Patents

Literature

83results about How to "Cost-efficient production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Medical devices comprising a reticulated composite material

InactiveUS20070003753A1Easy to modifyCost-efficient productionStentsLayered productsReady to useMedical device

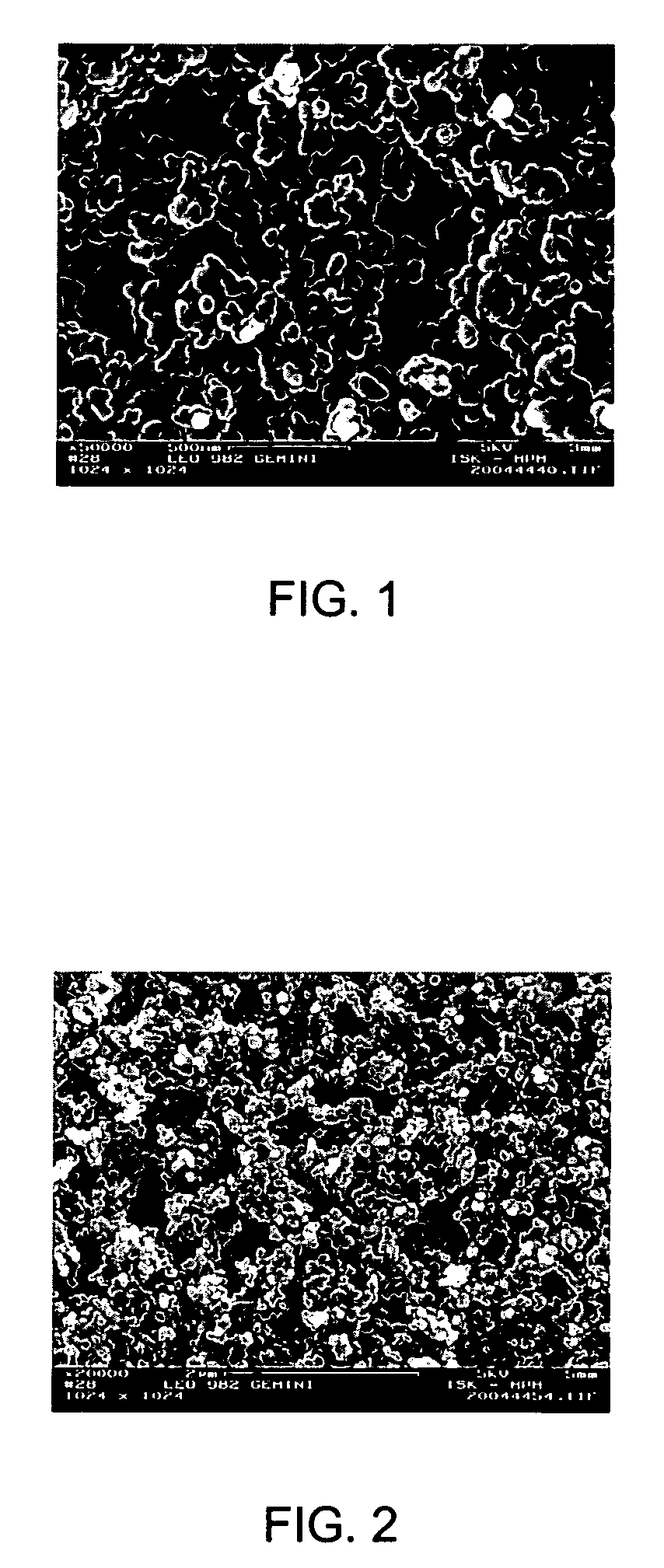

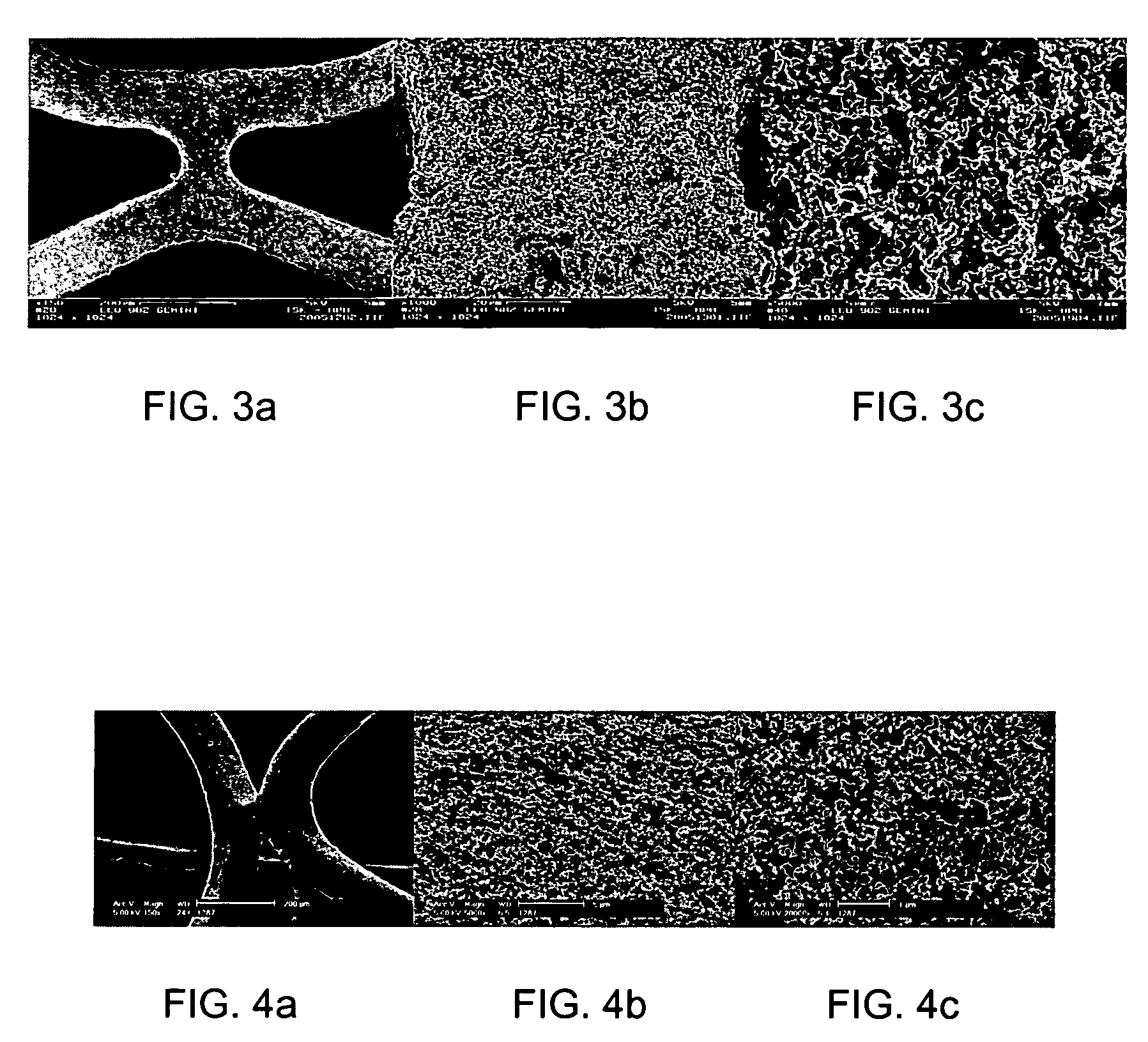

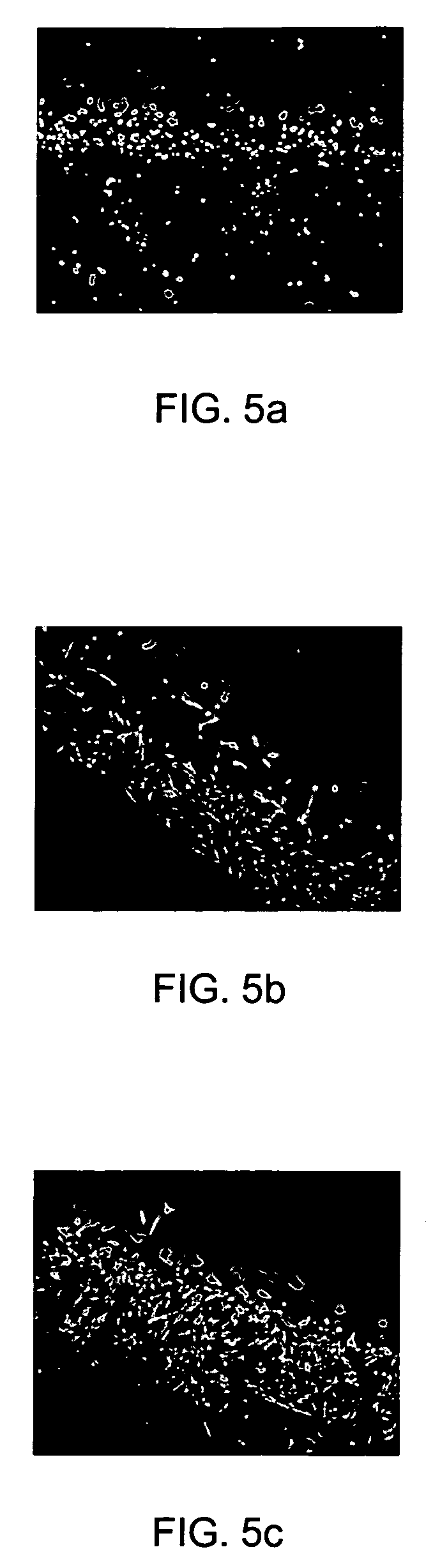

The present invention relates to medical devices, particularly for therapeutic and / or diagnostic purposes, which may coated or at least partially formed using porous reticulated composite materials. Specifically, the present invention relates to medical devices which include a porous composite material, where the composite material can be formed using a process comprising the steps of providing a liquid mixture that includes at least one inorganic and / or organic reticulating agent; and at least one matrix material that is a polymer or combination of polymers; and solidifying the liquid mixture.

Owner:CINVENTION AG

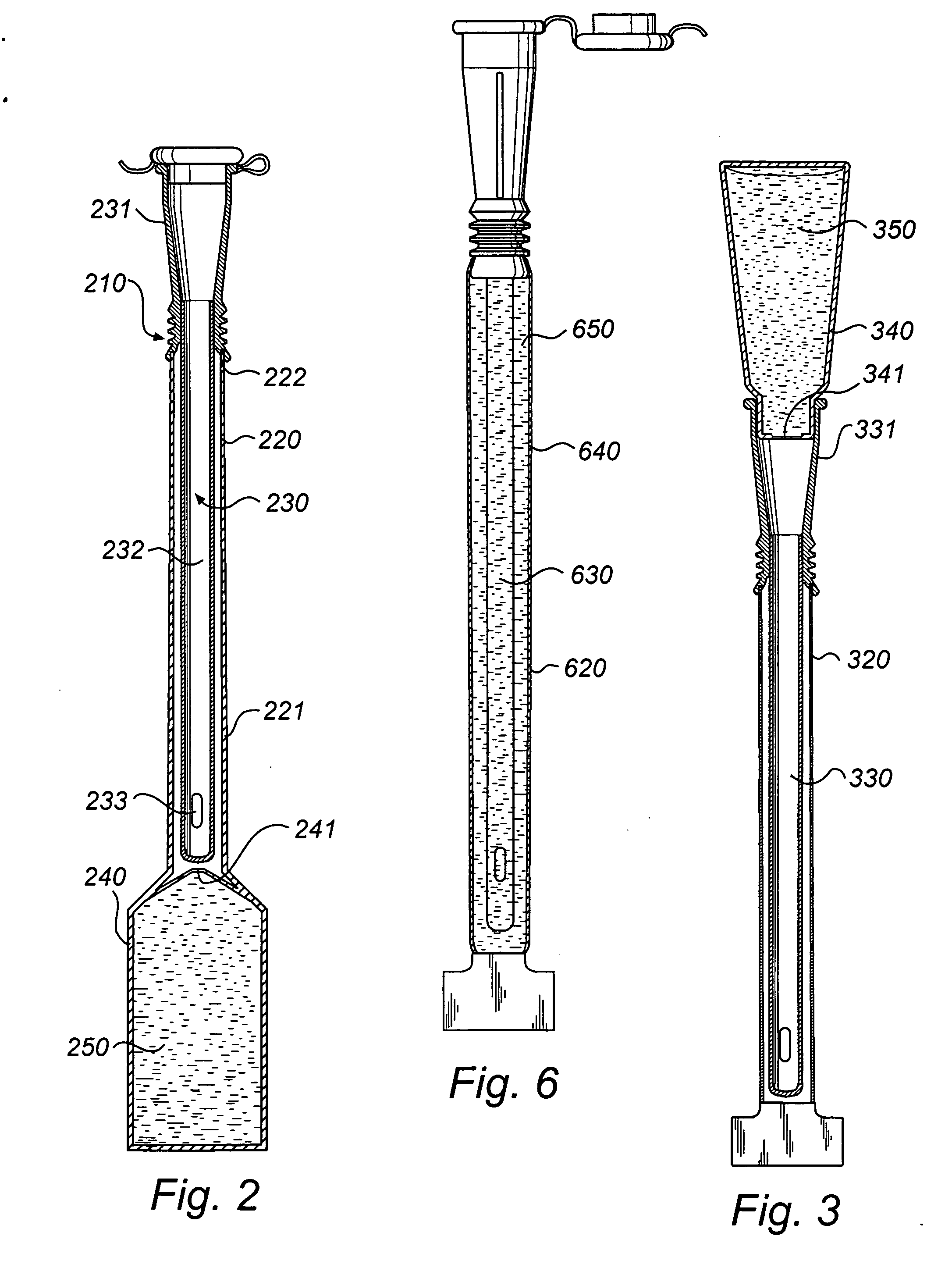

Assembly with osmolality-increasing fluid

InactiveUS20050137582A1Low friction characteristicSimple procedureWound drainsMixingUrologyReady to use

A catheter assembly is disclosed comprising: a hydrophilic catheter; a wetting fluid for wetting of the catheter; and a receptacle enclosing at least the insertable part of the catheter and the wetting fluid. Further, the wetting fluid is a solution incorporating at least one osmolality-increasing compound, and the total concentration of the osmolality-increasing compound(s) is very high, preferably exceeding 600 mOsm / dm3. The wetting fluid could either be arranged in contact with the hydrophilic surface layer of the catheter in the receptacle, for preservation of the hydrophilic surface layer in a wetted state during accommodation in said receptacle and provision of a ready-to-use catheter assembly, or be arranged to keep the wetting fluid separated from the hydrophilic surface layer of the catheter during storage, but to be brought into contact with said hydrophilic surface layer upon activation before an intended use of the catheter. A similar method and wetting fluid is disclosed as well. The provision of the osmolality-increasing compound in the wetting fluid provides several advantages per se, such as a improved properties of the hydrophilic coating, a more predictable and controllable wetting process, a more expedient and cost efficient production, etc. Further, the use of this very high concentration of osmolality-increasing compound in the wetting fluid has proven remarkably efficient.

Owner:ASTRA TECH SE

Process for production of porous reticulated composite materials

InactiveUS20070003749A1Easy to modifyCost-efficient productionLayered productsSurgeryMaterials sciencePolymeric matrix

The present invention relates to porous reticulated composite materials and processes for the production thereof. For example, a process for the production of porous composite materials can be provided in which a mixture capable of flowing comprising at least one inorganic and / or organic reticulating agent and at least one polymeric matrix material is provided, and the liquid mixture is caused to be solidified.

Owner:CINVENTION AG

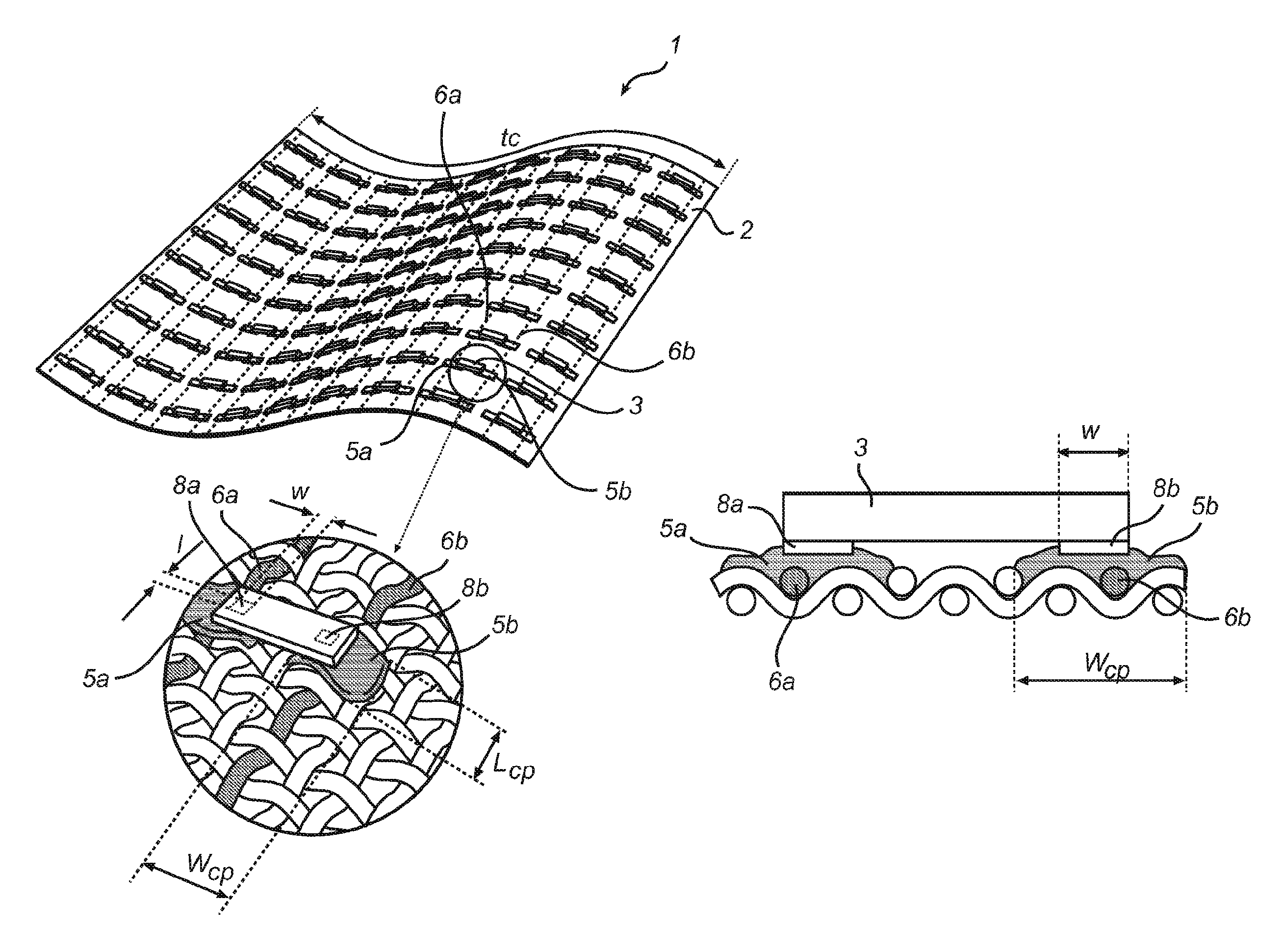

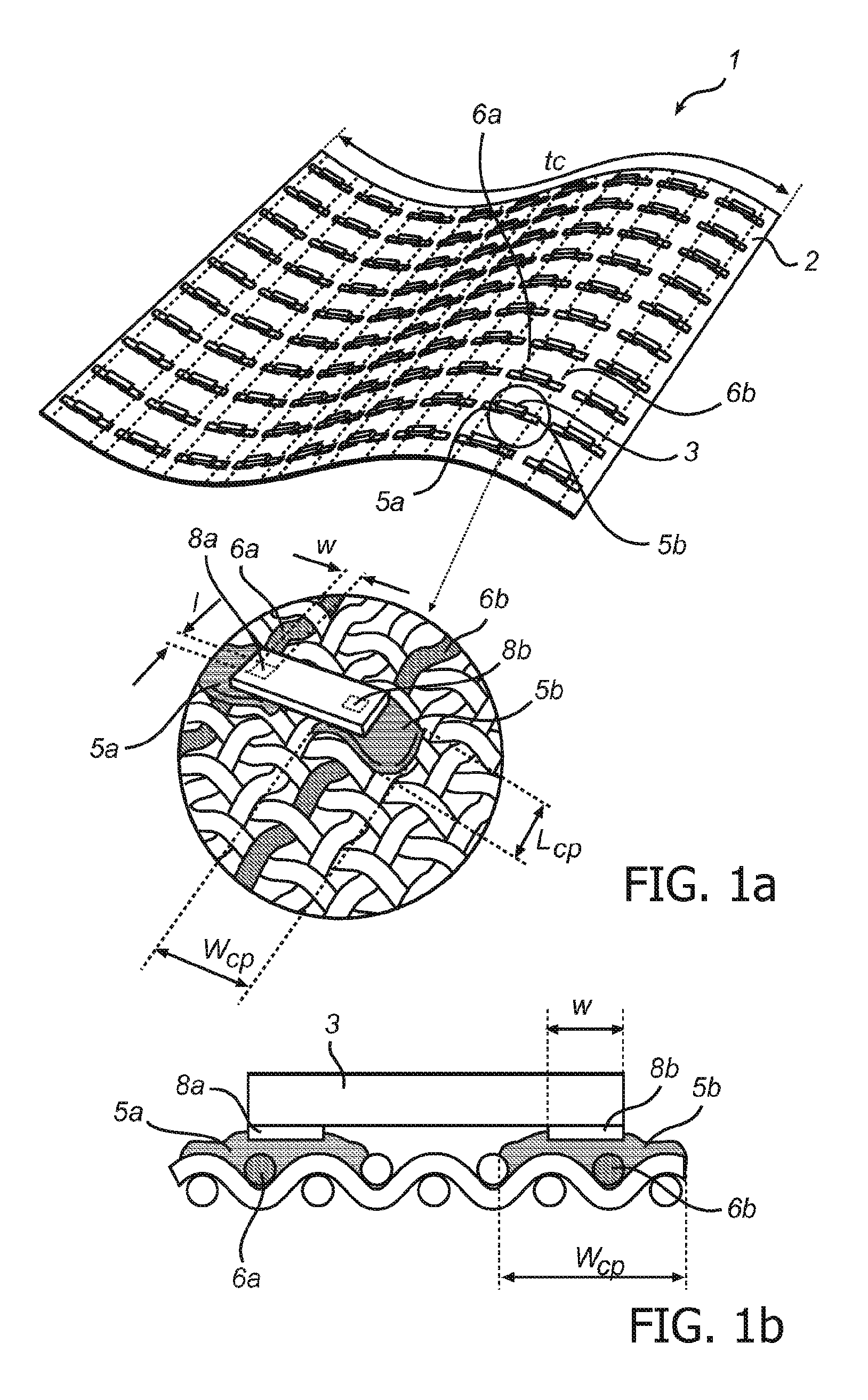

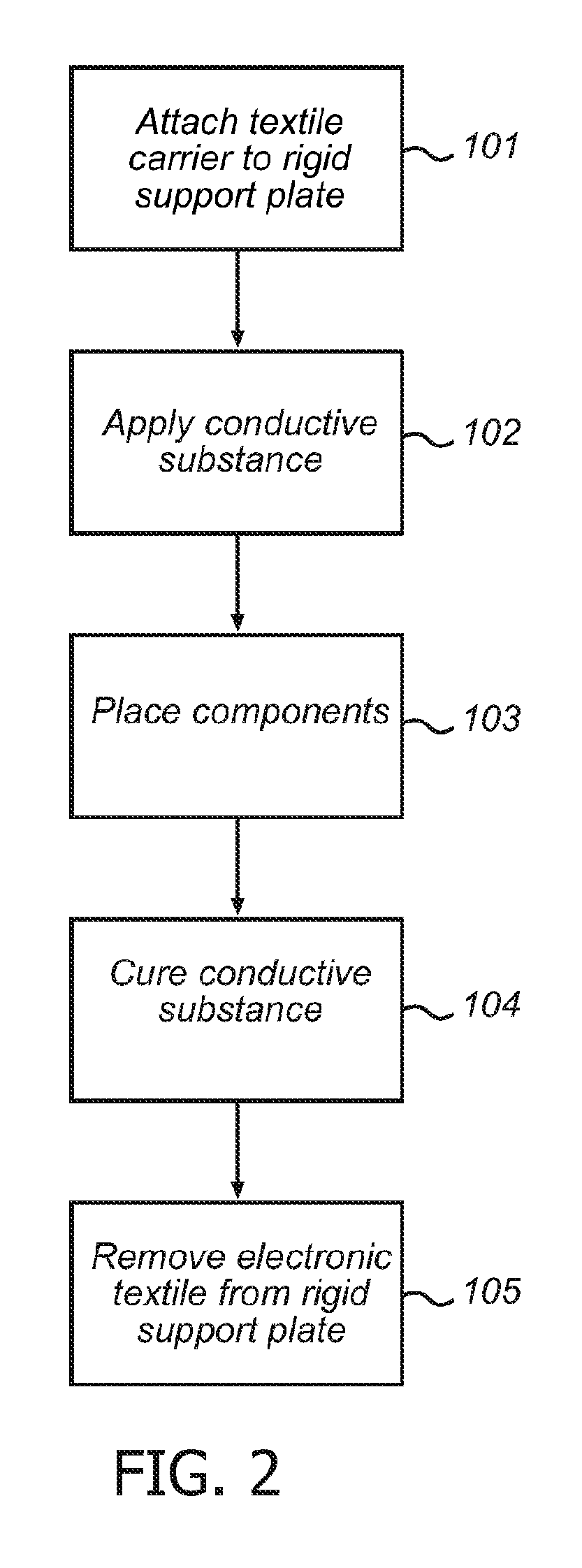

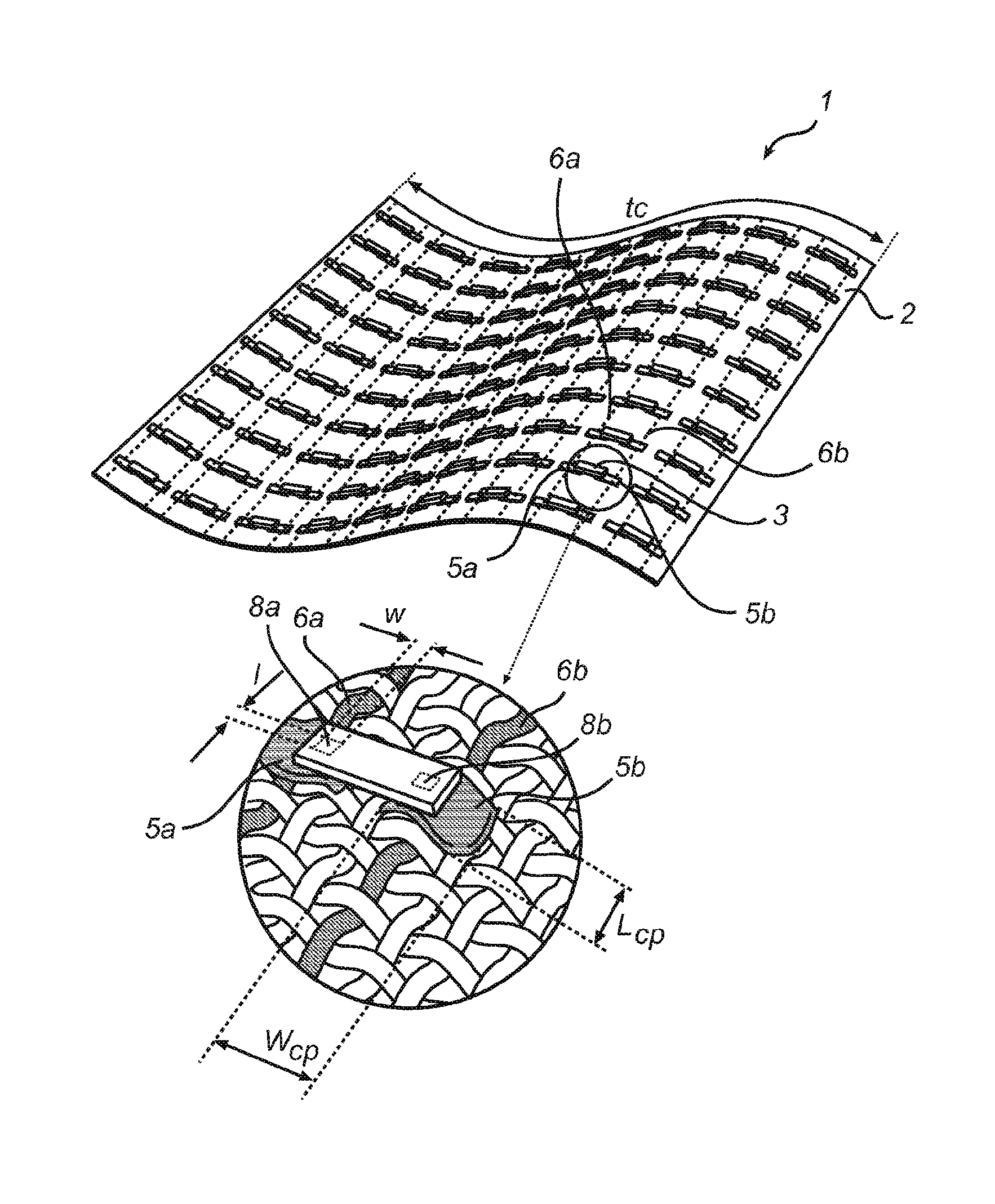

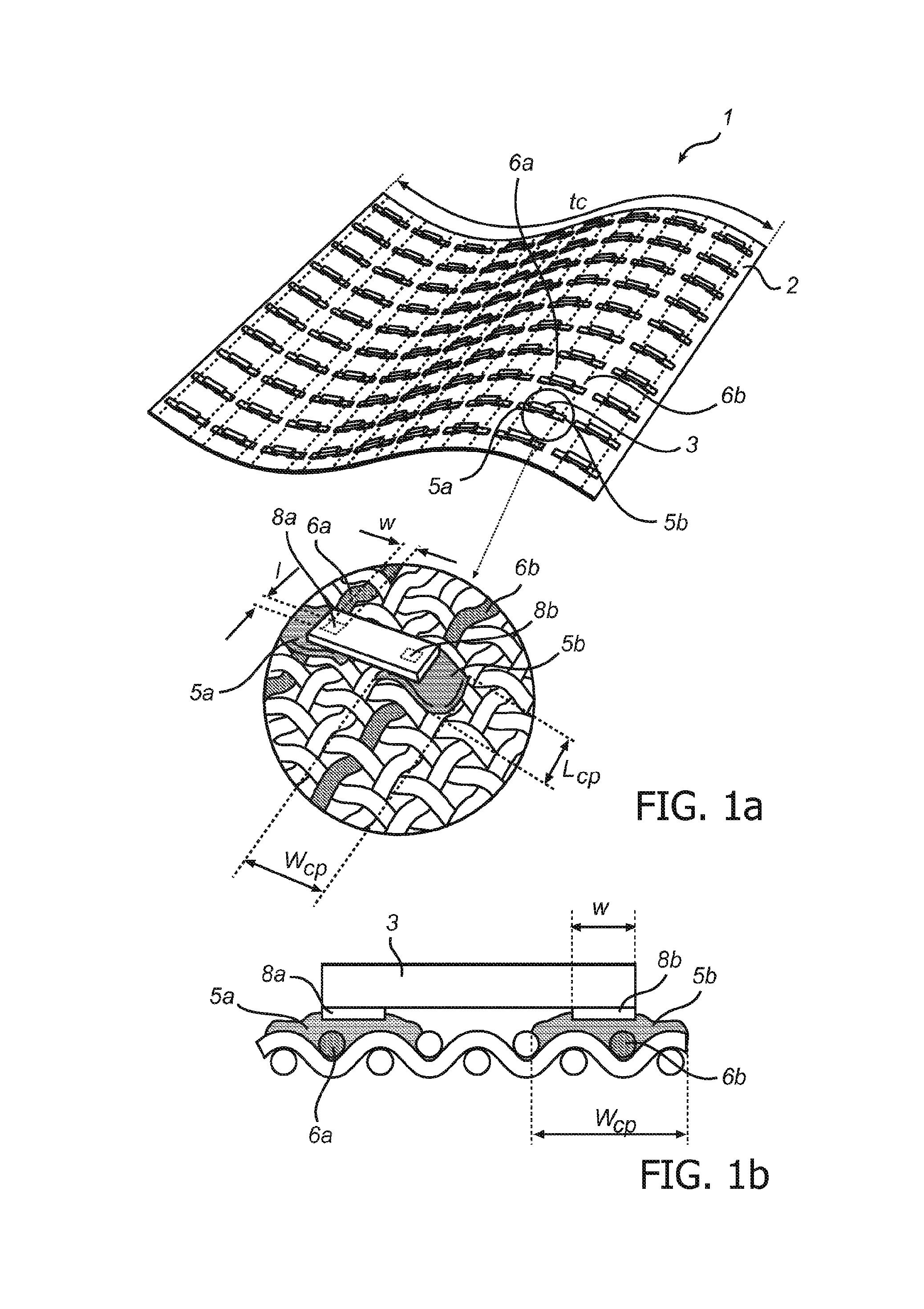

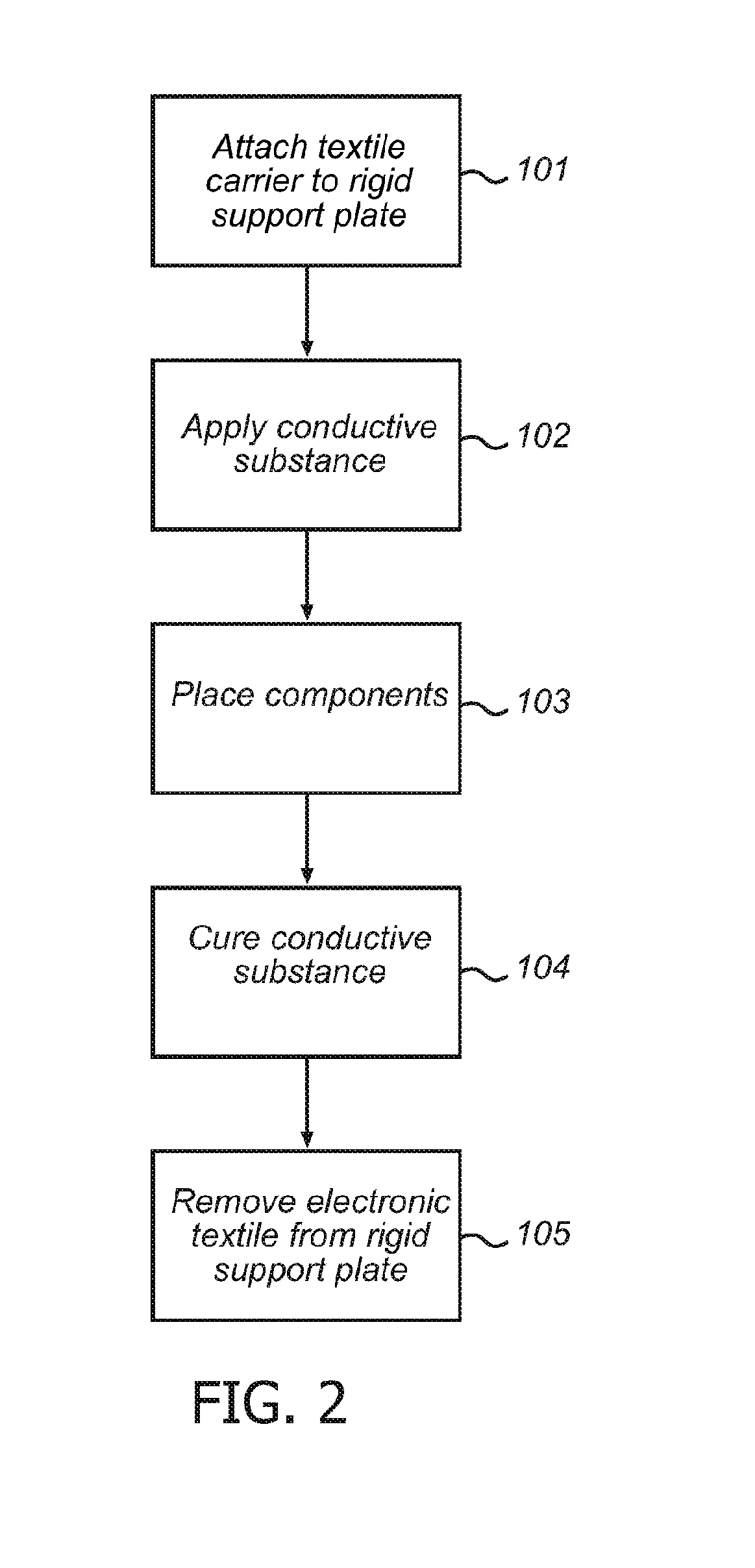

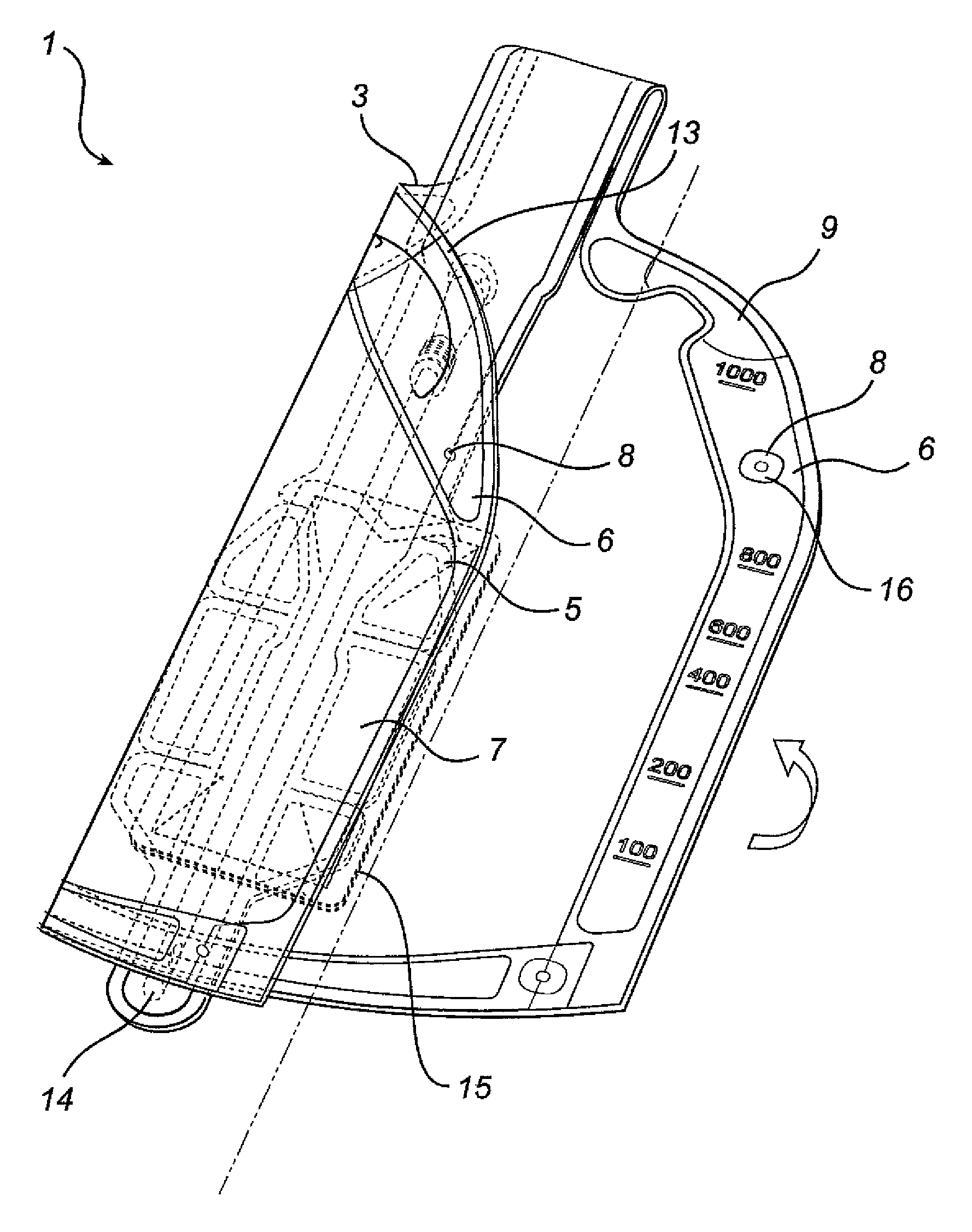

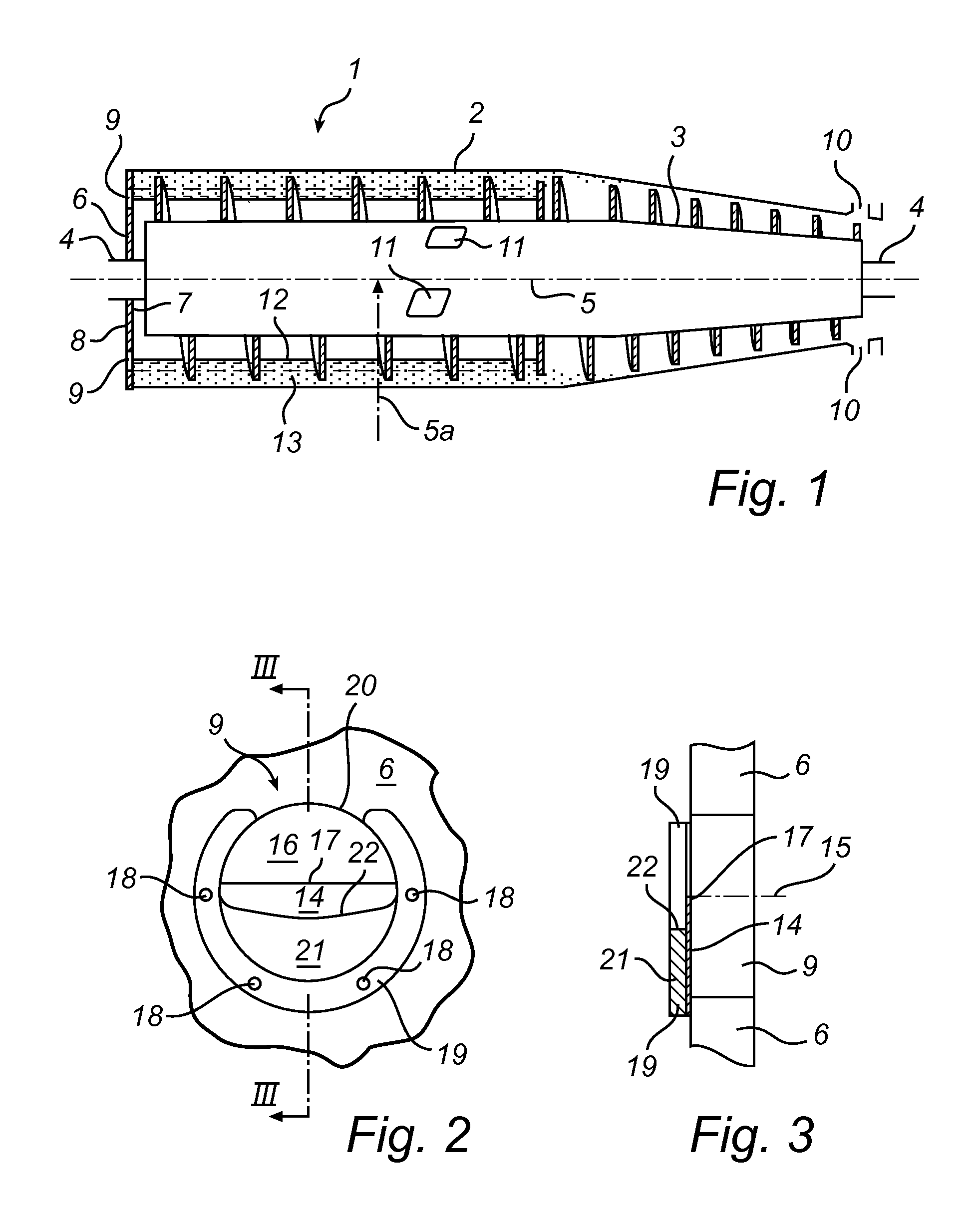

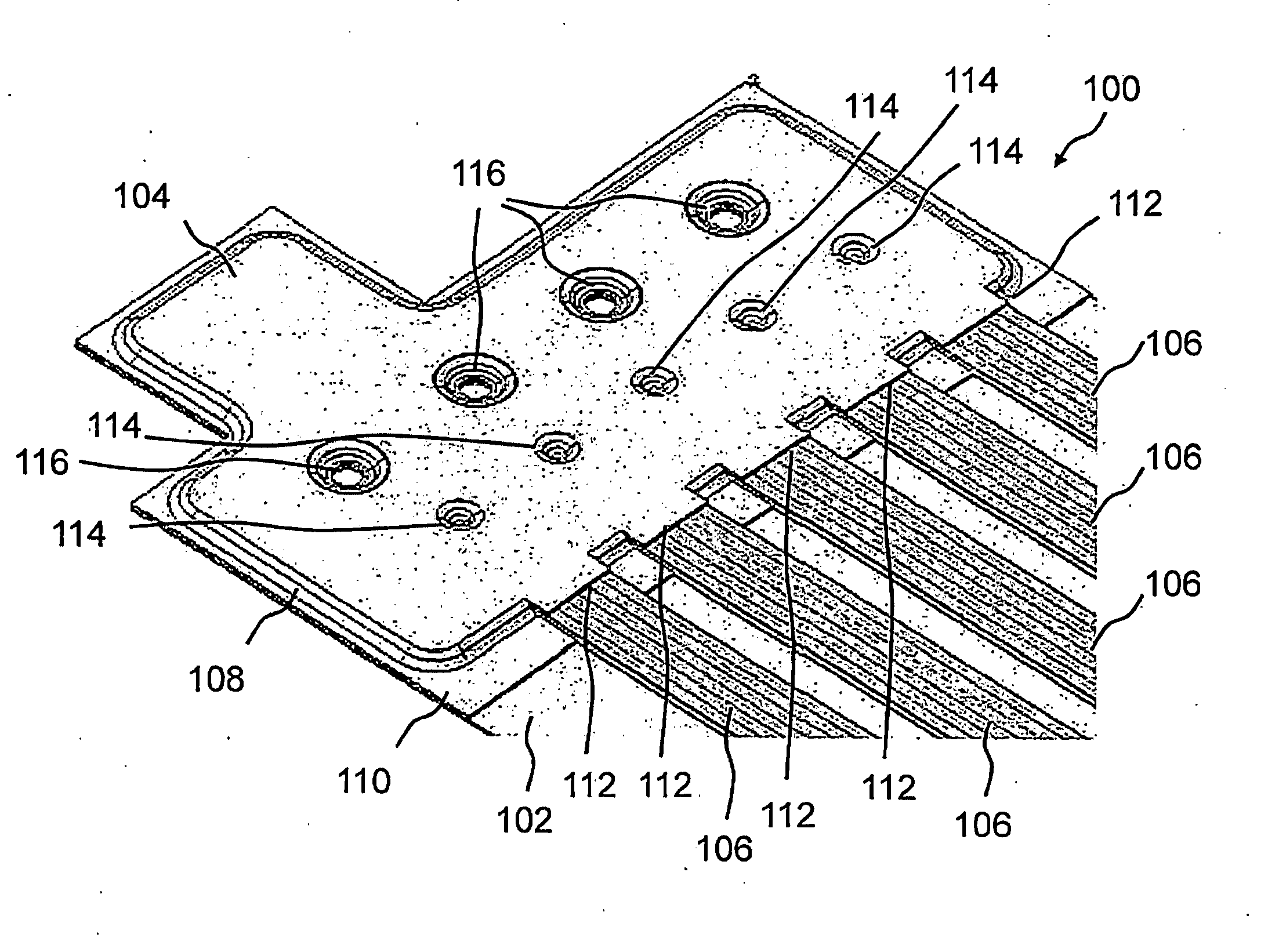

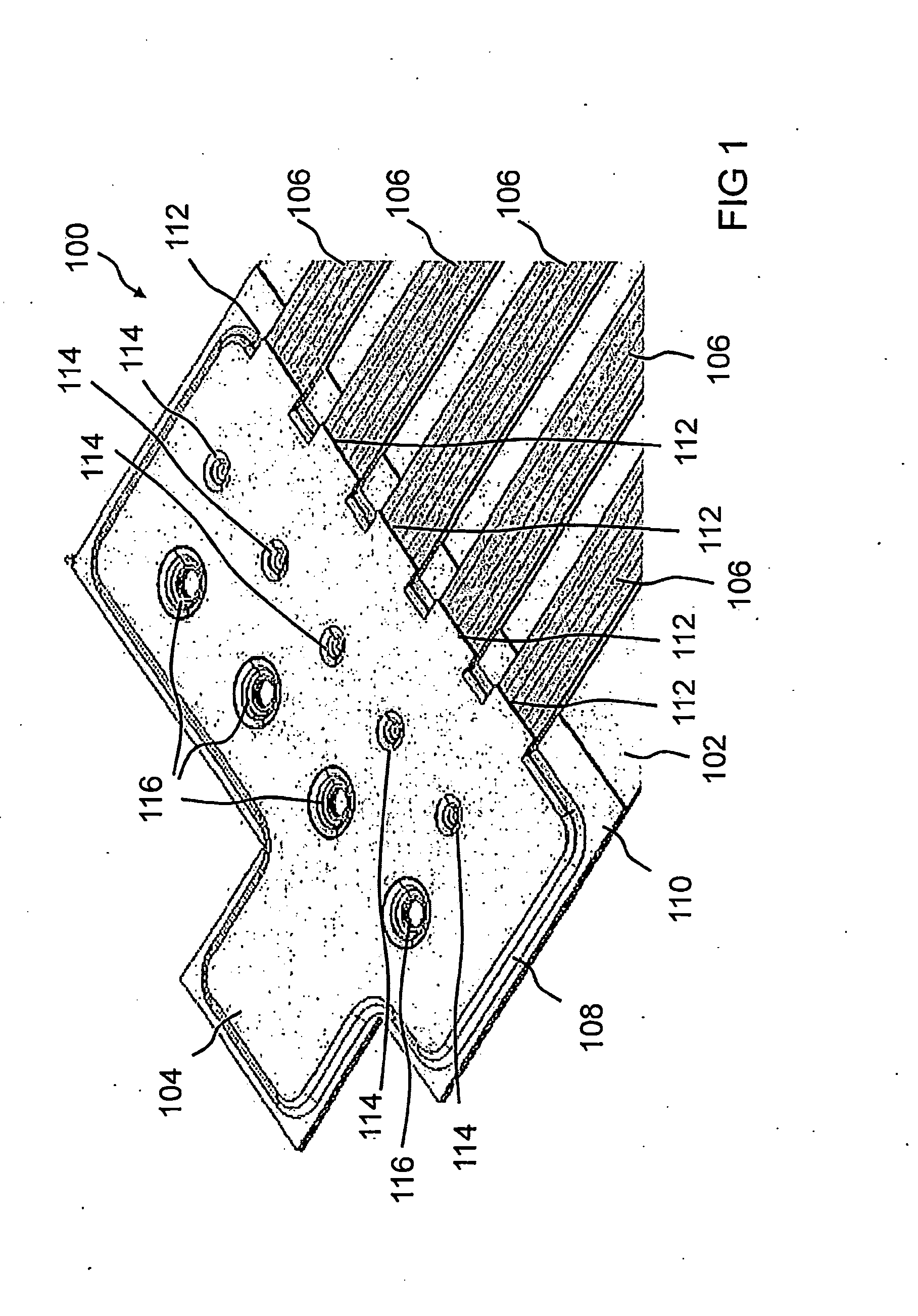

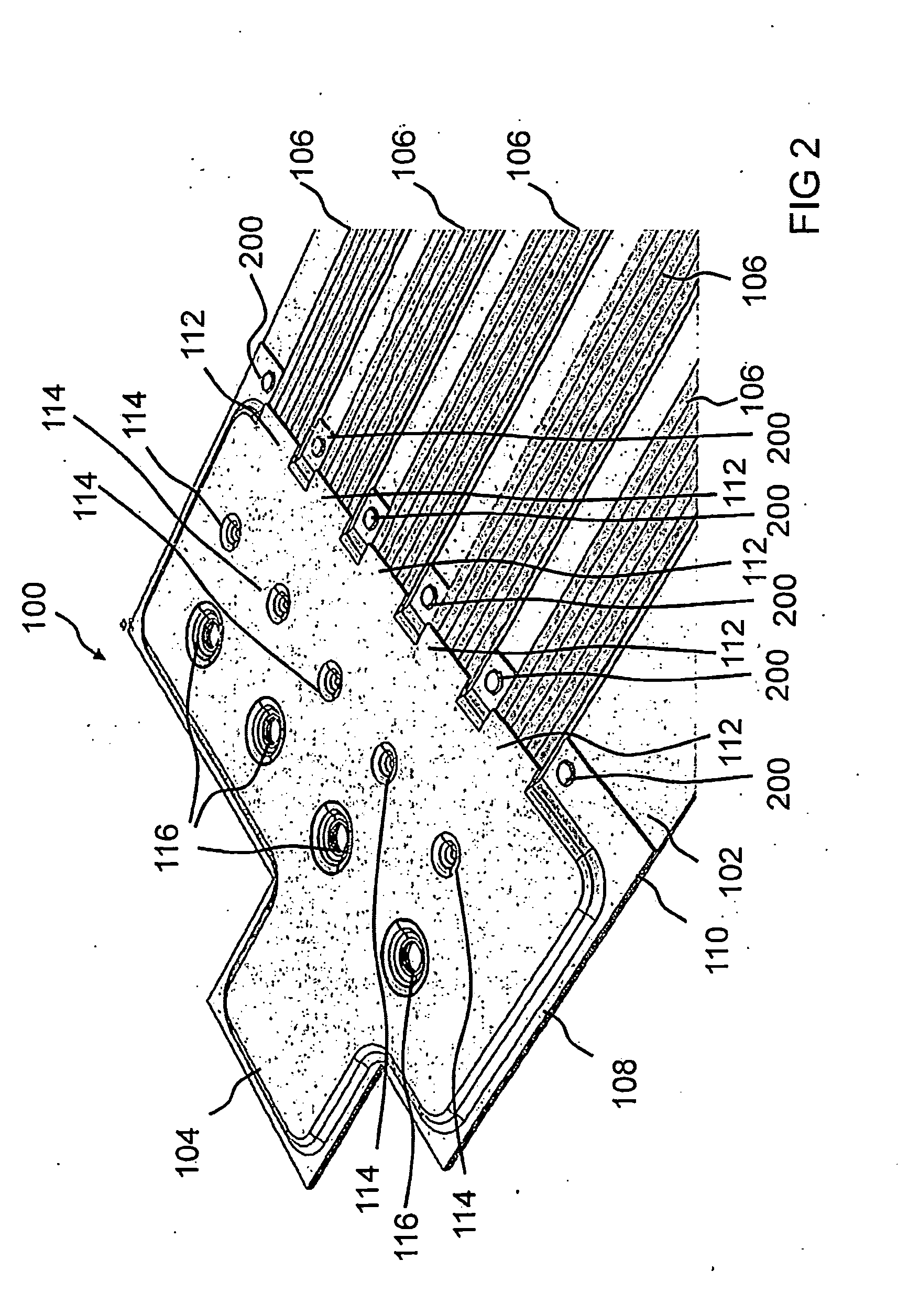

Electronic textile and method of manufacturing an electronic textile

InactiveUS9148949B2Cost-efficient productionIncrease productionPrinted circuit assemblingCircuit bendability/stretchabilityElectrical conductorEngineering

A method of manufacturing an electronic textile (1) comprising the steps of: providing a textile carrier (2) comprising a plurality of conductor lines (6a-b); releasably attaching (101) the textile carrier (2) to a rigid support plate (20); providing (102) a conductive substance on the textile carrier (2) in a pattern forming a plurality of sets of connection pads (5a-b) on the textile carrier (2), each set of connection pads defining a component placement position for placement of an electronic component (3), and each set of connection pads (5a-b) comprising a connection pad overlapping one of the conductor lines, the connection pad having a connection pad length (Lcp) in a direction parallel to the conductor line and a connection pad width (Wcp) in a direction perpendicular to the conductor line, wherein the connection pad width (Wcp) is at least one percent of an extension (Wtc) of the textile carrier (2) in the direction perpendicular to the conductor line; automatically placing (103) electronic components (3) at the component placement positions; curing (104) the conductive substance to attach the electronic components (3) to the textile carrier (2), thereby forming the electronic textile (1) and removing (105) the electronic textile from the rigid support plate.

Owner:SIGNIFY HLDG BV +1

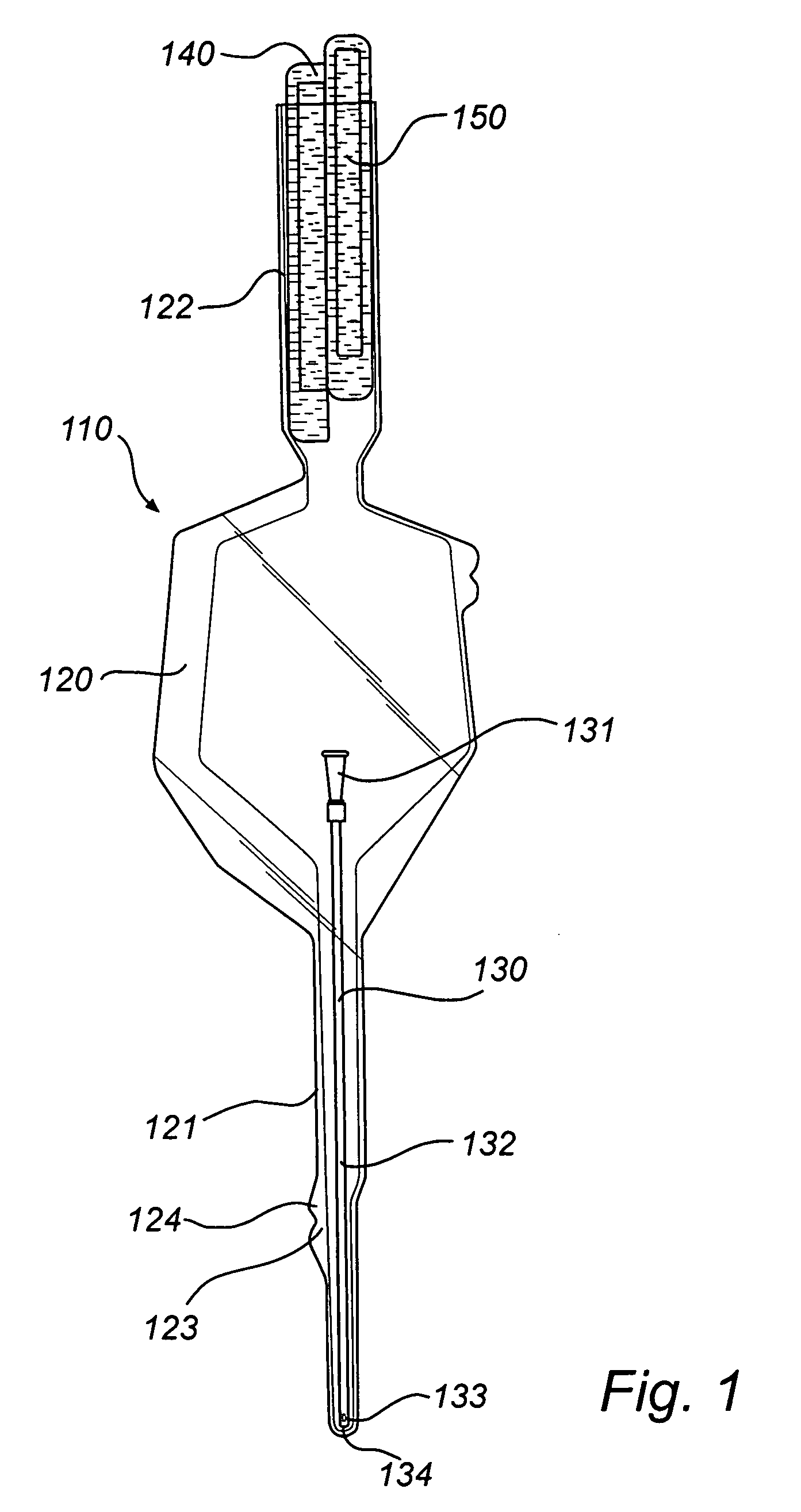

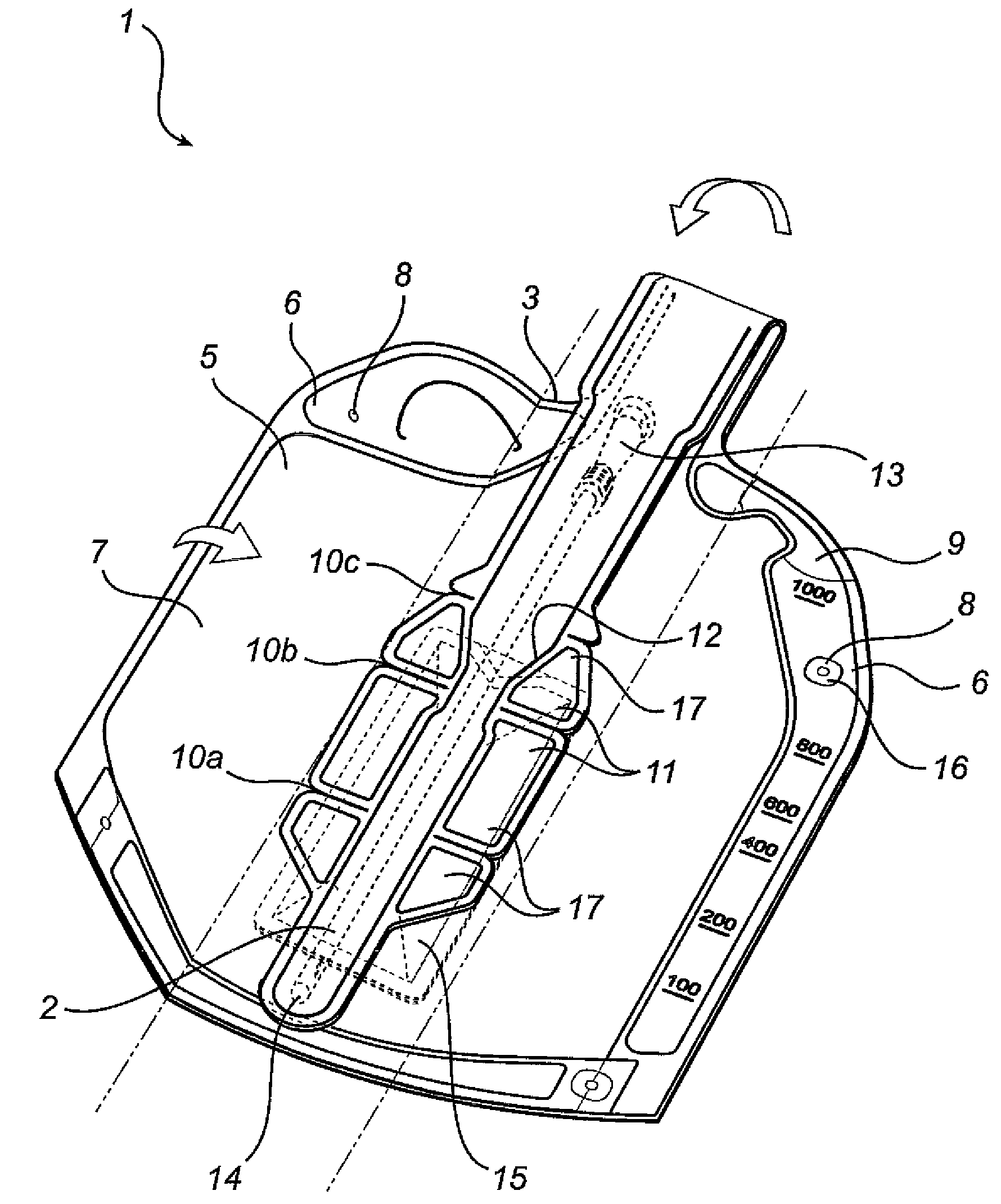

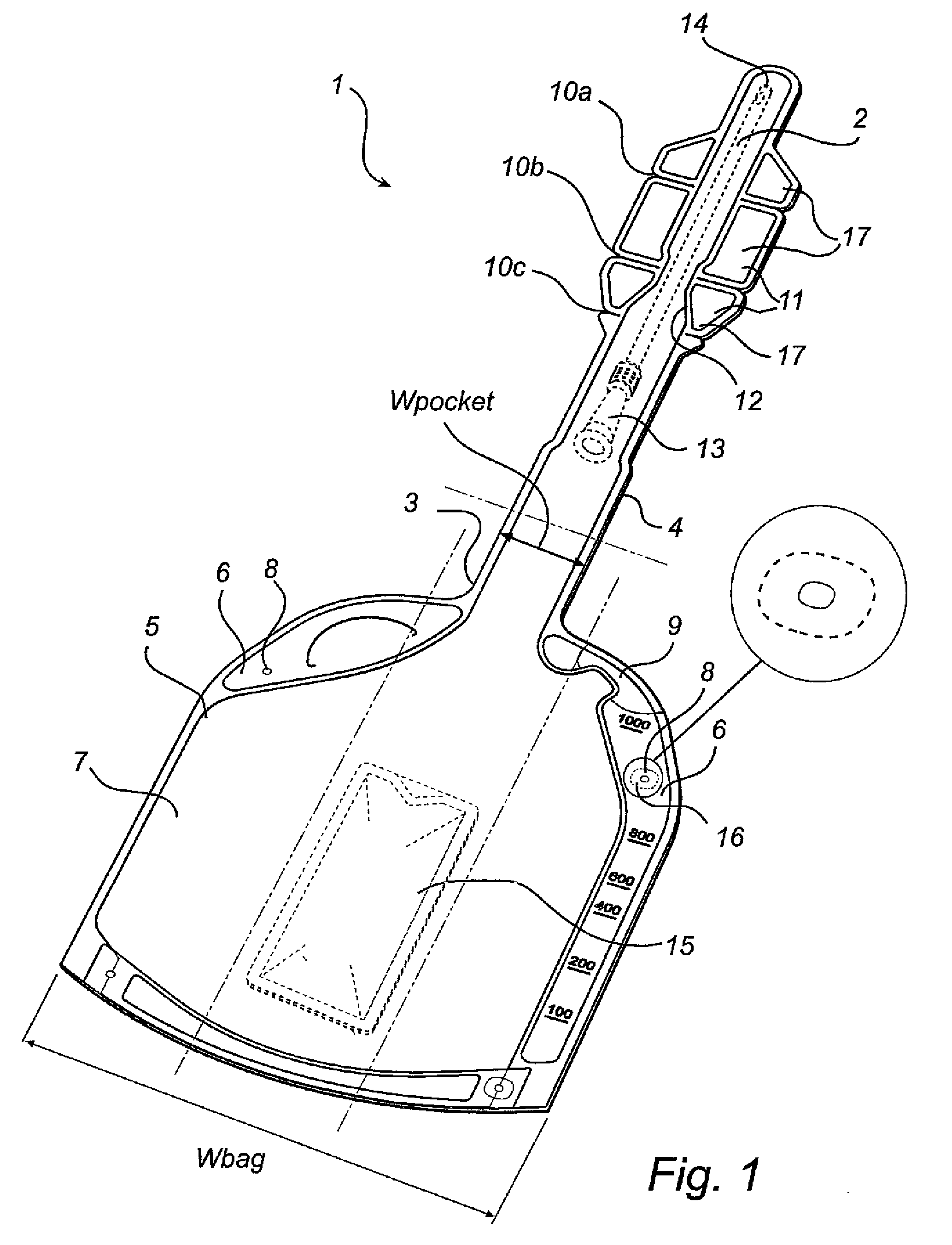

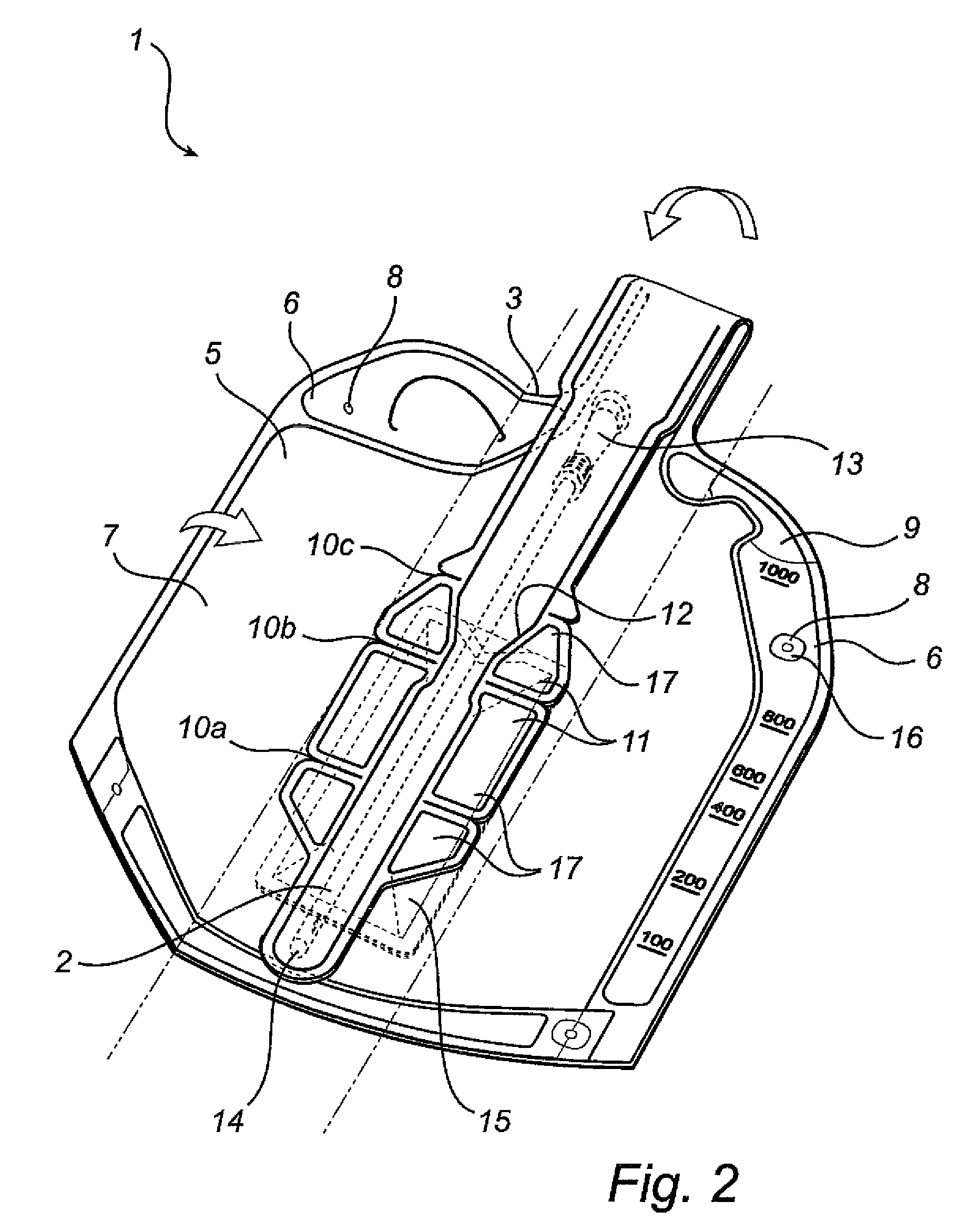

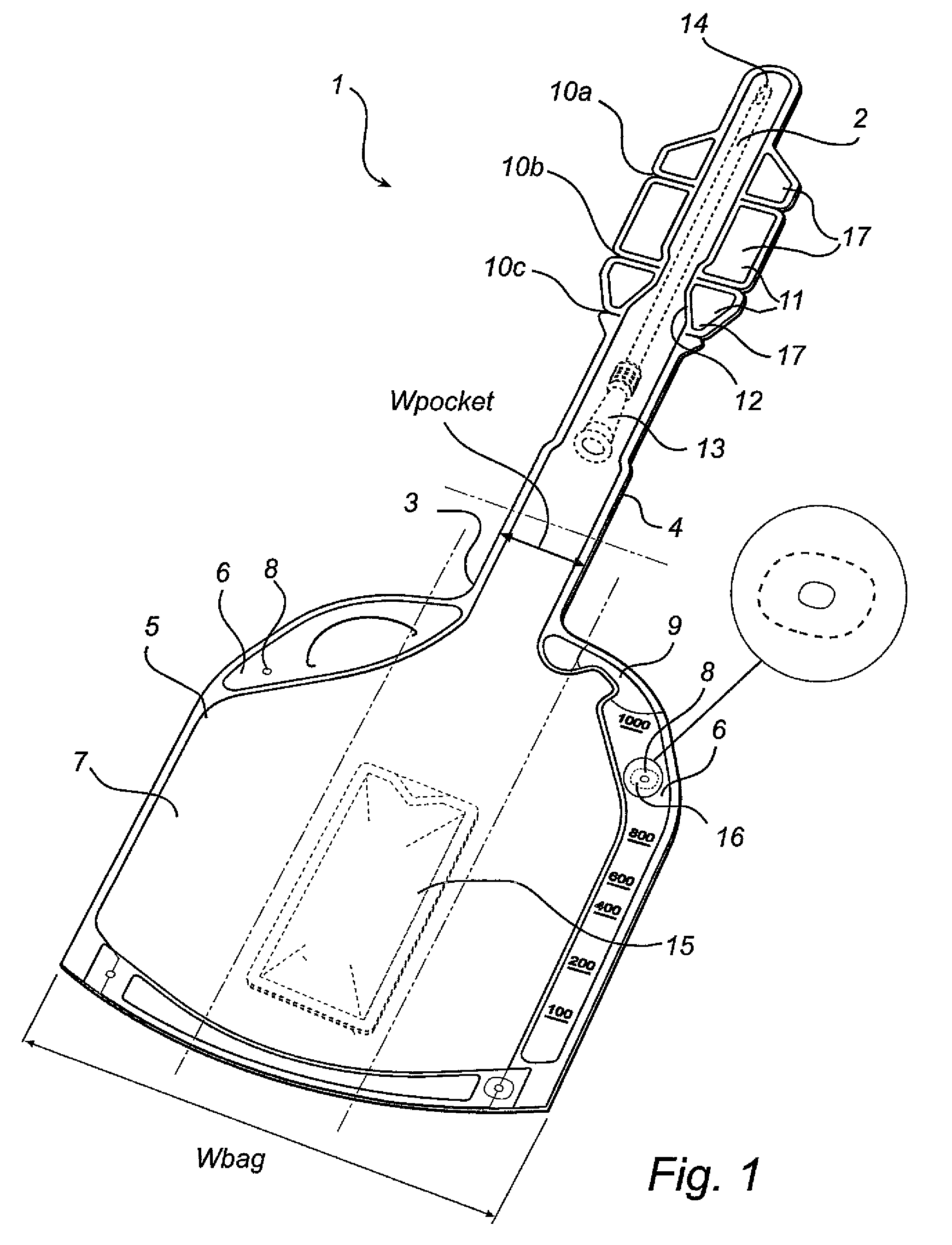

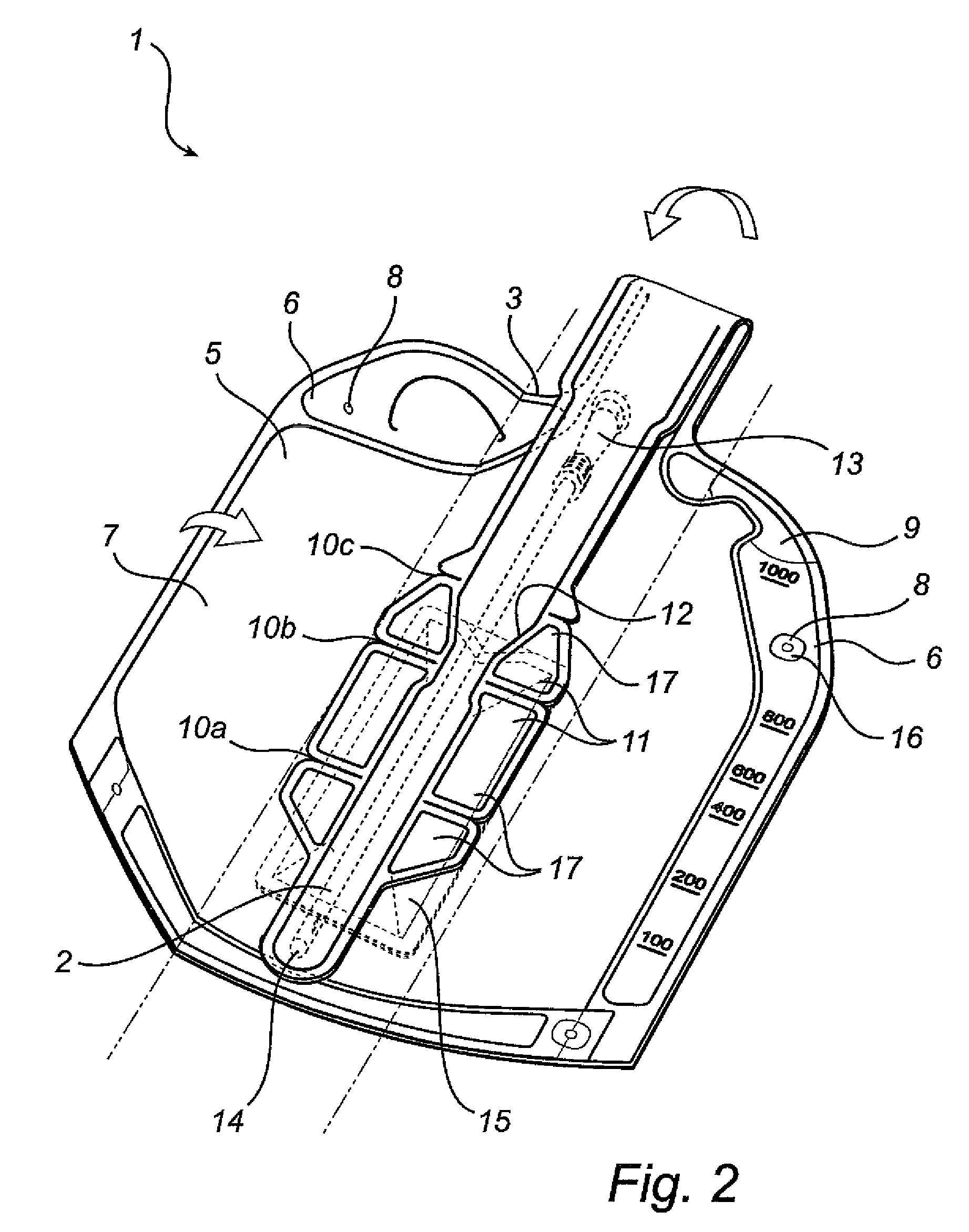

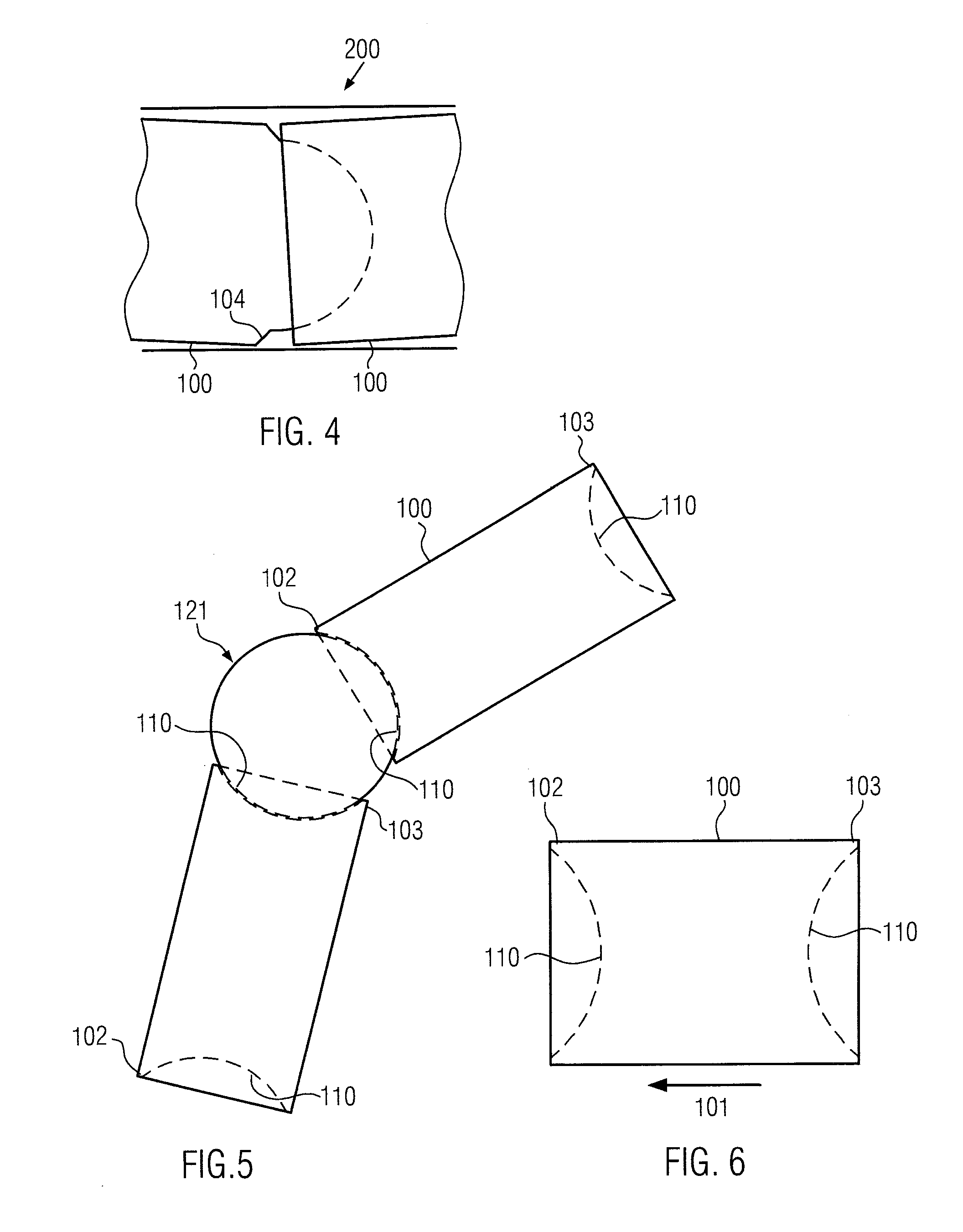

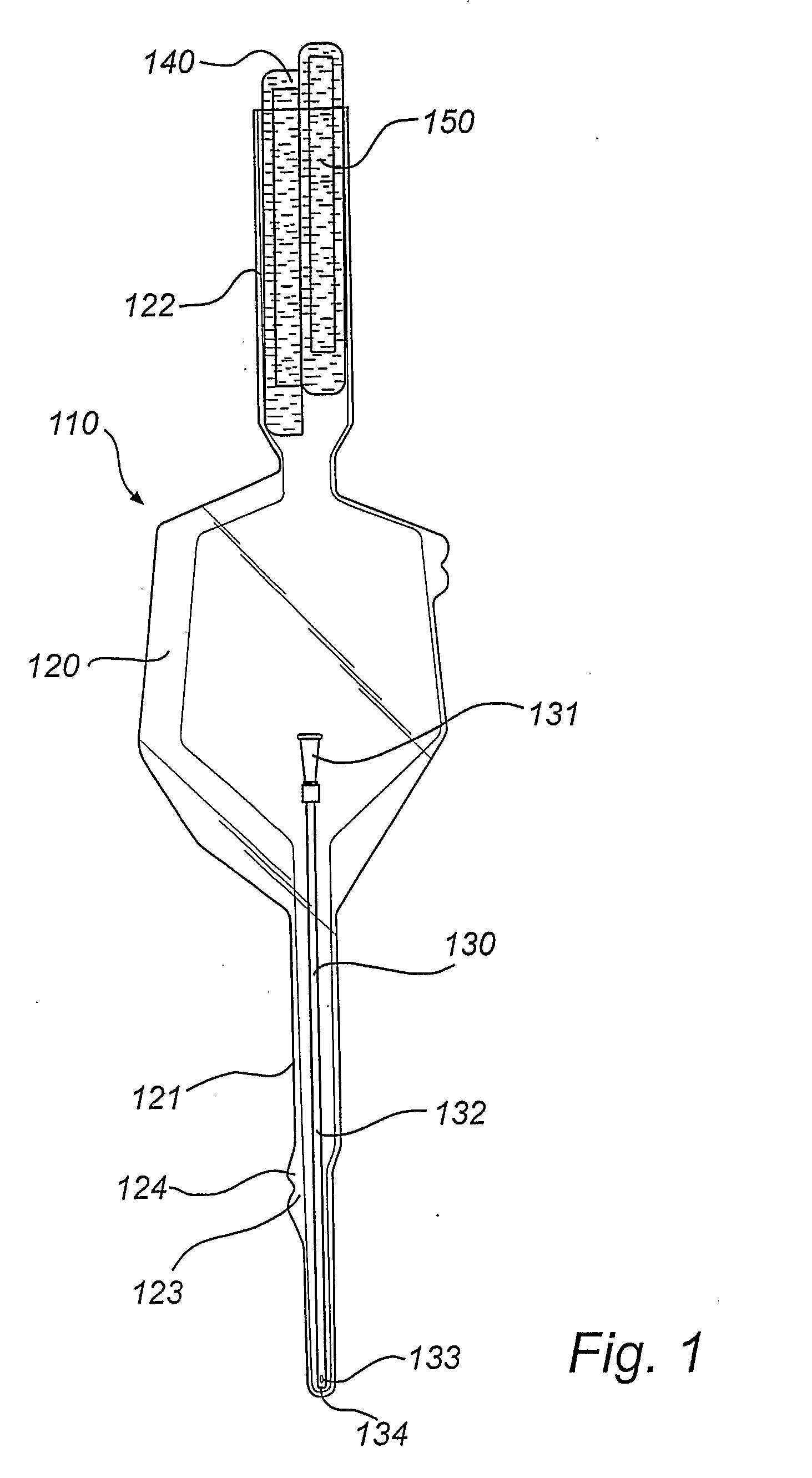

Catheter assembly with a folded urine collection bag

ActiveUS20090163884A1Maximum hold capacityEasy to storeWound drainsWrapper folding/bending apparatusUrologyUrine collection

There is disclosed a catheter assembly comprising a catheter and a receptacle. The receptacle has an elongate pocket, for accommodating at least an insertable end of said catheter, a urine collection bag, having a width extension wider than a greatest width of said elongate pocket, and at least two tab areas on at least one tab are arranged at the periphery of the urine collection bag on opposite sides of said bag. Further, in a storage state, said elongate pocket is folded over said urine collection bag, and lateral parts of said urine collection bag extending outside said elongate pocket are folded towards each other over said elongate pocket, said lateral parts being dimensioned to overlap each other in the folded disposition, and wherein said tab areas are arranged on said lateral parts and are attached to each other, in at least one point of attachment, to releasably maintain said catheter assembly in a folded disposition during storage.

Owner:ASTRA TECH SE

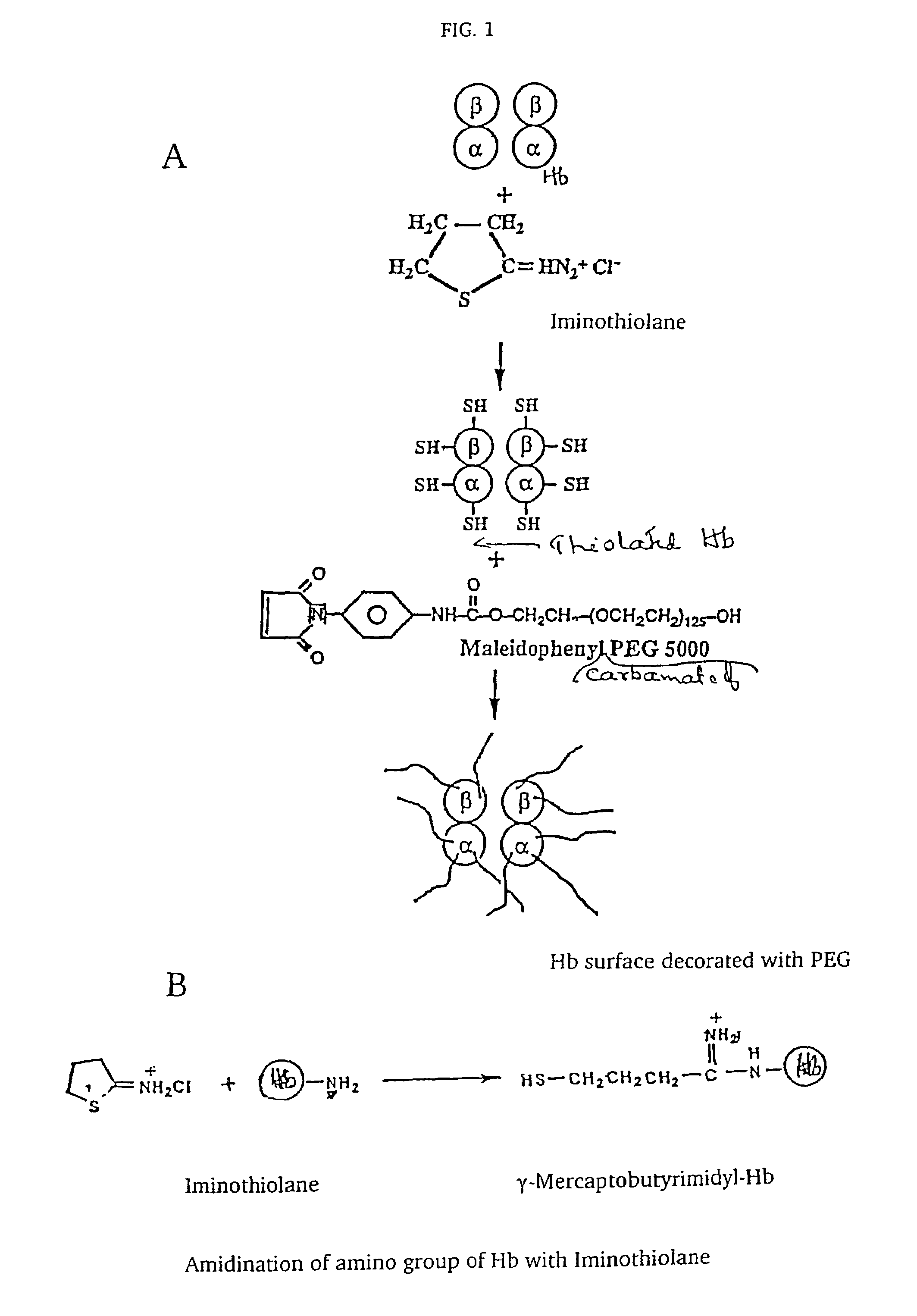

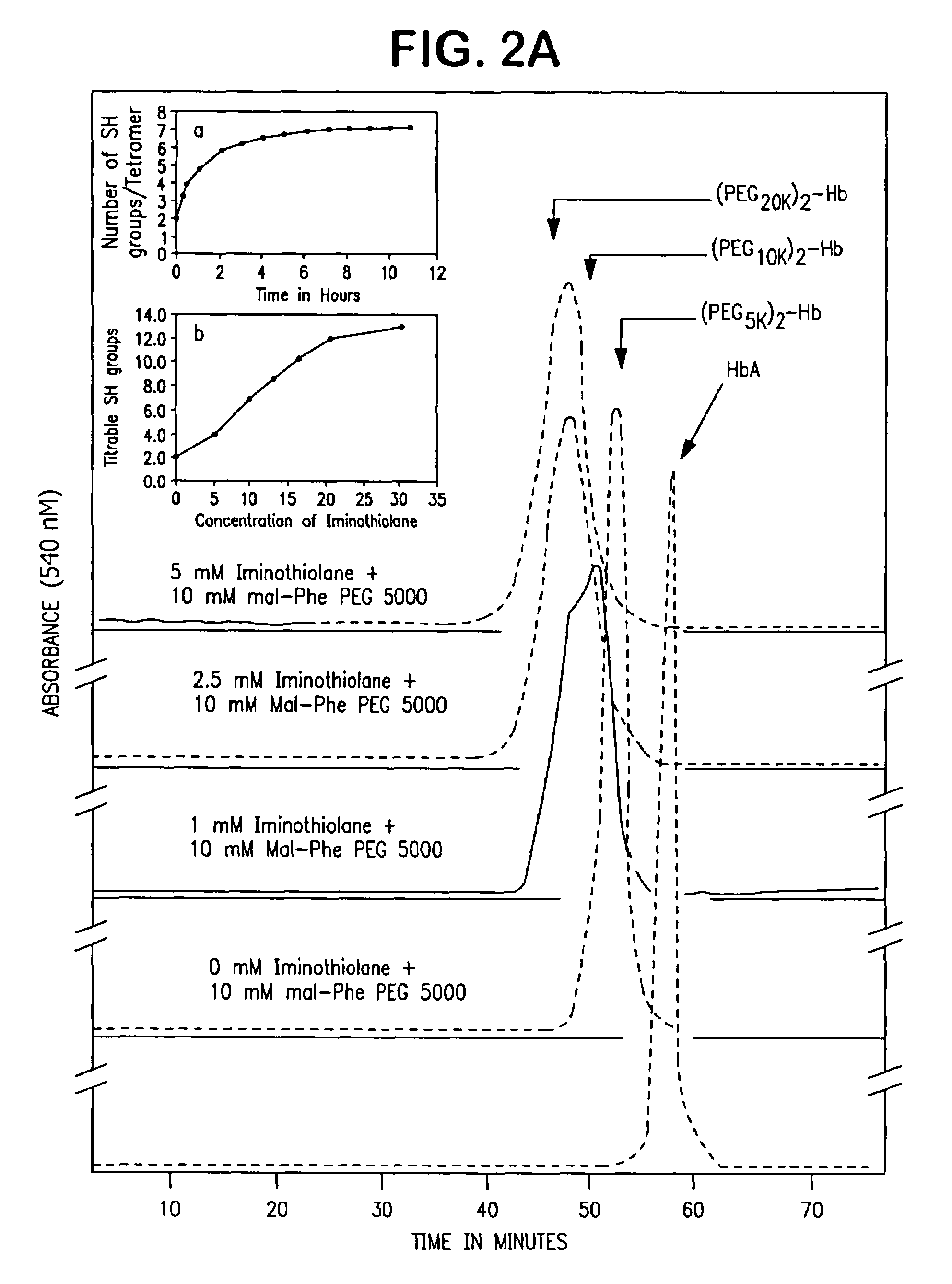

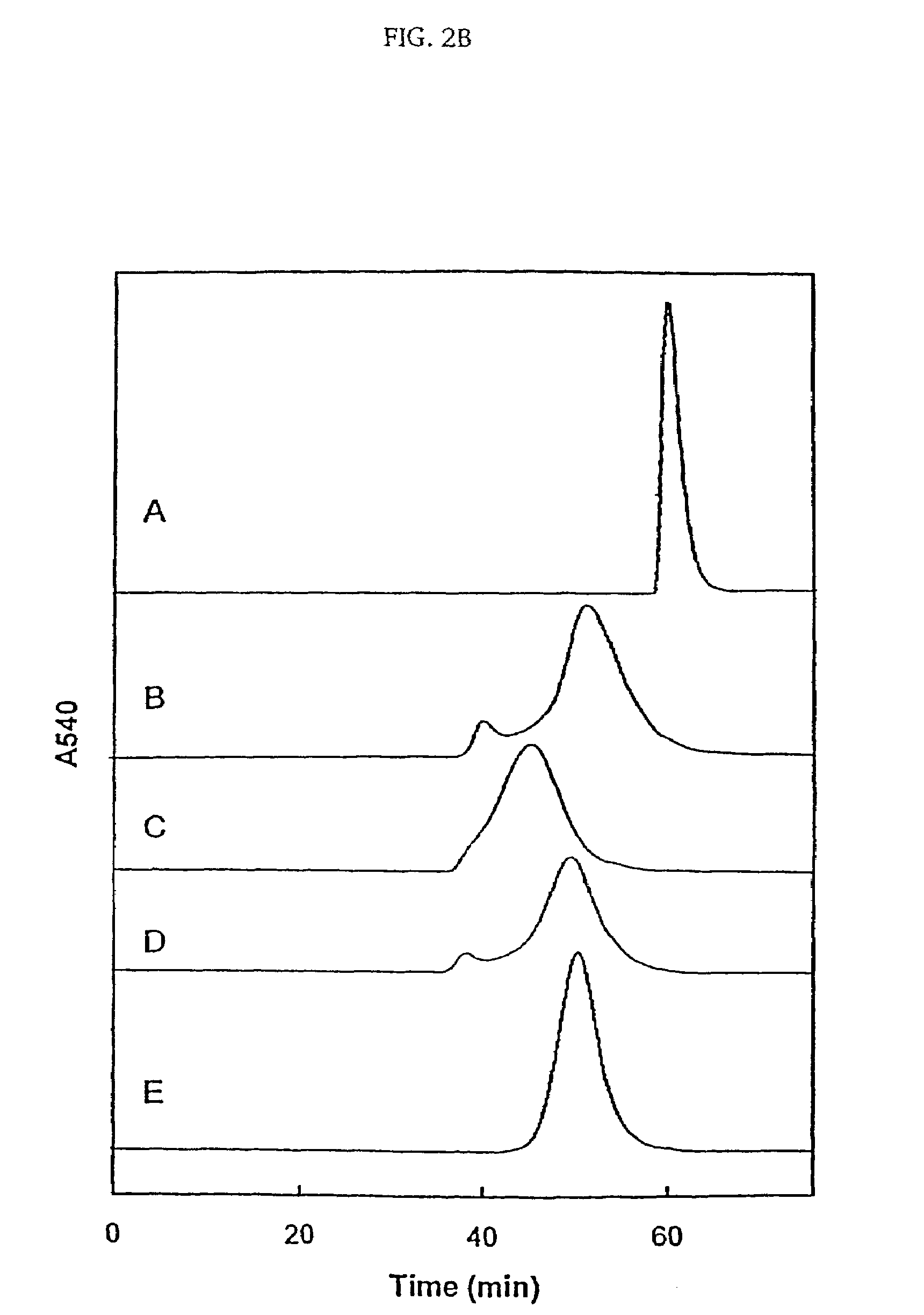

Modified hemoglobin and methods of making same

InactiveUS7501499B2Increase volumeHigh viscosityPeptide/protein ingredientsHaemoglobins/myoglobinsSulfurHemeprotein

The present invention provides a hemoglobin molecule (Hb) having six ± one PEG chains, wherein two of said PEG chains are bound to Cys-93 (β) of Hb, and the remaining PEG chains are bound to thiol groups introduced on ε-NH2 of Hb. The present invention also provides a process for preparing a modified hemoglobin molecule (Hb), comprising the steps of: (a) reacting Hb with 8-15 fold excess of iminothiolane to form thiolated Hb; and (b) reacting the thiolated Hb with 16-30 fold excess of PEG functionalized with a maleimide moiety, to form the modified Hb.

Owner:ALBERT EINSTEIN COLLEGE OF MEDICINE OF YESHIVA UNIV

Electronic textile and method of manufacturing an electronic textile

InactiveUS20130176737A1Cost-efficient productionIncrease productionPrinted circuit assemblingCircuit bendability/stretchabilityEngineeringElectronic component

A method of manufacturing an electronic textile (1) comprising the steps of: providing a textile carrier (2) comprising a plurality of conductor lines (6a-b); releasably attaching (101) the textile carrier (2) to a rigid support plate (20); providing (102) a conductive substance on the textile carrier (2) in a pattern forming a plurality of sets of connection pads (5a-b) on the textile carrier (2), each set of connection pads defining a component placement position for placement of an electronic component (3), and each set of connection pads (5a-b) comprising a connection pad overlapping one of the conductor lines, the connection pad having a connection pad length (Lcp) in a direction parallel to the conductor line and a connection pad width (Wcp) in a direction perpendicular to the conductor line, wherein the connection pad width (Wcp) is at least one percent of an extension (Wtc) of the textile carrier (2) in the direction perpendicular to the conductor line; automatically placing (103) electronic components (3) at the component placement positions; curing (104) the conductive substance to attach the electronic components (3) to the textile carrier (2), thereby forming the electronic textile (1) and removing (105) the electronic textile from the rigid support plate.

Owner:SIGNIFY HLDG BV +1

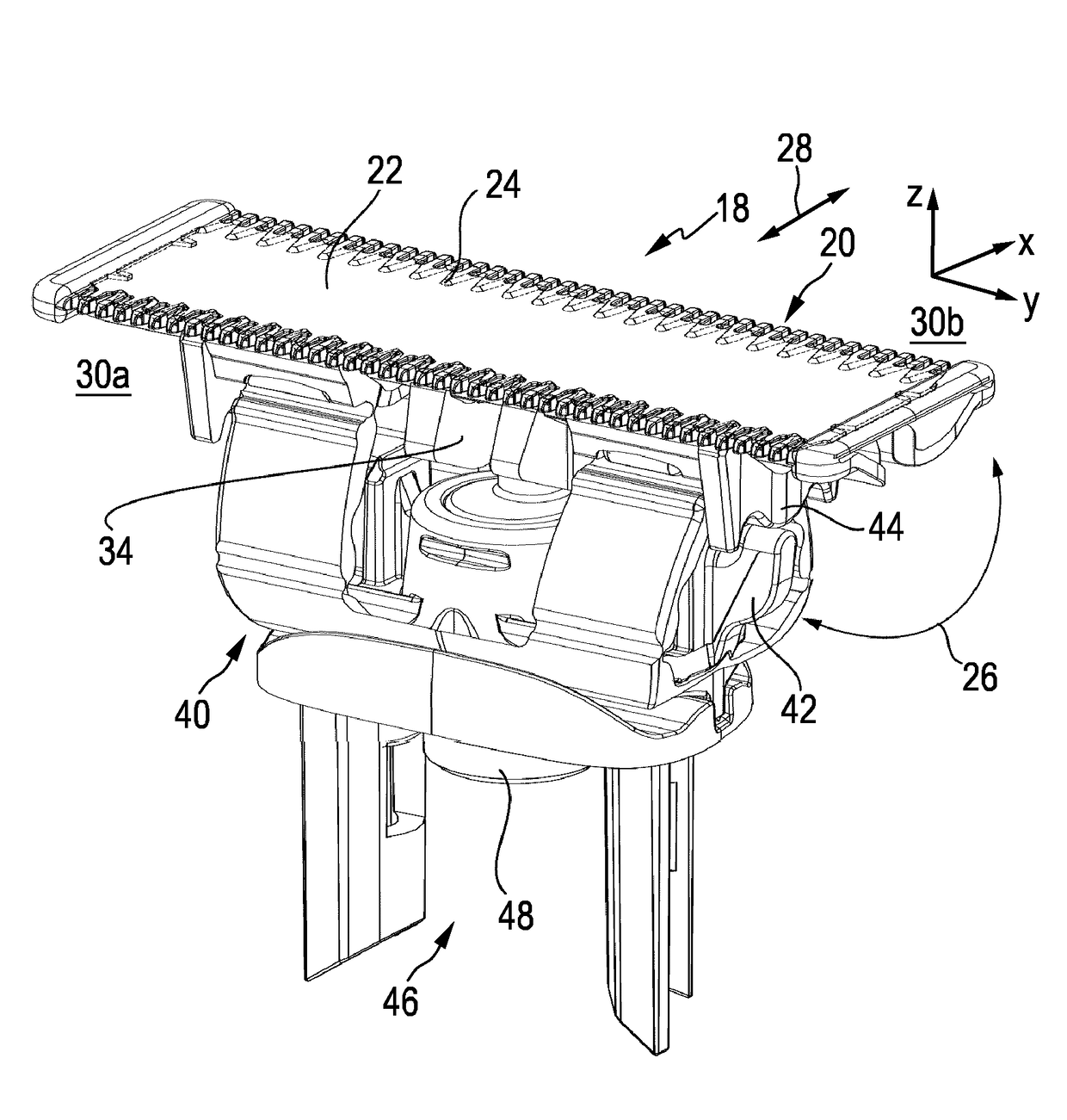

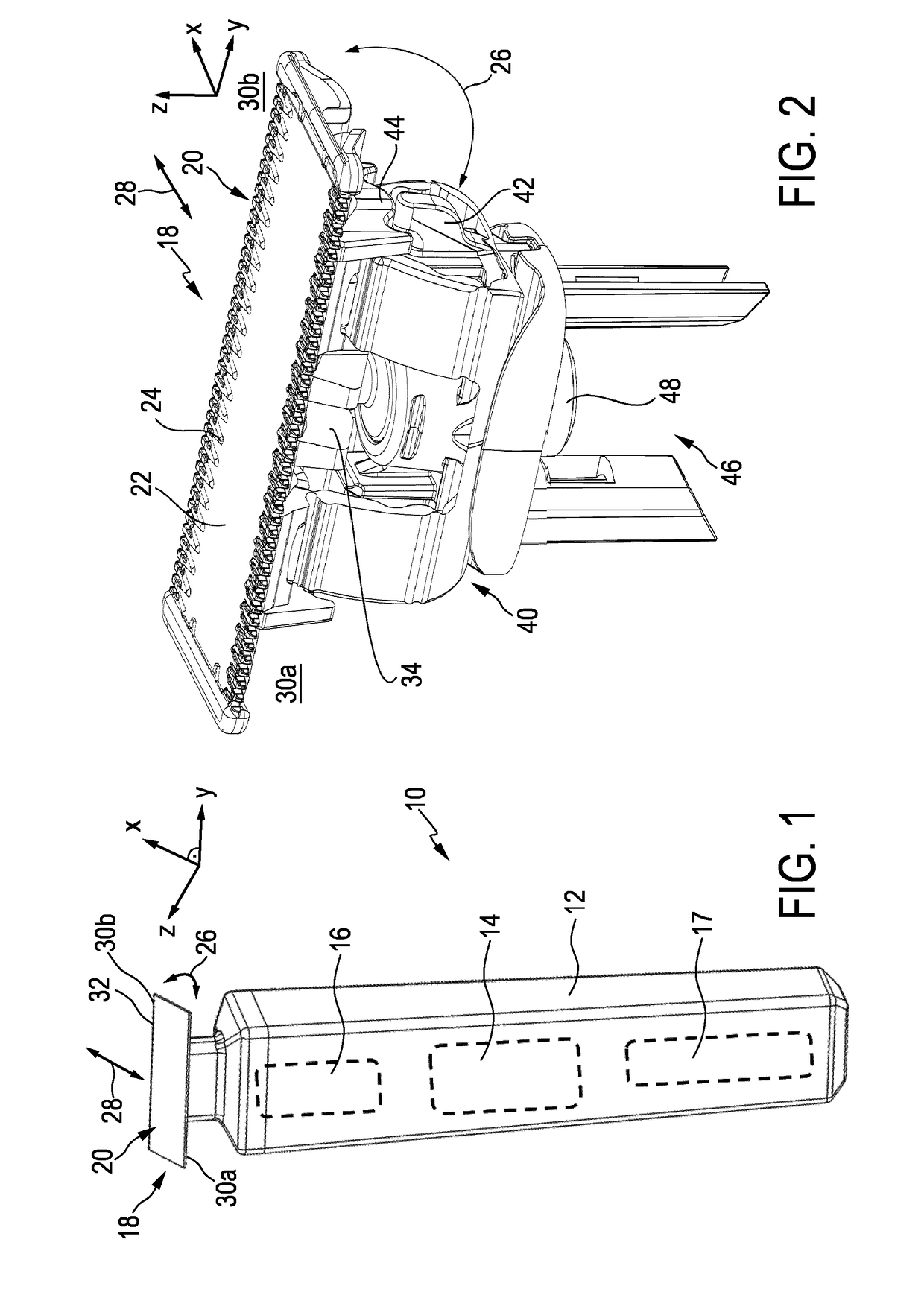

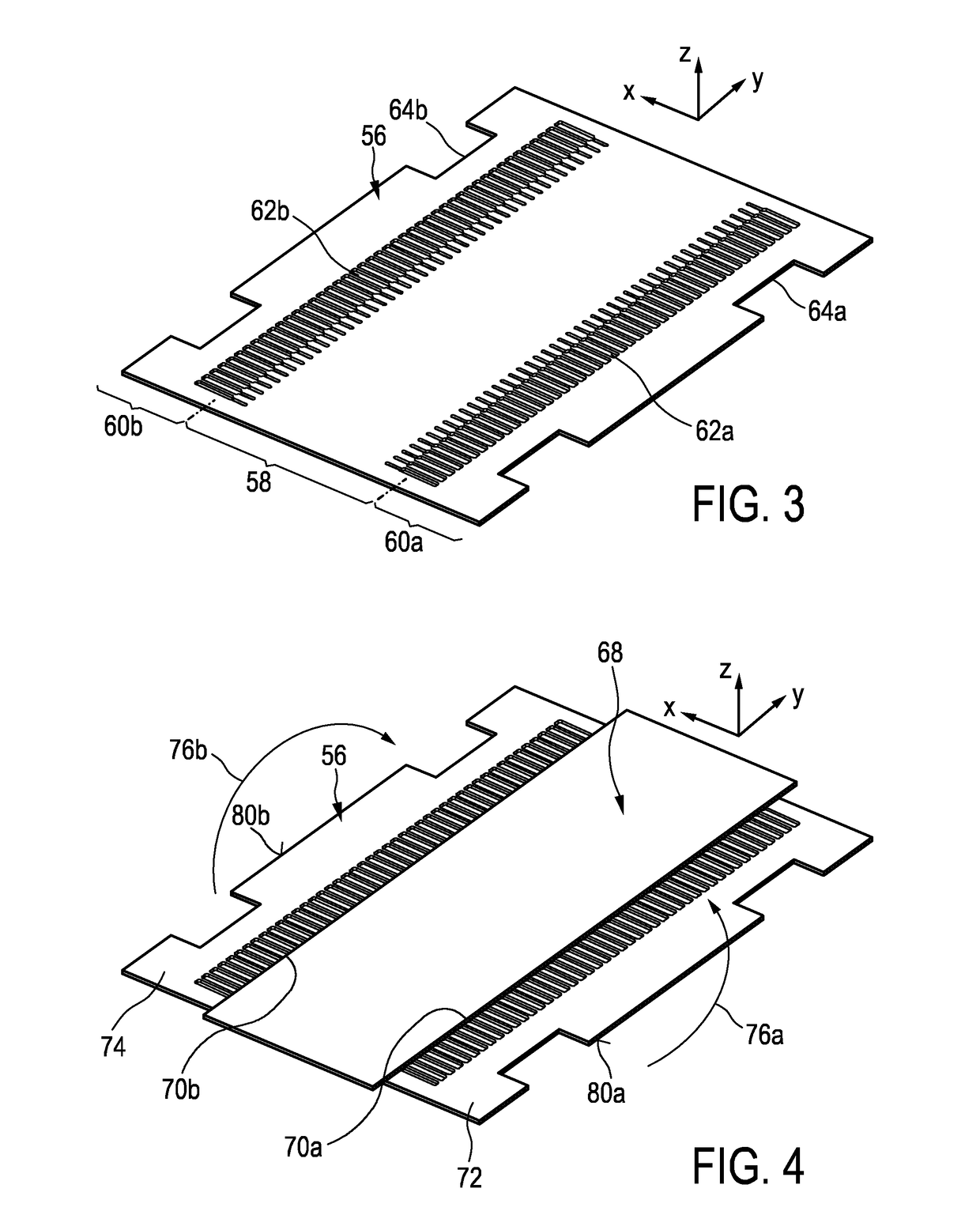

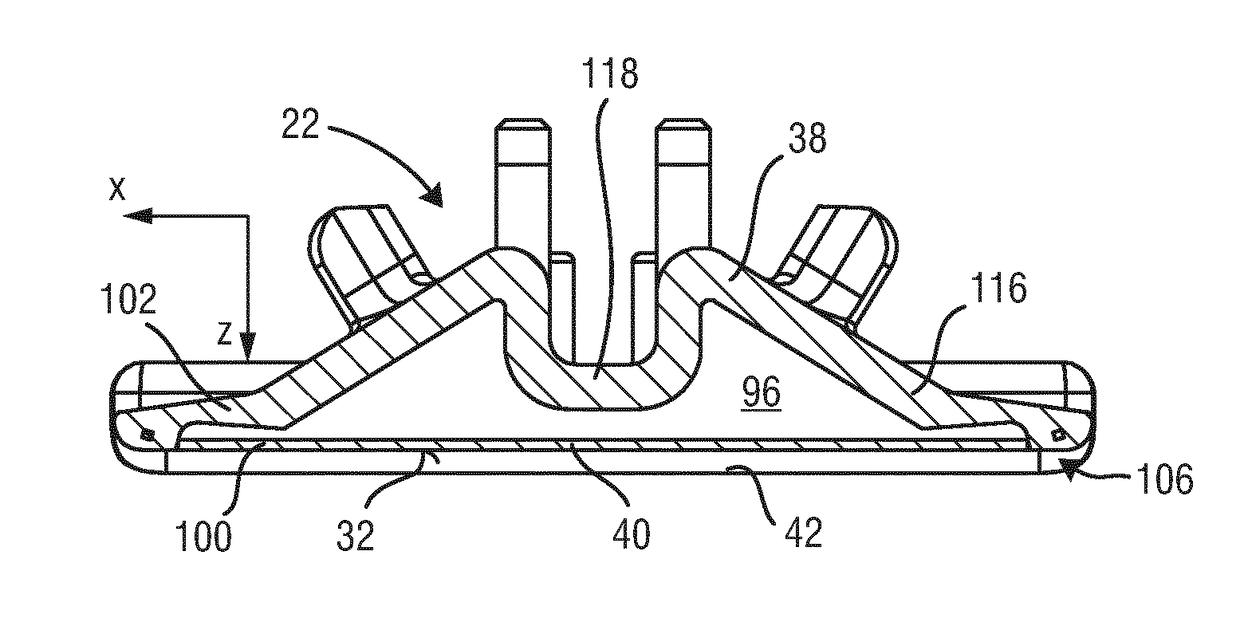

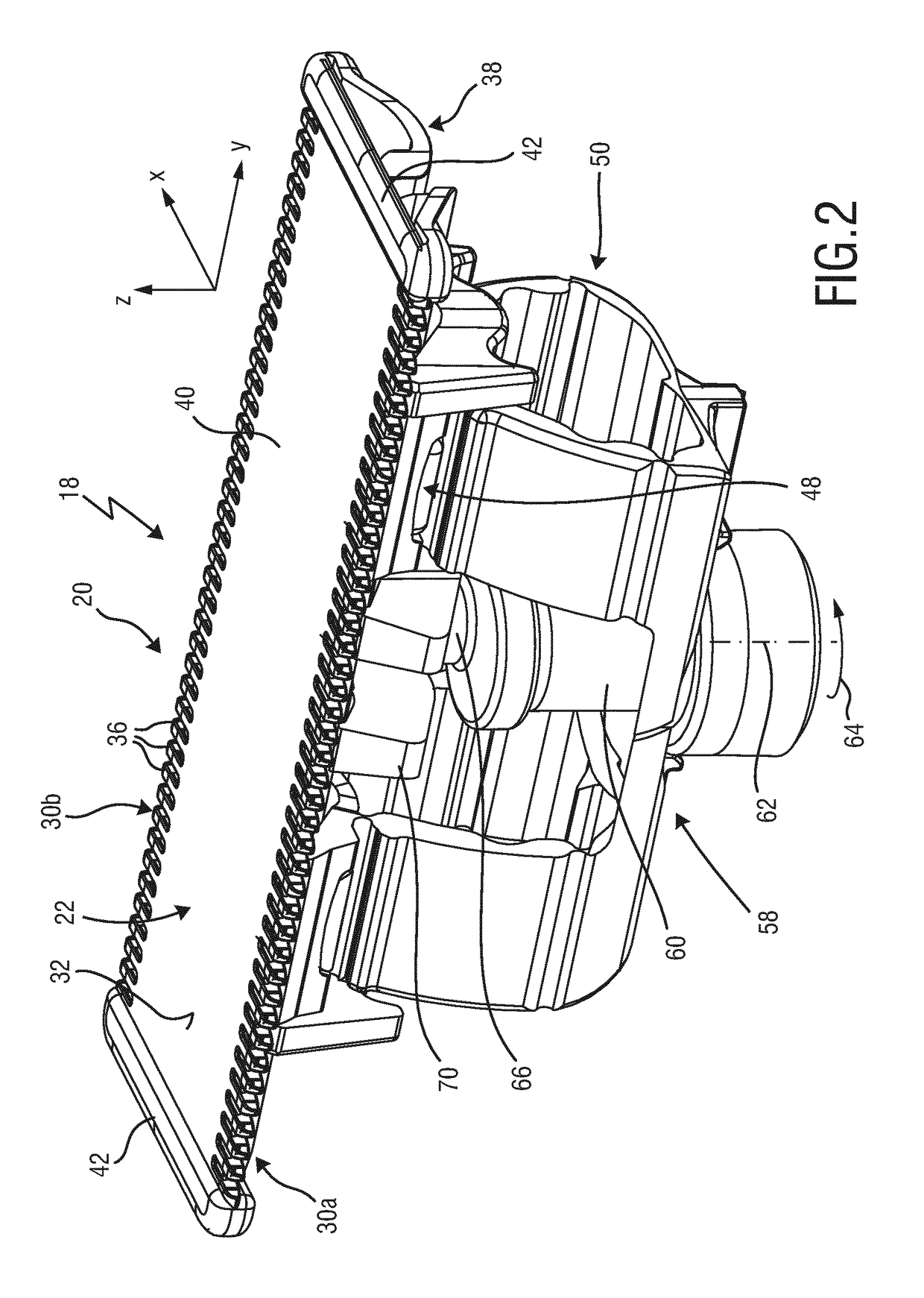

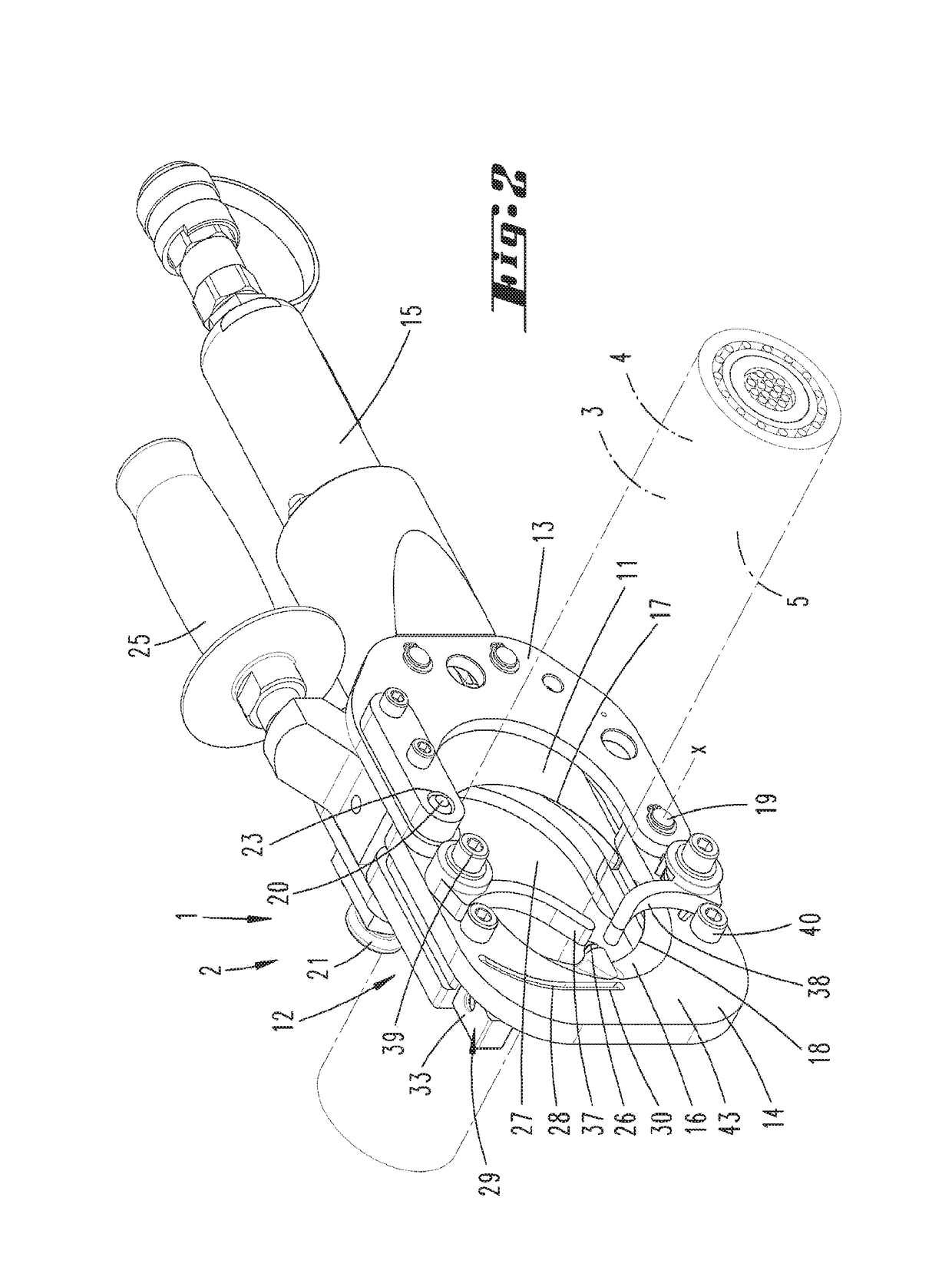

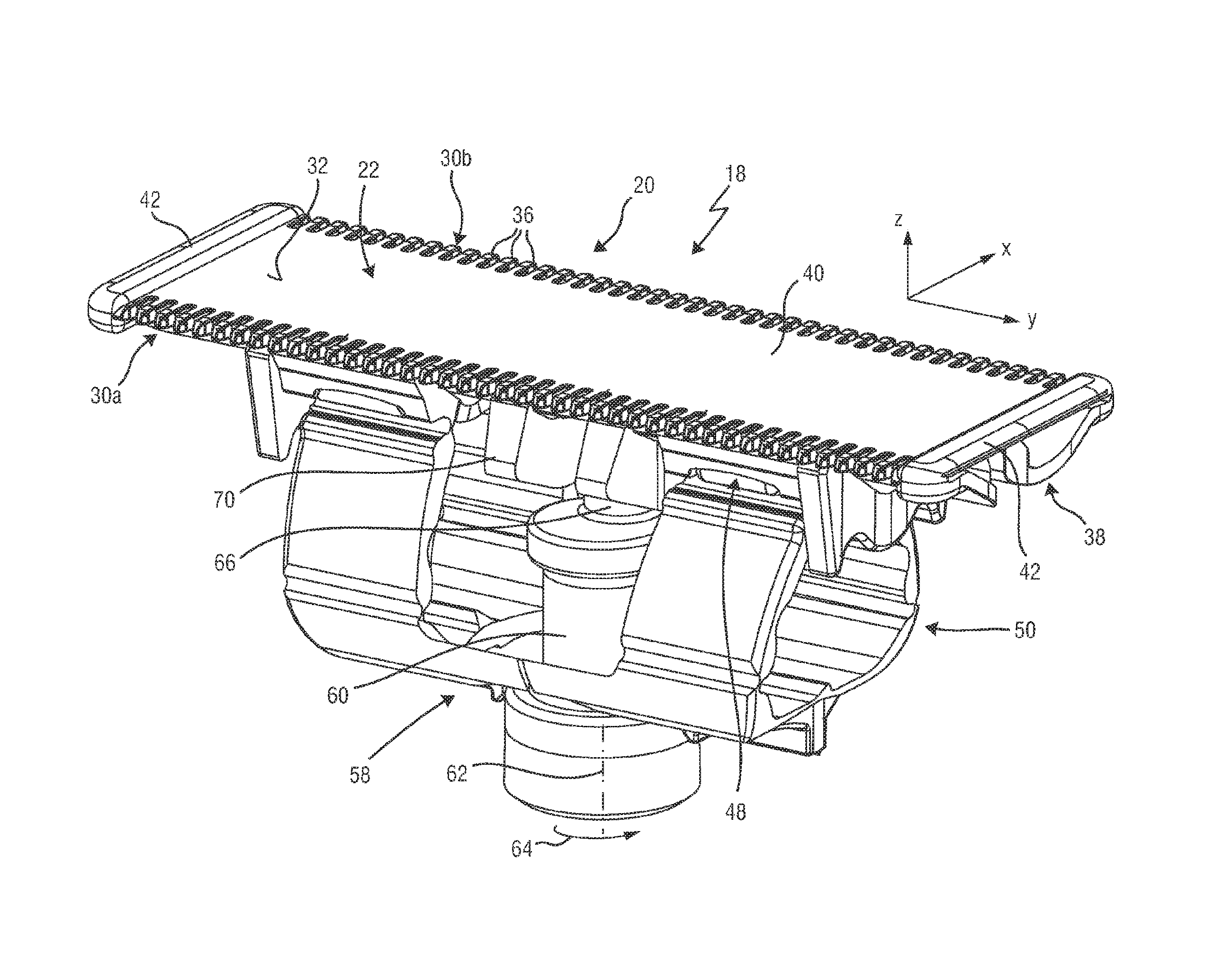

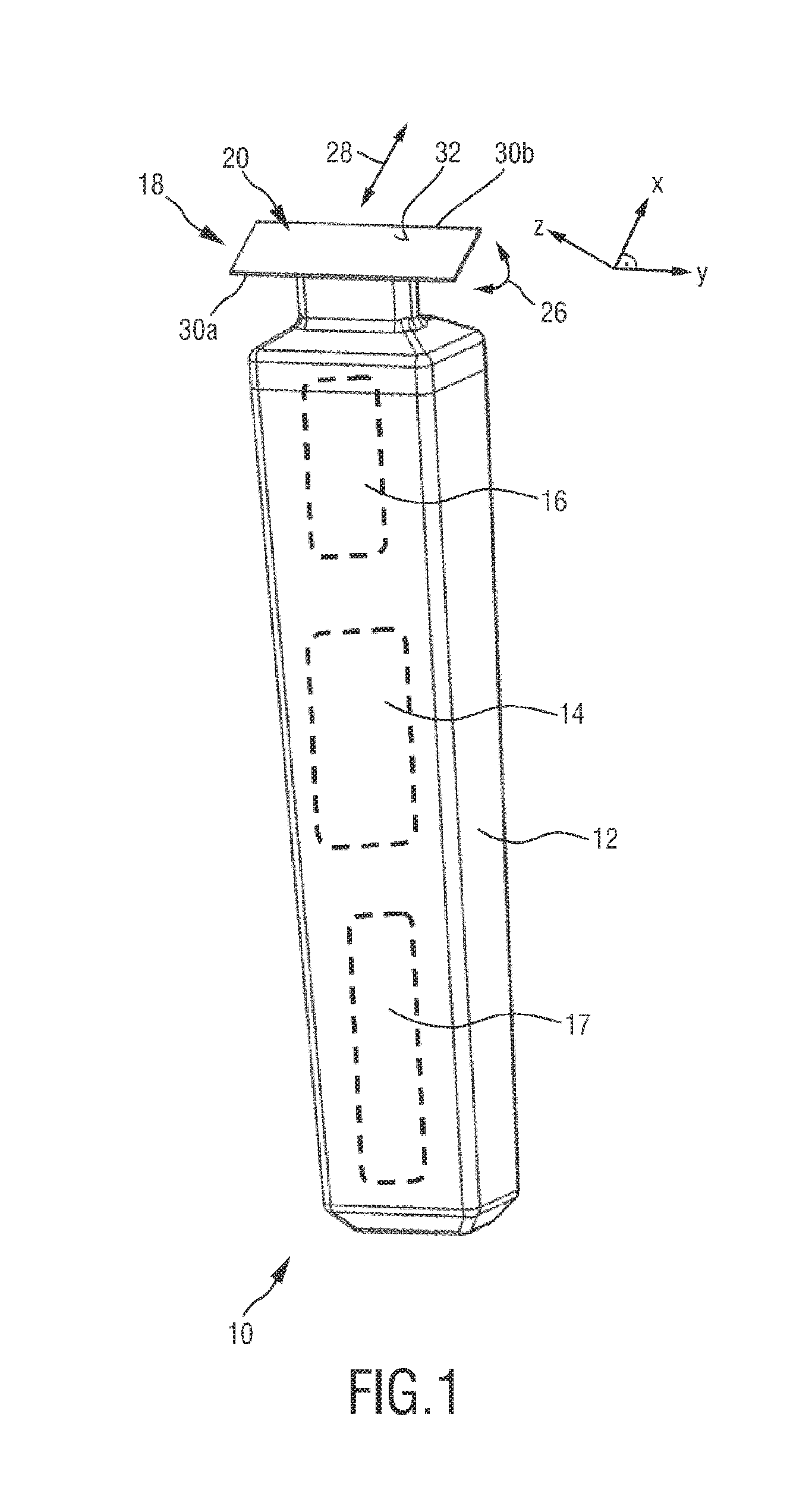

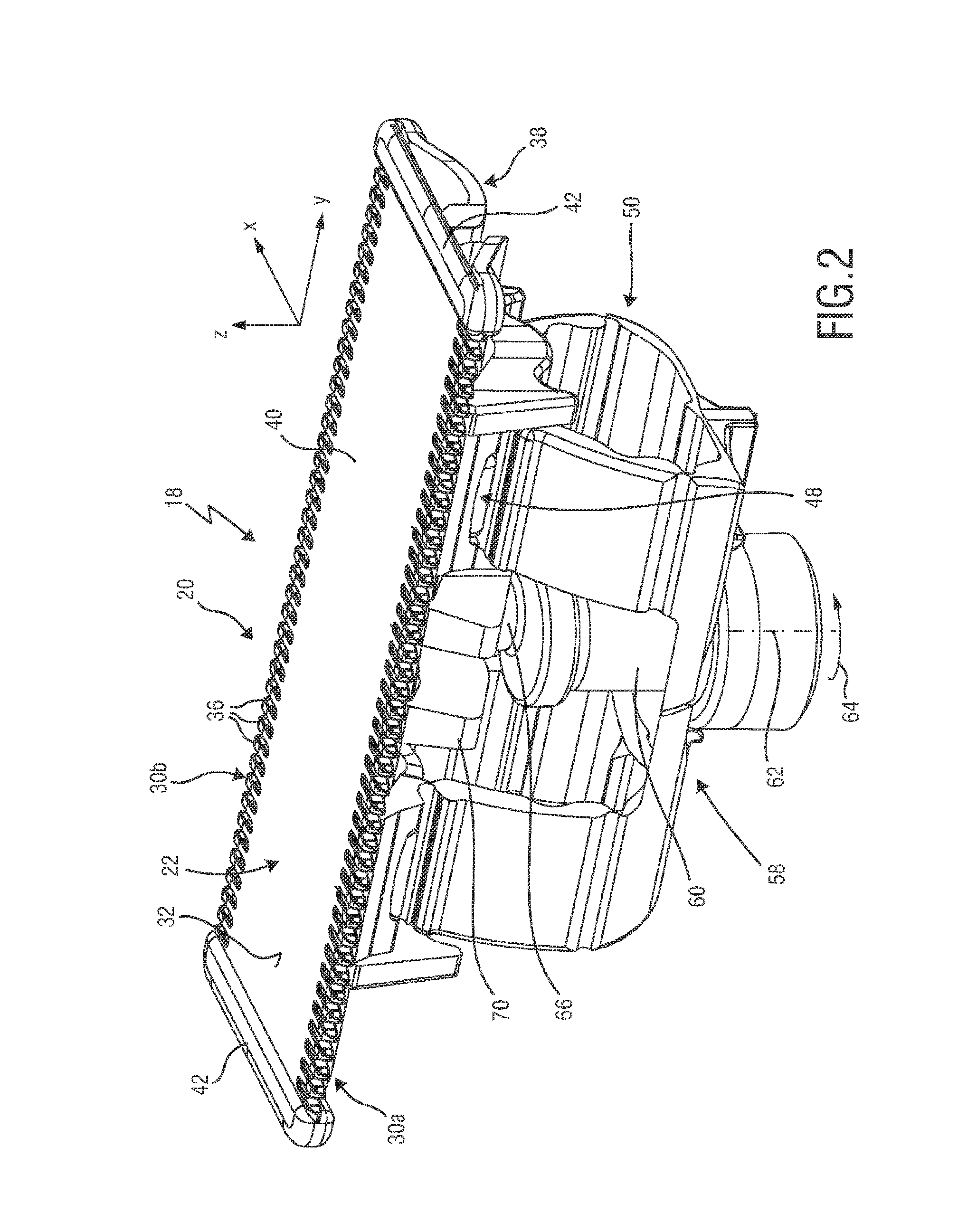

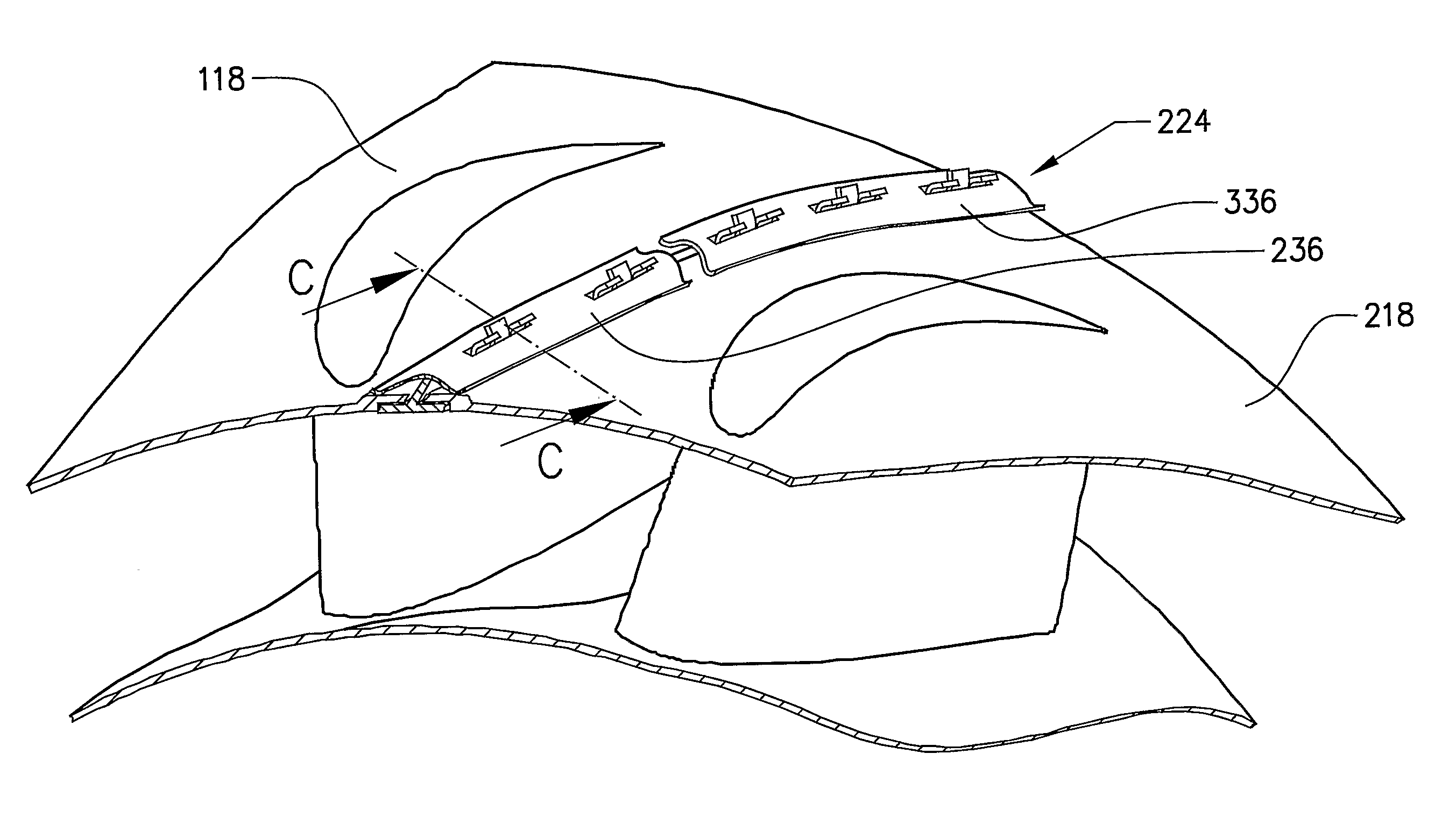

Blade set, hair cutting appliance, and related manufacturing method

ActiveUS20170144319A1Low experience requirementReduce stepsMetal working apparatusLeading edgeEngineering

The present disclosure relates to a hair cutting appliance (10), a blade set (20) for a hair cutting appliance (10),and to an integrally formed metal-plastic composite stationary blade (22) for said blade set (20). Said stationary blade (22) may comprise a first wall portion (58) arranged to serve as a skin facing wall when in operation, a second wall portion (60) at least partially offset from the first wall portion (58), such that the first wall portion (58) and the second wall portion (60) define therebetween a guide slot arranged to receive a movable cutter blade (24), at least one toothed leading edge (30) jointly formed by the first wall portion (58) and the second wall portion (60), and a plastic component (114) comprising at least one mounting element (36), wherein the at least one toothed leading edge (30) comprises a plurality of teeth (90), wherein the first wall portion (58) and the second wall portion (60) are integrally made from a metal component (56), particularly from a sheet metal component (56), wherein the first wall portion (58) and the second wall portion (60) mutually define an inner metal shell of the stationary blade (22), and wherein the plastic component (114) is molded to the second wall portion (60). The disclosure further relates to a method for manufacturing a respective blade.

Owner:KONINKLJIJKE PHILIPS NV

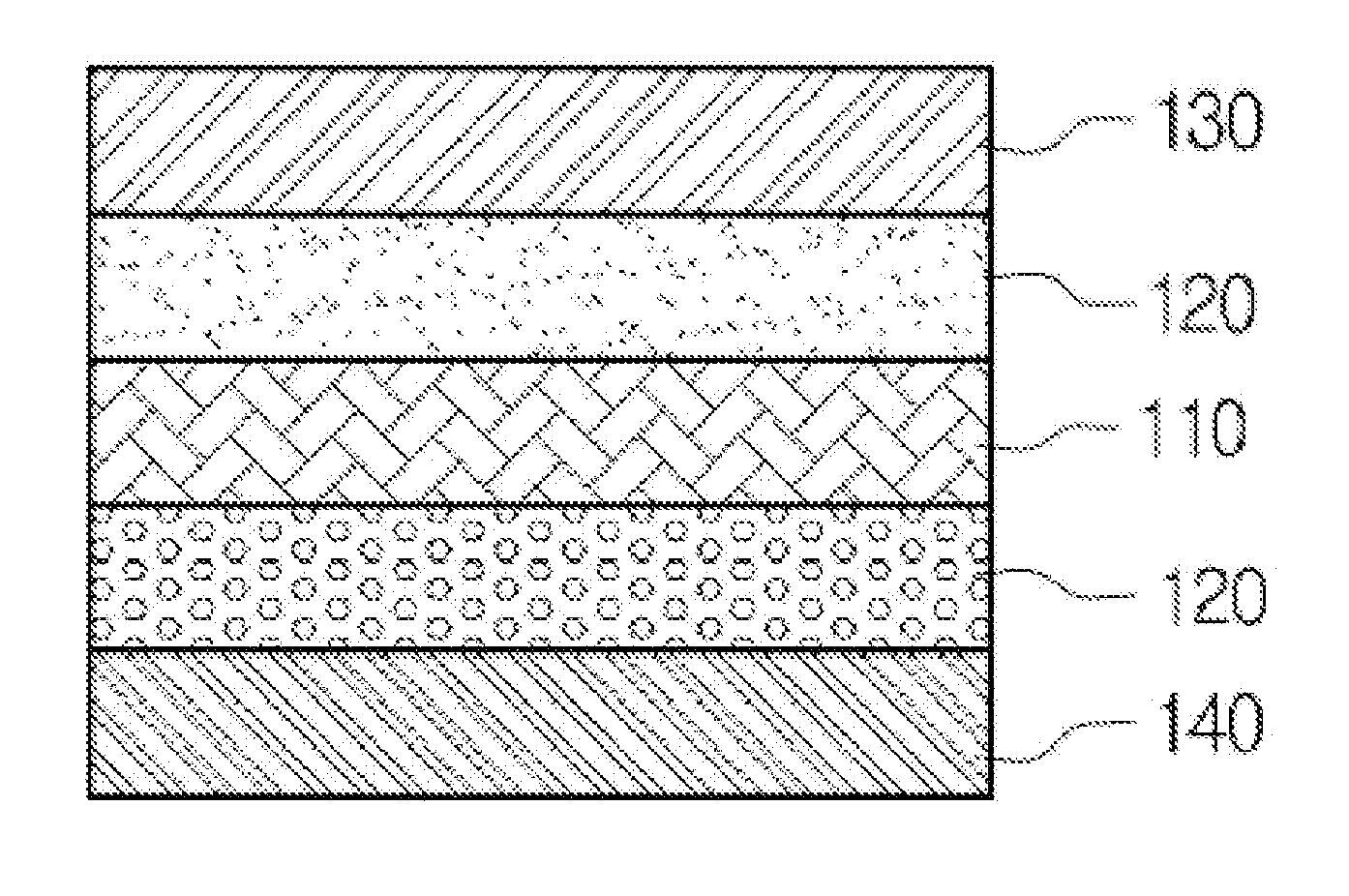

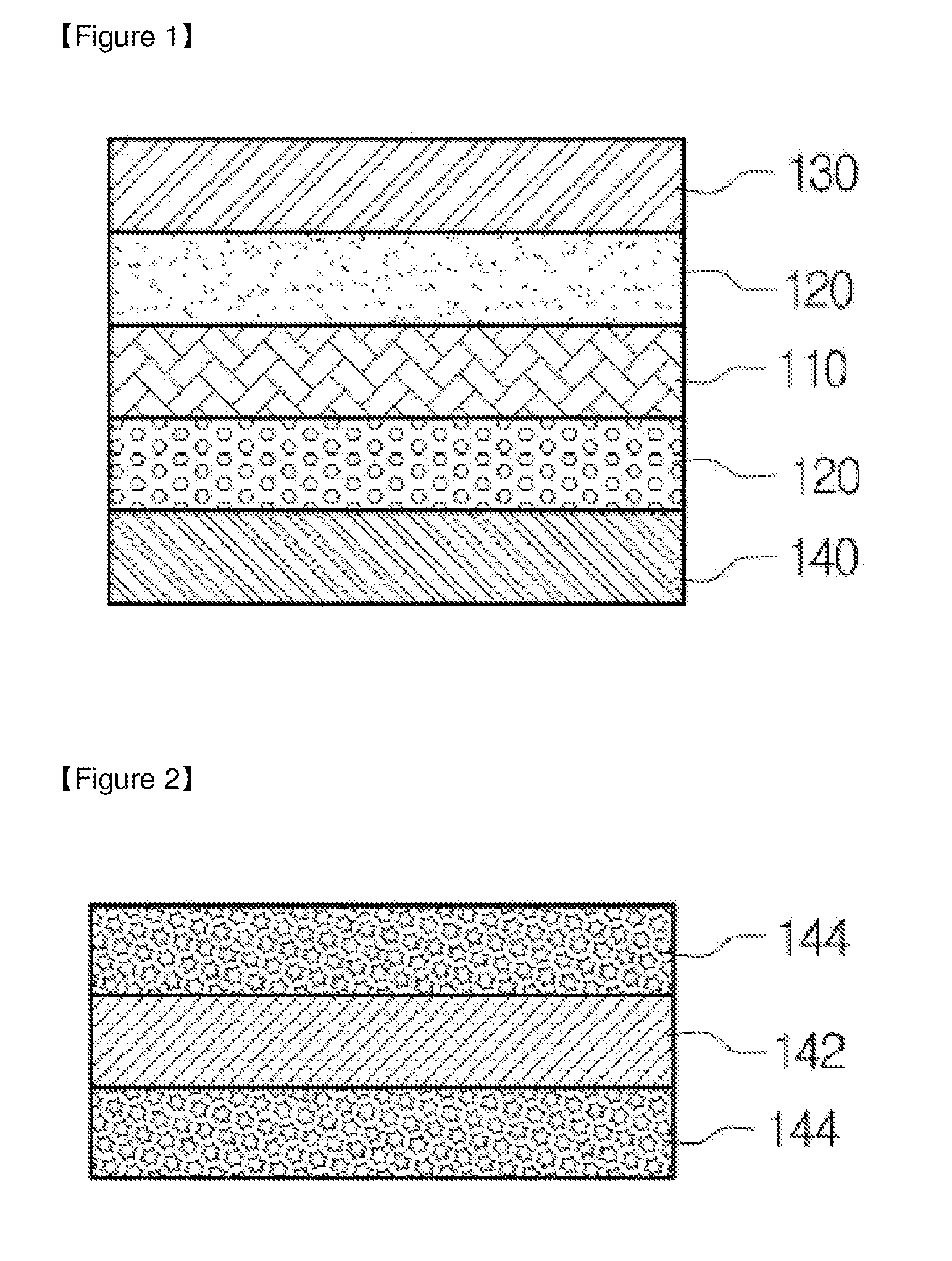

Back sheet for solar cells and method for preparing the same

InactiveUS20130263922A1Improve cooling effectIncreased durabilitySynthetic resin layered productsCoatingsEngineeringSolar cell

Owner:YOULCHON CHEM

Catheter assembly with a folded urine collection bag

There is disclosed a catheter assembly comprising a catheter and a receptacle. The receptacle has an elongate pocket, for accommodating at least an insertable end of said catheter, a urine collection bag, having a width extension wider than a greatest width of said elongate pocket, and at least two tab areas on at least one tab are arranged at the periphery of the urine collection bag on opposite sides of said bag. Further, in a storage state, said elongate pocket is folded over said urine collection bag, and lateral parts of said urine collection bag extending outside said elongate pocket are folded towards each other over said elongate pocket, said lateral parts being dimensioned to overlap each other in the folded disposition, and wherein said tab areas are arranged on said lateral parts and are attached to each other, in at least one point of attachment, to releasably maintain said catheter assembly in a folded disposition during storage.

Owner:ASTRA TECH SE

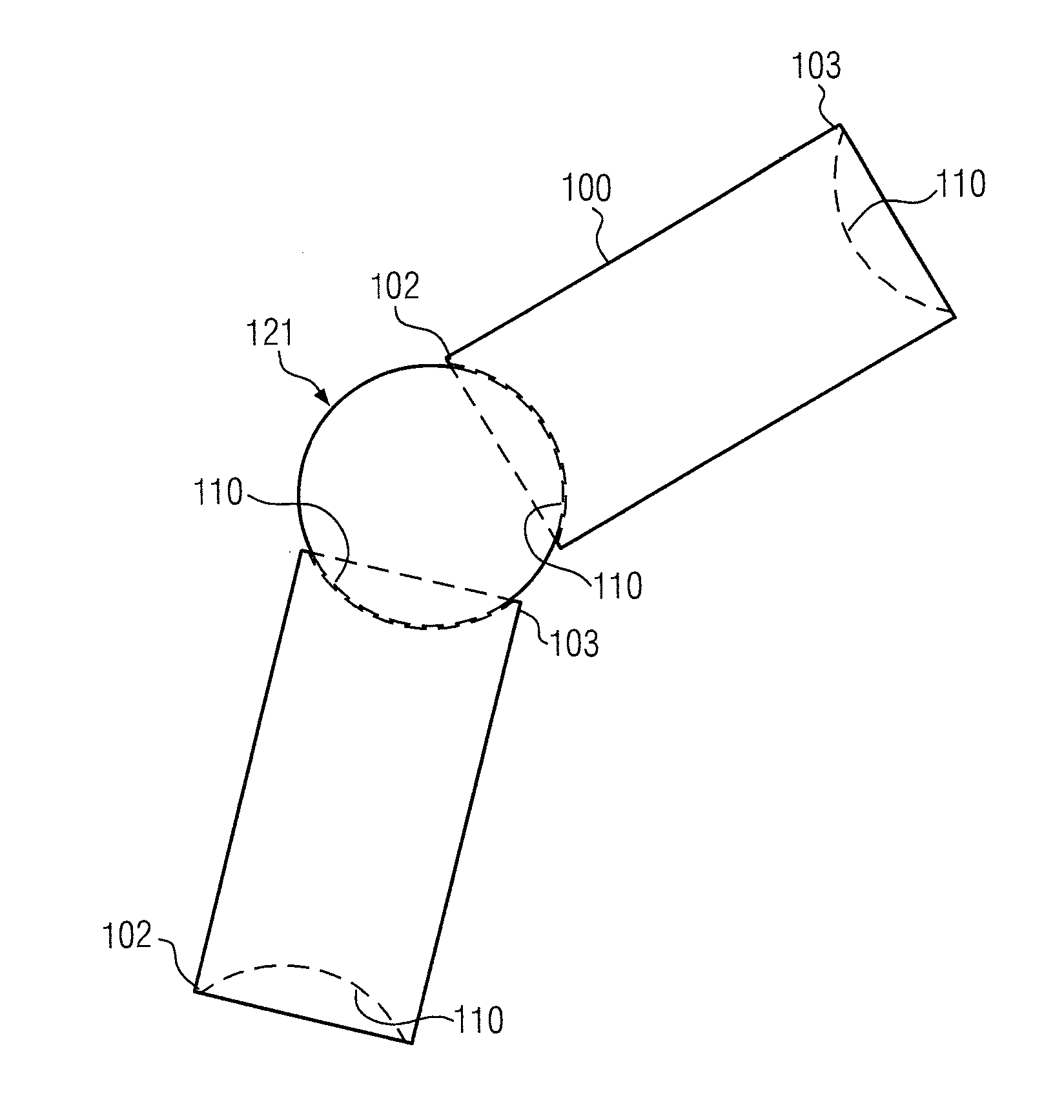

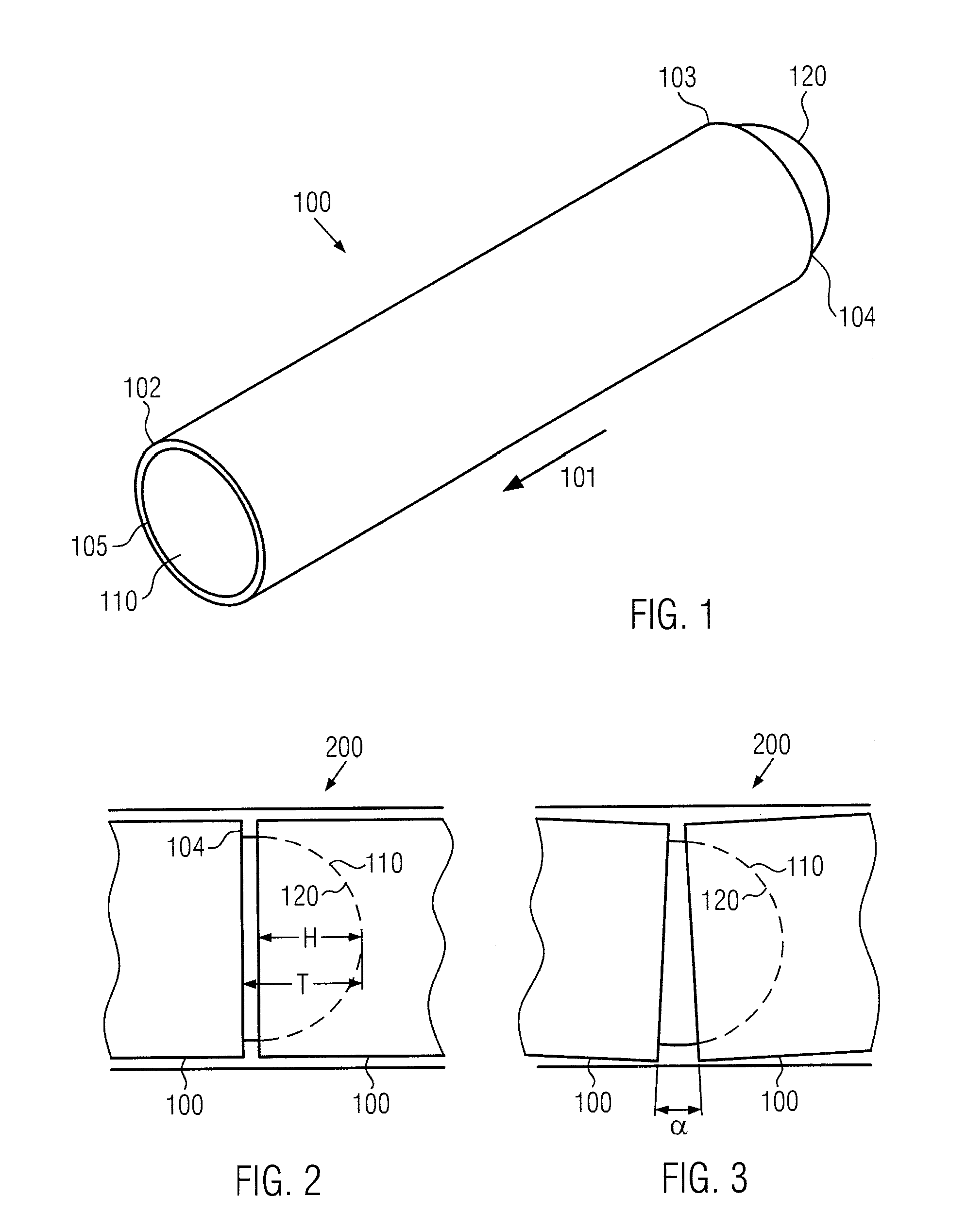

Magnetic core element, magnetic core module and an indictive component using the magnetic core module

ActiveUS20150123761A1Little magnetic leakageGreat coverageLoop antennas with ferromagnetic coreTransformers/inductances magnetic coresMagnetic coreEngineering

A rod-shaped magnetic core element, having a first end with a spherical or cylindrical recess or a spherical or cylindrical connecting protrusion, and a second end with a spherical or cylindrical recess or a spherical or cylindrical connecting protrusion so that a bent connection of at least two magnetic core elements is variably adjustable. Magnetic core elements comprising spherical or cylindrical magnetic core ends of this type allow a nearly gap-free construction with little magnetic leakage due to slightly larger end surfaces in comparison with ferrite rods having beveled plane end section surfaces. The enlarged end surface of the spherical surface advantageously allows a more stable connection of individual magnetic core elements without adhesive bonding. This allows the construction of flexible, multiple-member and inexpensive rod core coils and antennae.

Owner:SUMIDA COMPONENTS & MODULES

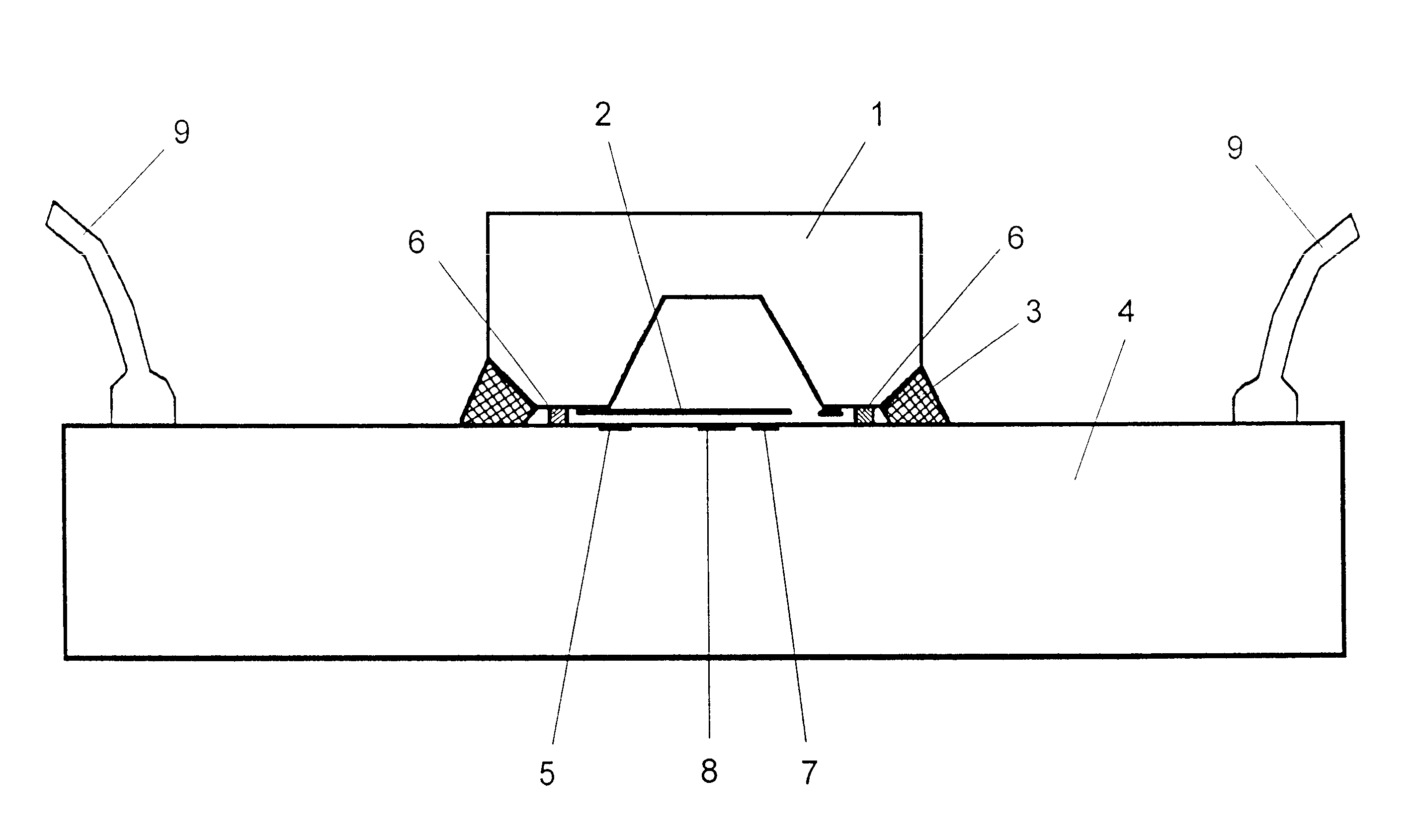

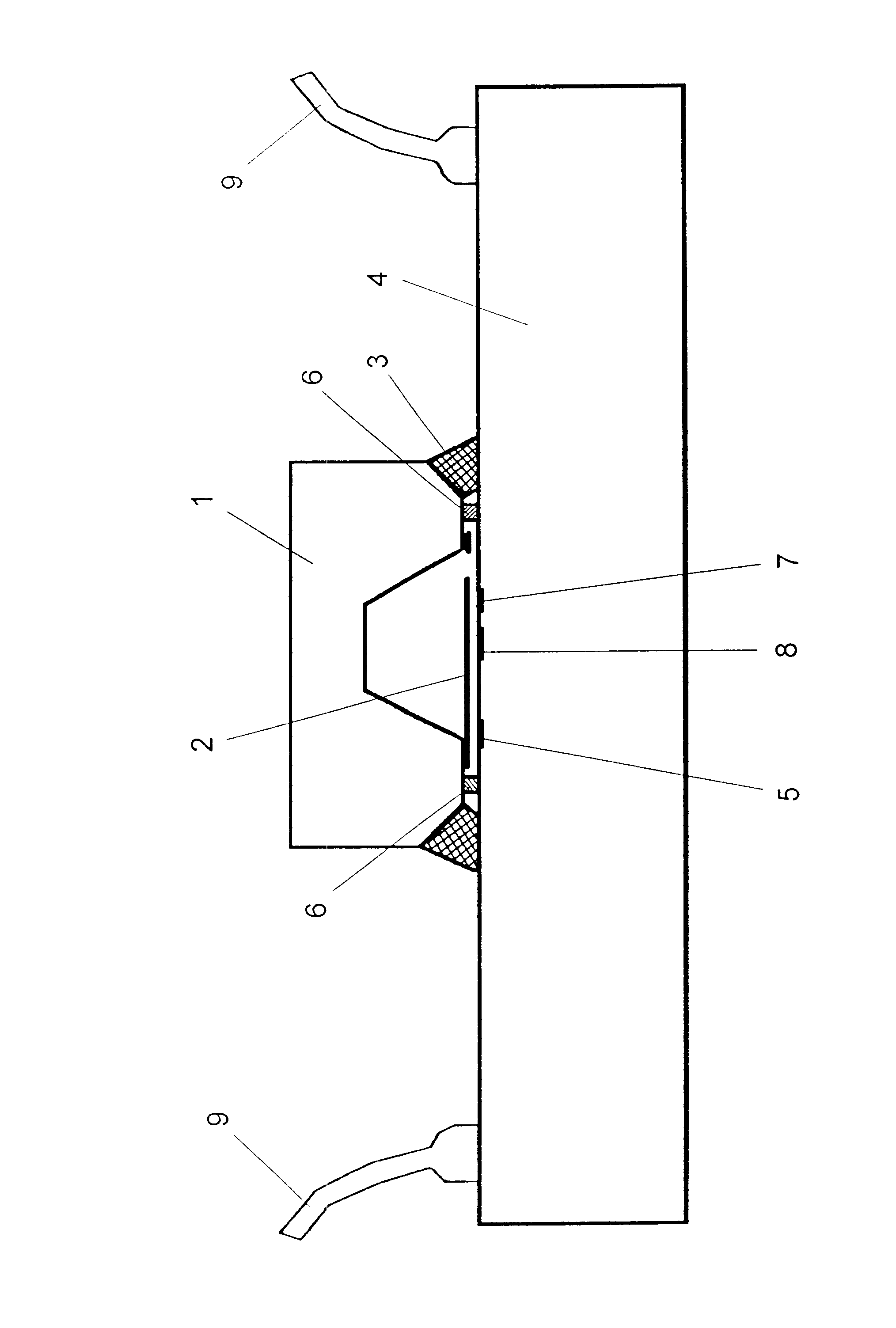

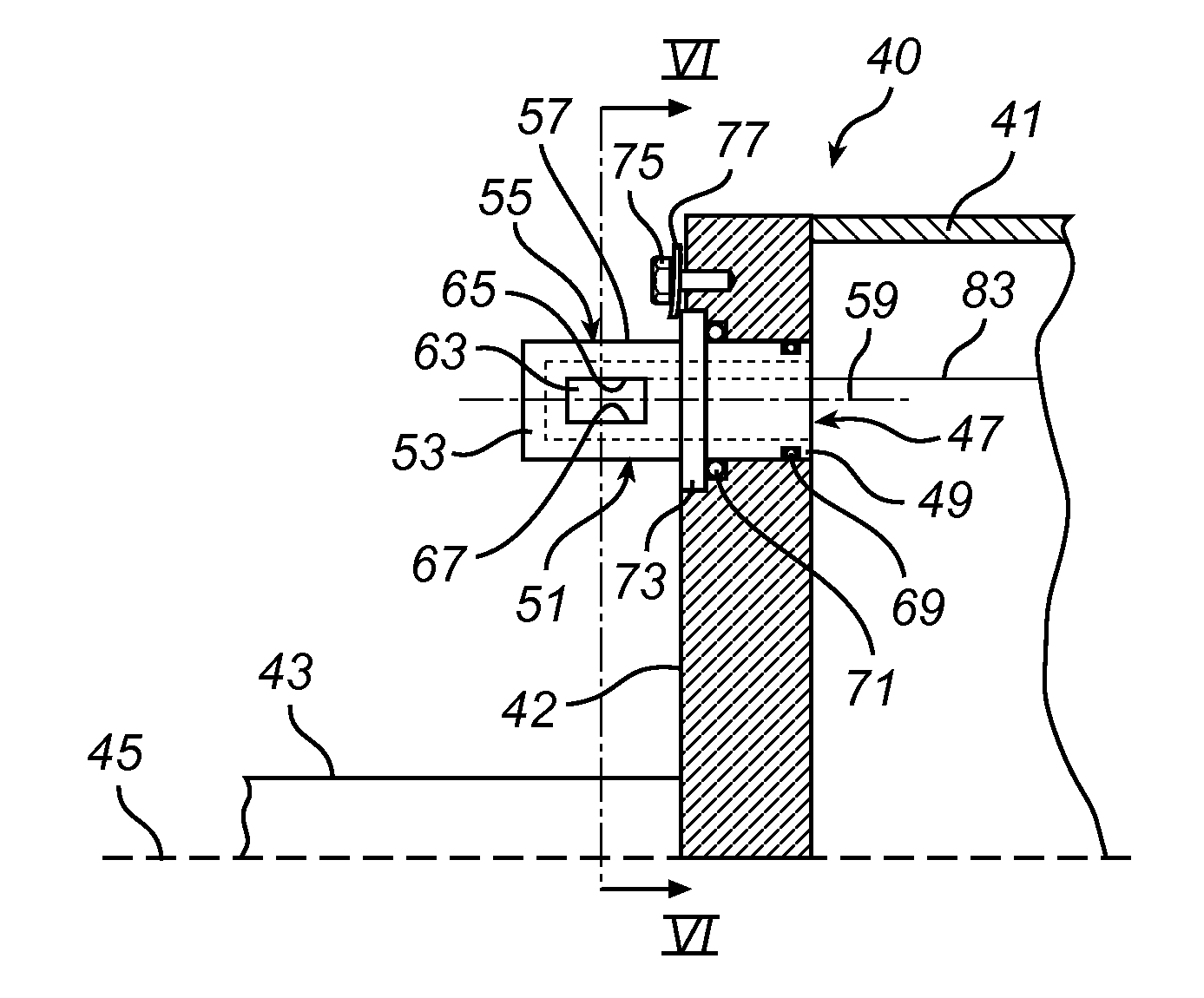

Microsensor having a sensor device connected to an integrated circuit by a solder joint

InactiveUS6520014B1Accurate measurementReduced risk of corrosionAcceleration measurement using interia forcesSemiconductor/solid-state device detailsElectricityIntegrated circuit

In a microsensor with a micro-electromechanical sensor element and an integrated circuit for measuring, calibration and compensation electronics, whereby the sensor is connected electrically to the integrated circuit (IC), the micro-electromechanical sensor element is arranged directly on the integrated circuit with accurate positioning, and is connected with electric conductivity via a circulating soldered joint.

Owner:AUSTRIA MIKRO SYST INT

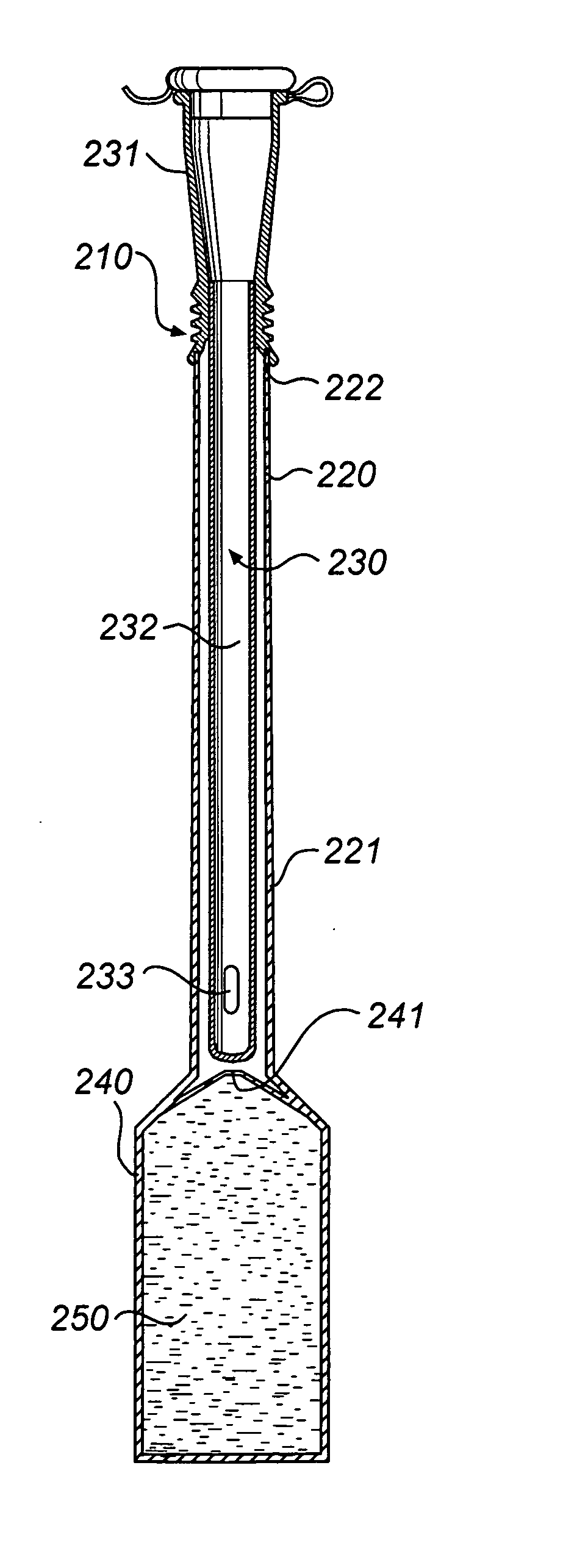

Catheter assembly with osmolality-increasing fluid

ActiveUS20070149929A1Improve propertiesReduce forceTransportation and packagingWound drainsHigh concentrationHydrophilic coating

A catheter assembly is disclosed comprising: a hydrophilic catheter; a wetting fluid for wetting of the catheter; and a receptacle enclosing at least the insertable part of the catheter and the wetting fluid. Further, the wetting fluid is a solution incorporating at least one osmolality-increasing compound, and the total concentration of the osmolality-increasing compound(s) is very high, preferably exceeding 600 mOsm / dm3. The wetting fluid could either be arranged in contact with the hydrophilic surface layer of the catheter in the receptacle, for preservation of the hydrophilic surface layer in a wetted state during accommodation in said receptacle and provision of a ready-to-use catheter assembly, or be arranged to keep the wetting fluid separated from the hydrophilic surface layer of the catheter during storage, but to be brought into contact with said hydrophilic surface layer upon activation before an intended use of the catheter. A similar method and wetting fluid is disclosed as well. The provision of the osmolality-increasing compound in the wetting fluid provides several advantages per se, such as a improved properties of the hydrophilic coating, a more predictable and controllable wetting process, a more expedient and cost efficient production, etc. Further, the use of this very high concentration of osmolality-increasing compound in the wetting fluid has proven remarkably efficient.

Owner:ASTRA TECH SE

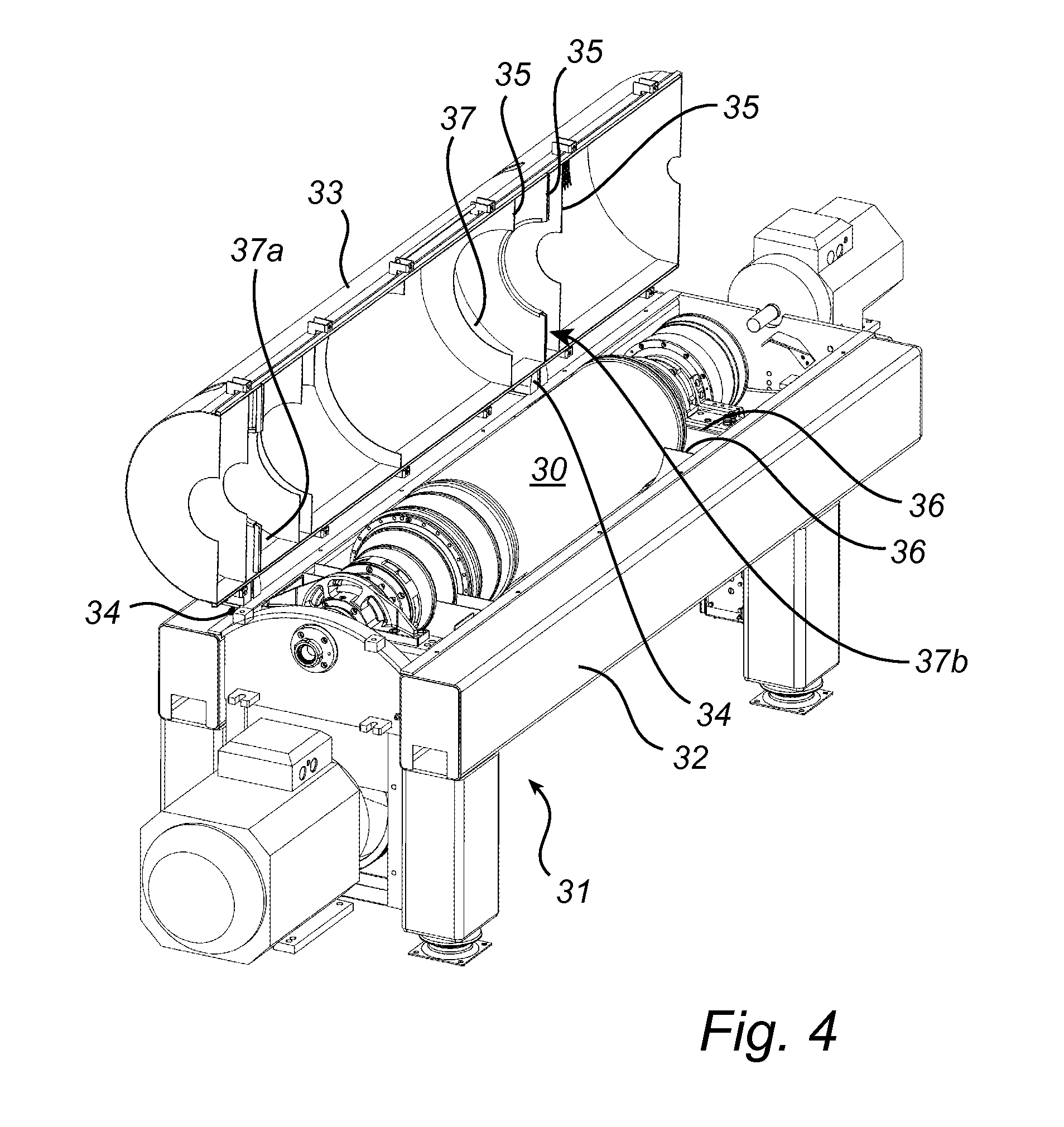

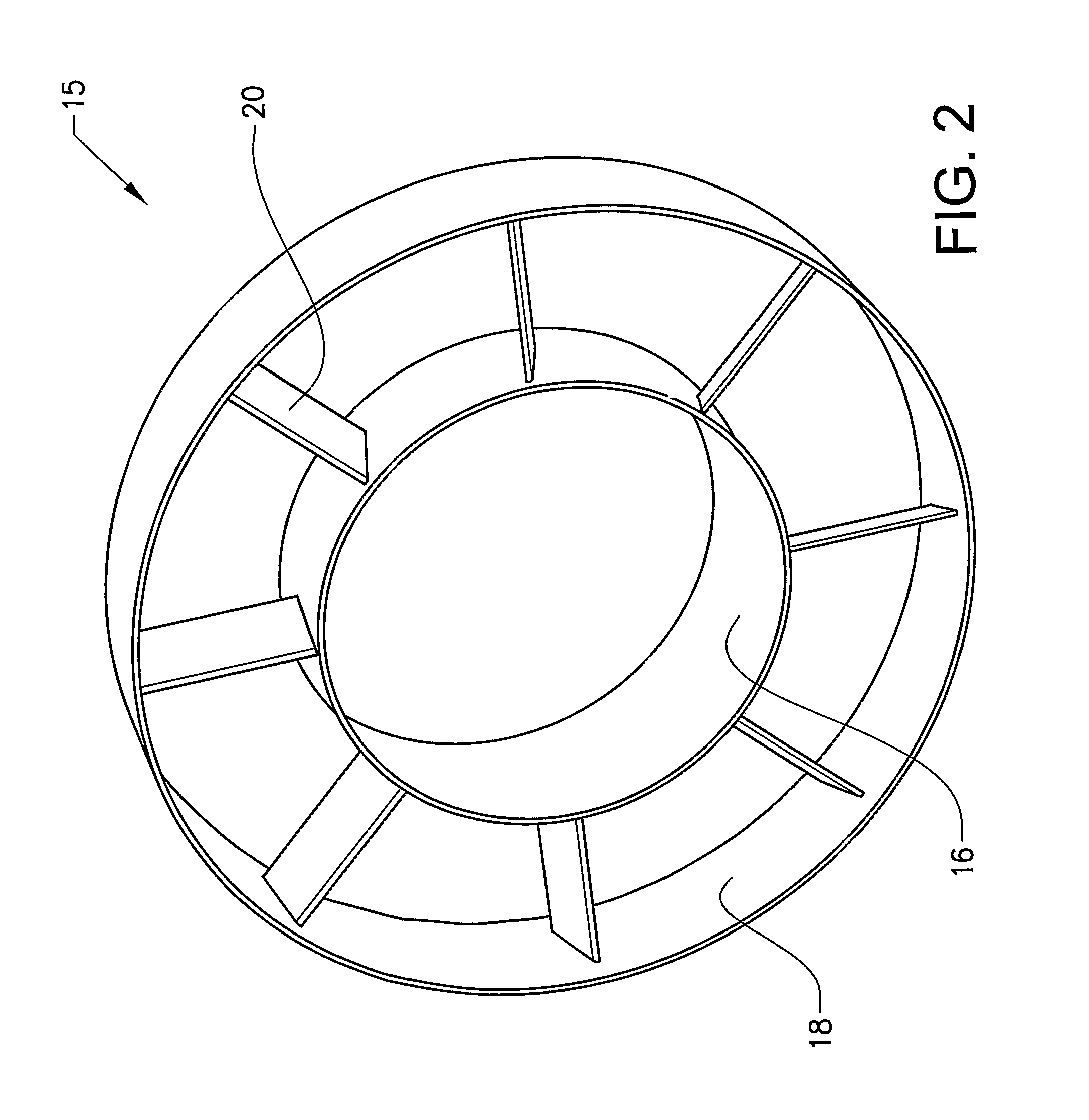

Centrifugal separator and an outlet element for a centrifugal separator

ActiveUS20130310242A1Easy constructionCost efficient productionRotary centrifugesEngineeringMechanical engineering

A centrifugal separator includes a rotating body rotating in use around an axis. The rotating body comprises a bowl, which comprises a base at one longitudinal end of said bowl, said base defining a rear longitudinal area. An outlet passage extends through the base and an outlet housing is provided in the rear longitudinal area. The outlet housing is communicating with the outlet passage to receive liquid therefrom and the outlet housing has an outlet opening discharging in use liquid from the rotating body. The outlet opening comprises a weir edge defining in normal use a level of a surface of a liquid in the bowl. The outlet housing is rotatable around an adjustment axis and the outlet opening is placed in a side wall offset from the adjustment axis.

Owner:ALFA LAVAL CORP AB

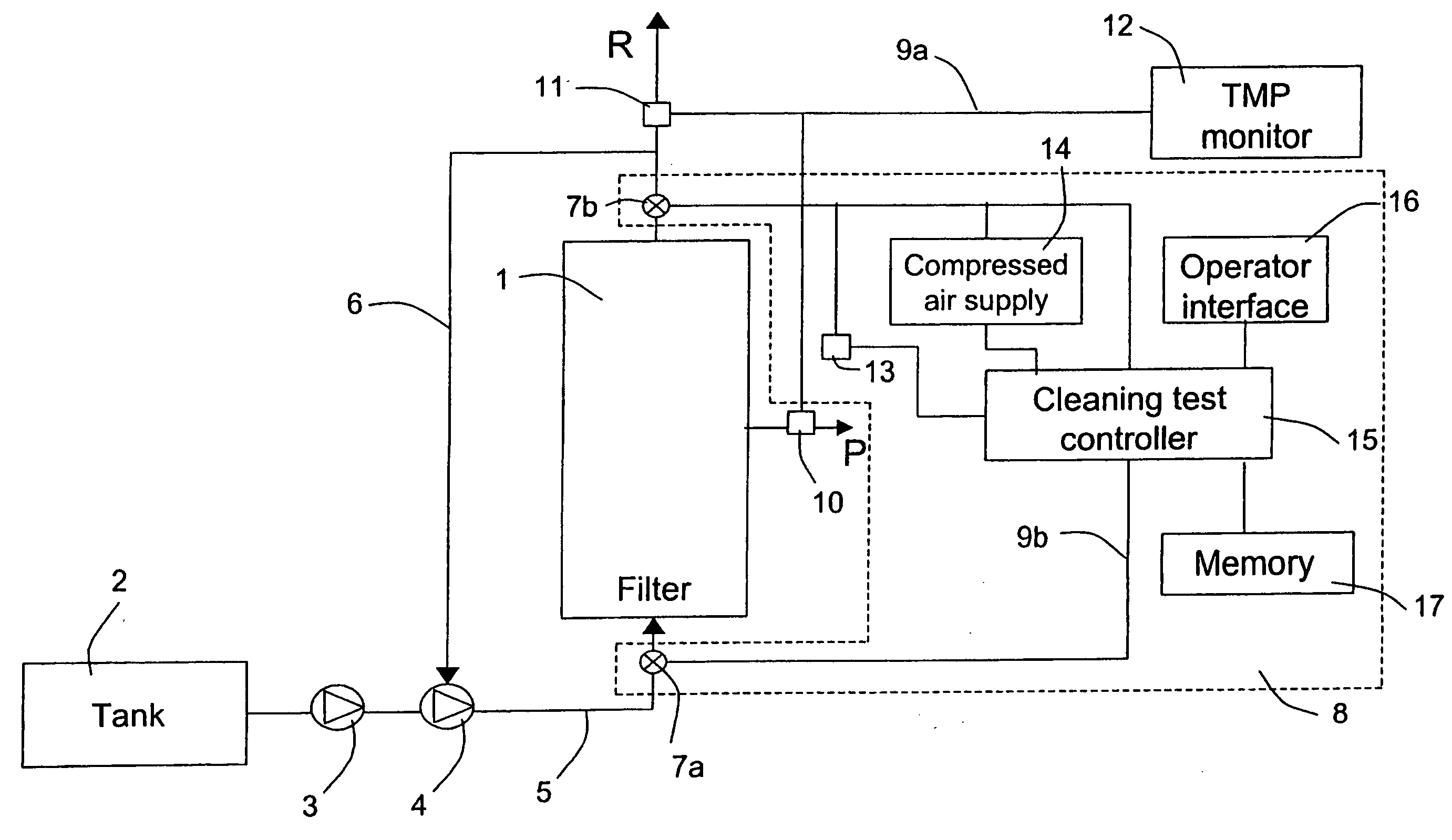

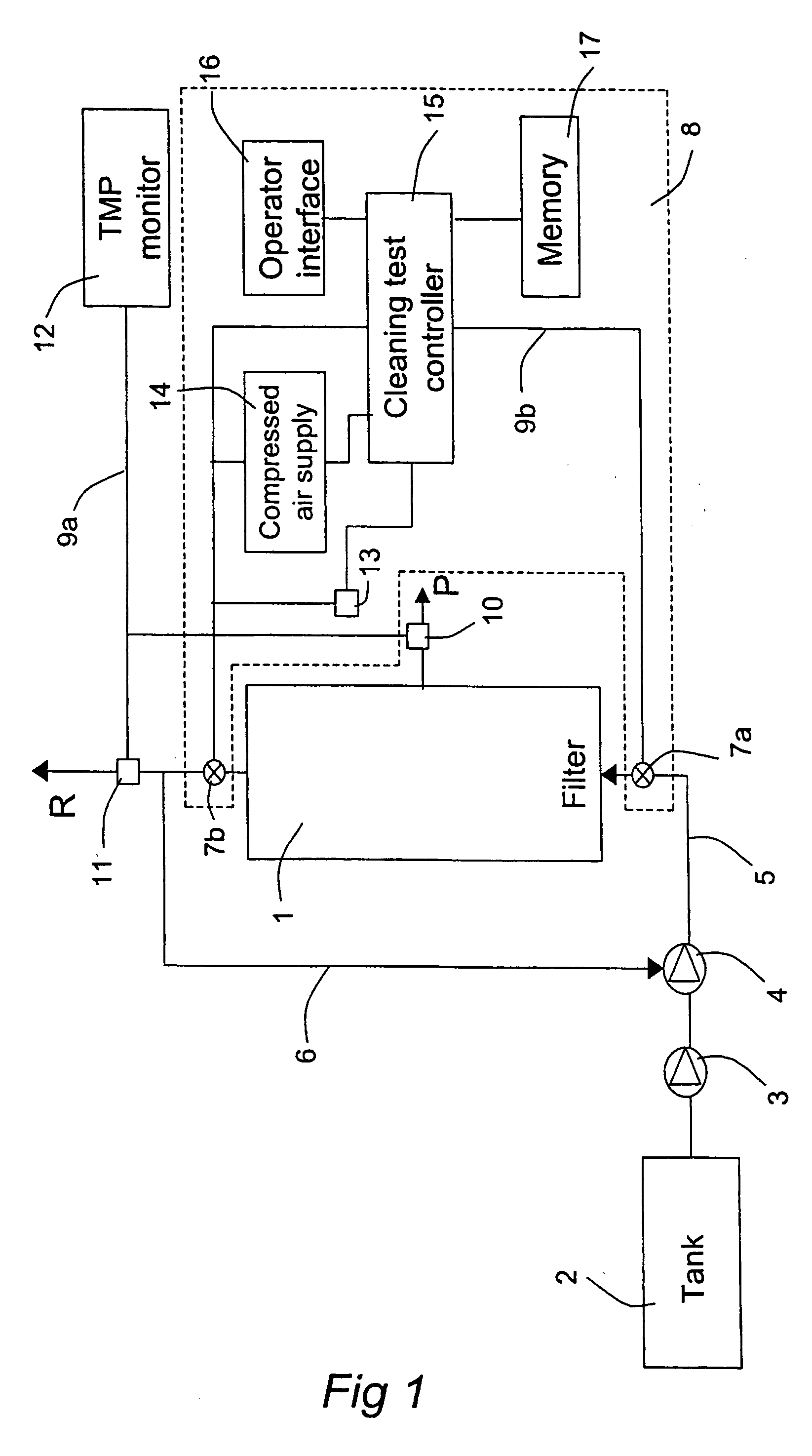

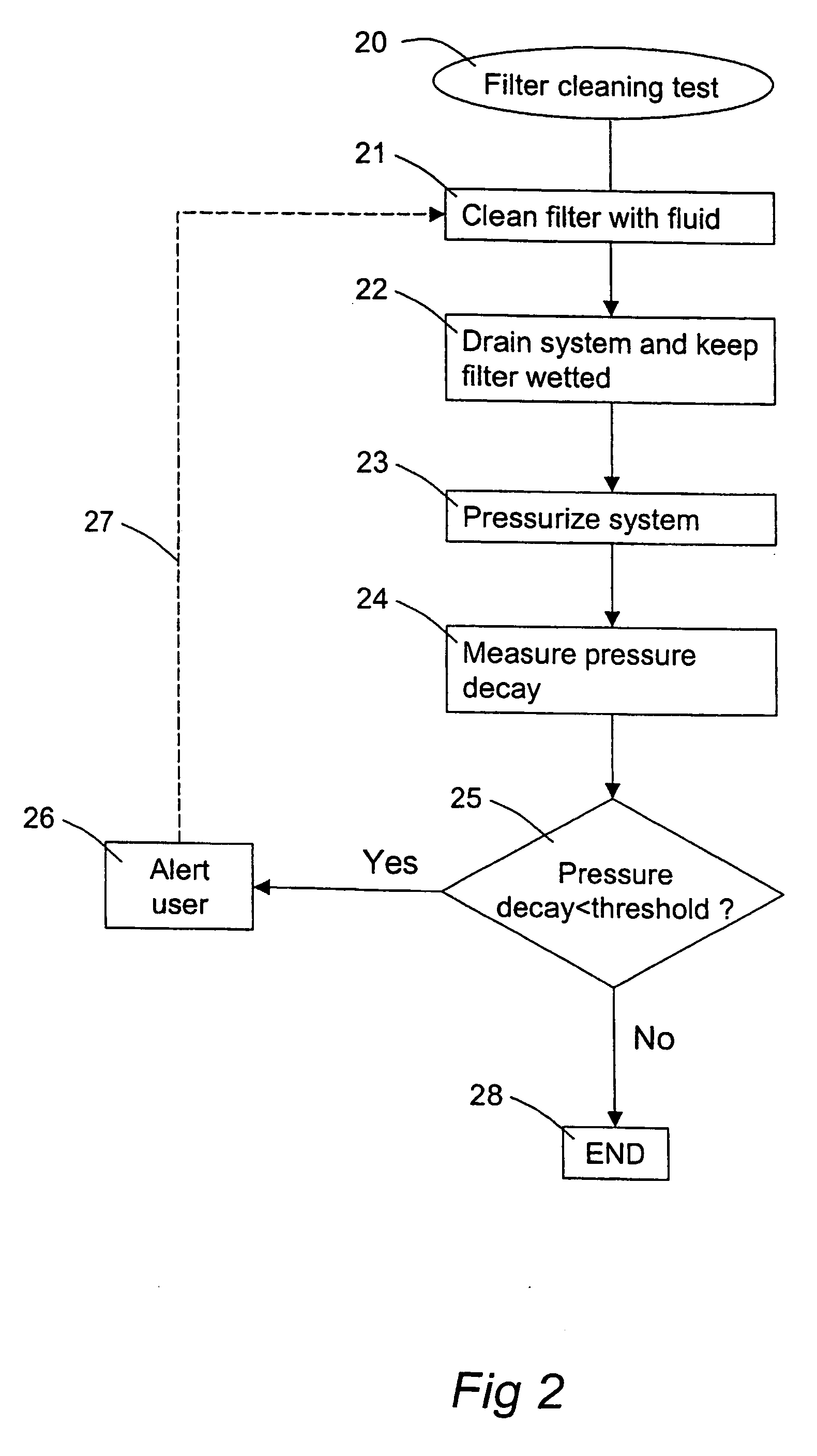

Cleaning efficiency testing method and apparatus for a filter in a filtering system

InactiveUS20050000894A1Reduce the amount requiredCost-efficient productionDetection of fluid at leakage pointUltrafiltrationTime segmentFilter system

A method and an apparatus are provided for testing the efficiency of a cleaning procedure for a filter in a filtering system. After the cleaning procedure (21) of the filter, the filter pores contain a fluid (22). The system is pressurized (23), and a decay in pressure over a predetermined time period is measured (24). Based on the pressure decay, it is determined whether or not the cleaning procedure has been effective (25); a pressure decay smaller than a predetermined threshold value indicates that the cleaning procedure has not been effective.

Owner:TETRA LAVAL HLDG & FINANCE SA

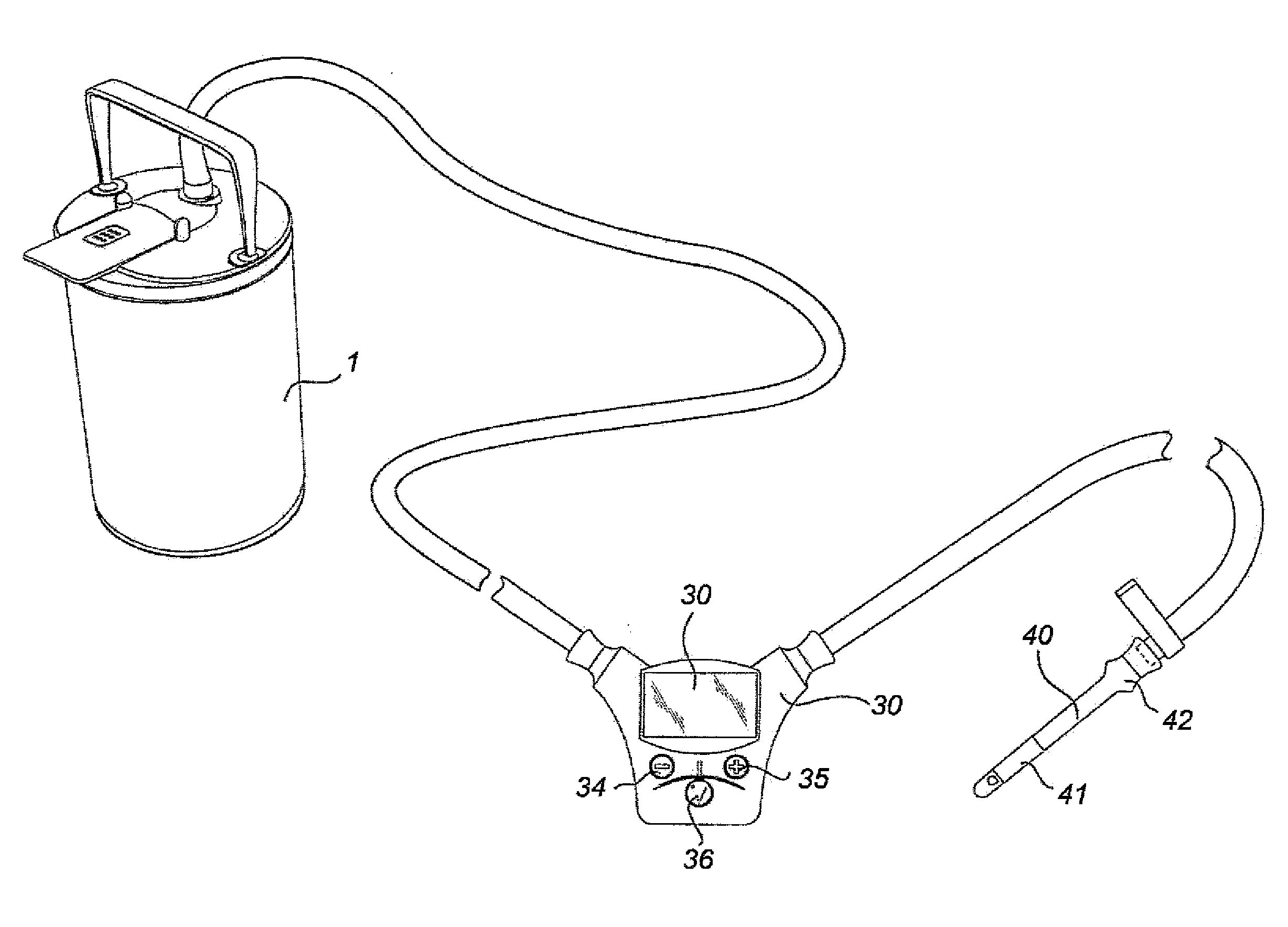

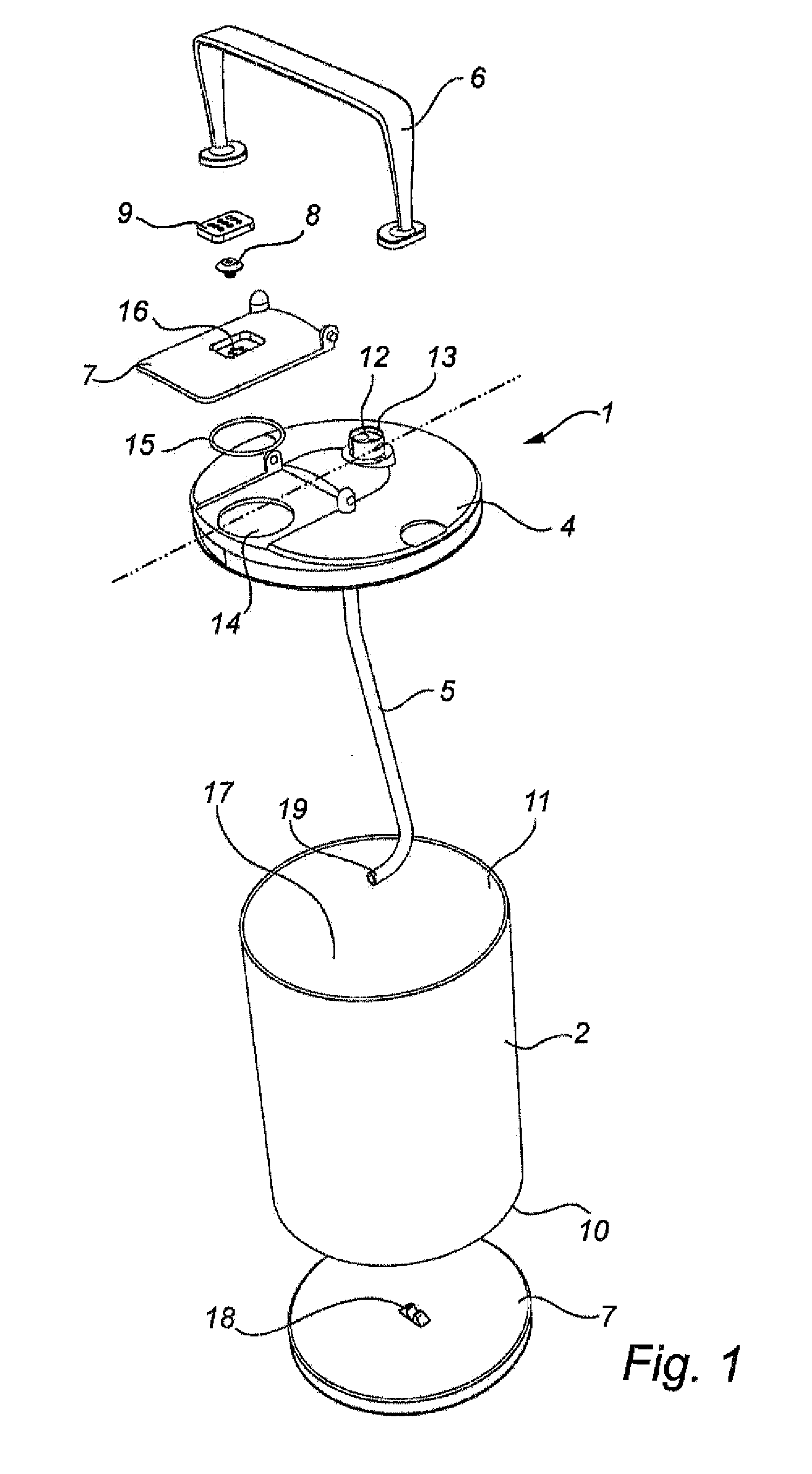

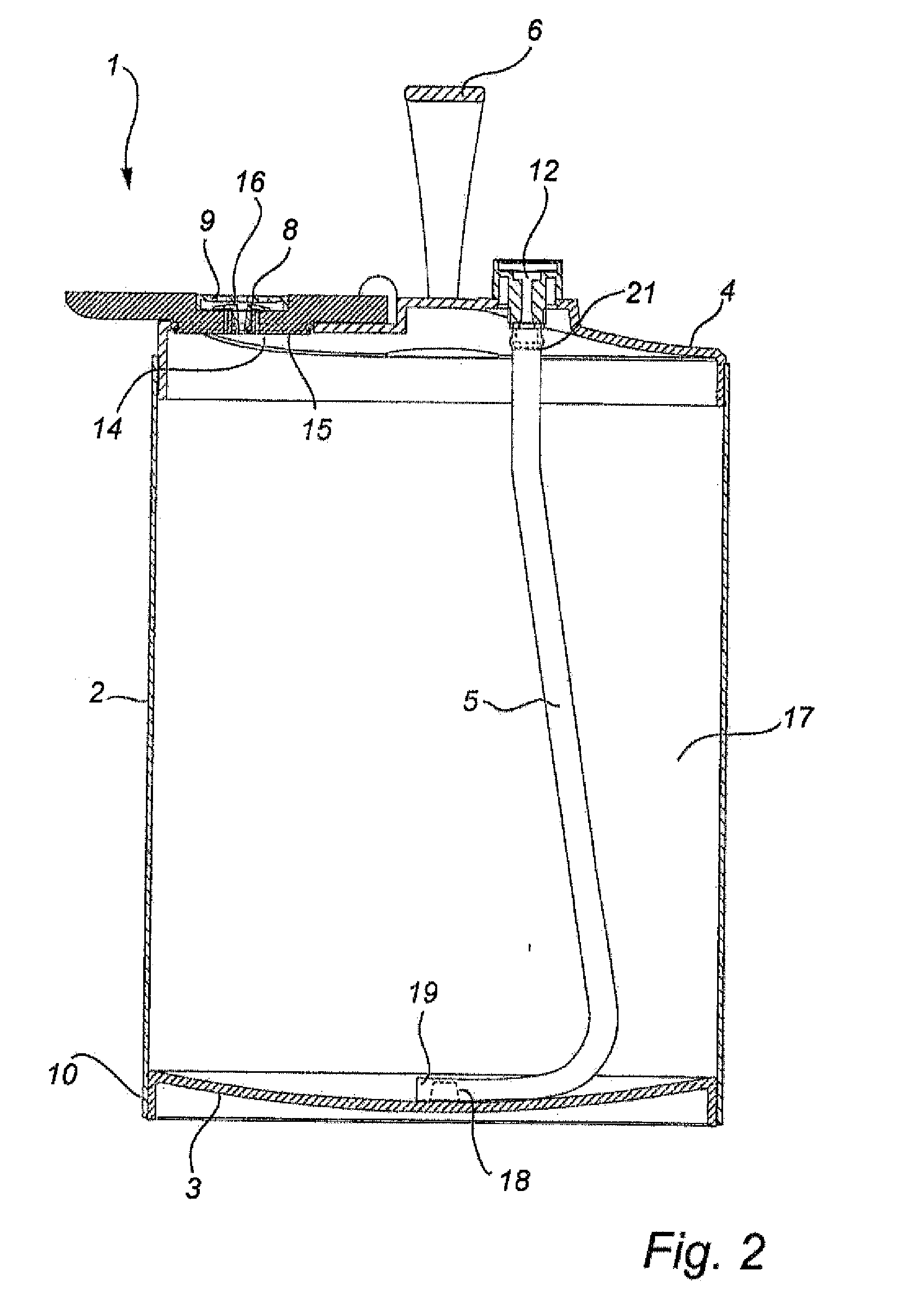

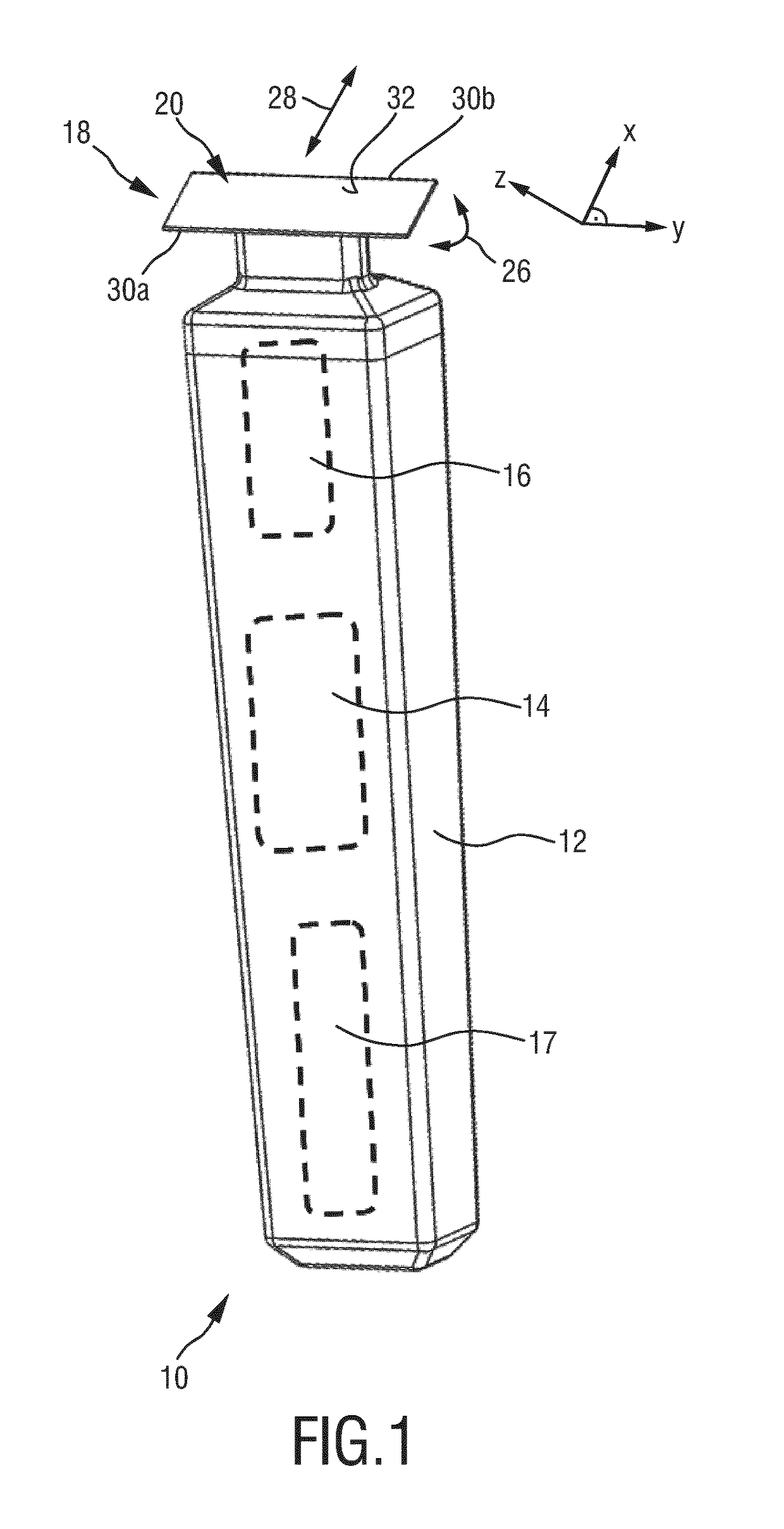

Cylindrical collapsible container

ActiveUS20150335529A1Facilitate productionCost-efficient productionDiagnosticsSurgical needlesRectal irrigationWater irrigation

There is provided a container (1) for medical use forming a closed compartment (17) for carrying a liquid. The container (1) comprises a flexible side wall (5), a rigid top portion (4) and a rigid bottom portion (3). In the top portion (4) there is at least one through-hole. The side wall (5), the top (4) and bottom (3) portions together form a compartment (17). Inside the compartment (17), a flexible tube (5) is arranged with one end (21) in fluid communication with a though-hole (12) in the top portion (4). A second end (19) of the tube is connected to the bottom portion (3) via a snap-in connection (18). Liquid from the inside of the container (1) may be withdrawn by pressurizing the compartment (17) in which liquid is stored, when in use. The container (1) is reversible folded and unfolded for convenient filling and storing of the container (1). The container (1) is adapted for use in an irrigation system, and preferably a system for rectal irrigation.

Owner:DENTSPLY IH

Blade set, hair cutting appliance, and related manufacturing method

ActiveUS10081114B2Low experience requirementReduce stepsMetal working apparatusLeading edgePlastic materials

The present disclosure relates to a hair cutting appliance (10), a blade set (20) for a hair cutting appliance (10), and to a stationary blade (22) for said blade set (20). Said stationary blade (22) may comprise a first wall portion (100) arranged to serve as a skin facing wall when in operation, a second wall portion (102) at least partially offset from the first wall portion (100), such that the first wall portion (100) and the second wall portion (102) define therebetween a guide slot (96) arranged to receive a movable cutter blade (24), at least one toothed leading edge (30) jointly formed by the first wall portion (100) and the second wall portion (102), wherein the at least one toothed leading edge (30) comprises a plurality of teeth (36), wherein the first wall portion (100) and the second wall portion (102) are connected at a frontal end of the at least one leading edge (30), thereby forming tips (86) of the teeth (36), wherein the stationary blade (22) is an integrally formed metal-plastic composite stationary blade (22), wherein the first wall portion (100) is at least partially made from metal material, and wherein the second wall portion (102) is at least partially made from plastic material. The disclosure further relates to a method for manufacturing a respective blade (22).

Owner:KONINKLJIJKE PHILIPS NV

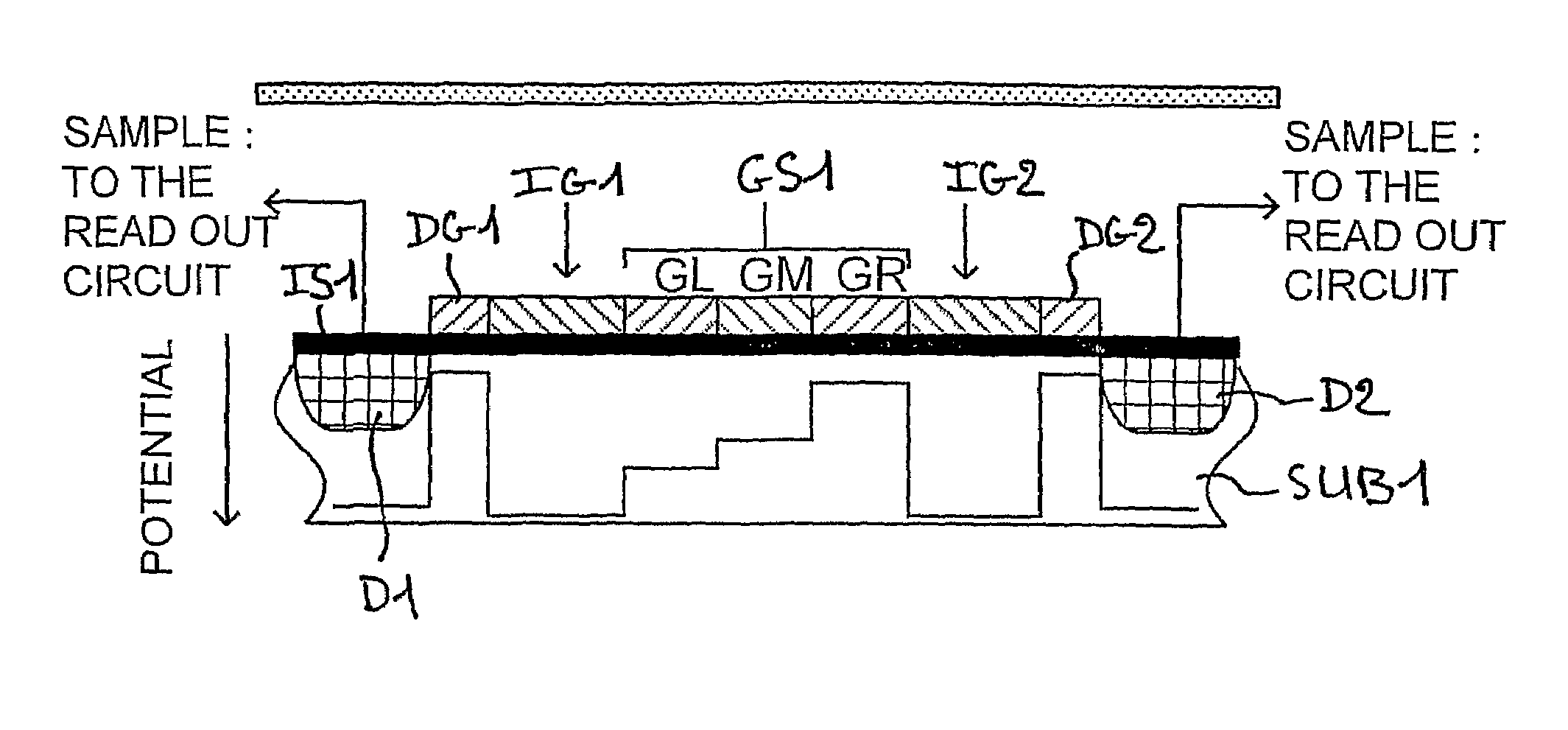

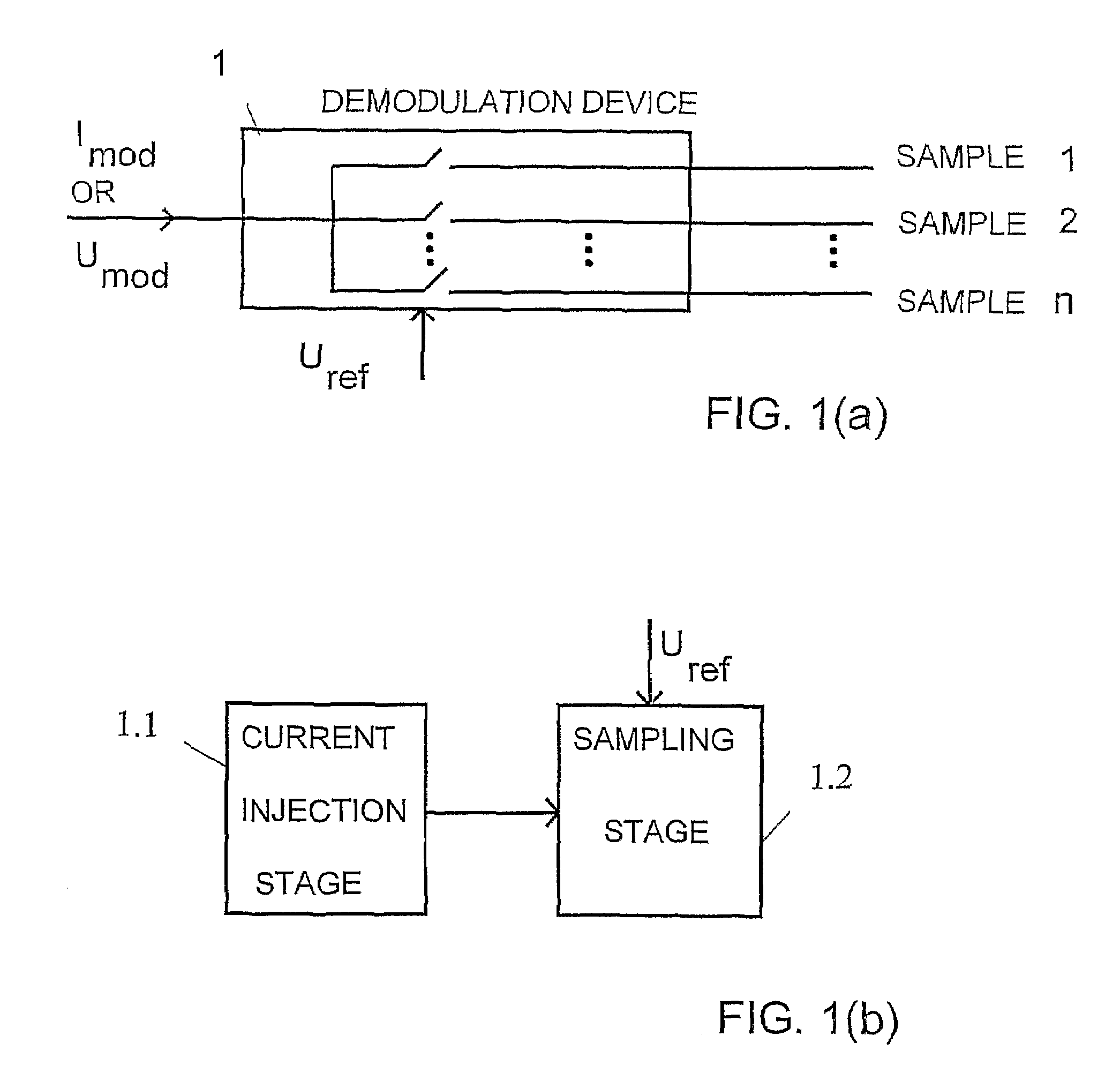

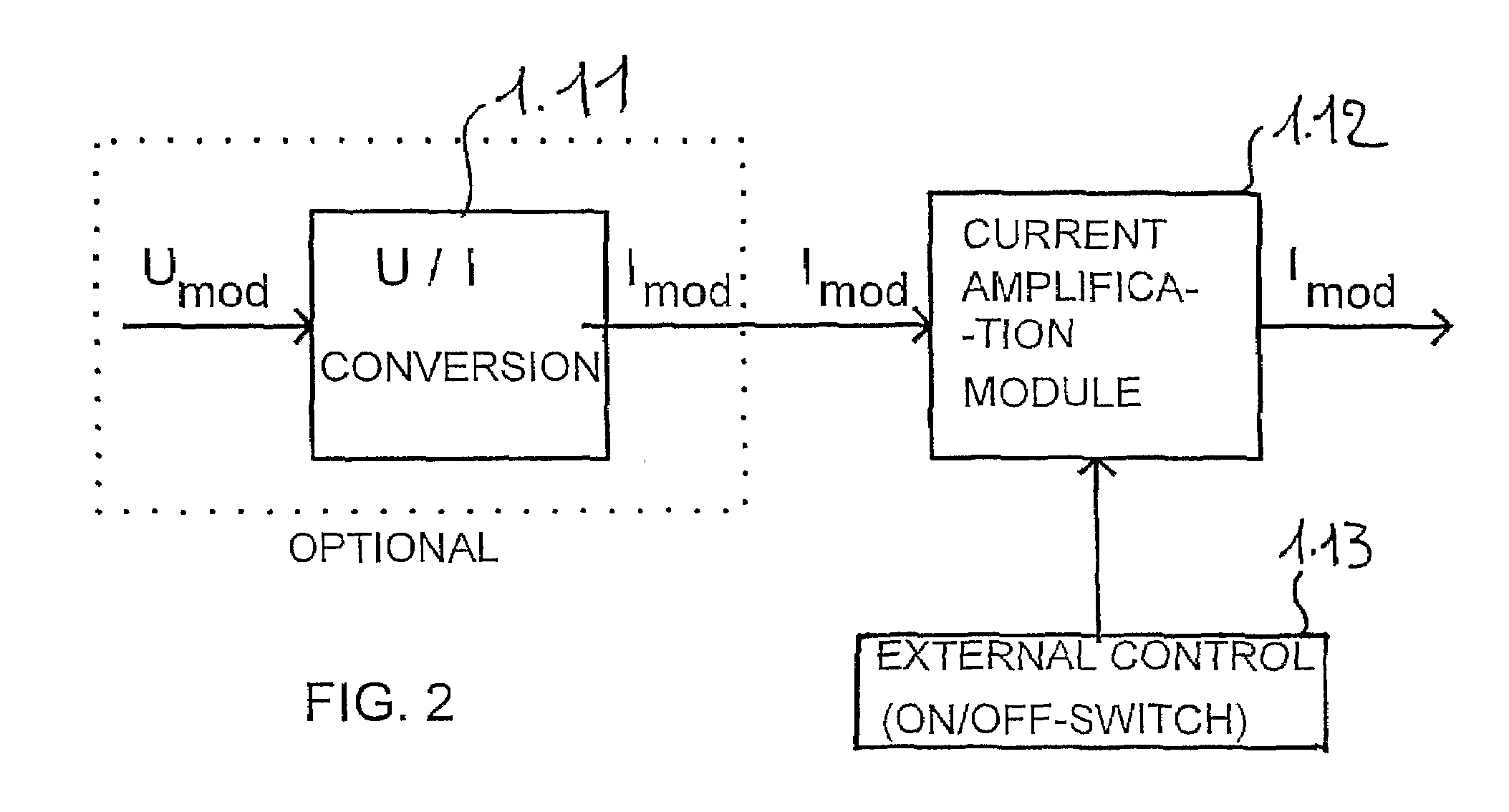

Device and method for the demodulation of modulated electric signals

ActiveUS7671671B2Highly integratedDevice integrationModulation transferenceSolid-state devicesCharge currentEngineering

A demodulation device (1) in semiconductor technology is disclosed. The device (1) is capable of demodulating an injected modulated current. The device (1) comprises an input node (IN1), a sampling stage (DG1, IG1, GS1, IG2, DG2) and at least two output nodes (D1, D2). The sampling stage DG1, IG1, GS1, IG2, DG2) comprises transfer means (GL, GM, GR) for transferring a modulated charge-current signal from the input node (IN1) to one of the output nodes (D1, D2) allocated to the respective time interval within the modulation period. The small size and the ability to reproduce the device (1) in standard semiconductor technologies make possible a cost-efficient integration of the device (1).

Owner:AMS SENSORS SINGAPORE PTE LTD

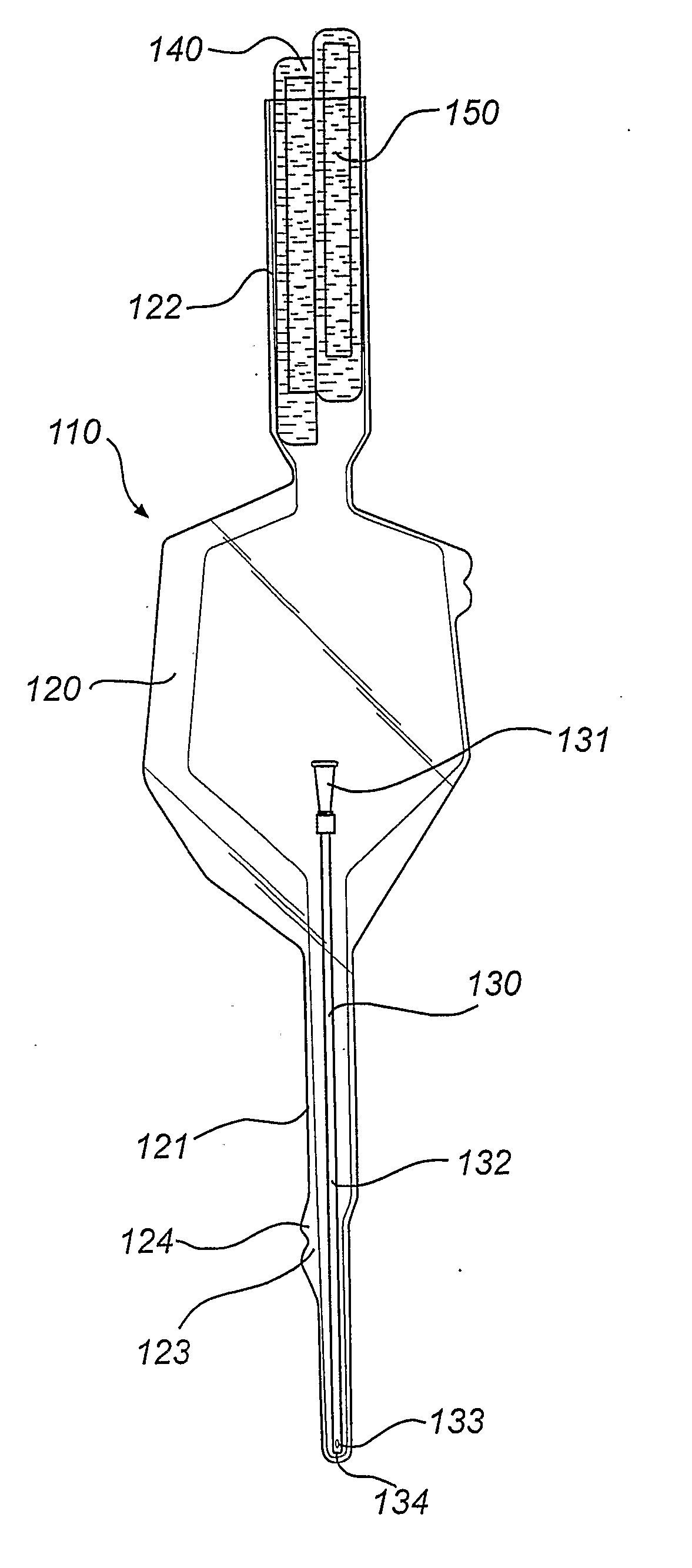

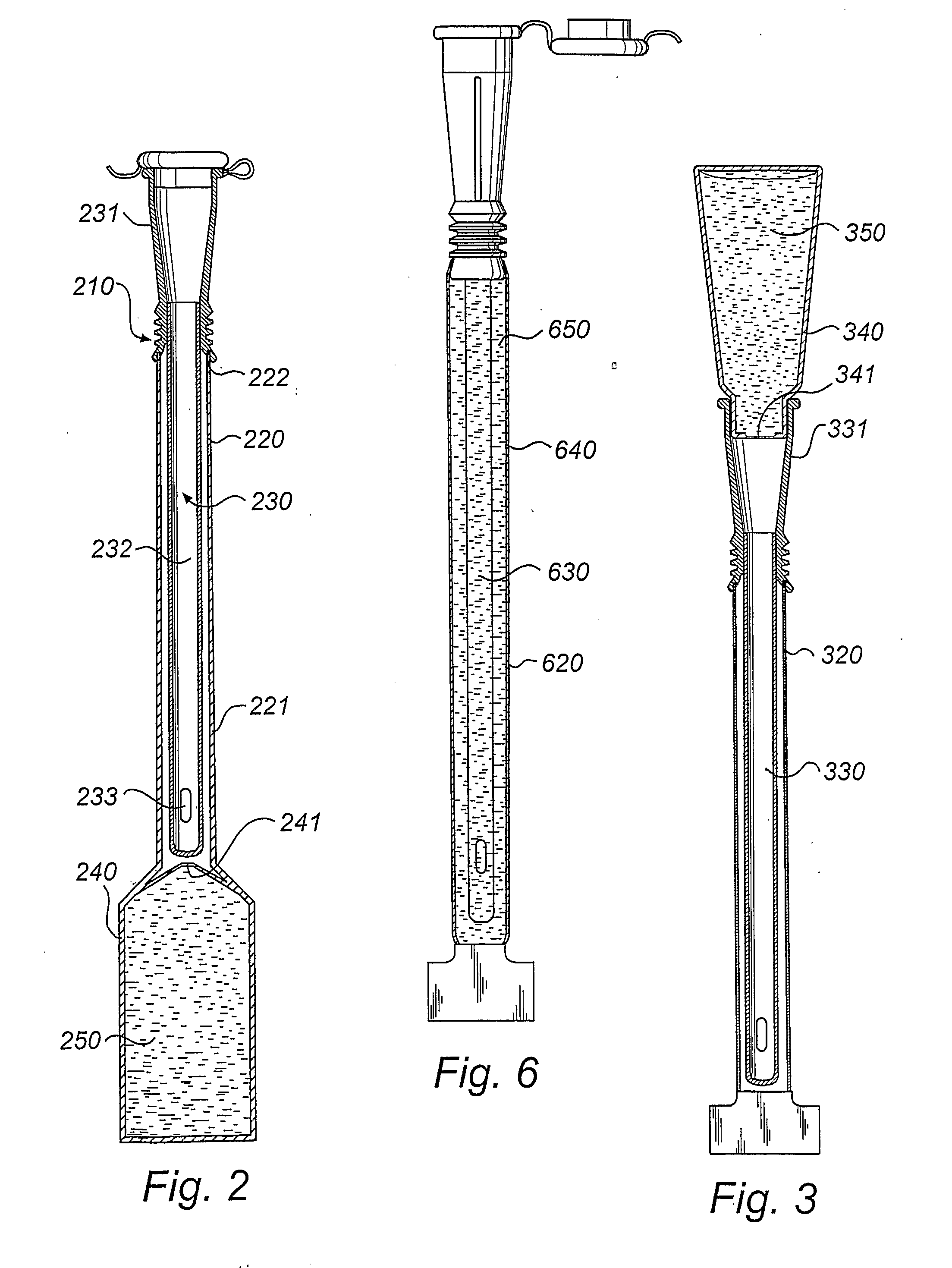

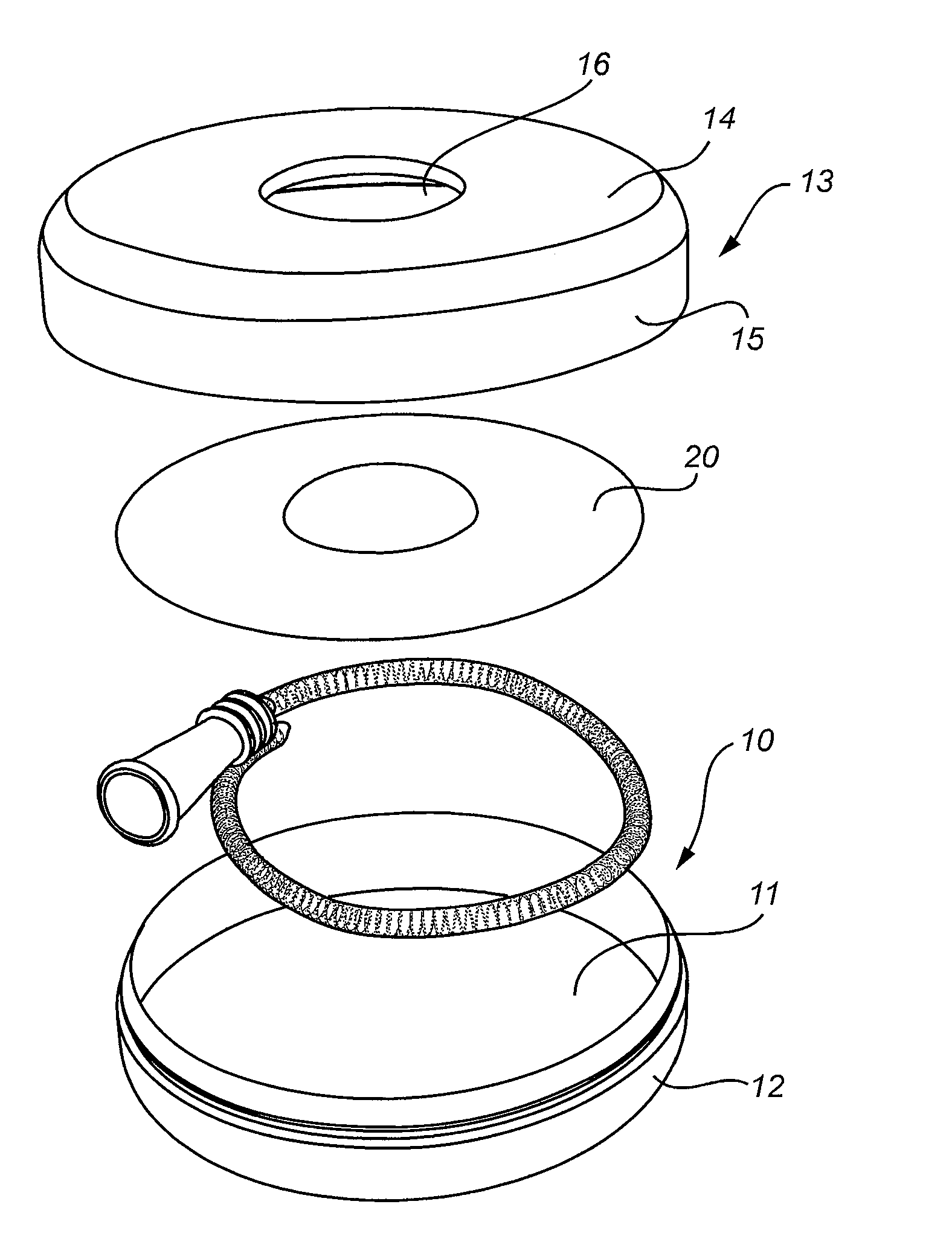

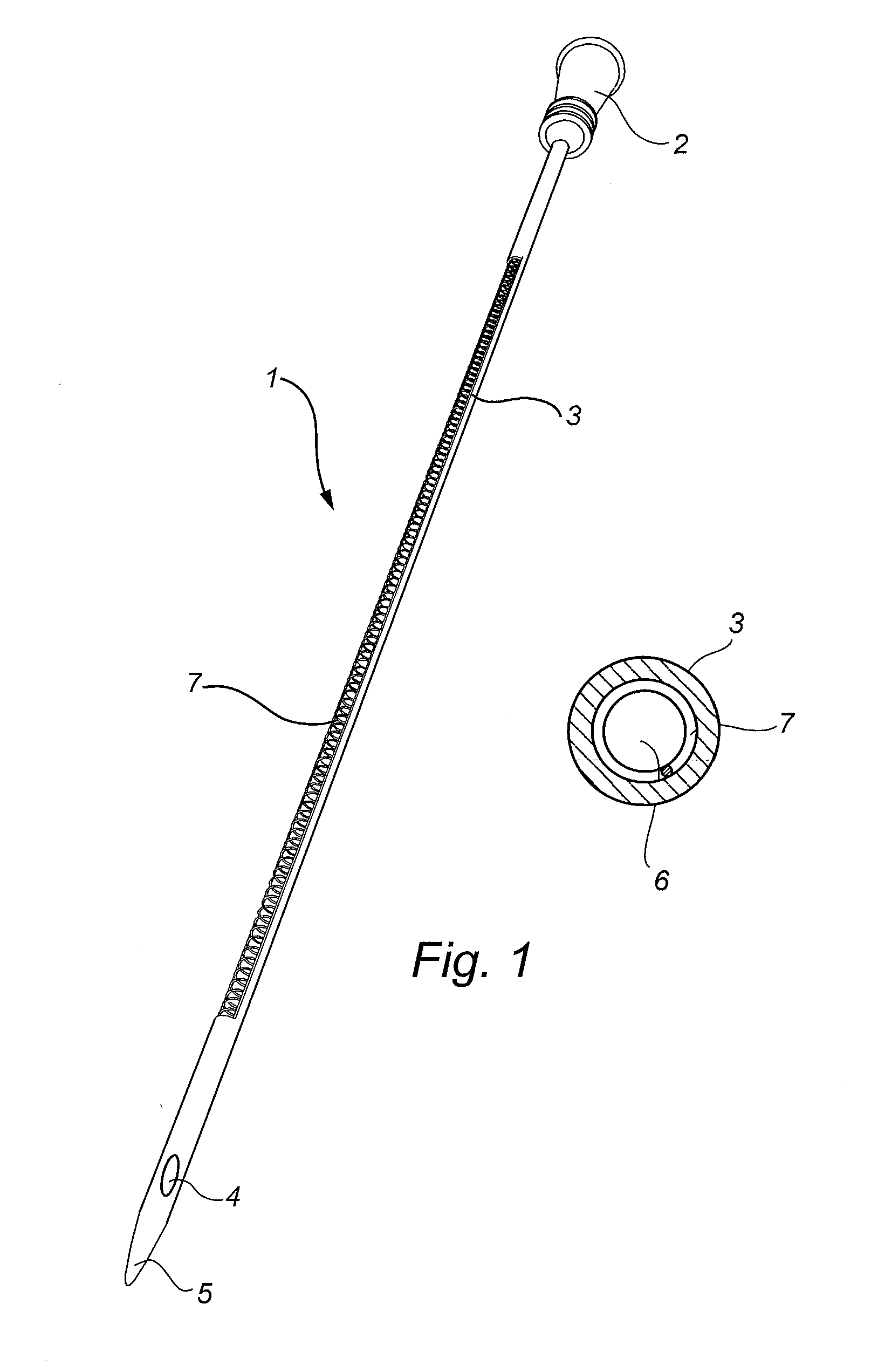

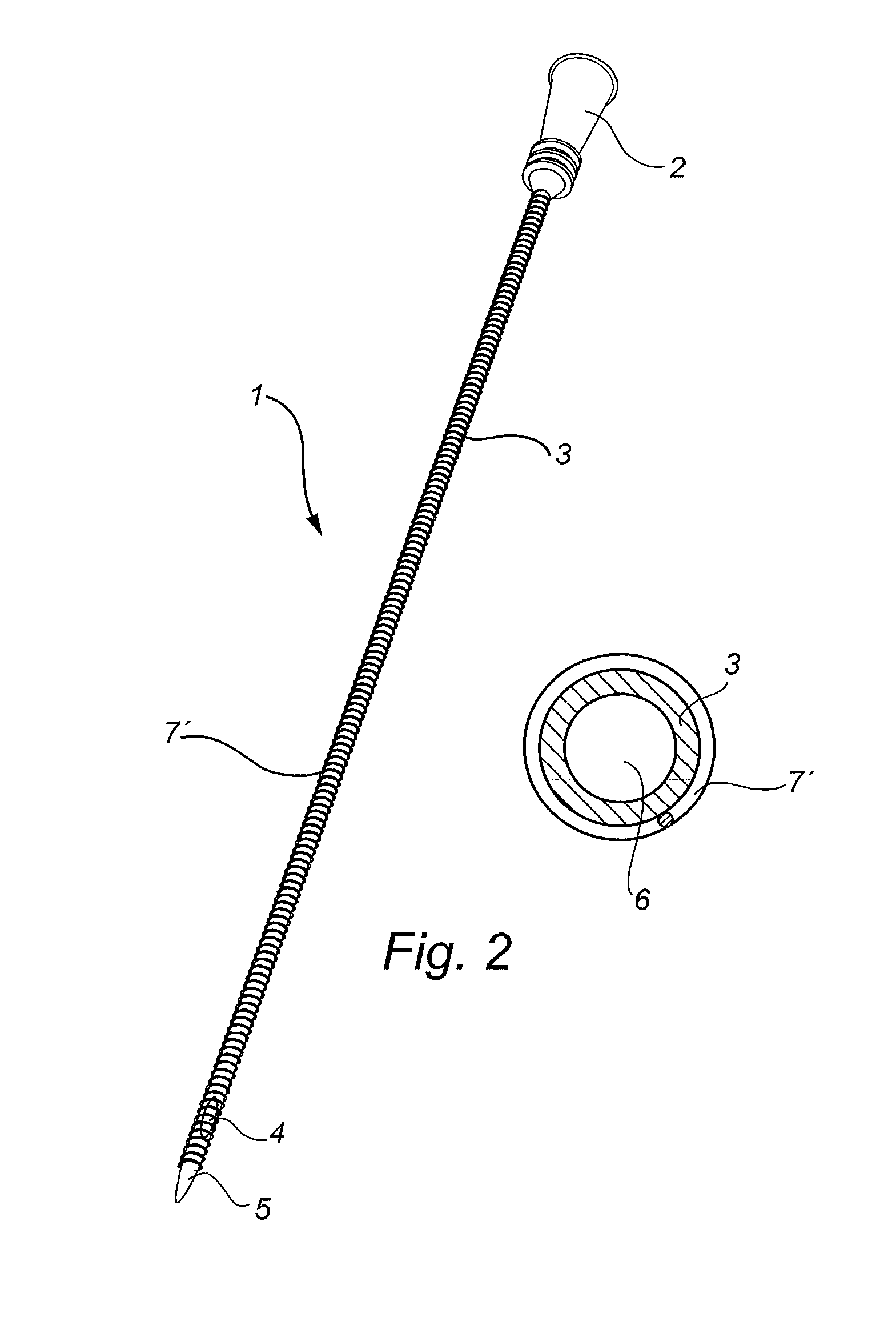

Reinforced urinary catheter

InactiveUS20150335854A1Reduce decreaseEasy to carryDispensing apparatusWound drainsUrinary catheterUrology

A urinary catheter assembly to be arranged in a curled disposition is disclosed. The assembly comprises a urinary catheter having a tubular shaft extending between a insertable end and a discharge end, wherein said tubular shaft is provided with an elastic reinforcement element having an extension in the axial direction of the tubular shaft; and a receptacle arranged to accommodate and maintain the urinary catheter in a curled storage state, in which the tubular shaft of the catheter is arranged in at least one coil. The reinforcement element is arranged to provide a force to uncurl the catheter when removed from said receptacle.

Owner:DENTSPLY IH

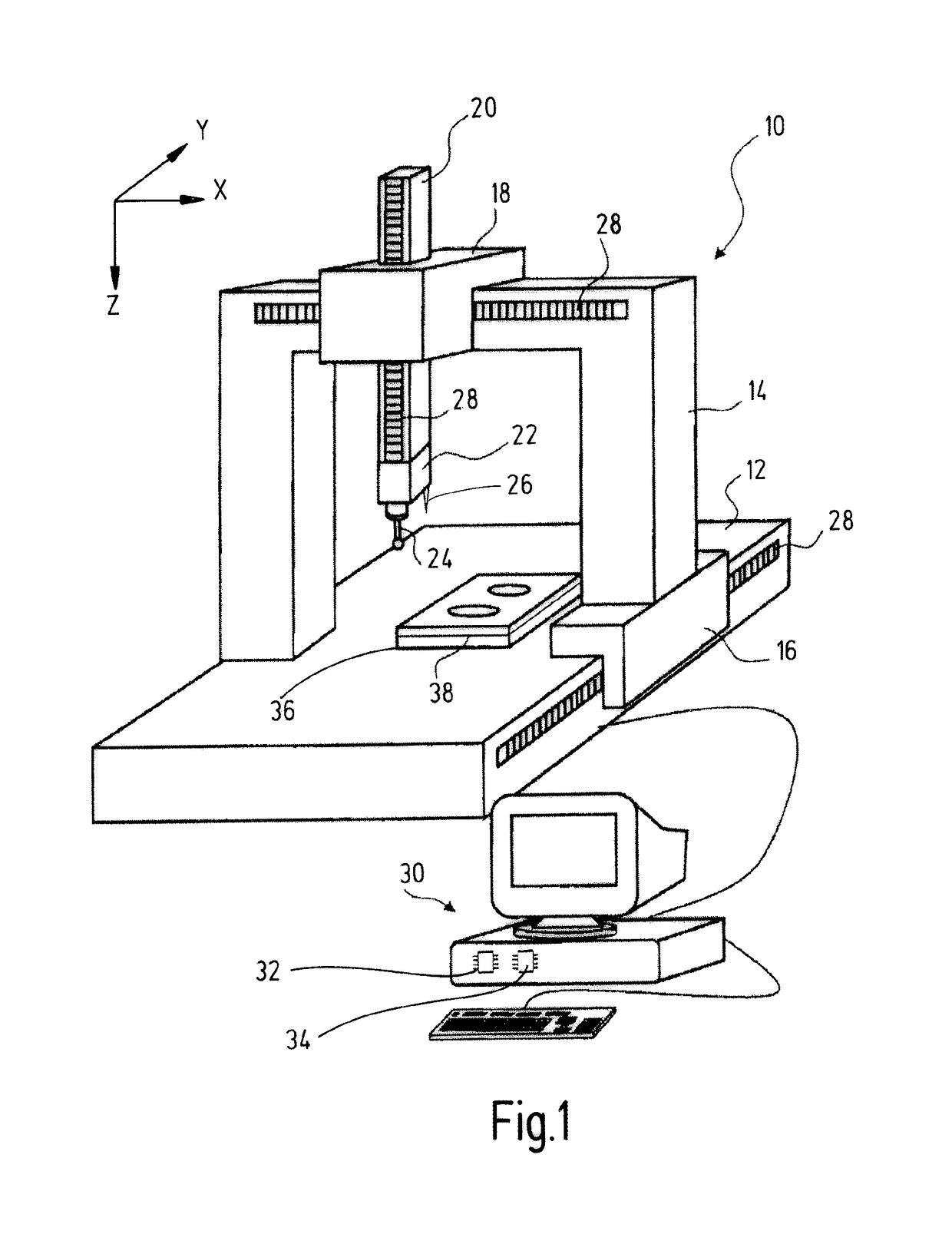

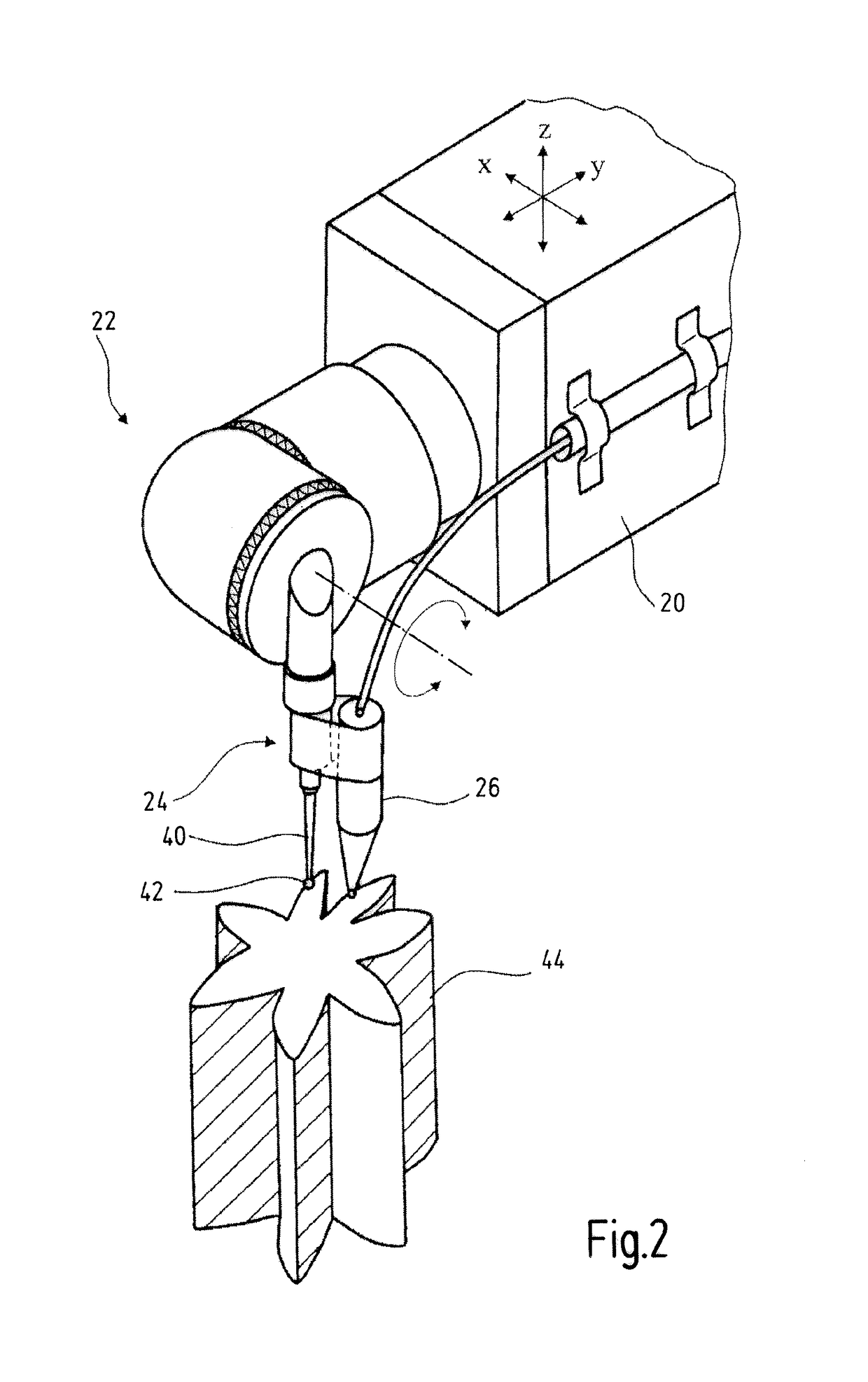

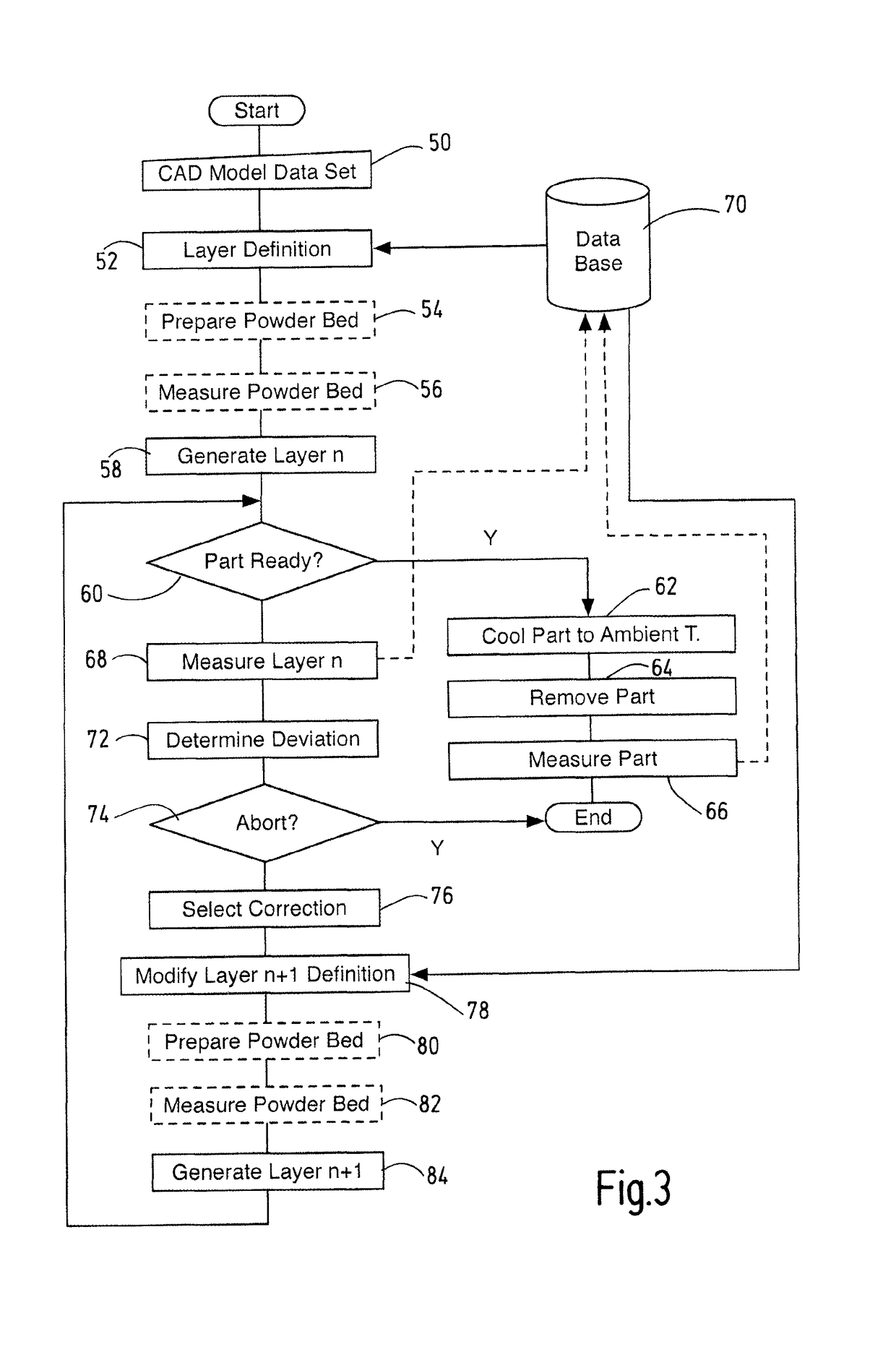

Method and arrangement for producing a workpiece by using additive manufacturing techniques

ActiveUS10220566B2Cost-efficient productionAdditive manufacturing apparatusIncreasing energy efficiencyManufacturing technologyProcess measurement

A method and an arrangement for producing a workpiece using additive manufacturing techniques involve in-process measurement in order to determine individual characteristics of one or more workpiece layers. In particular, dimensional and / or geometrical characteristics of a workpiece layer are measured before the next workpiece layer is produced. Advantageously, the measurement results are fed back into the production process in order to increase accuracy and precision of the production process.

Owner:CARL ZEISS IND MESSTECHN GMBH +1

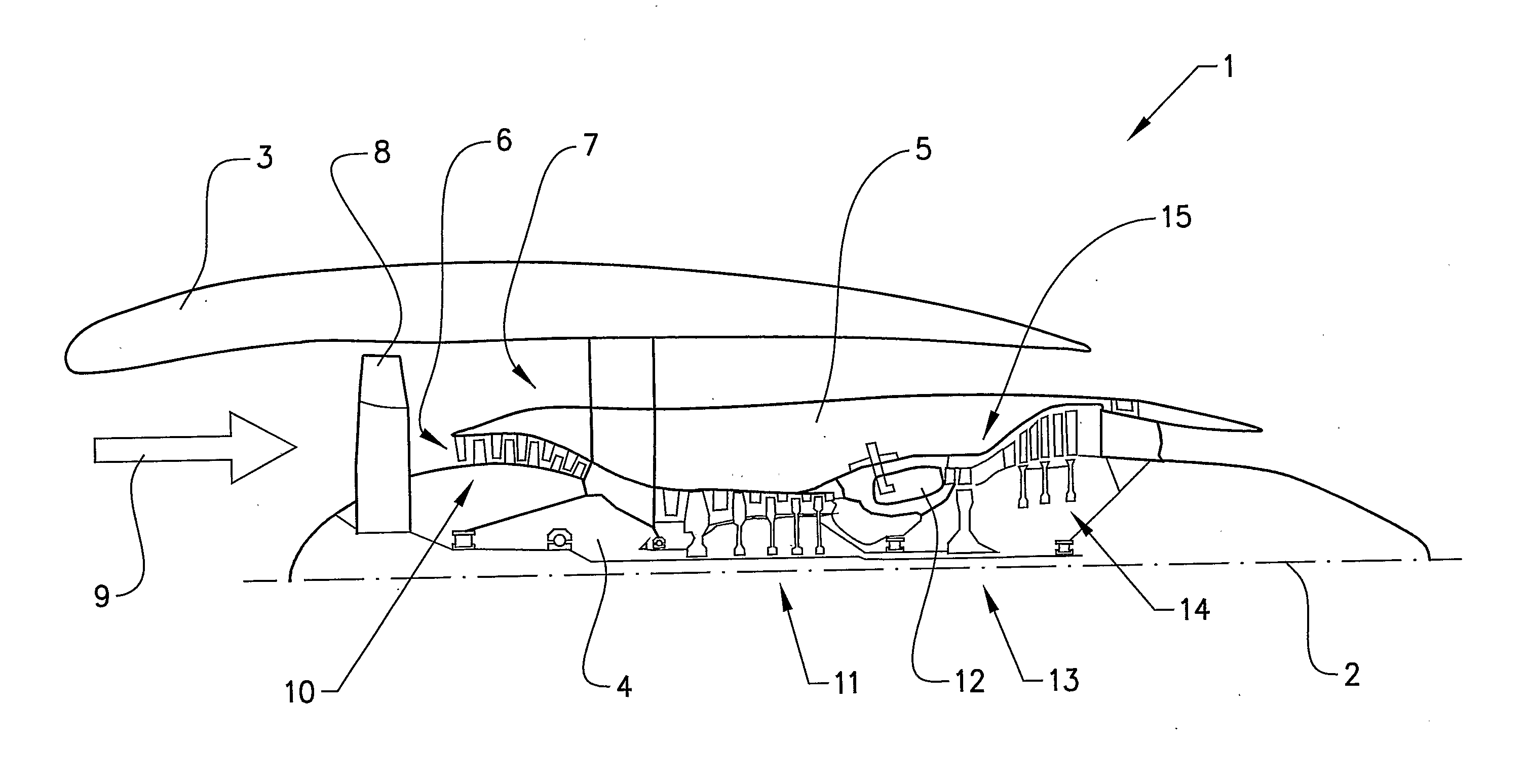

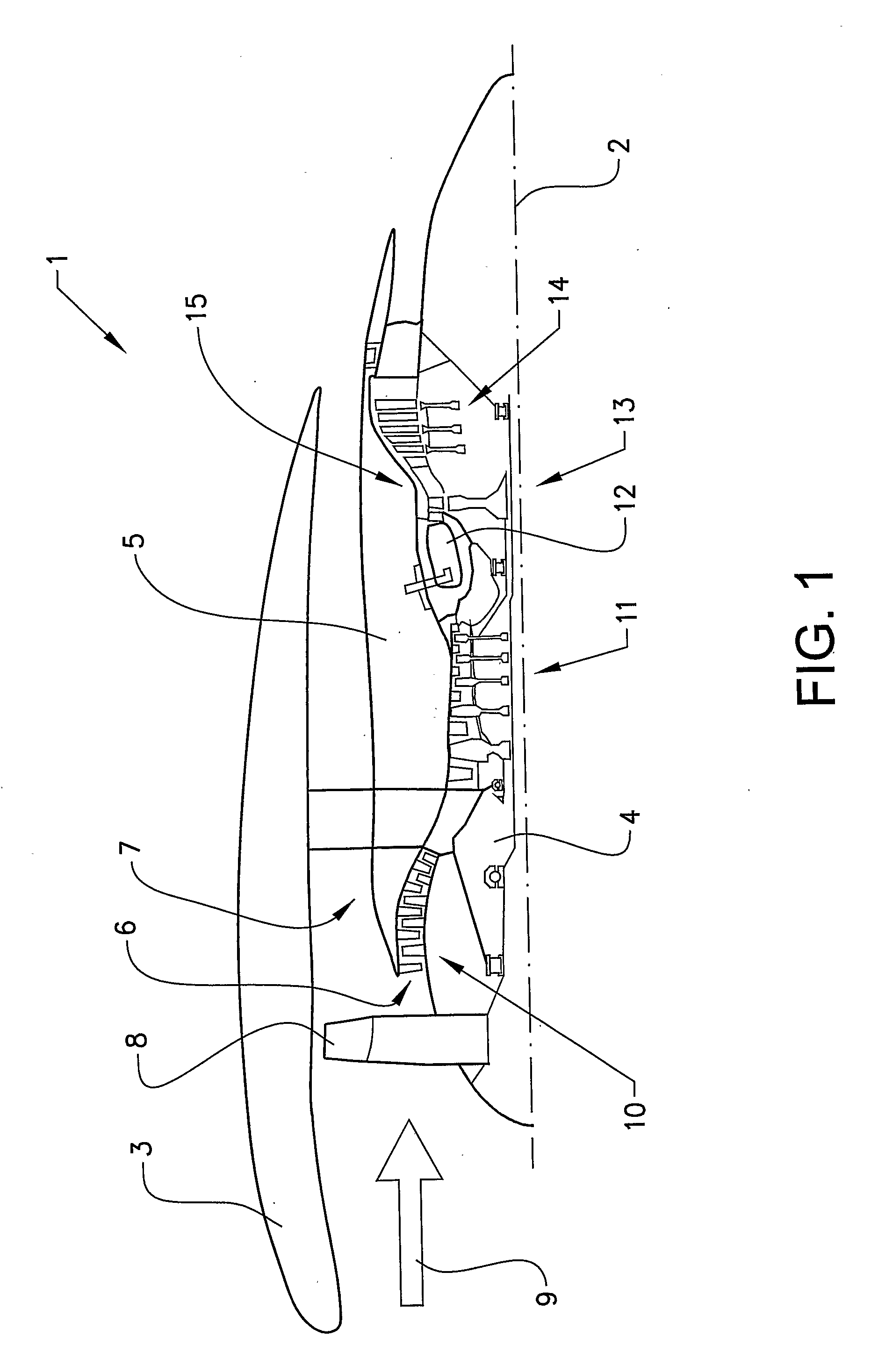

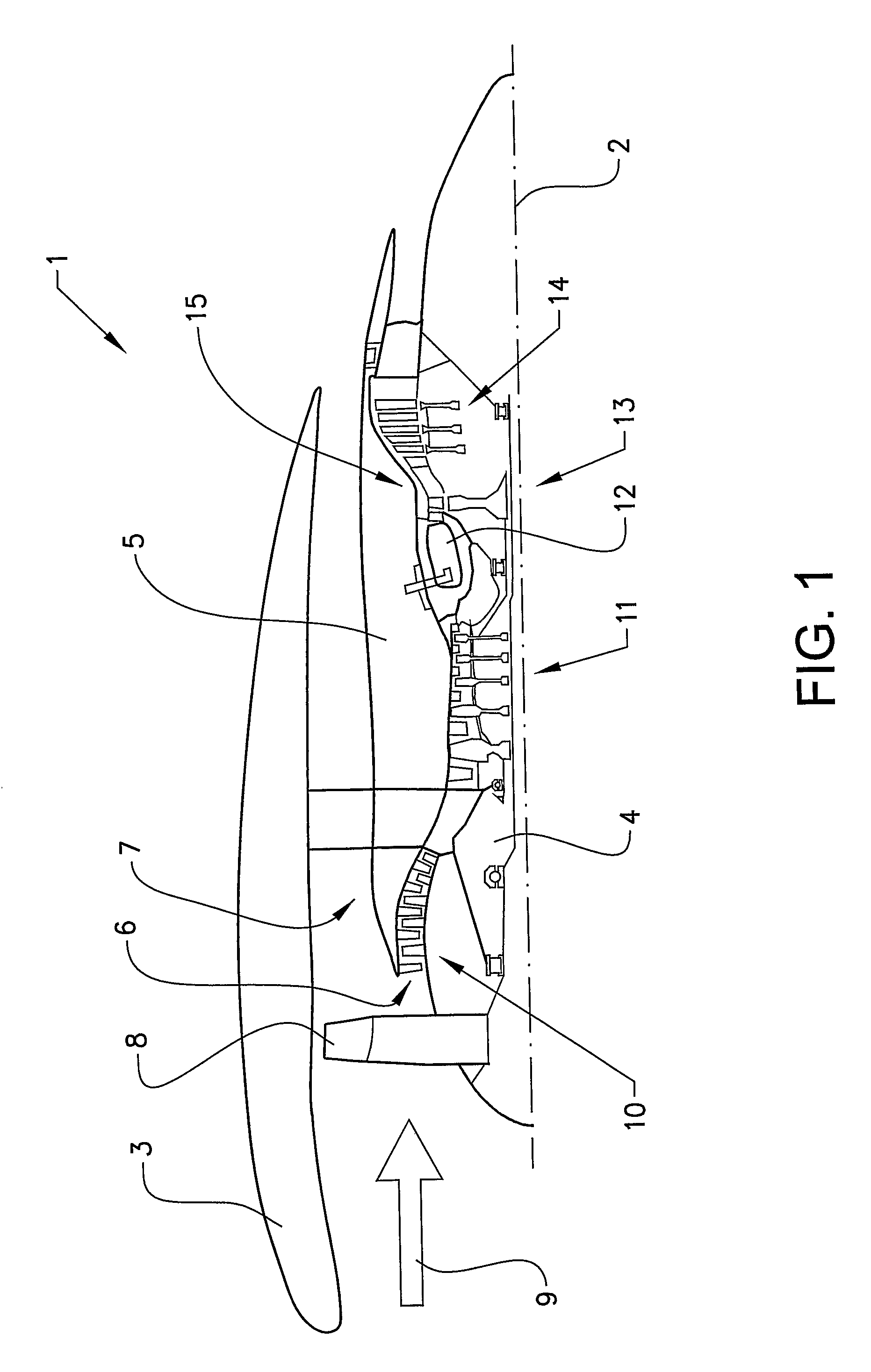

Gas turbine housing component

ActiveUS20110002778A1Improve sealingCost-efficient productionPump componentsRotary non-positive displacement pumpsEngineeringMechanical engineering

A gas turbine housing component includes a wall structure including two adjacent wall parts and a connection arrangement arranged between adjacent edges of the two wall parts. The connection arrangement includes an elongated seal strip positioned along the wall part edges and bridging the distance between the wall part edges.

Owner:GKN AEROSPACE SWEDEN AB

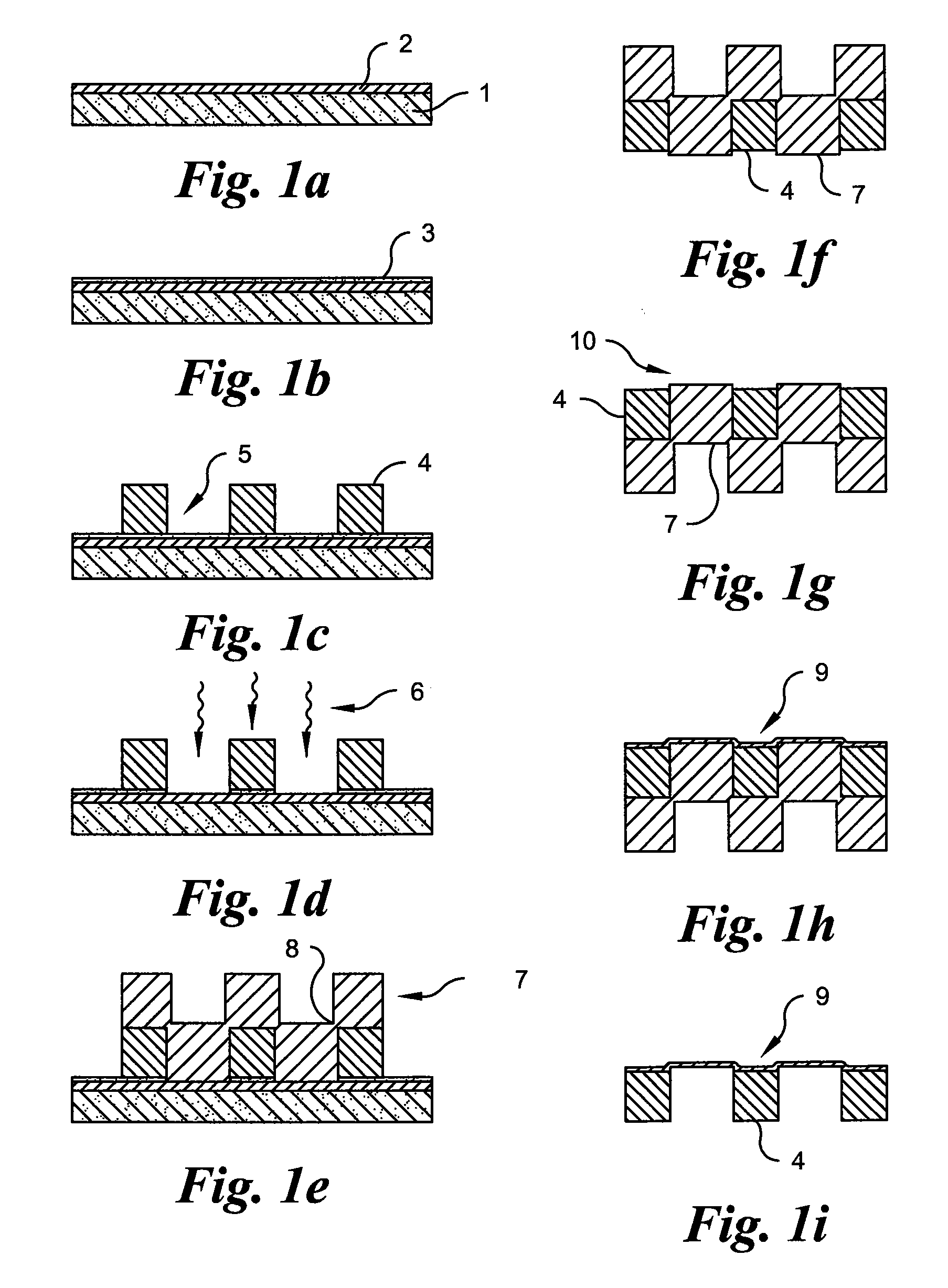

Thrombosis filter with cover layer

InactiveUS20100145380A1Simple production of netEfficiently able to filter out a thrombusSurgeryVacuum evaporation coatingPlanar substrateEngineering

A method is provided for applying a cover layer (9) to a net structure (4) to be used for medical purposes, in particular a thrombosis filter. The net structure (4) is applied to a planar substrate (1) that covers openings (5) of the net structure on one side, wherein the openings (5) across the uncovered side are filled with a sacrificial material (7), in particular copper. The net structure (4) is lifted from the substrate (1). A cover layer (9) is deposited on the surface previously covered by the substrate, and the sacrificial material (7) is removed.

Owner:ACANDIS

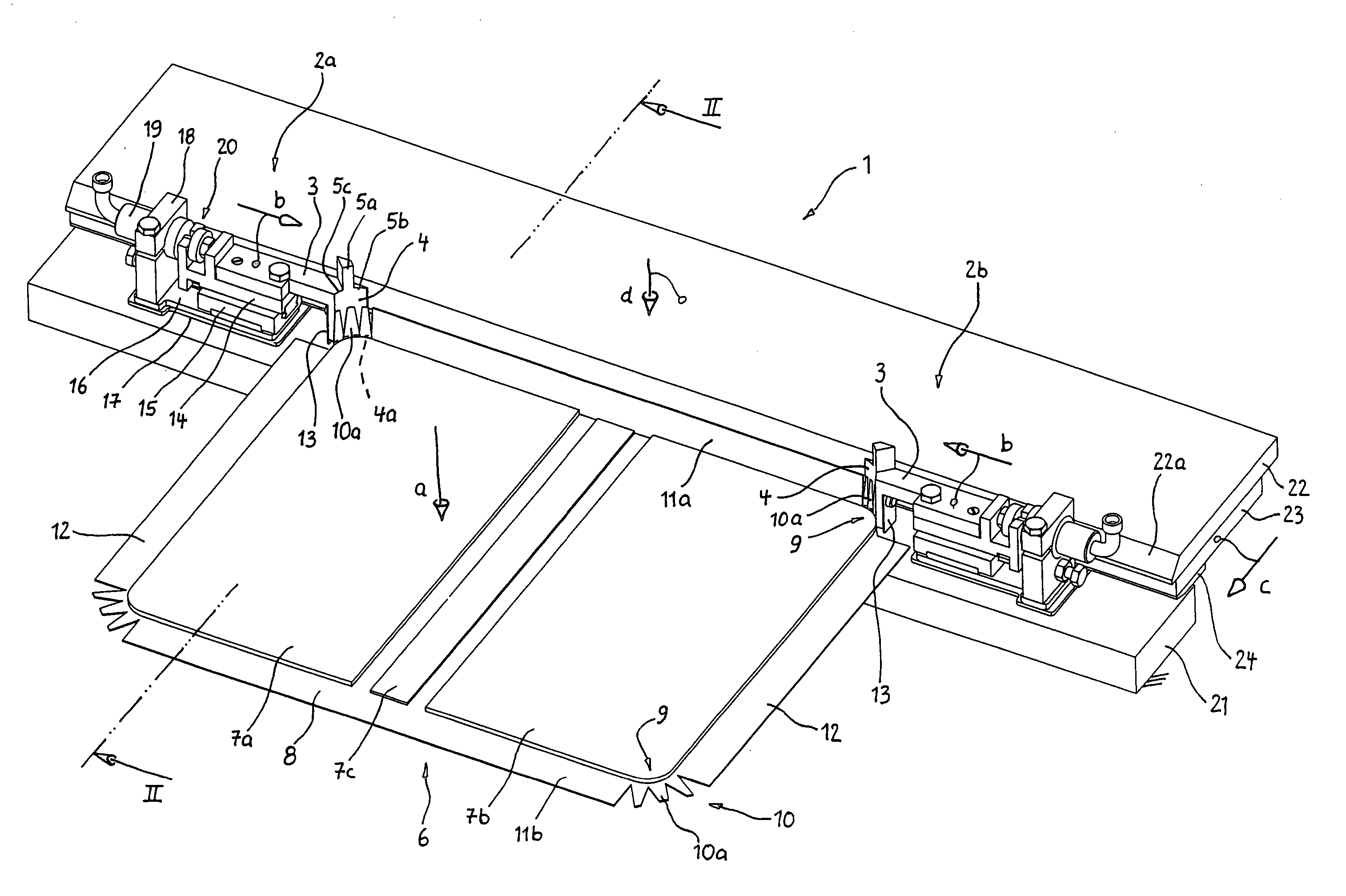

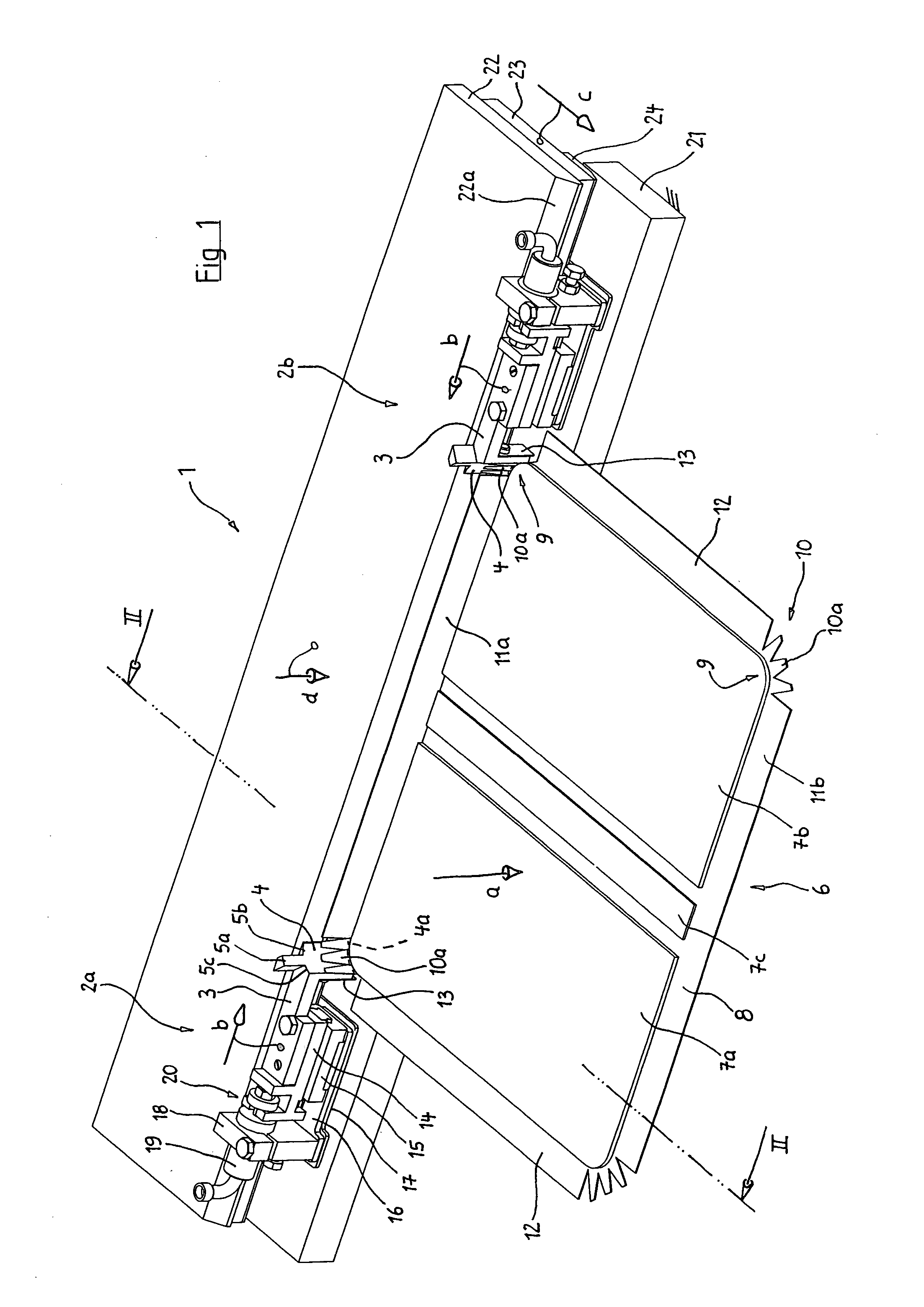

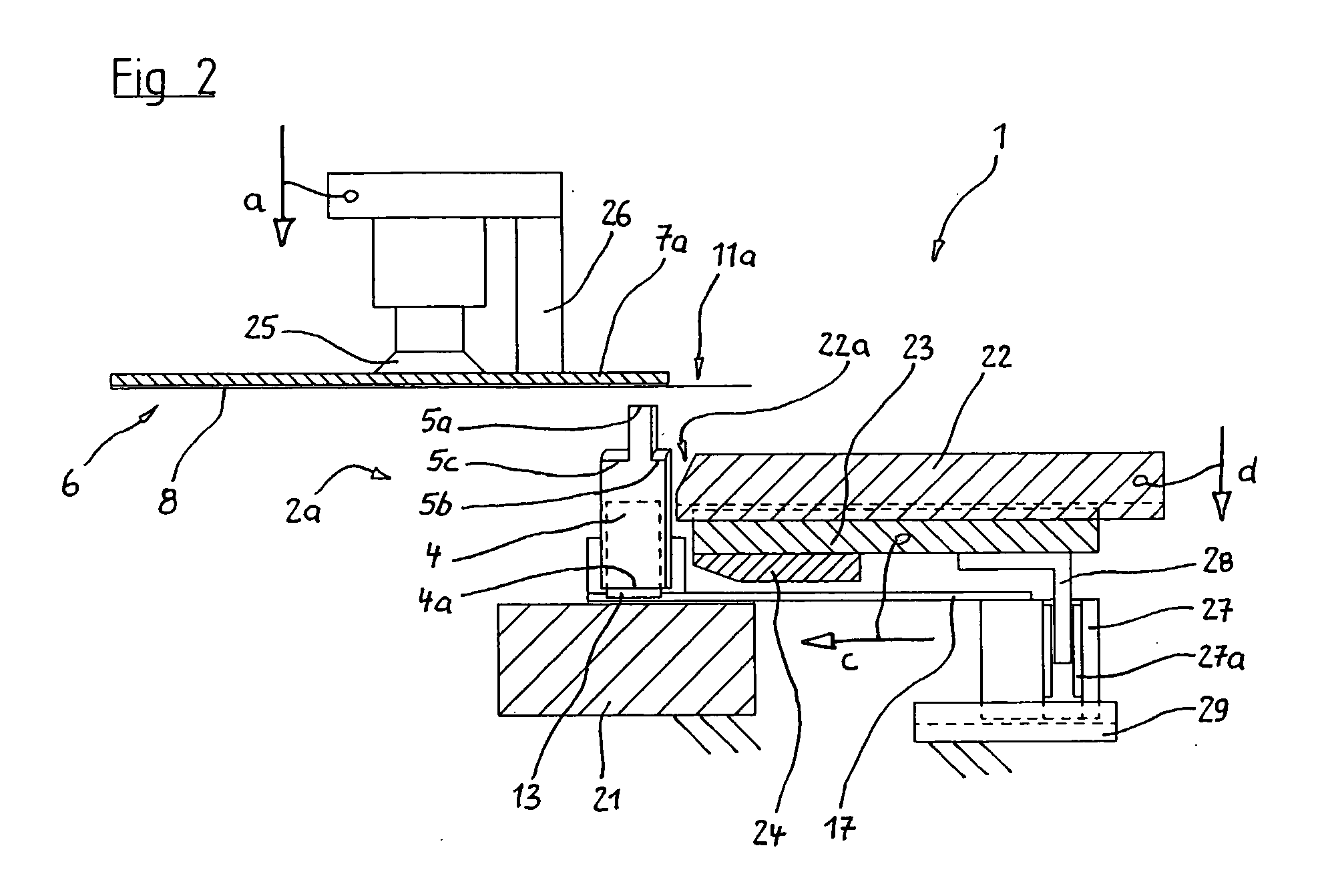

Method and device for producing cases with rounded corners

InactiveUS20060210378A1Simple structure designReliable fashionBookbinding casesCasing-inEngineeringLateral border

The invention pertains to a method and apparatus for producing cases with rounded corners. According to this method, the corner edge (10) that protrudes in the region of a rounded corner (9) is initially uprighted and turned over and subsequently pressed on the cover boards (7a, b, c) together with the turning-over and pressing-on of the lateral edge (11a) of an adjacent lateral border, in the same station (1). The apparatus comprises at least one rounded corner tool (3) that is arranged in the same station (1) in the which the lateral edges (11a, b) of opposed lateral borders that lie parallel to one another are uprighted, turned over, and pressed on the cover. The rounded corner tool (3) can be moved (b) toward the center of the case and out of the effective range of the lateral turn-in device (24) immediately before the turning-over and pressing-on movement (c, d) of the lateral turn-in device (24).

Owner:KOLBUS

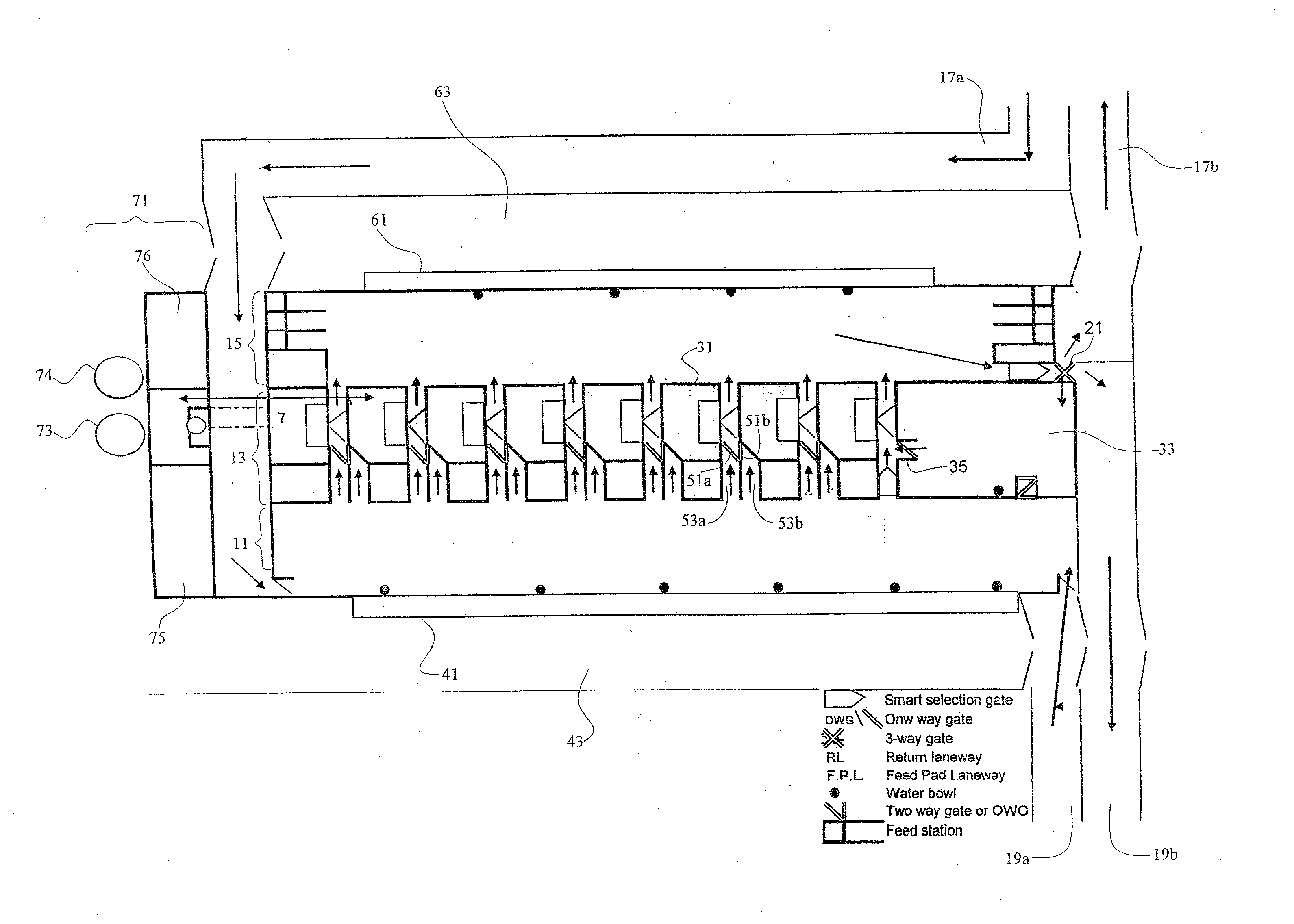

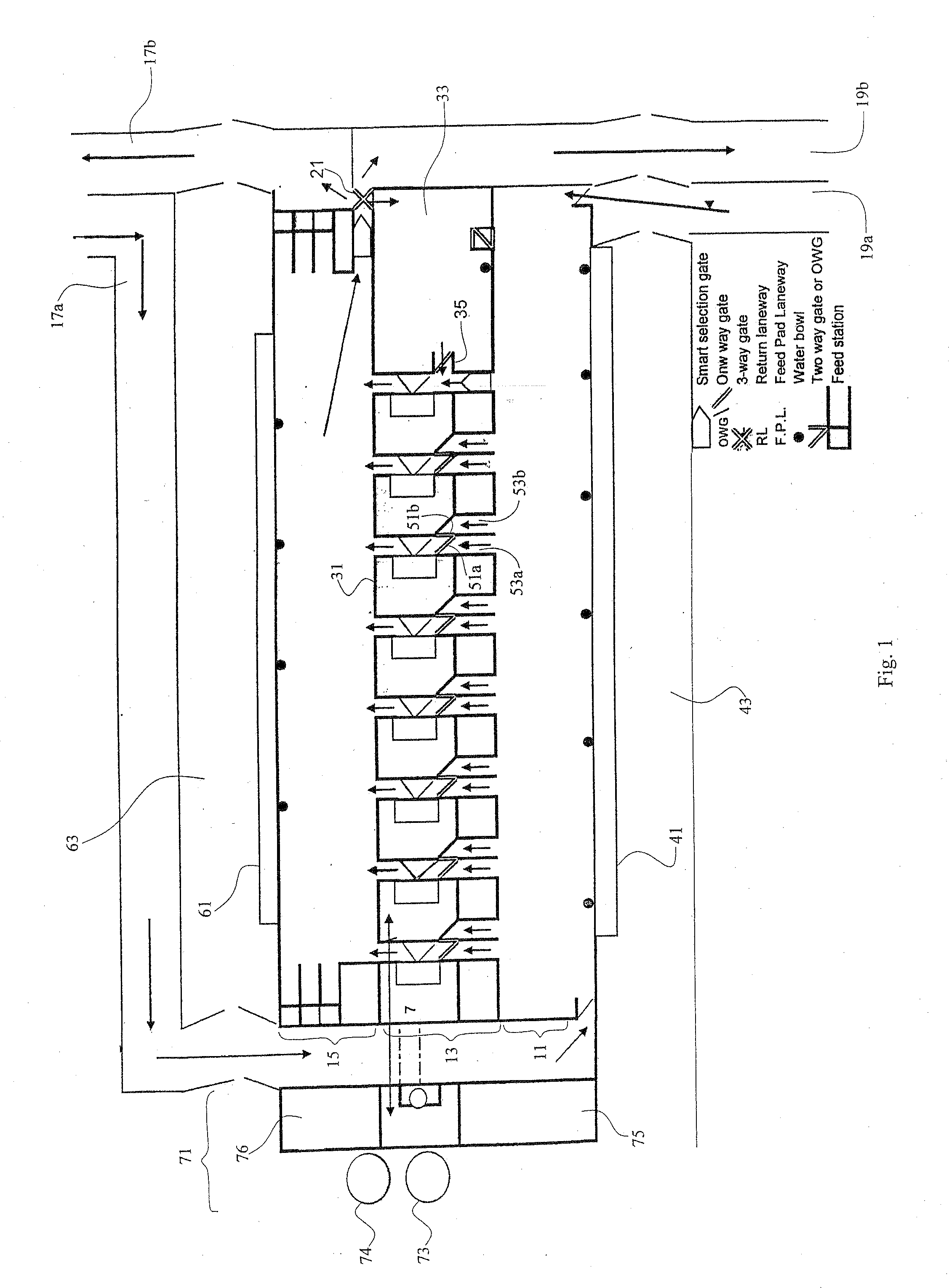

Milking facility and method for milking therein

ActiveUS20100192860A1Cost-efficient productionImprove overall utilizationCathetersAnimal housingHerdAutomatic milking

A space-saving milking facility includes an entrance passage way (17a) provided for receiving milking animals on a voluntary basis, a waiting area (11), a milking area (13) housing automatic milking stations (31), a post-milking area (15), and an exit passage way (17b), through which milking animals may leave the milking facility. The automatic milking stations (31) are arranged side by side along a row, the waiting area (11) and the post-milking area (15) are elongated and parallel with the row of automatic milking stations (31), the entrance passage way (17a) is joined to the waiting area (11) at a short side thereof, and the exit passage way (17b) is joined to the post-milking area (15) at a short side thereof. The milking facility is particularly aimed for herds of milking animals at grazing.

Owner:DELAVAL HLDG AB

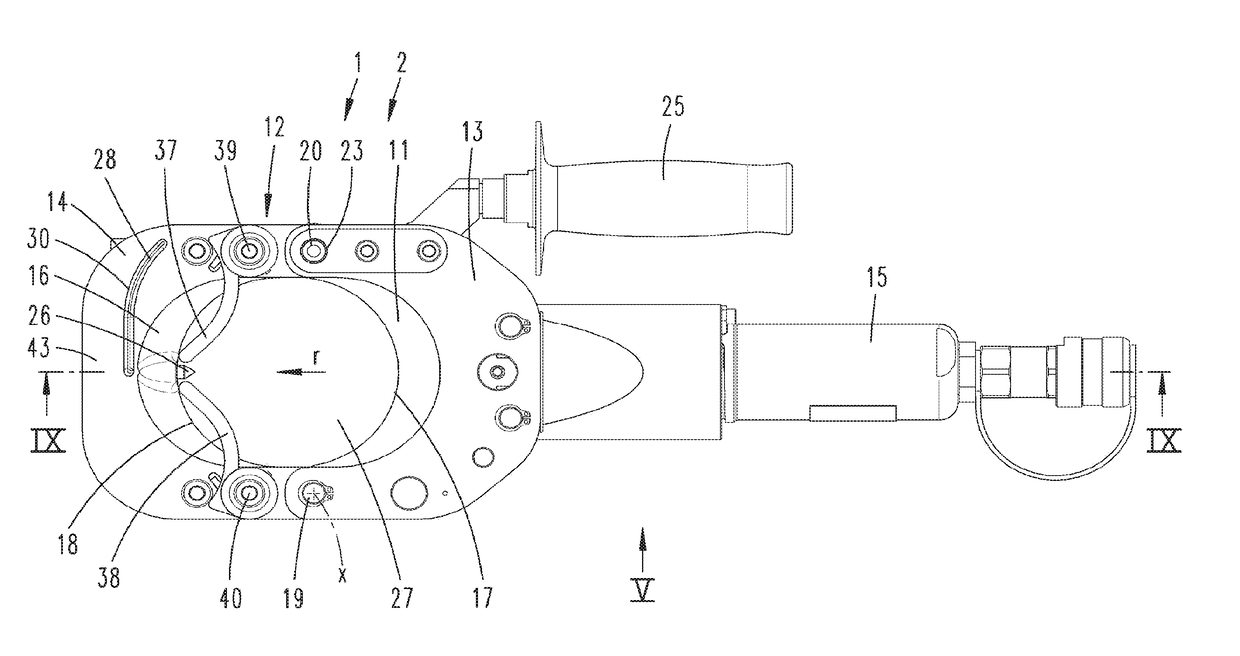

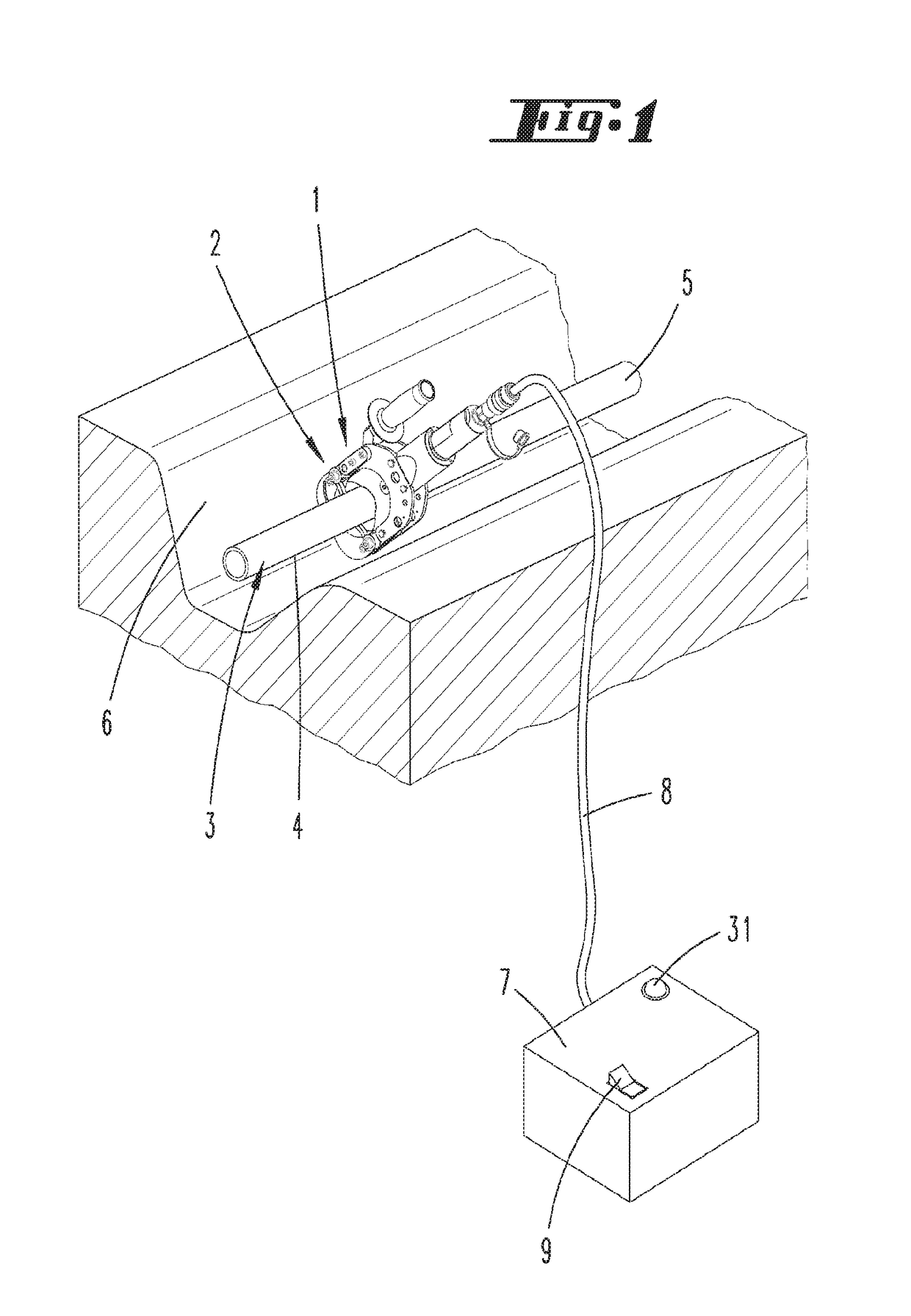

Method for the severance of an electrical power cable, or of a strand section, device therefor, as well as cutting device

InactiveUS20180006437A1Precise cuttingCost efficient to manufactureCable installations on groundApparatus for cutting/splicing cablesElectricityPower cable

A device is used to sever an electrical power cable for the transmission of high voltage. The cable has an insulation sheath, a screening layer and a conductive layer. The device includes a first frame having a first cutting blade mounted thereon, a second frame, and a measuring device mounted on the second frame. The first cutting blade is movable relative to the measuring device. The measuring device is capable of measuring an electrical load on the electrical power cable and capable of terminating the severing of the electrical power cable. A method of using the device is also provided.

Owner:GUSTAV KLAUKE GMBH +1

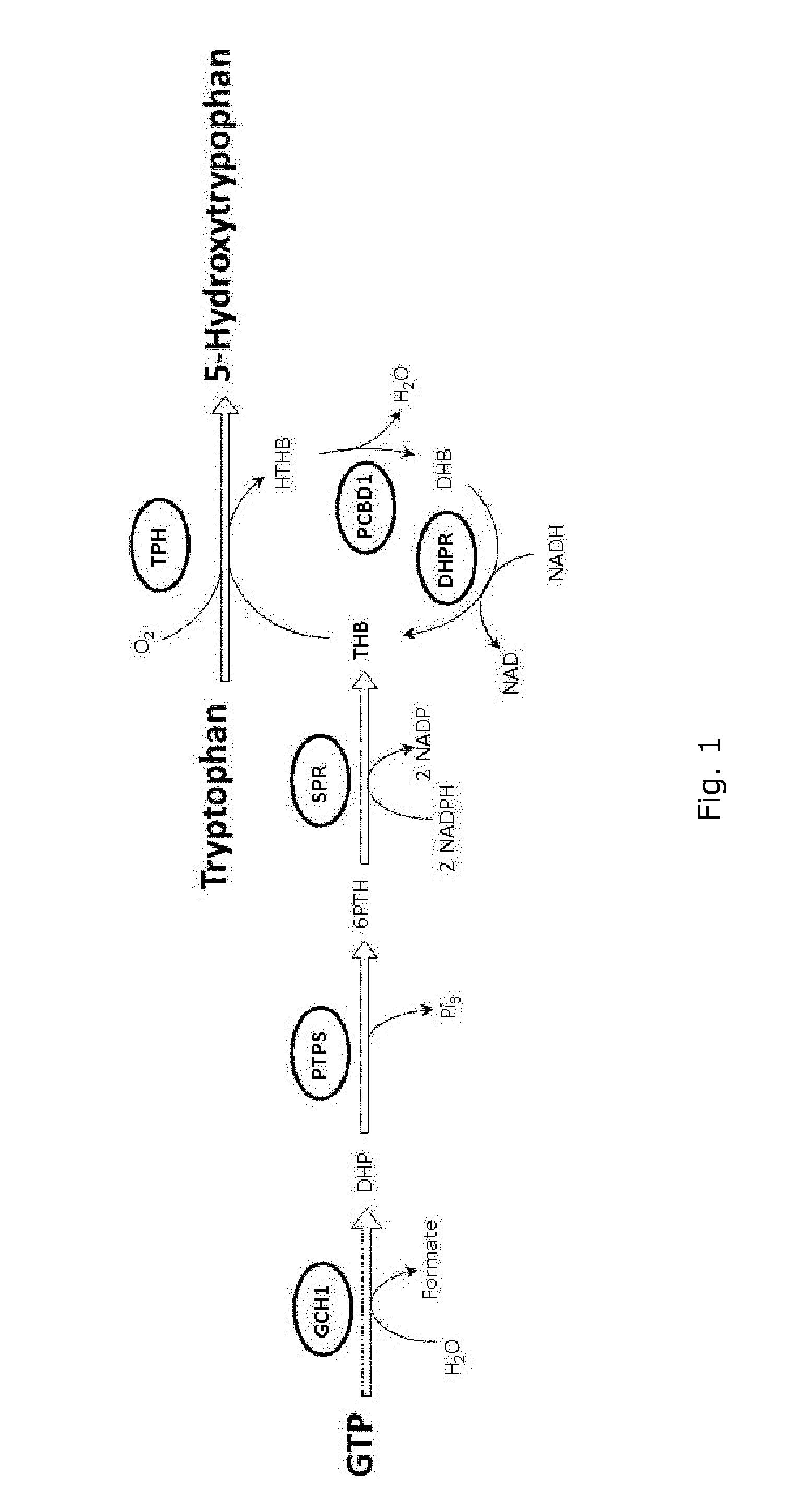

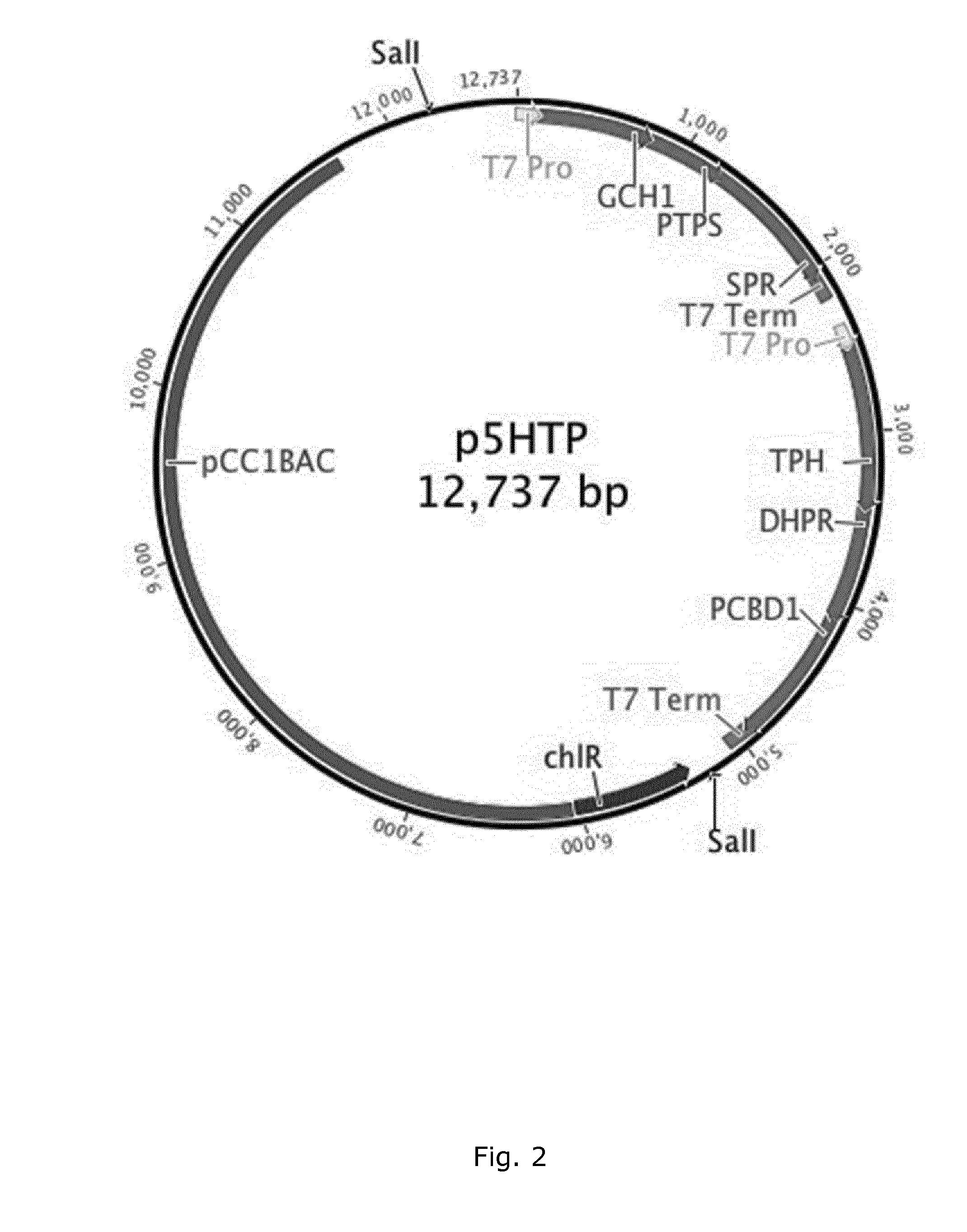

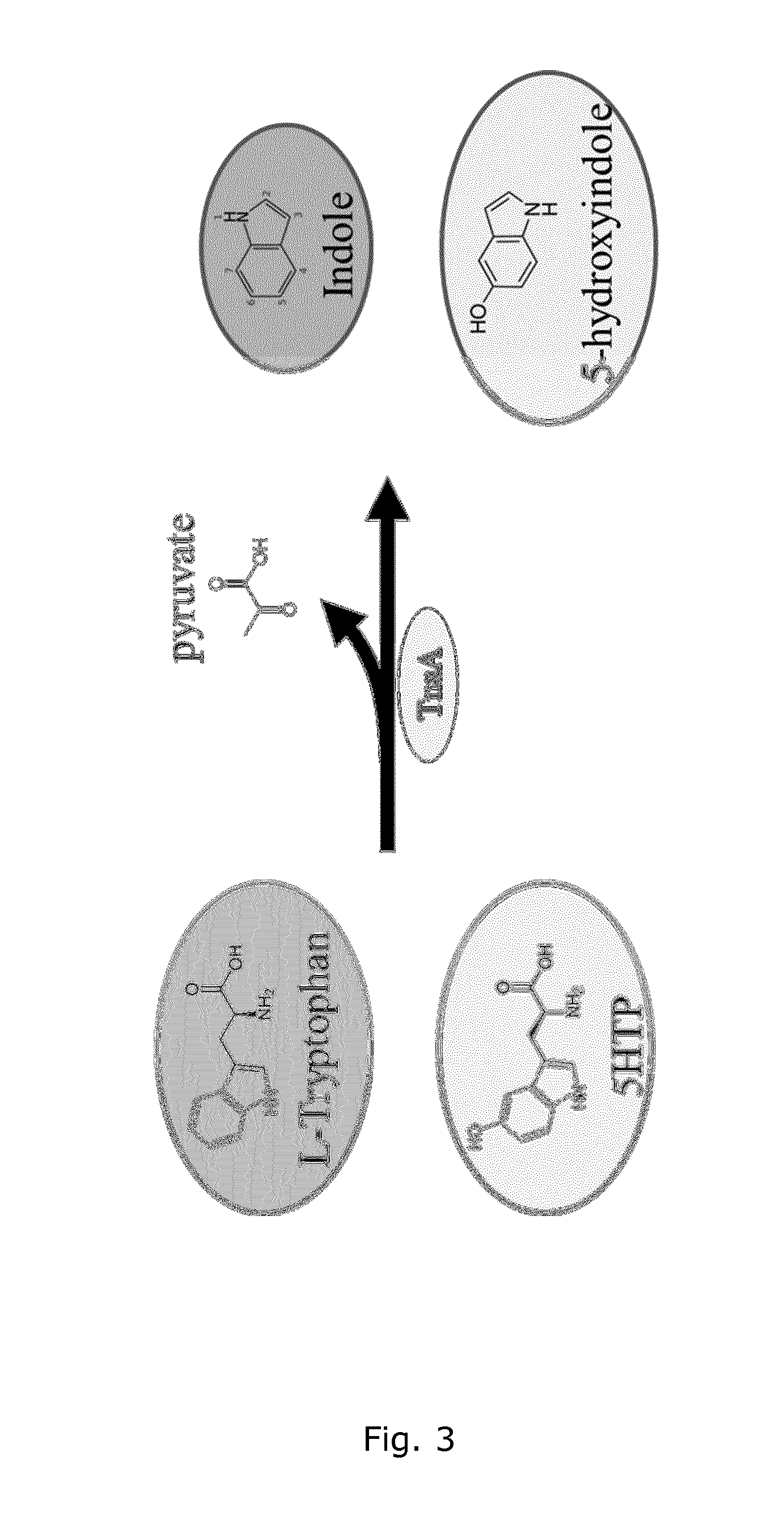

Microorganisms for the production of 5-hydroxytryptophan

InactiveUS20150037849A1Cost-efficient productionBacteriaHydrolasesMicroorganismTryptophan hydroxylase

Recombinant microbial cells and methods for producing 5-hydroxytryptophan (5HTP) using such cells are described. More specifically, the recombinant microbial cell comprises an exogenous gene encoding an L-tryptophan hydroxylase, and means for providing tetrahydrobiopterin (THB). Related sequences and vectors for use in preparing such recombinant microbial cells are also described.

Owner:DANMARKS TEKNISKE UNIV

Blade set, hair cutting appliance,and related manufacturing method

ActiveUS20170028576A1Operation performance be improveReduce timeMetal working apparatusEngineeringMechanical engineering

The present invention relates to a hair cutting appliance (10) and to a blade set (20) for a hair cutting appliance (10). Said blade set (20) comprises a stationary blade (22) comprising a first wall portion (100) and a second wall portion (102) that define therebetween a guide slot (96), a movable cutter blade (24) received at the guide slot (96), and a transmitting member (70) configured to be engaged by a driving member, wherein the transmitting member (70) is further configured to actuate the movable cutter blade (24) relative to the stationary blade (22), wherein the movable cutter blade (24) is laterally inserted into the guide slot (96), wherein the transmitting member (70) is fed to the stationary blade (22) in a feed direction (190) that is different from an insertion direction (188) of the movable cutter blade (24), and wherein the transmitting member (70) is coupled to the movable cutter blade (24), particularly to a main portion (78) thereof, such that the movable cutter blade (24) is secured at the stationary blade (22), particularly undetachably retained. The disclosure further relates to a method for manufacturing a respective blade (22).

Owner:KONINKLJIJKE PHILIPS NV

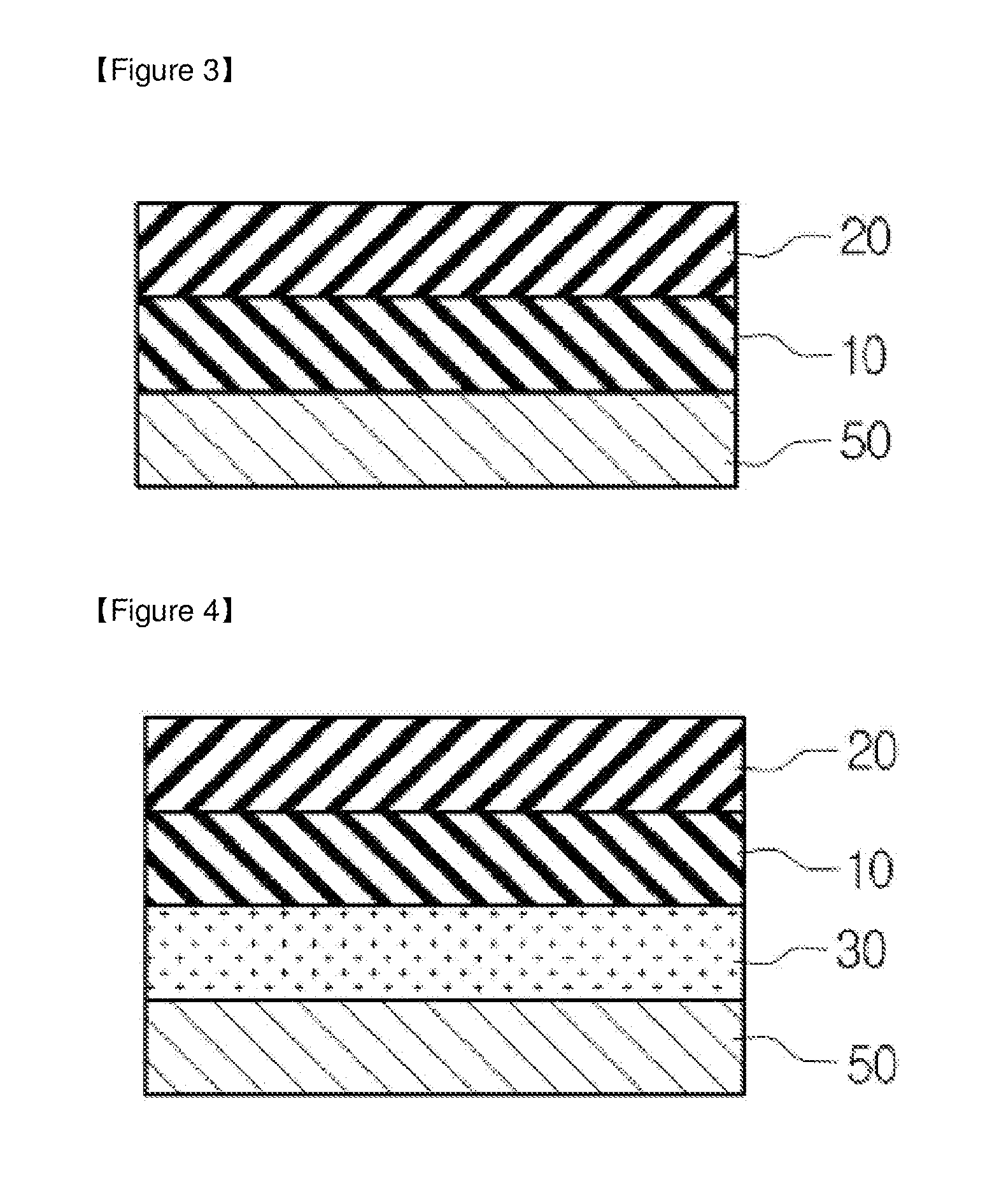

Temperature control device for the temperature control of a battery and method for the production of a temperature control device

InactiveUS20130011705A1Increase productionImproved thermal connectionPrimary cellsElectrode carriers/collectorsTemperature controlEngineering

A temperature control device is provided for the temperature control of a battery. The temperature control device has an upper part with an upper side and an underside, which has on the upper side a thermal interface to the battery. Furthermore, the temperature control device has at least one lower part, which has an embossed structure in order to embody a sealing edge and to embody a cavity for guiding temperature control fluid. The sealing edge is arranged on an upper side of the lower part, and is connectable to the underside of the upper part in a fluid-tight manner.

Owner:MAHLE INT GMBH

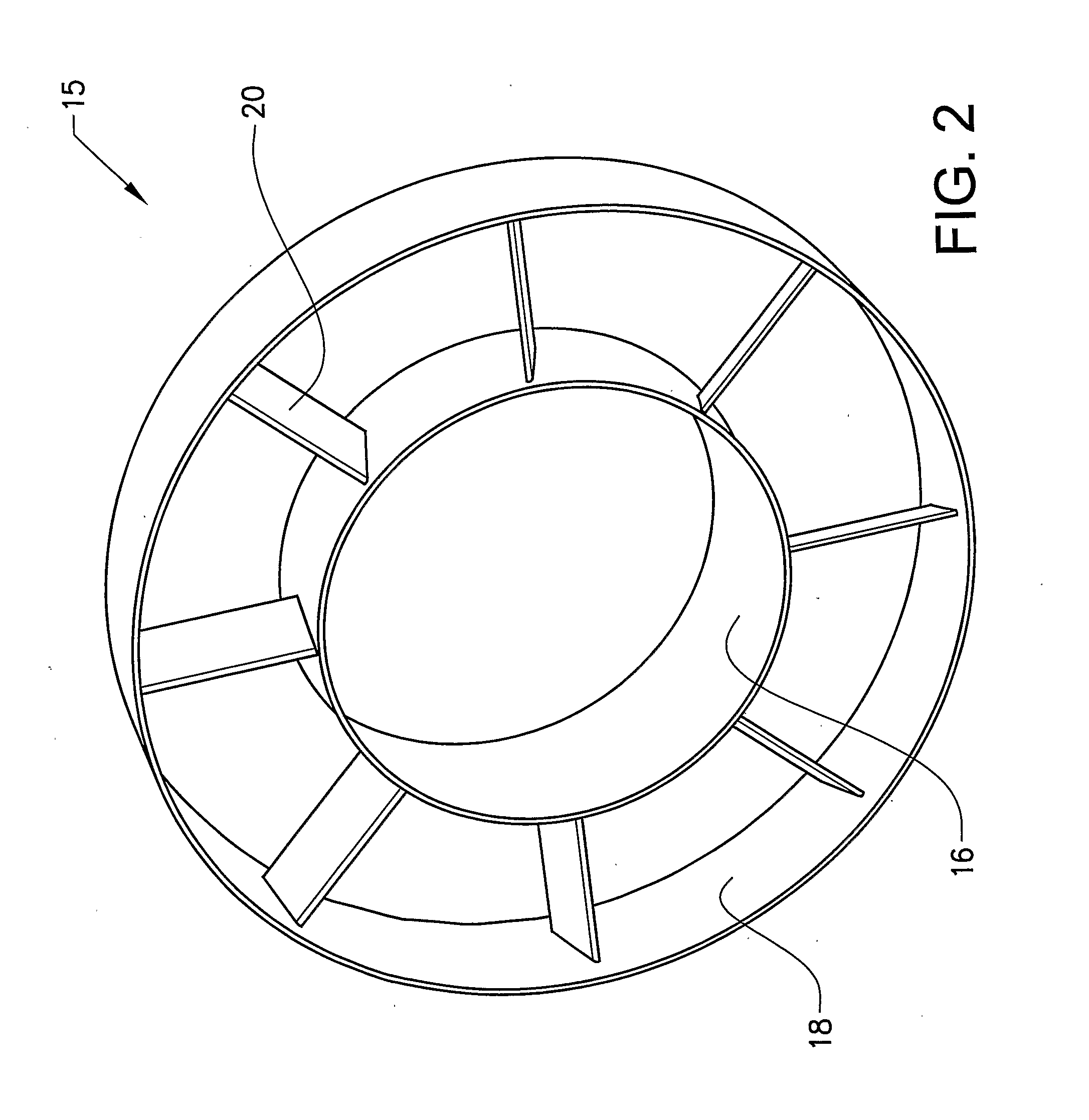

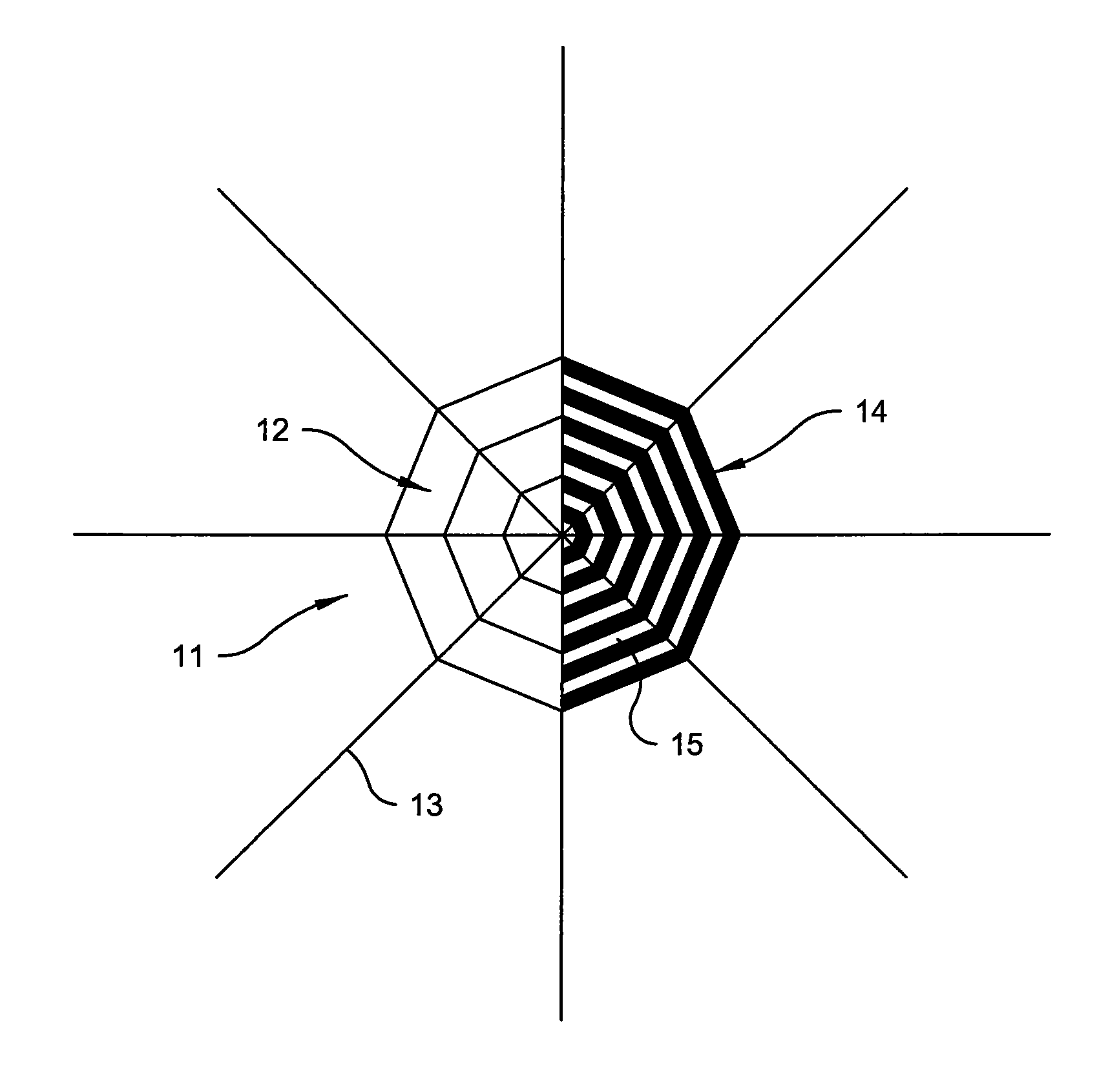

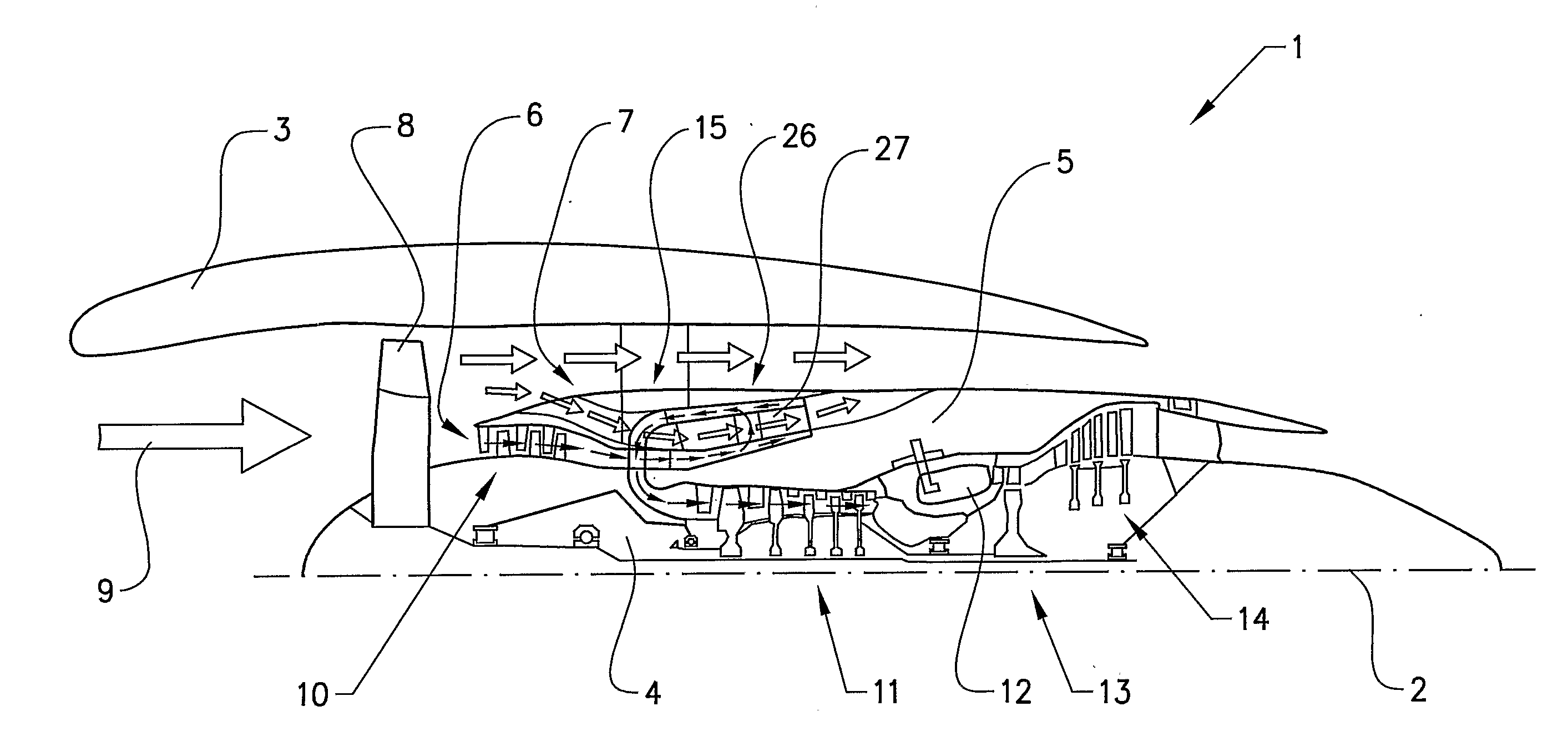

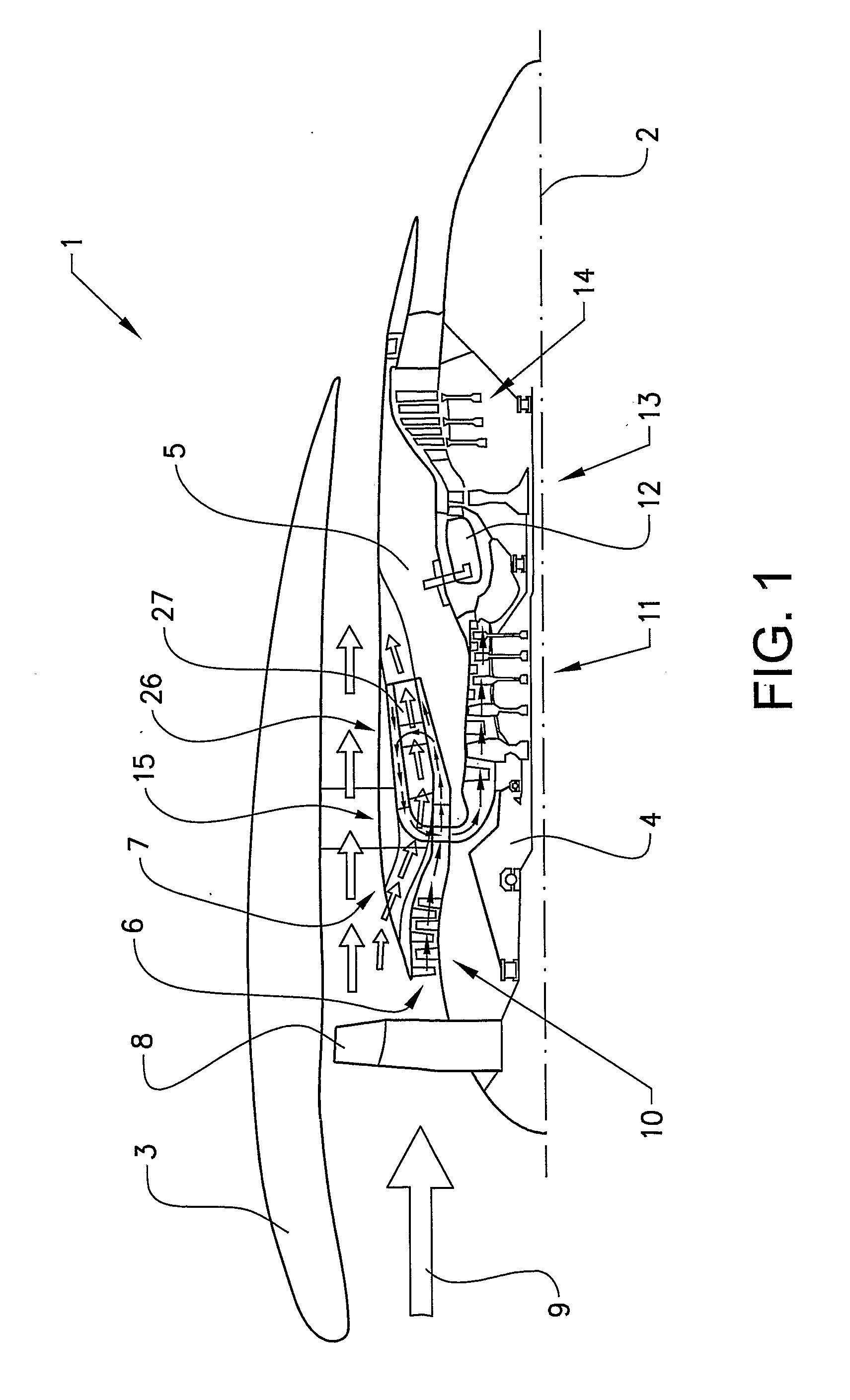

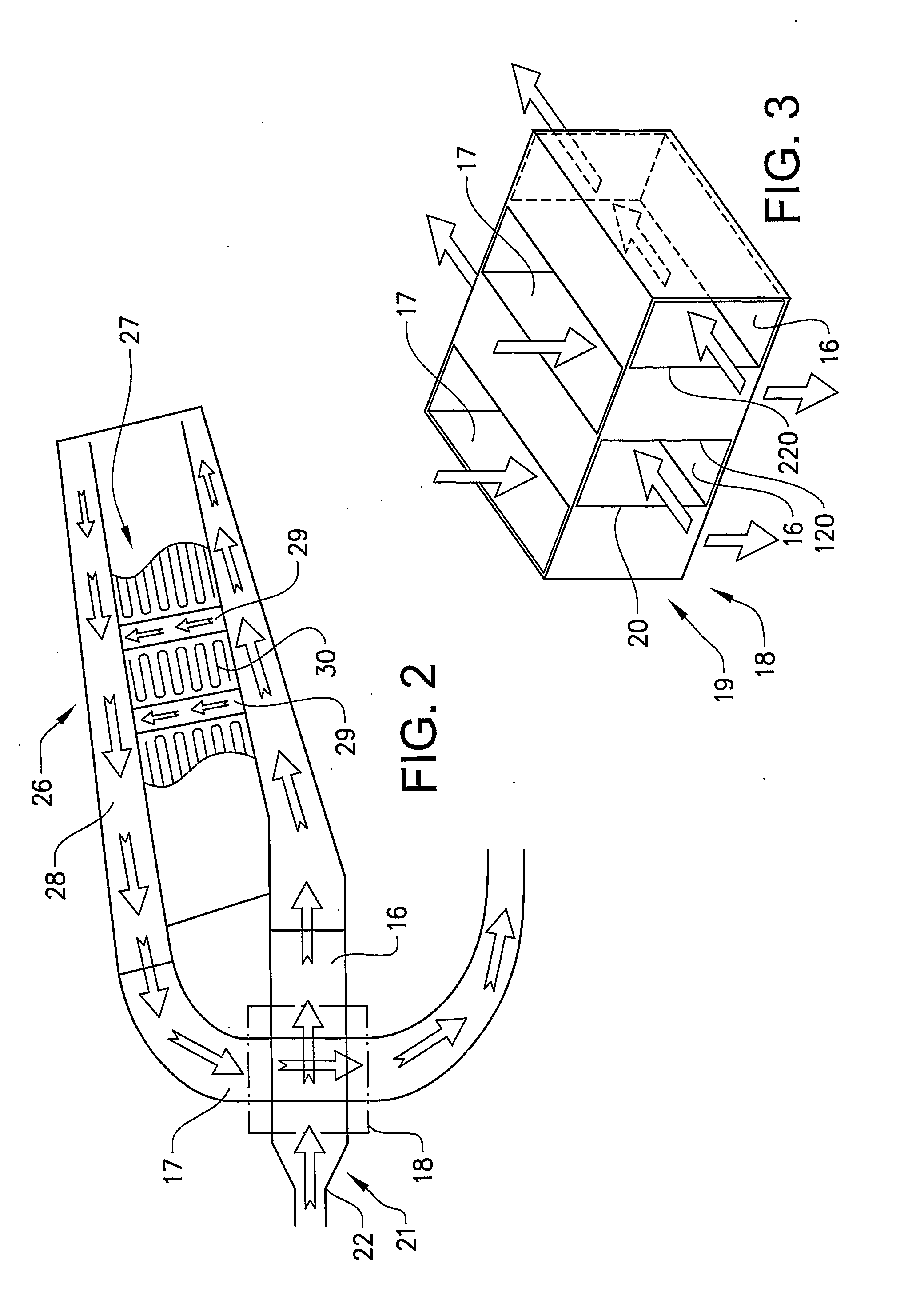

Annular gas turbine housing component and a gas turbine comprising the component

InactiveUS20120141256A1Convenient ArrangementImprove efficiencyPump componentsGas turbine plantsGas turbinesAirflow

The invention relates to an annular gas turbine housing component (15) comprising a plurality of circumferentially spaced first channels (16) for conveying a first gas flow in a first direction and a plurality of circumferentially spaced second channels (17) for conveying a second gas flow in a second direction across the first direction in a crossing position (18) of the first and second channels.

Owner:VOLVO AERO CORP

Gas turbine housing component

ActiveUS8747066B2Cost-efficient productionImprove operating characteristicsPump componentsRotary non-positive displacement pumpsGas turbinesEngineering

A gas turbine housing component includes a wall structure including two adjacent wall parts and a connection arrangement arranged between adjacent edges of the two wall parts. The connection arrangement includes an elongated seal strip positioned along the wall part edges and bridging the distance between the wall part edges.

Owner:GKN AEROSPACE SWEDEN AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com