Patents

Literature

426 results about "Component placement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Component placement is an electronics manufacturing process that places electrical components precisely on printed circuit boards (PCBs) to create electrical interconnections between functional components and the interconnecting circuitry in the PCBs (leads-pads). The component leads must be accurately immersed in the solder paste previously deposited on the PCB pads. The next step after component placement is soldering.

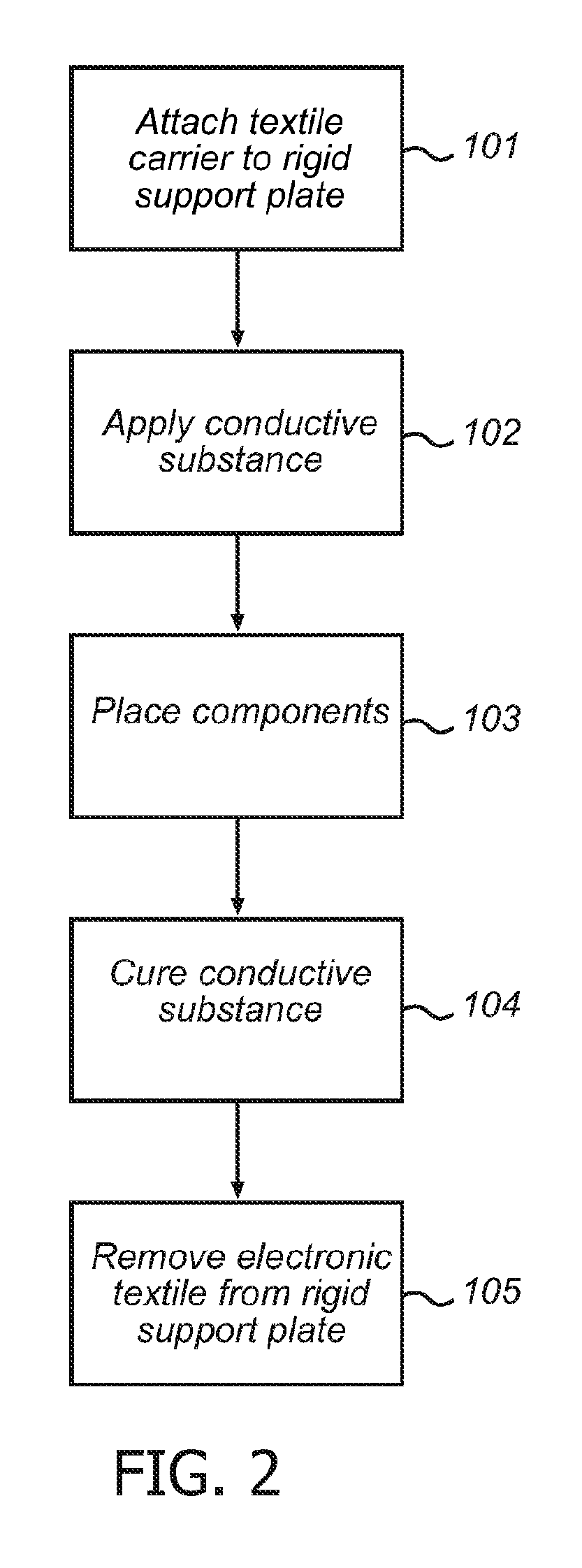

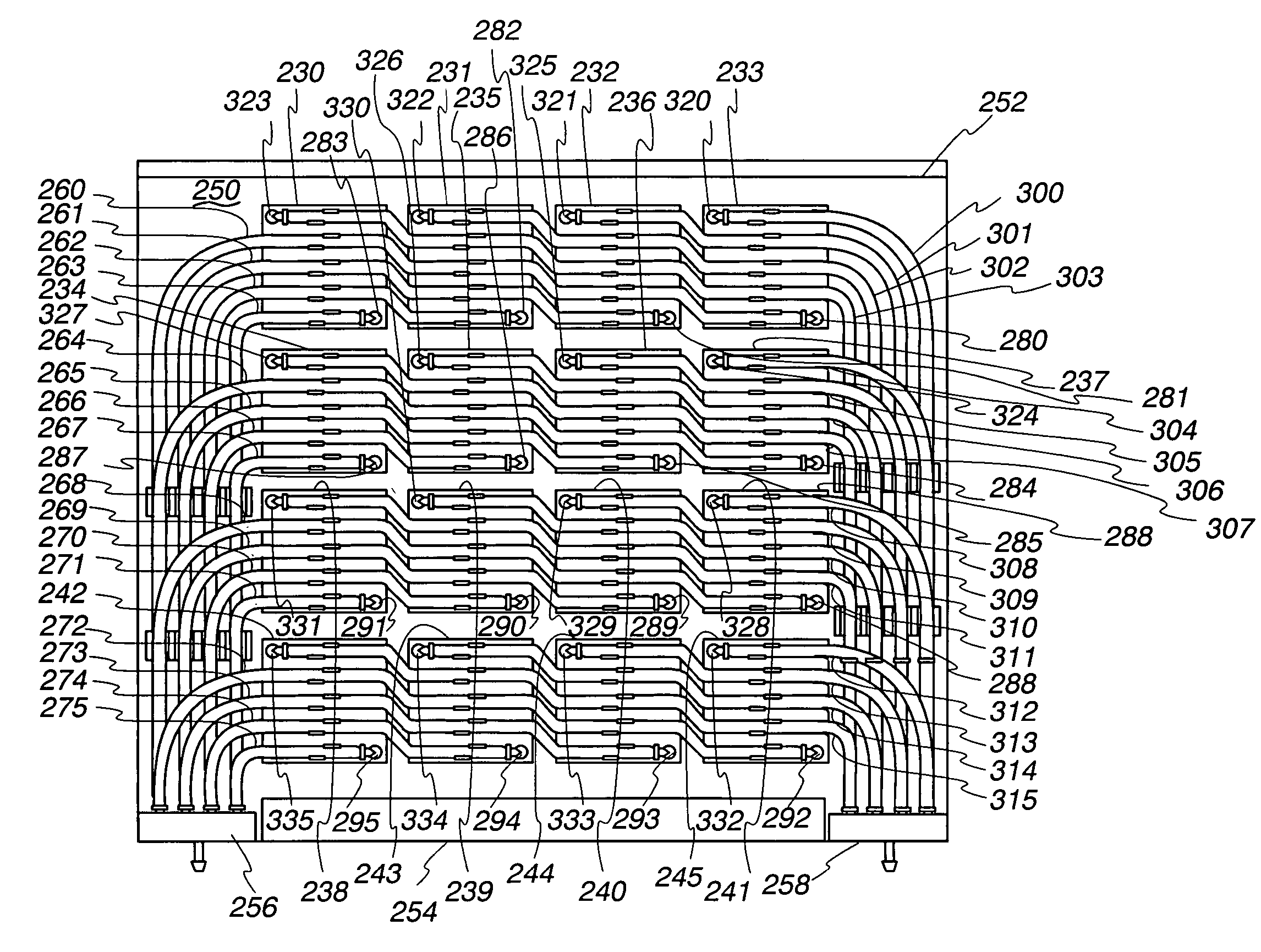

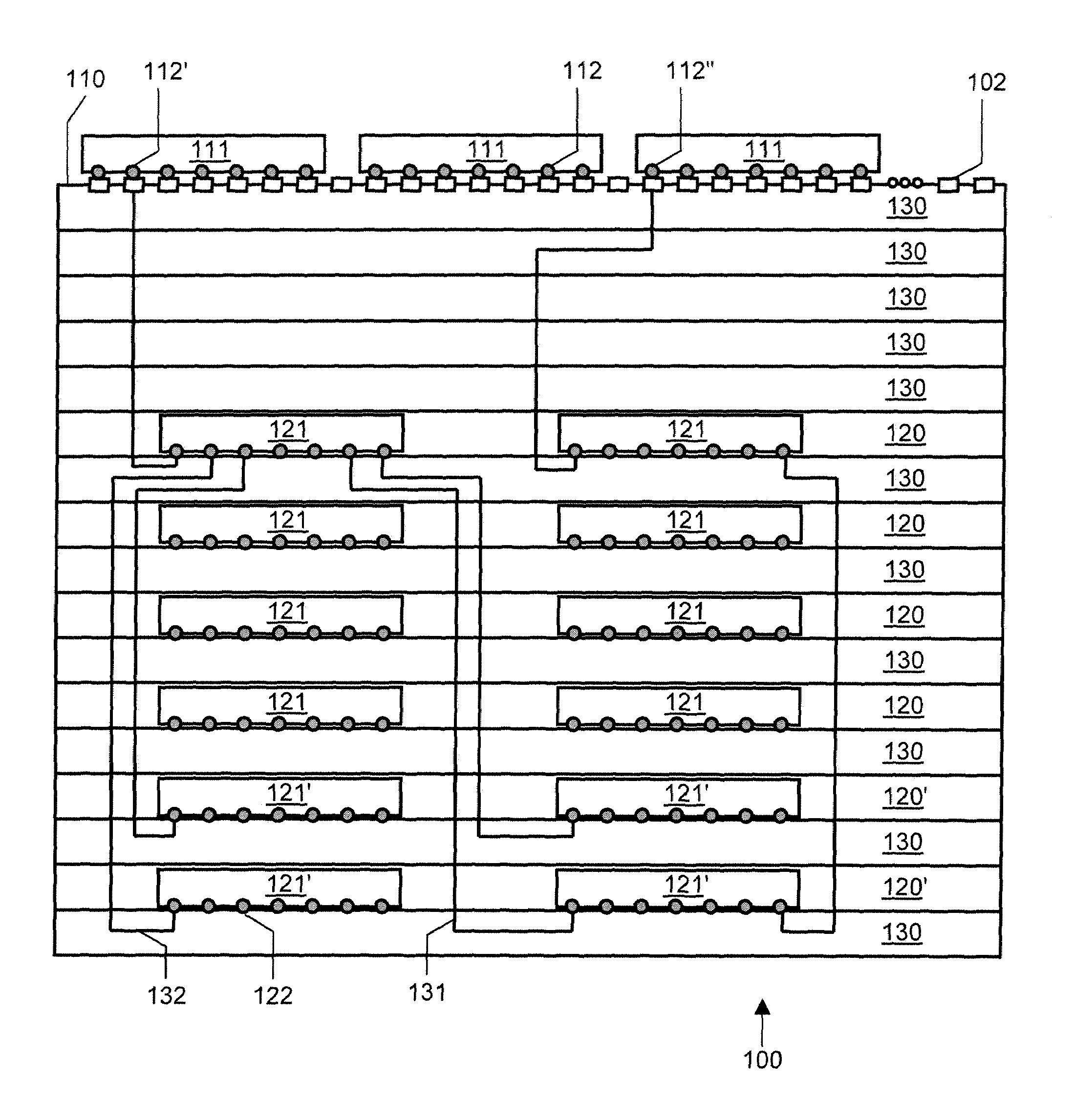

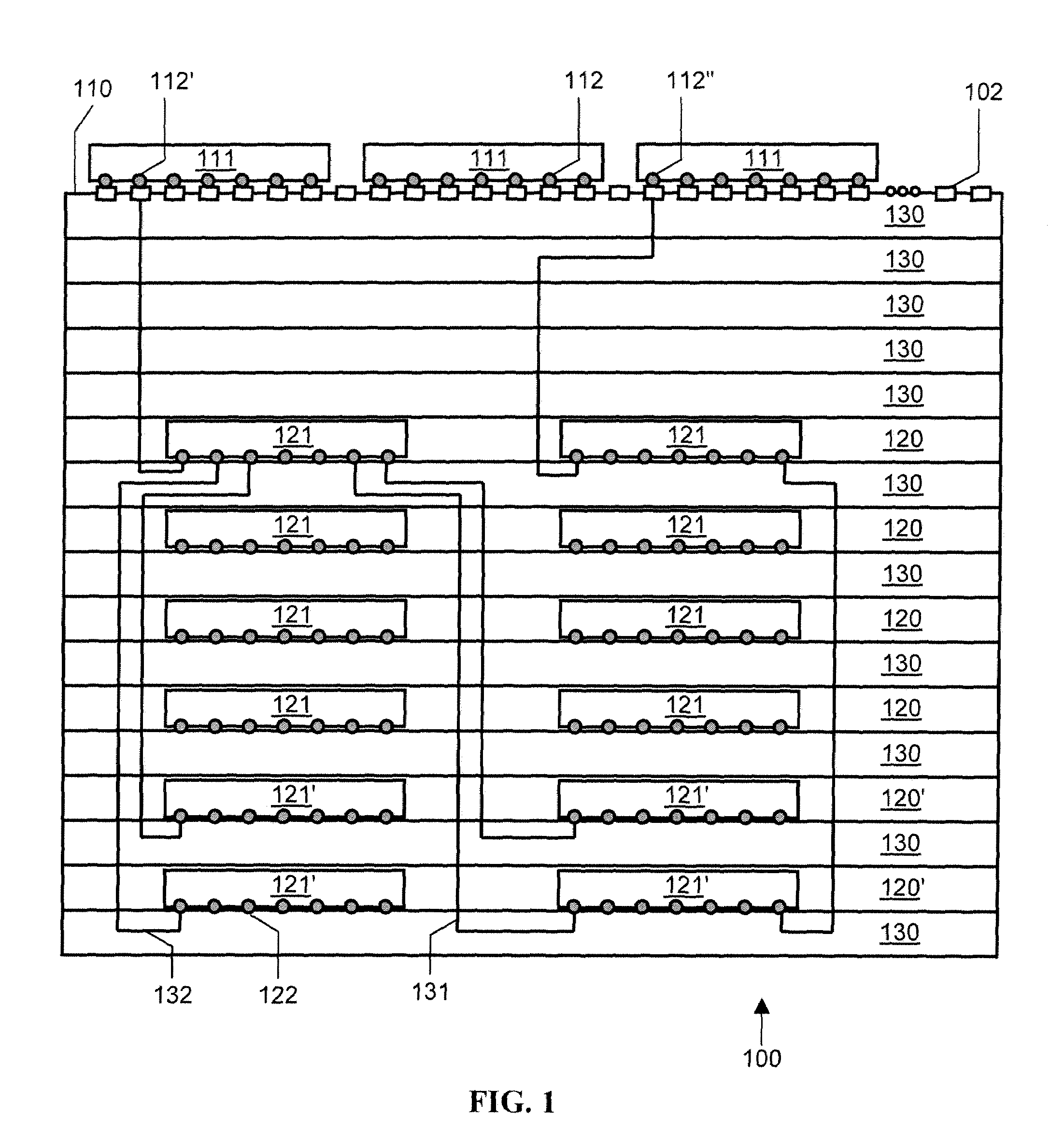

Reprogrammable circuit board with alignment-insensitive support for multiple component contact types

InactiveUS20080143379A1Semiconductor/solid-state device testing/measurementWave amplification devicesSignal conditioningContact type

The present invention is directed to a system that programmably interconnects integrated circuit chips and other components at near-intra-chip density. The system's contact structure allows it to adapt to components with a wide variety of contact spacings and interconnection requirements, the use of releasable attachment means allows component placement to be modified as needed, the system identifies the contacts and the components to facilitate specifying the inter-component connections, and the system provides signal conditioning and retiming to minimize issues with signal integrity and signal skew.

Owner:NORMAN RICHARD

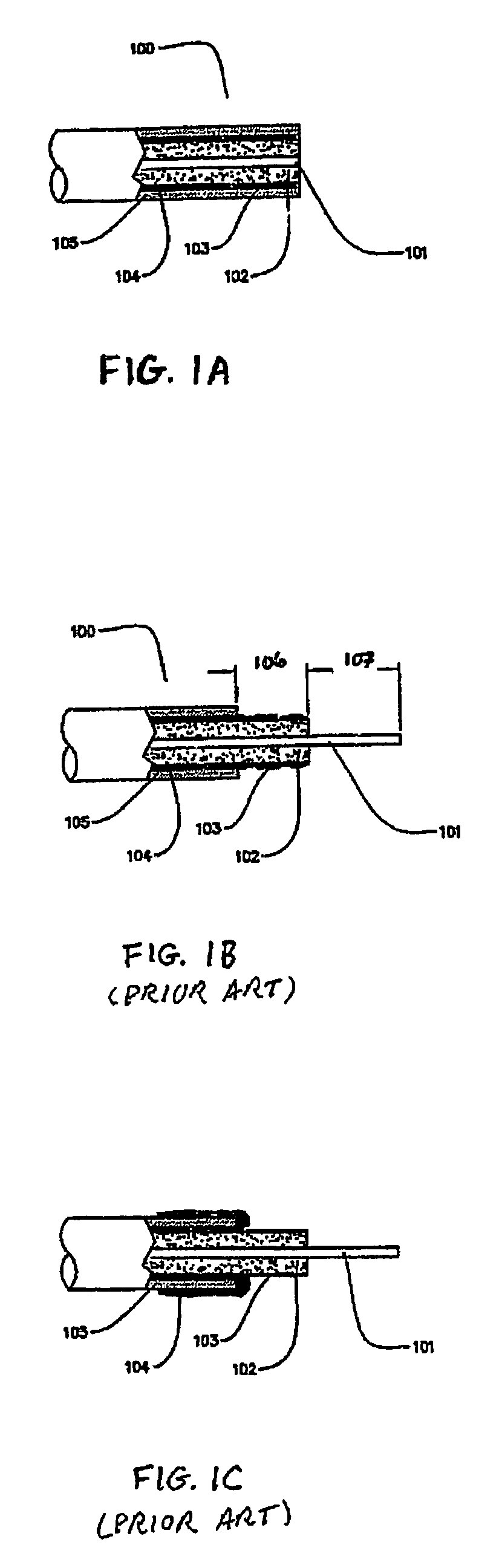

Multiple use analyte sensing assembly

InactiveUS7225008B1Immobilised enzymesBioreactor/fermenter combinationsAnalyteMechanical engineering

A method of making a multiple use analyte sensing assembly. The method includes placing a coated wire analyte sensing assembly on an article having a surface that defines a set of pockets so that the wire extends into each pocket. The coated wire is then typically covered by a layer of insulation material between pockets, either by placing an apertured insulation material layer over the pockets so that the apertures correspond to the pockets or by placing a liquid curable insulation material over the coated wire between pockets.

Owner:WAVEFORM TECH INC +1

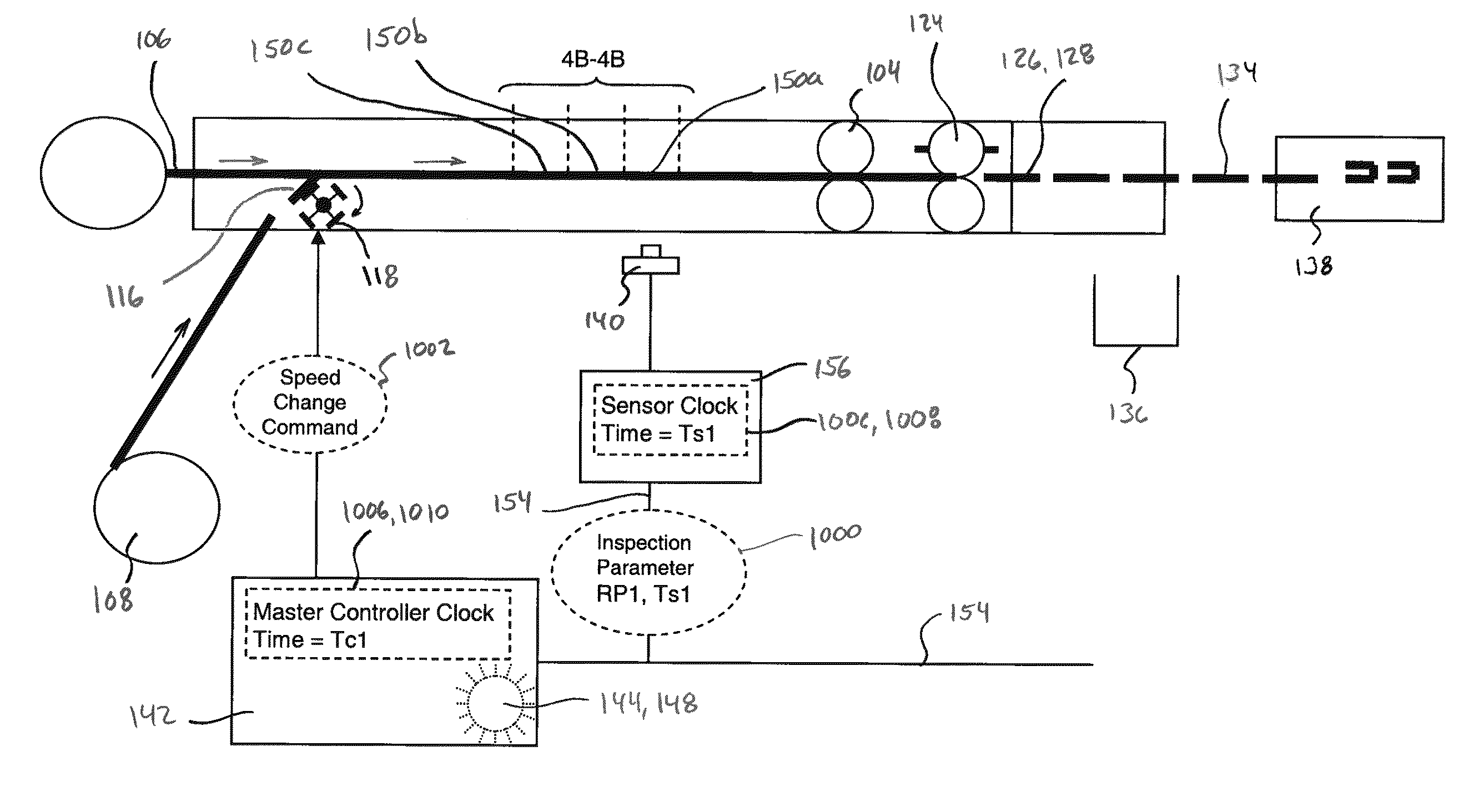

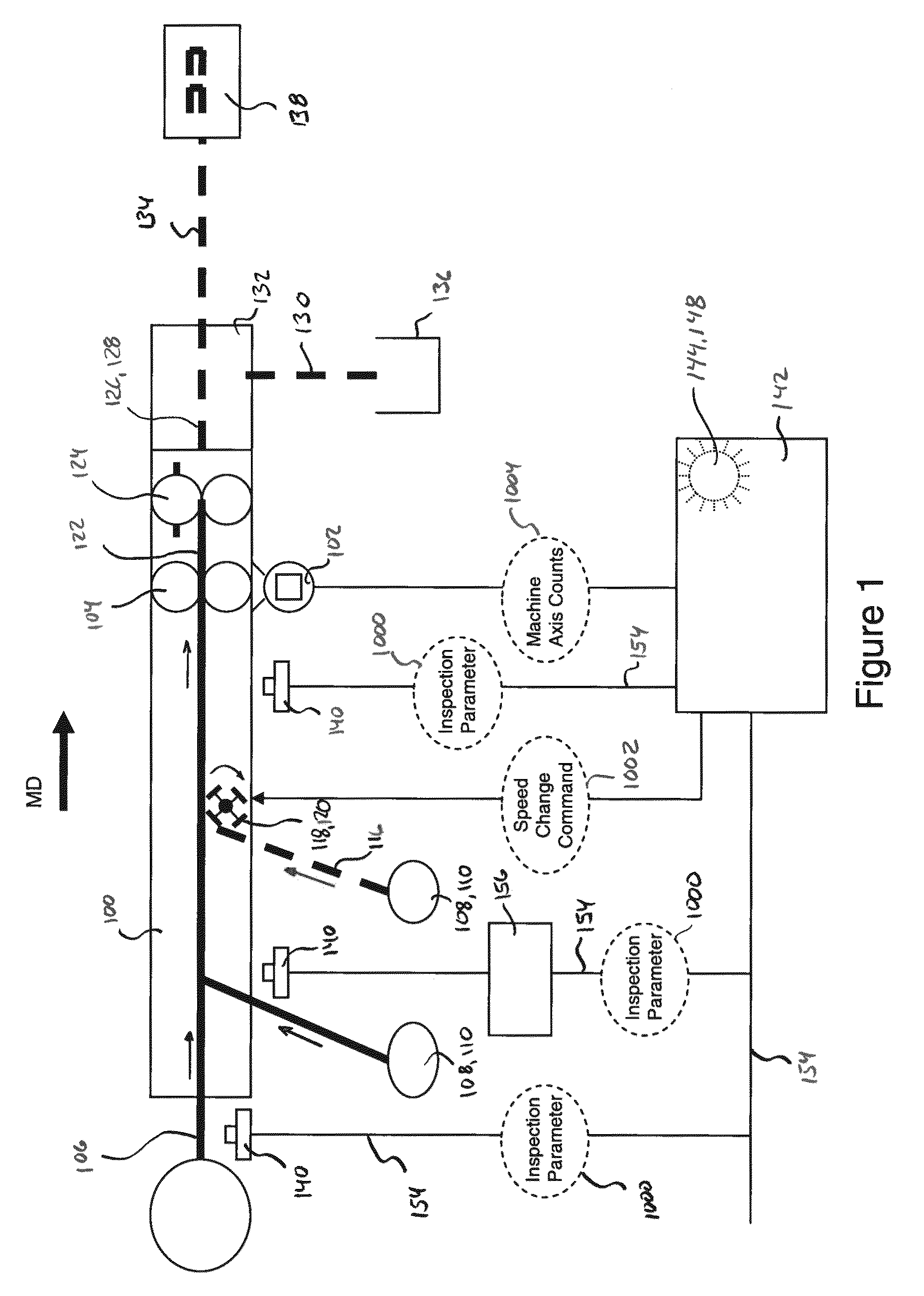

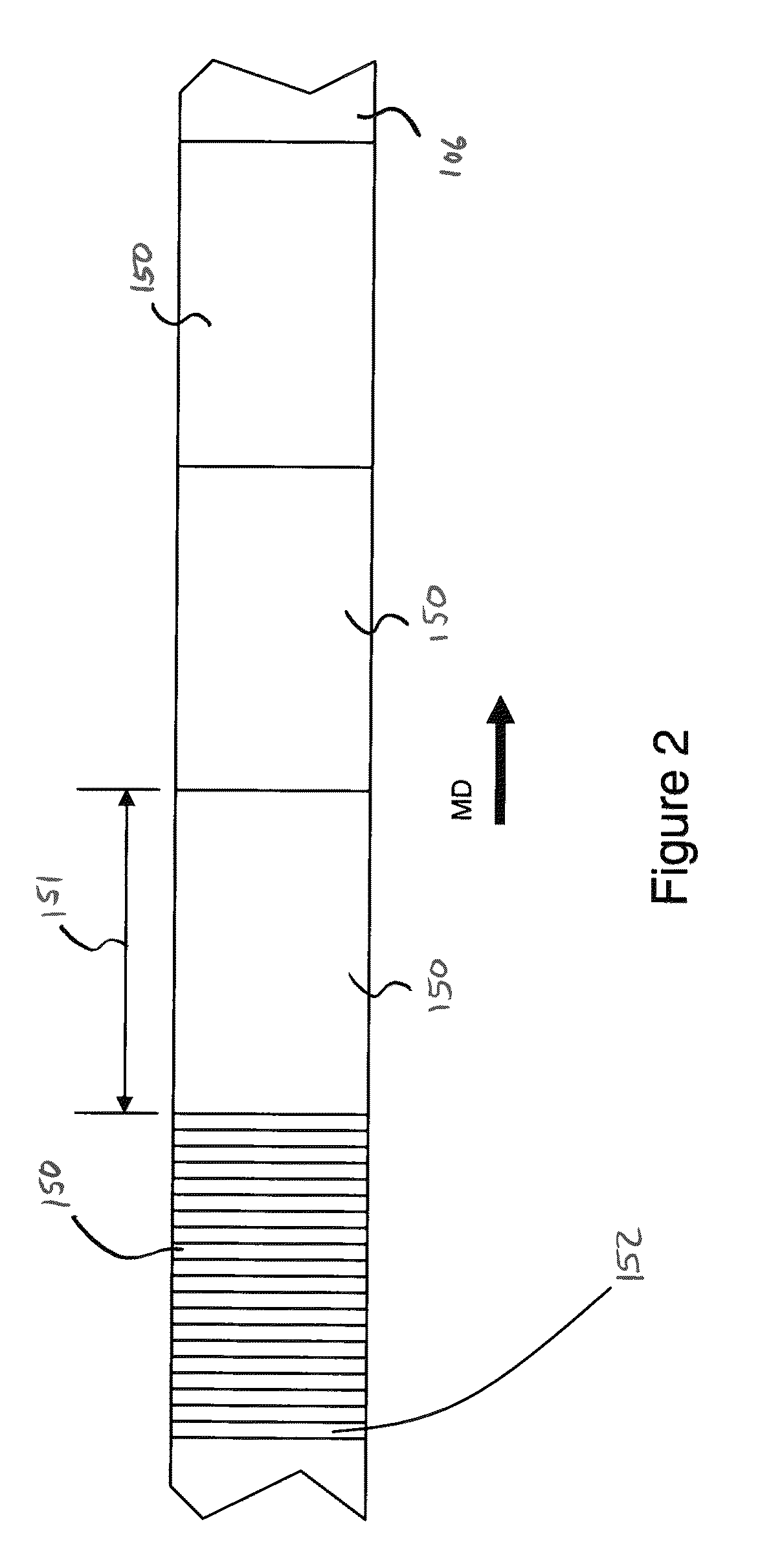

Systems and methods for controlling phasing of advancing substrates in absorbent article converting lines

ActiveUS8145344B2Precise applicationProgramme controlAutomatic control devicesControl systemEngineering

The present disclosure relates to systems and processes for controlling the relative positions or phasing of advancing substrates and / or components in absorbent article converting lines. The systems and methods may utilize feedback from technologies, such as vision systems, sensors, remote input and output stations, and controllers with synchronized embedded clocks to accurately correlate component placement detections and placement control on an absorbent article converting process. The systems and methods may accurately apply the use of precision clock synchronization for both instrumentation and control system devices on a non-deterministic communications network. In turn, the clock synchronized control and instrumentation network may be used to control the substrate position. As such, the controller may be programmed to the relative positions of substrates and components along the converting line without having to account for undeterminable delays.

Owner:THE PROCTER & GAMBLE COMPANY

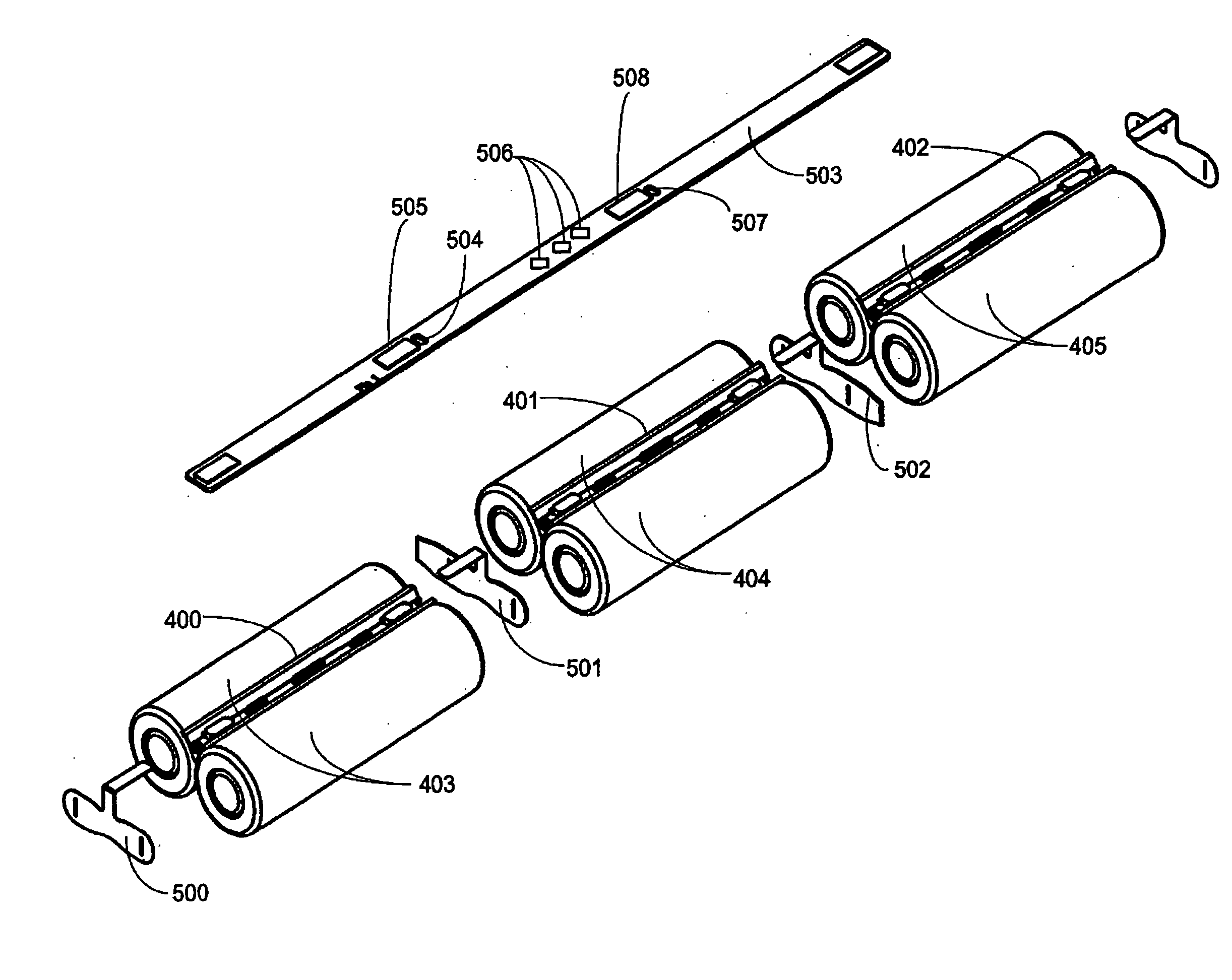

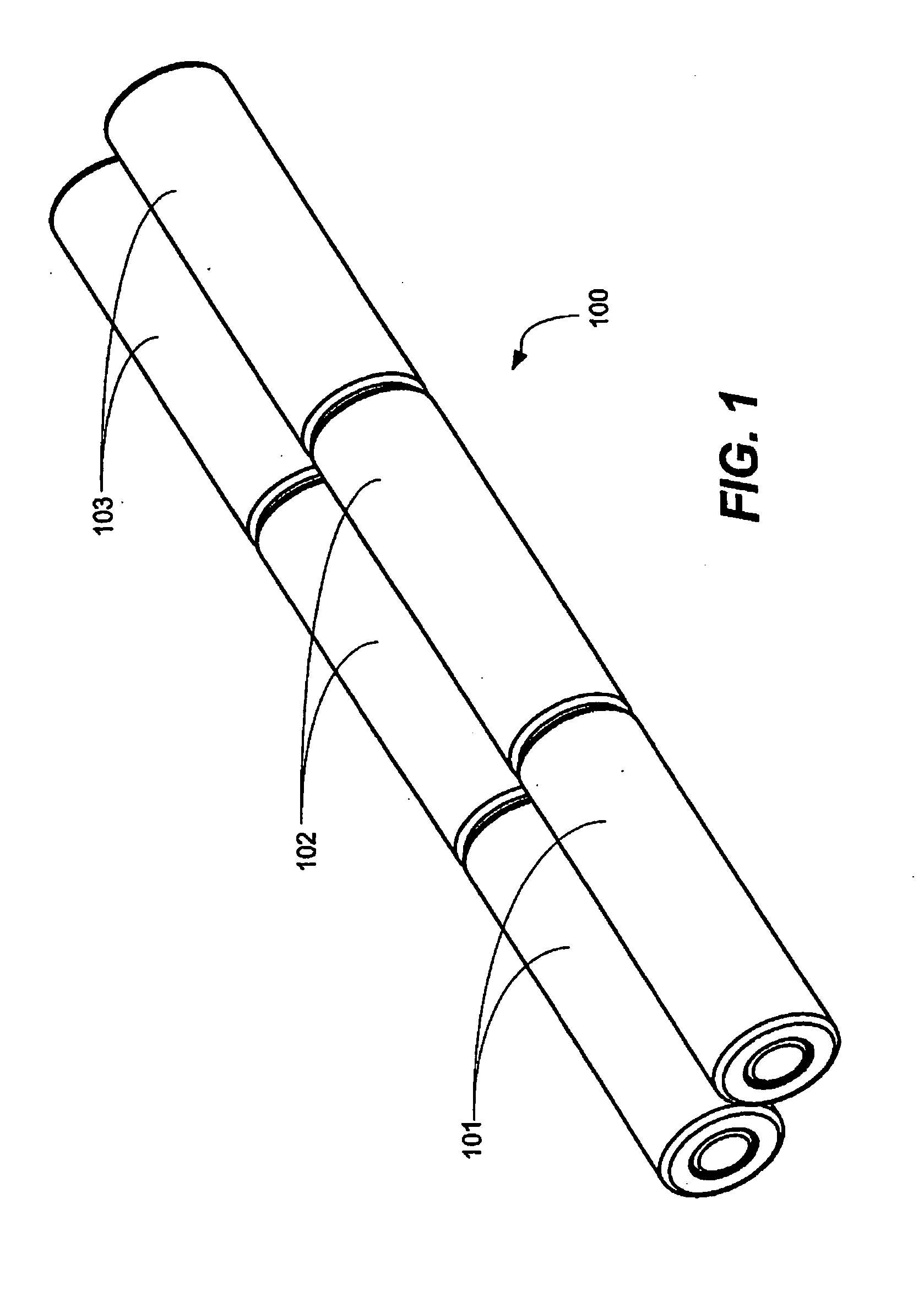

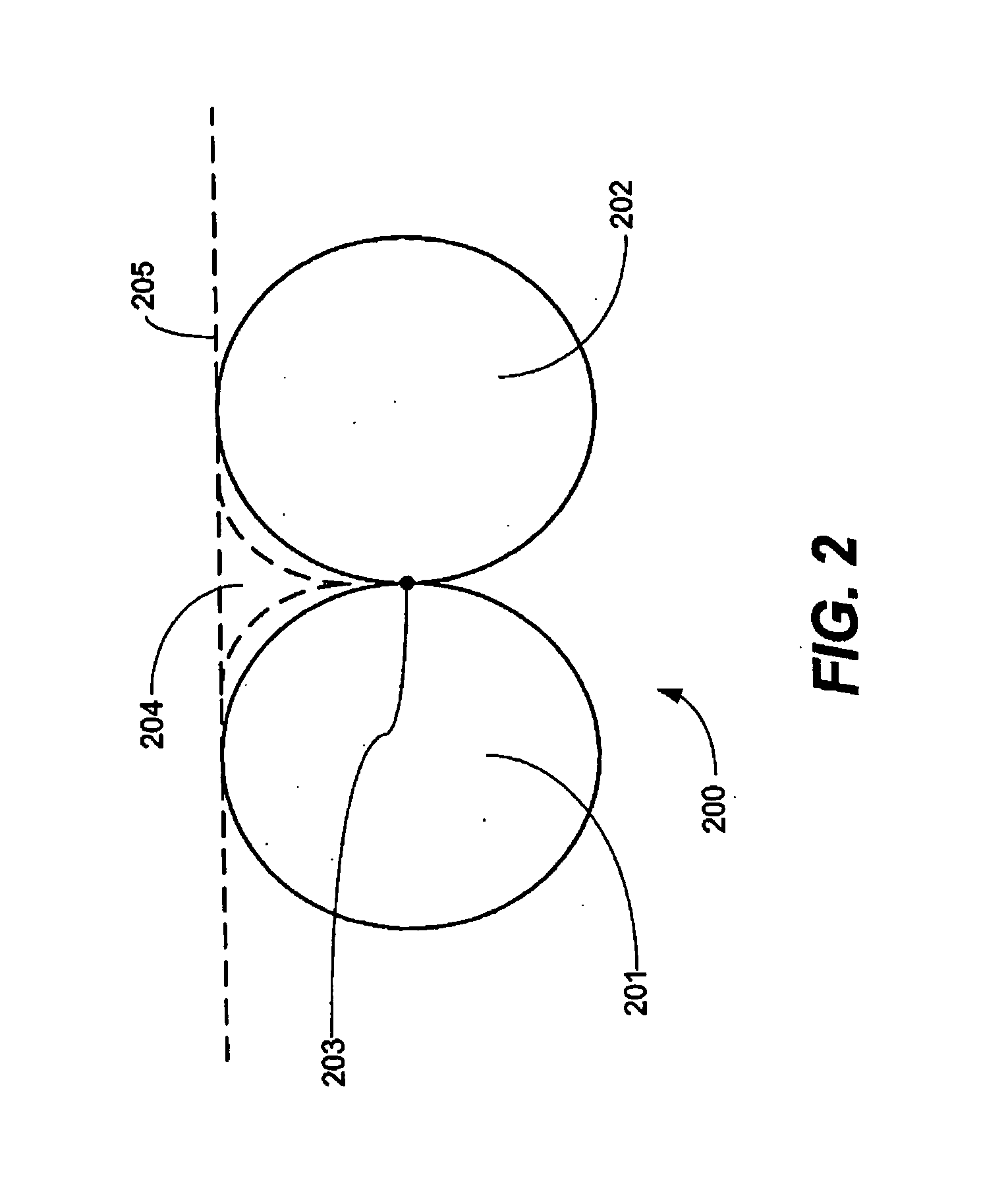

Battery pack assembly

InactiveUS20050271934A1Primary cell to battery groupingCells structural combinationAdhesiveRechargeable cell

A low-profile battery pack having an electrolyte barrier is provided. The pack includes a plurality of rechargeable cells, being arranged in end to end pairs of two cells. A cleavage void formed by the convex geometry of the cells accommodates at least one insulator and a first circuit board. Tabs couple the cells to the first circuit board. A flexible substrate couples the first circuit board to a second circuit board. The assembly is then placed in a housing having a first compartment and a second compartment, such that the cells are placed in the first compartment and the second circuit board is placed in the second compartment. Between the first and second compartments exists an electrolyte barrier. The flexible substrate passes through an opening in the electrolyte barrier. Adhesive placed in the opening, about the flexible substrate, ensures a seal that keeps electrolyte that may appear in the first chamber from passing to the second chamber. The overall battery pack is both compact in size and robust in performance.

Owner:MOTOROLA INC

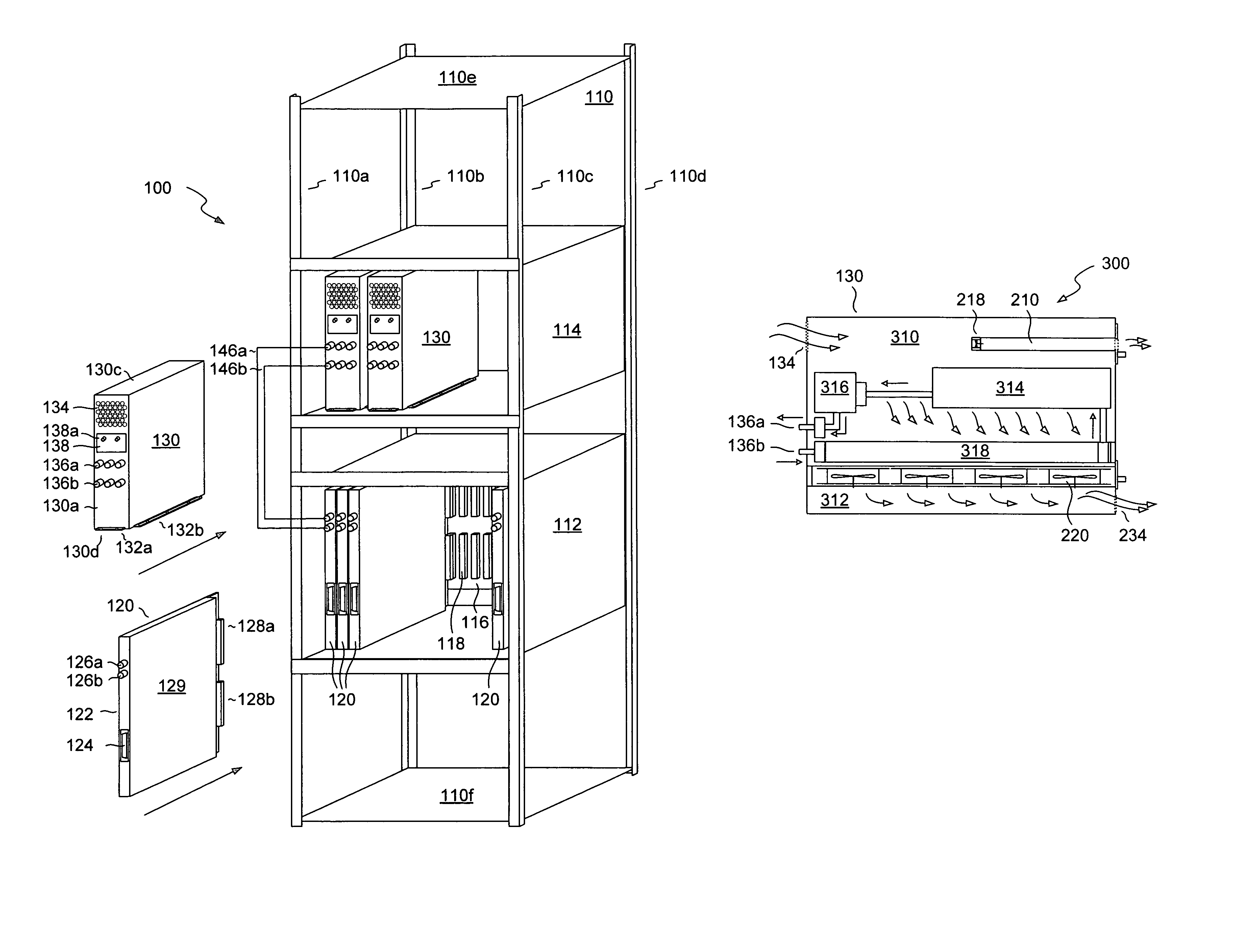

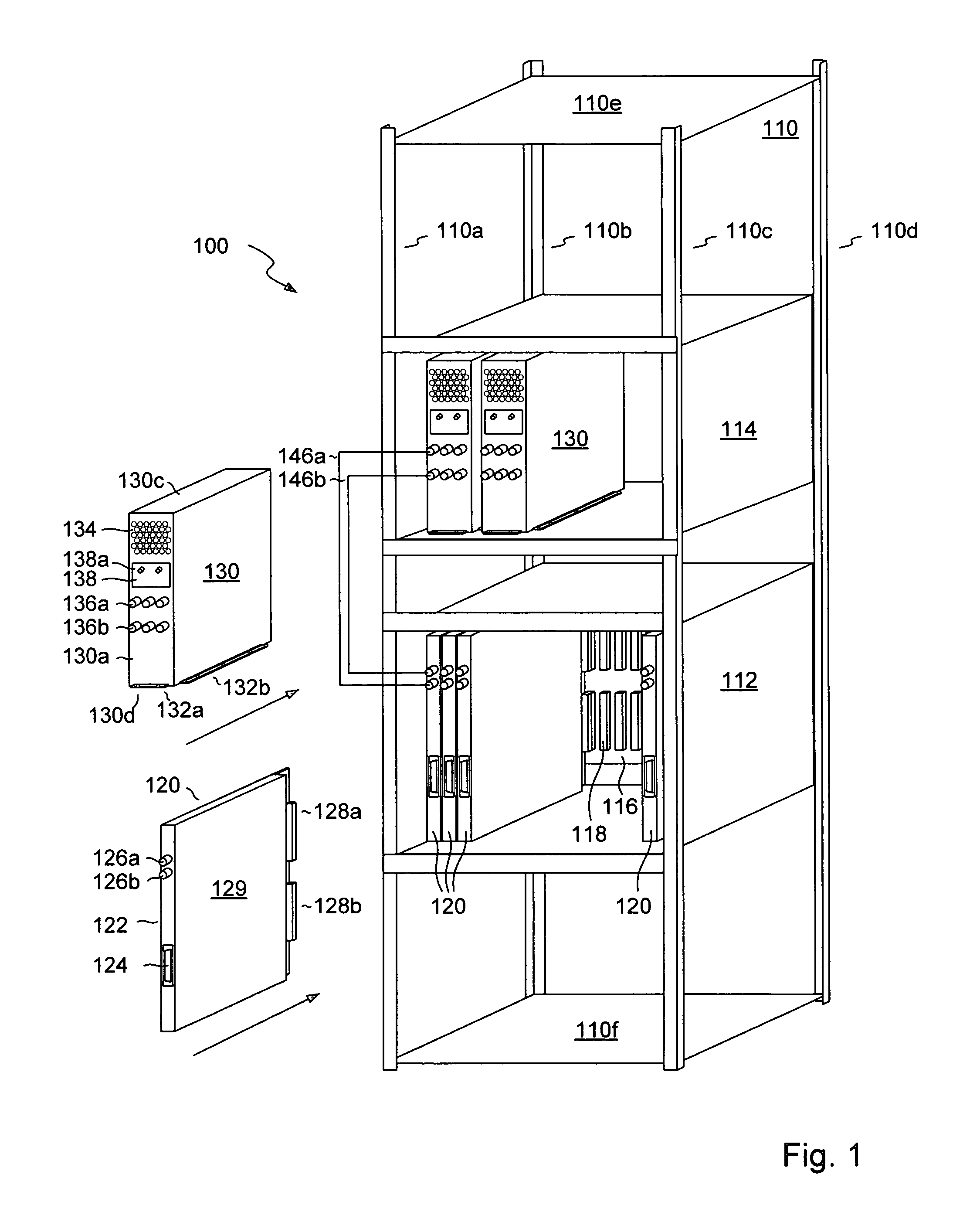

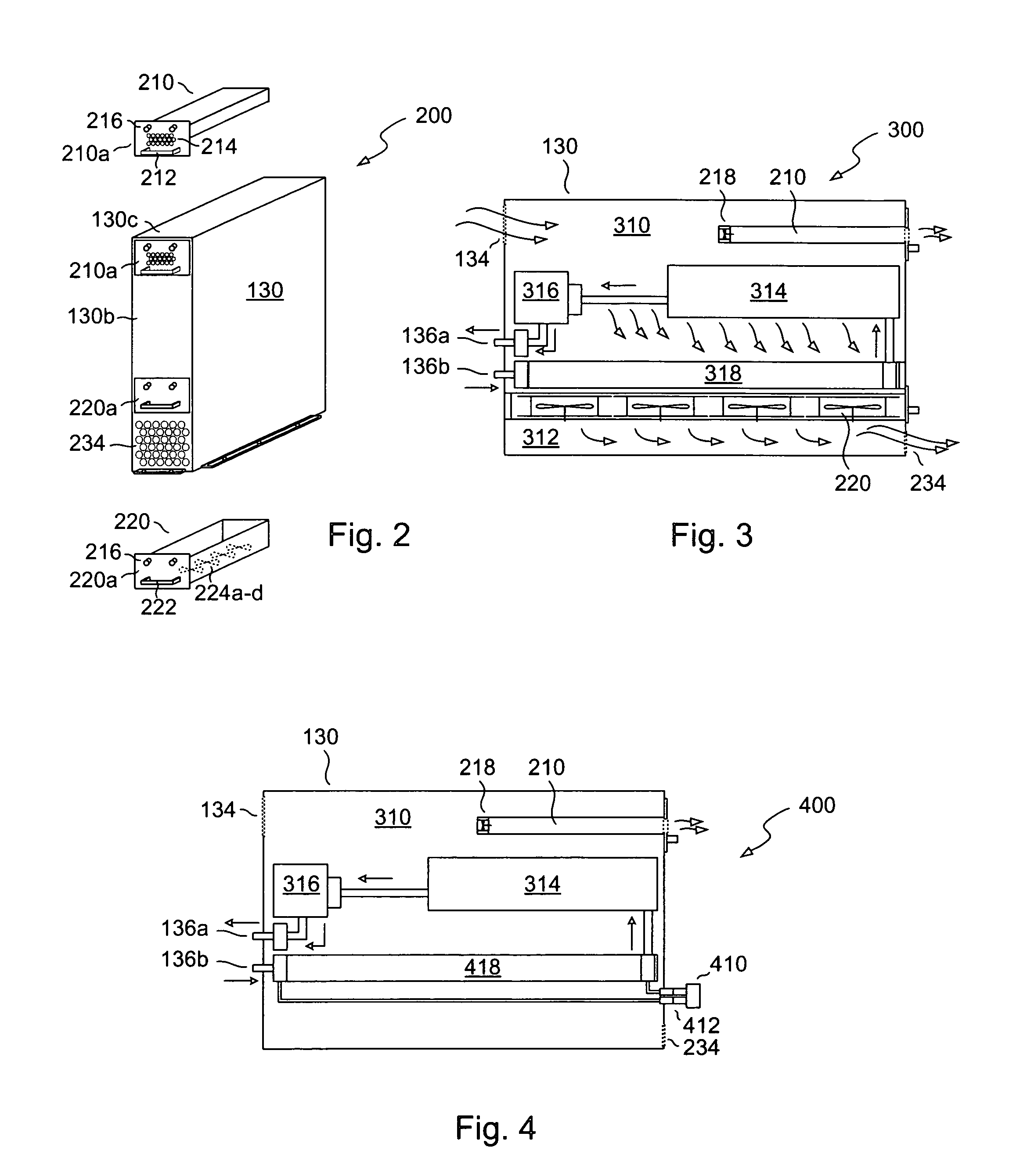

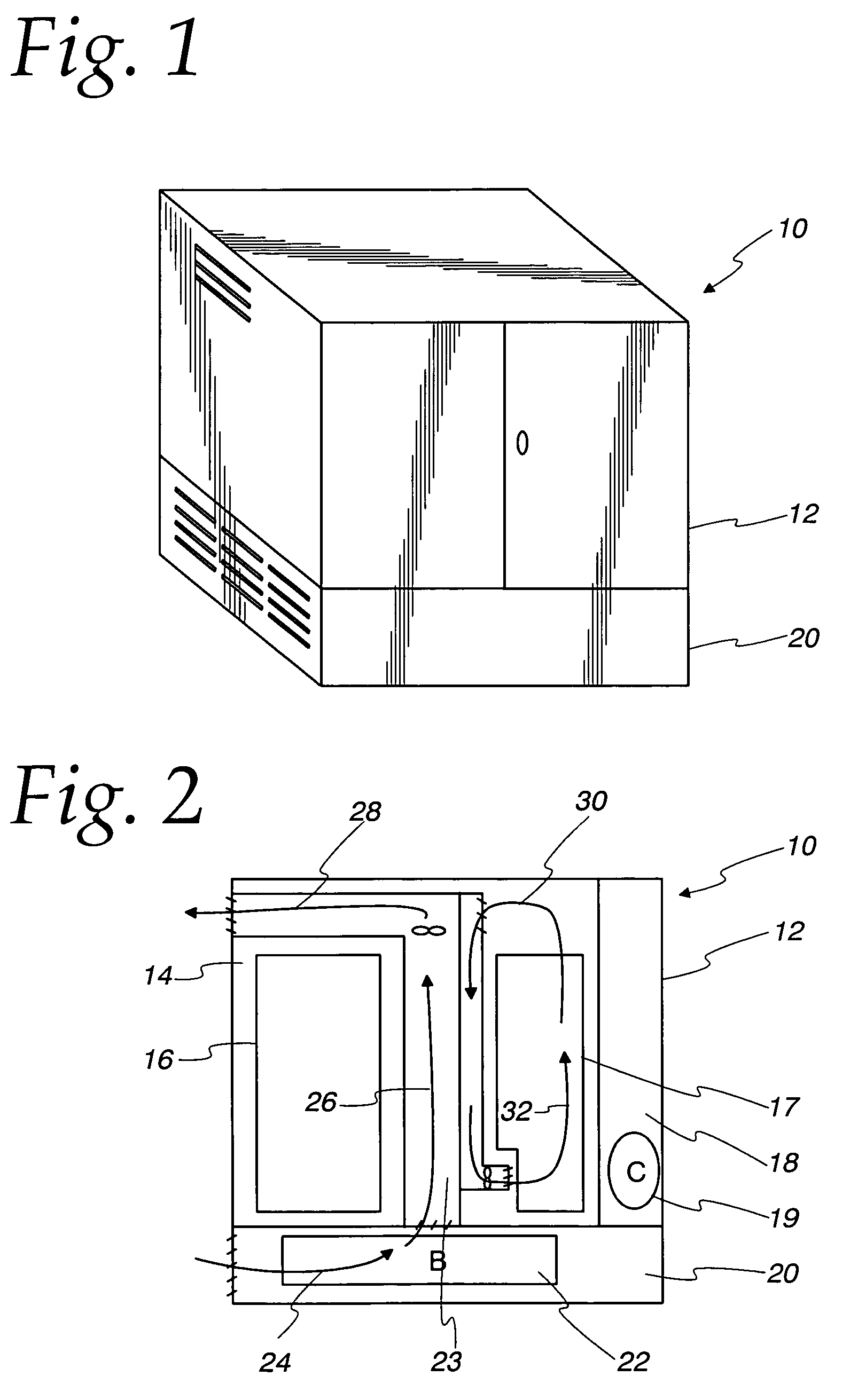

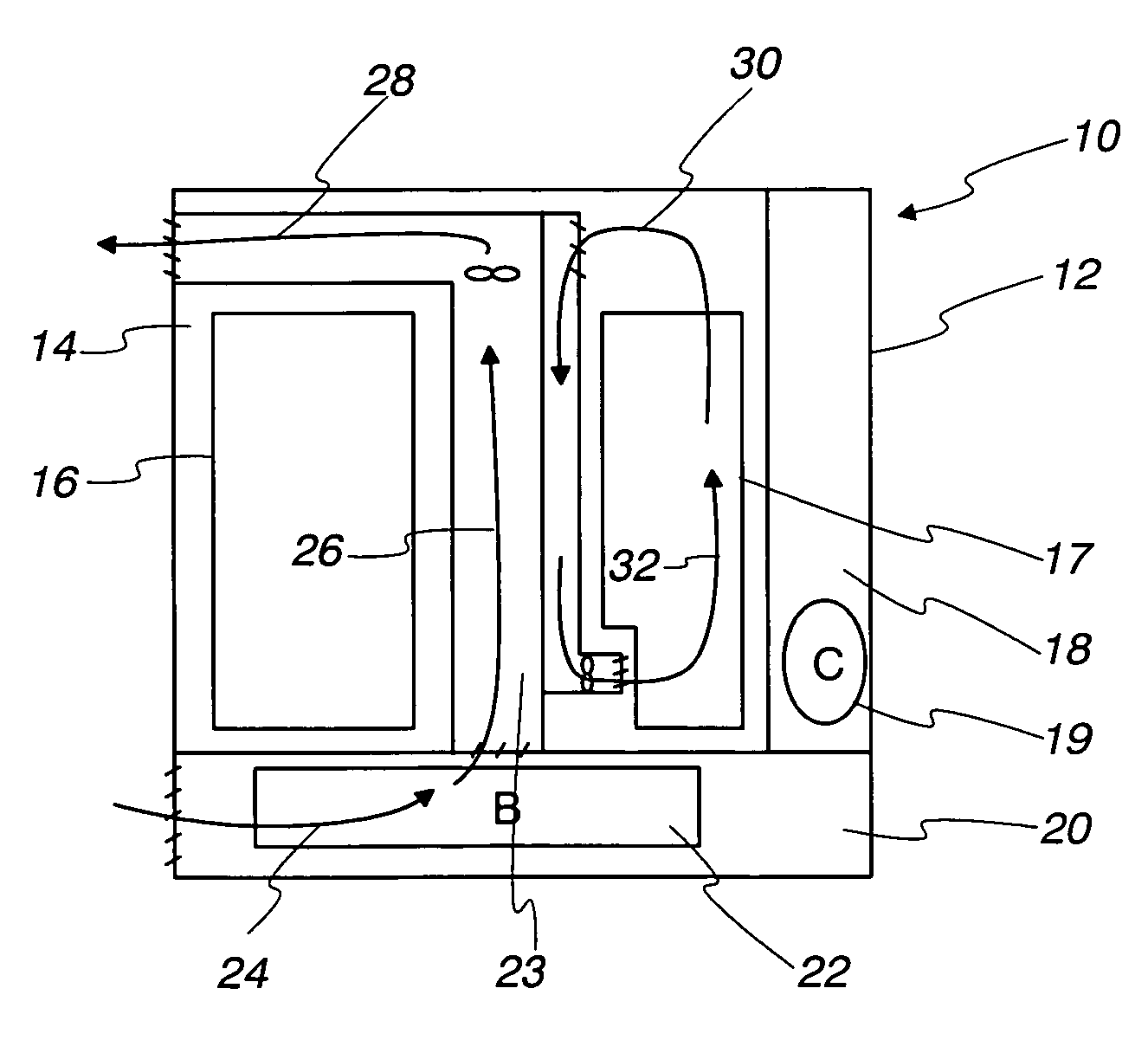

Modular liquid cooling of electronic assemblies

InactiveUS7355852B2Water treatment parameter controlDigital data processing detailsElectronic systemsModularity

An electronic system includes an array of electronic assemblies at a first location within a system. An array of liquid cooling assemblies is placed at a second location within the system. Hoses or other liquid transport pathways connect the cooling assemblies to the electronic assemblies, for cooling the electronic assemblies. As more electronic assemblies are added to the system, additional cooling assemblies may be provided to manage the increased thermal demands.

Owner:AMPHENOL CORP

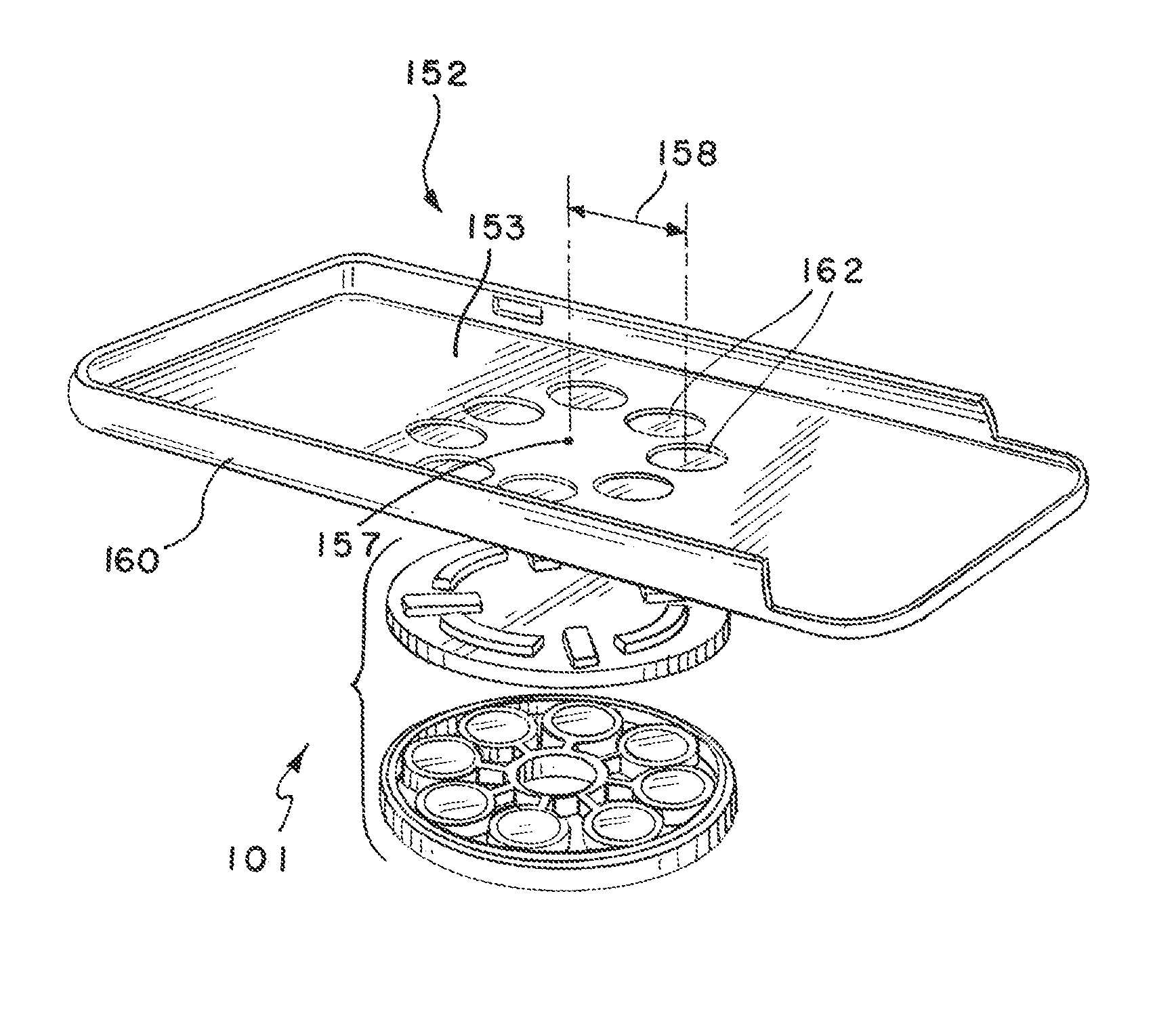

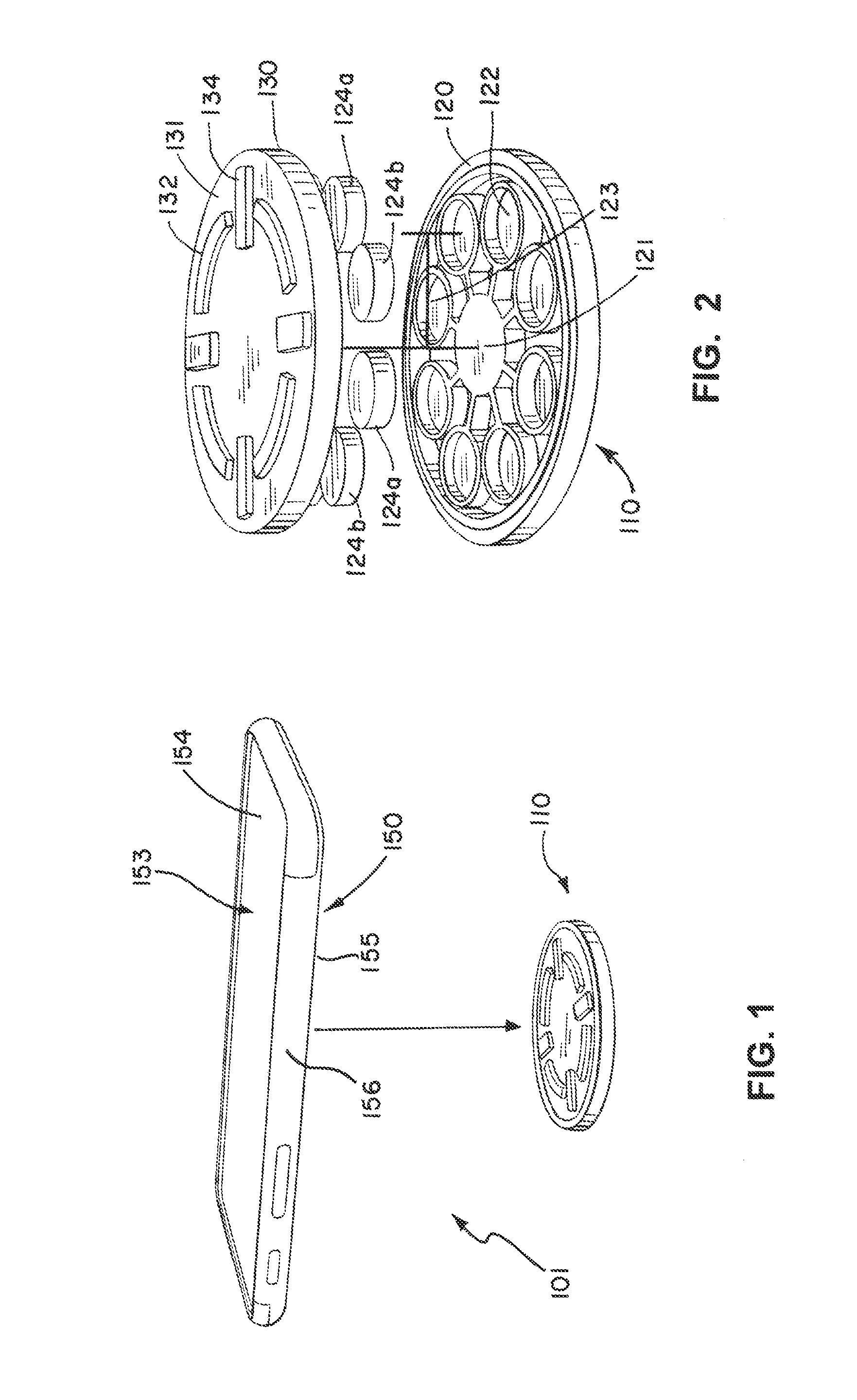

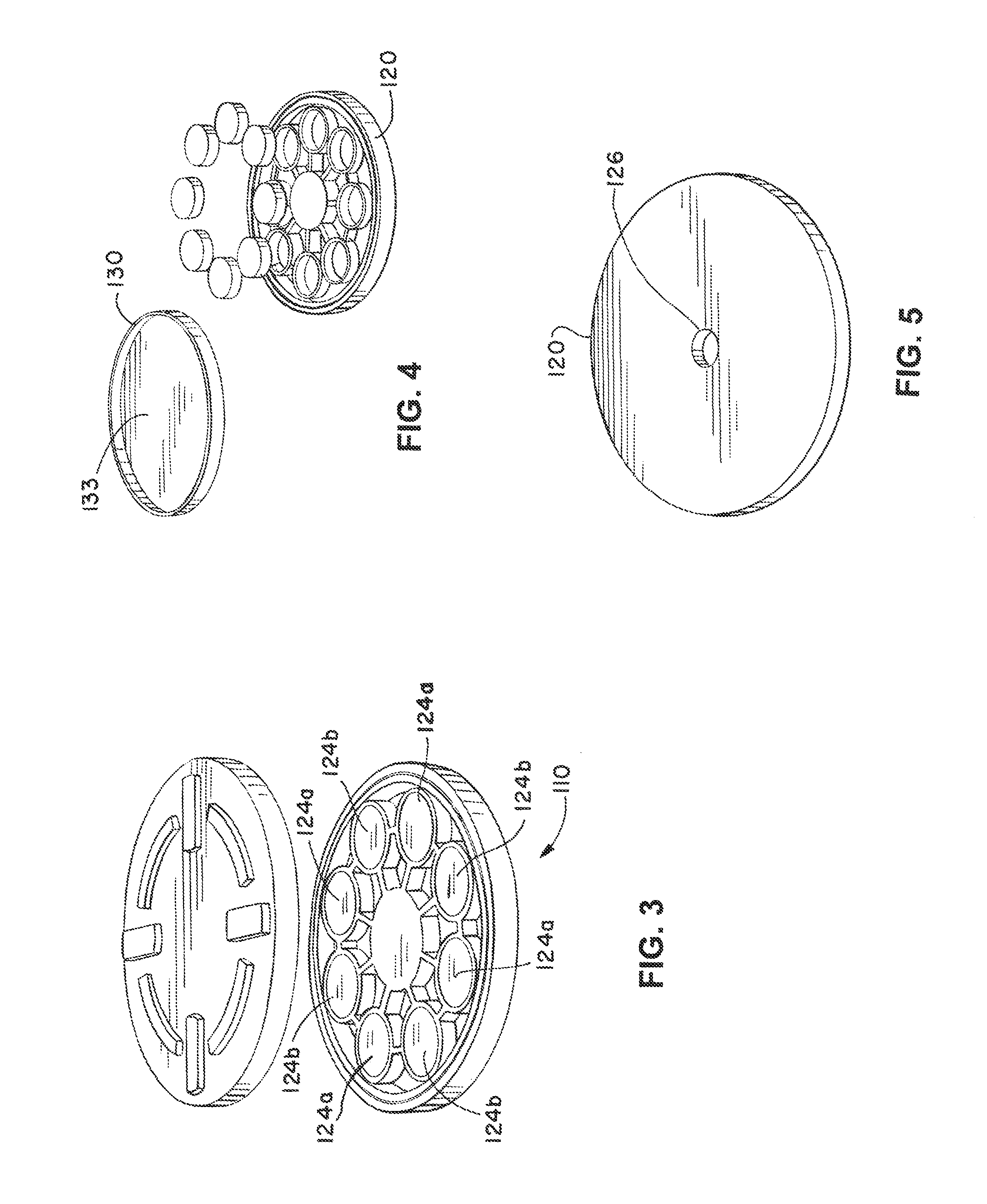

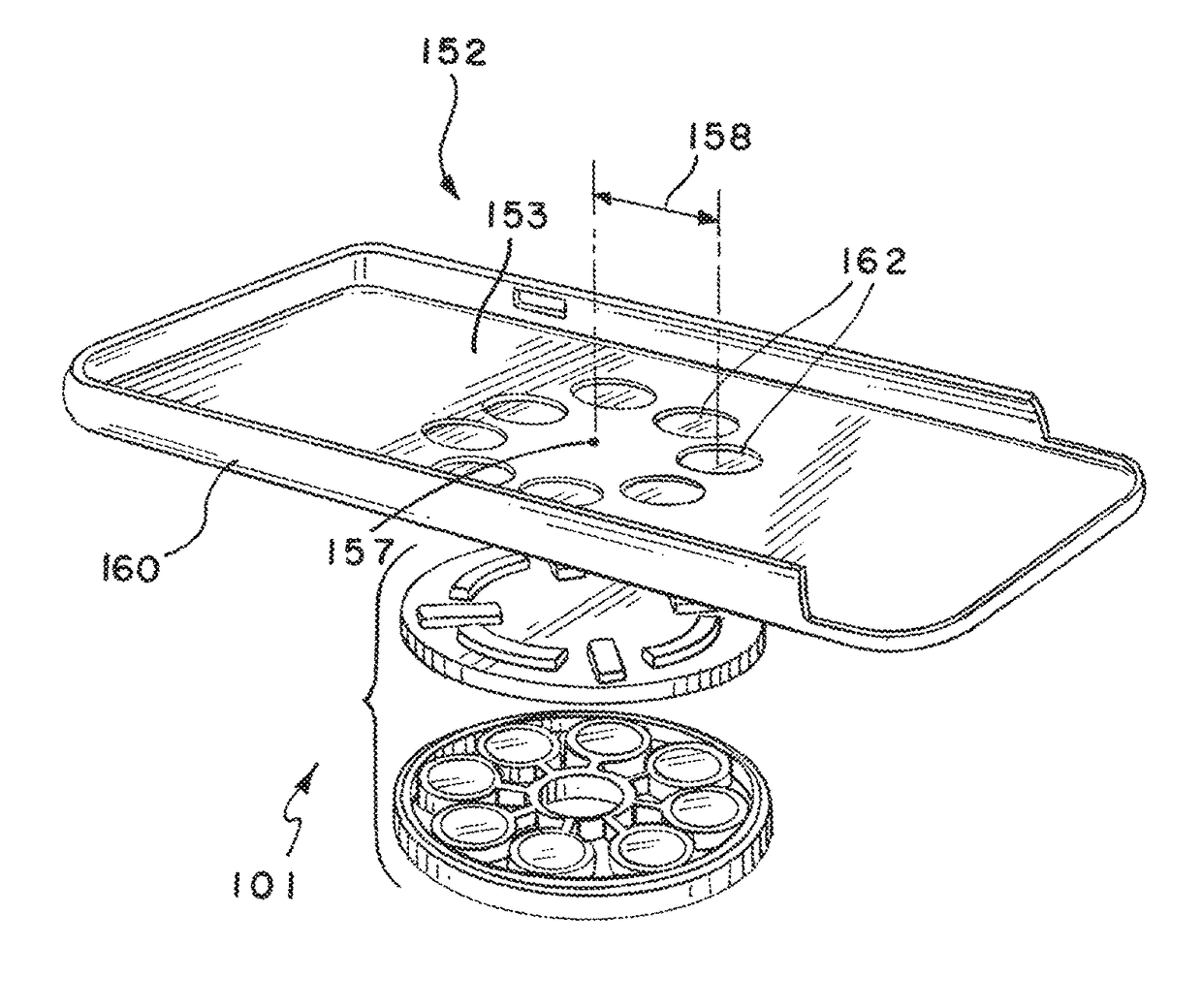

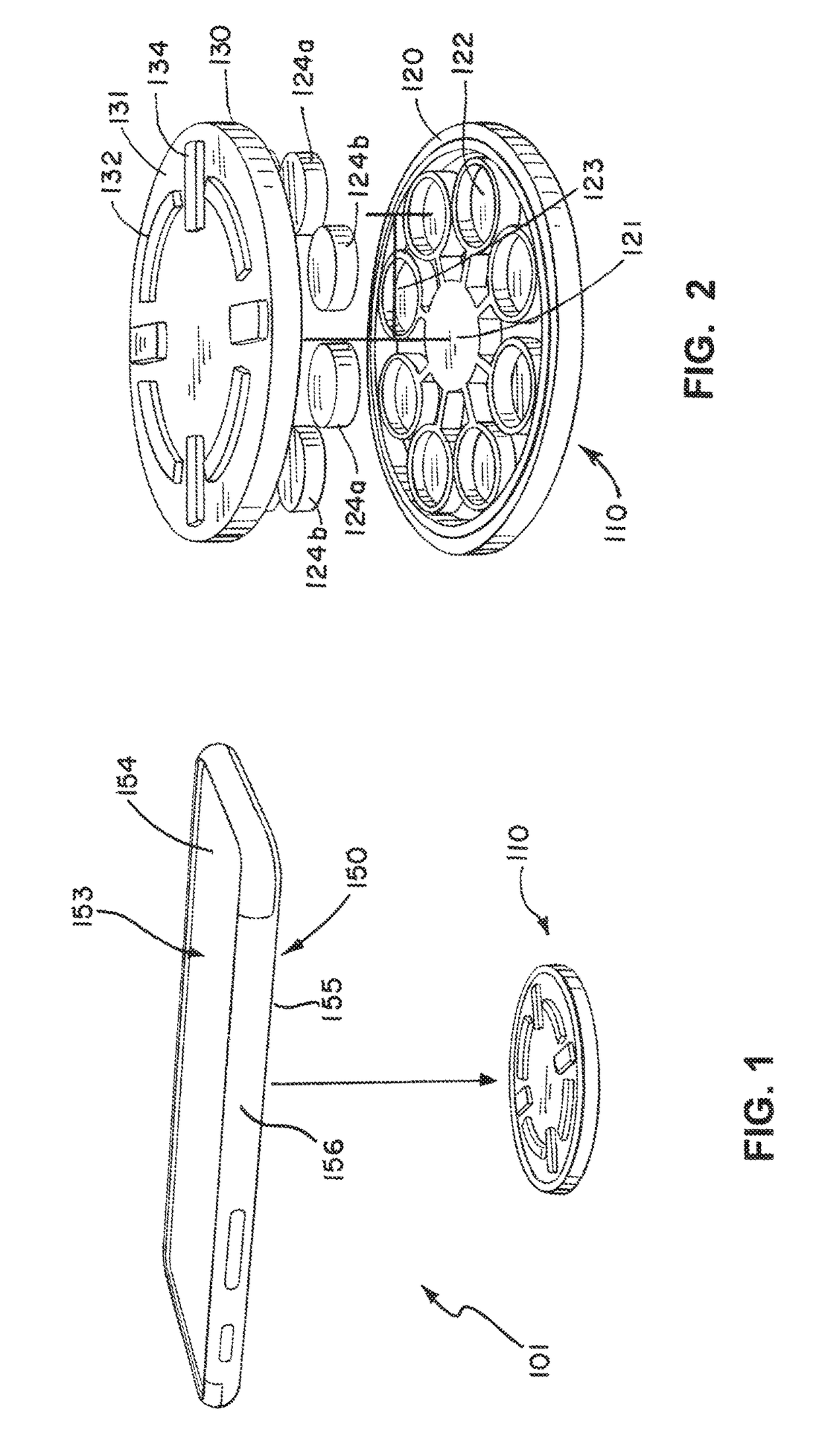

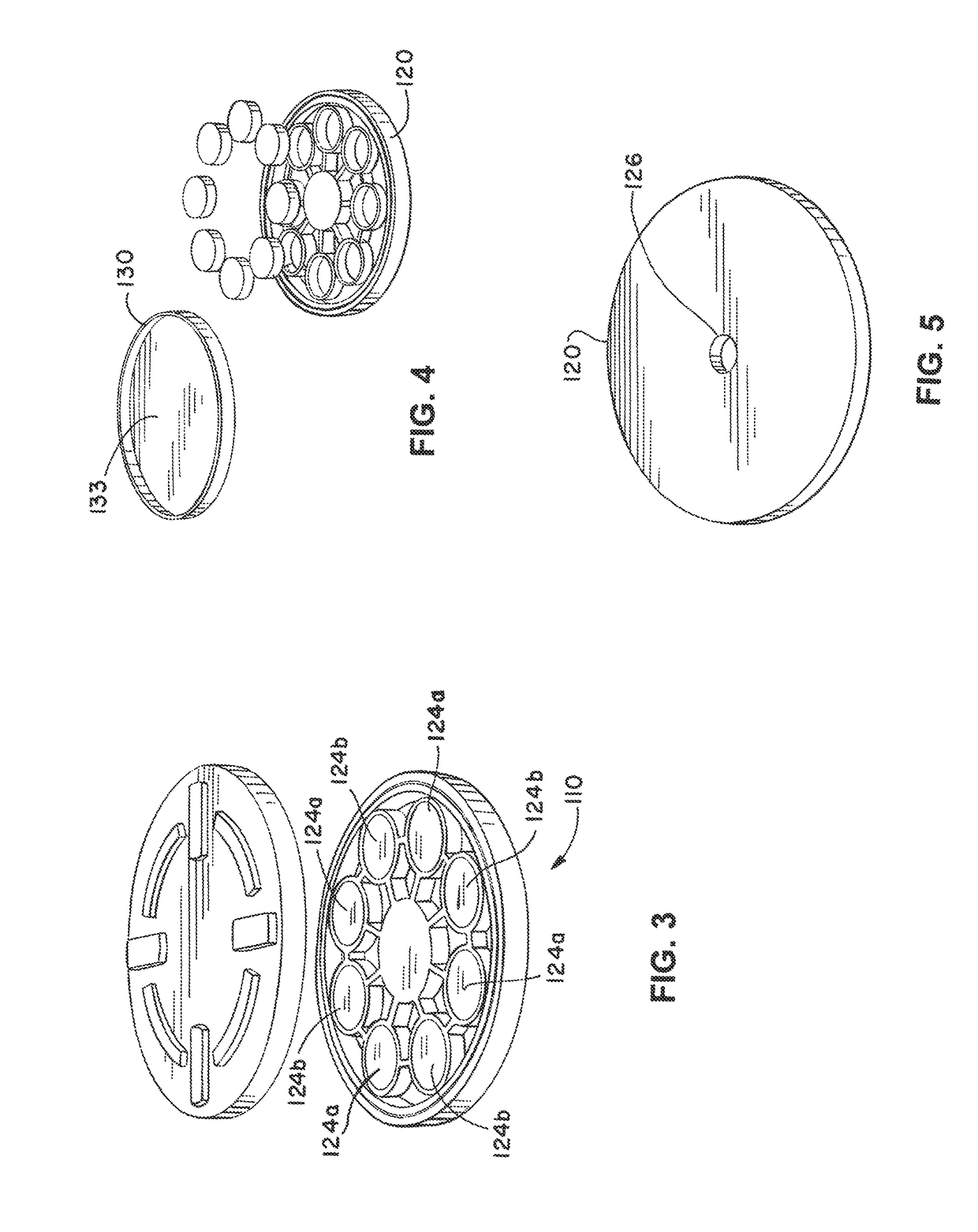

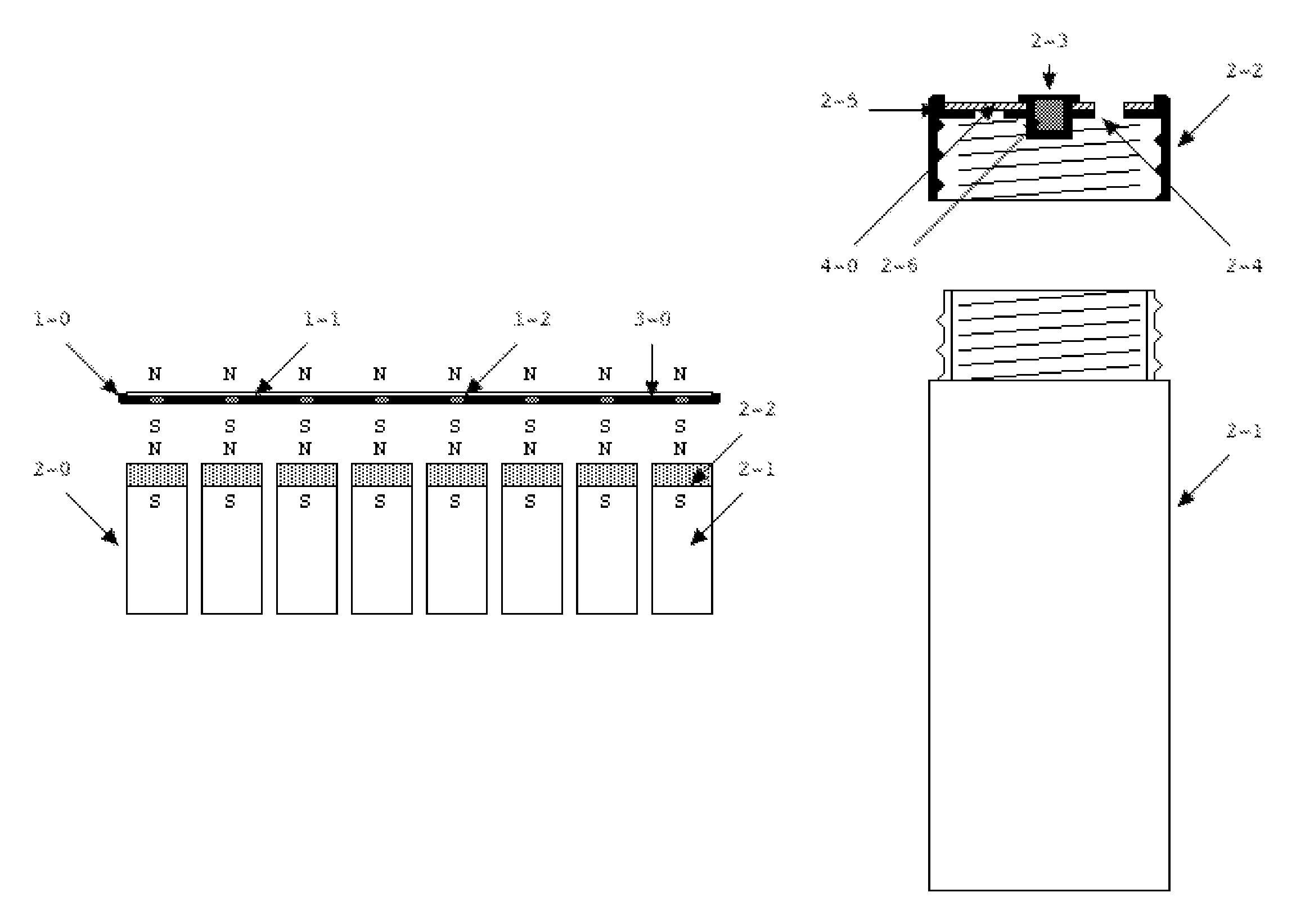

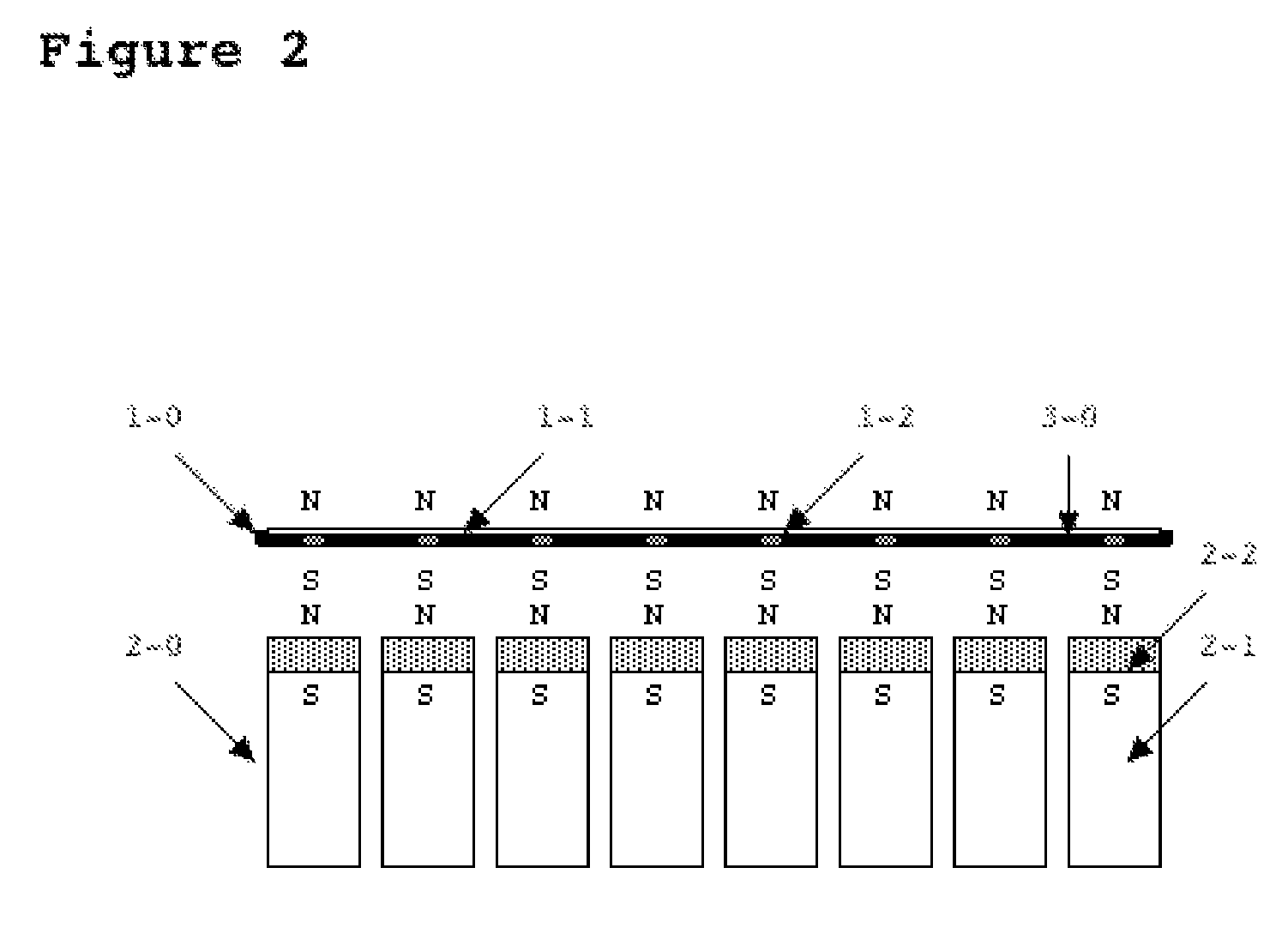

Mobile device holder

A two-piece mobile device holder having a case assembly and a mounting assembly is disclosed. The case assembly is configured to receive and secure a mobile device such as a smart phone. The mounting assembly is configured to be detachably coupled to other objects. Sets of permanent magnets are arranged in a circular pattern in the case assembly and the mounting assembly. The magnets in both the first and second set of magnets are arranged with alternating magnetic polarity. As the case assembly is placed on top of the mounting assembly, the magnets in the mounting assembly will attract magnets with opposite polarities in the case assembly. A user may detach the case assembly from the mounting assembly by rotating the case assembly such that the magnets in the case assembly are now adjacent to magnets in the mounting assembly of the same polarity.

Owner:AIRO COLLECTIVE INC

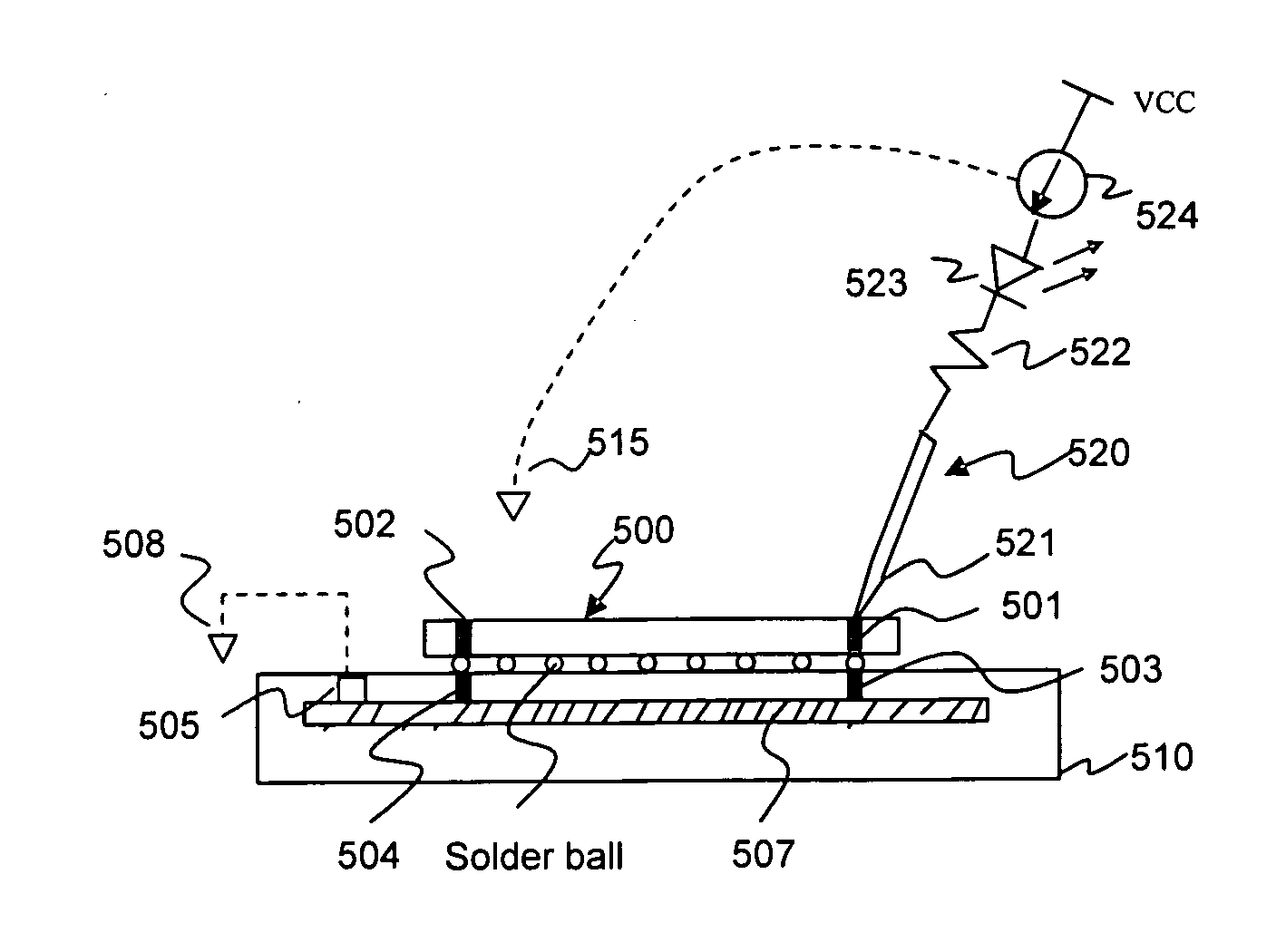

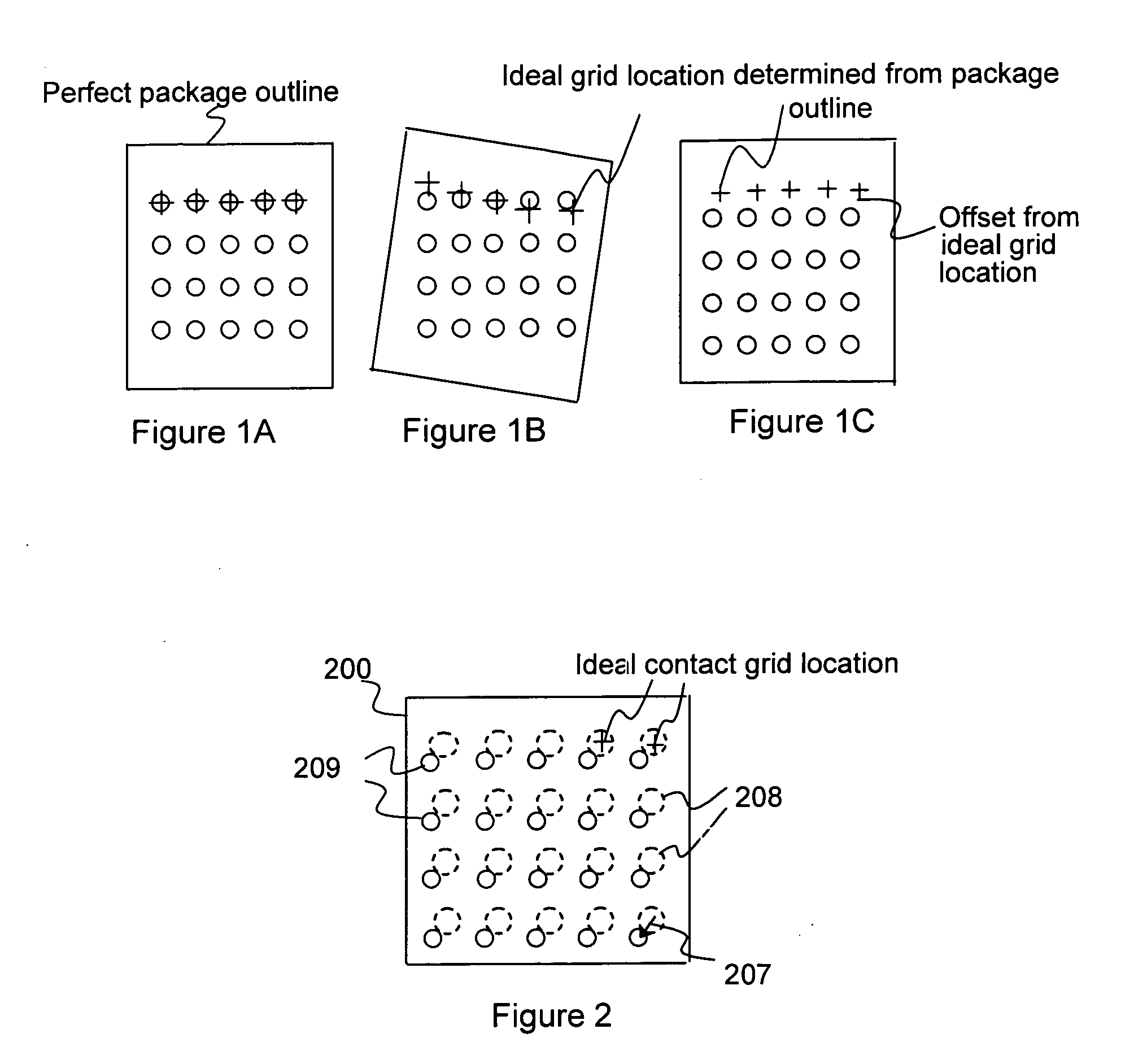

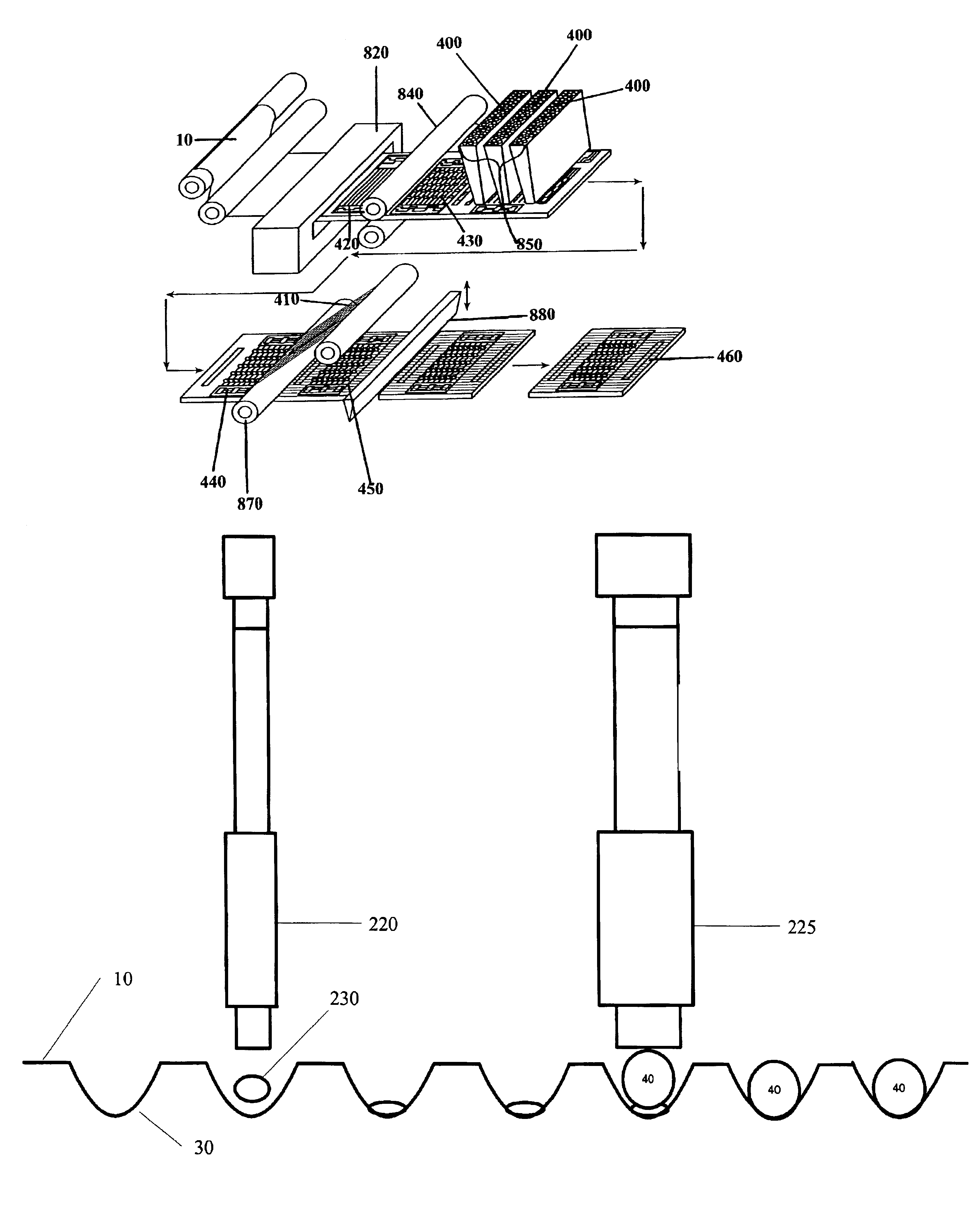

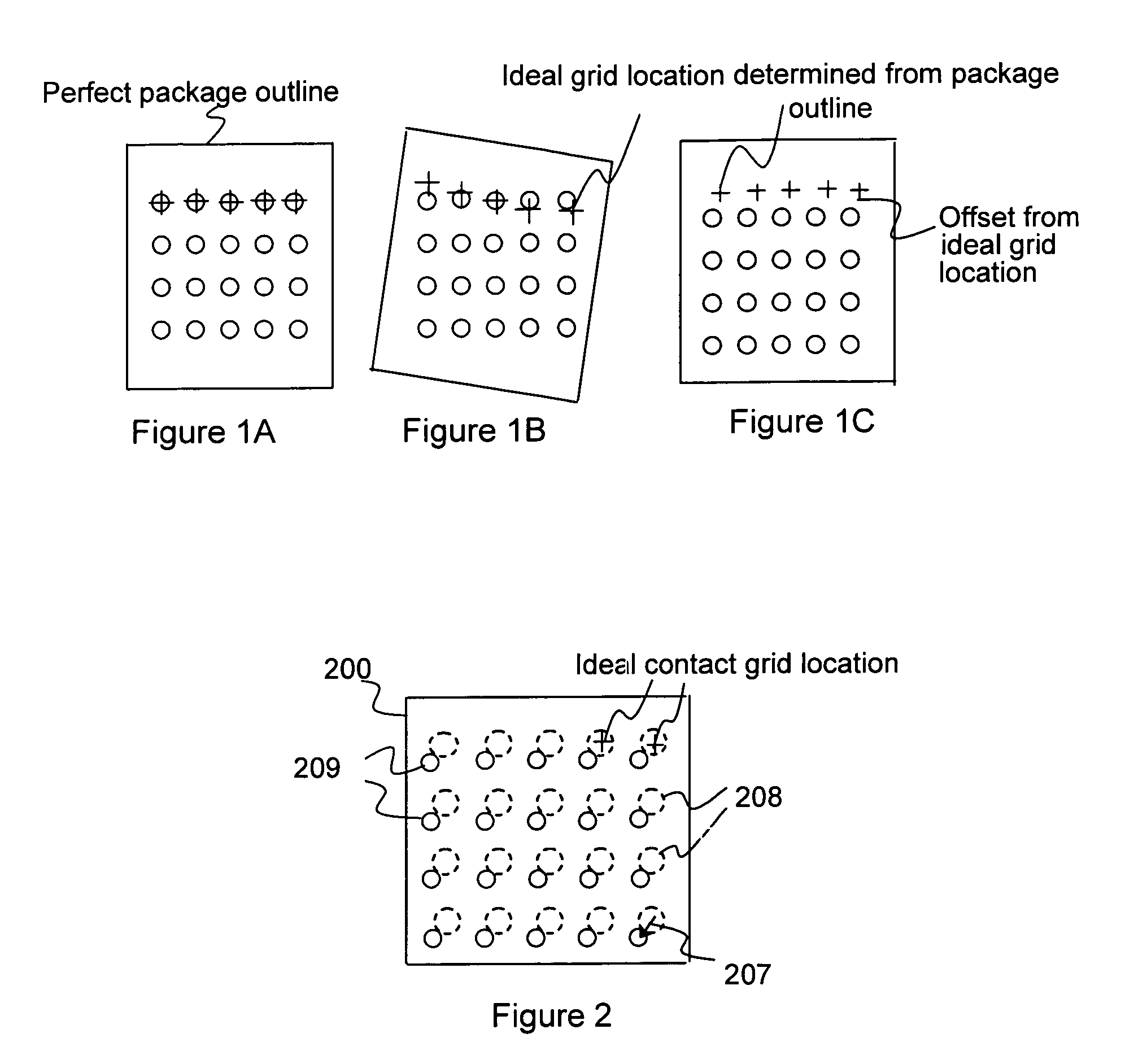

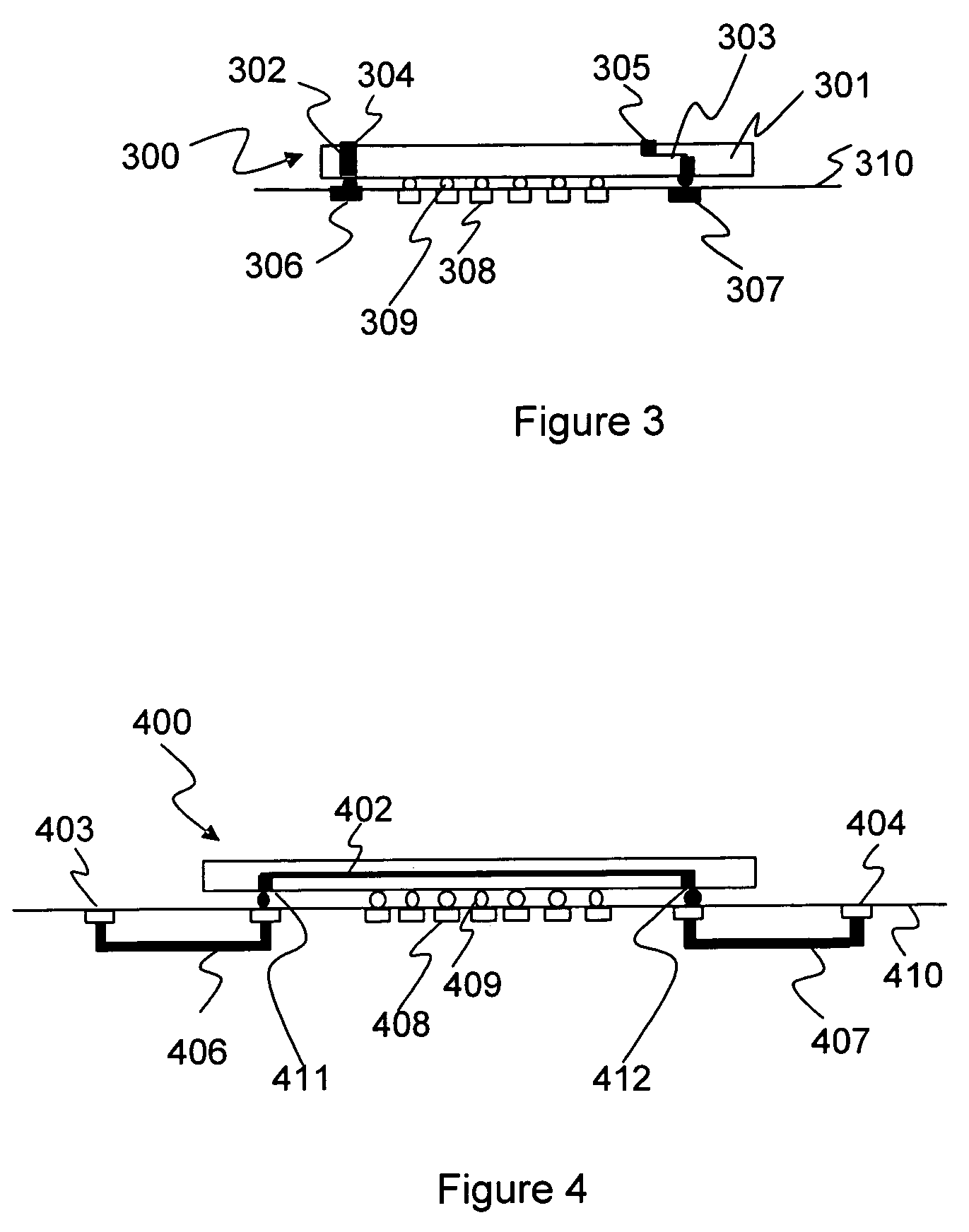

Apparatus and method for predetermined component placement to a target platform

ActiveUS20060202359A1Large toleranceHigh component yieldSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsMultiple sensorEngineering

The present invention relates generally to assembly techniques. According to the present invention, the alignment and probing techniques to improve the accuracy of component placement in assembly are described. More particularly, the invention includes methods and structures to detect and improve the component placement accuracy on a target platform by incorporating alignment marks on component and reference marks on target platform under various probing techniques. A set of sensors grouped in any array to form a multiple-sensor probe can detect the deviation of displaced components in assembly.

Owner:WINTEC IND INC

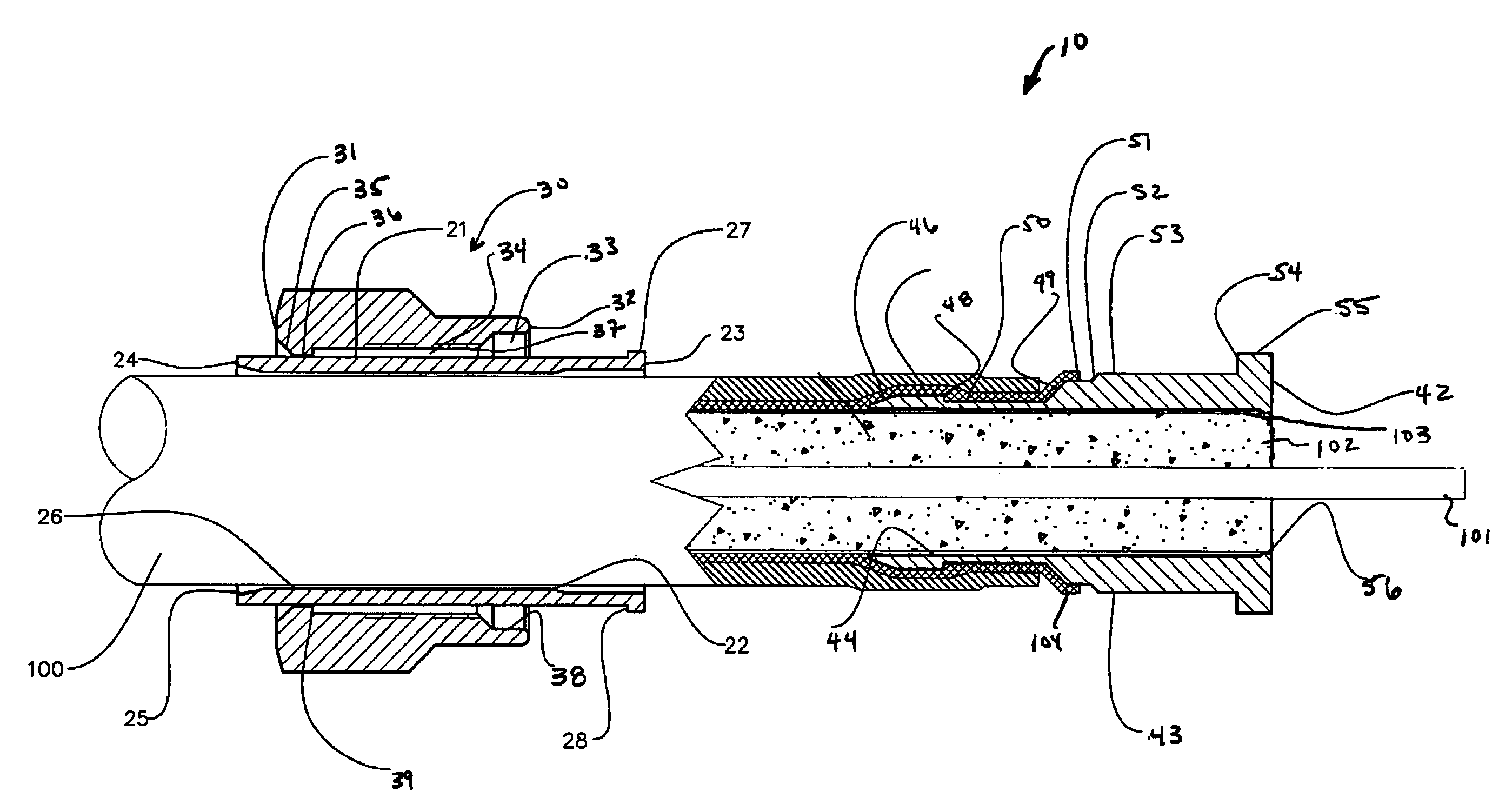

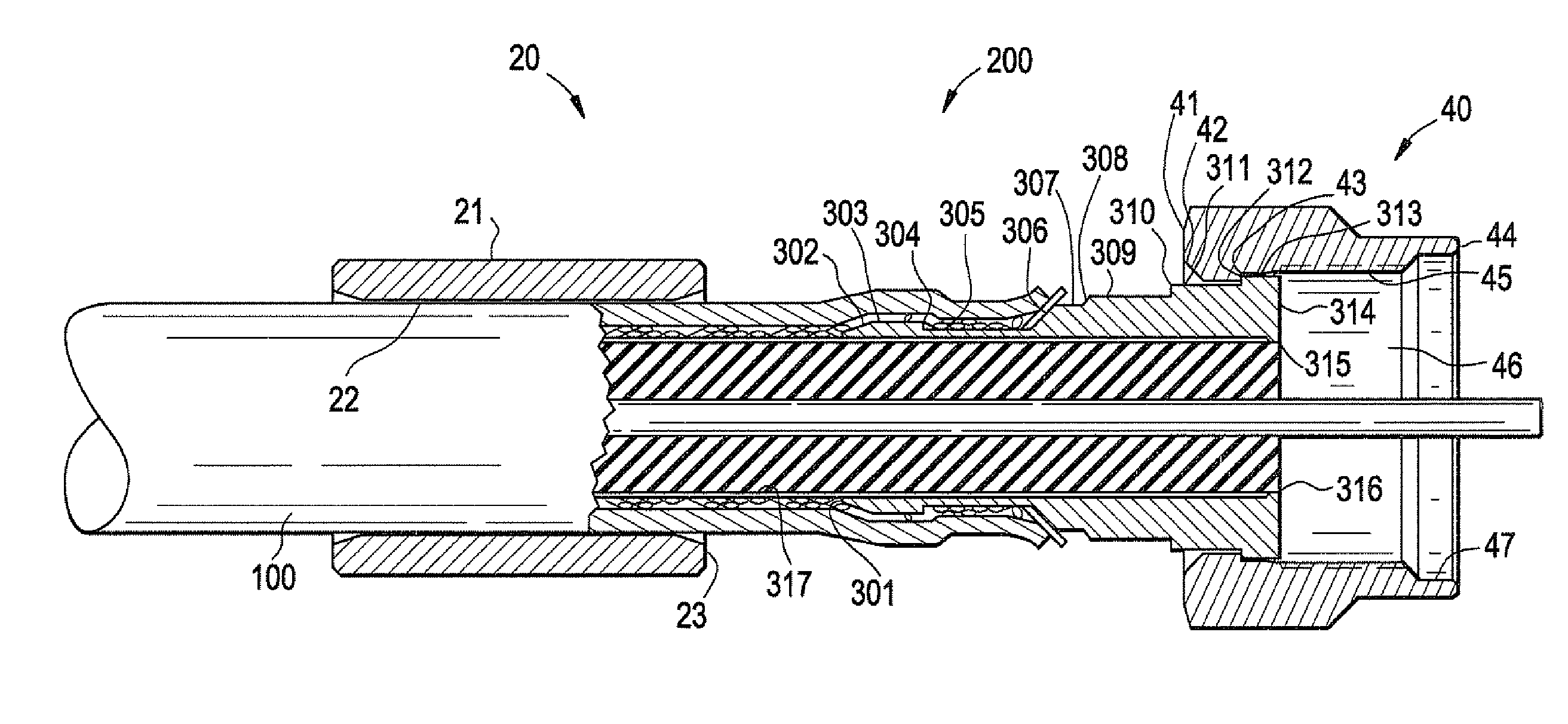

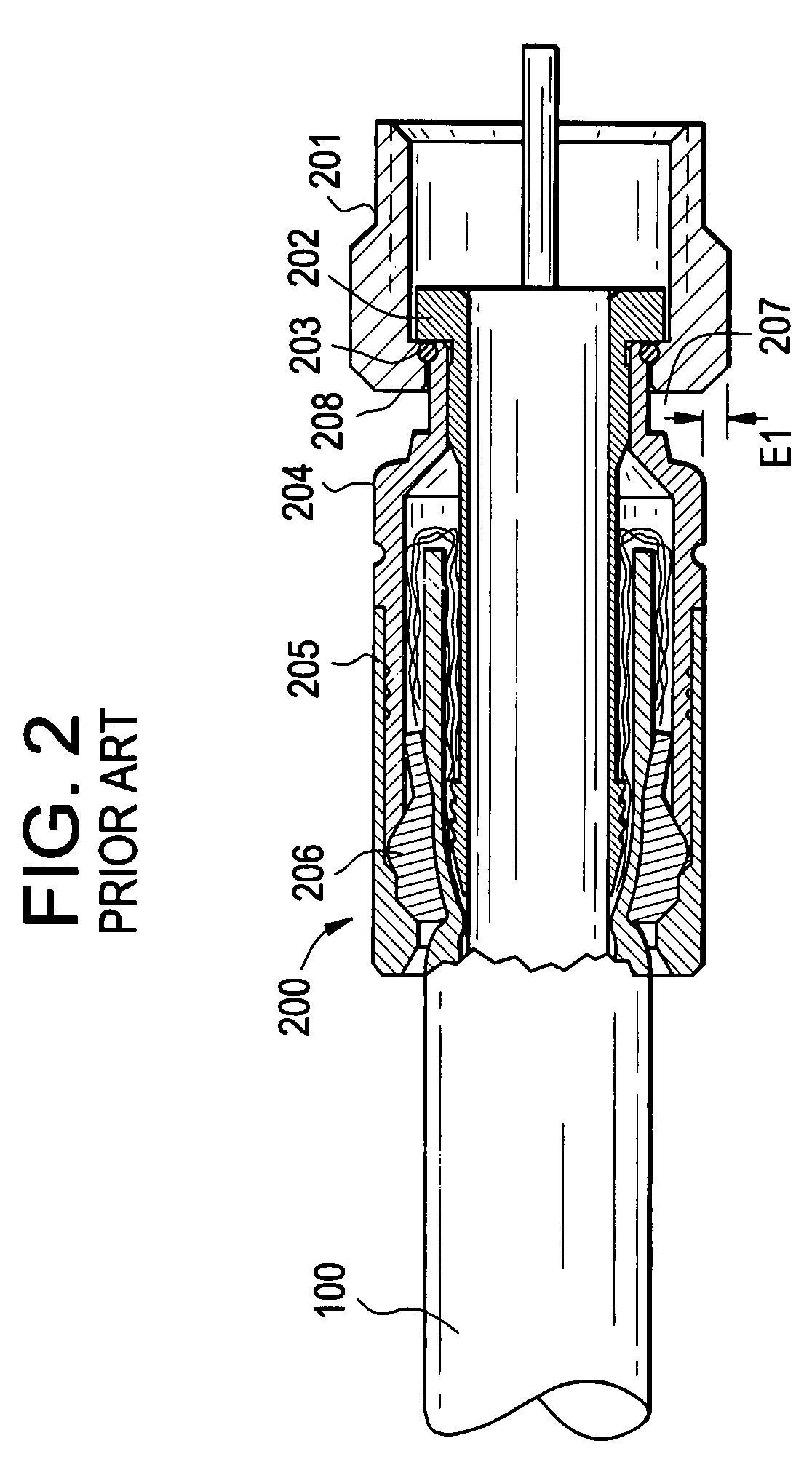

Coaxial connector and coaxial cable connector assembly and related method

ActiveUS7371112B2CostSufficient retentionElectrically conductive connectionsCoupling device detailsCoaxial cablePatch cable

A method of making a coaxial cable assembly is disclosed, the assembly comprising a coaxial cable and a connector, or connector termination, on at least one end of the cable. A connector, comprised of connector components, is also disclosed. The method comprises placing connector components into contact with the cable before the connector components are assembled into a connector. The connector is assembled simultaneously with securing the connector to the cable to make a coaxial cable assembly. A method of preparing coaxial cable in a manner suitable for making coaxial cable assemblies is also disclosed. The coaxial cable assembly can be a jumper, or a lead.

Owner:PPC BROADBAND INC

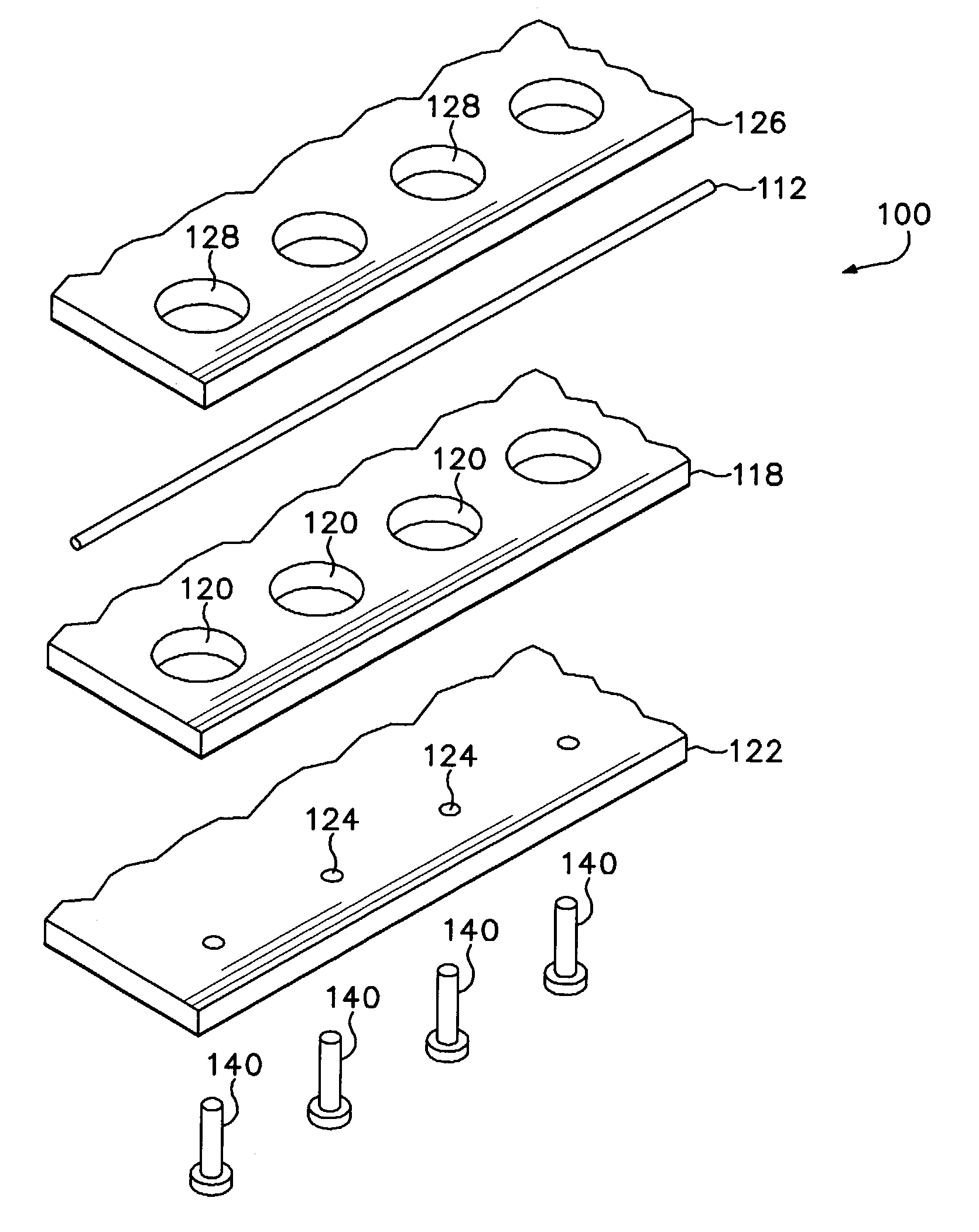

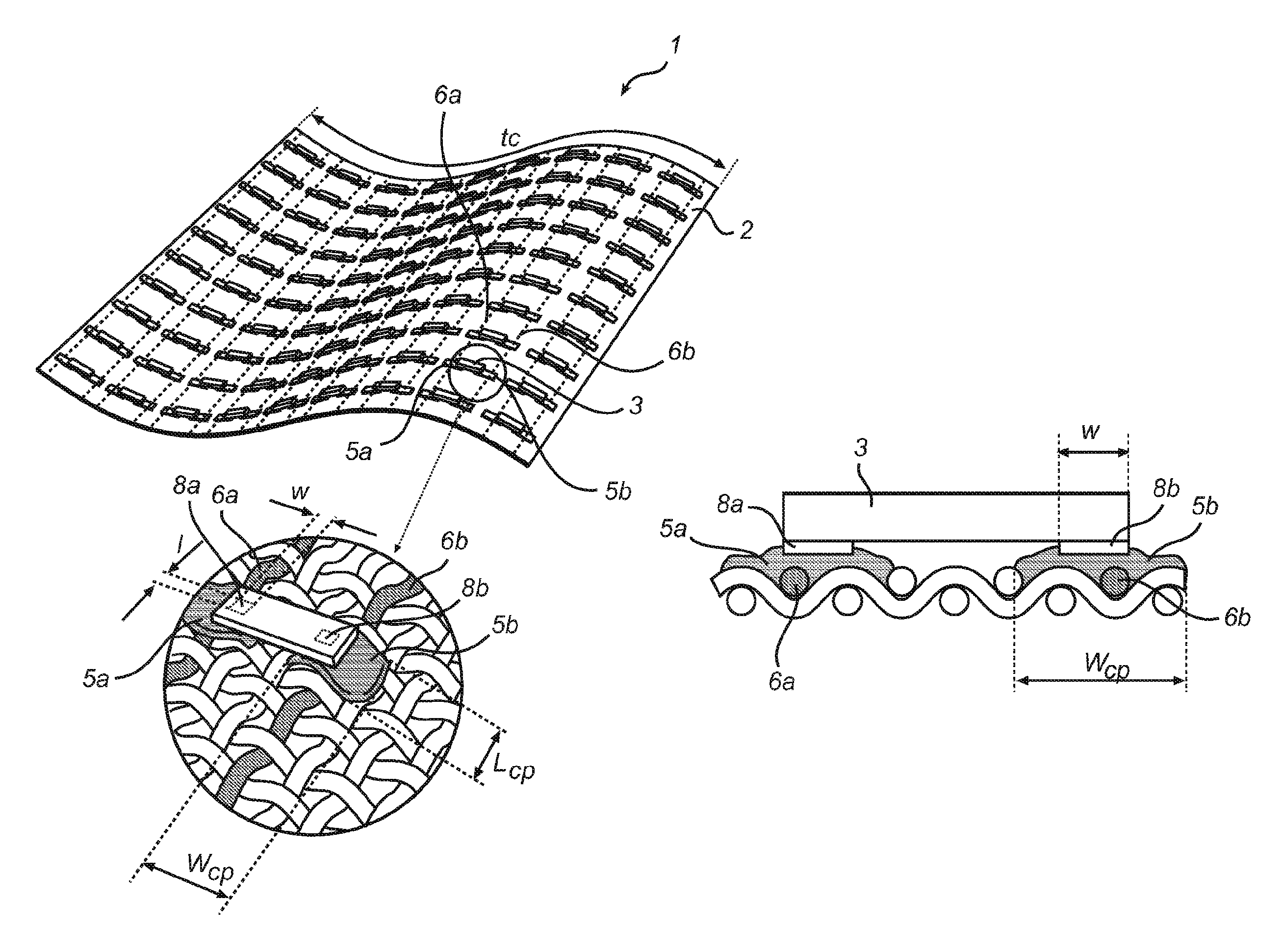

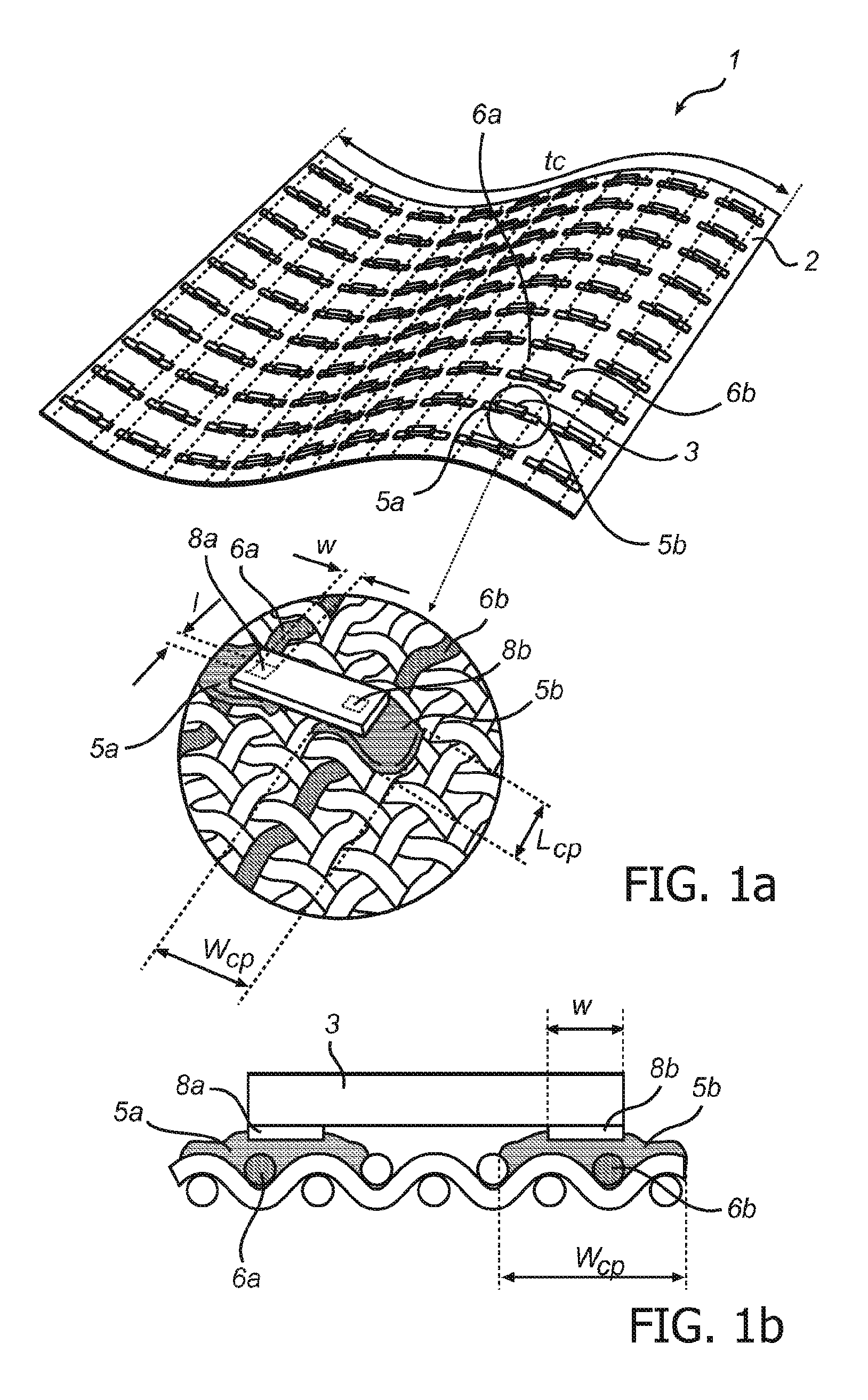

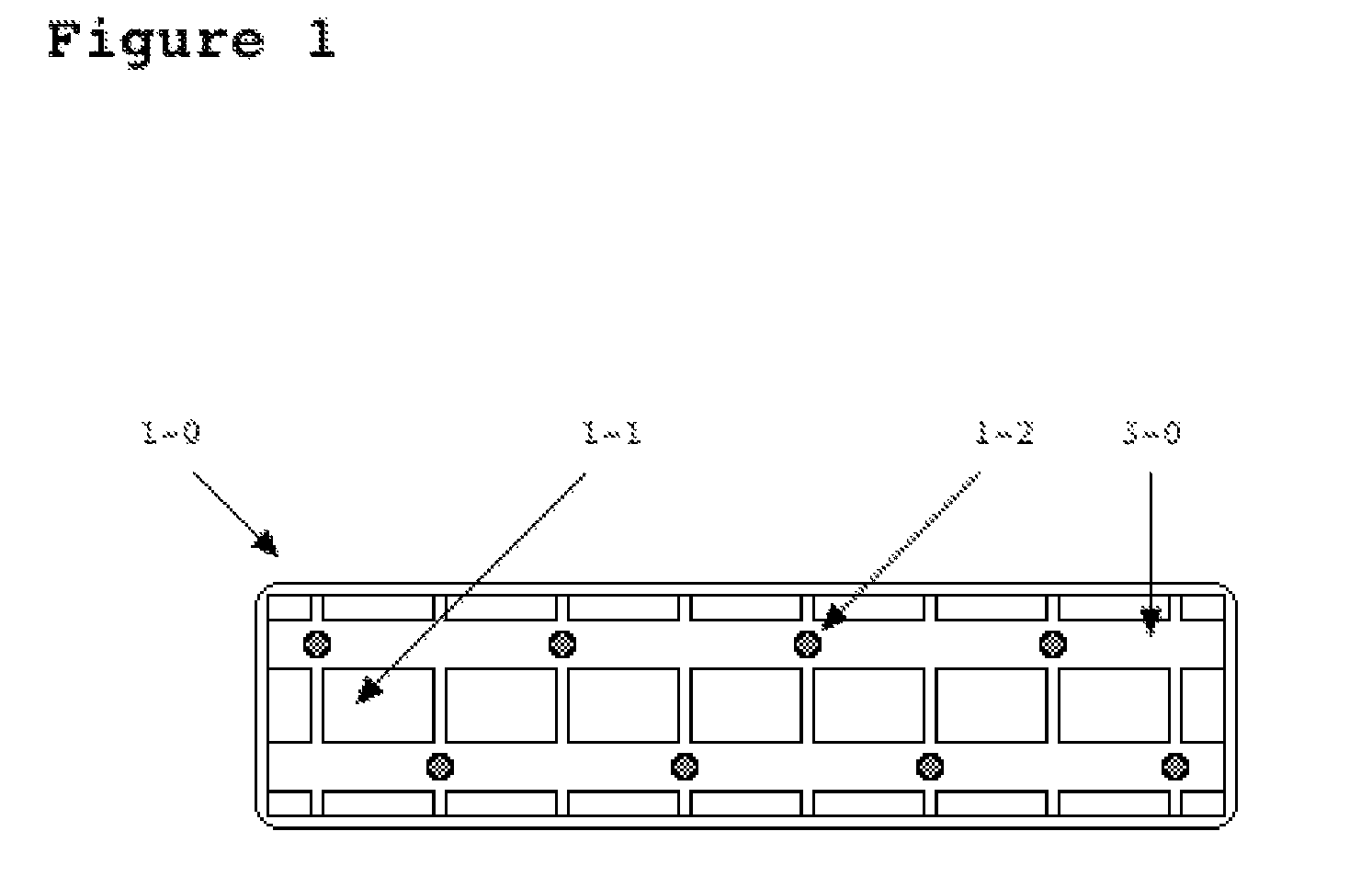

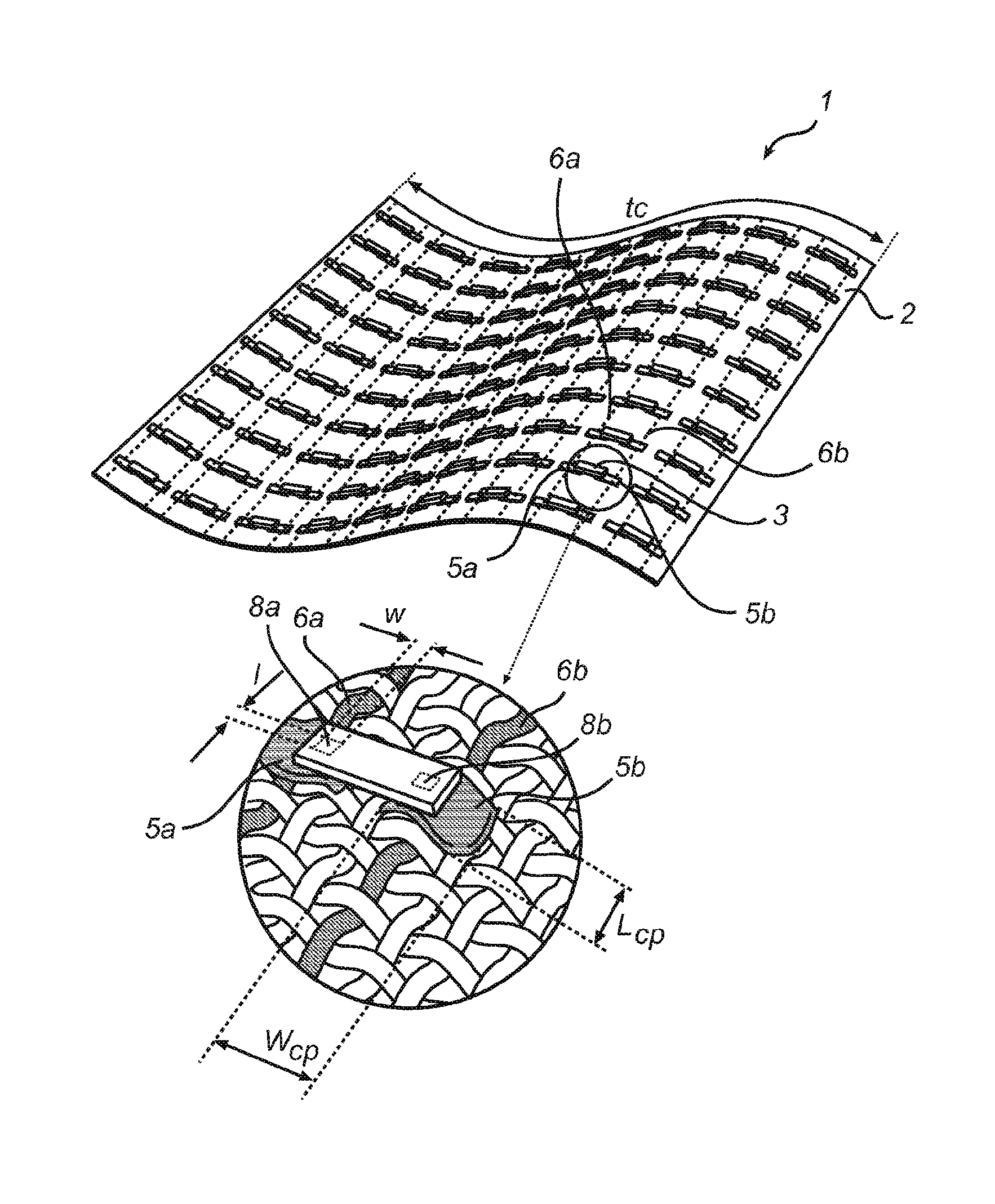

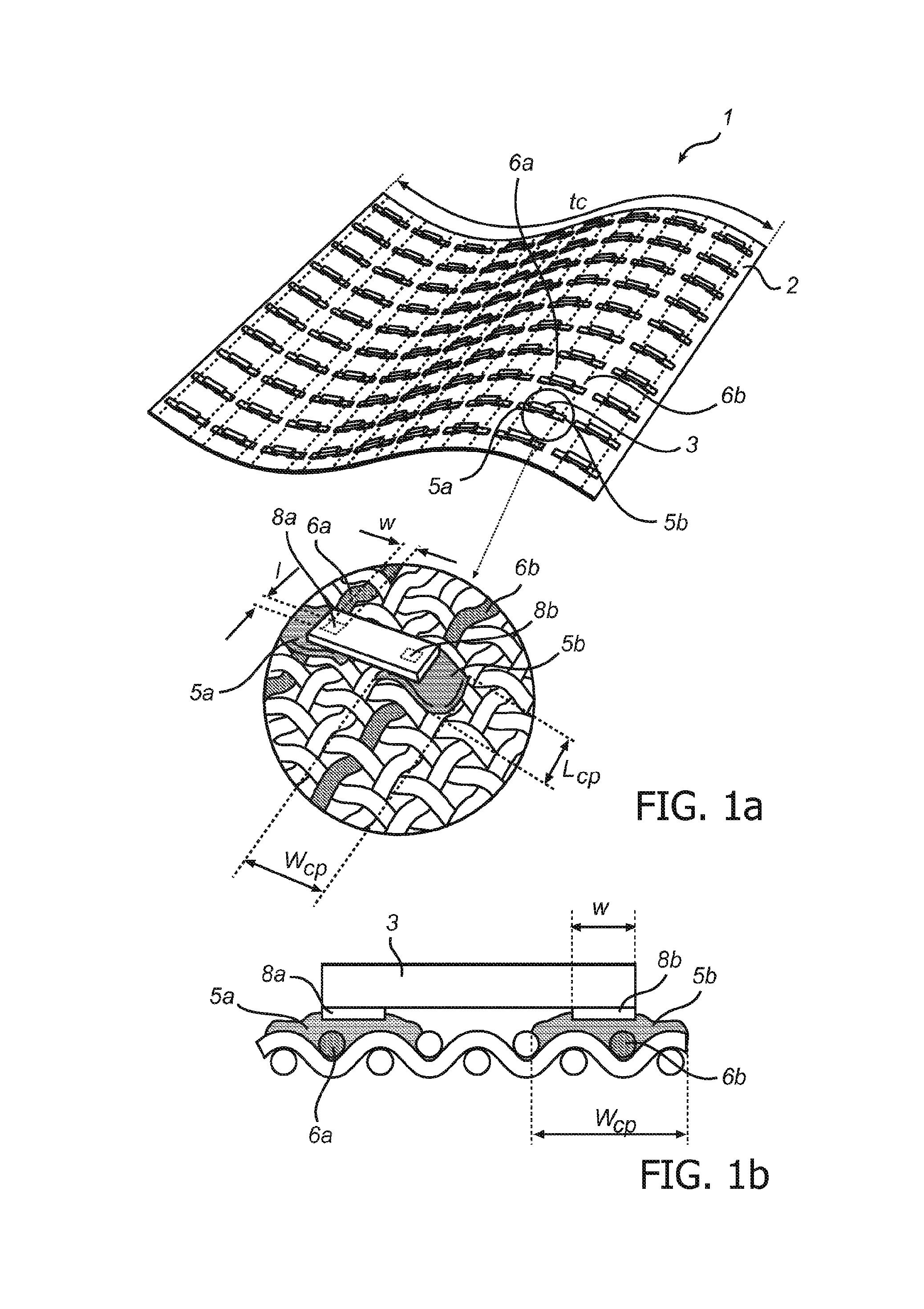

Electronic textile and method of manufacturing an electronic textile

InactiveUS9148949B2Cost-efficient productionIncrease productionPrinted circuit assemblingCircuit bendability/stretchabilityElectrical conductorEngineering

A method of manufacturing an electronic textile (1) comprising the steps of: providing a textile carrier (2) comprising a plurality of conductor lines (6a-b); releasably attaching (101) the textile carrier (2) to a rigid support plate (20); providing (102) a conductive substance on the textile carrier (2) in a pattern forming a plurality of sets of connection pads (5a-b) on the textile carrier (2), each set of connection pads defining a component placement position for placement of an electronic component (3), and each set of connection pads (5a-b) comprising a connection pad overlapping one of the conductor lines, the connection pad having a connection pad length (Lcp) in a direction parallel to the conductor line and a connection pad width (Wcp) in a direction perpendicular to the conductor line, wherein the connection pad width (Wcp) is at least one percent of an extension (Wtc) of the textile carrier (2) in the direction perpendicular to the conductor line; automatically placing (103) electronic components (3) at the component placement positions; curing (104) the conductive substance to attach the electronic components (3) to the textile carrier (2), thereby forming the electronic textile (1) and removing (105) the electronic textile from the rigid support plate.

Owner:SIGNIFY HLDG BV +1

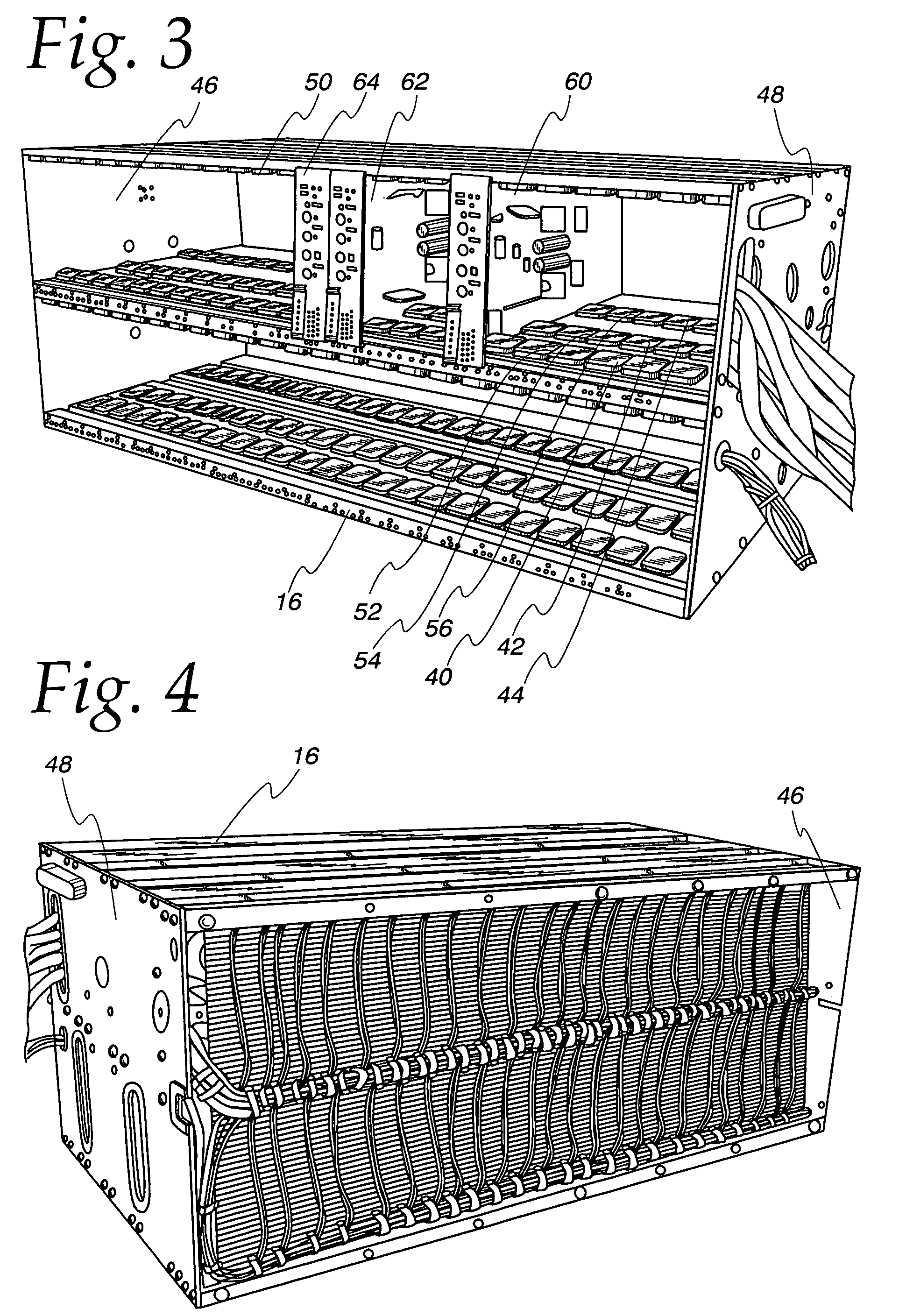

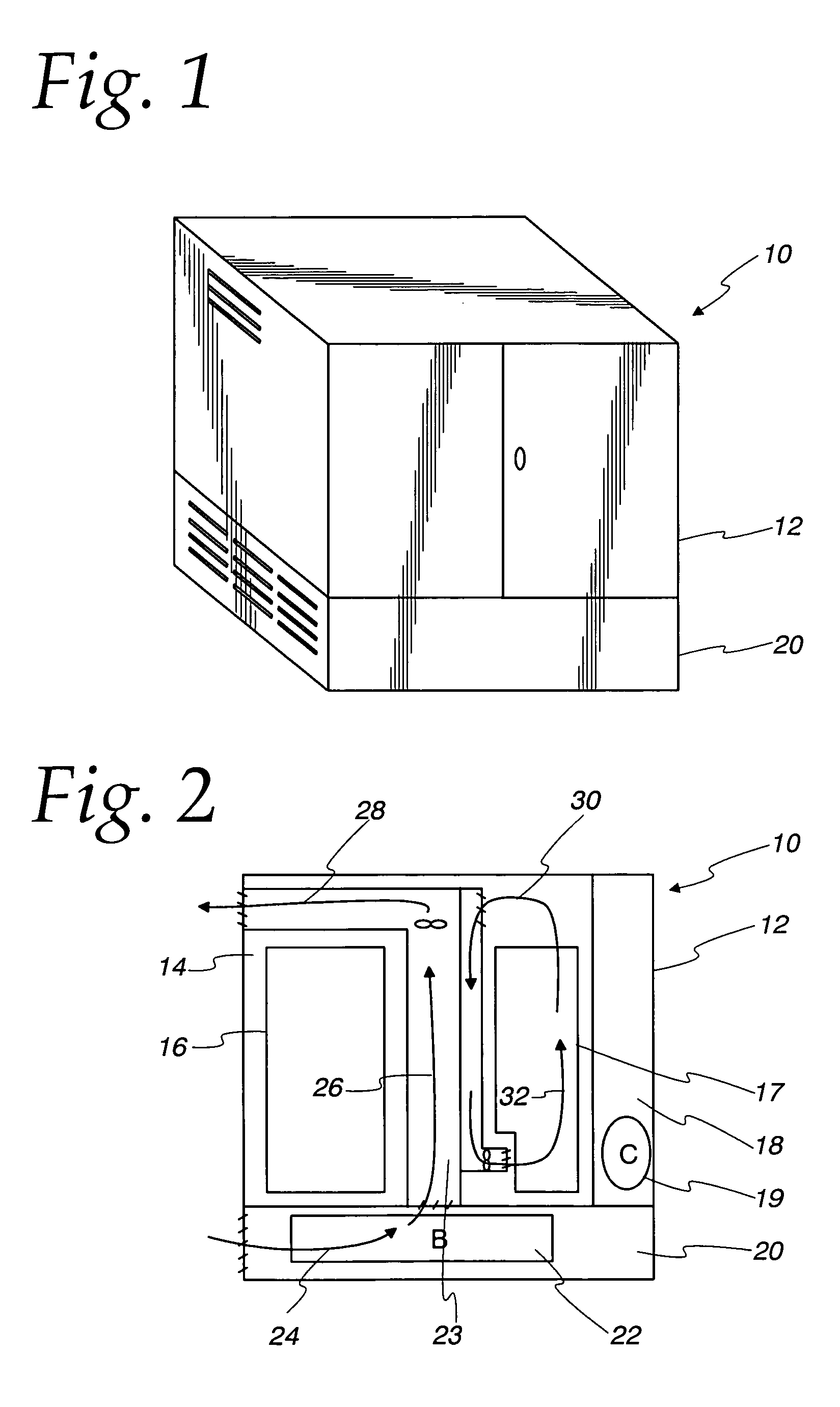

Cooling system for densely packed electronic components

InactiveUS7258161B2Increase component densityImprove cooling efficiencyMechanical apparatusSemiconductor/solid-state device detailsComputer moduleVolumetric Mass Density

A more efficient cooling system for densely packed electronic components for use in an out-of-doors equipment enclosure. An array of cooling assemblies are placed on heat generating components mounted to printed circuit boards mounted in enclosure racks. Each board has a manifold for intake and exhaust of refrigerant, and larger rack manifolds are substituted for rails and are attached to a backplane. A hybrid package including a ceramic hybrid power module and an attached array of cooling assemblies provide even more density of components and improved cooling.

Owner:EMERSON NETWORK POWER ENERGY SYST NORTH AMERICA

Use of printing and other technology for micro-component placement

InactiveUS6796867B2Sufficient resolutionManufactured very thinTelevision system detailsMechanical apparatusEngineeringImproved method

An improved light-emitting panel having a plurality of micro-components sandwiched between two substrates is disclosed. Each micro-component contains a gas or gas-mixture capable of ionization when a sufficiently large voltage is supplied across the micro-component via at least two electrodes. An improved method of manufacturing a light-emitting panel is also disclosed, which uses a web fabrication process to manufacturing light-emitting displays as part of a high-speed, continuous inline process.

Owner:LEIDOS

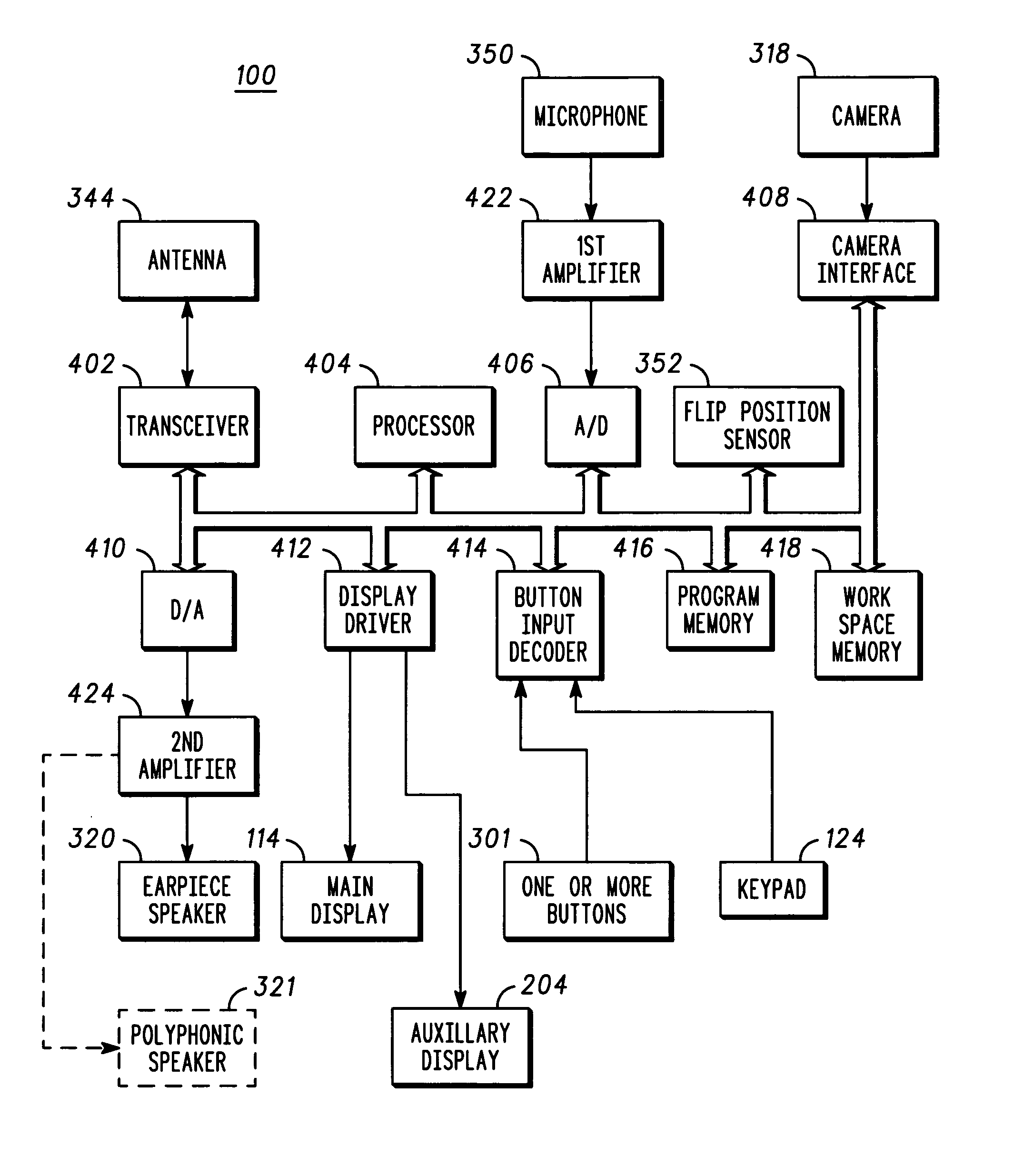

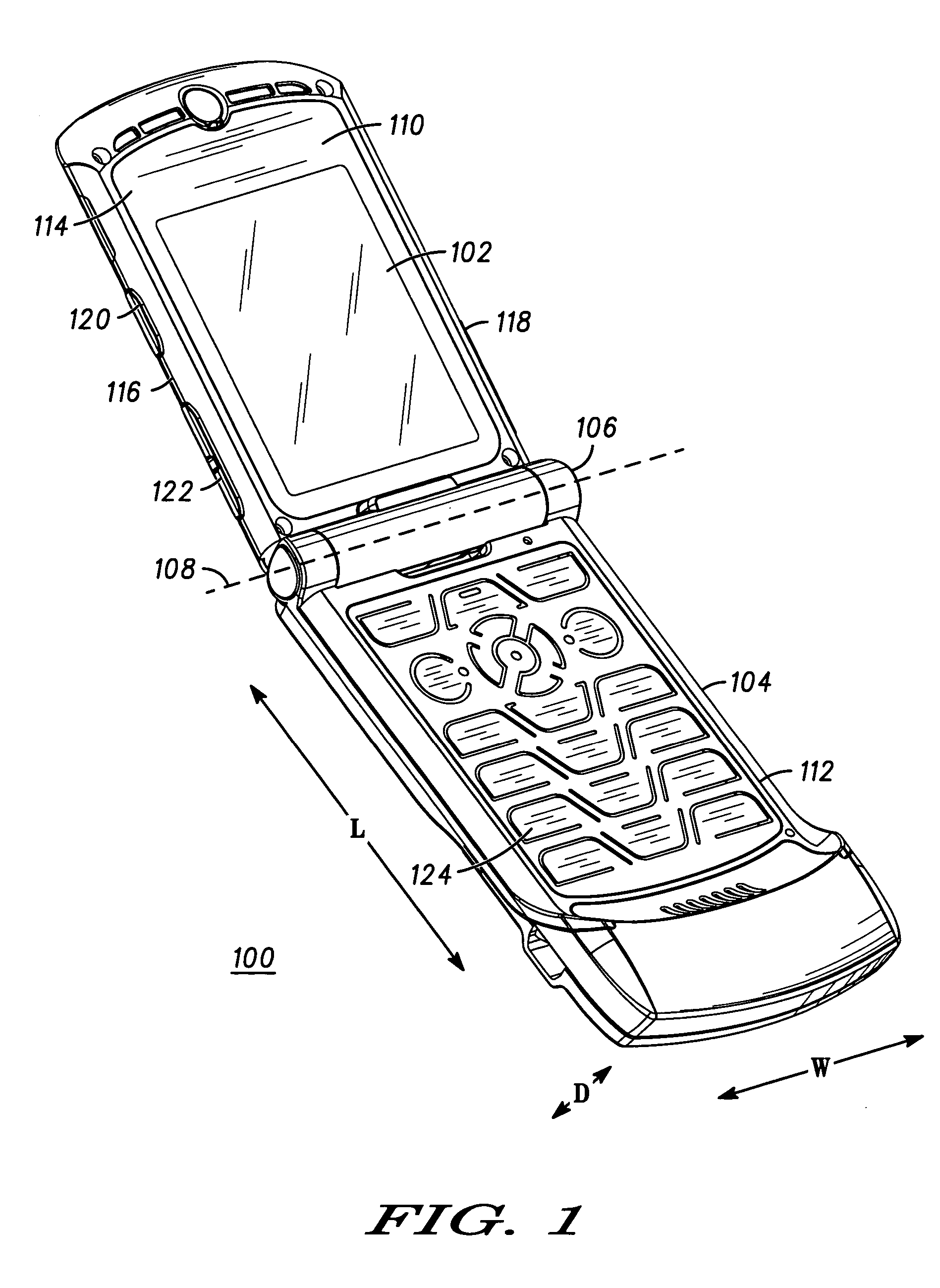

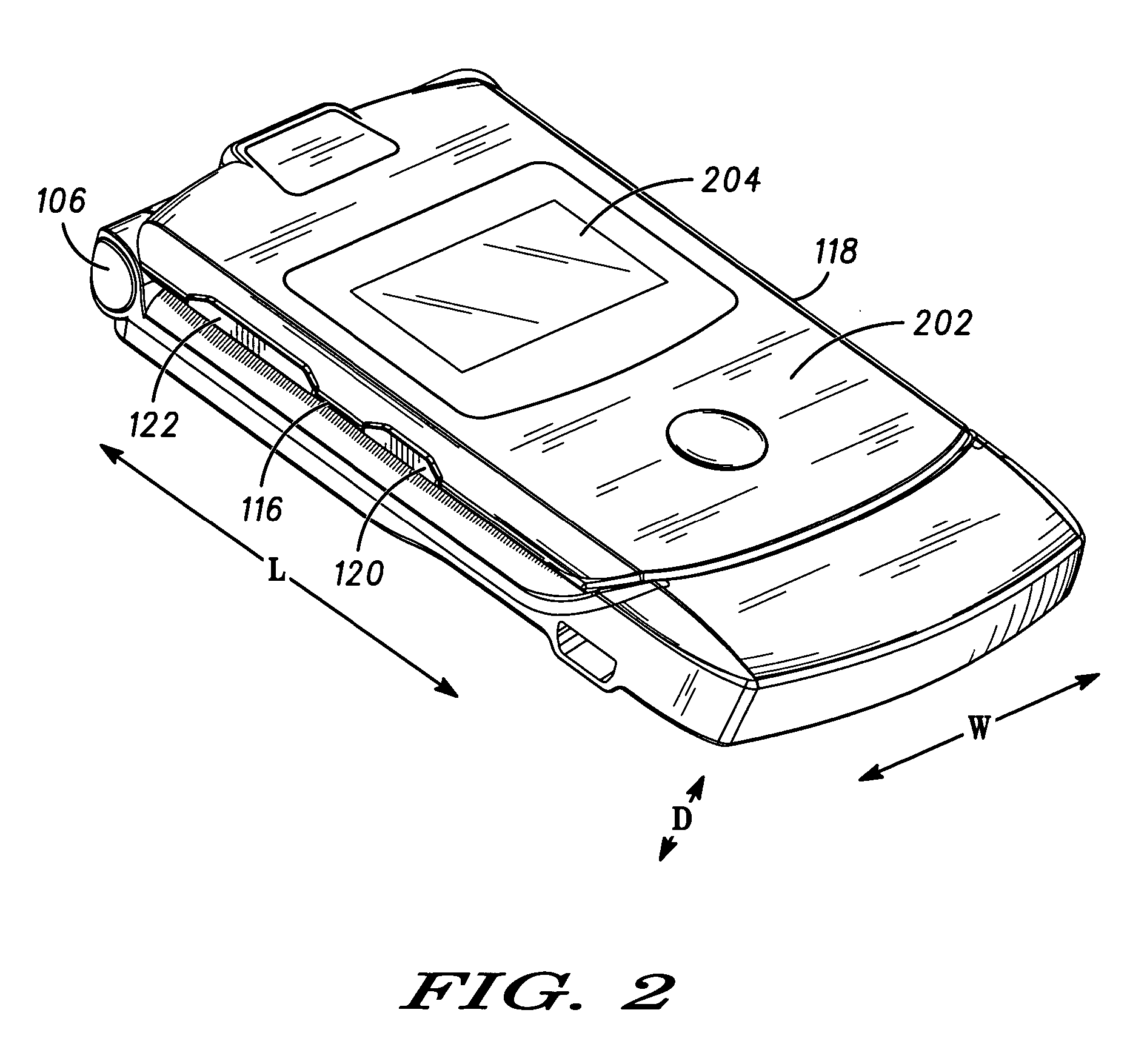

Mechanical layout and component placement for thin clamshell phone

Folding wireless communication devices incorporate a two-part housing, which includes a first part that is rotatably coupled to a second part. The overall depth of the device is reduced by adjusting the mechanical layout and component placement relative to one another, wherein previously stacked components have been reordered. More specifically, the hinge, the battery, and the communication and control circuitry have been organized so as to be in the same horizontal plane, and so as to not overlap in a vertical direction.

Owner:GOOGLE TECH HLDG LLC

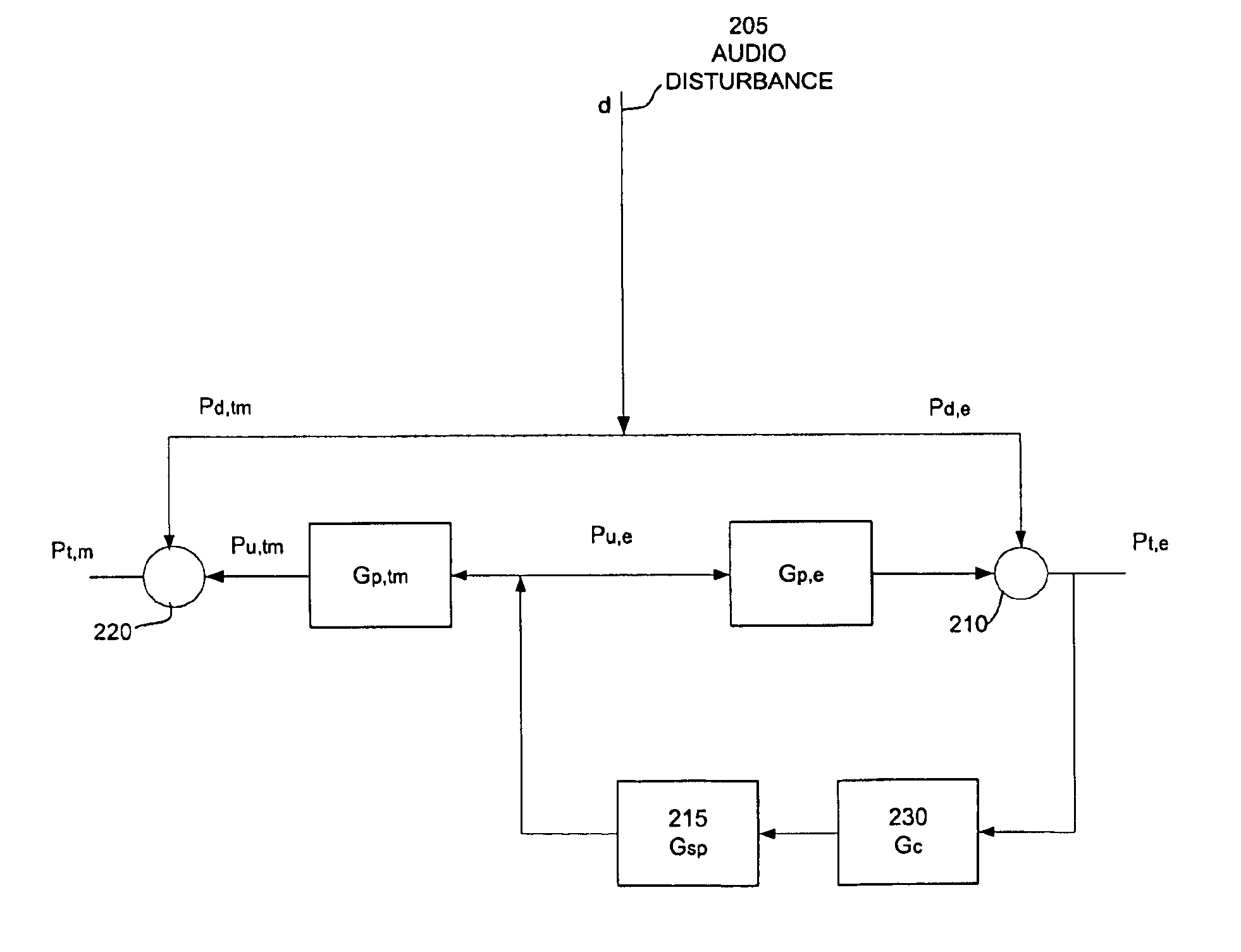

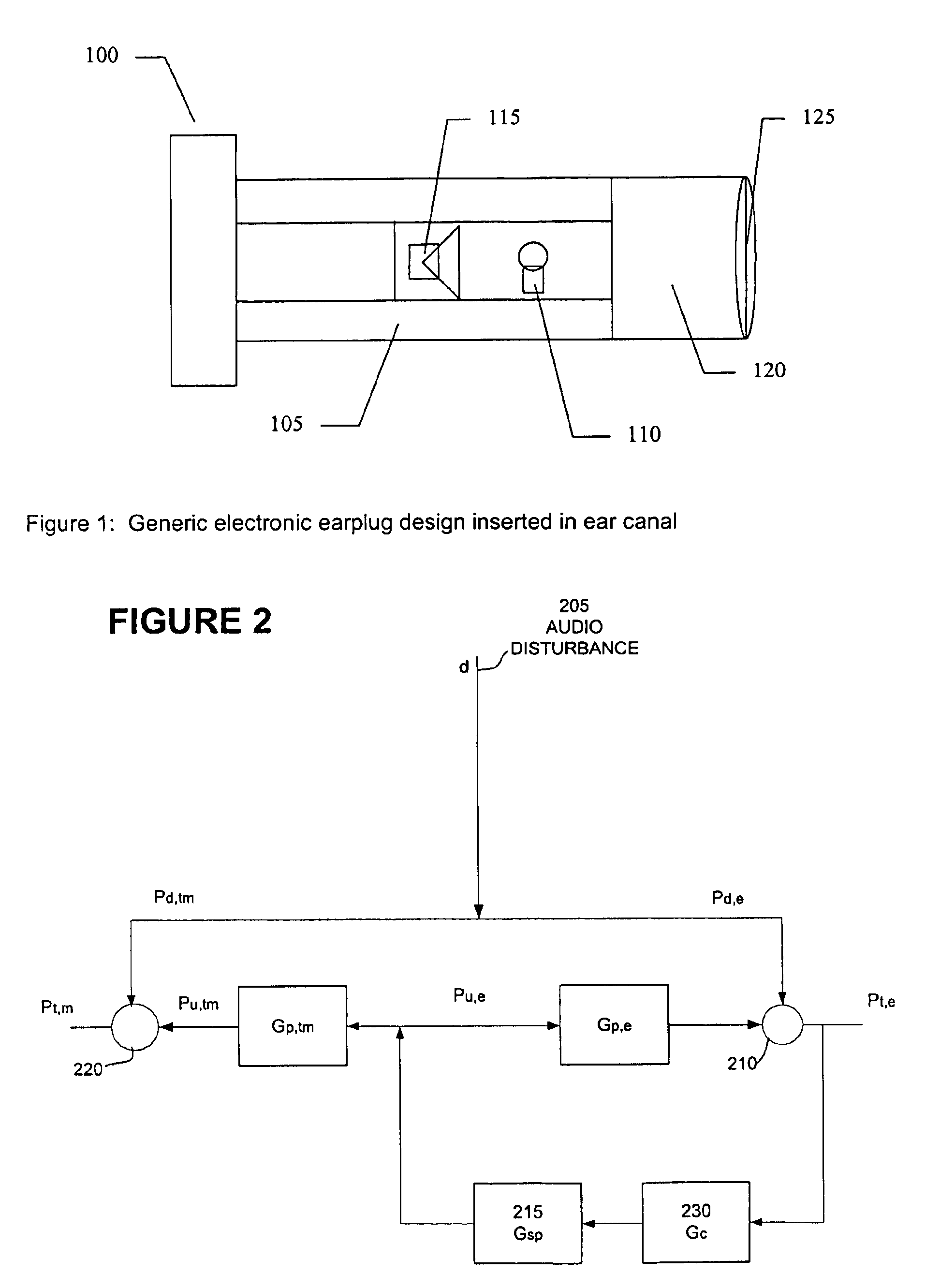

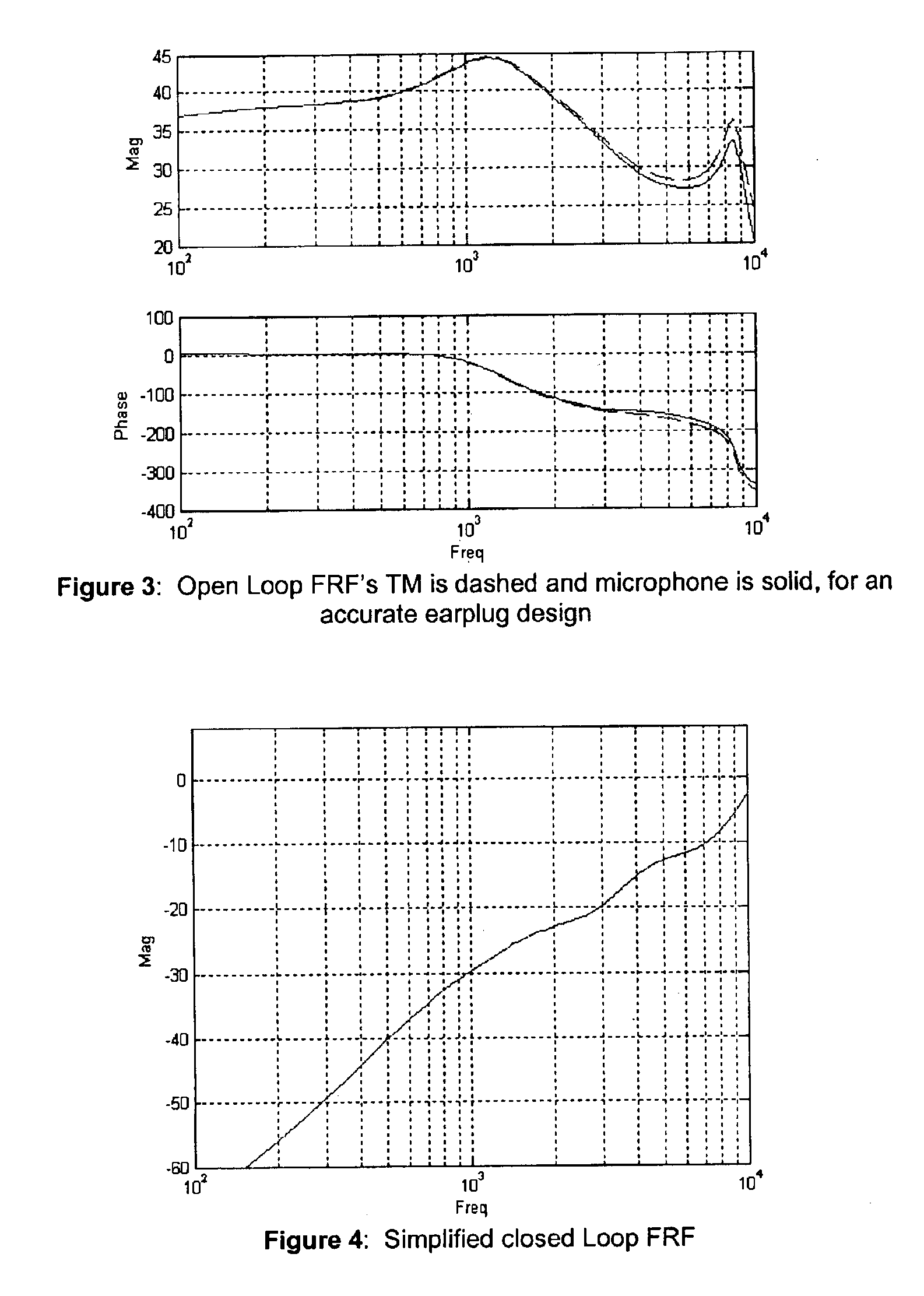

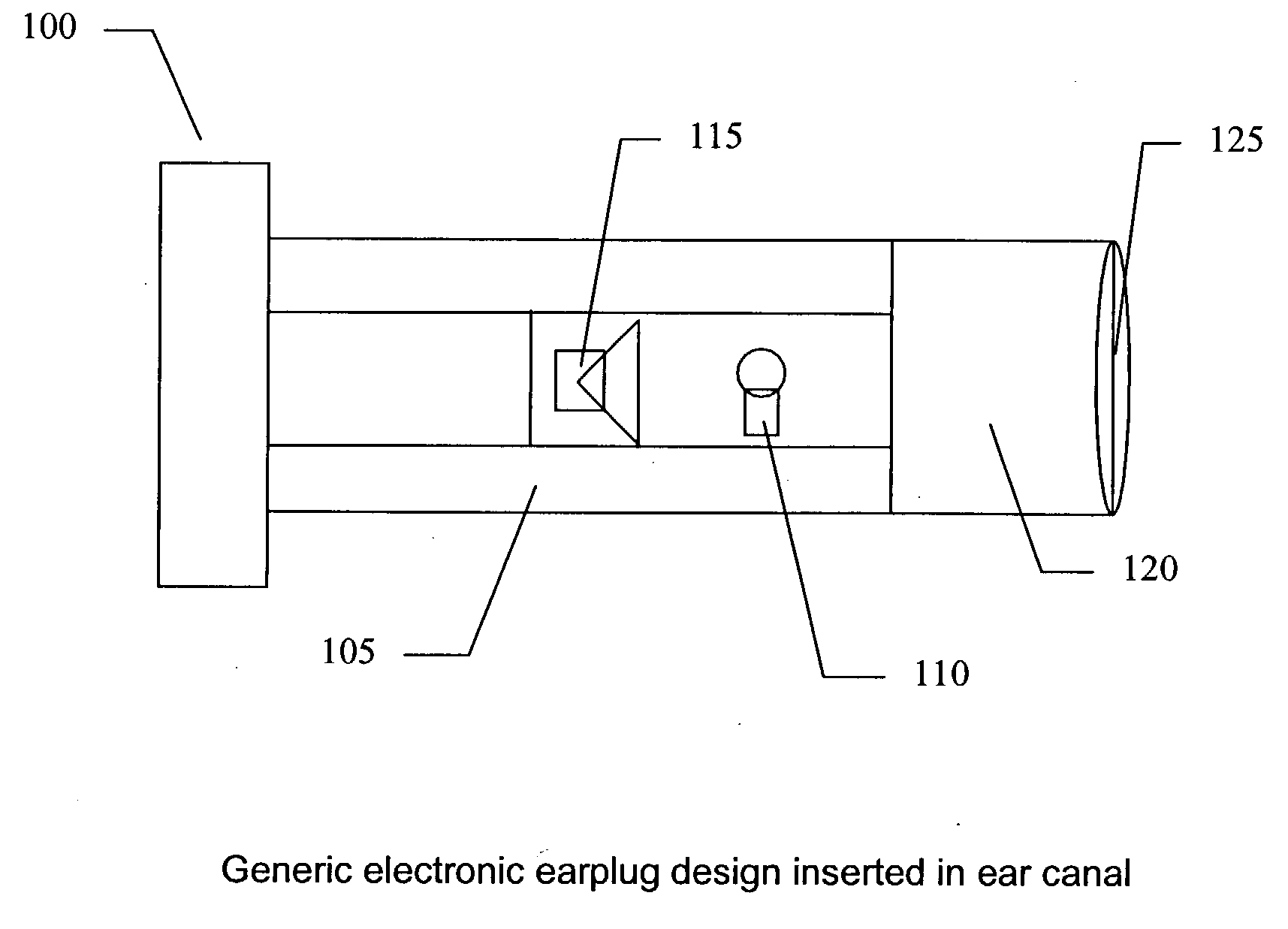

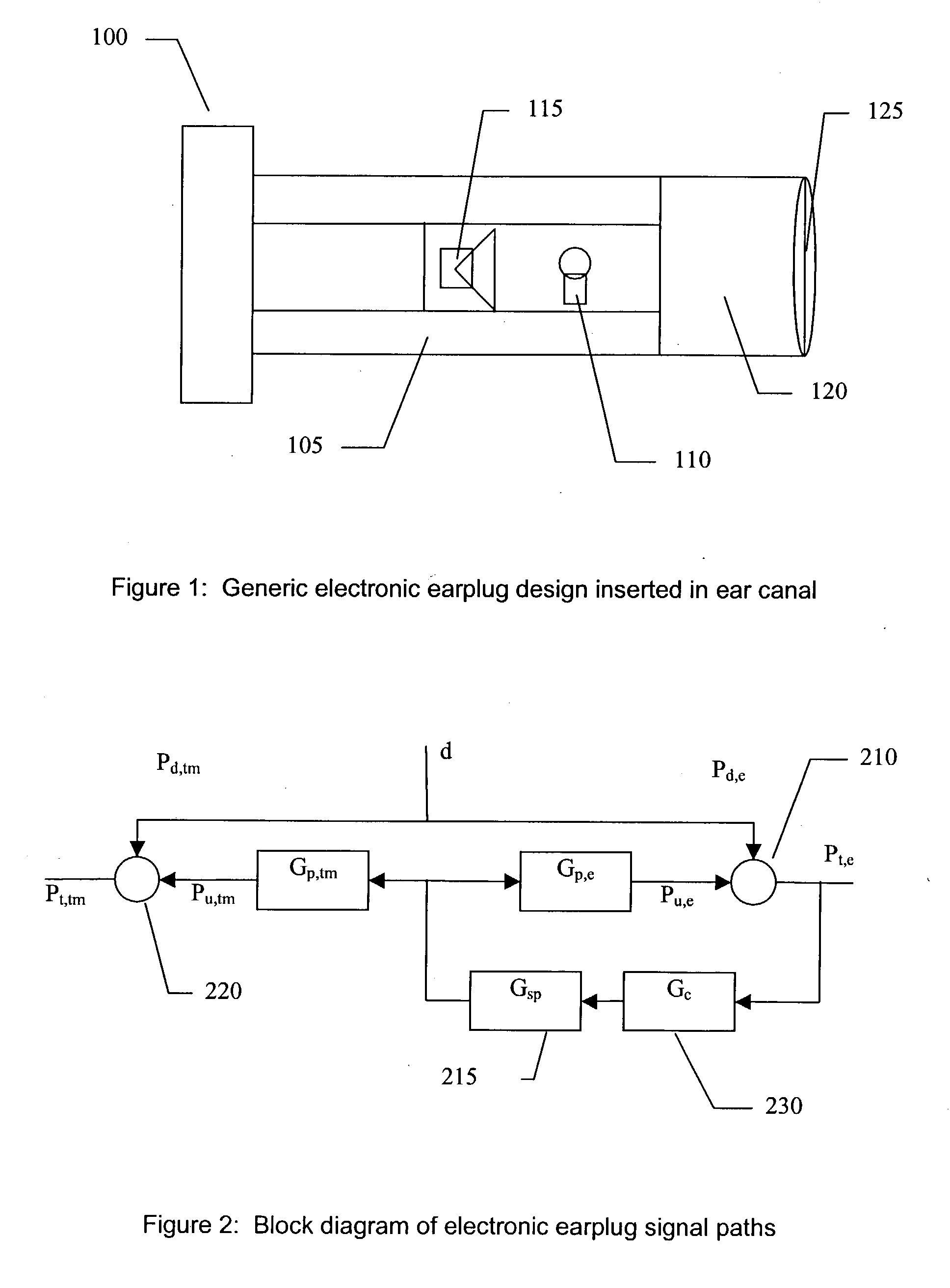

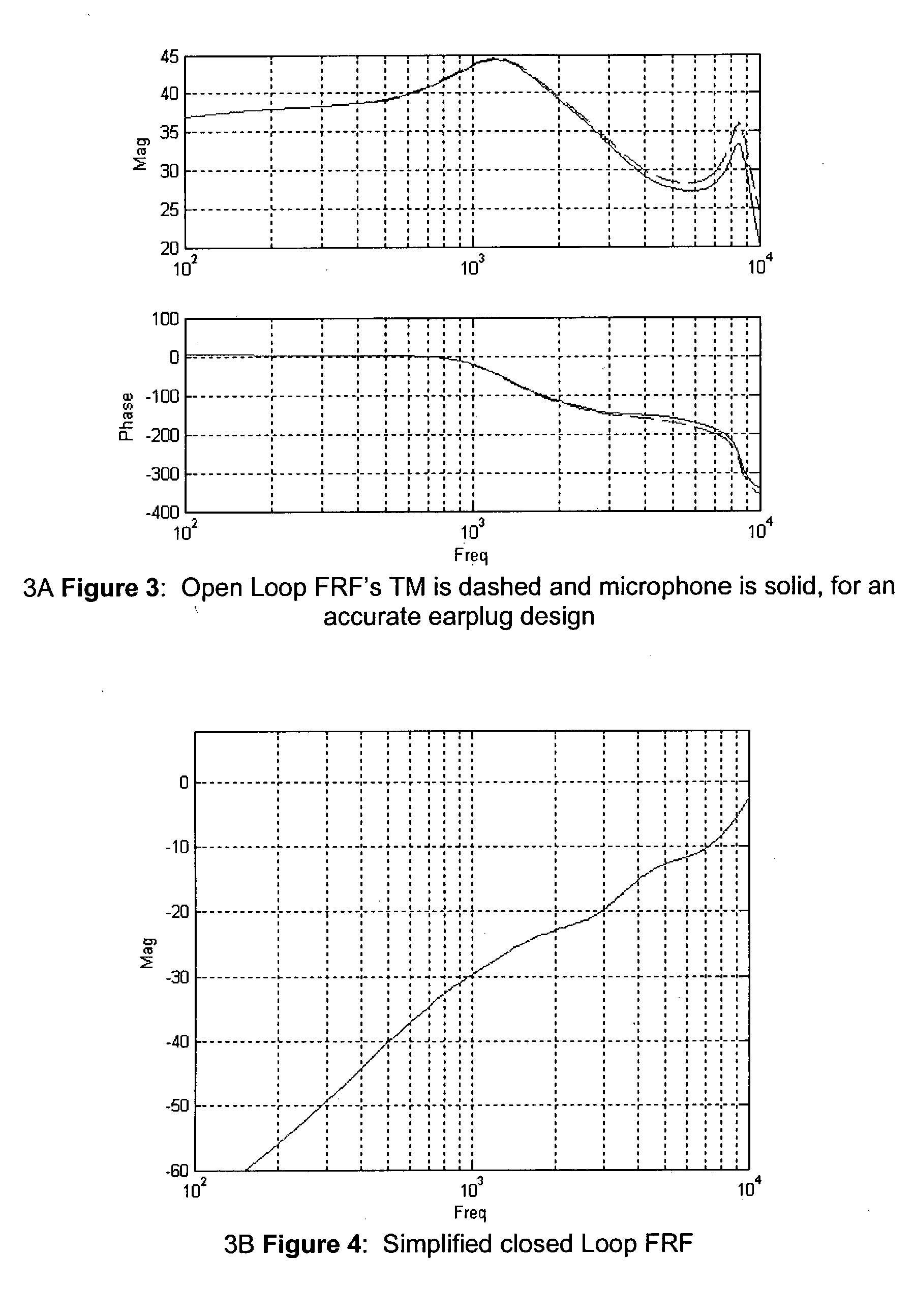

Electronic earplug for monitoring and reducing wideband noise at the tympanic membrane

ActiveUS7024010B2Accurate monitoringHigh degreeEarplugsNoise generationBroadband noiseEnvironmental noise

An electronic earplug for wideband control of pressures at, the tympanic membrane is presented. A unique methodology of determining effective component placement inside an earplug that provides acoustic isolation between the ambient noise and tympanic membrane is explained. Methods for providing accurate dosimetry and improved active control result from the unique earplug design process, leading to very wideband active noise reduction at the tympanic membrane.

Owner:GENTEX CORP

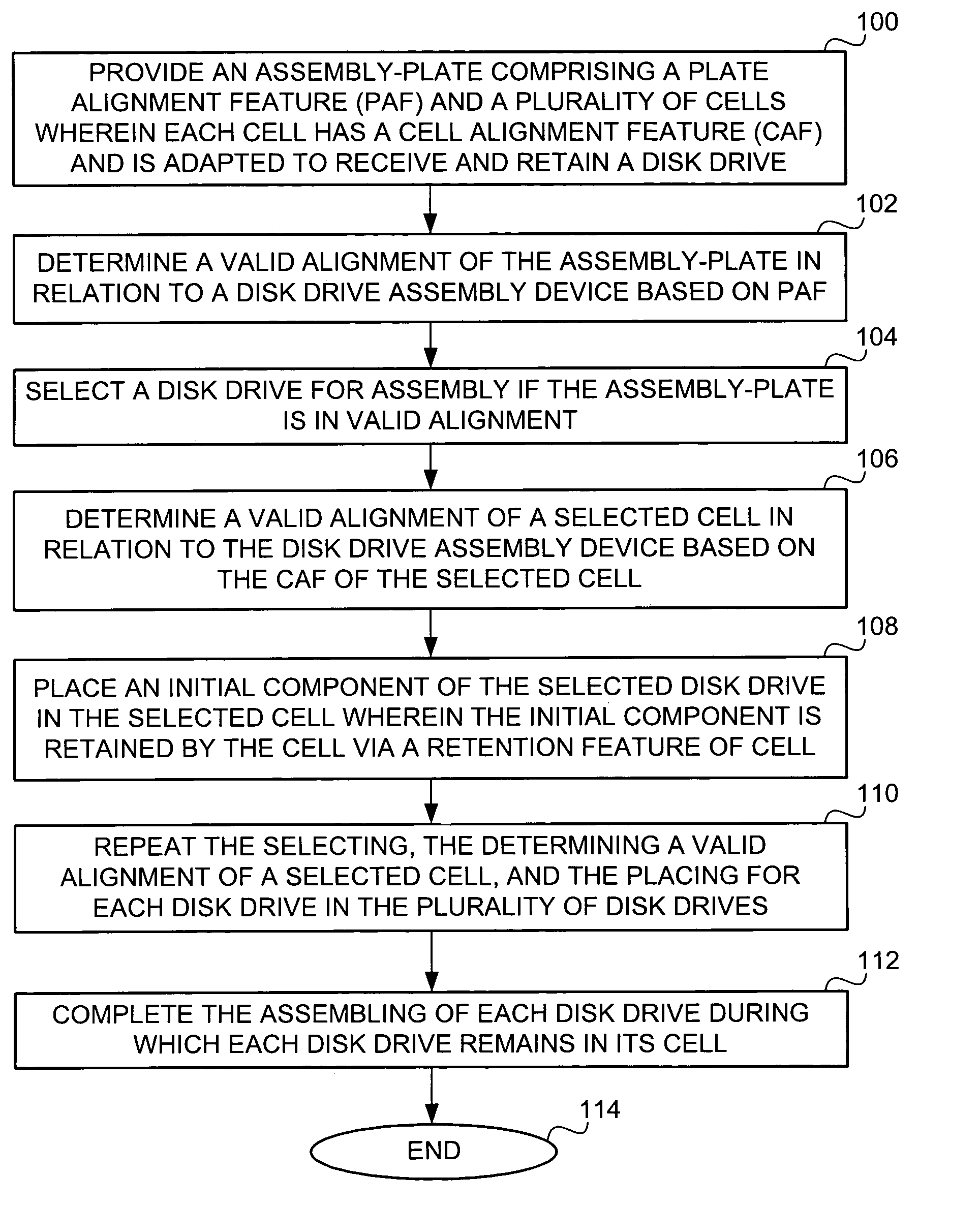

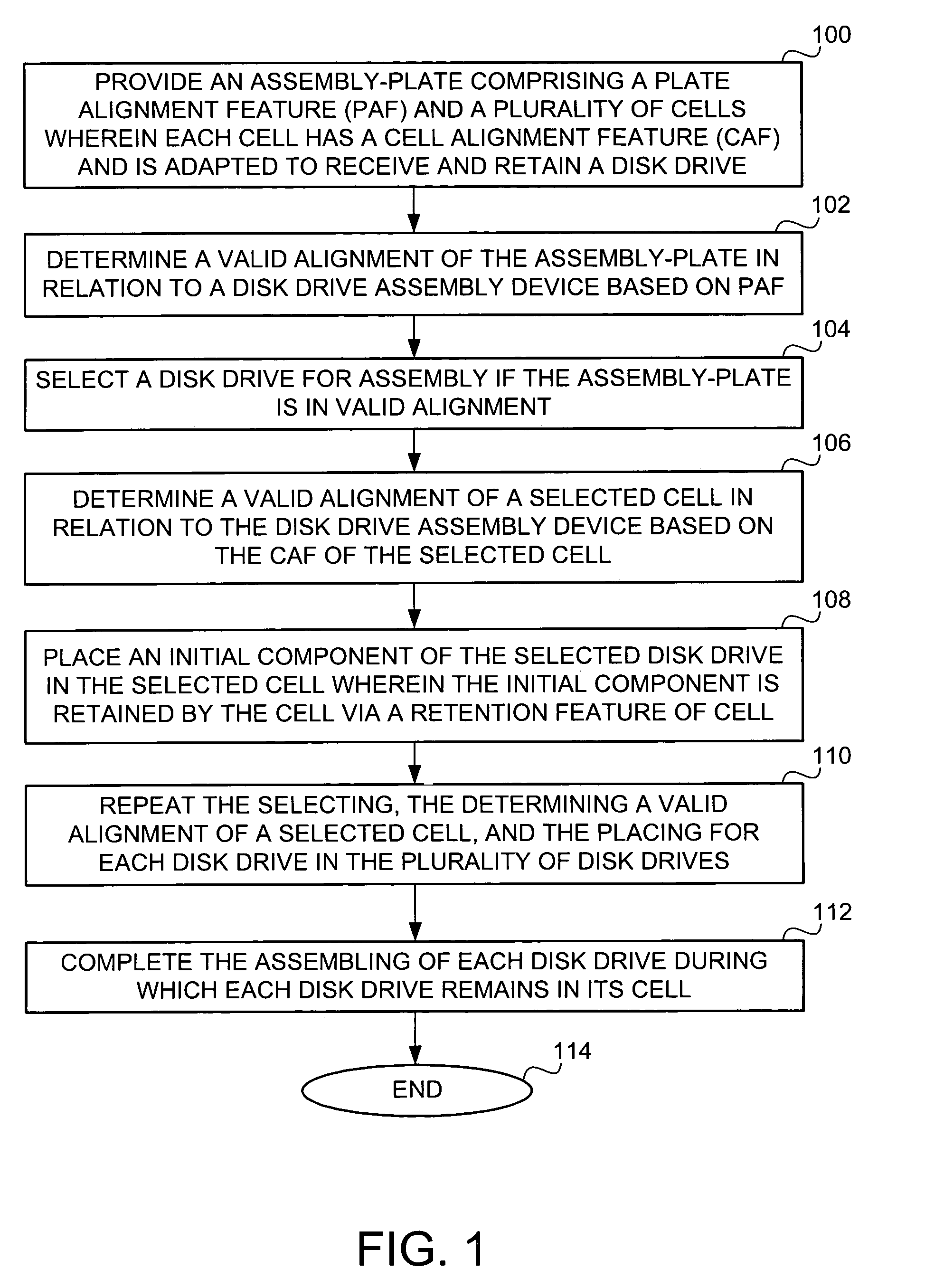

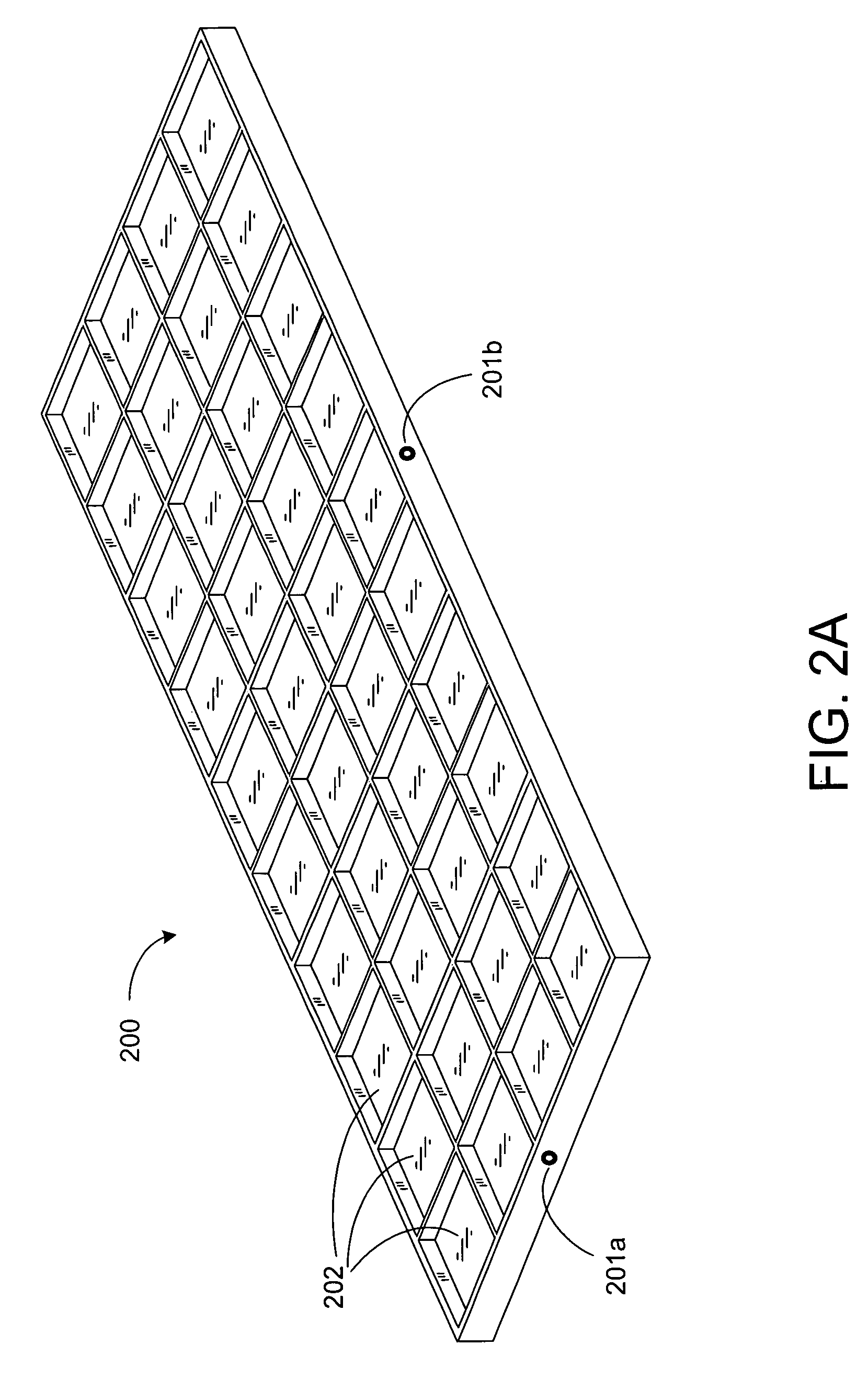

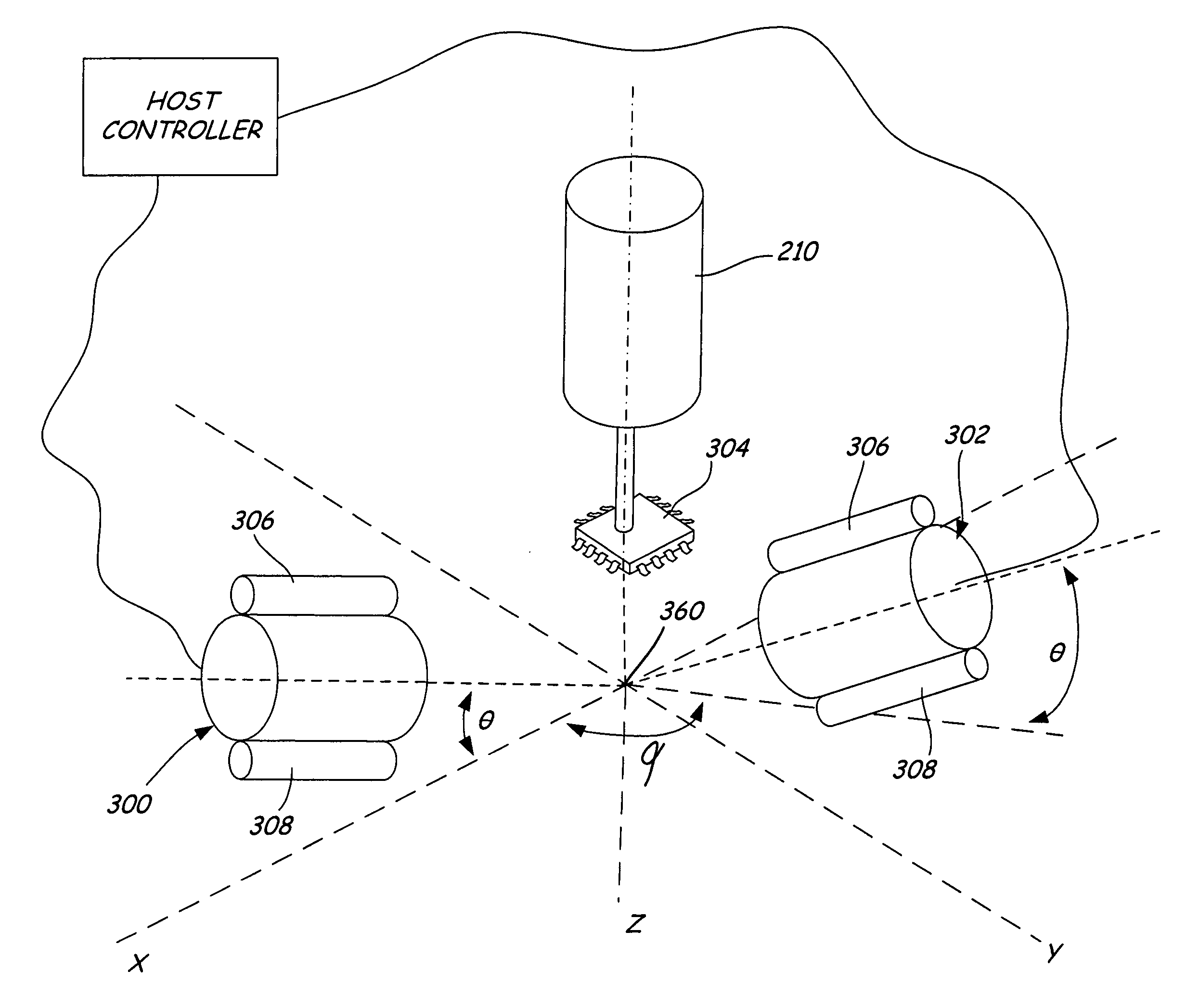

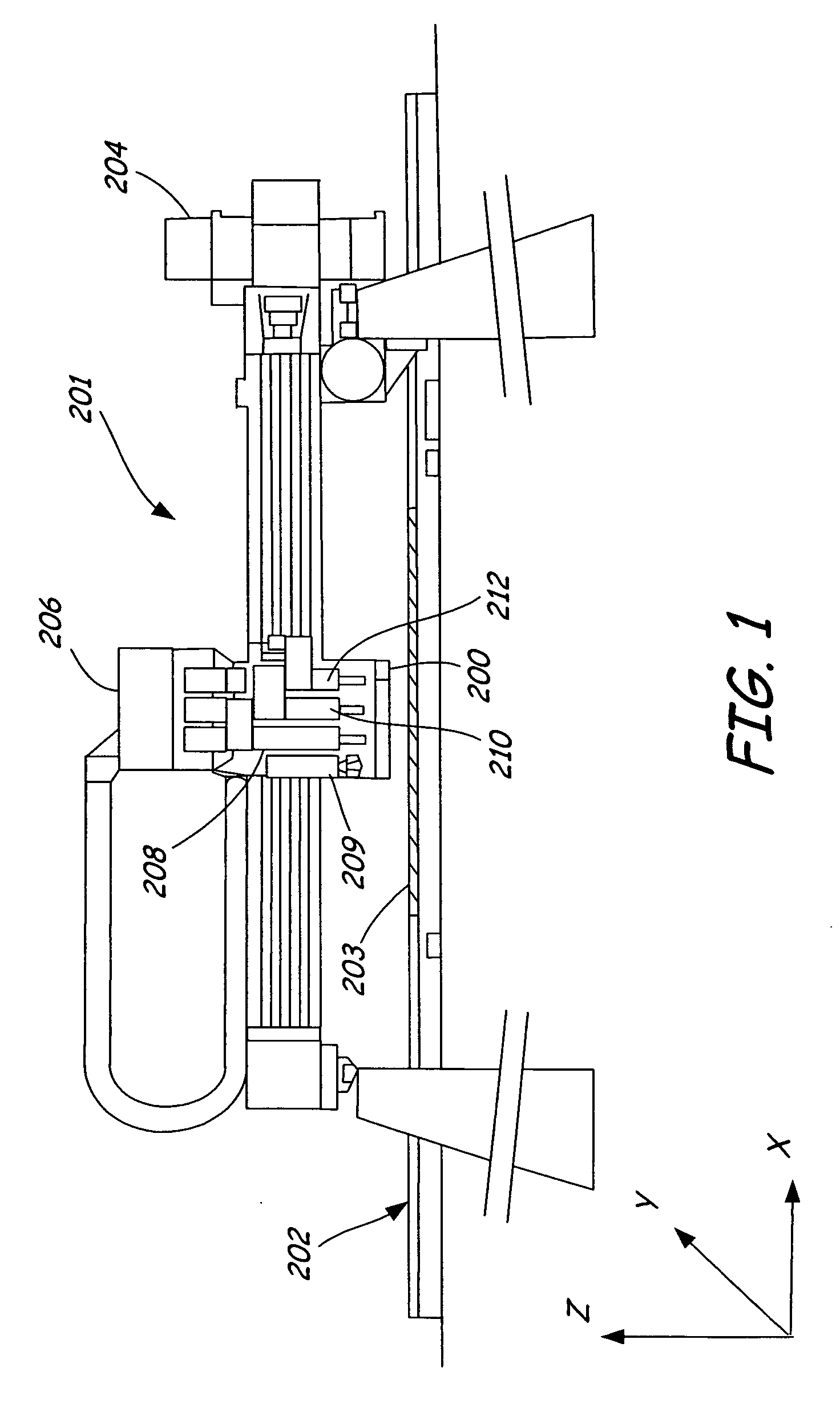

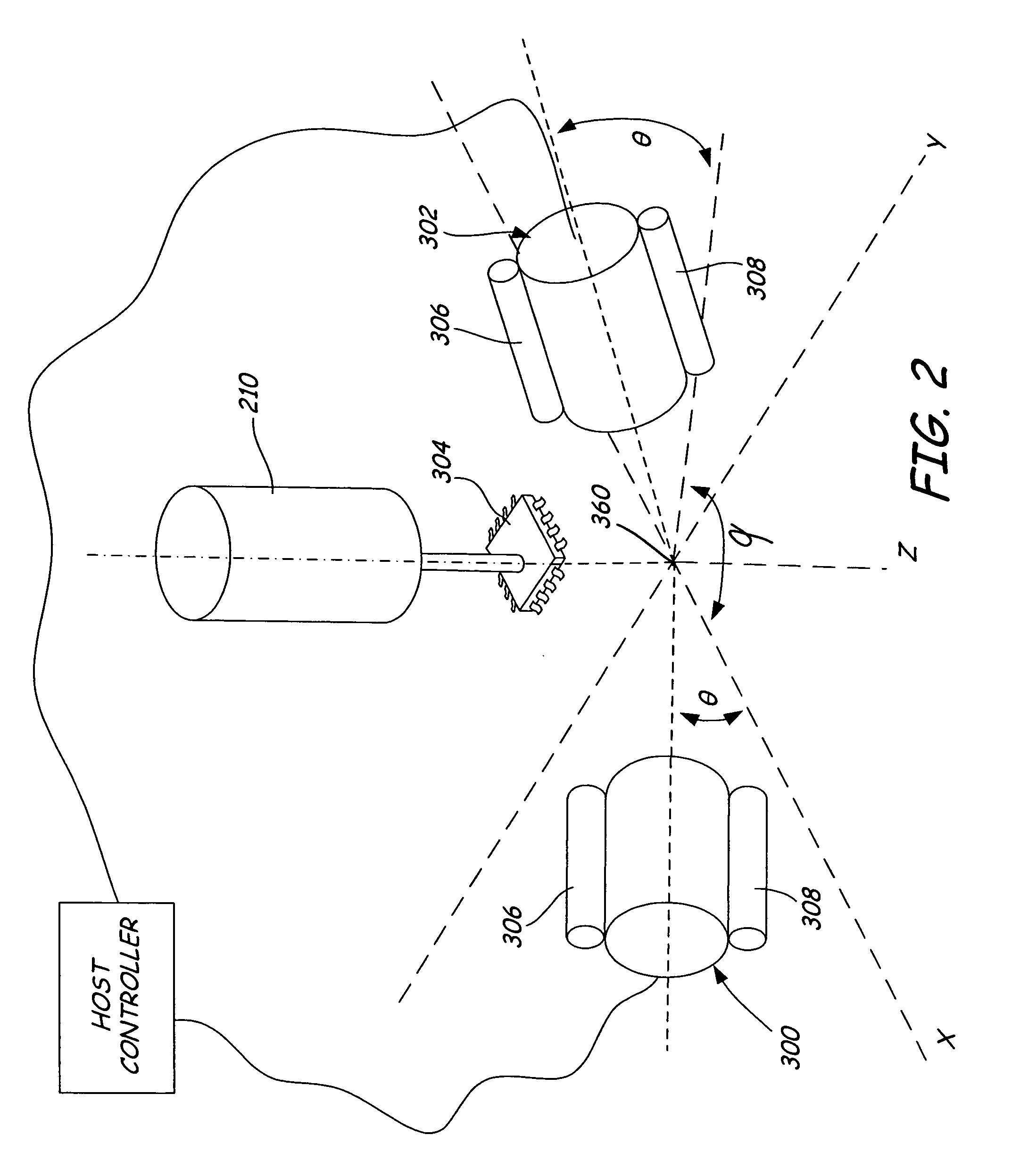

Method of assembling a plurality of disk drives

InactiveUS6996893B1Electrical transducersRecord information storageComputer engineeringComponent placement

A method of assembling a plurality of disk drives comprising providing an assembly-plate comprising a plate alignment feature (PAF) and a plurality of cells wherein each cell has a cell alignment feature (CAF) and is adapted to receive and retain a disk drive; determining a valid alignment of the assembly-plate in relation to a disk drive assembly device based on PAF; selecting a disk drive for assembly; determining a valid alignment of a selected cell in relation to disk drive assembly device based on CAF of selected cell; placing an initial component of selected disk drive in selected cell wherein the initial component is retained by the cell via a retention feature of cell; repeating the selecting, determining a valid alignment of a selected cell, and placing for each of disk drives; and completing the assembling of each disk drive during which each disk drive remains in its cell.

Owner:WESTERN DIGITAL TECH INC

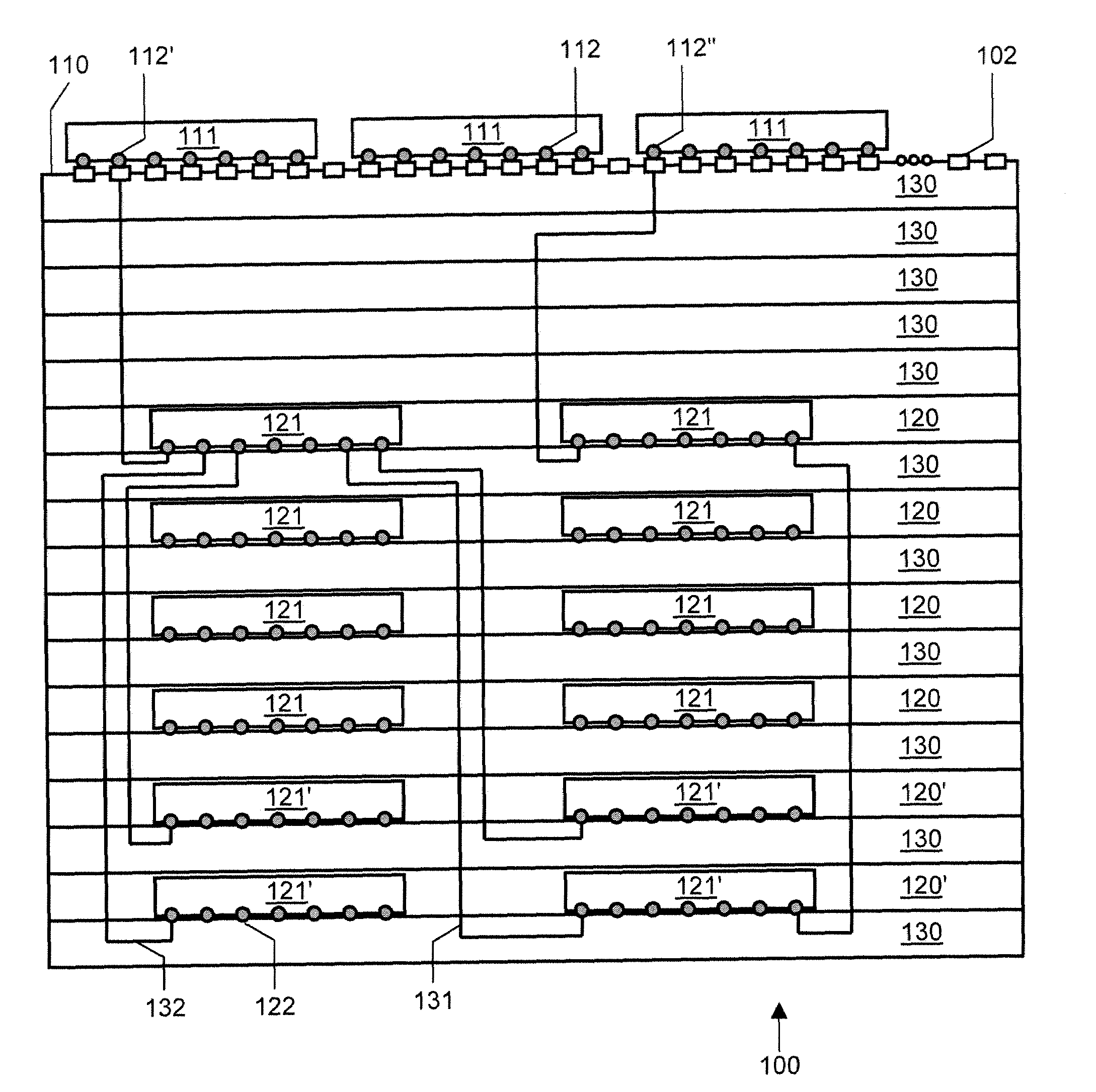

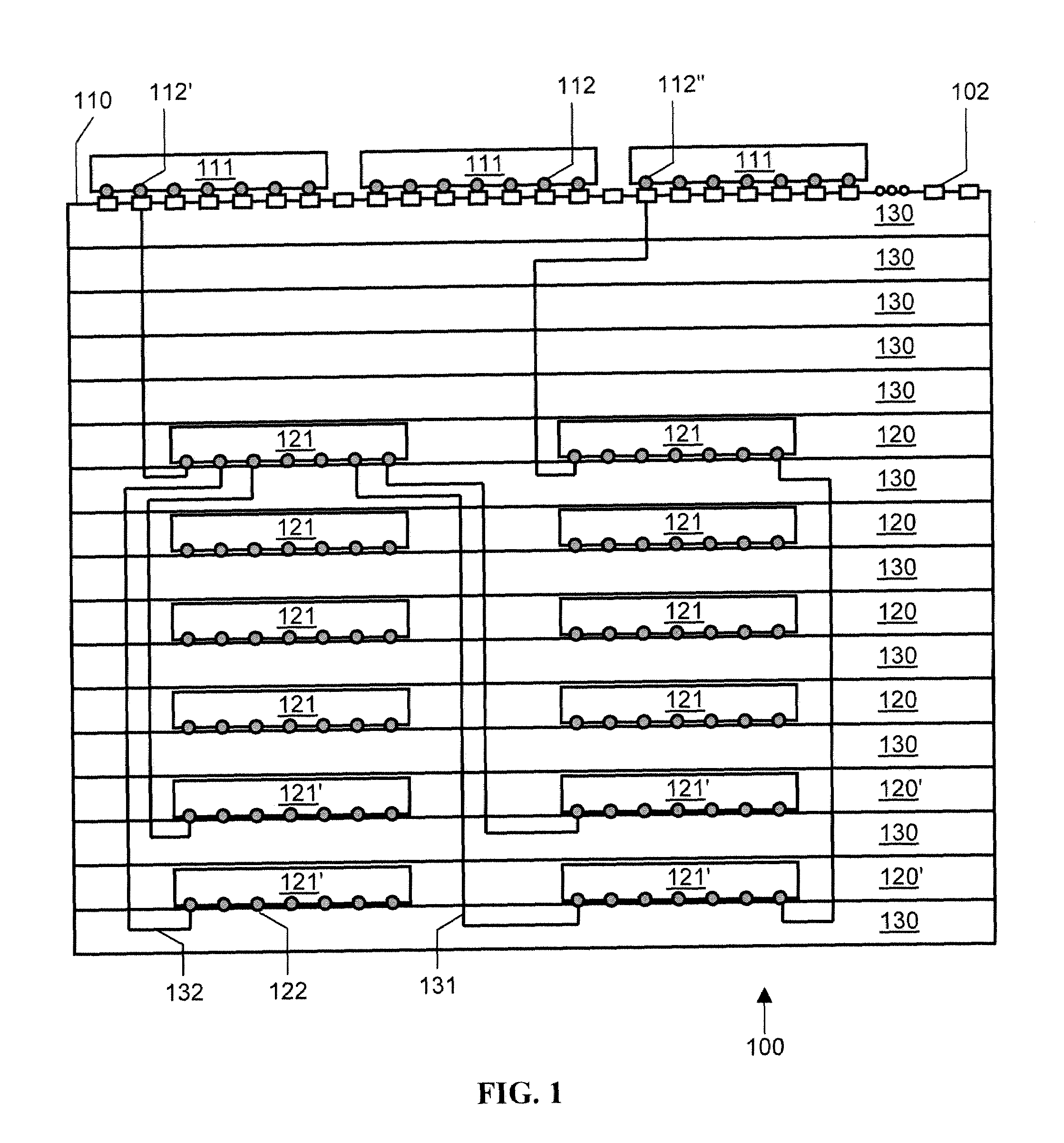

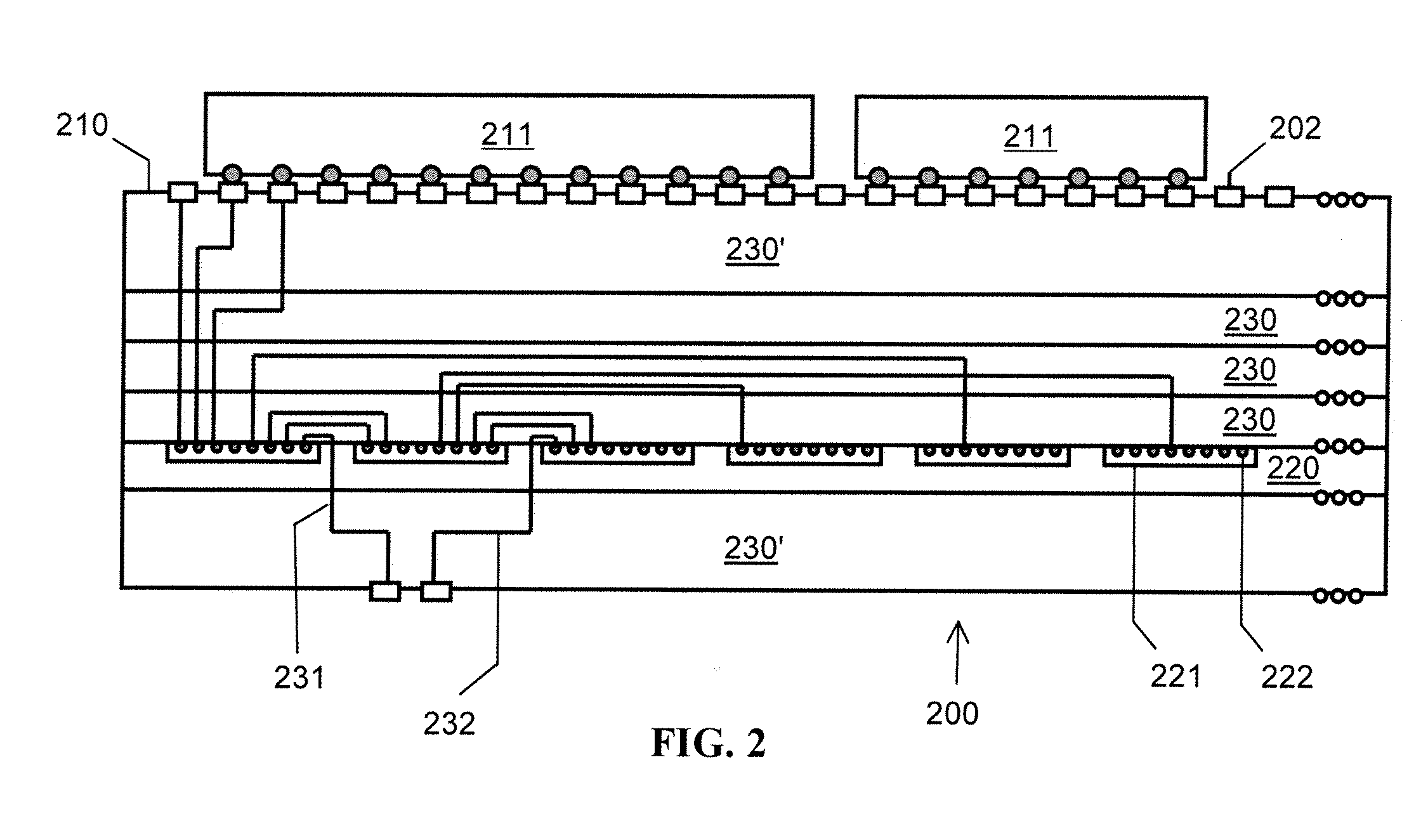

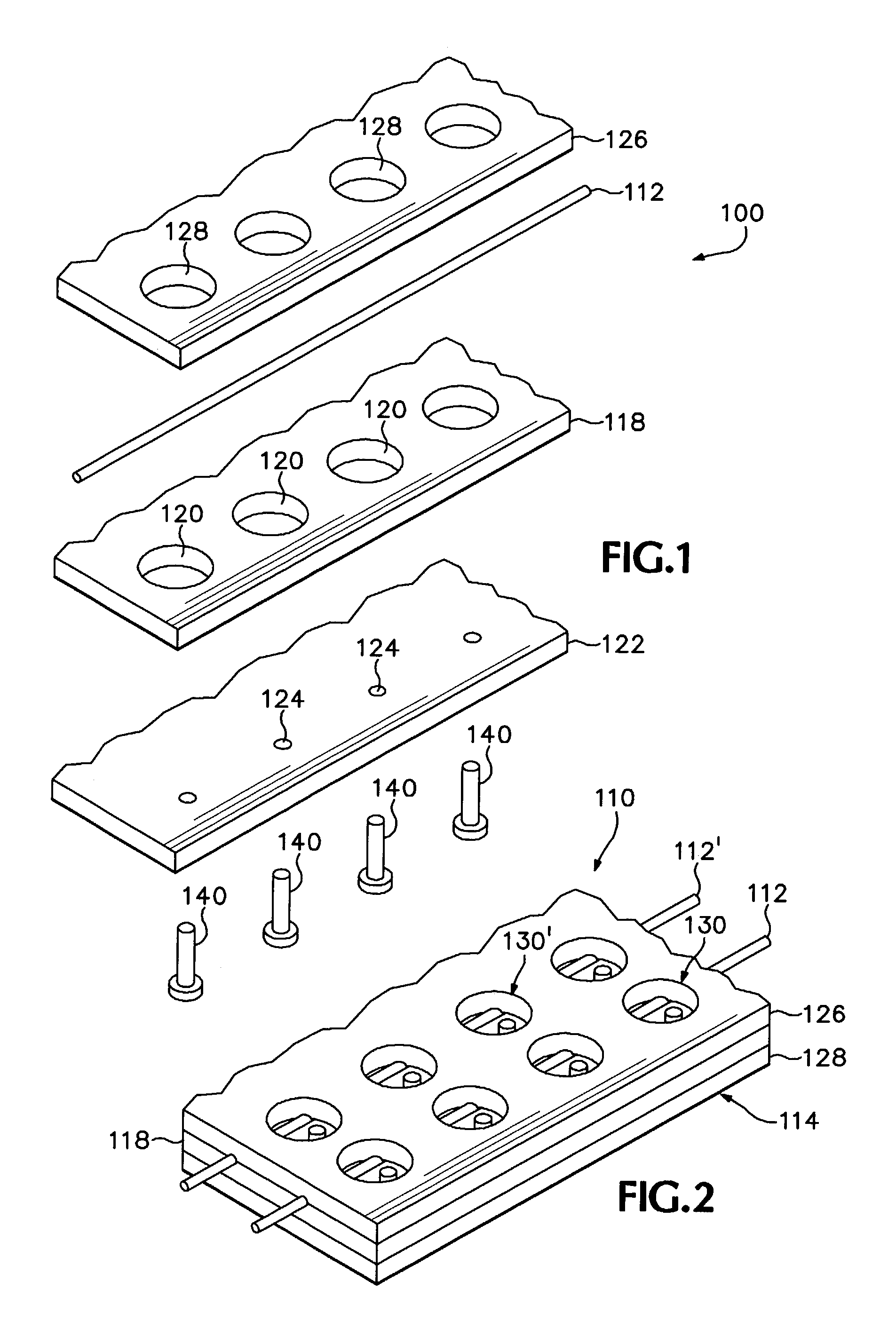

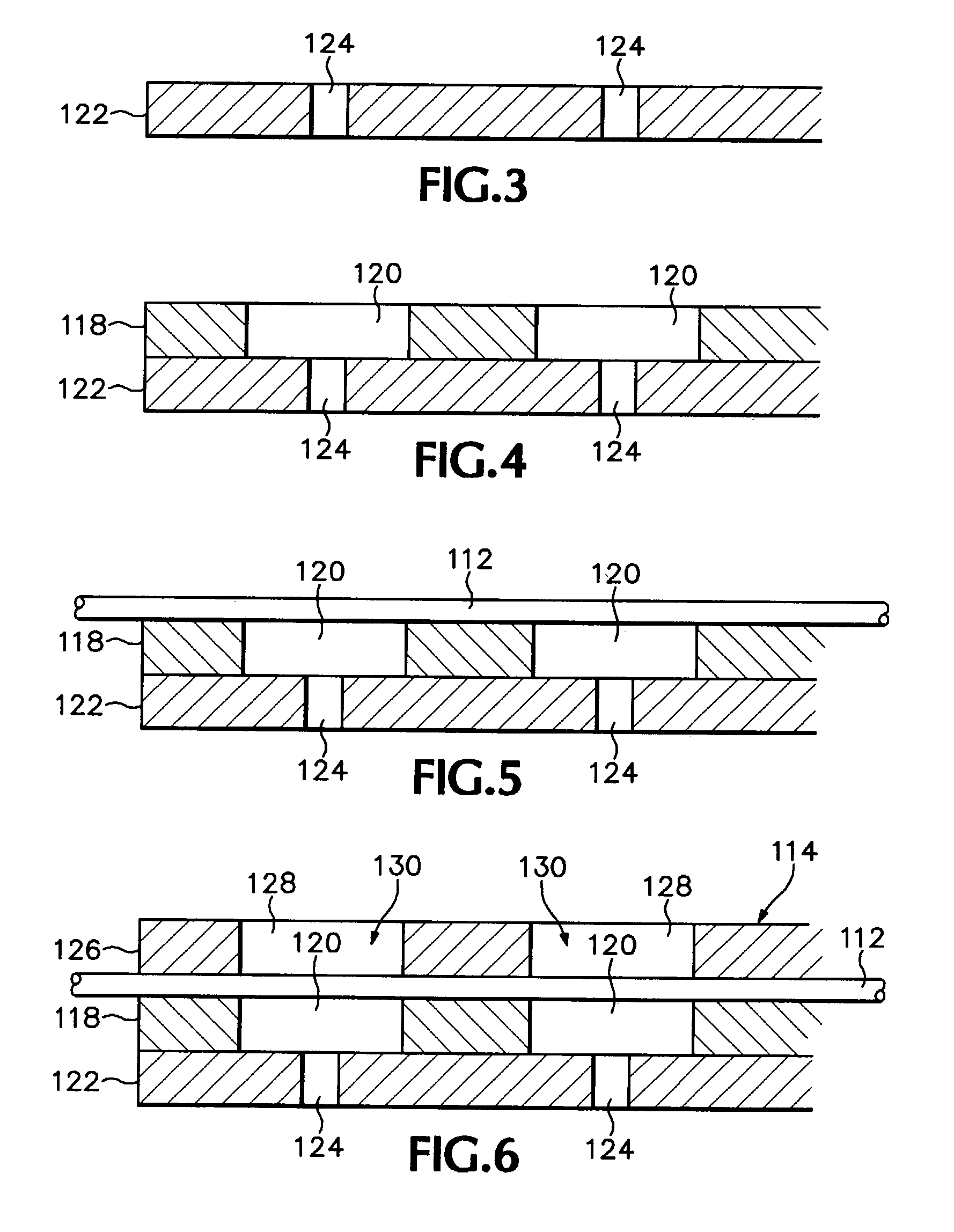

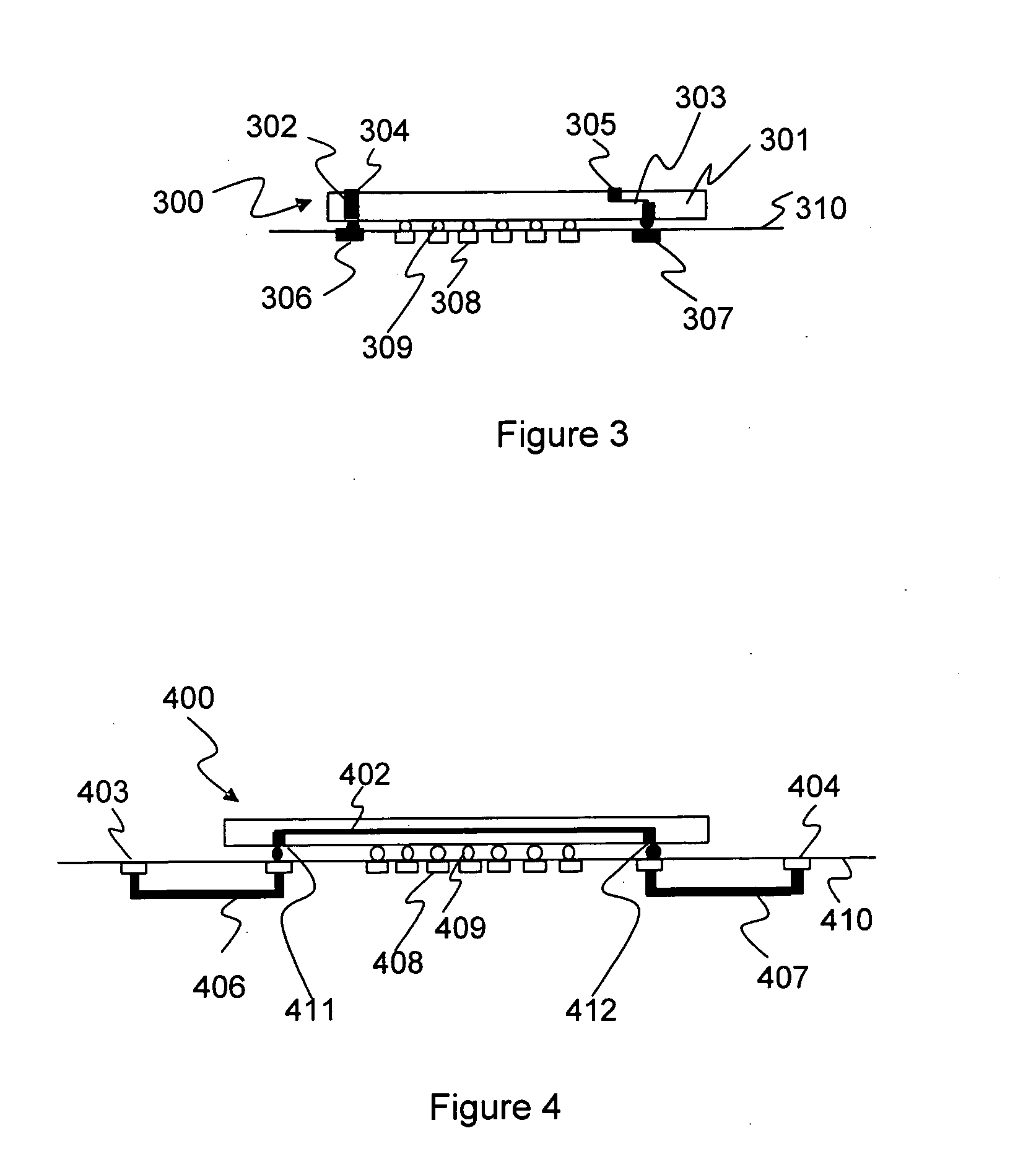

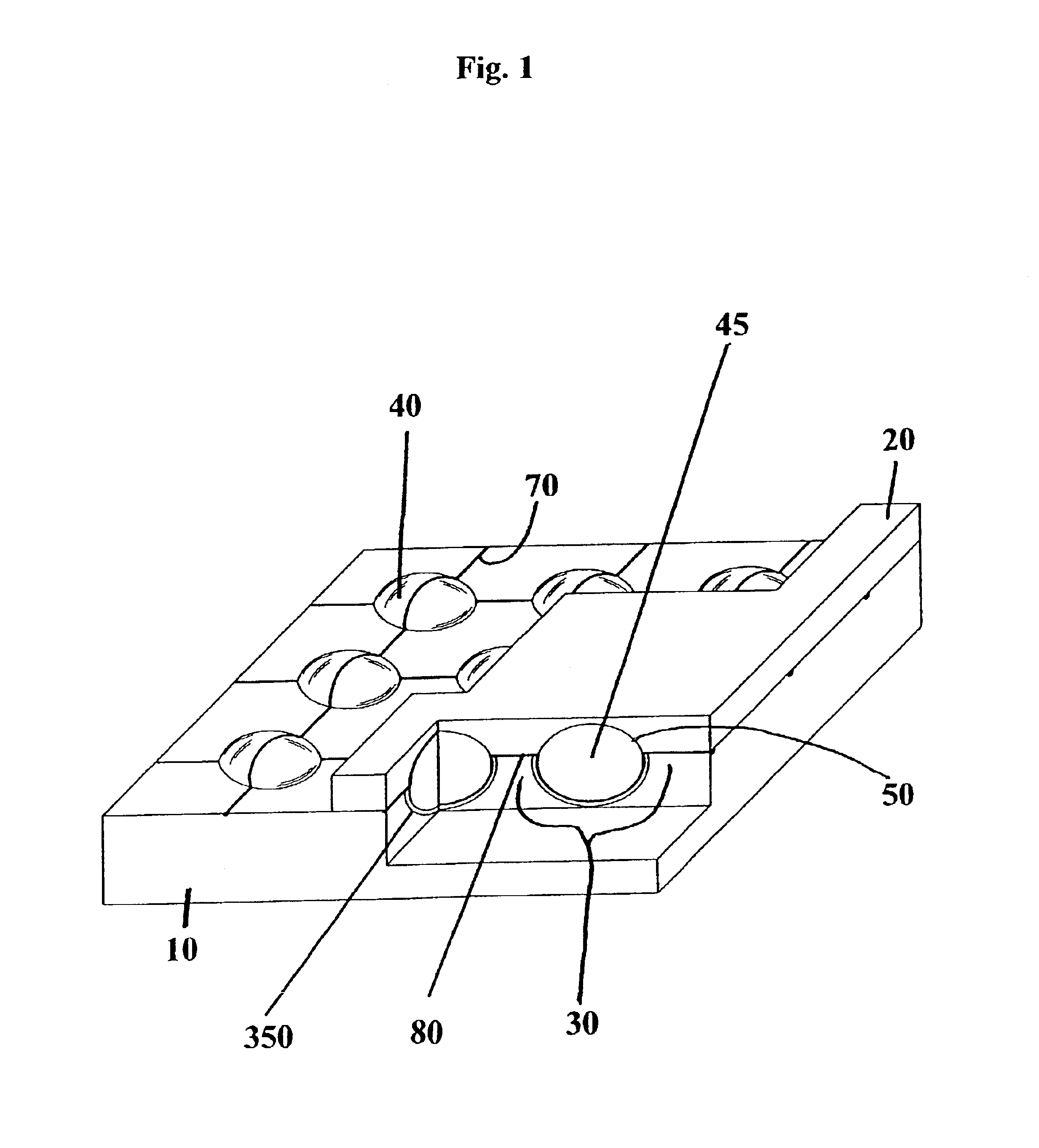

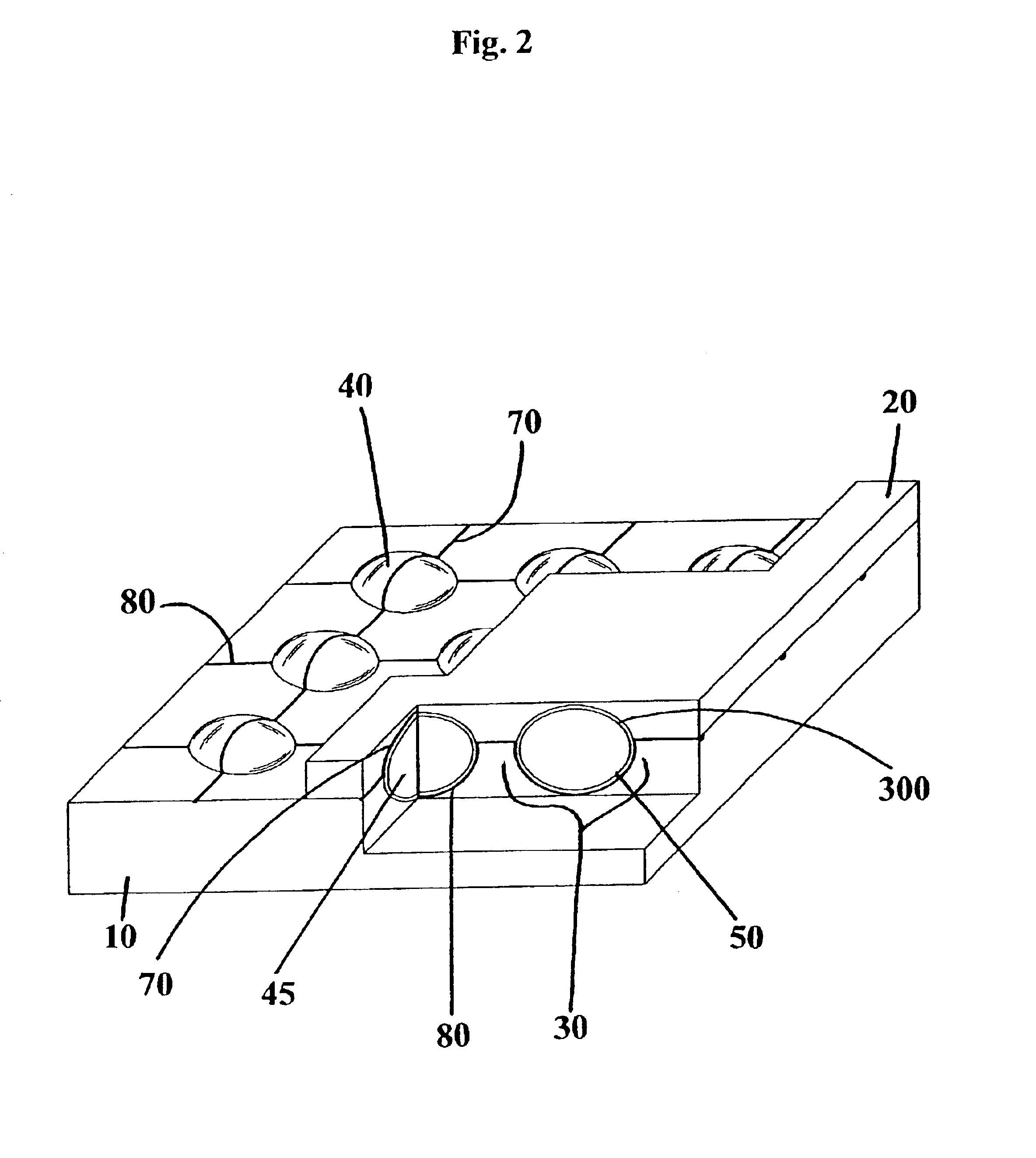

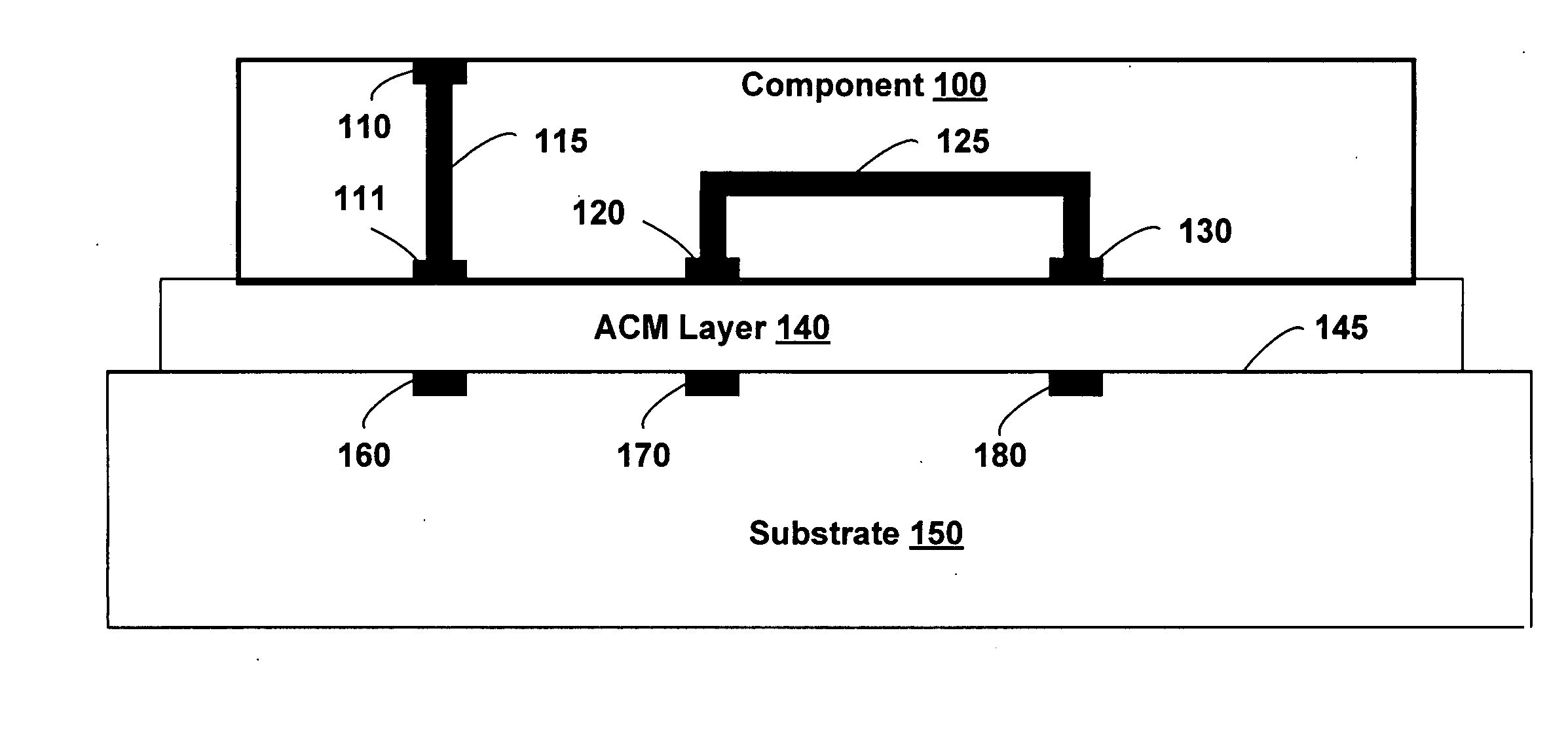

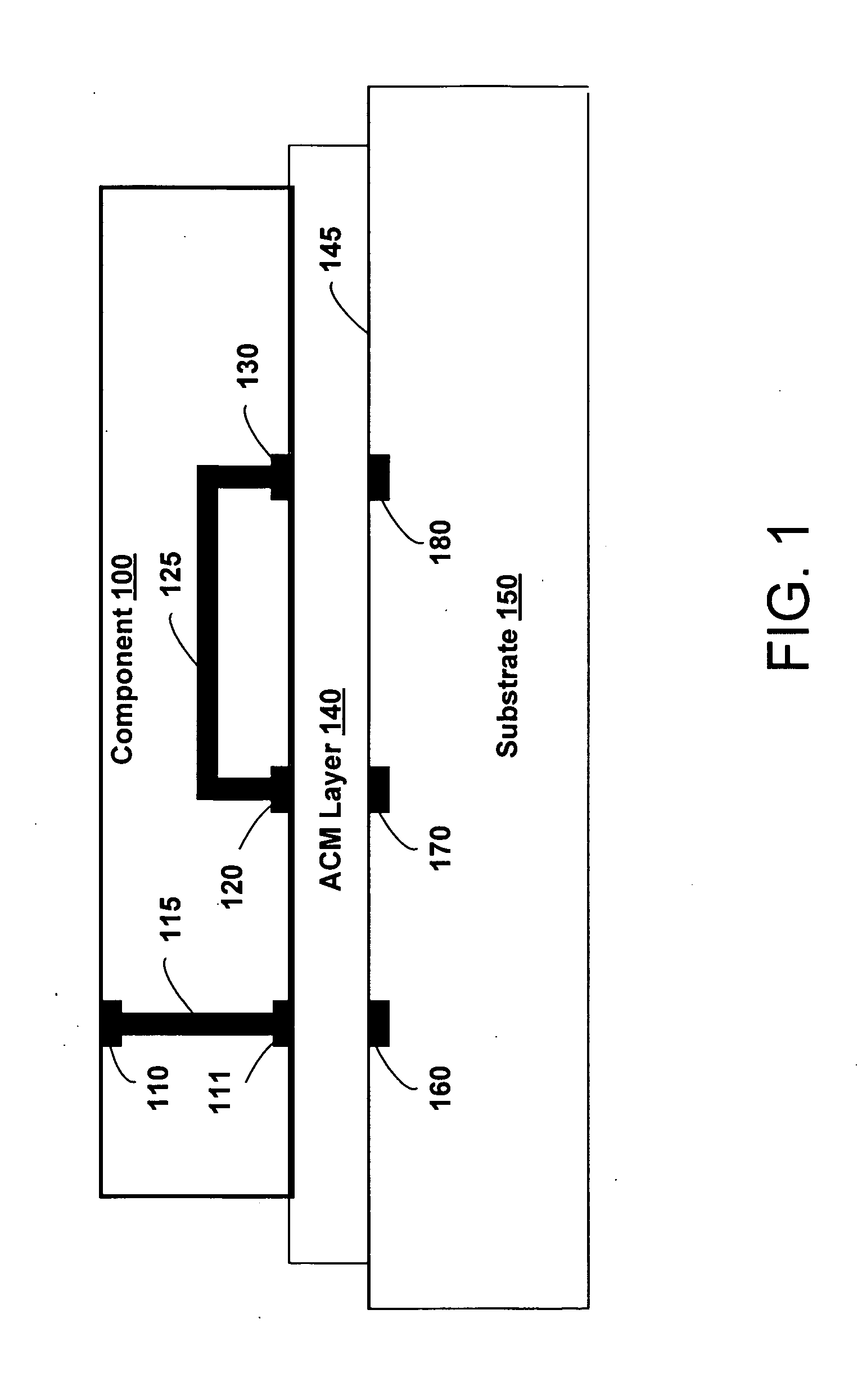

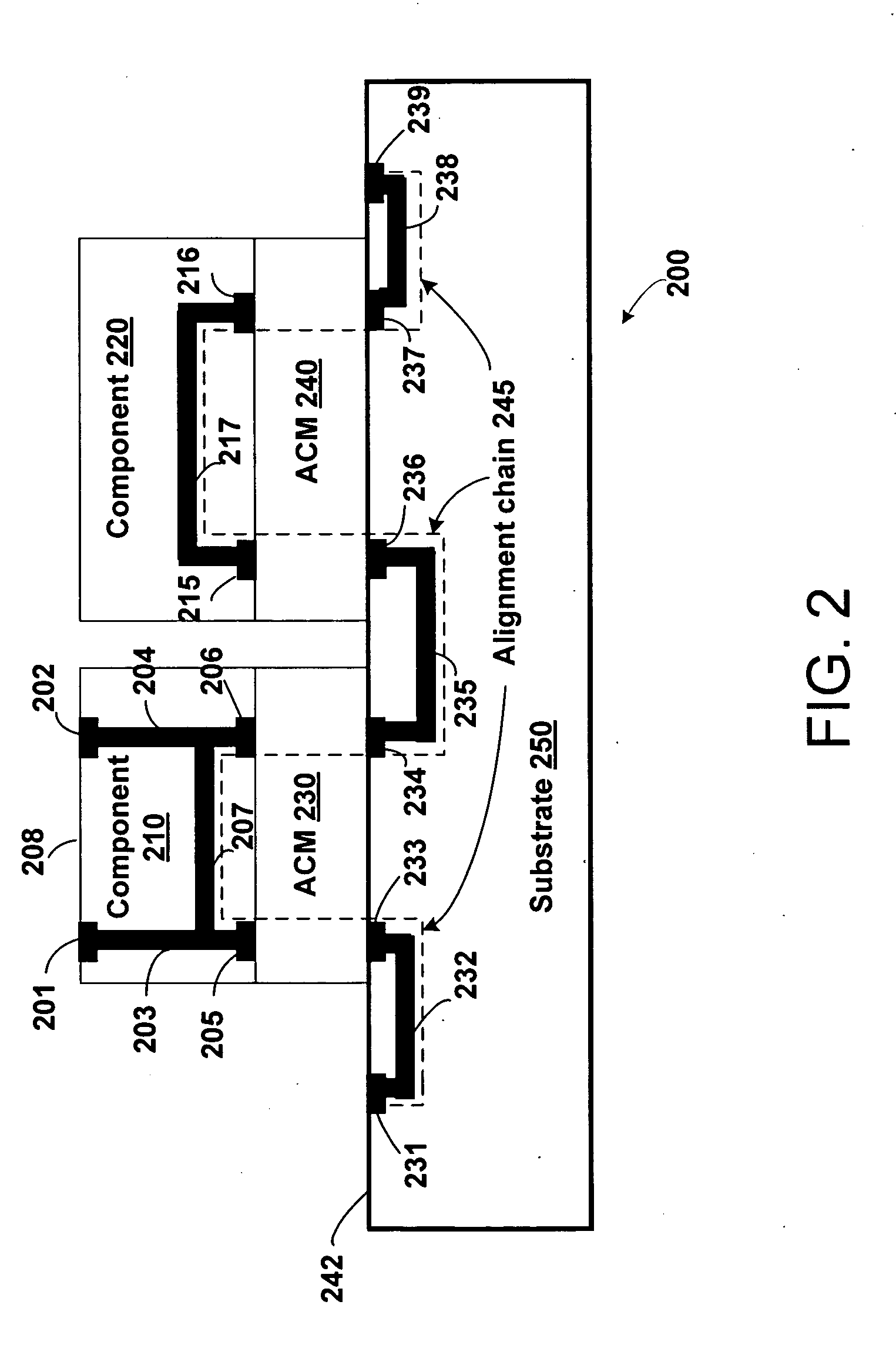

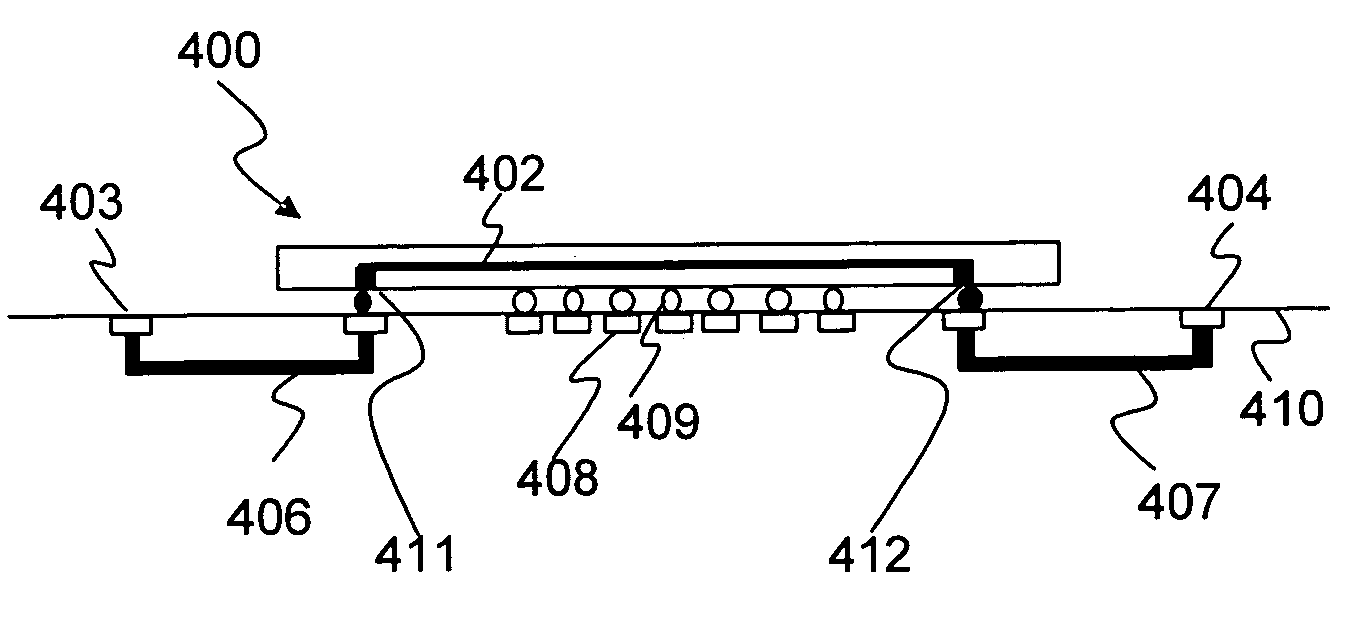

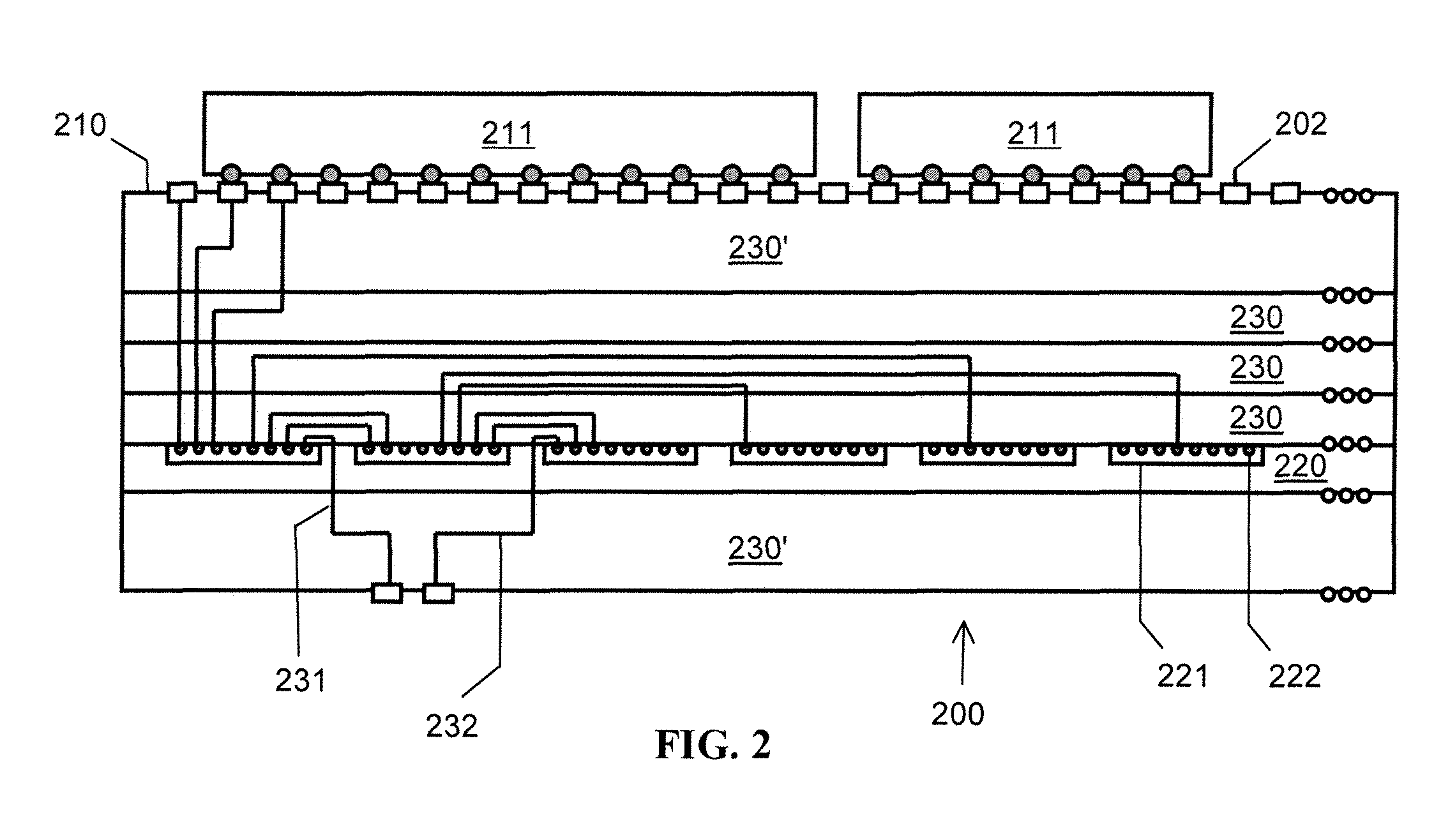

Electronic assembly with detachable components

InactiveUS20070187844A1Improve connectivitySimple designSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsAnisotropic conductive filmConduction pathway

The present invention provides systems and methods for assembling an electronic assembly using an anisotropic conducting membrane (ACM) as a component interconnect and a substrate embossed with placement cavities or a positional fixture to facilitate component placement on the substrate in the electronic assembly. The fixture may comprise multiple layers of interconnects to improve routing density for the electronic assembly enclosed in a housing. An alignment chain may be used to monitor positional and contact integrity of the ACM interfaced components in a complex assembly. The systems and methods allow components to be detached for reuse. Interconnection elements or conduction pathways at the components can be used to interconnect a plurality of neighboring substrates over the ACM layers into a stacked electronic assembly.

Owner:WINTEC IND INC

Mobile device holder

A two-piece mobile device holder having a case assembly and a mounting assembly is disclosed. The case assembly is configured to receive and secure a mobile device such as a smart phone. The mounting assembly is configured to be detachably coupled to other objects. Sets of permanent magnets are arranged in a circular pattern in the case assembly and the mounting assembly. The magnets in both the first and second set of magnets are arranged with alternating magnetic polarity. As the case assembly is placed on top of the mounting assembly, the magnets in the mounting assembly will attract magnets with opposite polarities in the case assembly. A user may detach the case assembly from the mounting assembly by rotating the case assembly such that the magnets in the case assembly are now adjacent to magnets in the mounting assembly of the same polarity.

Owner:AIRO COLLECTIVE INC

Self-sealing auto-aligning magnetically-hanging spice dispenser

A hanging spice dispenser comprises a plate assembly and a container assembly for storing spices. The plate assembly comprises a non-magnetic planer plate and a plurality of magnetic elements embedded at pre-determined locations. The container assembly comprises a generally cylindrical spice container, a removable cap and a magnetic element. Magnetic attraction force between the magnetic element of the container assembly and the magnetic element of the plate assembly is exerted when the container assembly is placed in proximity to the plate assembly. The container assembly is capable of detaching from the bottom surface of the plate assembly when force is applied to the container assembly. The removable cap and the plate assembly form self-seal in order to prevent air and moisture from entering into the generally cylindrical container. This invention relates to spice dispensers, and the principal use of the invention is for dispensing spices in a kitchen.

Owner:SUNATORI GO SIMON

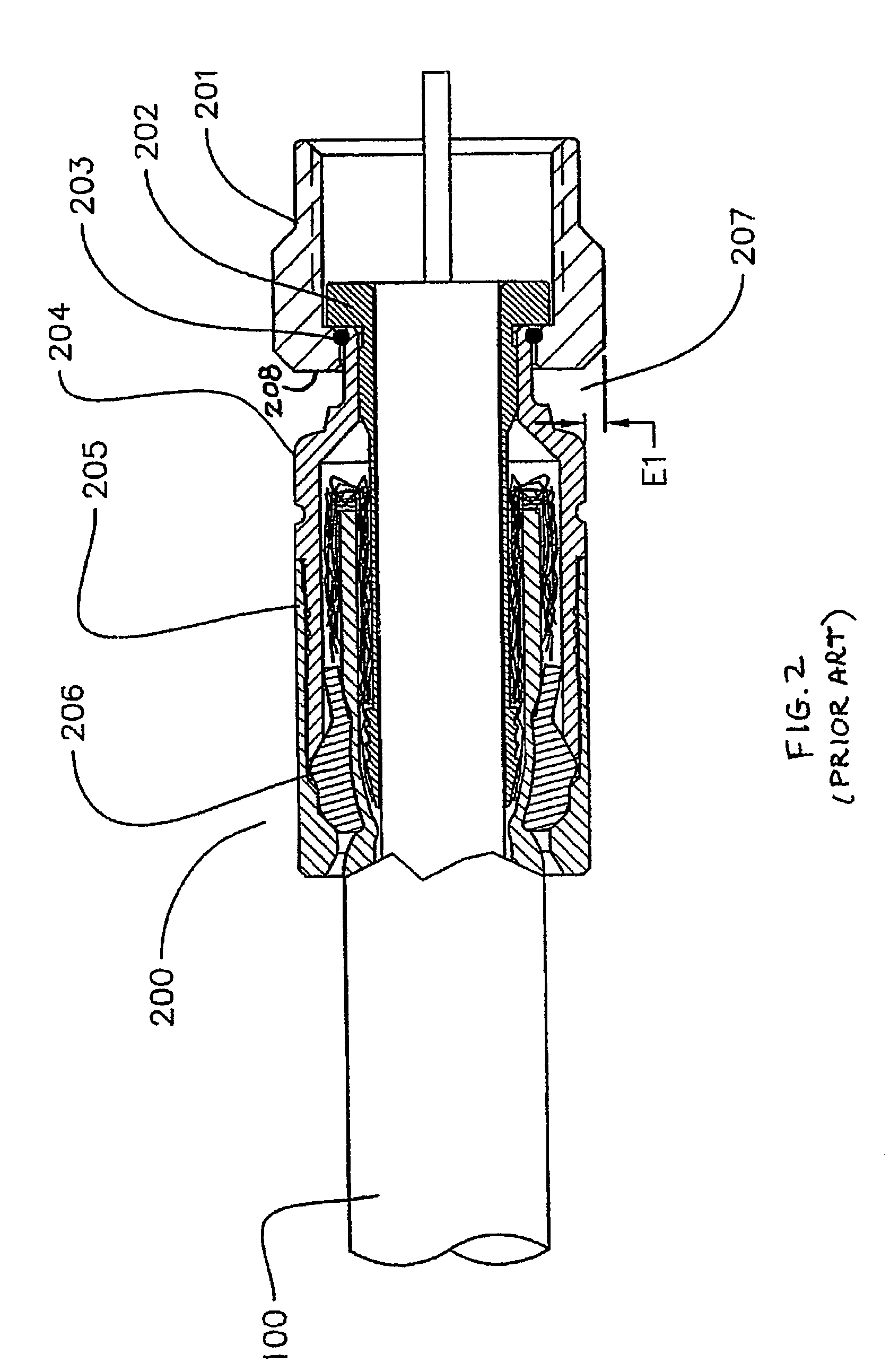

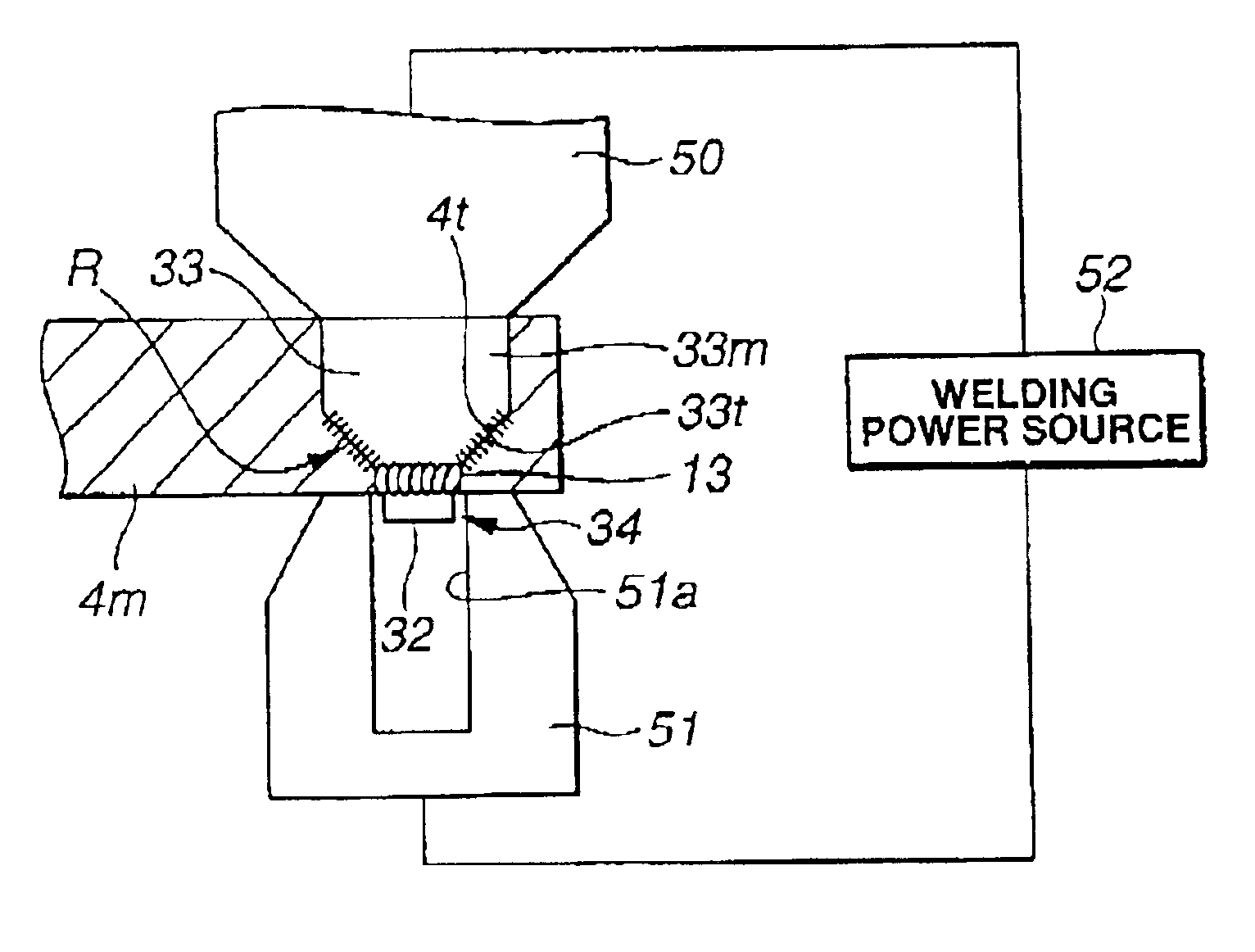

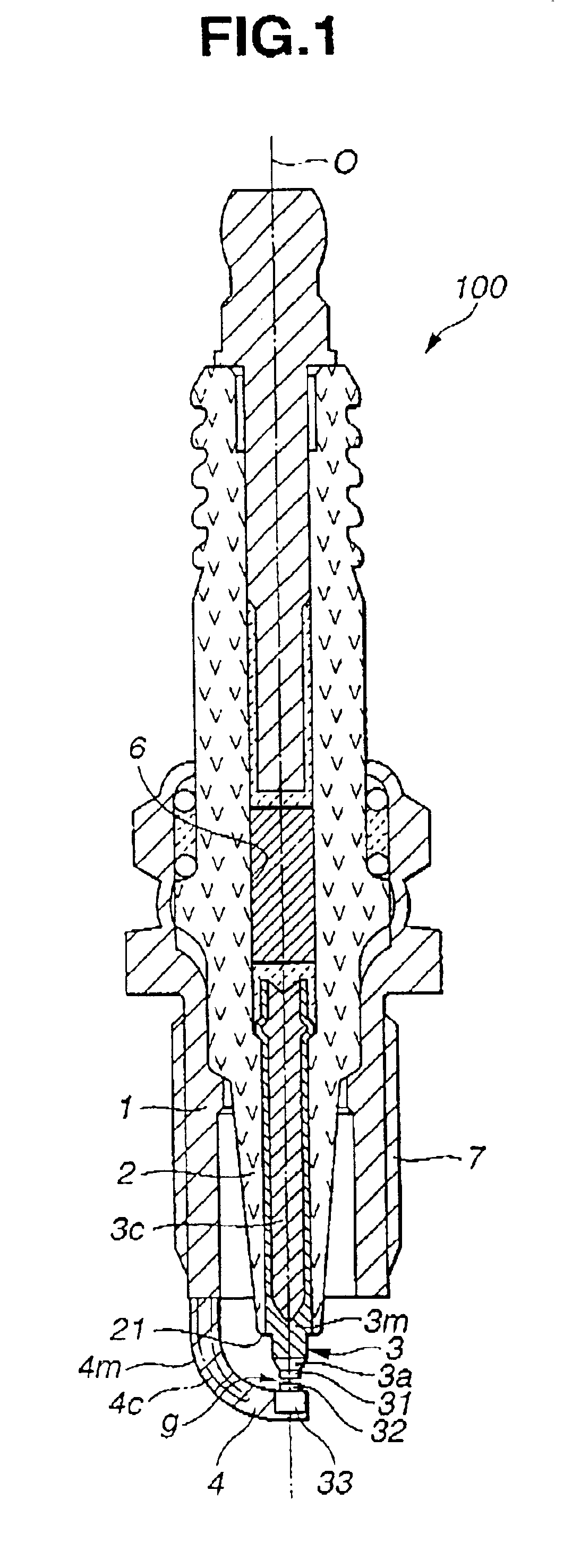

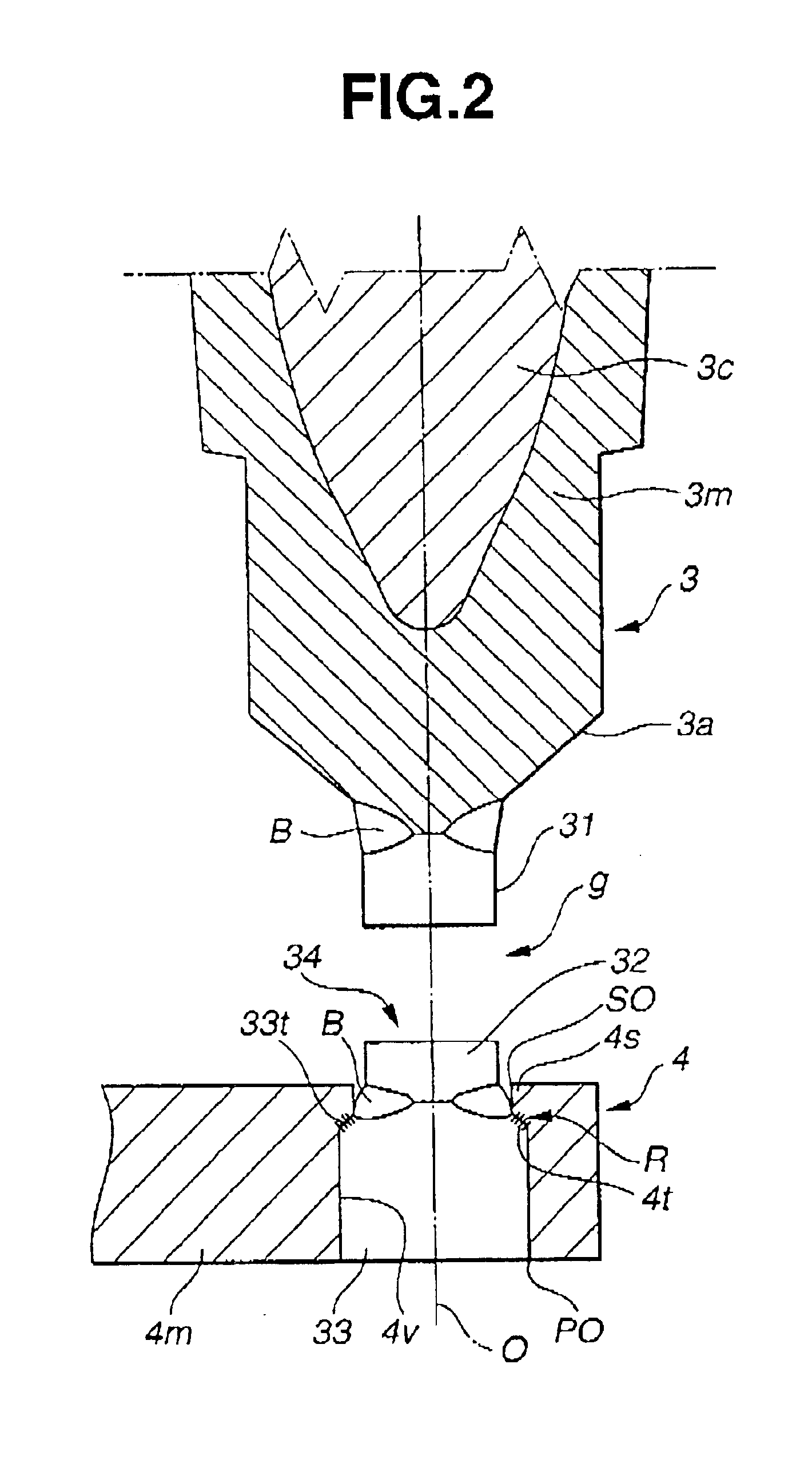

Method of making a spark plug

InactiveUS6923699B2Restrict movementHigh melting pointLine/current collector detailsSpark gapsBiomedical engineeringGrounding electrodes

A method of making a spark plug having a noble metal chip joined to an electrode main body of a ground electrode by interposing therebetween an intermediate member. The method comprises the steps of prior to joining the noble metal chip to the electrode main body, joining the intermediate member and the noble metal chip together, placing a noble metal chip and intermediate member assembly on the electrode main body in a way as to allow the intermediate member to contact the electrode main body, and welding the electrode main body and the intermediate member together while restricting relative movement of the electrode main body and the intermediate member without applying an urging force to a joint between the intermediate member and the noble metal chip.

Owner:NGK SPARK PLUG CO LTD

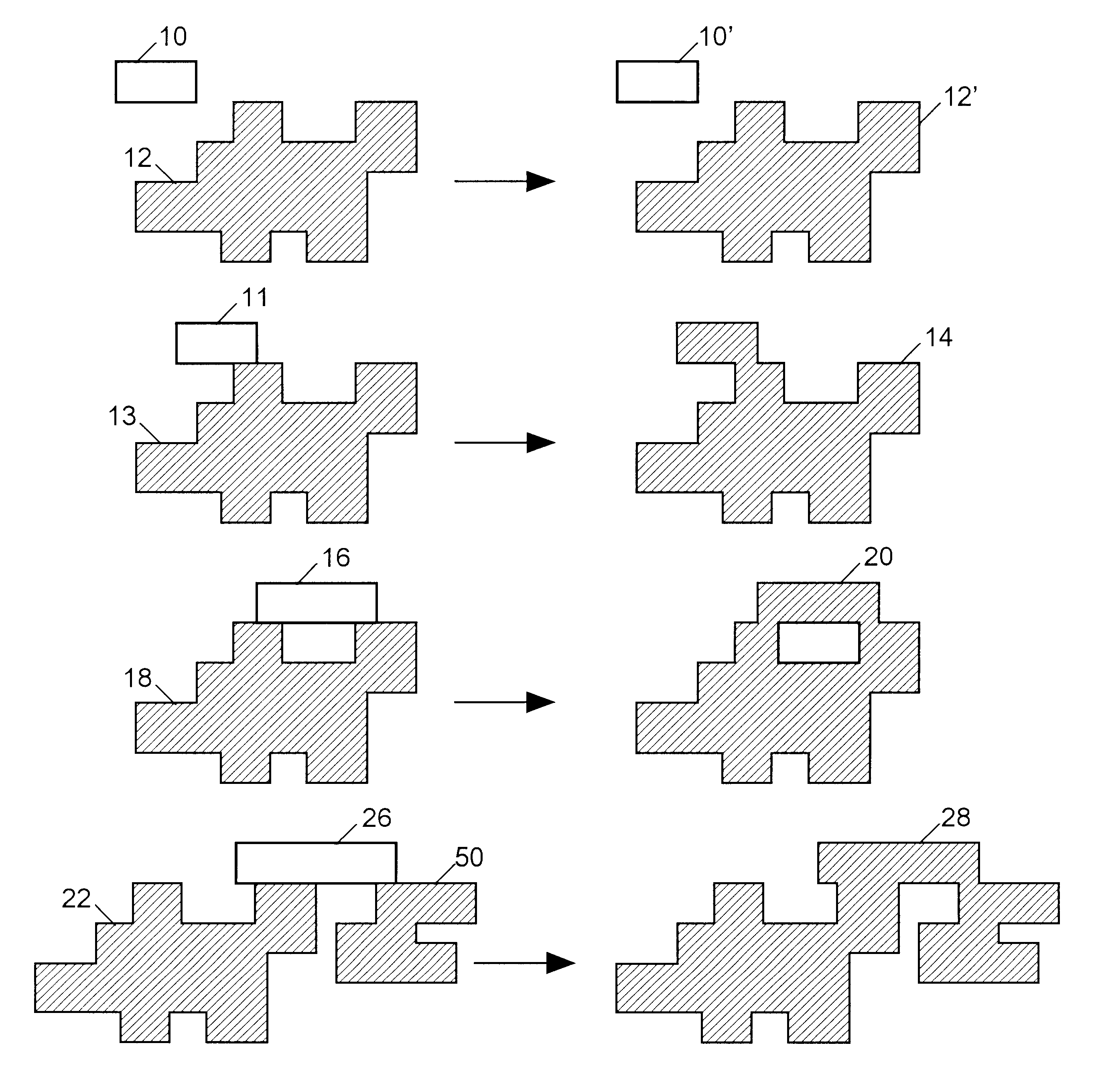

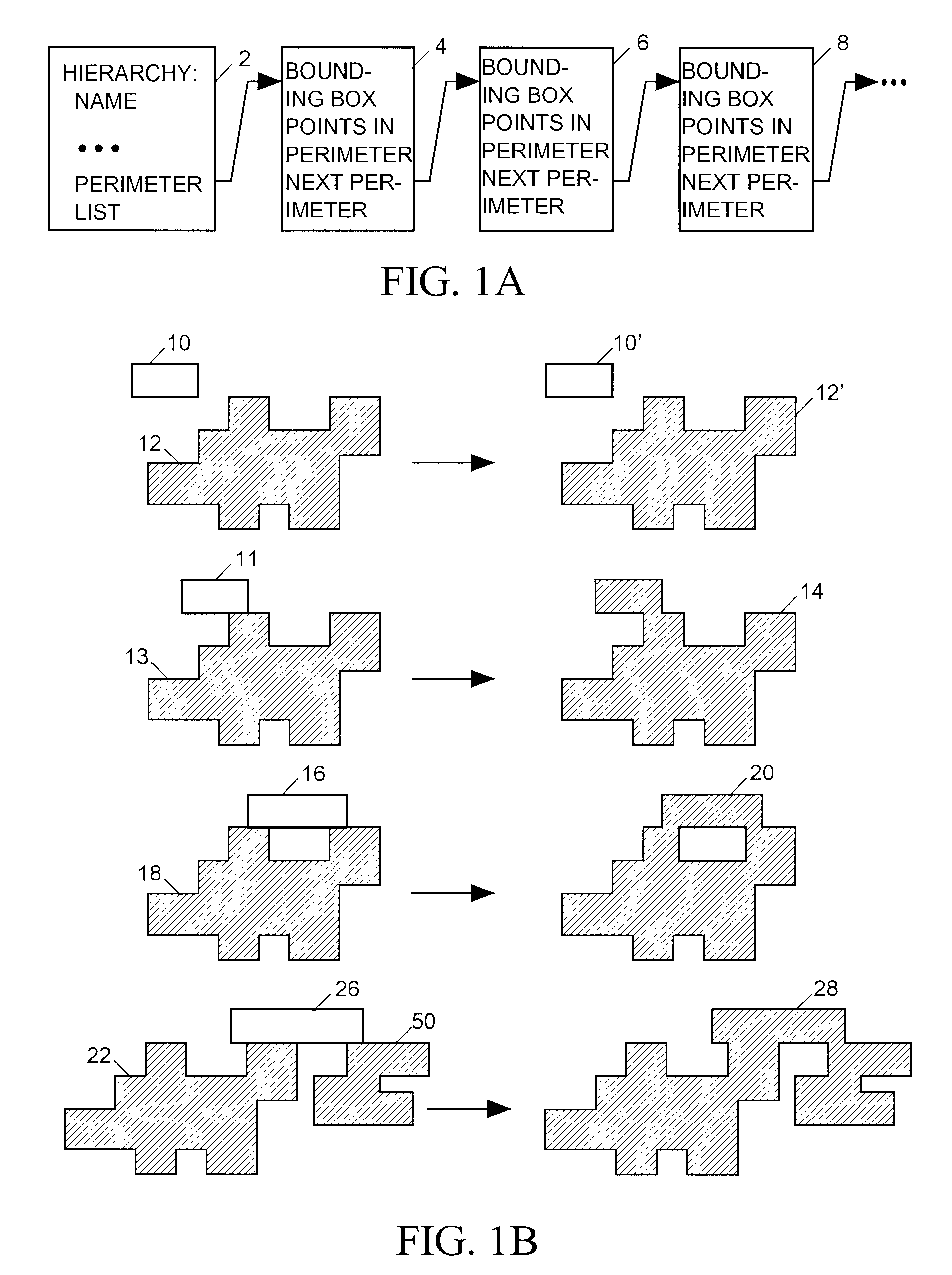

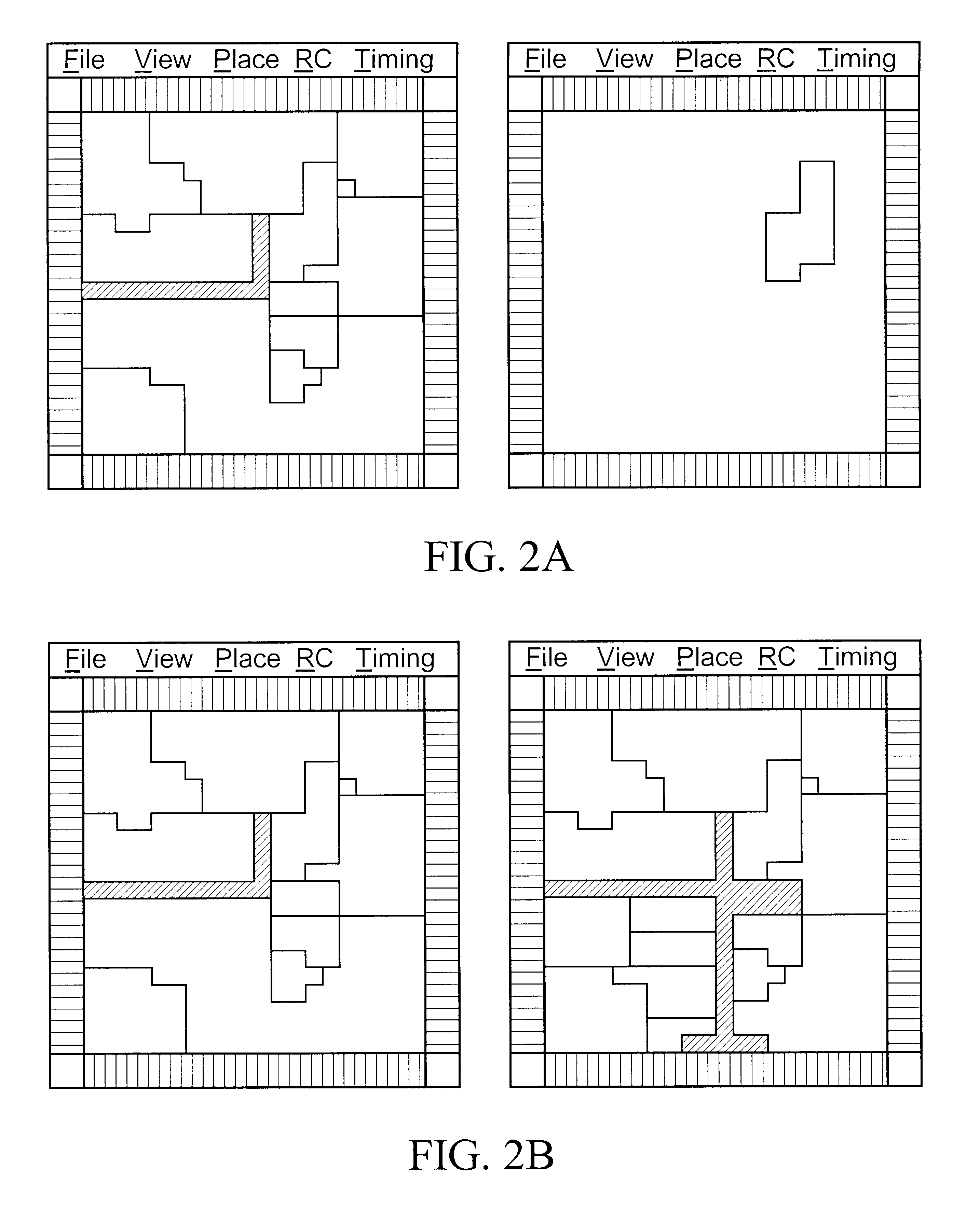

Amoeba display for hierarchical layout

InactiveUS6256768B1Computer programmed simultaneously with data introductionCAD circuit designComputer architectureLow speed

CAD software for automated circuit design provides improved display of hierarchical layout. Component placement perimeters are shown with "amoeba" characteristic for improved circuit floor-planning and analysis. Amoeba view of hierarchical design perimeter enables more intuitive observation of circuit floor-plan from actual component placement. Informational brevity conveyed by perimeters of hierarchies in design facilitates simpler interpretation of complex circuit layout, as well as distributed data access to remote sites through email or low-speed network.

Owner:CADENCE DESIGN SYST INC

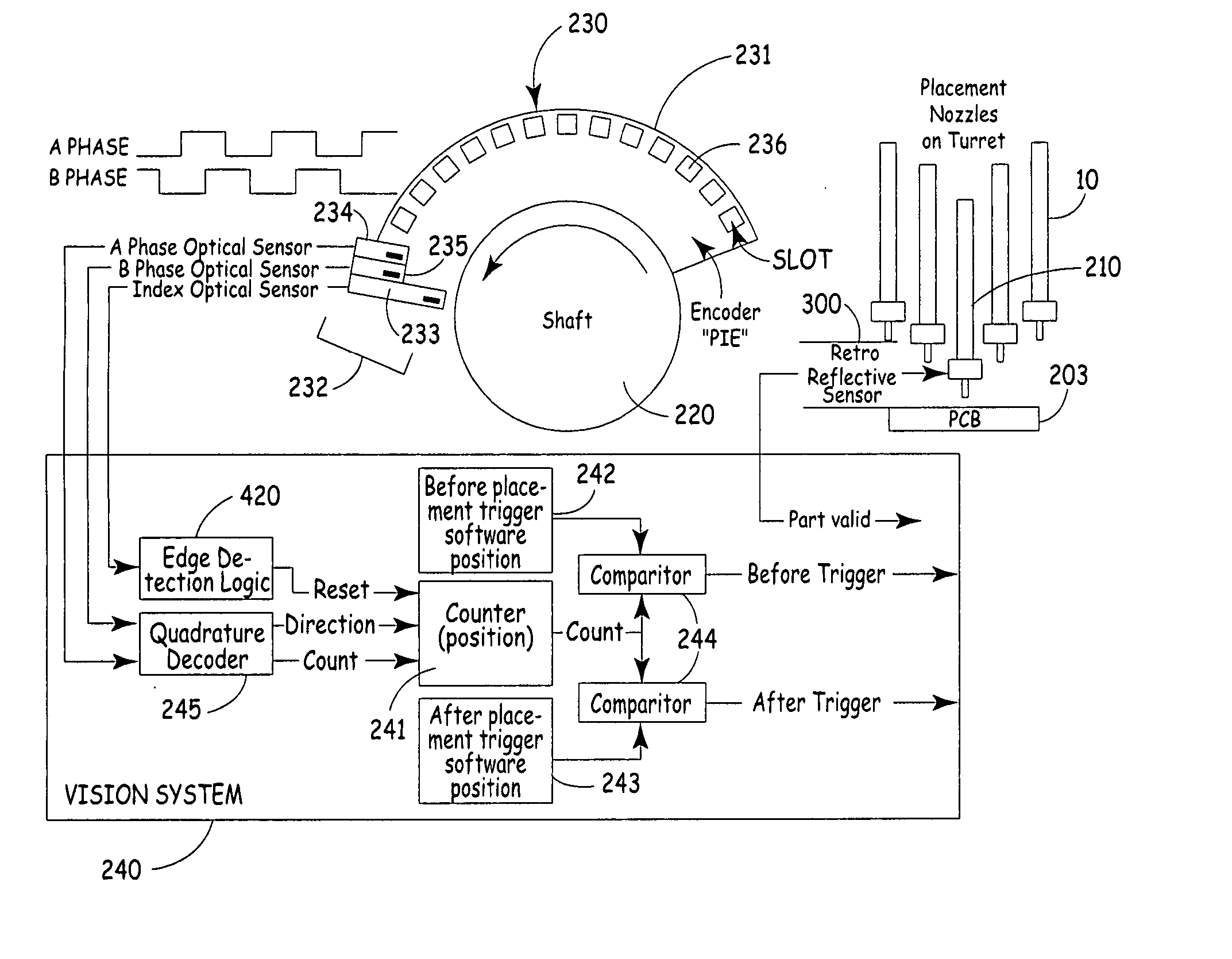

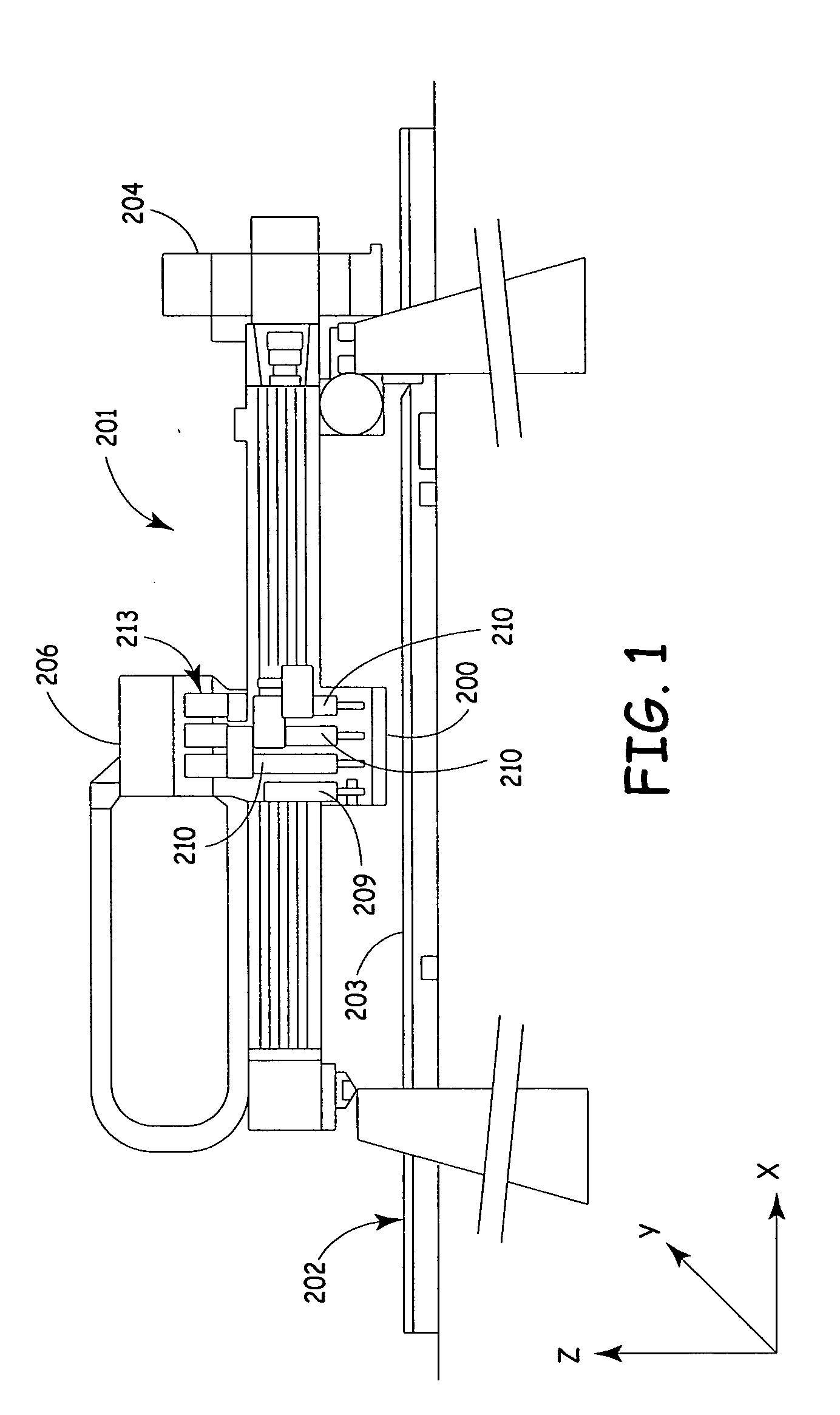

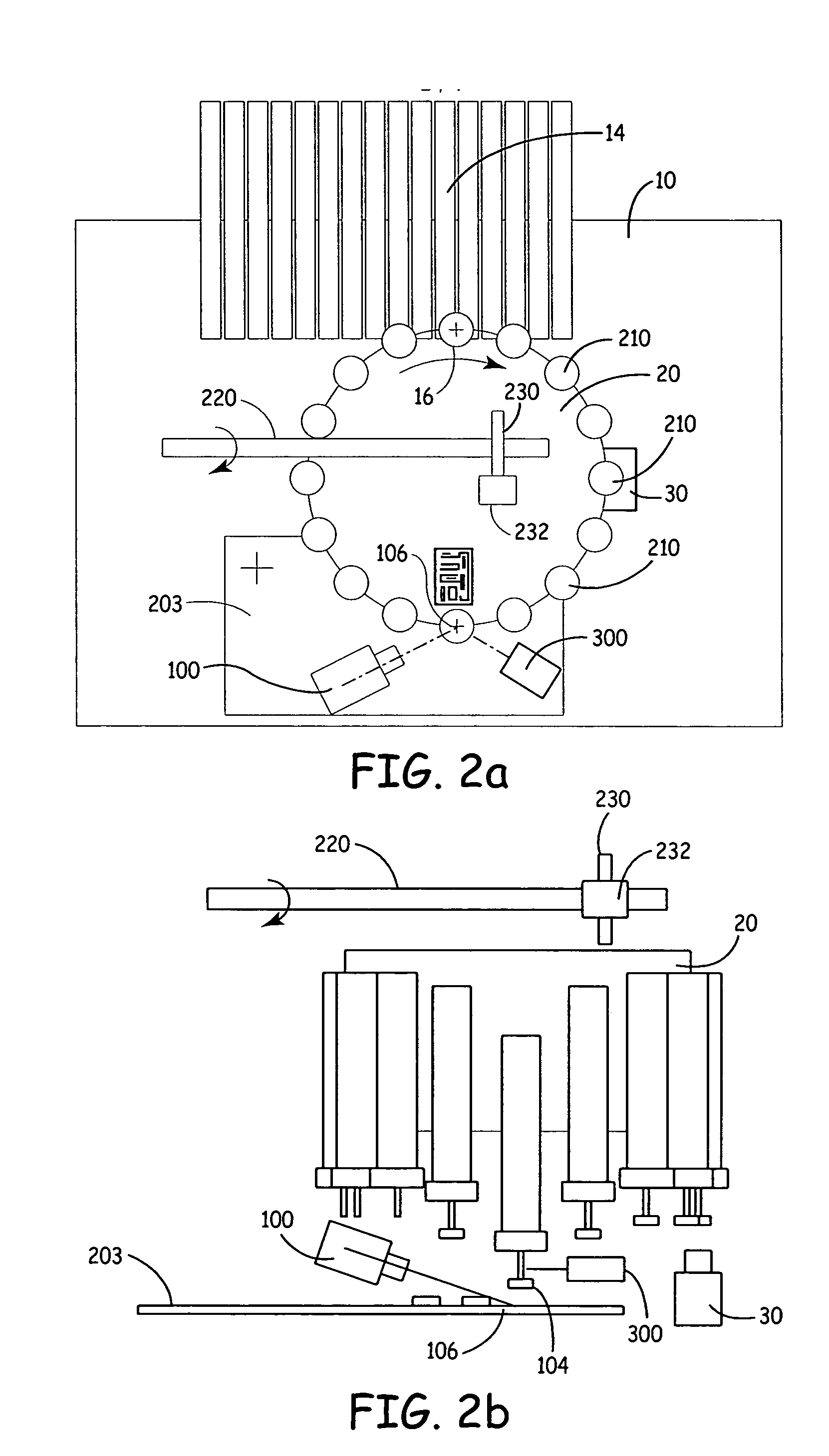

Pick and place machine with improved component placement inspection

InactiveUS20050117797A1Improve the level ofPrinted circuit assemblingAutomatic control devicesEngineeringImage acquisition

Embodiments of the present invention improve upon component level inspection performed by pick and place machines. Such improvements include using a position sensitive device that measures the position of the placement head relative to the workpiece as the placement head travels towards and away from the workpiece during a placement cycle. The output of this sensor is used to selectably trigger the acquisition of the images used to measure a placement characteristic of the component placement machine.

Owner:CYBEROPTICS

Cooling system for densely packed electronic components

InactiveUS20040163797A1Mechanical apparatusSemiconductor/solid-state device detailsComputer moduleVolumetric Mass Density

A more efficient cooling system for densely packed electronic components for use in an out-of-doors equipment enclosure. An array of cooling assemblies are placed on heat generating components mounted to printed circuit boards mounted in enclosure racks. Each board has a manifold for intake and exhaust of refrigerant, and larger rack manifolds are substituted for rails and are attached to a backplane. A hybrid package including a ceramic hybrid power module and an attached array of cooling assemblies provide even more density of components and improved cooling.

Owner:EMERSON NETWORK POWER ENERGY SYST NORTH AMERICA

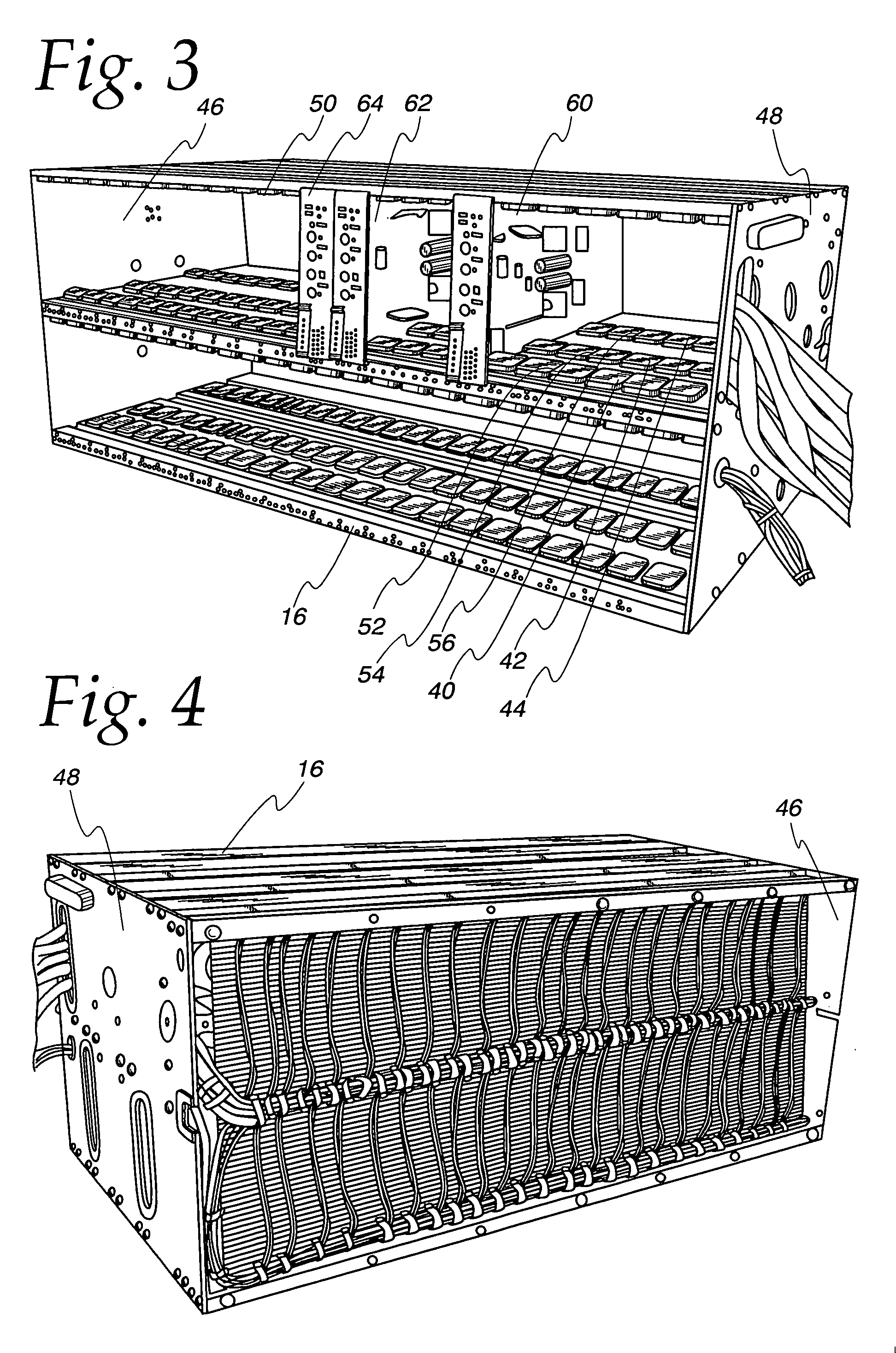

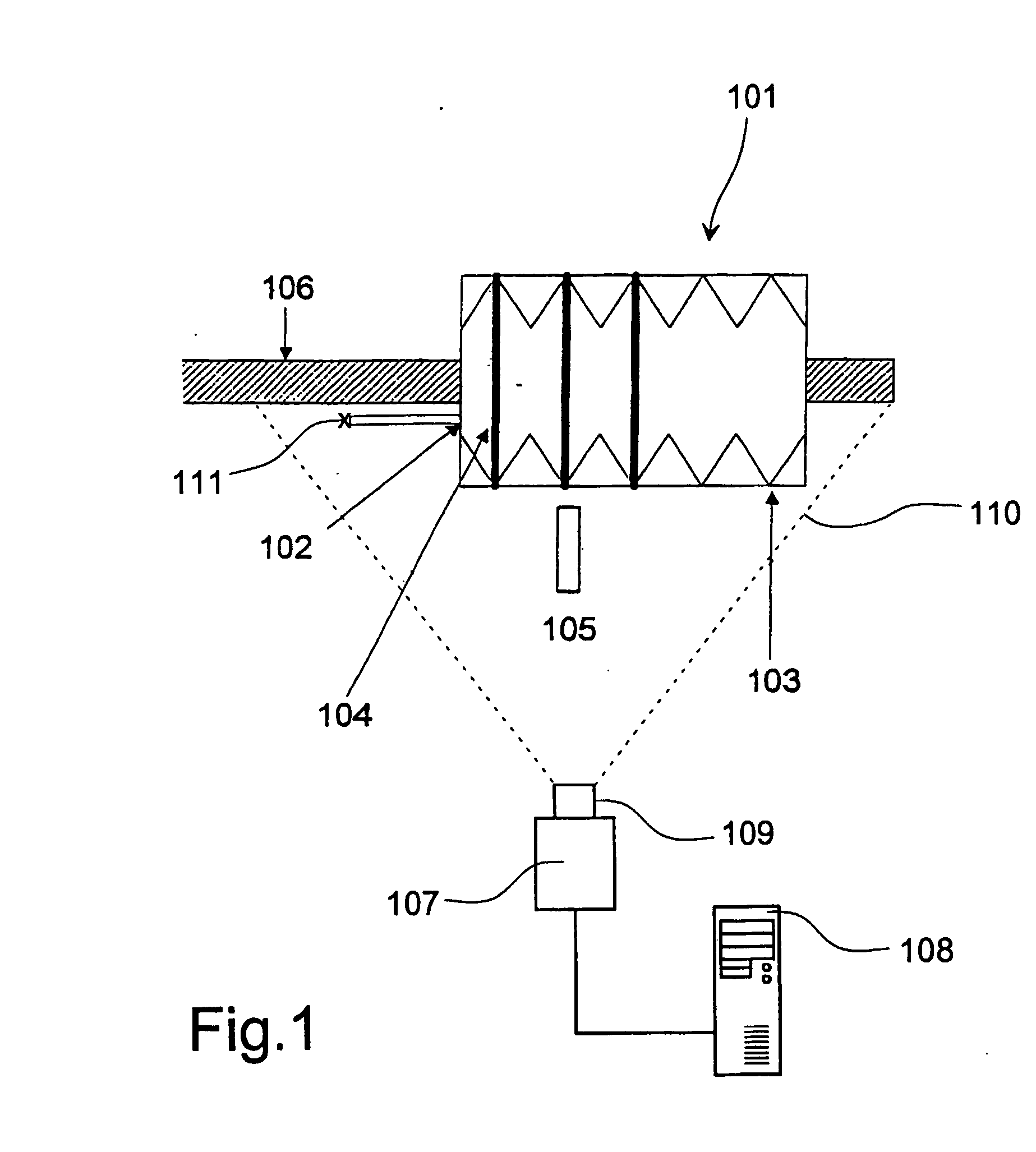

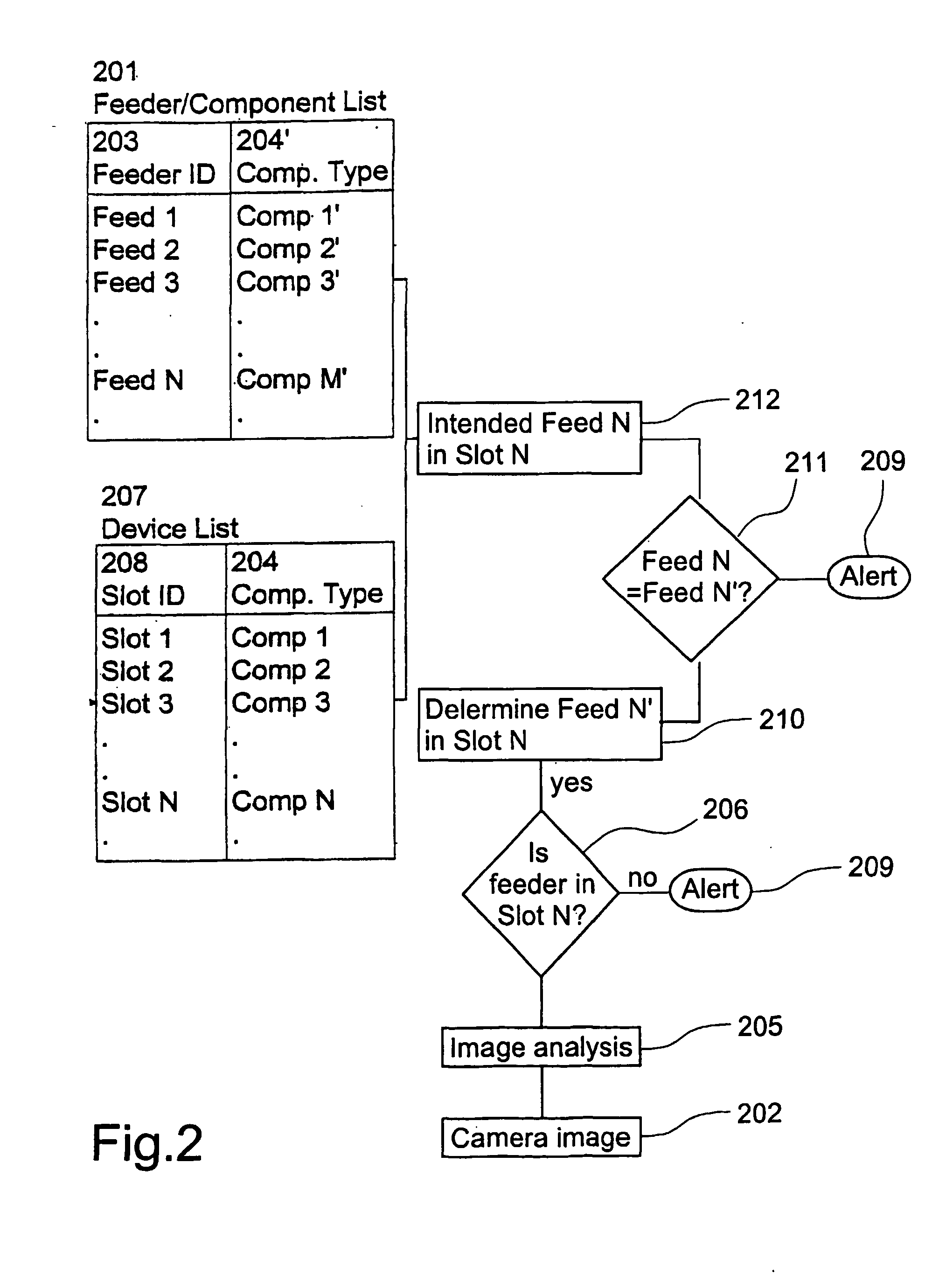

Feeder verification with a camera

InactiveUS20050161498A1Low costReduce riskDigital data processing detailsImage data processing detailsImaging analysisValidation methods

Method for component verification during operation of a component placement machine (101) having a series of feeder slots (103) for holding component feeders (104) with feeder markers, each feeder marker carrying a unique feeder ID, wherein each feeder slot (103) has a unique slot ID (208). On an image taken with a camera of the feeder slots, image analysis is performed to check whether the actual feeders in the slots corresponds to those feeders that are intended to be placed in these slots.

Owner:VALOR DENMARK AS

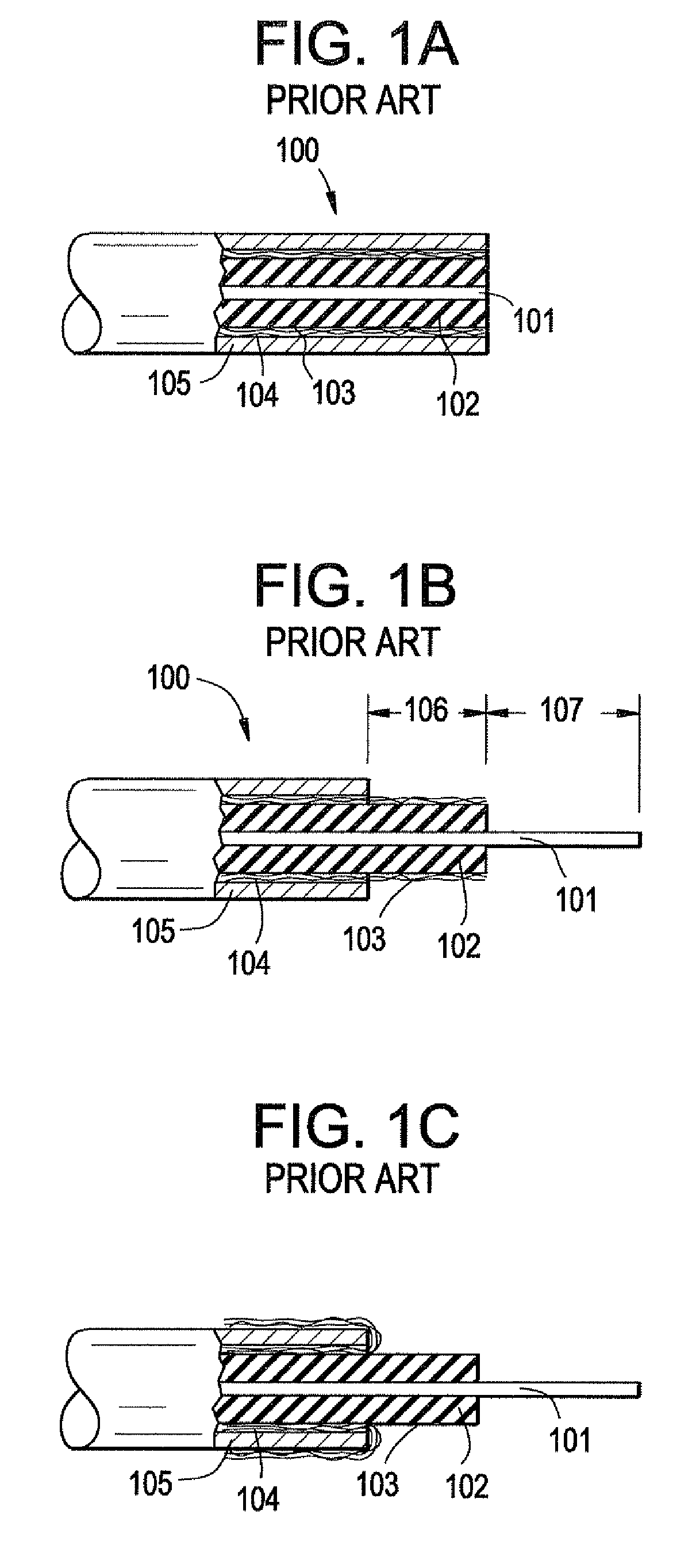

Coaxial connector and coaxial cable connector assembly and related method

ActiveUS7714229B2CostSufficient retentionElectrically conductive connectionsTwo pole connectionsCoaxial cableEngineering

A method of making a coaxial cable assembly is disclosed, the assembly comprising a coaxial cable and a connector, or connector termination, at least one end of the cable. A connector, comprised of connector components, is also disclosed. The method comprises placing connector components into contact with the cable before the connector components are assembled into a connector. The connector is assembled simultaneously with securing the connector to the cable to make a coaxial cable assembly. A method of preparing coaxial cable in a manner suitable for making coaxial cable assemblies is also disclosed. The coaxial cable assembly can be a jumper, or a lead.

Owner:PPC BROADBAND INC

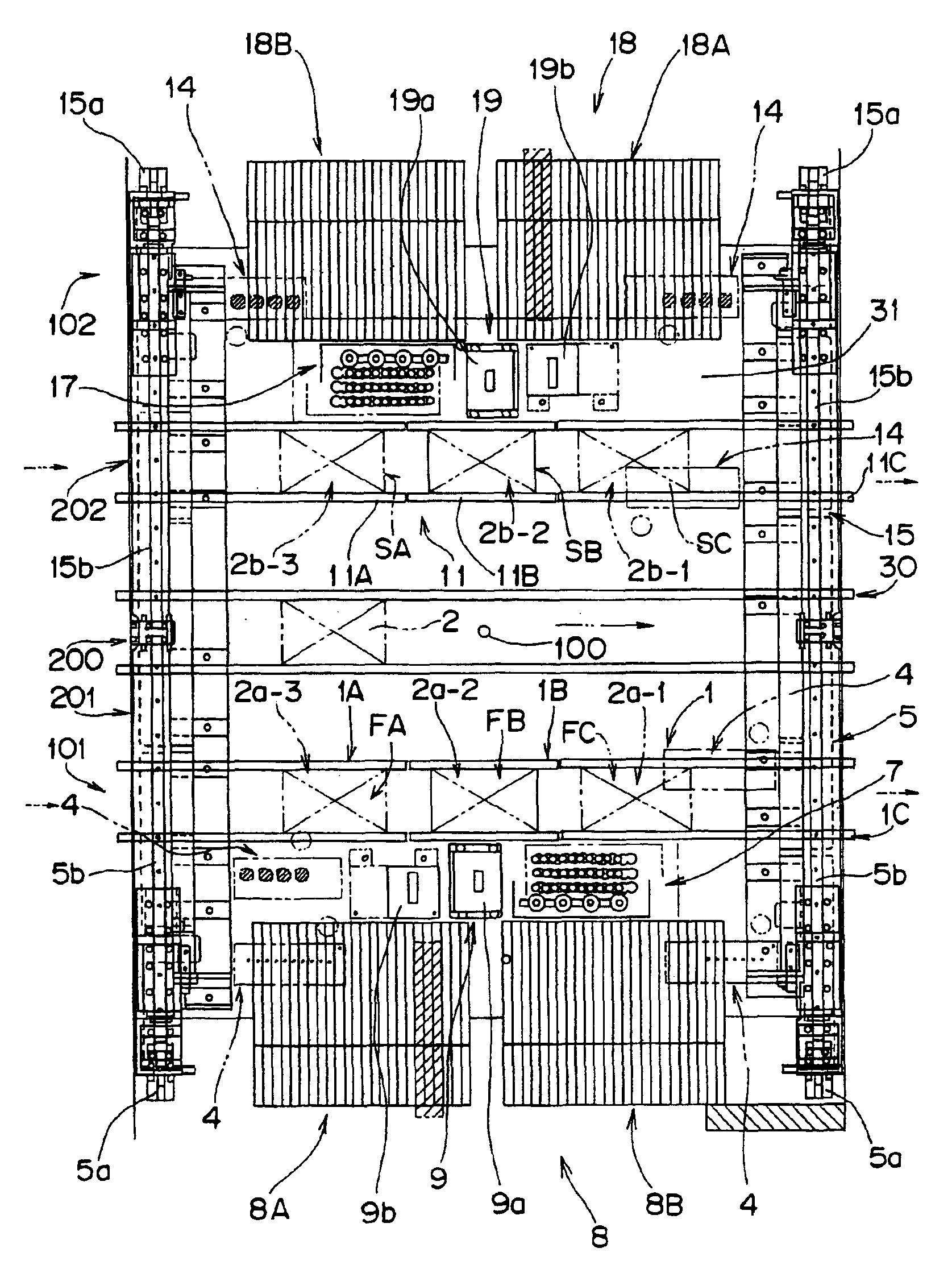

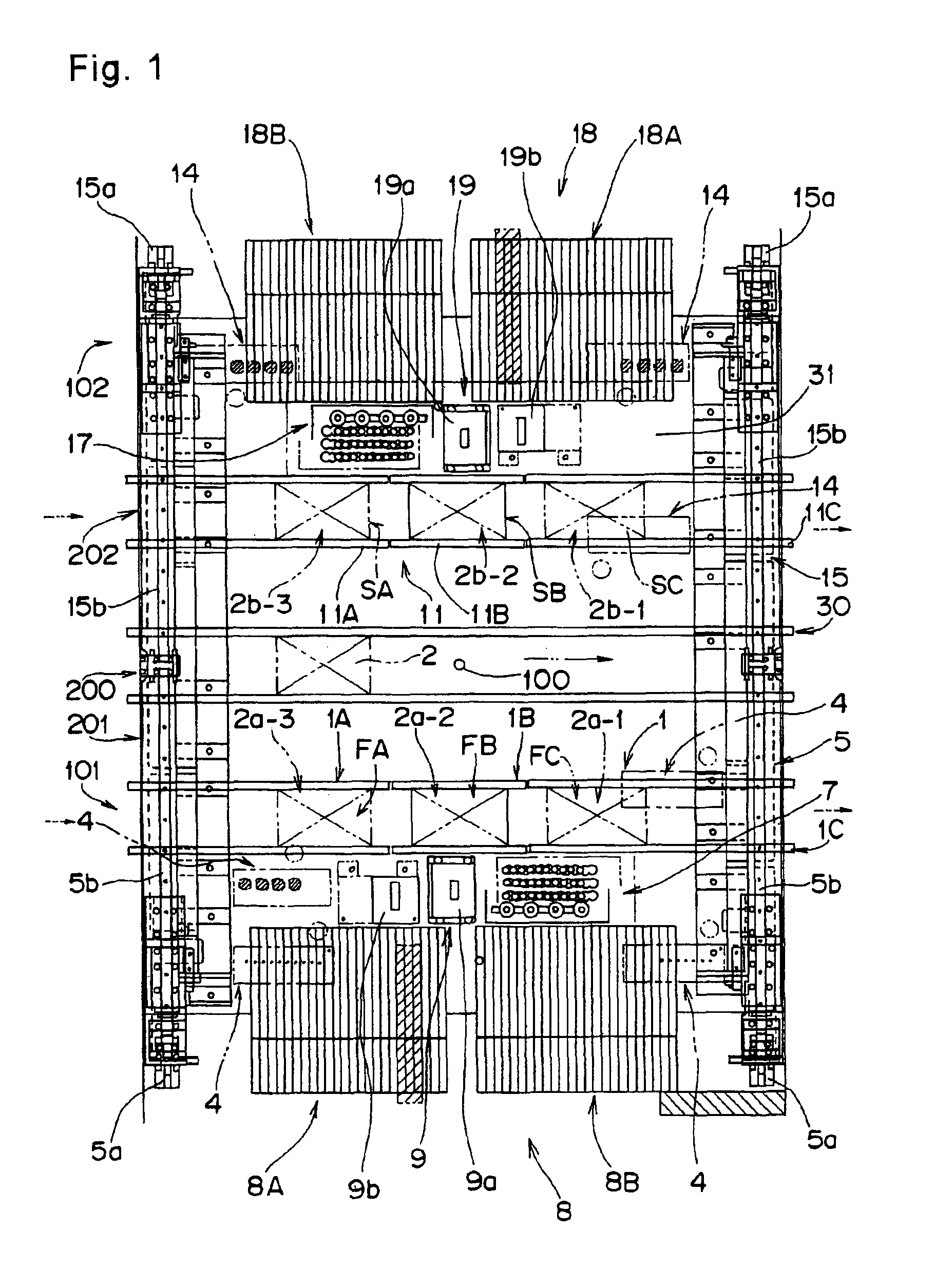

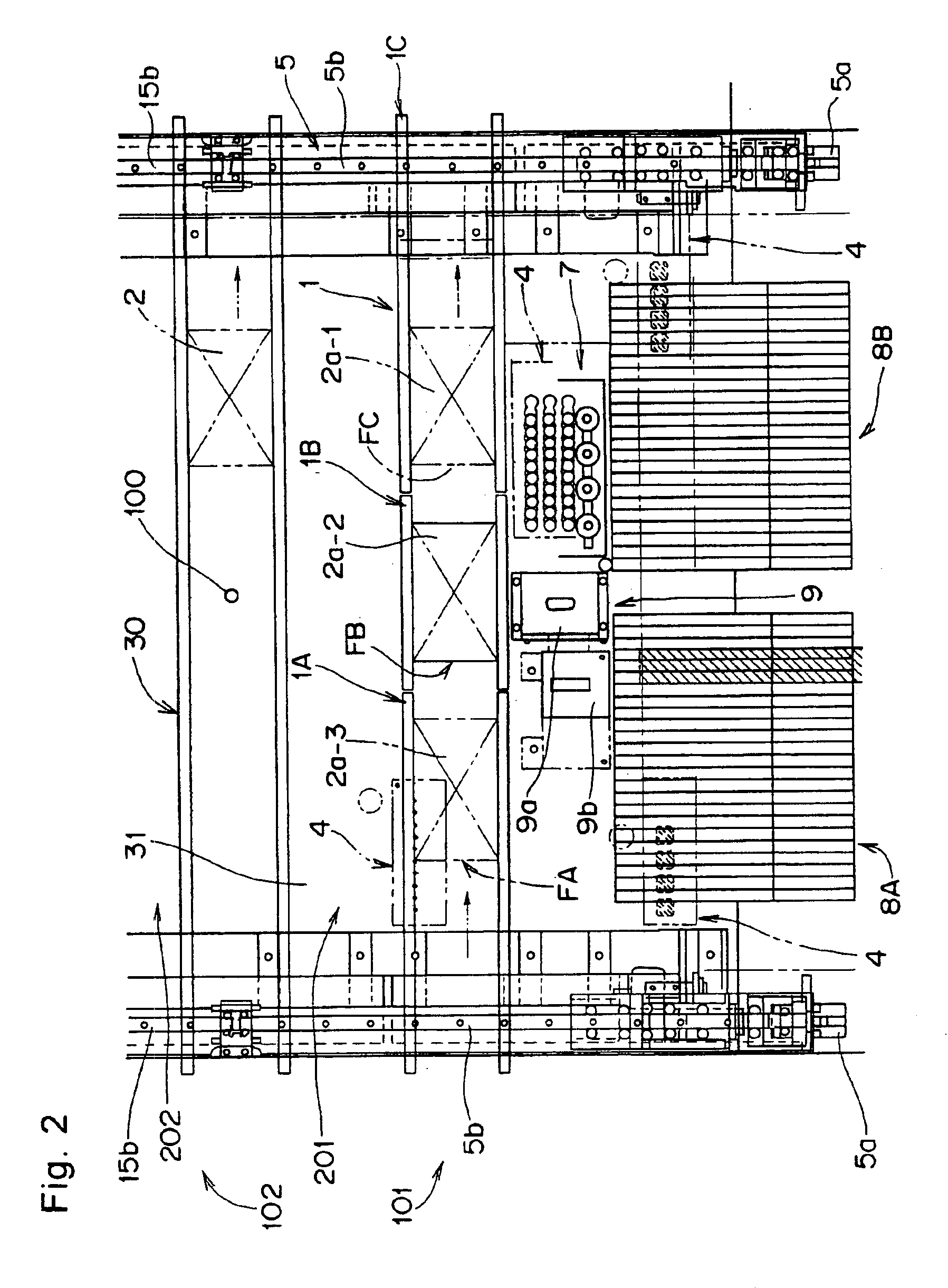

Device and method for mounting parts

A first mounting unit and a second mounting unit capable of performing component holding, component recognition, and component placement for two boards independently of each other are provided. A first conveyance path for loading and unloading the first board, and a second conveyance path for loading and unloading the second board, are independently arranged.

Owner:PANASONIC CORP

Apparatus and method for predetermined component placement to a target platform

ActiveUS7928591B2Simple surfaceImprove accuracySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsMultiple sensorEngineering

The present invention relates generally to assembly techniques. According to the present invention, the alignment and probing techniques to improve the accuracy of component placement in assembly are described. More particularly, the invention includes methods and structures to detect and improve the component placement accuracy on a target platform by incorporating alignment marks on component and reference marks on target platform under various probing techniques. A set of sensors grouped in any array to form a multiple-sensor probe can detect the deviation of displaced components in assembly.

Owner:WINTEC IND INC

Reprogrammable circuit board with alignment-insensitive support for multiple component contact types

InactiveUS8124429B2Semiconductor/solid-state device testing/measurementWave amplification devicesSignal conditioningContact type

Owner:NORMAN RICHARD

Electronic earplug for monitoring and reducing wideband noise at the tympanic membrane

ActiveUS20040234094A1Accurate monitoringHigh degreeEarplugsNoise generationEngineeringNoise reduction

An electronic earplug for wideband control of pressures at the tympanic membrane is presented. A unique methodology of determining effective component placement inside an earplug that provides acoustic isolation between the ambient noise and tympanic membrane is explained. Methods for providing accurate dosimetry and improved active control result from the unique earplug design process, leading to very wideband active noise reduction at the tympanic membrane.

Owner:GENTEX CORP

Pick and place machine with component placement inspection

InactiveUS20070120977A1Reduce the possibilityTo offer comfortCharacter and pattern recognitionColor television detailsImpact systemImaging processing

Improved component placement inspection and verification is performed by a pick and place machine. Improvements include stereovision imaging of the intended placement location; enhanced illumination to facilitate the provision of relatively high-power illumination in the restricted space near the placement nozzle(s); optics to allow image acquisition device to view the placement location from an angle relative to a plane of the placement location, thereby reducing the possibility of such images being obstructed by the component; techniques for rapidly acquiring images with commercially available CCD arrays such that acquisition of before and after images does not substantially impact system throughput; and image processing techniques to provide component inspection and verification information.

Owner:CYBEROPTICS

Electronic textile and method of manufacturing an electronic textile

InactiveUS20130176737A1Cost-efficient productionIncrease productionPrinted circuit assemblingCircuit bendability/stretchabilityEngineeringElectronic component

A method of manufacturing an electronic textile (1) comprising the steps of: providing a textile carrier (2) comprising a plurality of conductor lines (6a-b); releasably attaching (101) the textile carrier (2) to a rigid support plate (20); providing (102) a conductive substance on the textile carrier (2) in a pattern forming a plurality of sets of connection pads (5a-b) on the textile carrier (2), each set of connection pads defining a component placement position for placement of an electronic component (3), and each set of connection pads (5a-b) comprising a connection pad overlapping one of the conductor lines, the connection pad having a connection pad length (Lcp) in a direction parallel to the conductor line and a connection pad width (Wcp) in a direction perpendicular to the conductor line, wherein the connection pad width (Wcp) is at least one percent of an extension (Wtc) of the textile carrier (2) in the direction perpendicular to the conductor line; automatically placing (103) electronic components (3) at the component placement positions; curing (104) the conductive substance to attach the electronic components (3) to the textile carrier (2), thereby forming the electronic textile (1) and removing (105) the electronic textile from the rigid support plate.

Owner:SIGNIFY HLDG BV +1

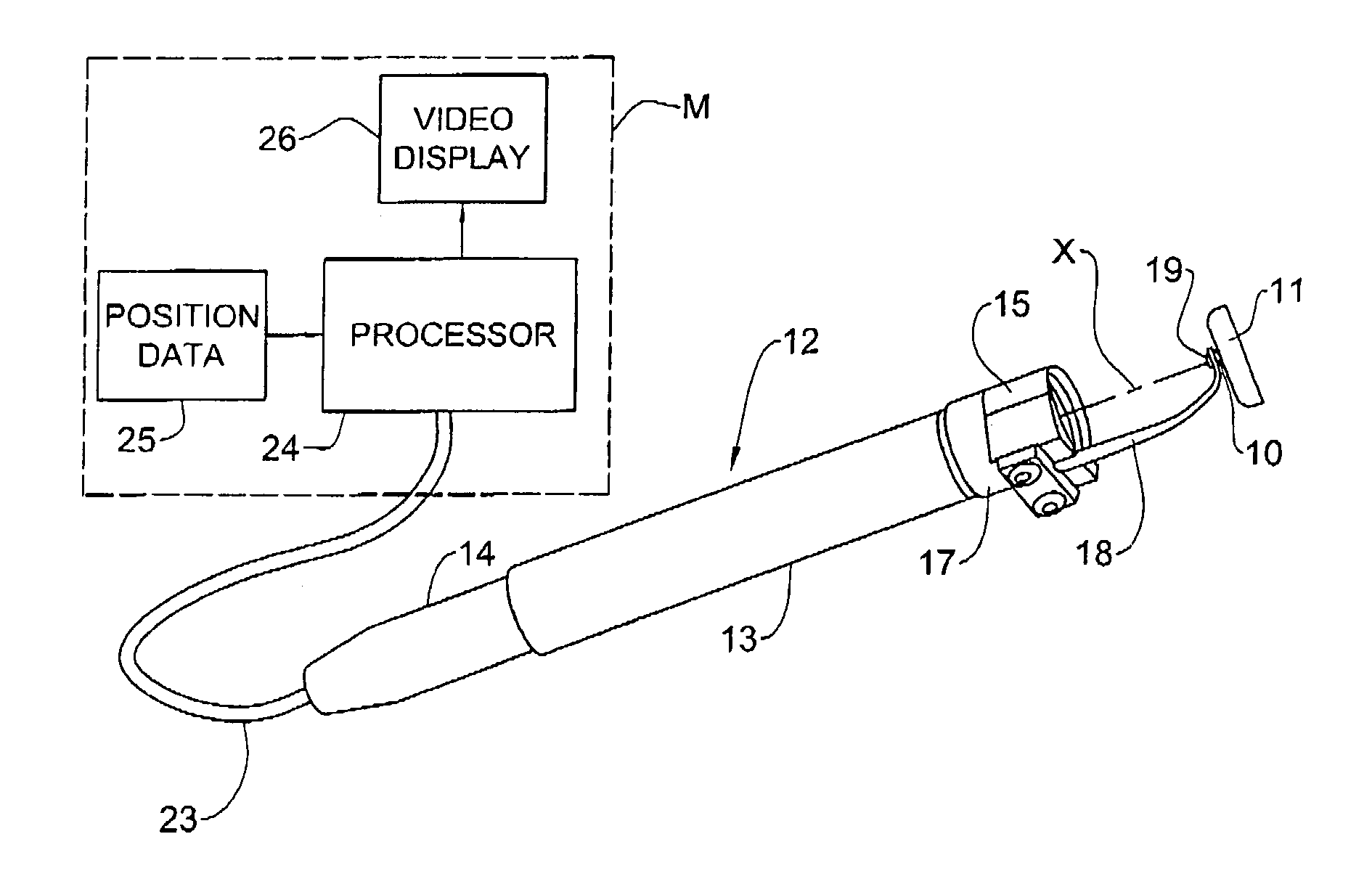

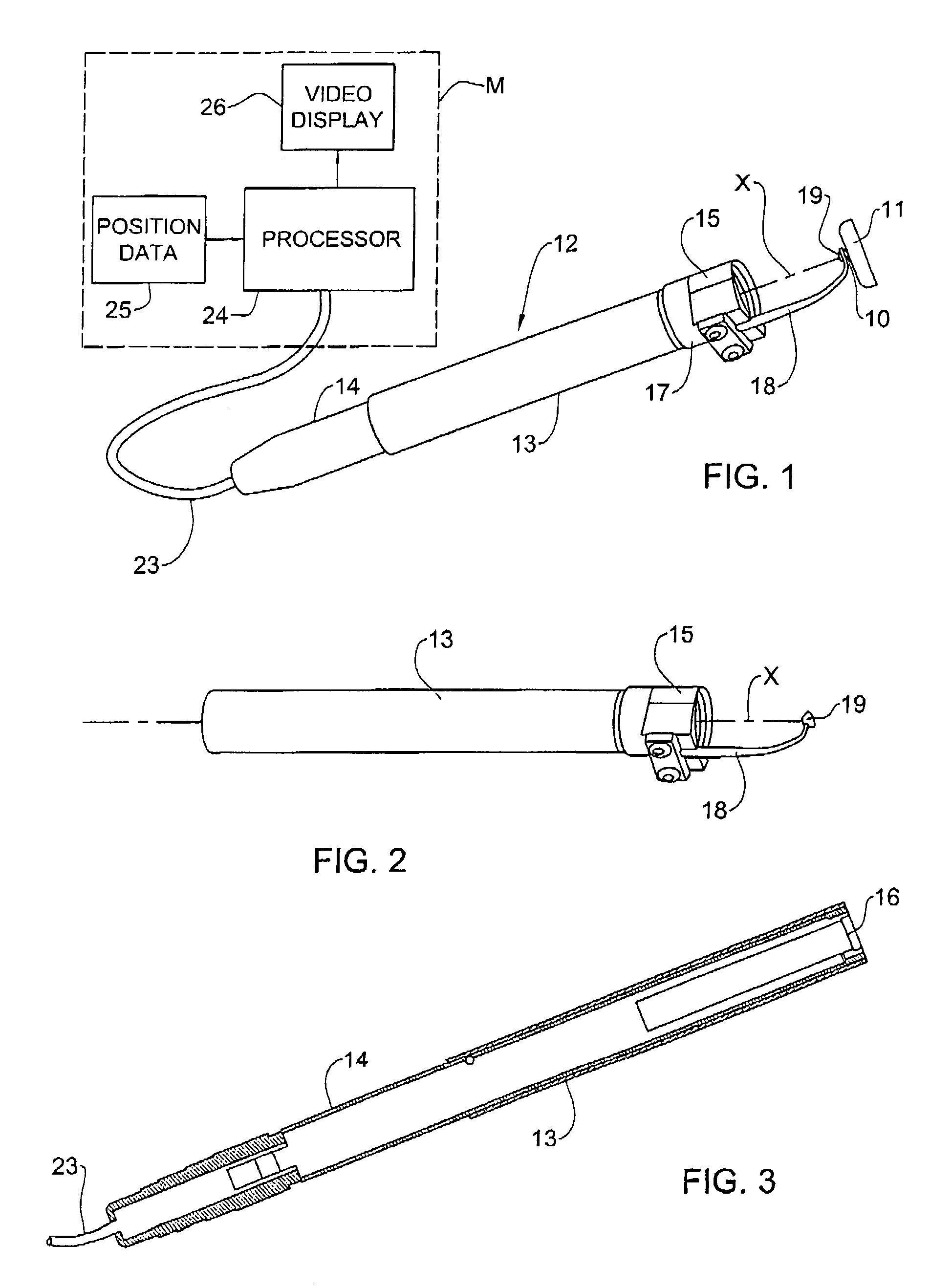

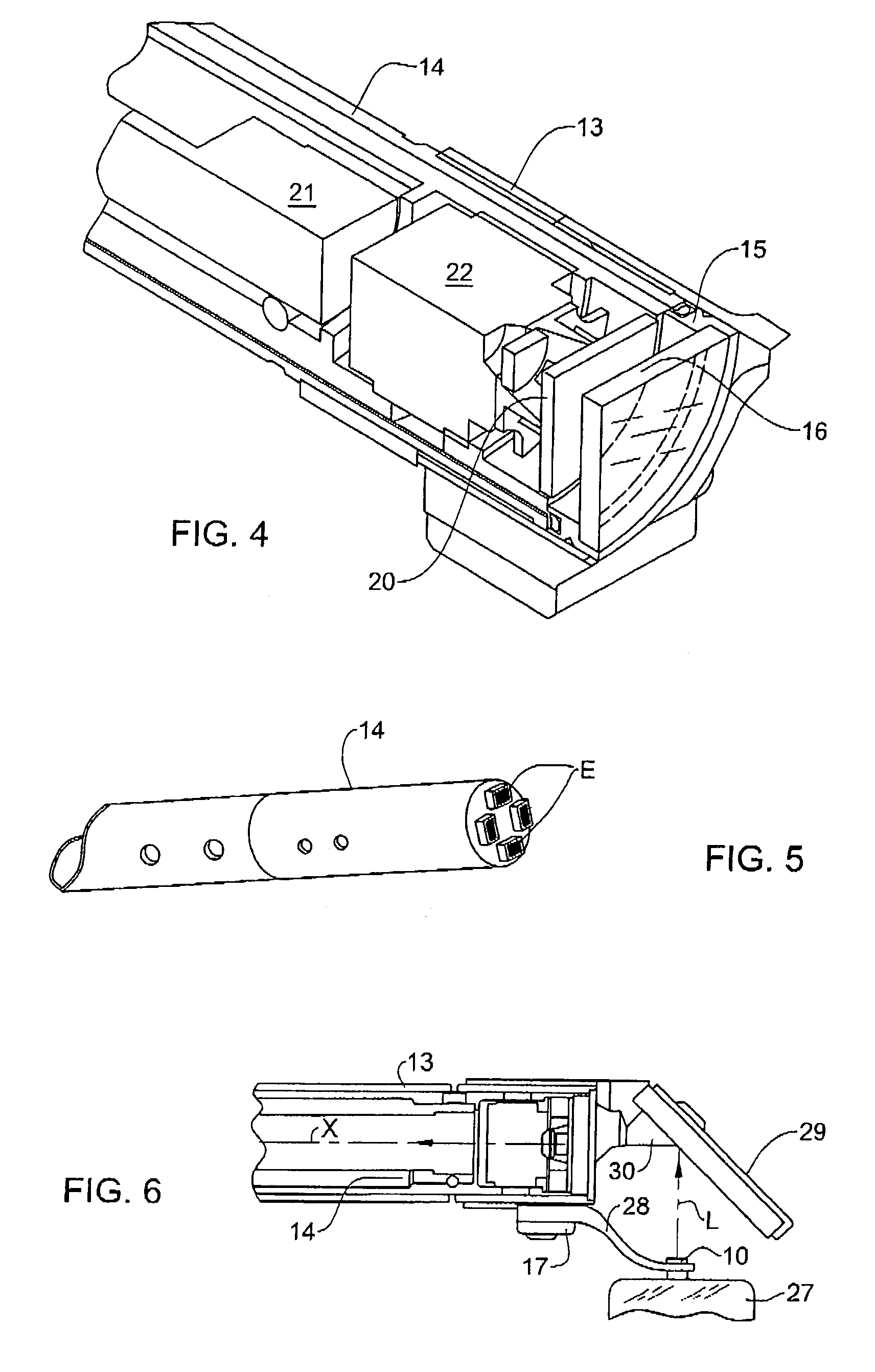

Appliance for positioning orthodontic components

A positioning appliance adapted to facilitate an orthodontics procedure in which a bracket or other orthodontic component is placed at a desired site on the surface of a tooth and affixed thereto. The appliance comprises a hand-held tubular wand that has a protective sleeve section and a camera section telescoped in the sleeve section. A window is mounted at the front end of the sleeve section and a finger projecting therefrom is adapted to hold the bracket at a position abutting the tooth surface. A camera is housed in the camera section to capture through the window an image of the bracket on the surface of the tooth. One or more light sources are housed in the camera section, for irradiating the bracket and the tooth surface with light detectable by the camera. Additional one or more light sources are housed in the camera section and are capable of irradiates light at a wavelength that can cure an adhesive used for affixing the bracket or other orthodontic component to the surface of a tooth.

Owner:ALIGN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com