Leveling and channel forming integrated machine

An all-in-one, flat-pressing technology, applied in book binding and flattening, printing, book binding, etc., can solve the problems of high labor intensity of workers, reduce production costs, and low production efficiency, improve market competitiveness, reduce The effect of shortening production cost and production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

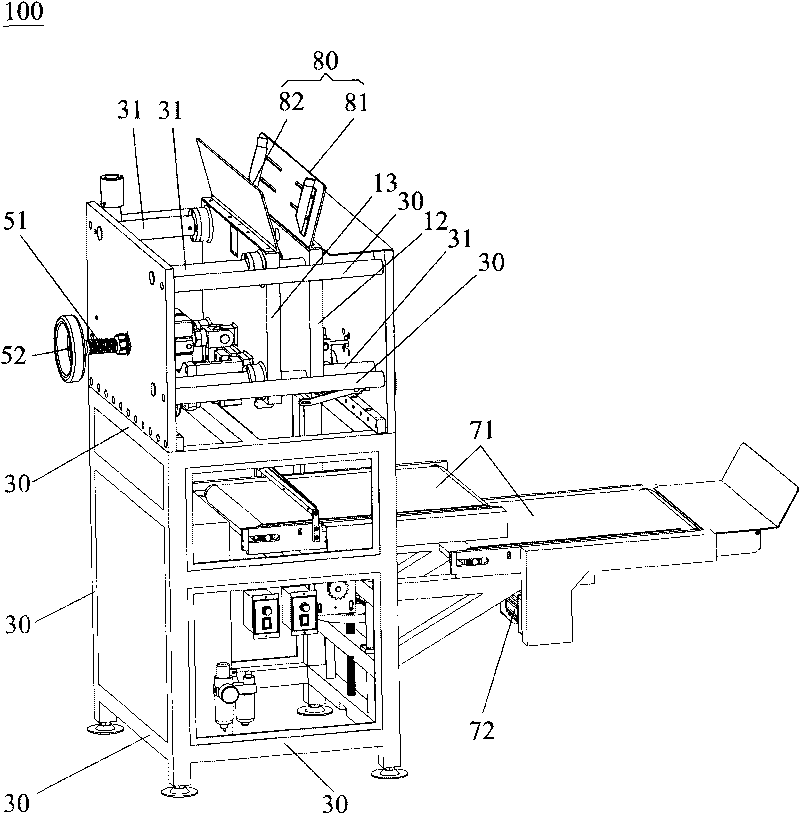

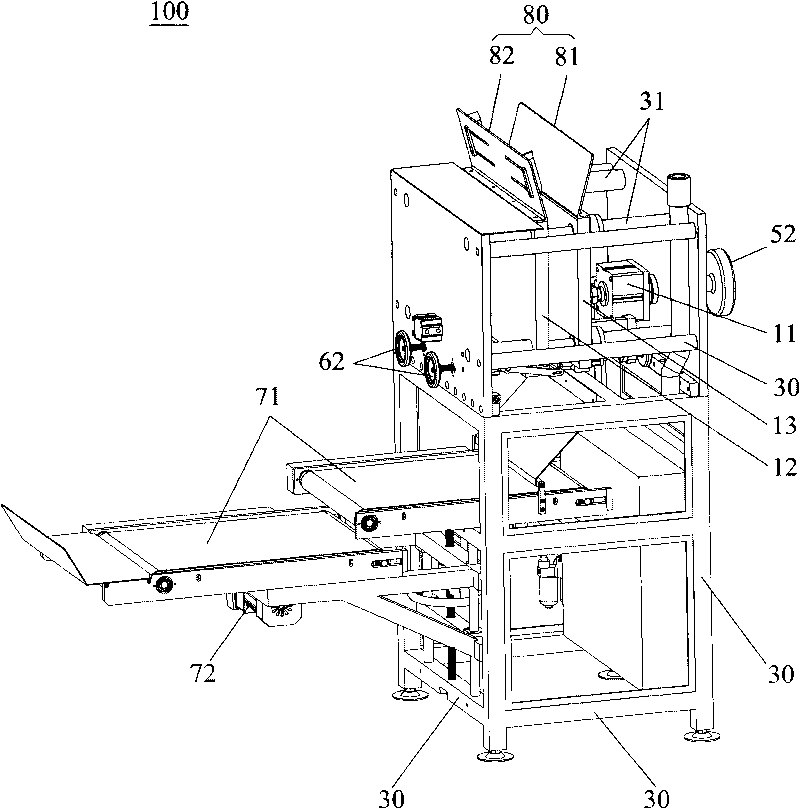

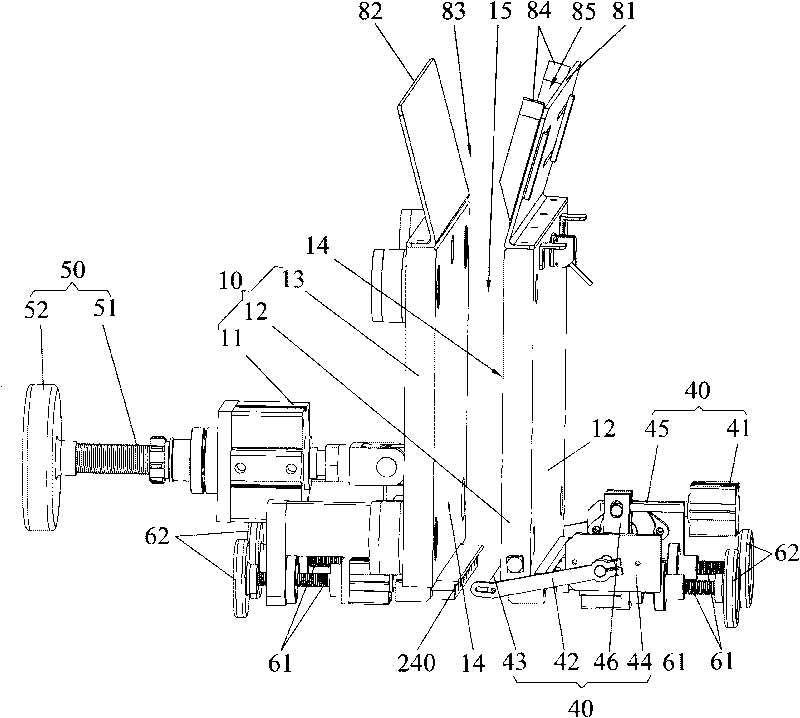

[0029] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. As mentioned above, such as figure 1 , figure 2 , image 3 and Figure 4As shown, the all-in-one machine 100 for flattening and groove forming provided by the present invention is used to flatten and groove the book case after the book case is mounted on the book block, so as to protect the book block from deformation and facilitate reading, so that the book case The appearance is more beautiful, and it includes a flattening mechanism 10, a groove mechanism 20 and an installation frame 30. The flattening mechanism 10 includes a flattening cylinder 11, a first pressing plate 12 and a second pressing plate 13, and the first pressing plate 12 and the The second pressing plate 13 has a flat pressing surface 14, and the pressing surface 14 is arranged opposite to form a flattening area 15. The flattening cylinder 11 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com