Trajectory tracking control methods and trajectory tracking systems

A control method and trajectory tracking technology, which is applied in the direction of program control manipulators, manufacturing tools, manipulators, etc., can solve the problems of large trajectory tracking error, unrealizable, cumbersome tracking system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

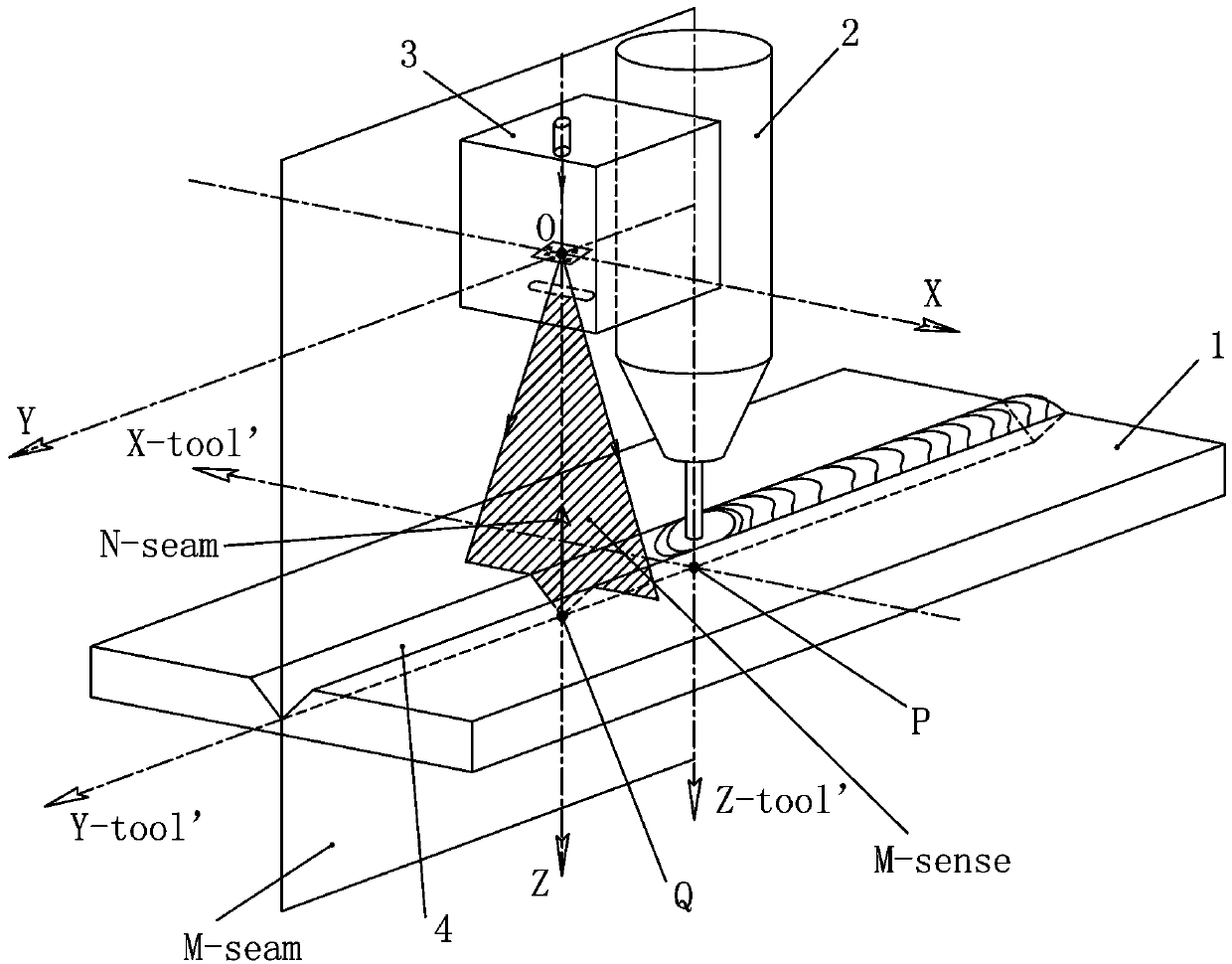

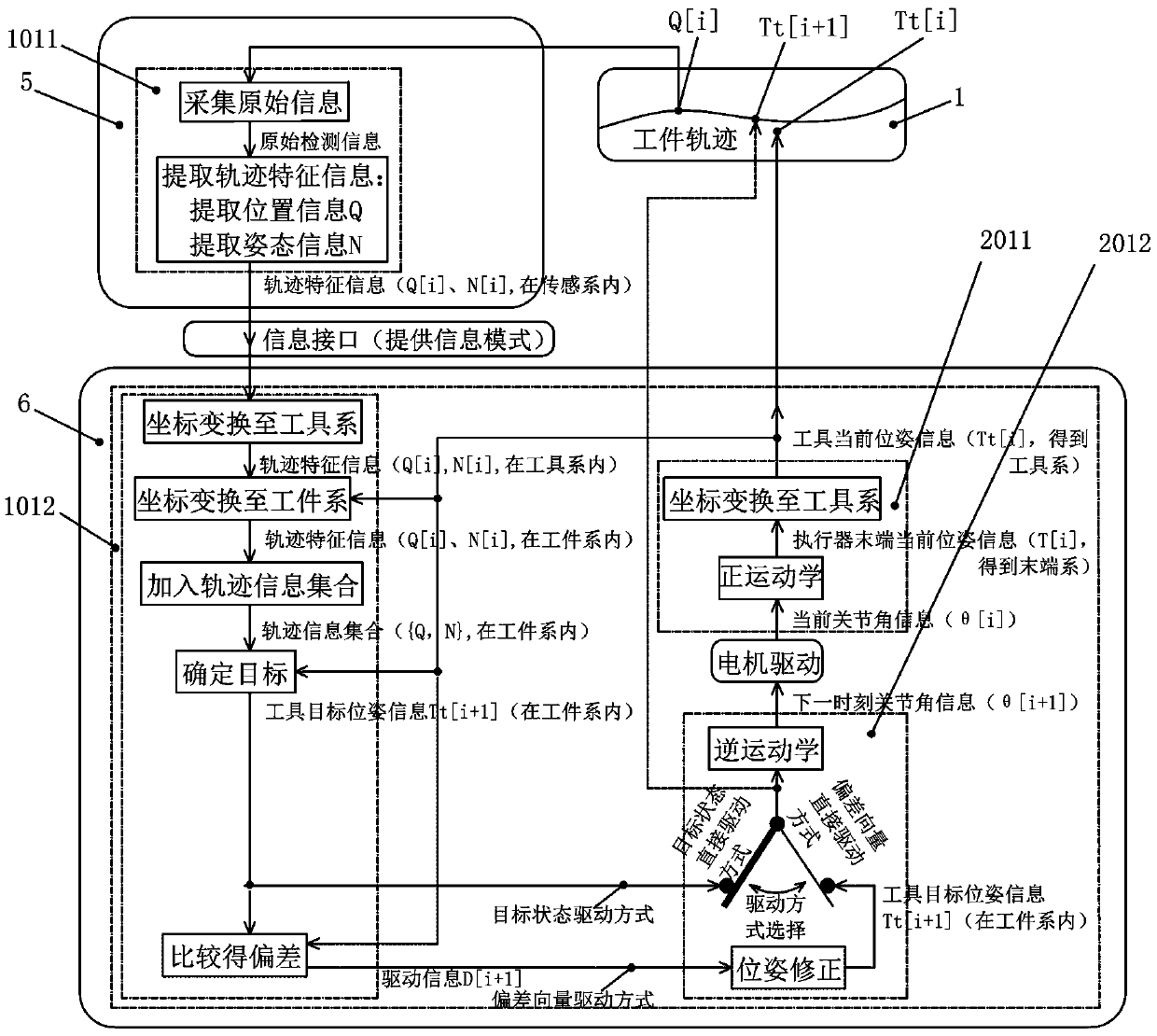

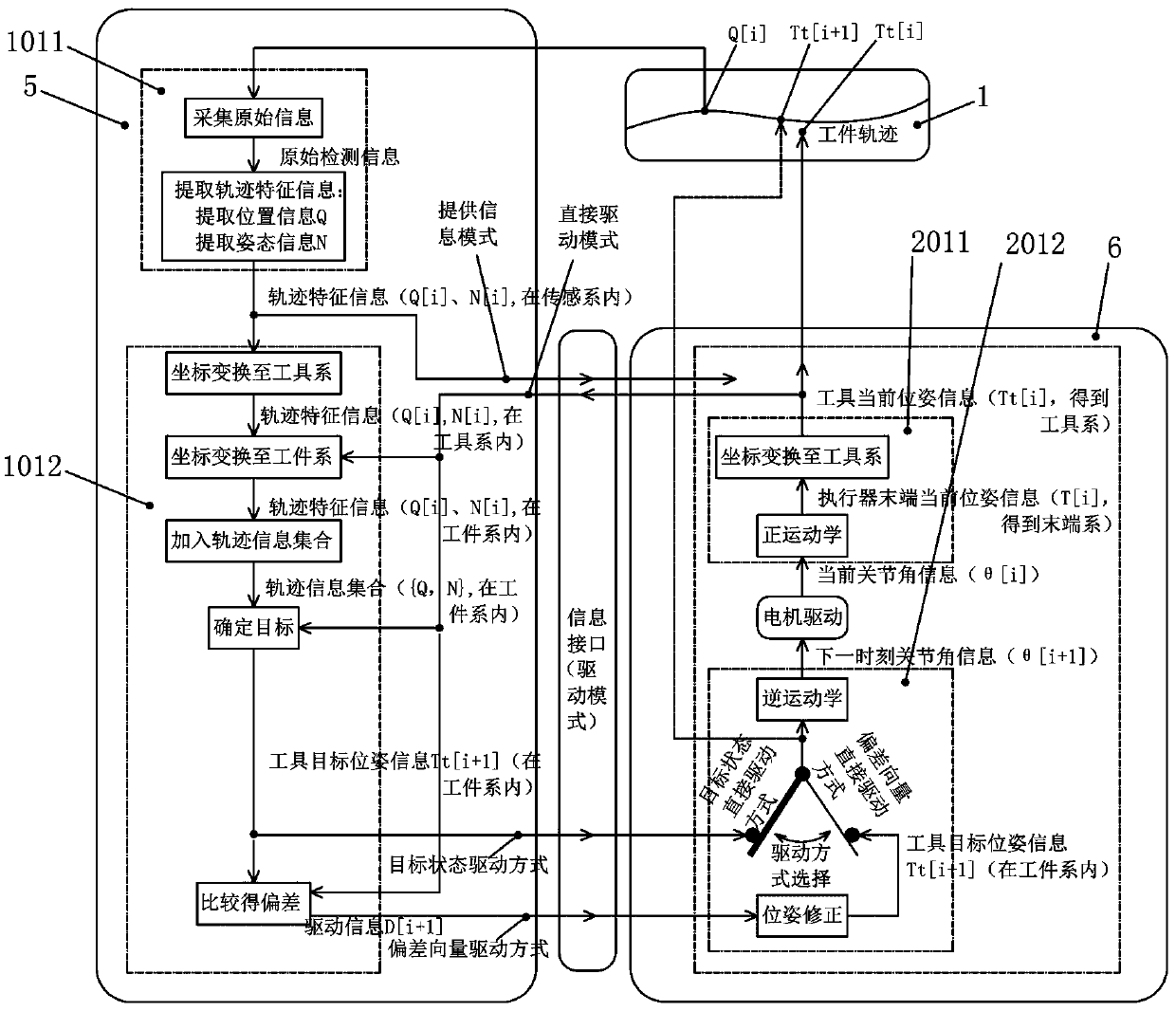

[0135] In the trajectory tracking control method described in this embodiment, the tool 2 is attached to the actuator, the sensor 3 is attached to the joint of the actuator or the sensor 3 is directly attached to the tool 2, and the relative position between the sensor 3 and the tool 2 has The determined geometric relationship specifically includes the following steps:

[0136] The first step: detection trajectory: the original trajectory information of the detection point on the trajectory on the workpiece 1 is collected by the sensor 3. The sensor 3 involved here can convert the detected visual information into the original trajectory information. At present, this type of sensor is generally a visual sensor , the present invention is described by taking a typical structured light vision sensor as an example.

[0137] The second step: Extract trajectory information: extract the position information of the detection point from the original trajectory information, and express t...

Embodiment 2

[0179] The difference between this embodiment and Embodiment 1 is that this embodiment is based on the reference point Ref-A, and instead of using the above-mentioned current control reference point Ref-A as the tracking target, it uses the control interval time t The subsequent control reference point Ref-A-next is the tracking target. In this embodiment, according to the trajectory position information set {Q}, the specific determination method for determining the target position of tool 2 at the next moment is as follows: take the reference point Ref-A as the center of the sphere, and use △=V*t as the radius to make a spherical surface, the There are two intersection points between the spherical surface and the characteristic line of the trajectory. Take the intersection of the spherical surface and the characteristic line of the trajectory in the forward direction of the tool as the control reference point Ref-A-next, and take the control reference point Ref-A-next as the t...

Embodiment 3

[0184] The difference between this embodiment and the first embodiment is that in the fourth step of determining the target, this embodiment determines the target position and attitude of the tool 2 at the next moment based on the track position information set {Q}, and also Further obtain the position and attitude deviation information between the target position of the tool 2 at the current moment and the target position of the tool at the next moment. The specific development of other steps of the trajectory tracking control method is the same as that of the first embodiment, and will not be repeated here. The specific trajectory tracking control method includes the following steps:

[0185] The first step: detecting the trajectory: the original trajectory information of the trajectory detection point on the workpiece is collected by the sensor 3 .

[0186] The second step: Extract trajectory information: extract the position information of the detection point from the orig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com