Patents

Literature

167results about How to "Increase fluid retention" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Absorbent article with multiple core

InactiveUS20030225385A1Promote formationImprove protectionInfusion syringesIntravenous devicesEngineeringFluid management

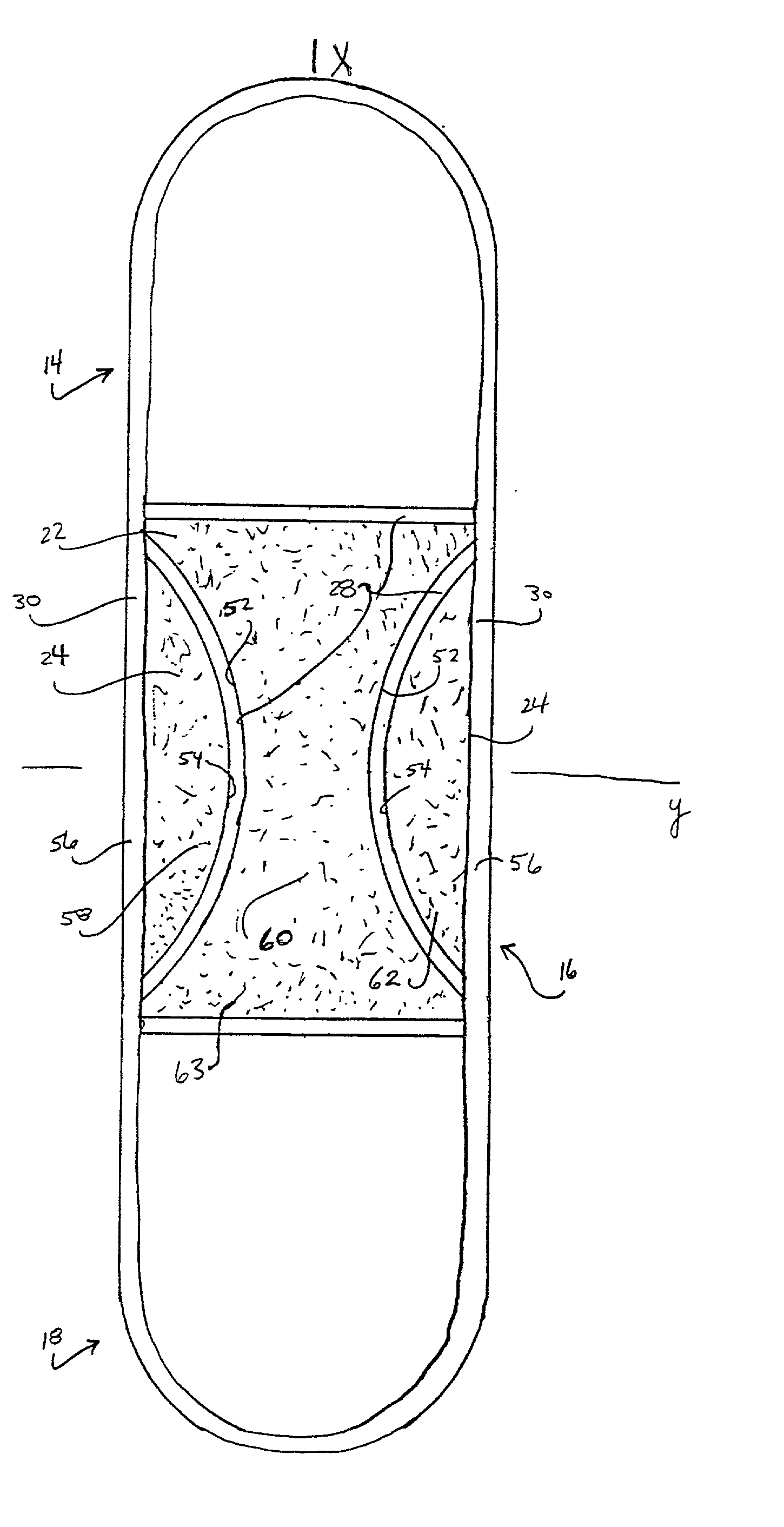

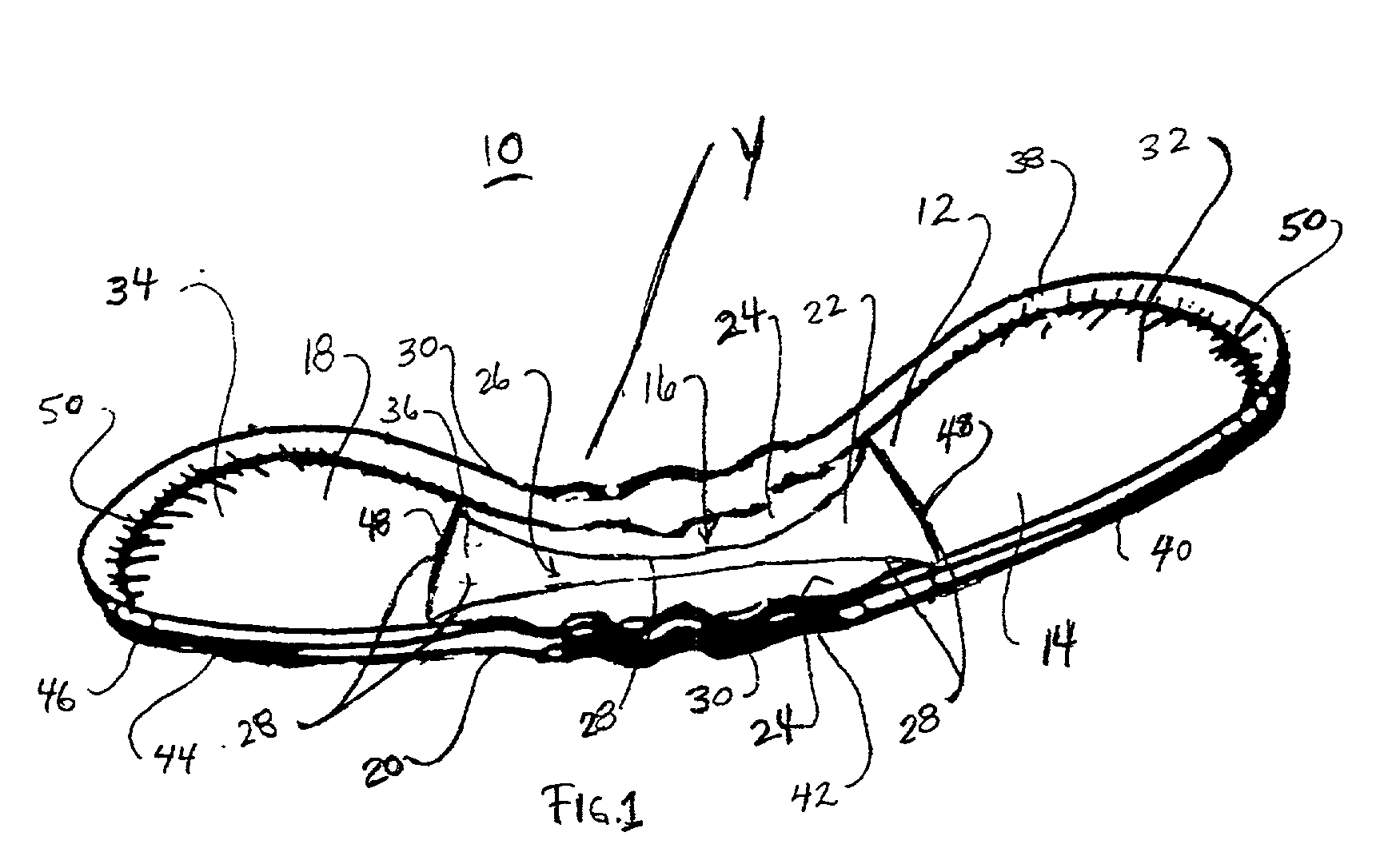

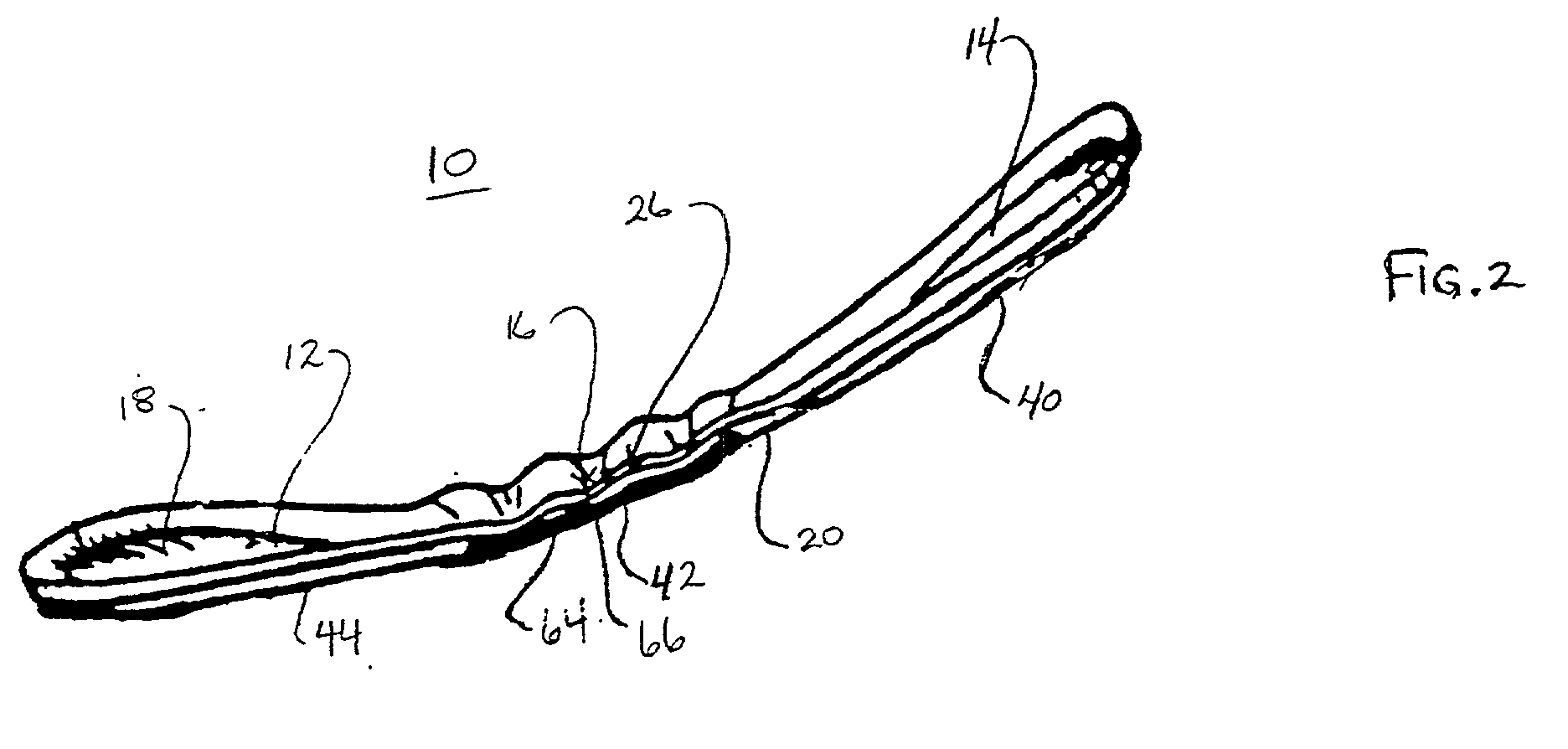

An absorbent article is provided which includes a fluid permeable top sheet and a first absorbent core being separate and in fluid communication with a second absorbent core. The second absorbent core is separate and in fluid communication with a third absorbent core. The first, second and third absorbent cores are supported between the fluid permeable top sheet and a fluid impermeable back sheet. The second absorbent core defines at least two separate absorbent core sections in fluid communication. The separate absorbent core sections define a body facing surface that engages the fluid permeable top sheet. In an alternate embodiment, the absorbent article defines a longitudinal length and includes a fluid permeable top sheet and a first absorbent core disposed adjacent a side of a central second absorbent core and pivotable, along the longitudinal length, relative to the second absorbent core. A third absorbent core is disposed adjacent to an opposing side of the second absorbent core and pivotable, along the longitudinal length, relative to the second absorbent core. The second absorbent core has a mid-section and lateral sections disposed on opposing sides of the mid-section. The mid-section and lateral sections are separate, in fluid communication and define a body-facing surface that engages the fluid permeable top sheet. In another alternate embodiment, fluid flow channels are disposed between the absorbent cores and core sections for fluid management.

Owner:FIRST QUALITY RETAIL SERVICES

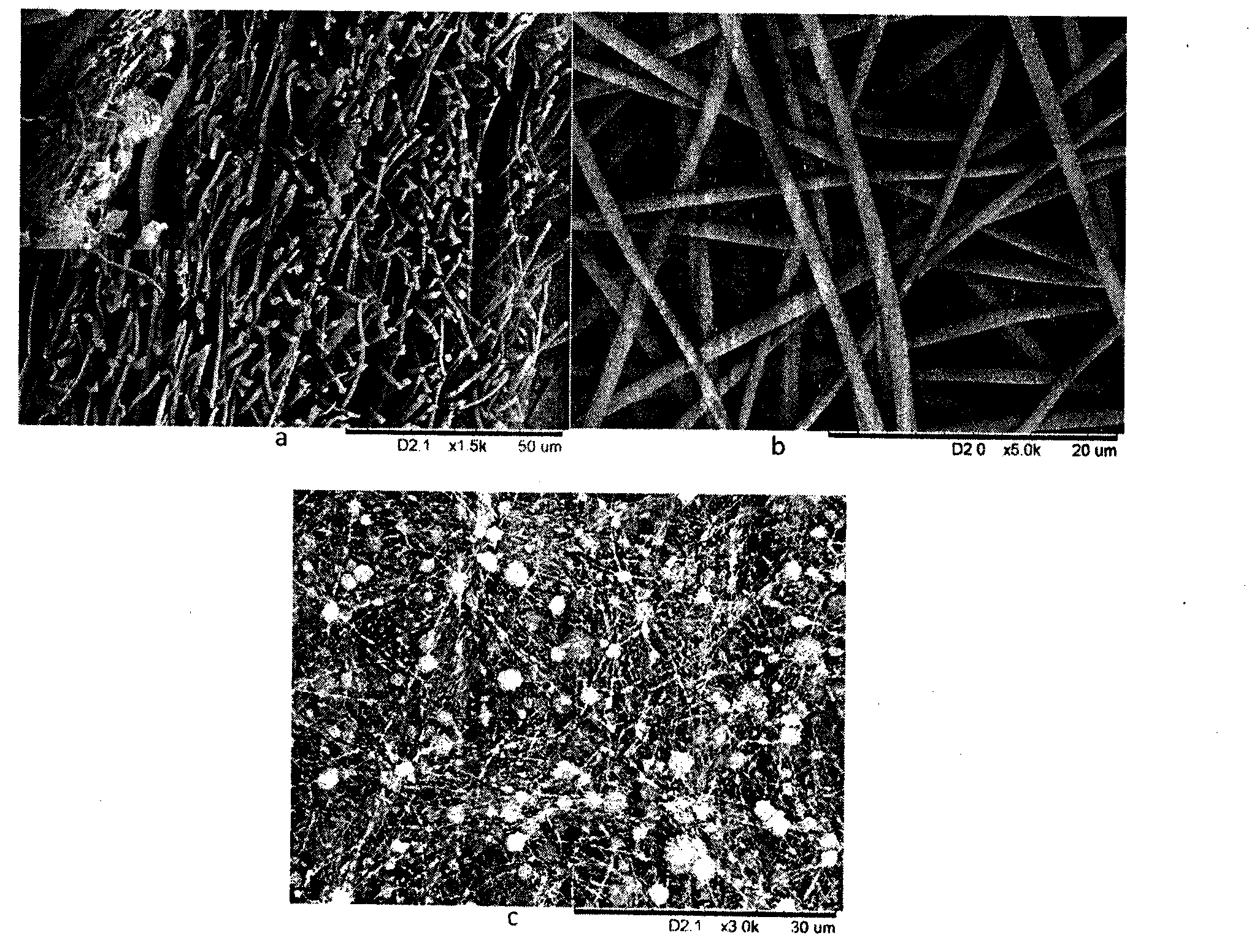

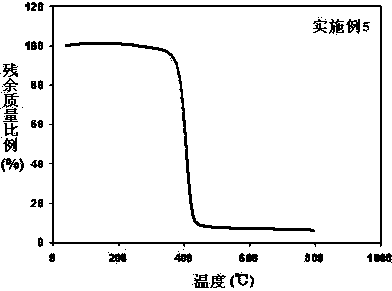

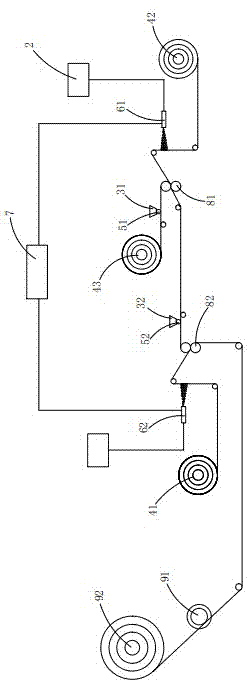

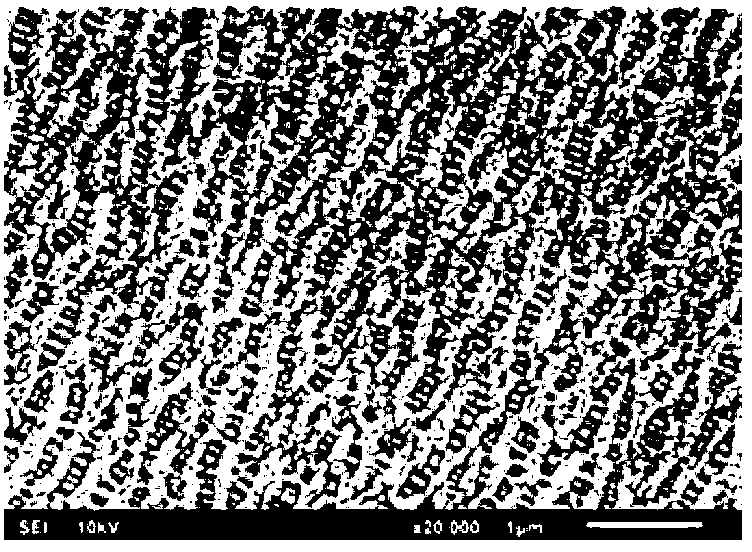

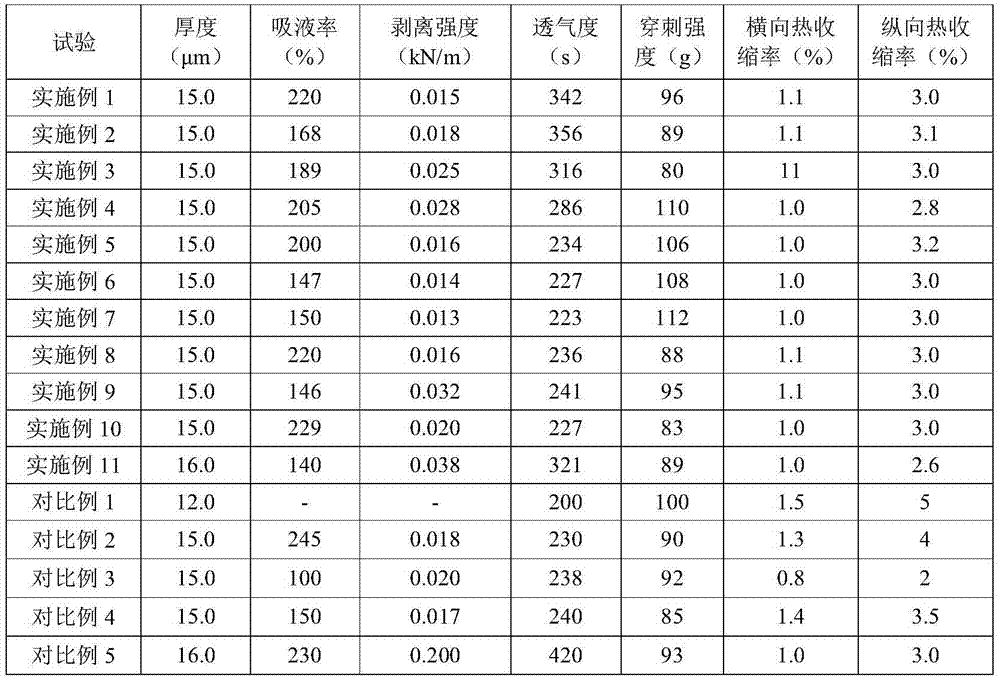

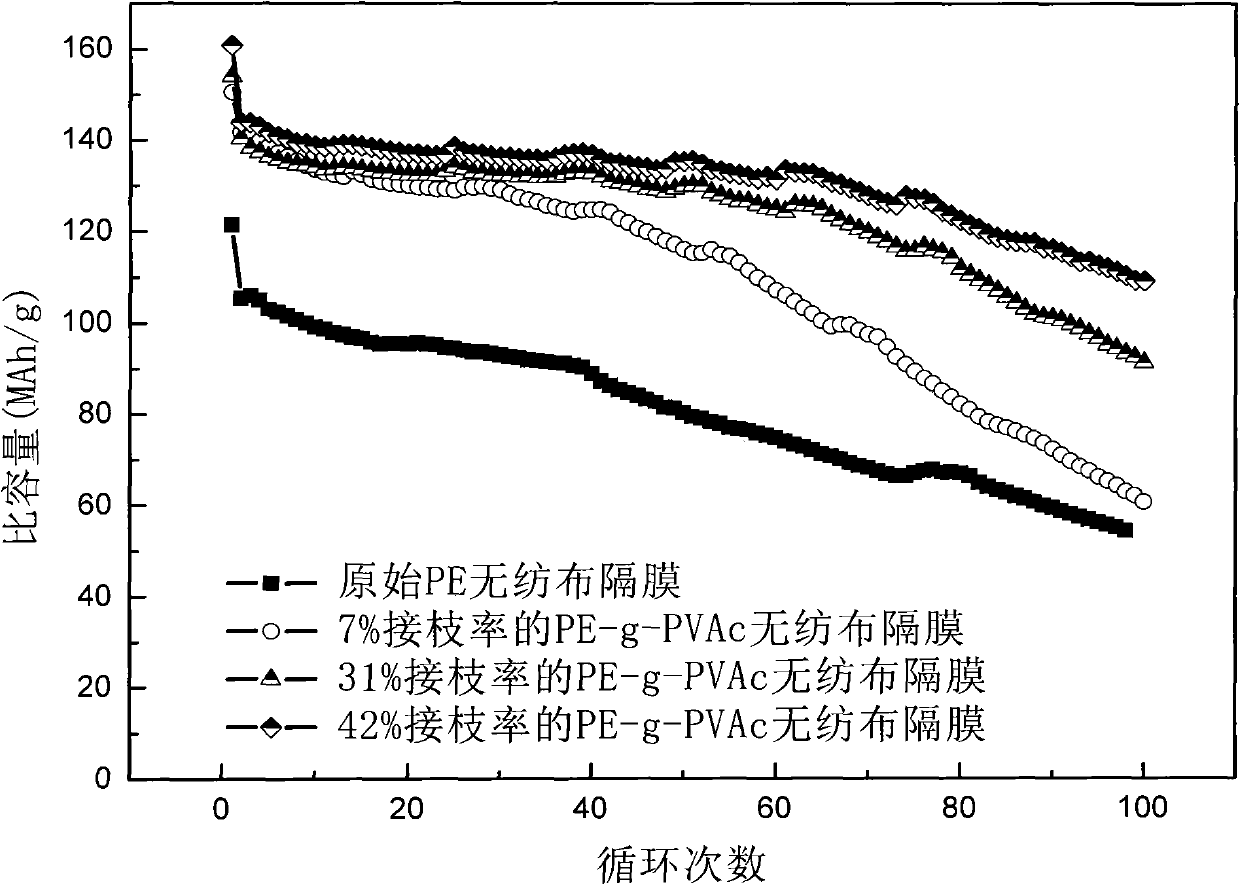

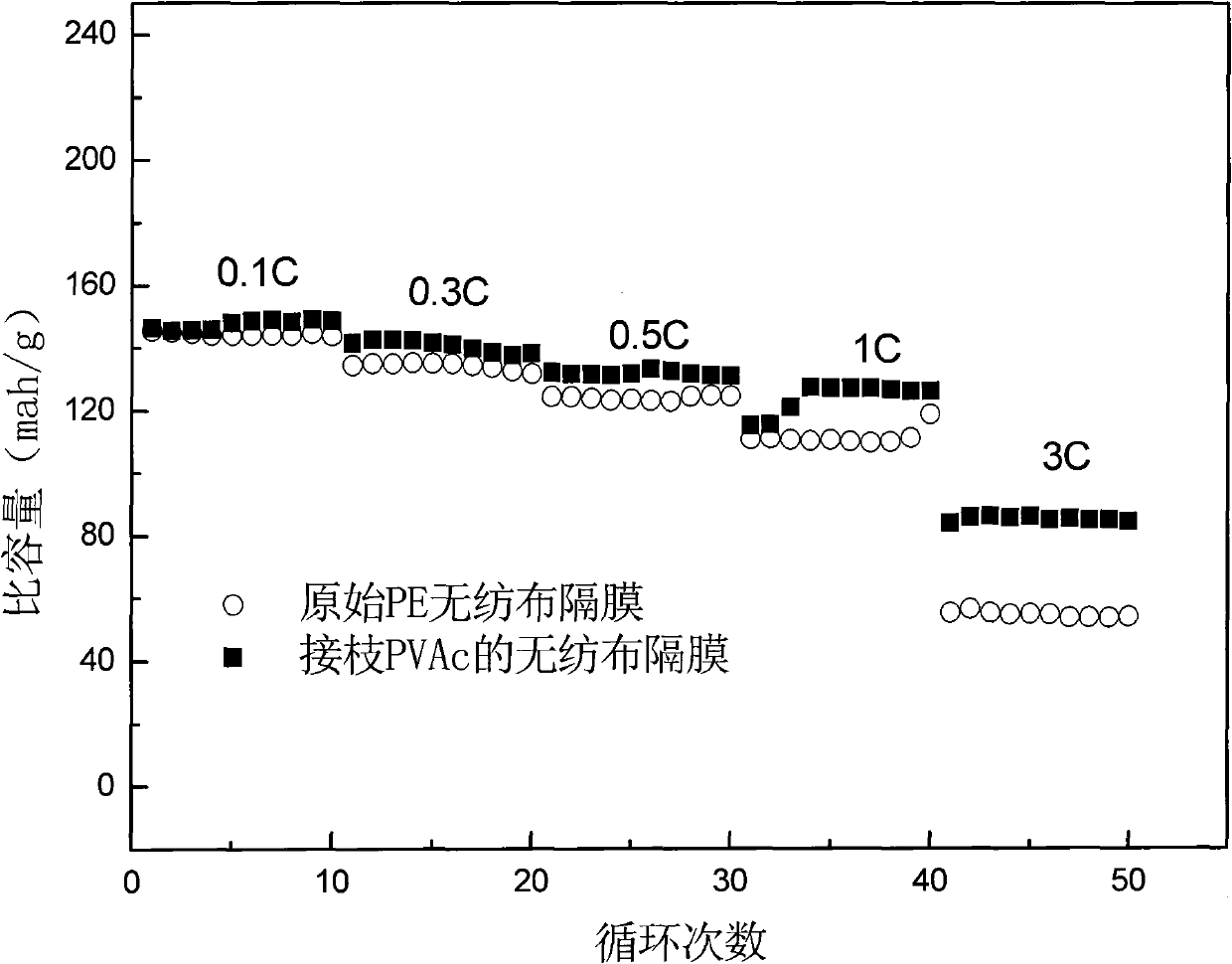

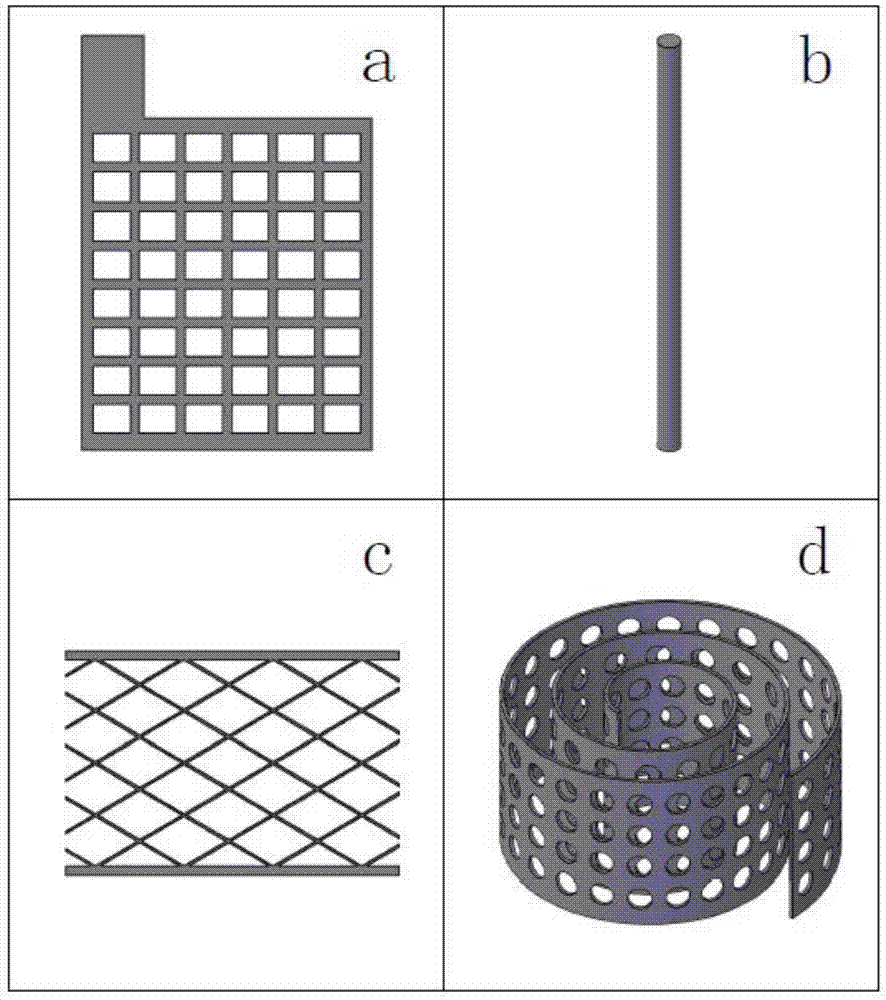

Method for preparing composite lithium-ion battery separator through electrostatic spinning/electrostatic spraying

InactiveCN103474610AExcellent heat shrinkage resistanceIncrease fluid retentionCell component detailsNon-woven fabricsFiberOrganic solvent

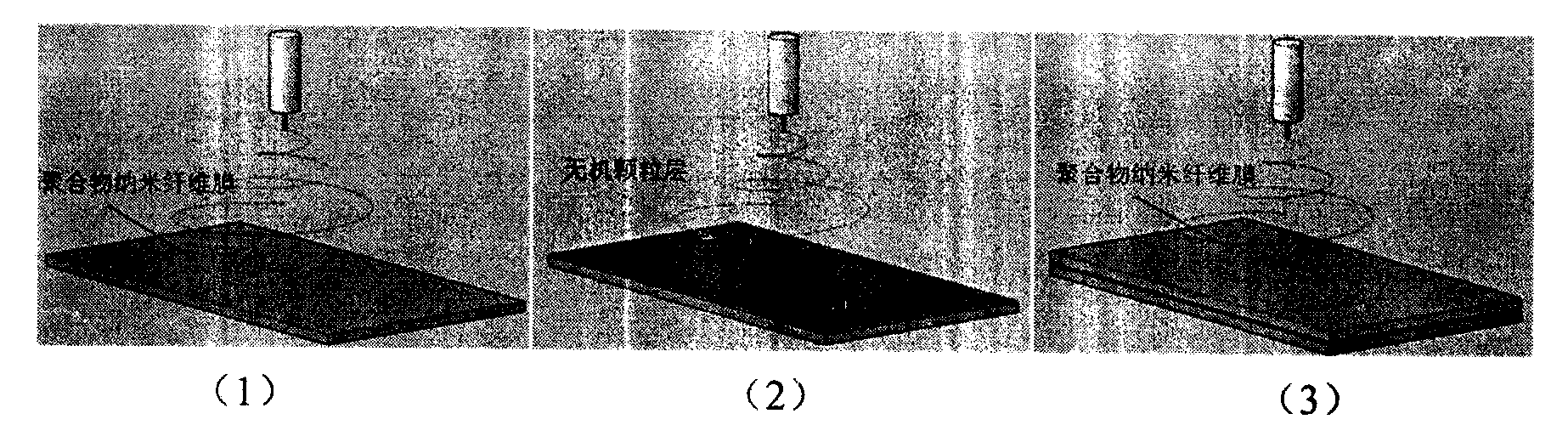

The invention relates to the field of lithium-ion batteries, in particular to a method for preparing a composite lithium-ion battery separator through electrostatic spinning / electrostatic spraying. The method specifically includes the steps of firstly, adding high molecular polymer into an organic solvent, dissolving the high molecular polymer through mechanical stirring to form a transparent solution, and obtaining an electrostatic spinning solution; secondly, mixing inorganic nanometer particles with the high molecular polymer and adding the mixture into the organic solvent, and conducting mechanical stirring to obtain inorganic nanometer particle suspension liquid; thirdly, conducting electrostatic spinning on the spinning solution prepared in the first step to prepare a lower layer nanometer fiber film, and enabling the inorganic nanometer particle suspension liquid prepared in the second step to be deposited on the lower layer nanometer fiber film through electrostatic spraying to obtain an interlayer; finally, receiving an electrostatic spun nanometer fiber layer on an inorganic particle layer to obtain the composite lithium-ion battery separator. The composite lithium-ion battery separator has the high imbibing rate and good electrochemical stability under the room temperature and has good heat shrinkage resistance performance at the same time.

Owner:TIANJIN POLYTECHNIC UNIV

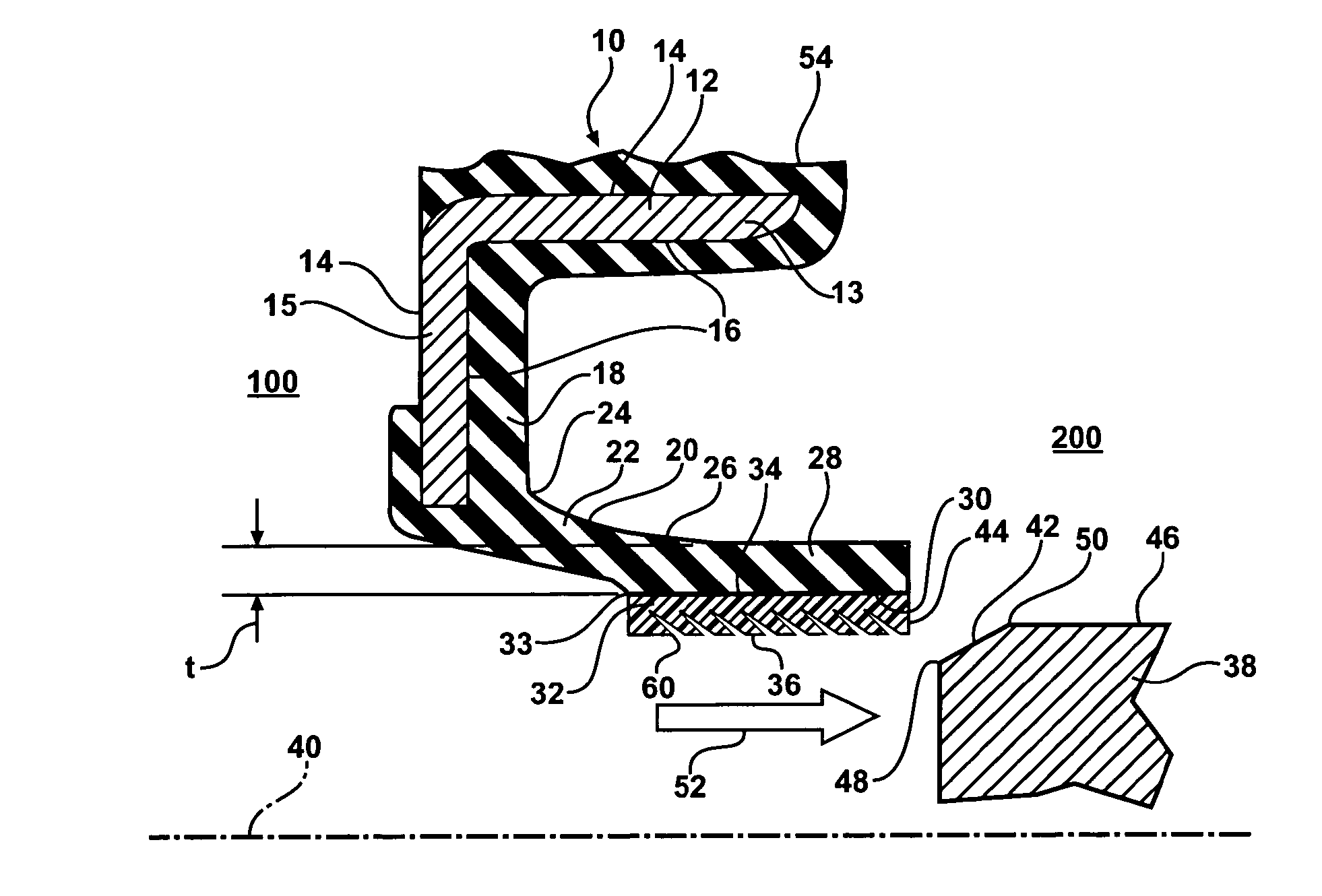

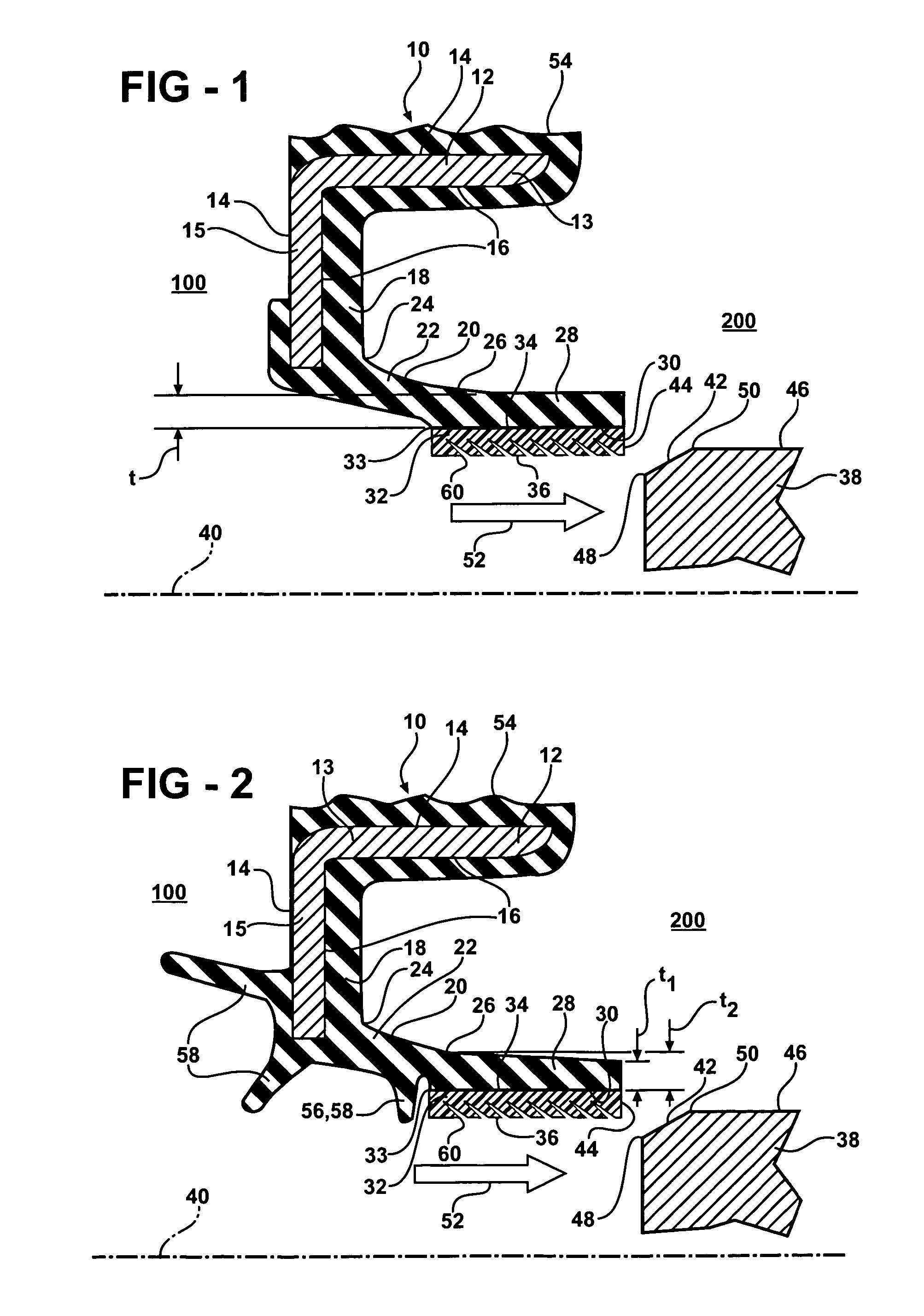

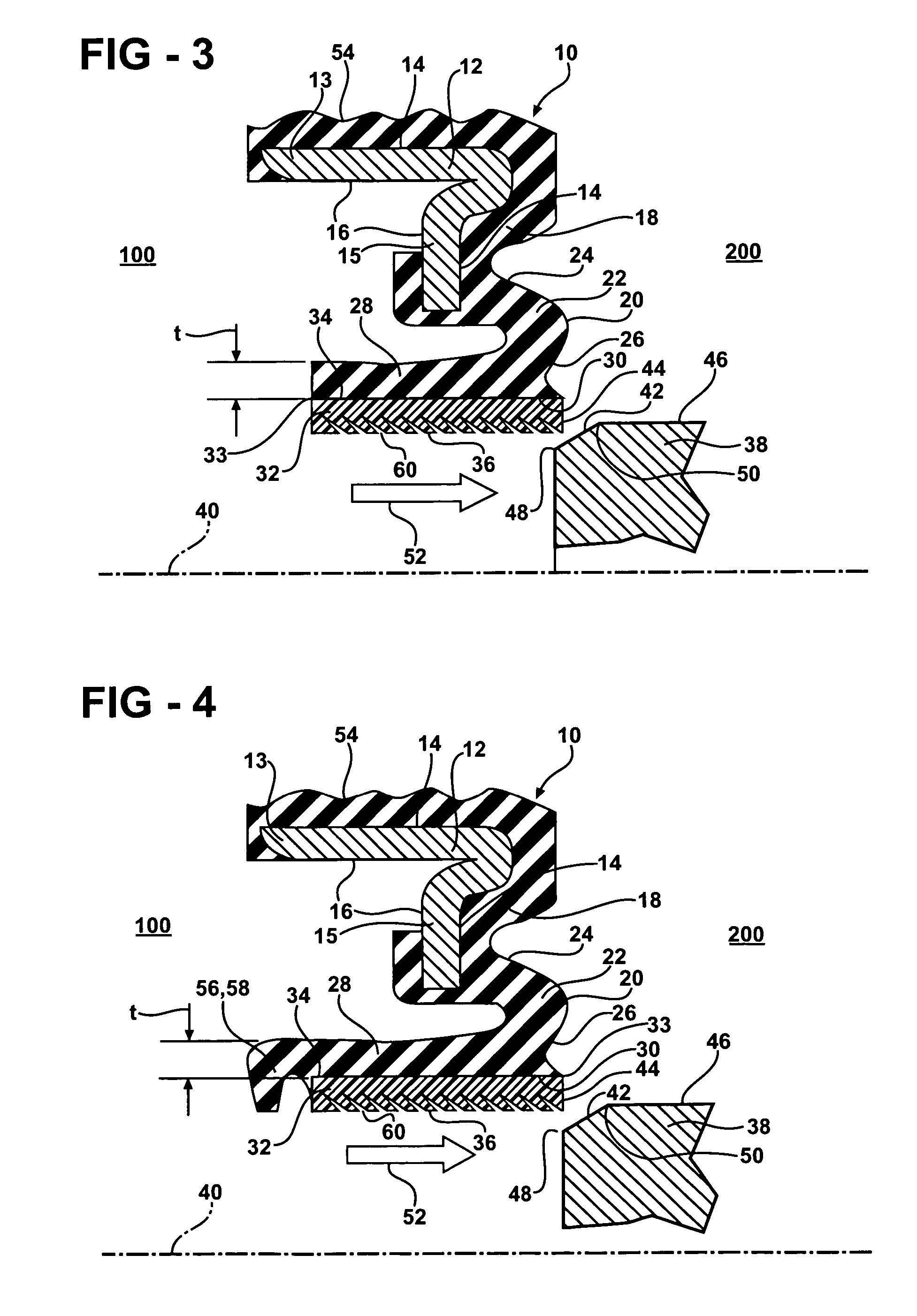

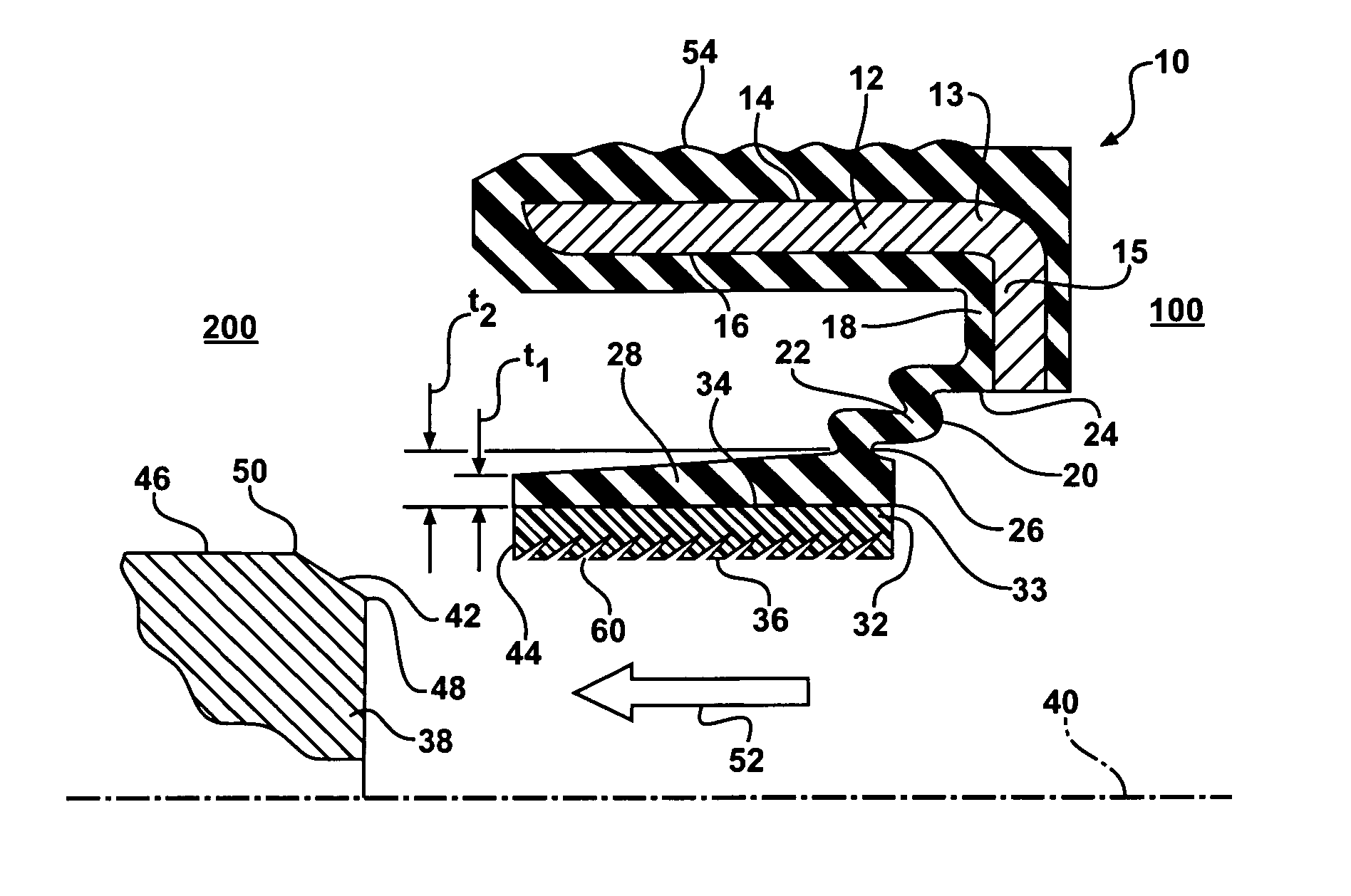

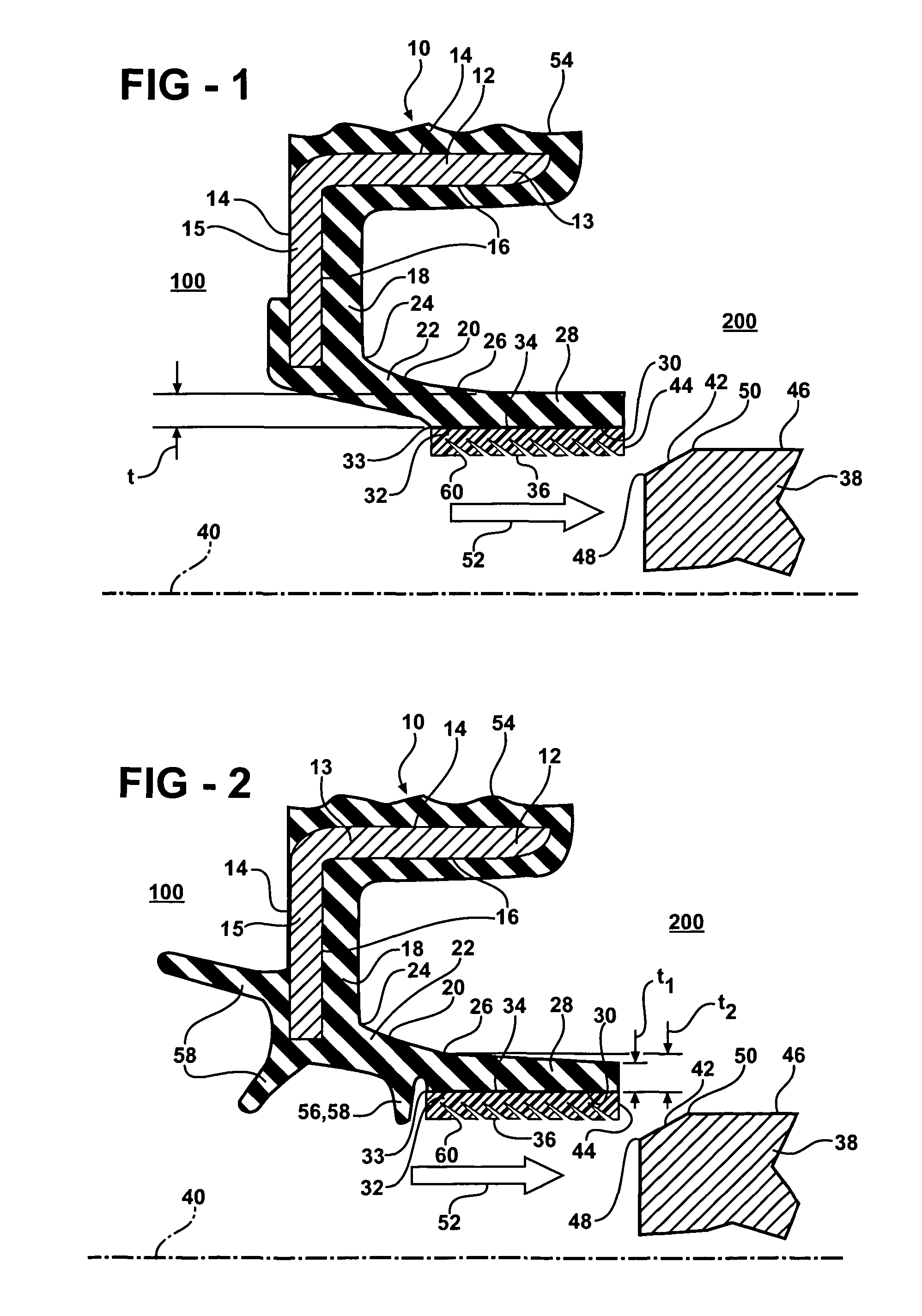

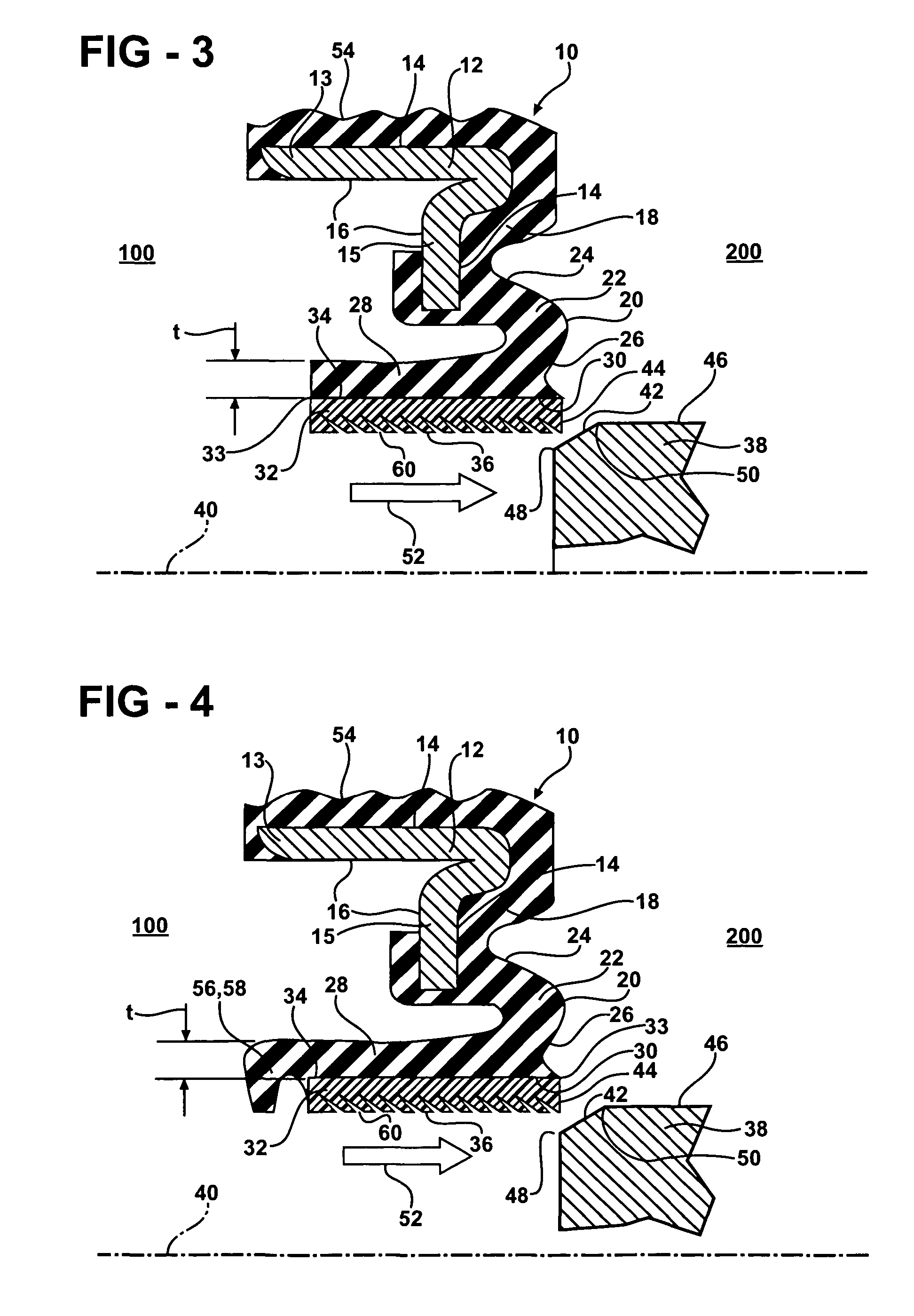

Radial seal and method of making

A dynamic radial seal includes a rigid casing. The seal also includes an elastomeric casing positioned interior of and bonded to the rigid casing. The elastomeric casing has an axial spring member which extends radially inwardly from and axially along the rigid casing. The axial spring member includes a neck portion which extends from the elastomeric casing and a seal attachment portion that is attached to the neck portion and has a bonding surface. The seal also includes a pre-stressed fluoropolymer seal which has a bonding surface and a sealing surface. A bond joins the bonding surface of the pre-stressed fluoropolymer seal to the bonding surface of the seal attachment portion. The seal attachment portion of the spring member is operative to provide sealing contact of the fluoropolymer seal along the entirety of its sealing surface when engaged with a mating surface of a shaft. The fluoropolymer seal may be formed from PTFE and may include a groove or grooves formed in the sealing surface to enhance the sealing performance of the seal. The elastomeric casing may also incorporate a static seal or temporary dynamic seal to facilitate in-process testing or dirt exclusion, as well as one or more additional dirt exclusion features to protect the fluoropolymer seal from damage caused by environmental contaminants during the use of the seal.

Owner:FEDERAL MOGUL WORLD WIDE LLC

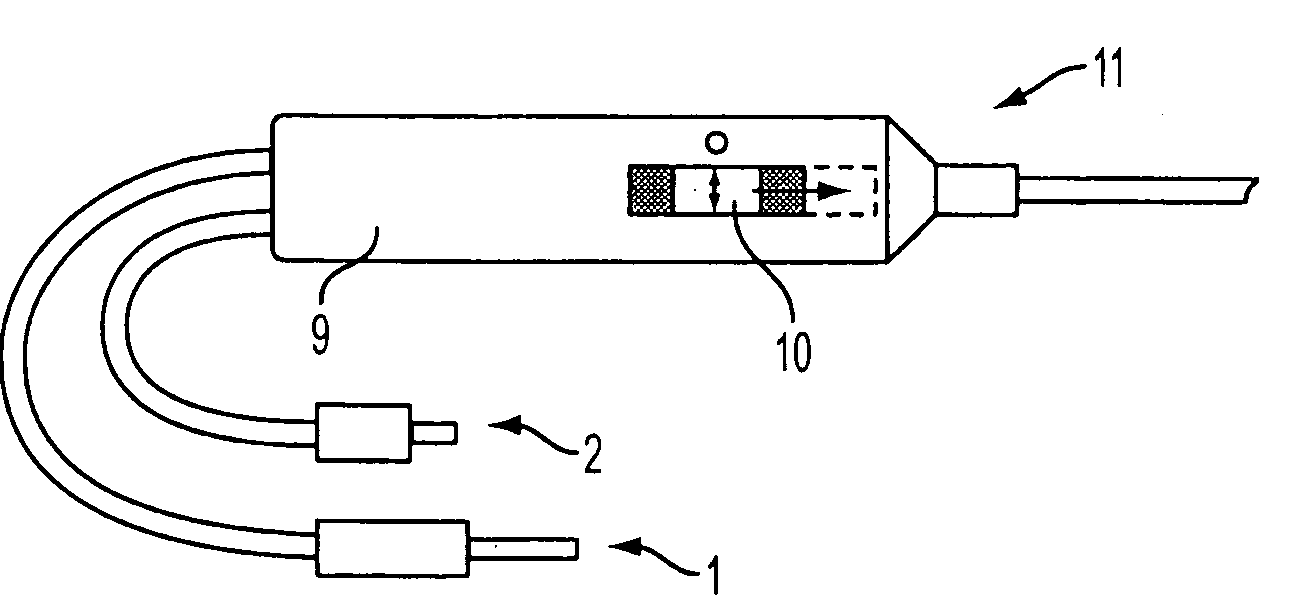

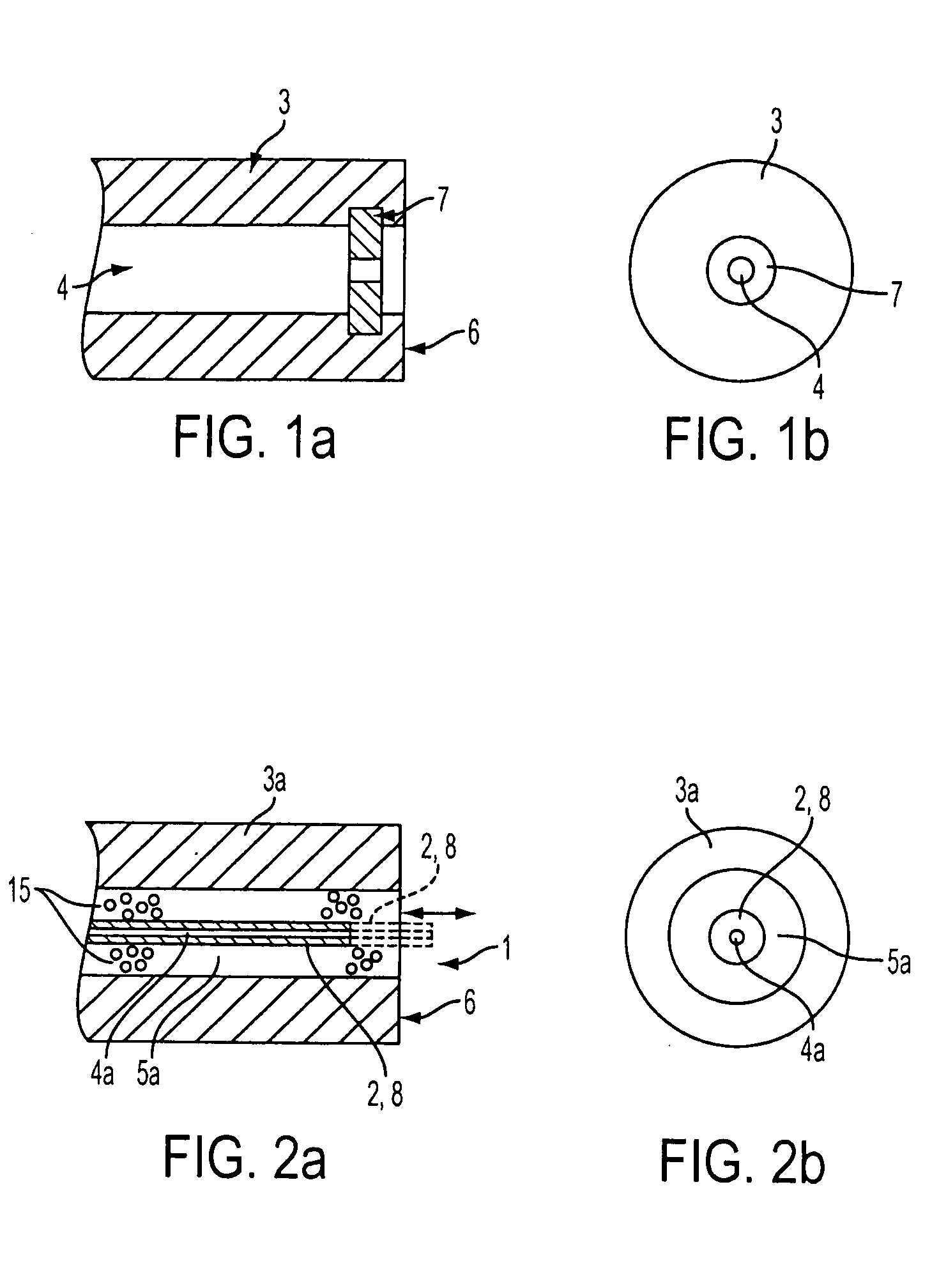

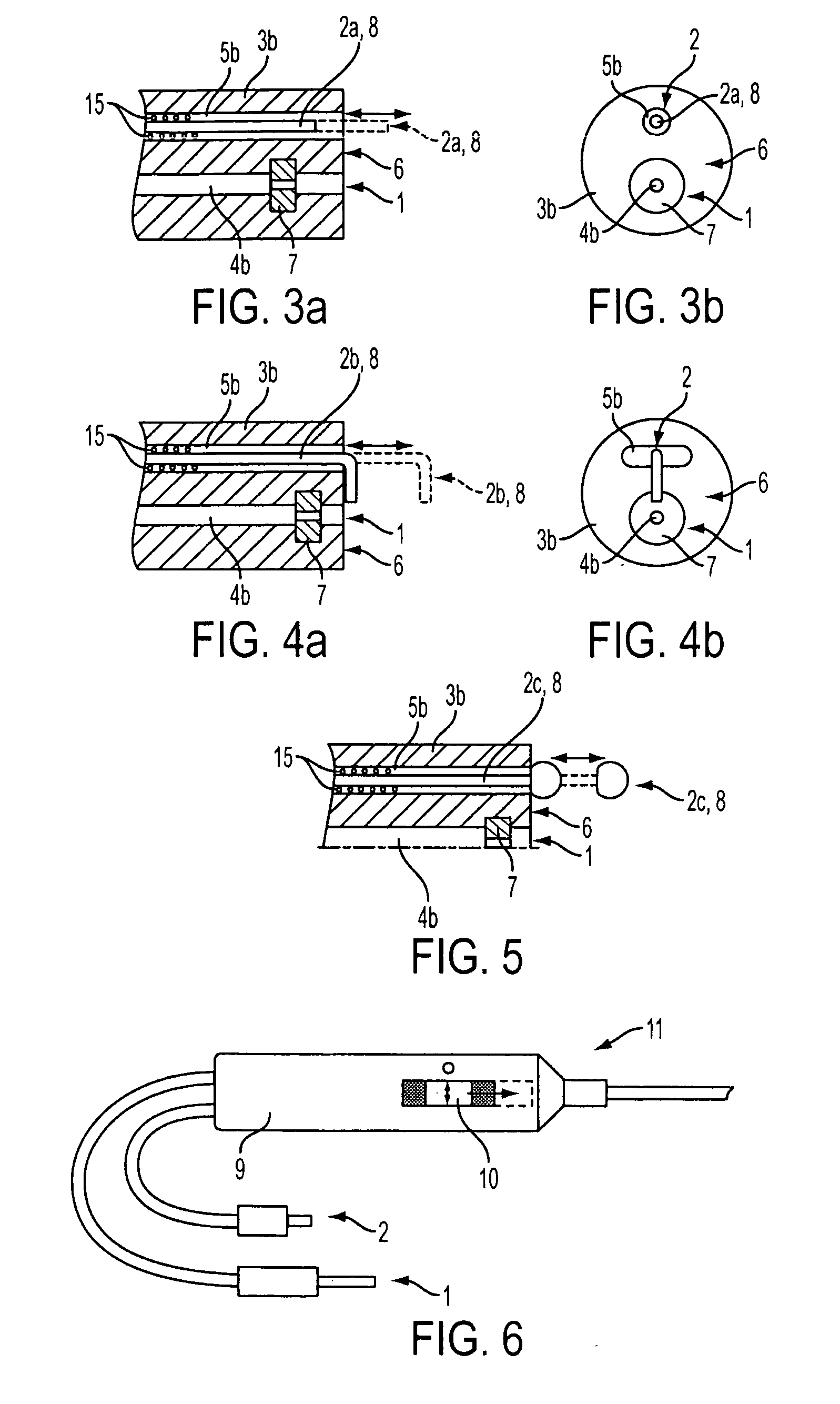

Method for selectively elevating and separating tissue layers and surgical instrument for performing the method

ActiveUS20090157114A1Expand selectionEasy to separateSurgical needlesDilatorsSurgical departmentSurgical device

Owner:ERBE ELEKTROMEDIZIN GMBH

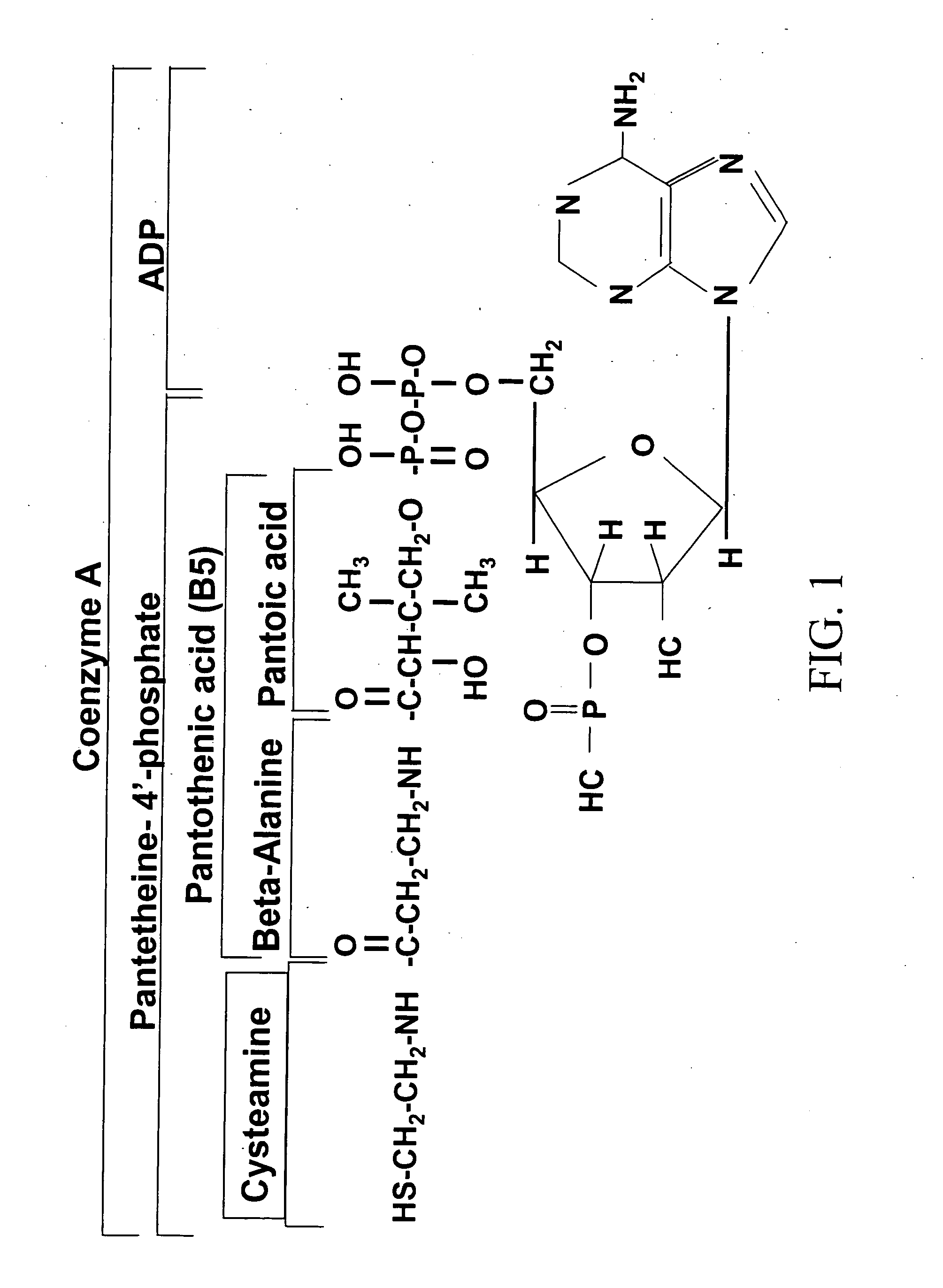

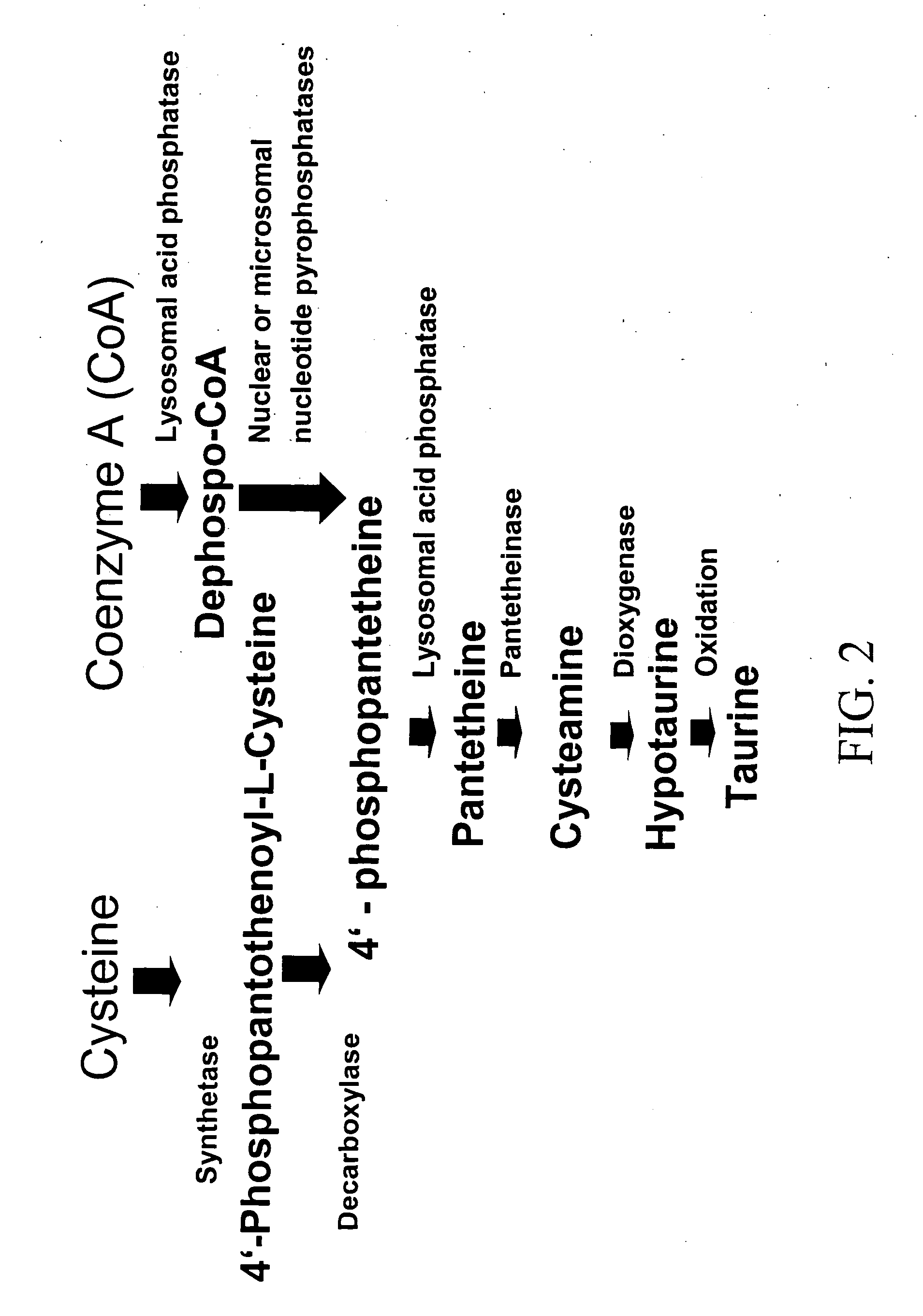

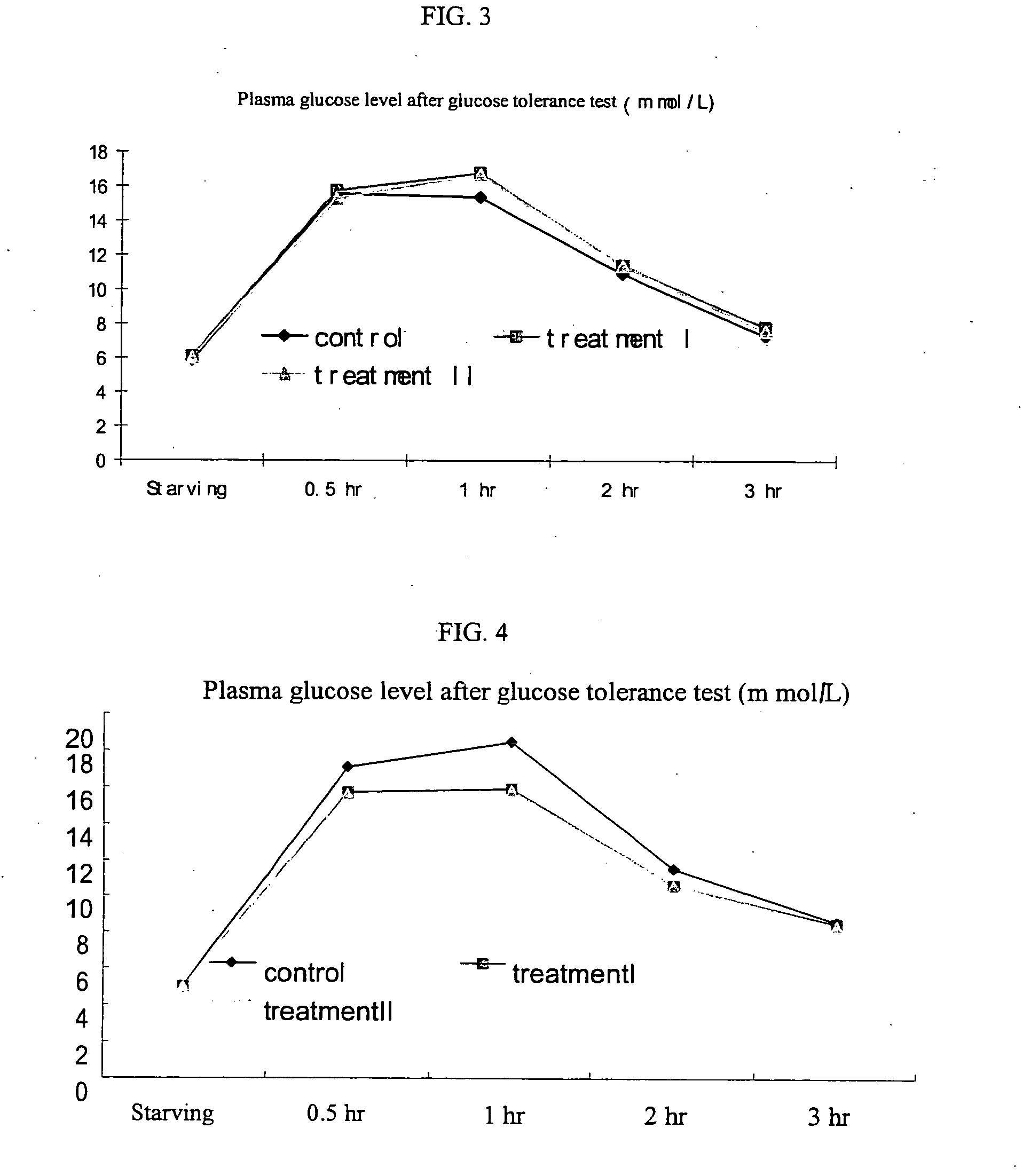

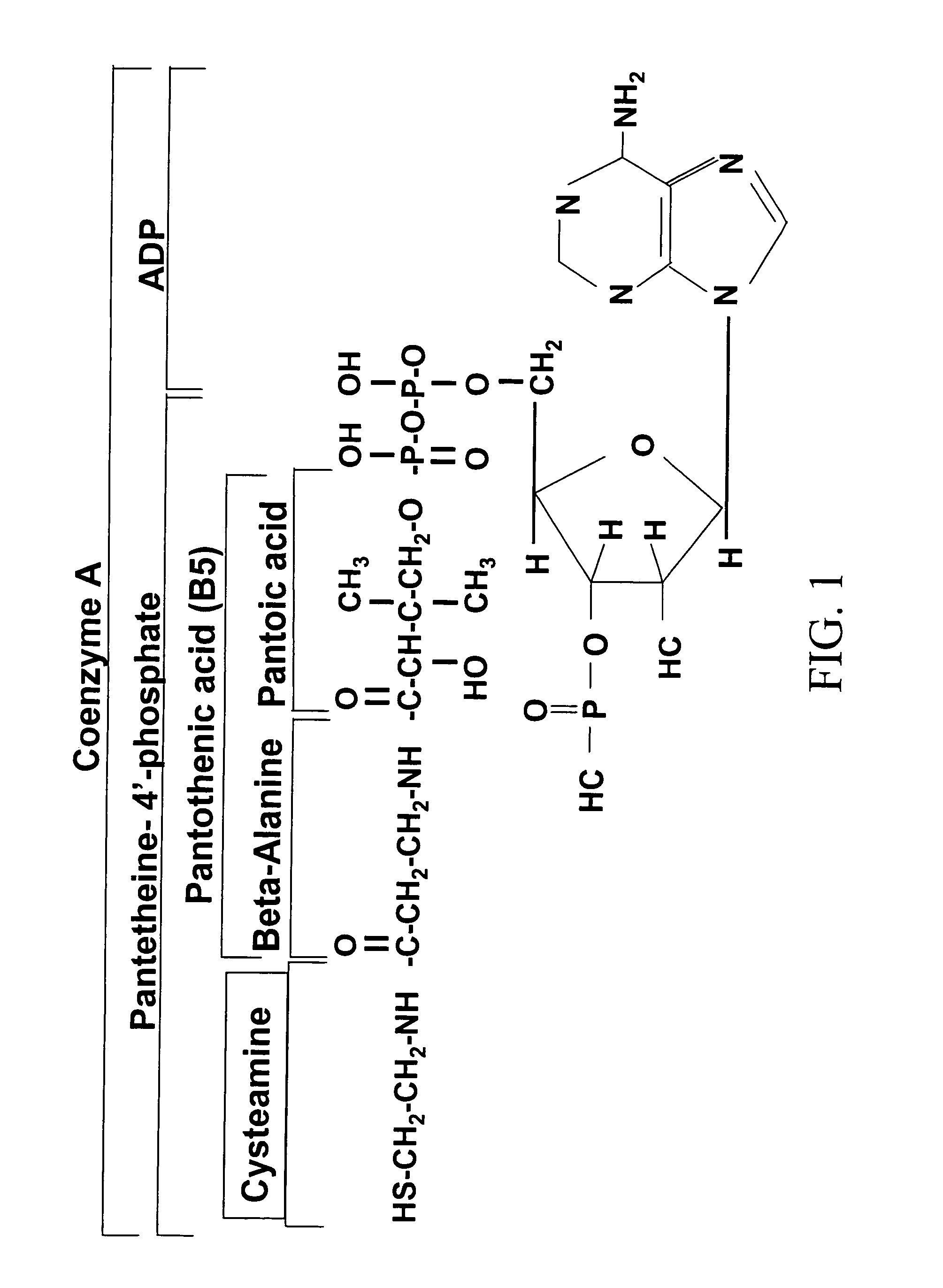

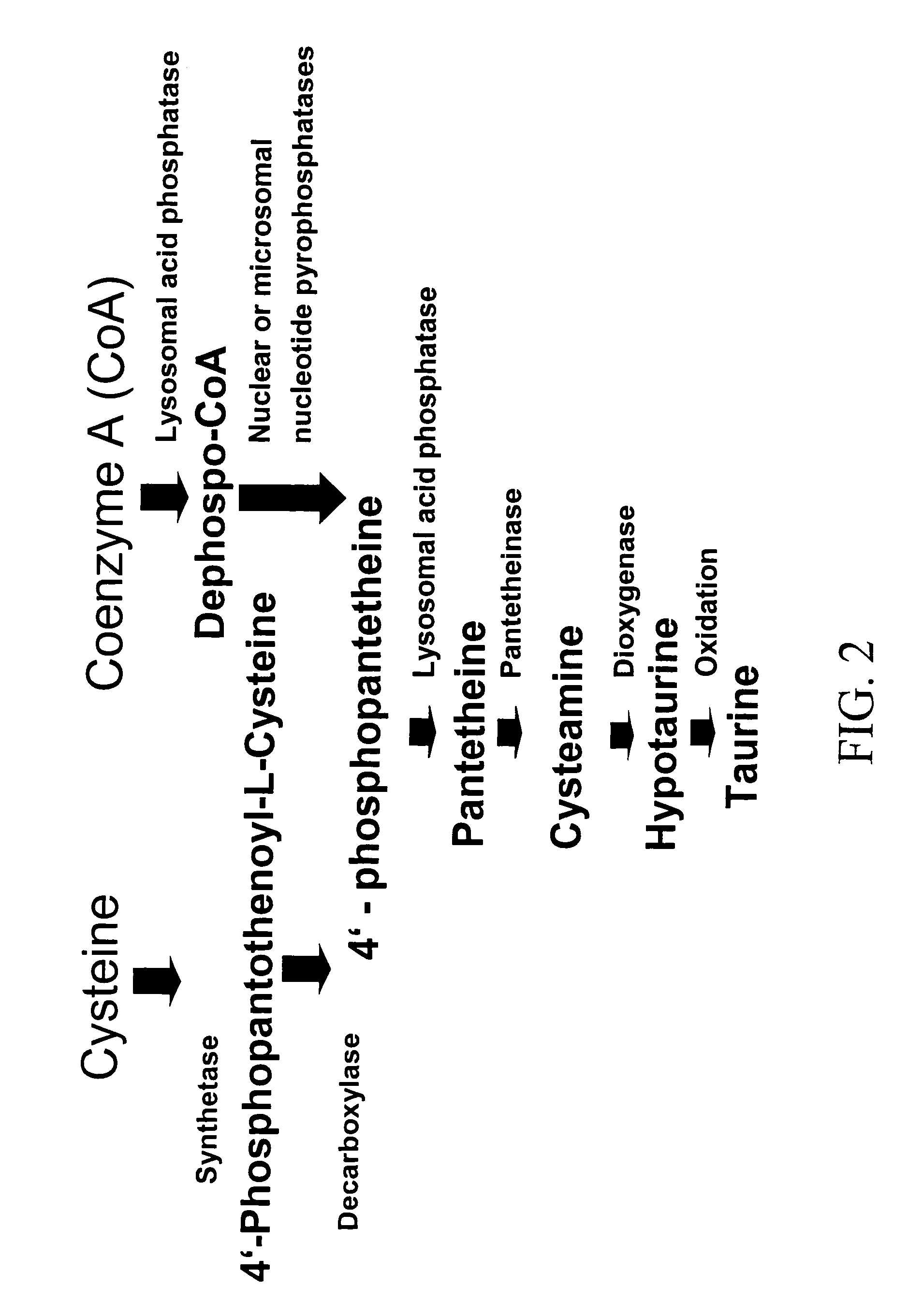

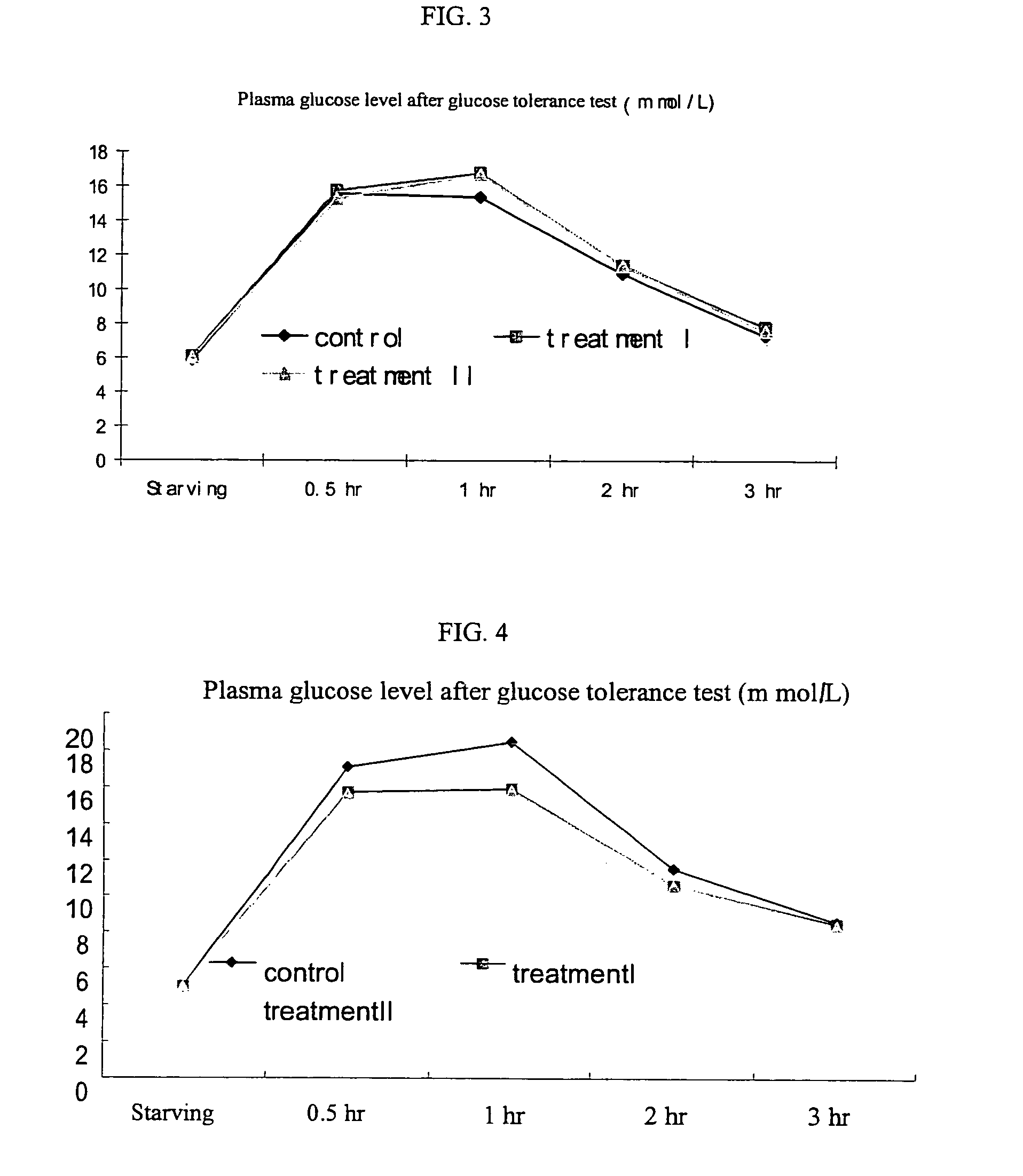

Compositions and methods for treating diabetes

InactiveUS20050137125A1Reducing and eliminating severityReducing and eliminating and intensityBiocideSenses disorderOral medicationGlucose polymers

The subject invention provides compositions and methods for treating diabetes in patients. In a preferred embodiment, the invention provides compositions methods for treating diabetes and / or preventing or alleviating complications associated with diabetes. Specifically exemplified herein is the concurrent administration of a cysteamine compound with at least one additional therapeutic agent to prevent and / or treat diabetes as well as prevent and / or treat complications associated with diabetes. In a preferred embodiment, oral administration of cysteamine hydrochloride with Metformin to a patient diagnosed with diabetes can substantially regulate the patient's glucose metabolism and insulin sensitivity.

Owner:OMEGA BIO PHARMA I P 3

Compositions and methods for treating diabetes

InactiveUS7442720B2Efficacious in lowering blood glucose levelReduce and eliminate and and durationAntibacterial agentsBiocideOral medicationGlucose polymers

The subject invention provides compositions and methods for treating diabetes in patients. In a preferred embodiment, the invention provides compositions methods for treating diabetes and / or preventing or alleviating complications associated with diabetes. Specifically exemplified herein is the concurrent administration of a cysteamine compound with at least one additional therapeutic agent to prevent and / or treat diabetes as well as prevent and / or treat complications associated with diabetes. In a preferred embodiment, oral administration of cysteamine hydrochloride with Metformin to a patient diagnosed with diabetes can substantially regulate the patient's glucose metabolism and insulin sensitivity.

Owner:OMEGA BIO PHARMA I P 3

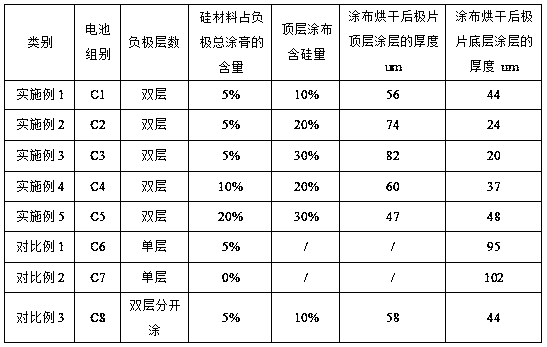

Negative plate and lithium ion battery

ActiveCN110148708AHigh porosityIncrease energy densitySecondary cellsNegative electrodesElectrical batteryHigh energy

The invention discloses a negative plate and a lithium ion battery, and belongs to the technical field of lithium ion batteries. The negative plate comprises a negative current collector and a film coated on the negative current collector; the film is divided into two layers, the first layer of coating is a bottom graphite coating close to the negative current collector, and the second layer of coating is a top silicon-containing coating layer far away from a copper foil. By adopting the technology of dual-layer coating, two types of slurry coats the negative current collector at the same time, after a dual-layer paste coating structure is formed on the same side of the negative current collector, a dual-layer coated negative plate with a silicon-containing coating on the top layer and a silicon-free pure graphite layer on the bottom layer is prepared, and the prepared negative plate has high compaction and high capacity performance, and the preparation method is simple and convenientin process; and the prepared lithium ion battery has the advantages of the high energy density and the good cycle performance, and can avoid lithium precipitation on the surface of the negative plateunder the condition of high-rate quick charging, so that the industrial application requirements are met.

Owner:ZHUHAI COSMX BATTERY CO LTD

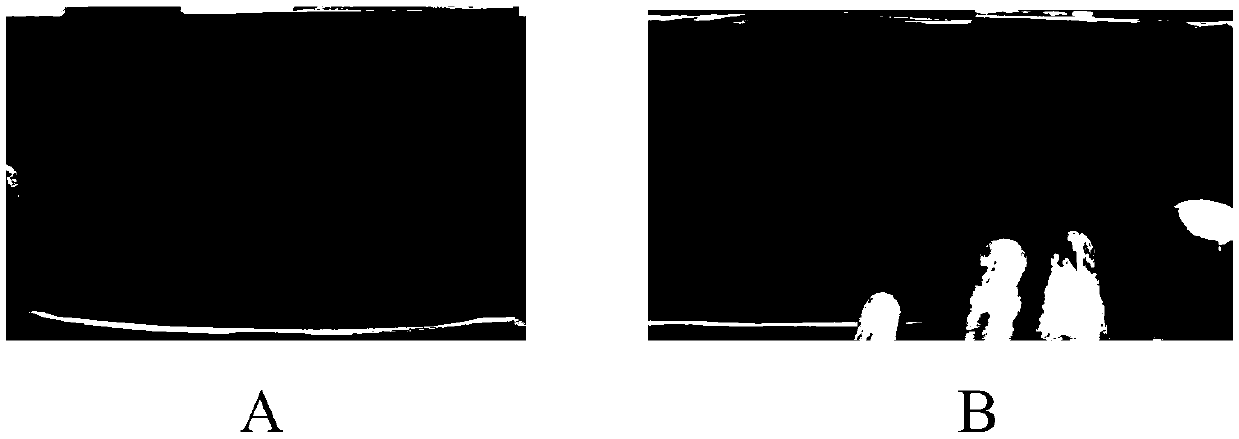

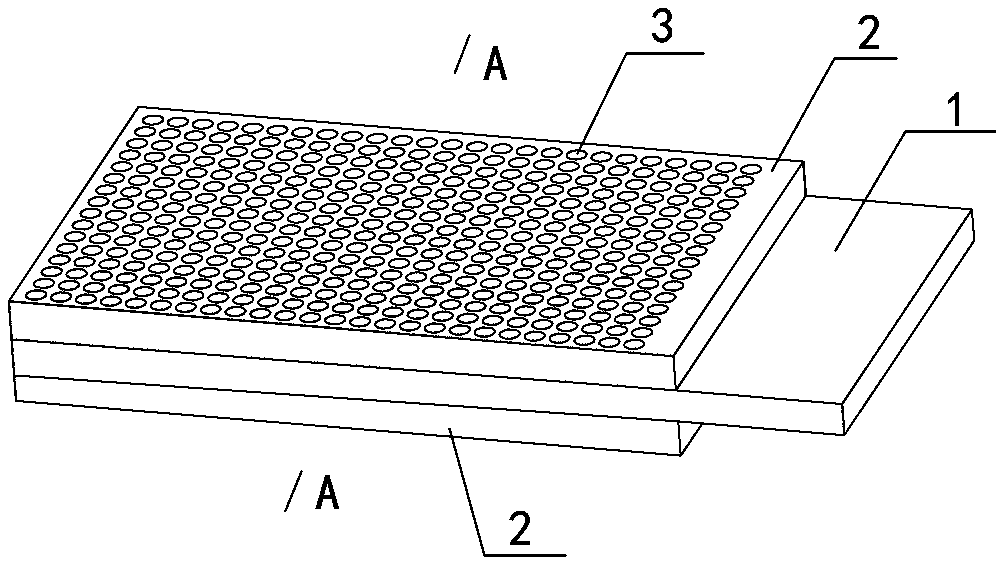

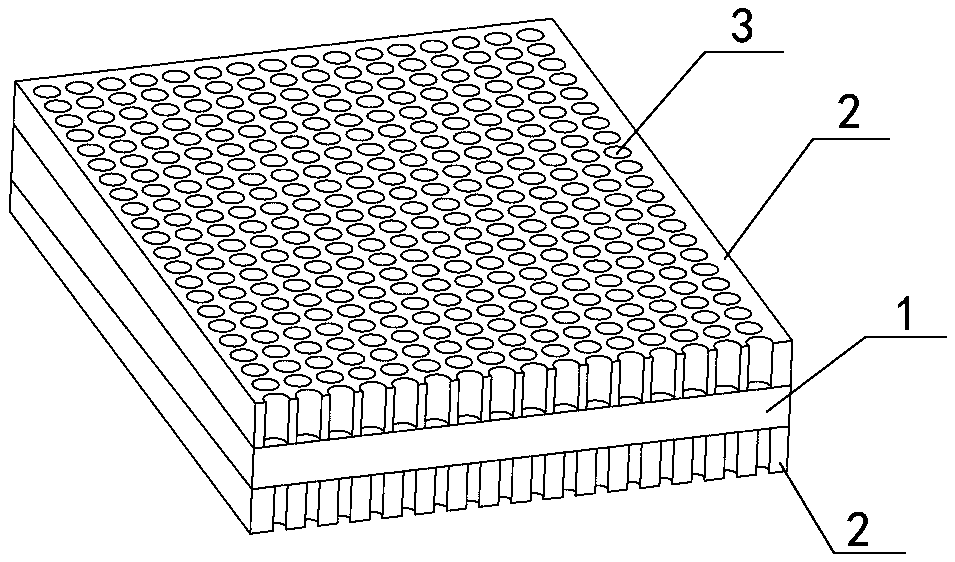

Porous pole piece and preparation method thereof and lithium ion battery

InactiveCN105633350AHigh porosityIncrease fluid retentionSecondary cellsNon-aqueous electrolyte accumulator electrodesPower performanceLithium electrode

The invention is suitable for the field of lithium ion batteries, and provides a preparation method of a porous pole piece. The preparation method comprises the following steps: mixing a pore forming material and slurry to obtain a mixture, and coating a pole piece with the mixture; and baking the pole piece at 100 to 150 DEG C to obtain a porous pole piece, wherein the porosity of the pole piece is 35 to 45 percent. The invention also provides a lithium ion battery containing the porous pole piece. The porous pole piece has higher porosity and further has higher liquid preserving capacity. The lithium ion battery containing the pole piece has higher multiplying power performance and higher cycling performance. Meanwhile, the formed pores are convenient for discharging gases, so that the service life of the battery is prolonged. According to the porous pole piece and the preparation method thereof and the lithium ion battery containing the porous pole piece, the preparation method is simple, the operation is simple and convenient, and the industrialized production can be realized.

Owner:OPTIMUM BATTERY CO LTD

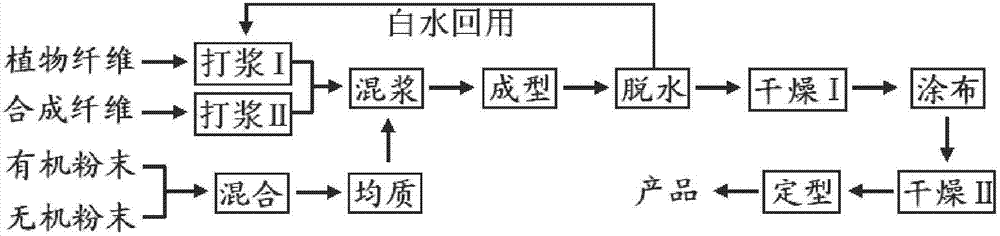

Battery capacitor membrane filtration material prepared by using wet papermaking forming process, and preparation method thereof

InactiveCN102728144AImprove uniformityImprove physical propertiesSpecial paperPaper/cardboardEconomic benefitsPolymer science

The present invention discloses a battery capacitor membrane filtration material prepared by using a wet papermaking forming process, and a preparation method thereof. Raw materials for preparing the material comprise, fibers, inorganic powder, organic powder and a reinforced material, wherein the fibers comprise, by weight, 3-10% of plant fibers and 90-97% of synthetic fibers, the weight of the inorganic powder is 1-40% of the weight of the fibers, the weight of the organic powder is 0.1-20% of the weight of the fibers, and the weight of the reinforced material is 10-30% of the weight of the fibers. The preparation method is characterized by: respectively carrying out pulping on the plant fibers and the synthetic fibers, and respectively carrying out high pressure homogenization mixing on the inorganic powder and the organic powder. The preparation method of the present invention has the following advantages that: the process is simple, the hole size can be effectively controlled, and the hole uniformity can be improved, wherein the holes are the labyrinth type curved holes. The material of the present invention has the following advantages that: filtration accuracy and filtration efficiency are high, internal resistance of the membrane prepared by the material is lowered, the membrane prepared by the material has characteristics of high liquid retention rate, good high temperature resistance, small deformation size, avoidance of dendrite generation and long service life. The raw material and the preparation cost of the material of the present invention are the same as the raw material and the preparation cost of full chemical fiber filtration material, and the performance price ratio of the material of the present invention is more excellent than the performance price ratio of the traditional materials, such that good economic benefits and social benefits are provided.

Owner:吕凯

Gel polymer electrolyte, polymer lithium ion battery and making method of polymer lithium ion battery

ActiveCN103633367AImprove electrochemical performanceLyophilicSolid electrolytesFinal product manufacturePolymer scienceLithium-ion battery

The invention provides a gel polymer electrolyte. A polymer membrane absorbs an electrolyte and swells to form the gel polymer electrolyte, and the polymer membrane is formed through thermocuring self-crosslinking of a liquid polymer mixture; and the liquid polymer mixture contains a pure acrylic emulsion, water and ammonia water, and the glass transition temperature of the pure acrylic emulsion is -30 - 50 DEG C. The invention also provides a polymer lithium ion battery adopting the gel polymer electrolyte, and a making method of the polymer lithium ion battery. The gel polymer electrolyte has the advantages of substantial improvement of the security, stable electrochemical performances and high voltage resistance, can realize the inhibition of the generation of lithium dendrites, no liquid leakage, substantial improvement of the security and good cycle stability when the gel polymer electrolyte is used in the polymer lithium ion battery, and is more suitable for lithium ion power batteries.

Owner:BYD CO LTD

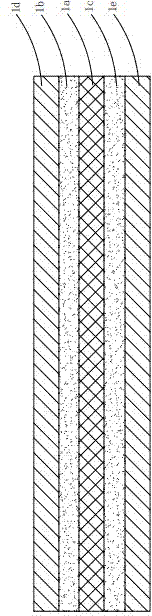

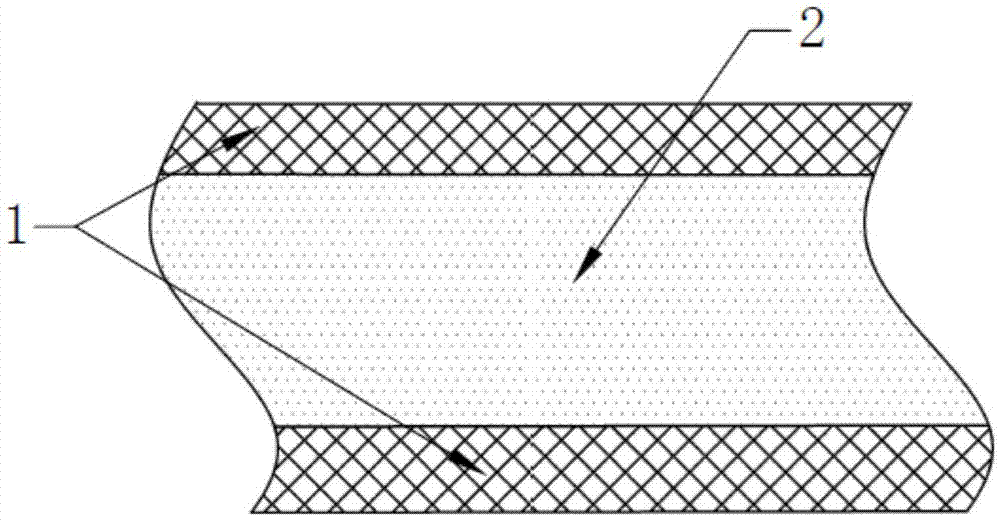

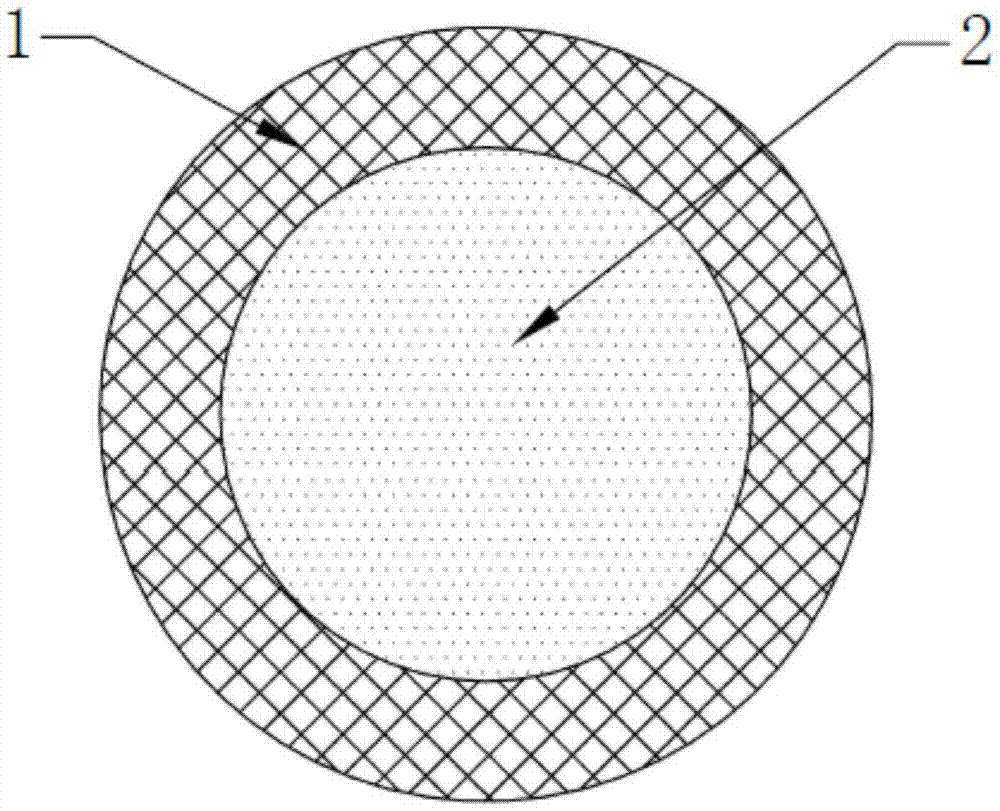

Multilayer compound wick material and its production technology

ActiveCN103085404AIncrease fluid retentionIncrease fluid storageSynthetic resin layered productsLaminationAdult diaperReverse osmosis

The invention discloses a multilayer compound wick material. The multilayer compound wick material comprises a non-woven fabric layer, wherein the upper surface and the lower surface of the non-woven fabric layer are respectively scattered with a wicking resin to form an upper wicking resin layer and a lower wicking resin layer, the upper wicking resin layer and the lower wicking resin layer are adhered with an upper wicking paper layer and a lower wicking paper layer formed by wicking paper through a hot melt adhesive respectively, and the non-woven fabric layer, the upper wicking resin layer, the lower wicking resin layer, the upper wicking paper layer and the lower wicking paper layer are compound-molded through roll compacting. The multilayer compound wick material has the advantages of high wicking time, small liquid reverse osmosis amount, large liquid storage capacity, lasting liquid storage time, dry and comfortable surface, and no skin dipping; a technology for producing the multilayer compound wick material has the advantages of simple process and less operation; and the multilayer compound wick material can be widely used as a main wicking material in infant and adult diapers and urine pads, a wicking material of women's sanitary wicking pads, and clinical nursing and health articles.

Owner:宁波东誉无纺布有限公司

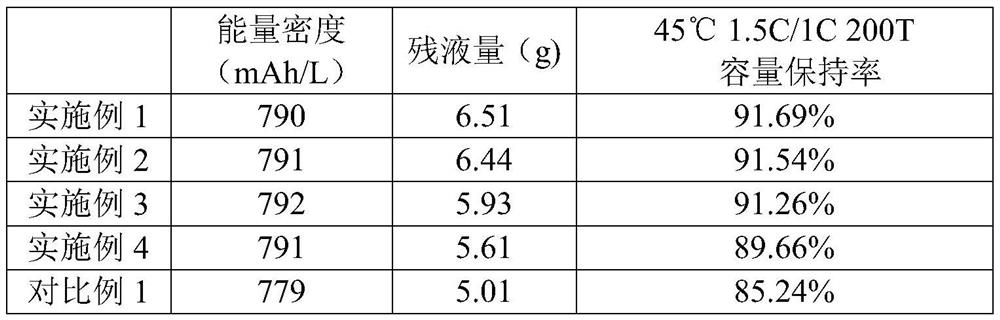

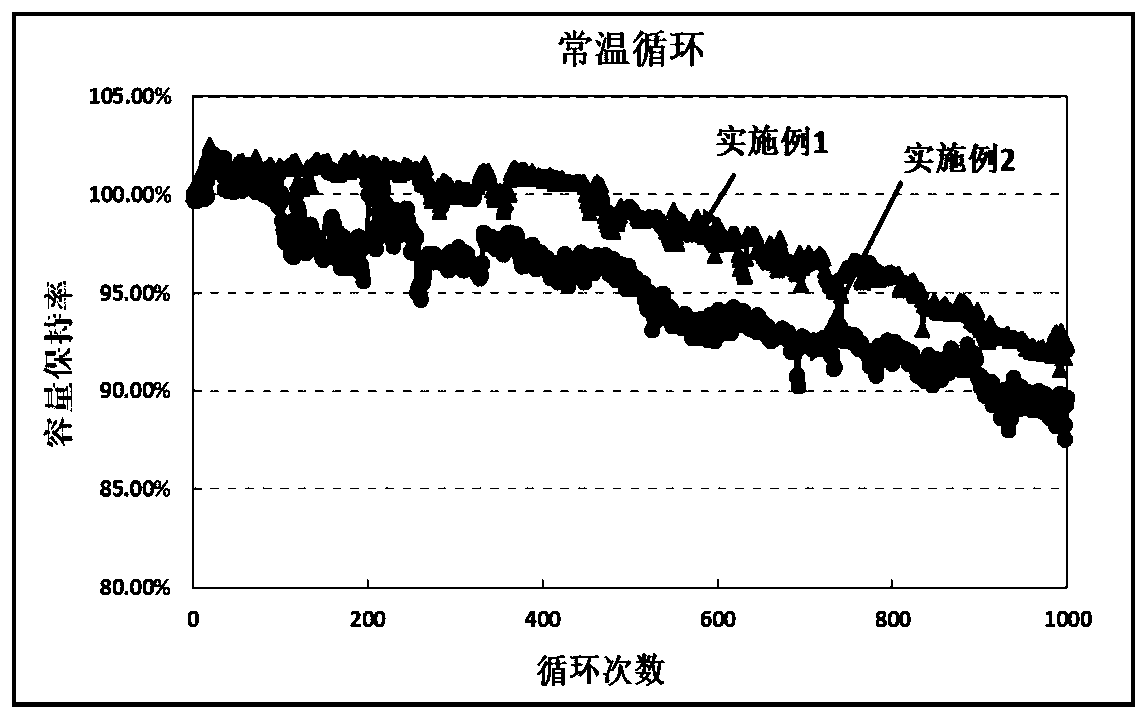

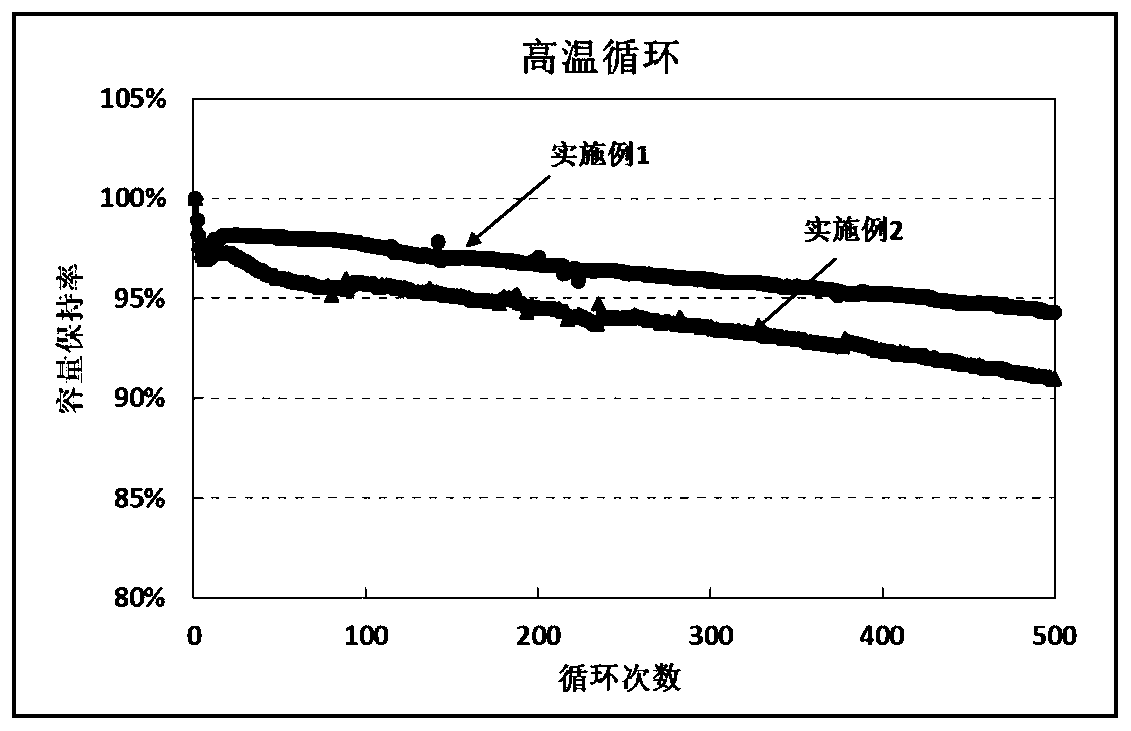

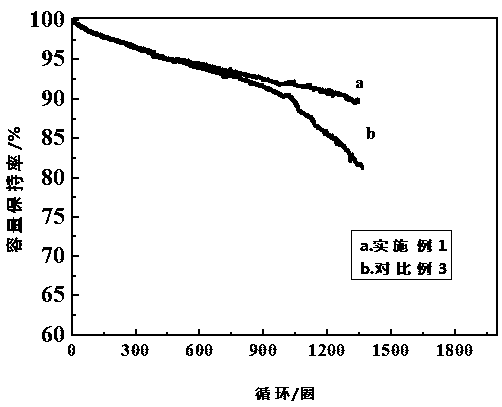

Silicon-containing negative plate and lithium ion battery comprising same

PendingCN112467079AIncrease fluid retentionIncrease gram capacityCell electrodesSecondary cellsSilicon oxygenPhysical chemistry

The invention discloses a silicon-containing negative plate and a lithium ion battery comprising the same. The negative plate comprises a current collector, a first active layer and a second active layer, wherein the second active layer is arranged between the current collector and the first active layer, active substances in the first active layer are a silicon-oxygen material and graphite, and the second active layer is arranged between the first active layer and the second active layer, and the active substance in the second active layer is graphite. a contact angle between the first activelayer active substance and the non-aqueous solvent is theta 1, the porosity of the first active layer active substance is a, the contact angle between the bottom active substance and the non-aqueoussolvent is theta 2, and the porosity of the bottom active substance is b, so 100 <theta1 / a<theta2 / b<450 is obtained, through the above specific structure, as the silicon expands greatly during the charging and discharging process, it is beneficial to improve the porosity of the surface electrode plate so as to improve the liquid retention of the battery. and meanwhile, the silica surface containsmore functional groups, and the particles are smaller than the graphite particles, so that the energy density, the liquid retention capacity and the cycle life of the battery can be remarkably improved.

Owner:ZHUHAI COSMX BATTERY CO LTD

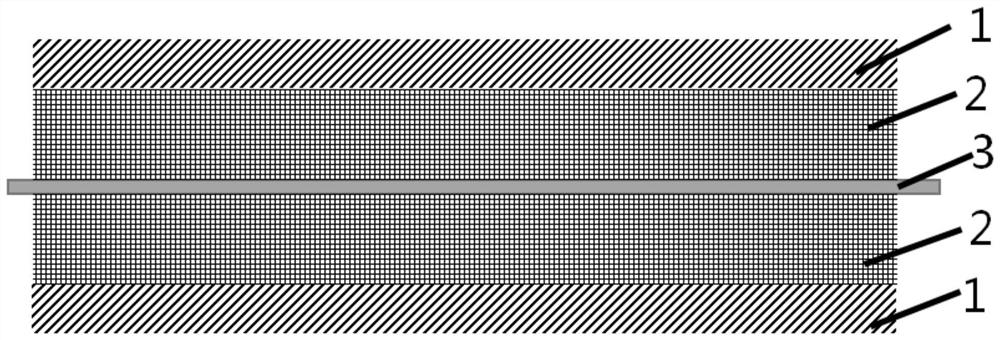

Composite membrane for lithium ion battery and lithium ion battery using same

InactiveCN101913862AHigh melting pointImprove wettabilityFinal product manufactureCell component detailsElectrolysisCeramic composite

The invention discloses a composite membrane for a lithium ion battery and the lithium ion battery using the same. The composite membrane comprises a membrane matrix and a polyelectrolyte composite layer, wherein the membrane is a ceramic composite membrane consisting of yttrium oxide-stabilized zirconium oxide and polyelectrolyte; in the yttrium oxide-stabilized zirconium oxide, the yttrium oxide accounts for 8 to 13 weight percent and the zirconium oxide accounts for 87 to 92 weight percent; and the polyelectrolyte of the ceramic composite membrane accounts for 0.1 to 2.0 percent of the total weight of the membrane. The lithium ion battery using the composite membrane comprises an electrode assembly and nonaqueous electrolyte which are sealed in a battery shell, and the composite membrane is the ceramic composite membrane. By compounding ceramic and the polyelectrolyte, the composite membrane can effectively improve the wetting property of organic electrolyte to the ceramic membrane, the solution holding capacity of ceramic pores, and the work safety of the battery.

Owner:海悉新能源科技(上海)股份有限公司

Safe high-voltage high-energy-density lithium ion battery and preparation method thereof

InactiveCN109755557AImprove stabilityDoes not cause structural collapseFinal product manufactureCell electrodesCeramic coatingElectrical battery

The invention discloses a safe high-voltage high-energy-density lithium ion battery and a preparation method thereof. The safe high-voltage high-energy-density lithium ion battery comprises a positiveplate, a negative plate, an electrolyte and a diaphragm; the positive plate comprises an aluminum foil current collector and a positive active material coating, the positive active material is a single crystal nickel cobalt lithium manganate mixture coated with titanium oxide according to a certain ratio, the negative plate comprises a copper foil current collector, a negative active material coating and a ceramic coating, the negative active material coating is coated with the ceramic coating, wherein the positive active material is one or two of single crystal NCM523 and single crystal NCM622 after being subjected to titanium oxide coating treatment, the negative active material is a high-capacity graphite material, the electrolyte is a high-voltage electrolyte, and the voltage range is4.0-6.0V. According to the lithium ion battery prepared by utilizing the material, the battery energy density is improved, and good safety performance is achieved while the battery has excellent cycling performance.

Owner:桑顿新能源科技(长沙)有限公司

Preparation method of composite polymer electrolyte membrane and lithium ion battery

ActiveCN108400380AImprove electrochemical stabilityImprove mechanical propertiesSolid electrolytesFinal product manufactureEvaporationSolvent

The invention discloses a preparation method of a composite polymer electrolyte membrane and a lithium ion battery. The preparation method of the electrolyte membrane comprises the following steps: mixing a carbonate functionalized vinyl monomer and a polyether structural monomer with a solvent under stirring in an inert gas atmosphere, then adding an initiator, reacting in the inert gas atmosphere, and drying and purifying to obtain a carbonate functionalized vinyl copolymer; adding the obtained carbonate functionalized vinyl copolymer and inorganic filler into the solvent, and mixing under stirring to obtain a uniform mixed solution; and uniformly coating the mixed solution on a mold, and performing vacuum drying and evaporation on the solvent to obtain a composite polymer electrolyte membrane. The electrolyte membrane disclosed by the invention has higher liquid retention rate, higher lithium ion conductivity, more superior mechanical property, high machining performance, higher electrochemical stability and better application prospect.

Owner:ZHUHAI COSMX BATTERY CO LTD

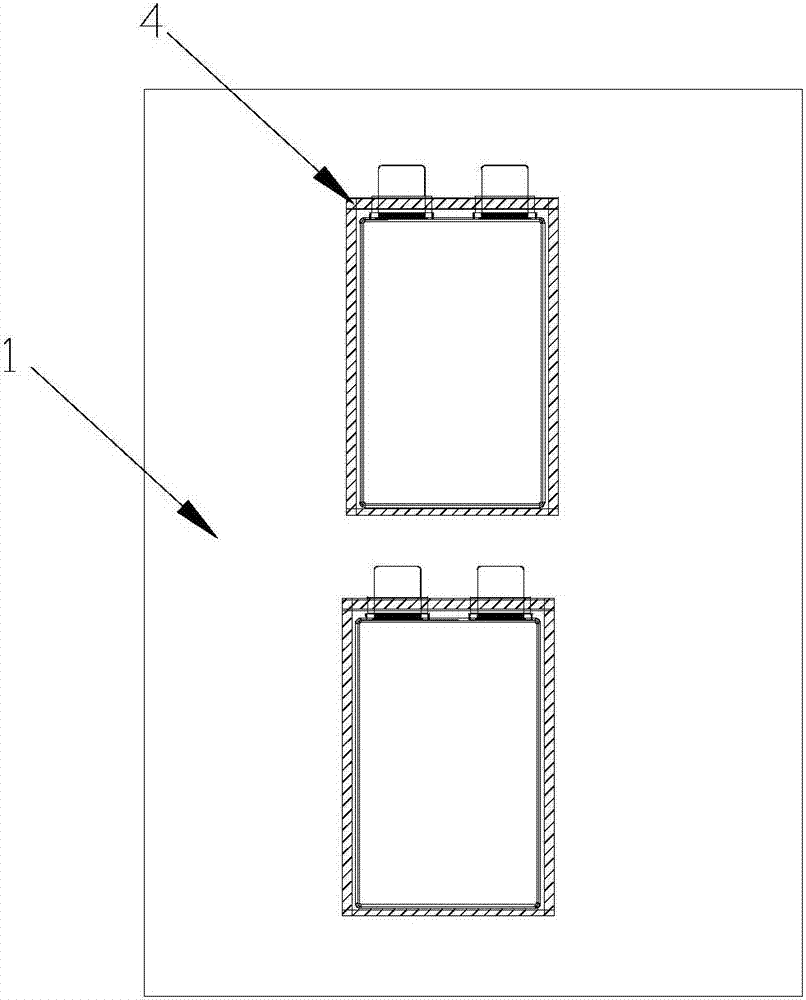

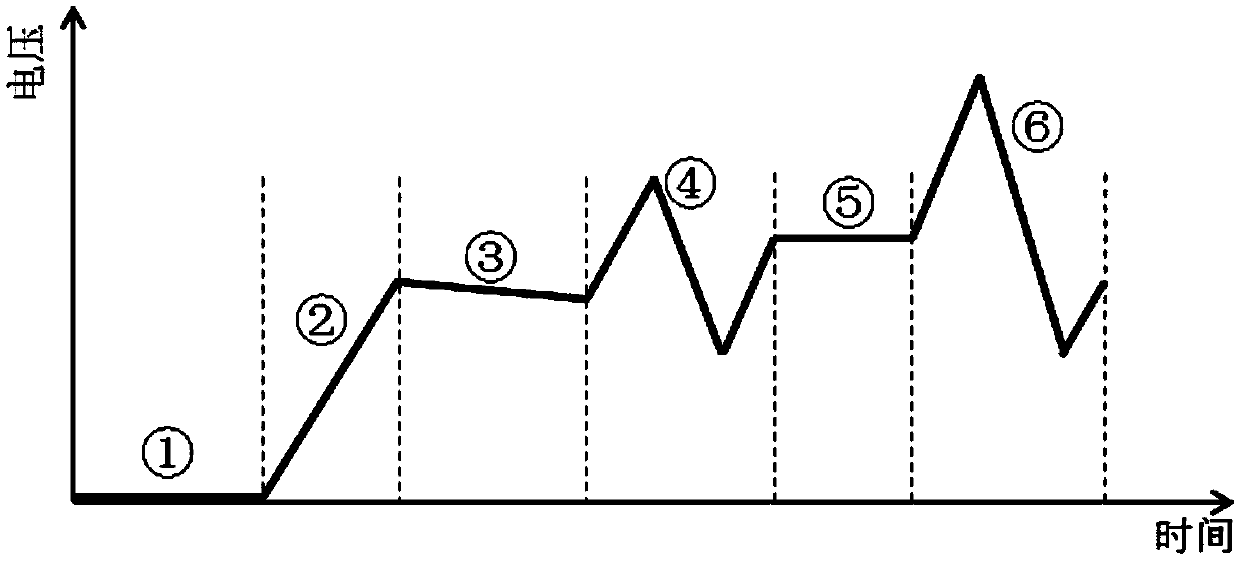

Formation and lamination method for flexible package lithium ion power battery

ActiveCN107403945ALarge fluid lossAvoid lostFinal product manufactureSecondary cells manufactureInternal resistancePre-charge

The invention relates to the technical field of lithium ion batteries and discloses a formation and lamination method for a flexible package lithium ion power battery. The method comprises the following steps: (a) carrying out hot pressing on a battery before pre-charging; (b) carrying out cold pressing on the battery before pre-charging; (c) pre-charging; (d) carrying out hot pressing on the battery after pre-charging; (e) carrying out cold pressing on the battery after pre-charging; (f) carrying out capacity grading; and (g) carrying out cold pressing on the battery after the capacity grading. The liquid maintaining amount of electrolyte processed by virtue of the formation and lamination method is high, the battery is rarely polarized, and the direct current internal resistance of the battery is low; and meanwhile, an anode group and a cathode group in the battery are in tight contact, so that the production of lithium dendrites in charging and discharging processes is avoided, the safety risk of the battery is reduced, meanwhile, the capacity expression of the battery is improved, and the cycle life of the battery is effectively prolonged.

Owner:WANXIANG 123 CO LTD

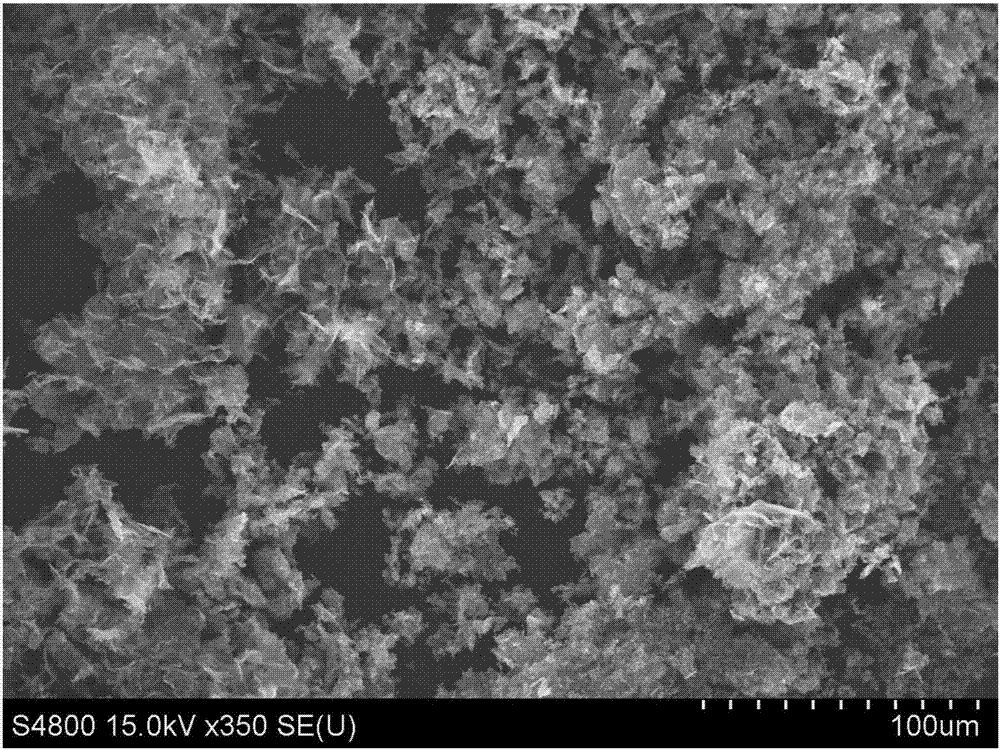

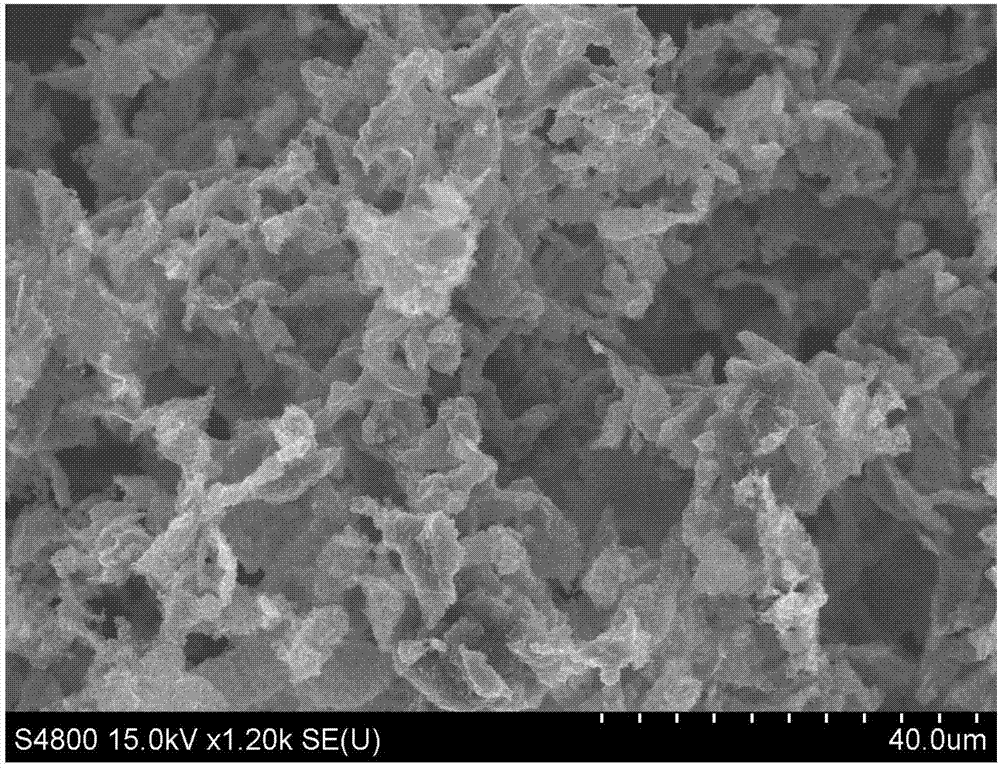

Graphene composite conductive powder and preparation method thereof

InactiveCN107394207ASimple processEasy to operateCell electrodesSecondary cellsPolypyrroleIn situ polymerization

The invention relates to graphene composite conductive powder. The graphene composite conductive powder comprises a graphene material and a macromolecule composite material, wherein the macromolecule composite material is a conductive macromolecule compound formed and obtained on the surface of conductive carbon material in an in situ polymerization manner through monomers; the graphene material is tightly combined with the macromolecule composite material through pi-pi conjugate action between the graphene material and the conductive macromolecule compound in the macromolecule composite material; and the conductive macromolecule compound is at least one of polyaniline, polypyrrole and polythiophene. The invention also provides a preparation method of the graphene composite conductive powder.

Owner:NINGBO MORSH TECH

Porous ceramic diaphragm slurry and preparation method thereof, battery diaphragm and battery

PendingCN109742298AGuaranteed heat resistanceGreat suctionCell component detailsHydrofluoric acidOrganic solvent

The invention relates to porous ceramic diaphragm slurry and a preparation method and application thereof. The preparation method comprises the following steps: corroding ceramic powder by using hydrofluoric acid to obtain porous ceramic powder, wherein the ceramic powder is made of at least two ceramic materials; mixing the porous ceramic powder and hydrochloric acid or nitric acid to perform activation so as to obtain activated porous ceramic powder; cladding a surface of the activated porous ceramic powder by using silane coupling agent to obtain sensitive porous ceramic powder; mixing thesensitive porous ceramic powder with adhesive and organic solvent, uniformly stirring to obtain the porous ceramic diaphragm slurry. The ceramic powder prepared from a plurality of ceramic materials is corroded through the hydrofluoric acid, the porous ceramic powder which is the porous structure is manufactured by utilizing the corrosion speed difference on different types of ceramic materials byutilizing the hydrofluoric acid, the porous ceramic powder obtains the porous ceramic diaphragm slurry through activation, sensitization and like treatment; the porous ceramic diaphragm slurry can obviously improve the electric performance of the battery.

Owner:SOUNDON NEW ENERGY TECH CO LTD

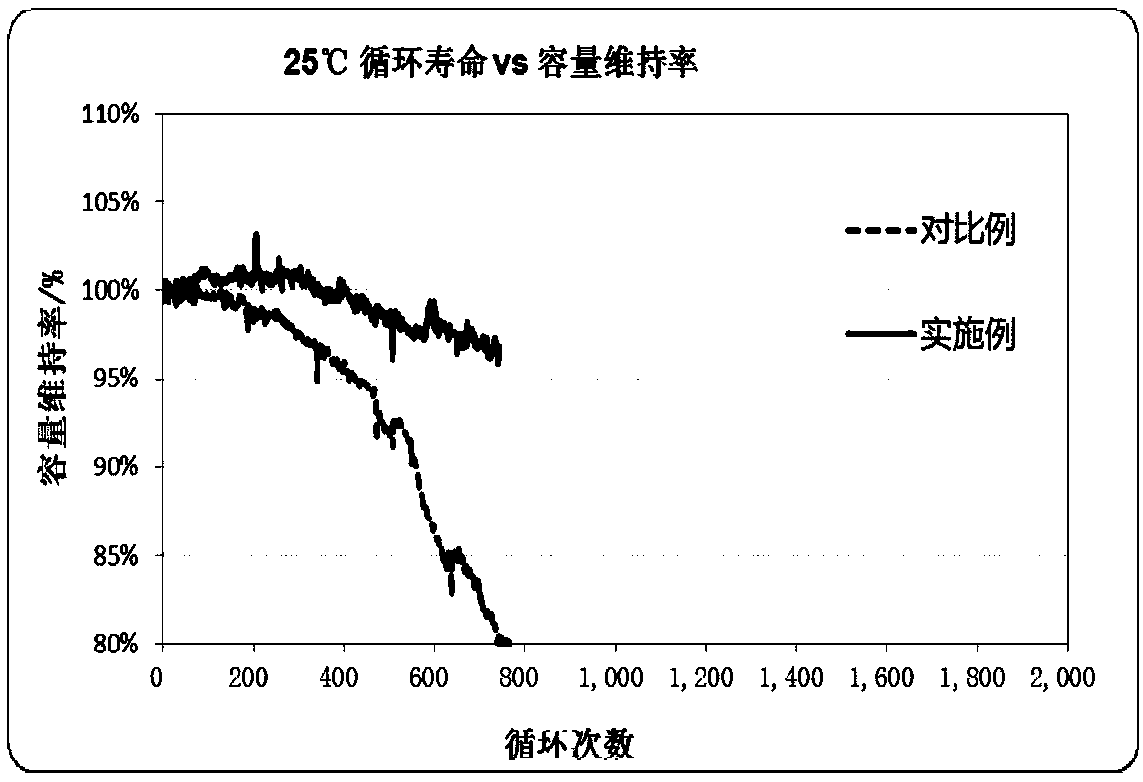

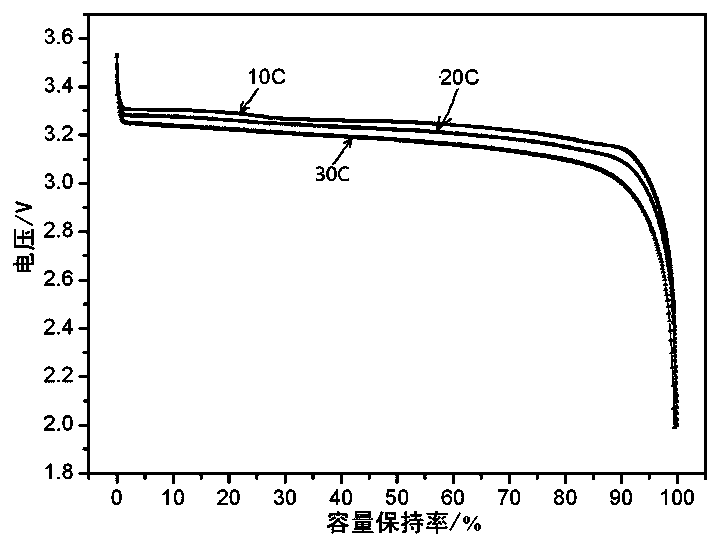

High-rate lithium ion battery, aging method and formation method

ActiveCN109888290AIncrease the average pore sizeIncrease fluid retentionElectrode manufacturing processesFinal product manufactureElectrolytic agentThermodynamics

The invention provides a high-rate lithium ion battery, an aging method and a formation method. The effectiveness of pole piece high porosity is characterized in that holdings and wettability of a pole piece electrolyte can be improved, and a conductive agent is compounded to reduce the direct-current internal resistance of a battery; during an aging process, the battery is subjected to high-temperature preheating and softening firstly, then pre-pressing and pressure relief operation are carried out, the battery is shaped, and high-temperature aging can promote uniform infiltration of the electrolyte of a pole piece coating layer; a three-step hot-pressing forming system is adopted, wherein a process step of "high-temperature shelf aging-constant-current discharging-constant-current charging" is executed additionally after the constant-current charging in each step, so that the infiltration effect of the electrolyte can be further improved, and an SEI membrane has sufficient nucleation, growth and reforming time, and by virtue of the charging and discharging cycles, the formation of the SEI membrane on the surfaces of the negative electrode active material particles can be more complete. The lithium ion battery prepared by the method disclosed by the invention is suitable for the fields having relatively high requirements for battery power performance of an unmanned aerial vehicle, an electric tool, a starting and stopping power supply and the like.

Owner:郑州中科新兴产业技术研究院

Gel electrolyte film of lithium battery and preparation method of gel electrolyte film

InactiveCN102170021ASolve the problem of mechanical strengthIncrease fluid retentionFinal product manufactureElectrolyte accumulators manufactureFiltrationPhysical chemistry

The invention relates to a gel electrolyte film of a lithium battery and a preparation method of the gel electrolyte film. The preparation method comprises the following steps of: making bacterial cellulose neutral; producing bacterial cellulose pulp by beating and dispersion; and performing suction-filtration, dehydration and electrolyte soaking to obtain the gel electrolyte film. The gel electrolyte film of the lithium battery provided by the invention has good ion conductivity and mechanical strength and effectively solves the problem of poor mechanical strength of the gel electrolyte film. By the preparation method of the gel electrolyte film, the thickness of the gel electrolyte film is reduced by means of beating and suction filtration, the surface smoothness of the gel electrolyte film of the lithium battery is improved, fibre distribution is more uniform, arrangement is dense, physical property is relatively strong, an application range is expanded, a preparation process is simple, and industrial production is easy to carry out.

Owner:海南椰国热带水果食品加工有限公司 +1

Formation capacity grading method of lithium ion battery

InactiveCN109659597AImprove wettabilityImprove conductivityFinal product manufactureSecondary cells charging/dischargingElectricityPower flow

The invention discloses a formation and capacity grading method for a lithium ion battery, and the method comprises a two-stage charging step of carrying out the constant-current charging of the two-stage charging at the current of 0.2 C or below and 0.5 C or above in sequence to a 40%-65% state of charge; an aging step, wherein the aging step is not performed for 24-48 hours at the ambient temperature; and a first charge and discharge cycle step of carrying out the first charge and discharge cycle at the ambient temperature of 0.7-1.0 DEG C, and finally performing charging to a state of charge of 30%-80%. A stable SEI film further improves the infiltration performance and the conductivity, and enhances the electrolyte retention amount of the battery cell, thereby improving the cycle performance of the lithium ion battery.

Owner:蜂巢能源(武汉)有限公司

Rapidly discharged/charged high power lithium ion battery and manufacturing method thereof

ActiveCN108306013ATake advantage ofHigh tap densityFinal product manufactureElectrode carriers/collectorsManganateCarbon nanotube

The invention discloses a rapidly discharged / charged high power lithium ion battery and a manufacturing method thereof. The positive current collector comprises an aluminum foil and a conductive coating. The negative current collector comprises a copper foil and a conductive coating. The diaphragm is a PE material, which is bidirectionally and synchronously stretched, and ceramic oxide is paintedon the surface of the PE material. The anode paste comprises following components in parts by weight: 10 to 35 parts of lithium cobaltate, lithium nickelate, lithium manganate, lithium iron phosphate,lithium manganese phosphate, lithium iron manganese phosphate, or lithium vanadium phosphate, 62 to 81 parts of nickel cobalt lithium manganate, 1 to 3 parts of Ketjen black or carbon nanotube, and 1to 3 parts of graphene or Super-P and modified 1,3-polyvinylidene fluoride. The cathode paste comprises following components in parts by weight: 55 to 75 parts of artificial graphite or meso-phase carbon micro beads, 20.5 to 36 parts of soft carbon or hard carbon, 1 to 2 parts of CMC, 2 to 4 parts of Super-P, and 1.5 to 3 parts of styrene butadiene rubber SBR or polystyrene-acrylate. The providedlithium ion battery can continuously discharge or charge (30C). The 30C constant current charge capacity can account for 70% or more of 1C capacity, and the 30C discharge capacity can account for 90%or more of 1C capacity.

Owner:FENGFAN

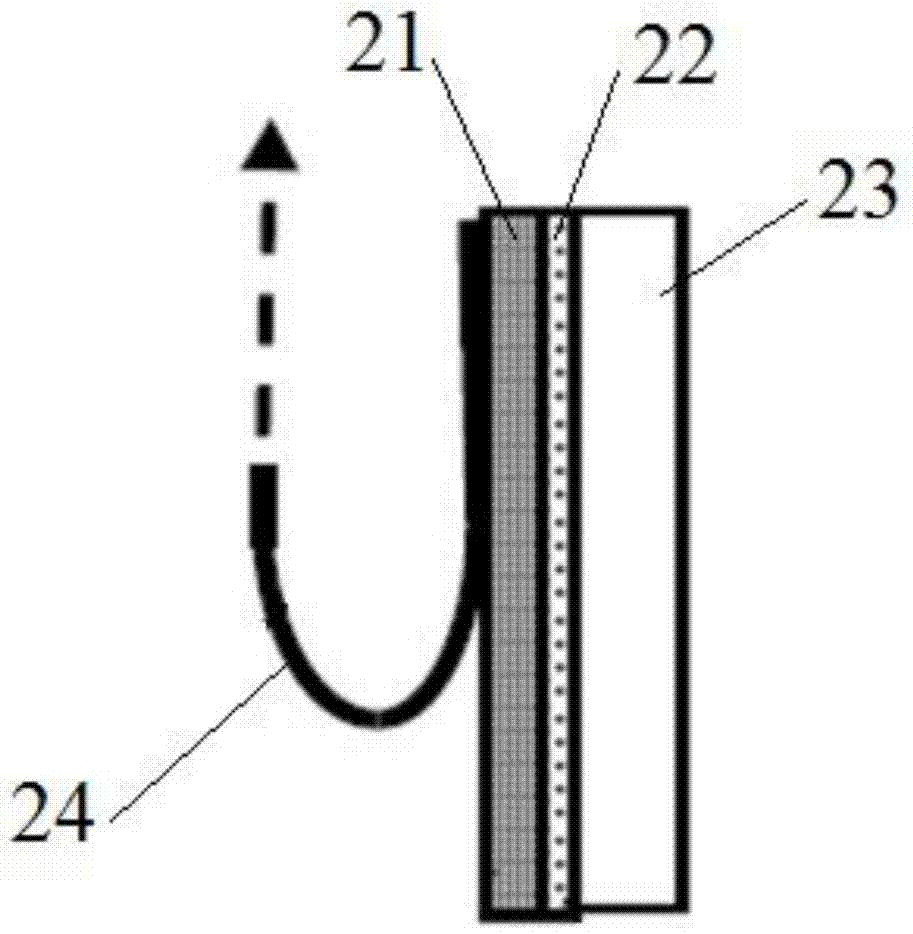

Lithium ion secondary battery polymer separation film corona processing method

ActiveCN103236510AImprove permeabilityImprove securityFinal product manufactureCell component detailsInternal resistanceSolvent

The invention relates to a lithium ion secondary battery polymer separation film corona processing method. According to the invention, a polymer molecule separation film is adopted as a substrate; various ions produced by air ionization under high-frequency and high-voltage discharge conditions are accelerated and impact the separation film under the effect of a strong electric field, such that polymer molecule chemical bonds are broken and degraded. Therefore, separation film surface roughness and surface area are increased, and print substrate surface adhesion capacity is improved. With large amount of strong oxidant ozone produced by air ionization, the film polymer molecules are oxidized, such that high-polarity groups such as carbonyl groups and peroxide are produced. Therefore, film surface energy is improved, wettability and film liquid retention of the film to a polar solvent can be improved, and ion permeability and safety are improved. According to a porous gel separation film lithium battery subjected to corona processing, the battery has excellent rate performance and small internal resistance, and a battery liquid retention can be improved by 2-3%, such that battery performance is improved.

Owner:CENT SOUTH UNIV +1

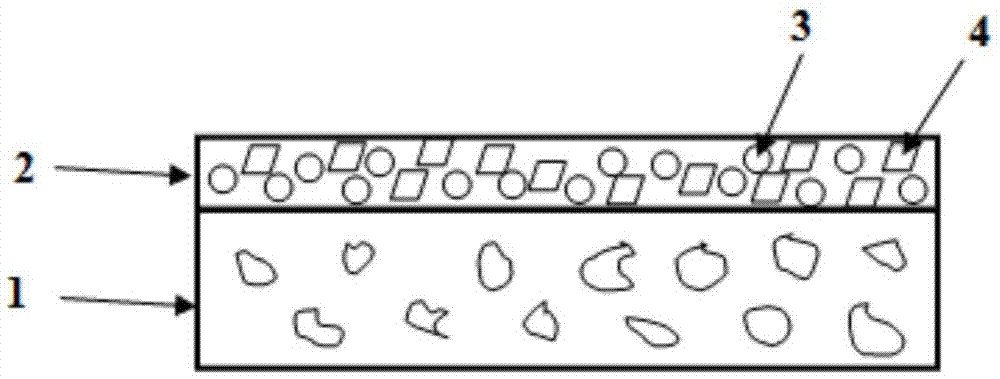

Preparation method of battery diaphragm and battery membrane

InactiveCN105449141AHigh liquid absorptionIncrease fluid retentionSecondary cellsCell component detailsSlurrySolvent

The application discloses a preparation method of battery membrane and a battery membrane. The preparation method of the invention comprises: evenly dispersing irregularly shaped inorganic particles with D50 of 0.4-2.0 mum and organic particles with particle diameters less than 1 mum in solvent, preparing into slurry, coating the slurry on base membrane, drying, removing the solvent, and obtaining the battery membrane; the solvent comprises deionized water and organic solvent; the volume ratio of the deionized water to the organic solvent is 50-100:1. The preparation method of the application is simple, convenient and easy in operation; the heat resistance of the battery membrane is ensured and the cohesiveness of the battery membrane and the cathode and anode sheets is improved by using inorganic particles and organic particles of different sizes and shapes in the slurry, simultaneously using the deionized water and the organic solvent and using complementation of the two kinds of particles; the liquid absorptivity and liquid retention rate of the battery membrane are improved by mixed use of the two kinds of solvents; the circulation of the battery is improved, and the foundation for preparing high safety performance lithium ion battery is established.

Owner:SHENZHEN ZHONGXING NEW MATERIAL TECH CO LTD

Radial seal and method of making

Owner:FEDERAL MOGUL WORLD WIDE LLC

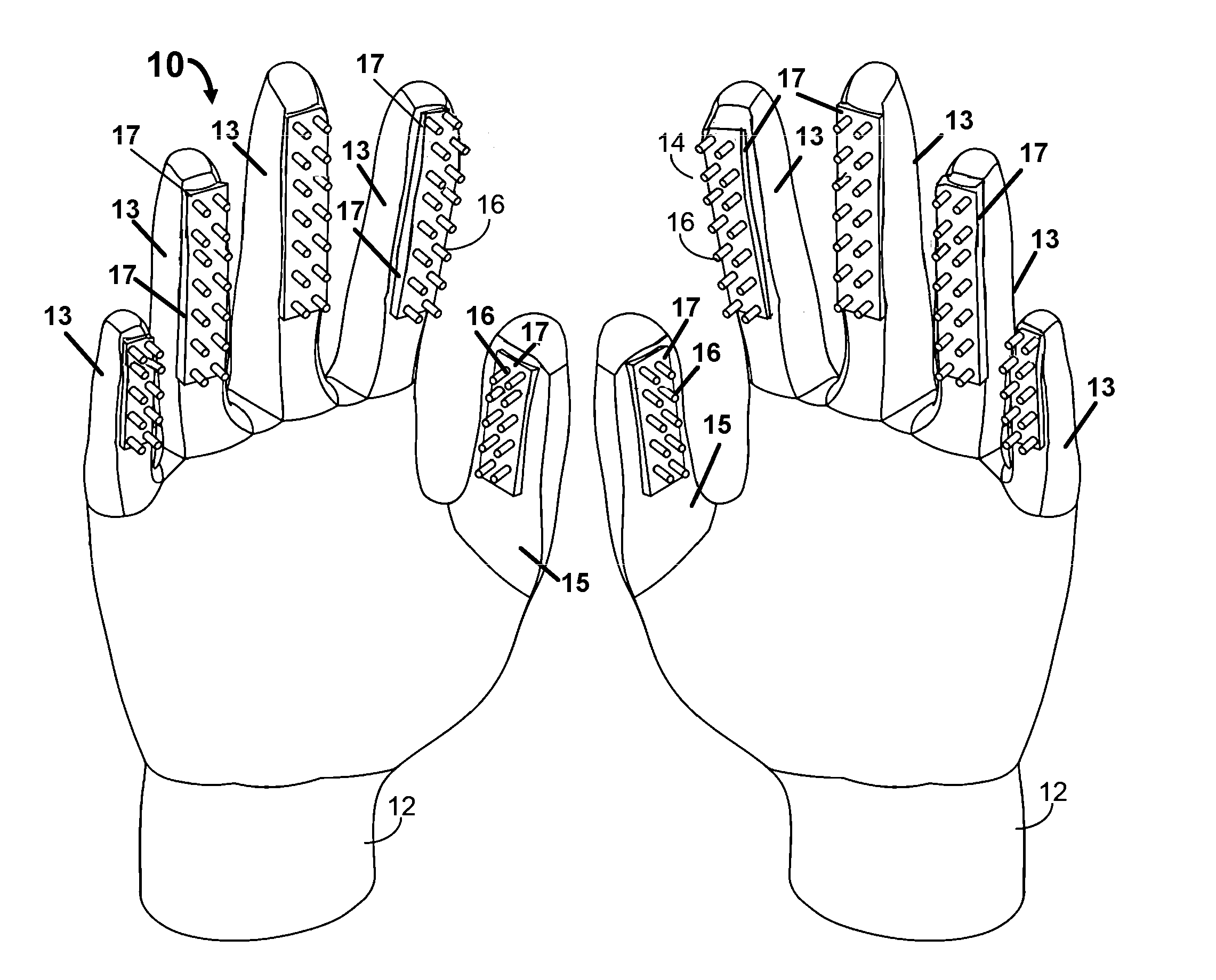

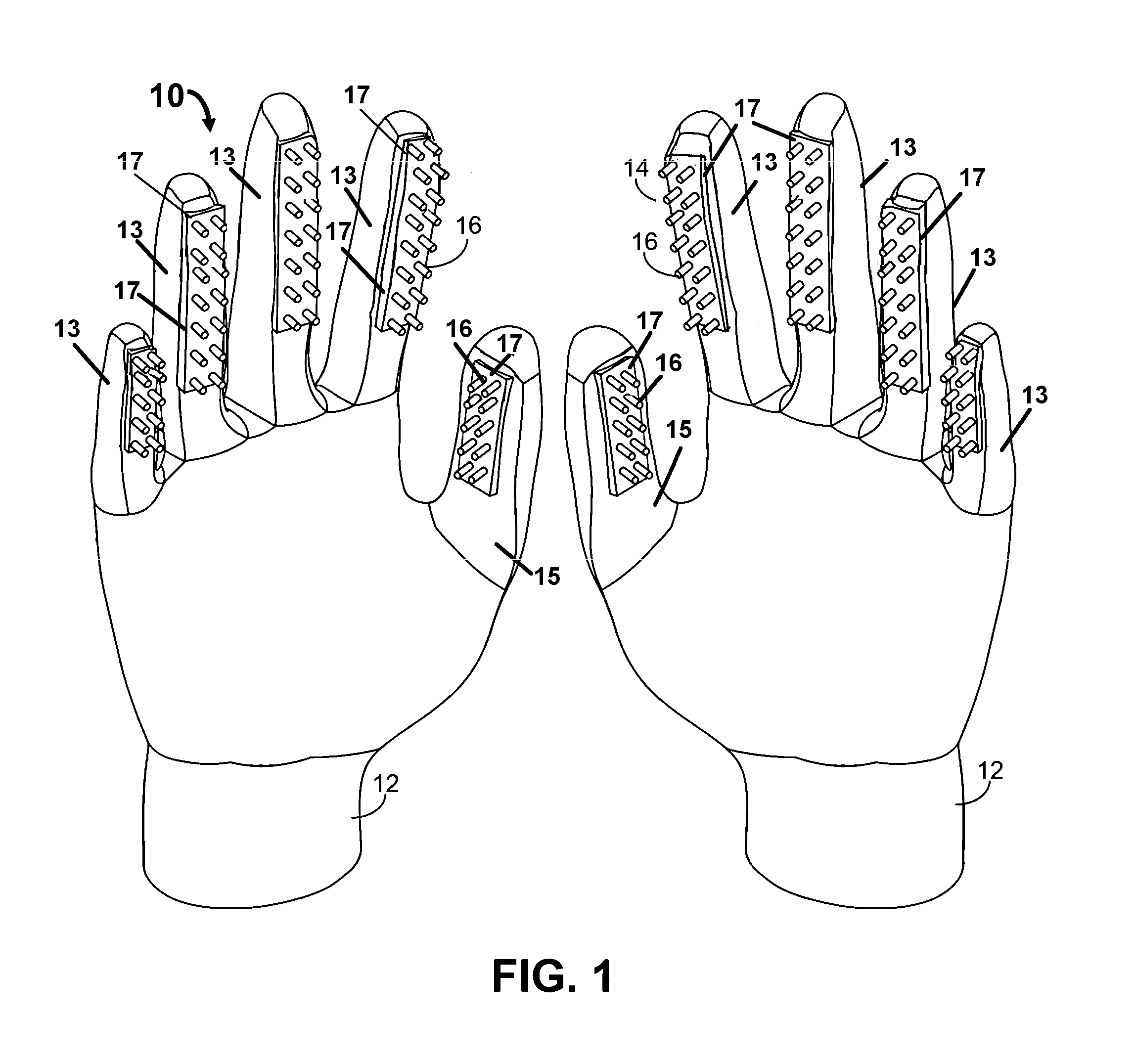

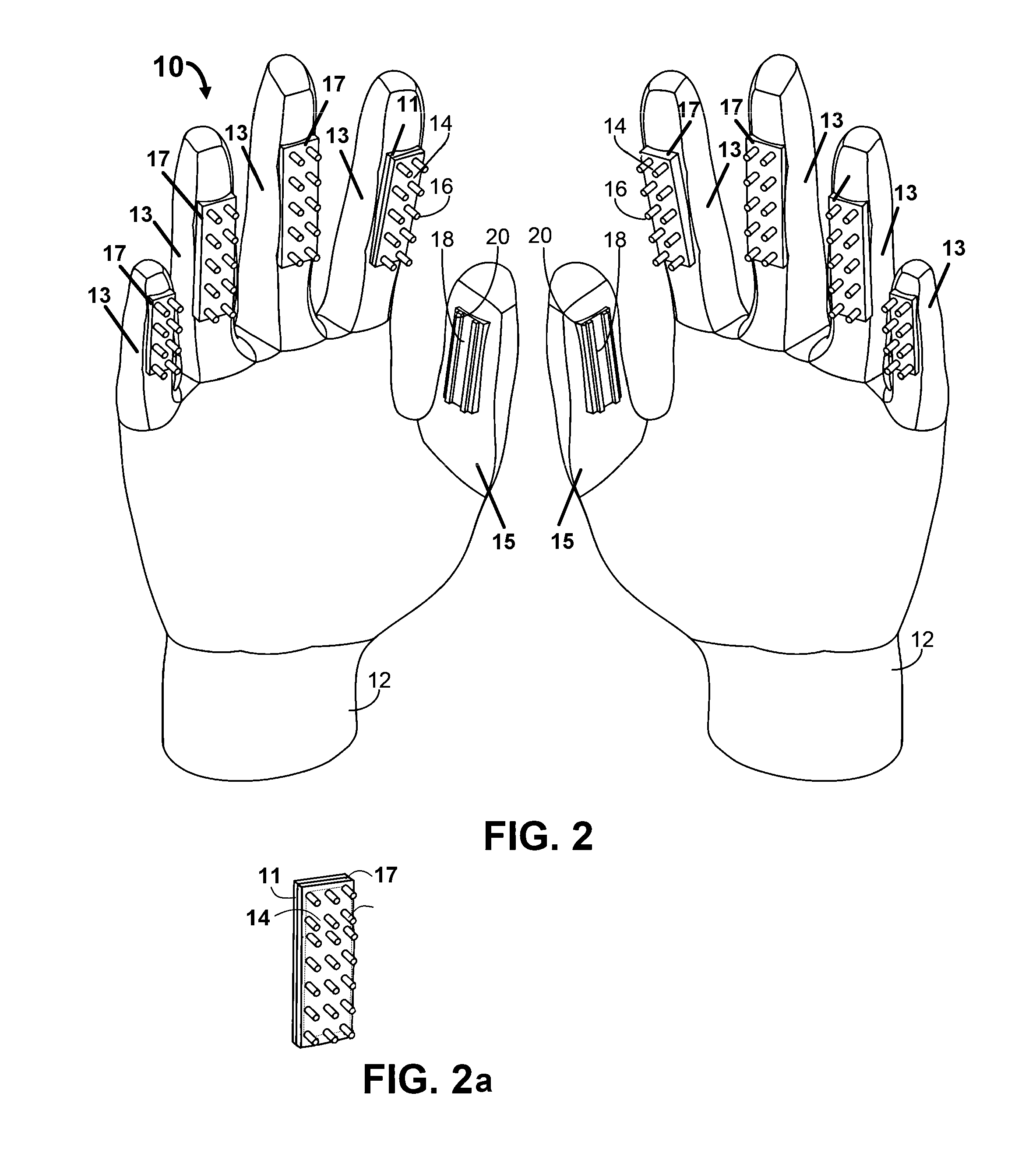

Cosmetic Application Gloves

InactiveUS20160192757A1Easy and enhanced communicationEasy and enhanced communication of fluidGlovesHair combsScalpBiomedical engineering

Owner:TAPIA EPIFANIO

Lithium ion battery pole piece and preparation method thereof

InactiveCN109686918AImprove cycle lifeIncrease the conductive interfaceNon-aqueous electrolyte accumulator electrodesElectrode moldingElectrical batteryCharge discharge

The invention discloses a lithium ion battery pole piece which comprises a current collector and a paste membrane applied to the current collector. The paste membrane is uniformly provided with micropores, and the micropores penetrate through the surfaces of two sides of the paste membrane. According to the battery pole piece, the paste membrane on the lithium battery pole piece is provided with aplurality of micropores, so that the conductive interface of active substances in a lithium ion battery is increased, the interface resistance is reduced, the absorption efficiency and the liquid retention amount are improved, the rate charge-discharge performance and the cycle life of poles are improved, and the requirements for rapid charge-discharge and the service life of the power battery are met. In addition, the thickness of the pole piece is increased, the energy density of the battery and the safety performance of the battery are improved, meanwhile, the charge transfer path betweenthe pole pieces is changed, the production efficiency is improved, and the manufacturing cost of the battery is reduced.

Owner:遵化市清吉电池科技有限公司

Method for manufacturing lithium ion battery by using gel diaphragm

InactiveCN112103566AAdvantages of production methodImprove temperature consistencyFinal product manufactureSecondary cells charging/dischargingPole pieceLithium-ion battery

The invention provides a method for manufacturing a lithium ion battery by using a gel diaphragm. The method comprises the following steps of manufacturing a positive pole piece, manufacturing a negative pole piece, baking the pole pieces, laminating, preheating, carrying out primary hot pressing, carrying out primary cold pressing, manufacturing a battery cell, pre-charging, ageing, carrying outsecondary hot pressing, carrying out secondary cold pressing, forming and finishing the manufacturing of the battery cell. According to the manufacturing method of the lithium ion battery using the gel diaphragm, the gel diaphragm is adopted, firstly, preheating, hot pressing and cold pressing are conducted on the core package after lamination, and in the stage, the pressure of hot pressing and cold pressing is small, so that the gel diaphragm slightly adheres to a pole piece to achieve a fixed core package structure. Secondly, pressure is applied to the battery cell in a pre-charging stage; and finally, the procedures of hot pressing and cold pressing are added before the formation procedure, so that the tight bonding of the positive / negative pole piece and the gel diaphragm is realized.

Owner:TIANJIN ENERGIES

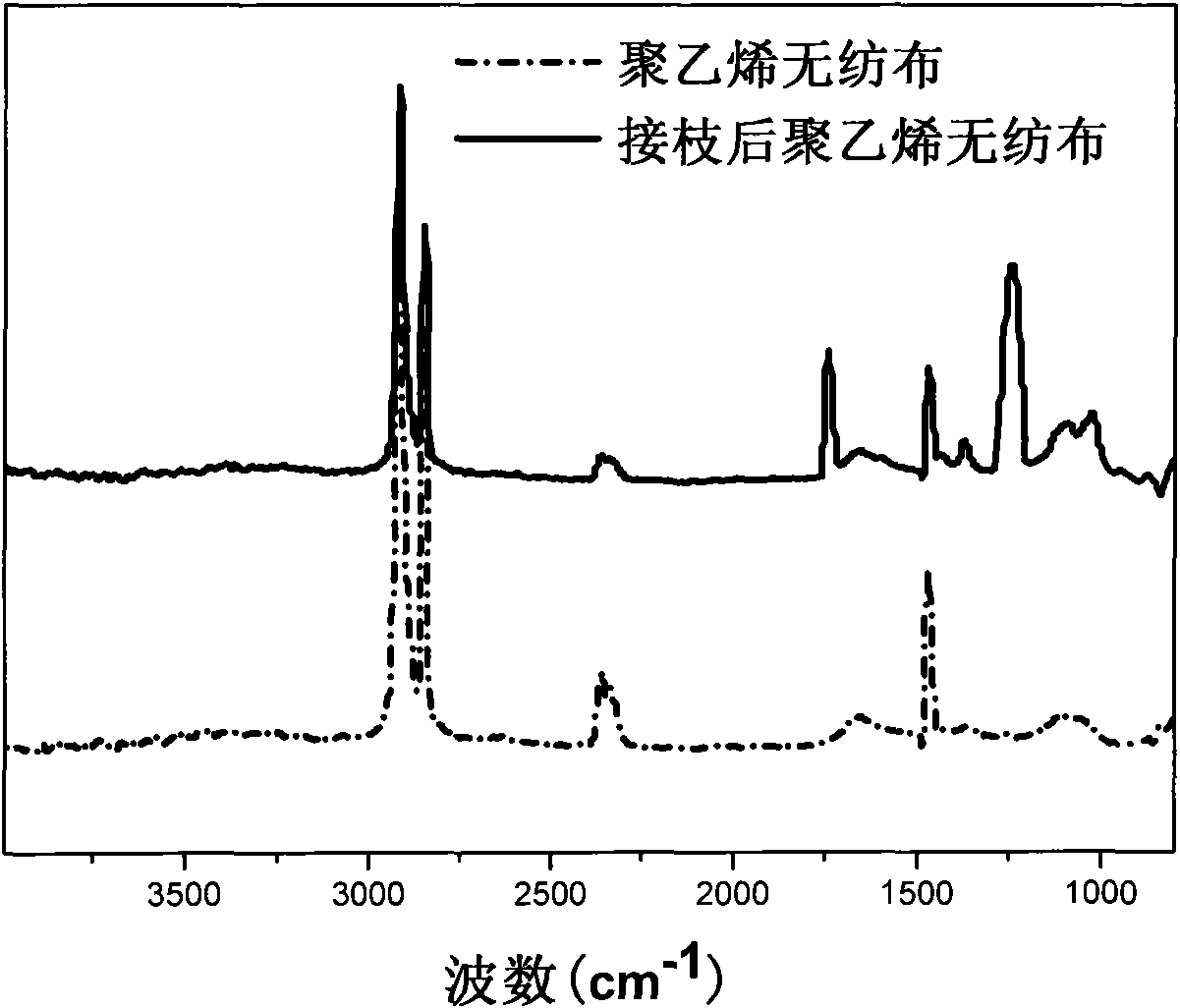

Grafting modified high polymer material, and preparation method and application thereof

ActiveCN102432906AReduce crystallinityImprove lithium ion conductivityFibre treatmentCell component detailsPolymer sciencePolyolefin

The invention discloses a grafting modified high polymer material which is a high polymer micro-porous membrane or a high polymer non-woven fabric with a graft chain, wherein the graft chain is a polymeric chain of more than one monomer; the polymeric chain is a homo-polymer chain formed by the same monomer or a random copolymer chain formed by different monomers; and the monomer is provided with at least one C=C double bond and at least one ether group or a group shown in the formula I. The invention overcomes the defect that the affinity of the polyolefin micro-porous membrane is improved by coating the affinity group, but the affinity group is easy to drop in the process of using the lithium ion battery, and provides the grafting modified polymer material and a preparation method thereof. The high polymer material is especially suitable for serving as the lithium ion battery separator, reduces the crystallinity of the polyolefin separator and has good affinity for the ester organic electrolyte, and at the same time, the polymer material is not easy to drop from the separator in the use process and can lengthen the use performance of the battery.

Owner:上海世龙科技有限公司

Current collector of lead-acid storage battery

InactiveCN106876718AThe apparent density of the material is smallStrong conductivityElectrode carriers/collectorsCarbon nanotubeCurrent collector

The invention discloses a current collector of a lead-acid storage battery. The current collector comprises a base body and a coating layer for coating the exterior of the base body; the material of the base body comprises one or more kinds of metal or metal alloy, carbon nanotubes and graphene, wherein the conductivity of the metal or metal alloy is higher than that of metallic titanium; and the material of the coating layer comprises one or more kinds of a non-metallic titanium compound, SnO<2> and a SnO<2> composite material. A composite material is adopted to form the current collector of the lead-acid storage battery disclosed by the invention; compared with the existing pure lead or lead alloy grid, the current collector has the advantages of low material apparent density, strong conductivity, high mechanical strength, corrosion resistance, high hydrogen evolution and oxygen evolution overpotential and the like; and in addition, the gravimetric specific energy, gravimetric specific power, cycle life, passivation resistance, electrolyte retention and the like of the lead-acid storage battery can be effectively improved.

Owner:杨春晓

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com