Patents

Literature

68 results about "Arm surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

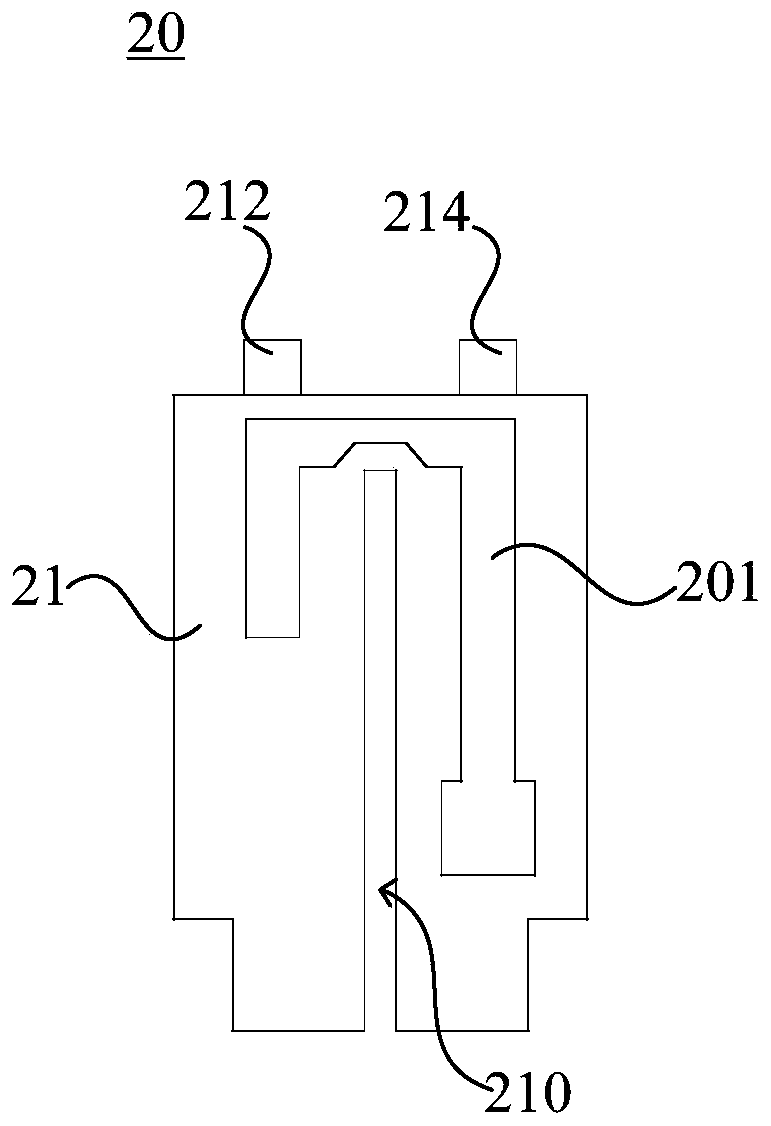

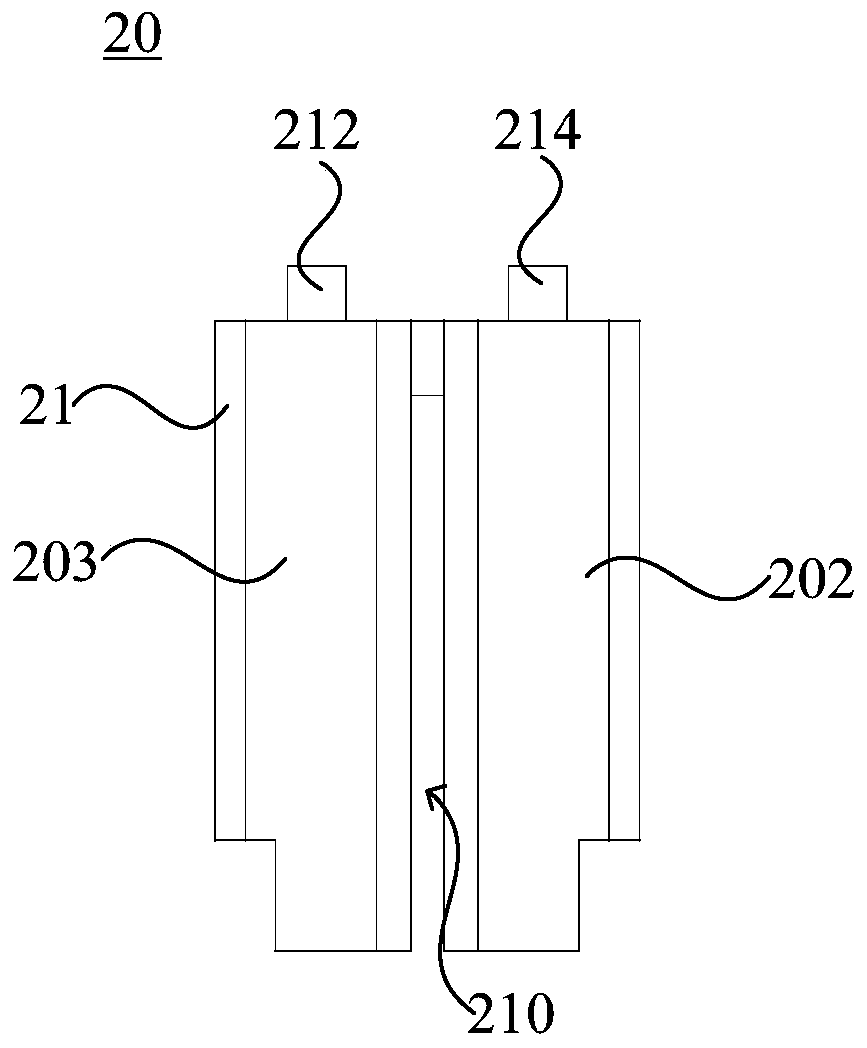

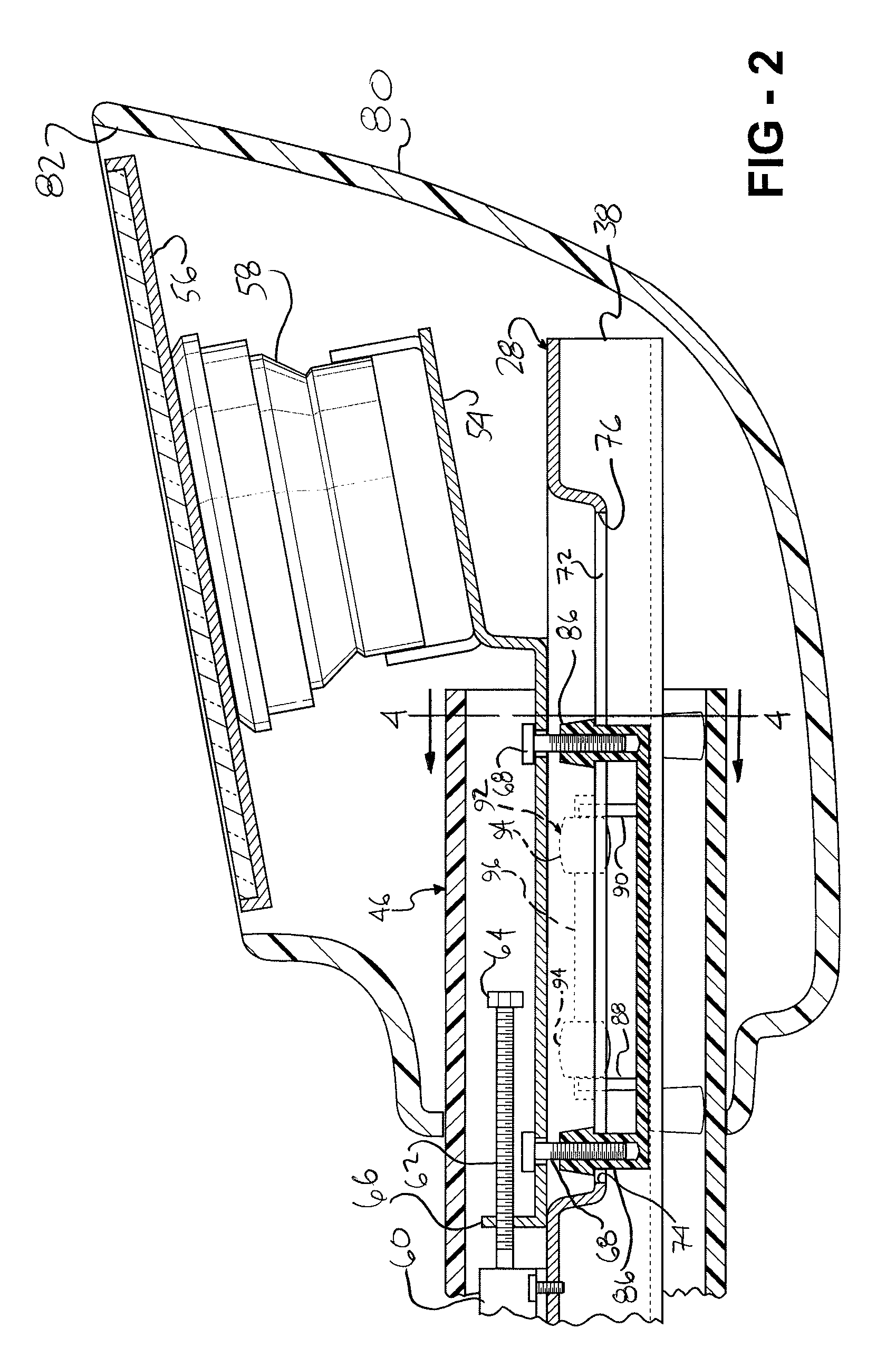

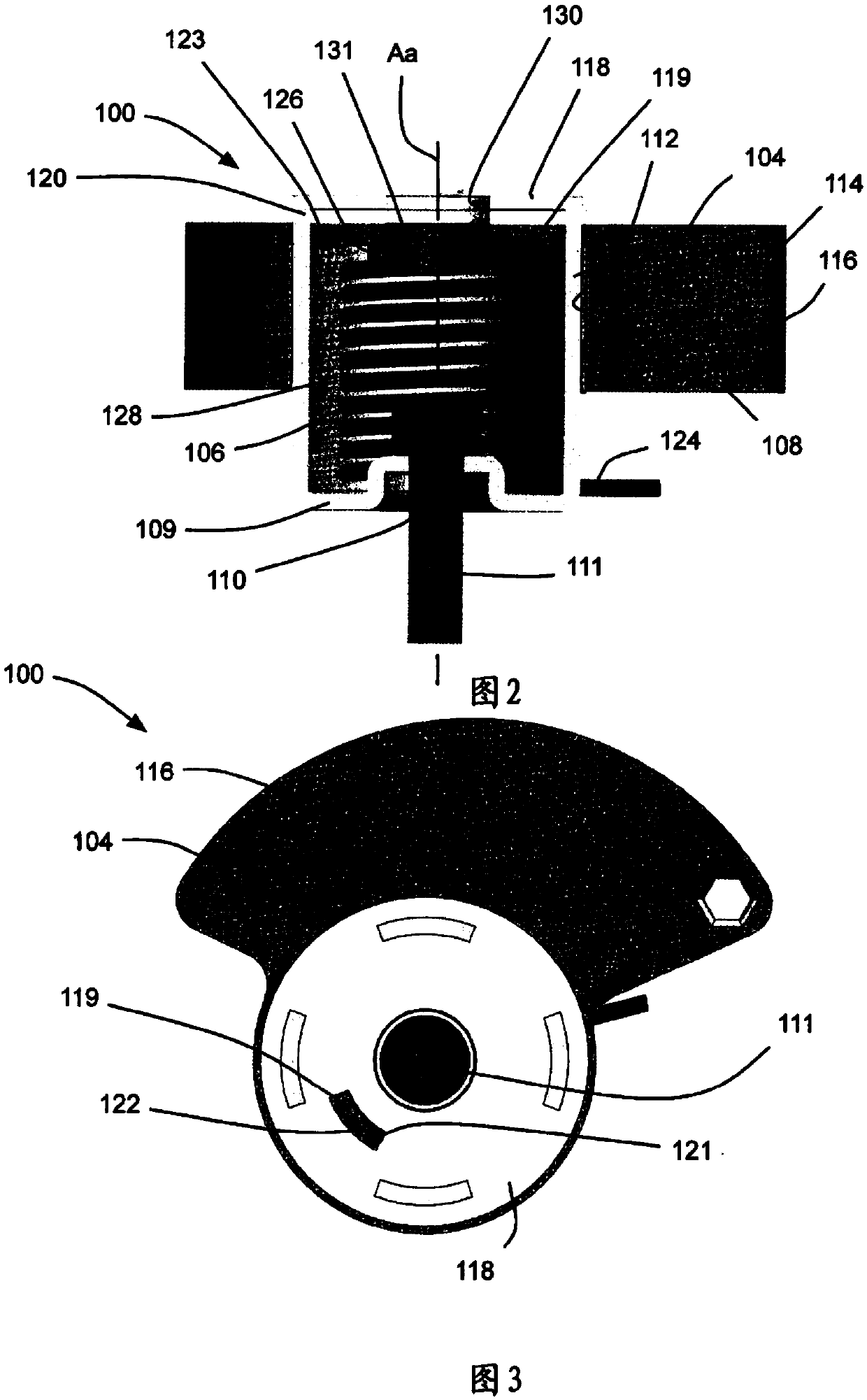

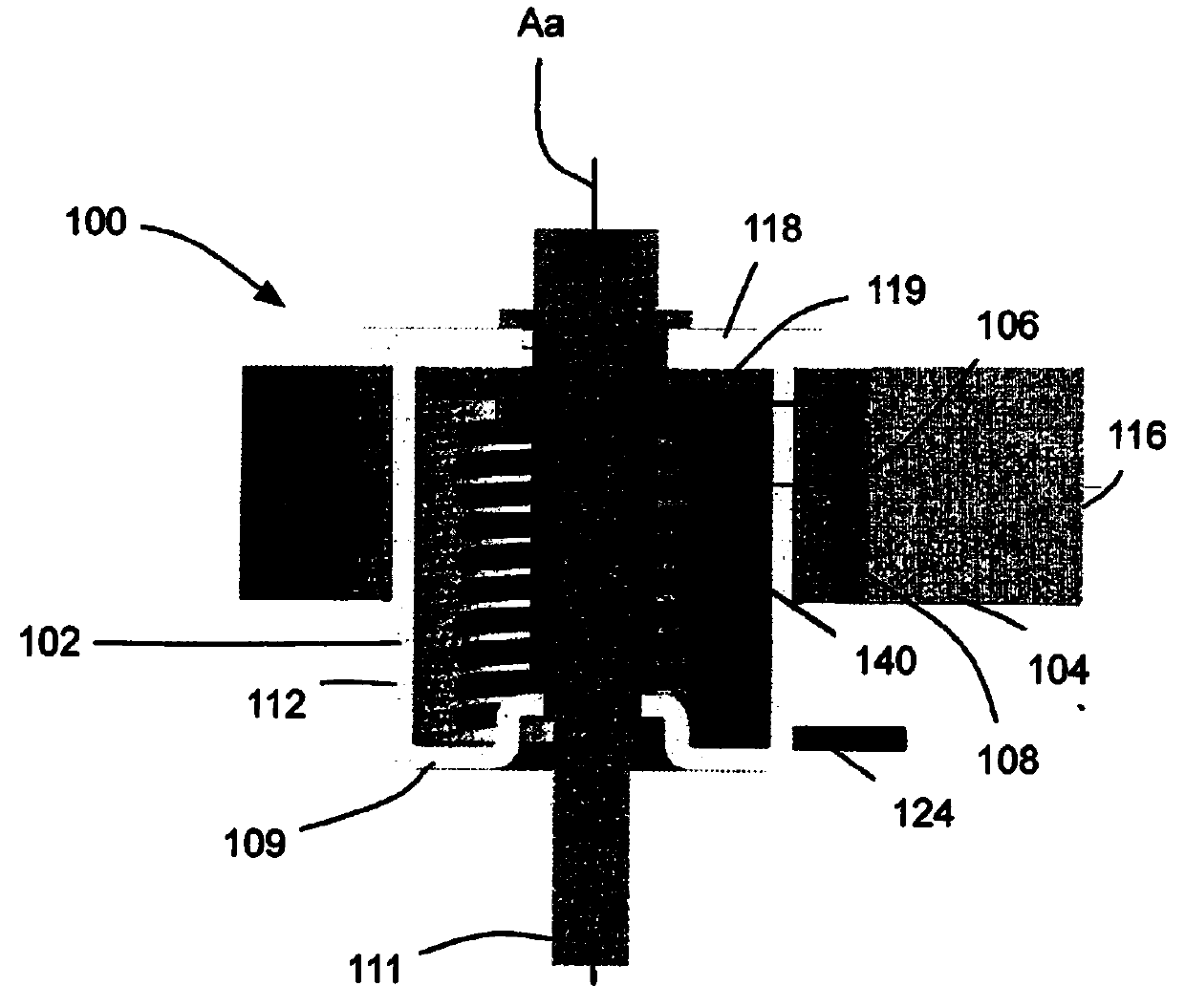

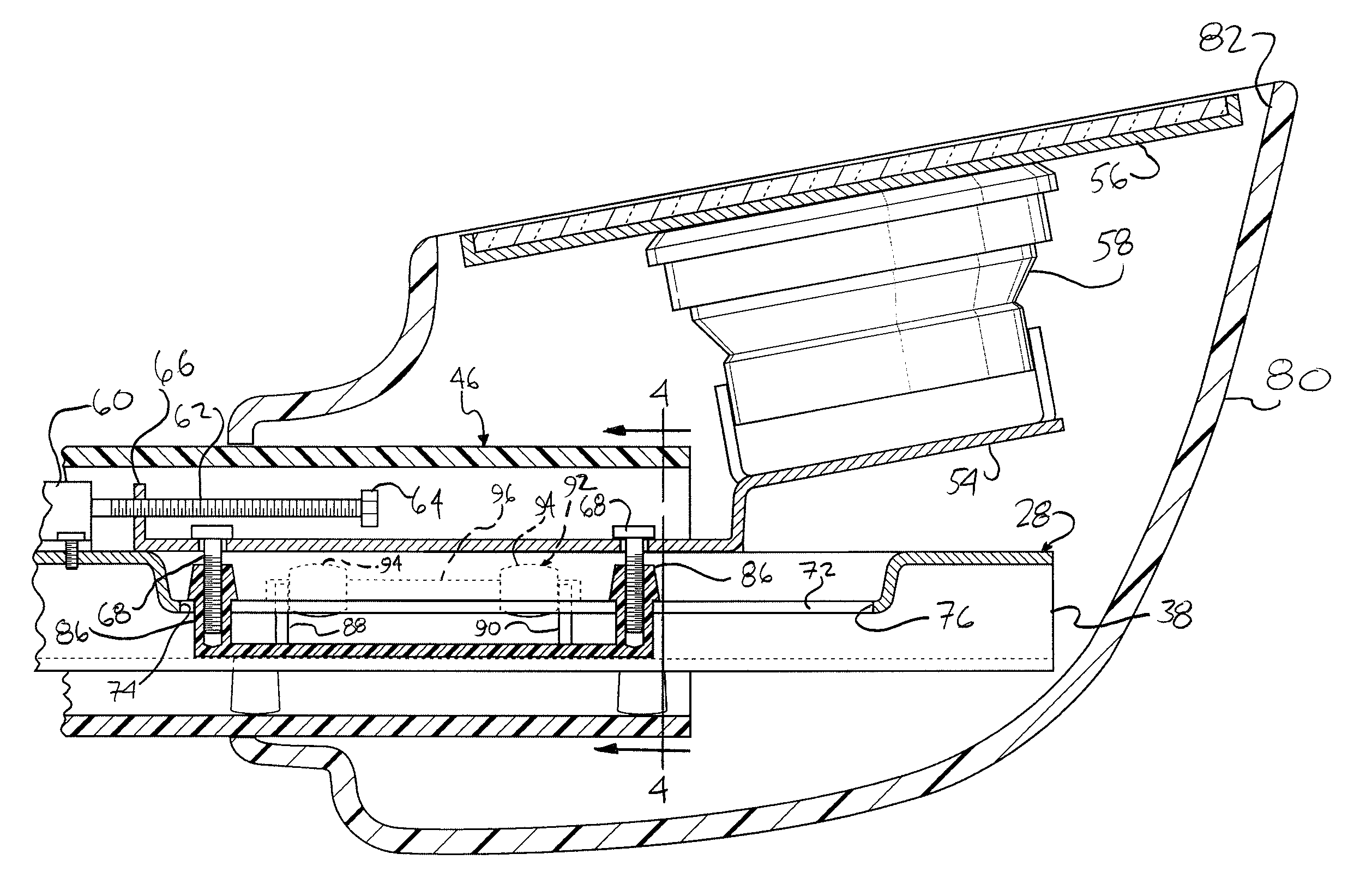

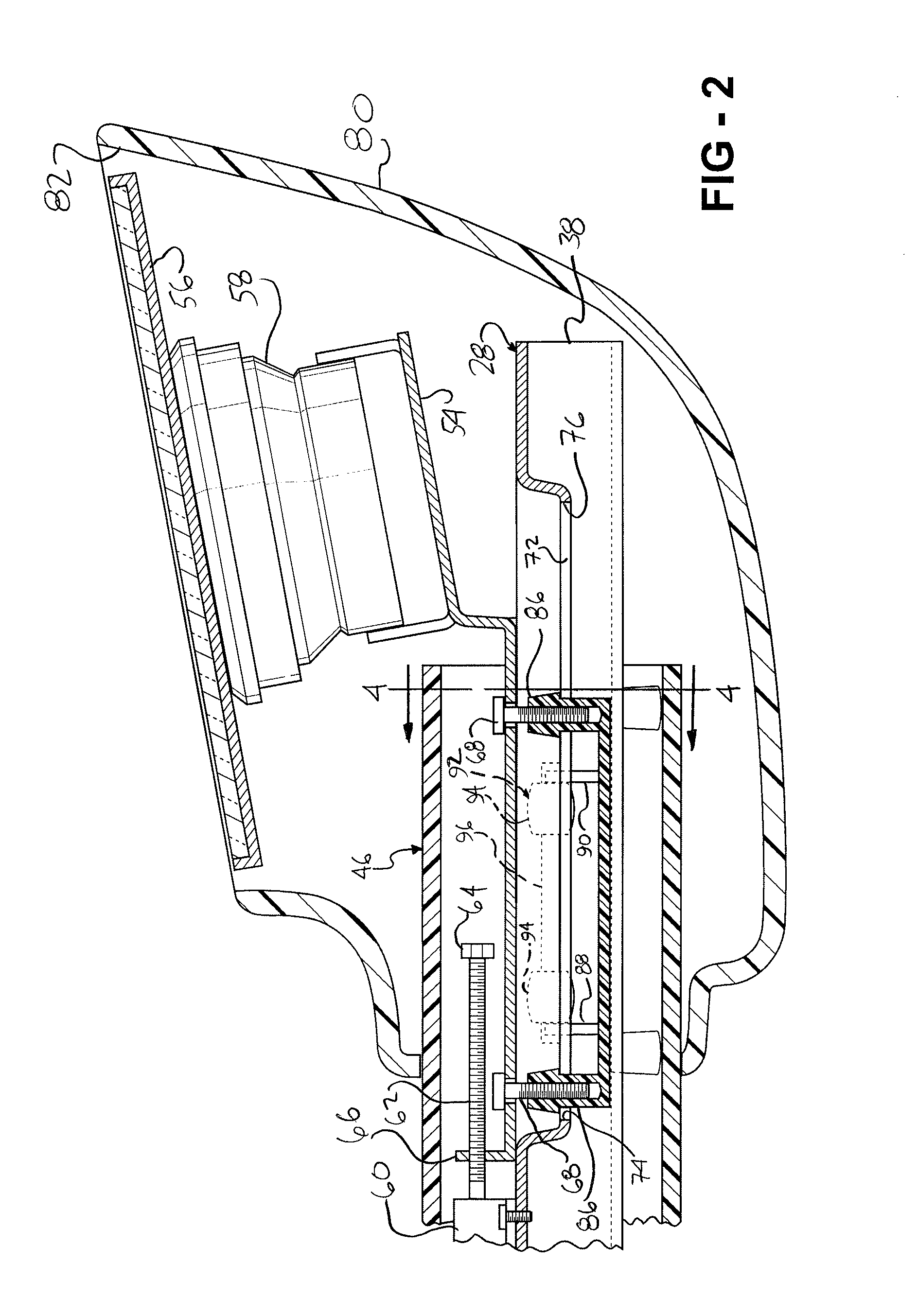

Disk drive having disk drive housing including airflow suppressor portion

InactiveUS6972926B1Carrier constructional parts dispositionApparatus for flat record carriersArm surfaceEngineering

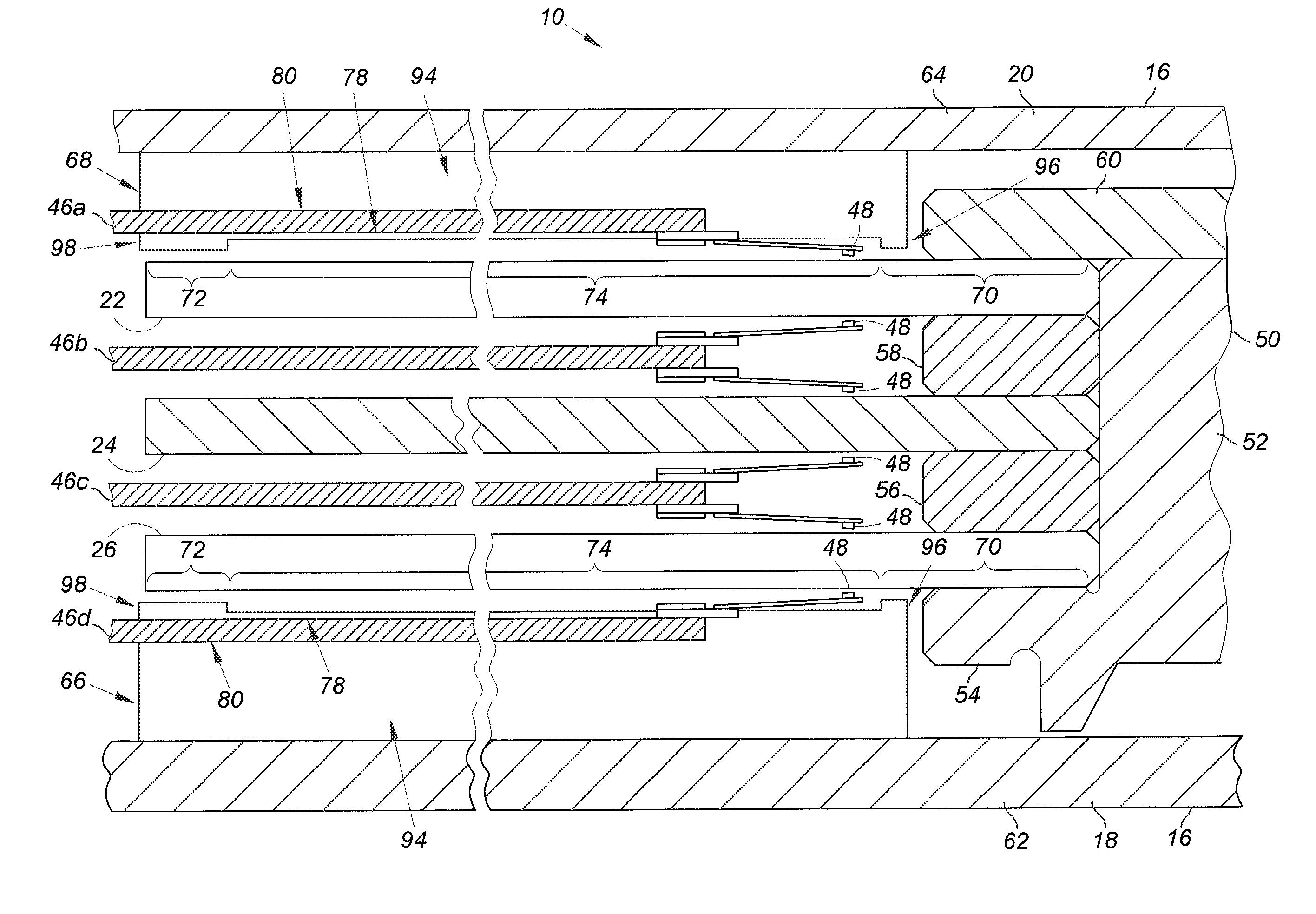

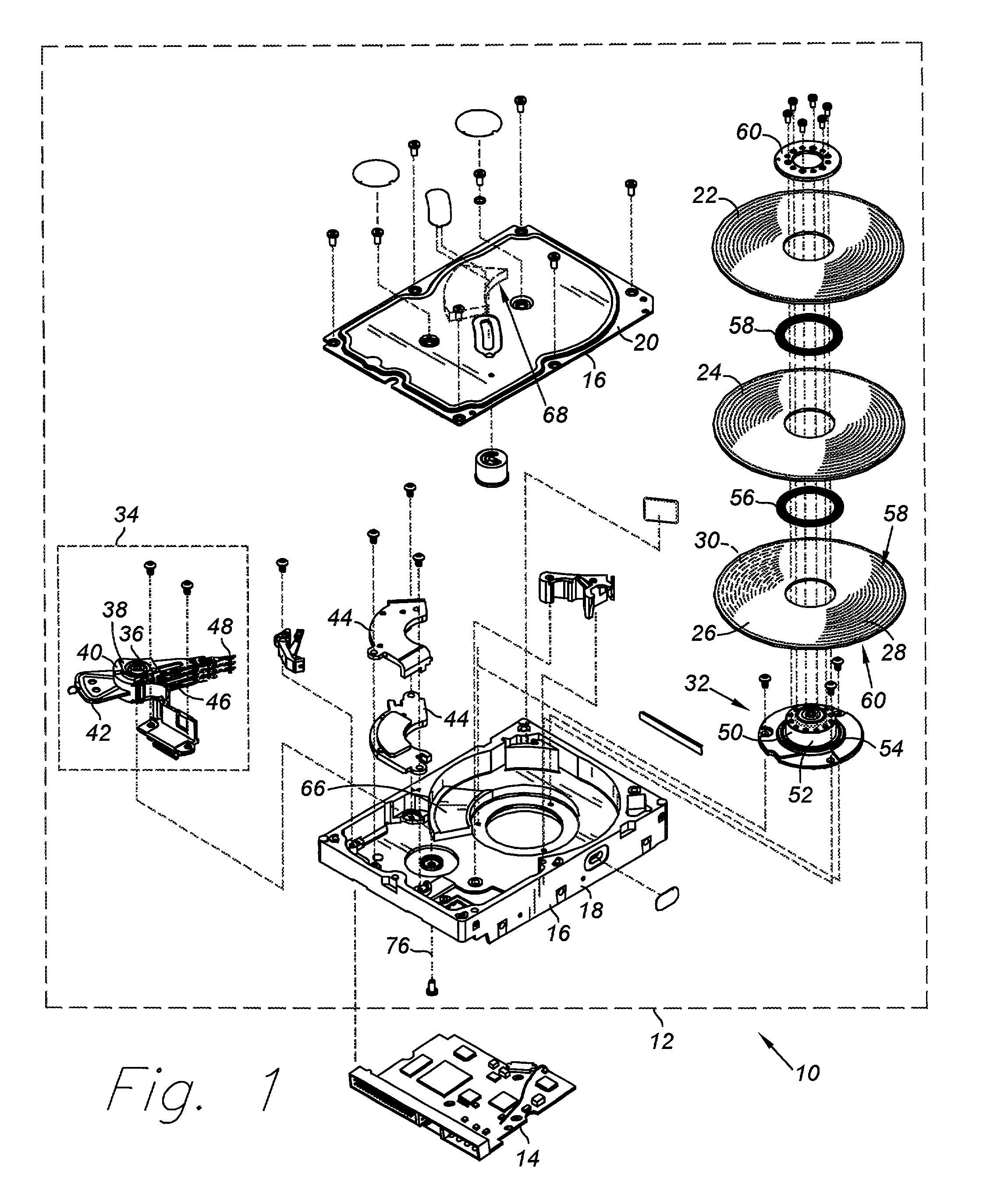

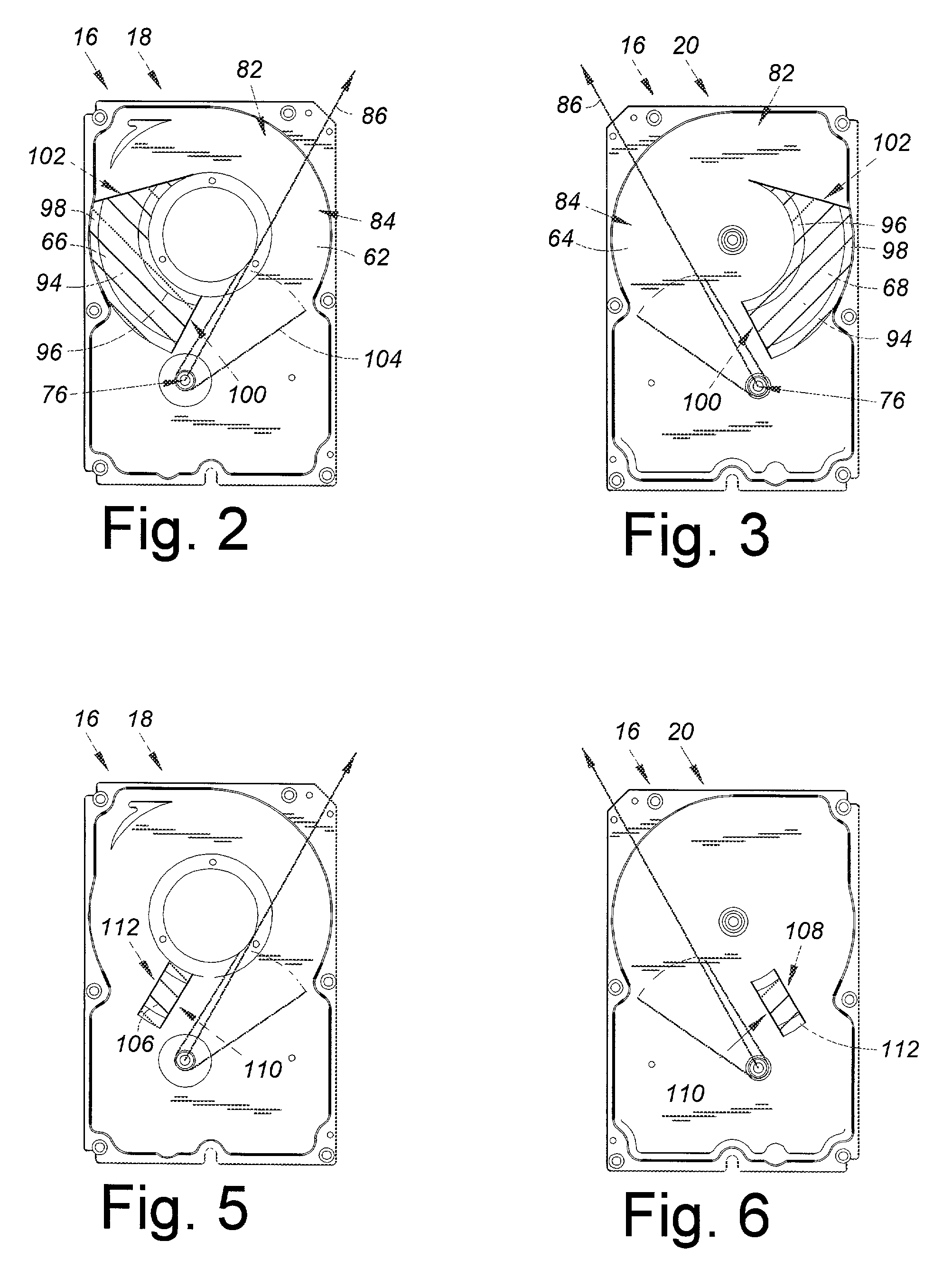

According to the present invention, there is provided a disk drive that includes a housing including a body portion and an airflow suppressor portion extending from the body portion. The disk drive includes a disk that includes an inner disk edge, an outer disk edge and a disk surface. The disk drive includes a head stack assembly rotatably coupled to the body portion. The head stack assembly includes an actuator arm including a first arm surface disposed adjacent the disk surface and an opposing second arm surface. The disk drive includes upstream and downstream regions. The airflow suppressor portion is radially disposed substantially between the inner and outer disk edges within the upstream region and extends entirely from the housing body portion beyond the second arm surface towards the disk surface for modifying disk rotation induced airflow upon the head stack assembly.

Owner:WESTERN DIGITAL TECH INC

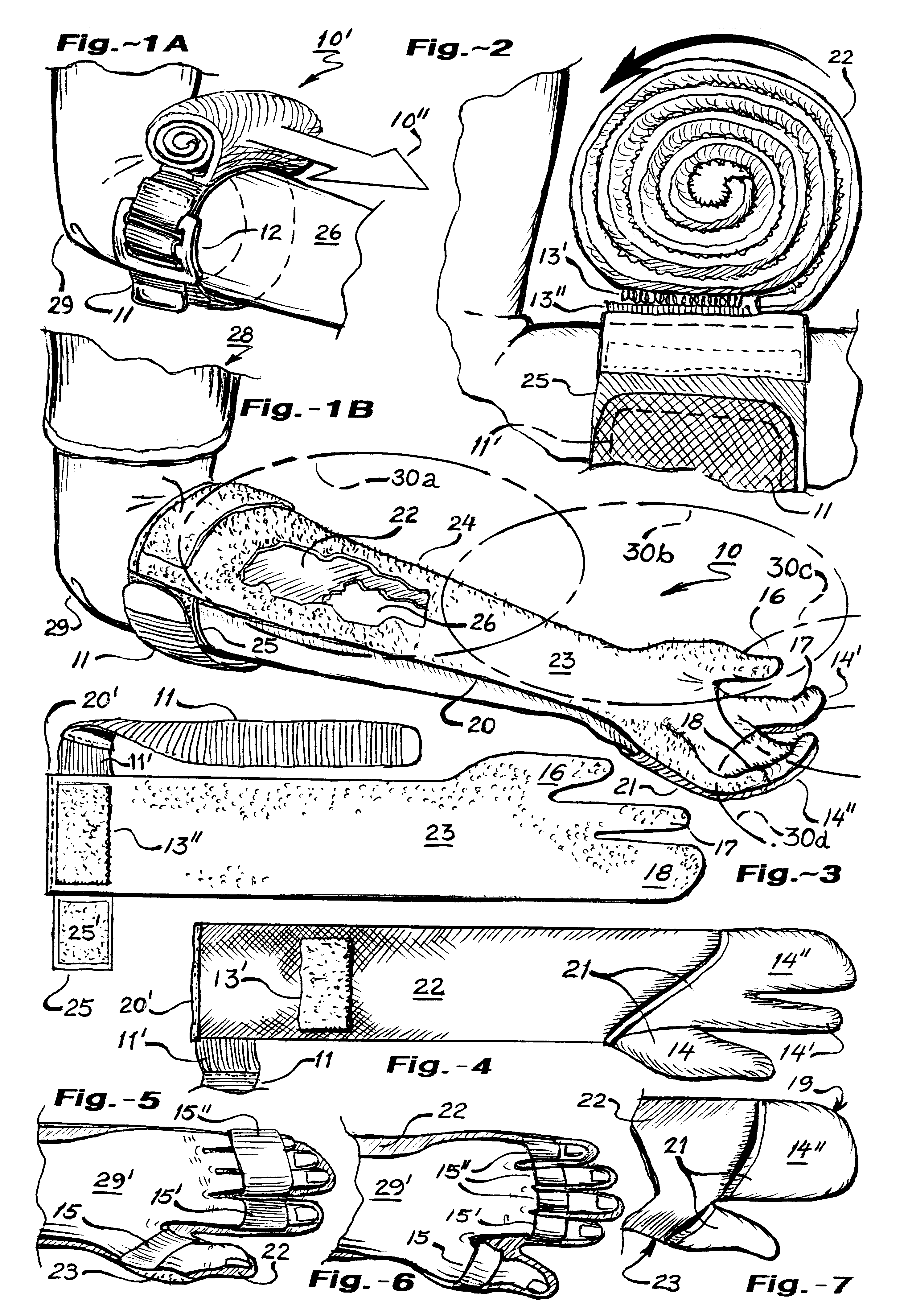

Waiter's hot plate arm-shield gauntlet

InactiveUS6240565B1Avoid injuryReduce in quantityChemical protectionHeat protectionArm surfaceEngineering

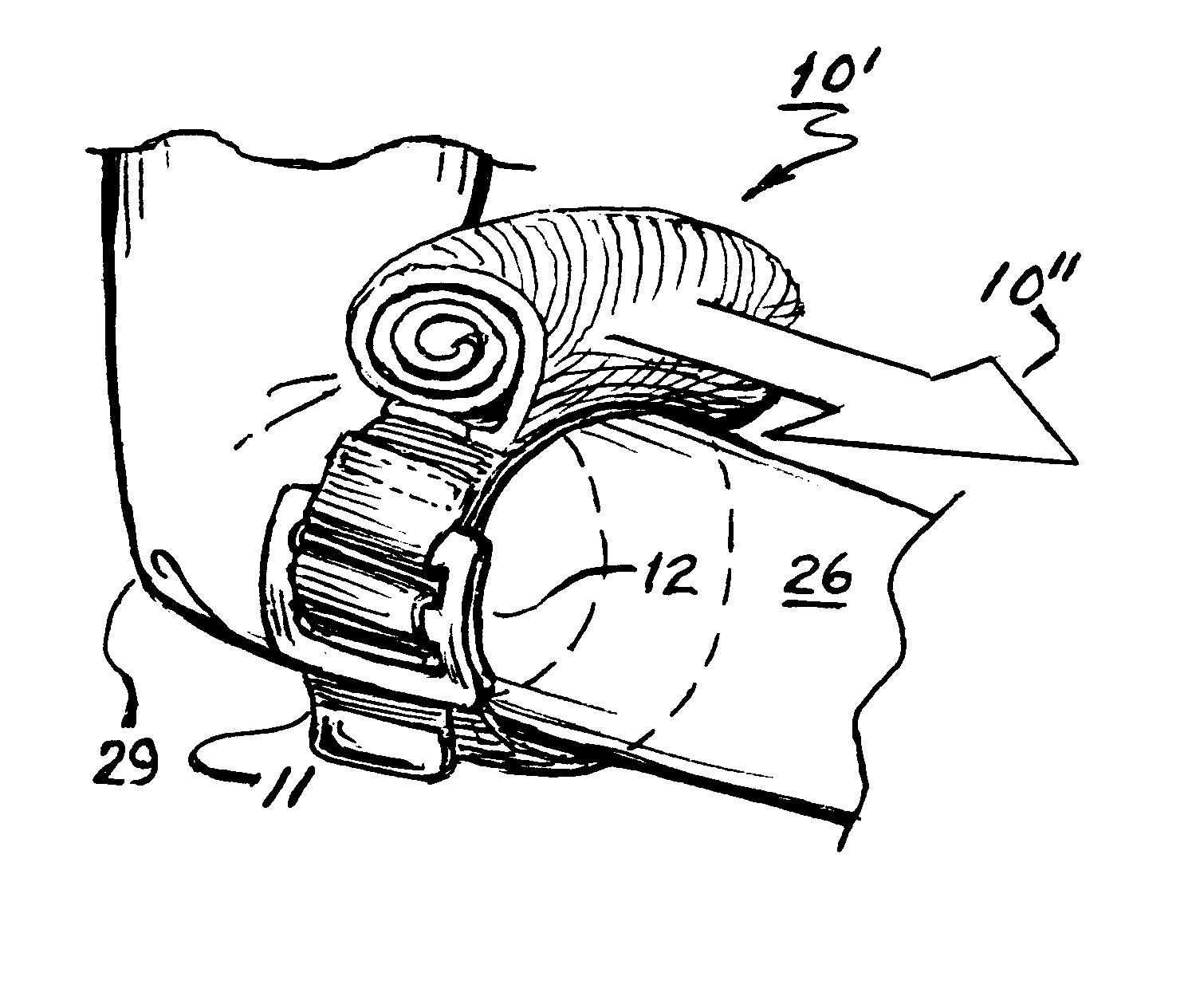

A conveniently deployable arm-shield safety-pad uniquely configured to protect a professional waiter's arm-surface from injurious heat-exposure to hot dinner-plates during routine arm-borne restaurant serving procedures. The fixed inward-end of the elongated arm-shield is secured to one's forearm via a hook-&-loop fastening-strap; -the opposite outward-end having convenient finger-tip and thump retention-pockets, facilitating quick and easy roll-out deployment of the normally rolled-up protective pad material. Also set forth is a preferred flexile-laminate material employing at least one layer of reflective Mylar-film material; and including an outwardly exposed layer of high-coefficient of friction surfacing material,-serving to reduce slippage of the balanced dinner-plates. Once the waiter has completed a serving procedure, the finger-tips and thumb are withdrawn from their retention-pockets, enabling the arm-shield to be readily rolled-up one's arm into a compact stow-roll ready for subsequent reuse.

Owner:SPEAR HELEN TERRY

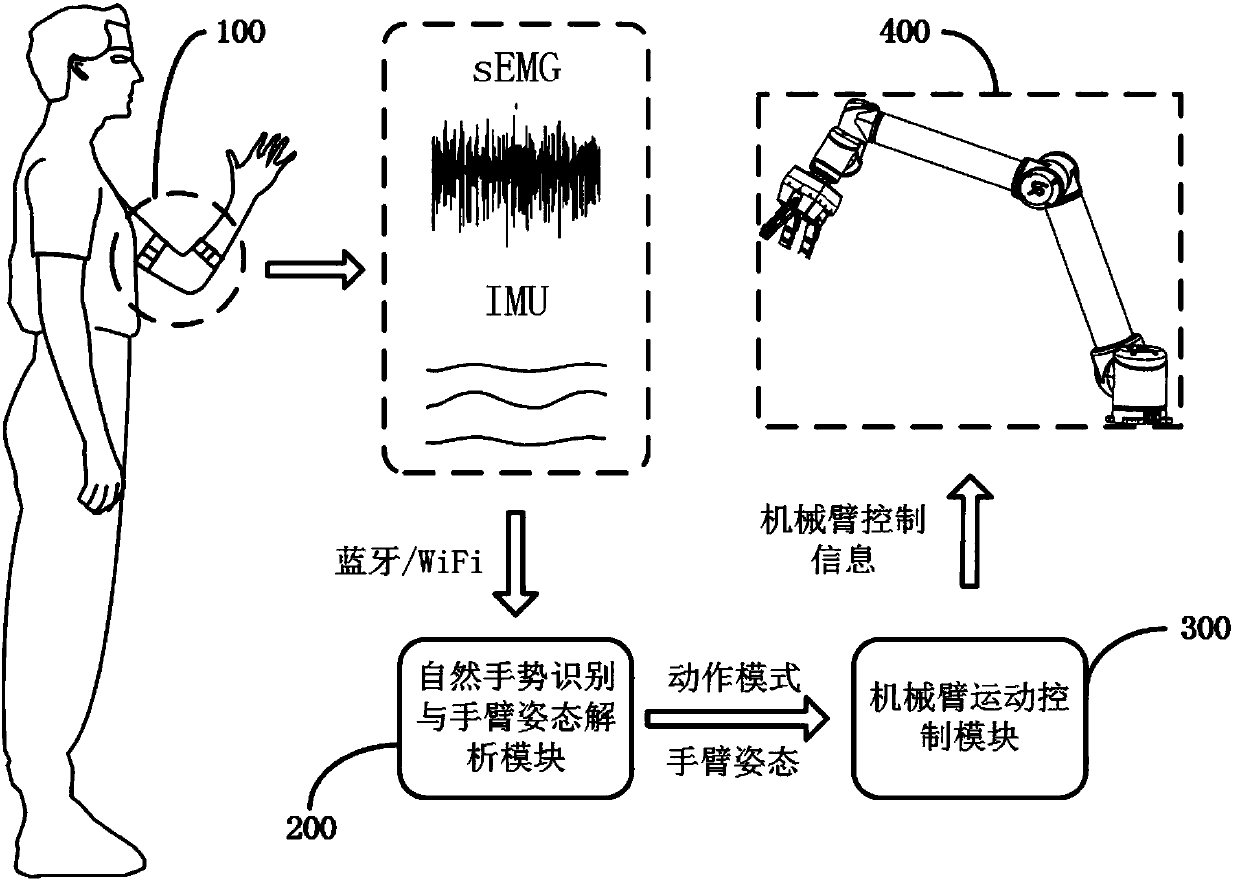

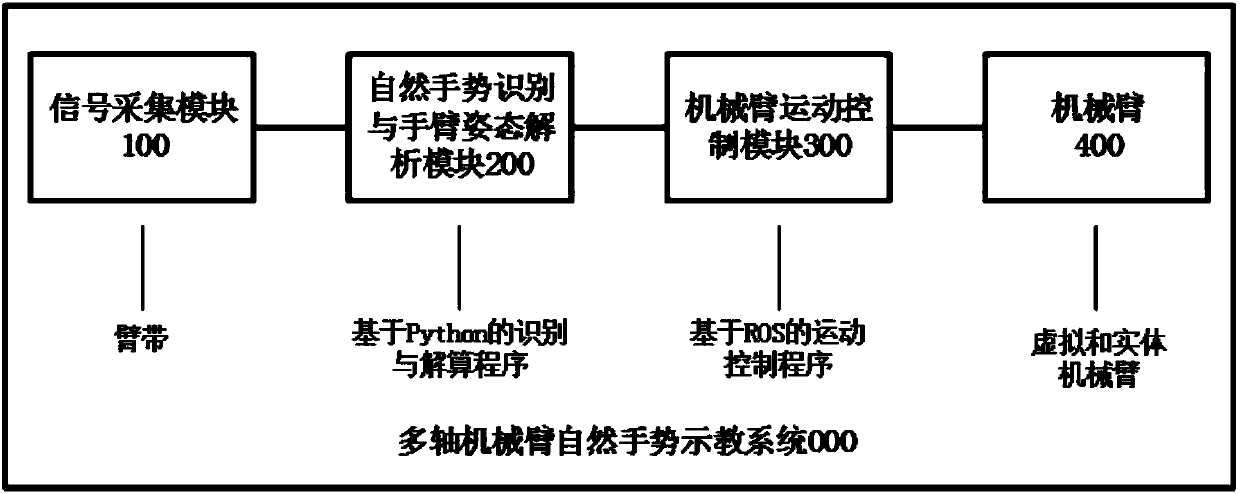

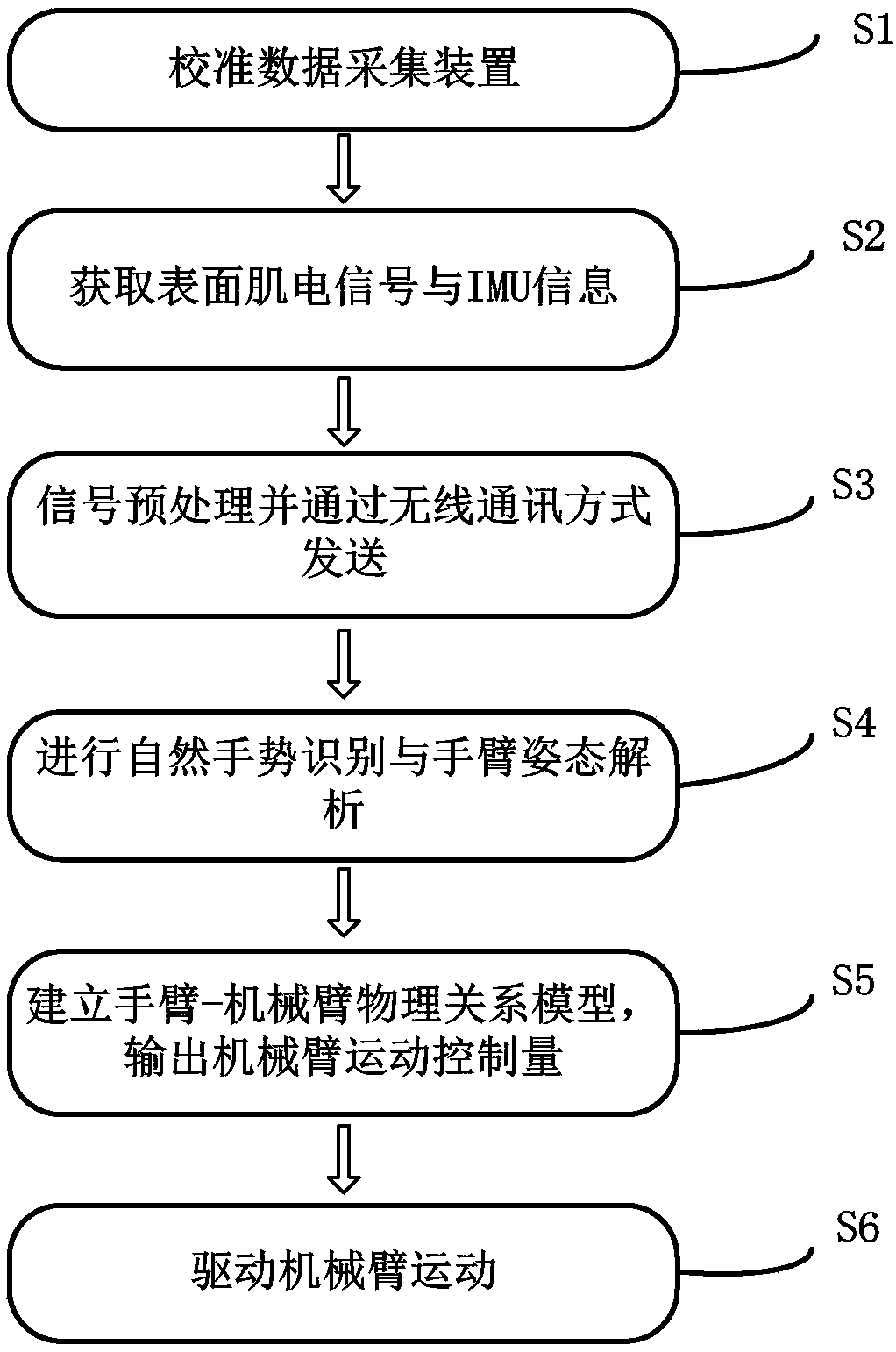

Physical gesture movement control system and method for multi-shaft mechanical arm

InactiveCN107553499AAccurate identificationControl natureProgramme-controlled manipulatorArm surfaceHuman body

The invention relates to a movement control system and method for a multi-shaft mechanical arm, the movement of the mechanical arm can be controlled by users through a natural gesture and an arm motion. According to the movement control system and method for the multi-shaft mechanical arm, the physical gesture is recognized and the arm posture is calculated and solved through detection of myoelectric signals and IMU motion information on the surface of the human arm; the mechanical arm is controlled to present the arm motion of the human body through establishment of an arm-mechanical arm physical relationship model; and the grabbing operation of a tail end actuator of the mechanical arm is controlled by the natural gesture. The movement control system and method for the multi-shaft mechanical arm can be widely used for the field of remote operations of the mechanical arm, the teaching and the like; and the intelligent control over a robot is realized, and the aims of human-computer interaction and intelligent interaction are achieved.

Owner:SHANGHAI JIAO TONG UNIV +1

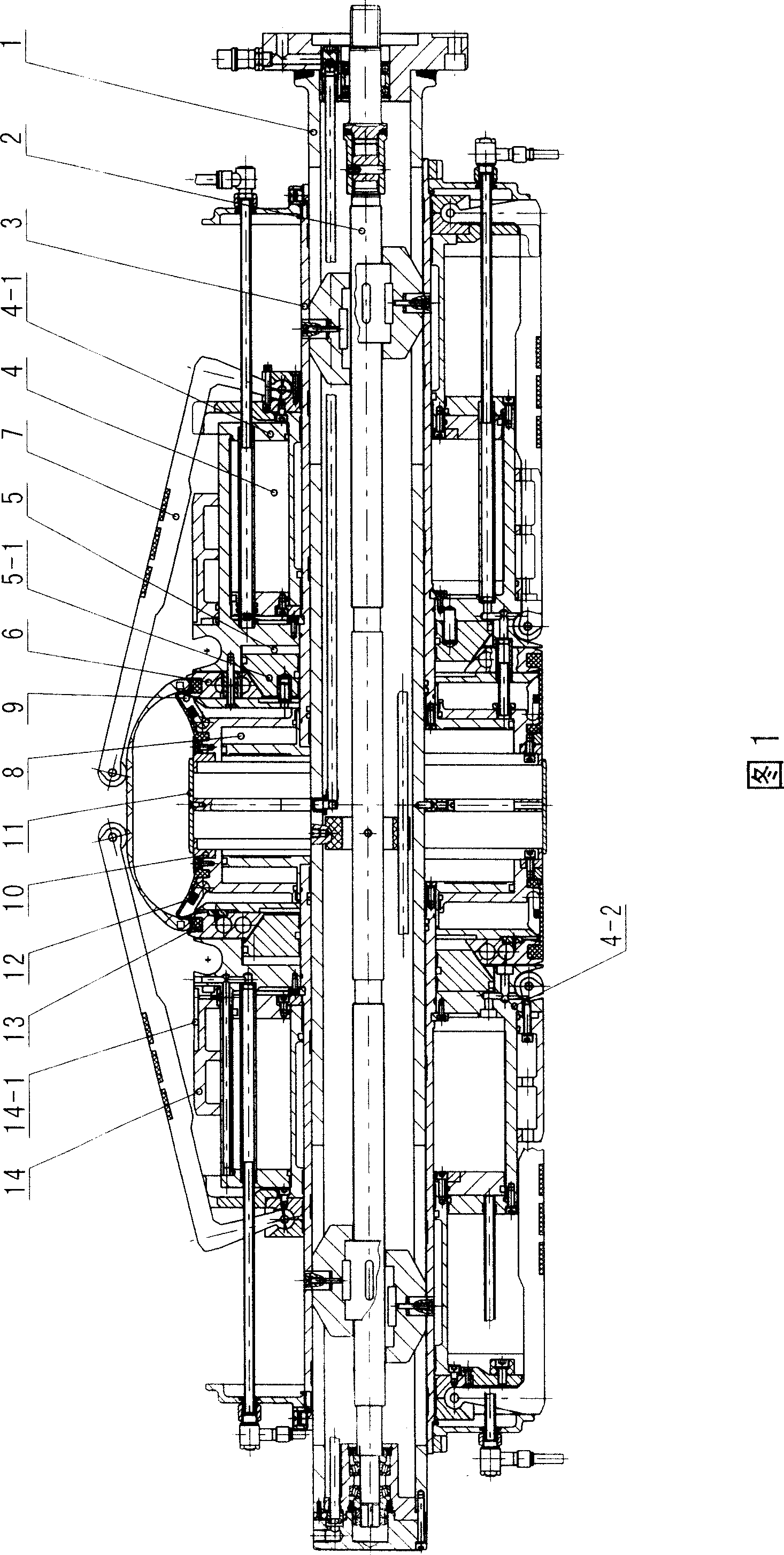

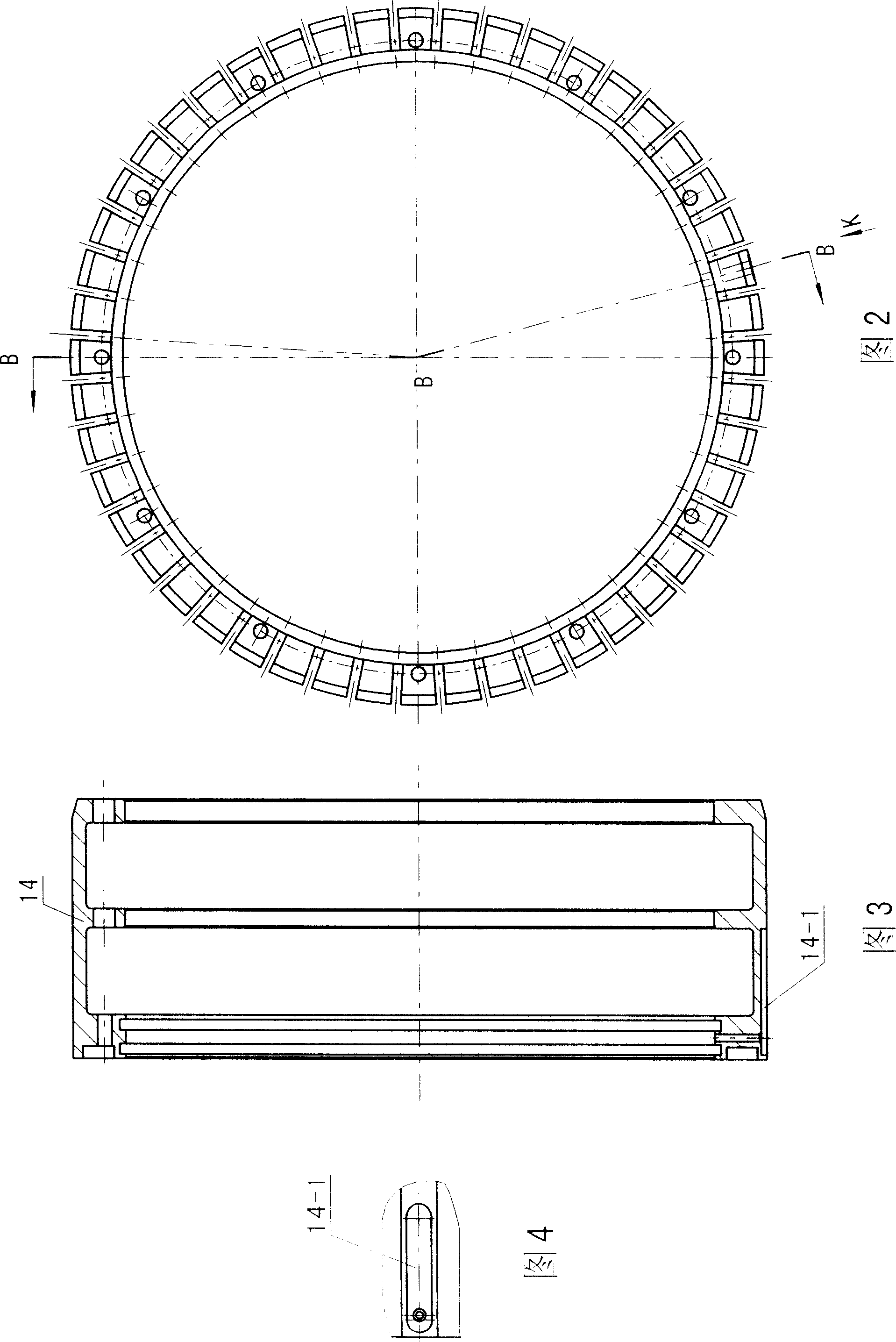

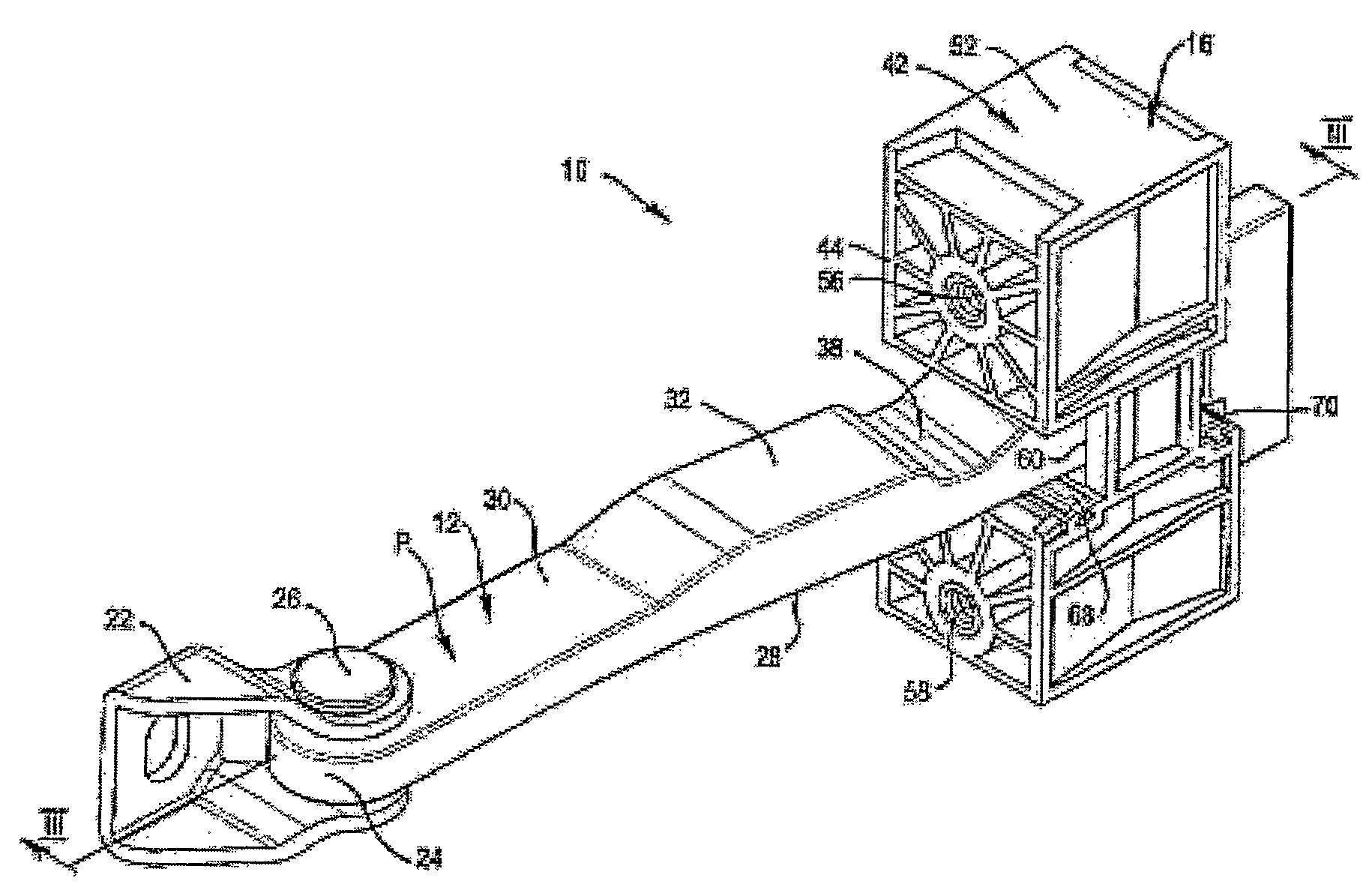

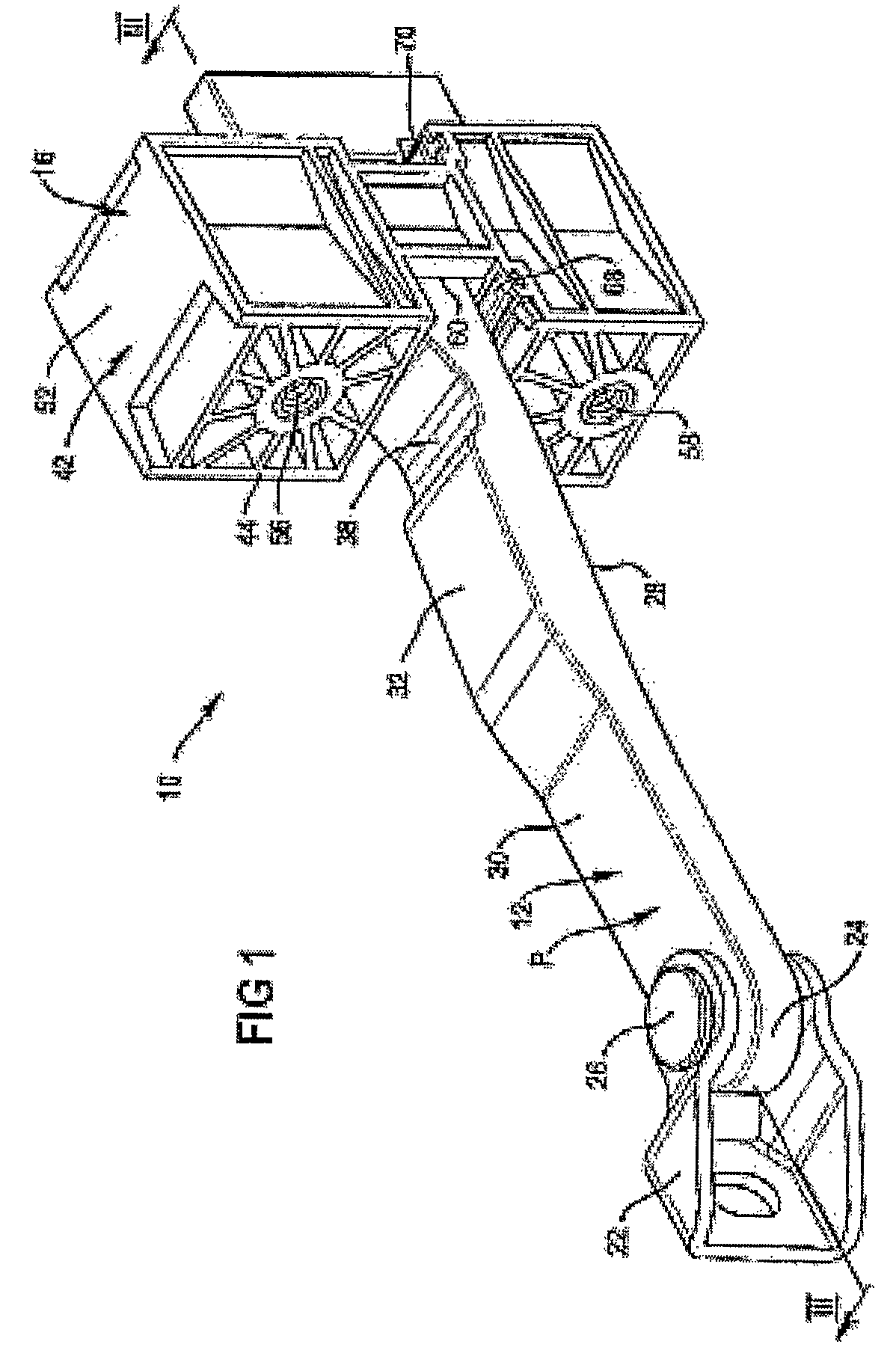

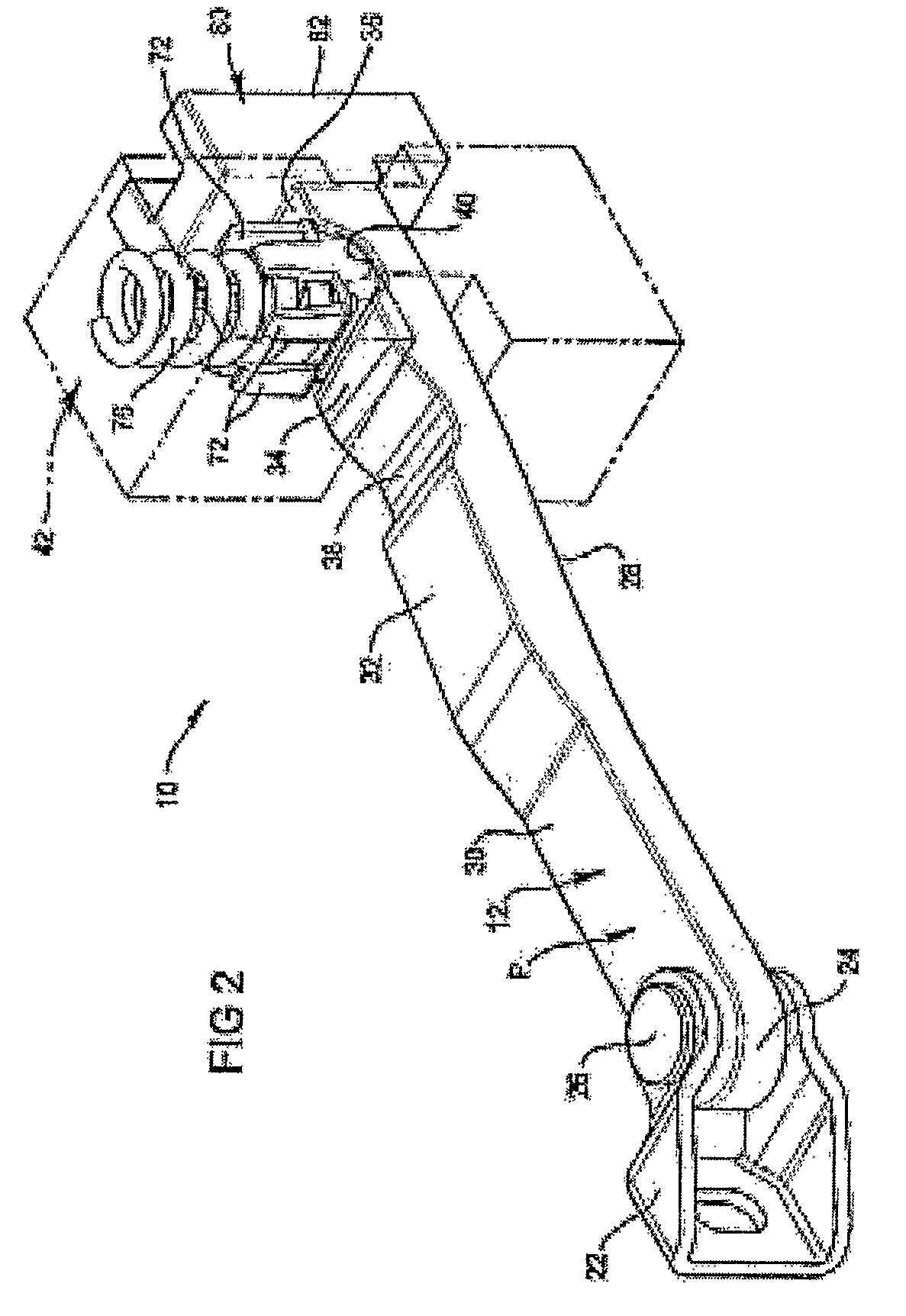

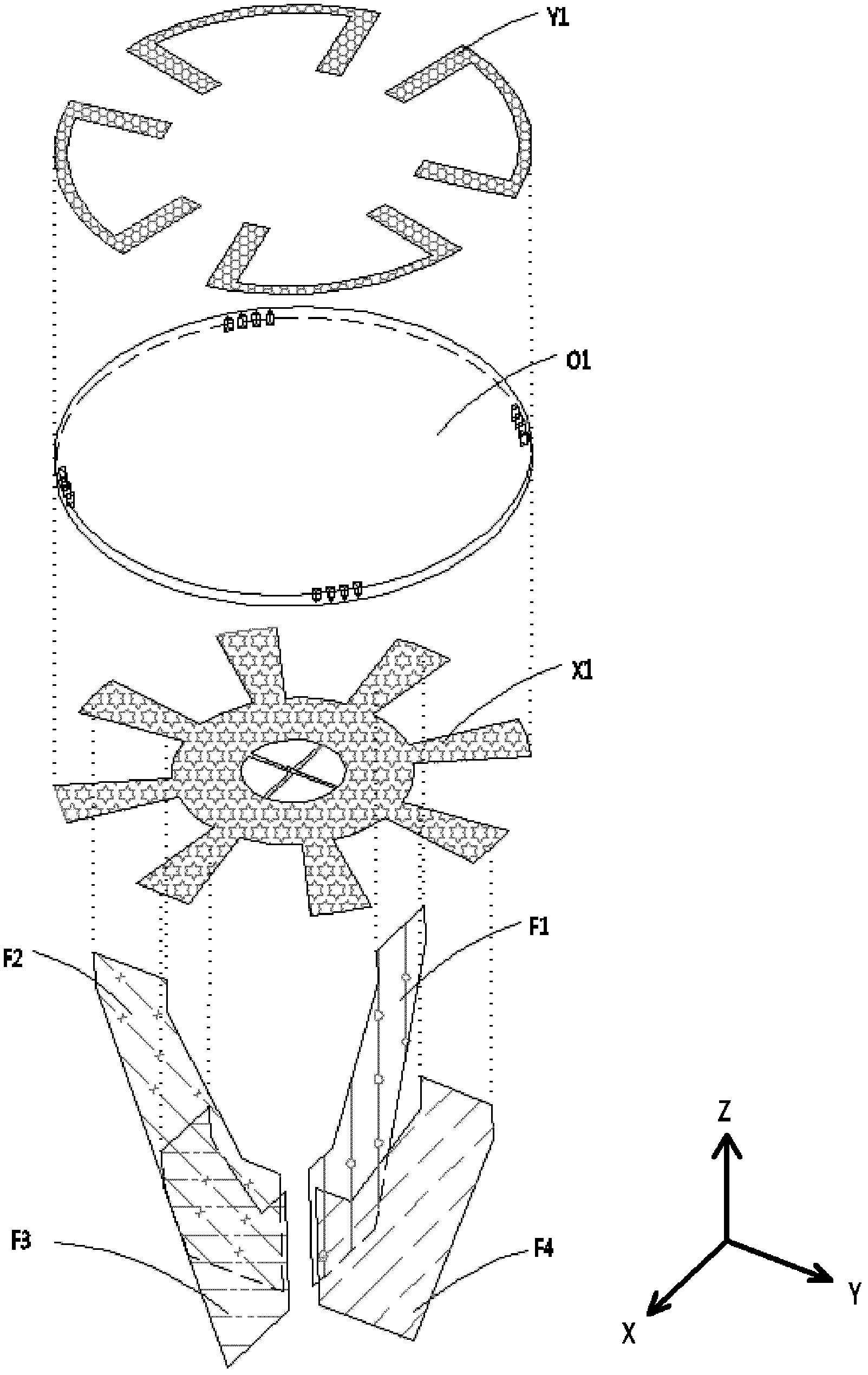

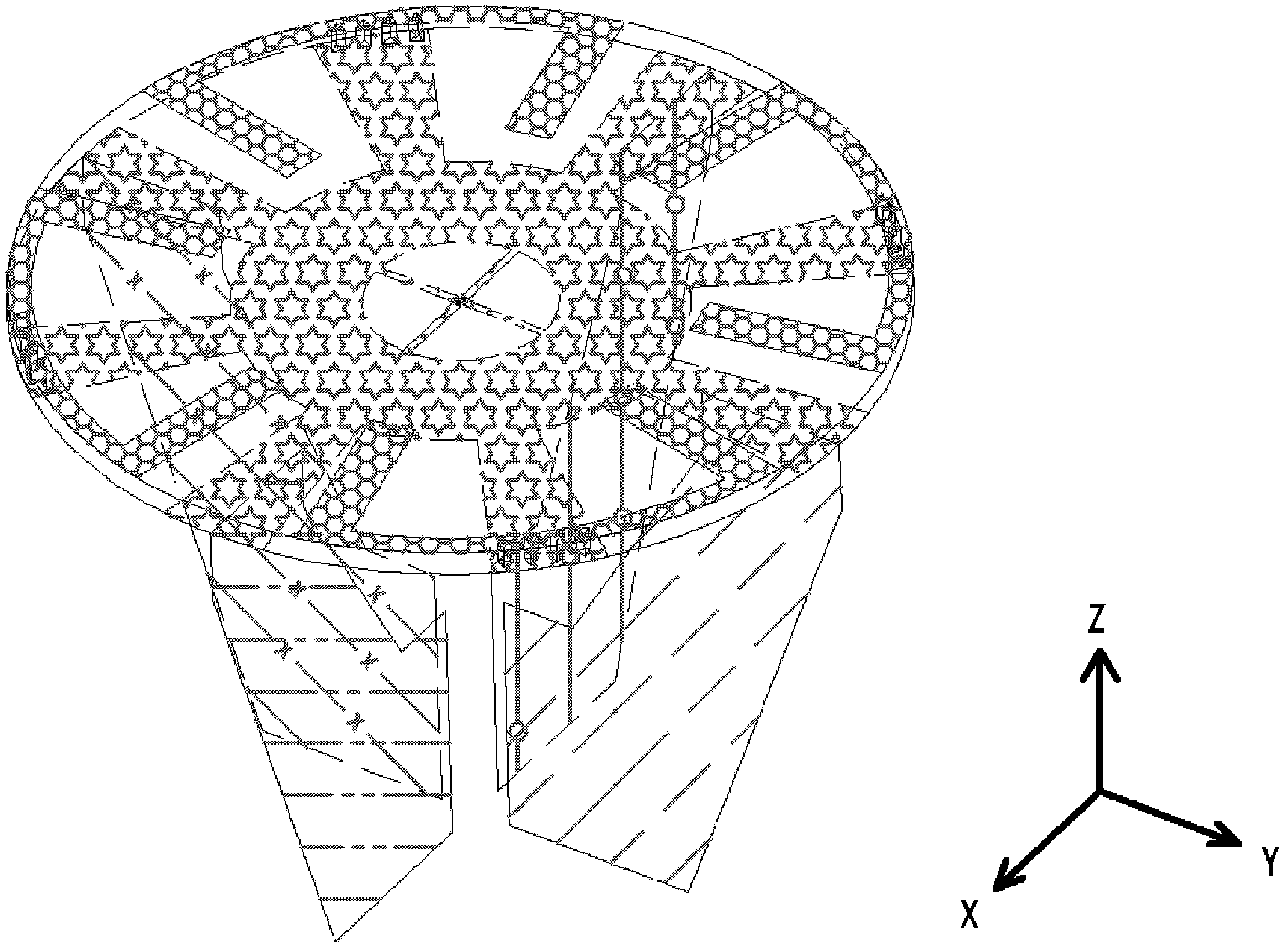

Mechanical assembly drum with attaching and compacting functions

The invention relates to a mechanical forming drum with compaction function, which is characterized in that on a main shaft sleeve adjacent to a fan-shaped block cylinder, the flap cylinders are also installed. A set of flap cylinders is installed on the outer circumference, which is disposed on the inner side of the fan-shaped block. On the outer circumference of the flap cylinder, a width adjusting side ring is also installed. A groove ring is jacketed on the outer circle of a turn up cylinder, which is linked with the front-end flange of the turn up cylinder. Between two side drums, a middle width-adjusting ring is fixed, which is overlapped with the width adjusting side ring and can be dislocated mutually. The groove ring surface is contained in the turn up roller arm surface in the groove ring, the width-adjusting side ring surface, the middle width adjusting ring surface and the sealed plastic ring surface. When the turn up roller arm is disposed on the original position, a basically complete cylinder surface is formed for the compaction of the carcass parts to support the tire body. With the invention, the tire compaction and forming processes are integrated, meanwhile the functions of compaction and the mechanical forming drums are also provided. Therefore, the invention provides conditions for the one stage forming of steel-belted tire. With high efficiency, the quality of the produced tires is excellent.

Owner:TIANJIN SAIXIANG M&E ENG CO LTD

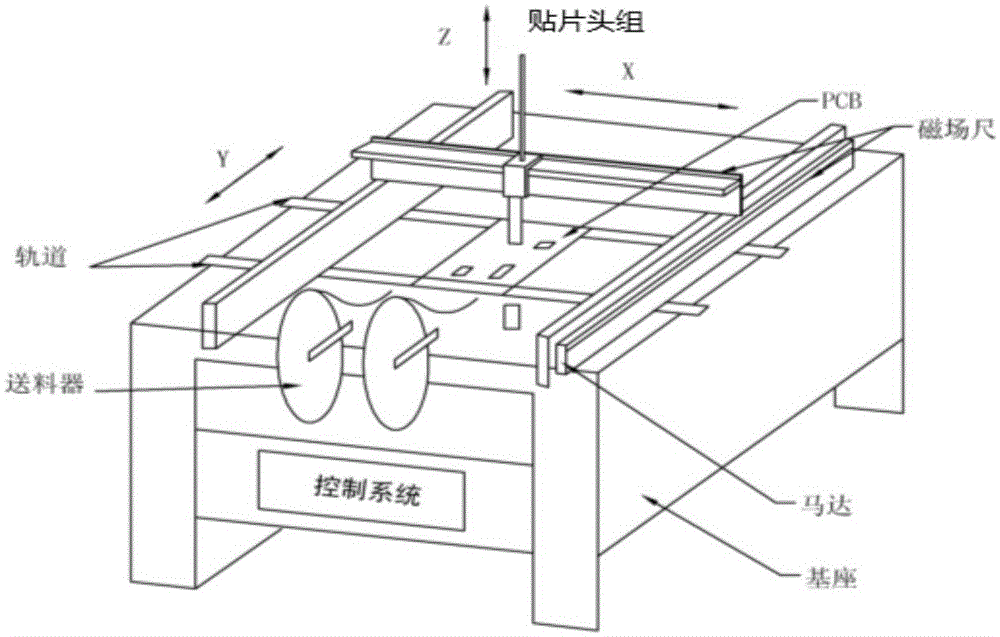

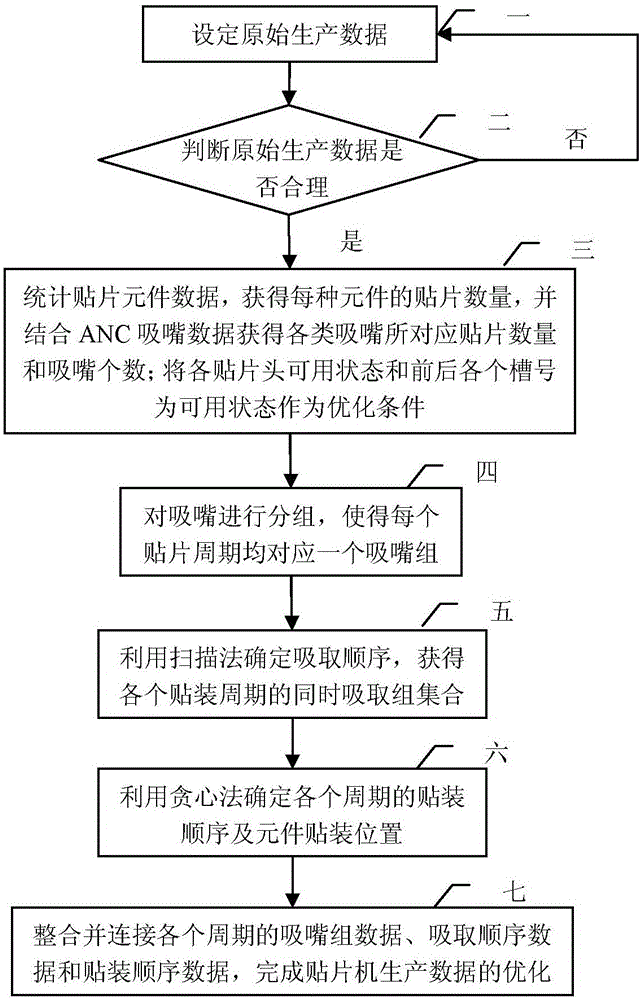

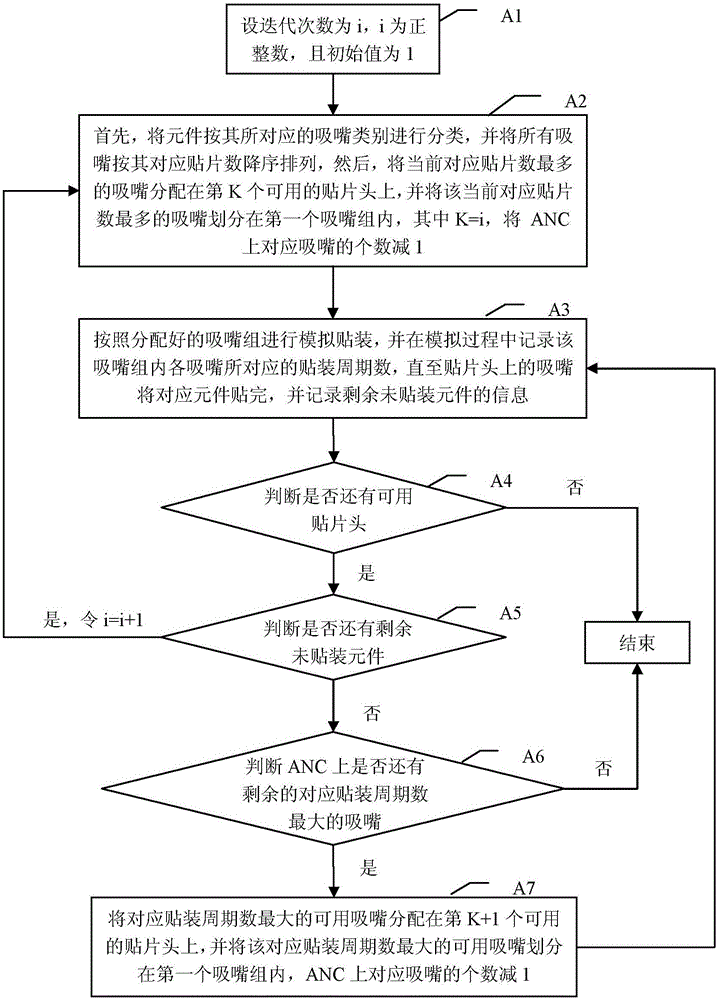

Surface mount machine production data optimization method based on feeder position determination

ActiveCN105120647AAvoid mistakesAvoid conflictPrinted circuit assemblingElectrical componentsArm surfaceSurface mounting

A surface mount machine production data optimization method based on feeder position determination relates to the field of production data optimization of movable arm surface mount machines. The invention aims to solve the problem that the production data of a movable arm surface mount machine can only be locally optimized by the existing method. The surface mount machine production data optimization method based on feeder position determination comprises the following steps: first, setting original production data, judging whether the original production data is reasonable, starting again if the original production data is not reasonable, and counting data of surface mounted elements to obtain the number of each element if the original production data is reasonable; then, using the available state of each surface mount head and the available state of each of slot numbers as conditions of optimization; grouping suction nozzles; determining the suction sequence by a scanning method, and determining the surface mount order of each cycle and the surface mount positions of elements by a greedy method; and finally, integrating and connecting suction nozzle group data, suction order data and surface mount order data of each cycle to complete surface mount machine production data optimization.

Owner:宁波智能装备研究院有限公司

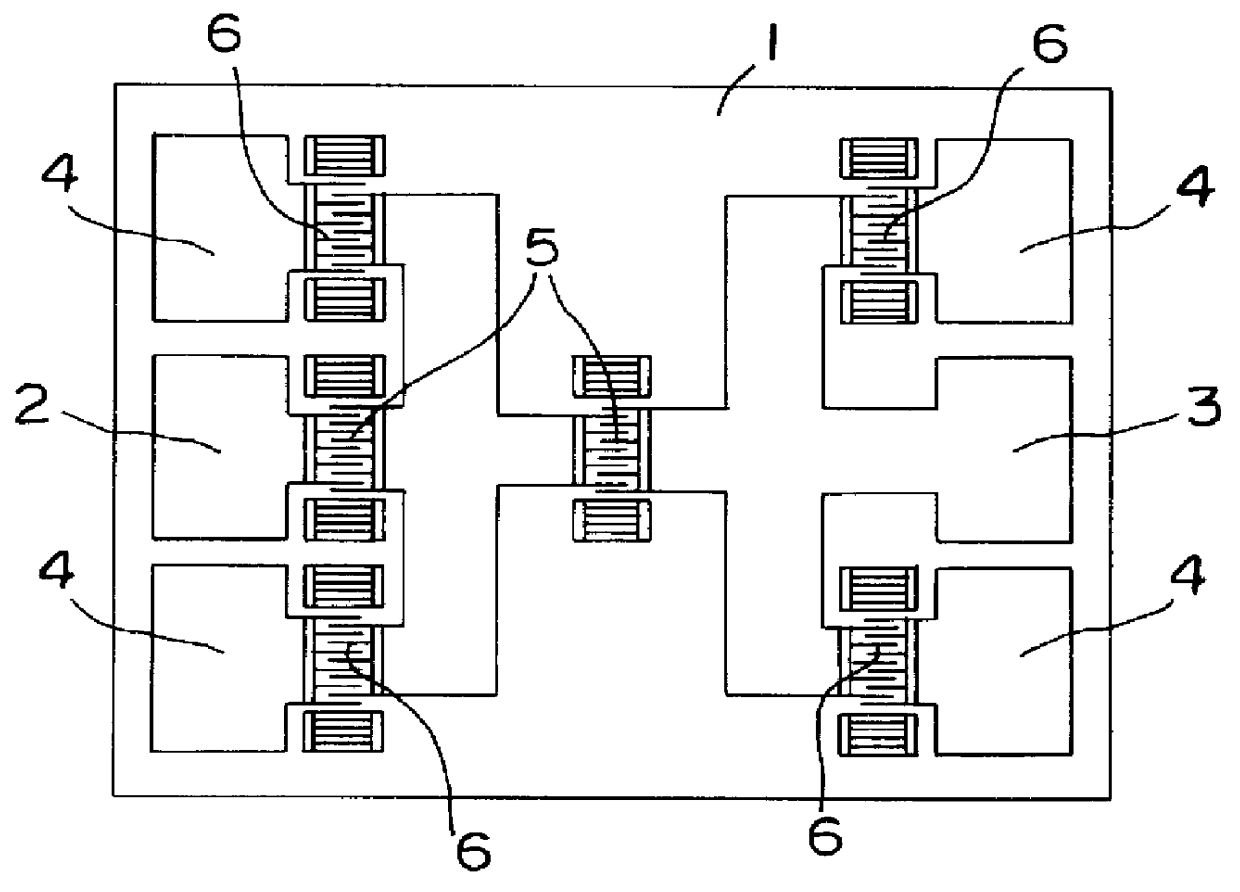

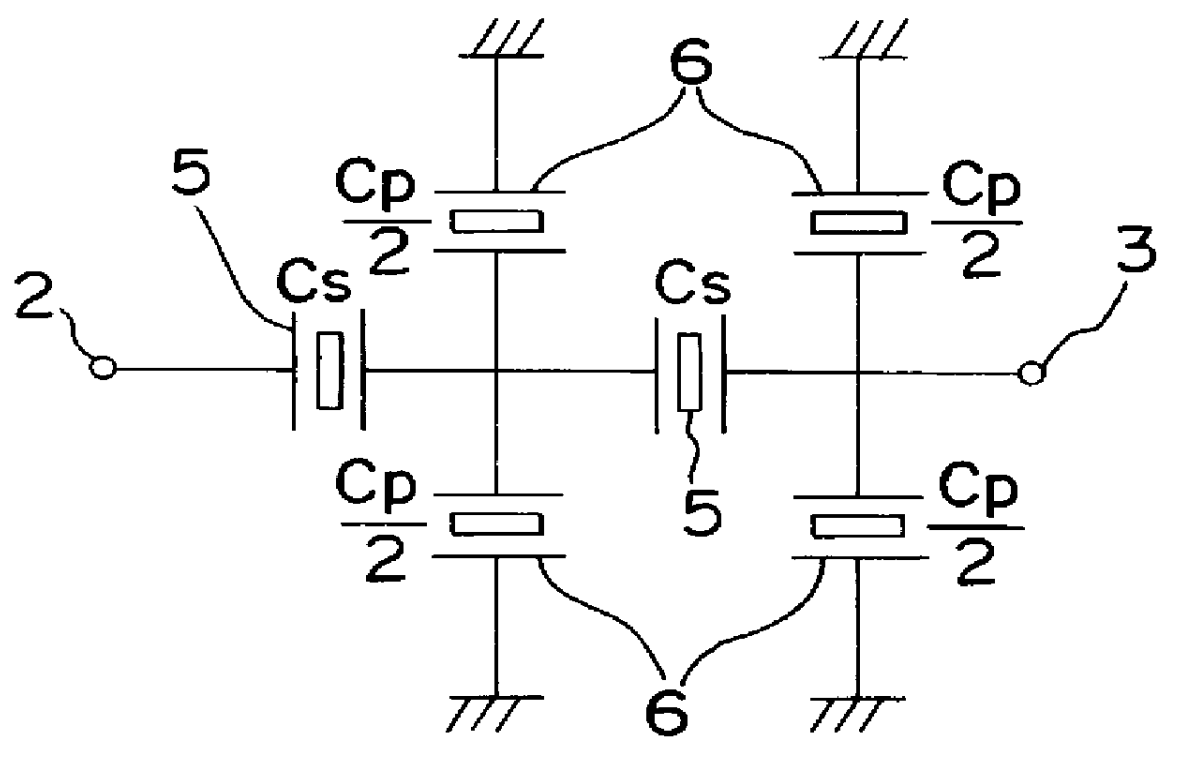

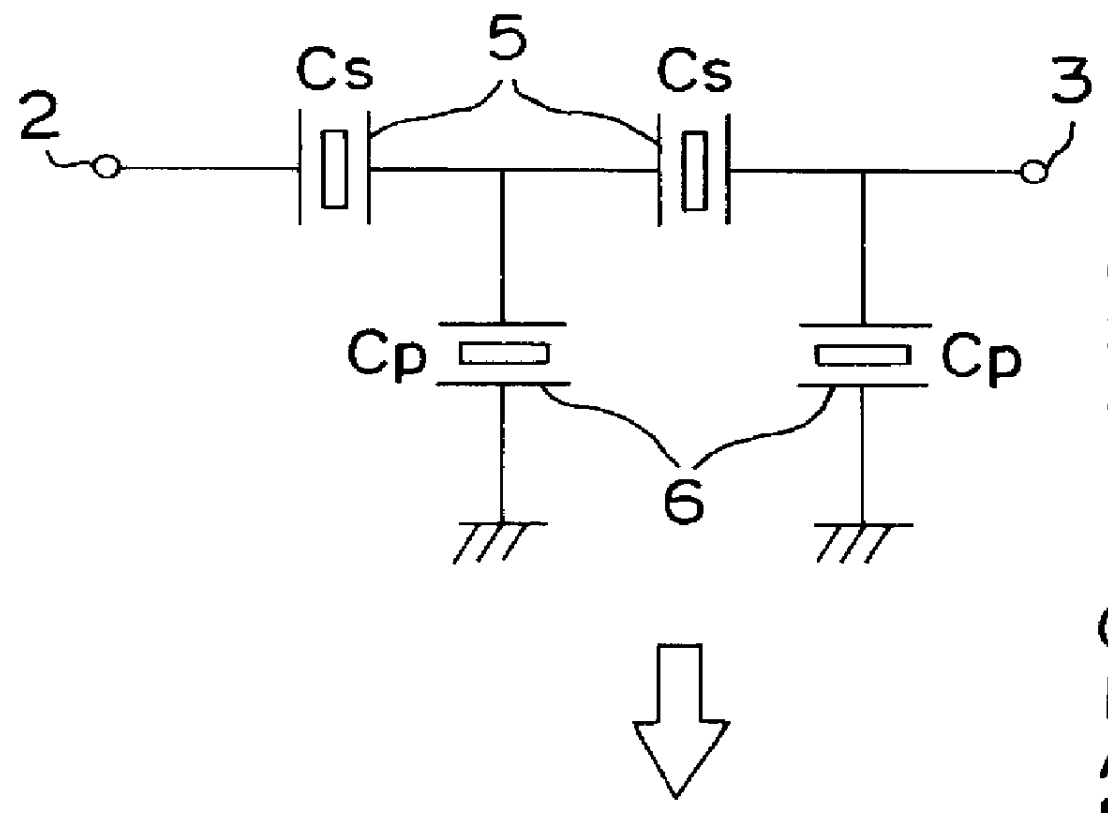

Resonator ladder type surface acoustic wave filter

InactiveUS6166611APiezoelectric/electrostriction/magnetostriction machinesImpedence networksArm surfaceCapacitance

A resonator ladder type surface acoustic wave filter, has an input electrical terminal, an output electrical terminal, and a grounding terminal being formed on a piezoelectric substrate, a series arm surface acoustic wave resonator and a parallel arm surface acoustic wave resonator, each constructed from an interdigital transducer for exciting a surface acoustic wave, being formed between said input electrical terminal and said output electrical terminal, and when the center frequency of said resonator ladder type surface acoustic wave filter is denoted by fc, and capacitance determined by the number of electrode finger pairs and electrode finger overlap width in said interdigital transducer of said parallel arm surface acoustic wave resonator is denoted by Cp (fc: center frequency [GHz], Cp: capacitance of the interdigital transducer of the parallel arm surface acoustic wave resonator), capacitance C of multiples of said parallel arm surface acoustic wave resonator, connected to the same node between said input electrical terminal and said output electrical terminal, always satisfies the relation fcxCp<4

Owner:SKYWORKS PANASONIC FILTER SOLUTIONS JAPAN

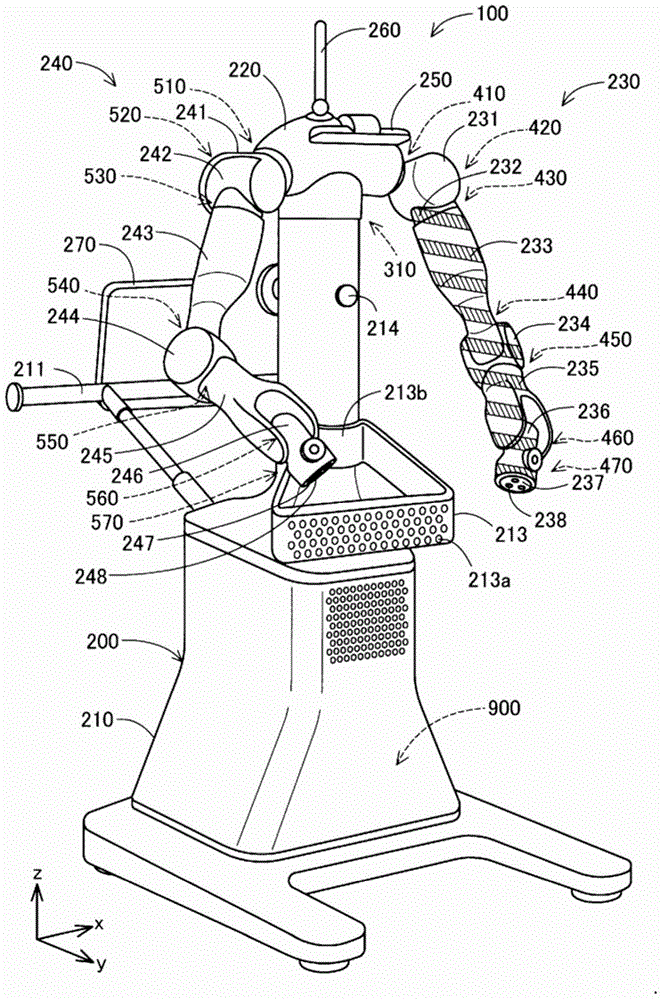

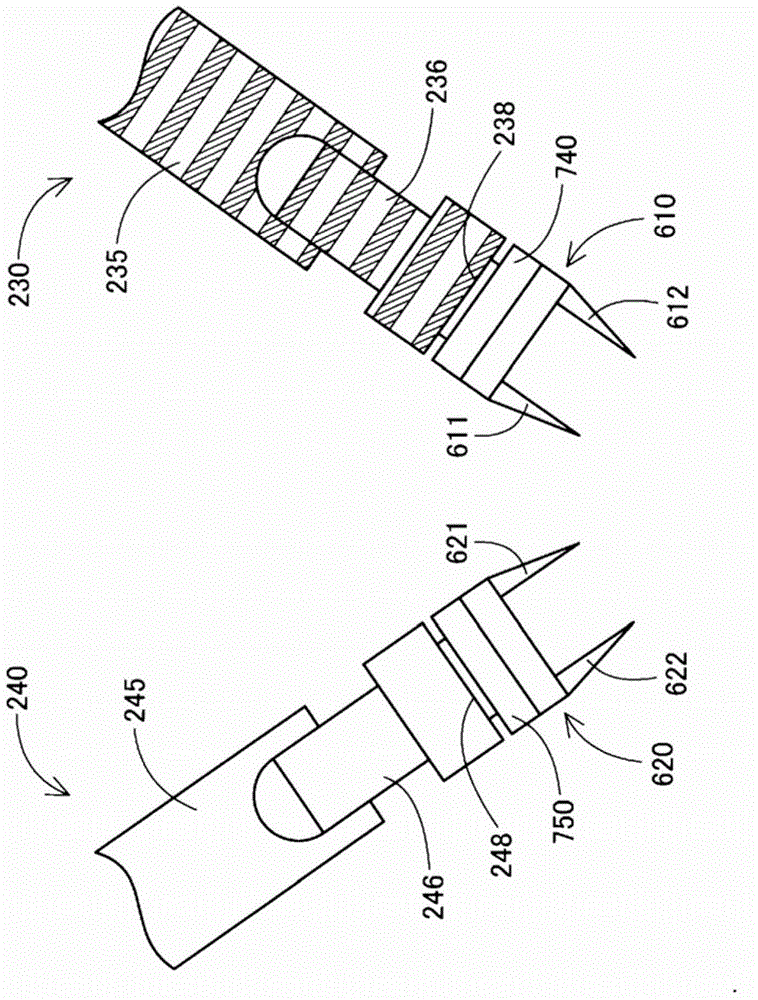

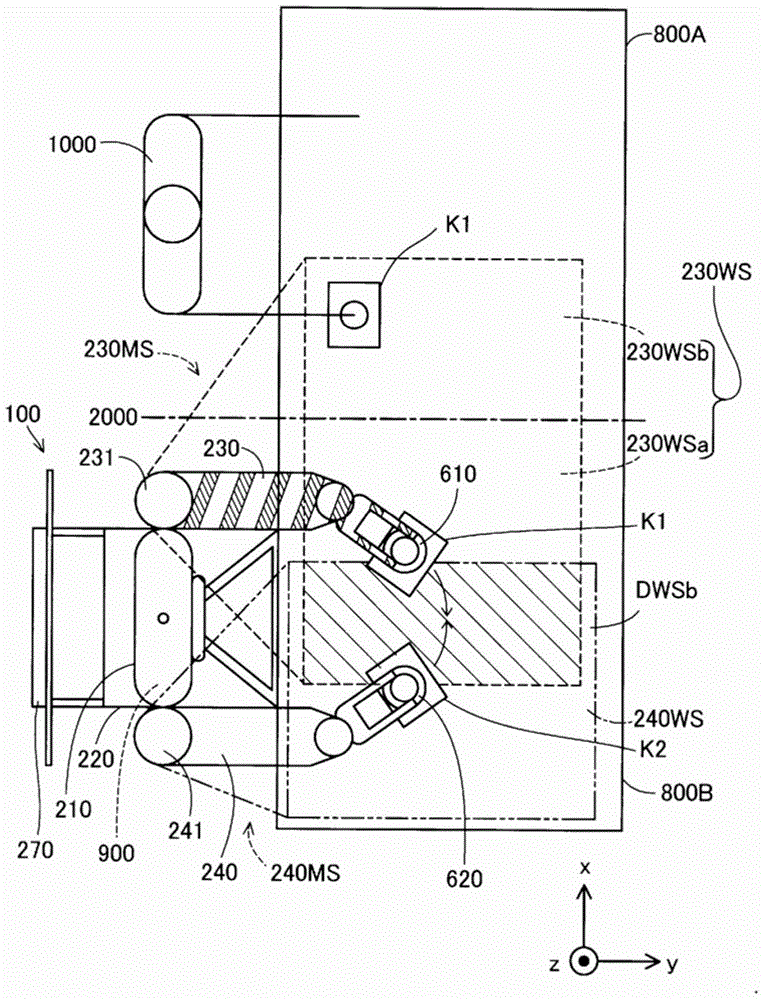

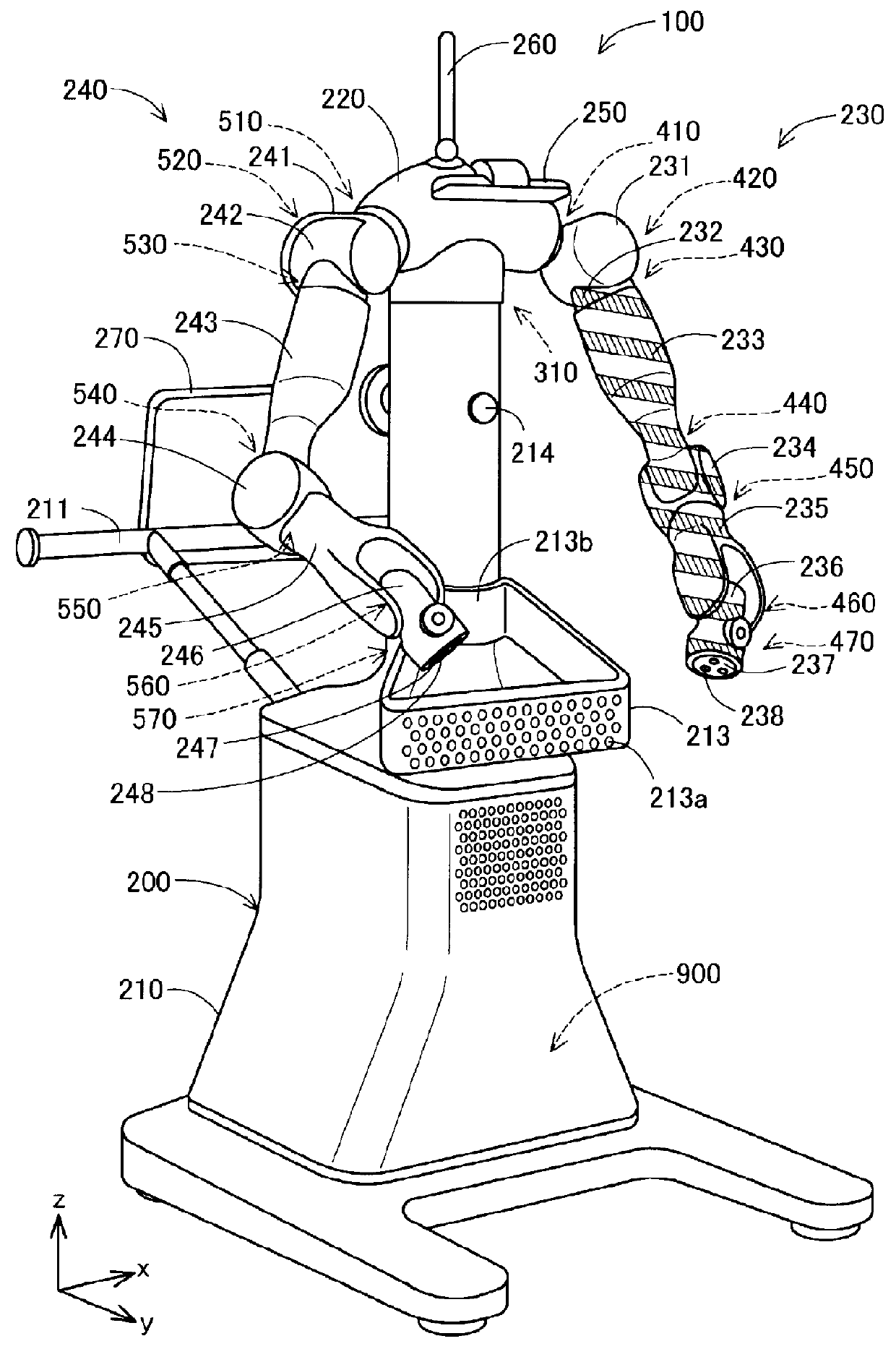

Double arm robot

InactiveCN105313103AImprove work efficiencyProgramme controlProgramme-controlled manipulatorArm surfaceEngineering

There is provided a double arm robot having a first arm to which a first end effector is attached and a second arm to which a second end effector is attached. The first arm and the second arm are different from each other in at least one of an arm length, an arm thickness, an arm surface shape, an arm surface color, an arm surface pattern, the number of arm joints, an arm joint shape, a shape of accessory components disposed on an arm surface, an arrangement of the accessory components, and the number of the accessory components.

Owner:SEIKO EPSON CORP

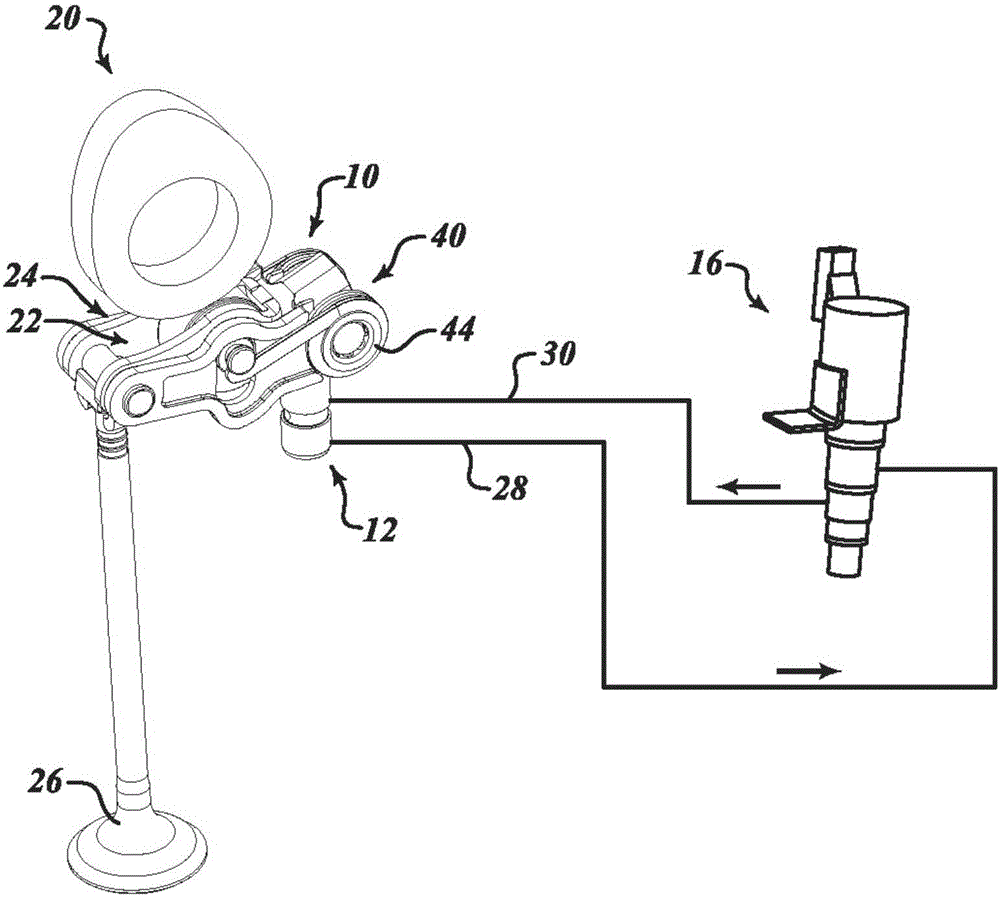

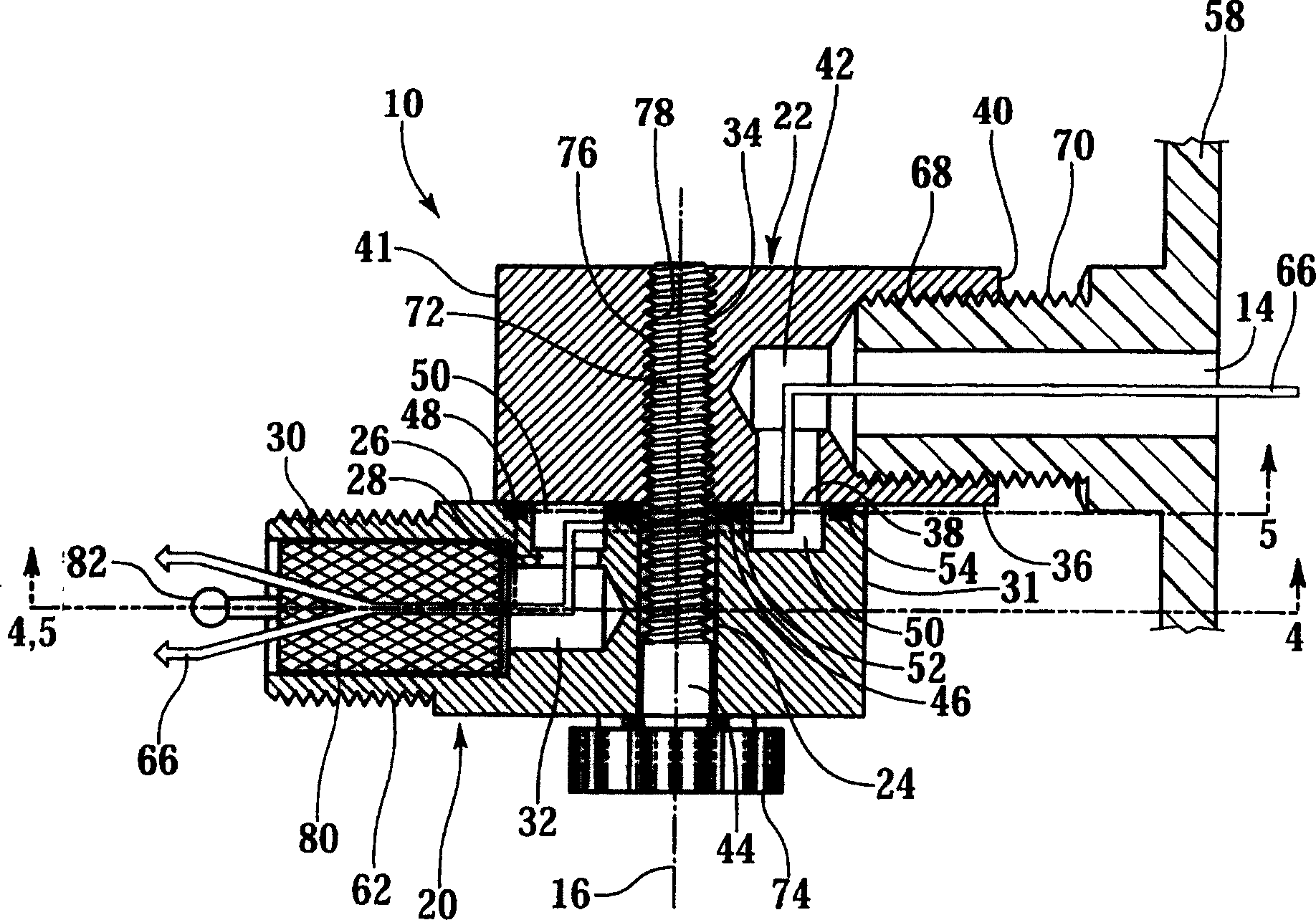

Door check

ActiveUS7793387B2Easy constructionReduce manufacturing costBuilding braking devicesWing fastenersArm surfaceEngineering

A door check including an arm with an arm mount is provided for mounting the arm to a vehicle door or frame. The arm includes a first surface and an oppositely disposed second surface. The door check further includes an arm guide including a housing, including a guide mount for mounting the housing to the vehicle door or frame, and a guideway for receiving the arm. The arm guide also includes two generally facing arm engaging structures mounted within the housing for receiving the arm therebetween. Each arm engaging structure faces its respective arm surface. The arm guide includes a spring between the housing and the second arm engaging structure. The spring biases that structure towards the first arm engaging structure to urge these structures into contact with the respective arm surfaces restricting longitudinal movement of the arm through the guideway.

Owner:M T M

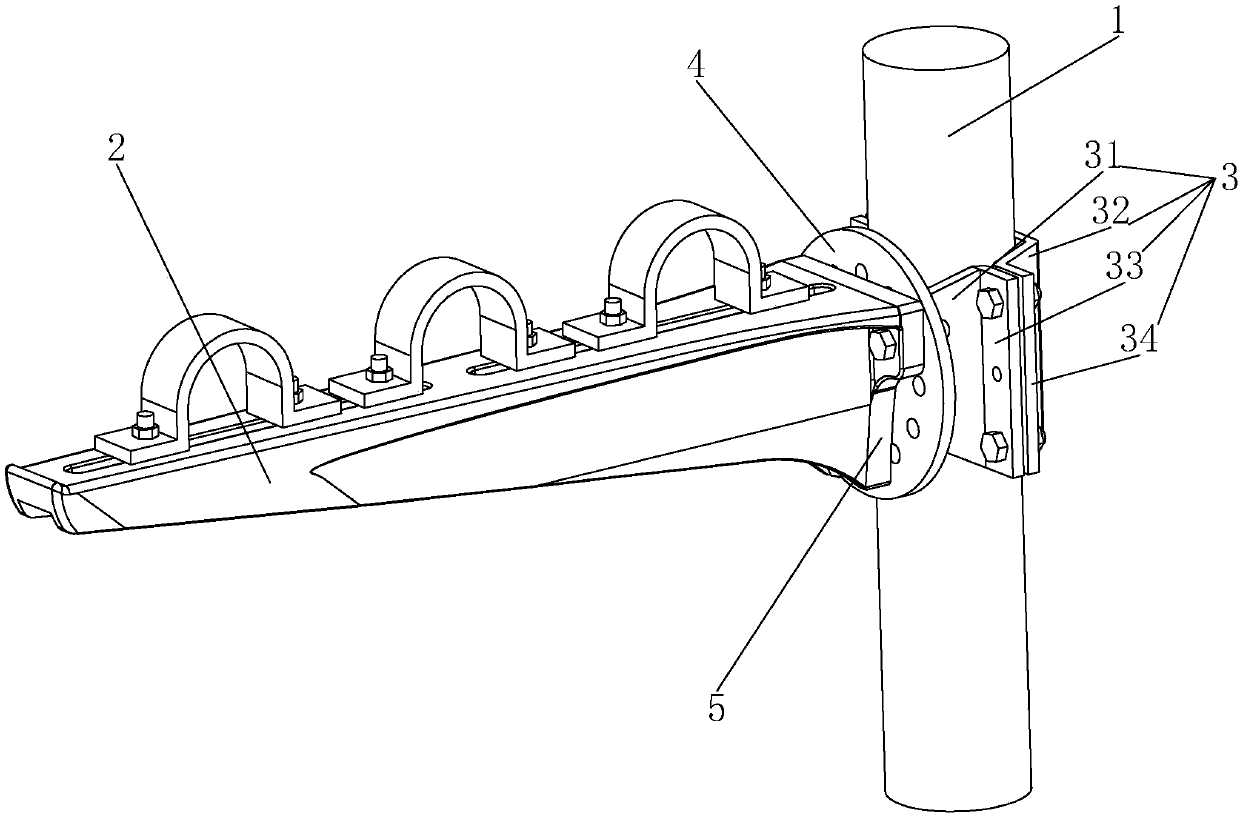

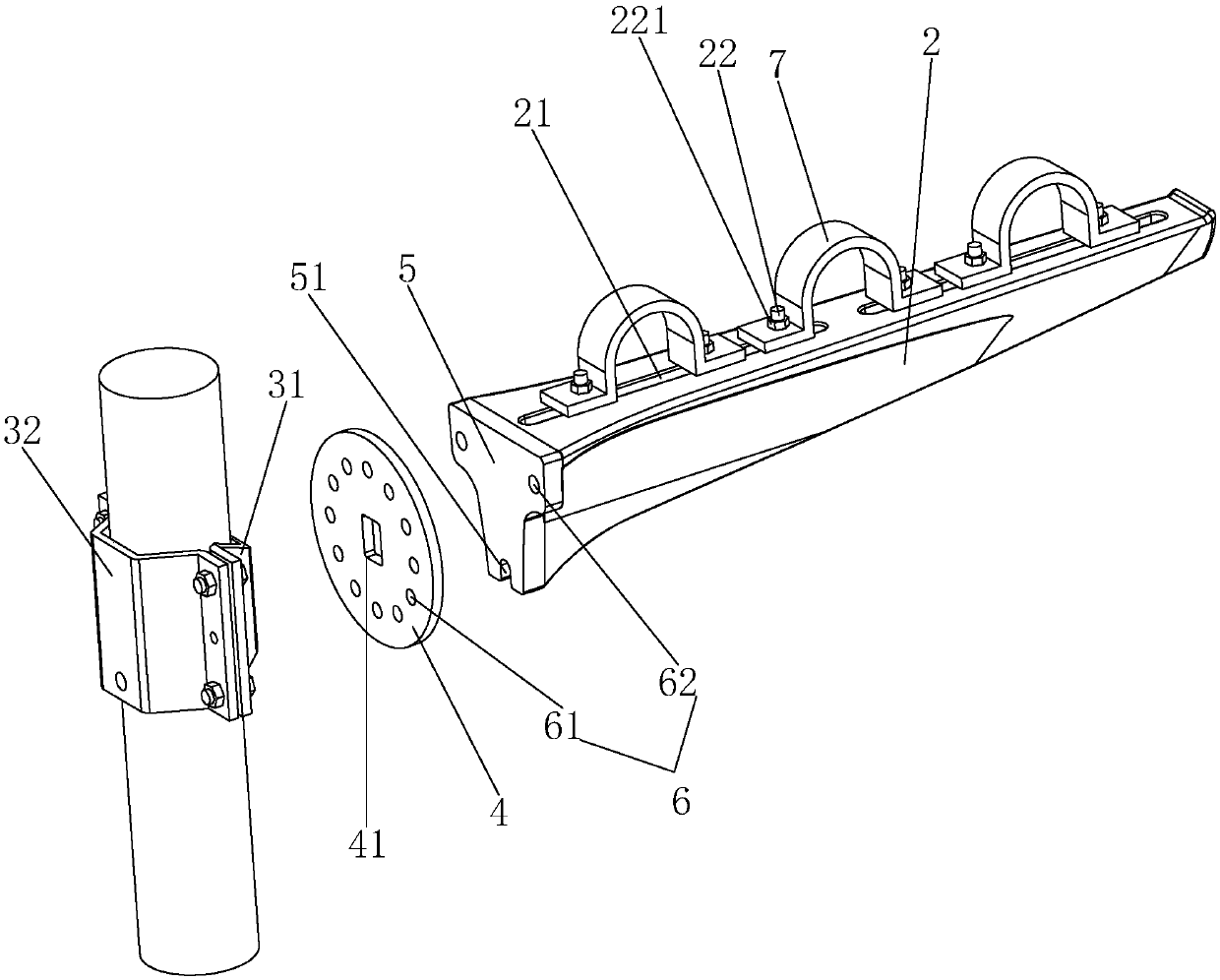

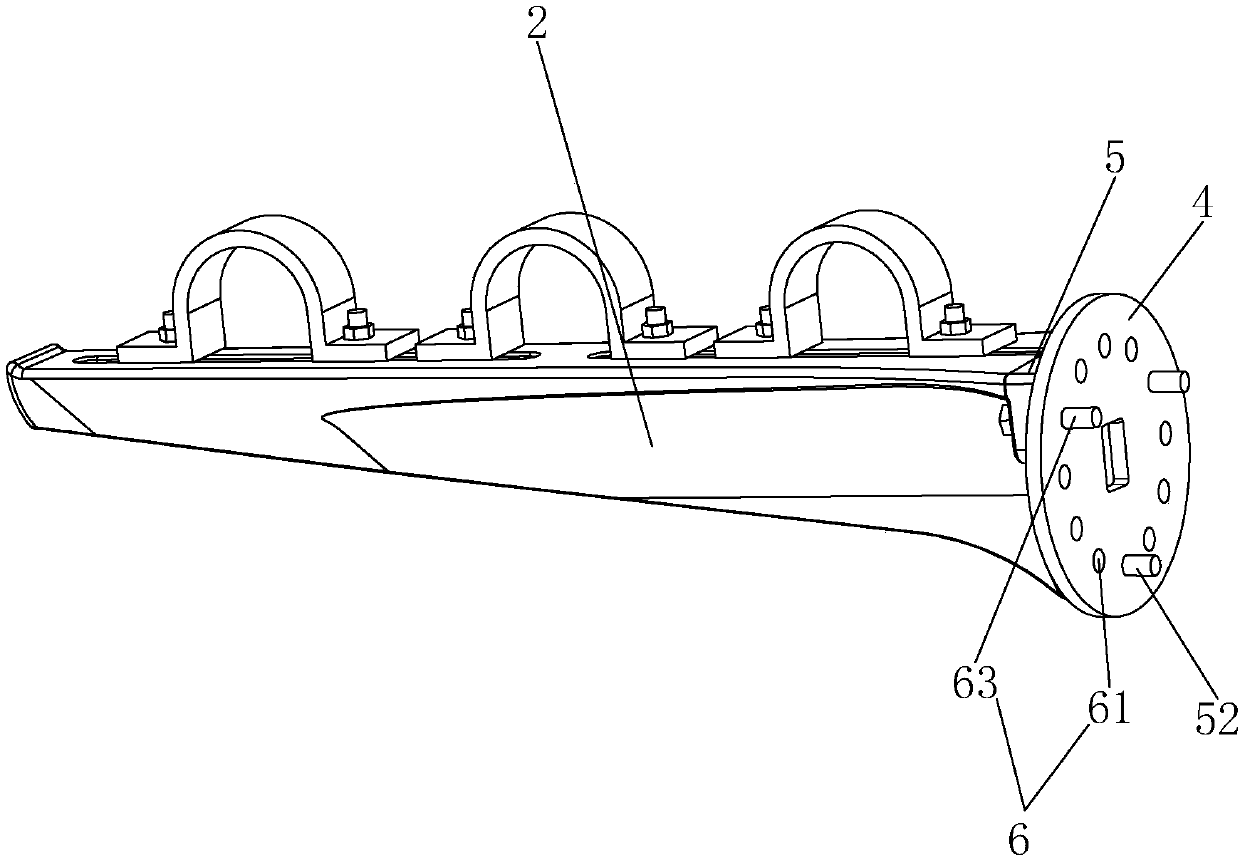

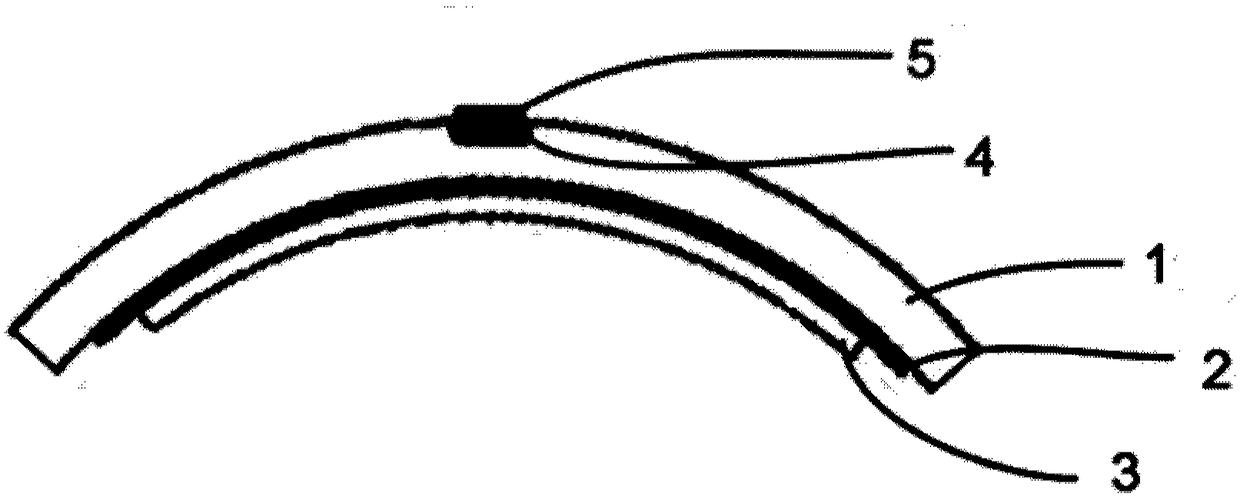

Cable holder with adjustable horizontal and vertical directions and axial direction of support arm

The invention, which relates to the technical field of cable laying, discloses a cable holder with adjustable horizontal and vertical directions and an adjustable axial direction of a support arm. Thecable holder comprises a standing post, a support arm, and a hoop. A mounting plate is fixed on the hoop; a connecting plate is fixed at one end of the support arm; and an adjusting element that enabling the connecting plate to be fixed at the mounting plate after autoroatation of the connecting plate at different angles on the mounting plate is arranged between the support arm and the mounting plate. When the support arm rotates in an inclination direction of the upper surface of the support arm and the inclination direction is in tangency with an arc track for turning of a cable, the support arm is fixed by the adjusting element and then the cable is installed on the upper surface of the support arm by an omega-shaped cable clamp. Compared with the horizontal upper surface of the support arm, the support arm upper surface with the inclination direction in tangency with the arc track for turning of tube cable enables the arc of bending needed by the cable to be reduced, so that the possibility of any damage of the cable is reduced; and the omega-shaped cable clamp can be installed conveniently and the local stress between the omega-shaped cable clamp and the cable is reduced.

Owner:绍兴市卓元电气科技有限公司

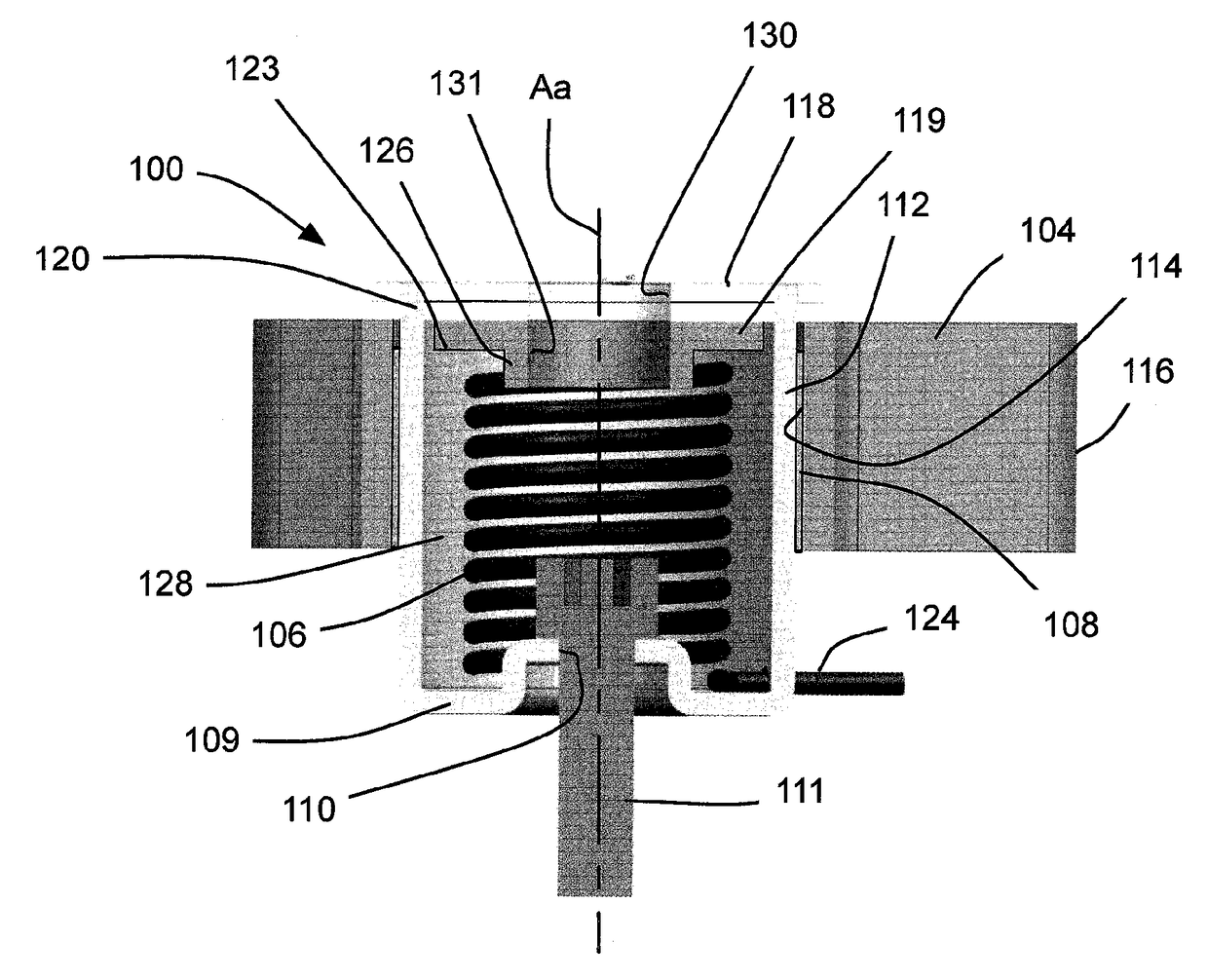

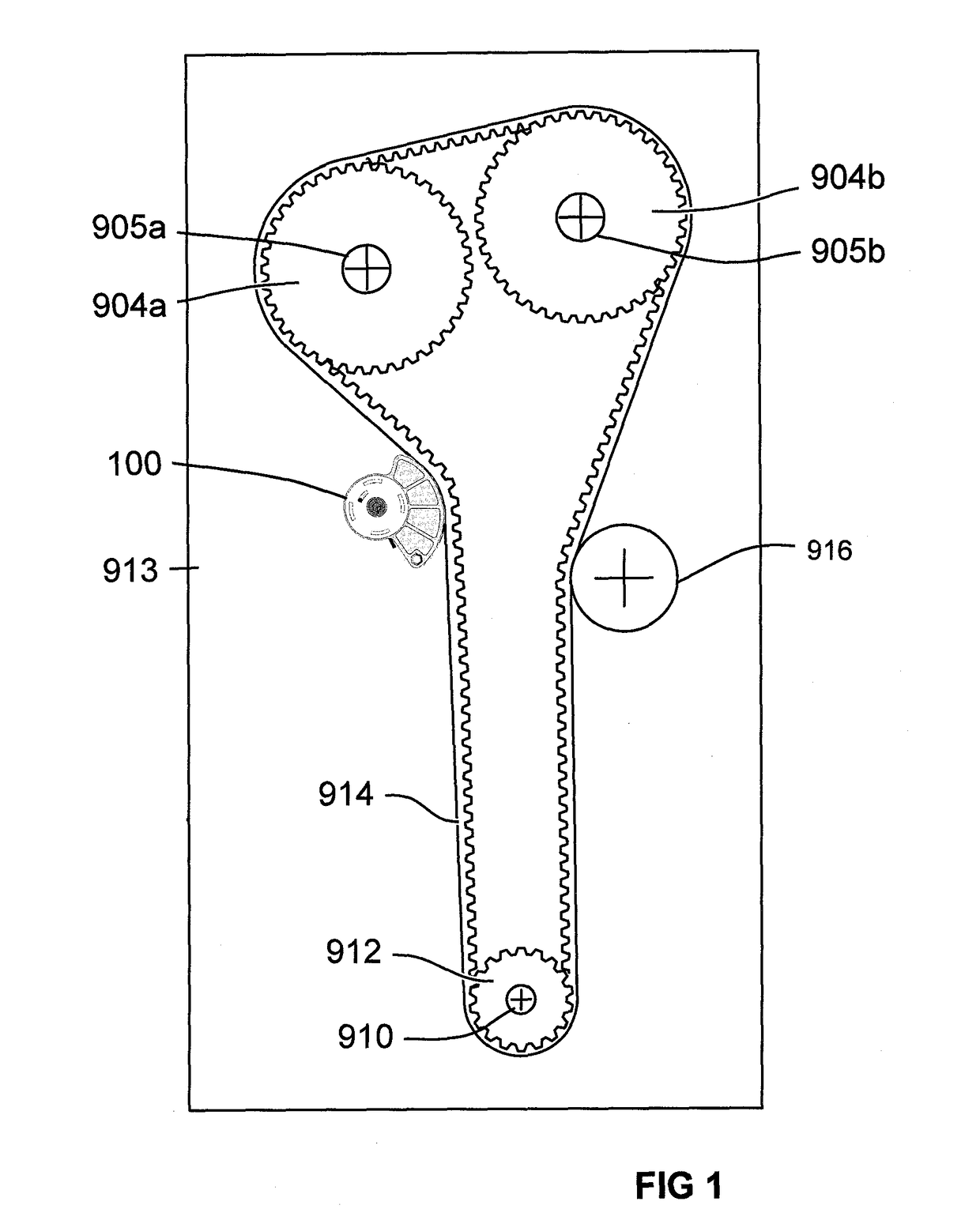

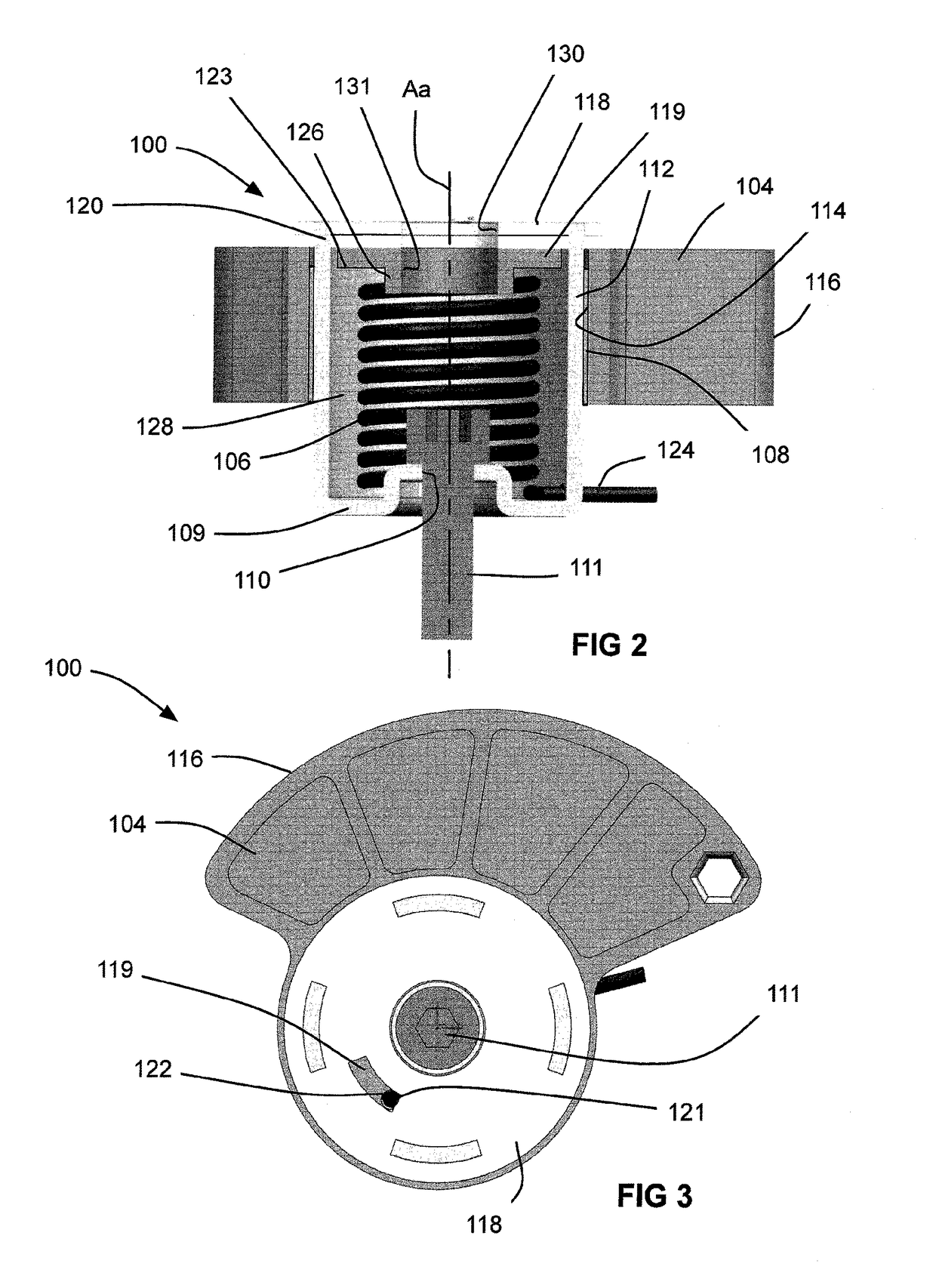

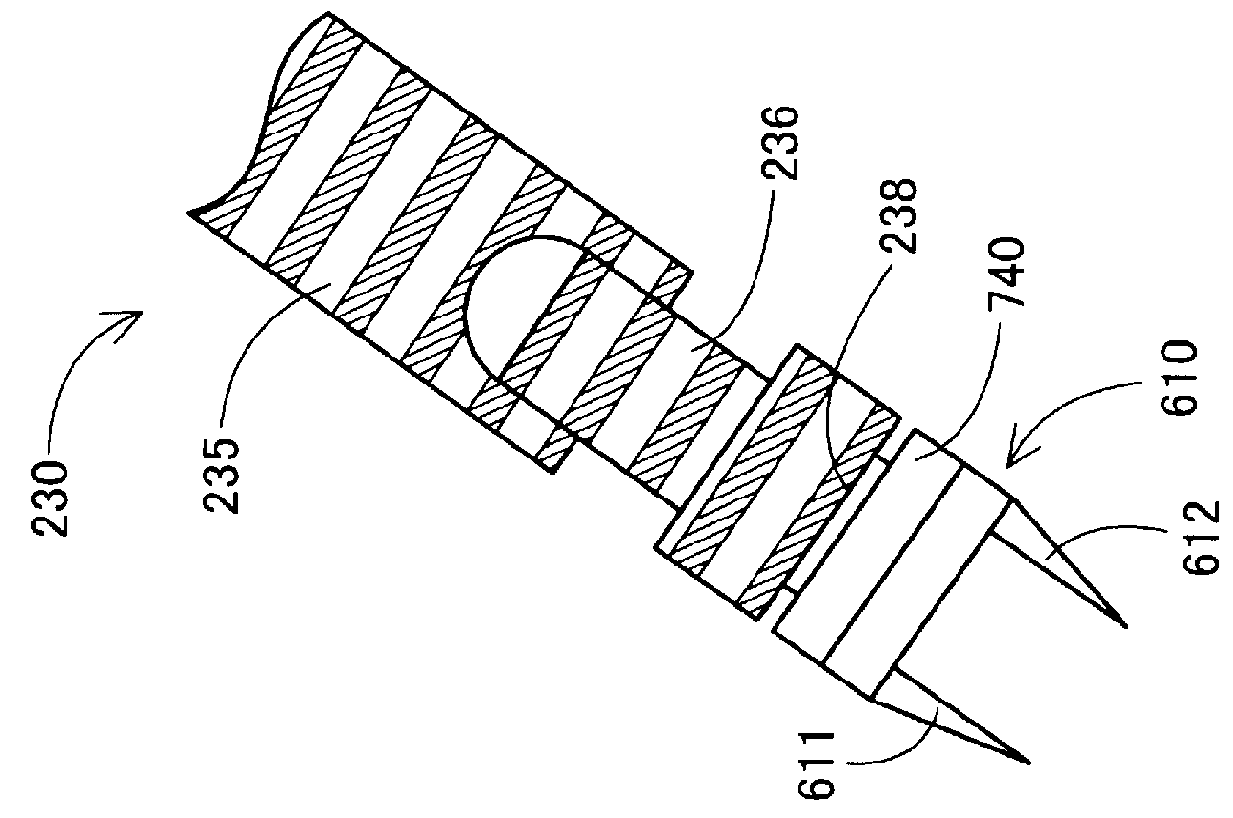

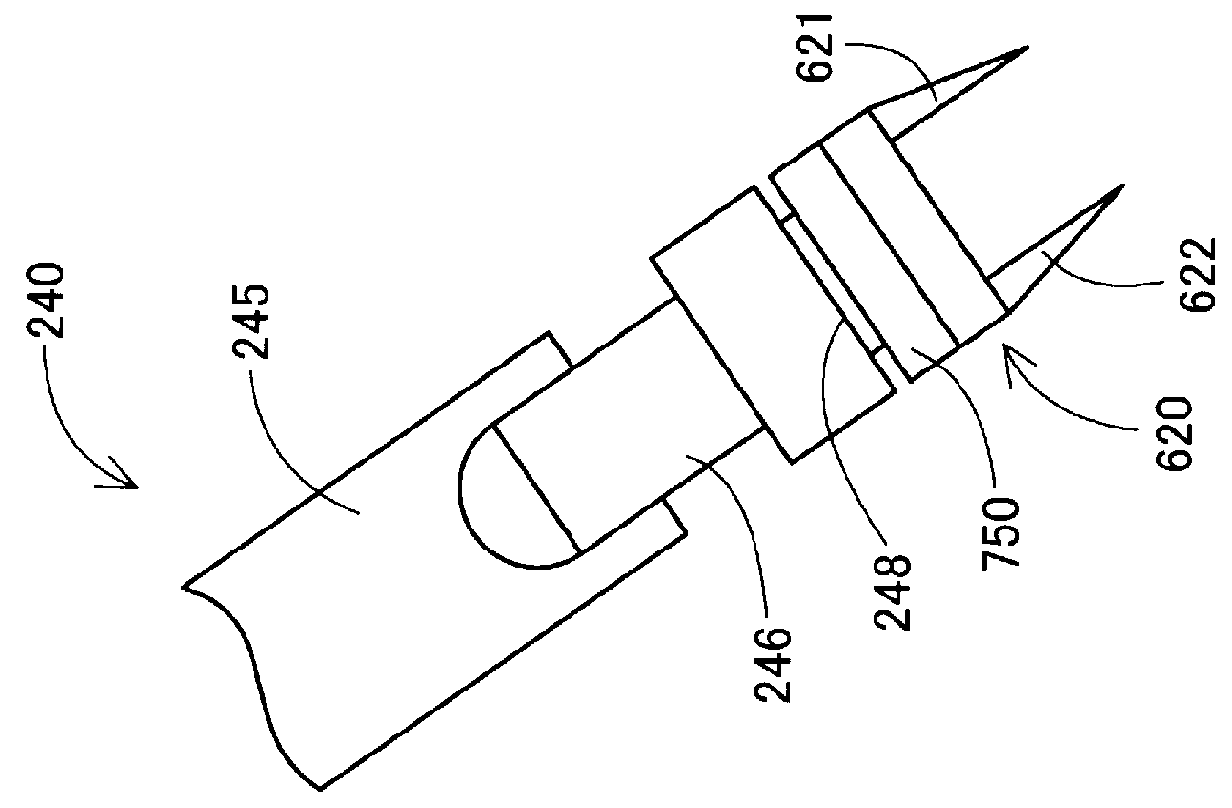

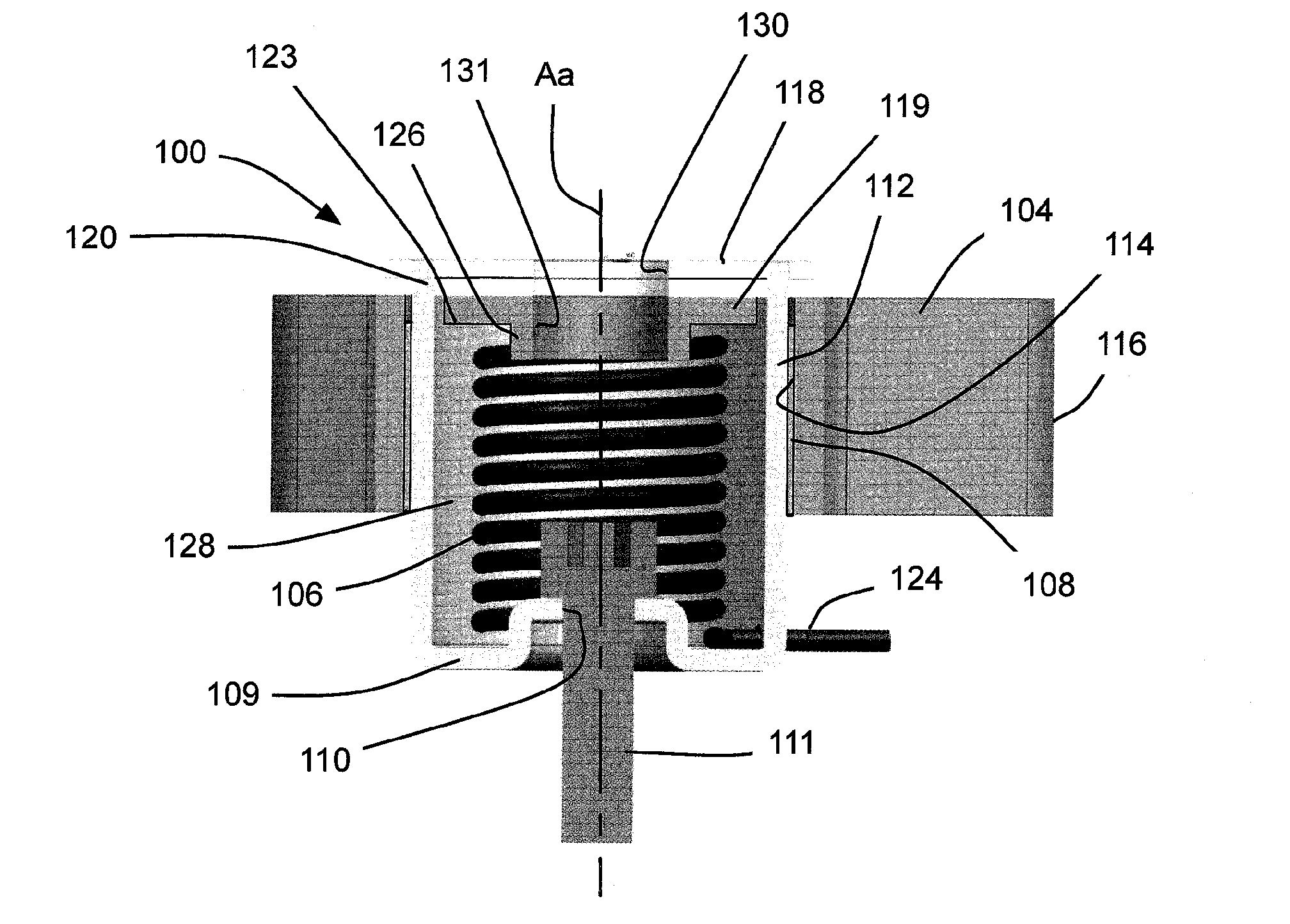

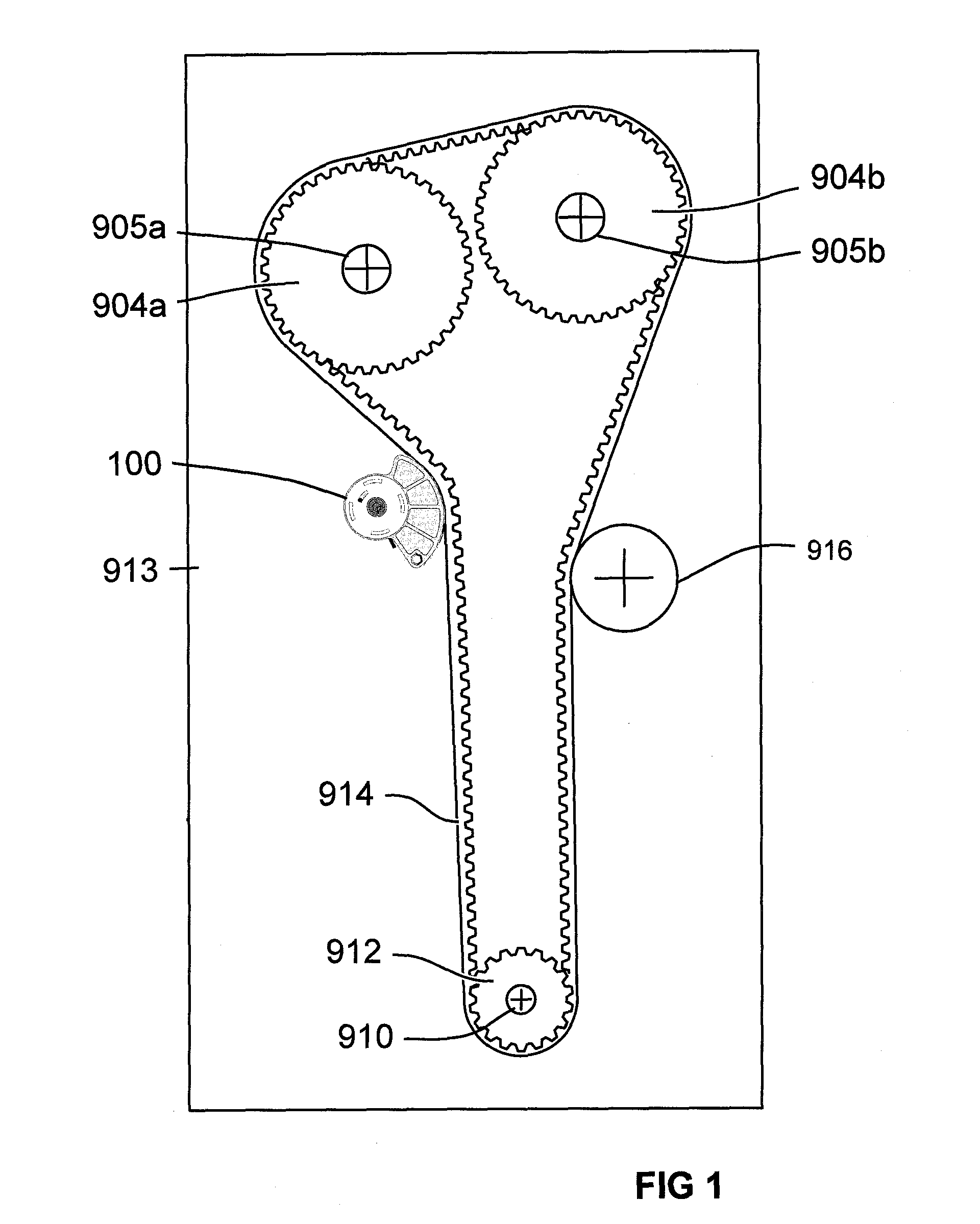

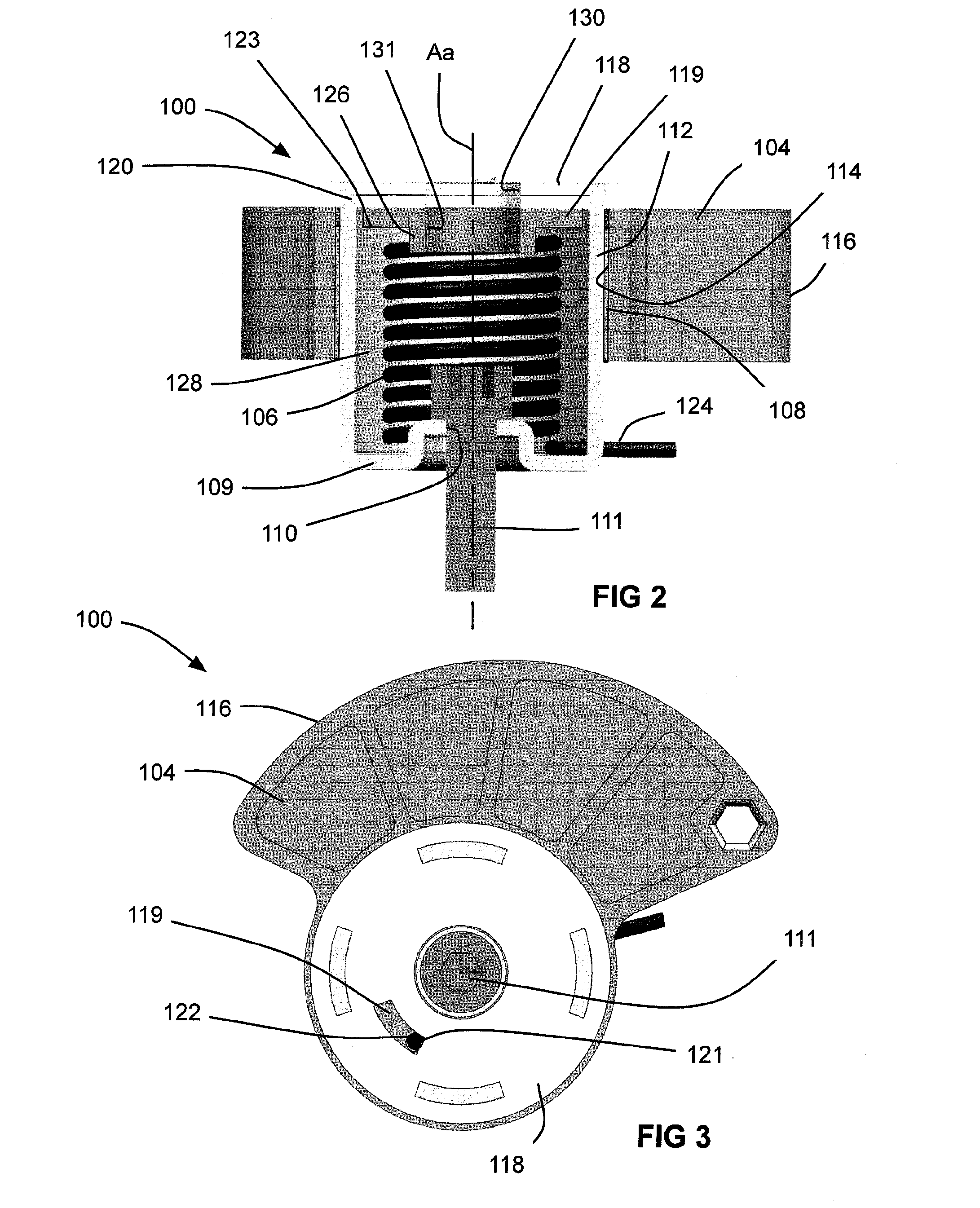

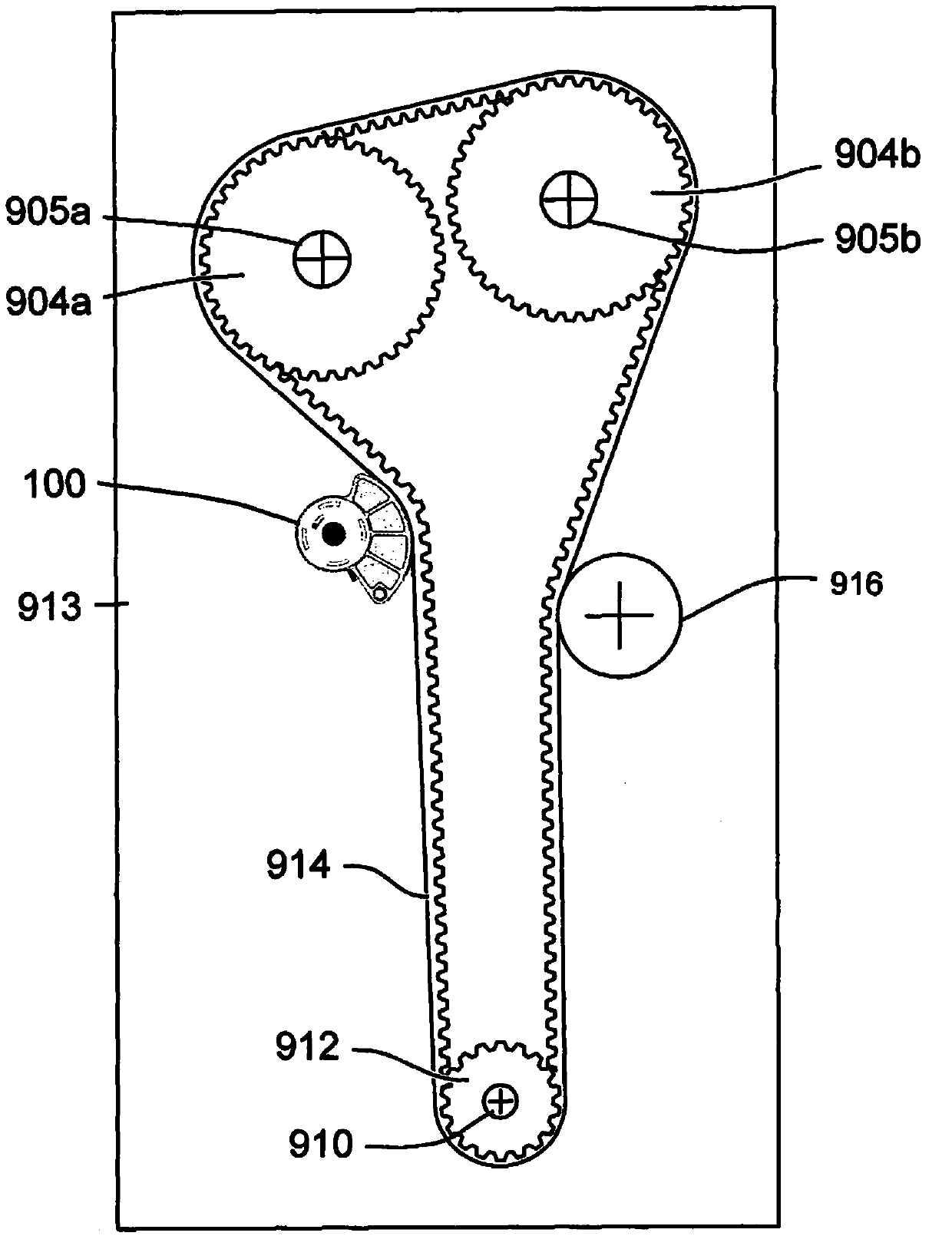

Tensioner with increased damping and arm on base cup configuration

In an aspect, a tensioner is provided for maintaining tension in an endless drive member in a belt-in-oil drive system. The tensioner includes a base that is mountable to a stationary structure and that has a circumferential wall that defines an arm pivot axis, an arm having a radially inner arm surface, and an endless drive member engagement surface that is engageable with an endless drive member, a bushing positioned between the radially inner arm surface and the circumferential wall of the base cup, and a tensioning spring. The arm is supported on the base cup via the bushing. The tensioning spring is positioned to bias the arm in a first direction about the arm pivot axis.

Owner:LITENS AUTOMOTIVE INC

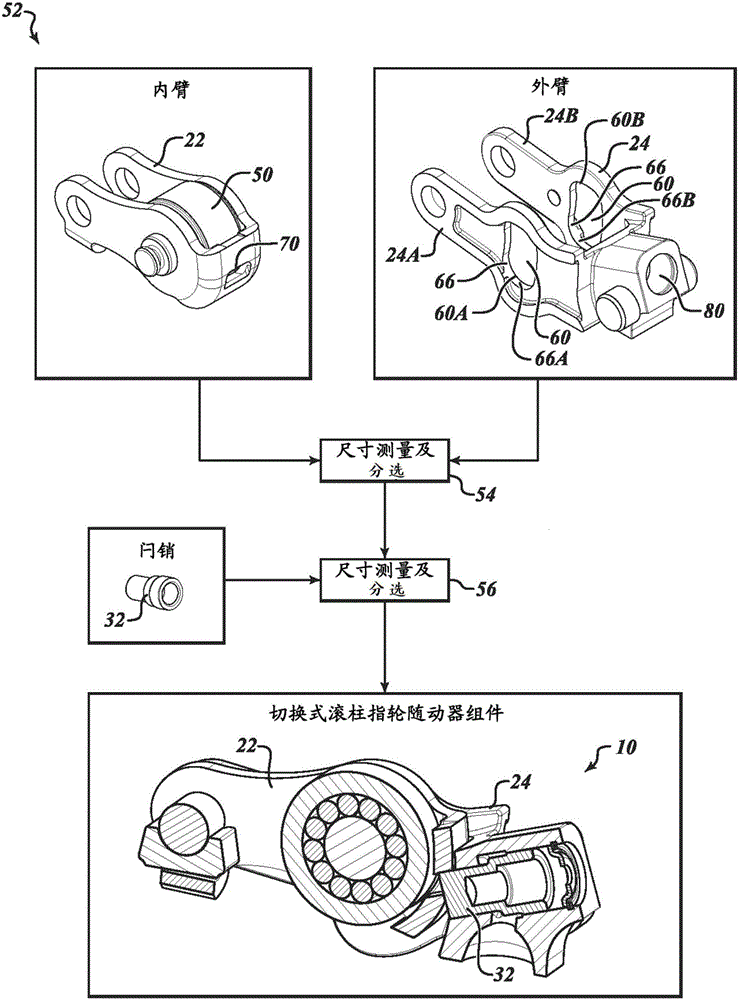

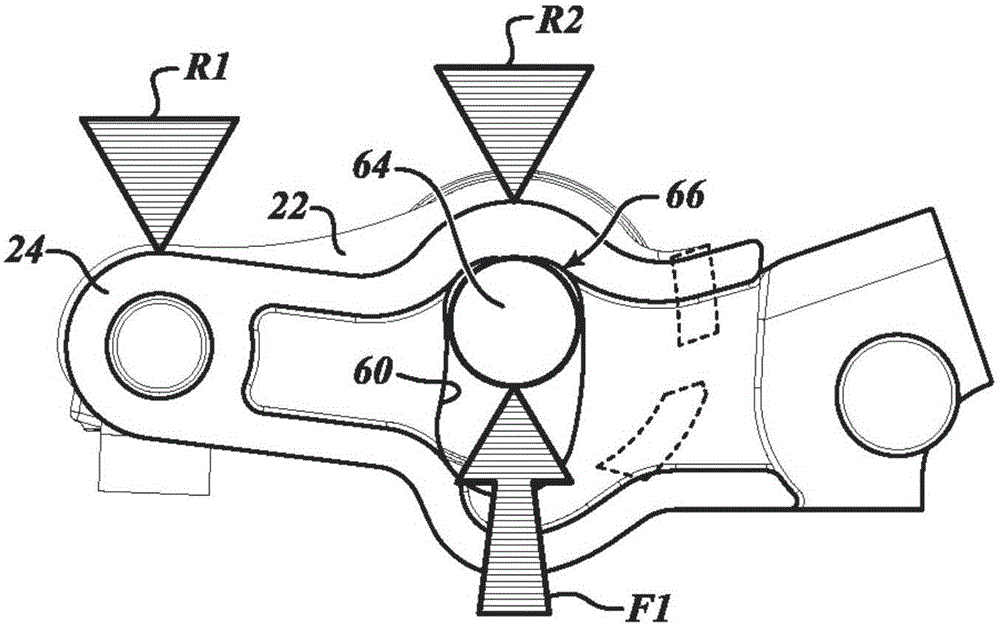

Valve actuating device and method of making same

A method of assembling a switching rocker arm assembly having an inner arm, an outer arm and a latch is provided. The method includes, indenting an outer arm surface on the outer arm, the outer arm surface defining an arcuate aperture. An inner arm surface can be indented on the inner arm at an inner arm latch shelf. A latch can be positioned relative to the inner and outer arms.

Owner:EATON INTELLIGENT POWER LTD

Double arm robot

InactiveUS20160031084A1Improve work efficiencyEnsure safetyProgramme controlProgramme-controlled manipulatorArm surfaceEngineering

There is provided a double arm robot having a first arm to which a first end effector is attached and a second arm to which a second end effector is attached. The first arm and the second arm are different from each other in at least one of an arm length, an arm thickness, an arm surface shape, an arm surface color, an arm surface pattern, the number of arm joints, an arm joint shape, a shape of accessory components disposed on an arm surface, an arrangement of the accessory components, and the number of the accessory components.

Owner:SEIKO EPSON CORP

Tensioner with increased damping and arm on base cup configuration

In an aspect, a tensioner is provided for maintaining tension in an endless drive member in a belt-in-oil drive system. The tensioner includes a base that is mountable to a stationary structure and that has a circumferential wall that defines an arm pivot axis, an arm having a radially inner arm surface, and an endless drive member engagement surface that is engageable with an endless drive member, a bushing positioned between the radially inner arm surface and the circumferential wall of the base cup, and a tensioning spring. The arm is supported on the base cup via the bushing. The tensioning spring is positioned to bias the arm in a first direction about the arm pivot axis.

Owner:LITENS AUTOMOTIVE INC

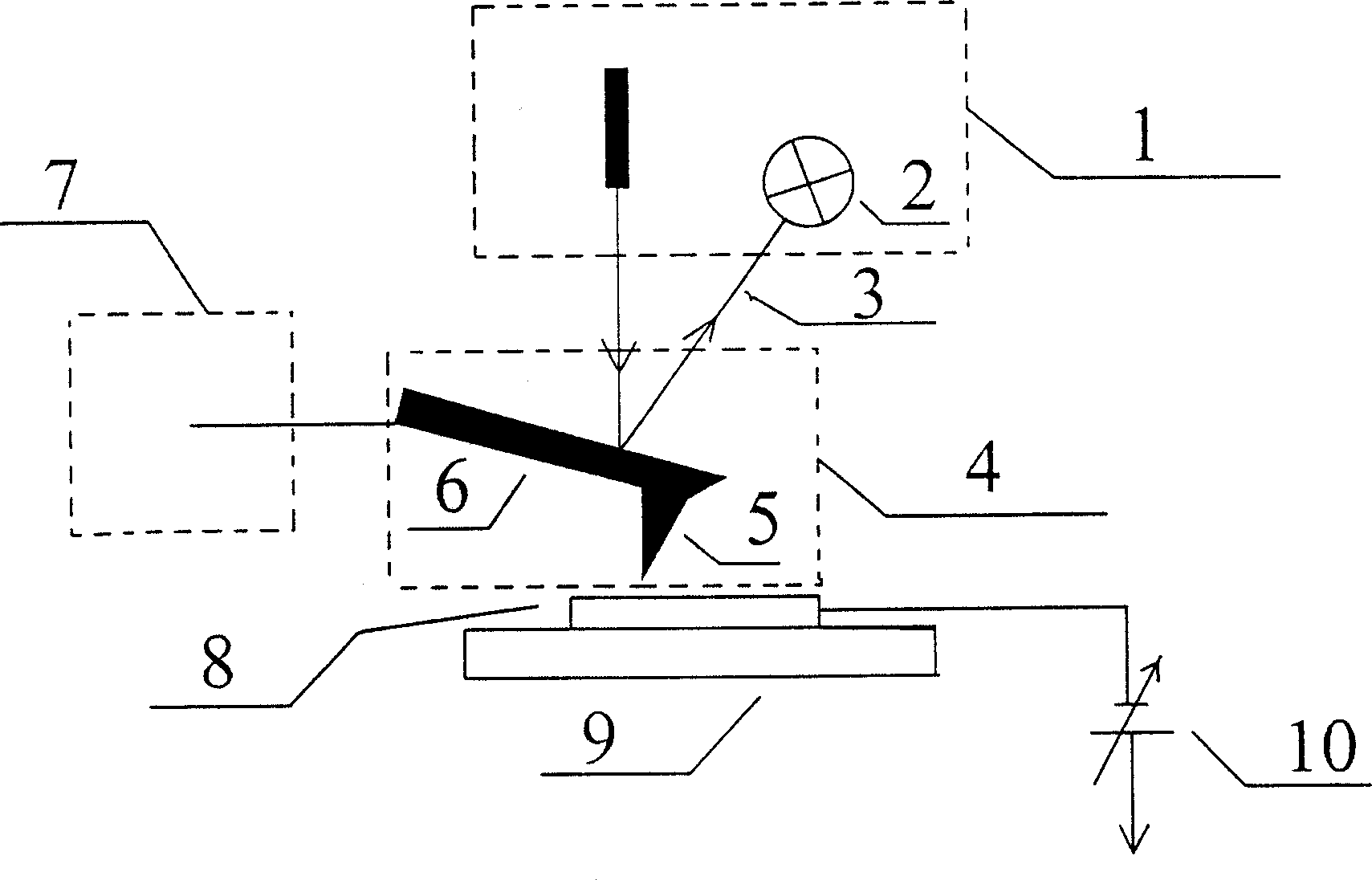

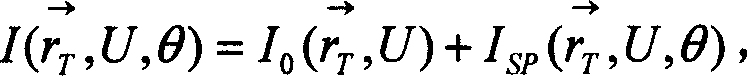

Spin polarized channel atomic force microtechnic

InactiveCN1560594AImprove resolutionHigh resolutionSurface/boundary effectScanning probe microscopyArm surfaceSpin polarized tunneling

The invention is an automatic rotating polarization tunnel atom force micro technology, which belongs to ultrahigh resolution magnetism sensitive imaging technology field. It uses conductive elastic micro suspending arm with magnetic pin, one end of the suspending arm is connected to the control system, another end is the magnetic pin, the control system controls the probe to approach the sample, the pin atom and the sample surface atom generate the atom force to bend the suspending arm, the laser radiates on the suspending arm surface and then reflected to the detector, and it is feed back to the control system, the three-dimension image of the sample surface can be acquired through recording the position coordinate x, y, and z of the probe in scanning process. A constant polarization is added on the sample, measures the current change in the total tunnel, records the plane position coordinate (x, y) and the correspondent total tunnel current value, and acquires the sample magnetism sensitivity information imaging.

Owner:SHANDONG UNIV

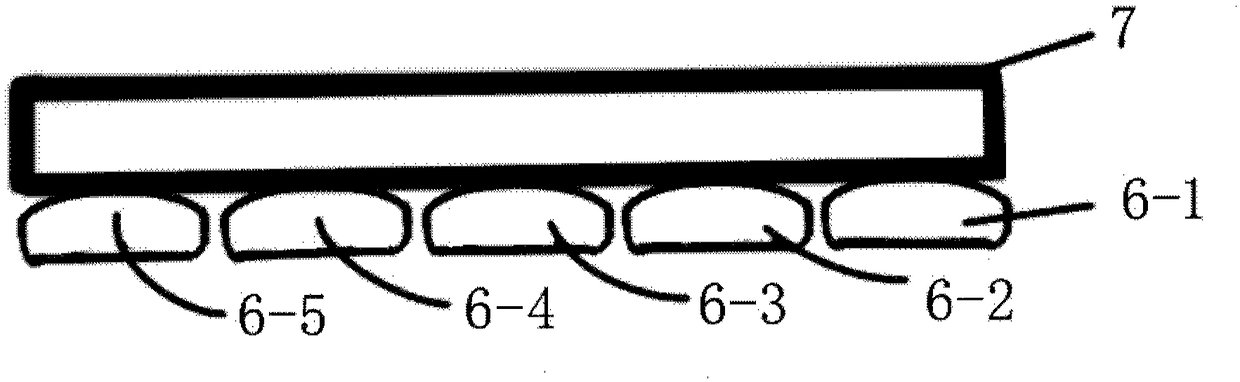

Pulse wave sensor, sensor array, and pulse wave measuring device adopting the same

ActiveCN109222918AOvercome inaccuracyOvercoming the problem of comprehensively reflecting the pulse information of the human bodyCatheterDiagnostic recording/measuringSensor arrayElectricity

The invention relates to a pulse wave sensor, a sensor array and a pulse wave measuring device adopting the same. The pulse wave sensor comprises a sensor skeleton, a flexible piezoelectric sensor anda static pressure sensor, wherein the flexible piezoelectric sensor is used for sensing pulse waves; The static pressure sensor is used for measuring the static pressure exerted on the pulse wave sensor. The sensor skeleton is used for fixing the flexible piezoelectric sensor and the static pressure sensor. The sensor of the invention measures the static pressure signal and the dynamic pulse wavepressure signal separately, the piezoelectric film is used to measure the dynamic pressure fluctuation, and the piezoresistive sensor measures the static pressure, so that the dynamic sensitivity isnot affected by the static pressure measuring range, and the high sensitivity to the pulse wave can be maintained under the wide range of static pressure; The sensor of the invention adopts a flexibleskeleton, so that the array composed of the sensor can meet the characteristics of the wrists of different crowds and realize good bonding to the surface of the arm.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

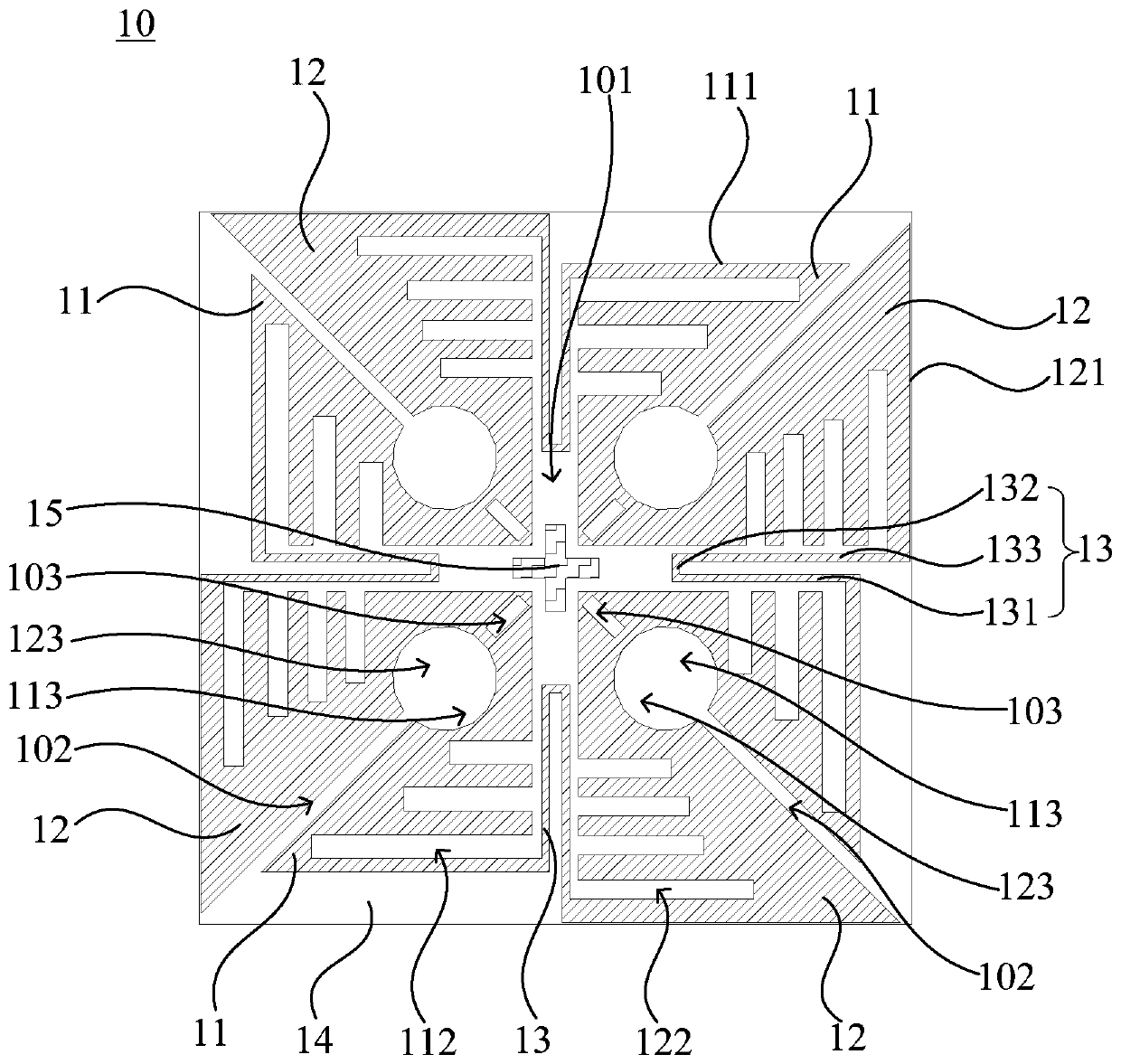

Dual-frequency dual-polarized antenna and radiating unit

InactiveCN110233343ASatisfies the dual-frequency working characteristicsEnhanced couplingSimultaneous aerial operationsRadiating elements structural formsArm surfaceWhole body

The invention relates to a dual-frequency dual-polarized antenna and a radiating unit. The radiating unit comprises two pairs of radiating arms which are arranged in an orthogonal polarization way anda balun used for feed to the radiating arms. A cross hollow area is formed between the two pairs of radiating arms. In the above-mentioned radiating unit, one pair of radiating arms is equivalent toa dual-frequency +45-degree polarized half-wave array, and the other pair of radiating arms is equivalent to a dual-frequency -45-degree polarized half-wave array, and the whole body form a dual-frequency dual-polarized radiating unit. Because the arm surface area of the high-frequency radiating arm is smaller than that of the low-frequency radiating arm, the distance between the side edge of thehigh-frequency radiating arm back to the center of the cross hollow area and the center of the cross hollow area is smaller than the distance between the side edge of the low-frequency radiation arm back to the center of the cross hollow area and the center of the cross hollow area, the plane beam symmetry and the cross polarization ratio of the antenna can be well improved, and the distance between the subarrays is relatively increased, so that the effect of improving the coupling degree between the subarrays is achieved, and the user experience effect is improved.

Owner:COMBA TELECOM TECH (GUANGZHOU) CO LTD +1

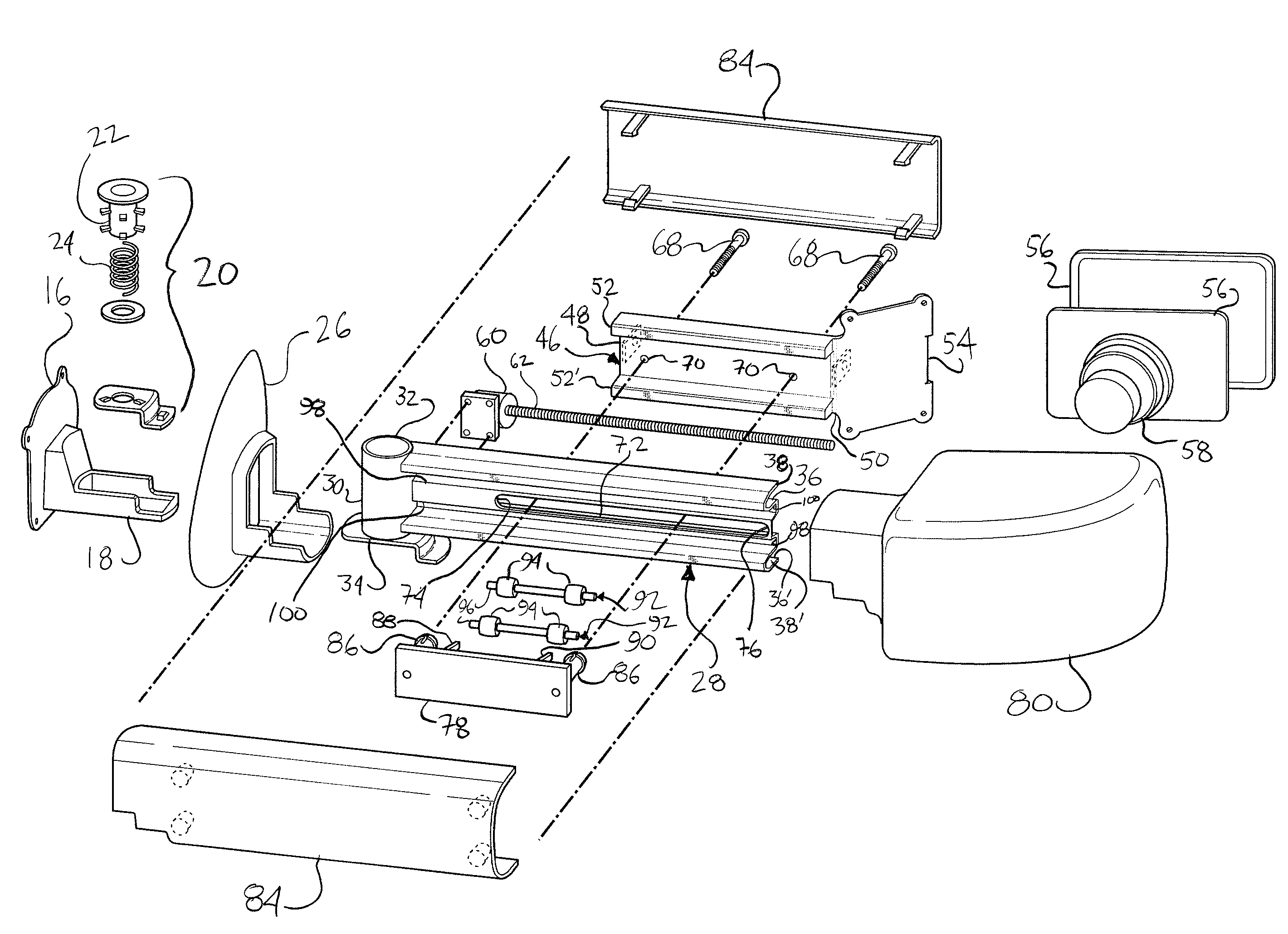

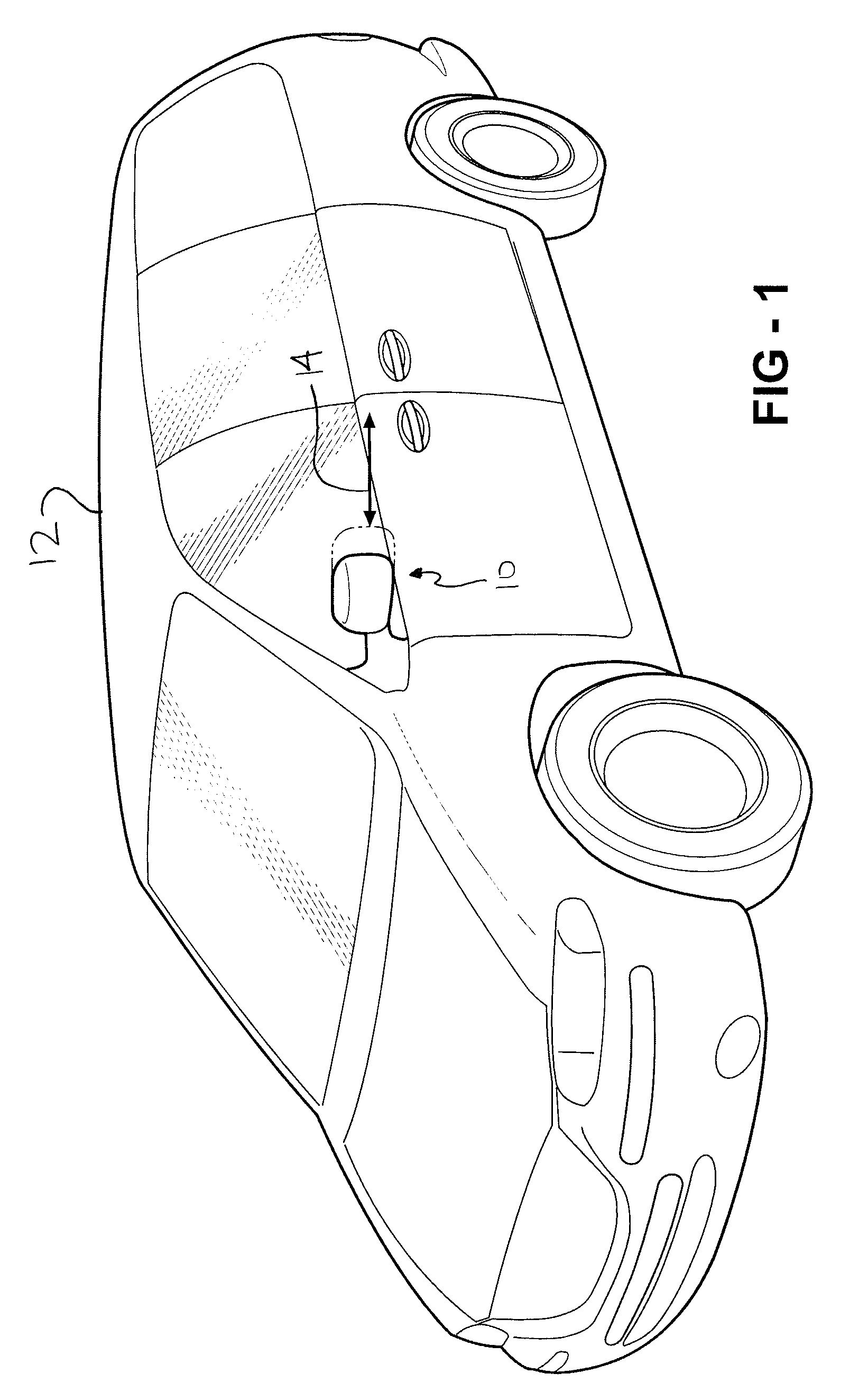

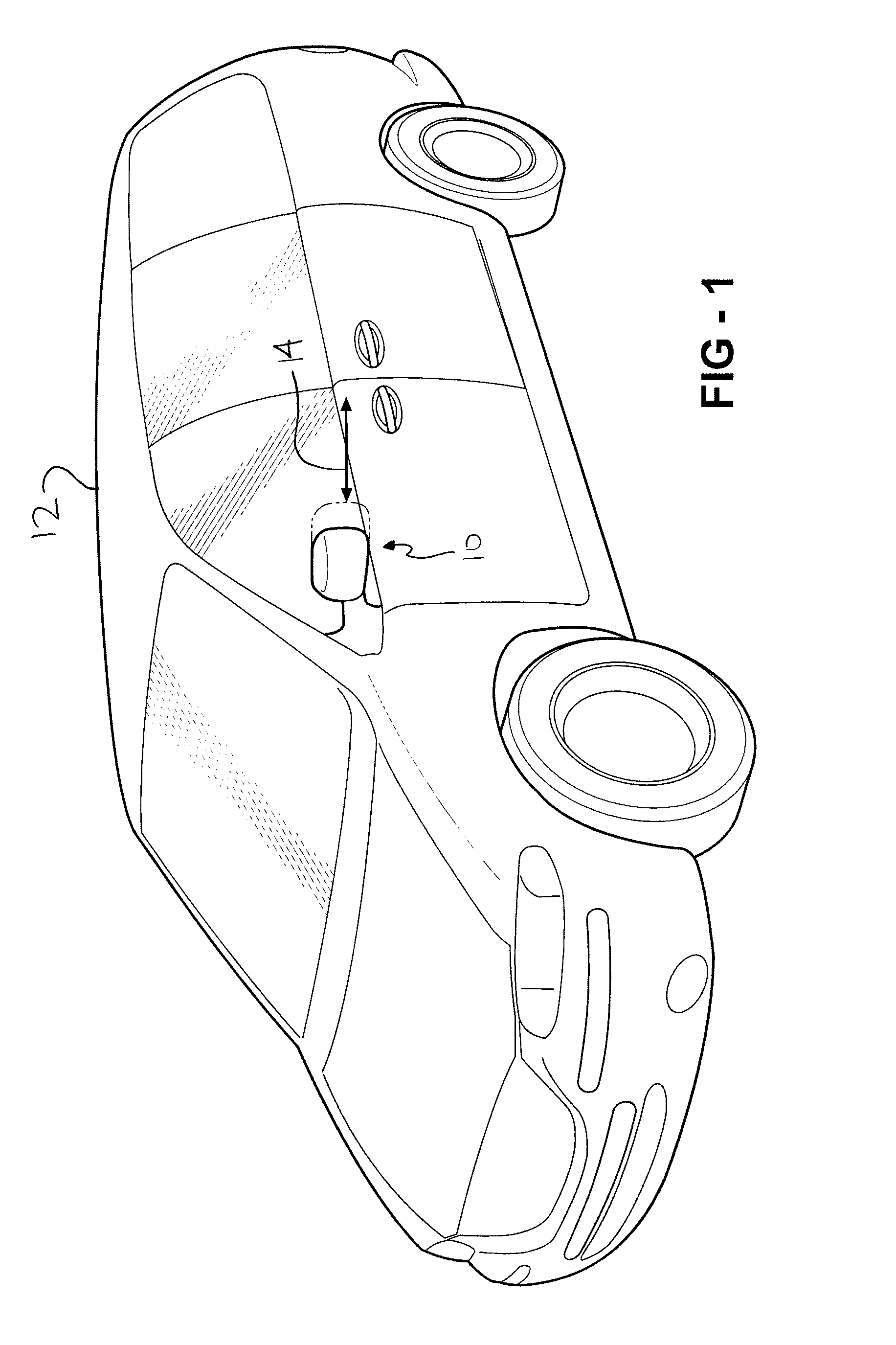

Single arm tow mirror assembly

An external rearview mirror assembly is fixedly secured to a motor vehicle. The external rearview mirror assembly includes a mounting bracket which is fixedly secured to the motor vehicle. An arm is pivotally secured to the mounting bracket. The arm defines an elongated channel having an upper arm surface, a lower arm surface, and an intermediate arm surface disposed between the upper and lower arm surfaces. A case frame extends between a bracket and a distal end. The case frame defines an elongated channel for receiving the elongated channel therein. A mirror is movably secured to the distal end of the case frame to provide a view rearward of the motor vehicle.

Owner:VISIOCORP PATENTS S A R L +1

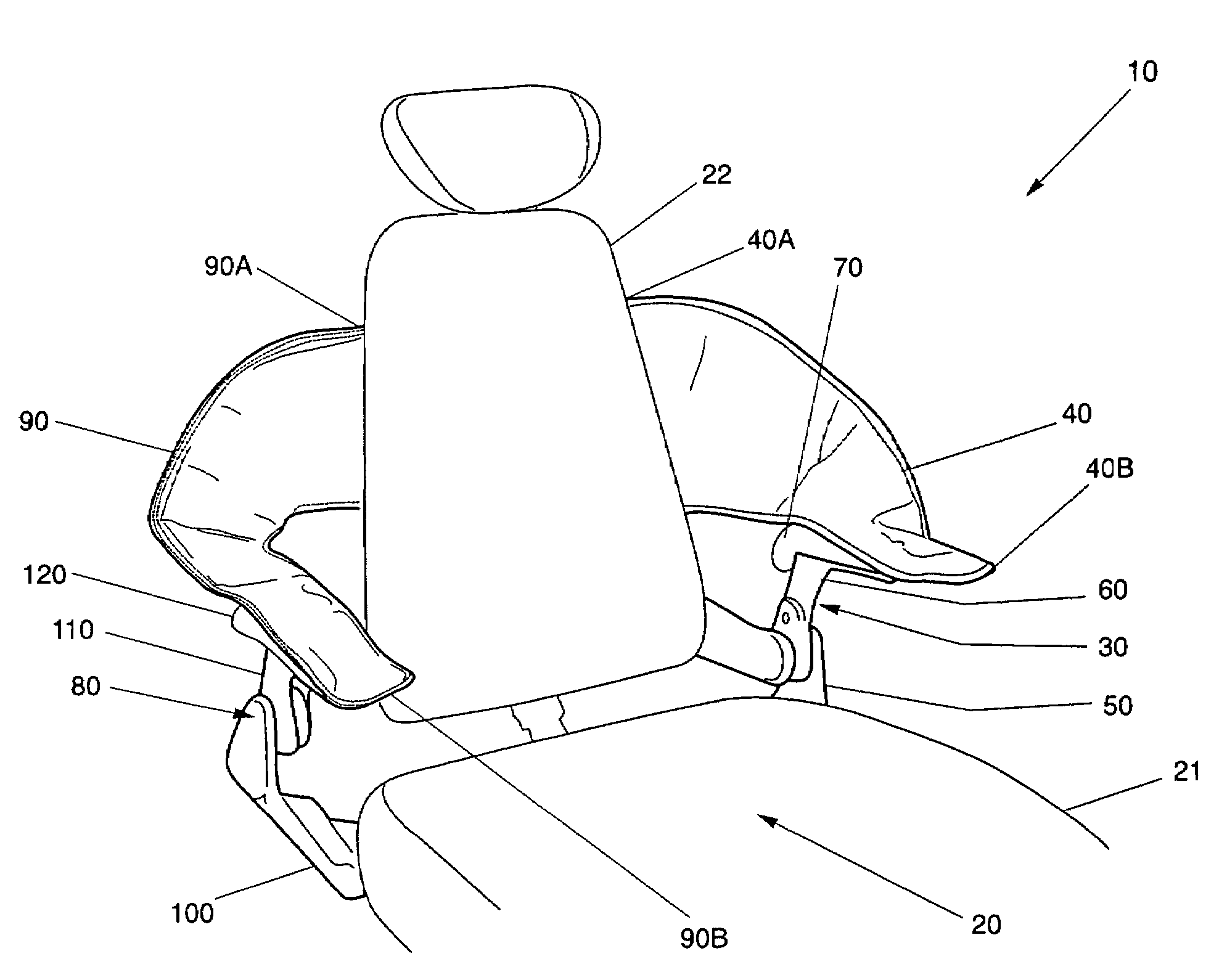

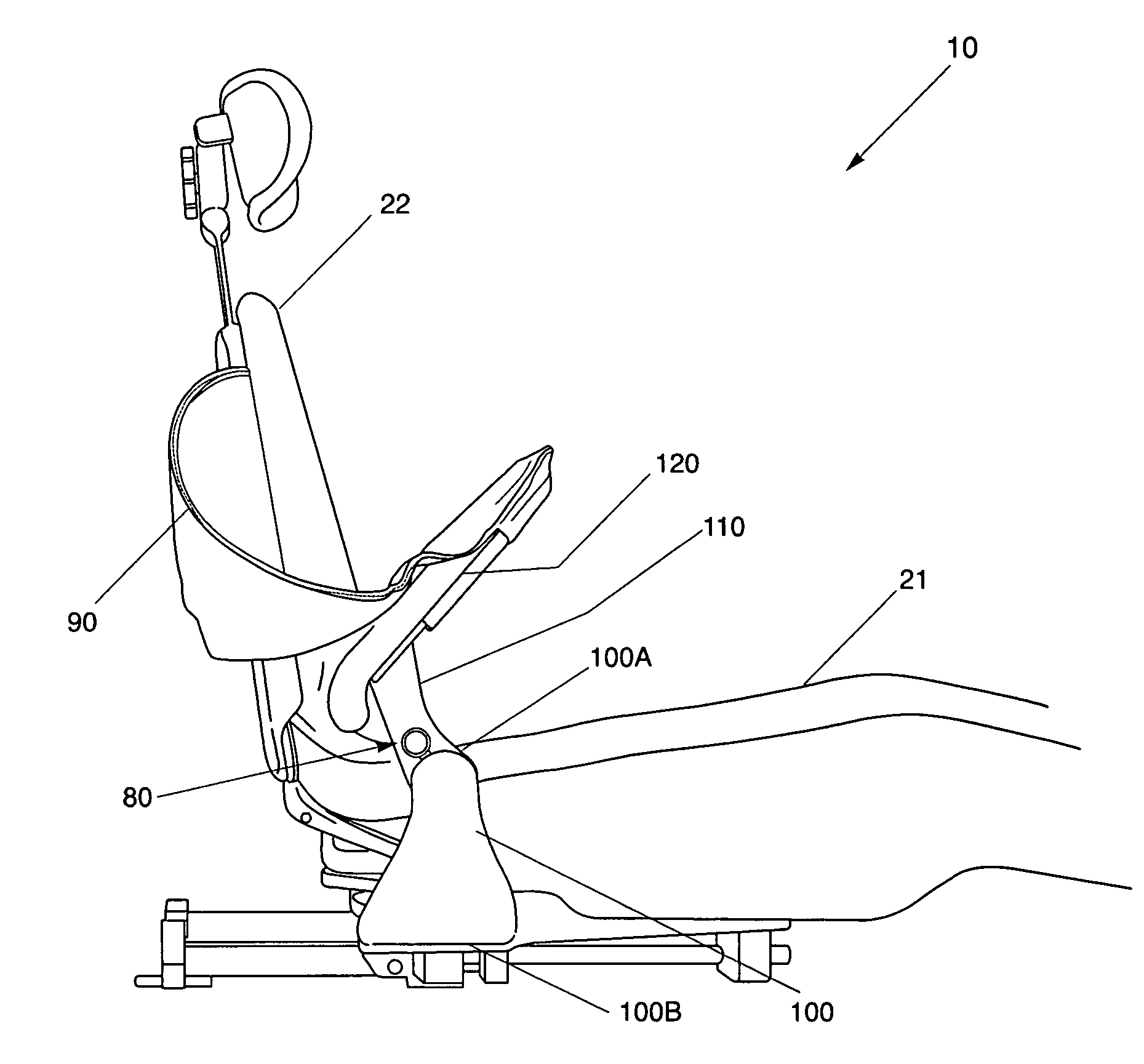

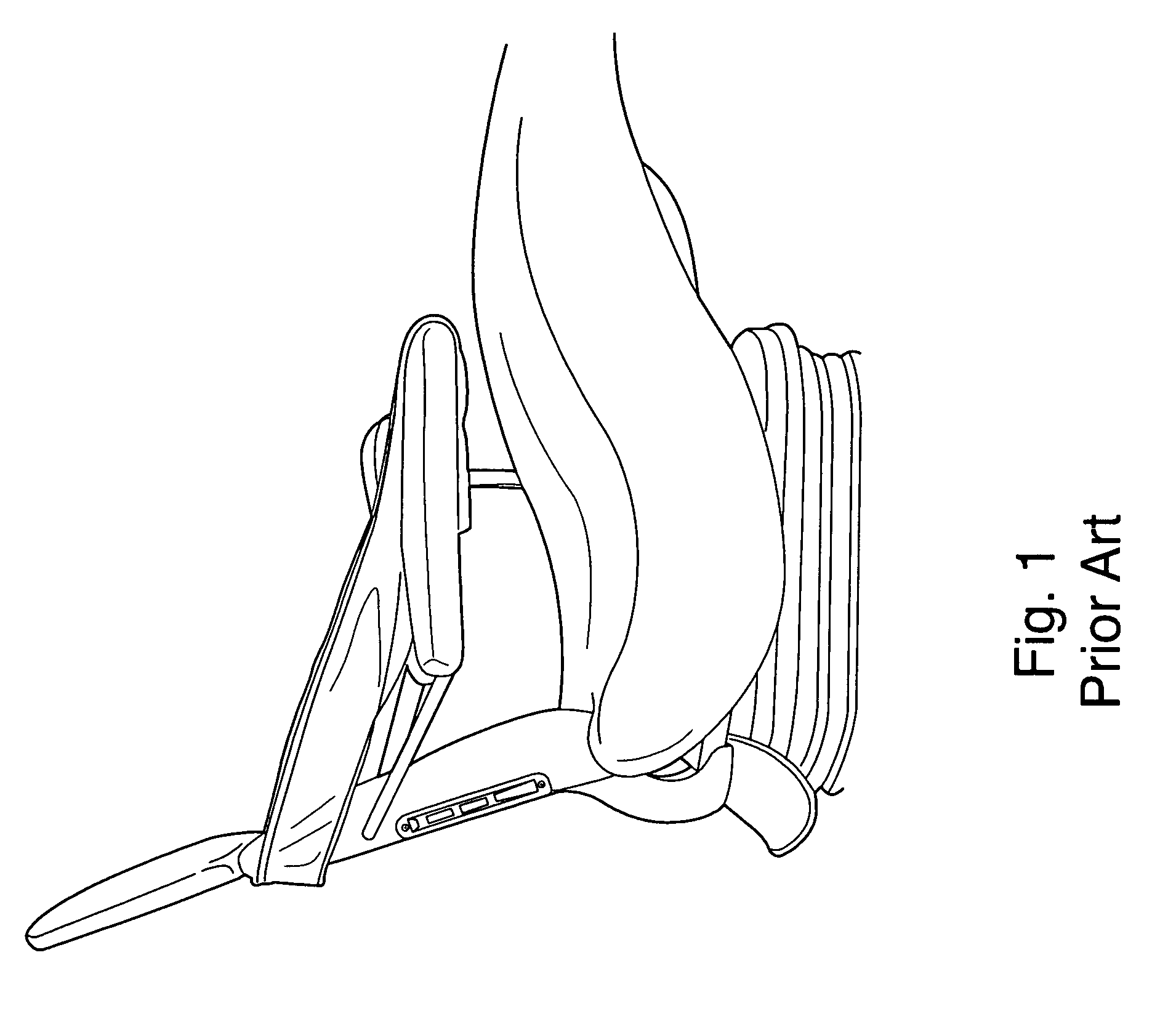

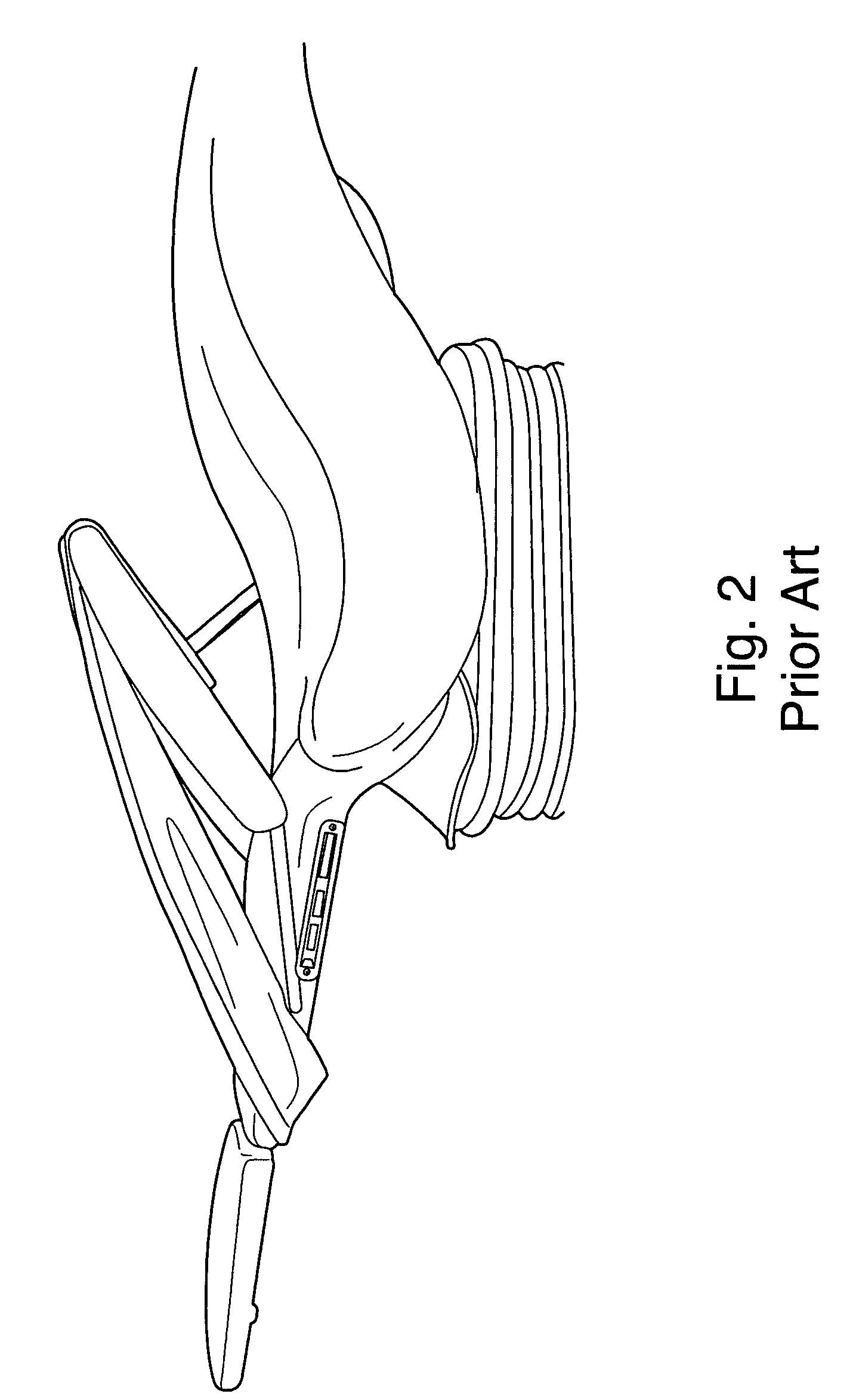

Chair arm rest system

ActiveUS7422288B2Comfortable postureComfortable supportVehicle seatsStuffed mattressesArm surfaceEngineering

A chair arm rest system containing a chair having a vertical chair member hingedly connected to a horizontal chair member. A base proximal to the vertical chair member is attached to the horizontal chair member. The arm rest post is spring-biased towards the horizontal chair member but pivots in opposition of the spring towards the vertical chair member. A distal end of the arm rest post is pivotally attached to the top end of the base. An arm rest surface is attached to a proximal end of the arm rest post. A first end of a sling is attached to the vertical chair member. A second end of the sling is connected to the arm rest surface. In operation, by moving the vertical chair member relative to the horizontal chair member, the sling self-adjusts and the spring-biased arm rest post pivots towards the vertical chair member.

Owner:AHEARN DAVID J

Intelligent artificial hand control system

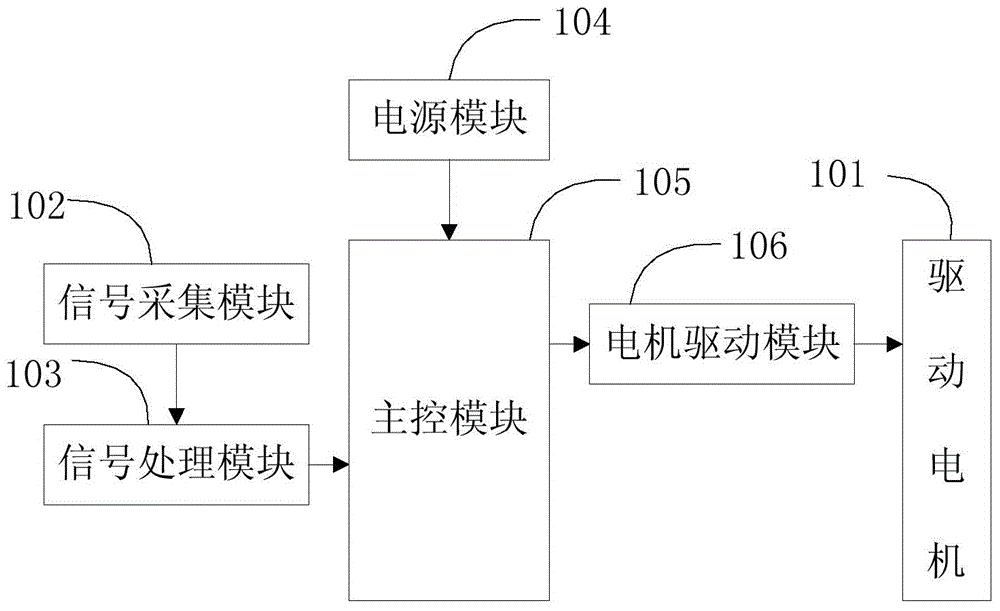

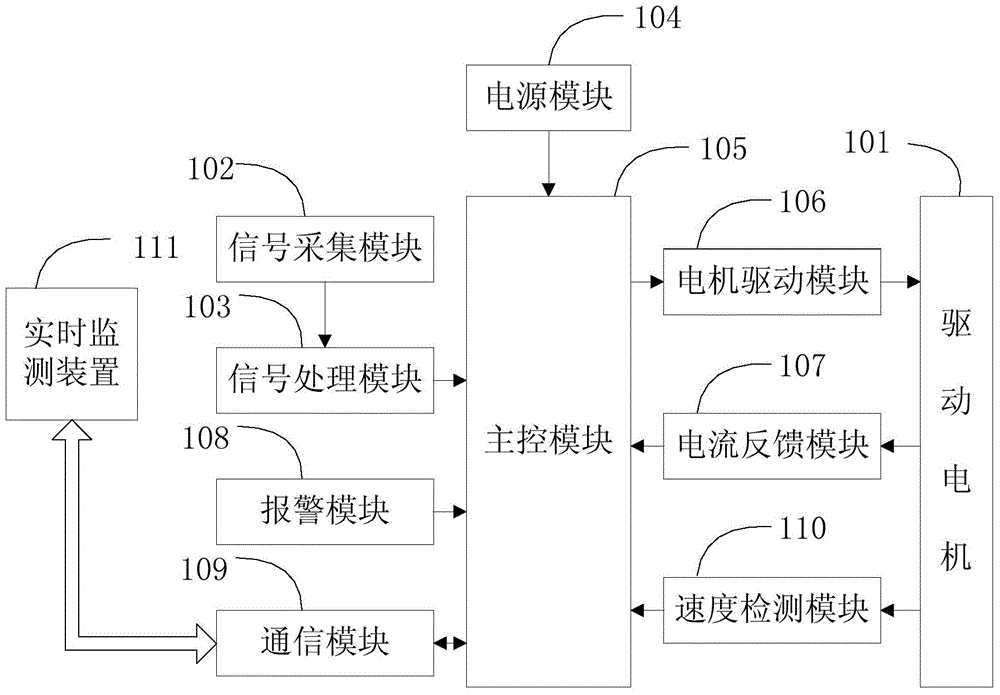

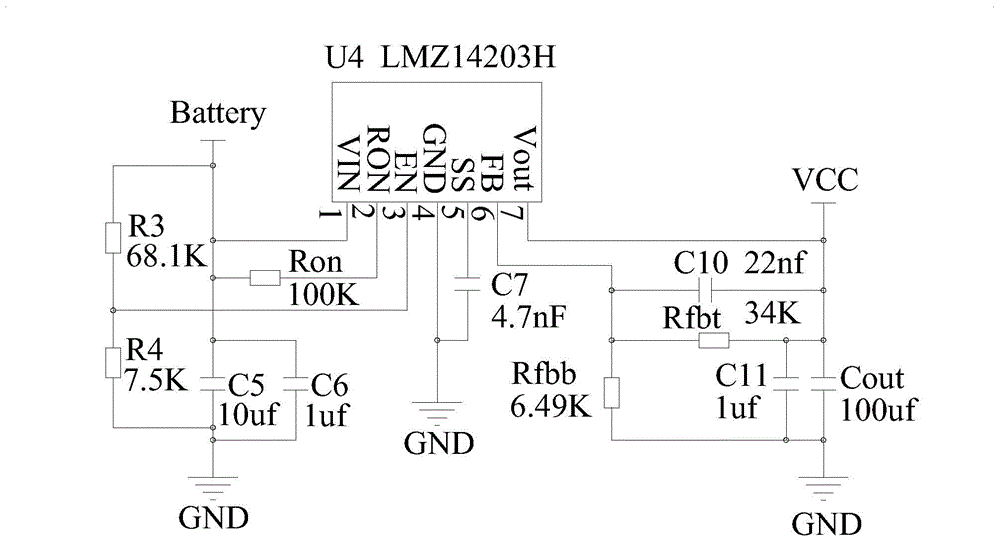

The invention discloses an intelligent artificial hand control system. The intelligent artificial hand control system comprises a driving motor, a signal acquisition module, a signal processing module, a power supply module, a master control module and a motor driving module. The signal acquisition module is used for acquiring electromyographic signals on the surface of an arm; the signal processing module is used for filtering and amplifying the electromyographic signals and then sends the electromyographic signals to the master control module; the master control module is used for carrying out motion classified calculation to the received electromyographic signals to obtain a control signal and sends the control signal to the motor driving module; the motor driving module is used for controlling the driving motor; and the power supply module supplies power to the driving motor and the master control module through secondary voltage conversion, and can provide different output voltages by changing parameter values of electronic components. Current isolation between the driving motor and the master control is achieved, influence of the driving motor on the master control module is avoided, at the same time, the intelligent artificial hand control system can control artificial hands of different models through different output voltages.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

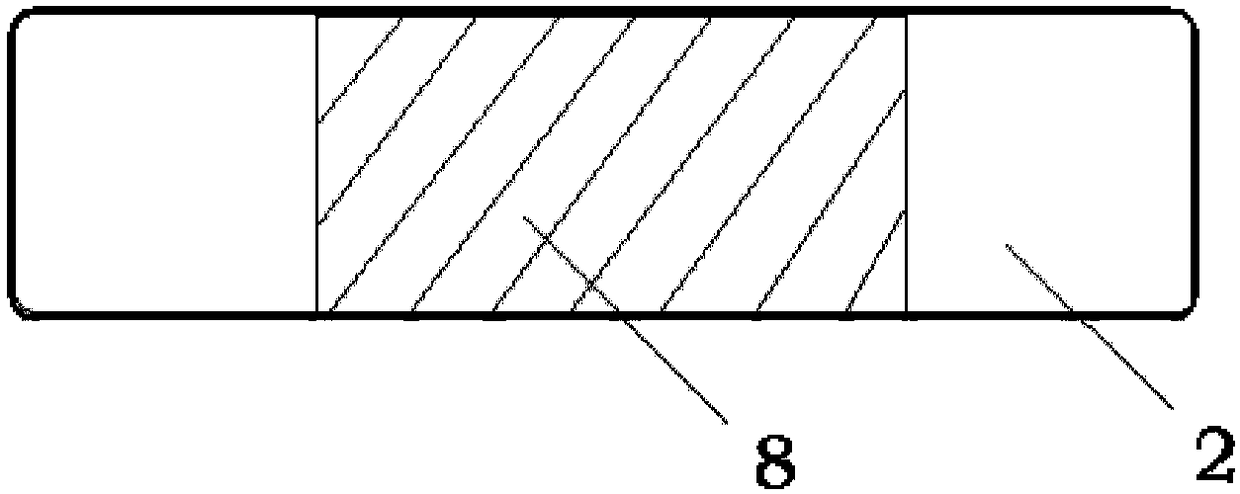

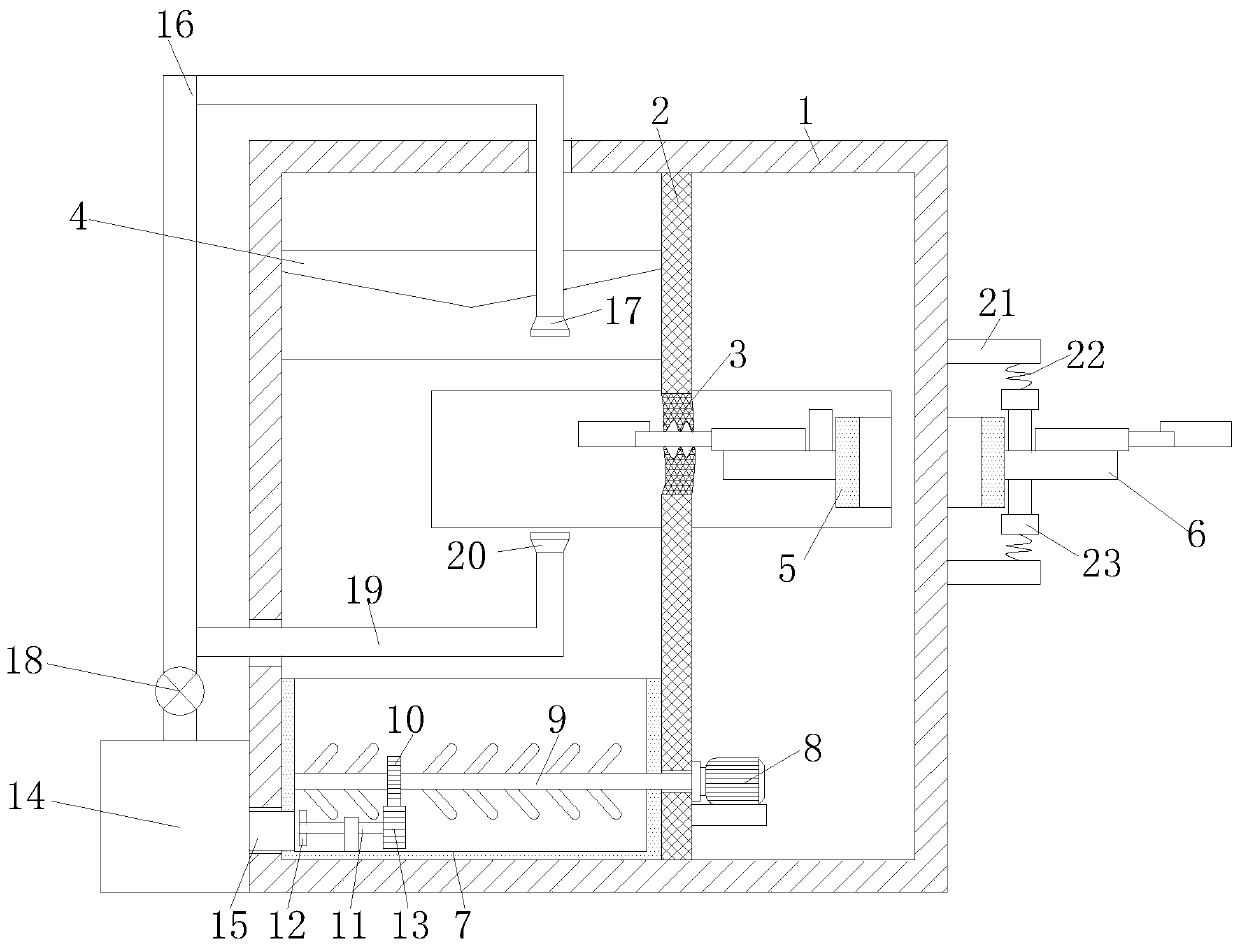

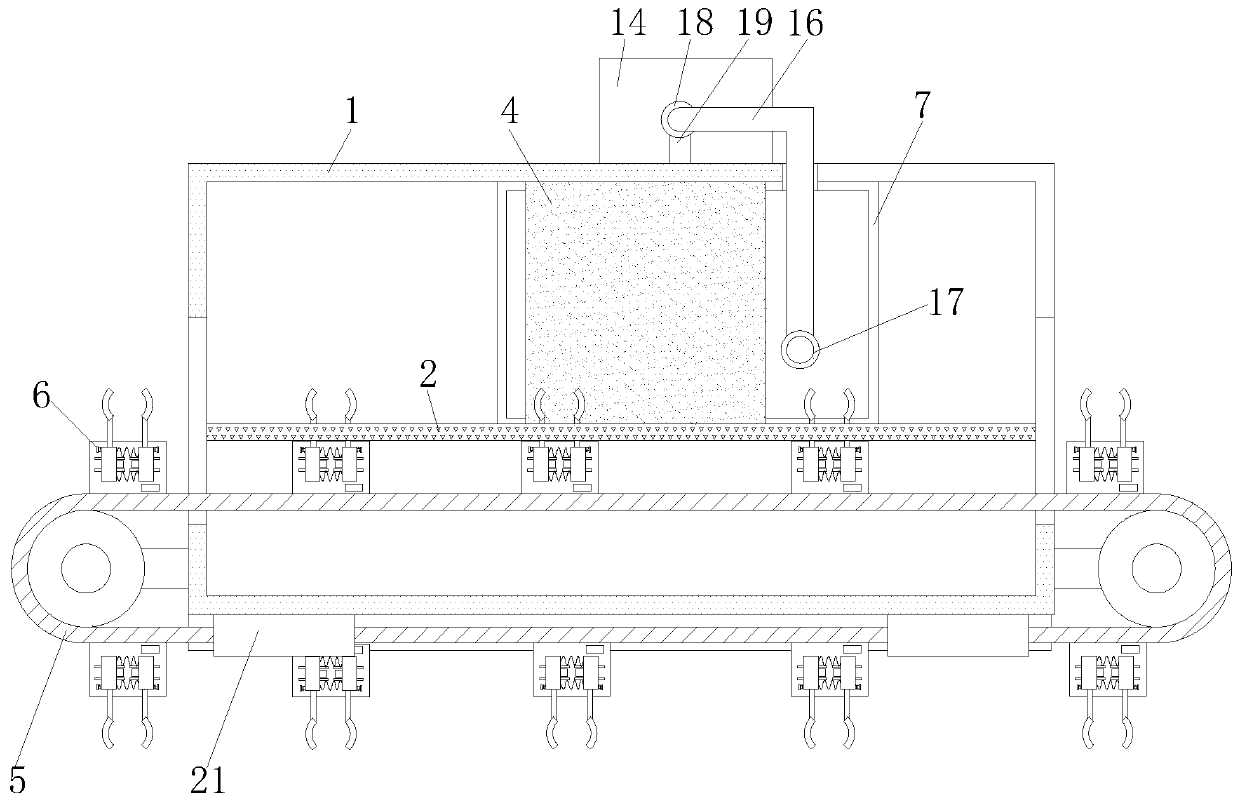

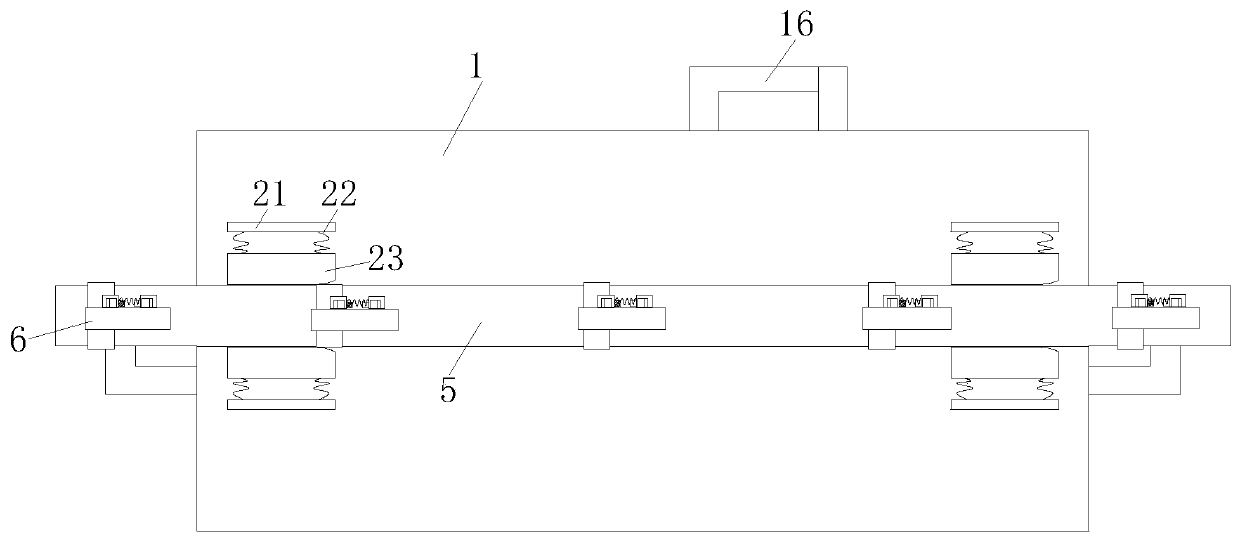

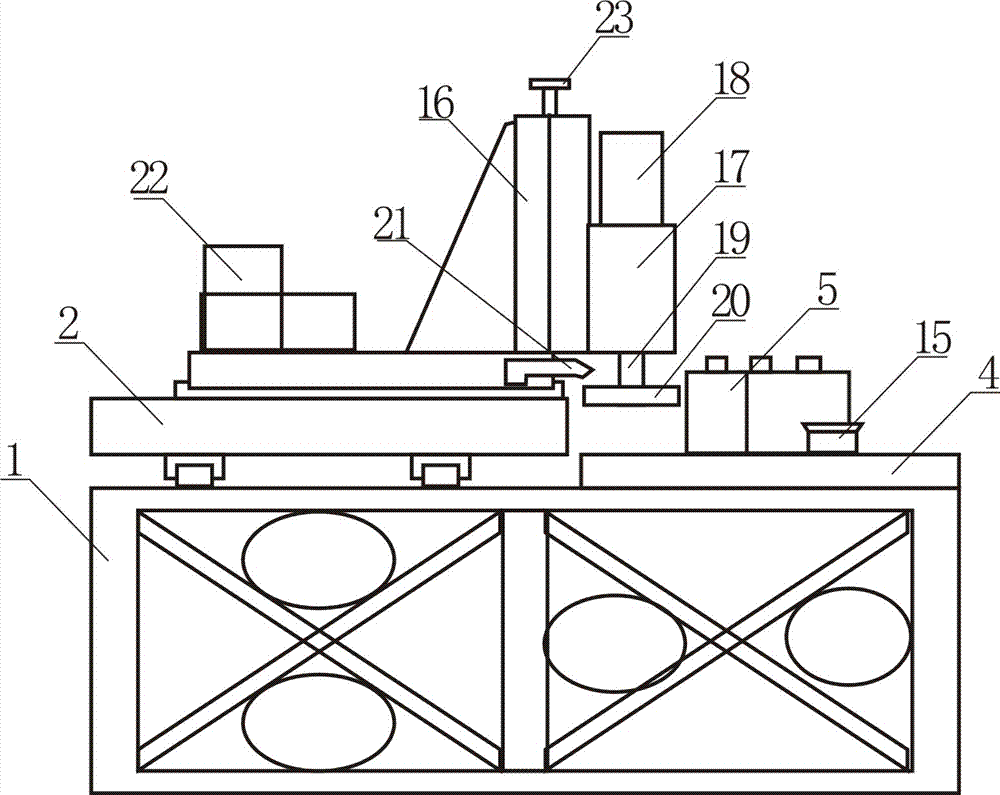

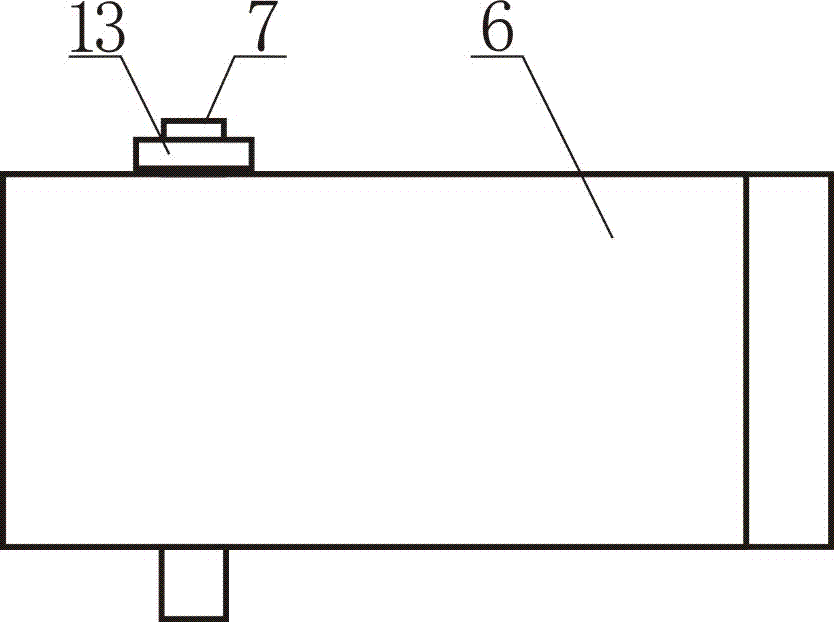

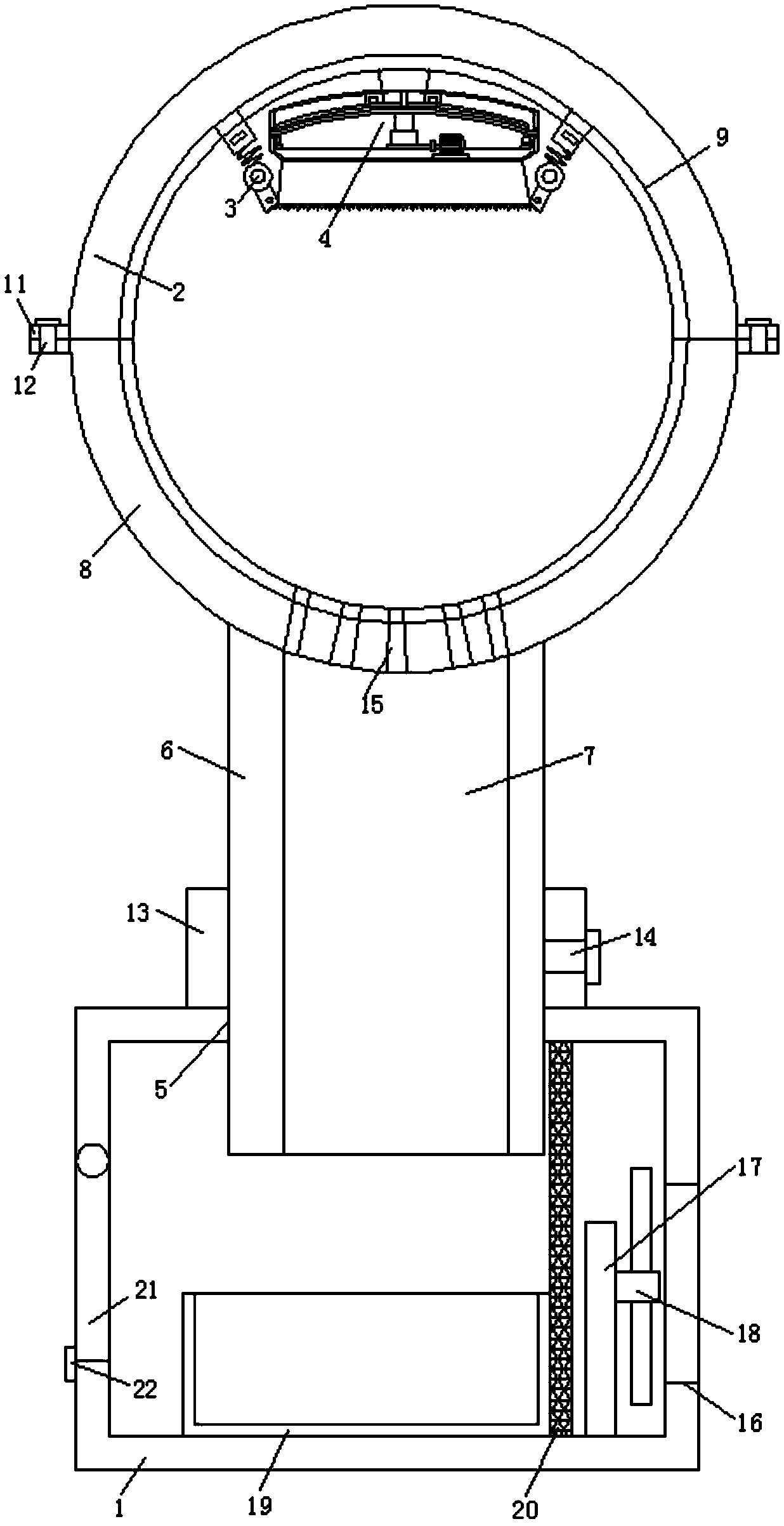

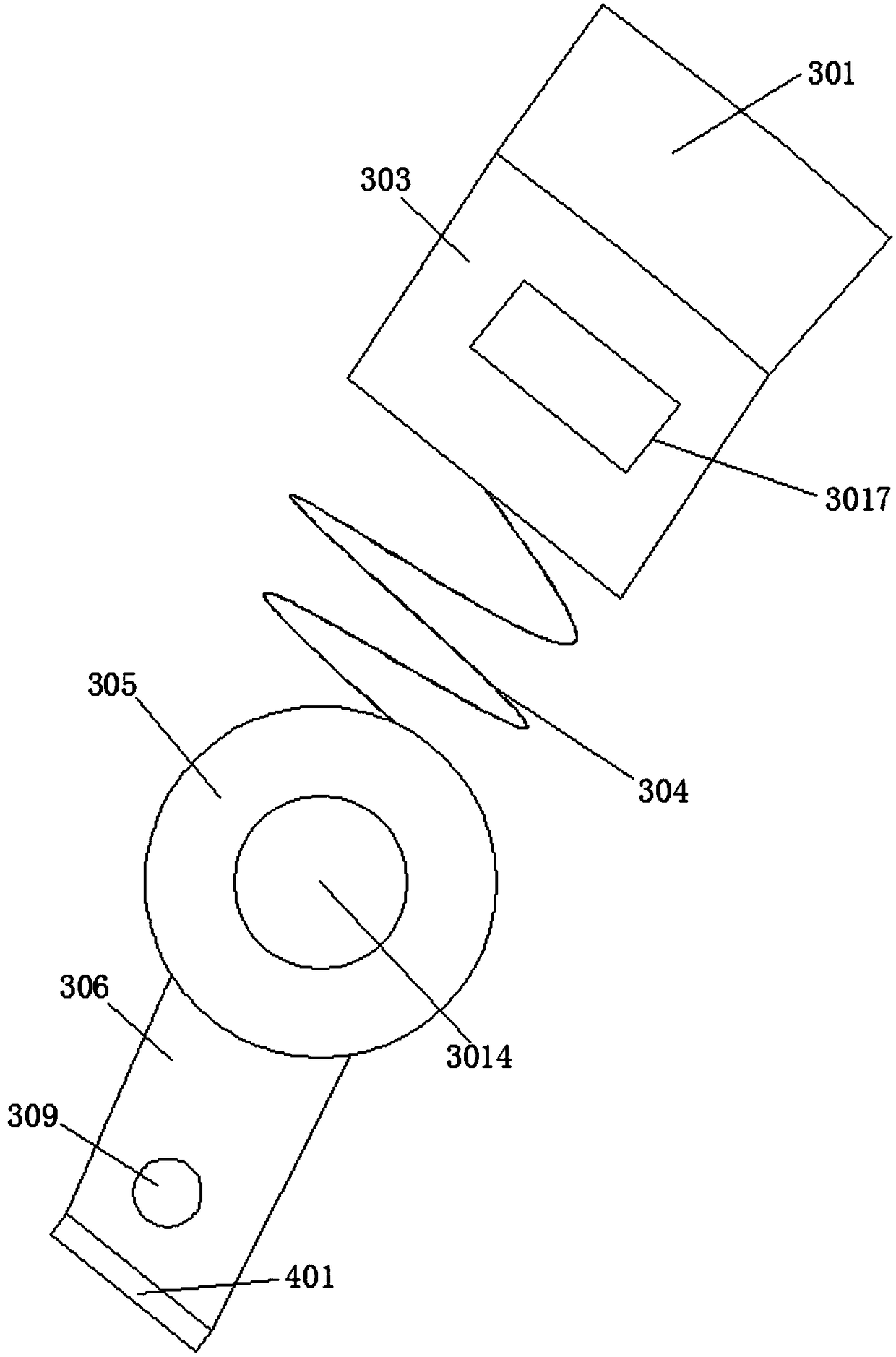

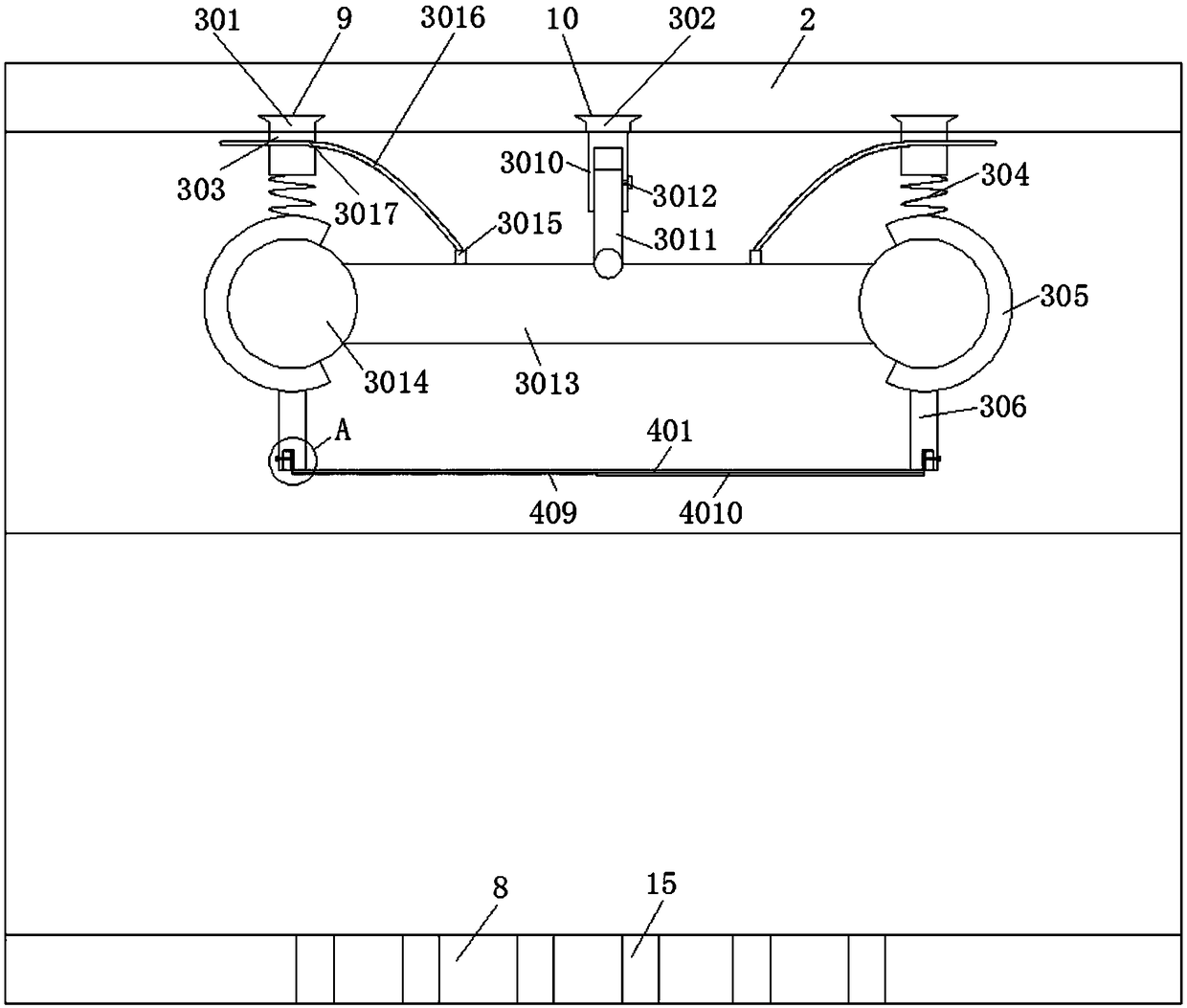

Precision cast swing arm surface spraying device

ActiveCN110152931AAvoid wastingPromote economical productionLiquid spraying apparatusSpray boothsArm surfaceEngineering

The invention relates to the technical field of surface spraying, and discloses a precision cast swing arm surface spraying device. The precision cast swing arm surface spraying device comprises a spraying box; the front side and the rear side of the spraying box are symmetrically provided with two openings; the inner top wall and the inner bottom wall of the spraying box are symmetrically and fixedly connected with two partition plates, and two pieces of stop cloth are fixedly installed on the side surfaces, close to each other, of the two partition plates; a baffle is fixedly connected to the position between the inner wall of the left side of the spraying box and the left side surface of the partition plate located on the upper side; a conveying belt is fixedly installed on the sprayingbox and penetrates through the openings formed in the front side and the rear side of the spraying box, and clamping mechanisms are fixedly connected to the outer surface of the conveying belt at equal intervals; a recycling bin is fixedly installed on the inner bottom wall of the spraying box; and a motor is fixedly connected to the right side surface of the partition plate located on the lowerside through a supporting plate. Through the precision cast swing arm surface spraying device, the problem that an existing automatic spraying device has the paint leakage defect commonly, and paint cannot be efficiently utilized is solved.

Owner:安徽宁隆机械科技有限公司

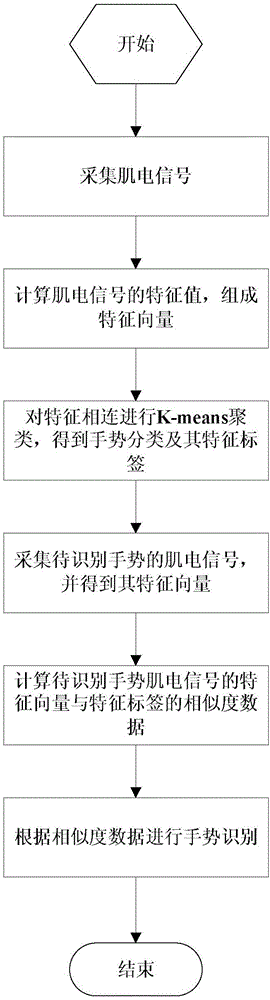

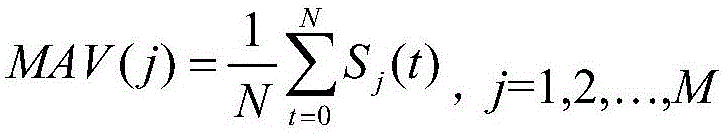

Arm surface electromyogram signal-based gesture recognition method

ActiveCN106845348AReduce processing complexityReduce power consumptionCharacter and pattern recognitionArm surfaceTime–frequency analysis

The invention discloses an arm surface electromyogram signal-based gesture recognition method. According to the method, specific features of electromyogram signals which are bio-electricity signal are utilized, so that the data processing complexity is reduced, and the gesture recognition efficiency can be up to a relatively high level. Compared with the traditional method, the method disclosed by the invention saves a signal time frequency analysis process, so that the complexity and calculation amount are greatly reduced, the requirements for performance of data processors are not high, and the cost is saved.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Chair arm rest system

ActiveUS20080179934A1Comfortable postureComfortable supportVehicle seatsStuffed mattressesArm surfaceEngineering

A chair arm rest system containing a chair having a vertical chair member hingedly connected to a horizontal chair member. A base proximal to the vertical chair member is attached to the horizontal chair member. The arm rest post is spring-biased towards the horizontal chair member but pivots in opposition of the spring towards the vertical chair member. A distal end of the arm rest post is pivotally attached to the top end of the base. An arm rest surface is attached to a proximal end of the arm rest post. A first end of a sling is attached to the vertical chair member. A second end of the sling is connected to the arm rest surface. In operation, by moving the vertical chair member relative to the horizontal chair member, the sling self-adjusts and the spring-biased arm rest post pivots towards the vertical chair member.

Owner:AHEARN DAVID J

Tensioner with increased damping and arm on base cup configuration

In an aspect, a tensioner is provided for maintaining tension in an endless drive member in a belt-in-oil drive system. The tensioner includes a base that is mountable to a stationary structure and that has a circumferential wall that defines an arm pivot axis, an arm having a radially inner arm surface, and an endless drive member engagement surface that is engageable with an endless drive member, a bushing positioned between the radially inner arm surface and the circumferential wall of the base cup, and a tensioning spring. The arm is supported on the base cup via the bushing. The tensioning spring is positioned to bias the arm in a first direction about the arm pivot axis.

Owner:LITENS AUTOMOTIVE INC

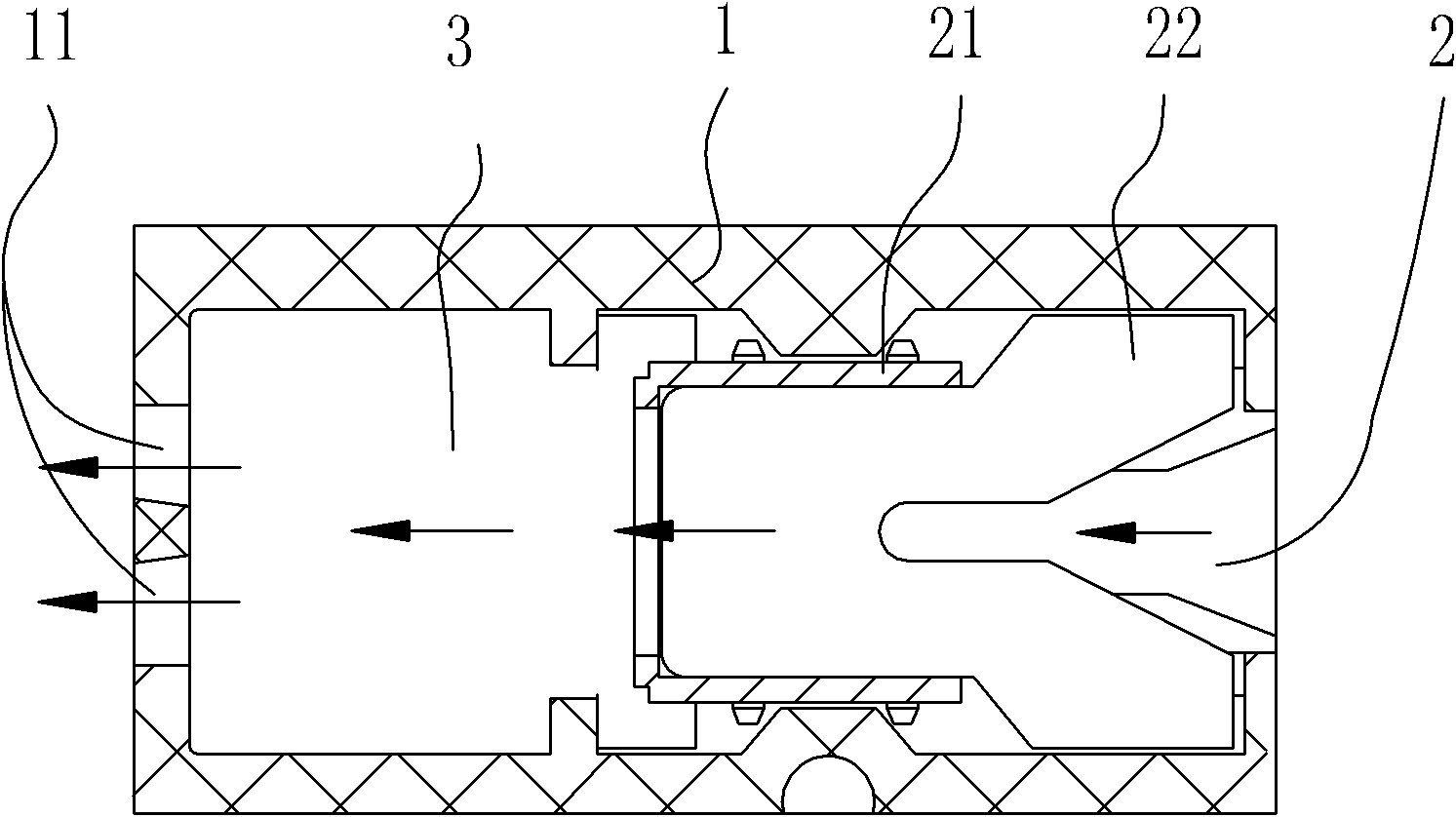

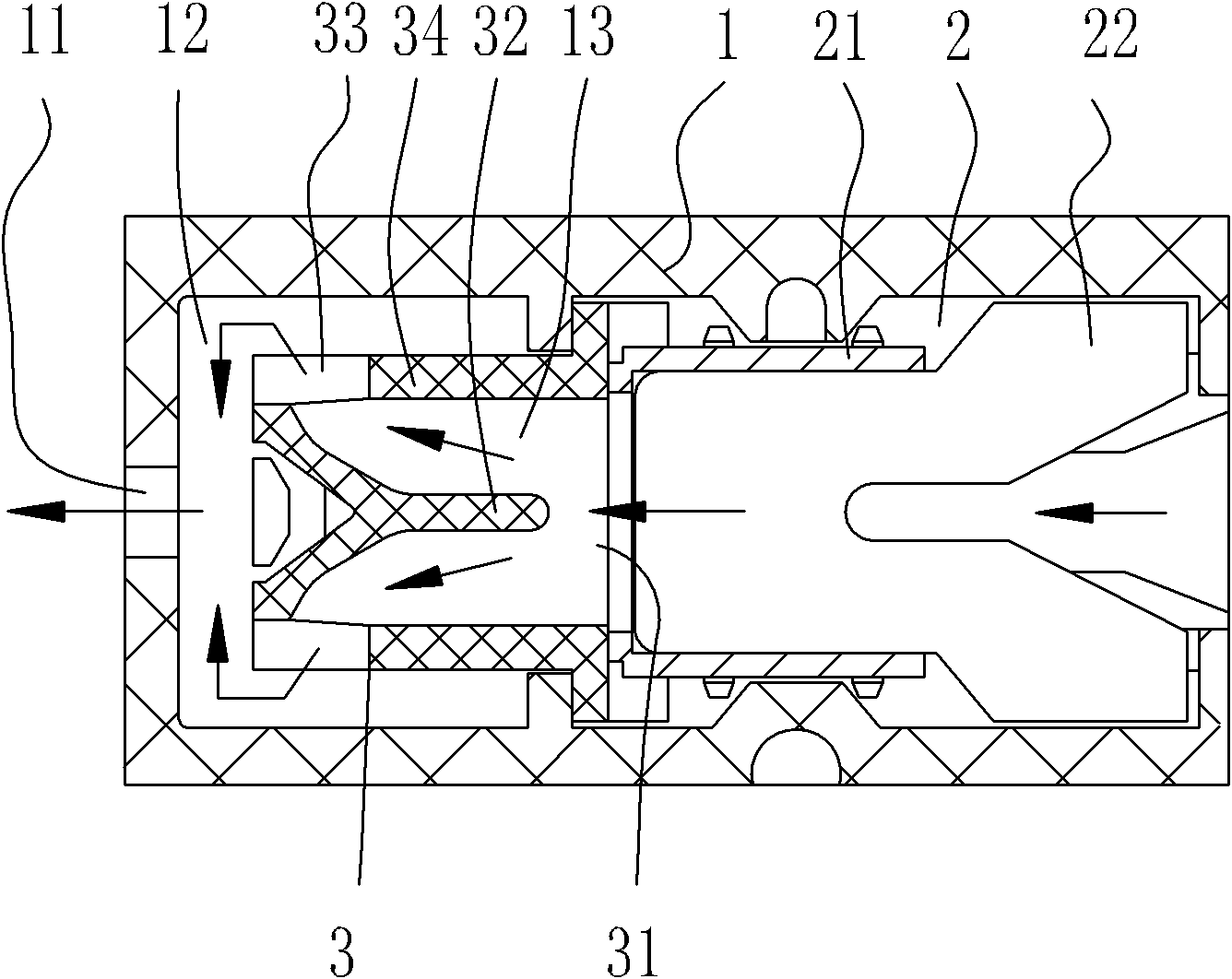

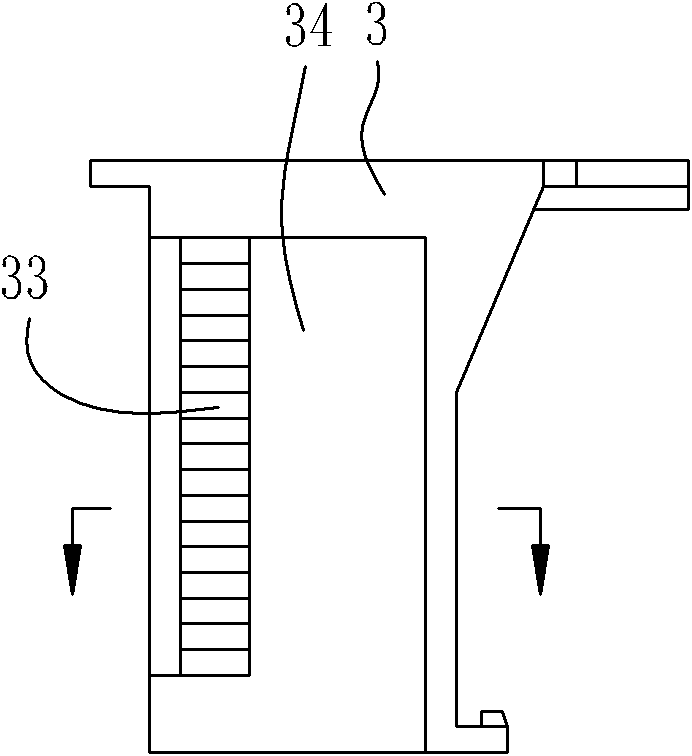

Arc control device of circuit breaker

ActiveCN102013365AIncrease contact areaExtended cooling pathCircuit-breaking switch detailsArm surfaceEngineering

The invention discloses an arc control device of a circuit breaker, wherein the arc control device is positioned in a shell of the circuit breaker. The arc control device of the circuit breaker comprises an arc control chamber 2 with an arc control grid sheet and an exhaust chamber 3, wherein the exhaust chamber 3 comprises a shunting cavity 13 and a winding roadway 12; the shell is provided withan exhaust port 11; the winding roadway 12 is communicated with atmosphere outside the circuit breaker; the shunting cavity 13 is communicated with the arc control chamber 2 by an air guidance slot 31; the exhaust chamber 3 separates the winding roadway 12 from the shunting cavity 13 by a shunting piece 32 and two shunting cavity side walls 34; the part, which is positioned in the shunting cavity13, of the shunting piece 32 is distributed in a Y shape and comprises a V-shaped support arm surface and a linear landing leg, the two support arm ends of the V-shaped support arm surface are fixedly connected to the end part of the shunting cavity side walls 34, and the linear landing leg is parallel to the shunting cavity side walls 34 and extends towards the air guidance slot 31 to divide airflow into two parts; and the shunting cavity 13 and the winding roadway 12 are communicated by a shunting cavity air guide port 33. The arc control device can ensure that airflow air pressure requiredfor improving arc blowing speed in the arc control chamber can be maintained, and the cooling path of arcing gas is increased.

Owner:SHANGHAI NOARK ELECTRIC

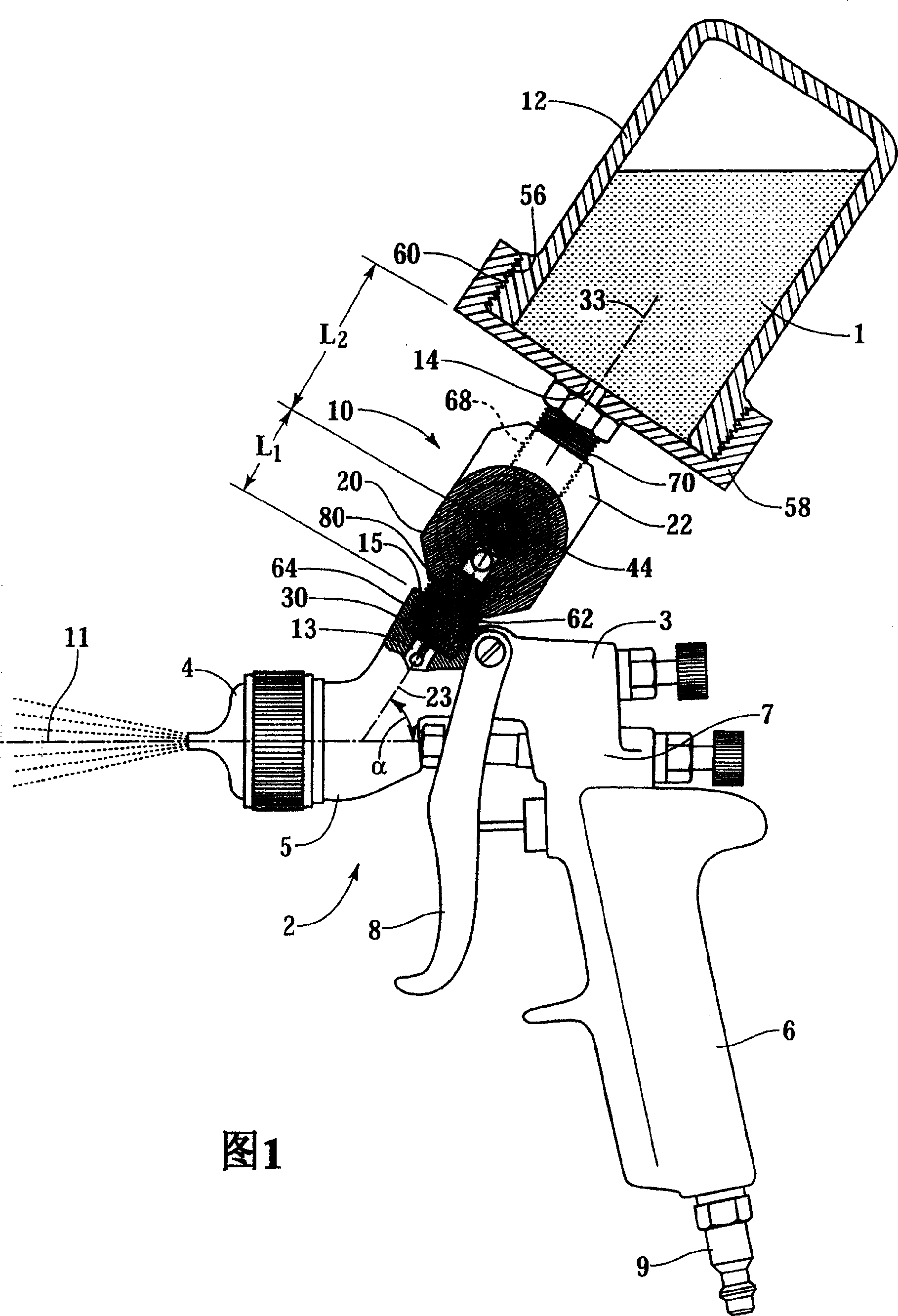

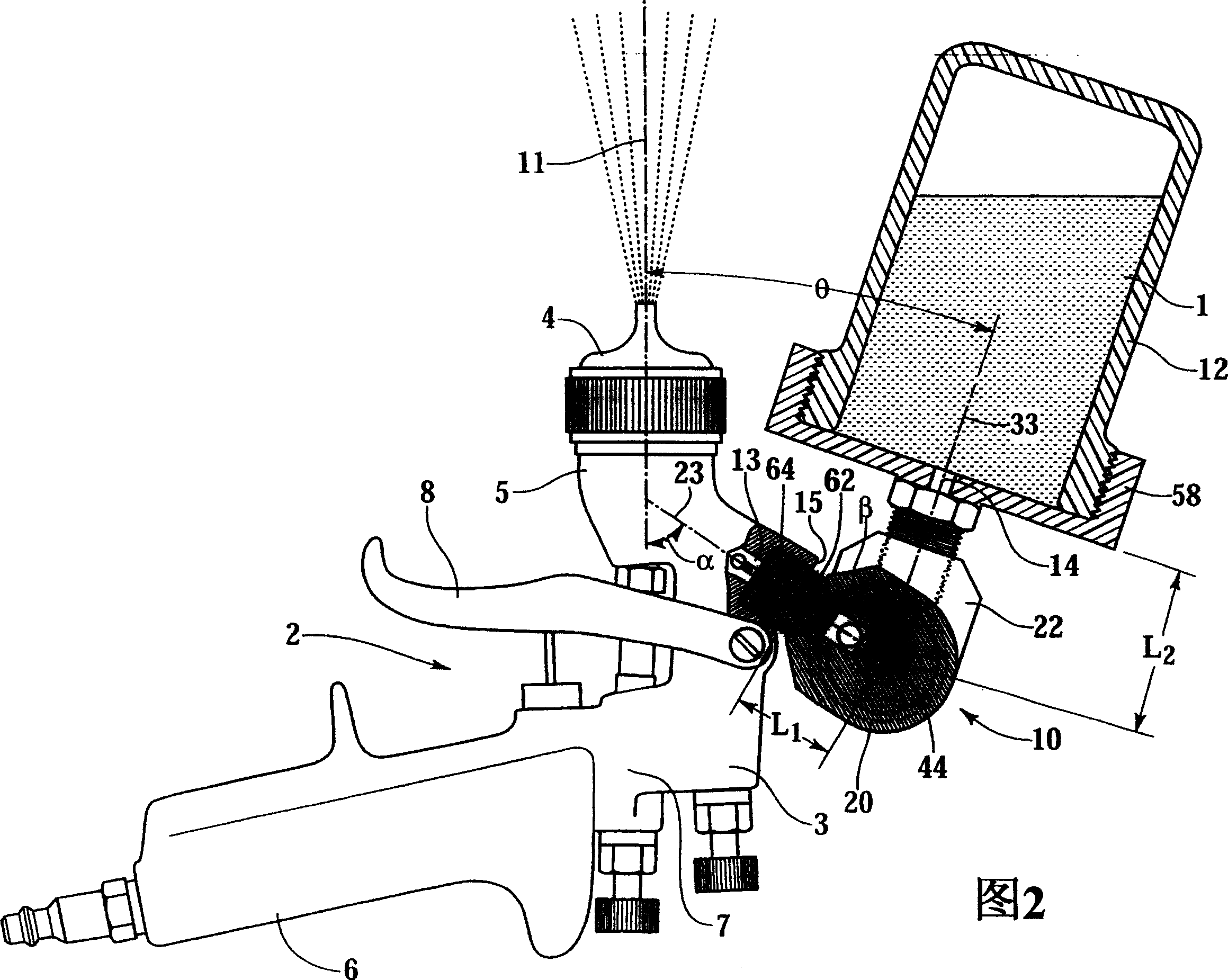

Adjustable adapter for gravity-feed paint sprayer

An adjustable adapter includes two arms, each having an axis, a surface substantially normal to the axis, wherein the surfaces of the arms face each other, an end and a passageway for fluid communication between the end and the opening, wherein one of the arm ends is for connection to an inlet of an applicator and the other arm end is for connection to an outlet of a container, and a fastener for pivotally coupling the arms. One of the arm surfaces is provided with a groove in fluid communication with both arm openings. The groove is sealed to prevent fluid from leaking from between the surfaces. When the fastener is in a rotation-resisting mode, the fastener forces the surfaces of the arm toward one another sufficiently to increase friction and resist rotation therebetween, and when the fastener is in a rotation-permitting mode, the fastener releases the surfaces sufficiently to decrease friction and permit rotation therebetween.

Owner:ILLINOIS TOOL WORKS INC

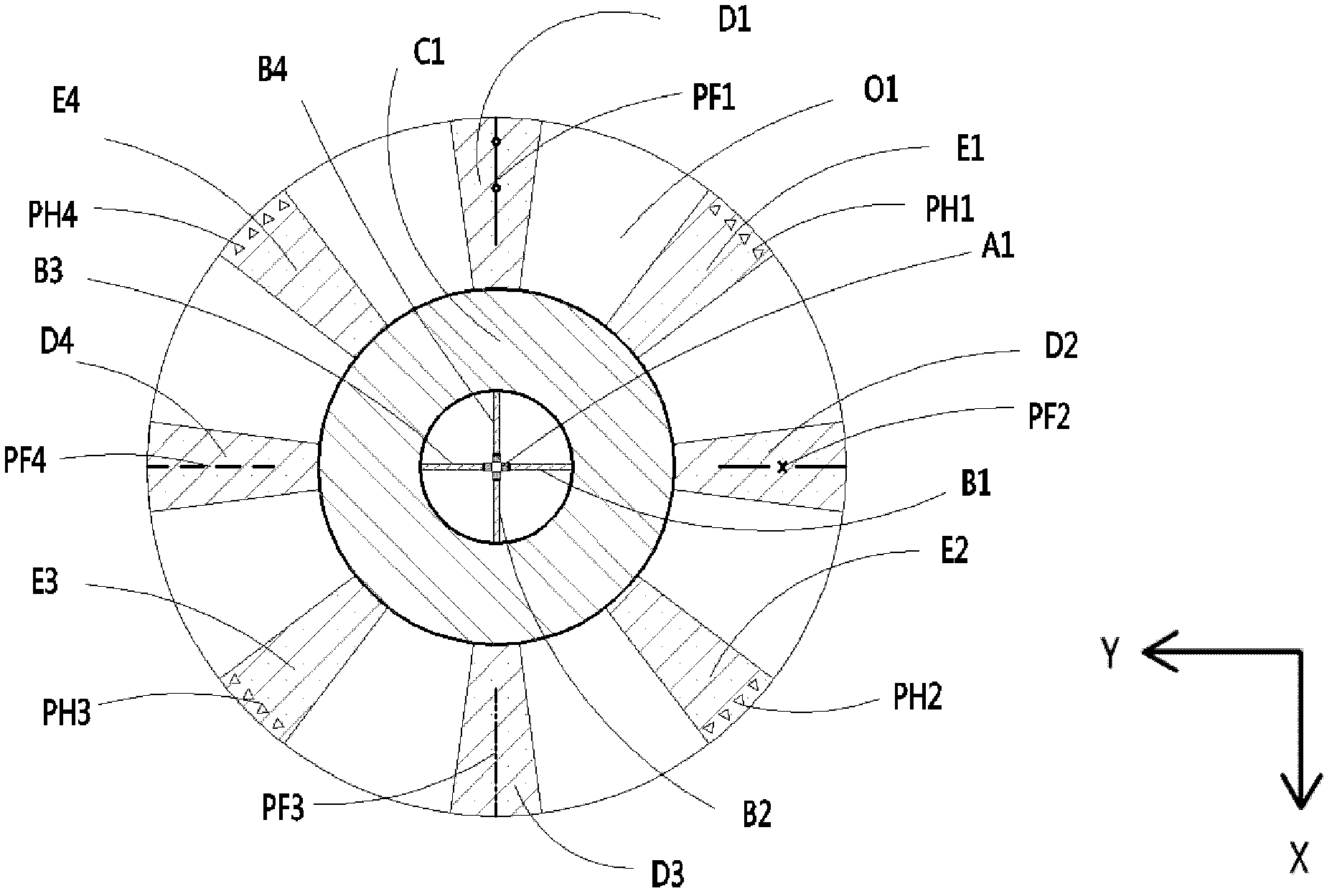

Omni-directional radio frequency identification tag antenna and radio frequency identification tag

InactiveCN102570025AAntenna supports/mountingsRadiating elements structural formsArm surfaceTag antenna

The invention provides an omni-directional radio frequency identification tag antenna, comprising a tag substrate, a resonance loop surface circuit pattern part, a circuit resonance arm surface circuit pattern part and four metal resonance arms, wherein the resonance loop surface circuit pattern part is arranged on the tag substrate and composed of at least one resonance loop; the circuit resonance arm surface circuit pattern part is arranged on the tag substrate and composed of at least two circuit resonance arms, the circuit resonance arms are connected with the resonance loop surface circuit pattern part and the circuit resonance arms correspond to each other pairwise and form a first plane radiation surface; four metal harmonic arms are all connected with the resonance loop surface circuit pattern part, correspond to each other pairwise and form a second plane radiation surface and a third plane radiation surface. The omni-directional radio frequency identification tag antenna has radiation surfaces on three coordinate axes and the corresponding radiation arms are uniformly distributed at phase points at intervals of 45 degrees, the generated antenna effective gain chart covers all the directions of the spherical surface, and thus the antenna is named a real omni-directional antenna.

Owner:QUINTET DIGITAL CORP

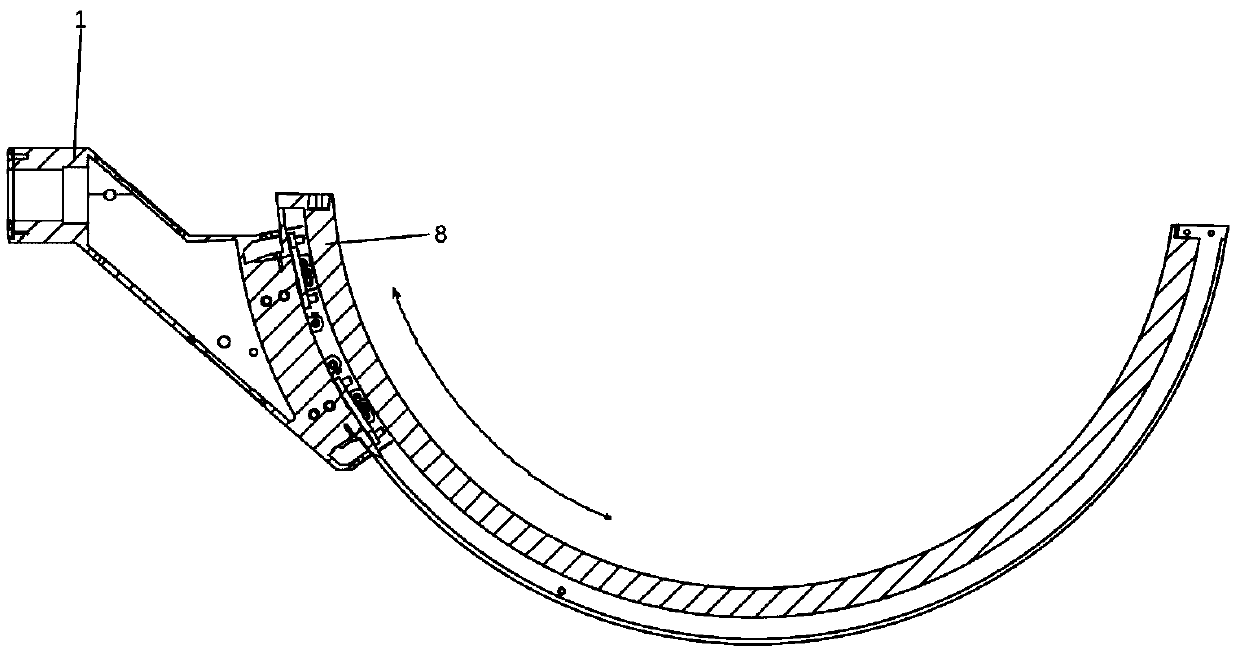

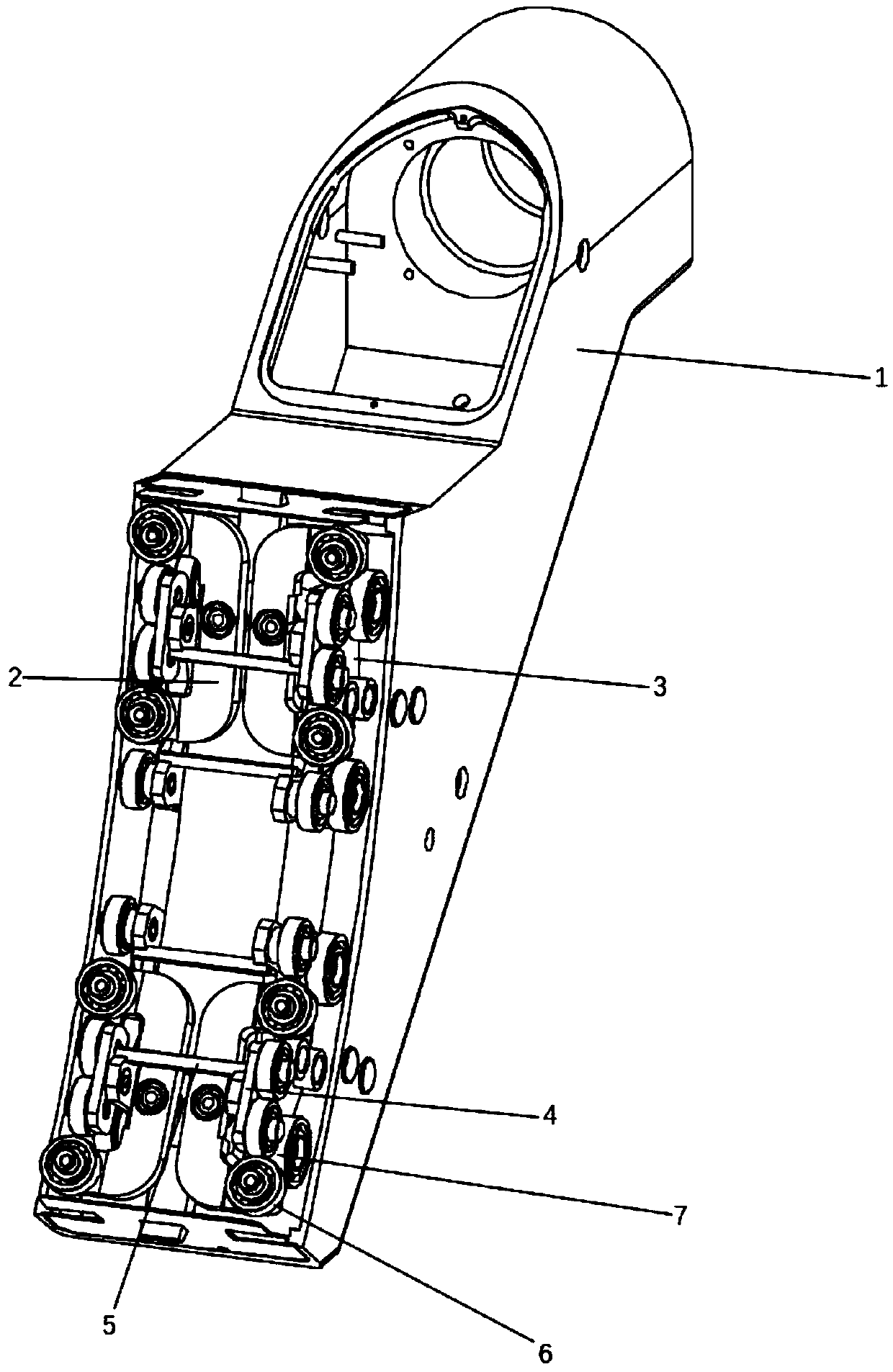

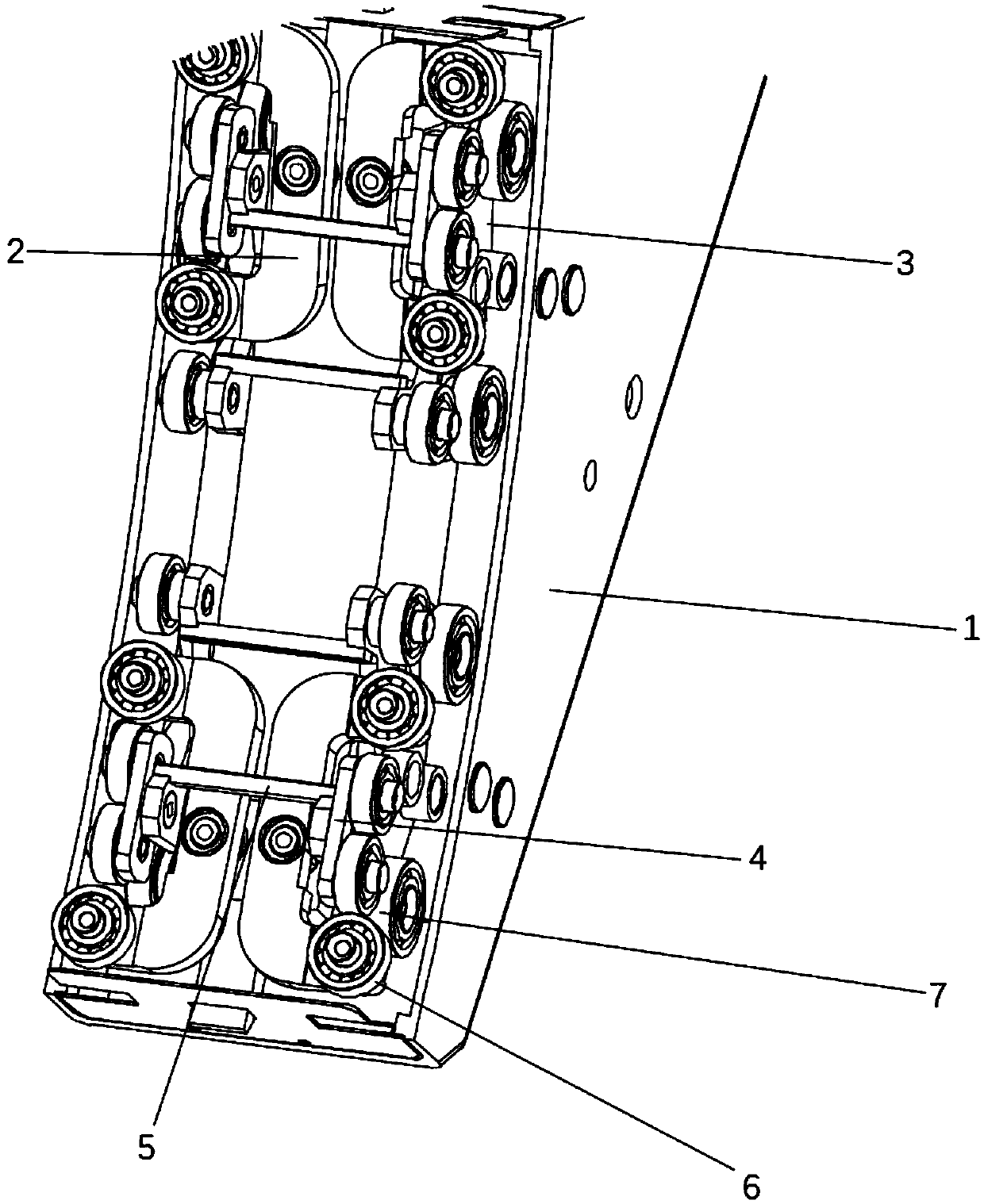

Automatic C-shaped-arm bearing laminating device

The invention discloses an automatic C-shaped-arm bearing laminating device. The automatic C-shaped-arm bearing laminating device comprises a straight arm and a C arm, wherein the straight arm is connected with the C arm in a non-fixed manner, and multiple sets of straight-arm upper roller rods are installed at the bottom of the straight arm. A straight-arm lower roller rod is installed on the outer side of each straight-arm upper roller rod, a straight-arm middle roller rod is installed on the inner side of each straight-arm lower roller rod, and a first deep groove ball bearing is installedon the outer side of each straight-arm middle roller rod. According to the automatic C-shaped-arm bearing laminating device, by means of the straight-arm middle connecting rod, the straight-arm lowerconnecting rod and the attached deep groove ball bearings, it can be guaranteed that 20 deep groove ball bearings are used for bearing when the C arm slides up and down, 8 deep groove ball bearings are used for bearing when the C arm slides left and right, and therefore the weights of the C arm, a ball pipe and a detector can be well dispersed on the whole straight-arm surface at each sliding position; and each deep groove ball bearing can do minor movement, assembly is convenient to achieve, and the C arm can be installed more smoothly in the installation process.

Owner:NANJING KPOUR TECH CO LTD

Single arm tow mirror assembly

An external rearview mirror assembly is fixedly secured to a motor vehicle. The external rearview mirror assembly includes a mounting bracket which is fixedly secured to the motor vehicle. An arm is pivotally secured to the mounting bracket. The arm defines an elongated channel having an upper arm surface, a lower arm surface, and an intermediate arm surface disposed between the upper and lower arm surfaces. A case frame extends between a bracket and a distal end. The case frame defines an elongated channel for receiving the elongated channel therein. A mirror is movaably secured to the distal end of the case frame to provide a view rearward of the motor vehicle.

Owner:VISIOCORP PATENTS S A R L +1

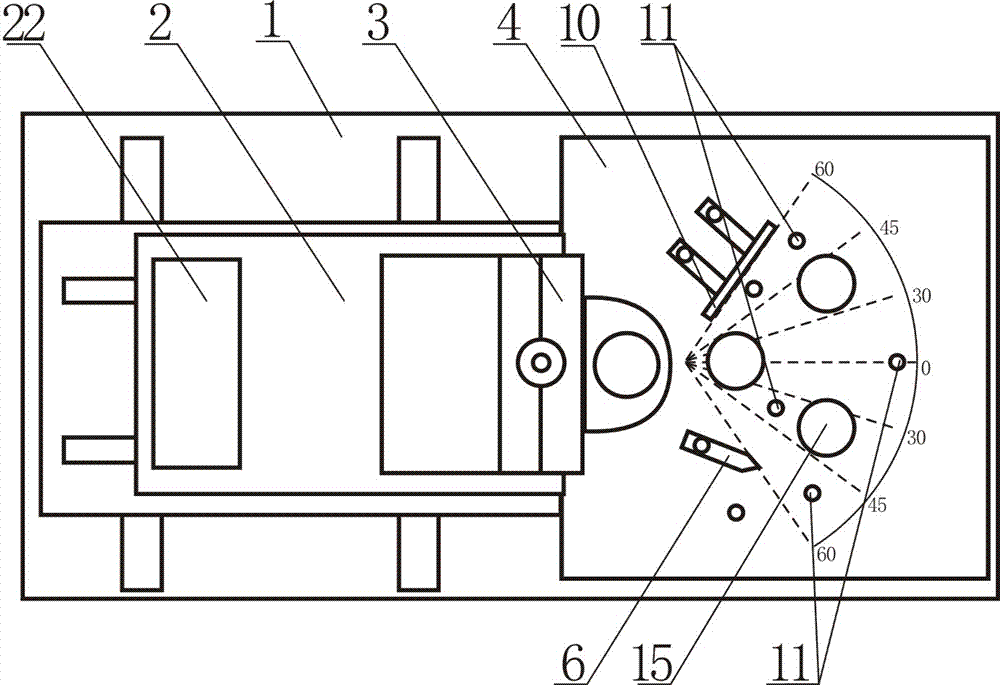

Multifunctional steel plate polishing machine

InactiveCN107538327ASimple structureImprove ergonomicsGrinding carriagesPolishing machinesArm surfaceSheet steel

The invention discloses a multifunctional steel plate polishing machine. The multifunctional steel plate polishing machine comprises a stand, a translation polishing table and a polishing mechanism; the translation polishing table is arranged on the stand; and the polishing mechanism is arranged on the translation polishing table. The multifunctional steel plate polishing machine is characterizedin that an angle scale plate and a polishing and positioning fixture are arranged on one side of the translation polishing table on the stand; the polishing and positioning fixture mainly consists ofa limiting rod, a fixed base, a connecting rod, two clamping rods and a limiting plate; a long hole is formed in an arm surface of the connecting rod; the clamping rods and the fixed base adopt structure forms of screw rods; the polishing mechanism mainly consists of a support steel frame, a shaft sleeve, a motor, a polishing power shaft and a polishing disc; a polishing disc height adjusting handle is arranged on the support steel frame; a counterweight is arranged at the other end of the translation polishing table; and the support steel frame is provided with a cooling liquid spraying pipeon one side of the polishing disc. The multifunctional steel plate polishing machine has the characteristics of simple structure, high working efficiency, high pass percent, accurate positioning and time and labor saving during clamping.

Owner:林成木

Wax statue cleaner for cleaning surfaces of naked arms of figure wax statue

InactiveCN109261555AAdapt to cleaning needsPrevent rotationUsing liquid separation agentDirt cleaningArm surfaceWax

The invention provides a wax statue cleaner for cleaning the surfaces of the naked arms of a figure wax statue, and relates to the field of wax statues. The cleaner includes a bottom supporting box, afirst arc shell, a four-corner supporting adjusting mechanism and a sectional cleaning mechanism. The surface of the bottom supporting box is provided with a box body supporting opening, the inner wall of the box body supporting opening is slidably connected with a telescopic support plate, the telescopic support plate is internally provided with a falling dust through hole, the surface of the telescopic support plate is provided with a second arc shell through welding, and the inner wall of the second arc shell and the inner wall of the first arc shell are provided with first arc support grooves. A brush and a wet towel are arranged, the brush can brush floating dust on the arms of the wax statue away, the wet towel wipes the arms at the positions where the floating dust is cleaned away,the dust is cleaned. and the problems are effectively solved that a general wax statue cleaning process is very complex, manual cleaning consumes much time, and the efficiency is very low.

Owner:南京六六创业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com