System and method of binding and trimming perfect bound book

A book cutting technology, applied in the direction of binding adhesives, book binding, book case, etc., can solve the problem of expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

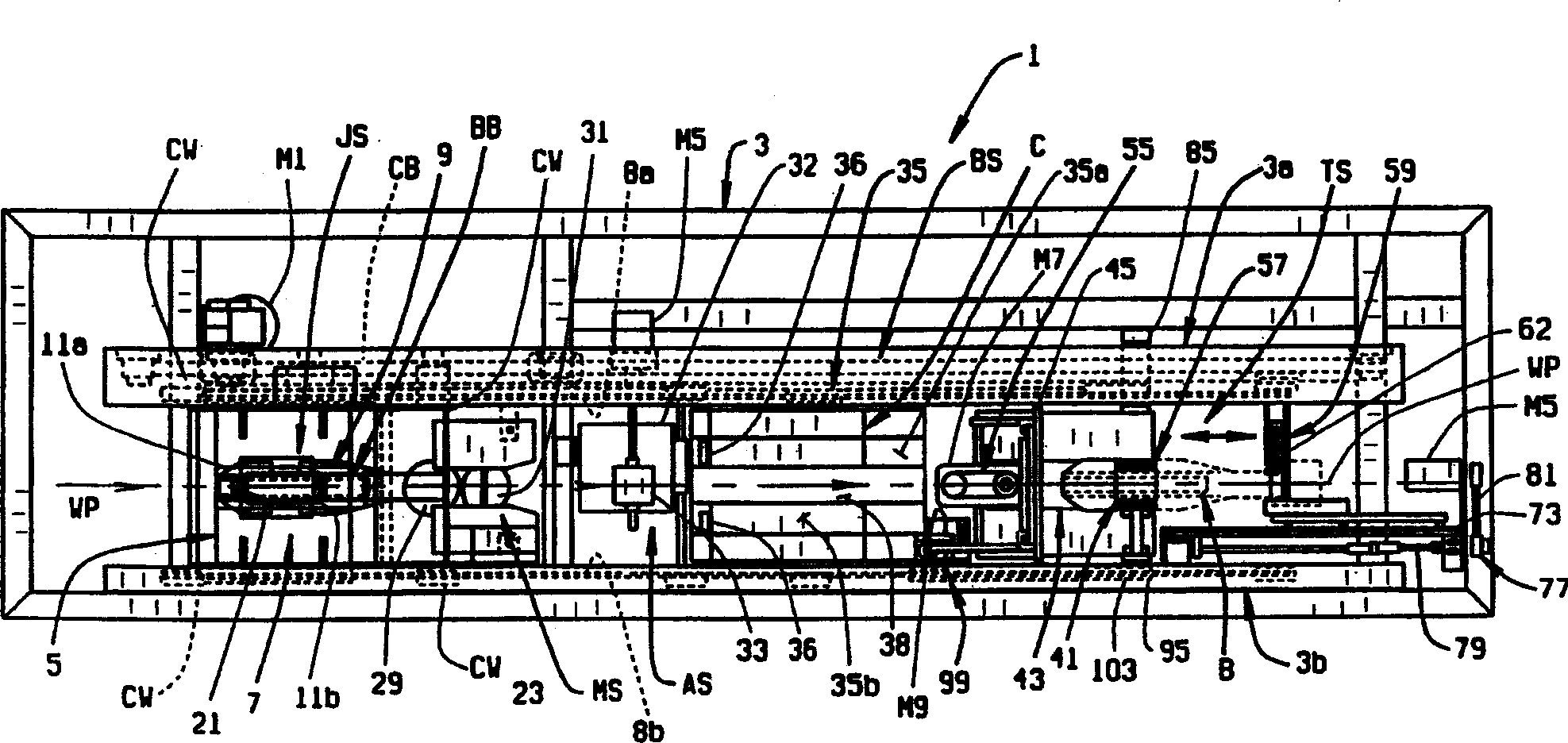

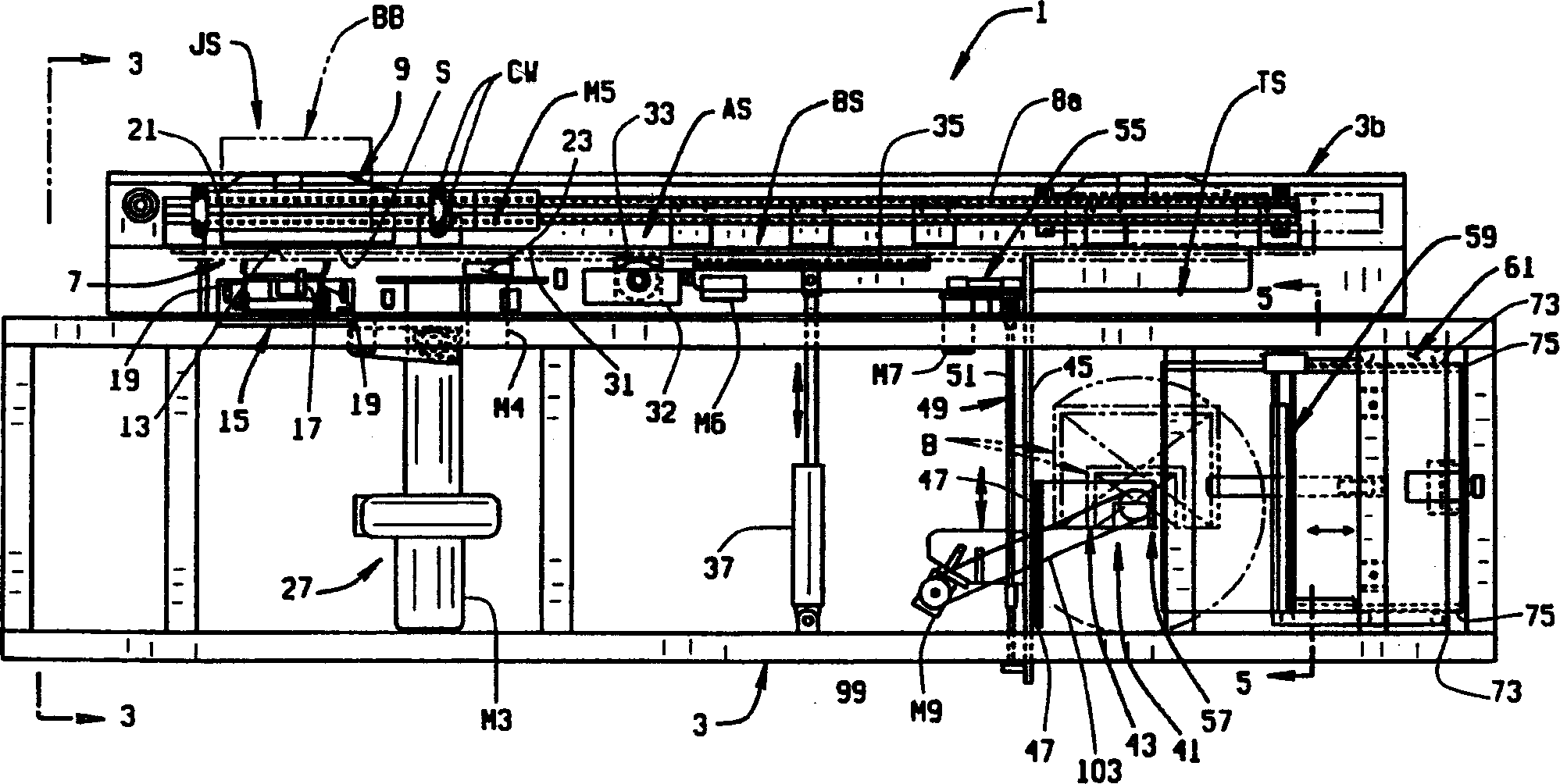

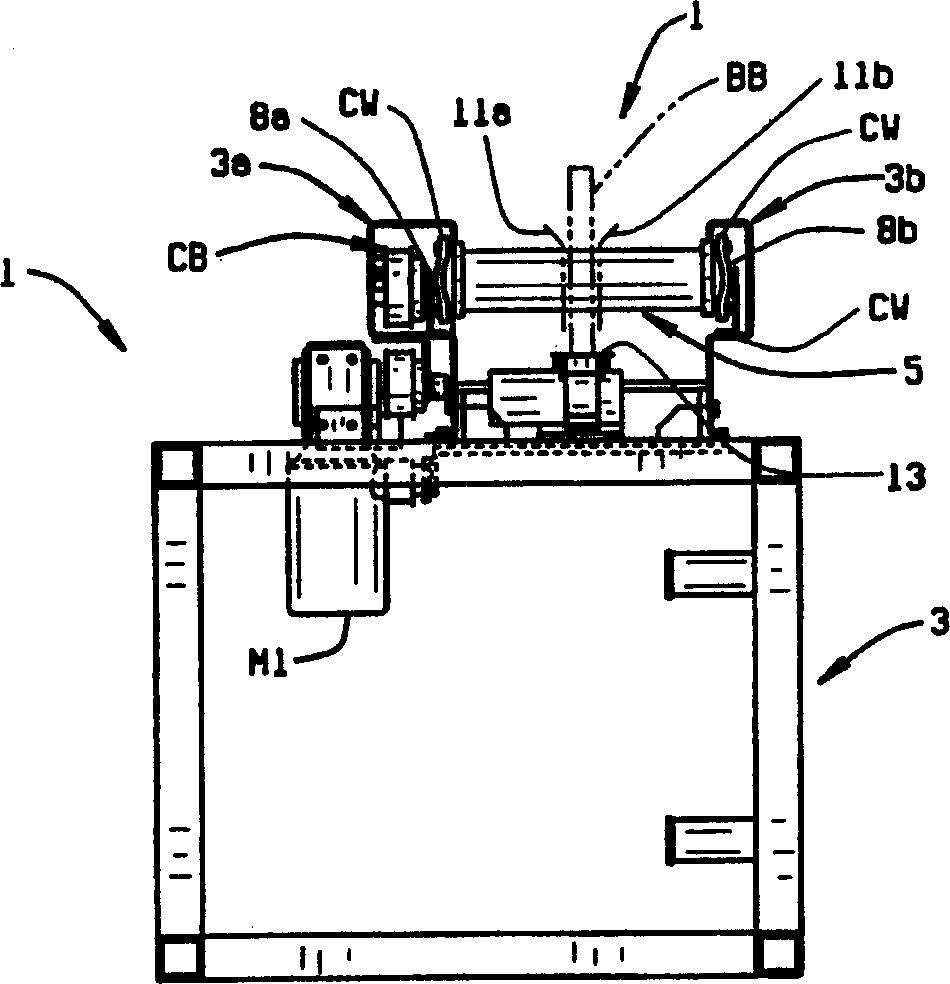

[0030] Referring now to the accompanying drawings, a binding / cutting device of the present invention is represented by a symbol 1 as a whole. This binding / cutting device has a support 3 welded by square steel pipes. A housing may be secured to the bracket, but this has been omitted for clarity. The support has a pair of alternate horizontal support guide rails 3a, 3b extending generally along the longitudinal direction of the binding / cutting device. A conveyor 5 is provided between the carriage rails for transferring or transporting a book block BB along the working path wp in the manner described below. Conveyor 5 comprises a trolley 7 movable in horizontal direction, said trolley 7 is supported on trolley rails 8a, 8b by sheave wheels CW, preferably as image 3 As shown, the trolley guide rails 8a, 8b are installed on the bracket guide rails 3a, 3b respectively. The conveyor stepper motor M1 powers the trolley along the trolley guide rail, and the conveyor stepper motor d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com