Patents

Literature

200 results about "Internal bonding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

International Bond. An international bond is a debt investment that is issued in a country by a non-domestic entity. International bonds are issued in countries outside of the United States, in their native country's currency. They pay interest at specific intervals and pay the principal amount back to the bond's buyer at maturity.

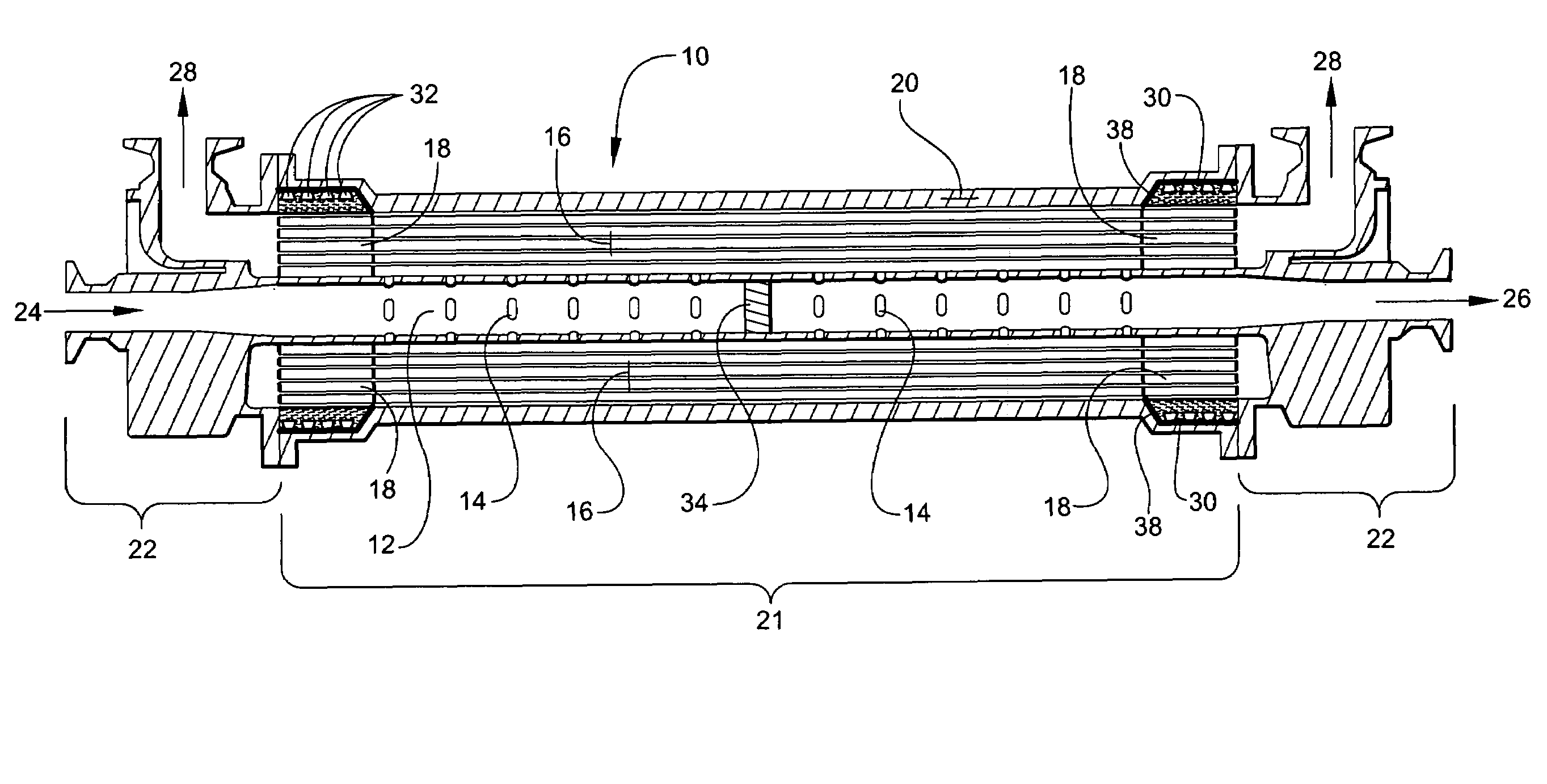

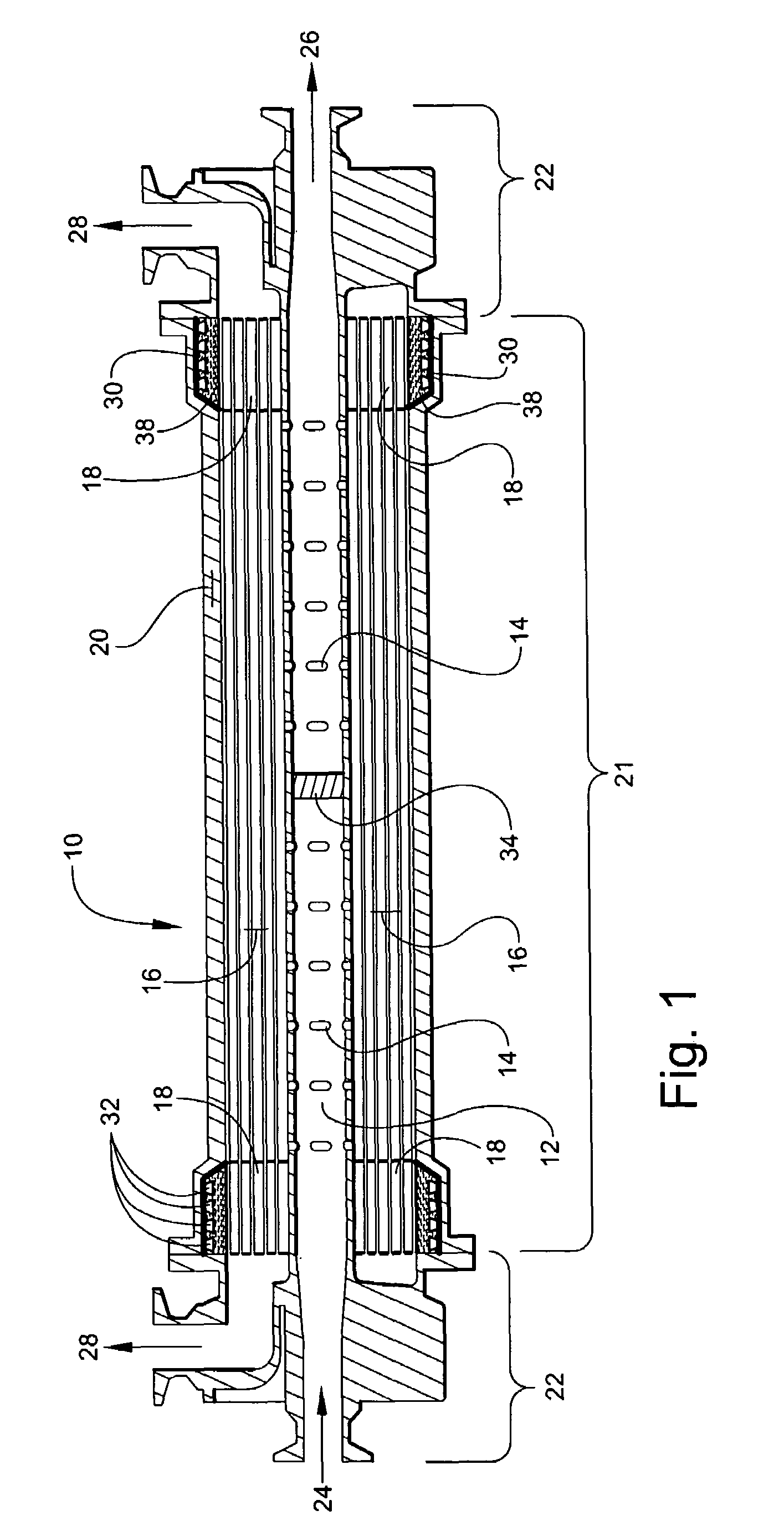

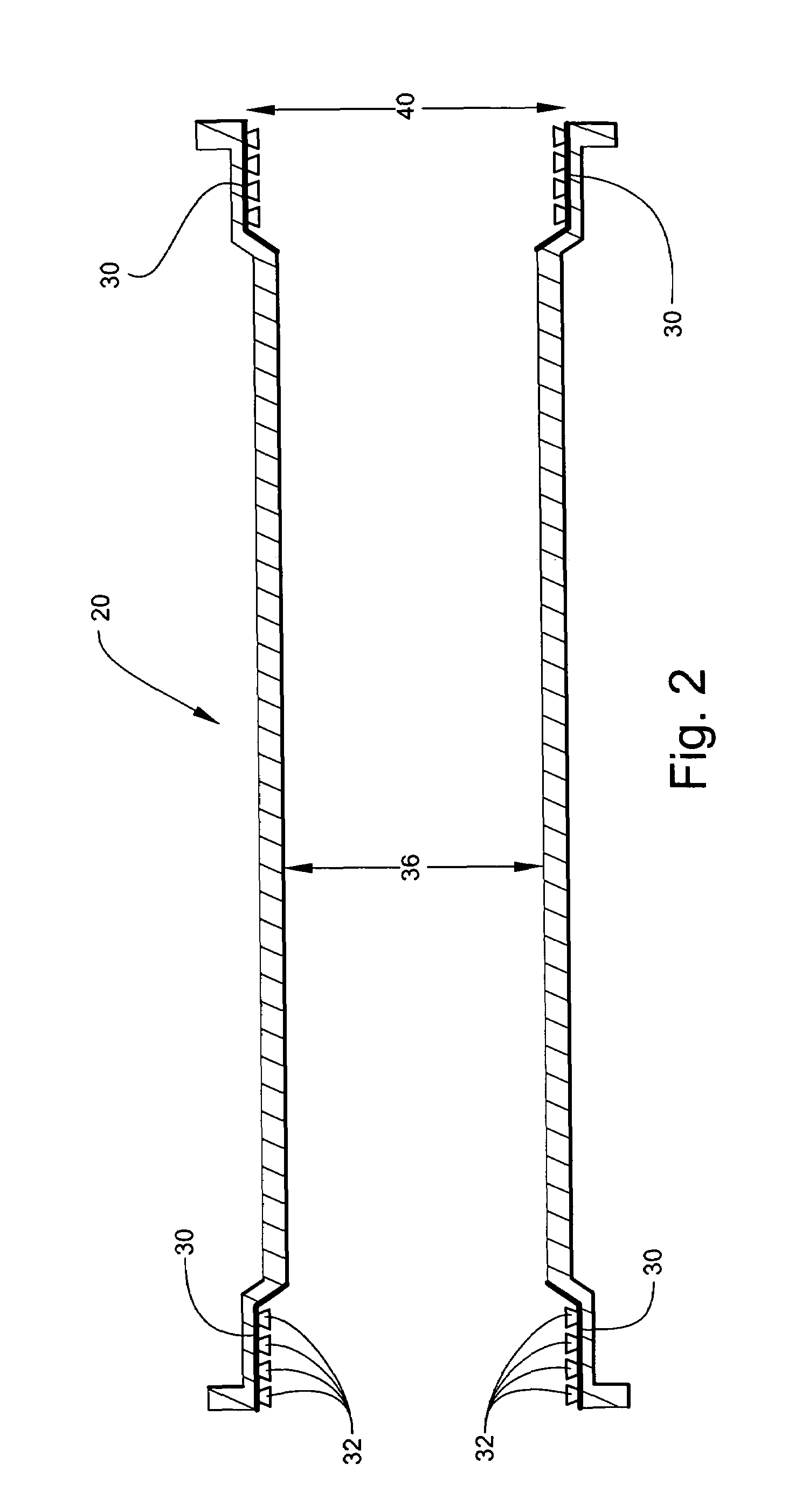

Hollow fiber membrane contactor and method of making same

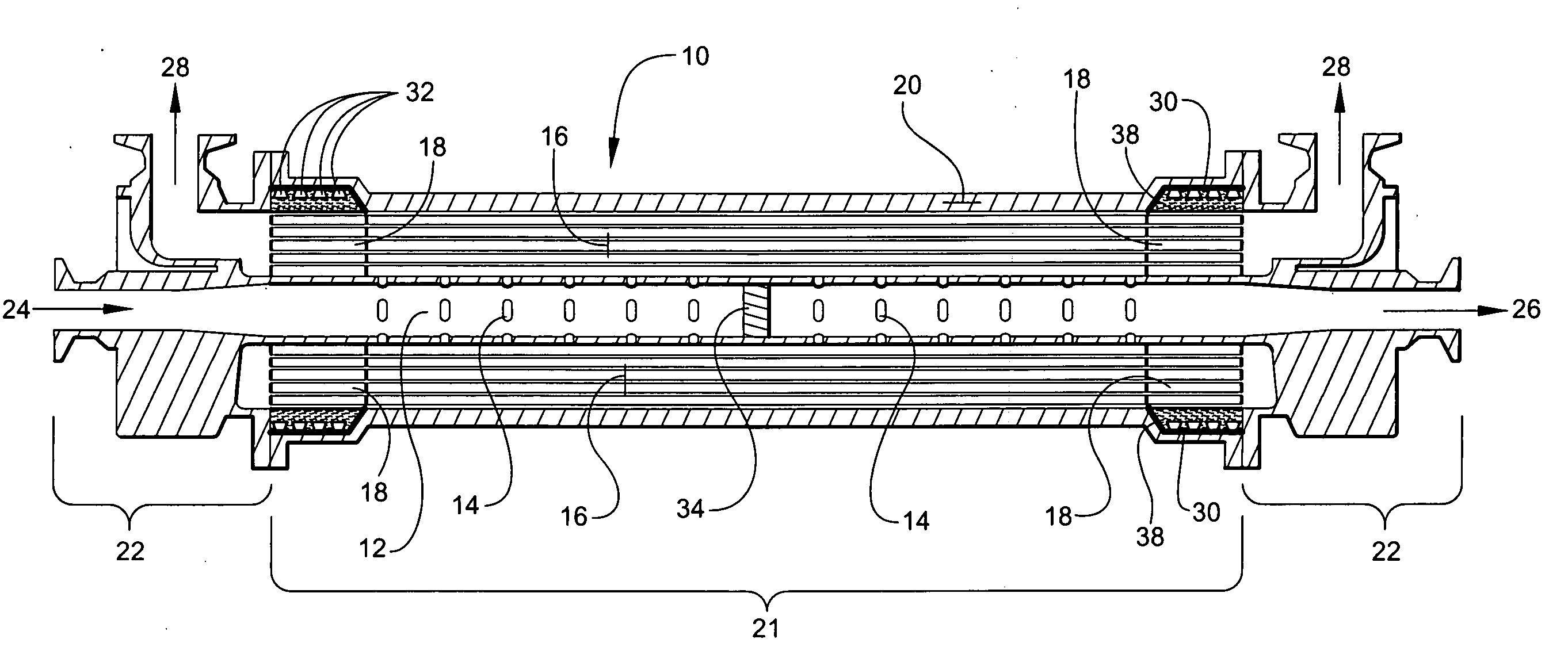

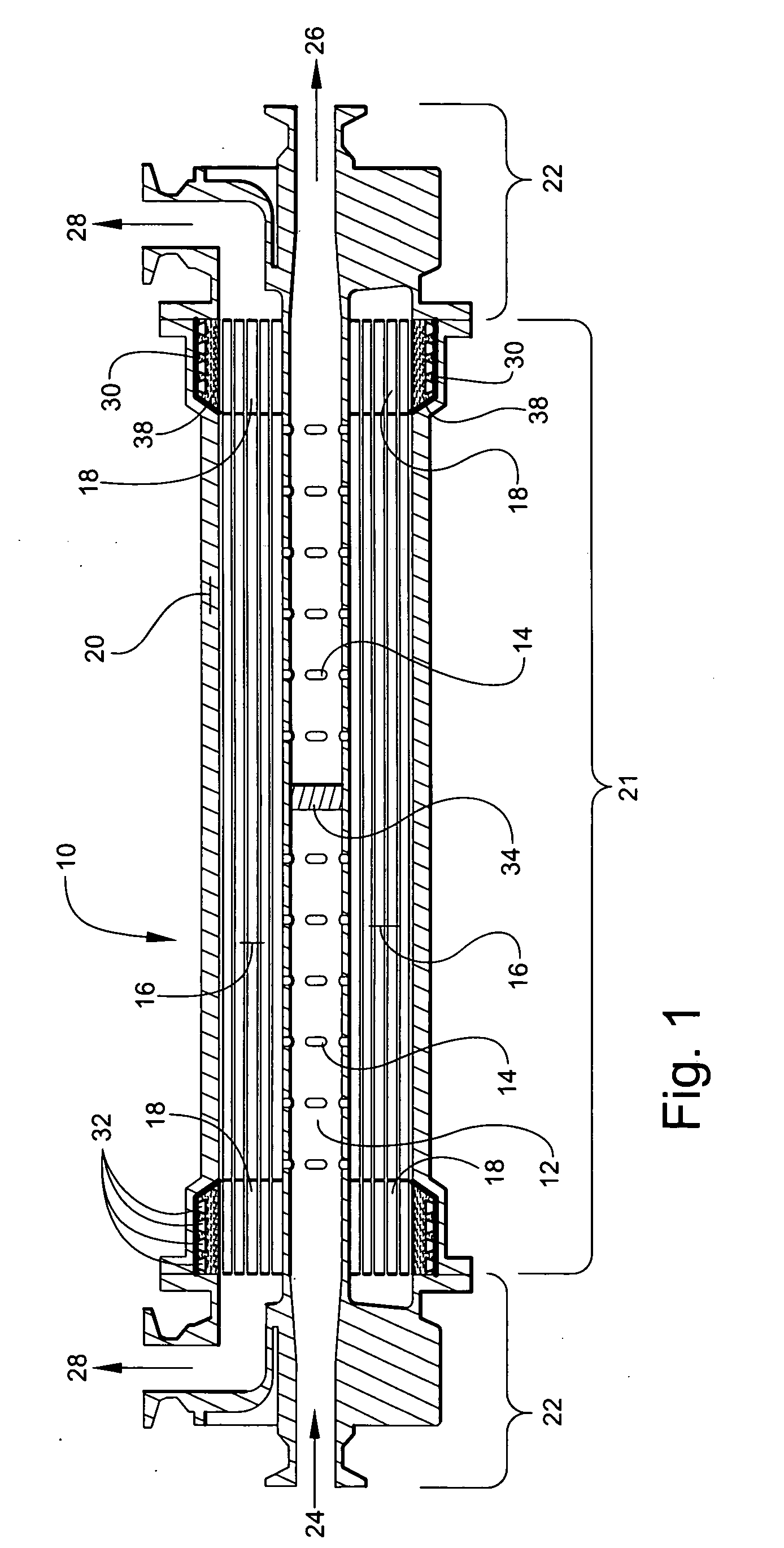

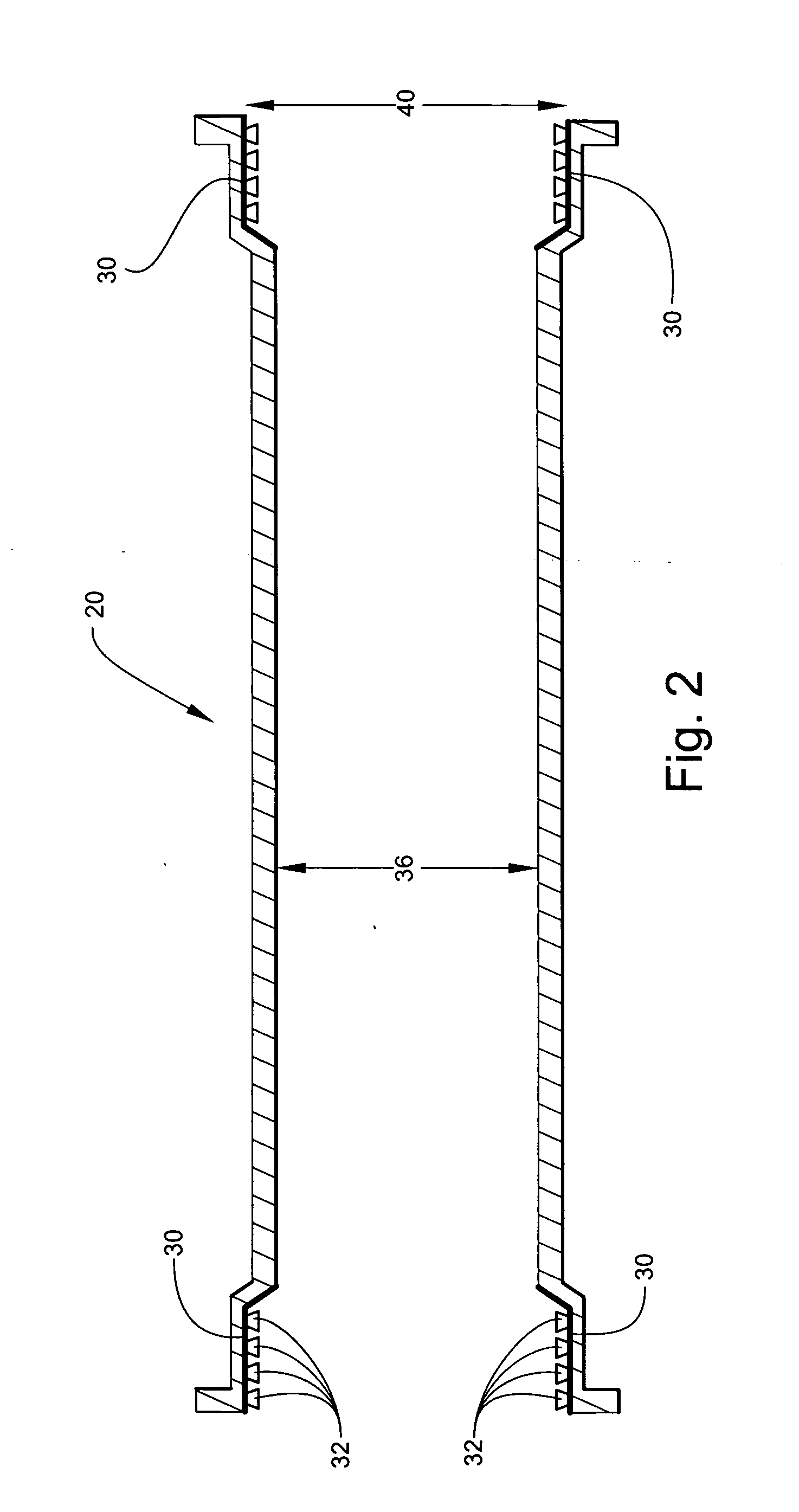

The instant invention is a hollow fiber membrane contactor, and method of making same. The hollow fiber membrane contactor includes (1) a shell, said shell having a internal bonding surface, an interlocking geometry ring being provided on said internal bonding surface; (2) a unitized structure; (3) a potting material joining said unitized structure to said shell at said interlocking geometry ring thereby forming an interlocking seal therebetween; and (4) end caps, said end caps being adjoined to lateral ends of said shell. The method of making a hollow fiber membrane contactor includes (1) providing a shell, said shell having a internal bonding surface; (2) providing an interlocking geometry ring on said internal bonding surface; (3) forming a unitized structure; (4) placing the unitized structure into said shell (5) potting said unitized structure to said shell at said interlocking geometry ring thereby forming an interlocking seal therebetween; and (6) adjoining end caps to lateral ends of said shell.

Owner:3M INNOVATIVE PROPERTIES CO

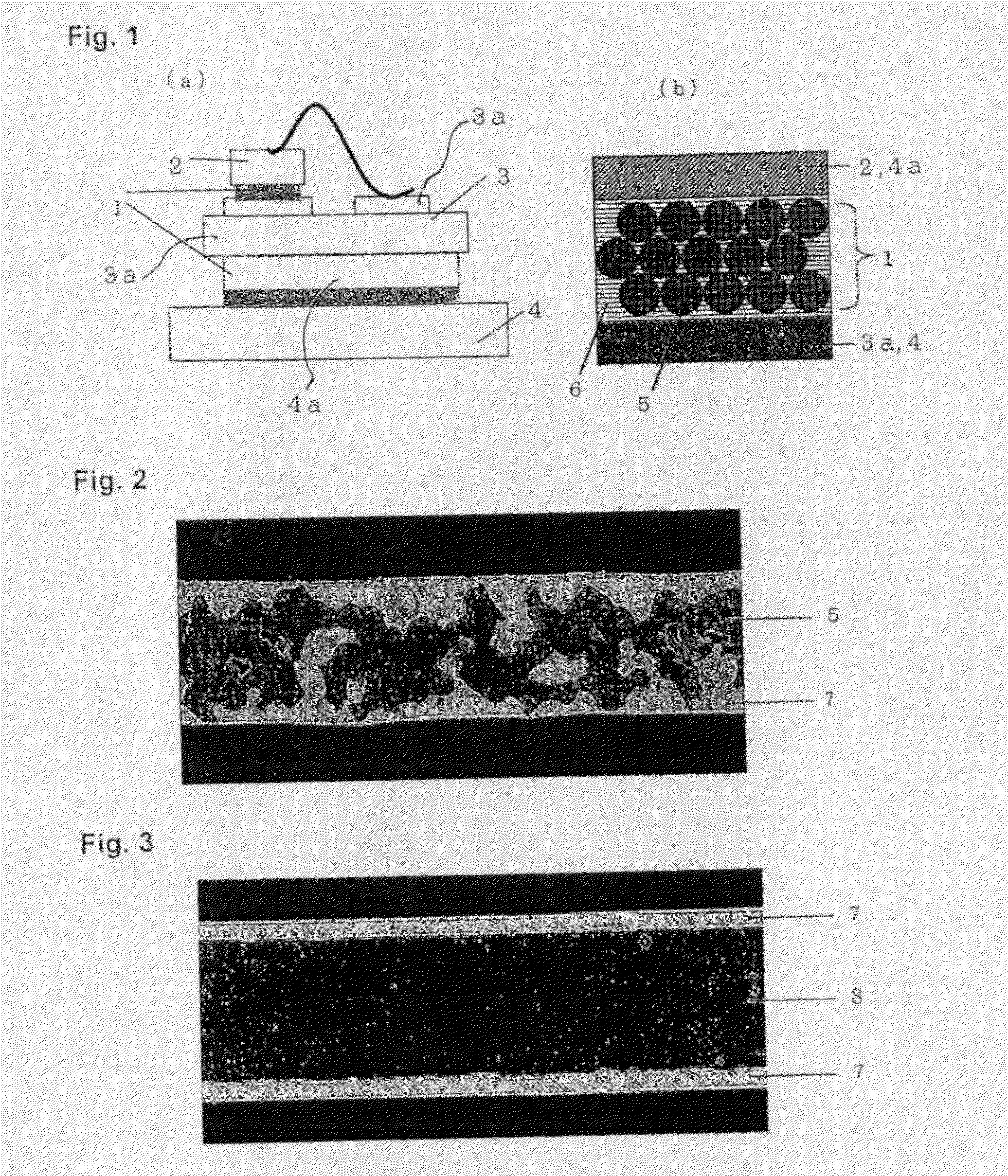

Bonding Material for Semiconductor Devices

ActiveUS20130134591A1Improve reliabilityFew voidPorous dielectricsLayered productsMetallurgyInternal bond

A semiconductor device is provided which has internal bonds which do not melt at the time of mounting on a substrate. A bonding material is used for internal bonding of the semiconductor device. The bonding material is obtained by filling the pores of a porous metal body having a mesh-like structure and covering the surface thereof with Sn or an Sn-based solder alloy.

Owner:SENJU METAL IND CO LTD

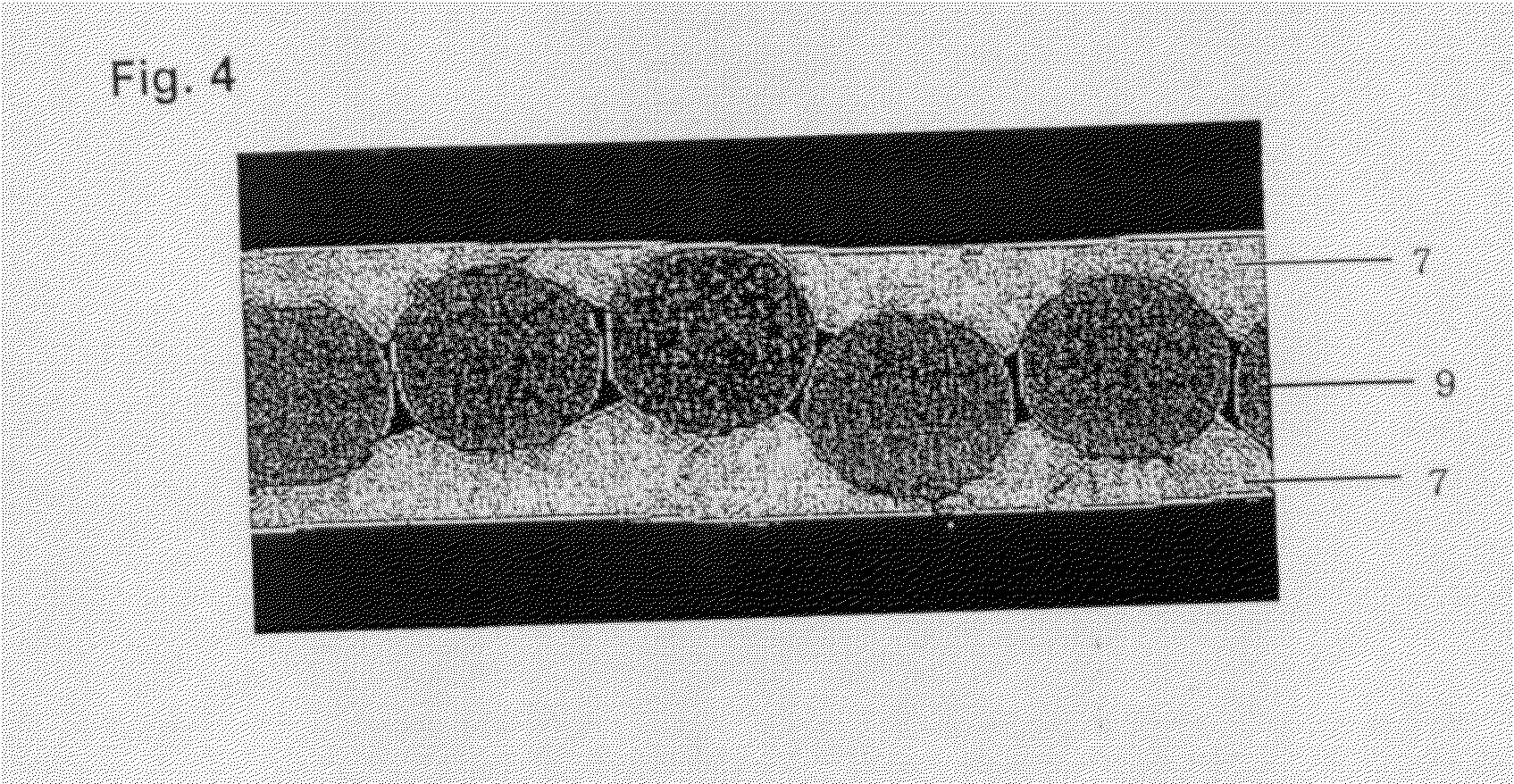

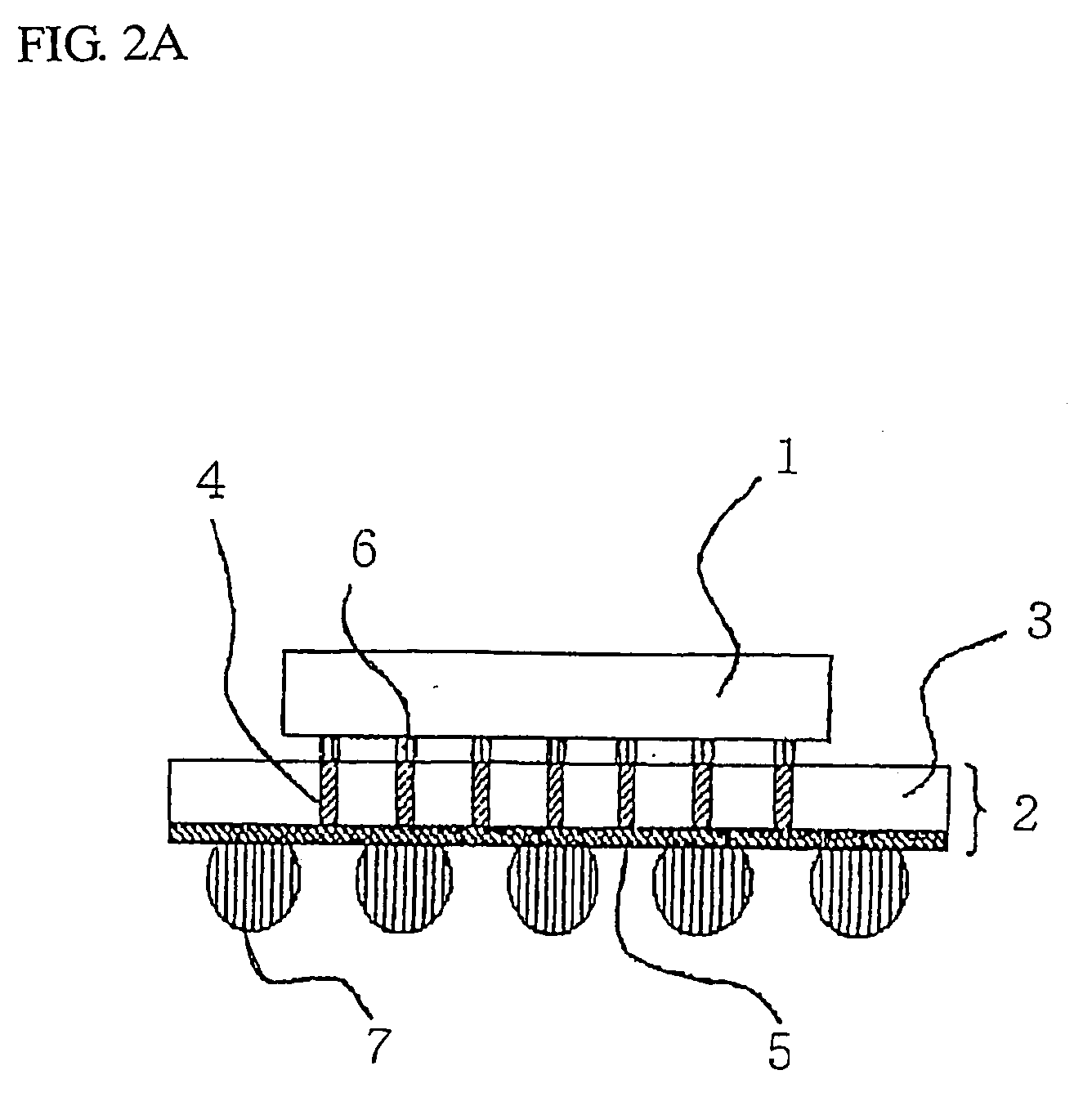

Semiconductor device, wiring substrate, and method for manufacturing wiring substrate

ActiveUS20060151870A1Improve reliabilityThermal expansion mismatchSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsDevice materialSemiconductor chip

The reliabilities of a wiring substrate and a semiconductor apparatus are improved by reducing the internal stress caused by the difference of thermal expansion coefficients between a base substrate and a semiconductor chip. A wiring layer (5) is provided on one surface of a silicon base (3). An electrode as the uppermost layer of the wiring layer (5) is provided with an external bonding bump (7). A through-electrode (4) is formed in the base (3) for electrically connecting the wiring layer (5) and an electrode terminal. The electrode terminal on the chip mounting surface is bonded to an electrode terminal of a semiconductor chip (1) by an internal bonding bump (6). The thermal expansion coefficient of the silicon base (3) is equivalent to that of the semiconductor chip (1) and not more than that of the wiring layer (5).

Owner:GK BRIDGE 1

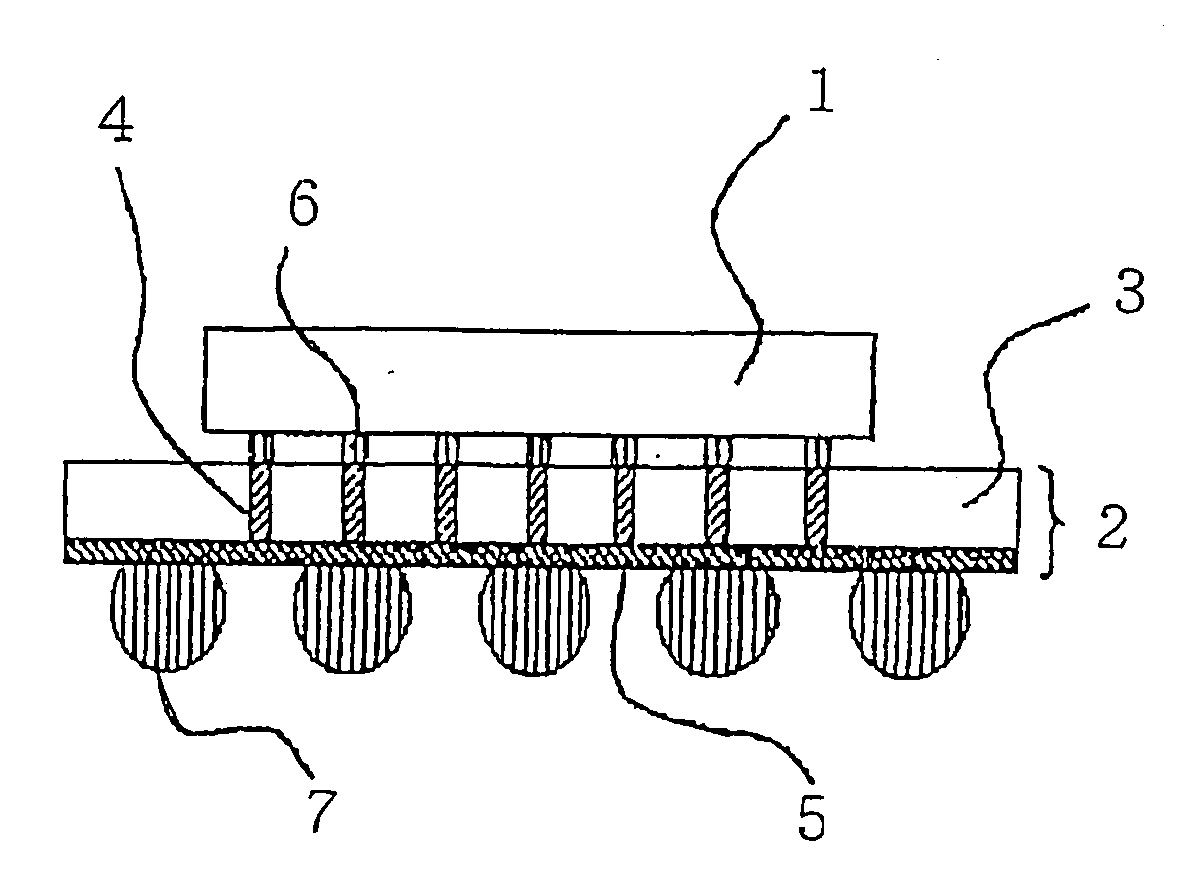

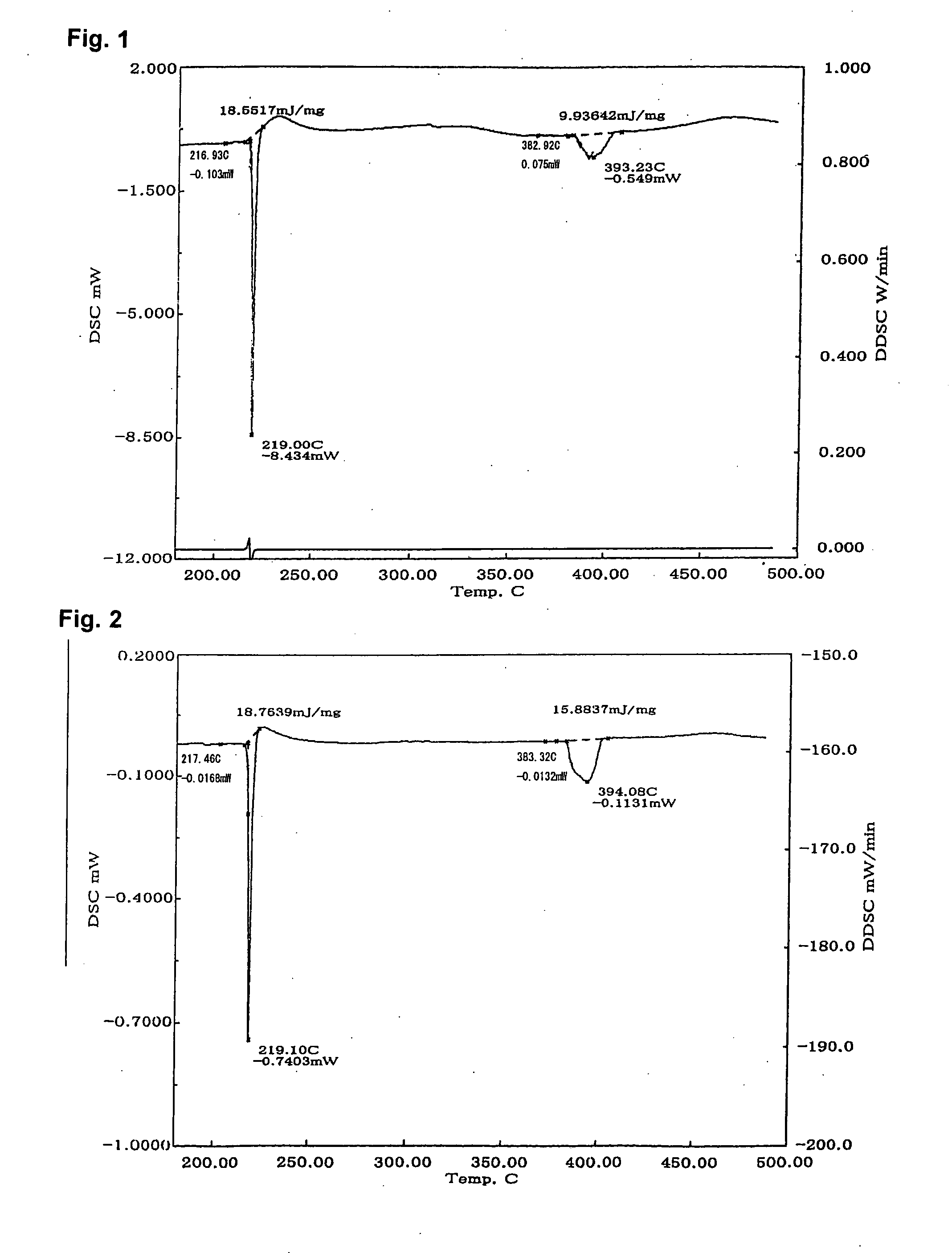

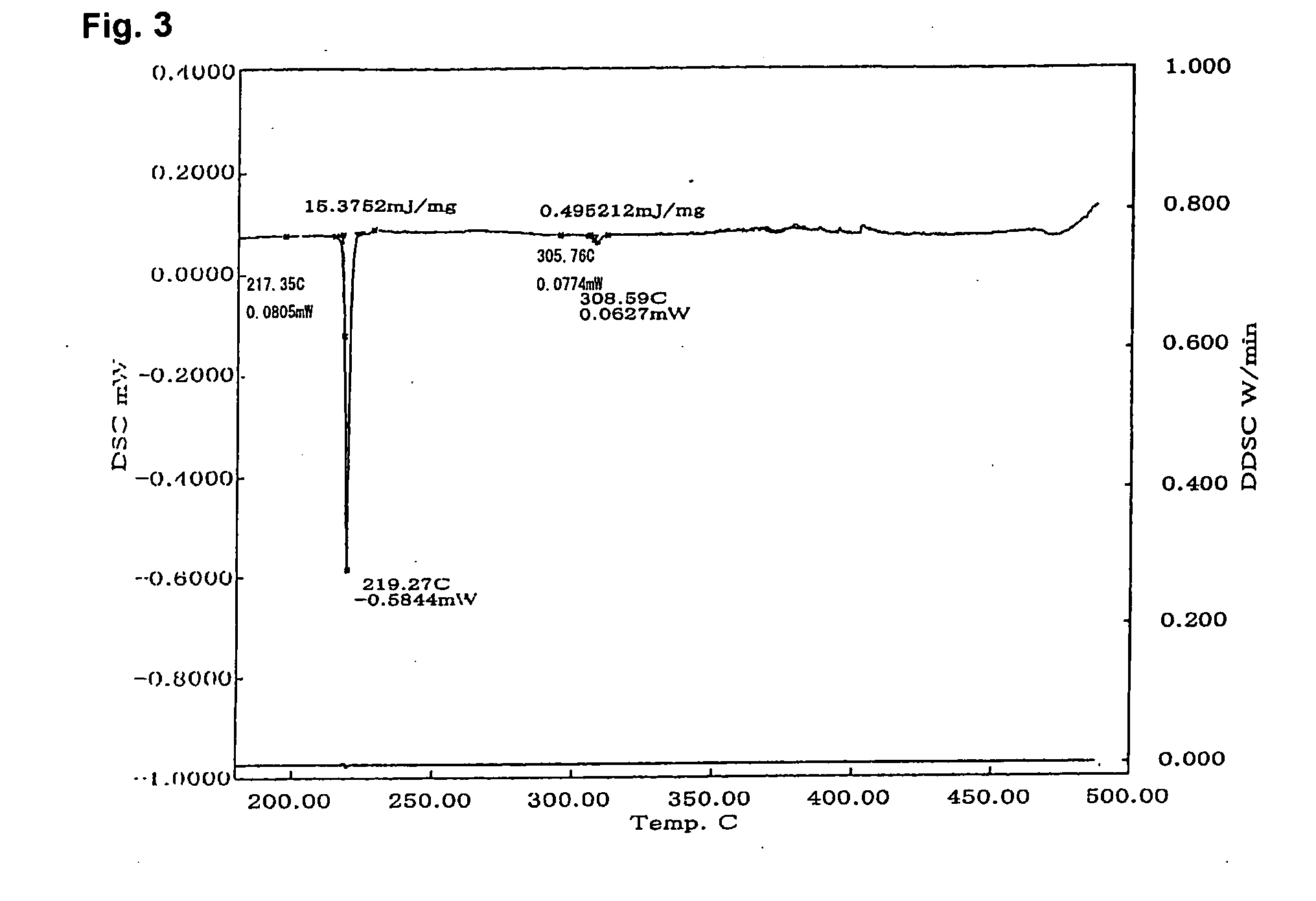

Solder Paste

ActiveUS20090220812A1Correct position deviationPrinted circuit aspectsPrinted circuit manufacturePowder mixtureSufficient time

High-temperature solders having a higher melting point than solder alloys used for soldering of printed circuit boards are used for internal bonding of electronic parts, but high-temperature solders which are free from Pb have not been developed. There exist high-temperature solders which comprises Sn balls and Cu balls and which perform bonding through the formation of an intermetallic compound without melting to form a single-phase structure, but they have poor wettability to the lands of a printed circuit board or electrodes of electronic parts and have not been used.A solder paste according to the present invention is provided by mixing flux with a powder mixture of Sn powder or an Sn based lead-free solder powder with Cu or Ag powder which has Ni plating formed on its surface. Although the solder paste performs bonding by means of an intermetallic compound without melting to form a single phase structure, the Ni plating acts as a barrier which retards the formation of the intermetallic compound so as to leave enough time to permit wetting of the lands of a printed circuit board or electrodes of an electronic part.

Owner:SENJU METAL IND CO LTD

Hollow fiber membrane contactor and method of making same

The instant invention is a hollow fiber membrane contactor, and method of making same. The hollow fiber membrane contactor includes (1) a shell, said shell having a internal bonding surface, an interlocking geometry ring being provided on said internal bonding surface; (2) a unitized structure; (3) a potting material joining said unitized structure to said shell at said interlocking geometry ring thereby forming an interlocking seal therebetween; and (4) end caps, said end caps being adjoined to lateral ends of said shell. The method of making a hollow fiber membrane contactor includes (1) providing a shell, said shell having a internal bonding surface; (2) providing an interlocking geometry ring on said internal bonding surface; (3) forming a unitized structure; (4) placing the unitized structure into said shell (5) potting said unitized structure to said shell at said interlocking geometry ring thereby forming an interlocking seal therebetween; and (6) adjoining end caps to lateral ends of said shell.

Owner:3M INNOVATIVE PROPERTIES CO

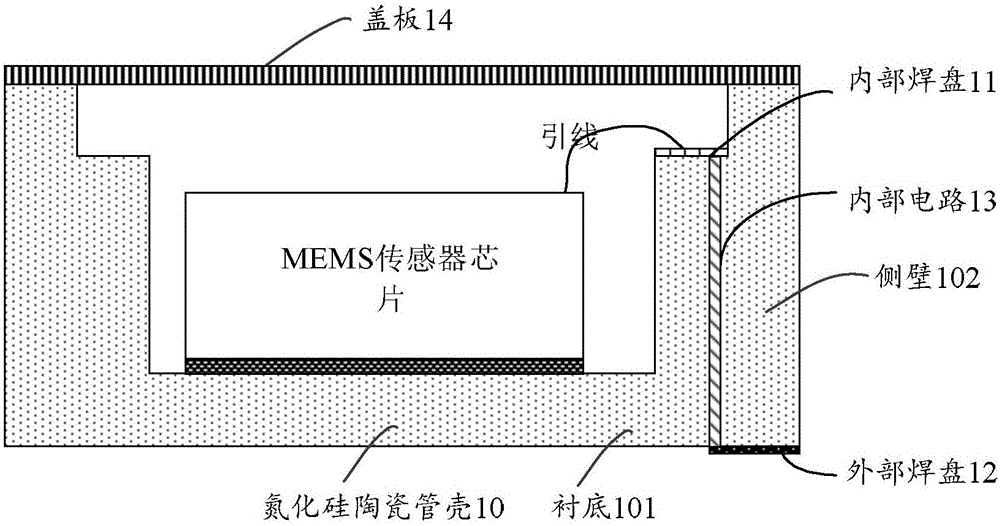

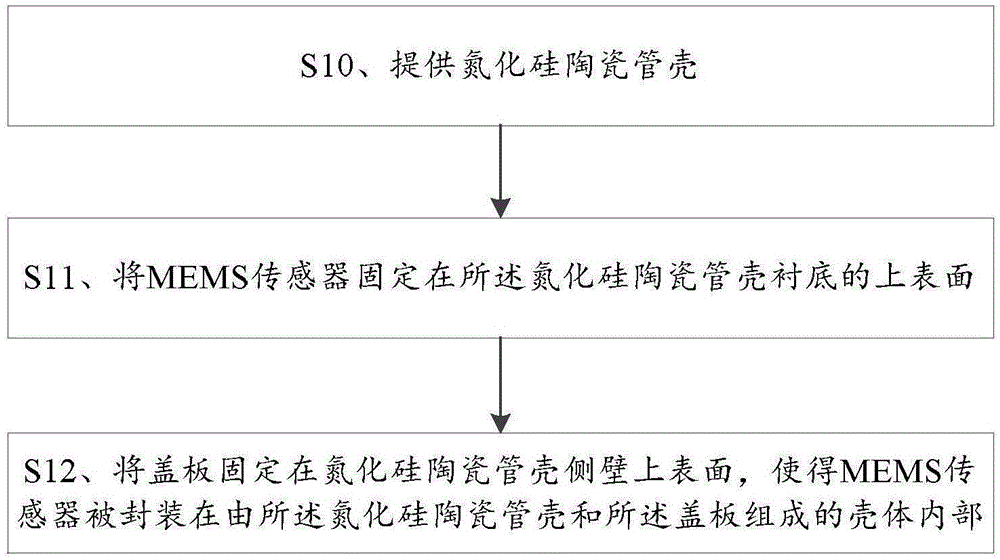

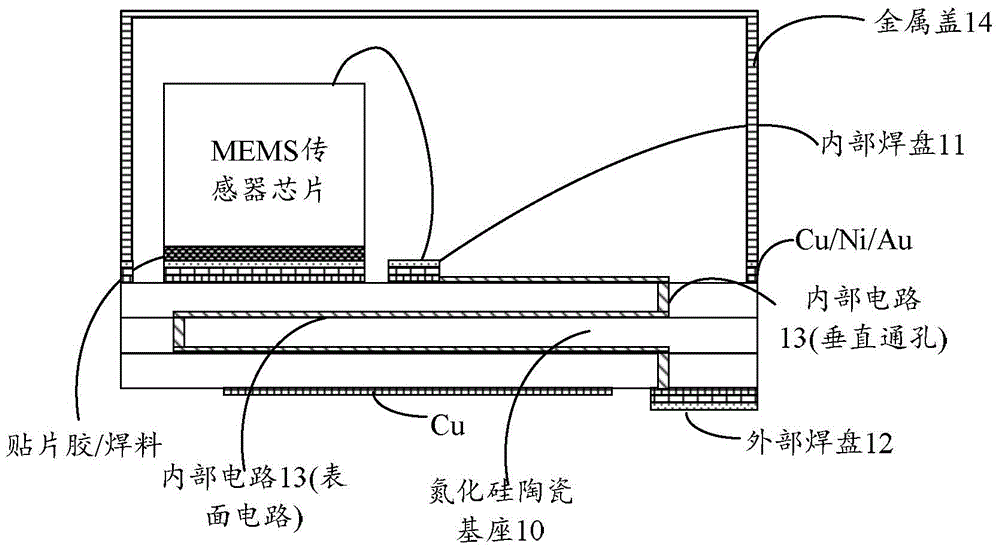

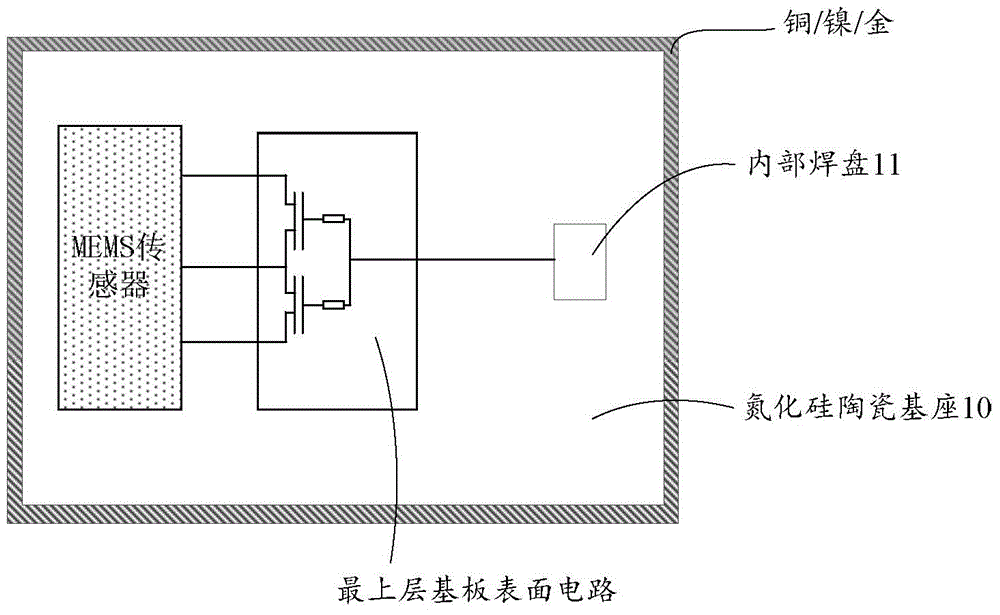

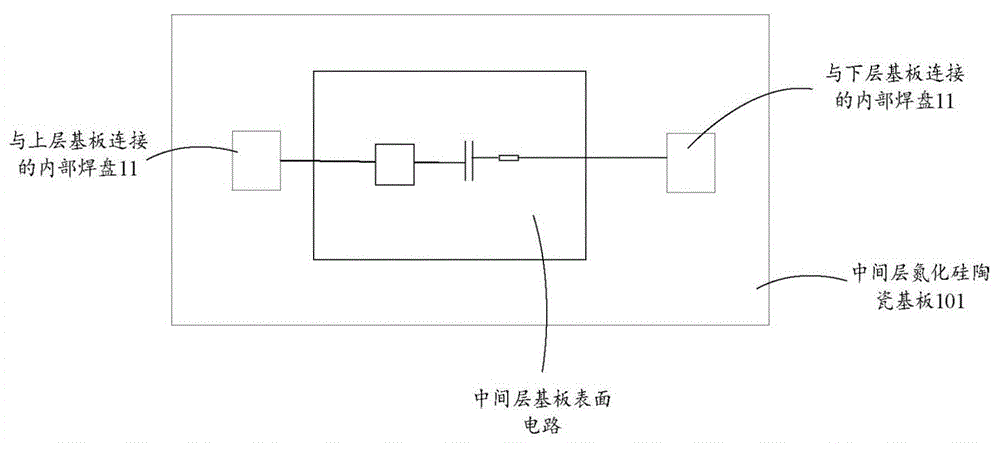

MEMS sensor packaging structure and method

InactiveCN105129720AImprove performanceTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesMems sensorsInternal bonding

The invention provides an MEMS sensor chip packaging structure and method. The packaging structure comprises a silicon nitride ceramic tube shell, an internal bonding pad, an external bonding pad, an internal circuit and a cover plate, wherein the silicon nitride ceramic tube shell comprises a substrate and sidewalls; the substrate is used for fixing an MEMS sensor chip and the sidewall located on the inner side of the silicon nitride ceramic tube shell is provided with a step; the internal bonding pad is located on the upper surface of the step and connected with the signal output end of the MEMS sensor chip; the external welding pad is located on the outer surface of the silicon nitride ceramic tube shell; the internal circuit is used for connecting the internal welding pad and the external welding pad; the cover plate is partially or completely located within the substrate and the sidewalls and used for sealing the silicon nitride ceramic tube shell. According to the MEMS sensor packaging structure, the influence of packaging thermal stress on the performance of the MEMS sensor chip device is effectively reduced, and therefore, the overall performance of the sensor is improved.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

Low-cost high-strength flame-retardant smoke-suppressing artificial board inorganic adhesive and preparation method thereof

ActiveCN103865404AImprove flame retardant and smoke suppression performanceNon-combustibleInorganic adhesivesPolyvinyl alcoholInternal bonding

The invention discloses a low-cost high-strength flame-retardant smoke-suppressing artificial board inorganic adhesive and a preparation method thereof. The low-cost high-strength flame-retardant smoke-suppressing artificial board inorganic adhesive comprises the following components in parts by weight: 30-50 parts of magnesium oxide, 20-40 parts of magnesium chloride, 30-60 parts of water, 3-8 parts of polyvinyl alcohol, 1-5 parts of trisodium phosphate, 2-7 parts of water glass, 0.08-0.1 part of tartaric acid, 0.5-3 parts of sulfonic acid, 0.05-0.3 part of octylphenol polyvinyl ether and 0.01-0.2 part of sodium carboxymethyl cellulose. The low-cost high-strength flame-retardant smoke-suppressing artificial board inorganic adhesive prepared through the method is noninflammable and achieves outstanding flame-retardant smoke-suppressing property on an artificial board. The fire-proof grade of the prepared artificial board achieves A2 grade through testing; the price of the prepared artificial board only accounts for 5% of the price of an isocyanate adhesive and accounts for 50% of the price of an urea-formaldehyde resin adhesive; the internal bonding strength of the produced artificial board achieves 1.05 MPa, the static bending intensity achieves 16.5 MPa, and the 24-hour water absorption thickness expansion ratio is only 1.1%. The low-cost high-strength flame-retardant smoke-suppressing artificial board inorganic adhesive disclosed by the invention can not release any harmful gas and achieves outstanding environmental-friendly property.

Owner:河南恒顺植物纤维板有限公司

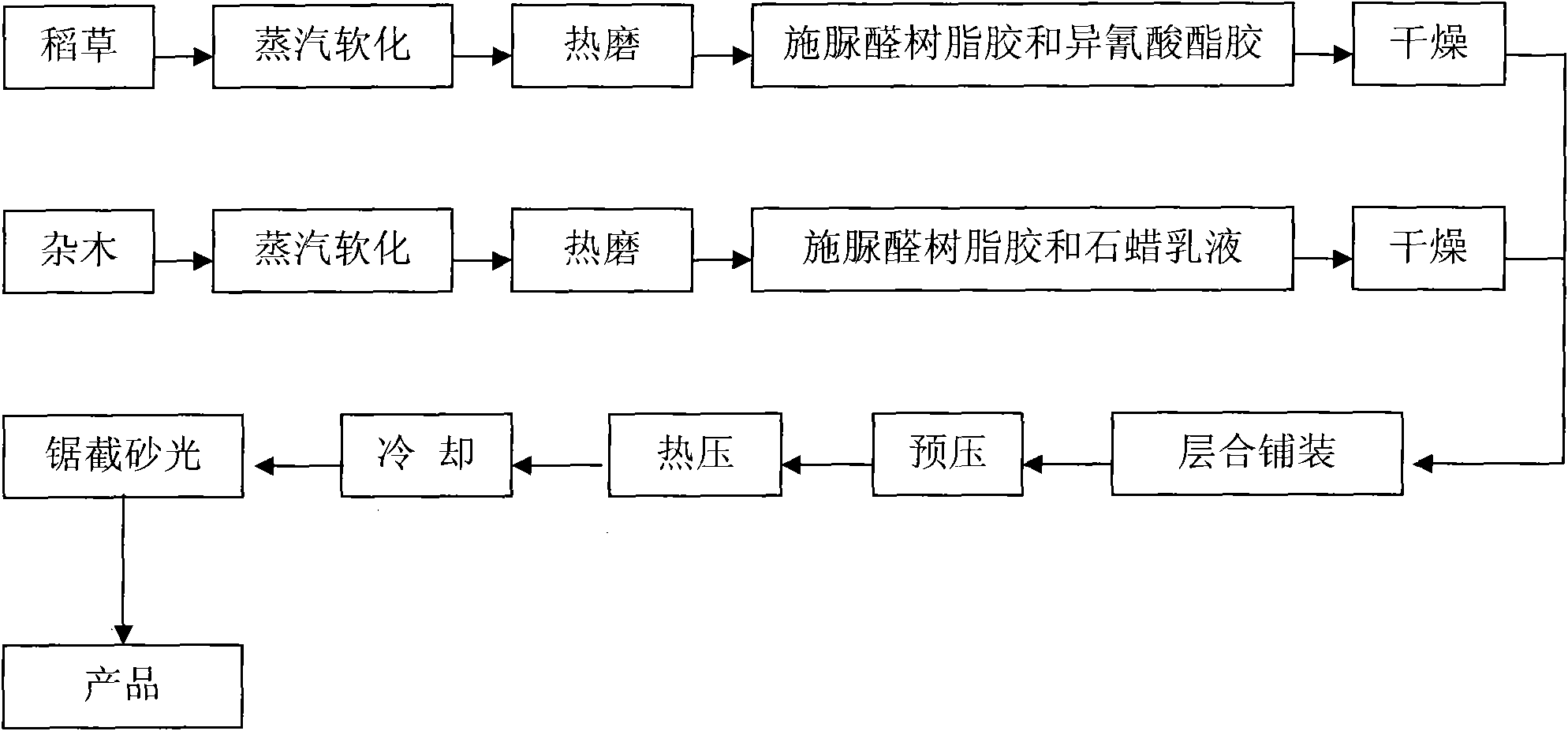

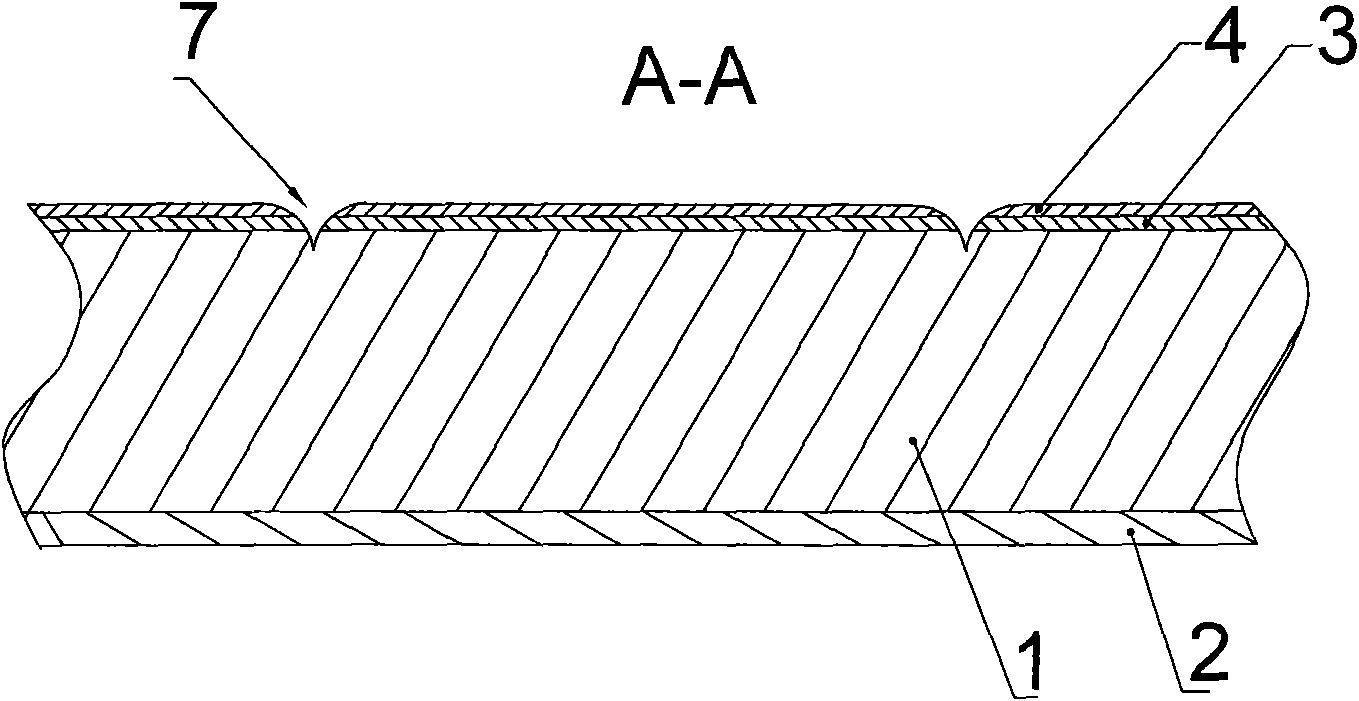

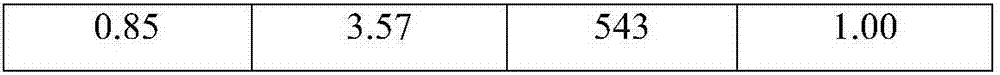

Three-laminated composite board type full-nutritional rice seedling breeding bedding and preparation method thereof

InactiveCN106542909AUniform textureQuality improvementGrowth substratesCulture mediaSurface layerUltimate tensile strength

The invention discloses three-laminated composite board type full-nutritional rice seedling breeding bedding and a preparation method thereof and relates to rice seedling breeding bedding and a preparation method thereof. The problems that existing seedling breeding bedding is poor in water-retaining property, fertilizer efficiency in the later period of seedling breeding is poor, strength is low, and the existing seedling breeding bedding is not suitable for being transported and carried are solved. The seedling breeding bedding is divided into three layers from top to bottom, the middle layer is a core layer, and the surface layers are located on the two sides of the core layer. The preparation method comprises the following steps that (1), straw is cut into sections; (2), steaming and softening are conducted; (3), the straw is ground and kneaded to be in a fiber shape and is dried; (4), mixing is conducted; (5), paving is conducted; and (6), hot-pressing is conducted. According to the three-laminated composite board type full-nutritional rice seedling breeding bedding (as shown in figure 1) produced through the preparation method, when no water is absorbed by the three-laminated composite board type full-nutritional rice seedling breeding bedding, the static bending intensity is 21-22.8 MPa, and the internal bonding strength is 0.35-0.40 MPa; and the three-laminated composite board type full-nutritional rice seedling breeding bedding is high in strength, not prone to breakage or damage and easy to cut and can be manufactured to be in different shapes.

Owner:刘越

Method for manufacturing weed wood and straw compounding medium density fiberboard with laminated structure

InactiveCN101659074ASave resourcesImprove flexural strengthFlat articlesDomestic articlesEcological environmentFlexural modulus

The invention relates to a method for manufacturing a weed wood and straw compounding medium density fiberboard with a laminated structure. The method adopts straw and weed wood as raw materials, andincludes the following steps: the straw and the weed wood are respectively processed by defibration, and urea formaldehyde resin adhesive and waterproof agent are added, and in the process of formation, straw fibres and wood fibres are proportionally assembled and laminated in the direction of thickness and then are processed by thermocompression to form boards. The method has the advantages thatproved by performance tests, the flexural modulus, the strength and the internal bonding strength of the medium density fiberboard, compared with a pure straw medium density fiberboard, are respectively and obviously increased under the same condition, and the expansion rate of water-absorbing thickness and the water absorption rate are lowered; and the relative performances of the compound material can be increased by changing the mode of lamination. The method efficiently and comprehensively utilizes the agricultural straws and saves wood resources, thereby protecting the ecological environment. The product can be applied to the occasions of furniture manufacturing and production, base materials for interior decoration, and the like.

Owner:NANJING FORESTRY UNIV

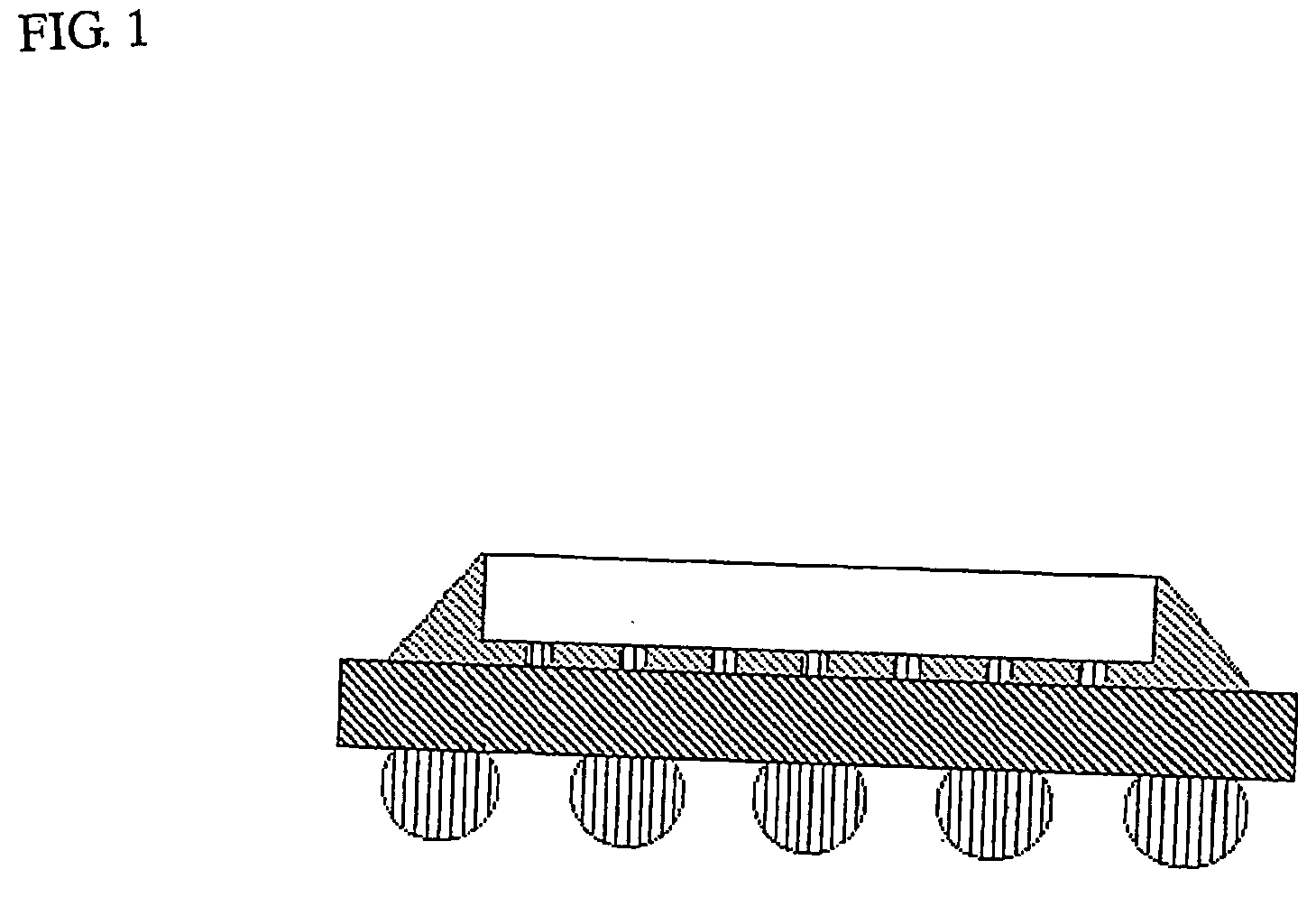

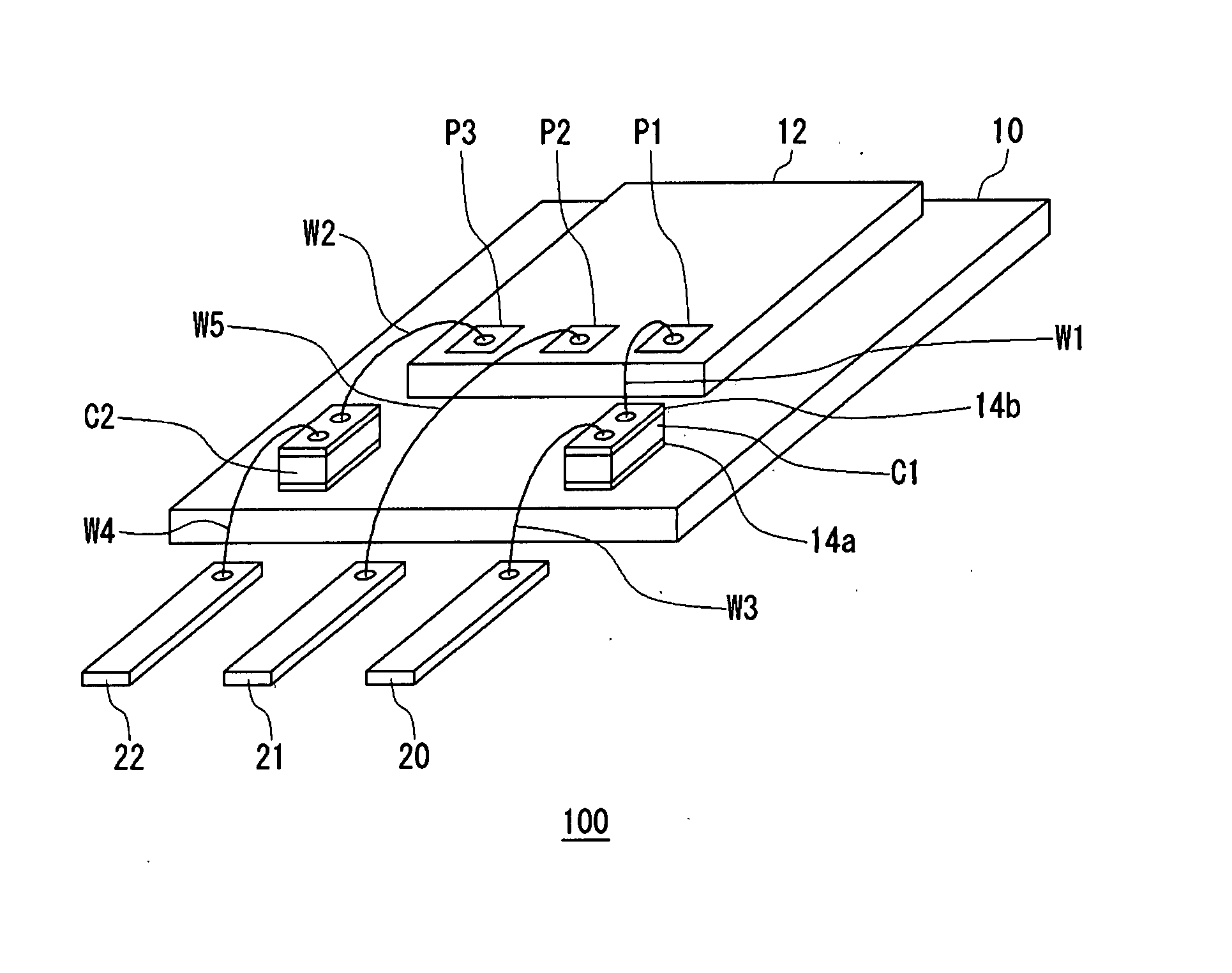

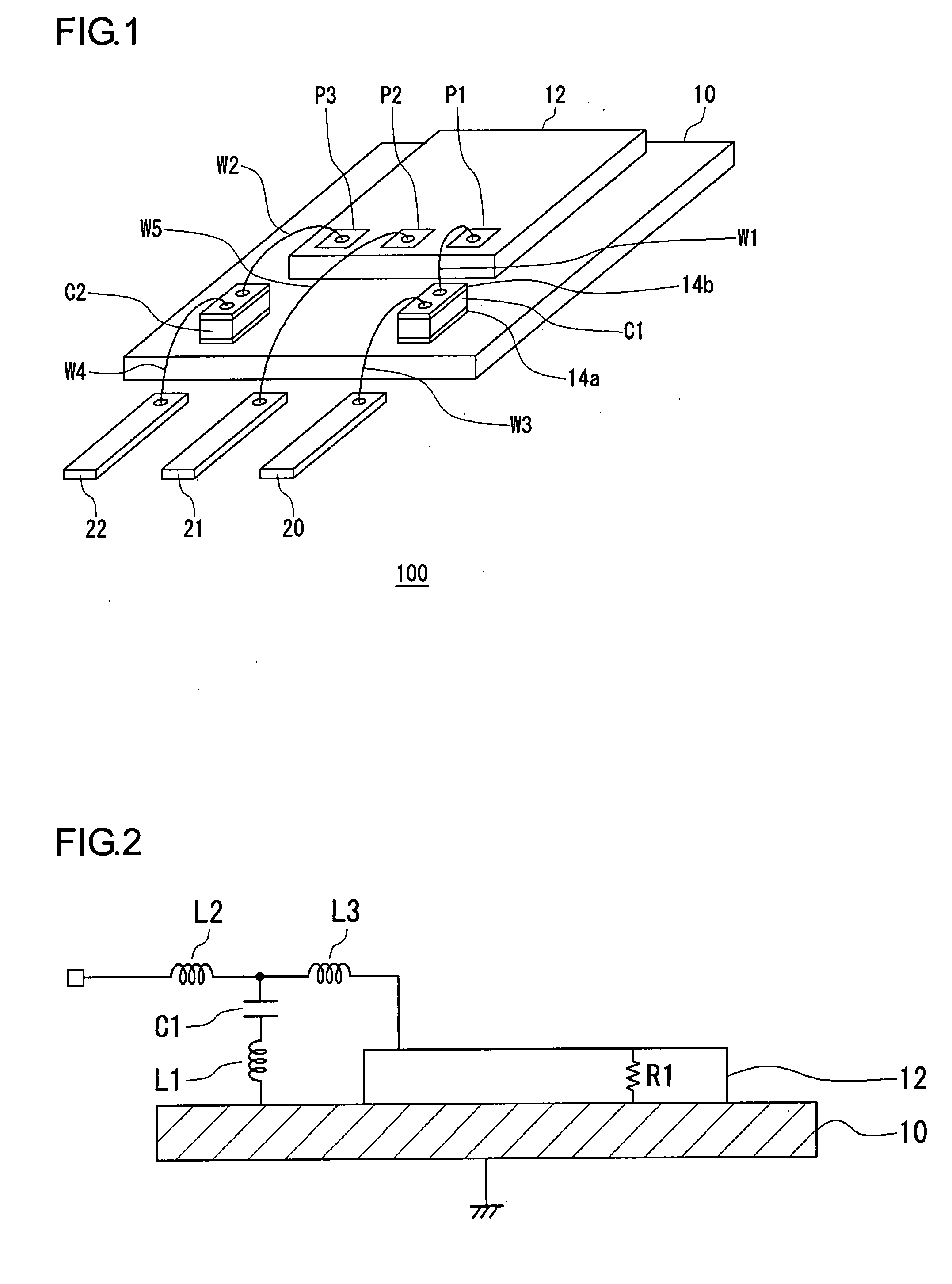

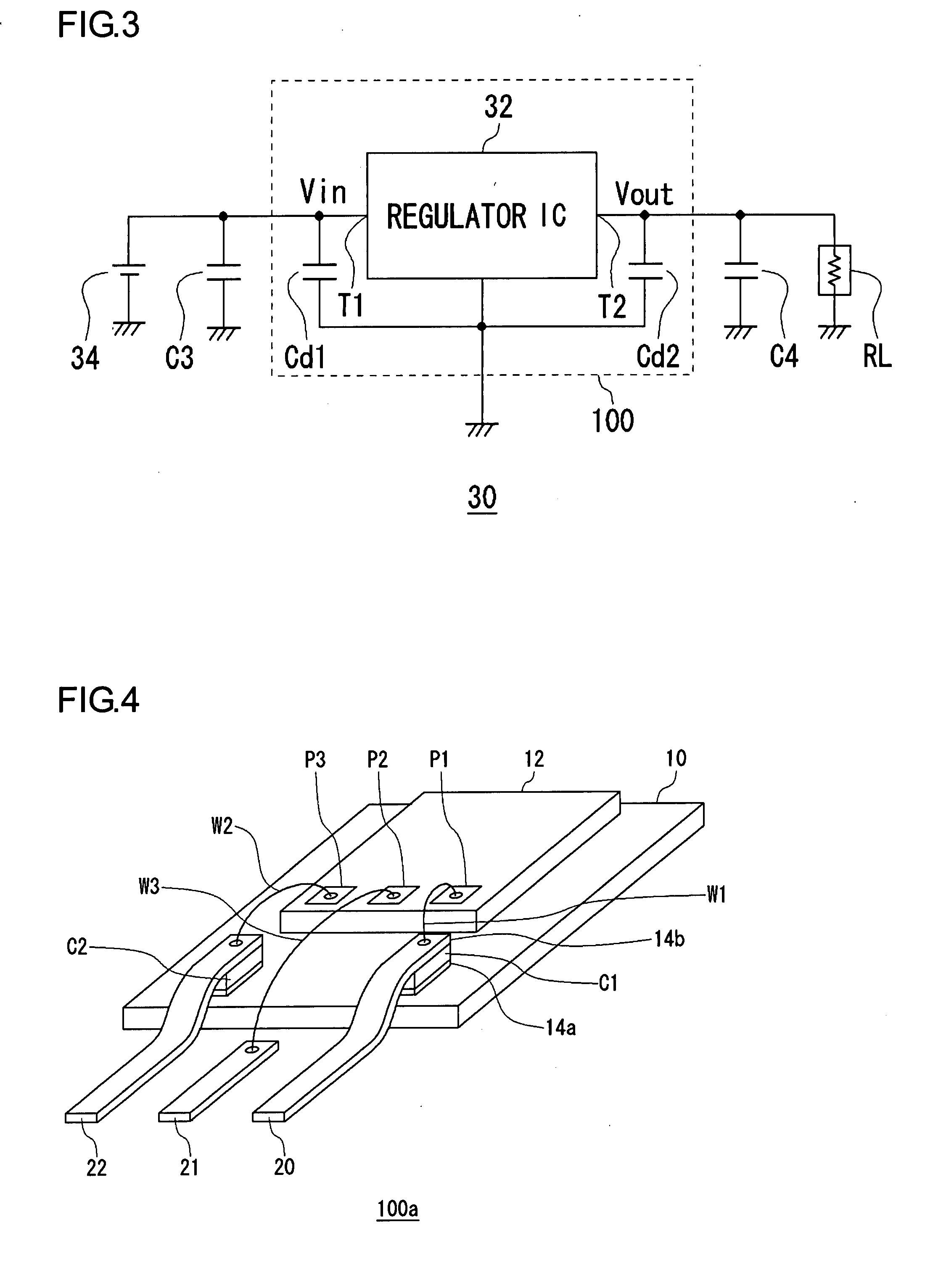

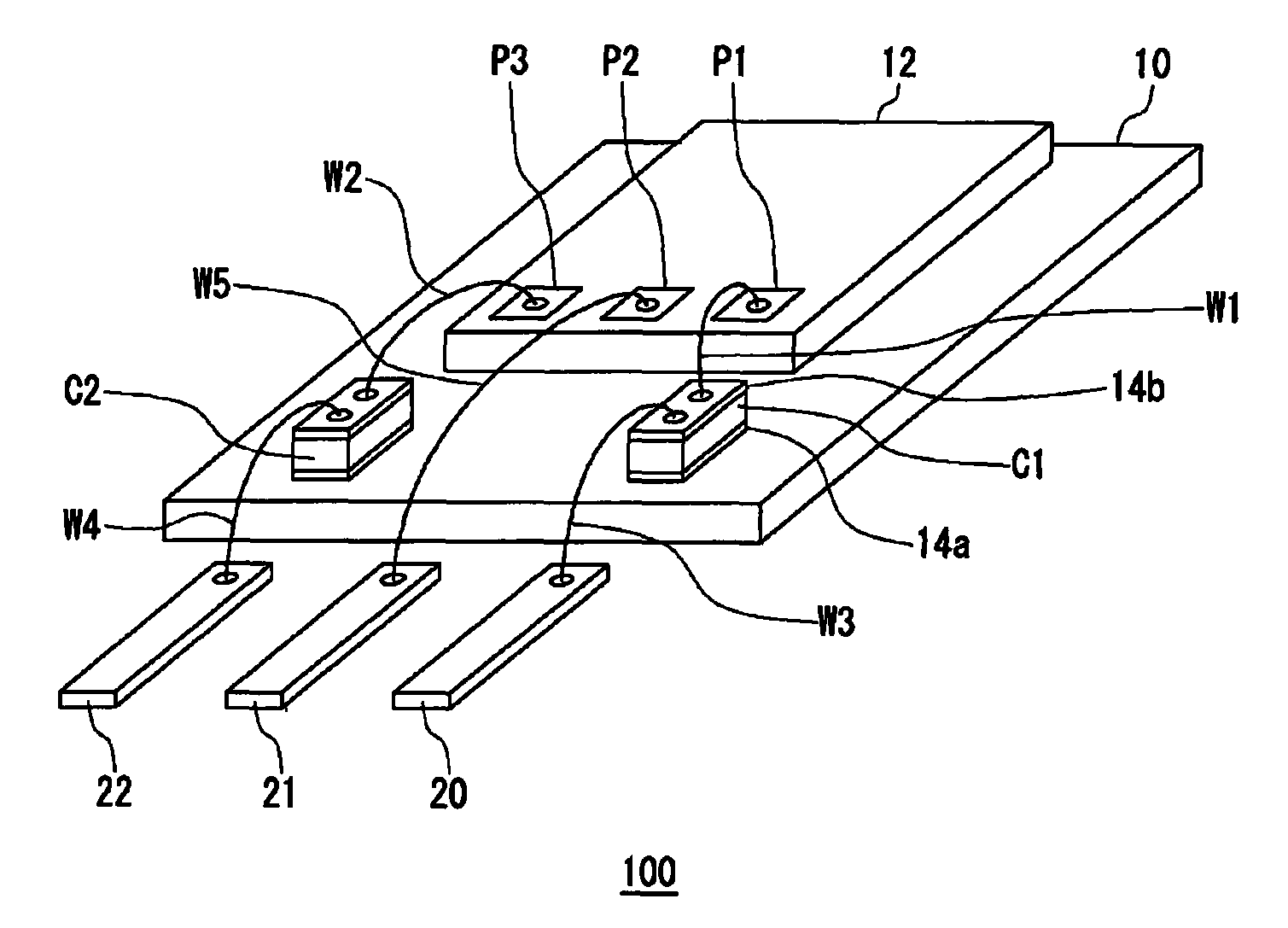

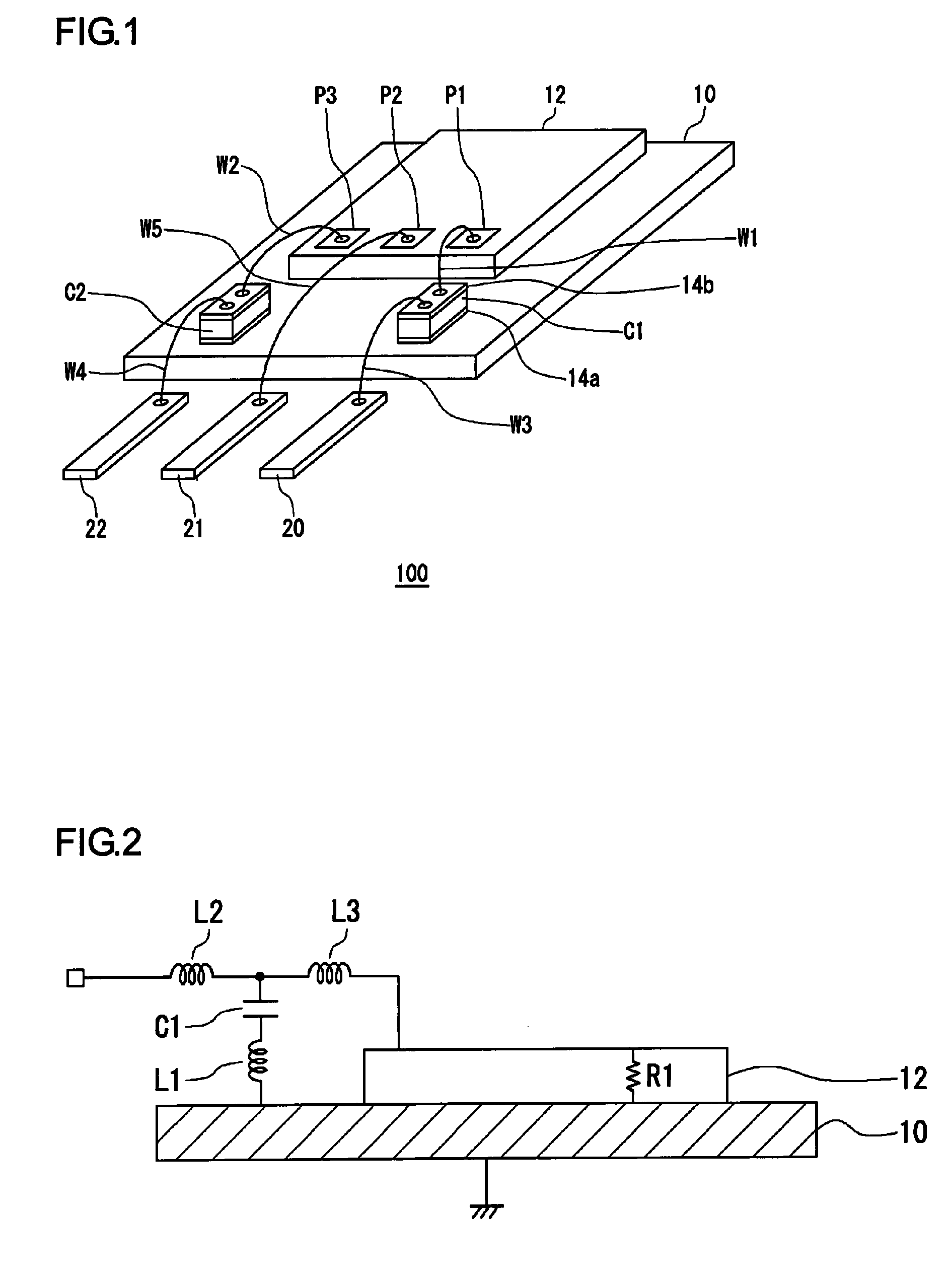

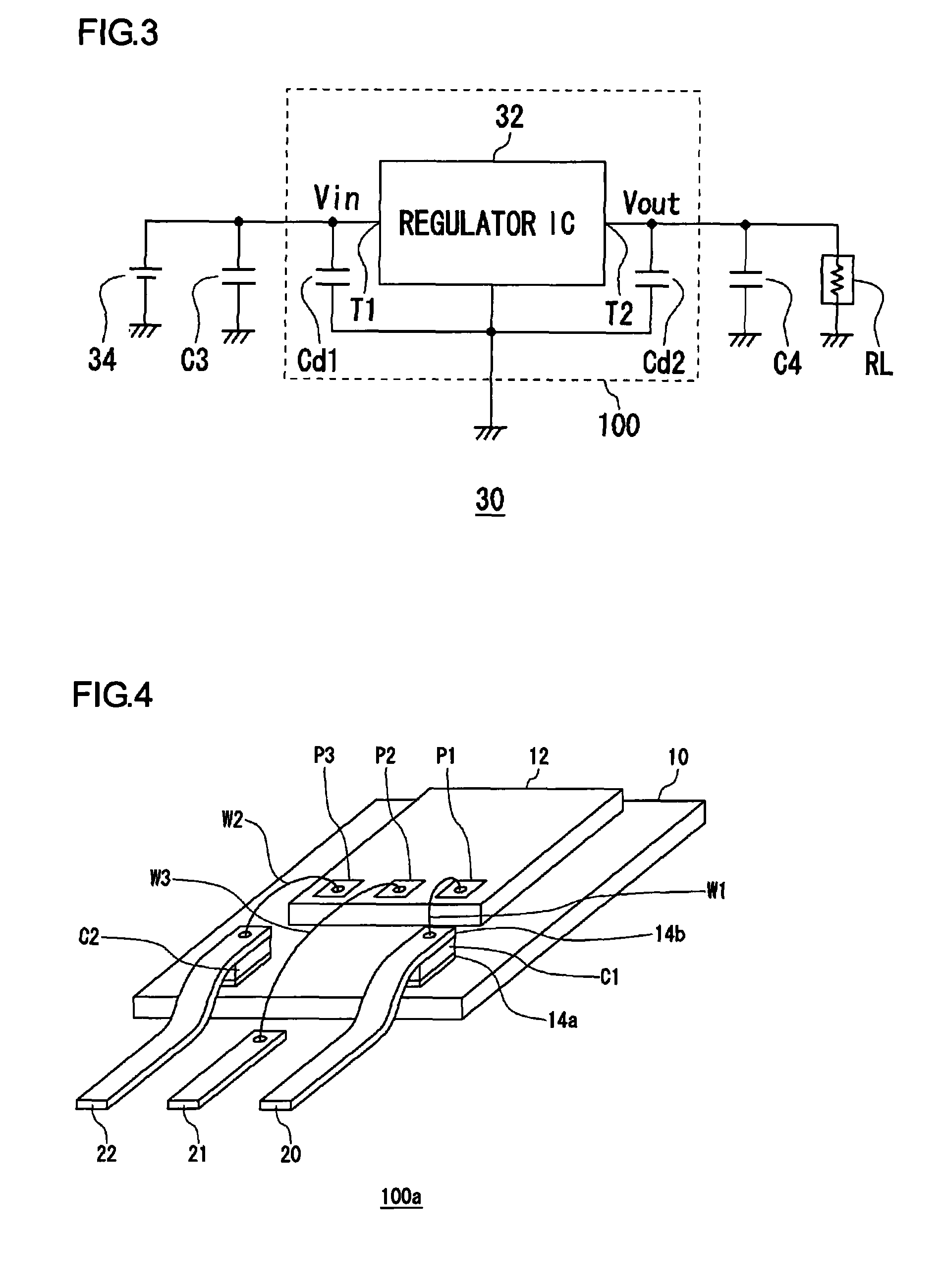

Semiconductor device

ActiveUS20080023843A1Inhibition effectStable characteristicsSemiconductor/solid-state device detailsSolid-state devicesShunt capacitorsEngineering

A semiconductor device has a package structure provided with leads that are external connection terminals. A base substance is an island, and at least the surface thereof is formed of a conductive material. A semiconductor substrate is mounted on the surface of the base substance, and a ground potential is supplied from the surface of the base substance. A shunt capacitor is provided with an electrode pair of a first electrode and a second electrode formed in parallel, and mounted with the first electrode being electrically connected to the surface of the base substance. An internal bonding wire connects a pad provided on the semiconductor substrate for external connection, to the second electrode of the shunt capacitor. The lead is the external connection terminal of the semiconductor device. An external bonding wire connects the lead to the second electrode of the shunt capacitor.

Owner:ROHM CO LTD

Bamboo fiber bundle plywood production technology

ActiveCN101774191AIncrease profitHigh bonding strengthWood veneer joiningFiber bundleVolumetric Mass Density

The invention relates to a bamboo fiber bundle plywood production technology, which comprises the following production steps: obtaining fresh bamboo raw material, removing green, splitting, removing yellow, bamboo joints and diaphragms, rolling, obtaining bundle bamboo long fiber, drying, cutting, gumming, drying, forming and paving, hot pressing, longitudinally and transversely sawing, checking, trimming plywood sides, rechecking and accepting and warehousing finish product. The technology is simple, the utilization ratio of the bamboo material is high, the production cost is low, the internal bonding strength of the produced bamboo plywood is higher, the production density is adjustable, the plywood surface strength is high, the bamboo fiber bundle plywood can be widely used as building templates, carriage bottom plates, decoration materials, furniture materials and the like, and the bamboo fiber bundle plywood is a high-performance building decoration engineering material.

Owner:南通长城装饰木制品制造有限公司

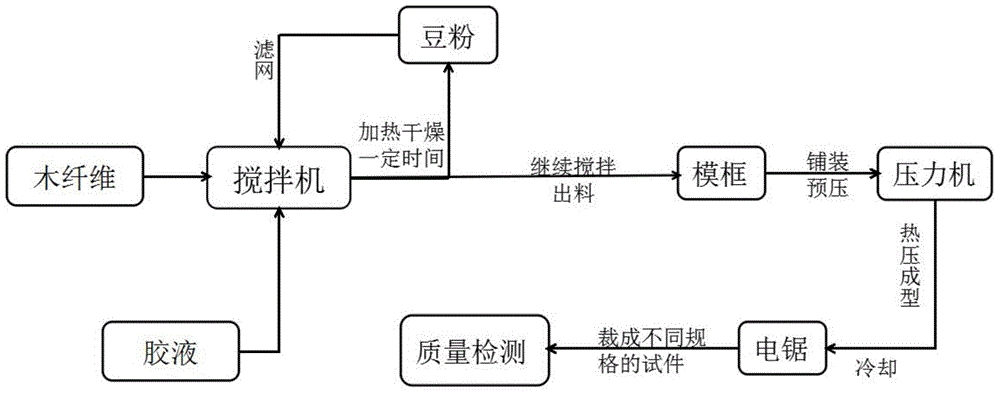

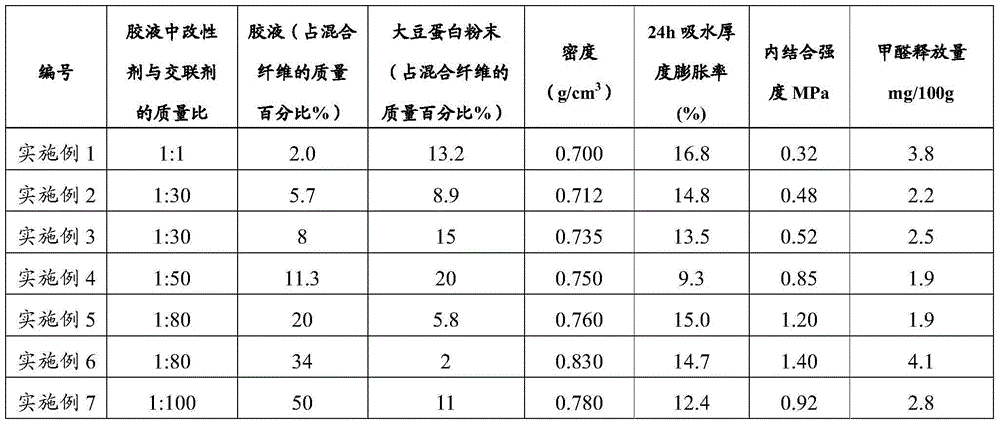

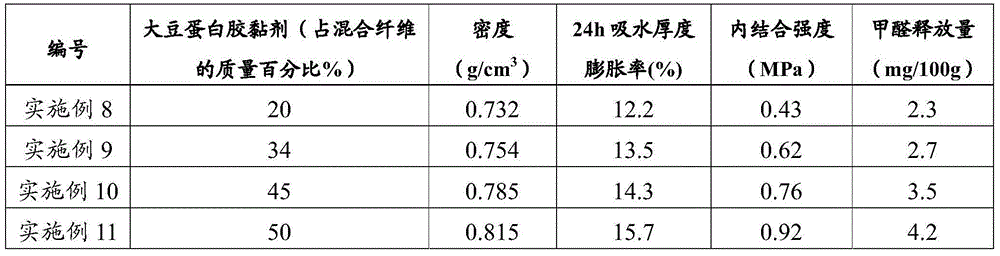

Preparation method of soybean-protein-adhesive-based medium-density fiberboard

ActiveCN104388043AReduce toxic gas contentSimple processNon-macromolecular adhesive additivesProtein adhesivesFiberEnvironmental resistance

The invention discloses a preparation method of a soybean-protein-adhesive-based medium-density fiberboard, which comprises the following steps: adding a certain amount of self-made soybean protein adhesive solution into mixed fibers with the water content of less than 30% and the particle size of 10-600 meshes, stirring uniformly, drying by heating for some time, adding soybean protein powder, continuing stirring for some time, discharging, paving, prepressing into a plate blank, sending the plate blank into a flat vulcanizing machine, carrying out hot pressing according to a certain hot pressing technique, cooling, sawing the edges, sanding and the like to obtain the medium-density fiberboard. The soybean protein adhesive is a zero-formaldehyde wood adhesive, and has the advantages of no free formaldehyde or any other toxic gas, high safety and environment protection. The prepared fiberboard has the advantages of moderate density, favorable physical properties and favorable mechanical properties. The density is 0.65-0.80 g / cm<3>, the thickness expansion ratio after 24-hour water absorption is less than 15%, the internal bonding strength is greater than 0.4 MPa, and the formaldehyde release amount is much better than national standard Grade E0 (at most 5 mg / 100g).

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

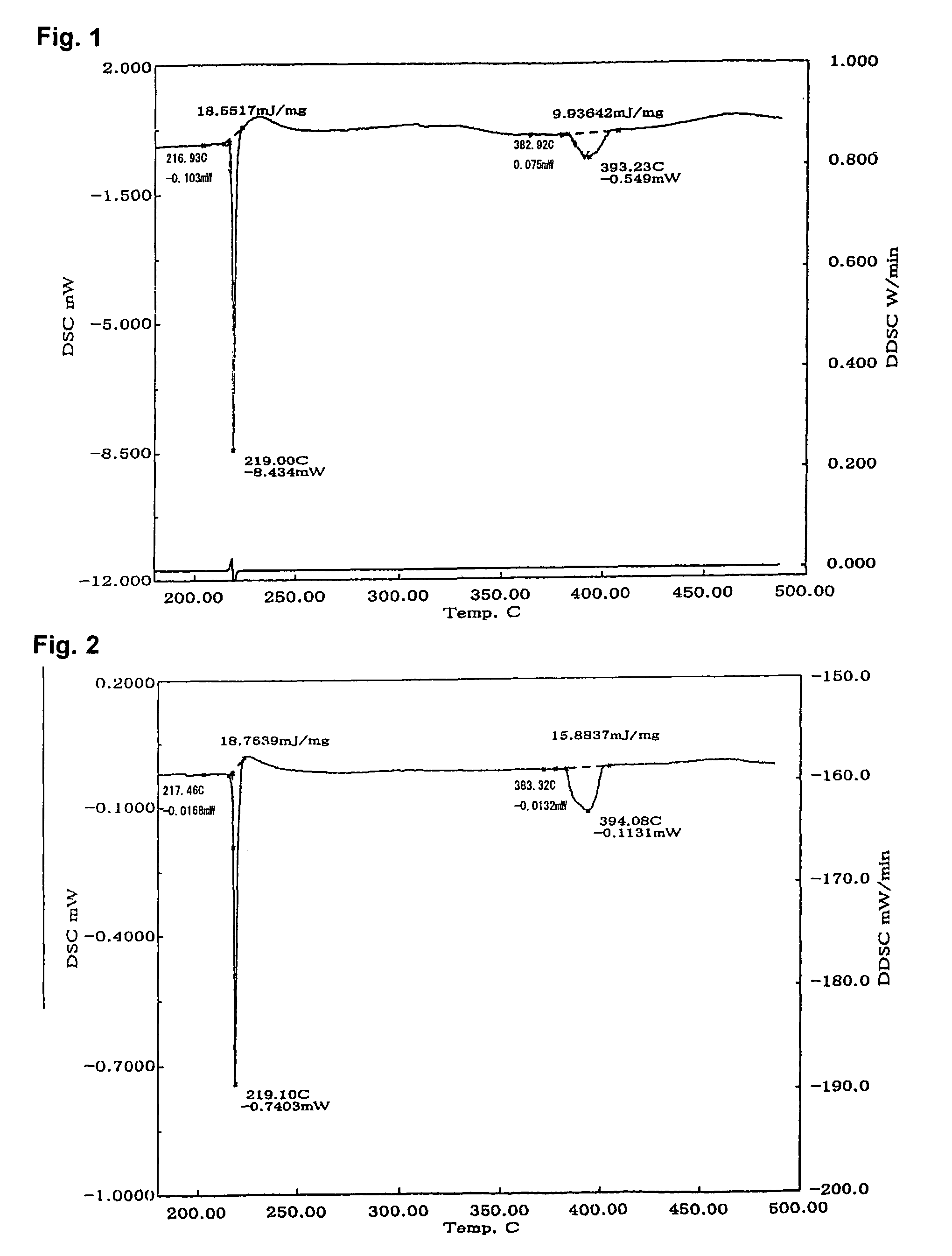

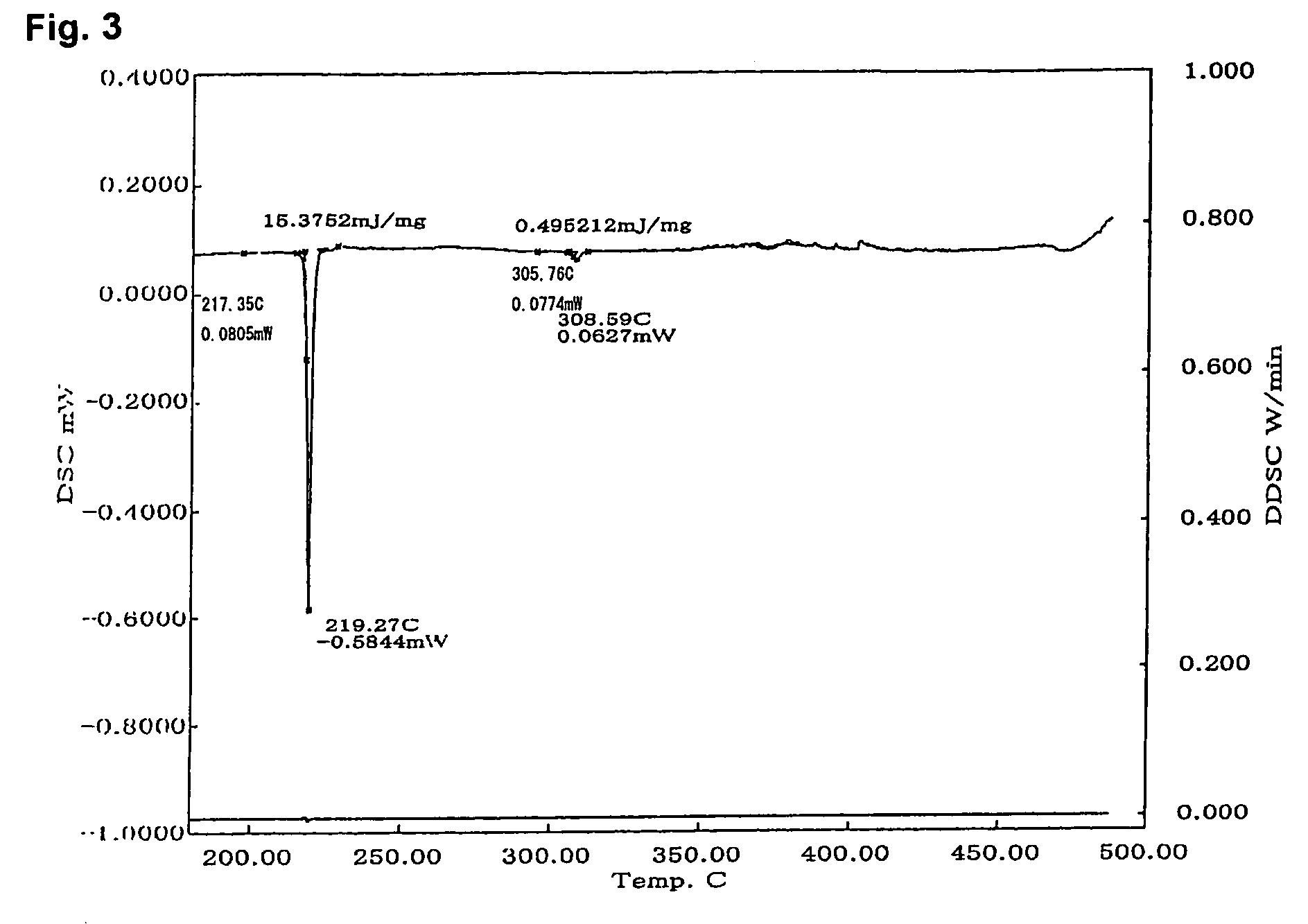

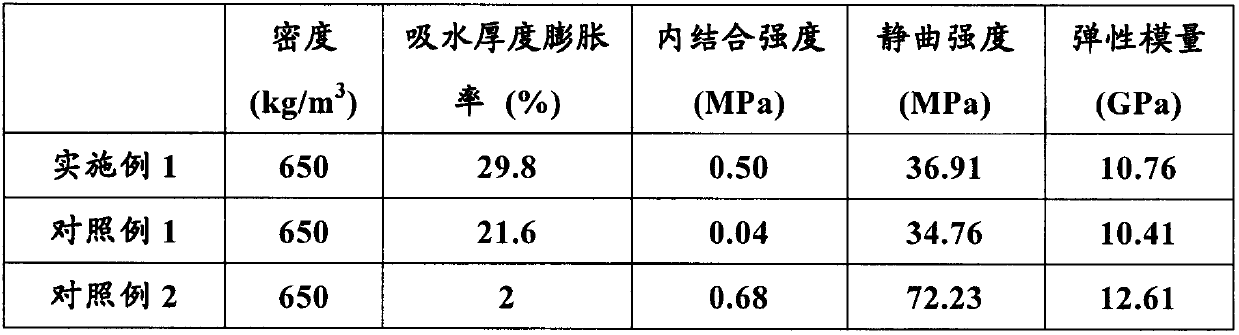

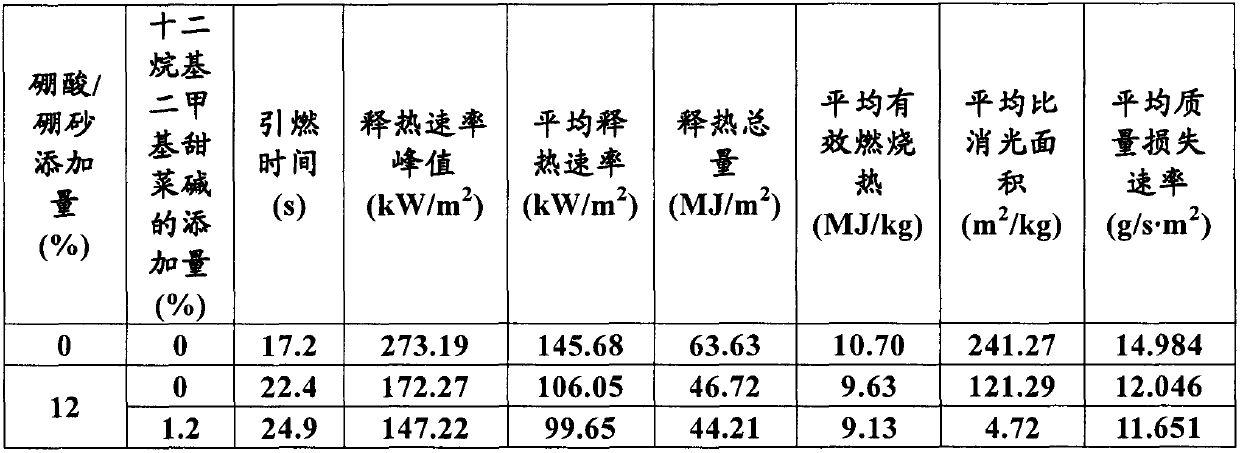

Preparation method for fireproof oriented strand board

InactiveCN104227820AImprove internal bond strengthDecreased internal bond strengthDomestic articlesFlat articlesWood shavingsEngineering

The invention relates to a preparation method for a fireproof oriented strand board. The method is characterized by comprising the following steps of (1) drying: drying a wood shaving by virtue of a drying oven, wherein the drying temperature is 103 DEG C; (2) addition of a flame retardant and an auxiliary: placing the wood shaving in a stirrer, and uniformly spraying a compounded aqueous solution of boric acid / borax and dodecyl dimethyl betaine onto the shaving; (3) re-drying: drying the shaving to which the flame retardant and the auxiliary are added, wherein the moisture content of the dried wood shaving is 3 to 5 percent; (4) adhesive application: placing the wood shaving into the stirrer again, and spraying a phenolic resin adhesive onto the shaving. According to the method, the prepared oriented strand board with a flame retardant property has strong internal bonding strength, and the method can be applied to the large-scale preparation of boards.

Owner:谭海韵

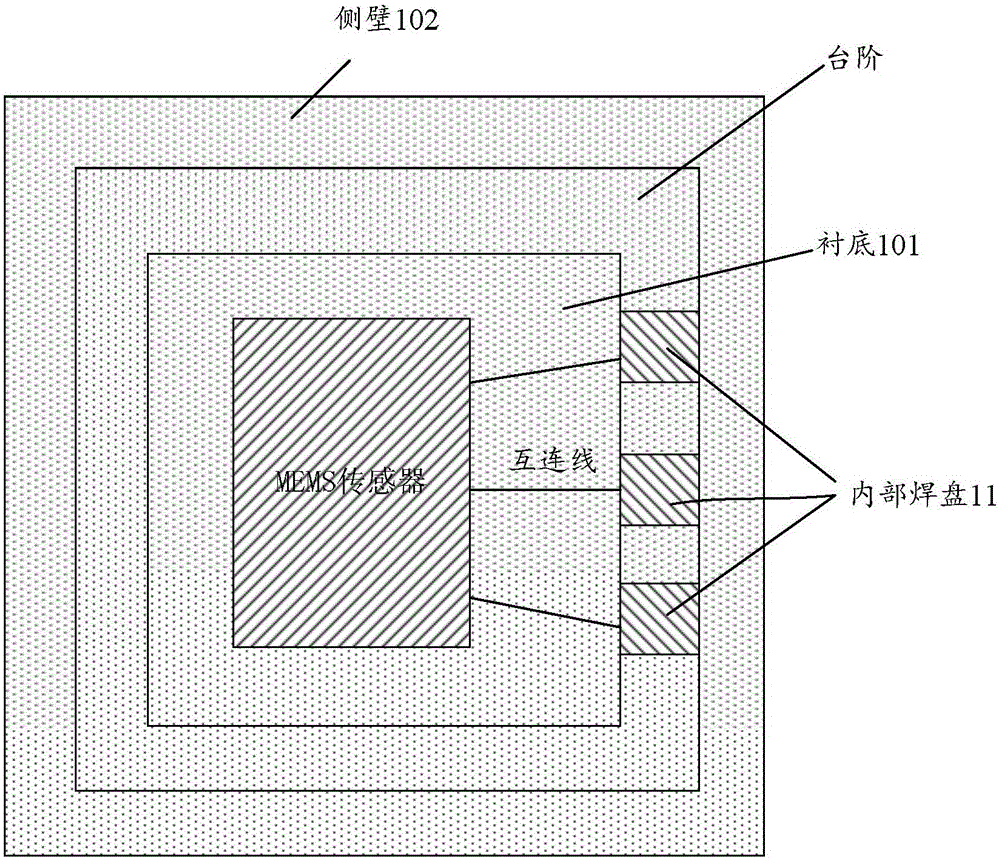

Packaging structure and packaging method of micro-electromechanical system (MEMS) sensor

ActiveCN105047615AImprove performanceReduce the impactTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesMems sensorsInternal bonding

The invention provides a packaging structure and a packaging method of a micro-electromechanical system (MEMS) sensor. The packaging structure comprises a silicon nitride ceramic base, an internal bonding pad, an external bonding pad, an internal circuit and a metal cover, wherein the silicon nitride ceramic base is used for fixing an MEMS sensor chip; the internal bonding pad is located on the upper surface of the silicon nitride ceramic base and is connected with a signal output end of the MEMS sensor chip; the external bonding pad is located on the lower surface of the silicon nitride ceramic base; the internal circuit is connected with the internal bonding pad and the external bonding pad; and the metal cover is fixed on the upper surface of the silicon nitride ceramic base. According to the packaging structure and the packaging method, the effects on the device performance of the MEMS sensor due to package thermal stress are effectively reduced, so as to improve the whole performance of the sensor.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

Manufacturing method of laminated flooring

InactiveCN101612750AAvoid secondary damageEasy to useWood veneer joiningWood mortising machinesFiberSheet steel

The invention discloses a manufacturing method of laminated flooring. The method comprises the following steps: A) machining a groove on an untreated fiber board at a certain interval, so that a lateral wall of the groove and a walking surface of the untreated fiber board have a smooth transition; B) laying equilibrium paper, the untreated fiber board with machined grooves, grainy paper and wear-resistant paper on a lower die steel sheet of a hot press in turn, with an upper die steel sheet of the hot press being ribs matched with the grooves on the untreated fiber board; C) matching and hot pressing the upper die steel sheet of the hot press and the lower die steel sheet of the hot press to obtain a panel of the laminated flooring; D) displaying the panel of the laminated flooring; and E) cutting the panel along a central line of the grooves to obtain floor battens, and then cutting out a splineway along periphery of the cut floor battens. Compared with conventional molded laminated flooring, the laminated flooring made by the method has the advantages of higher chamfering prevision, higher internal bonding strength at the chamfer, and longer service life; compared with production by conventional methods, production by the method helps save 30% of die cost, thus reducing production cost.

Owner:嘉丰木业(苏州)有限公司

Production technique for formaldehyde-free damp-proof high-density fiberboard

The invention discloses a production technique for a formaldehyde-free damp-proof high-density fiberboard. The production technique for the formaldehyde-free damp-proof high-density fiberboard comprises the steps of log debarking and slicing, washing and boiling, hot grinding, gluing, drying and molding, application of a releasing agent, hot pressing, cooling and curing, sanding and sawing, quality testing and grading, and packaging. The gluing process refers to that fibers obtained through hot grinding are mixed with waterborne polyurethane adhesives, water and catalysts through a fiber spraying pipe. The formaldehyde-free damp-proof high-density fiberboard obtained through the technique does not release formaldehyde or phenol substances, the internal bonding strength of the board is high, the dimension of the board is stable, and the damp resistance and water resistance of the board are good; compared with other boards, the formaldehyde-free board produced through aromatic waterborne polyurethane is high in cost performance, and the cost is not increased greatly; and the problem of formaldehyde pollution of indoor environments can be effectively solved, extensive application of the fiberboard in damp environment is broadened, and a novel technical solution to eliminating of formaldehyde release and broadening of using environments is provided for artificial board products.

Owner:LANZHOU KETIAN ENVIRONMENTAL PROTECTION ENERGY SAVING TECH CO LTD

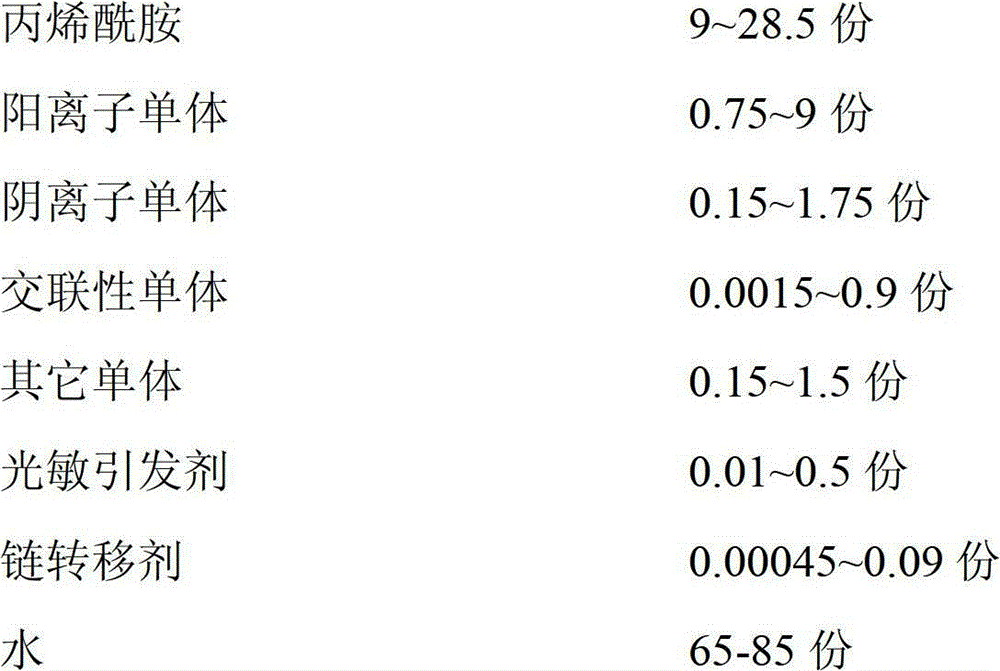

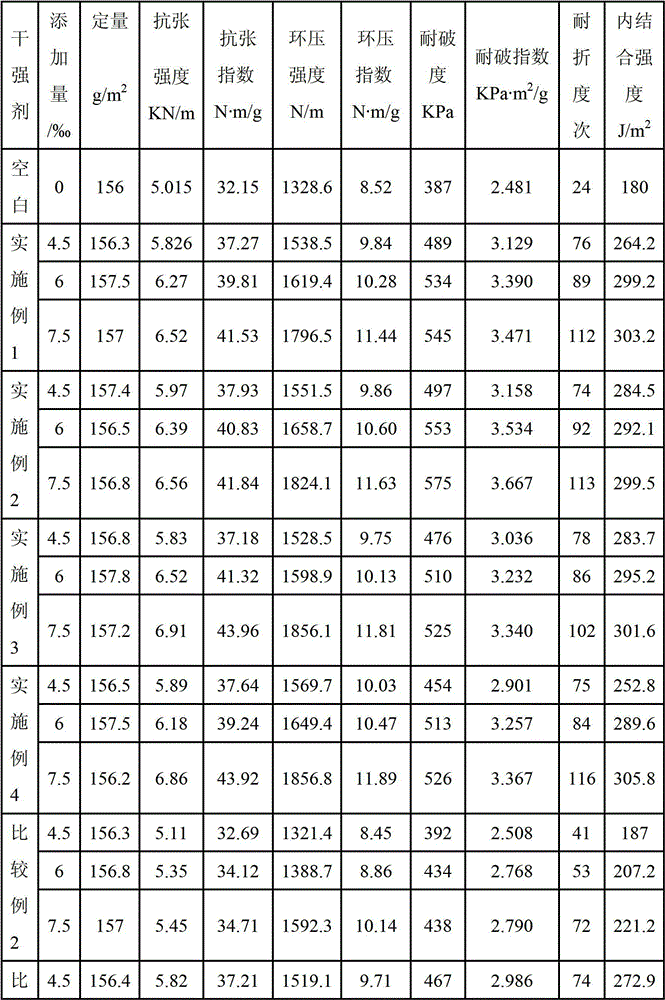

Branch type dry strength agent and preparation method thereof

ActiveCN102720094AAvoid one joinAvoid incremental dripping of respective issuesReinforcing agents additionFunctional monomerUltraviolet

The invention discloses a branch type dry strength agent and a preparation method thereof. The preparation method comprises the following steps of: firstly, mixing acrylamide, negative ion monomers, positive ion monomers, crosslinking agent monomers, a photoinitiator, water and other functional monomers to obtain solution A; secondly, mixing a chain transfer agent and water to obtain solution B; thirdly, polymerizing 40%-60% of the solution A and 20%-40% of the solution B by ultraviolet ray irradiation; fourthly, adding 20%-30% of the solution A and 20%-30% of the solution B into the mixed solution in the third step to be subjected to polymerization by ultraviolet ray irradiation; fifthly, adding the residual solution A and the residual solution B into the mixed solution in the fourth step to be subjected to polymerization by ultraviolet ray irradiation until the viscosity of the solution meets requirements; and sixthly, adjusting the pH and solid content of weight of the mixed solution in the fifth step, and adding free radical catcher into the mixed solution to obtain the branch type dry strength agent. According to the branch type dry strength agent and the preparation method, the operation is simple, the viscosity is easy to control, the dispersibility of the branch type dry strength agent in water is good, the properties of ring crush, fold resistance, breaking resistance, tension resistance, internal bonding strength and the like of paper can be improved.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Semiconductor device

ActiveUS7948078B2Inhibition effectStable characteristicsSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceShunt capacitors

A semiconductor device has a package structure provided with leads that are external connection terminals. A base substance is an island, and at least the surface thereof is formed of a conductive material. A semiconductor substrate is mounted on the surface of the base substance, and a ground potential is supplied from the surface of the base substance. A shunt capacitor is provided with an electrode pair of a first electrode and a second electrode formed in parallel, and mounted with the first electrode being electrically connected to the surface of the base substance. An internal bonding wire connects a pad provided on the semiconductor substrate for external connection, to the second electrode of the shunt capacitor. The lead is the external connection terminal of the semiconductor device. An external bonding wire connects the lead to the second electrode of the shunt capacitor.

Owner:ROHM CO LTD

Method for manufacturing body paper special for lotteries

InactiveCN106894277AHigh strengthImprove smoothnessWater-repelling agents additionMechanical paper treatmentSulfateUltimate tensile strength

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

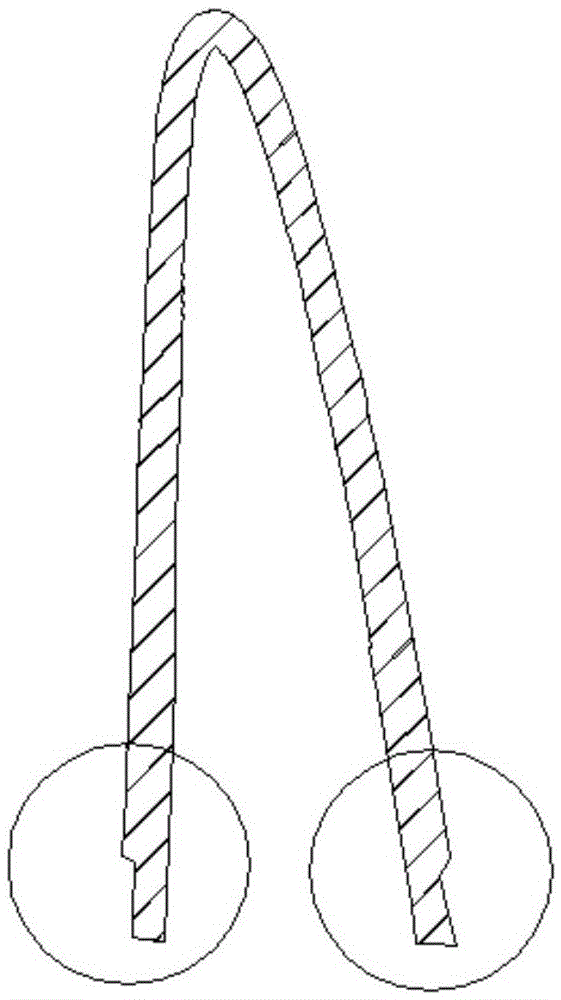

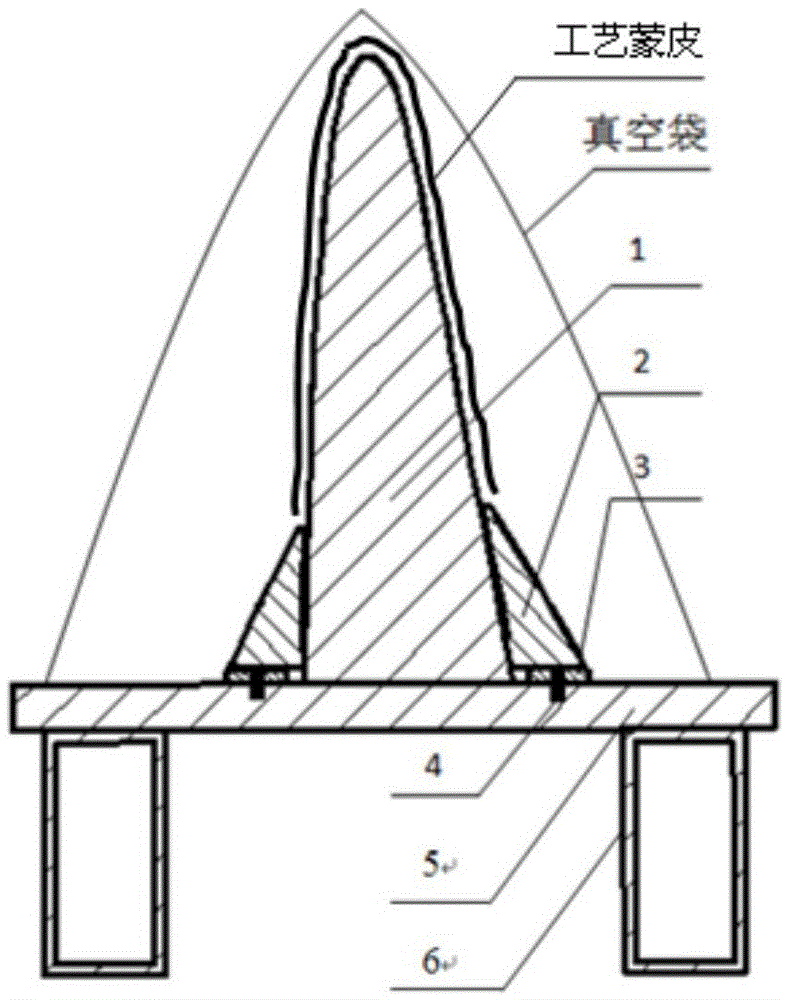

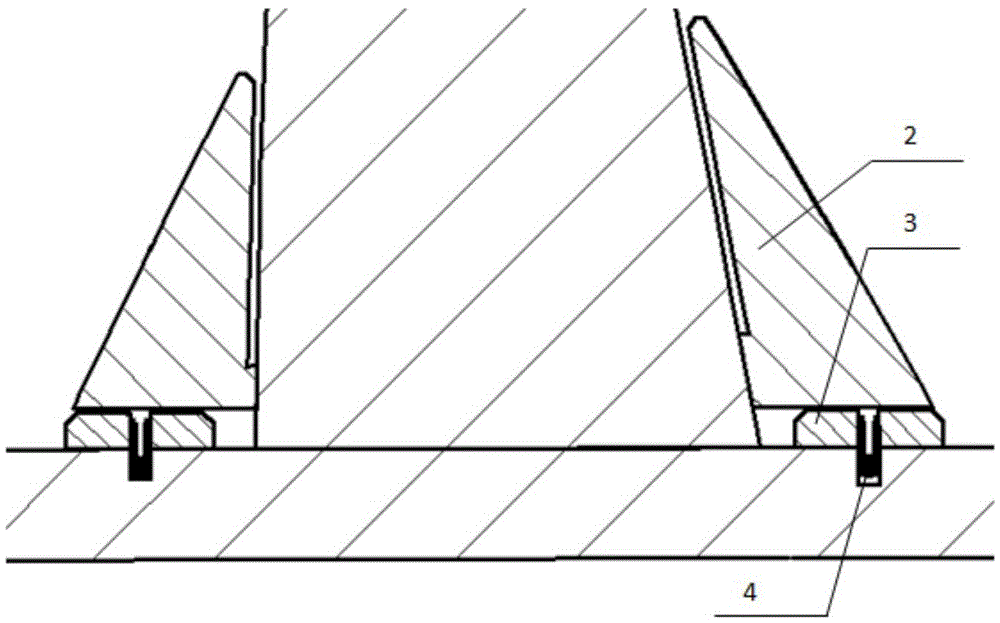

Mould and method for forming partial special-shape surface of large composite material workpiece in autoclave

ActiveCN105538746AAccurate internal and external profilesReliable internal qualityAbnormal shapedInternal bonding

The invention belongs to a composite material thermal forming technology, and particularly relates to a mould and a method for forming a partial special-shape surface of a large composite material workpiece in an autoclave. The mould is characterized in that a mould mode of a main body male die and special-shape position partial female and male die match is adopted for forming the large composite material special-shape workpiece in the autoclave. The main body male die is adopted, so that the forming precision of the inner surface of the workpiece is ensured, and the inner surface of the workpiece is applicable to internal bonding; for a partial special-shape position of the outer surface of the workpiece, the female and male die match is adopted, so that the size and the position precision of a special-shape moulding surface at an assembling part of the outer surface of the special-shape workpiece are ensured, and the internal quality of the workpiece can be ensured.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST +1

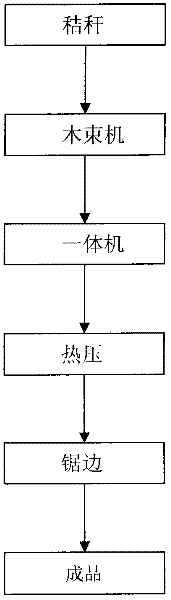

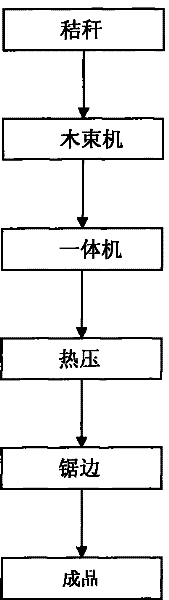

Technique for producing wood bundle board by using straws

The invention discloses a technique for producing a wood bundle board by using straws, and belongs to the field of artificial board production. The wood bundle board is an artificial board formed by processing the straws into elongated small straw sections with width of 5 millimeters and length of 70 millimeters, then applying resin adhesive and thermally pressing the elongated small straw sections. Because the small straw sections with width of 5 millimeters and length of 70 millimeters are convenient for applying the adhesive, pavement and assembly are convenient, and large-scale production is favorable; meanwhile, the elongated straw sections with width of 5 millimeters and length of 70 millimeters can enhance the internal bonding force of a board blank, so that the structure in the board is more scientific and reasonable; the board produced by using the method has high strength and low cost; and the board can be widely applied in the fields of building decoration, furniture manufacture, package, transportation and the like.

Owner:广西南宁明源木业有限公司

Manufacturing method of inorganic mineral board and profile

ActiveCN103771740AFlexibleReprocessableSolid waste managementPhysical chemistryManufactured material

The invention relates to the technical field of organic and inorganic boards and profiles for buildings and home decoration and particularly relates to a manufacturing method of an inorganic mineral board and profile. The inorganic mineral board and profile are manufactured by inorganic minerals and the like. By adoption of the manufacturing method, the difficulty in shortage of materials for the existing organic board is solved. Particularly, a product not only has the characteristics of flexibility and re-processability of the organic board as well as fireproof, flame-retardant and waterproof properties of the inorganic board, but also has the properties of heat preservation and heat insulation, and is a more-ideal material for furniture, indoor decoration and floor base materials. The performance index of the product meets the environment-friendly requirement, and can replace organic and inorganic boards and profiles applied in the existing market. By test, the product has the following parameters that the static bending strength is 14.1-14.3Mpa, the bending elastic modulus is 1849-1878Mpa, the internal bonding strength is 0.41-0.42Mpa, the thickness expansion rate in 2h water absorption is 0.1-0.8% and the formaldehyde emission is 8.5-8.7mg / 100g.

Owner:FUSONG COUNTY HEPING FURNITURE CO LTD

Base paper for carrier tape

ActiveCN102587220AQuality improvementChange the fiber distribution structureSpecial paperWater-repelling agents additionWaxSurface layer

The invention discloses a base paper for a carrier tape, belonging to the technical field of paper making, which comprises a surface layer, a middle layer and a bottom layer, wherein the tensile strength of the surface layer is 6.5-8.5Kn / M, the surface strength which is expressed by a critical wax sticker strength grade is 10-13A, and the water resistance degree is not less than 600s; the softness degree of the middle layer is 100-150mN, and the generation amount of the paper, which is measured by a taper abrasion experimental method, is less than 100ppm; the deflection of the bottom layer is 25-40mn; and the bonding strength among the layers, which is measured by a Scott internal bonding strength instrument, is not less than 150J / m<2>. Compared with the prior art, the invention has the advantages that the quality of the base paper for the carrier tape is effectively improved, and the prepared paper has large strength, good waterproof and bonding performances, good resilience, and small physical damage to electronic elements, and the like.

Owner:ZHEJIANG JIEMEI ELECTRONICS & TECH

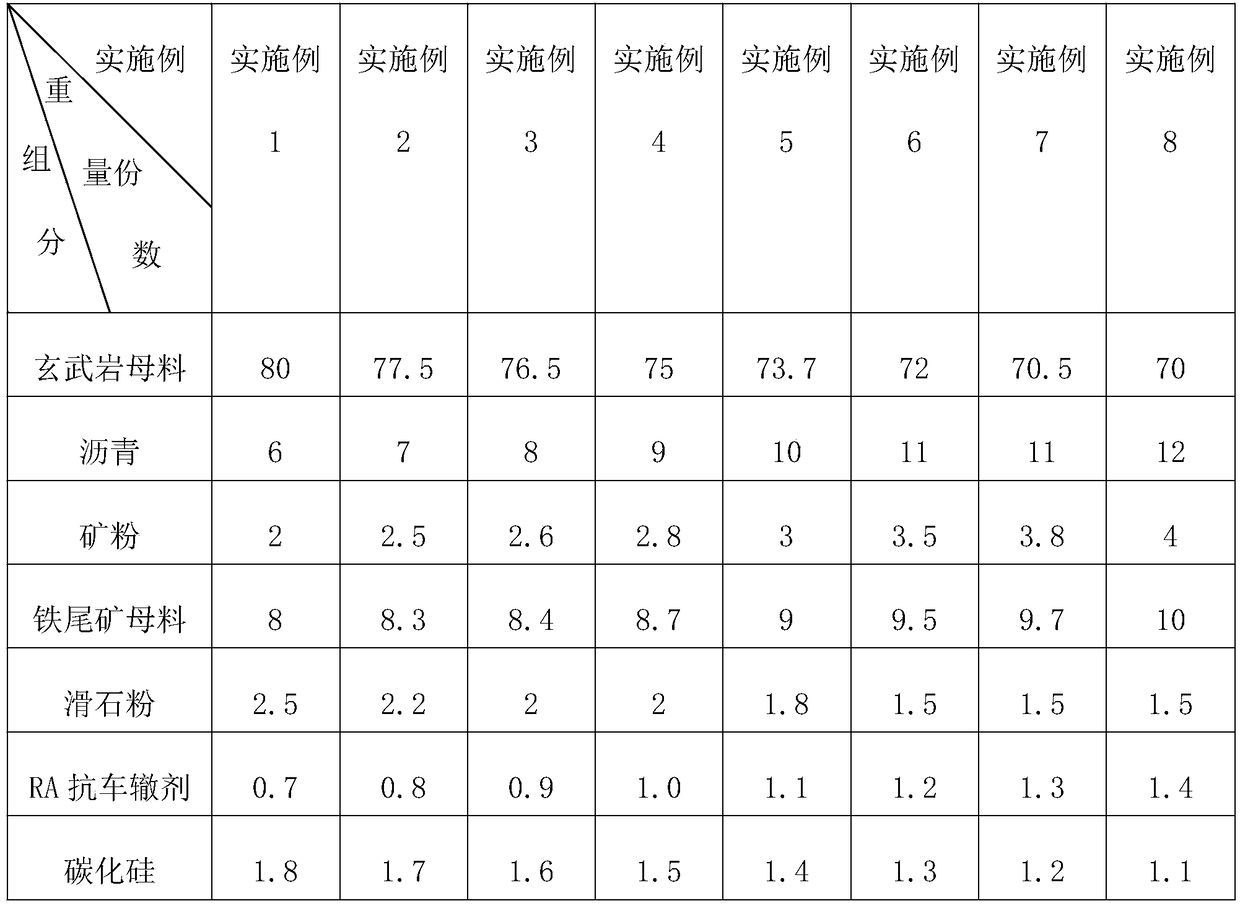

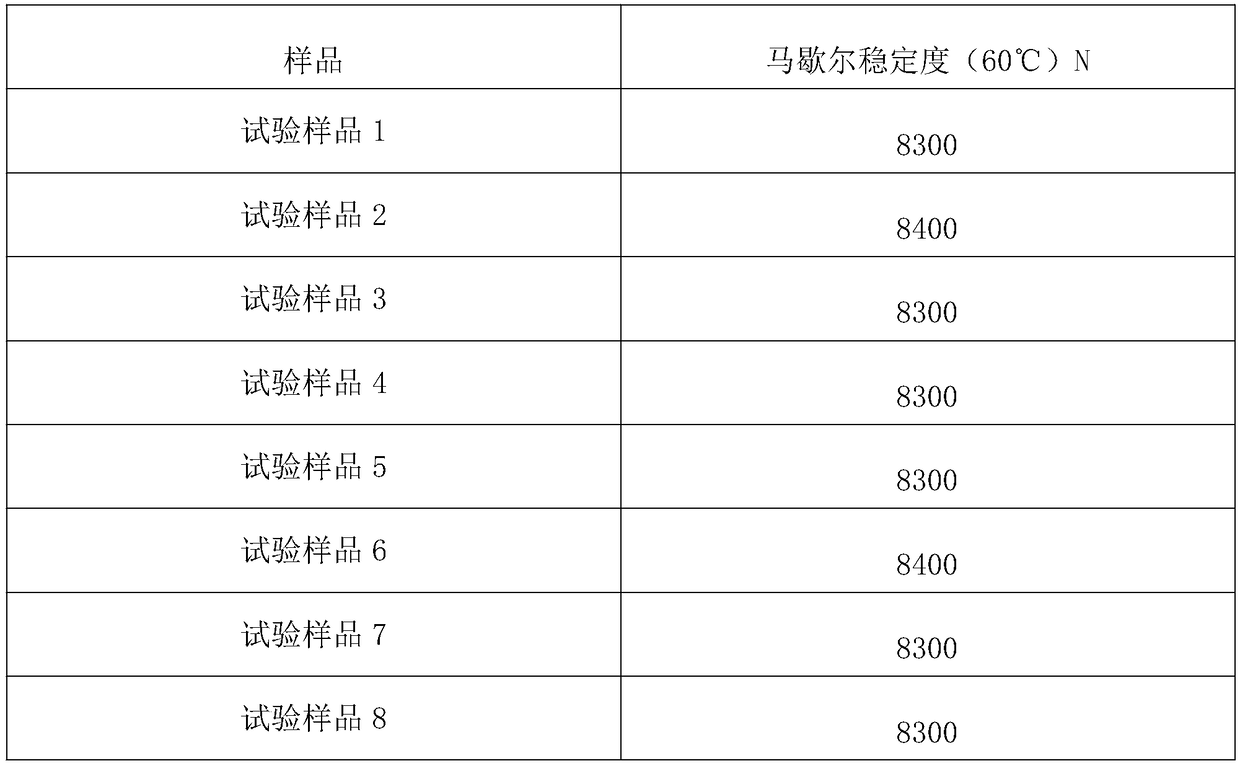

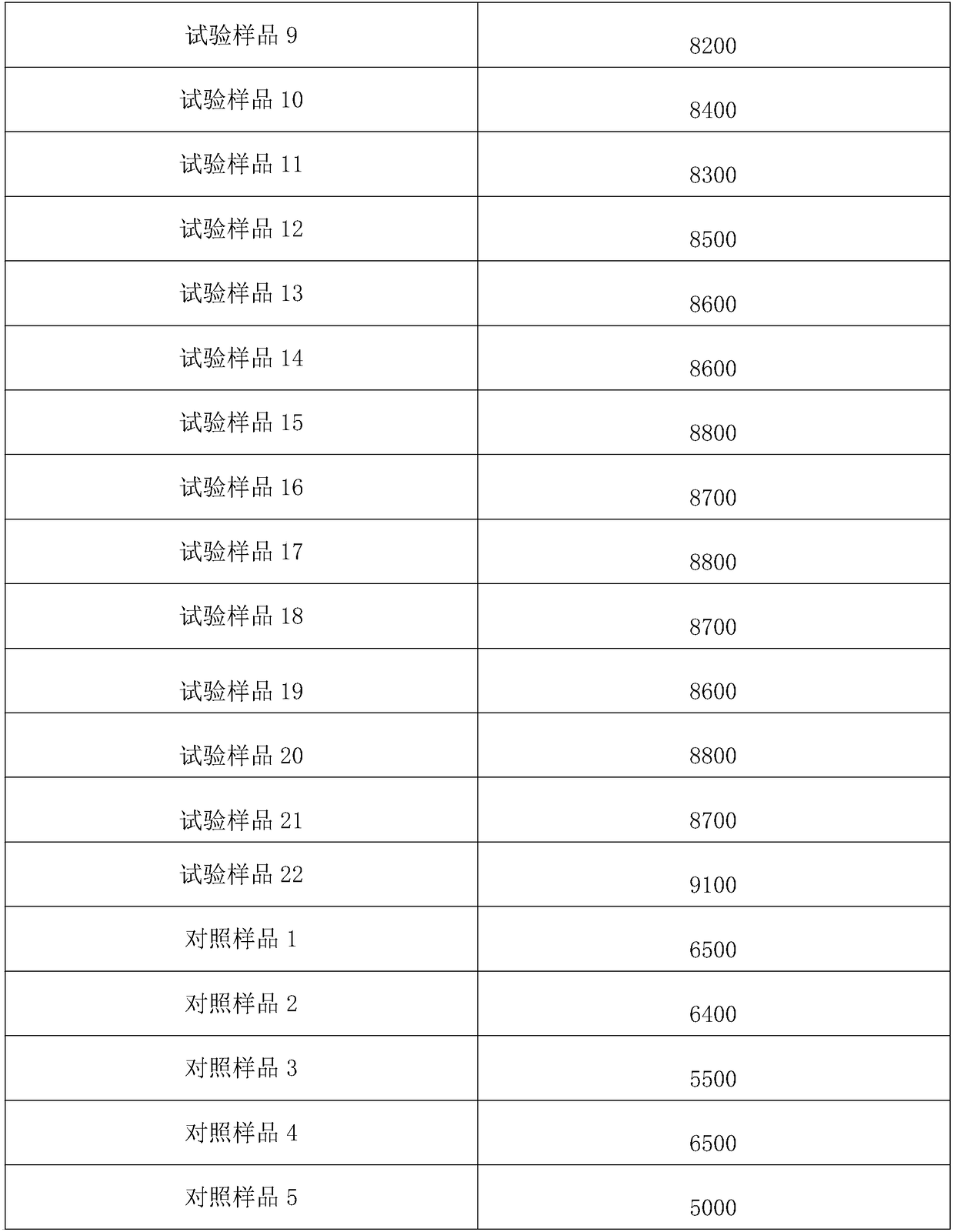

Asphalt concrete and preparation process thereof

The invention discloses an asphalt concrete and a preparation process thereof, which relate to the technical field of concrete production and manufacture, and solves the problem that the asphalt concrete in the prior art is prone to cracking due to low internal bonding strength during use. The asphalt concrete comprises the following components in parts by weight: 70-80 parts of basalt masterbatch; 6-12 parts of asphalt; 2-4 parts of ore powder; 8-10 parts of iron tailings masterbatch; 1.5-2.5 parts of a cementing agent; 0.7-1.4 parts of an anti-rutting agent; and 1.1 to 1.8 parts of silicon carbide. The asphalt concrete obtained by the invention has good structural strength after use and is not easily cracked.

Owner:平湖市中建沥青混凝土工程有限公司

Solder paste

ActiveUS8388724B2Correct position deviationPrinted circuit manufactureGlass/slag layered productsPowder mixtureSolder paste

High-temperature solders having a higher melting point than solder alloys used for soldering of printed circuit boards are used for internal bonding of electronic parts, but high-temperature solders which are free from Pb have not been developed. There exist high-temperature solders which comprises Sn balls and Cu balls and which perform bonding through the formation of an intermetallic compound without melting to form a single-phase structure, but they have poor wettability to the lands of a printed circuit board or electrodes of electronic parts and have not been used.A solder paste according to the present invention is provided by mixing flux with a powder mixture of Sn powder or an Sn based lead-free solder powder with Cu or Ag powder which has Ni plating formed on its surface. Although the solder paste performs bonding by means of an intermetallic compound without melting to form a single phase structure, the Ni plating acts as a barrier which retards the formation of the intermetallic compound so as to leave enough time to permit wetting of the lands of a printed circuit board or electrodes of an electronic part.

Owner:SENJU METAL IND CO LTD

Boron type flame retardant directional shaving board and preparation method thereof

InactiveCN103963132AImprove internal bond strengthReduce manufacturing costDomestic articlesFlat articlesWood shavingsBetaine

The invention discloses a preparation method for a flame retardant directional shaving board and products thereof. In the preparation process of the flame retardant directional shaving board, fast-growing wood shavings with low price are used as raw materials, boric acid / borax with good flame retardant property, low toxicity and good smoke suppression effect is used as a flame retardant, and dodecyl dimethyl betaine with the characteristics of zwitterionic compounds is used as an auxiliary agent. The shaving board has the advantages of simple production technology, low production cost and small pollution; each property of the prepared flame retardant directional shaving board reaches the national standard, especially the internal bonding strength and the flame retardance are greatly improved, and the shaving board has a wide applicable scope.

Owner:BEIJING FORESTRY UNIVERSITY

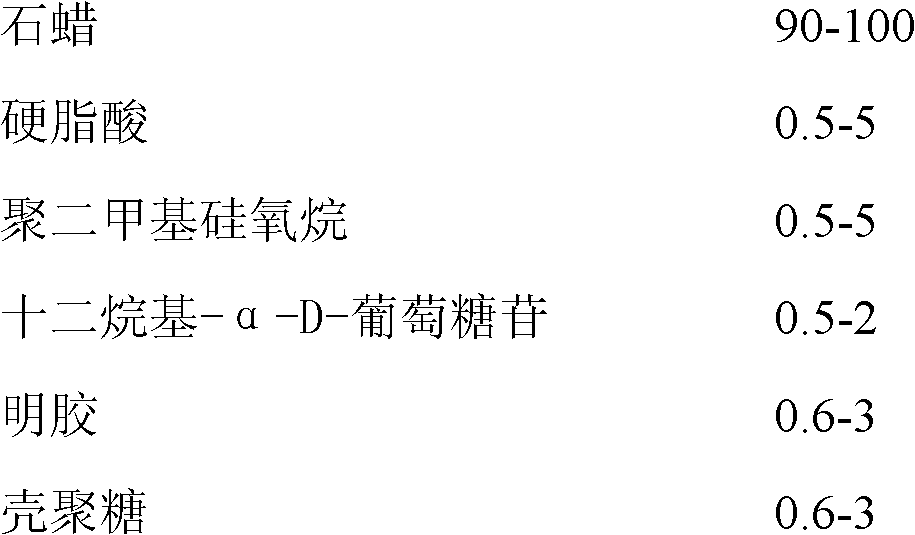

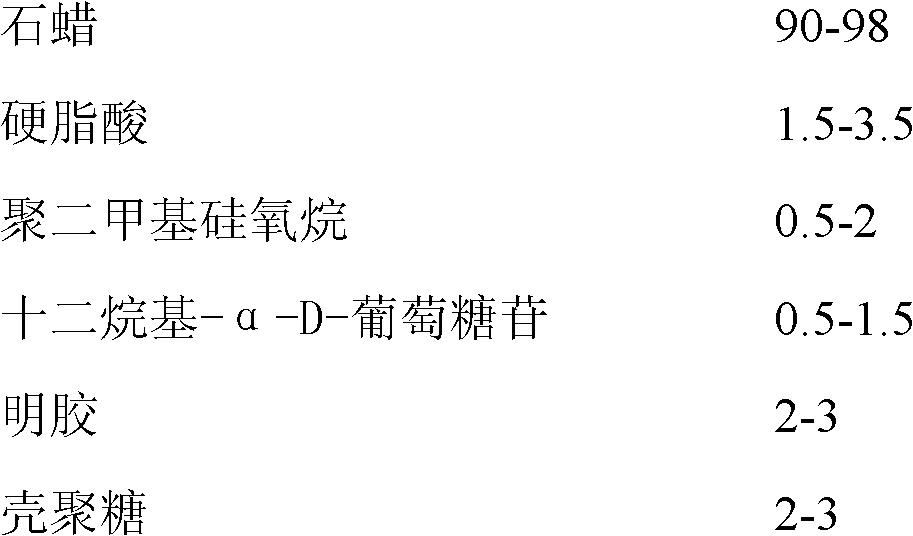

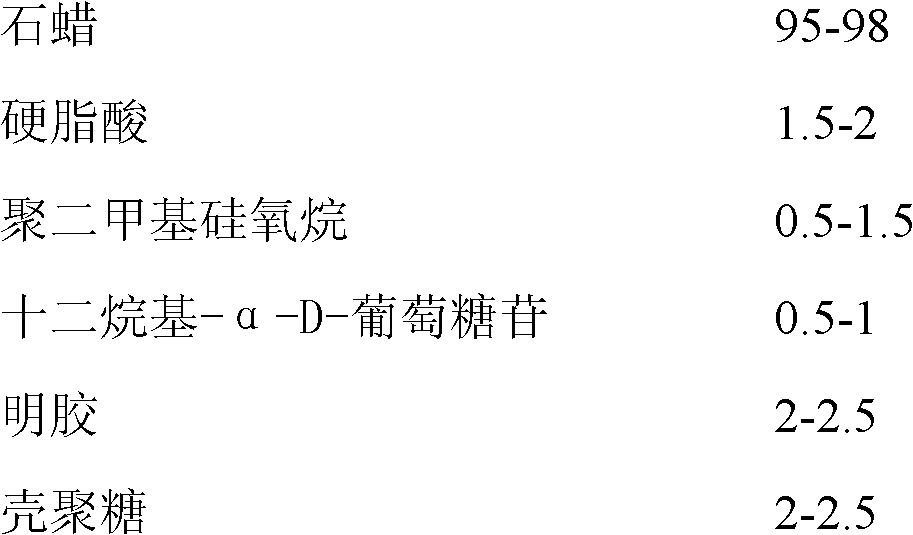

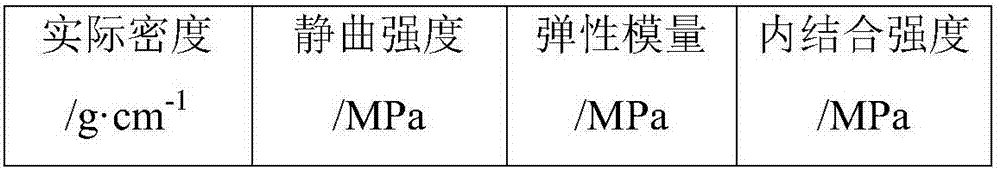

Water-proof and mildew-proof agent for artificial board and preparation method thereof

ActiveCN102952409AImprove waterproof and mildew resistanceEvenly distributedStearic acidUltimate tensile strength

The invention discloses a water-proof and mildew-proof agent for an artificial board and a preparation method thereof. The water-proof and mildew-proof agent comprises a capsule core and a capsule shell, wherein the capsule core is composed of paraffin, stearic acid and dodecyl-alpha-D-glucoside; and the capsule shell is composed of high molecular compound gelatin and chitosan. The preparation method comprises the following steps: melting the substances having water-proof property; under the action of the surfactant dodecyl-alpha-D-glucoside, dispersing in a hot gelatin and chitosan water solution in a nano particle state; and regulating the pH value, and quickly cooling to ensure that the gelatin and the chitosan are condensed into thin films coated on the nano particles of the substances having water-proof and mildew-proof property, thus forming nano capsules. The water-proof and mildew-proof agent prepared by the invention can reduce the instantaneous water absorption rate of the artificial board, improve the water-proof and mildew-proof property of the artificial board, enhance the internal bonding strength of the board, improve the product quality and save the cost by more than 20%.

Owner:ZHAOQING LIHE TECH DEV +3

Method of producing medium density fiberboard by the use of waste material

ActiveCN102139504AImprove qualitySave natural resourcesWood working apparatusDomestic articlesNatural resourceMedium density

The invention discloses a method of producing medium density fiberboards by the use of waste materials. The method produces medium density fiberboards by the use of waste timbers in Sinkiang as raw materials. Slabs (wasted scraps produced after manufactures with saws in Sinkiang use log saws for sawing plates), woods dying a nature death and dying in nature disasters, and tree branches are intensively transported for full comprehensive utilization, which takes the lead in the production of medium density fiberboards by waster materials. The produced medium density fiberboards have excellent quality with light pine fragrance, not only greatly increases the internal bonding strength, bending strength, elastic modulus and waterproof performance, but also saves plenty of natural resources for nation and simultaneously solves the practical issue of local harsh employment.

Owner:新疆金杨万华木业有限公司

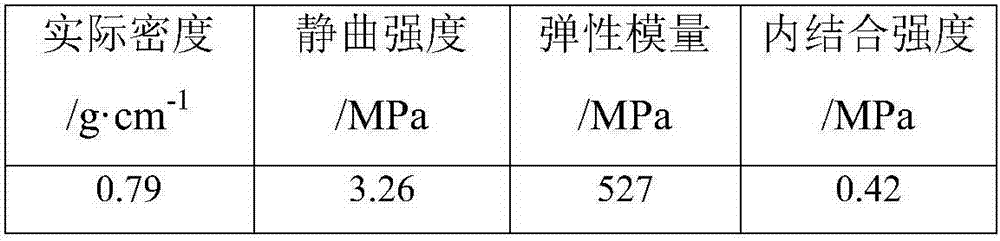

Method utilizing camellia oleifera shells to prepare plant fiber-based particle board and particle board

InactiveCN106945148AImprove surface wettabilityImprove permeabilityFlat articlesDomestic articlesFiberCamellia oleifera

The invention discloses a plant fiber-based particle board and a preparation method of the plant fiber-based particle board. Before gluing, camellia oleifera shells are pretreated, the pretreated camellia oleifera shells are mixed with glues evenly and then horizontally laid in a mould to be formed in a hot pressing mode, and the plant fiber-based particle board is obtained. The plant fiber-based particle board is good in mechanical performance, the static bending strength is 1.49 MPa-3.5 MPa, the elastic modulus is 383 MPa-530 MPa, and the internal bonding strength is 0.31 MPa-1.02 MPa. Compared with other biomass materials, the used camellia oleifera shells have the characteristics of being low price, reproducible, rich and intensive in yield and the like. The used overall working procedure is short, the method is simple, and the method has special significance for improving the high quality utilization way of camellia oleifera shell resources and relieving the current situation that forest resources are deficient.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Rubber material for wear-proof sealing part

The invention discloses a rubber material for a wear-proof sealing part. The rubber material for the wear-proof sealing part is characterized by being prepared from the following raw materials in parts by mass: 35-55 parts of butadiene-acrylonitrile rubber, 10-15 parts of ethylene propylene diene monomer rubber, 15-20 parts of epoxy resin, 10-15 parts of high-wear-resistance white carbon black, 3-4 parts of carbon fibers, 3-5 parts of allyl alcohol, 5-8 parts of a vulcanizing agent, 1-3 parts of an accelerator, 2-4 parts of an anti-aging agent and 2-4 parts of a plasticizer. According to the technical scheme, butadiene-acrylonitrile rubber is taken as matrix, and wear-resistant materials such as carbon fibers, epoxy resin and high-wear-resistance white carbon black are taken as filling materials, so that the rubber material for the wear-proof sealing part has high strength, internal bonding strength of rubber is improved, and the tensile strength and mechanical strength of the rubber are enhanced.

Owner:SHANGHAI CHANGLI INFORMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com