Patents

Literature

1358results about How to "Improve bending ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

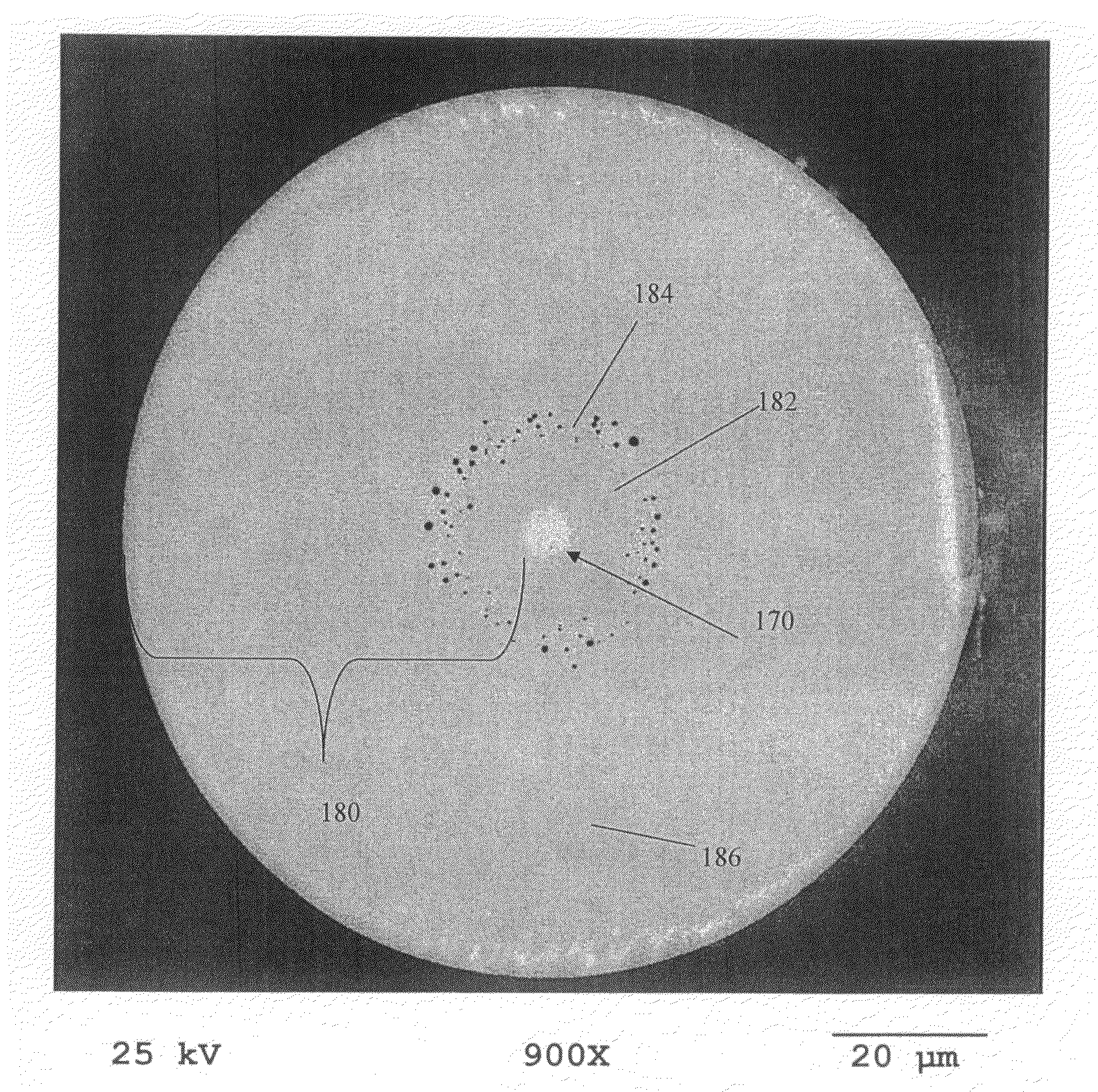

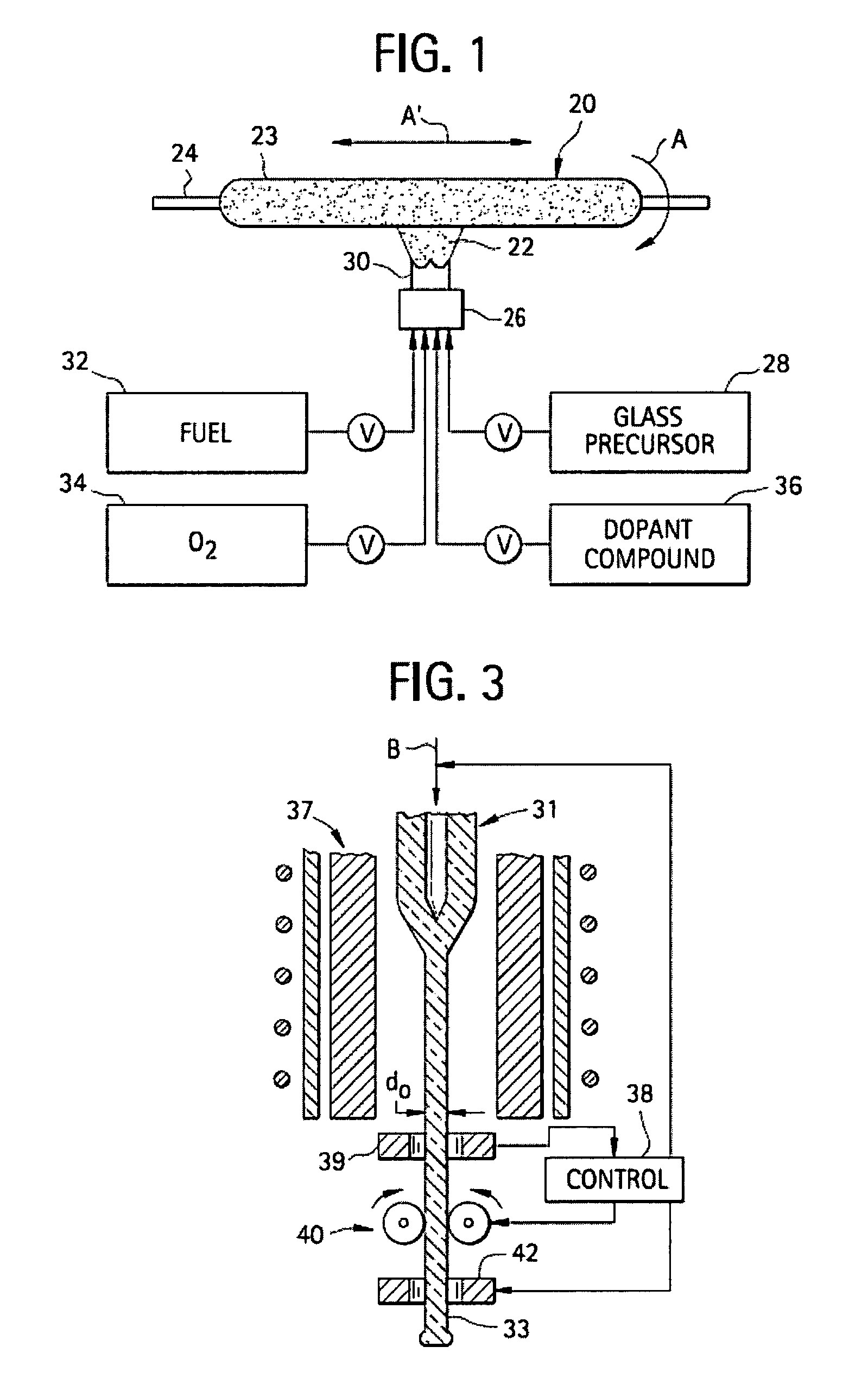

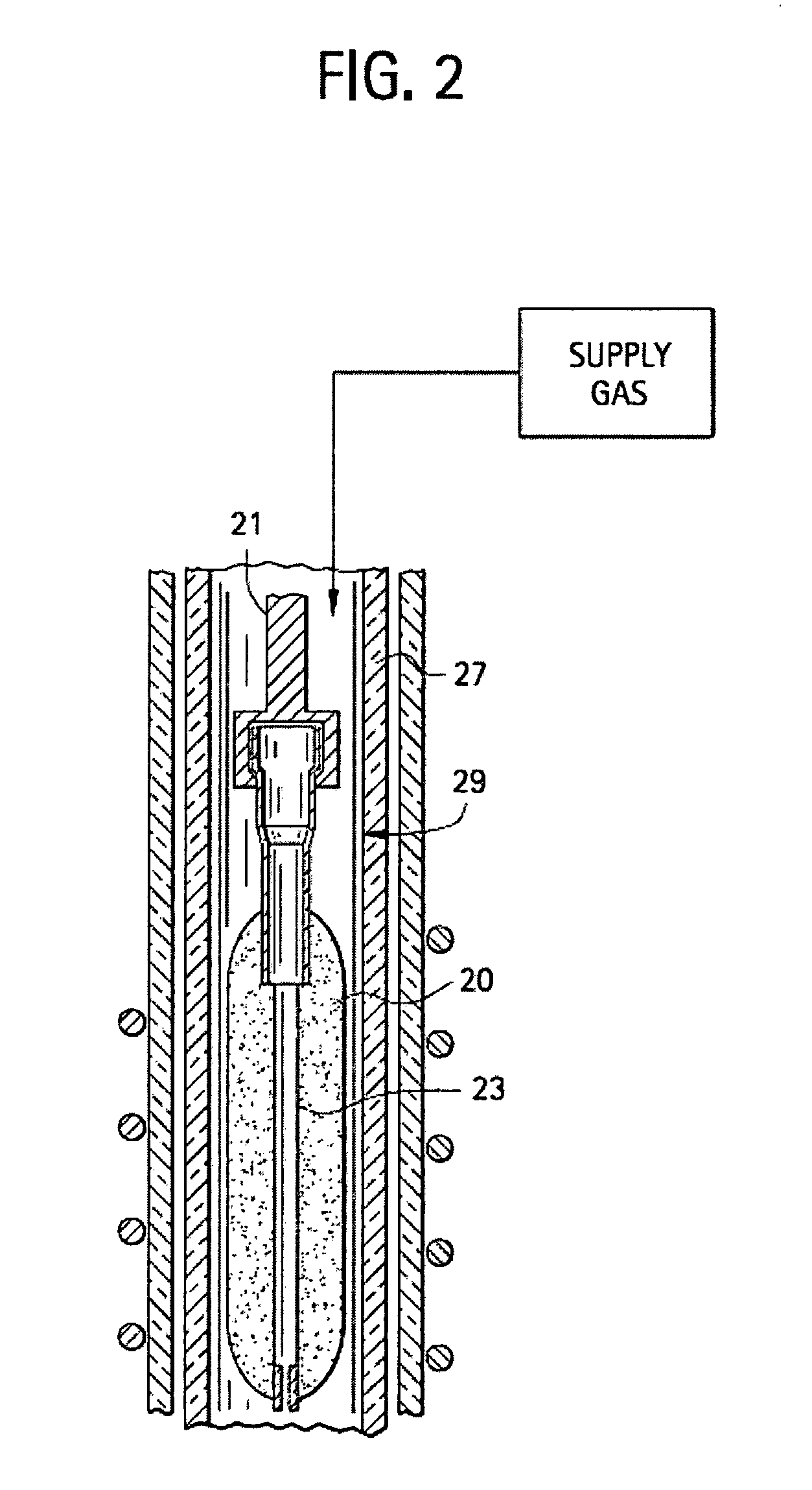

Microstructured optical fibers and methods

InactiveUS20070104437A1Improve bending performancePromote lowerGlass making apparatusOptical fibre with graded refractive index core/claddingNitrogen gasNitrogen

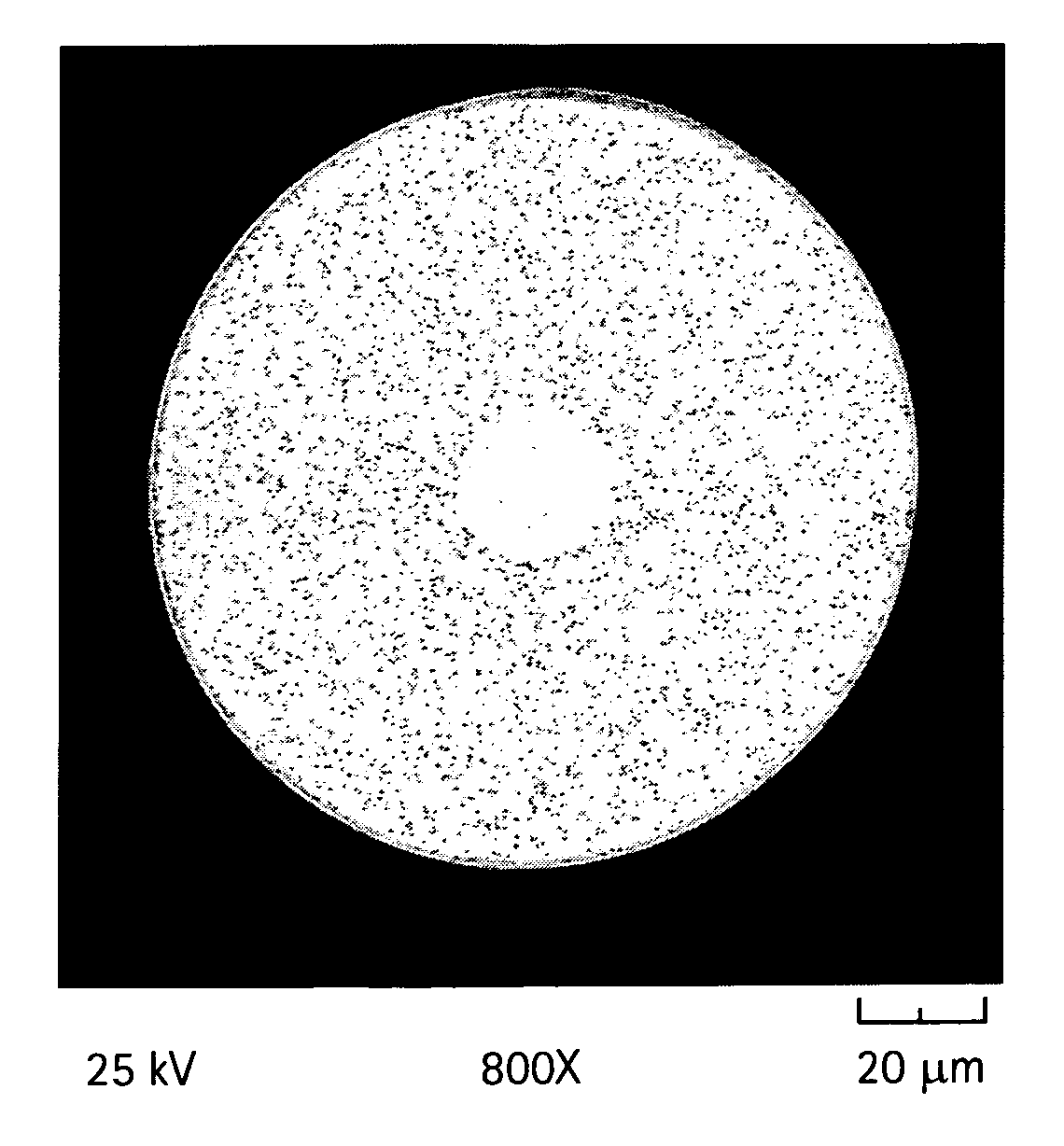

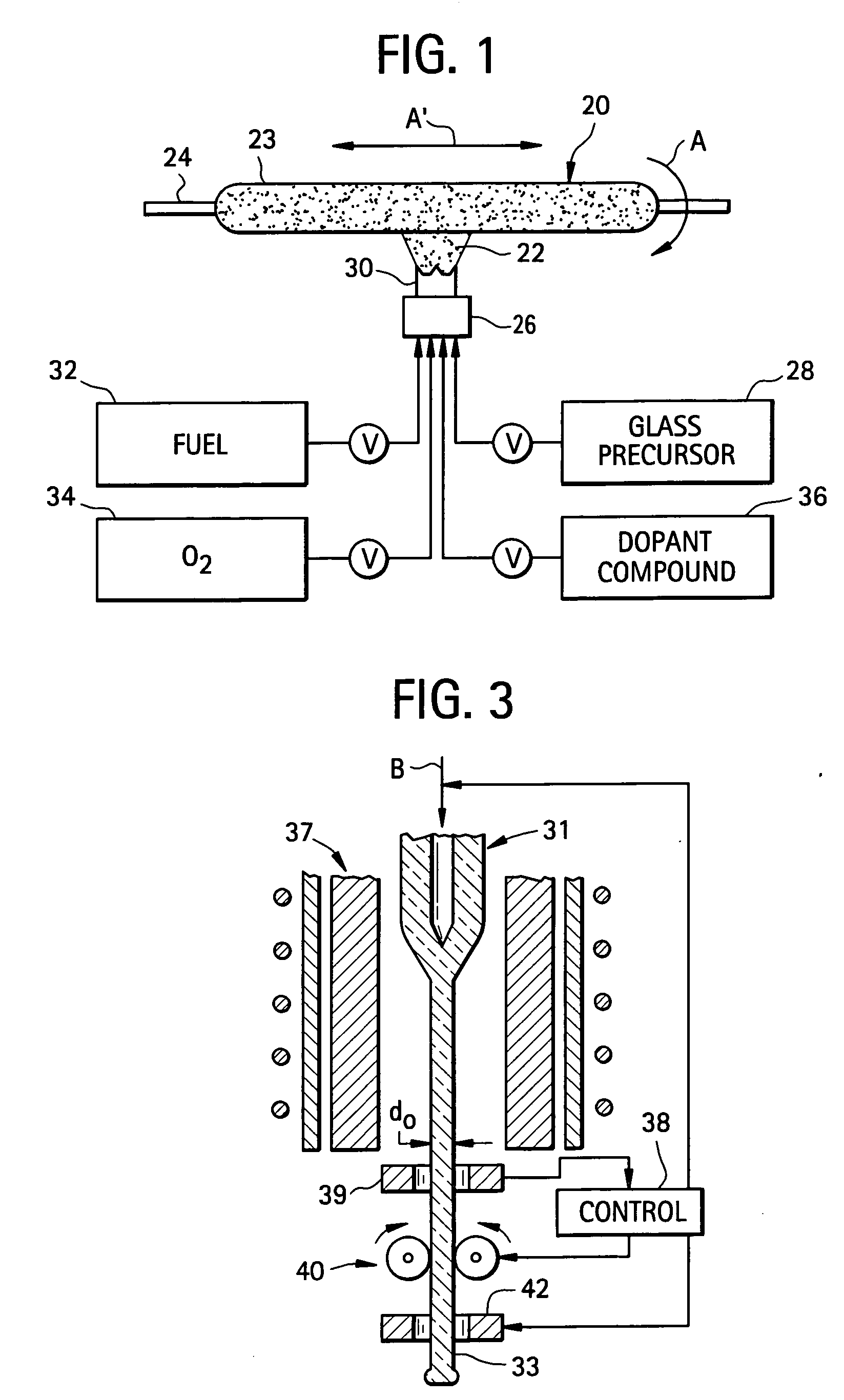

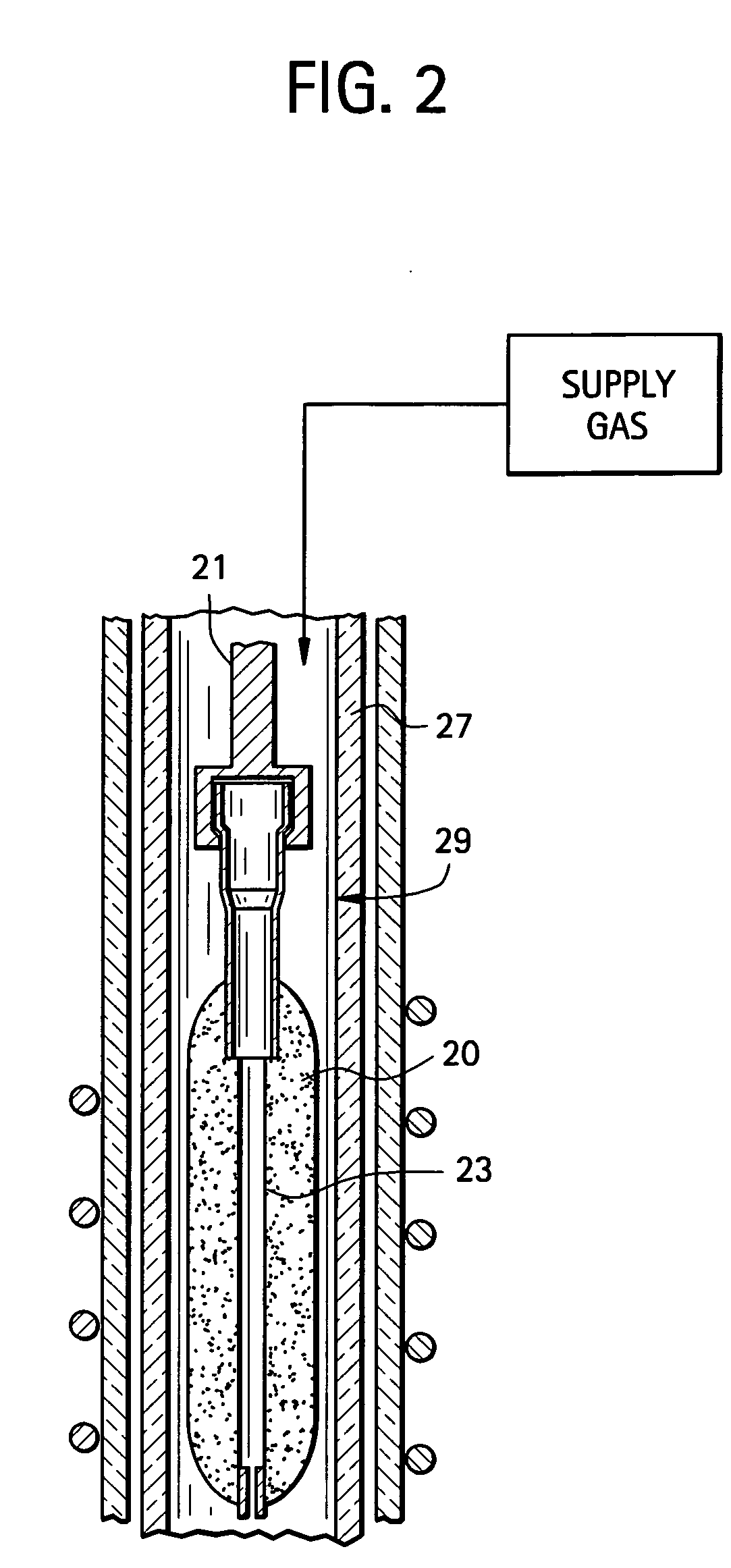

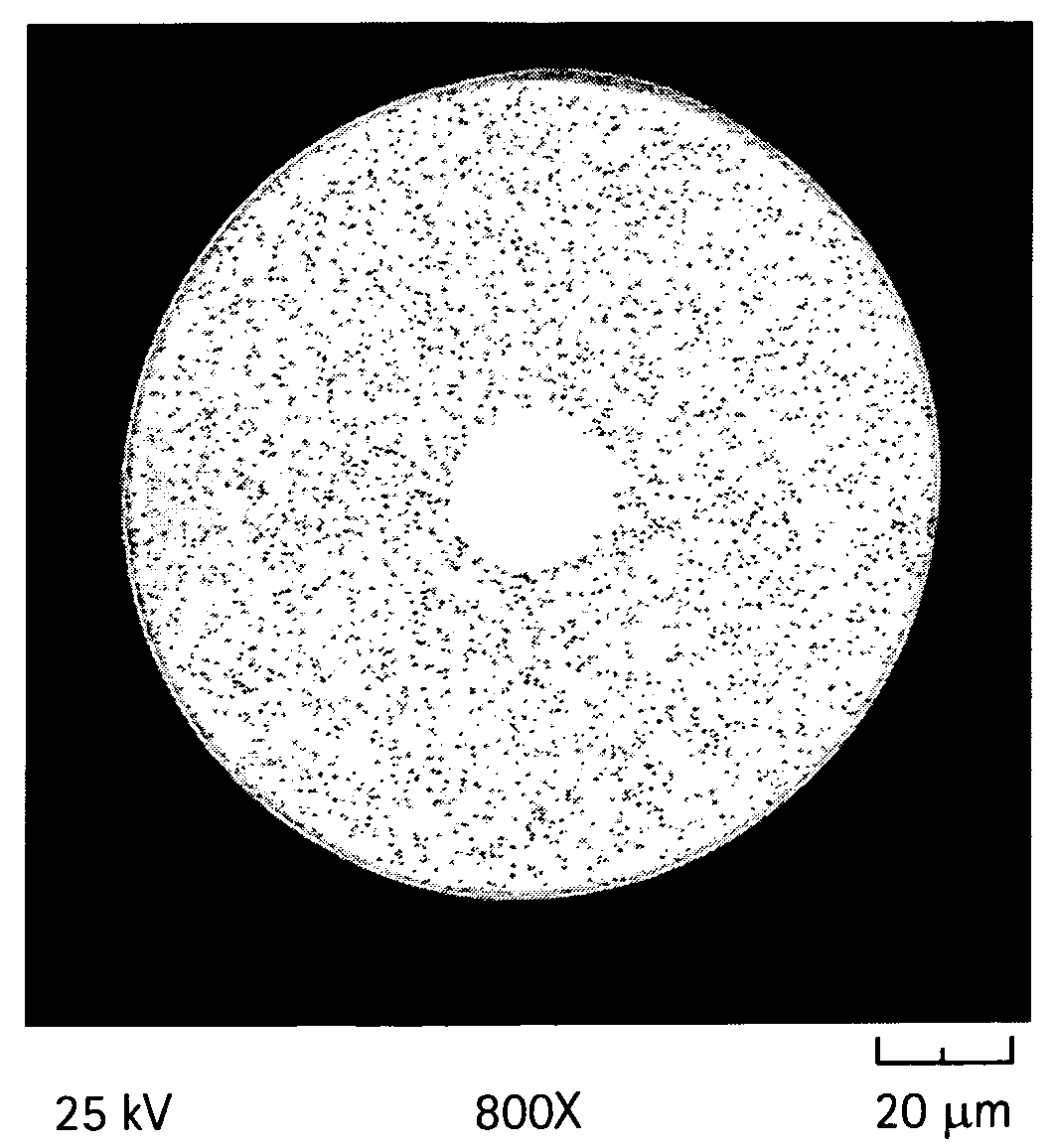

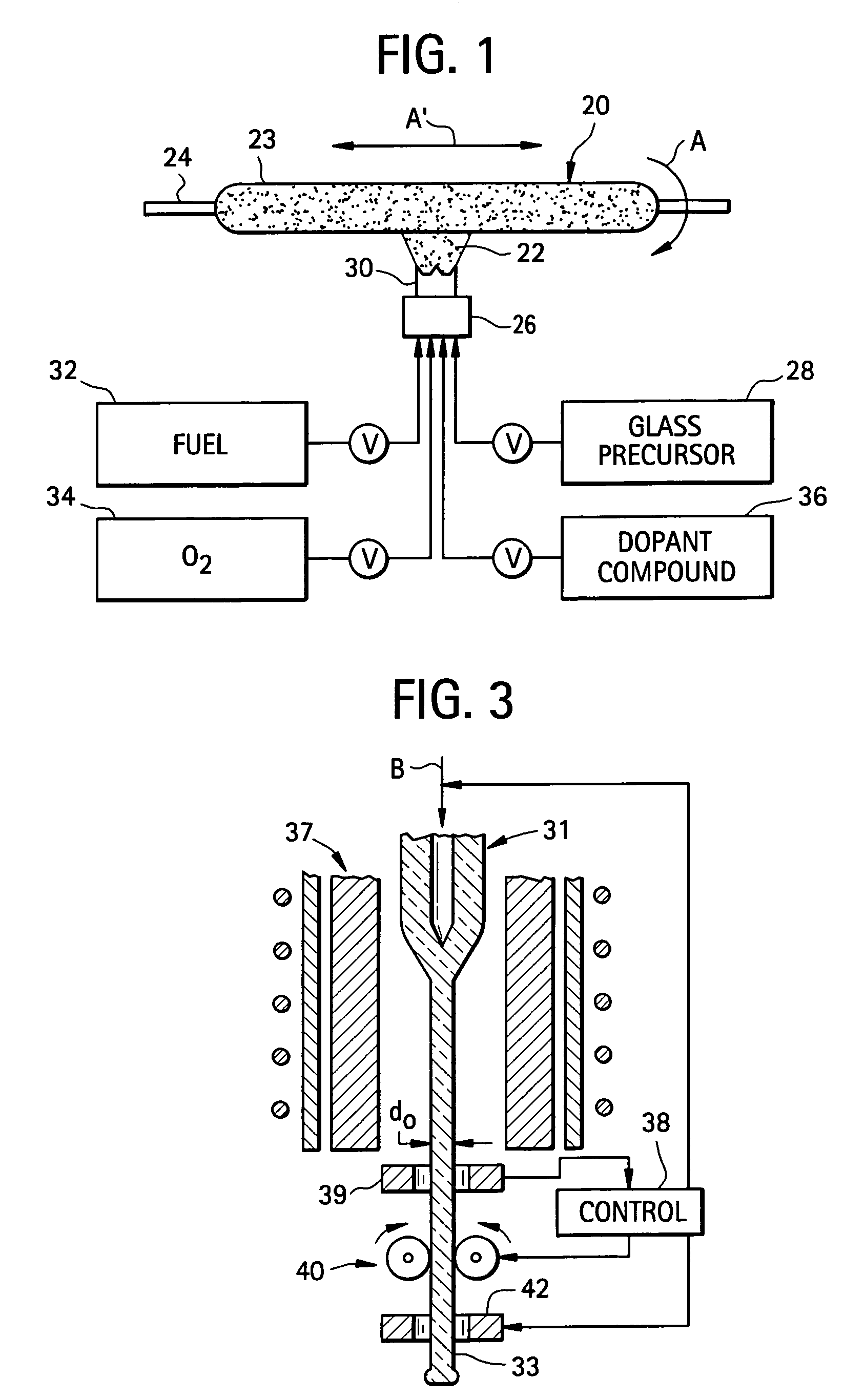

Microstructured optical fiber and method of making. Glass soot is deposited and then consolidated under conditions which are effective to trap a portion of the consolidation gases in the glass to thereby produce a non-periodic array of voids which may then be used to form a void containing cladding region in an optical fiber. Preferred void producing consolidation gases include nitrogen, argon, CO2, oxygen, chlorine, CF4, CO, SO2 and mixtures thereof.

Owner:CORNING INC

Microstructured optical fibers and methods

InactiveUS7450806B2Improve bending performanceLower refractive indexGlass making apparatusOptical fibre with graded refractive index core/claddingNitrogenNitrogen gas

Microstructured optical fiber and method of making. Glass soot is deposited and then consolidated under conditions which are effective to trap a portion of the consolidation gases in the glass to thereby produce a non-periodic array of voids which may then be used to form a void containing cladding region in an optical fiber. Preferred void producing consolidation gases include nitrogen, argon, CO2, oxygen, chlorine, CF4, CO, SO2 and mixtures thereof.

Owner:CORNING INC

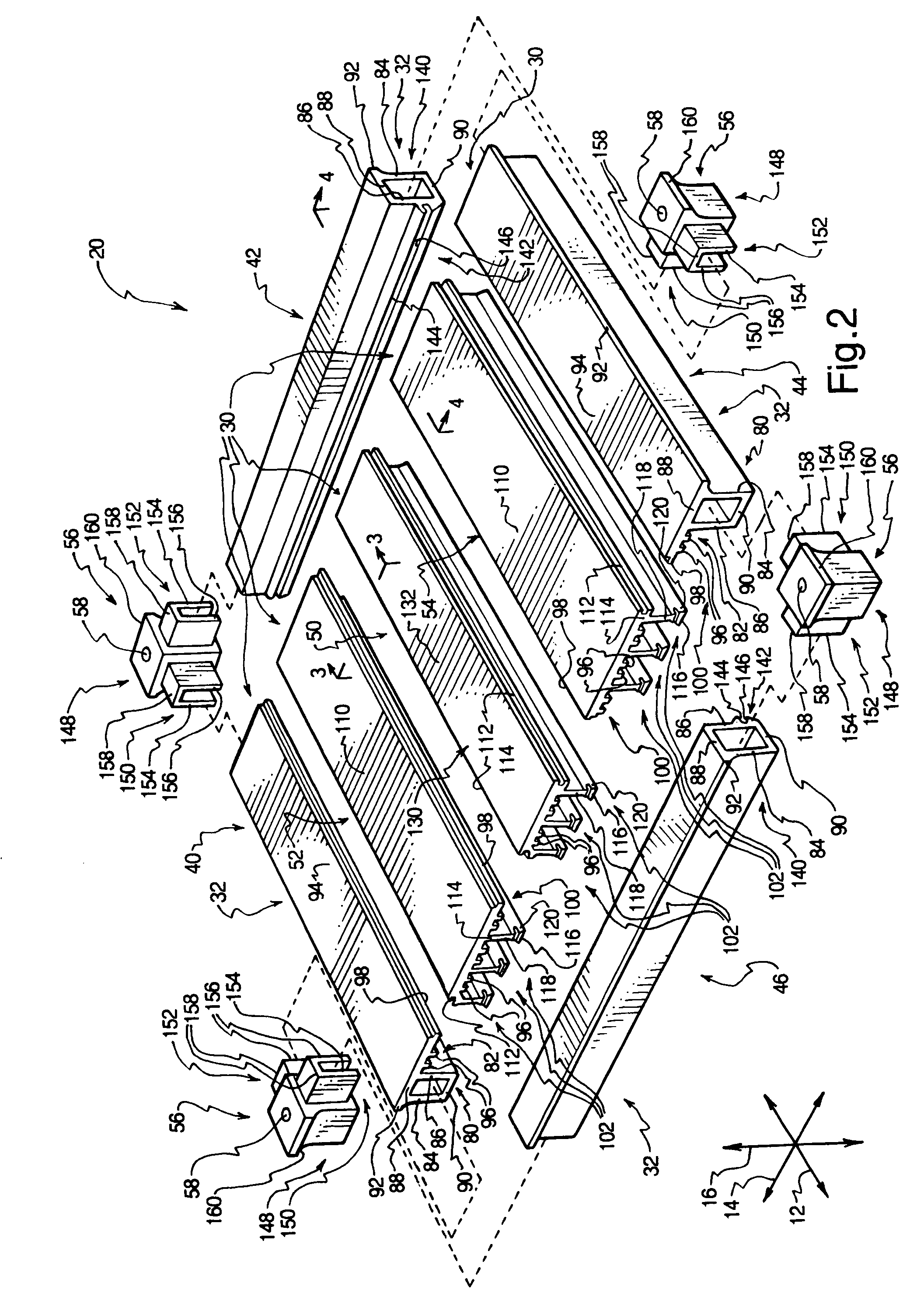

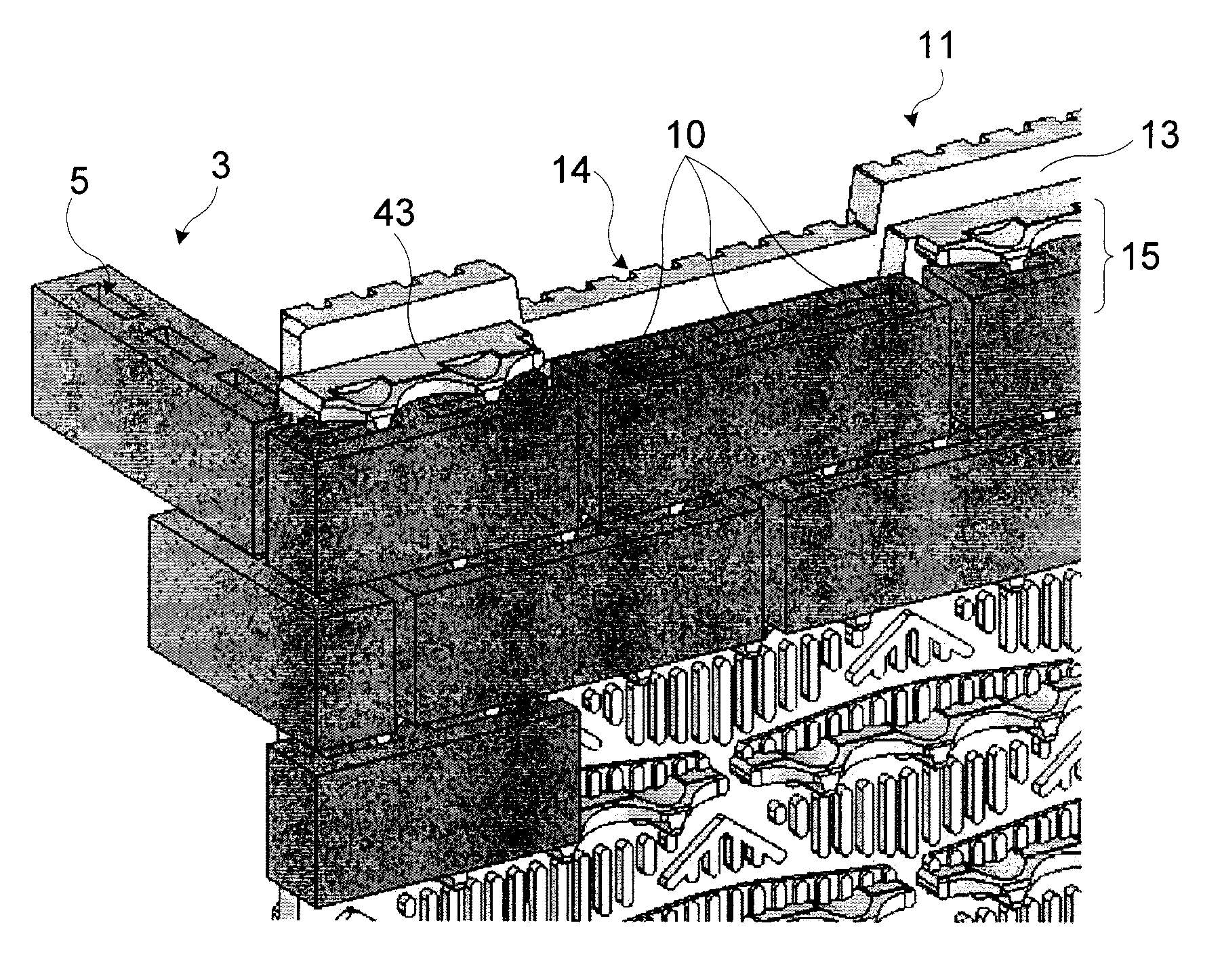

Raised access floor

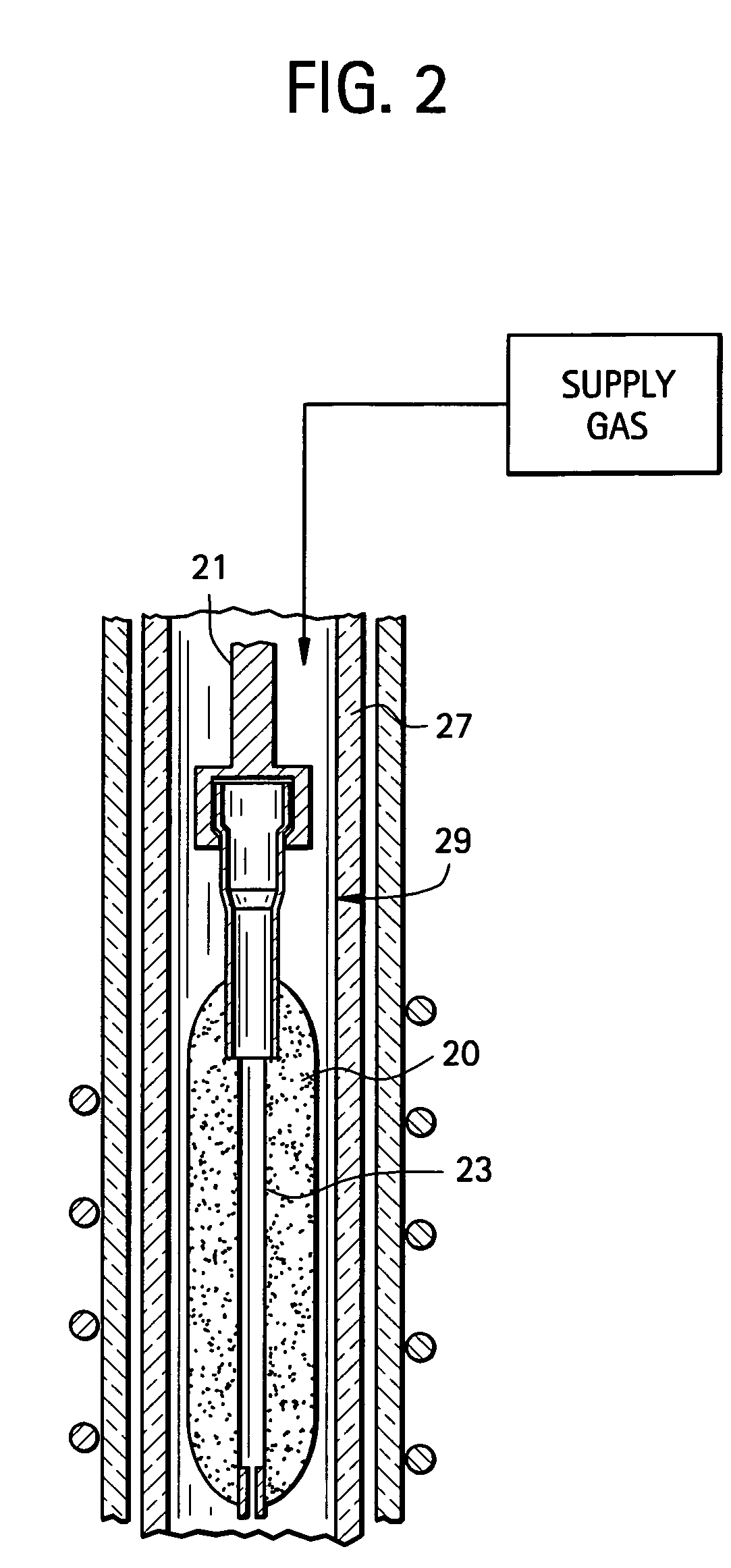

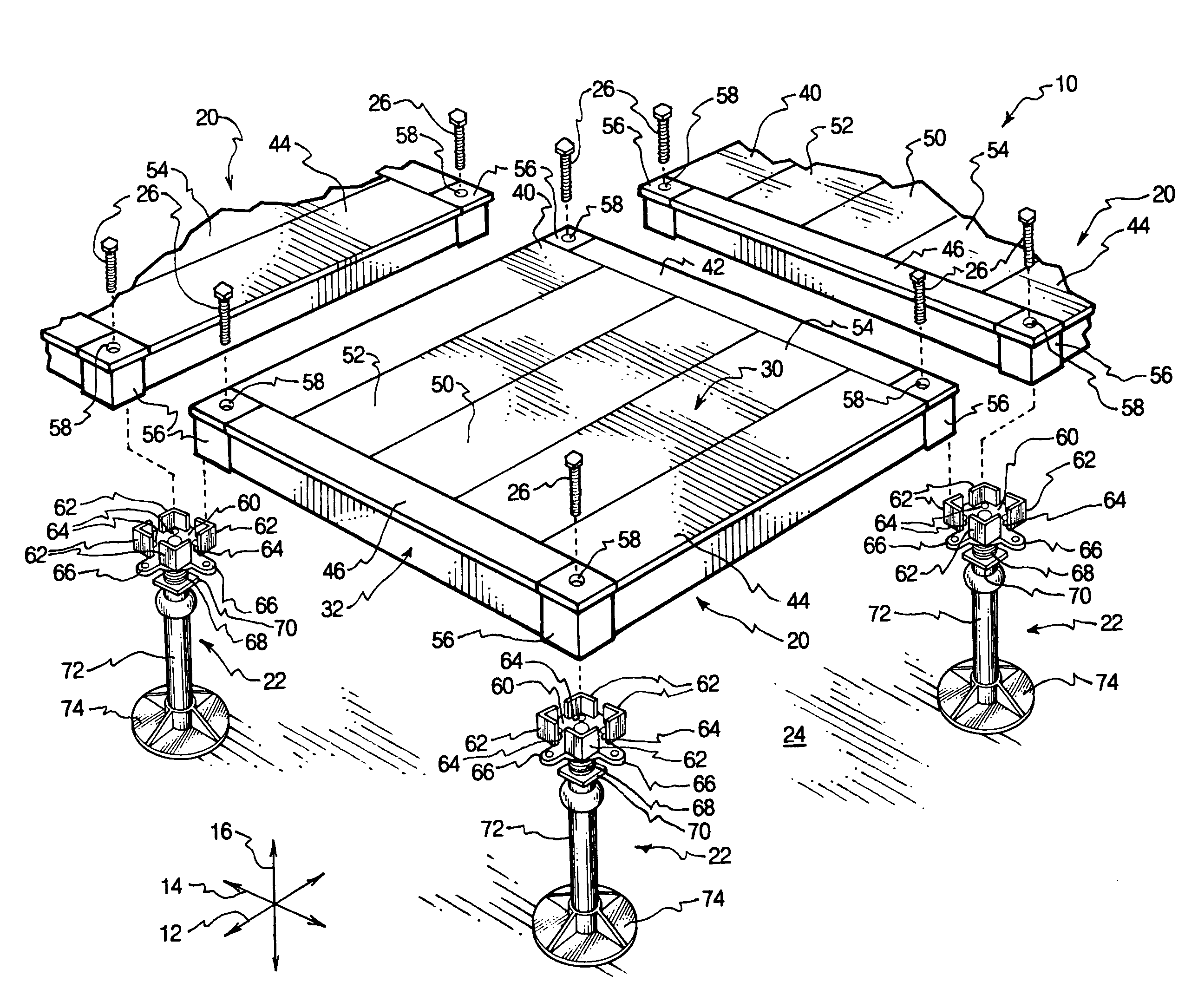

A raised access floor has panels suspended by pedestals. Each panel may have a top surface and a frame extending around the top surface. Each panel may have extruded aluminum components including four edge members, two intermediate members, and a center member. Each edge member may have a frame portion with a box beam configuration. The frame portions can be press-fitted with corner members to provide the frame. Two edge members, the intermediate members, and the center member may have top surface portions coupled together to form the top surface. The top surface may be supported by support ribs with enlarged bottom ends that resist bending. The ends of the support ribs are press-fitted against the frame. Components may be modified or removed to alter the panel geometry. A cover plate may be used to cover the top surface. The cover plate and / or top surface may be continuous or perforated.

Owner:AIRTEX MFG LLLP

Microstructured transmission optical fiber

InactiveUS7505660B2Improve bending abilityReduce decreaseGlass making apparatusOptical fibre with multilayer core/claddingEngineeringOptical fiber cable

Microstructured optical fiber for single-moded transmission of optical signals, the optical fiber including a core region and a cladding region, the cladding region including an annular hole-containing region that contains non-periodically disposed holes. The optical fiber provides single mode transmission and low bend loss.

Owner:CORNING INC

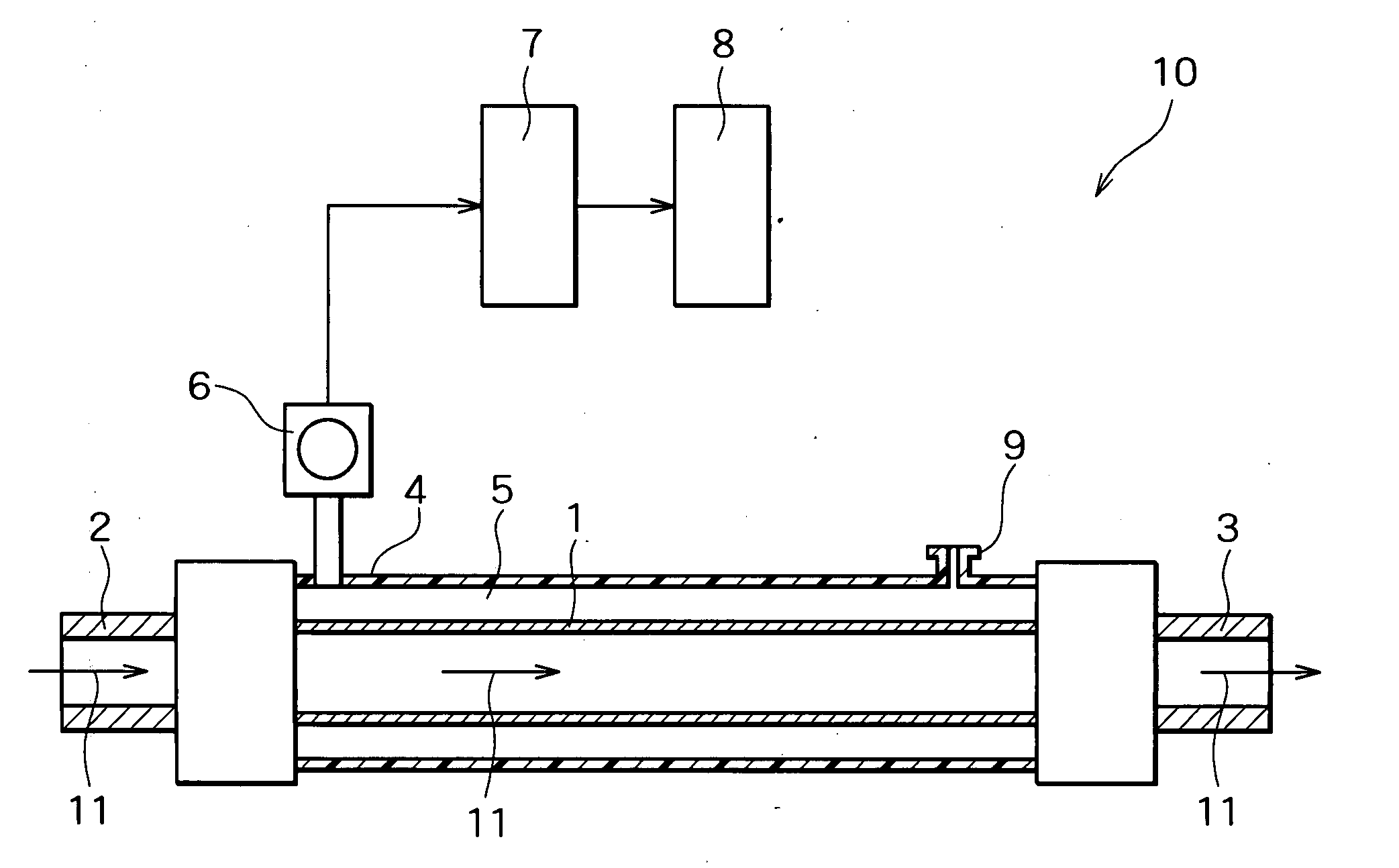

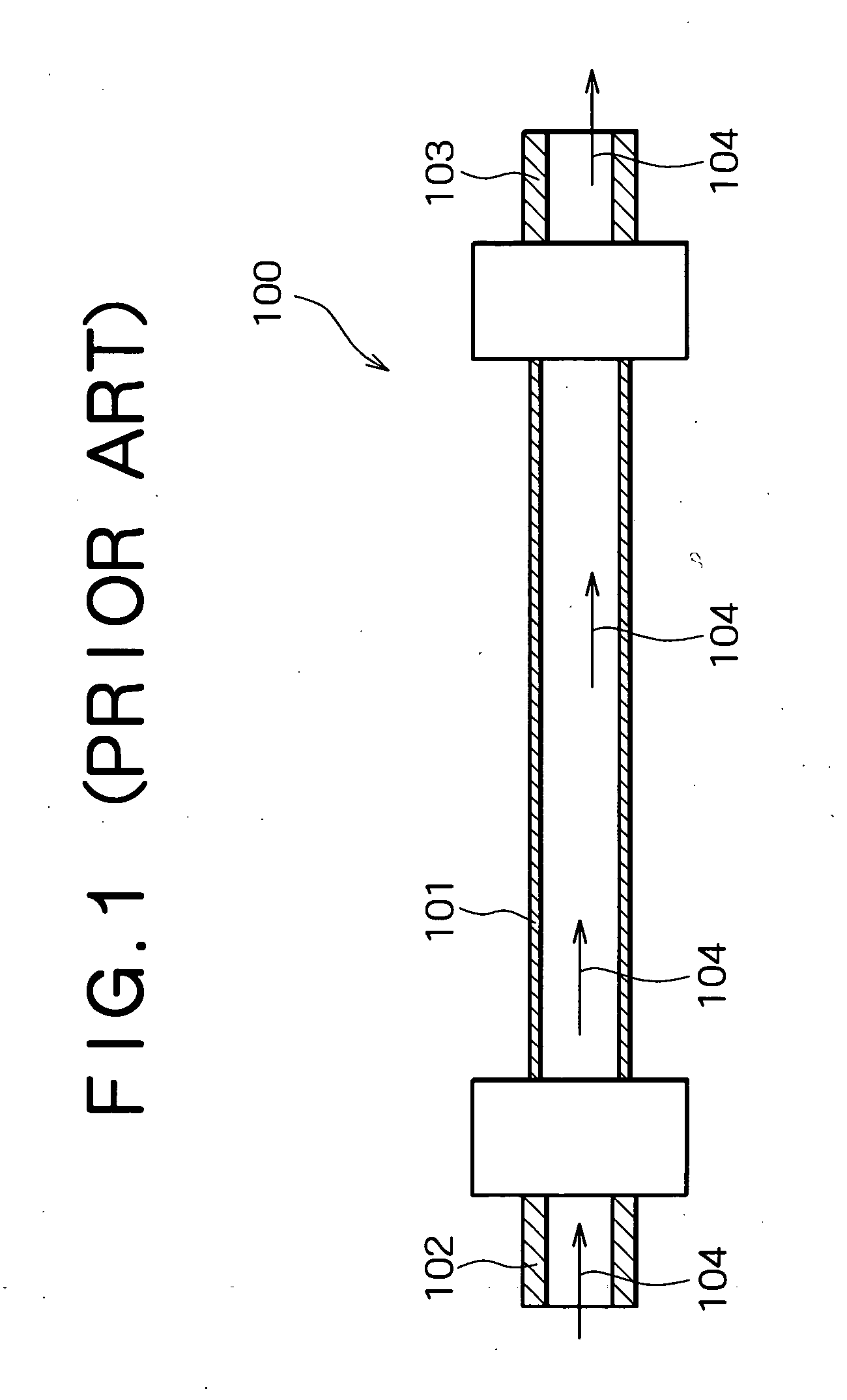

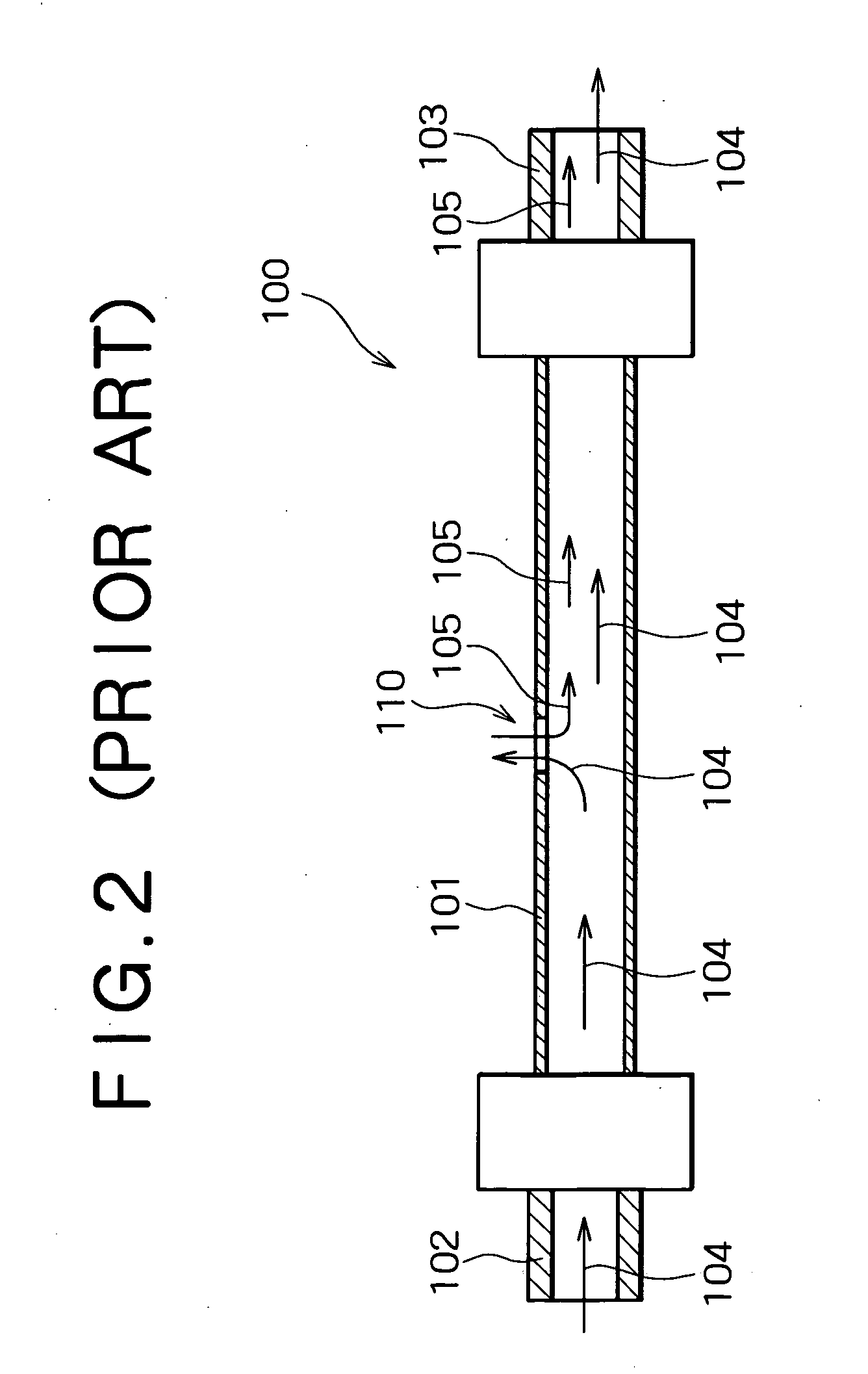

Piping structure having leak detection function and leak detector

InactiveUS20050166666A1Minimize impactIncrease pressureDetection of fluid at leakage pointMeasurement of fluid loss/gain rateDouble tubePipe fitting

A covering member having a valve encloses a flexible hose to form a double pipe. Gas supply pipe fittings are attached to respective ends of the double pipe to form a hermetic space between the flexible hose and covering member. The covering member also has a pressure-measuring device to which a decision unit equipped with an alarm device is connected. The same gas or liquid as the one flowing through the flexible hose is introduced to the hermetic space from the valve provided in the covering member, and sealed in the hermetic space by closing the valve. The pressure in the hermetic space is set so as to be higher than the pressure produced in the flexible hose when the gas or liquid is flowing. The pressure-measuring device measures the pressure in the hermetic space while the gas or liquid flows in the flexible hose, and the decision unit compares the measured value with a reference value. As a result, if the value measured by the pressure-measuring device is lower than the reference value, the decision unit decides that a breakage has occurred and then the alarm device activates an alarm.

Owner:LASERFRONT TECH

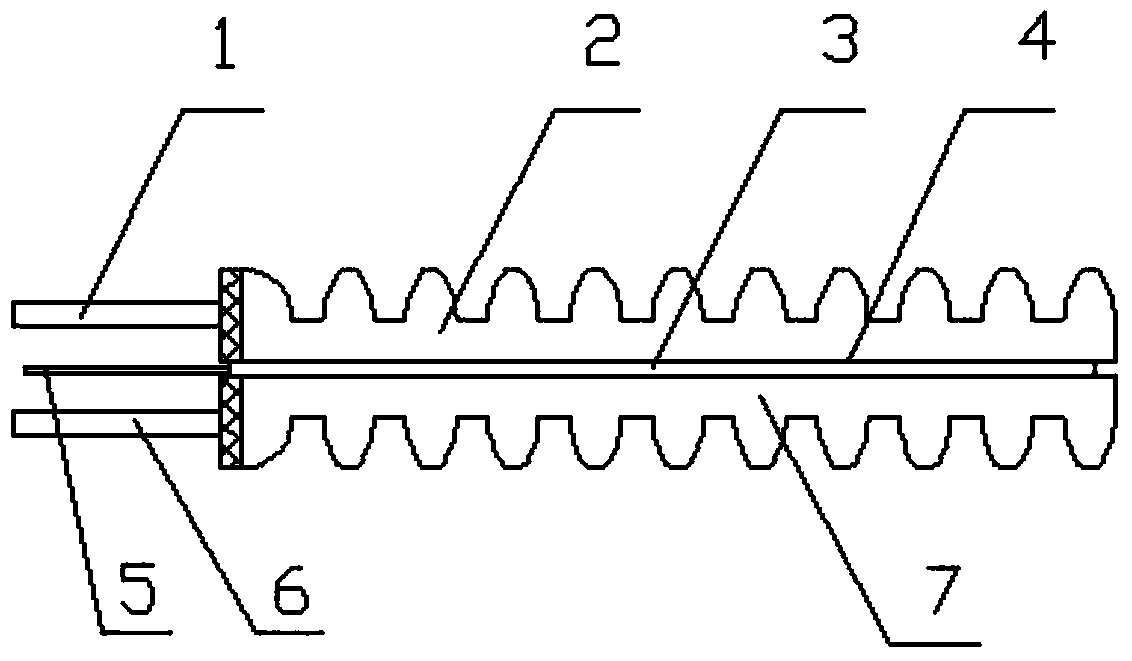

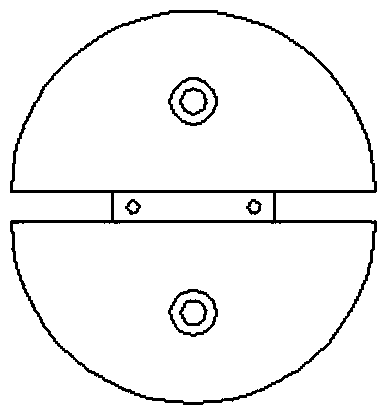

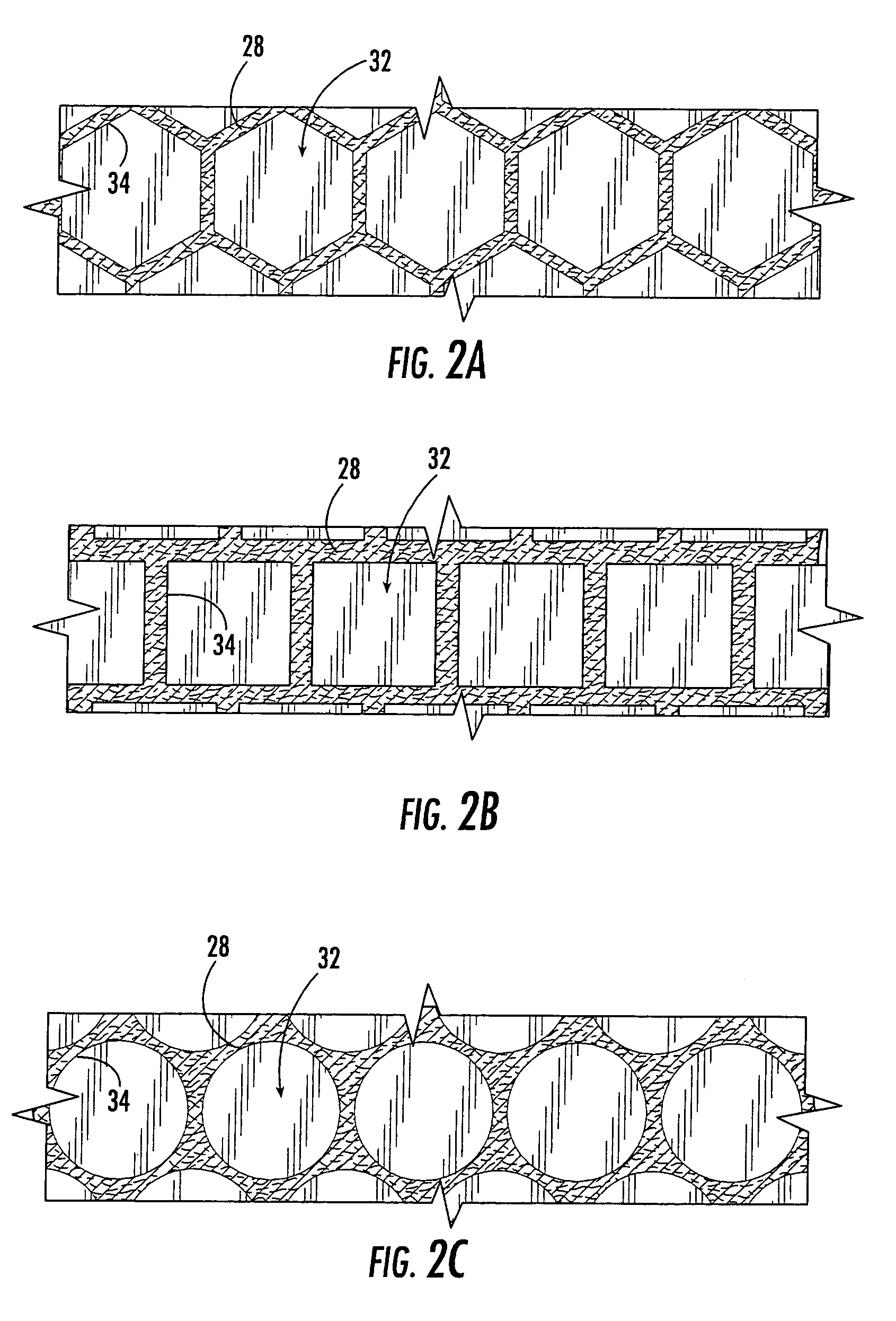

Corrugated double-inner-cavity gas-powered flexible micro finger, control method and grabbing system

The invention discloses a corrugated double-inner-cavity gas-powered flexible micro finger, a control method and a grabbing system. The corrugated double-inner-cavity gas-powered flexible micro finger comprises a double-inner-cavity gas-powered flexible micro finger body composed of two independent pneumatic half-corrugated hollow rubber tube half-fingers I and II which are symmetrically arranged. A thin sheet type bending tilt angle sensor making contact with the two half-fingers is arranged between the two half-fingers. The two half-fingers are provided with a gas inlet and outlet I and a gas inlet and outlet II respectively. The outer side of the top face of each independent pneumatic half-corrugated hollow rubber tube half-finger is a corrugated surface, the bottom face of each independent pneumatic half-corrugated hollow rubber tube half-finger is a horizontal plane, and the top face and the bottom face of each independent pneumatic half-corrugated hollow rubber tube half-finger are connected into a whole to form a hollow sealing cavity. The bottom faces of the two independent pneumatic half-corrugated hollow rubber tube half-fingers I and II are aligned with each other and then are pasted on the thin sheet type bending tilt angle sensor. The corrugated double-inner-cavity gas-powered flexible micro finger has the advantages of being low in cost, safe in cleaning, easy and convenient to install, good in flexibility, smooth in motion, low in noise and free of pollution, having mechanical performance similar to that of biological muscles, and the like.

Owner:SHANDONG ACAD OF SCI INST OF AUTOMATION

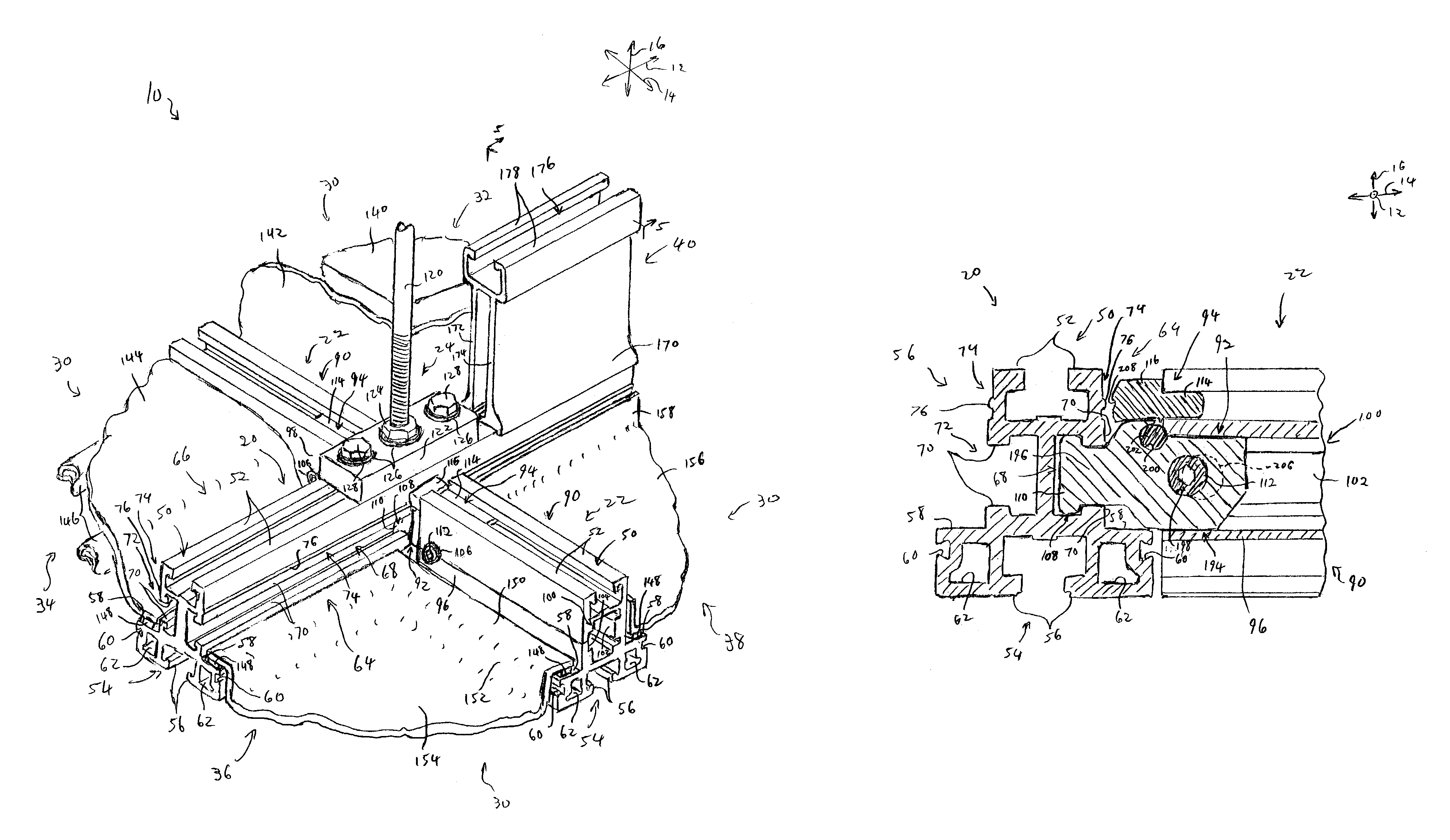

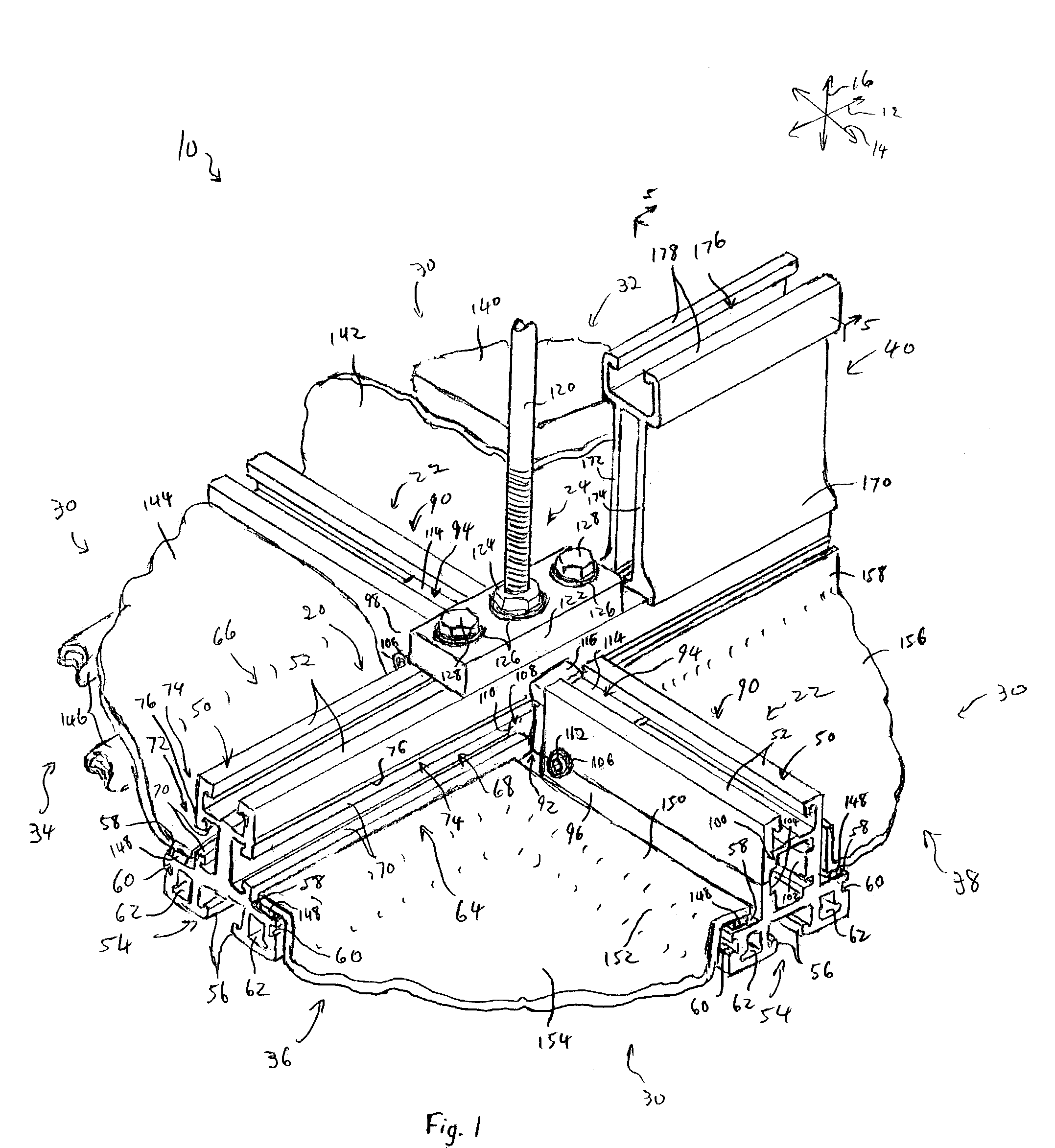

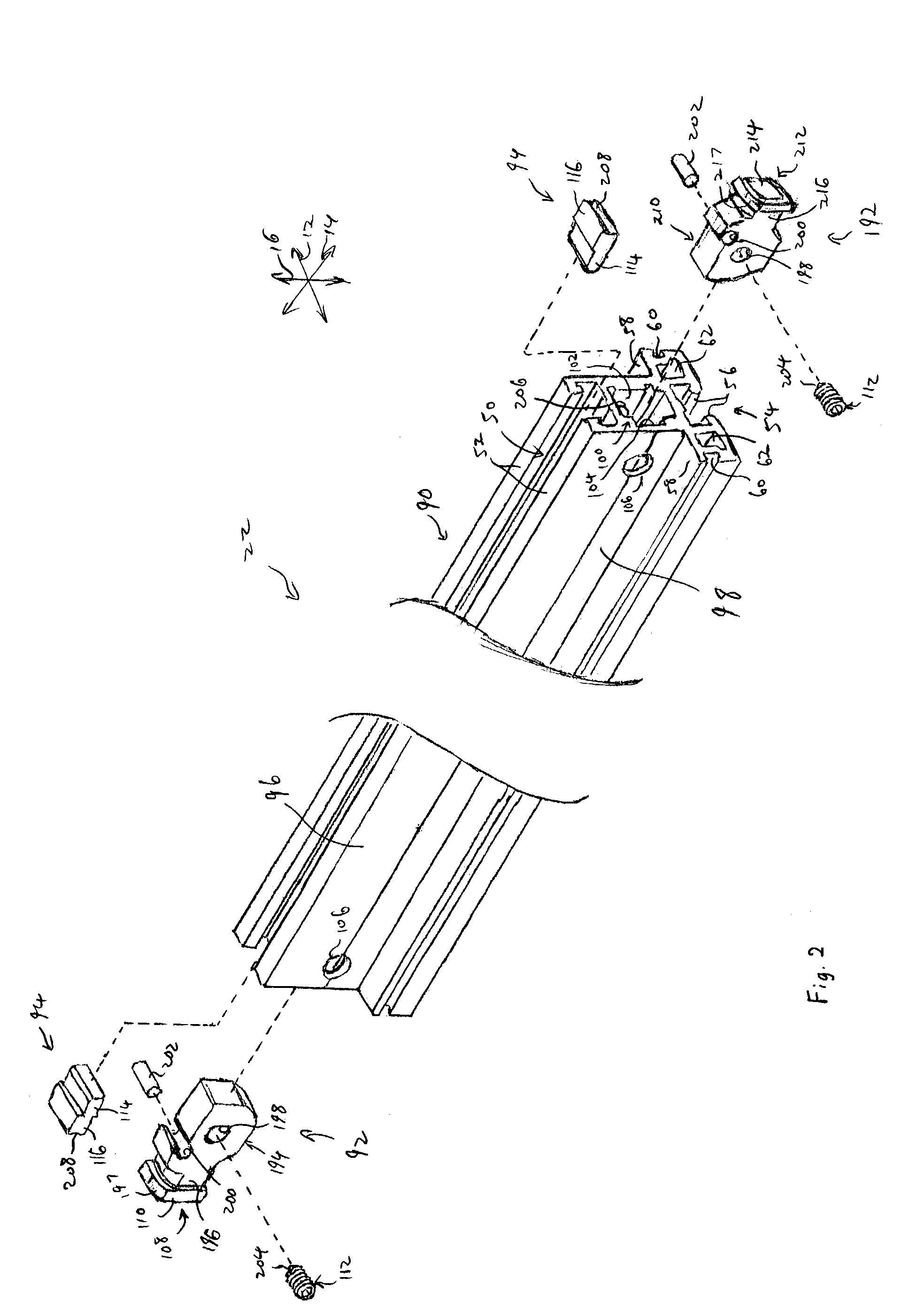

Sealable ceiling assembly

A sealable ceiling assembly is provided for use in applications such as clean rooms. The sealable ceiling assembly may include main beams suspended from a support ceiling parallel to each other and cross beams that run perpendicular to the main beams to attach the main beams together. Each cross beam has a bore from which coupling members extend to either side. Each coupling member has a head with a cam surface designed to interlock with a retention slot of the main beam in response to ninety-degree rotation of the coupling member. The coupling members are attached within the bores of the cross beams via set screws that can be rotated after engagement to urge retraction of the coupling members into the bore to tighten engagement of the cross beams with the main beams. Stiffeners may be attached to top nut slots of any of the beams that need reinforcement.

Owner:AIRTEX MFG LLLP

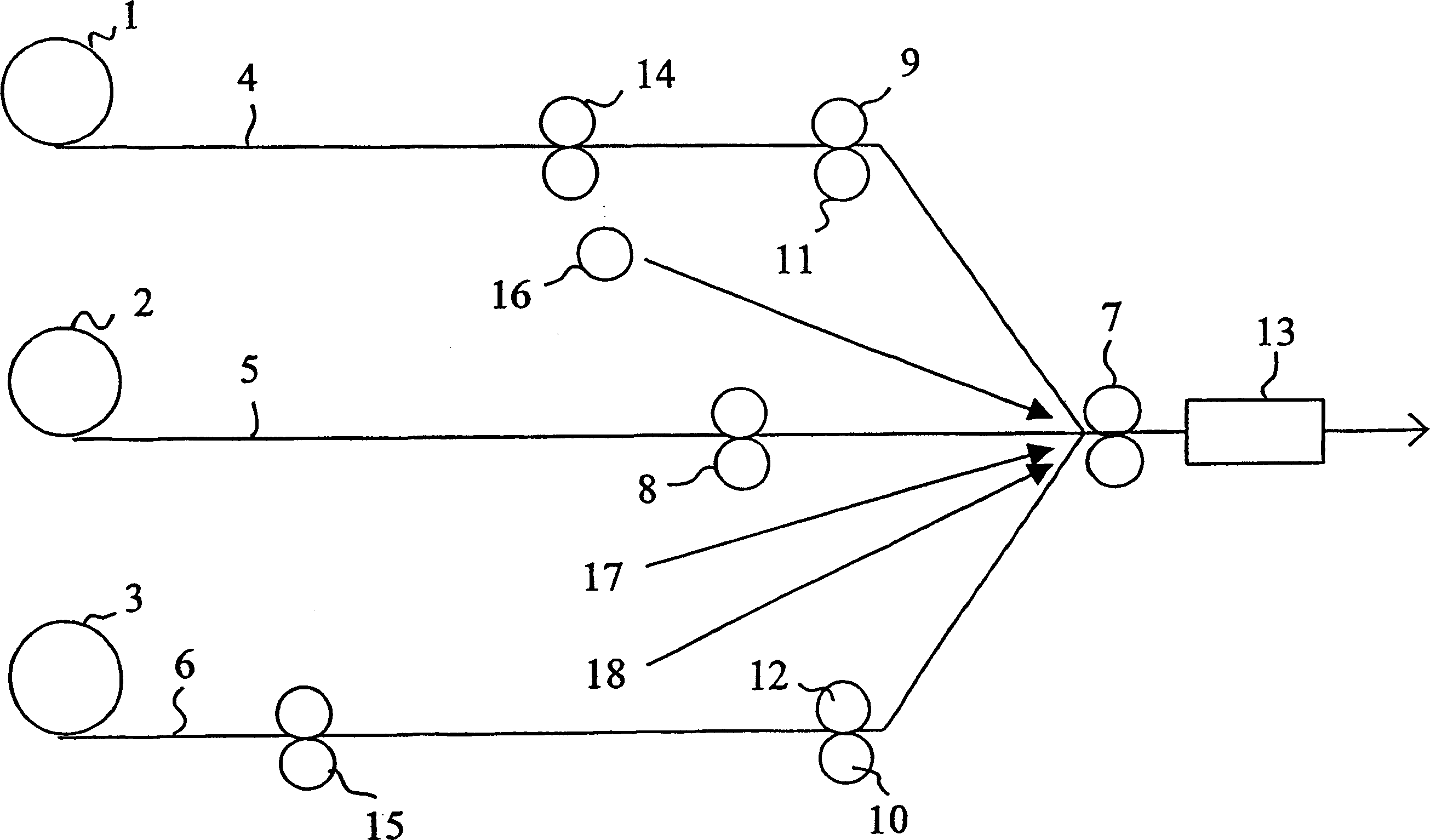

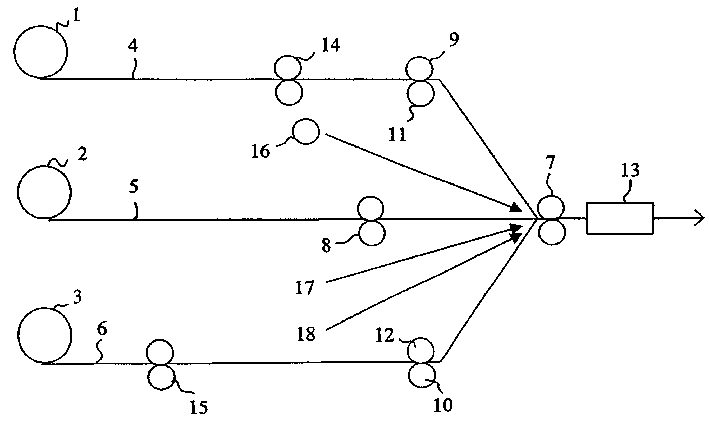

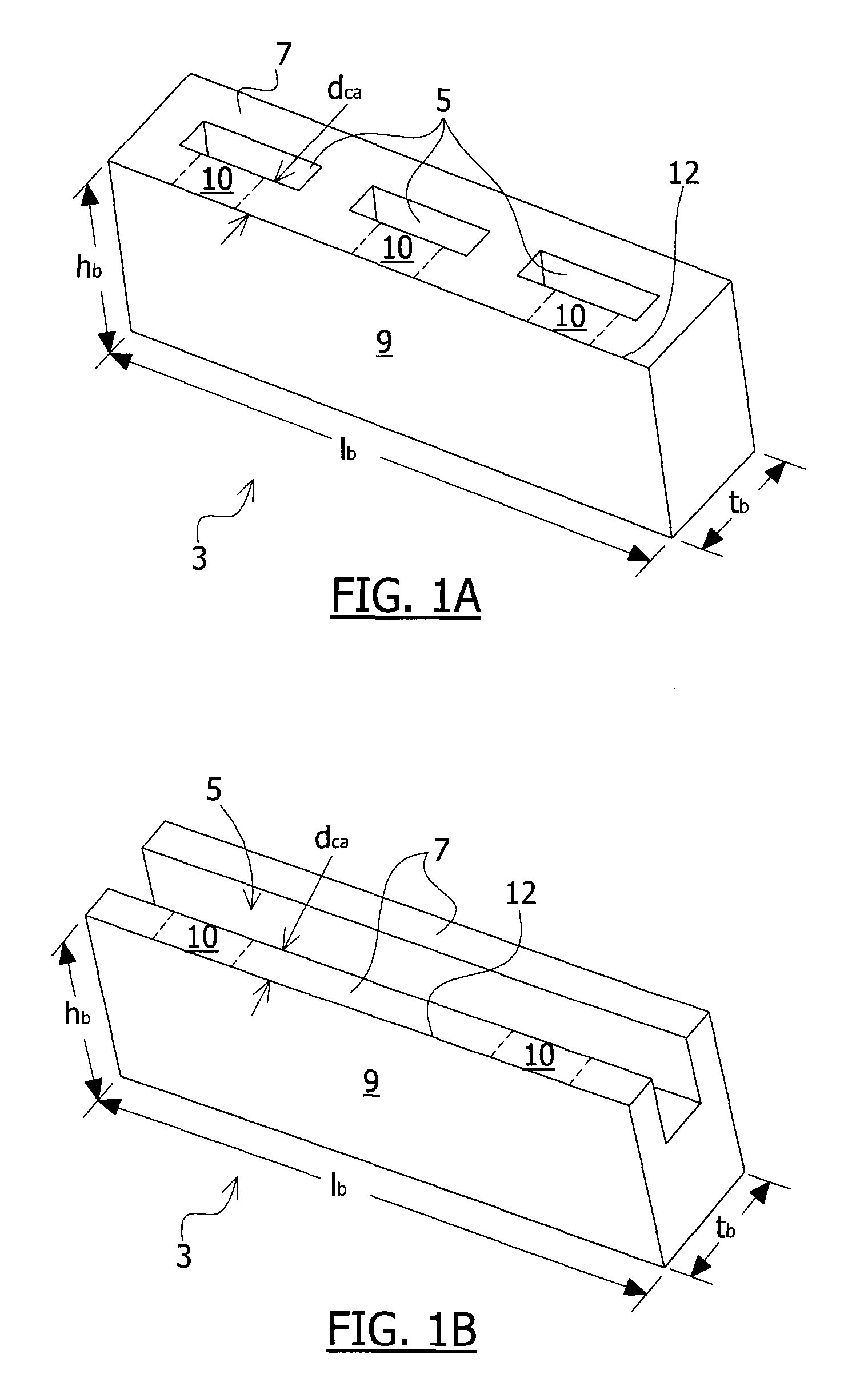

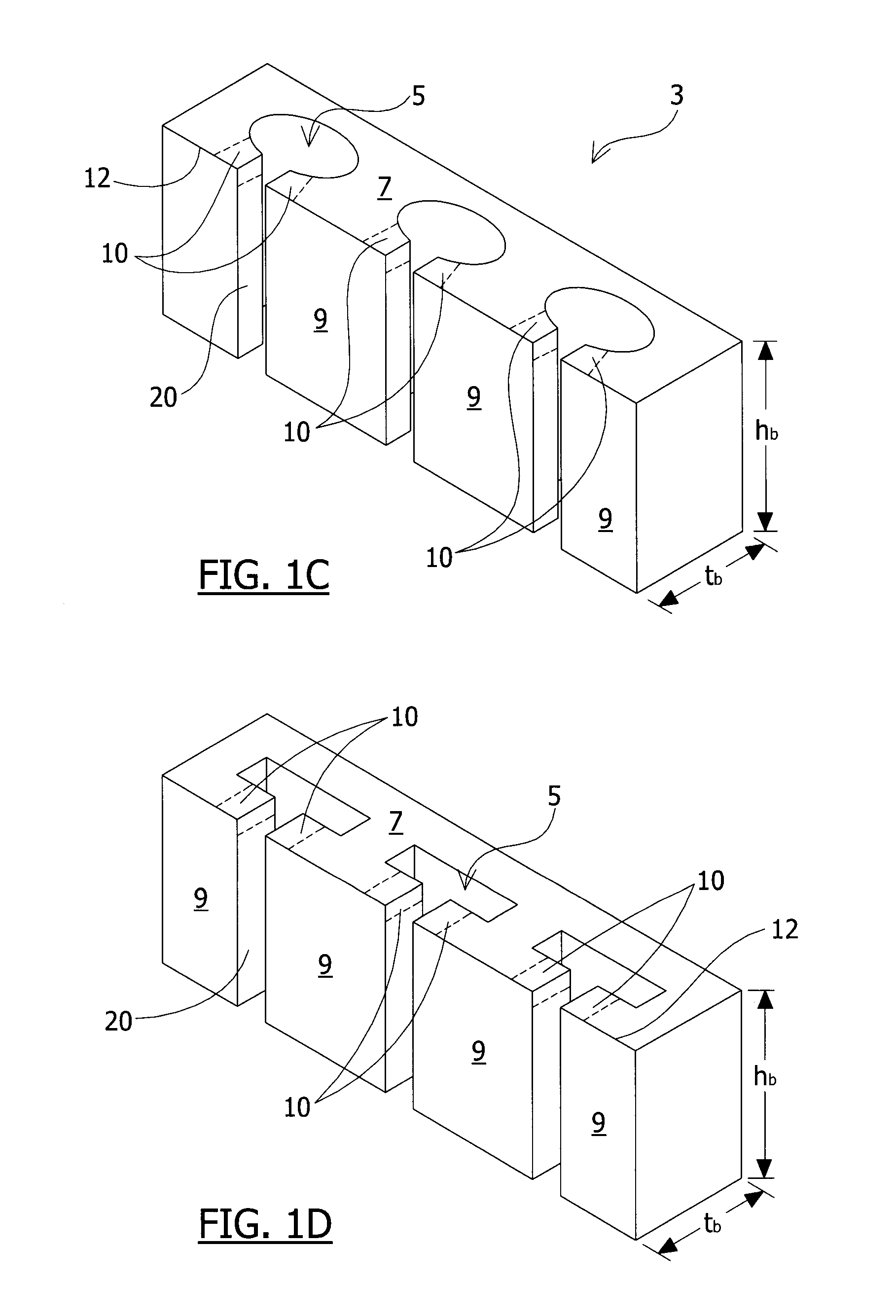

Method and apparatus for producing board and a board product

InactiveCN1469802AHigh cost-effectiveness ratioHigh strengthMechanical working/deformationPaper/cardboard layered productsFiberCardboard

A method is disclosed for producing a multilayer paperboard product, as well as an assembly suited for implementing the method and a paperboard manufactured according to the method, whereby the paperboard is made from at least two, advantageously three layers (4, 5, 6) bonded to each other by gluing, and the material of the middle layer (5) is subjected to mechanical working in a dry state (8) so as to deform the material prior to gluing through pressing thereon desired pattern that is raised from the surface of the material (5). The layers (4, 5, 6) are bonded to each other in a single step (7). The method is capable of providing a strong paperboard that uses less fiber than prior-art paperboards of equal thickness and strength.

Owner:AVENIRA

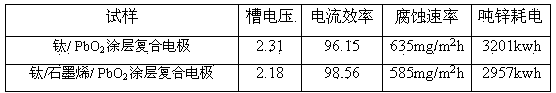

Titanium/graphene/oxide combined electrode

ActiveCN103526235APerfect quantum tunnelingImprove conductivityElectrodesCharge carrier mobilityTitanium

The invention relates to a titanium / graphene / oxide combined electrode, which belongs to the technical field of electroplating. The combined electrode is such structured that graphene and an oxide coating are successively coated on a matrix, wherein the oxide coating is an oxide of Mn, Pb or La, and the matrix is a titanium or titanium alloy plate or screen plate. A plurality of layers of graphene are coated on the matrix, each layer being 0.4 to 1.0 mm thick. The thickness of the oxide coating is 150 mu m to 700 mu m. The titanium or titanium alloy plate is 0.5 to 10 mm thick, and the mesh diameter of the screen plate is 0.1 to 5 mm. According to the invention, overall performance of the electrode is improved by using a stable lattice structure and high carrier mobility of graphene, advantages of each layer of graphene are performed, so the electrode has the advantages of high strength, good conductivity, high corrosion resistance, a long service life and the like.

Owner:KUNMING UNIV OF SCI & TECH

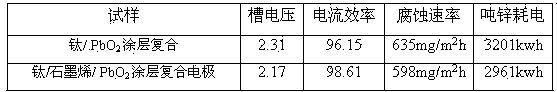

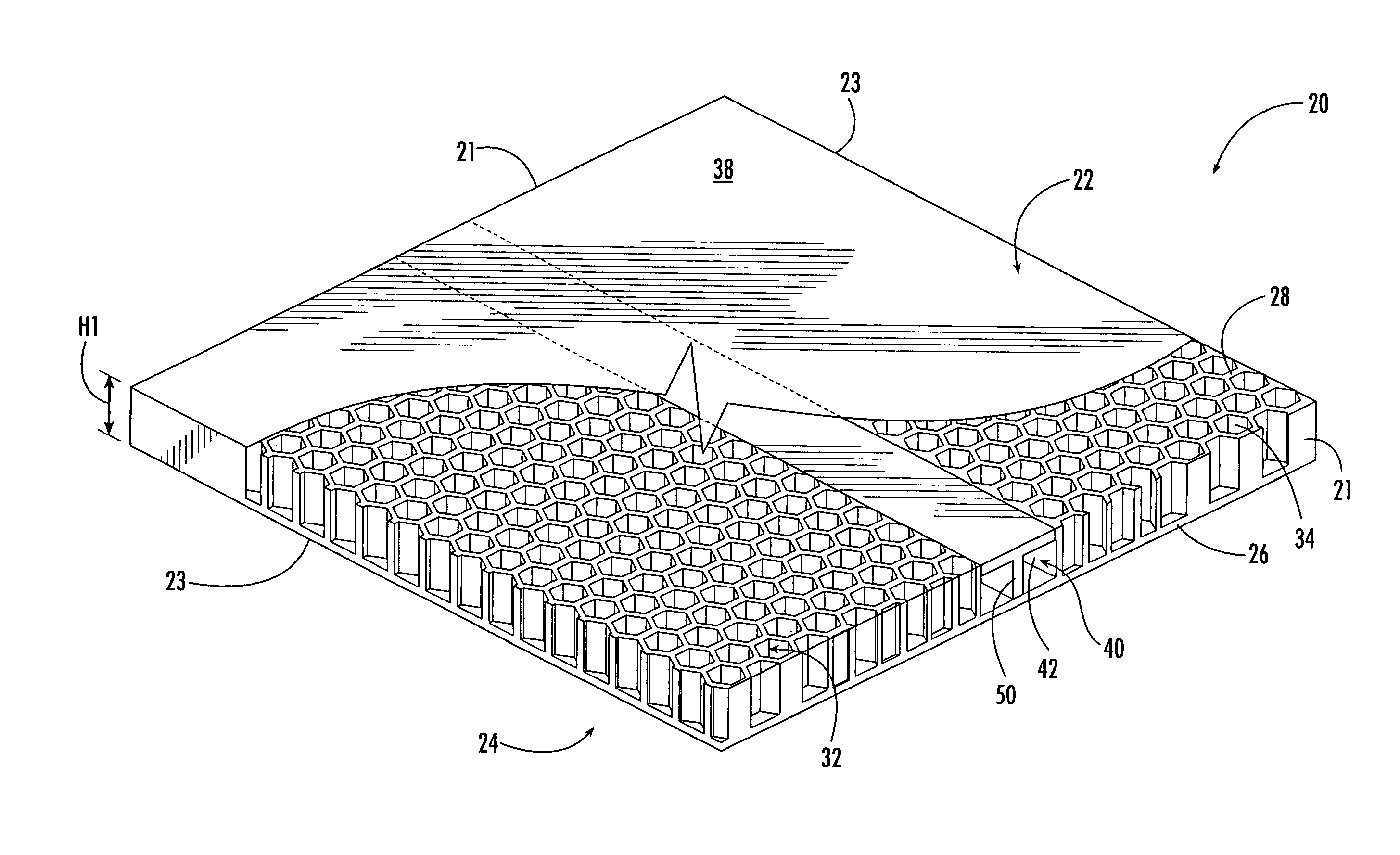

Reinforced fiber panel and method of forming same

InactiveUS7143564B2High strengthIncreased bending stiffnessConstruction materialBuilding repairsFiberEngineering

The present invention is directed to a reinforced panel that includes a face sheet having an interior side and an exterior side, a plurality of integral and intersecting ribs having distal ends and projecting from the interior side of the face sheet to form contiguous cells, and a reinforcing member positioned in a channel and secured thereto for increasing bending resistance of the panel.

Owner:SONOCO DEV INC

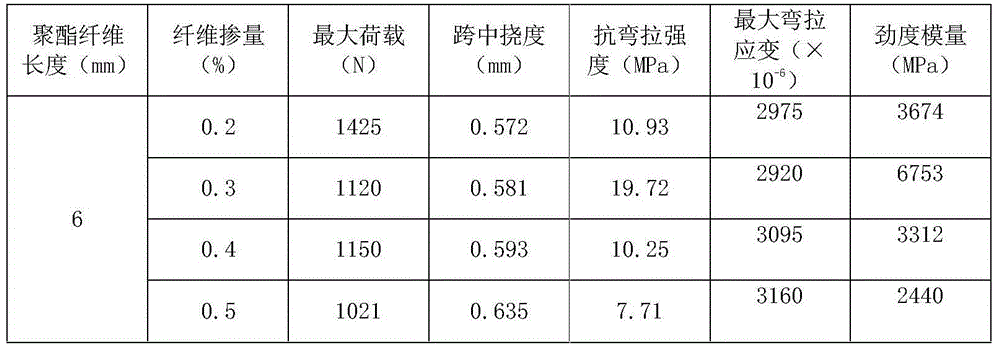

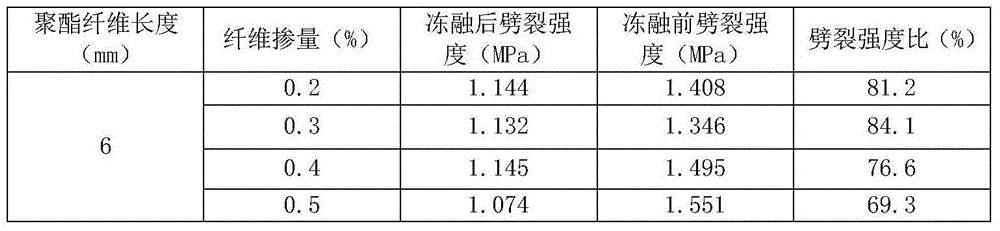

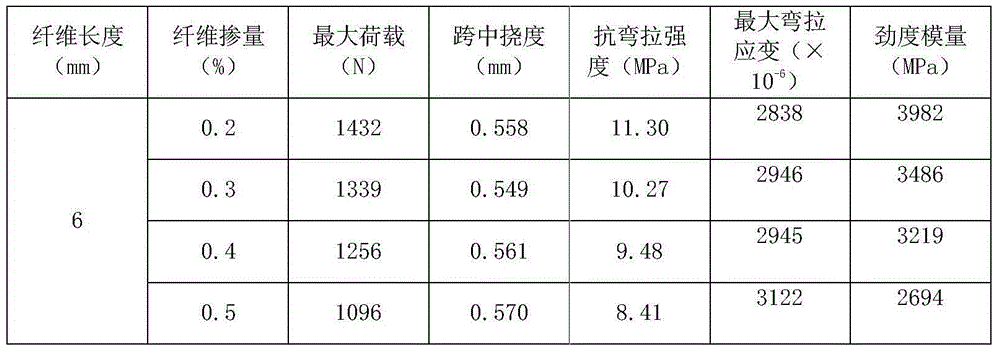

High-RAP-content asphalt mixture formula and preparation method

InactiveCN104926233AImprove bending abilityGood resistance to temperature stressSolid waste managementPolyesterPortland cement

The invention belongs to the technical fields of road paving materials and processing and preparation thereof. A high-RAP-content asphalt mixture formula comprises the following components in percentage by weight: 40-65% of milled waste material, 30-50% of aggregate, 1.5% of mineral powder, 1.5% of ordinary portland cement, 0.3% of polyester fiber or basalt fiber, 2.8-3.9% of substrate asphalt. The content of RAP can be increased to 40-65%.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST +1

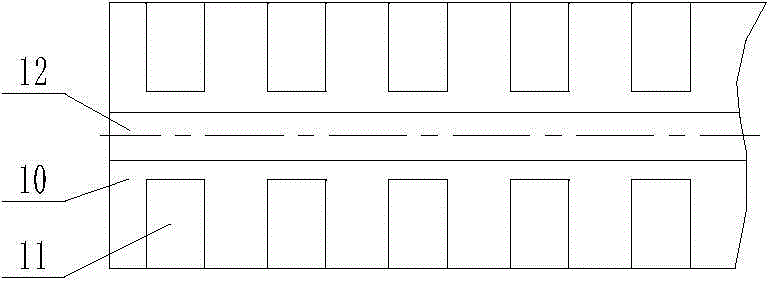

Masonry wall panel for retaining bricks

ActiveUS8627625B2Improve bending abilitySwift and easy insertionCeilingsCovering/liningsBrickStructural engineering

The present invention concerns a masonry wall panel assembly comprising a panel and a plurality of bricks. The panel is provided with a plurality of horizontally extending contiguous channels bounded by upper and lower protruding ribs, for fitting a row of bricks. Each channel is also fitted with a plurality of compressible retaining tabs positioned along the upper rib of each channel for retaining bricks inserted therein. The bricks are provided with at least one cavity and at least one compression area so that when a brick is inserted into a channel of the panel, the brick is positioned between the ribs such that the cavity of the brick faces one or more of the tabs located on the channel so that the tabs protrude into the cavity of the brick while at the same time compressing the compression area, thereby retaining the brick within the channel.

Owner:OLDCASTLE BUILDING PROD CANADA INC

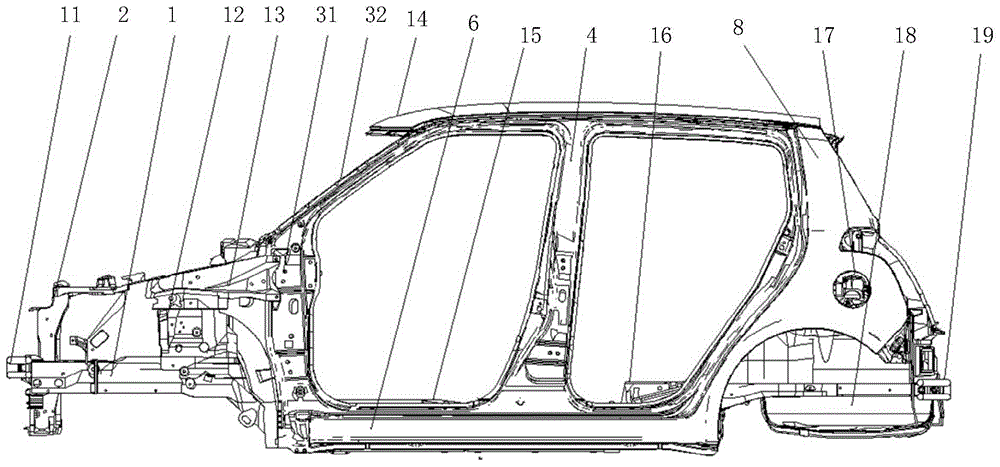

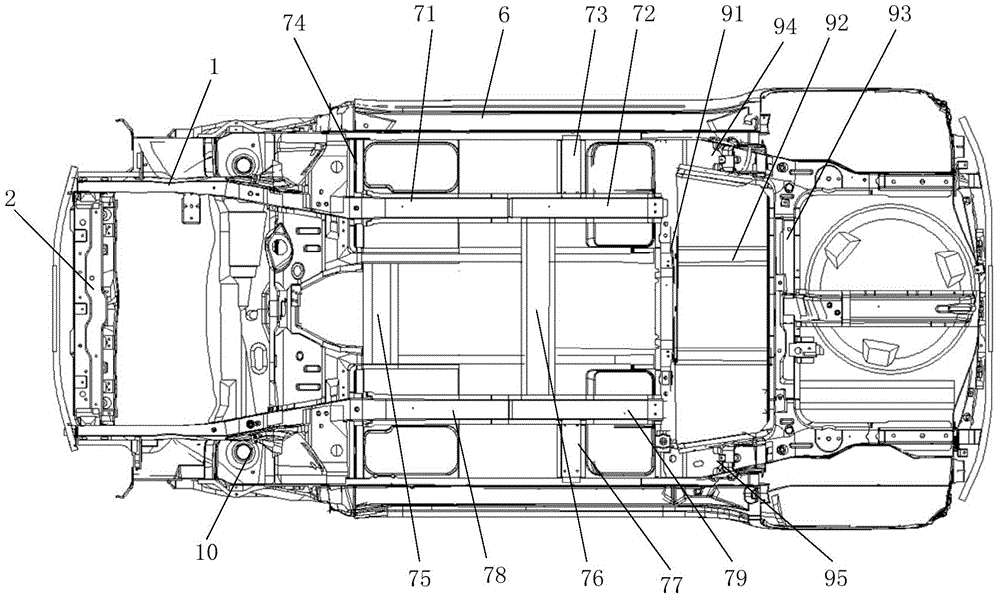

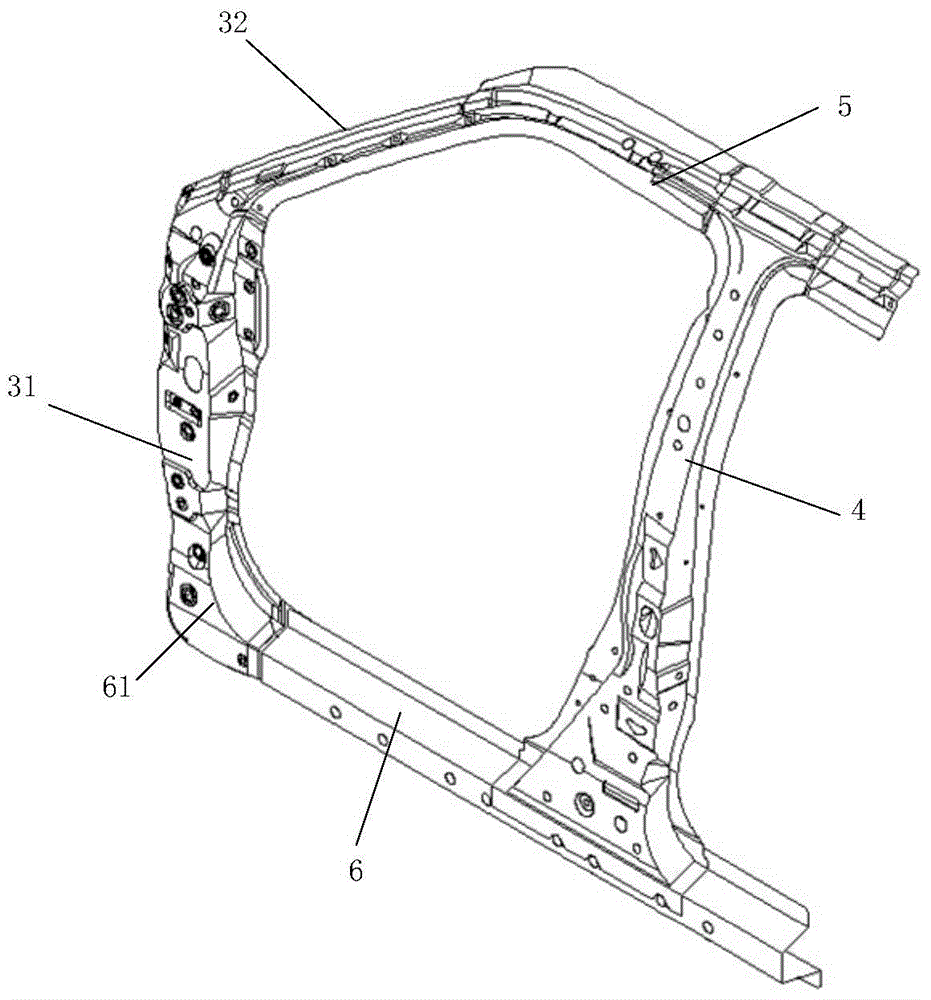

Body in white bend resistance structure and arrangement mode thereof

ActiveCN105015623AIncrease local overlapImprove bending resistanceSuperstructure subunitsMonocoque constructionsStructural engineeringEngineering

The invention provides a body in white bend resistance structure and an arrangement mode thereof. The lower end of a lower vertical plate of a column A is in overlap connection with a sill strip. The upper end of the lower vertical plate of the column A is in overlap connection with an outer plate of the column A. The outer plate of the column A is in overlap connection with an upper beam of a column B. The upper end of an outer plate of the column B is in overlap connection with the upper beam of the column B. The lower end of the outer plate of the column B is in overlap connection with the sill strip. Two to three layers of spot welding connection is formed at each overlap joint to form a closed structure. The bend resistance section of the sill strip, the bend resistance section of the vertical plate of the column A, the bend resistance section of the outer plate of the column A and the bend resistance section of the upper beam of the column B are each in a closed annular shape. Due to the fact that the bend resistance sections form the closed annular shapes and are composed of three or four sheet metal parts, the bend resistance is improved; due to extending sections at the upper and lower ends of the outer plate of the column B, the overlap connection efficiency of the upper beam and the sill strip of the column B and the outer plate of the column B is enhanced, and the bend resistance performance is improved; the transverse and longitudinal staggered closed structure has the effect of enhancing inertia torque, and the bend resistance performance is improved.

Owner:CHINA AUTOMOTIVE ENG RES INST

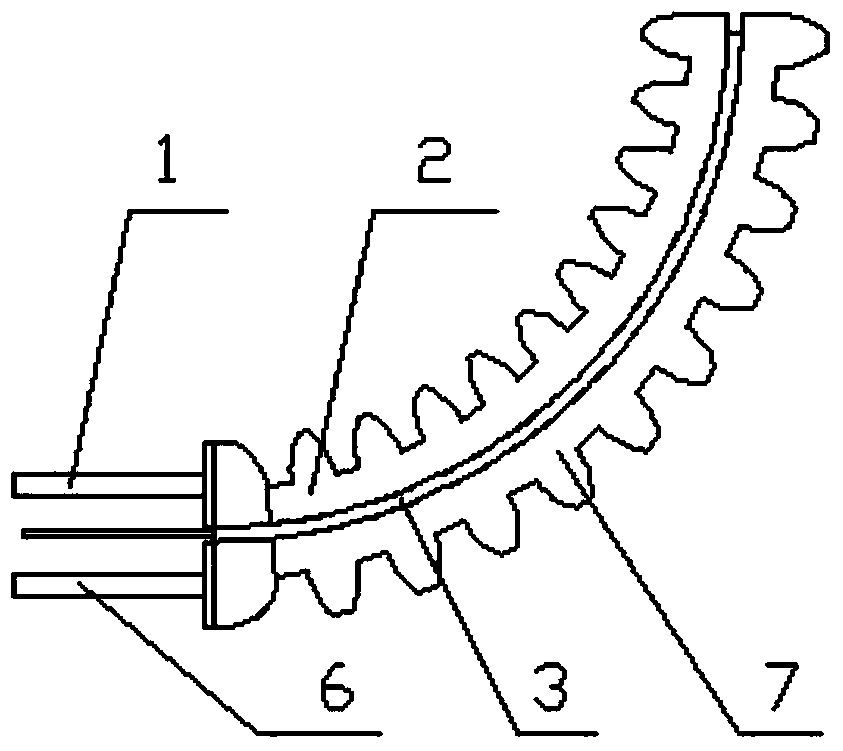

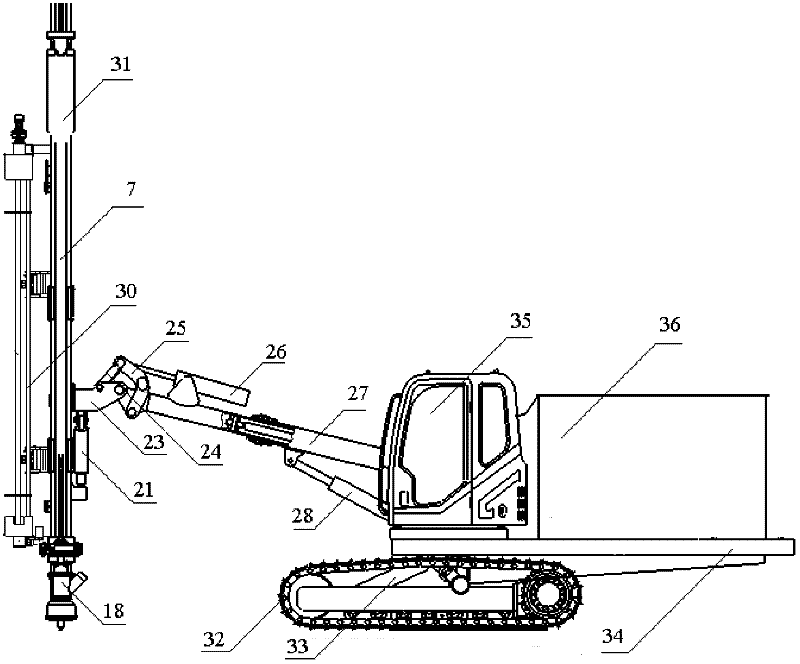

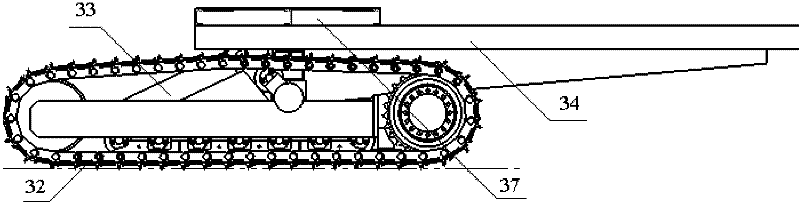

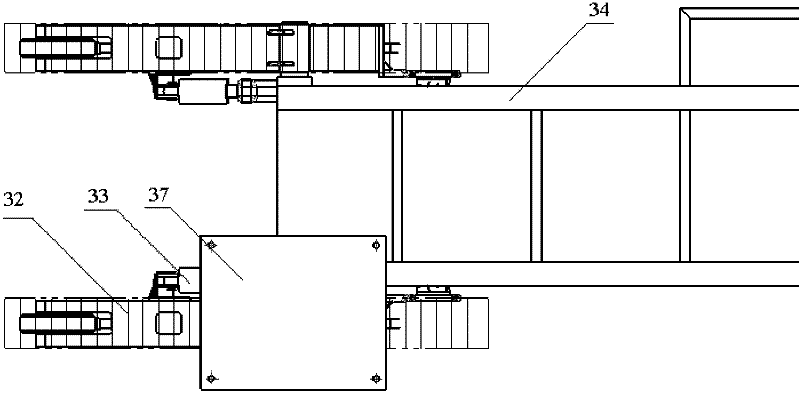

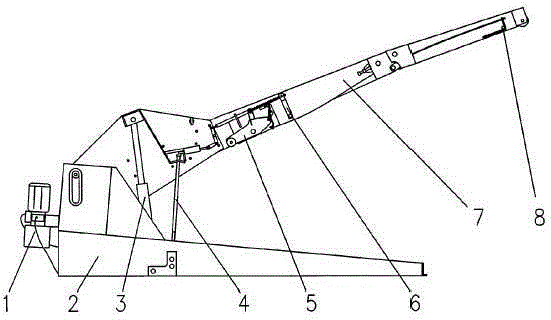

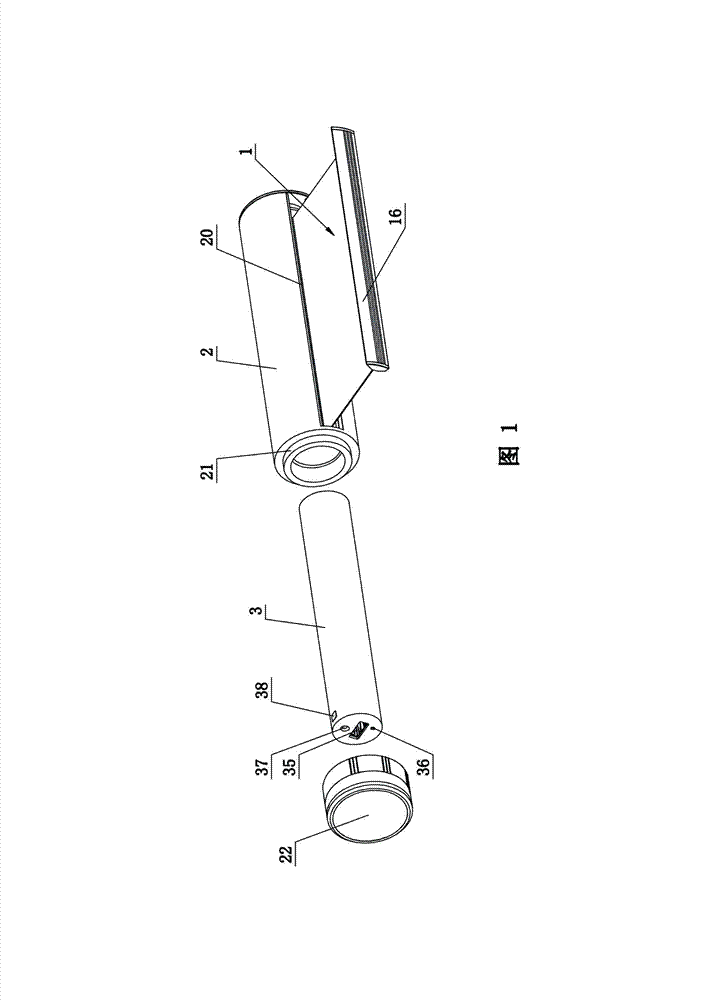

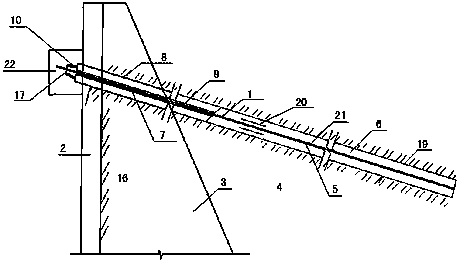

Telescopic arm open-cut rock drilling jumbo with drill rod replacing device

InactiveCN102418475AReduce design sizeReduce wearDrilling rodsDrilling casingsControl systemPropeller

The invention relates to a telescopic arm open-cut rock drilling jumbo with a drill rod replacing device. The telescopic arm open-cut rock drilling jumbo comprises a cab, a chassis assembly, a propeller assembly, a telescopic arm, the drill rod replacing device, a rock drill, a control system and a power and air control system 36; the cab is arranged on a cab bottom plate of the chassis assembly, the control system is arranged in the cab, and the control system is connected with the power and air control system; the telescopic length, the pitching angle and the deflection angle of the telescopic arm, the elongation of a propelling beam and the pitching angle of the cab are controlled by the control system; the arm seat of the telescopic arm is fixedly arranged at the front end of the cab, the propelling beam is in sliding fit with the telescopic arm through a bracket on a compensation cylinder, the telescopic end of the compensation cylinder is fixedly connected to the propelling beam, and extending compensation of the propelling beam can be realized by stretching of the compensation cylinder; and the drill rod replacing device is fixed on the propelling beam and positioned below a transmission rod, and the rock drill is fixed at the upper end of the propelling beam. The multi-azimuth drilling requirement of the jumbo can be met, and the gravity center of the whole jumbo is kept stable.

Owner:CSIC ZHONGNAN EQUIP

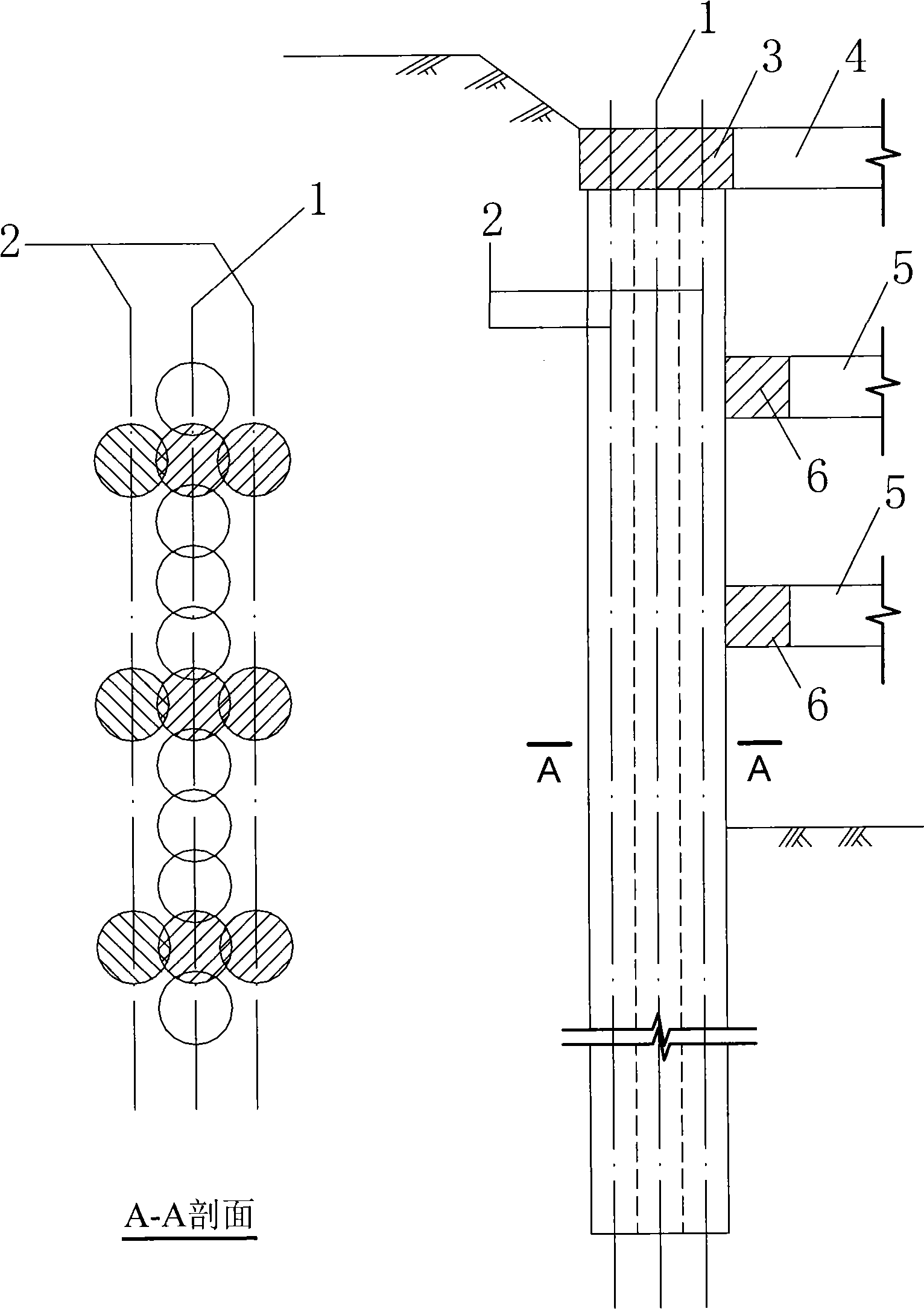

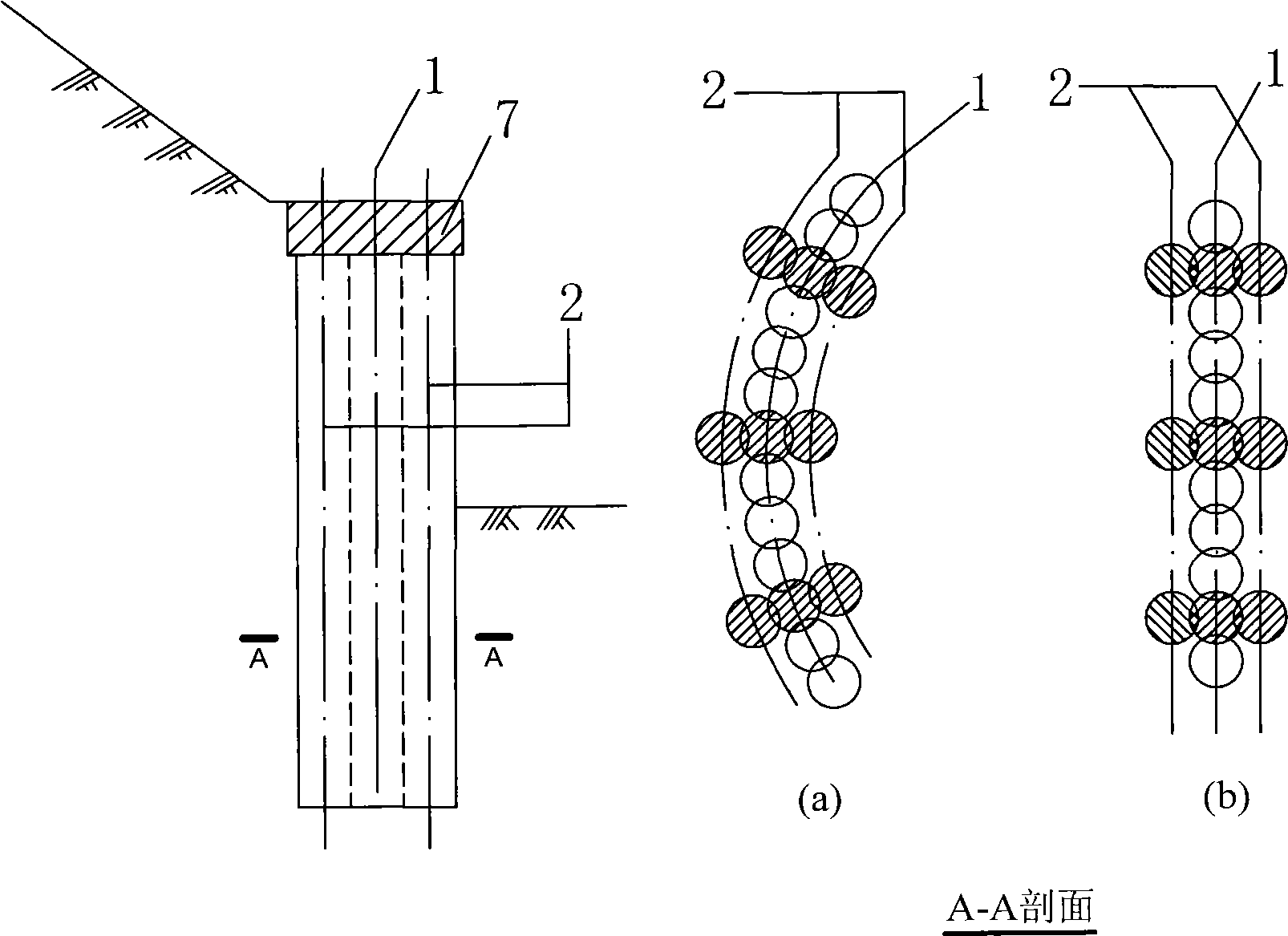

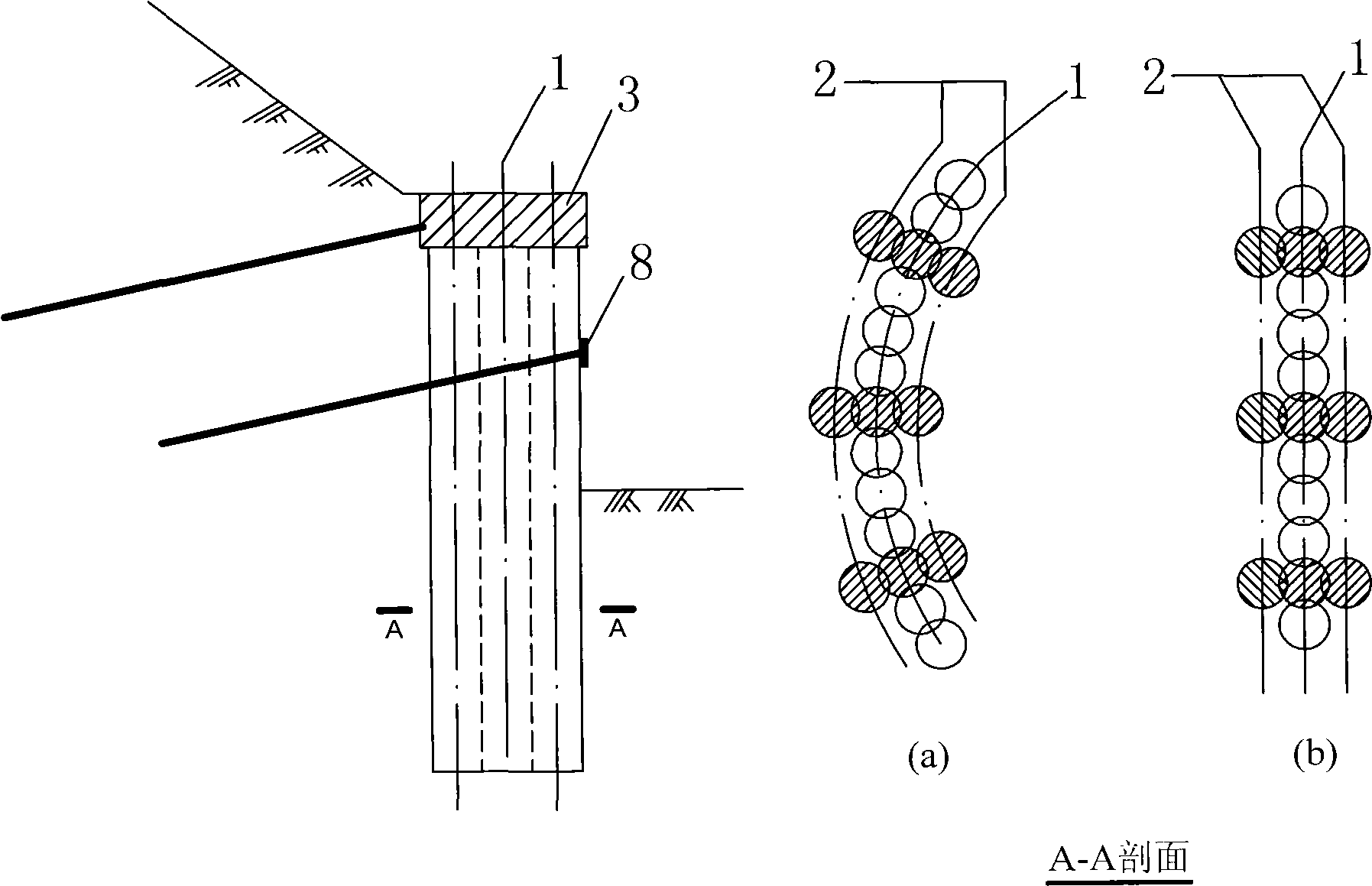

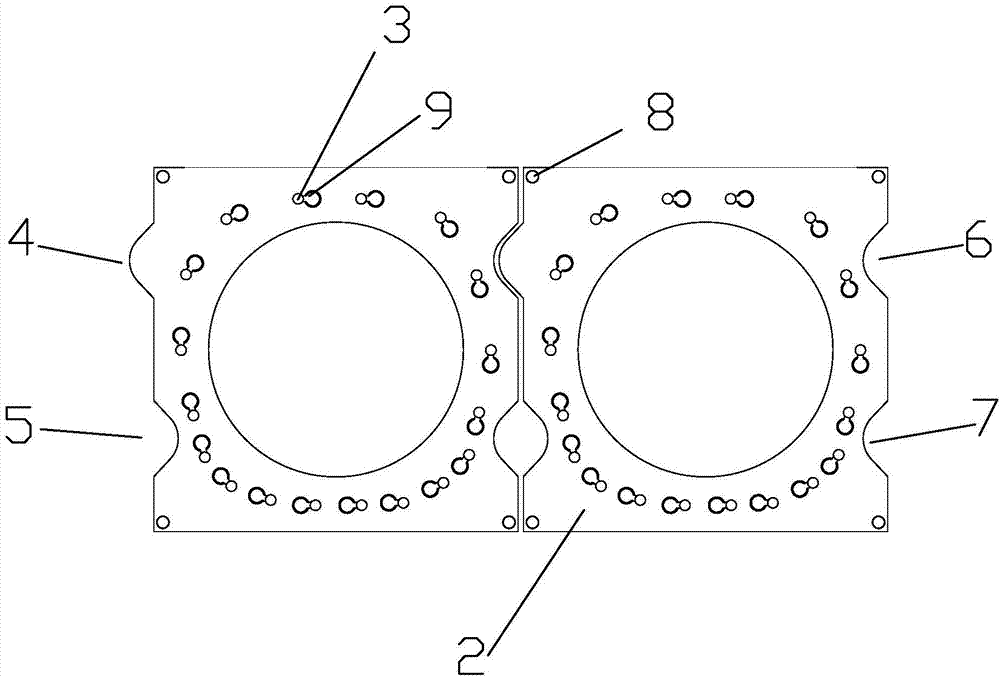

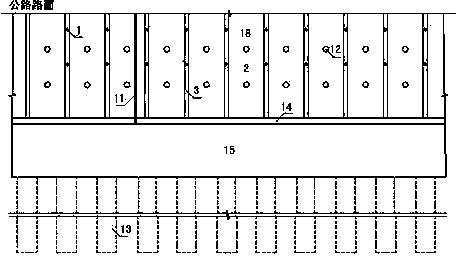

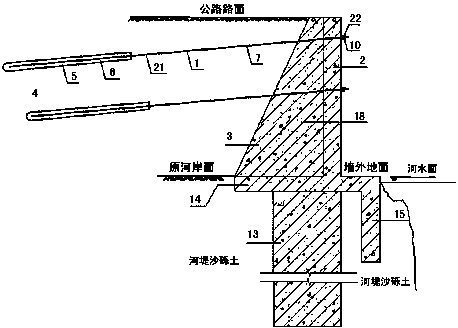

Method of using rotational multiaxial borehole pouring concrete occluding pile wall for enclosing deep foundation pit and slope protection project

The invention relates to a novel method for enclosing a deep foundation pit and a slope protection project, such as a multi-storey basement and a subway. A rotary multiaxial borehole pouring concrete occluding pile wall is combined with an internal supporting system or anchor rod to form an integral enclosing structure. The slope protection project can be enclosed by an cantilever pile wall without an internal supporting system and anchor rods inside. An enclosure wall adopting multiaxial borehole pouring concrete occluding piles can be constructed along the foundation pit enclosing axis; because the planes of the stressed multiaxial borehole pouring concrete occluding piles are rotated by 90 DEG at a fixed position, the long edges of the cross sections of the multiaxial borehole pouring concrete occluding piles are perpendicular to the foundation pit enclosing axis, so that the lateral resistant strength and the rigidity of the enclosure wall are improved, and the cost of the project is lowered. Compared with method of using the underground continuous wall for enclosing, the method is easy and rapid to implement with simple construction machines and the enclosure wall with strong rigidity, low manufacturing cost and the like. Calculation shows that the rigidity of the enclosure wall adopting conventional reinforcing steel bars can be improved by about six times, and the resistance to bending can be improved by about 2 times, and the amount of reinforcing steel bars used and the comprehensive manufacturing cost are all reduced by about half.

Owner:ZHEJIANG UNIV +2

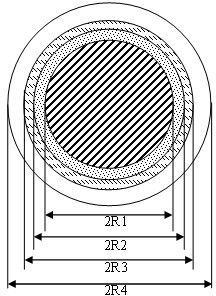

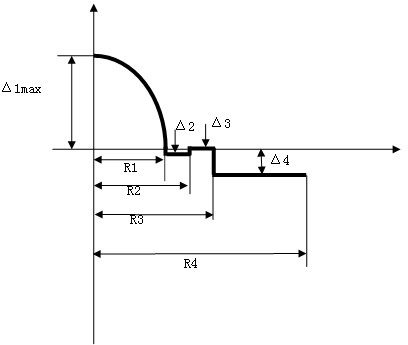

Gradual refractive index bending resistant multimode optical fiber

InactiveCN102692675AImprove transmission bandwidthReduce macrobending additive attenuationOptical fibre with graded refractive index core/claddingOptical fibre with multilayer core/claddingRelative refractive indexNumerical aperture

The invention relates to a gradual refractive index bending resistant multimode optical fiber, which includes a sandwich layer and a cladding, and is characterized in that the radius of the sandwich layer is 20 to 50 microns; the refractive index of the sandwich layer is distributed in a gradient gradation type, the distribution power exponent Alpha is 1.89 to 1.97, and the maximum relative refringence delta 1% max of the sandwich layer is 0.9% to 2.72%; the inner cladding is arranged adjacent to the sandwich layer, the radius of the inner cladding is 22 to 57 microns, and the relative refringence delta 2% is minus 0.02% to 0.02%; and a middle cladding and an outer cladding are arranged outwards the inner cladding sequentially, the middle cladding is a pure quartz glass layer, the radius of the middle cladding is 32 to 60 microns, the relative refringence delta 3% is minus 0.01% to 0.01%. The gradual refractive index bending resistant multimode optical fiber provided by the invention not only reduces the bending dissipation of the optical fiber, but also guarantees that optical fiber has high transmission bandwidth at a 1300 nm window, effectively improves the light collection and concentration capabilities of the optical fiber to LEDs, VCSELs or LDs through increasing the core diameter and numerical aperture, and improves the coupling fault-tolerant capability of luminous devices, namely between the light source and the light transmitting device, i.e. between optical fibers.

Owner:EVERPRO TECH COMPANY

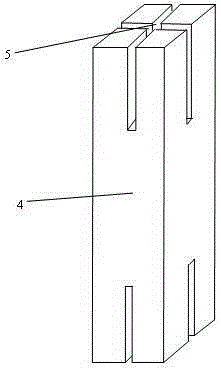

Prestressed concrete precast pile

ActiveCN103572755ANot easy to tiltImprove bending abilityBulkheads/pilesSquare cross sectionPre stress

The invention discloses a prestressed concrete precast pile. The prestressed concrete precast pile comprises a precast pile body with a square cross section, wherein the precast pile body comprises two end plates, a pile body and prestressed reinforcements, the pile body is arranged between the two end plates, and the prestressed reinforcements are arranged in the pipe body and connected with the two end plates; bulge rib which longitudinally extends to an end and a first groove which longitudinally extends and penetrates through the end are arranged on an outer side surface of the precast pile body; and a second groove and a third groove which are corresponding to positions of the bulge rib and the first groove respectively, matched in shape and size and longitudinally extend and penetrate through an end of the precast pile body are formed in one outer side surface which is not adjacent to the outer side surface. According to the prestressed concrete precast pile, the construction is convenient, the engineering cost can be reduced, the water stopping effect is enhanced, and the prestressed concrete precast pile has good bending and shearing resistance.

Owner:宁波中淳高科股份有限公司

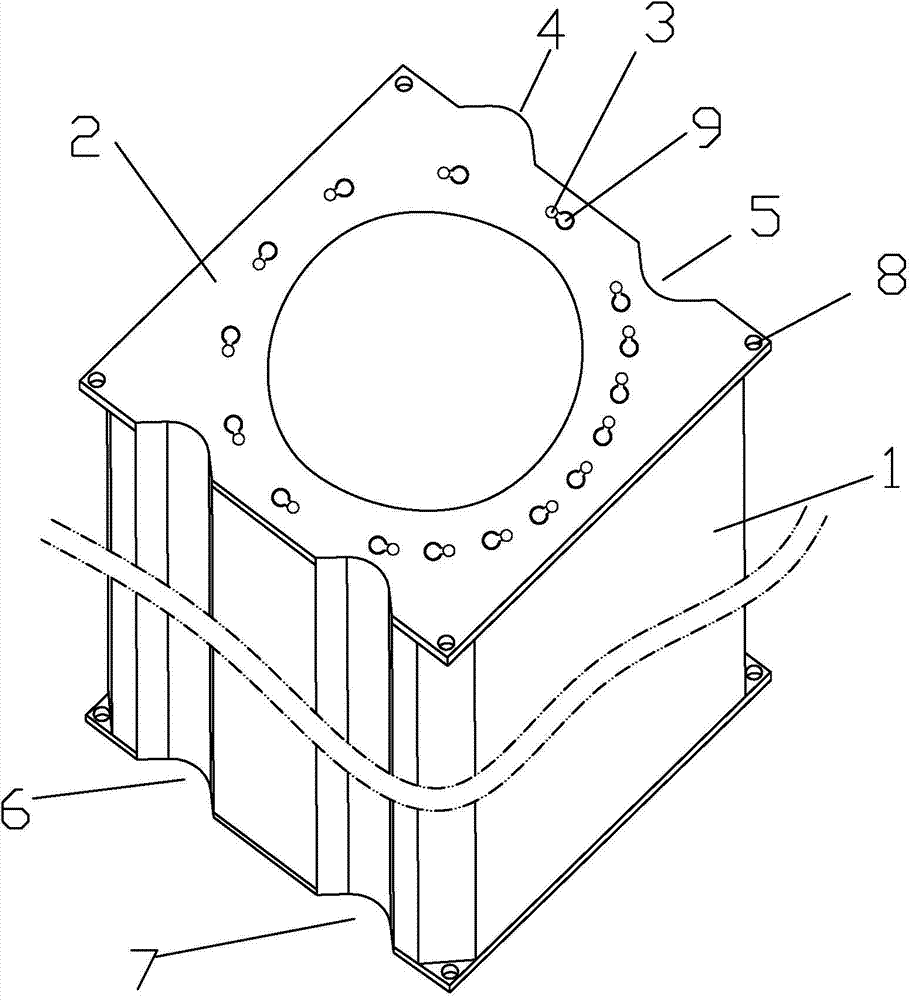

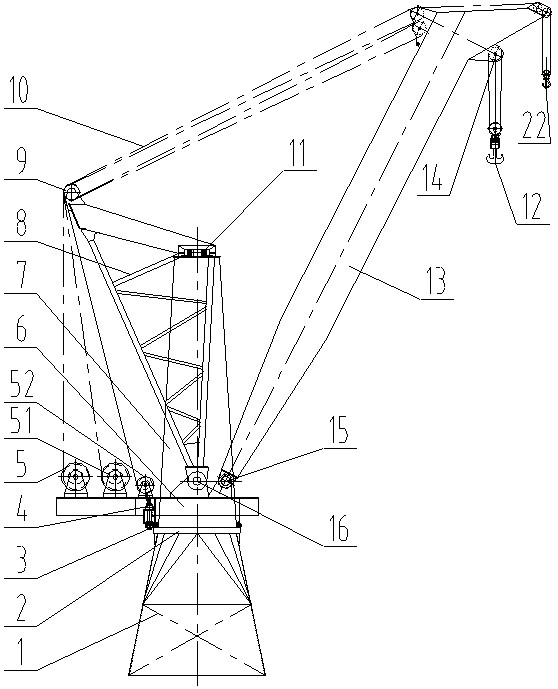

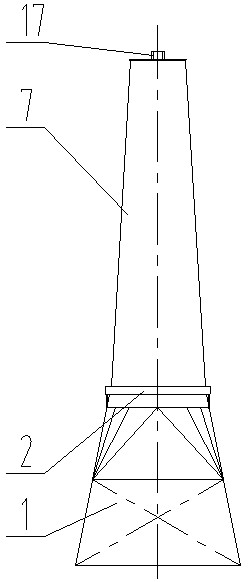

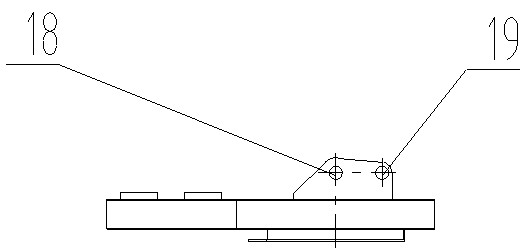

Fixed post type fully rotary crane

ActiveCN102431908ASimplify the load-bearing structureImprove the state of stressCranesEngineeringMarine navigation

The invention relates to a fixed post type fully rotary crane, which belongs to crane transportation machinery for a boat. A flange (2) is arranged on the outer surface of the middle lower section of a fixed post, a fixed post top shaft (17) is arranged in the end surface center of the top of an upper fixed post (7), a rotary supporter (3) is connected above the flange (2), the upper part of the rotary supporter (3) is fixedly connected with a rotary table (6), a hanging arm (13) and a top pulley frame (8) are respectively hinged on the rotary table (6), a top bearing (11) and a top pulley group (9) are respectively and fixedly arranged on the top pulley frame (8), the top bearing (11) is sheathed onto the fixed post top shaft (17), a rotary mechanism (4) is arranged on the rotary table (6) or a lower fixed post (1), the integral height of the crane is reduced, in addition, the full rotation is realized, the operation of the whole machine is stable, the load bearing and the bending resistance capability of the crane are greatly improved, the service life is greatly prolonged, and the fixed post type fully rotary crane is particularly suitable for being used on large-scale floatingcrane boats and ocean engineering boats with crane weight limitation and navigation height limitation.

Owner:QINGDAO HAIXI HEAVY DUTY MASCH CO LTD

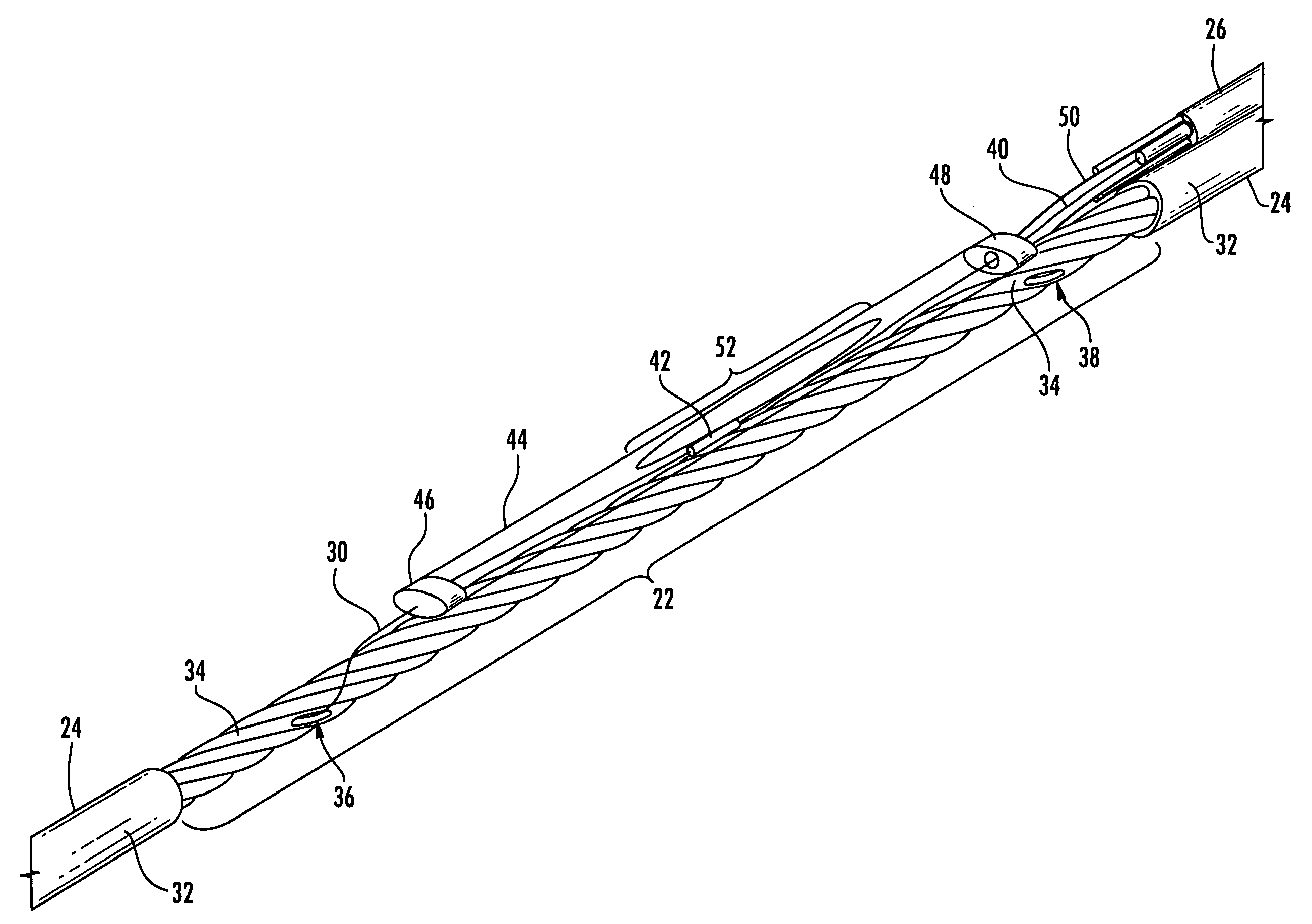

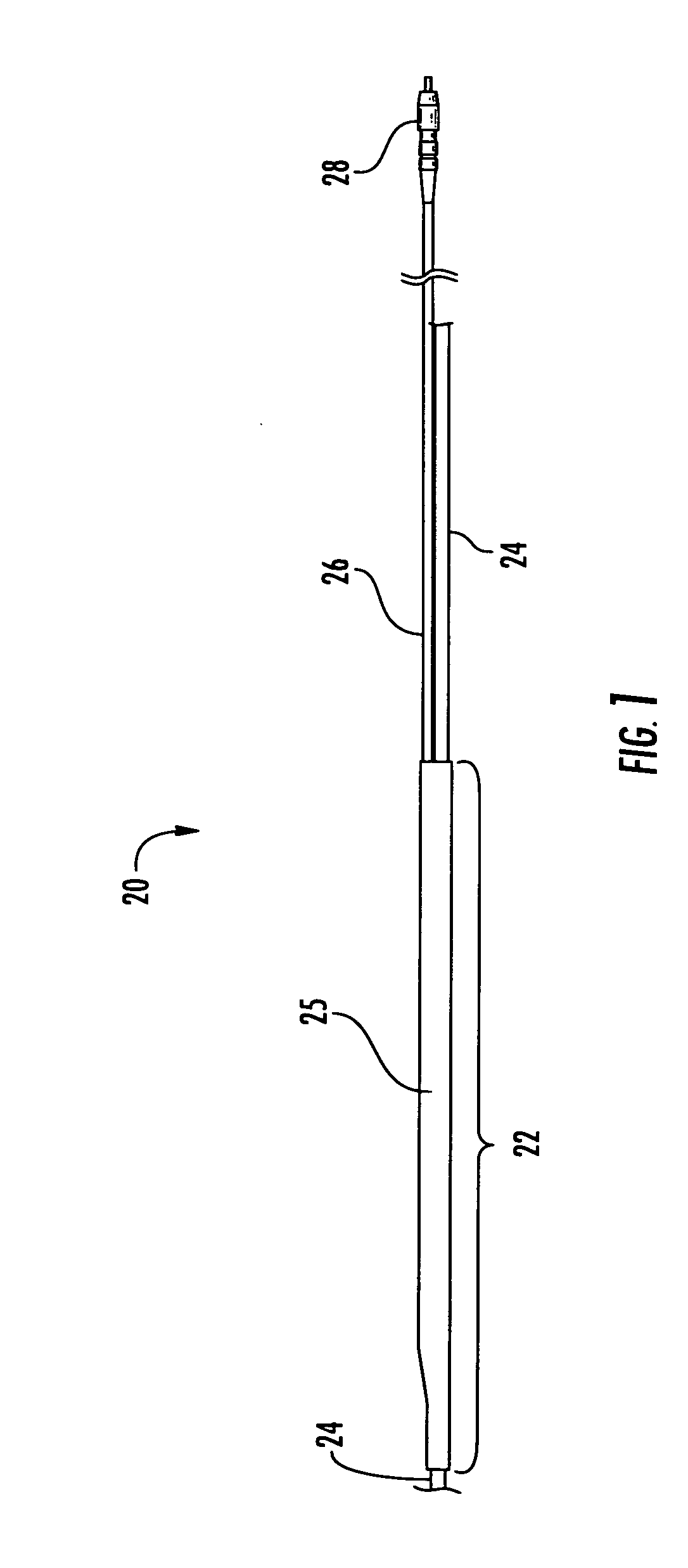

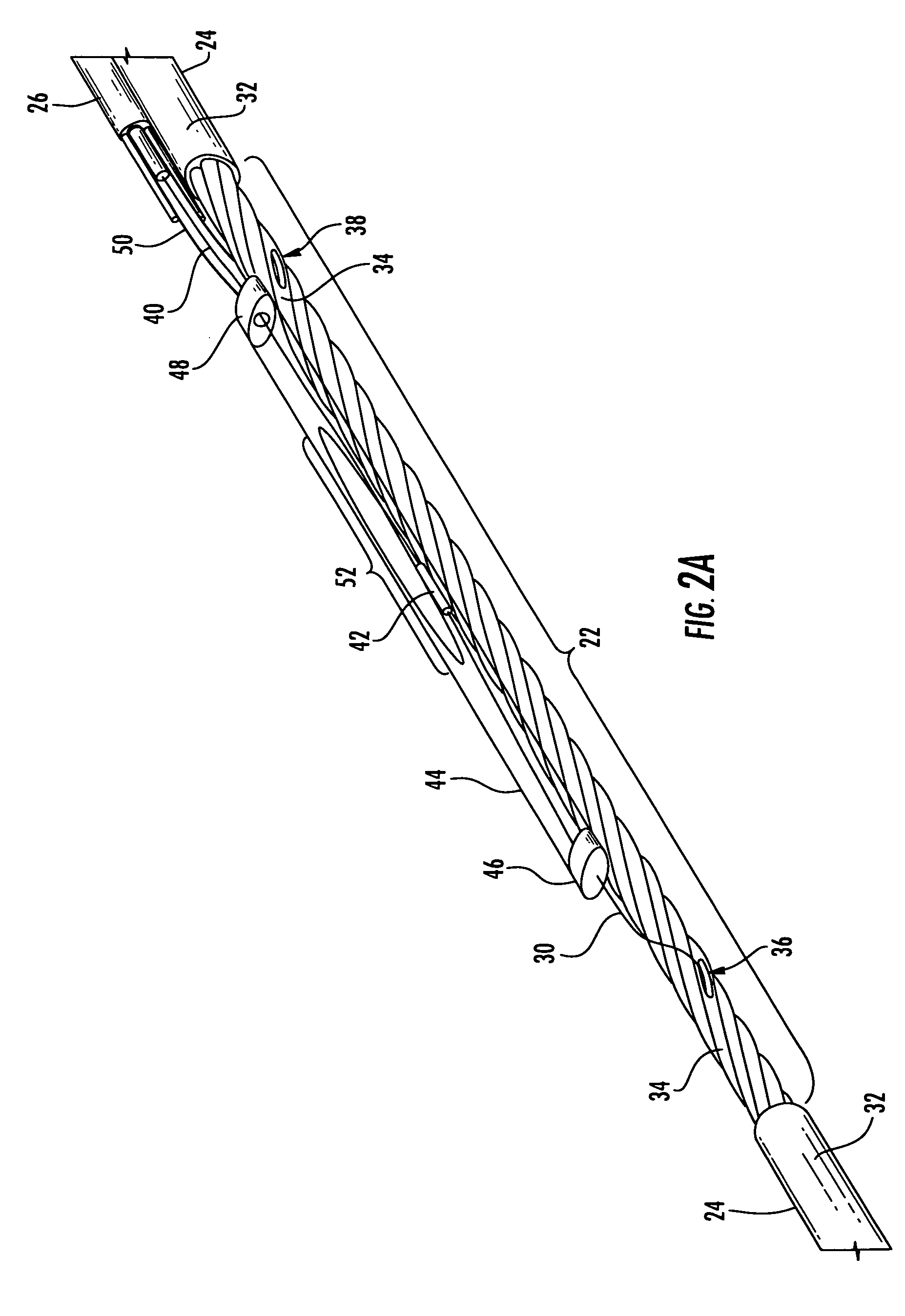

Cable assembly having bend performance optical fiber slack coil

ActiveUS20080112675A1Reduce diameterReduce the overall diameterCoupling light guidesFibre mechanical structuresEngineeringFiber

A fiber optic cable assembly including a mid-span access location, a cable having at least fiber therein, and a tether attached and spliced to at least one fiber of the cable. The access location and portions of the cables are substantially encapsulated within a flexible body having dimensions sufficient to accommodate a slack coil or loop of bend performance optical fiber therein. A method for making a fiber optic cable assembly including an access location, distribution cable, tether and slack coil of optical fiber maintained within a flexible overmolded body while providing an assembly having a cross-sectional diameter less than about 1.25 inches.

Owner:CORNING OPTICAL COMM LLC

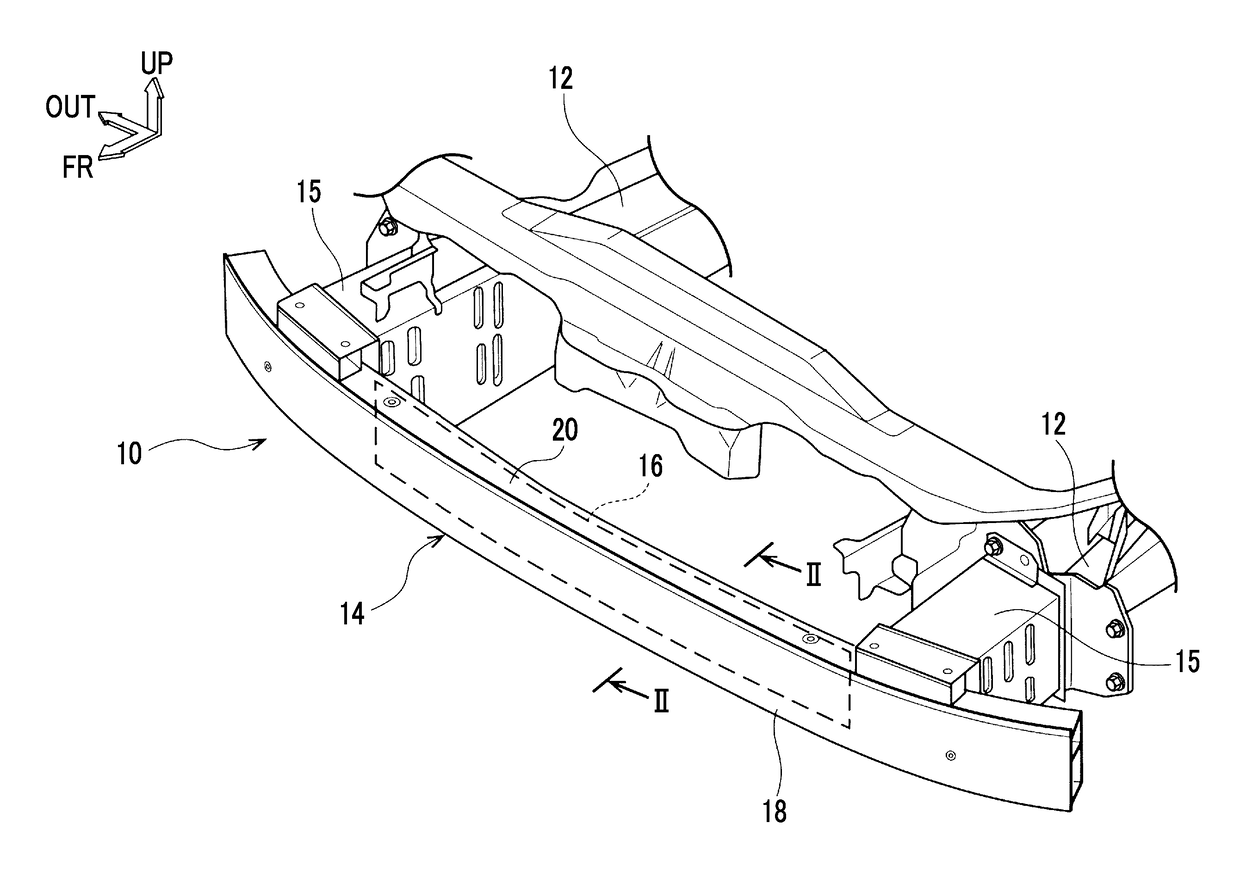

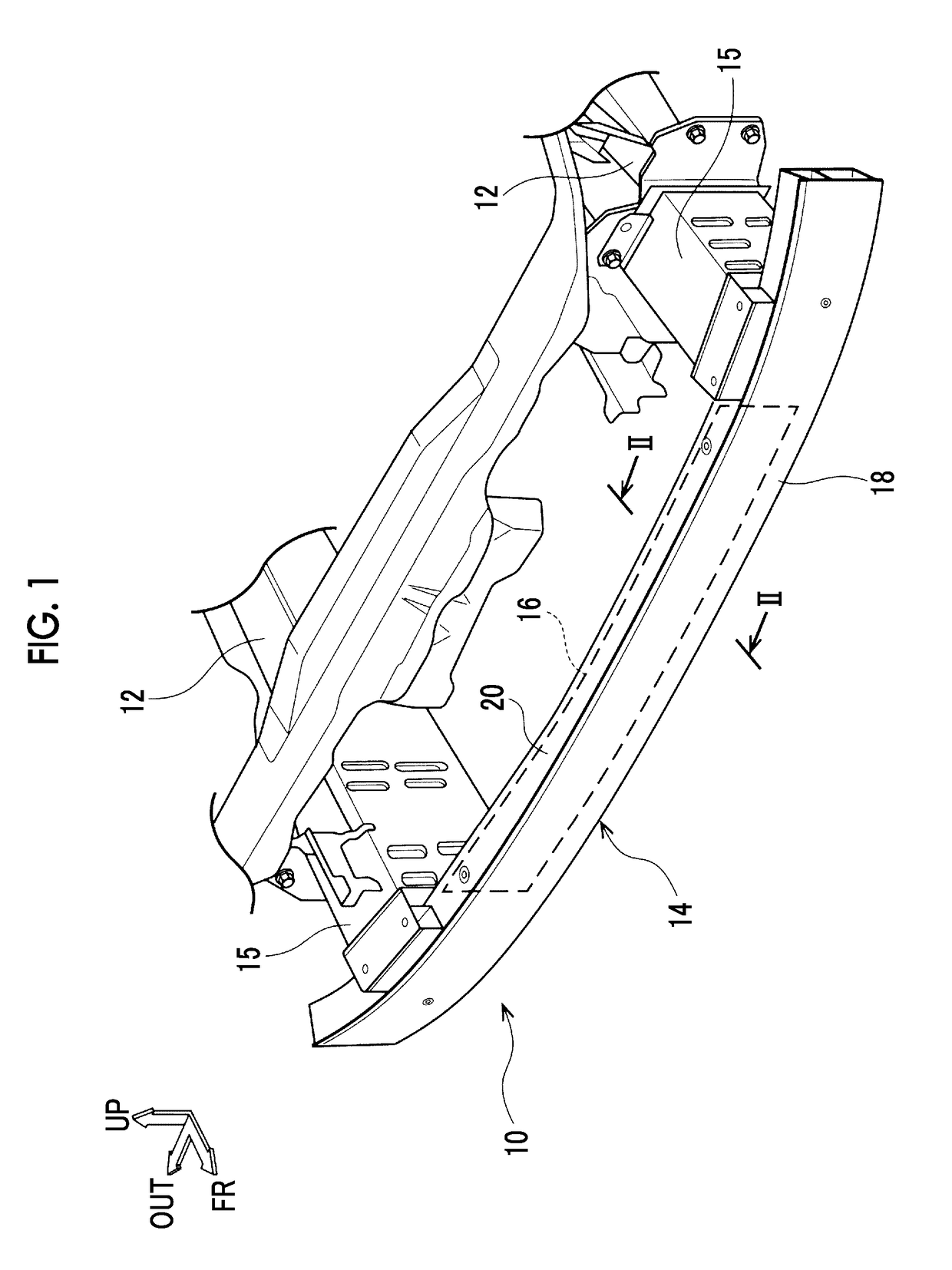

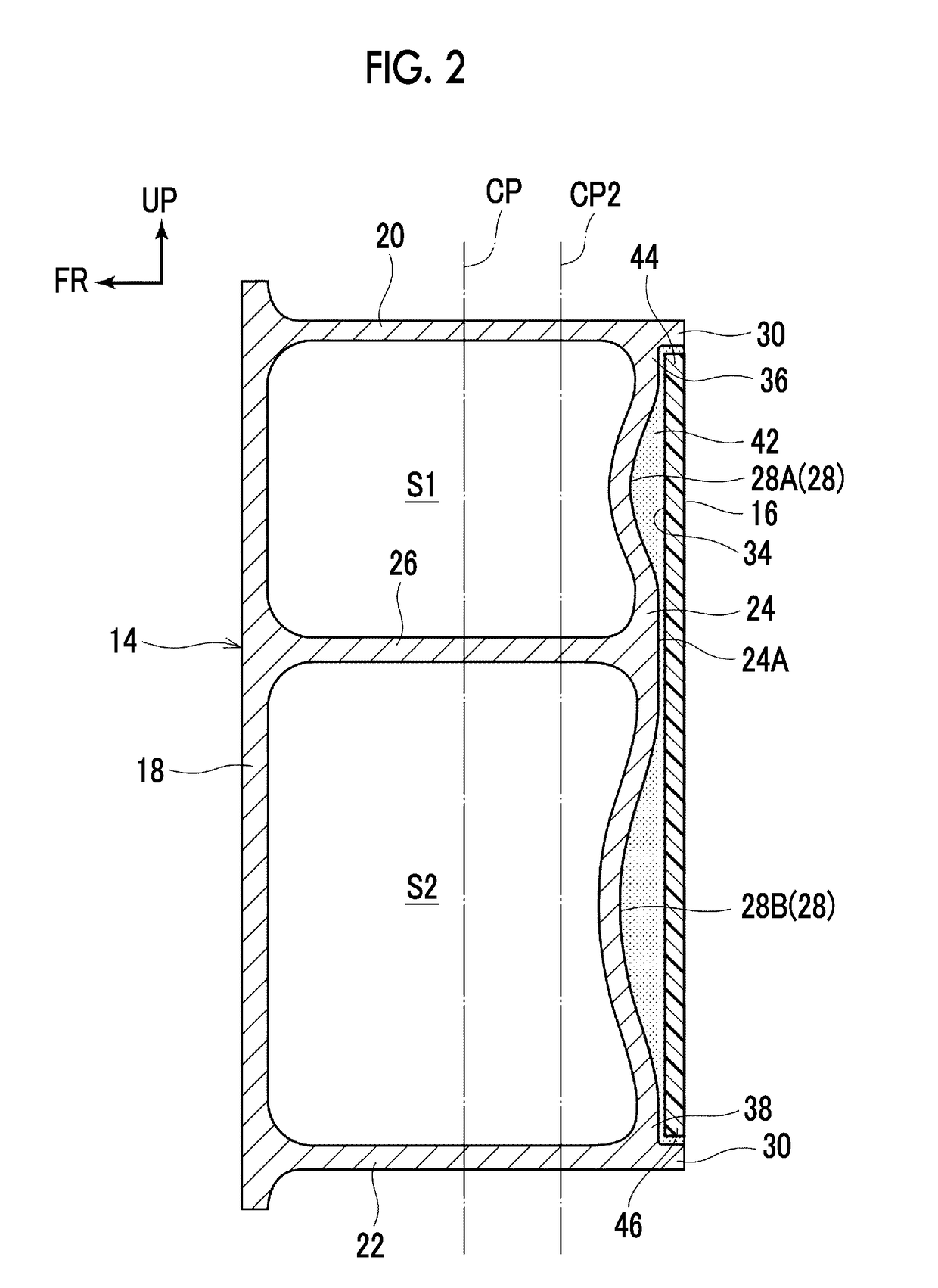

Vehicle body structure

ActiveUS20180257586A1Reduced adhesion strengthImprove bending abilityPedestrian/occupant safety arrangementSuperstructure subunitsFiberAdhesive

A vehicle body structure includes a reinforcing material layer formed of a fiber reinforced resin and a vehicle skeleton member having a closed sectional structure formed of metal. The reinforcing material layer is bonded to a surface of the vehicle skeleton member having a recessed portion recessed toward an inside of the closed sectional structure. An adhesive is disposed at least between the recessed portion and the reinforcing material layer.

Owner:TOYOTA JIDOSHA KK

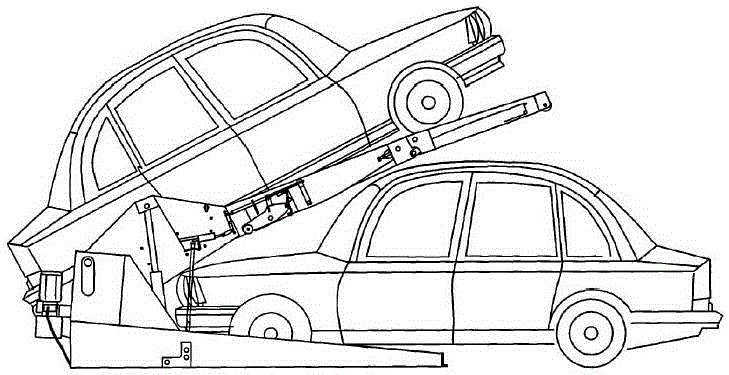

Side movement type parking system

The invention belongs to the technical field of vehicle parking, and particularly discloses a side movement type parking system. The system comprises a supporting frame and a bracket used for supporting a vehicle, wherein the supporting frame is pivoted to the bracket, the supporting frame is located below the bracket, and a supporting hydraulic cylinder is arranged between the supporting frame and the bracket; a cylinder tube of the supporting hydraulic cylinder is hinged to the supporting frame, a piston rod of the supporting hydraulic cylinder is hinged to the bracket, and a hydraulic station is arranged on the supporting frame and connected with the supporting hydraulic cylinder through a first hydraulic pipe. The system further comprises a telescopic mechanism, wherein the telescopic mechanism comprises a power part, a telescopic part and a fixed block fixed to the ground, the power part, the telescopic part and the fixed block are sequentially connected, the power part is fixed in the supporting frame, and the supporting frame is located within the projected area of the bracket in the horizontal plane. The system has the advantages of being high in adaptability in a parking lot, and capable of improving the parking rate of the parking lot.

Owner:杨自忠

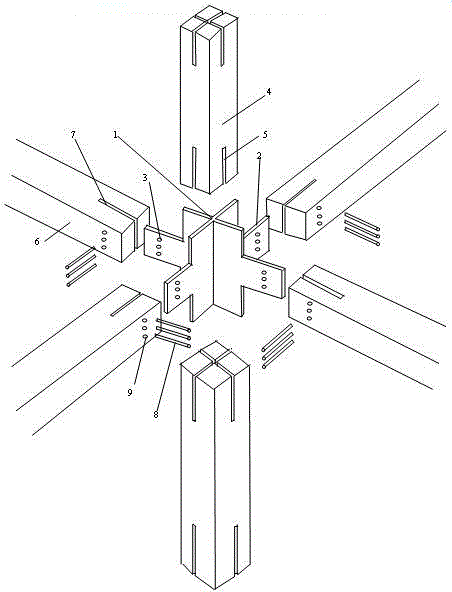

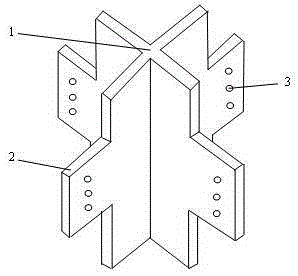

Wooden-structure building beam-column joint structure

ActiveCN105178448AImprove connection strengthImprove bending abilityBuilding constructionsMortise and tenonAdhesive

A wooden-structure building beam-column joint structure is provided. In this structure, a wooden column and a wooden beam are connected through a steel connector; the steel connector is formed by perpendicularly welding two steel sheets special in shape; the steel connector can be divided into two parts according to usable functions, namely a cross steel sheet part and a linear steel sheet part; the wooden column and the steel connector are reinforced with engineering adhesive; the wooden beam and the steel connector are fixed with a steel rod. The wooden-structure building beam and column are connected with the steel connector and the engineering adhesive instead of a mortise and tenon structure, the connective strength, bending resistance and tensile capacity of a joint are substantially higher than those of the mortise and tenon structure, and the wooden-structure building beam-column joint structure is particularly suitable for large wooden connections; the wooden-structure building beam-column joint structure is simple in structure, and members of this structure are easy to mechanically produce; the joint is simple to mount, quick to construct and low in manufacturing cost.

Owner:沈阳促晋科技有限公司

Molded fiber reinforced polymer artificial marble and its production method

The invention discloses an artificial marble of moulded shaped fiber reinforced polymer and making method, which comprises the following parts: 32-46% insaturated polyester resin, 0.2-0.9% hardener, 0.2-1. 4% thickener, 0.6-1. 5% inner stripper, 41-46% fill, 7. 2-11. 9% glass fiber and 4. 8-6. 3% artificial colorful grain, wherein the artificial colorful grain is composed of 32-49% insaturated polyester resin, 0.5-2% methyl-ethyl ketone peroxide, 0.5-2% cobalt isooctanoic acid, 49-60% calcium carbonate and 1-4% dye. The making method of marble comprises the following steps: allocating mould plastic with those raw materials; thickening; moulding; shaping.

Owner:WUHAN UNIV OF TECH

Method for processing rectangular-tooth spline sleeve using 42CrMoE high-quality alloy steel as material

InactiveCN102534374AImprove wear resistanceImprove bending abilityCouplings for rigid shaftsPhosphorylationThermal treatment

The invention discloses a method for processing a rectangular-tooth spline sleeve using 42CrMoE high-quality alloy steel as a material, belonging to the technical field of thermal treatment. The method comprises the steps of: free forging of a blank, normalizing treatment, rough turning, hardening and tempering thermal treatment, finish turning, spline drawing, drilling, burr gripping, carburization treatment, surface deposition treatment, phosphorylation treatment, electroplating, drying and detection. In the invention, due to the new material and new technology, the wear resistance of the produced rectangular-tooth spline sleeve is greatly enhanced, the phenomenon of crack of the rectangular-tooth spline sleeve is avoided, the surface is smooth, the friction is low, the heat dissipation is good, and the service life is prolonged, thus the processing technology is widely applied.

Owner:无锡市万邦机械制造厂

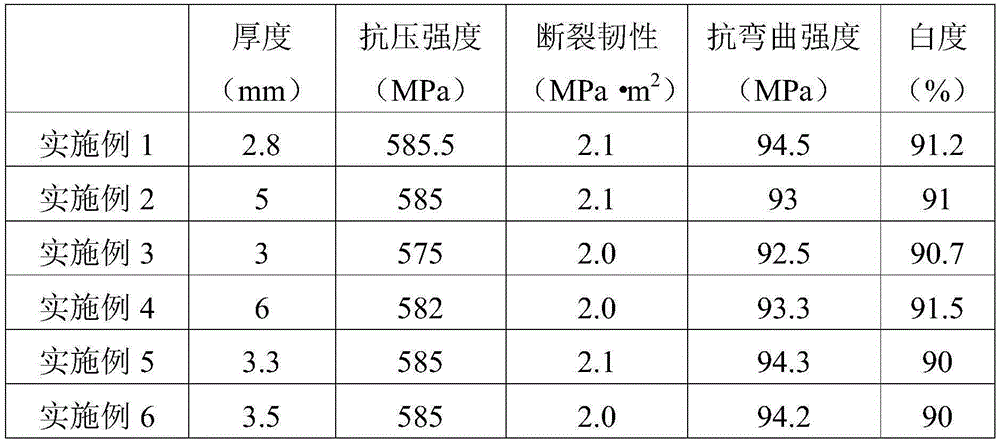

Preparation technology for glass ceramics sheet

ActiveCN105271642AImprove bending abilitySolve technical problems that are easily deformedGlass rolling apparatusFlexural strengthNucleation

The invention discloses a preparation technology for a glass ceramics sheet. The preparation technology includes the steps that 1, SiO2, Al2O3, K2O, Na2O, CaO, MgO, F and a clarifying agent are weighed to obtain batch; 2, the batch is added into a melting furnace, the melting temperature is controlled to be 1510 DEG C-1520 DEG C, and the melted batch is clarified on the stirring condition to generate glass melt; 3, the glass melt enters a three-roll roller press to be rolled and calendered to form a glass plate; 4, the glass plate enters a roller kiln, and a glass ceramics sheet is obtained through primary nucleation, intensified nucleation and crystallization; 5, annealing, cooling, polishing and trimming are carried out on the obtained glass ceramics sheet to obtain the glass ceramics sheet product. The thickness of the glass ceramics sheet prepared through the preparation process according to the component content is 2-10 mm, the technical effect of bending resistance of the sheet in the production technical process is achieved, bending resistance and compressive strength are high, industrialization of the glass ceramics sheet is achieved, and market promotion is easy.

Owner:JIANGXI XINFENG MICROCRYSTALLINE JADE CO LTD

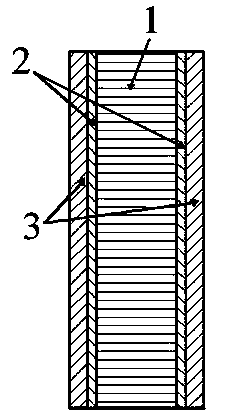

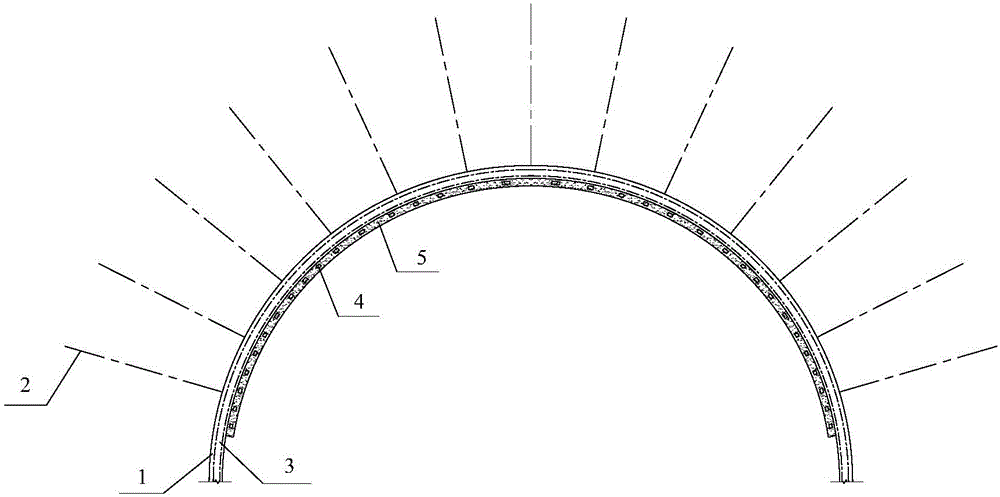

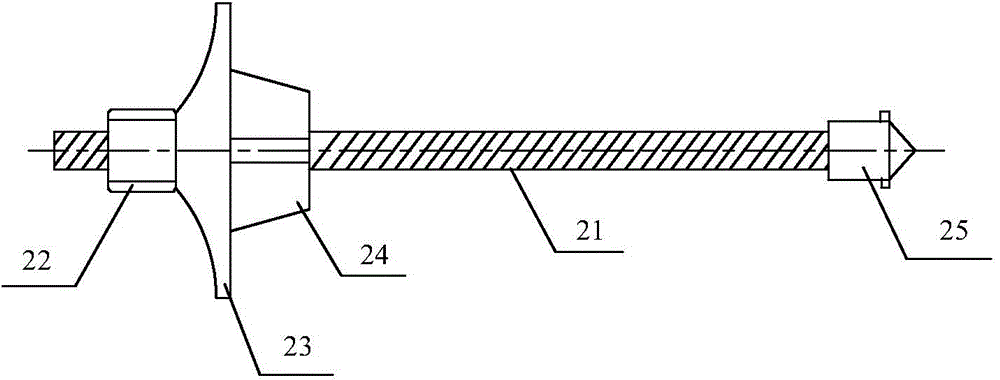

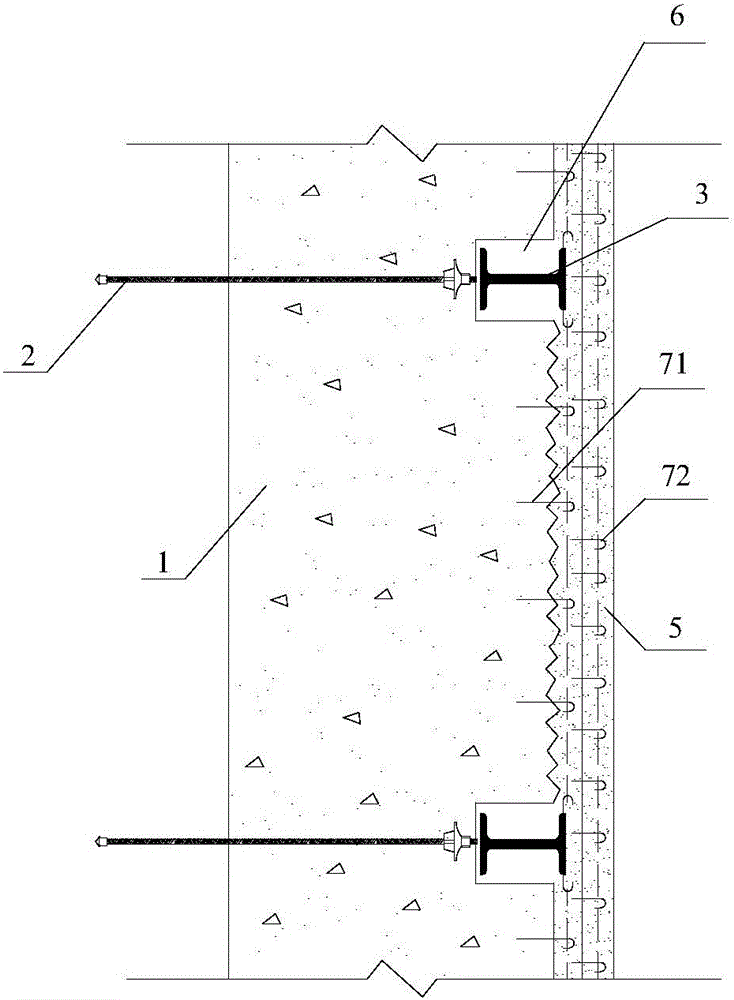

Tunnel lining rapid repair structure based on carbon fiber woven mesh and repair method thereof

ActiveCN104895581AImprove bearing capacityReduce external water pressureUnderground chambersTunnel liningFiberJoist

The invention relates to a tunnel lining rapid repair structure based on a carbon fiber woven mesh and a repair method thereof. The tunnel lining rapid repair structure based on the carbon fiber woven mesh comprises self-propelled hollow grouting anchors, joist steel, the carbon fiber woven mesh, U-shaped hooks and a composite mortar layer. The joist steel is arranged on a tunnel lining to be repaired, one end of each self-propelled hollow grouting anchor stretches into the tunnel lining to be repaired in the radial direction of the tunnel lining to be repaired, the other end of each self-propelled hollow grouting anchor is connected with joist steel, the carbon fiber woven mesh is laid on the inner wall of the tunnel lining to be repaired and connected with the joist steel through the U-shaped hooks, and the composite mortar layer is sprayed on the inner surface of the carbon fiber woven mesh. The tunnel lining rapid repair structure based on the carbon fiber woven mesh and the repair method thereof aims to solve the problems existing in the existing tunnel lining reinforcing technology, the structure is reasonable in design, the mechanical property is good the steps of the method is simple, the operability is high, and the project cost is low.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

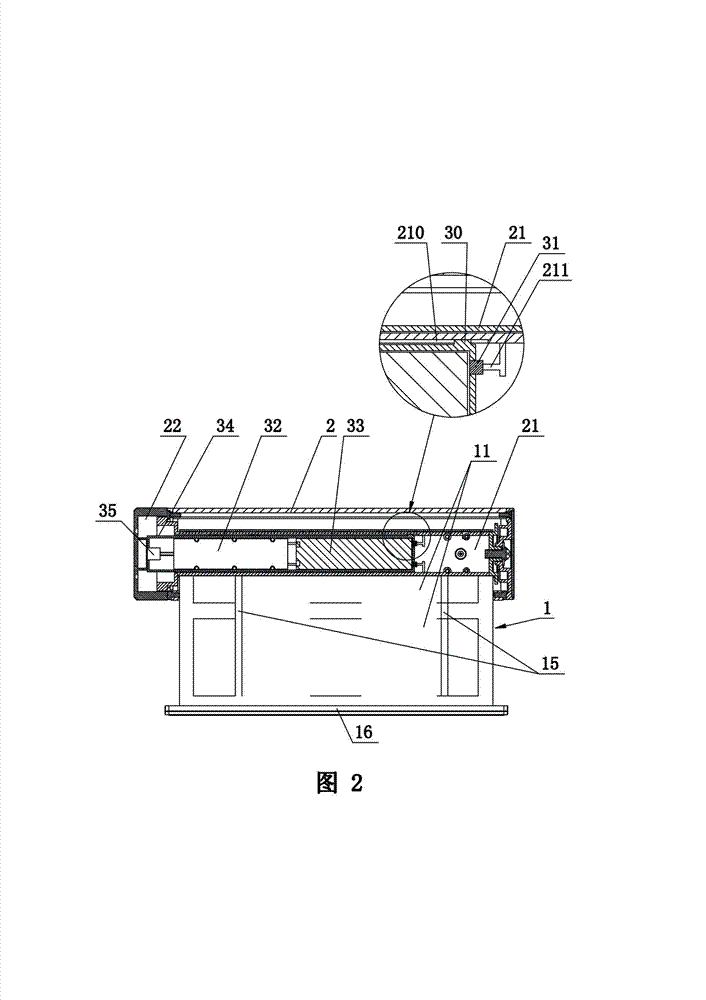

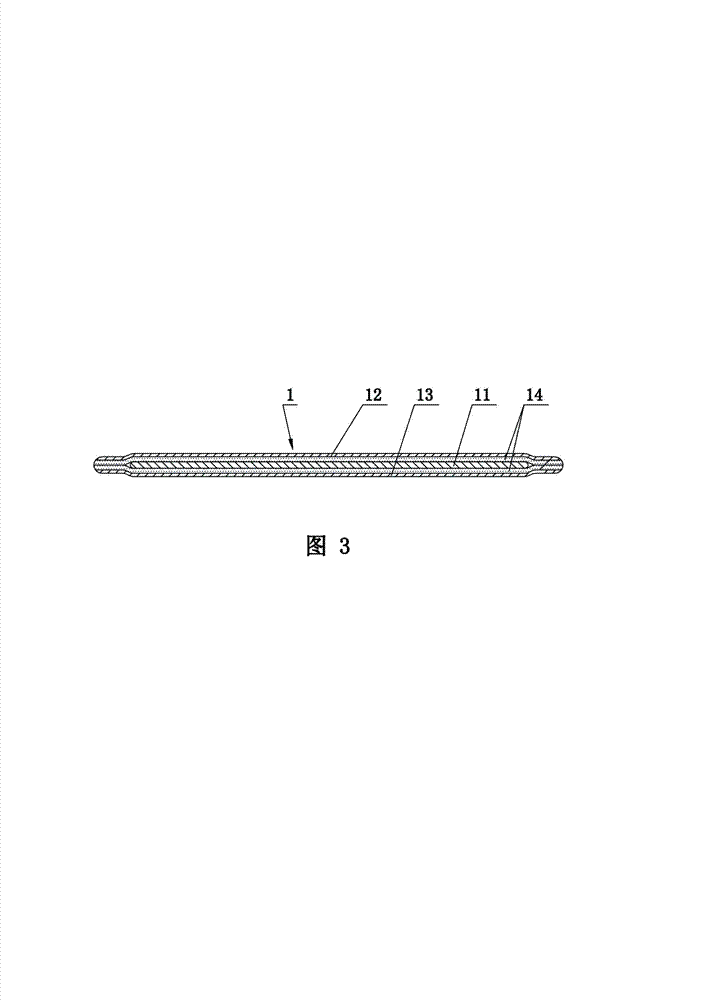

Combined portable solar power supply

InactiveCN102780252AReduce volumeSmall footprintBatteries circuit arrangementsEnergy storageElectrical batteryRechargeable cell

The invention discloses a combined portable solar power supply which comprises a flexible solar cell group, a main shell in which a cavity structure is formed, and a rolling shaft which is arranged inside the main shell and can rotate around the shaft, wherein the flexible solar cell group is wound on the rolling shaft; the cavity structure is formed inside the rolling shaft; a battery box is detachably inserted into the cavity structure; and the battery box is provided with a charging input interface connected with the flexible solar cell group. The battery box of the power supply can be detached, is small in size, occupies a small space, is suitable for being put in a bag and is convenient to carry. In addition, according to the power supply, the solar cell group is rolled by use of the rolling shaft, is freely shrunk and conveniently positioned and is flexible to use; the solar cell group is manufactured by a lamination process, the positive and negative poles are led out by using an ultrathin wire, the bending capacity is high, and the product is compact in structural design; and moreover, a circuit board and a rechargeable battery are arranged in the battery box inside the rolling shaft with large space, the battery capacity is high, and the product is more reasonable in structure.

Owner:尤怀恩

Novel barricade supporting structure for road or river bank dam and construction method thereof

InactiveCN103469814AImprove stabilityImprove bending abilityArtificial islandsCoastlines protectionButtressReinforced concrete

The invention relates to a novel barricade supporting structure for a road or river bank dam and a construction method thereof. A pre-stressed anchor (1) passes through a shingle (2) and a buttress (3) and is embedded in a reinforced soil mass (4); a cement mortar (6) is injected around an anchoring section (5) of the pre-stressed anchor (1); an end part of the pre-stressed anchor (1) is anchored on the shingle (2) by an anchor head (10); and expansion joints (11) and draining openings (12) are arranged in sections. The construction method comprises the following construction steps: constructing a base pile (13); pouring a wall base plate (14) and a reinforced concrete river bank dam (15); constructing the pre-stressed anchor (1); constructing the shingle (2) and the buttress (3) thereof; reserving the expansion joints (11) and draining openings (12) in sections; compacting wall-behind filling (16); applying a pre-stressing force by the pre-stressed anchor (1); fixedly locking the anchor head (10) fixedly connected with the pre-stressed anchor (1) by an anchoring tool (17); and constructing a next working surface according to the steps.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

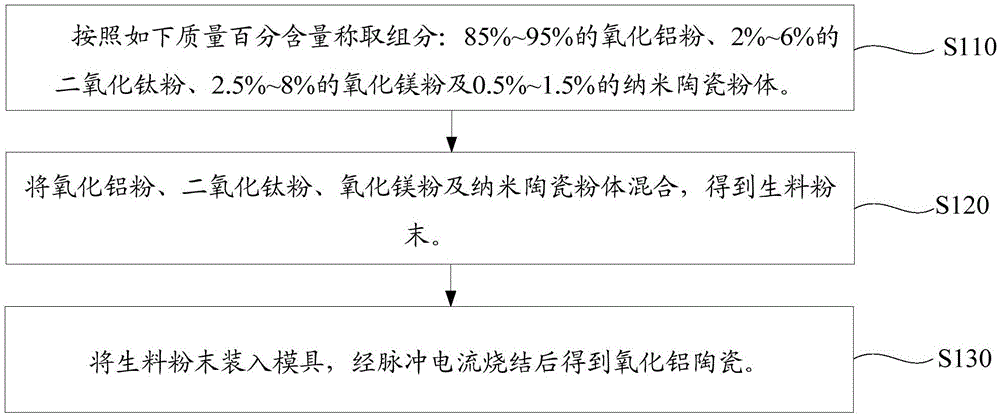

Alumina ceramic powder, alumina ceramic and preparation method of alumina ceramic

The invention relates to alumina ceramic powder, alumina ceramic and a preparation method of the alumina ceramic. The alumina ceramic powder comprises components in percentage by mass as follows: 85%-95% of alumina powder, 2%-6% of titanium dioxide powder, 2.5%-8% of magnesia powder and 0.5%-1.5% of nano-ceramic powder which is chromium oxide powder or silicon nitride powder. The alumina ceramic with better bending strength can be prepared from the alumina ceramic powder.

Owner:SHENZHEN SUNTECH ADVANCED CERAMICS

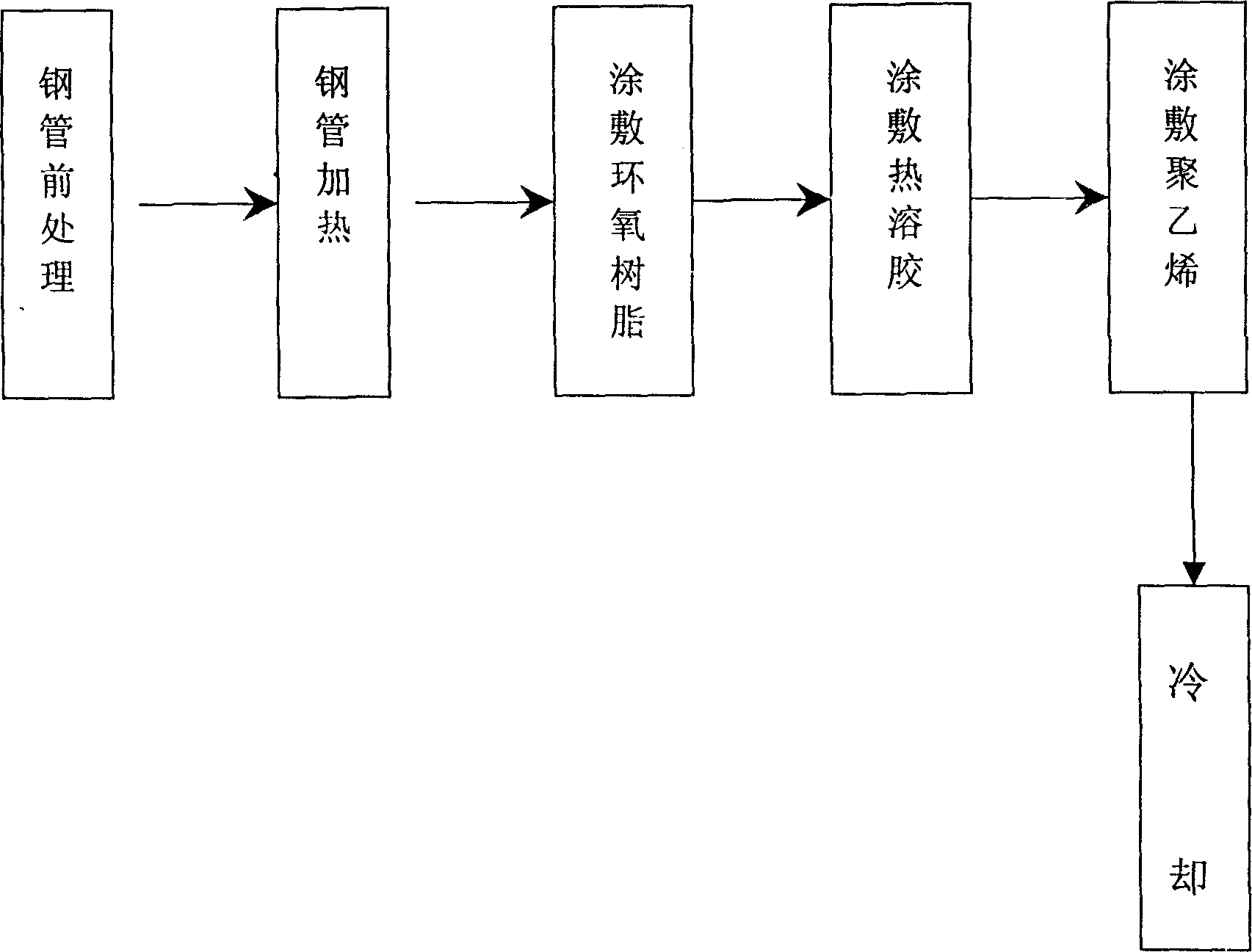

Anti-corrosion painting material treatment method for pipeline external surface

InactiveCN1673604AImprove anti-corrosion performanceImprove insulation performanceCorrosion preventionPipe protection against corrosion/incrustationMetallurgyCompound (substance)

The present invention discloses modern pipe outer anticorrosion spraying method. The pipe outer anticorrosion spraying process includes the following steps: processor-treatment of steel pipe, preheating steel pipe, spraying one layer of thermosol in the thickness of 0.1-0.2 mm, spraying polyethylene layer of 1-5 mm thickness, curing and leveling for 20-35 min, discharging from furnace and cooling. The present invention is suitable for the surface anticorrosion treatment of conveying pipe for petroleum, natural gas, chemical material, etc.

Owner:左树清

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com