narrow gap between the beam slab and the cover beam, the load-bearing beams are reliably connected to the platform structure through high-strength bolt hoops, and the entire reaction force device is reliably connected to the cover beam through the clamping device. The jack is placed on the platforms on both sides and the bridge jacking operation can be carried out. The bridge jacking device of the present invention has the advantages of small self-weight, high bearing capacity, and wide application range. It can save a lot of manpower and material resources when used in the jacking of hollow slab bridges in the narrow space between the beam bottom and the cover beam.

Owner:CCCC ROAD & BRIDGE BEIJING TECH CO LTD

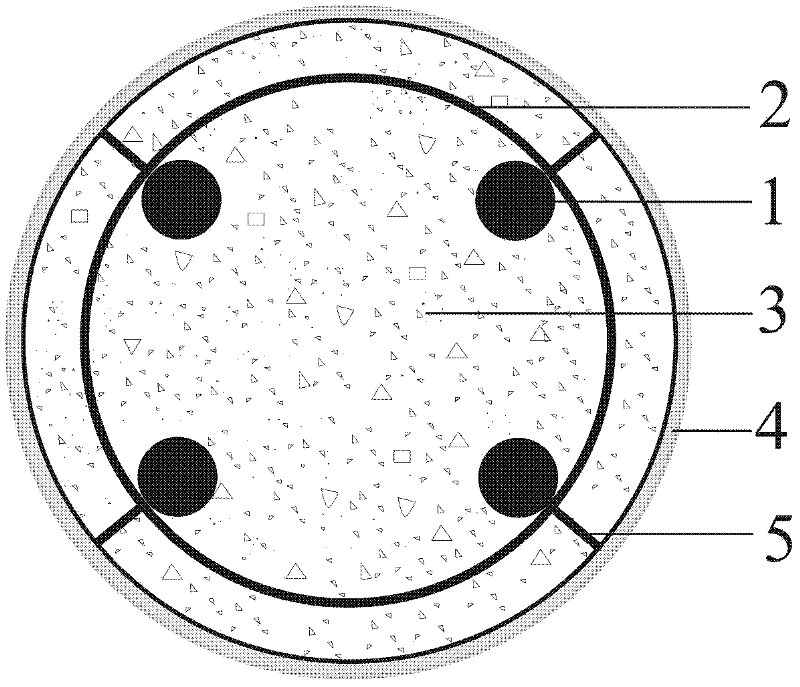

Fiber reinforced plastics-steel composite pipe restricted structural steel high-strength concrete column

InactiveCN102108761AIncreased durabilityReduce steel consumptionStrutsBridge structural detailsHigh strength concreteHooping

The invention discloses a fiber reinforced plastics-steel composite pipe restricted structural steel high-strength concrete column, which comprises longitudinal bars, hoopings, high-strength concrete, a structural steel and a fiber reinforced plastics-steel composite pipe; the longitudinal bars are distributed in the height direction of the column, the circular hoopings are sleeved in the height direction of the longitudinal bars, the structural steel is distributed in the hoopings along the height direction of the column, and the fiber reinforced plastics-steel composite pipe is sleeved outside of the hoopings in the height direction of the column; the fiber reinforced plastics-steel composite pipe is composed of a steel pipe used as an inner wall and a fiber reinforced plastics pipe used as an external wall, high-strength solid concrete is poured in the fiber reinforced plastics-steel composite pipe, and the fiber reinforced plastics-steel composite pipe is broken at two ends of the column. With the column provided by the invention, the axial compression ratio and the seismic performance of the structural steel high-strength concrete column are improved, and the endurance quality of the steel pipe restricted structural steel high-strength concrete column is also improved; and problems, such as high dosage of steel, troubles in connection with reinforced concrete beams, and the like, of the steel pipe structural steel high-strength concrete column are solved.

Owner:DALIAN UNIV OF TECH

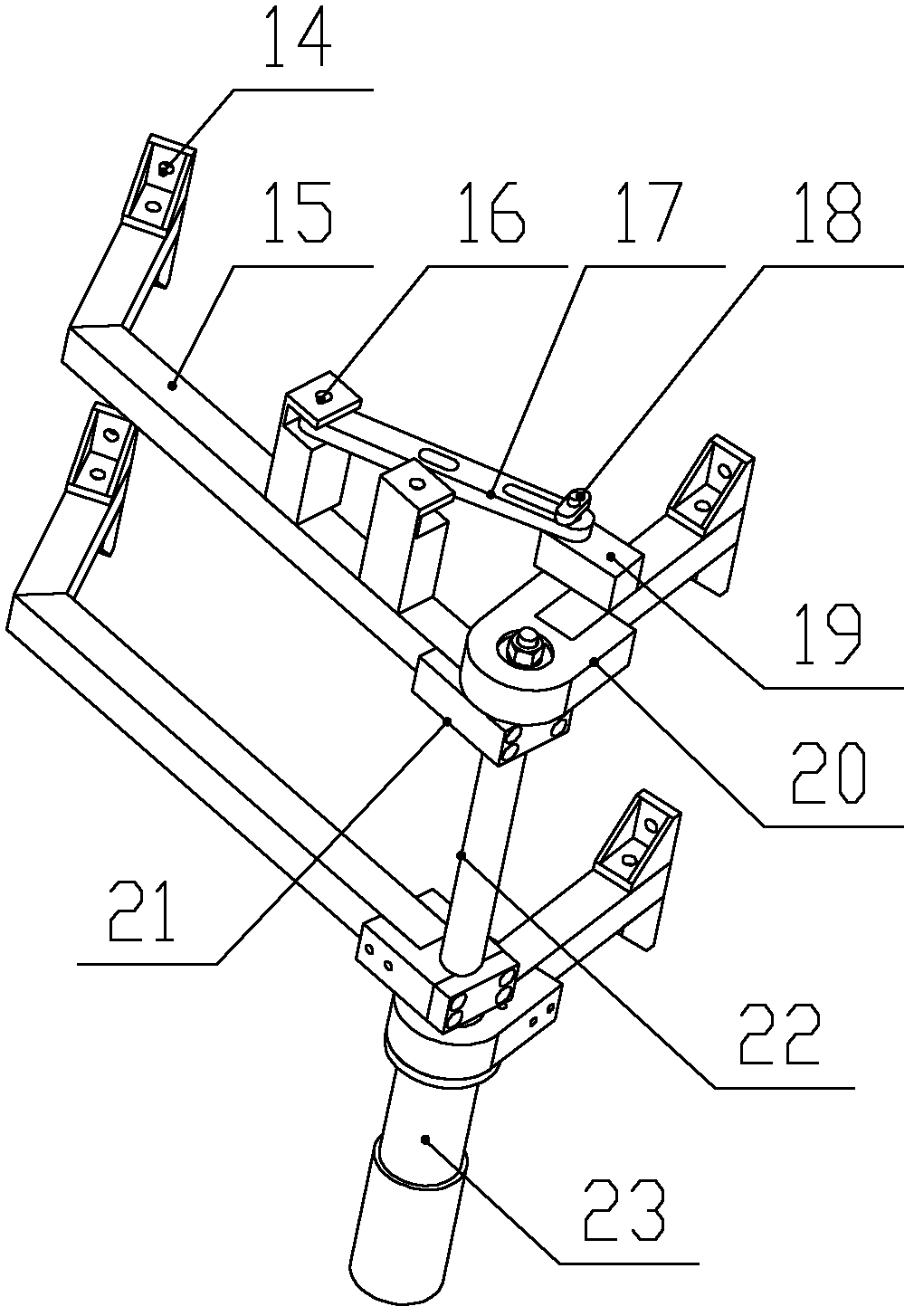

Multi-finger hooping and elastic shifting rod cluster adaptive robot hand device

InactiveCN105619441AAchieve multi-directional grip effectImplement adaptive crawlingGripping headsHoopingRobot hand

A multi-finger hooping and elastic shifting rod cluster adaptive robot hand device belongs to the technical field of robot hands. The multi-finger hooping and elastic shifting rod cluster adaptive robot hand device comprises a chassis, a driver, a plurality of fingers, a porous elastic block, a plurality of sliding push rods and a spring component. The device comprehensively realizes a discrete space adaptive grabbing function by adopting the chassis, the driver, the porous elastic block, the plurality of fingers, the plurality of sliding push rods and the like, realizes an object size and shape adapting function by utilizing the plurality of sliding push rods, and realizes a multi-directional object grabbing effect by utilizing the driver and a driving mechanism to drive the fingers to extrude the porous elastic block or slide the push rods and gathering the plurality of sliding push rods towards the center of the device. The device can effectively grab objects which are in various shapes and are placed in different directions, is simple in structure as only one set of rod cluster is needed, easily achieves a grabbing purpose by gathering the plurality of sliding push rods towards the center of the device through the hooping movement of the fingers, and is low in energy consumption.

Owner:TSINGHUA UNIV

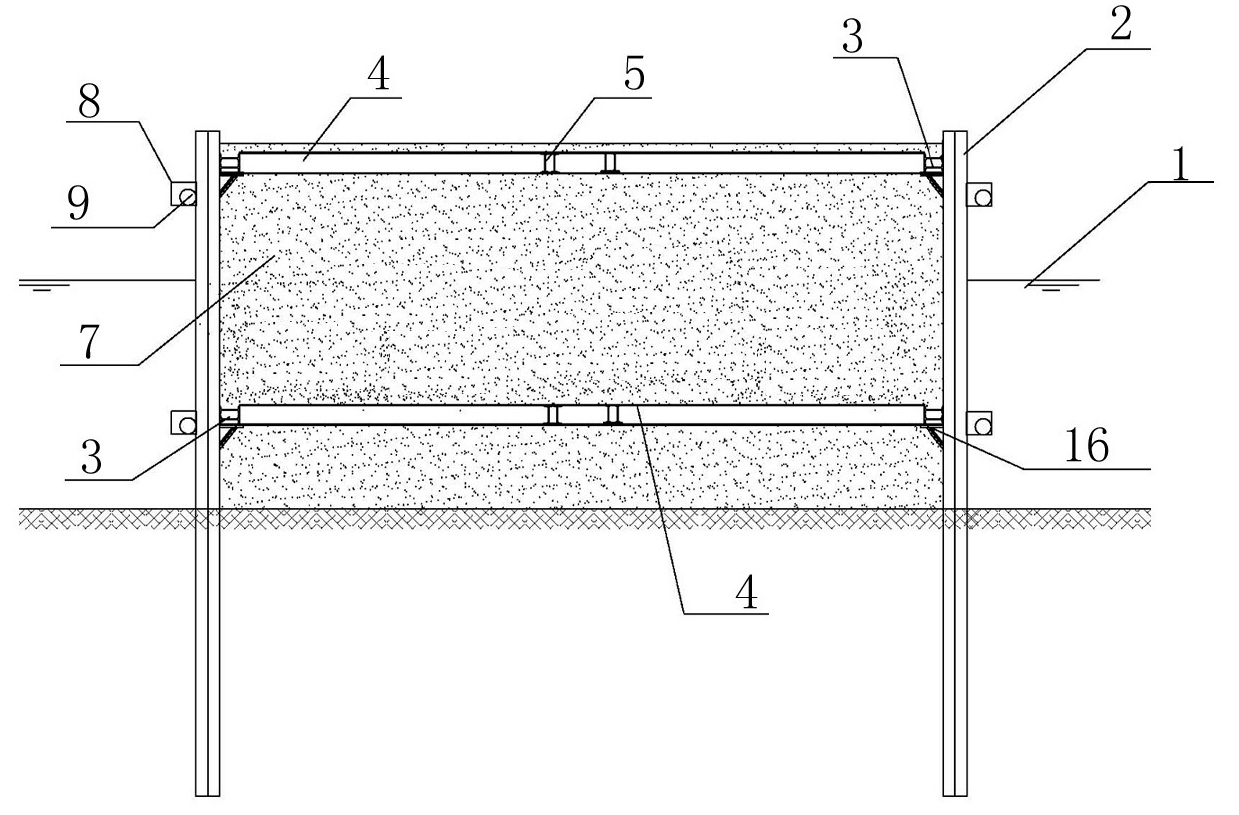

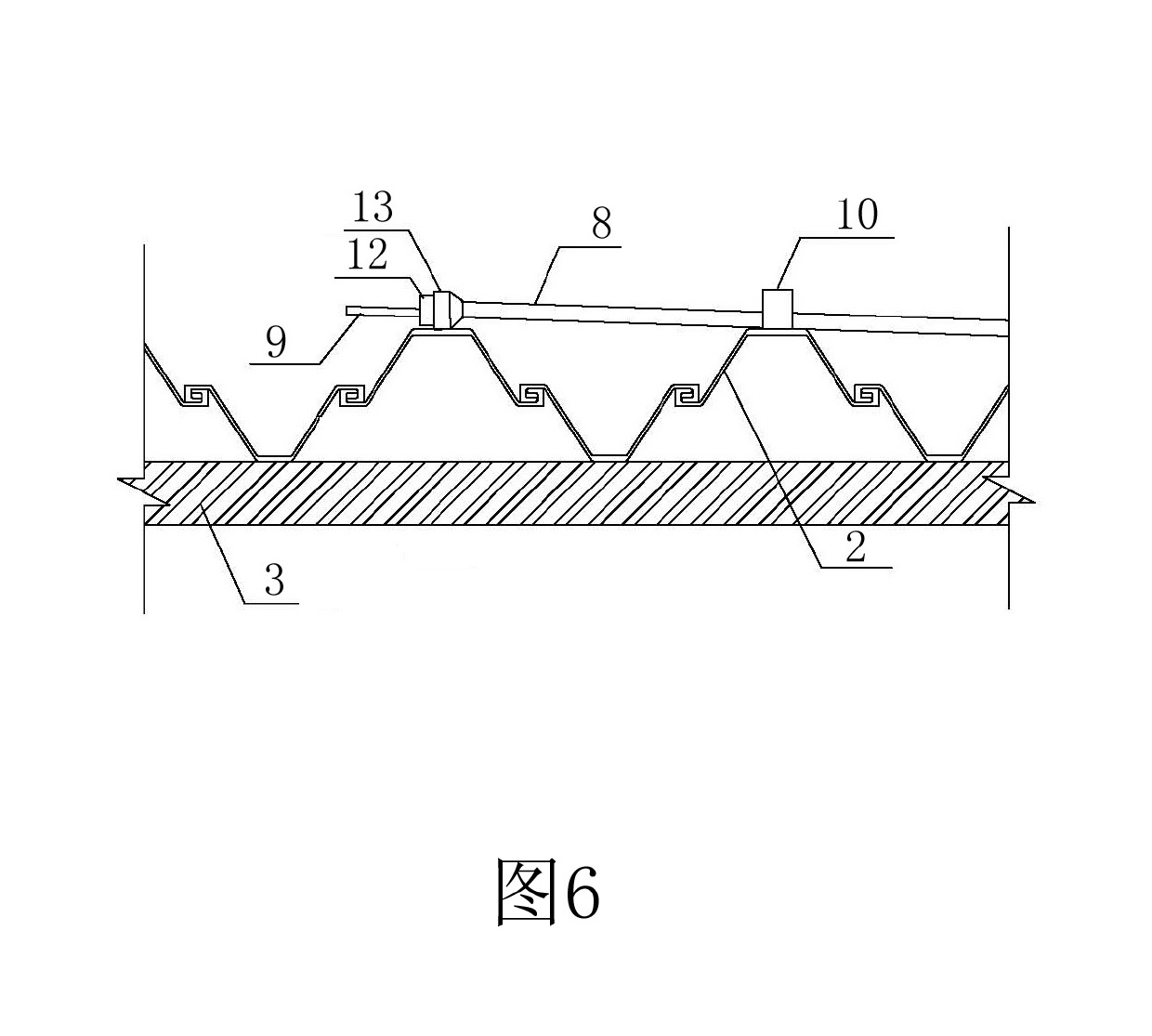

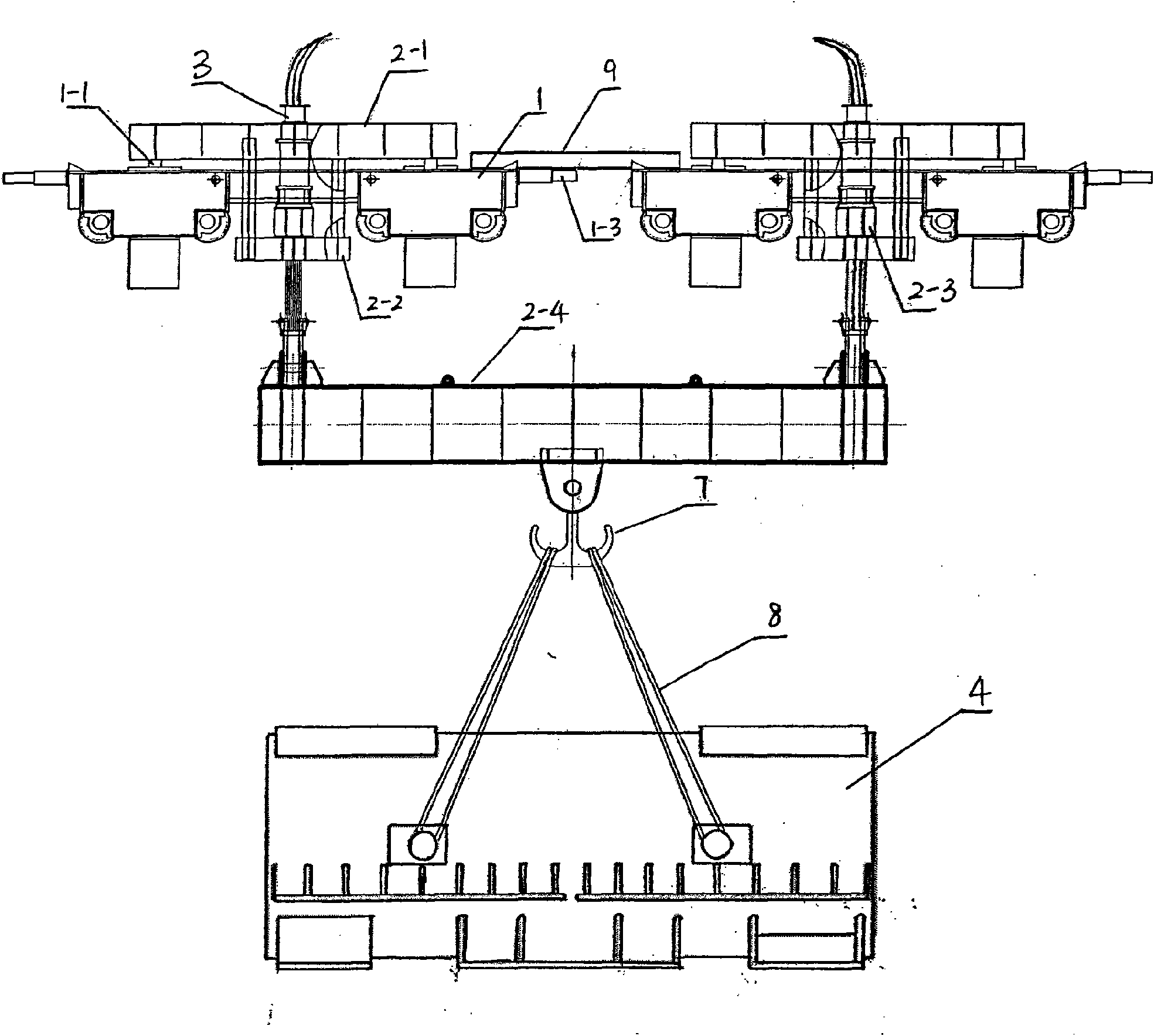

Hooping type steel sheet pile cofferdam platform and integrated construction method depending on cofferdam platform

The invention relates to a hooping type steel sheet pile cofferdam platform and an integrated construction method depending on the cofferdam platform. Fillers are filled in the inner space of a cofferdam; at least two circles of steel tendons are arranged around the periphery of the cofferdam; one end of each steel tendon is fixed on an anchor bearing plate at the fixed end through an anchor device at the fixed end, and the other end of each steel tendon is fixed on an anchor bearing plate at the stretching end through an anchor device at the stretching end; and the steel tendons also pass through a positioning ring which is fixed at the convex part of the periphery of a steel sheet pile. By additionally providing facilities and measures for reinforcing the steel sheet pile cofferdam, the construction of the underwater pile foundation can be finished only depending on the steel sheet pile cofferdam required for the platform construction under the condition that a waterborne overhead pile drilling platform does not need to be arranged, and the integrated construction of the platform can be finished only depending on the steel sheet pile cofferdam arranged in the construction of the underwater pile foundation without additionally arranging a steel sheet pile cofferdam. The method of the invention has the advantages of saving the overall cost of the engineering, shortening the construction period, reducing the unsafe factors in construction, saving the energy, reducing the emission, and the like. The invention can be widely applied to construction of engineering, such as underwater bridges, wharfs, and the like.

Owner:GUANGDONG GUANYUE HIGHWAY & BRIDGE

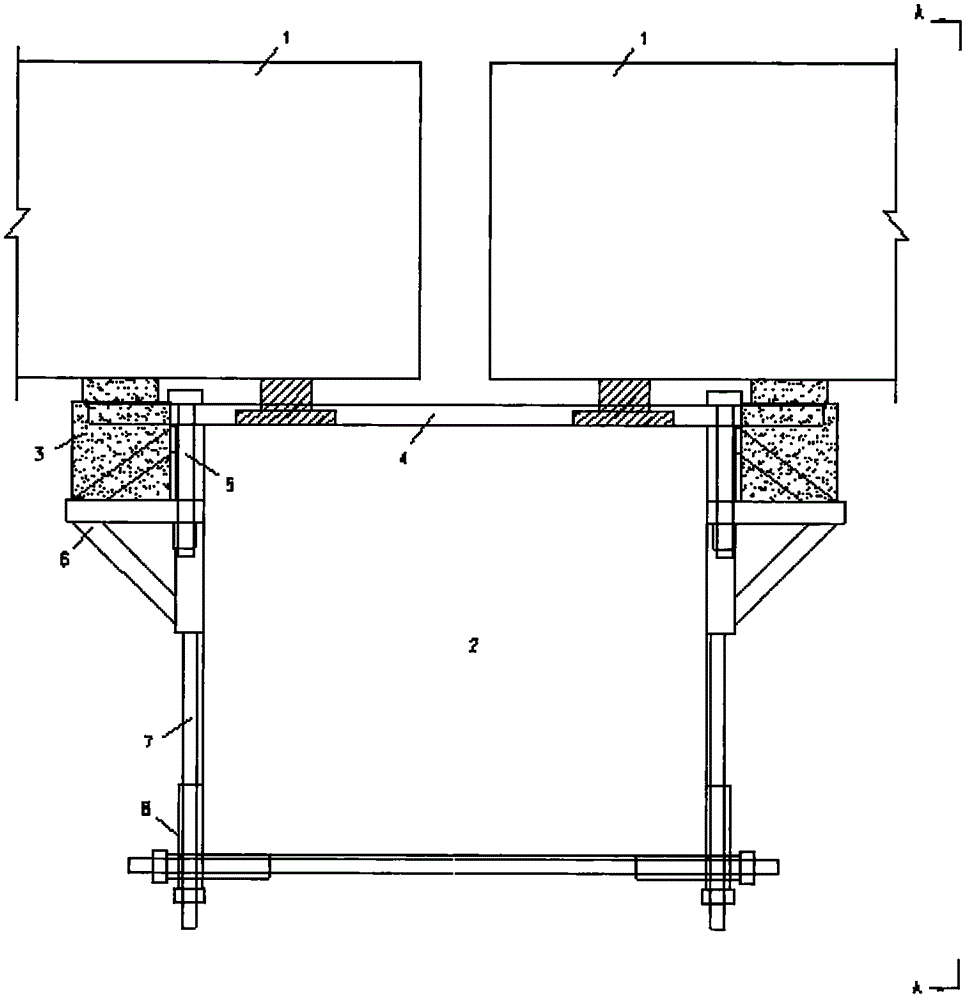

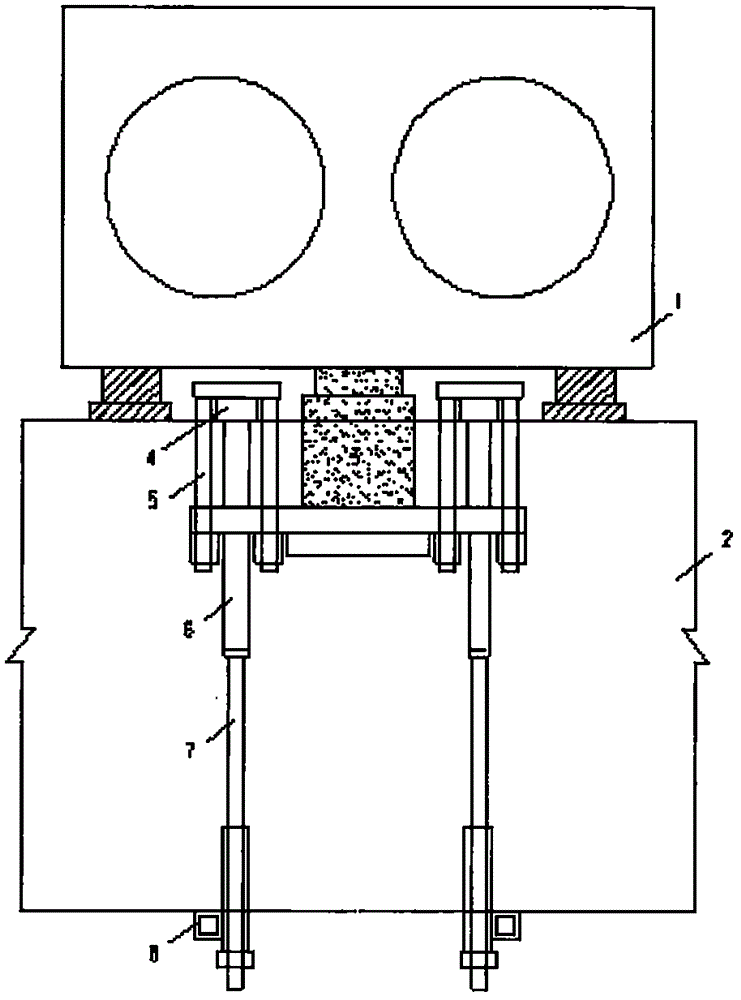

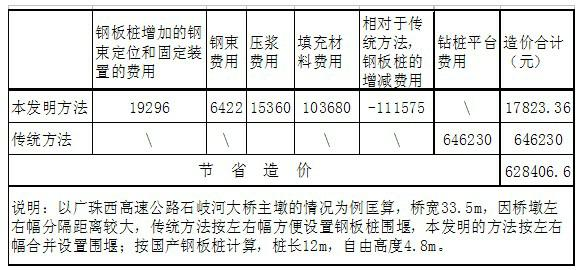

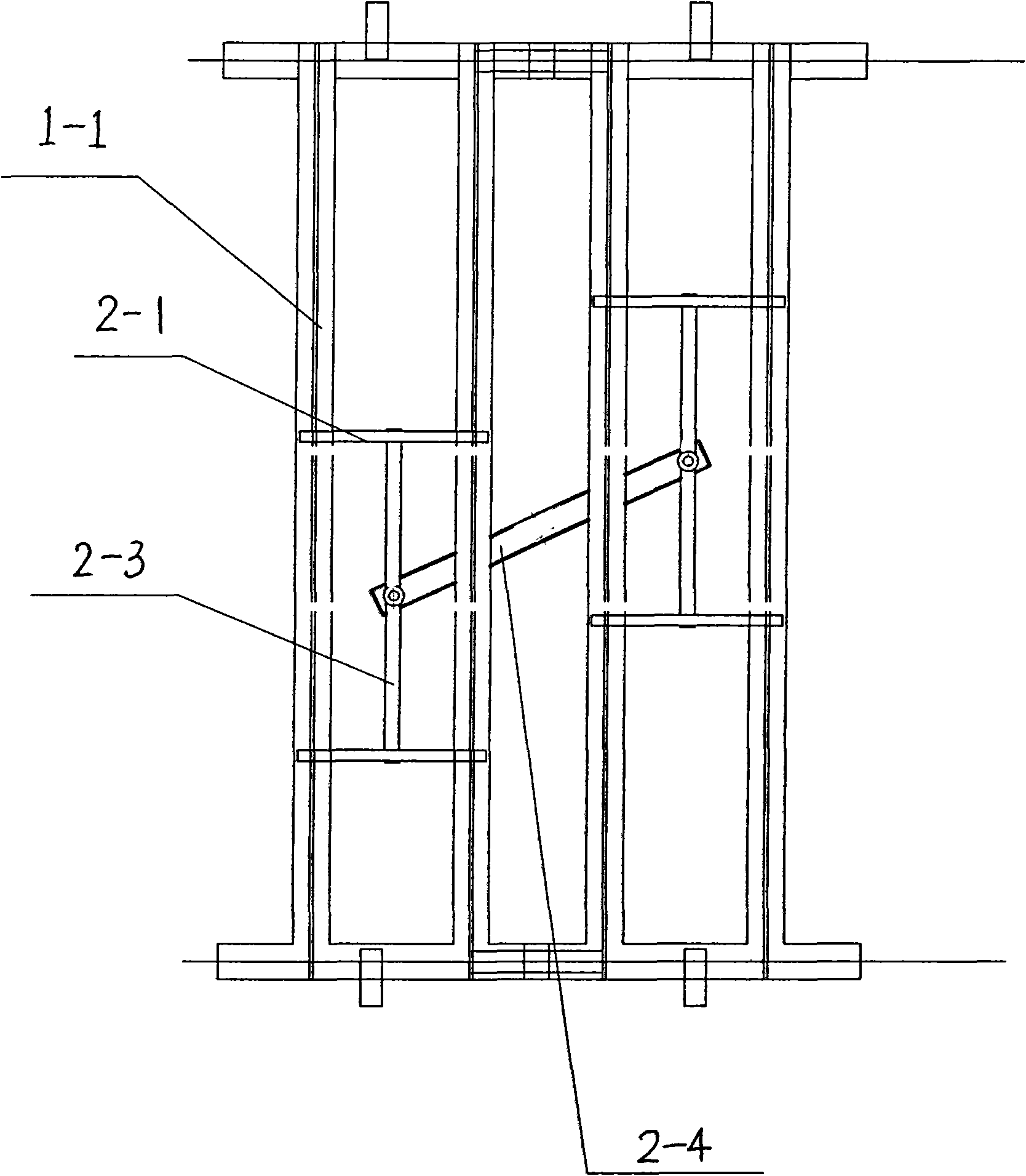

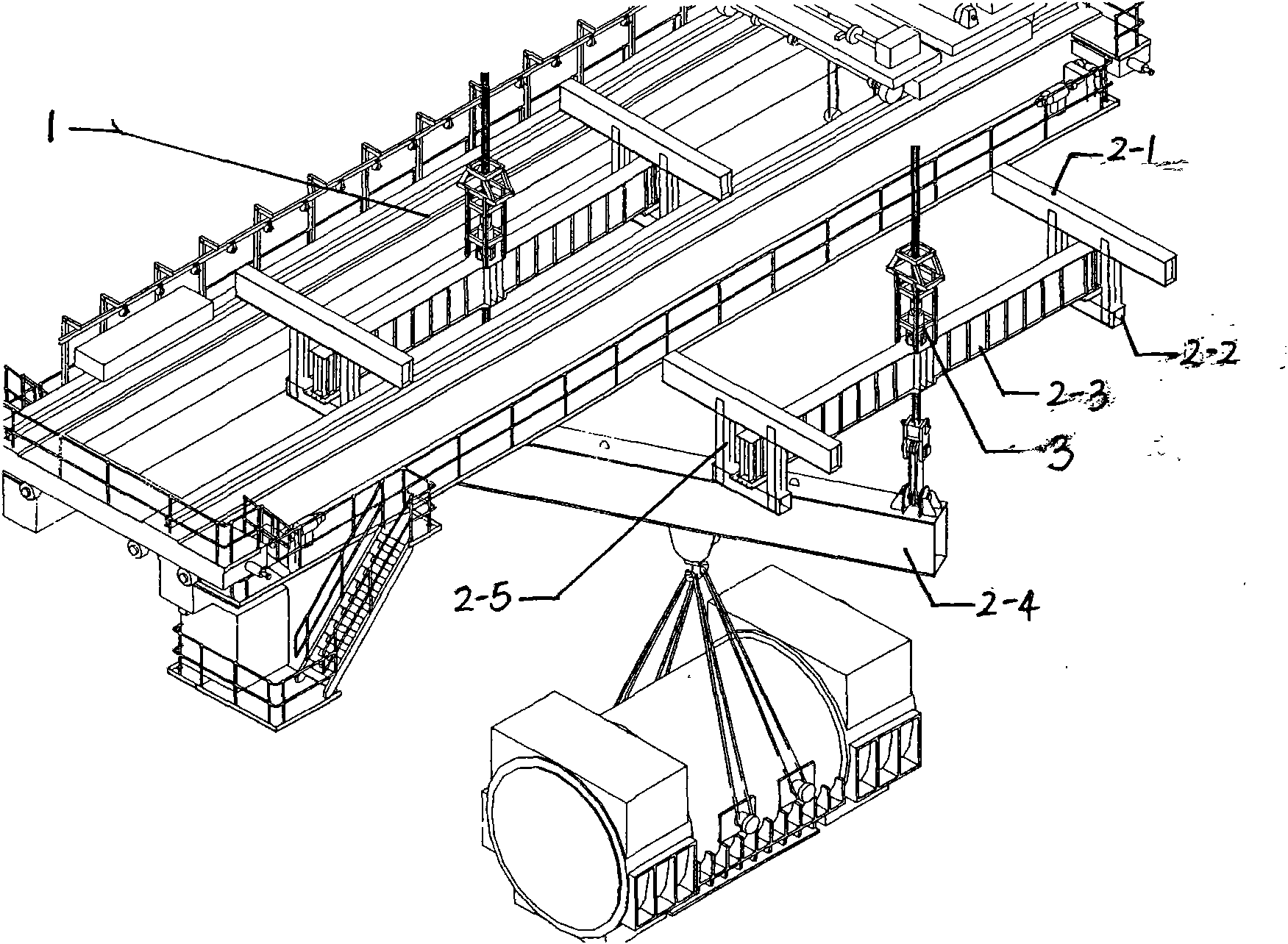

Hoisting method of machine set generator stator and special mechanism thereof

InactiveCN101624164AImprove bending abilityOptimize layoutTravelling cranesWinding mechanismsHoopingEngineering

The invention relates to a hoisting method of a machine set generator stator and a special mechanism thereof, which is characterized in that an assistant beam frame structure (2) is in bridge joint on two travelling crane rails (1-1) of two 80-ton travelling crane mechanisms (1) in a main factory, and a hydraulic pressure hoisting device (3) is arranged on the assistant beam frame structure (2); thus, the travelling crane rails change from one-point stress into multi-point stress or region stress so as to improve the anti-bending ability of the travelling crane rails. The invention dispenses with extra hanger frames, a girder of the travelling crane dispenses with re-hooping, and a dolly of the travelling crane dispenses with dissembling and is suitable for installation and stator maintaining and hoisting operations of 300MW-firepower machine set generator stators in China; the invention has the benefits of simple arrangement, short operation time, no need of deferred installation of the main factory structure and quick and safe hoisting operation.

Owner:GUANGDONG POWER ENG

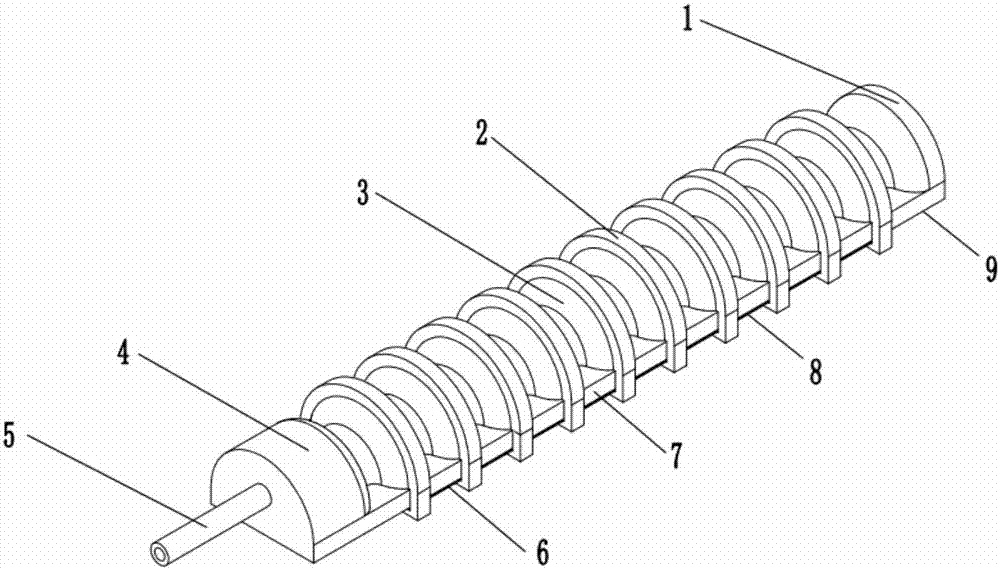

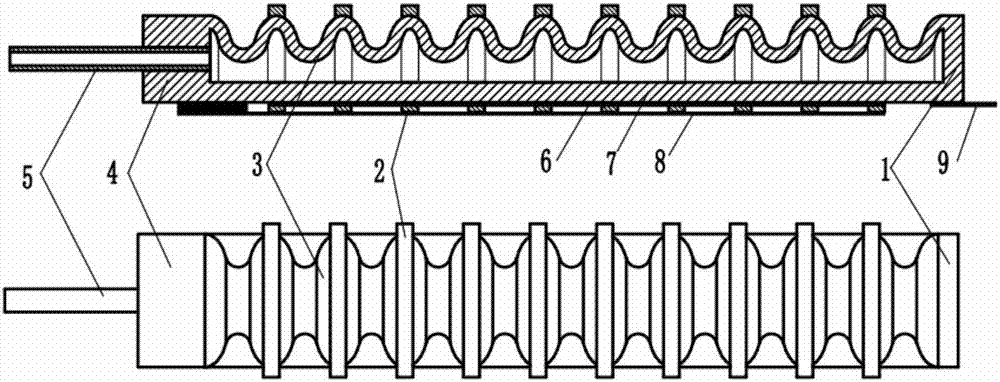

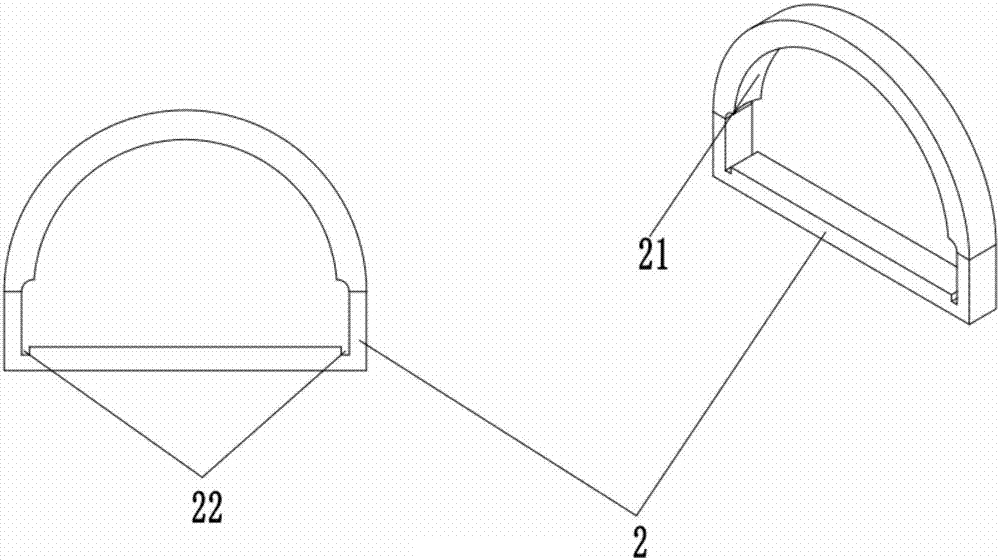

Wearable hooped pneumatic air inflation bent flexible actuator

PendingCN107088884AImprove flexibilityHigh affinityChiropractic devicesManipulatorHoopingEngineering

The invention discloses a wearable hooped pneumatic air inflation bent flexible actuator which comprises a front end cover, a tail end cover, an upper-side corrugated structure, a bottom layer, hoops, ropes and a hose. The front end cover and the tail end cover are located at the two ends of the corrugated structure correspondingly, and the bottom layer is located at the lower end of the corrugated structure. A cavity structure with the interior in a corrugated shape is formed by the front end cover, the tail end cover, the corrugated structure and the bottom layer. Each hoop is of a semicircular structure, and the hoops are arranged at the wave crest positions of the corrugated structure and the outer portion of the bottom layer in a hooping and sleeving manner. The ropes are mounted at the two ends of the lower end of the bottom layer, and the length direction of the ropes is consistent with the axial direction of the corrugated structure. The hose is mounted on the front end cover and communicates with an inner cavity of the corrugated structure. The front end cover, the tail end cover and the corrugated structure are each made of an elastic material. The actuator has good flexibility and is high in pressure bearing capacity, large in tail end output force and especially suitable for the field of medical rehabilitation.

Owner:NANJING UNIV OF SCI & TECH

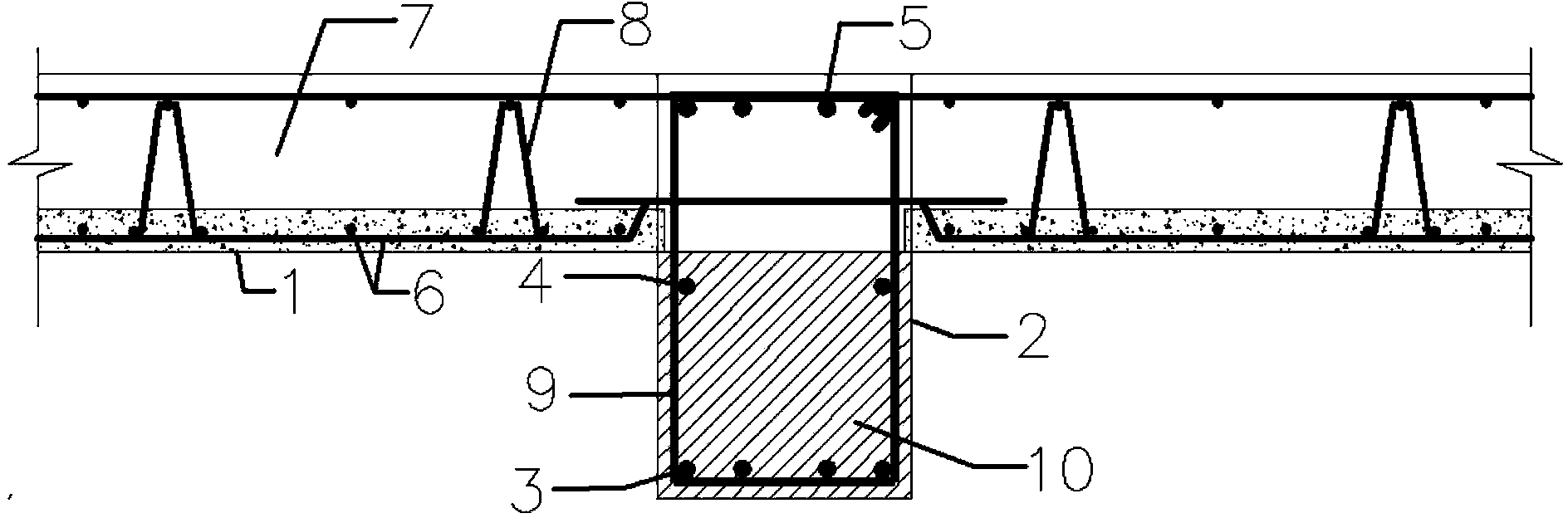

Method of splicing laminated floor slab and beam

The invention discloses a method of splicing a laminated floor slab and a beam. The method comprises the following steps of providing a precast slab, a beam, a lower longitudinal bar of the beam, a middle longitudinal bar of the beam, an upper longitudinal bar of the beam, a reinforcing steel bar at the slab bottom, an additional reinforcing steel bar at the slab top, a truss bar and a hooping; pouring the beam at two times, wherein the first pouring height is a difference between the beam depth and the thickness of the slab, and only binding the lower longitudinal bar of the beam, the middle longitudinal bar of the beam and the hooping in the beam during the pouring; when cast-in-place concrete reaches a certain intensity, hoisting the precast slab, placing slab edges at the side of the beam, and extending the reinforcing steel bar at the slab bottom into the beam; lastly, adding the upper longitudinal bar of the beam and the additional reinforcing steel bar at the slab top, and casting the concrete in place again so as to complete construction of the beam and the slab. According to the method described by the invention, the reinforcing steel bar at the edge of the slab can be accurately anchored in the beam so as to meet requirements of current specifications of nation, and the method has the advantages of simple construction and reasonable stress.

Owner:NANJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com