Patents

Literature

121results about How to "Improve internal bond strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carboxylated lignin based binders

InactiveUS20110159768A1Improve curing speedEasy curingSpecial tyresWoven fabricsLignosulfonatesWet strength

The present invention provides binder compositions comprising an ethylenically unsaturated carboxy acid grafted lignin or lignosulfonate component, and an oxazoline-functional group containing polymer or resin component, the two components in a solids weight ratio of from 50:50 to 98:2. As formulated, the compositions may comprise from 40 to 98 wt. % of the acid grafted lignosulfonate, preferably, 50 wt. % or more. Preferably, the binder composition further comprises one or more in situ acid generator compound to insure more rapid cure on heating or pressing. The binder enables the provision of low cost composite materials comprising a majority component derived from natural materials, and having a reasonable wet strength.

Owner:CRESCIMANNO STEPHEN A +1

Method for preparing adhesive for grade-E0 medium density fiberboards

InactiveCN102134468ALow free formaldehyde contentModerate curing timeAldehyde/ketone condensation polymer adhesivesAdhesivePolyvinyl alcohol

The invention provides an adhesive for grade-E0 medium density fiberboards. The raw materials of the adhesive include formaldehyde, polyvinyl alcohol, urea and tripolycyanamide. The production process of the adhesive comprises: firstly, adding all formaldehyde into a reaction kettle, regulating the pH value of formaldehyde solution to 7.5 to 8.5 by using sodium hydroxide solution, adding the 40 to 50 percent of polyvinyl alcohol and urea and adding 80 to 90 percent of tripolycyanamide and adding the 10 to 20 percent of urea; secondly, adjusting the pH value to 5 to 6 by using formic acid, reacting for 20 to 30 minutes till a cloud point, regulating the pH value to 705 to 8.5 with caustic soda solution, and adding the 10 to 20 percent of tripolycyanamide and 20 to 30 percent of urea; and finally, adding 10 to 20 percent of urea, regulating the pH value of the adhesive to 6.6 to 7.5, and discharging. The adhesive has the advantages that: the free formaldehyde content is very low, and the manufactured medium density board is of grade E0; the curing time is proper, the storage stability is high, and the normal-temperature storage period is about 1 month; and the manufactured medium density board has high internal combining strength and high waterproof and dampproof performance.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

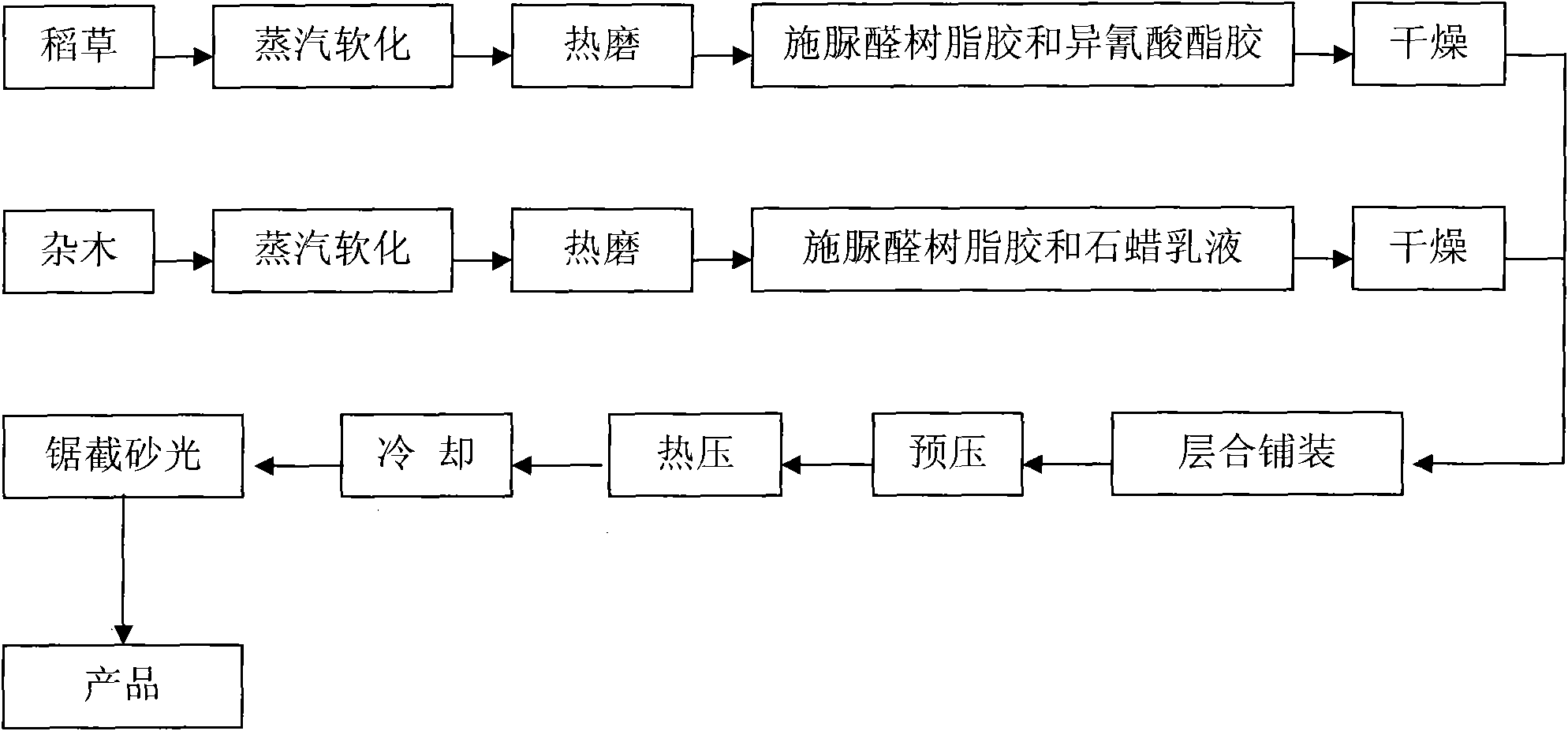

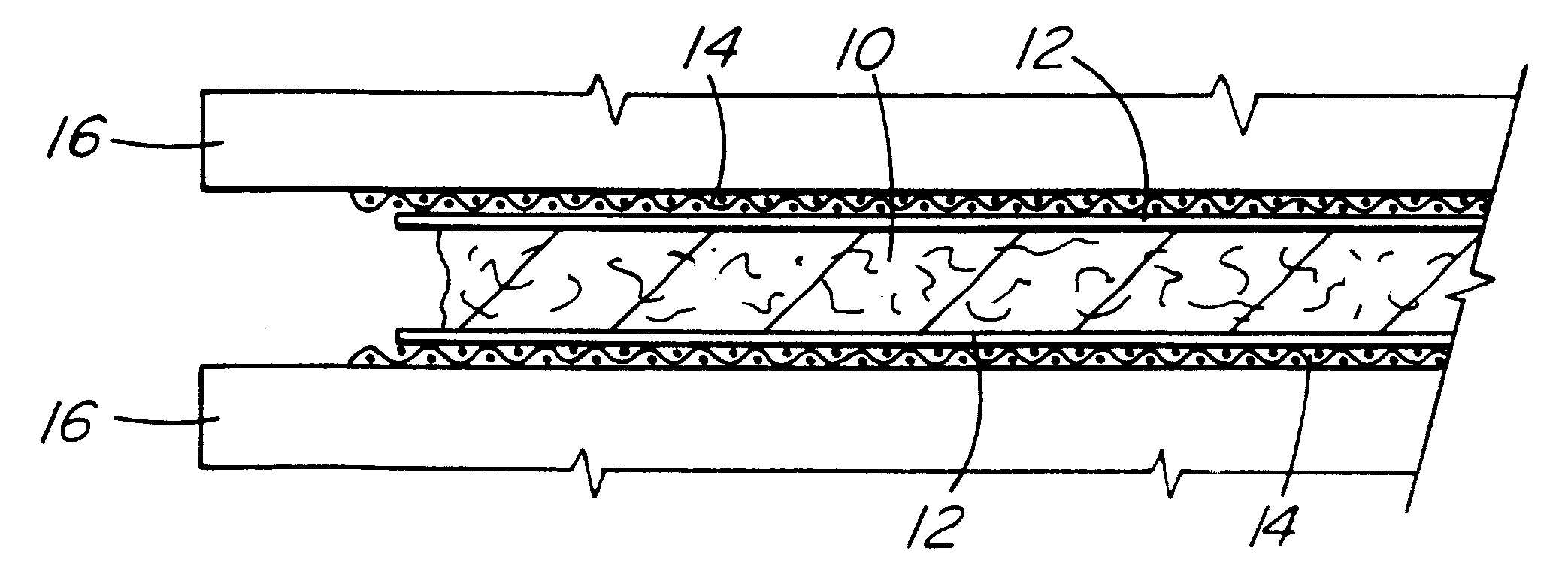

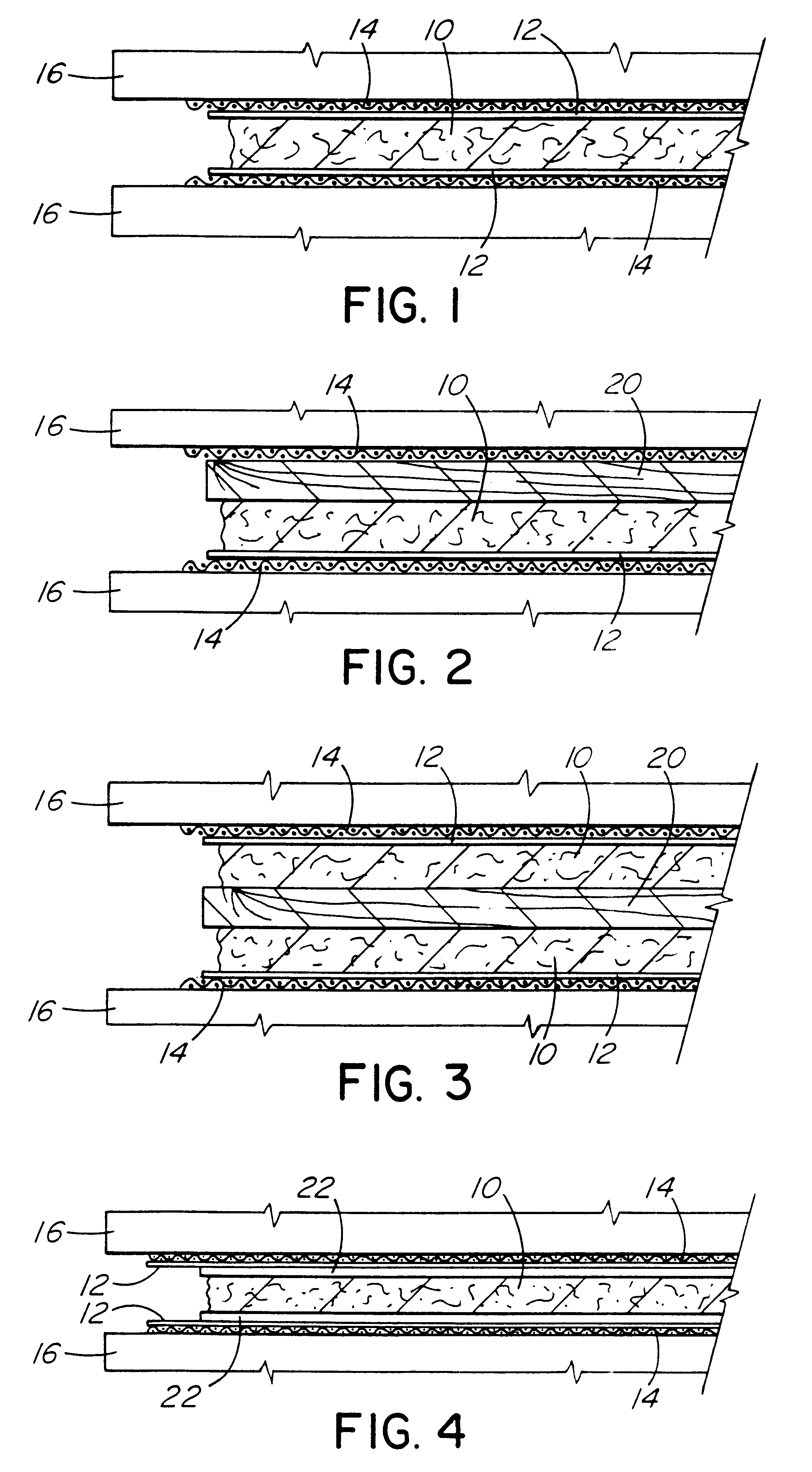

Method for manufacturing weed wood and straw compounding medium density fiberboard with laminated structure

InactiveCN101659074ASave resourcesImprove flexural strengthFlat articlesDomestic articlesEcological environmentFlexural modulus

The invention relates to a method for manufacturing a weed wood and straw compounding medium density fiberboard with a laminated structure. The method adopts straw and weed wood as raw materials, andincludes the following steps: the straw and the weed wood are respectively processed by defibration, and urea formaldehyde resin adhesive and waterproof agent are added, and in the process of formation, straw fibres and wood fibres are proportionally assembled and laminated in the direction of thickness and then are processed by thermocompression to form boards. The method has the advantages thatproved by performance tests, the flexural modulus, the strength and the internal bonding strength of the medium density fiberboard, compared with a pure straw medium density fiberboard, are respectively and obviously increased under the same condition, and the expansion rate of water-absorbing thickness and the water absorption rate are lowered; and the relative performances of the compound material can be increased by changing the mode of lamination. The method efficiently and comprehensively utilizes the agricultural straws and saves wood resources, thereby protecting the ecological environment. The product can be applied to the occasions of furniture manufacturing and production, base materials for interior decoration, and the like.

Owner:NANJING FORESTRY UNIV

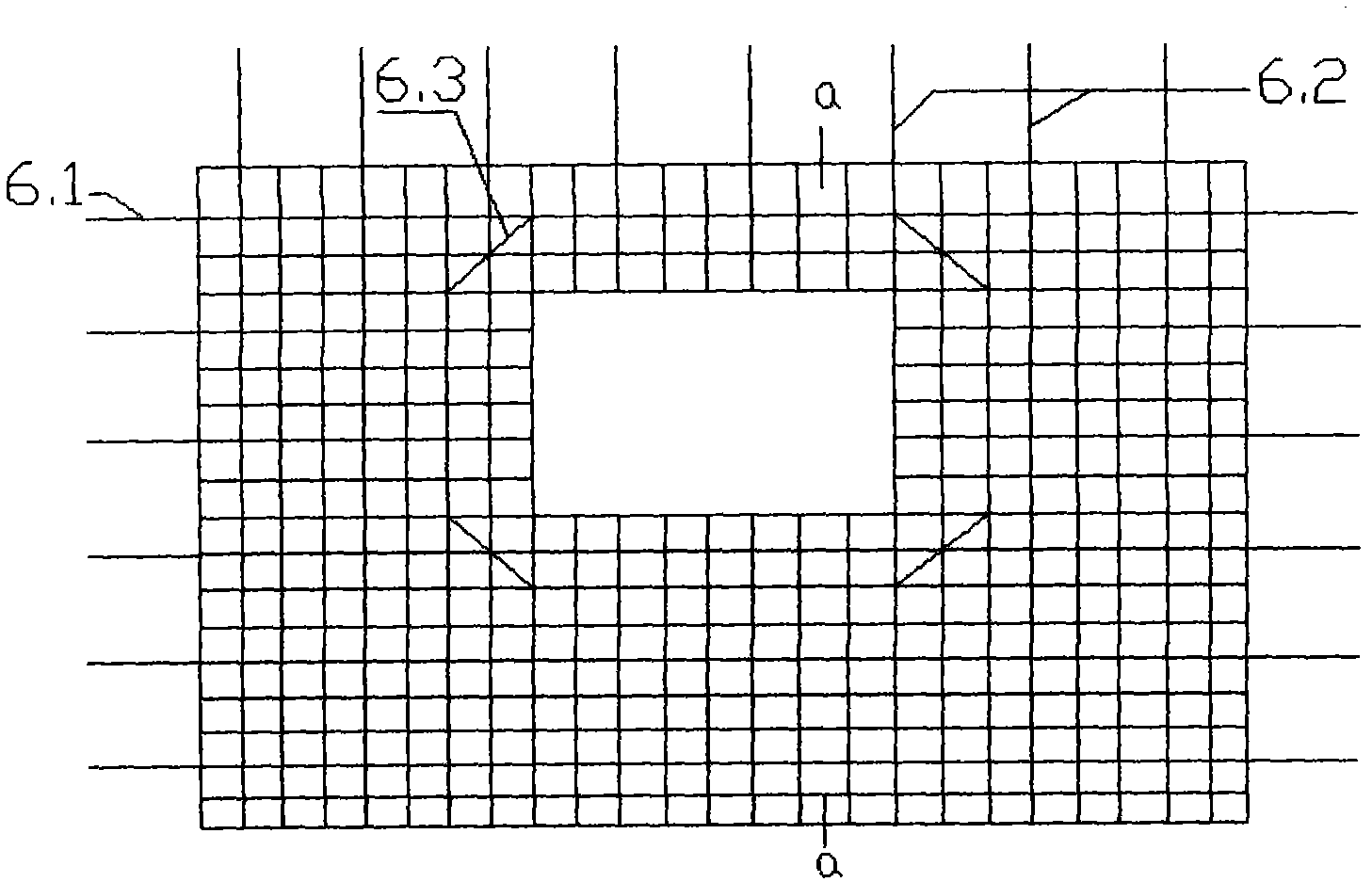

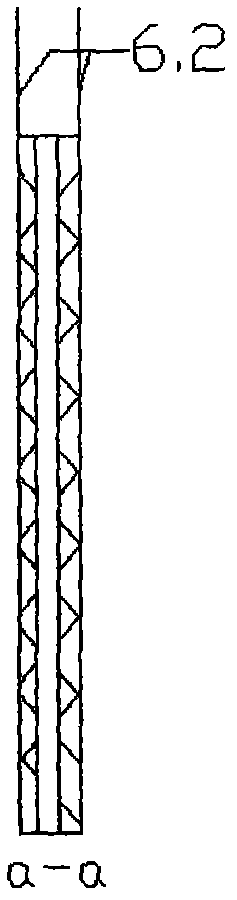

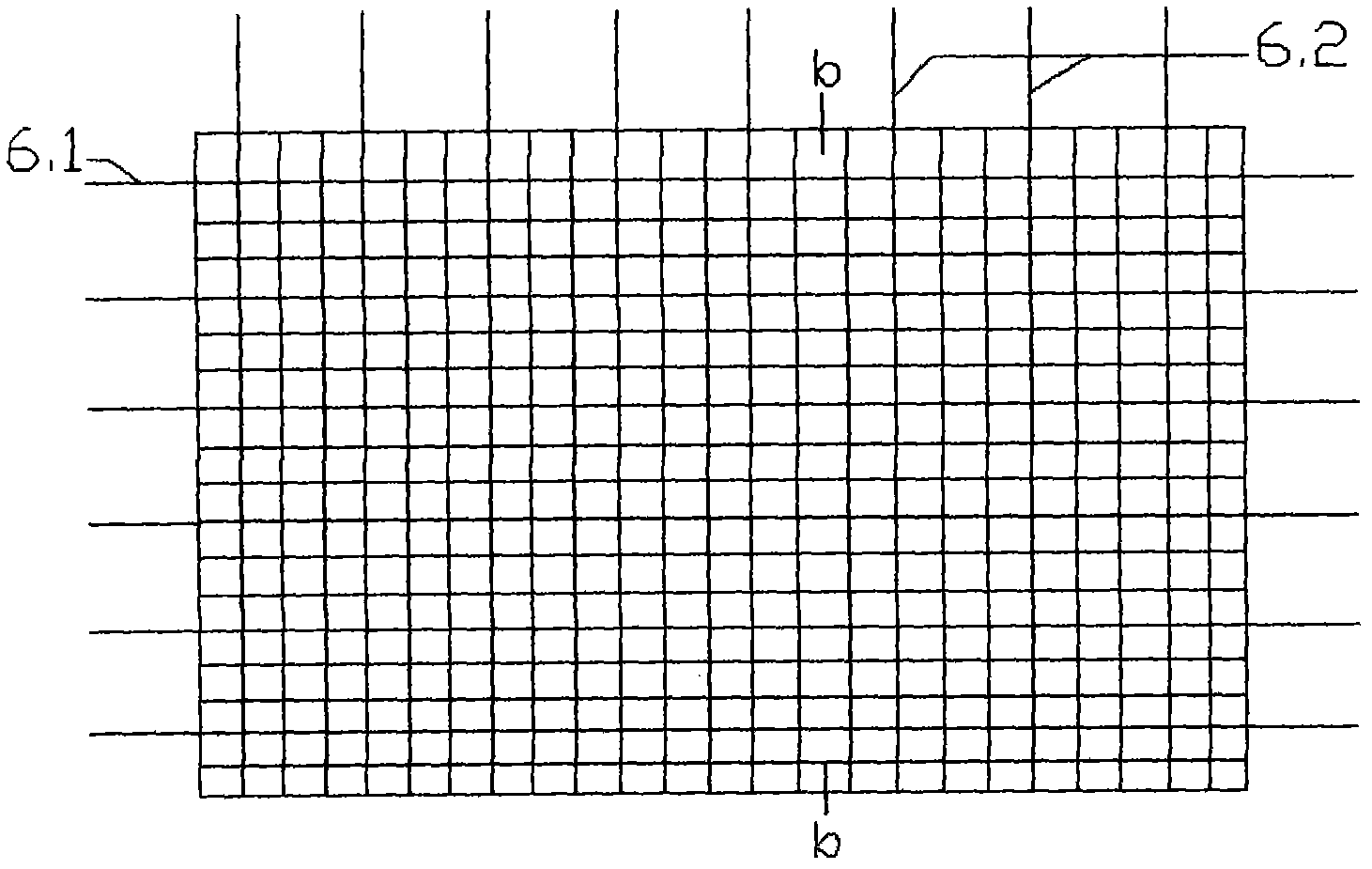

Concrete spray steel mesh sandwich formwork cast-in-place shear wall construction method and shear wall

InactiveCN102182317ARealize integrationImprove integrityWallsBuilding material handlingInsulation layerShear force

The invention relates to a concrete spray steel mesh sandwich formwork cast-in-place shear wall construction method and a shear wall manufactured by using the method. The construction method comprises the following steps: (1) mounting matched inner and outer steel mesh sandwich light plates on the preserved formwork positions; (2) spraying concrete on site on the inner side surface of the inner steel mesh sandwich light plate and the outer side surface of the outer steel mesh sandwich light plate; and (3) and casting concrete in place between the inner and outer steel mesh sandwich light plates. The shear wall is provided with the inner and outer steel mesh sandwich light plates; a middle concrete layer is cast between the inner and outer sandwich light plates; and inner and outer side surface concrete layers are sprayed on the outer side surface of the outer sandwich light plate and the inner side surface of the inner sandwich light plate respectively. By adopting the method in the invention, integration of formwork, insulation and structure is realized, the construction speed is obviously improved, the service life of wall, particularly insulation layer, is obviously prolonged, and the capability of the wall resisting shear force is obviously improved.

Owner:BEIJING HUAMEIKEBO TECH DEV

A method for preparing straw particle board

InactiveCN101157241AImprove wettabilityHigh bonding strengthDomestic articlesFlat articlesChemical treatmentMass ratio

The invention discloses a straw particle board manufacture method, which relates to a particle board manufacture method. The invention solves the problem that the straw surface includes a plurality of waxy layers and SiO2 substance, common urea formaldehyde resin glue and phenolic resin are hard to wet the straw surface to cause a plurality of gluing difficulty. The invention has the method that: the straw is cut into pieces and performed ash removal at first, and straw crushed aggregates which are performed with the pretreatment through the blending ratio of the 1:4 to 5.0 according to the mass ratio of the straw and alkali liquor is soaked in the alkali liquor of 1.4 to 1.6 wt percent (mass) for 10 to 15 hours, and the straw particle board can be manufactured after drying, glue applying, paving, pre-pressing, hot pressing, and cooling. The equipment performance request of the straw particle board manufacture through the invention is low, the method is simple, and the operation parameter is easy to control. The method of the invention for performing chemical treatment to the straw raw material surface improves the wetting property of the raw material, greatly enhances the inner combination intensity, enlarges the application scope of the straw, releases the lack of the timber resources, and the invention has great economic and social efficiency in the situation that the conflict between supply and demand becomes more prominent.

Owner:NORTHEAST FORESTRY UNIVERSITY

Manufacturing method of Pinfeng base paper

ActiveCN105586802AEasy to shapeImprove uniformityCoated paper substrateNon-macromolecular organic additionLogistics managementSlurry

The invention discloses a manufacturing method of Pinfeng base paper. The method comprises the following processing steps: pulping and preparing softwood pulp and hardwood pulp respectively; adding auxiliary materials; making wet paper sheets; carrying out pre-drying and surface sizing treatment; and carrying out post-drying, calendaring and finishing. Through research on slurry selection, slurry proportioning, a beating technology, a functional chemical additive added to the slurry and a digital printing assistant, measures of calendaring and the like are carried out by film-transfer surface sizing treatment by soft calendaring equipment; and the qualified Pinfeng base paper is manufactured by referring to related paper machine parameters. Compared with ordinary logistics label middle paper, the Pinfeng base paper has the advantages of low gram weight, high tensile strength, good internal bonding strength, high smoothness, low hygroscopic property, good surface strength, good digital printing effect, fine paper surface and good hand feeling, and is capable of completely replacing the ordinary logistics label middle paper and reducing the production cost for customers.

Owner:YUEYANG FOREST & PAPER CO LTD

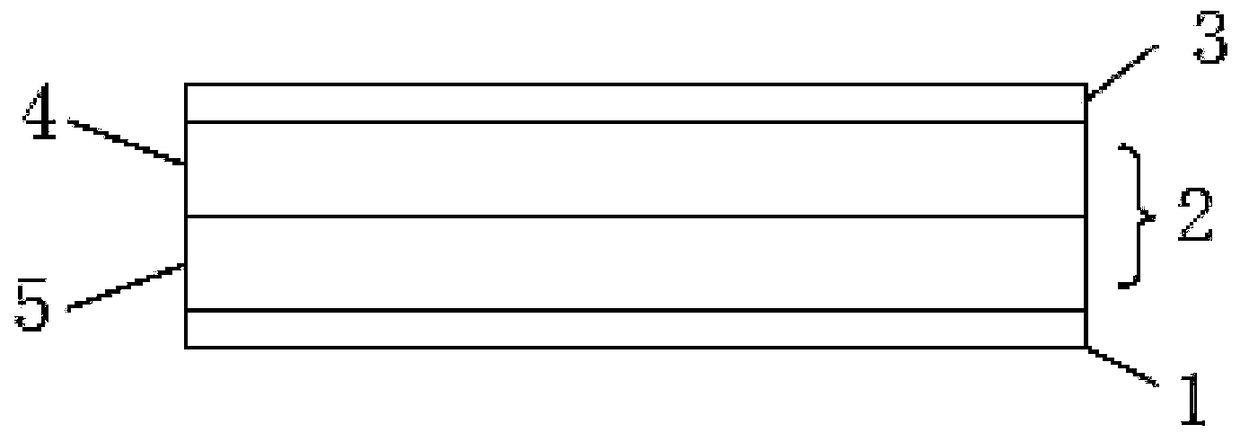

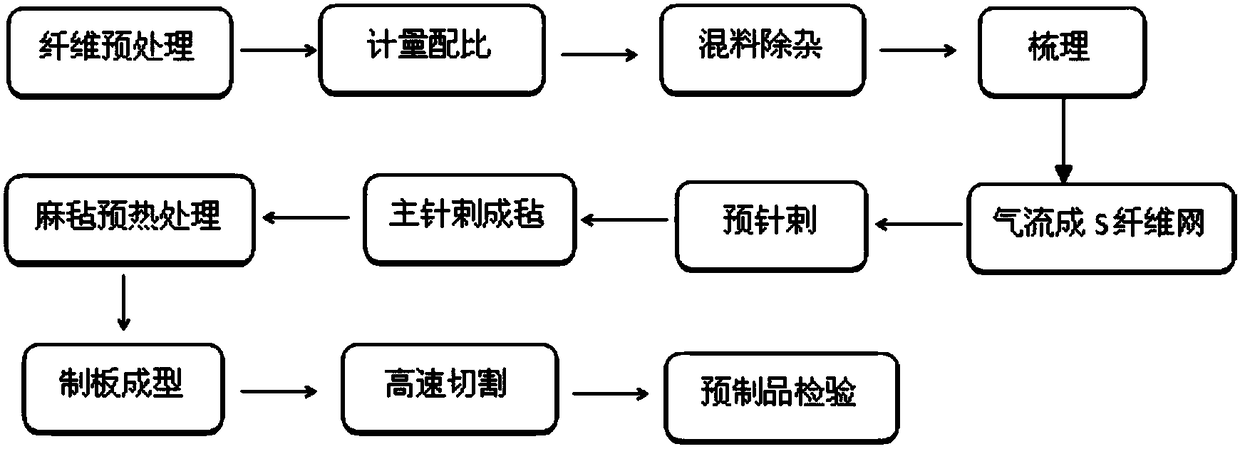

Environment-friendly ecological bast fiber integrated wall decorating plate and preparation method thereof

PendingCN109113289AHigh strengthAct as a bondCovering/liningsSynthetic resin layered productsEnvironmental resistancePolyester

The invention relates to the technical field of wall decorating plates for buildings and discloses an environment-friendly ecological bast fiber integrated wall decorating plate and a preparation method thereof. The bast fiber integrated wall decorating plate comprises a bottom layer, a middle layer and a surface layer which are sequentially overlapped and hot-pressed together. Both the bottom layer and the surface layer adopt polyester non-woven fabric layers, and the middle layer adopts a bast fiber felt layer. The bast fiber felt layer is formed in the mode that two or more pieces of precast and formed bast fiber felt are overlapped and preheated, the precast and formed bast fiber felt is mixed fiber felt with bast fibers and polypropylene fibers, and the bast fibers and the polypropylene fibers in the mixed fiber felt are both coiled fibers. The preparation method of the integrated wall decorating plate comprises the steps that the middle layer is manufactured; the polyester non-woven fabric layers are taken as the bottom layer and the face layer; and the bottom layer, the middle layer and the face layer are overlapped, heated and subjected to rolling forming, and the bast fiber integrated wall decorating plate is prepared after cutting. The wall decorating plate is environmentally friendly and ecological.

Owner:JIANGYIN YANLI AUTOMOBILE DECORATIVE PARTS

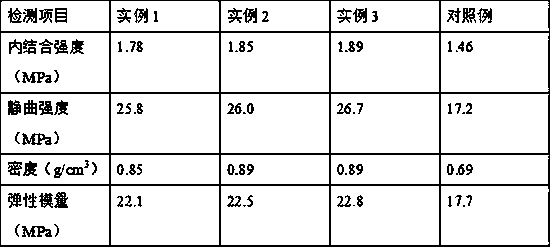

Preparation method of plant straw plate

InactiveCN104802276AReduce releaseStrong resistance to hydrolysisPolyureas/polyurethane adhesivesWood working apparatusAdhesivePlant stalk

The invention provides a preparation method of a plant straw plate. The preparation method takes full components of dried corn straws, rice straws, wheat straws, sunflower straws, rapeseed straws and cotton straws as raw materials and utilizes a special adhesive of polyether polyol and a prepolymer of isocyanate, so that the water-resisting capability is strong, and the inner bonding intensity of a product is improved; the related indexes of the produced plant straw plate are equal to or better than quality standards of national standards (GB / T4897-92) of a wood artificial plate. The indexes including the inner bonding intensity, the static bending strength, the formaldehyde releasing amount, the water absorption thickness expansion rate and the like. The production process is simplified and the production cost is reduced.

Owner:CHANGCHUN YINGLONG MATERIAL TECH CO LTD

Polyolefin synthetic pulp and use thereof

InactiveUS6338772B1Large fiber breaking lengthImprove internal bond strengthNon-fibrous pulp additionSpecial paperPolymer sciencePolyolefin

A polyolefin synthetic pulp comprising a polyolefin resin graft-modified with an unsaturated carboxylic acid or a derivative thereof, and / or a polyolefin resin composition which comprises an ethylene / alpha,beta-unsaturated carboxylic acid copolymer and a polyethylene resin. Further, there is provided a heat sealing paper comprising a base fiber layer whose at least one surface is laminated and integrated with a layer of the polyolefin synthetic pulp. This polyolefin synthetic pulp has a large breaking length and an excellent internal bond strength, and exhibits stable heat sealing and hot tack properties over a wide temperature range from low to high temperature. The polyolefin synthetic pulp is suitable to use in battery separators, molding fiberboards, heat sealing papers and the like. The heat sealing papers have excellent heat sealing properties, and are characterized by having a large breaking length and an excellent internal bond strength and by exhibiting stable heat sealing and hot tack properties over a wide temperature range from low to high temperature.

Owner:MITSUI CHEM INC

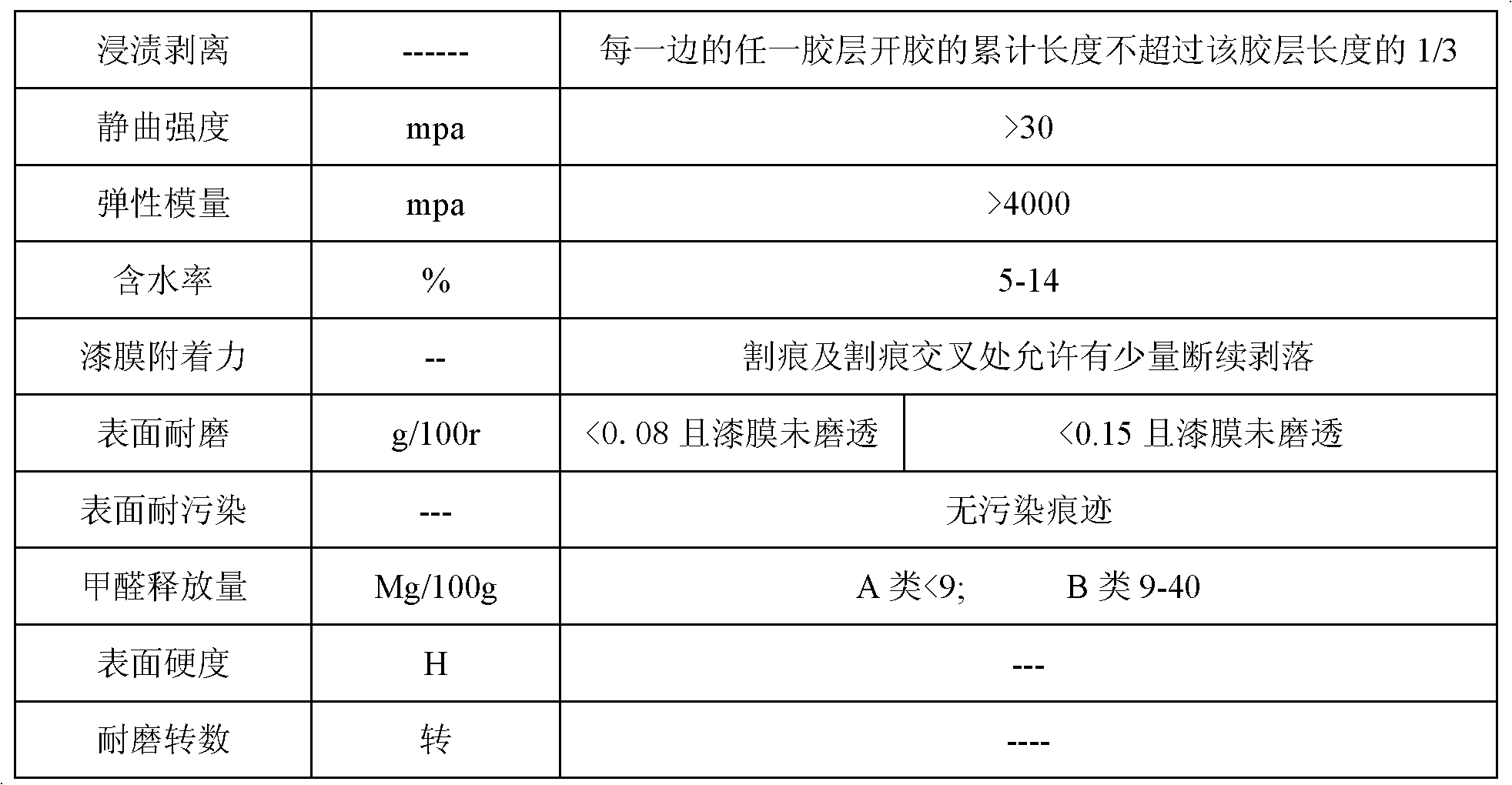

Solid wood composite floor and preparation method thereof

ActiveCN103171015AImprove physical and mechanical propertiesHigh densitySynthetic resin layered productsLaminationSolid woodWood veneer

The invention relates to a preparation method of solid wood composite floor which uses compacted and hardened scientific wood skin as a surface layer. The preparation method of the solid wood composite floor comprises the steps of dyeing and drying a gum wood veneer and a poplar veneer, carrying out gum dipping and sealing on the wood skin with a ultrasonic vibration method, assembling the wood skin after the gum dipping is carried out on the wood skin, carrying out semi-solidification hot pressing on the wood skin through a curve mold high-frequency pressing machine, slicing or saw cutting technology square wood into wood skin, assembling the wood skin in the same direction according to required height, carrying out hot-pressing sealing, trimming deflashing, and sanding on the wood skin, surface hardness of painting-free floor manufactured and prepared by the technology wood skin composite raw material with a method for manufacturing solid wood composite floor can reach to more than 3 H, surface hardness of painted solid wood floor can reach to more than 6H, wear-resisting rotating speed can reach to more than 4000 revolutions per minute, cracking can not occur easily, durability of products is improved by more than one time, the service life of the floor is prolonged, and using field of the floor is widened.

Owner:SINO MAPLE JIANGSU CO LTD

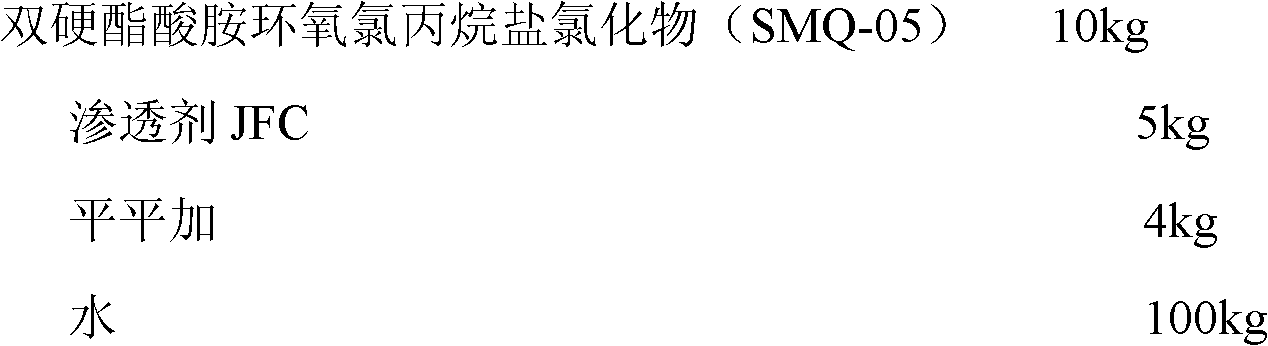

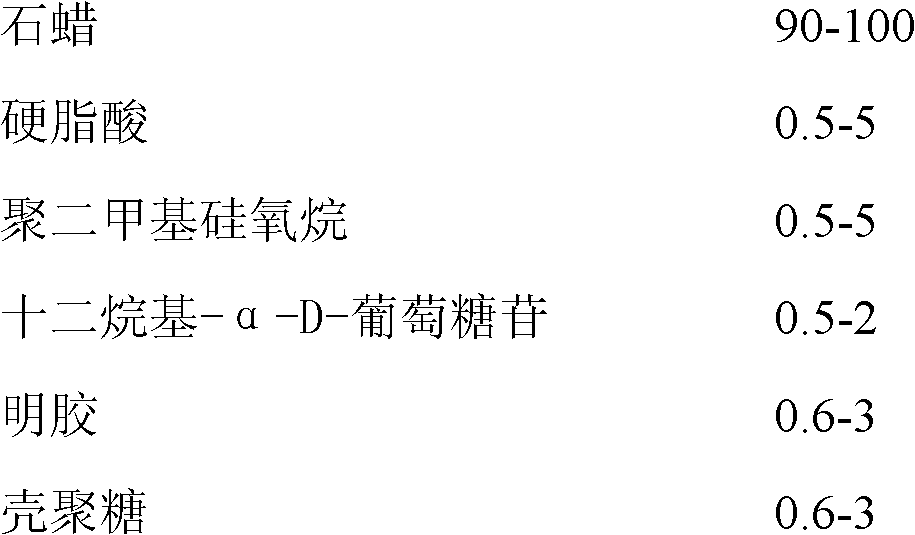

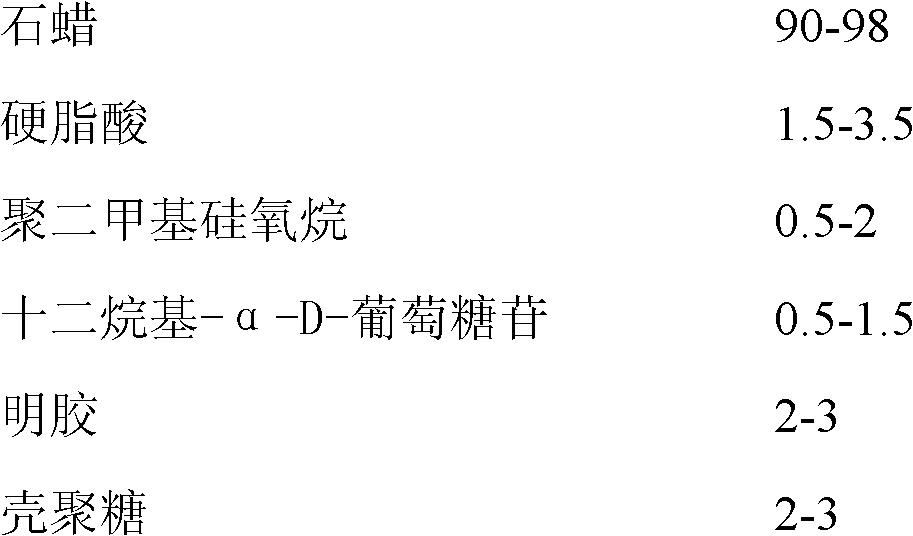

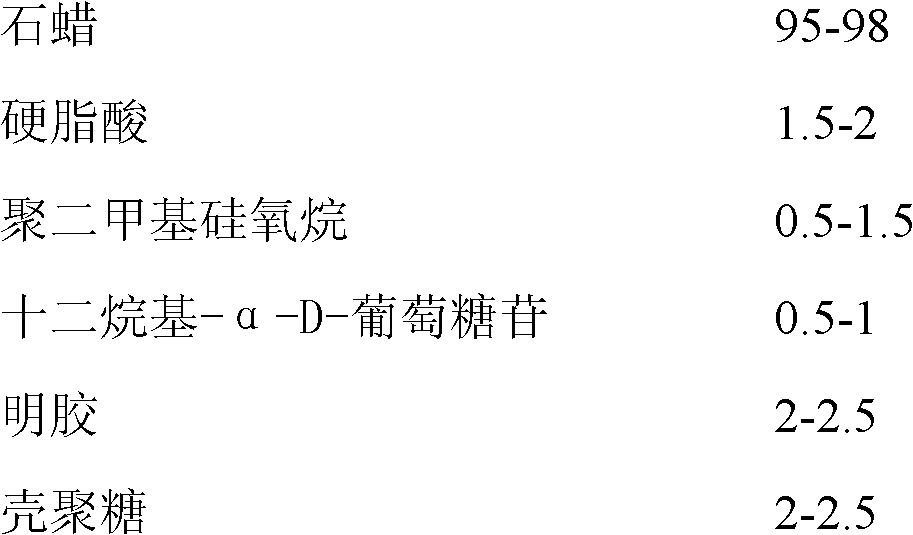

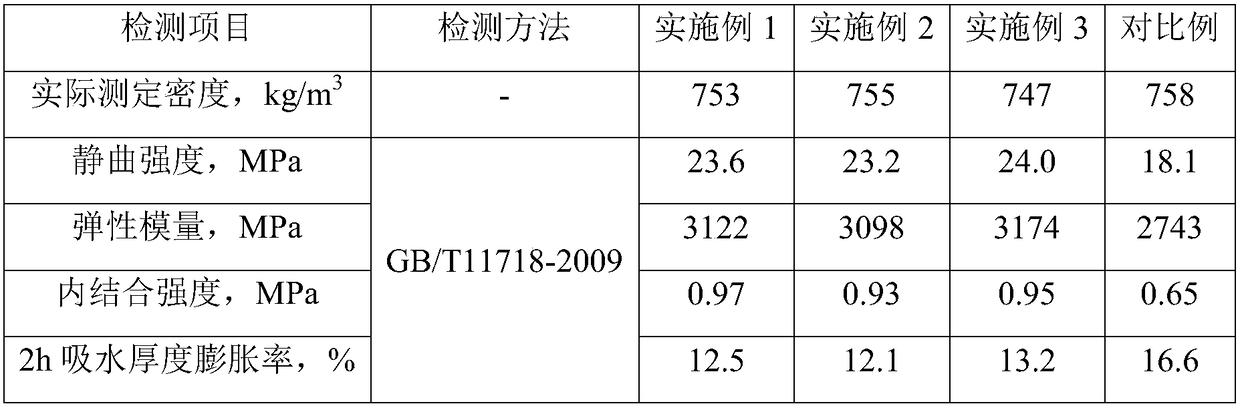

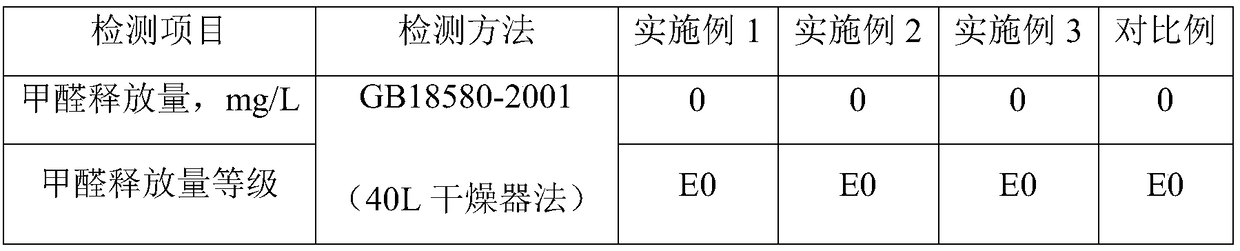

Water-proof and mildew-proof agent for artificial board and preparation method thereof

ActiveCN102952409AImprove waterproof and mildew resistanceEvenly distributedStearic acidUltimate tensile strength

The invention discloses a water-proof and mildew-proof agent for an artificial board and a preparation method thereof. The water-proof and mildew-proof agent comprises a capsule core and a capsule shell, wherein the capsule core is composed of paraffin, stearic acid and dodecyl-alpha-D-glucoside; and the capsule shell is composed of high molecular compound gelatin and chitosan. The preparation method comprises the following steps: melting the substances having water-proof property; under the action of the surfactant dodecyl-alpha-D-glucoside, dispersing in a hot gelatin and chitosan water solution in a nano particle state; and regulating the pH value, and quickly cooling to ensure that the gelatin and the chitosan are condensed into thin films coated on the nano particles of the substances having water-proof and mildew-proof property, thus forming nano capsules. The water-proof and mildew-proof agent prepared by the invention can reduce the instantaneous water absorption rate of the artificial board, improve the water-proof and mildew-proof property of the artificial board, enhance the internal bonding strength of the board, improve the product quality and save the cost by more than 20%.

Owner:ZHAOQING LIHE TECH DEV +3

Environment-friendly flame-retardant non-adhesive fiberboard of crop straw and preparation method thereof

ActiveCN108656305AHigh bonding strengthImprove mechanical propertiesWood working apparatusDomestic articlesFiberFiberboard

The invention relates to an environment-friendly flame-retardant non-adhesive fiberboard of crop straw and a preparation method thereof. The fiberboard is prepared by the following steps that 1 ) wheat straw and sorghum straw are taken to be cut off correspondingly, and the wheat straw and the sorghum straw are soaked in water to obtain a softened material; 2 ) steam explosion is correspondingly carried out on the softened material to obtain wheat straw fiber and sorghum straw fiber; 3 ) nano calcium carbonate, nano zinc oxide are mixed with nano copper oxide, and modifying is carried out toobtain a modified additive A; nano zinc borate, the nano zinc oxide are mixed with the nano copper oxide, and modifying is carried out to obtain a modified additive B; 4 ) the wheat straw fiber and the sorghum straw fiber are mixed with the modified additive A to obtain a core layer mixture; the wheat straw fiber is mixed with the modified additive B to obtain a surface layer mixture; and 5 ) thecore layer mixture is taken as a core layer, the surface layer mixture is taken as a surface layer to be laid and pre-pressed to obtain a slab, after hot-pressing forming and post-treatment are carried out, the environment-friendly flame-retardant non-adhesive fiberboard is obtained. The fiberboard has no formaldehyde release and has good mechanical property, good anti-water, moisture-proof, anti-corrosion and antibacterial properties; and good in fireproof and flame-retardant effects, and suitable for popularization and application.

Owner:霸州市光洋人造板制造有限公司

Method for preparing maize straw board

InactiveCN101691044AImprove internal bond strengthIncrease profitAldehyde/ketone condensation polymer adhesivesFlat articlesCorn stoverAmmonium chloride mixture

The invention discloses a method for preparing a maize straw board, which comprises the steps of dehydrating maize straws, cutting off the maize straws, compressing the maize straws into an isopycnic straw board-preparation raw material, drying the raw material, sieving the raw material into a coarse material and a fine material, spraying an adhesive, and performing hot press molding, wherein the weight percentage of the straws and the adhesive is 85-90: 10-15. The adhesive for preparing the board consists of 75 to 90 percent of urea-formaldehyde resin, 5 to 8 percent of ammonia water, 0.5 to 1 percent of polyvinyl alcohol, 6 to 12 percent of melamine, and 0.5 to 1 percent of ammonium chloride (weight proportion). The method is characterized by utilizing all components (peels, pulp and leaves) of the maize straws, adopting special equipment to directly compress the cut straws into the board-preparation raw material with the equidensity of between 0.8 and 1.0g / cm3, ensuring the same density of the raw material in sizing and pressing links of the board, improving the internal bonding strength of products, and also improving the utilization rate of the raw material and simplifying production technology so as to reduce production cost at the same time. The maize straw board has the advantages of adequate raw materials, low cost, high board quality, good biological degradability, and no pollution to the environment.

Owner:王维海

Method for manufacturing medium and high density fiberboards without pre-cured layers

InactiveCN101733811AReduce lossIncrease profitWood working apparatusDomestic articlesProduction lineHigh density

The invention relates to a method for manufacturing medium and high density fiberboards by a multi-layer press. The existing method for manufacturing the medium and high density fiberboards by using the multi-layer press has the problem of thicker pre-cured layers. The invention provides the method for manufacturing the medium and high density fiberboards with no or few pre-cured layers by using the multi-layer press, which can save loss of raw materials and not only be used for manufacturing the thick fiberboards, but also be used for manufacturing the thin medium and high density fiberboards. The technology can be applied in a production line of manufacturing the medium and high density fiberboards of the multi-layer press.

Owner:唐善学

Oriented strand board composite decorative board and manufacturing method

InactiveCN105966143ASimple processImprove internal bond strengthSpecial ornamental structuresWood working apparatusWood shavingsRoom temperature

The invention provides an oriented strand board composite decorative board which comprises a substrate layer and an overlaying layer or overlaying layers, wherein the overlaying layer or overlaying layers is / are glued at the single side or double sides of the substrate layer through a formaldehyde-free adhesive, and the substrate layer is an oriented strand board taking wood or wheat straw shavings as the raw material and taking isocyanate resin and / or phenolic resin as the adhesives or the adhesive. A manufacturing method of the oriented strand board composite decorative board comprises the following steps that by taking the wood or wheat straw shavings as the raw material and taking isocyanate resin and / or phenolic resin as the adhesives or the adhesive, the oriented strand board is manufactured according to directional pavement and hot-pressing technologies; the both sides of the oriented strand board are sanded and puttied; one side or both sides of the substrate layer is / are coated with the formaldehyde-free adhesive, and is / are bonded with the overlaying layer or the overlaying layers; and room temperature cold pressing treatment is carried out to allow the adhesive(s) to be solidified, wherein the pressing temperature is 20-35 degrees, the pressing pressure is 0.5-1.5MPa, and the pressing time is 0.5-4h. According to the oriented strand board composite decorative board, the problems that the conventional decorative board is high in formaldehyde content, complicated in technology, and high in cost are solved.

Owner:NINGBO ZHONGJIA LOW CARBON NEW TECH RES INST

Method of manufacturing thick medium high density fiber boards using single face spraying vacuum hot pressing technology

InactiveCN1555969AGood effectSmall deviation of section density distributionWood working apparatusDomestic articlesFiberThick plate

A technology for preparing the medium-or high-density thick fibreboard includes hot-pressing the raw fibreboard while spraying steam onto its one surface for 1-10 min, and vacuum sucking for removing condensed water for 5-40S. Its advantage is short hot-pressing time and high productivity.

Owner:NANJING FORESTRY UNIV

Flame-retarded shaving board and manufacturing method thereof

InactiveCN103386701ANegative effects of weakening physical and mechanical propertiesReduce negative impactWood working apparatusDomestic articlesMolecular sieveWood shavings

The invention discloses a flame-retarded shaving board with an inflaming retarding property and a manufacturing method thereof. The flame-retarded shaving board comprises wood shavings, adhesive and a flameresistant material, and is characterized in that the flameresistant material is mixed solution of diammonium hydrogen phosphate, ammonium dihydrogen phosphate and a 4A molecular sieve; the addition amount of the flameresistant material is 15-20% of the weight of the wood shavings; the addition amount of the adhesive is 12-15% of the weight of the wood shavings. The flame-retarded shaving board manufactured by the formula and the method is suitable for the fields of furniture, packaging, building, interior and outdoor decoration and the like.

Owner:BEIJING FORESTRY UNIVERSITY

Method of manufacturing medium density fiber board thick plate using spray evaporation-vacuum hot pressing technology

InactiveCN1493438AGood effectSmall deviation of section density distributionWood working apparatusFlat articlesFiberThick plate

A process for preparing the thick medium-density fibreboard by steam spraying-vacuum hot pressing technology includes hot pressing to make its density be 0.2-0.7 g / cu.cm while spraying steam under 0.2-1.0 MPa for 2-20S, and vacuumizing for 5-40 S for removing condensed water.

Owner:NANJING FORESTRY UNIV

Method for producing wood fibre-plastics composite products

ActiveUS20120172494A1Improve mechanical propertiesGood dispersionGlass/slag layered productsFlat articlesCelluloseOligomer

A process for producing a composite product comprising fibres of a lignocellulosic material or natural fibres and a plastics material utilises a liquid or particulate binder formulation comprising a thermoset resin and a thermoplastic polymer, monomer, or oligomer. A composite product is formed for use as or in forming a feedstock in plastics manufacture may be broken down under heat and mechanical shearing in a plastics extrusion machine to release the major fraction of the fibres, or the product may be useful as an intermediate product in other form or as an end product.

Owner:NEW ZEALAND FOREST RES INST

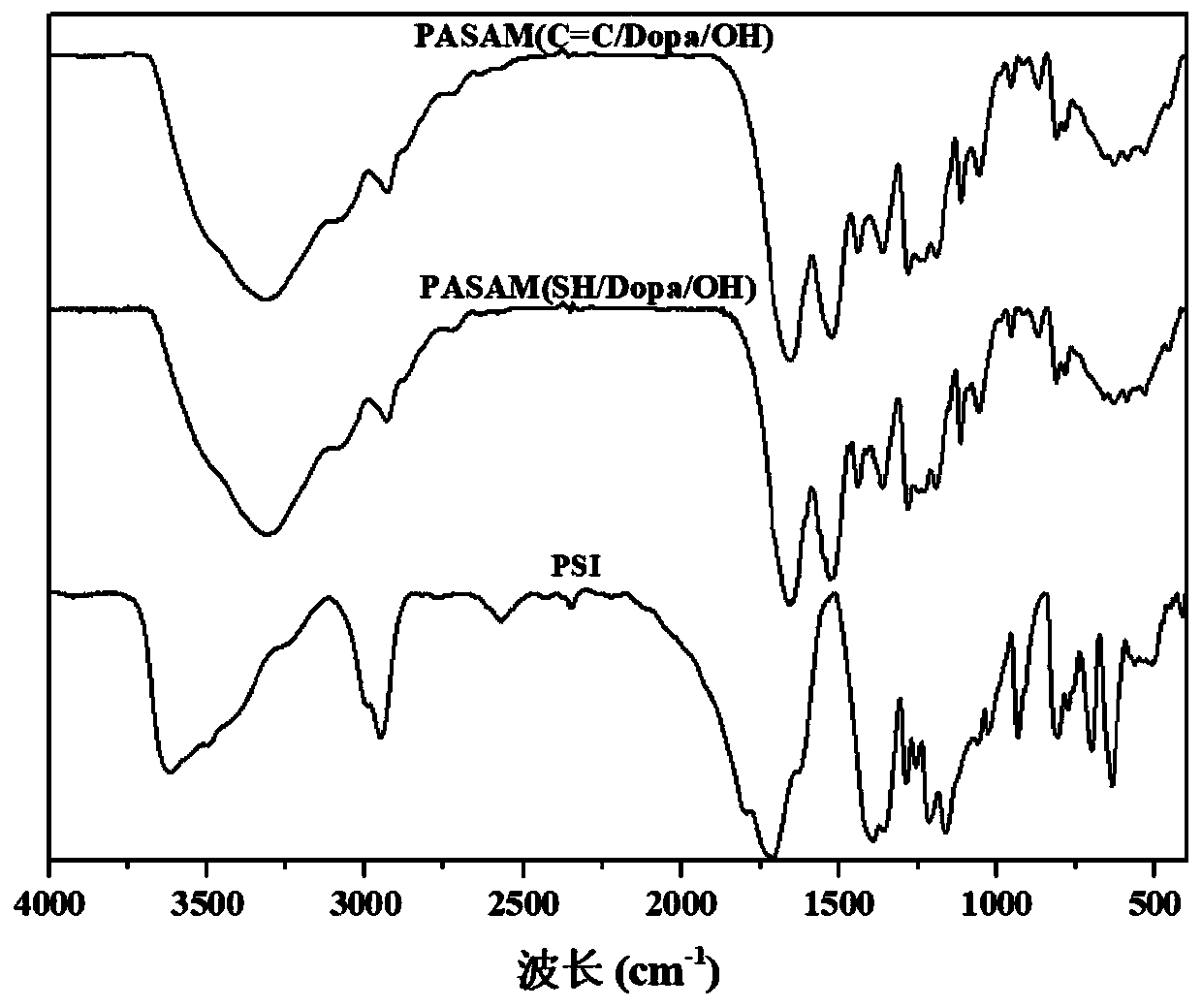

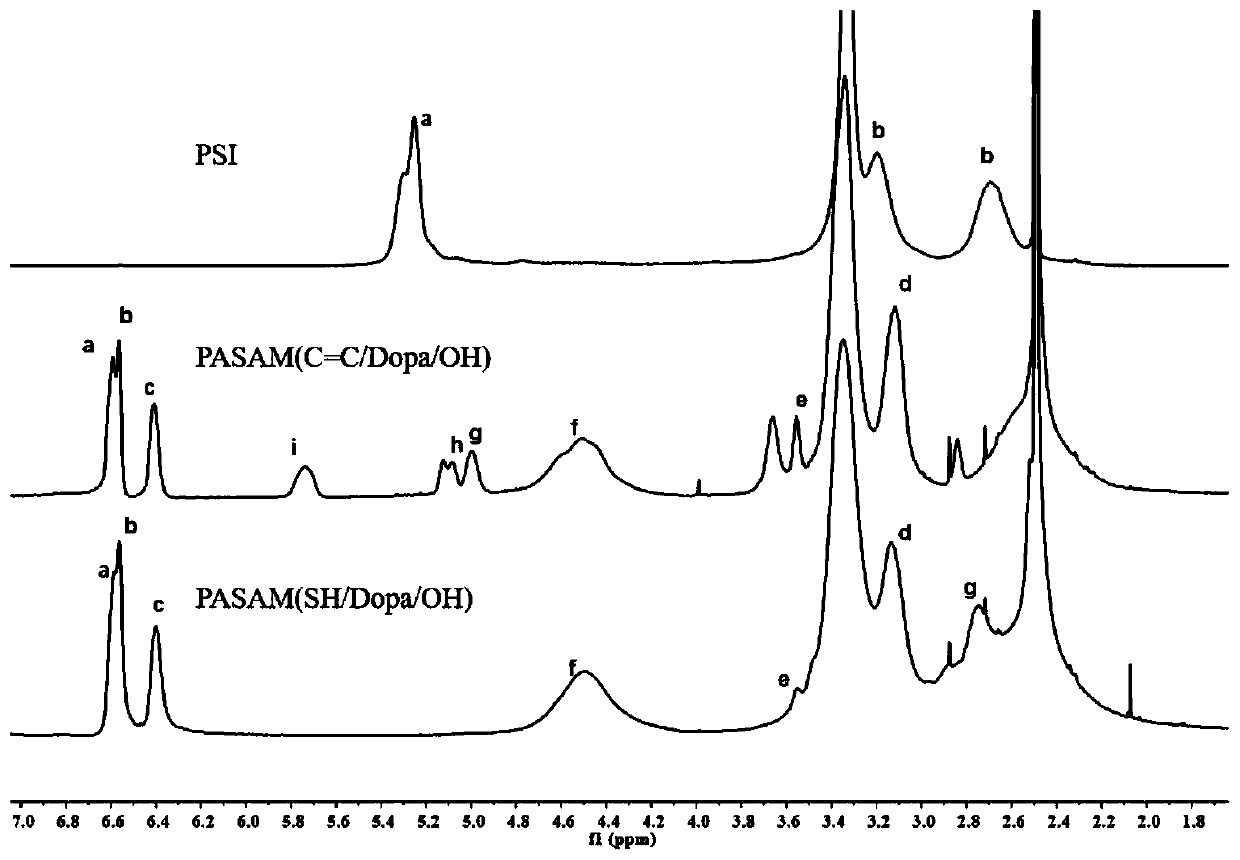

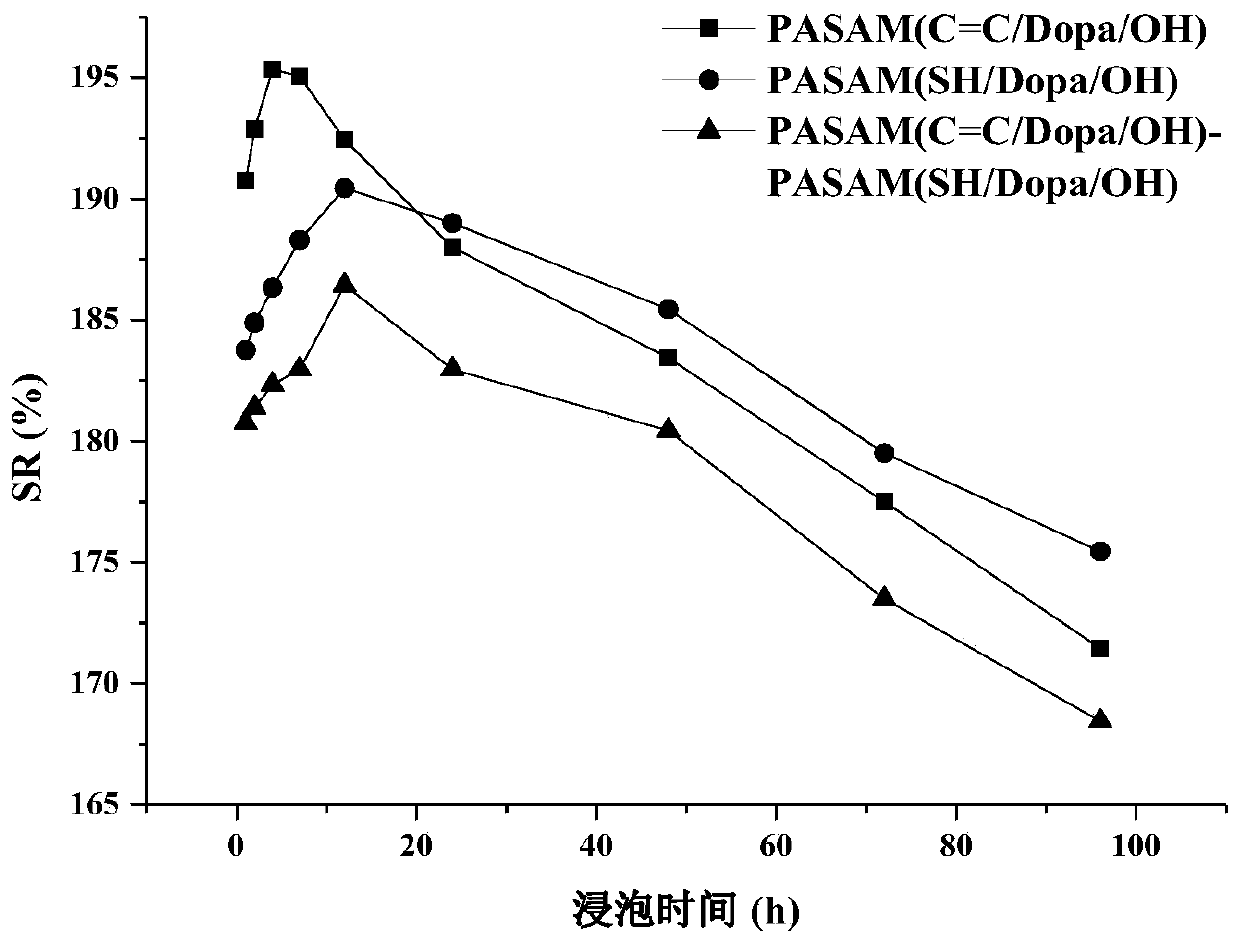

Dual-component in-situ injection type polyasparagine bionic tissue adhesive and preparing method thereof

ActiveCN110101898AImprove water solubilityImprove adhesionSurgical adhesivesPharmaceutical delivery mechanismPolyasparagineSolvent

The invention discloses a dual-component in-situ injection type polyasparagine bionic tissue adhesive and a preparing method thereof. The tissue adhesive is composed of a first polyasparagine component solution and a second polyasparagine component solution with different reactive functional groups. A first component is polyasparagine with a vinyl functional group, a catechol functional group anda hydroxyl functional group, a second component is polyasparagine with a sulfydryl functional group, a catechol functional group and a hydroxyl functional group, a solvent of the first component is ahydrogen peroxide solution, and a solvent of the second component is a horse radish peroxidase solution. The catechol functional groups in the first component and the second component have the marinemussel imitation adhesion characteristic and can have noncovalent interaction with a tissue surface, the adhesive has tissue adhesiveness, and tissue repairing is realized. The tissue adhesive has excellent tissue adhesive strength and use convenience and has important significance in replacing surgical sutures and healing wounds.

Owner:SOUTH CHINA UNIV OF TECH

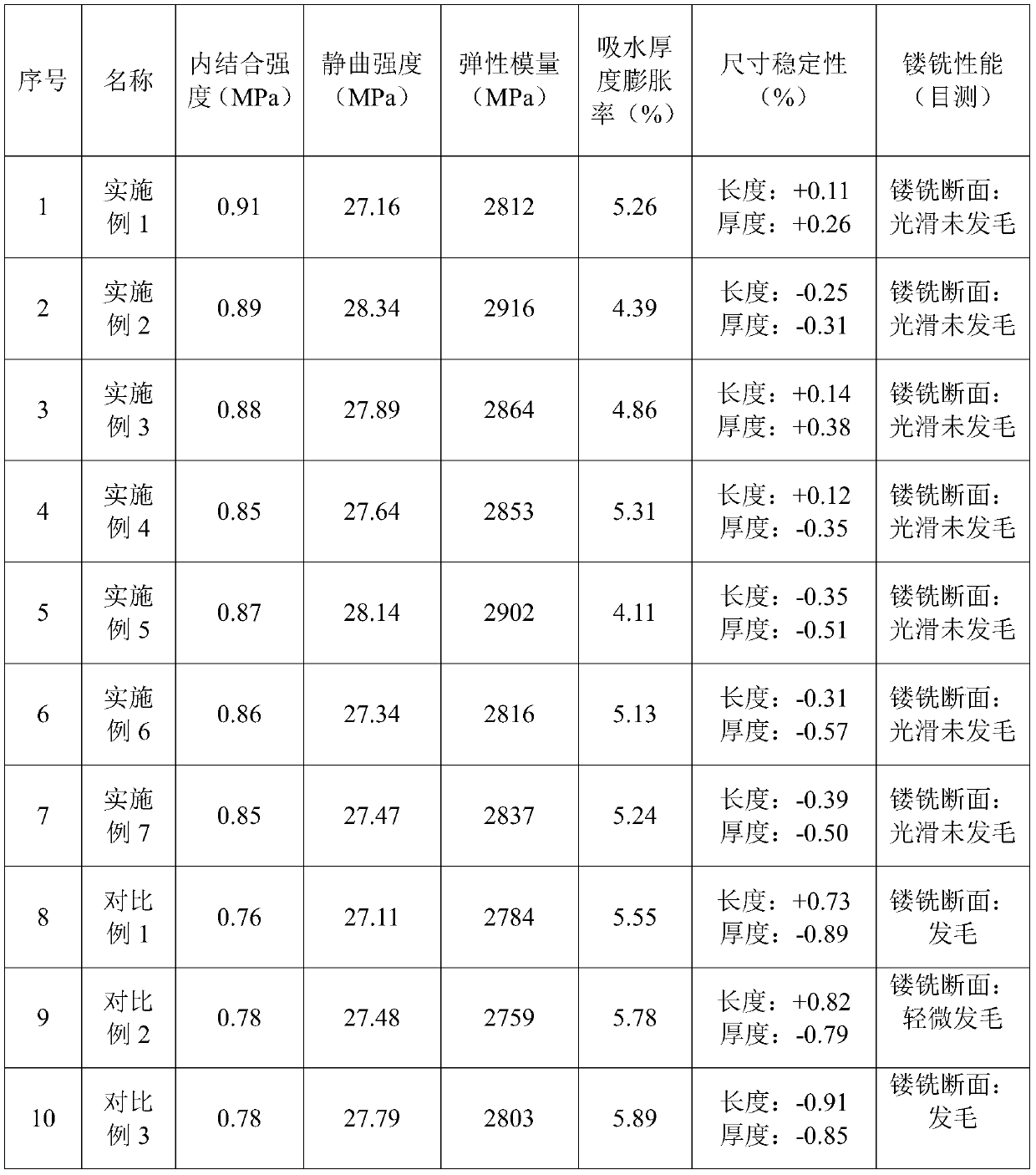

Isocyanate adhesive composition and routing fiberboard prepared from isocyanate adhesive composition

ActiveCN110272707AValid packageGuaranteed to be completely wrappedNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesFiberAdhesive

The invention relates to an isocyanate adhesive composition for a fiberboard and a routing fiberboard prepared from the isocyanate adhesive composition. The isocyanate adhesive composition comprises an isocyanate adhesive, a double-crown-layer silicon dioxide composite material and a lignin wood material. The routing fiberboard is formed by mixing separated fibers and the adhesive and performing hot press molding. The fiberboard prepared by using the adhesive provided by the invention has good routing performance, and the dimensional stability is better maintained.

Owner:WANHUA CHEM GRP CO LTD

Method for manufacturing formaldehyde-free plant fiber packaging material

InactiveCN102268847AAchieving self-gluingImprove internal bond strengthFibreboardPretreatment with water/steamSteam pressureFiber bundle

The invention relates to a method for manufacturing formaldehyde-free plant fiber packaging materials, and belongs to the technical field of wood composite material manufacturing. The technique is to firstly process the plant fiber raw material into a unit of a certain size, and evenly mix it with the enzymatic lignin whose dry weight accounts for 30-50% of the dry plant fiber unit weight. Then put the mixture into the steam explosion processor, explode and dissociate into fiber bundles under the condition of steam pressure of 0.8~1.3MPa and treatment time of 3~10min, and then separate them after fine grinding in a regular temperature mill for 1~3min Fibers are dried to a moisture content of 10-20%, and then paved and shaped. Under the conditions of temperature 190-210°C, pressure 4.0-5.0MPa, time 30-50s / mm, it is hot-pressed into a plate with a density of 0.9-1.2g / cm3 and a thickness of 2-4mm. This material does not contain free formaldehyde and any chemicals, and can be widely used in the food packaging industry.

Owner:NANJING FORESTRY UNIV

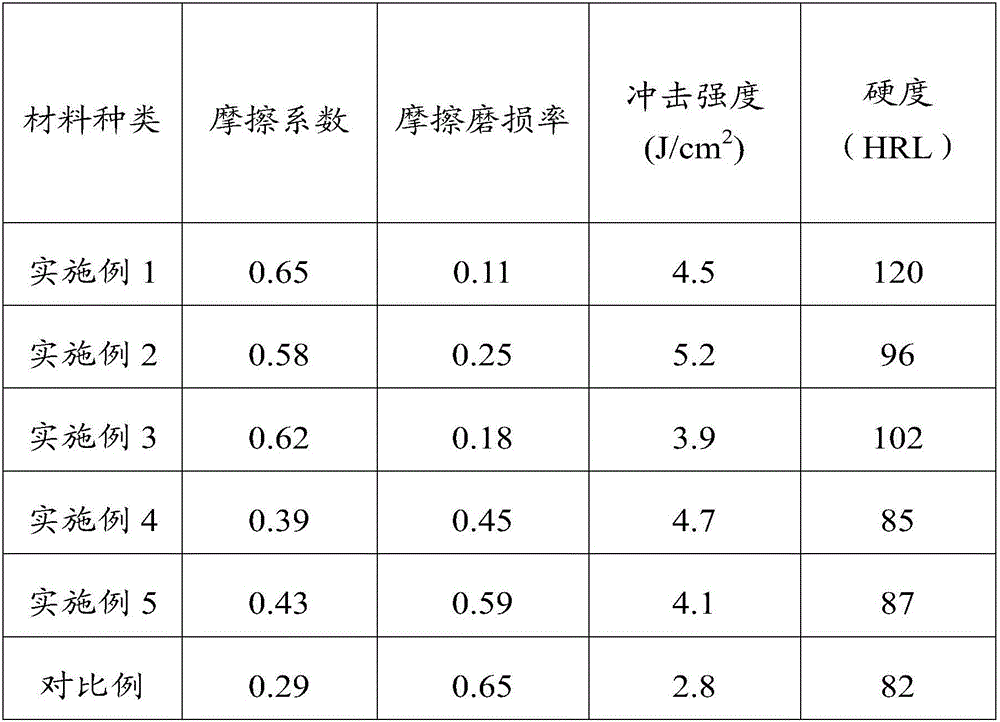

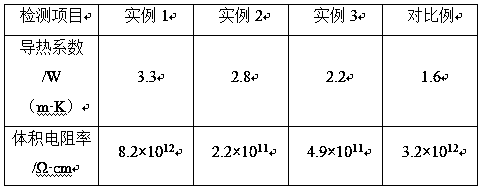

Friction plate material and preparation method thereof

InactiveCN107524740AImprove wear resistanceExtended service lifeOther chemical processesFriction liningBrassFiber

The invention discloses a friction plate material and a preparation method thereof. The friction plate material comprises an enhanced type foam alloy framework and a packing material, wherein the enhanced type foam alloy framework comprises aluminum alloy powder, tungsten carbide and titanium hydride, and the packing material comprises modified fibers, phenolic resin, an abrasion-resistant modifying agent, kieselguhr, brass powder, graphite, carbon fibers and silicon dioxide. A friction plate prepared through the friction plate material and the preparation method provided by the invention has the characteristics of being small in friction coefficient, low in wear rate, high in strength and good in shock resistance; and the preparation method is simple, the production technological process is easy to operate, and the friction plate material and the preparation method thereof are suitable for large-scale popularization.

Owner:章德恩

Manufacturing method of novel environment-friendly bio-based lignin glue formaldehyde-free plate

InactiveCN110394873AGood moisture resistance and waterproof effectHigh strengthFlat articlesDomestic articlesWood shavingsEngineering

The invention relates to a manufacturing method of a novel environment-friendly bio-based lignin glue formaldehyde-free plate. The method comprises the following steps of slicing; screening; flaking;shaving drying; sizing; paving; pre-pressing; hot pressing; plate airing; plate sawing; sanding; checking and grading; and packaging and warehousing. In general, the plate has the advantages of high strength, low formaldehyde emission, environmental friendliness and safety.

Owner:商丘市鼎丰木业股份有限公司

Method for making paper special for E-commerce

InactiveCN105603803AFeel goodImprove surface finenessWater-repelling agents additionPulp beating methodsE-commerceUltimate tensile strength

The invention relates to a method for making paper special for E-commerce. The method includes the steps of beating, pulp mixing, accessory adding, wet paper sheet making, predrying, surface sizing, postdrying, calender finishing and the like conducted on softwood pulp and hardwood pulp; the fixed quantity of the made paper special for E-commerce is 60 g / m<2>, moisture is 5-6%, raw white or ISO whiteness is 100%, tensile strength is larger than or equal to 4.0 KN / m, internal bond strength is larger than or equal to 400 J / m<2>, the ash content is smaller than or equal to 15%, the average value of smoothness is larger than or equal to 100 S, water absorption stability is 20-25 g / m<2>, a long broken roll of paper is larger than 7000 m in the longitudinal direction, transverse folding strength is larger than or equal to 15 times, and the transverse ratio of expansion and contraction is smaller than or equal to 3.0%; high yield pulp is not contained; the paper is good in evenness, fine in appearance, good in flatness and good in touch handfeel.

Owner:YUEYANG FOREST & PAPER CO LTD

Preparation method of high-strength water-proofing clay sculpture material

InactiveCN107602049AIncrease stickinessImprove hydrophobicity and water resistanceClay mineralsSlurry

The invention relates to the technical field of sculpture material preparation and particularly relates to a preparation method of a high-strength water-proofing clay sculpture material. In the method, orthosilicic acid precipitate is mixed with quick lime to obtain a paste mixture, and flax straw and the paste mixture are soaked and fermented for a long time, so that the flax straw is mildewed, wherein grass tendon, which is high in toughness and strength, remain and is precipitated with the lime; the materials are heated and boiled so that the orthosilicic acid precipitate is heated and decomposed to generate nano SiO2 which is packed in the slurry, wherein the high-strength nano SiO2 can further increase the mechanical strength of cured and shaped slurry so as to finally obtain self-made tendon slurry which has very high viscosity and high strength; then clay mineral kaolin is blended with flour and castor oil to perform fermentation, so that castor oil is degraded to generate estergroups under effect of microorganisms, finally the ester groups are introduced to the surface of kaolin for improving the hydrophobicity and water resistance of clay to fially produce the high-strength water-proofing clay sculpture material, which has broad application prospect.

Owner:常州富思通管道有限公司

Method for manufacturing an improved hog fuel board using a catalyst

InactiveUS6544649B1High strengthGood dimensional stabilityWood working apparatusCork mechanical workingEngineeringUltimate tensile strength

A hog fuel board is made by placing a hog fuel mat including an ammonium chloride catalyst with flexible non-sticking layers on outside surfaces between screens in a preheated platen press and pressing the mat to preset stops and for a predetermined time and pressure to cause adhesives naturally present in the hog fuel to disperse throughout the board. The presence of ammonium chloride as a catalyst uniformly distributed through the hog fuel mat significantly lowers the temperature required at the heating press platens to form a board which also has improved properties. There is also described a hog fuel veneer board with a hog fuel mat sandwiched between veneer sheets and a lumber product with a hog fuel coating thereon. These additional products are both formed using the ammonium chloride catalyst to reduce press temperatures and create a product with improved properties, particularly, internal bond strength.

Owner:FPINNOVATIONS INC

Process for producing modified urea-formaldehyde resin, products produced thereby and uses thereof

InactiveCN101402715ADisadvantages of reduced bond strengthOvercoming the disadvantages of bond strengthAldehyde/ketone condensation polymer adhesivesSilanolChemistry

The invention relates to a method for preparing a modified urea resin. During the production process of urea resin, a small molecule methyl silanol aqueous solution which accounts for 0.4 percent to 30 percent of the total feeding amount by weight is added into raw material to carry out modification; or a small molecule methyl silanol aqueous solution with weight percentage of 0.4 percent to 30 percent is directly added into and mixed with the prepared urea resin. The method achieves the purpose of reducing formaldehyde release through changing the molecule structure and controlling the existence of free formaldehyde and methylene ether link and can also improve the resistance to water, weather and aging resistance and bonding strength of the urea resin.

Owner:张忠和

Preparation method of high-strength bamboo shoot shell packing materials

InactiveCN108214725AHigh adsorption activityHigh bonding strengthFlexible coversWrappersAdhesiveCorona discharge

The invention relates to a preparation method of high-strength bamboo shoot shell packing materials and belongs to the technical field of packing material preparation. According to the preparation method, firstly through a molecular sieve dewaxing principle, the surface of a bamboo shoot shell is subjected to dewaxing treatment, molecular sieve powder absorbing bamboo wax, lemon juice and bacterial suspension liquid are mixed for fermentation, then fermentation products and nickel boride are mixed and react in a high-pressure reaction kettle to obtain a reinforced material, and then the reinforcing material, urea resin and starch paste are utilized to prepare an adhesive. Then the surface of the dewaxed bamboo shoot shell is subjected to corona treatment, after the adhesive is applied, hotpressing is conducted, and thus the high-strength bamboo shoot shell packing paper is obtained. According to the preparation method, the surface of the bamboo shoot shell is subjected to corona treatment, corona discharge is utilized, low-temperature plasma is generated, thus free radicals are generated on the surface of the bamboo shoot shell, so that crosslinking occurs, the surface of the bamboo shoot shell is coarsened, the wettability to the modified adhesive is improved, the free radicals generated on the surface of the bamboo shoot shell can generate intermolecular adsorption and hydrogen bond adsorption with active groups in the modified adhesive, and the mechanical strength of a plate is improved.

Owner:黄旭东

Production method of epoxy resin-based thermal-conductive insulating paste

PendingCN110184009AEvenly dispersedHigh thermal conductivityNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyChemistry

The invention discloses a production method of epoxy resin-based thermal-conductive insulating paste, and belongs to the technical field of high-polymer materials. The production method of the epoxy resin-based thermal-conductive insulating paste comprises the steps of sequentially weighing the components in parts by weight: 60-80 parts of epoxy resin, 30-40 parts of a diluent, 5-8 parts of a silane coupling agent KH-550, 10-20 parts of an additive and 10-12 parts of a curing agent, mixing the epoxy resin and the diluent in a stirrer, adding the additive and the silane coupling agent into thestirrer, under conditions of temperature of 30-50 DEG C and rotating speed of 300-400 r / min, conducting stirring and mixing for 30-50 min to obtain a mixed blank, mixing the mixed blank and the curingagent, under conditions of temperature of 30-60 DEG C and rotating speed of 300-350 r / min, conducting stirring and mixing for 20-50 min, and then under a condition of temperature of 150-180 DEG C, conducting heating and curing for 30-60 min to obtain the epoxy resin-based thermal-conductive insulating paste.

Owner:秦臻

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com