Patents

Literature

84results about How to "Correct position deviation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

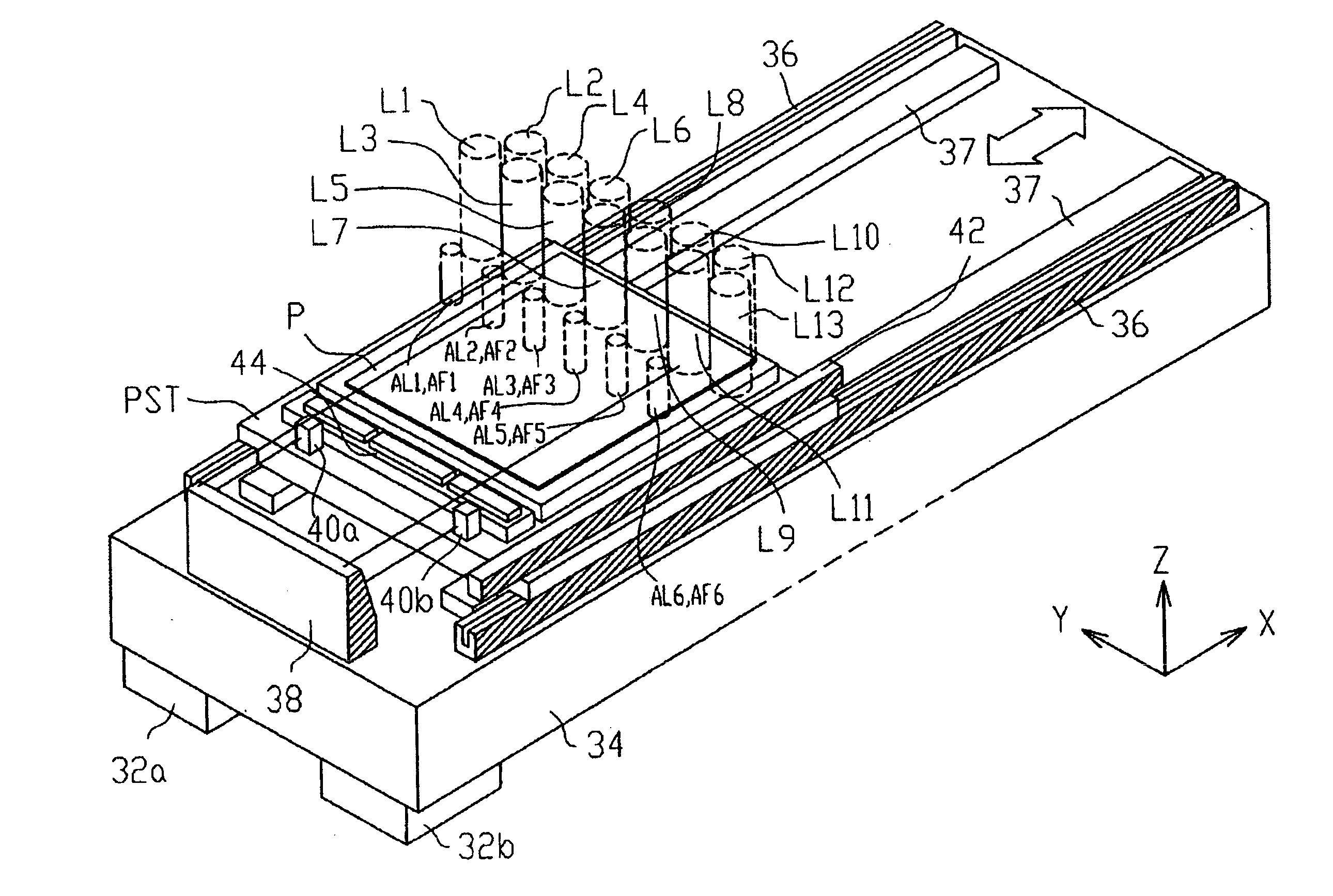

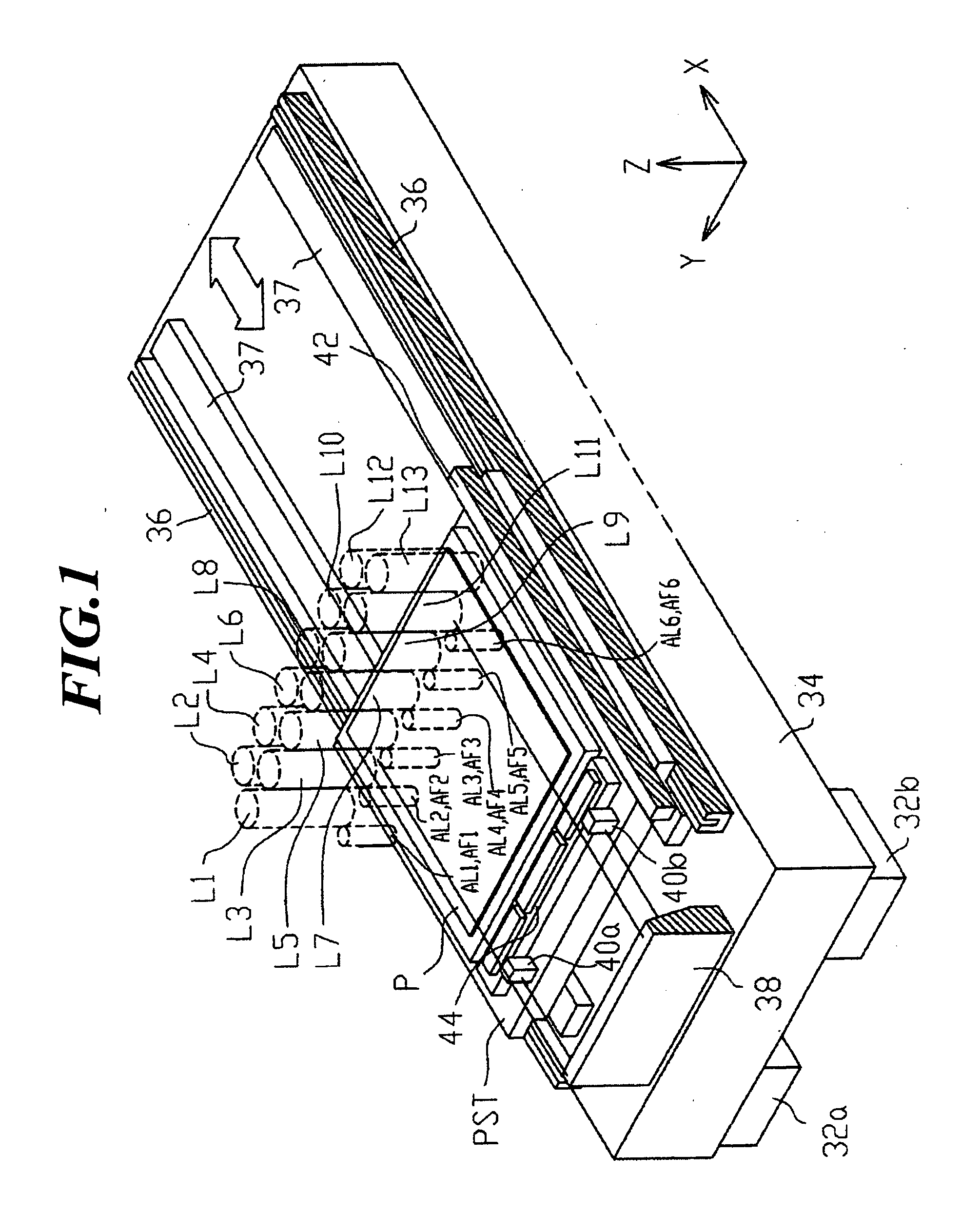

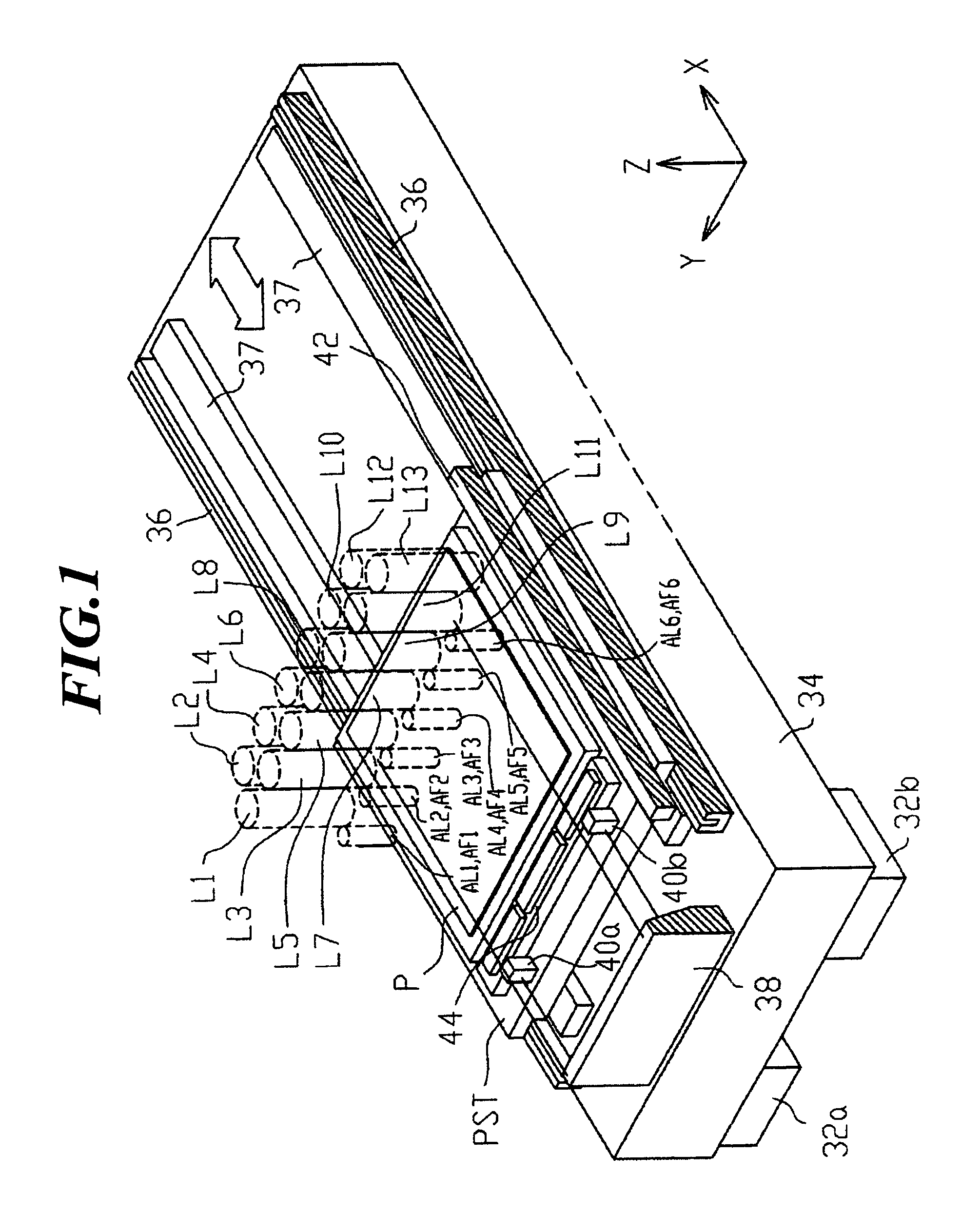

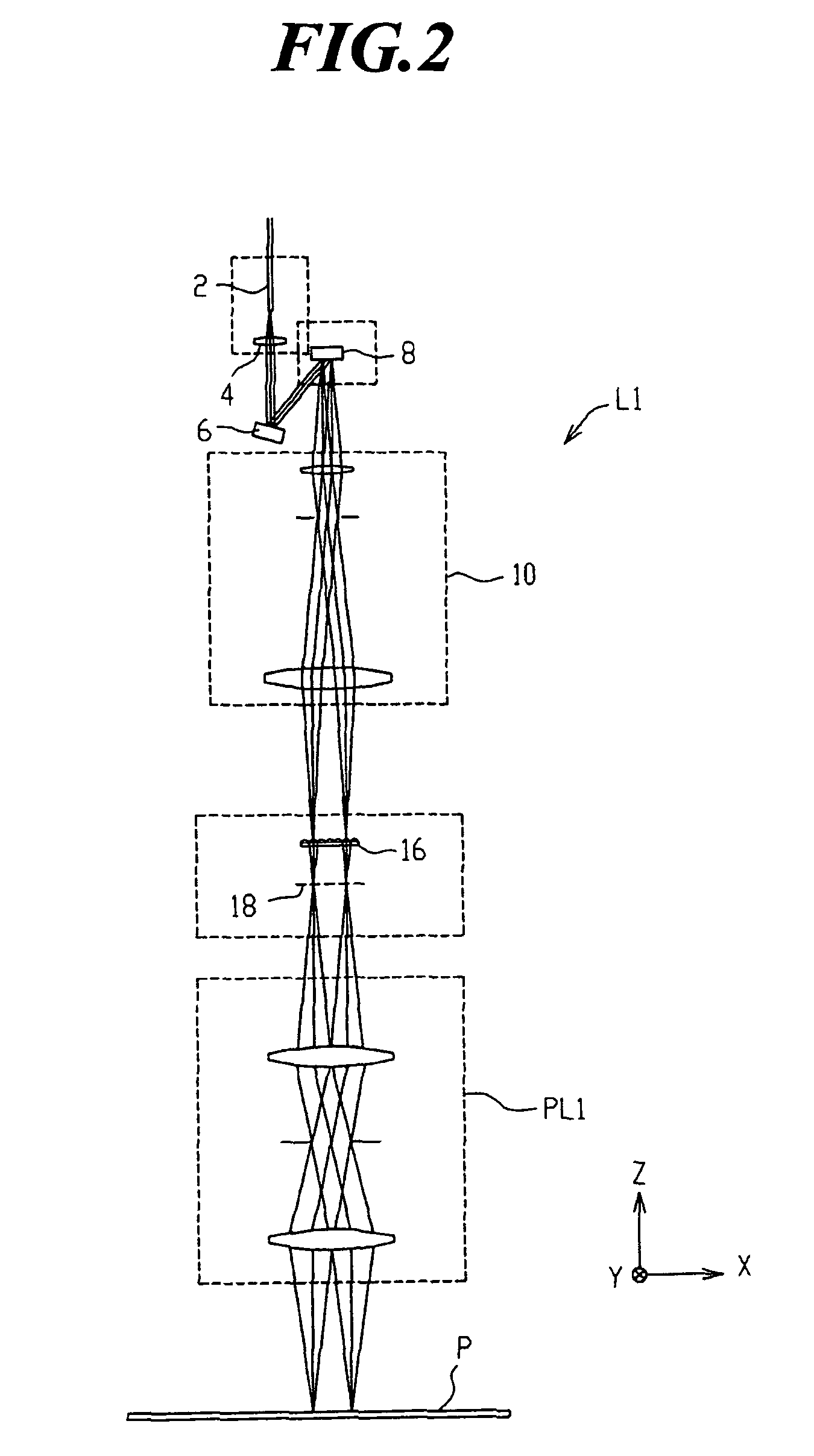

Exposure Apparatus, Exposure Method, and Producing Method of Microdevice

InactiveUS20070296936A1Improve performanceQuality improvementPhotomechanical apparatusPhotographic printingComputer science

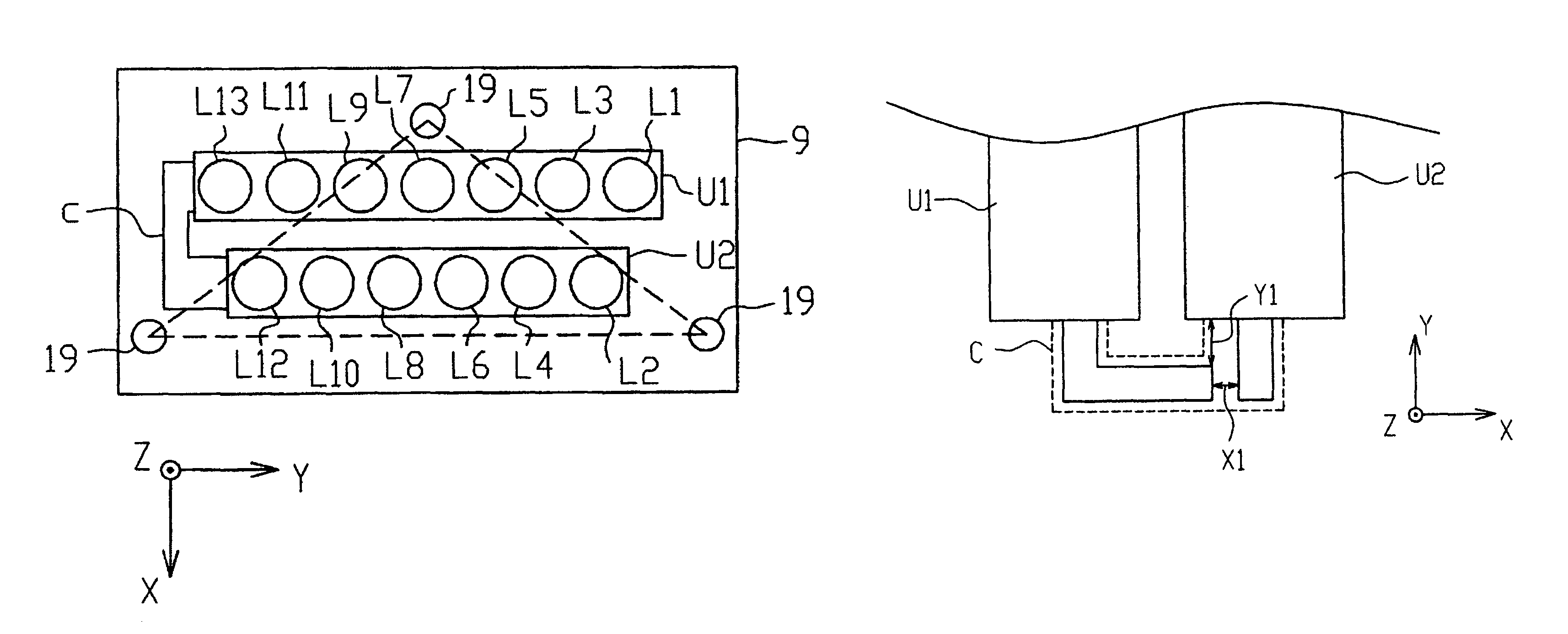

An exposure apparatus for exposure-transferring an image of a pattern projected through an optical system having a plurality of optical units L1 to L13 onto an object P, comprises a correcting device which corrects a position of at least one of a plurality of images to be projected onto the object P by the plurality of optical units L1 to L13 so that displacements of the optical units L1 to L13 are compensated.

Owner:NIKON CORP

Position control apparatus and method of the same, numerical control program preparation apparatus and method of the same, and methods of controlling numerical control machine tool

InactiveUS6097168AEasy to controlPrecise positioningProgramme-controlled manipulatorComputer controlNumerical controlTarget setting

Owner:TOSHIBA MASCH CO LTD

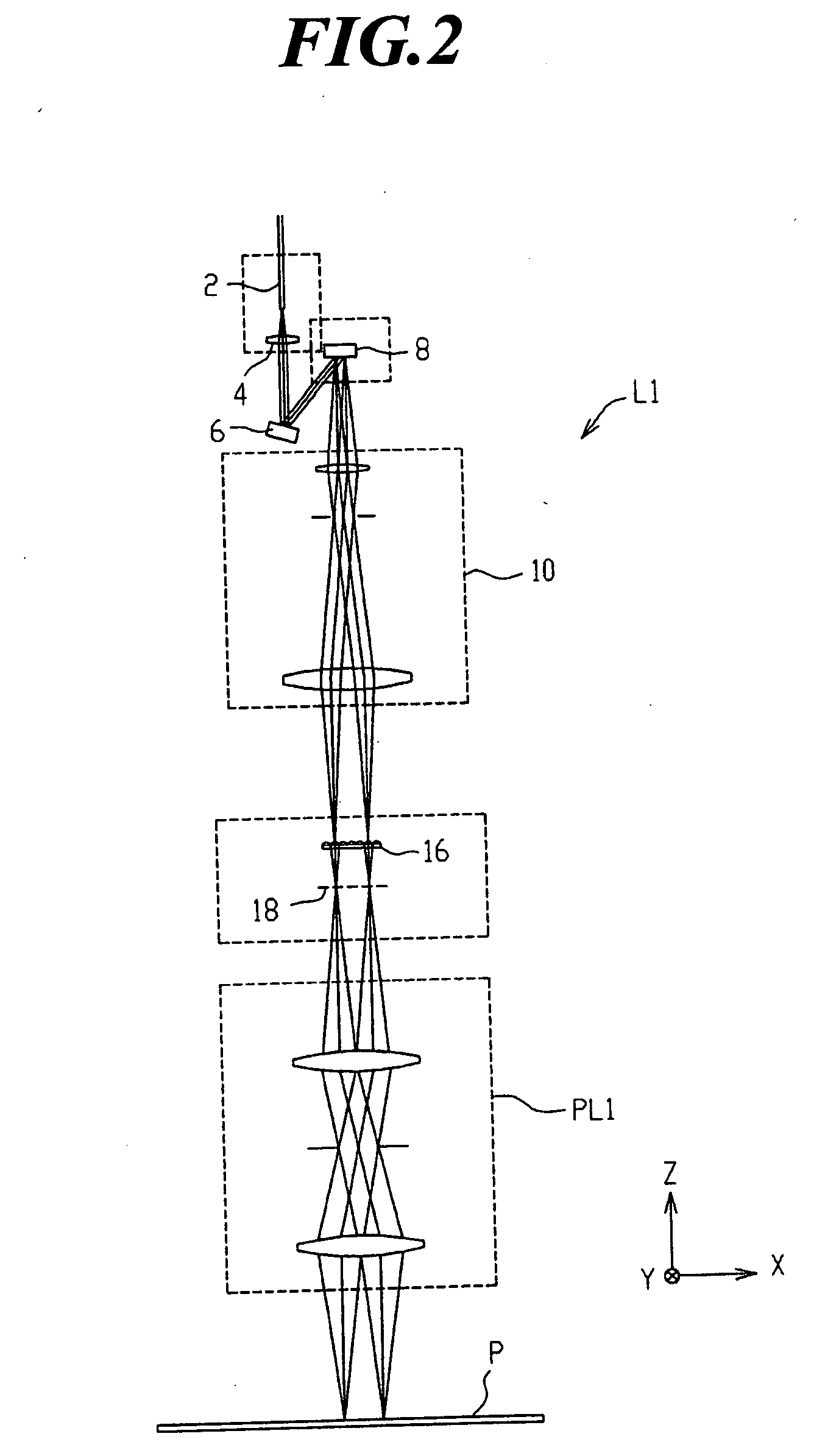

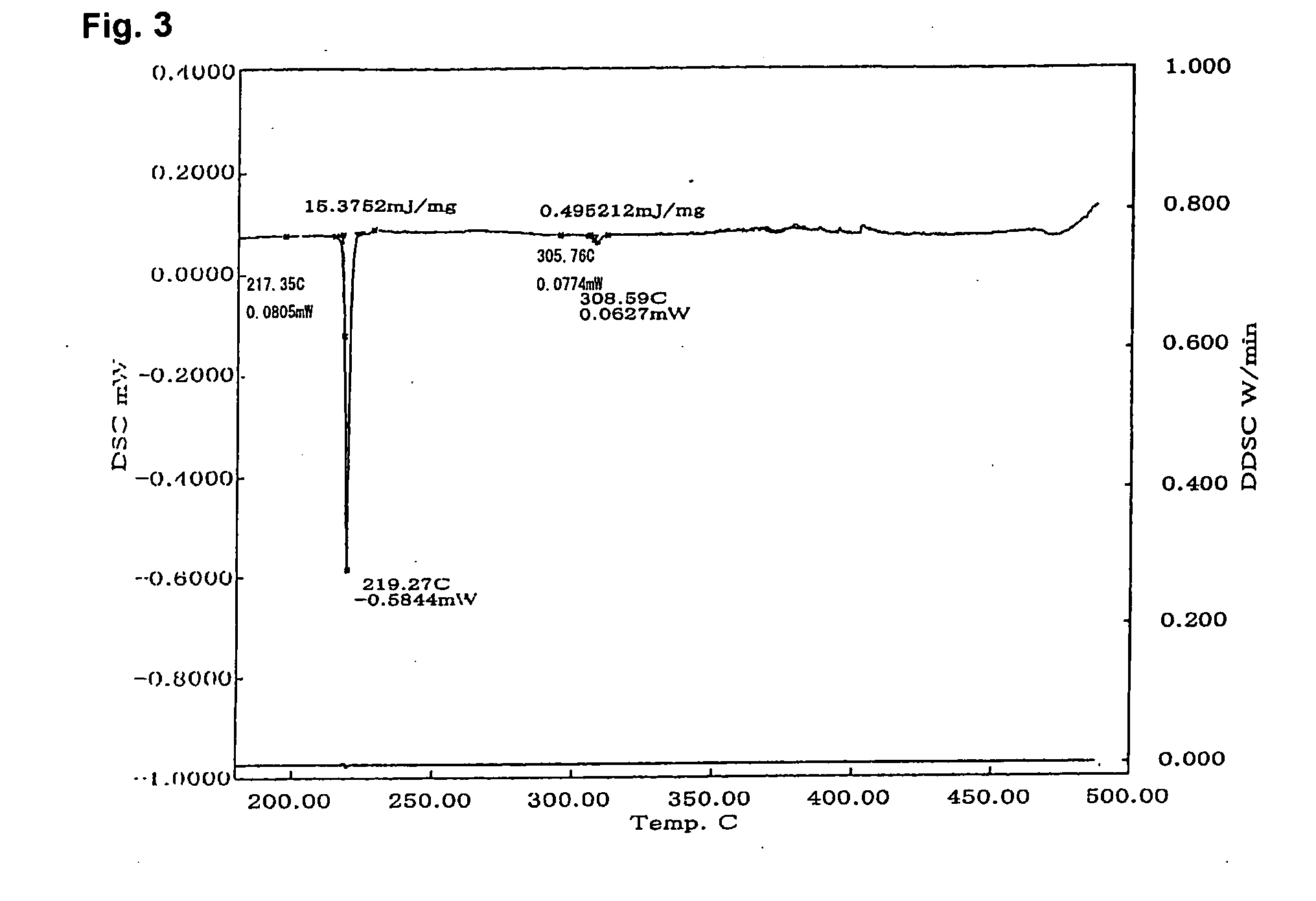

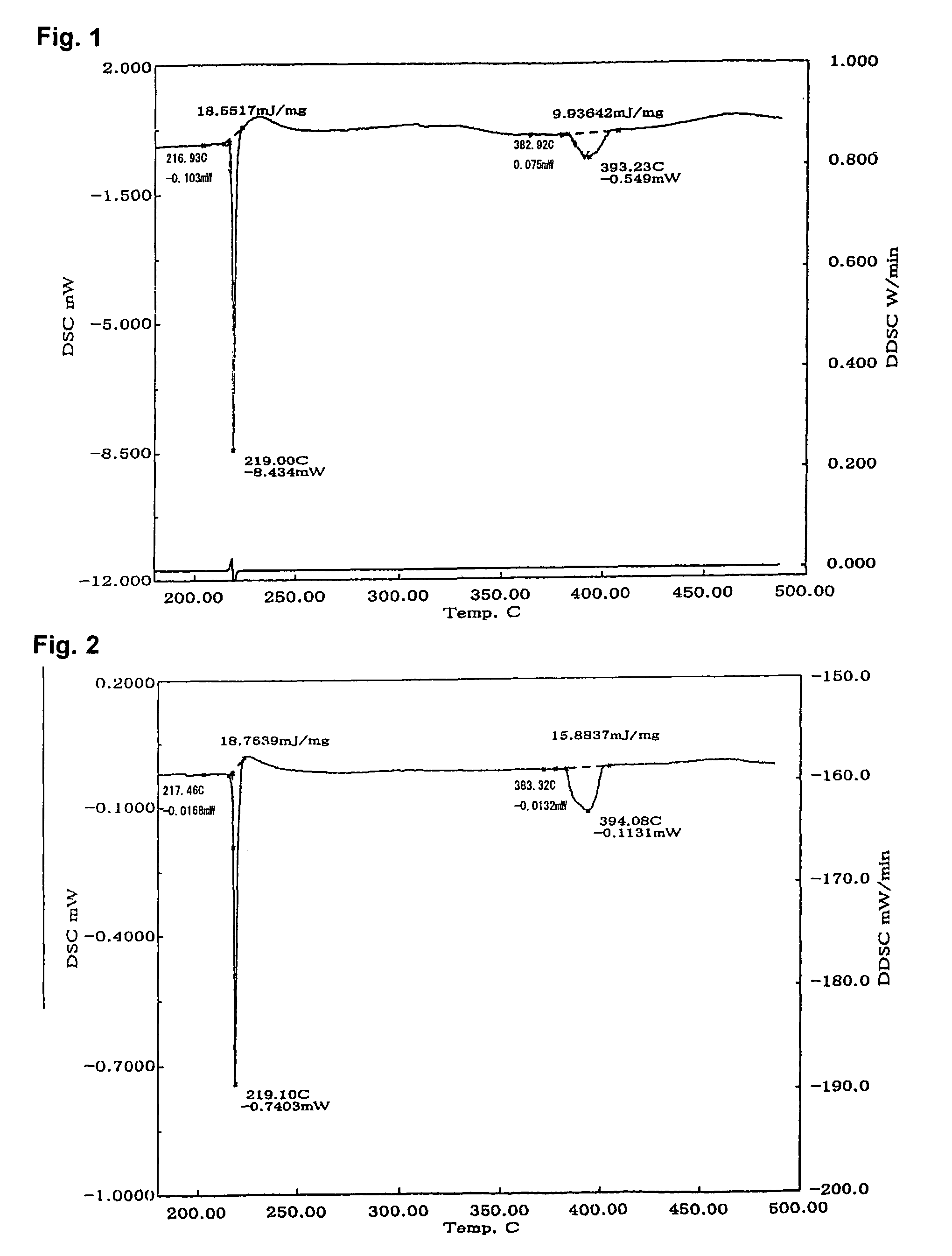

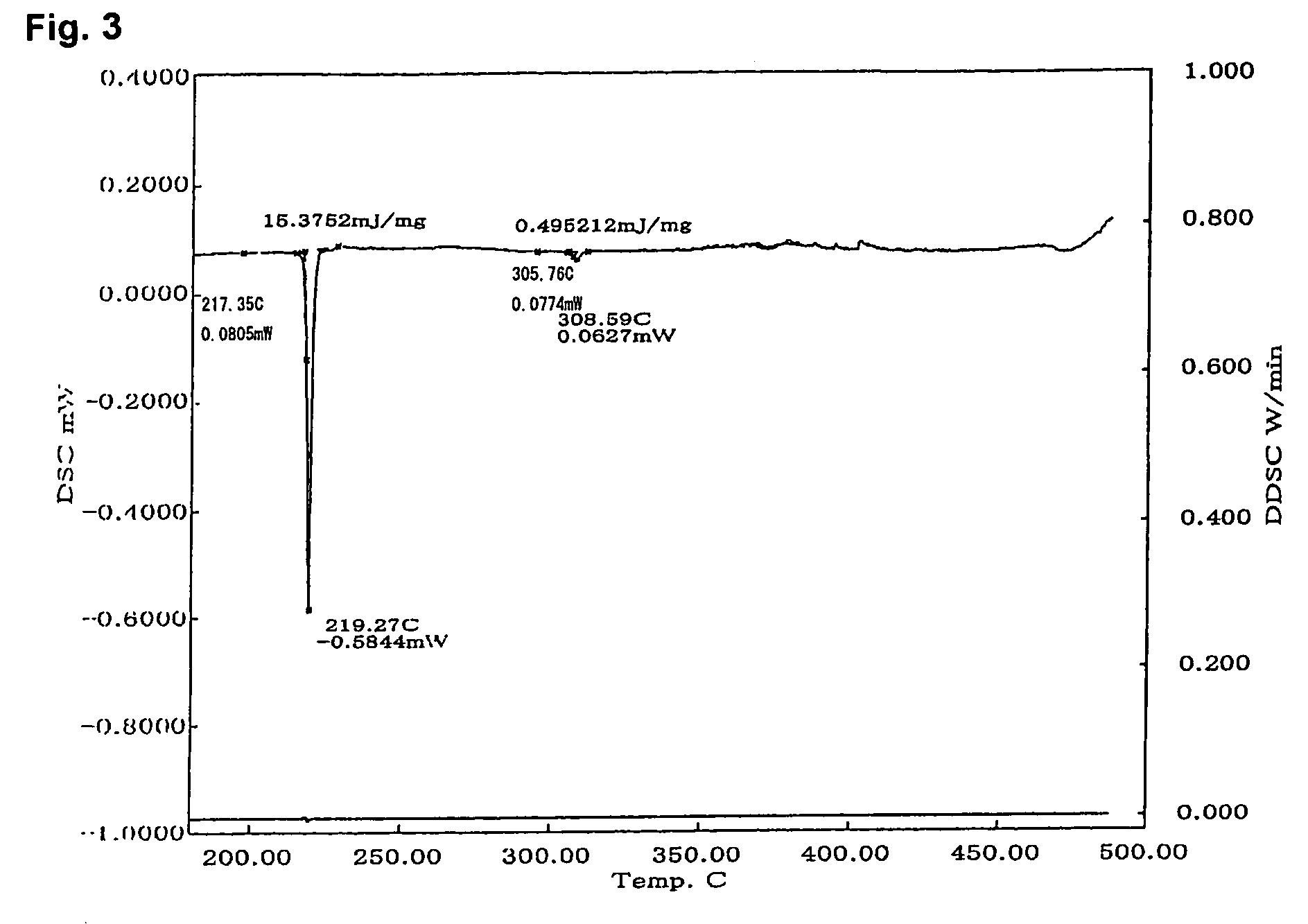

Solder Paste

ActiveUS20090220812A1Correct position deviationPrinted circuit aspectsPrinted circuit manufacturePowder mixtureSufficient time

High-temperature solders having a higher melting point than solder alloys used for soldering of printed circuit boards are used for internal bonding of electronic parts, but high-temperature solders which are free from Pb have not been developed. There exist high-temperature solders which comprises Sn balls and Cu balls and which perform bonding through the formation of an intermetallic compound without melting to form a single-phase structure, but they have poor wettability to the lands of a printed circuit board or electrodes of electronic parts and have not been used.A solder paste according to the present invention is provided by mixing flux with a powder mixture of Sn powder or an Sn based lead-free solder powder with Cu or Ag powder which has Ni plating formed on its surface. Although the solder paste performs bonding by means of an intermetallic compound without melting to form a single phase structure, the Ni plating acts as a barrier which retards the formation of the intermetallic compound so as to leave enough time to permit wetting of the lands of a printed circuit board or electrodes of an electronic part.

Owner:SENJU METAL IND CO LTD

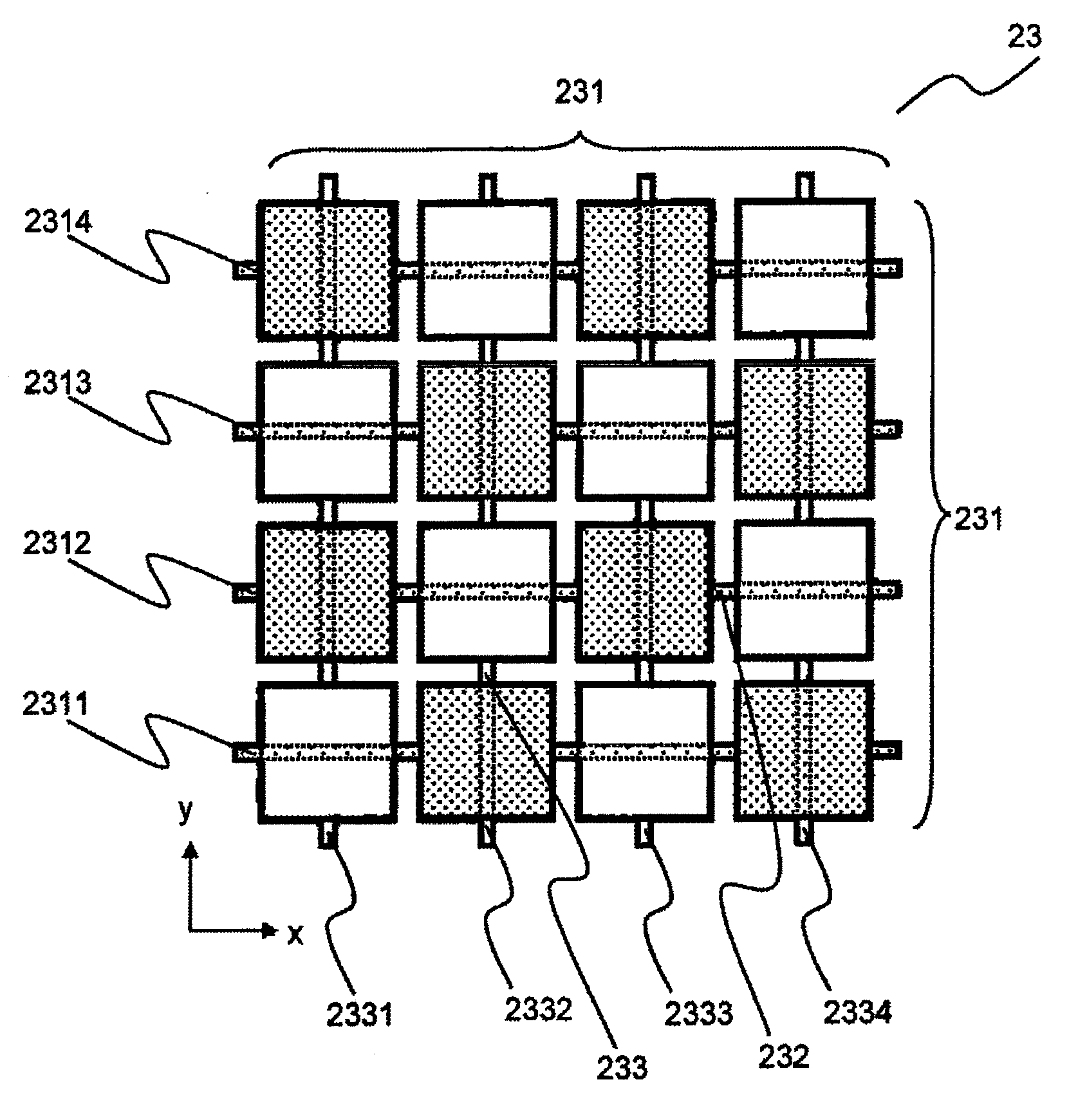

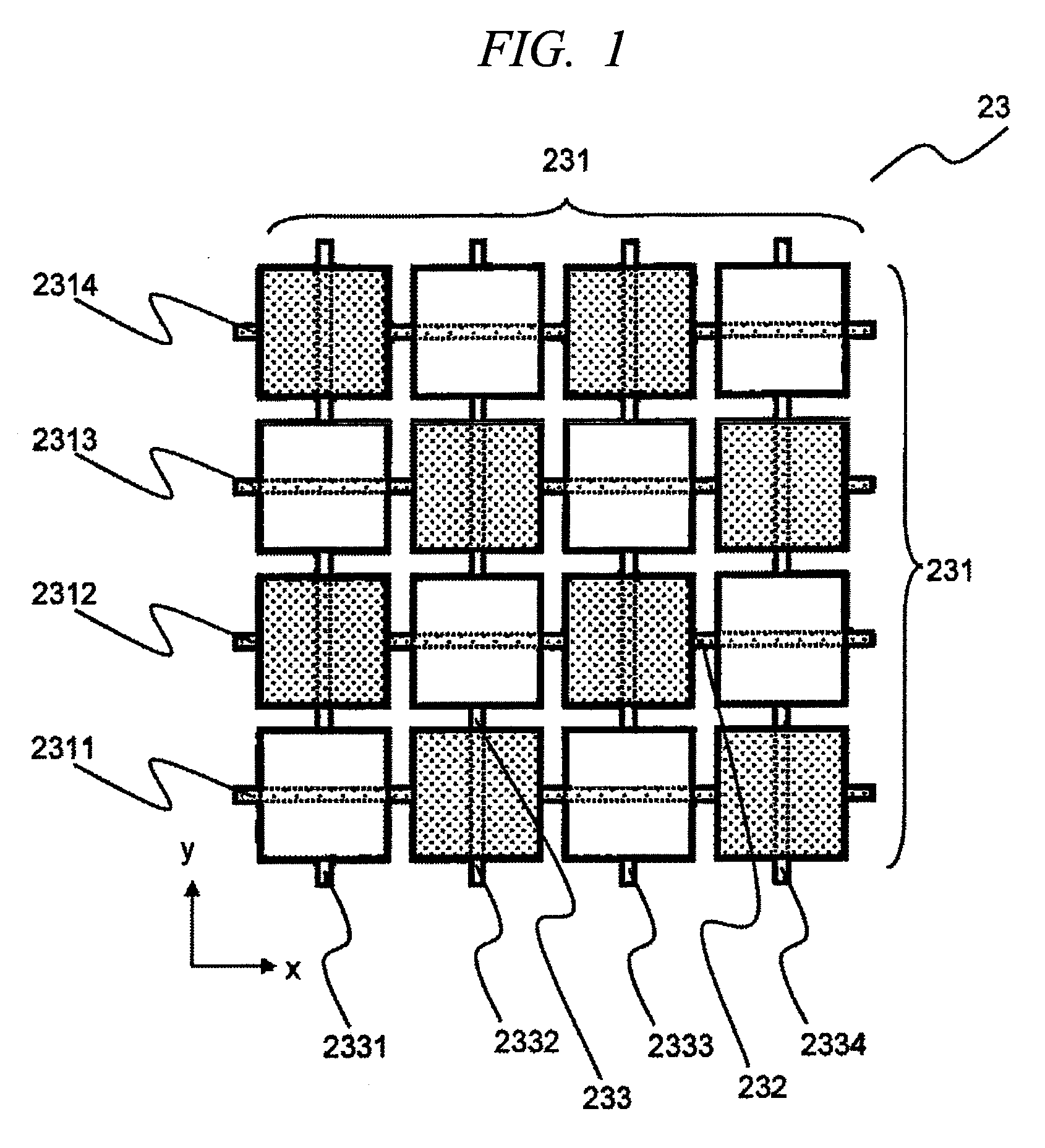

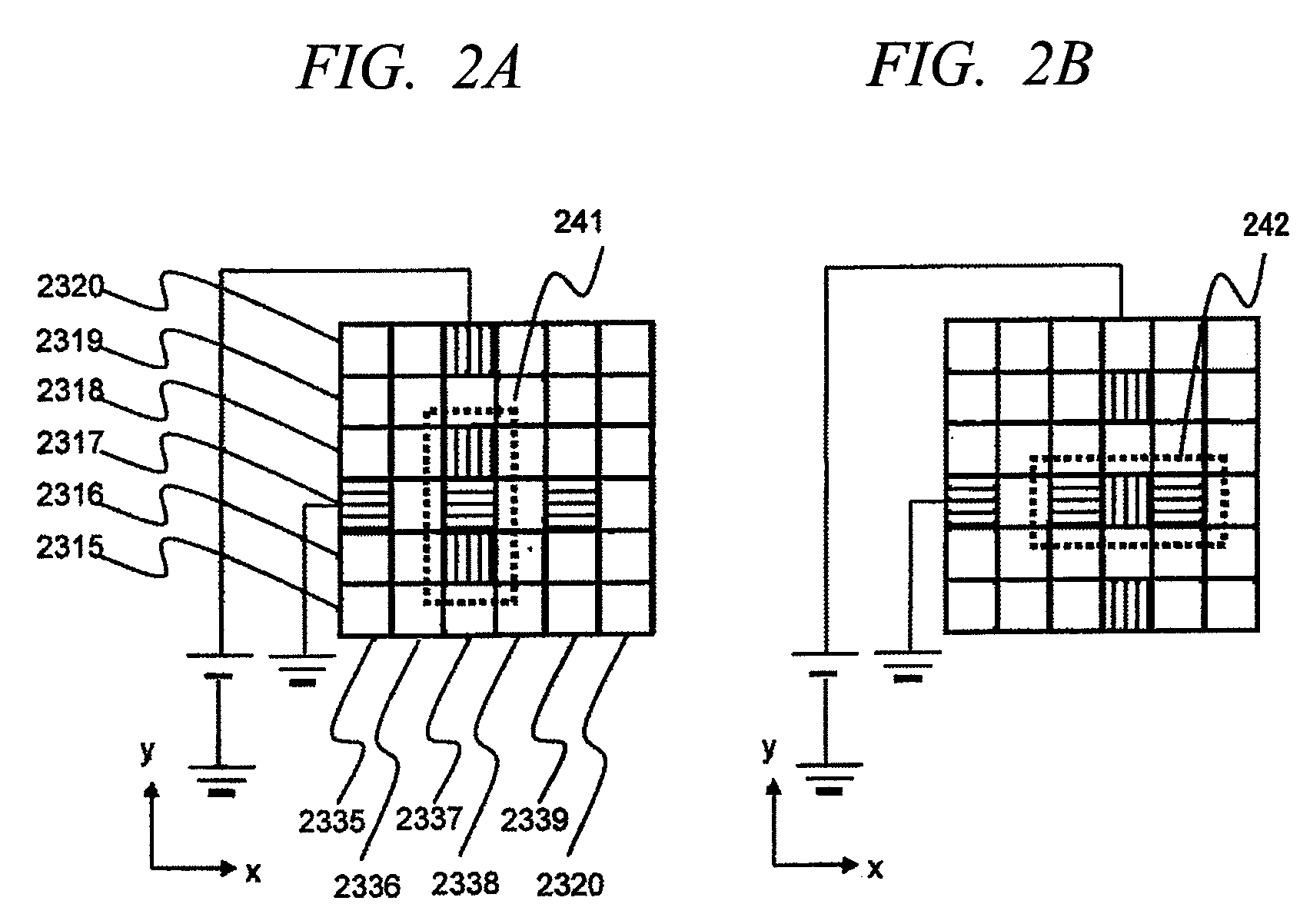

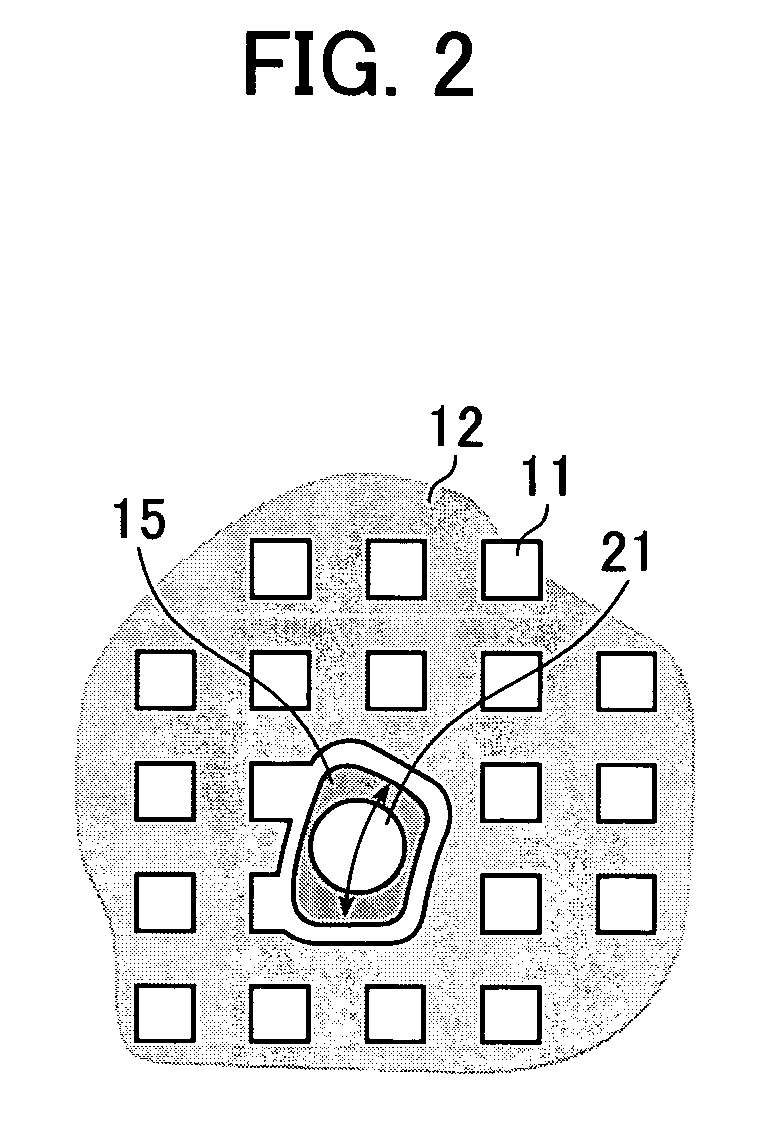

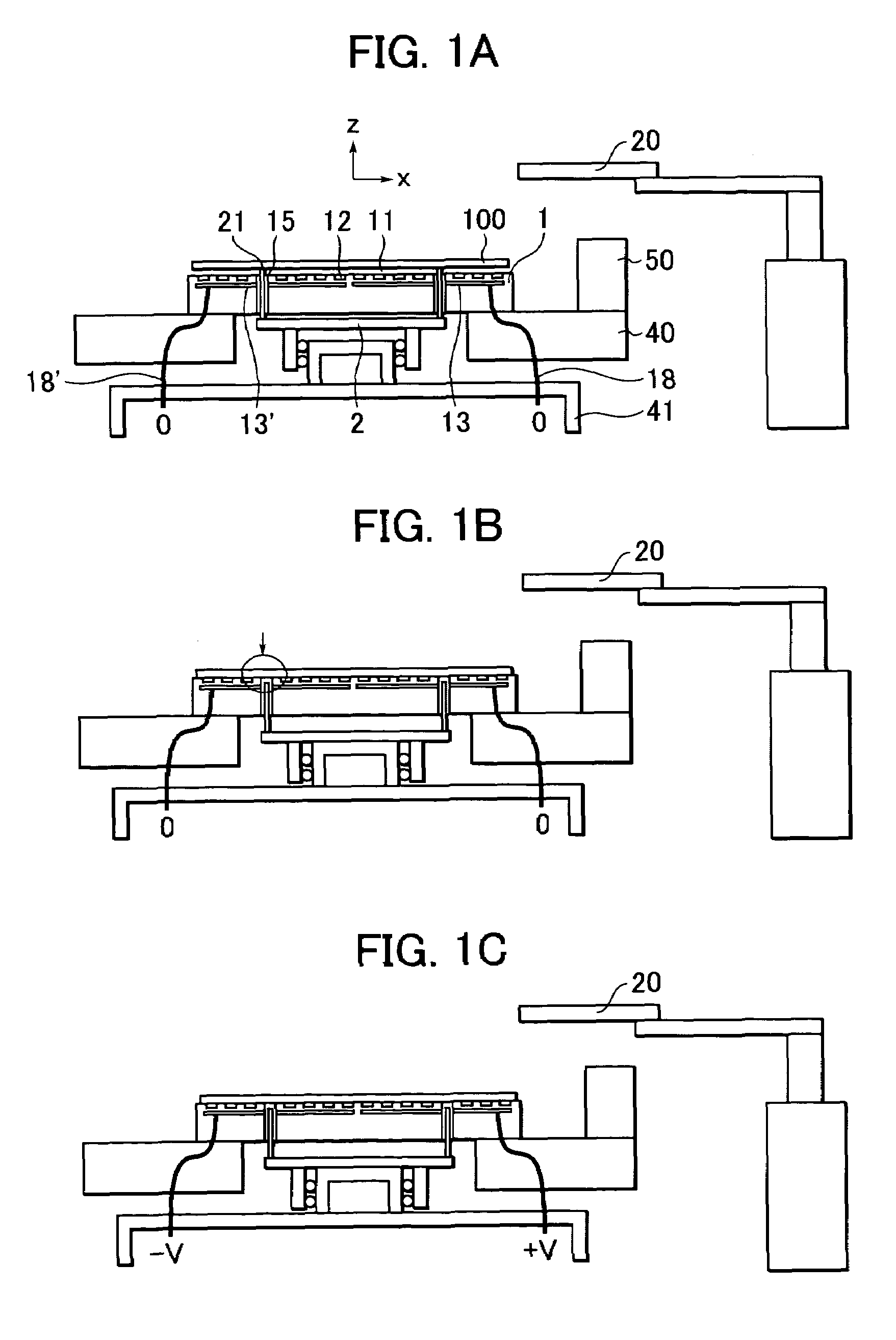

Actuator for Manipulation of Liquid Droplets

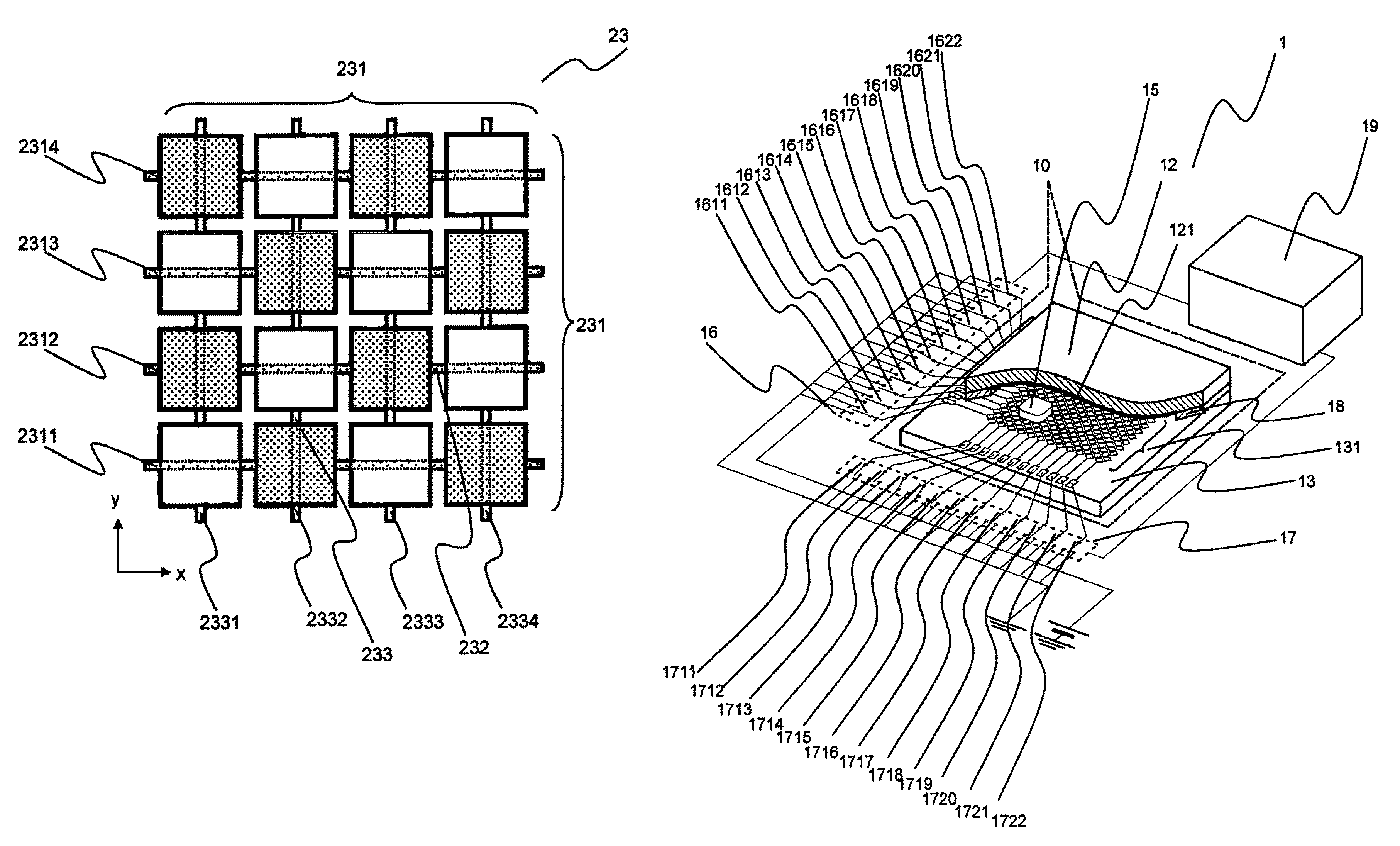

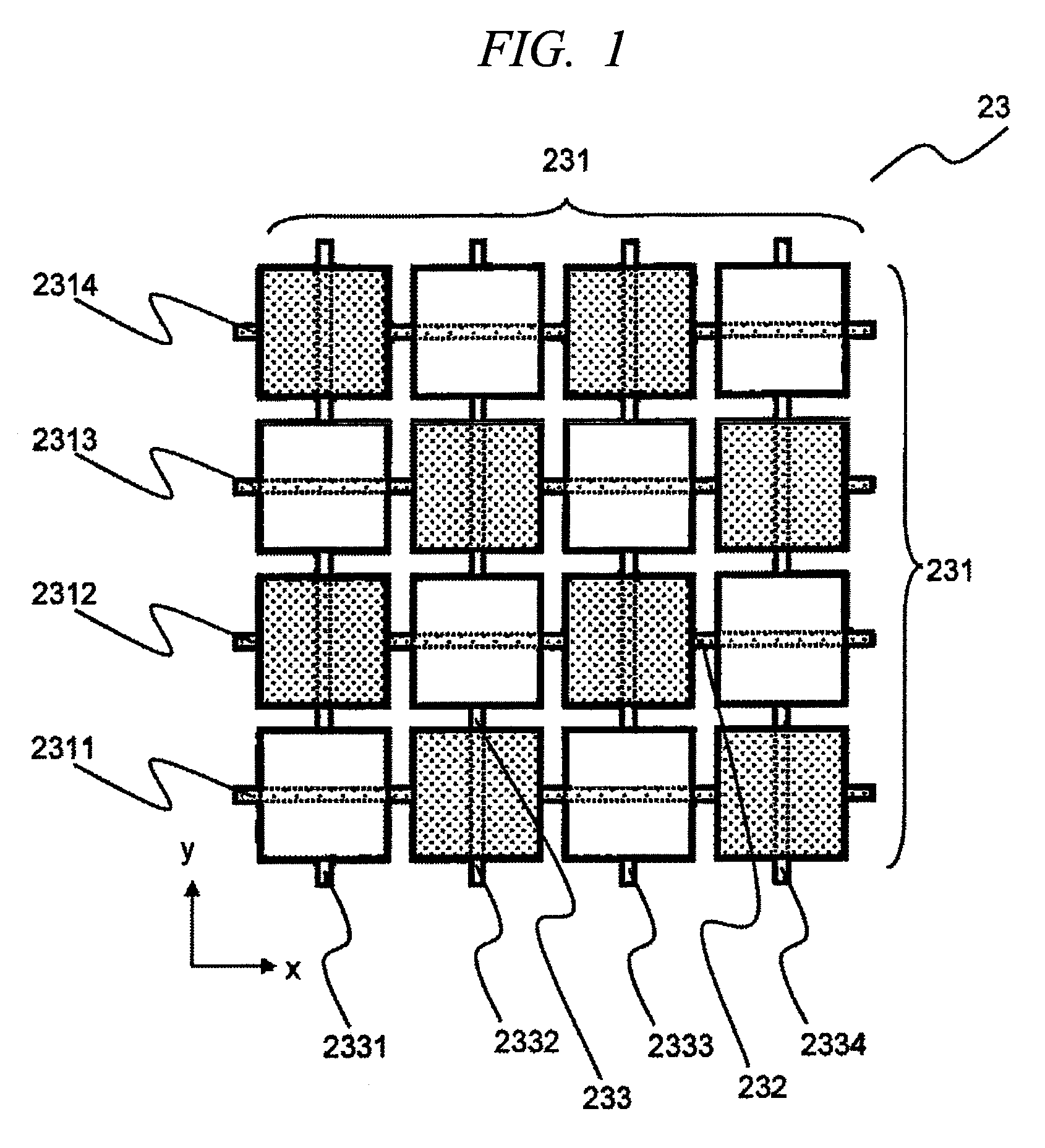

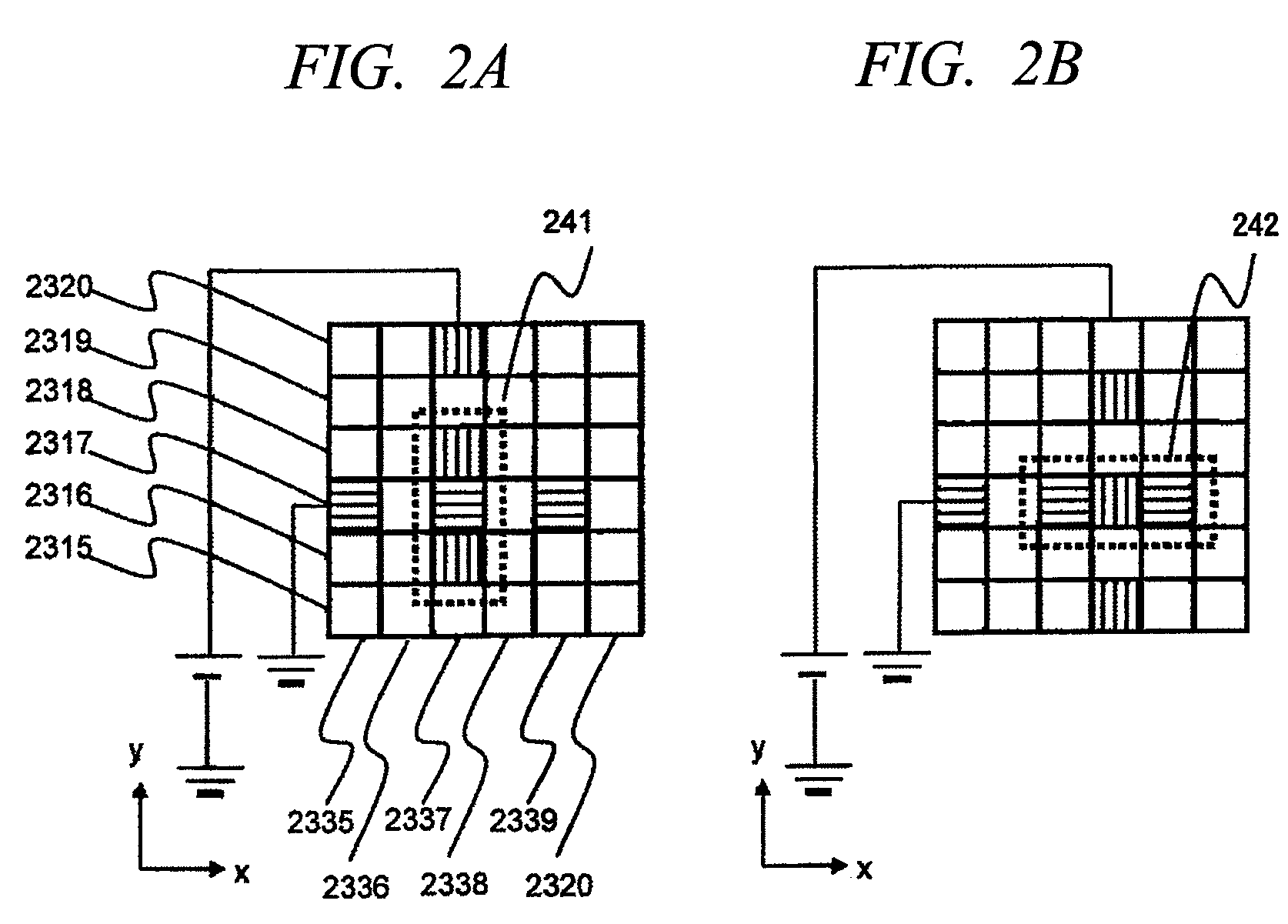

InactiveUS20080018709A1Easy loadingIncrease the number ofSludge treatmentVolume/mass flow measurementDielectricSubstrate surface

A liquid conveying substrate comprises: rectangular electrodes which are disposed on the substrate surface and whose surfaces are covered with a dielectric with a water repellent surface; first axial electrode columns where the rectangular electrodes are coupled in an x direction; and second axial electrode columns where the rectangular electrodes are coupled in a y direction. Accordingly, electrodes necessary for conveying liquid droplets can be arranged on one substrate, and the number of mechanisms for controlling the potential can be suppressed.

Owner:HITACHI LTD

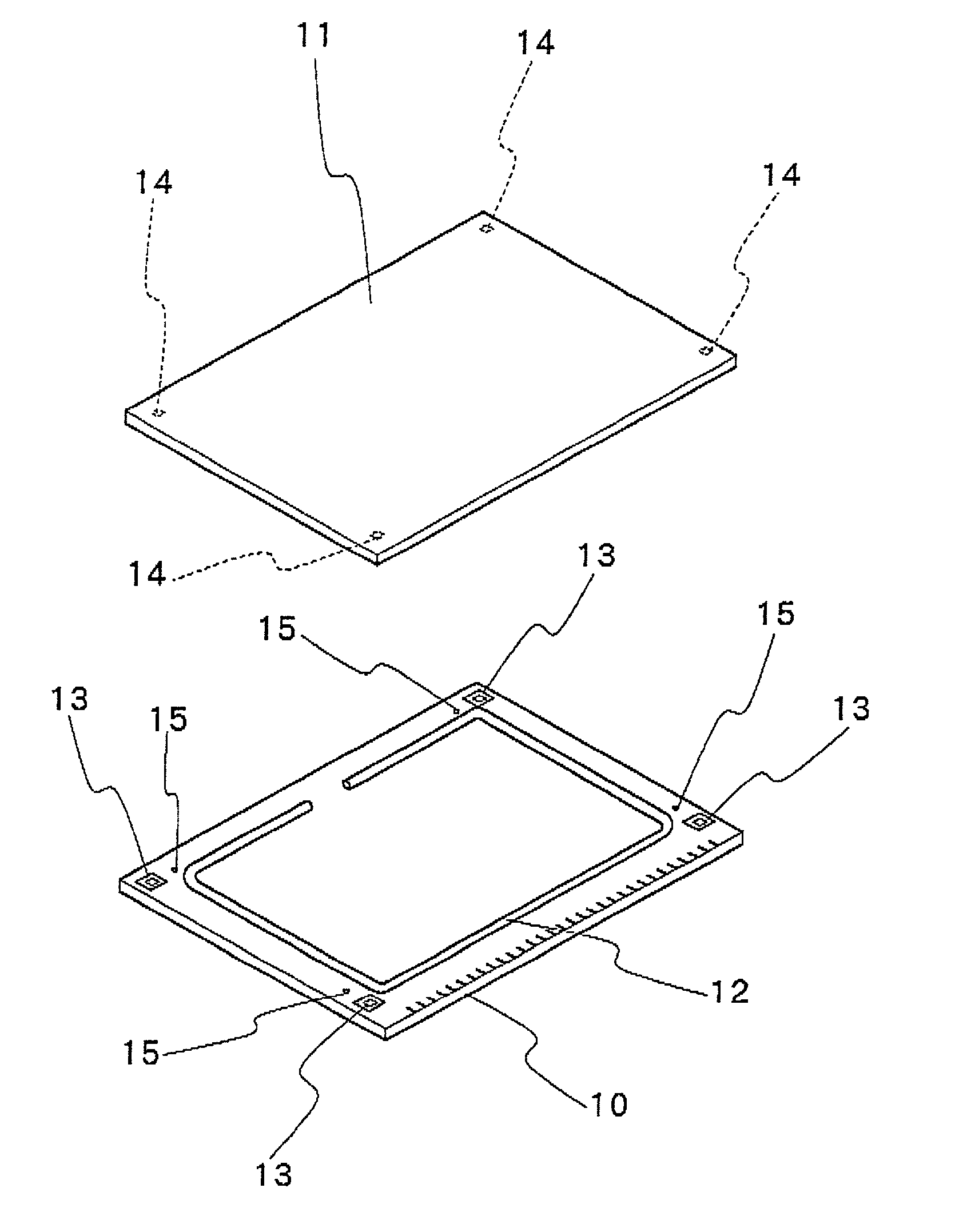

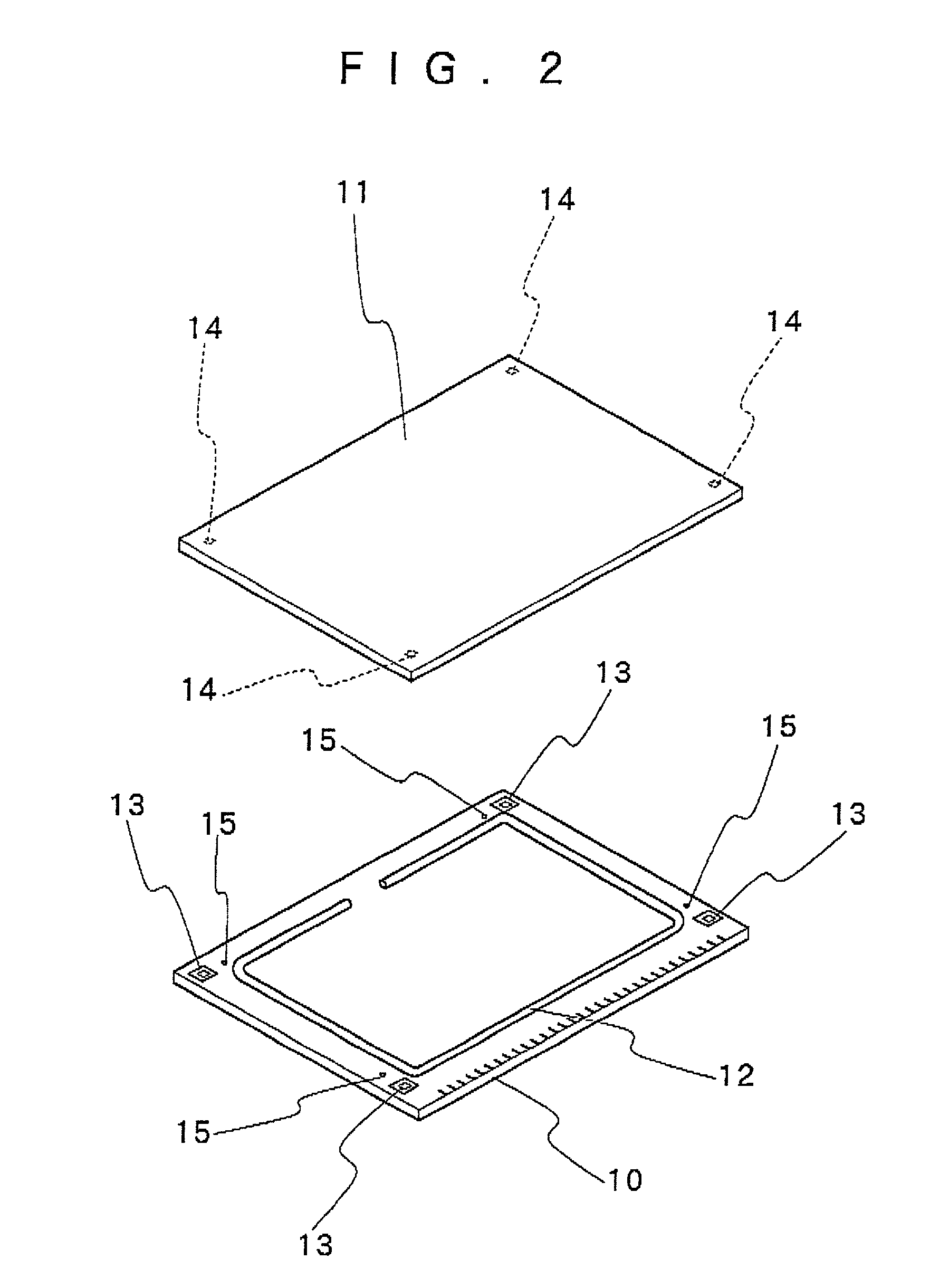

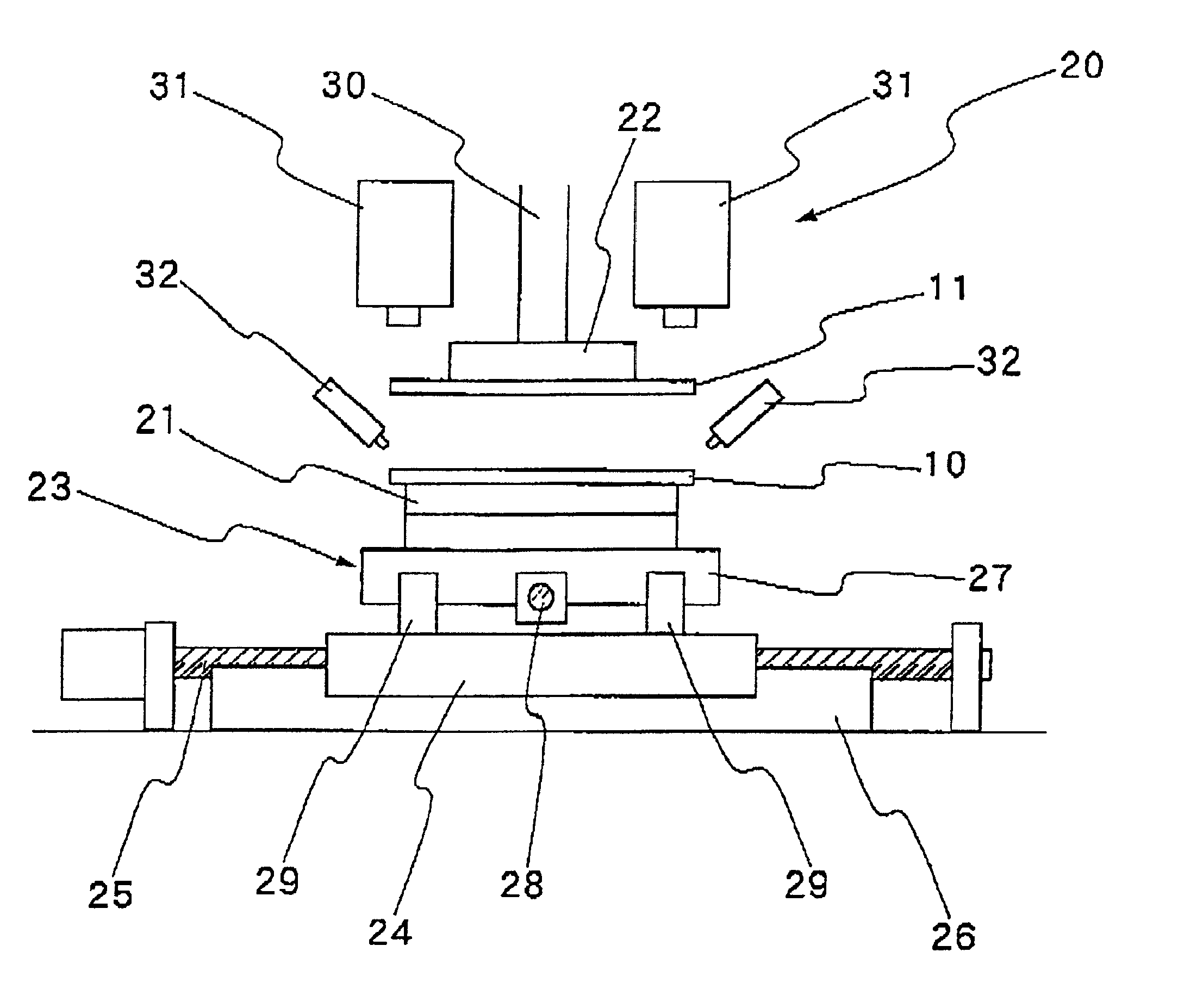

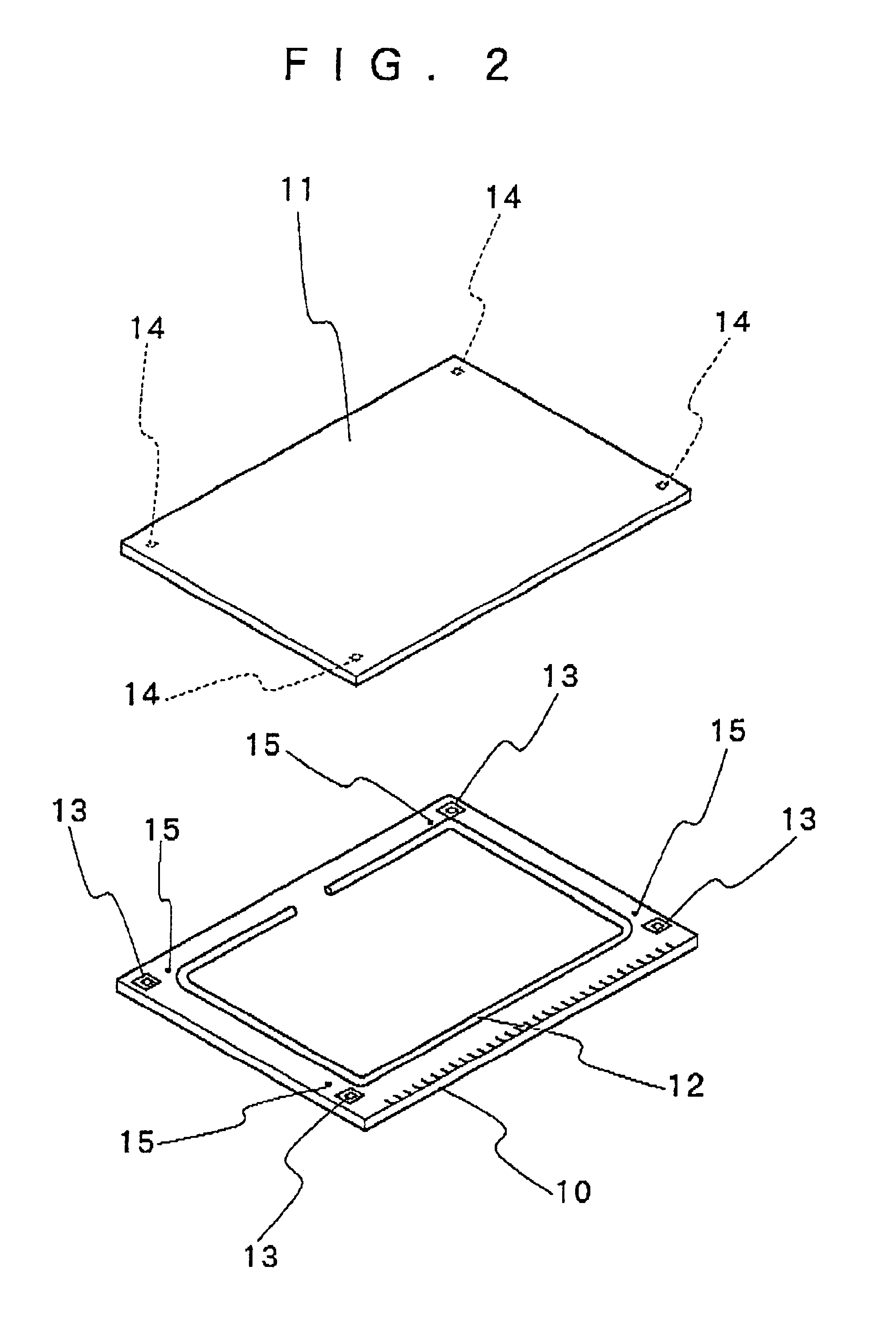

Method and apparatus for bonding substrate plates together through gap-forming sealer material

InactiveUS20020043344A1Correct position deviationHot-press substrate plates accuratelyLamination ancillary operationsCovering/liningsHot pressHot pressing

Method and apparatus for registering and bonding upper and lower substrate plates together through a sealer material and in such a way as to form a gap of a predetermined width between the two substrate plates. Registered substrate plates are provisionally pressed to form a joined substrate assembly, which is then pressed under heated conditions at a hot press station, thereby compressing the sealer material into a flattened form and at the same time thermally hardening the sealer material to form a predetermined gap space between the two substrate plates. In order to correct positional deviations which occur to the upper and lower substrate plates in the course of the hot pressing, on the basis detected positional deviations of upper and lower substrate plates of a hot-pressed substrate assembly, upper and lower substrates are set in offset positions instead of aligned positions when registering them at the provisional press station to cancel predicted positional deviations at the hot press station.

Owner:HITACHI ELECTRONICS ENG CO LTD

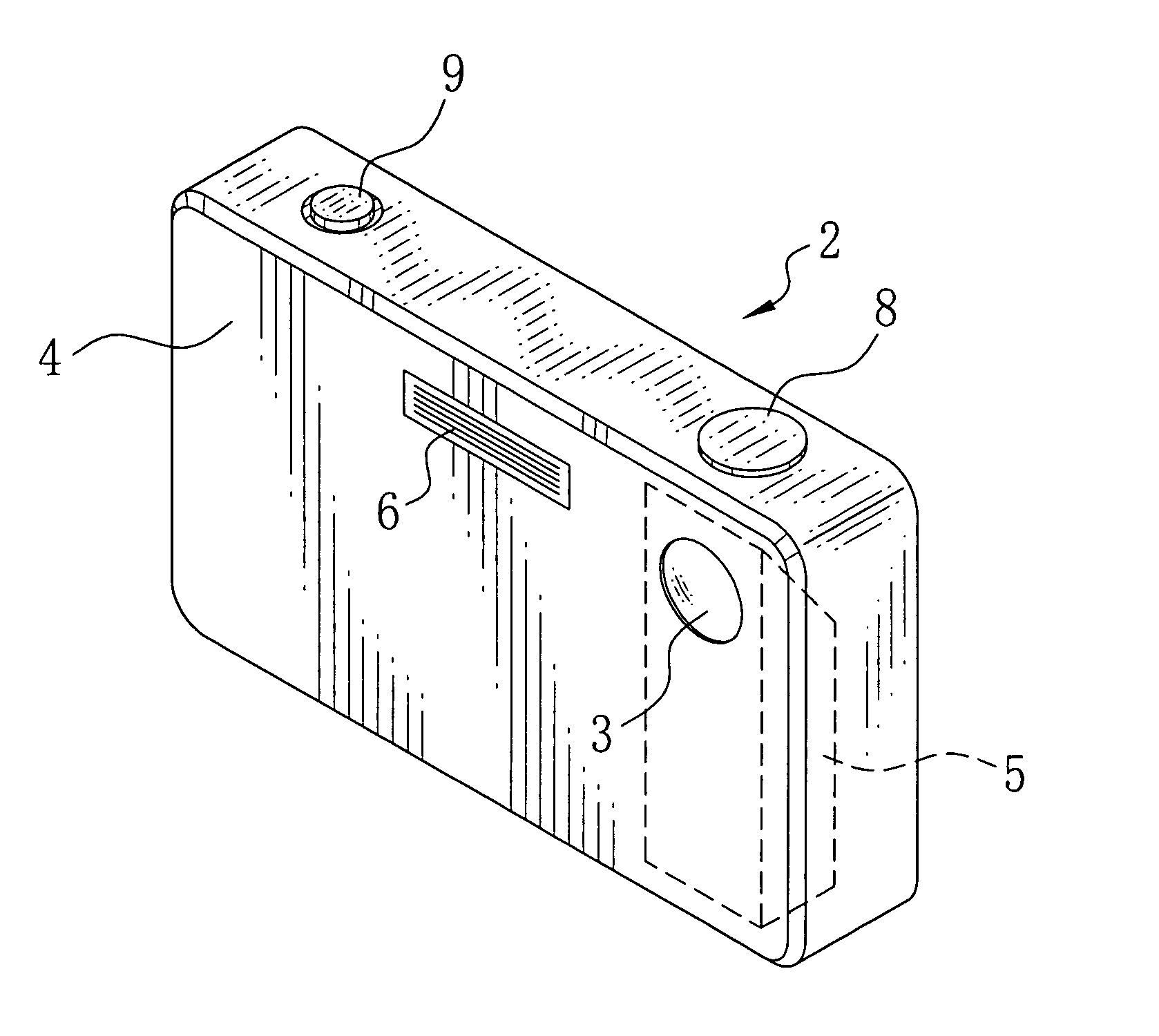

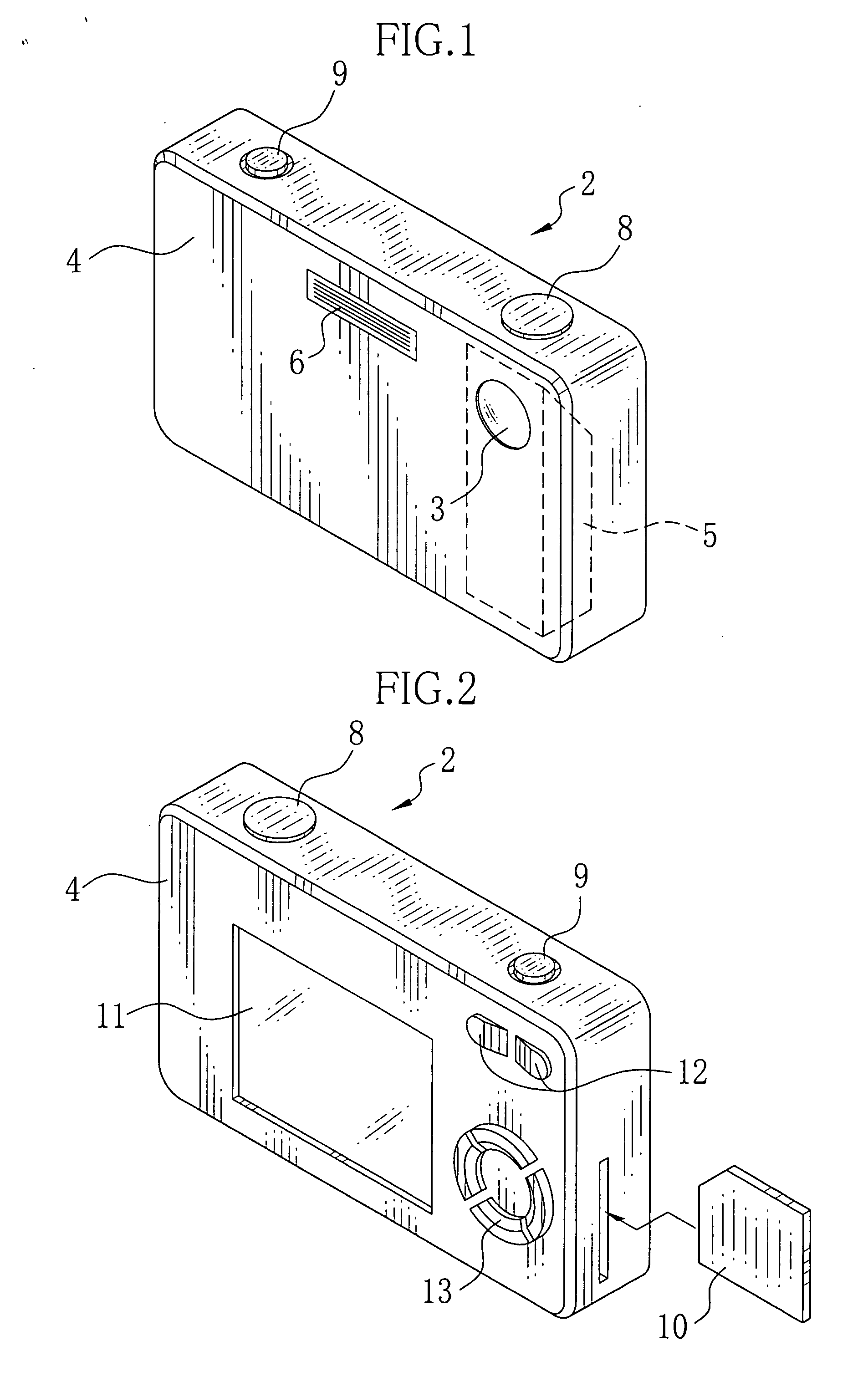

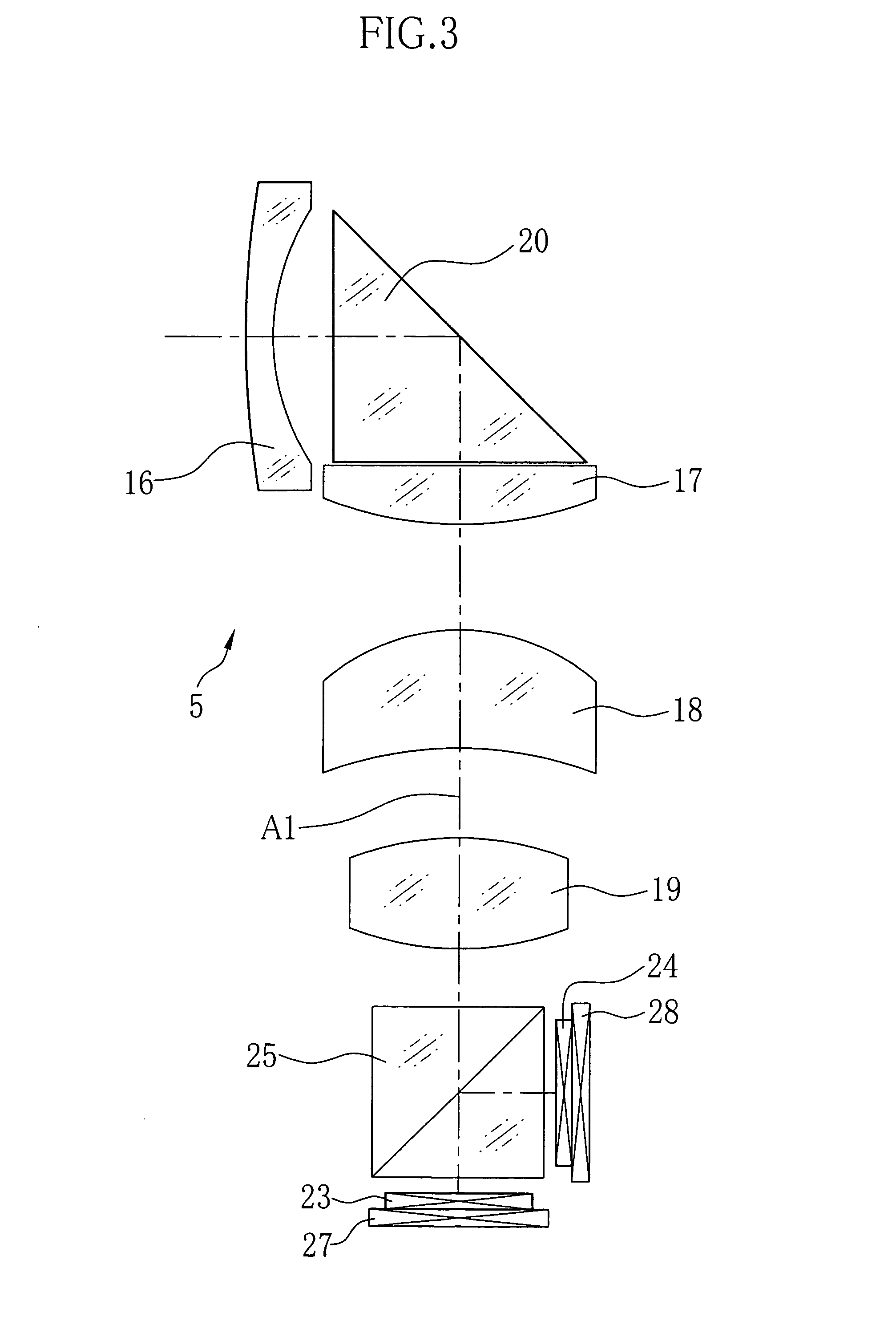

Imaging apparatus

InactiveUS20060177208A1Low costSmall sizeTelevision system detailsCamera body detailsOptical axisDichroic prism

A lens unit is provided with two CCD image sensors and a color-separation prism for separating subject light into green light (G light), and a mixture of red light (R light) and blue light (B light). The color-separation prism allows the G light to enter into one of the CCD image sensors, and the mixture of the R and B light to enter into the other CCD image sensor. Sensor moving mechanisms drive the CCD image sensors individually in a plane perpendicular to an optical axis when camera shake is detected, thereby preventing the image from blurring.

Owner:FUJIFILM CORP +1

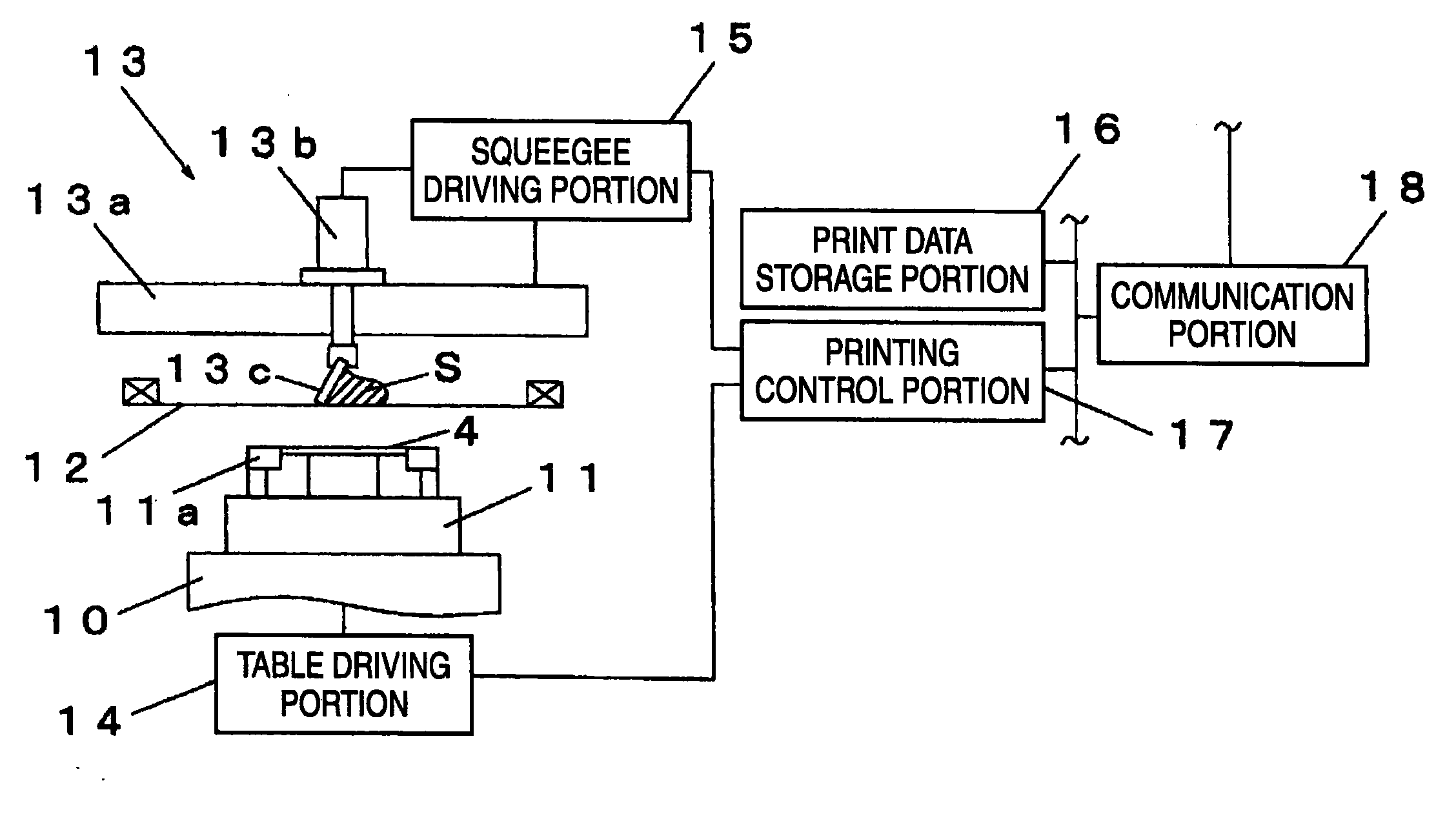

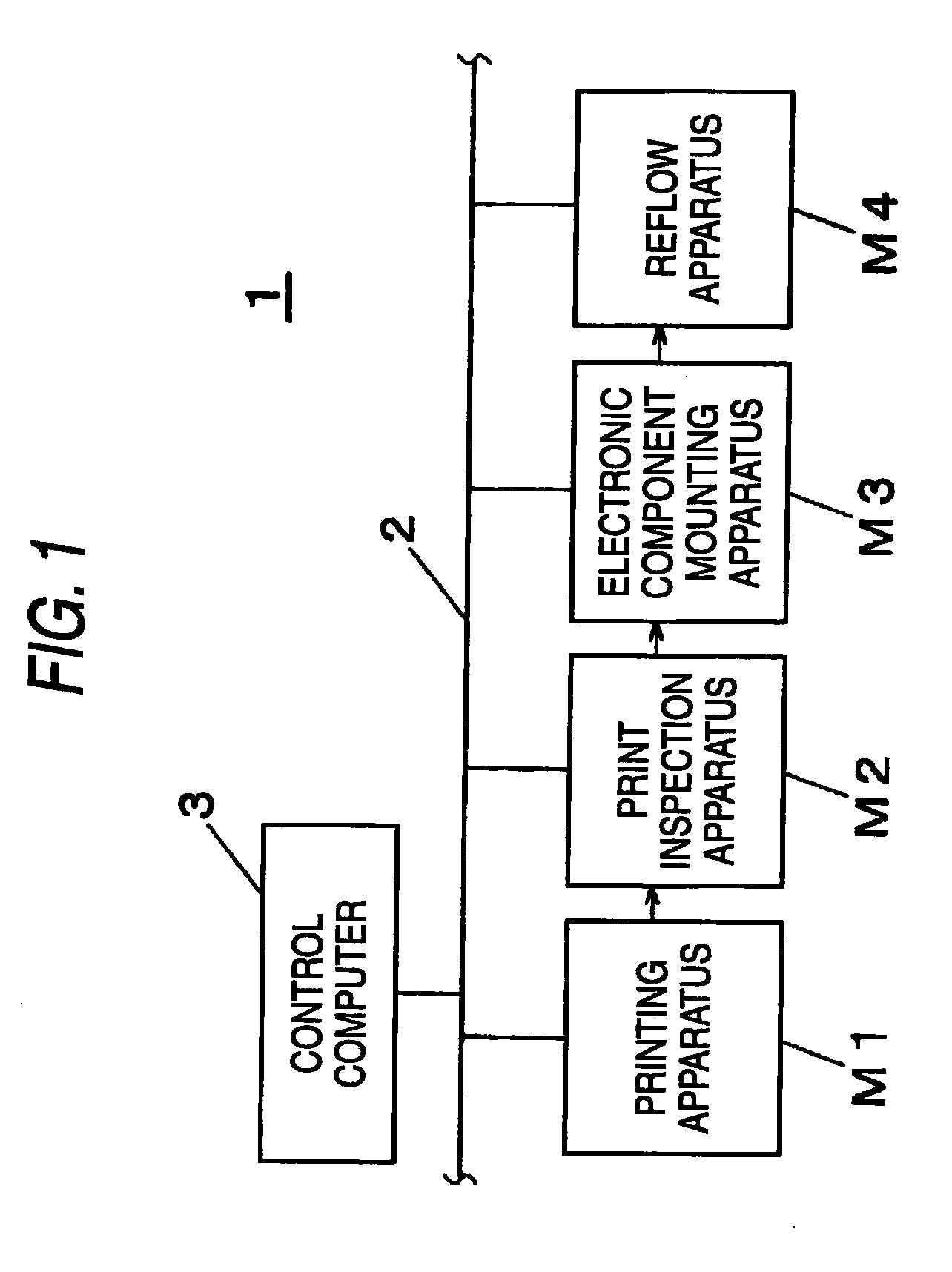

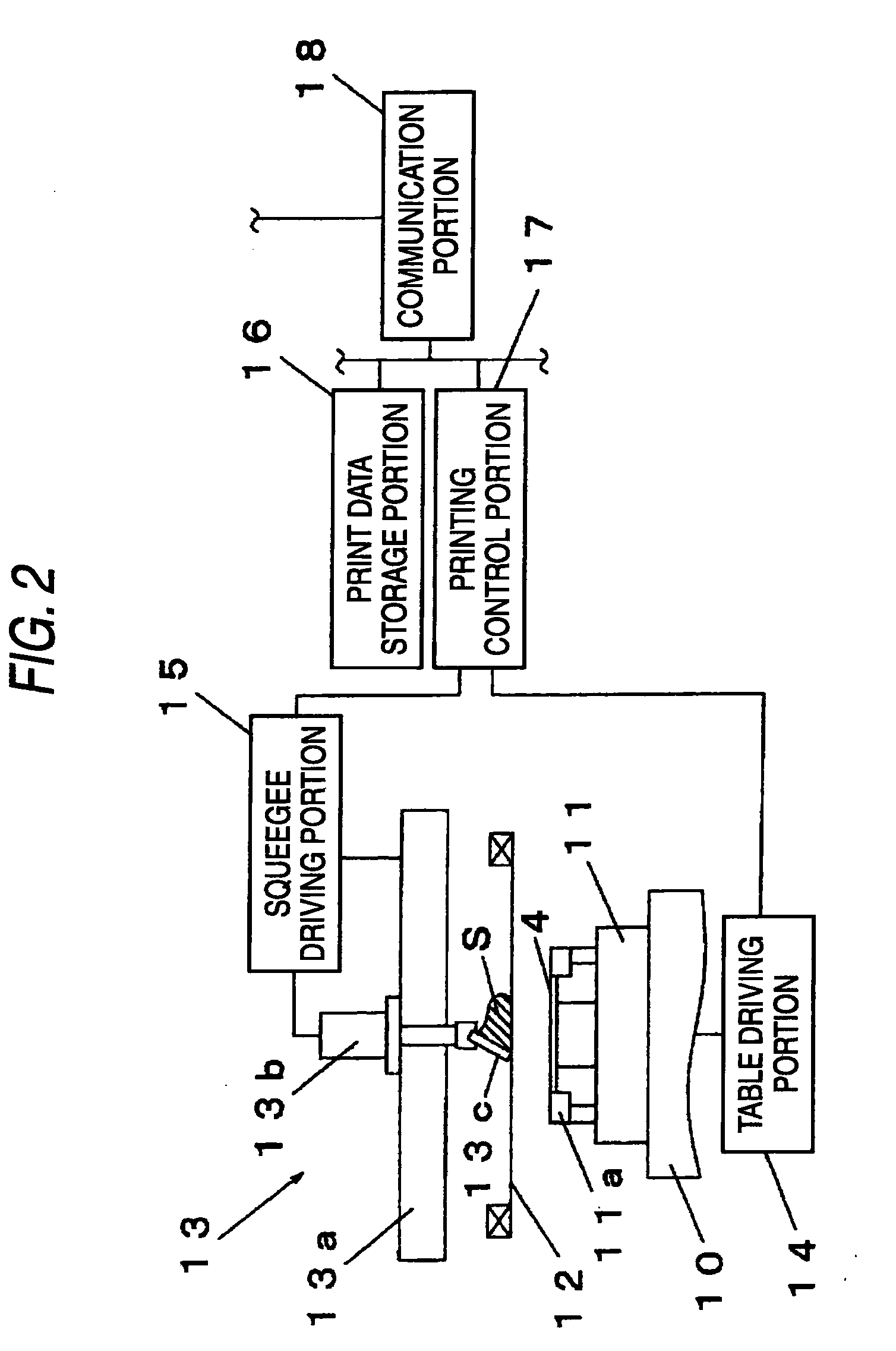

Electronic component mounting system and electronic component mounting method

ActiveUS20080289175A1Correct position deviationEfficient executionPrinted circuit assemblingLine/current collector detailsElectronic componentPosition bias

In electronic component mounting for a plurality of individual substrates held on a carrier, solder position deviation data is calculated for each individual substrate based on a mark position recognition result on a carrier after solder printing, a solder position recognition result, and electrode position information indicating the position of an electrode on each individual substrate, an operation of calculating position correction data, which is used to correct the positional deviation to mount electronic components at proper positions, is performed for each individual substrate based on the calculated solder position deviation data and the calculated position correction data is feed-forwarded to an electronic component mounting apparatus, and an electronic component mounting operation of a component mounting mechanism is controlled based on the mark position recognition result and the position correction data.

Owner:PANASONIC CORP

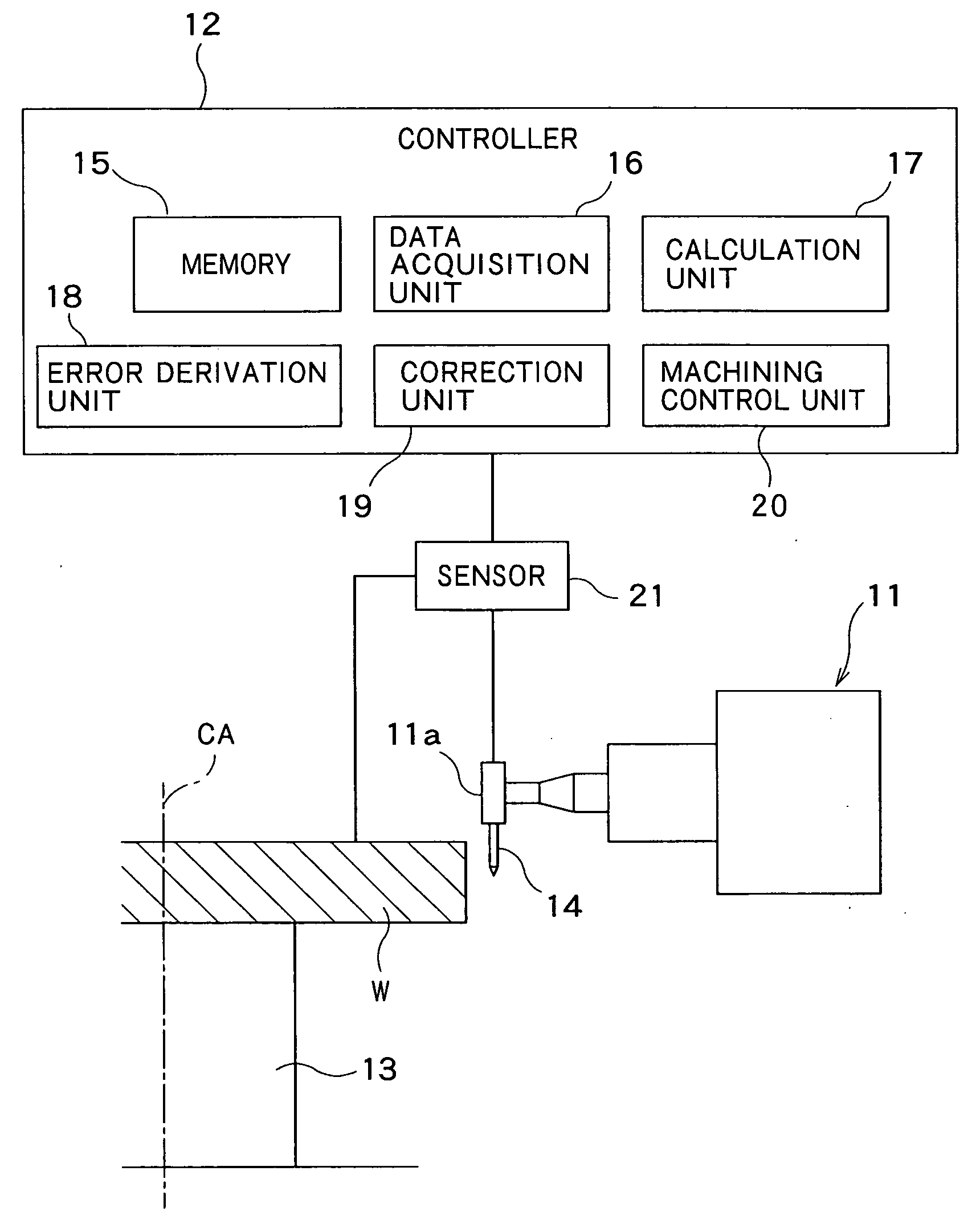

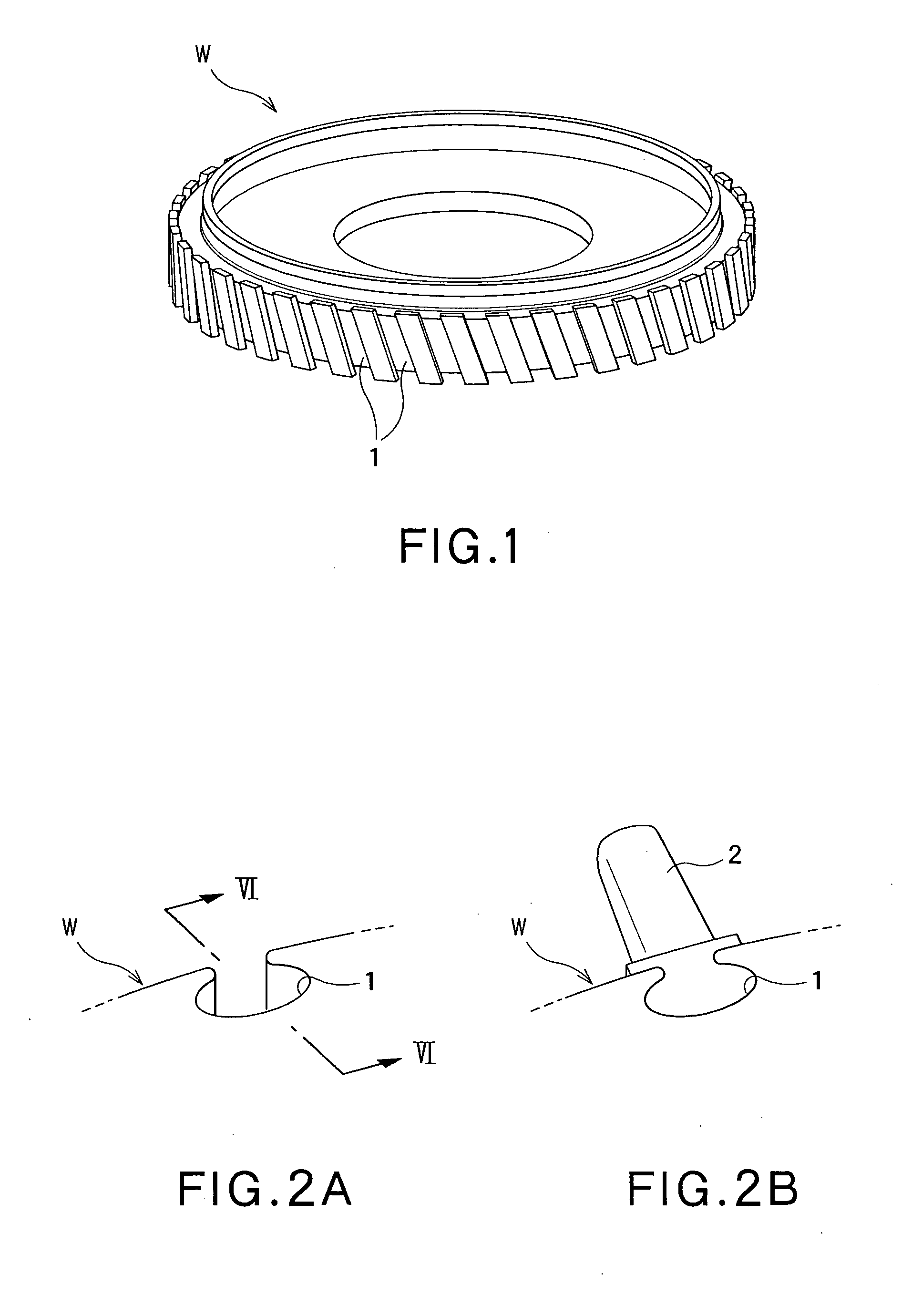

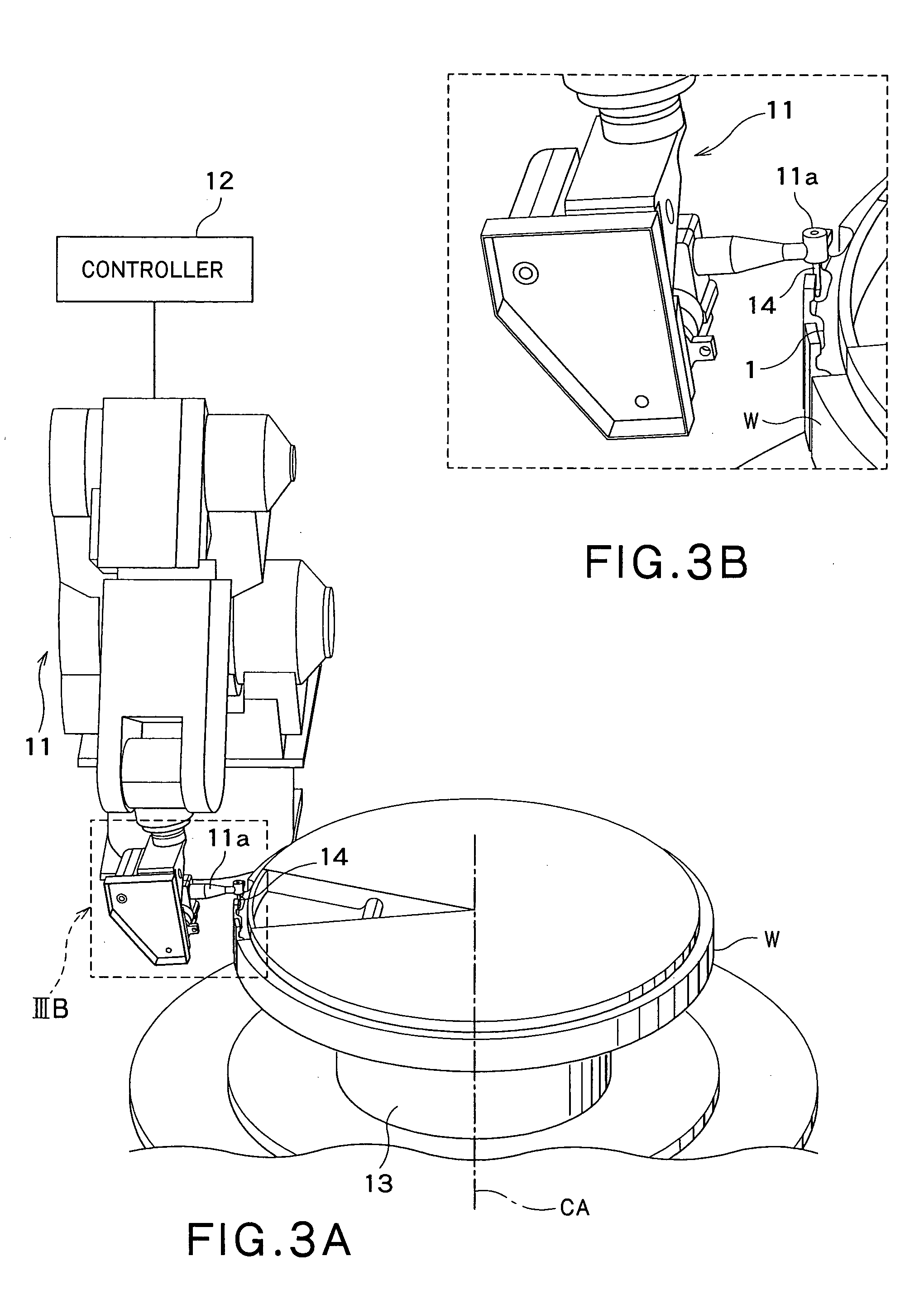

Automatic finishing machine and control method thereof

ActiveUS20100057257A1Reduce timeStable and accurateComputer controlSimulator controlThree dimensional modelObject point

This method controls an automatic finishing machine using a robot with a tool through a model storage step, a data acquisition step, a calculation step, an error derivation step, a correction step and a machining step. In the model storage step, shape data of an unfinished work or data of a three-dimensional model is stored in a memory. In the data acquisition step, the tool is brought into contact with the unfinished work W, thereby obtaining measurement data. Then, in the calculation step, actual-position data on a comparative object point is calculated based on the measurement data. Subsequently, in the error derivation step, a data difference between the calculated actual-position data and position data on the comparative object point in the three-dimensional model is obtained. Thereafter, in the correction step, teaching data indicative of the position of the tool corresponding to the shape data of the three-dimensional model is corrected, based on the data difference. Finally, in the machining step, the finishing process is performed, while the robot (11) is controlled, based on the corrected teaching data.

Owner:KAWASAKI HEAVY IND LTD

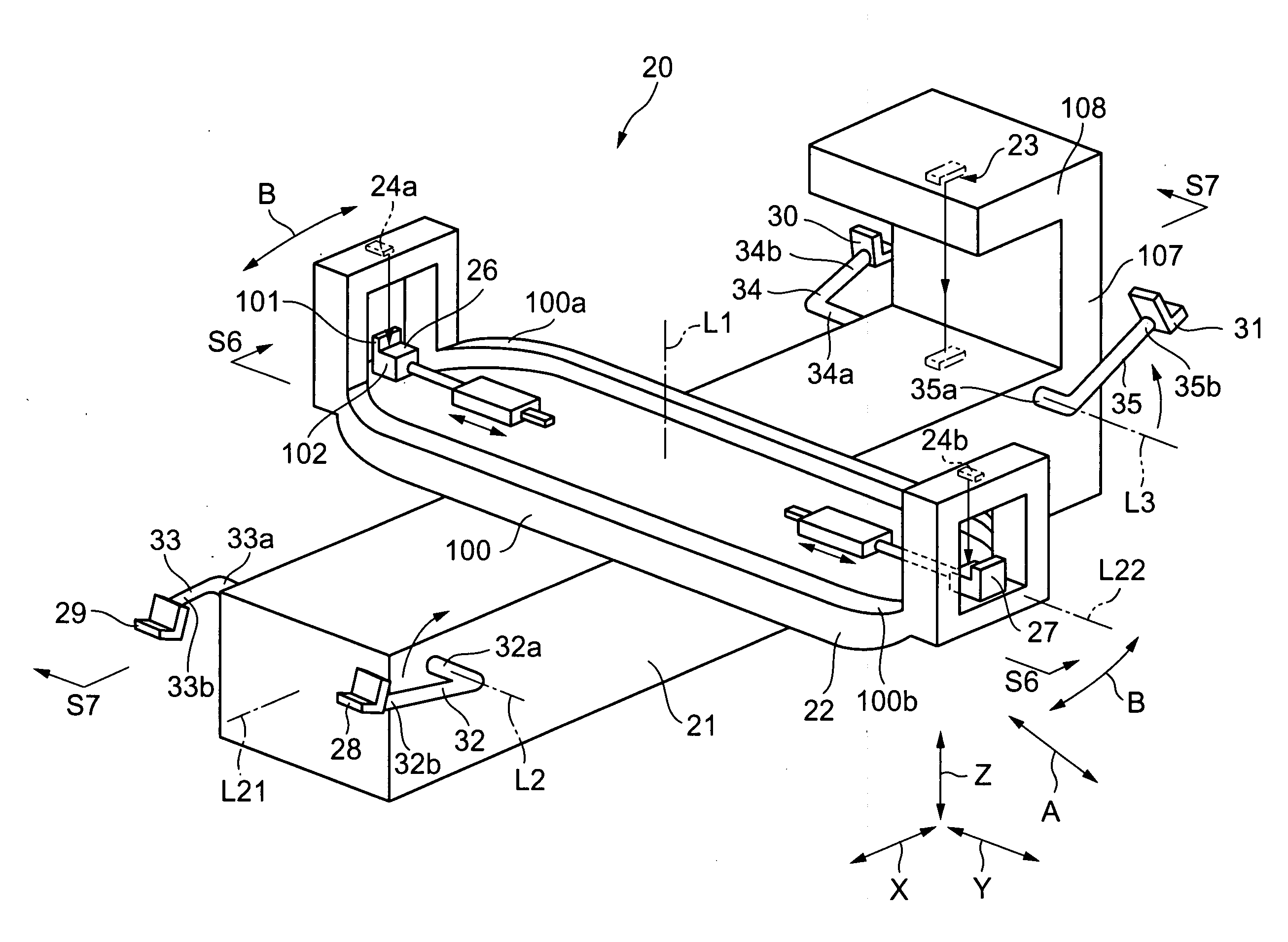

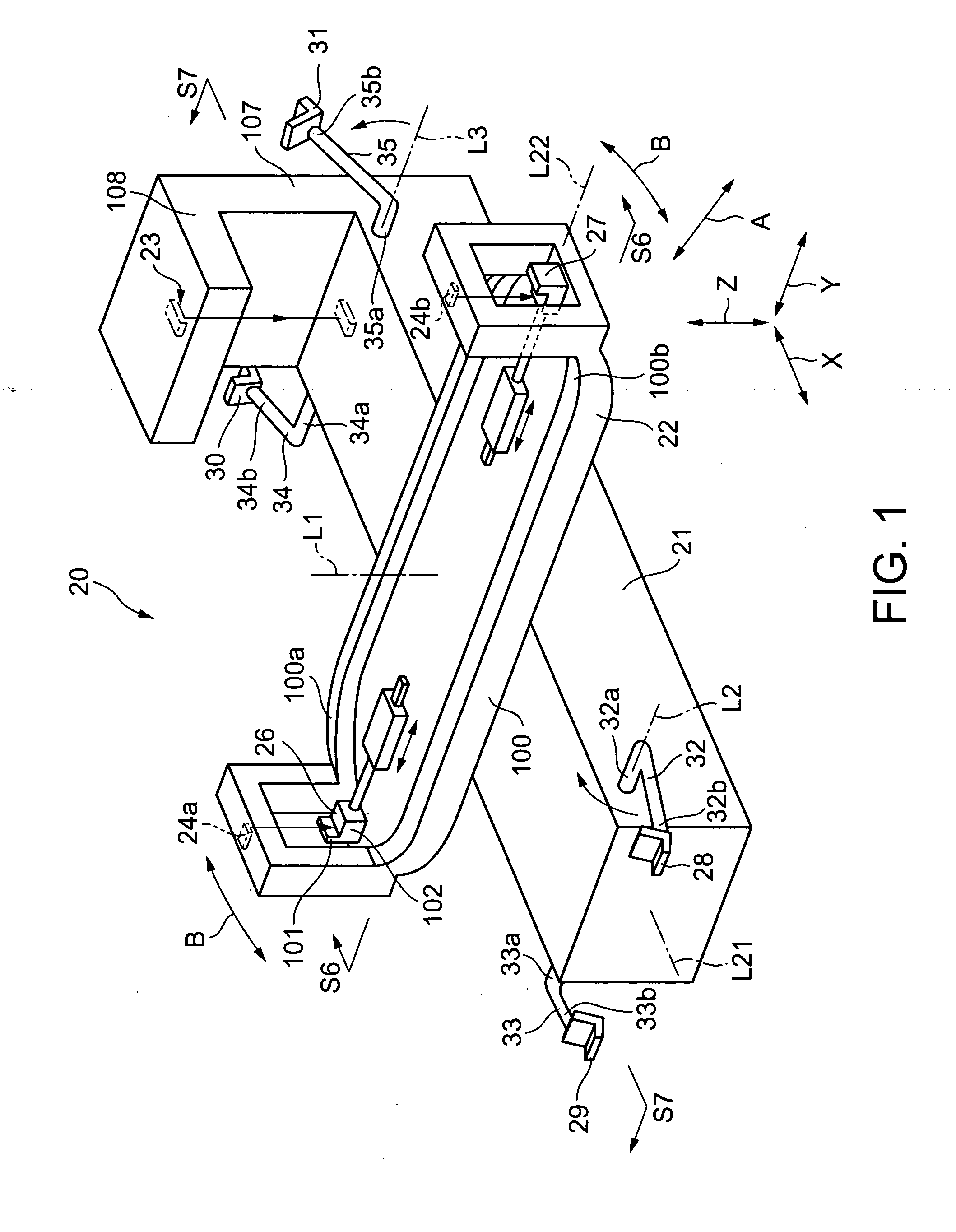

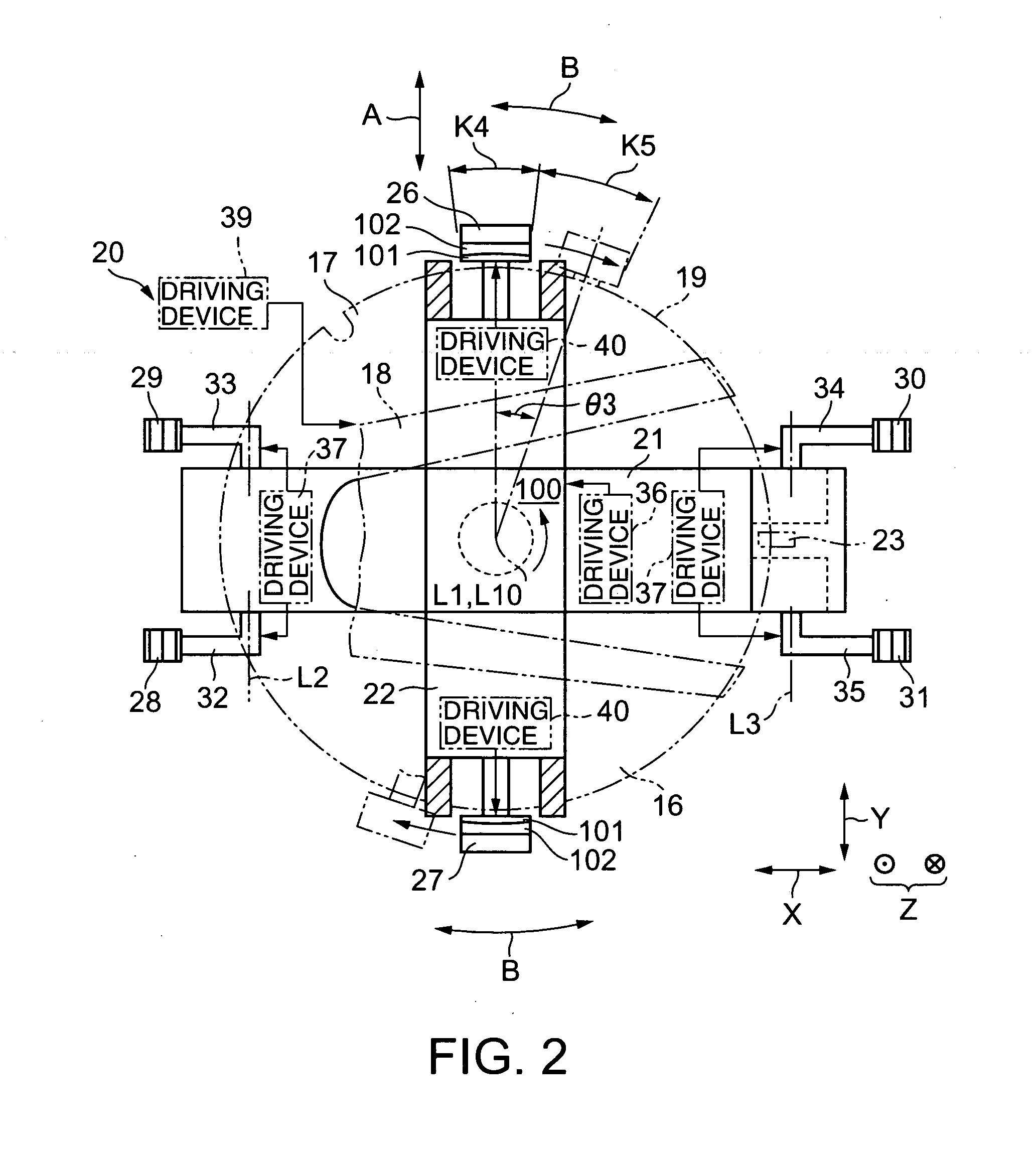

Edge-holding aligner

ActiveUS20050110974A1Shorten teaching timeCorrect position deviationSemiconductor/solid-state device manufacturingPhotographic printingEngineeringElectrical and Electronics engineering

The angular position of a notch 17 is determined on the basis of data provided by second notch detectors 24a and 24b and an encoder 25. A controller 38 turns a rotational arm 22 for angular displacement such that holders 26 and 27 are displaced in a circumferential direction B from the notch 17, and then the holders 26 and 27 hold a wafer 19. Since the holders 26 and 27 are in touch with edges in which the notch 17 is not formed, the first notch detector 23 is able to detect the notch 17 without difficulty. Thus the position of the wafer 19 relative to the rotational arm 22 does not need to be changed several times depending on positions at which the holders 26 and 27 hold the wafer 19, which is necessary in the prior technology. The aligner 20 touches parts, not including the notch 17, of the wafer 19 and is capable of adjusting the position of the wafer 19 in a short time.

Owner:KAWASAKI HEAVY IND LTD

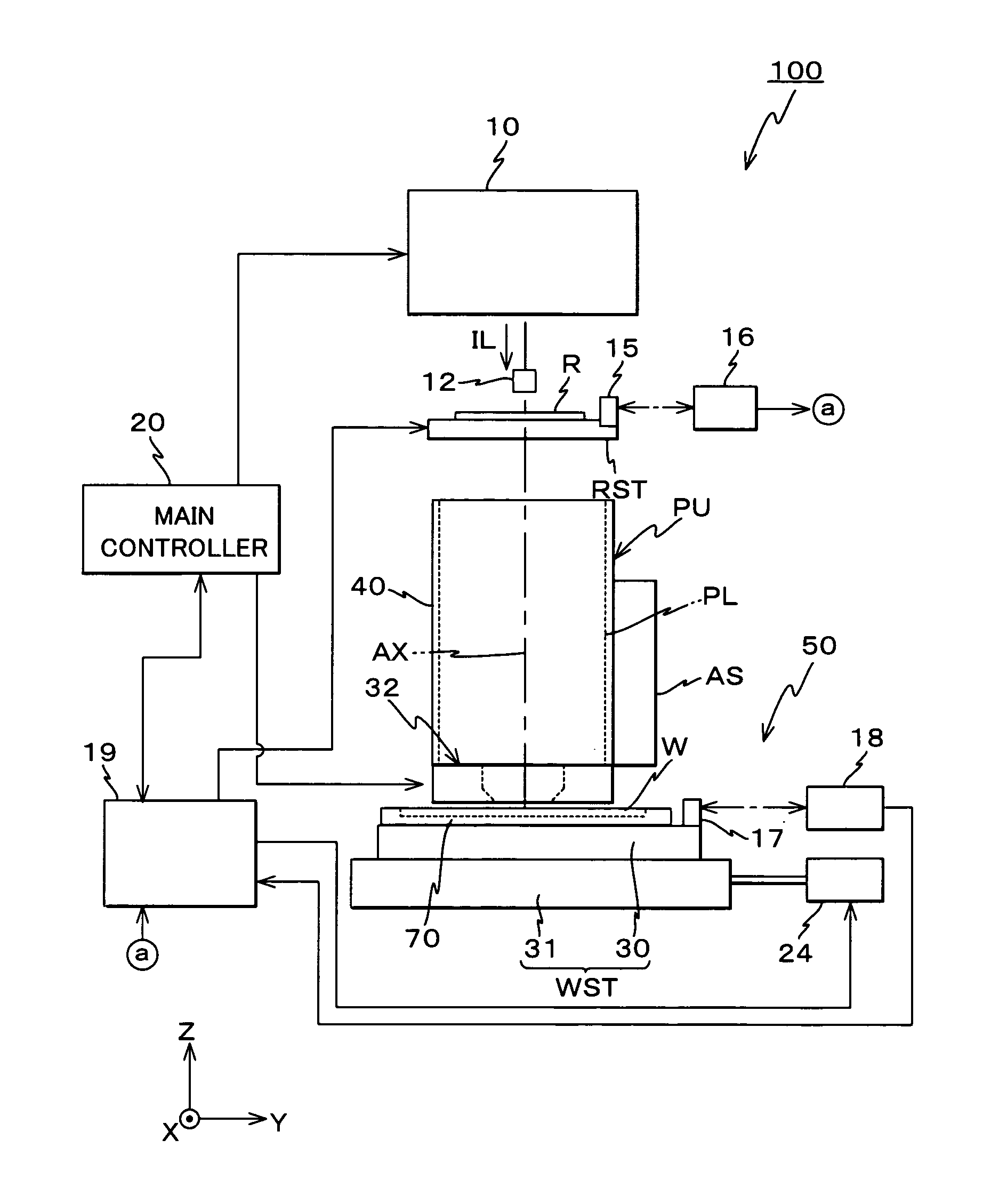

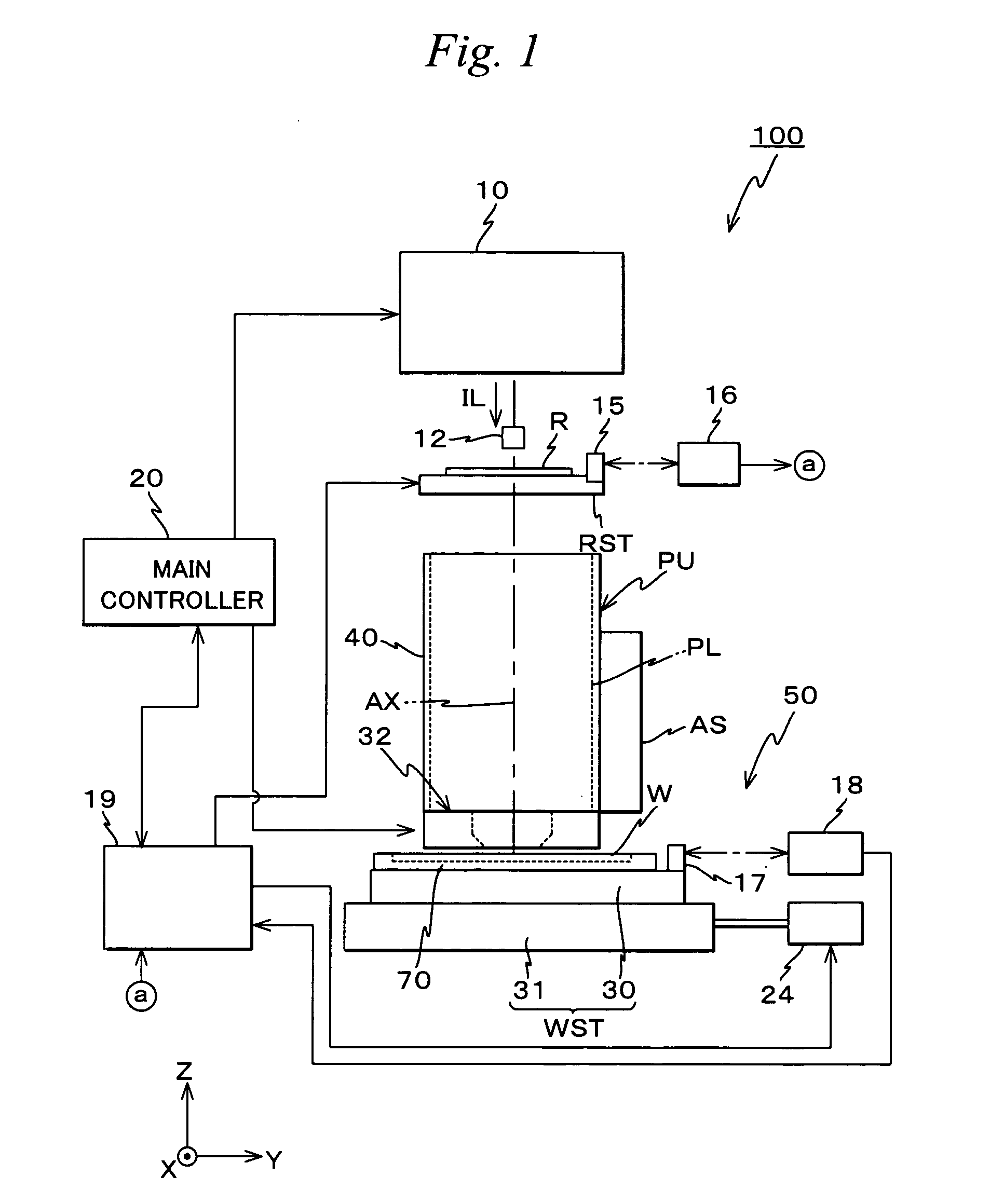

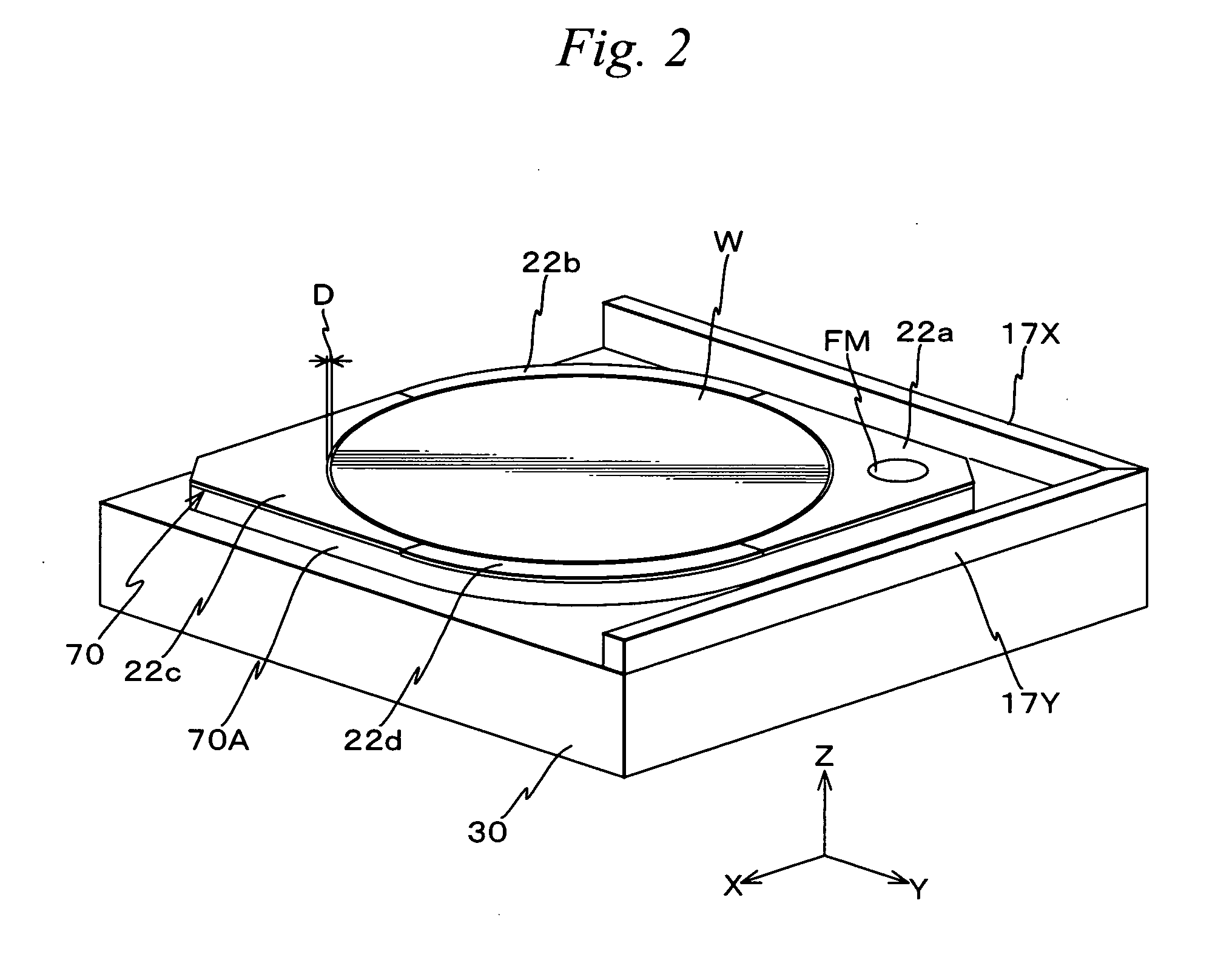

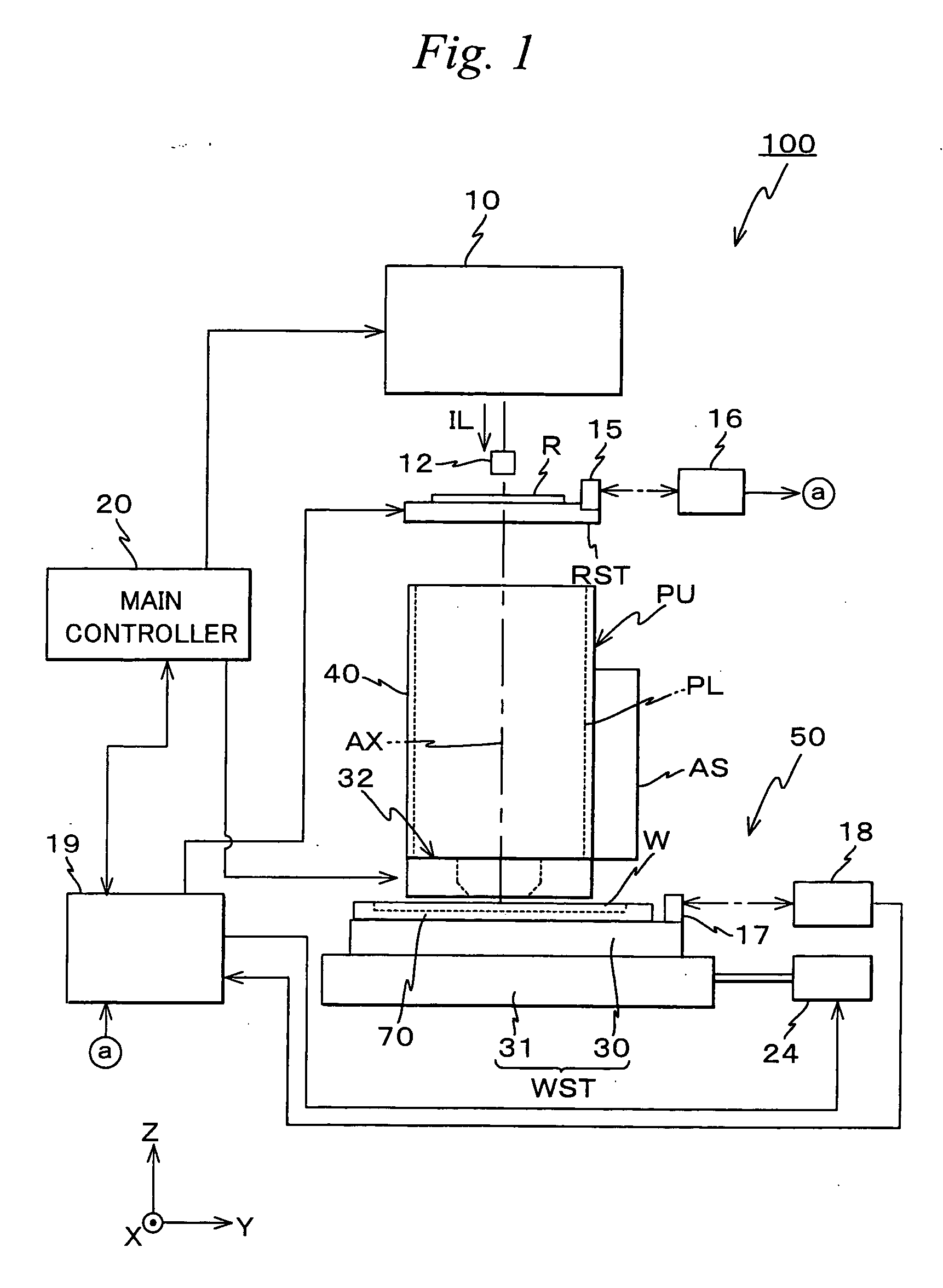

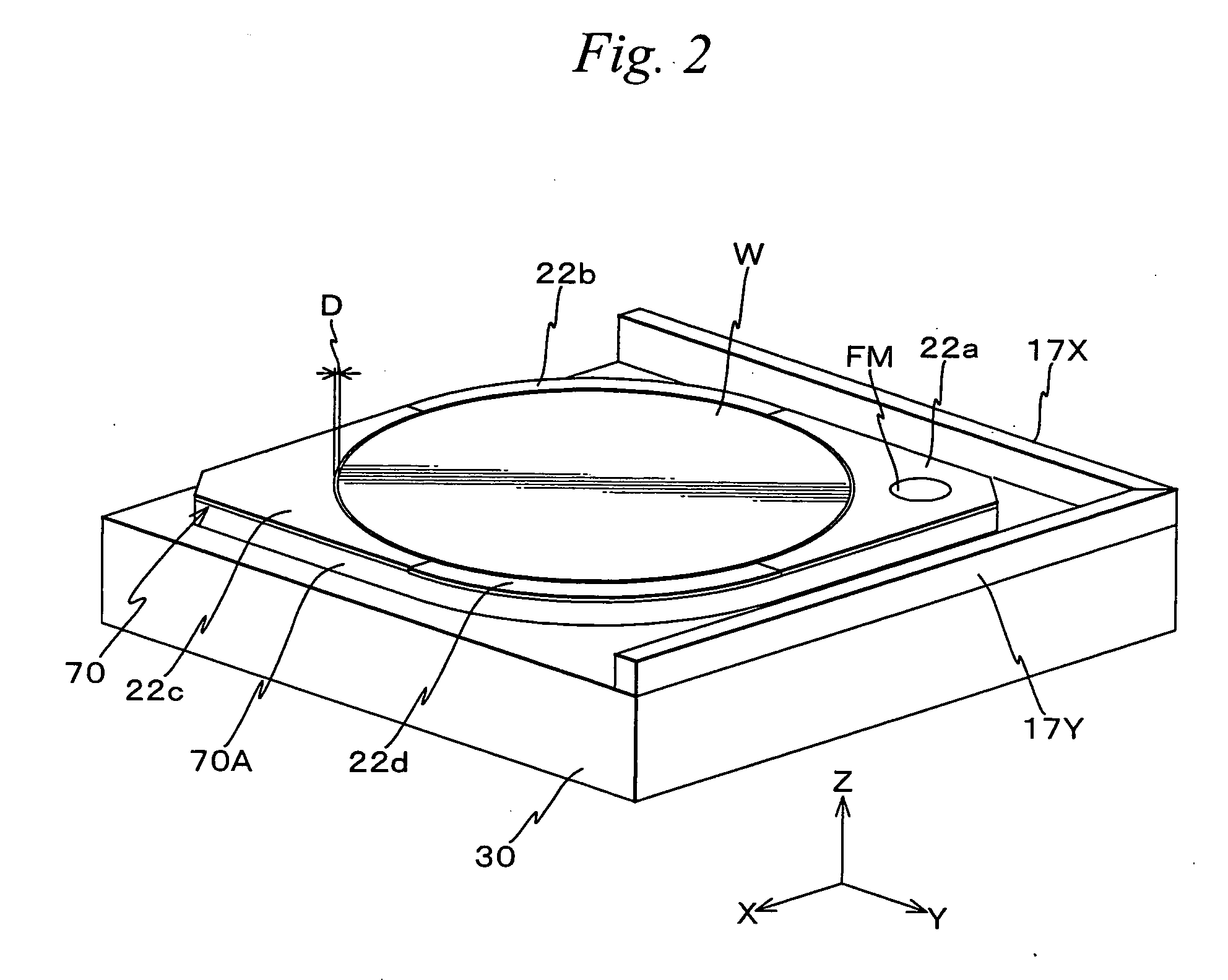

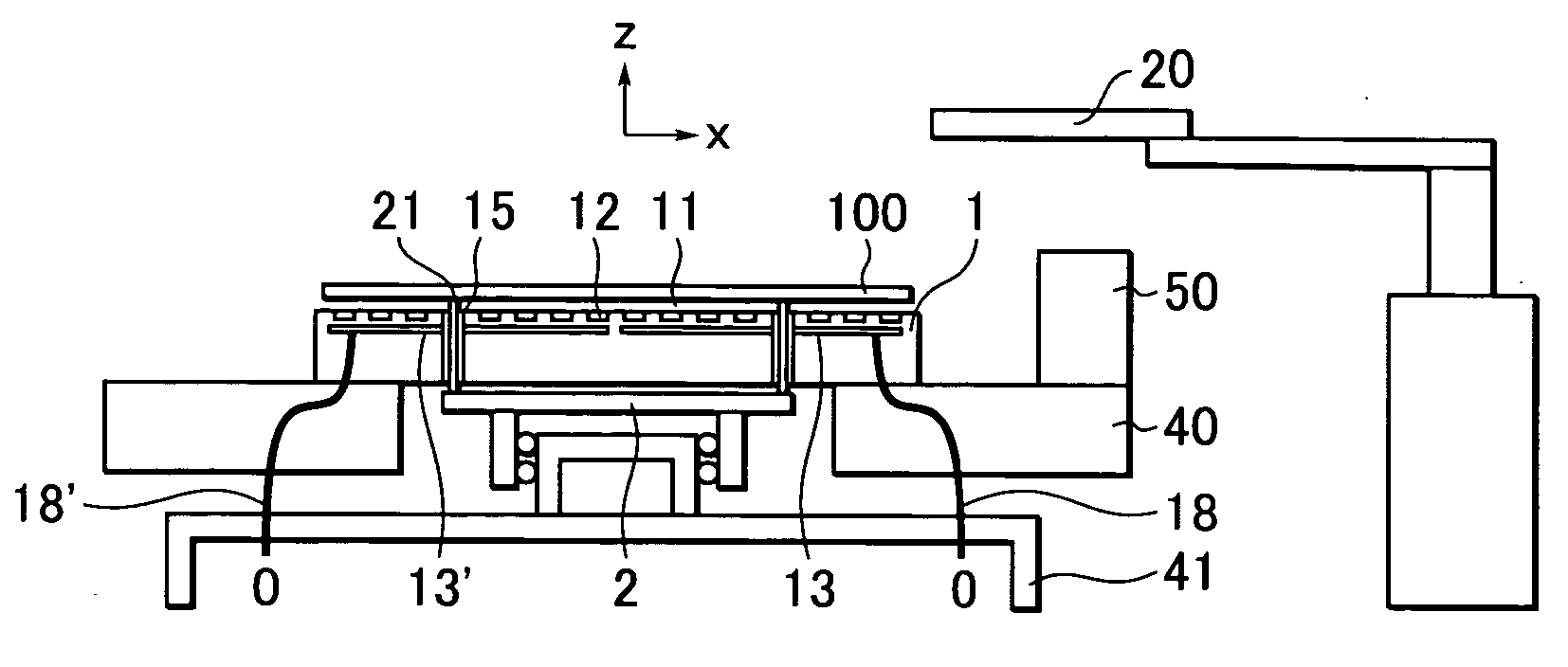

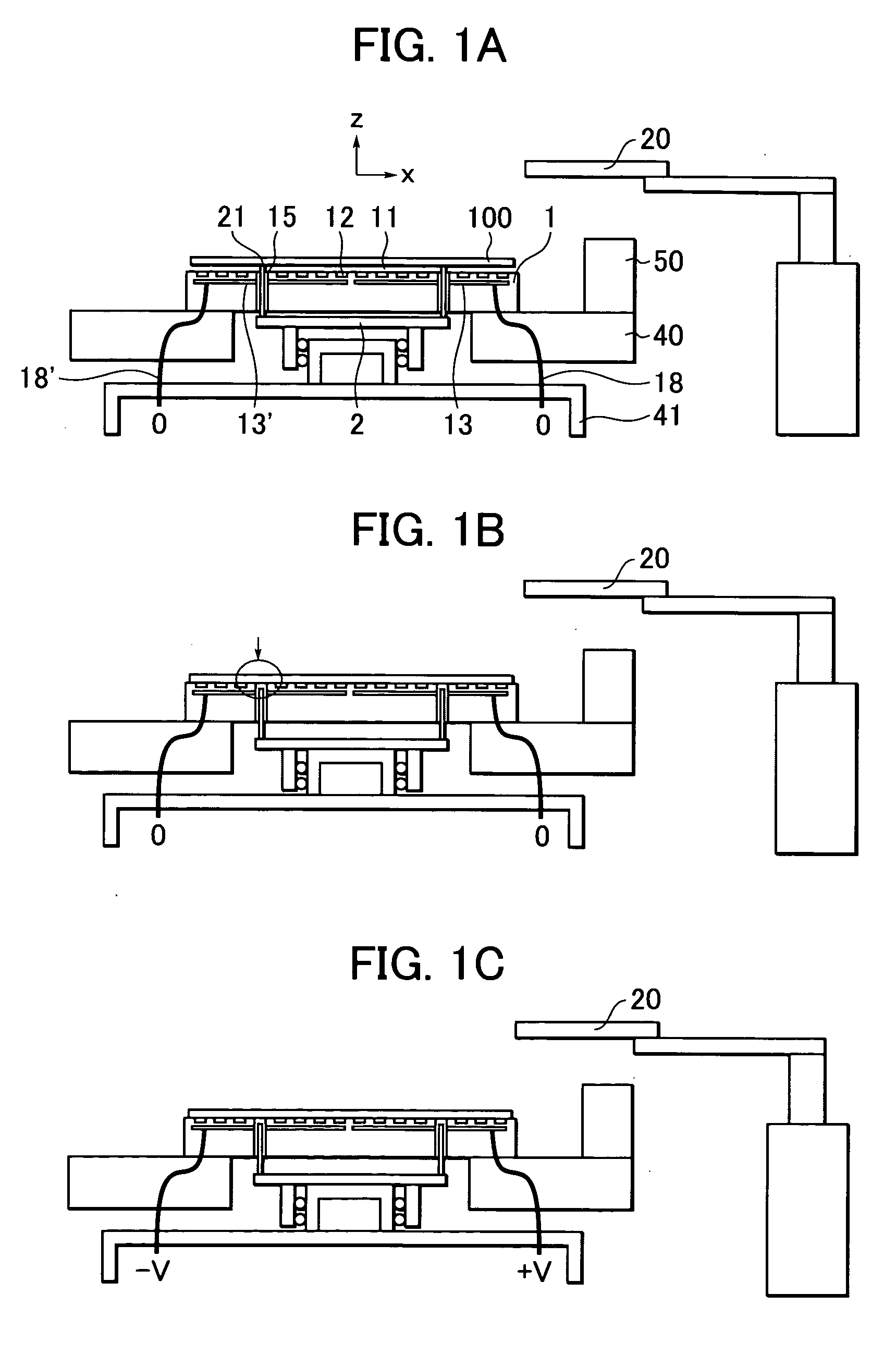

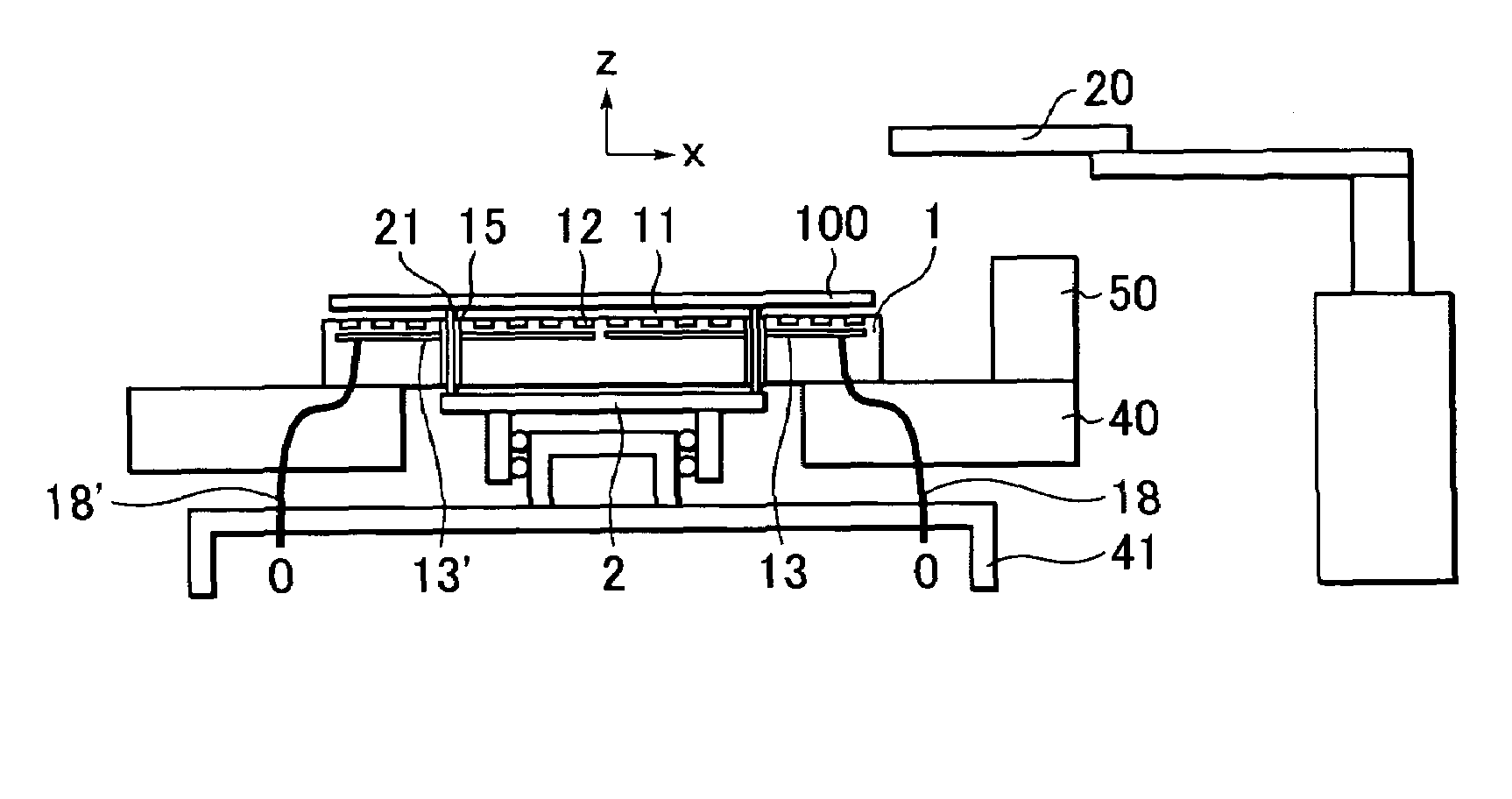

Projection exposure apparatus and stage unit, and exposure method

InactiveUS20070081133A1Improve accuracyCorrect position deviationPhotomechanical apparatusPhotographic printingOptics

A projection exposure apparatus (100) has a substrate table (30) on which a substrate (W) is mounted that can be moved holding the substrate, a position measuring system (18 and others) that measures positional information of the substrate table, and a correction unit (19) that corrects positional deviation occurring in at least either the substrate or the substrate table due to supply of a liquid. In this case, the correction unit corrects the positional deviation occurring in at least either the substrate or the substrate table due to the supply of the liquid. Accordingly, exposure with high precision using a liquid immersion method is performed on the substrate.

Owner:NIKON CORP

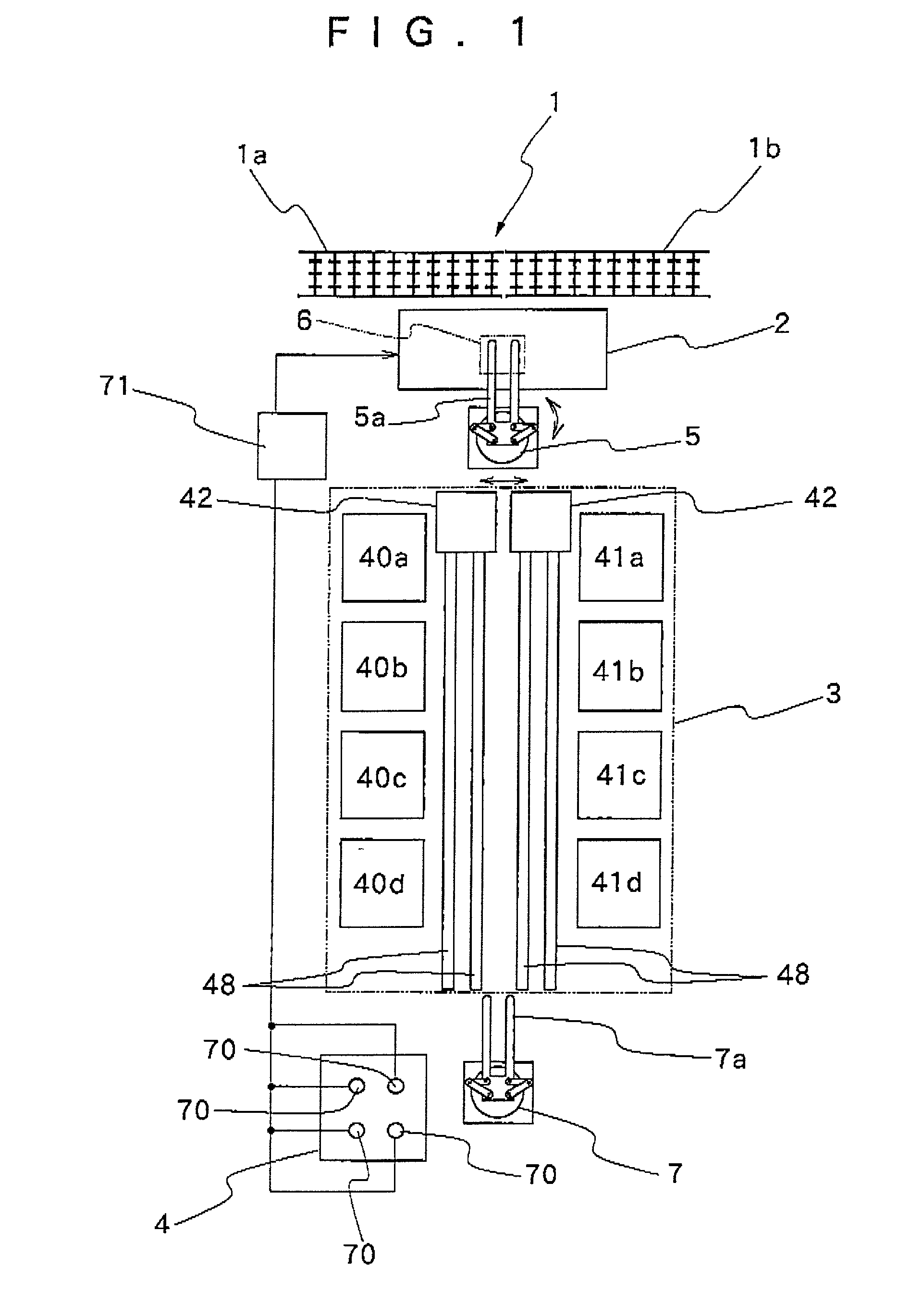

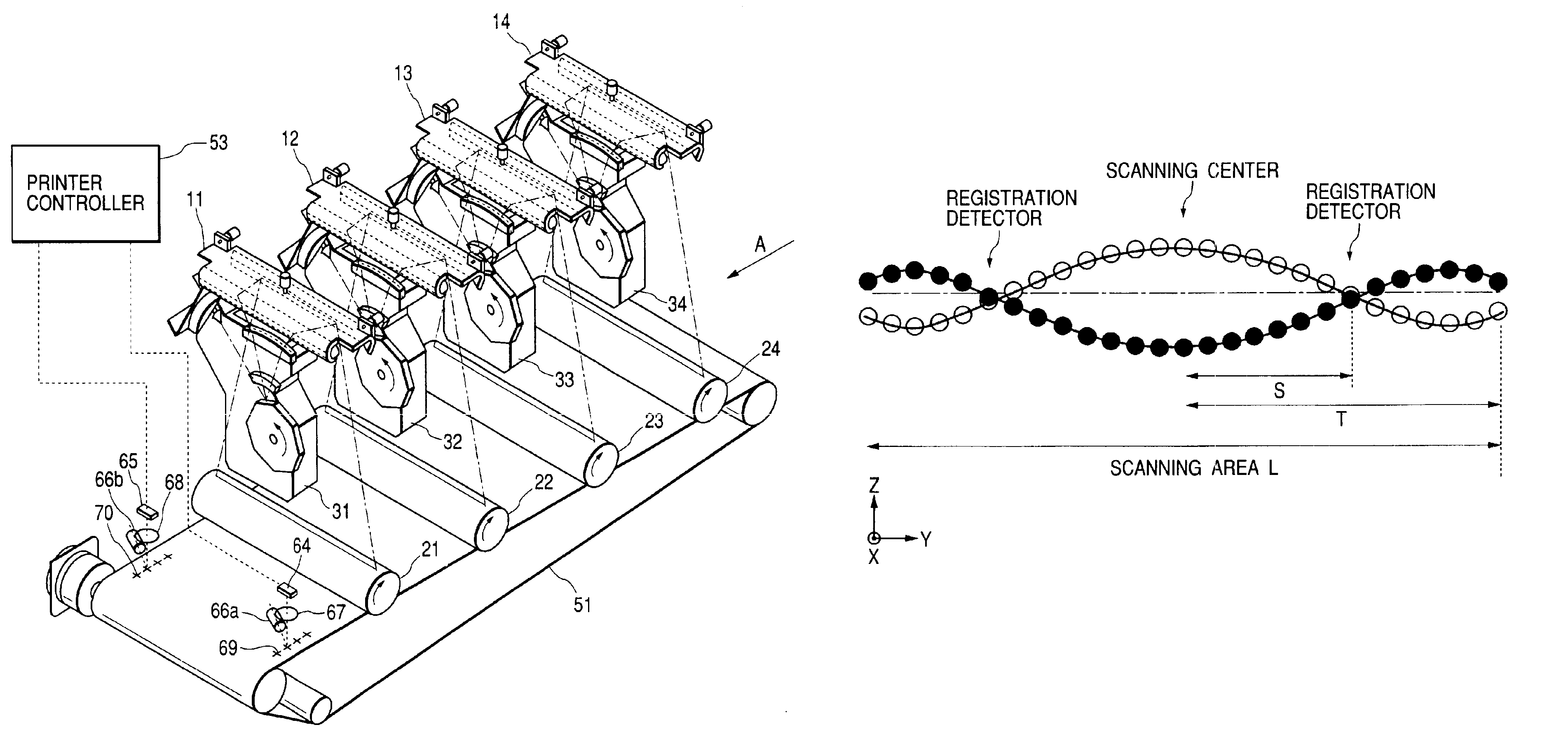

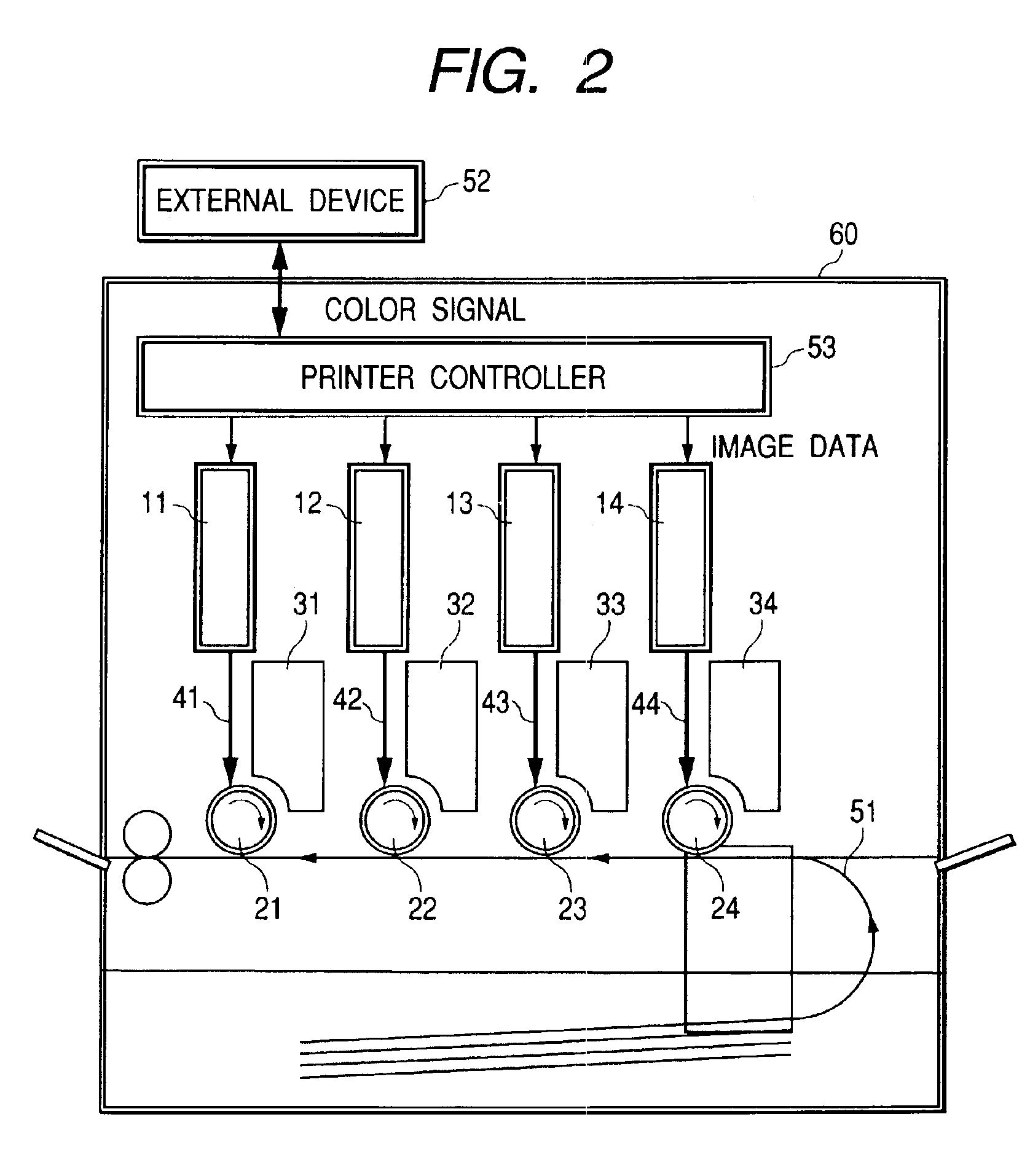

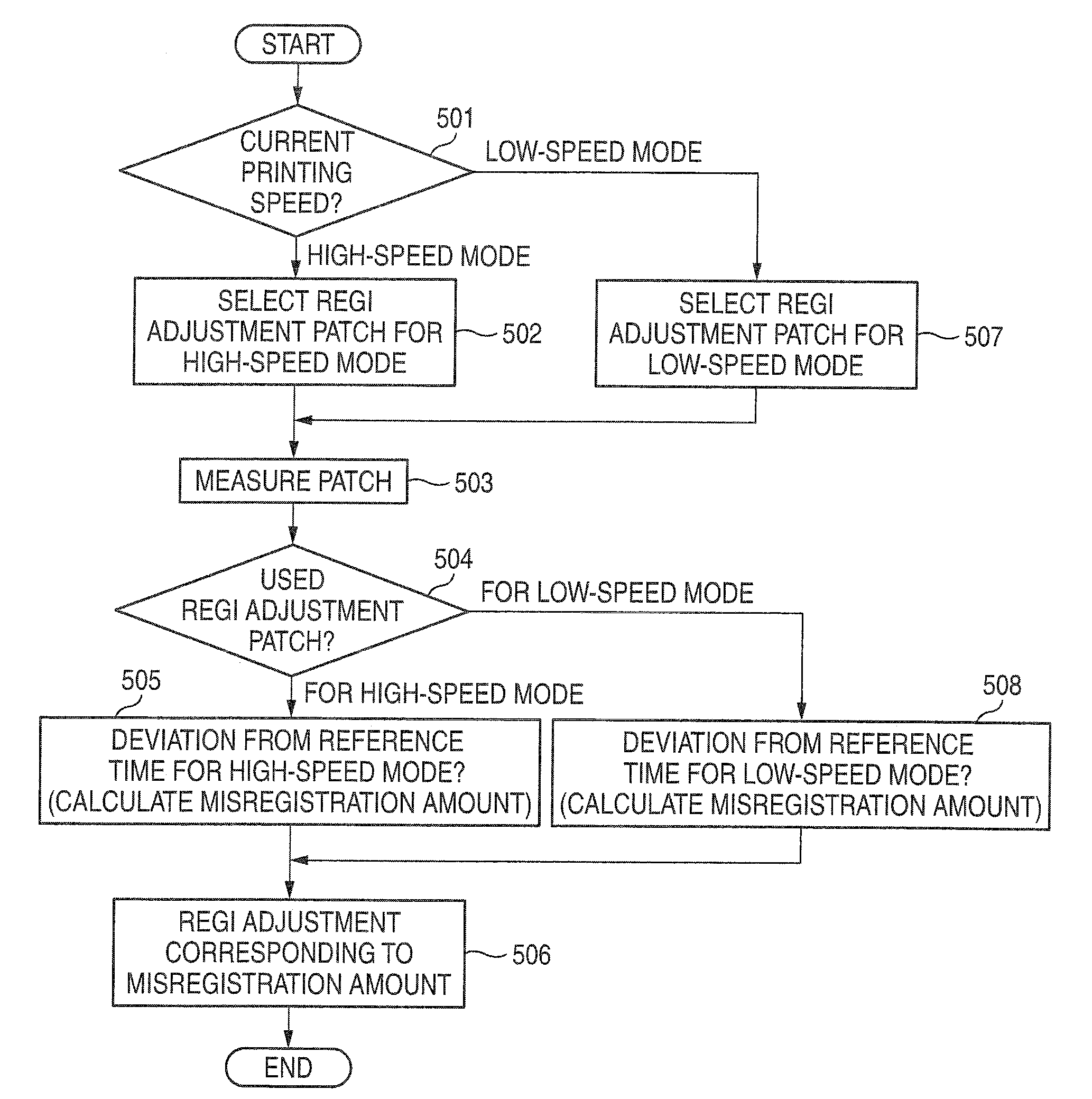

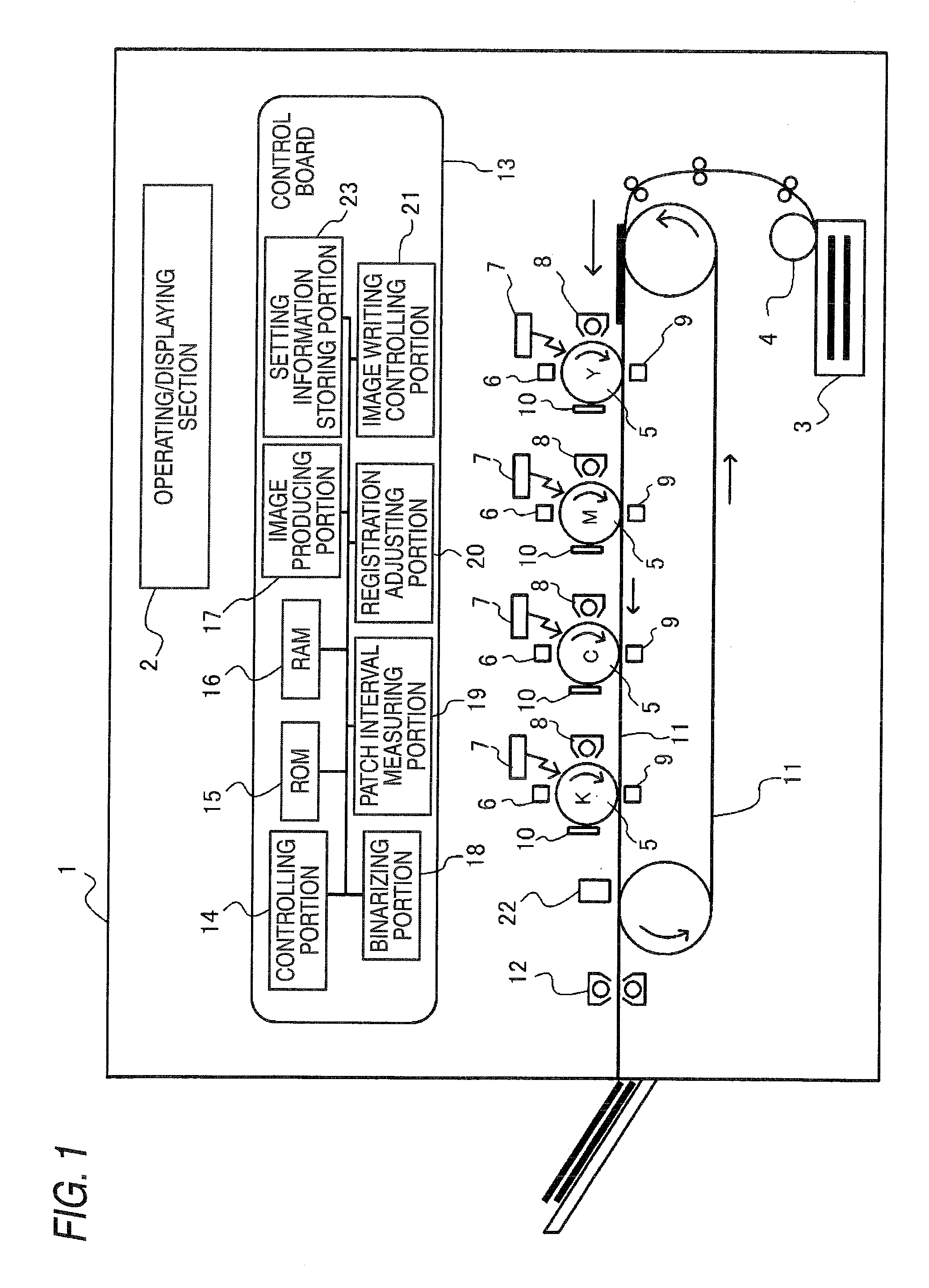

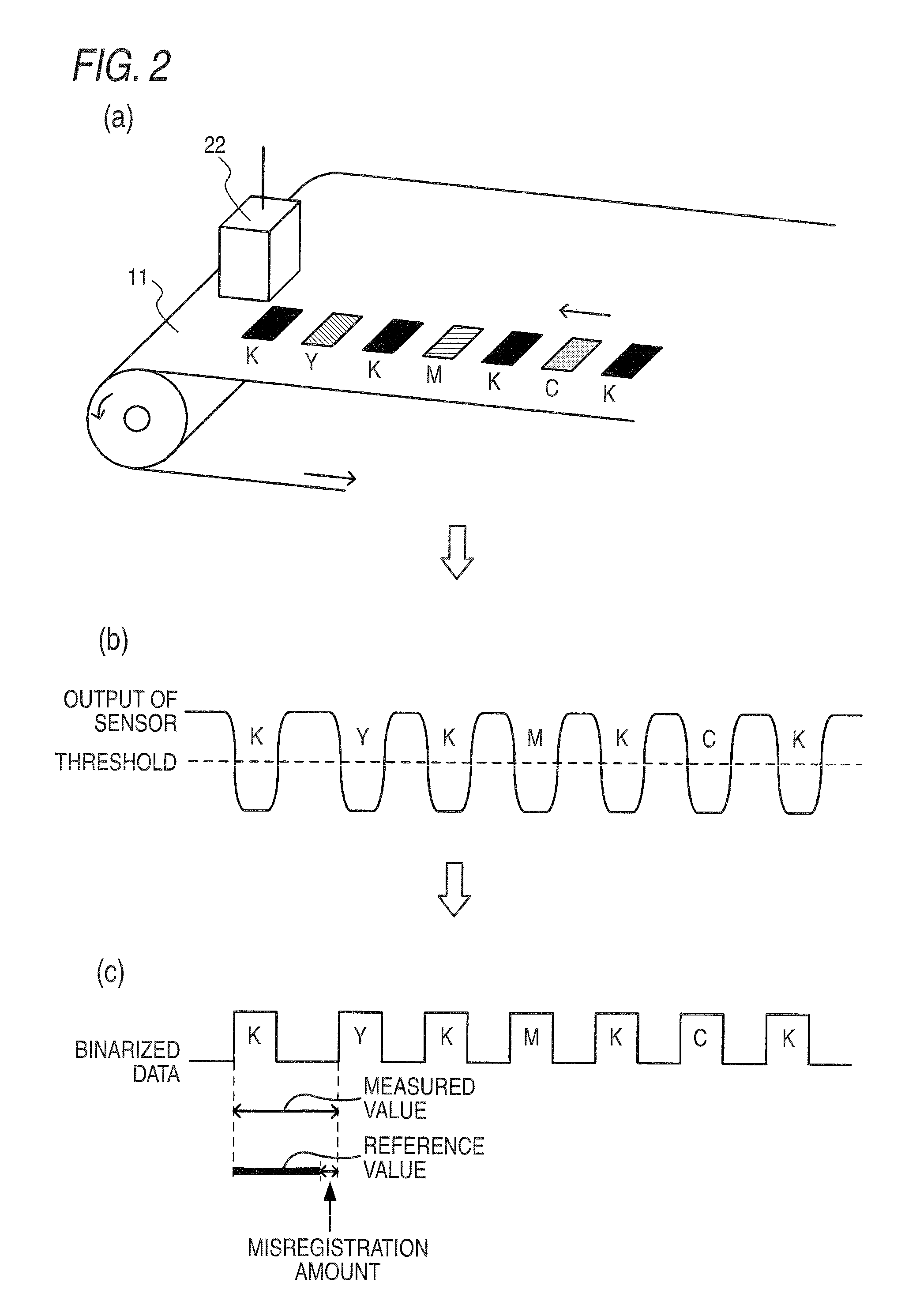

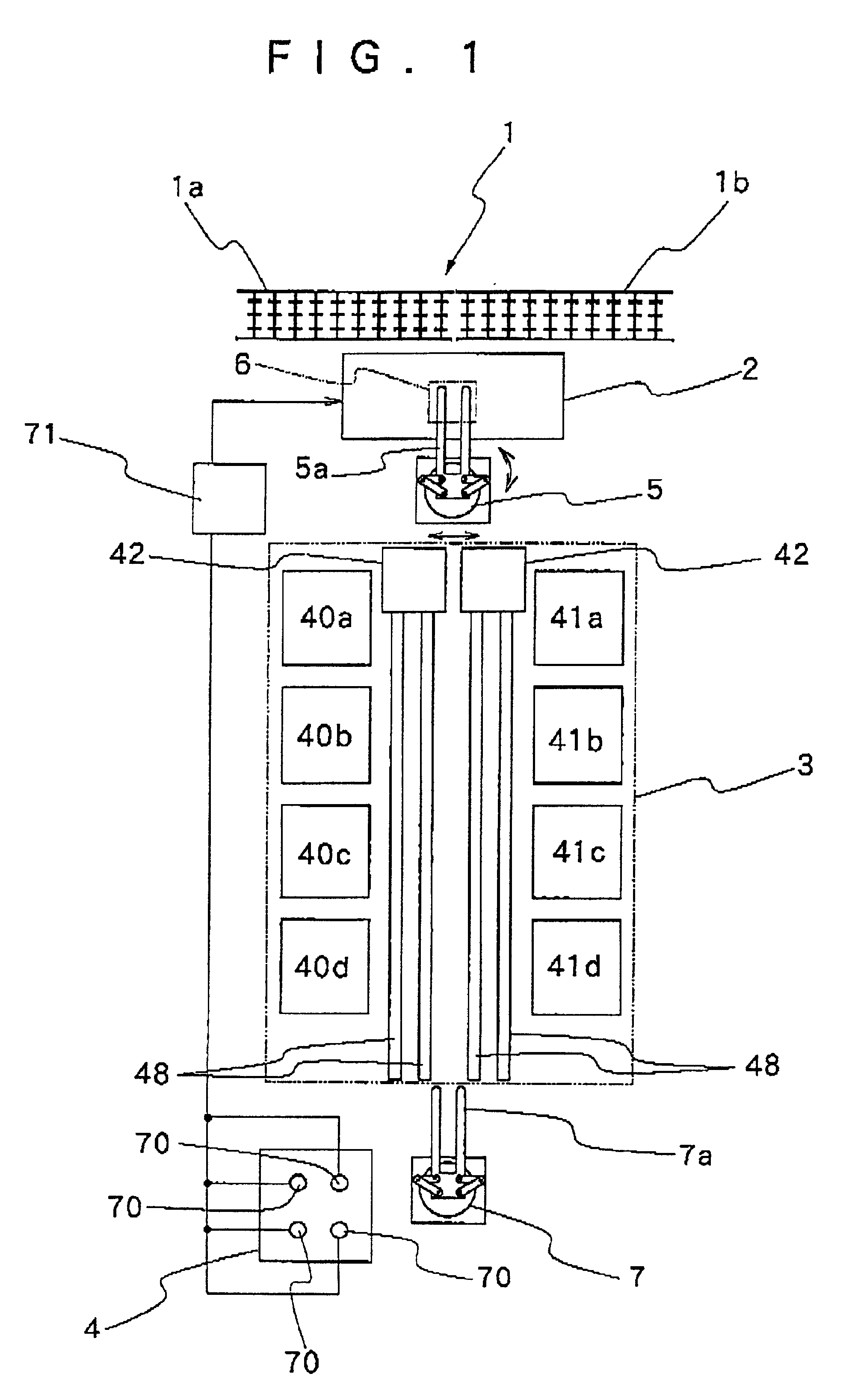

Color image forming apparatus with color registration detector

InactiveUS6856336B2Correct position deviationSmall componentRecording apparatusElectrographic process apparatusColor imageScan line

Disclosed is a scanning optical apparatus which can reduce color misregistration in a sub scanning direction to thereby obtain a good color image output, and a color image forming apparatus using the same. In the scanning optical apparatus, a beam emitted from light source means 1 is deflected by deflecting means 5, and the beam deflected by the deflecting means is imaged in a spot shape on a surface 7 to be scanned by scanning optical device, and light-scans on the surface to be scanned, and a scanning line scanning on the surface to be scanned has two or more extremums within the effective range of a scanning area.

Owner:CANON KK

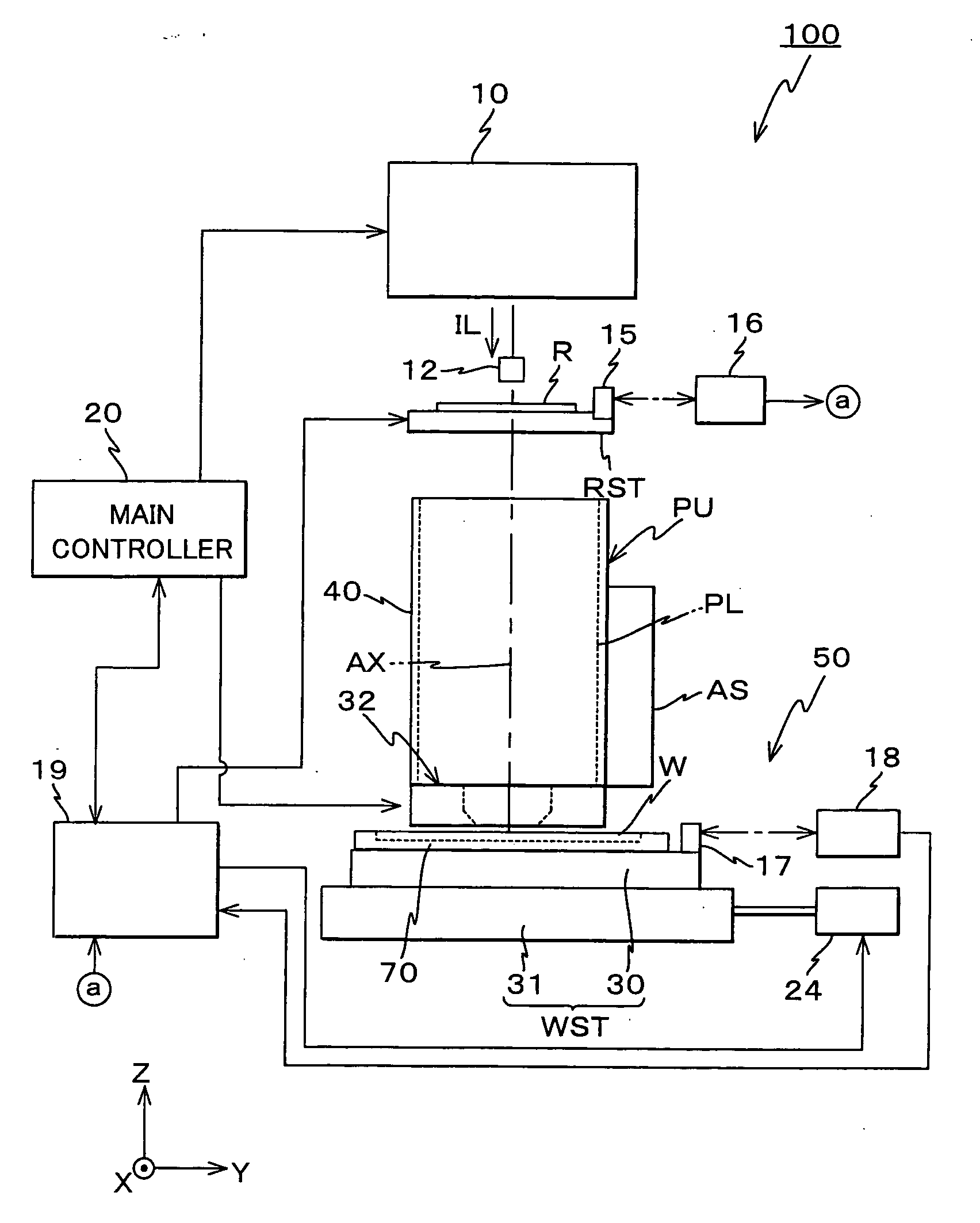

Projection exposure apparatus and stage unit, and exposure method

InactiveUS20070064212A1Improve accuracyCorrect position deviationPhotomechanical exposure apparatusMicrolithography exposure apparatusOptics

A projection exposure apparatus (100) has a substrate table (30) on which a substrate (W) is mounted that can be moved holding the substrate, a position measuring system (18 and others) that measures positional information of the substrate table, and a correction unit (19) that corrects positional deviation occurring in at least either the substrate or the substrate table due to supply of a liquid. In this case, the correction unit corrects the positional deviation occurring in at least either the substrate or the substrate table due to the supply of the liquid. Accordingly, exposure with high precision using a liquid immersion method is performed on the substrate.

Owner:NIKON CORP

Positioning structure for PCB and upper insulation support

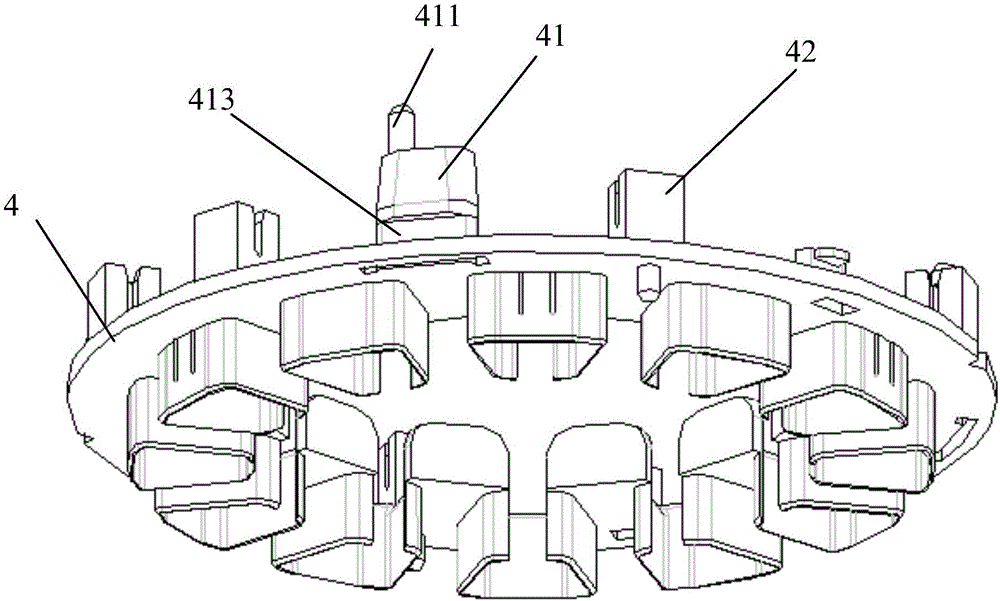

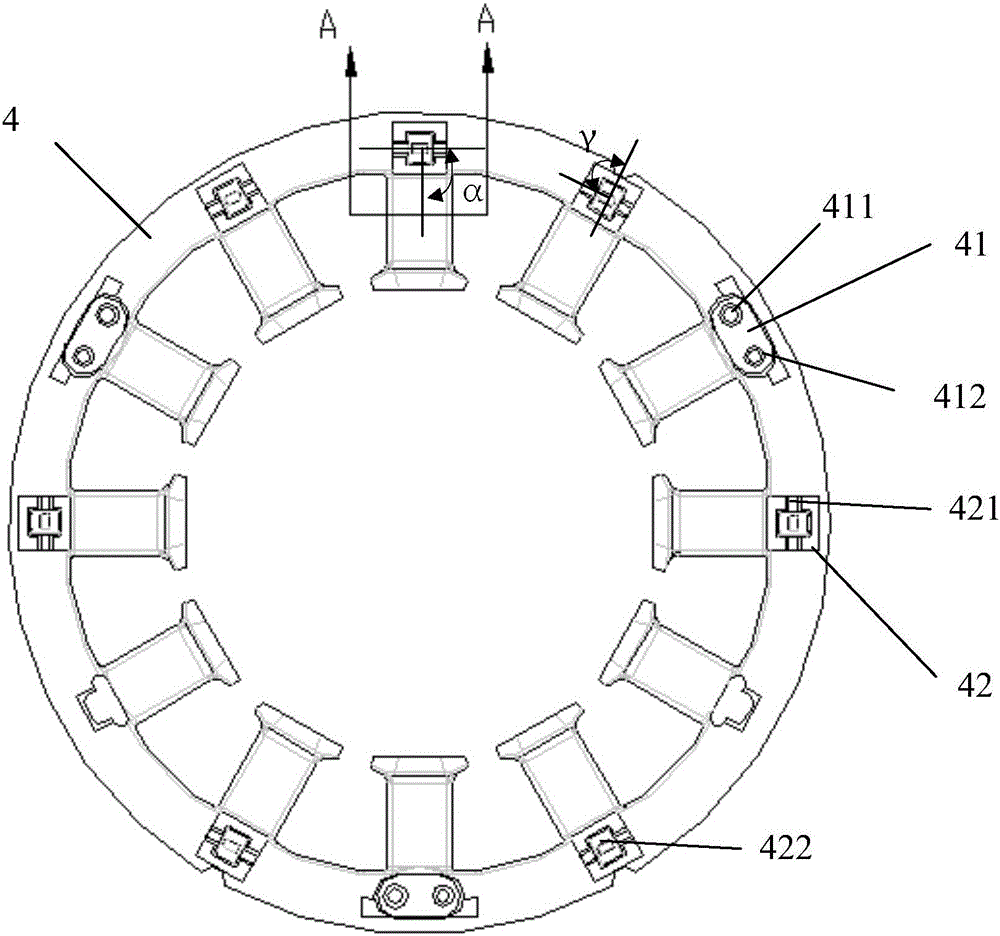

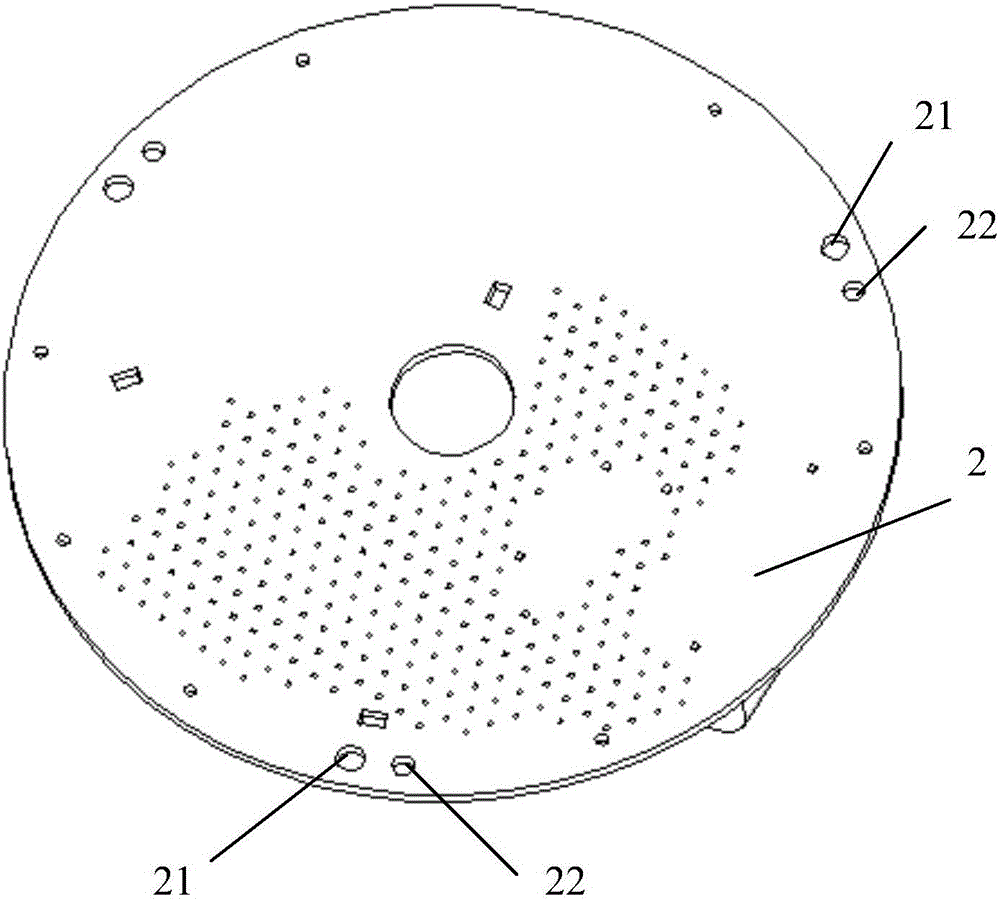

ActiveCN105071600ASimple structureGuaranteed accuracyAssociation with control/drive circuitsSupports/enclosures/casingsBrushless motorsEngineering

The invention discloses a positioning structure for a PCB and an upper insulation support, and belongs to the technical field of brushless motors. The positioning structure comprises the PCB and the upper insulation support, the upper surface of the upper insulation support is provided with a plurality of positioning benches, the top surfaces of the positioning benches are h higher than the top surfaces of terminal fixing seats, the top surface of each positioning bench is provided with a guide positioning column matched with a positioning hole and a fixing hole matched with an installing hole, one end of the guide positioning column, matched with the positioning hole, is a tapered structure, and a sidewall of each positioning bench is provided with a wire-passing groove for limiting a conducting wire. According to the positioning structure, in the assembling process of the PCB and the upper insulation support, the guide positioning column and the positioning holes are matched so that accurate positioning between terminals of the upper insulation support and terminal connection holes of the PCB can be realized, the quantity of defective products in the automatic generation can be reduced, and the yield is increased.

Owner:BERGSTROM CHINA GRP

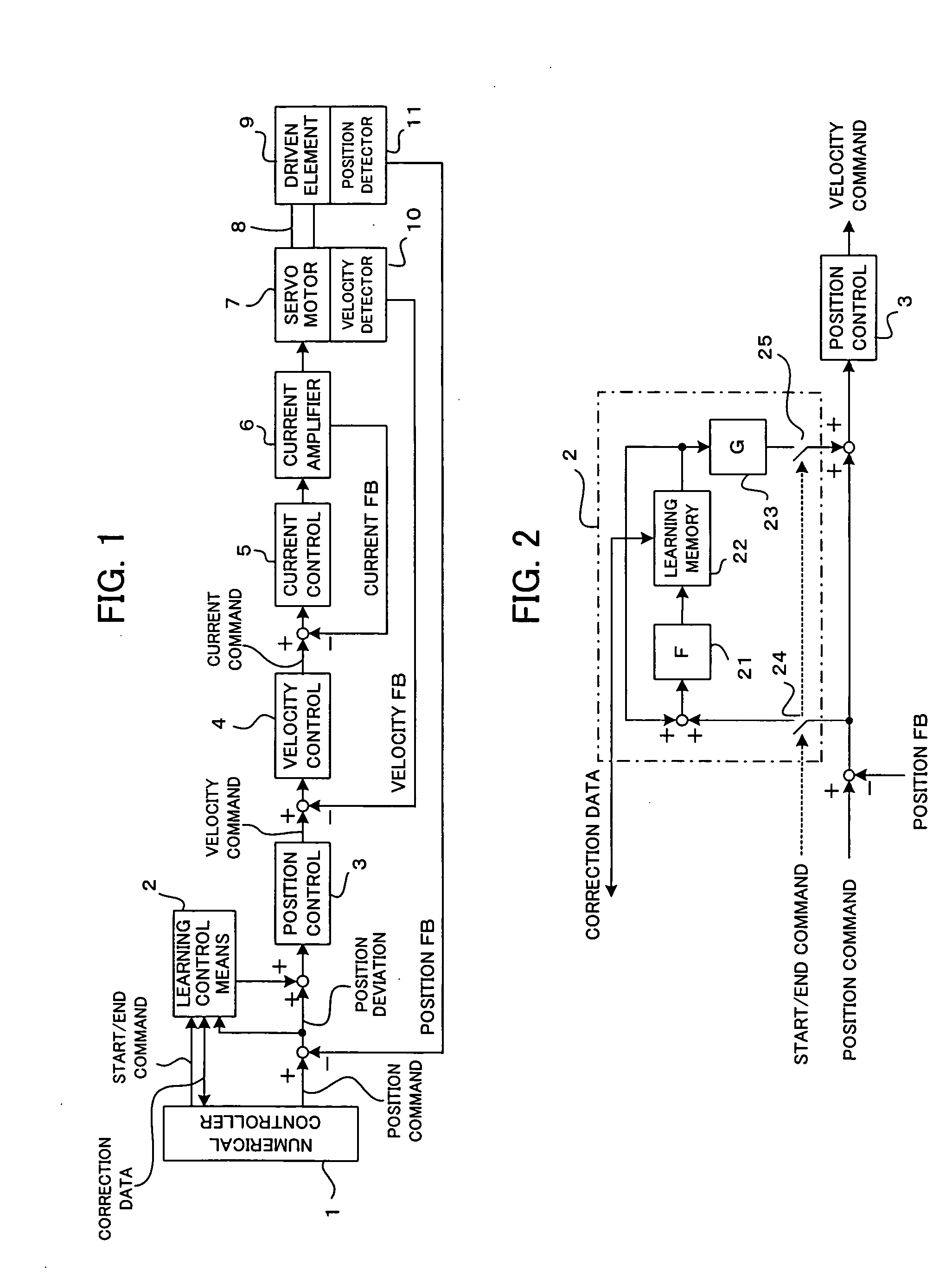

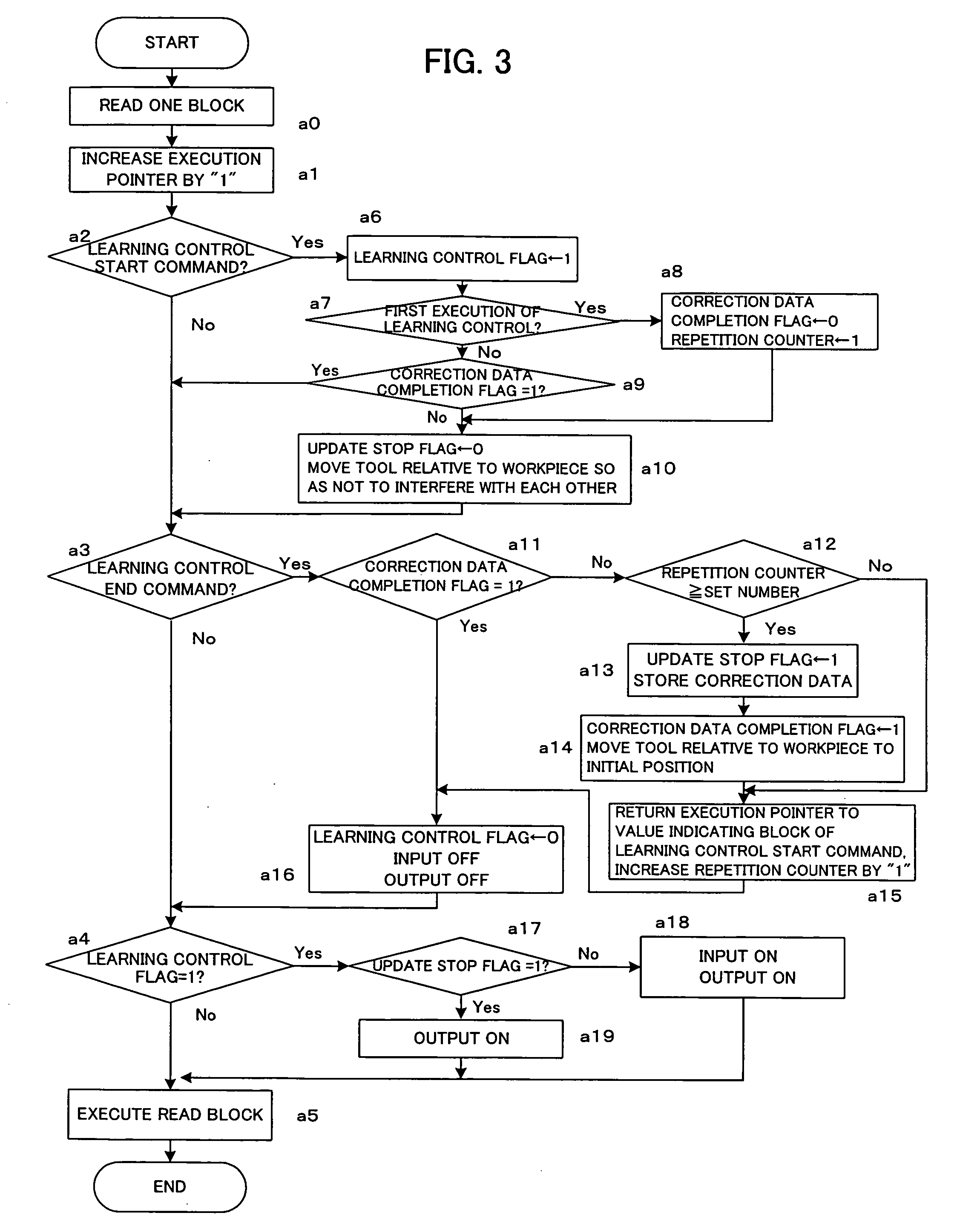

Numerical controller

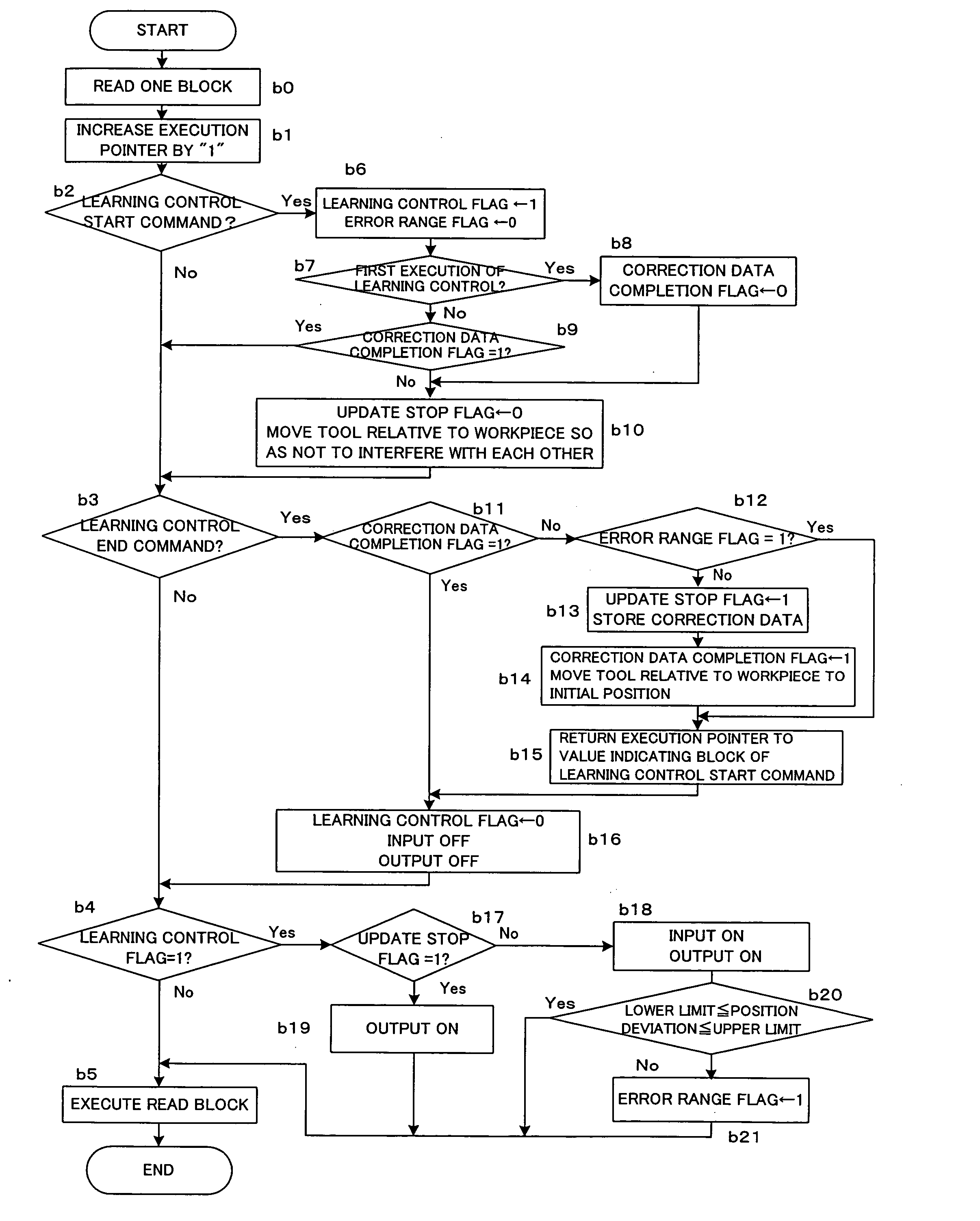

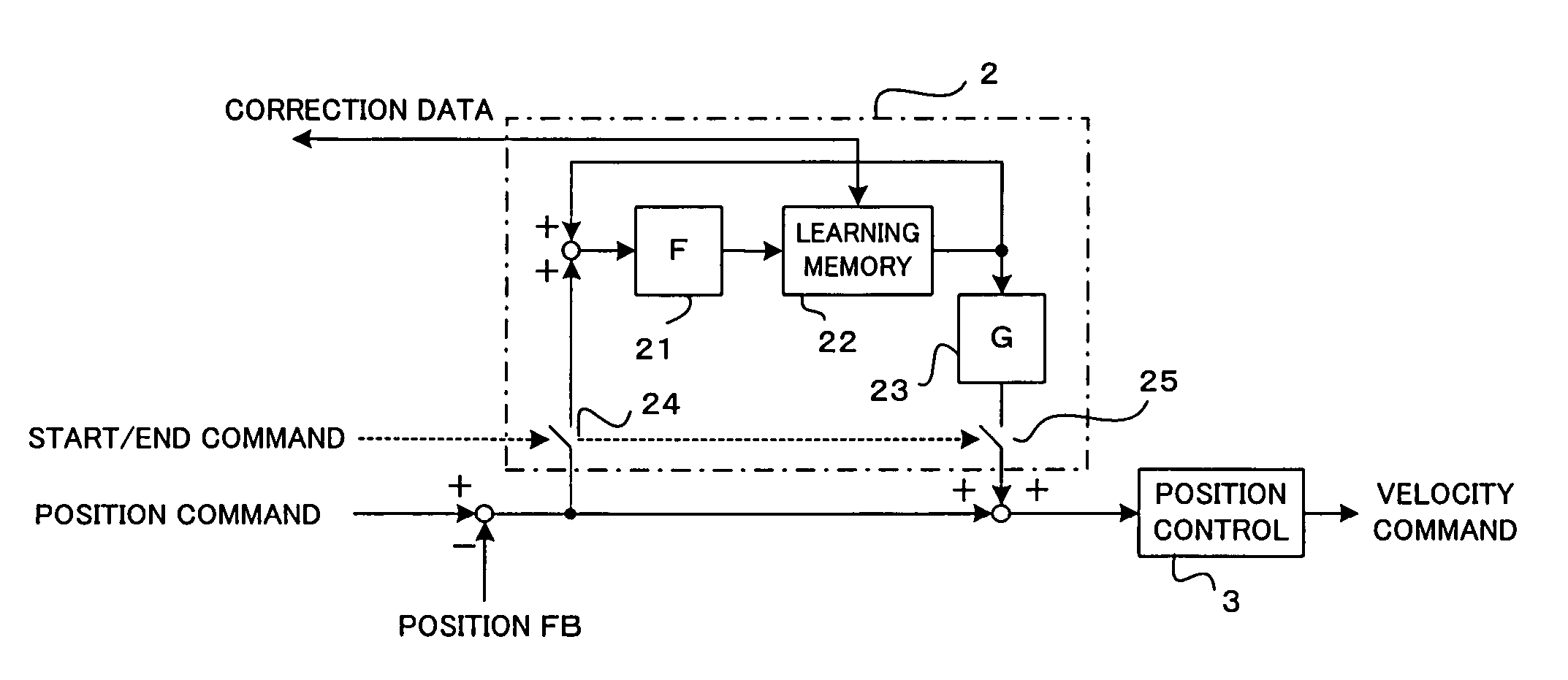

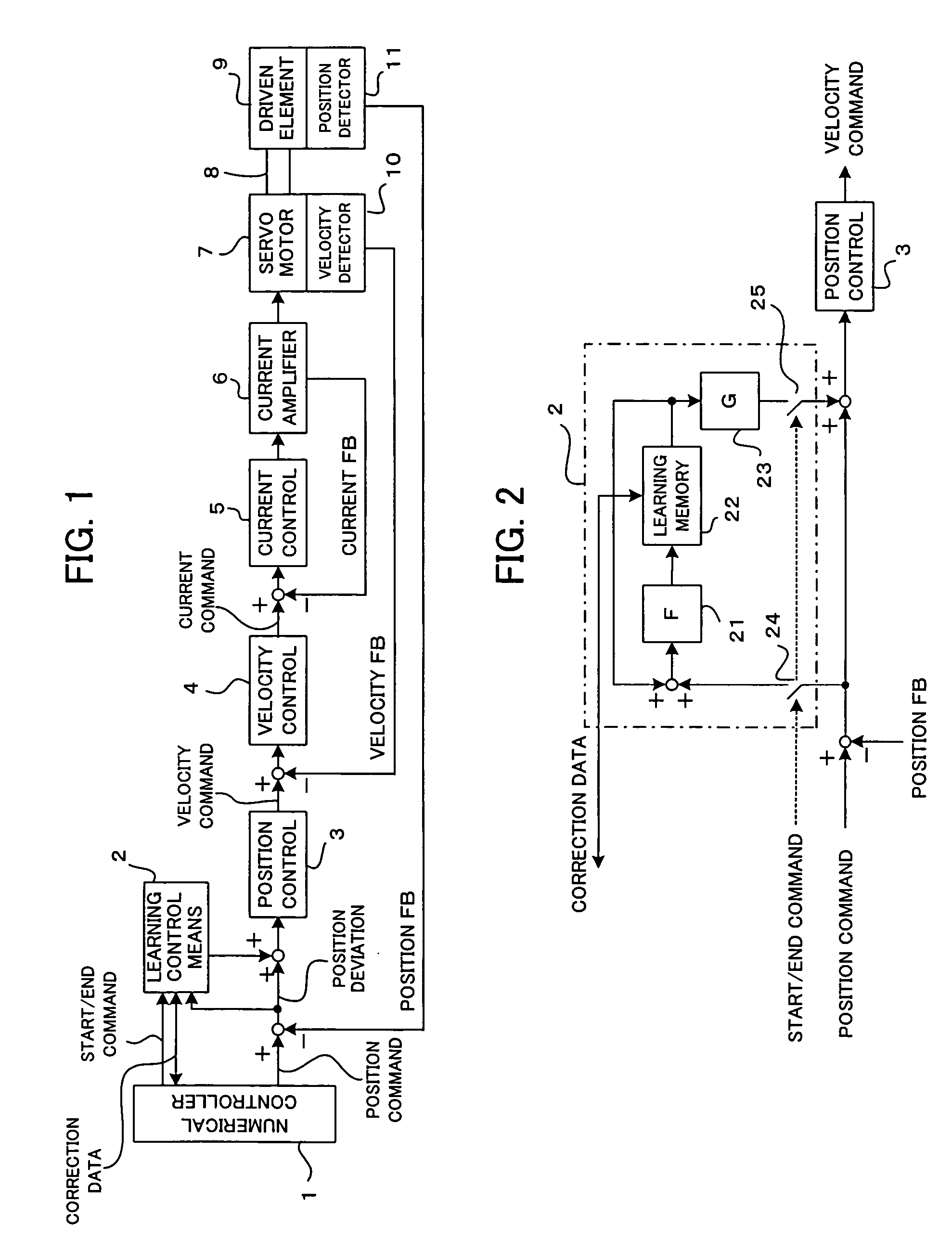

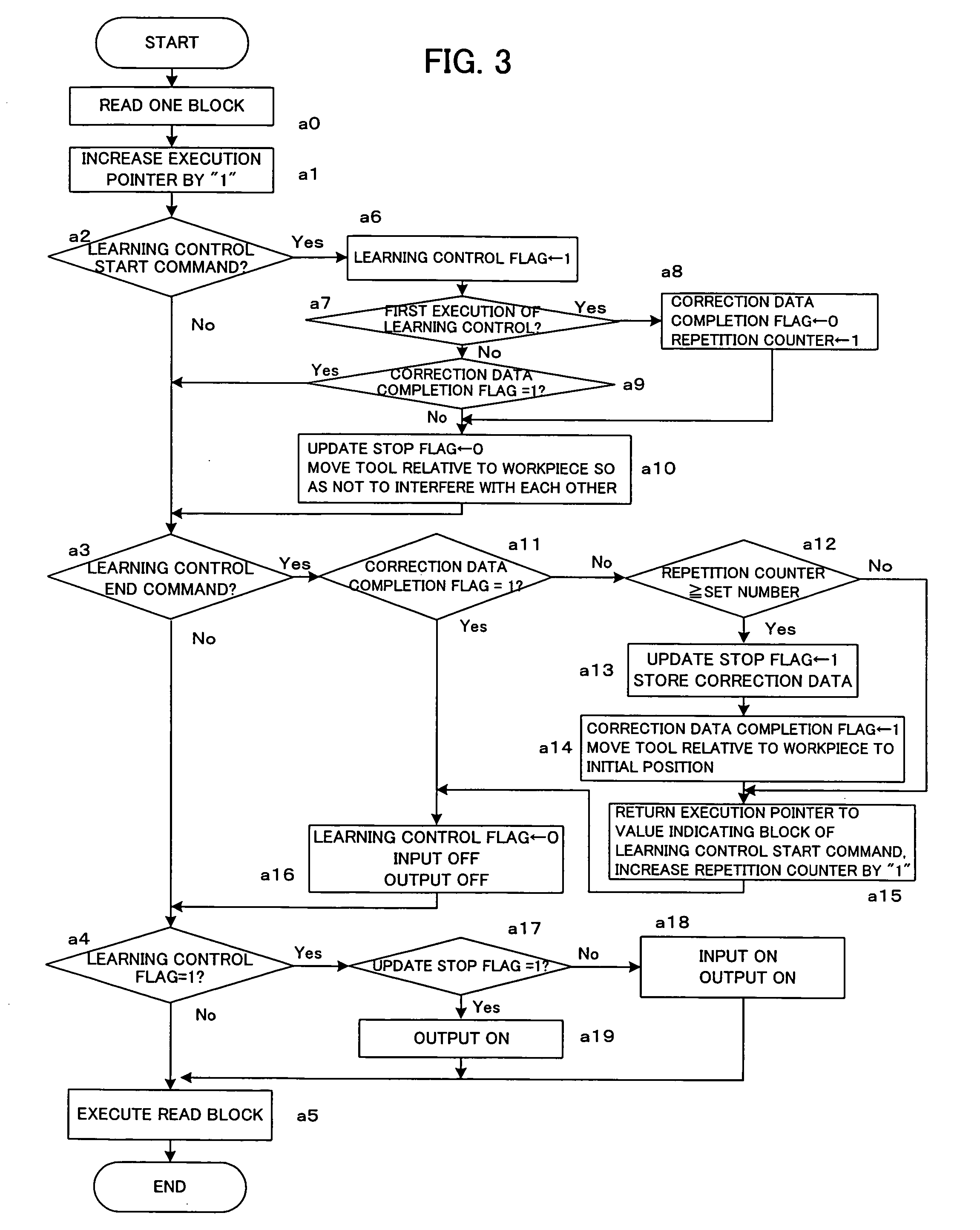

ActiveUS20060173573A1Not wastefully consumedReduce machining cycle timeProgramme controlComputer controlCycle timeComputer science

A numerical controller capable of obviating the waste of a workpiece by machining such that a position deviation by learning control is converged and automatically performing storage of correction data and actual machining. A tool and the workpiece are moved to noninterfering positions. In a learning control interval from the issuance of a learning control start command to the issuance of a learning control end command, the input and output are turned on so that the learning control is performed to input the position deviation and create and output the correction data. Processing in the learning control interval that involves the learning control is repeatedly executed a set number of times by idling operations. The obtained data is automatically stored in the numerical controller, the tool and the workpiece are moved to interfering positions, and the position deviation is corrected based on the correction data, whereby actual machining is performed. The correction data is automatically stored and the actual machining is performed using the correction data without wasting the workpiece, so that the cycle time can be shortened.

Owner:FANUC LTD

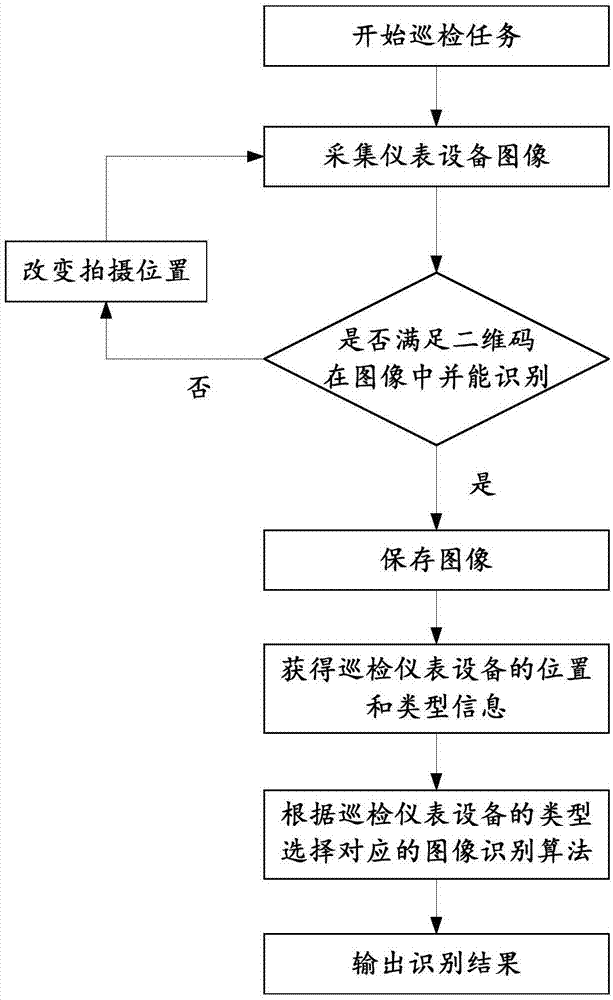

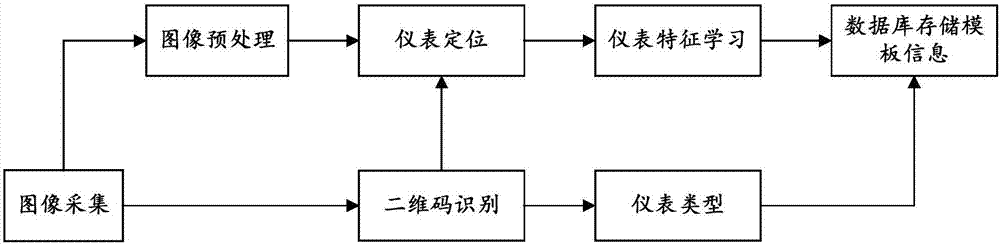

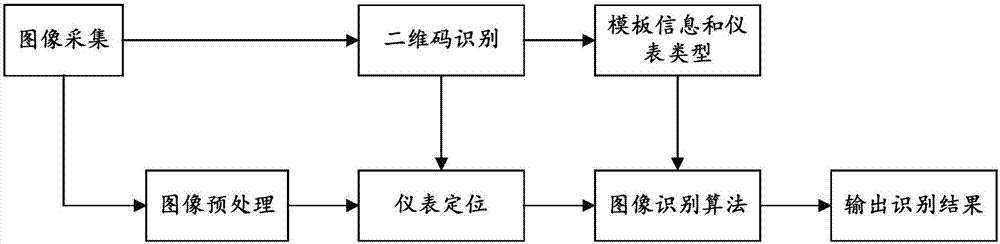

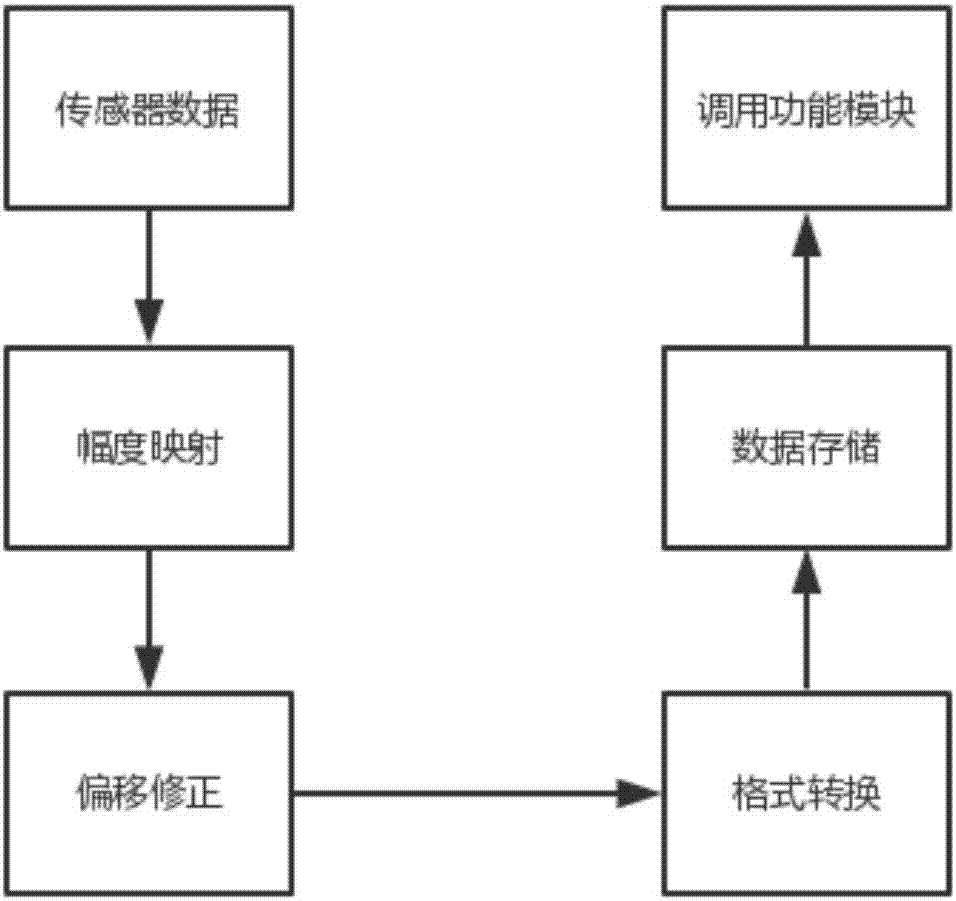

Power plant instrumental equipment image identification method and system based on handheld intelligent patrol inspection

InactiveCN107507174AAccurate collectionCorrect position deviationImage analysisGeometric image transformationEmbedded systemDevice type

The invention discloses a power plant instrumental equipment image identification method and a power plant instrumental equipment image identification system based on handheld intelligent patrol inspection. The power plant instrumental equipment image identification method comprises the steps of: 1) acquiring a high-quality instrumental equipment state image by utilizing an image acquisition method based on two-dimensional code matching quickly and precisely, acquiring position and type information of patrol inspection instrumental equipment, and correcting positional deviation of the instrumental equipment state image; 2) acquiring a type of instrumental equipment according to the type information obtained in the step 1), selecting corresponding image identification algorithms according to different instrumental equipment types, analyzing and processing the instrumental equipment state image, and identifying state of the equipment. The power plant instrumental equipment image identification method and the power plant instrumental equipment image identification system adopt an image positioning and matching algorithm based on two-dimensional codes, and the two-dimensional codes can be used for determining position information of the patrol inspection instrumental equipment as well as type information of the patrol inspection instrumental equipment, thus the problems caused by complicated field environment of a substation and poor precision of handheld equipment can be solved, and the method and the system have high robustness and practicality.

Owner:HANGZHOU E ENERGY ELECTRIC POWER TECH

Substrate holding device, substrate processing apparatus using the same, and method for aligning and holding substrate

InactiveUS20050018168A1Short timeCorrect position deviationSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineering

Owner:CANON KK

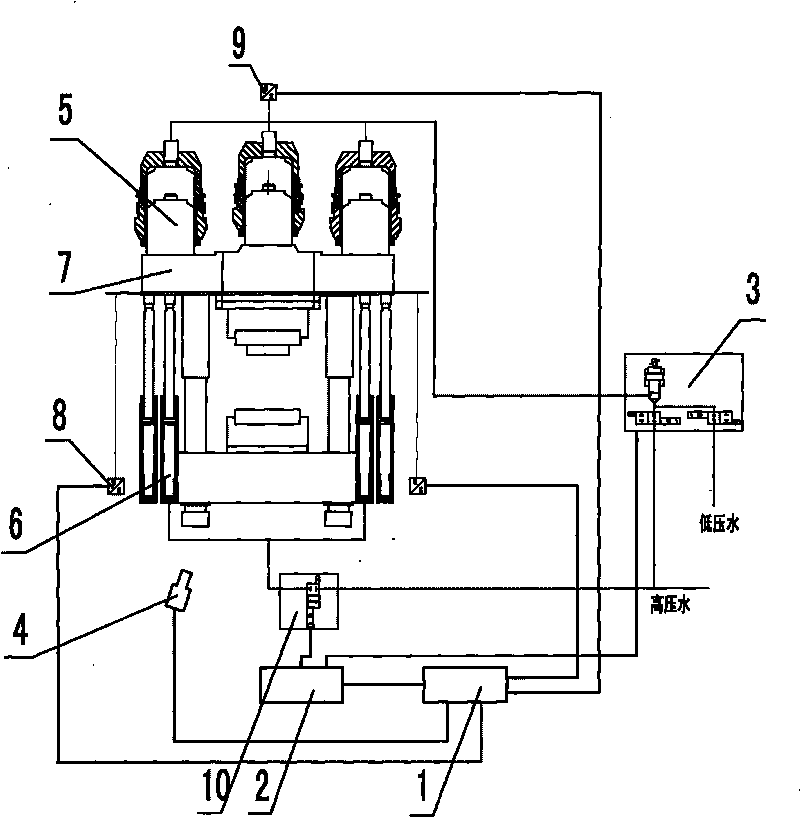

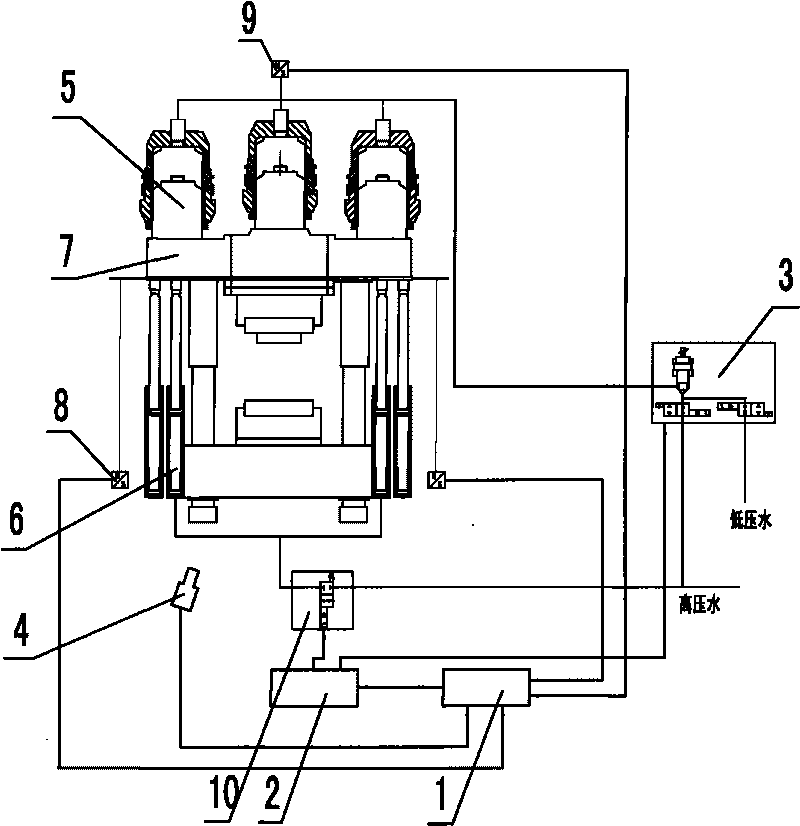

Self-adaptive pre-control method for movable beam position of oversize water press

ActiveCN101704060ACorrect position deviationGuaranteed controllableForging press drivesLoop controlClosed loop

The invention relates to a self-adaptive pre-control method for movable beam position of oversize water press, aiming to develop a method with the function of self-adaptive pre-control of movable beam besides the function of normal position closed loop control according to the characteristics of the oversize hydraulic press for free forging in forging process such as heavy pressure, large inertia and multiple types; a predictive control calculating model is designed based on the comprehensive consideration of the factors such as various forgings, forging pressure of water press, inertia and lag of control valve assembly to pre-control the position through simple engineering arithmetic, thereby solving the difficulty for the movable beam of the water press to control the size precision of the forging in forging process; and the method efficiently solves the problem that the variation of the forgings, large pressure, large inertia and lag of control valve assembly influence the control of the forging precision, thereby reducing the follow-up processing time, improving working efficiency and decreasing the energy and material consumptions.

Owner:DALIAN DESIGN INST CO LTD CHINA FIRST HEAVY IND +1

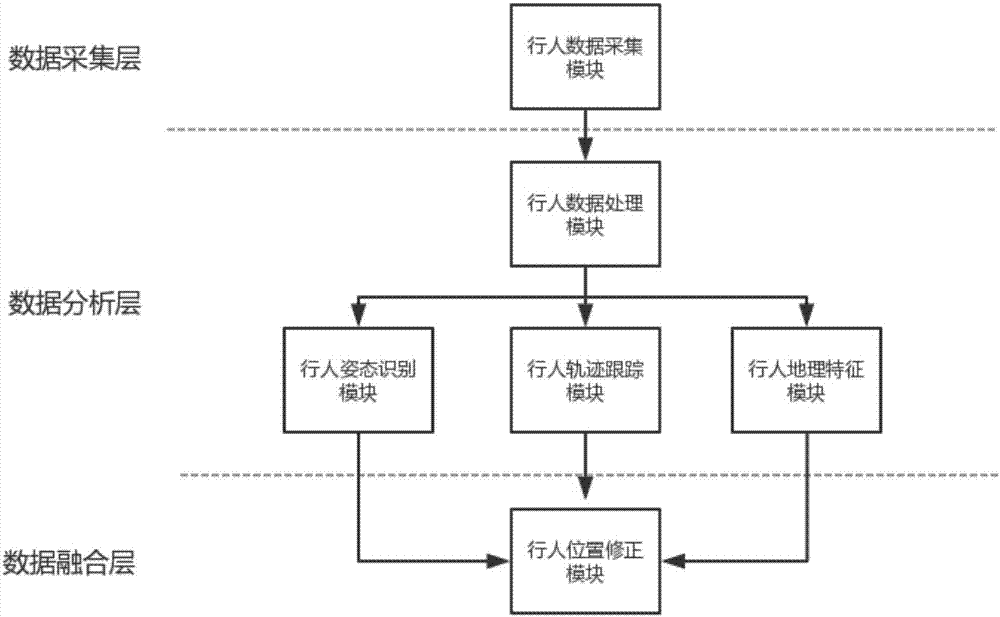

Ultralow-deployment indoor positioning system and method

ActiveCN107014375AUndisturbedImprove stabilityNavigational calculation instrumentsNavigation by terrestrial meansInformation processingGeographic feature

The invention provides an ultralow-deployment indoor positioning system and method. The system comprises a data acquisition module, a data processing module, a posture recognition module, a target tracking module, a geographic feature module and a position correction module, wherein the data acquisition module is used for providing a data source; the data processing module is used for providing preprocessing information; the posture recognition module is used for recognizing a target moving posture; the tracking module is used for recording a target moving trail; the geographic feature module is used for assisting positioning information processing; the position correction module is used for providing an accurate three-dimensional position through an optimization algorithm, and outputting the target moving posture. According to the ultralow-deployment indoor positioning system and the method provided by the invention, signal transmitters have no need to be densely distributed, an angle change of object movement is sensed through a gyroscope, and a speed change of object movement is sensed through an accelerometer, so that information such as a current position and the moving posture of an object are acquired; a terrestrial magnetism signal, a temperature signal, an air pressure signal and the like are combined for assisting positioning, and positional deviation caused by error accumulation is corrected, so that the positioning accuracy is greatly improved.

Owner:上海谦尊升网络科技有限公司

Numerical controller

ActiveUS7206659B2Not wastefully consumedReduce machining cycle timeProgramme controlComputer controlCycle timeComputer science

A numerical controller capable of obviating the waste of a workpiece by machining such that a position deviation by learning control is converged and automatically performing storage of correction data and actual machining. A tool and the workpiece are moved to noninterfering positions. In a learning control interval from the issuance of a learning control start command to the issuance of a learning control end command, the input and output are turned on so that the learning control is performed to input the position deviation and create and output the correction data. Processing in the learning control interval that involves the learning control is repeatedly executed a set number of times by idling operations. The obtained data is automatically stored in the numerical controller, the tool and the workpiece are moved to interfering positions, and the position deviation is corrected based on the correction data, whereby actual machining is performed. The correction data is automatically stored and the actual machining is performed using the correction data without wasting the workpiece, so that the cycle time can be shortened.

Owner:FANUC LTD

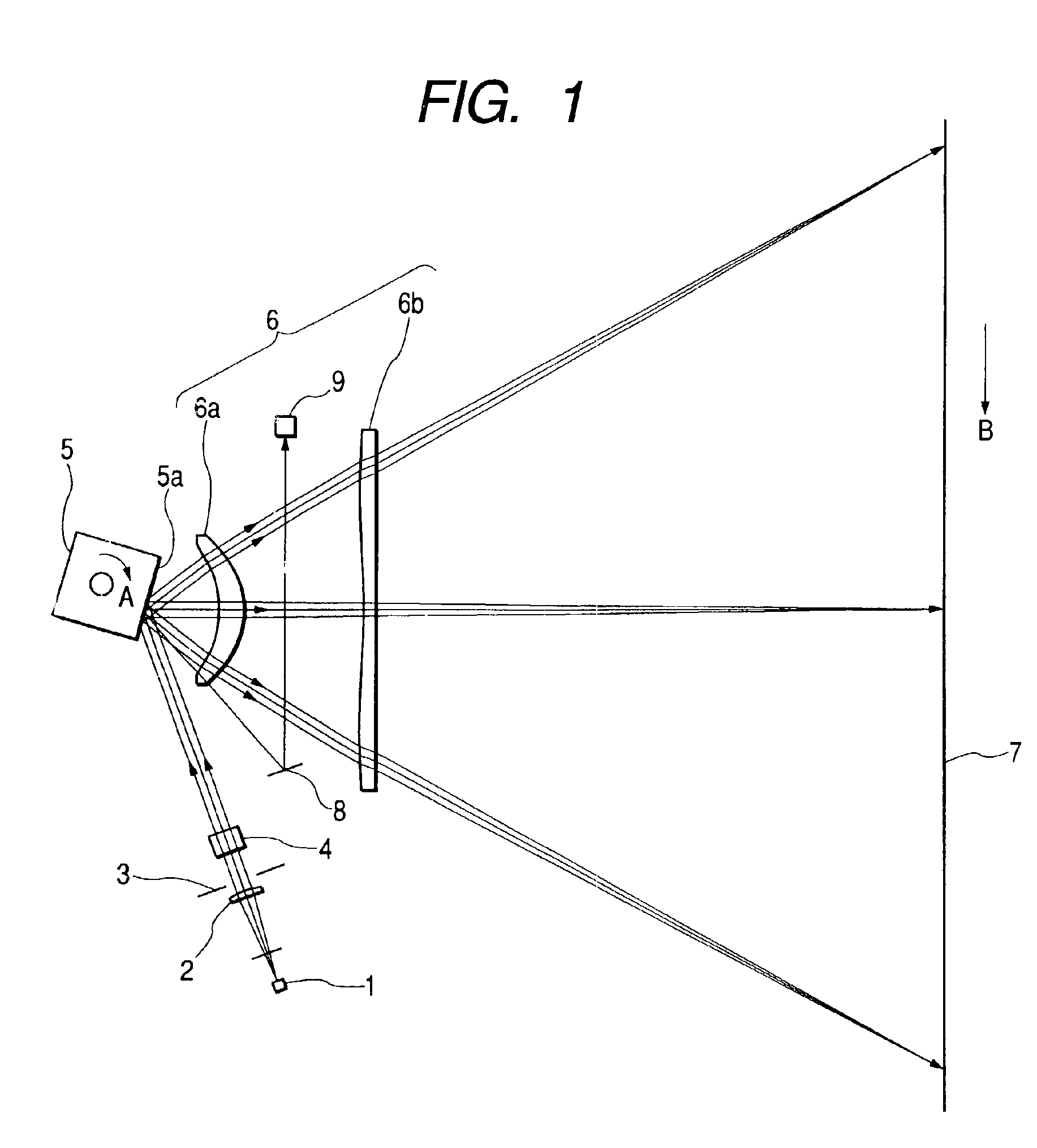

Exposure apparatus, exposure method, and producing method of microdevice

InactiveUS7864293B2Accurate displacementCompensation displacementPhotomechanical apparatusPhotographic printingComputer science

An exposure apparatus for exposure-transferring an image of a pattern projected through an optical system having a plurality of optical units L1 to L13 onto an object P, comprises a correcting device which corrects a position of at least one of a plurality of images to be projected onto the object P by the plurality of optical units L1 to L13 so that displacements of the optical units L1 to L13 are compensated.

Owner:NIKON CORP

Image forming apparatus

InactiveUS20100226694A1Correct position deviationElectrographic process apparatusImage formationComputer vision

Owner:FUJIFILM BUSINESS INNOVATION CORP

Solder paste

ActiveUS8388724B2Correct position deviationPrinted circuit manufactureGlass/slag layered productsPowder mixtureSolder paste

High-temperature solders having a higher melting point than solder alloys used for soldering of printed circuit boards are used for internal bonding of electronic parts, but high-temperature solders which are free from Pb have not been developed. There exist high-temperature solders which comprises Sn balls and Cu balls and which perform bonding through the formation of an intermetallic compound without melting to form a single-phase structure, but they have poor wettability to the lands of a printed circuit board or electrodes of electronic parts and have not been used.A solder paste according to the present invention is provided by mixing flux with a powder mixture of Sn powder or an Sn based lead-free solder powder with Cu or Ag powder which has Ni plating formed on its surface. Although the solder paste performs bonding by means of an intermetallic compound without melting to form a single phase structure, the Ni plating acts as a barrier which retards the formation of the intermetallic compound so as to leave enough time to permit wetting of the lands of a printed circuit board or electrodes of an electronic part.

Owner:SENJU METAL IND CO LTD

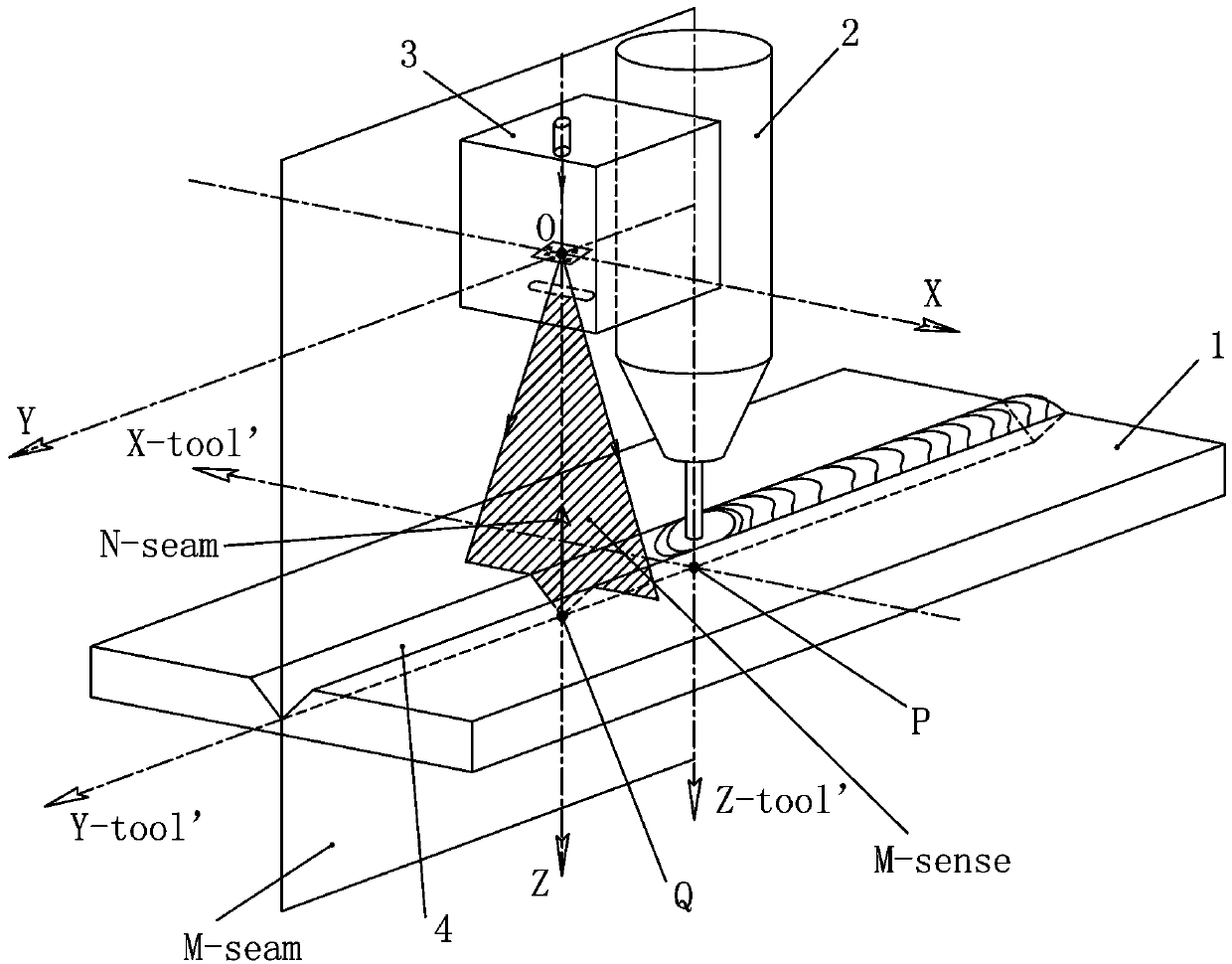

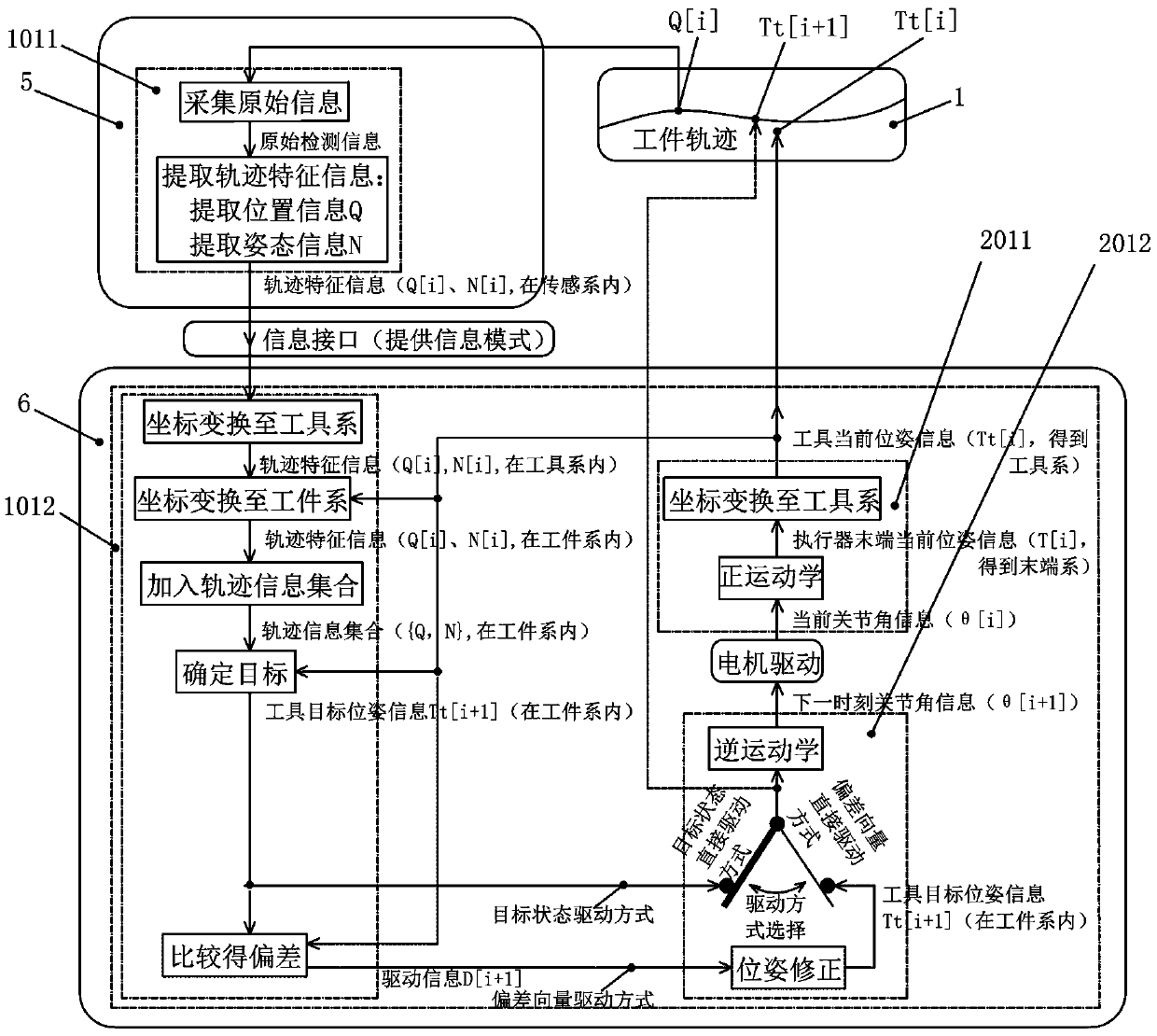

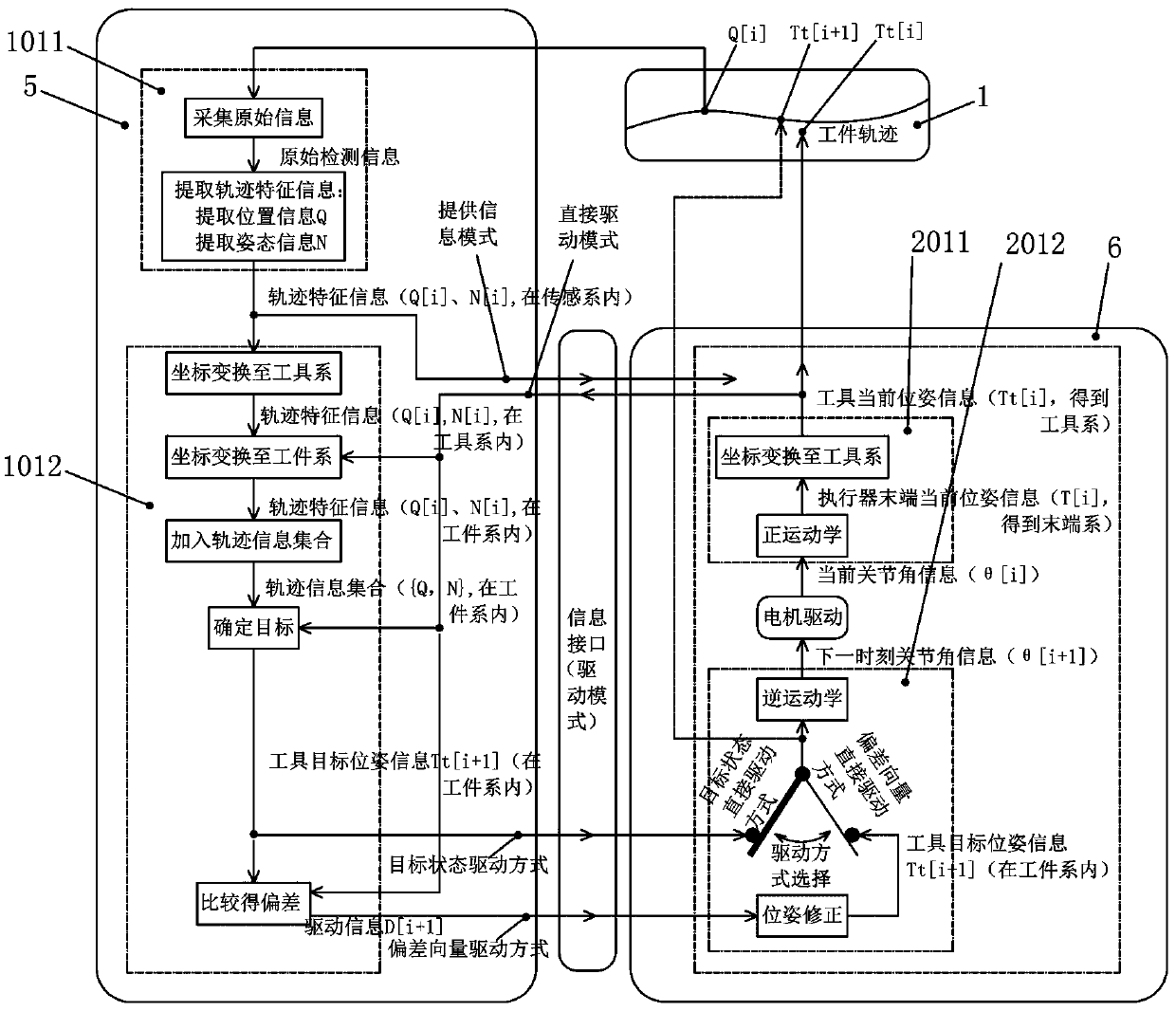

Trajectory tracking control methods and trajectory tracking systems

ActiveCN110450150AEasy to set upBuild flexibleProgramme-controlled manipulatorActuatorComputer science

The invention discloses four trajectory tracking control methods and trajectory tracking systems corresponding to the trajectory tracking control methods. The basic ideas of the four trajectory tracking control methods are consistent, trajectory information which is obtained through a sensor and described through a variable sensor coordinate system is fixed firstly, that is, after detection, the information is converted to be suitable for being marked in a form of being described by the coordinate system for overall recording the trajectory information, a real trajectory is shown step by step,a basis is provided for the subsequent solution target, finally, according to the target, the ideal state which should be shown by a tool at the current moment is found, or the state about to be achieved when the correction moment of next time arrives after correction of the this time is completed is found, and then an executer is driven according to the above information to correct the trajectory of the tool. According to the four trajectory tracking control methods and the trajectory tracking systems corresponding to the trajectory tracking control methods, errors brought by detecting pointadvancing are overcome, the methods can be separated from teaching information to independently run, position deviation of the tool can be corrected, posture deviation of the tool can also be corrected, and the trajectory tracking effect is good.

Owner:SUZHOU RUINIU ROBOT TECH CO LTD

Method and apparatus for bonding substrate plates together through gap-forming sealer material

InactiveUS6790300B2Correct position deviationHot-press substrate plates accuratelyCovering/liningsLamination ancillary operationsEngineeringMechanical engineering

Method and apparatus for registering and bonding upper and lower substrate plates together through a sealer material and in such a way as to form a gap of a predetermined width between the two substrate plates. Registered substrate plates are provisionally pressed to form a joined substrate assembly, which is then pressed under heated conditions at a hot press station, thereby compressing the sealer material into a flattened form and at the same time thermally hardening the sealer material to form a predetermined gap space between the two substrate plates. In order to correct positional deviations which occur to the upper and lower substrate plates in the course of the hot pressing, on the basis detected positional deviations of upper and lower substrate plates of a hot-pressed substrate assembly, upper and lower substrates are set in offset positions instead of aligned positions when registering them at the provisional press station to cancel predicted positional deviations at the hot press station.

Owner:HITACHI ELECTRONICS ENG CO LTD

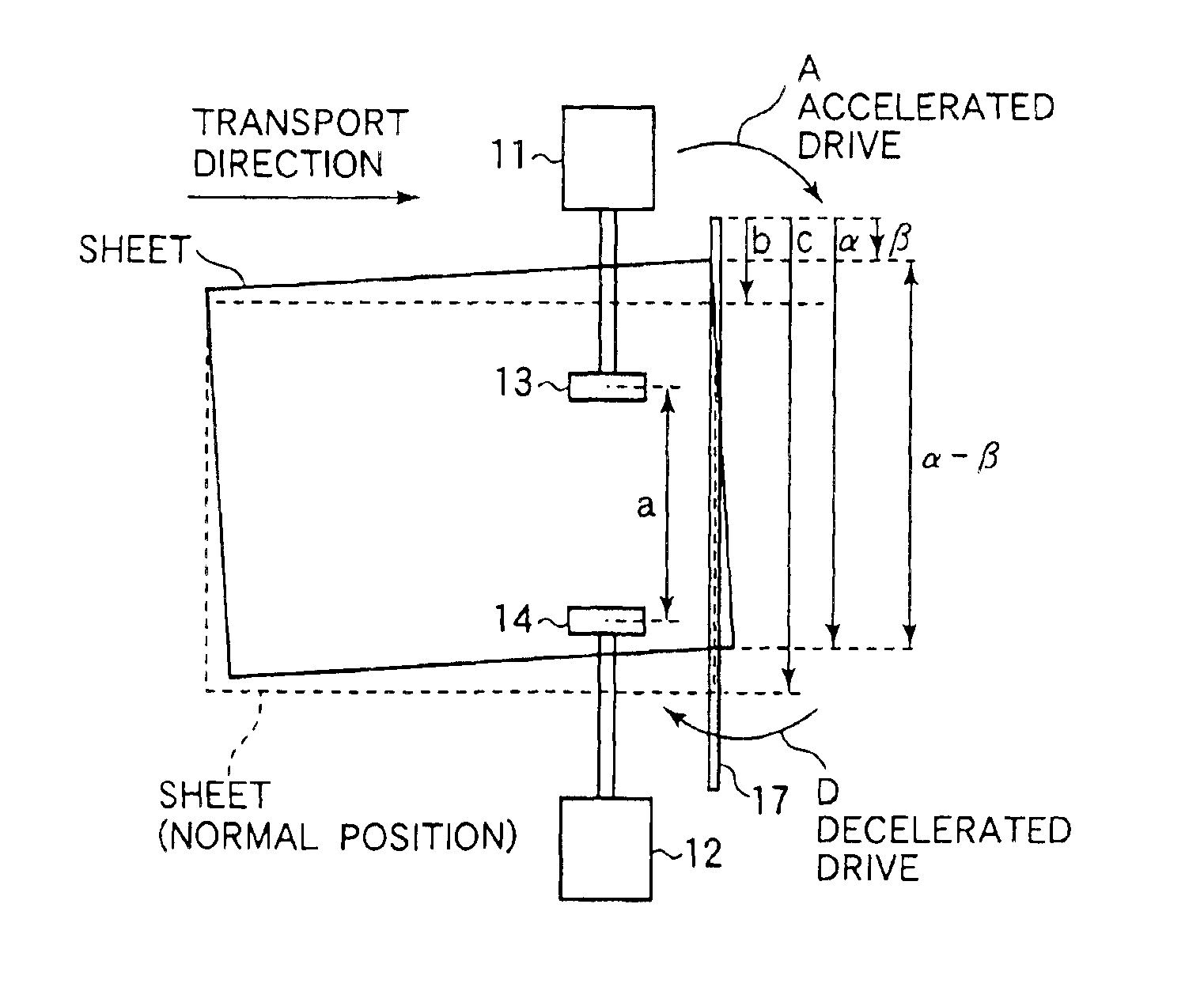

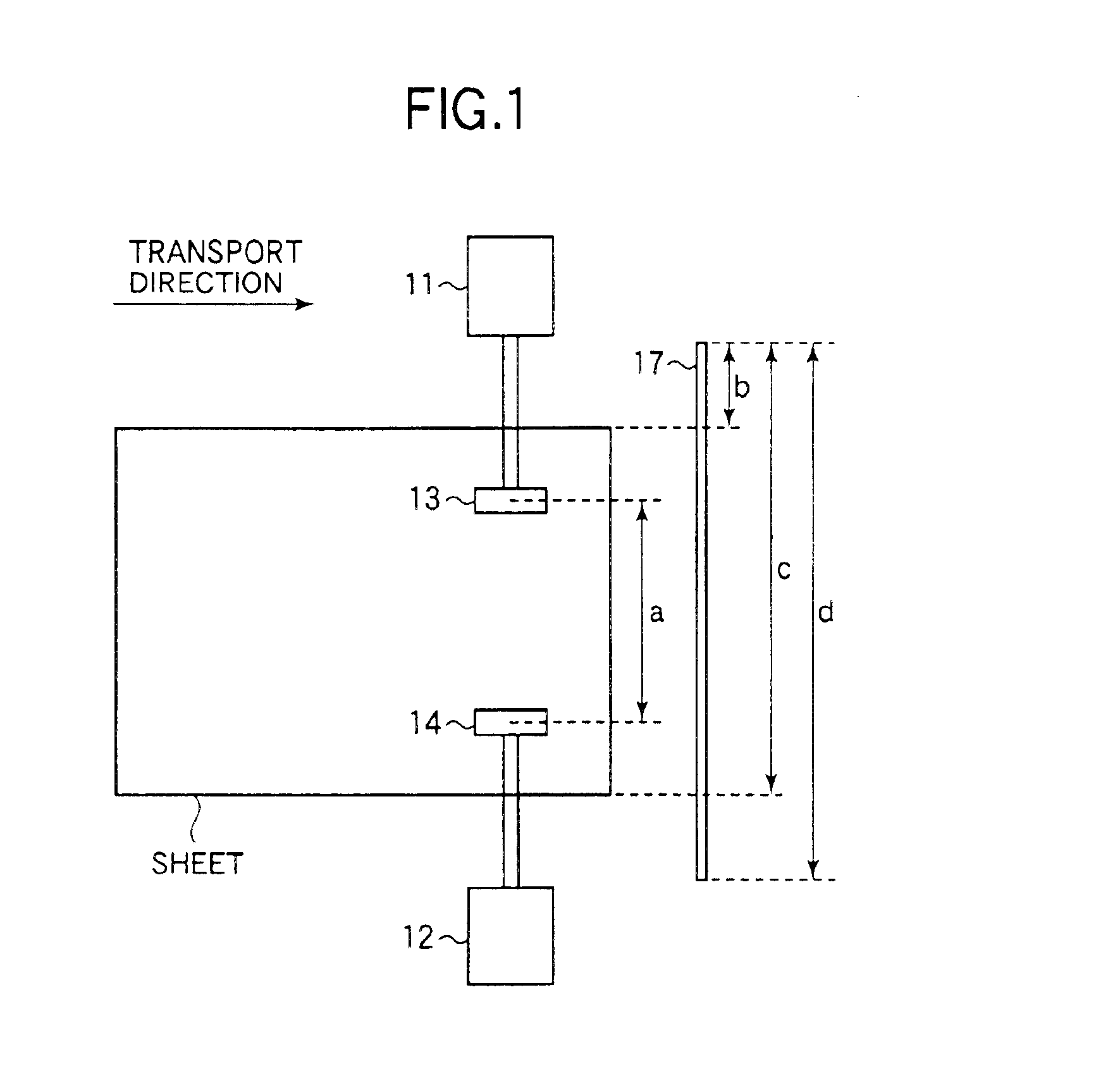

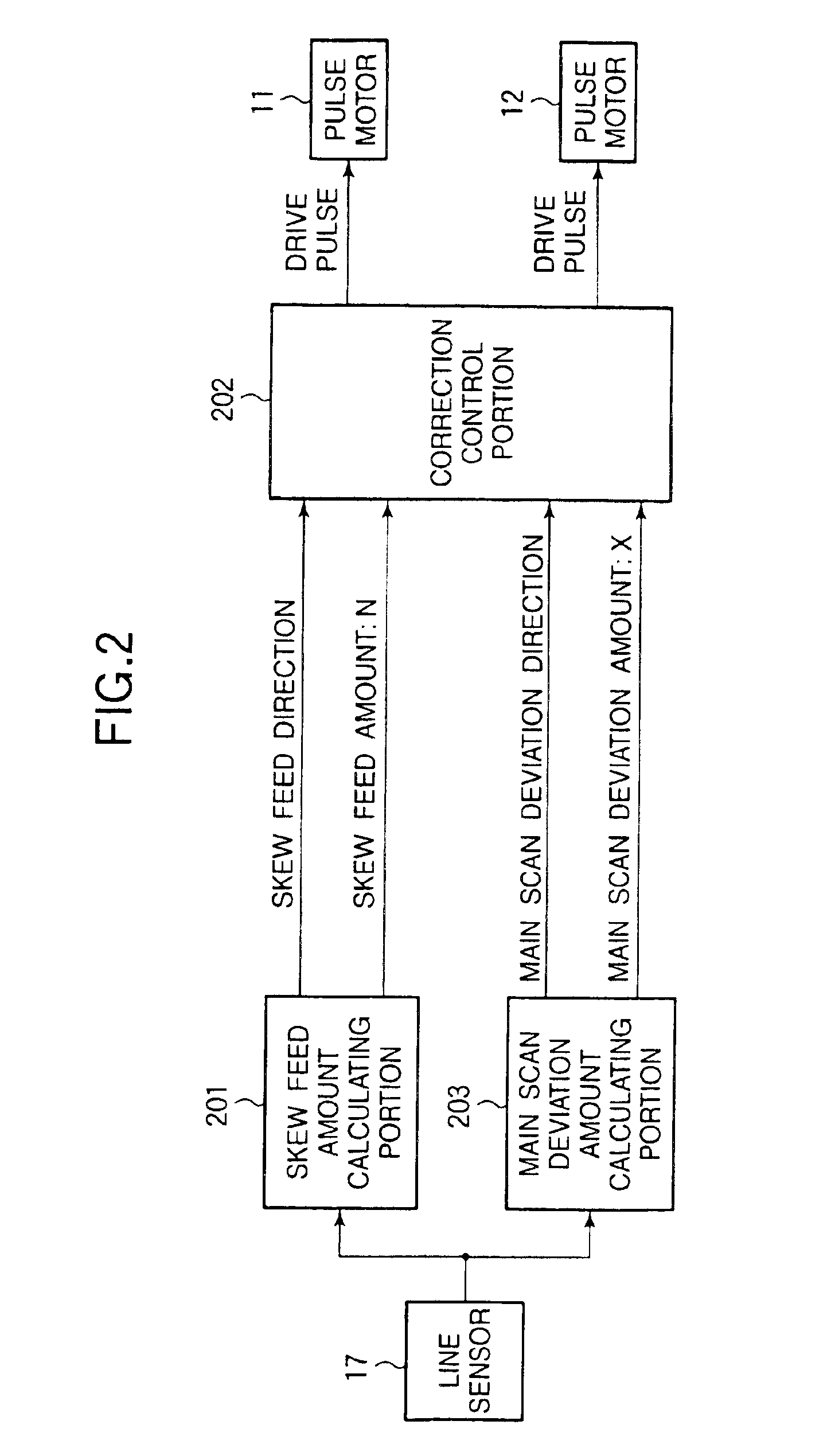

Sheet transporting apparatus

InactiveUS6862081B2Correct position deviationRegistering devicesOhmic-resistance heatingMechanical engineering

An image forming apparatus having a pair of sheet transporting members having rotary shafts on the same axis in a direction perpendicular to the transport direction of a sheet, and rotatively driven independently of each other to thereby transport the sheet, a detector provided along a cross direction perpendicular to the transport direction of the sheet for detecting the transported state of the sheet transported by the sheet transporting members, and a controller for drive-controlling the pair of sheet transporting members on the basis of the detection information of the detector, and effecting the correction of a sheet position in the cross direction and the correction of the skew feed posture of the sheet relative to the transport direction.

Owner:CANON KK

Substrate holding device, substrate processing apparatus using the same, and method for aligning and holding substrate

InactiveUS7123350B2Short timeCorrect position deviationSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineering

Owner:CANON KK

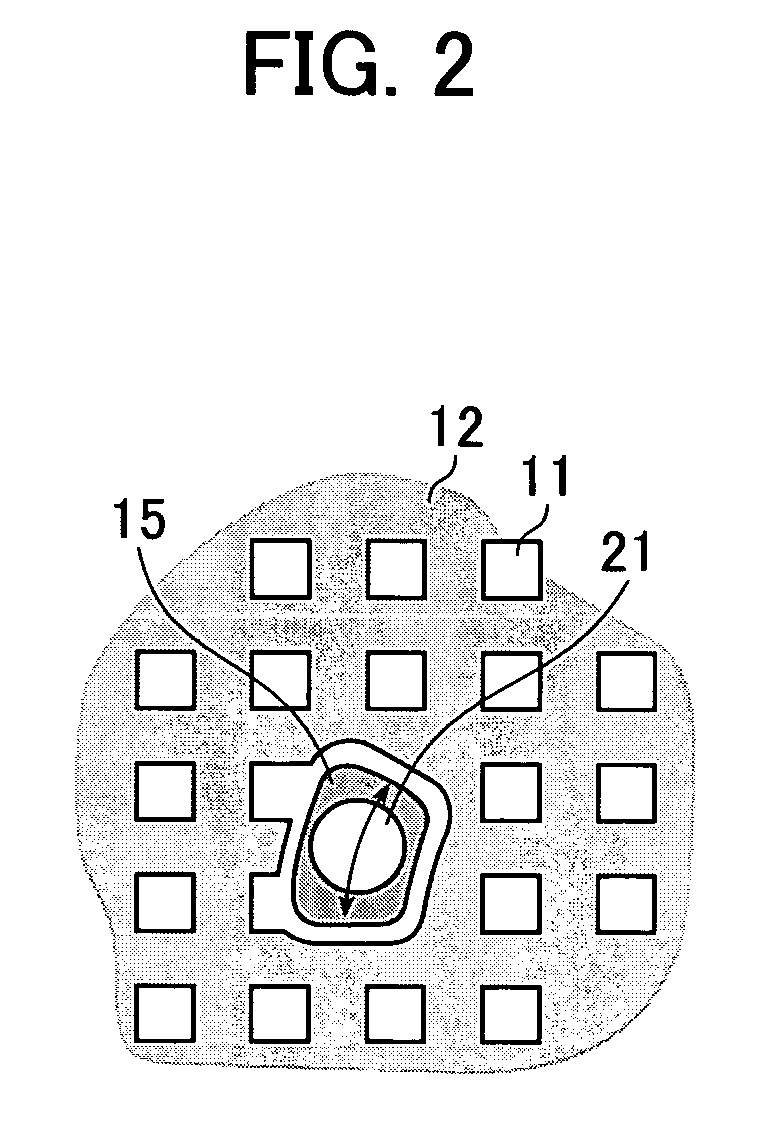

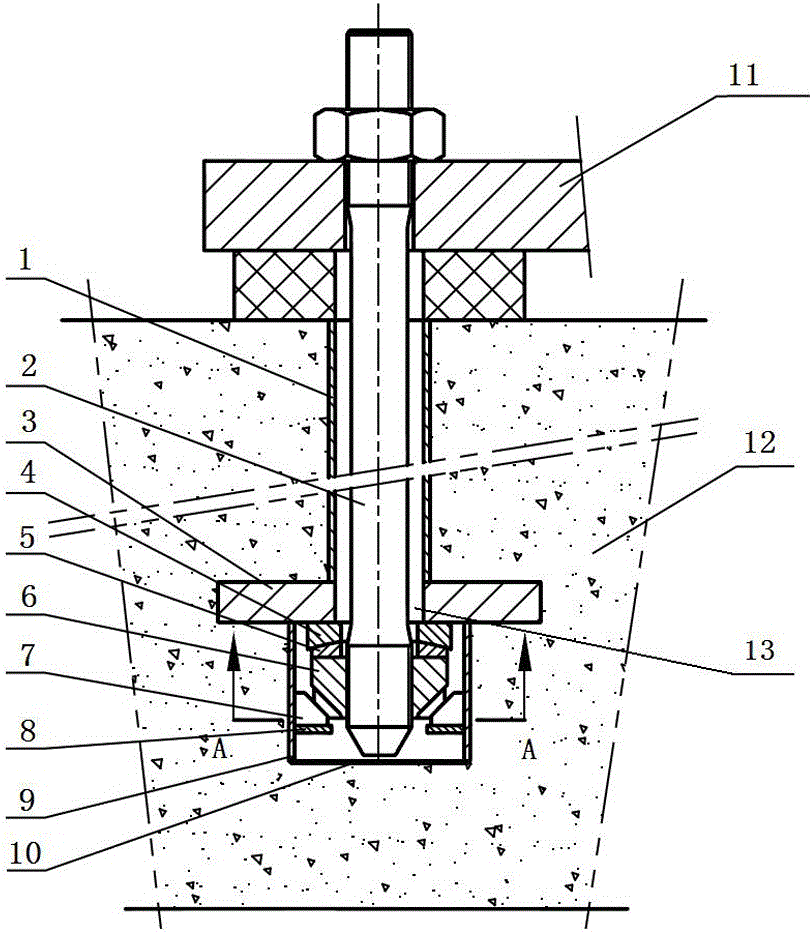

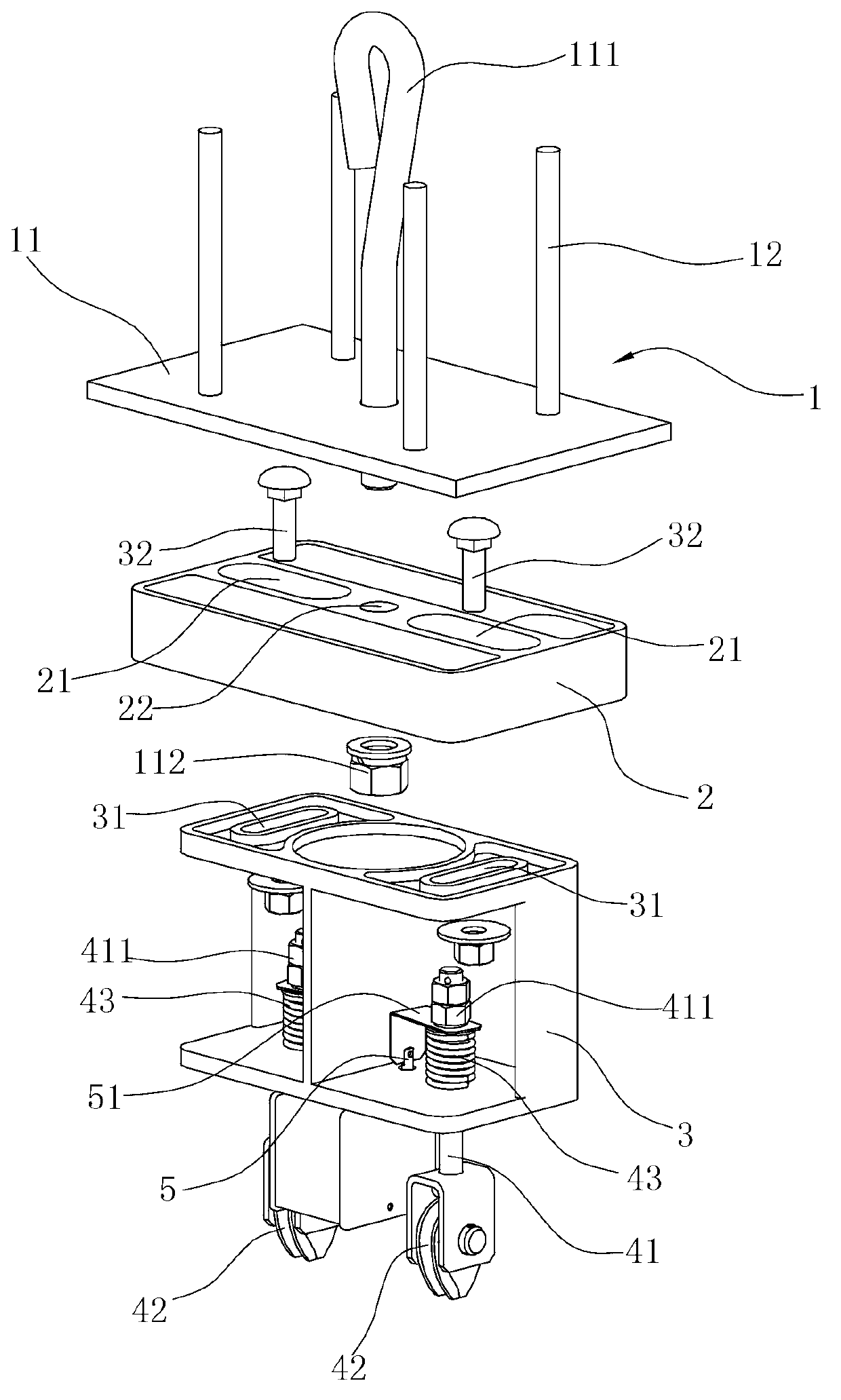

Adjustable foundation bolt pre-buried nut structure

ActiveCN106321587AEasily correct position deviationCorrect position deviationEngine sealsNutsAnchor boltConcave surface

The invention discloses an adjustable foundation bolt pre-buried nut structure. The adjustable foundation bolt pre-buried nut structure is characterized by comprising a sleeve, a foundation bolt, a buried plate, a concave surface ring, a convex surface ring and a pre-buried nut, wherein the sleeve is integrally welded to the buried plate and is buried in concrete; the ground bolt penetrates through the sleeve to a position below the buried plate; a concave surface ring, a convex surface ring and the buried nut sequentially sleeve the bolt below the buried plate; the outer diameter of the concave surface ring is larger than the inner diameter of the sleeve; a space for the concave surface ring, the convex surface ring and the pre-buried nut to move is preserved below the buried plate; and the inner diameter of the sleeve is larger than the outer diameter of the ground bolt, so that a horizontal displacement space for the foundation bolt exists in the sleeve. By using the structure, position degree deviation and perpendicularity deviation of the foundation bolt pre-buried component can be corrected, so that the phenomenon that equipment interference or reworking is caused when design requirement cannot be met during on-site assembly, so that assembly progress is affected is avoided.

Owner:DONGFANG TURBINE CO LTD

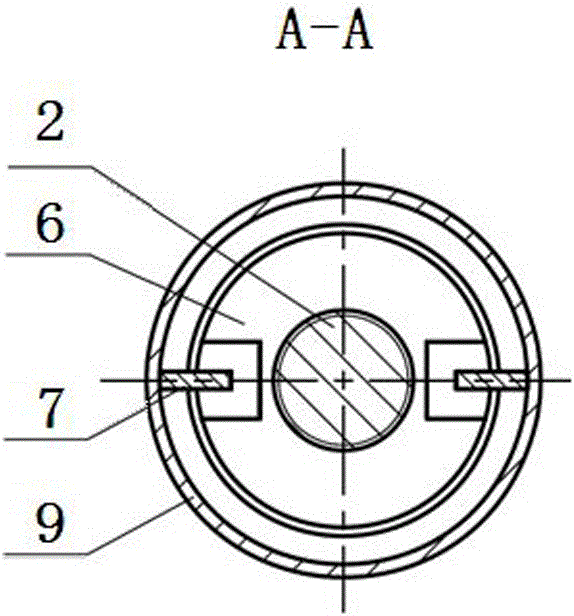

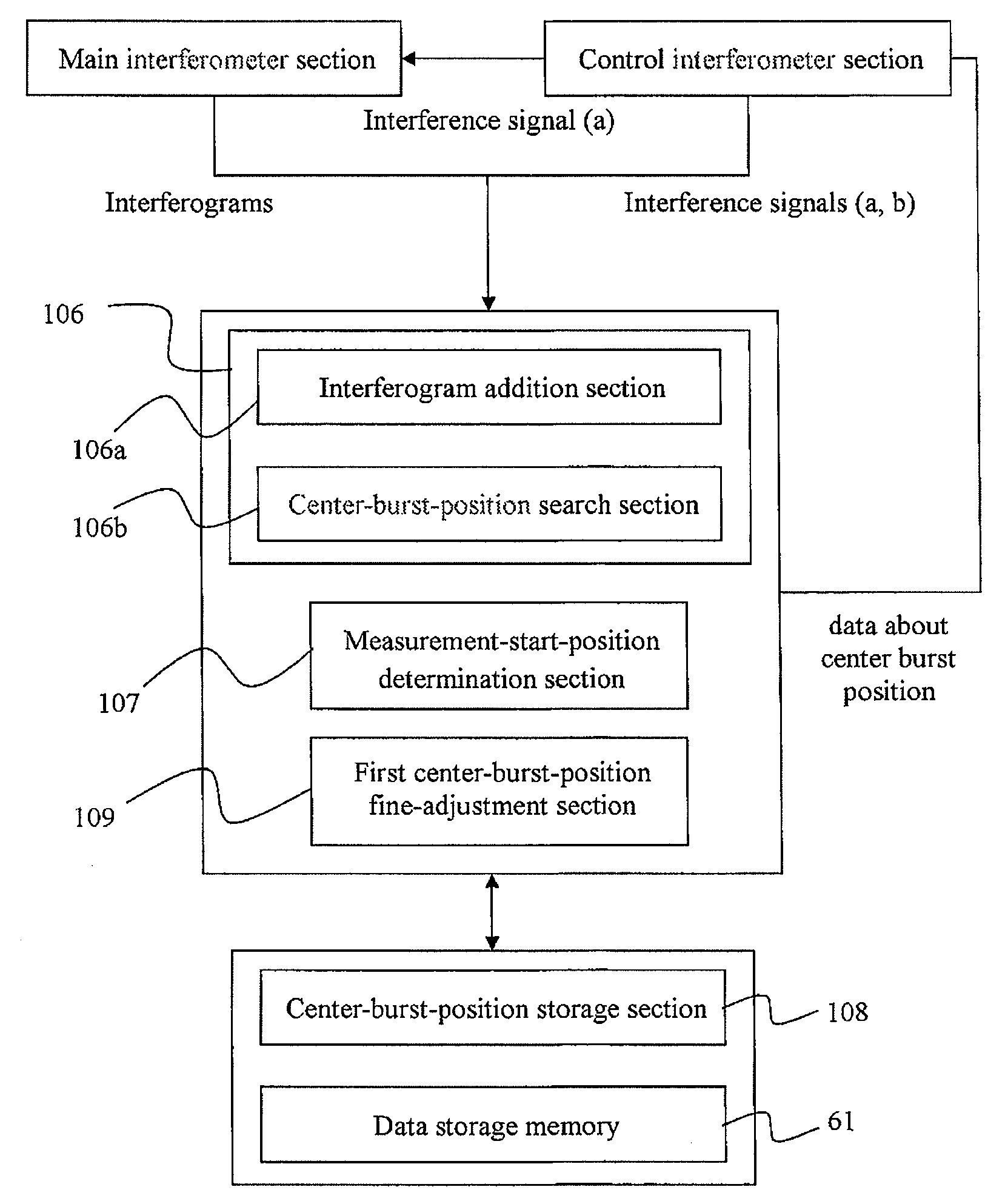

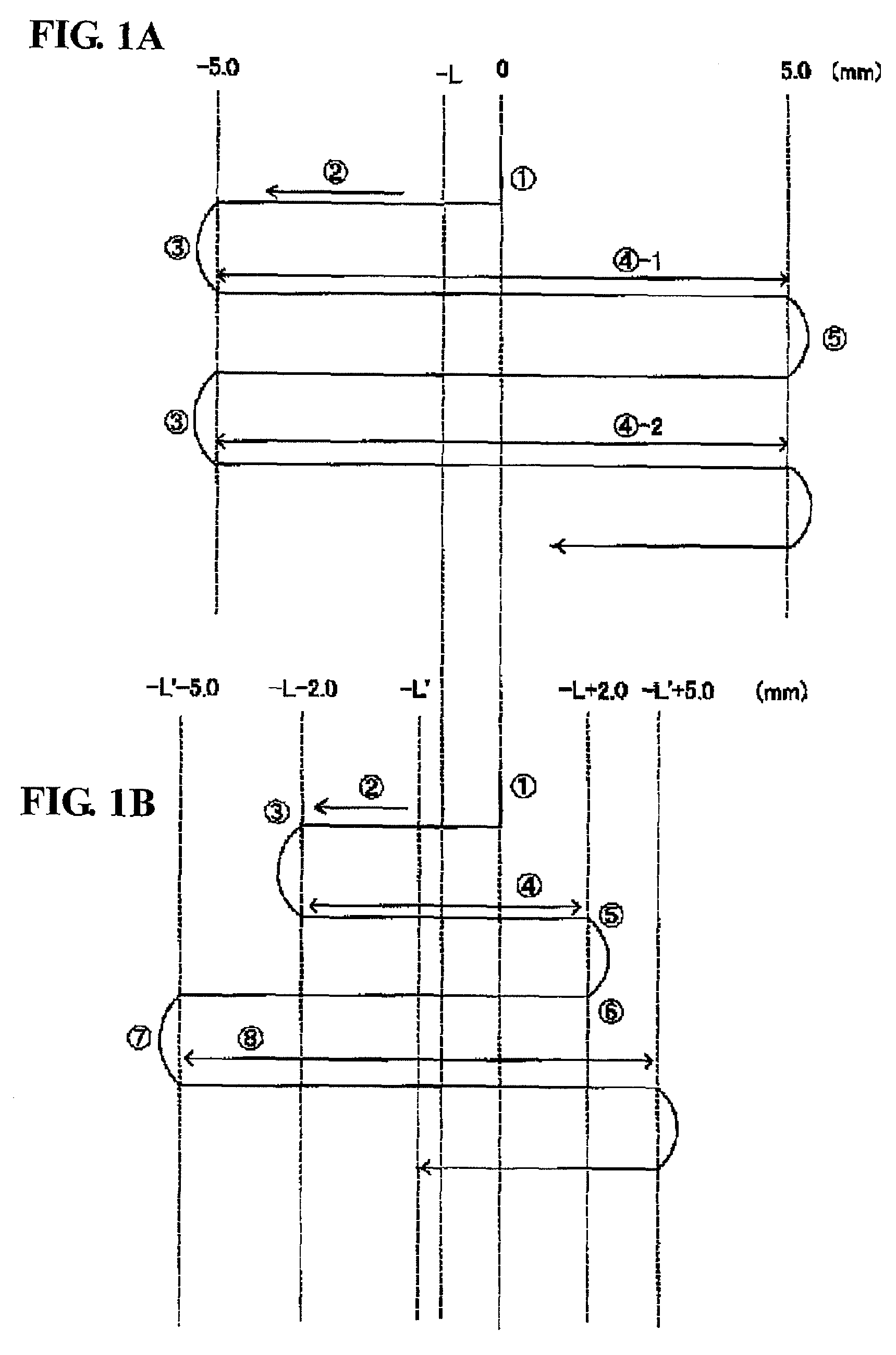

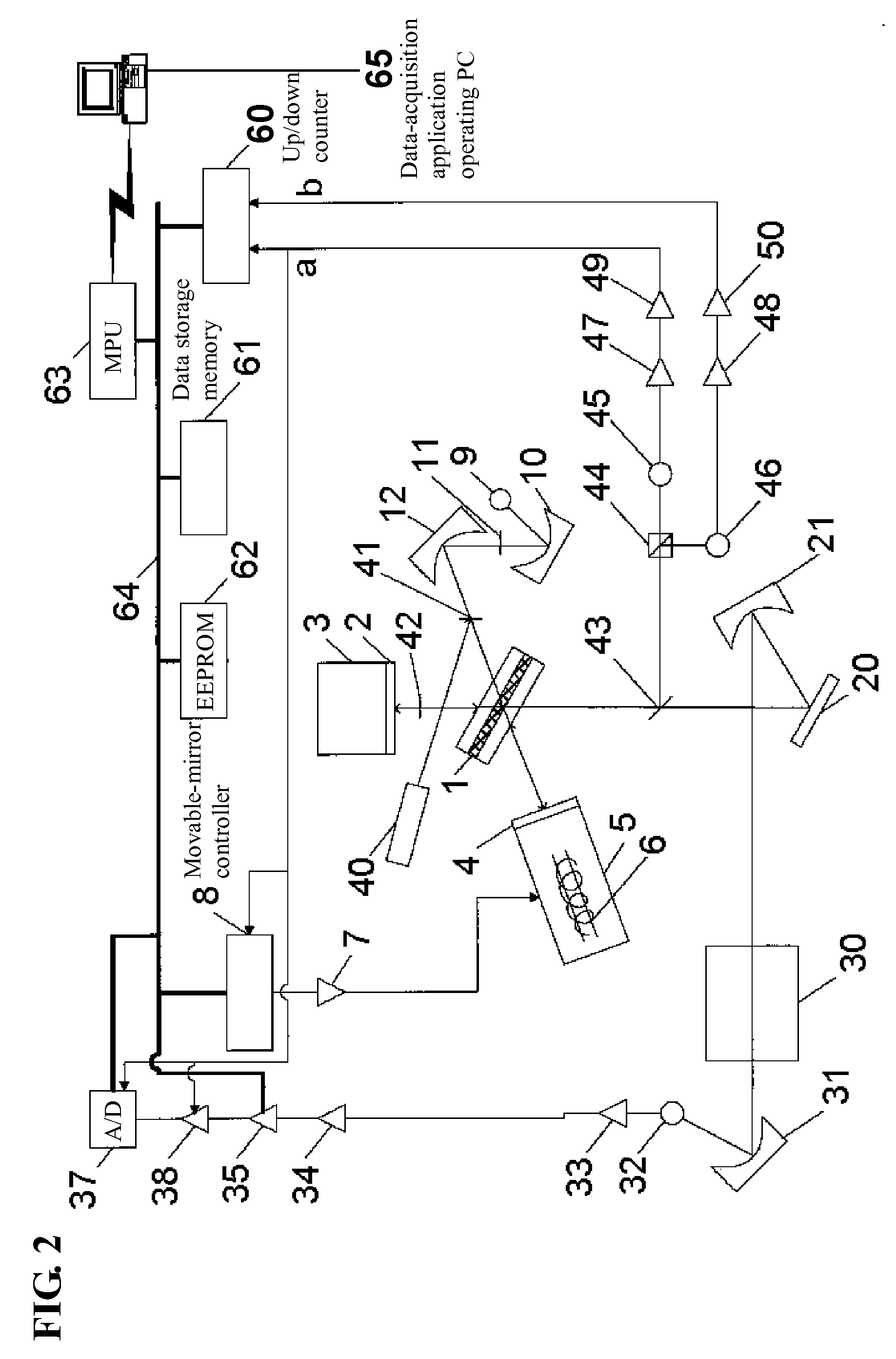

Fourier transform infrared spectrophotometer

InactiveUS20080315103A1Accurate detectionIncrease the number ofRadiation pyrometryInterferometric spectrometryLocation detectionBeam splitter

Disclosed is a Fourier transform infrared spectrophotometer, which comprises: a main interferometer section including a beam splitter, a fixed mirror, a movable mirror, and a phase plate disposed between the beam splitter and the fixed mirror; a control interferometer section having a quadrature control system for calculating a position of the movable mirror; a center-burst-position detection section operable, based on an input of interference signals and interferograms, to subject respective intensities of the interferograms to an addition processing while correcting a positional deviation of the movable mirror, so as to obtain a cumulative interferogram, and detecting a center burst position having a maximum intensity value in the cumulative interferogram; a center-burst-position storage section operable to store the detected center burst position; and a measurement-start-position determination section operable, based on the stored center burst position, to determine a measurement start position of the movable mirror during the measurement operation.

Owner:SHIMADZU CORP

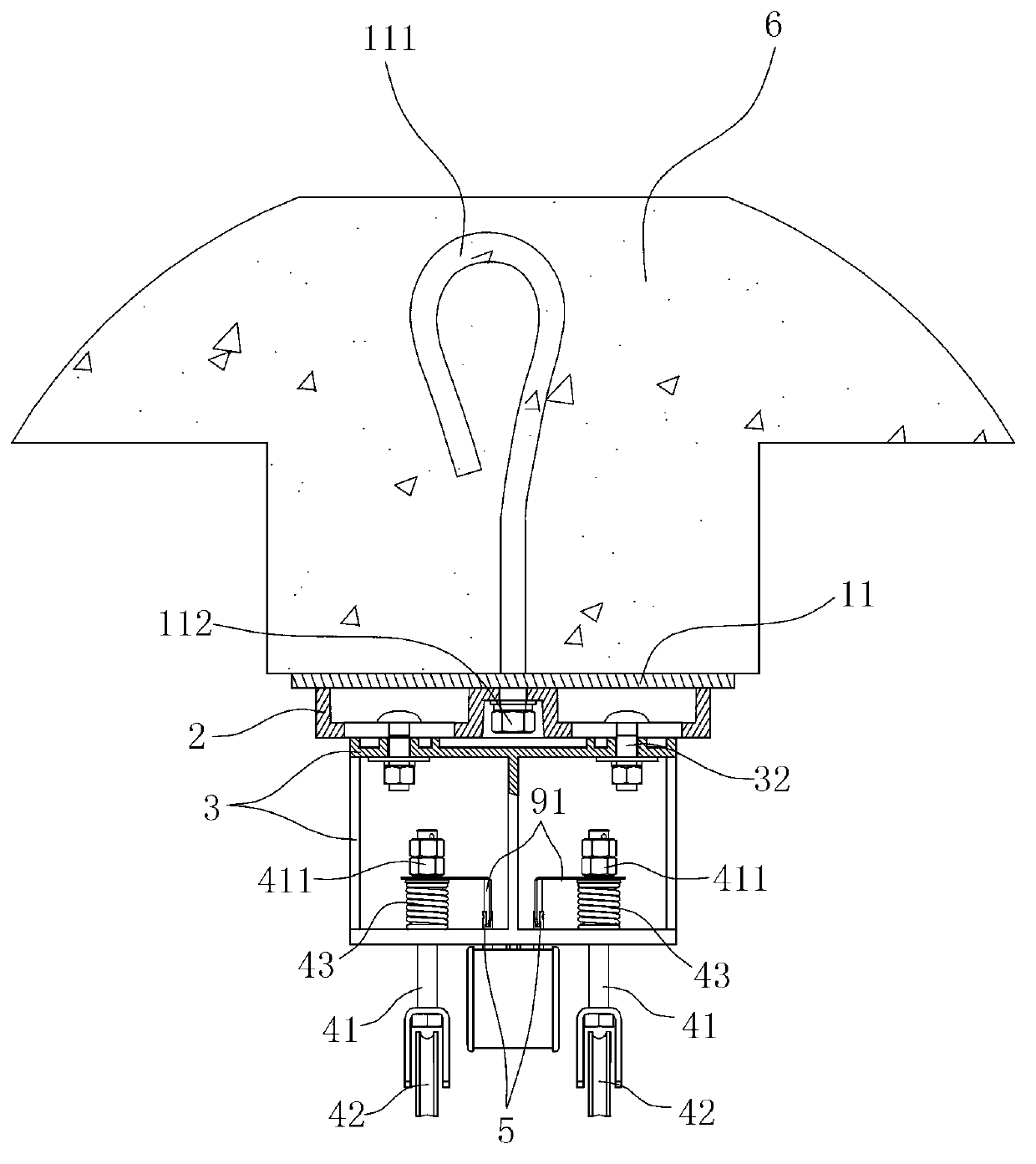

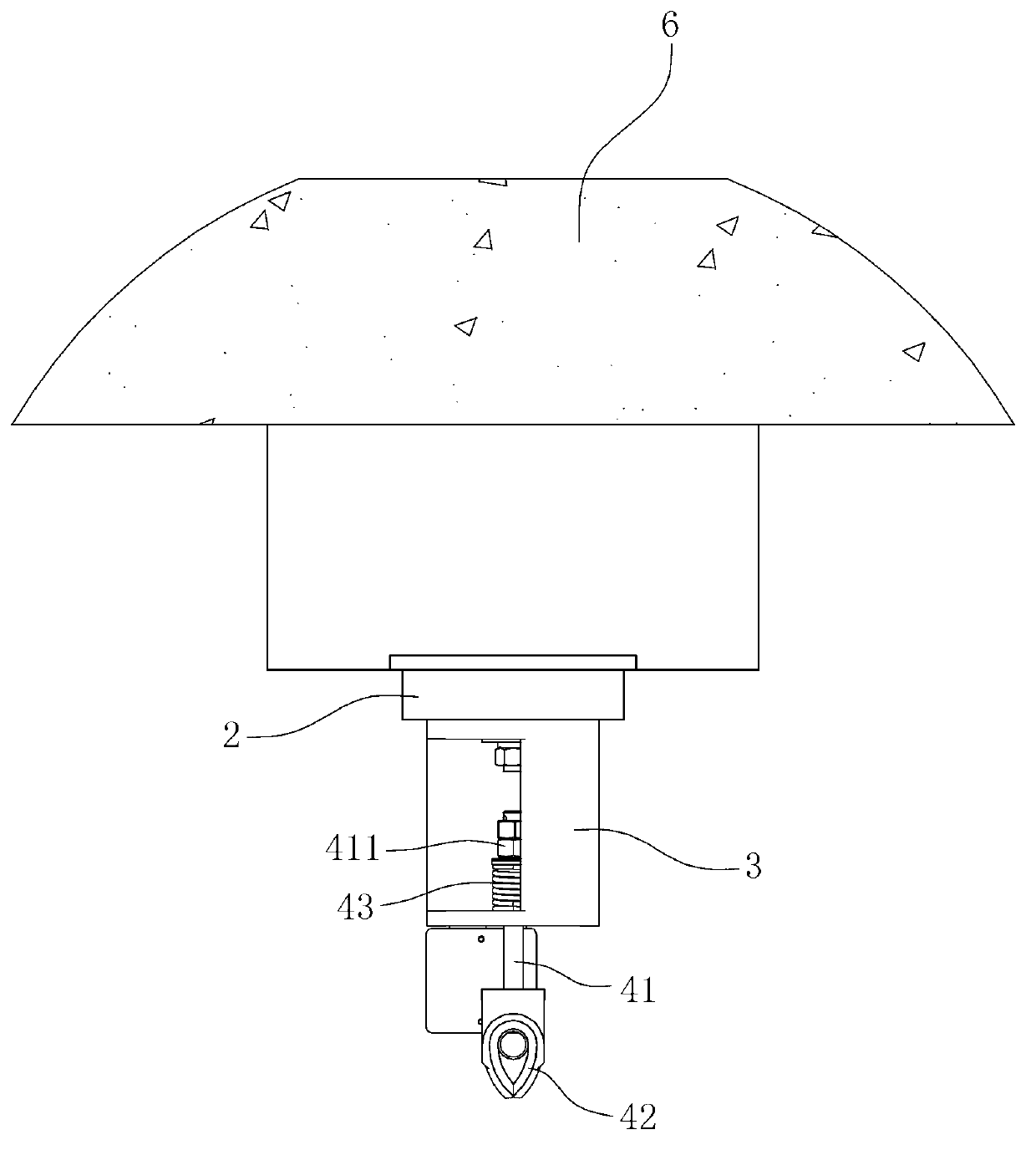

Pre-buried-type hanging device

ActiveCN103104118ACorrect position deviationRealize intelligent controlParkingsElectronic switchEngineering

A pre-buried-type hanging device is characterized by comprising a pre-buried part, a hanging part, a rope-loosening-prevention device and an adjustment device, wherein the pre-buried part is connected in a construction top plate and is fixedly connected with the construction top plate, the hanging part is connected with a loading car plate through a hoisting rope in a hanging mode, when the hoisting rope of the loading car plate is loosened or broken, the rope-loosening-prevention device cuts off a power source and stops operation of the loading car plate, the adjustment device is used for adjusting the position of the hanging part relative to a hanging end of the loading car plate, the top of the adjustment device is connected with the pre-buried part, and the hanging part is connected with the bottom of the adjustment device. The pre-buried-type hanging device is simple in structure, high in overall connection strength and capable of achieving the position adjustment along the X-axis coordinate and the Y-axis coordinate, corrects the position deviation in the installation process of the pre-buried part, conveniently and flexibly adjusts the position of the hanging device relative to the hanging end of the loading car plate, and guarantees the positioning accuracy between the hanging device and the loading car plate. The hanging device is provided with an electronic switch, and therefore intelligent control of operation of the loading car plate is benefited, and safety and reliability of the operation of the loading car plate are guaranteed.

Actuator for manipulation of liquid droplets

InactiveUS7735967B2Easy loadingIncrease the number ofSludge treatmentVolume/mass flow measurementDielectricActuator

Owner:HITACHI LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com