Automatic adhesive sticking equipment

A technology of gluing and equipment, applied in the field of automatic gluing equipment, can solve the problems of poor quality, low efficiency and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below with reference to the drawings and embodiments.

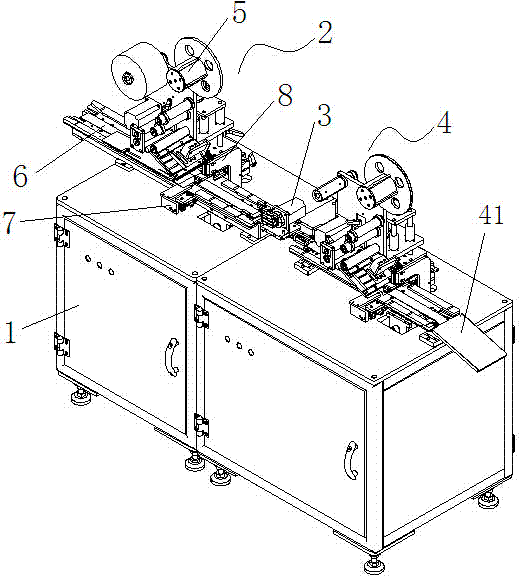

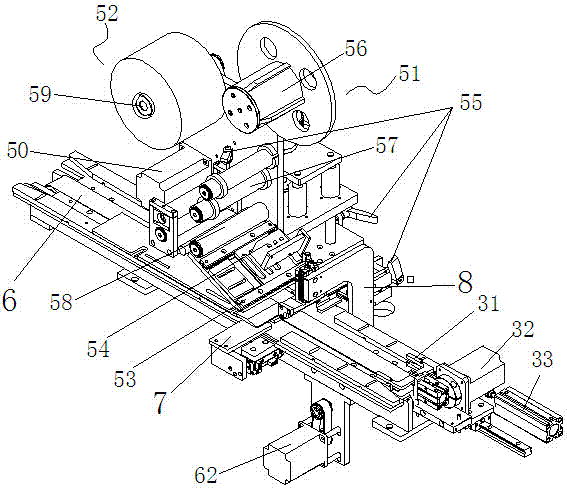

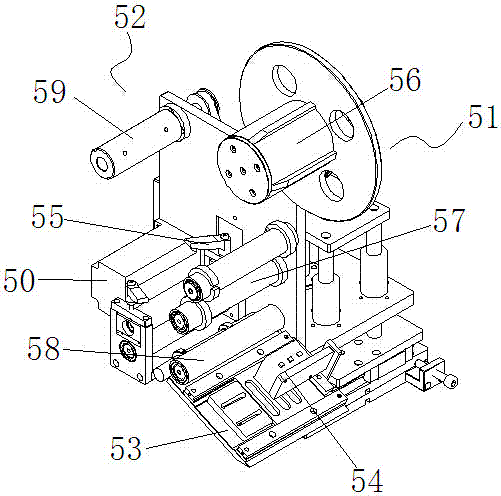

[0023] Such as figure 1 As shown, an automatic glue sticking equipment is used for double-sided glue sticking of lithium battery cells before sticking steel shells, including a frame 1 with a built-in programmable logic controller PLC, and a pair of battery cells set on the frame 1 The front glue-applying mechanism 2 for pasting the double-sided tape on the front, the turning mechanism 3 for flipping the cell after the front double-sided tape is pasted 180 degrees, and the back-side glue-applying mechanism for pasting the double-sided tape on the reverse side of the flipped cell 4. The reverse gluing mechanism 4 is composed of the same structure as the front gluing mechanism 2 and the discharge port 41. The front gluing mechanism 2, the turning mechanism 3 and the reverse gluing mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com