Patents

Literature

571results about "Bookbinding presses" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

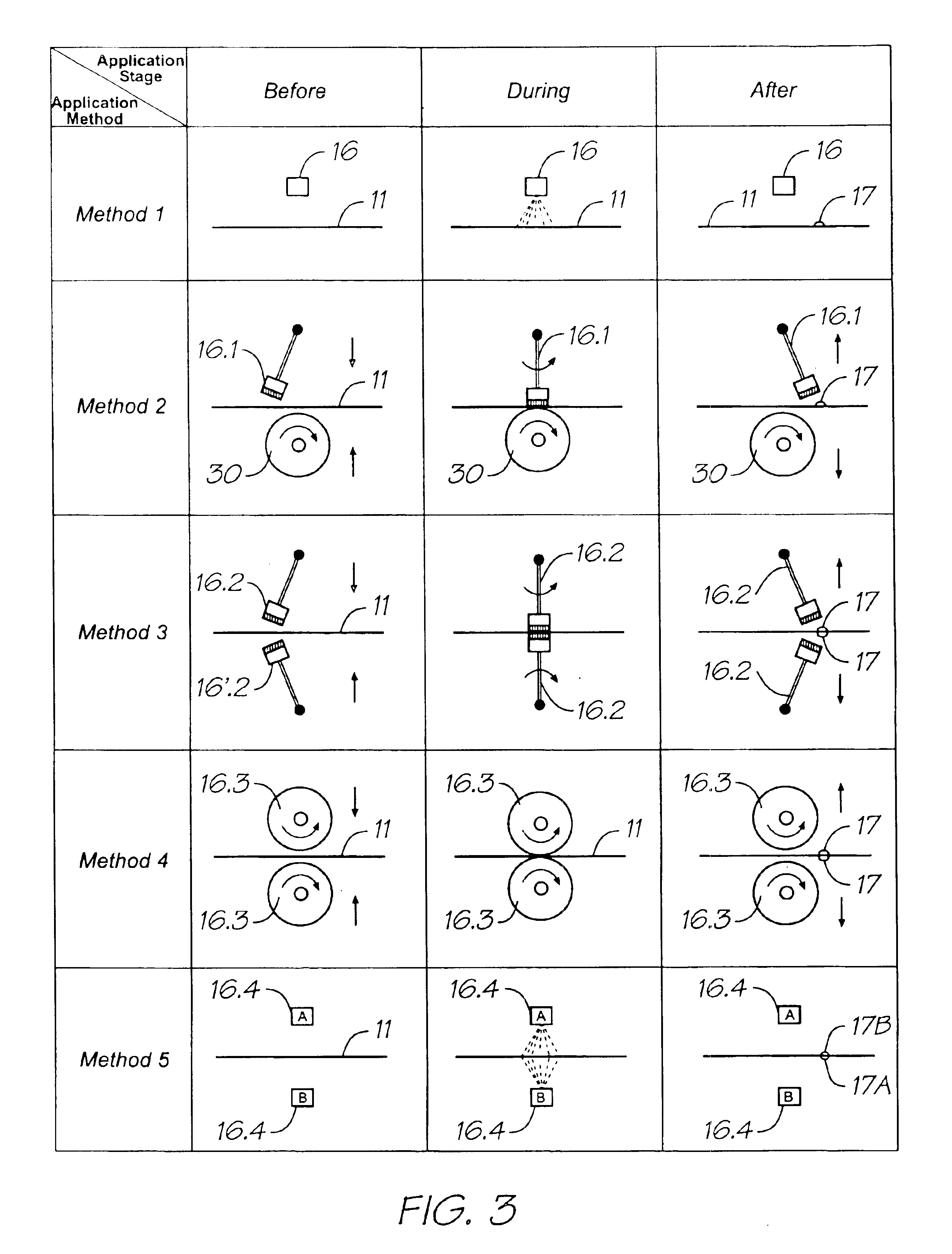

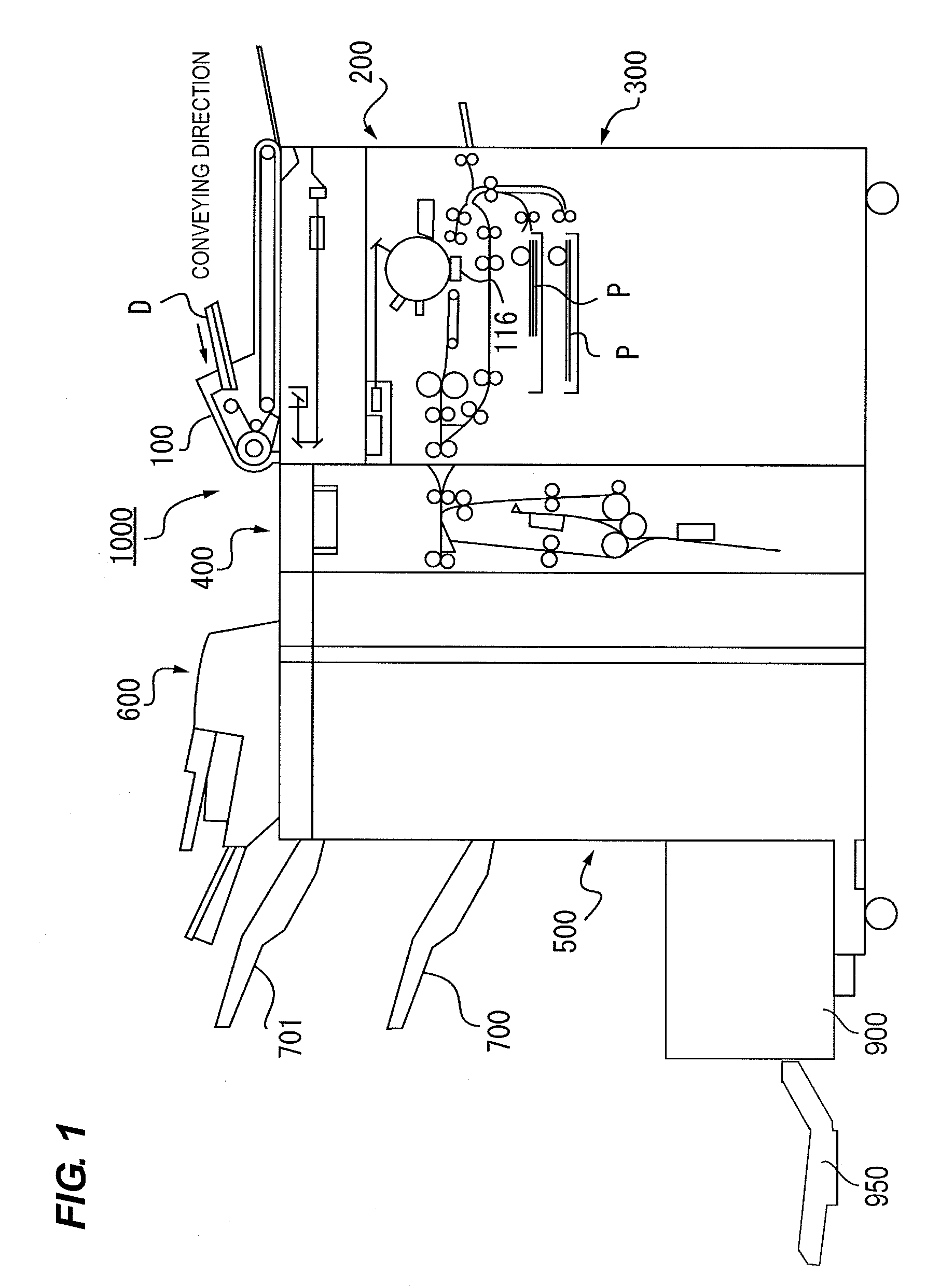

Booklet maker

A low cost, high speed, high resolution laser printer method and apparatus for re-writable media is presented. A method for finishing of printed sheets into booklets is described. Novel mechanical operations permit the manufacture of a very low-cost, off-line booklet maker for use with desktop laser and ink jet printers. The technology can scale to medium-speed, in-line booklet manufacture. The method is novel because most of the finishing operations are performed on a sheet-by-sheet basis using precision paper positioning and a transverse tool carrier that cuts, scores, folds, punches, and staples the sheets. To form a finished saddle-stitched booklet, each sheet is cut to length determined by its sequence in the booklet and paper thickness, scored, punched (if required), folded, accumulated in a stack, and stapled. The sheet-wise method allows finishing operations to be done with low-cost tools and low actuation forces.

Owner:HEWLETT PACKARD DEV CO LP

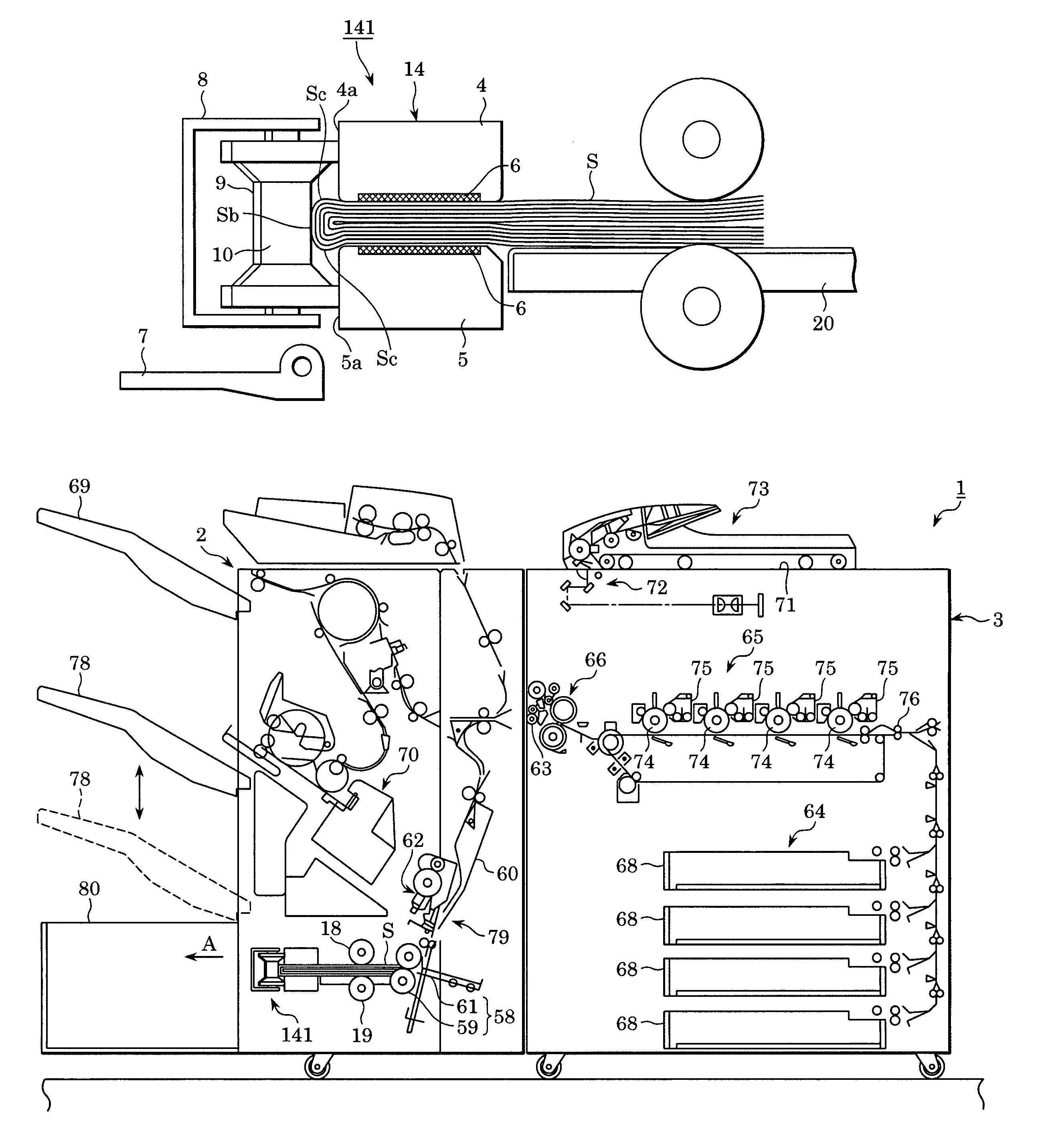

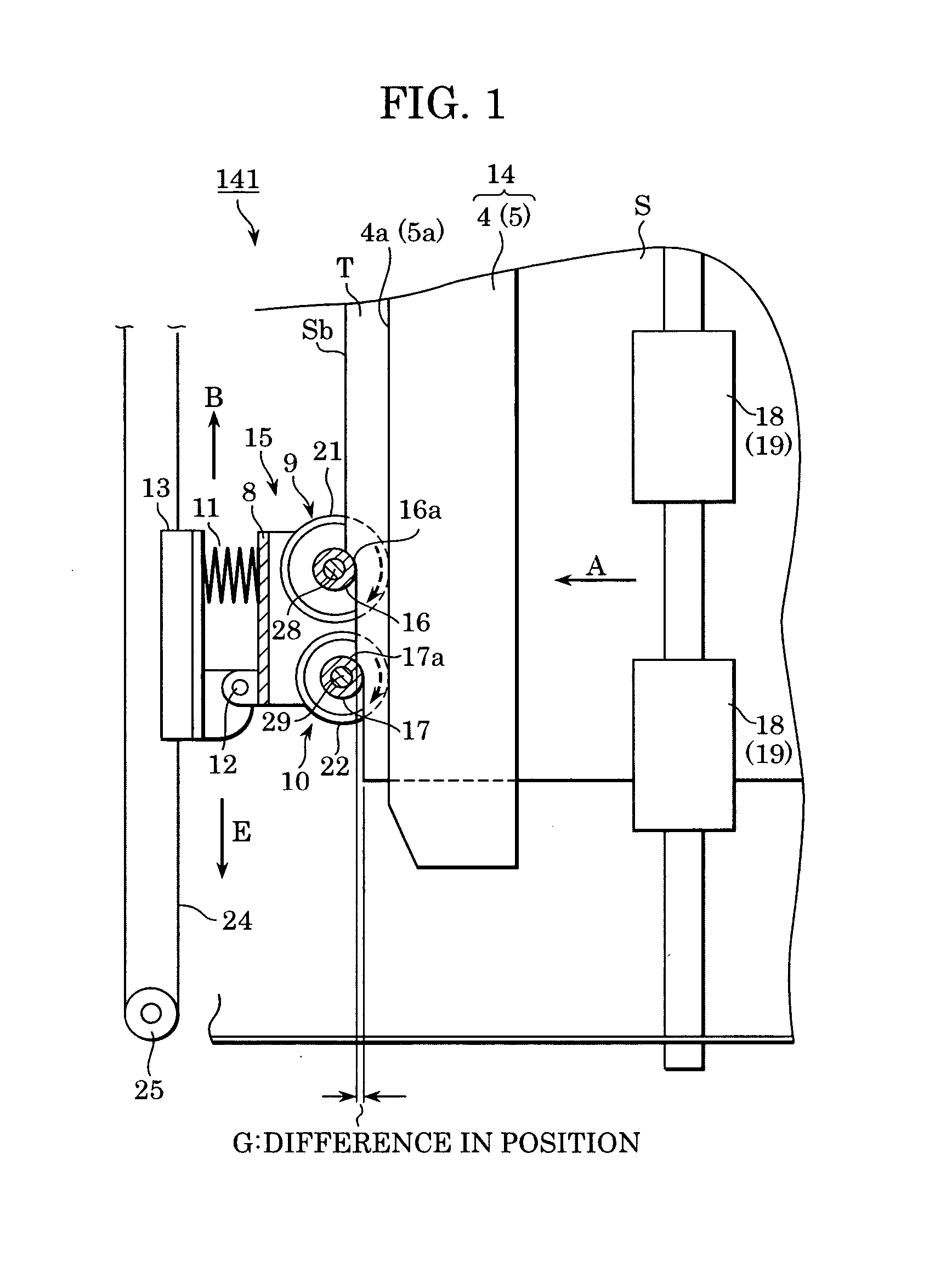

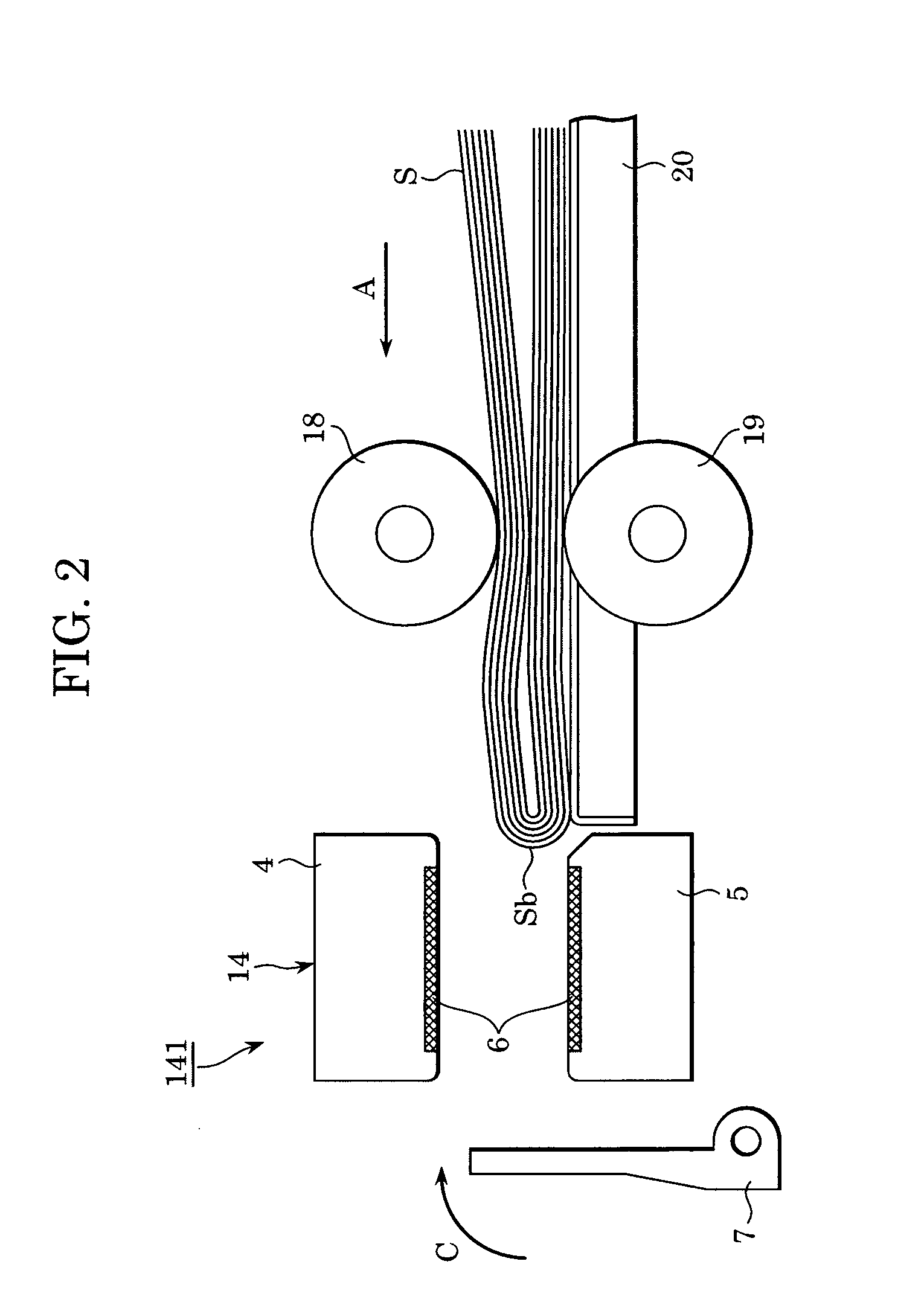

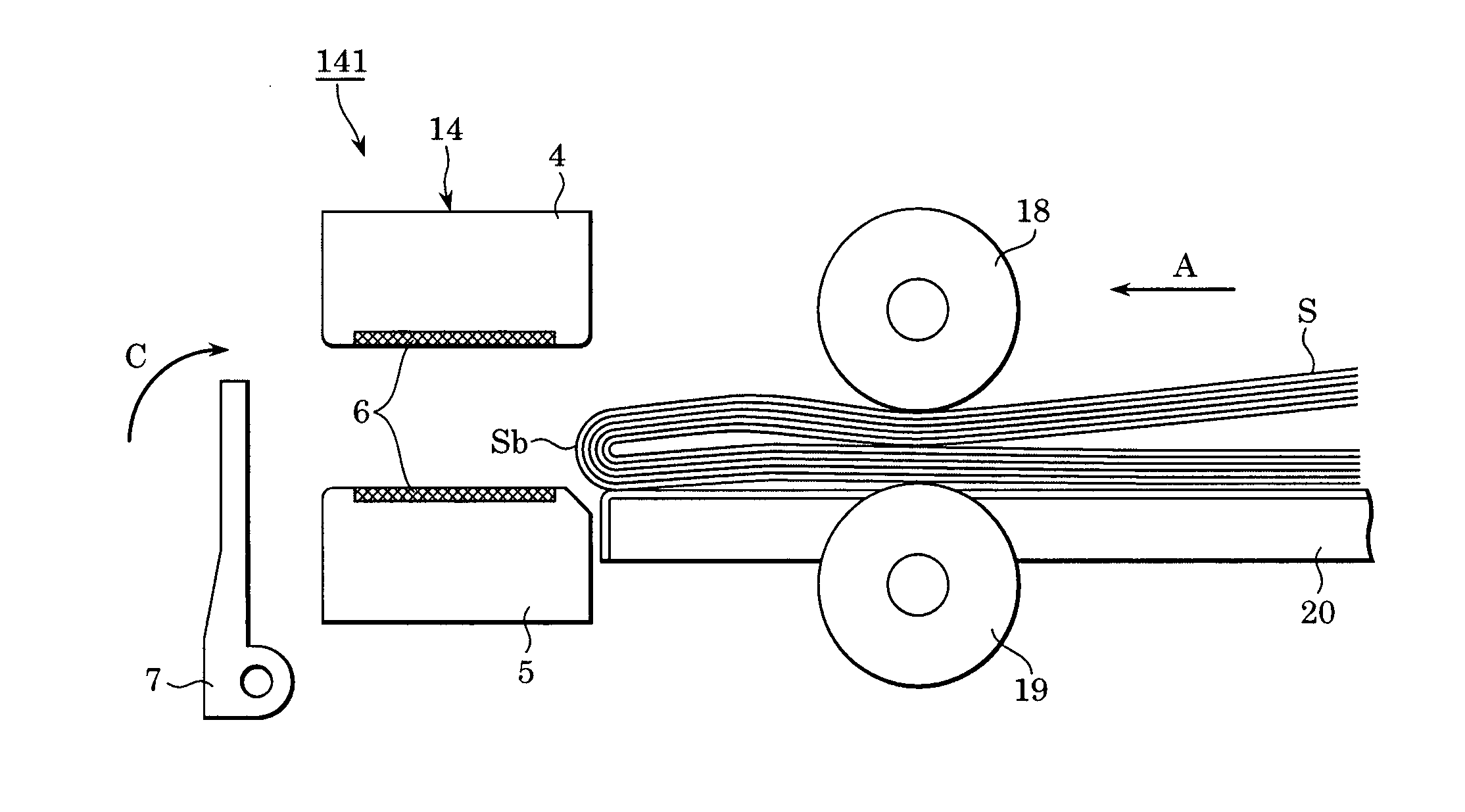

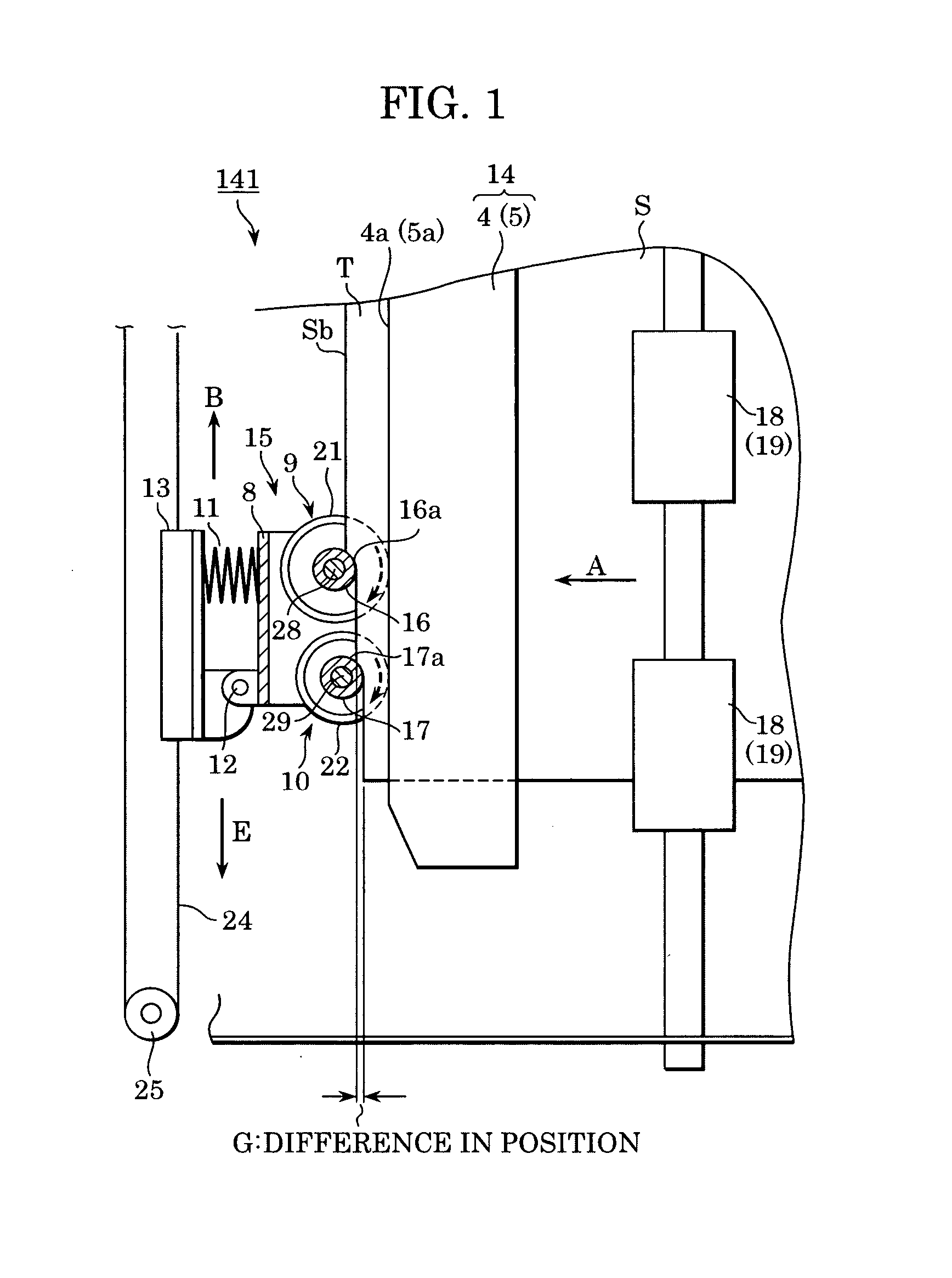

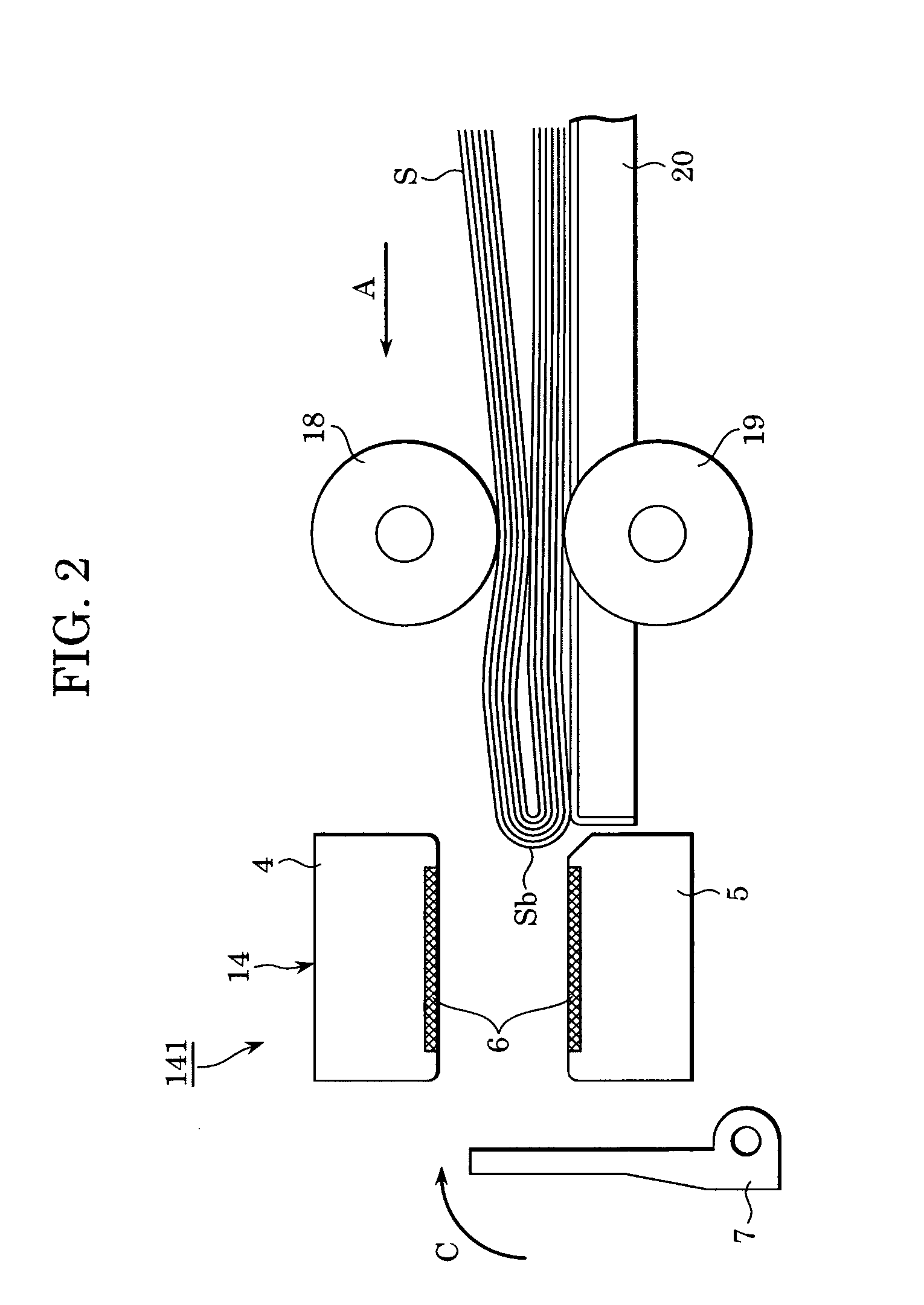

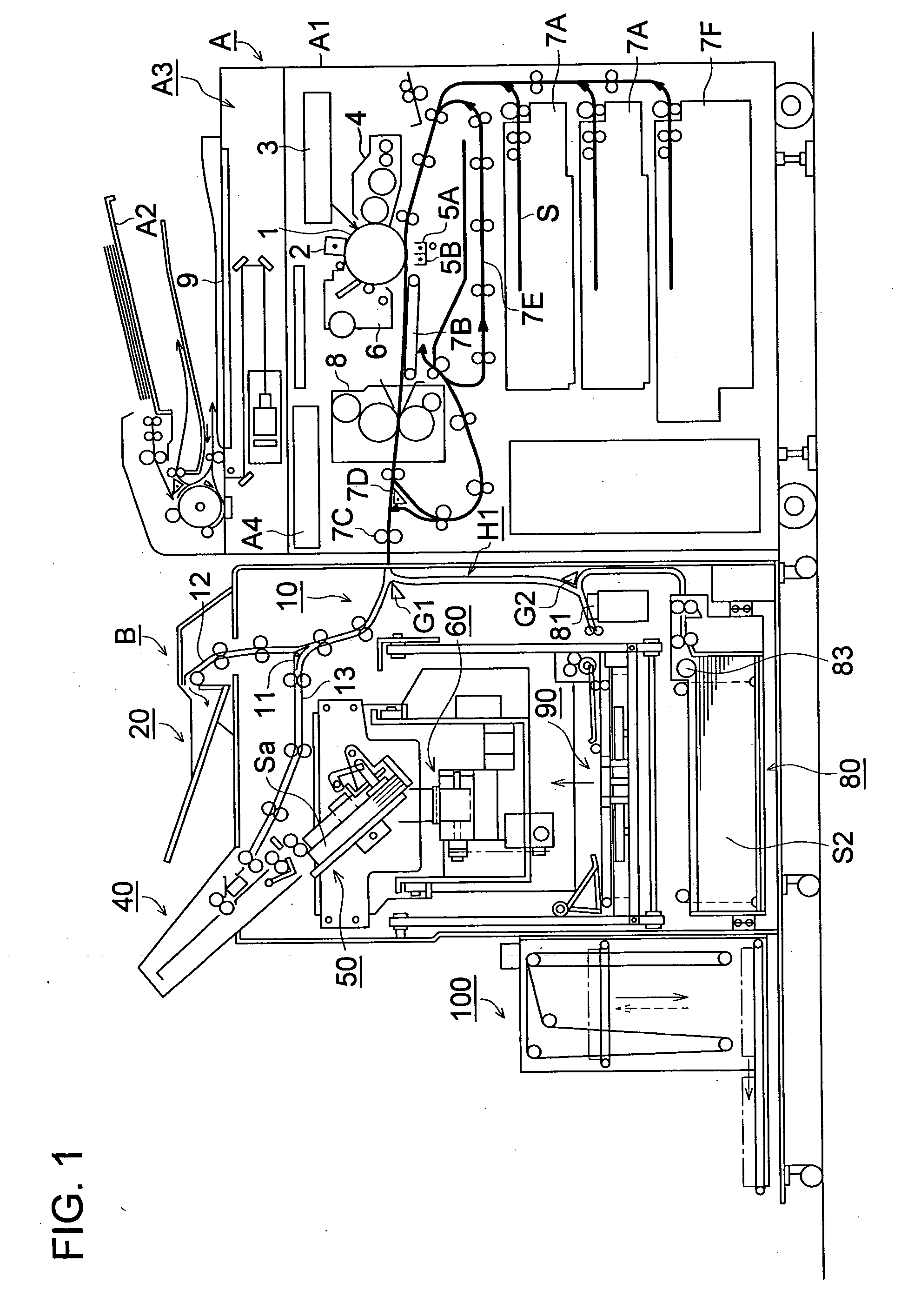

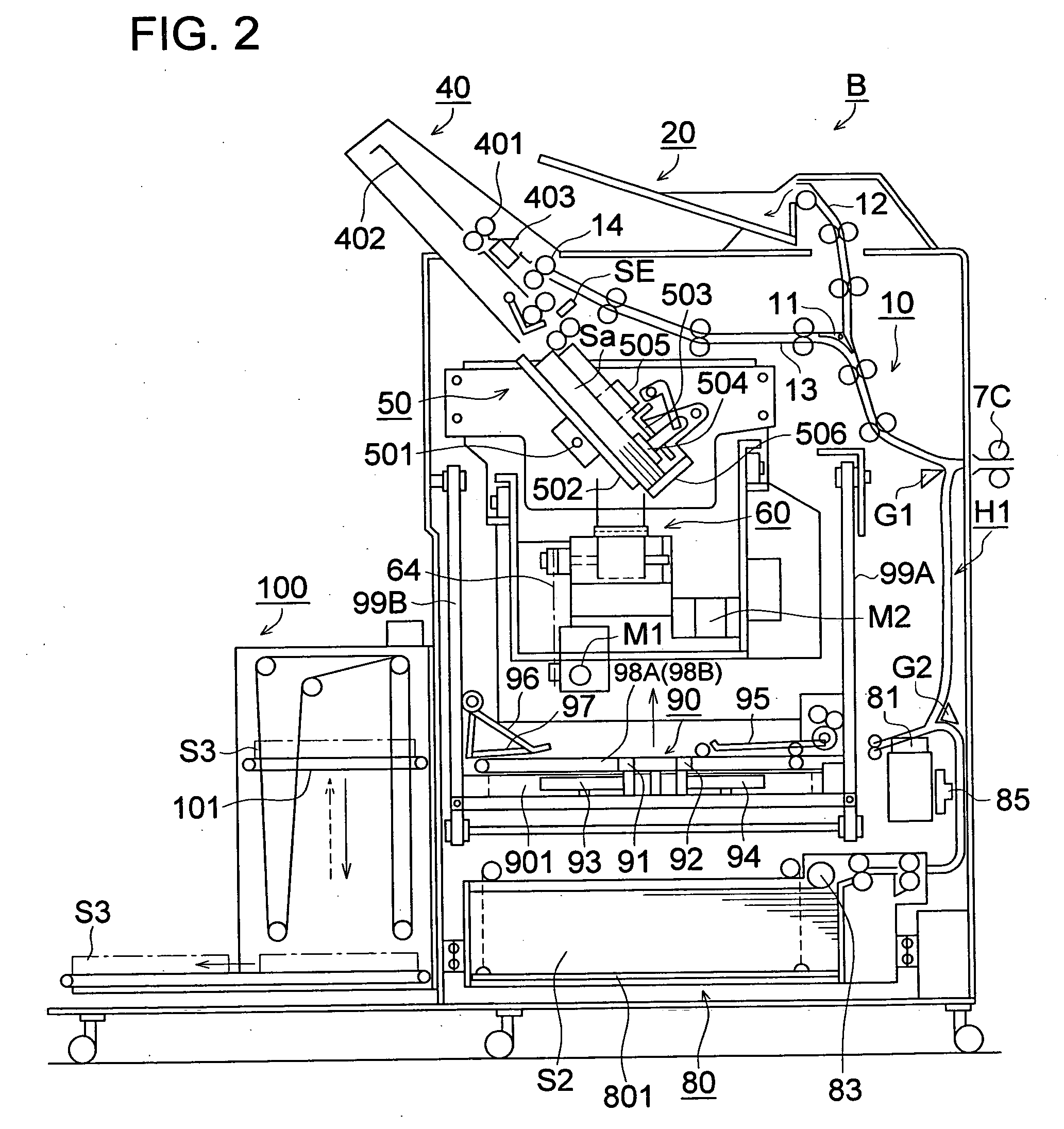

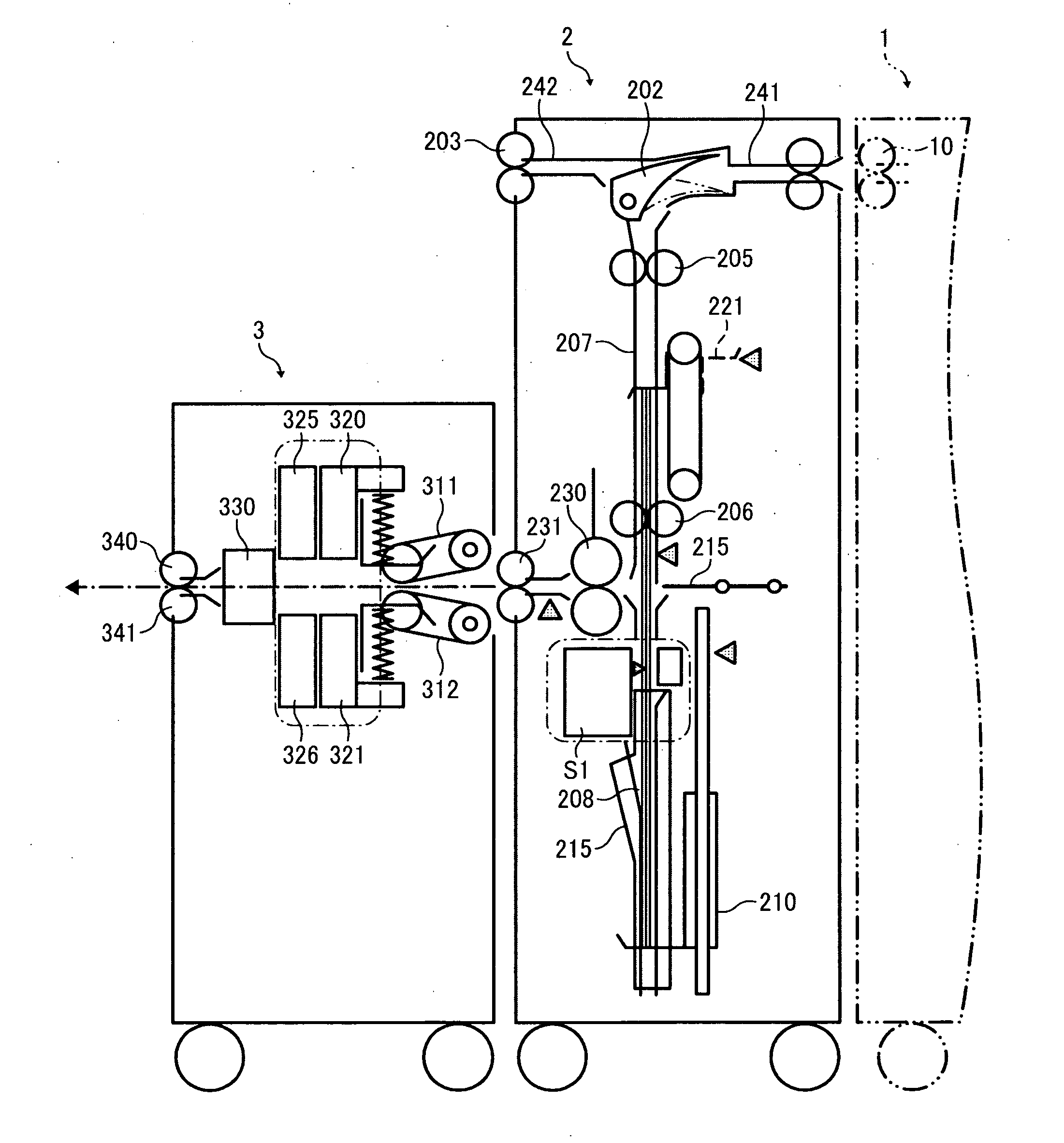

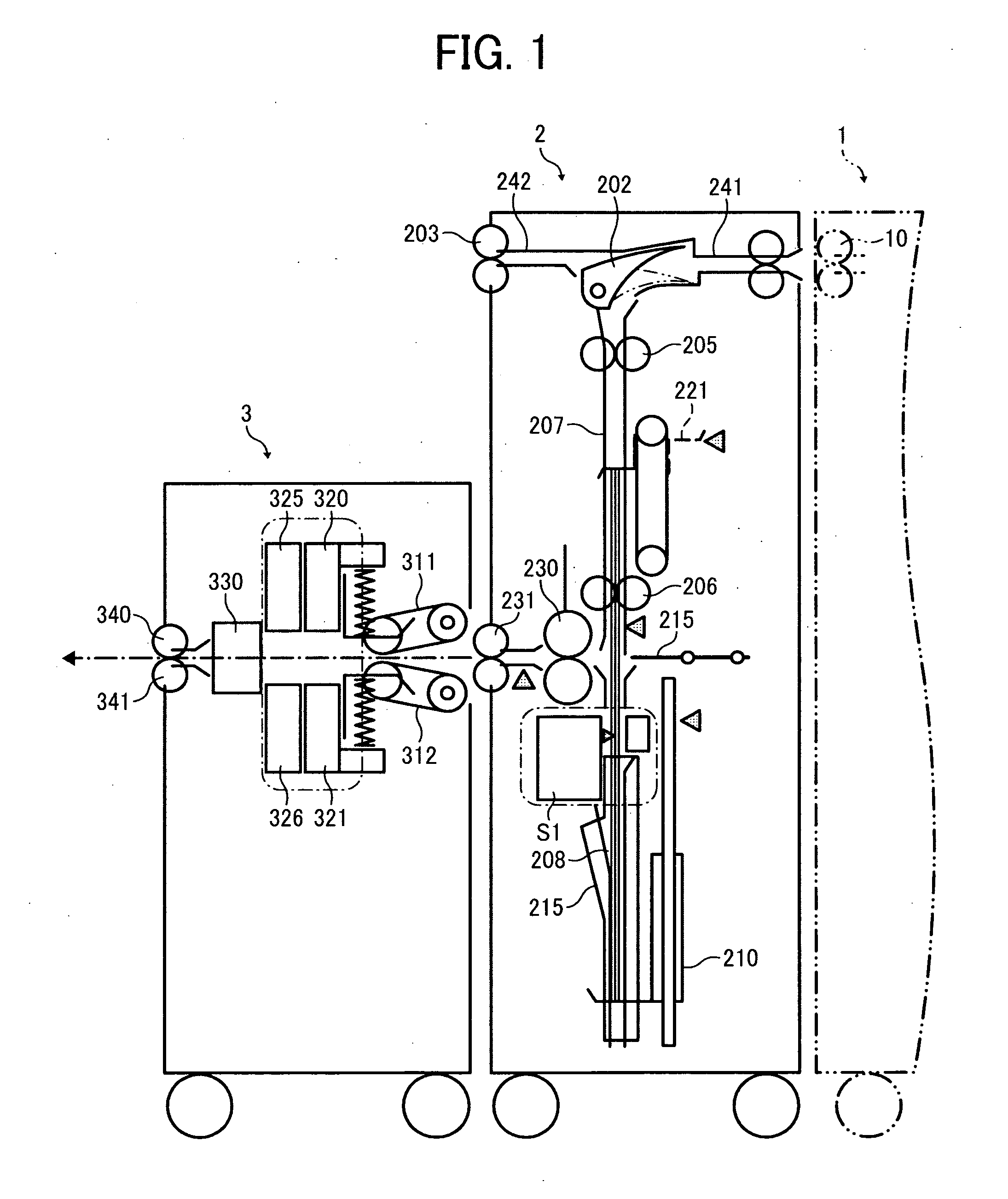

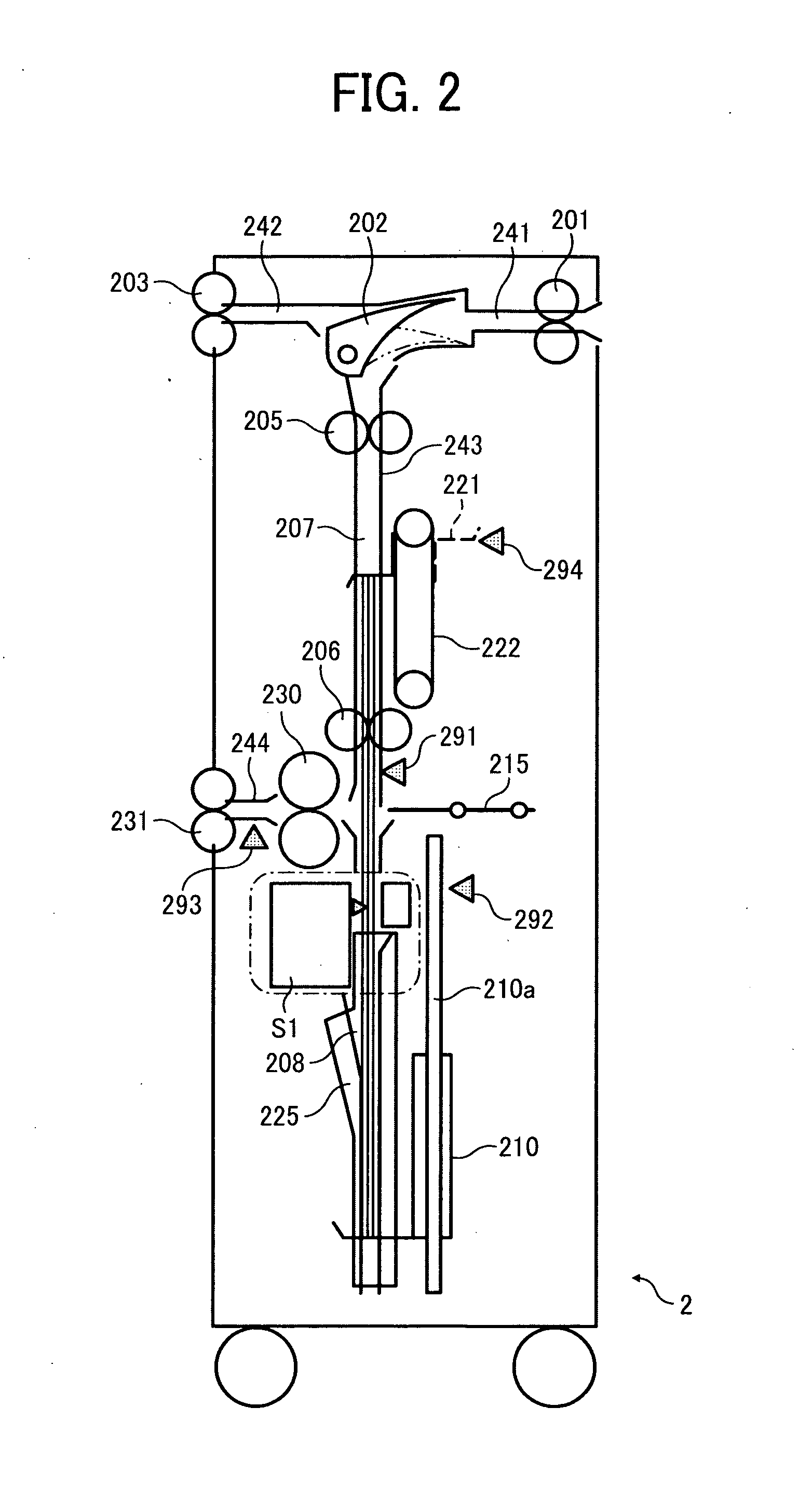

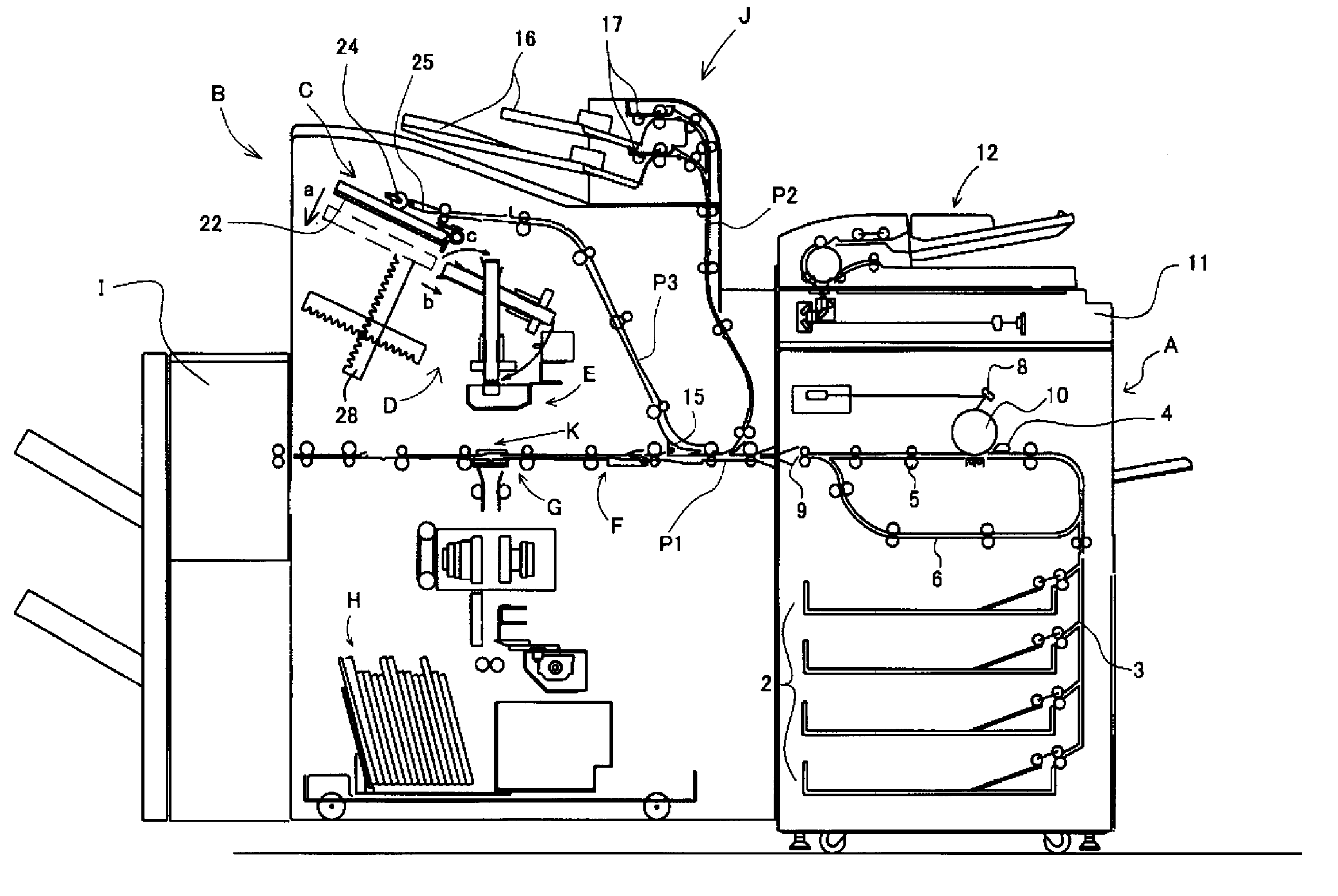

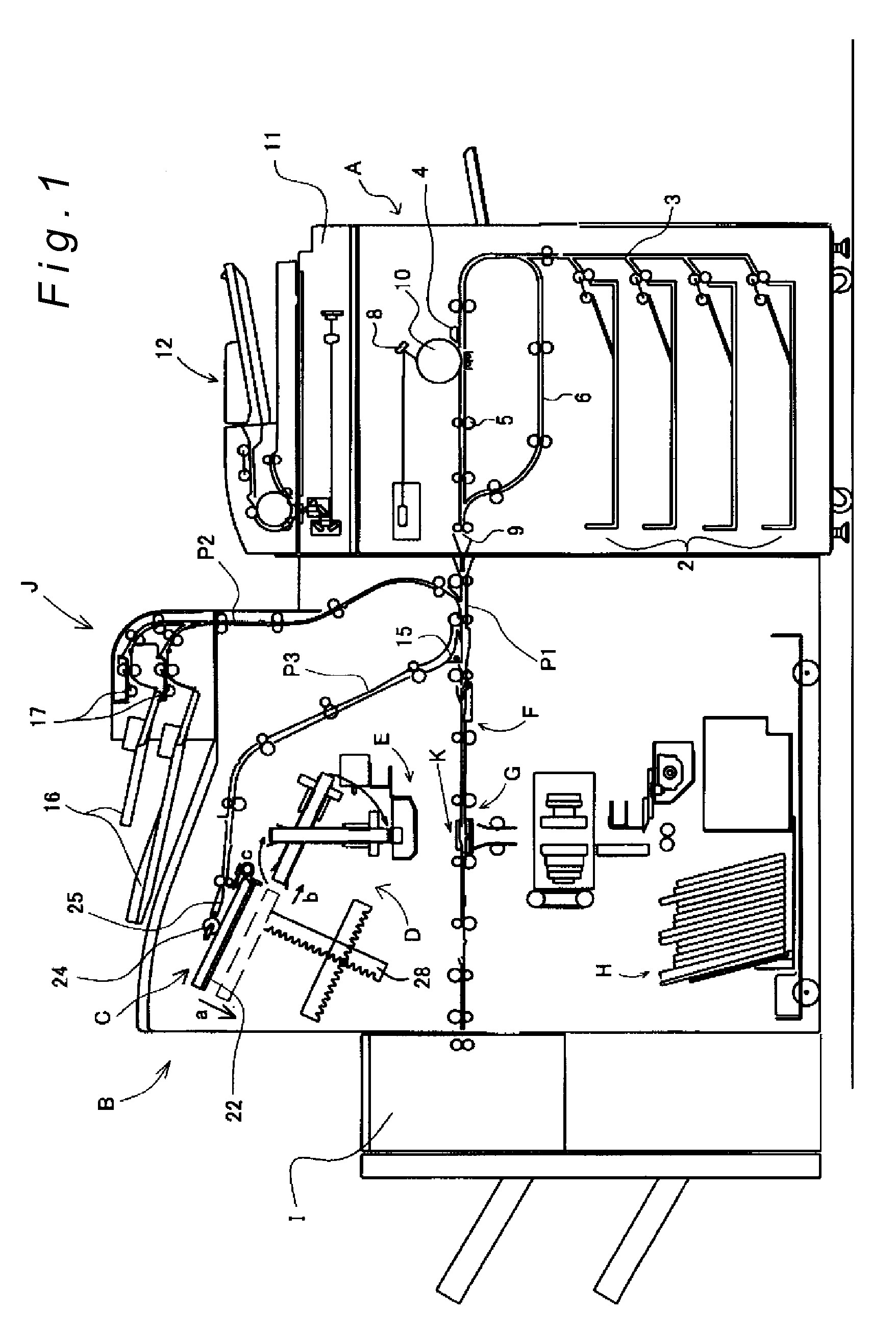

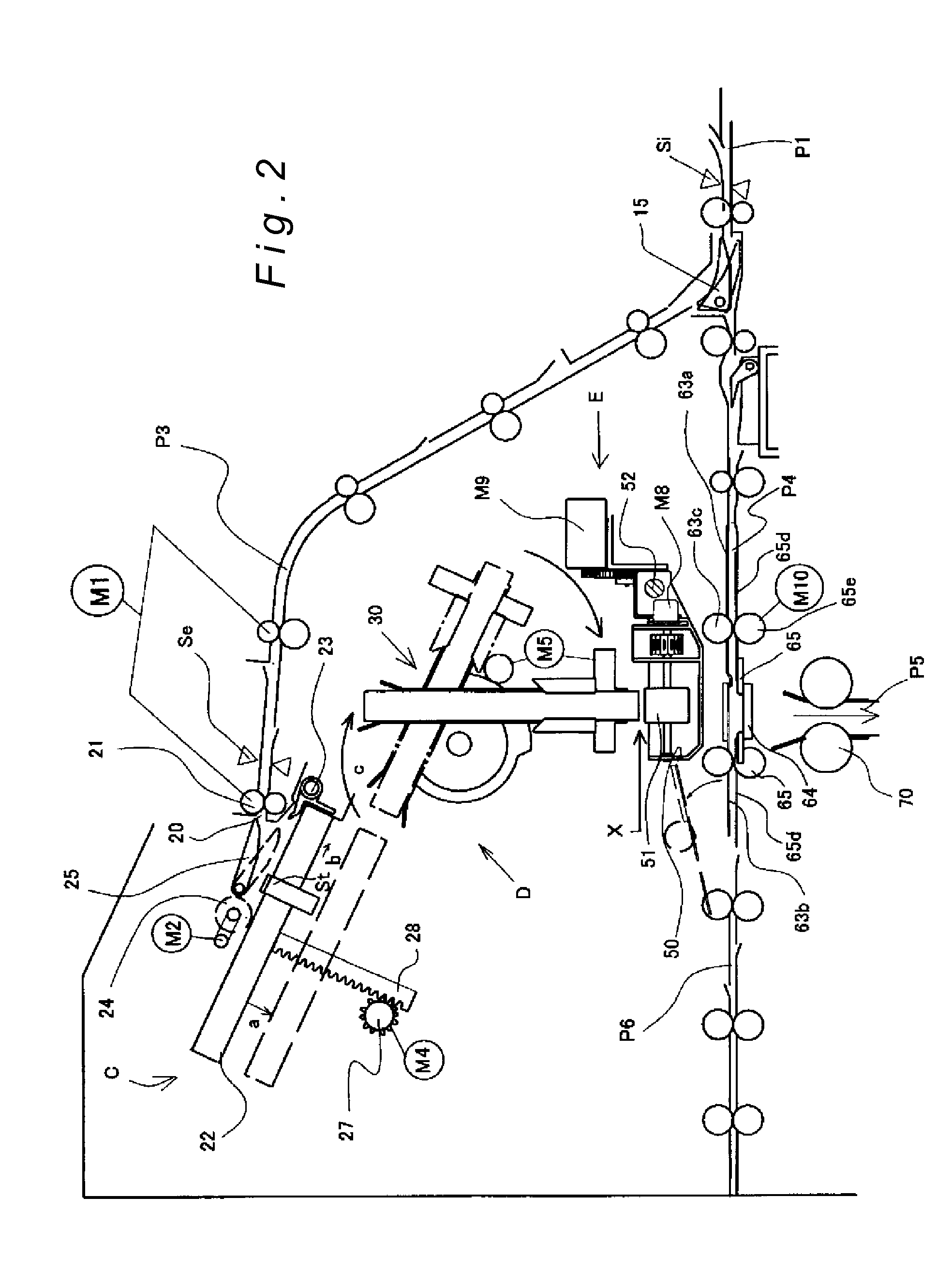

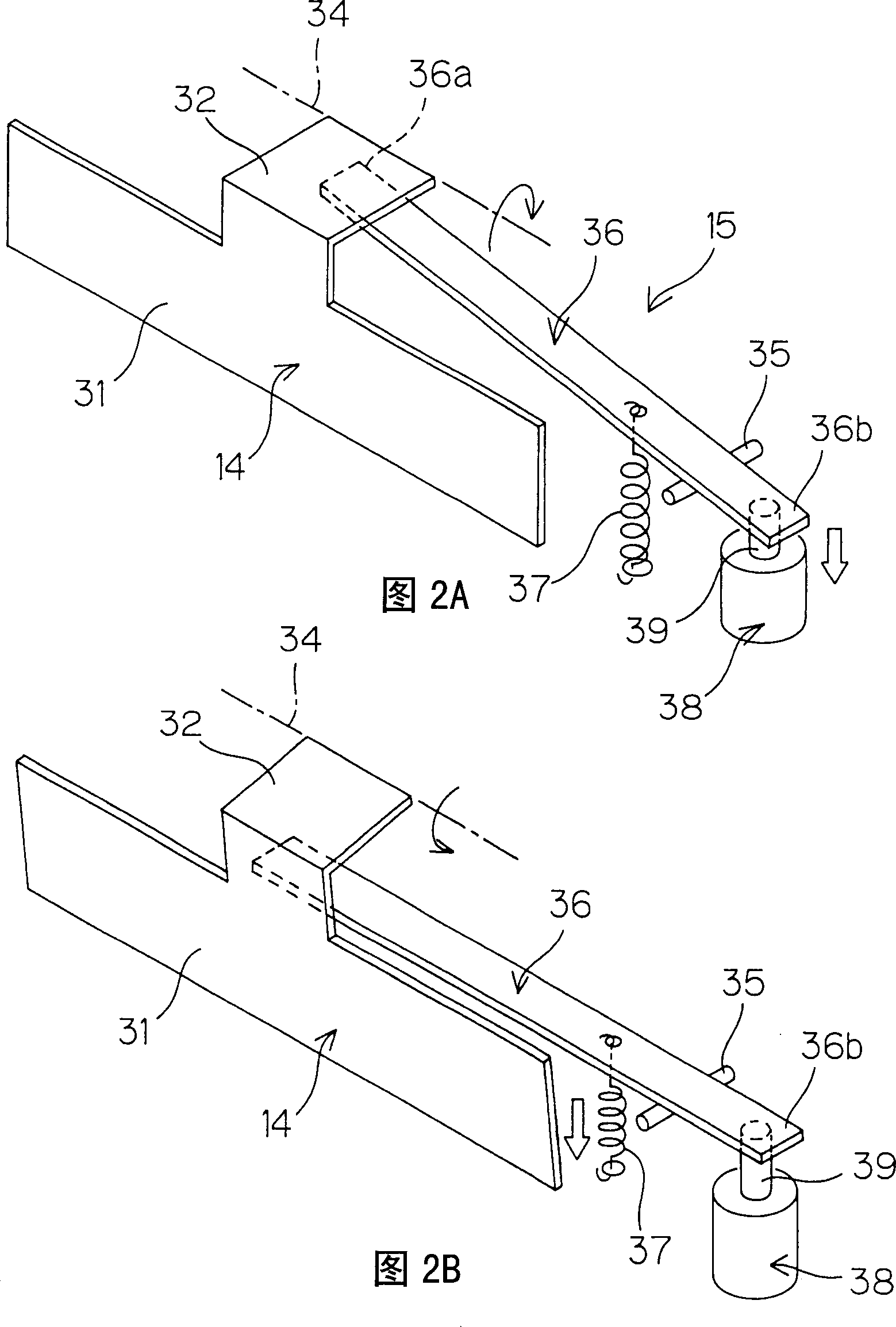

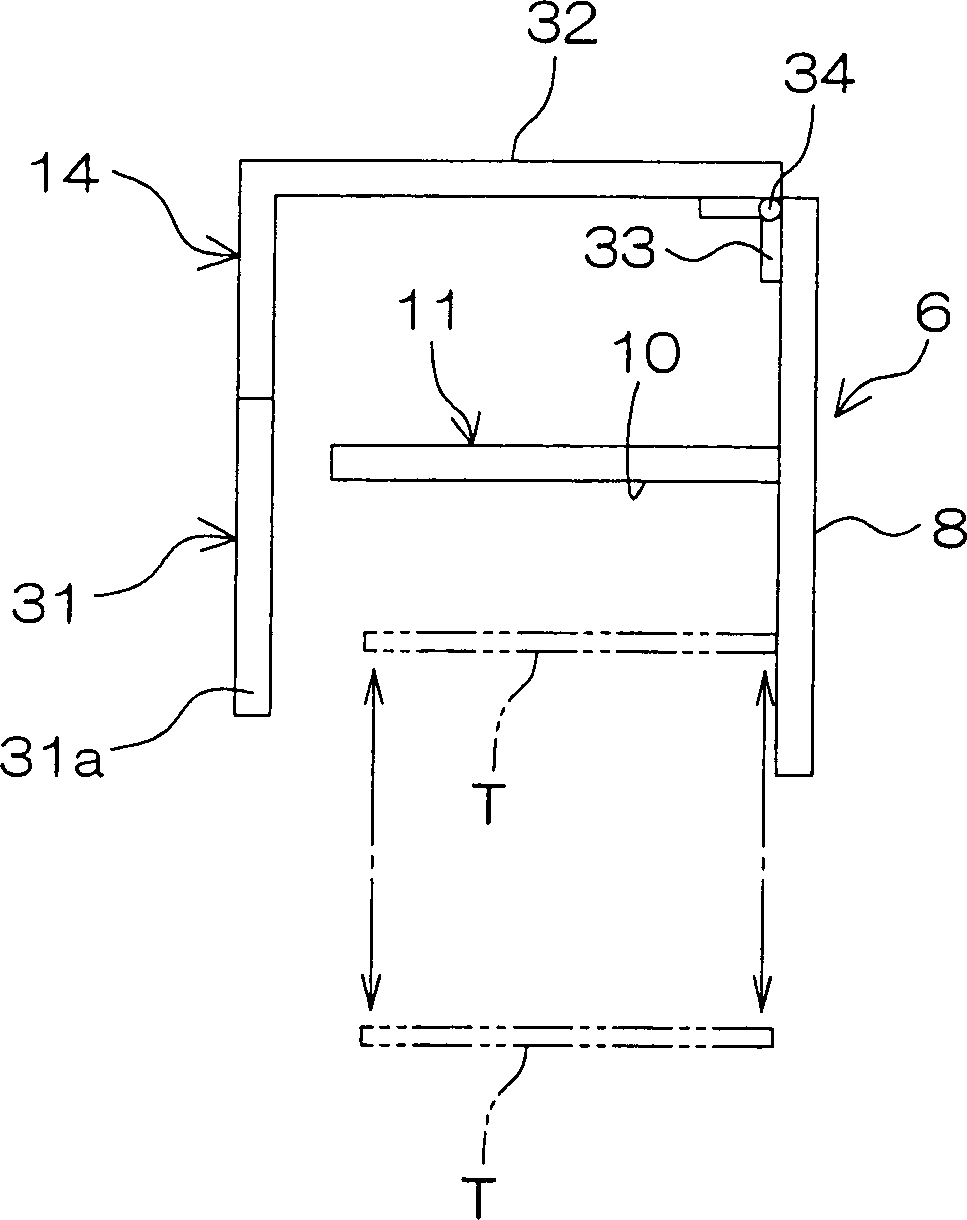

Folded back portion flattening device, sheet processor, and image forming apparatus

ActiveUS7147598B2Reduce loadImprove processing efficiencyMechanical working/deformationBook making processesEngineeringMechanical engineering

Owner:CANON KK

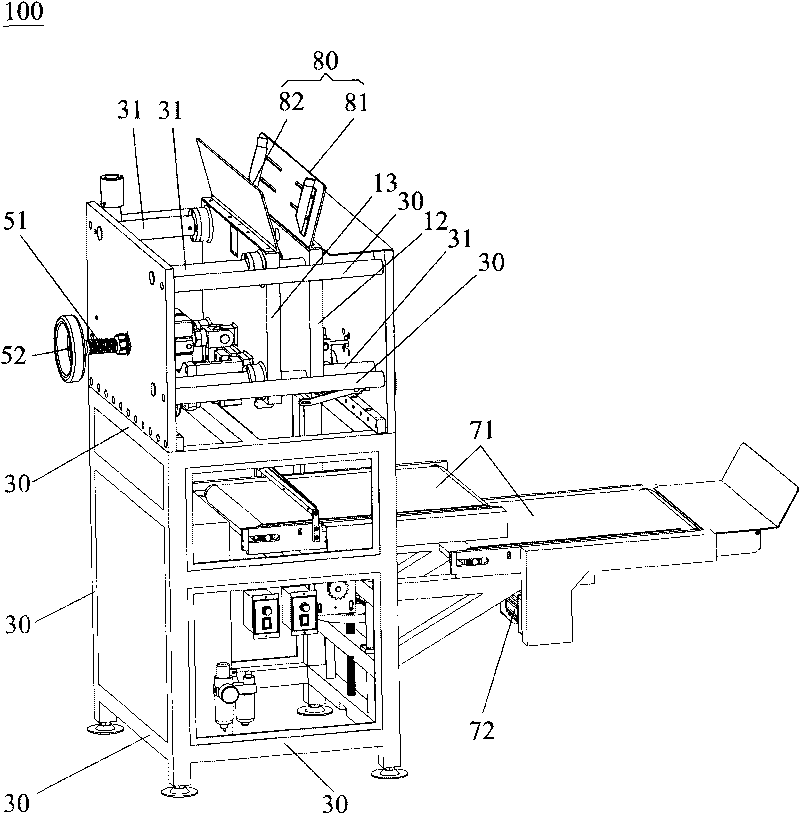

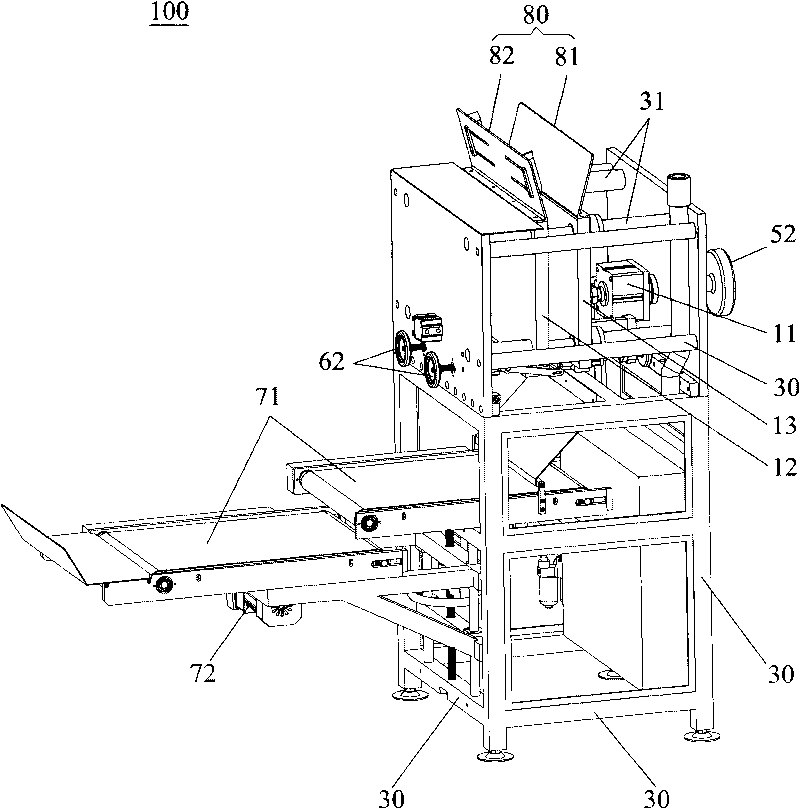

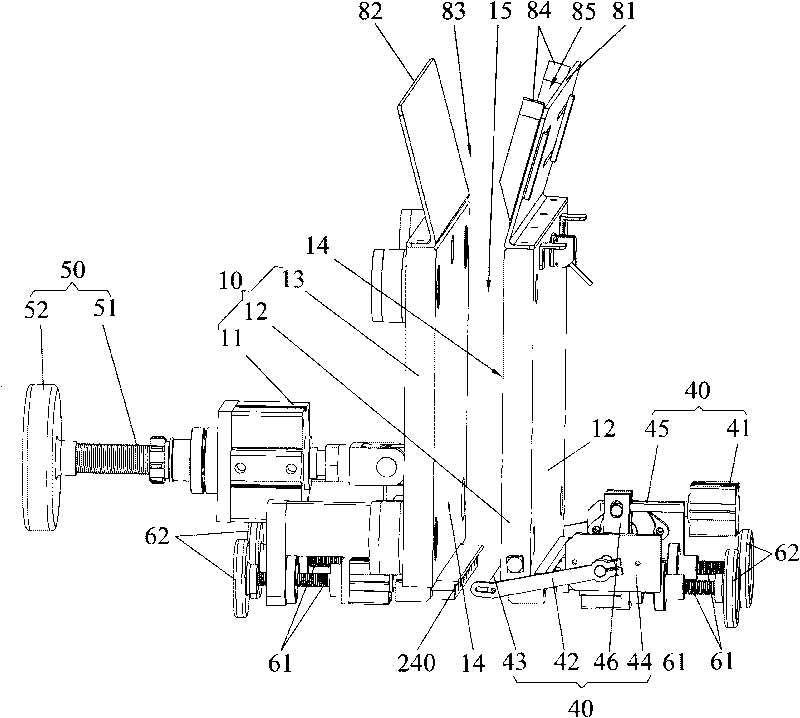

Leveling and channel forming integrated machine

InactiveCN101734038AShort processShorten the production cycleBookbinding pressesLeveling mechanismElectrical and Electronics engineering

The invention discloses a leveling and channel forming integrated machine, wherein a leveling mechanism comprises a leveling cylinder, a first pressure plate and a second pressure plate; both the first pressure plate and the second pressure plate are provided with flat press surfaces which are oppositely arranged to form a leveling area; the leveling cylinder is connected with the second pressure plate; a channel forming mechanism comprises a first channel forming cylinder, second channel forming cylinder, a first channel forming plate and a second channel forming plate; the first channel forming cylinder is connected with the first channel forming plate; the second channel forming cylinder is connected with the second channel forming plate; the edges of the first and the second channel forming plates are provided with channel forming protruding parts which are oppositely arranged to form a channel forming area, and the channel forming area is just positioned below the leveling area; and the leveling mechanism and the channel forming mechanism are arranged on a mounting frame. The machine can complete leveling and channel forming for books and periodicals with hard covers in one step, and has the advantages of simple and compact structure, easy operation, convenient maintenance and low cost.

Owner:何钰婷

Folded back portion flattening device, sheet processor, and image forming apparatus

ActiveUS20050191154A1Reduce loadImprove processing efficiencyMechanical working/deformationBook making processesMechanical engineeringPinch grip

Owner:CANON KK

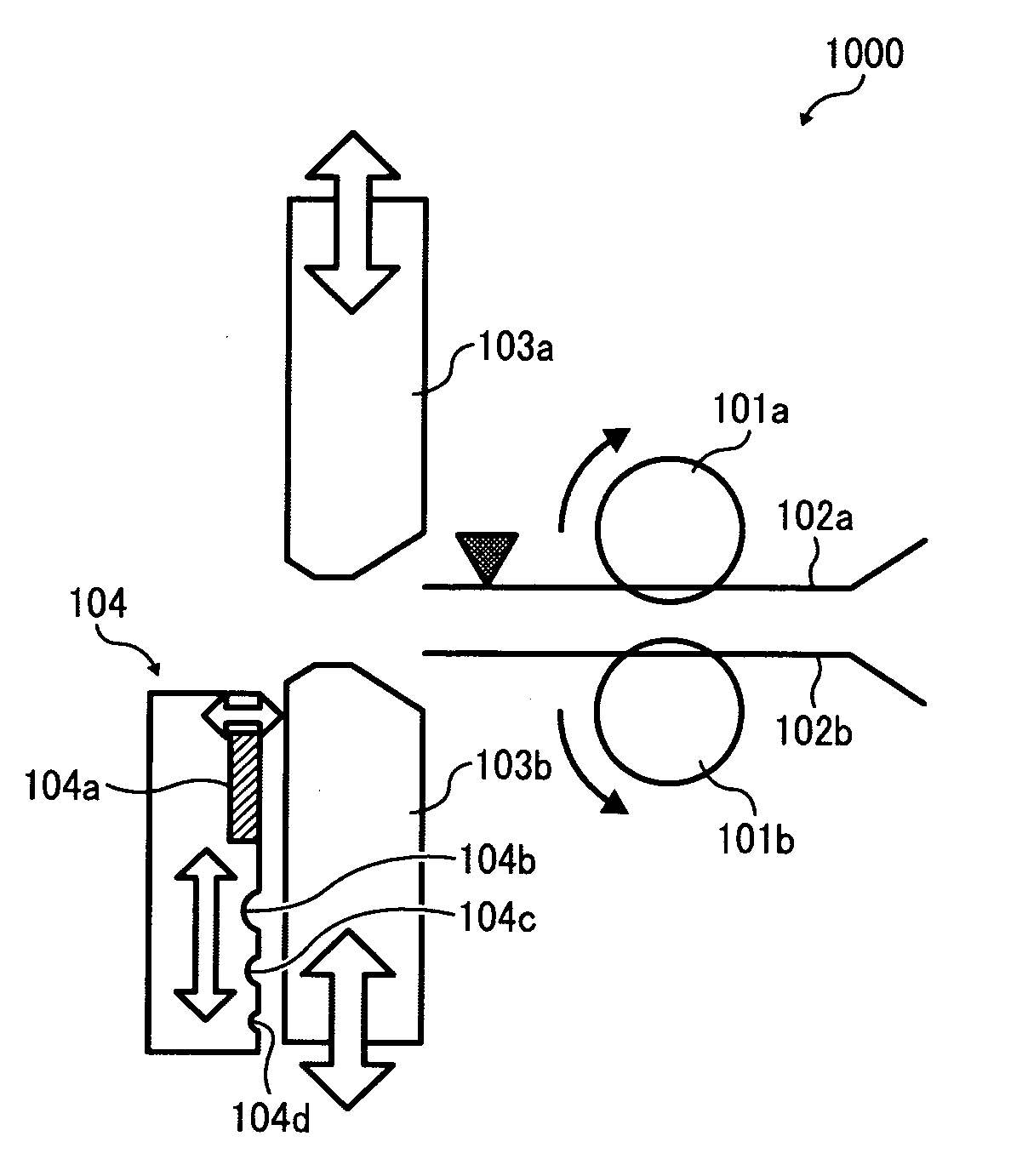

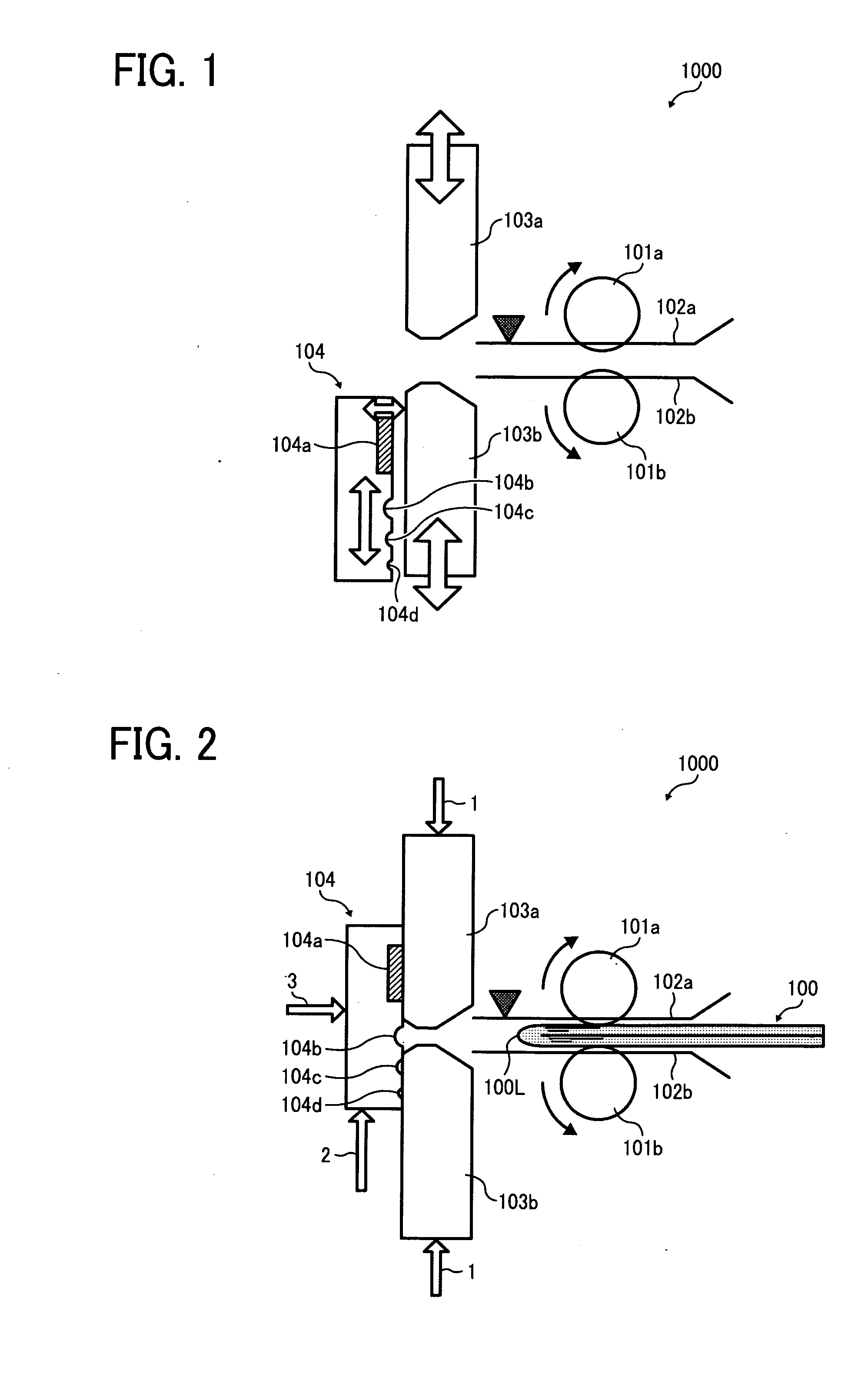

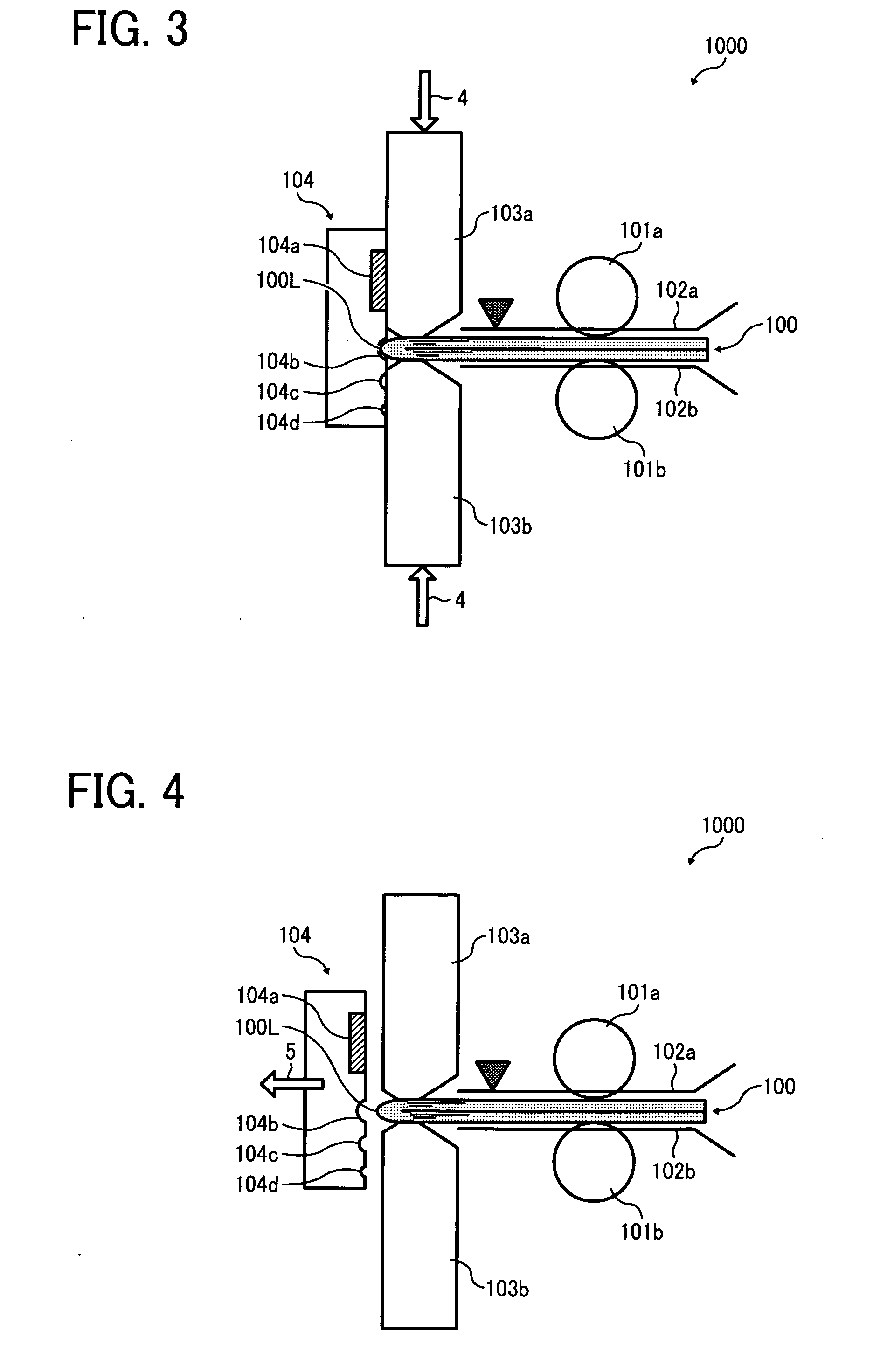

Spine formation device, post-processing apparatus, and bookbinding system

InactiveUS20110064541A1Improve flatnessFolding thin materialsElectrographic process apparatusEngineeringSheet material

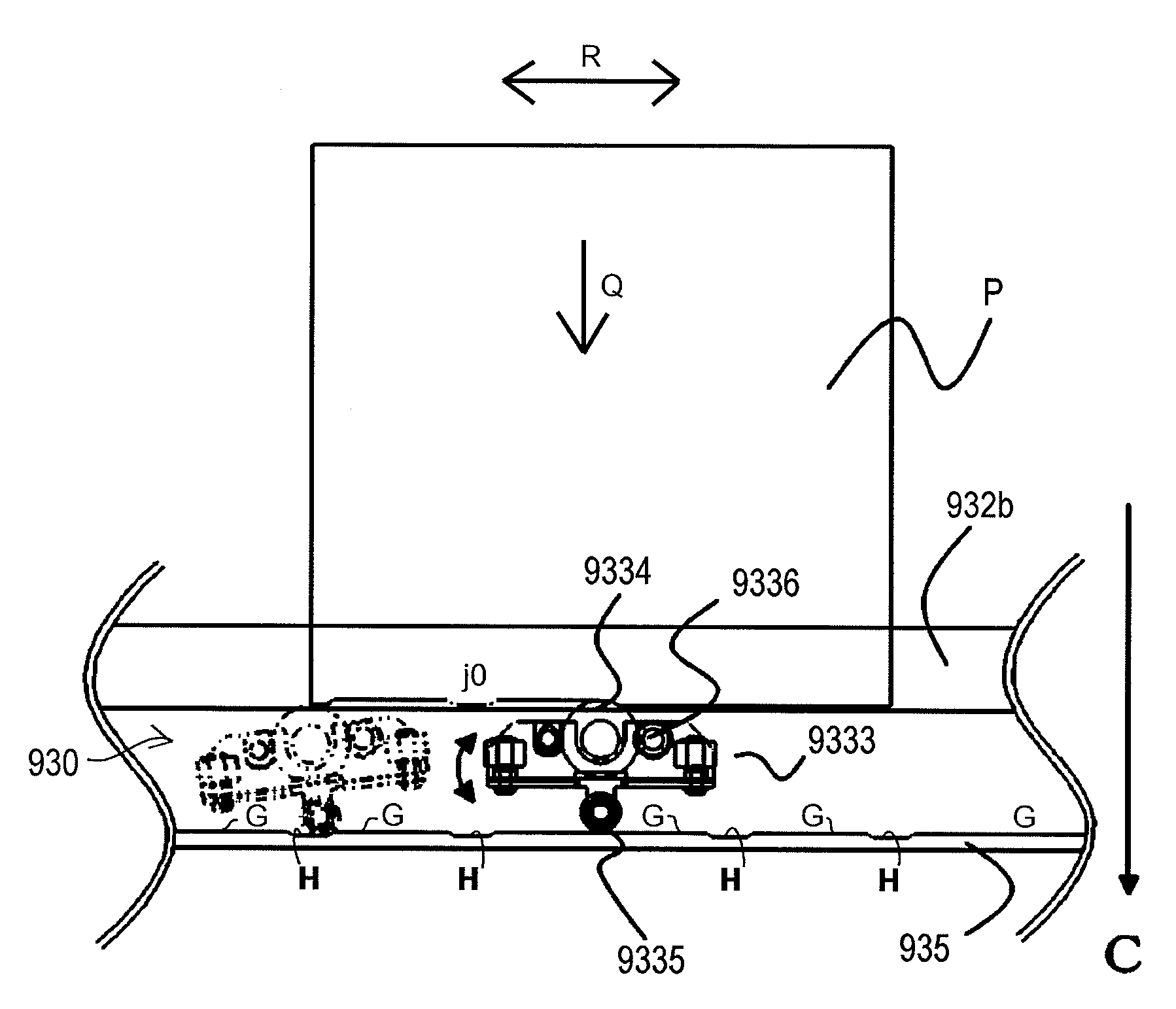

An spine formation device includes a sheet conveyer, a contact member including a first row of grooves provided in a contact surface thereof to house a projection projecting from a folded portion of a bundle of folded sheets, a driving unit to move the contact member, first and second sandwiching units to squeeze the bundle, a discharge unit, and a controller. The first row of grooves extends in parallel to the folded portion of the bundle and includes at least a first pair of grooves inclined in different directions with an interval therebetween varying in size with location of the grooves in a first direction perpendicular to a sheet conveyance direction. The contact member is moved to change the size of interval between the first pair of grooves at a position aligned with the projection projecting from the folded portion of the bundle of folded sheets.

Owner:RICOH KK

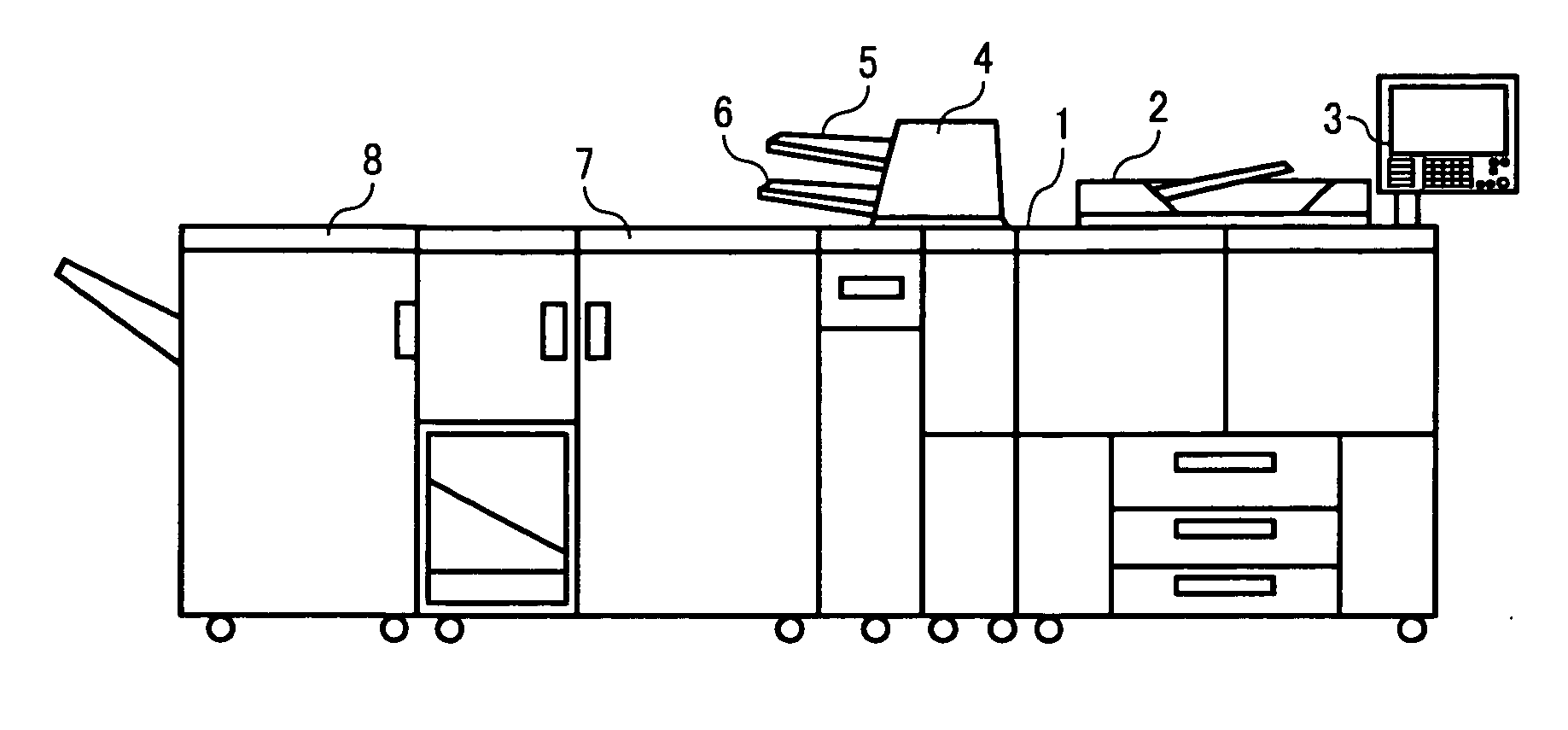

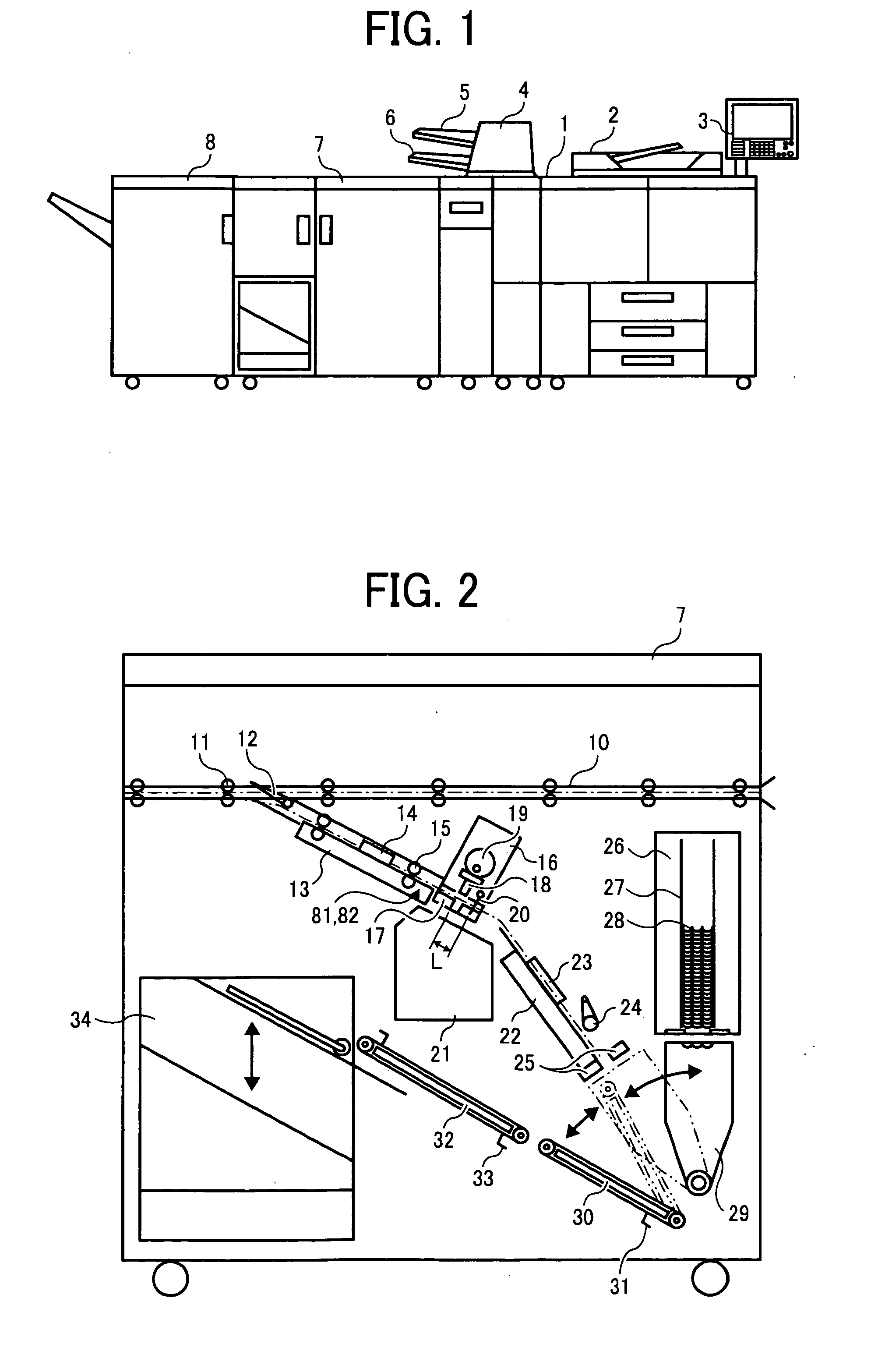

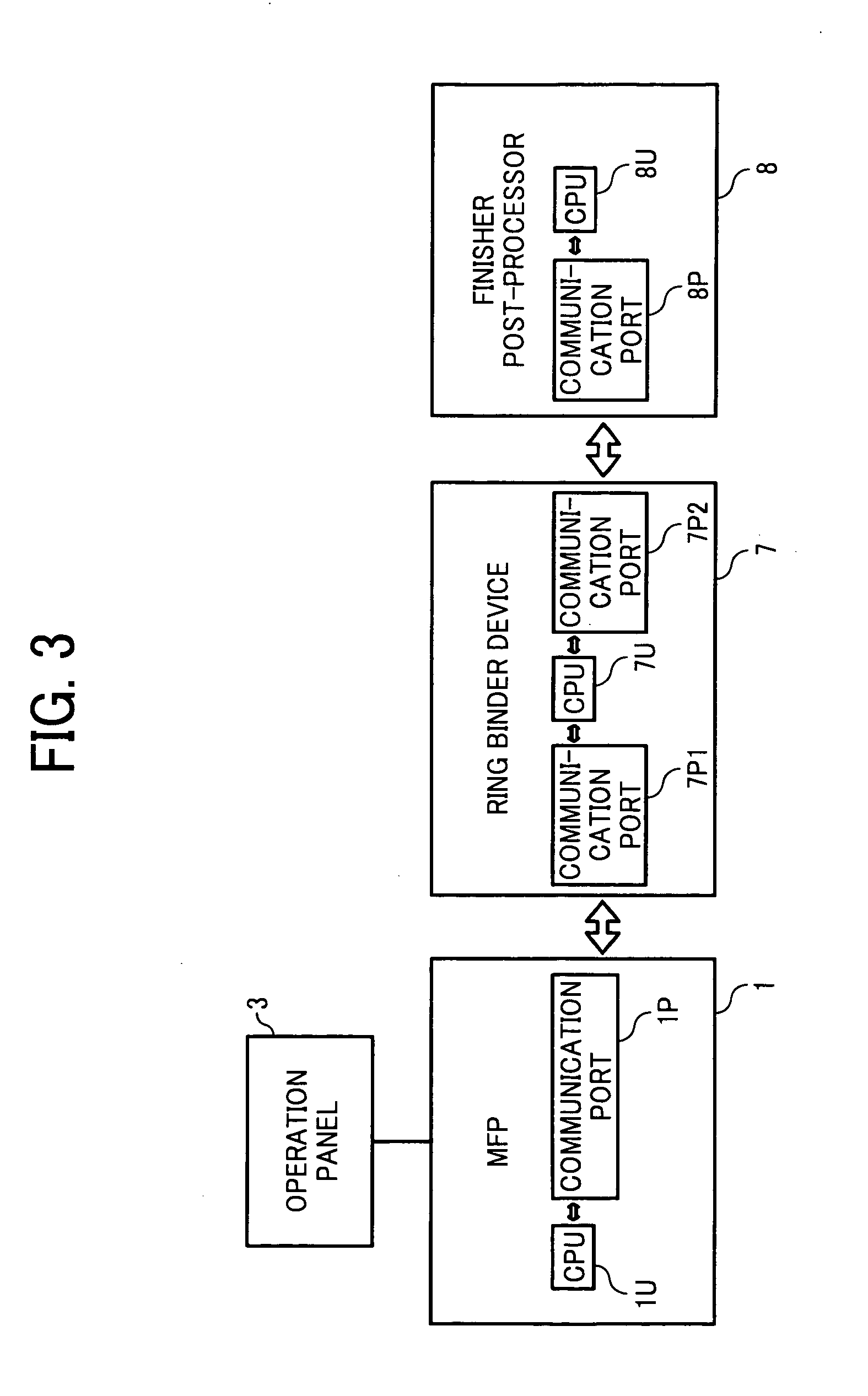

Bookbinding system, bookbinding method, and recording medium storing bookbinding program

ActiveUS20090257846A1Electrographic process apparatusMetal working apparatusEngineeringRecording media

A bookbinding system to bind together a batch of sheets transported from an image forming apparatus. The bookbinding system includes a punch unit to form a predetermined number of ring holes in a predetermined portion along a side of the sheets to be bound one by one or in a batch, a ring-binding unit disposed downstream from the punch unit in a direction in which the sheet is transported to insert rings of a ring member into the ring holes formed on the batch of sheets by the punch unit, a ring detector disposed at a portion where the ring member is set to detect a type of the ring member, and a determination unit to determine whether or not an ring-binding operation is executable based on a type of the ring member and a size of the sheets to be bound together.

Owner:RICOH KK

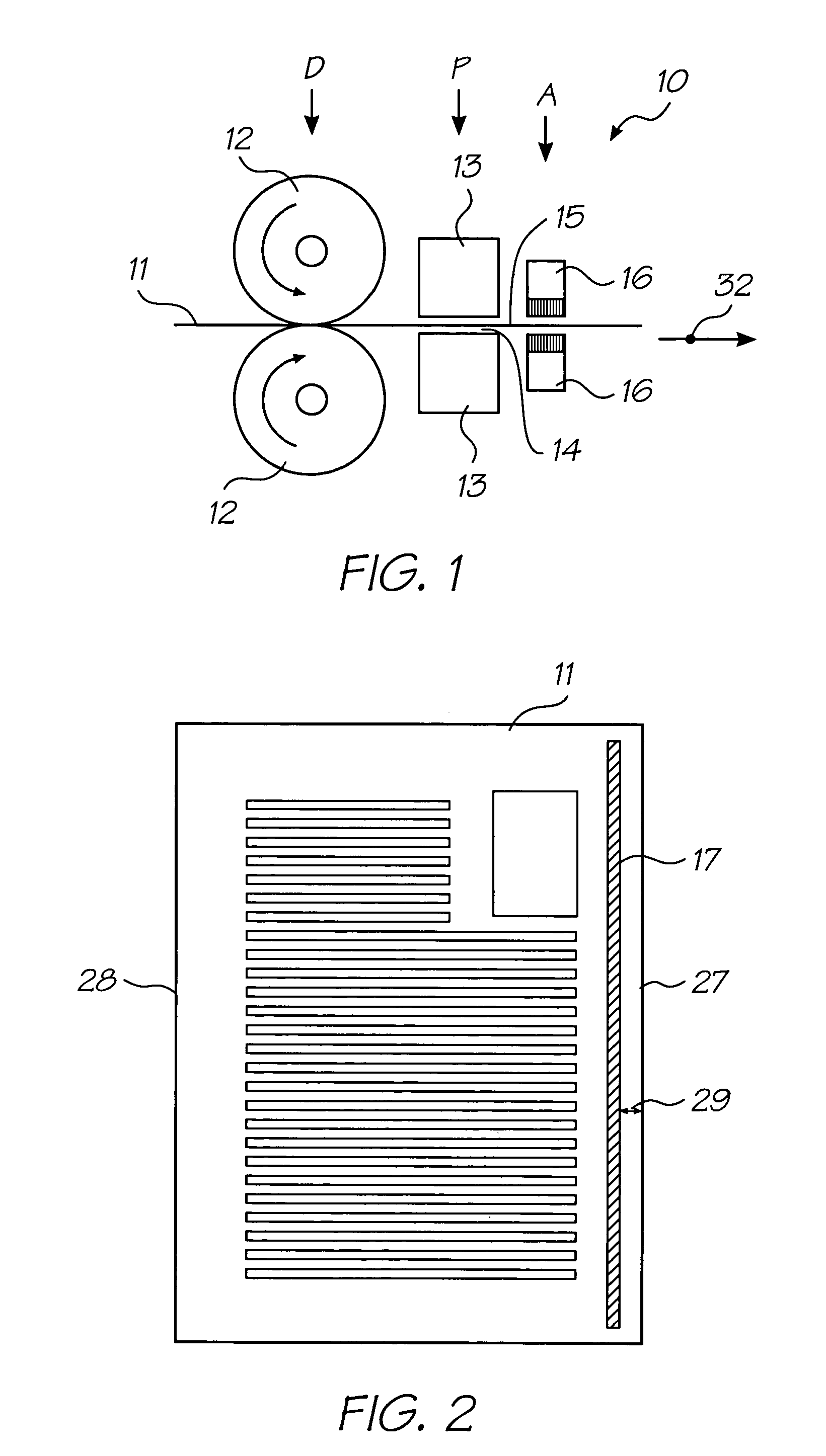

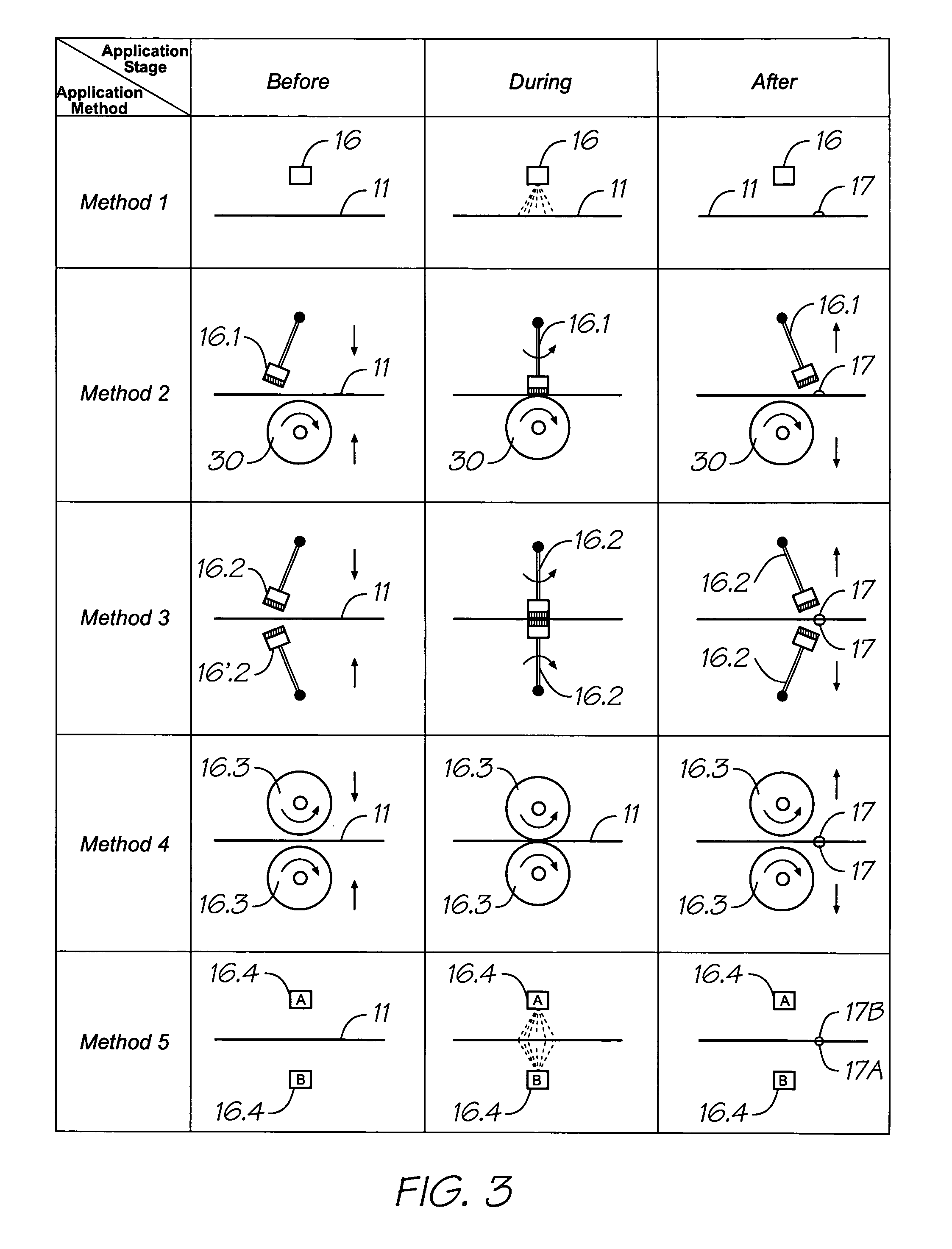

Printer that incorporates a binding apparatus for binding sheets

A printer includes a roller assembly for feeding sheets of print media along a feed path. A print head is positioned downstream of the roller assembly for carrying out a printing operation on the sheets of print media. An adhesive application mechanism is positioned downstream of the print head and includes first and second aligned adhesive applicators that are positioned on opposite sides of the feed path and are configured to apply adhesive simultaneously to the sheets of media as the sheets pass between the applicators along the feed path, such that the sheets each have aligned strips of adhesive on respective sides. A support structure positioned downstream of the adhesive application mechanism defines a floor onto which sheets to be bound are conveyed and a wall that extends from the floor to define a stop for the sheets that are fed onto the floor. A binding mechanism is arranged on the support structure and is displaceable with respect to the support structure to act on each sheet fed into the support structure such that the sheets are adhered together with the strips of adhesive.

Owner:SILVERBROOK RES PTY LTD +1

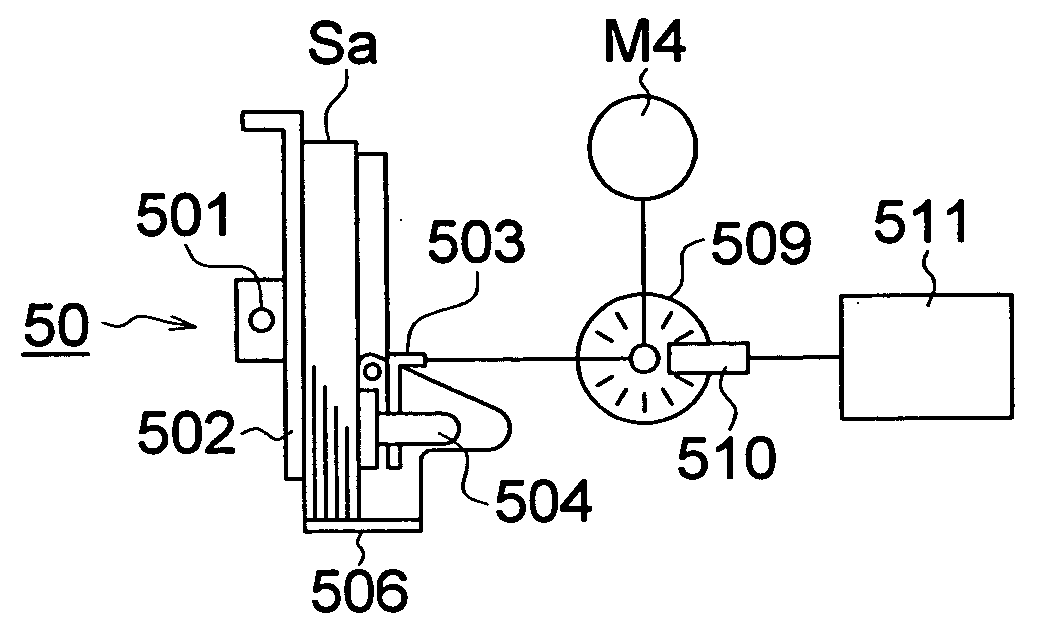

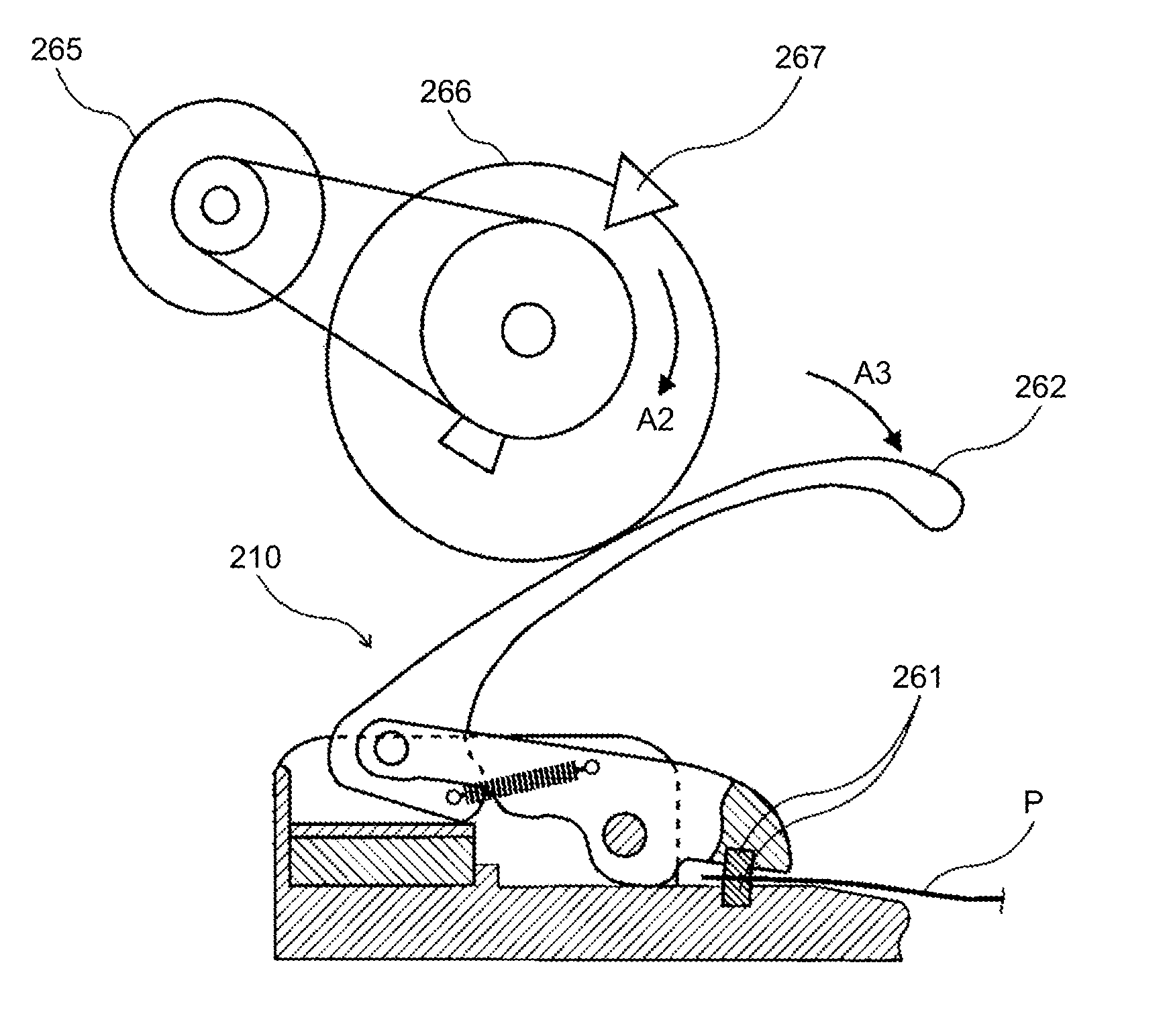

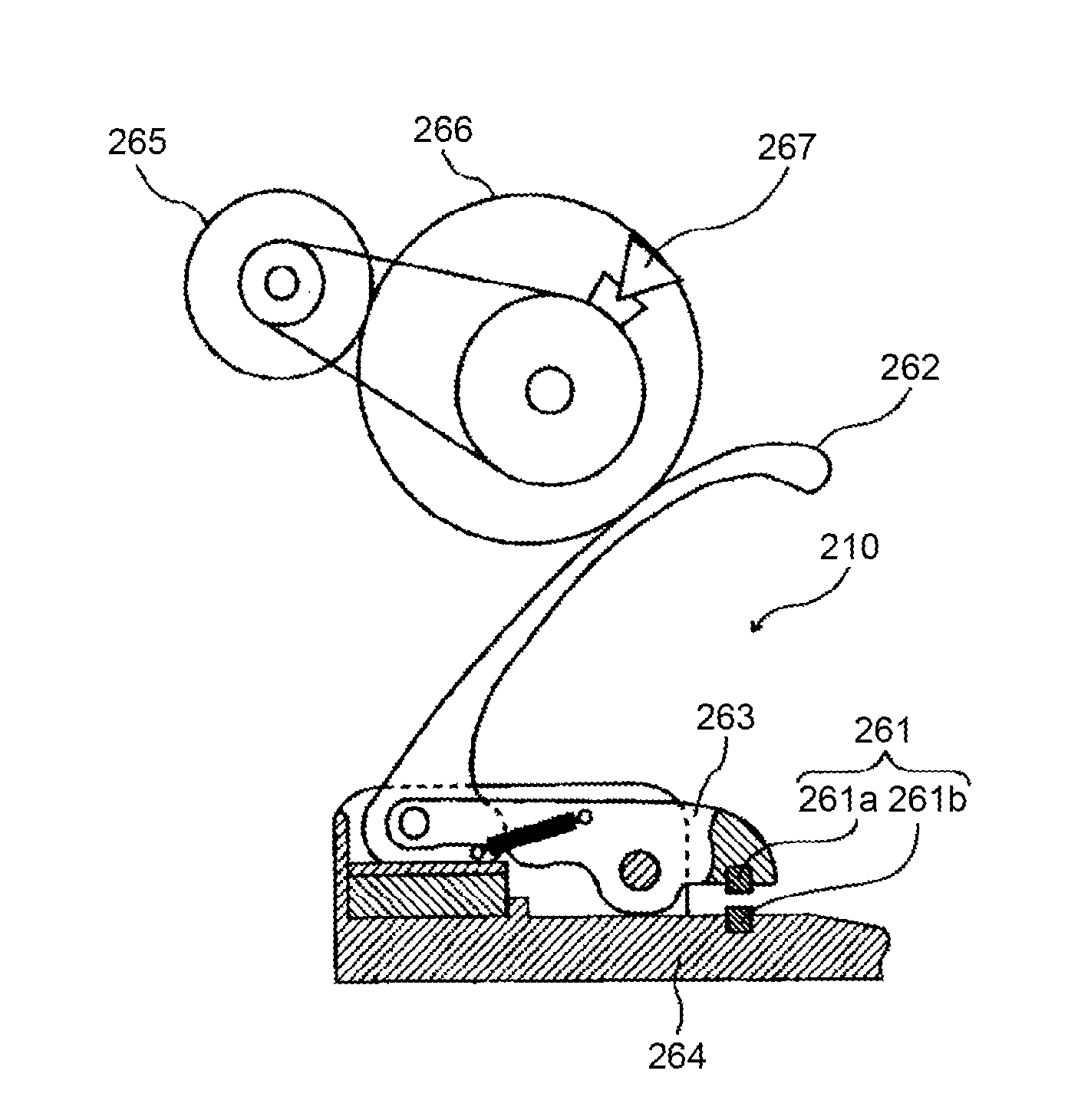

Sheet processing apparatus

A sheet processing apparatus includes: a holding portion which holds a booklet containing a two-folded sheet; and a pressing portion which presses a spine of a booklet into shapes during movement along the spine of the booklet held by the holding portion. The pressing portion can decrease, or release a pressing force to be applied to the booklet spine within a predetermined area of a moving range in which the pressing roller moves along the booklet spine.

Owner:CANON KK

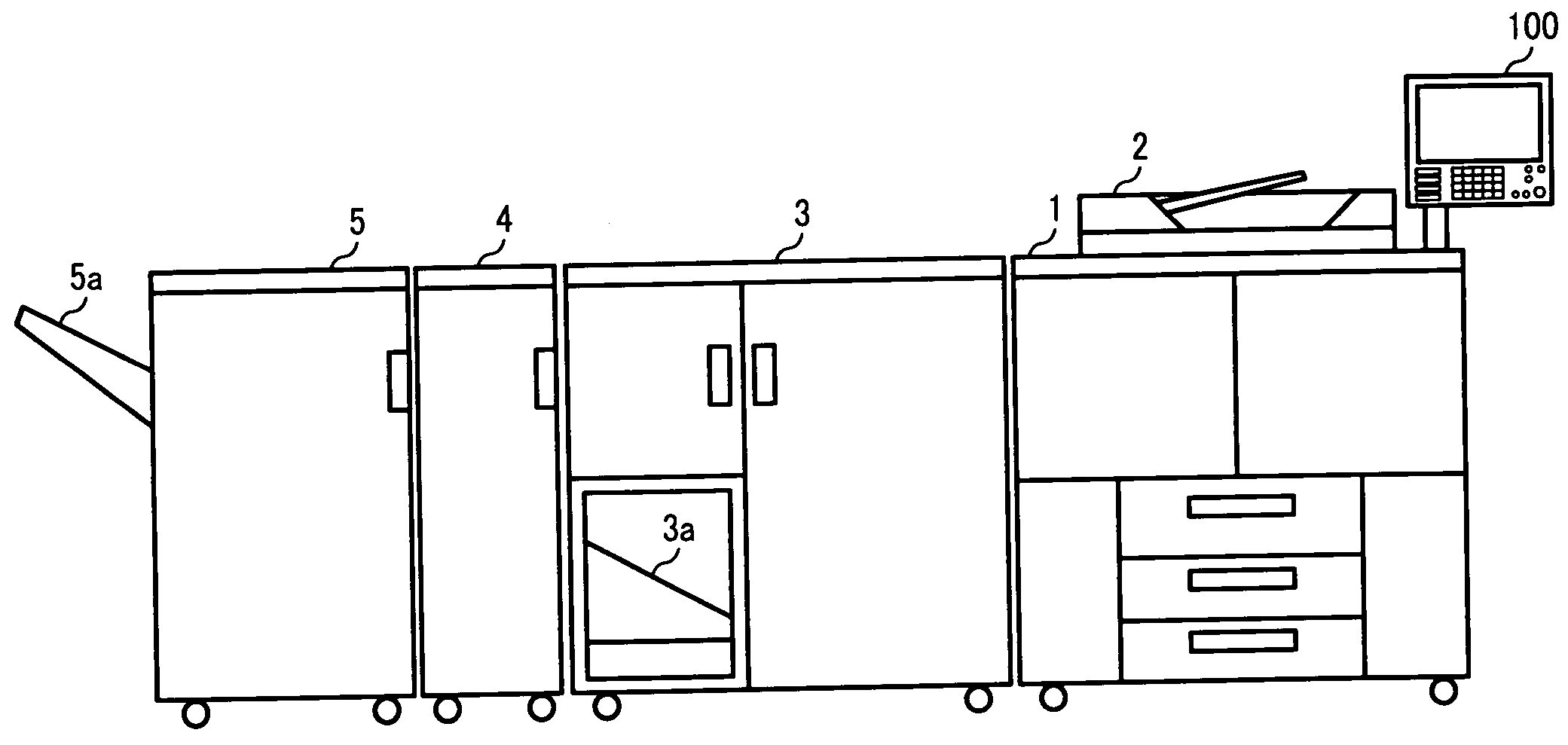

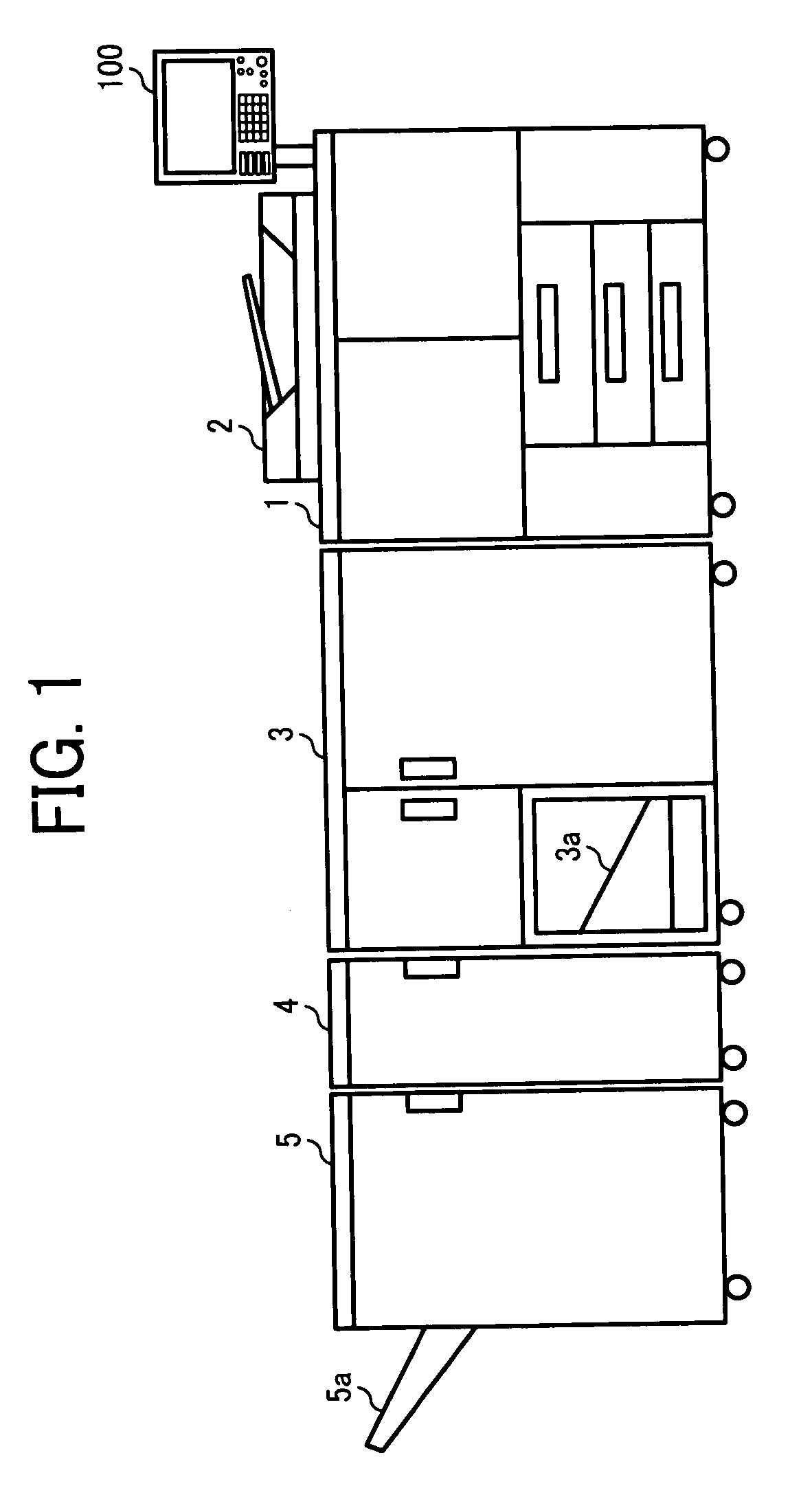

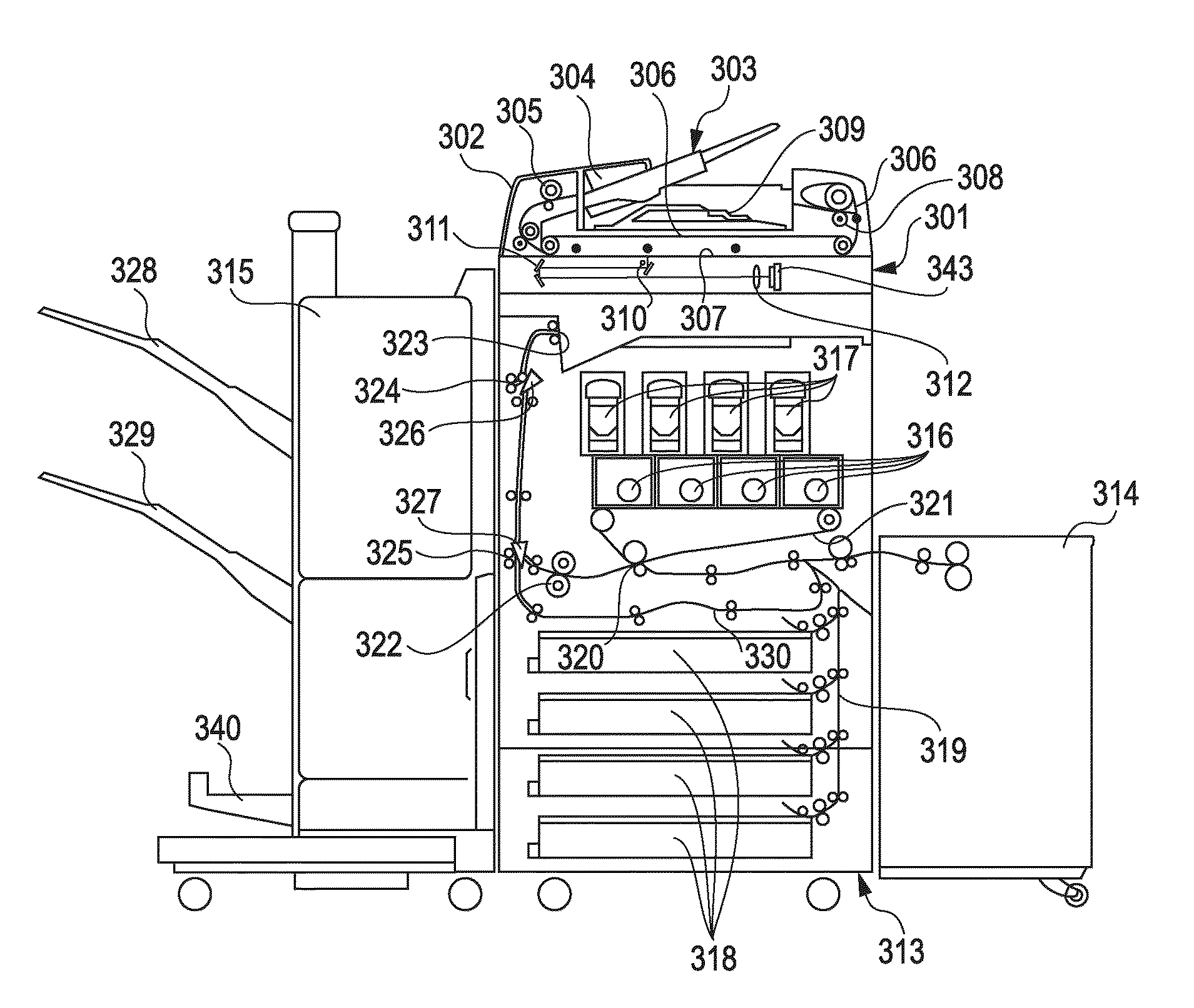

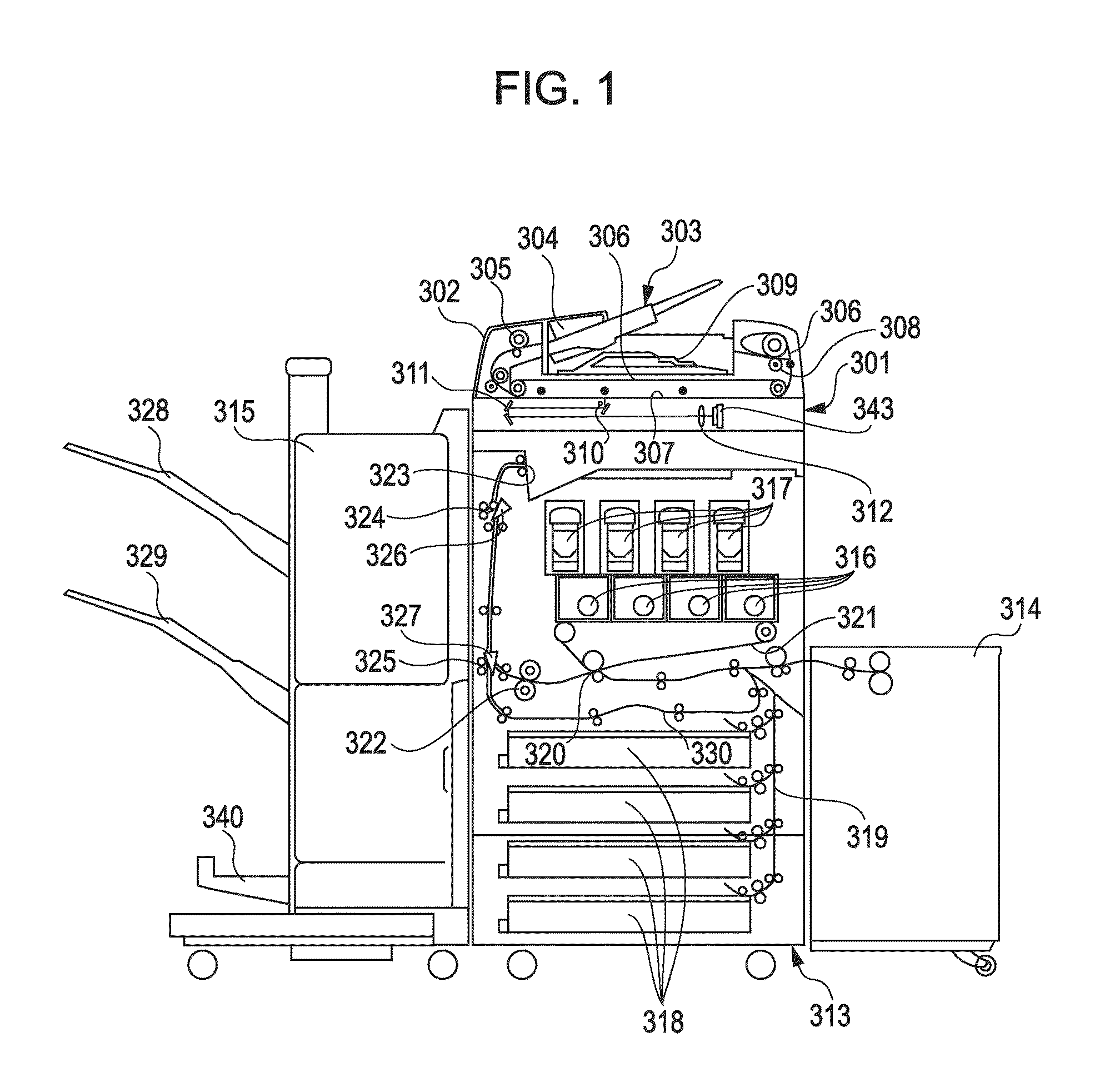

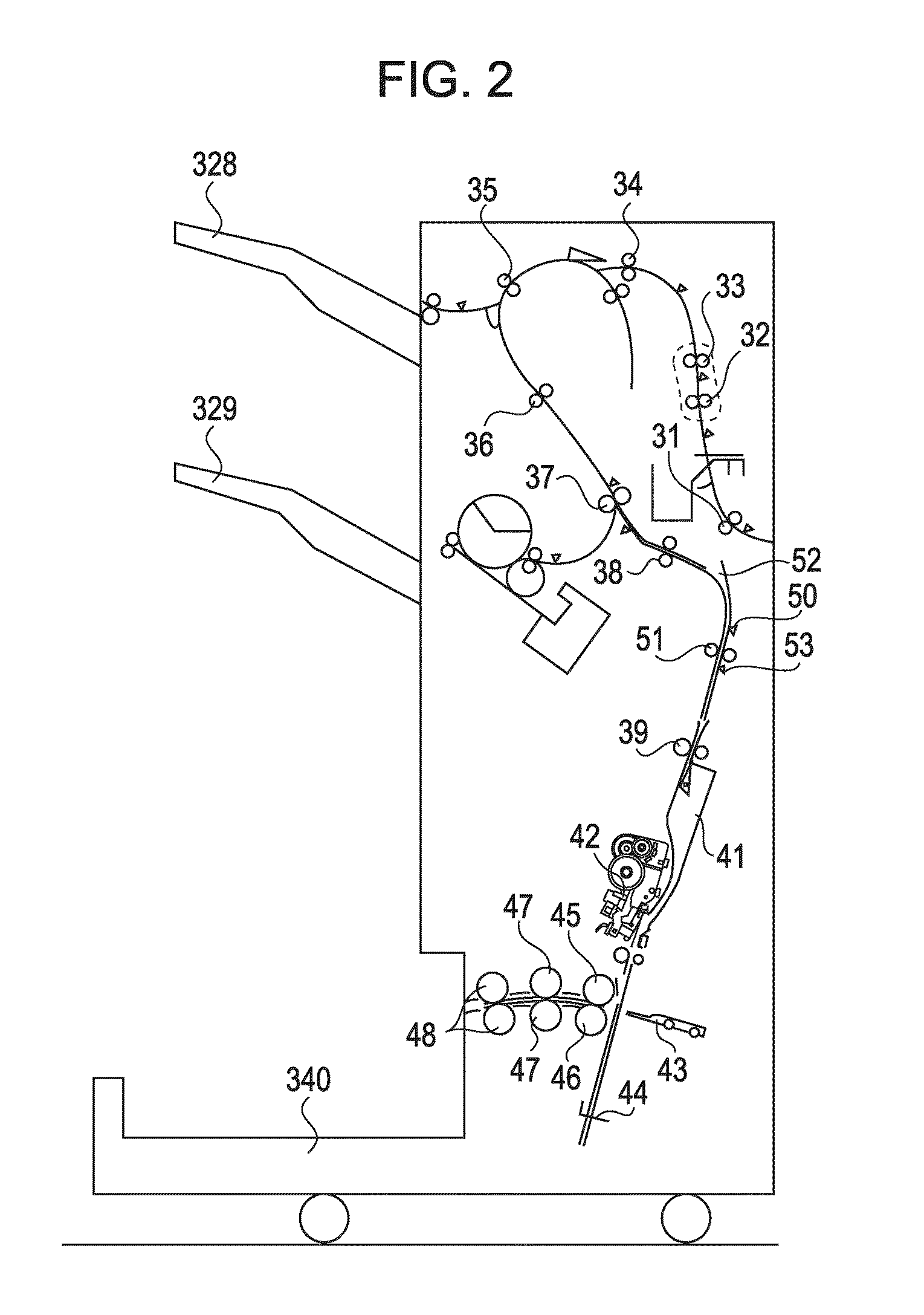

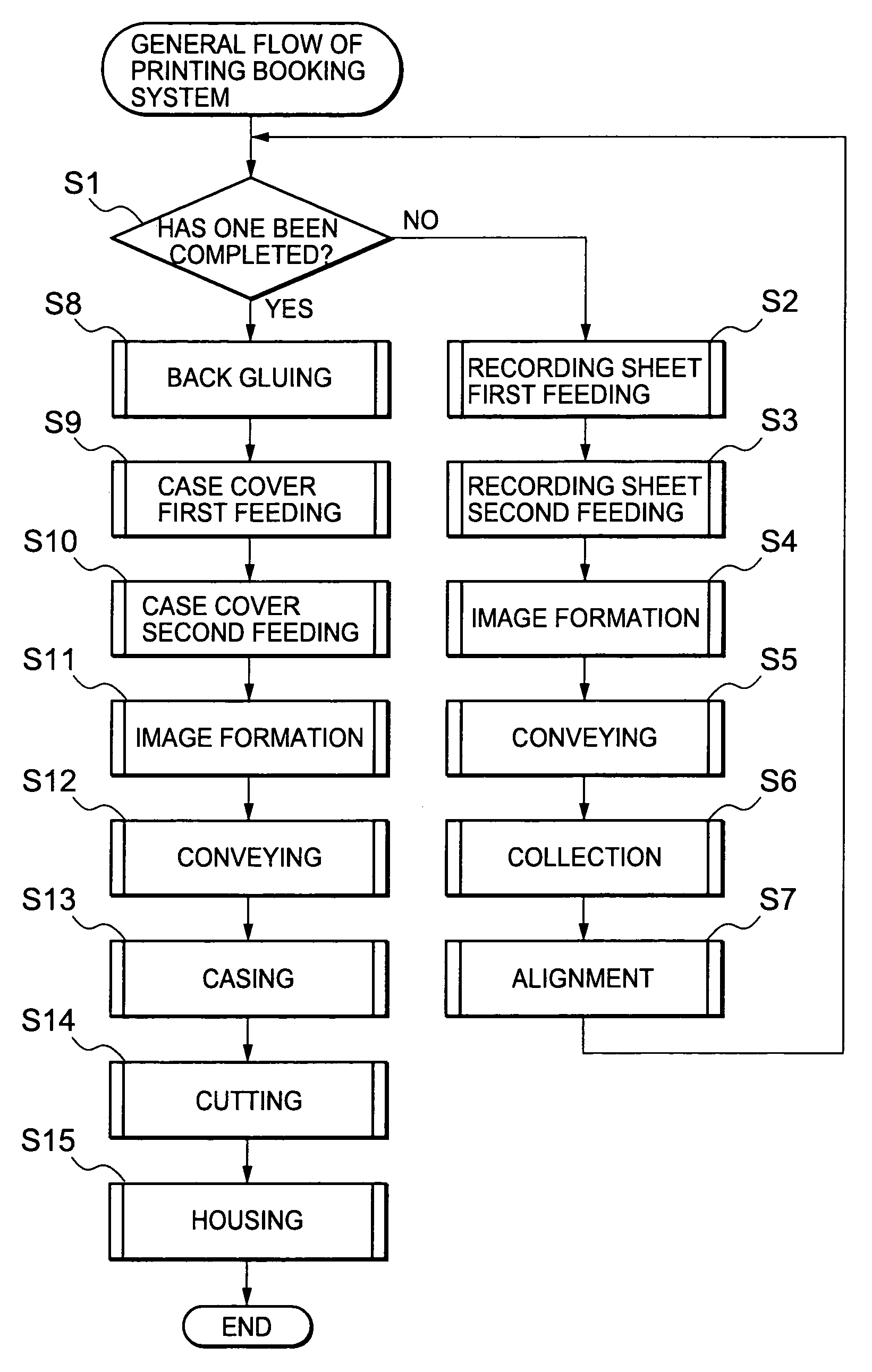

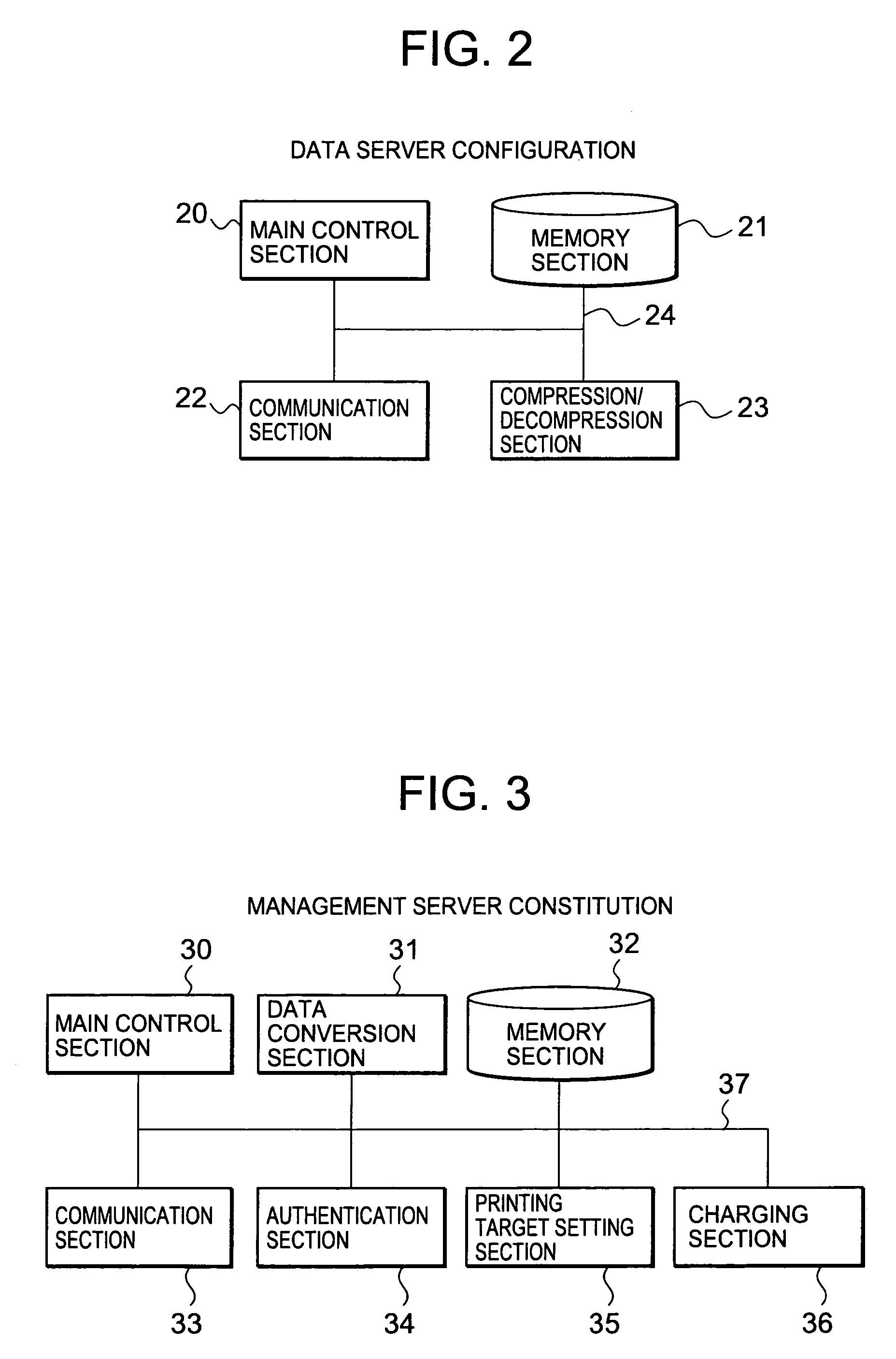

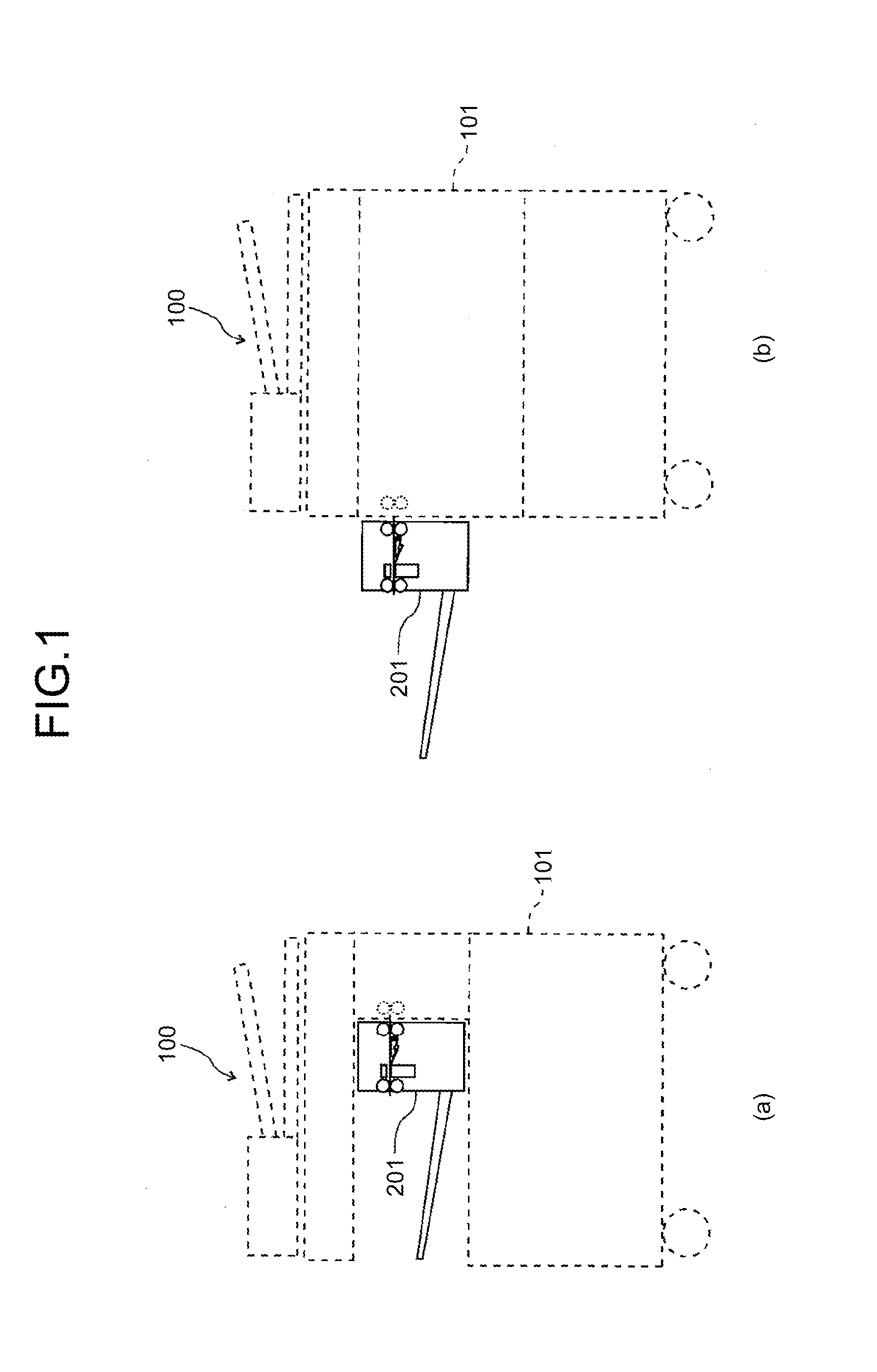

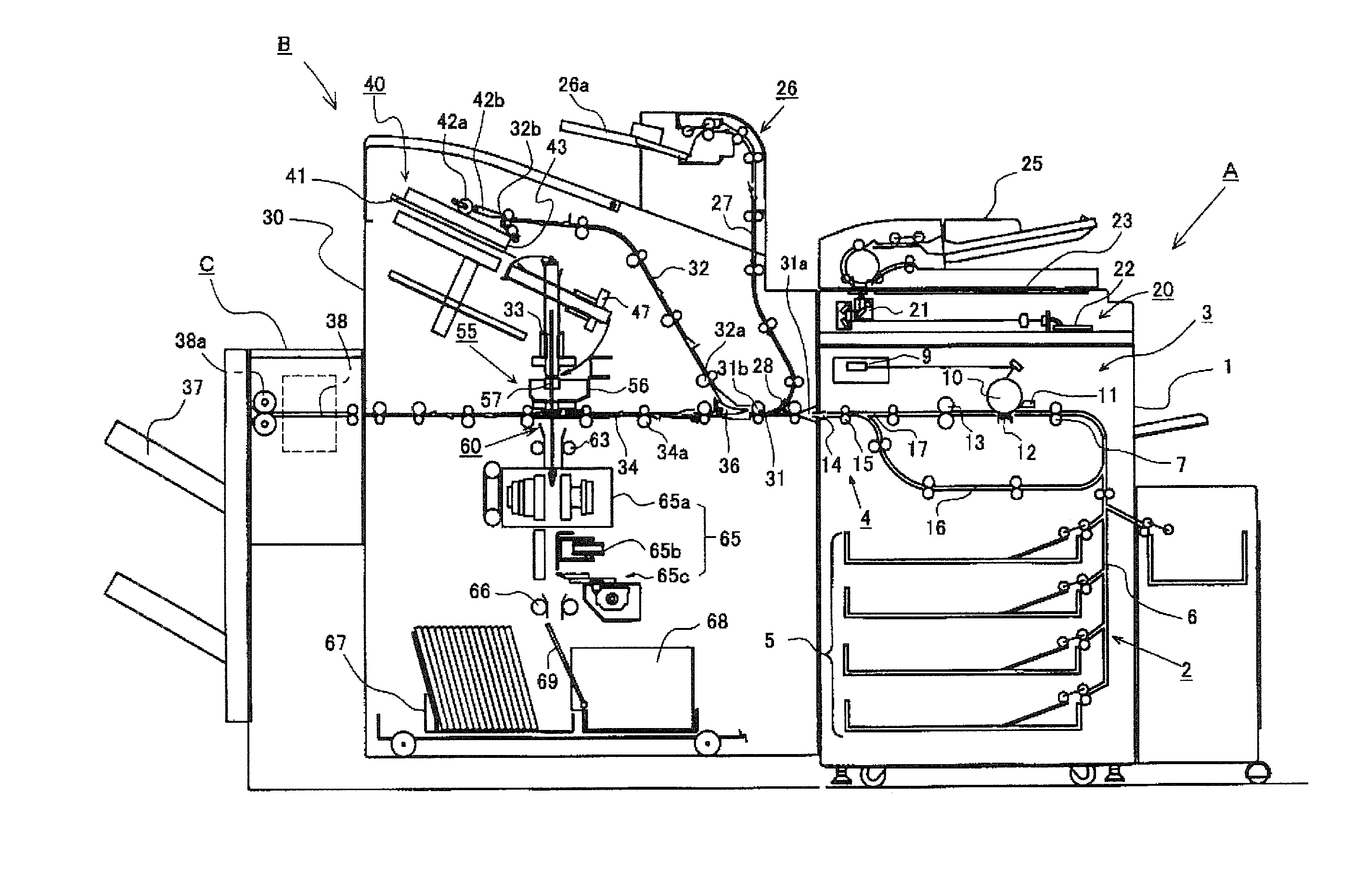

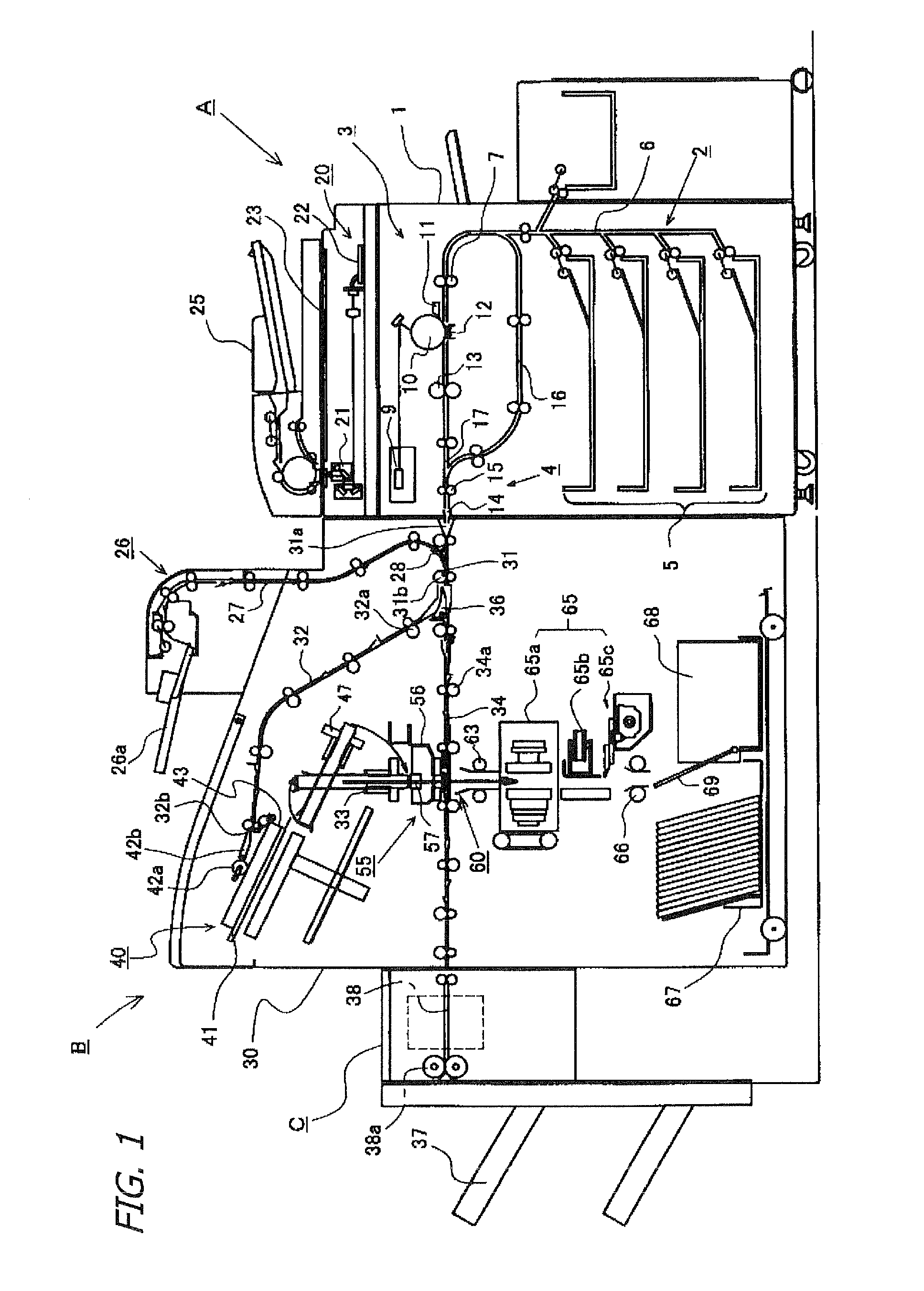

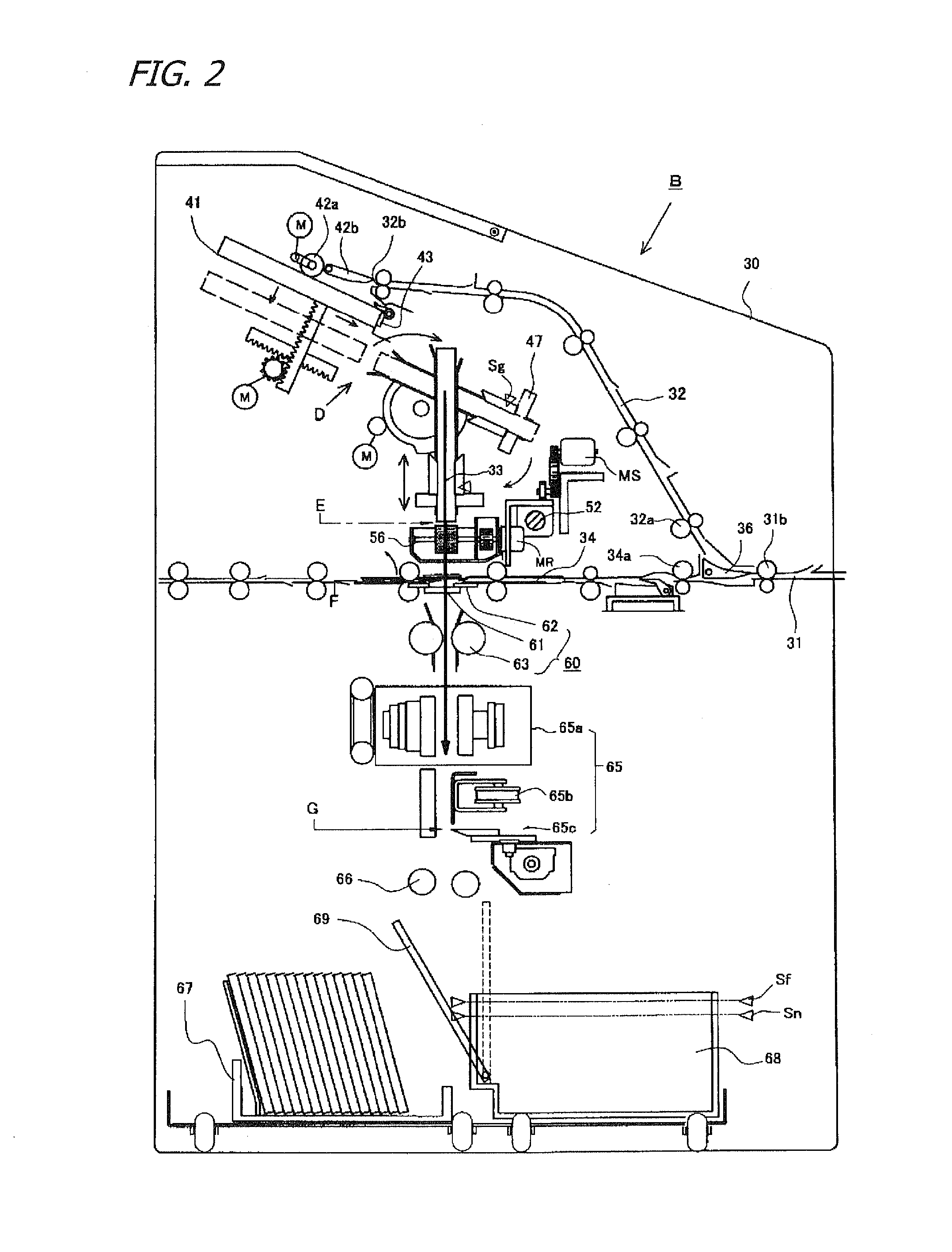

Bookbinding system, image forming apparatus, and bookbinding apparatus

By controlling the recording position of images on the cover sheet by the image recording section based on the thickness information of the bundle of sheets, image recording at the appropriate position has been made possible irrespective at the amount of trimming of the cover sheet that is trimmed to an appropriate length in accordance with the thickness of the bundle of sheets to be wrapped and bound with the cover sheet.

Owner:KONICA MINOLTA BUSINESS TECH INC

Method and apparatus for binding a plurality of sheets

A method for binding together a plurality of paper sheets. The binding process comprises providing a book binding sheet coated on one side with hot-melt adhesive, orienting and securing sheets of paper that will comprise the book to be bound relative to the binding sheet, securing the leading edge of the binding sheet to the front of the book to be bound, severing the secured portion from the remaining binding sheet material, wrapping the binding severed strip around the spine and rear cover and heating the adhesive to produce a permanent bond with the edges of the spine and covers.

Owner:POWIS PARKER INC

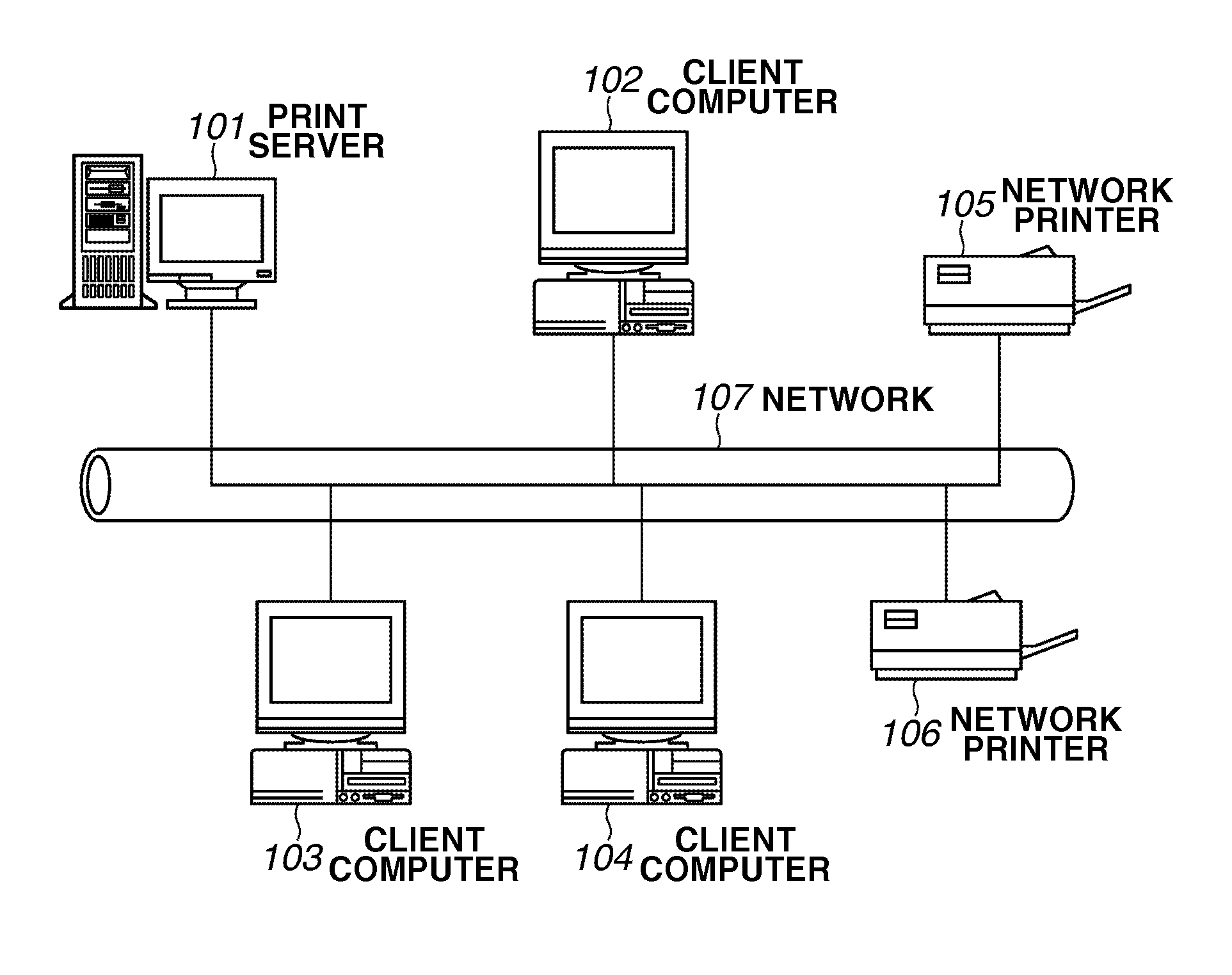

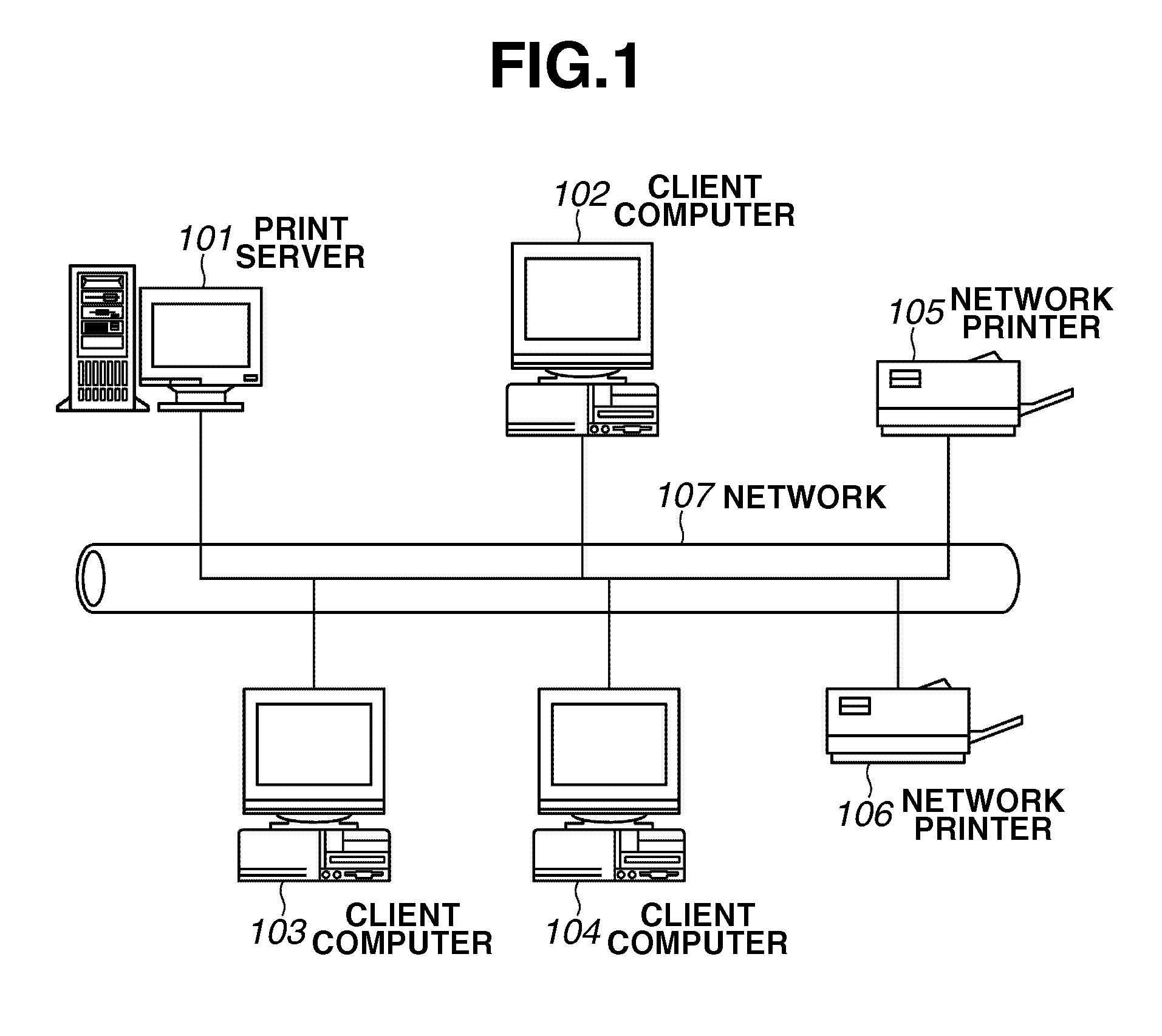

Print processing system, print processing method, and storage medium

InactiveUS20100149565A1Reduces and prevents changeExtra processingDigitally marking record carriersBookbinding casesHandling systemDatabase

A print server checks a job ticket for a print job to be processed. When a method of printing set in the printing attributes of the job ticket is case binding, a first thickness of a bookblock is calculated using the paper type set in the printing attributes. The print server calculates a second thickness of a bookblock using the paper type after a change. The print server changes the paper type set in the job ticket when the difference between the first thickness and the second thickness is within a permissible range.

Owner:CANON KK

Spine formation device, bookbinding system, and spine formation method

InactiveUS20110103919A1Folding thin materialsElectrographic process apparatusEngineeringContact position

A spine formation device includes a sheet conveyer, a clamping unit disposed downstream from the sheet conveyer in a sheet conveyance direction, for squeezing a folded portion of a bundle of folded sheets, a contact member against which the folded portion of the bundle is pressed, disposed downstream from the clamping unit, and a controller to cause the bundle of folded sheets to bulge by stopping the sheet conveyer after the bundle of folded sheets is transported a predetermined conveyance distance from a contact position between the contact member and the folded portion of the bundle and to cause the clamping unit to squeeze a bulging portion of the bundle created between the sheet conveyer and the contact member with the folded portion pressed against the contact member. The predetermined distance is set in accordance with a predetermined sheet-related variable.

Owner:RICOH KK

Bookbinding system, bookbinding method, and computer program product

InactiveUS20090263212A1Solve problemsElectrographic process apparatusMetal working apparatusPunchingEngineering

A bookbinding device receives a sheet on which an image is formed from an image forming apparatus. In the bookbinding device, a punching unit performs a punching process on a sheet; an aligning unit aligns a plurality of sheets on which holes are punched; and a ring binding unit mounts, in the holes of the sheets aligned by the aligning unit, a ring-shaped binding tool to create a booklet. A prohibiting unit, if a sheet received from the image forming apparatus is a punched sheet having a hole thereon, causes the punching unit not to perform the punching process on the punched sheet.

Owner:RICOH KK

Binding assembly for binding sheets incorporating an alignment mechanism

A binding assembly for generating bound documents includes a support structure that defines a floor onto which sheets to be bound are conveyed. A wall extends from the floor to define a stop for the sheets that are fed onto the floor. Each sheet has a strip of adhesive proximate a leading edge of the sheet. A vibration imparting mechanism is operatively engaged with the support structure and is operable to vibrate the support structure. A binding mechanism is arranged on the support structure and is displaceable with respect to the support structure to act on each sheet fed into the support structure such that the sheets are adhered together with the strips of adhesive.

Owner:SILVERBROOK RES PTY LTD

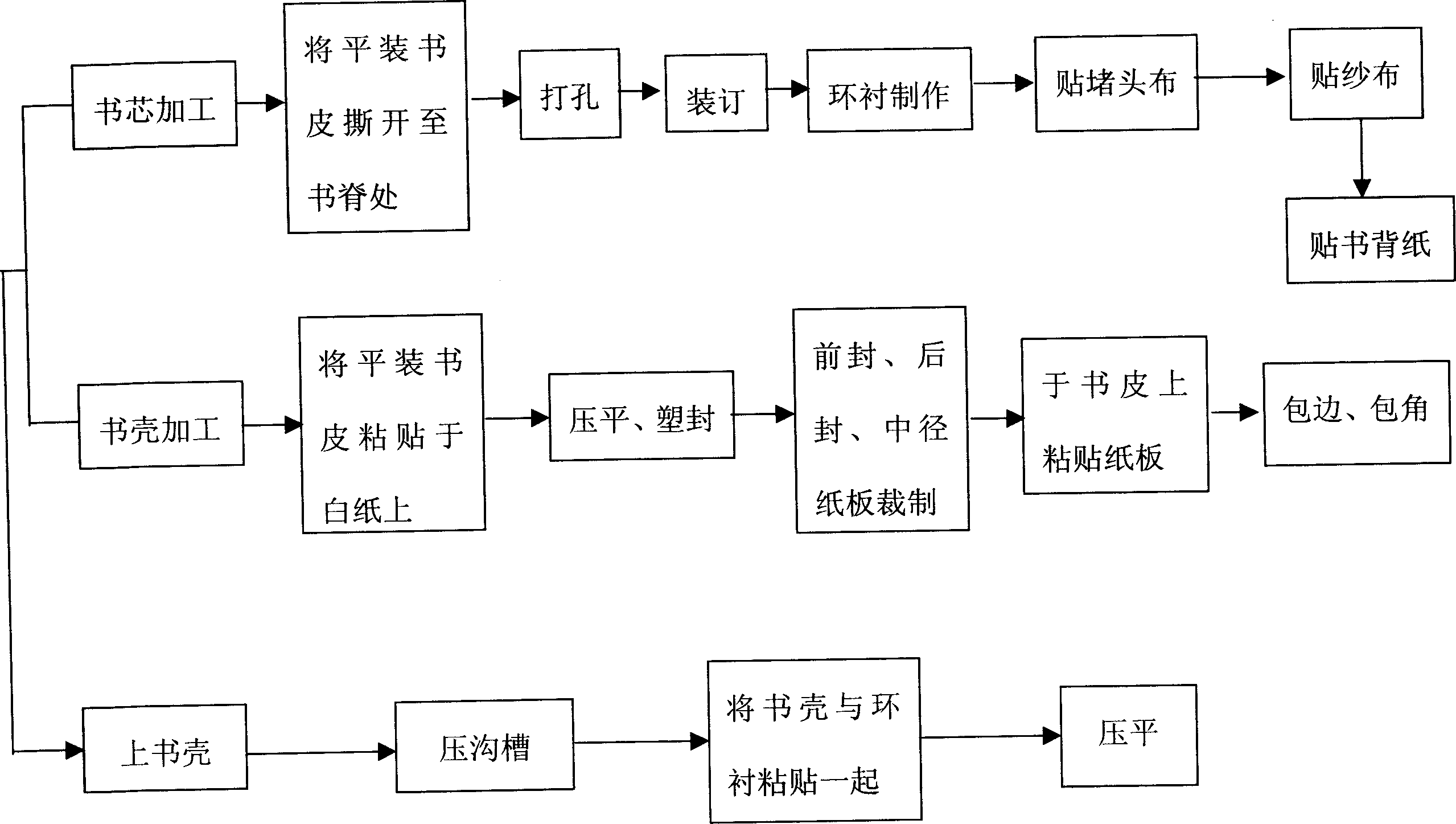

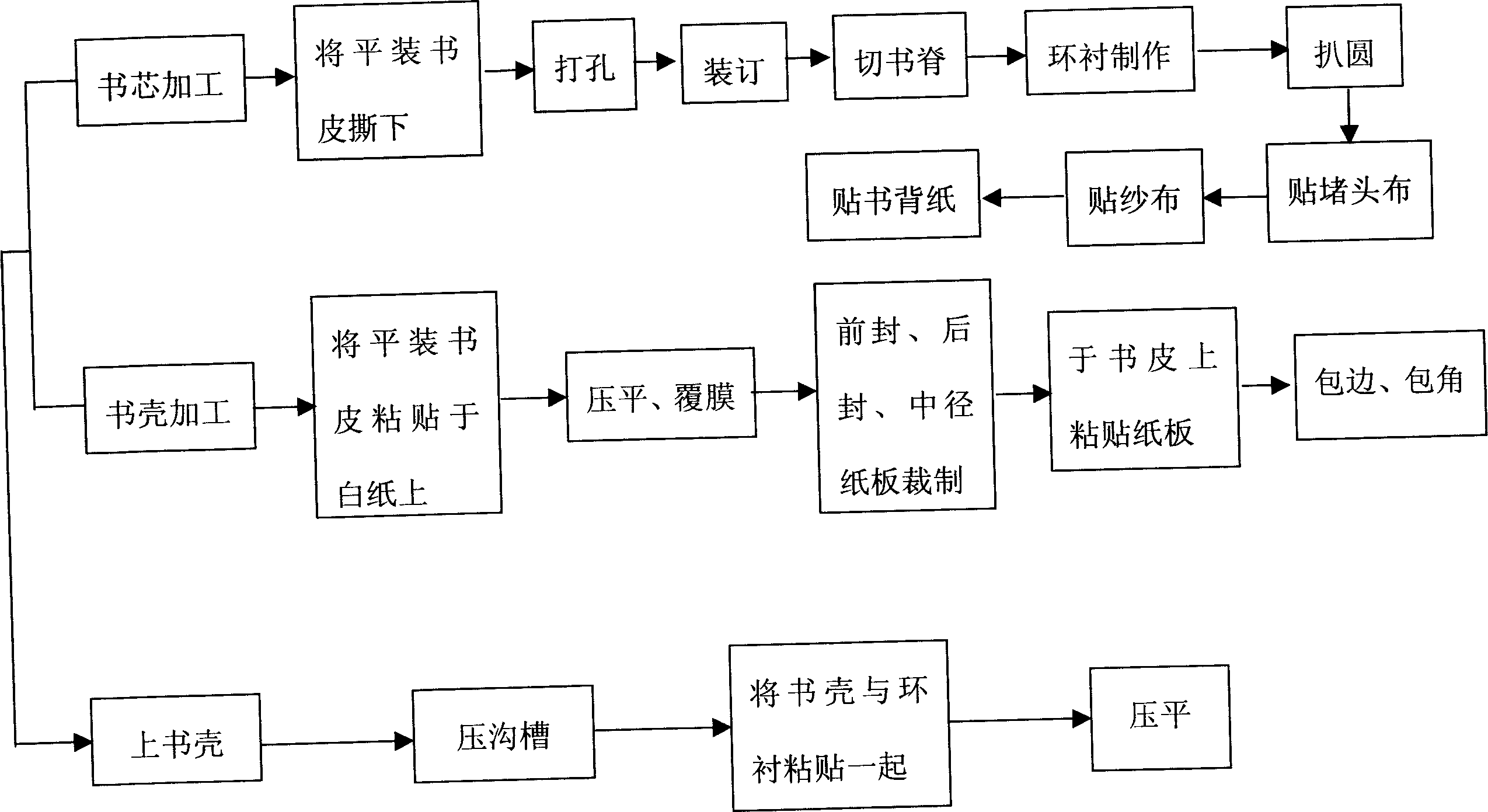

Method for changing paperback to exquisitely binding book

InactiveCN1865018AGood effectMeet quality requirementsBookbinding casesBook rebindingPulp and paper industryPaper sheet

The invention relates to a method for changing the soft-covered book into hard-cover book, which comprises three steps as processing book core, processing book cover, and mounting the book cover. Wherein, first, removing the cover of soft-covered book; then making holes, binding, preparing annular liner, adhering block cloth, adhering gauze, adhering book back paper to complete processing the book core; the second step is that adhering the cover on the white paper, then flattening the coat film, cutting the front and back seal, and the middle paper sheet, then folding edge and packing corner; the third step comprises pressing groove, adhering annular liner and flattening. The inventive method can overcome the defects of present technique, with simple operation and lower cost.

Owner:王超 +1

Bookbinding Apparatus

ActiveUS20070280805A1Extended hold timeIncrease travel speedFiling appliancesElectrographic process apparatusStart timeReciprocating motion

In binding a cover sheet together with a sheet bundle, ever-accurate spine-creasing irrespective of bundle thickness is made possible. A sheet stacker stacks sheets into bundles, an adhesive applicator applies adhesive to a spine part of the sheet bundles, and a cover-sheet binder binds cover sheets together with the spine parts. The cover-sheet binder is constituted from a left-and-right pair of spine-creasing press members arranged free to shift between standby and spine-creasing positions; a shifter that reciprocates the spine-creasing press members between the standby and spine-creasing positions; and a controller. The controller functions to vary, in accordance with sheet bundle thickness, any of: (1) the standby position of the press members; (2) the start time of an operation whereby the press members are shifted from the standby to the spine-creasing position; or (3) the traveling speed of the press members in shifting from the standby to the spine-creasing position.

Owner:NISCA KK

Sheet processing apparatus, image forming system, and image forming apparatus

InactiveUS20150003938A1Solve problemsMechanical working/deformationElectrographic process apparatusImage formationEngineering

A sheet processing apparatus includes: a sheet fastening unit of a pressing fastener method in which a bundle of sheets is fastened by using a pair of pressing fastener members; a conveying unit that conveys the bundle of sheets that are fastened by the sheet fastening unit; a separating unit that, after the sheet fastening unit performs a fastening operation on the bundle of sheets, moves both one and the other pressing fastener members, between which the bundle of sheets is interposed, so as to separate a sheet that adheres to the pressing fastener member; and a control unit that, after the separating unit finishes an operation to separate the sheet, controls the conveying unit so as to convey the bundle of sheets that are fastened by the sheet fastening unit.

Owner:RICOH KK

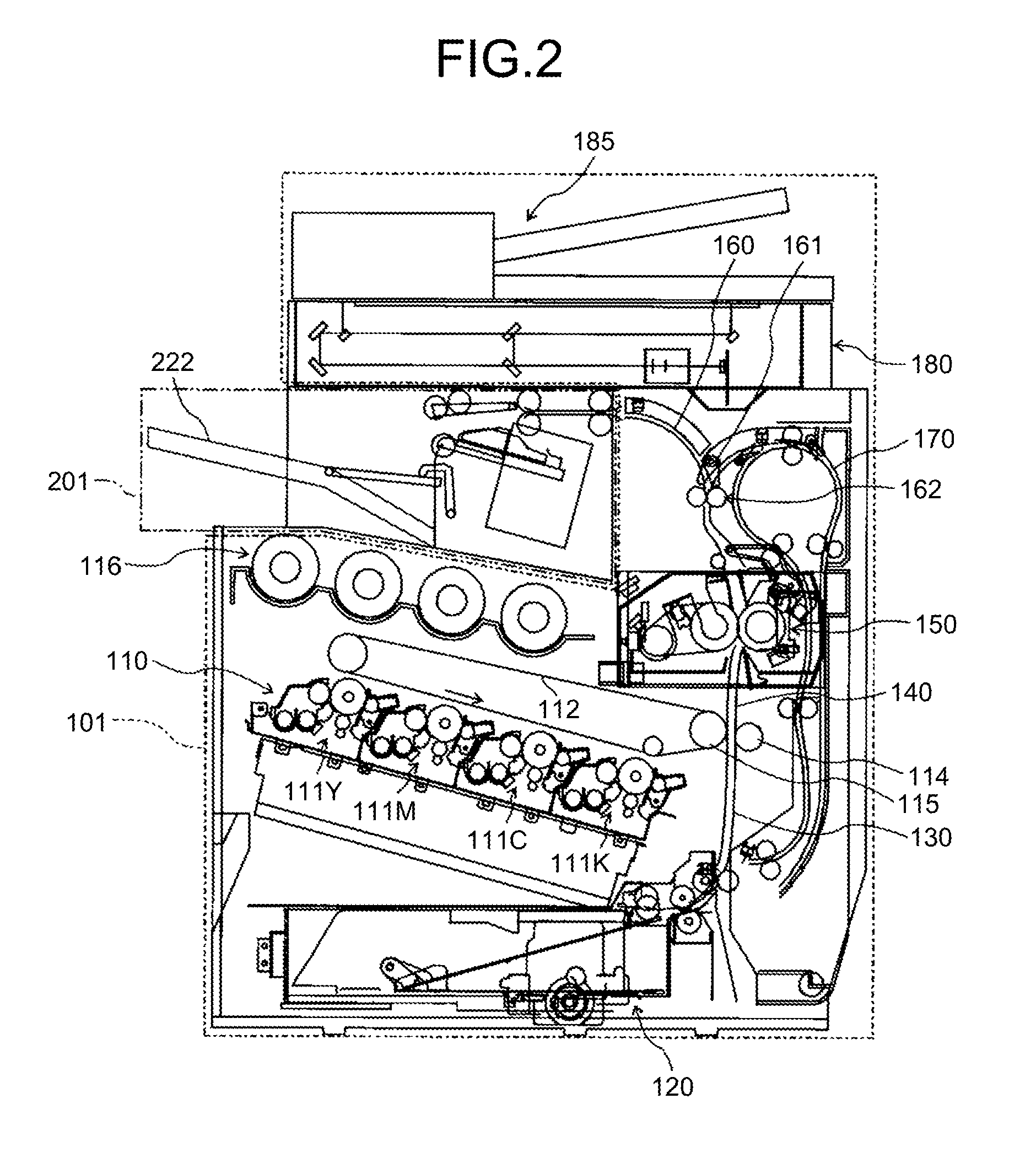

Sheet processing apparatus, method for controlling the same, storing medium, and program

A control includes causing a processing unit to perform a saddle-stitching binding process in which a plurality of sheets are subjected to a binding process and a folding process or a center-folding binding process in which a plurality of sheets are subjected to the folding process, permitting the processing unit to perform the saddle-stitching binding process or the center-folding binding process on a predetermined number of sheets, and controlling such that the number of sheets which are permitted to be subjected to the center-folding binding process is smaller than the number of sheets which are permitted to be subjected to the saddle-stitching binding process.

Owner:CANON KK

Bookbinding system

Owner:KONICA MINOLTA INC

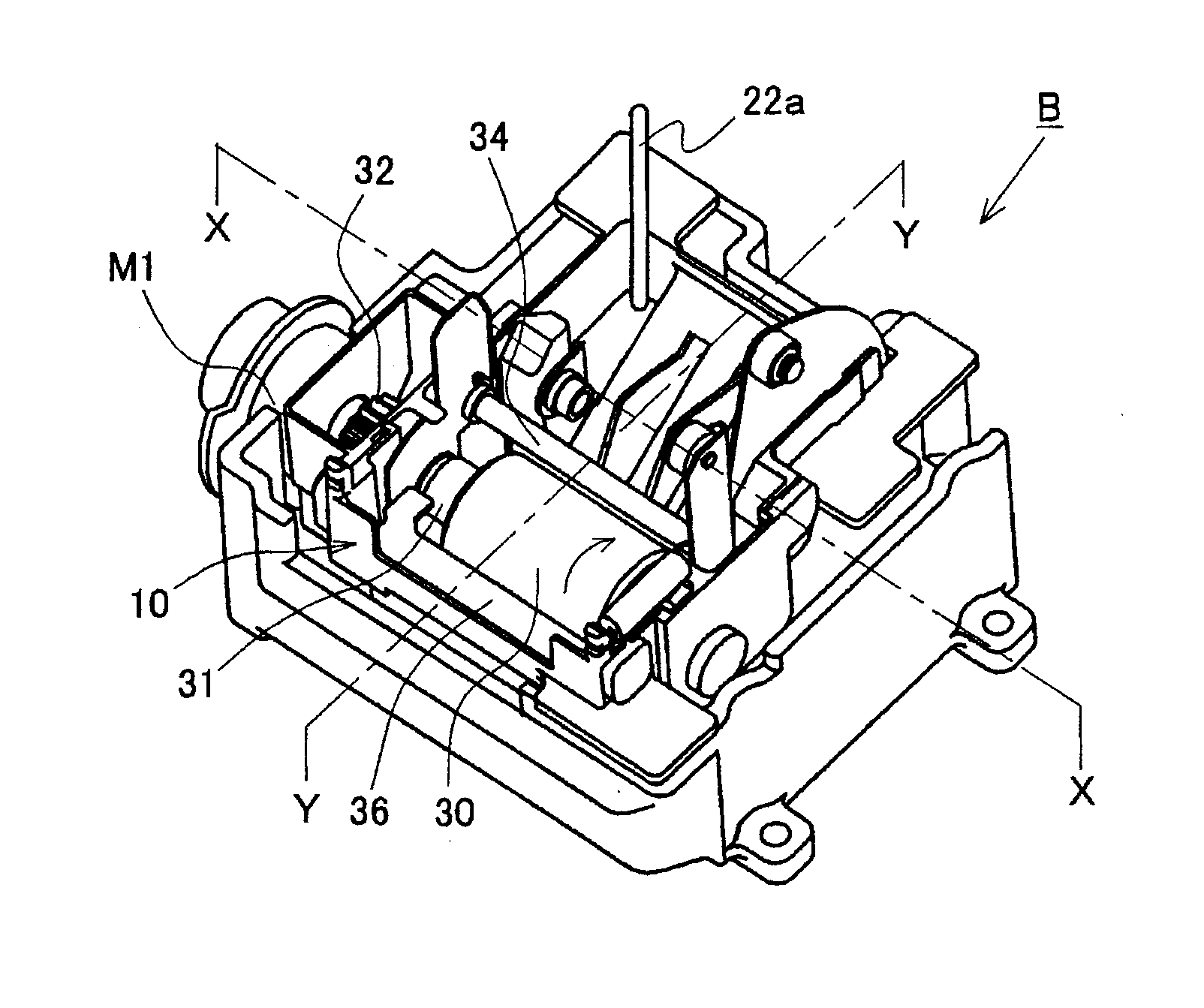

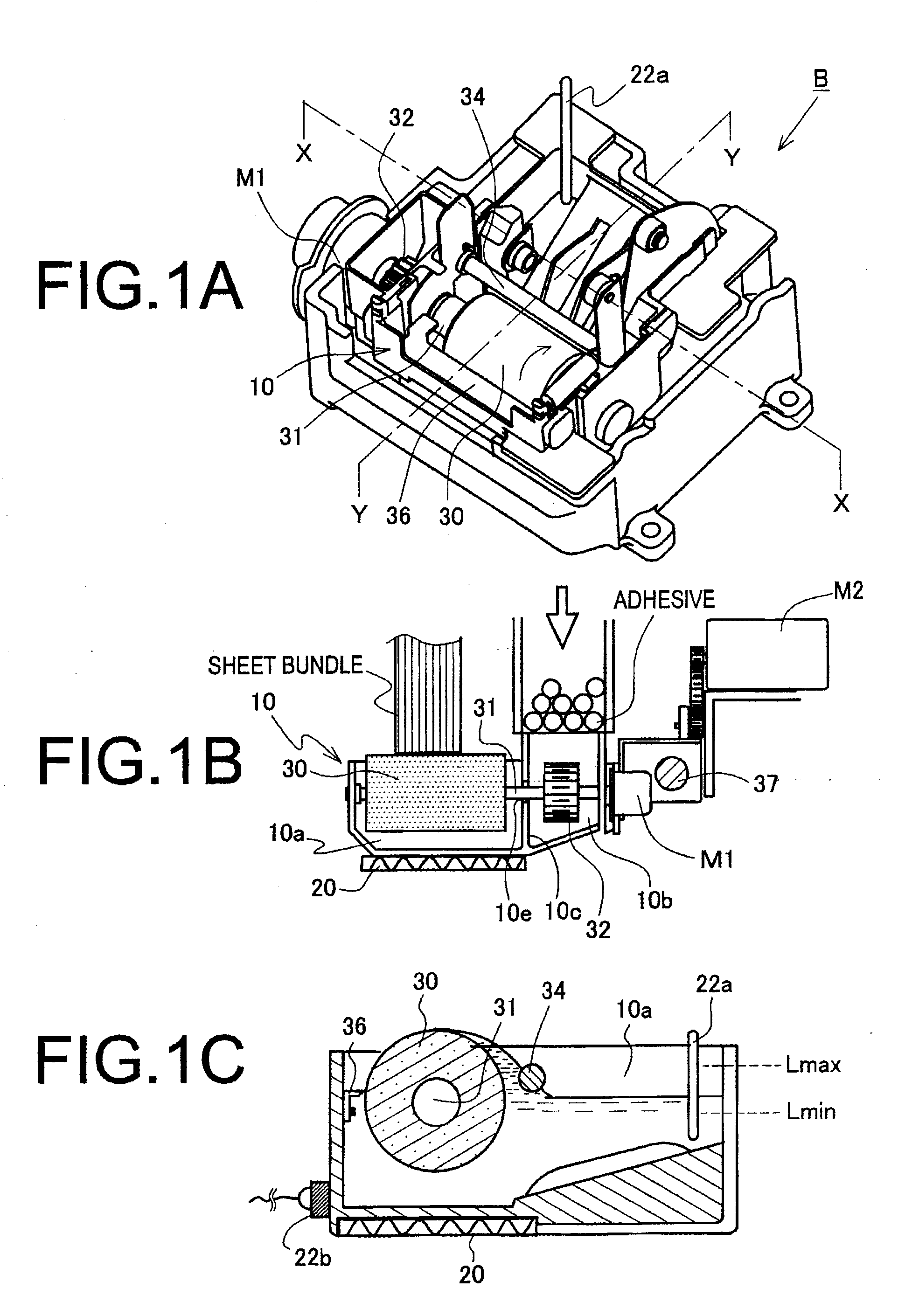

Adhesive application apparatus and bookbinding apparatus

ActiveUS20100209215A1Efficient application processingEasy to adjustLiquid surface applicatorsElectrographic process apparatusAdhesiveProtocol Application

The present invention provides an adhesive application apparatus that can form a uniform application layer when applying an adhesive to an end face of a sheet bundle by an application roller even though a length or a width of the sheet bundle is not less than or not greater than a predetermined size, and a liquid amount in an immersed coating layer formed between the surface of the application roller and the application surface of the sheet bundle can be adjusted by increasing or decreasing based on an application length and / or an application width of the sheet bundle. Therefore, level adjusting means for adjusting a liquid surface level in an equipped accommodating chamber including an application roller to increase or decrease is provided in a glue container. This level adjusting means increases the liquid surface level above a predetermined value by resupplying a solid adhesive to the glue container, or is configured to enable adjusting a position of a reflux amount restricting member that restricts (stems) an adhesive amount refluxed along the surface of an application roller, or configured to enable moving an occupied position of an accommodated liquid capacity adjusting member that adjusts an allowable accommodation amount of the adhesive in the accommodating chamber.

Owner:NISCA KK

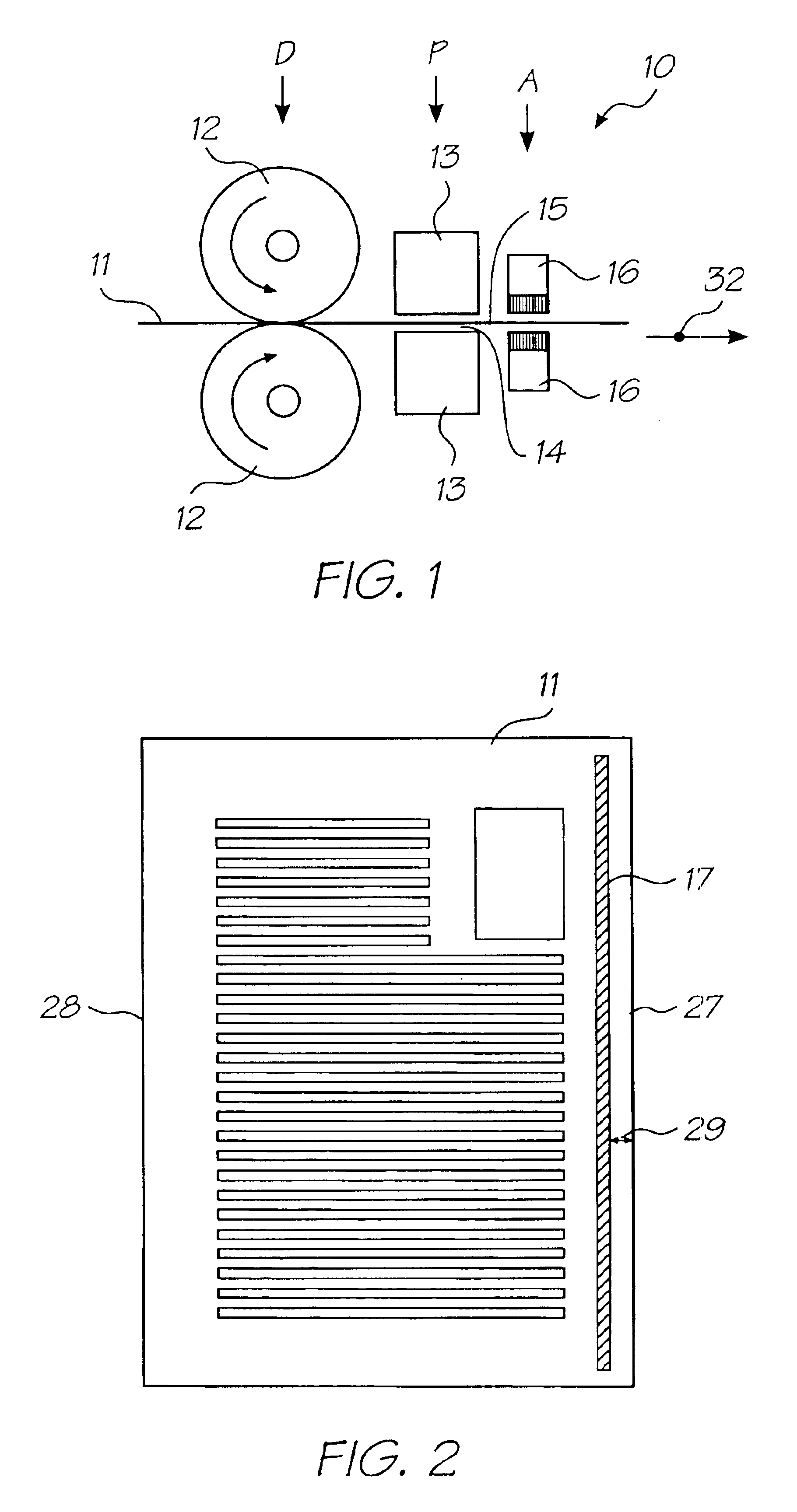

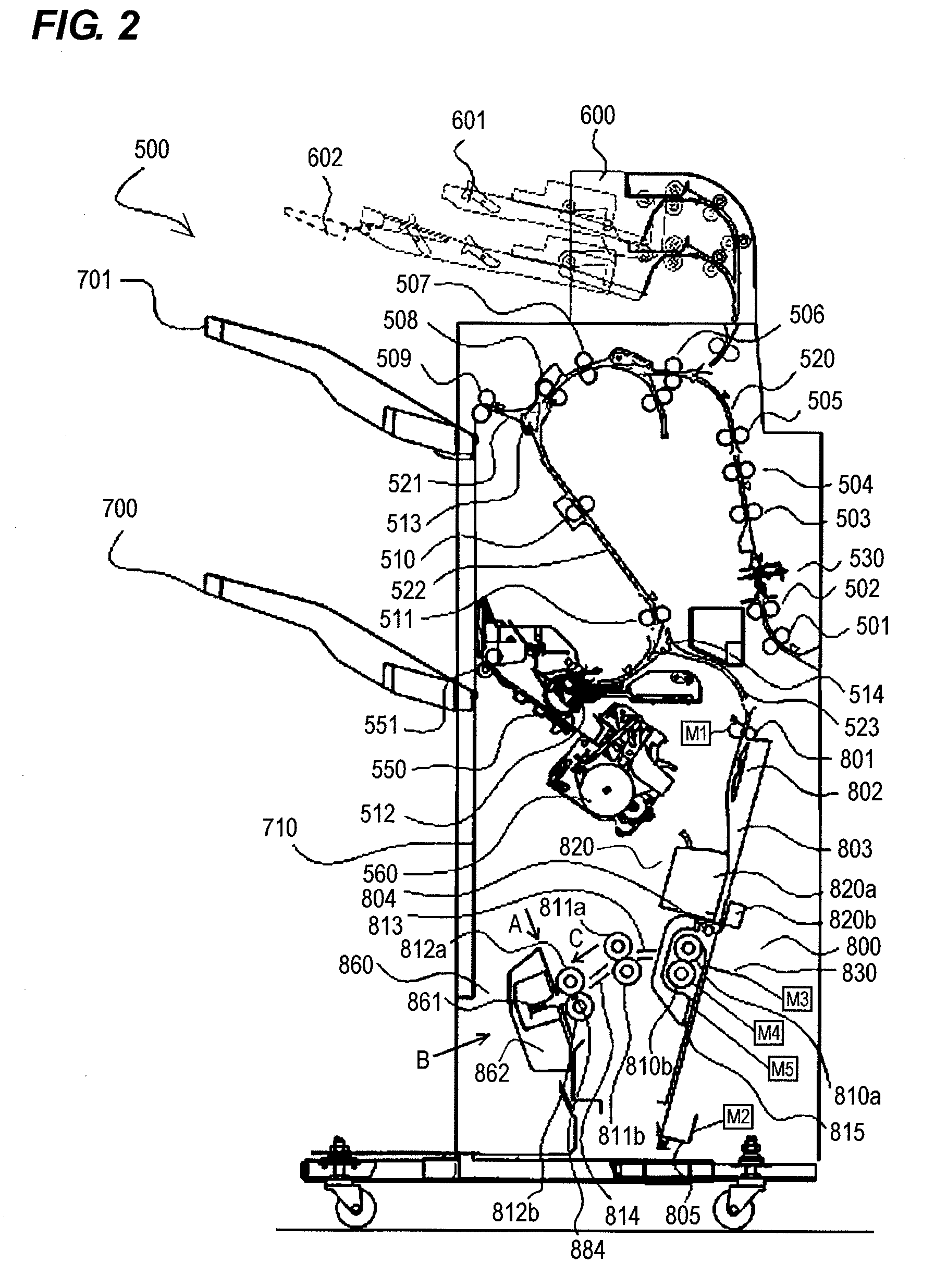

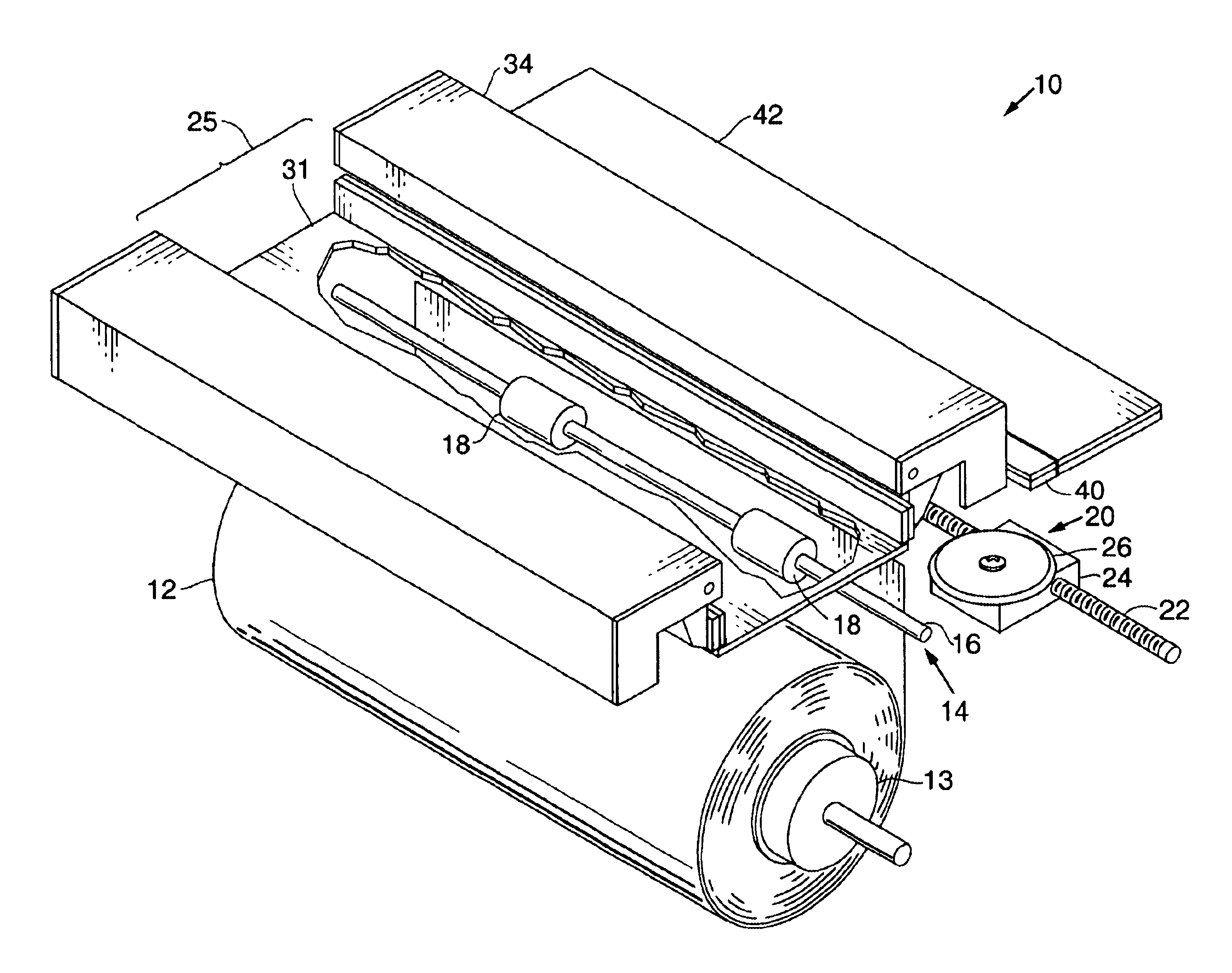

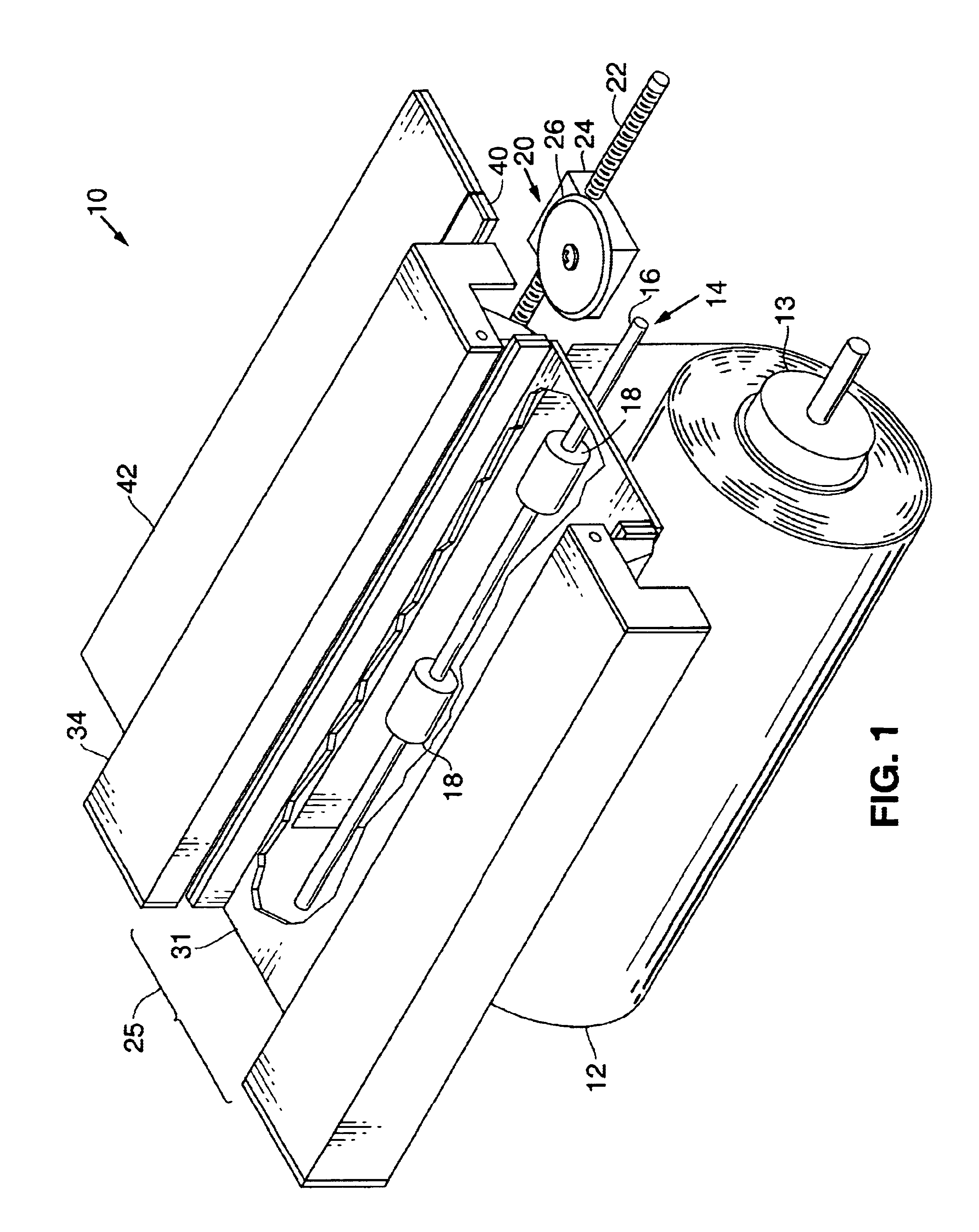

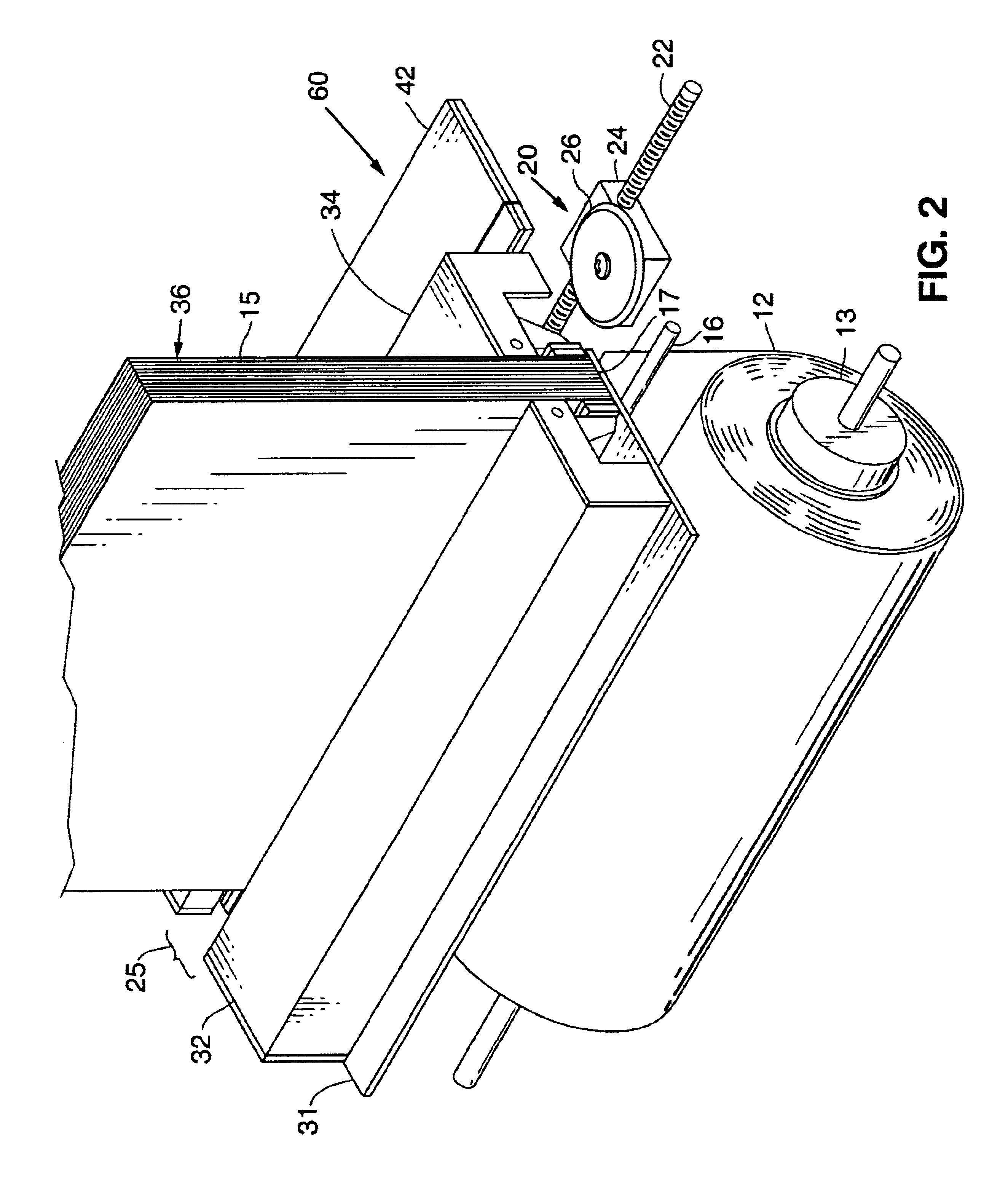

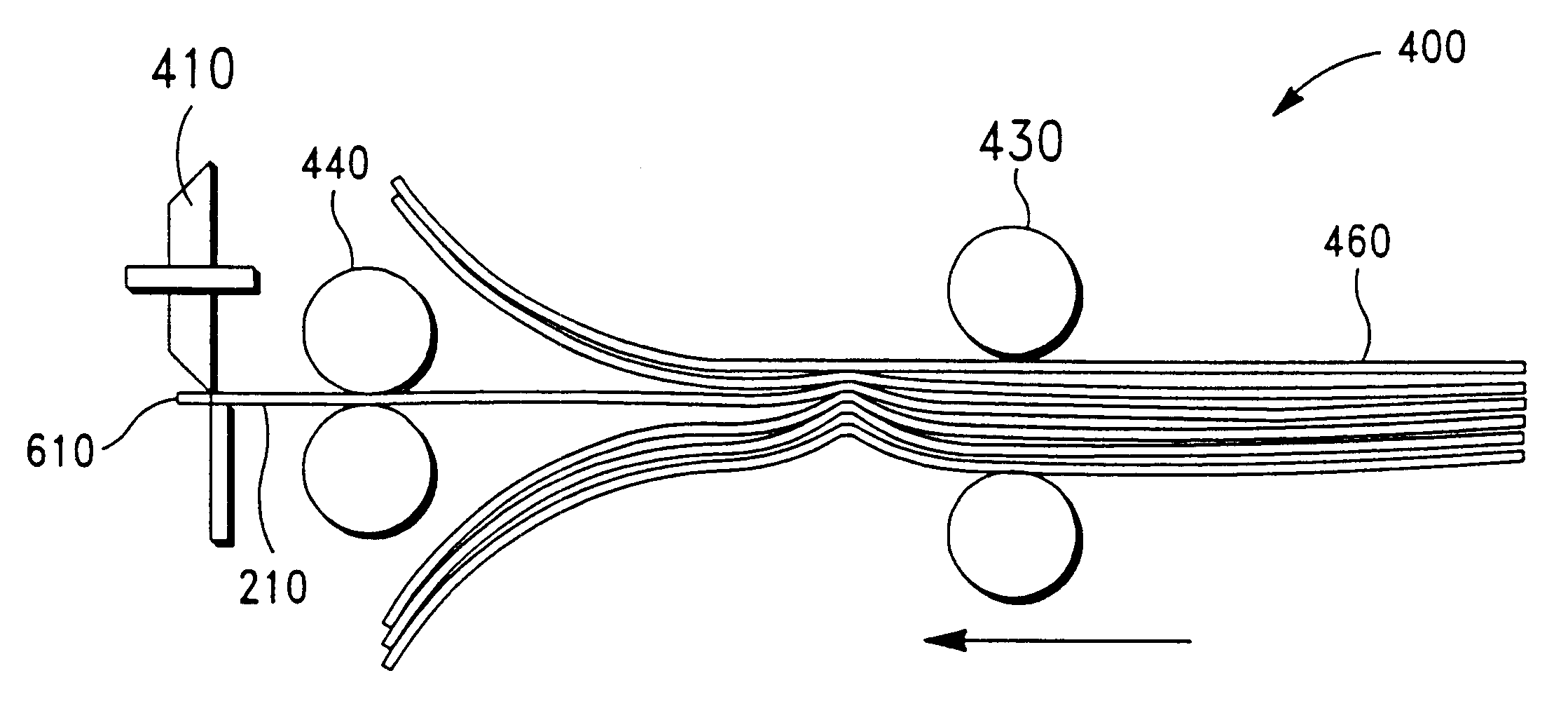

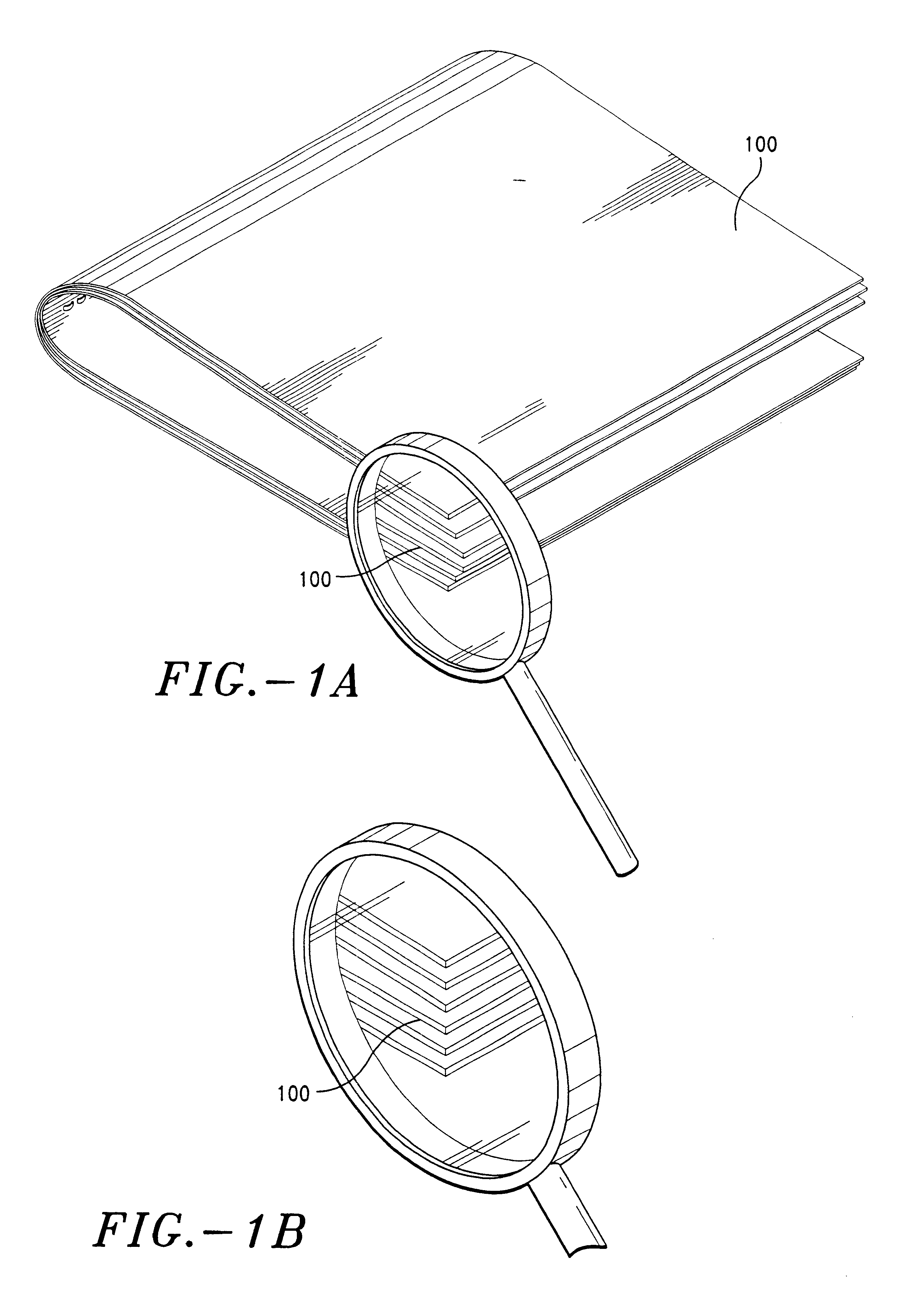

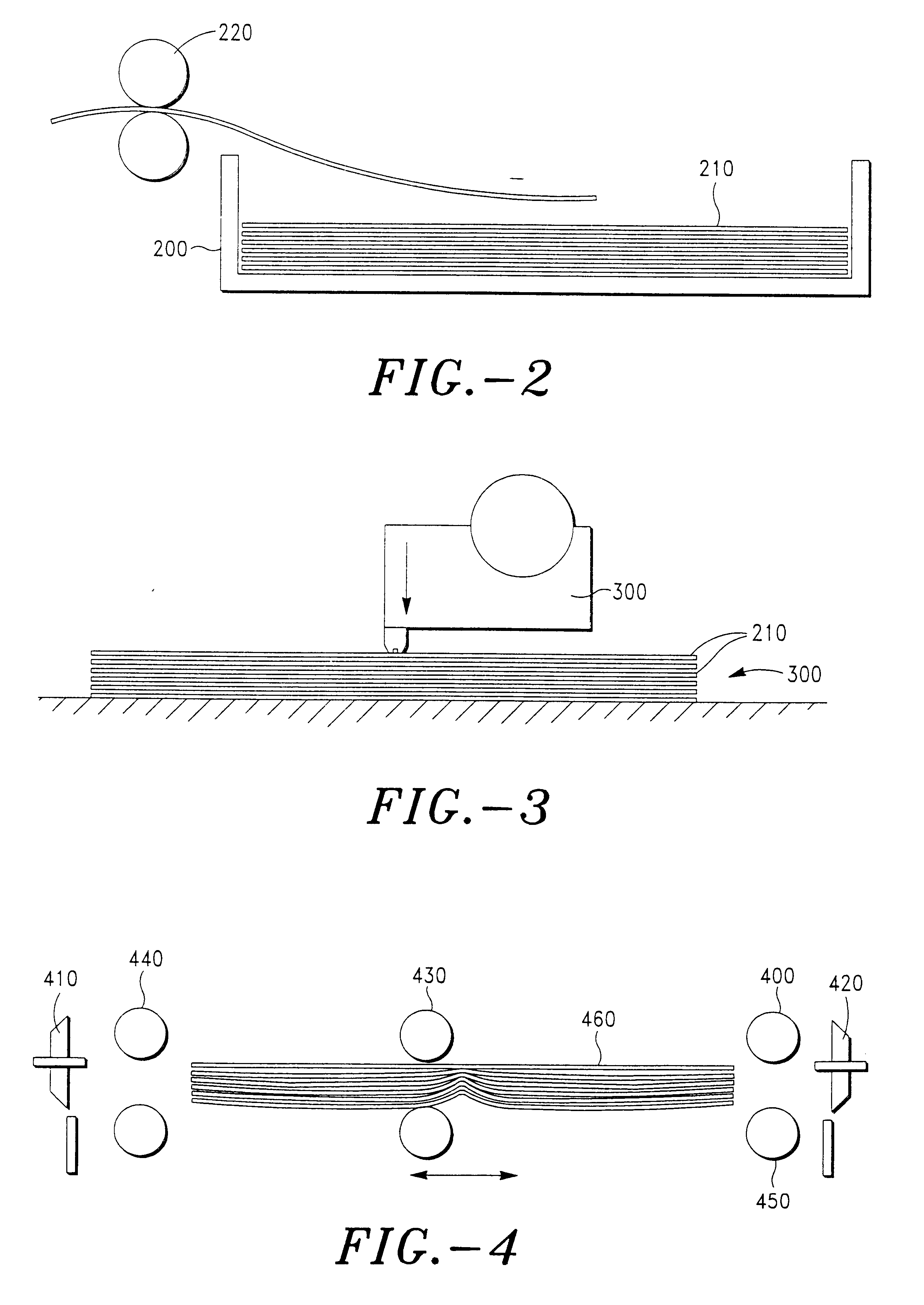

Booklet maker with sheet wise trim

InactiveUS6632061B2More compactLess expensiveOther printing matterRegistering devicesWood veneerEngineering

A trimming apparatus for a booklet maker is described which provides a compact and low cost booklet maker for desktop publishing. The booklet maker includes a sheet receiving tray for receiving a stack of sheets to be stapled into a booklet, a stapler unit arranged to staple the stack of sheets, and a trimming system for trimming the sheets in a sheet wise manner. The trimming system includes first and second pick and separate mechanisms arranged to separate each of the sheets in the stack of sheets and first and second cutters arranged to cut each of the separated sheets after the have been separated by the first and second pick and separate mechanisms. A controller positions the sheets and controls the trimming system to cut each of the separated sheets at a location determined based on a trimming schedule. The trimming schedule varies the position of the cut depending on a position of the sheet in the booklet and a thickness of the sheets.

Owner:HEWLETT PACKARD DEV CO LP

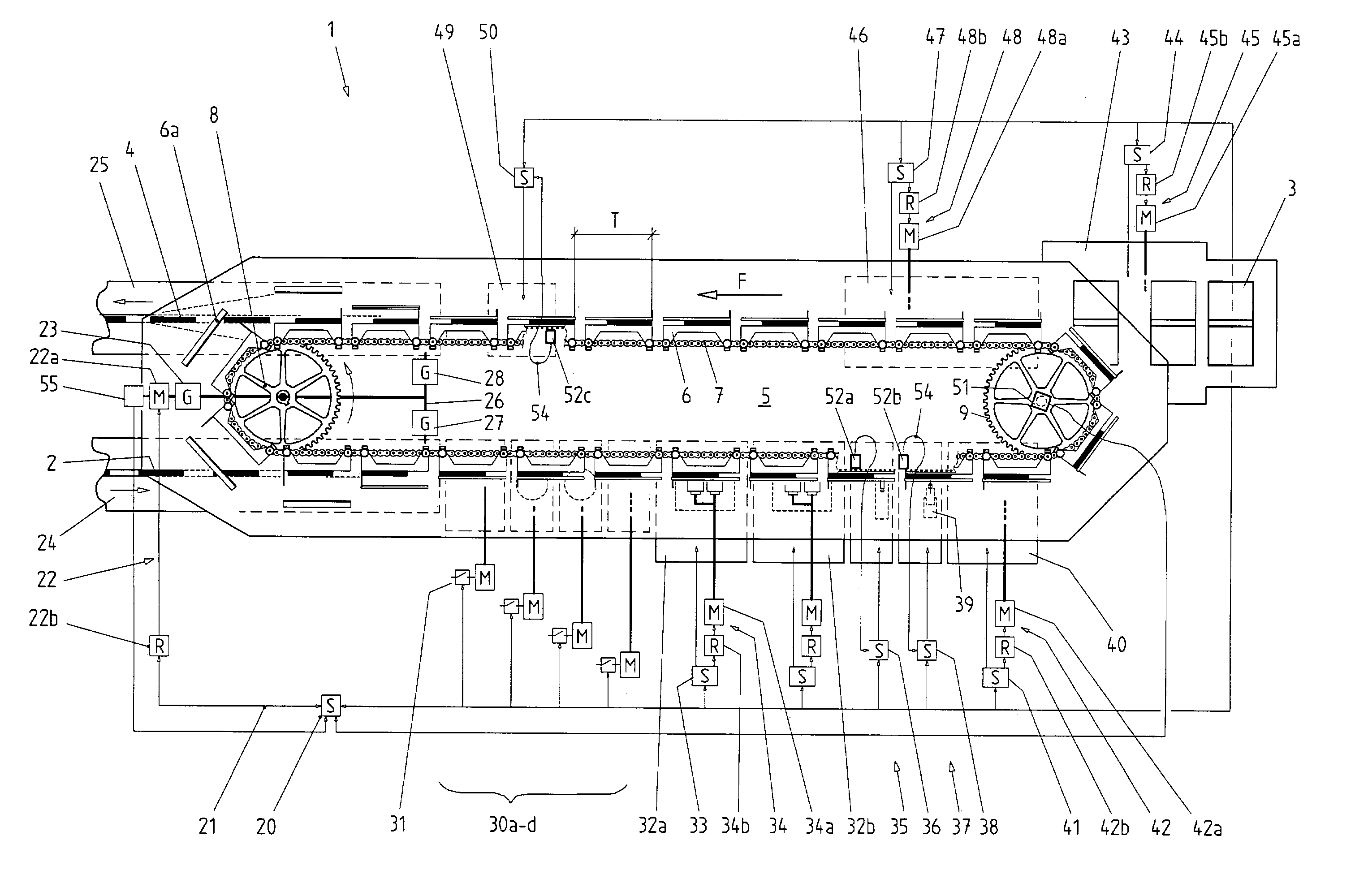

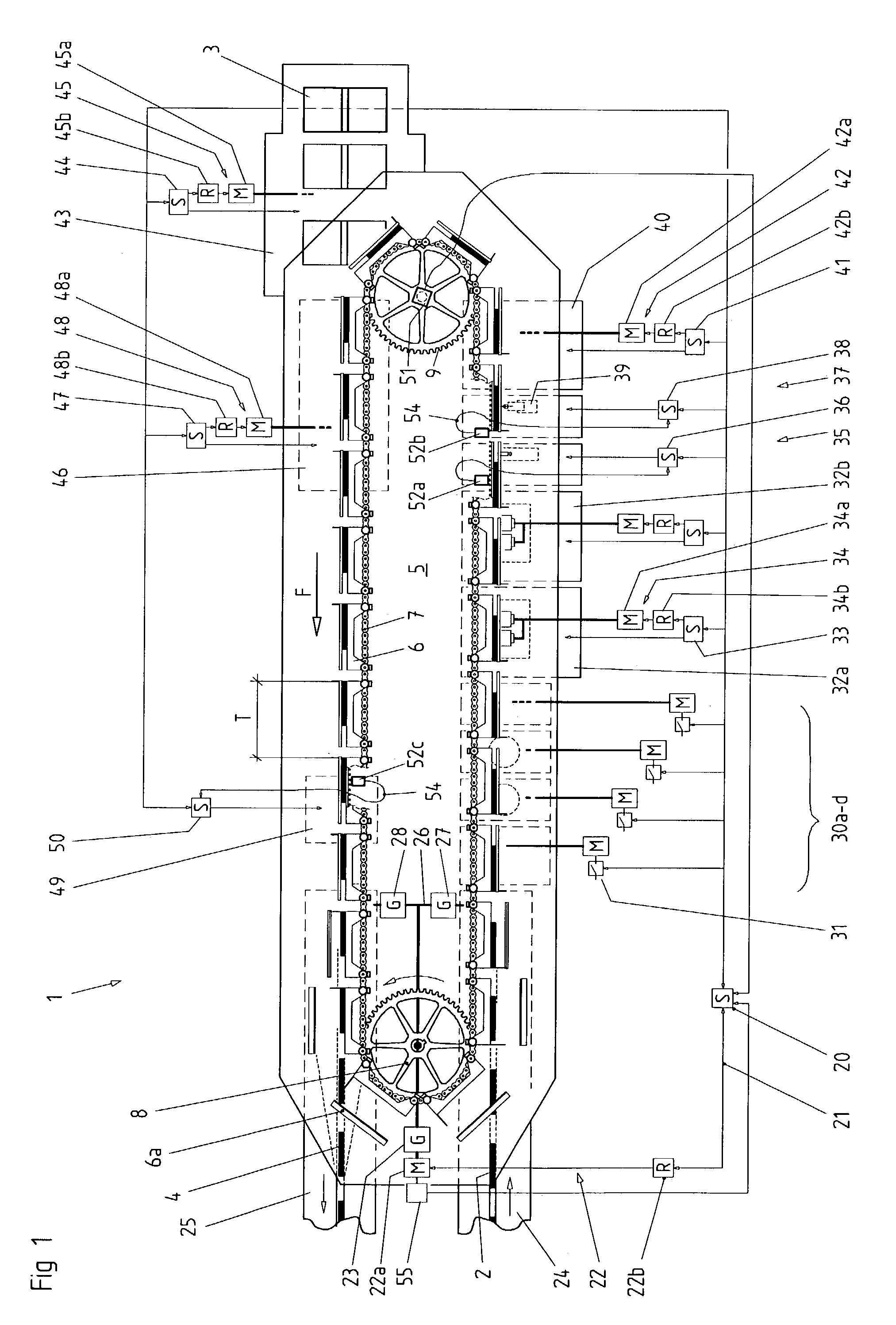

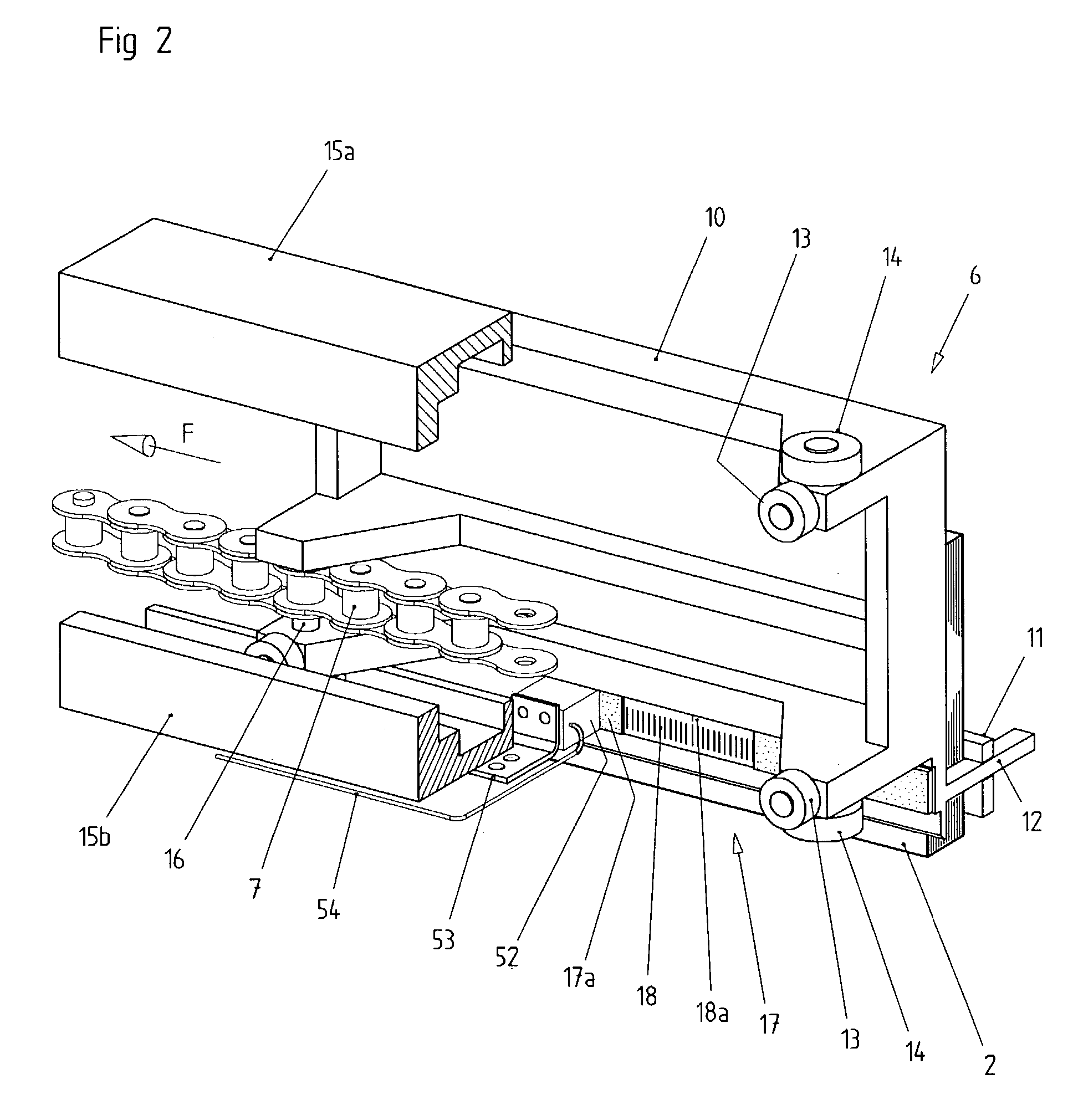

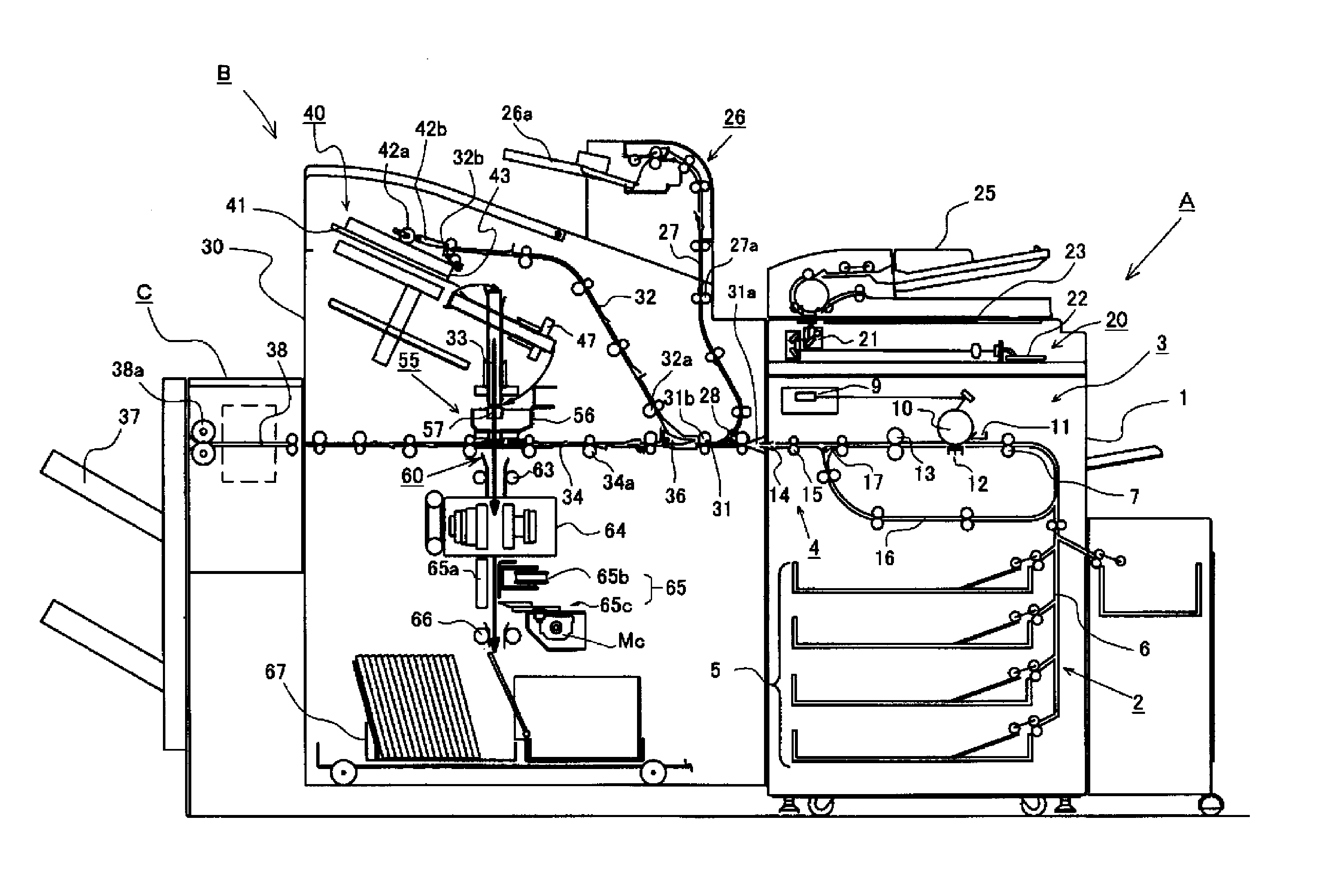

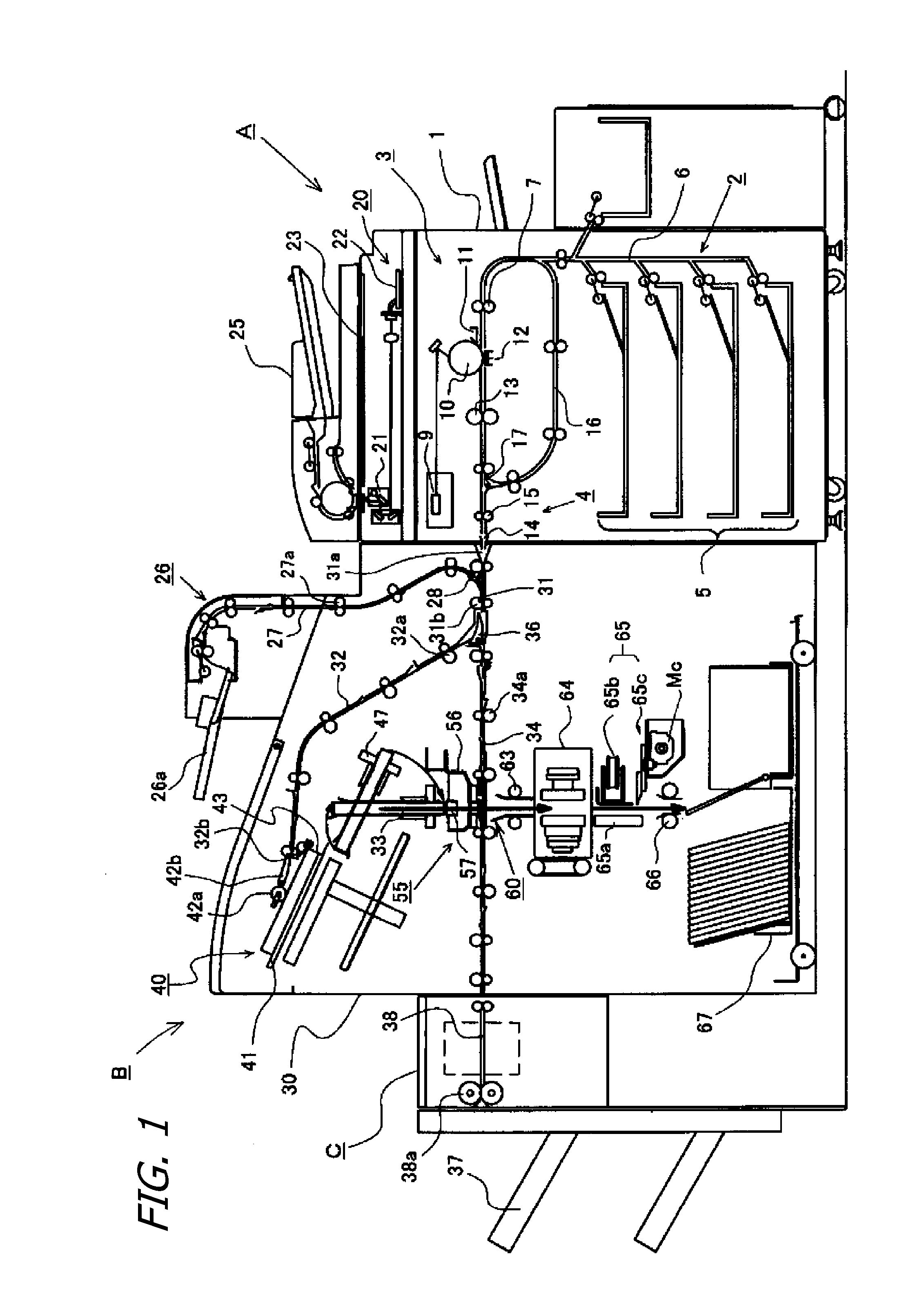

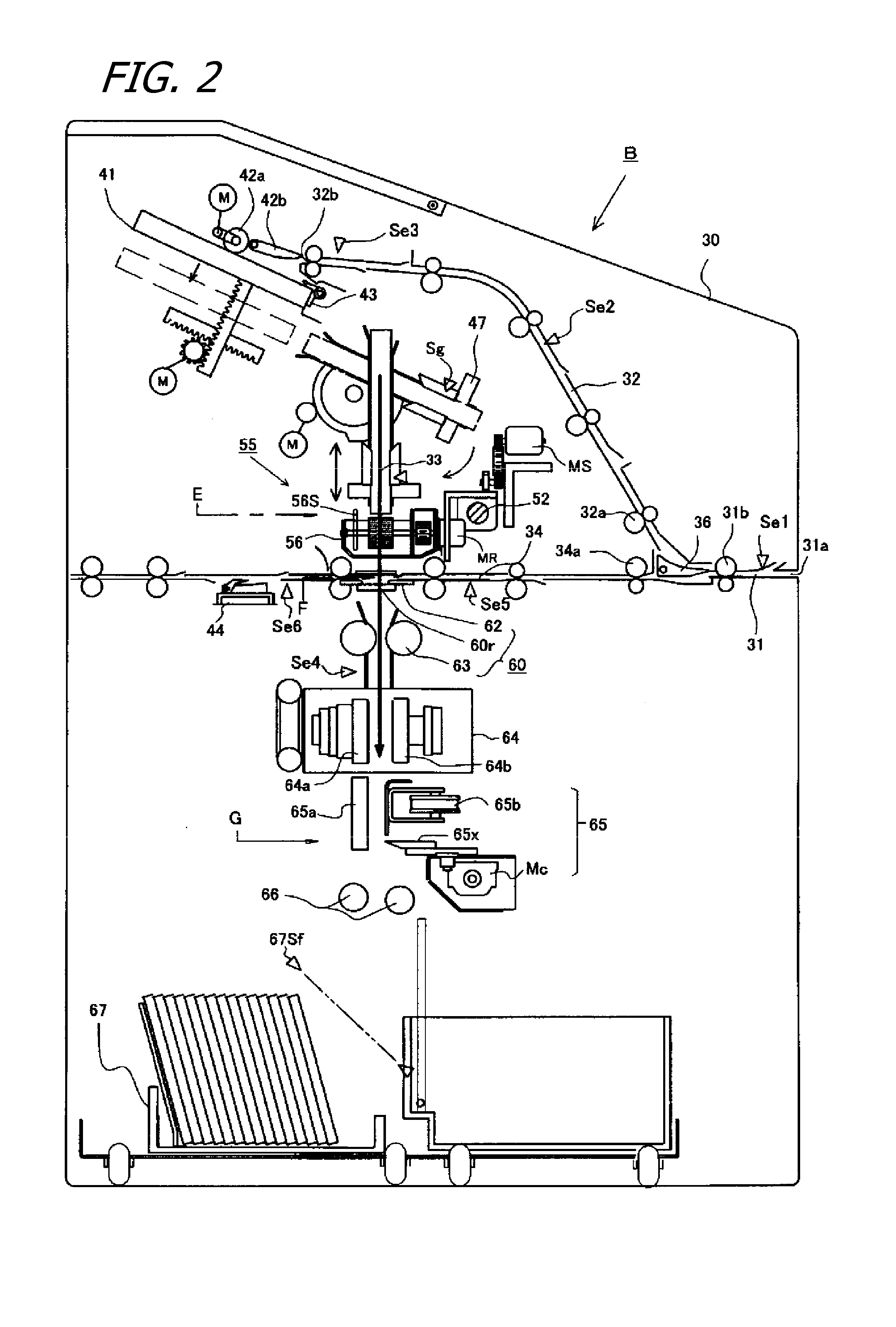

Bookbinding machine

InactiveUS7210887B2Easy constructionAccurate operationBook making processesArticle feedersTransport systemEngineering

A bookbinding machine for processing inner books includes a transport system with a multiplicity of inner-book clamps continually movable in a closed continuous track. Each of the inner book clamps is articulated to a circulating roller chain and has a rear-edge stop for aligning the inner books. The bookbinding machine includes workstations that perform positionally accurate operations on the inner books including the application of glue, the application of reinforcement or gauze sections, the application of jackets, binding with wire stitches, the introduction of utilisation features (e.g. punched holes, tear-off perforations, etc.) and the like. The transport system of the inner-book clamps and at least one workstation are driven independently of one another. A measuring system for positional detection of the inner-book clamps or of the inner books is provided in proximity to the independently driven workstation. The measuring system provides inner book or clamp position data used to control the workstation performing positionally accurate operation on the relevant inner book.

Owner:KOLBUS

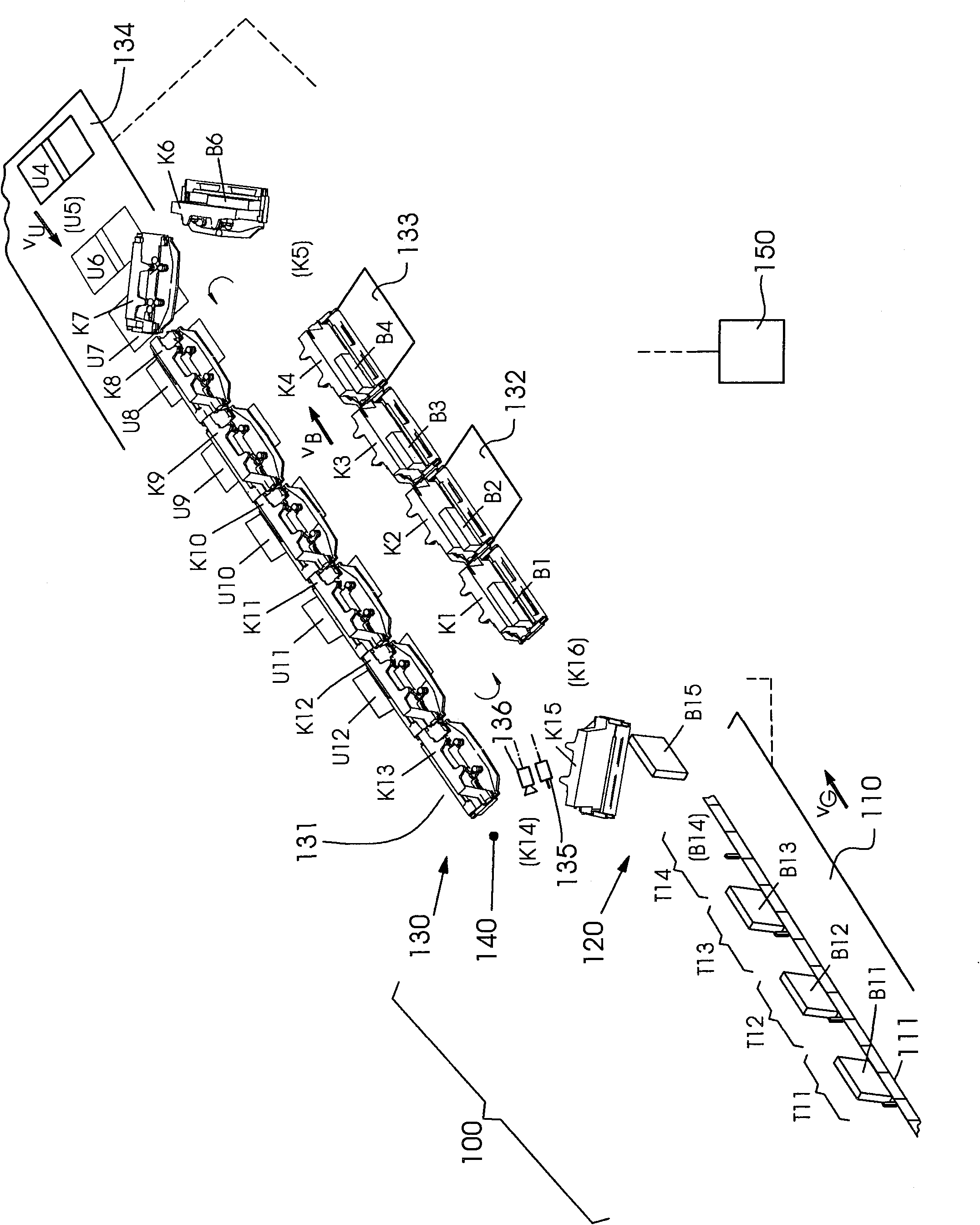

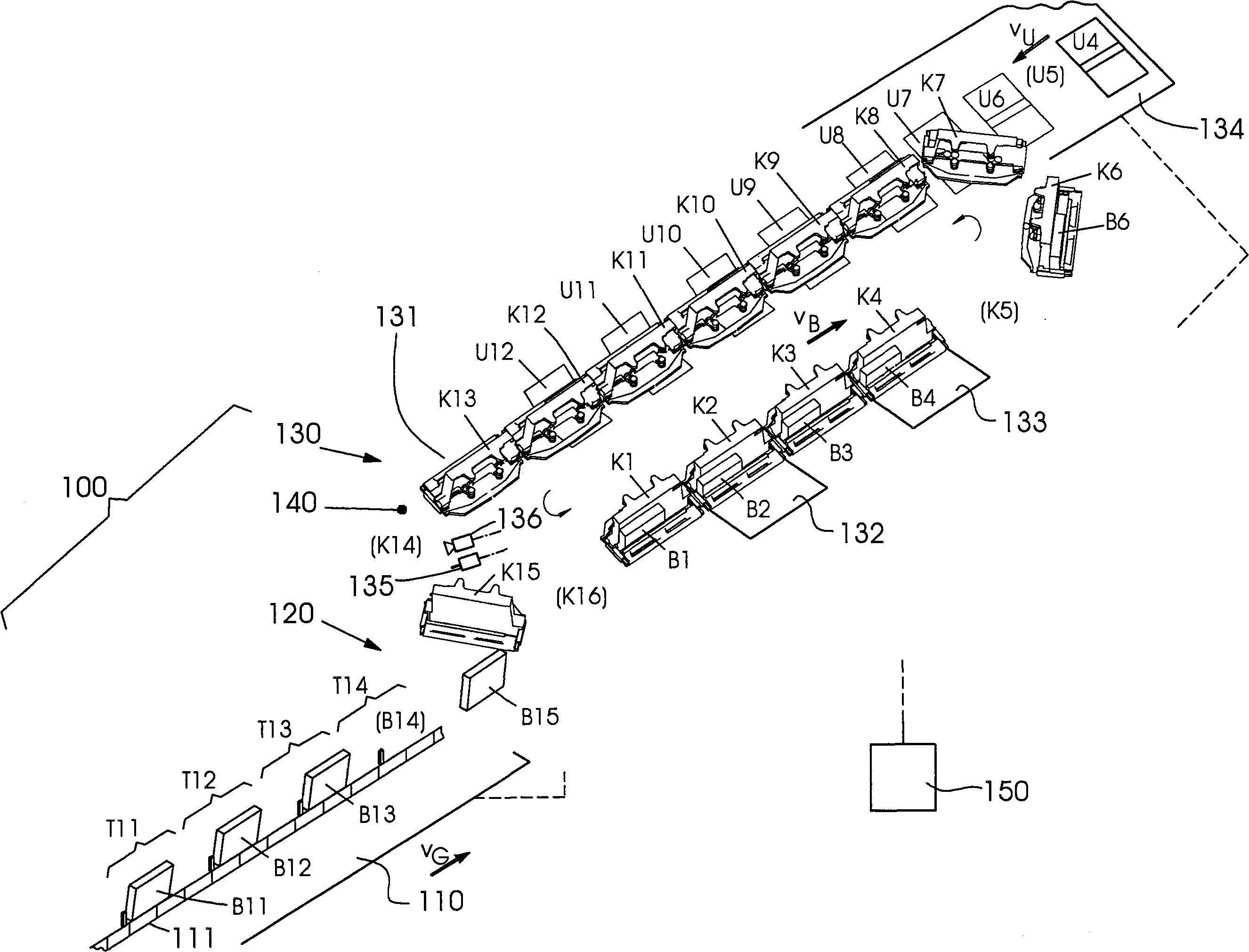

Book binding machine and method for operating same

A book binding machine includes a collating machine, a perfect binder and a transfer device disposed between the collating machine and the perfect binder. The collating machine and the perfect binder are actuated by a common control device. In each case, one transport segment is assigned to a respective book block clamp by the control device. The control device also has a program which, if a defective or missing book block clamp is detected, actuates the collating machine in such a way that no book block is collated for that book block clamp.

Owner:MULLER MARTINI HLDG

Method for attaching crimping members, sheet binding device, and image forming apparatus

ActiveUS20150030414A1Solve problemsMechanical working/deformationElectrographic process apparatusEngineeringBiomedical engineering

Owner:RICOH KK

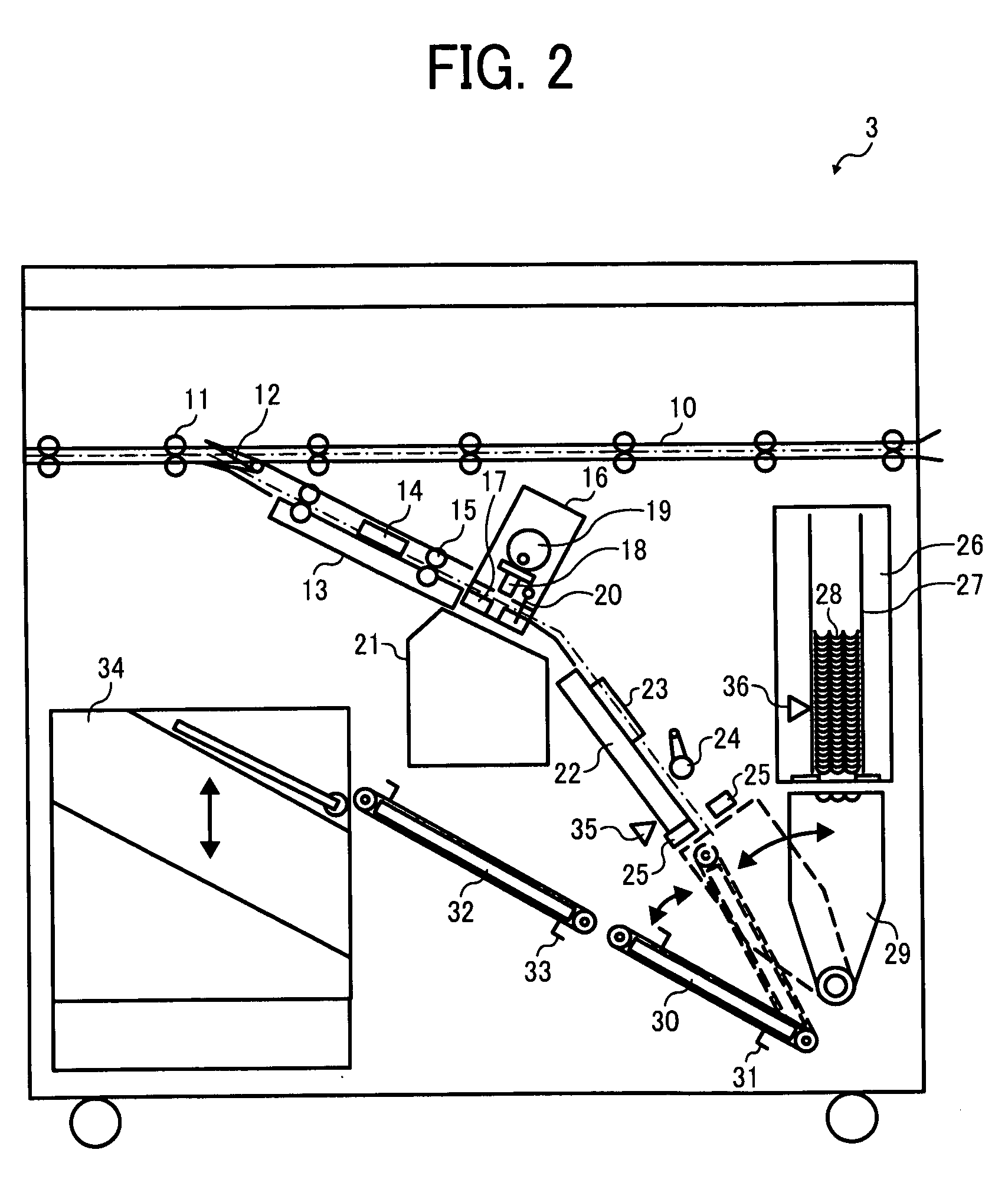

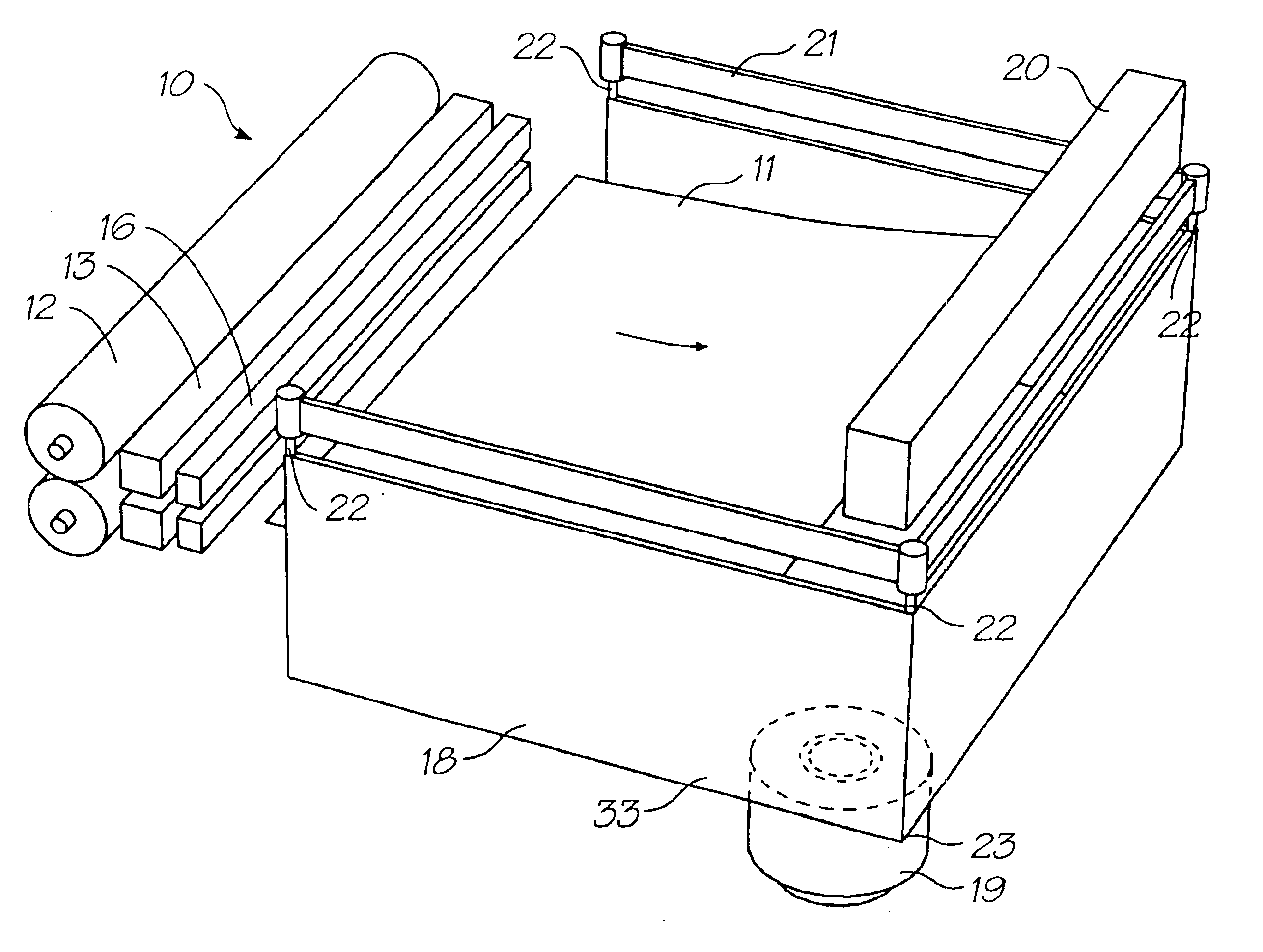

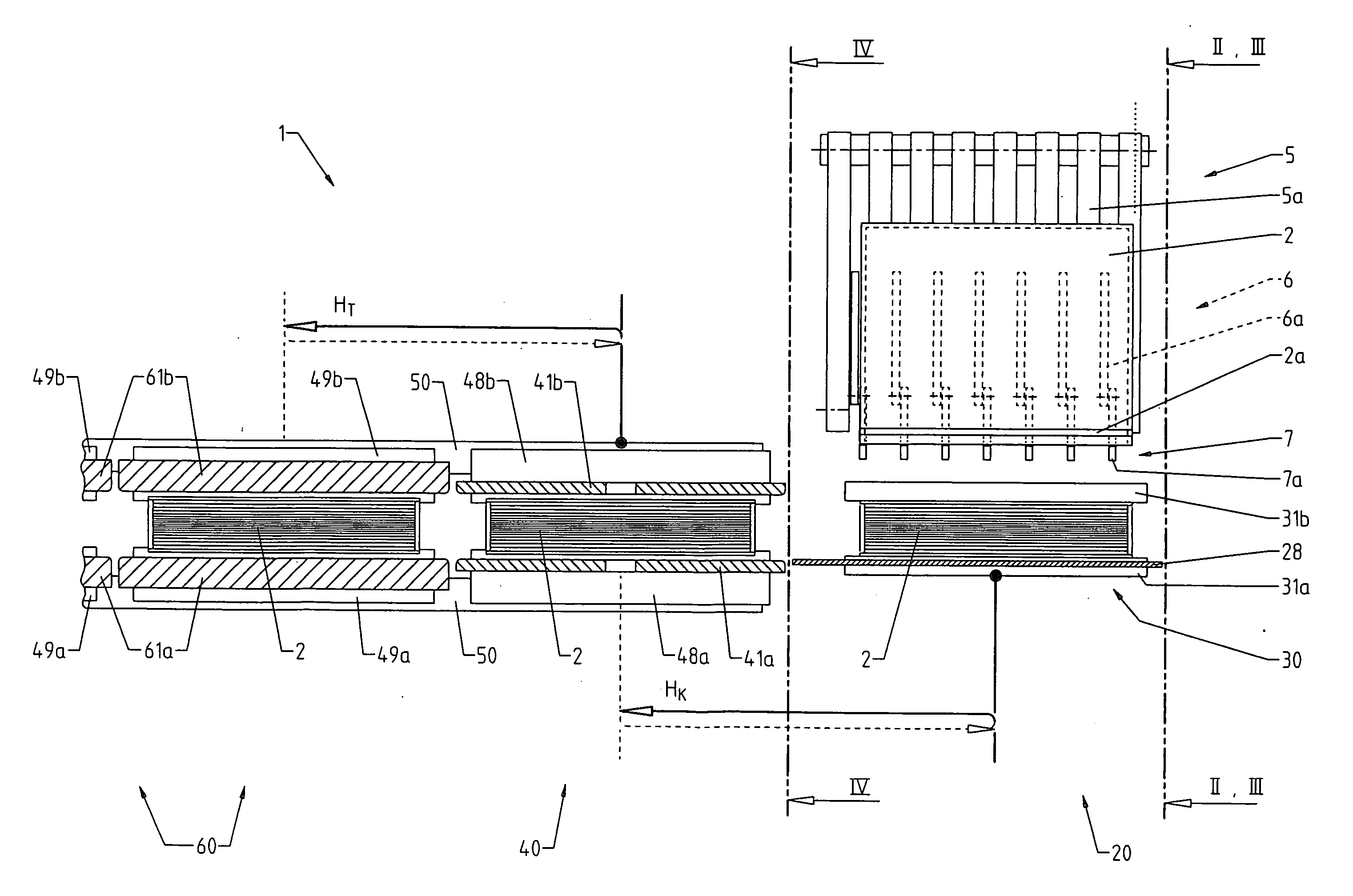

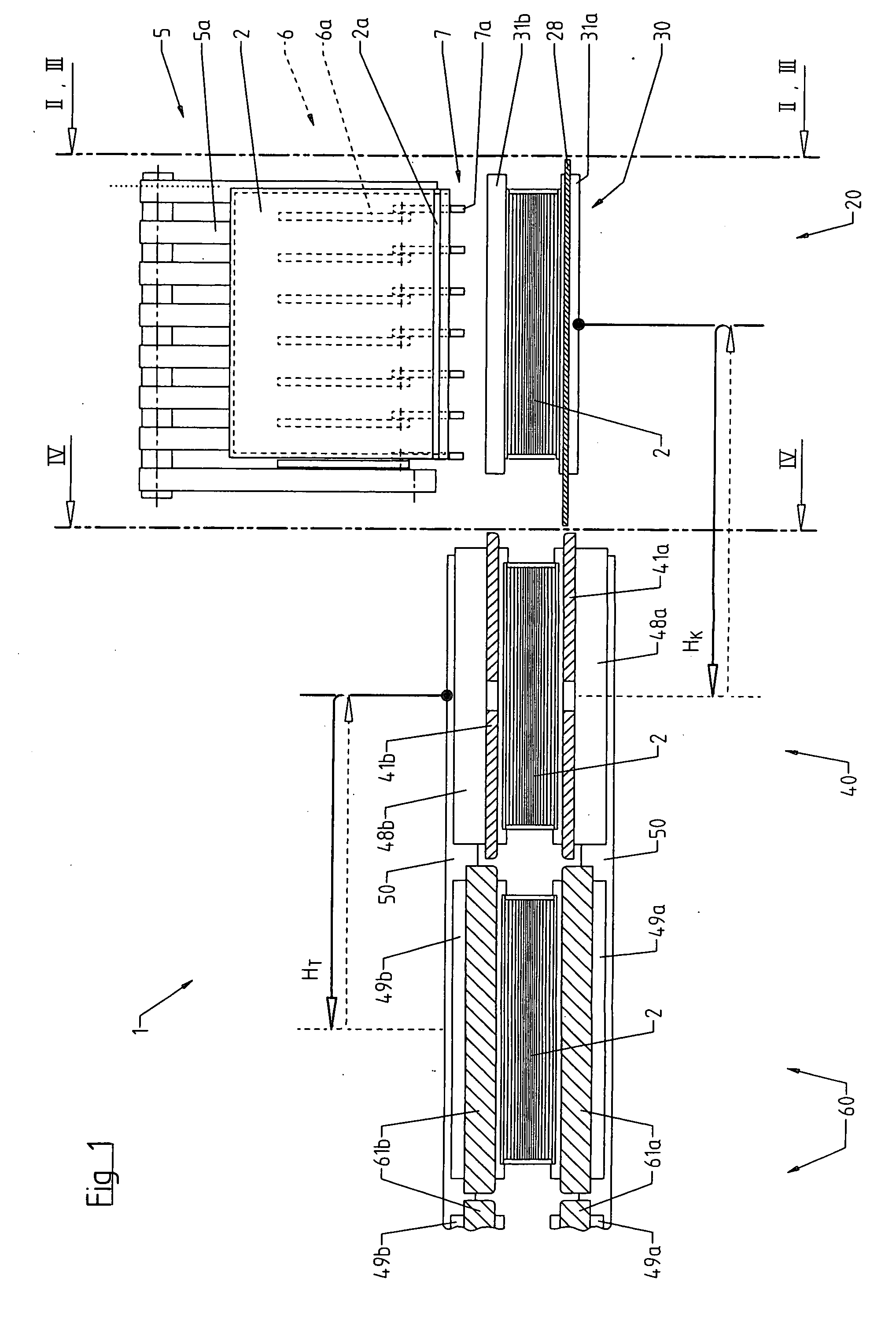

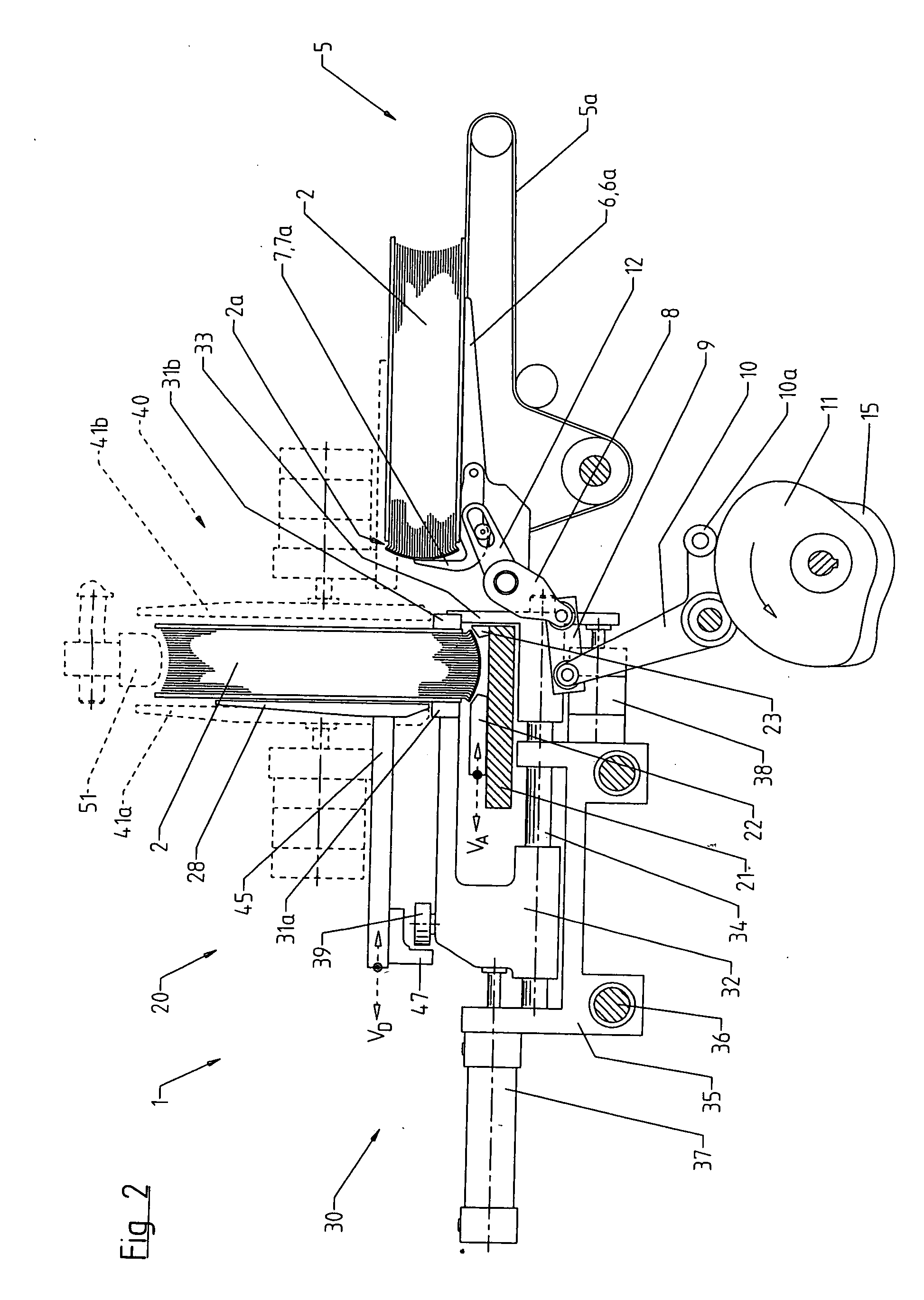

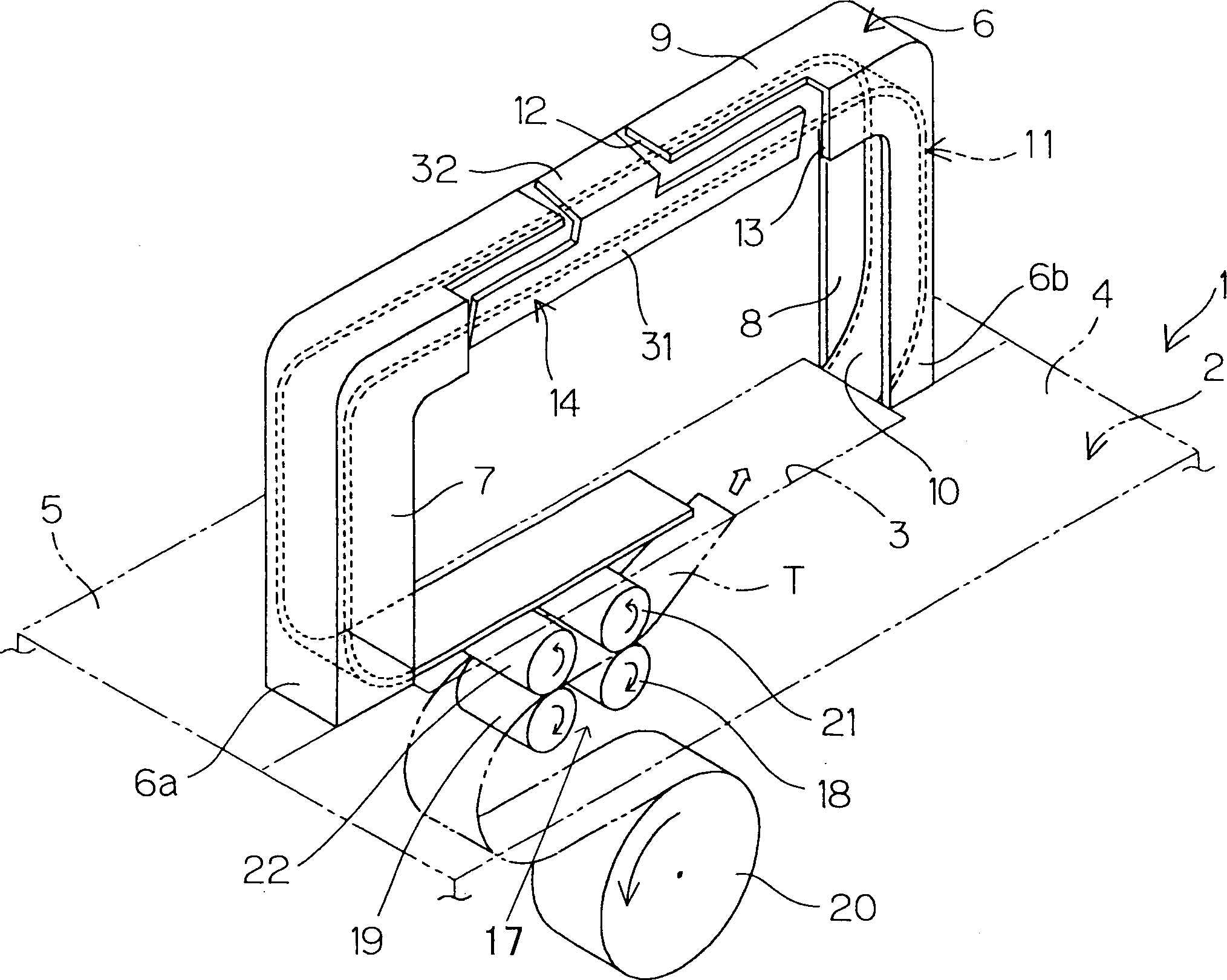

Binding-in and pressing machine

InactiveUS20060140742A1Simple and cost-efficient designQuality improvementBookbinding casesCasing-inLateral regionEngineering

A binding-in and pressing machine (1) with a plurality of pressing stations (60) and heated joint forming rails situated on a reciprocating carriage (50). An alignment station (20) is provided for aligning the book case joints (2a) at the height of the joint forming rails (49a, b), including a height-adjustable alignment table (21) with rails (22, 23) for supporting the book (2) on the outer edges of its spine and guide elements (28, 6) for centering the book on the alignment table. A separate pre-forming station (40) is also provided that comprises the forming rail (51), clamping plates (41a, b), and joint rails (48a, b) that engage into the book case joints (2a) and counteract a downward movement of at least the book case joints (2a). The books (2) aligned in the alignment station (20) are transferred into the pre-forming station (40) while being clamped in lateral regions near the joints. The effective times available for realizing a functionally safe alignment and a permanent pre-forming of the books are extended due to the assignment of the alignment and pre-forming functions to two separate stations.

Owner:KOLBUS

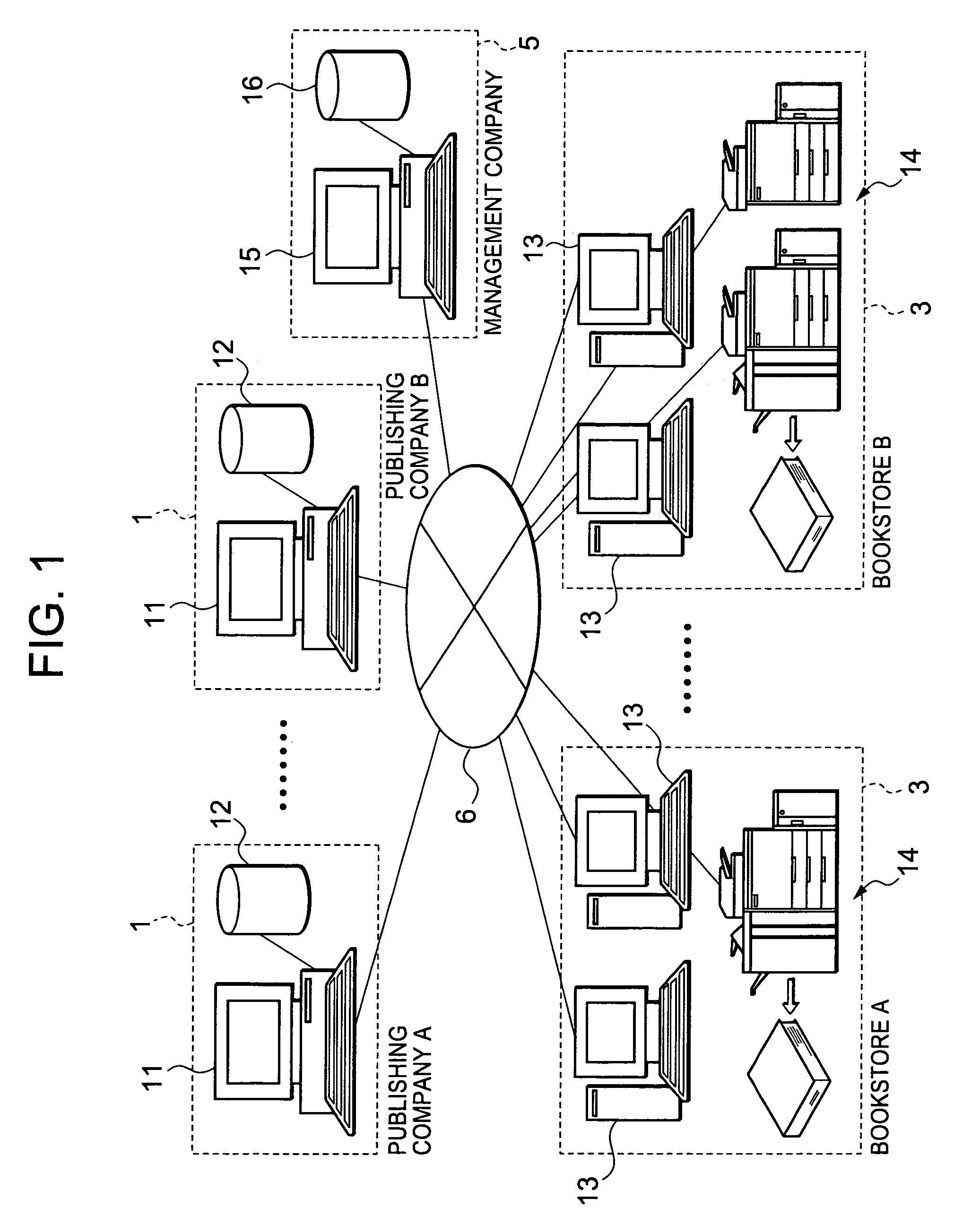

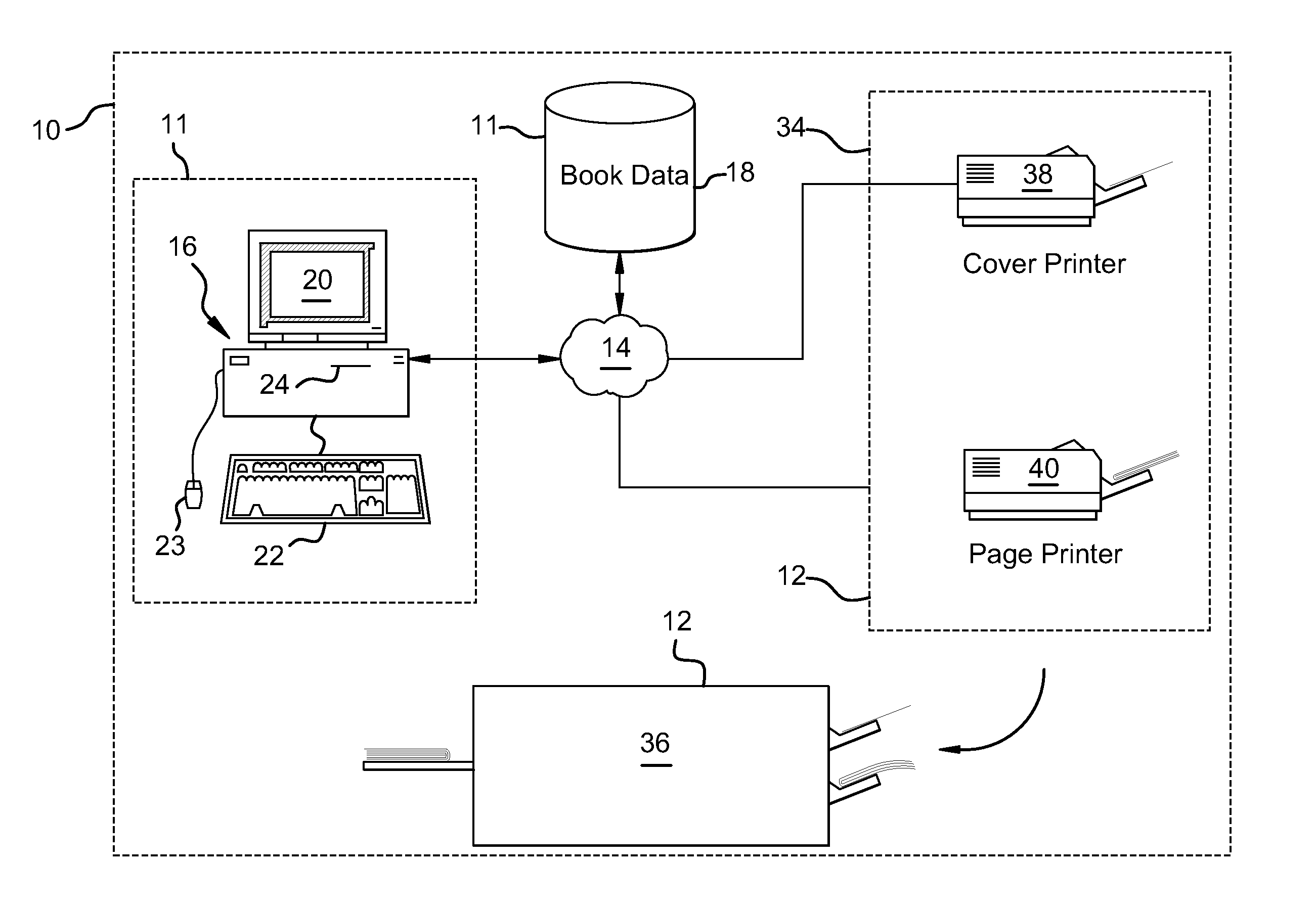

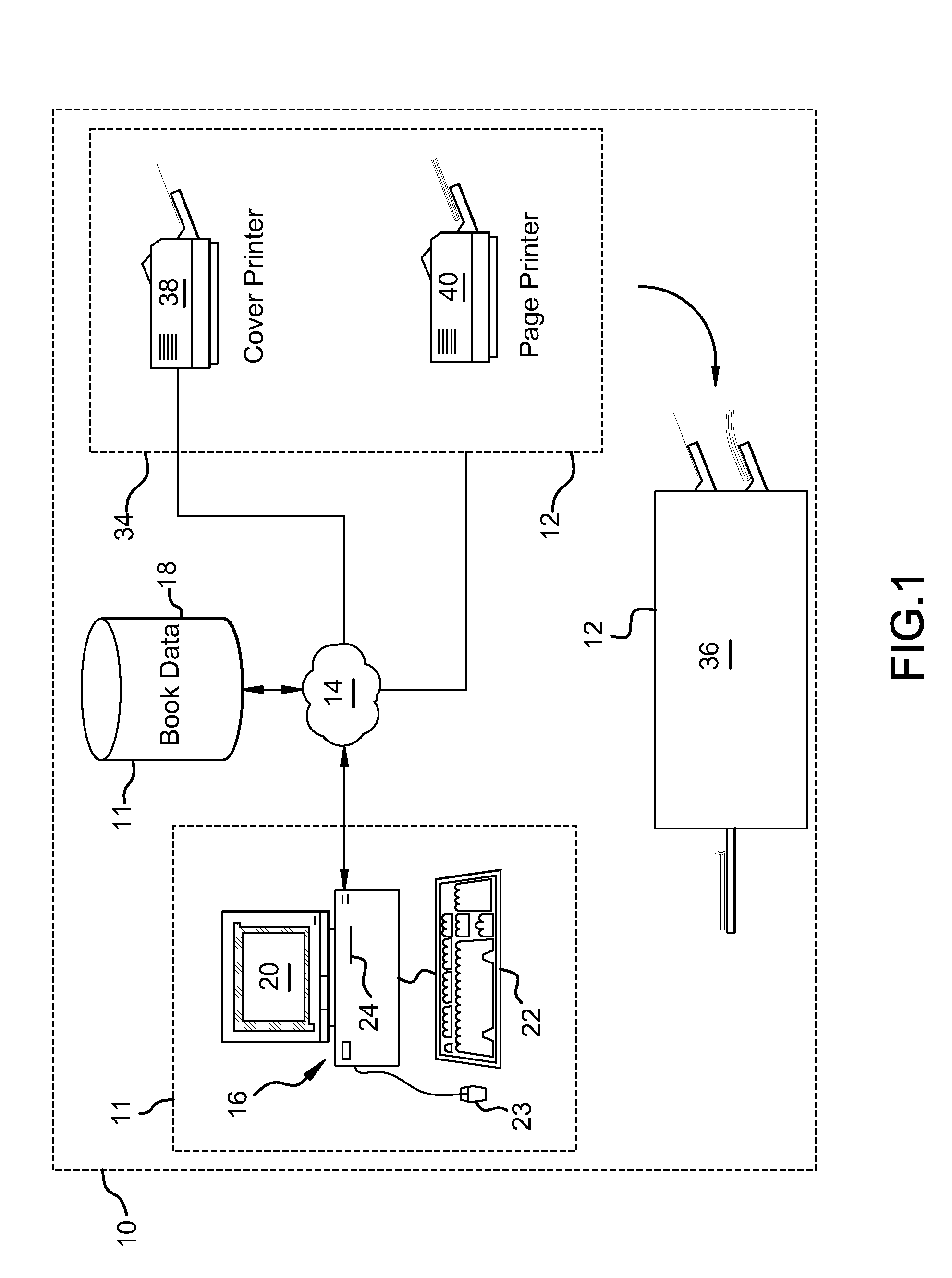

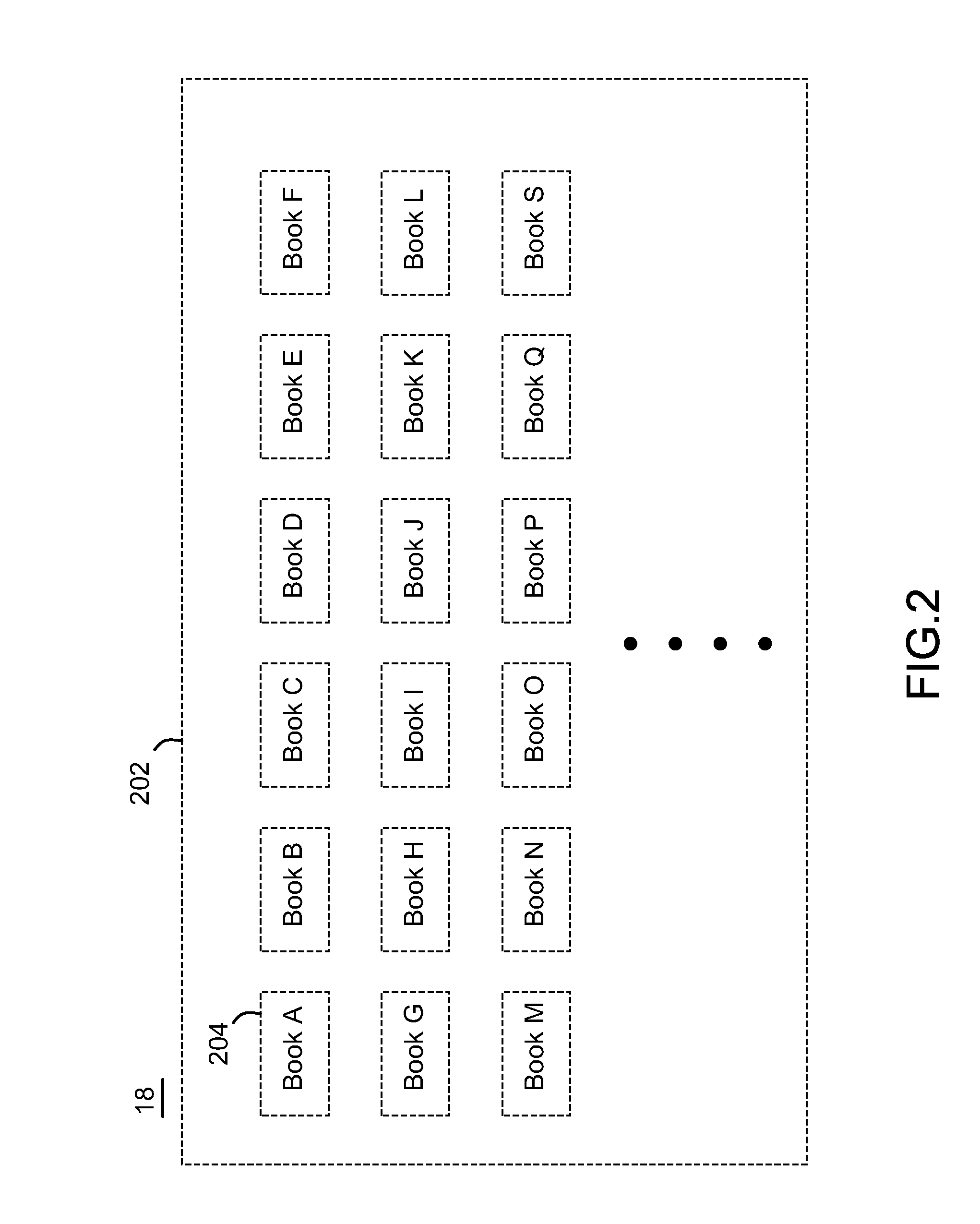

Tailored method and system for custom manufactured books

A book on demand system for manufacturing a set books. The system includes an order placement system and a book manufacturing system. The order placement system includes a computer and a database for storing books in an electronic form. A customer can operate the computer to access the database and to select a set of books to purchase. In addition, the customer can define the storage space will be used to store the set of books. The computer responds to this customer input by manufacturing the set of books so that the books can be placed physically within the storage space.

Owner:HEWLETT PACKARD DEV CO LP

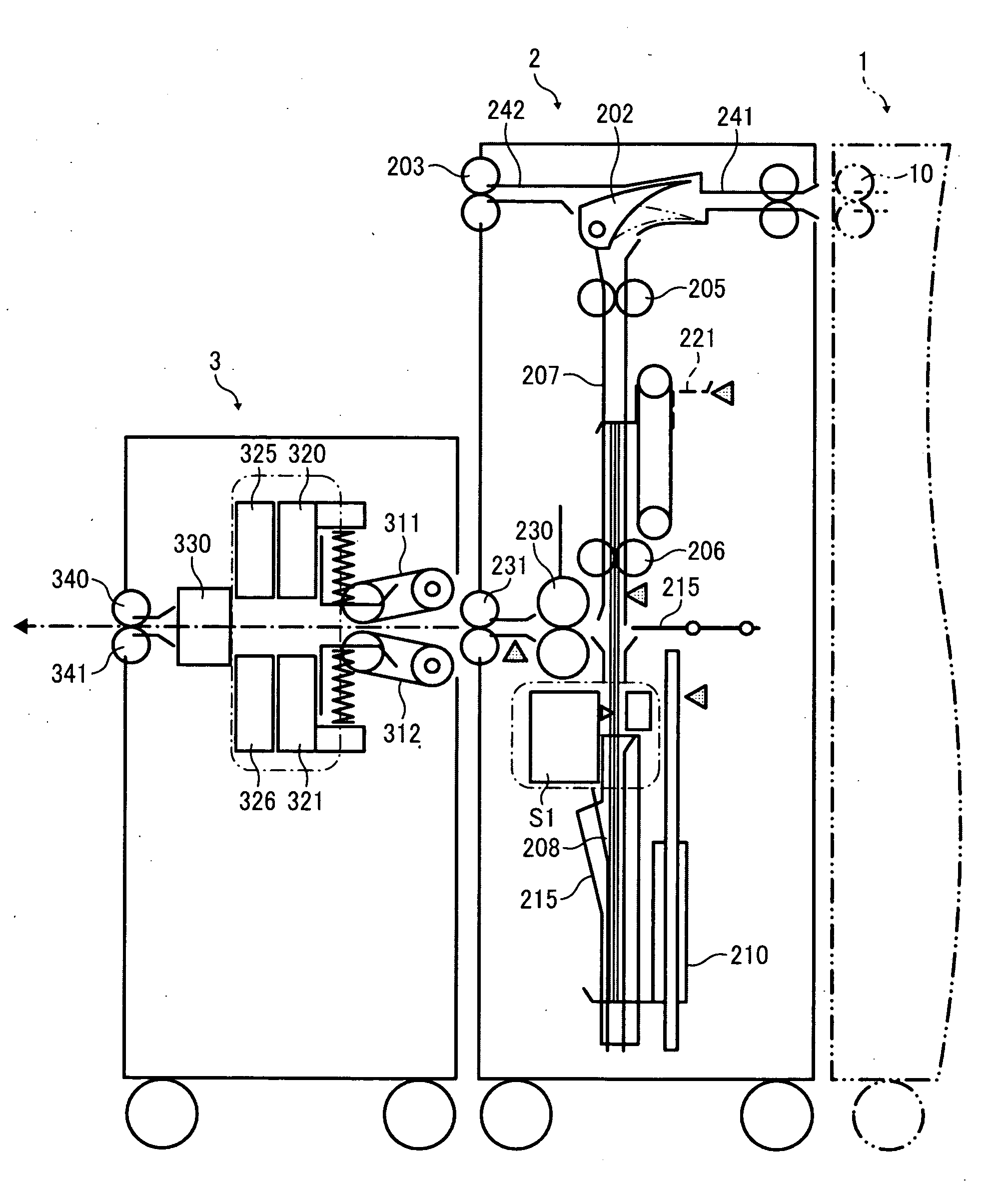

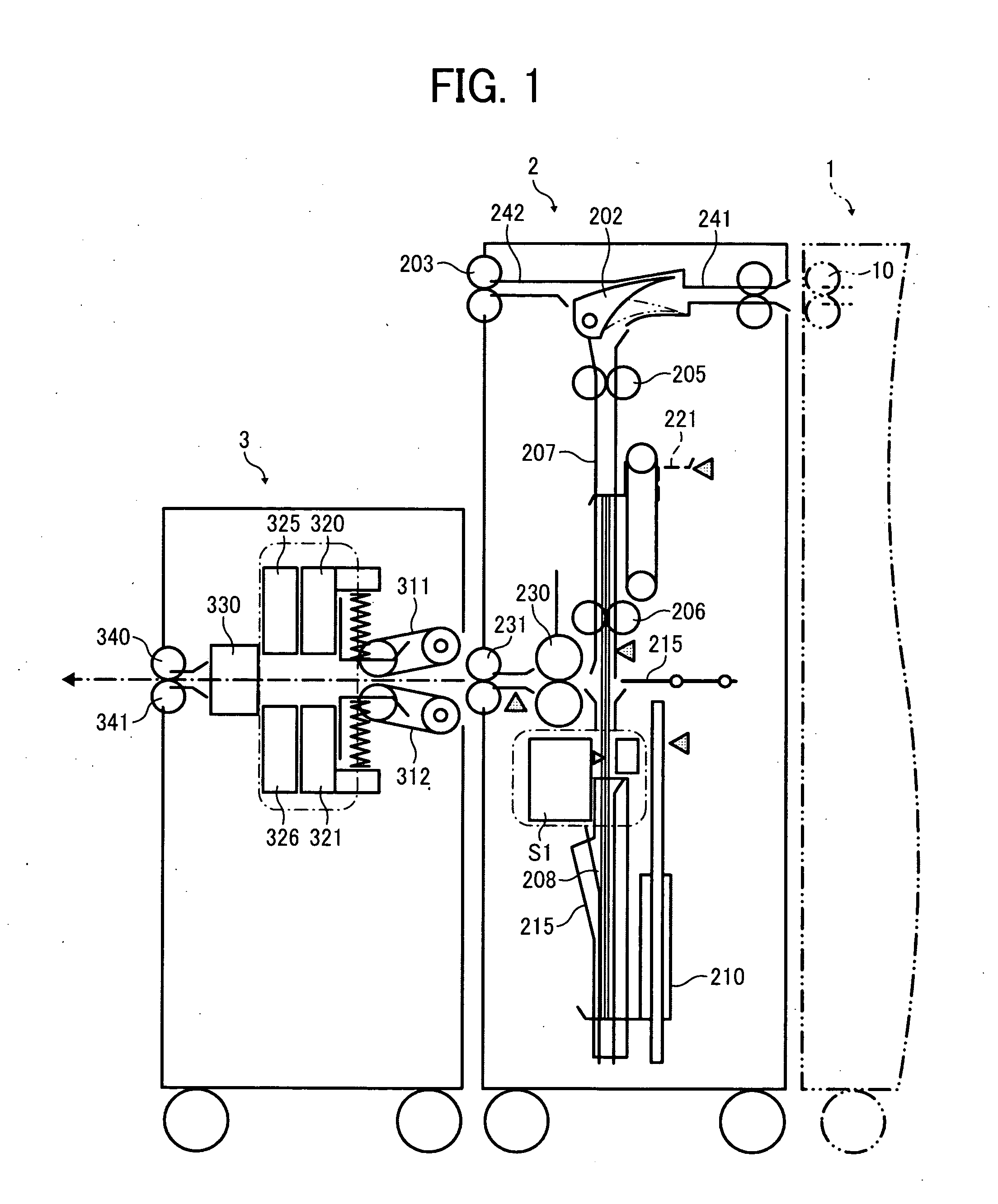

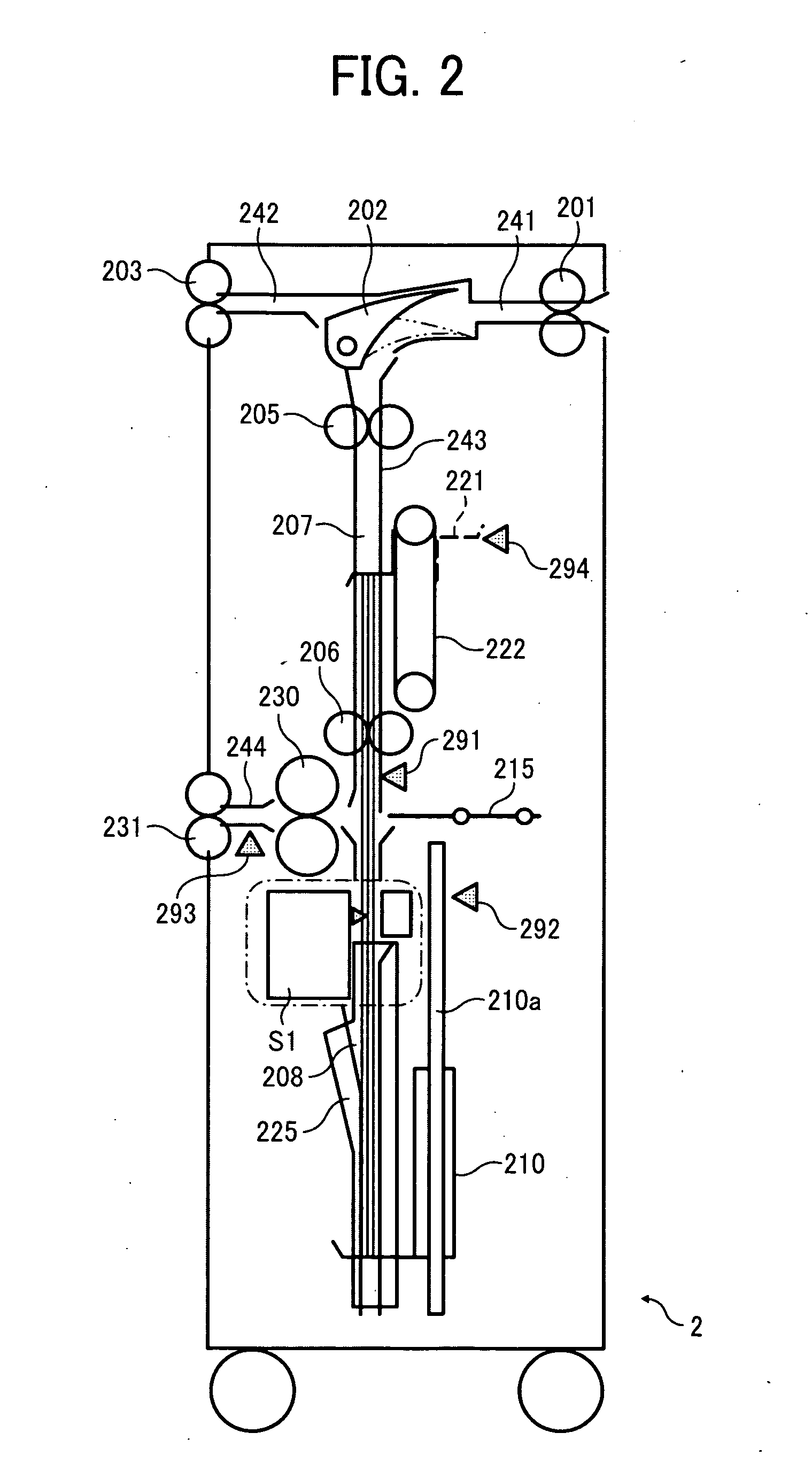

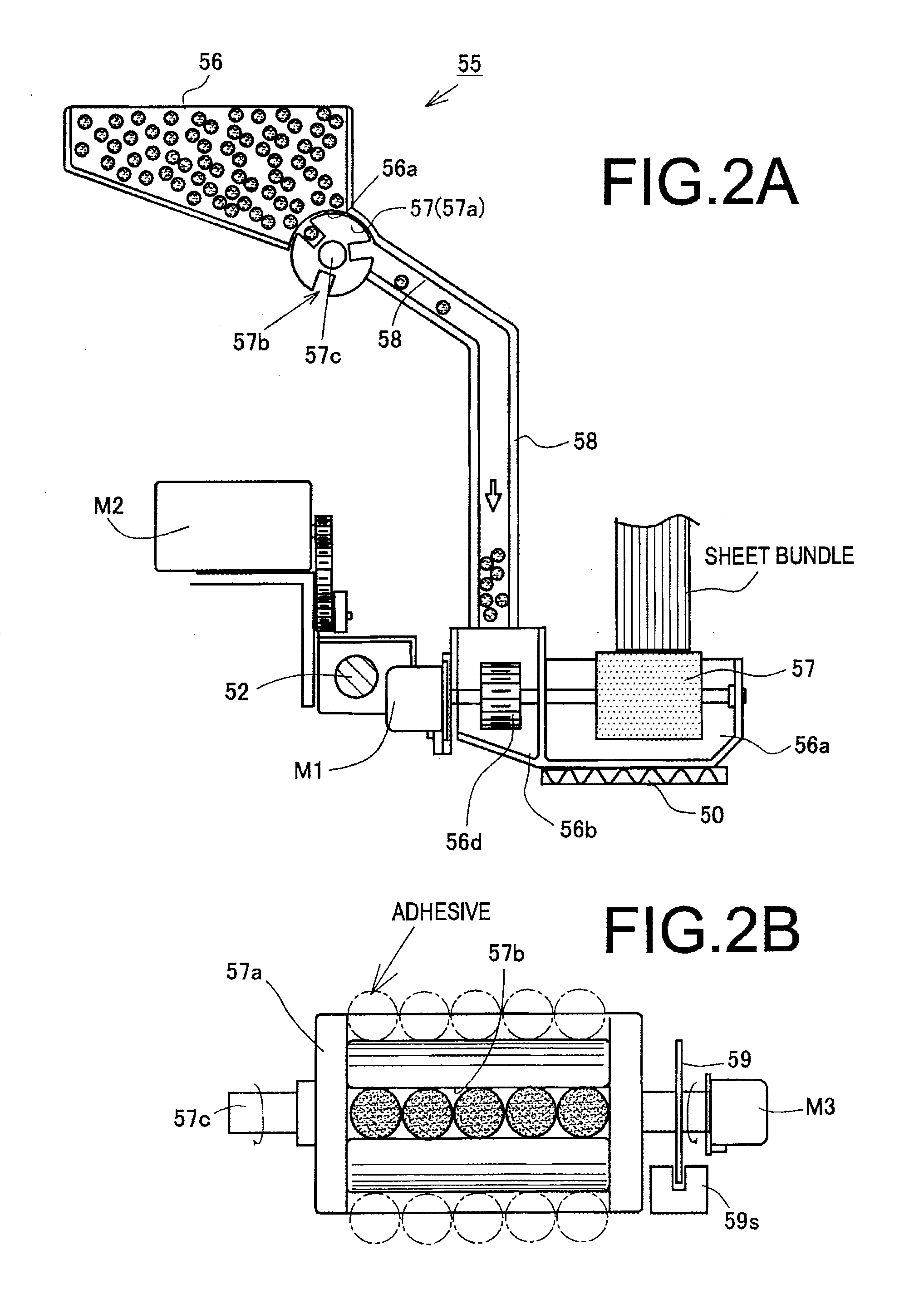

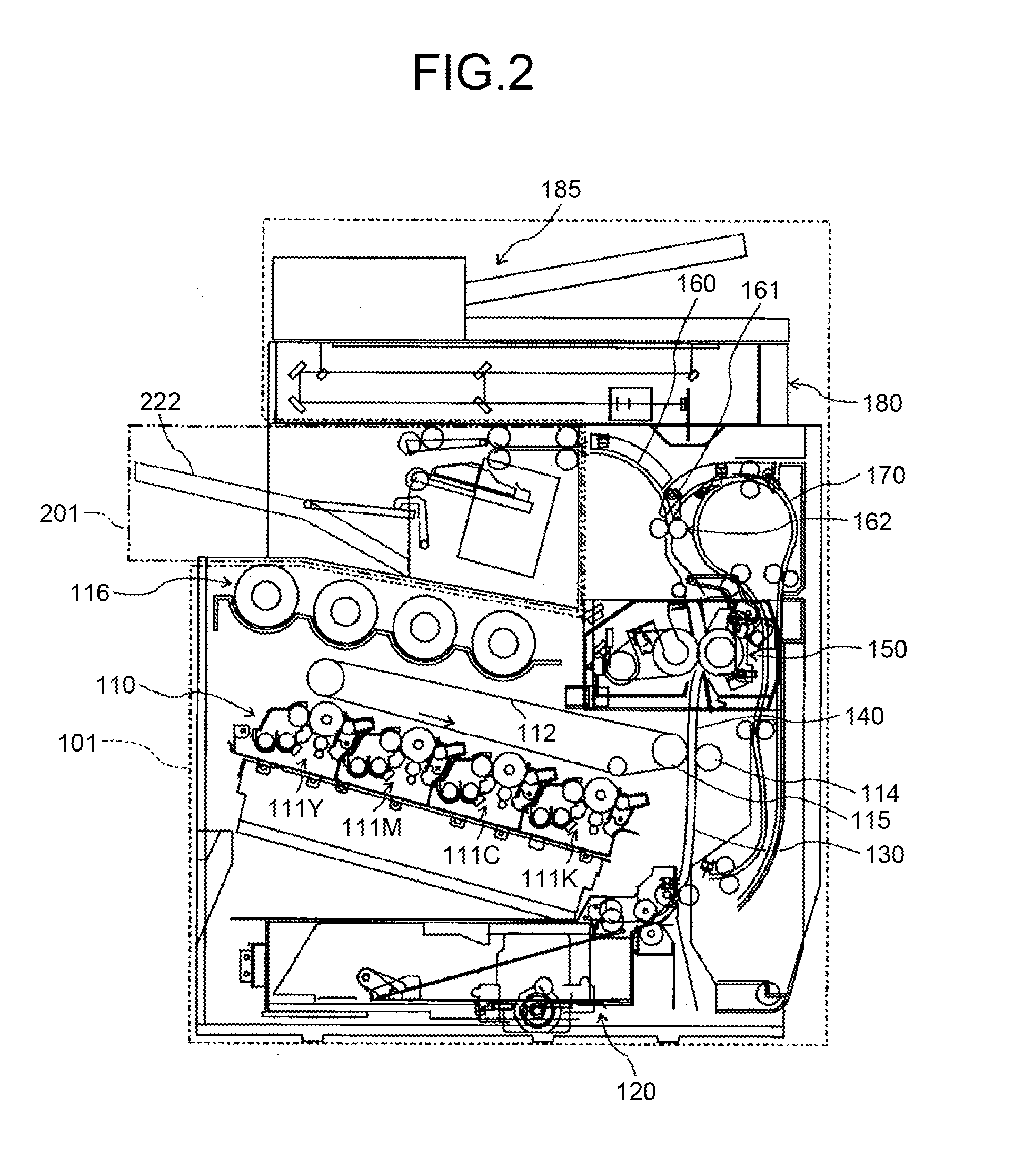

Bookbinding Method, and Bookbinding Unit and Image-Forming System Equipped with the Same

ActiveUS20090035093A1Small sizePrevent leakageFolding thin materialsElectrographic process apparatusImage formationBiomedical engineering

Bookbinding unit that in binding an inner-leave sheet bundle together with a cover enables accurate binding of the cover onto the bundle's spine and meanwhile forms folding scores in the cover flaps. Furnished with: a stacking tray unit; a process path for sequentially transporting bundles from the tray unit into adhesive-application and cover-binding locations; an adhesive application unit, disposed in the adhesive-application location, that applies adhesive to bundles from the tray unit; a cover-supply unit that supplies covers to the cover-binding location; and a cover-binding unit, disposed in the cover-binding location, that binds sheet bundles from the adhesive-application location together with covers. The cover-binding unit has a shoulder-pressing unit that forms spine creases in the spine portion of the covers, and a flap-pressing unit that forms folds in the spine-creased sides of the covers.

Owner:NISCA KK

Adhesive Applicator, and Bookbinding Apparatus and Image-Forming System Equipped with the Applicator

ActiveUS20080056735A1Stable supplyShorten melting timeLiquid surface applicatorsBook making processesTemperature controlEvaporation

In replenishing a glue container with hot-melt glue, to enable stable supply of the glue in solid form without it clogging the resupply path from the hopper, provided are: a sheet retaining unit for retaining a sheaf in a glue application position; a glue applier in a hot-melt-glue-receiving container, disposed in the glue application position, for applying glue to an endface of a sheaf there; a heater, disposed in the glue container, for heating / melting the glue inside; a heater temperature controller; a resupply hopper above the glue container for replenishing it with solid glue; a vacuum ducting unit above the container and adjoining the resupply hopper, for suctioning up glue evaporation derivatives; and a control unit configured to run the vacuum ducting unit when the glue container is being replenished with glue, to prevent or mitigate invasion of evaporation derivatives into the resupply hopper.

Owner:NISCA KK

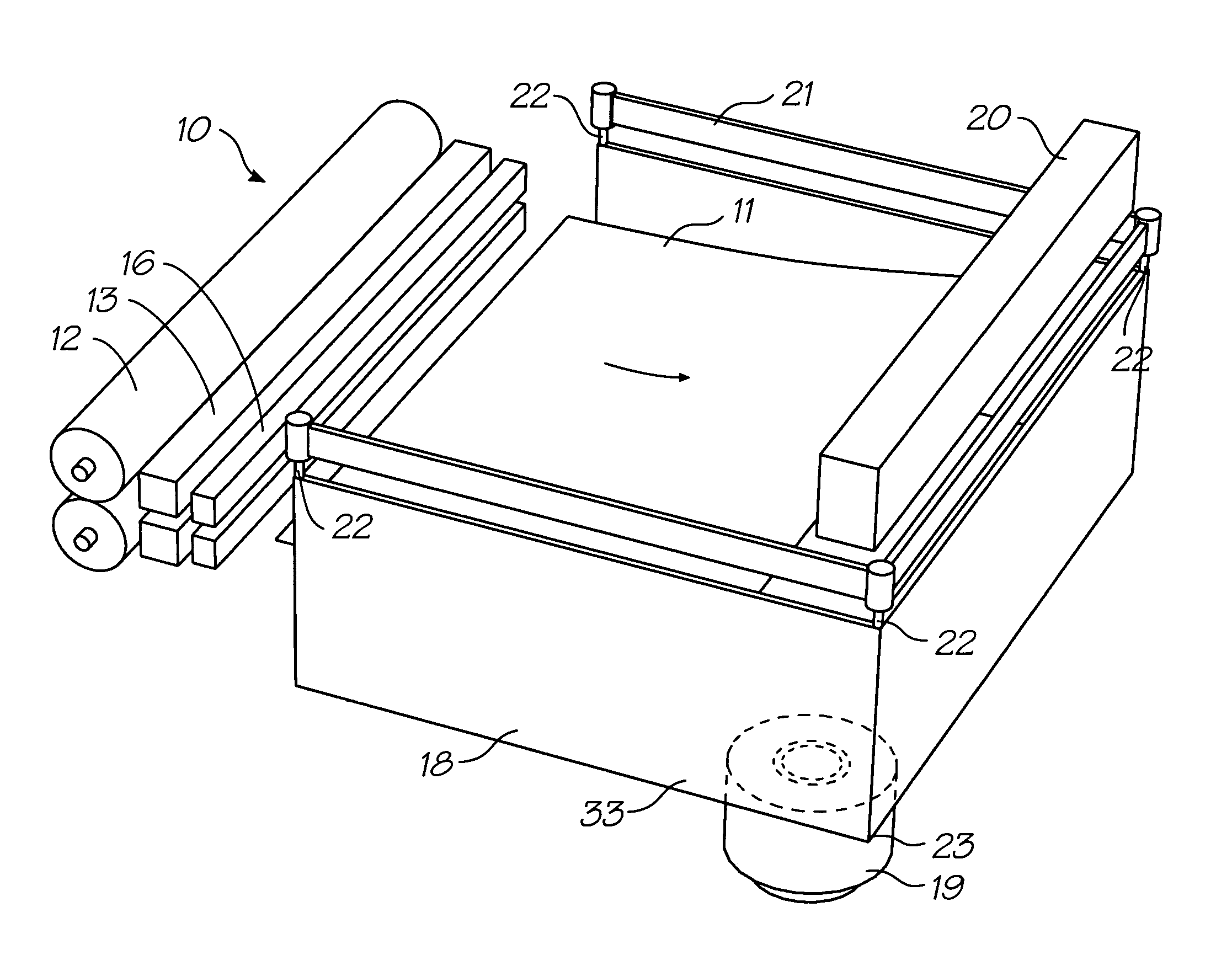

Band bundling machine

InactiveCN1396091APrevent saggingReliably maintains shapeBinding material applicationBundling machine detailsEngineeringElectrical and Electronics engineering

A binding machine with a tape comprises a table (2) for putting a material (A) to be bound, a tape passage groove (3) formed on the table (2), and a guiding member (11) in an arch shape provided above the tape passage groove (3). A loop (L) formed by a tape (T) of a predetermined size is formed along the guiding member (11). There is provided a tape receiving member (14) which can be displaced to first and second positions. At least a part of the tape receiving member (14) at the first position advances into the loop (L), to prevent the top of the loop (L) from hanging.

Owner:畑谷宽

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com