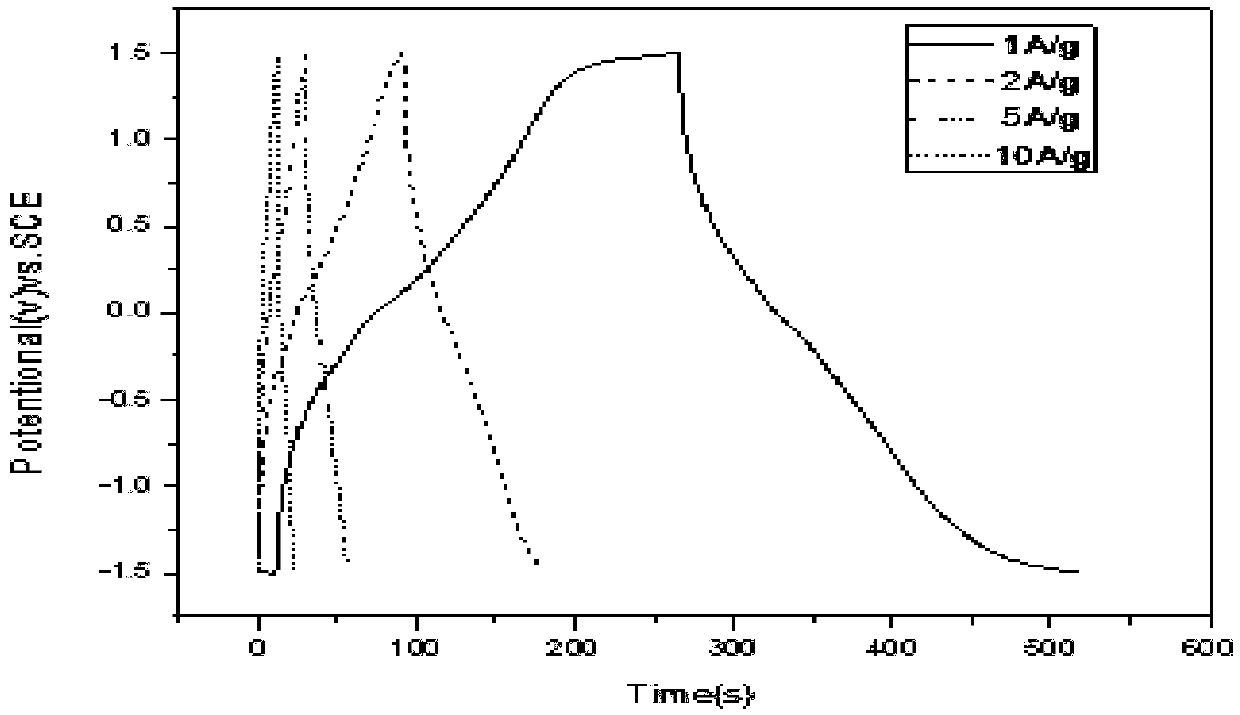

Preparation method of graphene polyaniline layered nano composite material for supercapacitor

A technology of nanocomposite materials and supercapacitors, which is applied in the manufacture of hybrid/electric double layer capacitors and electrodes of hybrid capacitors. The effect of little hindrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

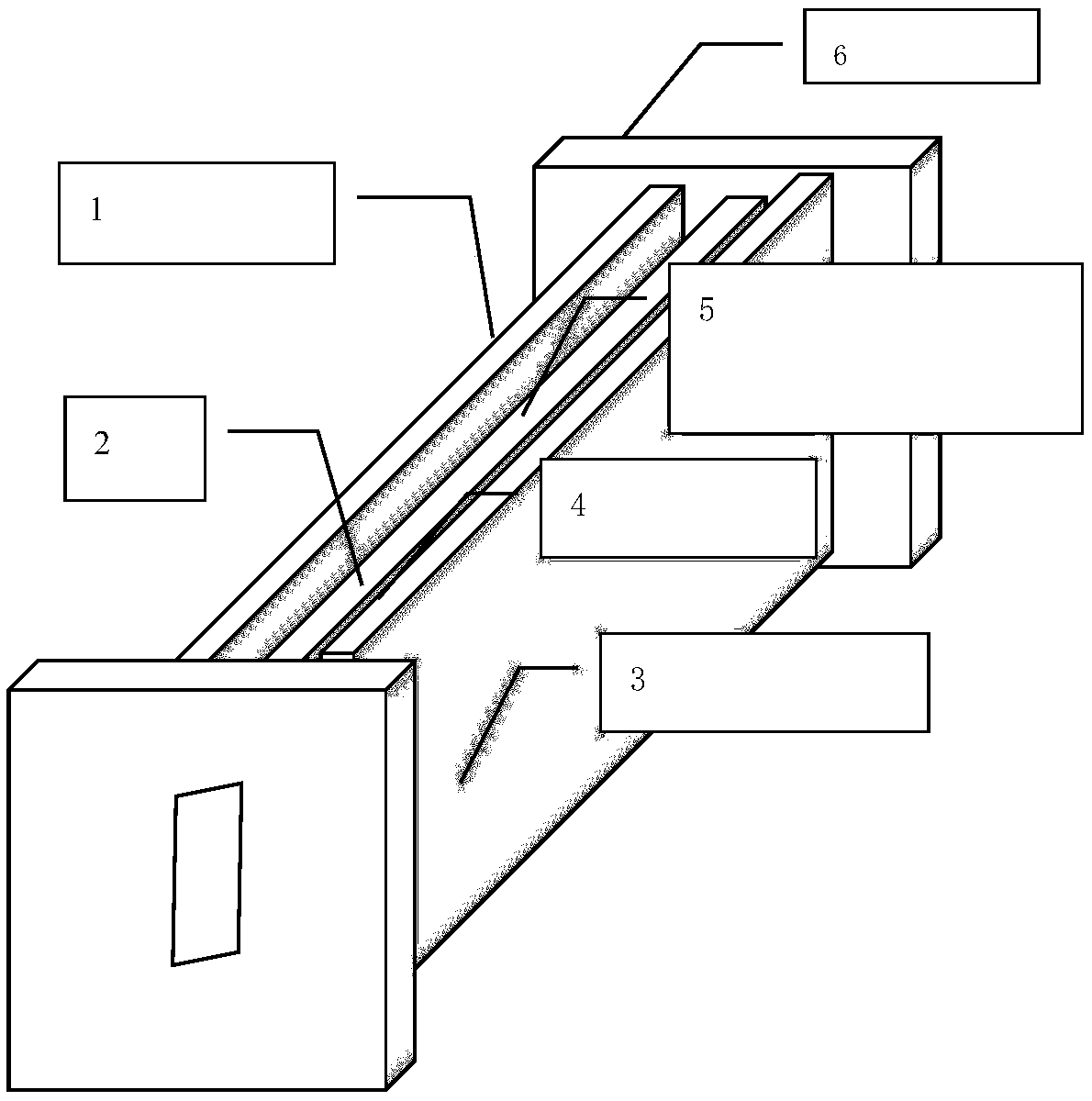

Image

Examples

Embodiment 1

[0073] Graphene oxide was prepared by Hummer oxidation method:

[0074] 1) Take 120mL concentration of 98% concentrated H 2 SO 4 Add to a 1L beaker, weigh 2g of P 2 o 5 And 5g of graphite powder added concentrated H 2 SO 4 , stir with a magnetic stirrer for 2.5h, set the temperature at 5°C;

[0075] 2) Add 13g of KMnO to the stirred solution 4 , add slowly to prevent the beaker from bursting due to excessive heat release, keep the temperature of the solution below 20°C, heat to 34°C, and keep it warm for 2 hours;

[0076] 3) Add 230 mL of deionized water, control the temperature at 98°C, and stir for 15 minutes;

[0077] 4) Add 0.7L of deionized water to terminate the reaction, meanwhile, add 13mL of H 2 o 2 ;

[0078] 5) Wash the obtained solution twice in a centrifuge with HCL prepared with a mass concentration of 20% hydrochloric acid and water at a volume ratio of 1:10, and then use deionized water to continue washing until the solution is neutral;

[0079]6) Po...

Embodiment 2

[0094] Graphene oxide prepared by Hummer oxidation method:

[0095] 1) Take 115 mL of 98% concentrated H 2 SO 4 Add it to a 1L beaker and weigh 3g of P 2 o 5 And 6g of graphite powder added concentrated H 2 SO 4 , stir with a magnetic stirrer for 3 hours, and set the temperature at 6°C;

[0096] 2) Add 10g of KMnO to the stirred solution 4 , add slowly to prevent the beaker from bursting due to excessive heat release, keep the temperature of the solution below 20°C, heat to 32°C, and keep it warm for 1.5h;

[0097] 3) Add 235 mL of deionized water, control the temperature at 96°C, and stir for 17 minutes;

[0098] 4) Add 0.7L deionized water to terminate the reaction, and at the same time, add 15mL of H 2 o 2 ;

[0099] 5) Wash the obtained solution twice in a centrifuge with HCL prepared with hydrochloric acid with a mass concentration of 20% to 36% and water at a volume ratio of 1:10, and then use deionized water to continue washing until the solution is neutral; ...

Embodiment 3

[0115] Graphene oxide was prepared by Hummer oxidation method:

[0116] 1) Take 115 mL of 98% concentrated H 2 SO 4 Add to a 1L beaker, weigh 2g of P 2 o 5 And 4g of graphite powder added concentrated H 2 SO 4 , stirred with a magnetic stirrer for 2 hours, and set the temperature at 4°C;

[0117] 2) Add 14g of KMnO to the stirred solution 4 , add slowly to prevent the beaker from bursting due to excessive heat release, keep the temperature of the solution below 20°C, heat to 34°C, and keep it warm for 2.5h;

[0118] 3) Add 225 mL of deionized water, control the temperature at 96°C, and stir for 12 minutes;

[0119] 4) Add 0.5L of deionized water to terminate the reaction, meanwhile, add 15mL of H 2 o 2 ;

[0120] 5) Wash the obtained solution twice in a centrifuge with HCL prepared with a mass concentration of 36% hydrochloric acid and water at a volume ratio of 1:10, and then use deionized water to continue washing until the solution is neutral;

[0121] 6) Pour th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com