Preparation process of golden magnetic sleeve and magnetic roller applying process

A preparation process, technology of magnetic sleeve, applied in the field of printing, can solve the problem that the magnetic sleeve cannot keep up with the rhythm of production, and achieve the effect of good effect, uniform surface, high wear resistance and high roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

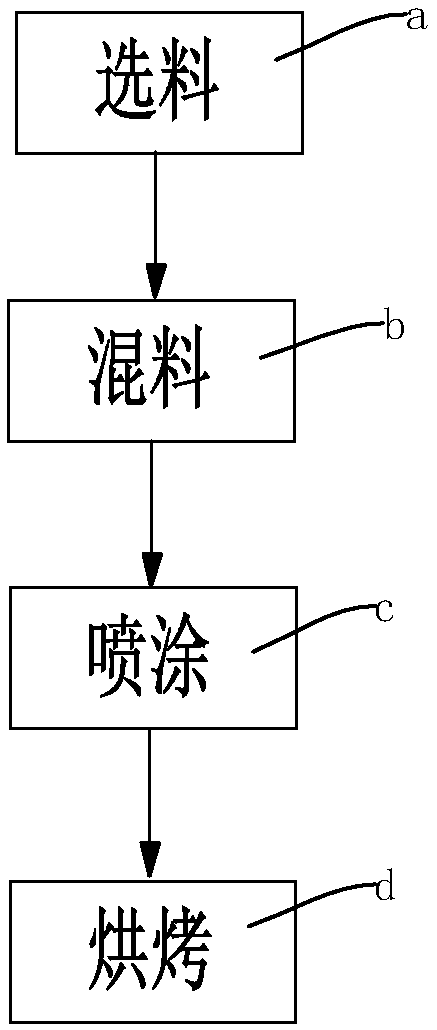

[0018] Such as figure 1 Shown, a kind of preparation technology of golden magnetic cover, its manufacture step comprises:

[0019] a, material selection, select a certain proportion of ethanol, xylene, ethylene glycol, phenolic resin, epoxy resin, epoxy curing agent, curing agent, dispersant, graphite, gold powder as the raw material for preparation, wherein the curing agent is p-hydroxybenzene Sulfonic acid;

[0020] b. Mixing, the preparation raw materials are mixed;

[0021] c, spraying, the mixture after the completion of mixing is sprayed on the inner hollow metal tube to make an embryo body;

[0022] d. Baking, putting the sprayed embryo body into an oven to bake and shape.

[0023] In step a, the ratio of the preparation raw materials by weight is 45 parts of ethanol, 30 parts of xylene, 5 parts of ethylene glycol, 30 parts of phenolic resin, 25 parts of epoxy resin, 10 parts of epoxy curing agent, curing agent 2 parts, 1 part of dispersant, 10 parts of graphite, 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com