Preparation of silicon nanowire array

A technology of silicon nanowire arrays and silicon nanowires, which is applied in the field of nanomaterials, can solve the problems of increased cost, difficulty in obtaining silicon nanowires with uniform diameter and orderly arrangement, and reduced production efficiency of silicon nanowires, and achieves the effect of simple conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

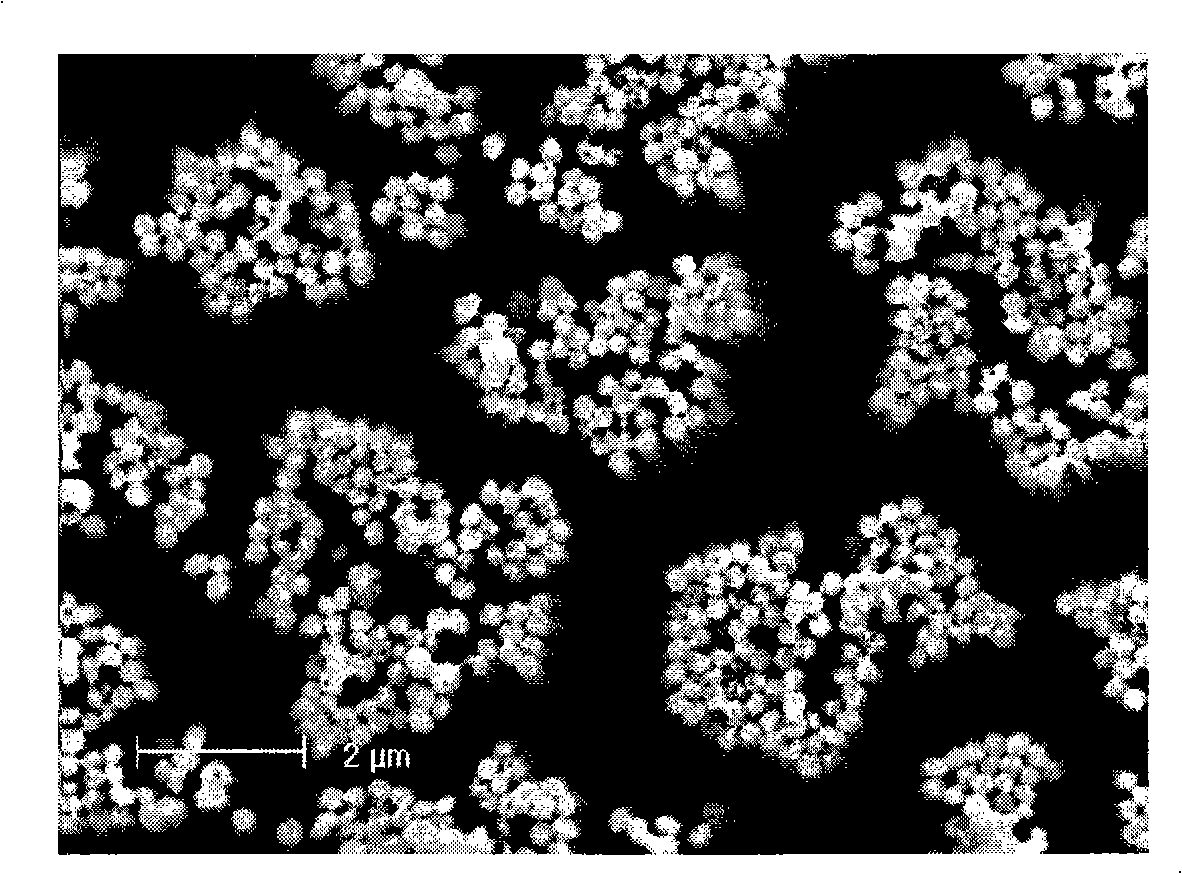

Embodiment 1

[0026] According to the surface area of the silicon substrate, drop the silicon dioxide pellet solution with a concentration of 0.1% onto the surface of the cleaned silicon wafer, and let it dry naturally. The silicon substrate on which the silicon dioxide balls are arranged is annealed for 3 hours at a temperature of 900 degrees Celsius under the protection of argon and hydrogen. Then use diluted hydrofluoric acid to corrode the balls for 5 minutes, and then deposit a 30nm thick Ag film by electroplating on the surface of the silicon chip array of the ball array, and then immerse the sample deposited with the silver film in a solution containing hydrofluoric acid and hydrogen peroxide. Silicon nanowires and their arrays arranged in a large area can be obtained by treating hydrogen oxide mixed solution in a closed container kettle (concentrations of hydrofluoric acid and hydrogen peroxide are 1.0 mol / L and 0.1 mol / L respectively) for 10 minutes .

Embodiment 2

[0028] According to the surface area of the silicon substrate, a solution of 0.3% silicon dioxide spheres was dropped onto the surface of the cleaned silicon wafer and allowed to dry naturally. The silicon substrate on which the silicon dioxide balls are arranged is annealed for 3 hours at a temperature of 950 degrees Celsius under the protection of argon and hydrogen. Then use diluted hydrofluoric acid to corrode the balls for 10 minutes, and then use vacuum thermal evaporation to deposit a 30nm thick Ag film on the surface of the silicon chip array with the ball array, and then immerse the sample with the silver film deposited in the hydrofluoric acid solution. and hydrogen peroxide mixed solution in a closed container kettle (concentrations of hydrofluoric acid and hydrogen peroxide are 4.0mol / L and 0.1mol / L respectively) for 30 minutes to obtain large-area ordered silicon nanowires and its array.

Embodiment 3

[0030]According to the surface area of the silicon substrate, drop the silicon dioxide pellet solution with a concentration of 1.0% onto the surface of the cleaned silicon wafer, and let it dry naturally. The silicon substrate on which the silicon dioxide balls are arranged is annealed for 3 hours at a temperature of 950 degrees Celsius under the protection of argon and hydrogen. Then, the silicon substrate on which the silicon dioxide spheres are arranged is annealed for 3 hours at a temperature of 950 degrees Celsius under the protection of argon and hydrogen. Then use diluted hydrofluoric acid to corrode the balls for 15 minutes, and then deposit a 50nm thick Ag film by electroplating on the surface of the silicon wafer with the array of small balls, and then immerse the sample deposited with the silver film in a solution containing hydrofluoric acid and hydrogen peroxide. The silicon nanowires and their arrays arranged in a large area can be obtained by treating the hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com