Patents

Literature

1997 results about "Fluorhydric Acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrofluoric Acid: HF. Also known as: hydrogen fluoride, hydrofluoride, hydrogen monofluoride, fluorhydric acid. Although it is highly corrosive, hydrofluoric acid is considered a weak acid because it doesn't usually dissociate completely. The acid will eat glass and metals, so HF is stored in plastic containers.

Stabilization of li-ion battery anodes

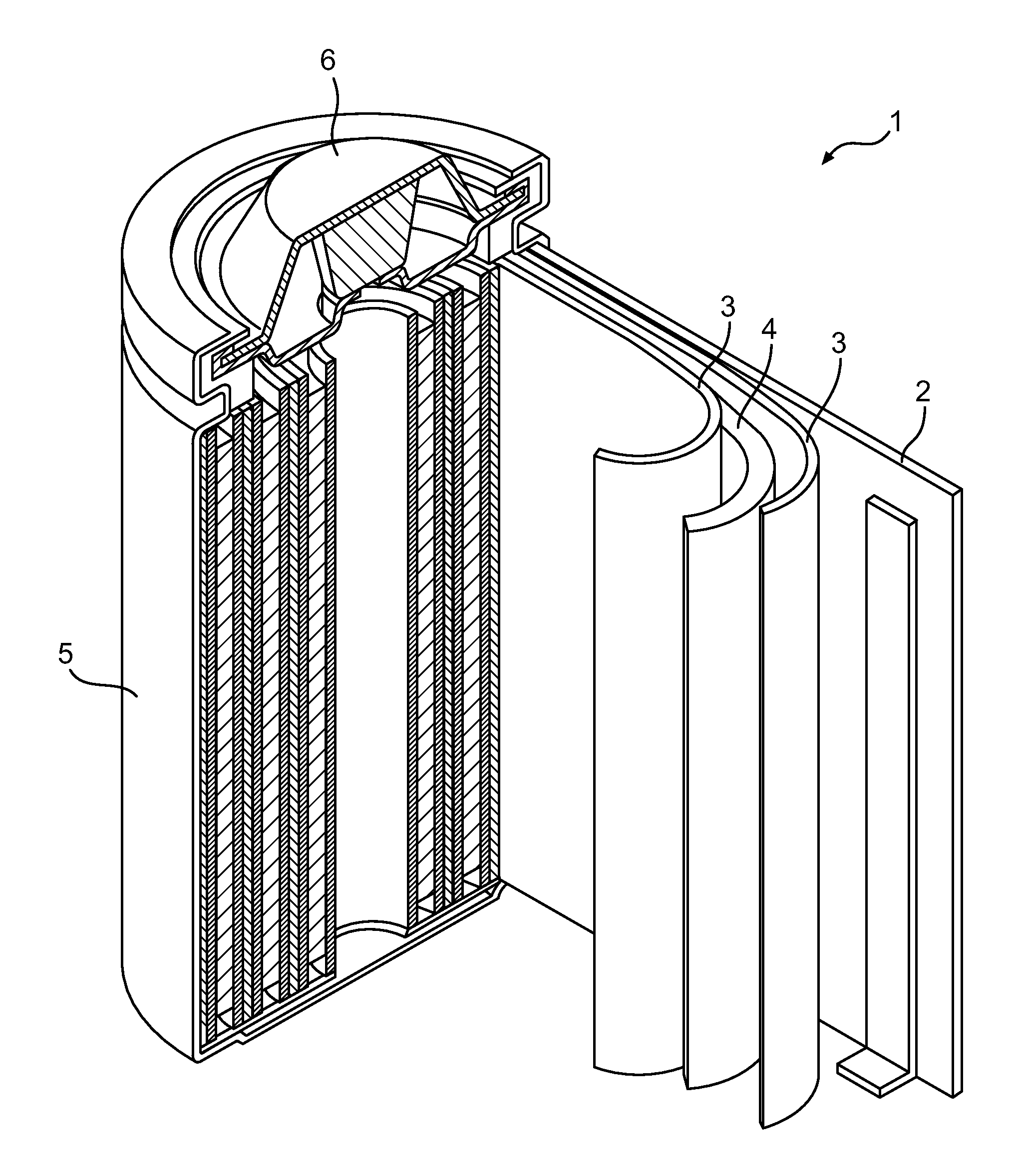

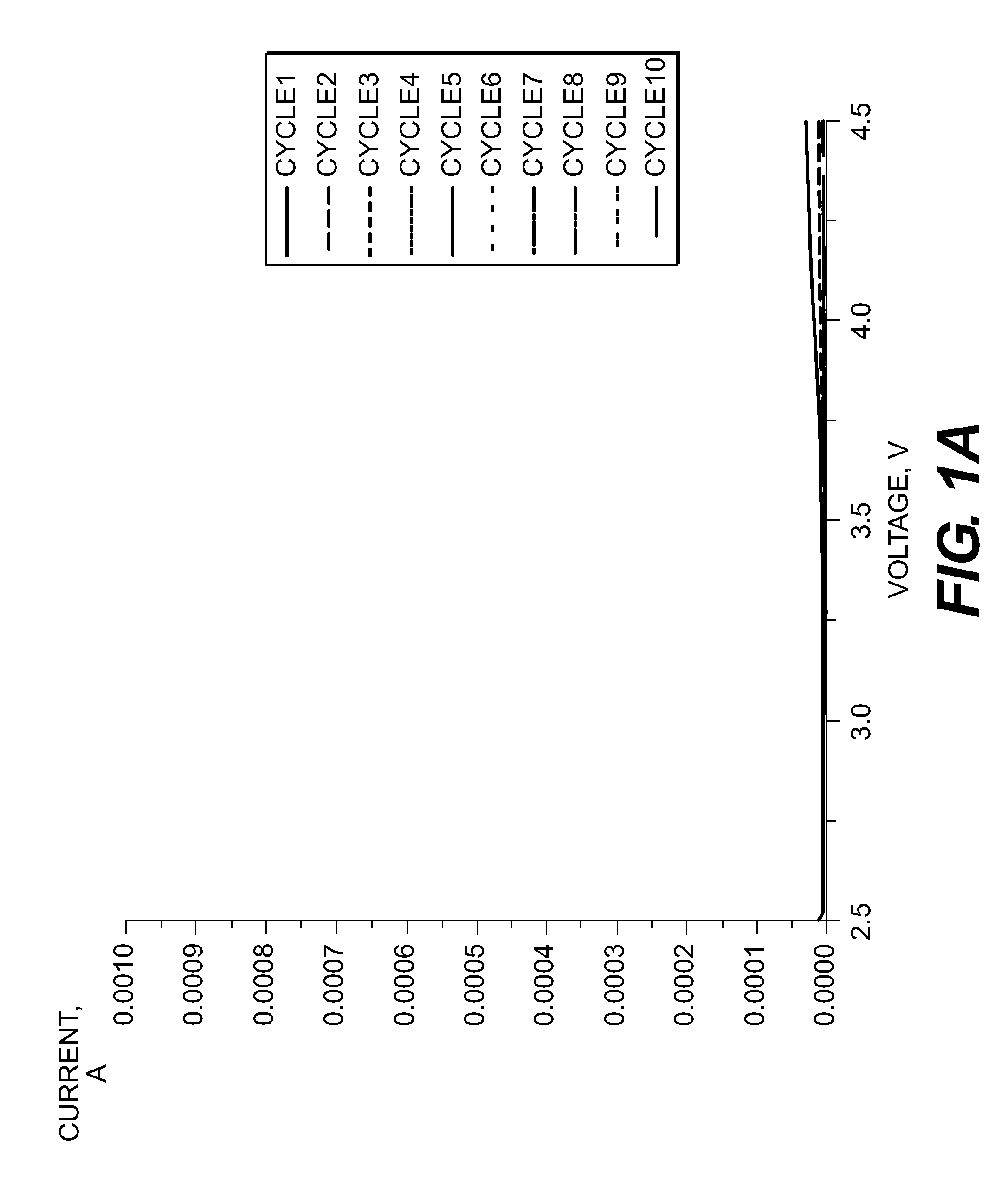

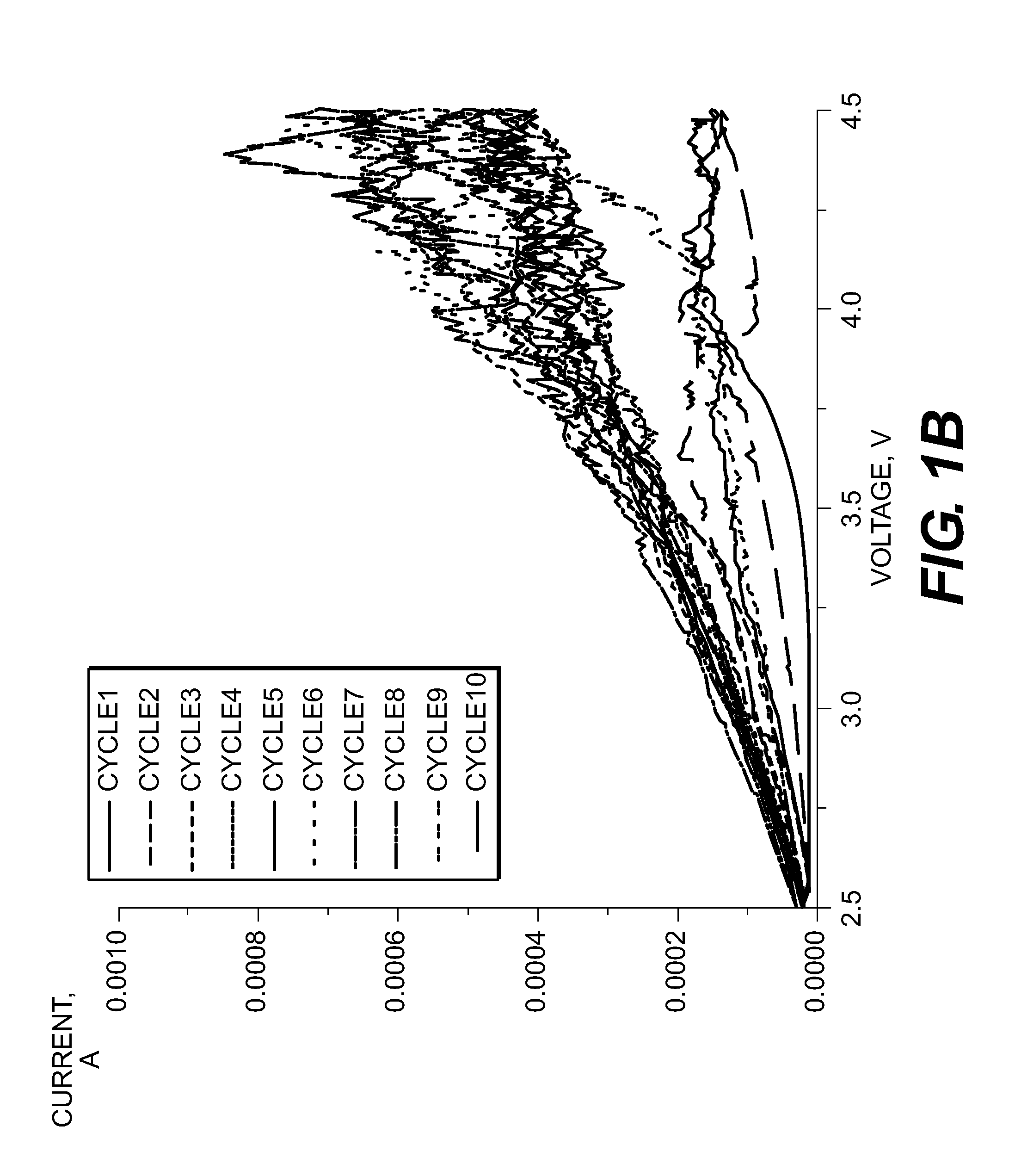

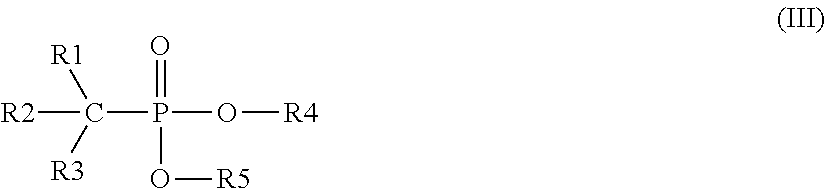

ActiveUS20120202112A1Active material electrodesNon-aqueous electrolyte accumulator electrodesIonElectrolyte

Li-ion batteries are provided that include a cathode, an anode comprising active particles, an electrolyte ionically coupling the anode and the cathode, a separator electrically separating the anode and the cathode, and at least one hydrofluoric acid neutralizing agent incorporated into the anode or the separator. Li-ion batteries are also provided that include a cathode, an anode comprising active particles, an electrolyte ionically coupling the anode and the cathode, and a separator electrically separating the anode and the cathode, where the electrolyte may be formed from a mixture of an imide salt and at least one salt selected from the group consisting of LiPF6, LiBF4, and LiClO4. Li-ion battery anodes are also provided that include an active material core and a protective coating at least partially encasing the active material core, where the protective coating comprises a material that is resistant to hydrofluoric acid permeation.

Owner:GEORGIA TECH RES CORP +1

Electrothermal film and manufacturing method thereof

ActiveCN101668359ASimple processEfficient processHeating element materialsResistors adapted for applying terminalsTitanium chlorideMetallurgy

The invention relates to an electrothermal film and a manufacturing method thereof, belonging to the technical field of semiconductor heating. The electrothermal film is mainly prepared by adopting stannic chloride, titanium tetrachloride, stannic chloride, titanium trichloride, ferric chloride, antimony trichloride, calcium chloride, potassium chloride, cadmium chloride, stannic dioxide, stannictetroxide, hydrofluoric acid, boric acid, ethanol, isopropyl alcohol and inorganic water. By adopting the above formula, the mixture is mixed, stirred and heated to prepare into electrothermal film treating fluid, a semi-finished product of the electrothermal film is obtained by spraying the electrothermal film treating fluid at negative pressure on the electrothermal film carrier, and then silveroxide slurry is coated on the semi-finished product of the electrothermal film for baking to form a finished product of the electrothermal film. The electrothermal film has reasonable proportion andsimple manufacturing process, can be manufactured into various electrothermal film heating devices, has a working temperature capable of being up to 500 DEG C, and has wider application range. The electrothermal film of the invention also has the function of far infrared radiation, can play a role of physical therapy and health care to human body, and can help improve the quality and output of agricultural products.

Owner:GUANGDONG HALLSMART INTELLIGENCE TECH CORP LTD

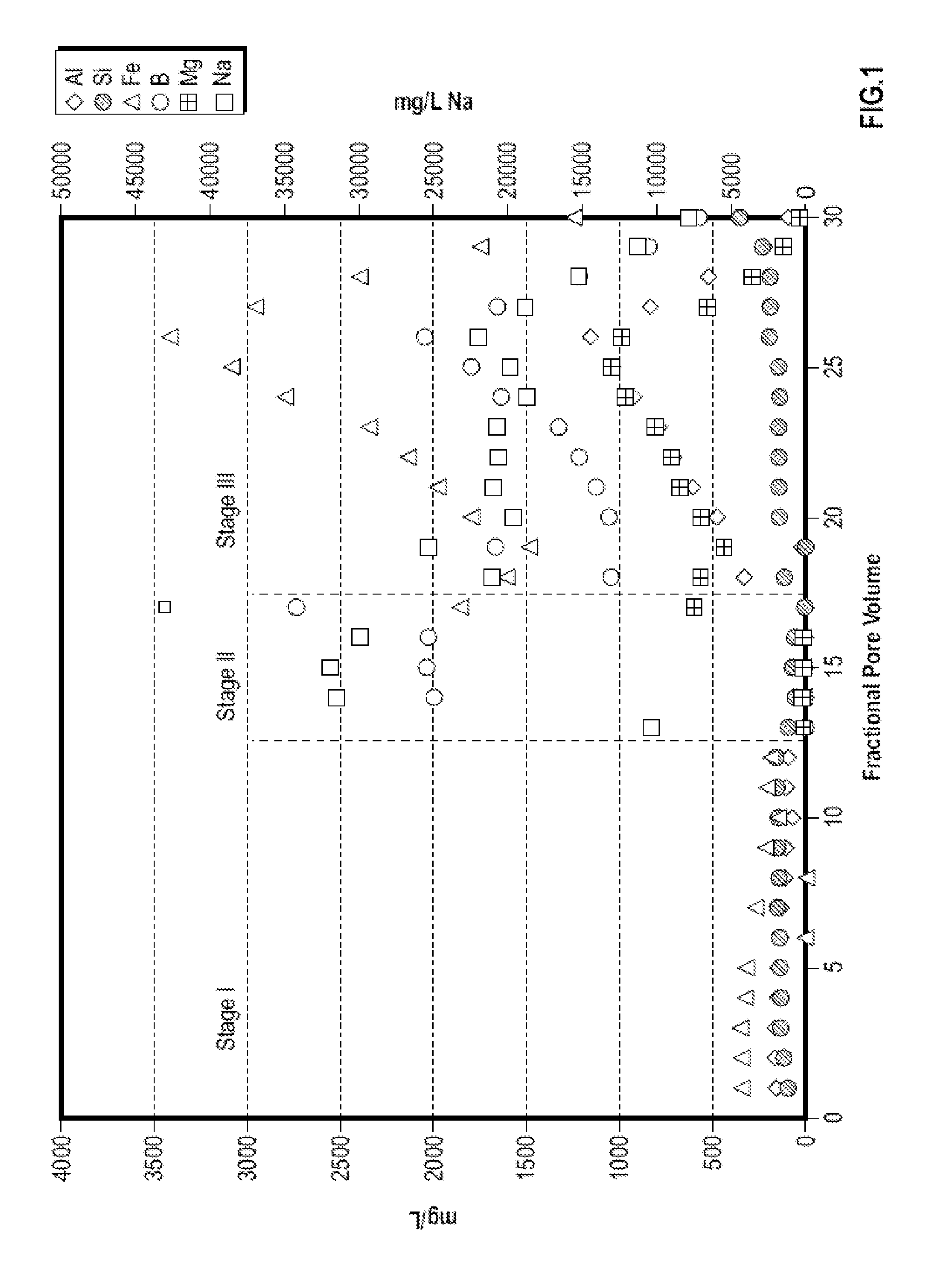

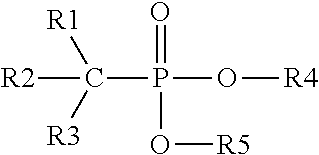

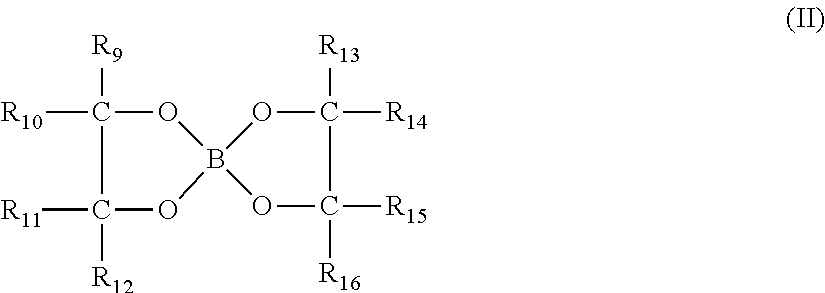

Treatment fluids containing a boron trifluoride complex and methods for use thereof

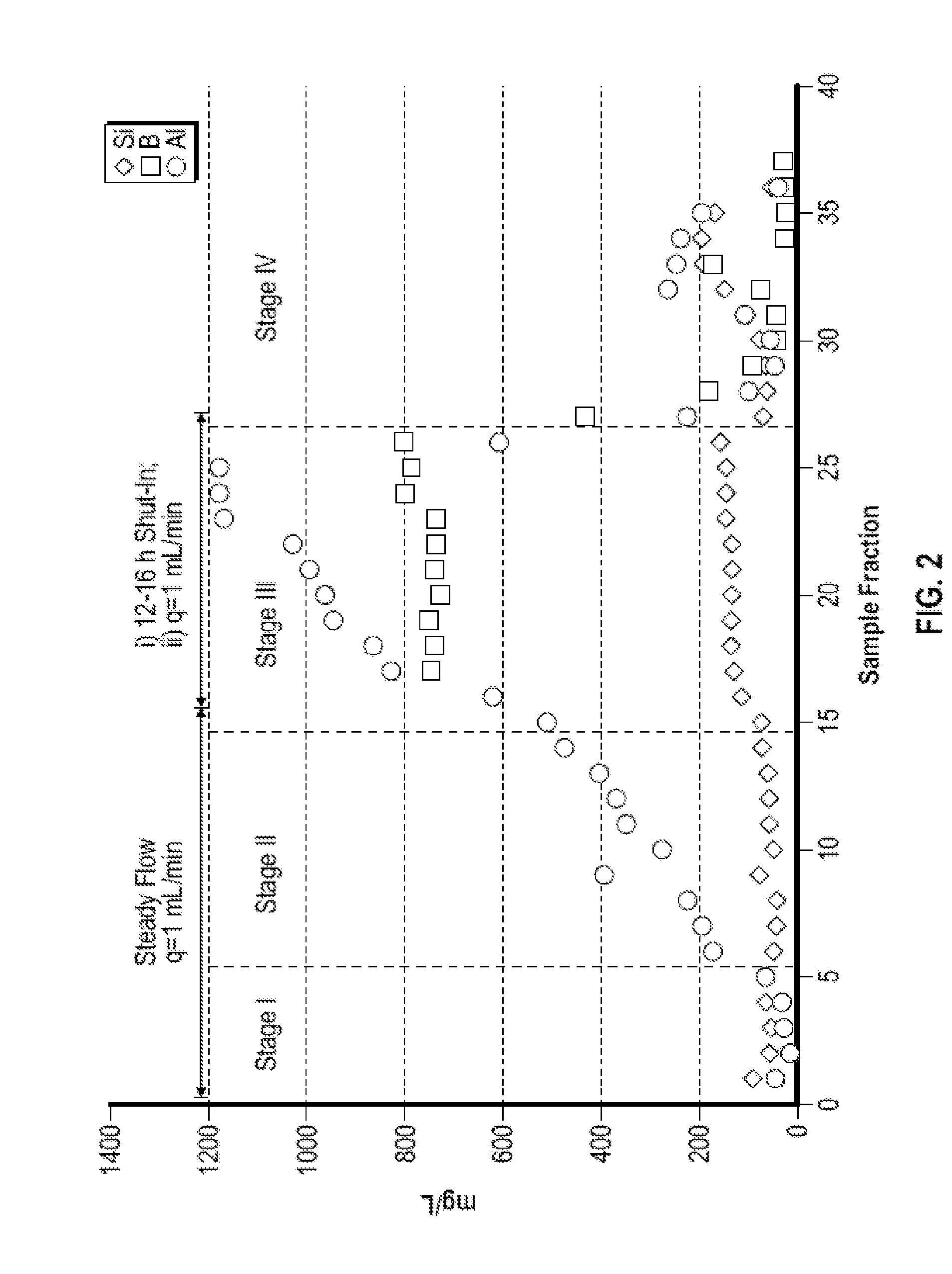

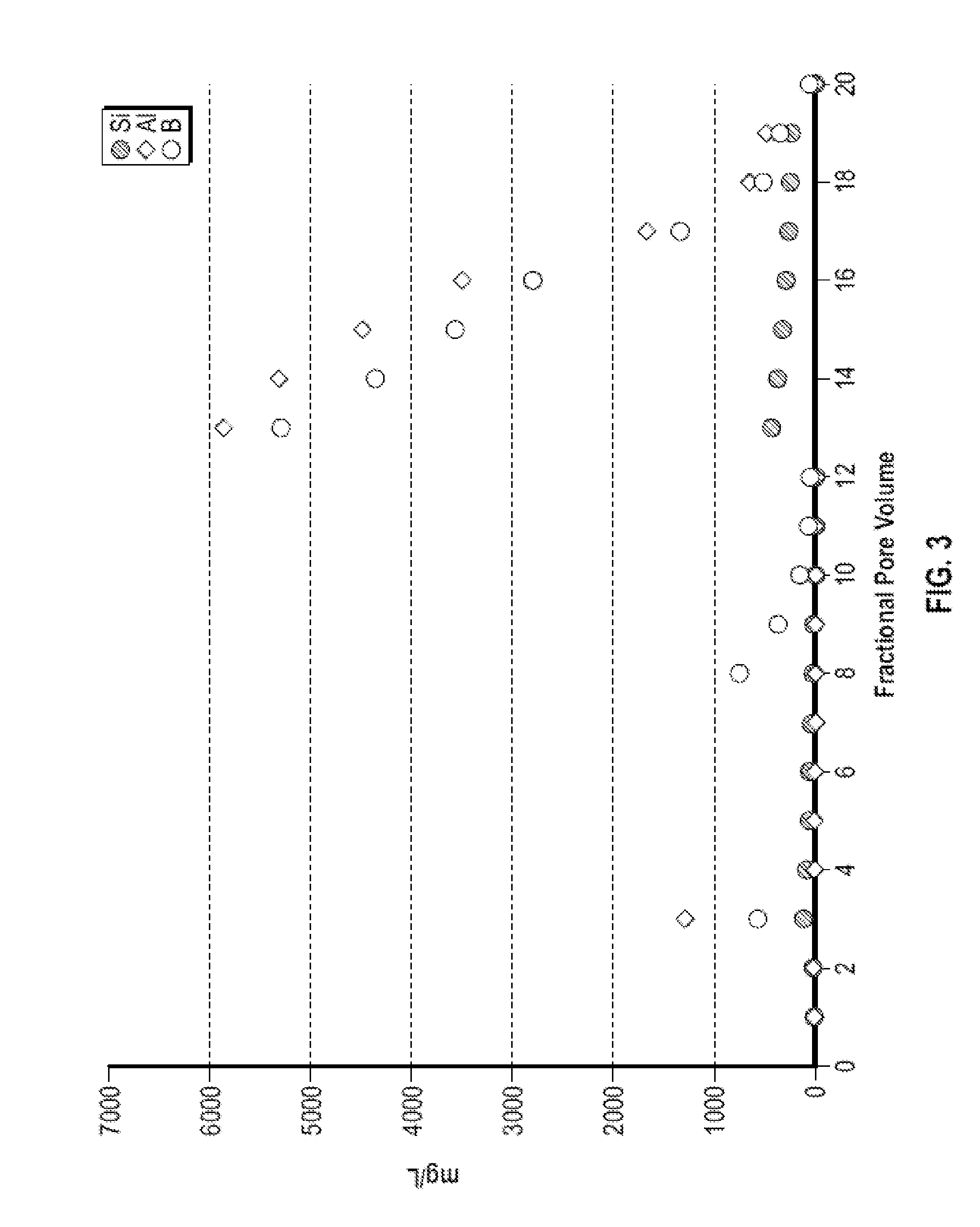

Treatment fluids for use in subterranean formations, particularly sandstone and other siliceous formations, may contain a source of fluoride ions to aid in mineral dissolution. In some cases, it may be desirable to generate the fluoride ions from a fluoride ion precursor, particularly a hydrofluoric acid precursor, such as a boron trifluoride complex. Methods described herein can comprise providing a treatment fluid that comprises an aqueous base fluid, a boron trifluoride complex, and a chelating agent composition, and introducing the treatment fluid into a subterranean formation,

Owner:HALLIBURTON ENERGY SERVICES INC

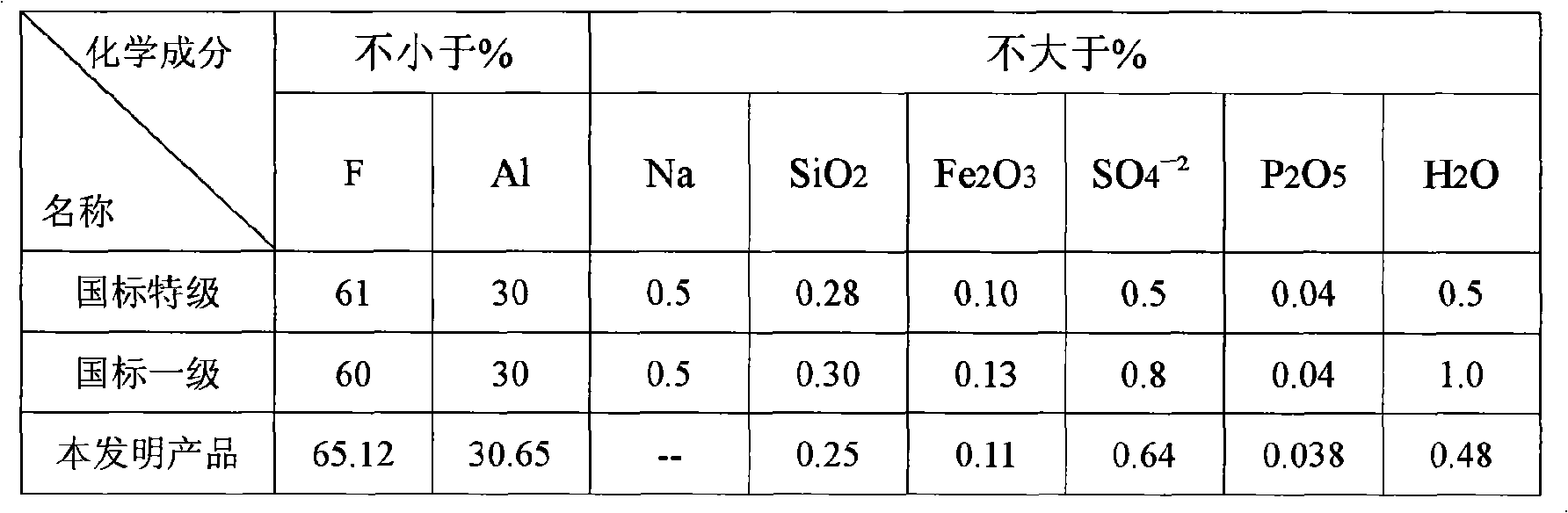

Method for producing fluorine series compounds and white carbon black

The invention relates to a method utilizing waste gas containing fluoride in fertilizer production or fluorine-containing gas or sodium fluorosilicate in fluorine chemical production as raw materials to product series compounds of fluorine and white carbon black. The ammonium fluoride and / or ammonia are / is introduced into an absorption system to get a (NH4) 2SiF6 solution with the absorbing solution concentration of 25 to 37 percent or the ammonium fluoride and the sodium fluorosilicate react to get a reaction product of sodium fluoride crystallization, fluosilicic acid solution and septenary-fluorine compound NH4F.(NH4)2SiF6 crystallization. The absorption liquid or the reaction product is aminated to get precipitated silica (white carbon black) with the specific surface of 100-180m<2> / g, and the latter can get a sodium fluoride product and an NH4F solution with the concentration of 30 to 45 percent. The solution used as a starting point can nearly prepare all inorganic fluoride chemical products, and ammonium fluoride, sodium fluoride, potassium fluoride, ammonium bifluoride, cryolite, aluminum fluoride, sodium hydrogen diffluoride and hydrofluoric acid production, etc. are main. The method has simplicity, effectiveness and higher economic benefit, and simultaneously, fluorine and silicon in the waste gas containing fluoride of phosphate fertilizer for the pollution of environment can be basically eliminated, and basically no waste water, waste gas and waste residue are discharged.

Owner:夏克立

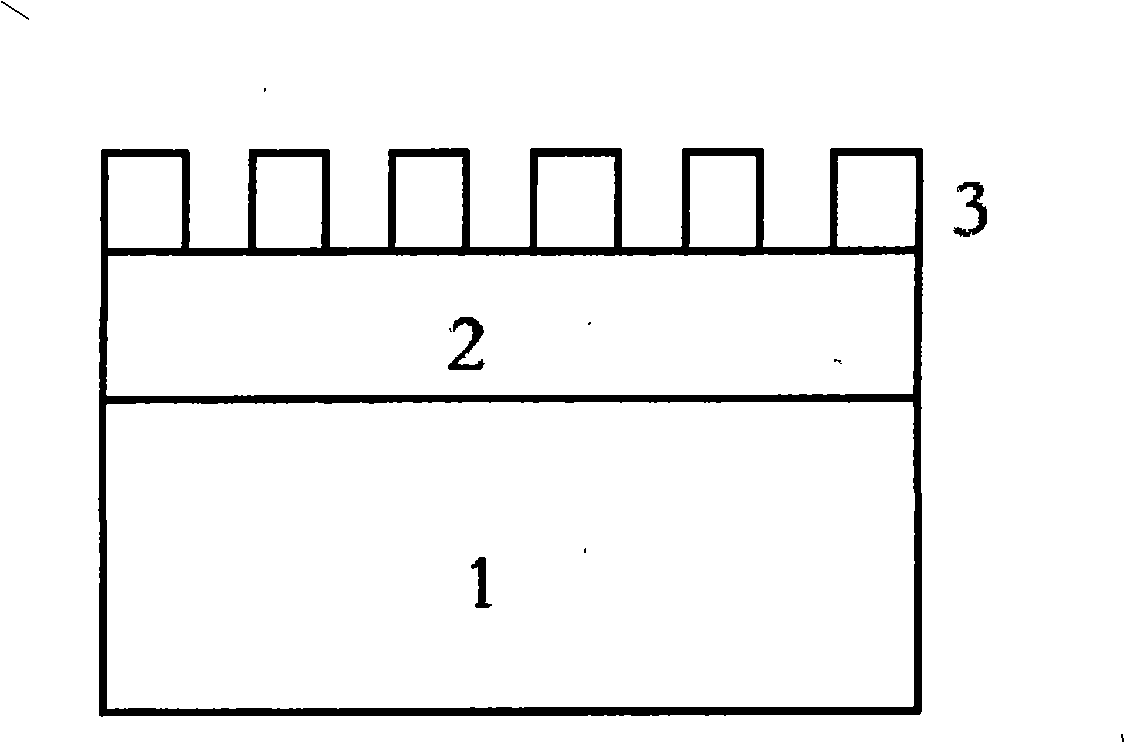

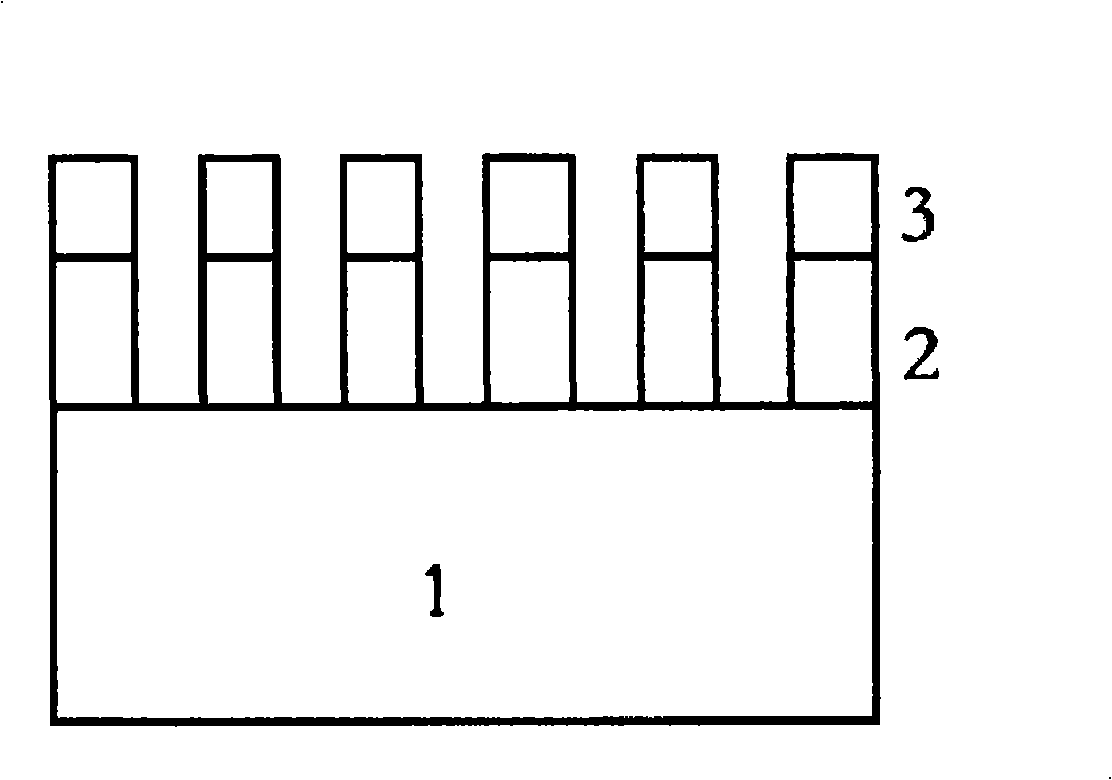

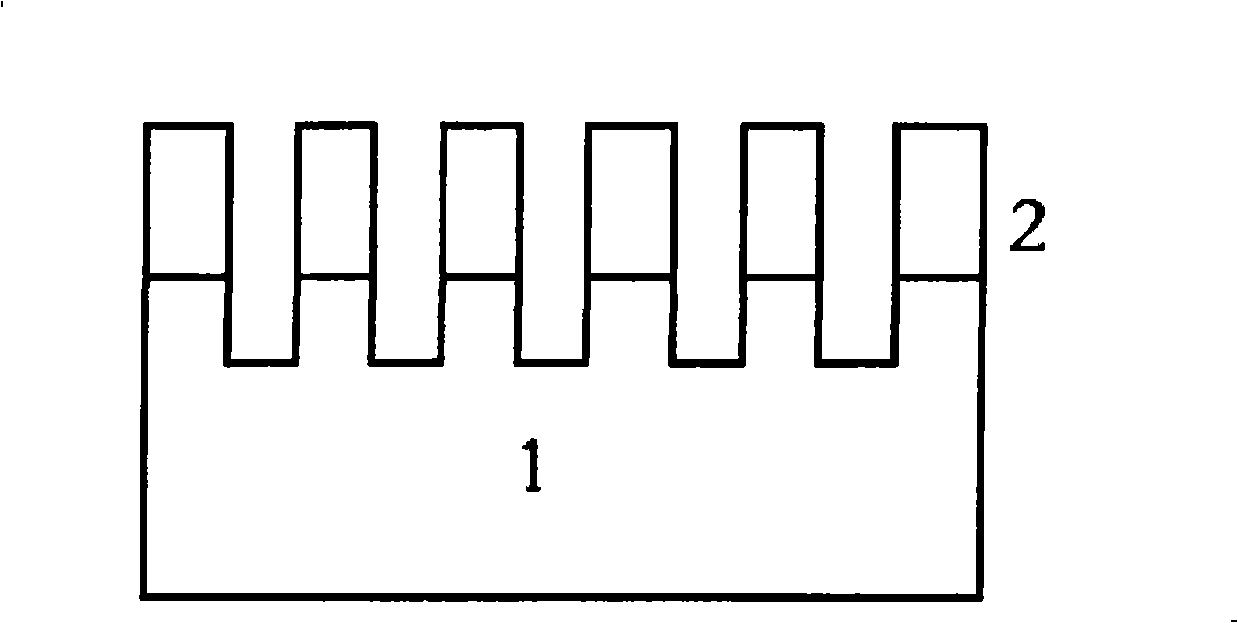

Method for preparing graphical sapphire substrate for nitrifier epitaxial growth

InactiveCN101330002AFree from dry etch damageLow costLaser detailsFinal product manufactureHydrofluoric acidPhosphoric acid

The invention discloses a production method of the patterned sapphire substrate for the nitride epitaxial growth, which comprises the following steps: a silica coating is deposited on the sapphire substrate used for the nitride epitaxial growth; a general photetch technology is utilized to prepare a mask of photetch patterns; the photetch patterns are etched on the silica coating by utilizing the doped liquid of hydrofluoric acid, ammonium fluoride and H2O; with the patterned silica coating as a mask, the sapphire substrate are etched by adopting the doped liquid of sulphuric acid and phosphoric acid in a wet manner so that the patterns are etched on the sapphire substrate; a dilute hydrofluoric acid solution is used for wet etching so as to remove the residual silica coating and clean the sapphire substrate, and then the preparation of the patterned sapphire substrate is completed. The production method has the advantages of low cost, preventing the sapphire substrate from being damaged by dry etching, etc. The patterned sapphire substrate can be used for the epitaxial growth of nitrides with low dislocation density and high crystal weight.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

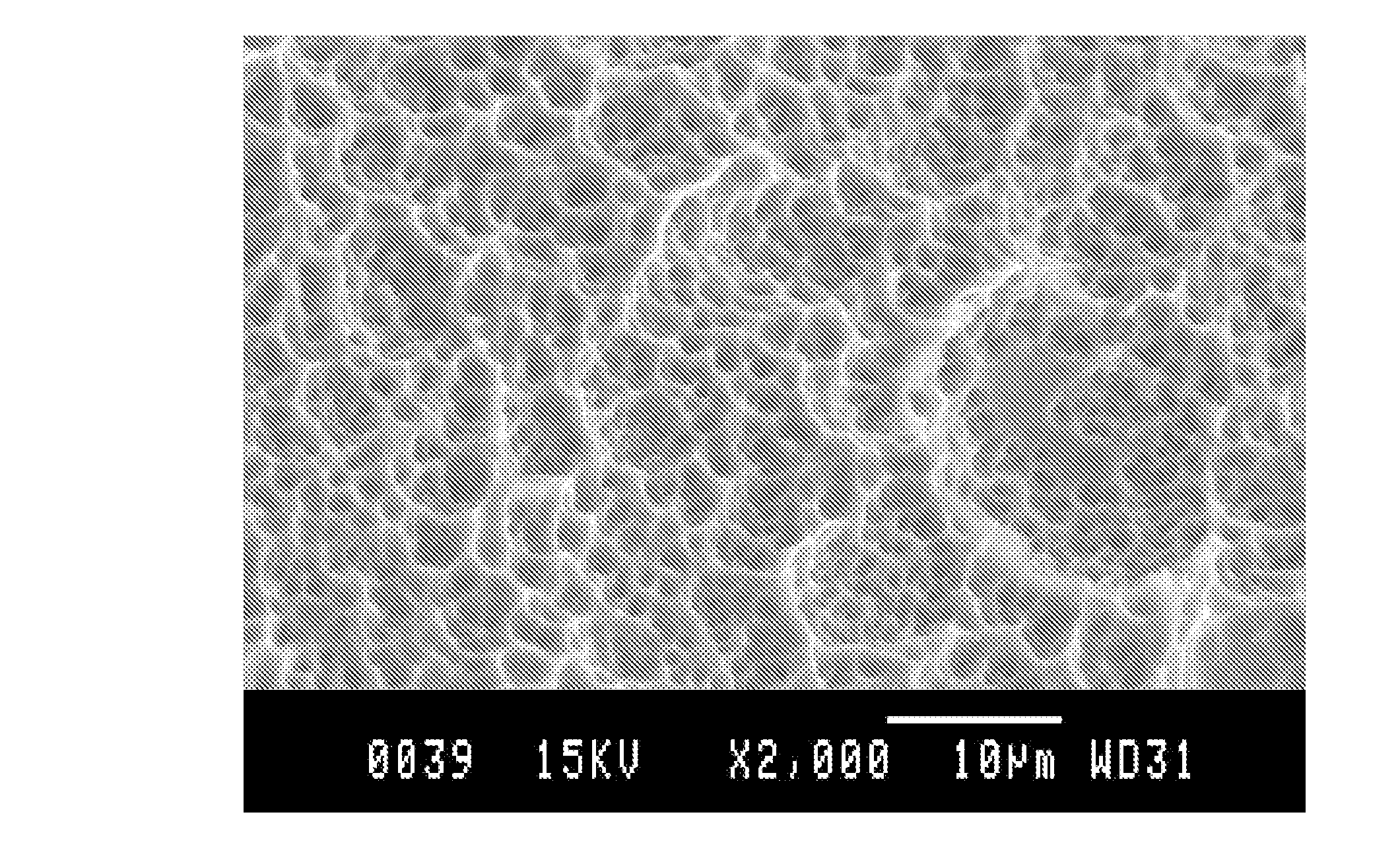

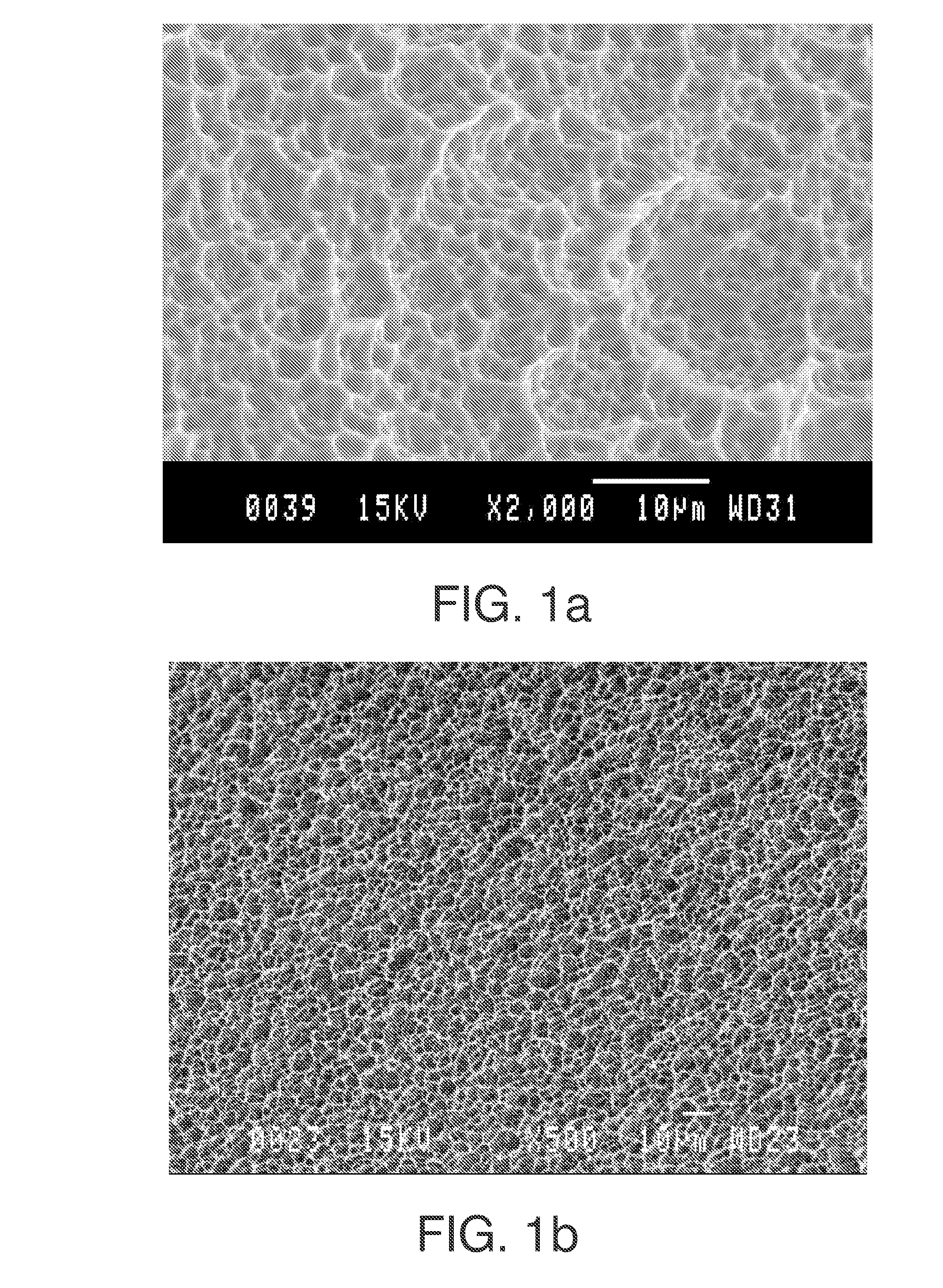

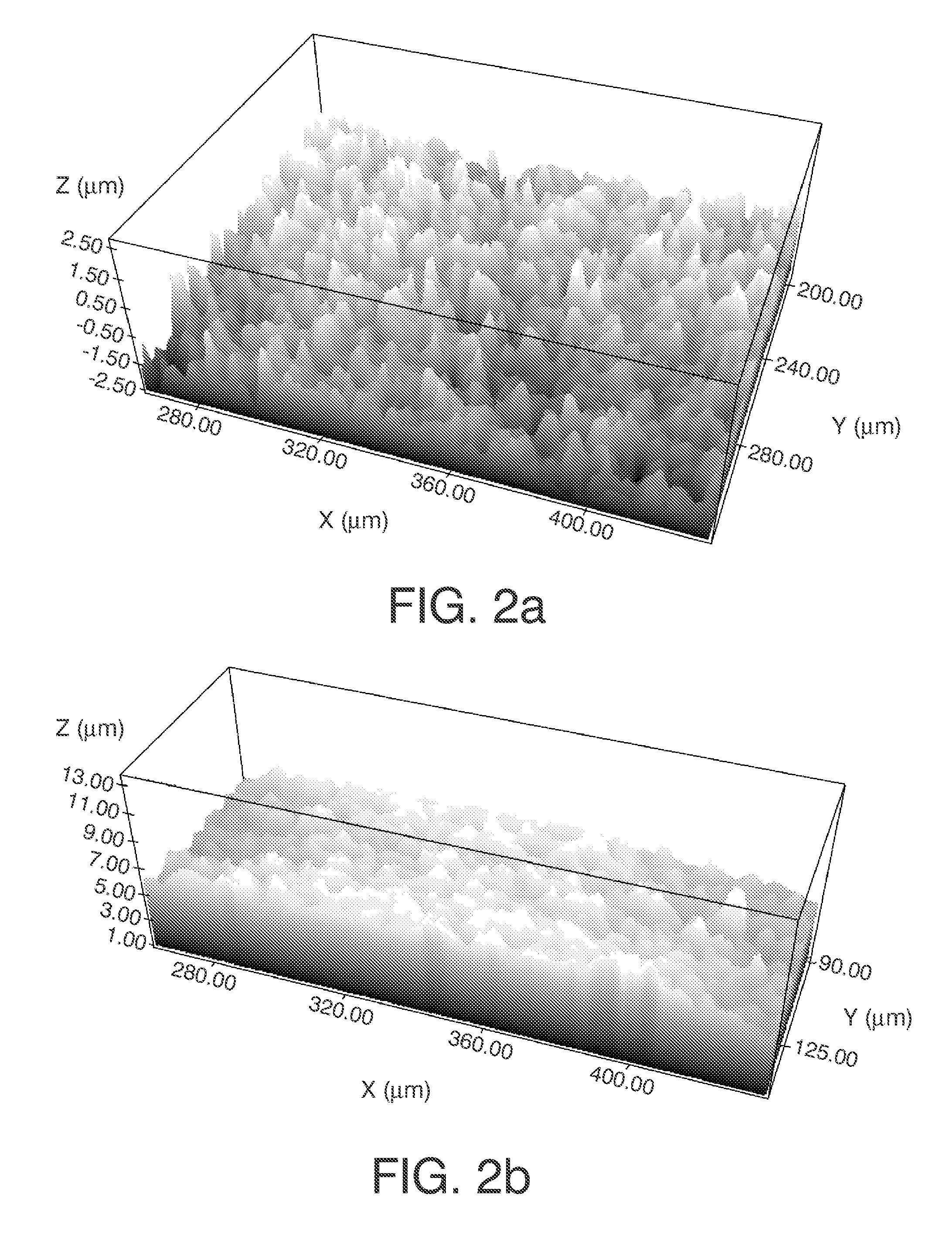

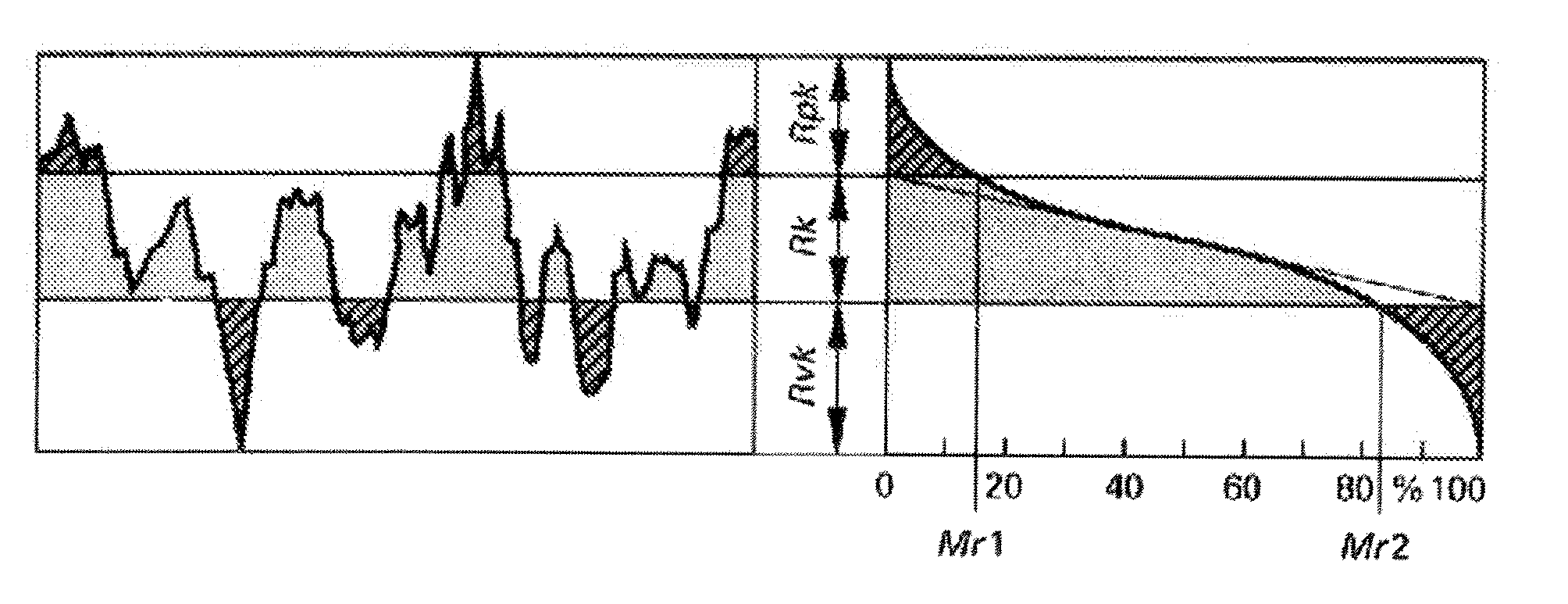

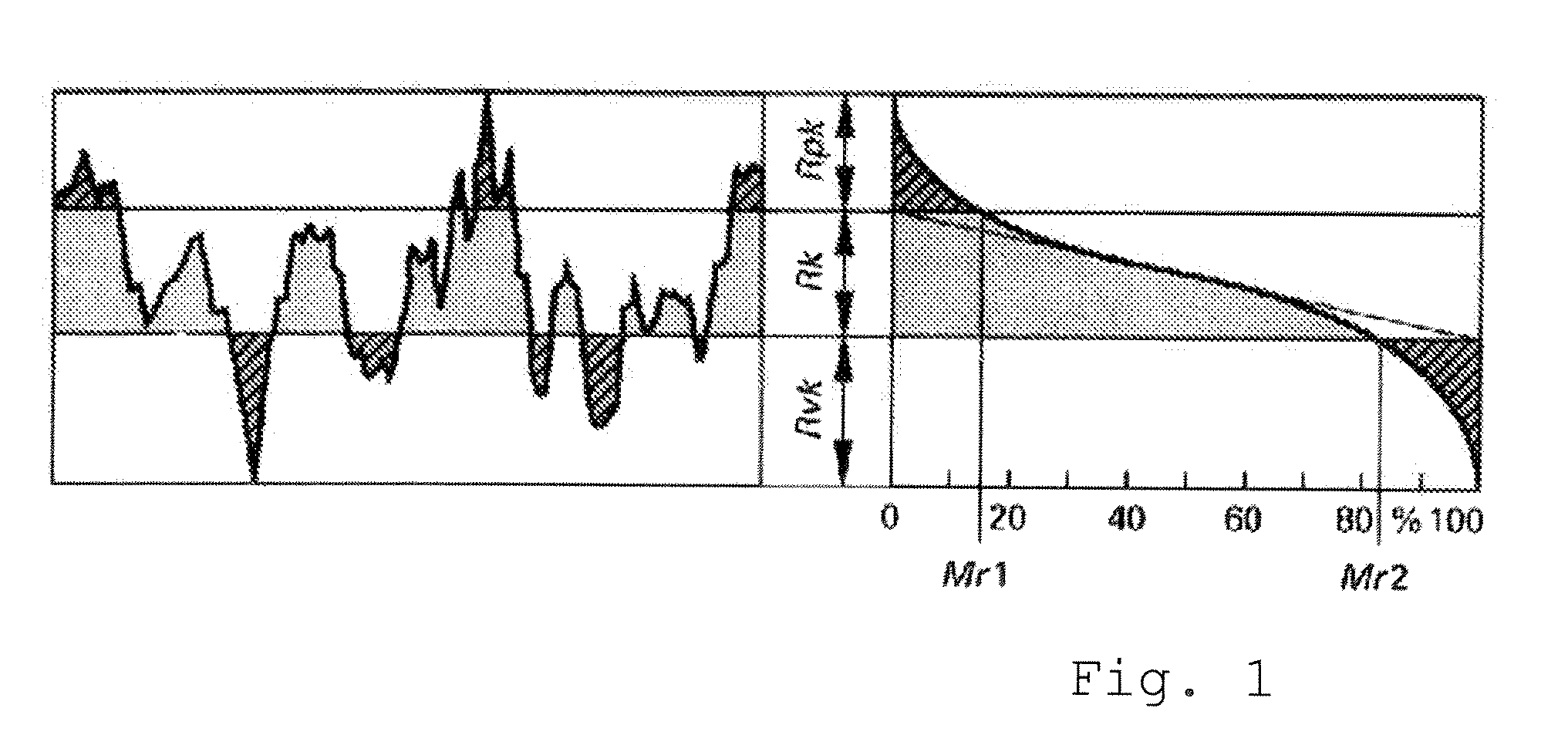

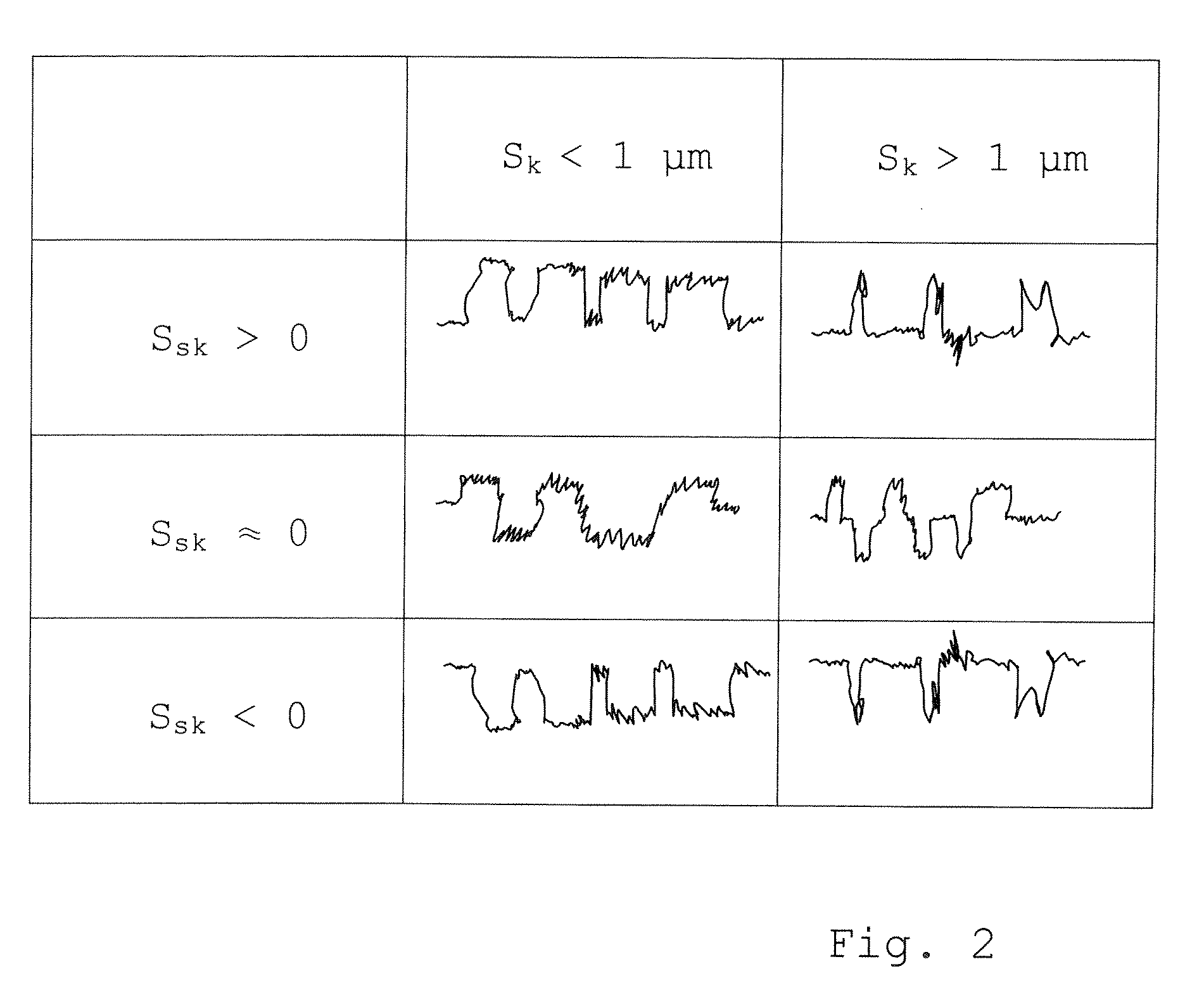

Method for obtaining a surface of titanium-based metal implant to be inserted into bone tissue

The invention relates to a method for obtaining a surface of a titanium-based metal implant intended to be inserted into bone tissue, comprising: (a) projecting particles of aluminium oxide under pressure on the external area of the implant; (b) chemically treating the sandblasted external area of the implant with an acid composition comprising sulfuric acid and hydrofluoric acid; and (c) thermally treating the sandblasted external area of the implant by heating at a temperature of 200-450° C. for 15-120 min. The invention likewise defines a metal implant having said surface. The surface thus obtained has good micrometer-scale roughness with a suitable morphology, as well as a composition which is virtually free of impurities and a thickness which is approximately three times the thickness of conventional surfaces, which characteristics provide it with very good osseointegration properties.

Owner:PHIBO DENTAL SOLUTIONS

Method for treating low-grade tungsten concentrate and tungsten slag

ActiveCN103614545AImprove resource utilization efficiencyAchieve selective separationMagnetic separationProcess efficiency improvementNiobiumSlag

The invention discloses a method for treating low-grade tungsten concentrate and tungsten slag. The method comprises the steps of mixing low-grade tungsten concentrate or tungsten slag and coal powder with a reduction roasting enhancer, and then performing reduction roasting; grinding the product obtained through the reduction roasting, then performing neutral leaching to obtain a tungstate solution and leaching residues, and performing magnetic separation on the leaching residues by adopting a magnetic field so as to obtain iron concentrate and valuable metal tailings; removing silicon from the valuable metal tailings by using dilute hydrochloric acid and leaching out manganese from the valuable metal tailings by using concentrated hydrochloric acid in sequence, and then leaching out tantalum and niobium by using hydrofluoric acid to prepare tantalum and niobium products. By adopting the method, valuable elements including tungsten, iron, copper, manganese, bismuth, cobalt, tantalum, niobium and the like which are difficult to extract in the low-grade tungsten concentrate and tungsten slag can be efficiently enriched, separated and recovered effectively, so that the resource comprehensive utilization of the valuable elements in the low-grade tungsten concentrate or tungsten slag is realized; moreover, the method is simple in equipment, short in flow, simple and convenient in operation, is economical and reliable, and is favorable for industrial production.

Owner:CENT SOUTH UNIV

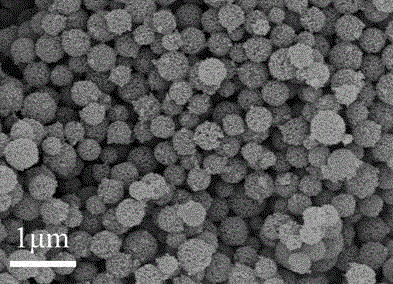

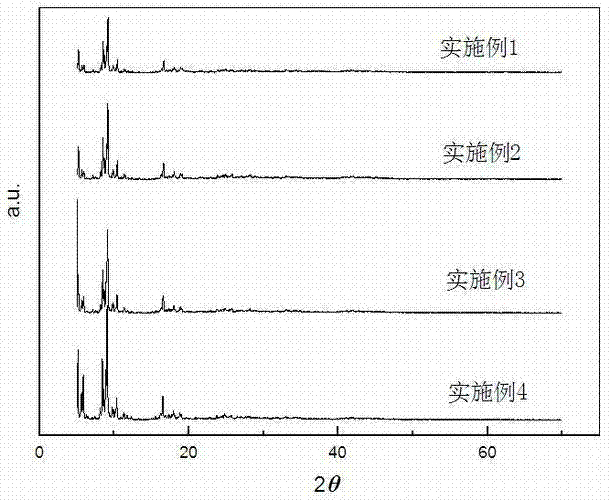

Preparation method and application of iron-nitrogen co-doped porous carbon sphere material

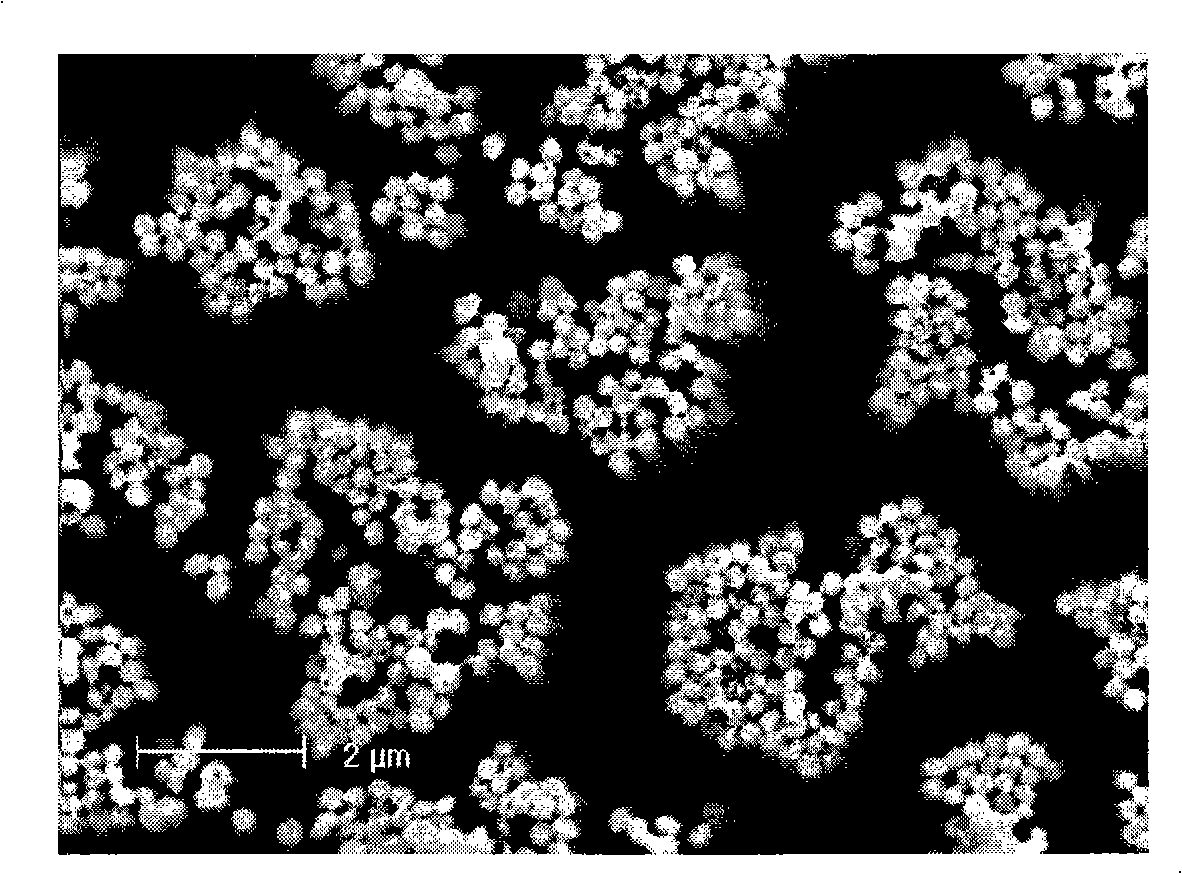

InactiveCN104624154ASimple processSave raw materialsPhysical/chemical process catalystsOther chemical processesPtru catalystPorous carbon

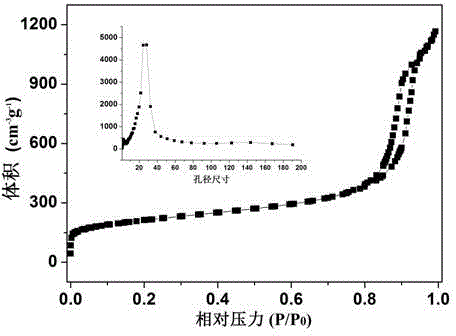

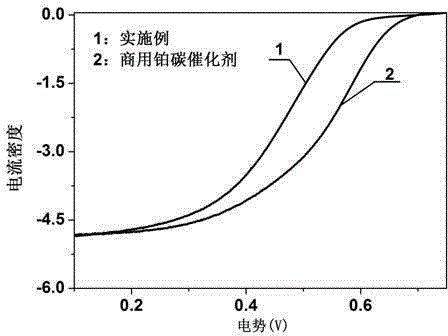

The invention discloses a preparation method for an iron-nitrogen co-doped porous carbon sphere material. The preparation method comprises the following steps: by taking 2-aminopyridine as a monomer and taking ammonium persulfate and ferric chloride as oxidants, performing in-situ polymerization reaction in a duct of a porous silicon dioxide template to obtain a precursor; performing high-temperature carbonization treatment on the precursor in a tubular furnace and an inert gas nitrogen-gas environment; and removing the silicon dioxide template by hydrofluoric acid to obtain the iron-nitrogen co-doped porous carbon sphere material which is taken as an electric catalyst to achieve good catalytic effect in oxygen gas reduction reaction. The preparation method has the advantages that the process is simple and easy to perform and the raw materials are cheap. The prepared carbon material contains a three-dimensional communicated pore structure, has a high specific surface area and a large pore volume, can effectively improve the electric catalytic activity through the heteroatom nitrogen-iron doping, has relatively high electric catalytic efficiency while being applied as a low-price electric catalyst, and has an important value and significance in the fields of doped type porous carbon material preparation and proton membrane fuel battery electric catalysis.

Owner:NANKAI UNIV

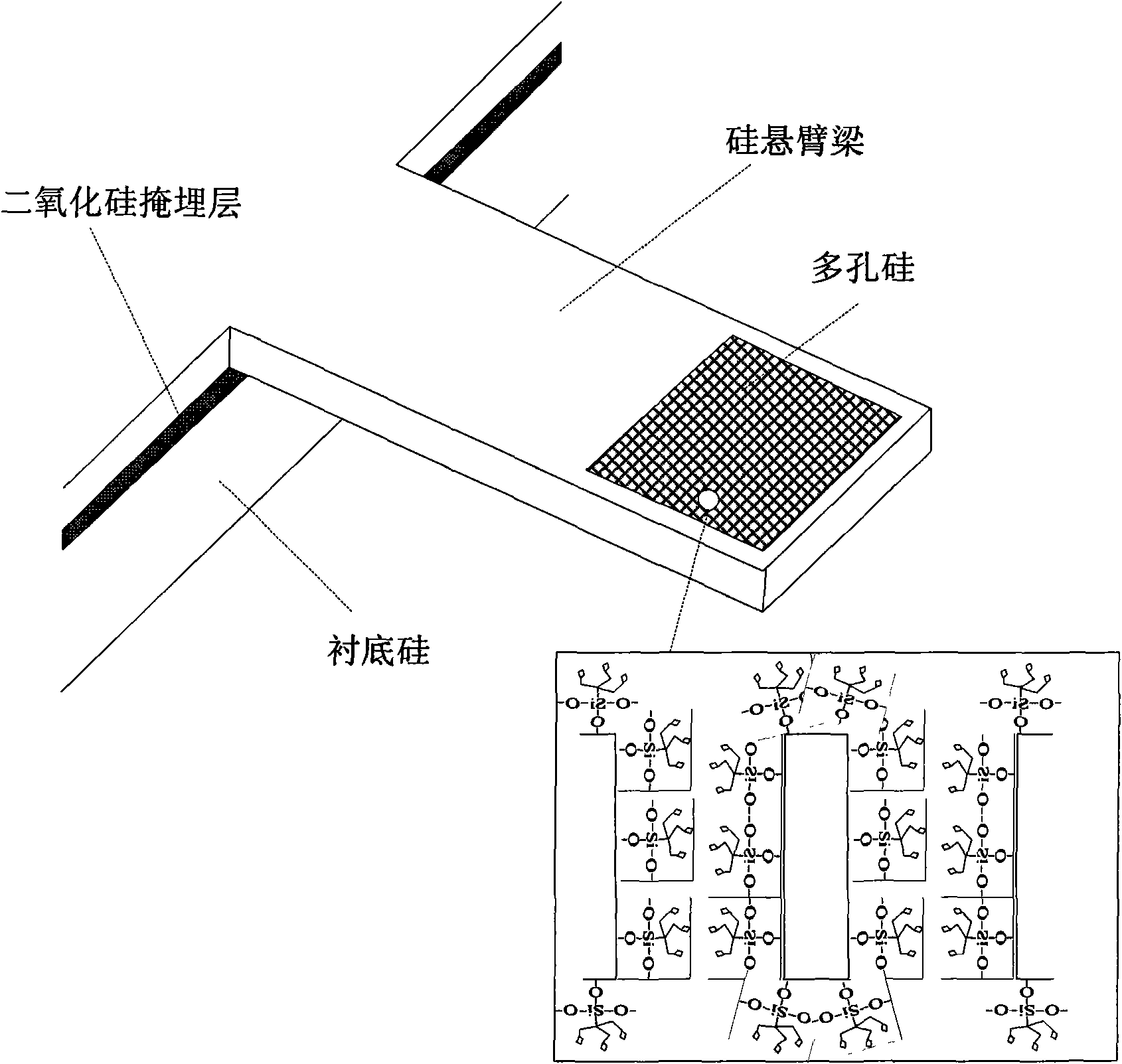

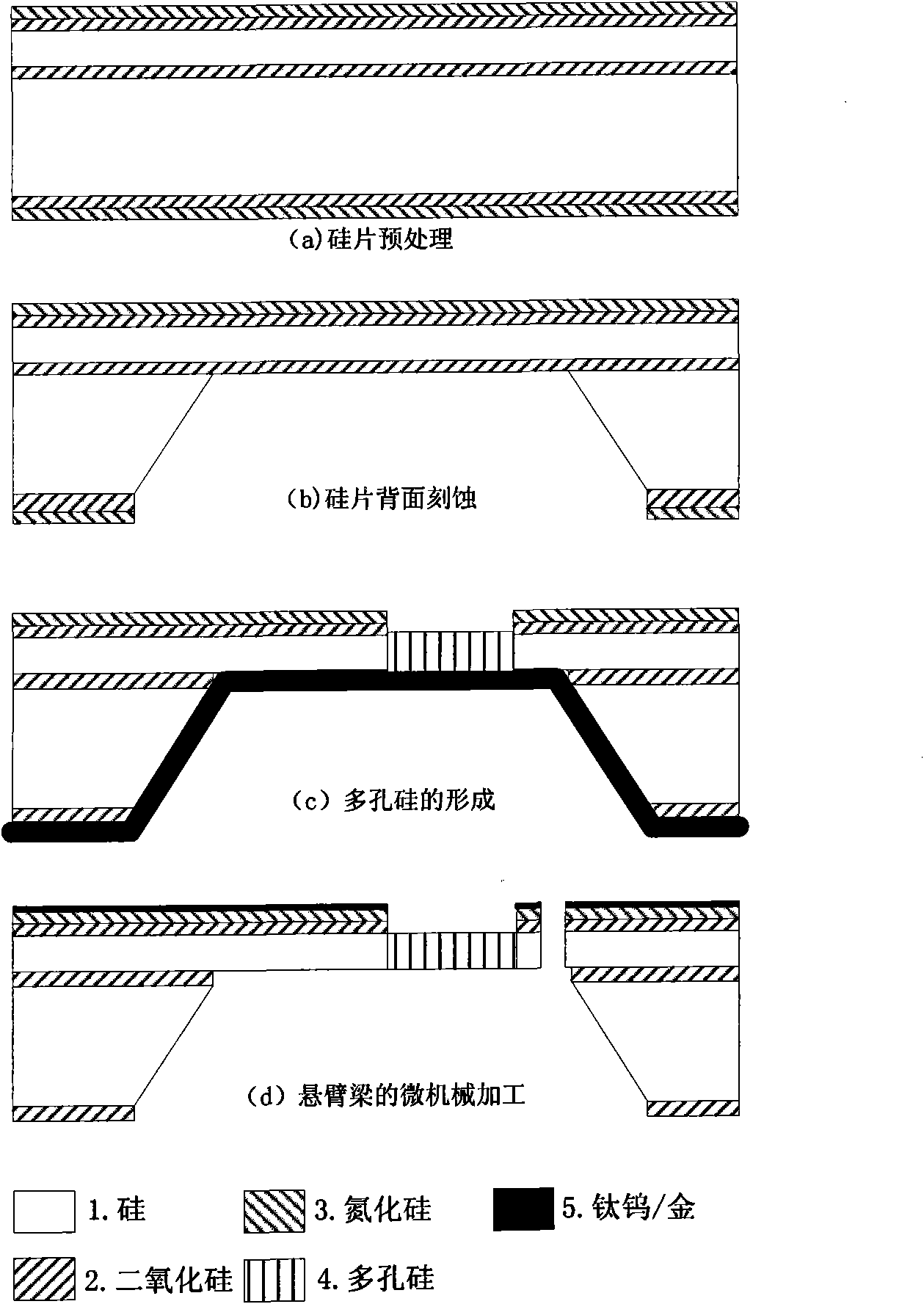

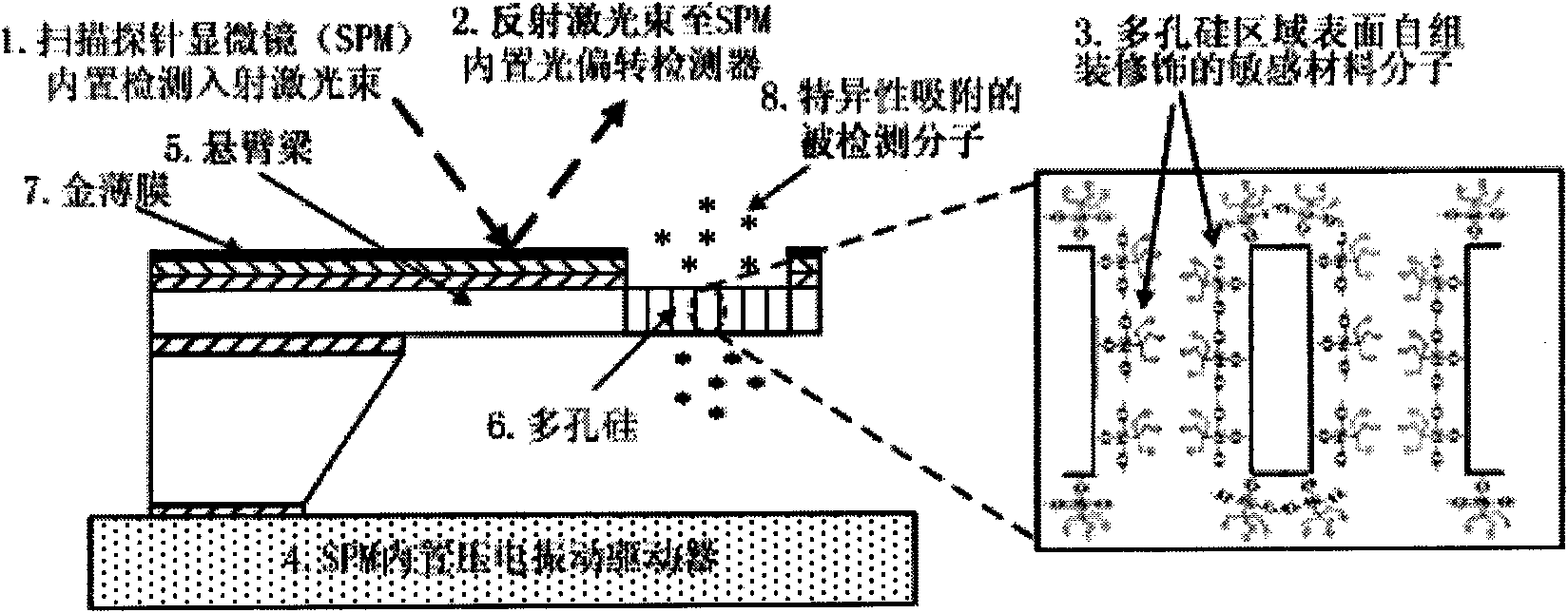

Silicon cantilever sensor, preparation method and application thereof

InactiveCN101592578AEnables trace detectionTelevision system detailsSemiconductor/solid-state device detailsMicro nanoSilicon oxygen

The invention relates to a silicon cantilever sensor, a preparation method and application thereof, and belongs to the field of micro-nano sensors. A porous silicon structure is formed in hydrofluoric acid solution nearby a free tail end of a cantilever through a selective anodic oxidation method. By using the increased specific surface structure of a porous silicon area, large amount of linear polymer or hyper-branched polymer sensitive molecules with silicon-oxygen head groups and specific tail groups for specificity identification are self-assembled on the inner wall of a silicon hole, and large amount of detected chemical molecules can be specifically captured to accumulate the capturing mass of larger detected substances. The silicon cantilever sensor has the advantages of simple structure, convenient manufacture and easy realization, and can be applied to trace chemical gas detection.

Owner:SHANGHAI APPLIED TECHNOLOGIES COLLEGE

Process for treating metal surfaces

ActiveUS20080280046A1Pretreated surfacesMetallic material coating processesHydrofluoric acidAqueous solution

The corrosion resistance of a metal substrate surface treated with an acidic aqueous composition to form a conversion coating is improved by first contacting the surface with an oxidizing acidic pre-rinse, such as an aqueous solution of nitric acid and hydrogen peroxide, or nitric acid and hydrofluoric acid, or Fe+3 cations and hydrofluoric acid.

Owner:HENKEL KGAA

Fluoropolymer organic lining anticorrosive material for chimney, flue and other pipelines and containers and construction method thereof

ActiveCN101891993AImprove temperature resistanceImprove acid resistanceBio-packagingLarge containersVulcanizationAdhesive

The invention provides an anticorrosive material for a chimney, a flue and other containers and pipelines and an anticorrosive construction process. The construction method of the anticorrosive material comprises the following steps: using crude rubber with higher fluorine content as a raw material, then adding curing agent, stabilizer, special stuffing and other components, and mixing to form precuring gross rubber; dissolving the rubber by using low-molecular weight esters and ketones as the solvent to form a putty type rubber paste; and finally, adding special additives, uniformly mixing, coating to the inner walls of a chimney, a flue and a chemical container, and curing into the polymerized fluororubber organic lining under the room-temperature condition. The material can be independently used as the anticorrosive material, and can also be used for protecting common foam glass bricks (ceramic bricks) and adhesive for anticorrosive purpose in the domestic chimney (flue) at present. The invention well solves the technical problems of fluororubber room-temperature curing and difficult anticorrosive construction, can be used in a high-temperature environment of more than 230 DEG C, and can endure high-concentration sulfuric acid, nitric acid, hydrochloric acid, phosphoric acid, hydrofluoric acid, corresponding salts and a mixture thereof. The anticorrosive lining material is economically affordable, has extremely high comprehensive anticorrosive properties such as temperature resistance, acid resistance and the like, and is applicable to the anticorrosive treatment of a cured chimney.

Owner:重庆大众防腐股份有限公司

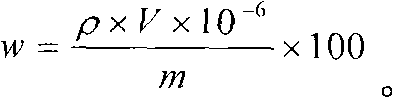

Titanium dioxide nano tube electrode and its preparation process and application

InactiveCN1598075ASimple processLarge specific surface areaPhysical/chemical process catalystsWater/sewage treatment by irradiationPhotocatalytic reactionVolumetric Mass Density

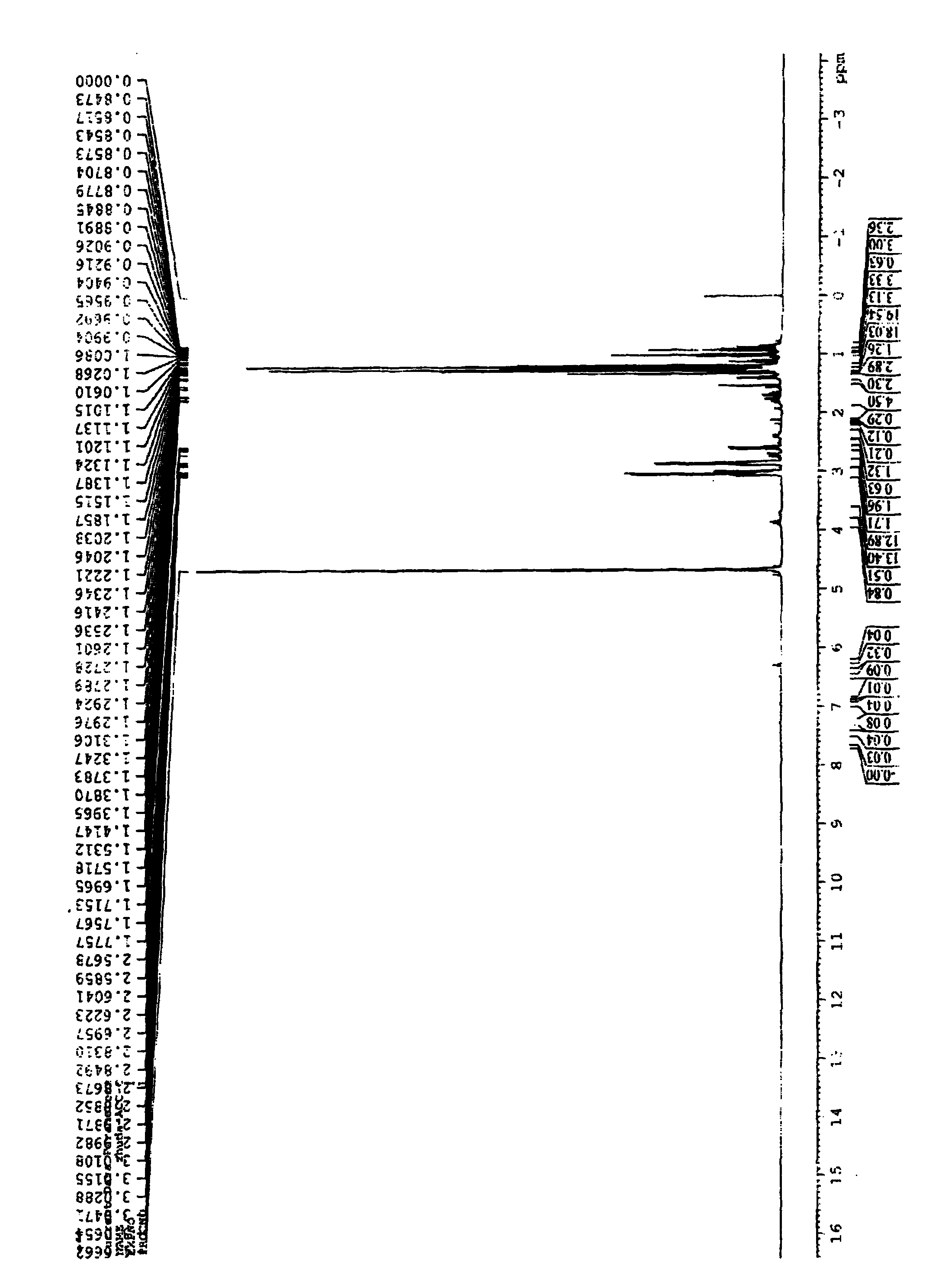

The invention relates to a titanium dioxide nanometer tube electrode in the technology field of fathering the environmental pollution and its preparation method as well as its application. Its features lie in: choose the pure titanium or titanium alloy as the substrate, carry out the electrochemical oxidation in the condition of hydrofluoric acid with its density between 0.01wt% and 0.5wt%, form a titanium dioxide nanometer tube with its diameter between 40nm and 100nm and its length between 20nm and 50nm on the substrate vertically and get the integrative titanium dioxide nanometer tube electrode. The preparation features lie in: choose the substrate as the anode after grinding, etching and drying and the platinum sheet as the cathode, control the distance between the two electrodes between 10mm and 50mm, put them into the reactor, power on the stabilized voltage power supply with it voltage between 15V and 25V, after 1-to-30-minute reaction calcine them at the temperature of 400deg.C to 600deg.C for 40nin to 80min, cool it in natural condition and get the titanium dioxide nanometer tube electrode. The titanium dioxide nanometer tube electrode can be applied to the photocatalysed degradation and photoelectroncatalysed degradation to the organic pollutants. It has larger surface area and simple preparation method.

Owner:DALIAN UNIV OF TECH

Method of removing inorganic scales

InactiveUS20120325485A1Minimize corrosion potential on downhole metal tubularsImprove breathabilityCleaning apparatusFluid removalMining engineeringSilanes

The productivity of hydrocarbons from hydrocarbon-bearing calcareous or siliceous formations is enhanced by contacting the formation with a well treatment composition which contains a hydrofluoric acid source, a phosphonate acid, ester or salt thereof, a quaternary ammonium salt and an organosilane and, optionally, a boron-containing compound.

Owner:BAKER HUGHES INC

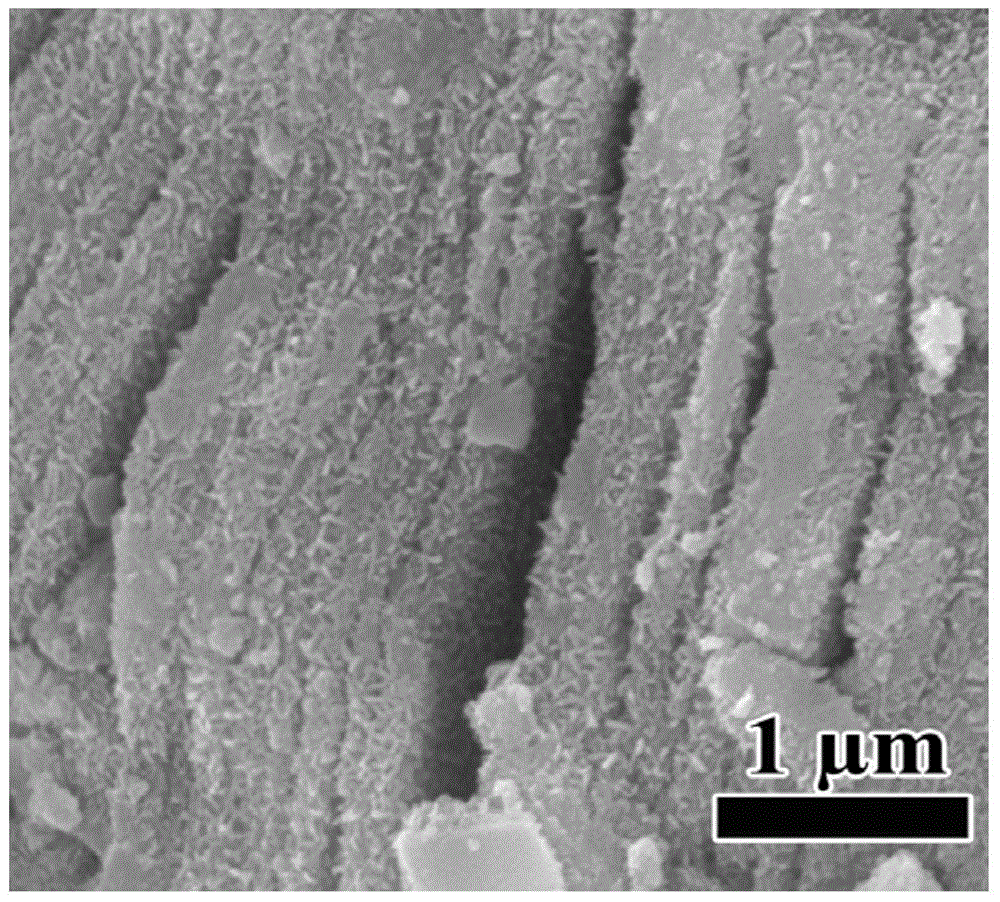

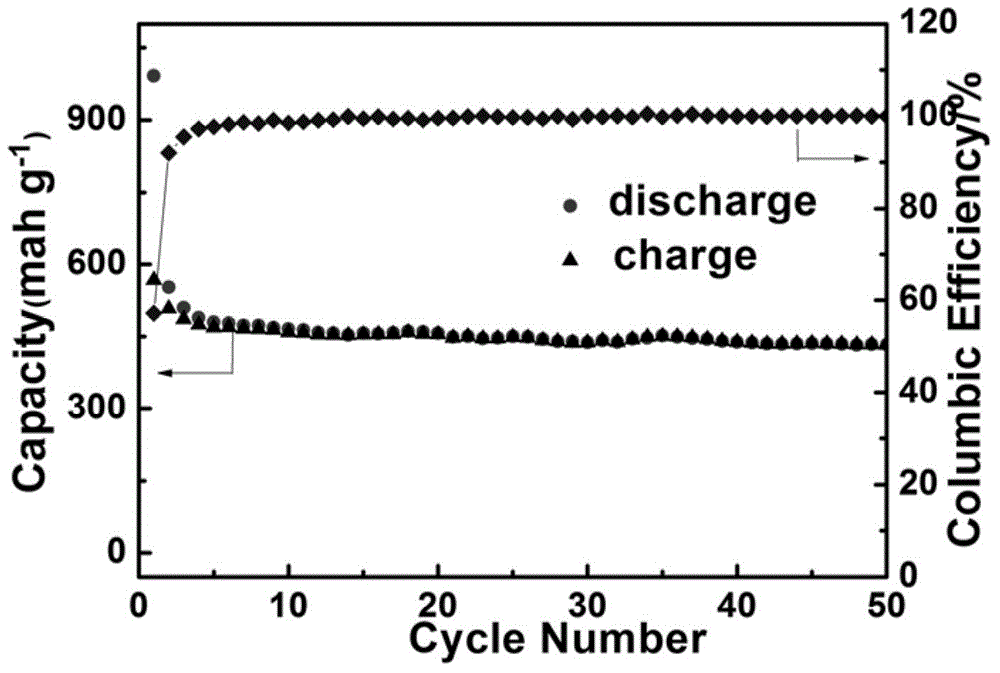

Porous silicon carbon composite material and preparation method therefor

The invention provides a porous silicon carbon composite material and a preparation method therefor. The method specifically comprises the steps of (1) providing silicon-active metal alloy; (2) performing reaction between the alloy and a liquid phase pore forming agent to remove the active metal so as to obtain a porous silicon nanometer material; (3) cleaning the porous silicon nanometer material by a hydrofluoric acid solution so as to remove silicon oxide and thus to obtain a porous silicon nanometer material being cleaned by the hydrofluoric acid; (4) mixing the obtained nano-silicon material with a polymer, and then performing ball milling to obtain a porous nano-silicon / polymer uniform mixture; and (5) calcining the nano-silicon / polymer uniform mixture to obtain the porous silicon-carbon composite material. The preparation method can effectively control the proportion of the silicon element to the carbon element in the silicon carbon composite material; and when the prepared material is used as the negative electrode active material for lithium ion batteries, the lithium ion batteries are high in cycling stability and coulombic efficiency.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Non-flammable, high-solvency compositions comprising trans-1,2-dichloroethylene, solvent, and inerting agent

InactiveUS6852684B1Easy to cleanNon flammableOrganic detergent compounding agentsOther chemical processesChlorofluorocarbonKetone

Disclosed are non-flammable, high-solvency compositions having utility as cleaning agents in the electronics and refrigeration industries, and as a medium for mold release agents. The compositions are non-flammable by Flame Extension Test ASTM D-3065 and Flash Point-Tag Closed Cup Test ASTM D-56-82, and have a Kauri Butanol value of at least about 40 by ASTM 1133-94. The compositions comprise the components: a.) trans-1,2-dichloroethylene; and b.) solvent selected from: i.) oxygen-containing solvents selected from alcohols, ketones, esters, siloxanes, and ethers; and ii.) hydrocarbon solvents represented by CtH2t+2 or CtH2t, wherein t is from 4 to 8; and c.) an inerting agent selected from: i.) hydrofluorocarbon inerting agents represented by the formula CxHyF(2x+2−y), wherein x is from 3 to 8, y is from 1 to 4, and the mole ratio of F / H in the hydrofluorocarbon inerting agent is greater than 1.6; ii.) hydrofluorocarbon ether inerting agents represented by the formula CrF2r+1OCsH2s+1, wherein r and s are independently selected from 1 to 6, and r is greater than or equal to 2s; and iii.) hydrochlorofluorocarbon inerting agents represented by the formulae C2HCl2F3, C2HClF4, and C3HCl2F5.

Owner:MICRO CARE A CONNECTICUT +1

Process for providing a topography to the surface of a dental implant

InactiveUS20080261178A1Present inventionThe process is simple and clearDental implantsDentistry preparationsHydrofluoric acidTopography

A process for providing a topography to the surface of a dental implant, said surface being made of a ceramic material. At least a part of the surface of the dental implant is etched with an etching solution comprising hydrofluoric acid at a temperature of at least 70° C. Thereby, discrete grains or agglomerates of grains are removed from the ceramic material.

Owner:STRAUMANN HLDG AG

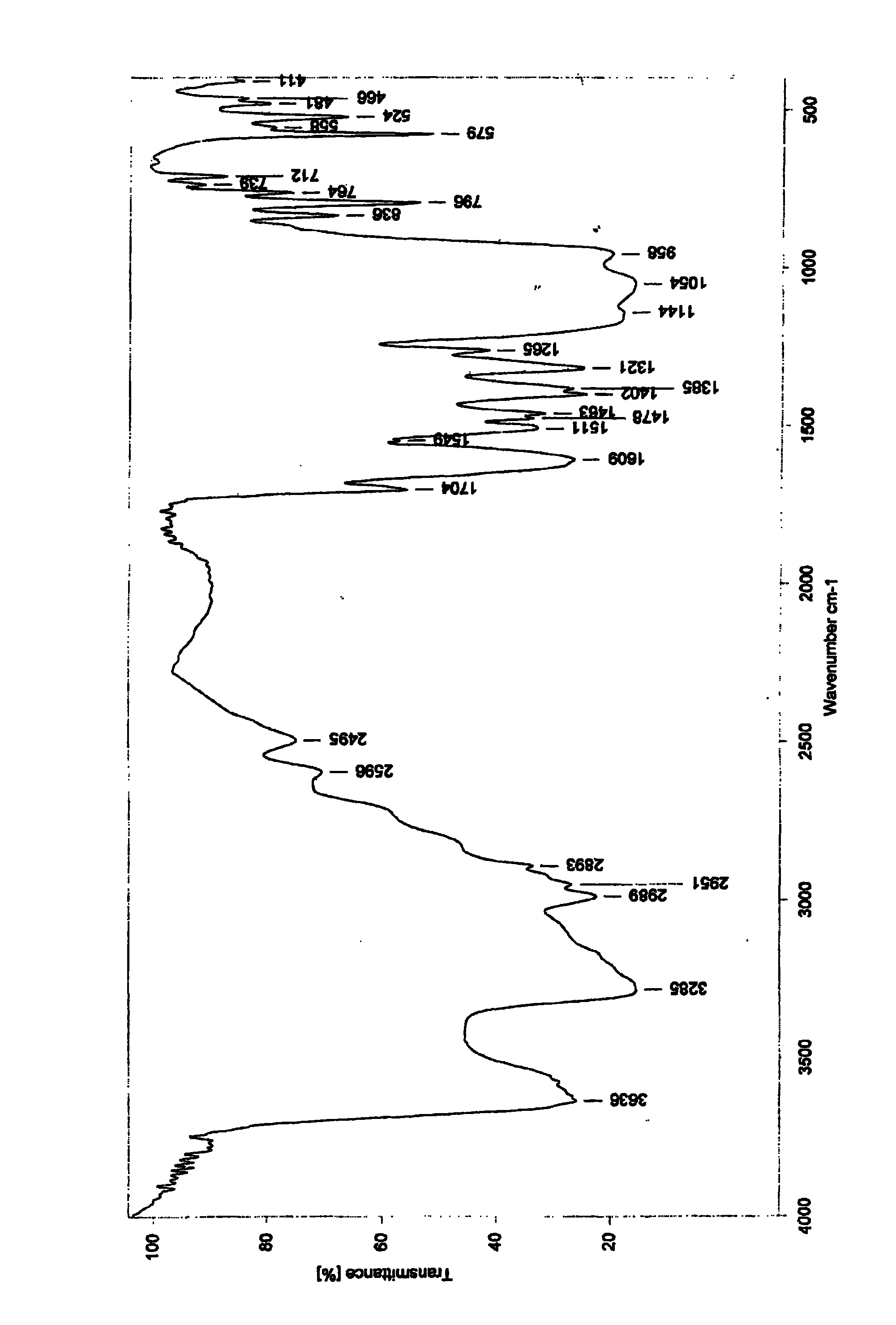

Metal organic skeleton-graphite oxide nano composite adsorption material and preparing method thereof

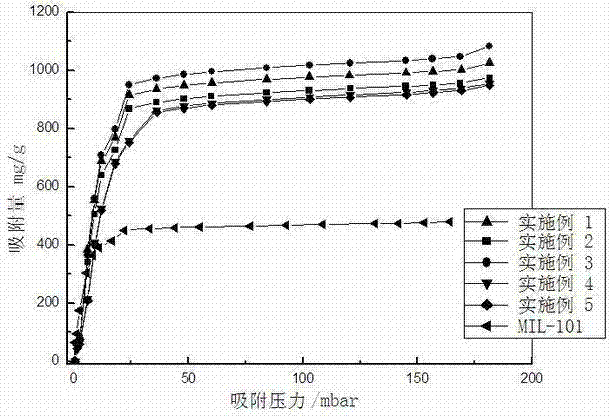

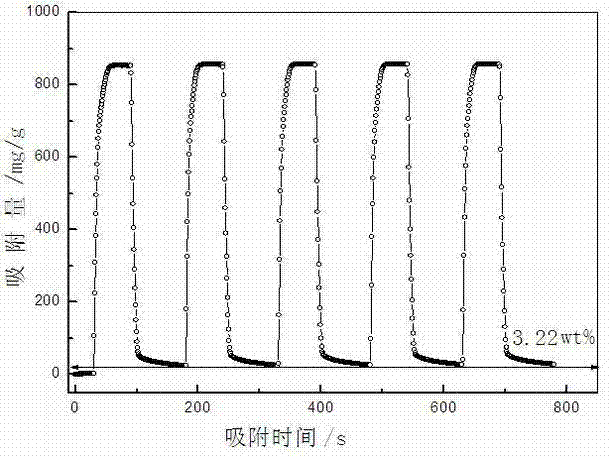

ActiveCN102335592ALarge specific surface areaHigh porosityOther chemical processesMetal-organic frameworkChromium nitrate

The invention discloses a metal organic skeleton-graphite oxide nano composite adsorption material and a preparing method thereof. The material is composed of graphite oxide and chromium-based metal organic skeleton. The preparing method of the material comprises the following steps of: dissolving chromium nitrate and terephthalic acid in deionized water, stirring and simultaneously adding hydrofluoric acid dropwise, then adding graphite oxide and uniformly stirring to obtain reaction liquid, and conducting hydro-thermal reaction under program temperature controlling; and after sequentially conducting washing with water and washing with ethanol for the decomposed materials, centrifuging, drying and obtaining the metal organic skeleton-graphite oxide nano composite adsorption material. Theadsorption capacity of the adsorption material for hydrocarbon volatile organic matters is greatly increased, and the adsorption material is easy for desorption and regeneration. The preparing methodhas simple process and low cost.

Owner:SOUTH CHINA UNIV OF TECH

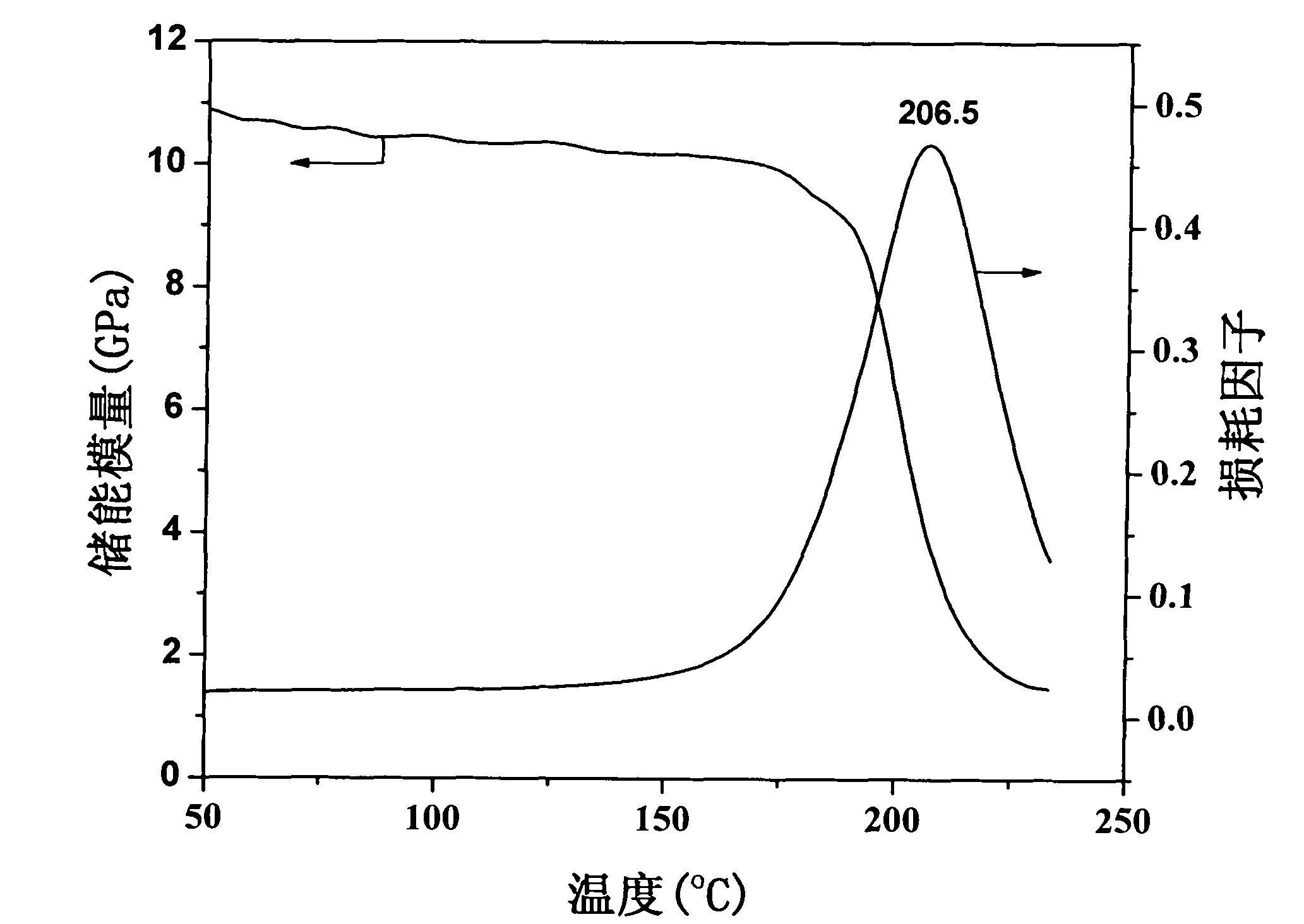

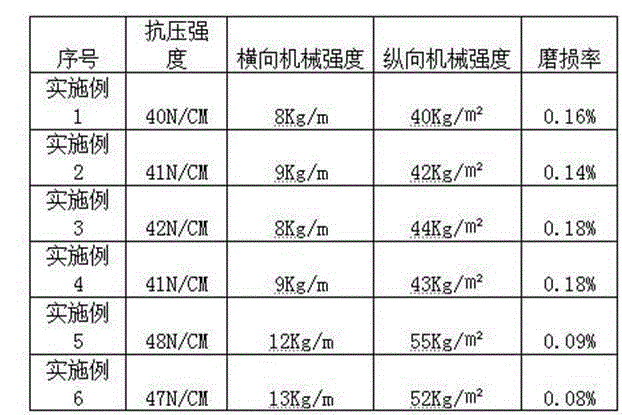

High-temperature resistance carbon fiber/epoxy resin composite material, preparation method and use

The invention discloses a high-temperature resistance carbon fiber / epoxy resin composite material, a preparation method and use. The method comprises the steps of preimpregnation material preparation and composite material curing forming. Through introducing a kind of latent accelerating agents of fatty amine hydrofluoride, the method reduces the forming time of the composite materials in a mold, effectively improves the production efficiency, reduces the production cost, and can not shorten the storage period of the preimpregnation materials. Through the high-temperature heat treatment, the invention further improves the crosslink density of the resin, and is favorable for improving the vitrification conversion temperature of the composite materials, and at the same time, the high-temperature heat treatment can effectively eliminate the inner stress produced by fast curing. The prepared composite material has good mechanical property and abrasion resistance performance, the vitrification conversion temperature of the composite material is between 190 and 210 DEG C, and the 180 DEG C high-temperature environment resistance requirements can be met.

Owner:SUN YAT SEN UNIV +1

Pickling passivation method of stainless steel

ActiveCN102965675AImprove corrosion resistanceEnsure surface decorationMetallic material coating processesSS - Stainless steelFluorhydric Acid

A pickling passivation method of stainless steel is characterized in that the method comprises the following steps of: (1) oil removing; (2) first rinsing; (3) pickling passivation, wherein a specially-prepared pickling passivating solution is proportioned by 20% of nitric acid, 10% of hydrofluoric acid, and 70% of purified water, and the workpiece is soaked in groove liquid completely; (4) second rinsing; (5) meutralization by alkali liquor, wherein the workpiece is soaked in an alkaline groove liquid completely; (6) first water washing; (7) third rinsing; (8) air drying; (9) stoving; (10) confining liquid spraying; (11) natural air drying; (12) packaging with air-cushion films. The invention combines two original steps of pickling and passivation into one step, which effectively increases the corrosion resistance of the stainless steel, improves the hand fingerprint contamination resistance of the stainless steel, ensures the surface decoration performance of the stainless steel products, and the method has the characteristics of simple process, low production cost, less environment pollution, easy operation, low labor intensity, low energy consumption, and high efficiency.

Owner:SHENYANG YUANDA ALUMINUM IND GROUP

Phosphorus-free film forming agent and preparation method thereof

ActiveCN101643898AImprove anti-corrosion performanceStrong adhesionMetallic material coating processesHydrofluoric acidAlcohol

The invention relates to a phosphorus-free film forming agent comprising the following components by weight percent: 0.5-4 percent of silane coupling agent, 0.5-2 percent of titanate coupling agent, 1-10 percent of fluozirconate or zircon salt, 3-5 percent of alcohol solvent, 0.5-2 percent of hydrofluoric acid or fluorid, 1-5 percent of hydrogen peroxide, 0.5-2 percent of notric acid or nitrate and the balance of deionized water or tap water. The phosphorus-free film forming agent is environment-friendly and can increase adhesive force and corrosion resistance.

Owner:CHANGZHOU JUNHE TECH

Preparation of silicon nanowire array

InactiveCN101302118AThe preparation method is simpleIndividual molecule manipulationSilicon dioxideMICRO PIPETTE

The invention relates to a method for preparing silicon nanowires, belonging to the nanophase material preparation technical field. The method comprises the following steps that: a silicon chip is washed and shaken by acetone and alcohol and is processed by an acid cleaning liquid and a No.1 standard cleaning solution; a silicon dioxide spheres solution with a weight percentage density between 0.02 and 2.0 percent is added on the silicon chip surface which is washed off in the step one drop by drop by a micro pipette, the processed silicon chip is placed in air to air naturally; the silicon chip with silicon dioxide sphere arrays is annealed for one to three hours at a temperature of between 900 and 1000 DEG C; afterwards, the silicon chip is put into a diluent hydrofluoric acid solution to be eroded for 2 to 20 minutes so that the diameters of the spheres become small; an Ag film with a thickness between 20 and 80nm is deposited on the silicon chip surface by the plating technique or the vacuum evaporating technique; and a sample deposited with the Ag film is dipped into the hydrofluoric acid and hydrogen peroxide etching solution (or ferric nitrate) to be eroded for 4 to 100 minutes. The preparation method can rapidly prepare a large area of silicon nanowire arrays, thereby being suitable for the large-scale industrial production.

Owner:BEIJING NORMAL UNIVERSITY

Branch controllable titanium dioxide nanotube array thin film and preparation method thereof

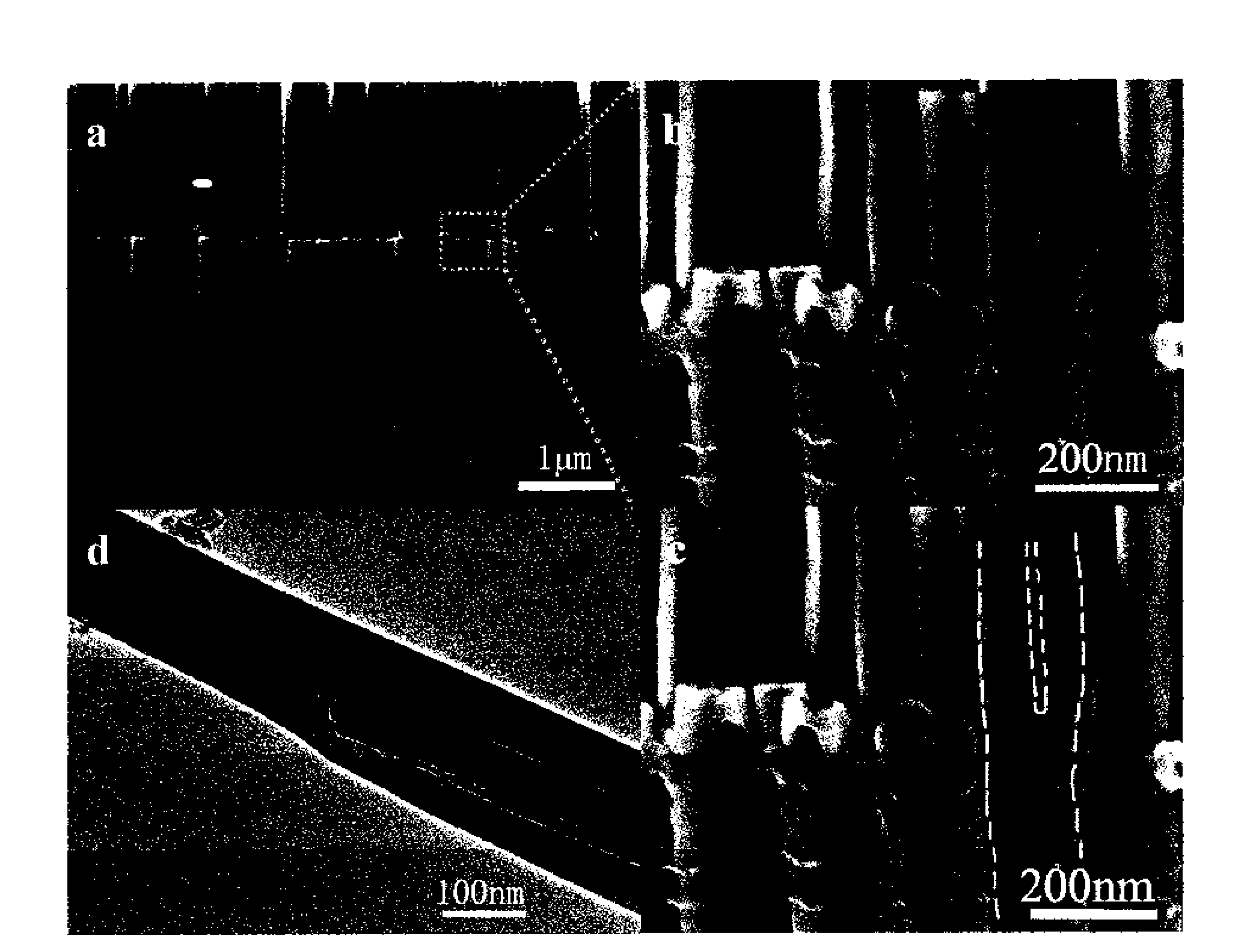

InactiveCN101660189ALarge adjustment rangeShape is easy to controlPolycrystalline material growthNanostructure manufacturePorosityDc voltage

The invention discloses a branch controllable titanium dioxide nanotube array thin film and a preparation method thereof. The thin film consists of an array of a titanium dioxide nanotube formed by connecting a main tube and a branch tube in series; the thickness of the thin film is 1-100mum, and the porosity factor is 40-60 percent. The preparation method comprises the following steps: preparinga main tube electrolyte according to the proportion that the mole ratio of ammonium fluoride to glycol to water is 0.05-0.15:17.7:0.015-0.025, and preparing a branch tube electrolyte according to theproportion that the mole ratio of hydrofluoric acid to glycol is 0.15-0.25:17.7; then firstly, putting one surface of a titanium sheet in the main tube electrolyte to serve as the anode; carrying outanode oxidization under the conditions that the DC voltage is 55-65V and the temperature is 0-35 DEG C for 0.5-6h; then using the glycol to clean the anode; subsequently, putting the surface which isanodized in the branch tube electrolyte to serve as the anode, and carrying out anode oxidization under the conditions that the DC voltage is 30-120V and the temperature is 0-35 DEG C for more than 30min, thereby preparing the thin film. The thin film can be widely used for fields of dye-sensitized solar cells, gas sensors, photolytic water hydrogen production and photonic crystal.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Ferric fluoride nano material and preparation method thereof

The invention discloses a ferric fluoride nano material and a preparation method thereof. The preparation method comprises the following steps of: dissolving inorganic ferric salt in an alcohol solvent to obtain alcohol solution containing iron; dispersing an inorganic fluorine source into the alcohol solution containing iron and adding the solution into a hydrothermal reaction kettle; carrying out the hydrothermal reaction kettle solution for 1 hour to 7 days at a temperature of 40 to 140 DEG C, naturally cooling, carrying out centrifugal separation, washing by ethanol and carrying out vacuum drying to obtain the ferric fluoride nano material. According to the preparation method of ferric fluoride, a volatile hydrofluoric acid fluorine source does not need to be used as a raw material, low-toxicity fluoride is used as the fluorine source, common ferric salt is used as a ferric source, the FeF3.0.33H2O nano material containing trace moisture is obtained by the simple solvent heat treatment, the preparation process is simple, the yield is high and the obtained material has high crystallinity. The method disclosed by the invention is a novel and practical process route for preparing the ferric fluoride nano material and has high actual application value.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

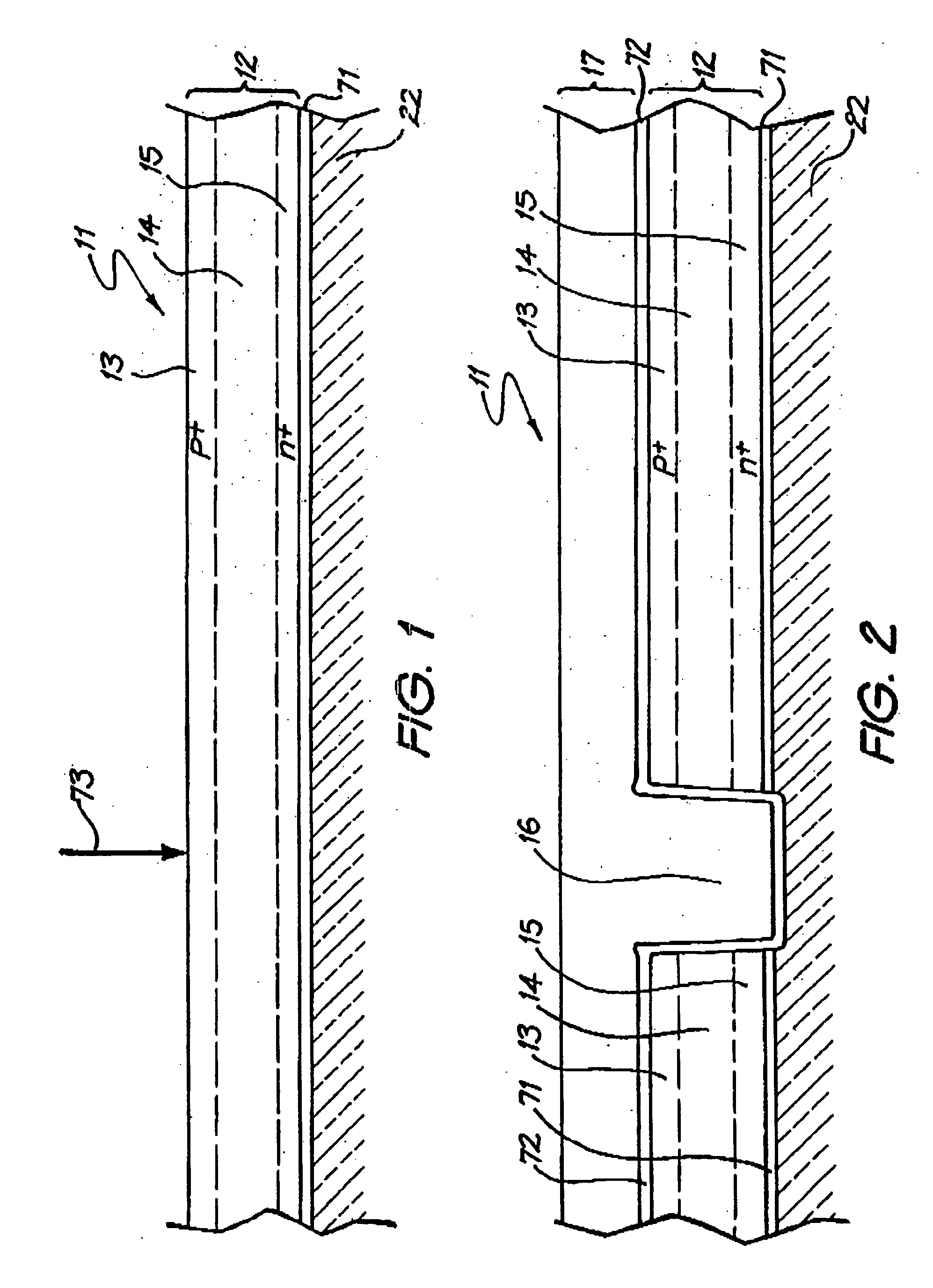

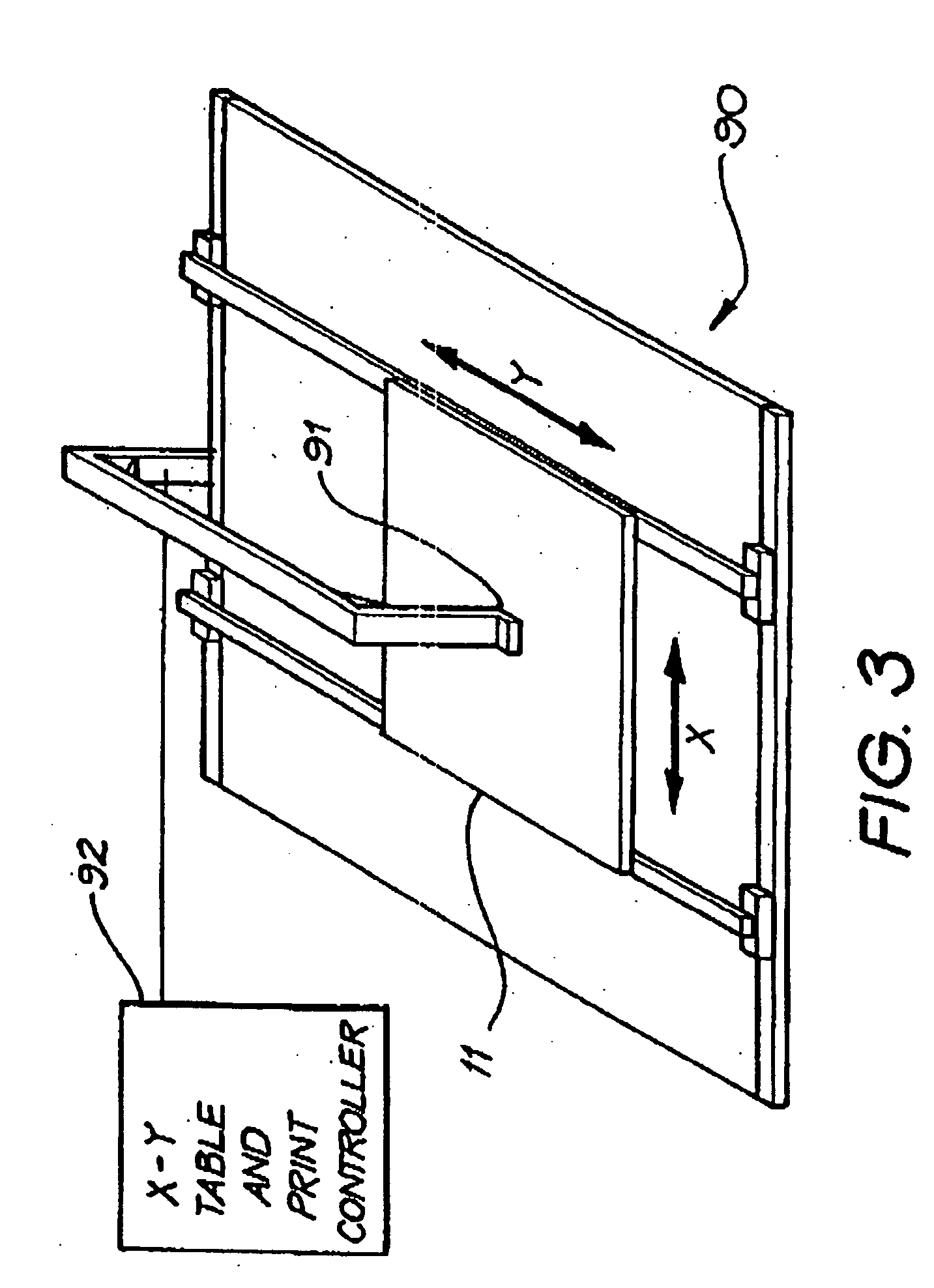

Method of etching silicon

Silicon (12) is etched through a mask (11) comprising a layer of organic resin material (such as novolac) through which openings (32) are formed in the areas to be etched. The layer of organic resin is first deposited over a free surface of the device to be etched. The openings (32) are then formed by depositing droplets of a caustic etchant such as sodium hydroxide (NaOH) or potassium hydroxide (KOH) with an inkjet printer. The etchant reacts with the resin to expose the silicon surface in areas to be etched. The etching of the silicon surface is performed by applying a dilute solution of hydrofluoric acid (HF) and potassium permanganate (KMnO4) to the exposed surface through the openings in the mask to etch the silicon to a desired depth (83).

Owner:CSG SOLAR AG

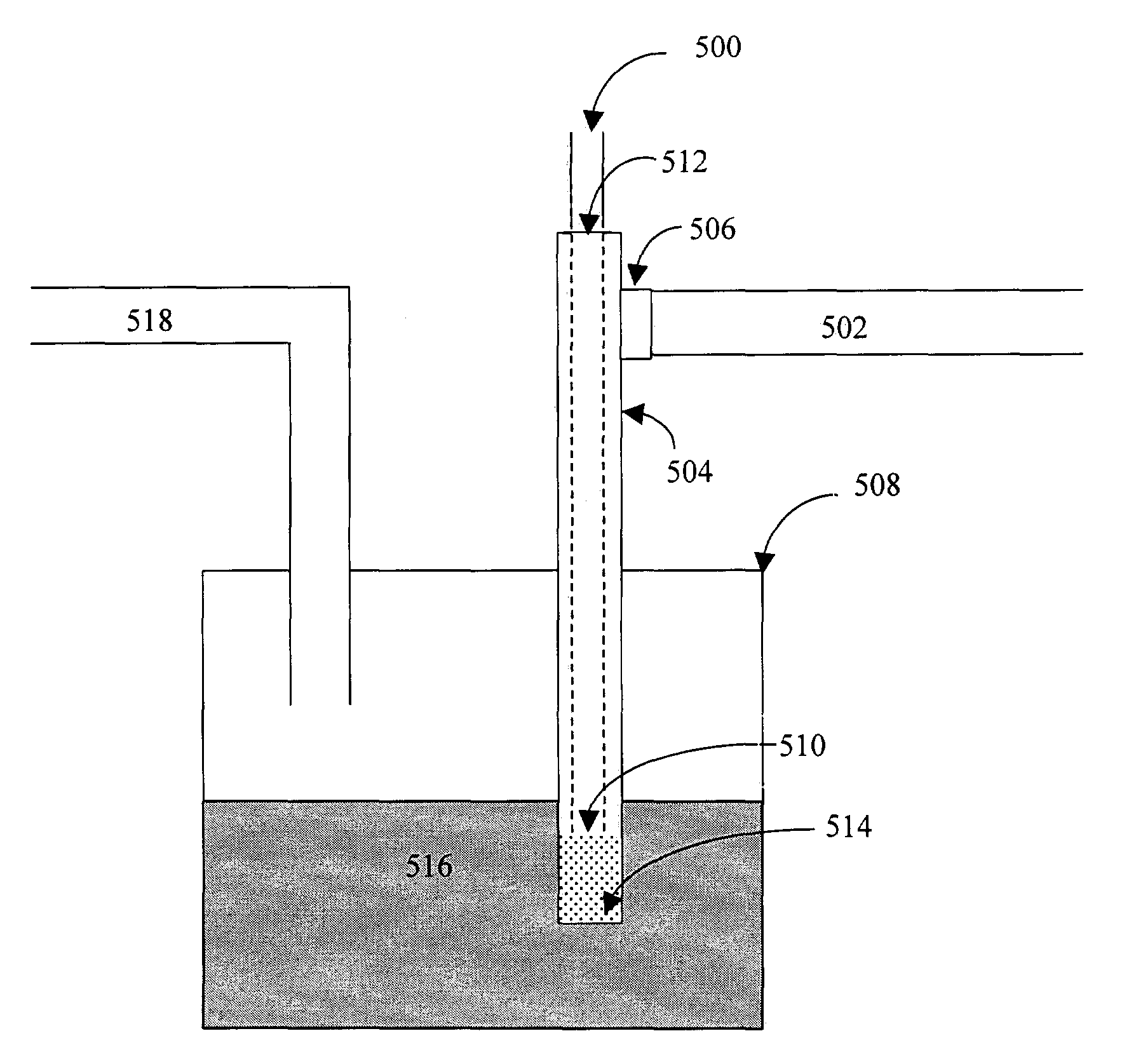

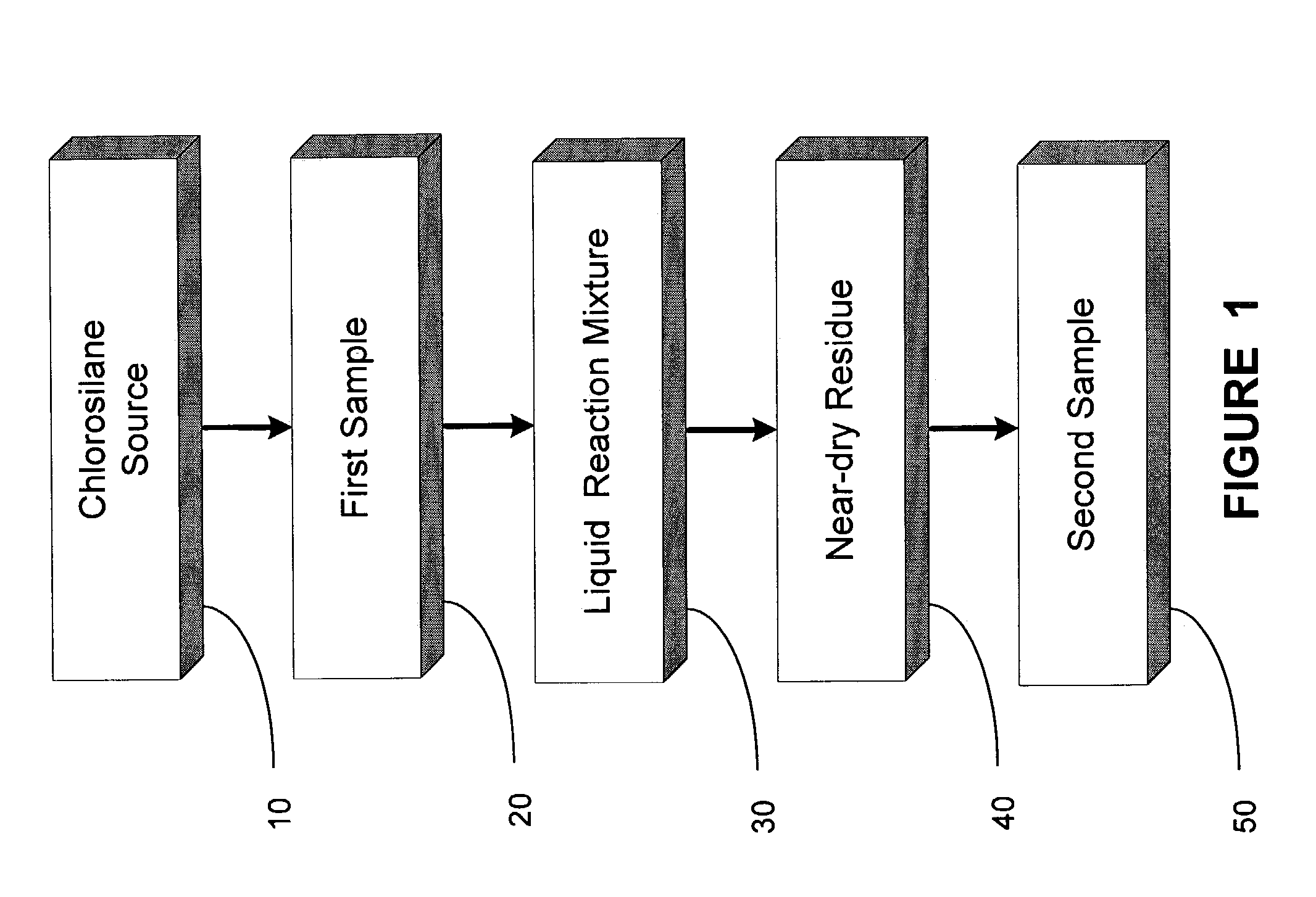

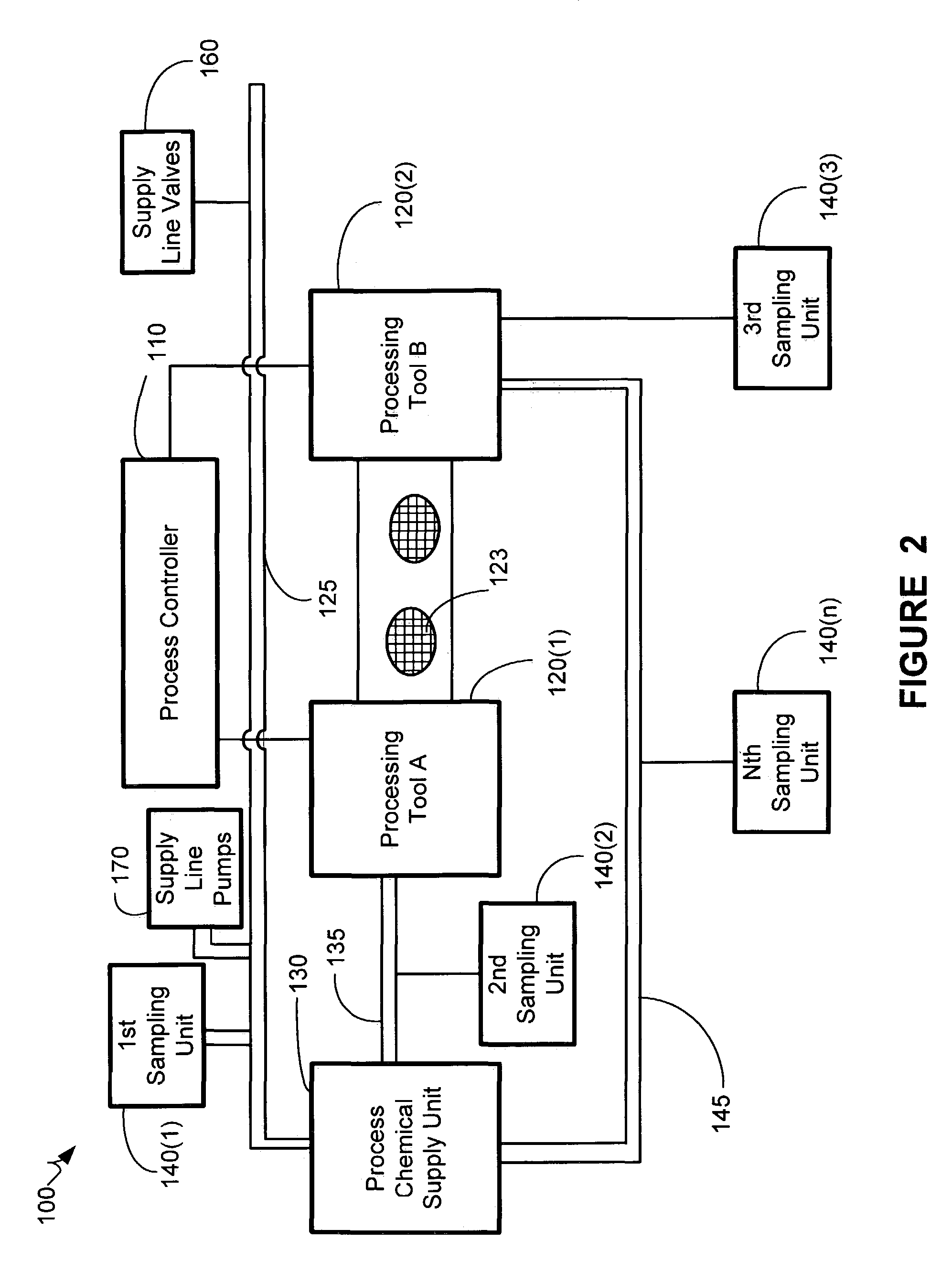

Methods of sampling halosilanes for metal analytes

Methods for determining the amount of at least one metal analyte present in a liquid or gas sample of a halosilane supply (e.g., a chlorosilane supply) are disclosed herein. A sample of a halosilane supply is contacted and reacted with an aqueous hydrofluoric acid solution to produce a liquid reaction mixture. Liquid from the liquid reaction mixture is evaporated under controlled temperature and pressure conditions to near dryness. The nearly-dry residue is prepared for spectral analysis. The presence of a detectable amount of at least one metal analyte is determined for the sample.

Owner:AIR LIQUIDE AMERICA INC

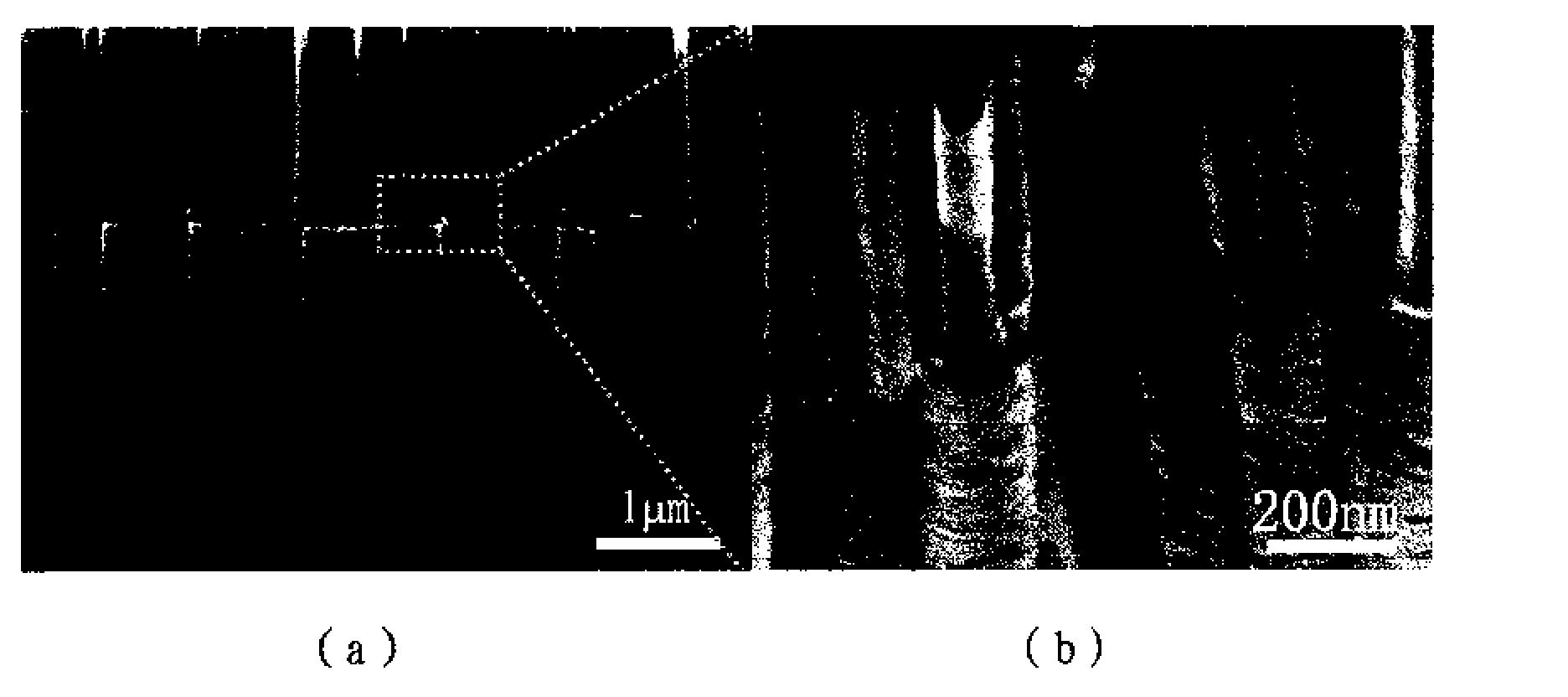

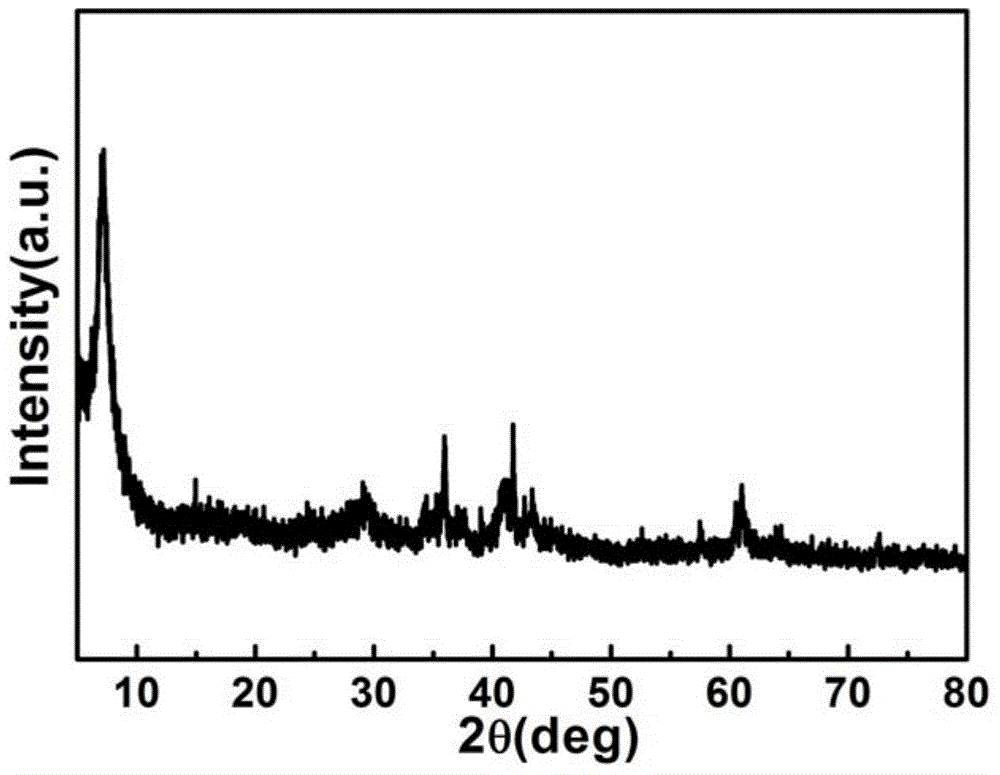

Two-dimensional layered titanium carbide/metal ion composite material and application thereof

InactiveCN104868104AIncrease capacityImprove cycle performanceCell electrodesSecondary cellsHydrofluoric acidPower flow

The invention discloses a two-dimensional layered titanium carbide / metal ion composite material and an application thereof. The composite material comprises a two-dimensional layered titanium carbide carrier and a metal ion compound loaded on the surface and between layers of the carrier. A preparation method of the composite material comprises the following steps of (1) taking a Ti3AlC2 material, treating the Ti3AlC2 material with a hydrofluoric acid solution to obtain Ti3C2 powder, (2) performing alkali treatment on the Ti3C2 powder obtained in Step (1) to obtain Ti3C2 powder subjected to the alkali treatment, and (3) treating the Ti3C2 powder subjected to the alkali treatment in a solution containing metal salt and a surfactant to obtain the two-dimensional layered titanium carbide / metal ion composite material. When the two-dimensional layered titanium carbide / metal ion composite material serves as a cathode material of a lithium ion battery, the capacity of the cathode material of the lithium ion battery can be greatly improved; and the cycle performance is good, so that high capacity and the capability of continuous charging and discharging under heavy current density are met.

Owner:ZHEJIANG UNIV OF TECH

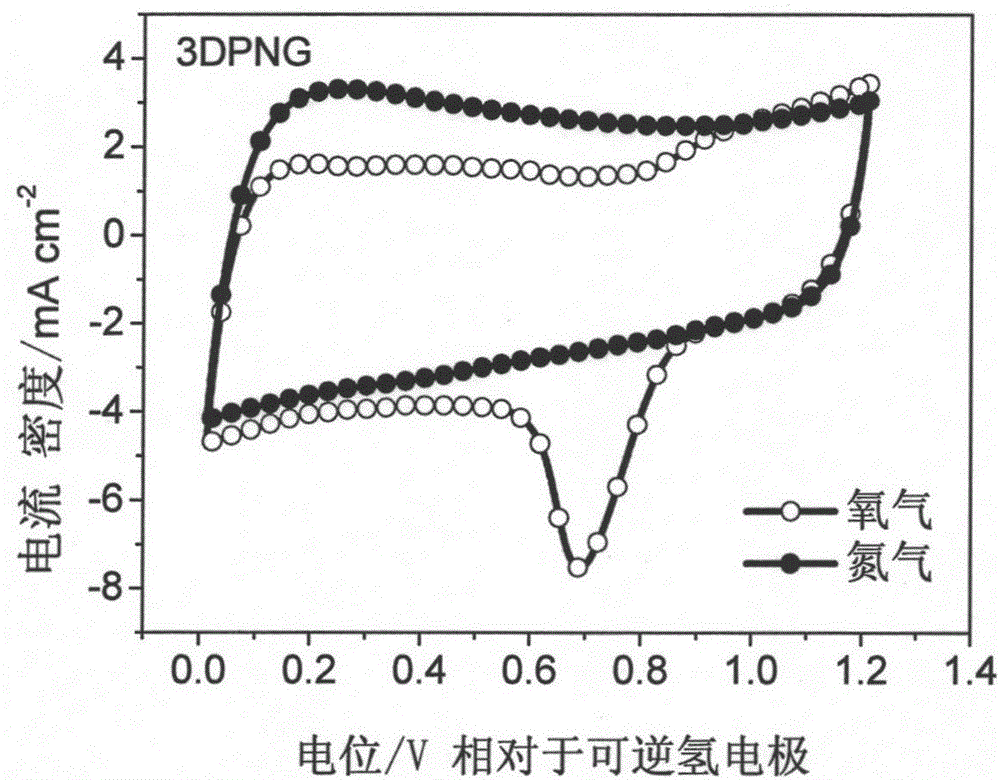

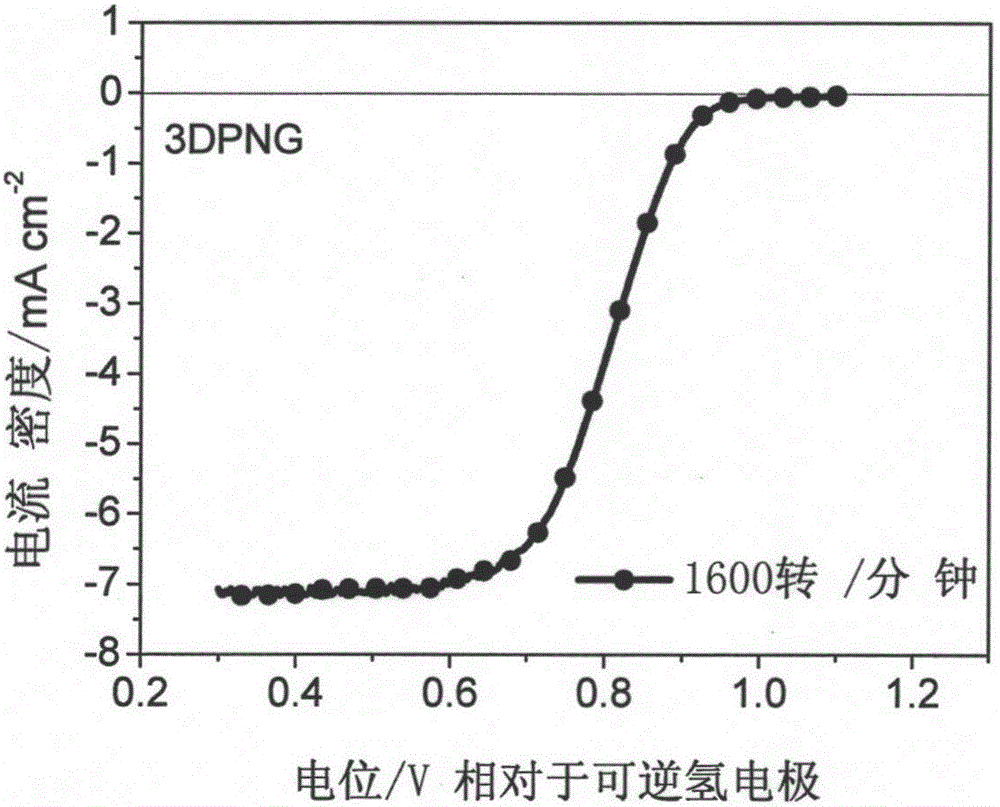

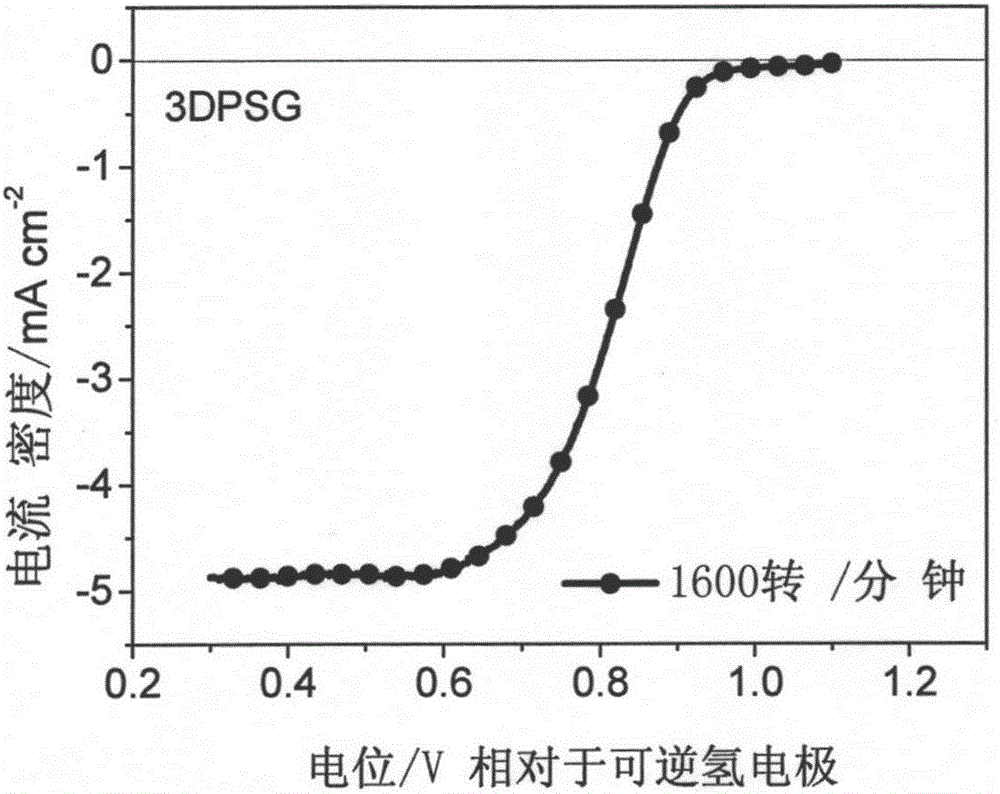

Preparation and application of nitrogen, sulphur or chlorine-doped three-dimensional porous graphene catalyst

InactiveCN105680060AIncrease the areaIncreased porous structureCell electrodesPorous grapheneReduction treatment

The invention provides a preparation and an application of a nitrogen, sulphur or chlorine-doped three-dimensional porous graphene catalyst. The preparation comprises the following steps: dissolving graphene oxide, an alkyl compound, a transition metal salt containing nitrogen, sulphur or chlorine and hydrochloric acid into a solvent, and carrying out ultrasonic treatment and drying to obtain a precursor; heating the precursor to 600-1,000 DEG C under inert gas protection and carrying out roasting reduction treatment for 1-3 hours to obtain primary carbide; carrying out pickling treatment on the obtained primary carbide with a mixed solution of hydrofluoric acid and hydrochloric acid at a room temperature for 12-24 hours, centrifuging the primary carbide, cleaning the primary carbide with deionized water and then drying the primary carbide to obtain the three-dimensional porous graphene material containing nitrogen, sulphur or chlorine; and heating the three-dimensional porous graphene material to 600-1,000 DEG C under inert gas protection, and carrying out roasting reduction treatment for 1-3 hours to obtain the nitrogen, sulphur or chlorine-doped three-dimensional porous graphene catalyst. The nitrogen, sulphur or chlorine-doped three-dimensional porous graphene catalyst has the characteristics of being high in stability, not easy to poison and the like, and has a good application prospect in the fields of wastewater treatment of a fuel cell, a metal-air cell, a super capacitor, an energy storage battery and a microbial fuel cell and the like.

Owner:DONGHUA UNIV

Method for measuring content of boron in cobalt-base alloy

ActiveCN101718688AAvoid interferenceImprove accuracyPreparing sample for investigationColor/spectral properties measurementsElement analysisMaterial resources

The invention belongs to a technique for analyzing trace elements of an alloy, and relates to a method for measuring the content of boron in a cobalt-base alloy. By adopting an inductively coupled plasma emission spectrometer and treating a sample of the cobalt-base alloy in particular a high-tungsten sample by using 20mL of hydrochloric acid, nitric acid and hydrofluoric acid, the method solves the puzzling problems that the past dissolved sample has large reagent dosage and high reagent blank and cannot be measured normally by an instrument; by performing interference experiments and spectrogram analyses, the method finds the optimal analytical line, overcomes the interferences caused by a plurality of elements such as major elements of cobalt, chromium, tungsten and the like in the cobalt-base alloy, and improves the measuring accuracy; the method has wide measuring ranges, the measuring lower limit is 0.002 percent, and the measuring upper limit is 0.20 percent and is 101 times of the measuring lower limit; and the method can perform measurement quickly, is simple and convenient to operate, and saves a large quantity of manpower and material resources.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

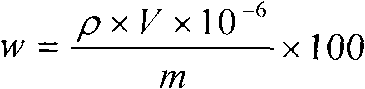

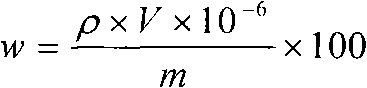

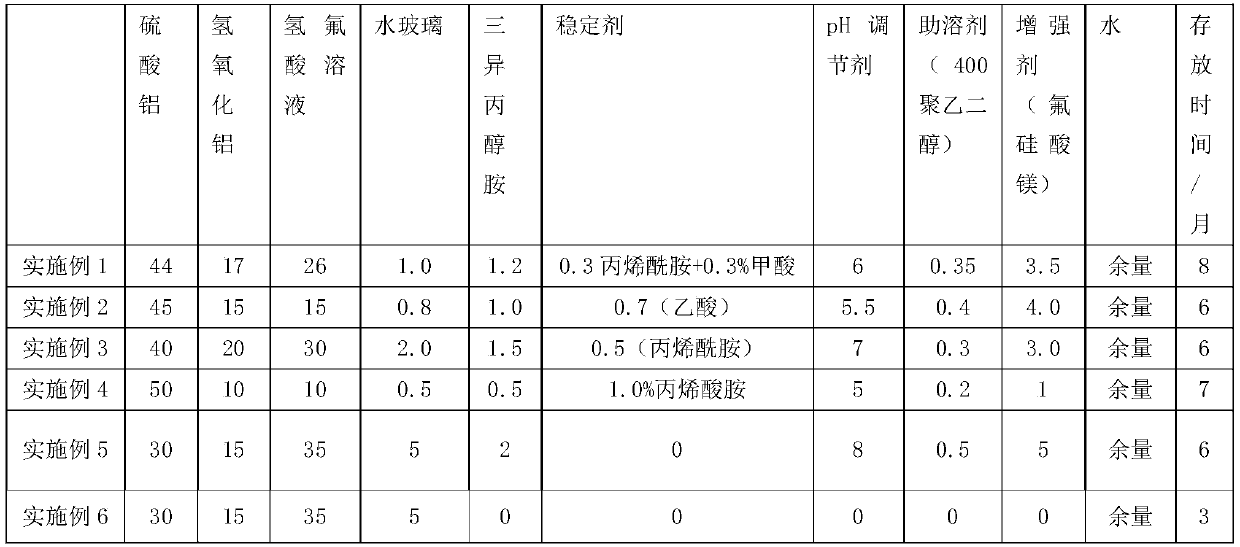

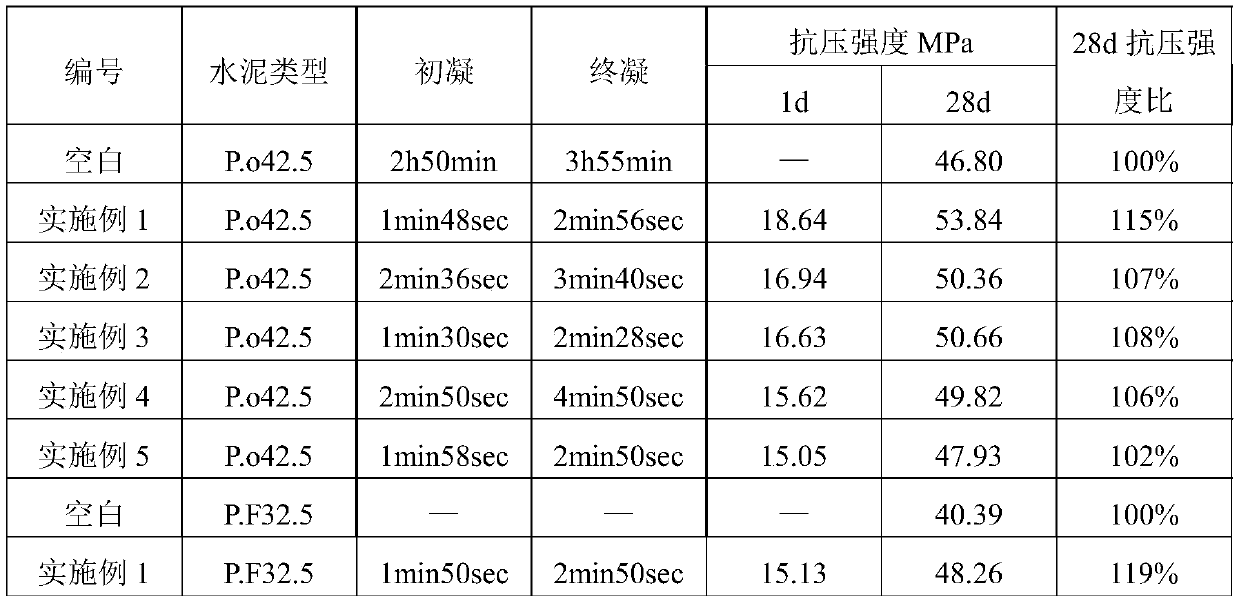

Liquid alkali-free accelerator and preparation and application thereof

The invention brings forward a liquid alkali-free accelerator and preparation and application thereof. The liquid alkali-free accelerator comprises the following ingredients (by weight): 20-45% of aluminum sulfate, 15-25% of aluminium hydroxide, 10-35% of hydrofluoric acid, 0.5-2% of triisopropanolamine, 0.5-5% of water glass, 0-1% of a stabilizing agent, 1-5% of a reinforcing agent, 5-8% of a pHregulator, 0.2-0.5% of a cosolvent, and the balance water. The liquid alkali-free accelerator has the following advantages: the production process is simple, heating is not required, and ''three wastes (waste gas, waste water and industrial residue)'' are not generated; alkali etch of concrete structures is reduced, strength is enhanced, and durability of sprayed concrete is increased. With low dosage, Portland cement grout can be initially coagulated within 2 min and finally coagulated within 4 min; 1d strength of cement mortar can reach 15 MPa and above, and ratio of 28d compressive strengthis greater than 100%; and the liquid alkali-free accelerator has good adaptation to different kinds of cement.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

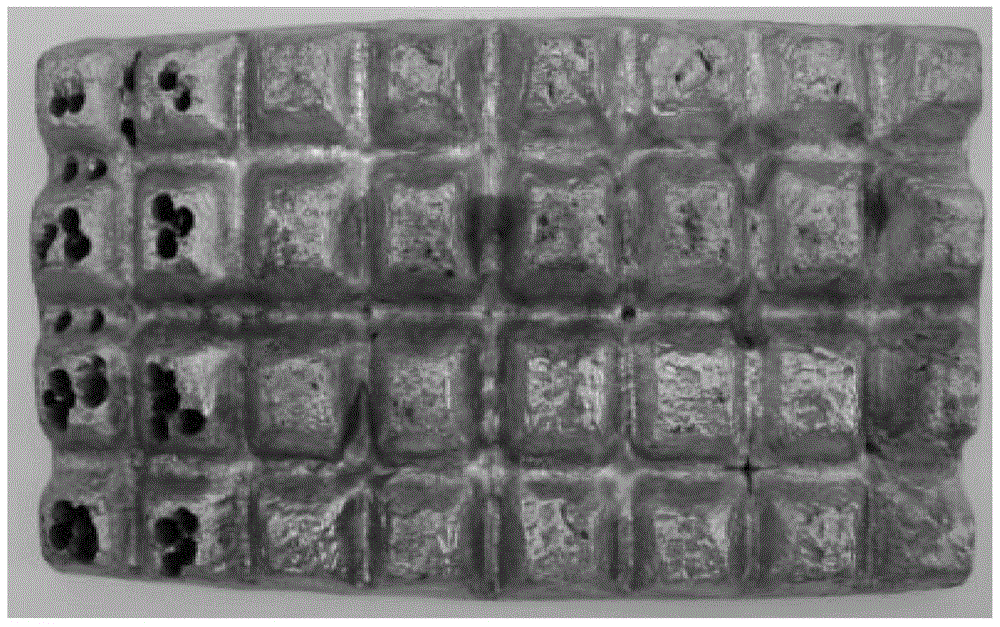

Regenerating method of invalid SCR denitration catalyst

ActiveCN104475174AHigh out-of-stock activityActivate Active IngredientsDispersed particle separationCatalyst regeneration/reactivationHydrofluoric acidActive component

The invention discloses a regenerating method of an invalid SCR denitration catalyst. The regenerating method comprises the following steps: (1) purging; (2) carrying out thermal treatment; (3) washing; (4) carrying out acid pickling, namely, putting the SCR denitration catalyst after washing into a mixed solution of 10wt% sulfuric acid and 5wt% hydrofluoric acid, and carrying out ultrasonic dispersion for 2 hours; and (5) carrying out activity regeneration, namely, soaking the SCR denitration catalyst after acid pickling into an active mixed solution containing 5wt% ammonium paratungstate and 1wt% ammonium metavanadate for 2 hours, taking out, and drying. The regenerating method has the beneficial effects that a catalyst which is invalid because of multiple reasons can be comprehensively treated in practical production, so that not only can the surface deposition of the catalyst be removed, but also can the poisoned catalyst be restored, and the active components of the catalyst can be activated; the regenerated catalyst is high in denitration activity and cannot generate pollution in the use process.

Owner:安徽迪诺环保新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com