Current collector of lead-acid storage battery

A lead-acid battery and current collector technology, applied in battery electrodes, electrode carriers/current collectors, circuits, etc., can solve problems such as restricting the performance of lead-acid batteries, being less than ideal, limiting the application level and development space of lead-acid batteries, etc. The effect of material with low apparent density, strong electrical conductivity and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

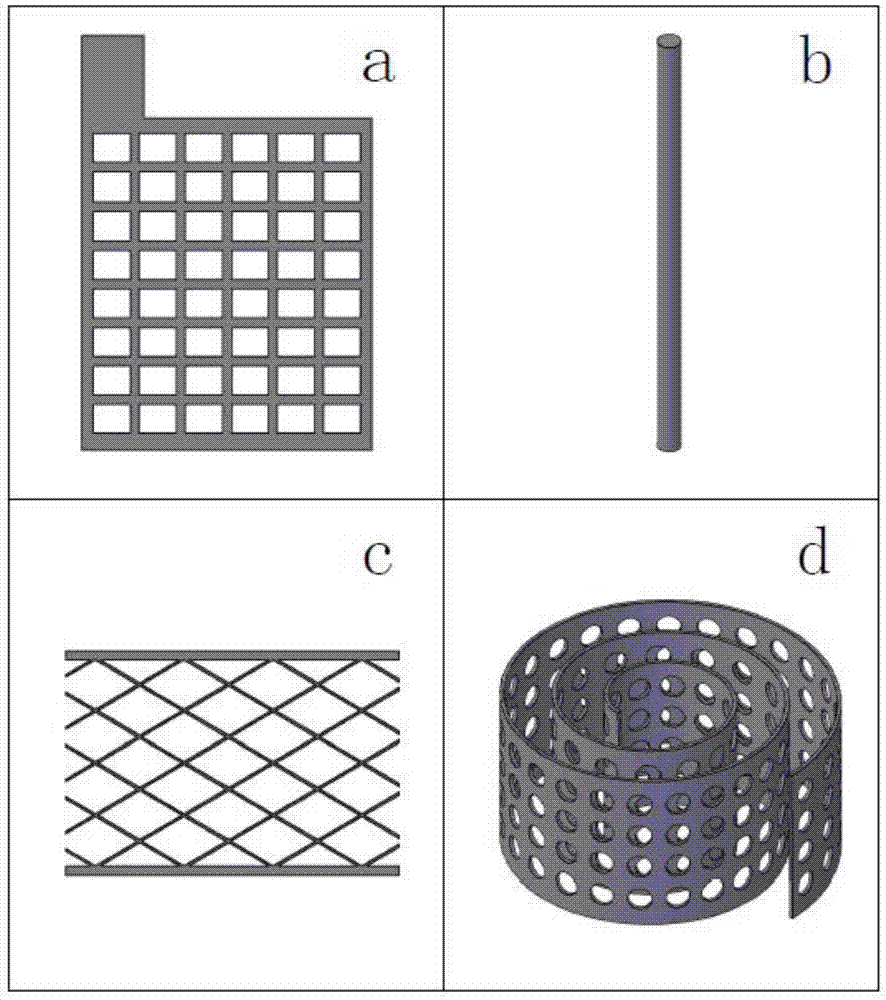

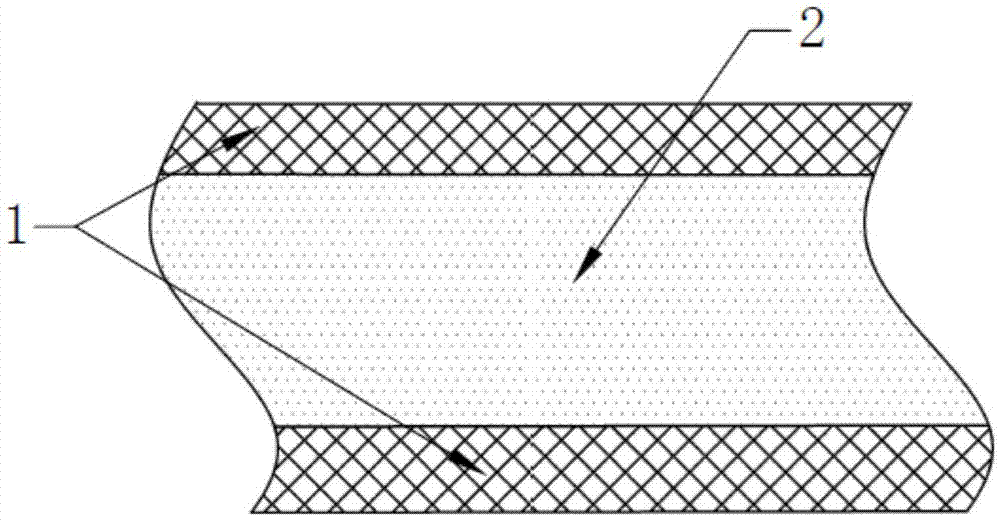

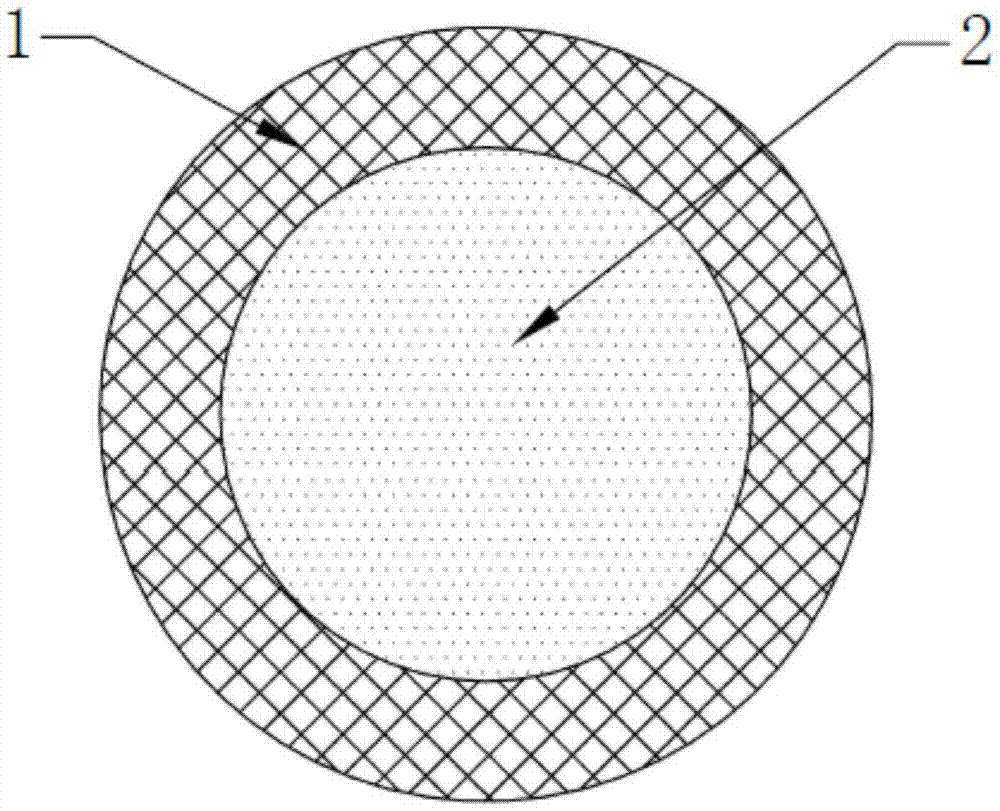

[0035] The current collector of this embodiment is TiO 2 / Al composite material current collector, the structure of the current collector and the composition of the composite material are as follows figure 1 a and figure 2 As shown, it is a flat grid structure, in which the thickness of the positive grid is 2 mm, and the thickness of the negative grid is 1.3 mm; the material is composed of an Al matrix and a cladding layer TiO wrapped around the Al matrix. 2 Composed of TiO 2 The thickness is 1nm.

[0036] Applying the composite current collector to the positive and negative electrodes of the lead-acid battery, compared with pure lead or lead alloy grid, can increase the specific power of the applied lead-acid battery by 20% to 61%, and increase the weight specific energy by 23%. ~40%, and the amount of gas evolution is reduced by 30%~52%.

Embodiment 2

[0038] The current collector of the present embodiment is ((TiO 2 -TiB 2 ) 99.9 -Sb 0.1 ) / Al composite current collector, the structure of the current collector and the composition of the composite material are as follows figure 1 c and figure 2 As shown, it is an expanded grid structure, the grid thickness is 2mm, and the material is composed of Al matrix and doped ((TiO 2 -TiB 2 ) 99.9 -Sb 0.1 ) cladding layer material composition. Among them, ((TiO 2 -TiB 2 ) 99.9 -Sb 0.1 ) The cladding layer material is composed of TiO doped with 0.1% mole ratio of Sb at the atomic cluster level 2 -TiB 2 Made of hybrid material with a thickness of 600nm.

[0039] Applying the composite current collector to the positive electrode of the lead-acid battery, compared with pure lead or lead alloy grid, can increase the weight-specific power of the applied lead-acid battery positive electrode by 37% to 82%, and increase the weight-specific energy by 27%. ~63%, the amount of gas e...

Embodiment 3

[0041] The current collector of the present embodiment is ((Ti 3 N 4 -SnO 2 ) 99.9 Sb 0.1 ) / Al composite current collector, the structure of the current collector and the composition of the composite material are as follows figure 1 d and figure 2 As shown, it is a coiled porous wall plate, the thickness of the wall plate is 1mm, the diameter of each round hole is 4mm, and the hole center distance is 6mm; its material is composed of Al matrix and ((Ti 3 N 4 -SnO 2 ) 99.9 Sb 0.1 ) cladding layer composition, wherein, the cladding layer ((Ti 3 N 4 -SnO 2 ) 99.9 Sb 0.1 ) material consists of Ti 3 N 4 -SnO 2 The hybrid material at the atomic cluster level is formed by doping 0.1% Sb in molar ratio, and the thickness is 50 μm.

[0042] Applying the composite material current collector to the positive electrode of the wound lead-acid battery, compared with pure lead or lead alloy grid, can increase the weight specific power of the applied lead-acid battery positive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com