Telescopic arm open-cut rock drilling jumbo with drill rod replacing device

A telescopic boom, open-air technology, used in drill pipes, drill pipes, drilling equipment, etc., can solve the problems of no vertical or upward drilling, poor rock hardness adaptability, no side swing mechanism, etc., to ensure the drilling quality. , reduce wear and ensure the effect of drilling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing;

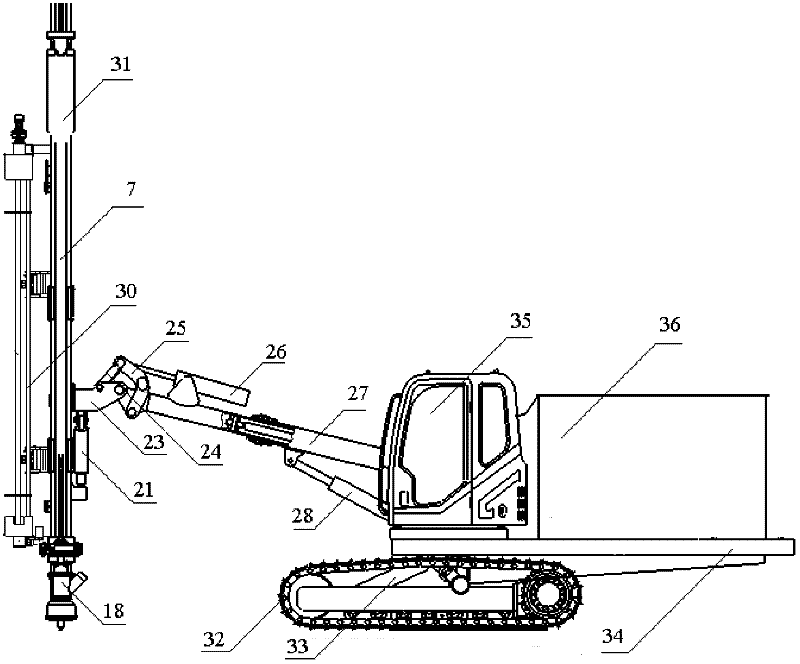

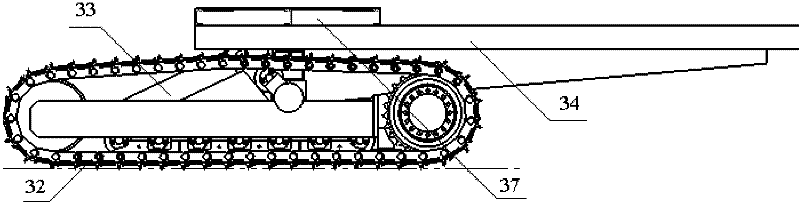

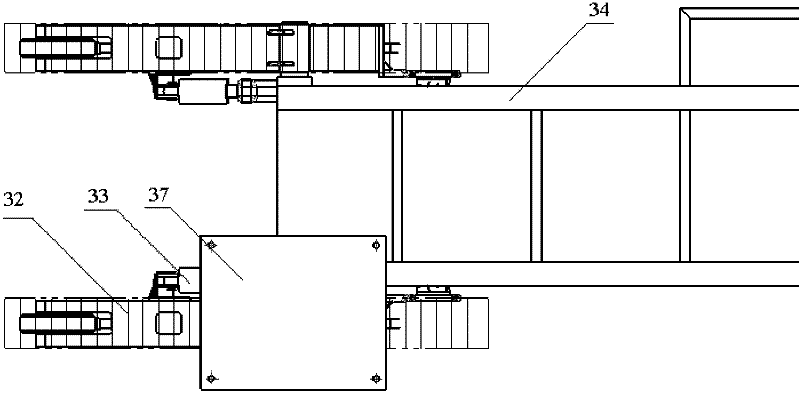

[0022] as attached figure 1 As shown, a telescopic arm surface rock drilling rig with a drill changing device of the present invention includes a cab, a chassis assembly, a propeller assembly, a telescopic arm, a drill changing device 30, a rock drill 31, a control system and power and Air control system 36; wherein the chassis assembly includes a vehicle frame platform 34, a cab floor 37, a crawler belt assembly 32 and a leveling cylinder 33, and the crawler belt assemblies 32 are respectively located on both sides of the vehicle frame platform 34, and the crawler belt assemblies are respectively installed A leveling cylinder is connected with the fulcrum of the vehicle frame platform to control the pitch angle of the vehicle frame platform 34 on the horizontal plane, and the cab floor 37 is also installed on the vehicle frame platform 34; the telescopic arm includes a bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com