Patents

Literature

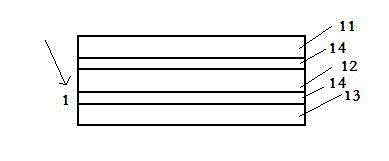

2312 results about "Wood processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wood processing is an engineering discipline comprising the production of forest products, such as pulp and paper, construction materials, and tall oil. Paper engineering is a subfield of wood processing. The major wood product categories are: sawn timber, wood-based panels, wood chips, paper and paper products and miscellaneous others including poles and railway sleepers. Forest product processing technologies have undergone extraordinary advances in some of the above categories. Improvements have been achieved in recovery rates, durability and protection, greater utilization of NTFPs such as various grain stalks and bamboo, and the development of new products such as reconstituted wood-panels. Progress has not been homogenous in all the forest product utilization categories. Although there is little information available on the subjects of technology acquisition, adaptation and innovation for the forest-based industrial sector, it is clear that sawmilling has been far less affected by the spread of innovations than the manufacturing of panel products.

Fuel pellet briquettes from biomass and recovered coal slurries

The invention makes burnable renewal fuel (RF) briquettes from recovered coal from coal slurry ponds, biomass, and a binder. The briquettes may be augmented with one or more of recovered environmental burnable fraction from municipal solid waste (MSW), agricultural livestock waste, lumber processing residue, solid wood waste material, agricultural by-products and crops, and like burnable waste material. Accordingly, the method for making burnable renewal fuel (RF) briquettes includes the steps of recovering coal from coal slurry ponds; recovering biomass; adding a binder to said recovered coal and said biomass; and forming solid burnable RF fuel briquettes therefrom.

Owner:NEW ENERGY USA

Method for improving solidifying point of Fischer-Tropsch wax

InactiveCN103980940AImprove stabilityHigh melting pointPetroleum wax recoveryChemical industryTwo step

The invention relates to a method for preparing high-melting-point refined wax capable of being applied to plastics, rubber processing, wood processing, food processing and other industries and particularly relates to a method for improving the solidifying point of Fischer-Tropsch wax. According to the method for preparing high-melting-point refined wax with excellent performances, distillation refining is carried out on light-weight oil serving as a raw material by means of continuous high-vacuum distillation, wherein the light-weight oil is produced by indirect coal liquefaction; According to the technical scheme, the method comprises two steps, namely, firstly, feeding the raw material in an evaporator by a feed pump so as to heat and evaporate the oil components and other low-boiling-point substances under the conditions of high temperature and high vacuum degree; secondly, feeding the coal-based synthetic oil without oil components and other low-boiling-point substances into a distiller, heating and evaporating the coal-based synthetic oil products by using heat-conduction oil under extremely high vacuum condition, condensing and capturing in a condenser to obtain the target product. The method disclosed by the invention can be widely used in the field of chemical industry.

Owner:SHANXI LUAN MINING GRP

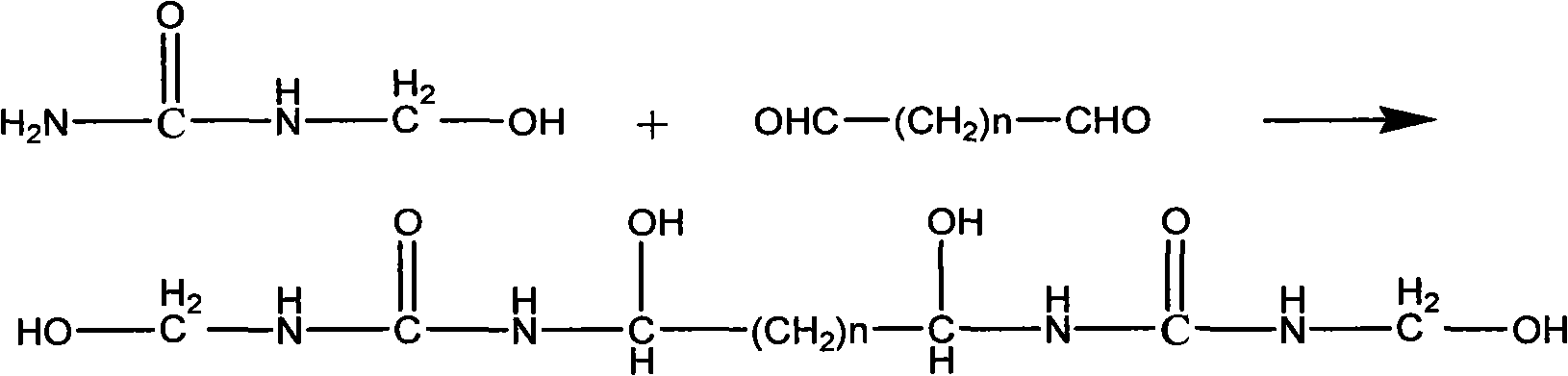

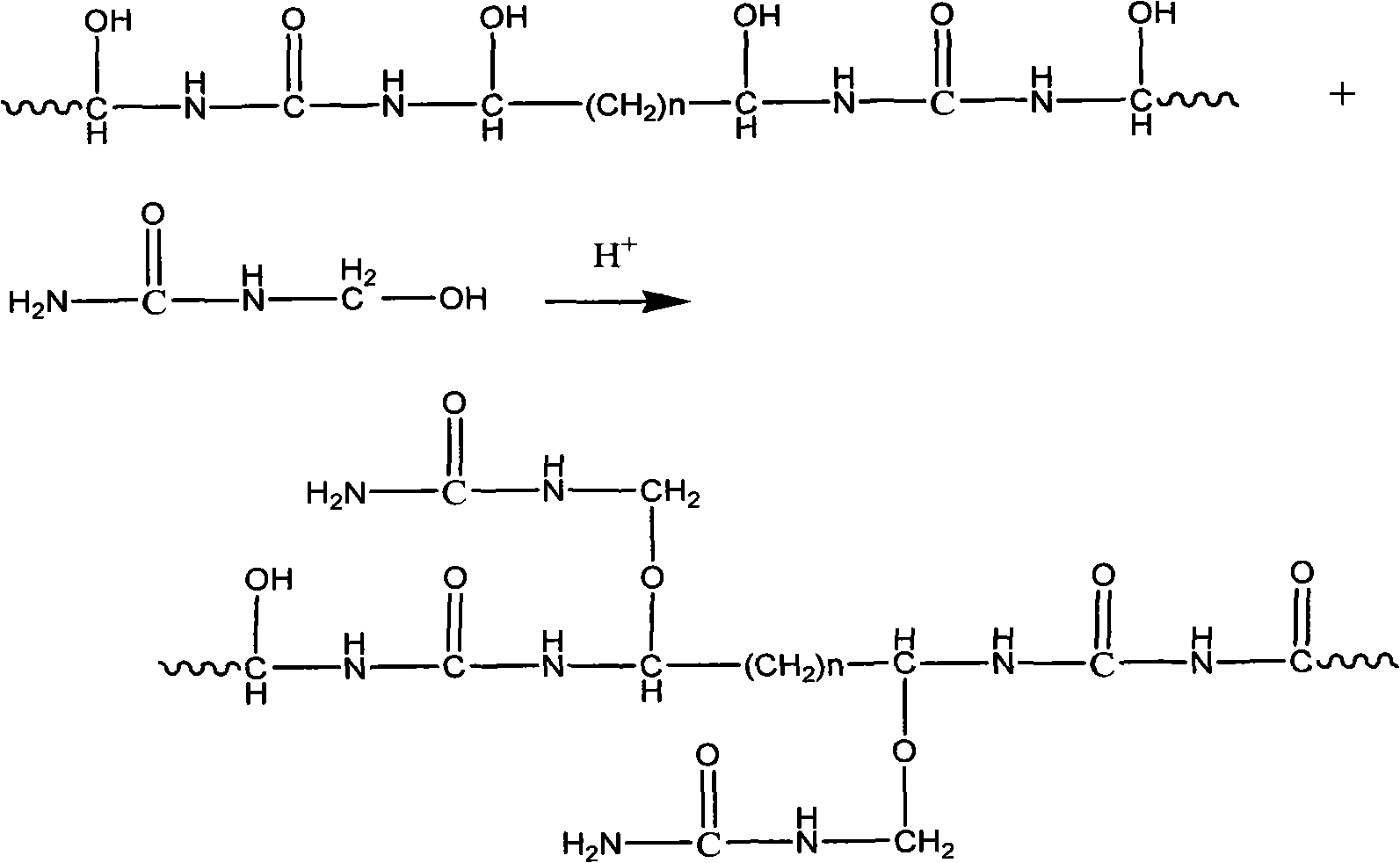

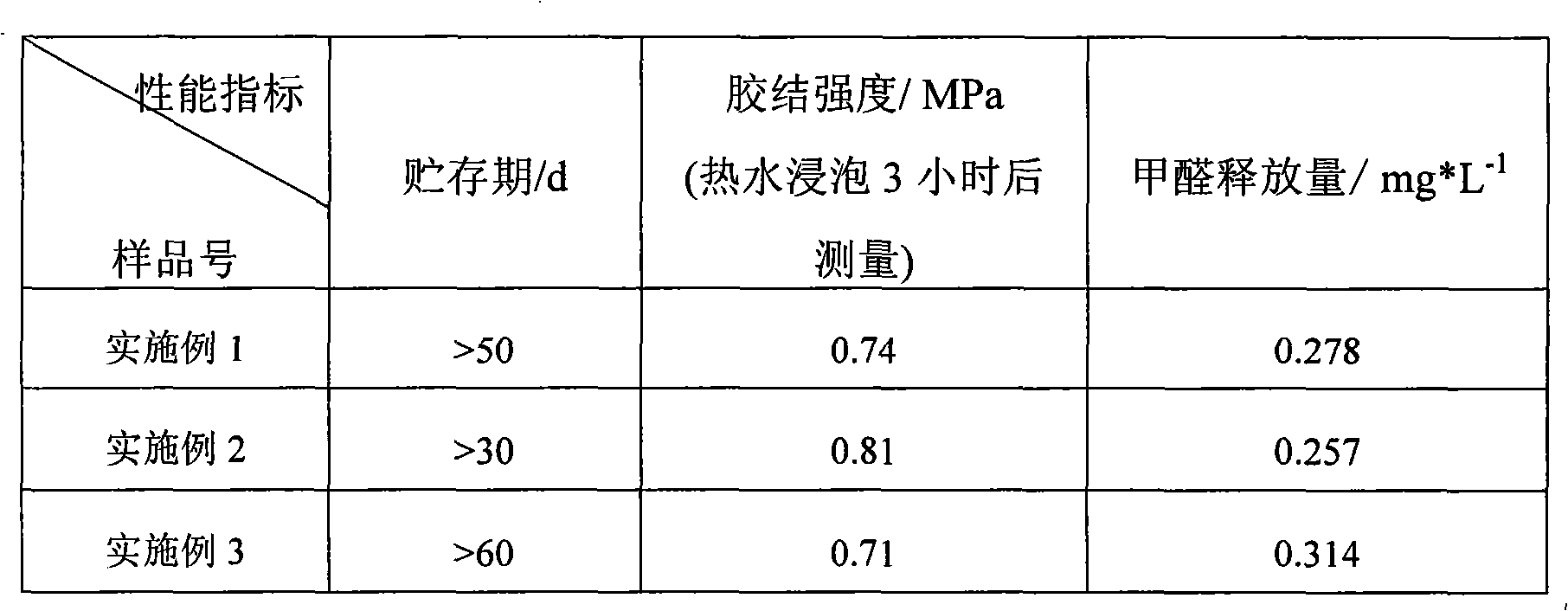

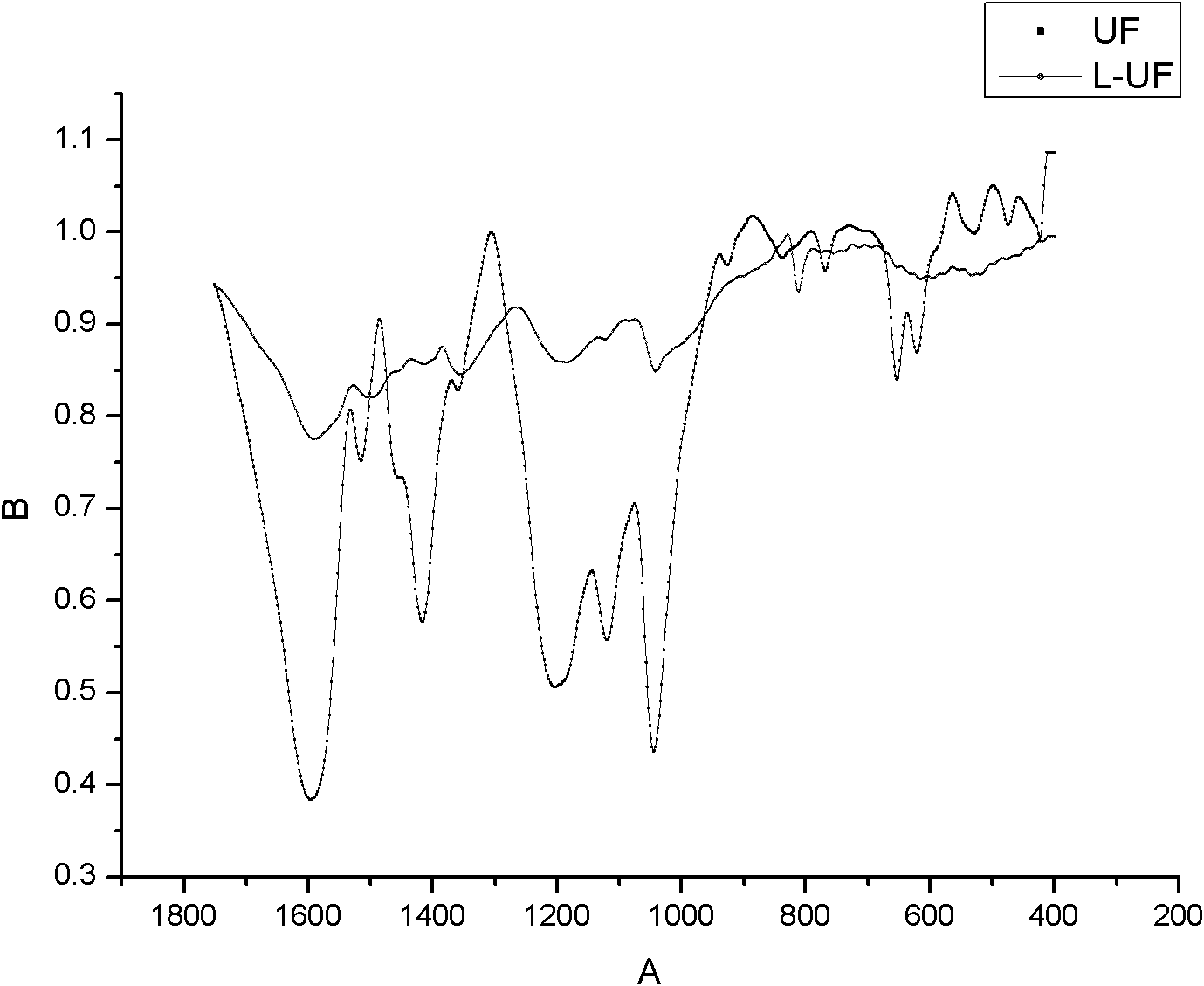

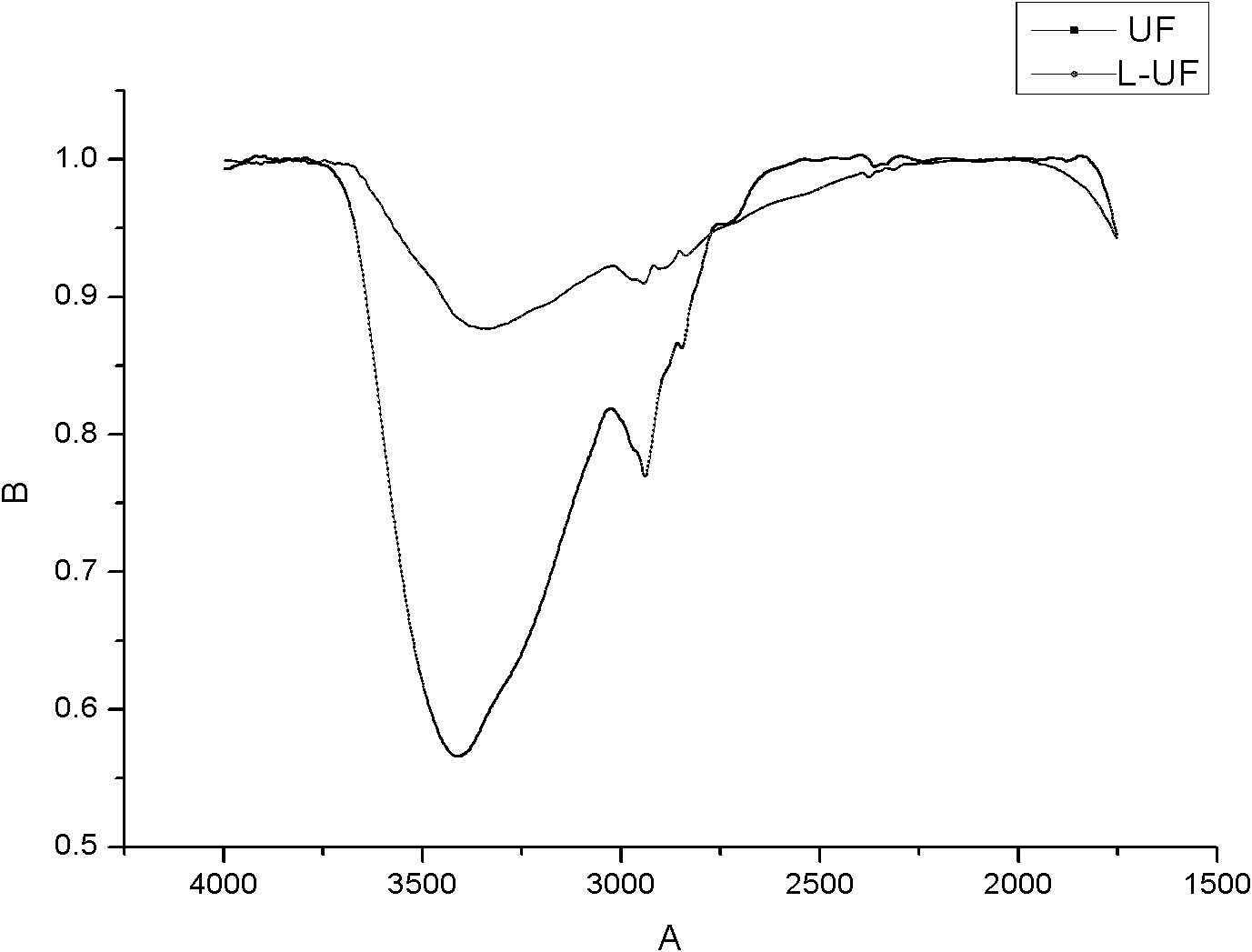

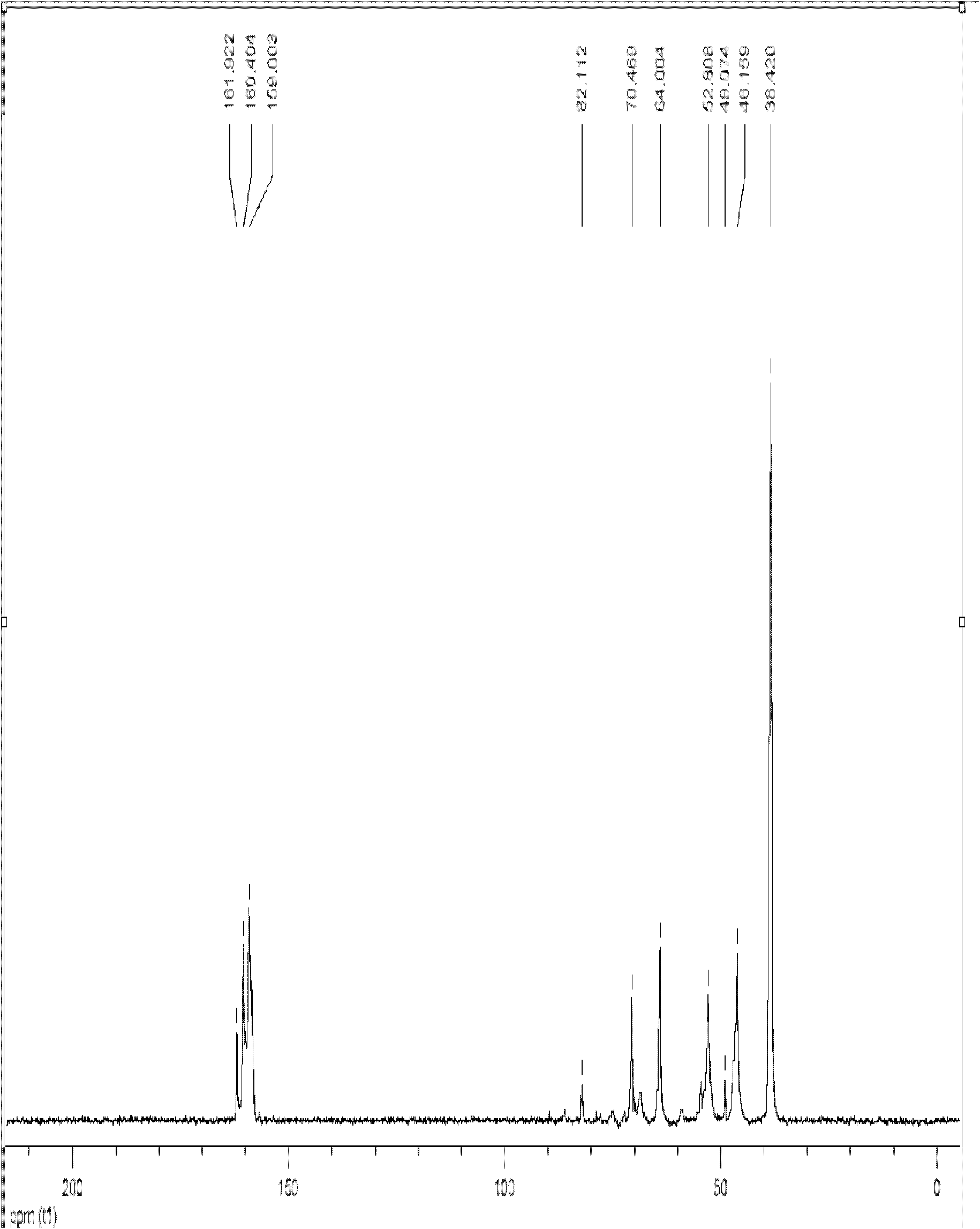

Environmental protection urea-formaldehyde resin and preparation method thereof

InactiveCN101265314ALow free formaldehyde contentExtended shelf lifeAldehyde/ketone condensation polymer adhesivesThermal waterWeak base

A novel environmental protective urea-formaldehyde resin and a preparation method belong to the field of wood processing adhesives. The urea-formaldehyde resin is formed by the reaction of urea, formaldehyde, aldehyde, one or more stabilizers and modifier according to the route of weak base-weak acid-weak base. The method firstly controls the F / U feed ratio, the pH value and the temperature during the reaction process to reduce the content of free formaldehyde in the resin; then the aldehyde is introduced to allow the resin to generate the stable alkyl ether (-(CH2)n-O-(CH2)n-) structure, thus reducing the content of methylene-ether bond (-CH2-O-CH2-) in the resin structure, simultaneously reducing the using amount of the formaldehyde and further greatly reducing the release amount of the formaldehyde during the using process of a plate from the two aspects; in addition, the introduction of a long chain and polyaldehyde can ensure the resin to have great bonding strength and water resistance. The urea-formaldehyde resin which is prepared by the invention has the advantages of low content of free formaldehyde, simple process, low cost, etc., the release amount of the formaldehyde of the plate which is prepared by using the adhesive achieves the E0 level standard, and the high bonding strength can be maintained after being boiled in hot water.

Owner:BEIJING UNIV OF CHEM TECH

Fuel for firing into rotary kiln cement clinker

A fuel which is used for rotary kiln cement clinker firing is composed of raw materials with the following weight percentage: coal 3-80, straw substances 0-90, forest products wastes 0-95 and food industry by-product residues 0-70. The straw substances refer to rice straws, wheat straws, cotton stalks, sesame stalks, soybean straws, corn stalks, sorghum stalks, rice husks, peanut shells, soybean shells and corn sticks, the forest products wastes refer to defective bamboo, wood, tree branches, leaves, shrubs, faggot straws and sawdust and wood wool corner scrap materials in the bamboo and wood-processing industry, the food industry by-product residues refer to bran, wheat skin, squeezing meal cake, bean dregs and wine lees, and the coal refers to bituminite, anthracite and coke coal powder. The flue raw materials which are used for the rotary kiln cement clinker firing have wide selecting range, simple preparation, convenient use and rapid burning speed and are beneficial for protecting atmosphere circumstances.

Owner:吴飞龙

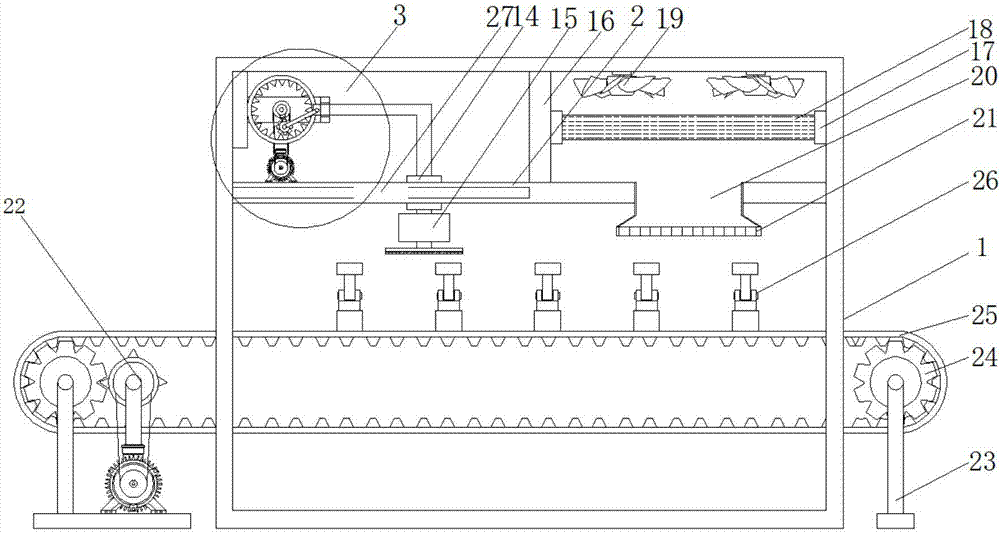

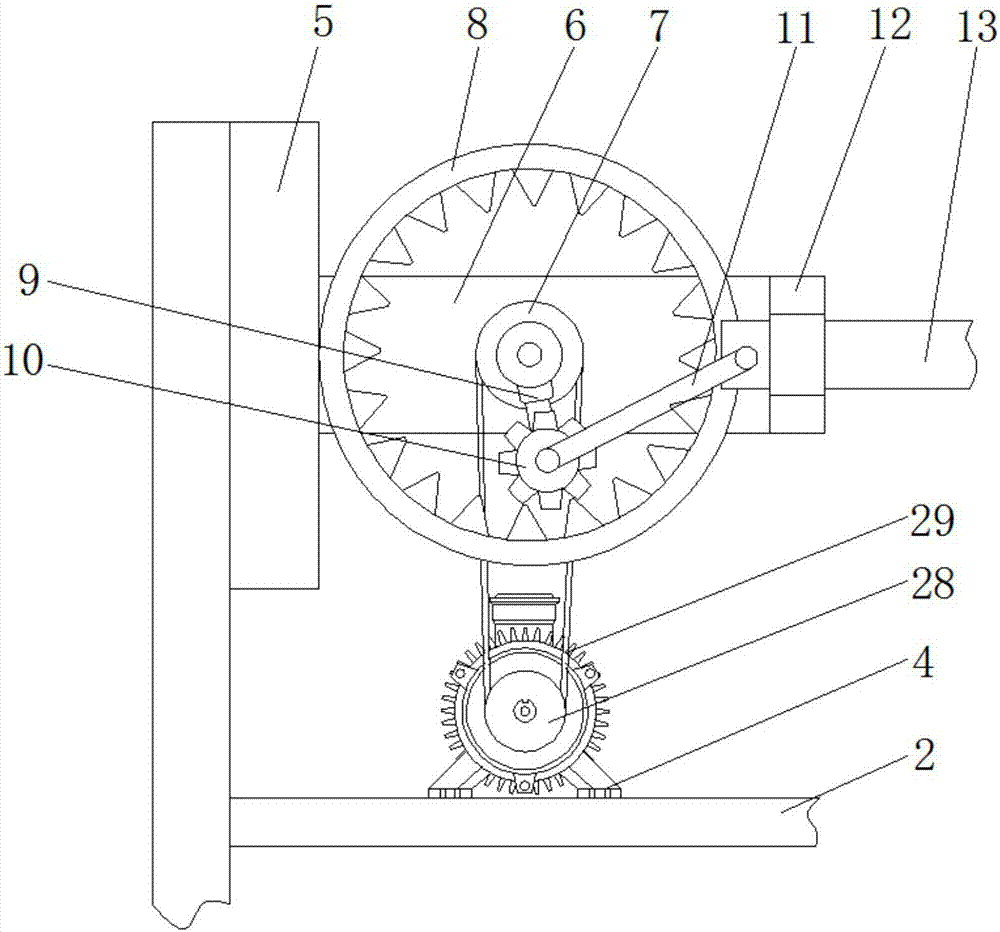

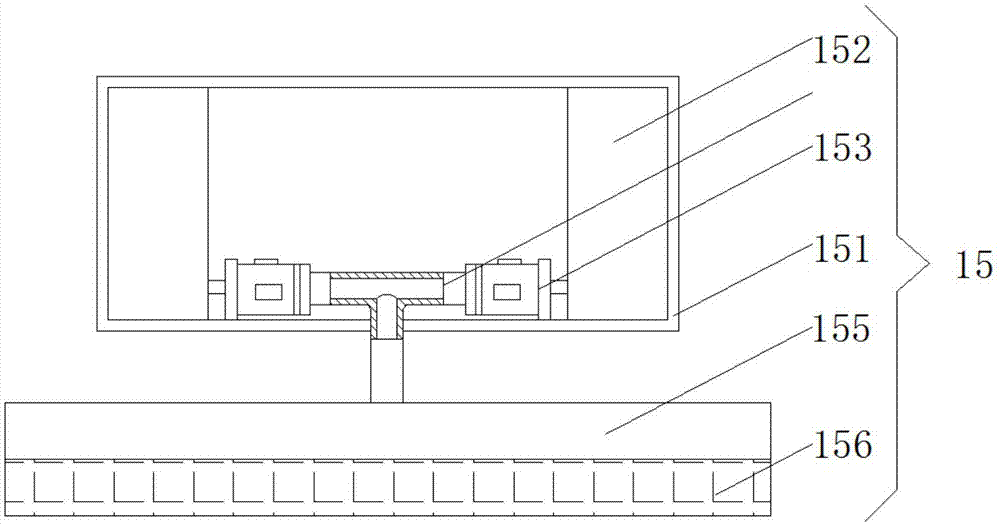

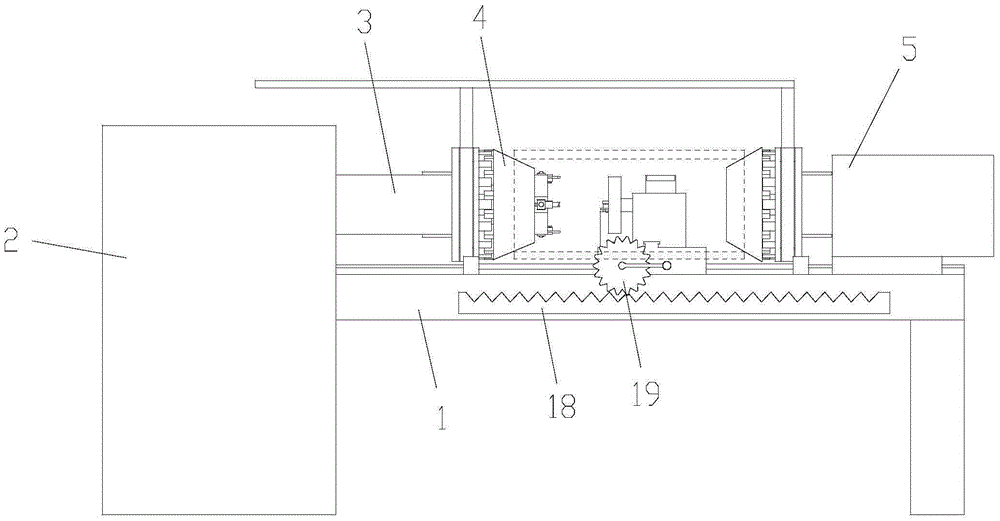

Bamboo wood toy paint spraying and drying device

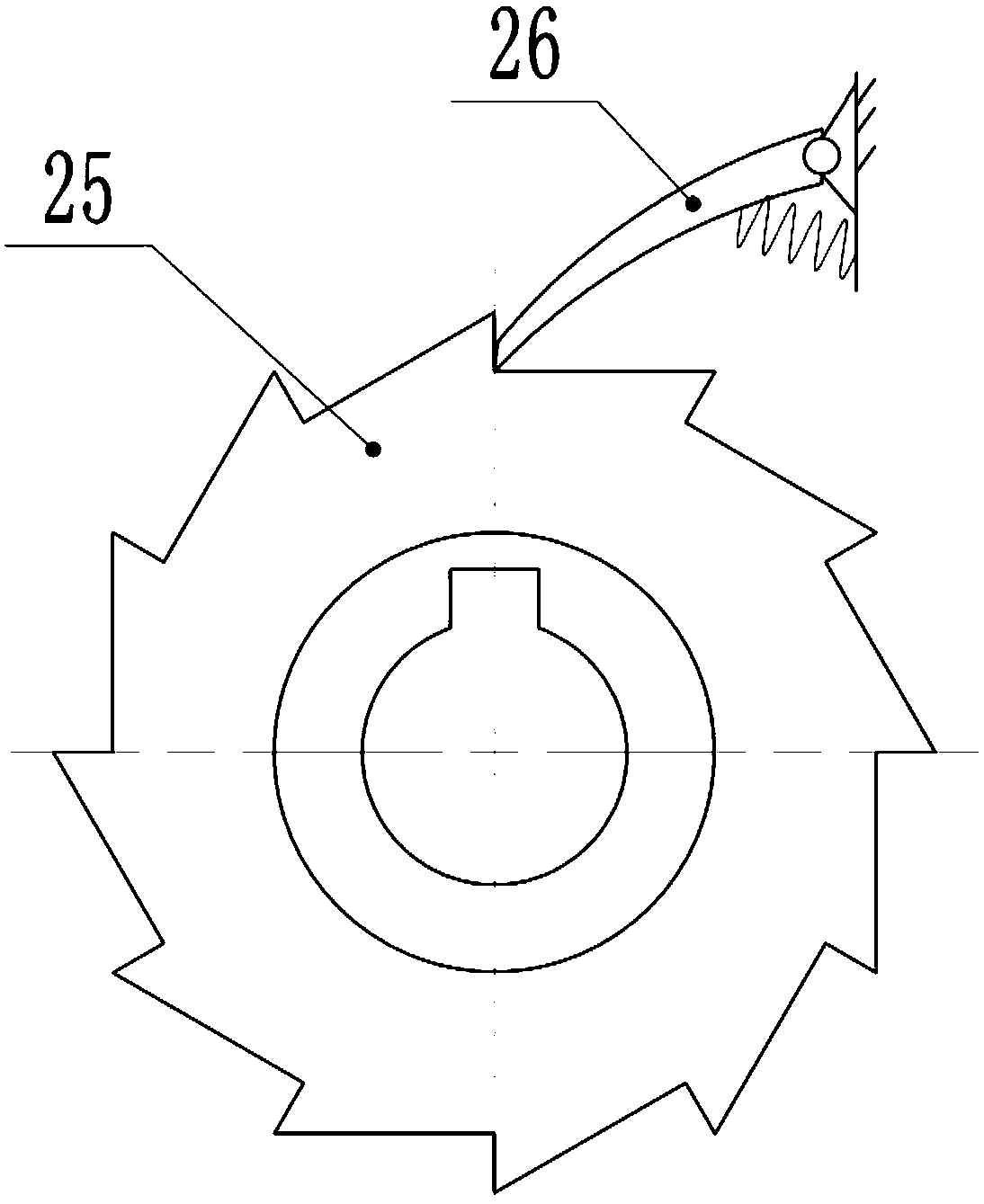

InactiveCN107309119ATo achieve the purpose of reciprocating movementAchieve the purpose of turningSpraying apparatusPretreated surfacesDrive wheelGear wheel

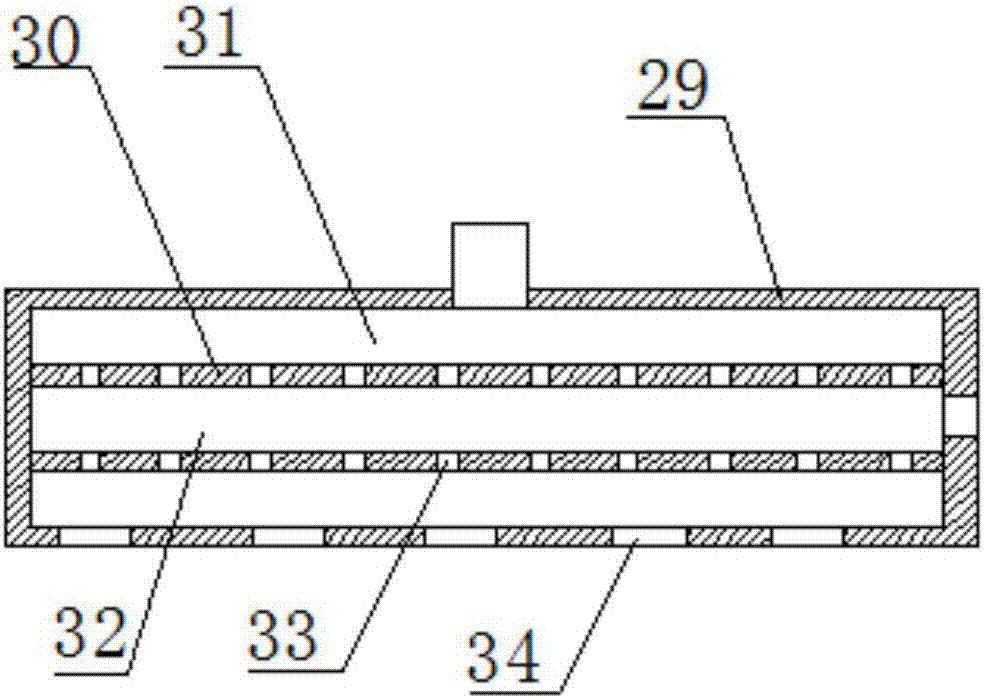

The invention discloses a paint spraying and drying device for bamboo and wood toys, which comprises an outer frame, a moving device is fixedly connected to the top of the support plate, an internal gear is fixedly connected to the right side of the vertical plate, and the concentric gear of the second driven wheel The pinion is rotatably connected to the shaft through the rotating shaft connecting rod, and the pinion is meshed and connected to the internal gear. The pinion is rotatably connected to a transmission link, and the transmission link is rotatably connected to a push rod. The bottom end is fixedly connected with a spraying device, and the left side outside the outer frame is provided with an output end of a transmission device, and the surface of the straight-toothed conveyor belt is fixedly connected with a bamboo and wood toy clamping device. The present invention relates to the technical field of bamboo and wood toy processing machinery . The paint spraying and drying device for bamboo and wood toys solves the problems that the existing bamboo and wood toy spray paint causes harm to the workers' bodies, and the spraying and drying are not comprehensive and the efficiency is low. s damage.

Owner:安吉县怡成竹木工艺品厂

Modified lignin and urea-formaldehyde resin synthesized from same and preparation methods of modified lignin and urea-formaldehyde resin

InactiveCN102241826AHigh bonding strengthReduce formaldehyde emissionAldehyde/ketone condensation polymer adhesivesSynthesis methodsEther

The invention discloses a modified lignin and a urea-formaldehyde resin synthesized from same and preparation methods of the modified lignin and the urea-formaldehyde resin, belonging to the field of bonding agents used in wood processing. A technological synthetic route with weak base-weak acid-weak base is adopted, the molar ratio of formaldehyde to urea is controlled during an addition stage to generate a reasonable structure, the modified lignin as well as residual hydroxymethyl and free formaldehyde are added at the later stage of reaction in order to accomplish reaction, thus the content of methylene ether link (-CH2-O-CH2-) and the content of hydroxymethyl in the resin are reduced to a certain extent, the formaldehyde emission of the resin is lowered, and simultaneously, higher bonding strength and water resistance are ensured. The urea-formaldehyde resin in the invention is simple and brief in process and low in cost, the formaldehyde emission of the plate prepared by adoptingthe bonding agent reaches the E0-level standard and the plate can maintain high bonding strength after being cooked in hot water. The modified lignin is simple in synthesis method and low in cost andis especially suitable for the modification of the urea-formaldehyde resin with low molar ratio.

Owner:BEIJING UNIV OF CHEM TECH

Method for blending and setting wood

ActiveCN101596730AAlleviate the prominent contradiction between supply and demandExpand the scope of useWood compressionWood treatment detailsPulp and paper industryDistortion

The invention relates to the technique field of wood processing treatment, in particular to a method for blending and setting wood. The method for blending and setting wood comprises steps of sorting treatment, softening process, blending and deforming, setting, temperature reduction and humidifying, and cooling and health preserving. The method solves the problems existing in the existing traditional wood blending and distortion technique that wood utilization ratio is low, obtained products have poor size stability and high recovery rate of radius of curvature and is easy to crack, deform, decay and go moldy, etc.

Owner:ZHEJIANG SHIYOU TIMBER

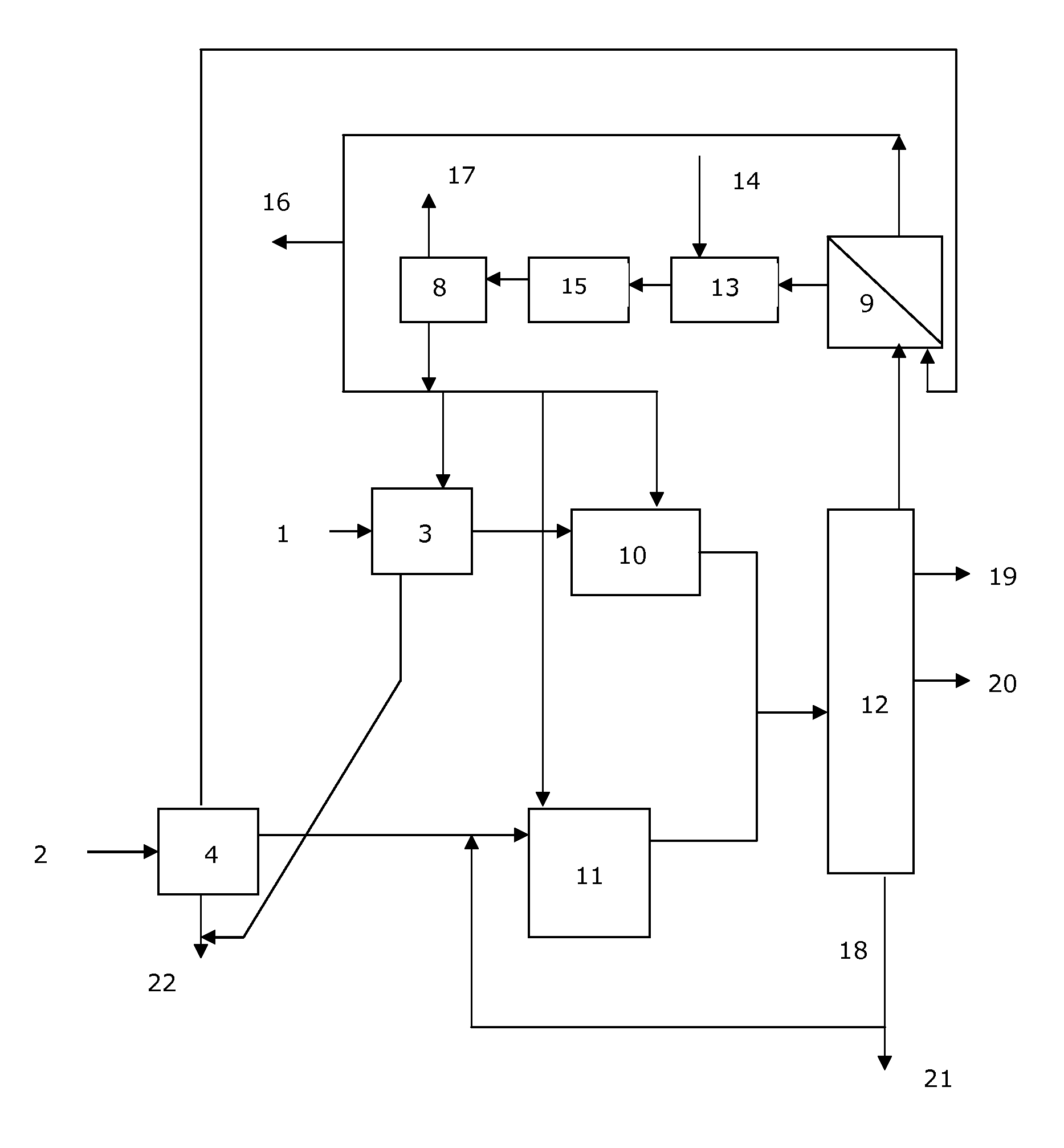

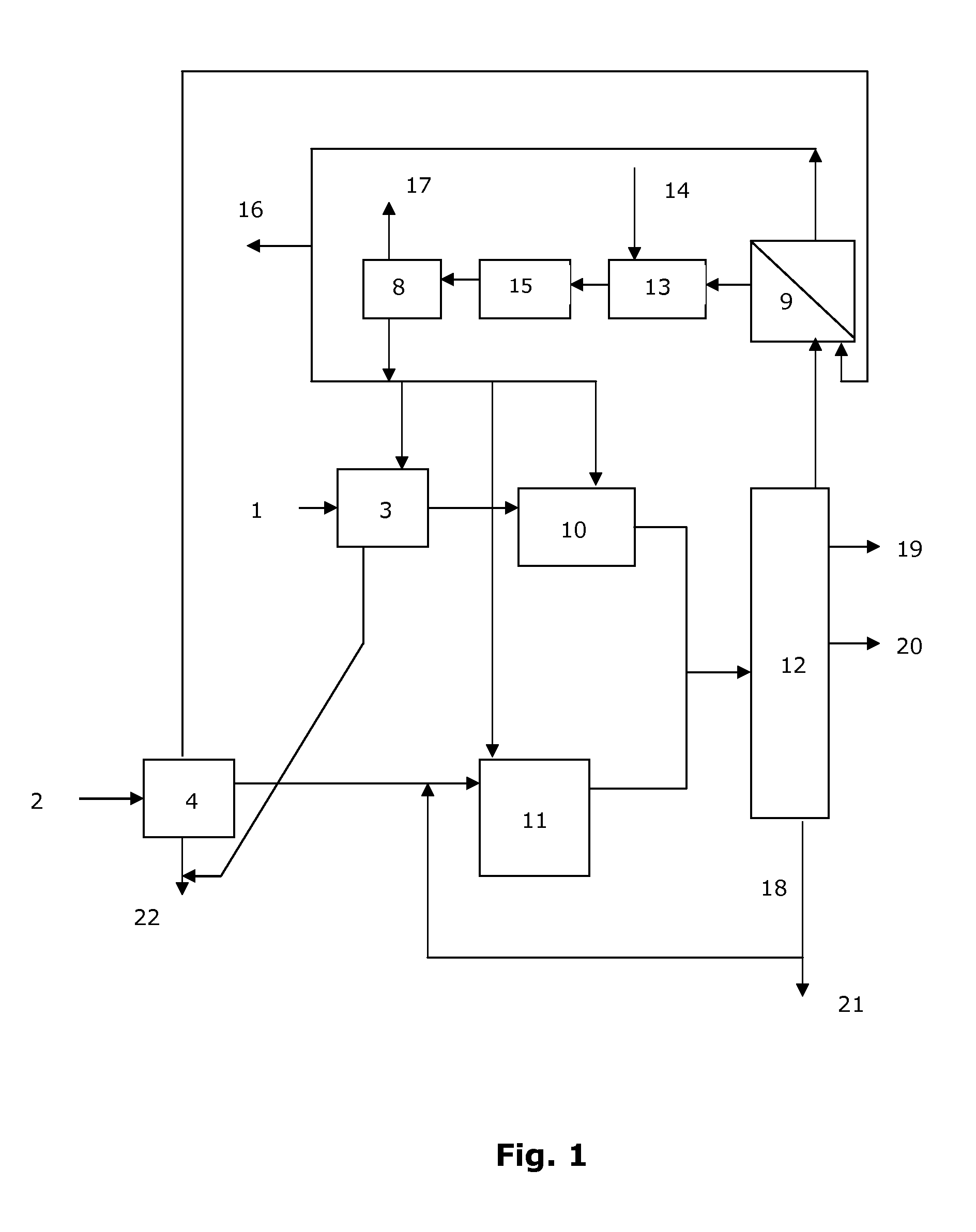

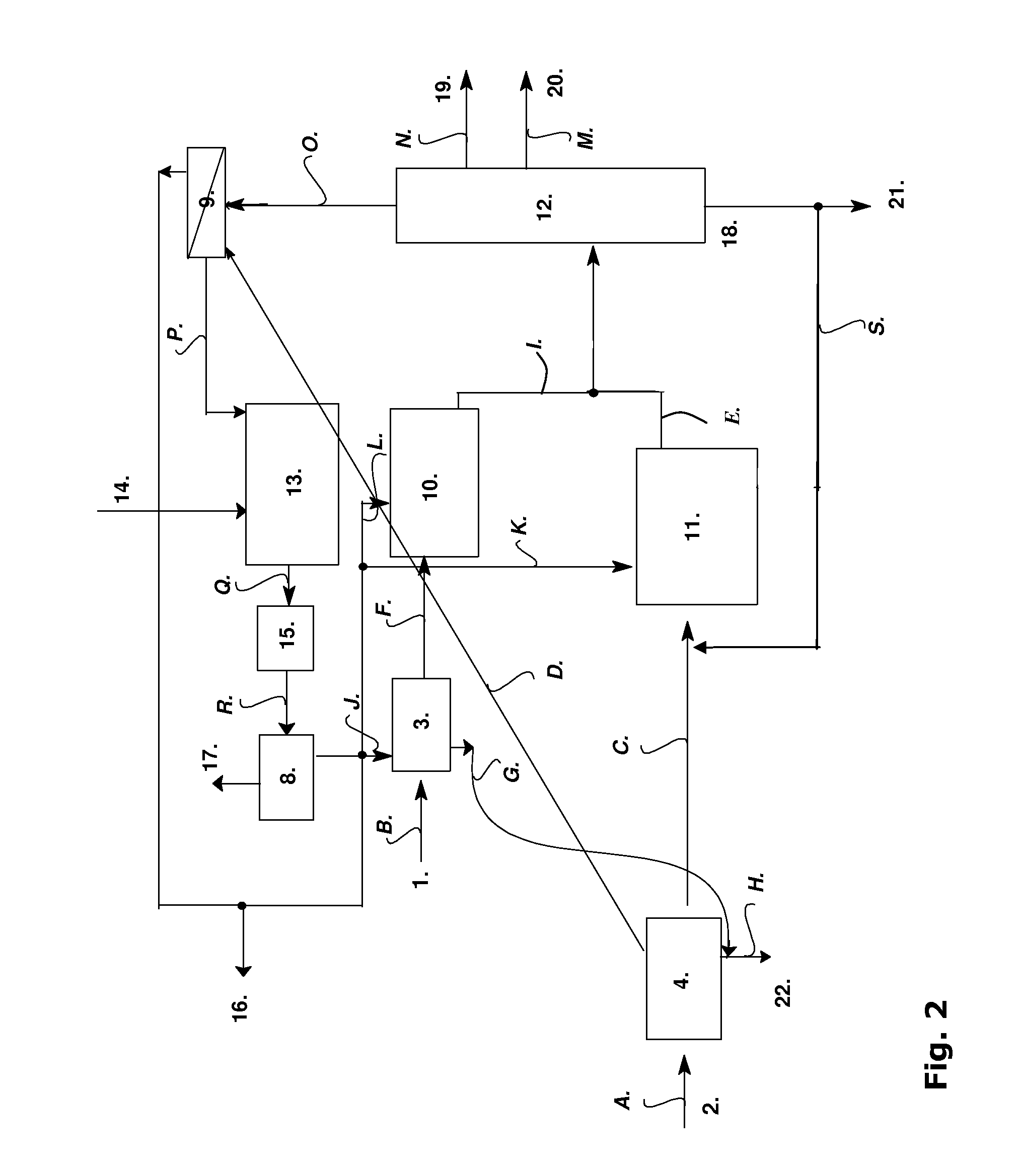

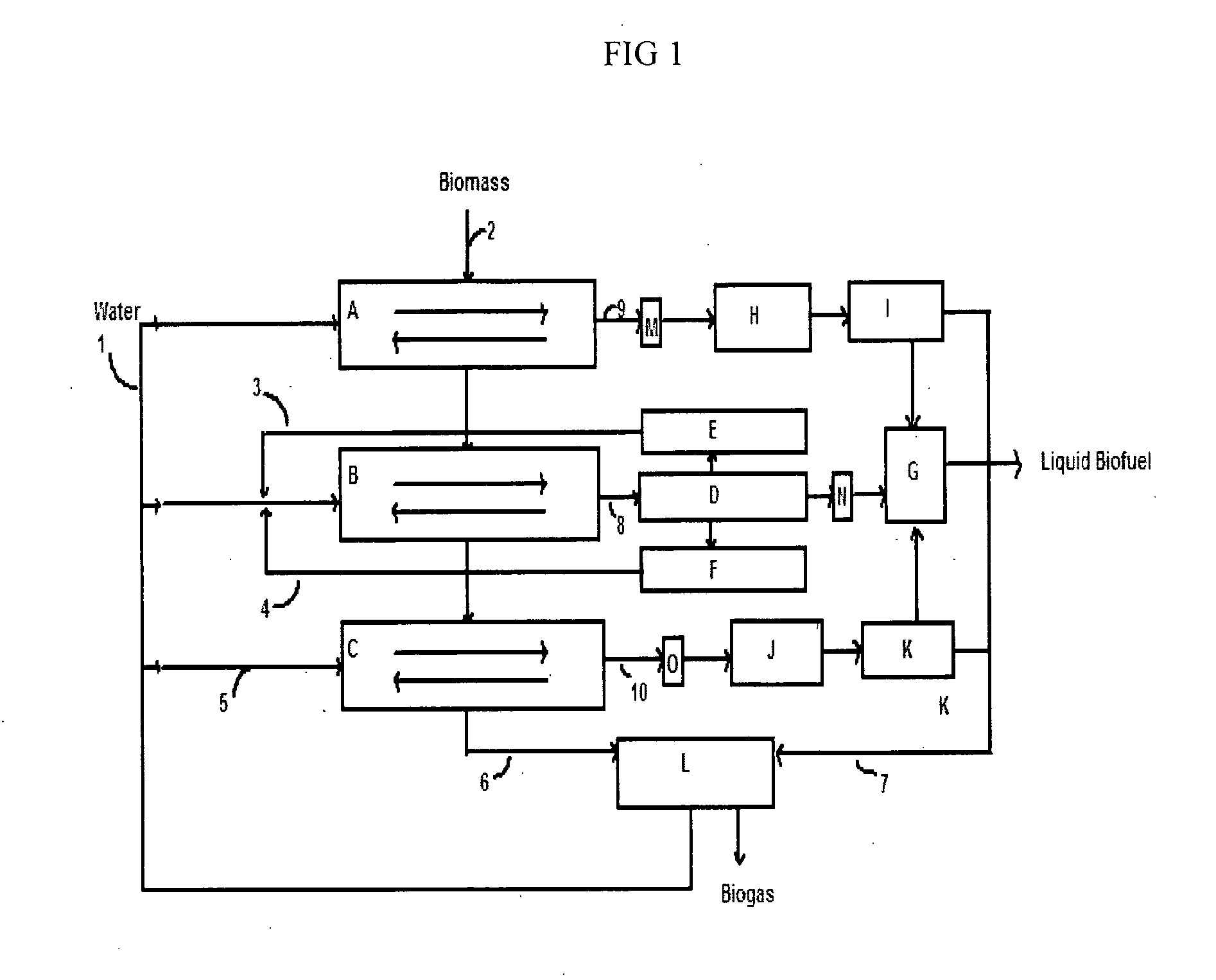

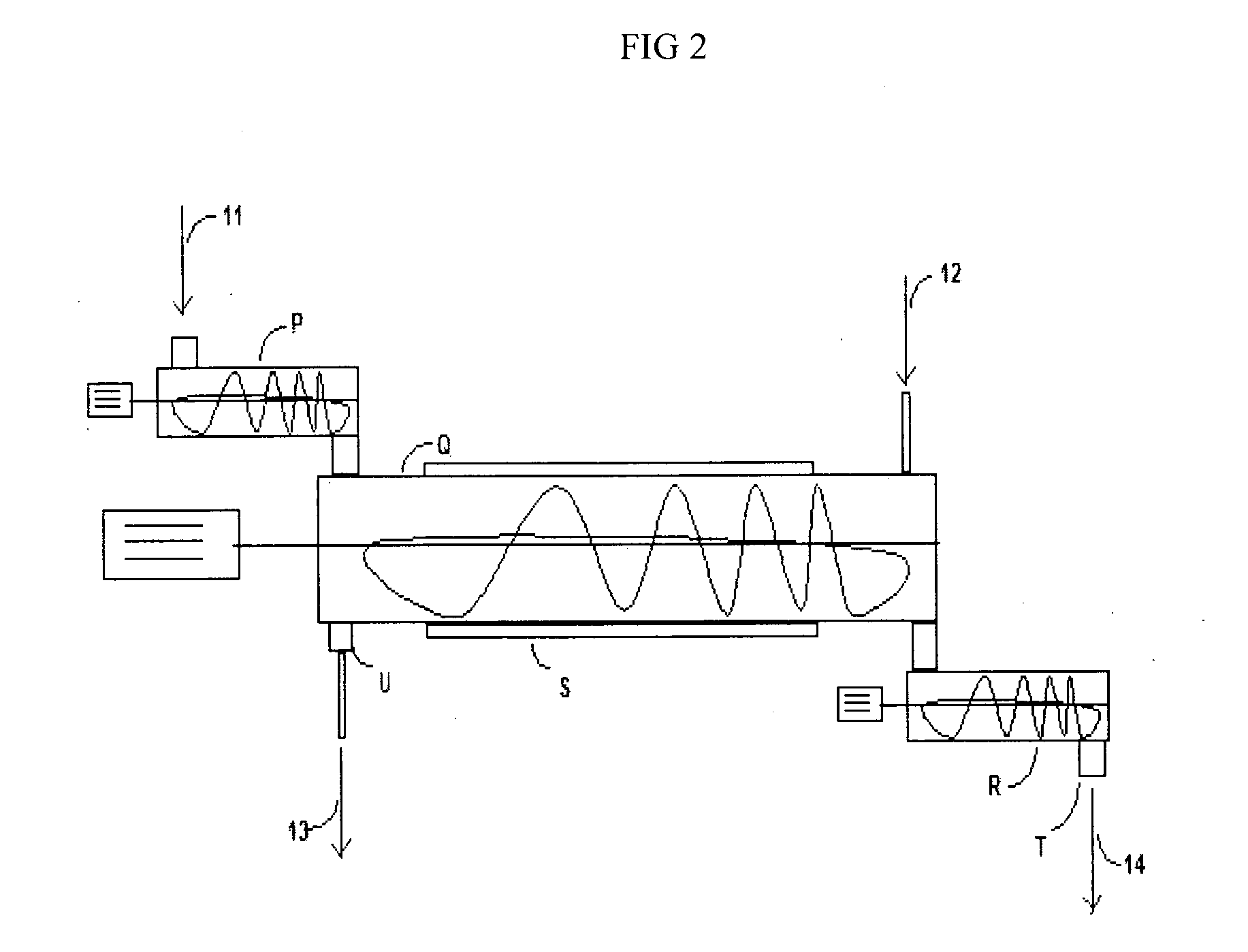

Integrated Process for Producing Diesel Fuel from Biological Material and Products, Uses and Equipment Relating to Said Process

InactiveUS20100317903A1Quality improvementMaximize utilizationRefining to change hydrocarbon structural skeletonCombustible gas catalytic treatmentCelluloseHydrocotyle bowlesioides

The present invention relates to an integrated process for producing diesel fuel or fuel additive from biological material by producing paraffins by a Fischer-Tropsch reaction on one hand and by a catalytic hydrodeoxygenation of bio oils and fats on the other hand. The two hydrocarbon streams are combined and distilled together. The invention also relates to the use of lignocellulosic material, such as by-products of the wood-processing industry for producing diesel fuel and to a method for narrowing the chain length distribution of Fischer-Tropsch derived diesel fuel. The invention provides a high-quality middle distillate fraction from various biological sources and most preferably from by-products of the wood-processing industry. The invention also relates to equipment for producing fuel form biological material, which comprises a hydrodeoxygenation reactor (3) for hydrocarbons, a cracking / isomerization reactor (11) for FT paraffins and a separation unit (12) for the combined hydrocarbons. Hydrogen is separated from light fractions in a separation unit (9) and reformed in the process. The equipment is advantageously integrated with a pulp and paper mill, which provides biological material and receives waste and energy.

Owner:UPM-KYMMENE OYJ

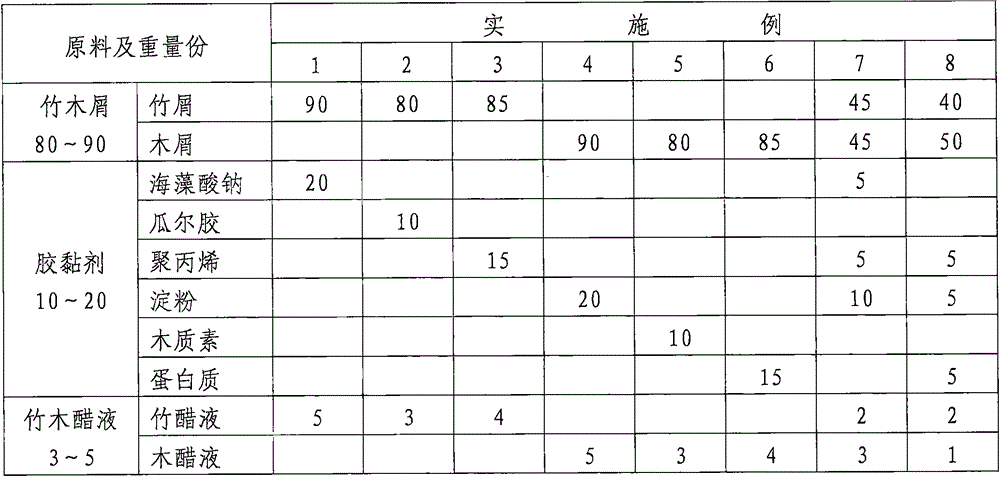

Bamboo-wood sawdust pet clustering padding material and preparation method thereof

The invention relates to a bamboo-wood sawdust pet clustering padding material. The bamboo-wood sawdust pet clustering padding material is prepared from, by weight, 80-90 parts of bamboo sawdust or wood sawdust, 10-20 parts of an adhesive, 3-5 parts of bamboo vinegar or wood vinegar and 50-100 parts of water, the formed particle padding material is light yellow or yellow or brown yellow, and the particle size is 1-8 mm. Aromatic wood sawdust of pine wood, Chinese fir wood and camphorwood is adopted as the wood sawdust. The particle size of the bamboo sawdust or wood sawdust is 60-80 mesh. At least one of sodium alginate, guar gum, food-grade polypropylene, starch, a lignin adhesive and a protein adhesive is adopted as the adhesive, and the adhesive is solid and needs to be ground into 100-120-mesh powder. The bamboo vinegar or wood vinegar is a scorched flavor removing type. According to the bamboo-wood sawdust pet clustering padding material, the adopted bamboo sawdust or wood sawdust are both waste obtained after natural wood processing, the adhesive is in a food grade, the padding material can serve as organic fertilizer to be completely and naturally biodegraded after being used, and therefore the padding material can be directly flushed into a sewer without blocking the sewer; the padding material is green and environmentally friendly.

Owner:ZHEJIANG FORESTRY UNIVERSITY

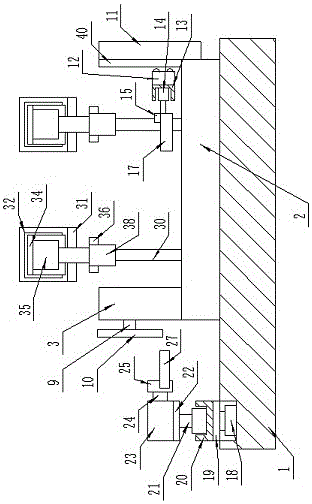

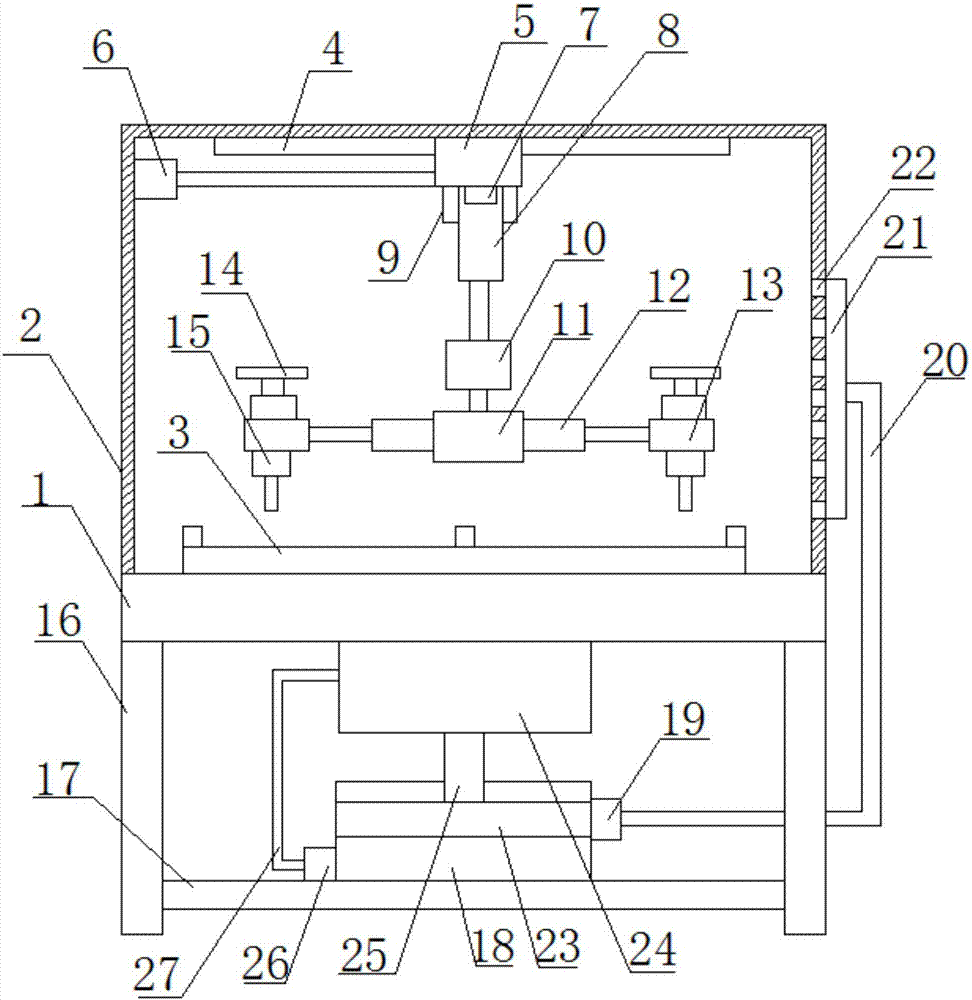

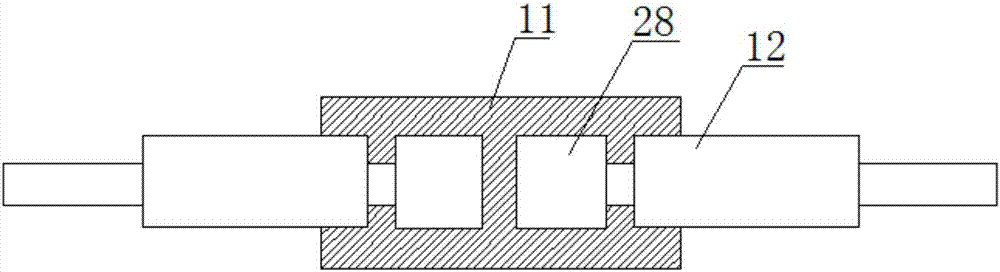

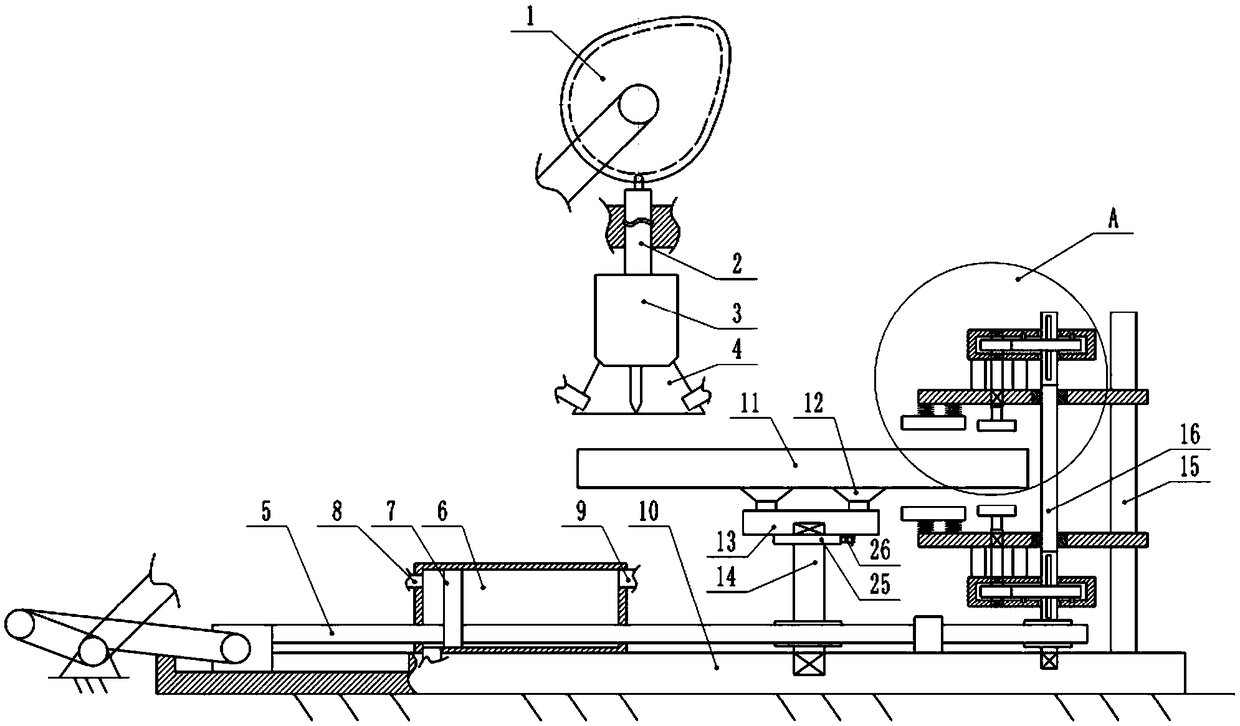

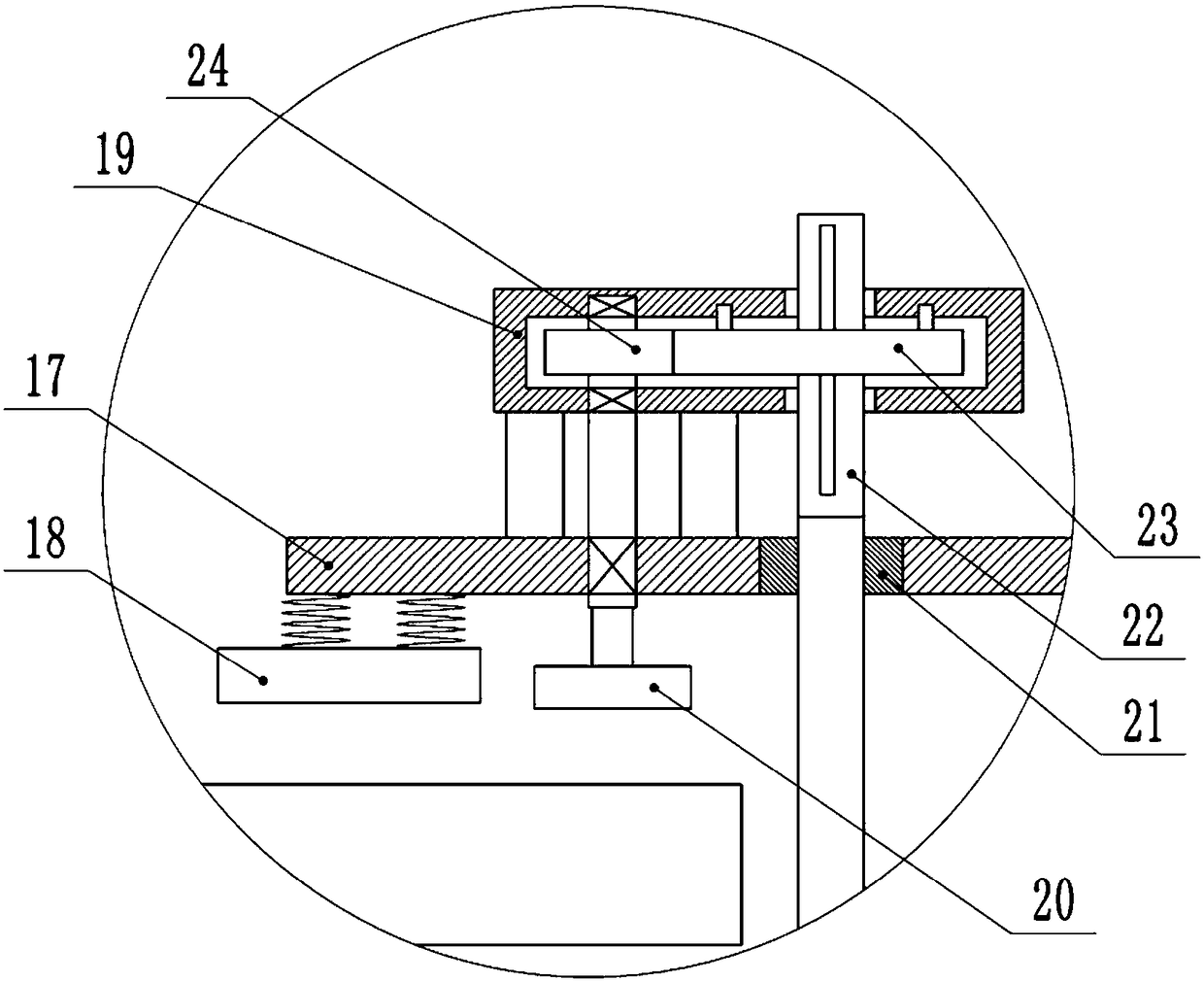

Assistant treatment device for wood processing

InactiveCN106393290AAvoid indirect contactImprove work efficiencyProfiling/shaping machinesEngineeringWood processing

The invention discloses an assistant treatment device for wood processing. The assistant treatment device comprises a working table, wherein a carrying mechanism and a fixed cutting mechanism are arranged on the upper surface of the working table; a No.4 round groove is processed on the upper surface of the working table and is positioned on one side of a placing platform; a No.4 driving part with an upward driving end is arranged on the lower surface in the No.4 round groove; a No.1 support plate is arranged at the driving end of the No.4 driving part; a No.3 mounting block is arranged on the upper surface of the No.1 support plate; a No.5 round groove is processed on the upper surface of the No.3 mounting block; a No.2 pushing cylinder with an upward telescopic end is arranged on the lower surface in the No.5 round groove; a carrier plate is arranged on the telescopic end of the No.2 pushing cylinder; and a No.2 mouth-shaped mounting rack is arranged on the upper surface of the carrier plate. The assistant treatment device disclosed by the invention has the beneficial effects of achieving automatic feeding, improving the working efficiency, and automatically propelling cutting.

Owner:CHENGDU PUJIANG KEXIAN TECH

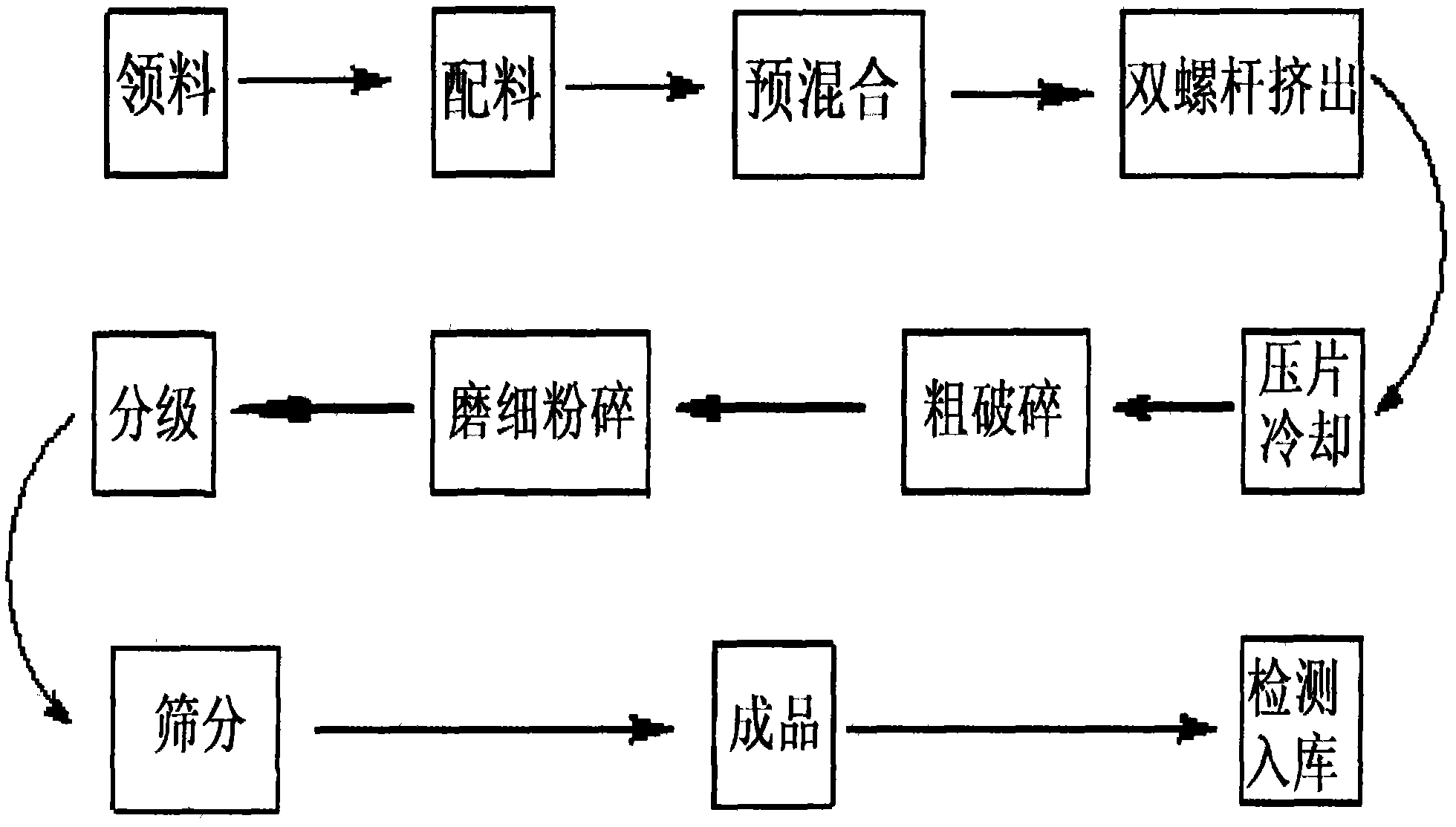

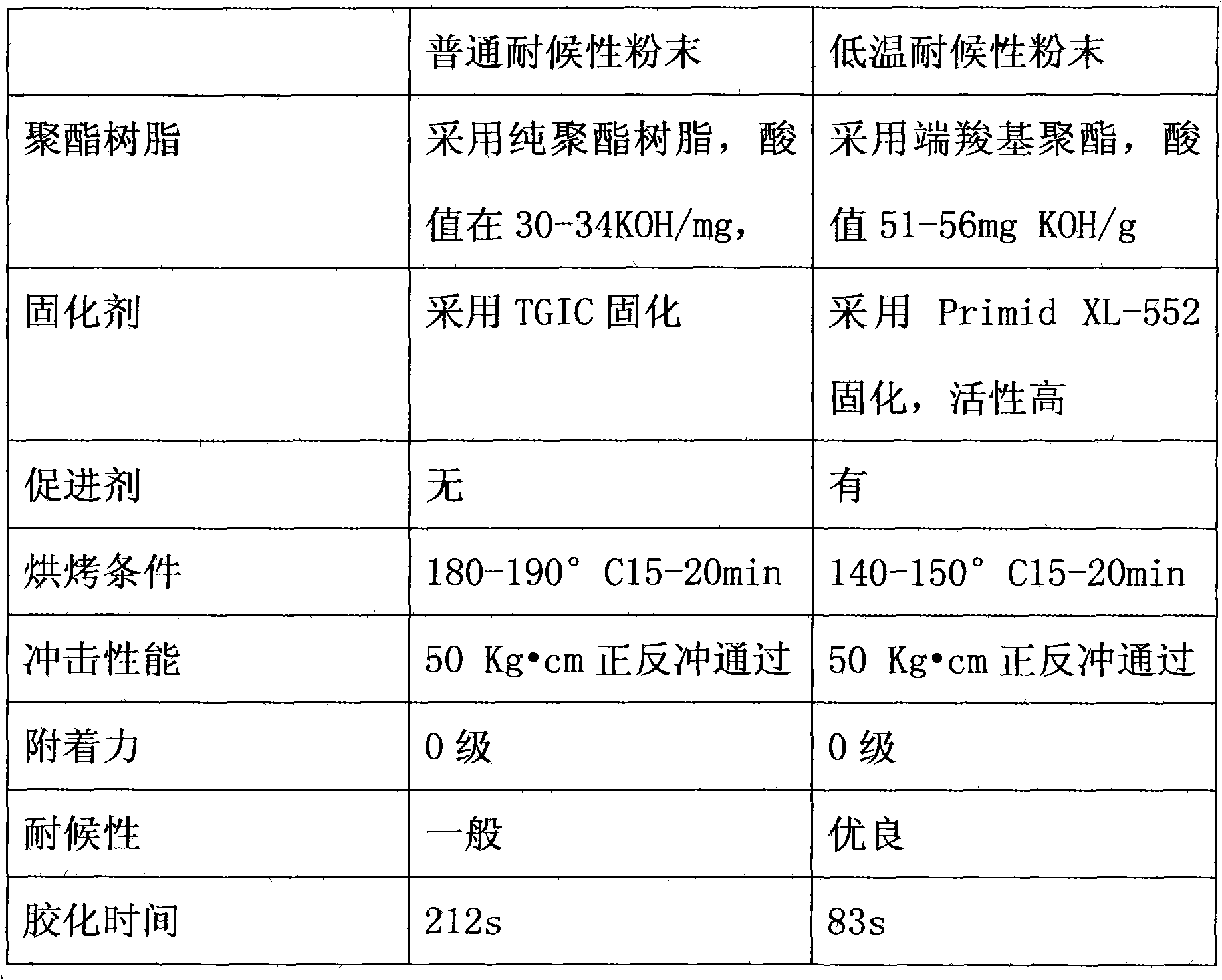

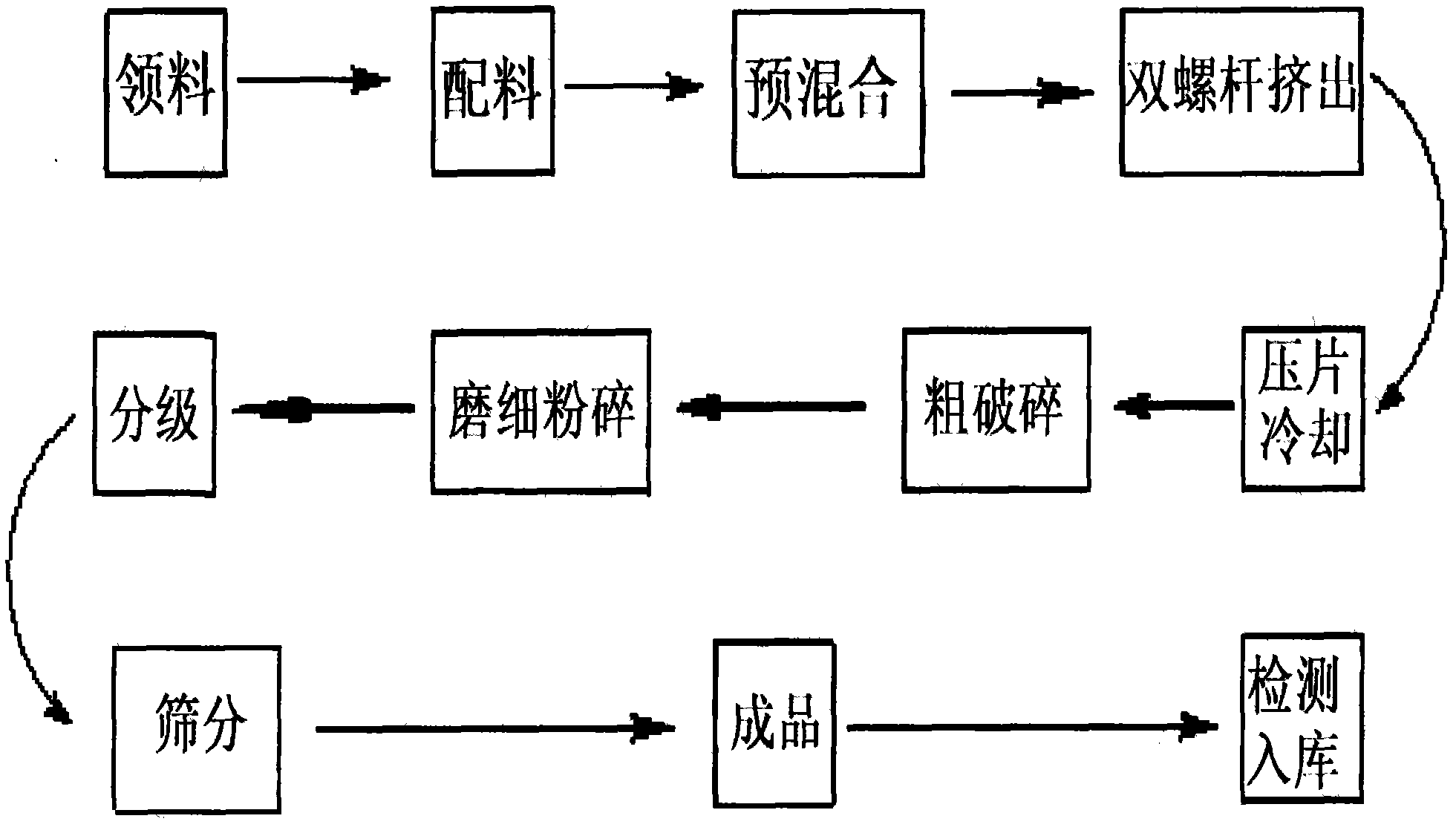

Thermosetting weather-resistant low-temperature curing powder

InactiveCN102277067ALow curing temperatureShort curing timePretreated surfacesPowdery paintsWeather resistancePlastic materials

The invention discloses thermosetting weather-resistant low-temperature curing powder, which belongs to the technical field of new materials. 0.3%-0.6% of accelerator, 15%-25% of filler, 3%-15% of pigment, 0.5%-2% of auxiliary agent after mixing, the invention has the beneficial effect of curing the coating film The required baking conditions are only 140-150 ℃, 20min, the curing temperature is lower, the curing time can be shortened by 2 to 3 times compared with ordinary products, the mechanical properties are not affected, and it has good weather resistance, which can meet the needs of production and life. , can be used in wood processing, engineering plastics and some metal alloy materials and other fields, expanding the application field of traditional powder.

Owner:SHANGHAI YUANFANG PAINT CO LTD

Whole bamboo flattening method and processing equipment

ActiveCN105235030AImprove processing qualityNovel structureCane mechanical workingEngineeringWood processing

The invention provides a whole bamboo flattening method. The method includes the following steps that firstly, old bamboo which is 3-5 years is selected, after branches are removed, the bamboo is sawn into a bamboo tube with the corresponding length; secondly, the bamboo tube is arranged on the bamboo wood processing equipment, an outer bamboo joint and an inner bamboo joint are removed, bamboo green with the thickness of 2-3 mm is removed, and a groove is formed in the bamboo tube; thirdly, the bamboo tube obtained in the second step is placed in an oven, baked for 5-10 min at the temperature of 300 DEG C to 500 DEG C, and softened; fourthly, the softened bamboo tube is placed on a flattening machine to be flattened, cooled for 20-30 min, and flattened into a bamboo plate in a cold pressing manner; fifthly, bamboo inner skin on the inner surface of the flattened bamboo plate is removed by 3-5 mm in a planing manner, and the outer surface and the periphery of the bamboo plate are ground to be smooth; and sixthly, the bamboo plate is baked for 5-6 hours in a baking room at the temperature of 30 DEG C, baked for 10-11 hours after temperature is raised to 40 DEG C, baked for 2-3 hours when temperature is raised to 50 DEG C, and manufactured into whole bamboo. The outer bamboo joint, the bamboo green and the inner bamboo joint of the bamboo tube are automatically cut off, working efficiency is high, and the processing quality of the bamboo tube is improved.

Owner:LIUZHOU LONGTAI BAMBOO IND CO LTD

Biomass solid fuel and processing technique thereof

InactiveCN103374427AAchieve innovative resultsAchieving a circular economy modelBiofuelsSolid fuelsAlternative fuelsToxic material

The invention relates to a biomass solid fuel and a processing technology thereof. The biomass solid fuel is prepared by pressing the following raw materials in percentage by weight: 90% of a biomass raw material and 10% of water, wherein the biomass raw material adopts crop derelicts, bamboo-wood processing residues or residual branches and leaves after timber cutting. The biomass solid fuel can replace coal, oil and other primary energy sources and serves as an alternative fuel; because the biomass solid fuel is a renewable energy source, the short supply of energy sources is alleviated; the biomass solid fuel is an environment-friendly fuel, and the combustion emission data reaches the national environmental protection standard, so that the pollution to the air is reduced, and the living environment is improved; and meanwhile, the biomass solid fuel is simple in processing technique, and the production process does not generate toxic substances and can not cause damages to the environment, so that the biomass fuel has an important significance for promoting the construction of a new socialist countryside.

Owner:佛山市三水环能再生能源有限公司

Method for preparing bleached chemi-mechanical pulp fore culture paper making by using cotton wood to process remainder

ActiveCN101613975ATake advantage ofEnergy saving and environmental protection in pulping processPretreatment with water/steamPulp bleachingHigh intensityProcessing plants

The invention discloses a method for preparing bleached chemi-mechanical pulp fore culture paper making by using cotton wood to process remainder, which belongs to the field of pulp refining for making paper. The method mainly comprises presteaming, double screw extrusion, chemical impregnation, high-consistency pulp refining by a double-screw fiberizer, adding medicament in the pulp refining process, high-consistency stay, middle-consistency pulp refining and other steps. The pulp refining process adopts single-section double-screw extrusion and single-section alkaline hydrogen peroxide impregnation, has simple process flow and compact equipment, completely adopts home equipment and saves the investment. The chemi-mechanical pulp prepared by processing cotton wood remainder through the method has the characteristics of high bulk, strength, whiteness and the like, and is suitable for pulp to be used for paper making of medium-high grade culture paper. The method achieves the cleanness and high-efficiency utilization of the remainder of the cotton wood processing factories, and is suitable for medium-small paper making enterprises for producing culture paper dependent on outsourcing goods.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Method for processing wood and wood manufactured by same

InactiveCN101623887AShort processing timeShort processing cycleWood treatment detailsWood dampingHeat lossesSuperheated steam

The invention relates to a method for processing wood, which belongs to the technical field of heat treatment of wood. The method comprises the steps of sequentially carrying out decompressing, preheating, high-temperature pressurizing and humidifying on wood placed into a container. Because the higher equilibrium water content is maintained in the process of processing the wood by the method, the manufactured wood overcomes the dry defects of cracking, shrinkage, and the like. The manufactured wood has reinforced size stability, strength and bending strength; the cracking generation proportion, the hygroscopicity and the water absorption performance of the wood are greatly reduced; and the weather and corrosion resistance of the wood is improved. The wood manufactured by the method reaches the standard of carbonized wood SB / T 10508-2008. The superheated steam with large specific heat and heat transfer coefficient is used as a heat transfer medium by the method and has small medium transfer resistance, short processing time and less heat loss; and the method saves energy sources and has low wood processing cost.

Owner:WUXI YUSHENG KITCHEN & BATH APPLIANCE

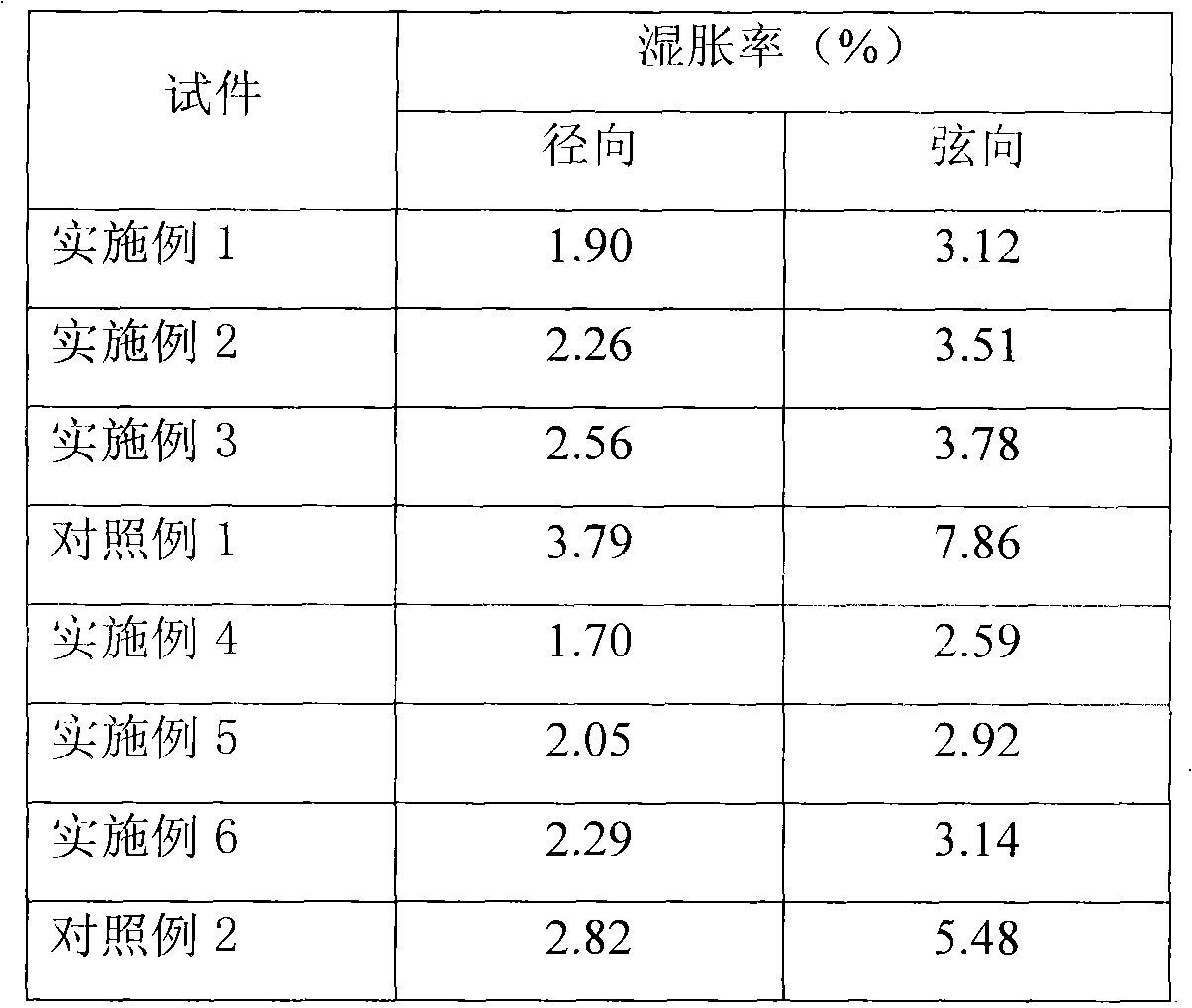

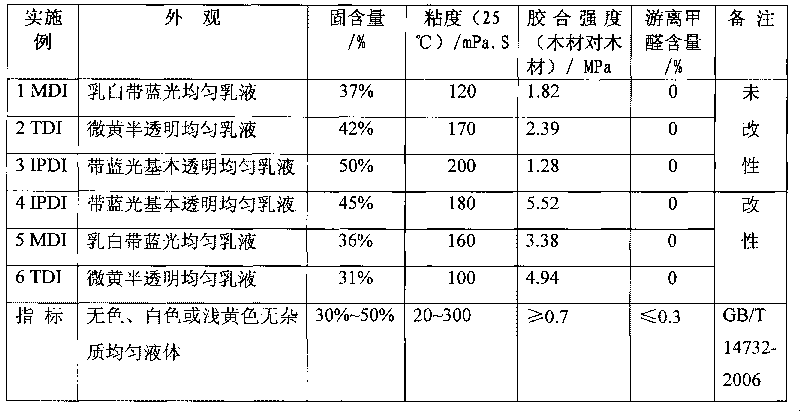

Preparation method and application in wood processing of water-based polyurethane adhesive

InactiveCN101701140ALow viscosityImprove performancePolyureas/polyurethane adhesivesWater basedHydrophilic monomer

The invention relates to a water-based polyurethane adhesive, in particular to a preparation method of a water-based polyurethane adhesive used in the wood processing. The preparation method comprises three stages, wherein the first stage is stepwise polymerization, namely polyol oligomer, hydrophilic monomer, isocyanate and modified monomer are adopted to prepare modified polyurethane prepolymer through stepwise polymerization and radical polymerization; the second stage is to disperse the modified polyurethane prepolymer in water after neutralization and salt formation; the third stage is to add chain extender to form water-based polyurethane emulsion, wherein the R value of the modified polyurethane prepolymer is 1.02-2.0 and R value refers to the ratio of the total mole number of NCO to the total mole number of OH in the system, the synthesis conditions are as follows: the vacuum degree is 0.090-0.1MPa, the polymerization temperature is 65-90 DEG C, the polymerization reaction time is 2-4h, the neutralization temperature is 40-60 DEG C and the solid content is 20-50%. The preparation method of the invention adopts proper amount of modified monomer to graft and crosslink with polyurethane so as to obviously increase the water resistance, solvent resistance and bonding strength, thus optimizing the product performance.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

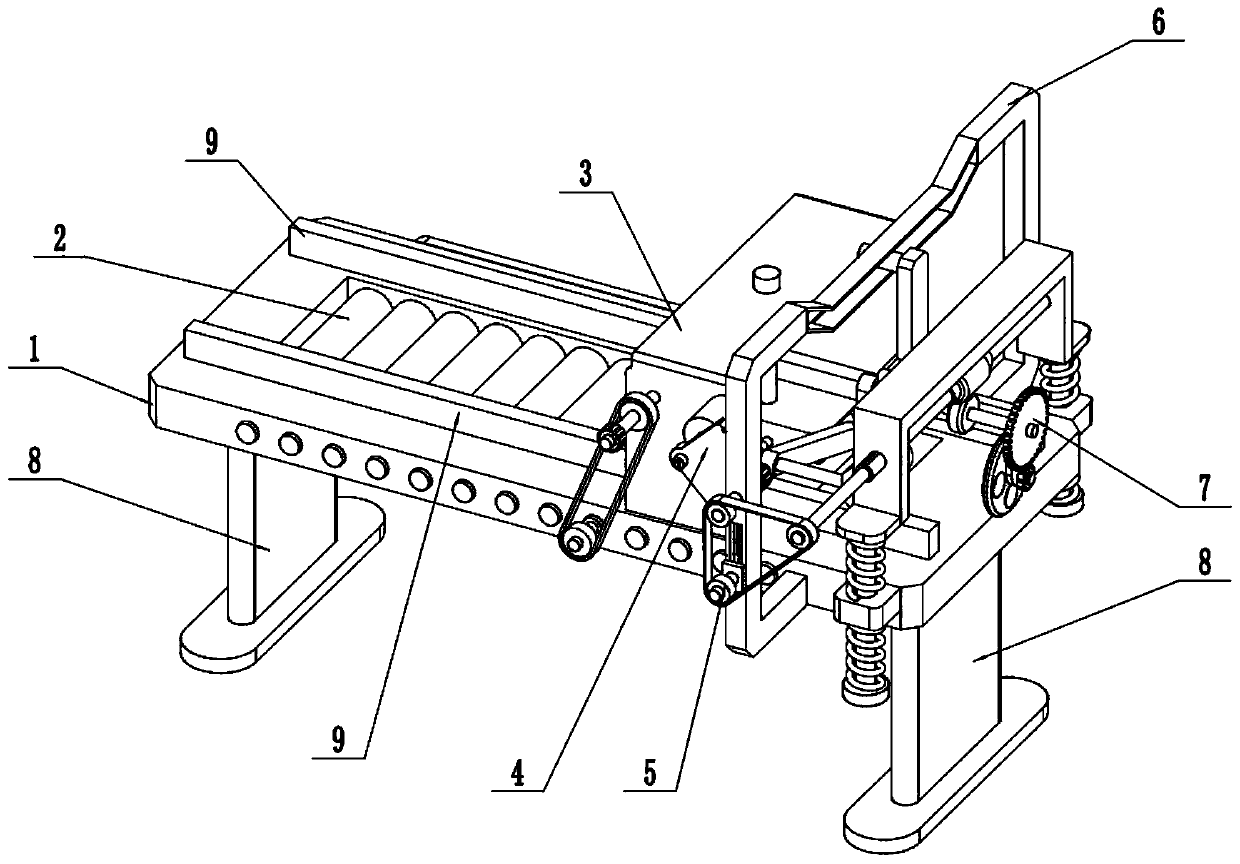

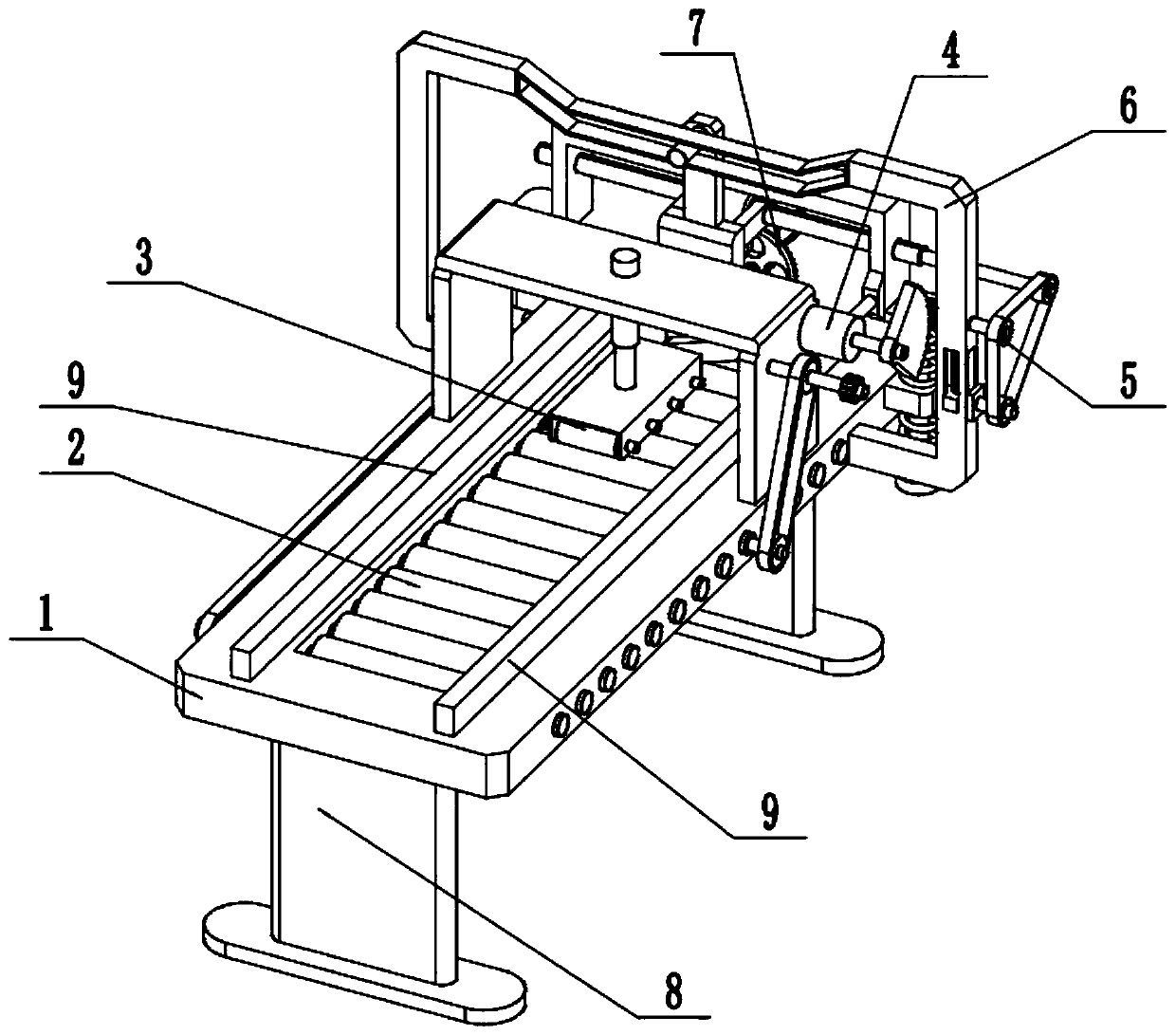

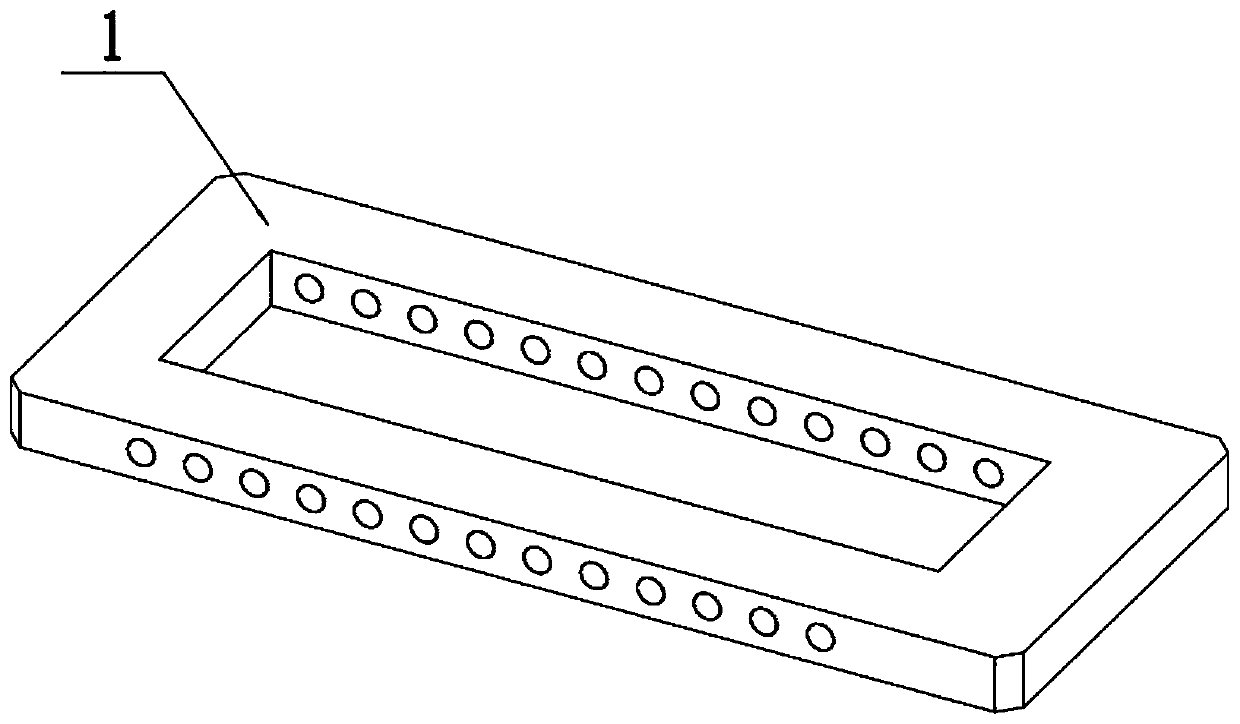

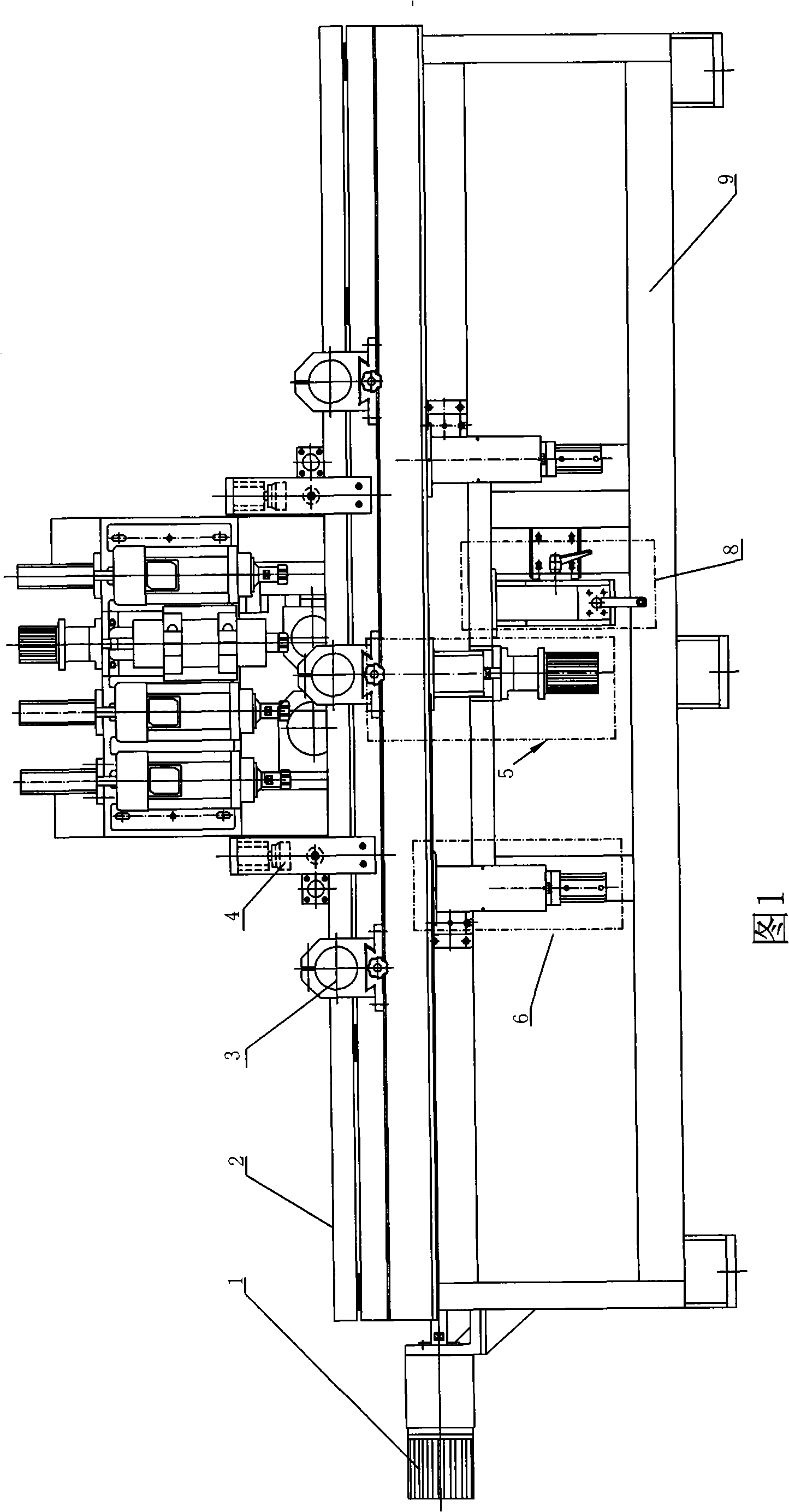

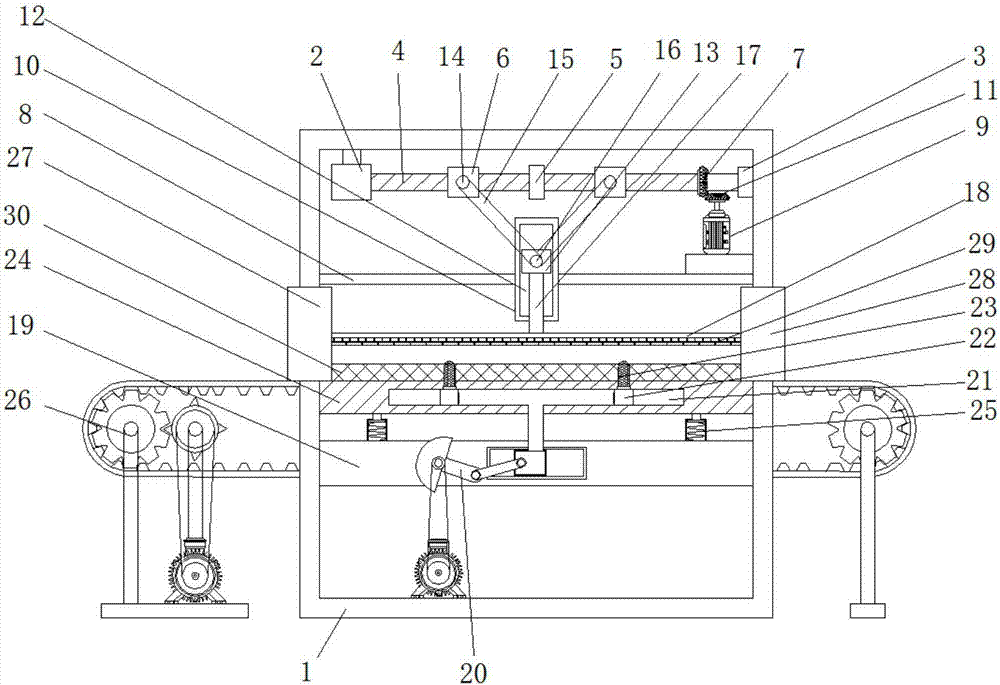

Wood board fixed-length cutting device

InactiveCN110238914AImprove cutting efficiencyImprove stabilityFeeding devicesGripping devicesEngineeringFixed length

The invention relates to the field of wood processing, in particular to a wood board fixed-length cutting device. The wood board fixed-length cutting device comprises a rack, a board conveying roller assembly, a pressure roller, a driving mechanism, a tensioning linkage wheel, a guide frame, a cutting mechanism, supporting legs and side baffles; the supporting legs are fixed at the front end and the rear end of the bottom face of the rack separately; the side baffles are fixed at the left end and the right end of the top face of the rack separately; the board conveying roller assembly is connected in an installation groove in the top face of the rack; the board conveying roller assembly is located between the two side baffles; the pressure roller is arranged at the front end of the top face of the rack; and the board conveying roller assembly is connected to the side end of the pressure roller. According to the wood board fixed-length cutting device, continuous fixed-length cutting is carried out on a wood board by adopting an automatic feeding and fixed length cutting mode, the cutting efficiency is high, and the labor force is low.

Owner:李锋

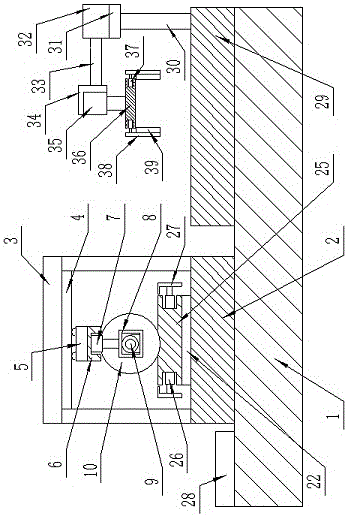

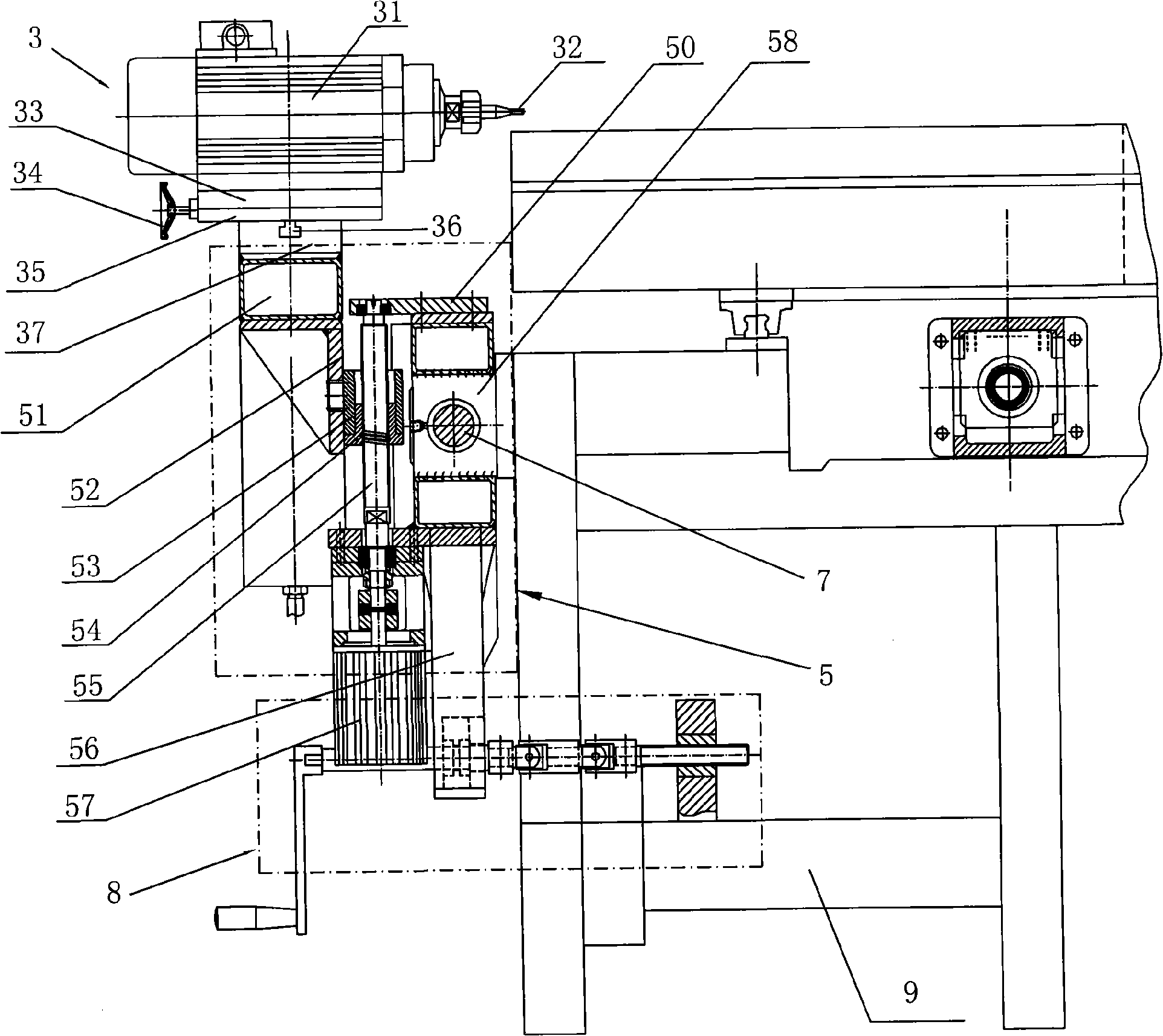

Full-automatic wood door lock, hinge groove and hole processor

InactiveCN101279454ASolve processing problemsImprove processing efficiencyDrilling machinesWood mortising machinesMilling cutterEngineering

The invention relates to a wood processing device, in particular to a full-automatic lock for wooden door, the groove of a hinge and a hole processing machine, which comprises a frame. The invention is characterized in that: a working table which is controlled by a motor to move horizontally and used for placing a wooden door forms a sliding fitting with the frame, and a clamping device for wooden door is arranged at the side edge of the frame; an electric milling cutter device for hinge which can horizontally move along the X direction relative to the frame is arranged at the front side of the frame, an electric drilling and milling device for fade lockhole which can move in the Y direction is arranged at the rear side of the frame and an electric drilling and milling device for door side lock groove which can move along the Y direction is arranged below the electric drilling and milling device for fade lockhole. Various motors and cylinders of the wood processing device are controlled by a computer chip controller, thus ensuring that the drills, and milling knives lift and prone automatically according to the program or simultaneously sequentially complete a plurality of cutting and manufacturing of holes and grooves required for arrangement of locks or hinges on the fade or at the side of a door. The problem of processing the inclined plane groove is solved, and the processing efficiency, the slotting quality and the processing precision are significantly enhanced. Furthermore, the wood processing device can process an inclined plane groove, thus solving the problems of processing of inclined plane grooves and significantly enhancing the processing efficiency, the grooving quality and the processing precision.

Owner:TAIZHOU EVOK MASCH CO LTD

A preparation method of flame-retardant and heat-insulating acrylic sheet

The invention relates to a preparation method of an antiflaming heat insulation acrylic plate. The plate is prepared through the following steps: carrying out dissolution, mixing, pouring and polymerization on the following raw materials by weight: 100g of methyl methacrylate, 0.3-0.5g of benzoperoxide, 60-100g of waste organic glass, 25-40g of wastes in a wood processing plant, 0-10g of colouring pigment, 30-60g of fire retardant and 0.4-0.8g of defoamer. According to the plate, the defects of the traditional acrylic plate, such as low strength, low hardness, poor toughness, poor heat resistance and the like, are overcome; the waste utilization rate is increased, environment pollution is reduced, and the production cost is lowered; and simultaneously, the plate prepared by the method hasantiflaming and heat insulation functions and can be widely applied to building and home decoration industries.

Owner:SHAANXI UNIV OF TECH

Preparation method of aldehyde-free artificial board

ActiveCN102632535AImprove permeabilityImprove internal bond strengthWood treatment detailsDomestic articlesAdhesiveUltimate tensile strength

The invention discloses a preparation method of an aldehyde-free artificial board, and belongs to the technical field of wood processing. The invention provides a method for preparing an artificial board by adopting wood raw materials combing with an environment-friendly aldehyde-free adhesive, wherein the wood raw materials are pretreated by a bio-enzyme technology. The preparation process of the artificial board provided by the invention comprises the following steps of: pretreating the wood raw materials used for preparing the artificial board by the bio-enzyme technology; then sizing the treated wood raw materials by adopting the aldehyde-free adhesive; and then carrying out hot-pressing by adopting a two-section-type hot-pressing method, thereby obtaining the artificial board. The preparation method of the aldehyde-free artificial board provided by the invention has the advantages that through the pretreatment on the wood materials by bio-enzyme, the bonding strength of the artificial board is improved obviously, and the using requirements on the adhesive are lowered; formaldehyde-type adhesives are not added in the preparation process, the two-section-type hot-pressing treatment process is matched, the prepared artificial board does not emit free formaldehyde which is harmful to human bodies and the environment in the preparing and using processes, thus the preparation industry of the artificial board can break through the green barrier abroad and develop soundly.

Owner:JIANGNAN UNIV

Laccase and preparation method and special production strain thereof

InactiveCN101880632AEasy to prepareIncrease enzyme activityFungiContaminated soil reclamationMicroorganismAdhesive

The invention discloses a laccase and a production method and a special production strain thereof and relates to the industrial field of microorganism fermentation. The strain provided by the invention is pycnoporus sanguineus MK 2001 CGMCC No.2932. The laccase provided by the invention is prepared by fermenting the pycnoporus sanguineus MK 2001 CGMCC No.2932. The enzyme activity of fermented liquid laccase prepared by fermenting the pycnoporus sanguineus MK 2001 CGMCC No.2932 provided by the invention is up to 300 U / ml, and the laccase can be widely applied to biodegradation of phenols, arylamine, aromatic carboxylic acid and the derivatives of the phenols, the arylamine, and the aromatic carboxylic acid, enzyme bleaching of paper making and pulping, waste water treatment and dye degradation and can substitute a chemical adhesive in the wood processing.

Owner:INST OF MICROBIOLOGY - CHINESE ACAD OF SCI

Efficient wood plate processing equipment

InactiveCN107336292AReduce difficultyReduce pollutionProfiling/shaping machinesBark-zones/chip/dust/waste removalArchitectural engineeringSlide plate

The invention discloses a high-efficiency wood board processing equipment, which comprises a workbench. A protective cover is arranged on the upper side of the workbench. A horizontal first sliding rail is arranged on the inner upper end of the protective cover, and a longitudinally arranged sliding plate is arranged on the first sliding rail. , the lower side of the skateboard is provided with a longitudinal second slide rail, the second slide rail is provided with a second electric telescopic rod, the lower end of the second electric telescopic rod is provided with a first motor, and the output end of the first motor is provided with a mounting seat , the inside of the mounting seat is left and right symmetrically provided with a second motor, the output ends of the two second motors are provided with a fourth electric telescopic rod, the outer end of the fourth electric telescopic rod is provided with a mounting plate, and the upper side of the mounting plate is provided There is a grinding device, a cutting device is arranged on the lower side of the mounting plate, a supporting plate is arranged on the lower part of the legs, and a dust collection box is arranged on the upper side of the supporting plate. The invention has the advantages of simple structure, convenient use, high processing efficiency, reduced work intensity and reduced dust pollution.

Owner:侯添有

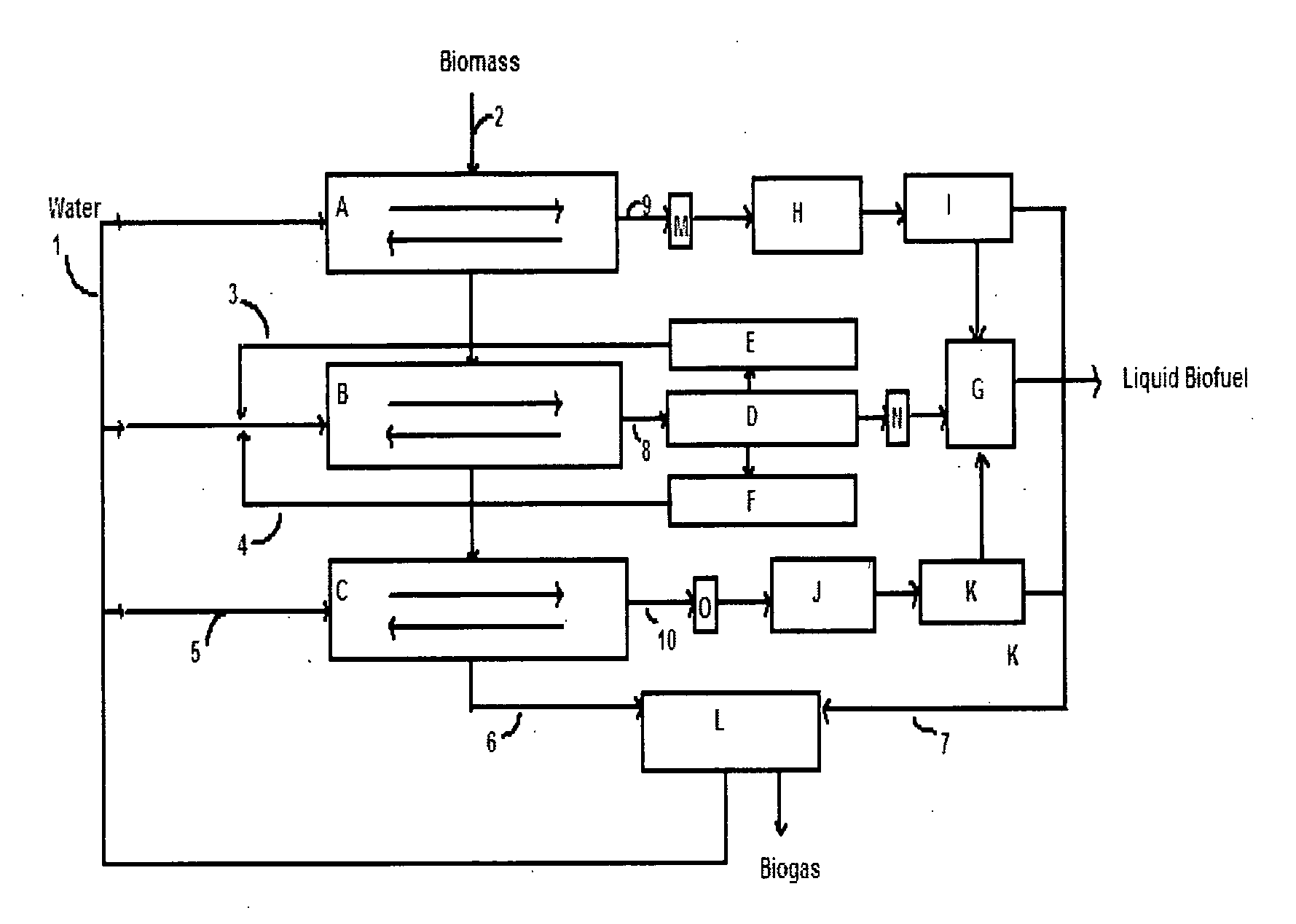

Complete liquefication of lignocellulosic agrowaste to form liquid biofuels

ActiveUS20100317070A1Increase energy yieldLower cost per GJMicroorganismsBiofuelsCelluloseMiscanthus

A process for converting lignocellulosic materials which are field residues such as cotton stalks and corn stover, process residues such as sugarcane bagasse and sweet sorghum bagasse, woody parts of energy crops such as switchgrass and miscanthus, forest residues or byproducts of the wood processing industries such as sawdust from sawmills to a liquid biofuel by a series of processing steps wherein the feed materials are hydrolysed in three stages and withdrawn as three product streams each consisting of solubilized fragments of one of the three major components of the feed materials and a set of concurrently operating processing steps wherein each of the three product streams is transformed through chemical or biochemical processes into products, such as pure lignin and ethanol, that have a high calorific value and process wherein these products with high calorific value are combined to form a liquid biofuel.

Owner:LIGNOIL TECH PRIVATE

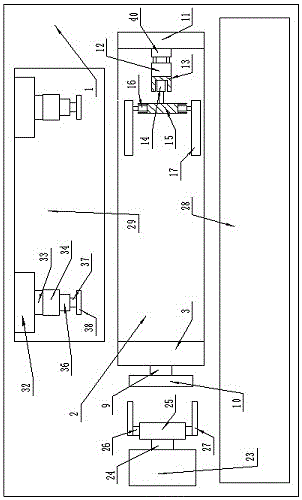

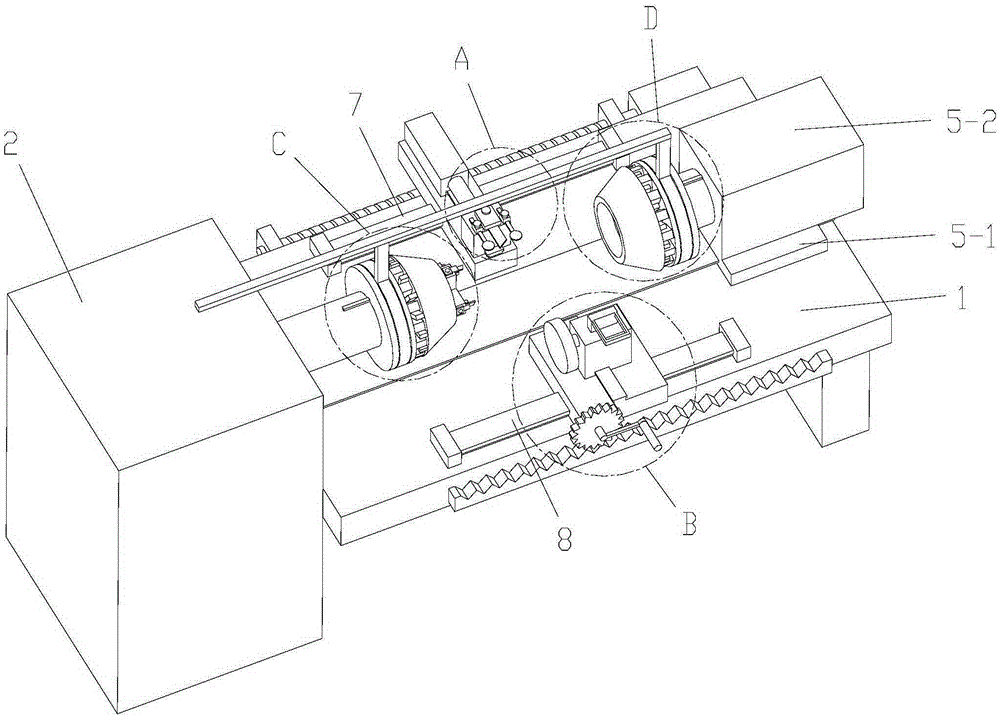

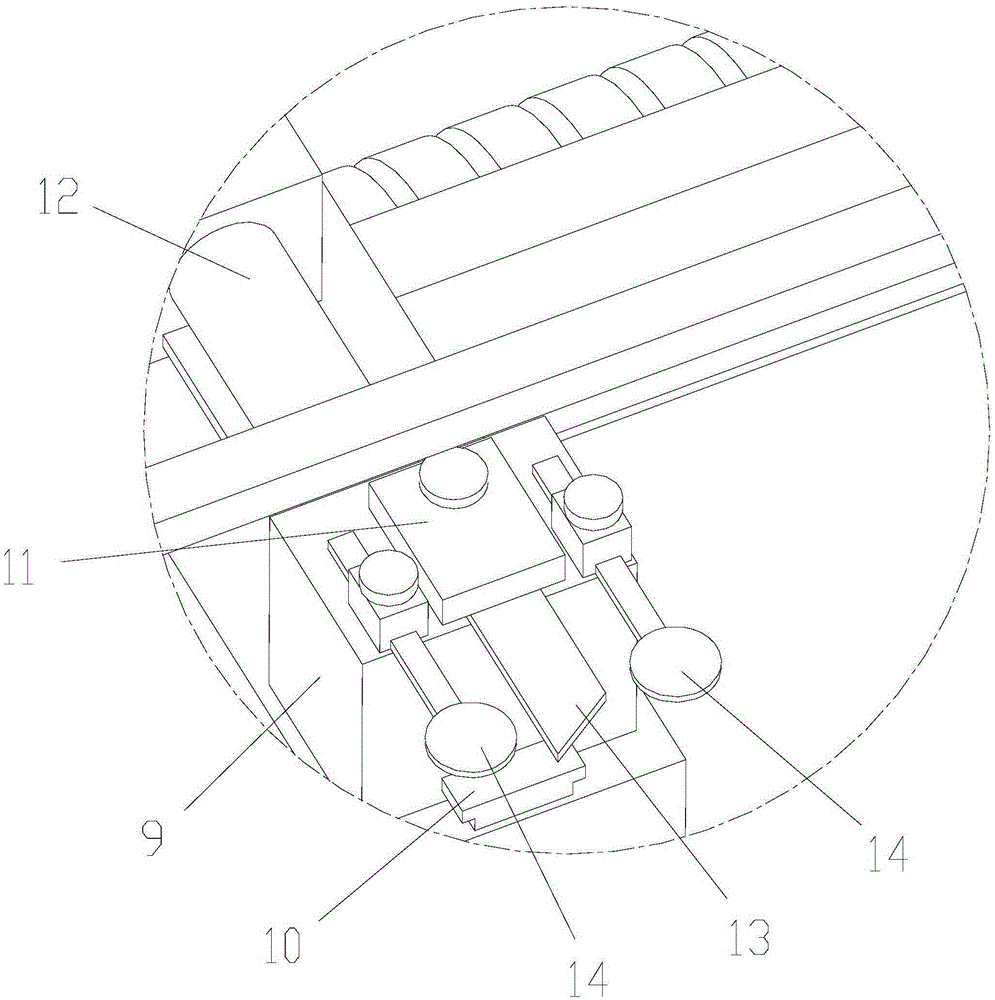

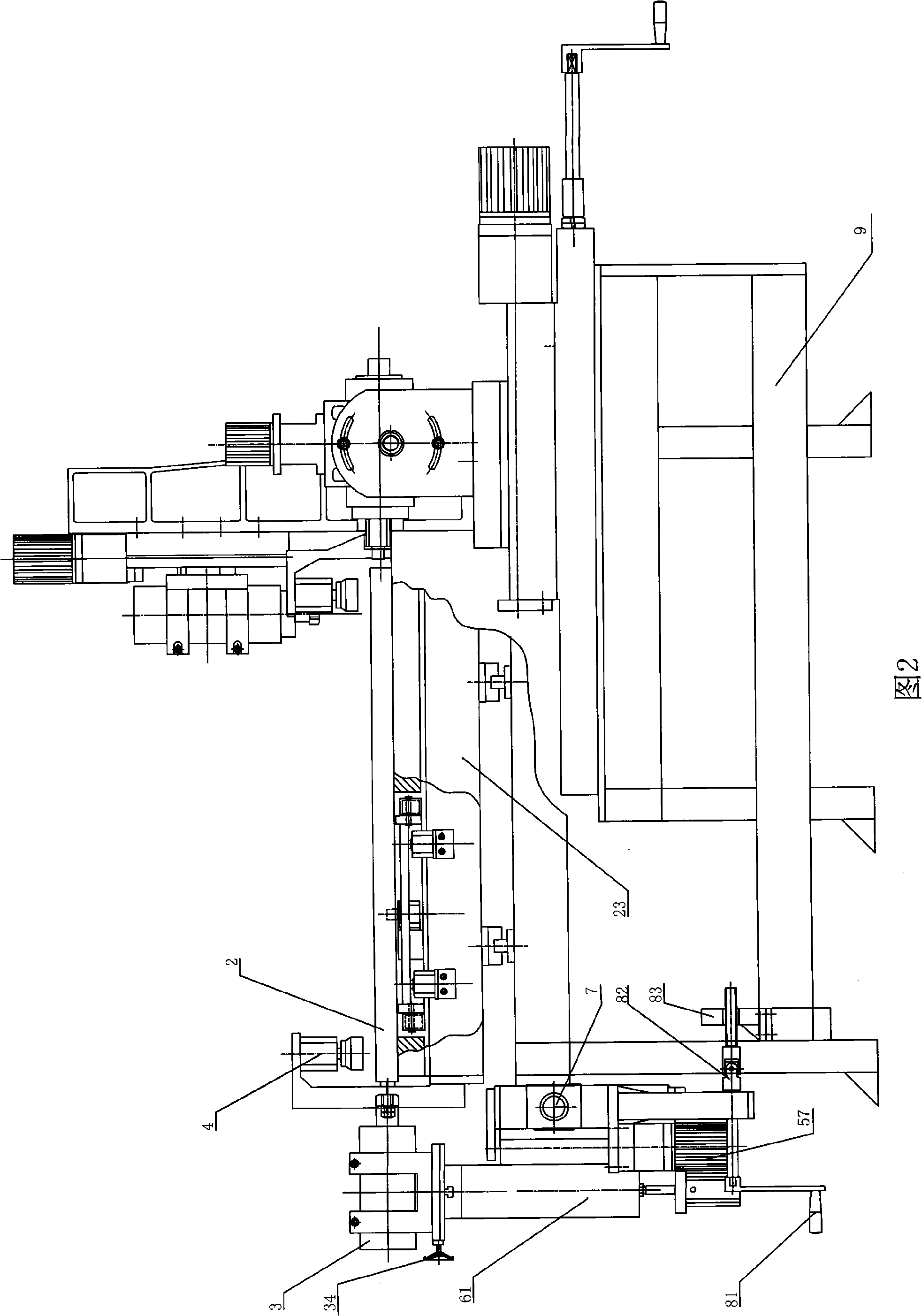

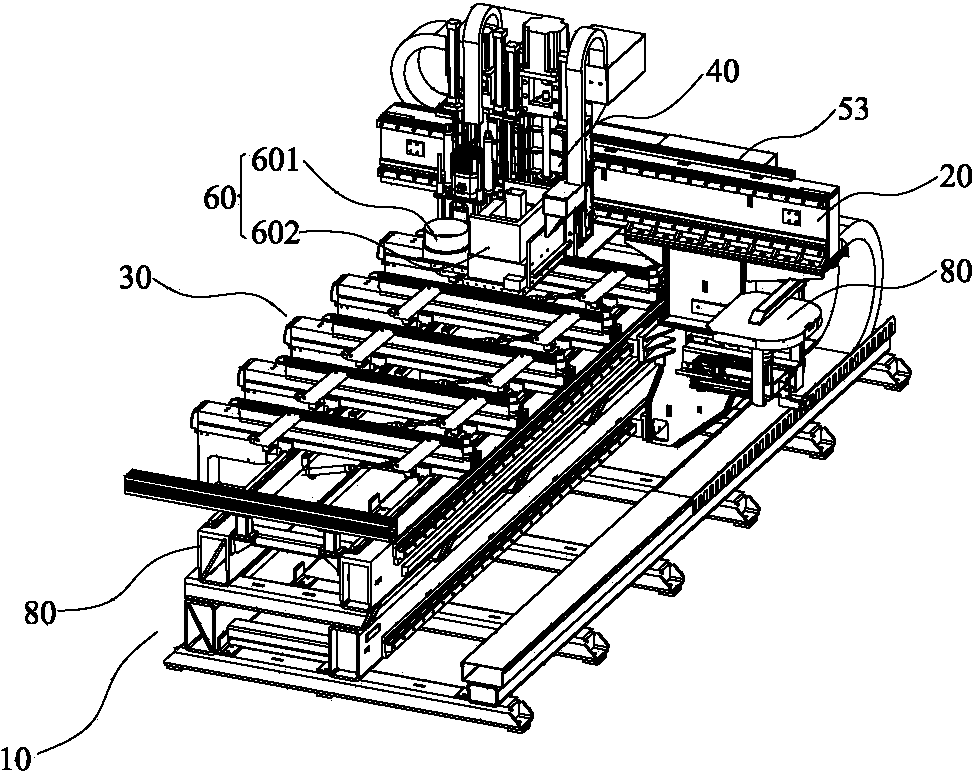

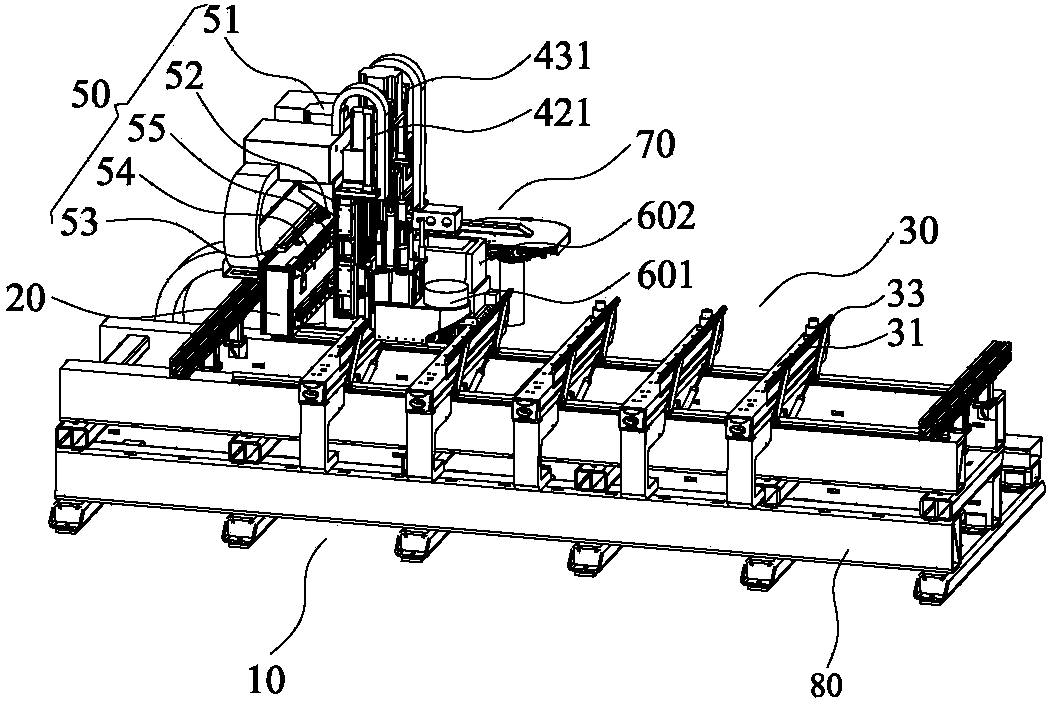

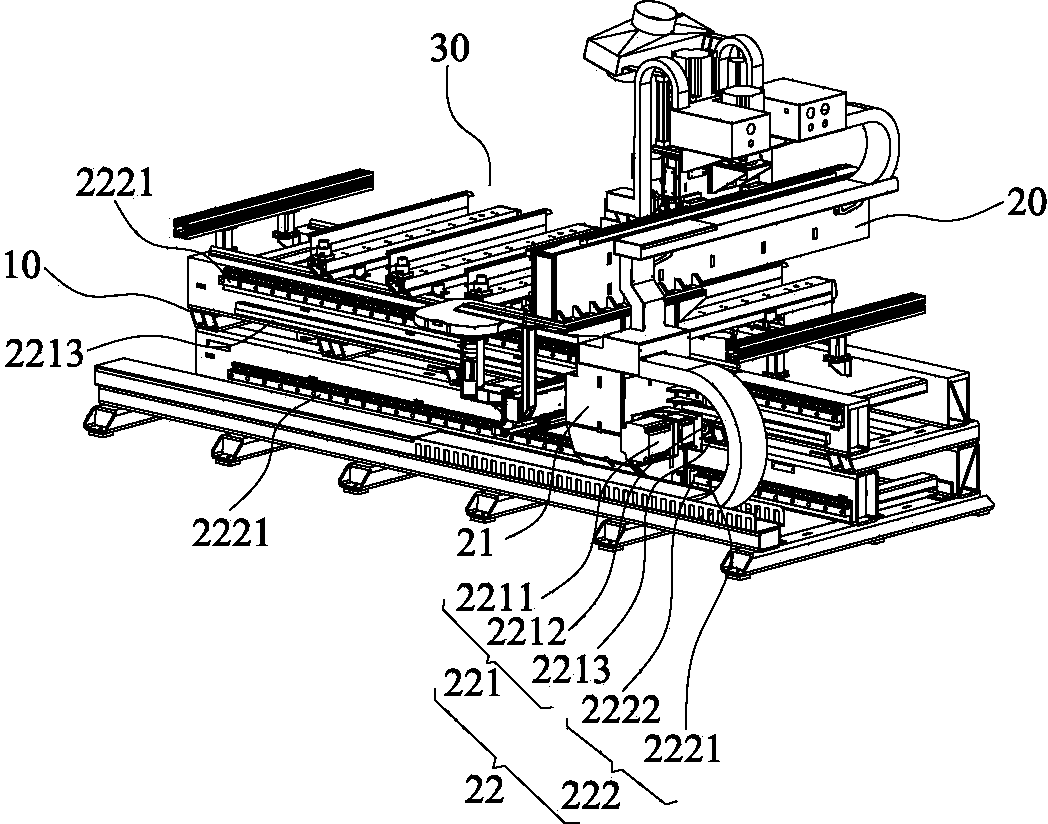

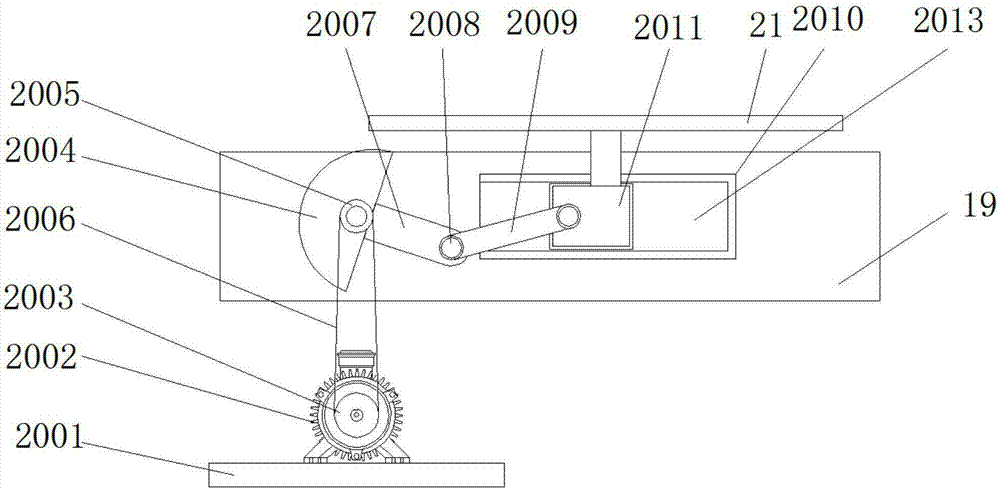

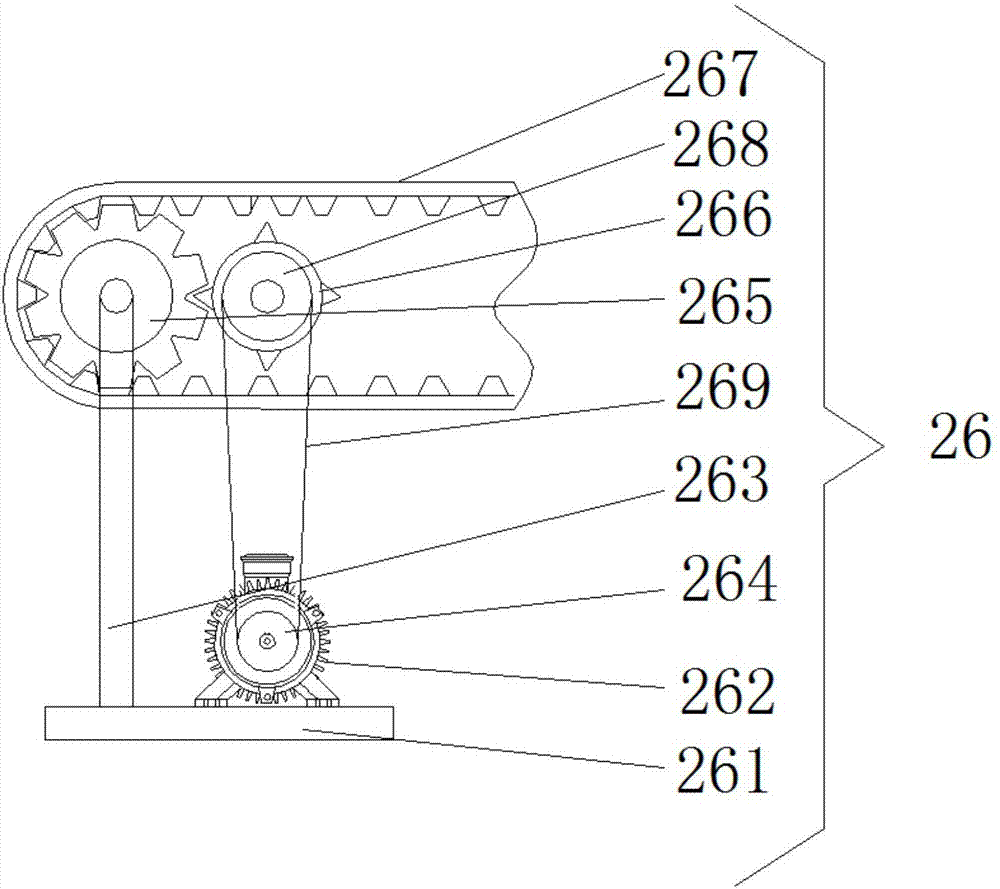

Cantilever type wood compound processing center

ActiveCN103448105AFlexible moving processEasy tool changeMulti-purpose machinesMobile deviceCantilever

The invention discloses a cantilever type wood compound processing center which comprises a base, a cross beam, a plurality of work tables, a longitudinal mobile device, a wood processing device, a vertical mobile device, a horizontal mobile device and a cutter storeroom, wherein the cross beam and the work tables are arranged on the base; the longitudinal mobile device drives the cross beam to longitudinally move on the base; the wood processing device is arranged on the cross beam; the vertical mobile device drives the wood processing device to move up and down; the horizontal mobile device drives the wood processing device to horizontally move; the cutter storeroom is arranged at one side of the cross beam and is used for replacing a cutter for a main shaft. According to the center, the vertical mobile device and the horizontal mobile device are arranged on the cross beam, so that the wood processing device can flexibly move according to processing requirements; the cutter storeroom capable of horizontally moving is arranged on the cross beam, so that the cutter replacement of the wood processing device is relatively convenient, and the complex step of manual cutter replacement is prevented; the convenience for wood processing is further enhanced through the movable work tables which can be adjusted in position at any time according to the sizes of woods. Thus, the production efficiency of the processing center is improved, the manual labor amount is reduced, and the production cost is reduced.

Owner:NANXING MACHINERY CO LTD

Bamboo wood plate edge grinding device

The invention discloses a bamboo and wood board edging device, which comprises an outer frame, and a first fixed block and a second fixed block are respectively fixedly connected to the two ends of the top inside the outer frame, and the first fixed block and the second fixed block A screw rod is fixedly connected between the blocks, a slider is slidably connected to the surface of the screw rod, an upper splint is fixedly connected to the end of the push rod away from the second slider, and both sides of the bottom end inside the outer frame are fixedly connected There is a second fixed plate, and a reciprocating device is fixedly connected to the second fixed plate, lower splints are fixedly connected to both sides inside the outer frame and above the second fixed plate, and the outer side of the outer frame is provided with The invention relates to a bamboo and wood board conveying device, and the invention relates to the technical field of bamboo and wood processing. The bamboo and wood board edging device solves the problems of time-consuming and laborious edging and low edging efficiency of the existing bamboo and wood boards, achieves a more accurate and efficient grinding effect, reduces labor force, and improves the grinding efficiency.

Owner:安吉县瑞旺竹木制品厂

Board punching device

PendingCN108638225AEvenly punchedRealize Angle SwitchingEdge grinding machinesGrinding carriagesPunchingGear wheel

The invention belongs to the technical field of wood processing equipment, and particularly discloses a board punching device. The board punching device comprises a machine frame. A rotary table is arranged on the machine frame, a punching mechanism and a power mechanism are arranged on the upper portion of the machine frame, and the power mechanism drives the punching mechanism to ascend and descend. A crank and sliding block mechanism is arranged on the machine frame, a push rod which is fixedly connected with a sliding block is connected to the machine frame in a sliding mode, and an intermittent mechanism which drives the rotary table to conduct one-way intermittent rotation is connected between the push rod and the rotary table. A clamping mechanism is further arranged on the machineframe, and comprises a supporting rod. Two supporting plates are connected to the supporting rod in a sliding mode. A two-way lead screw is connected to the machine frame in a rotating mode, the two supporting plates are matched with the two-way lead screw through nuts, and the two-way lead screw and the push rod are connected through a gear and rack pair. Clamping plates and polishing discs are arranged on the inner sides of the two supporting plates, and transmission mechanisms which are used for driving the polishing discs to rotate are connected between the polishing discs and the two-waylead screw. By the adoption of the scheme, automatic rotation and clamping of a board are achieved in the drilling process, the working efficiency is high, and the labor intensity of workers is reduced.

Owner:重庆哲骁装饰工程有限公司

Single-veneer composite decoration board

InactiveCN101637928AWith flame retardant functionWith anti-corrosion functionWood veneer joiningWood layered productsSingle plateBatten

The invention relates to a single-veneer composite decoration board which is a novel decoration board and belongs to a novel technical invention in the filed of wood processing. The single-veneer composite decoration board is formed by adopting the following steps: taking different colors and species of decorative hardwood veneers or artificial fast-growing forest veneers after being bleached, dyed and carbonized as raw materials; cutting the veneers into veneer strips with a certain length and width; gluing, and then arranging and paving and pressing different veneer strips according to proportions as well as colors and textures of decorative hardwood which is designed in advance. Products produced by adopting the method are called single-veneer composite decoration boards in general. Thesingle-veneer composite decoration board has the advantages of low manufacturing cost and wood resources saving and is suitable for a plurality of occasions, such as furniture, indoor decorations, outdoor wood structures, and the like.

Owner:深圳嘉汉林业科技有限公司

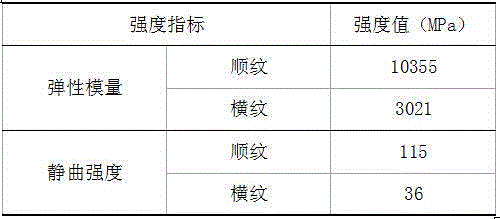

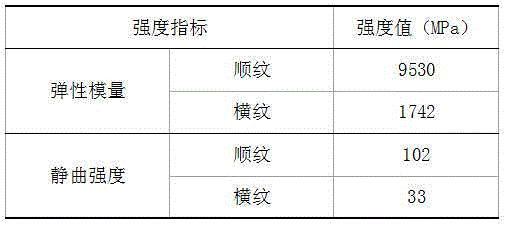

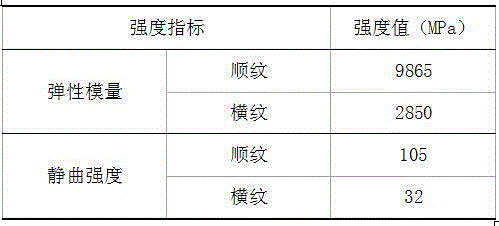

Manufacturing method of bamboo-wood composite laminated timber

InactiveCN105196368AImprove longitudinal strengthReduce horizontalCane mechanical workingWood veneer joiningComposite laminatesFiber array

The invention provides a manufacturing method of a bamboo-wood composite laminated timber and belongs to the technical field of bamboo-wood processing. The manufacturing method comprises the following process steps: (1) preparing raw materials; (2) drying; (3) braiding bamboo bundles; (4) immersing in glue; (5) drying; (6) assembling; (7) prepressing; (8) hot pressing; and (9) ageing. Compared with a traditional process for manufacturing recombined bamboo by adopting a mold pressing manner, mechanization is realized in a manufacturing process of a bamboo bundle single board; the spreading of a plate blank is similar with the spreading of a plywood; and compared with the spreading of a recombined bamboo plate blank, the spreading is relatively simple, and the production efficiency is relatively high. Meanwhile, a traditional recombined bamboo product has the same fiber array direction so that the longitudinal strength of the product is remarkably higher than transverse strength. According to the bamboo-wood composite material manufactured by the manufacturing method, the method is carried out by symmetrically assembling the bamboo bundle single board and a wood single board, so that the difference of the transverse strength and the longitudinal strength of the material is reduced and the transverse strength is remarkably improved.

Owner:国家林业局竹子研究开发中心 +1

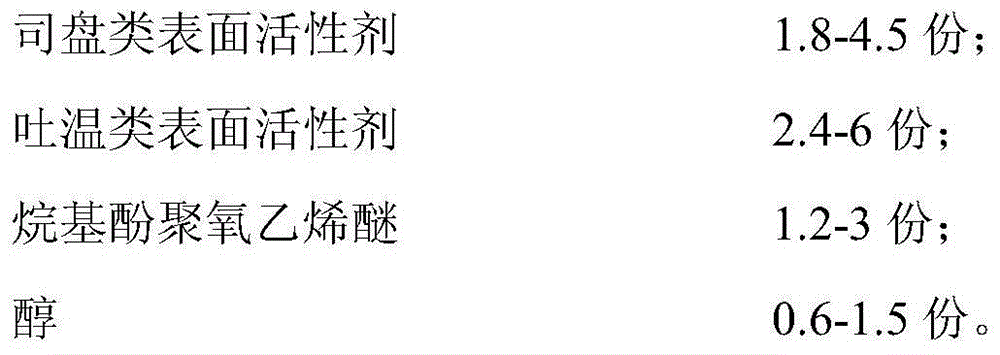

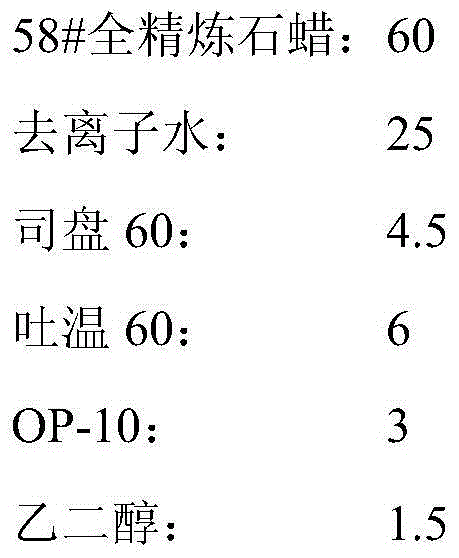

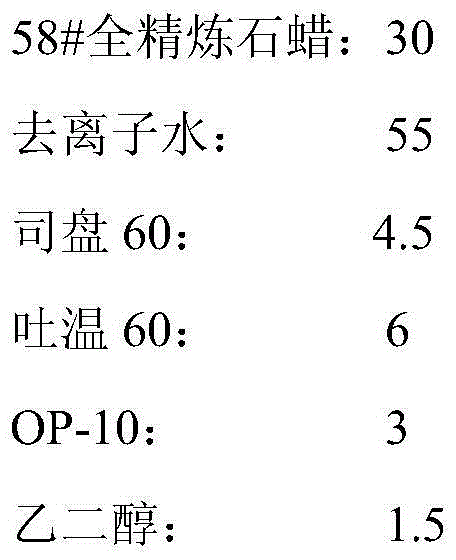

Emulsified paraffin for wood processing and preparation method thereof

The invention belongs to the technical field of chemical engineering, and particularly relates to emulsified paraffin for wood processing and a preparation method thereof. The emulsified paraffin for wood processing is prepared from paraffin, a compound emulsifier and water, wherein the compound emulsifier is a mixture of a Span type surfactant, a Tween type surfactant, alkylphenol polyoxyethylene and alcohol. The emulsified paraffin disclosed by the invention is non-toxic and tasteless, good in dispersibility, good in stability, acid-resistant and alkali-resistant; in the wood processing industry, the emulsified paraffin can completely substitute paraffin to be used as a waterproof and dampproof auxiliary, and is simple to use, low in cost and good in effect, compared with the paraffin; the preparation method is simple and feasible; the three wastes cannot be generated in the preparation process; the preparation method is environment-friendly and efficient.

Owner:CHINA PETROLEUM & CHEM CORP

Formaldehyde purification inflaming retarding oriented strand board and manufacturing method thereof

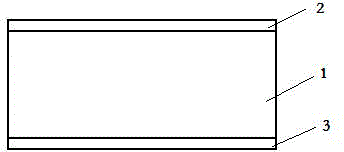

The invention relates to a paint-free decorative overlay fitment board, in particular to a formaldehyde purification inflaming retarding oriented strand board and a manufacturing method thereof, and belongs to the wood processing industry. The formaldehyde purification inflaming retarding oriented strand board comprises a base material layer, an upper surface layer decorative film adhesive layer and a lower surface layer decorative film adhesive layer. The upper surface layer decorative film adhesive layer and / or the lower surface layer decorative film adhesive layer are immersed with an amino resin adhesive solution and a formaldehyde decomposition adhesive solution, the base material layer is an oriented strand board layer, the oriented strand board layer comprises an upper surface layer, a lower surface layer and a core layer shaving layer, wherein the glue mixing wood shavings on the upper and lower surface layers are longitudinally arranged in the fiber direction, the glue mixing wood shavings on the core layer shaving layer are transversely arranged in the fiber direction, an inflaming retarding layer is arranged between the lower surface shaving layer and the core layer shaving layer, and an inflaming retarding layer is arranged between the upper surface shaving layer and the core layer shaving layer. The manufacturing method of the paint-free decorative overlay fitment board comprises the steps of base material sanding, formaldehyde decomposition adhesive solution preparation, decorative film adhesive manufacturing, assembling and pressing and sticking. The formaldehyde purification inflaming retarding oriented strand board is realistic in effect, low in cost and good in formaldehyde purification effect.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com