Patents

Literature

505results about "Casing-in" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Booklet maker

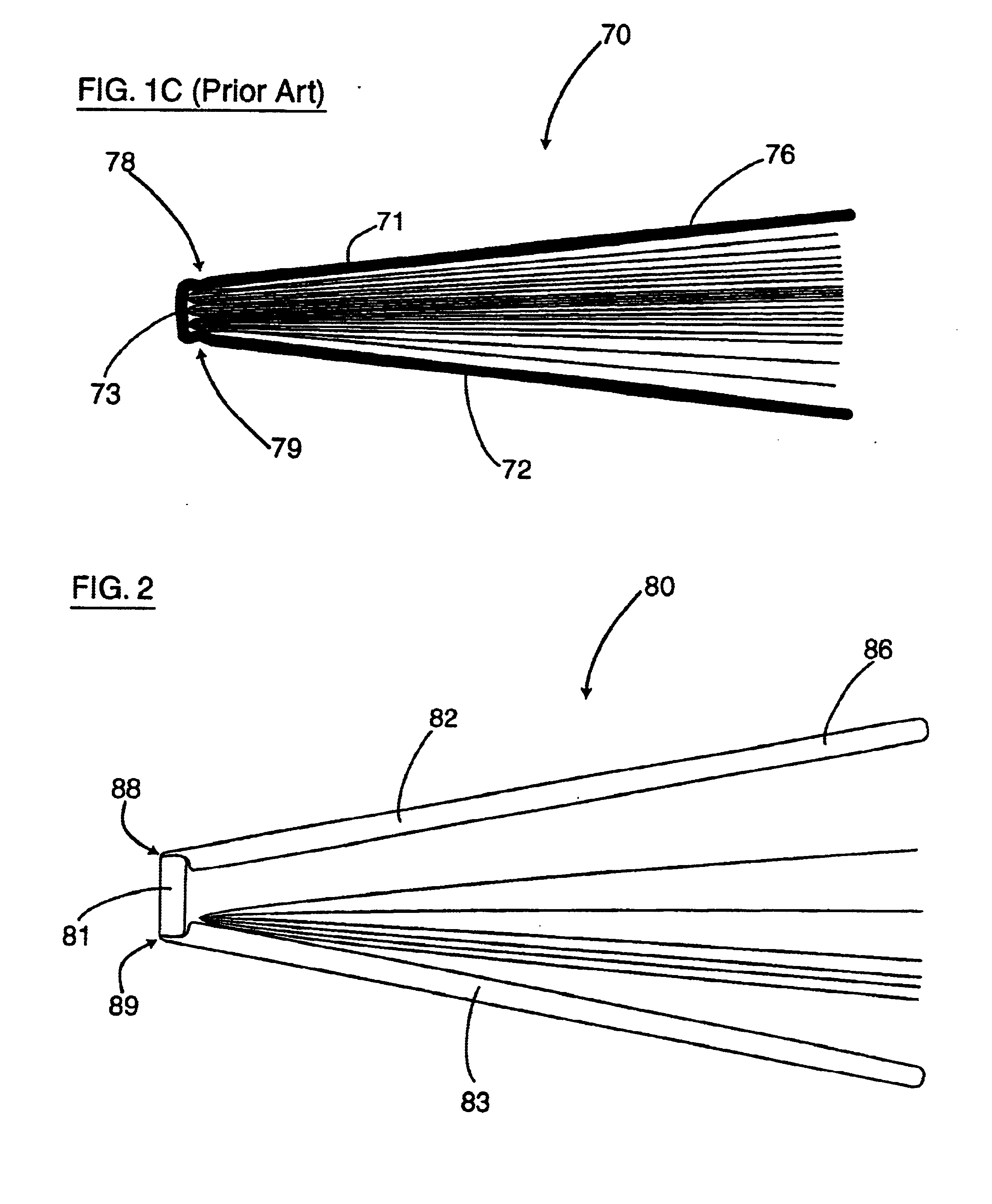

A low cost, high speed, high resolution laser printer method and apparatus for re-writable media is presented. A method for finishing of printed sheets into booklets is described. Novel mechanical operations permit the manufacture of a very low-cost, off-line booklet maker for use with desktop laser and ink jet printers. The technology can scale to medium-speed, in-line booklet manufacture. The method is novel because most of the finishing operations are performed on a sheet-by-sheet basis using precision paper positioning and a transverse tool carrier that cuts, scores, folds, punches, and staples the sheets. To form a finished saddle-stitched booklet, each sheet is cut to length determined by its sequence in the booklet and paper thickness, scored, punched (if required), folded, accumulated in a stack, and stapled. The sheet-wise method allows finishing operations to be done with low-cost tools and low actuation forces.

Owner:HEWLETT PACKARD DEV CO LP

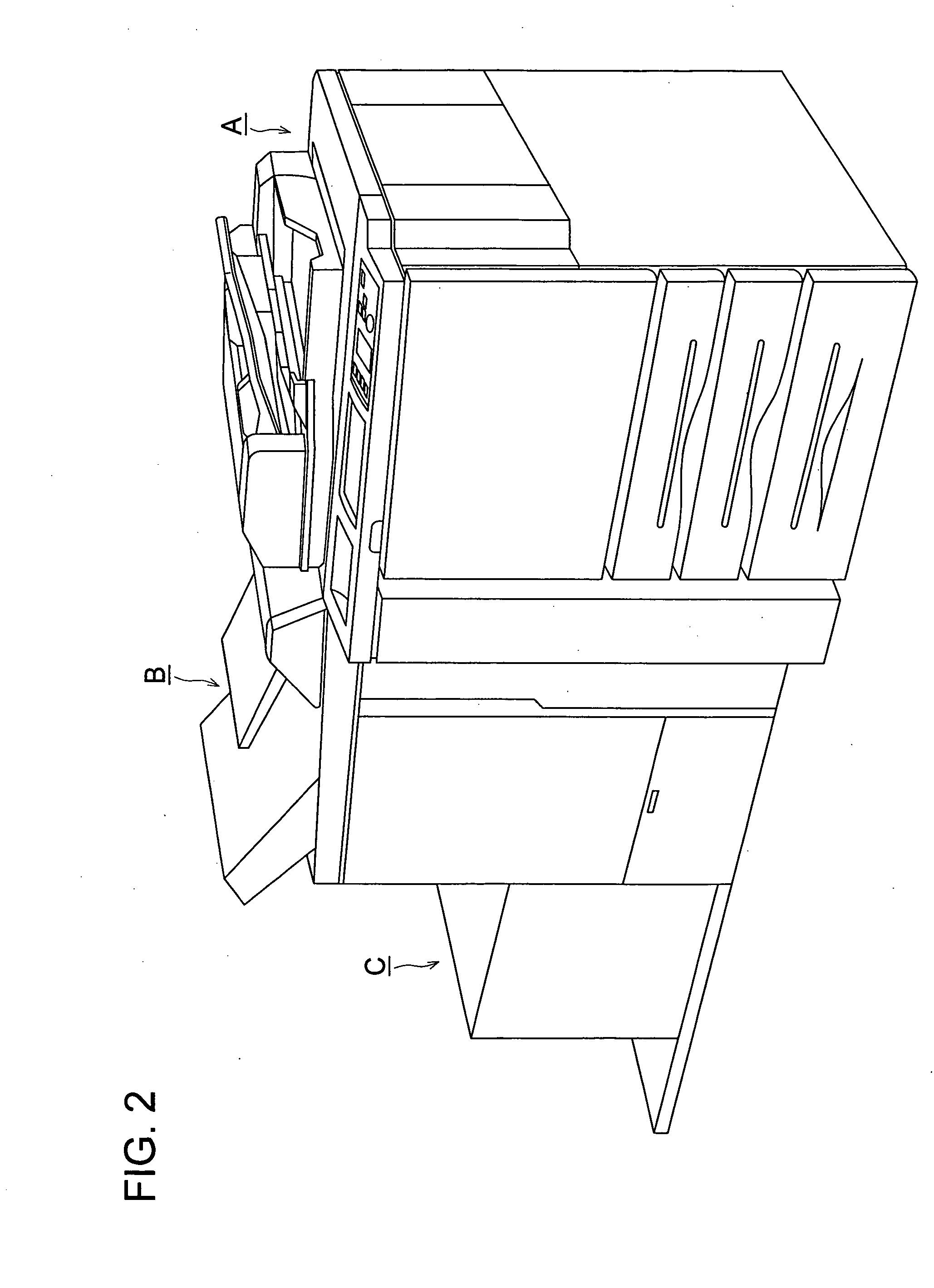

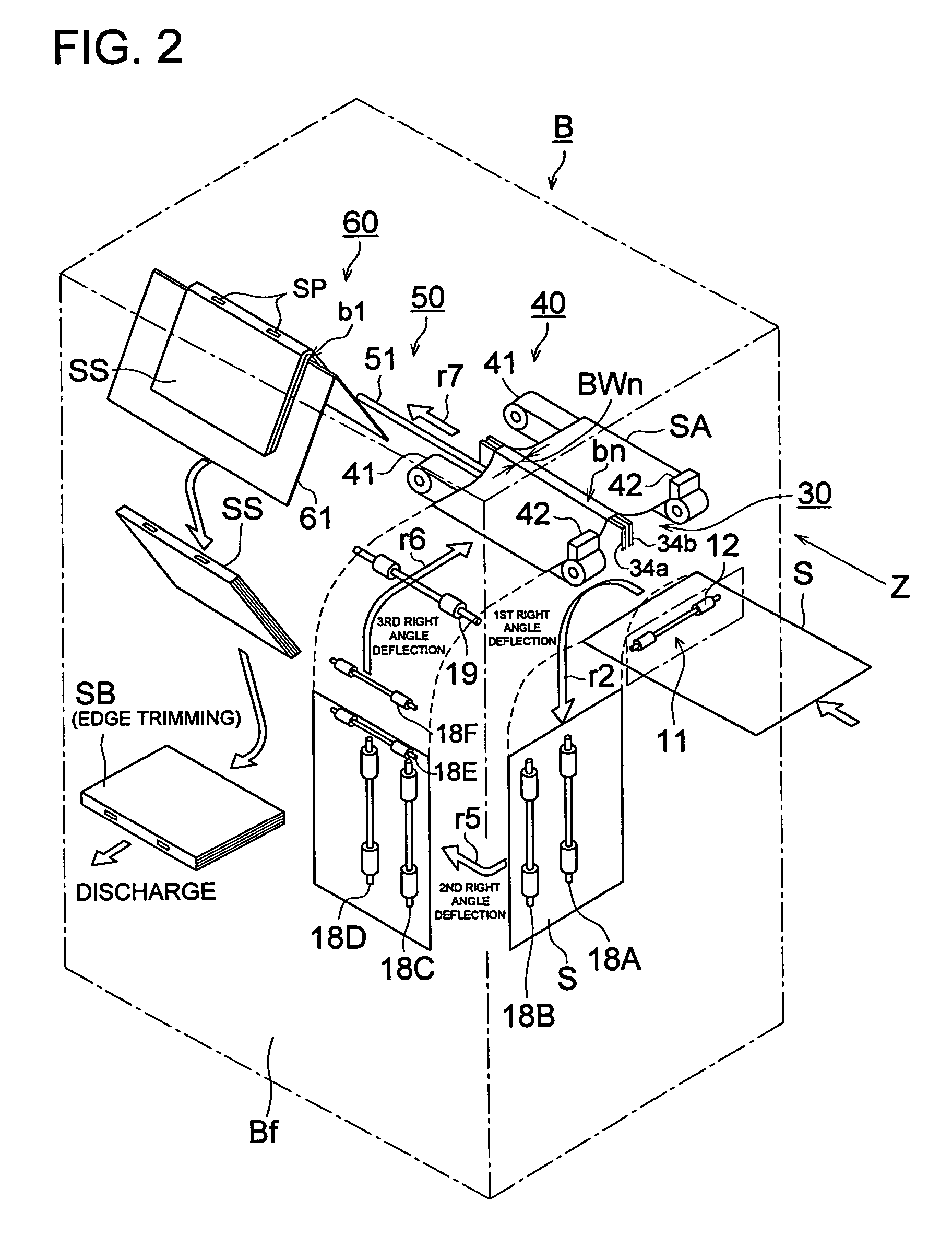

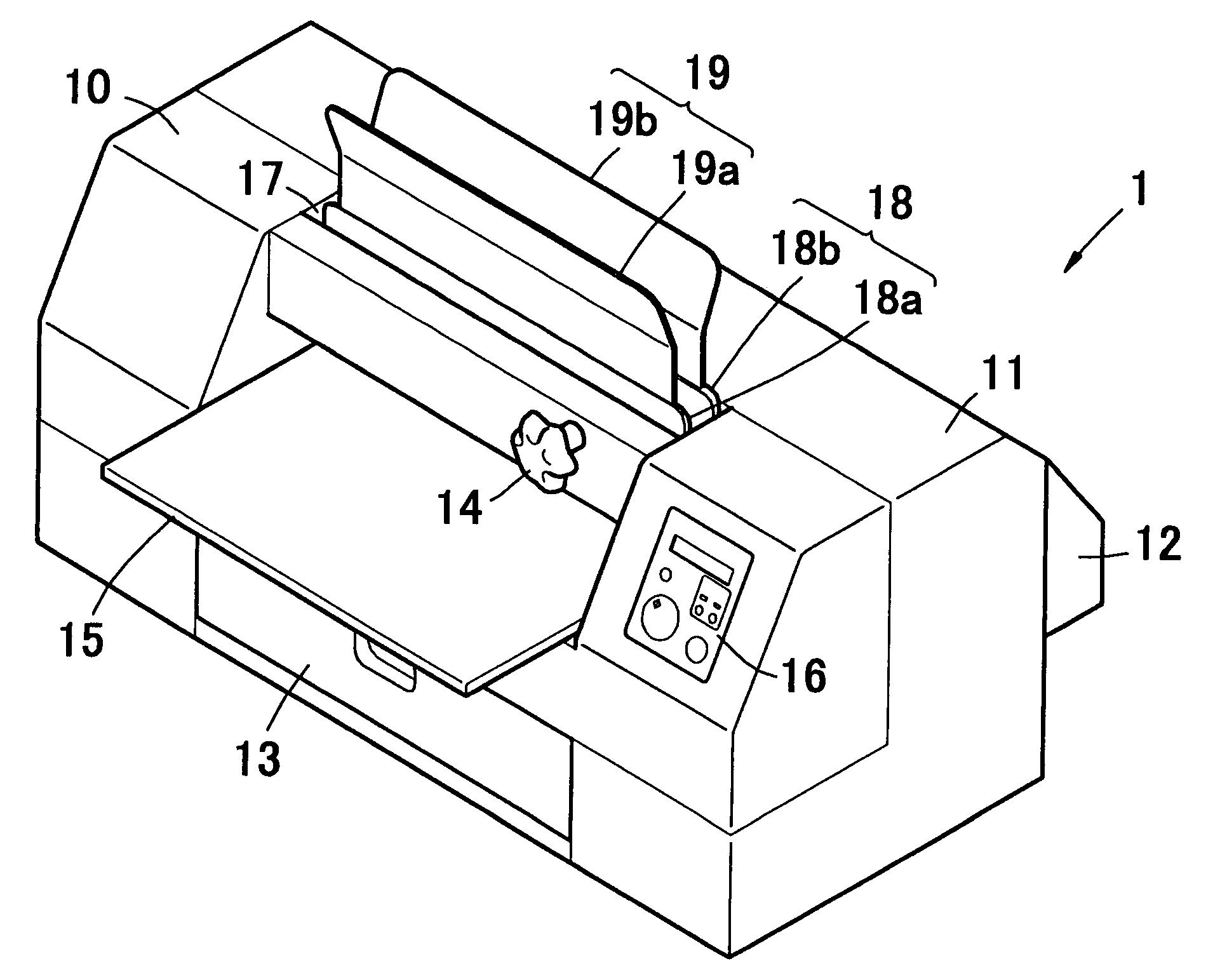

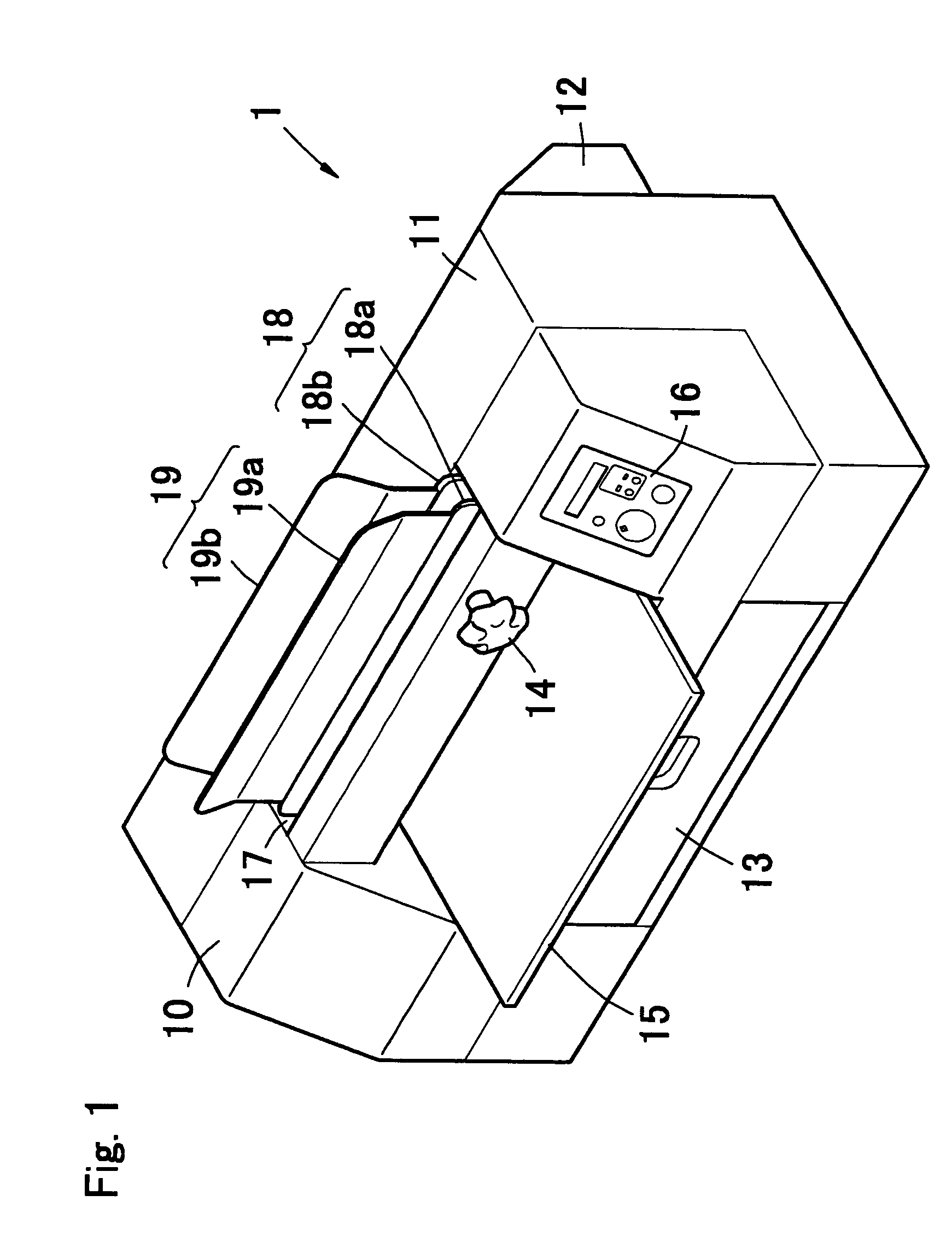

Apparatus and method of on demand printing, binding, and trimming a perfect bound book

InactiveUS7014182B2Improve productivityFast productionOther printing matterBook making processesComputer graphics (images)On demand

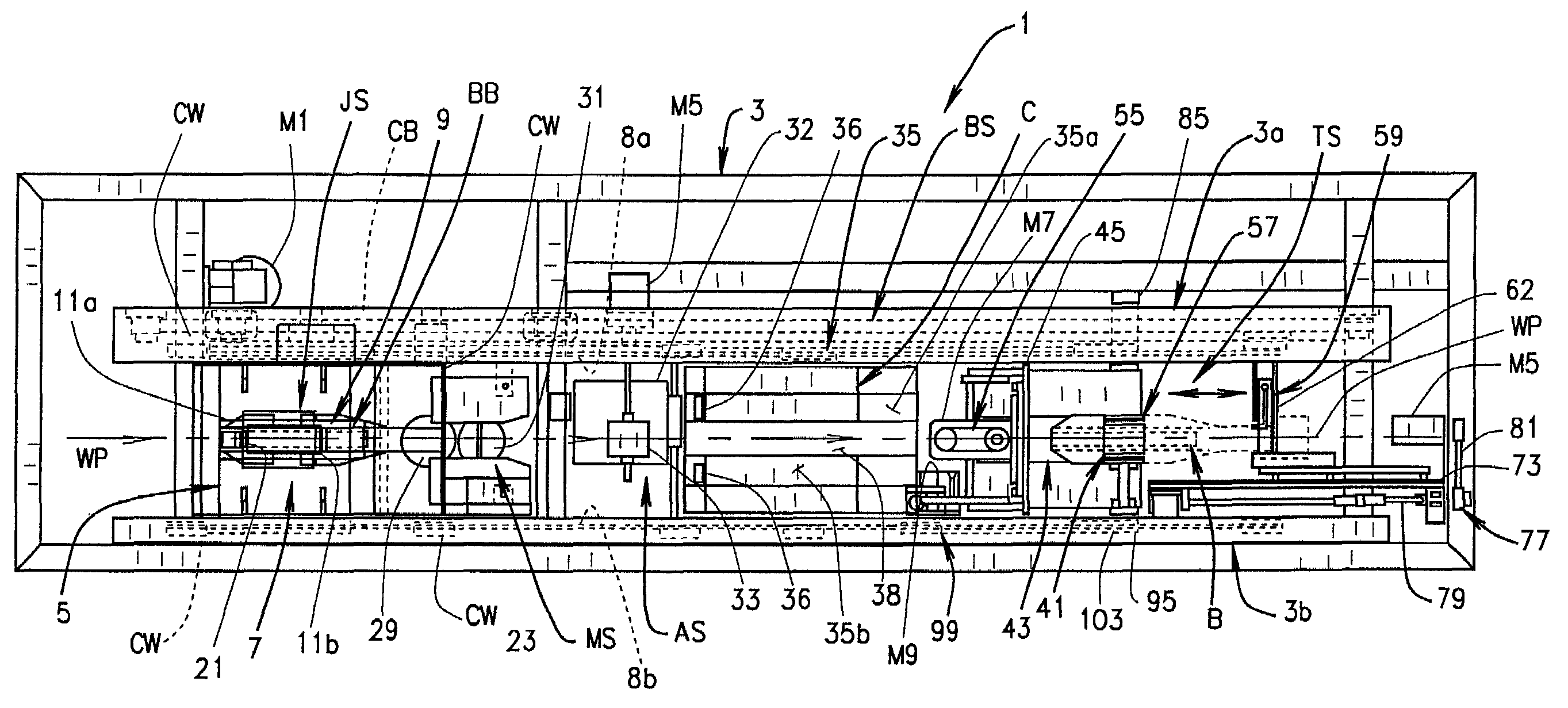

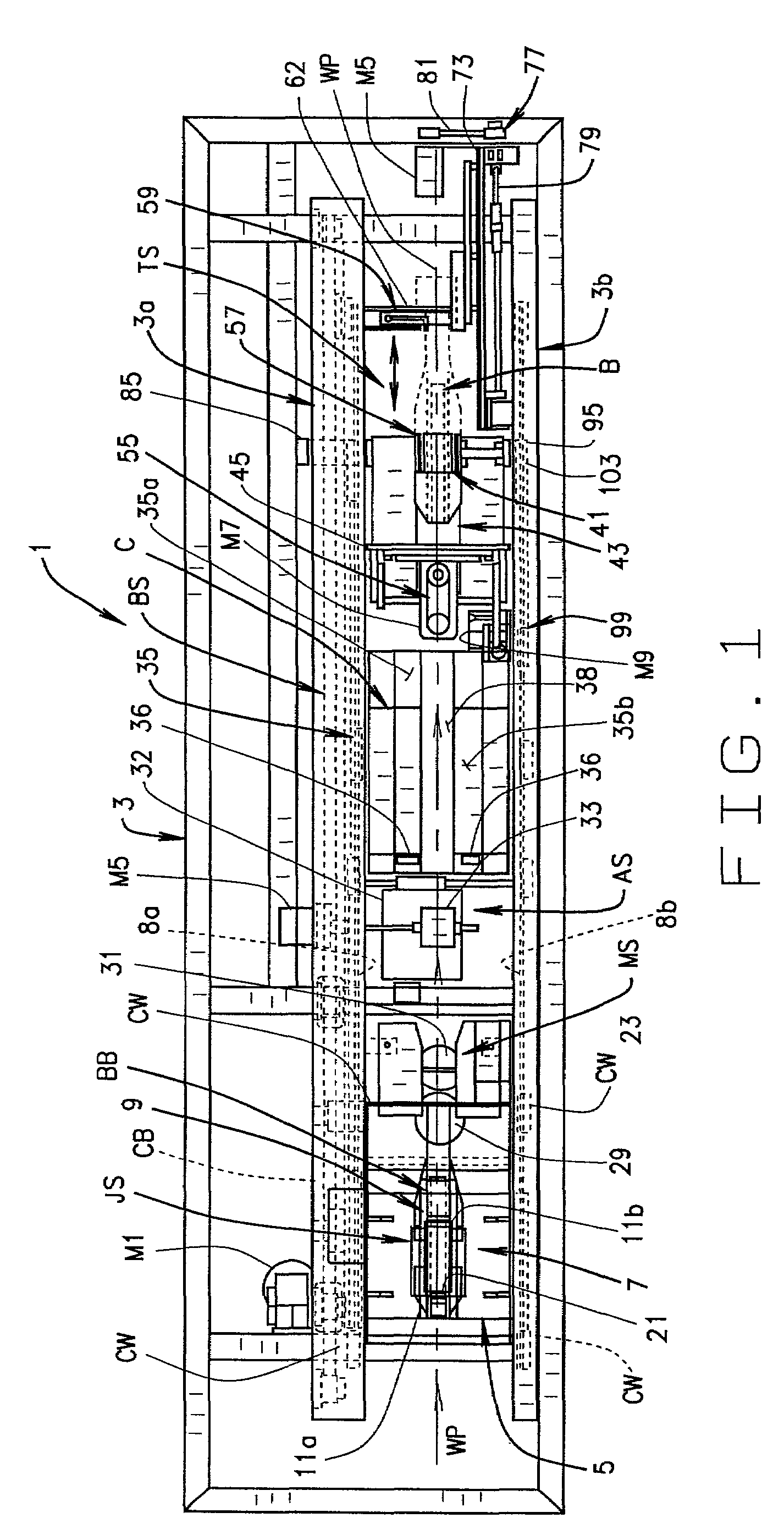

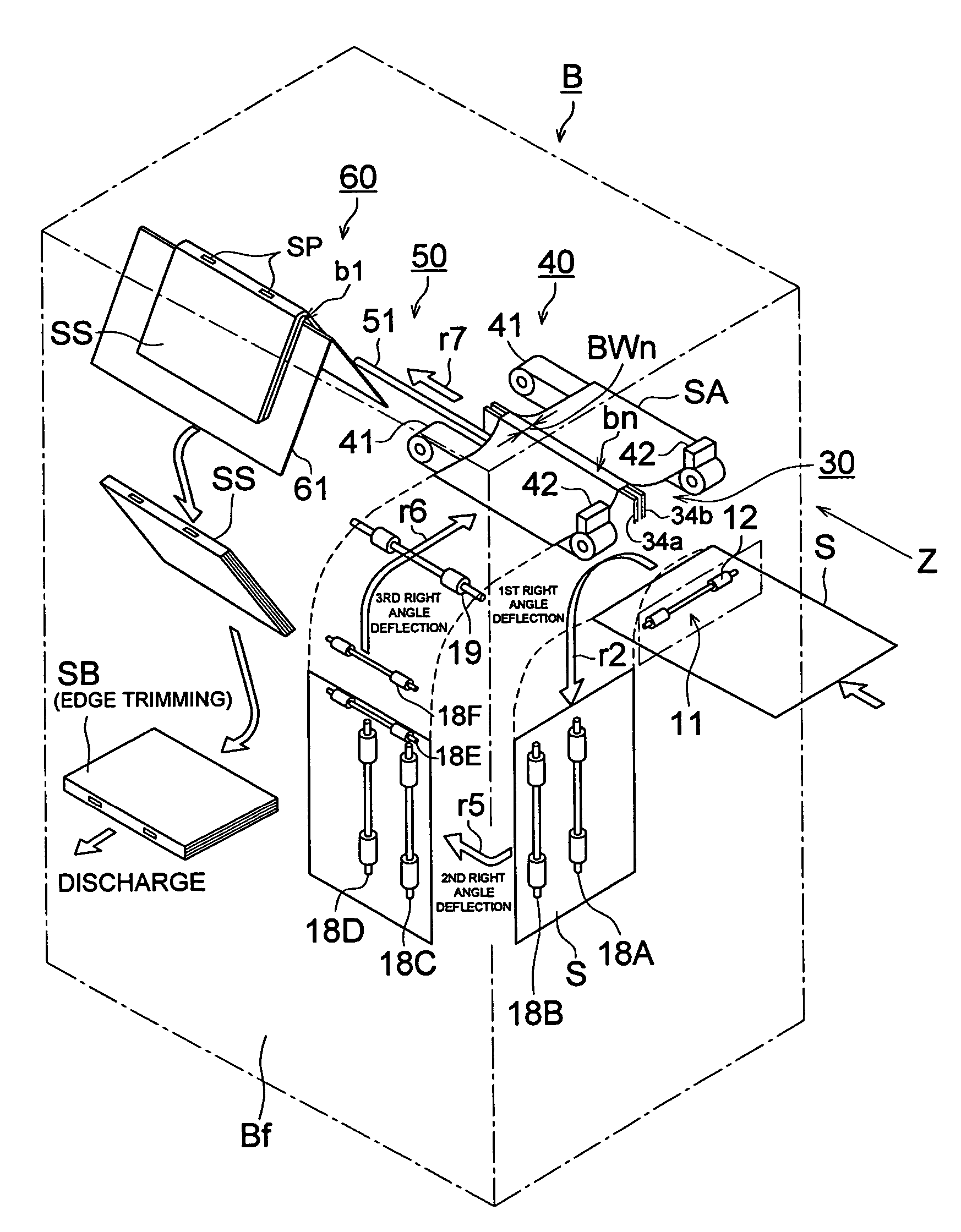

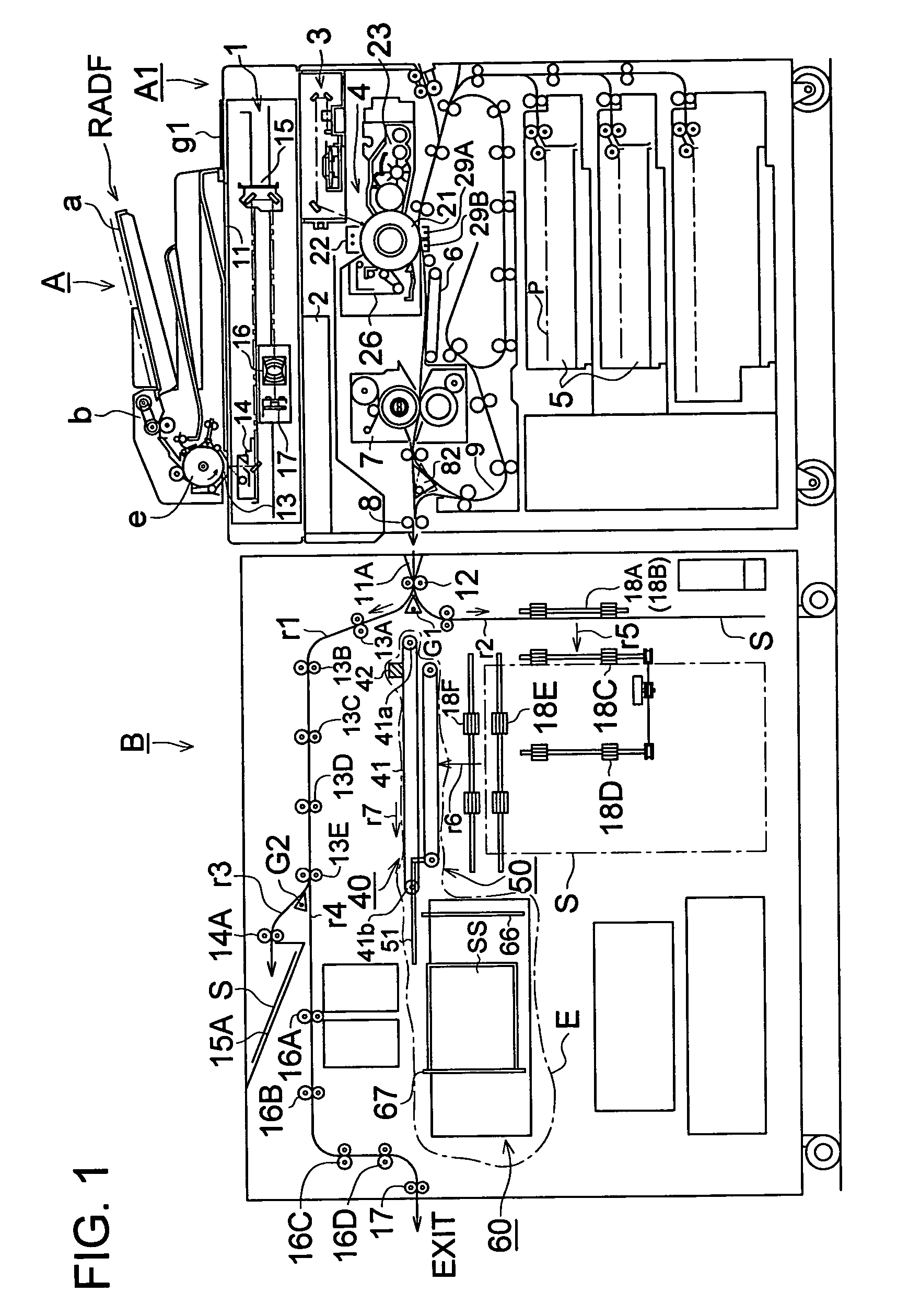

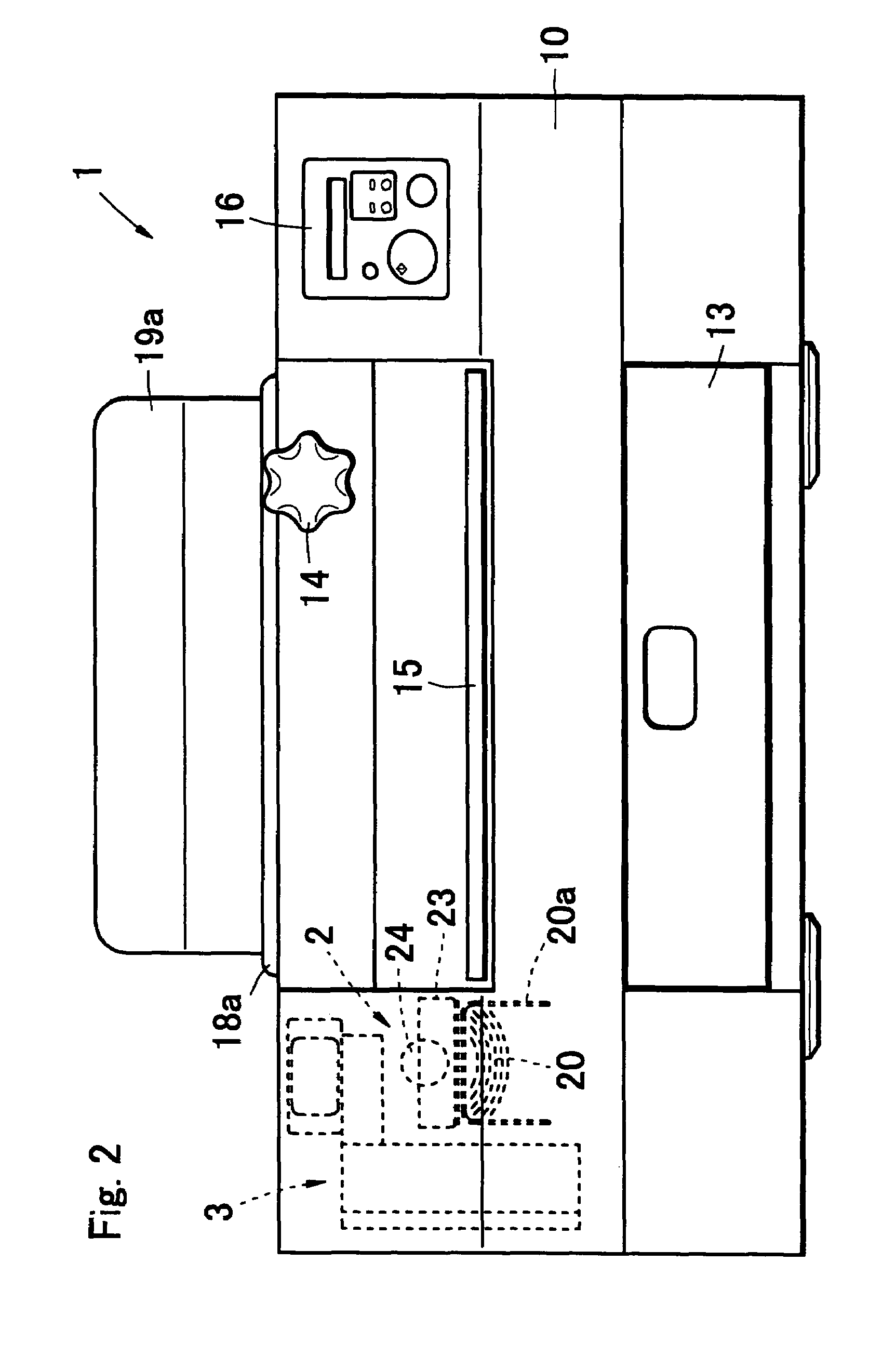

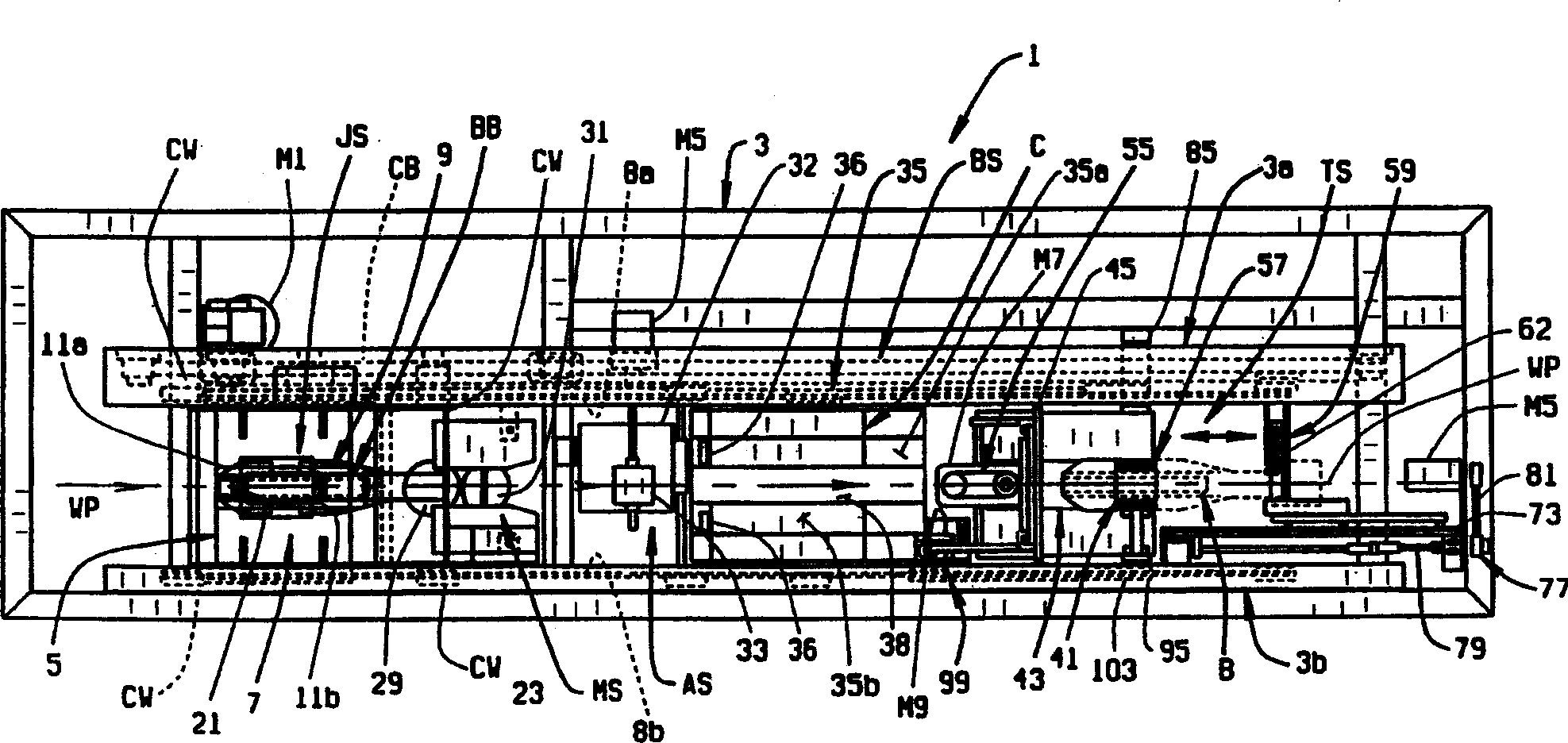

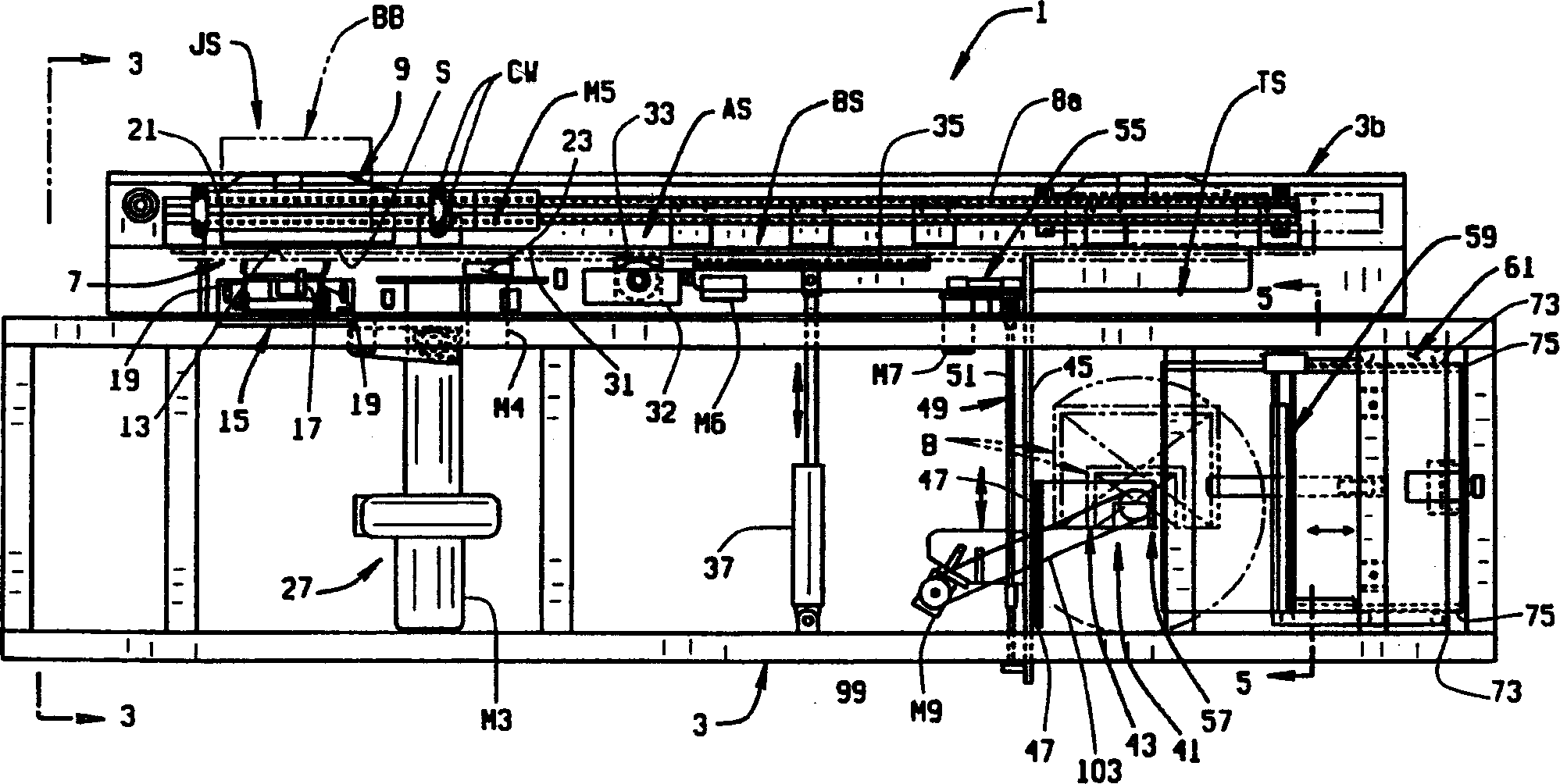

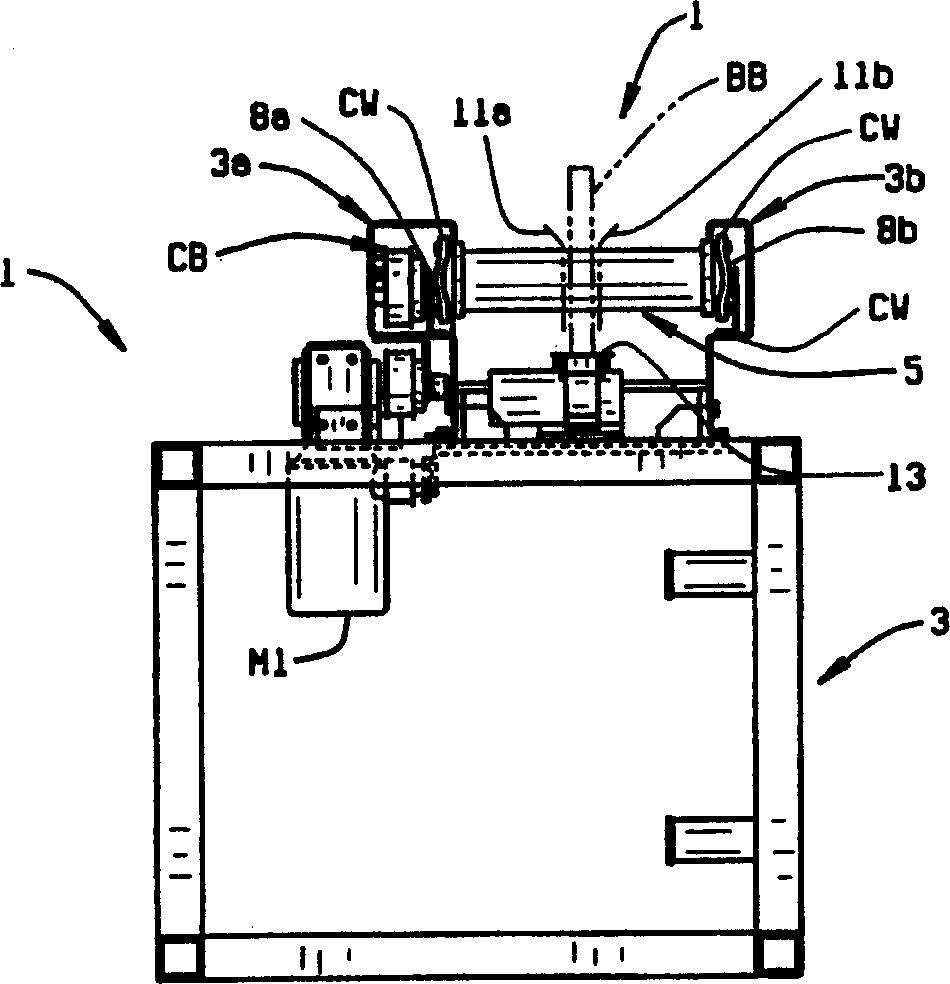

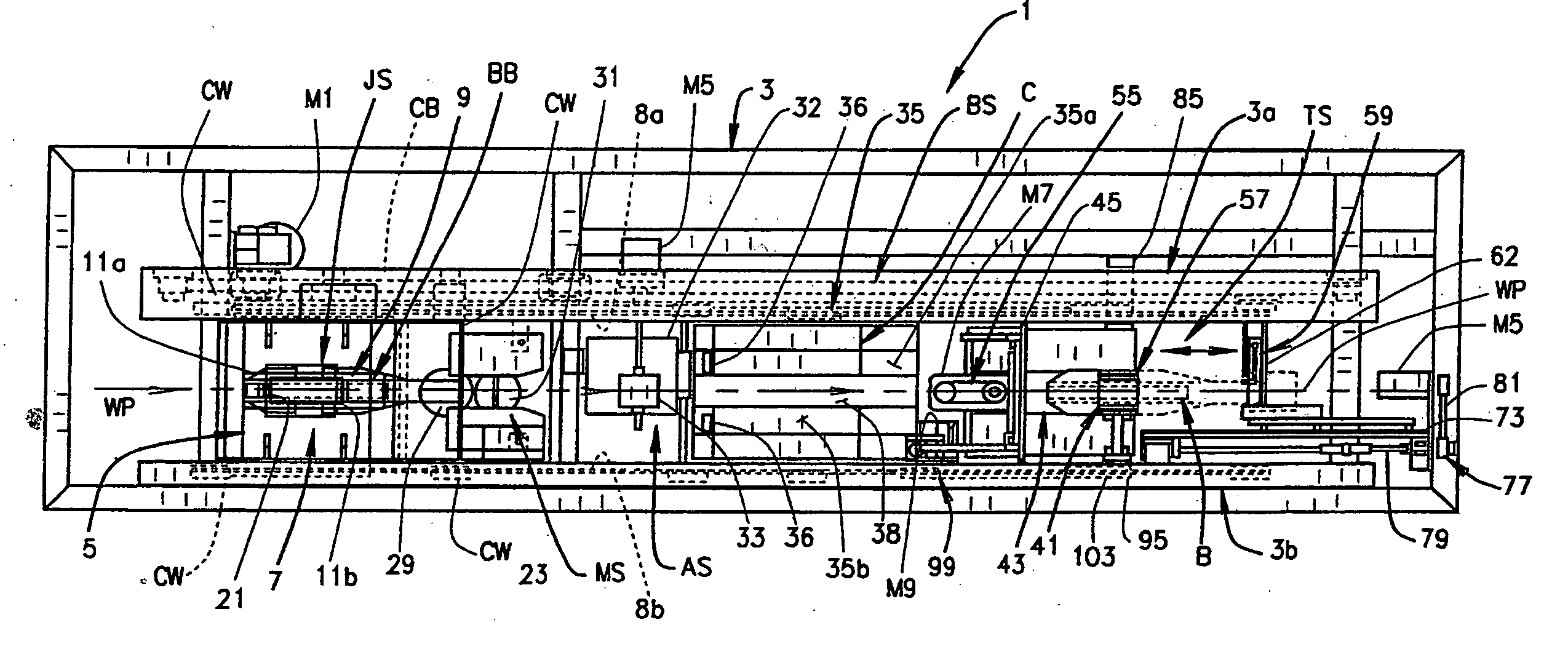

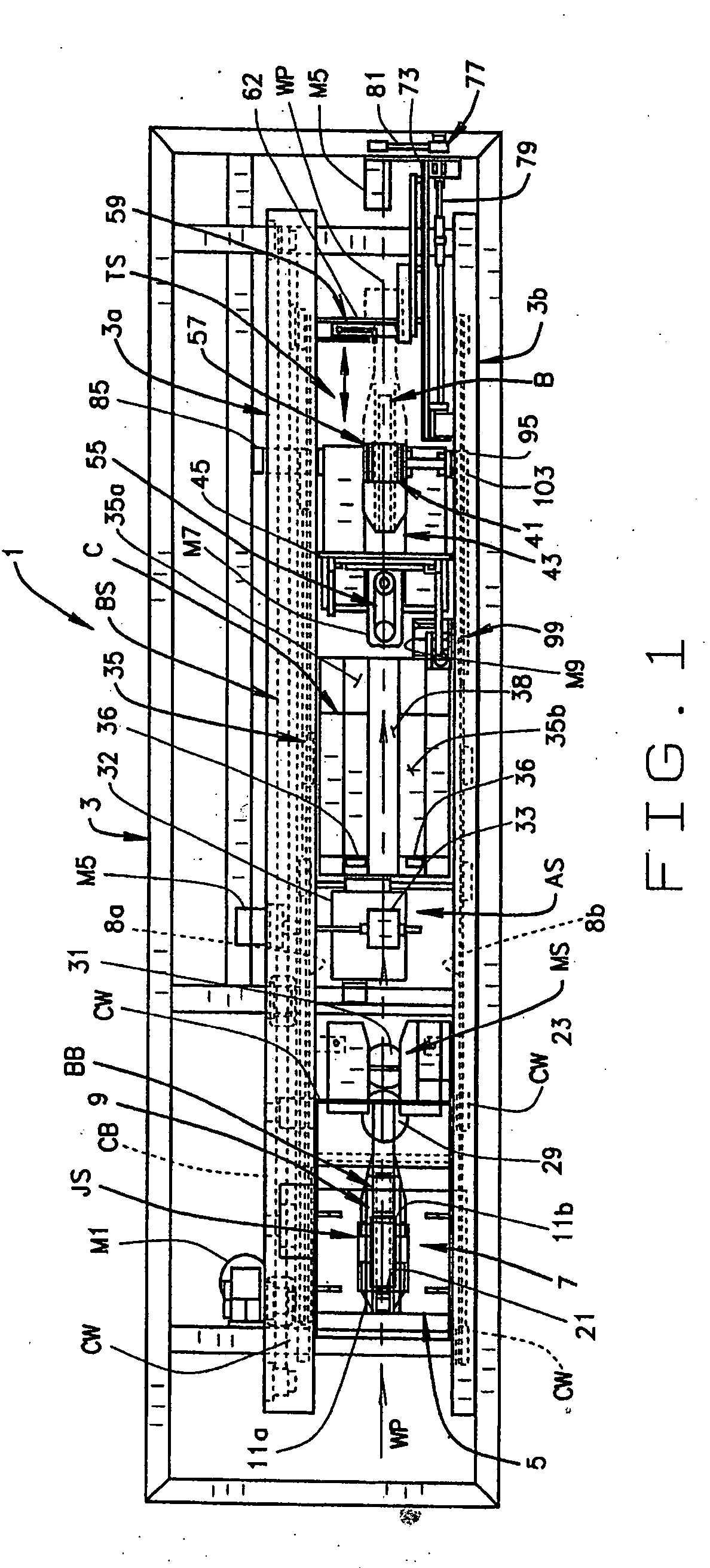

A printing and binding apparatus (1) is disclosed which can print on demand, bind, and trim a perfect bound book. The apparatus includes one or more text page printers (110, 200) and a color cover printer (114). The text page printers print the text pages of a book and form the text pages into a book block (BB). The color cover printer (114) prints a cover for the book. The book block and the cover are delivered to a binding station at which the spine (S) of the book block is adhesively bound to the cover. The bound book is then delivered to a trimming station (TS) at which excess margins (are trimmed from the book. A method of printing and binding a perfect bound book on demand is also disclosed.

Owner:PERFECT SYST

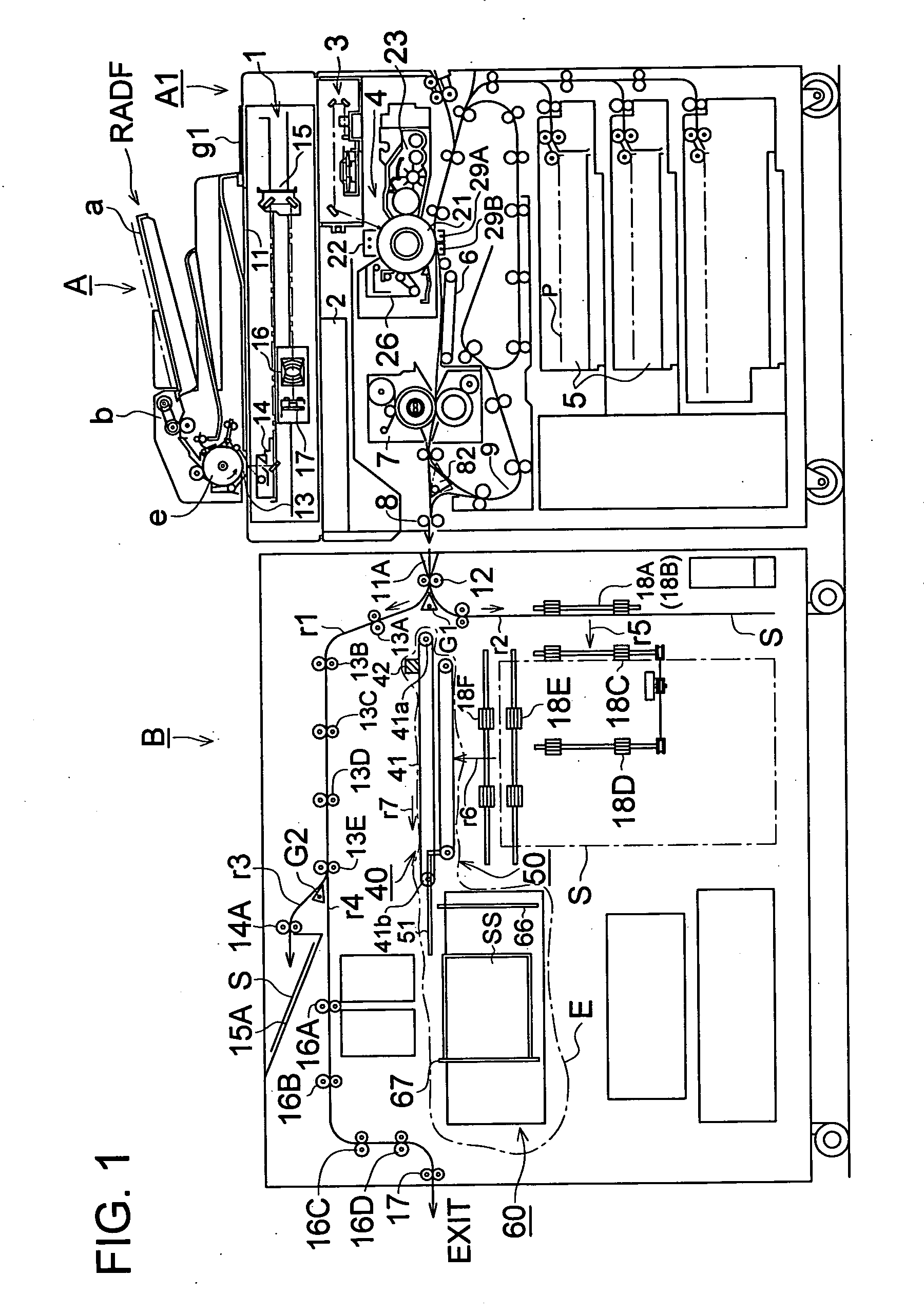

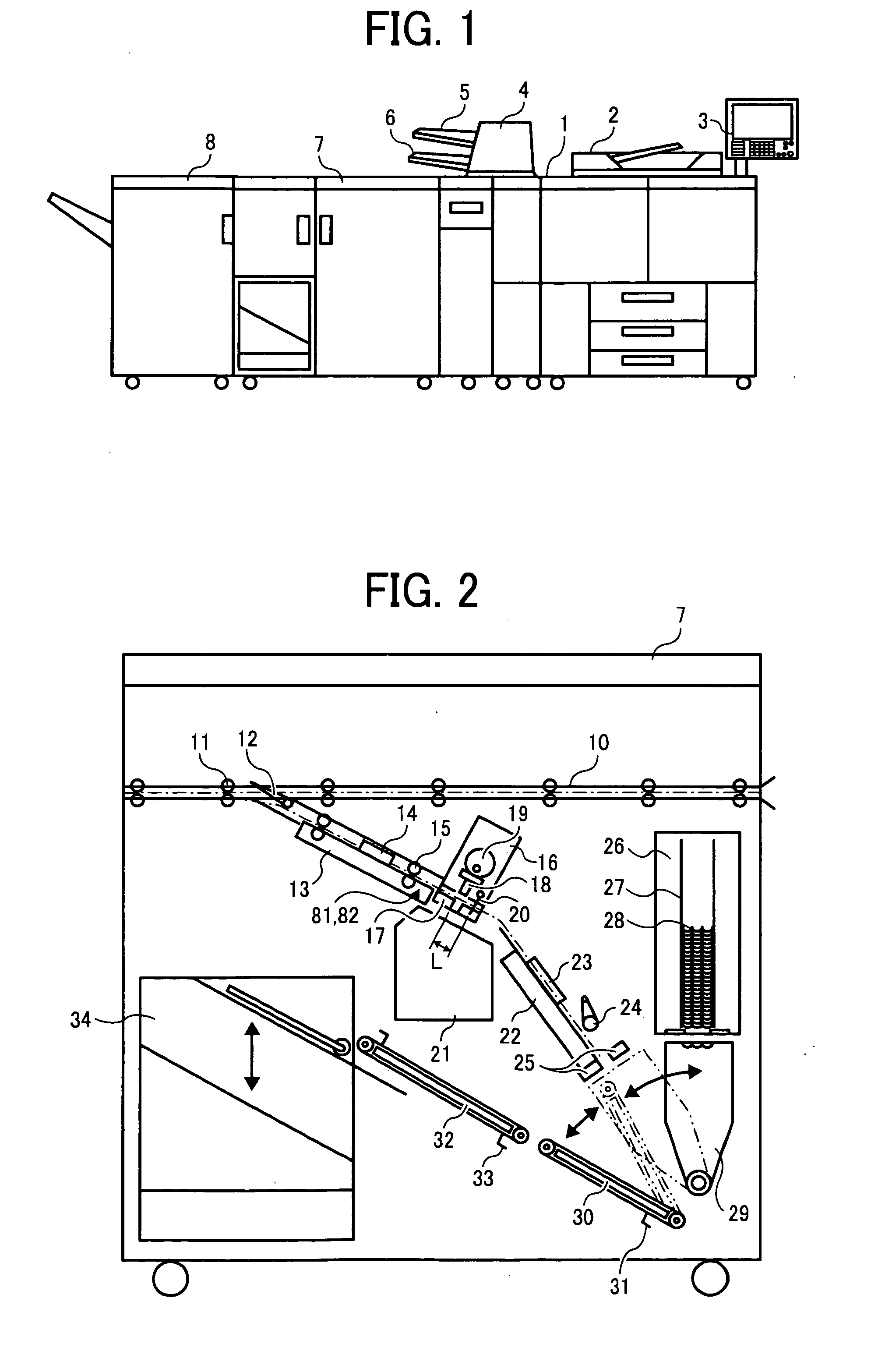

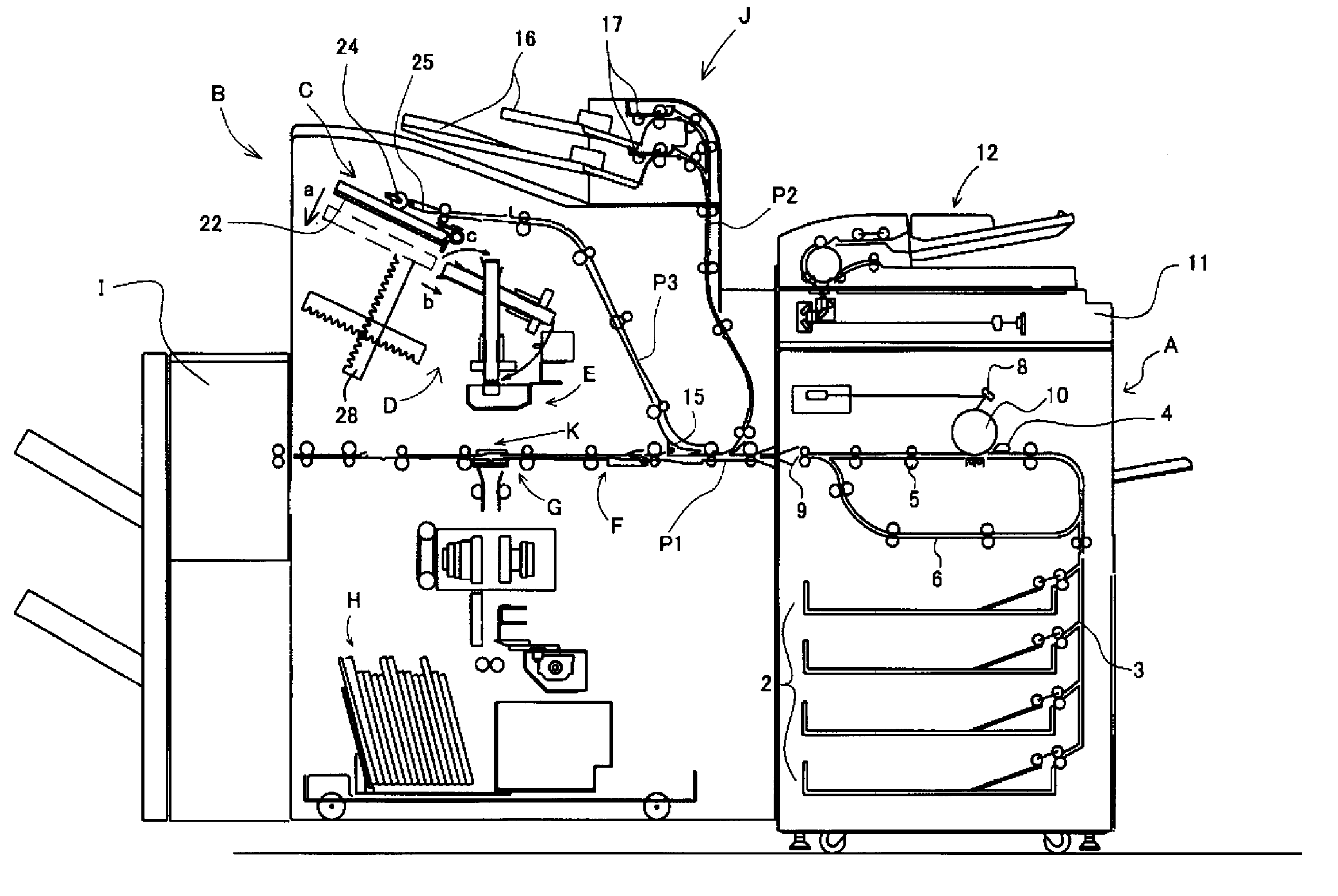

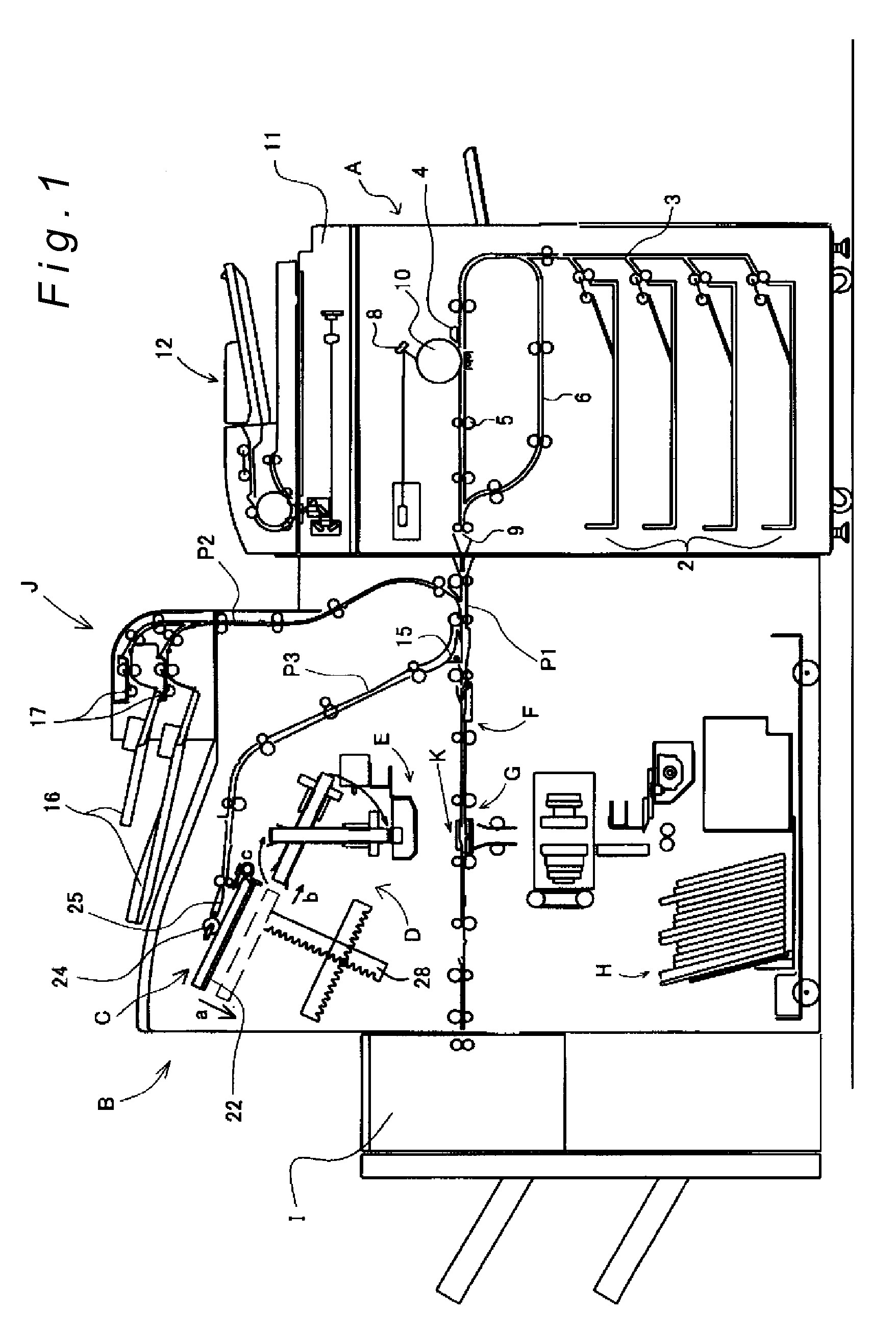

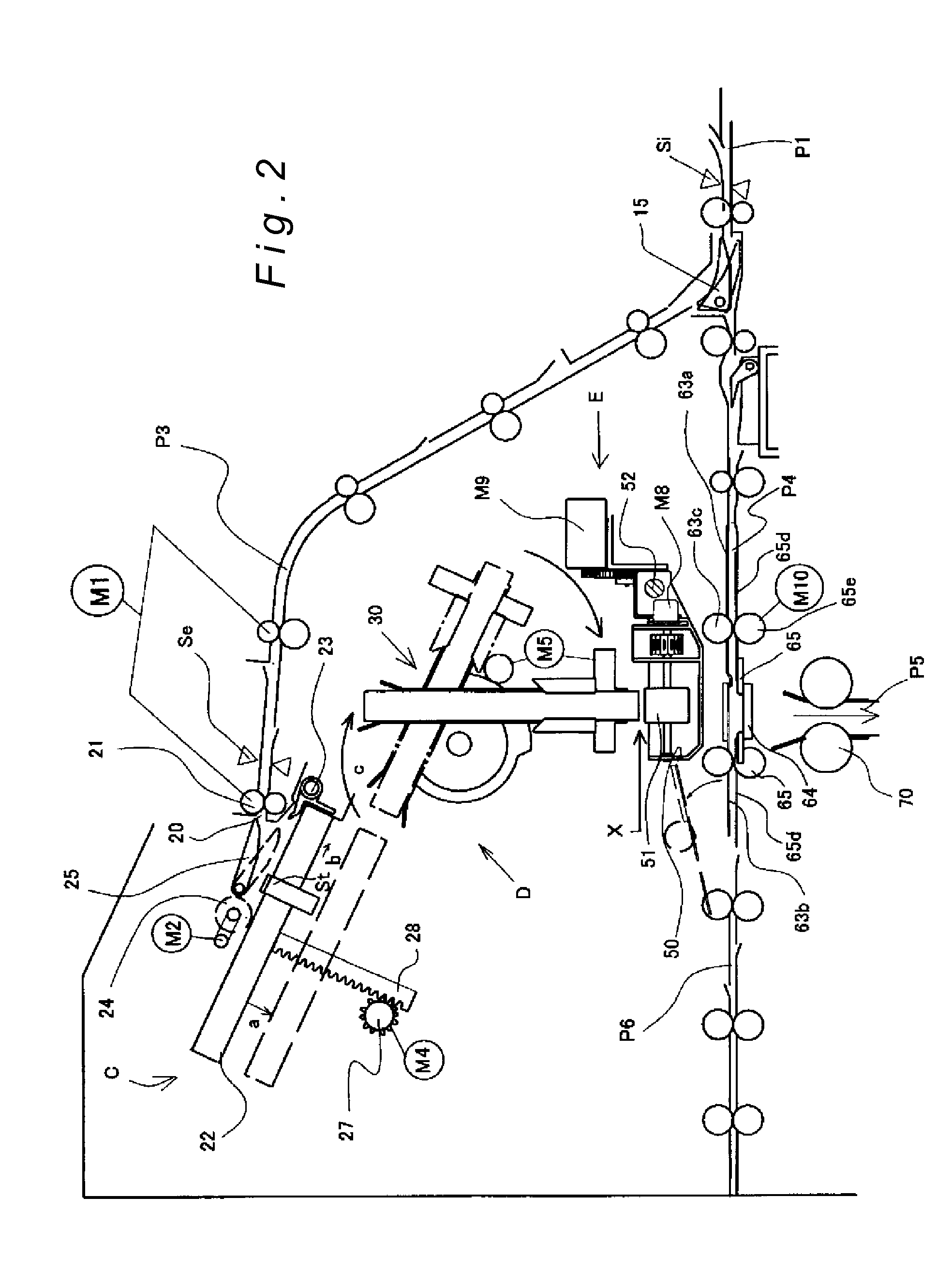

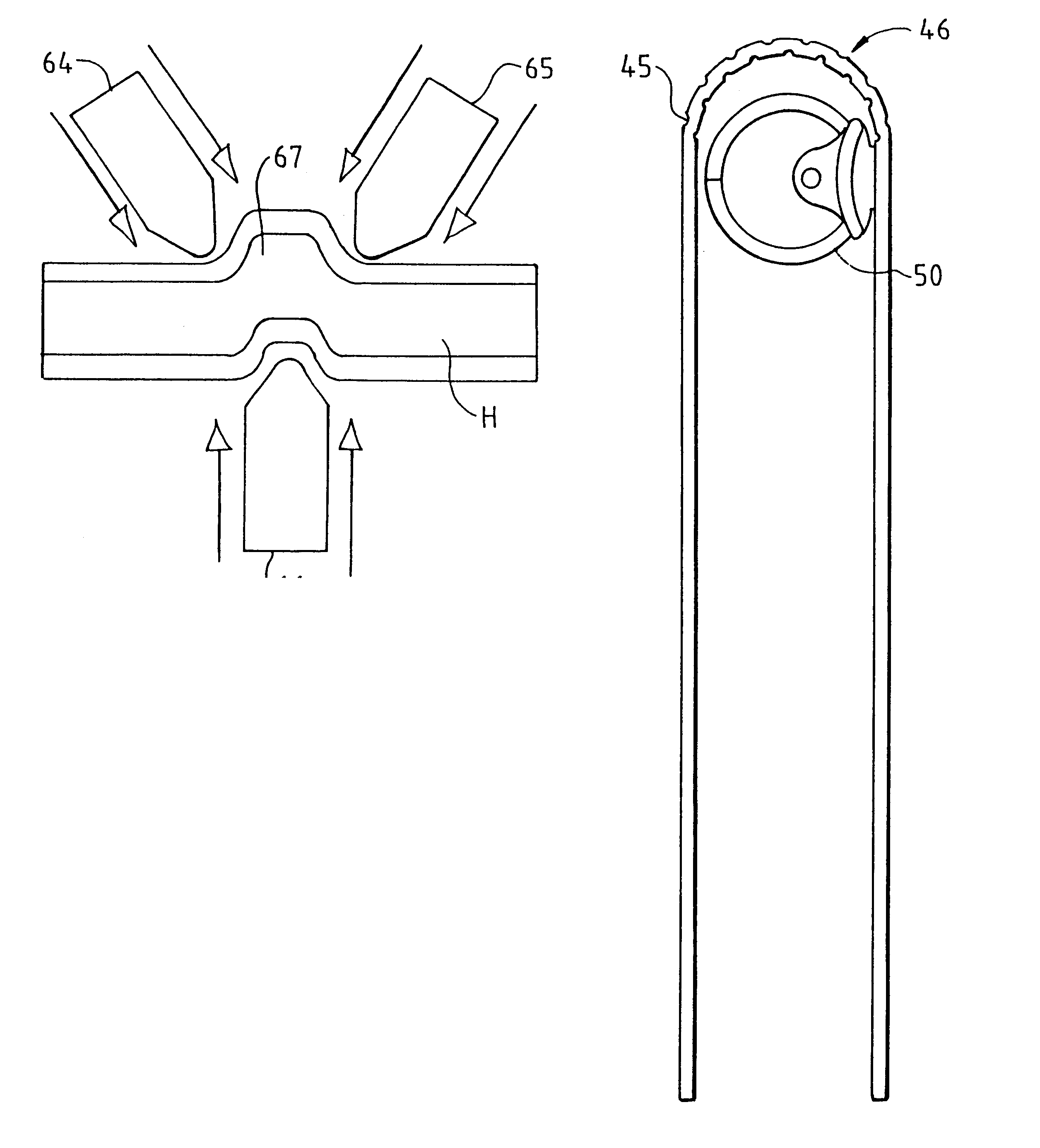

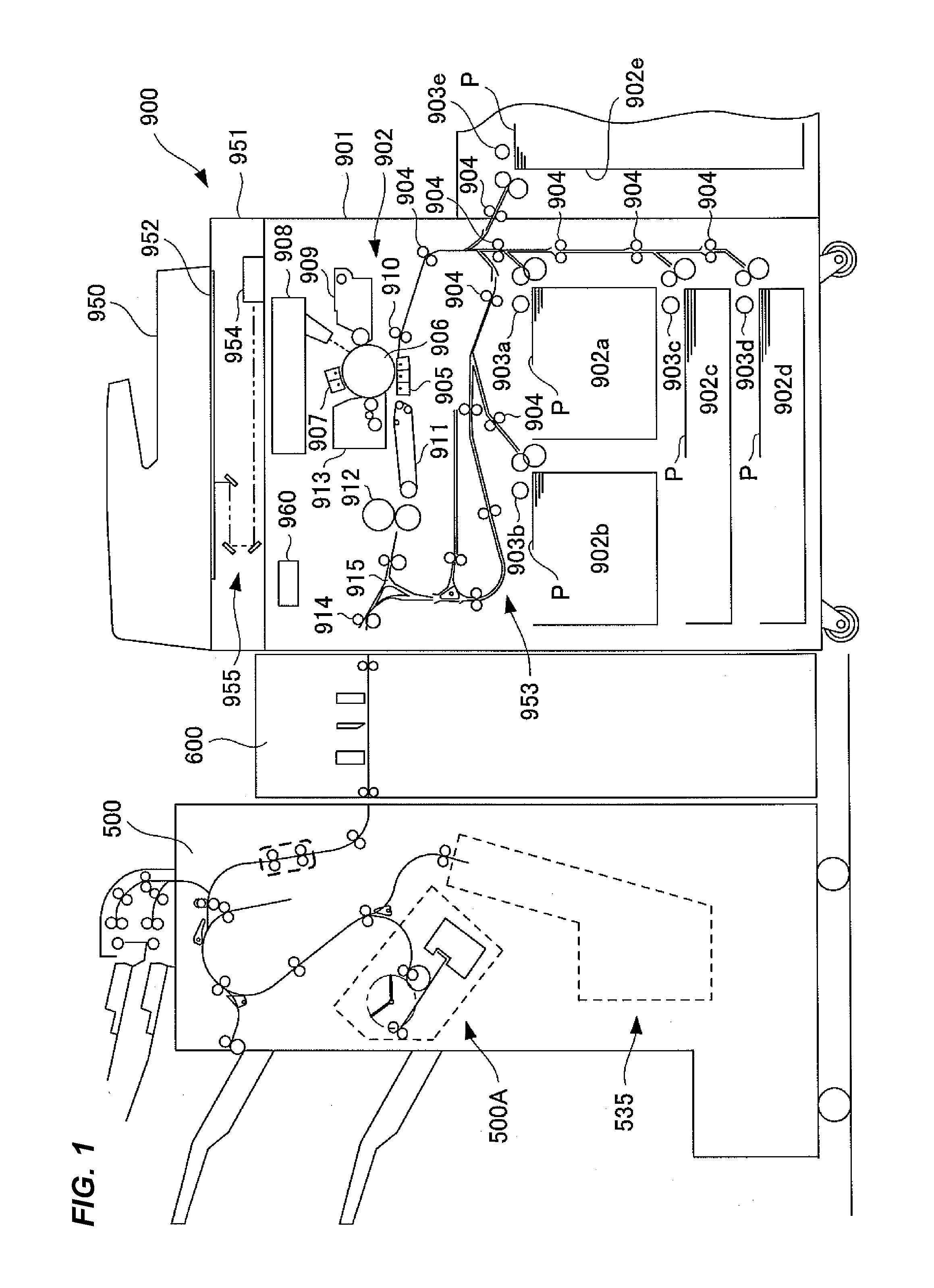

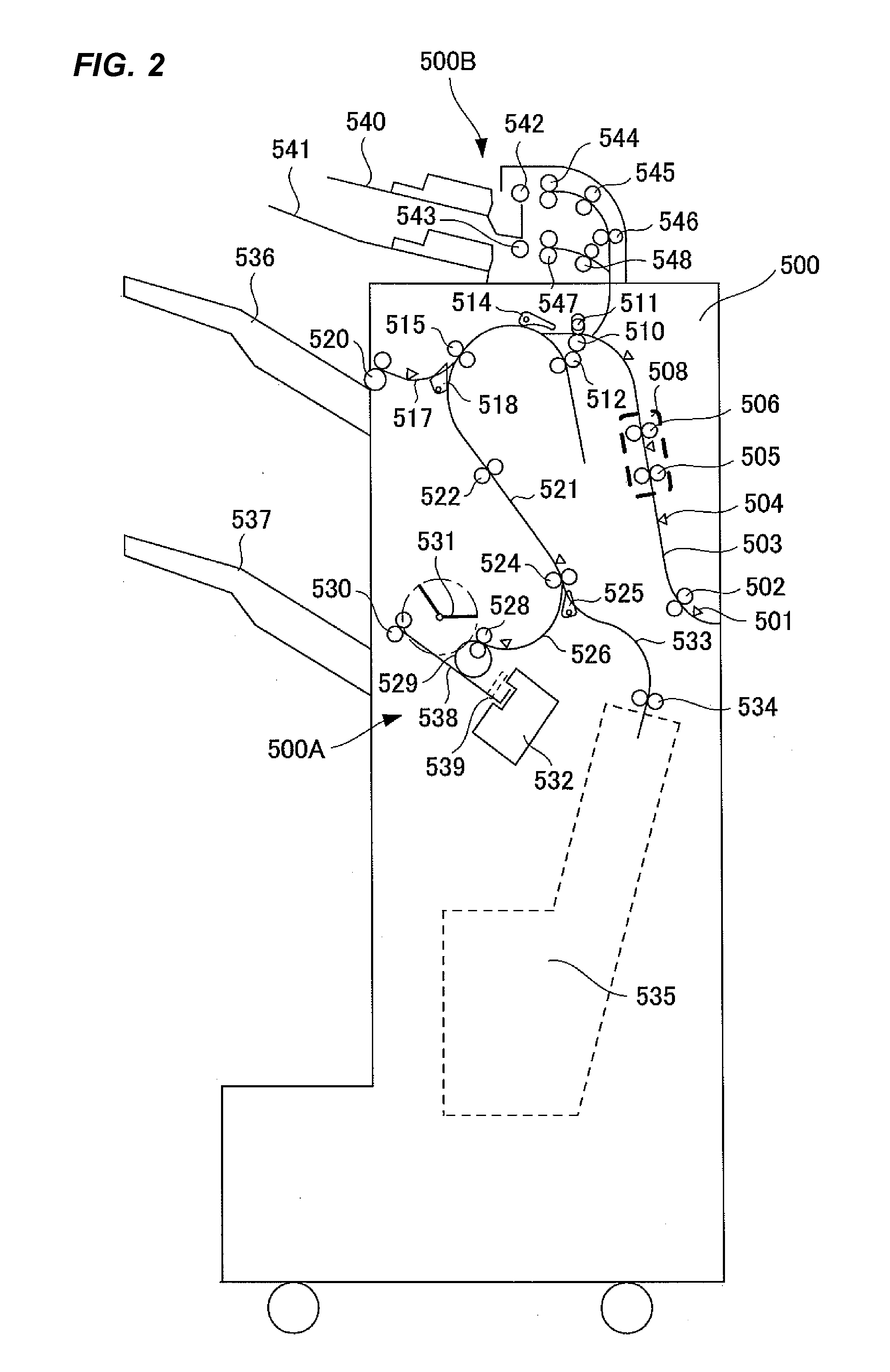

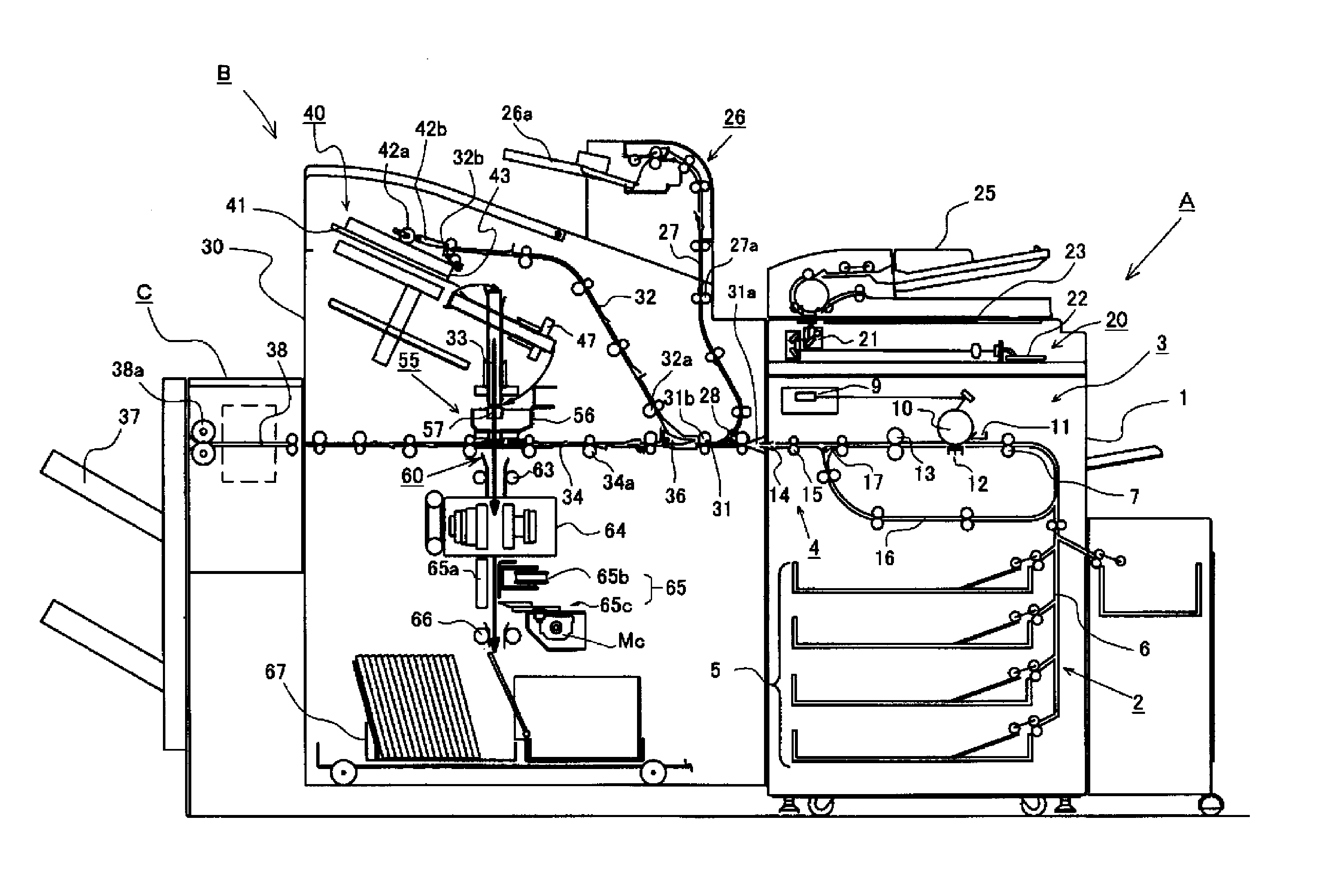

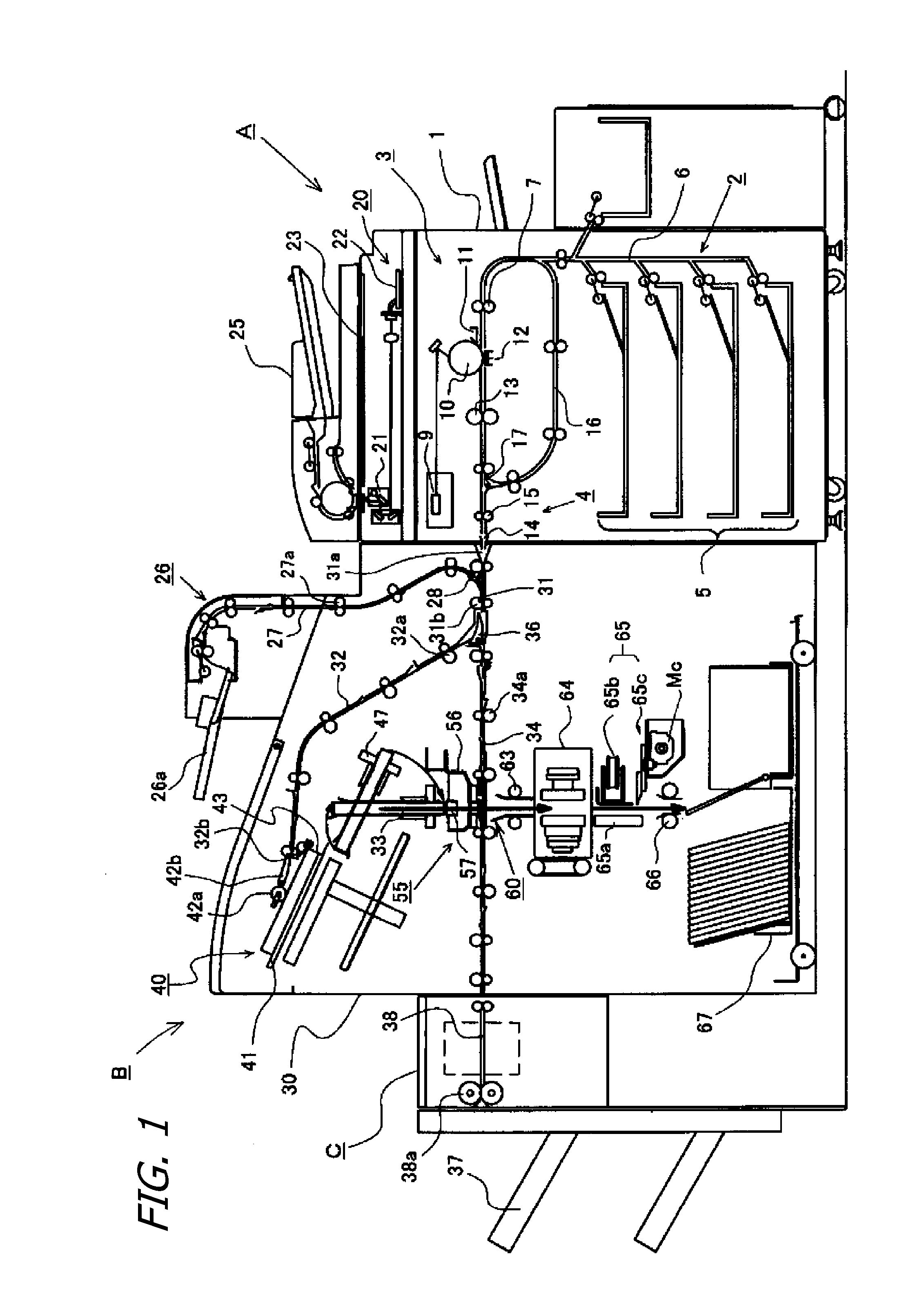

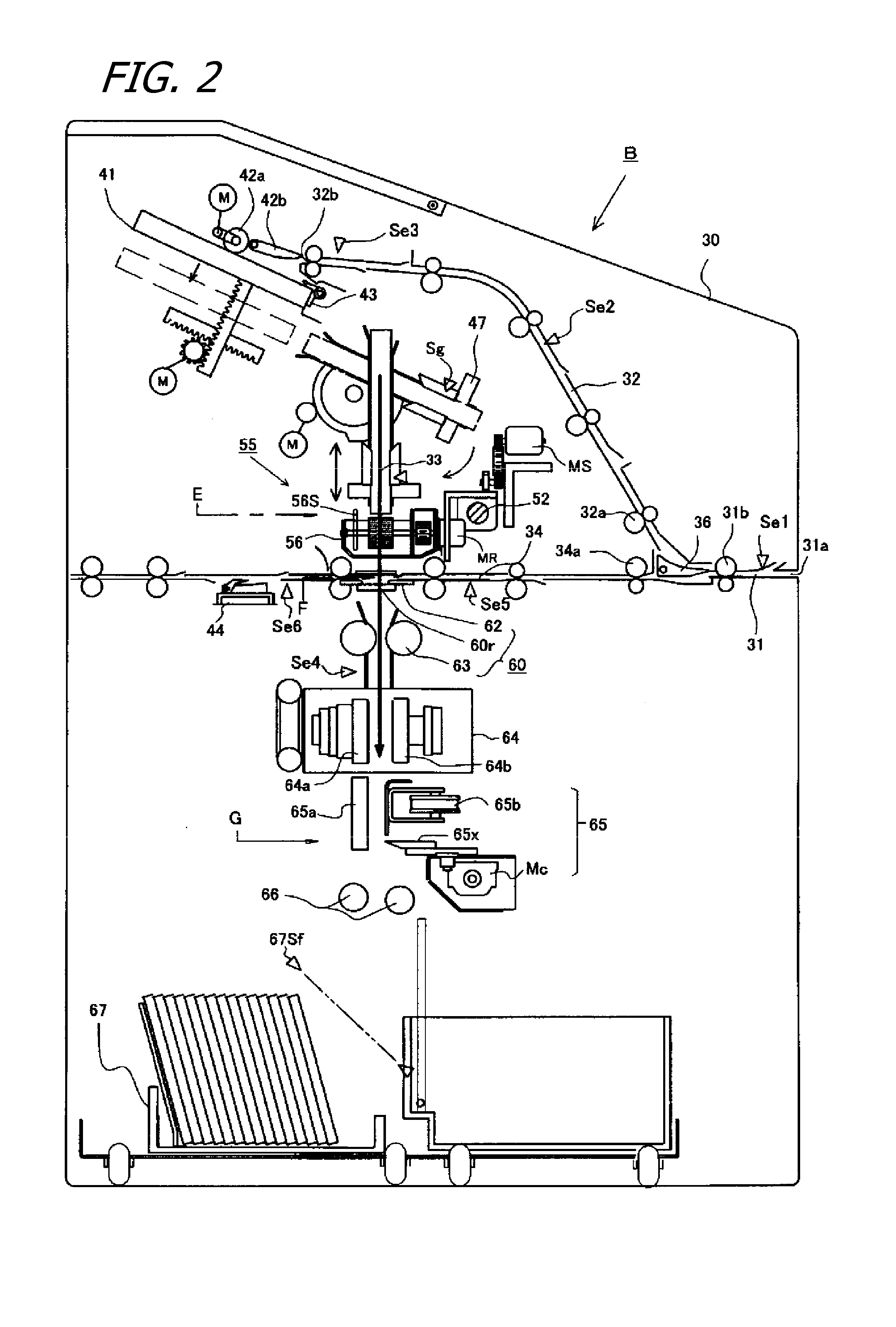

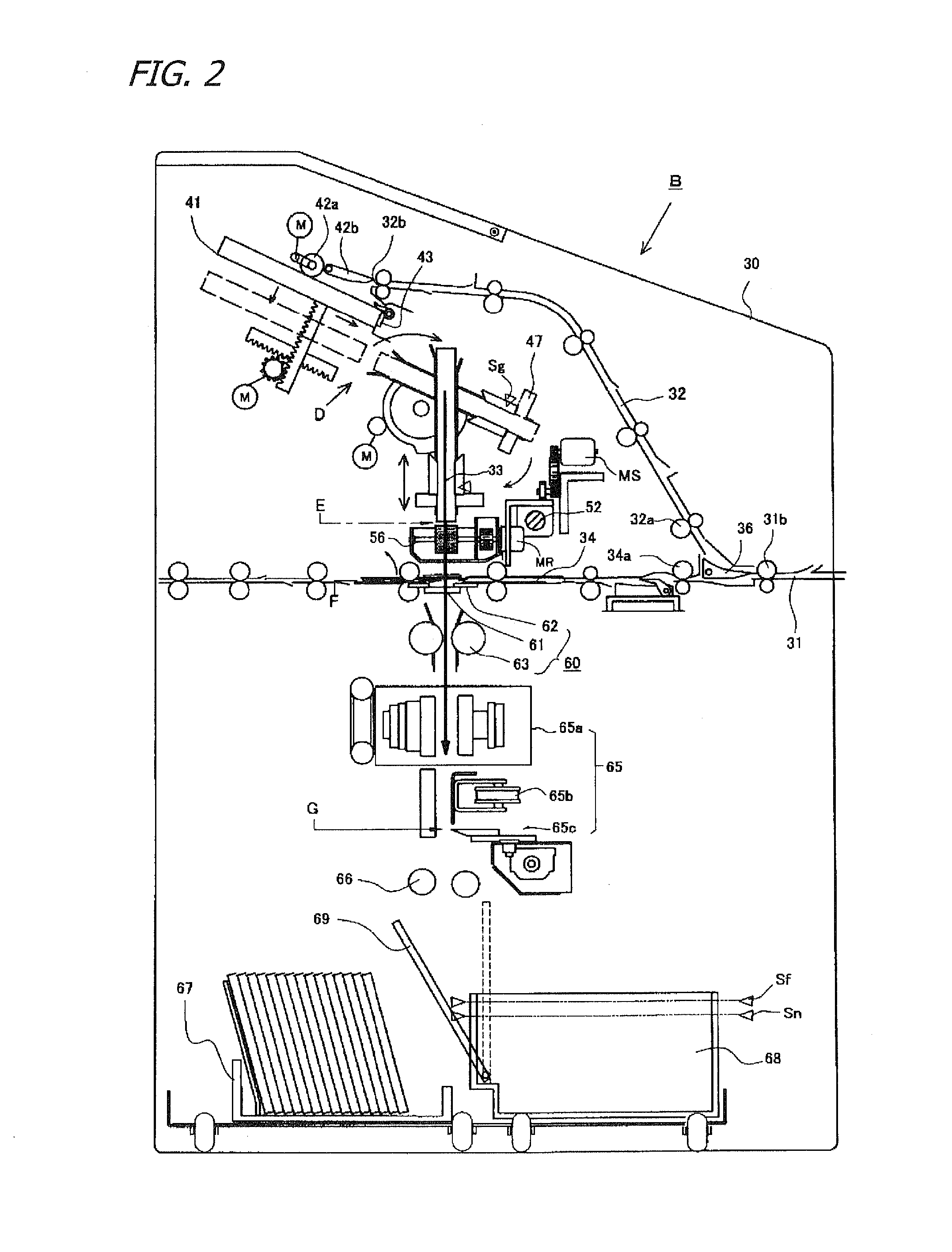

Sheet post processing apparatus and image forming system

InactiveUS20060153612A1Good body shapeIncrease changeOther printing matterBook making processesImage formationEngineering

In a sheet post processing apparatus having a folding device that carries out the process of book folding by folding either one sheet or a plurality of sheets at a time on the sheets discharge from the image forming apparatus, a sheet stacking section that successively stacks the booklet-folded sheets, and a control unit that controls the sheet post processing apparatus, said control unit controls said folding device so that said booklet folding process of said sheets is carried out at the portions of two folding lines which are almost parallel thereby obtaining a square-shaped back of booklet.

Owner:KONICA MINOLTA BUSINESS TECH INC

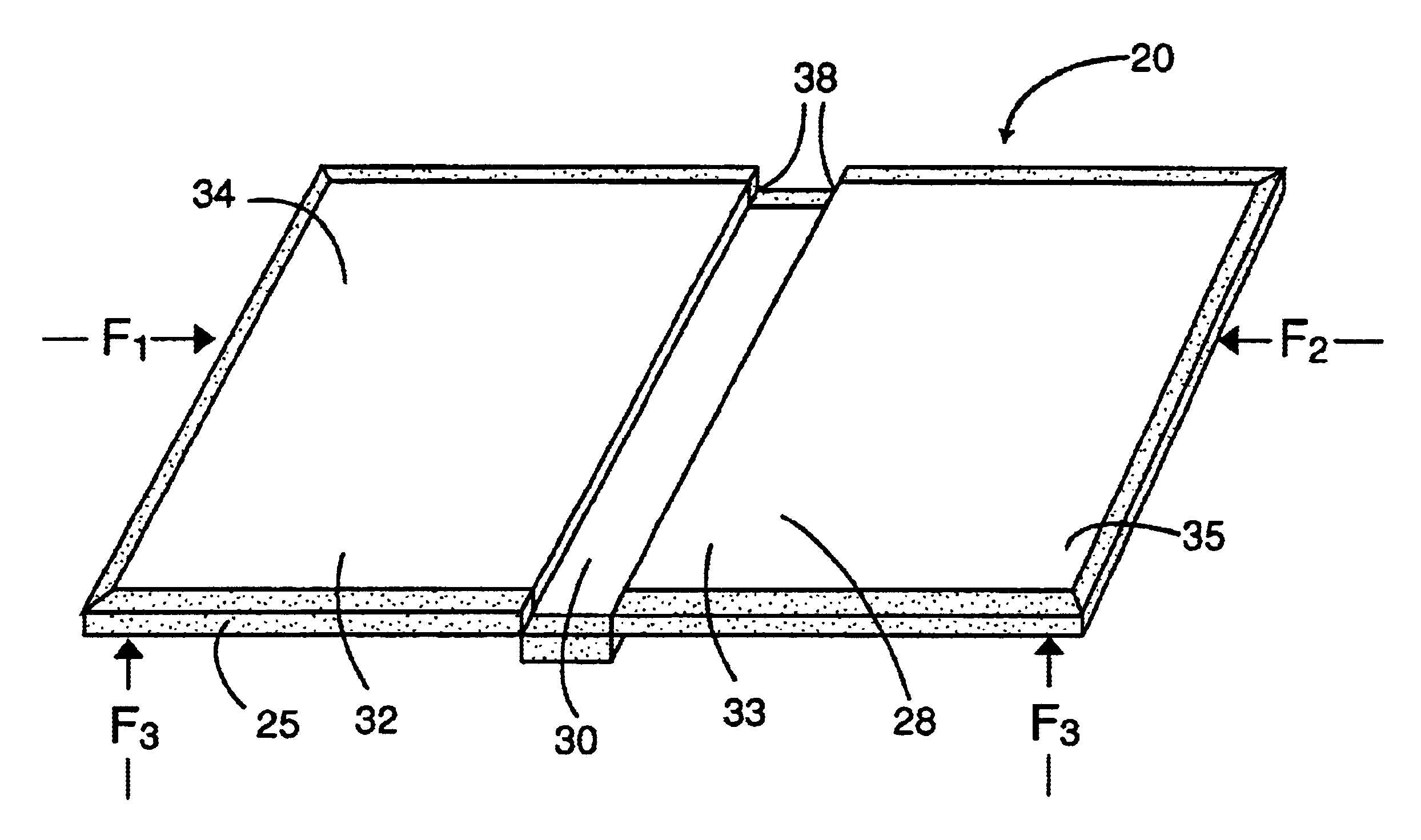

Outside-hinged cover for protecting articles stored therein and method for fabricating same

InactiveUS6910717B1No wasted materialEasy to openBookbinding casesToysEngineeringBiomedical engineering

An object resembling the cover of a hardbound book comprises two panels connected by a spine. The outside hinge configuration of the invention prevents the spine from collapsing, even if there are no contents between the two panels. The invention lends itself to a wide variety of book-like products (e.g., a book-like holder for a compact disc and accompanying booklet) where the contents are of changing width (thickness) or where the spine must be of a specific width, irrespective of the width of the contents, and further allows for a binding for a book to be fabricated prior to assembly or insertion of its pages. A hinged cover consistent with the invention comprises a spine and two rigid panels, each panel coupled to the spine and disposed rotatably with respect to the spine, and the spine serves as a hinge stop for each rigid panel, such that each panel, when rotated toward the other panel, is constrained from rotating substantially beyond 90 degrees with respect to the spine. A method of constructing a cover consistent with the invention comprises disposing a rigid front, rear, and spine panel core onto a sheet of pliable material, such that the width of the space between the spine panel core and the other panel cores is based on at least the sum of the thickness of the spine panel core and twice the thickness of the sheet of pliable material.

Owner:MOYER WILLIAM FREDERICK

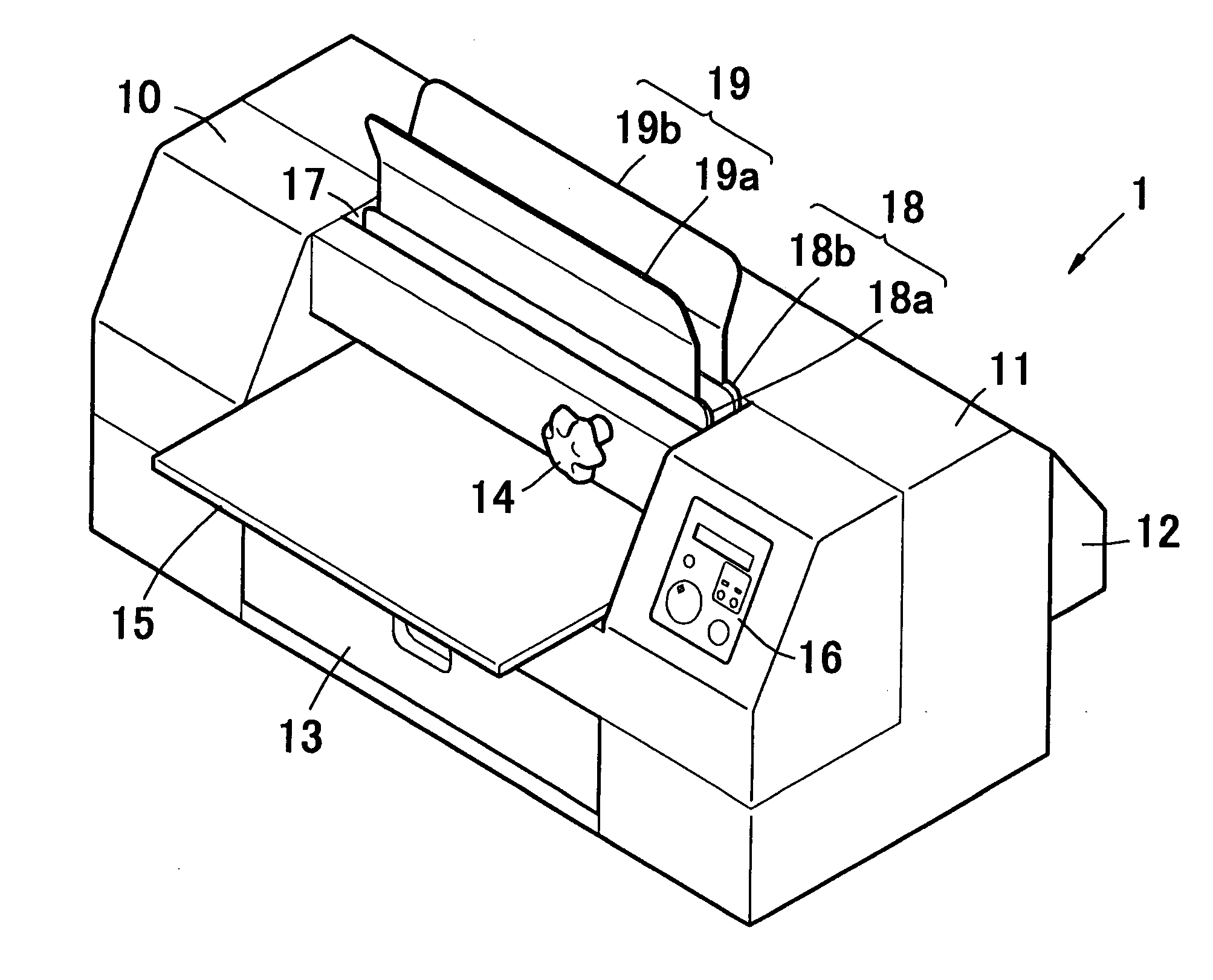

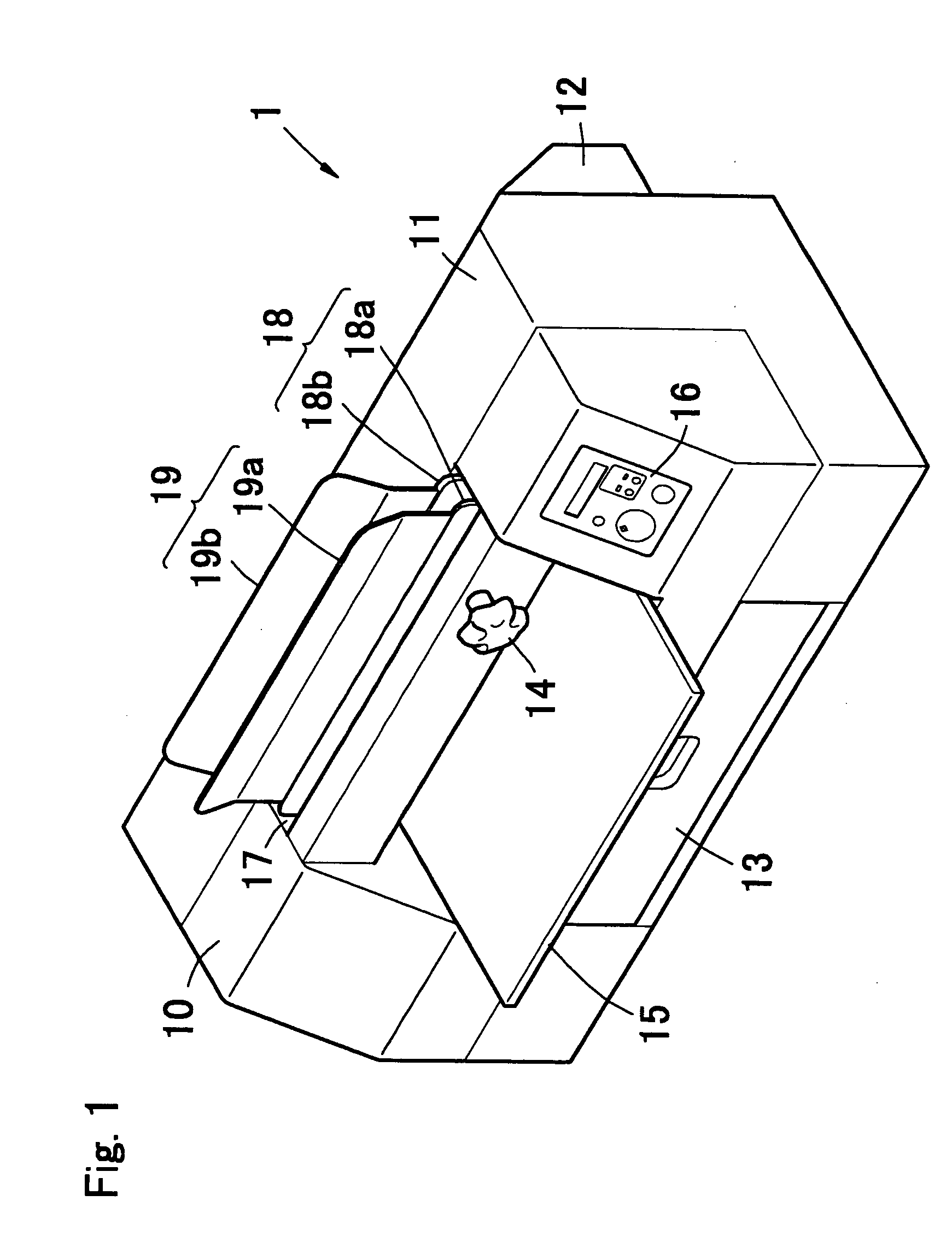

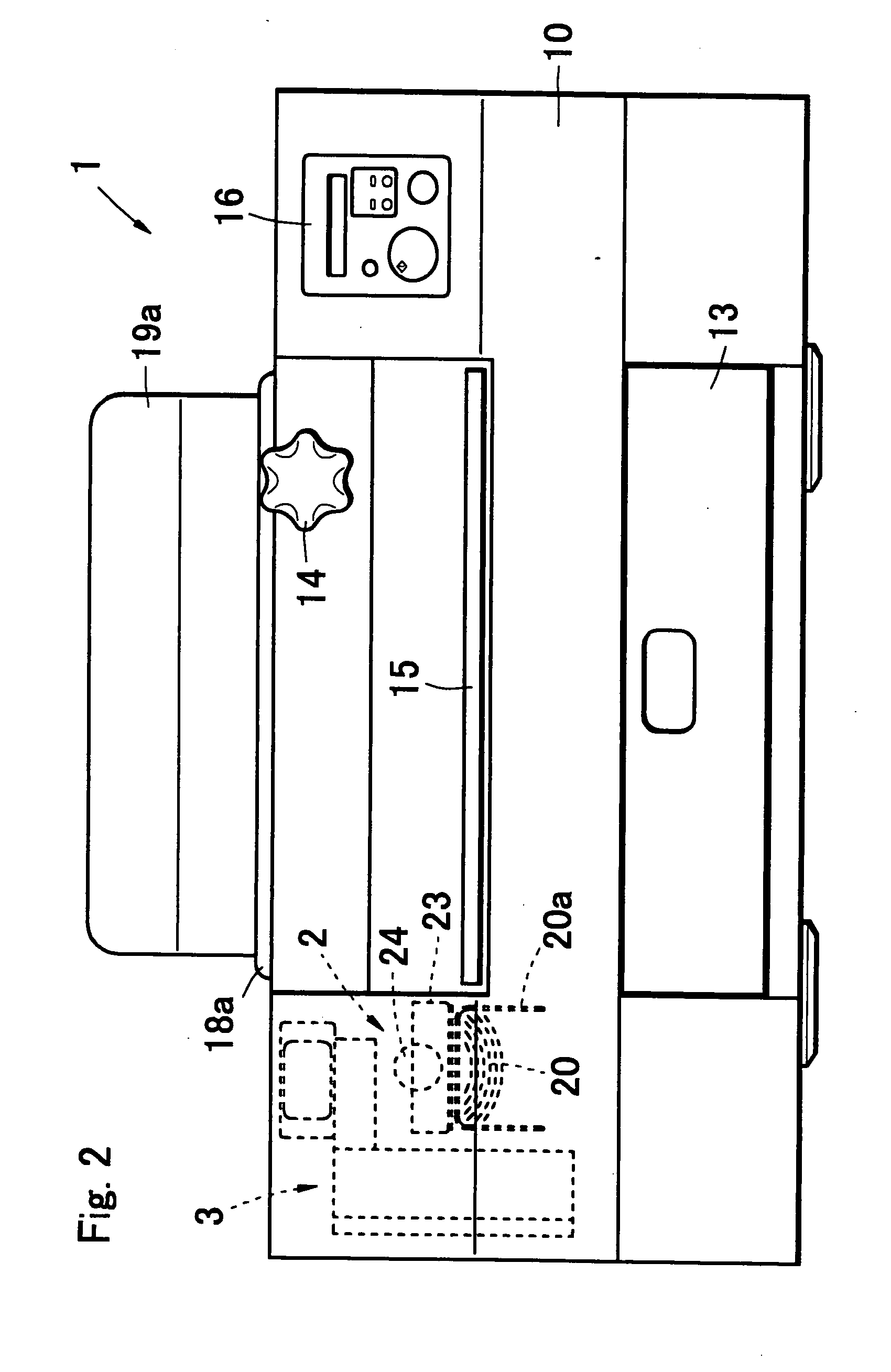

Bookbinding apparatus

InactiveUS20050238462A1Defect in finishAvoid depositionLiquid surface applicatorsCoatingsAdhesivePaper sheet

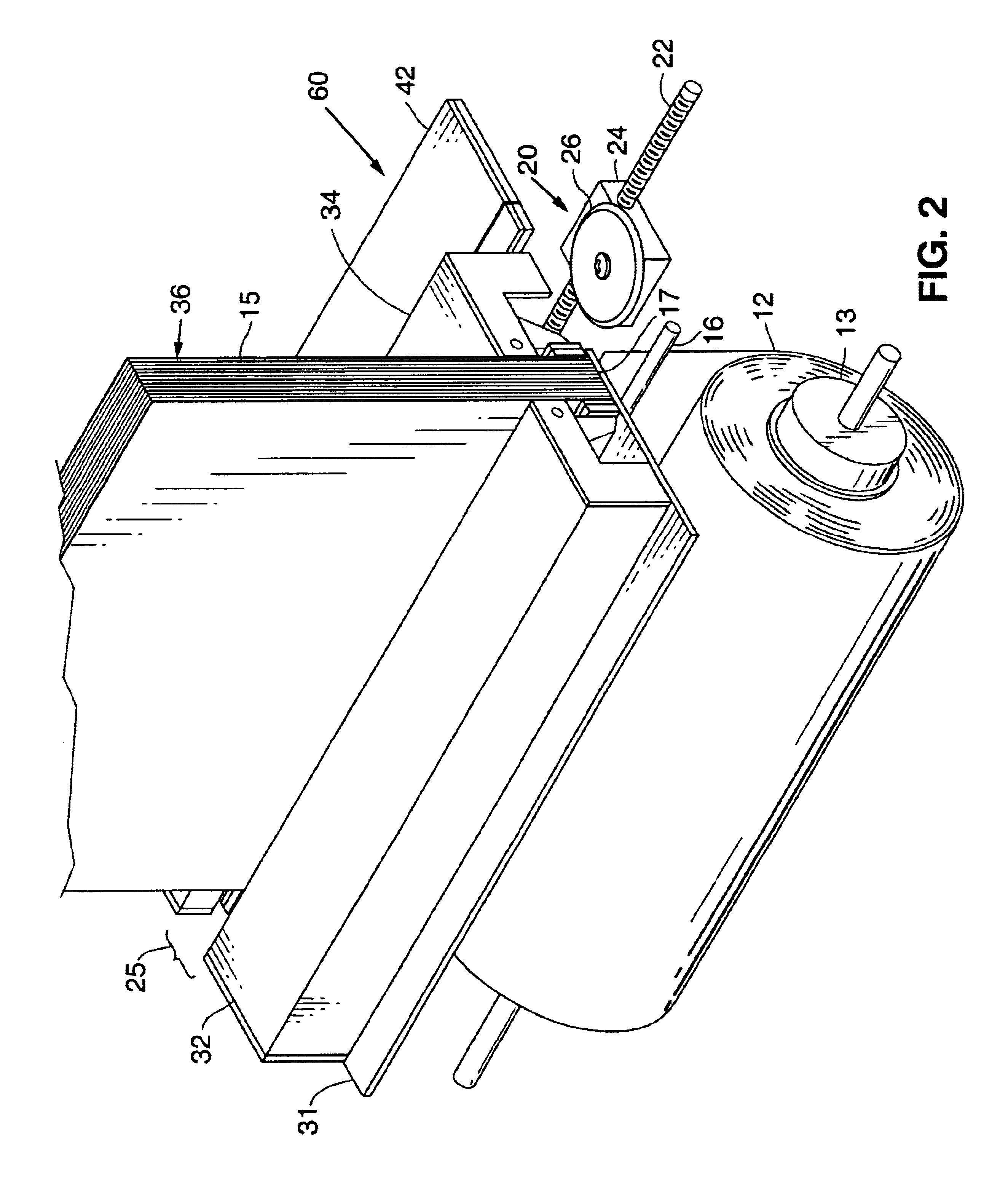

In a bookbinding apparatus (1) comprising an adhesive tank (23) for retaining therein an adhesive melted by heat, a roller (24) ratatably supported with the adhesive tank so as to dip a lower portion thereof in the adhesive retained in the adhesive tank, for applying the adhesive to a sheet stack along a lateral edge thereof, and a holding unit (18) capable of holding the sheet stack, an adhesive tank carrier (76, 78), the movably constituted adhesive tank (23) and the roller (24) are disposed at a stand-by position located outside a longitudinal end face of the sheet stack held by the holding unit (18) in a stand-by stage so that the adhesive tank is contactlessly heated to melt the adhesive, and are moved together from the stand-by position in a longitudinal direction of the sheet stack substantially through an entire area under a back face thereof in a bookbinding stage.

Owner:DUPLO SEIKO CORP

Bookbinding system, image forming apparatus, and bookbinding apparatus

By controlling the recording position of images on the cover sheet by the image recording section based on the thickness information of the bundle of sheets, image recording at the appropriate position has been made possible irrespective at the amount of trimming of the cover sheet that is trimmed to an appropriate length in accordance with the thickness of the bundle of sheets to be wrapped and bound with the cover sheet.

Owner:KONICA MINOLTA BUSINESS TECH INC

Desktop book binder having means for aligning sheets to be bound with a preformed binding material

InactiveUS6056493APrecise alignmentSimplifying binder apparatus designFilm/foil adhesivesBook coversPolytetrafluoroethyleneSheet material

Owner:ADVANCED HI TECH CORP

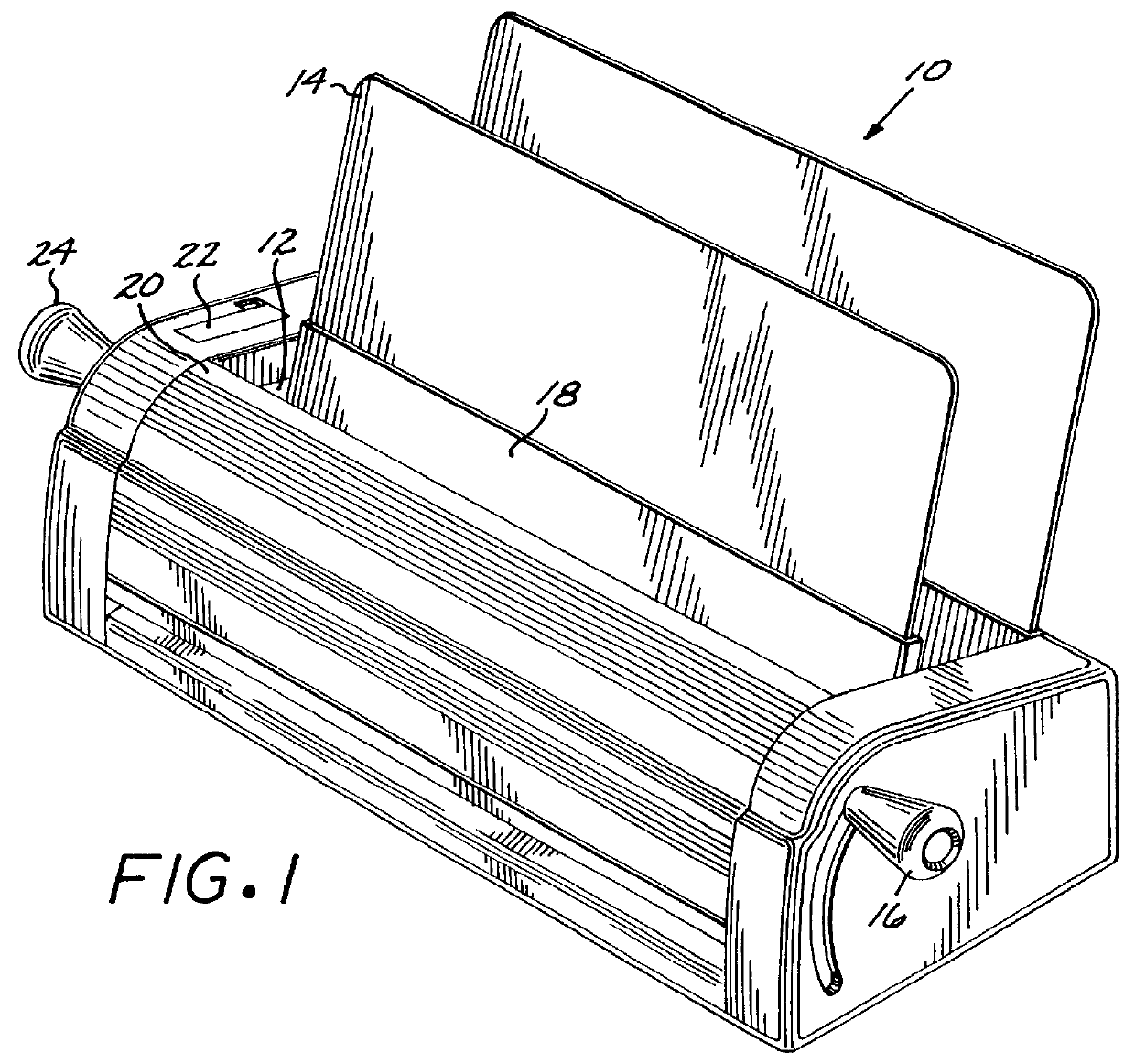

Method and apparatus for binding a plurality of sheets

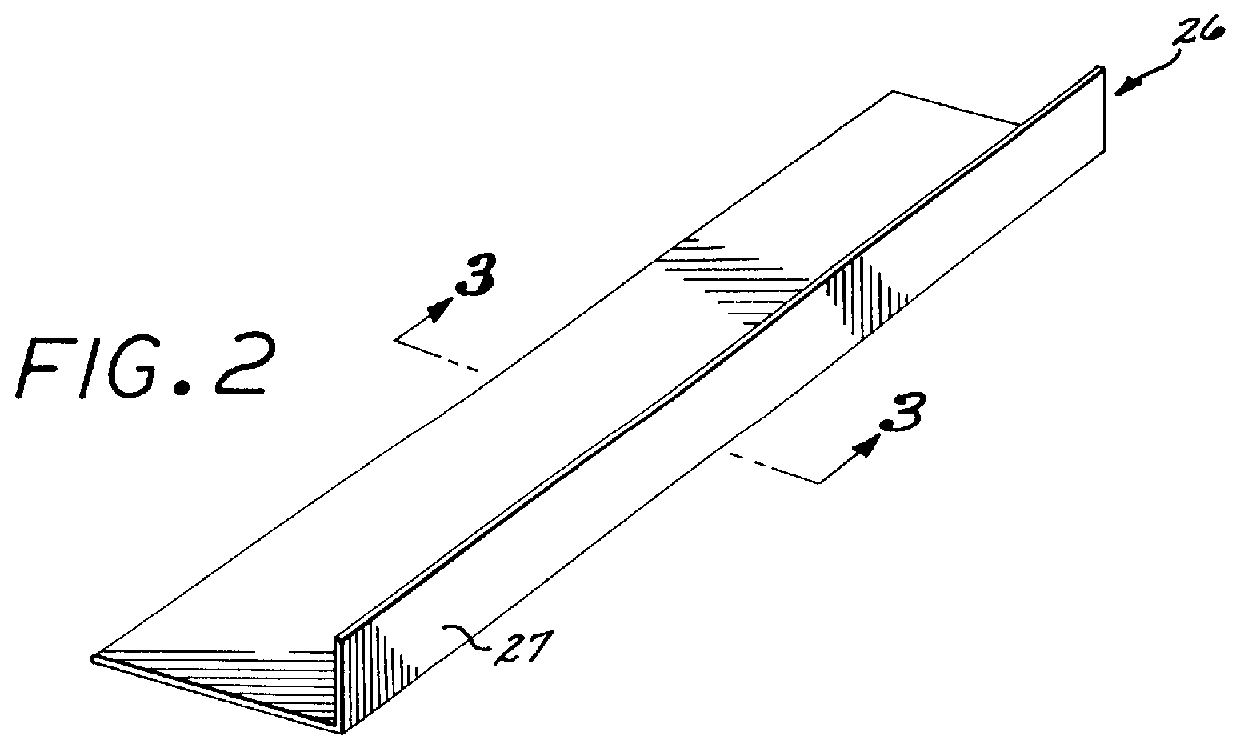

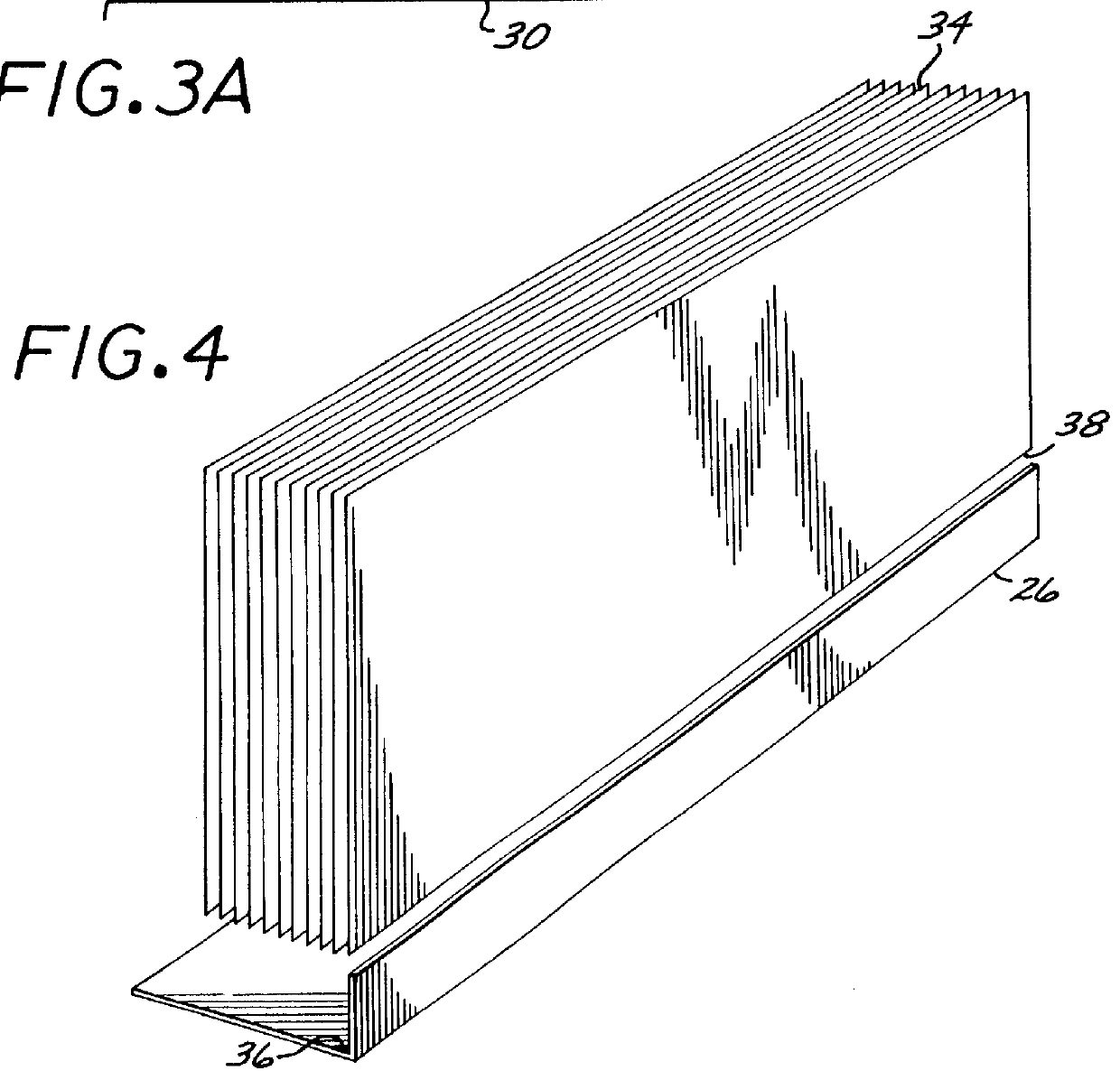

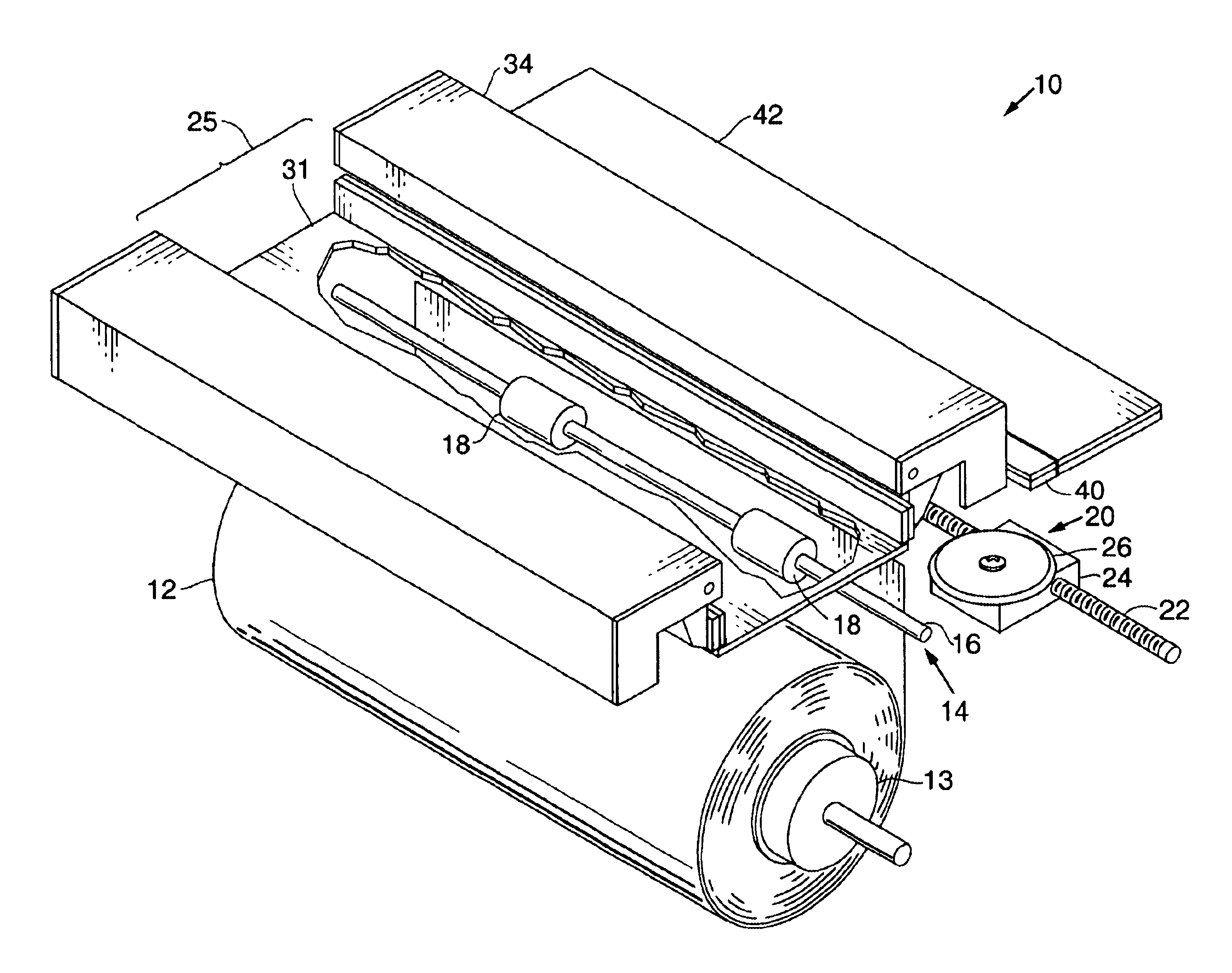

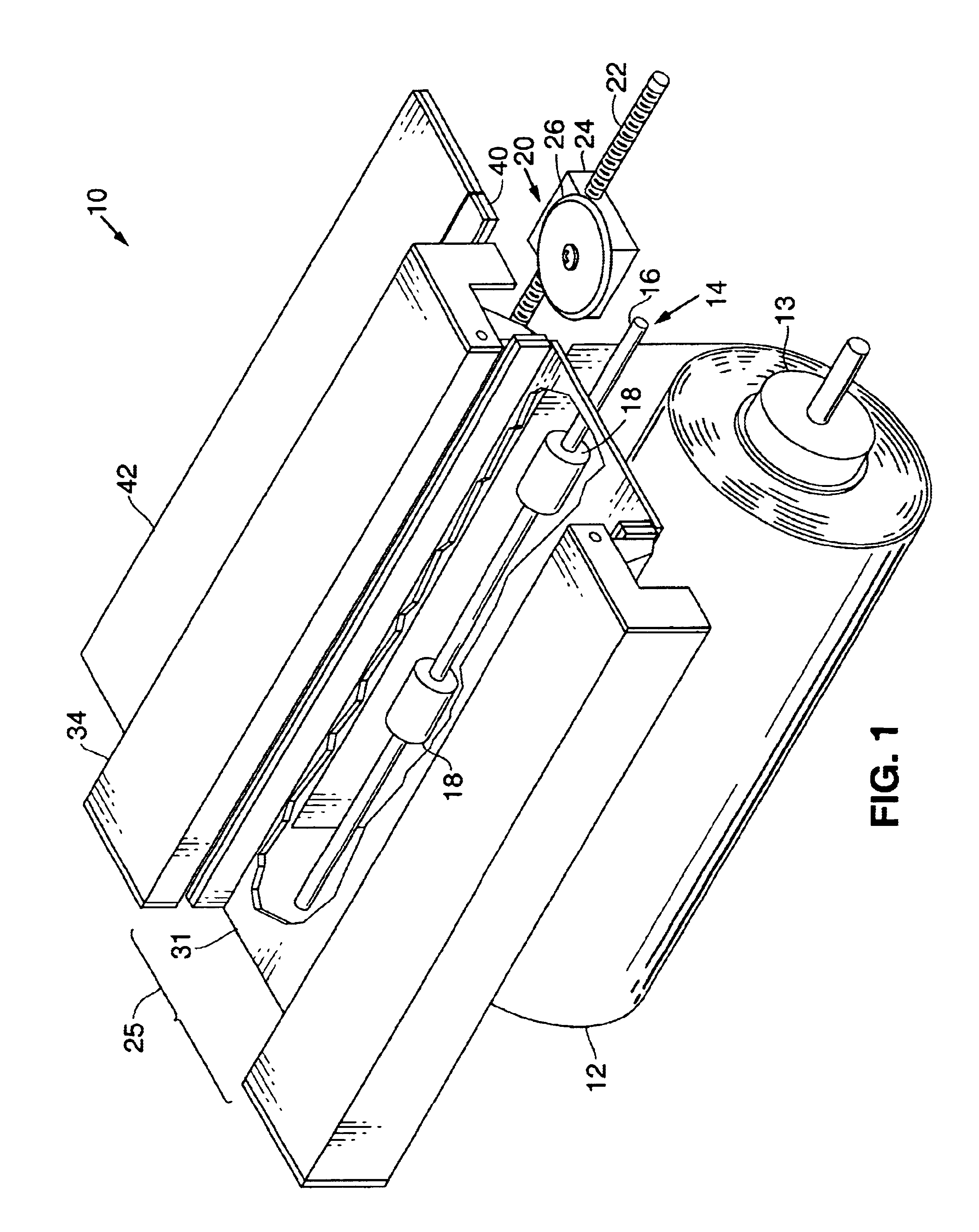

A method for binding together a plurality of paper sheets. The binding process comprises providing a book binding sheet coated on one side with hot-melt adhesive, orienting and securing sheets of paper that will comprise the book to be bound relative to the binding sheet, securing the leading edge of the binding sheet to the front of the book to be bound, severing the secured portion from the remaining binding sheet material, wrapping the binding severed strip around the spine and rear cover and heating the adhesive to produce a permanent bond with the edges of the spine and covers.

Owner:POWIS PARKER INC

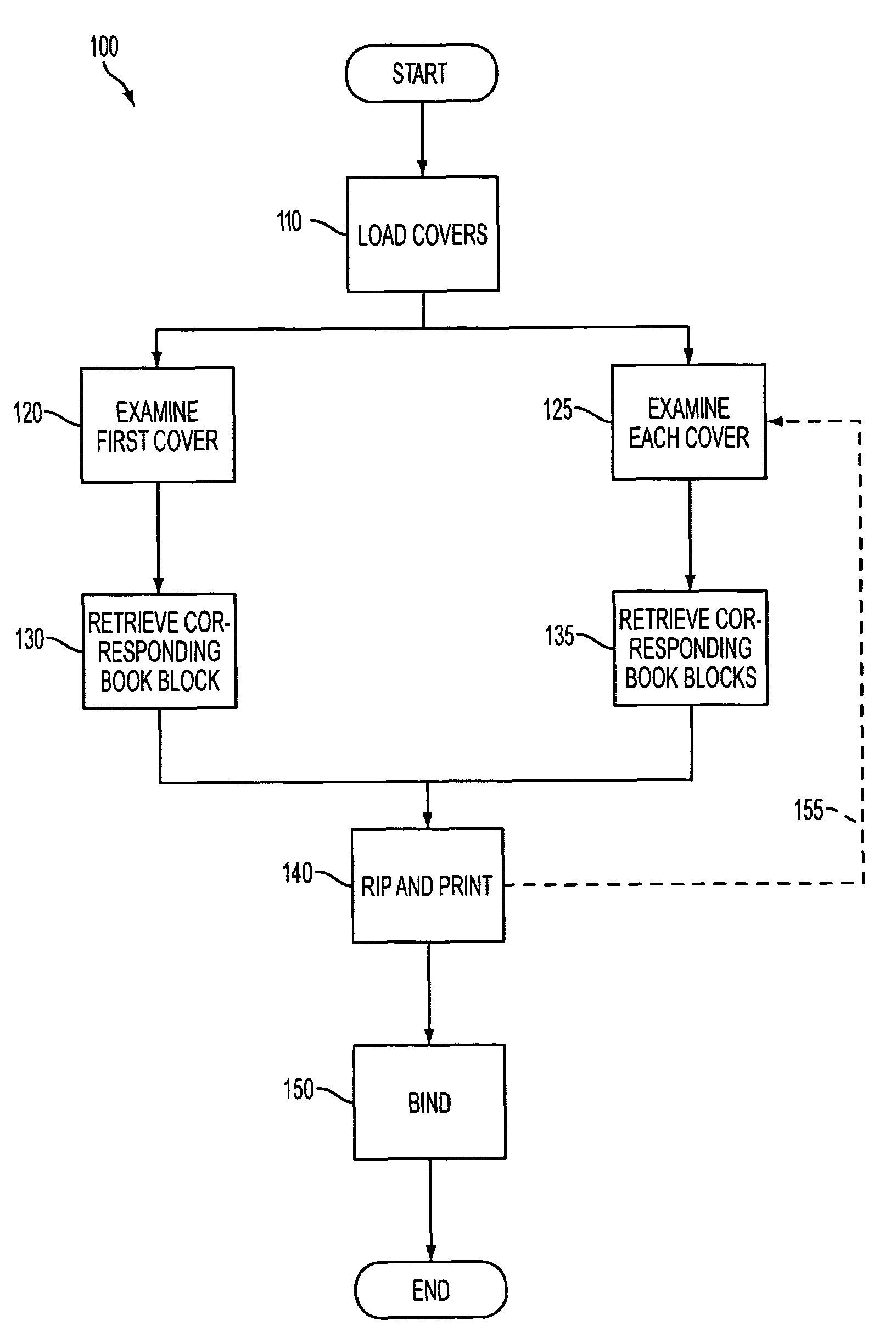

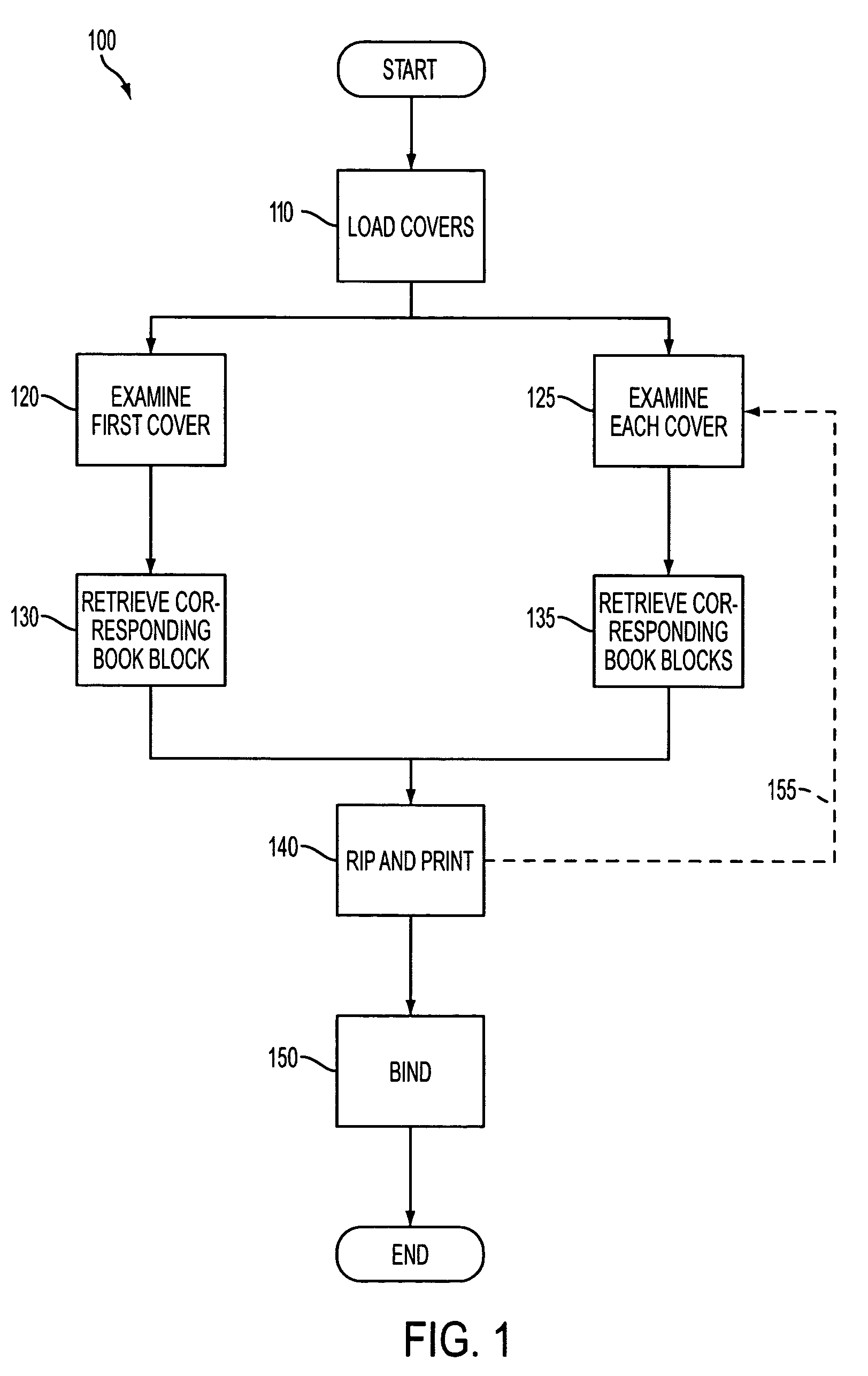

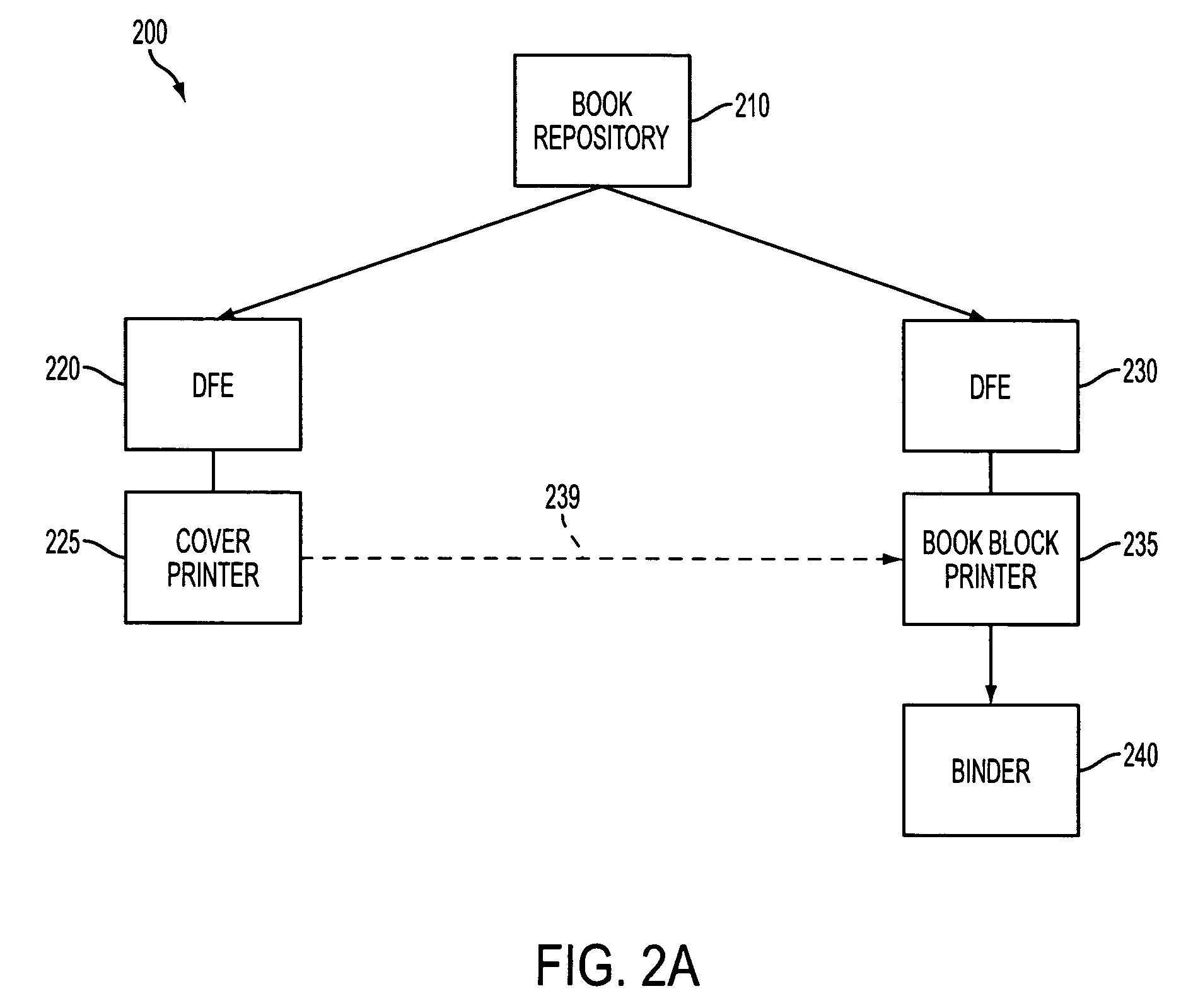

Automated cover-driven workflows for manufacturing books in a production environment

A cover-driven book production method and system are disclosed. The method of cover-driven book production includes providing a plurality of book covers. The book covers can be identified using, for example, a scanner. A book block can then be retrieved from a book repository based on the identified cover. After performing raster image processing (RIP) of the book block, copies of the book block can be printed. Finishing can be accomplished by binding the printed book blocks to the book covers using an in-line binder or off-line binder.

Owner:XEROX CORP

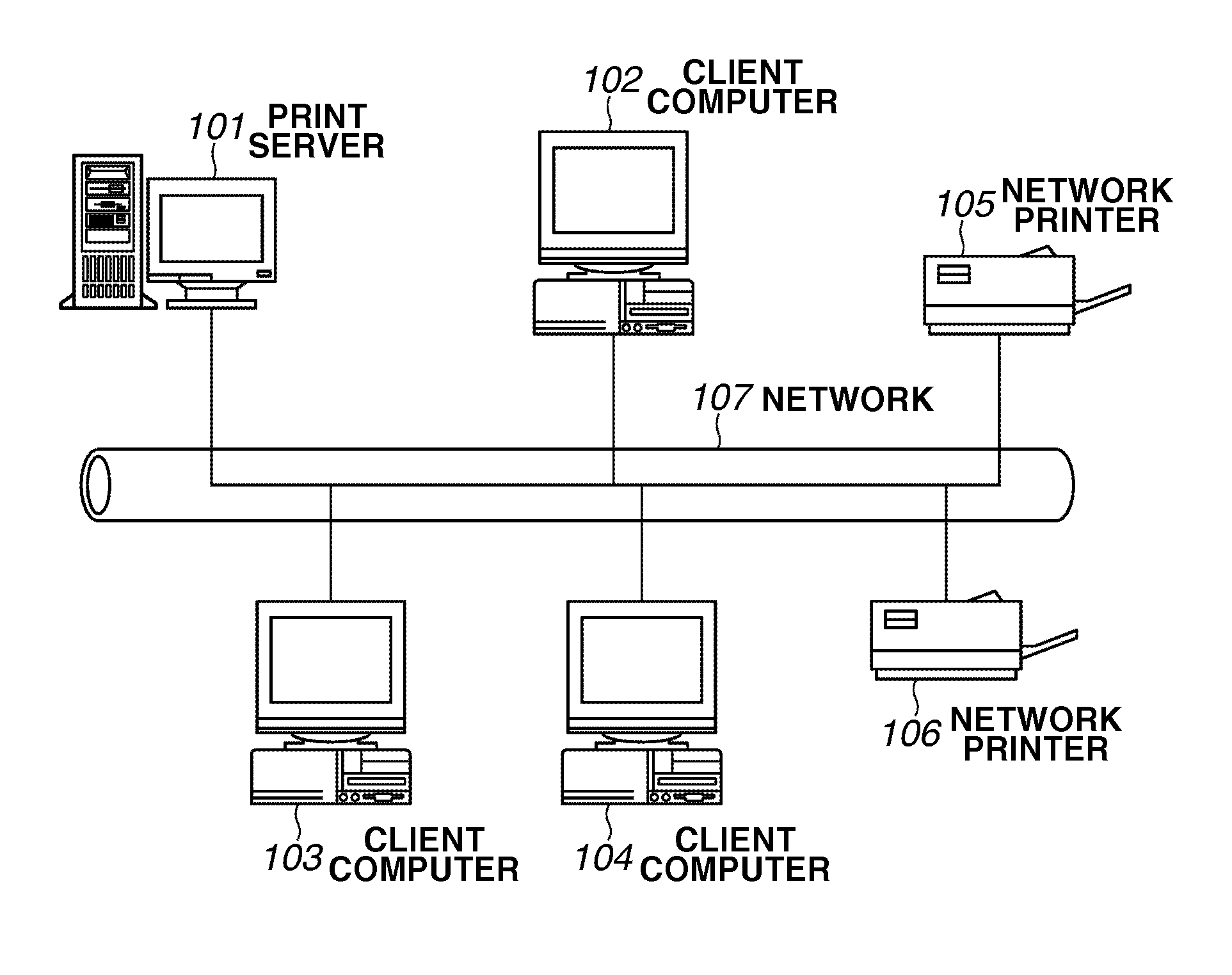

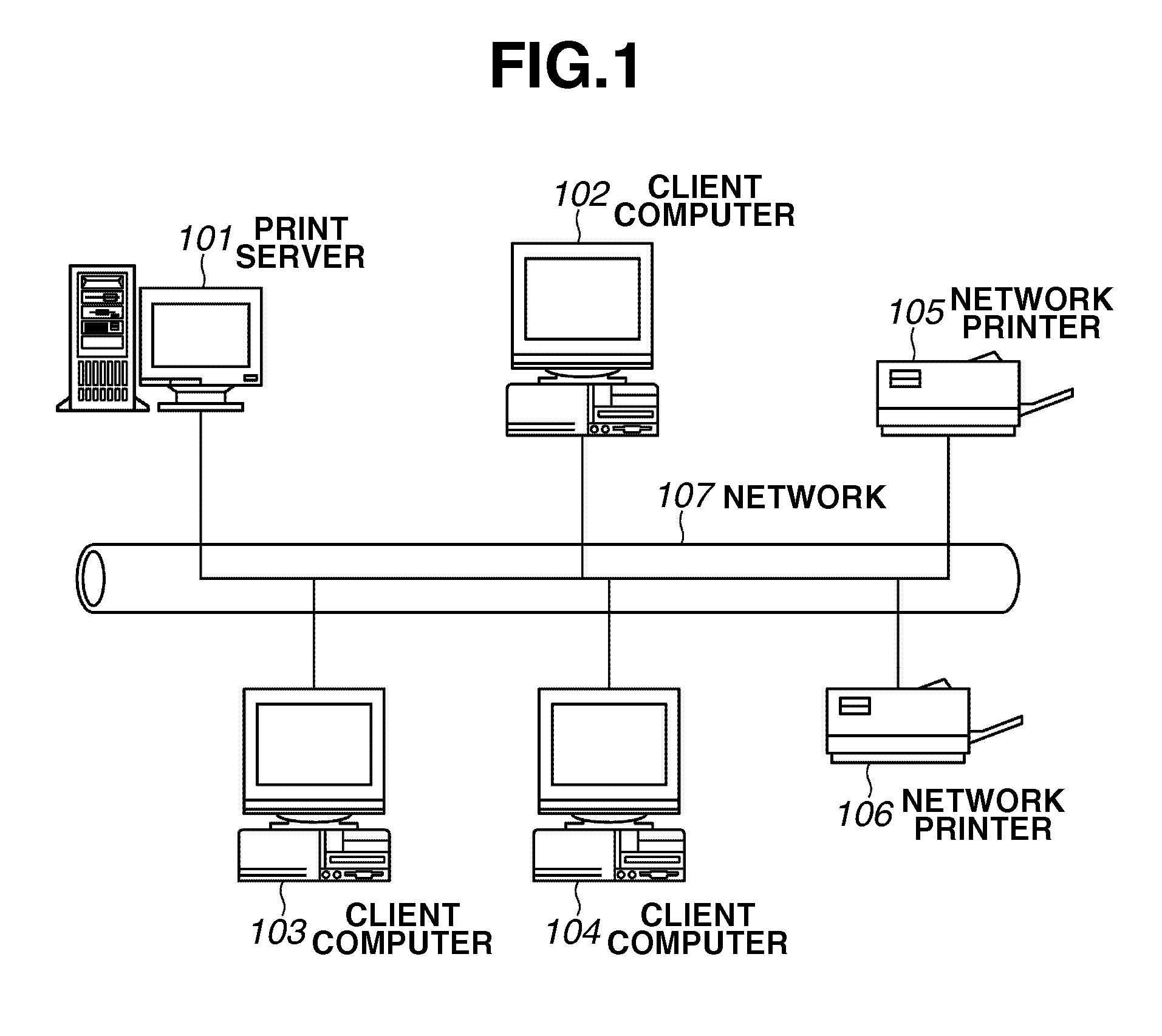

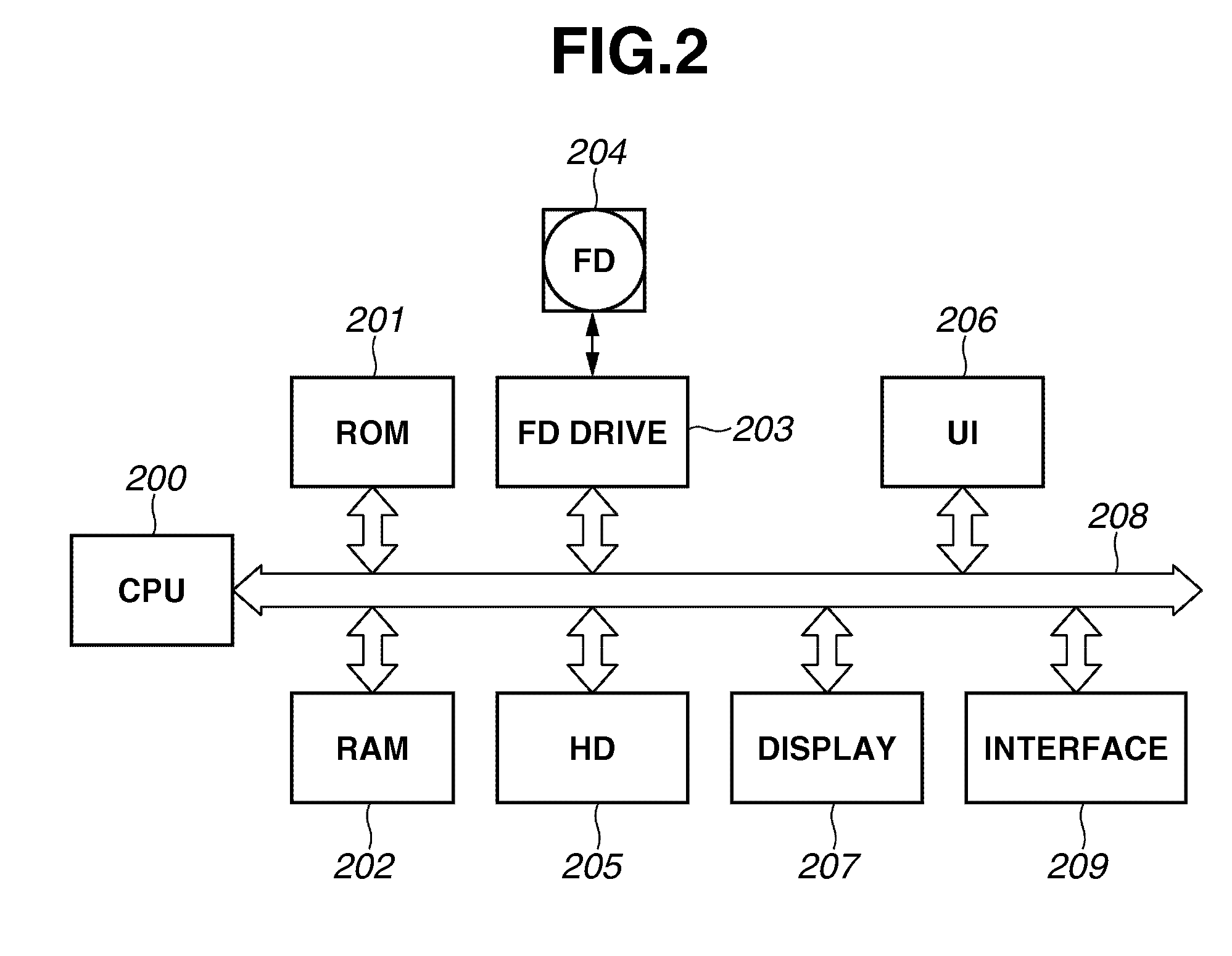

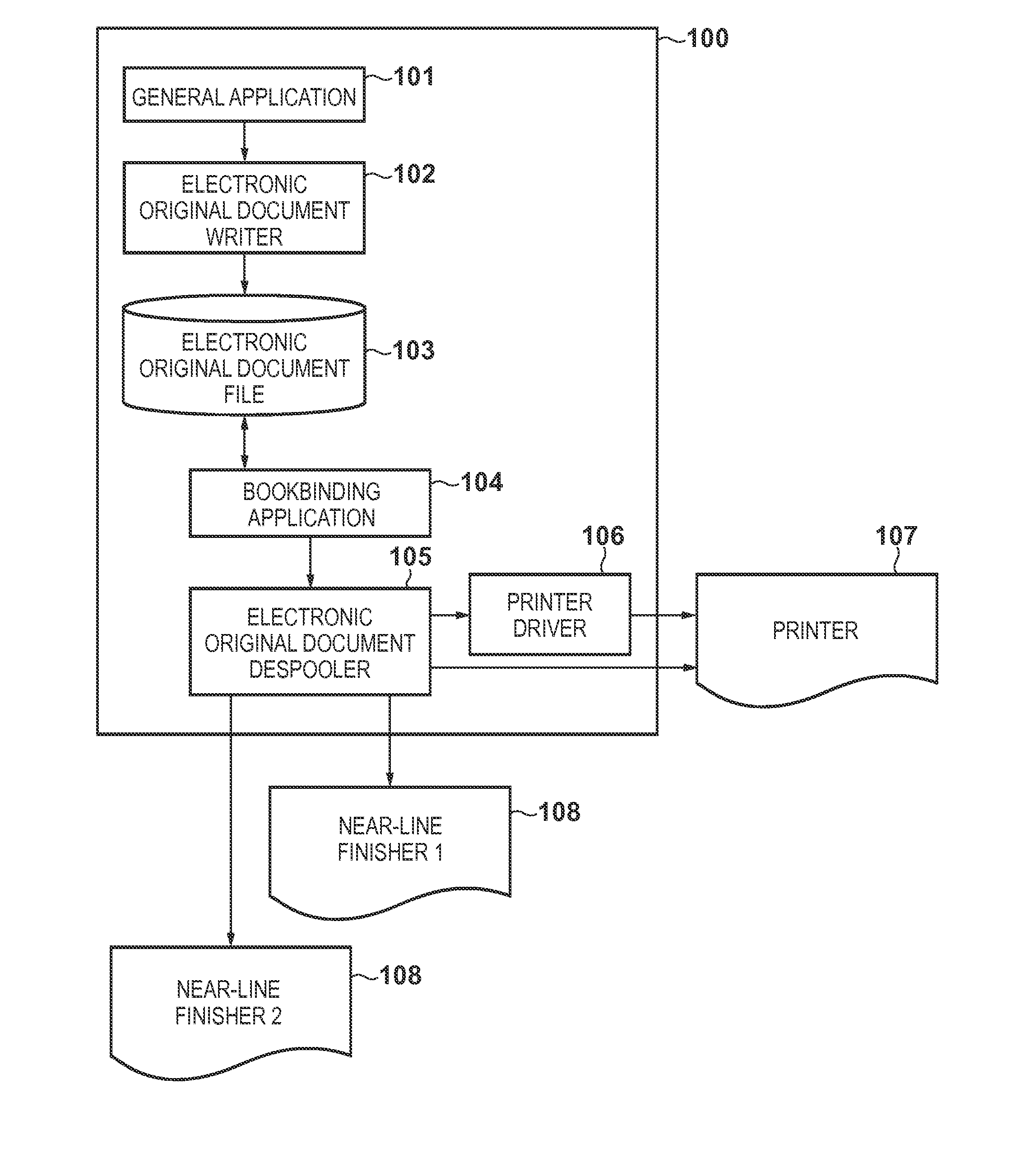

Print processing system, print processing method, and storage medium

InactiveUS20100149565A1Reduces and prevents changeExtra processingDigitally marking record carriersBookbinding casesHandling systemDatabase

A print server checks a job ticket for a print job to be processed. When a method of printing set in the printing attributes of the job ticket is case binding, a first thickness of a bookblock is calculated using the paper type set in the printing attributes. The print server calculates a second thickness of a bookblock using the paper type after a change. The print server changes the paper type set in the job ticket when the difference between the first thickness and the second thickness is within a permissible range.

Owner:CANON KK

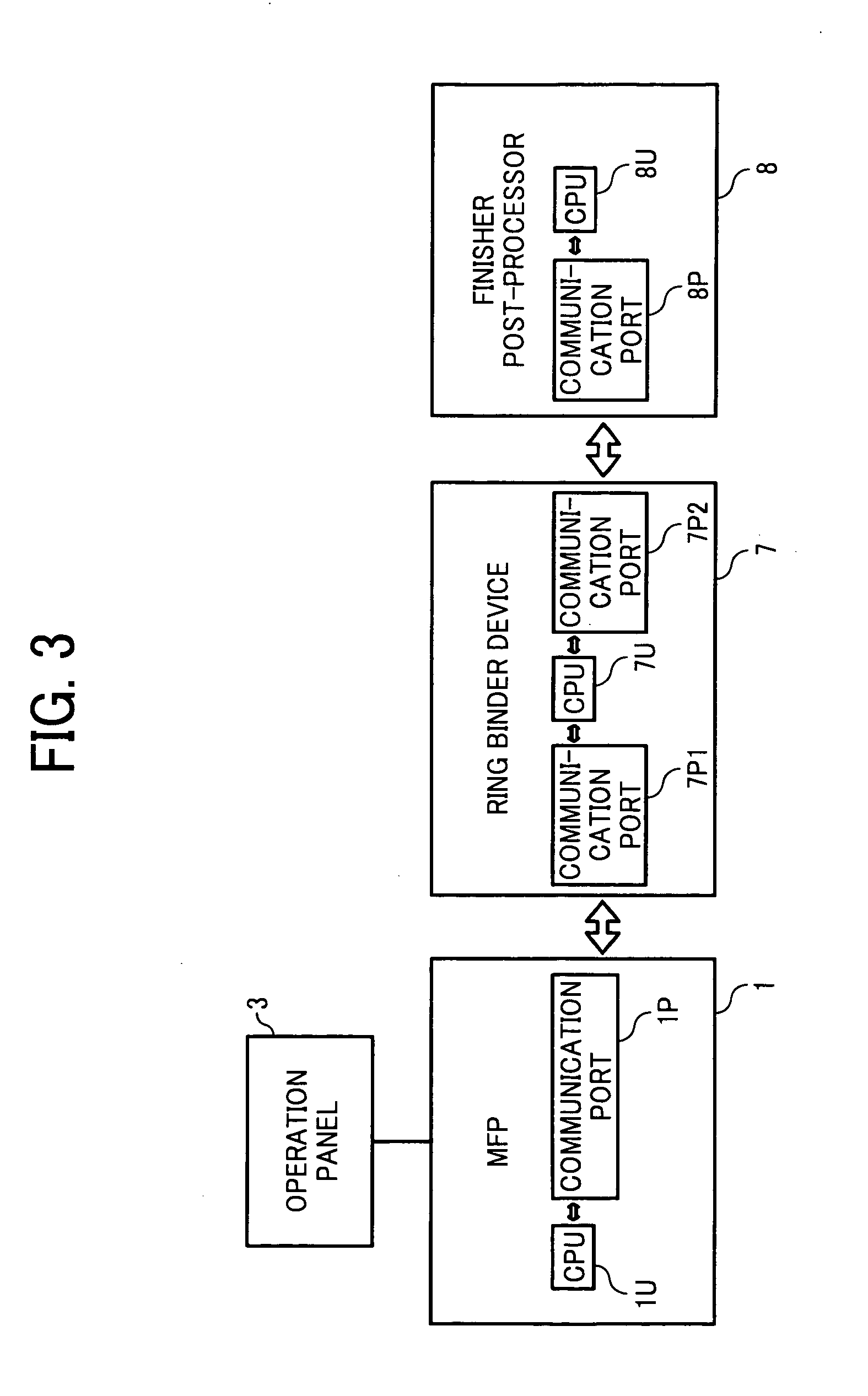

Bookbinding system, bookbinding method, and computer program product

InactiveUS20090263212A1Solve problemsElectrographic process apparatusMetal working apparatusPunchingEngineering

A bookbinding device receives a sheet on which an image is formed from an image forming apparatus. In the bookbinding device, a punching unit performs a punching process on a sheet; an aligning unit aligns a plurality of sheets on which holes are punched; and a ring binding unit mounts, in the holes of the sheets aligned by the aligning unit, a ring-shaped binding tool to create a booklet. A prohibiting unit, if a sheet received from the image forming apparatus is a punched sheet having a hole thereon, causes the punching unit not to perform the punching process on the punched sheet.

Owner:RICOH KK

Bookbinding apparatus and image forming system

A bookbinding apparatus for providing wrapping-binding of a booklet by bonding a cover sheet on the spine portion of a sheet bundle to wrap the sheet bundle with the cover sheet, wherein the sheet conveyance path of the bookbinding apparatus includes a notch forming device to form notches on the end to be coated with adhesive when the sheet is subjected to bookbinding process.

Owner:KONICA MINOLTA BUSINESS TECH INC

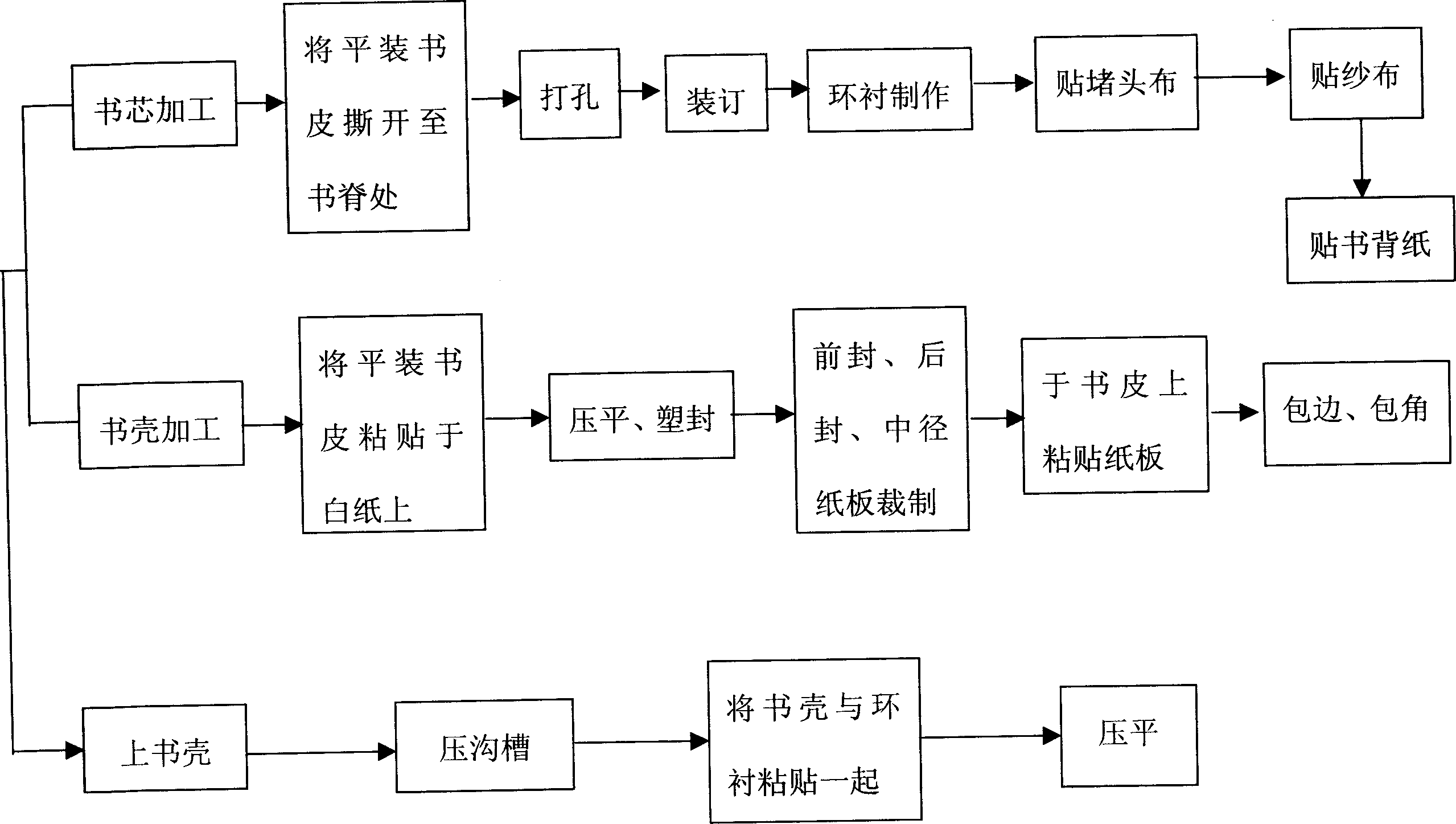

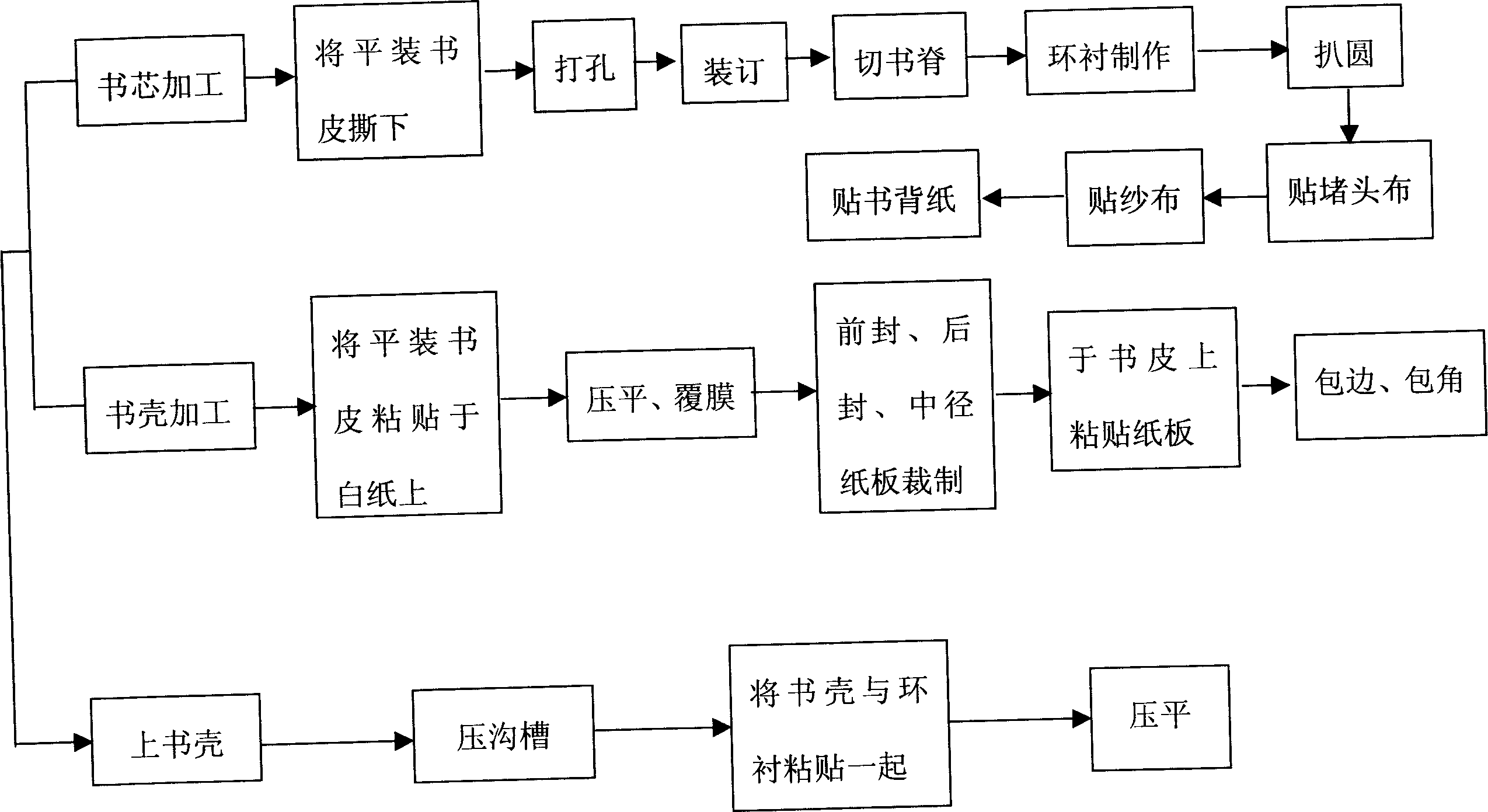

Method for changing paperback to exquisitely binding book

InactiveCN1865018AGood effectMeet quality requirementsBookbinding casesBook rebindingPulp and paper industryPaper sheet

The invention relates to a method for changing the soft-covered book into hard-cover book, which comprises three steps as processing book core, processing book cover, and mounting the book cover. Wherein, first, removing the cover of soft-covered book; then making holes, binding, preparing annular liner, adhering block cloth, adhering gauze, adhering book back paper to complete processing the book core; the second step is that adhering the cover on the white paper, then flattening the coat film, cutting the front and back seal, and the middle paper sheet, then folding edge and packing corner; the third step comprises pressing groove, adhering annular liner and flattening. The inventive method can overcome the defects of present technique, with simple operation and lower cost.

Owner:王超 +1

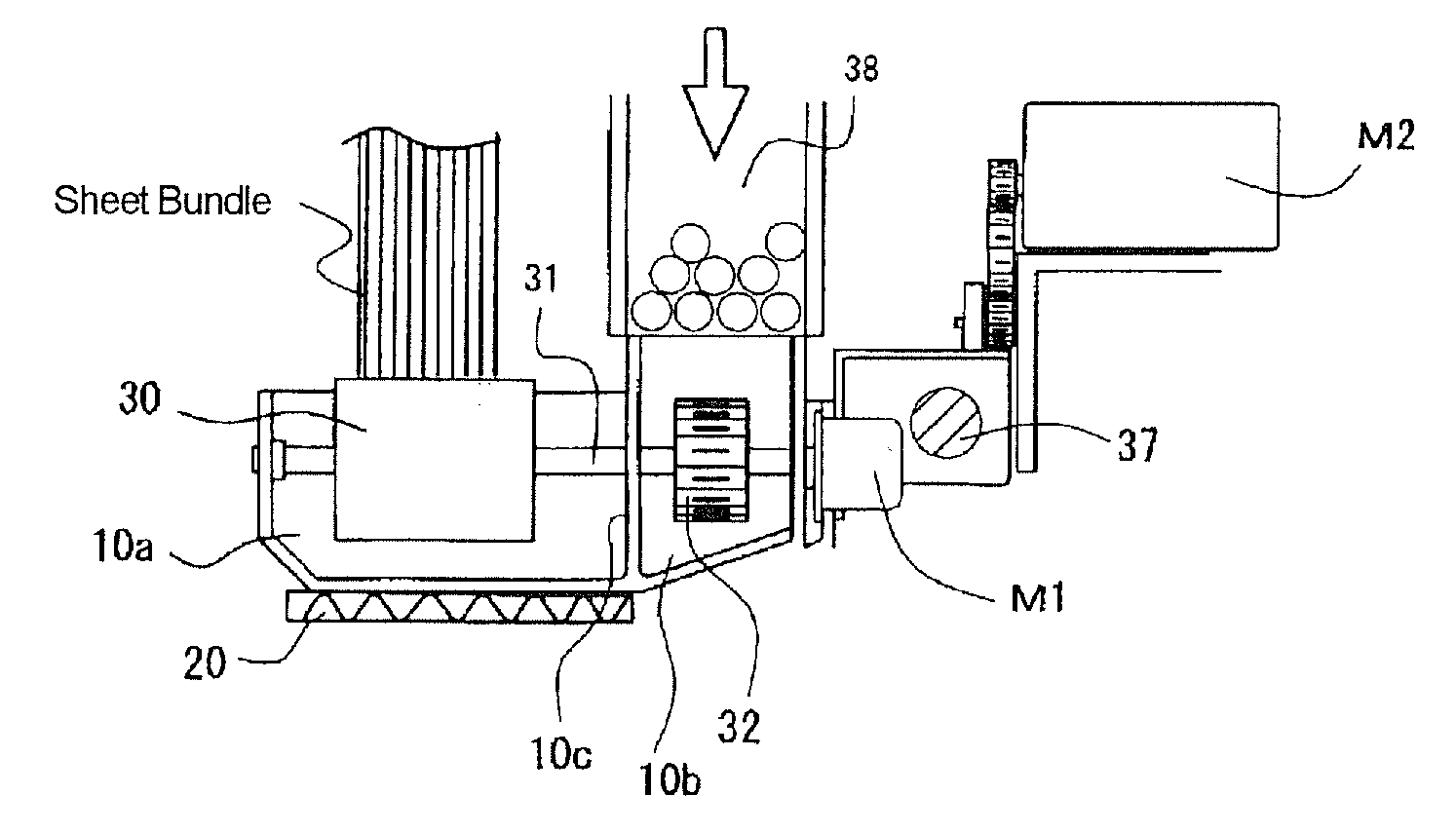

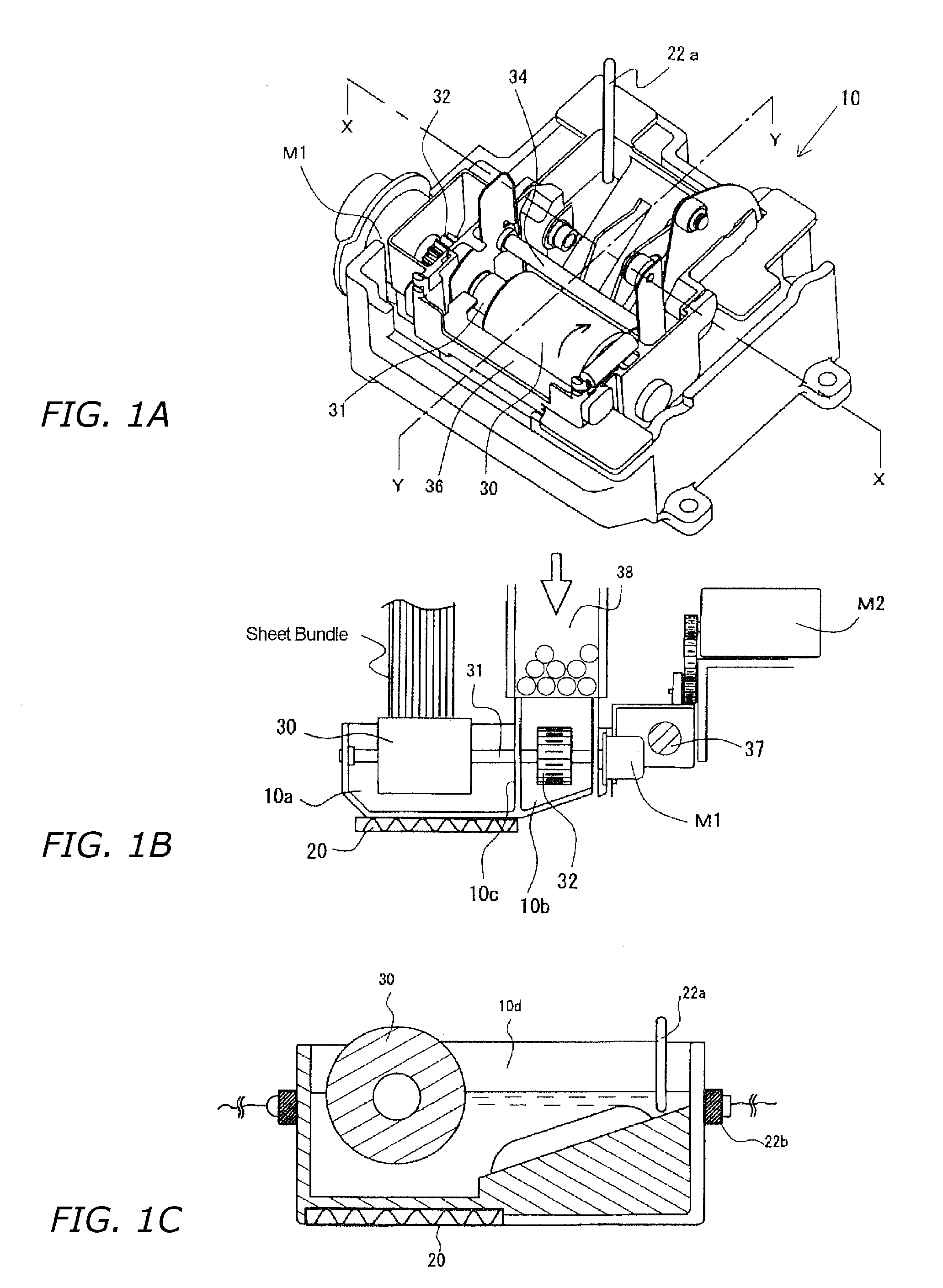

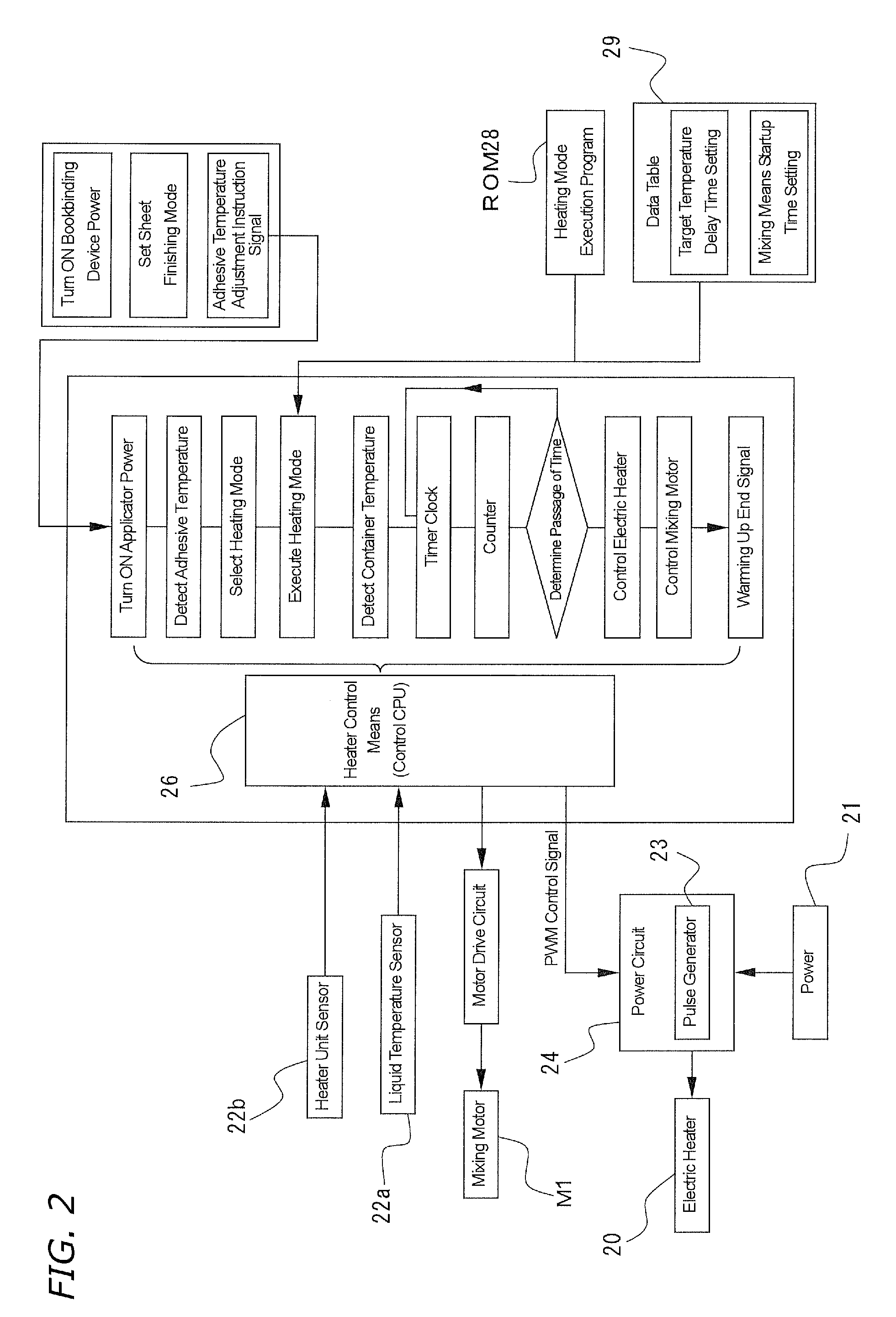

Hot-melt Adhesive Temperature Control Method, Applicator Therefor, and Bookbinding Apparatus

ActiveUS20070193511A1Increase in sizeWarm-up for machine operation in a comparatively short amount of timeLiquid surface applicatorsManual label dispensersTemperature controlProcess engineering

Bookbinding apparatus adhesive applicator accurately, briefly controls adhesive temperature to a set value by selecting, in accordance with adhesive initial temperature, one of a plurality of temperature-controller heating modes defining different supply powers and supply durations for supplying power to an adhesive-container heater to control its heating temperature. A sensor detects the temperature of the adhesive in the container at applicator start-up, or on restarting a post-standby applicator. In accordance with the detected temperature, one of the heating modes is selected to heat the adhesive. The applicator warm-up time is thus set in response to the state of the adhesive: If solidified, the adhesive is heated and melted in a maximum supply-power, supply-duration mode; if low-temperature liquefied at, it is heated and melted in a second-magnitude supply-power, supply-duration mode; and if the adhesive temperature is high, it is heated and melted in a minimal supply-power, supply-duration mode.

Owner:NISCA KK

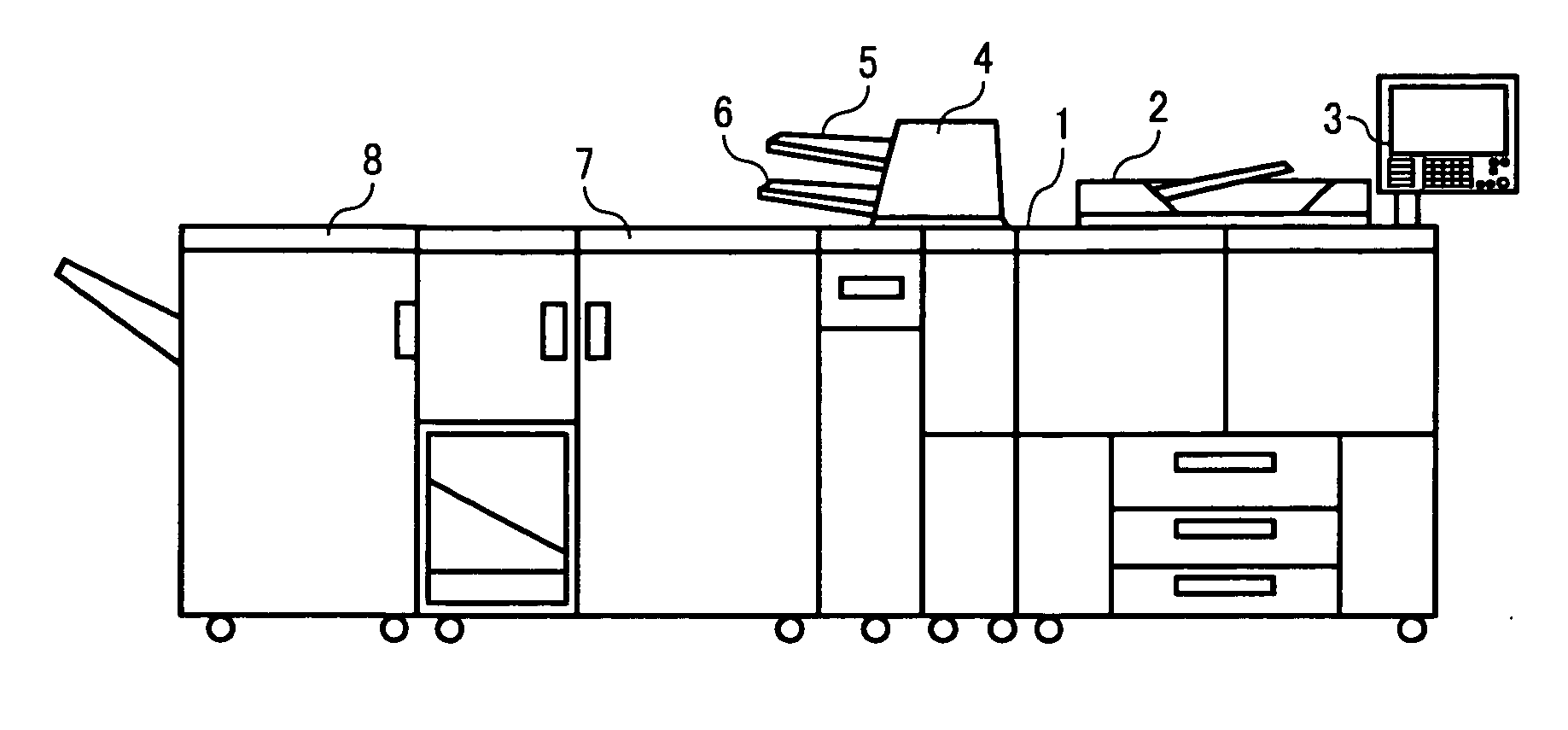

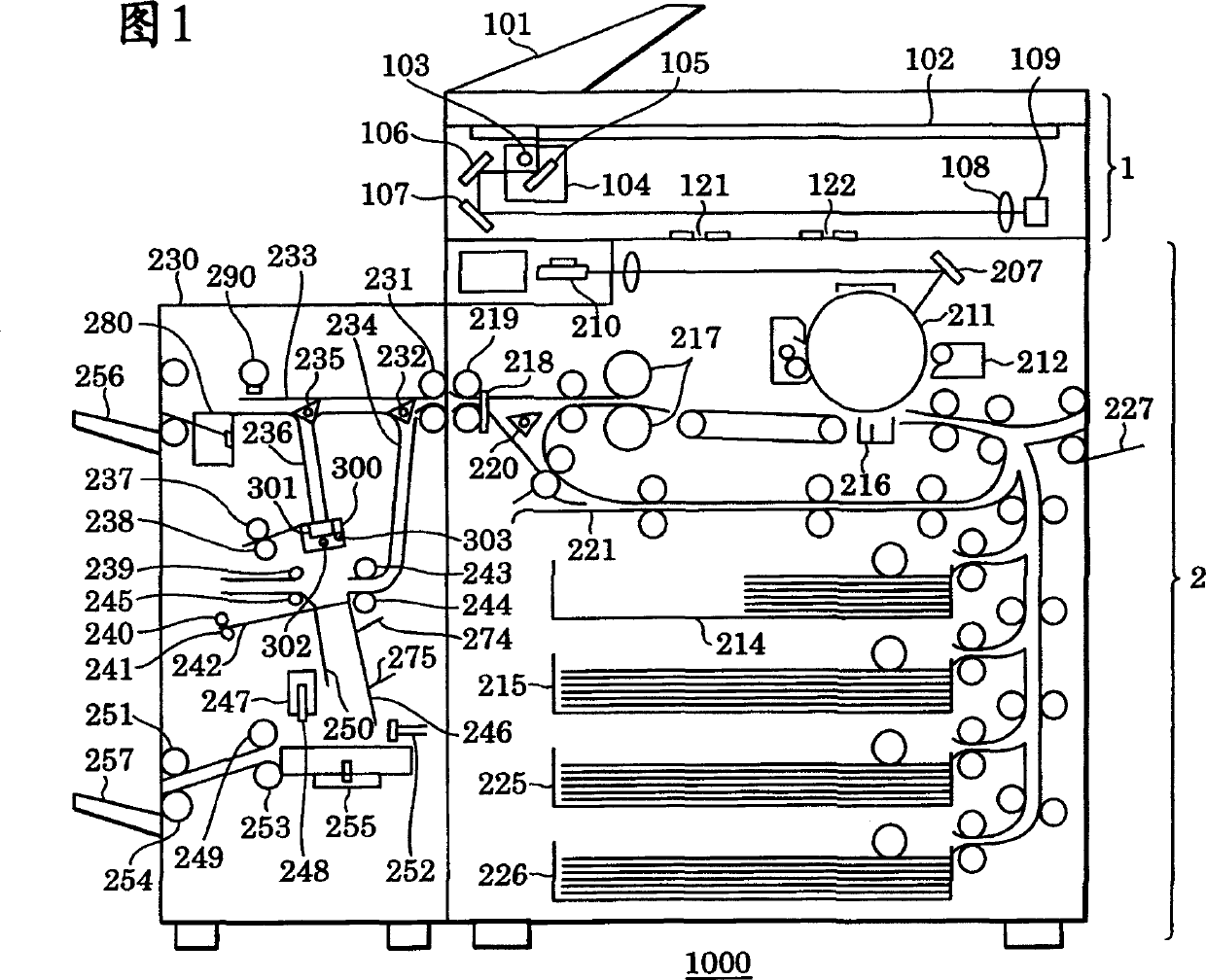

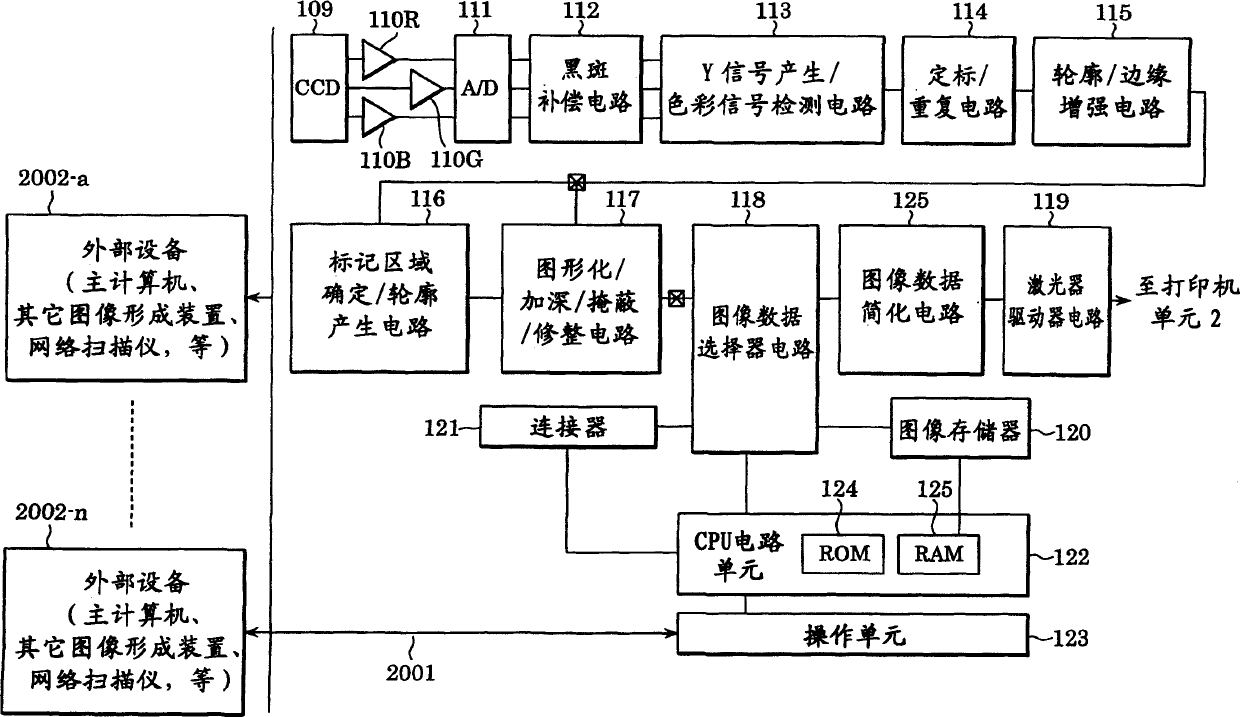

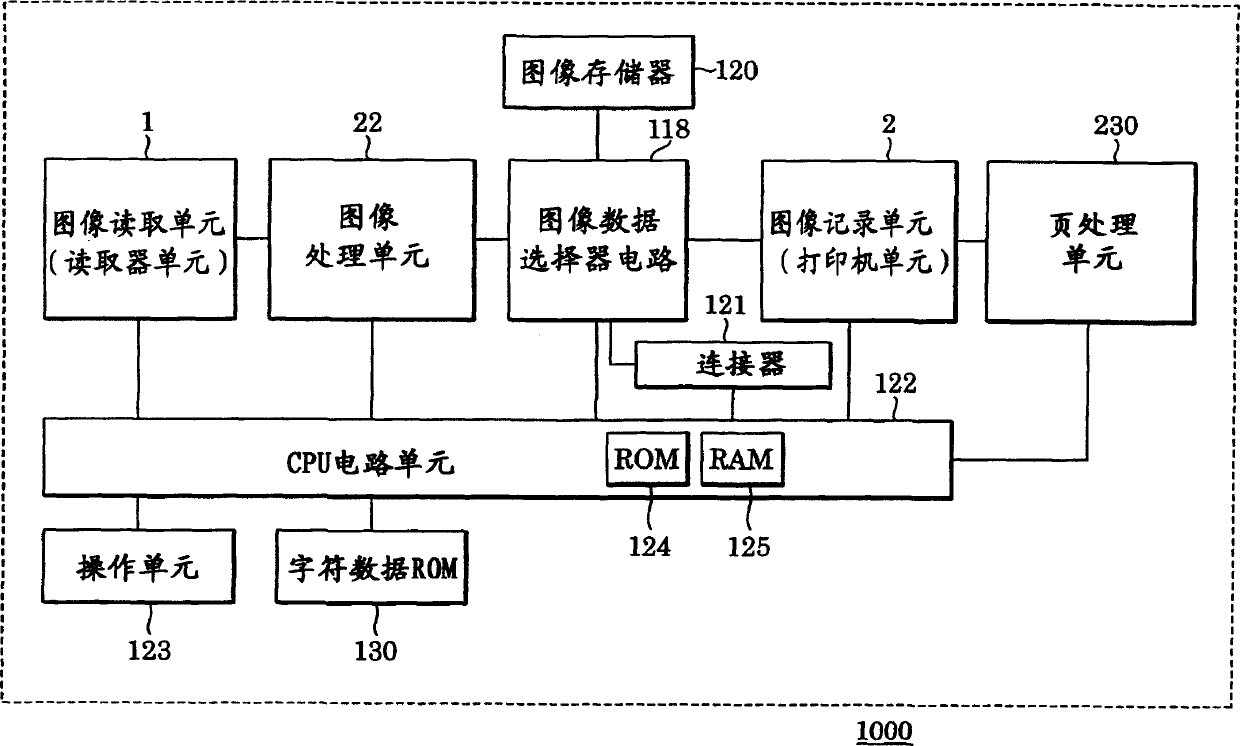

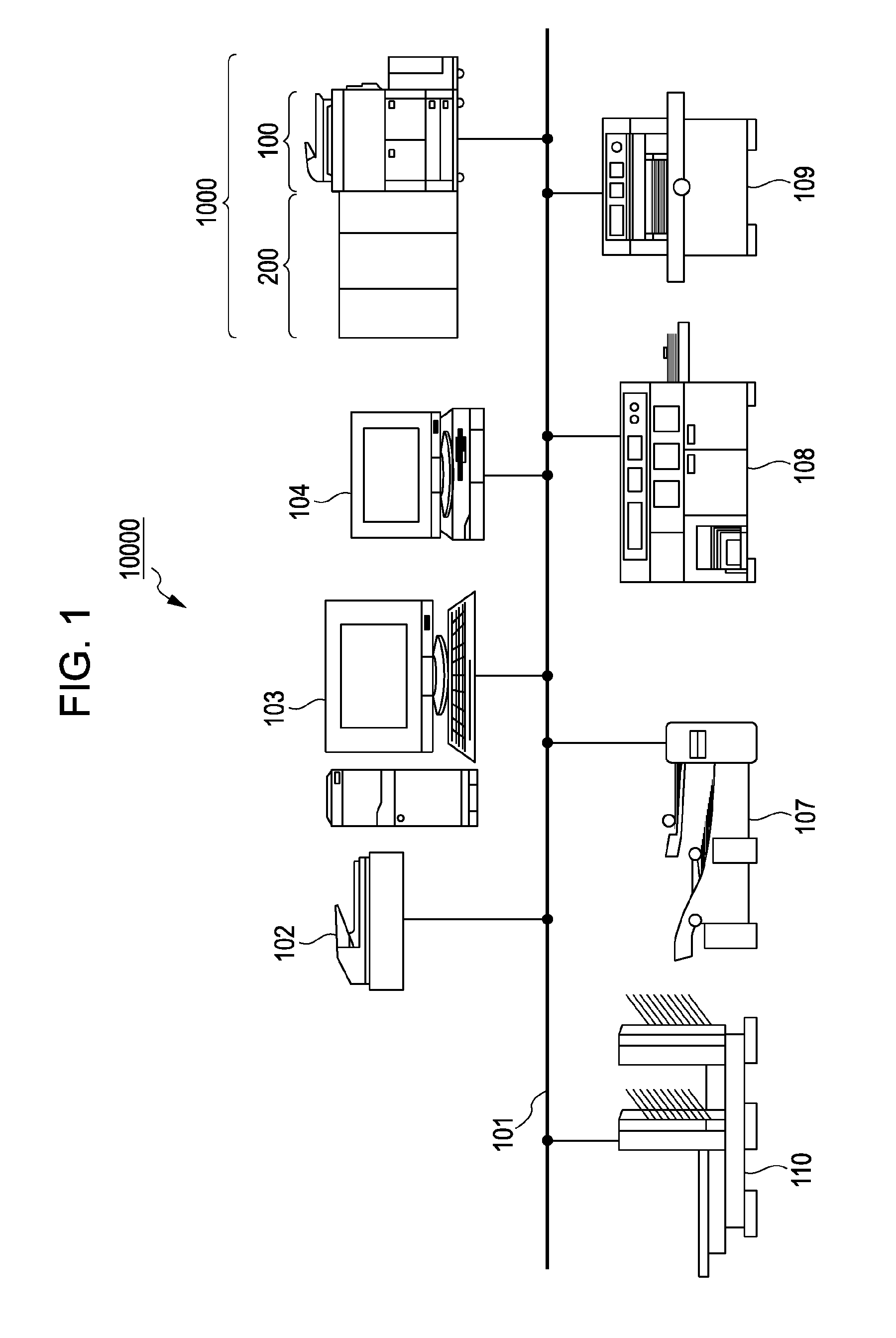

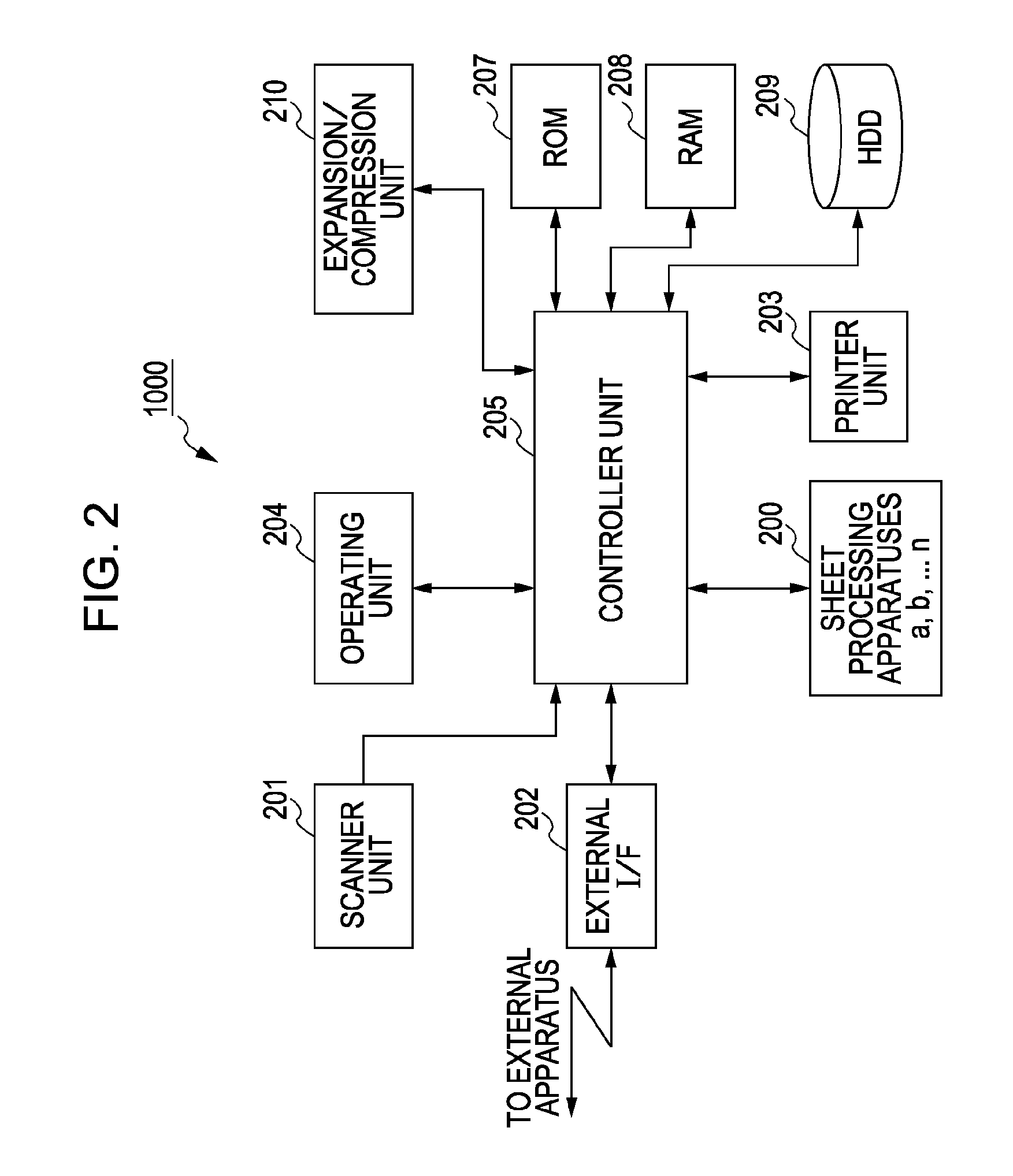

System, control method, recording medium and program for an image forming apparatus

ActiveCN1702565ASolve the uneasy usabilityDemand processingElectrographic process apparatusCasing-inImage formationEngineering

An image forming system has an image forming apparatus which has a printing unit which can perform a printing process of data of a storage unit which can store data of a plurality of jobs and which has a conveying unit which can convey a sheet from the print unit to a sheet processing device which can perform sheet processing, including at least a gluing process, for sheets from the printing unit, the system comprising: a controller adapted to permit a predetermined process related to the gluing process when the job to be processed is a job which meets a predetermined condition, and to inhibit the predetermined process related to the gluing process when the job to be processed is not a job which meets the predetermined condition, thereby overcoming obstacles to realization of an image forming system capable of a gluing process.

Owner:CANON KK

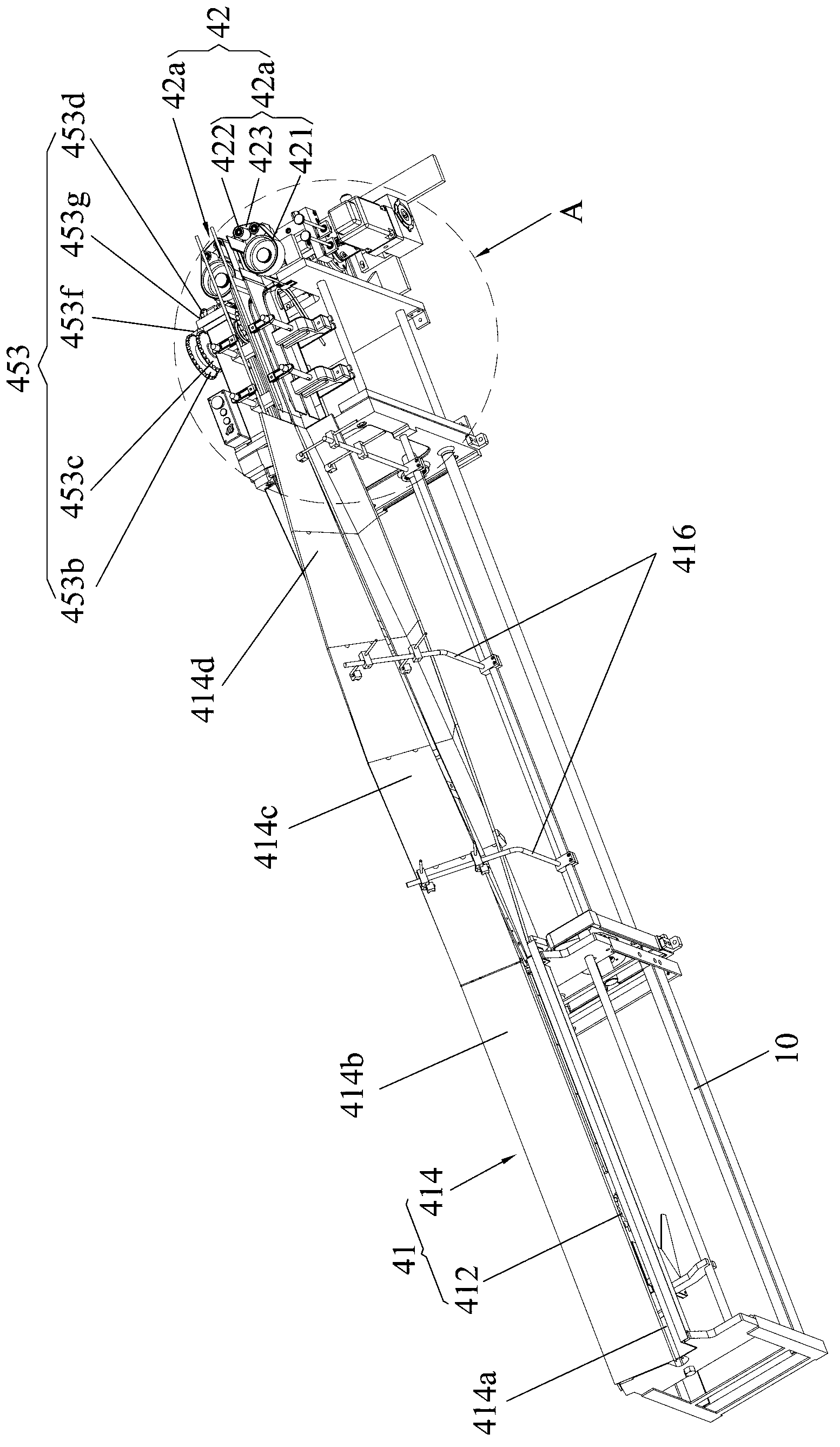

Automatic spine covering machine

InactiveCN102795020AEnsure consistencyQuality improvementCasing-inBookbinding adhesiveMechanical engineeringAutomatic testing

The invention provides an automatic spine covering machine electrically connected with a controller. The automatic spine covering machine is used for gluing a book, covering a piece of gauze and cutting the gauze covered on the book. The automatic spine covering machine comprises a frame, a gluing gauze-covering mechanism, a gauze cutting mechanism and a book conveying mechanism, wherein the book conveying mechanism is provided with a conveying channel for conveying the book; the gluing gauze-covering mechanism and the gauze cutting mechanism are arranged on the frame in turn and are both corresponding to the conveying channel; the book conveyed by the book conveying mechanism passes through the gluing gauze-covering mechanism and the gauze cutting mechanism in turn; the gluing gauze-covering mechanism is used for coating glue on a spine of the book conveyed by the book conveying mechanism and covering the gauze on the book; and the gauze cutting mechanism is used for cutting the gauze covered on the book conveyed by the book conveying mechanism. Thus, the automatic spine covering machine provided by the invention can be used for automatically gluing the book, covering the gauze and cutting the gauze covered on the book, so as to increase the working efficiency and the processing quality.

Owner:东莞城市装钉器材有限公司

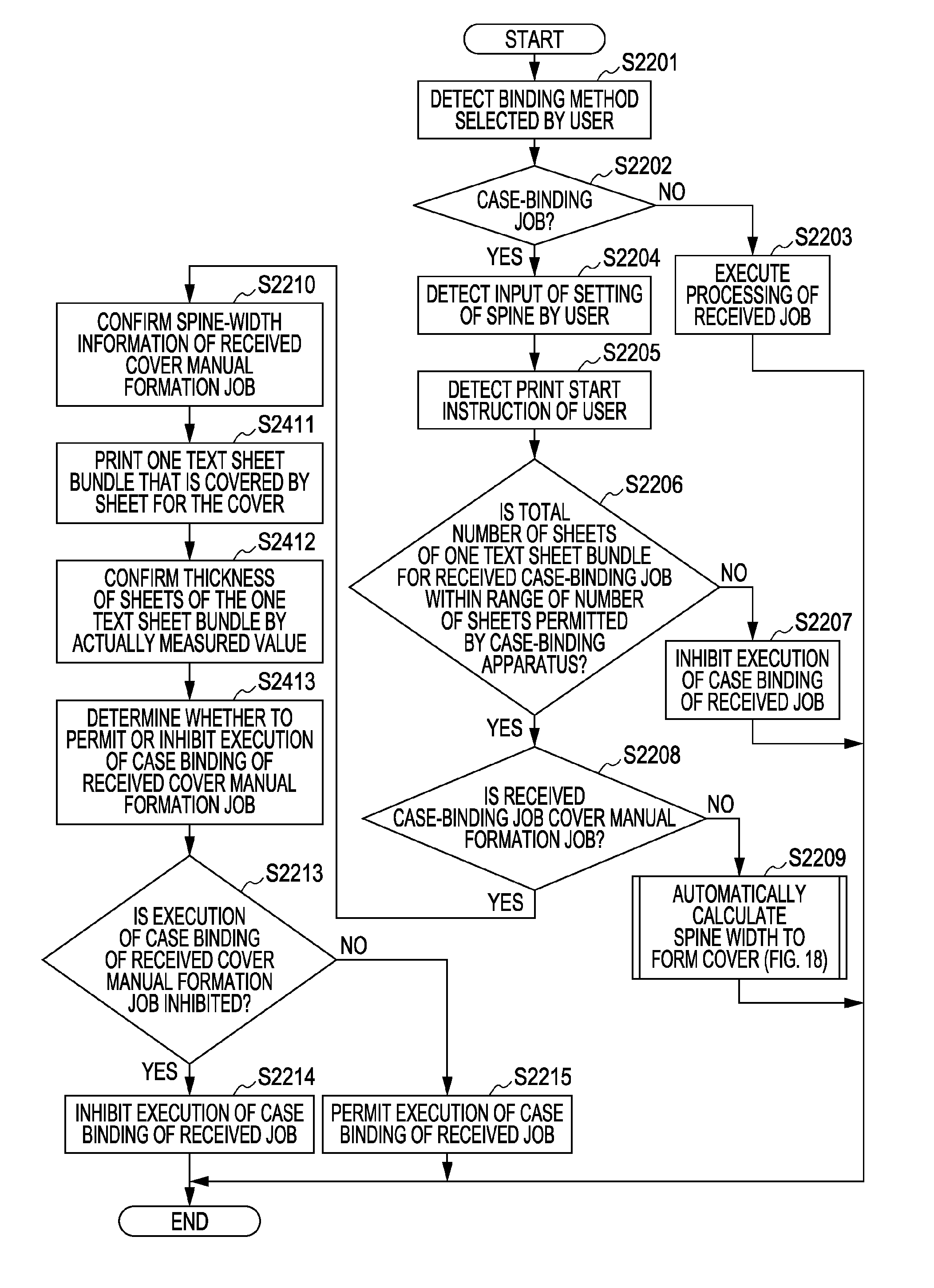

System and a program product

InactiveUS20080174825A1Reduce generationDigital computer detailsElectrographic process apparatusEngineeringUser interface

A system controls at least one of a printer and a binder to perform processing for a case-binding job. The binder performs a case binding by attaching a cover to a bundle of sheets. The printer is used to print the cover which includes a spine region between a front-cover region and a back-cover region. A size of the spine region is selected based on a setting input by an operator via a user interface. The system inhibits the processing for the case-binding job by at least one of the printer and the binder, when a mismatch between the size of the spine region and thickness of the bundle of sheets is determined. On the other hand, when no mismatch is determined, the system permits the processing for the case-binding job by at least one of the printer and the binder.

Owner:CANON KK

Bookbinding Apparatus

ActiveUS20070280805A1Extended hold timeIncrease travel speedFiling appliancesElectrographic process apparatusStart timeReciprocating motion

In binding a cover sheet together with a sheet bundle, ever-accurate spine-creasing irrespective of bundle thickness is made possible. A sheet stacker stacks sheets into bundles, an adhesive applicator applies adhesive to a spine part of the sheet bundles, and a cover-sheet binder binds cover sheets together with the spine parts. The cover-sheet binder is constituted from a left-and-right pair of spine-creasing press members arranged free to shift between standby and spine-creasing positions; a shifter that reciprocates the spine-creasing press members between the standby and spine-creasing positions; and a controller. The controller functions to vary, in accordance with sheet bundle thickness, any of: (1) the standby position of the press members; (2) the start time of an operation whereby the press members are shifted from the standby to the spine-creasing position; or (3) the traveling speed of the press members in shifting from the standby to the spine-creasing position.

Owner:NISCA KK

Unibody binder and the process of making the binder

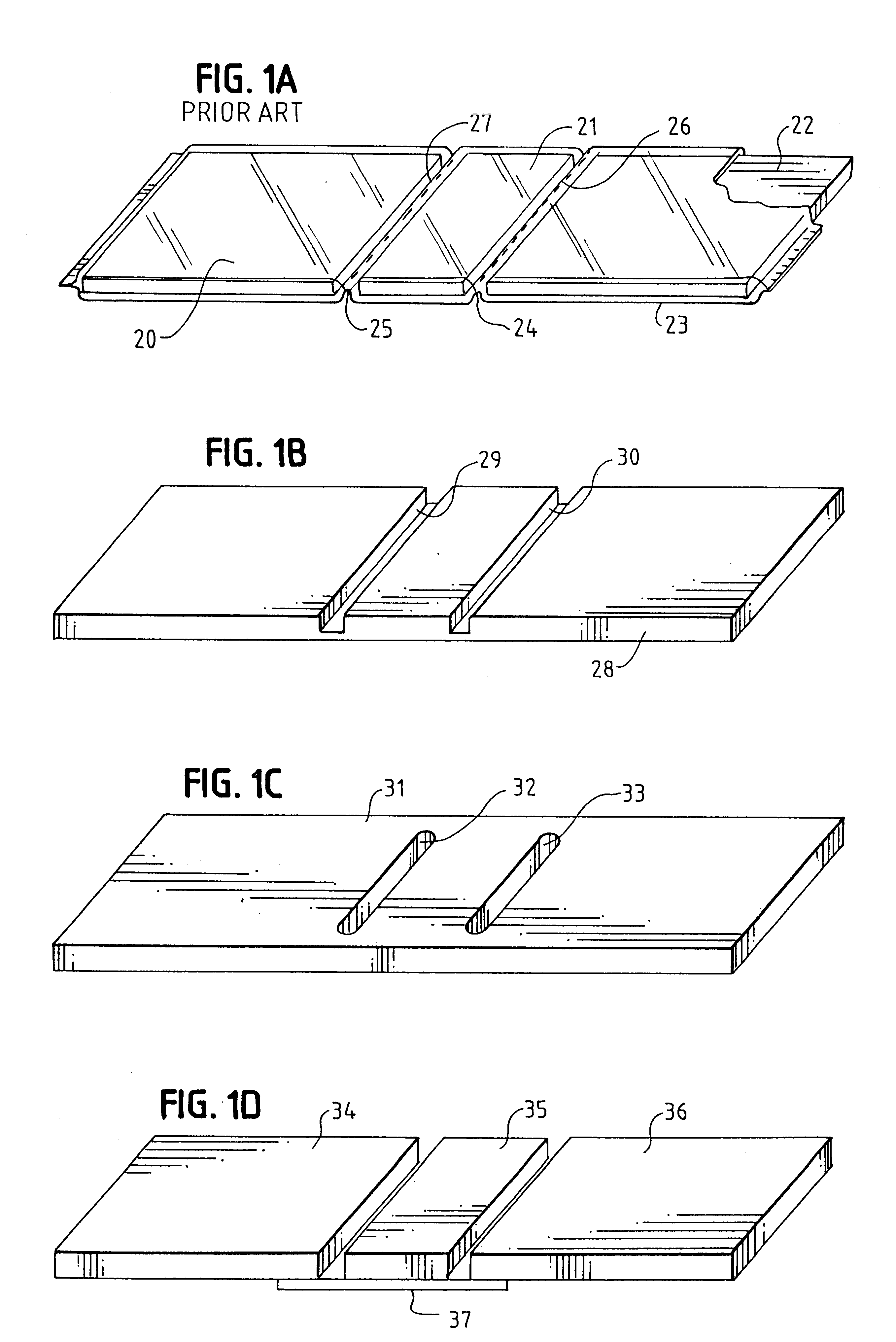

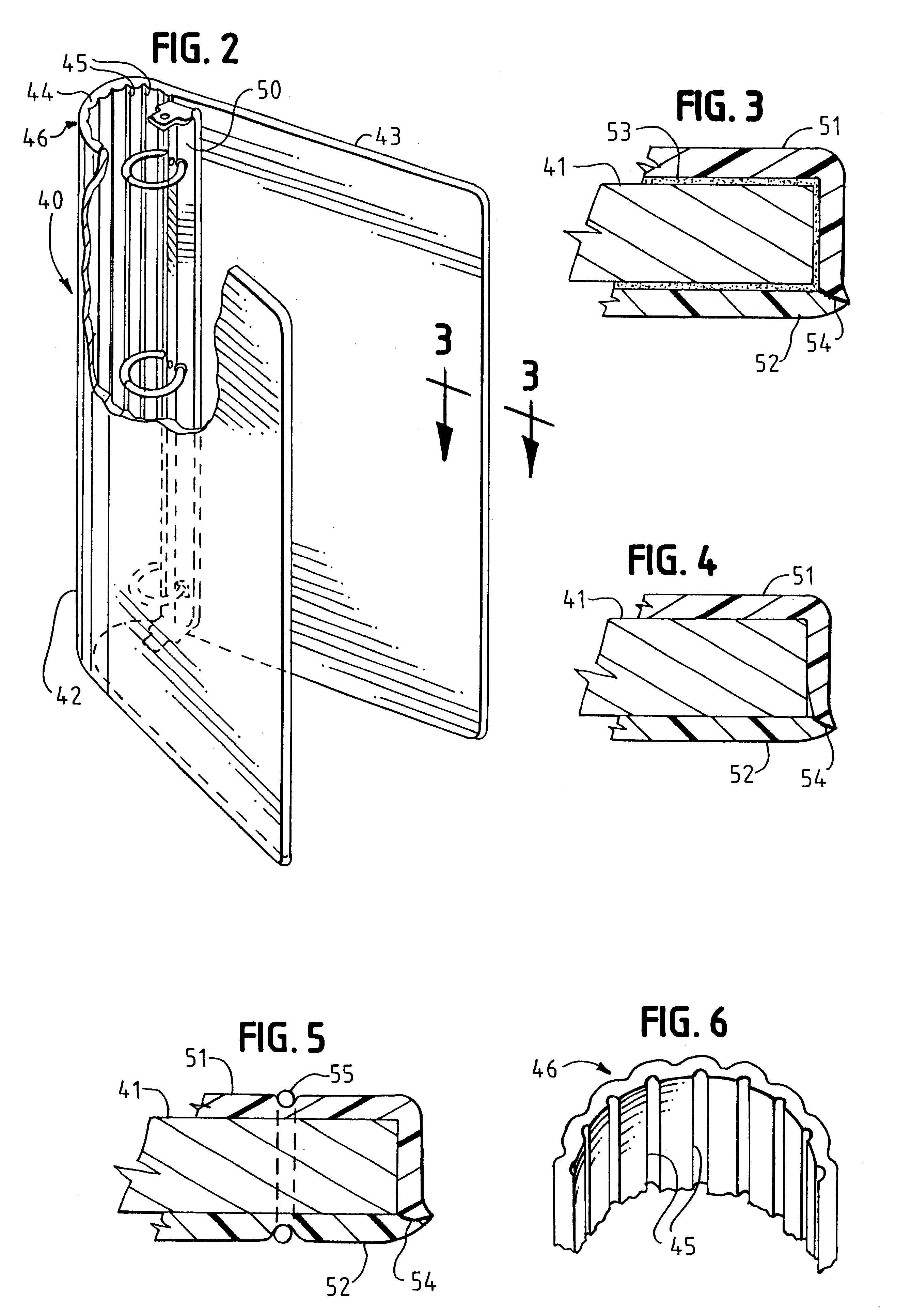

The invention includes novel unibody binder constructions and the process of making same. The binder is composed of two plastic sheets comprising such material as polyvinyl chloride, polyolefin, polypropylene, polyvinyl acetate or other similar plastics. An uncompromised single piece of board or similar rigid material, such as chipboard, microflute board, corrugated board, fiberboard, etc., or a synthetic substrate, is then coated with a glue such as a resin glue, a U.V. adhesive, etc., on both sides and sandwiched between the plastic sheets. This sandwich is then formed into the unibody construction by welding the entire outer perimeter. At the time of welding, the air between the plastic sheets and the board is pressed or vacuumed out. To create the hinges on the binder, the unibody construction is then hydraulically creased to the extent necessary by using three moving blades to provide living hinges. Many different spine configurations may be achieved depending on the number of creases desired for flexibility. Various capacities of ring metals may be accommodated by increasing or decreasing the number of creases or distances therebetween. Also, various round or flat back profiles can be formed after the flat board has been sealed into a sandwich between two plastic sheets that have been welded together. A clear plastic sheet secured to the bottom and side edges of the outer plastic sheet to provide a pocket for visible inserts and plastic sheets can be secured to the inner plastic sheet to provide inner pockets for inserts.

Owner:WELCH STEPHEN R

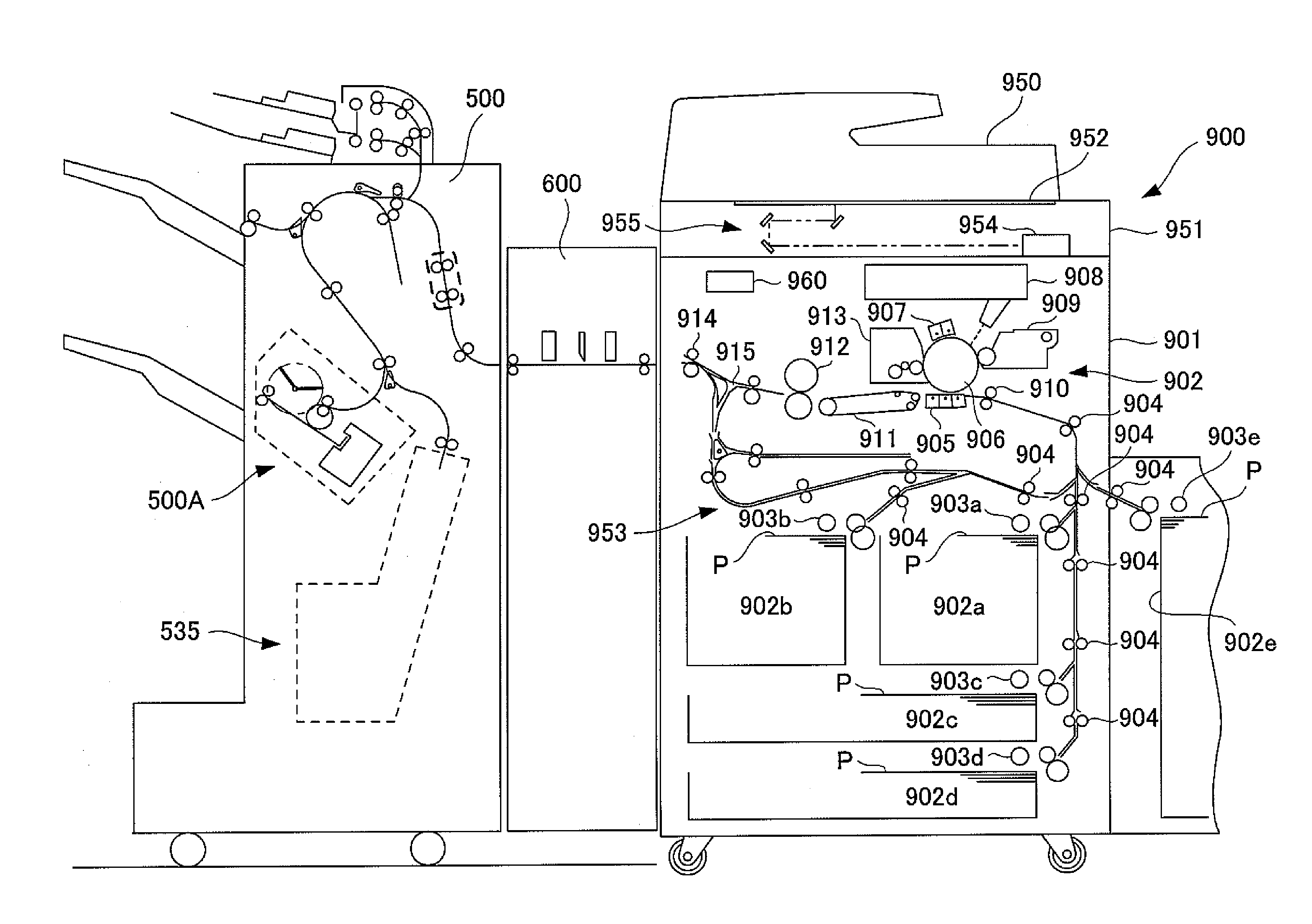

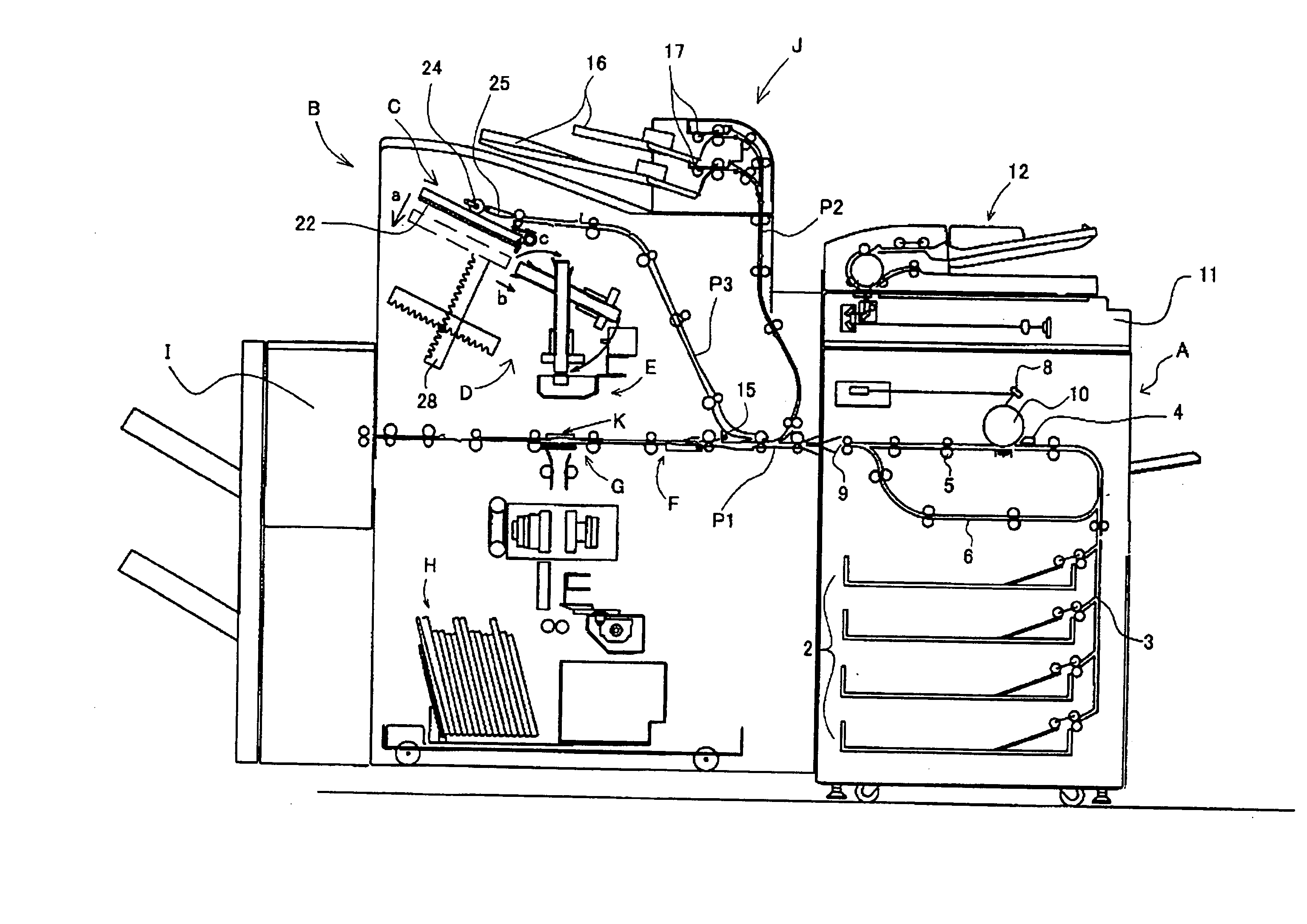

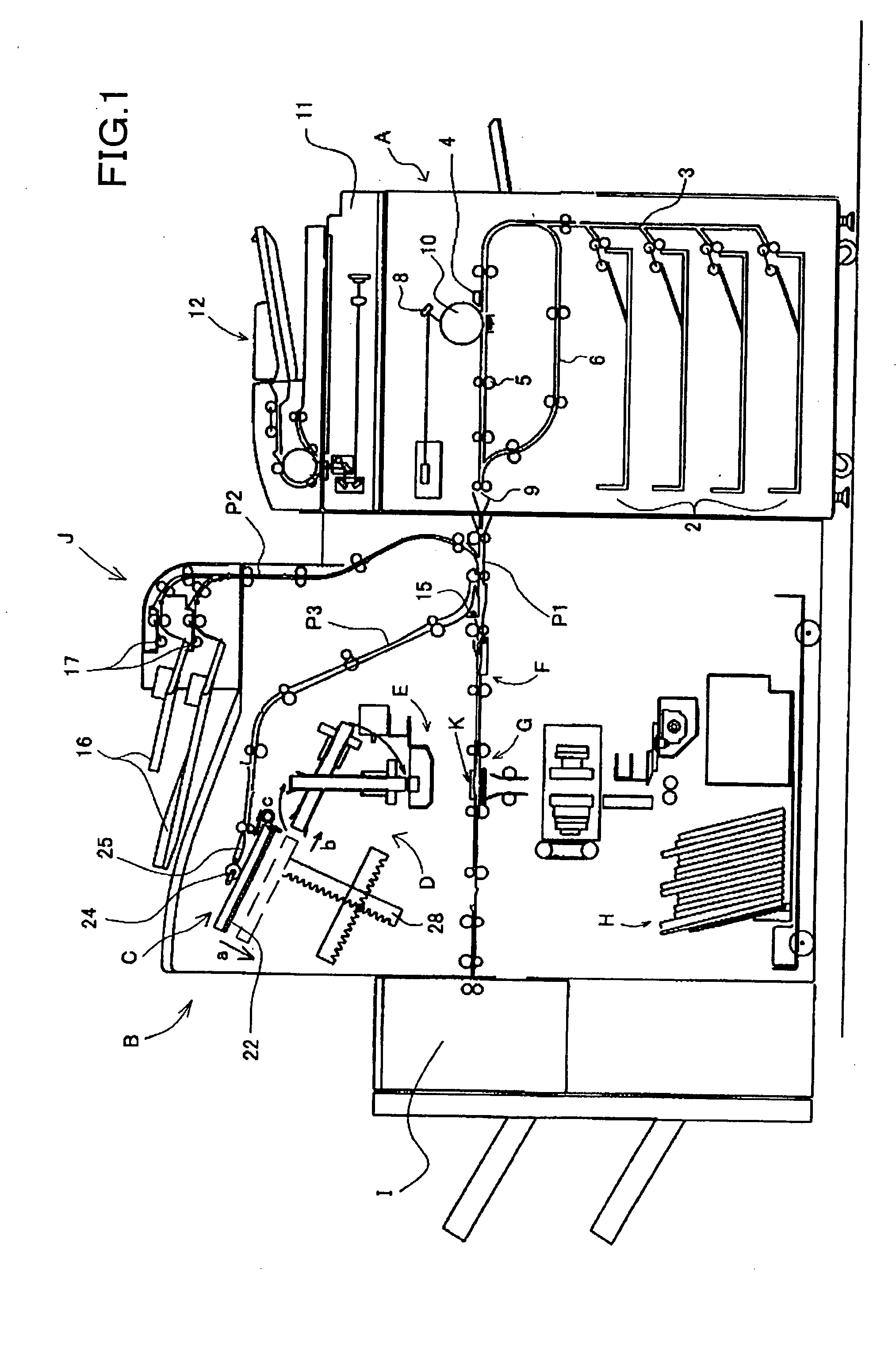

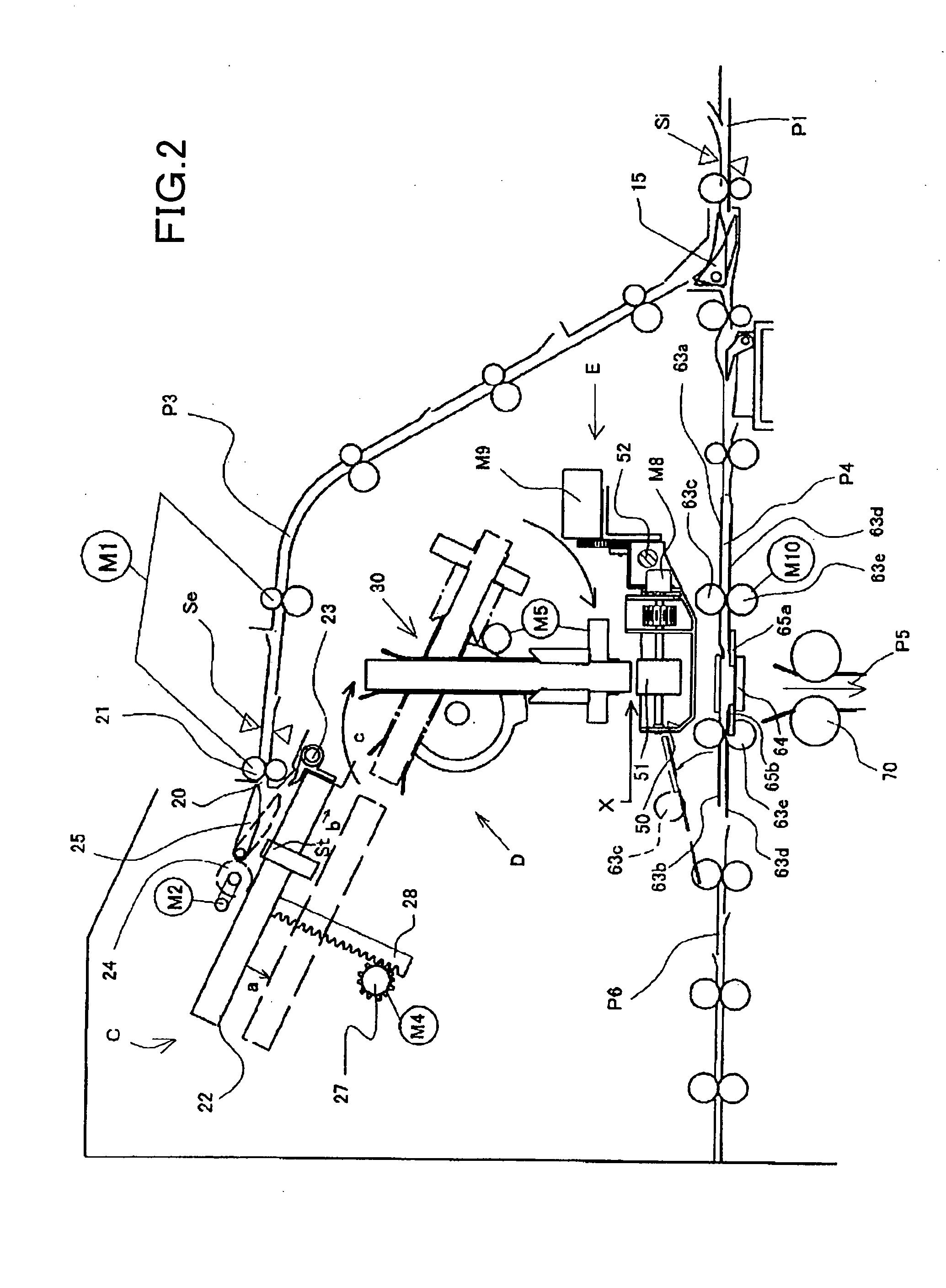

Sheet post processing apparatus and image forming system

InactiveUS7660556B2Good body shapeReduce generationOther printing matterBook making processesImage formationEngineering

In a sheet post processing apparatus having a folding device that carries out the process of book folding by folding either one sheet or a plurality of sheets at a time on the sheets discharge from the image forming apparatus, a sheet stacking section that successively stacks the booklet-folded sheets, and a control unit that controls the sheet post processing apparatus, said control unit controls said folding device so that said booklet folding process of said sheets is carried out at the portions of two folding lines which are almost parallel thereby obtaining a square-shaped back of booklet.

Owner:KONICA MINOLTA BUSINESS TECH INC

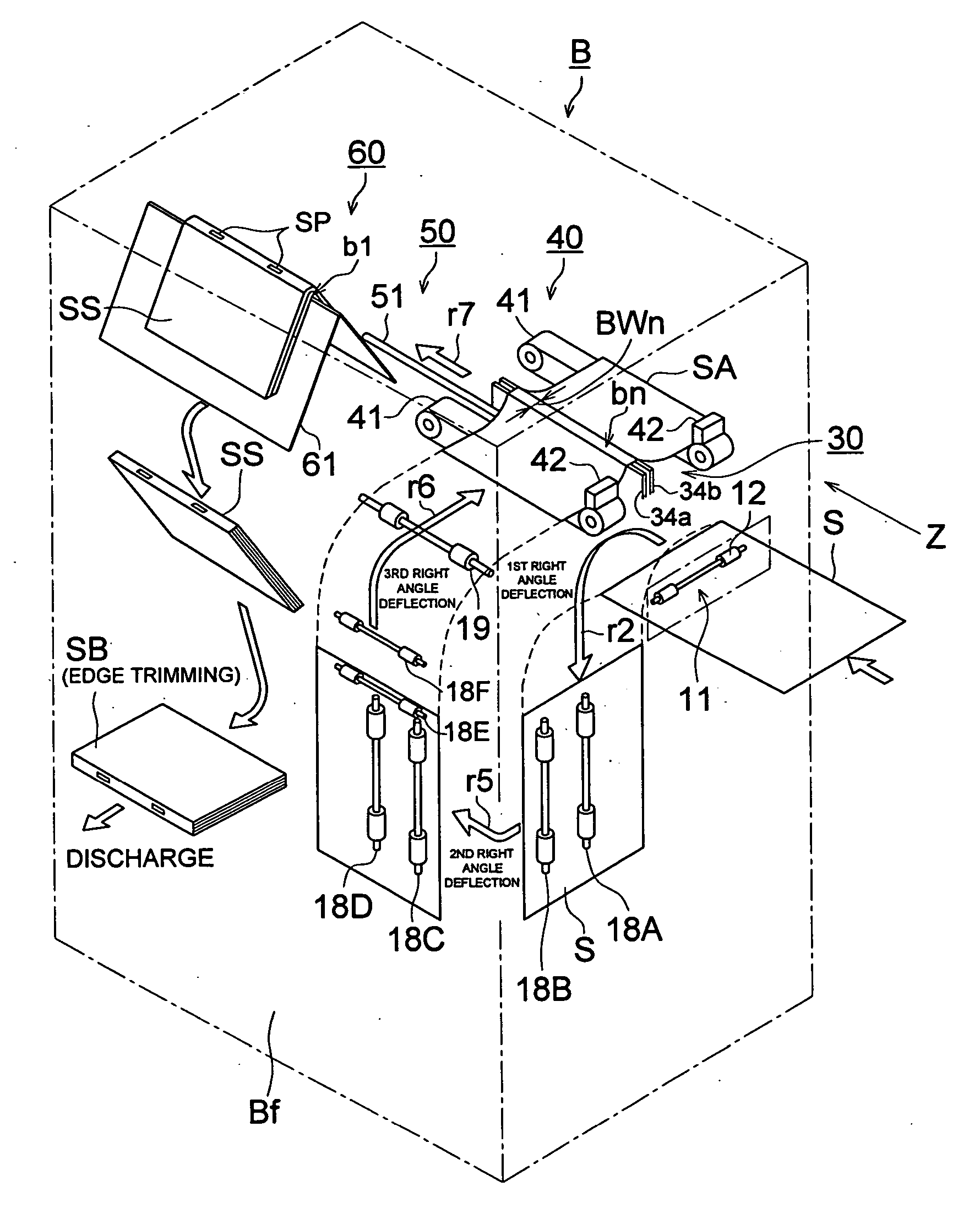

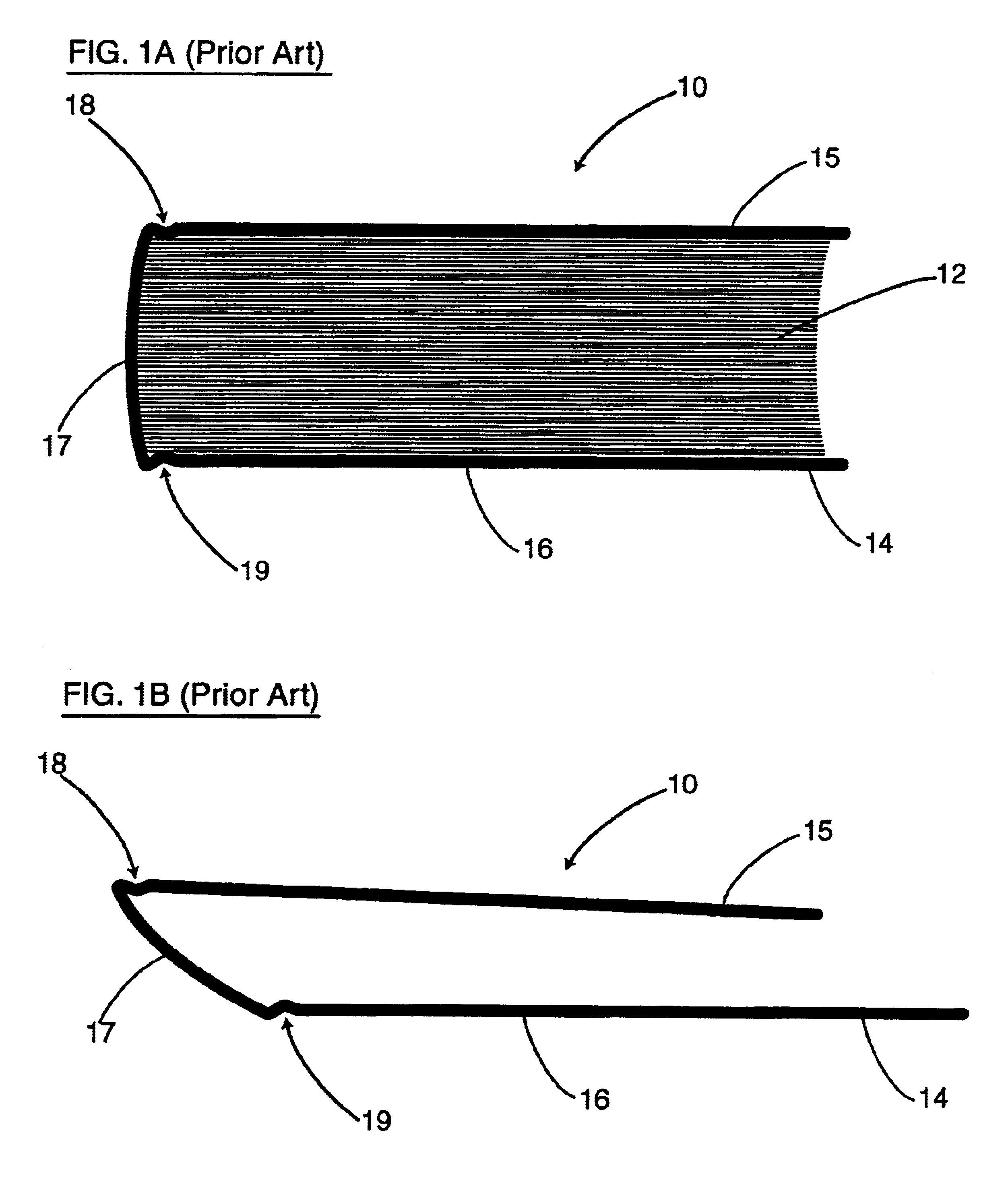

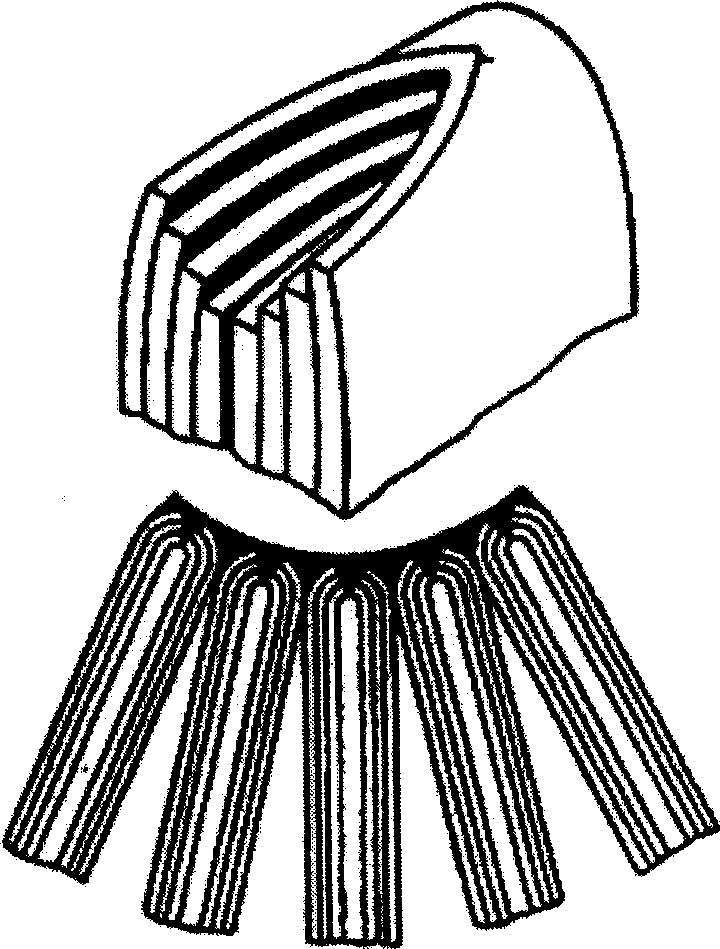

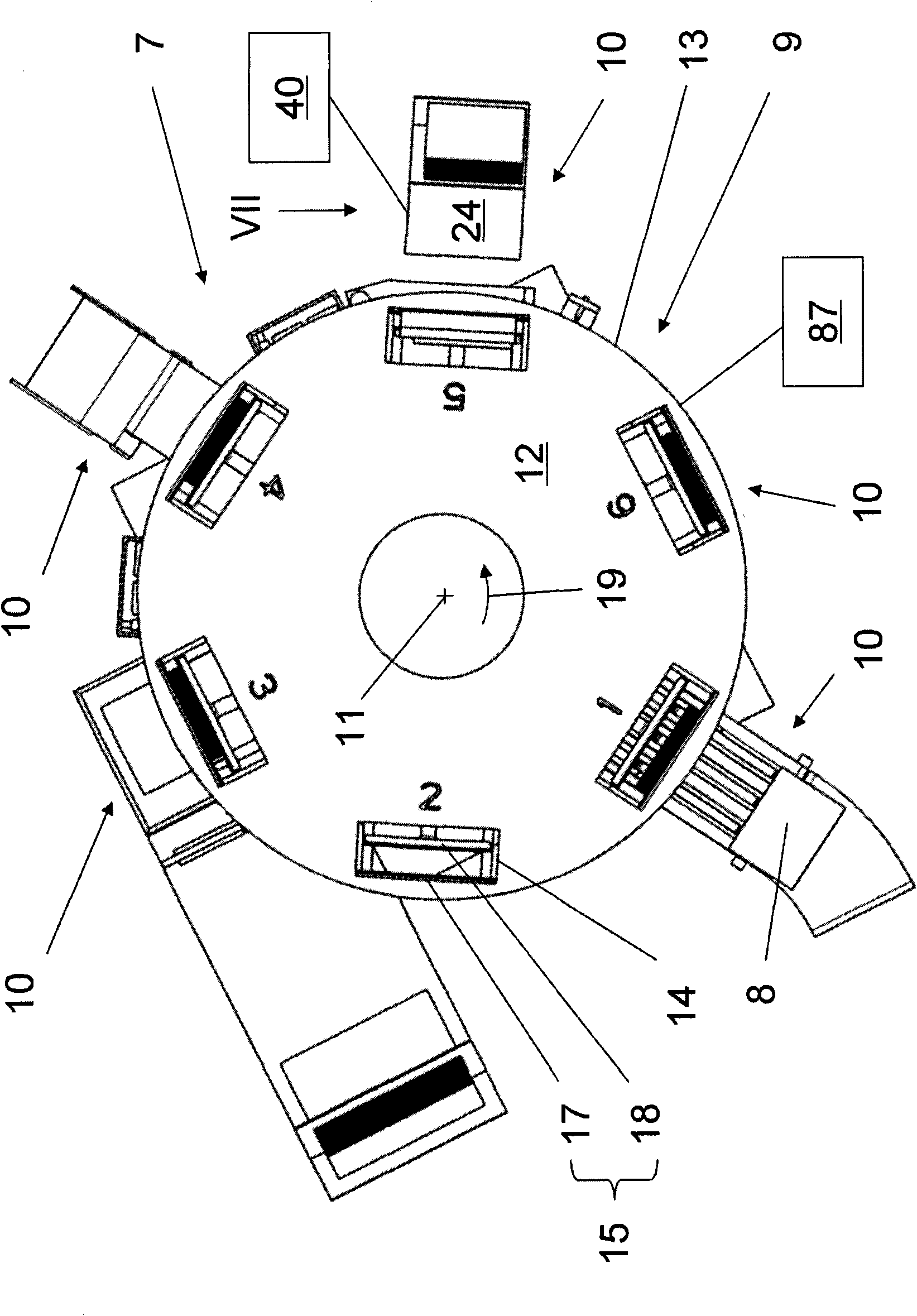

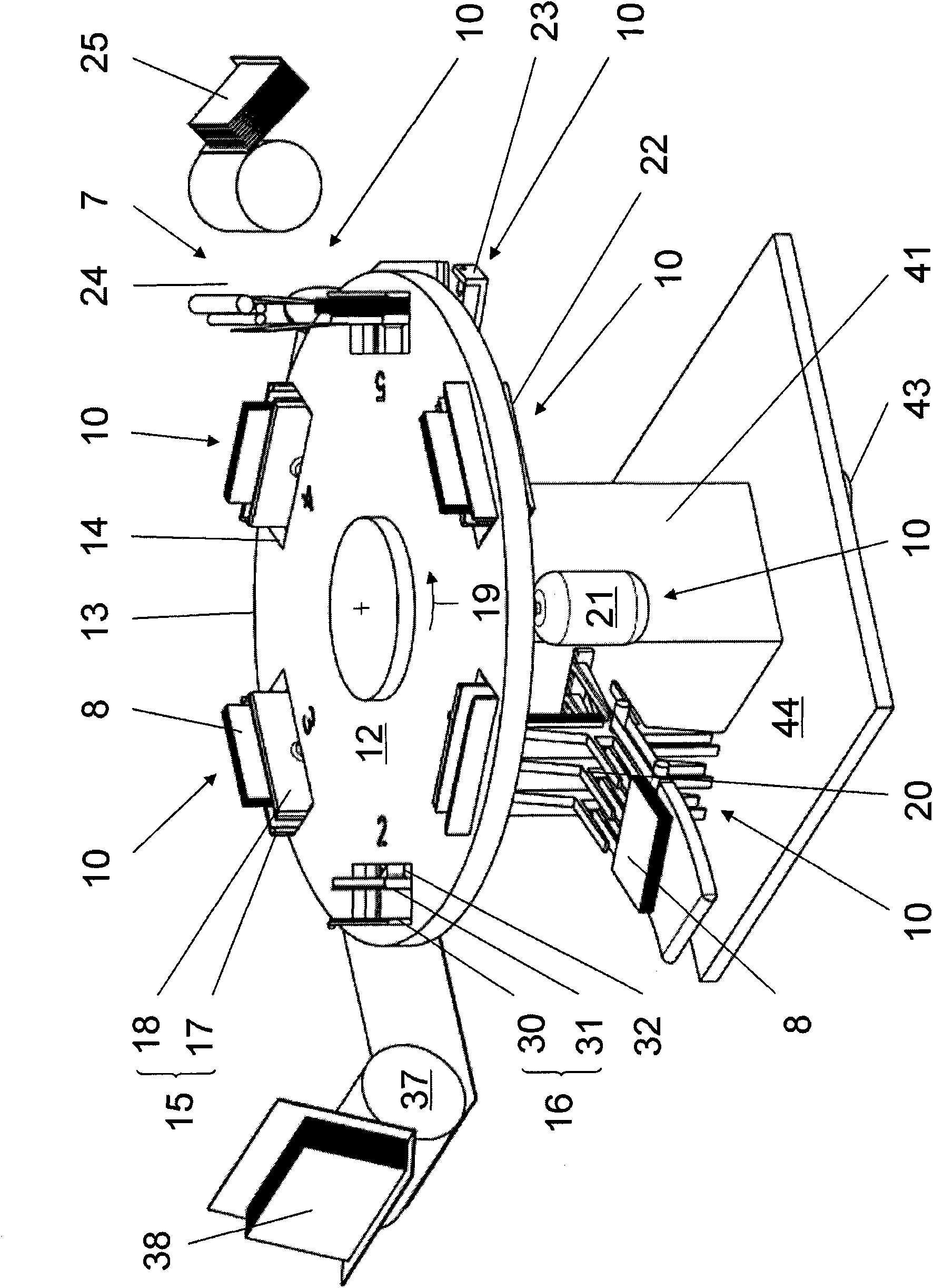

Binder to process book blocks and method of binding

A perfect binder for processing book blocks, including: a conveying device adapted to convey the book blocks along a closed circulating path, the conveying device including a plurality of clamping devices each adapted to convey a book block; and a plurality of processing stations arranged successively along the closed circulating path. One of the processing stations includes a spine-processing station, and another one of the processing stations includes an end sheet feed station following the spine-processing station. According to another aspect of the invention there is provided a method forthe perfect binding of book blocks, comprising: conveying the book blocks around a closed circulating path with each book block clamped in a clamping device of a conveying device, wherein a pluralityof processing stations are arranged successively along the closed circulating path; milling the spine of each book block at one of the processing stations; and subsequently, inserting at least one endsheet into the clamping device at a downstream end sheet feed station.

Owner:MULLER MARTINI HLDG

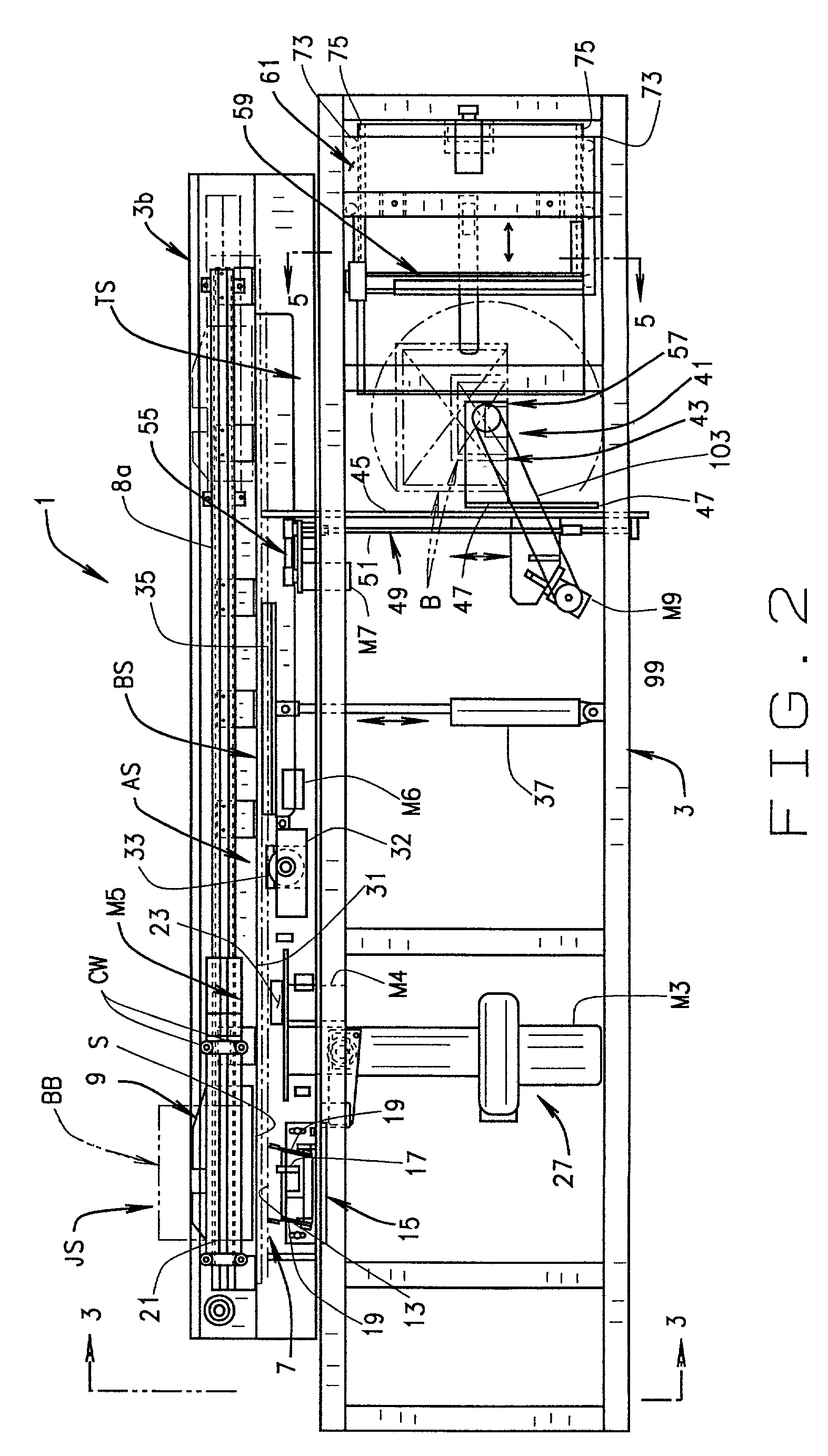

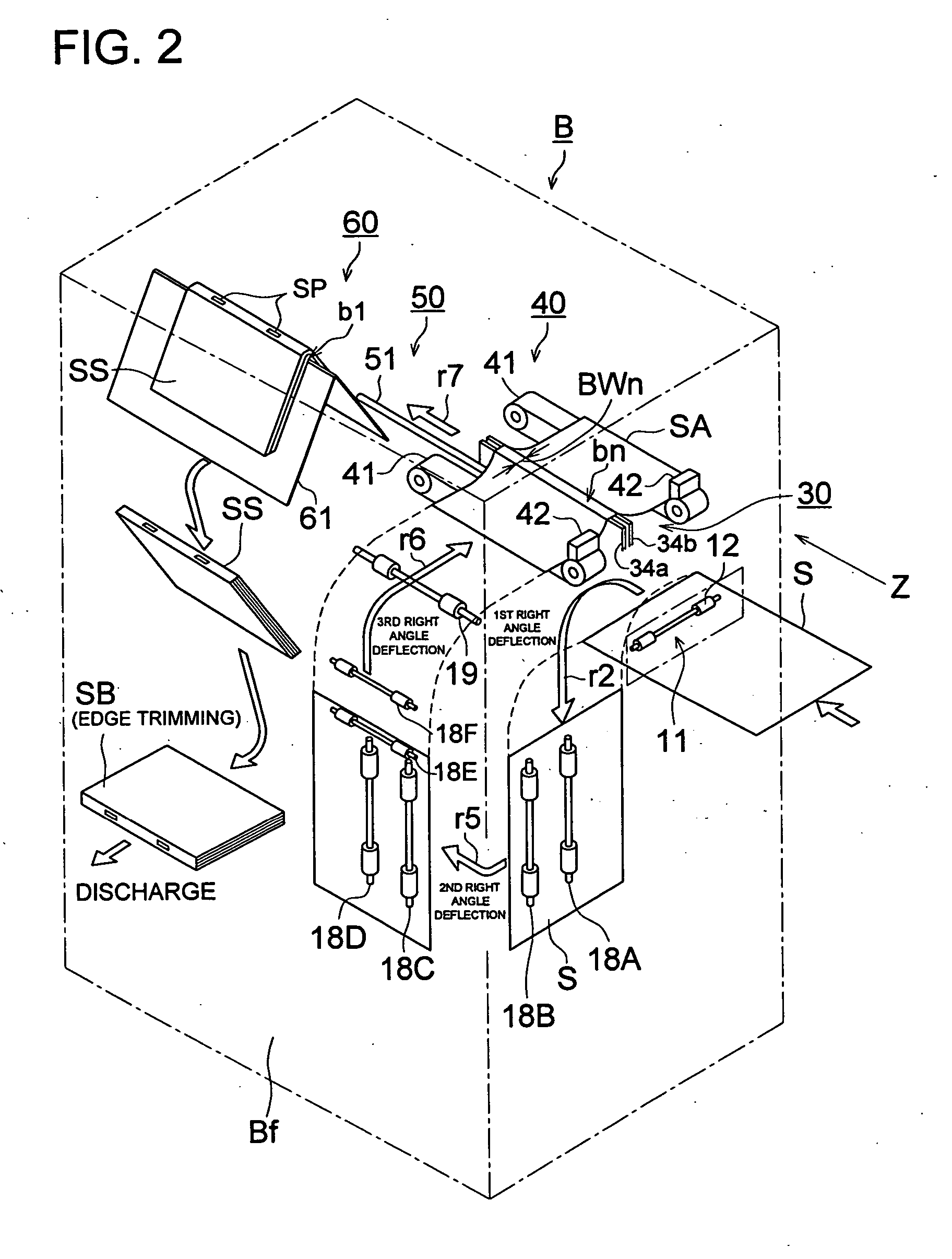

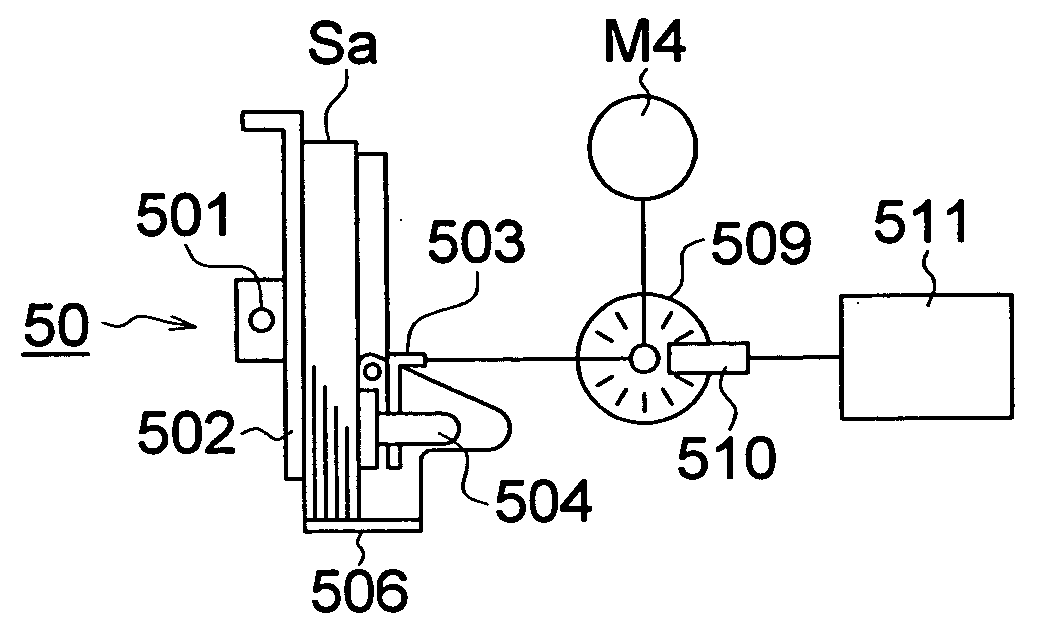

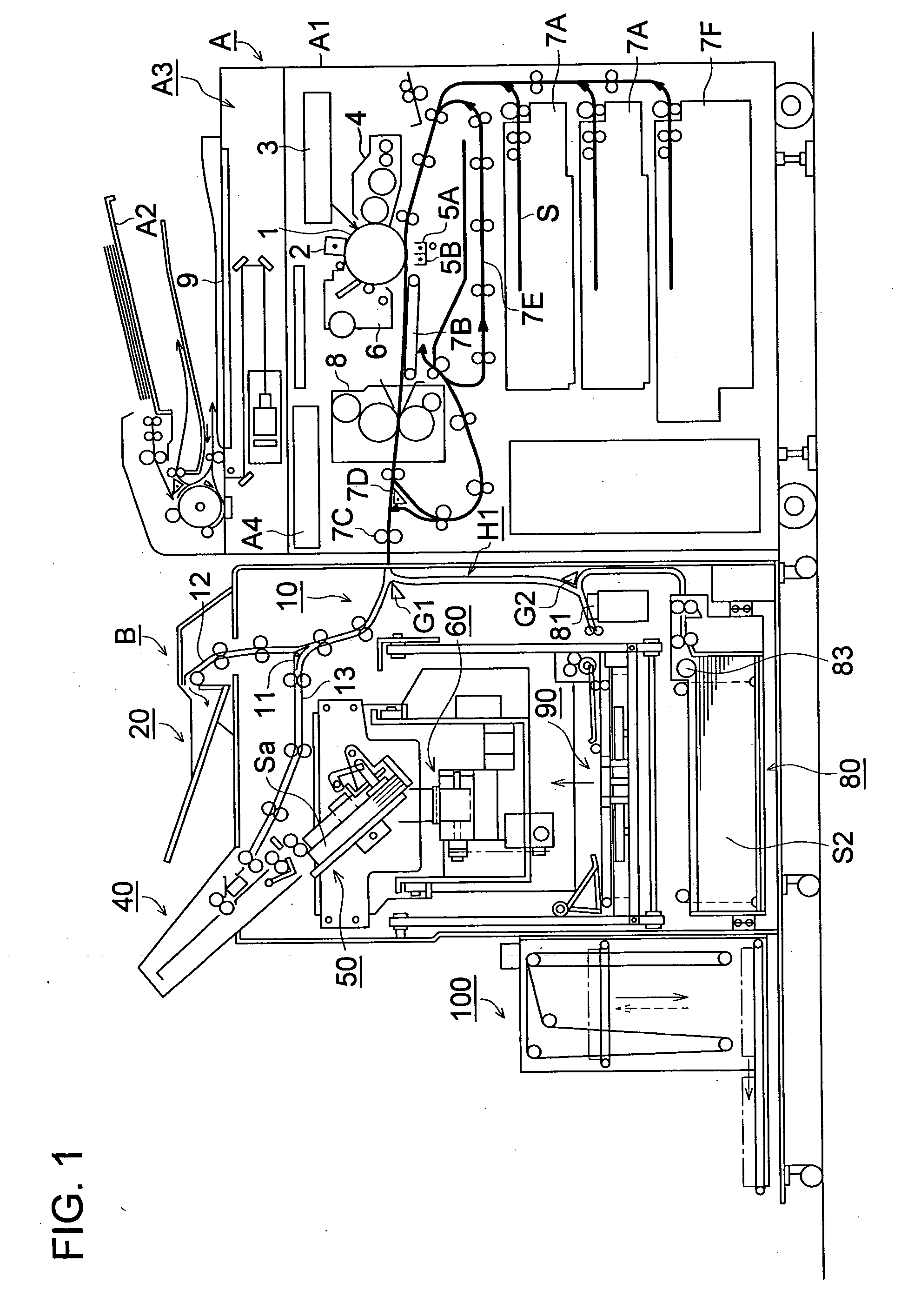

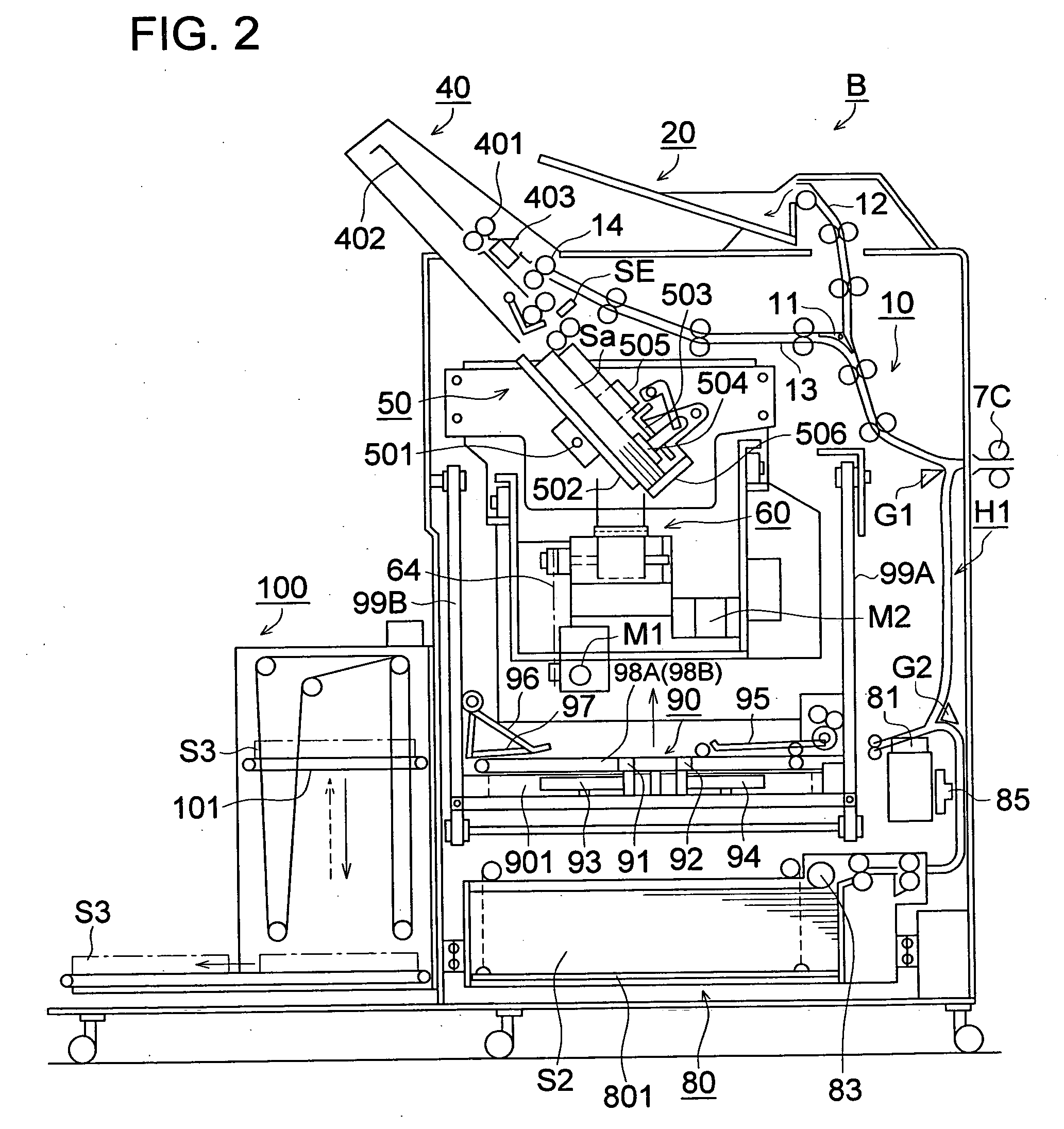

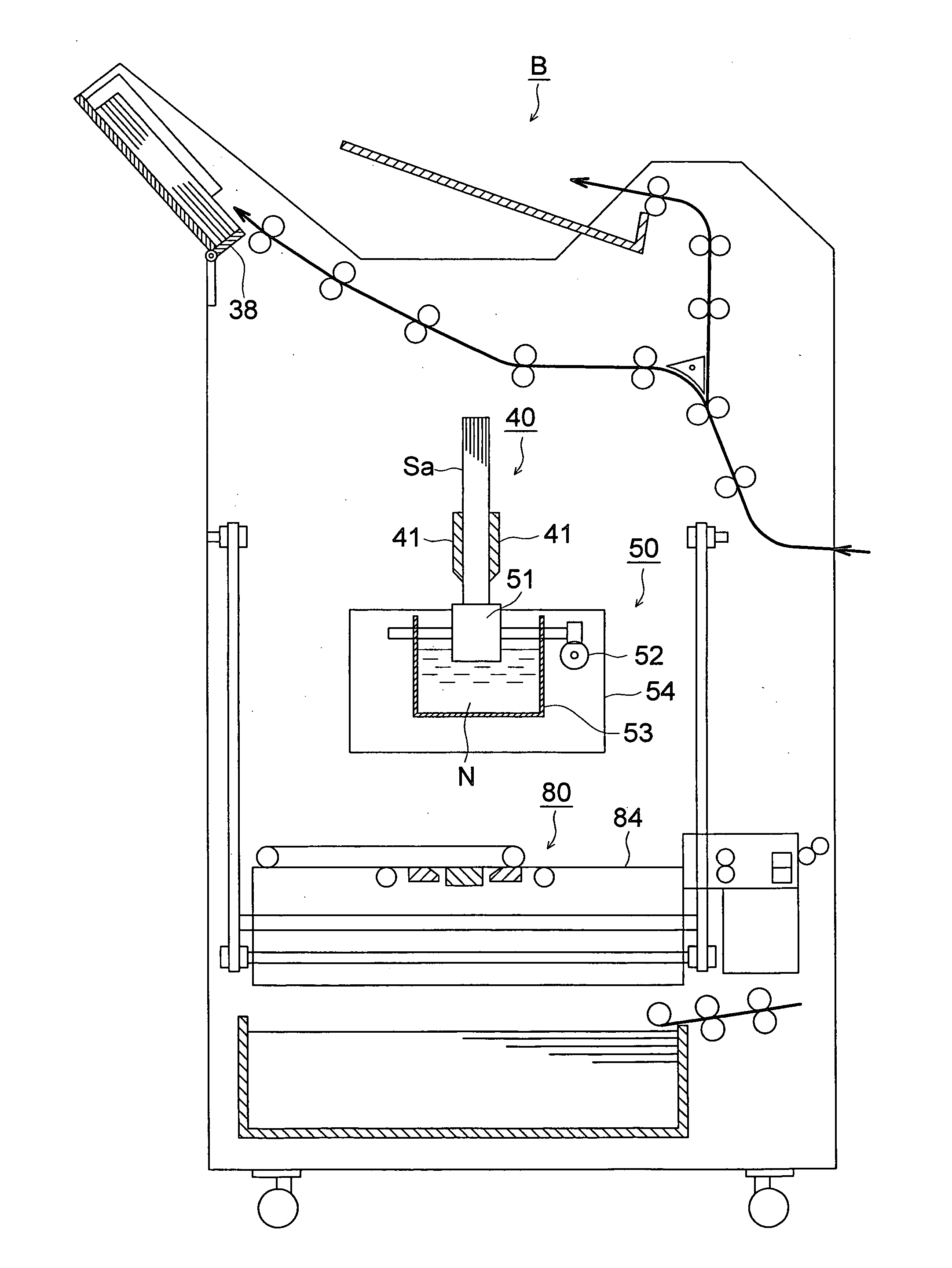

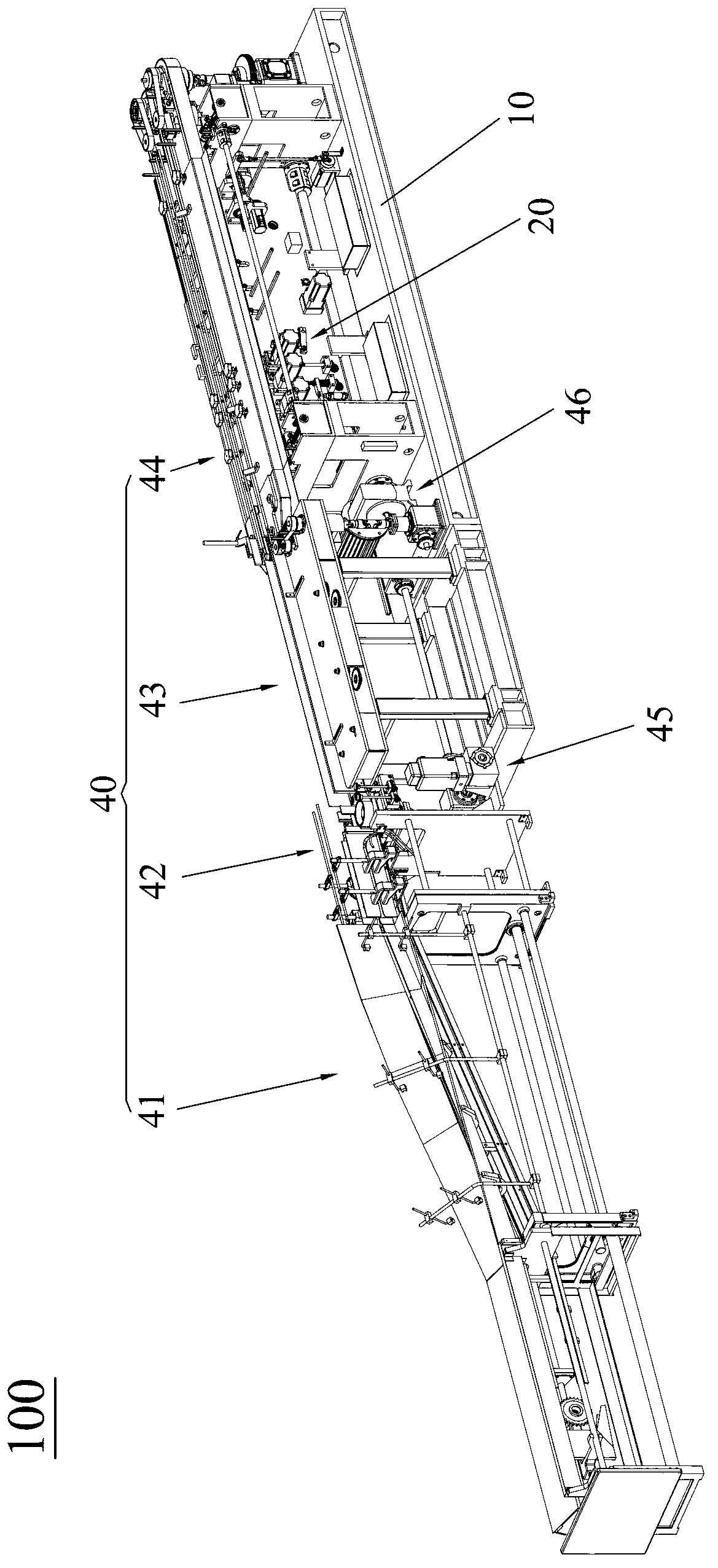

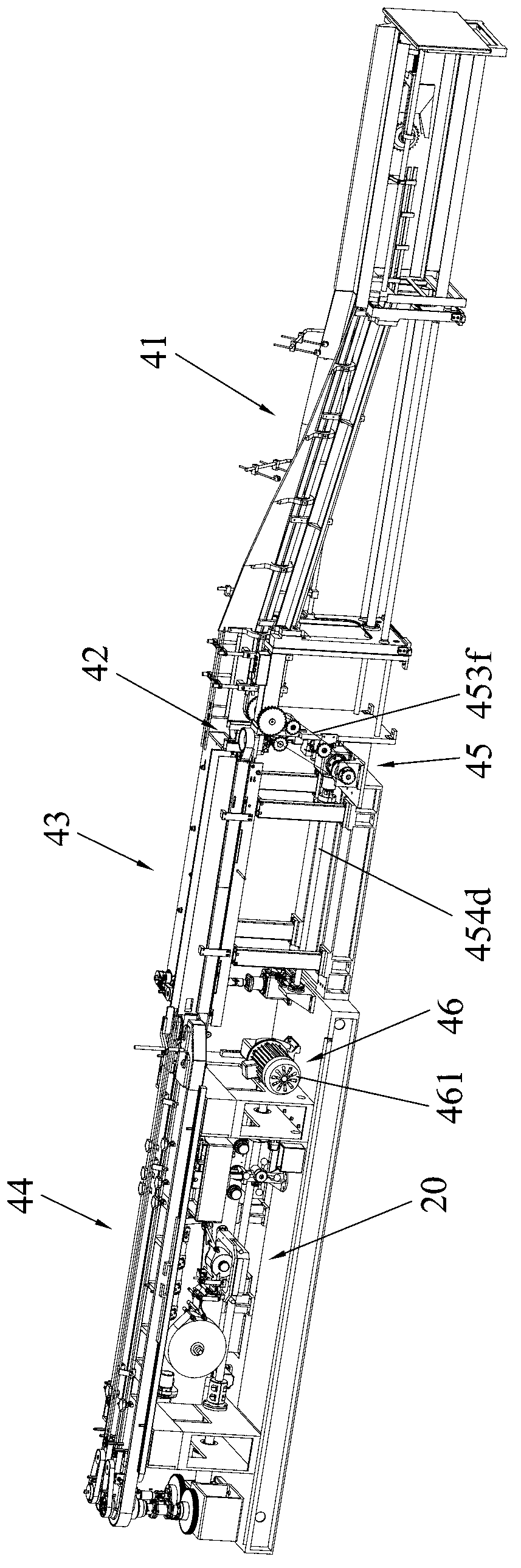

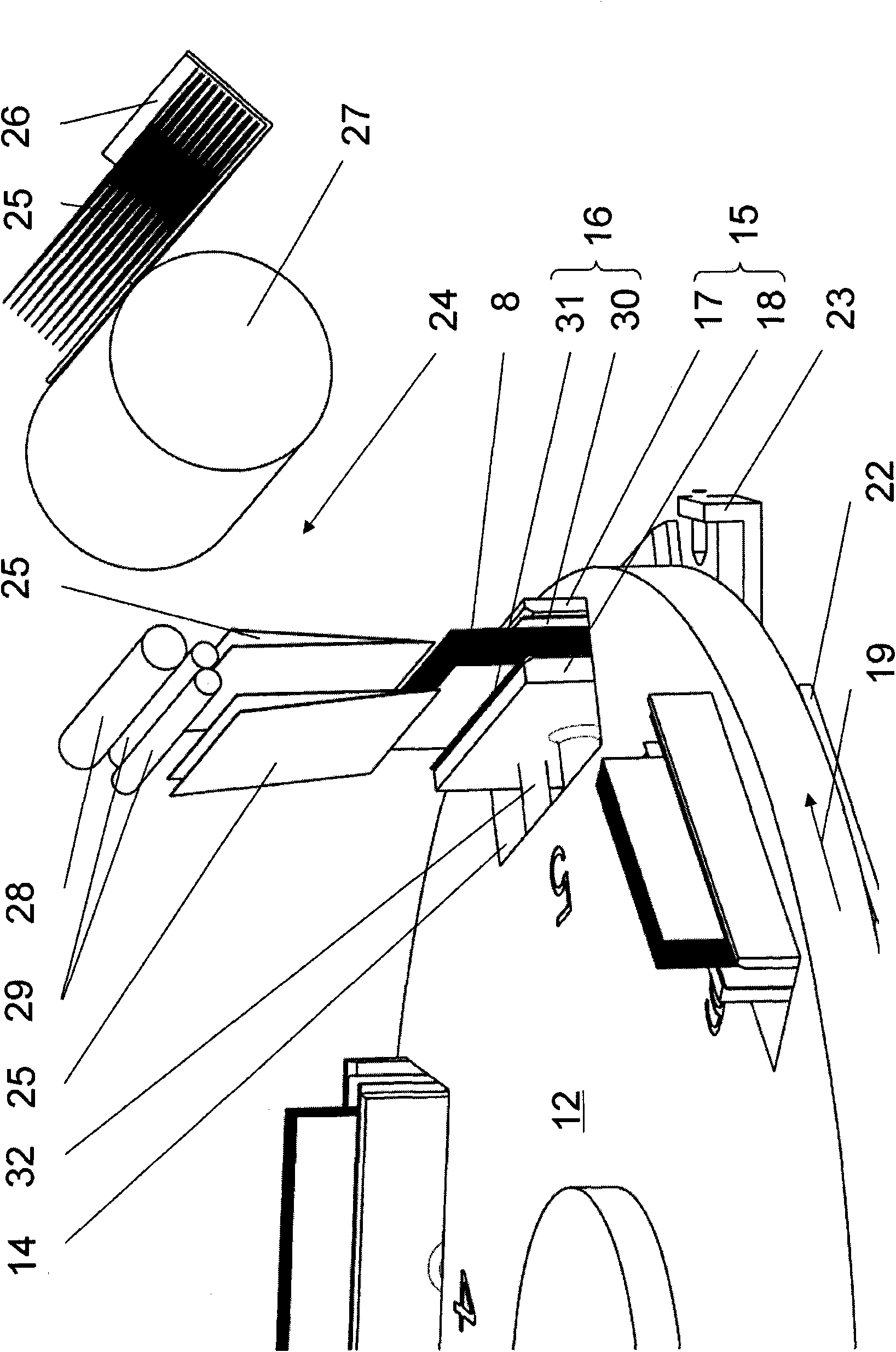

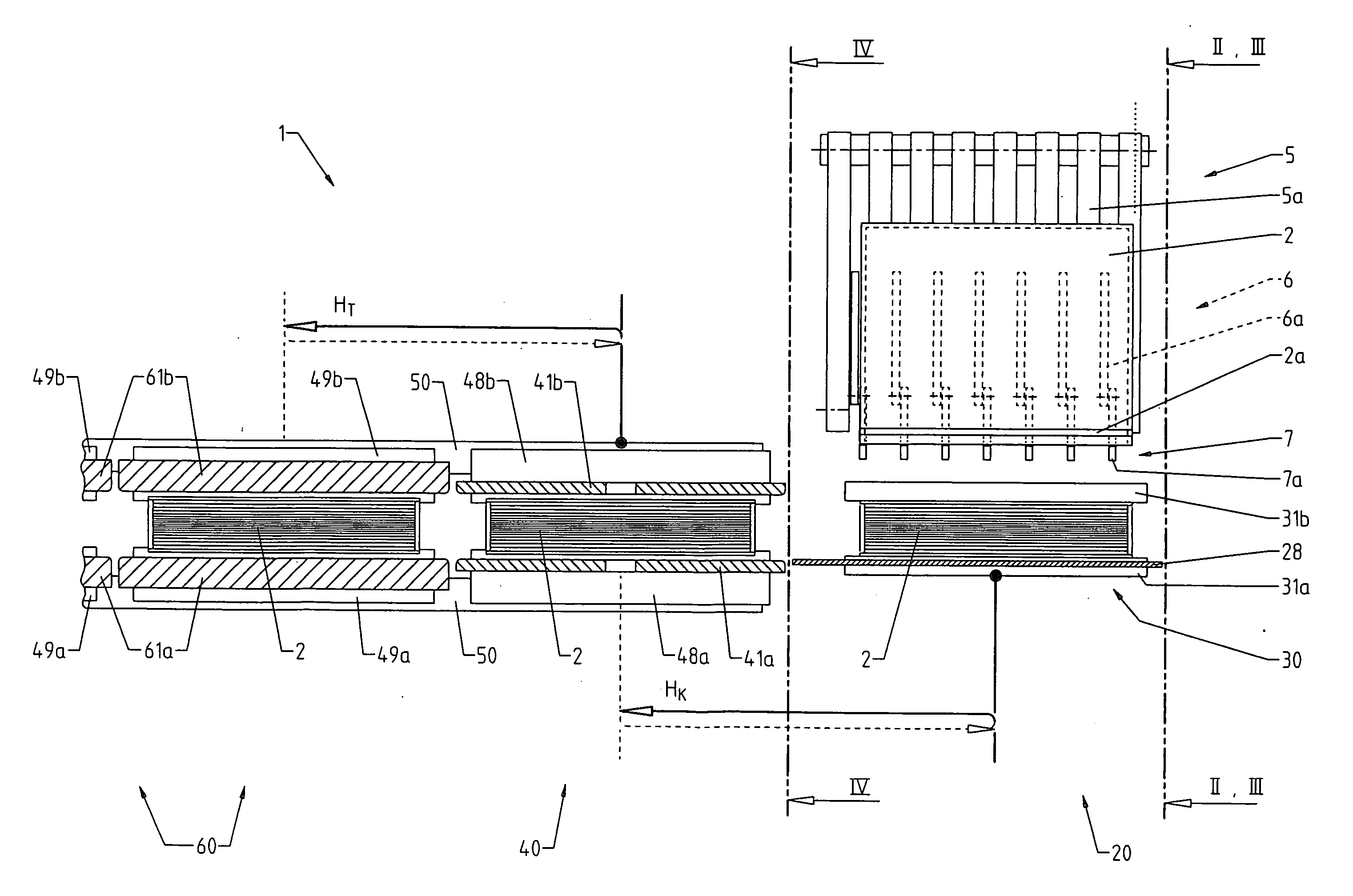

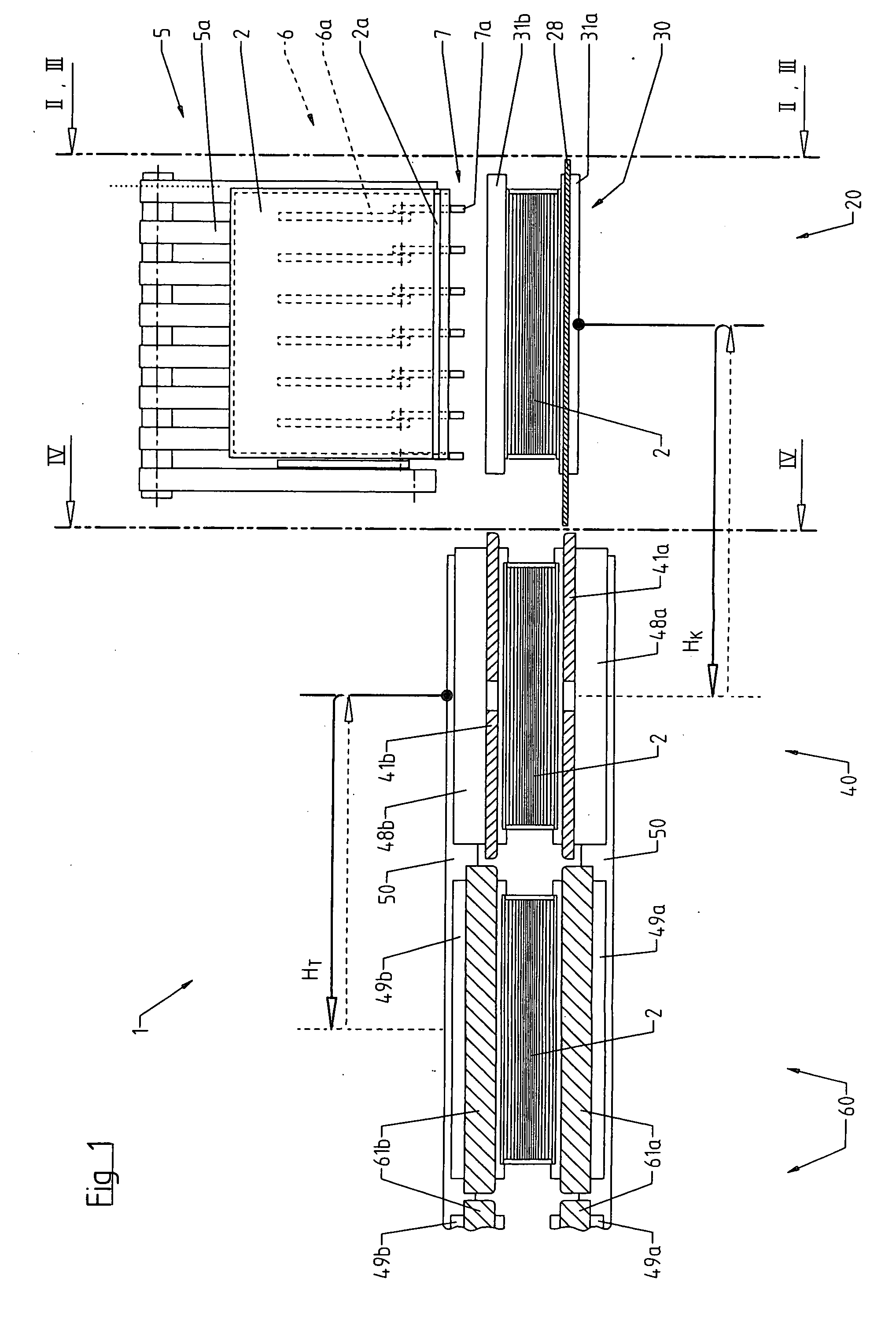

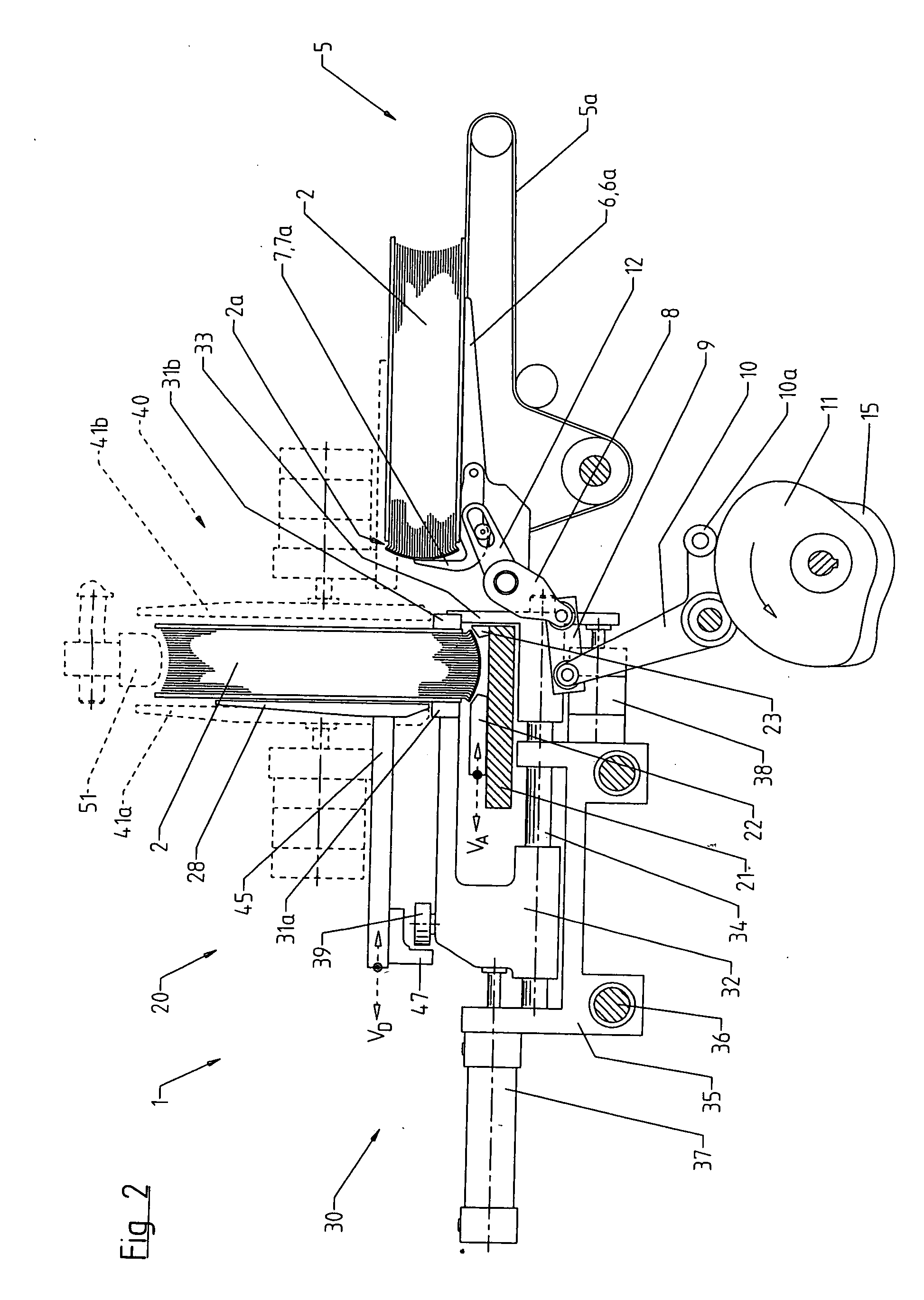

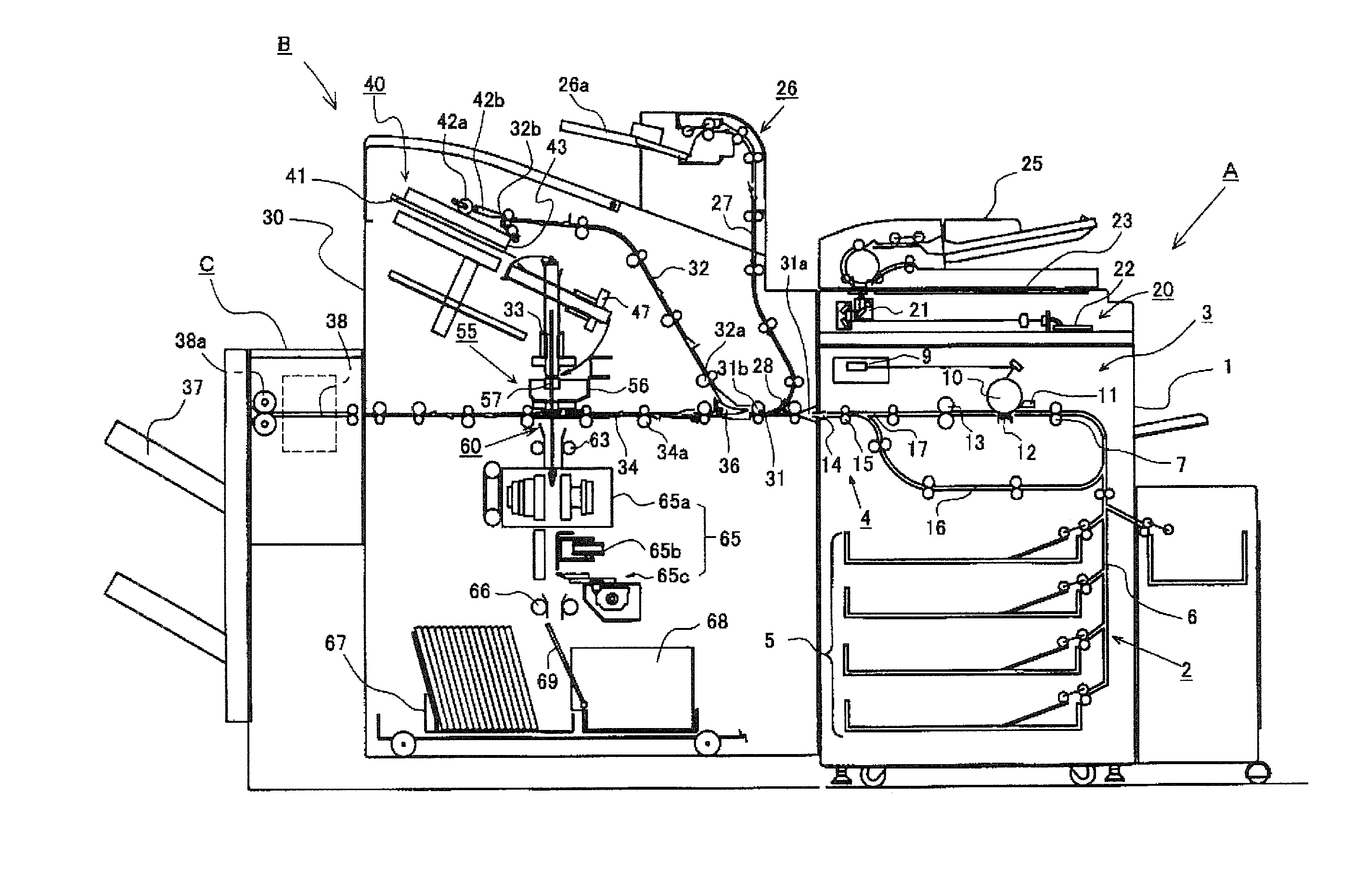

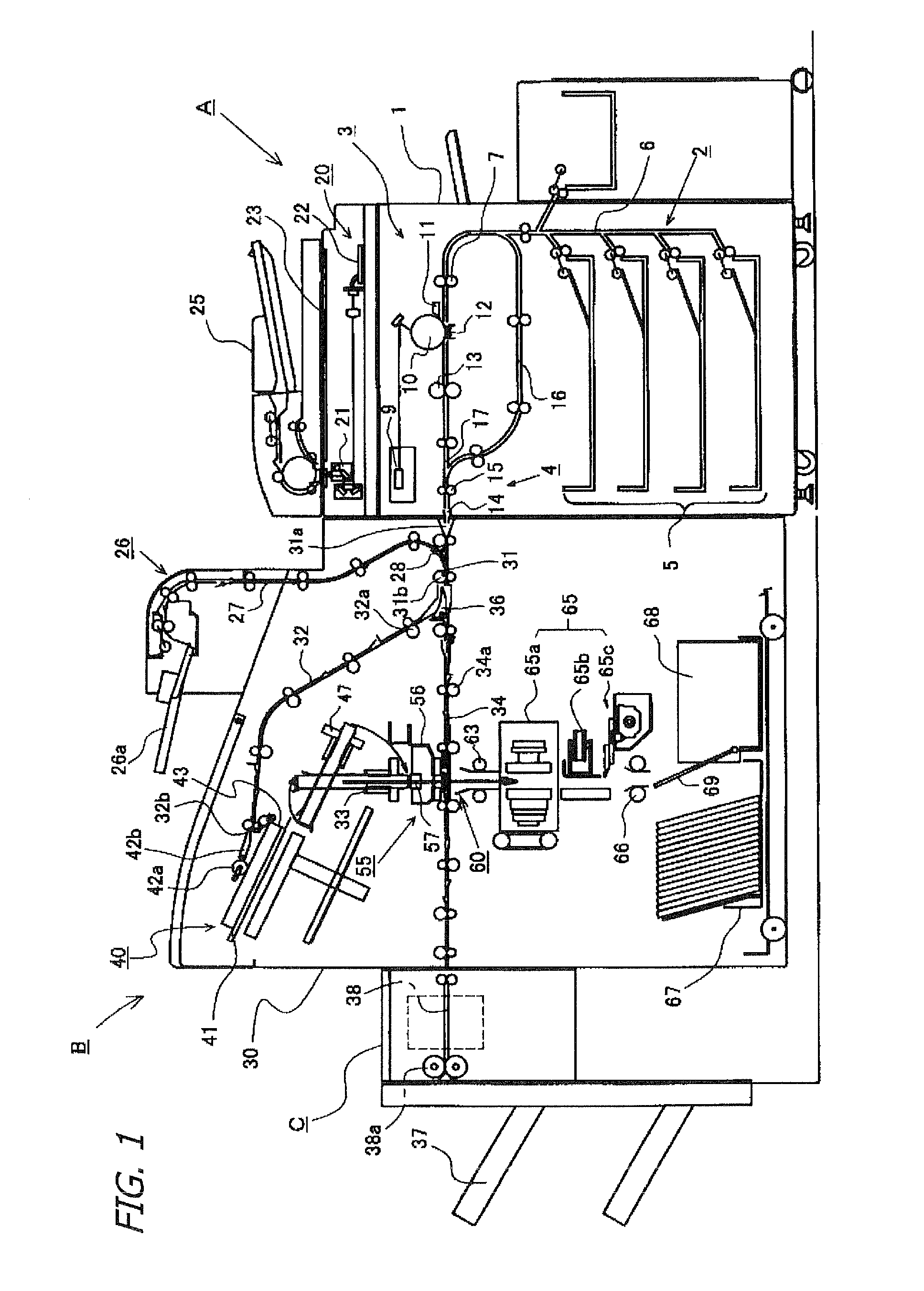

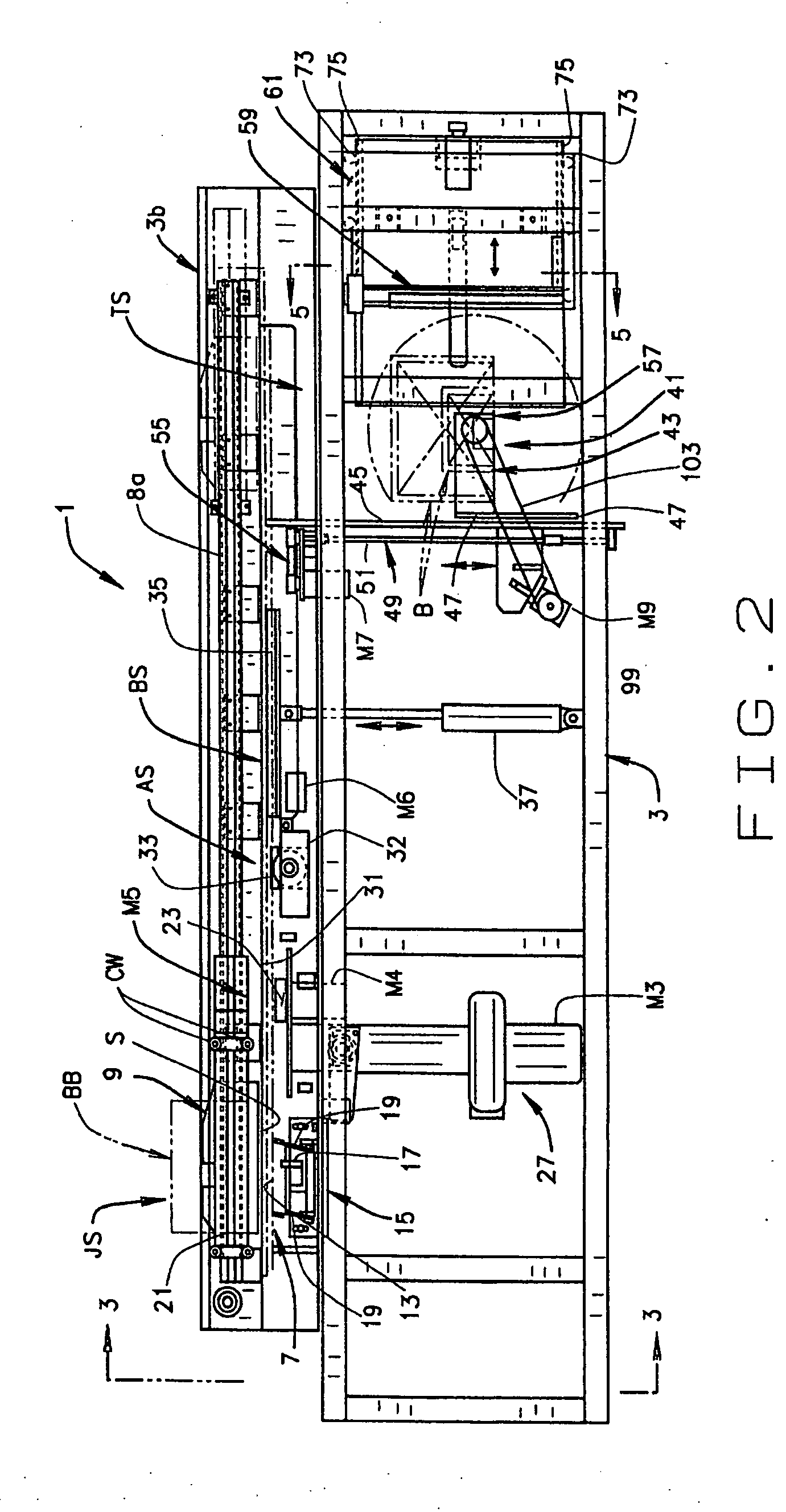

Binding-in and pressing machine

InactiveUS20060140742A1Simple and cost-efficient designQuality improvementBookbinding casesCasing-inLateral regionEngineering

A binding-in and pressing machine (1) with a plurality of pressing stations (60) and heated joint forming rails situated on a reciprocating carriage (50). An alignment station (20) is provided for aligning the book case joints (2a) at the height of the joint forming rails (49a, b), including a height-adjustable alignment table (21) with rails (22, 23) for supporting the book (2) on the outer edges of its spine and guide elements (28, 6) for centering the book on the alignment table. A separate pre-forming station (40) is also provided that comprises the forming rail (51), clamping plates (41a, b), and joint rails (48a, b) that engage into the book case joints (2a) and counteract a downward movement of at least the book case joints (2a). The books (2) aligned in the alignment station (20) are transferred into the pre-forming station (40) while being clamped in lateral regions near the joints. The effective times available for realizing a functionally safe alignment and a permanent pre-forming of the books are extended due to the assignment of the alignment and pre-forming functions to two separate stations.

Owner:KOLBUS

Sheet processing apparatus and image forming apparatus

A current invention provides a sheet processing apparatus and an image forming apparatus capable of obtaining a sheet bundle which can be double-leaved and released without use of any binding device. A slit S to which a projection Pa provided at an end portion opposite to a side to be bound by a binding portion of a front cover P1 is formed in a back cover P3 of a sheet bundle PA by an insertion portion forming portion. Further, creases L1, L2 for inserting the projection Pa into the slit S while surrounding sheets P2 existing between the front cover P1 and the back cover P2 are formed in the back cover P3 of the sheet bundle PA by a crease forming portion.

Owner:CANON KK

Bookbinding apparatus

In a bookbinding apparatus (1) comprising an adhesive tank (23) for retaining therein an adhesive melted by heat, a roller (24) ratatably supported with the adhesive tank so as to dip a lower portion thereof in the adhesive retained in the adhesive tank, for applying the adhesive to a sheet stack along a lateral edge thereof, and a holding unit (18) capable of holding the sheet stack, an adhesive tank carrier (76, 78), the movably constituted adhesive tank (23) and the roller (24) are disposed at a stand-by position located outside a longitudinal end face of the sheet stack held by the holding unit (18) in a stand-by stage so that the adhesive tank is contactlessly heated to melt the adhesive, and are moved together from the stand-by position in a longitudinal direction of the sheet stack substantially through an entire area under a back face thereof in a bookbinding stage.

Owner:DUPLO SEIKO CORP

System and method of binding and trimming perfect bound book

A binder / trimmer is disclosed in which a book block is placed in a carriage, jogged to align the pages, and then transported to a milling station in which the spine of the book block is milled to roughen the spine, then to an adhesive application station at which a suitable adhesive is applied to the spine, and thence to a binding station at which the spine of the book is brought into engagement with the center portion of a cover and at which a binding clamp forces the cover against the outer faces of the book block proximate the spine, and then to a trimming station. At the trimming station, the book is deposited in a nest and is positioned relative to a trimming blade which is actuated to trim a first edge of the book to a predetermined dimension. The book is then rotated to trim second and third edges thus resulting in a perfect bound book accurately trimmed to a predetermined size. A method of binding and trimming a perfect bound book is also disclosed.

Owner:杰弗里 D 马什

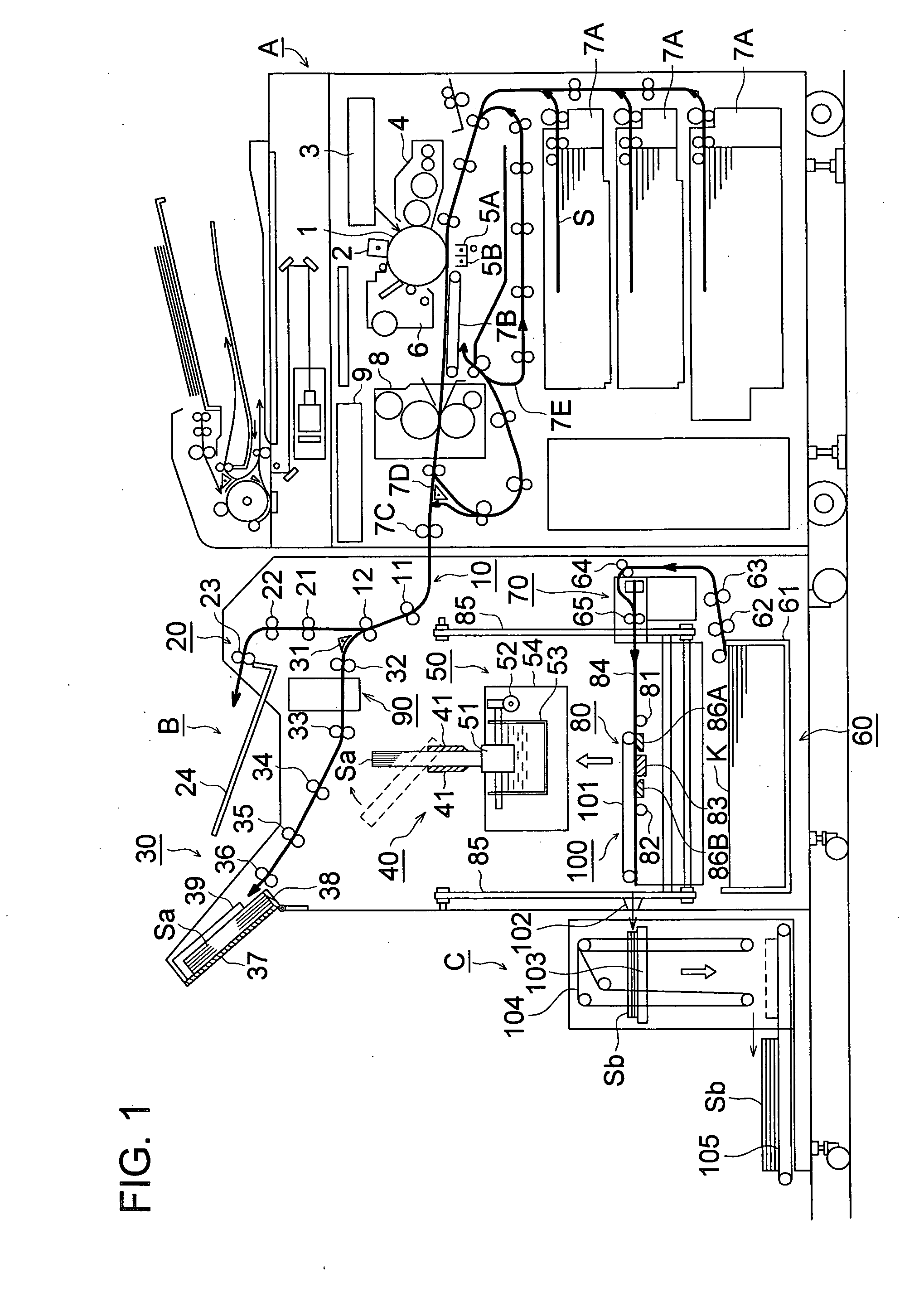

Bookbinding Method, and Bookbinding Unit and Image-Forming System Equipped with the Same

ActiveUS20090035093A1Small sizePrevent leakageFolding thin materialsElectrographic process apparatusImage formationBiomedical engineering

Bookbinding unit that in binding an inner-leave sheet bundle together with a cover enables accurate binding of the cover onto the bundle's spine and meanwhile forms folding scores in the cover flaps. Furnished with: a stacking tray unit; a process path for sequentially transporting bundles from the tray unit into adhesive-application and cover-binding locations; an adhesive application unit, disposed in the adhesive-application location, that applies adhesive to bundles from the tray unit; a cover-supply unit that supplies covers to the cover-binding location; and a cover-binding unit, disposed in the cover-binding location, that binds sheet bundles from the adhesive-application location together with covers. The cover-binding unit has a shoulder-pressing unit that forms spine creases in the spine portion of the covers, and a flap-pressing unit that forms folds in the spine-creased sides of the covers.

Owner:NISCA KK

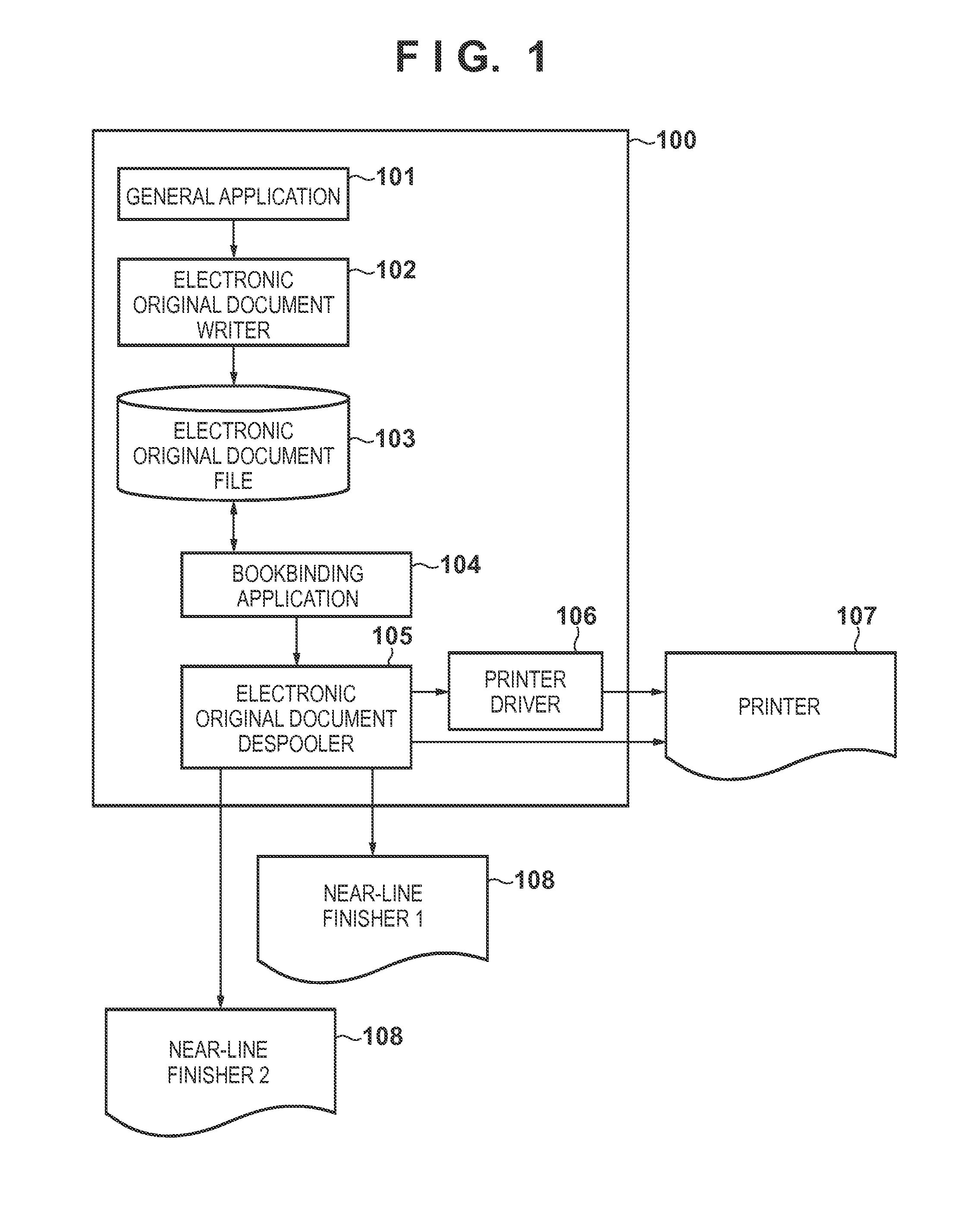

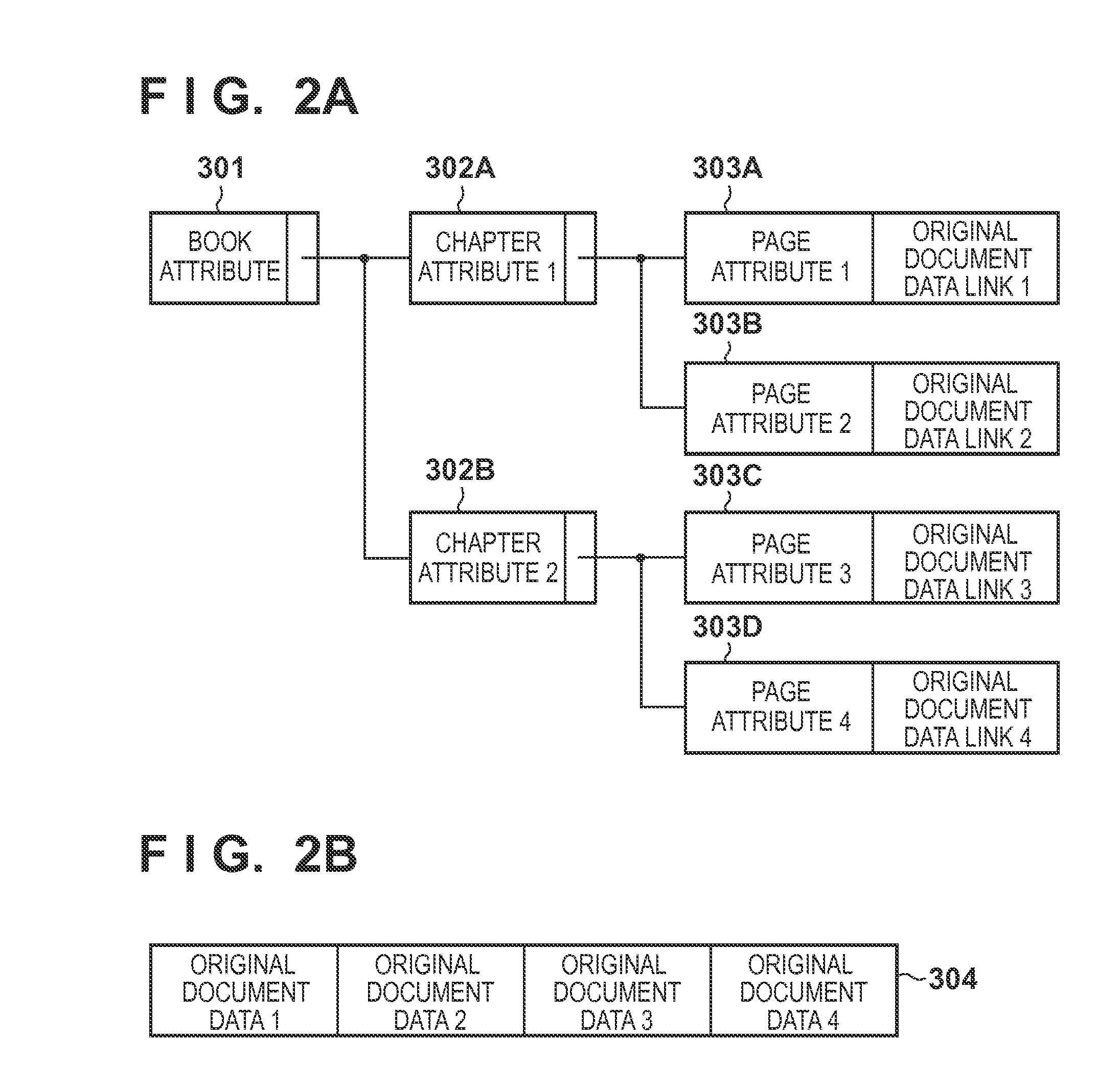

Information processing apparatus and information processing method thereof

InactiveUS20140064882A1Reduce workloadImprove working precisionCasing-inInput/output processes for data processingInformation processingData mining

When two or more post-processing devices are designated for a print job, two or more attribute values (finished size, imposition method, finishing, etc.) of each print attributes which can be set for the print job are allowed to set. When two or more finished size attribute values are set, finished pages having a size smaller than a given finished size and register marks are sequentially laid out in a finished page having the given finished size in a nested manner.

Owner:CANON KK

Adhesive Applicator, and Bookbinding Apparatus and Image-Forming System Equipped with the Applicator

ActiveUS20080056735A1Stable supplyShorten melting timeLiquid surface applicatorsBook making processesTemperature controlEvaporation

In replenishing a glue container with hot-melt glue, to enable stable supply of the glue in solid form without it clogging the resupply path from the hopper, provided are: a sheet retaining unit for retaining a sheaf in a glue application position; a glue applier in a hot-melt-glue-receiving container, disposed in the glue application position, for applying glue to an endface of a sheaf there; a heater, disposed in the glue container, for heating / melting the glue inside; a heater temperature controller; a resupply hopper above the glue container for replenishing it with solid glue; a vacuum ducting unit above the container and adjoining the resupply hopper, for suctioning up glue evaporation derivatives; and a control unit configured to run the vacuum ducting unit when the glue container is being replenished with glue, to prevent or mitigate invasion of evaporation derivatives into the resupply hopper.

Owner:NISCA KK

Apparatus and method of on demand printing, binding, and trimming a perfect bound book

InactiveUS20060140743A1Inexpensive provisionImprove productivityOther printing matterBook making processesComputer graphics (images)Computer printing

Owner:PERFECT SYST

Bookbinding device and image forming apparatus

InactiveUS20070286705A1Long cooling timeShort cooldownBook making processesElectrographic process apparatusAdhesiveEngineering

A bookbinding device includes a collecting device for collecting sheets into a bundle and a bookbinding path that includes a sheet bundle conveying device, an adhesive applying device, a cover binding device, and a cover sheet feeding path. The cover binding device includes a back folding press member for the cover sheet and a back rest plate member to back up the cover sheet. A control device allows the back folding press member to execute a back folding process with a small gap formed between the back rest plate member and a back of the sheet bundle. The control device further allows the back of the sheet bundle to abut against the back rest plate member to forcibly cool the adhesive. The control device varies the time required for the cooling depending on the thickness of the sheet bundle.

Owner:NISCA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com