Patents

Literature

144results about How to "Stable and accurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

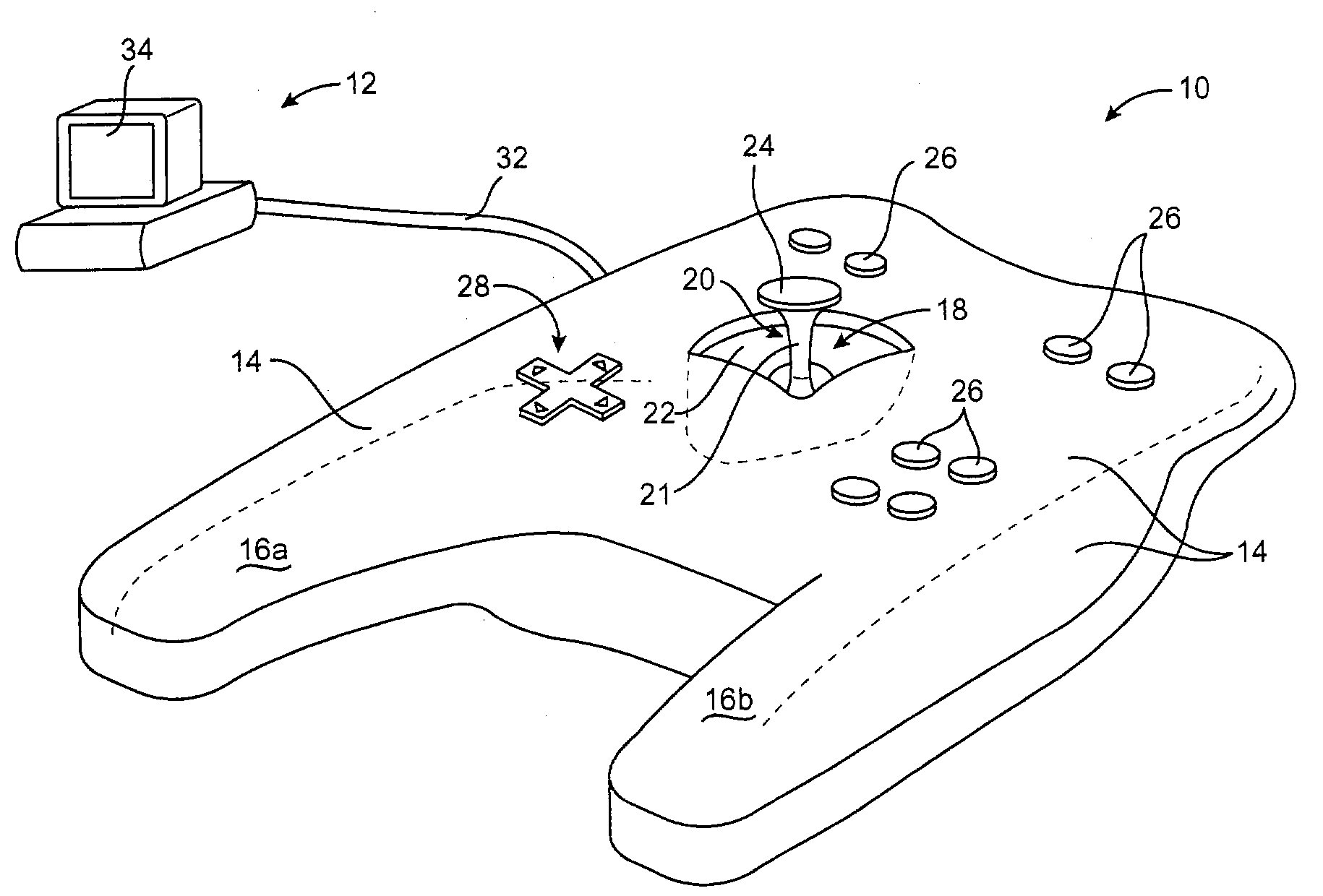

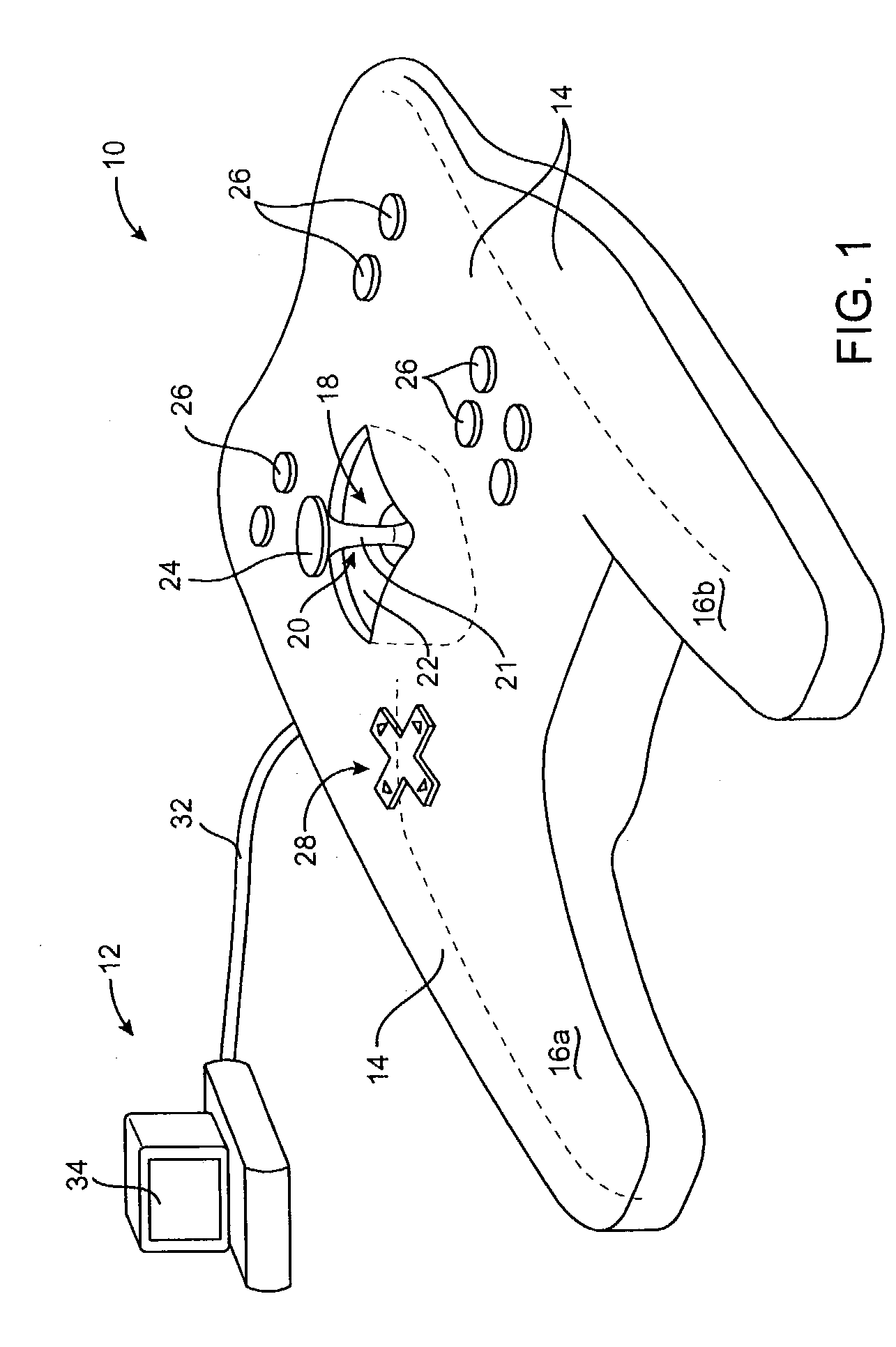

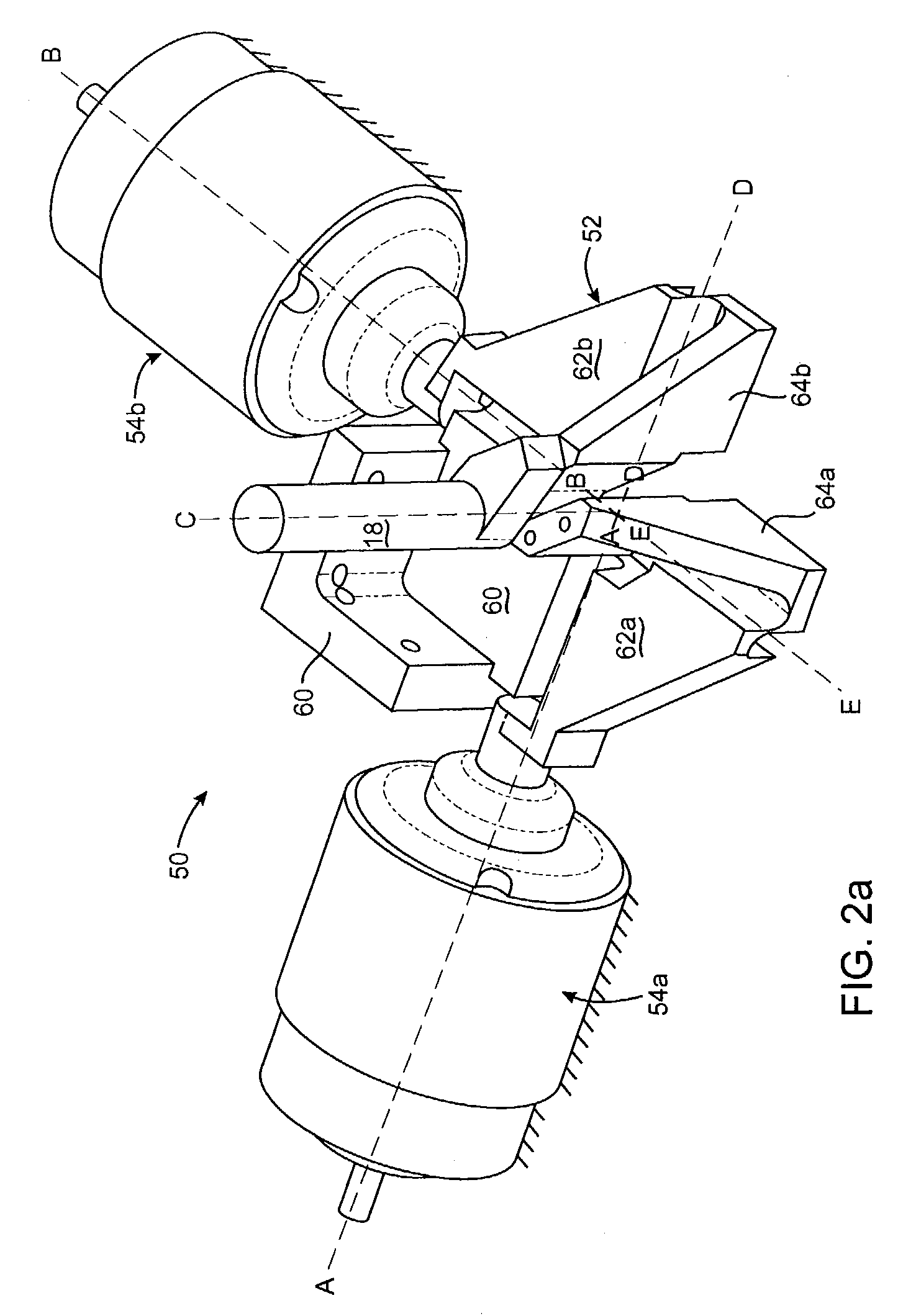

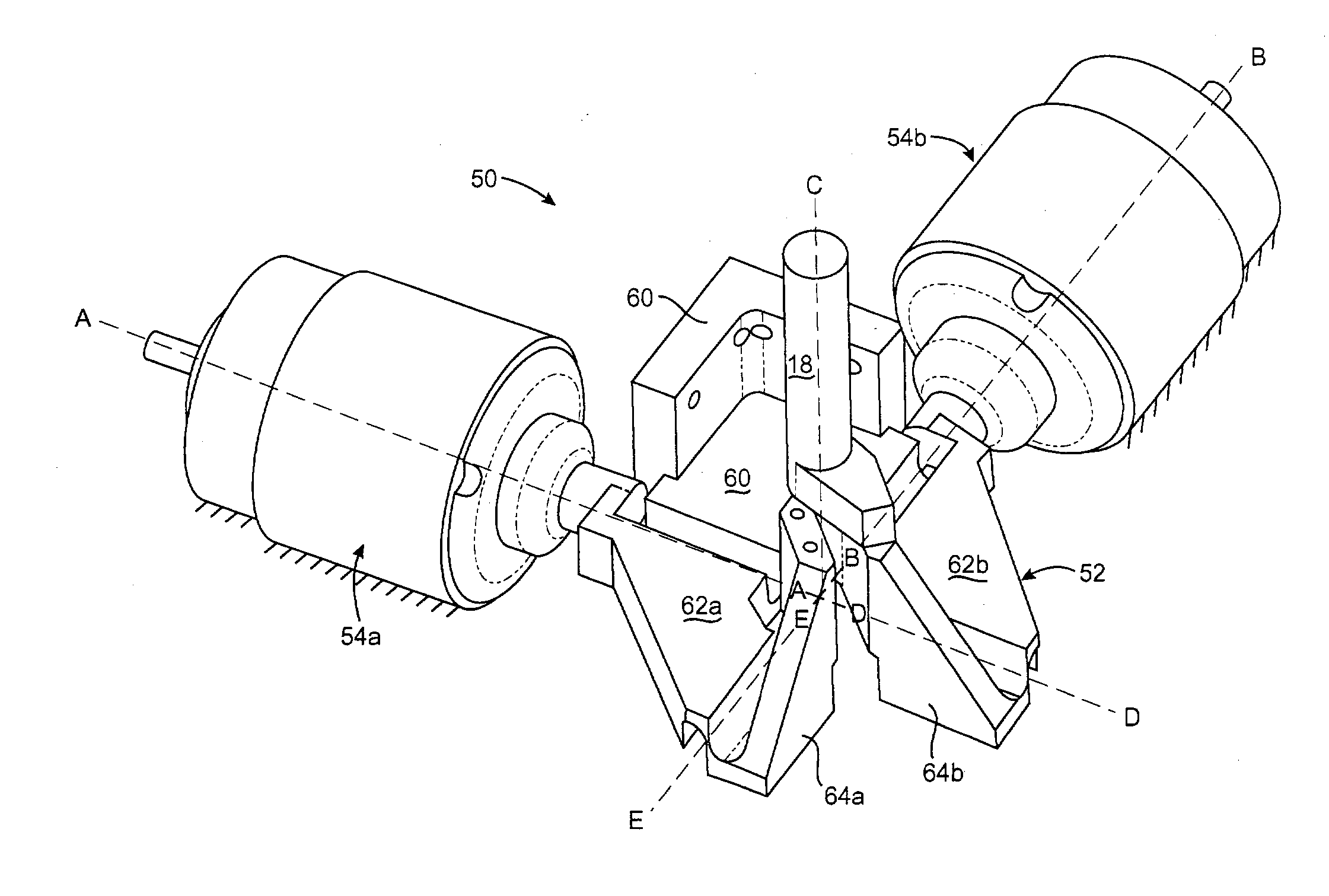

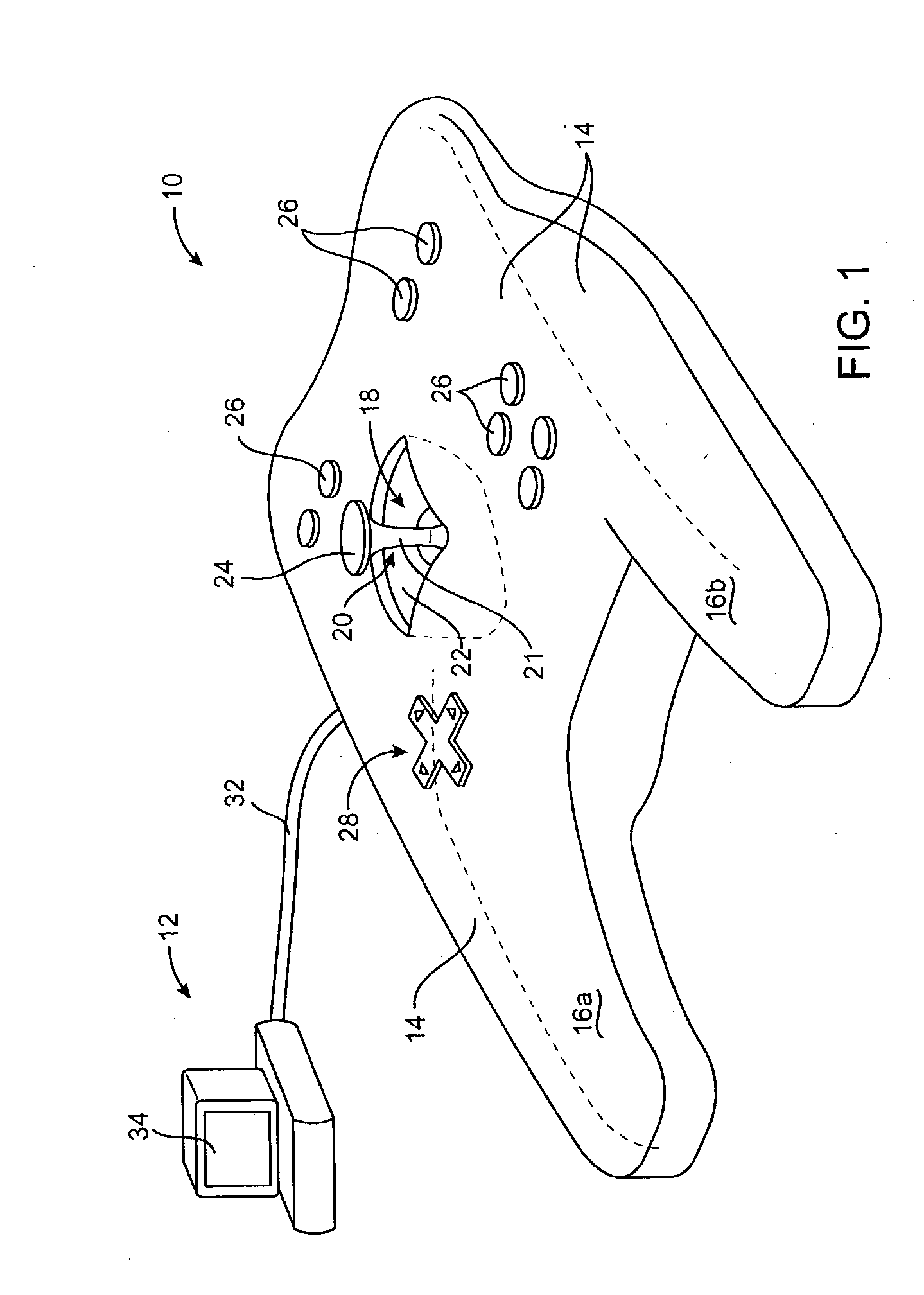

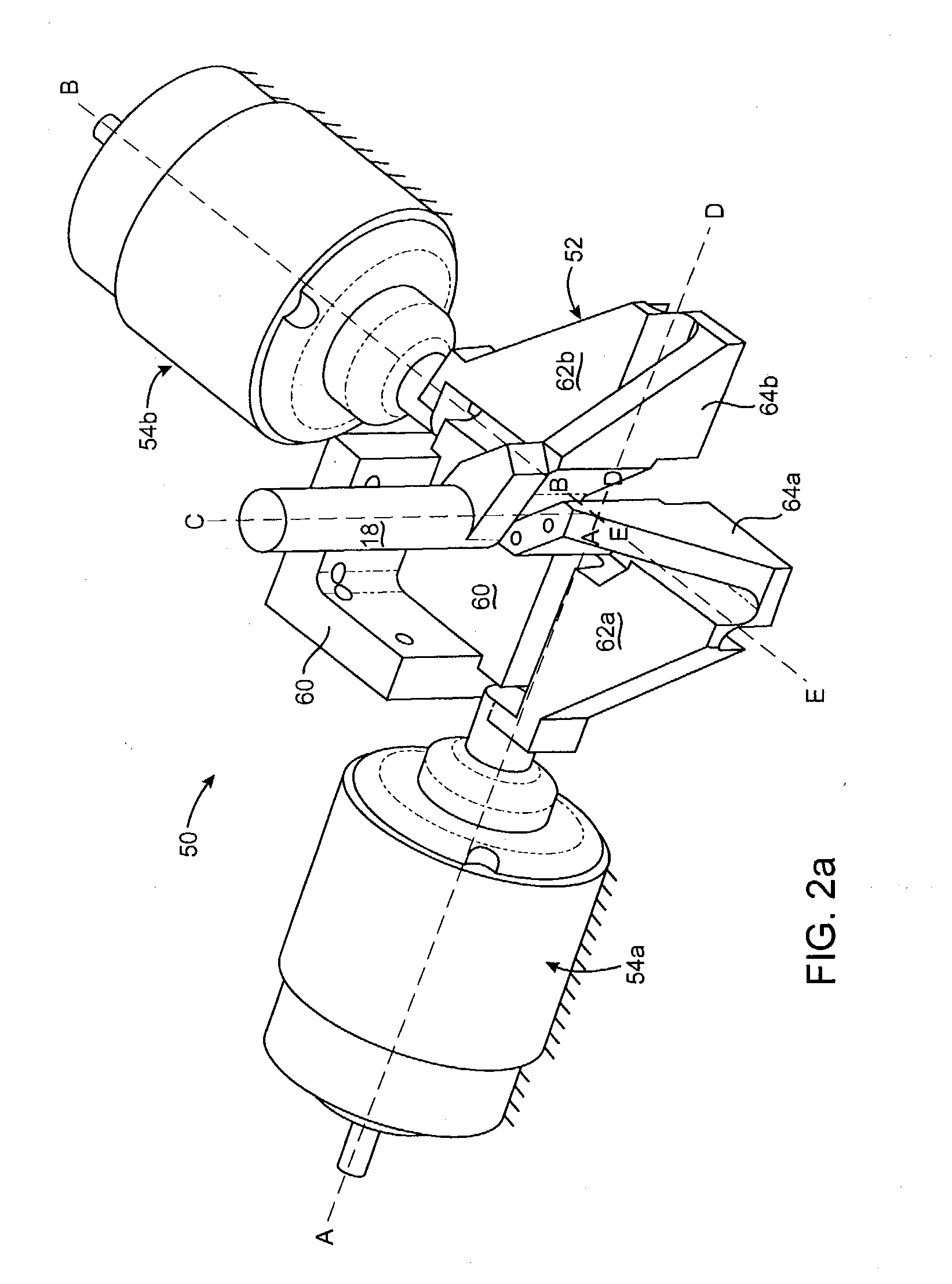

Flexure mechanism for interface device

InactiveUS7193607B2Low costEasy to manufactureInput/output for user-computer interactionManual control with multiple controlled membersCouplingClosed loop

A flexure mechanism for an interface device that interfaces a user with a computer system. An interface device includes a manipulandum physically contacted by the user. A five-bar closed-loop mechanism is coupled to the manipulandum to provide two rotary degrees of freedom to the manipulandum. The mechanism includes members coupled to each other by flexible couplings allowing rotation of the members. In preferred embodiments, four or five of the members are coupled together by flexible couplings that allow bending, thereby forming a unitary piece, where the couplings are oriented along axes of rotation of the mechanism. A senor senses a position of the manipulandum outputs a sensor signal, and in some embodiments actuators are coupled to the mechanism to output a force to the manipulandum in particular degrees of freedom. The manipulandum can be a joystick handle or portion of a sphere, where the device in one embodiment can be a handheld gamepad or similar controller.

Owner:IMMERSION CORPORATION

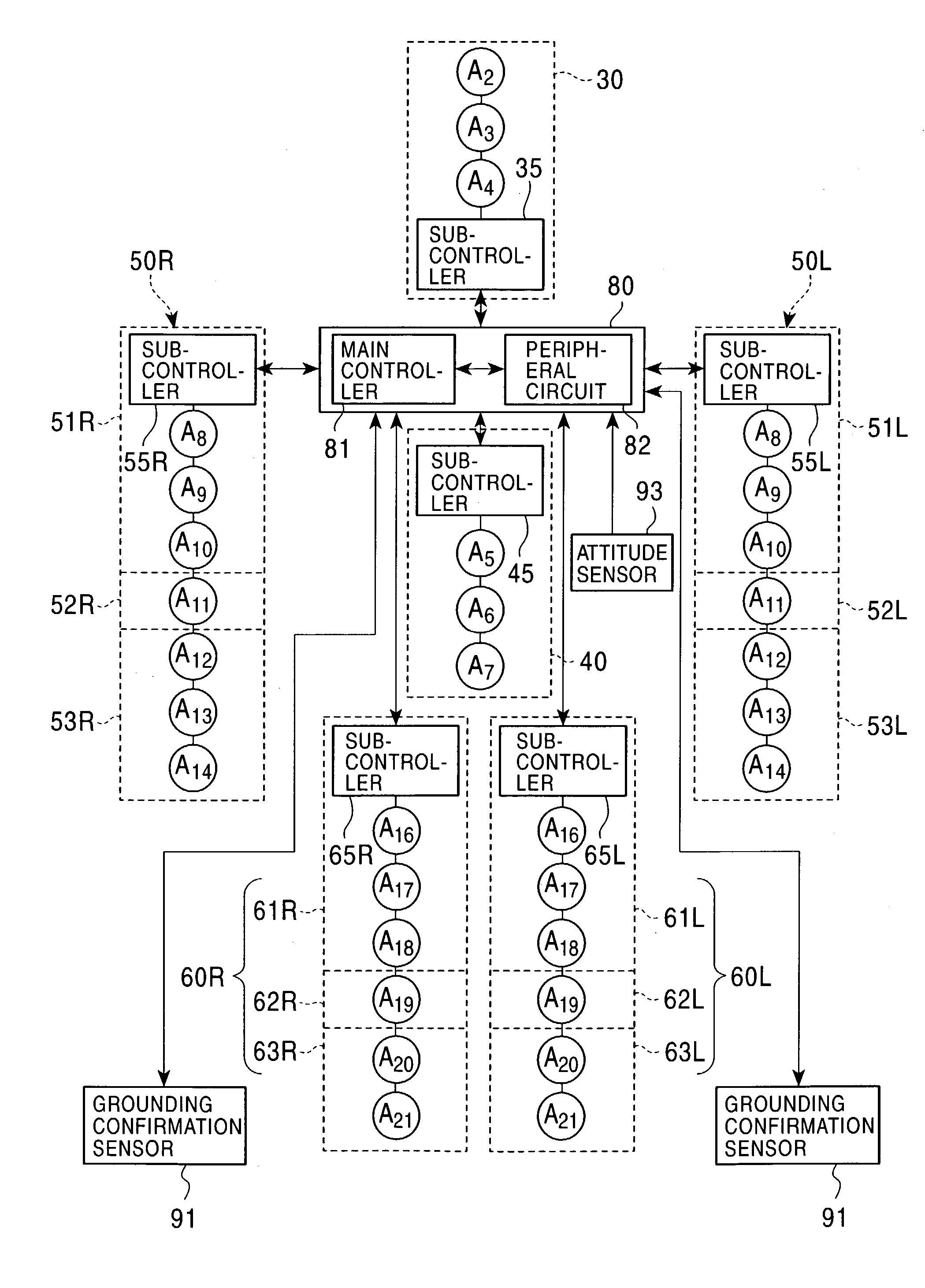

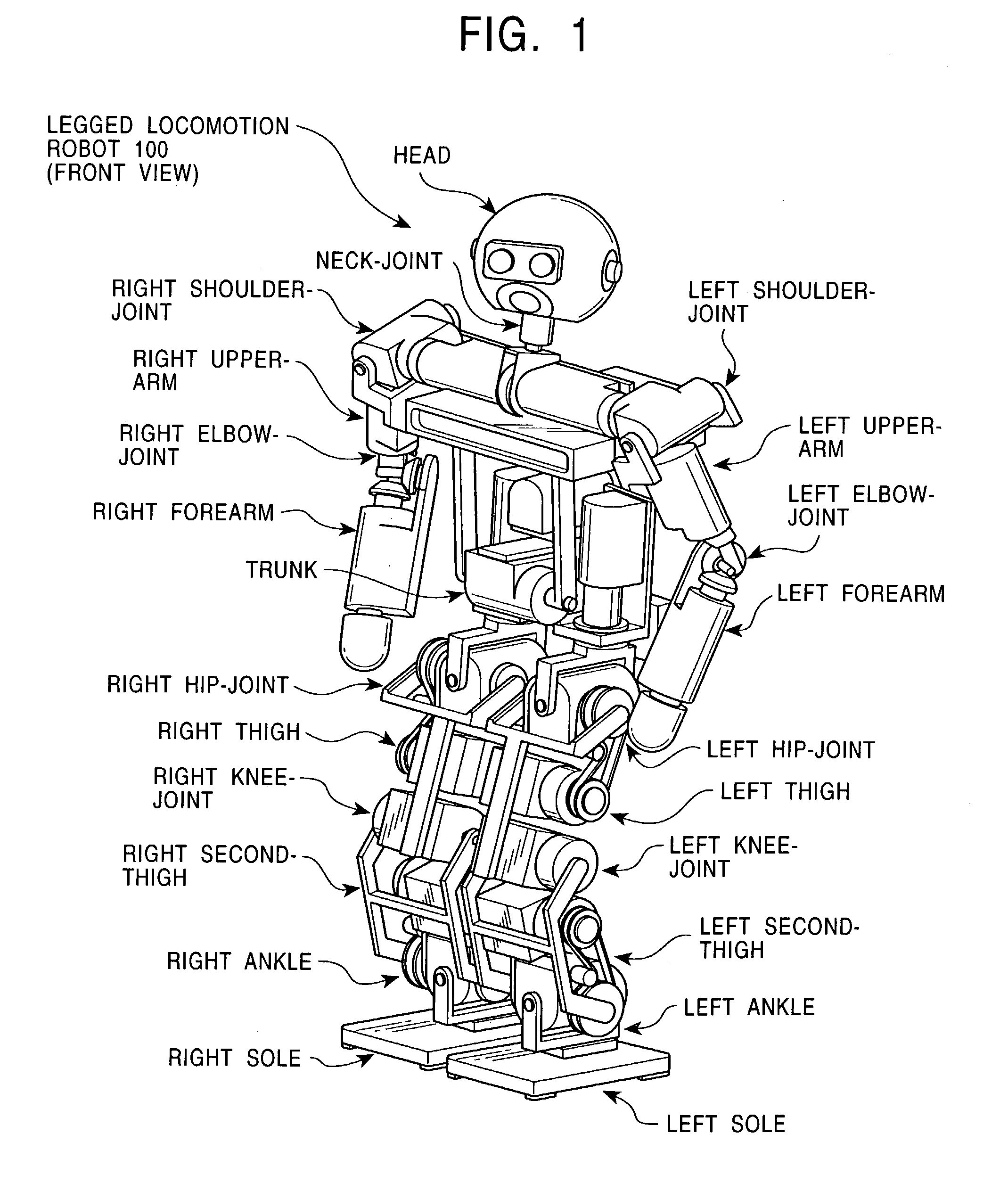

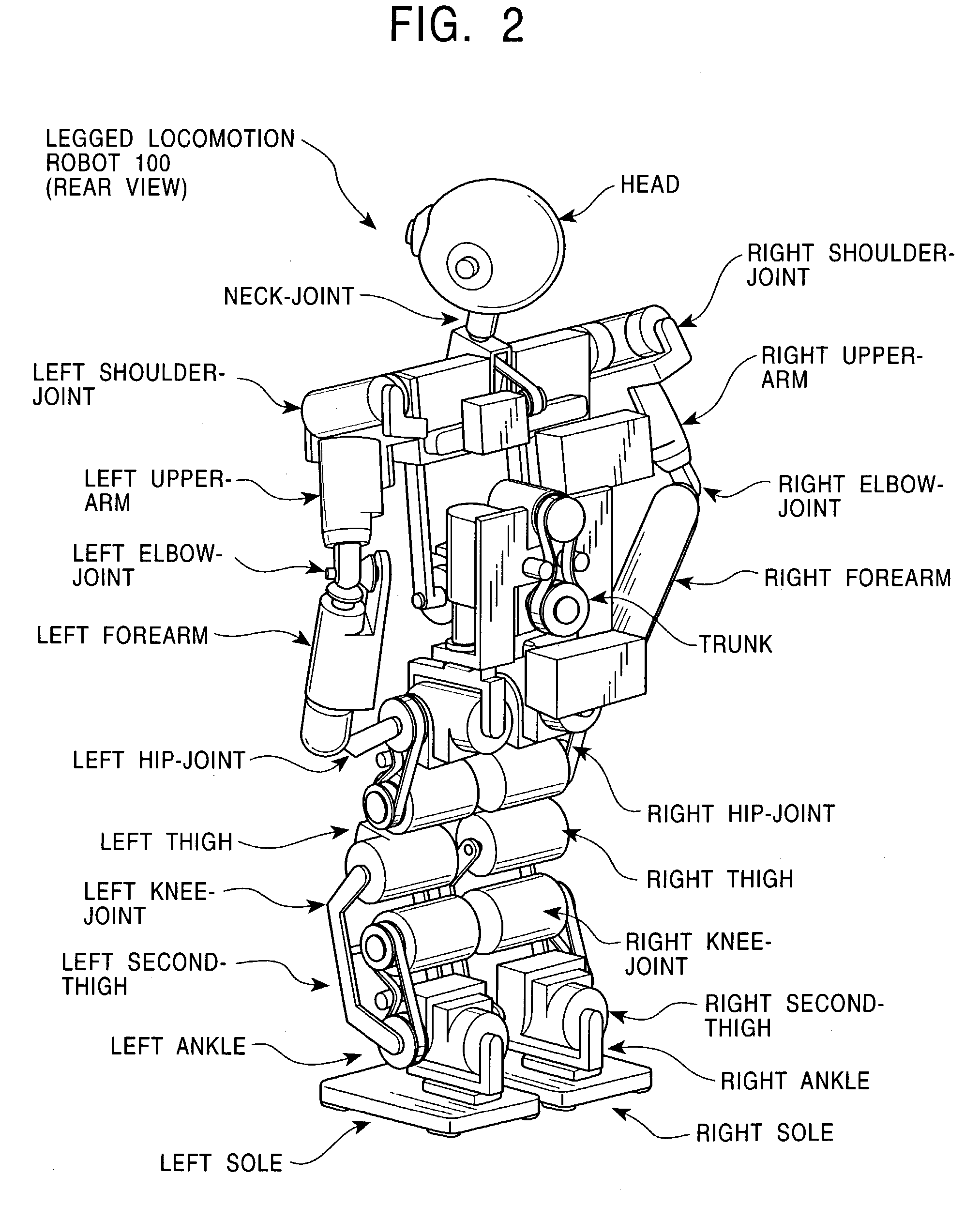

Device and method for controlling operation of legged robot, and robot device

InactiveUS20030120388A1Stable and accurateStably and accurately achievesProgramme-controlled manipulatorComputer controlUpper limbLower limb

The present invention allows a robot to operate accurately while canceling an affect of pitch-axis, roll-axis, and yaw-axis moments, these moments being applied on the robot body during a leg-moving operation such as walking. First, by calculating a pitch-axis moment and / or a roll-axis moment generated on the robot body at a preset ZMP by set motions of upper limbs, a trunk, and lower limbs, motions of the lower limbs and the trunk for canceling the pitch-axis moment and / or the roll-axis moment are obtained. Then, by calculating a yaw-axis moment generated on the robot body lying at the preset ZMP by the calculated motions of the lower limbs and the trunk, a motion of the upper limbs for canceling the yaw-axis moment is obtained.

Owner:SONY CORP

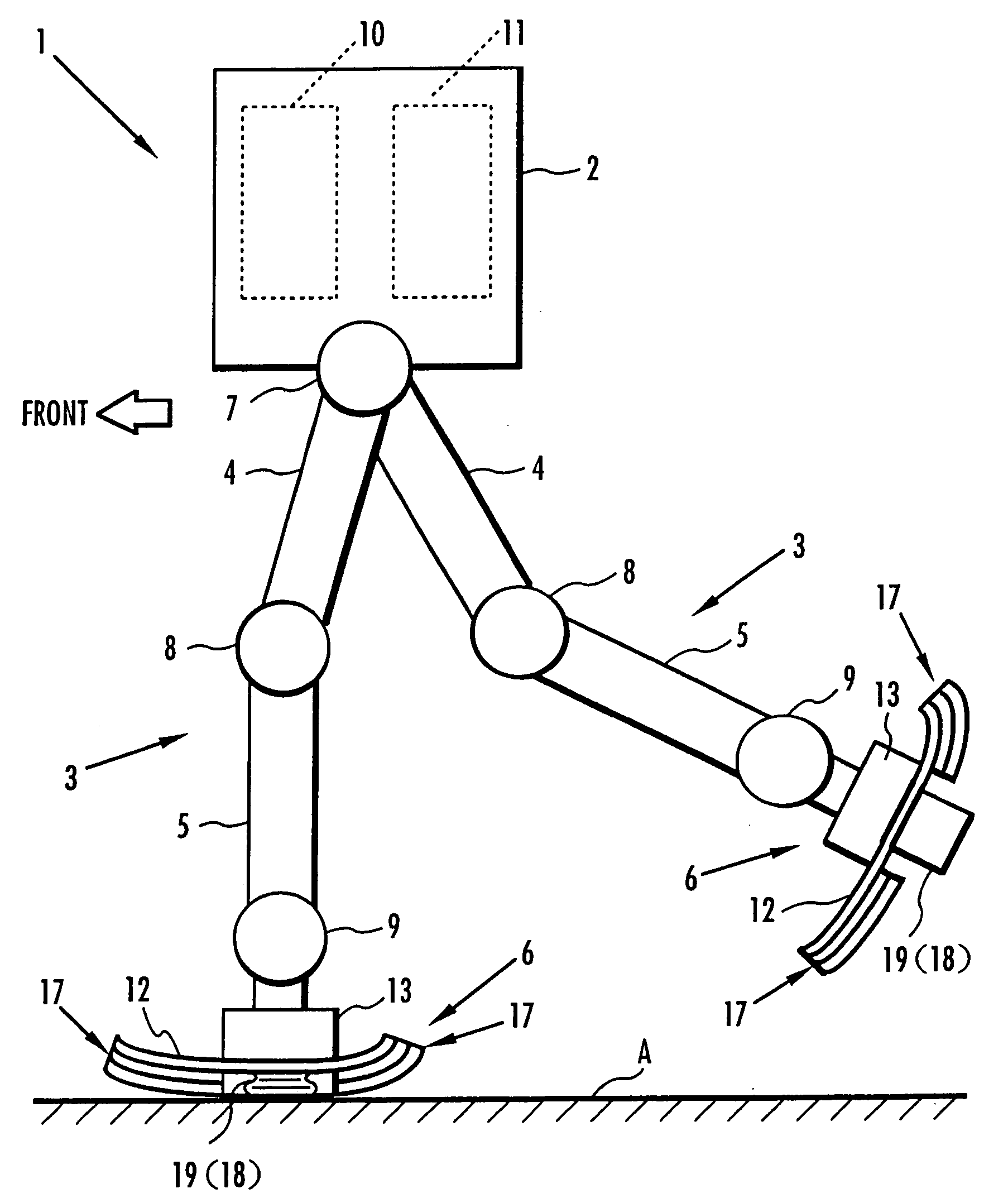

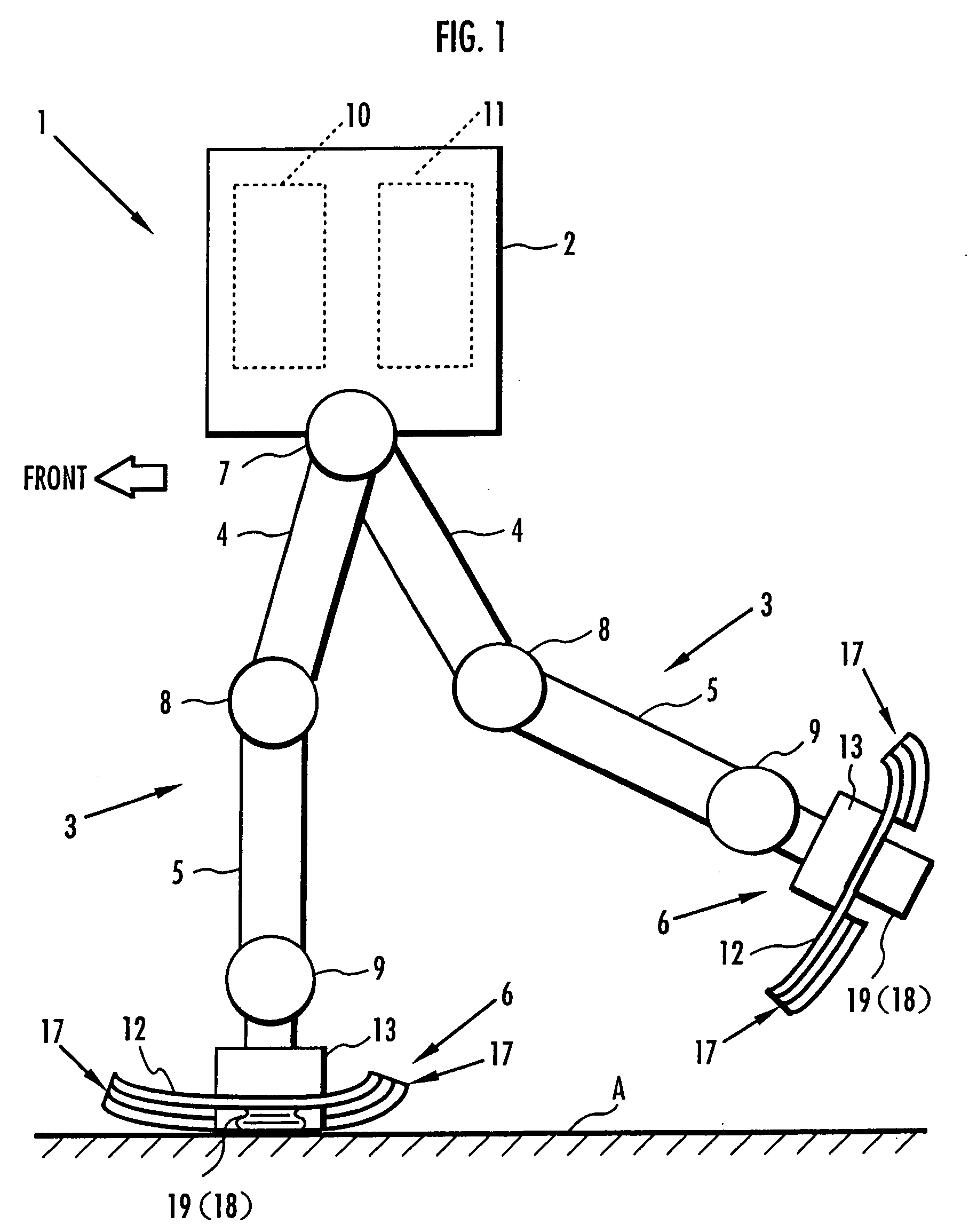

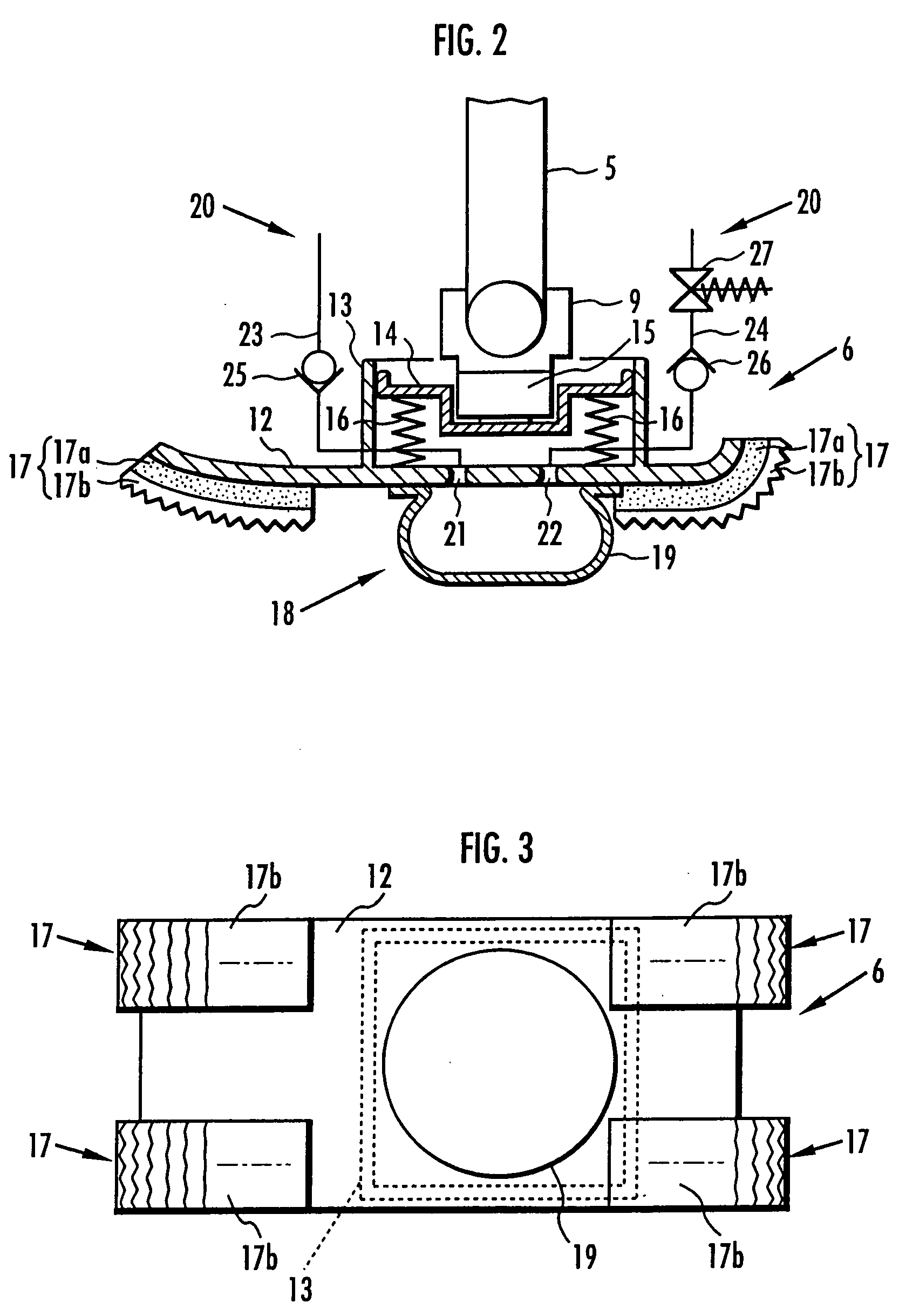

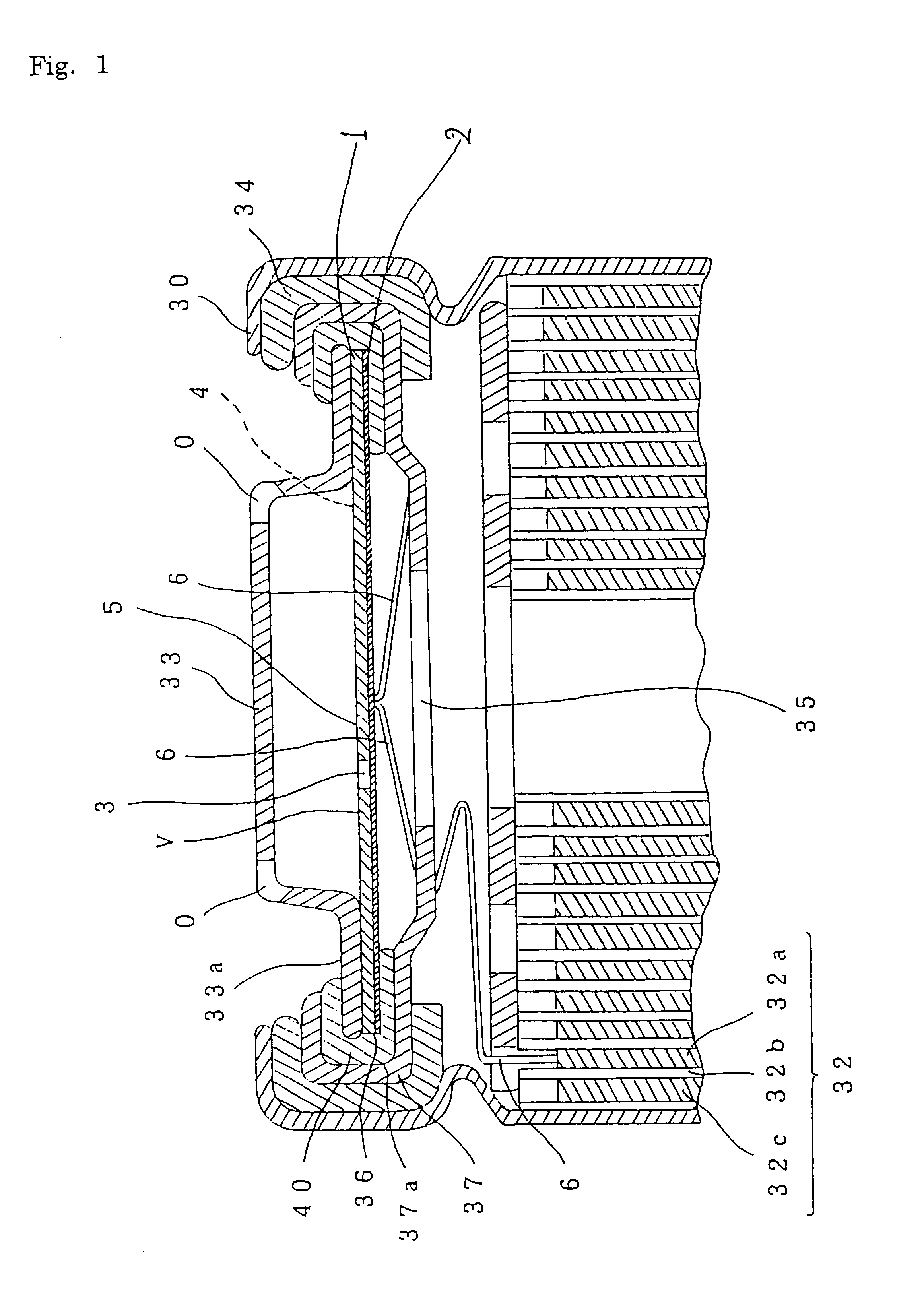

Device for absorbing floor-landing shock for legged mobile robot

InactiveUS20050120820A1Increase shock loadIncrease contactGas based dampersProgramme control in sequence/logic controllersFinal heightSolenoid valve

A landing shock absorbing device 18 disposed in a foot mechanism 6 of a leg of a robot, wherein an inflatable bag-like member 19 (variable capacity element) is provided at a bottom face side of the foot mechanism 6. The bag-like member 19 is constructed of an elastic material such as rubber. The air in atmosphere may flow into and out of the bag-like member 19 by inflow / outflow means 20 equipped with a solenoid valve 27, and the like. In a lifting state of the foot mechanism 6, inflow of the air into the bag-like member 19 is controlled, thereby controlling the final height of the bag-like member 19 in an inflated state to the height in response to a gait type of the robot. While properly reducing an impact load during a landing motion of the leg of a legged mobile robot depending on the gait type of the robot, stability of a posture of the robot may easily be secured, resulting in allowing a configuration to be lighter in weight.

Owner:HONDA MOTOR CO LTD

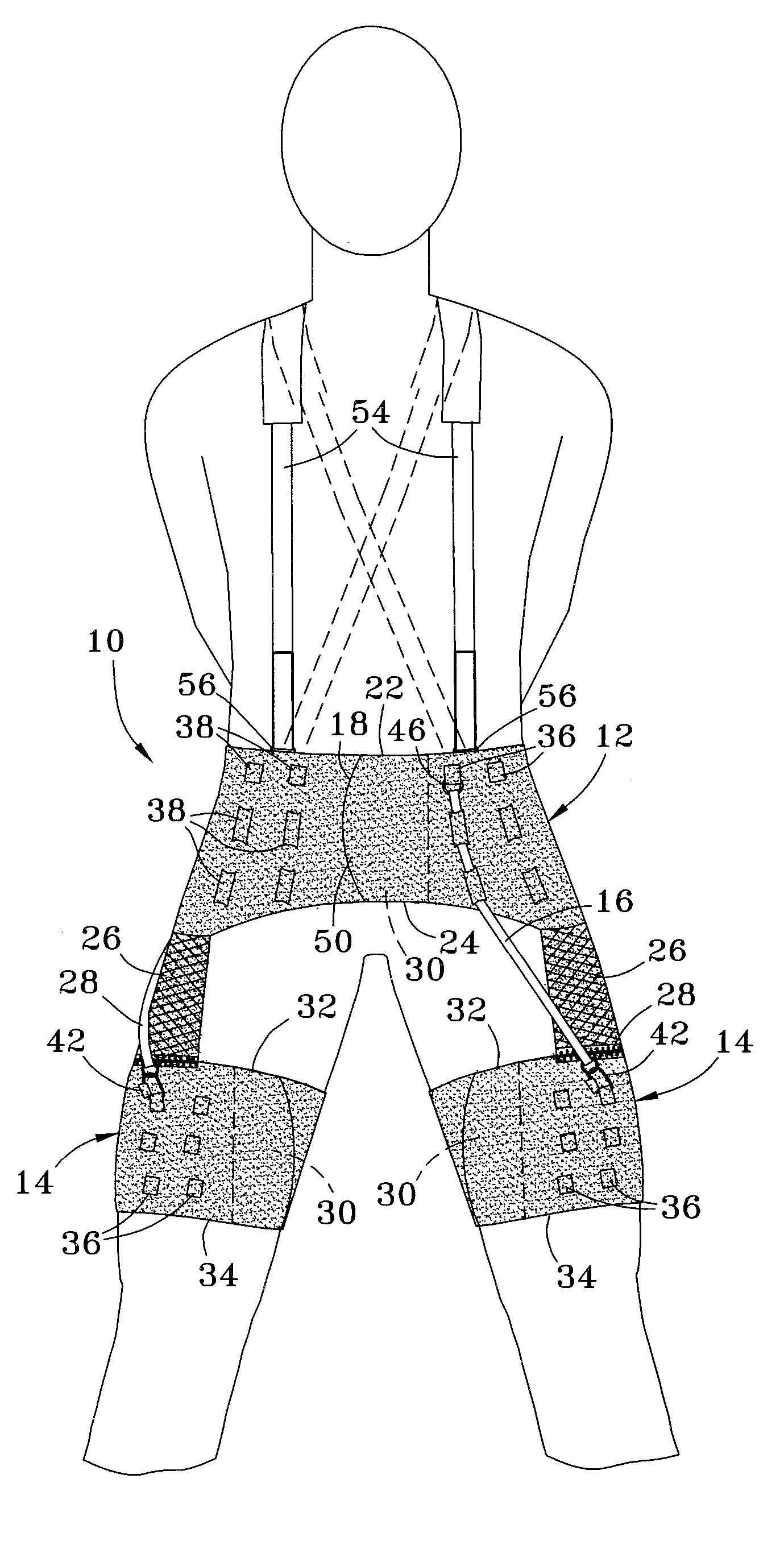

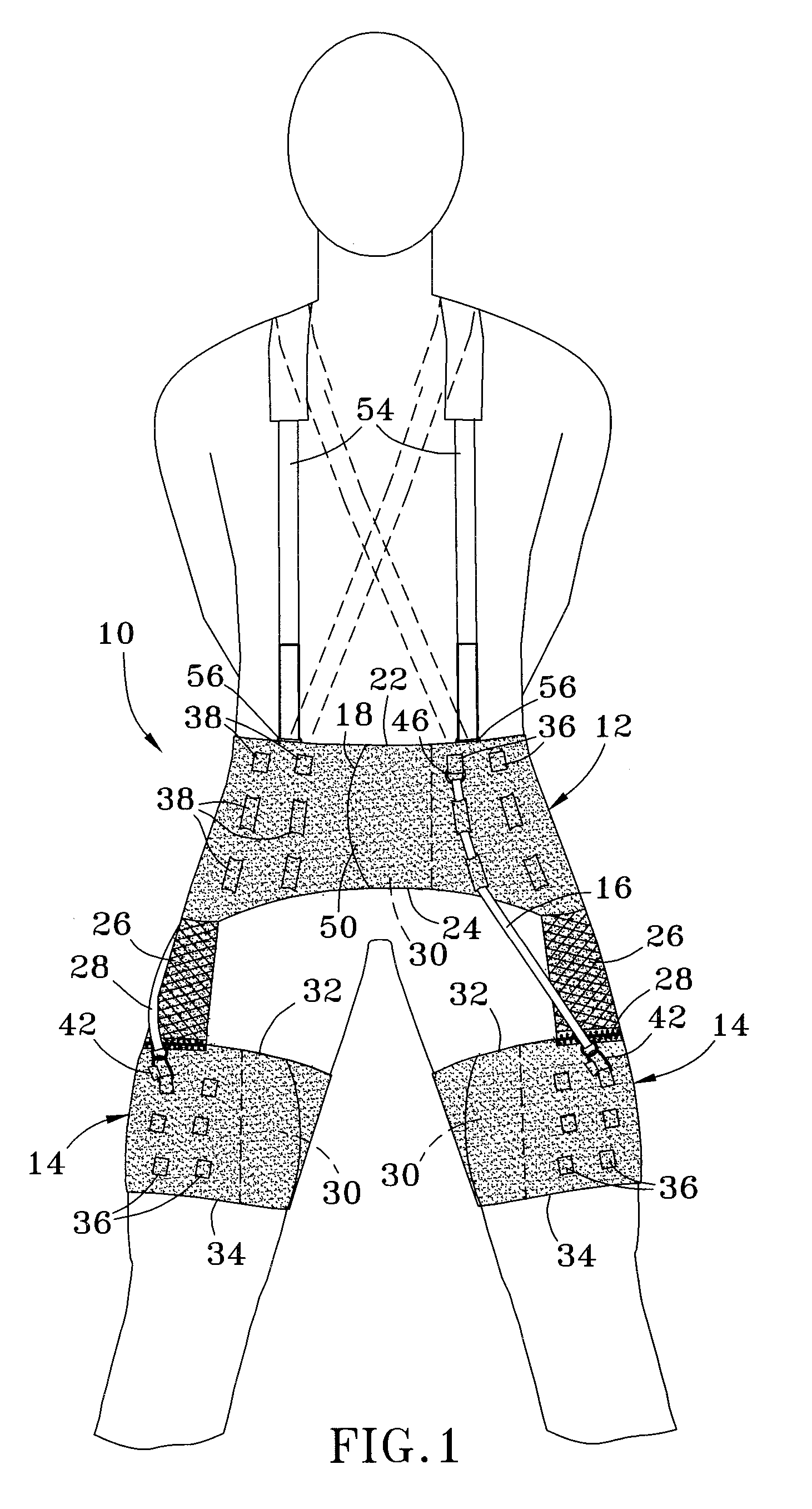

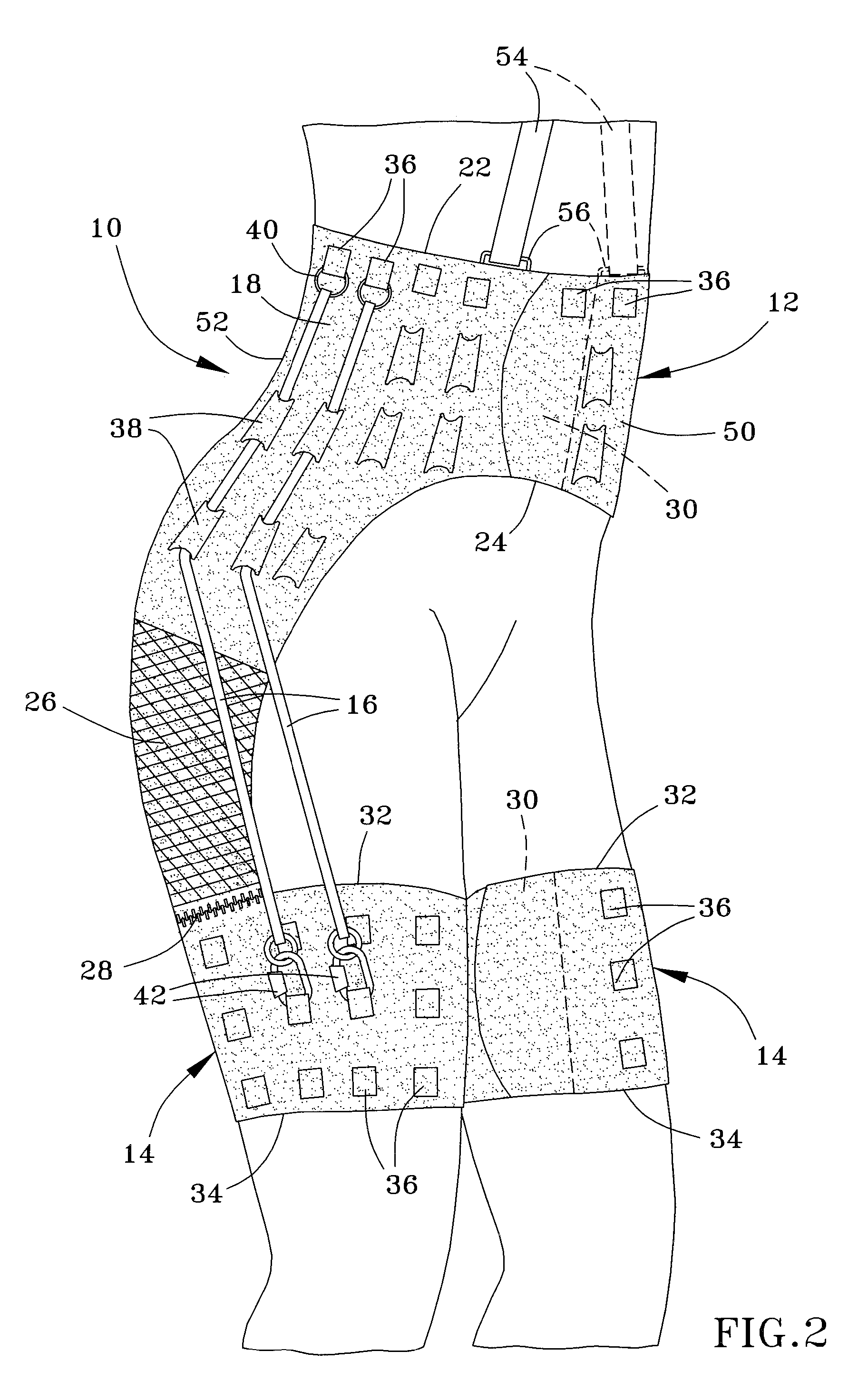

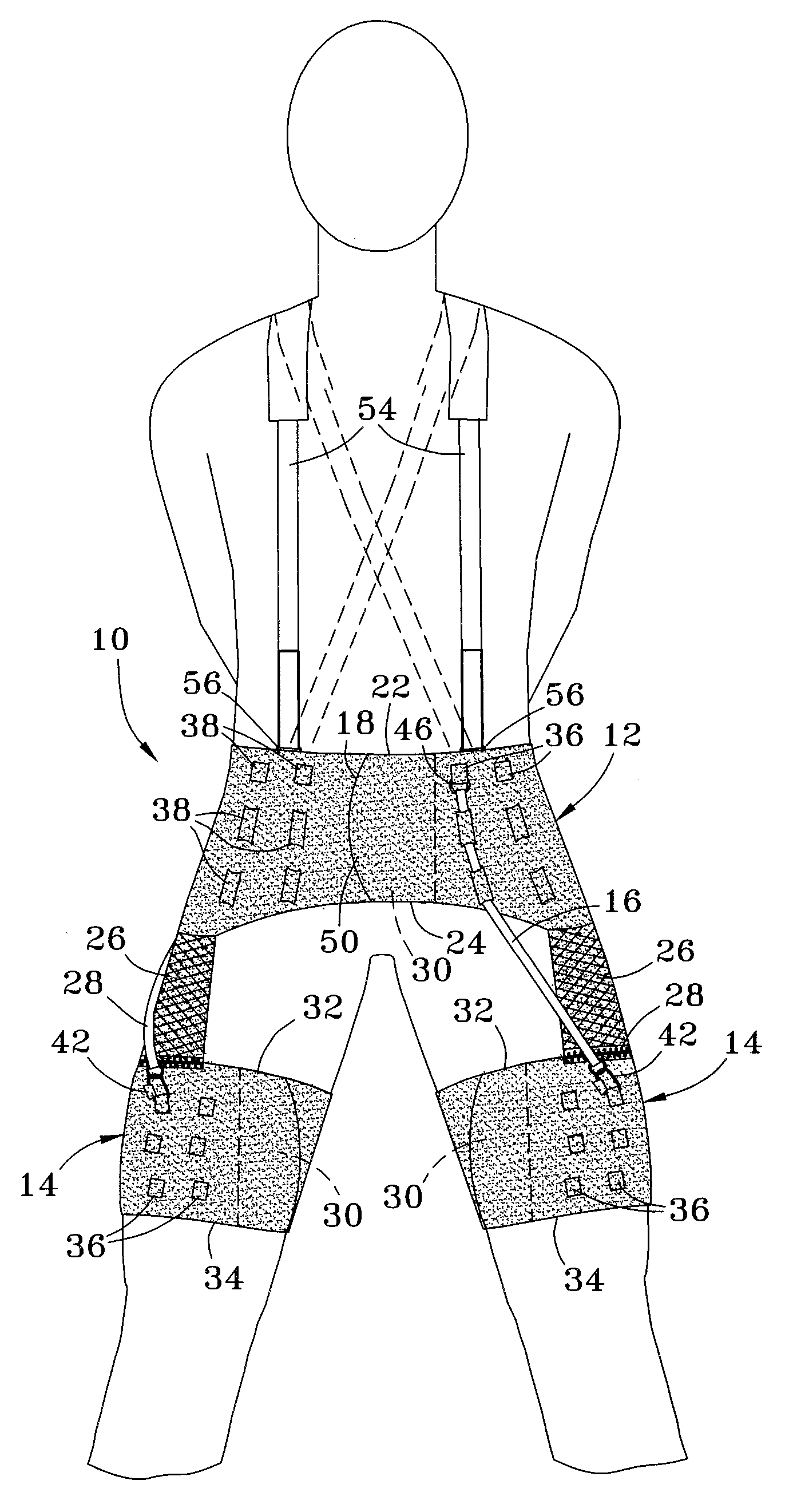

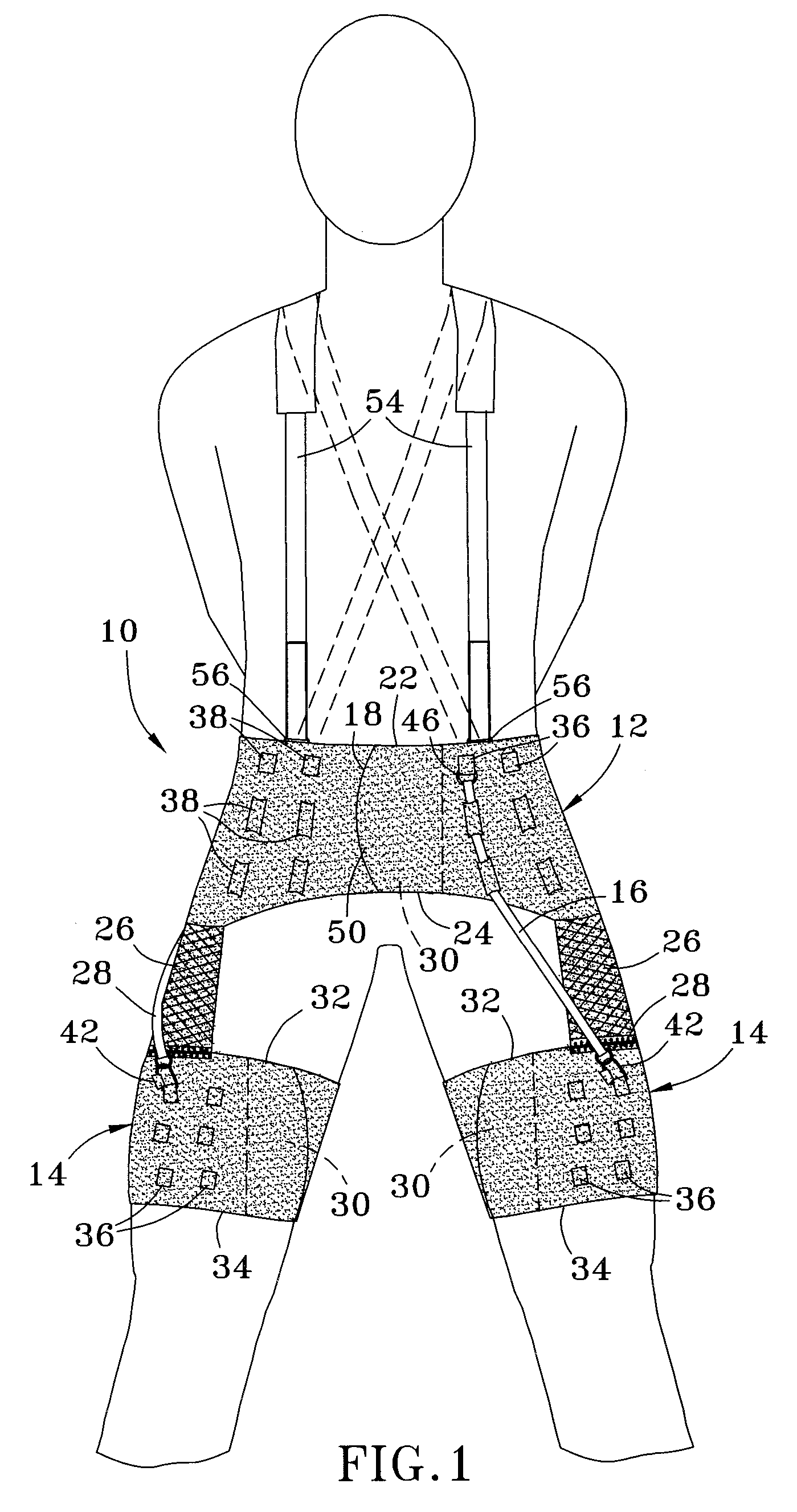

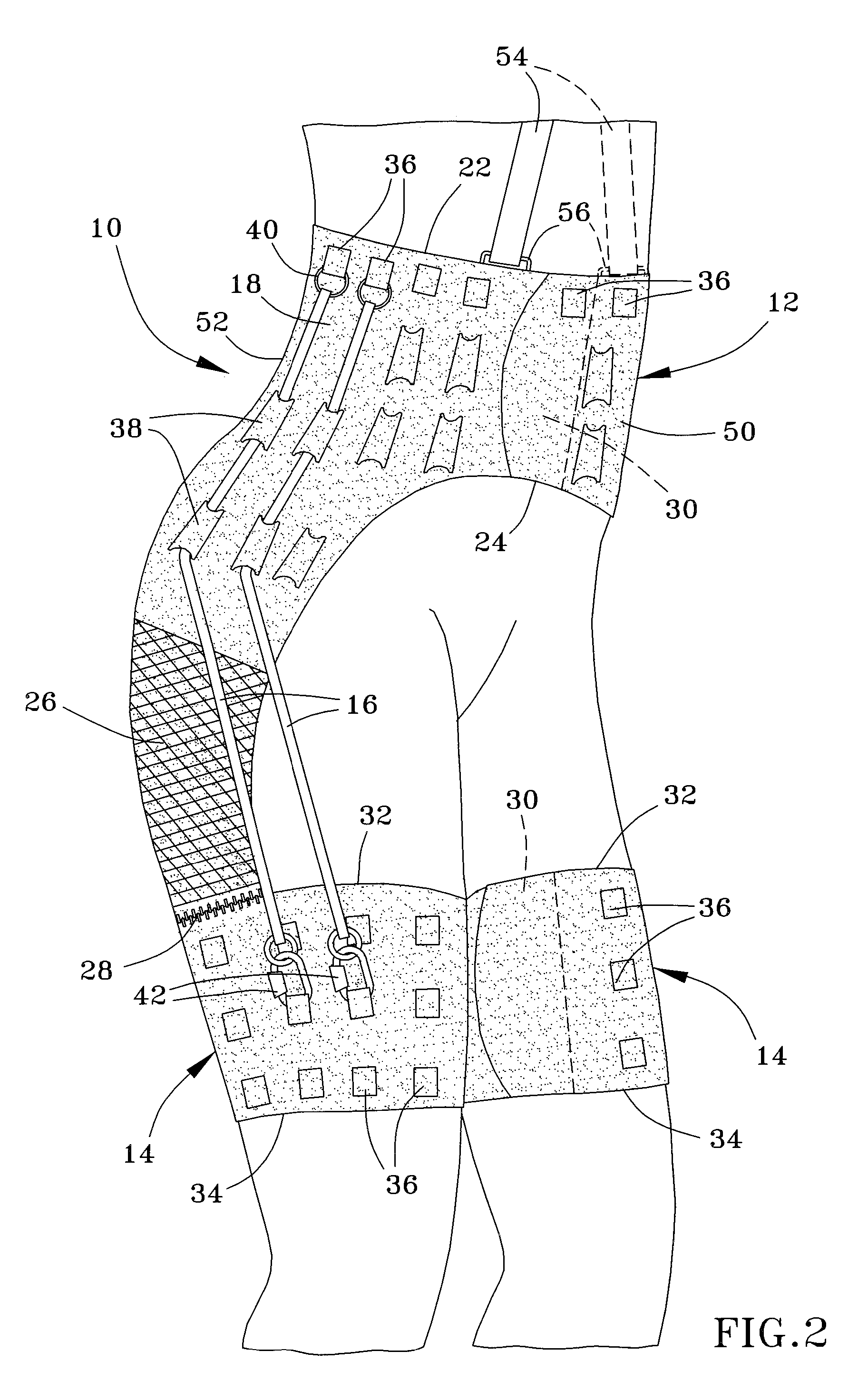

Dynamic hip stabilizer

InactiveUS20070027419A1Reduce riskRestrict movementResilient force resistorsNon-surgical orthopedic devicesPhysical medicine and rehabilitationPelvic girdle

A dynamic hip stabilizer utilized to reduce the risk of postoperative and recurrent traumatic hip dislocations. The hip stabilizer includes a pelvic girdle, at least one thigh cuff, and one or more elements for generating an elastic tensile force between the girdle and cuff. The girdle has an upper portion configured for defining an upper opening for the wearer's waist, a lower portion configured for defining a lower opening for the wearer's hips, and a posterior portion configured for engaging the wearer's lower back. The hip stabilizer further includes one or more elements for engaging the wearer's shoulders to limit movement of the girdle toward the thigh cuffs caused by the elastic tensile force, and one or more elements for stiffening the posterior portion of the girdle.

Owner:DRENNAN DENIS BURKE

Illumination device and method

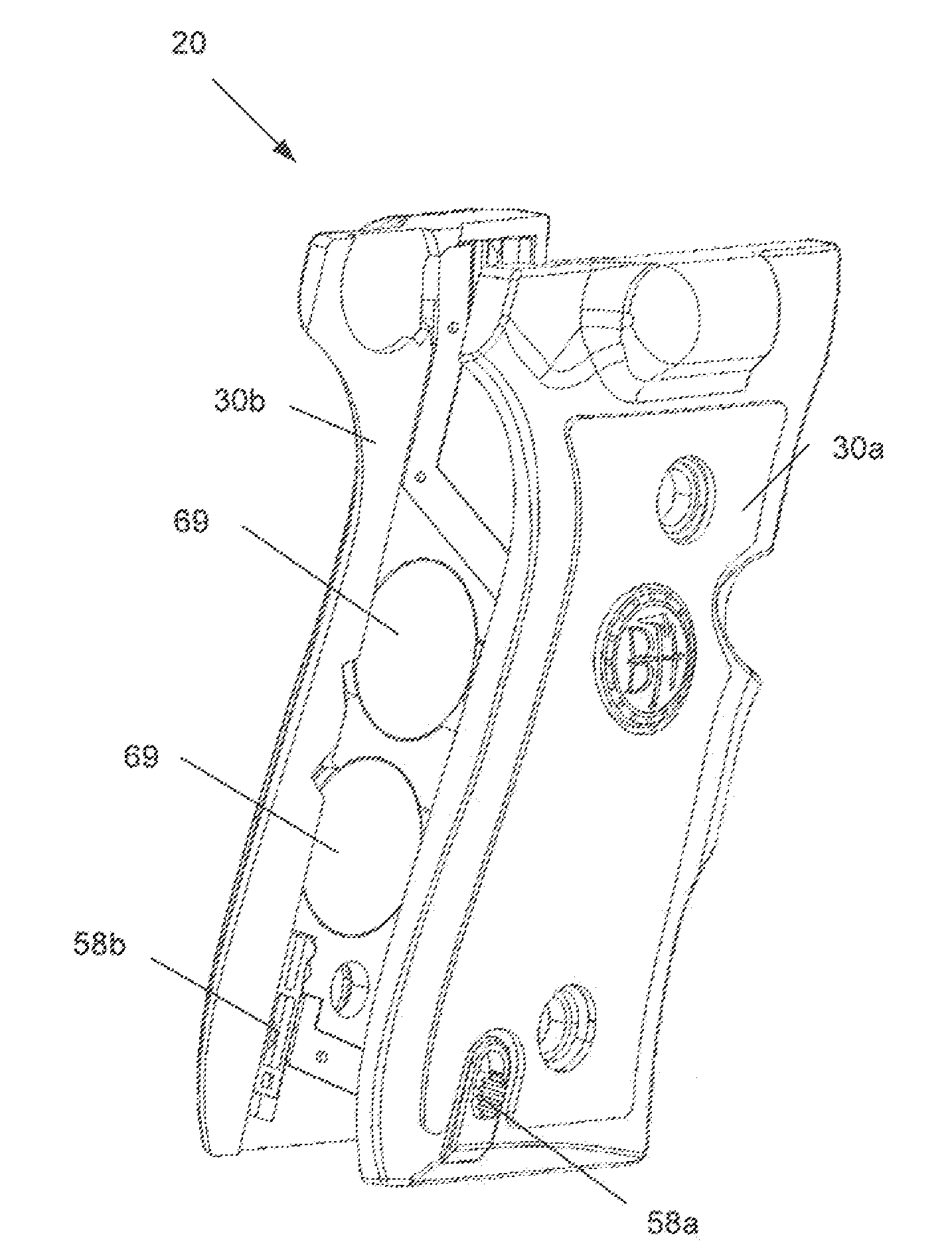

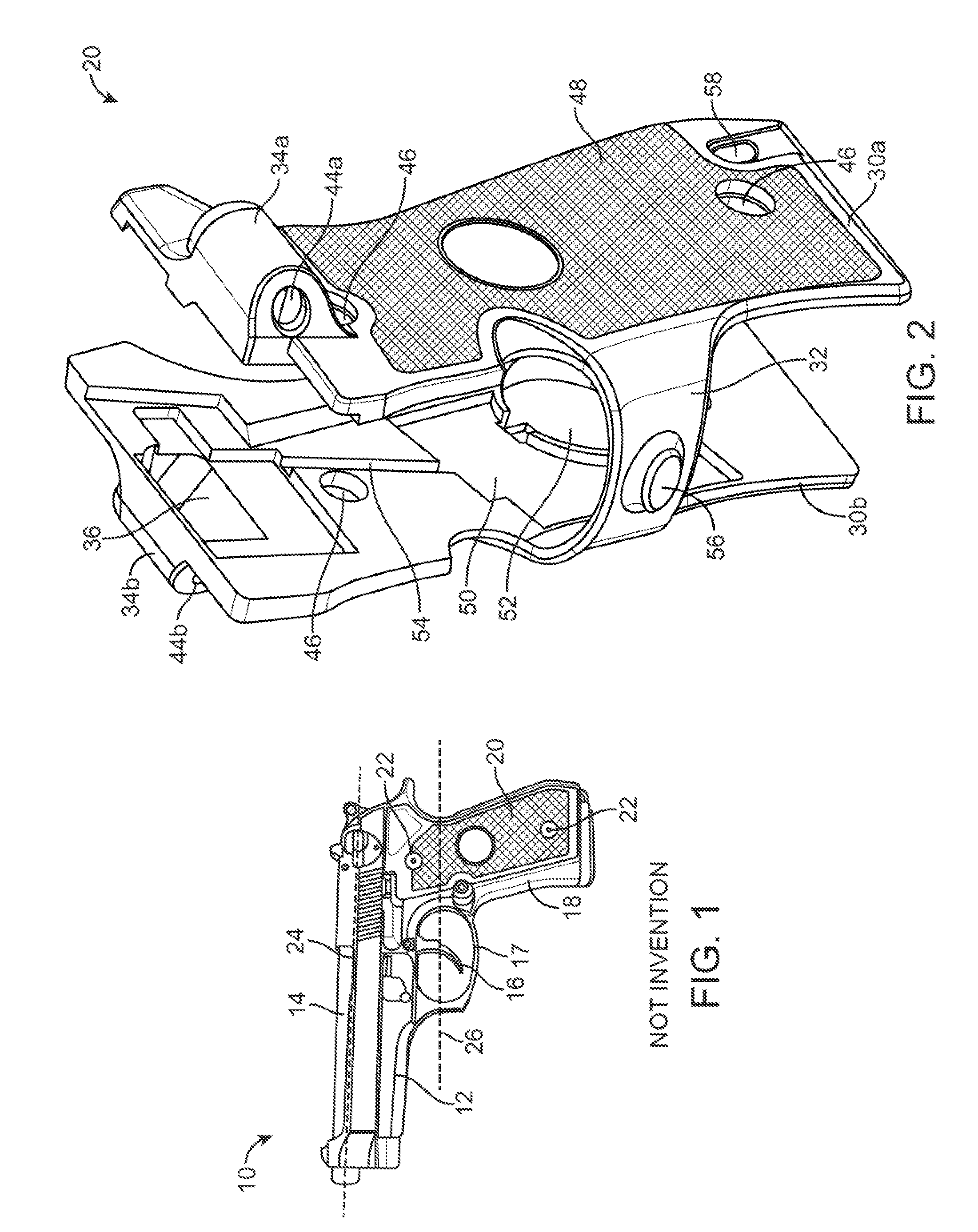

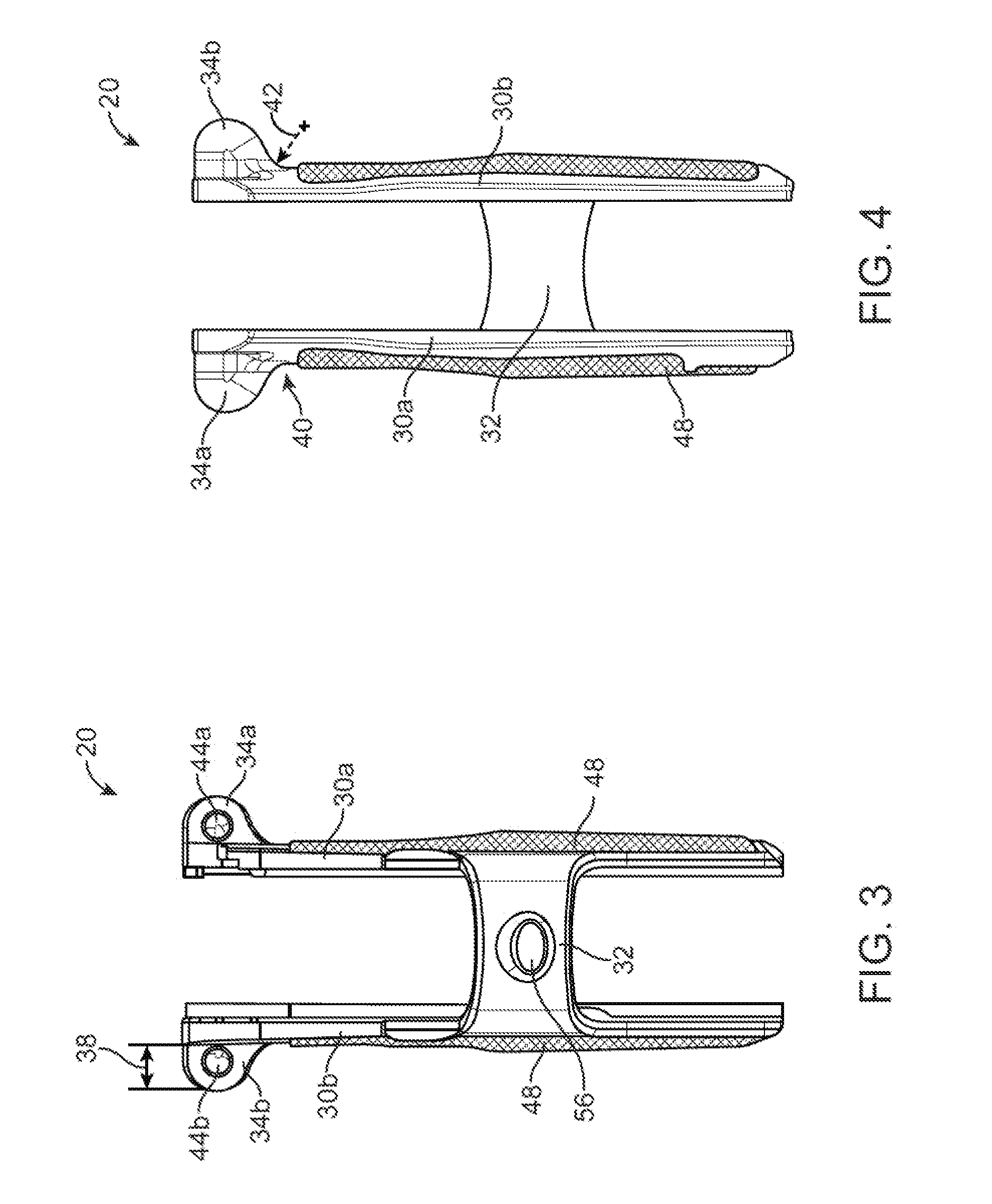

InactiveUS8662694B1Stable and accurateLimited utilityLighting elementsSighting devicesEngineeringControl switch

An illumination device for use with a firearm and a method of using the same are disclosed. The illumination device can include a gun grip cover configured to attach to a gun grip. The illumination device can have a first illumination element extending to the left of the gun grip cover and a second illumination element extending to the right of the gun grip cover. The illumination elements can deliver a spread of light to illuminate a large area. The illumination elements can be laterally adjacent to the barrel. The illumination elements can be controlled by a control switch positioned below the trigger.

Owner:SELLMARK CORP

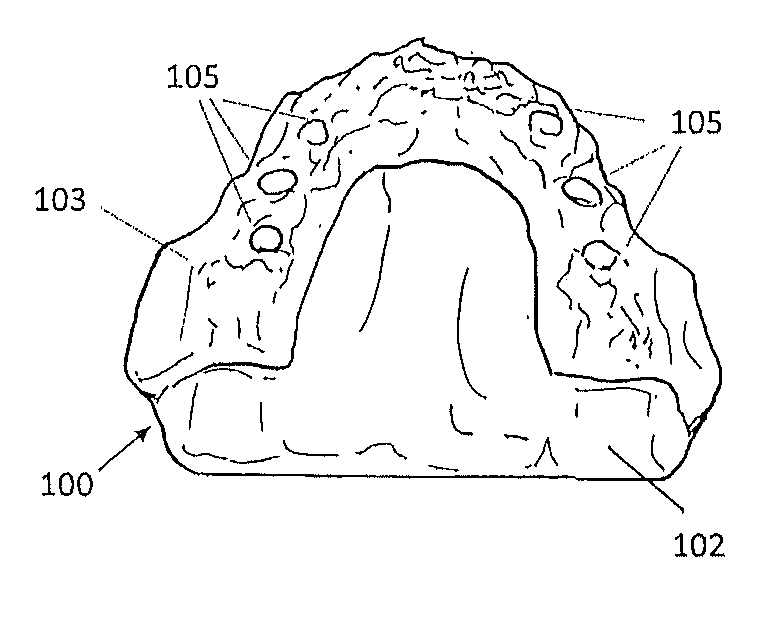

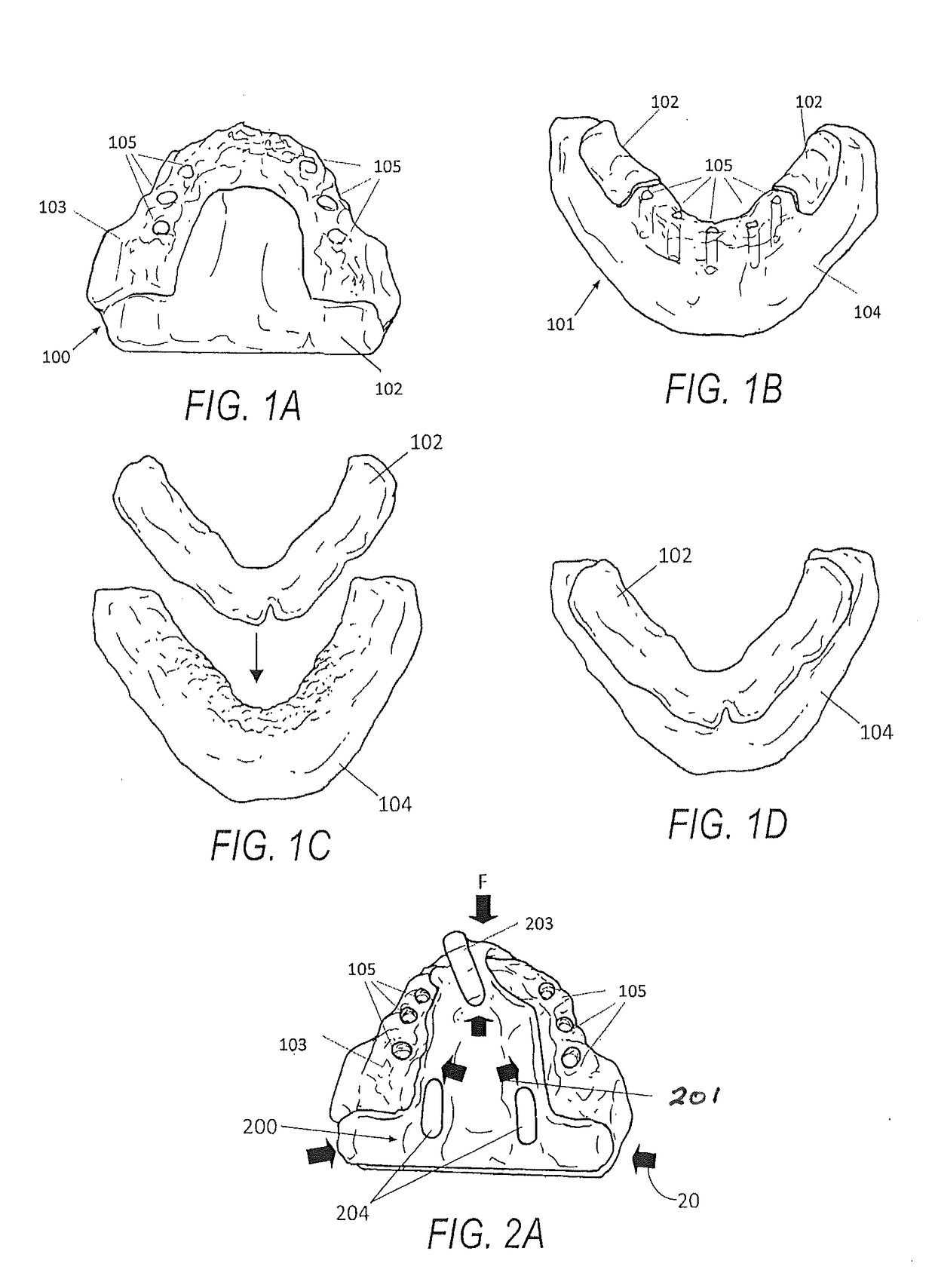

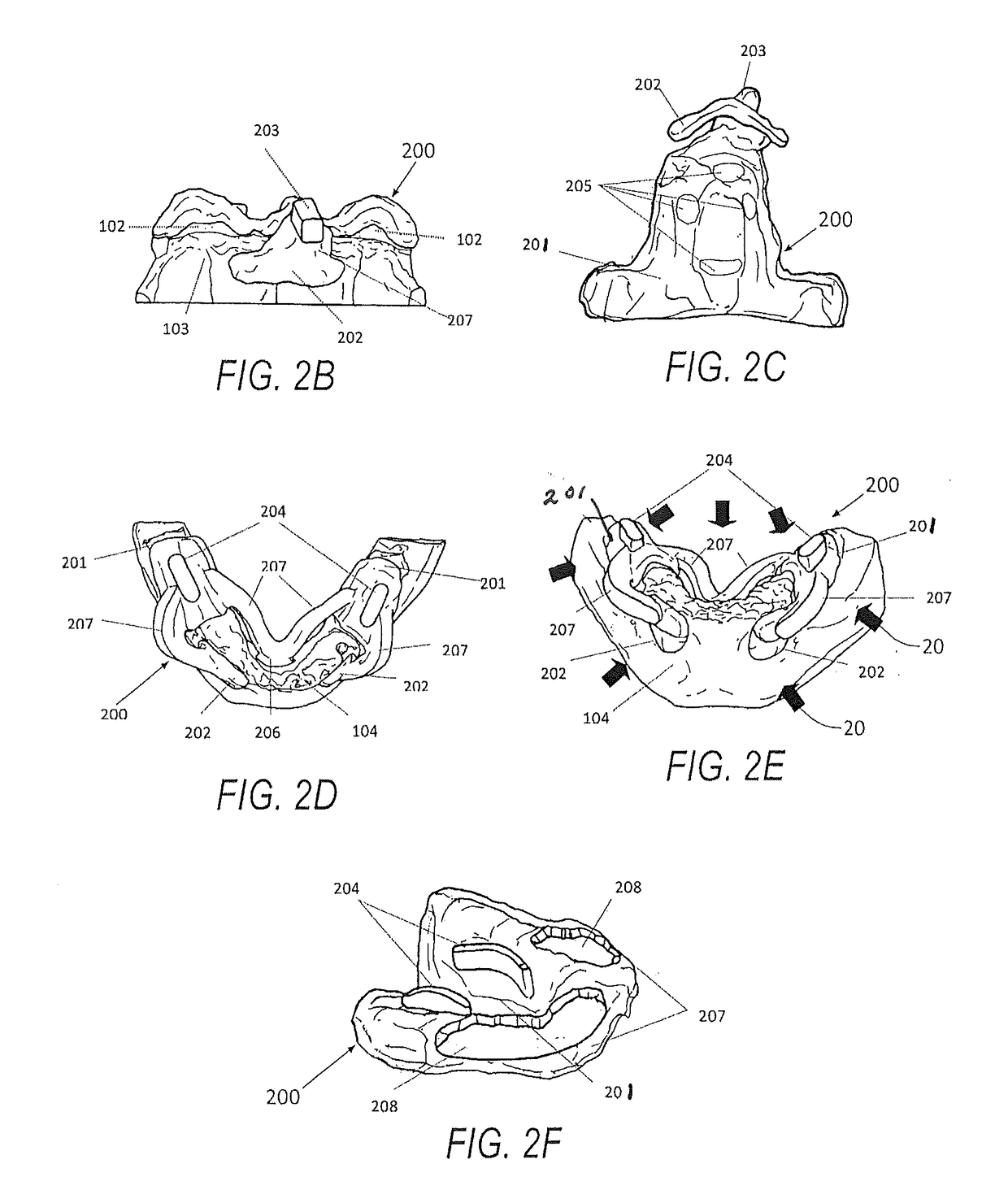

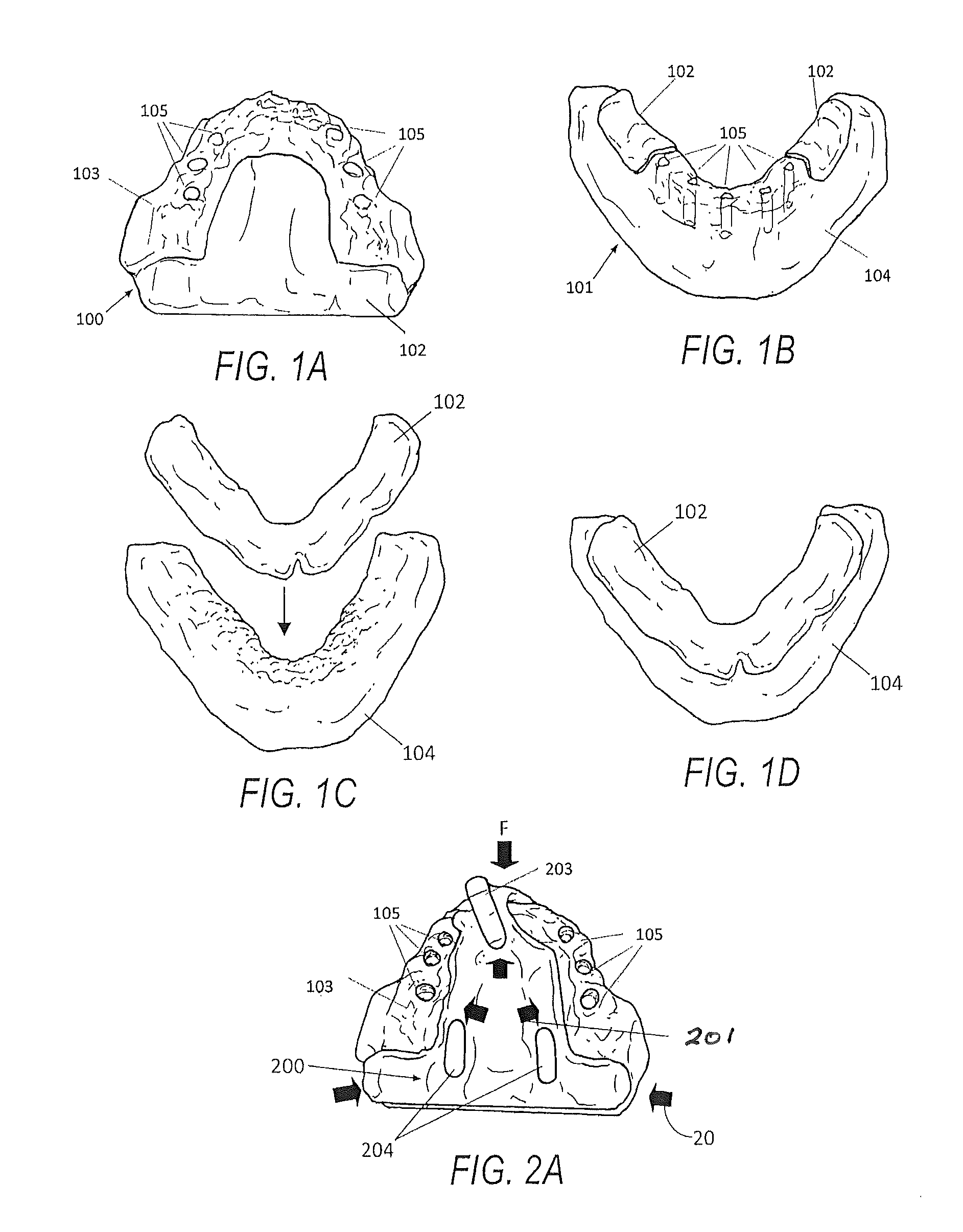

Method of using an endentulous surgical guide

ActiveUS20170112592A1Shorten the timeRelieve pressureDental implantsAdditive manufacturing apparatusBite registrationDental Models

An approach is disclosed that involves creating an updated master dental model of a patient's mouth after an implant surgery by aligning new postoperative oral scan data to pre-existing preoperative oral scan data that is more comprehensive (e.g., it includes bite registration). Before surgery a multi-piece stackable surgical guide set is created using the preoperative oral scan data. The surgical guide set is used to facilitate the surgery. After the surgery at least one piece of the surgical guide set is placed back in a patient's mouth and may act as a reference marker because it was created using the preoperative oral scan data, but is also part of the postoperative mouth configuration since it was used to facilitate the surgery. The affected portion of the mouth may then be digitally scanned directly or indirectly by way of a physical impression with the reference marker in place to determine the new characteristics resulting from the surgery such as new implant installation locations and orientations. The new postoperative oral scan data may be combined with the pre-existing preoperative oral scan data by way of the reference marker (since it is a constant between the two sets of scan data) without having to do such things as take a new bite registration, on which a new implant restoration can be easily created.

Owner:IBUR

Dynamic hip stabilizer

InactiveUS7758481B2Reduce riskRestrict movementResilient force resistorsNon-surgical orthopedic devicesThighPhysical medicine and rehabilitation

A dynamic hip stabilizer utilized to reduce the risk of postoperative and recurrent traumatic hip dislocations. The hip stabilizer includes a pelvic girdle, at least one thigh cuff, and one or more elements for generating an elastic tensile force between the girdle and cuff. The girdle has an upper portion configured for defining an upper opening for the wearer's waist, a lower portion configured for defining a lower opening for the wearer's hips, and a posterior portion configured for engaging the wearer's lower back. The hip stabilizer further includes one or more elements for engaging the wearer's shoulders to limit movement of the girdle toward the thigh cuffs caused by the elastic tensile force, and one or more elements for stiffening the posterior portion of the girdle.

Owner:DRENNAN DENIS BURKE

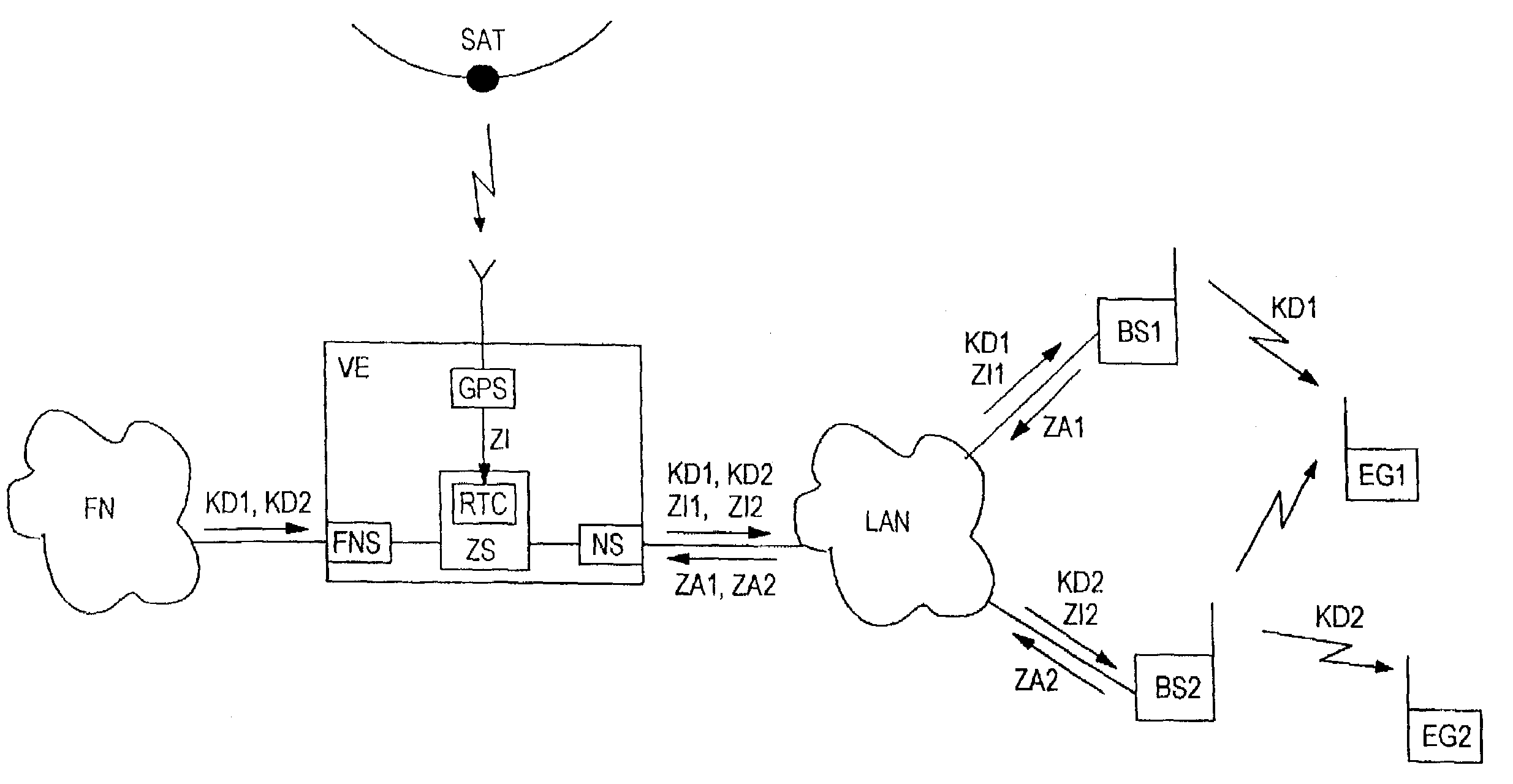

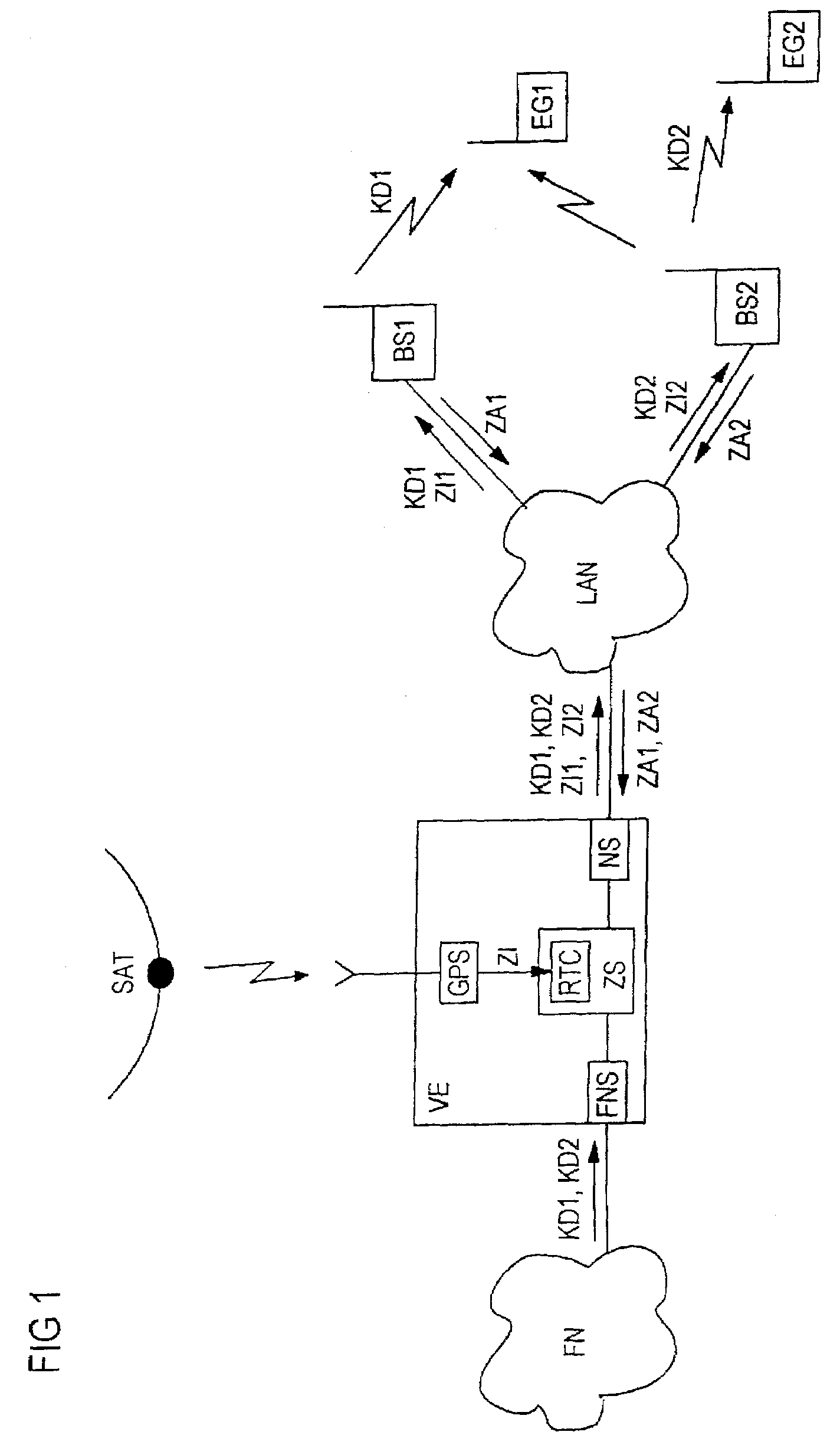

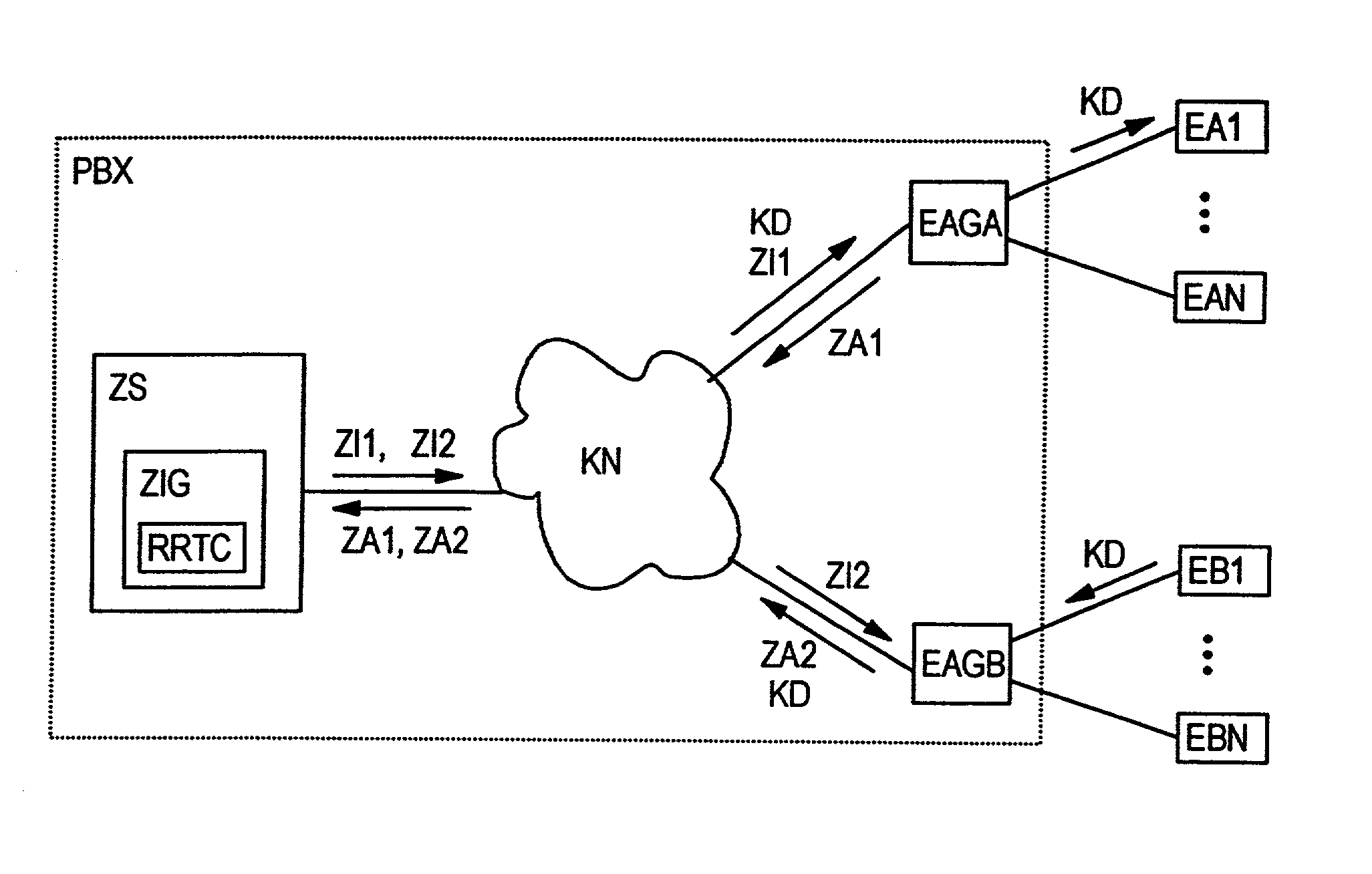

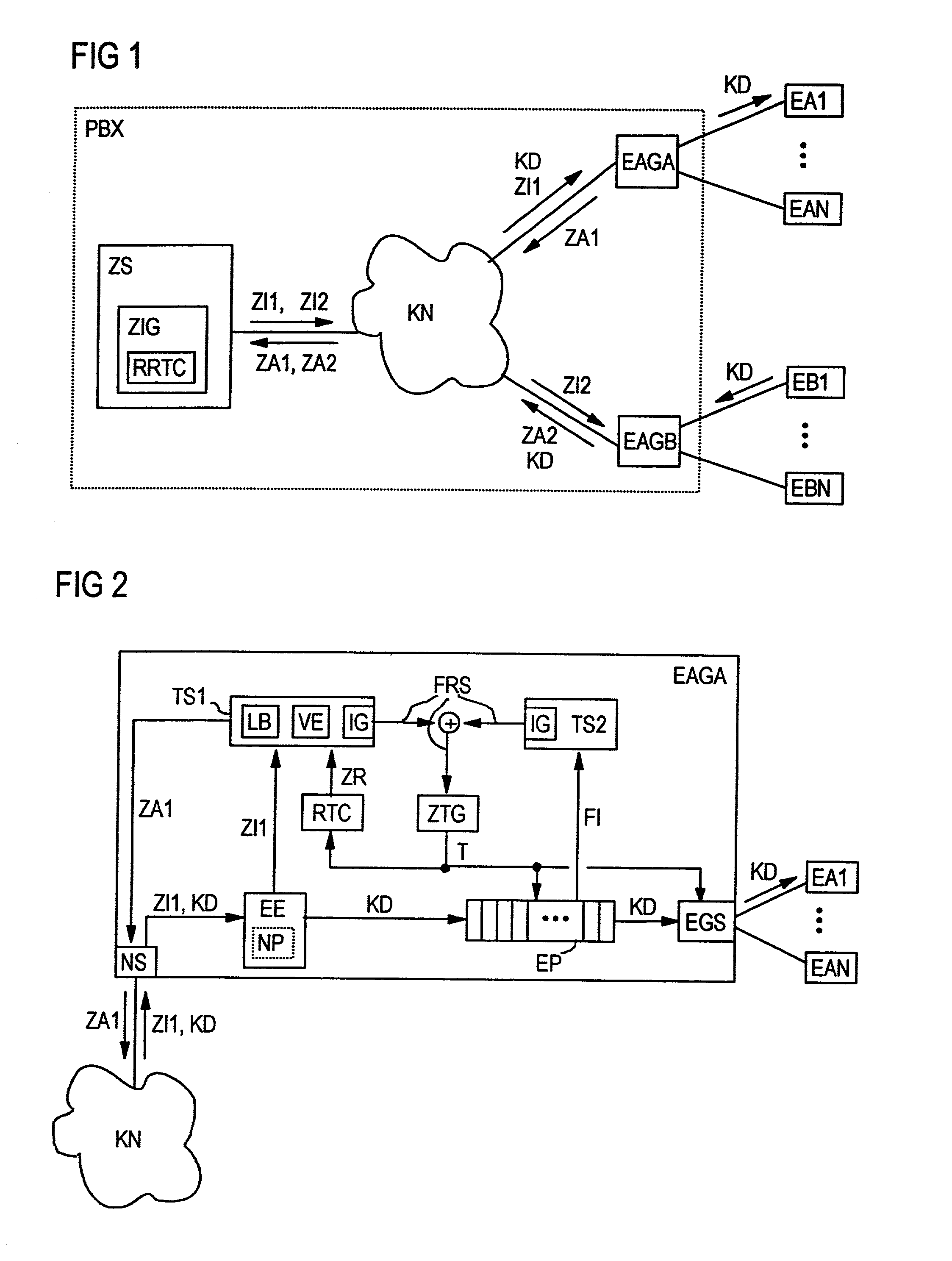

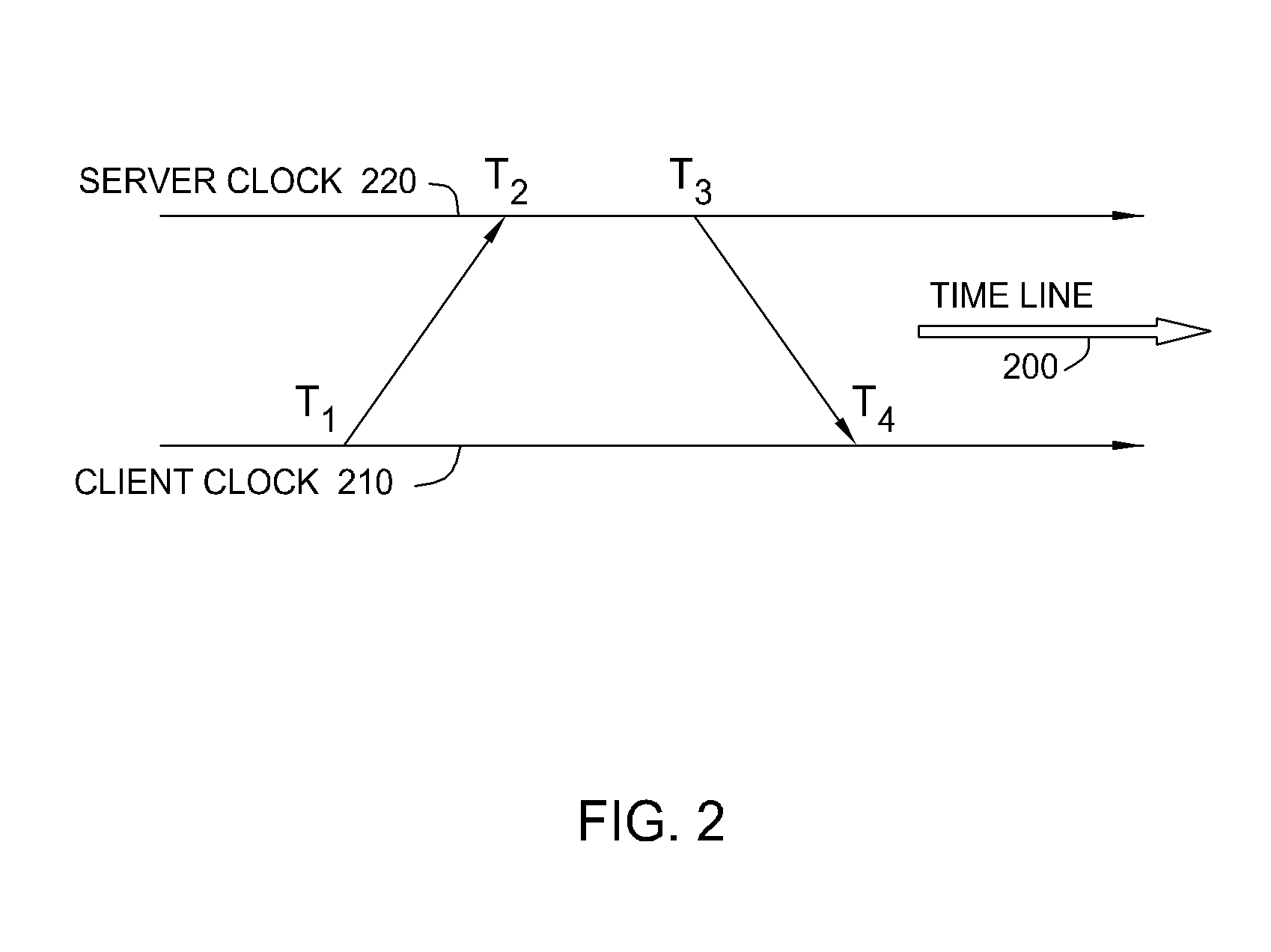

Method and device for synchronizing base stations of a mobile communications network

ActiveUS7190703B1Precise maintenanceStable and accurateTime-division multiplexData switching by path configurationTime informationPropagation time

Method and system for synchronization of base stations in a mobile communications network, in particular for the purpose of a seamless handover, time information is transmitted, possibly on request, to the base stations from a time information server via a local area network. Since base stations which are involved in a seamless handover are generally adjacent, and the respective propagation times and / or propagation time fluctuations of time information differ only slightly in the local area network between the time information server and the base station when the base stations are adjacent, highly accurate synchronization may be achieved, especially for a seamless handover.

Owner:ENTERPRISE SYST TECH S A R L

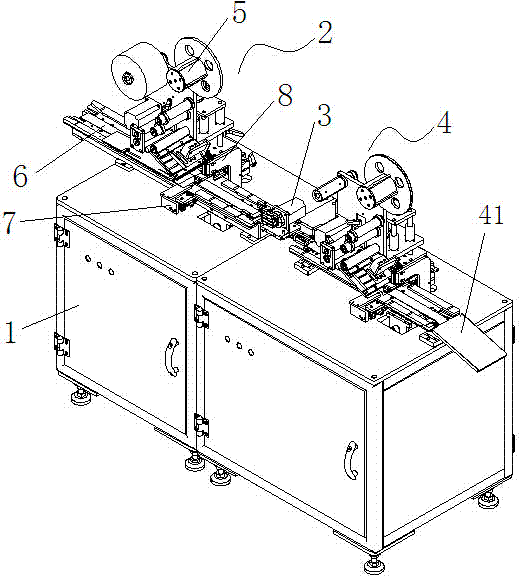

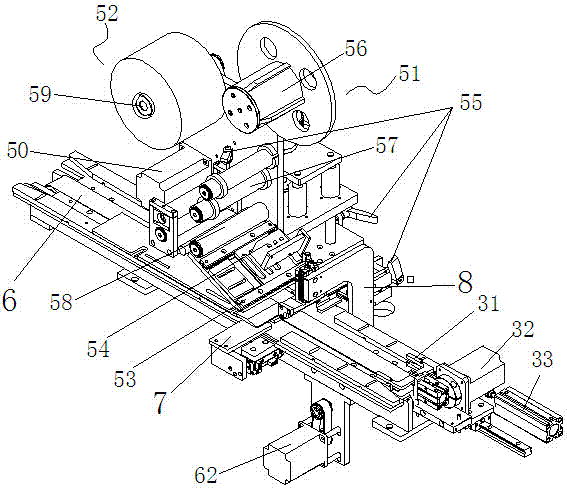

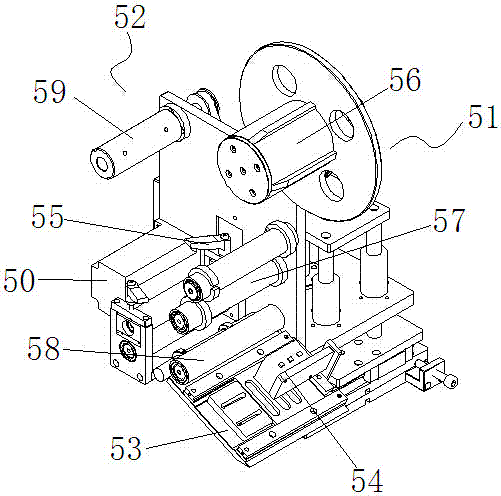

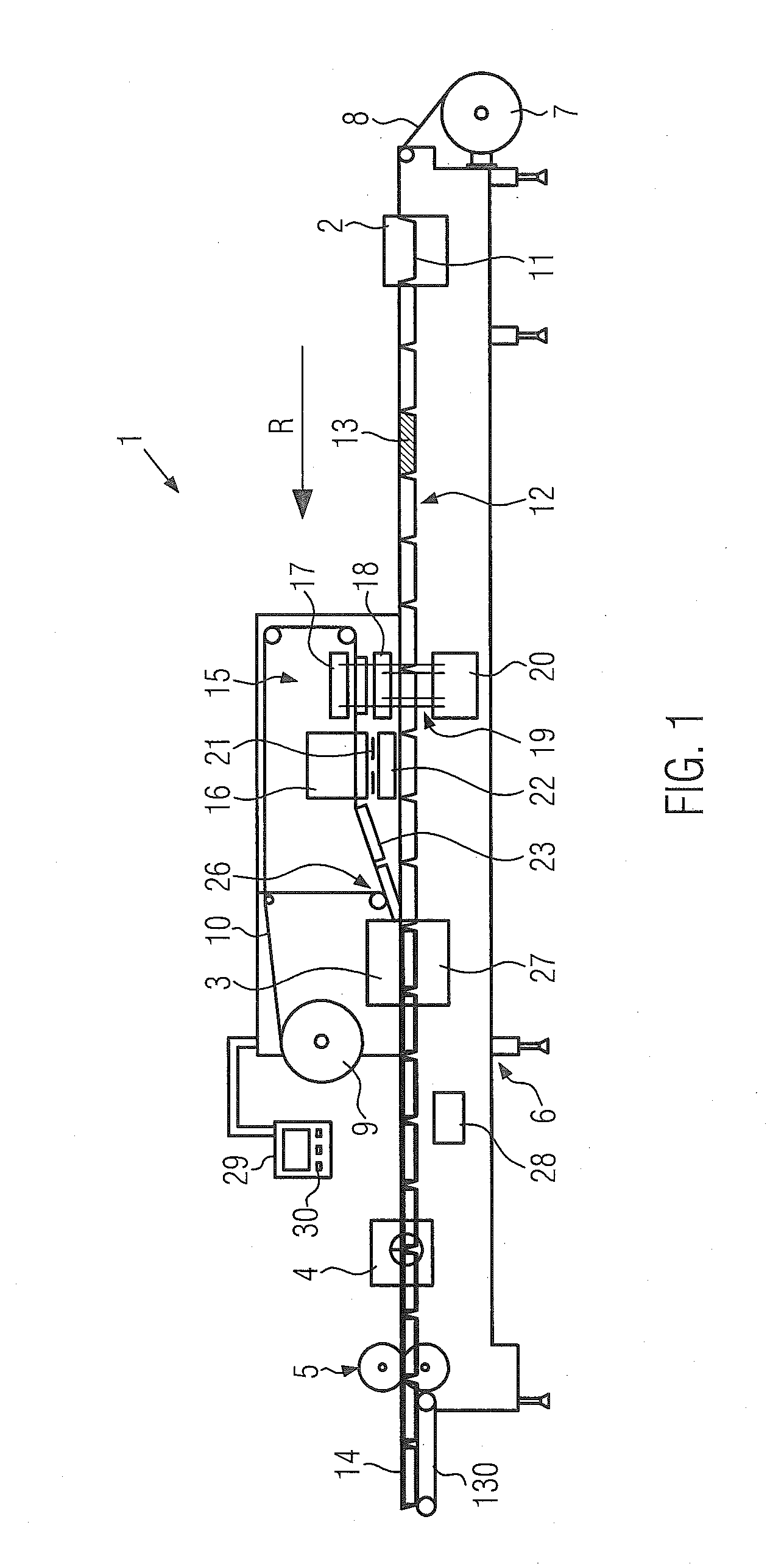

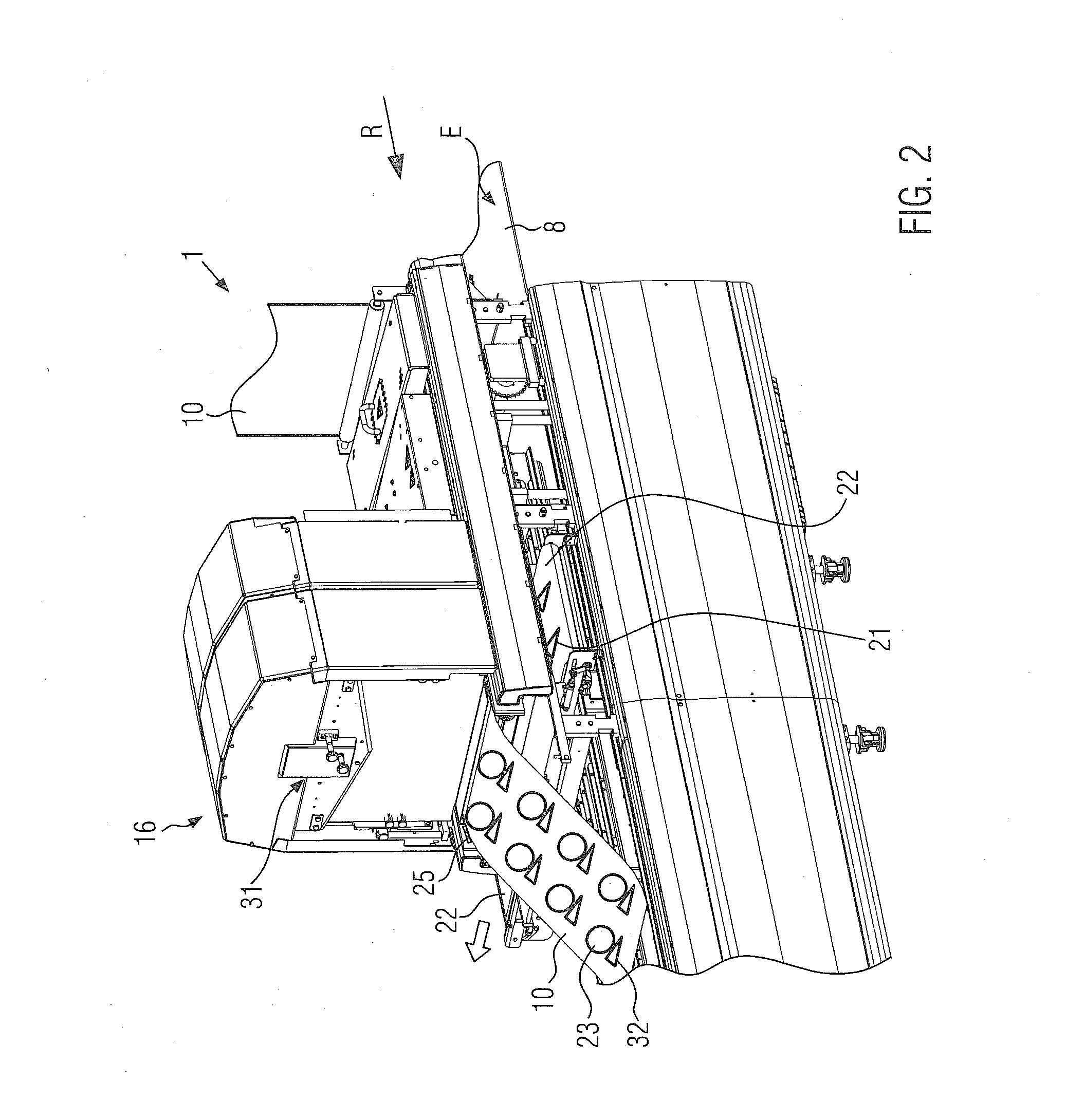

Automatic adhesive sticking equipment

The invention provides automatic adhesive sticking equipment. The automatic adhesive sticking equipment comprises a frame, a front adhesive sticking mechanism, an overturning mechanism of an overturning core and a reverse adhesive sticking mechanism, wherein the front adhesive sticking mechanism, the overturning mechanism of the overturning core and the reverse adhesive sticking mechanism are sequentially arranged on the frame; the front adhesive sticking mechanism comprises an extruding device, a stepping conveyor belt, a secondary locating device and a daubing device, wherein the extruding device is used for transmitting a double faced adhesive tape and peeling off a backing paper of the double faced adhesive tape, the stepping conveyor belt is used for transmitting a core, and the secondary locating device is arranged on the stepping conveyor belt and is used for precisely locating the core; the daubing device used for laminating the double faced adhesive tape and the core is arranged outside a connector between the stepping conveyor belt and the extruding device, and the reverse adhesive sticking mechanism has the same structure as the front adhesive sticking mechanism. According to the equipment provided by the invention, the full automation of sticking the adhesive on the front and reverse surfaces of a lithium battery can be realized, and the production efficiency can be improved; furthermore, the precision of the equipment can be further improved by a color mark sensor, a secondary positioning device and the like; meanwhile, all parts can be precisely cooperated to realize the precise process of automatically sticking the double faced adhesive tape; in addition, the double faced adhesive tape and the core can be laminated by adopting a roll-sticking way, therefore bubbles can be effectively prevented in an adhesive sticking process, and the production quality can be ensured.

Owner:HUIZHOU DESAY BATTERY

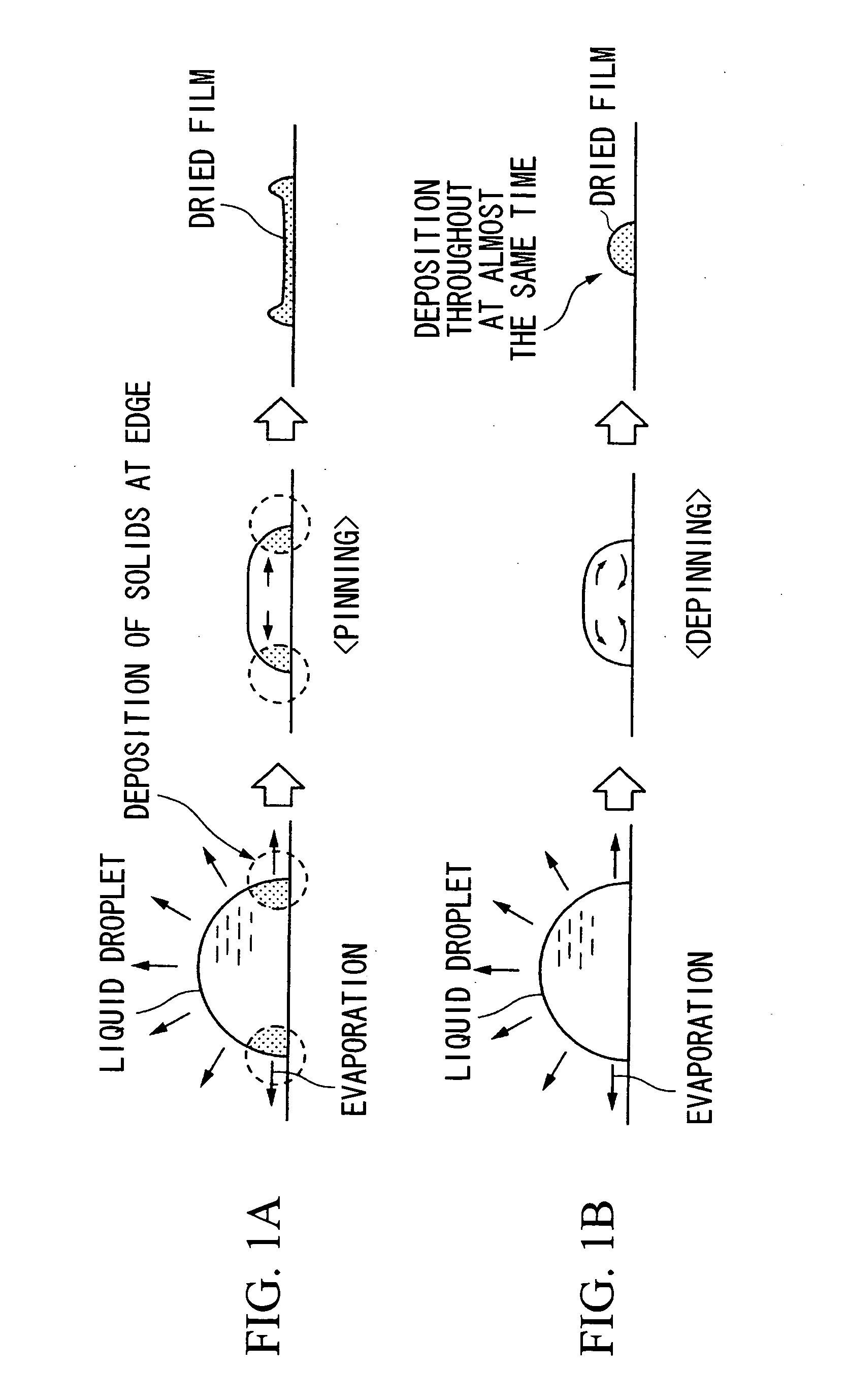

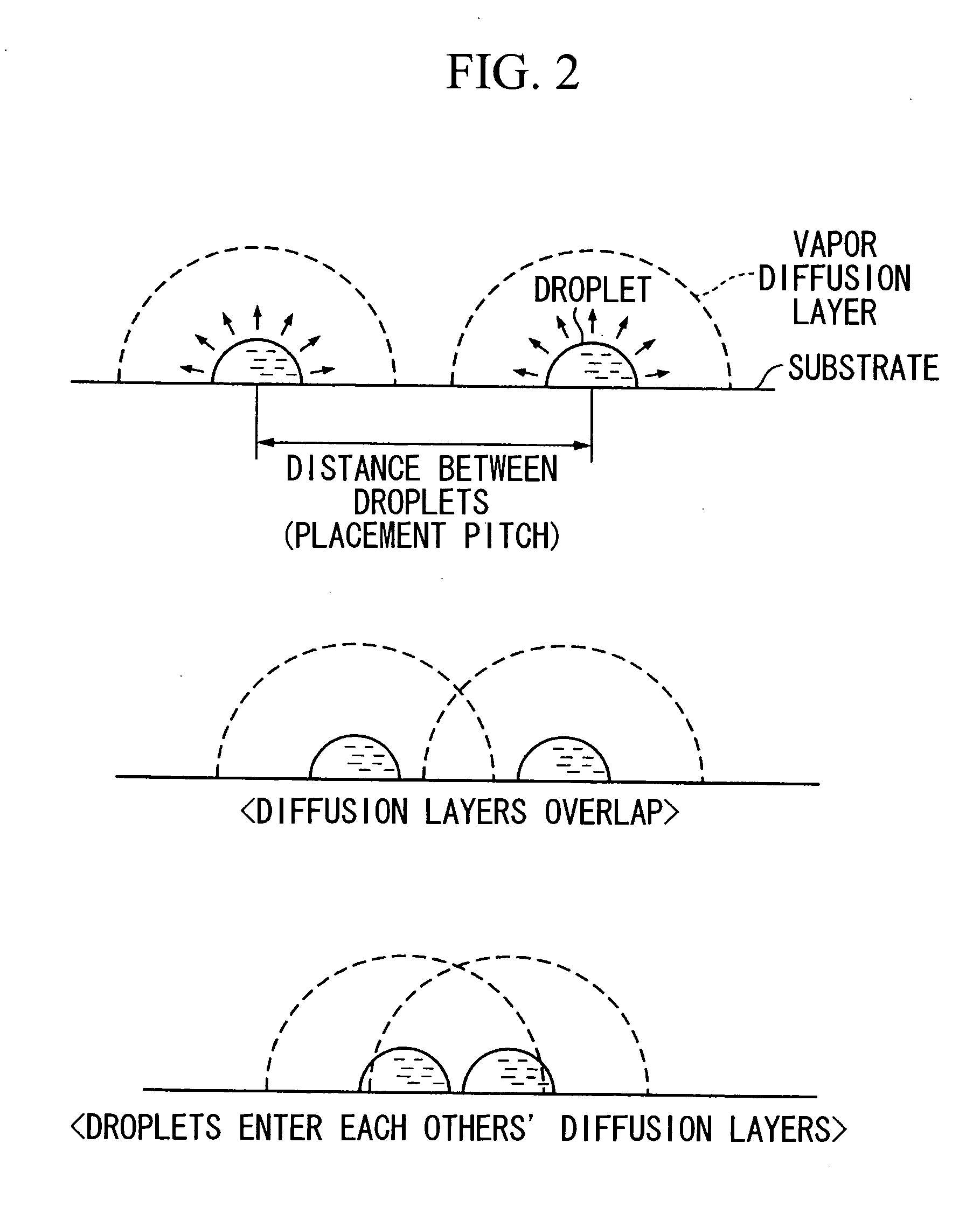

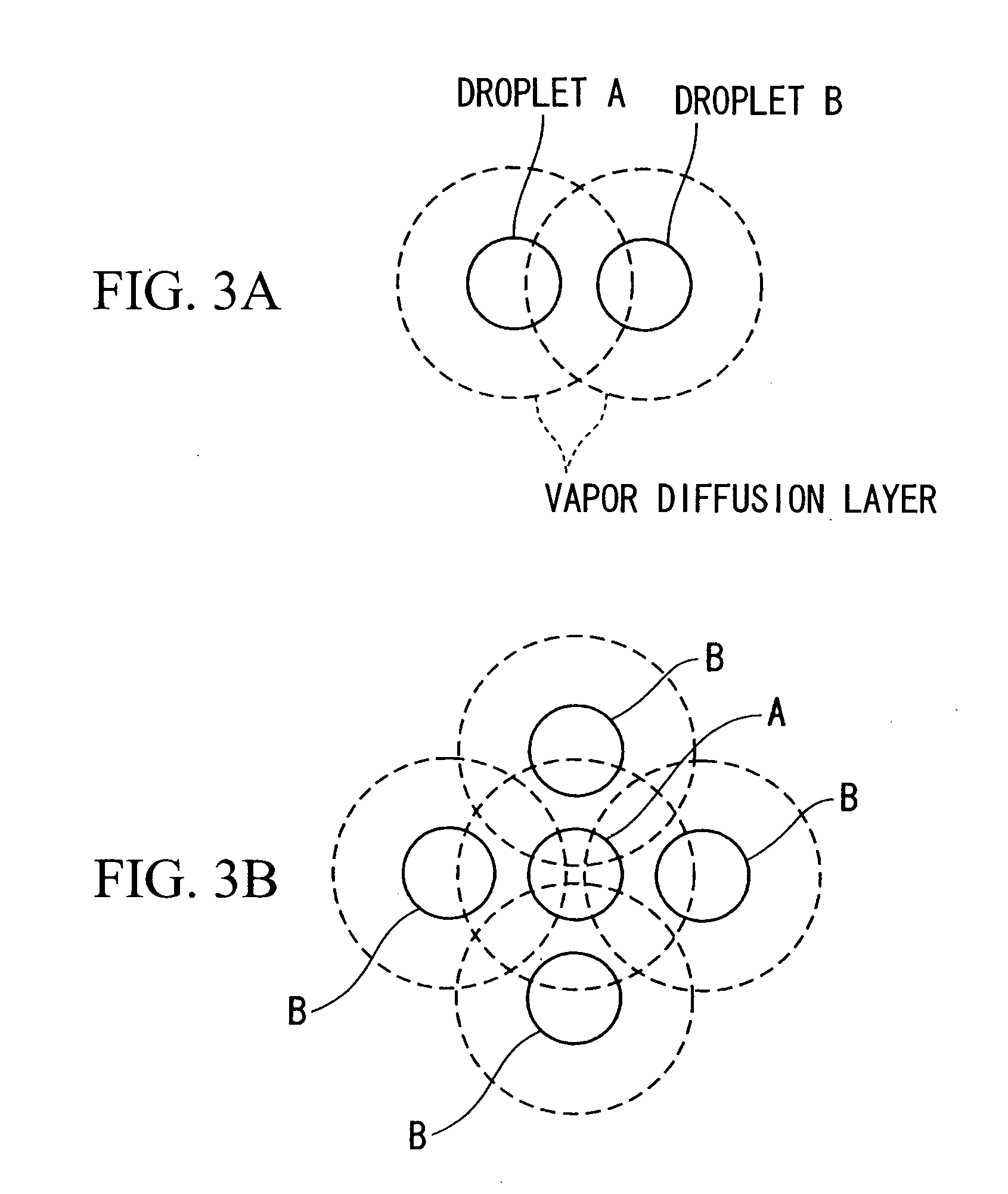

Process for forming a film, process for manufacturing a device, electro-optical device and electronic equipment

InactiveUS20050025880A1Stable and accurateAccurately and stably formedMaterial nanotechnologyNanoinformaticsEngineeringElectron

A liquid material is placed on a substrate as a droplet to form a film on the substrate. At least either one of a concentration of solids in the liquid material and a drying rate of the droplets is used as a parameter to control a form of a dried film of the droplets. Moreover, a first droplet is placed on a substrate, the first droplet is dried to form a dried film of a form in which a thickness of an edge is larger than that of a central part, and a second droplet is placed in a region surrounded by the edge section of a dried film of the first droplet to form a dried film of the second droplet. Furthermore, the liquid material is placed on the substrate as a droplet to form a film on the substrate, and a dried film of the droplet is formed by contracting the droplet.

Owner:SEIKO EPSON CORP

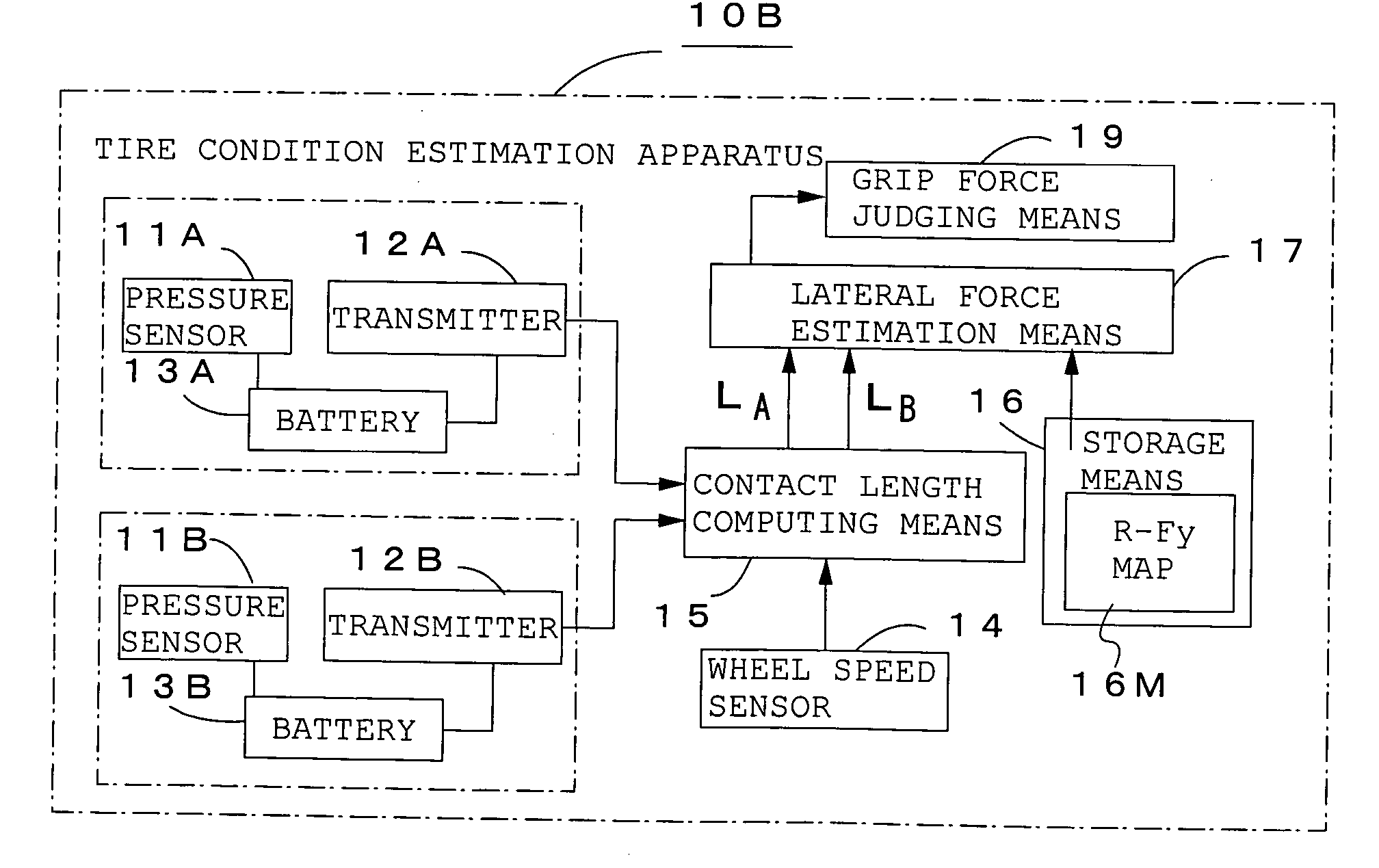

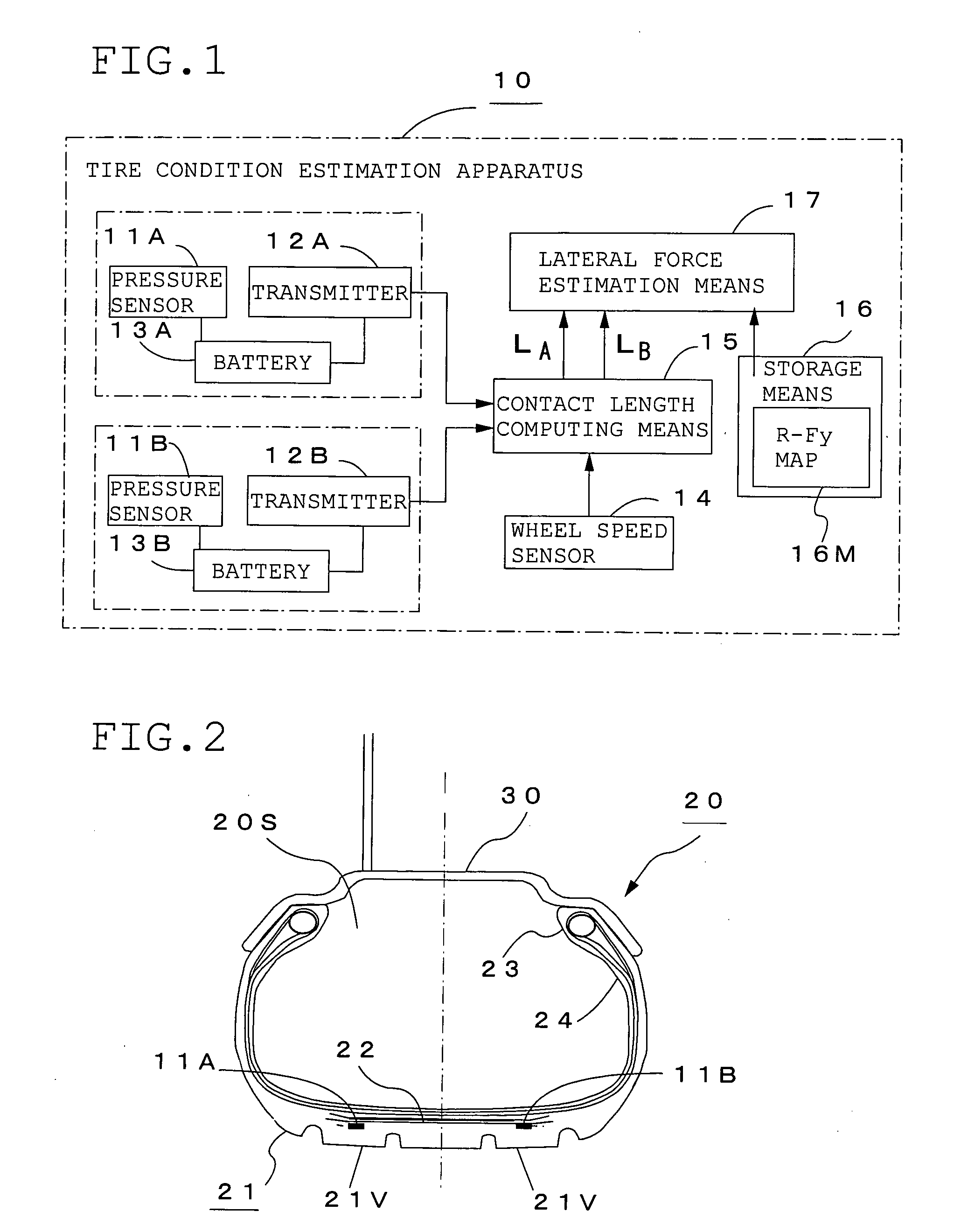

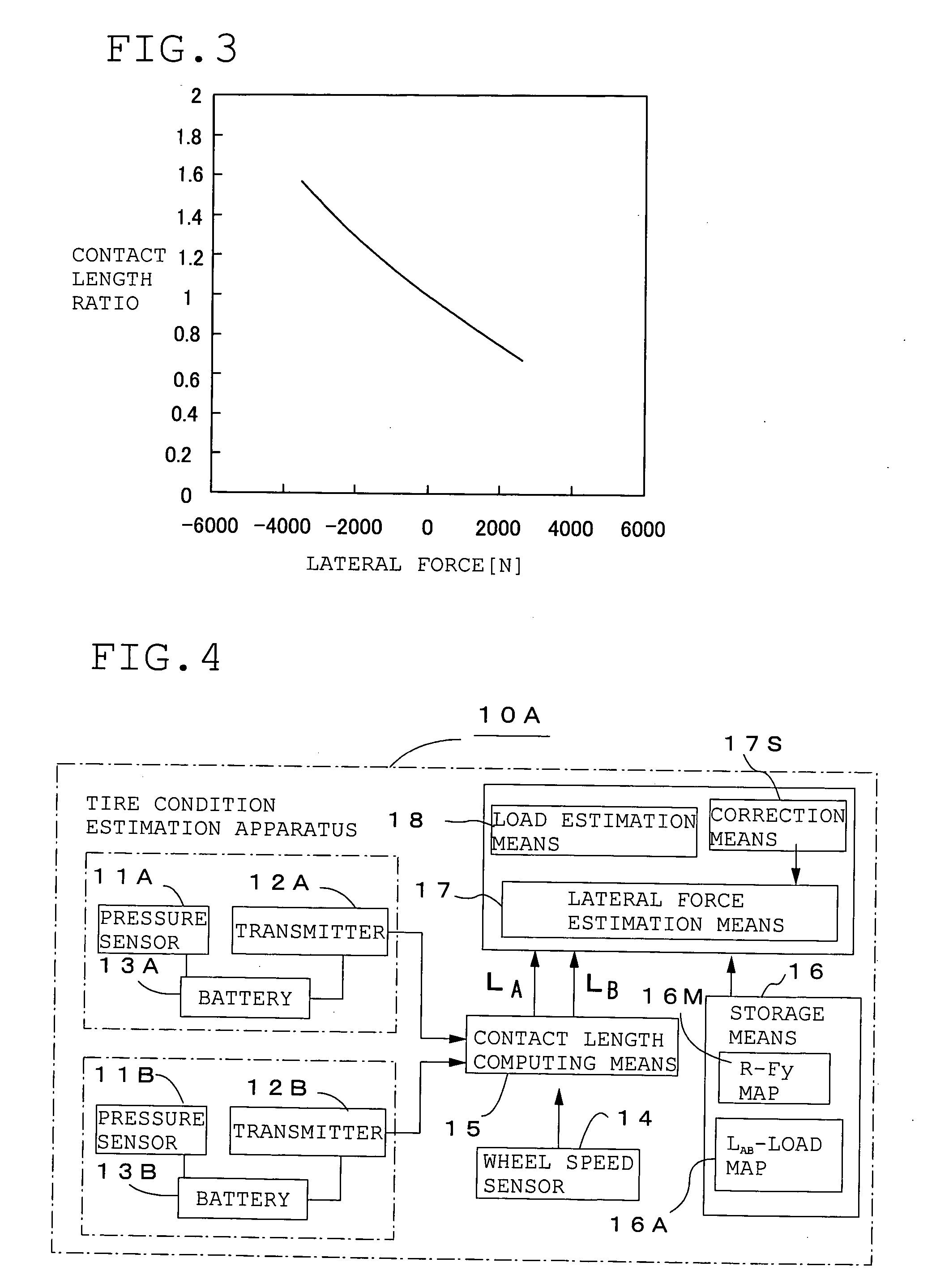

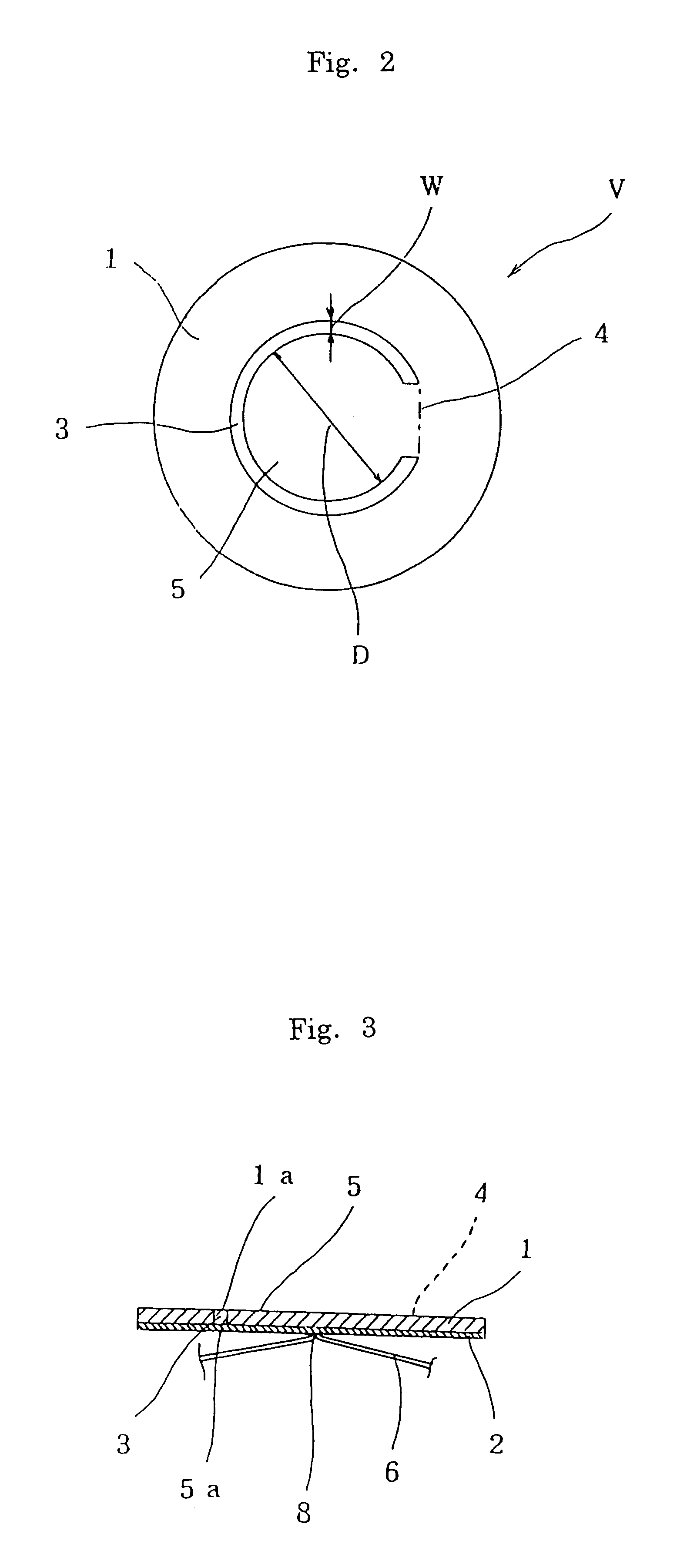

Sensor-incorporated tire and tire condition estimating method

ActiveUS20060201240A1Accurate detectionAccurate estimateTyre measurementsTyre tread bands/patternsWheel speed sensorEstimation methods

In order to accurately and stably estimate the conditions of a running tire, a vehicle is equipped with a sensor-incorporating tire having, at an equal distance from the center in the axial direction of the tire, pressure sensors (11A, 11B) buried in a tread rubber positioned on the outer side in the radial direction of the tire belt layer of a tire tread portion and on the inner sides in the radial direction of tread blocks, the contact length LA of the car body side and the contact length LB of the opposite side of the center in the axial direction of the tire are detected by using the duration times of pressure values from the pressure sensors (11A, 11B) and a wheel speed from a wheel speed sensor (14), and the ratio R=LA / LB of the contact length LA to the contact length LB is computed to estimate lateral force generated by the tire, or the average contact length LAB which is the average value of the contact lengths LA and LB is computed to determine a load applied to the tire.

Owner:BRIDGESTONE CORP

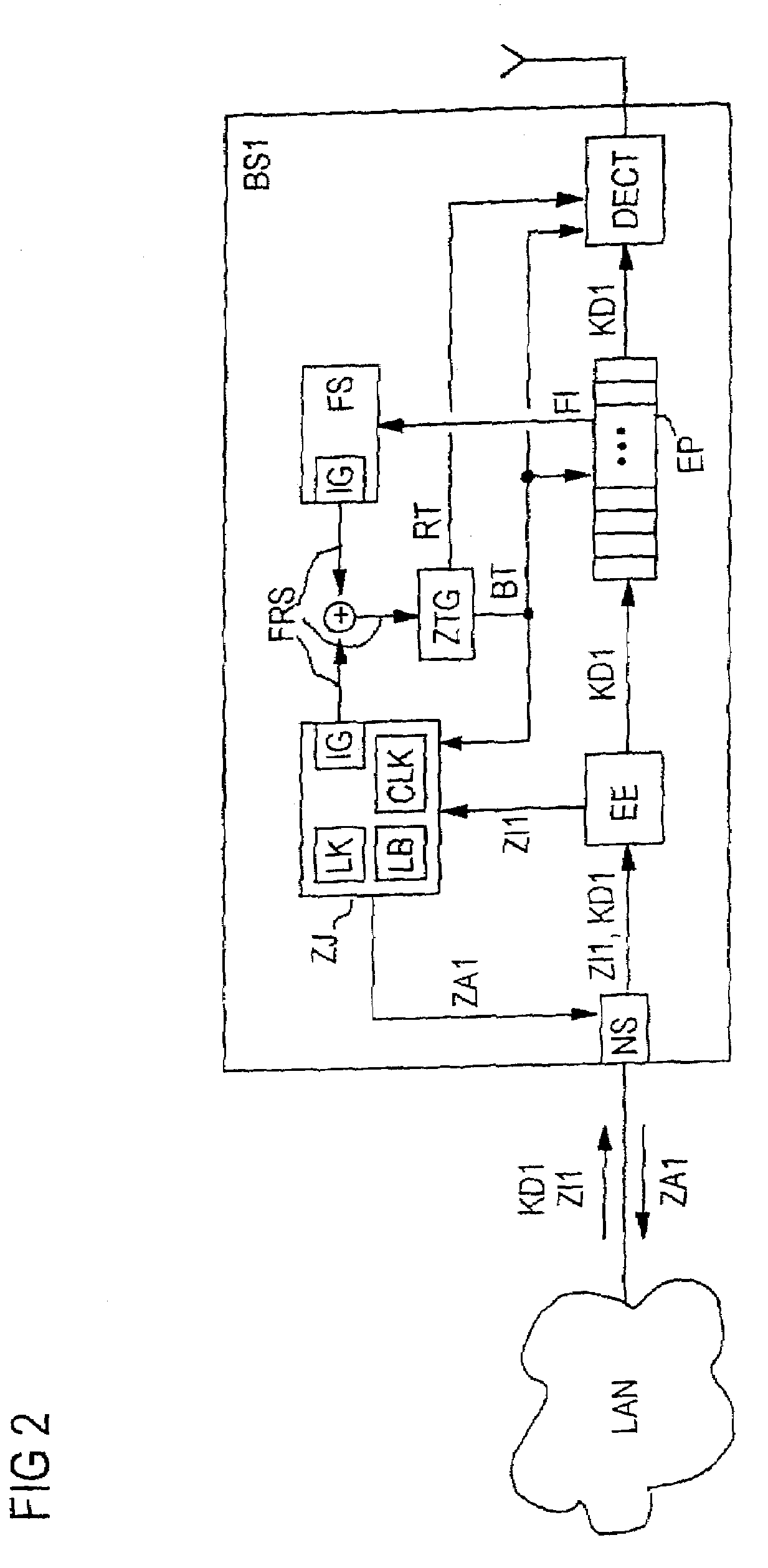

System for synchronizing communications system components coupled via a communications network

InactiveUS7085276B1Improve clock accuracyAccurate synchronizationTime-division multiplexData switching by path configurationTime informationReal-time clock

To synchronize communications system components coupled via a communications network, a time information transmitter is provided which is used to transmit time information, possibly on request, relating to the communications system components. The communications system components each have a clock generator, which needs to be synchronized, and a real time clock, where the clock generator both determines the transmission rate for communications data which are to be transmitted and prescribes the time base for the real time clock. In addition, the communications system components each have a comparison device for comparing received time information with a current time value indicated by the real time clock, and a clock frequency controller for regulating the clock frequency of the clock generator on the basis of the comparison result.

Owner:RINGCENTRAL INC

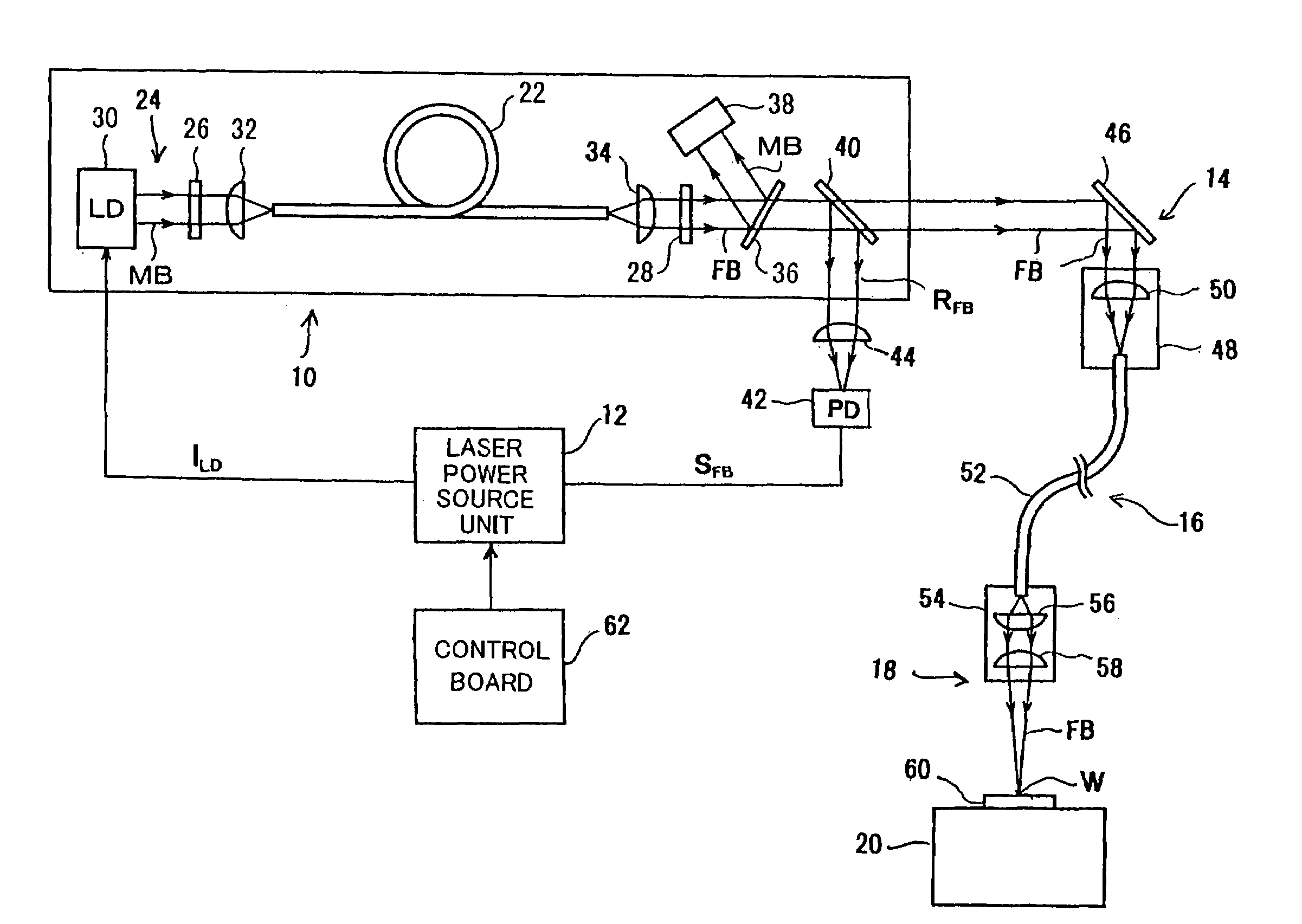

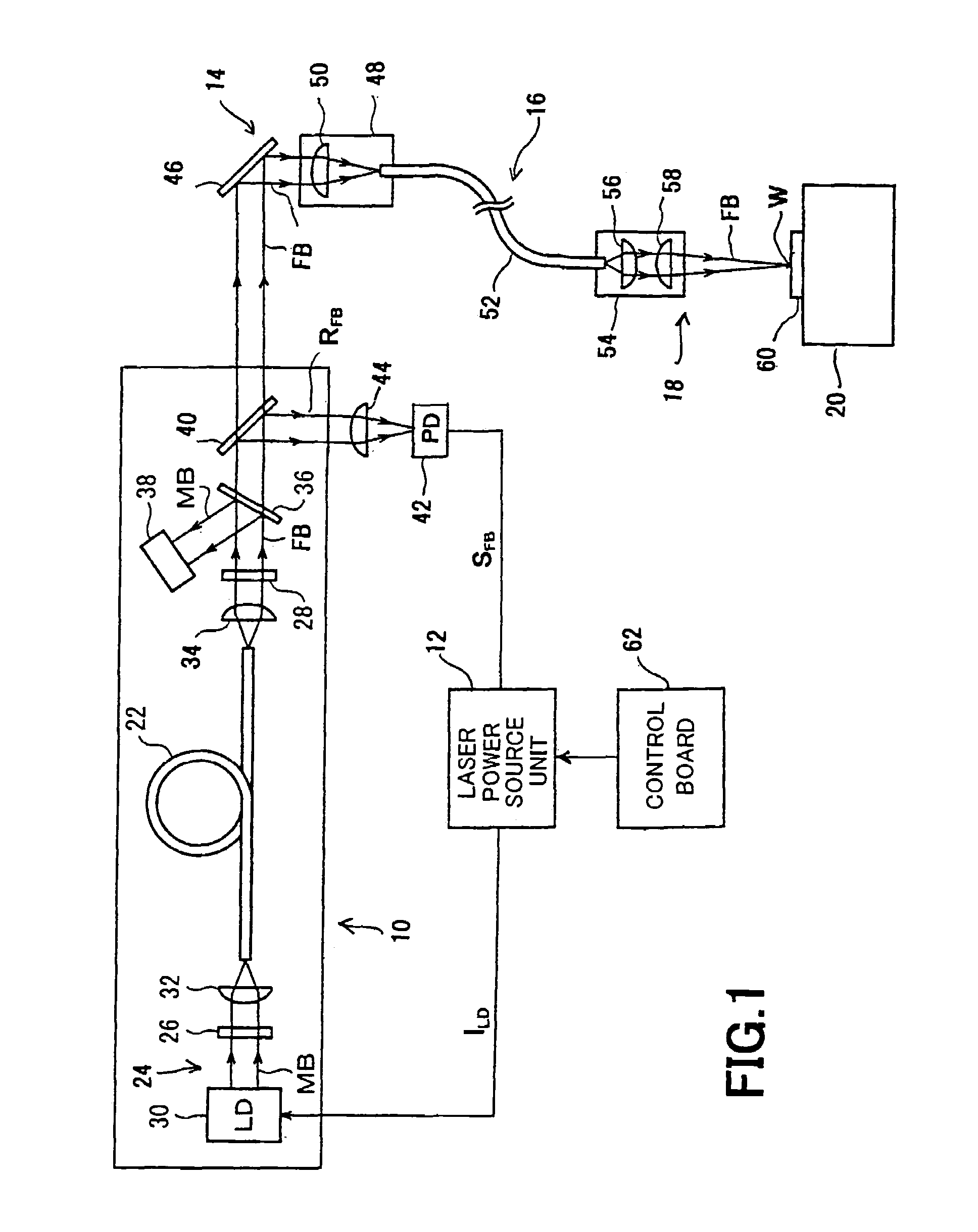

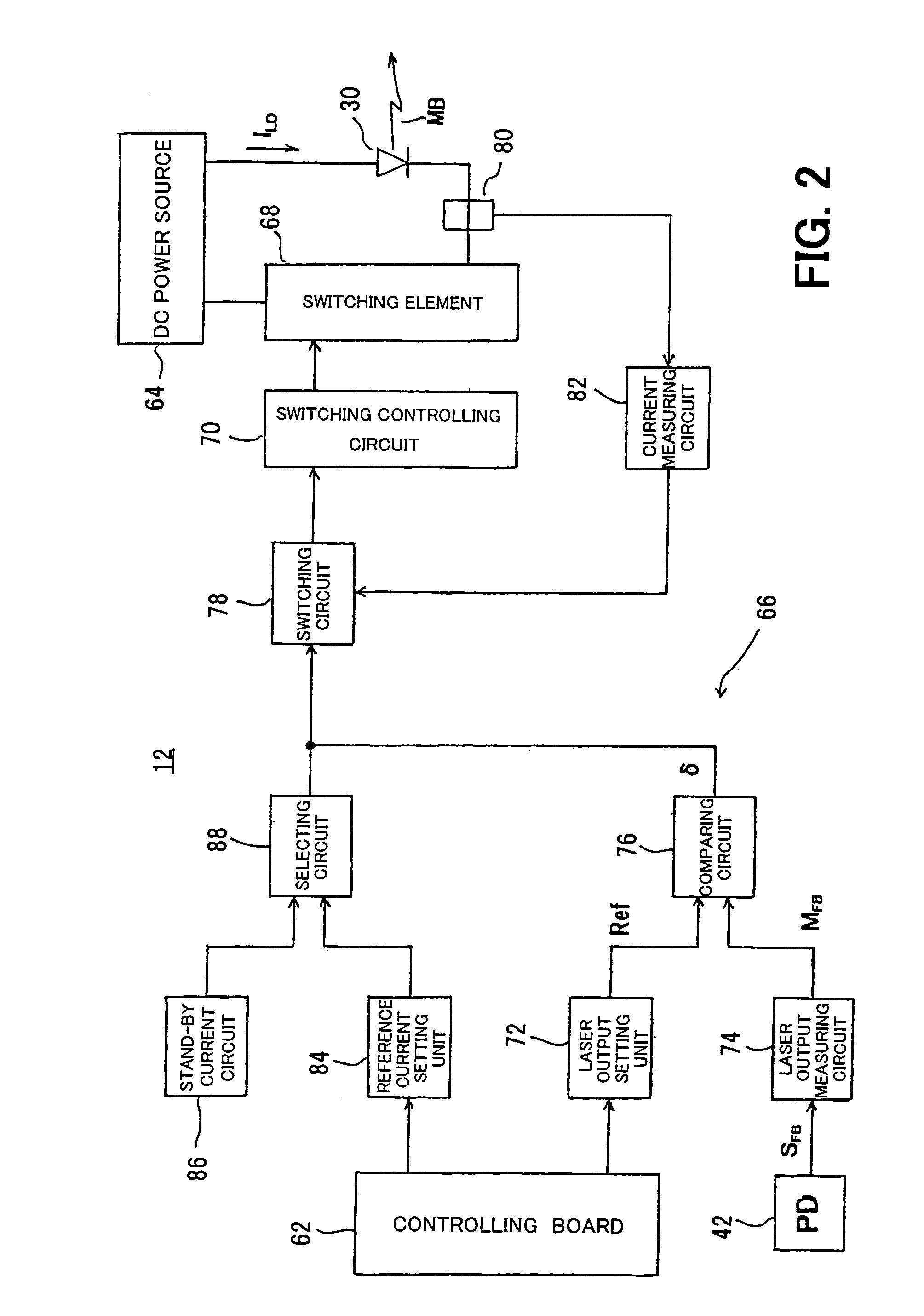

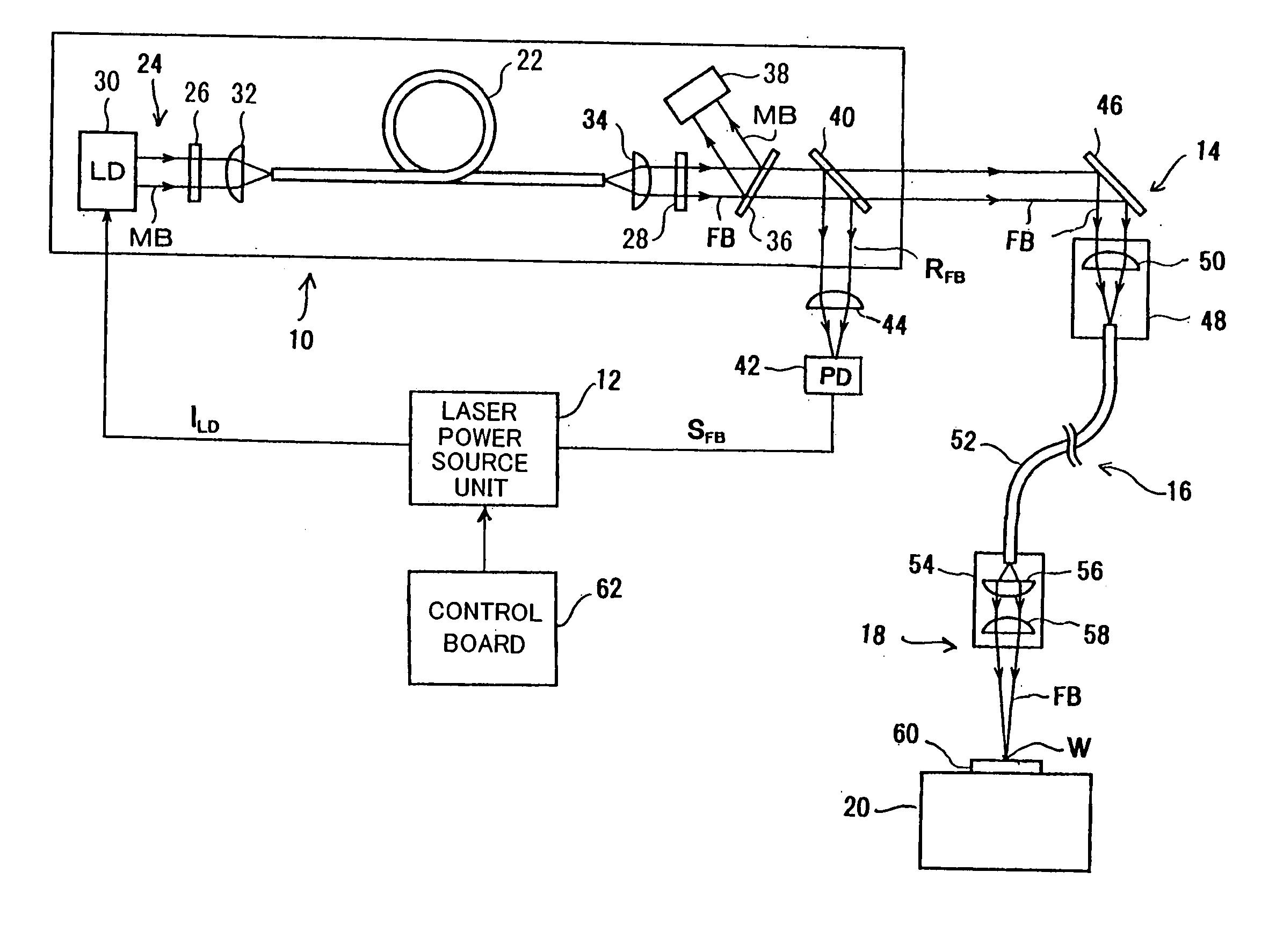

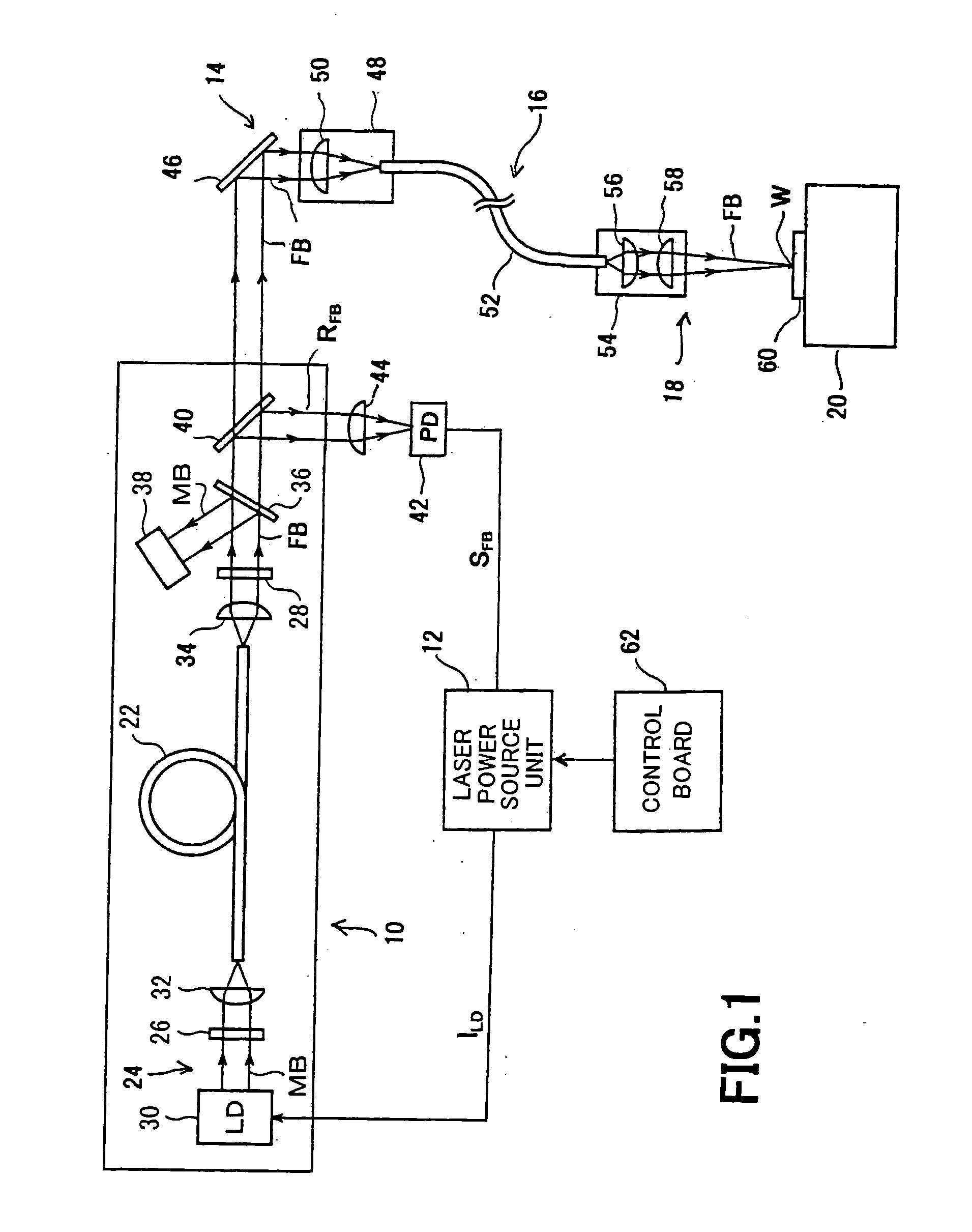

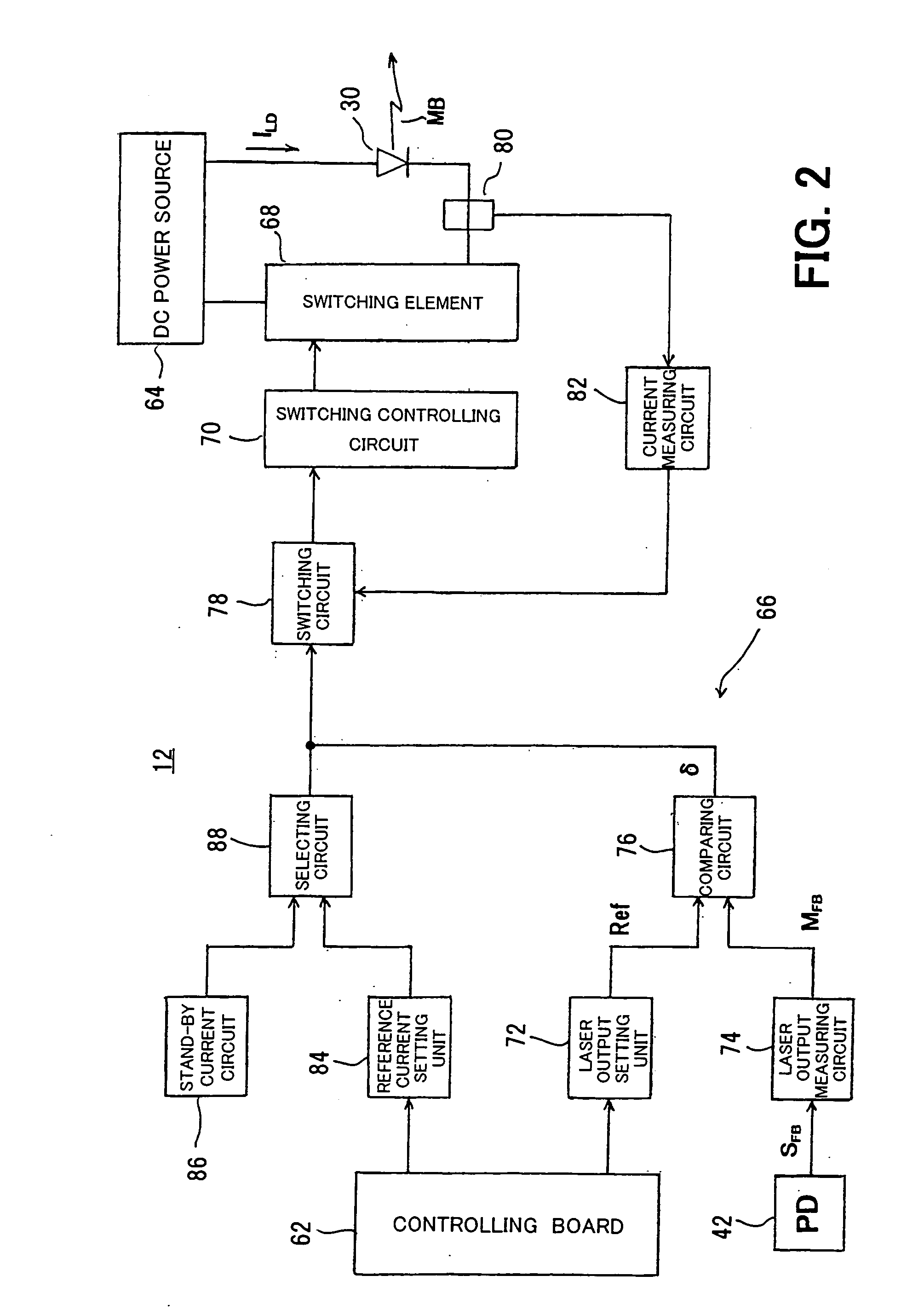

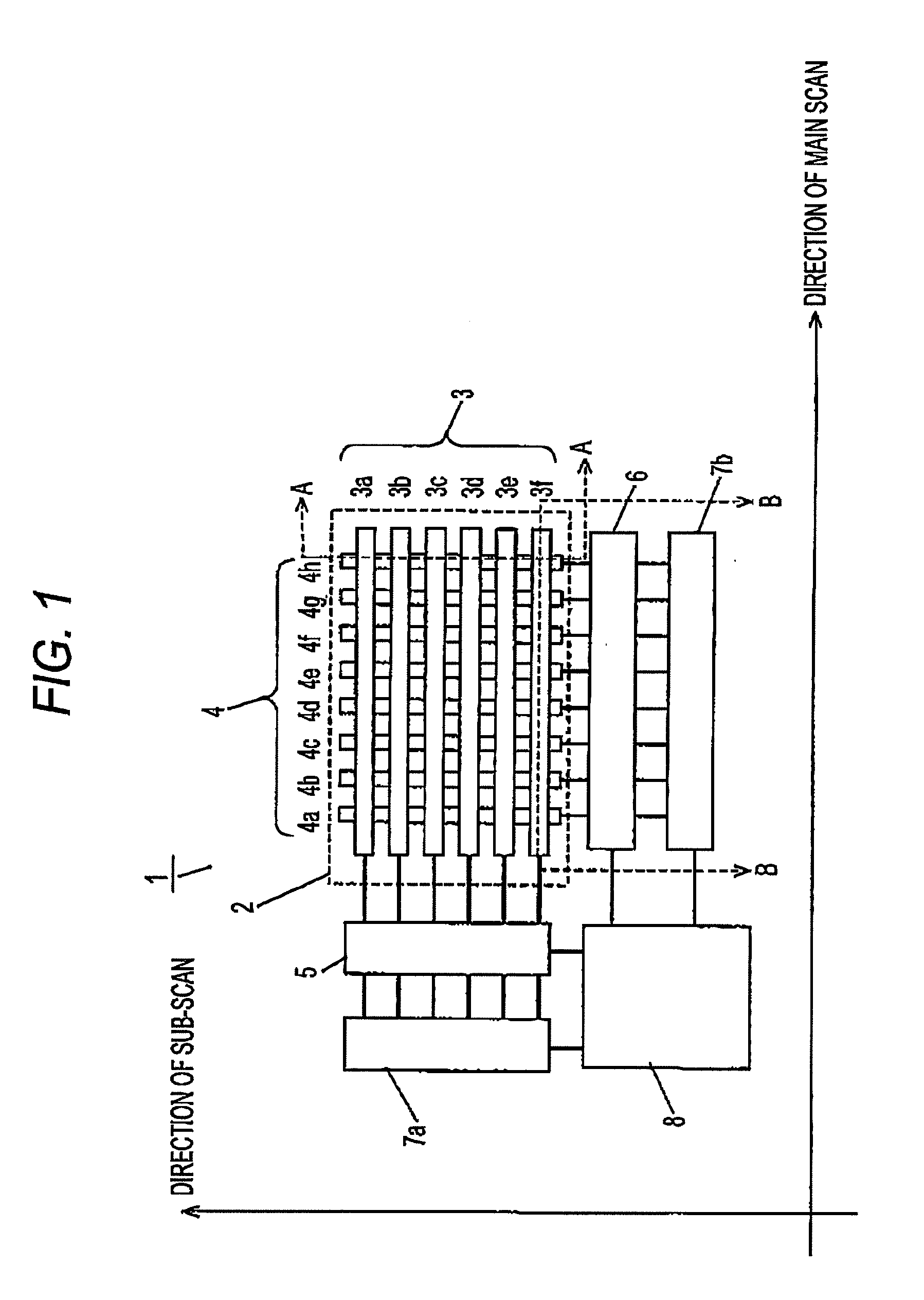

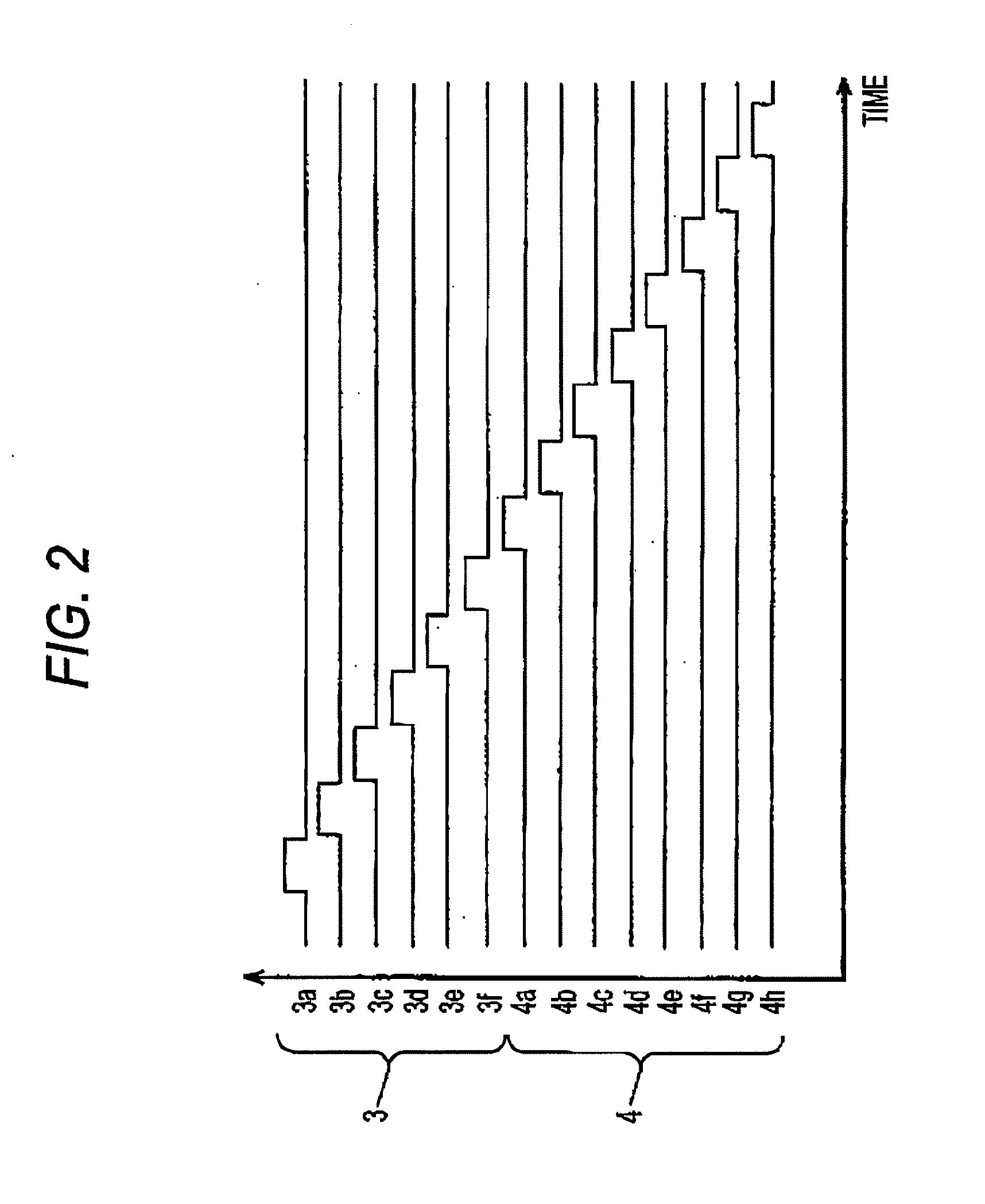

Fiber laser beam processing apparatus

InactiveUS7436863B2Stable outputImprove reliabilityLaser using scattering effectsOptical resonator shape and constructionBeam splitterPhotodiode

A fiber laser beam processing apparatus is configured by a fiber laser oscillator, a laser power source unit, a laser beam injecting unit, a fiber transmission system, a laser beam irradiating unit, a processing table, etc. A portion of a fiber laser beam oscillated and outputted by the fiber laser oscillator is received by a photo diode for monitoring the power through a beam splitter. An output signal of the photo diode is sent to a laser power source unit. The power source unit receives the output signal of the photo diode as a feedback signal and controls a driving current or an excitation current to be supplied to a laser diode of a pumping unit such that the laser output of the fiber laser beam equals a set value.

Owner:MIYACHI TECHNOS CORP

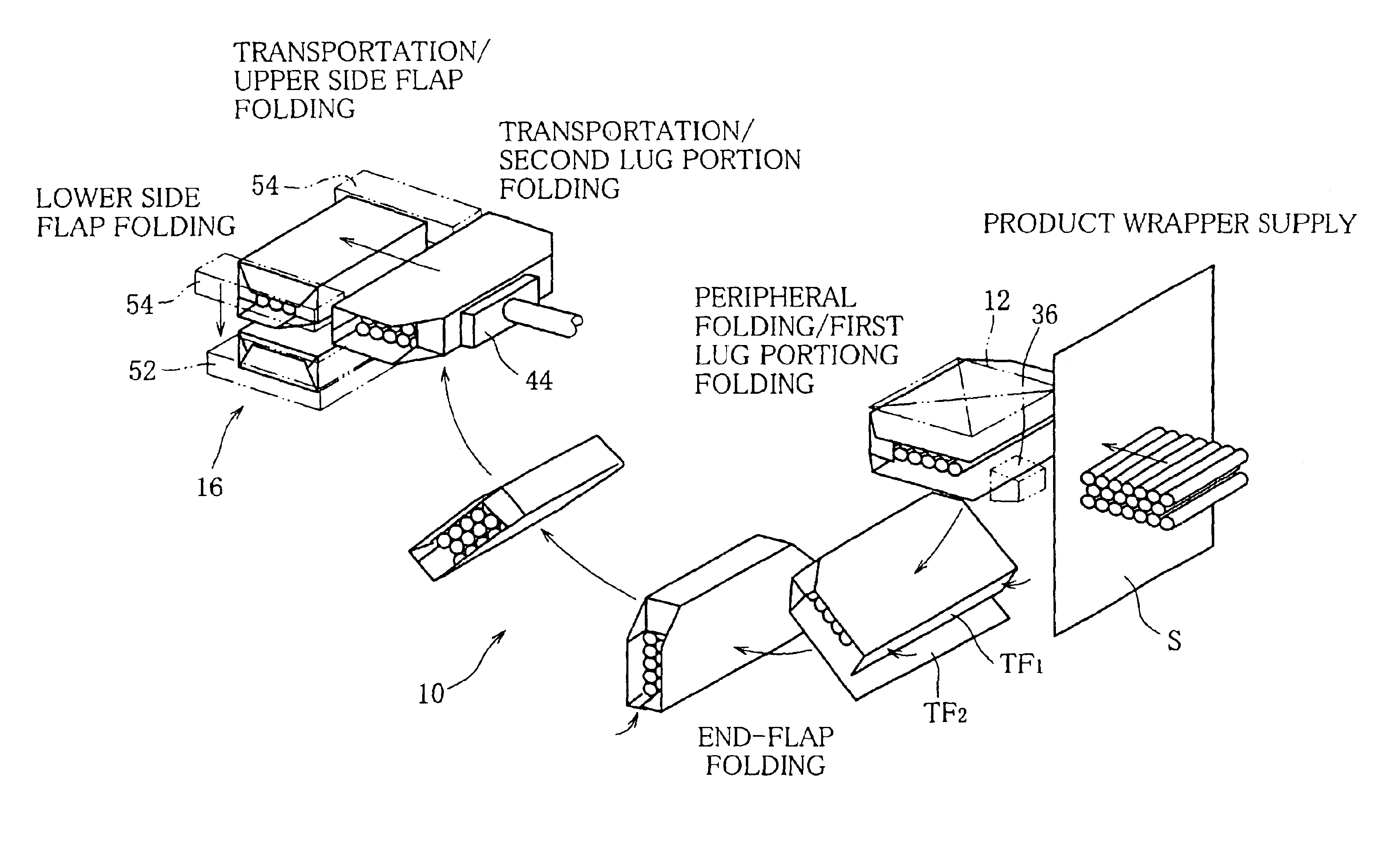

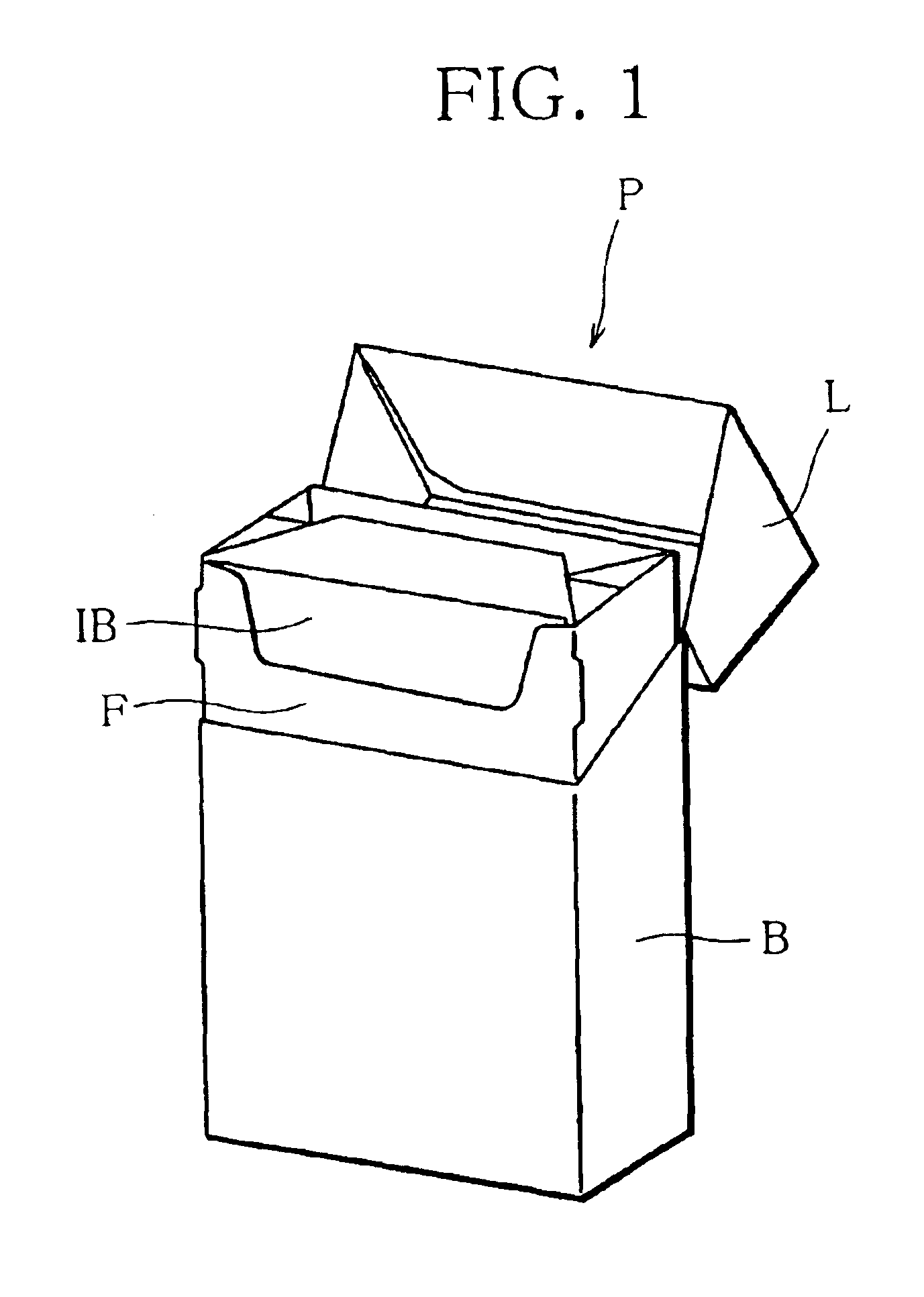

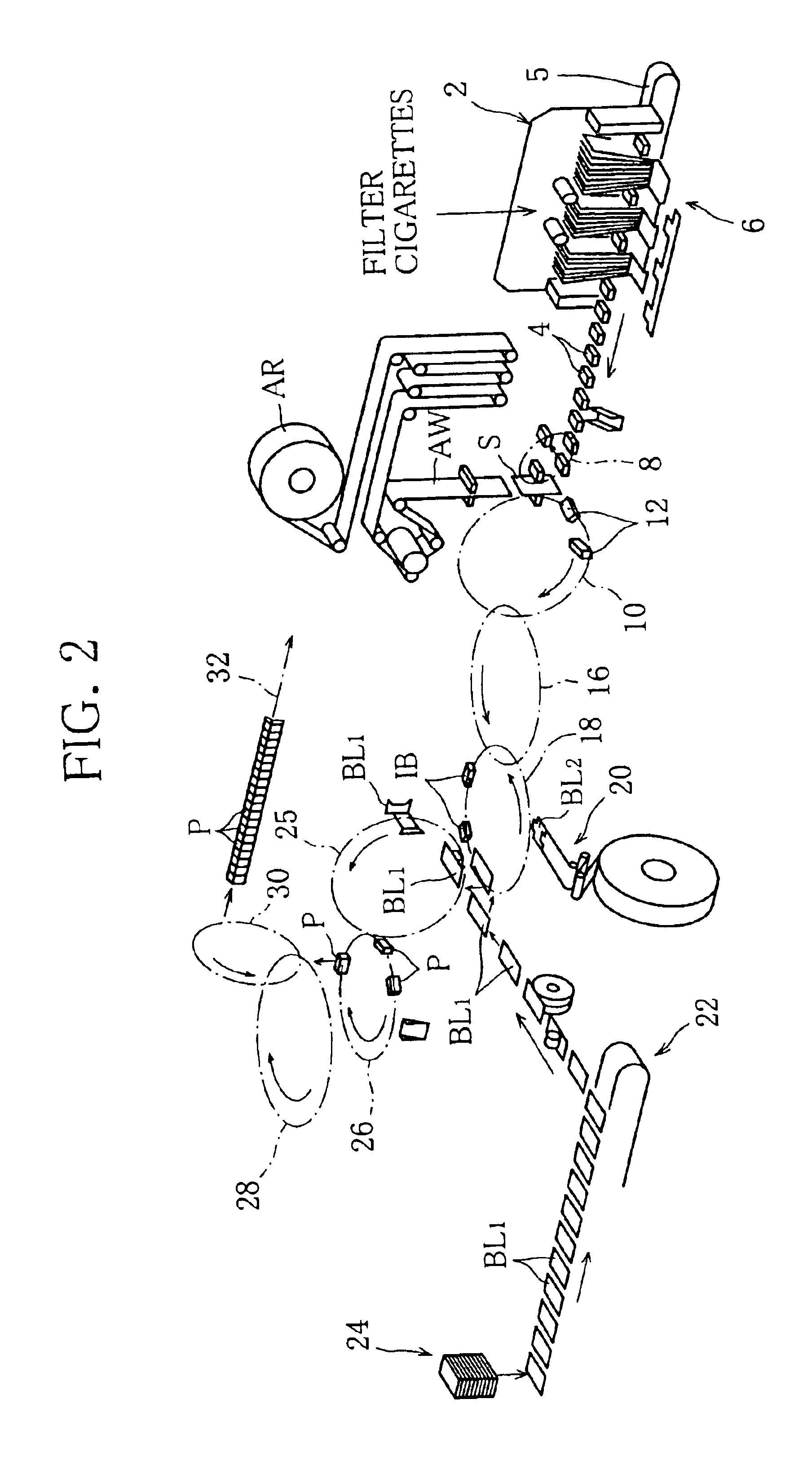

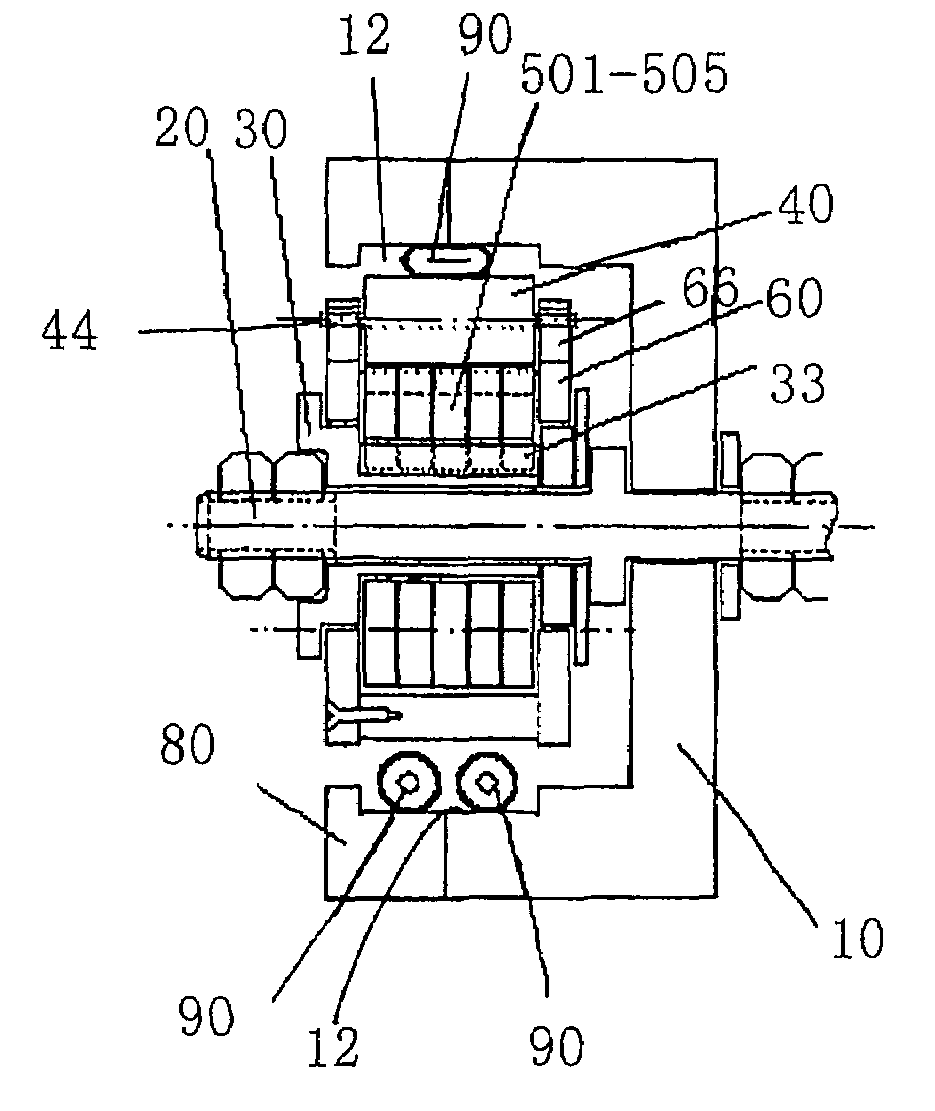

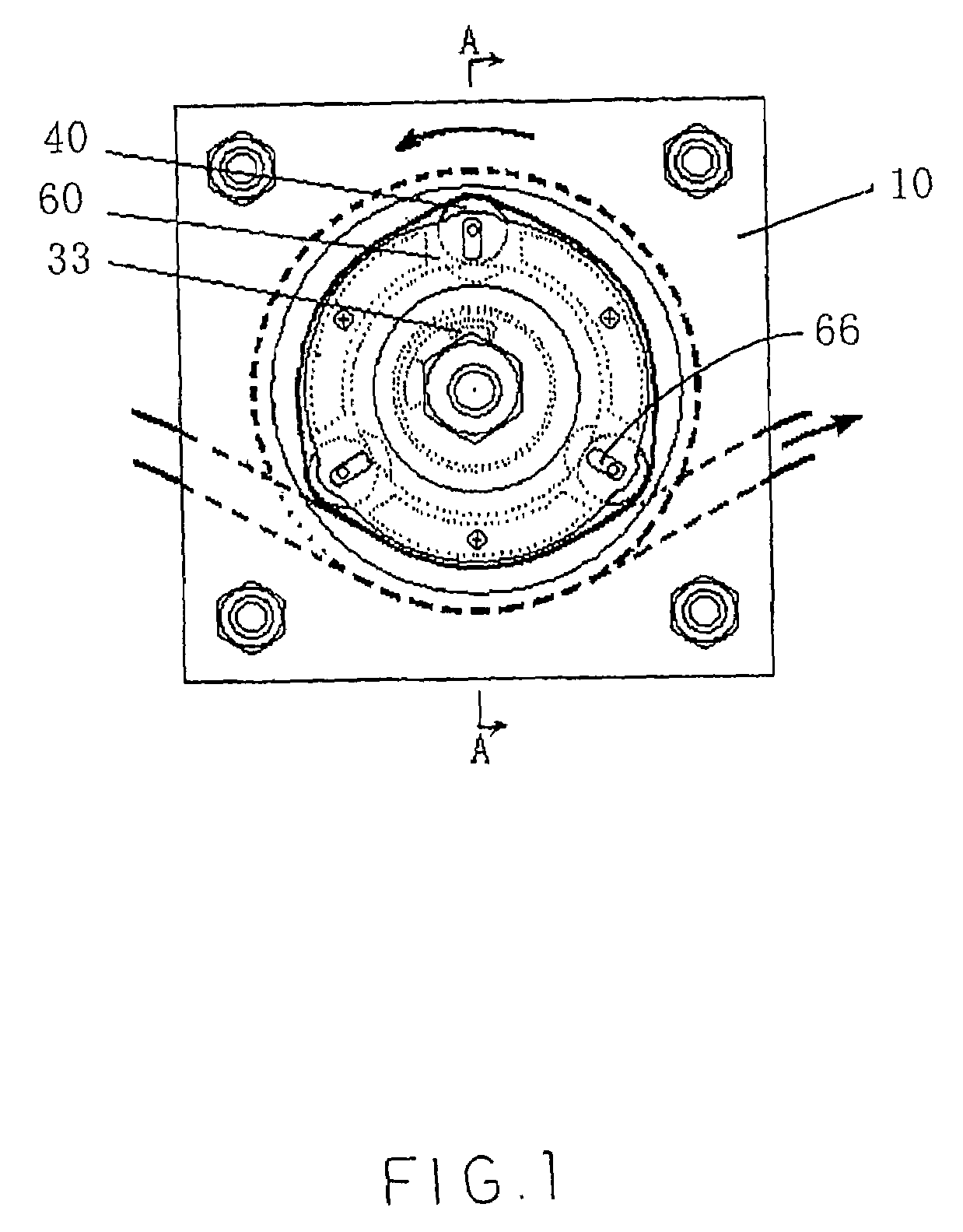

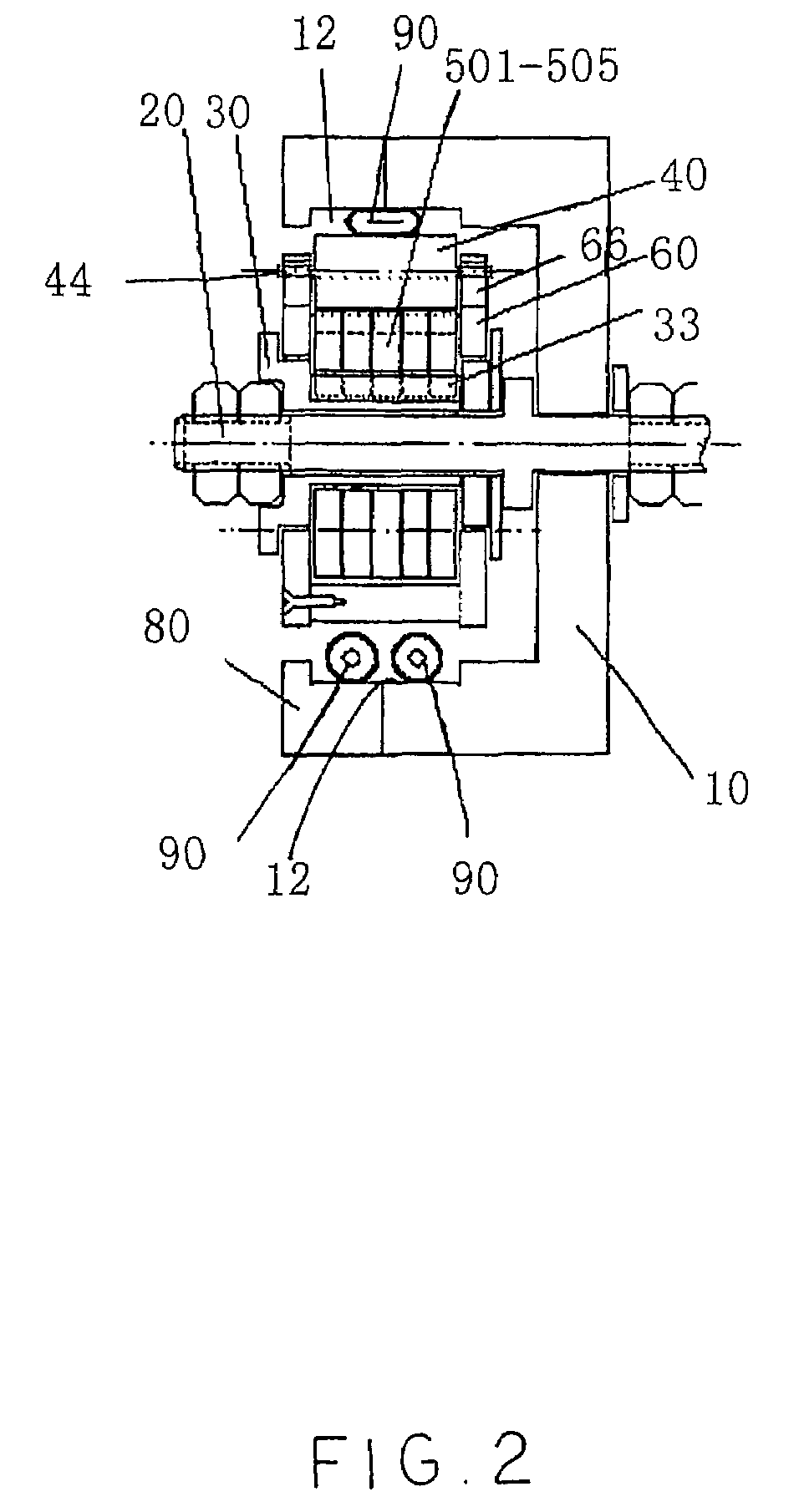

Packaging material folding device of packaging machine

InactiveUS6854243B2Stable and accurateReduce coefficient of frictionPackaging cigaretteWrapper folding/bending apparatusEngineeringTurret

A wrapper folding apparatus of a packaging machine has a second wheel (10) for use as a folding turret. The second wheel (10) is supplied with a cigarette bundle and an aluminized sheet (S) in an inlet position. As this is done, the aluminized sheet (S) is folded around the periphery of the cigarette bundle, and lug portions formed by the peripheral folding are folded by the use of primary lug folding guides (36). Since the lug protions are kept folded by the use of holding guides (38) thereafter, they cannot be freed until an outlet position is reached. When the cigarette bundle is discharged in the outlet position of the second wheel (10), the lug portions on the end-flap side are folded by the use of secondary lug folding guides (46). After the folding, side flaps continue to be folded without allowing the lug portions to be free.

Owner:JAPAN TOBACCO INC

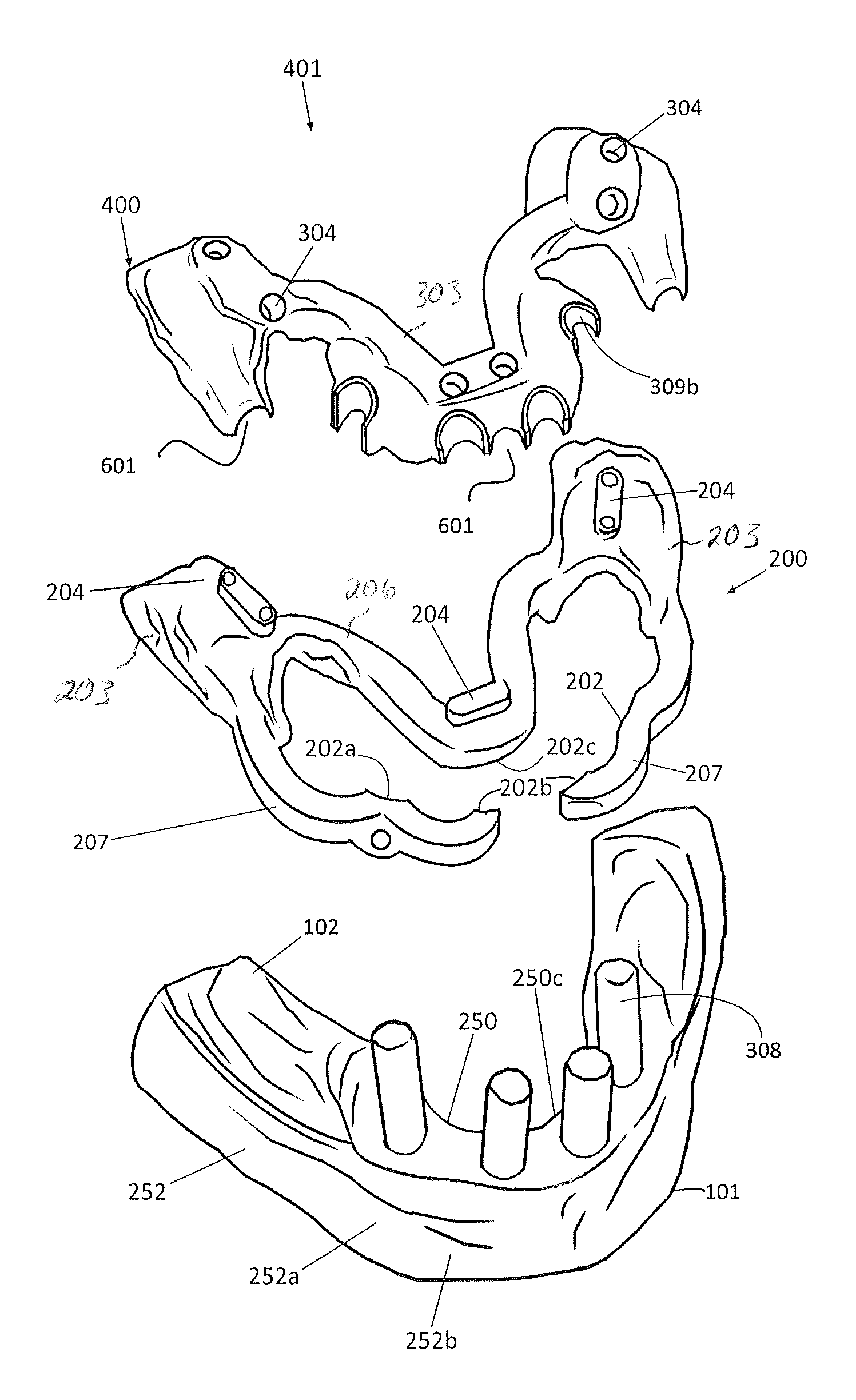

Edentulous surgical guide

ActiveUS9504533B2Raise the possibilityStable and accurateDental implantsAdditive manufacturing apparatusSurgical drillEngineering

A dental surgical drill guide assembly and method includes a surgical guide housing and a base frame that fits to both gum tissue and one or multiple small areas of jawbone. The apparatus may be configured to accurately place dental implants according to planned positions. Such apparatus may increase the stability of the surgical guide by clasping and / or contacting the jawbone, while improving the overall fit and minimizing the need of invasive surgery and flapping by also clasping and / or contacting selected areas of the gum tissue at the same time. Self-locking alignment members aid in easy removal, and re-installation, of the surgical guide housing to the base frame.

Owner:IBUR

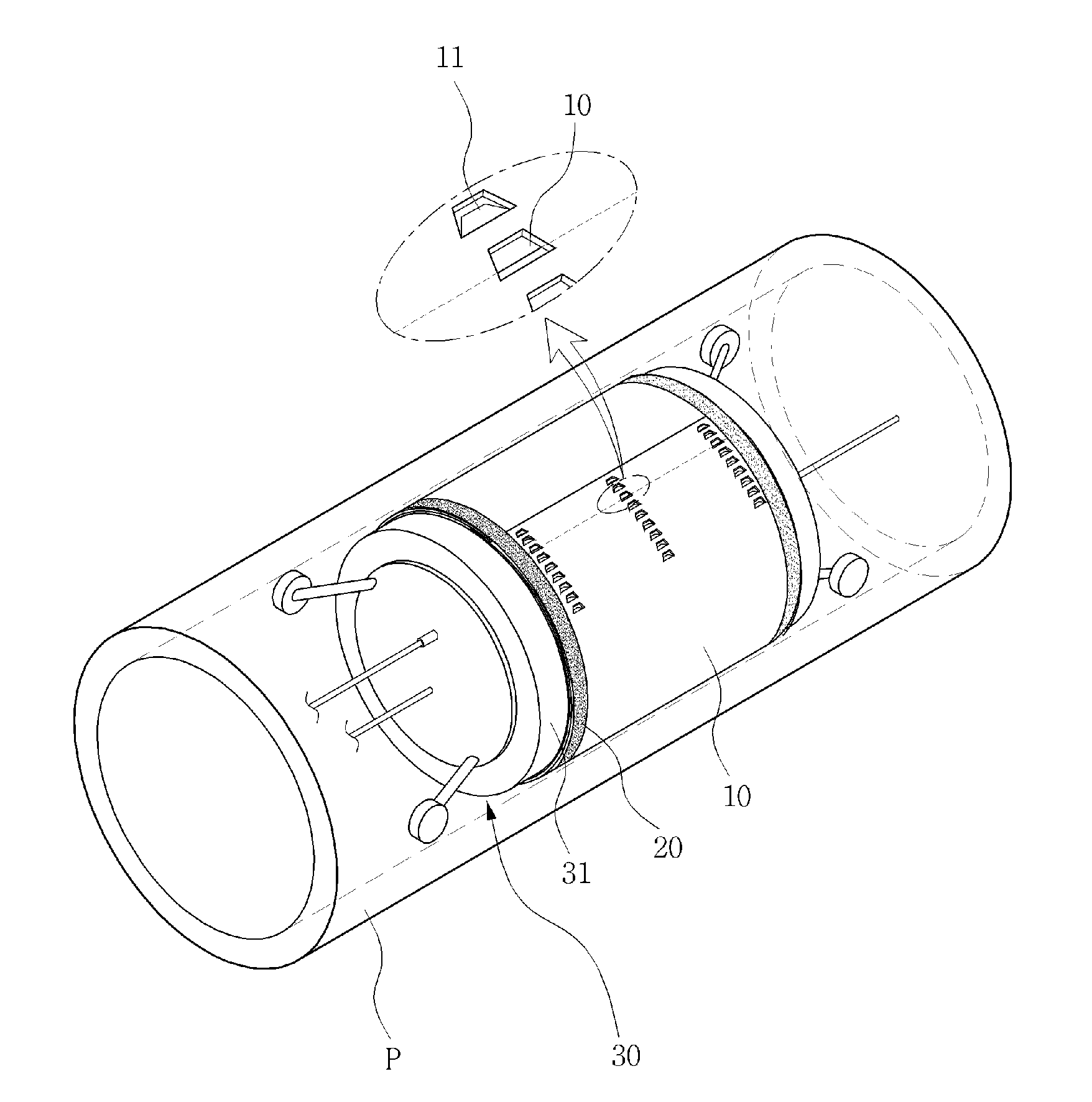

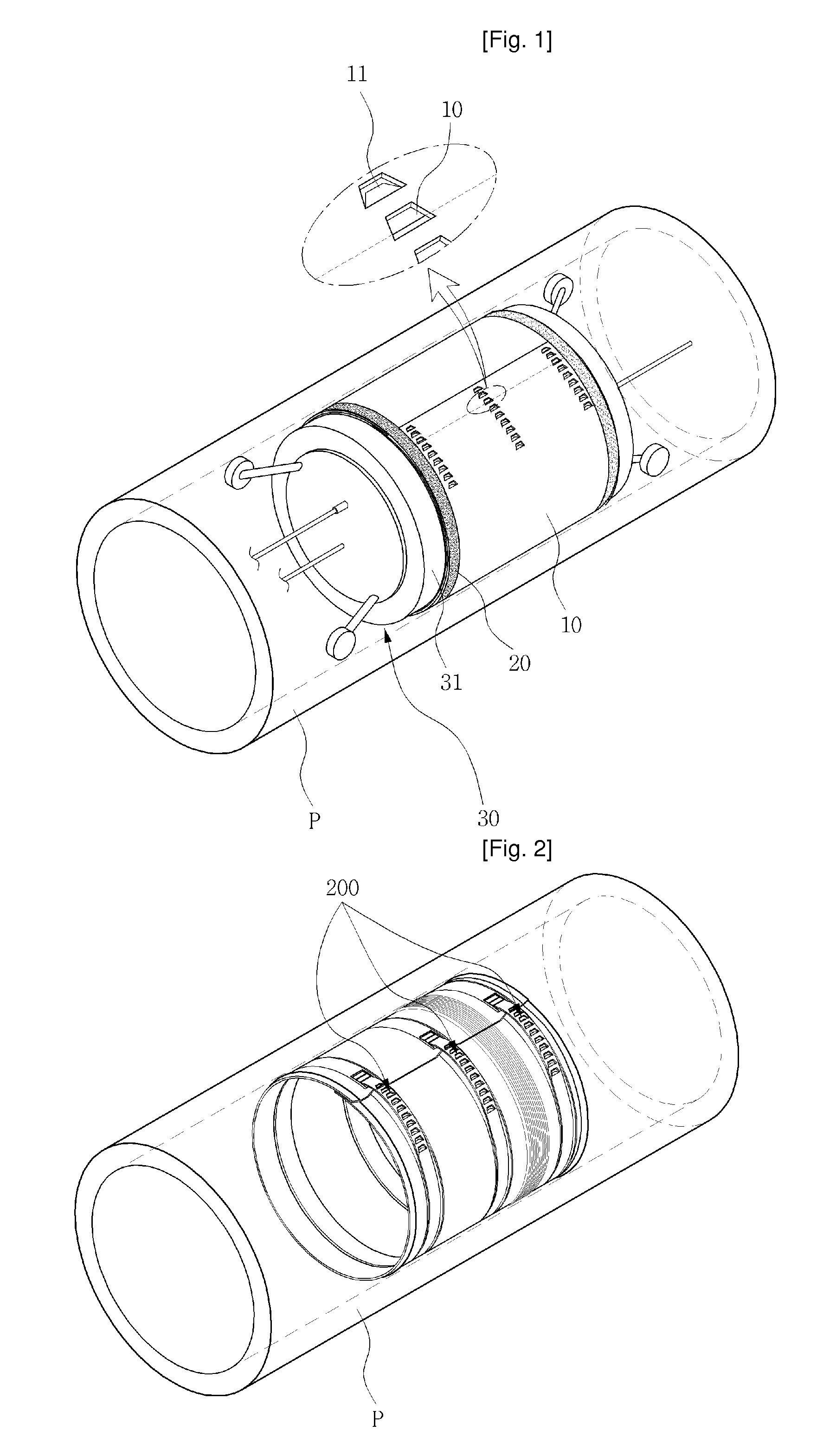

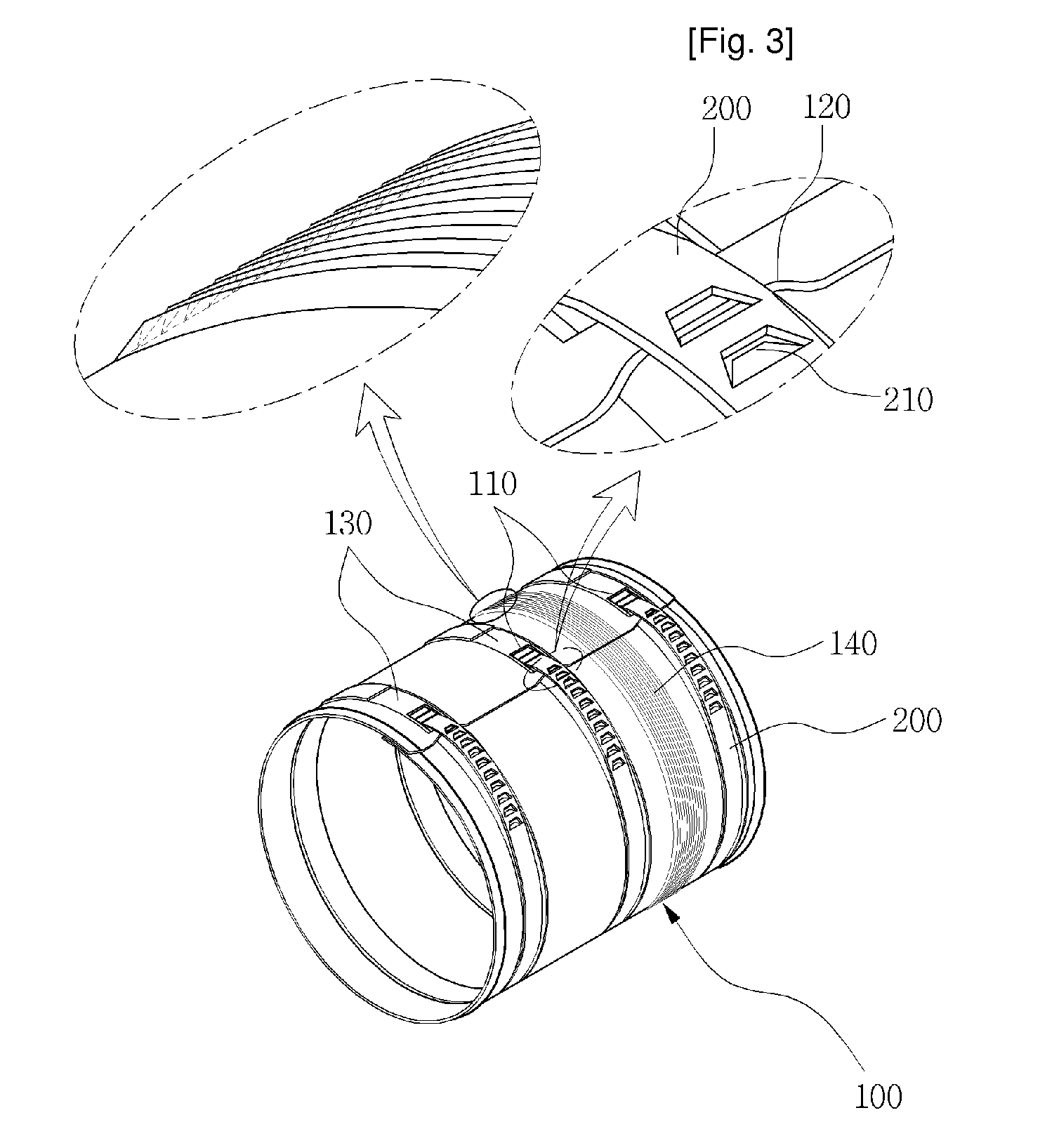

Reinforcing Materials For Repairing Underground Water Pipeline Without Excavation And Method For Repairing Thereof

InactiveUS20080193221A1Avoid separationStable and accuratePipe elementsRepair materialMachining process

A method and reinforcing materials are developed for repairing underground water pipeline without excavation. The reinforcing materials, which have forcibly rolled to form a cylindrical shape is inserted into the pipeline. Then, it will be expanded to tightly seal the damaged or cracked inner wall areas of the pipeline. A series of guiding belts are employed for circumferentially mounting on the outer surface of the reinforcing materials to form a sleeve. Thus, it is smoothly inserted into the water pipeline by pulling one end. Once the sleeve is inserted into the pipeline, the sleeve is steadily expanded to seal and tighten the damaged area. Accordingly, the repair work is easily facilitated to seal the damaged area of the pipeline without excavation. The repair materials have formed as a simple sleeve with smooth inner surface for minimizing the finishing process, such as a cutting. Thereby, the leakage is efficiency prevented without disconnecting the water supply.

Owner:HANGANGCC

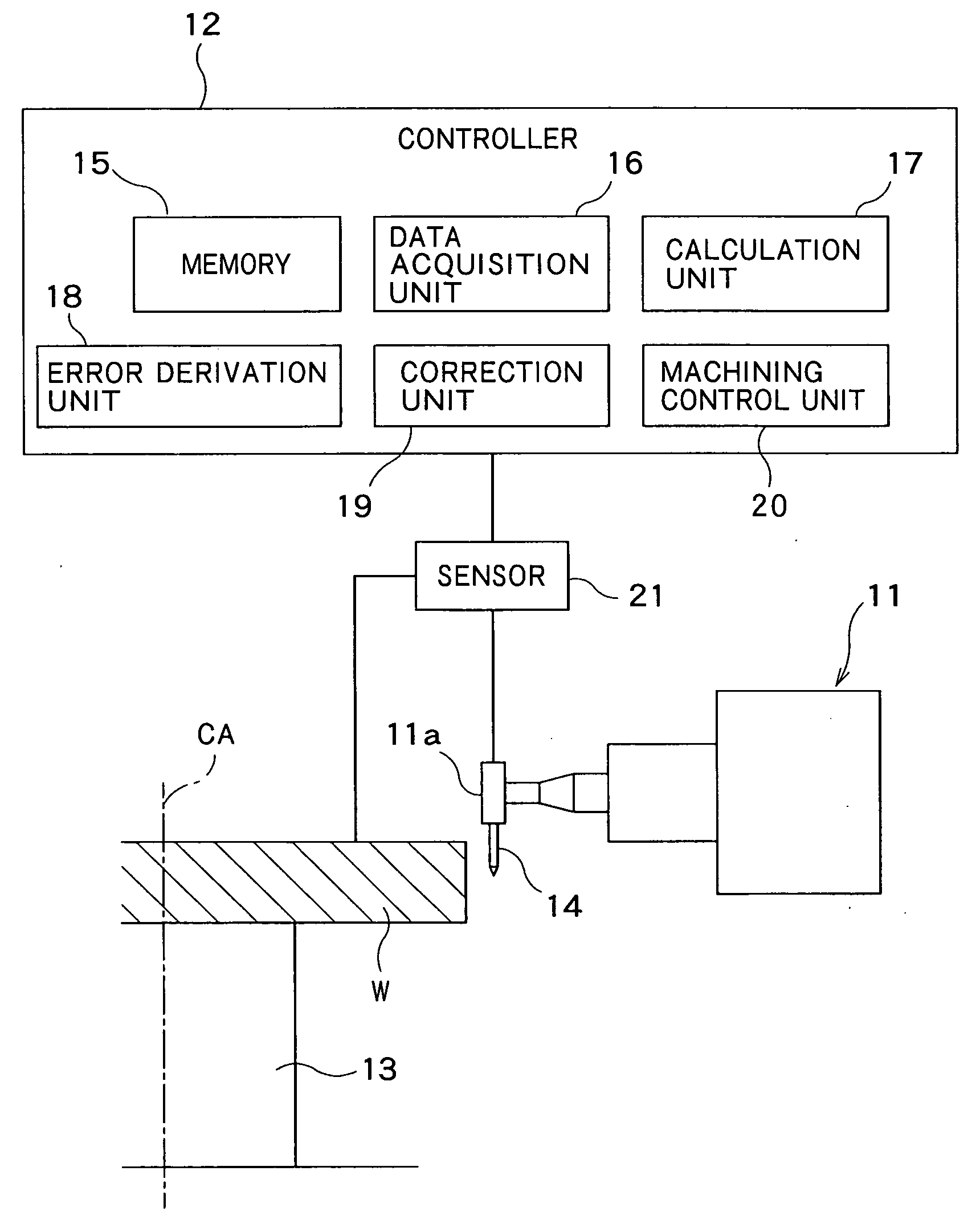

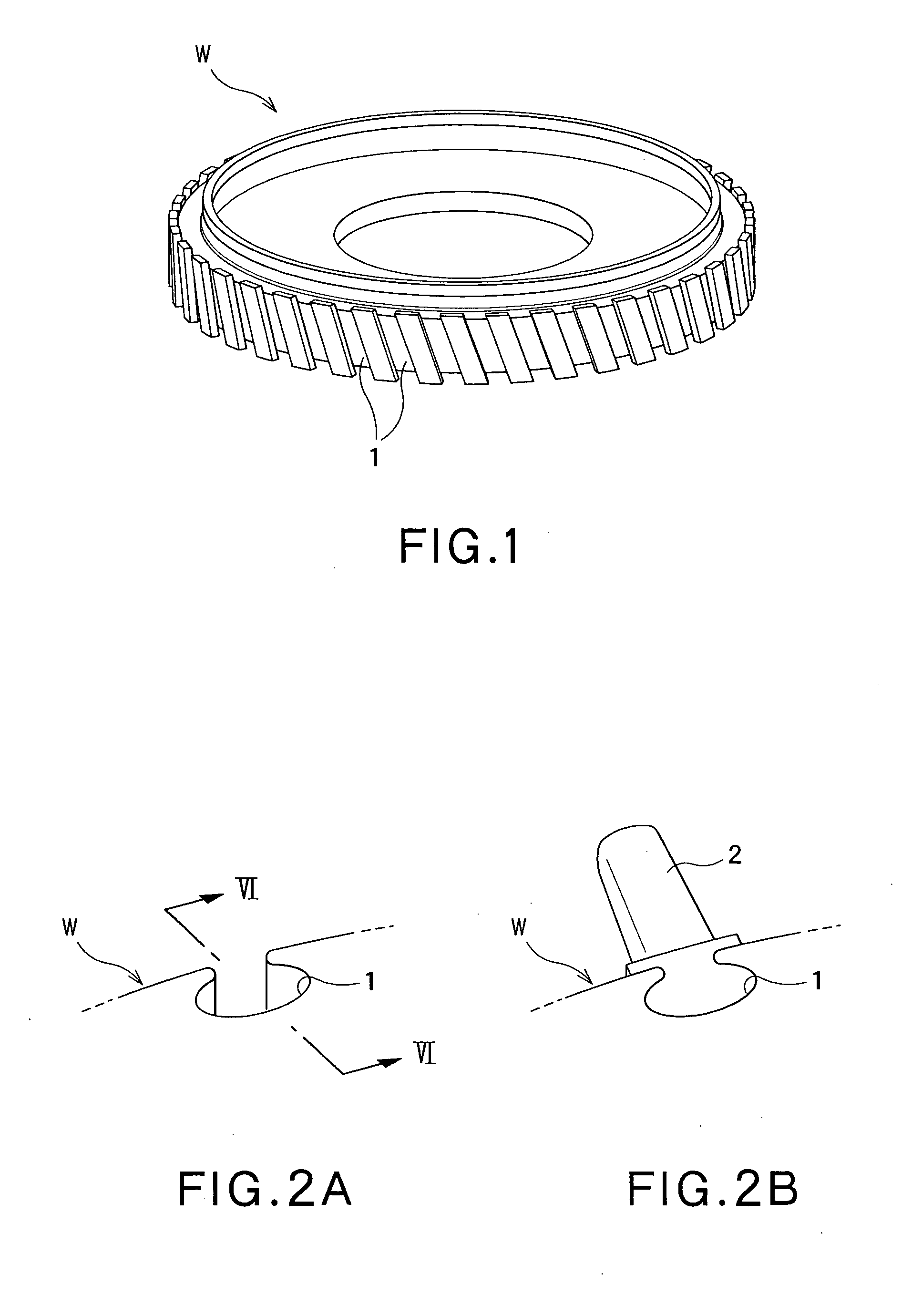

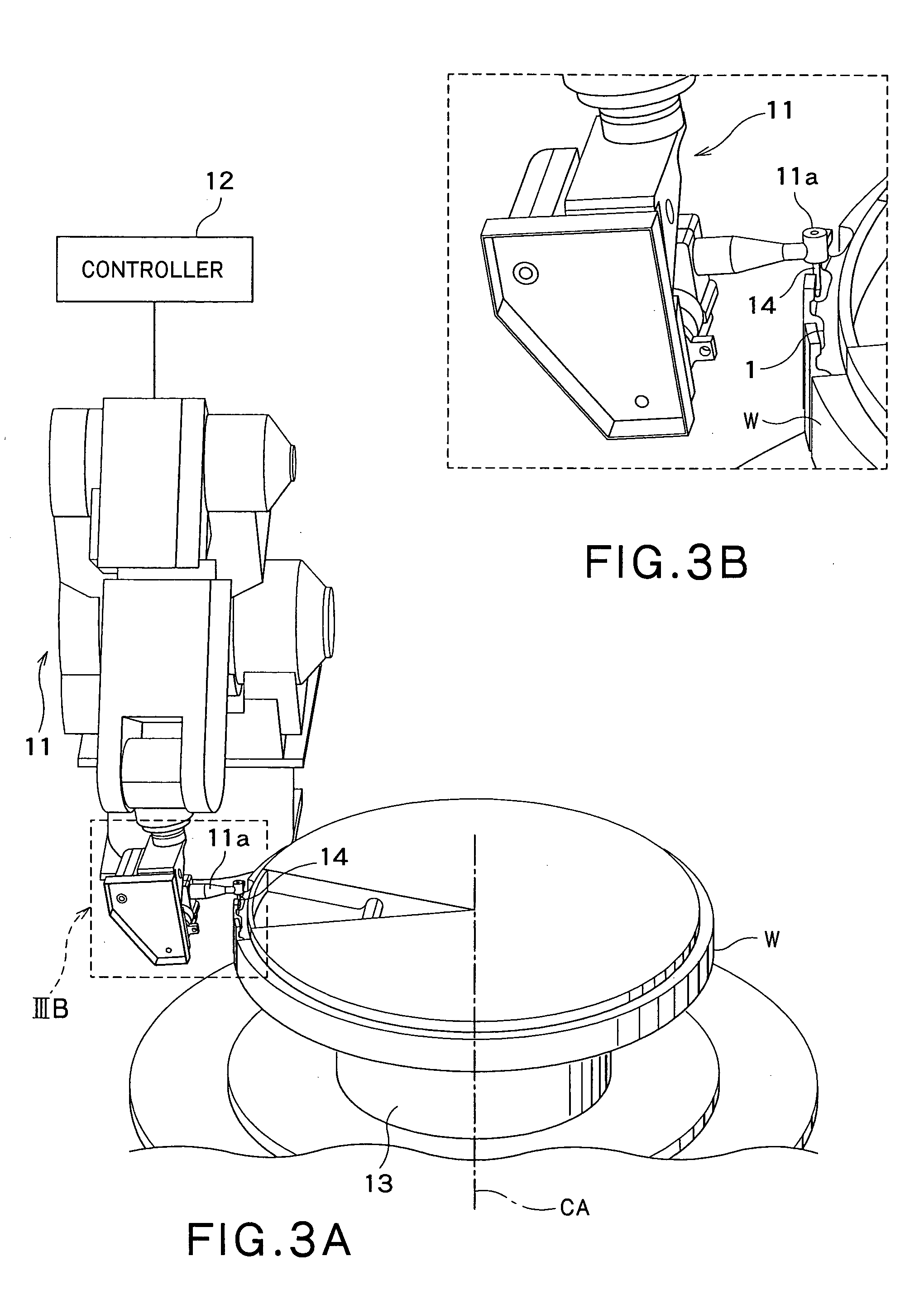

Automatic finishing machine and control method thereof

ActiveUS20100057257A1Reduce timeStable and accurateComputer controlSimulator controlThree dimensional modelObject point

This method controls an automatic finishing machine using a robot with a tool through a model storage step, a data acquisition step, a calculation step, an error derivation step, a correction step and a machining step. In the model storage step, shape data of an unfinished work or data of a three-dimensional model is stored in a memory. In the data acquisition step, the tool is brought into contact with the unfinished work W, thereby obtaining measurement data. Then, in the calculation step, actual-position data on a comparative object point is calculated based on the measurement data. Subsequently, in the error derivation step, a data difference between the calculated actual-position data and position data on the comparative object point in the three-dimensional model is obtained. Thereafter, in the correction step, teaching data indicative of the position of the tool corresponding to the shape data of the three-dimensional model is corrected, based on the data difference. Finally, in the machining step, the finishing process is performed, while the robot (11) is controlled, based on the corrected teaching data.

Owner:KAWASAKI HEAVY IND LTD

Flexure mechanism for interface device

InactiveUS20050073496A1Low costEasy to manufactureInput/output for user-computer interactionManual control with multiple controlled membersJoystickCoupling

A flexure mechanism for an interface device that interfaces a user with a computer system. An interface device includes a manipulandum physically contacted by the user. A five-bar closed-loop mechanism is coupled to the manipulandum to provide two rotary degrees of freedom to the manipulandum. The mechanism includes members coupled to each other by flexible couplings allowing rotation of the members. In preferred embodiments, four or five of the members are coupled together by flexible couplings that allow bending, thereby forming a unitary piece, where the couplings are oriented along axes of rotation of the mechanism. A senor senses a position of the manipulandum outputs a sensor signal, and in some embodiments actuators are coupled to the mechanism to output a force to the manipulandum in particular degrees of freedom. The manipulandum can be a joystick handle or portion of a sphere, where the device in one embodiment can be a handheld gamepad or similar controller.

Owner:IMMERSION CORPORATION

Peristaltic pump

InactiveUS7625189B2Minimizes problemLow costFlexible member pumpsPositive-displacement liquid enginesPeristaltic pumpEngineering

A peristaltic pump, for propelling liquid through a flexible pump tube, includes an outer casing having a guiding channel wherein an operating portion of the pump tube extends along the guiding channel. The peristaltic pump further includes at least two pressuring rollers supported at the outer casing in a radially movable manner which can move outwardly to press against the operating portion of the pump tube. A center driving mechanism is supported at a center portion of the outer casing to radially push the pressure rollers and to drive the pressuring rollers to concurrently rotate such that the pressuring rollers roll against the operating portion of the pump tube for continuously propelling the fluid in the pump tube in the direction of rotation.

Owner:CHENG ZAIJUN

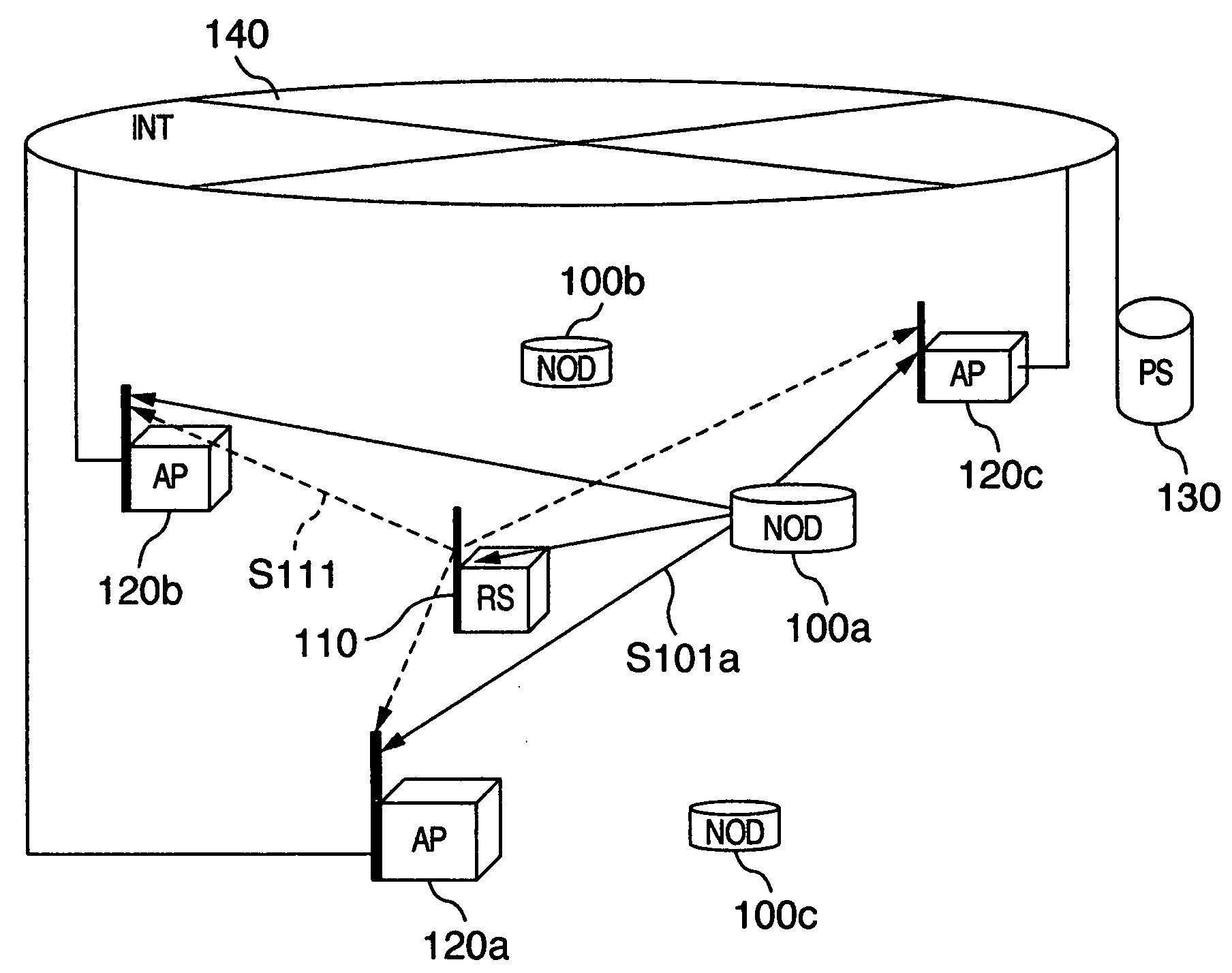

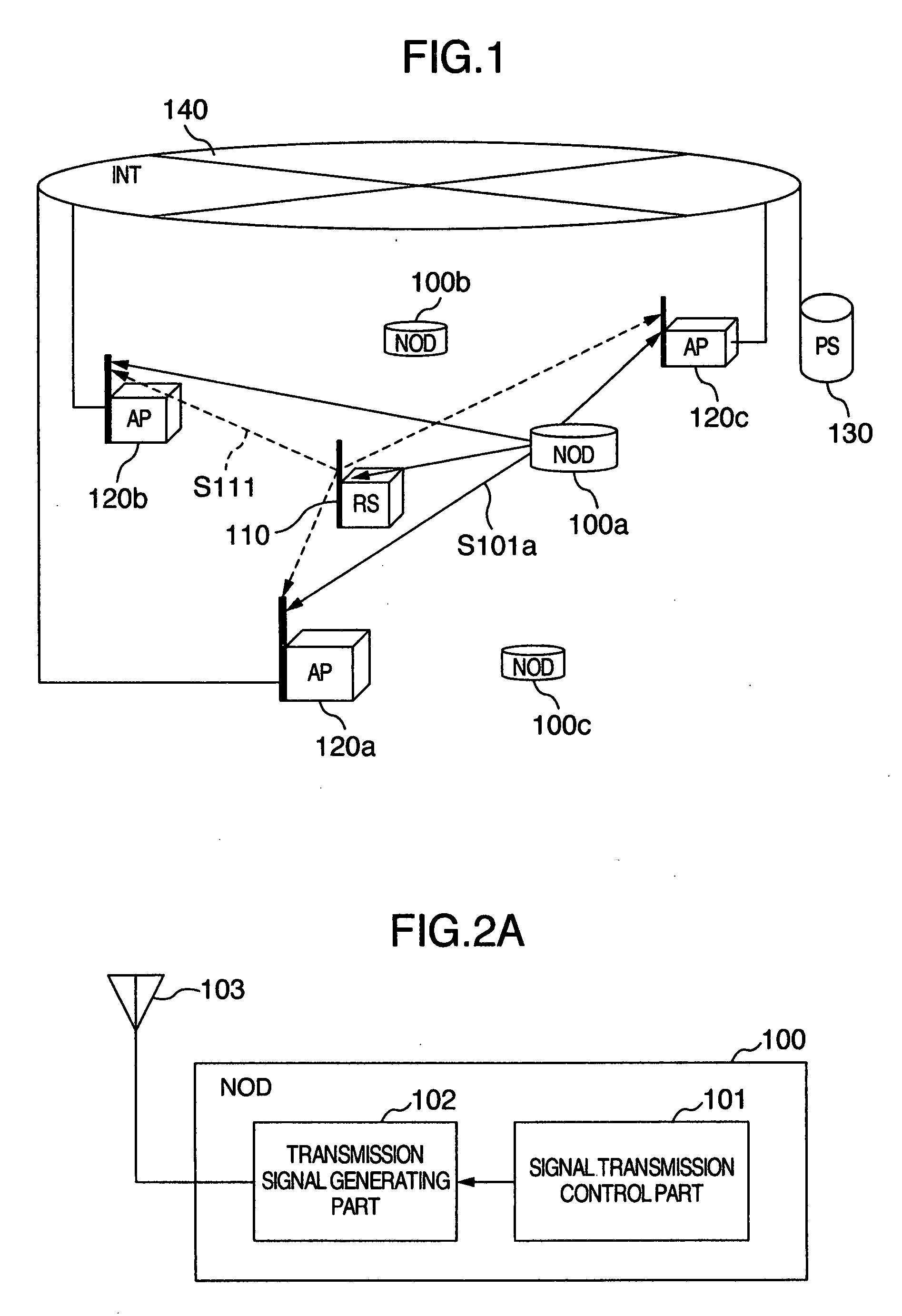

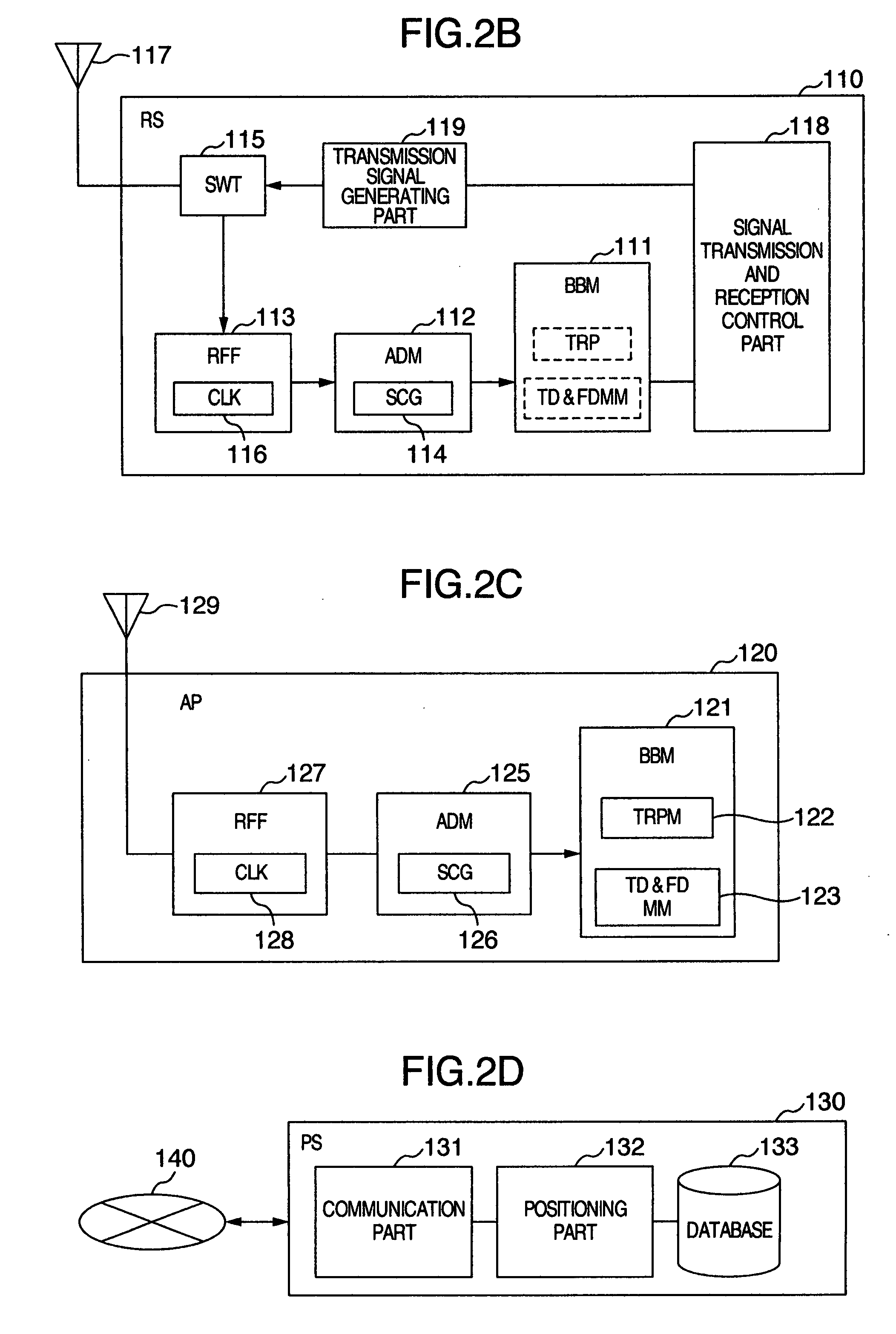

Positioning system

InactiveUS20080090588A1MiniaturizationReduce power consumptionNetwork topologiesSubstation equipmentTime deviationNetwork connection

A positioning system having a node (subject to positioning) transmitting a positioning signal; a reference station transmitting a reference signal; at least three base stations having a receiving part receiving the aforementioned positioning signal and the aforementioned reference signal; and a server connected to the base stations by a network;wherein the aforementioned server measures, using a clock signal and a signal shifting the concerned clock signal, the time difference with which the aforementioned positioning signal and the aforementioned reference signal are received by the aforementioned plurality of base stations as well as the frequency deviation with the aforementioned base stations;decides whether to carry out a correction with respect to the aforementioned measured time difference, on the basis of the measurement result of the aforementioned positioning signal; andcomputes the position of the aforementioned node, based on the aforementioned time deviation for which appropriate processing has been performed.

Owner:HITACHI LTD

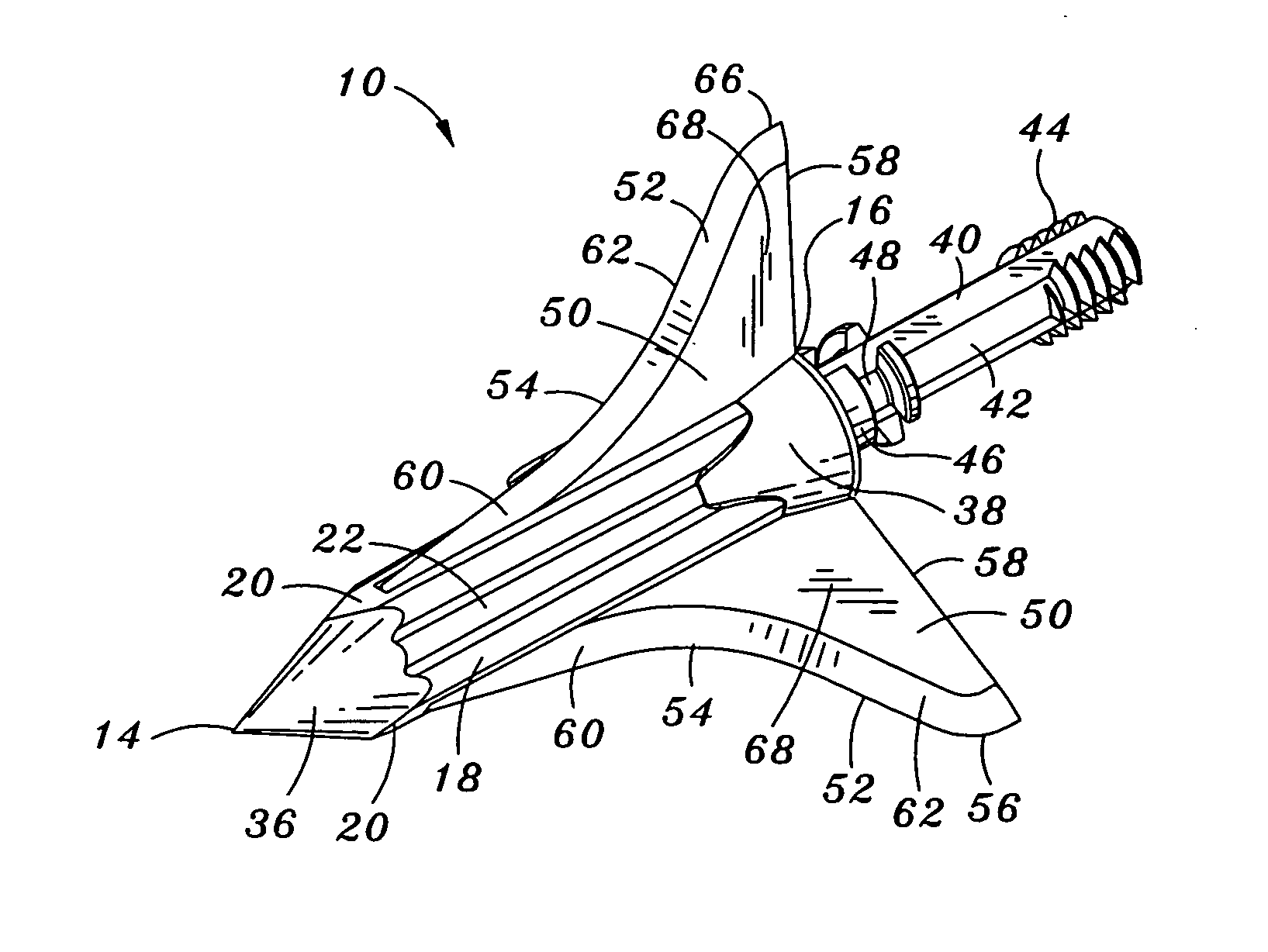

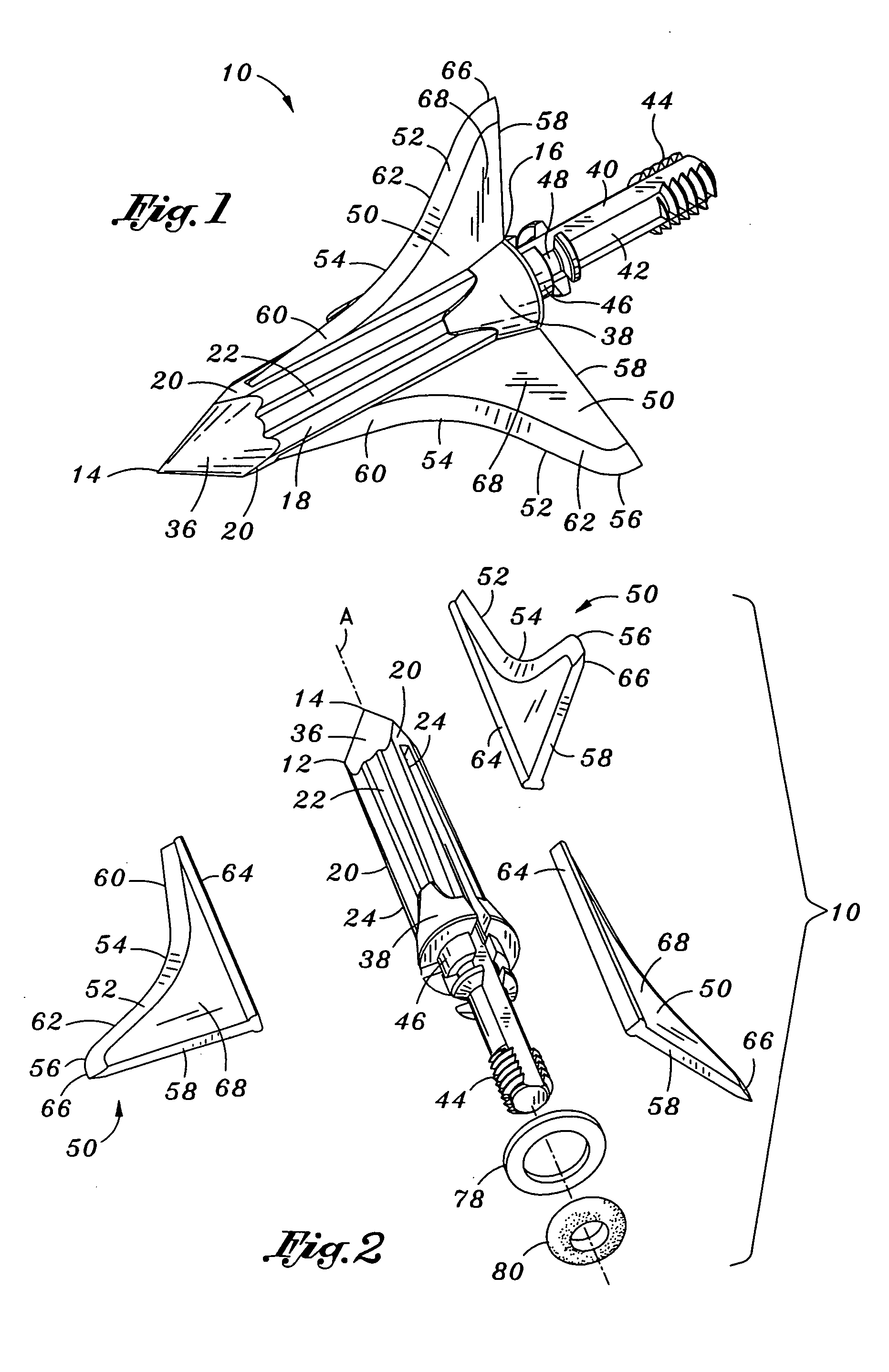

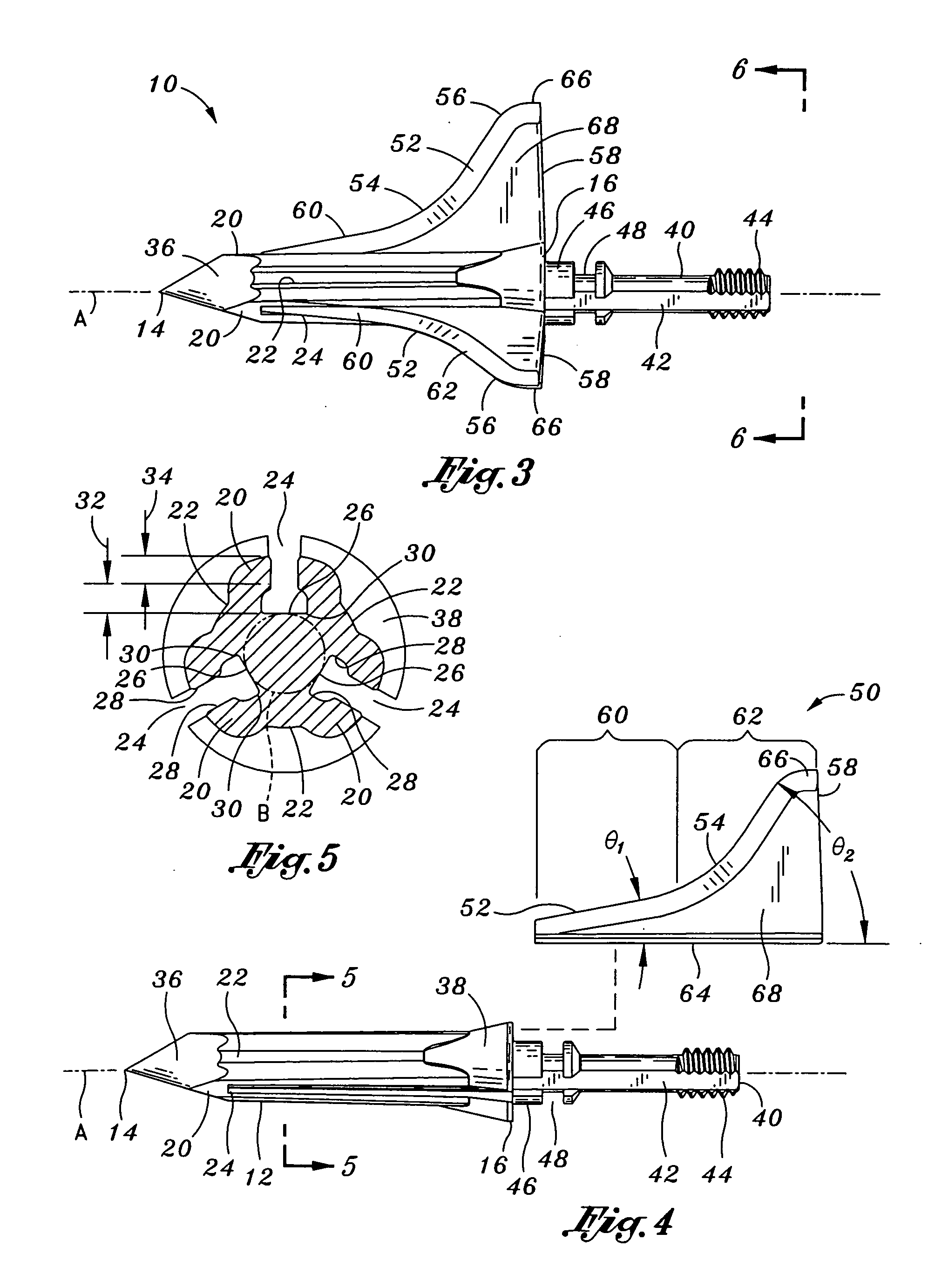

T-lock broadhead and tight point matched balance point archery point system

ActiveUS20050124443A1Avoid relative motionEffective edge profileMechanical apparatusThrow gamesPoint matchEngineering

Provided is a broadhead for an arrow having a shaft with a shaft bore. The broadhead comprises a ferrule and a plurality of blade members. The ferrule has a mating end and a tip end with a plurality of convex ridges being equiangularly spaced around the ferrule such that the ferrule has a tri-oval cross section. Each one of the ridges has a blade groove formed therein for receiving one of the blade members. The blade members each have a base portion that is shaped complementary to the blade groove so that the blade member may be axially insertable into the blade groove. The broadhead includes a shank extending outwardly from the mating end and which is threadably engagable into the shaft bore. An O-ring mounted on the shank is captured between the shank and the shaft bore when the broadhead is secured to the arrow at the mating end.

Owner:TROPHY TAKER LLC

Fiber laser beam processing apparatus

InactiveUS20070164004A1Improve reliabilityGood reproducibilityLaser using scattering effectsOptical resonator shape and constructionBeam splitterLaser beam machining

A fiber laser beam processing apparatus is configured by a fiber laser oscillator, a laser power source unit, a laser beam injecting unit, a fiber transmission system, a laser beam irradiating unit, a processing table, etc. A portion of a fiber laser beam oscillated and outputted by the fiber laser oscillator is received by a photo diode for monitoring the power through a beam splitter. An output signal of the photo diode is sent to a laser power source unit. The power source unit receives the output signal of the photo diode as a feedback signal and controls a driving current or an excitation current to be supplied to a laser diode of a pumping unit such that the laser output of the fiber laser beam equals a set value.

Owner:MIYACHI TECHNOS CORP

Position detector

InactiveUS20100271048A1Reduction in adjacent-interline capacitanceIncrease the amount of changeResistance/reactance/impedenceInput/output processes for data processingCapacitanceEngineering

There is provided a multilayer made up of: a support member 11 with first electrodes 3 including a plurality of electrodes arranged parallel to each other and the second electrodes 4 including a plurality of electrodes that are arranged parallel to each other so as to cross the first electrodes 3; a protective layer (a front member) 12 that is provided opposite one side of the support member 11 and with which a predetermined position pointing member is brought into contact; and a reinforcing material (a rear member) 13 provided opposite the other side of the support member 11. A gas layer (space) 15 is provided between the first electrodes 3 or the second electrodes 4 and at least one of the support member 11, the protective layer (the front member) 12, and the reinforcing material (the rear member) 13, thereby blocking electrical coupling paths that increase electrostatic capacitance C.

Owner:PANASONIC CORP

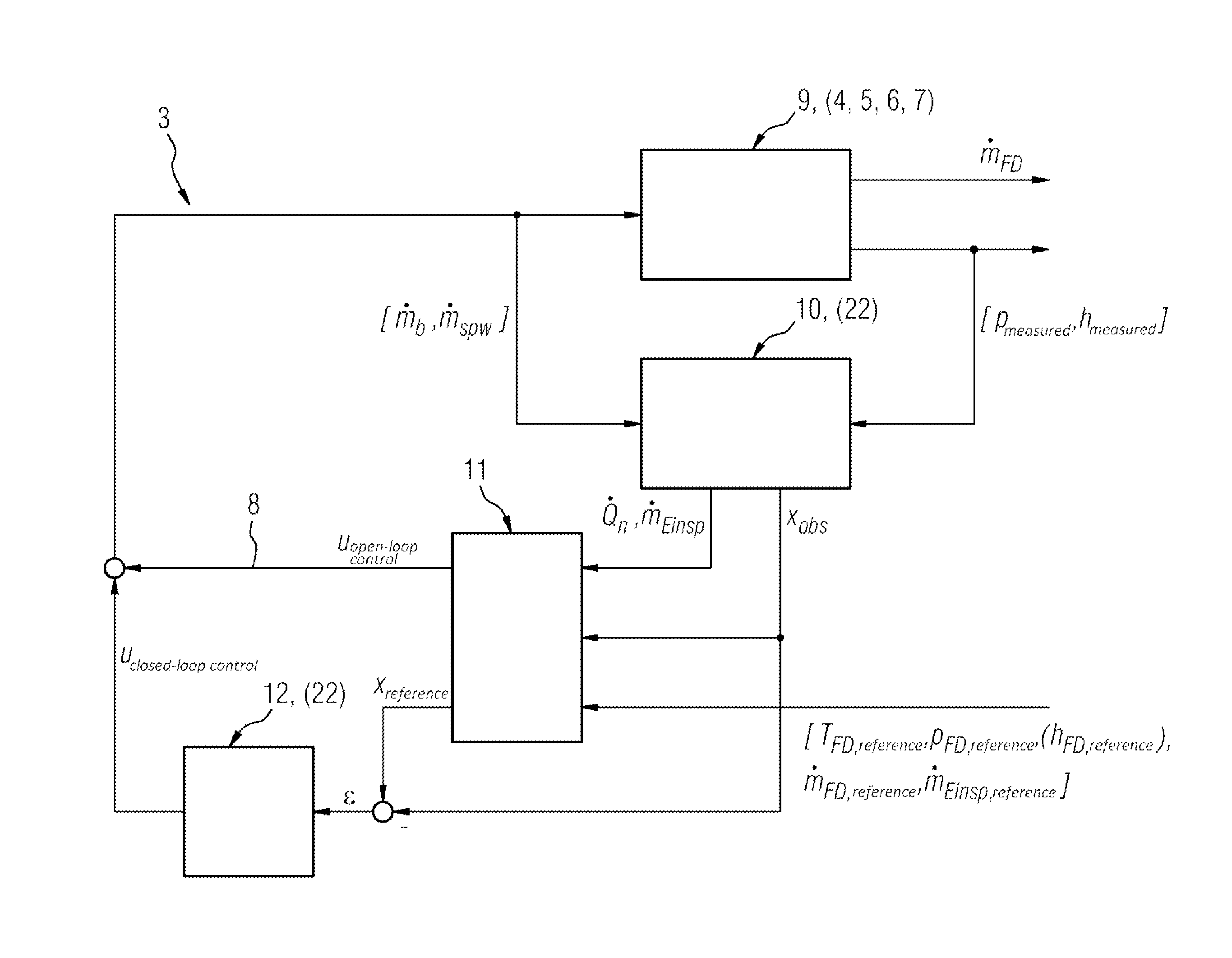

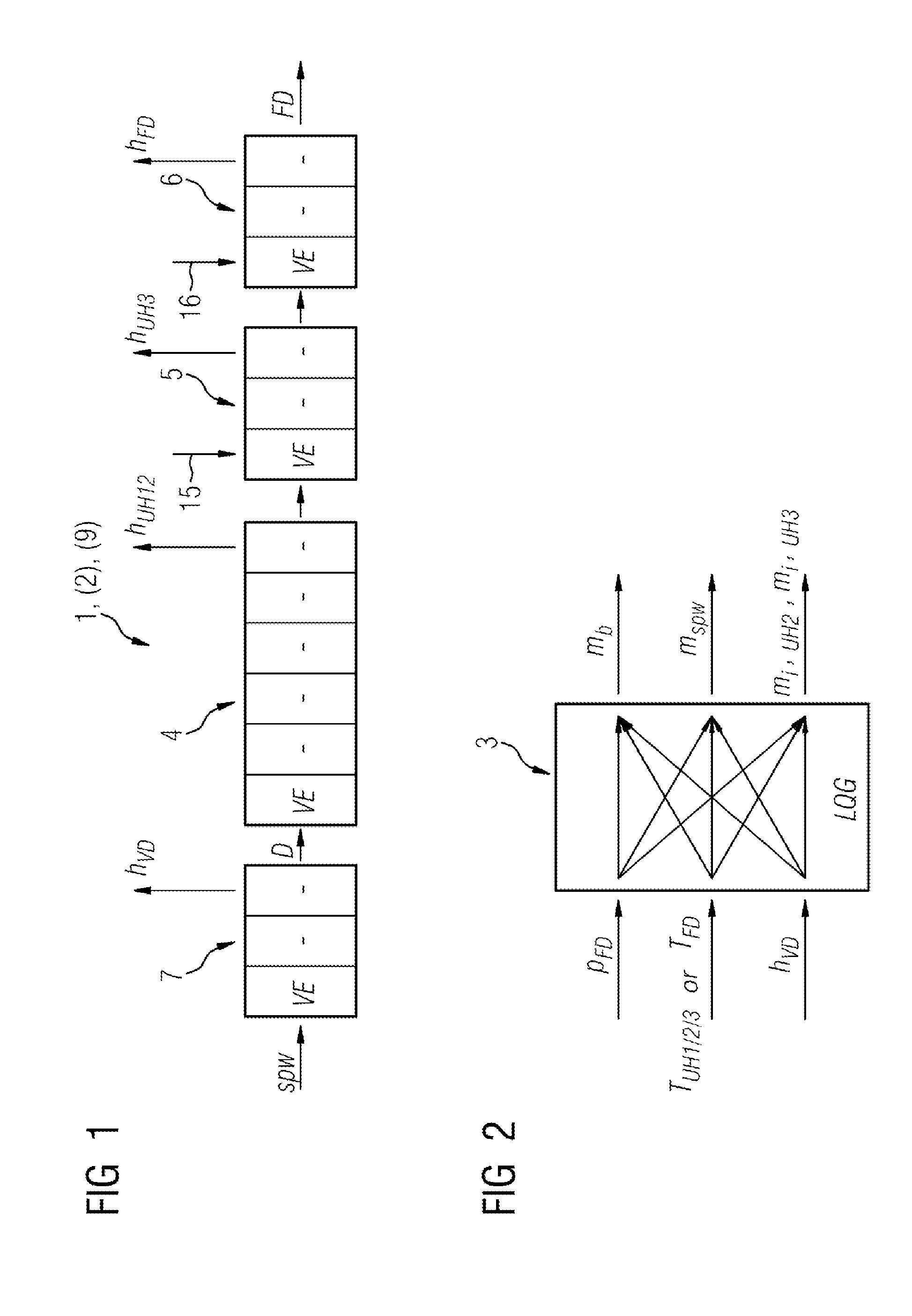

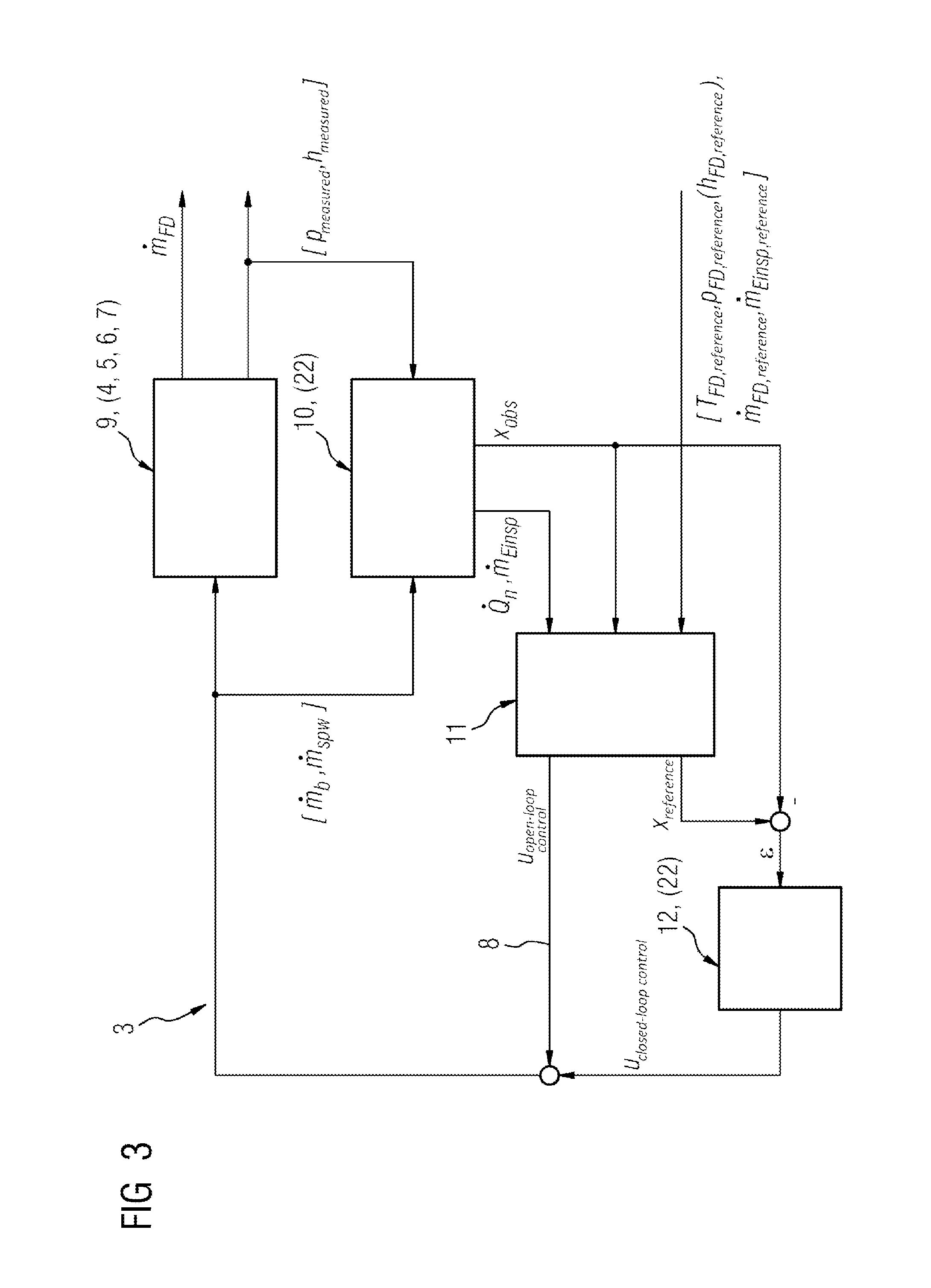

Multi-variable state closed-loop control for a steam generator of a thermal power plant

ActiveUS20150276209A1Overcome disadvantageReduce computation timeFuel supply regulationSuperheating controlLinear quadratic controllerThermal power station

A device for closed-loop control of a plurality of state variables of a steam generator of a thermal power plant is provided. In order to achieve stable and exact closed-loop control of the plurality of state variables, a multi-variable control / controller controls the plurality of state variables and uses a linear quadratic controller for this multi-variable control / controller.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

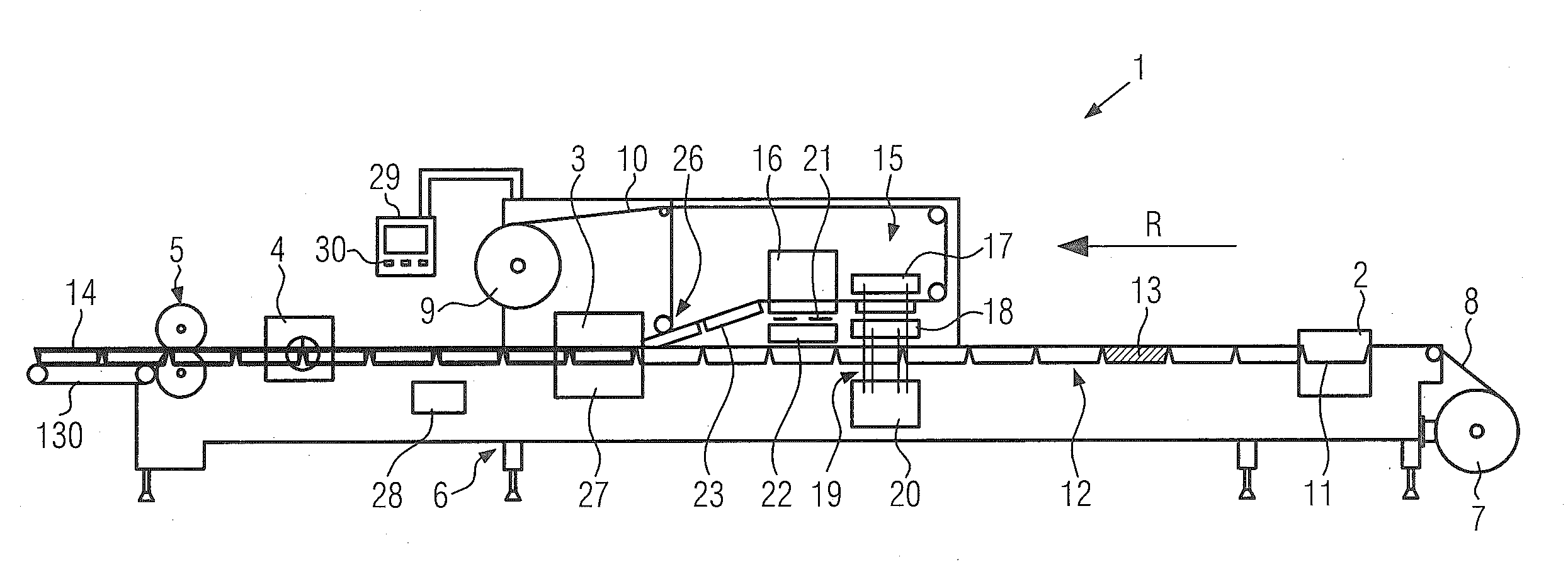

Thermoforming packaging machine with a top film forming station

ActiveUS20150203223A1Eliminate disadvantagesStable and accurateBoxes/cartons making machineryPackaging under vacuum/special atmosphereEngineeringPackaging machine

The invention relates to a thermoforming packaging machine with a top film forming station, the forming tool upper part and the forming tool lower part of which are disposed above a lower film transportation plane and via a traverse system connected to a lifting mechanism and where said lifting mechanism is disposed below said lower film transportation plane.

Owner:MULTIVAC SEPP HAGGENMULLER GMBH & CO KG

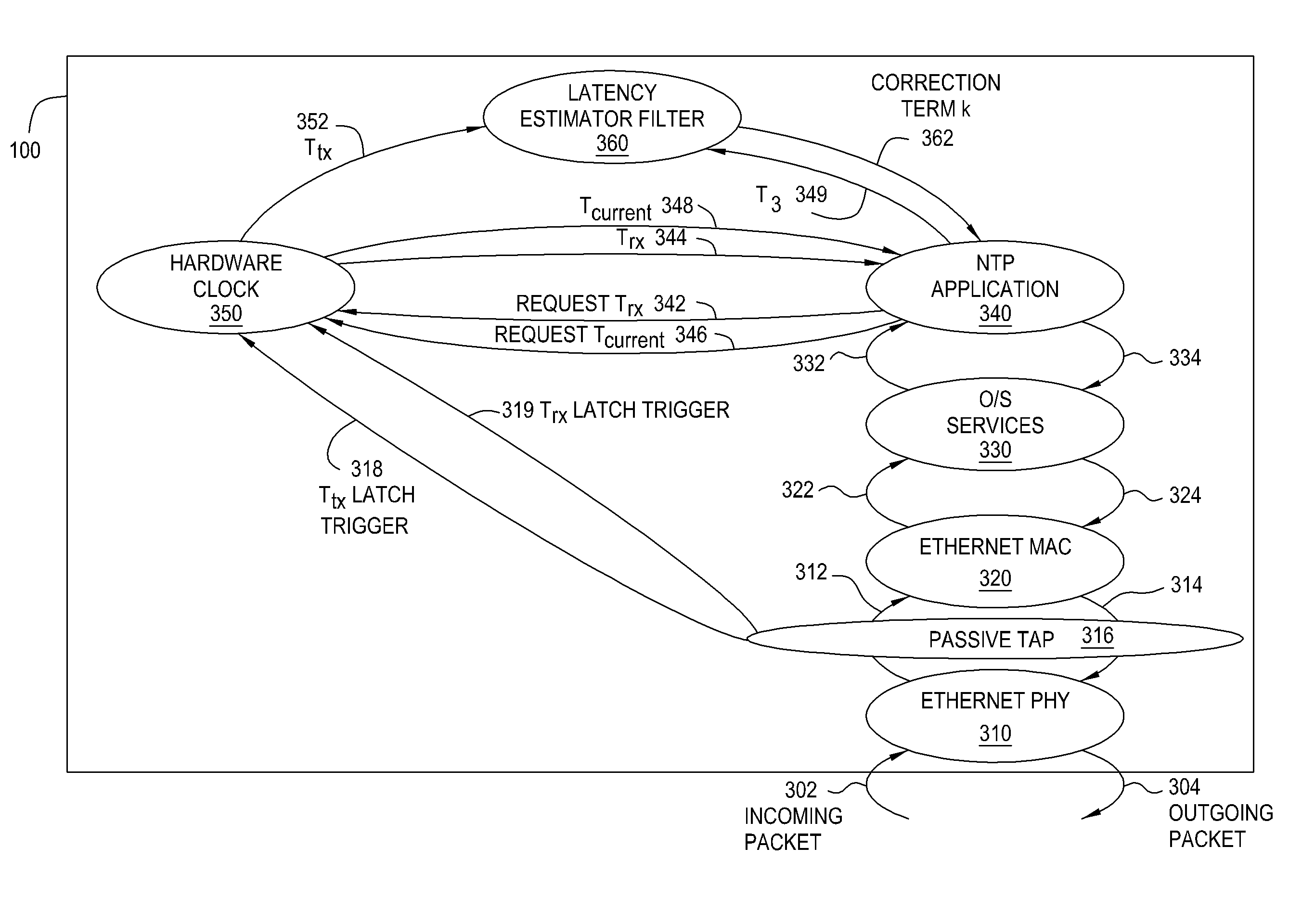

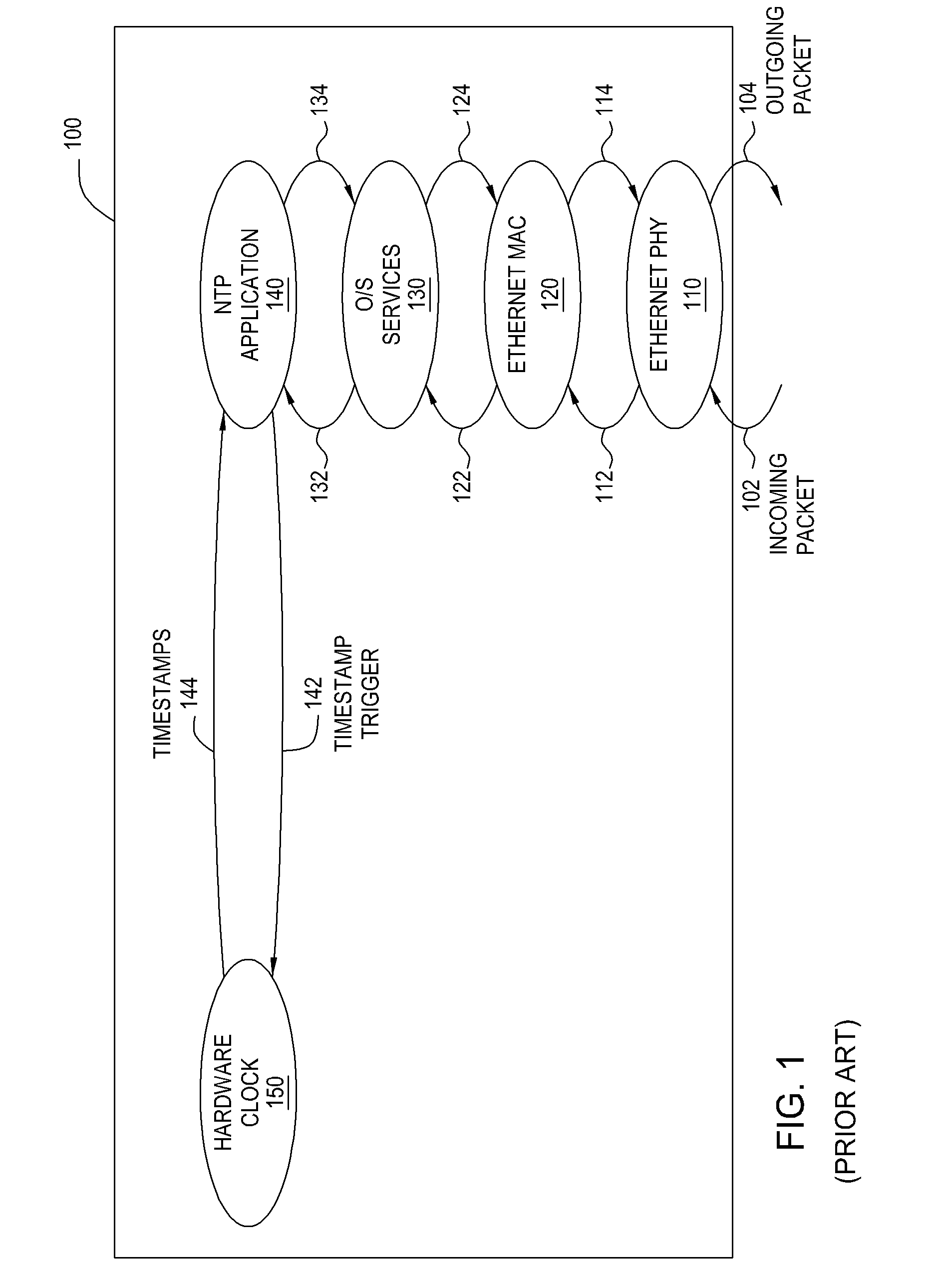

Network time protocol precision timestamping service

ActiveUS8451867B2Easy to controlHigh precisionTime-division multiplexSynchronising arrangementTimestampTransmission latency

Embodiments of the present invention set forth a method and system for reducing uncertainty in receive and transmit timestamps created by an NTP server. The uncertainty in the receive timestamps is removed by recording the time-of-arrival in the hardware clock of the NTP server before the incoming packets may be delayed by traversing the various layers of software in a timestamping system. The uncertainty in the transmit timestamps is removed by giving the outgoing packets a timestamp in the future using an estimate of the transmission latency calculated by the latency estimator filter. Subsequently, the actual time-of-departure is used to re-calculate and update the estimate of the transmission latency. In this fashion, superior control of the timestamping function may be implemented in existing NTP servers in a manner that retains interworking compatibility with the current NTP standards.

Owner:IP GEM GRP LLC

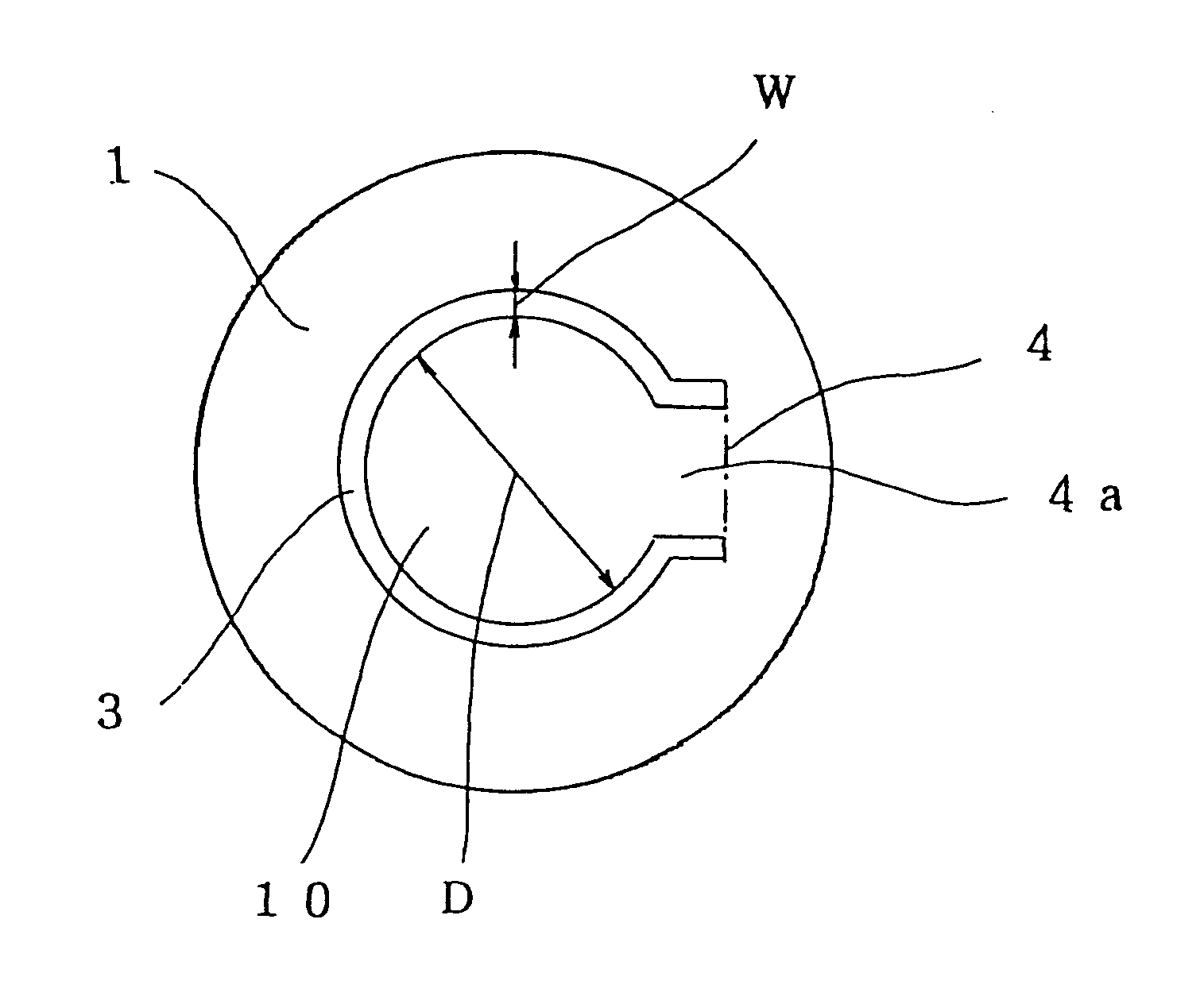

Closed battery and closing member

InactiveUS6423440B1Rise smoothlyStable and accurateCell component detailsInternal pressureMetal foil

The object of the present invention is to provide a closed battery capable of rapidly releasing the internal pressure thereof and at the same time disconnecting the current to effectively prevent itself from temperature rising and exploding so that in such a completely closed battery it may assure the safety and reliability thereof, when the internal pressure is elevated due to short circuit, overcharge, reverse charge, or the like. A valve element 5 is provided with a slit 3 between the circumference thereof and a metal substrate 1. When the internal pressure of a battery is elevated, the valve element 5 is smoothly raised up together with a metal foil 2 from a bending fulcrum portion 4 to thereby cut a lead wire 6 or permit a braze portion 8 to detach from the lead wire 6, thus disconnecting the current reliably. Then, the metal foil which usually closes the slit formed around the circumference of the valve element 5 is allowed to burst stably and accurately at a prescribed pressure to thereby form a valve opening portion 7 so that the internal gas of the battery can be discharged.

Owner:TOYO KOHAN CO LTD +1

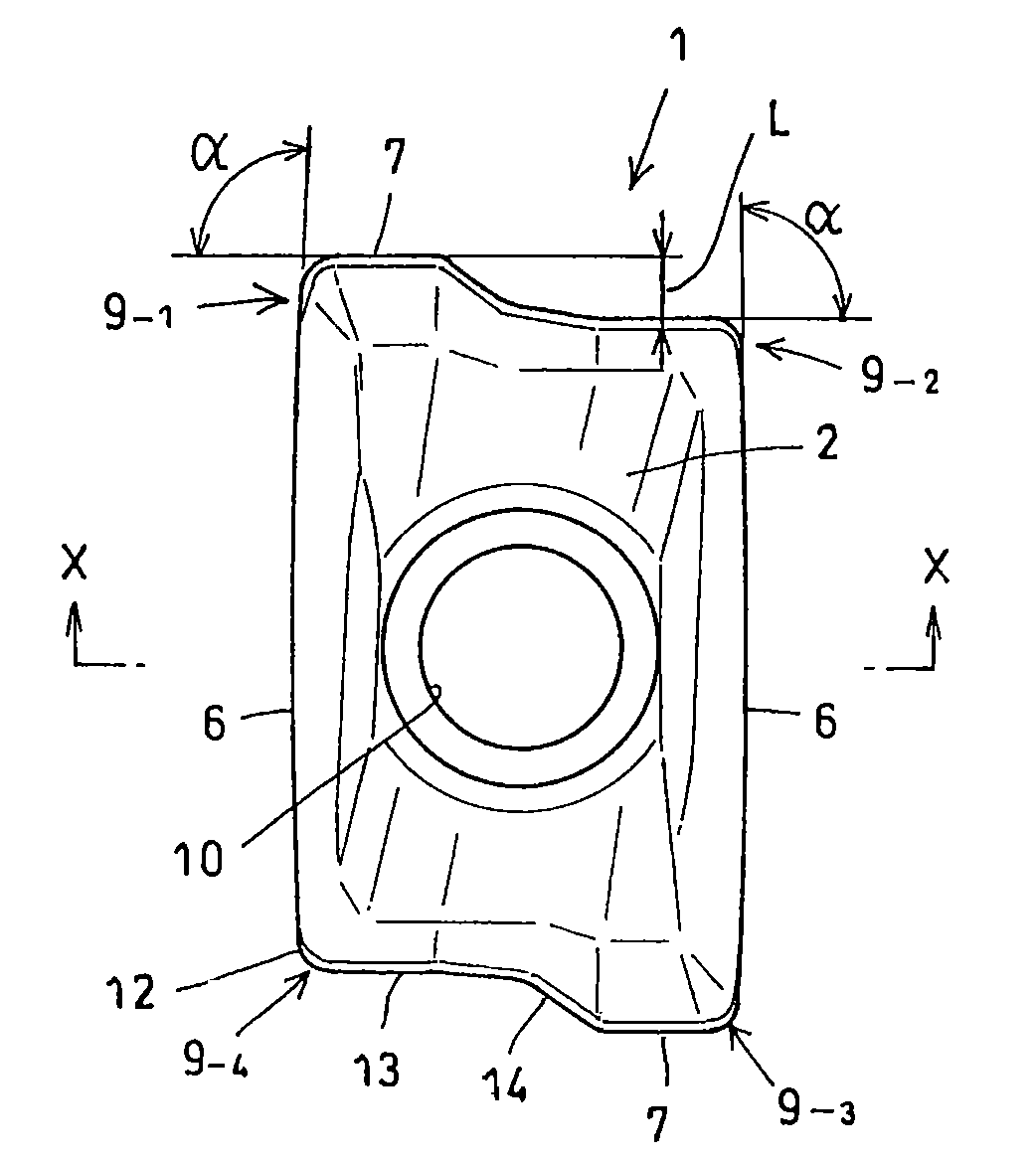

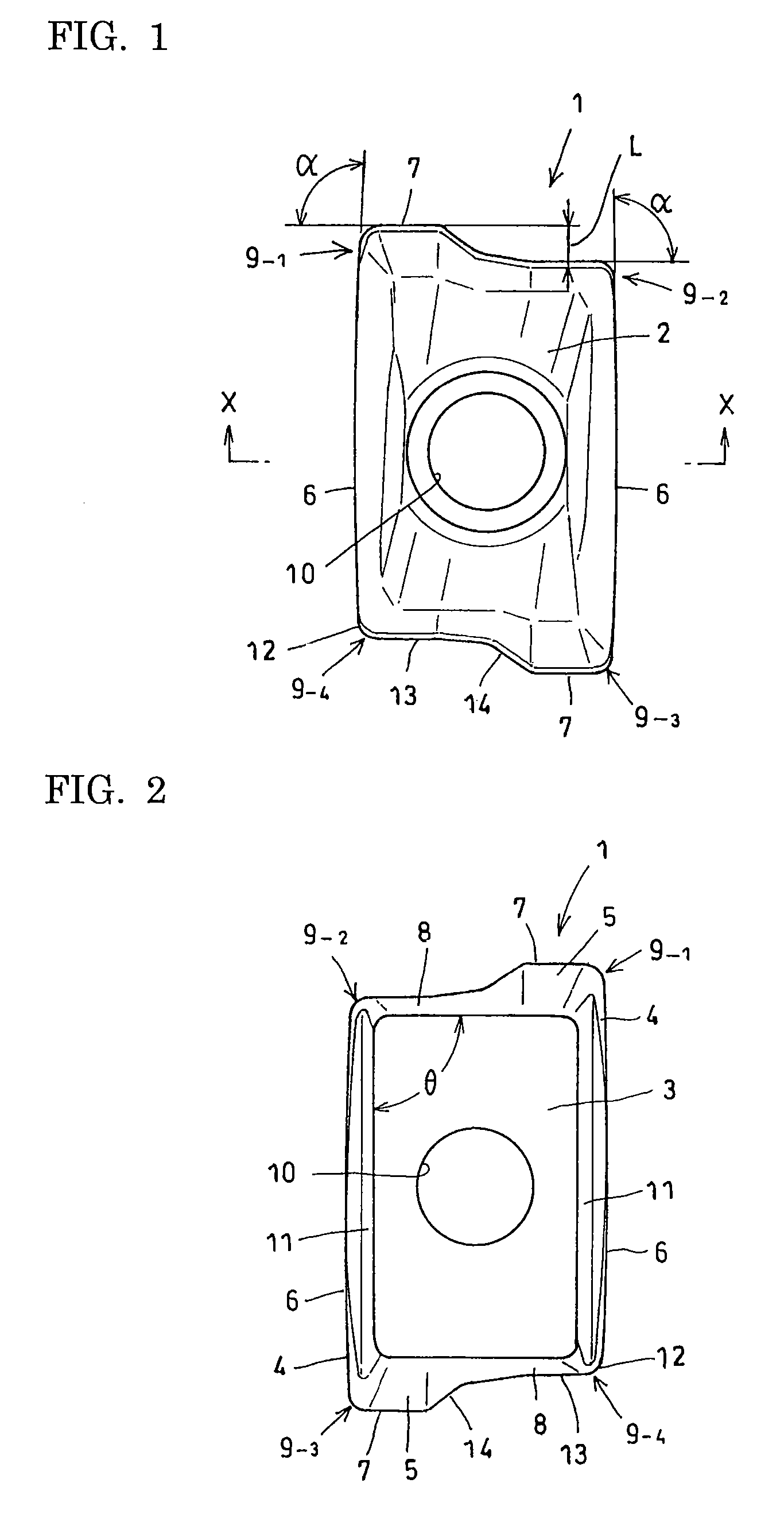

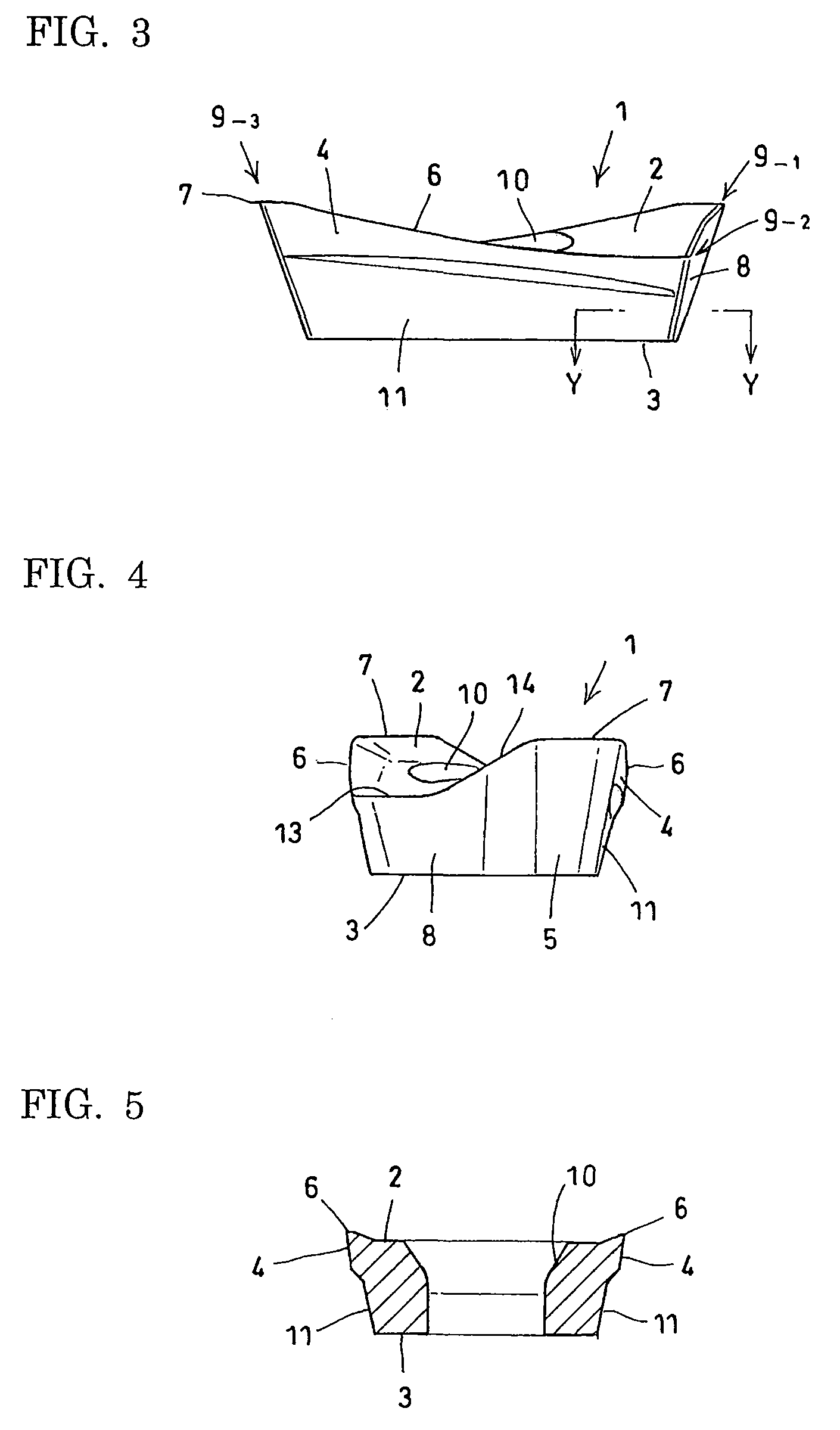

Throw-away insert and milling cutter using throw-away insert

A throw-away insert includes: an upper and bottom surface; two side surfaces; two end surfaces; a main cutting section formed from a ridge line positioned at the intersection between the side surfaces and the upper surface; a secondary cutting section formed from a ridge line positioned at the intersection between the end surfaces and the upper surface; an axial support surface supported by an insert pocket of a cutter body; and noses formed at the corners of the upper surface. The corner angles of the noses when seen from above are essentially right angles. The axial support surface is formed as a section of the end surface. The secondary cutting section is parallel to the ridge line at the upper end of the axial support surface and the bottom surface. The upper end of the axial support surface is positioned so that it is projected more in the direction of the longitudinal axis of the main cutting section than the ridge line of the upper end.

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

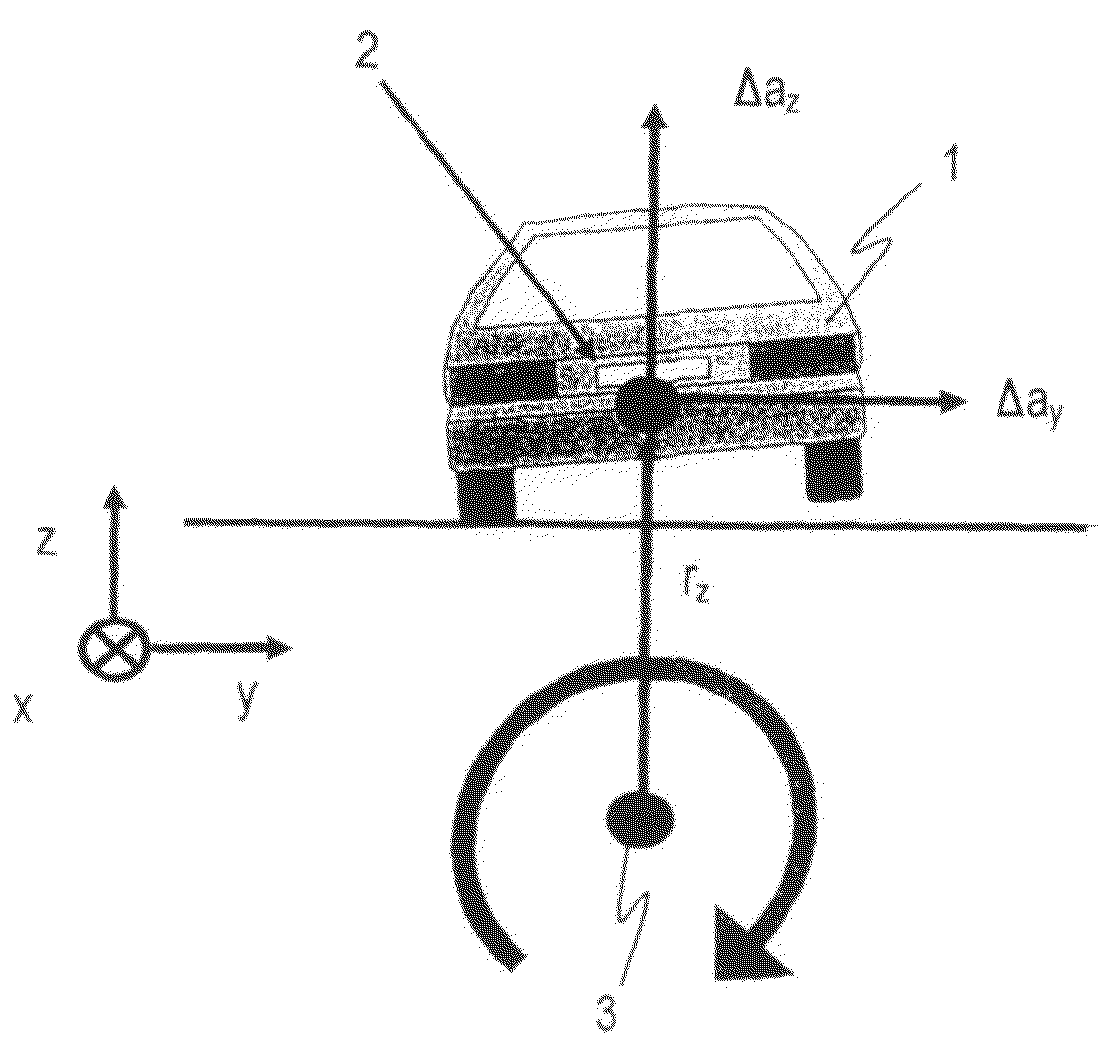

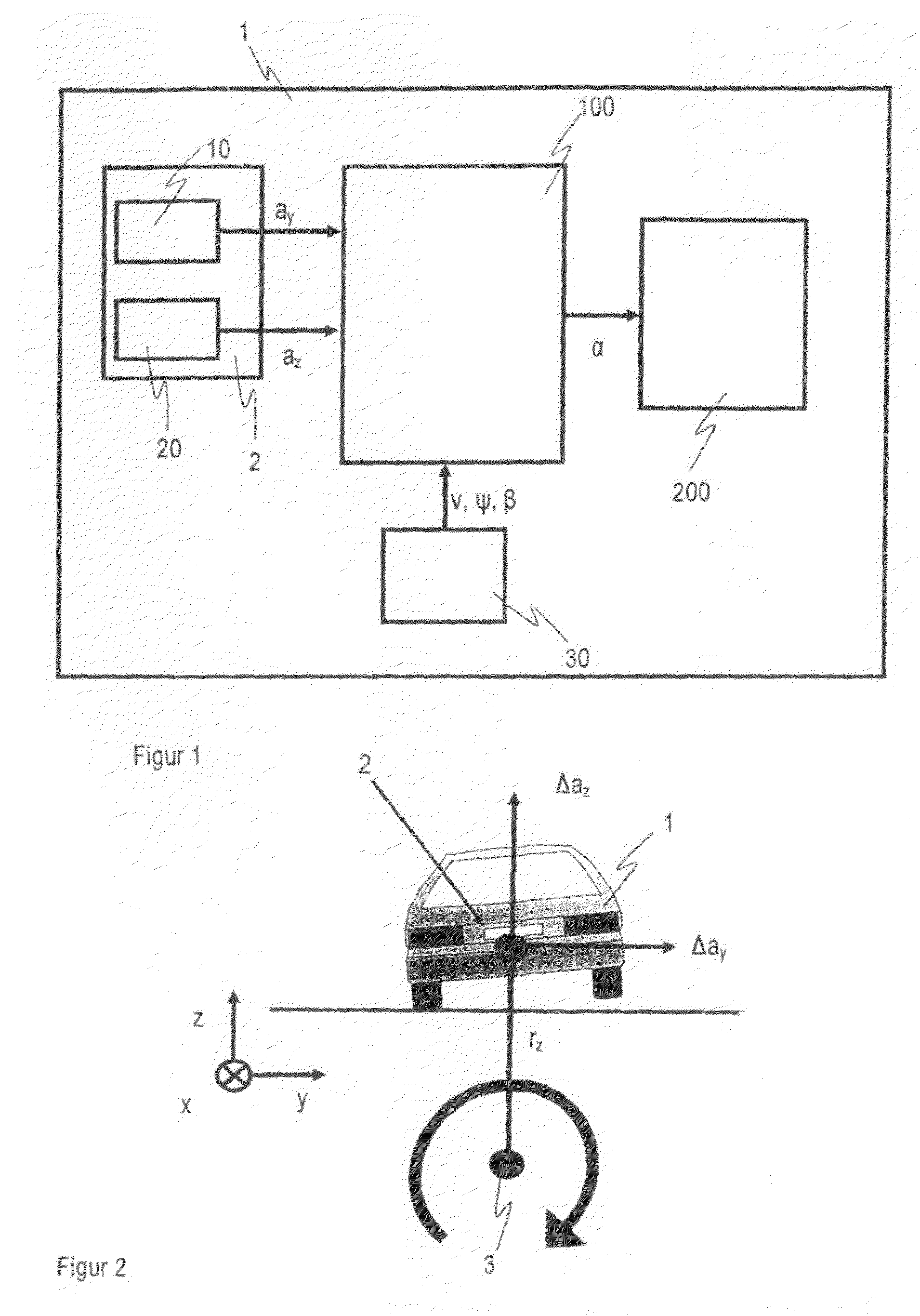

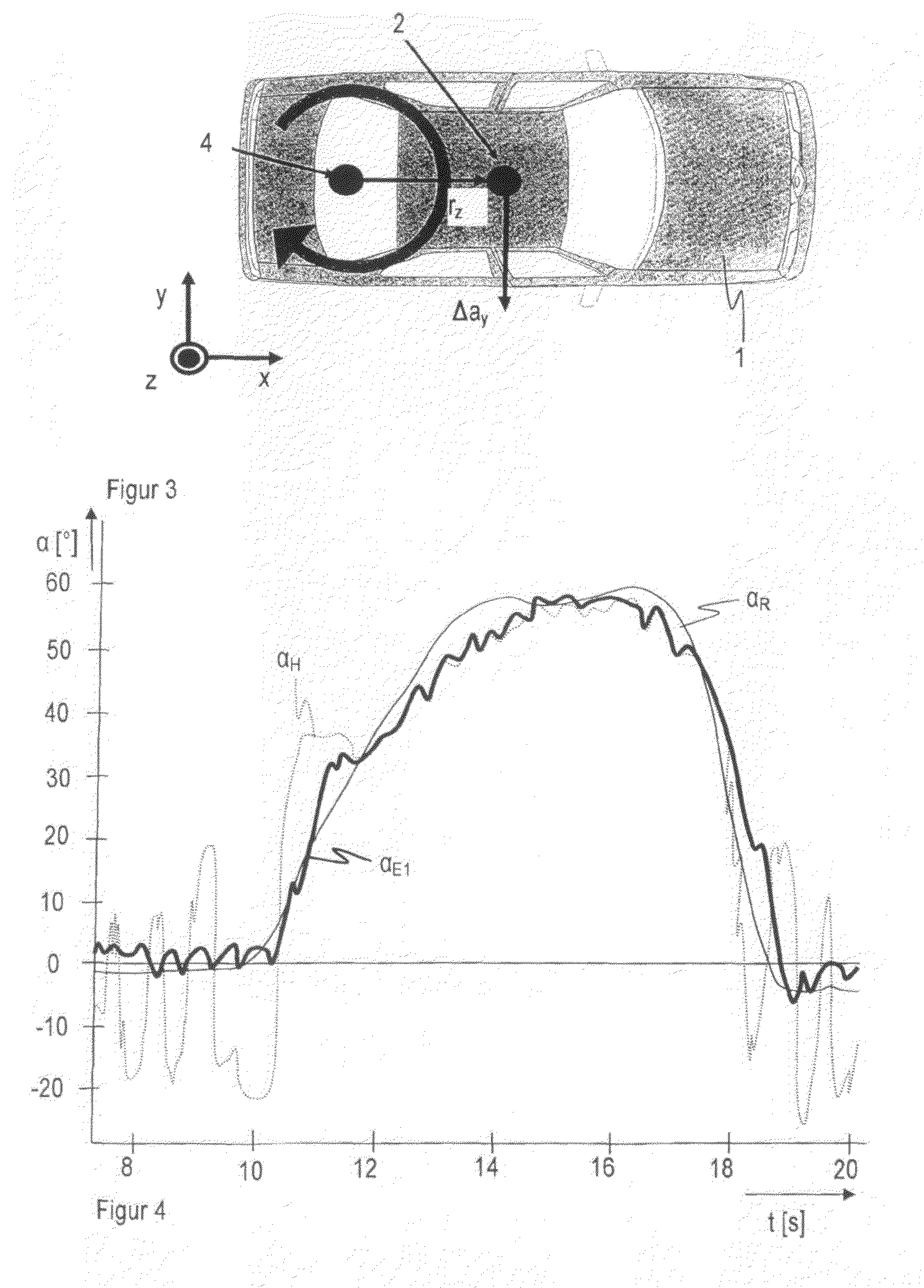

Methods and Device for Determining the Roll Angle for Occupant Protection Devices

ActiveUS20110082614A1Improve accuracyReduce volatilityVehicle testingRegistering/indicating working of vehiclesEngineeringRolling angle

A method and device for determining a roll angle for occupant protection devices. Transverse acceleration and vertical acceleration of a vehicle are detected, and the roll angle of the vehicle is estimated on the basis of the detected lateral acceleration and the detected vertical acceleration, additional driving dynamics quantities, including a vehicle speed, a yaw angle and a float angle being determined, and centripetal acceleration being calculated from these driving dynamics quantities, formula, to improve the estimate of the roll angle.

Owner:ROBERT BOSCH GMBH

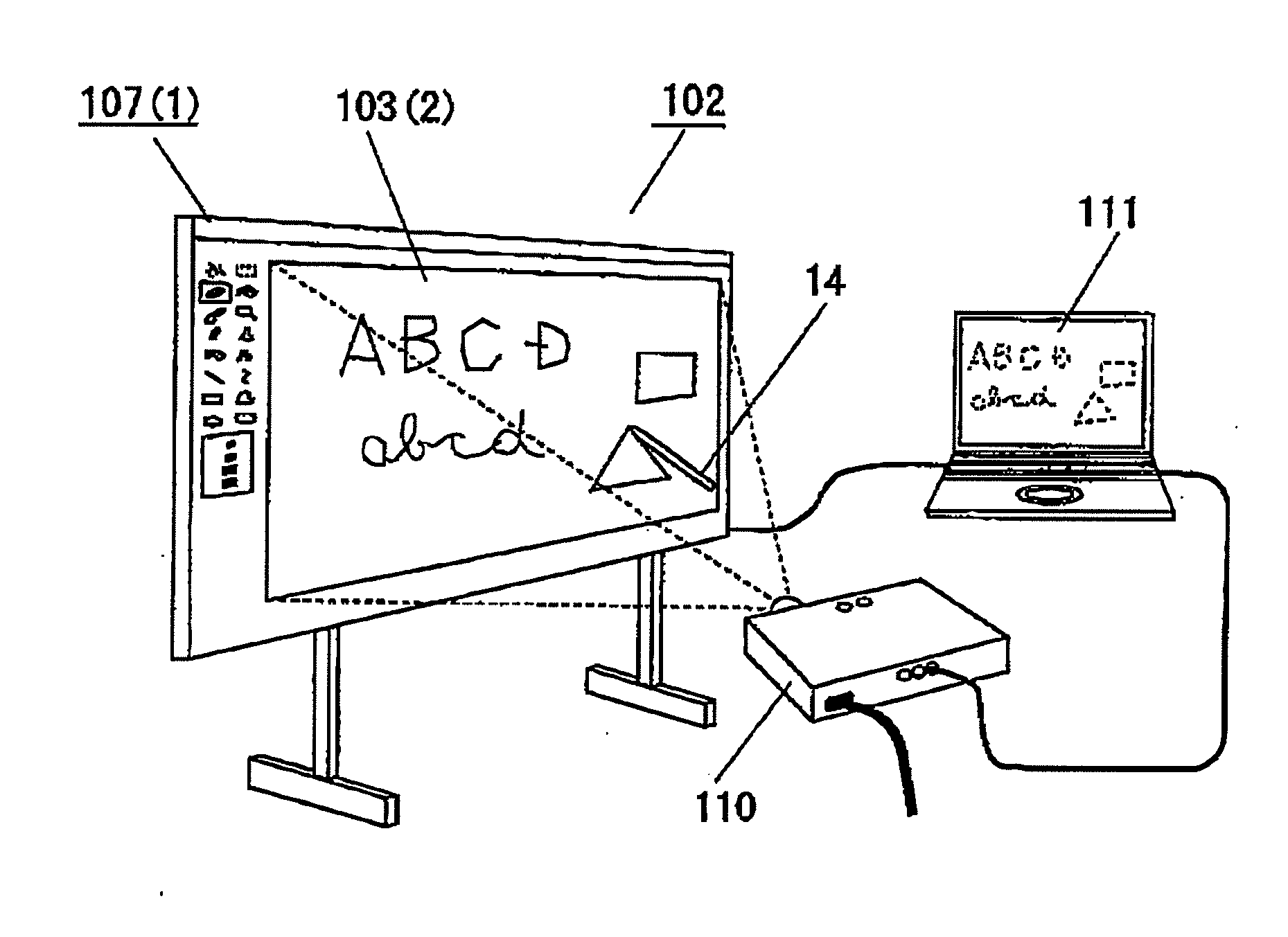

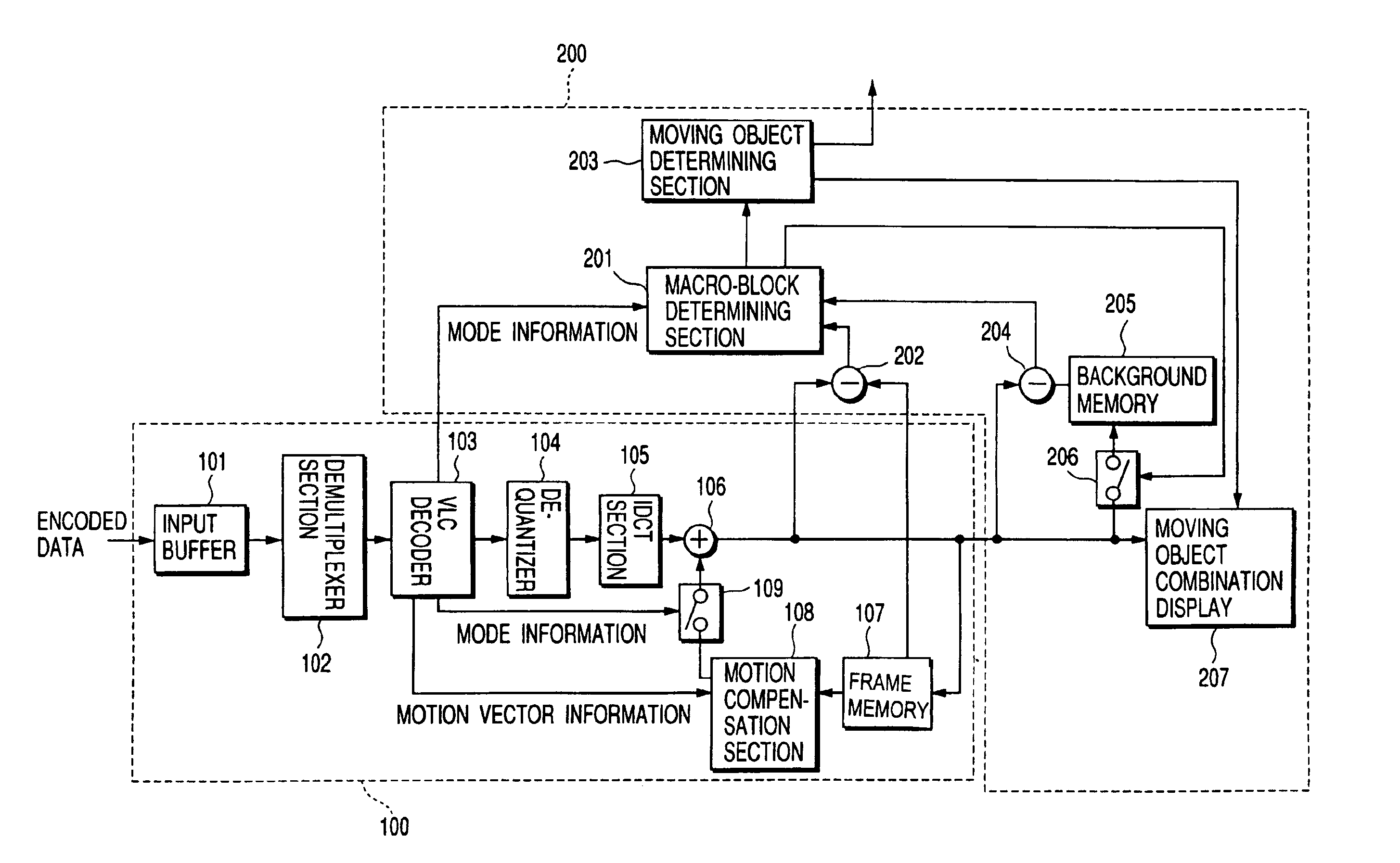

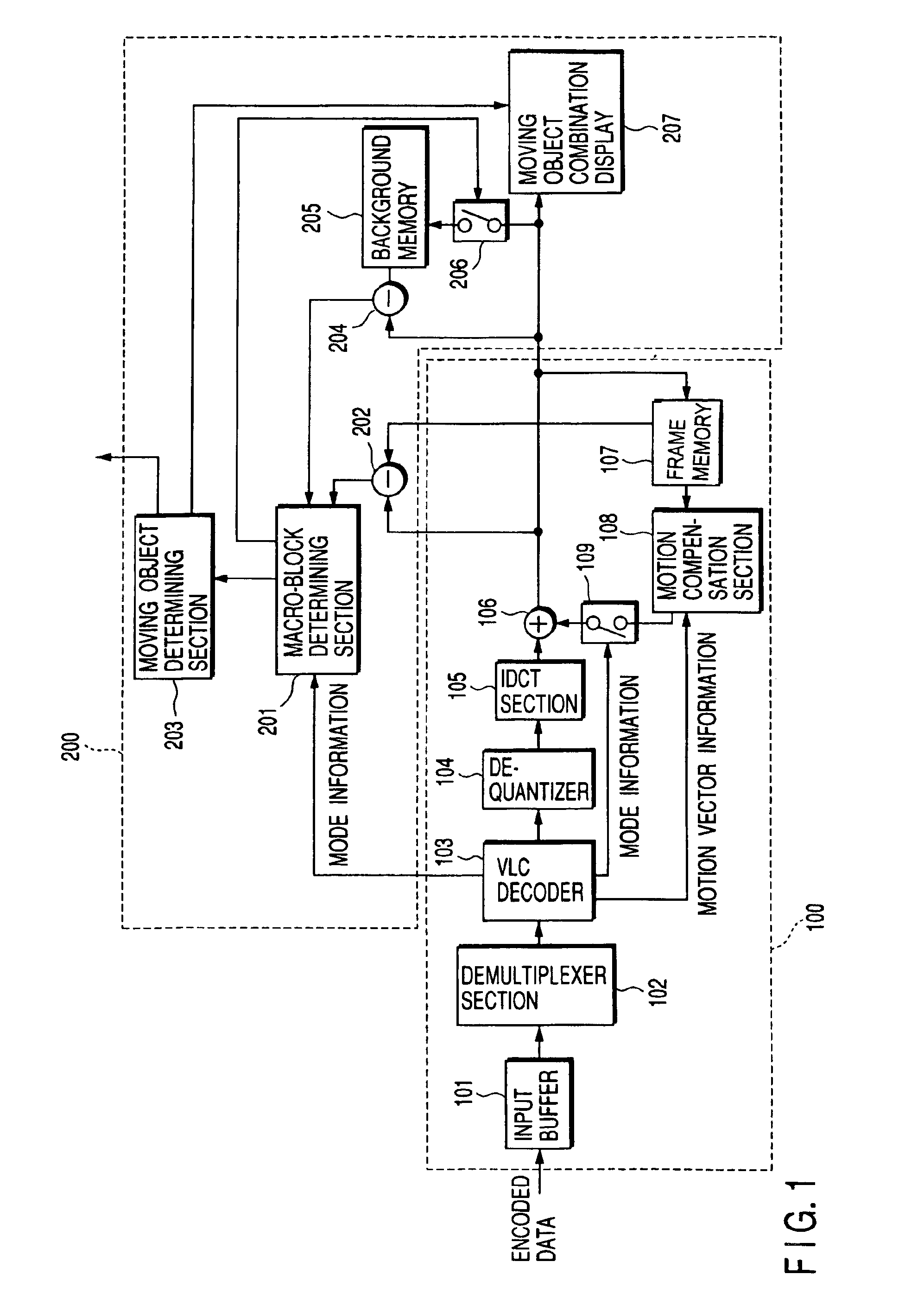

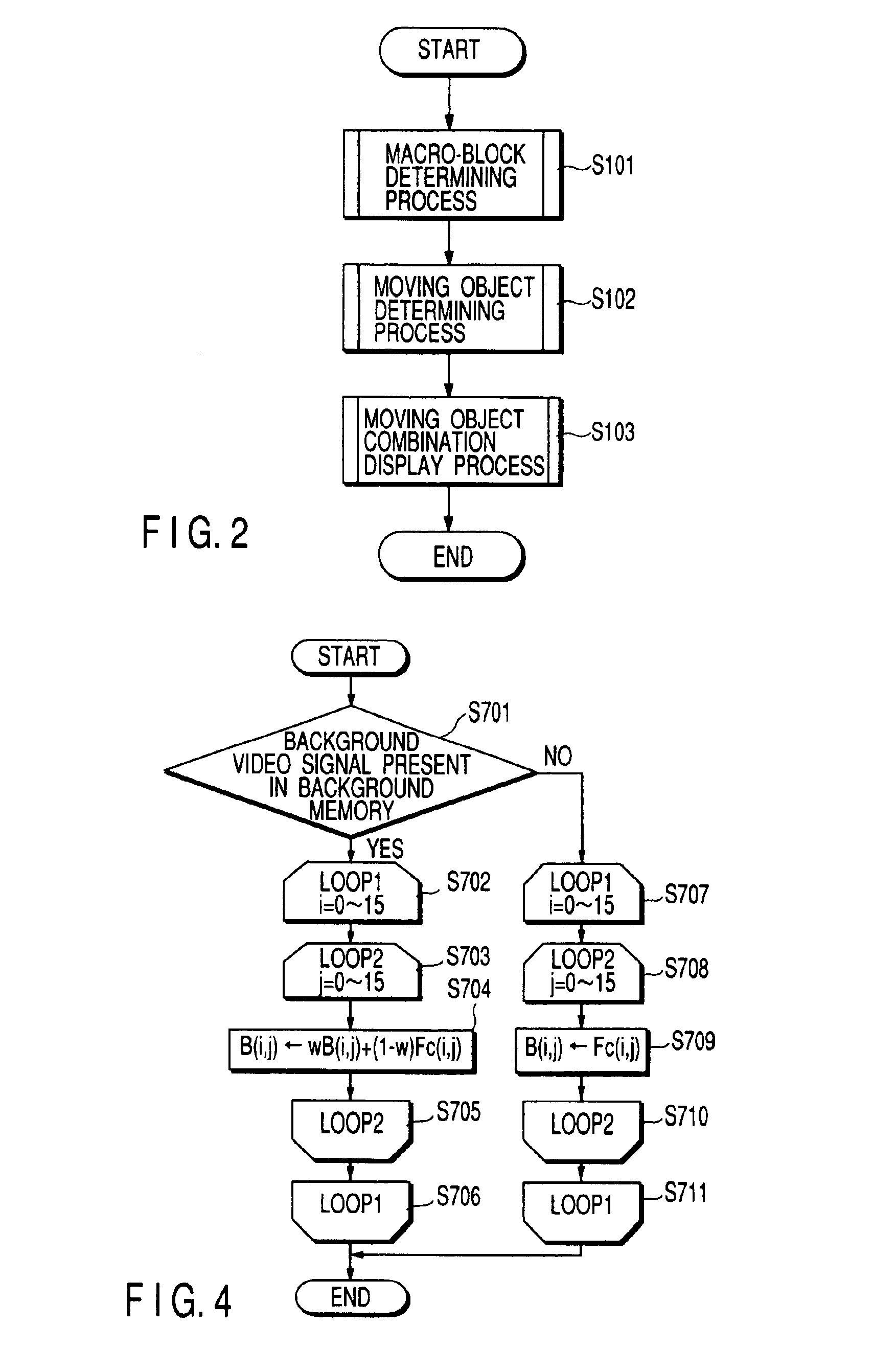

Method for detecting a moving object in motion video and apparatus therefor

InactiveUS6876701B1Detecting moving fast and stably and accuratelyMove quicklyImage enhancementImage analysisDisplay deviceComputer vision

An apparatus for detecting a moving object in motion video comprises a macro-block determining section for determining the background / non-background of each macro-block of a reconstructed video signal from a video decoder section which decodes encoded data obtained by compression-encoding a motion video signal, a moving object determining section for determining an area of the moving object from the result of the determination on the background / non-background, and a moving object combination display for displaying information indicating the area of the moving object on a display screen for the reconstructed video signal. The macro-block determining section determines if a macro-block represents a background area or a non-background area, based on mode information from the video decoder section and a cross correlation value between a present frame of the reconstructed video signal and a signal of a frame preceding the present frame by one frame, obtained by a first cross correlation calculator, and a cross correlation value between the present frame of the reconstructed video signal and a background video signal stored in a background memory, obtained by a second cross correlation calculator.

Owner:KK TOSHIBA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com