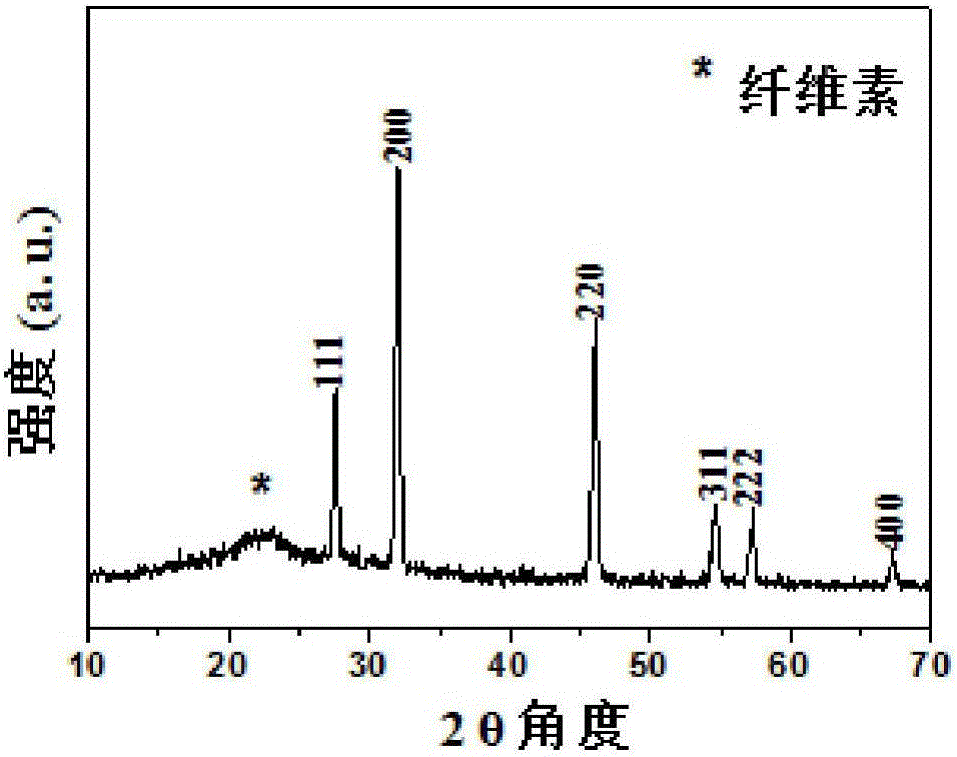

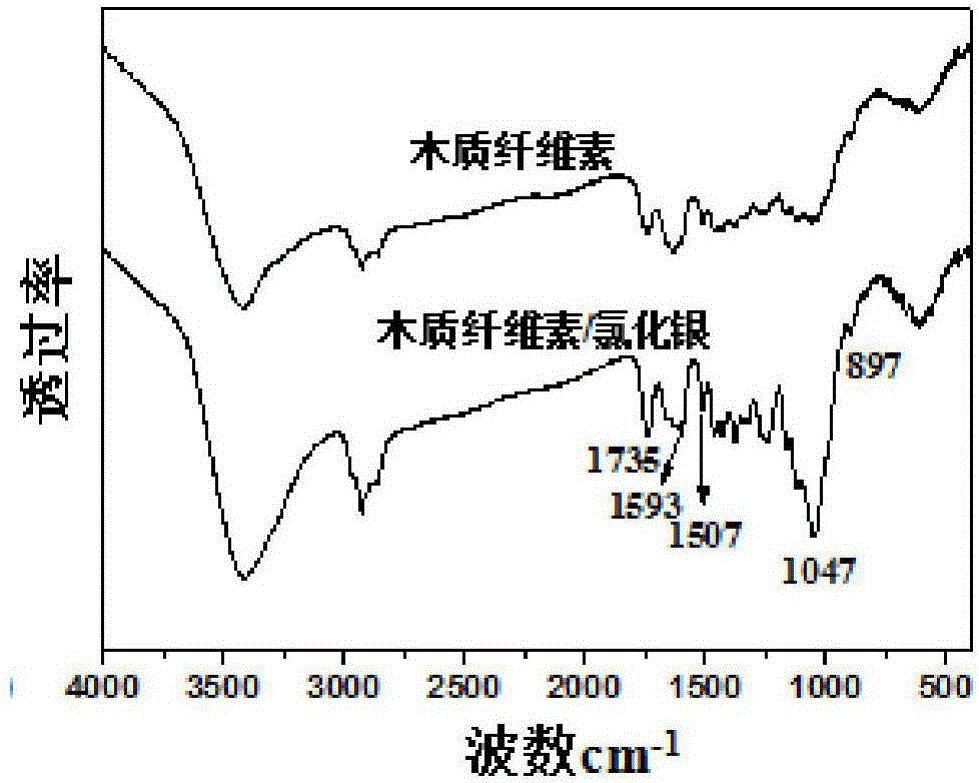

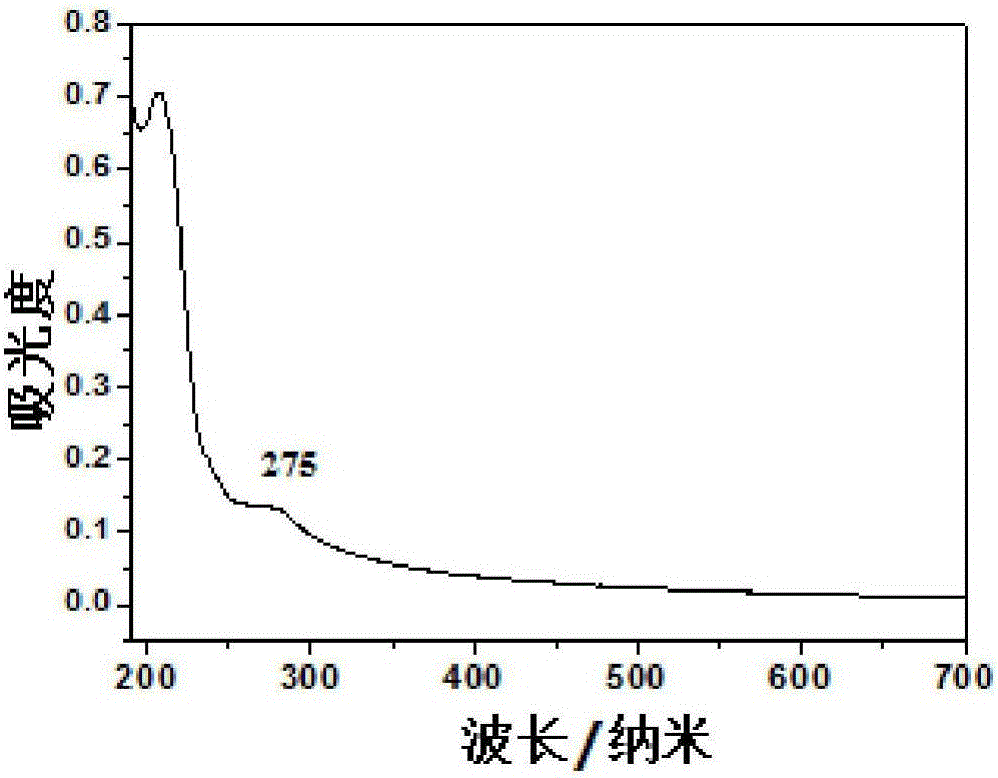

Lignocellulose/silver halide composite material with photocatalytic activity and preparation method thereof

A technology of lignocellulose and composite materials, applied in the field of preparation of composite materials and photocatalytic materials, to achieve the effects of broadening applications, good photocatalytic performance, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] In the preparation method according to the present invention, only three substances, lignocellulose, ionic liquid and silver-containing compound, are used, wherein the ionic liquid is used as a reaction medium and also acts as a reactant to provide halogen ions. In step c) of the preparation method according to the present invention, the mass ratio of lignocellulose to ionic liquid is preferably 1-5:20, more preferably 1-3:20, most preferably 2:20. When the mass ratio of lignocellulose and ionic liquid is less than 1:20, that is, when the relative content of lignocellulose is low, although the lignocellulose is basically dissolved, the amount of lignocellulose is too small, resulting in a large amount of unlinked lignocellulose in the later stage. The individual silver halide grains of the cellulose composite precipitate, thereby affecting the purity and photocatalytic effect of the product. When the mass ratio of lignocellulose to ionic liquid is greater than 5:20, due...

Embodiment 1

[0036] 1. Pulverize the wood, pass it through a 40-60 mesh sieve, and place it in an oven at 50°C for more than 16 hours. Put the dried wood powder into a bag made of gauze, seal it, put it into the extraction cylinder of the Soxhlet extraction device, add toluene-ethanol solution, heat treatment for 5-8 hours, and siphon 4-6 hours per hour. times until the siphon solution is colorless and transparent. After the treatment, the wood powder was taken out, spread on tin foil, and dried in an oven at 50° C. to obtain lignocellulose. Wherein, the wood used is the processing residue of poplar branches, and the model of the pulverizer used is FZ102 miniature plant pulverizer; the mass ratio of the wood powder to the toluene-ethanol solution is 1:20, that is, per 1 gram of wood powder 20 ml of toluene-ethanol solution was added; in the toluene-ethanol solution, the volume ratio of toluene and ethanol was 2:1; the ethanol used was absolute ethanol, and the reaction was carried out in ...

Embodiment 2

[0046] In addition to adding 0.5 g of silver nitrate to the lignocellulose-ionic liquid solution, the mixture was subjected to microwave heating synthesis reaction, the reaction temperature was 110 °C, and the reaction time was 30 minutes. Wherein, the mass ratio of silver nitrate to lignocellulose is 1:2, and the concentration of silver ions in the lignocellulose-silver nitrate-ionic liquid mixture is about 0.3 mol / L, and the rest are the same as in Example 1.

[0047] The FE-SEM photograph of the obtained sample is as Figure 4 (b): In the obtained composite, the content of silver chloride particles increased, and smaller cubic and spherical structures (about 100-300 nm in diameter), and larger concave cubes and flower-like structures (long axis is about 900 nm).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com