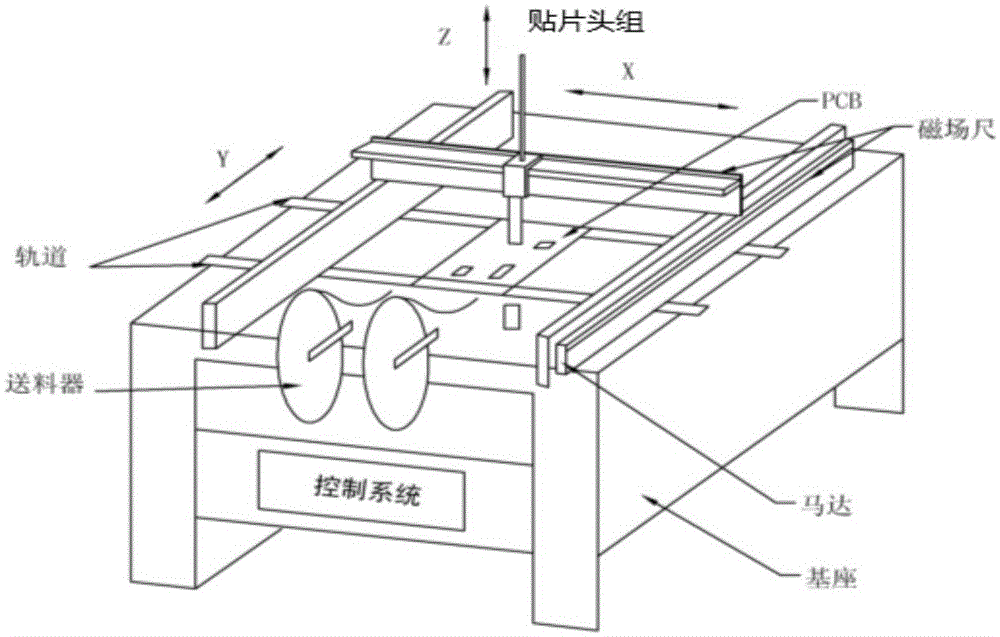

Surface mount machine production data optimization method based on feeder position determination

A technology for producing data and optimizing methods, which is applied in the direction of electrical components, electrical components, and electrical components to assemble printed circuits, etc., to achieve clear logic, simple methods, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

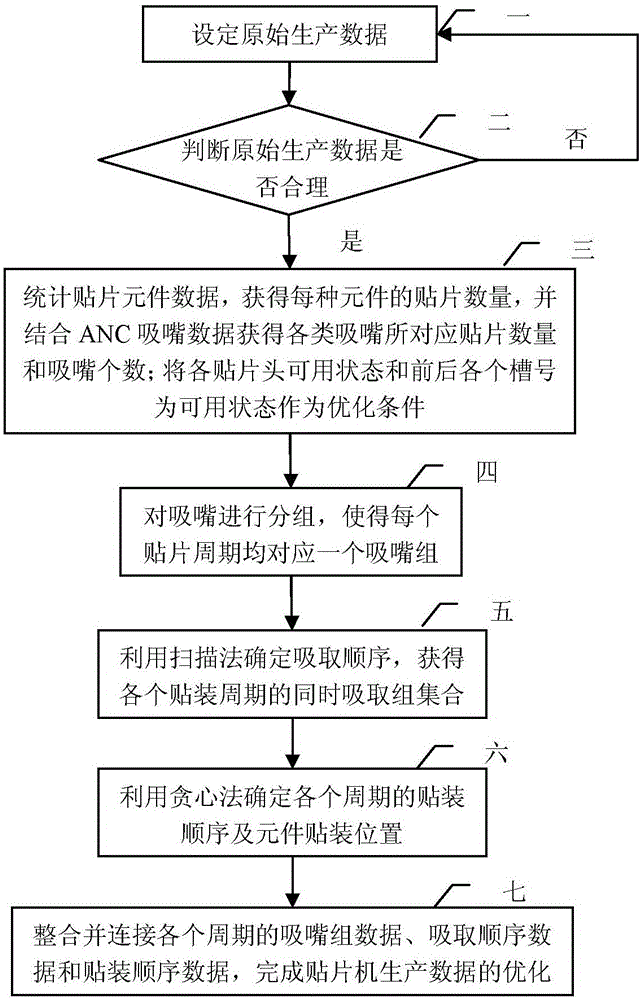

[0029] Specific implementation mode one: refer to figure 2 Specifically explain this embodiment, a method for optimizing production data of a mounter based on feeder position determination described in this embodiment, the method includes the following steps:

[0030] Step 1: Set the original production data of the placement machine. The original production data of the placement machine includes: substrate data, ANC data, component placement data and feeder data;

[0031] Step 2: Determine whether the original production data of the placement machine is reasonable, if yes, execute step 3, otherwise return to step 1;

[0032] Step 3: Count the patch component data, obtain the number of patches for each component, and combine the ANC nozzle data to obtain the number of patches and the number of nozzles corresponding to each type of nozzle; the available status of each chip head and the front and rear slots The number is the available state as the optimization condition;

[00...

specific Embodiment approach 2

[0042] Specific embodiment 2: This embodiment is a further description of the production data optimization method of the placement machine based on the determination of the feeder position described in the specific embodiment 1. In this embodiment, the original production data is judged in step 2. The method of whether it is reasonable is: if the original production data fully meets the judgment conditions, the original production data is reasonable, and the judgment conditions are:

[0043] According to the size and position of the PCB board, determine that the position of the patch component does not exceed the boundary of the board;

[0044] Make sure that the component positions do not overlap;

[0045] Traversing the patch component data and confirming that there is a corresponding nozzle on the ANC;

[0046] Determine the feeder arrangement that has the corresponding chip component data on the feed chute.

specific Embodiment approach 3

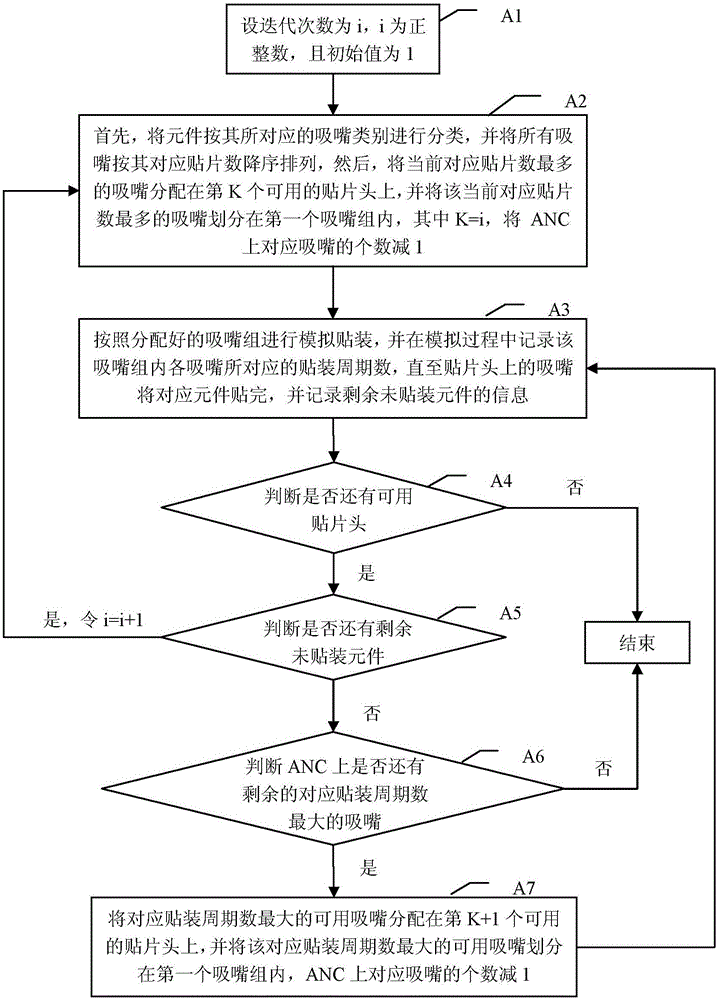

[0047] Specific implementation mode three: refer to image 3 and Figure 4 Describe this embodiment in detail. This embodiment is a further description of the production data optimization method of the placement machine based on the determination of the feeder position described in the first embodiment. In this embodiment, the suction nozzle described in step four The specific method of allocation is as follows:

[0048] To determine the first nozzle group, the steps are as follows:

[0049]Step A1: Set the number of iterations as i, i is a positive integer, and the initial value is 1;

[0050] Step A2: First, classify the components according to their corresponding nozzle categories, and arrange all the nozzles in descending order according to the number of corresponding patches, and then assign the nozzle with the largest number of corresponding patches to the K available on the patch head, and divide the nozzle with the largest number of corresponding patches into the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com