Method for manufacturing weed wood and straw compounding medium density fiberboard with laminated structure

A layered structure and manufacturing method technology, applied in the field of miscellaneous wood/straw composite medium density fiberboard manufacturing technology, can solve the problems of high hygroscopicity and low bonding strength, etc., to reduce hygroscopicity, improve bonding strength, and save wood resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

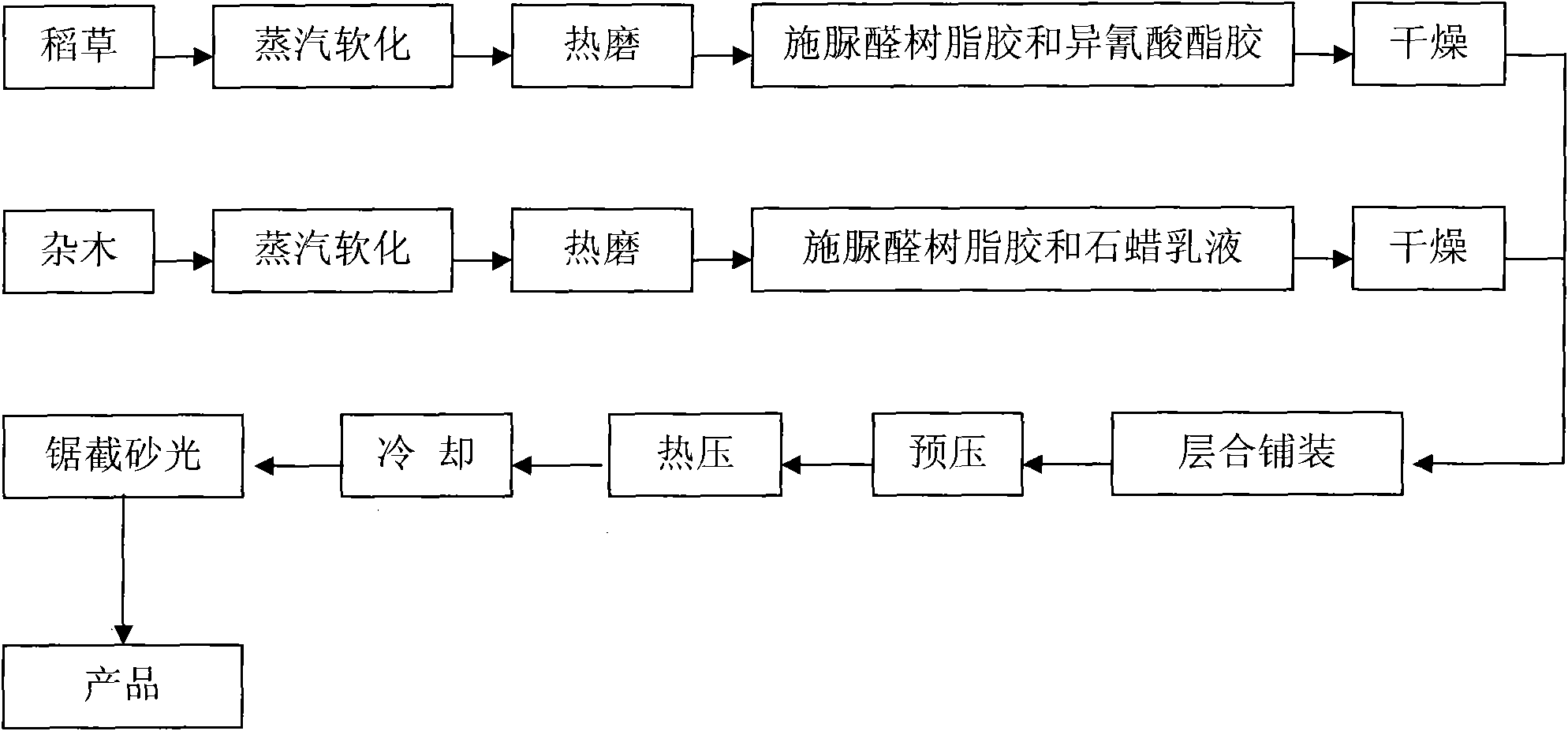

Method used

Image

Examples

Embodiment 1

[0009] Example 1, the miscellaneous wood is made into chips of 25-35mm by a chipper, and sent to a screw feeder for steam preheating. The temperature is 120 ° C and the retention time is 5 minutes. After preheating, it is passed into the internal steam of the thermal mill The pressure is 0.8MPa for fiber separation, apply 10% urea-formaldehyde resin glue, 1.0% paraffin emulsion, and dry; the straw is made into 20-40mm fragments through the pulverizer, and sent to the screw feeder for steam preheating, the temperature is 90 ° C, The retention time is 5 minutes. After preheating, it is passed into a thermal grinder with an internal steam pressure of 0.6 MPa for fiber separation. Apply 0.8% isocyanate glue and 12% urea-formaldehyde resin glue and dry. The dried wood fiber and grass fiber are laminated, pre-pressed, and hot-pressed in the order of surface layer-core layer-surface layer in the thickness direction of the slab with grass fiber: wood fiber: grass fiber = 20:60:20 and ...

Embodiment 2

[0012] Embodiment 2, in the separation, sizing and waterproofing agent, drying process of straw fiber and miscellaneous wood fiber, similar to embodiment 1, the difference is that the wood fiber and grass fiber that have been dried are arranged according to the surface layer in the thickness direction of the slab. -The sequence of core layer-surface layer is wood fiber:grass fiber:wood fiber=20:60:20 for lamination, pre-pressing, hot pressing and post-treatment to produce boards. The performance of the product is shown in Table 2.

[0013] Table 2 is measured by the performance of the sheet material prepared by example 2

[0014] test performance

Embodiment 3

[0015] Example 3, miscellaneous wood is made into chips of 25-35 mm by a wood chipper, sent to a screw feeder for steam preheating, the temperature is 150 ° C, and the retention time is 3 minutes. After preheating, it is passed into the internal heat mill Steam pressure 1.0MPa for fiber separation, apply 11% urea-formaldehyde resin glue, 0.8% paraffin emulsion, and dry; the straw is made into 20-40mm fragments through a pulverizer, and sent to a screw feeder for steam preheating at a temperature of 120°C , The retention time is 3min, and the internal steam pressure of 0.8MPa is passed into the thermal refiner for fiber separation, 1.0% of isocyanate glue and 11% of urea-formaldehyde resin glue are applied, and dried. The dried wood fiber and grass fiber are laminated, pre-pressed, and hot-pressed in the order of surface-core-surface in the thickness direction of the slab with grass fiber: wood fiber: grass fiber = 25:50:25 and post-processing to produce panels. The performanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com