Patents

Literature

733results about "Superheating control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

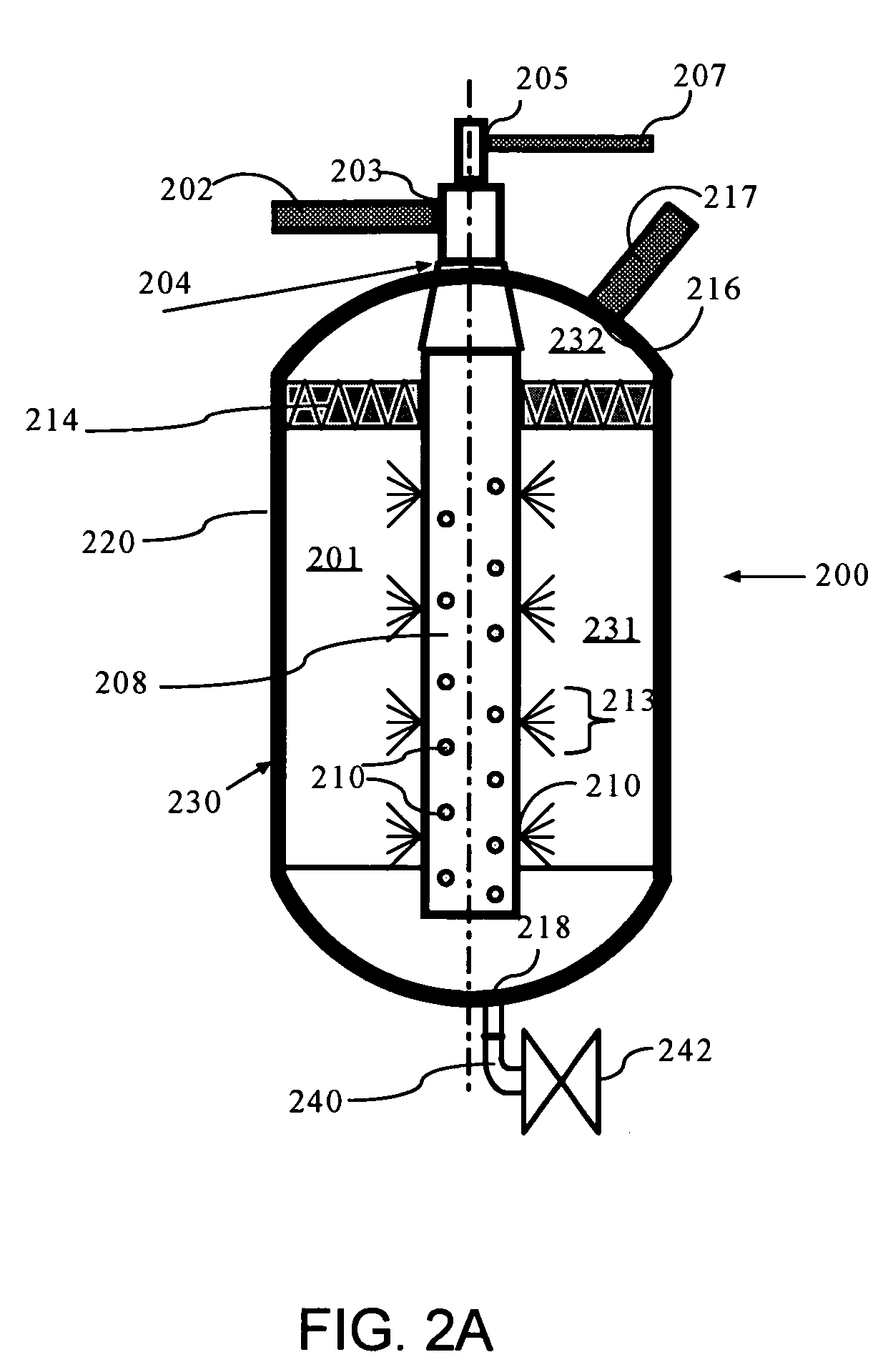

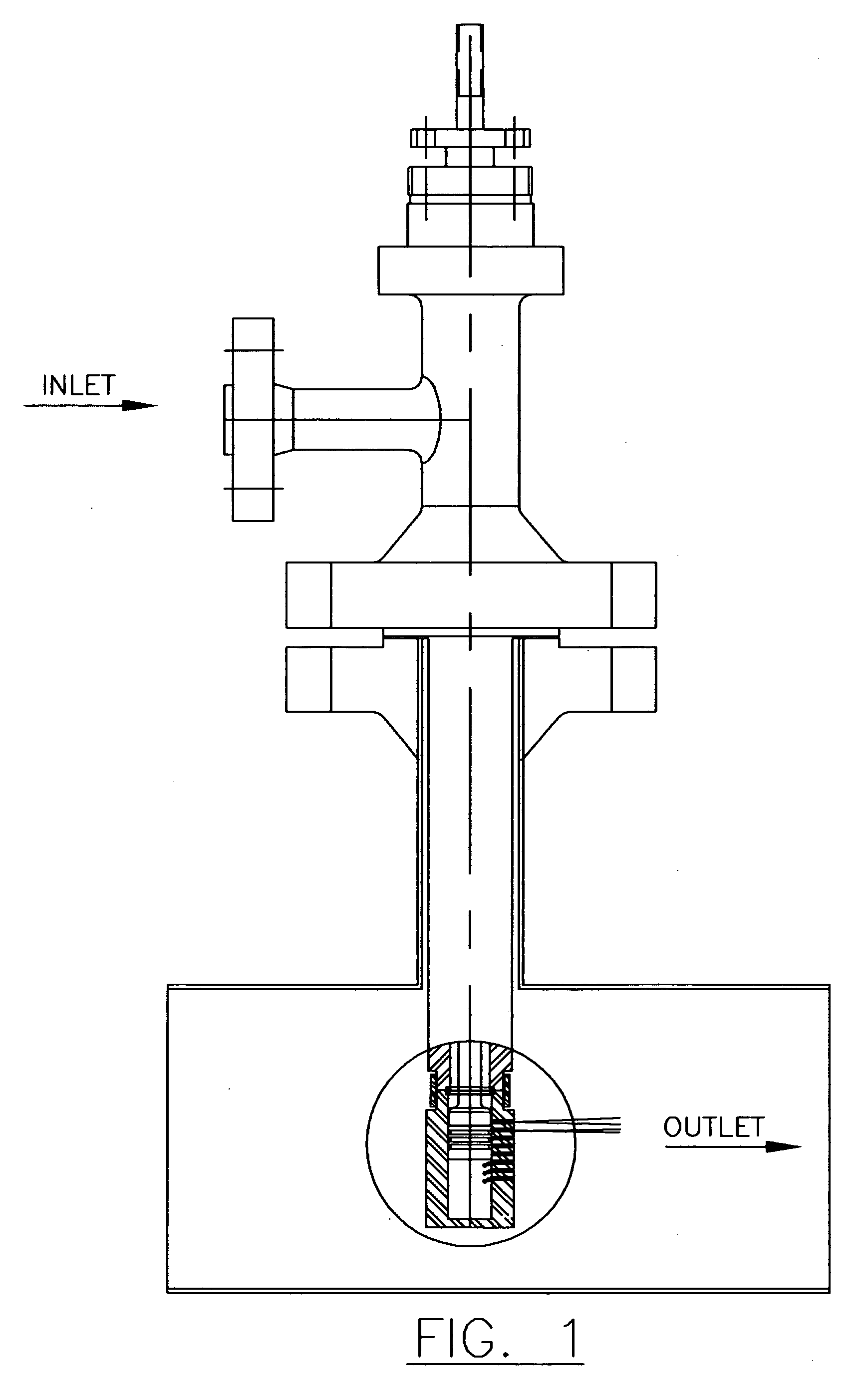

Hot to cold steam transformer for turbine systems

A steam transformer (200) receives steam through a steam inlet (203), and the steam is mixed in a mixing zone (231) with water entering through a water inlet (205). Steam cooled by contact with the water exits the steam transformer through a cold steam outlet (216). Between the mixing zone (231) and the cold steam outlet (216) is positioned a demister (214) that restricts the passage of water droplets.The steam transformer (200) is used to condition the steam temperature in steam turbine and combined cycle turbine facilities when adjustment of steam temperature is required, such as for cold starts of turbines. The steam transformer (200) may be installed into a bypass circuit or directly inline. A number of differing configurations and designs are disclosed.

Owner:SIEMENS ENERGY INC

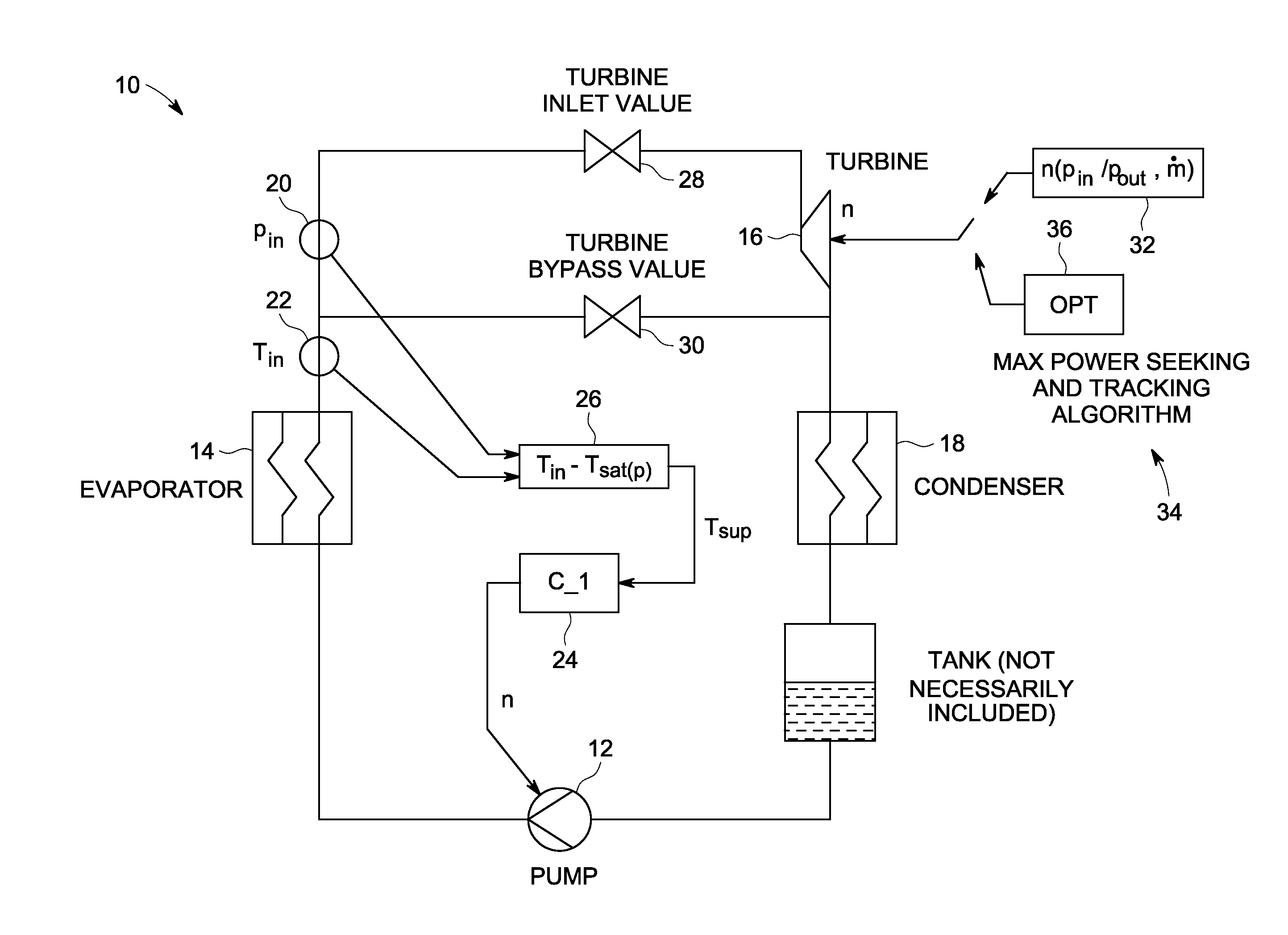

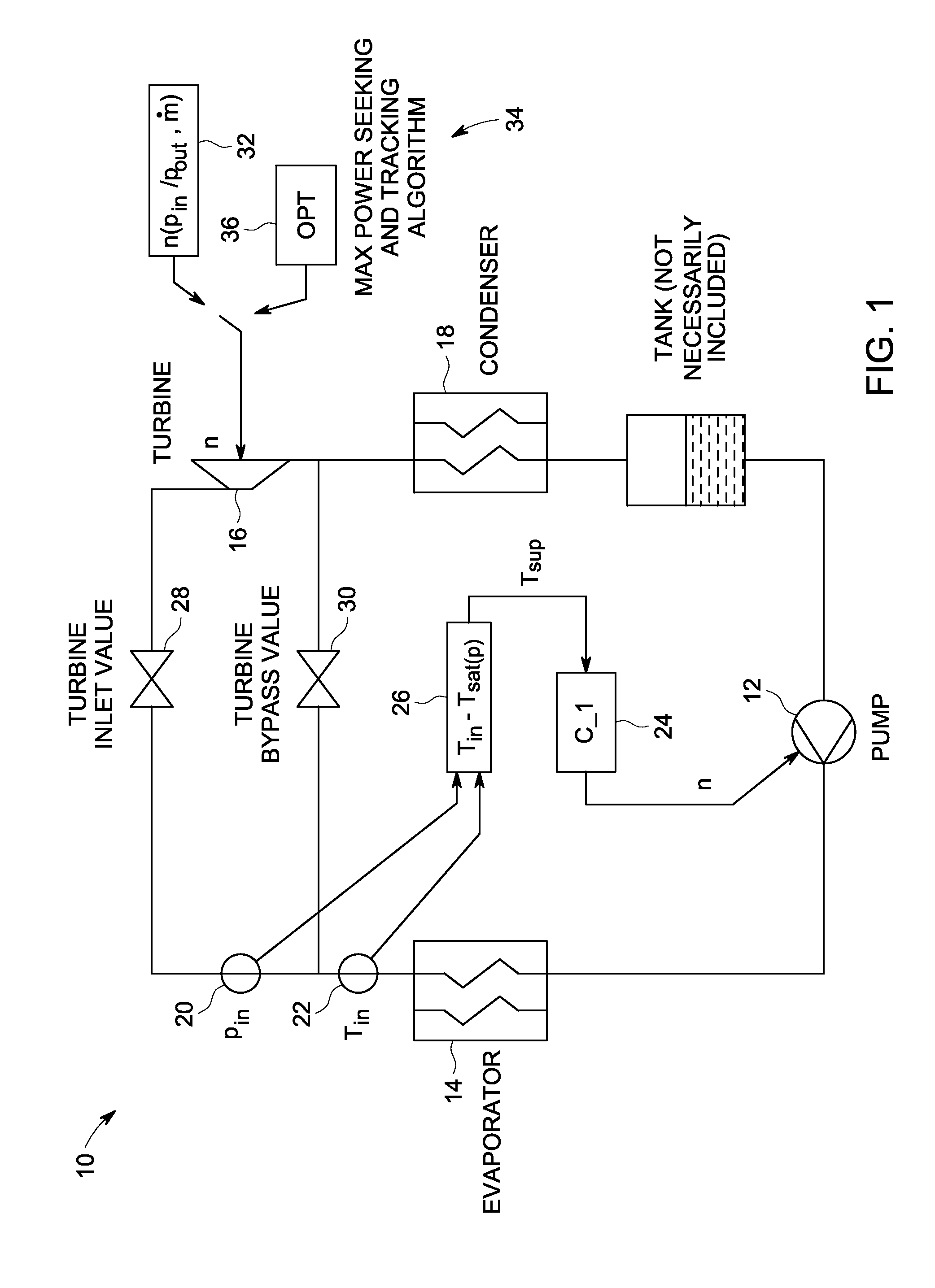

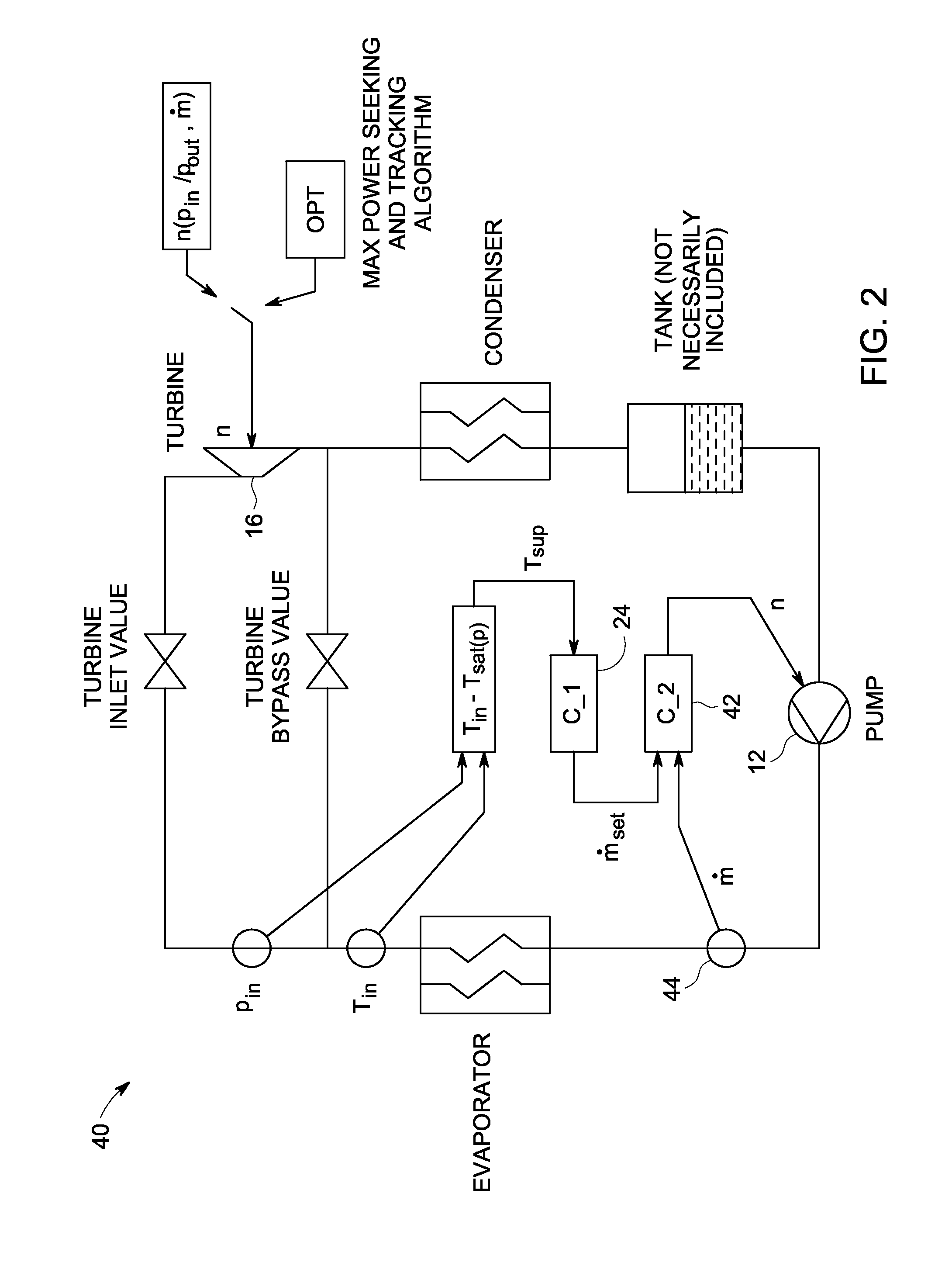

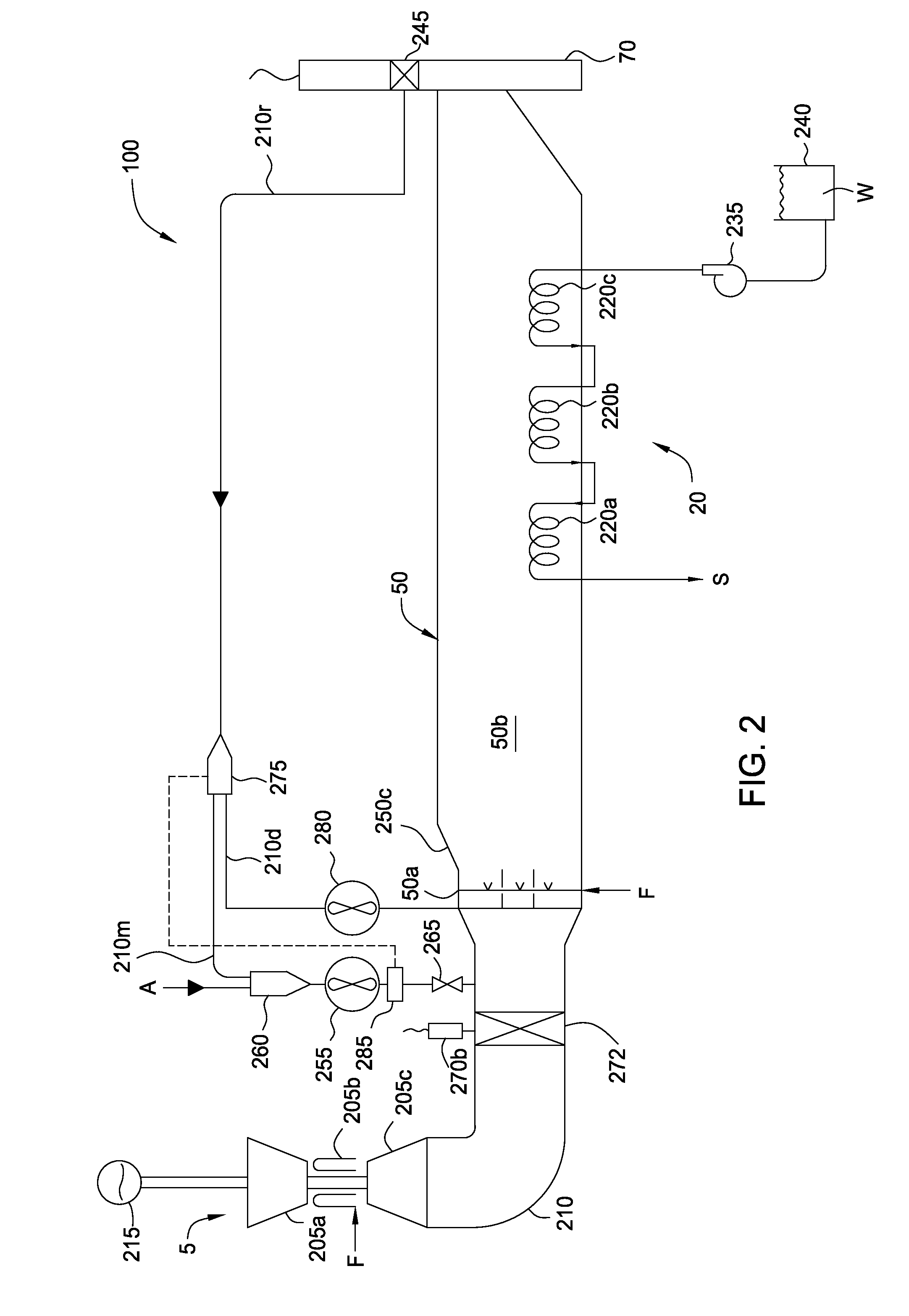

Turbine inlet condition controlled organic rankine cycle

A pressure sensor measures an organic Rankine cycle (ORC) working fluid pressure in front of a radial inflow turbine, while a temperature sensor measures an ORC working fluid temperature in front of the radial inflow turbine. A controller responsive to algorithmic software determines a superheated temperature of the working fluid in front of the radial inflow turbine based on the measured working fluid pressure and the measured working fluid temperature. The controller then manipulates the speed of a working fluid pump, the pitch of turbine variable inlet guide vanes when present, and combinations thereof, in response to the determined superheated temperature to maintain the superheated temperature of the ORC working fluid in front of the radial inflow turbine close to a predefined set point. The superheated temperature can thus be maintained in the absence of sensors other than pressure and temperature sensors.

Owner:AI ALPINE US BIDCO INC

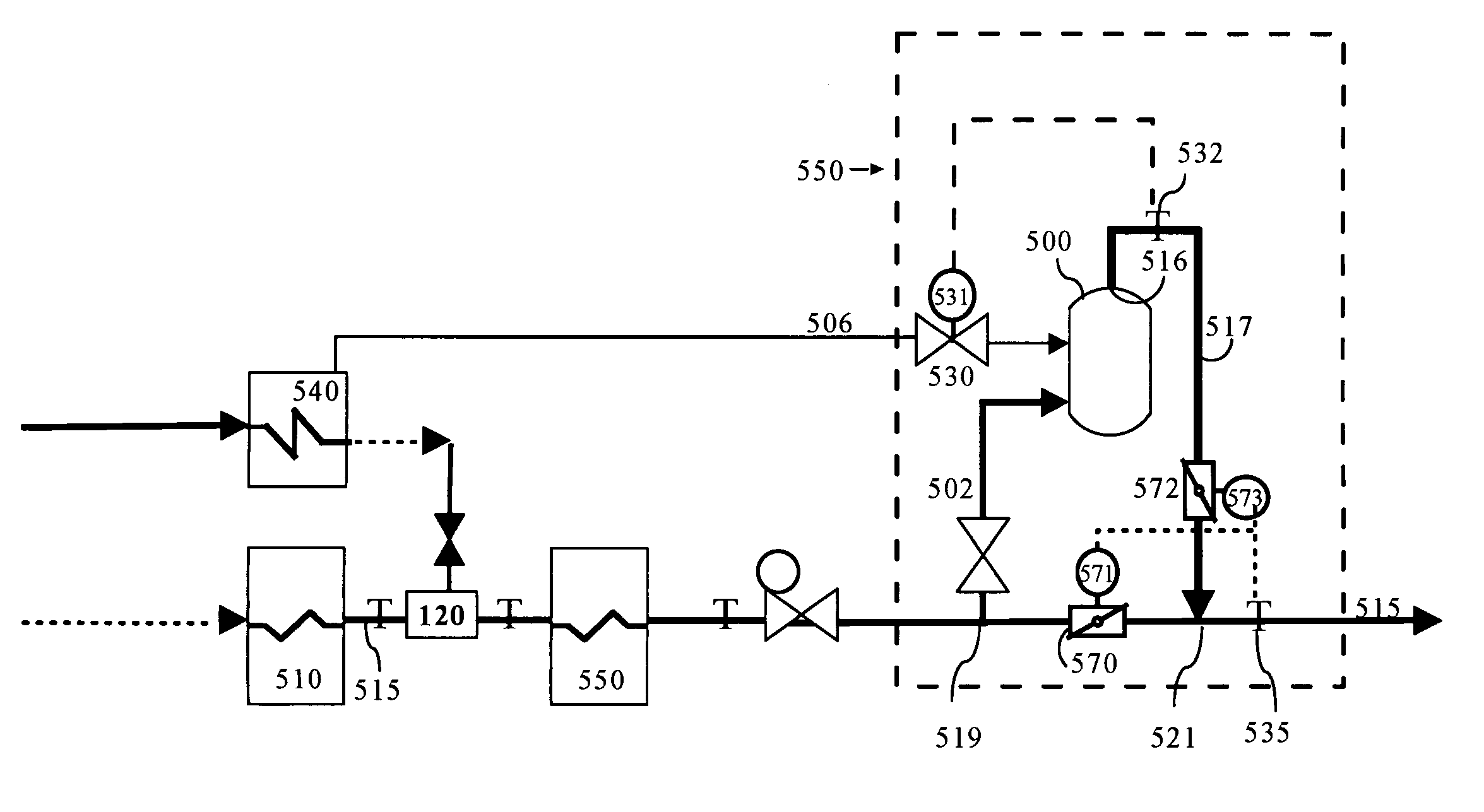

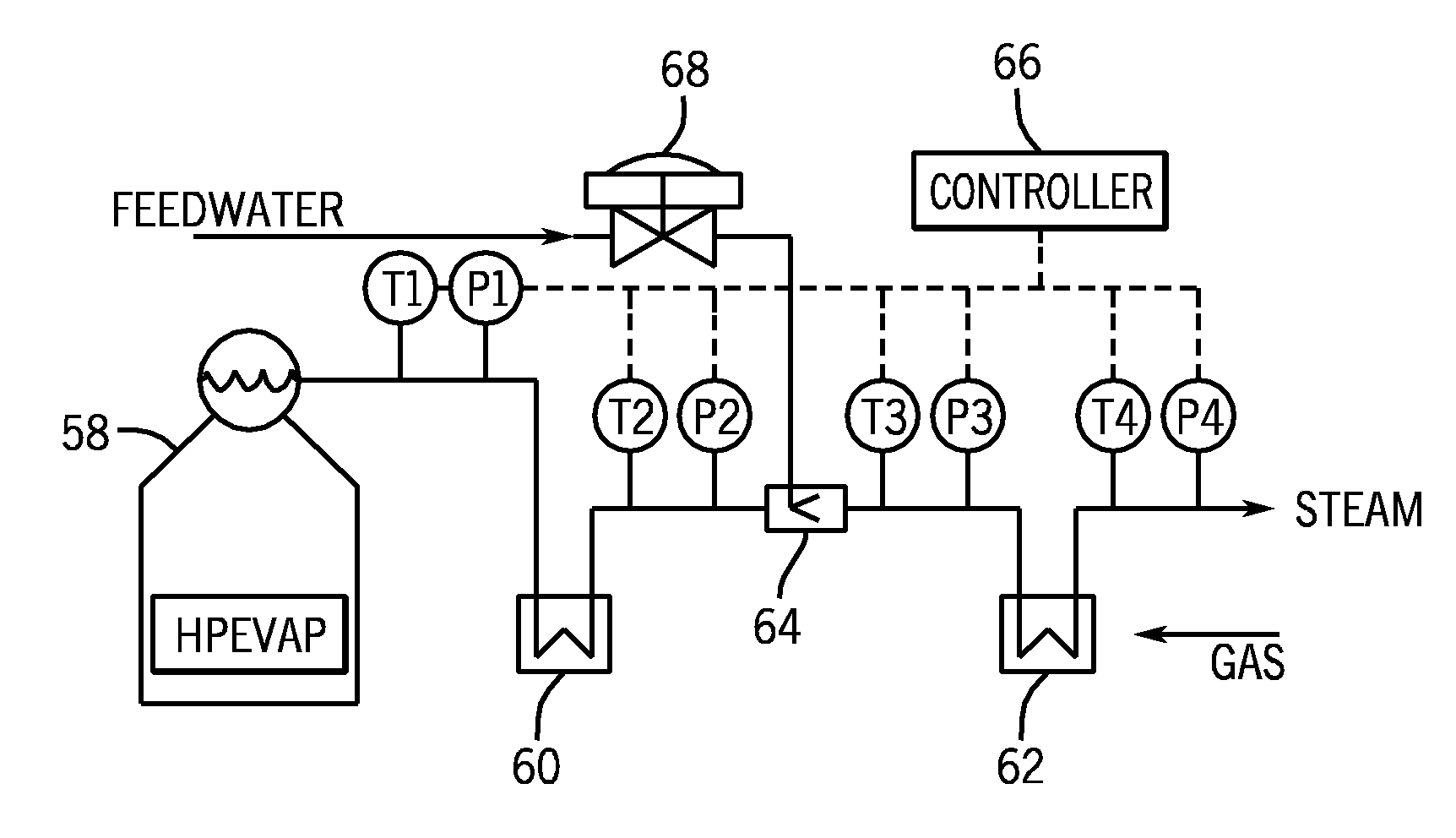

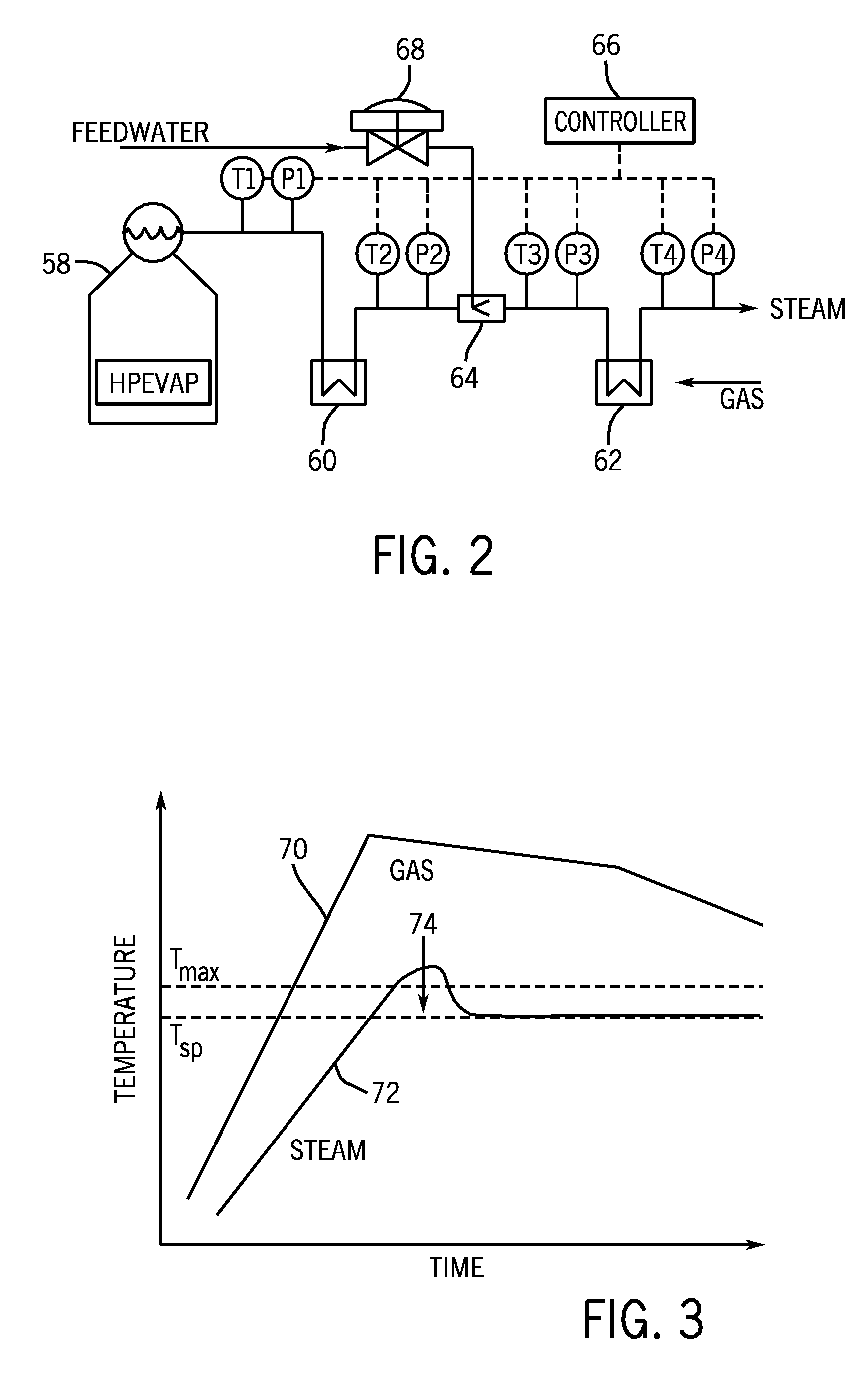

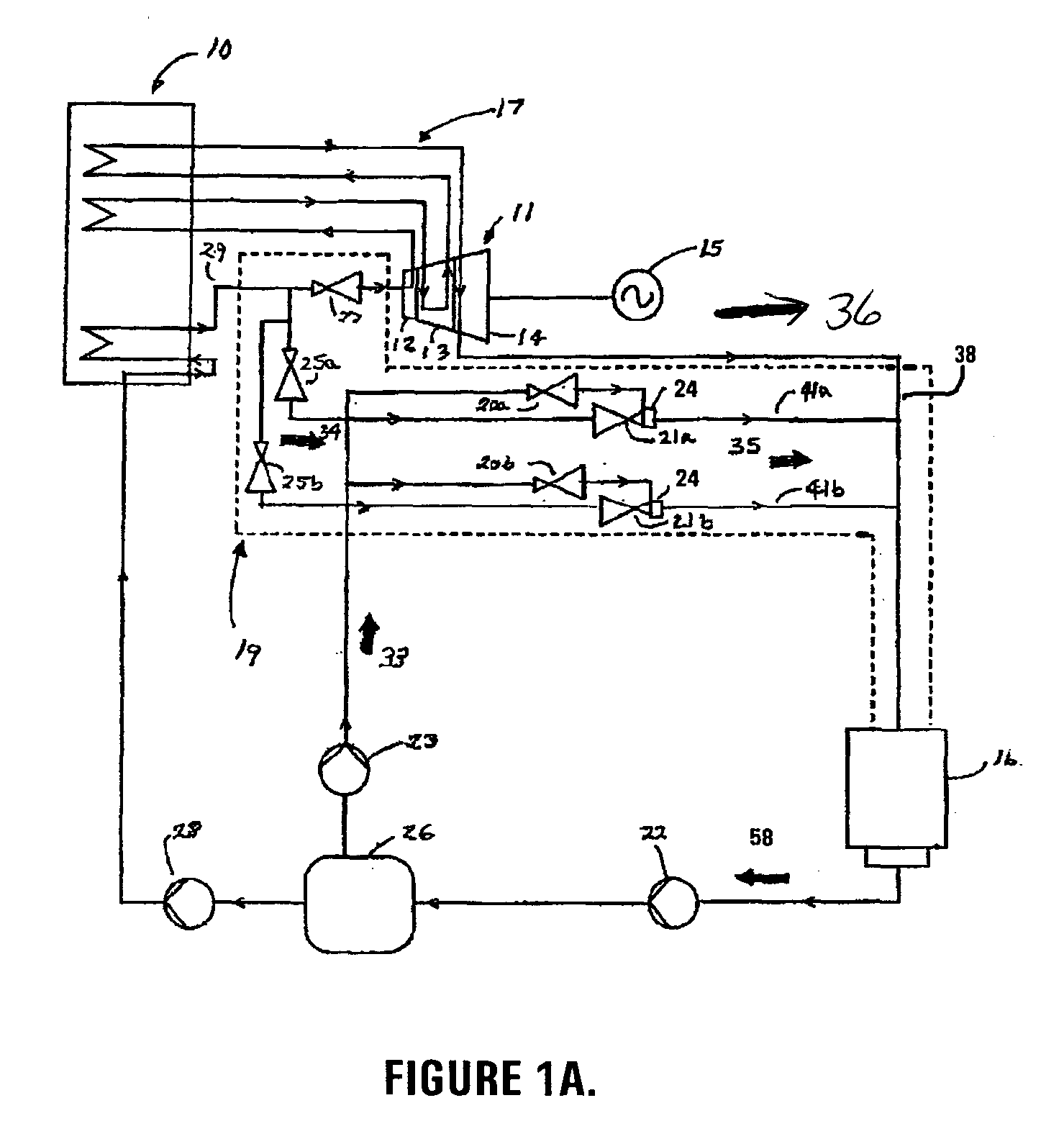

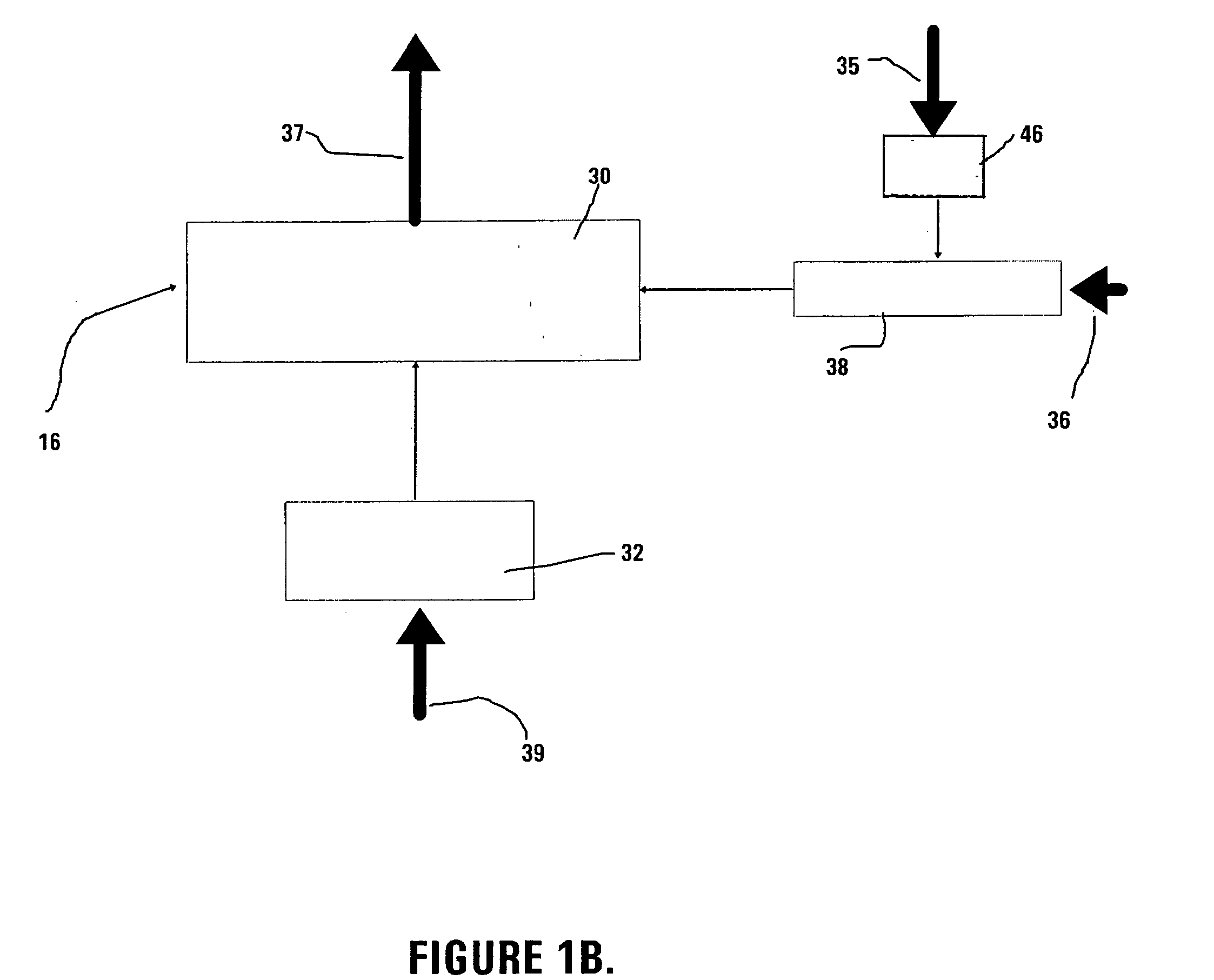

Inter-stage attemperation system and method

Systems and methods for controlling exhaust steam temperatures from a finishing superheater are provided. In certain embodiments, the system includes a controller which includes control logic for predicting an exhaust temperature of steam from the finishing superheater using model-based predictive techniques (e.g., based on empirical data or thermodynamic calculations). Based on the predicted exhaust temperature of steam, the control logic may use feed-forward control techniques to control the operation of an inter-stage attemperation system upstream of the finishing superheater. The control logic may determine if attemperation is required based on whether the predicted exhaust temperature of steam from the finishing superheater exceeds a set point temperature as well as whether the inlet temperature of steam into the finishing superheater drops below a set point temperature of steam. The attemperation system may include a characterizing function to linearize the valve operation controlled by the control logic to inject cooled, high-pressure feedwater into the steam upstream of the finishing superheater, which may, in turn, control the exhaust temperature of steam from the finishing superheater. The disclosed embodiments may also be applied to any systems where an outlet temperature of a fluid from a heat transfer device may be controlled.

Owner:GENERAL ELECTRIC CO

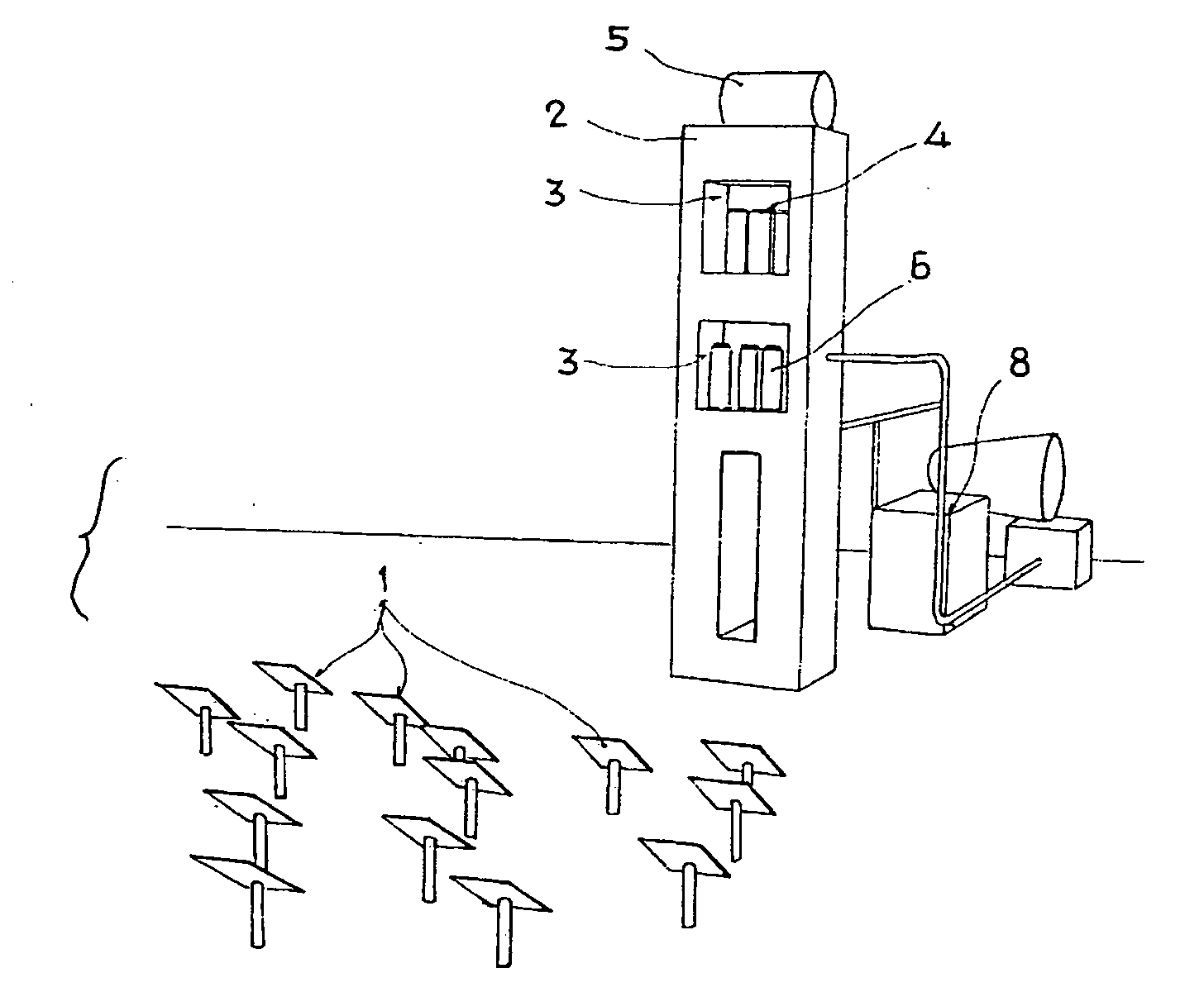

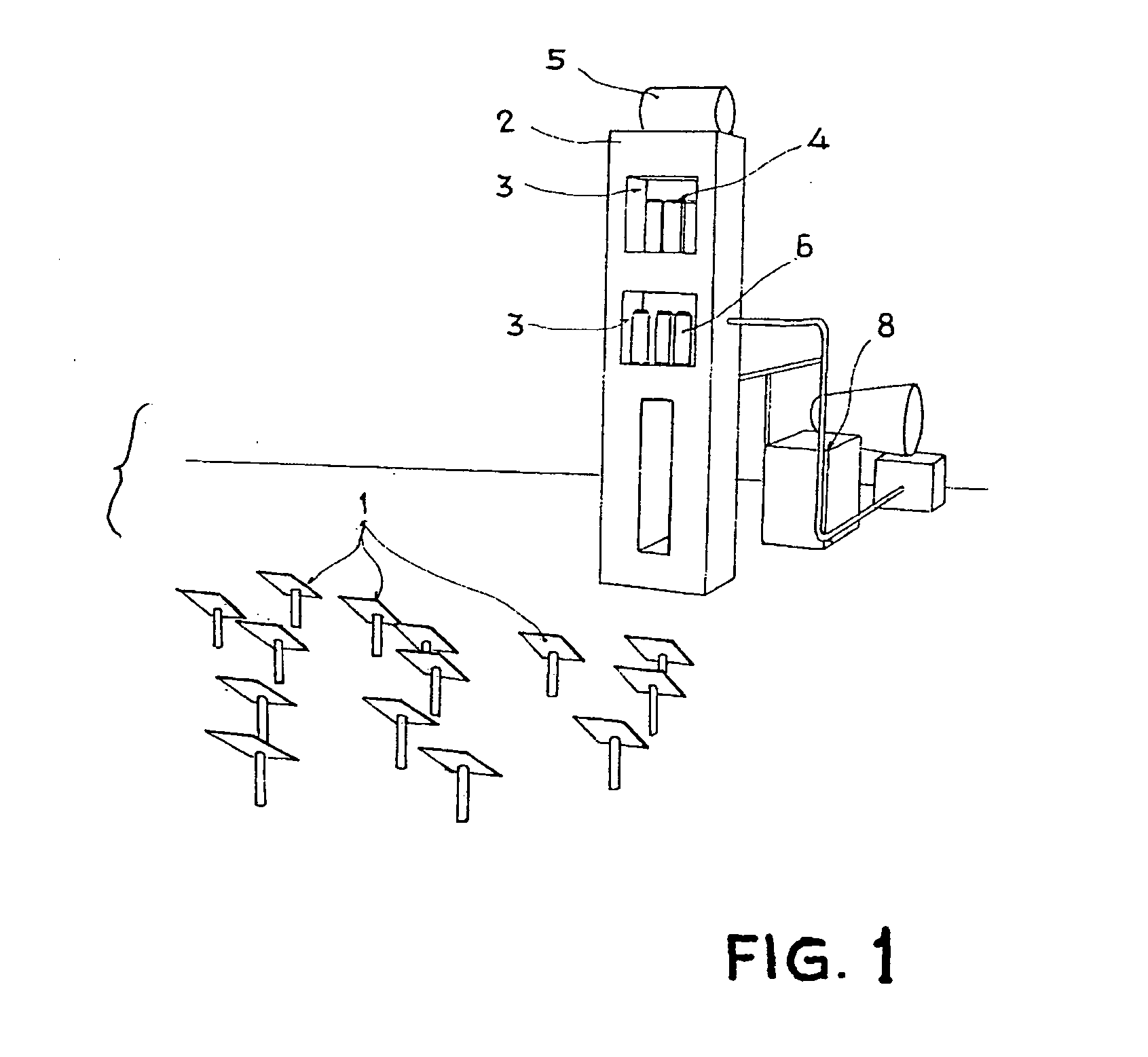

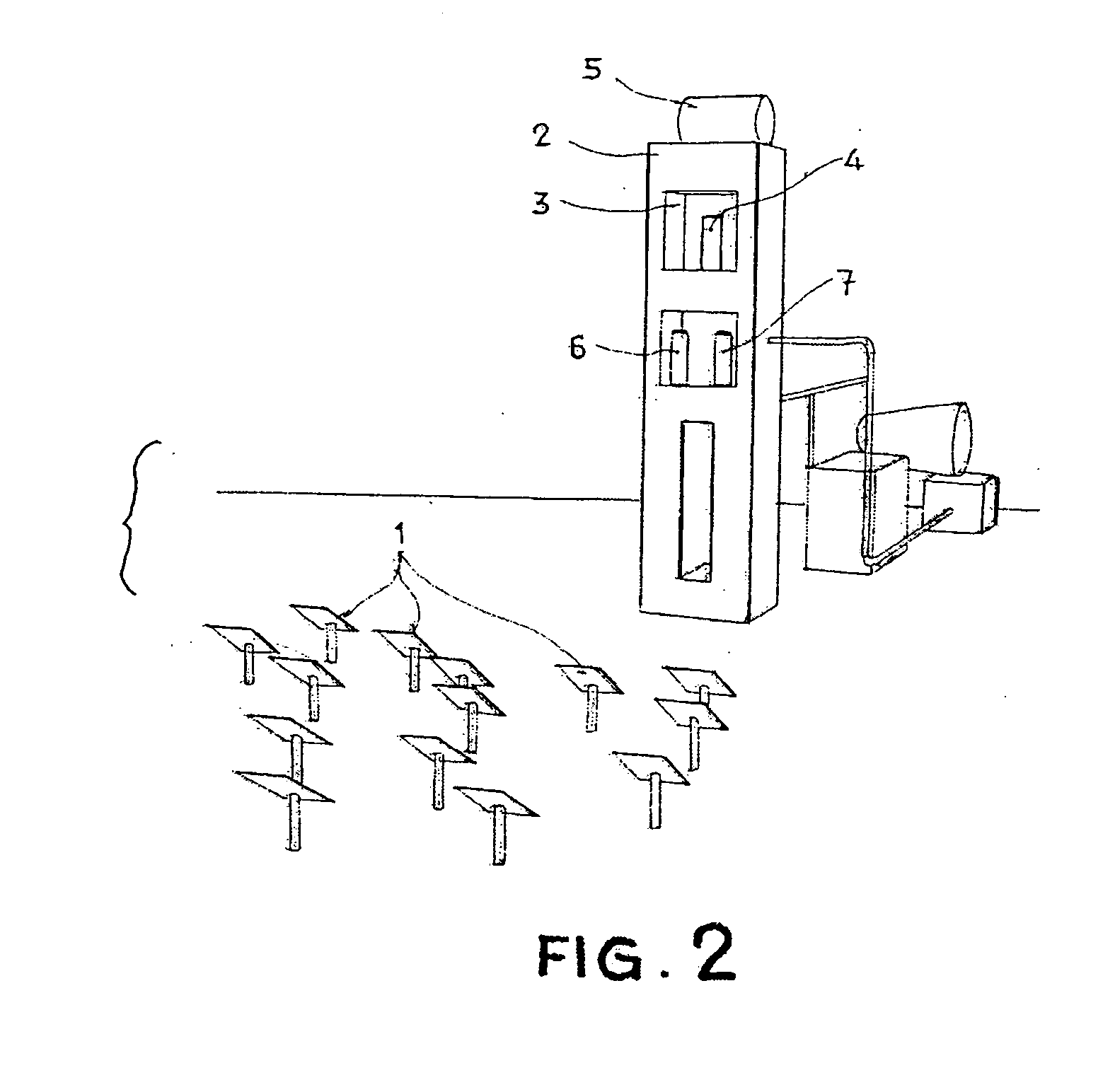

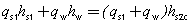

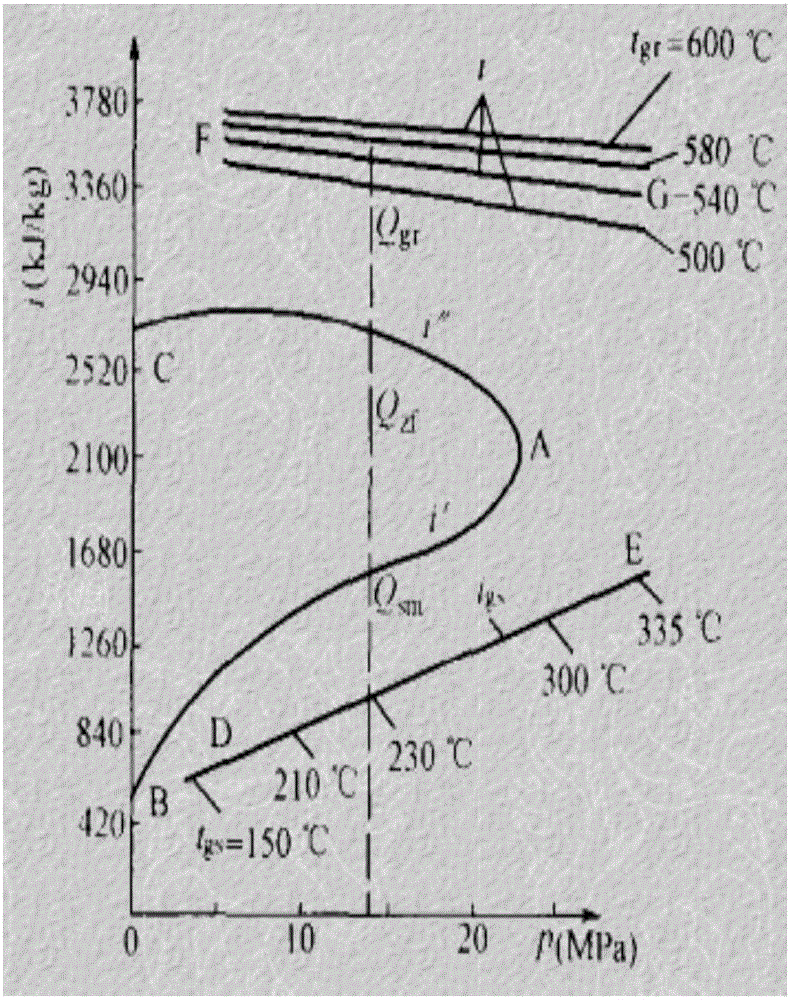

Solar concentration plant for the production of superheated steam

InactiveUS20080302314A1Easy to controlReduce riskSolar heating energySuperheating controlHeliostatEvaporation

A solar concentration plant which uses water / steam as a heat-carrying fluid, in any thermodynamic cycle or system for the exploitation of process heat, which is comprised of an evaporation subsystem, where saturated steam is produced under the conditions of pressure of the system, and a superheater subsystem through which the steam reaches the required conditions of pressure and temperature at the turbine inlet, and in which an attemperation system (10) may be incorporated, these being physically separated and interconnected by means of a drum (5) in which the separation of water and steam takes place, and in which a strategic control of the pointing of the field of heliostats (1) towards either of the subsystems (evaporator or superheater) may be carried out, with individual or group pointing of the heliostats, in such a way that they jointly control both the pressure within the drum (5) and the outlet temperature of the superheated steam (11).

Owner:ABENGOA SOLAR NEW TECH SA

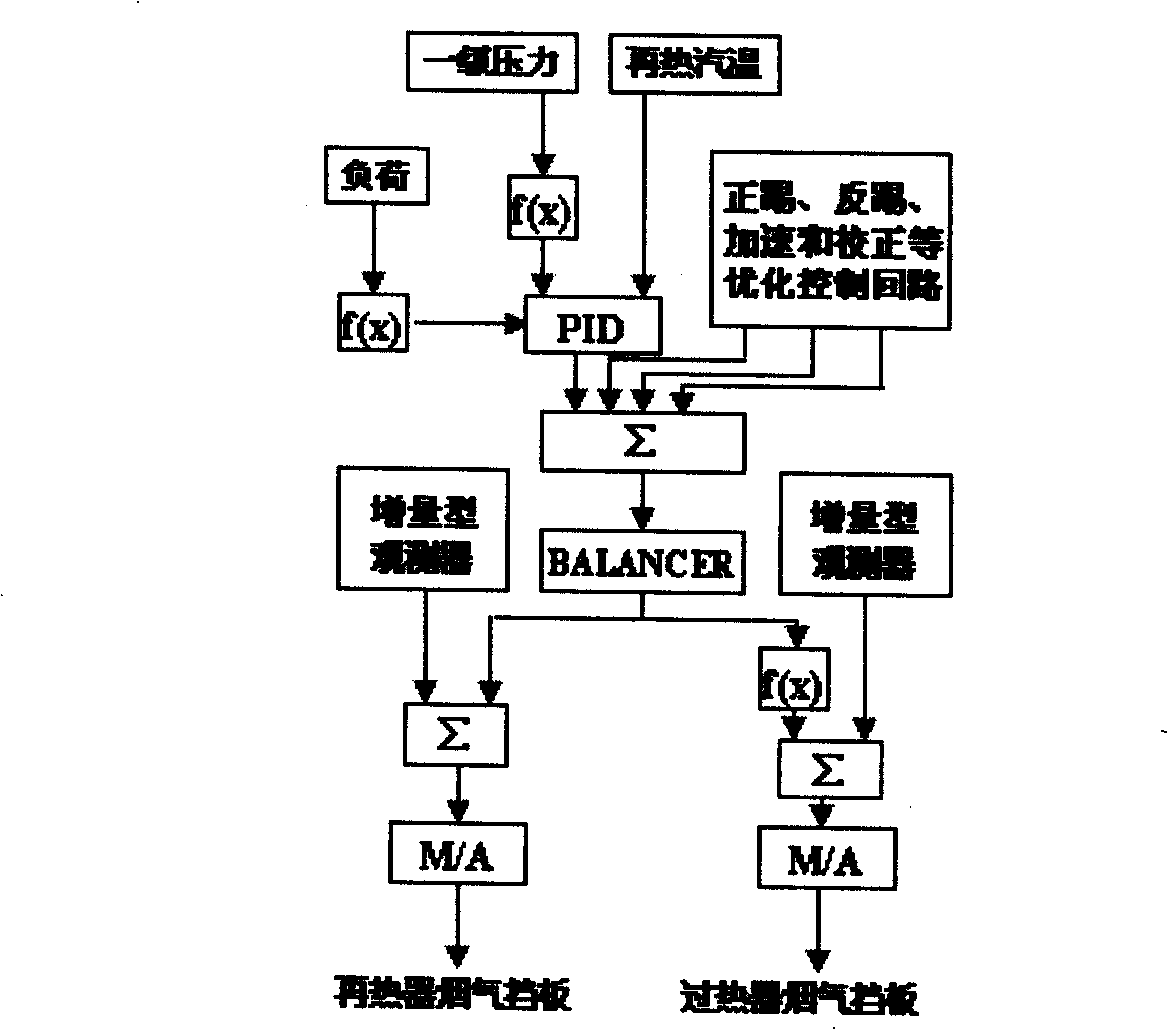

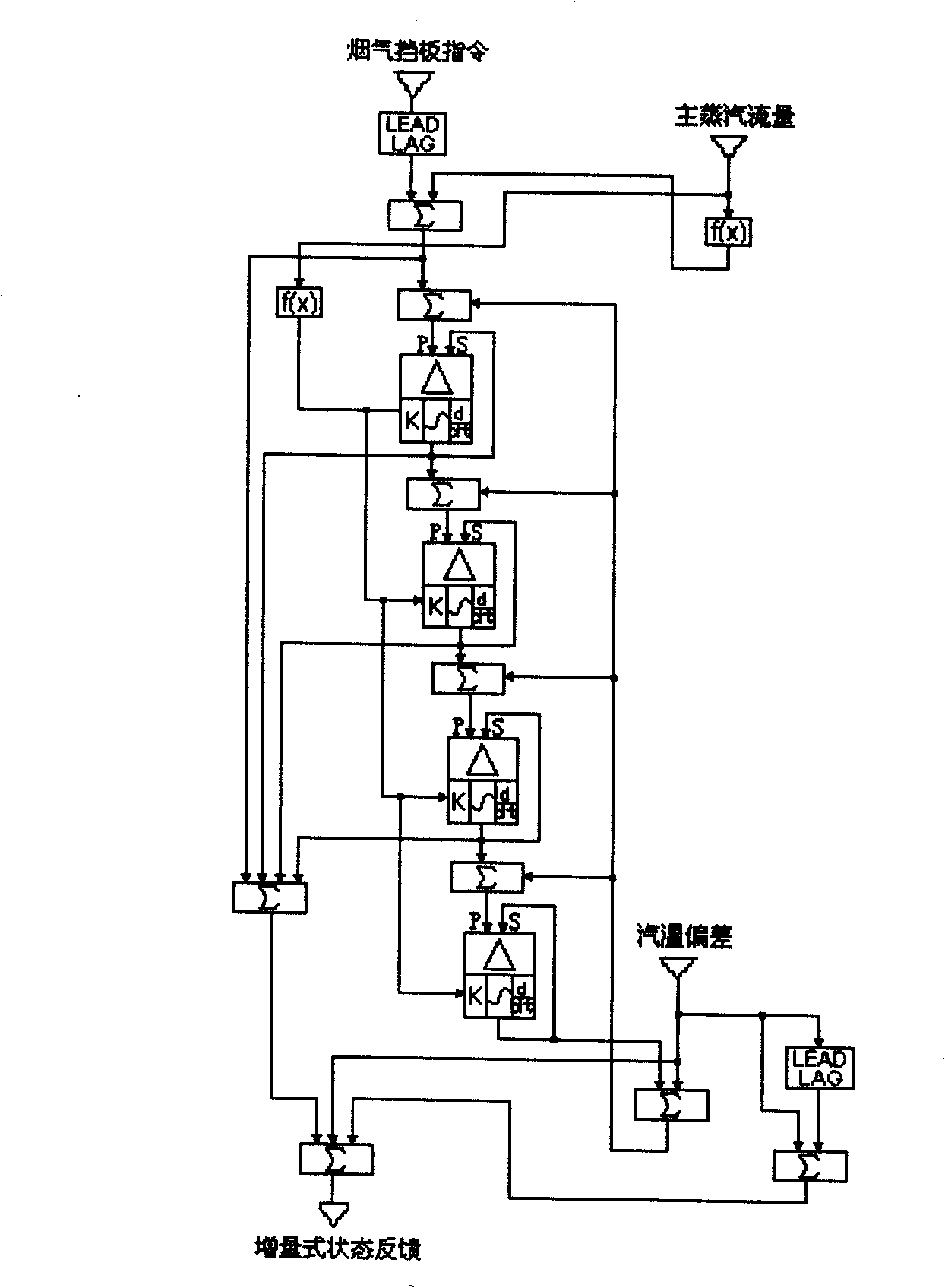

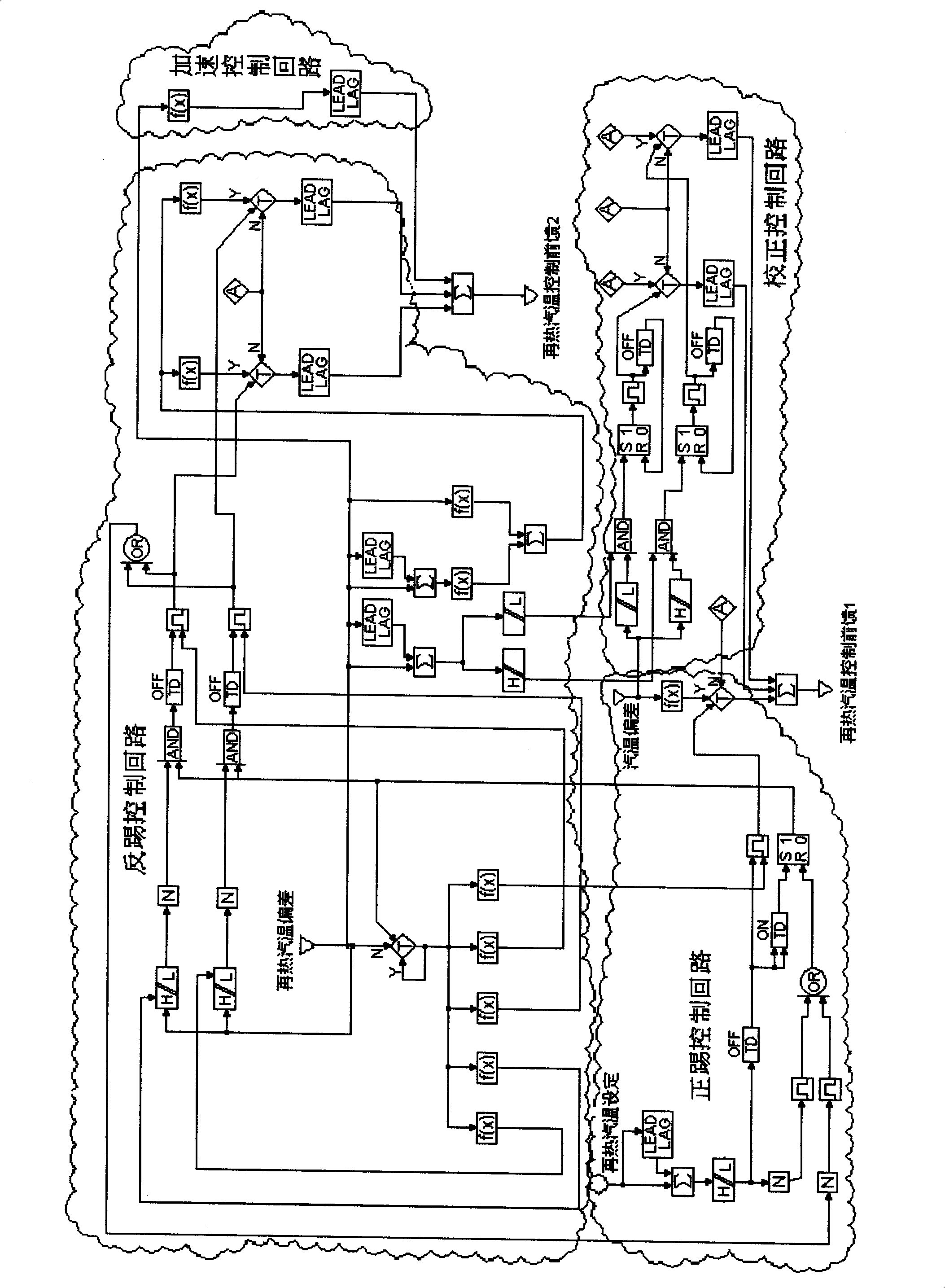

Thermal power unit reheated steam temperature control method

ActiveCN101338892APrevent overshootReduce Signal ErrorSuperheating controlTemperature control using electric meansFeedback controlLoad following power plant

The invention relates to a thermal power generating unit reheated steam temperature controlling method. According to the operating characteristics of the boiler reheater and the theoretic study on a steam-temperature control system, a state feedback control method based on incremental state observer is adopted, and the concept of an algebraically equivalence observer is used to direct the parameter setting of an incremental state observer; in addition, a special control circuit is arranged in the steam-temperature control circuit to resolve the problems that the process of steam-temperature adjustment is relatively long when the reheated steam temperature set value is changed, non-linearity exists during steam-temperature control, the process of steam-temperature variation is very slow, etc., and variation parameter PID regulator is combined to jointly form a comprehensive reheated temperature automatic adjusting system. The invention is capable to ensure reheated steam temperature control to escape spray water upon large-range load variation, and effectively overcomes the disadvantage of the poor effect of the traditional PID regulation on the control of big lagged object; the reheated temperature control effect is improved remarkably; and a sample is provided for controlling the controlled object with big inertia and serious lagging in relation to reheated steam temperature.

Owner:CHINA ELECTRIC POWER RES INST +2

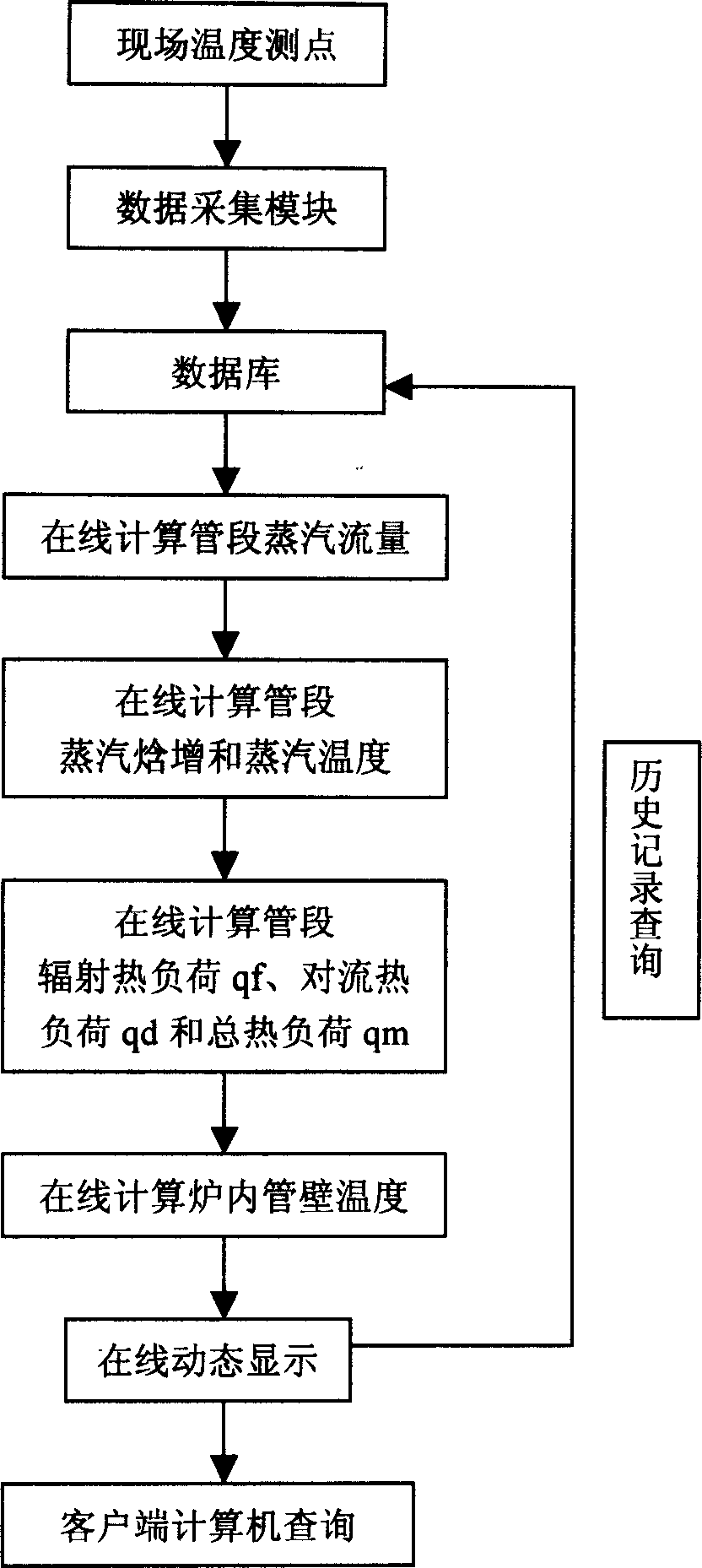

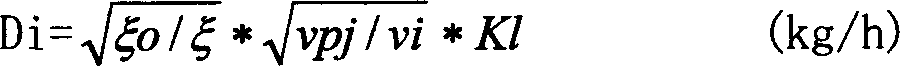

Method and apparatus for online monitoring tube wall temperature in boiler overheater and reheater

InactiveCN1877193AImprove accuracyReduce mistakesSuperheating controlTemperatue controlSuperheaterTemperature difference

The invention relates to a detecting method used to on-line detect the wall temperature and life consumption of the tubes of boiler over-heater and regenerator. Wherein, it inputs the temperature detected at the entrance external gas temperature detecting point and other parameters of boiler into the computer, to real-time calculate out the wall temperature of each section of tube, to judge if there is over heated and calculate out the life consumption and the smoke temperature difference, while the result will be displayed on the detector and recorded in the database.

Owner:王孟浩

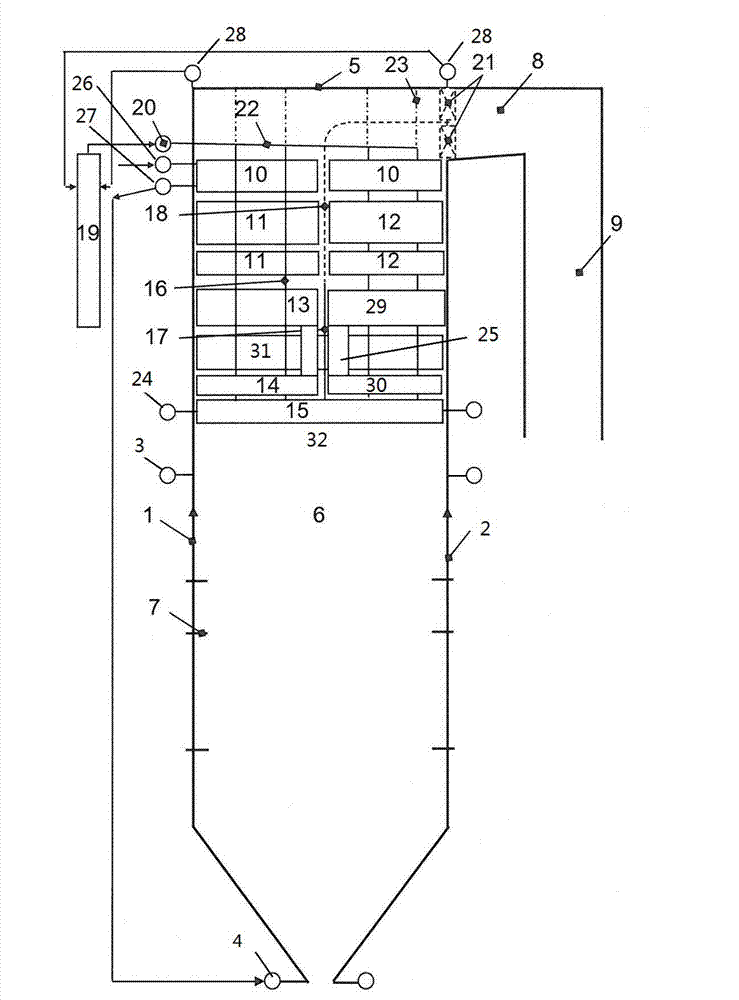

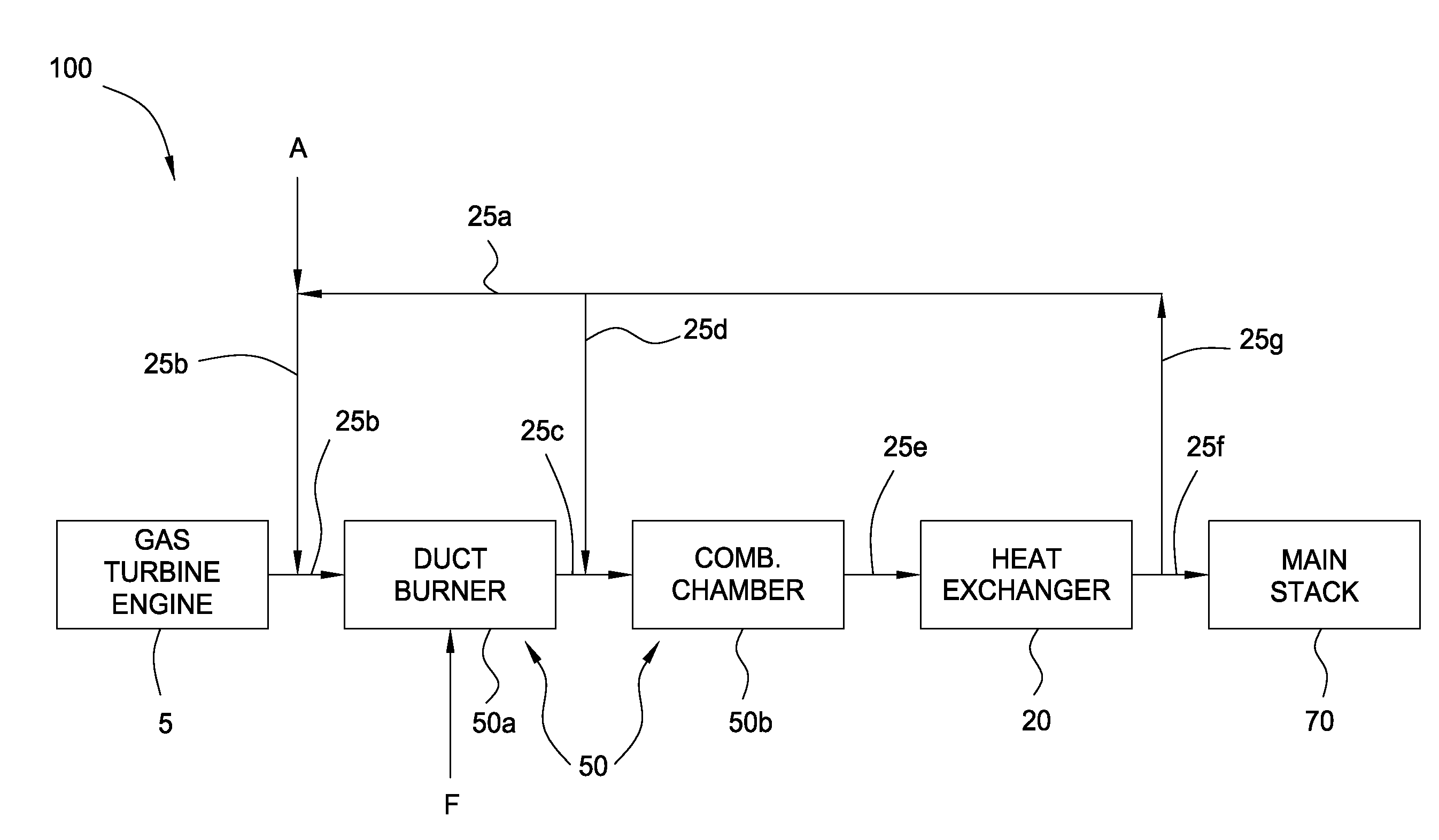

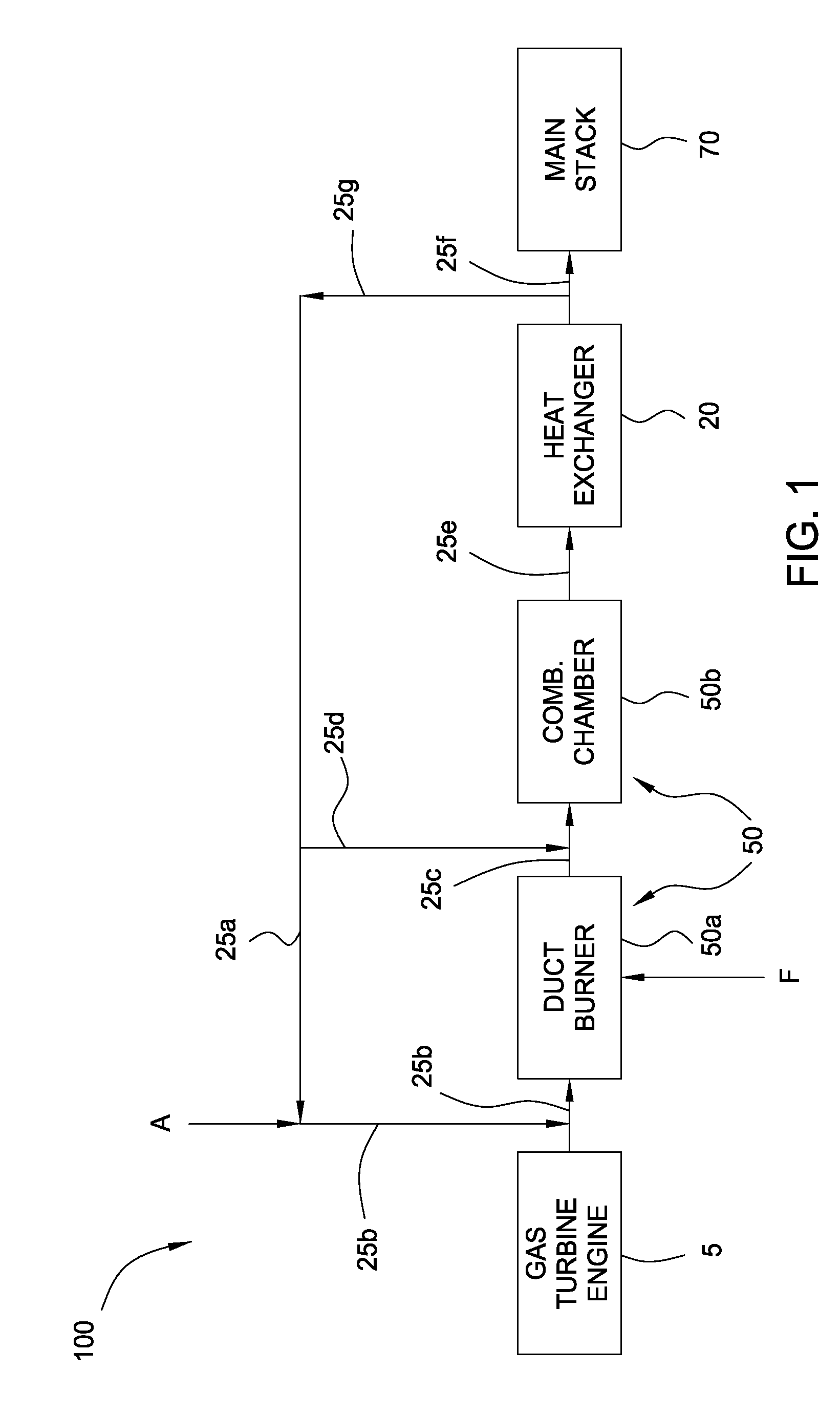

Combustion system with recirculation of flue gas

InactiveUS20060199120A1Superheating controlFuel injection apparatusCombustion systemCombustion chamber

An improved combustion method and corresponding apparatus is disclosed, where the method includes oxidizing a fuel in a combustion chamber with an oxidizing stream including an air stream and a first recycled flue gas stream and mixing a produced hot flue gas stream with a second recycled flue gas stream to form reduced temperature flue gas stream which can be used directly in a power generator or to heat a reactor. The method and apparatus allow flow rates of the streams to be adjusted so that temperatures in the combustion chamber and in the heat transfer unit or units of the power generator or reactor can be kept below temperature that would thermally damage the combustion chamber, heat transfer unit or units or the reactors.

Owner:KALINA POWER LTD

System for controlling steam temperature

A system for controlling steam temperature that includes steam circuit including a reheater circuit, at least one reheater dilution region, at least one reheater dilution conduit, and at least one reheater supply region disposed upstream of the at least one reheater dilution region, wherein the at least one reheater supply region and the at least one reheater dilution region are associated via the reheater circuit and the at least one reheater dilution conduit.

Owner:GENERAL ELECTRIC CO

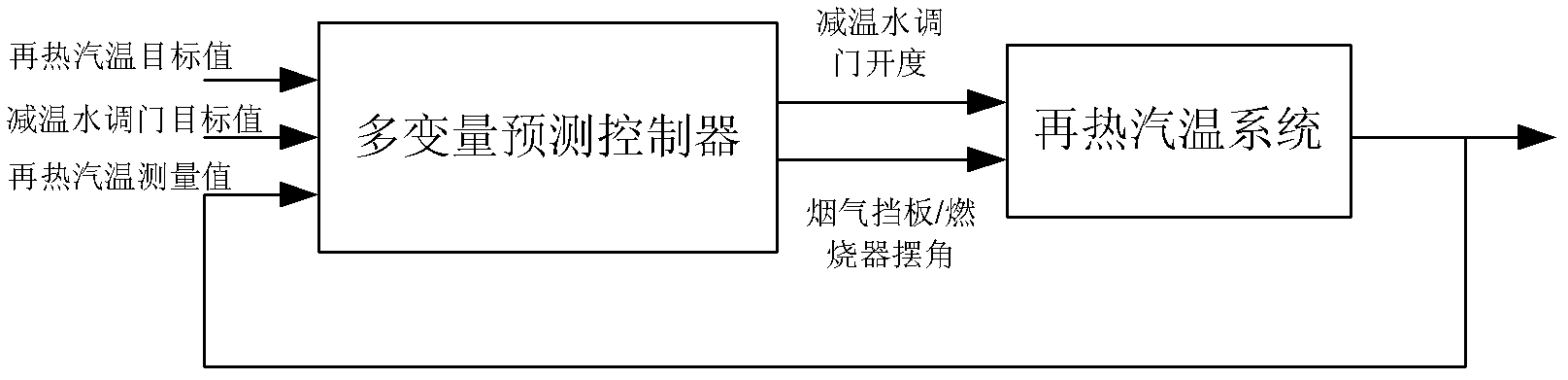

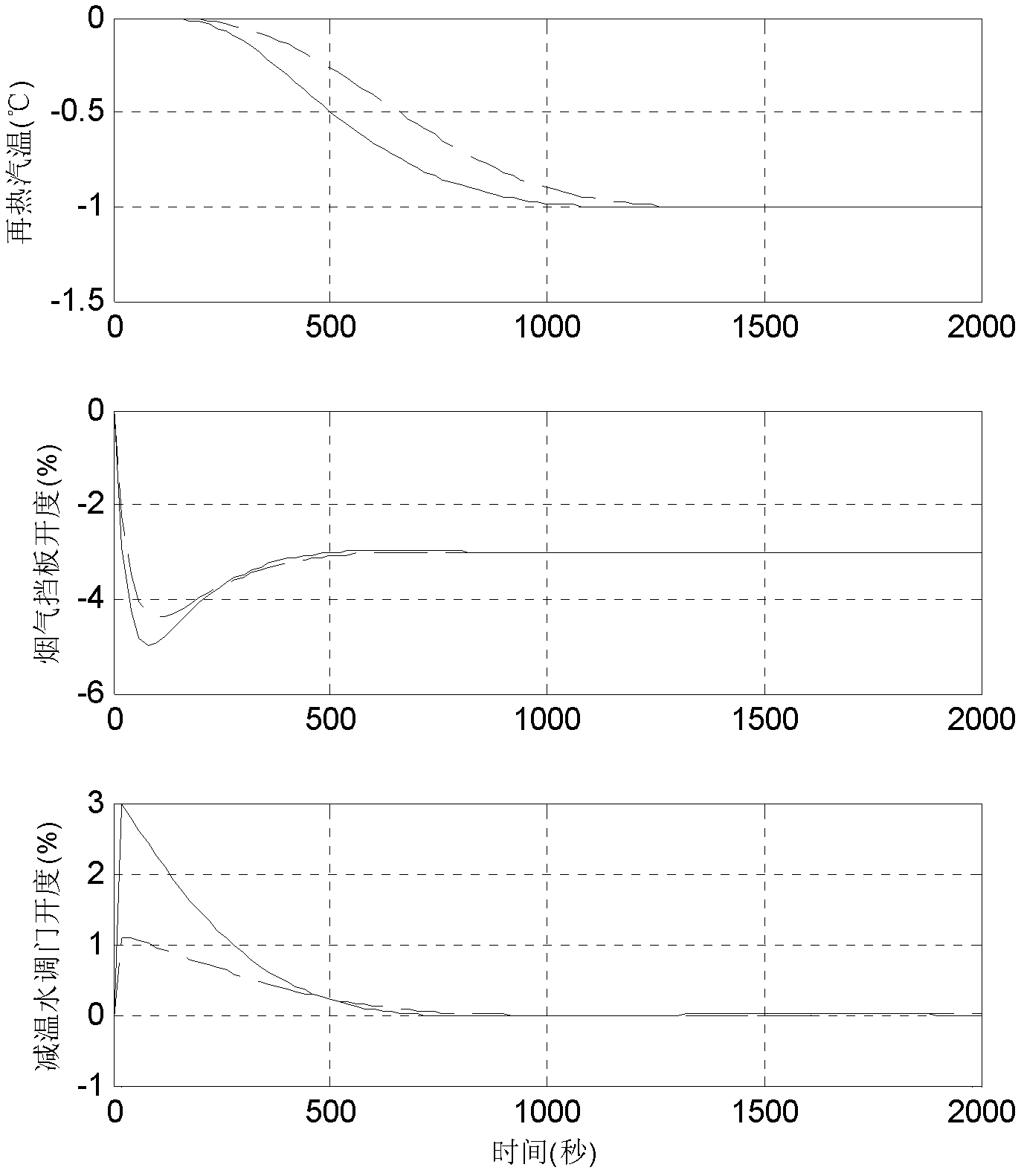

Reheated gas temperature optimization control method based on multi-variable predictive control

InactiveCN102401371AImprove economyDealing with large latency characteristicsSuperheating controlFlue gasPerformance index

The invention discloses a reheated gas temperature optimization control method based on multi-variable predictive control. According to the method, the whole hot steam temperature system is regarded as a two-in one-out multi-variable object, and the flow rate of reheated de-superheating jet water and the opening of a flue gas baffle plate are simultaneously controlled by adopting a multi-variable predictive control method; moreover, optimization of economical efficiency of the system is realized by adding a steady state target value of the opening of a reheated de-superheating jet water adjusting valve into optimization indexes of the conventional predictive control. By adopting the multi-variable predictive control method, coordination of side adjustment of flue gas and side adjustment of steam can be better realized, and the dynamic adjusting quality of the reheated steam temperature is further improved; and meanwhile, by adding the steady state target value of the de-superheating water adjusting valve into the conventional predictive control performance indexes, optimization of the de-superheating water jet quantity is realized, so that the circulating efficiency of a unit can be effectively improved.

Owner:SOUTHEAST UNIV

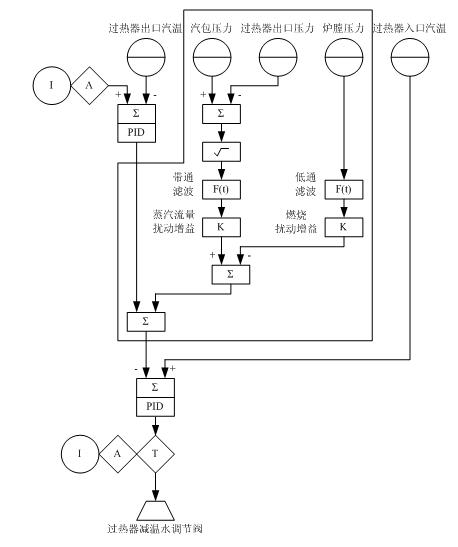

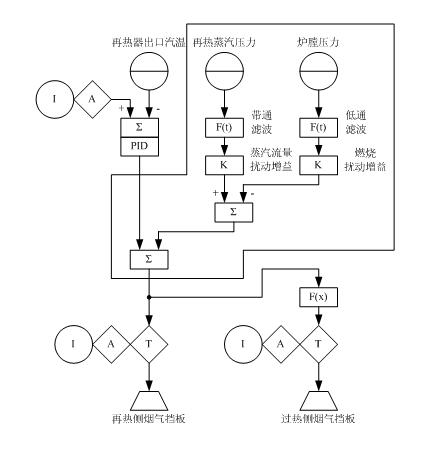

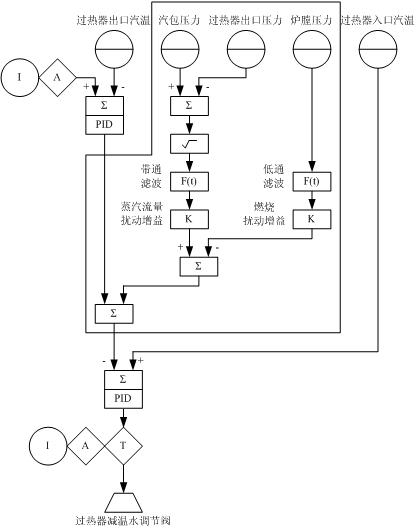

Feedforward signal control method in boiler steam temperature automatic control system

InactiveCN102012017AImprove qualityReduce steam temperature fluctuationsSuperheating controlSteam pressureAutomatic control

The invention discloses a feedforward signal control method in a boiler steam temperature automatic control system, which is used for improving quality of boiler steam temperature control. The technical scheme comprises the following steps of: measuring boiler furnace pressure, boiler steam pocket pressure (or steam-water separator pressure), boiler overheater outlet steam pressure, and boiler reheater outlet steam pressure; and calculating by utilizing the signals to form a combustion disturbing signal, an overheat steam flow disturbing signal, a reheat steam flow disturbing signal, an overheat steam temperature control system feedforward signal and a reheat steam temperature control system feedforward signal in turn. The method can effectively improve the quality of boiler steam temperature control, reduces steam temperature fluctuation caused by combustion disturbance and steam flow disturbance, does not need any additional hardware equipment, only needs increasing a little of software control logic, has low cost and cannot reduce the system reliability.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

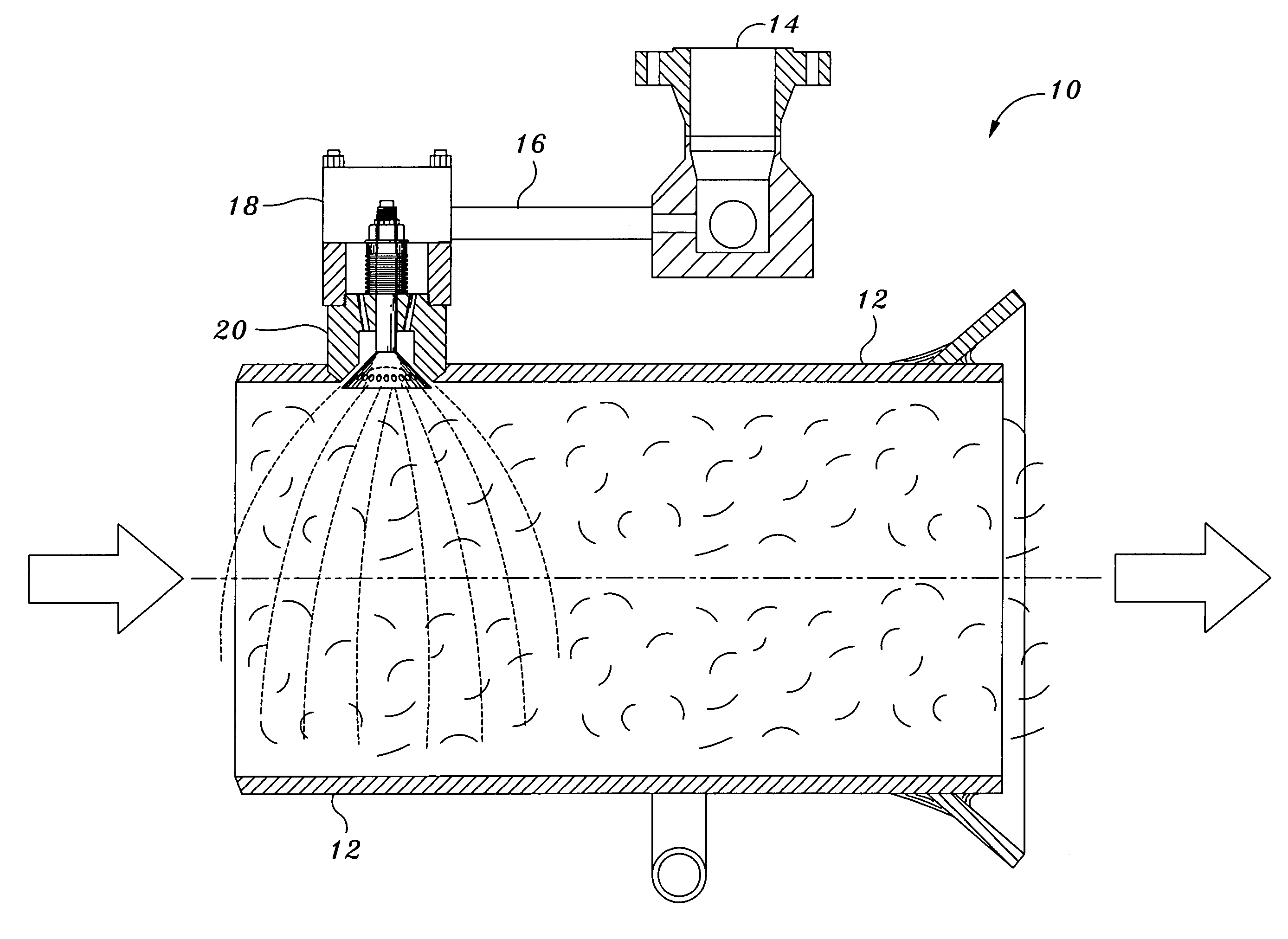

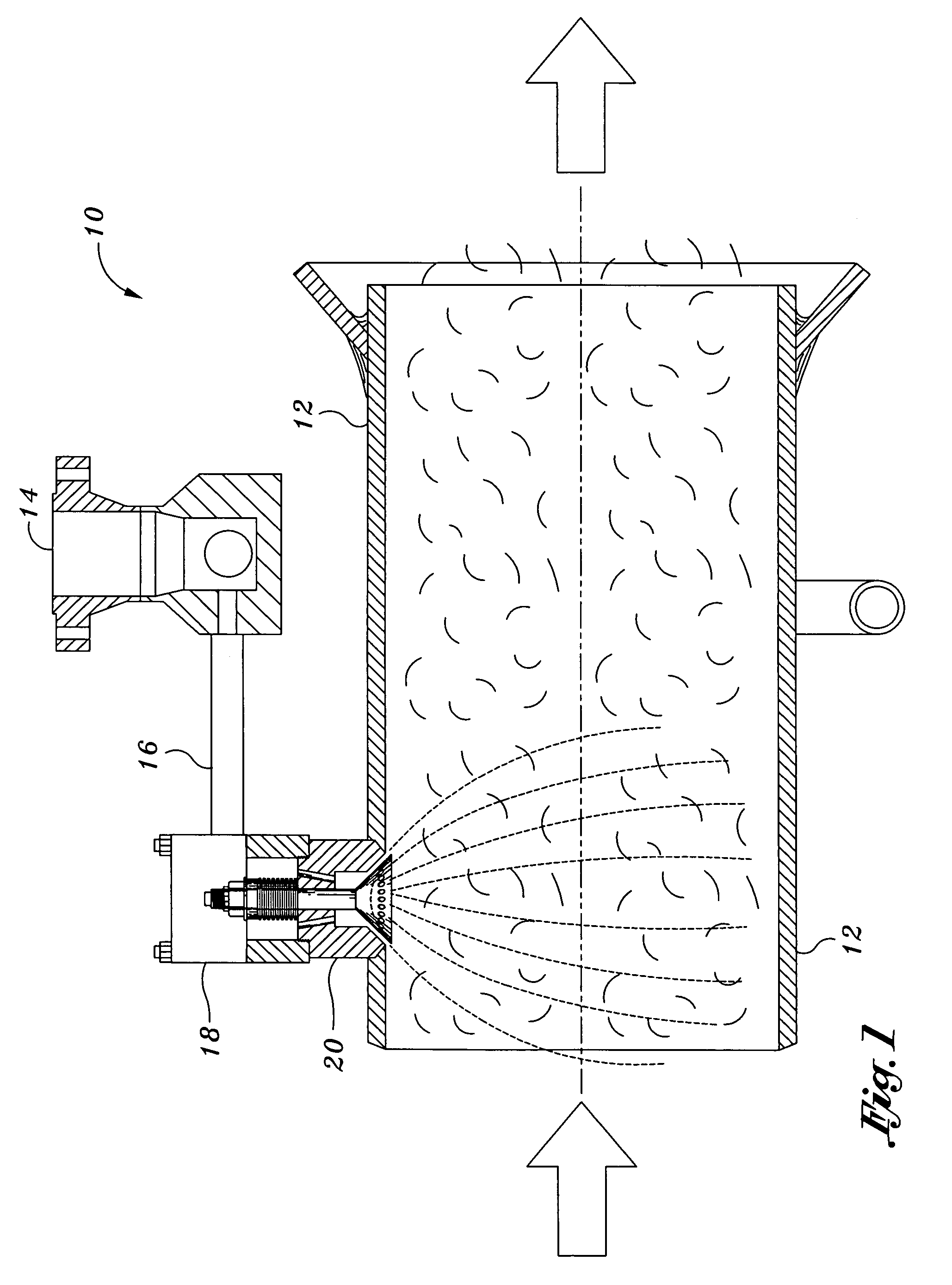

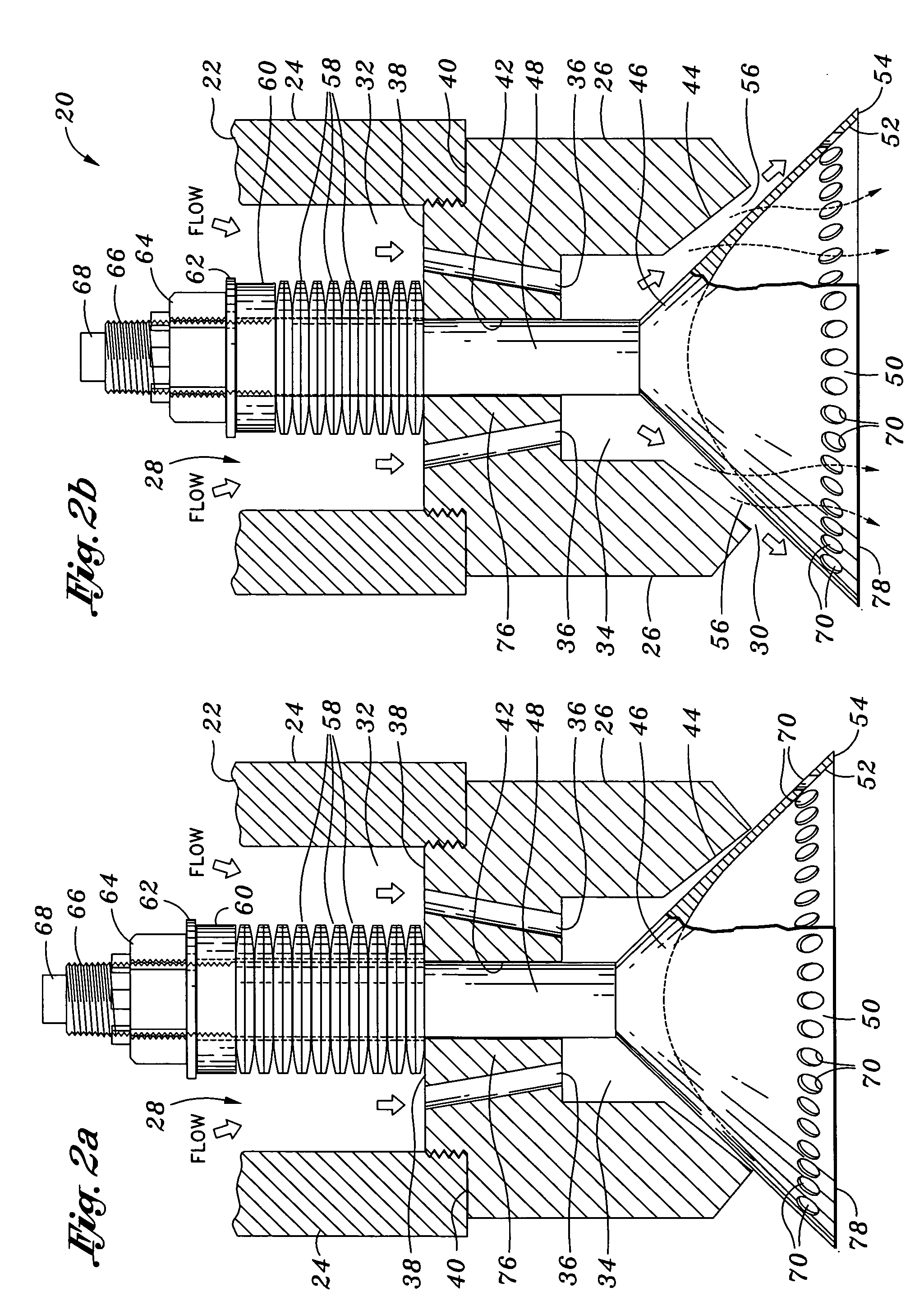

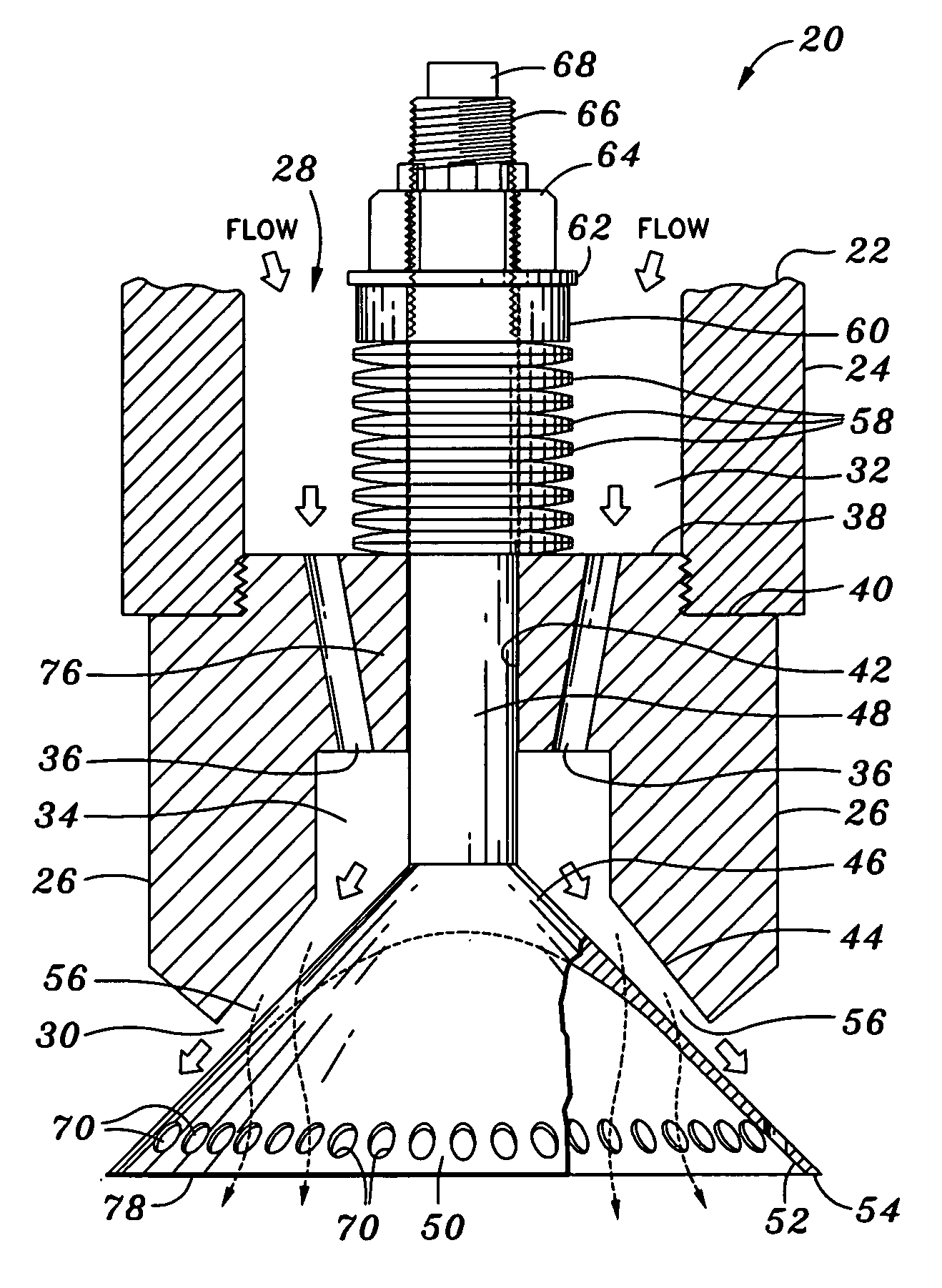

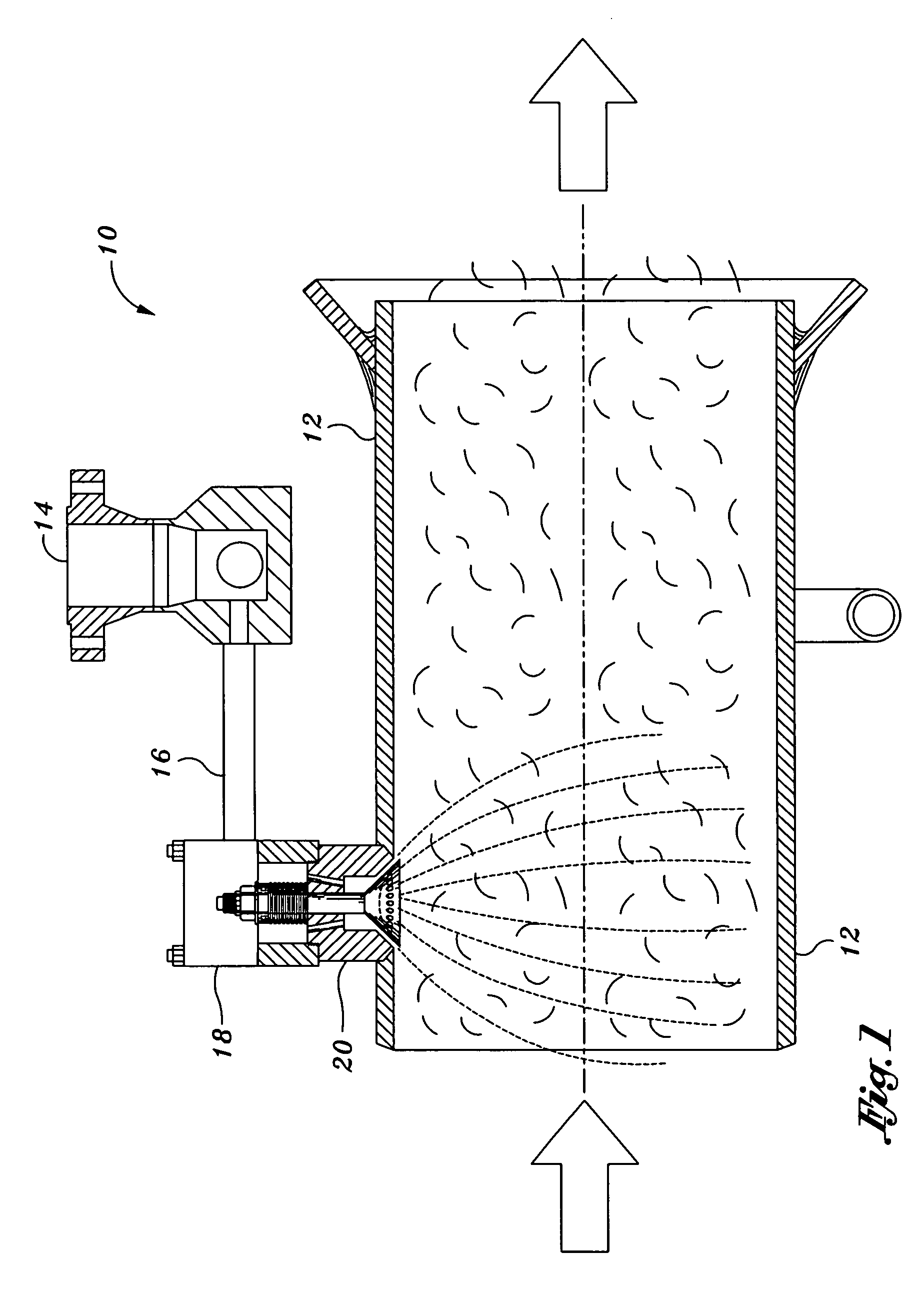

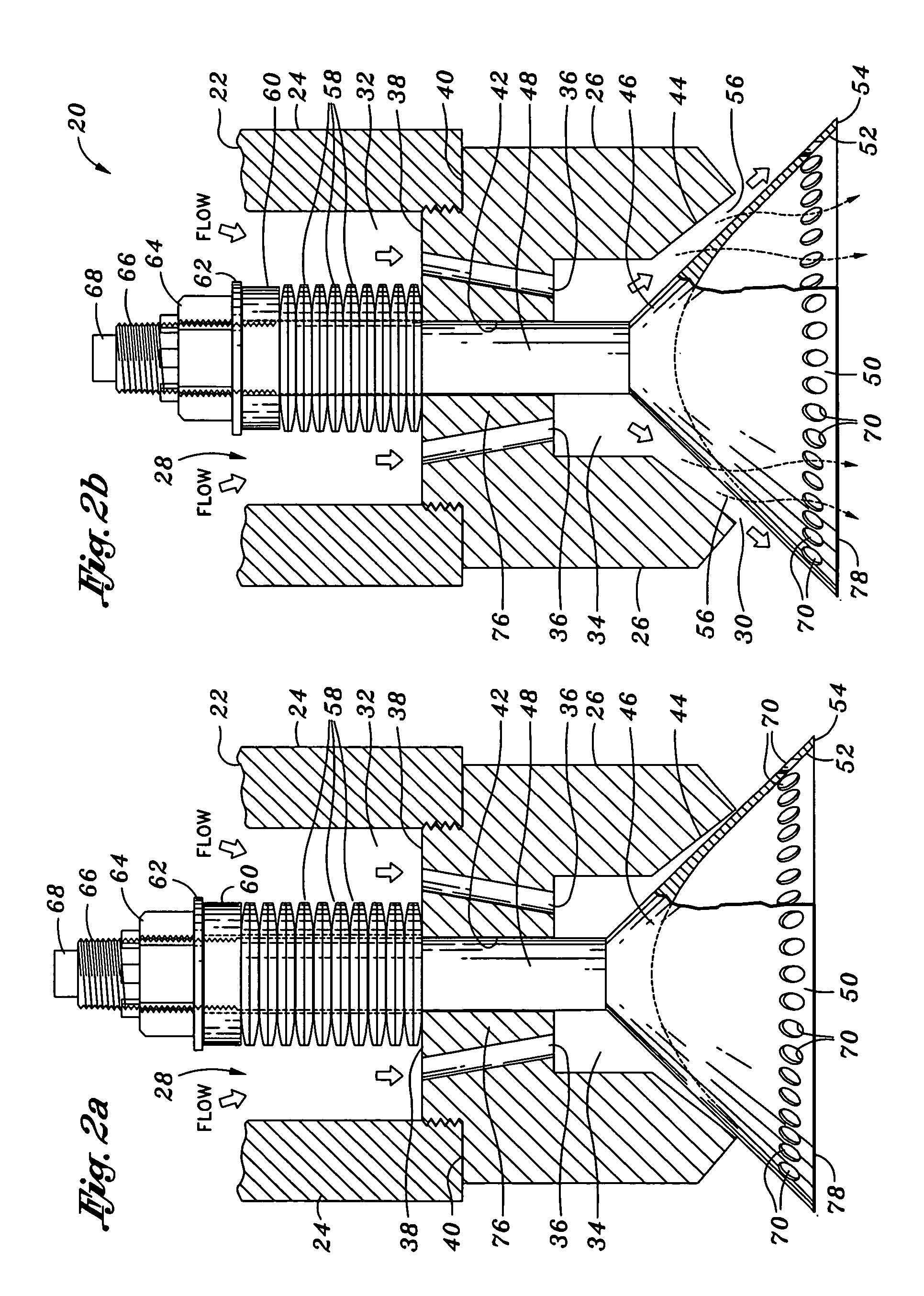

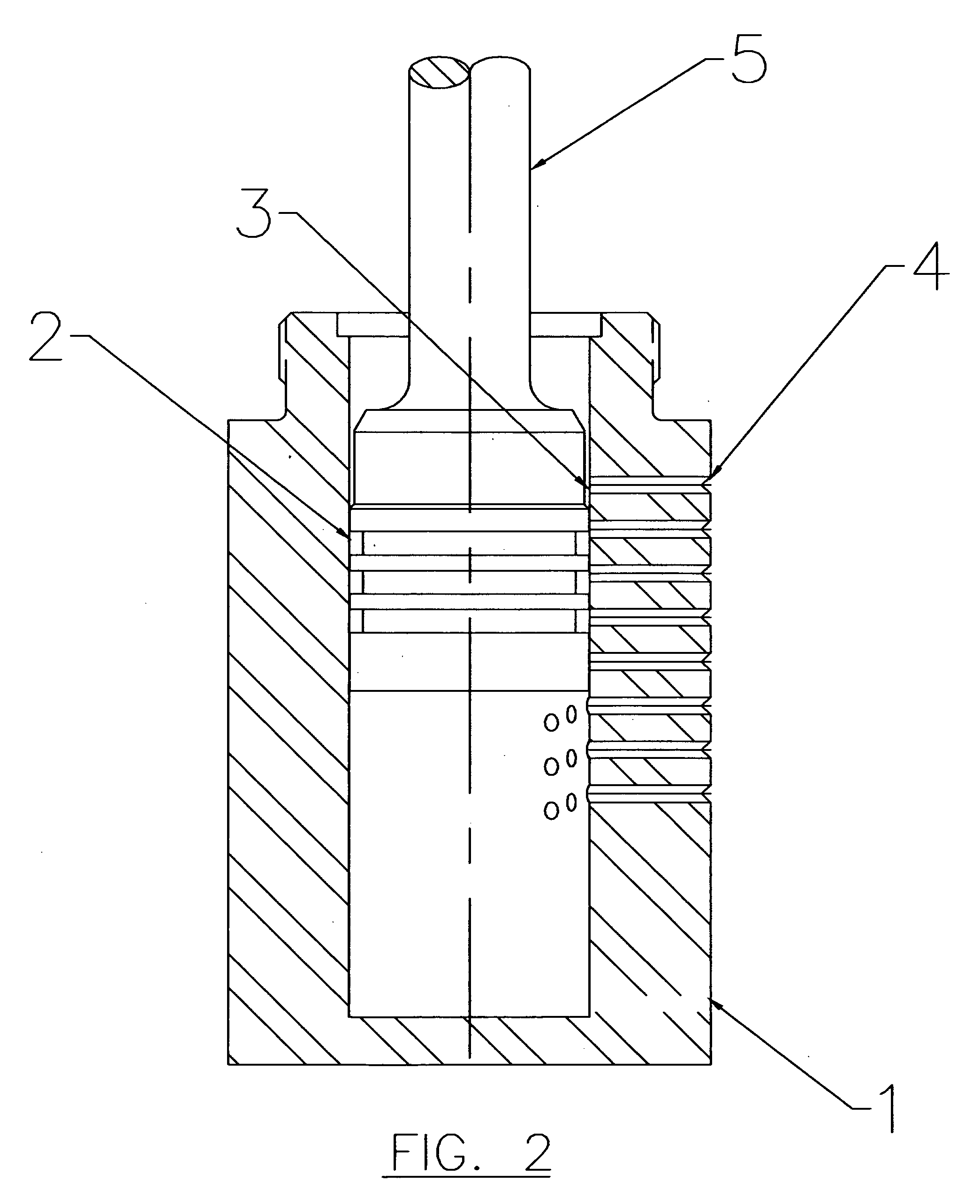

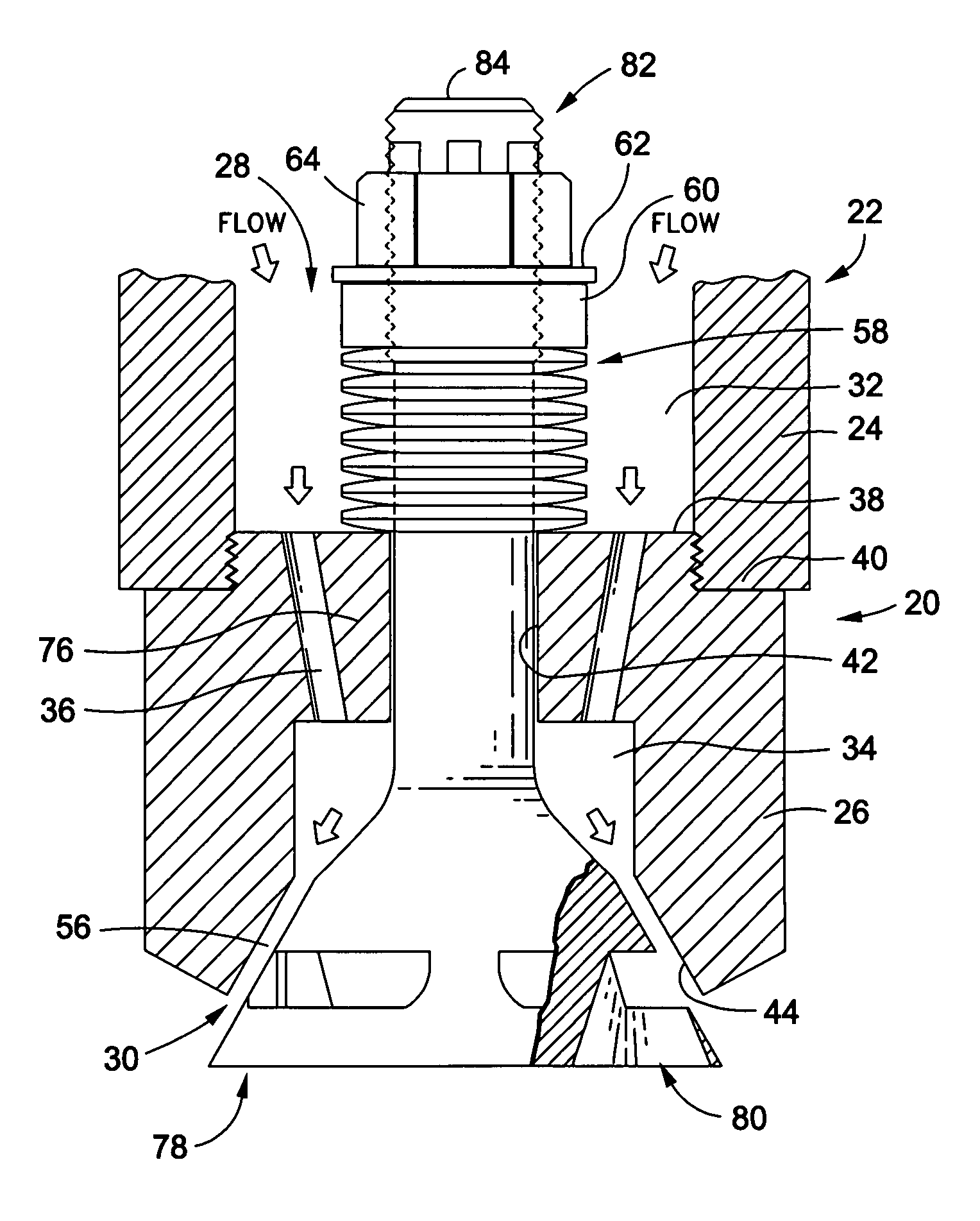

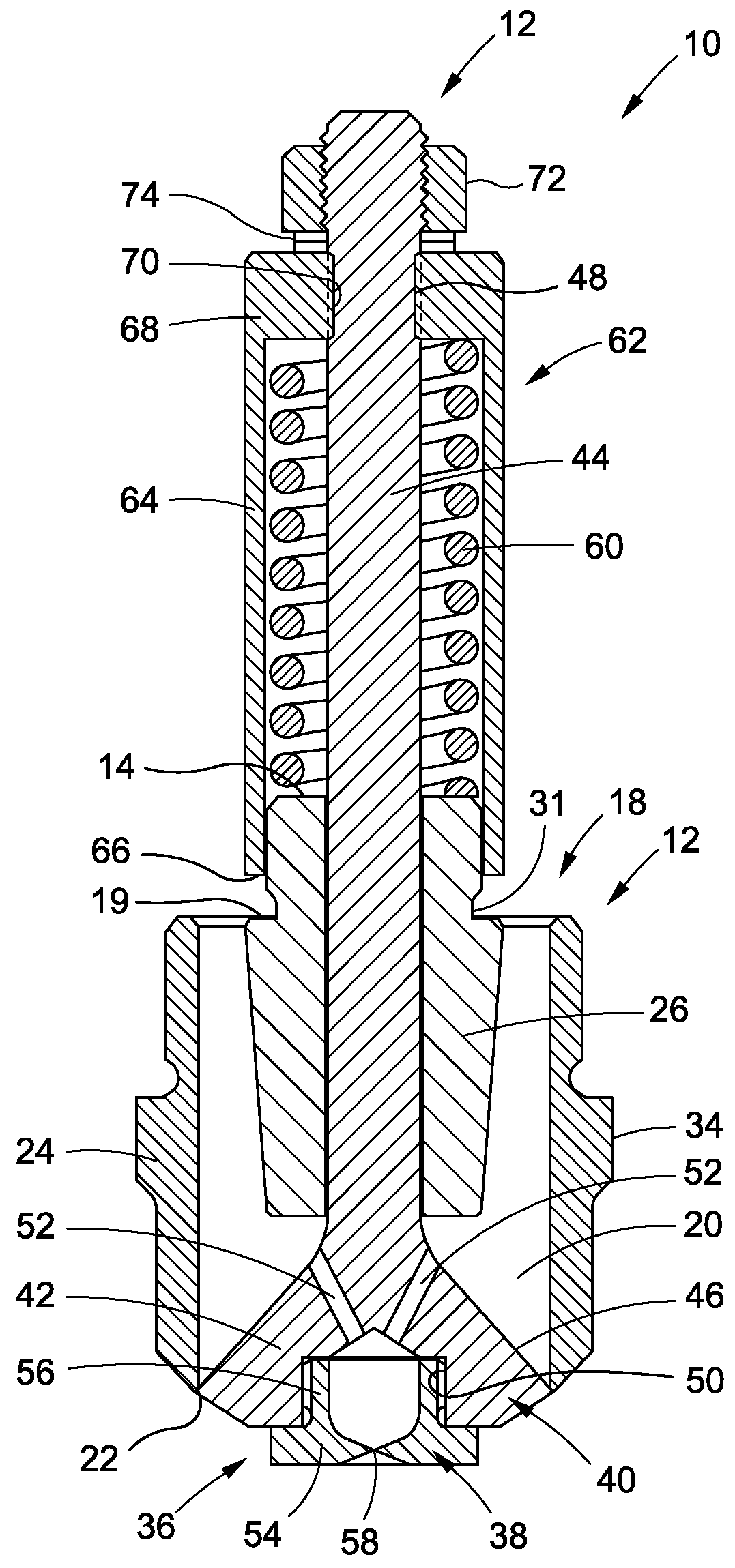

Pressure blast pre-filming spray nozzle

ActiveUS20060125126A1Efficient inductionIncrease spatial distributionUsing liquid separation agentMixing methodsSpray nozzleWater flow

Disclosed is a nozzle assembly comprising a nozzle housing and a valve element axially slidable therewithin between a closed and an open position. The nozzle housing has a housing inlet and a housing outlet fluidly interconnected by a plurality of housing passages. The valve element has a truncated conical valve body including a conical outer surface and a concave inner surface with a plurality of valve apertures extending through the valve body. The outer surface is sealingly engagable to a valve seat formed in the housing outlet such that the flow of cooling water through the valve apertures is prevented when the valve element is in the closed position. The outer surface and valve seat collectively define an annular gap when the valve element is axially displaced to the open position such that a portion of the cooling water flowing through the annular gap may pass through the valve apertures.

Owner:IMI VISION LTD

Pressure blast pre-filming spray nozzle

ActiveUS7028994B2Increase spatial distributionPromote absorptionSuperheating controlFunctional valve typesWater flowSpray nozzle

Disclosed is a nozzle assembly having a nozzle housing and a valve element axially slidable therewithin between a closed and an open position. The nozzle housing has a housing inlet and a housing outlet fluidly interconnected by a plurality of housing passages. The valve element has a truncated conical valve body including a conical outer surface and a concave inner surface with a plurality of valve apertures extending through the valve body. The outer surface is sealingly engagable to a valve seat formed in the housing outlet such that the flow of cooling water through the valve apertures is prevented when the valve element is in the closed position. The outer surface and valve seat collectively define an annular gap when the valve element is axially displaced to the open position such that a portion of the cooling water flowing through the annular gap may pass through the valve apertures.

Owner:IMI VISION LTD

One piece liquid injection spray cylinder/nozzle

A one piece spray cylinder / nozzle, with integrally machined nozzles, for use on a high pressure and temperature, probe style, variable nozzle, gas and steam coolers. The nozzle holes can be made by deep drilling techniques such as laser, gun drilling and others methods that produce a hole, with a diameter to depth ratio of less than 1:3. No separately machined nozzles are used. On the outlet end of the nozzle (on the outside of the cylinder only), there are surface machining treatments to produce small, controllable liquid droplets that vaporize quickly into the gas or vapor stream. The spray cylinder bore can be coated, lined or hard faced to resist the ware of the piston rings sliding in it without adding stresses to the spray cylinder body at braze and weld joints. The flow and patterns and valve characteristics can be modified.

Owner:BAUER CHARLES GUSTAV

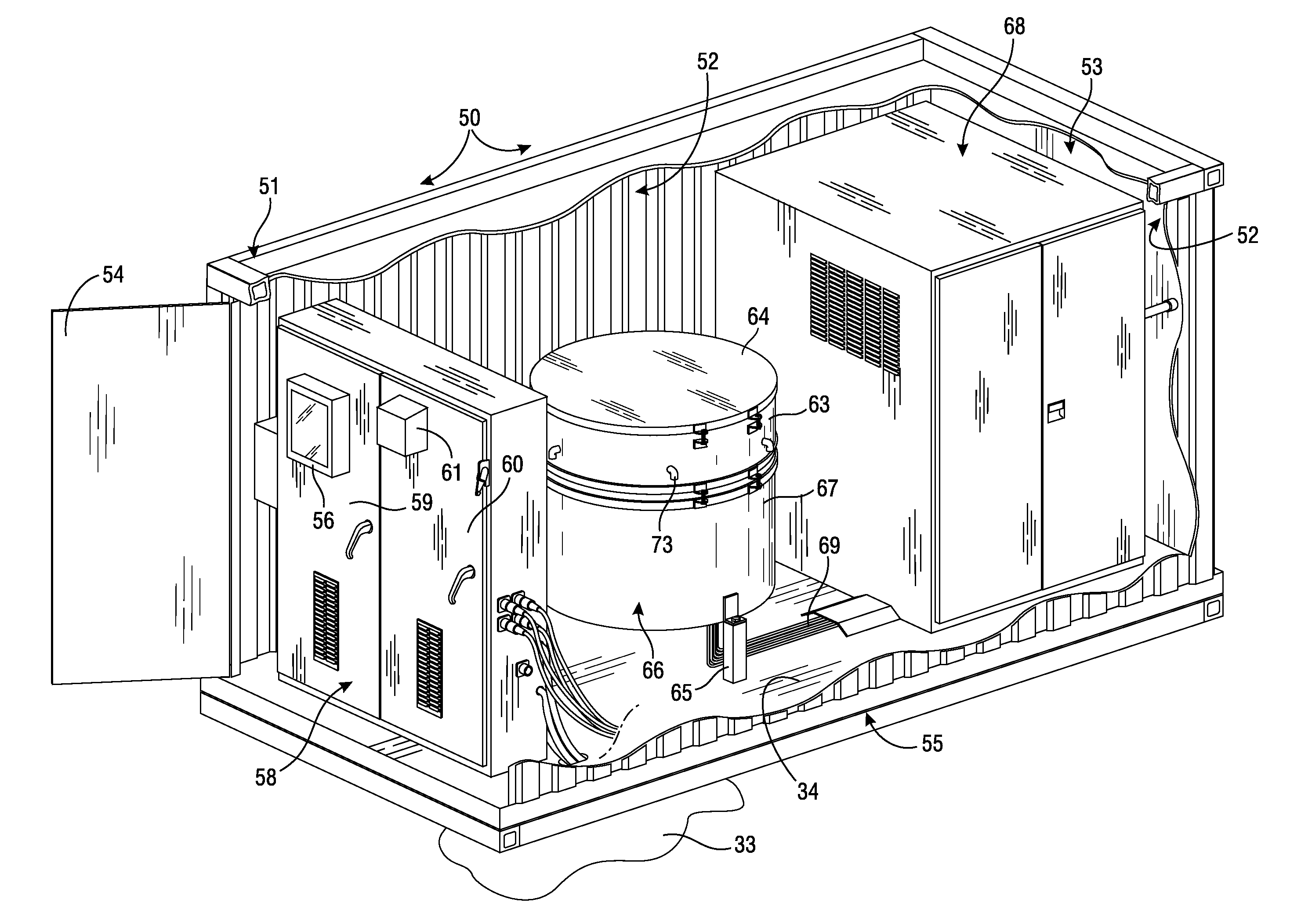

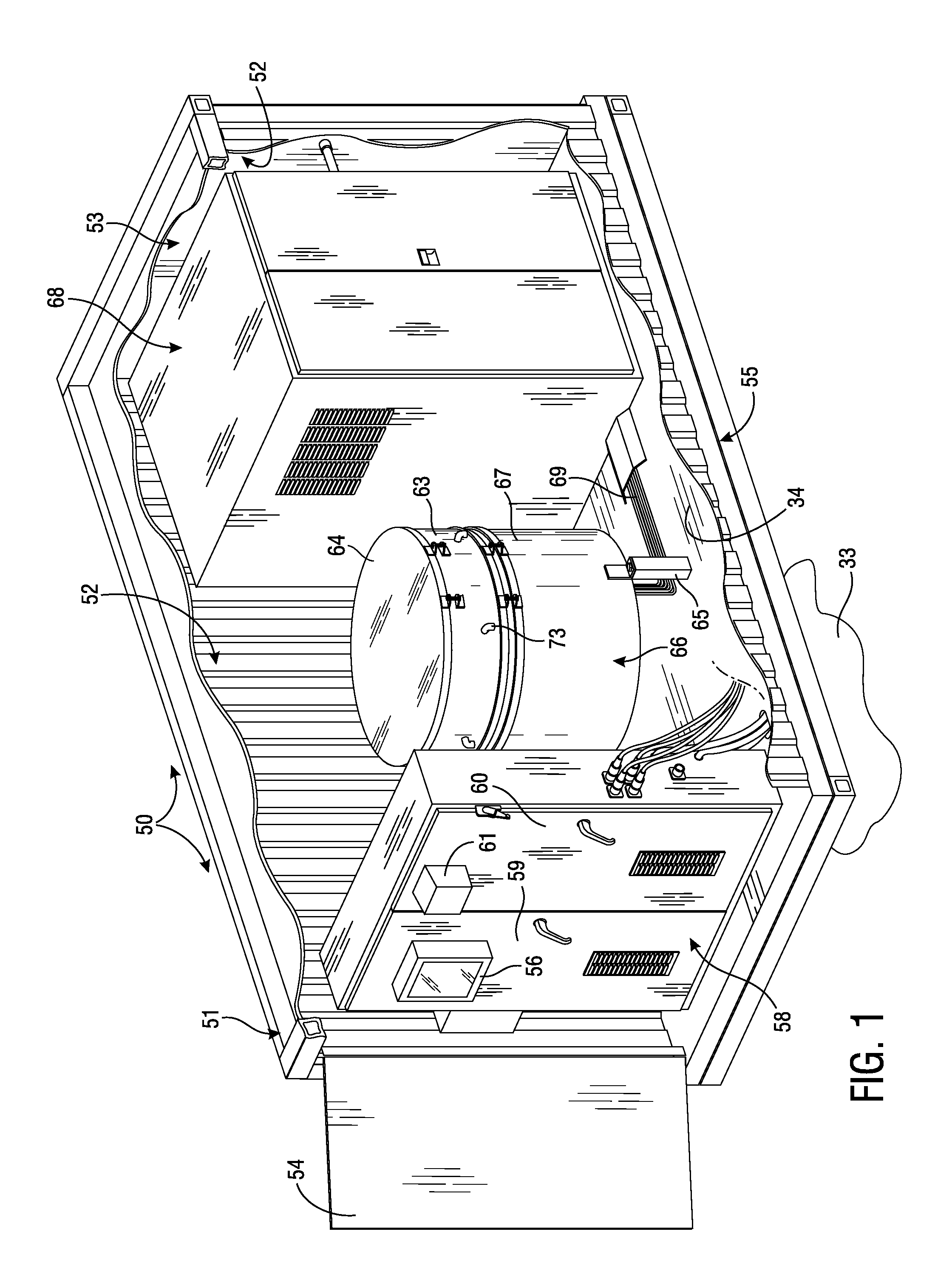

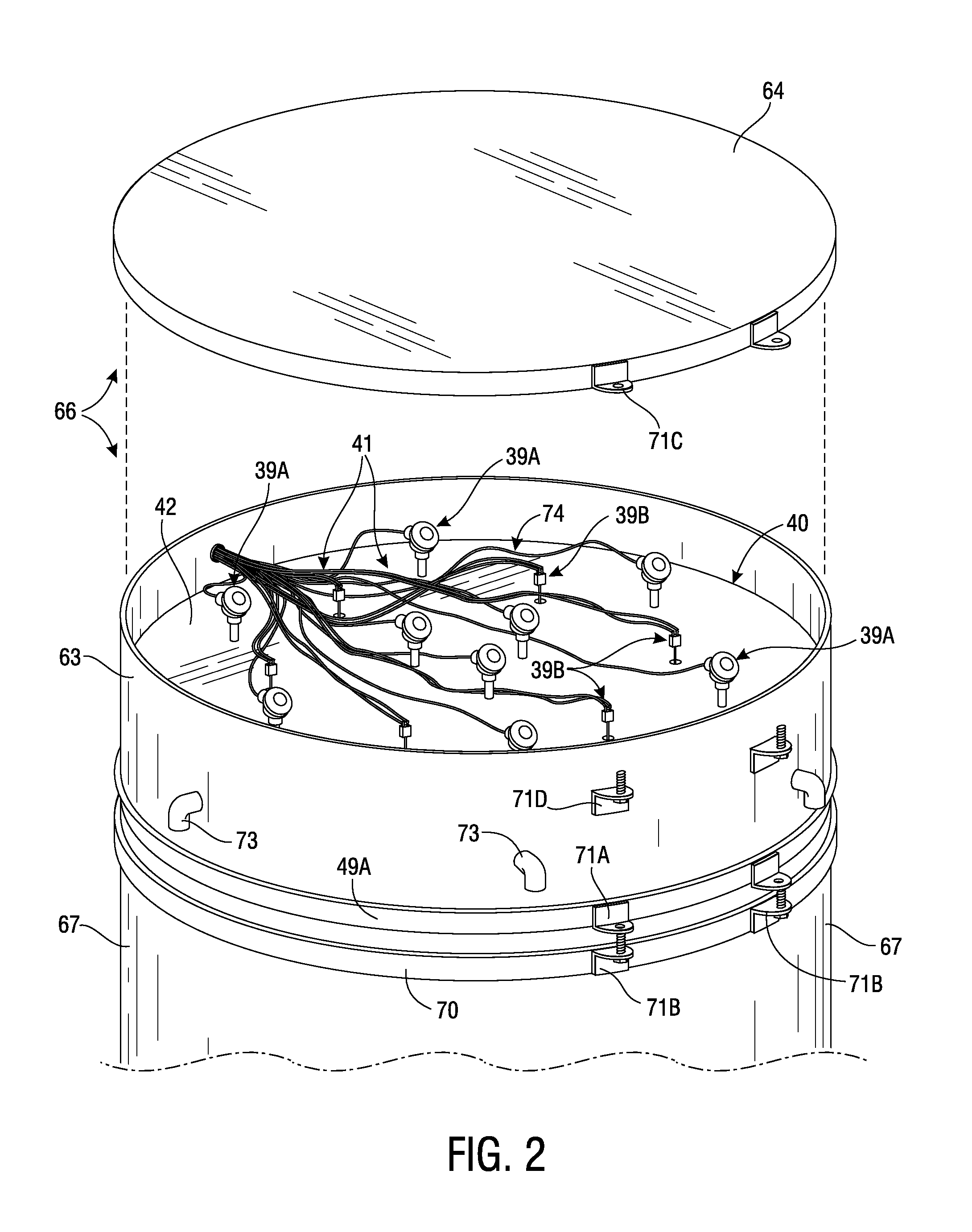

Methods for Super Heated Steam Generation

InactiveUS20130136435A1Increase superheatAccurate monitoringMachines/enginesFlash steam boilersEngineeringSuperheated steam

Modularized, superheated steam generators comprise a steam module (46), a thermocouple module (41), and an electrode module (45) assembled within a containment enclosure (66). The multi-stage steam module (46) comprises a plurality of first stage pressure vessels (77) surrounding and feeding a second stage pressure vessel (78). The steam module (46) is coaxially surrounded by insulation (48) disposed within a cylindrical shroud (72). The electrode module (45) radiantly heats the steam module with resistive heating elements (119). The thermocouple module (41) includes thermocouples monitoring first stage temperatures within and between pressure vessels (77). PLC computer SCADA software (600) operates the generators. Thermocouple data is analyzed to control heater temperatures, the water feeding system (340), and outputted steam temperature. PLC software (600) provides operating logic (602) establishing a start up subroutine (602), a ramp up subroutine (603), a steady state subroutine (605), and a shut down subroutine (606).

Owner:TRIMETEOR OIL & GAS CORP

Dynamic compensation method of attemperation water impact leading steam temperature measuring point in boiler steam temperature control system

InactiveCN103343961AImprove control qualityImprove operational safetySuperheating controlPower stationCompensation effect

Provided is a dynamic compensation method of an attemperation water impact leading steam temperature measuring point in a boiler steam temperature control system. According to the method, an attemperation water impact leading steam temperature measuring point correction factor on-line computation module is arranged in the overheating and reheating steam temperature cascade control system of a power station boiler, the correction factor of the attemperation water impact leading steam temperature measuring point is computed on line through the module, the difference between a steam temperature set value and a controlled steam temperature feedback value is divided by the correction factor to compensate changing of inertia zone object gain, output of an auxiliary adjuster is multiplied by the correction factor to compensate changing of leading zone object gain, and accordingly dynamic compensation of the attemperation water impact leading steam temperature measuring point is achieved. The method achieves dynamic compensation of the attemperation water impact leading steam temperature measuring point in the steam temperature control system and has the advantages of being good in compensation effect, field conduction is convenient, control effect is good, control quality of the overheating and reheating steam temperature cascade control system of the power station boiler can be guaranteed, and safety and economy of operation of the power station boiler are improved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

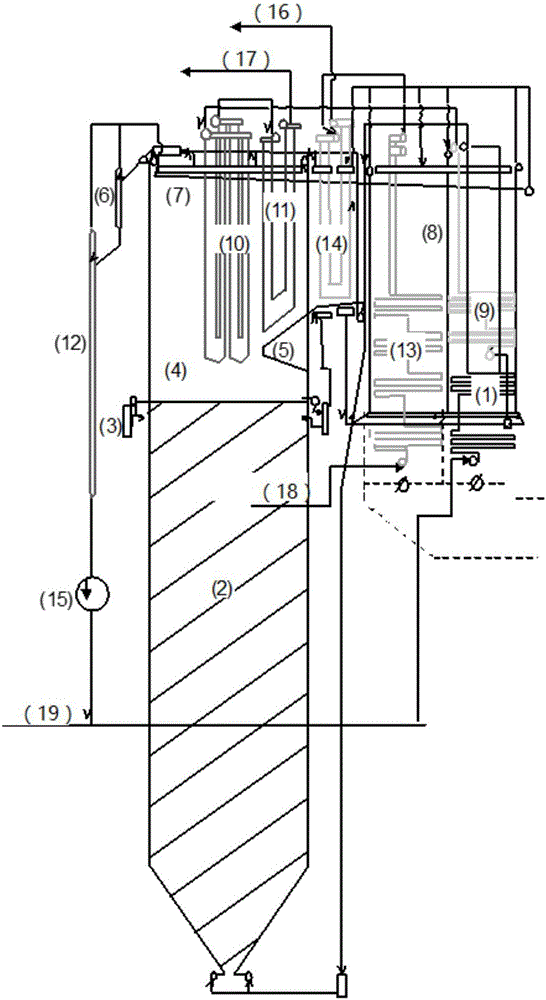

Tower-type boiler with primary reheater and secondary reheater

ActiveCN102889570AImprove heat transfer characteristicsImprove heat transfer efficiencySuperheating controlBoiler flue tubes/fire tubesEngineeringSuperheater

The invention discloses a tower-type boiler with a primary reheater and a secondary reheater. A superheater of the boiler comprises a low-temperature superheater and a high-temperature superheater; a technological process of a main steam system comprises the following steps that: feeding water enters a front flue coal economizer and a rear flue coal economizer which are arranged in parallel; water from outlets of the coal economizers enters water-cooling walls from the lower part of a hearth; outlets of the water-cooling walls are connected with a separator; and steam of an outlet of the separator enters the low-temperature superheater and the high-temperature superheater sequentially. According to a low-to-high flow direction of temperatures on a steam side, the primary reheater sequentially comprises primary reheating low-temperature reheaters and a primary reheating high-temperature reheater, the secondary reheater sequentially comprises secondary reheating low-temperature reheaters and a secondary reheating high-temperature reheater, and the primary reheater and the secondary reheater are connected with each other in parallel in a perpendicular flue.

Owner:SHANGHAI BOILER WORKS

Aerodynamic noise abatement device and method for air-cooled condensing systems

ActiveUS20050045416A1Reduce air resistanceReduce pressureSuperheating controlFlow mixersPower stationEngineering

The noise abatement device and method described herein makes known an apparatus and method for reducing the aerodynamic resistance presented by a fluid pressure reduction device in a large duct. More specifically, a noise abatement device is disclosed having at least one sparger with an aerodynamic profile that significantly reduces the fluid resistance within a turbine exhaust duct of an air-cooled condensing system that may be used in a power plant.

Owner:BOMBARDIER RECREATIONAL PROD INC +1

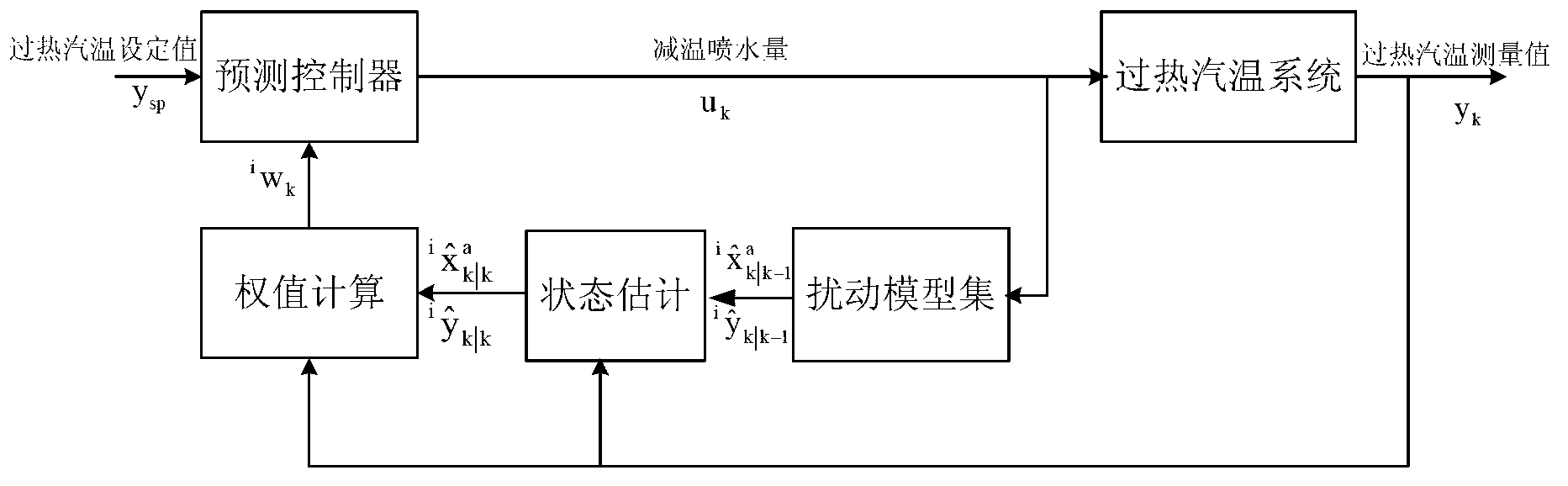

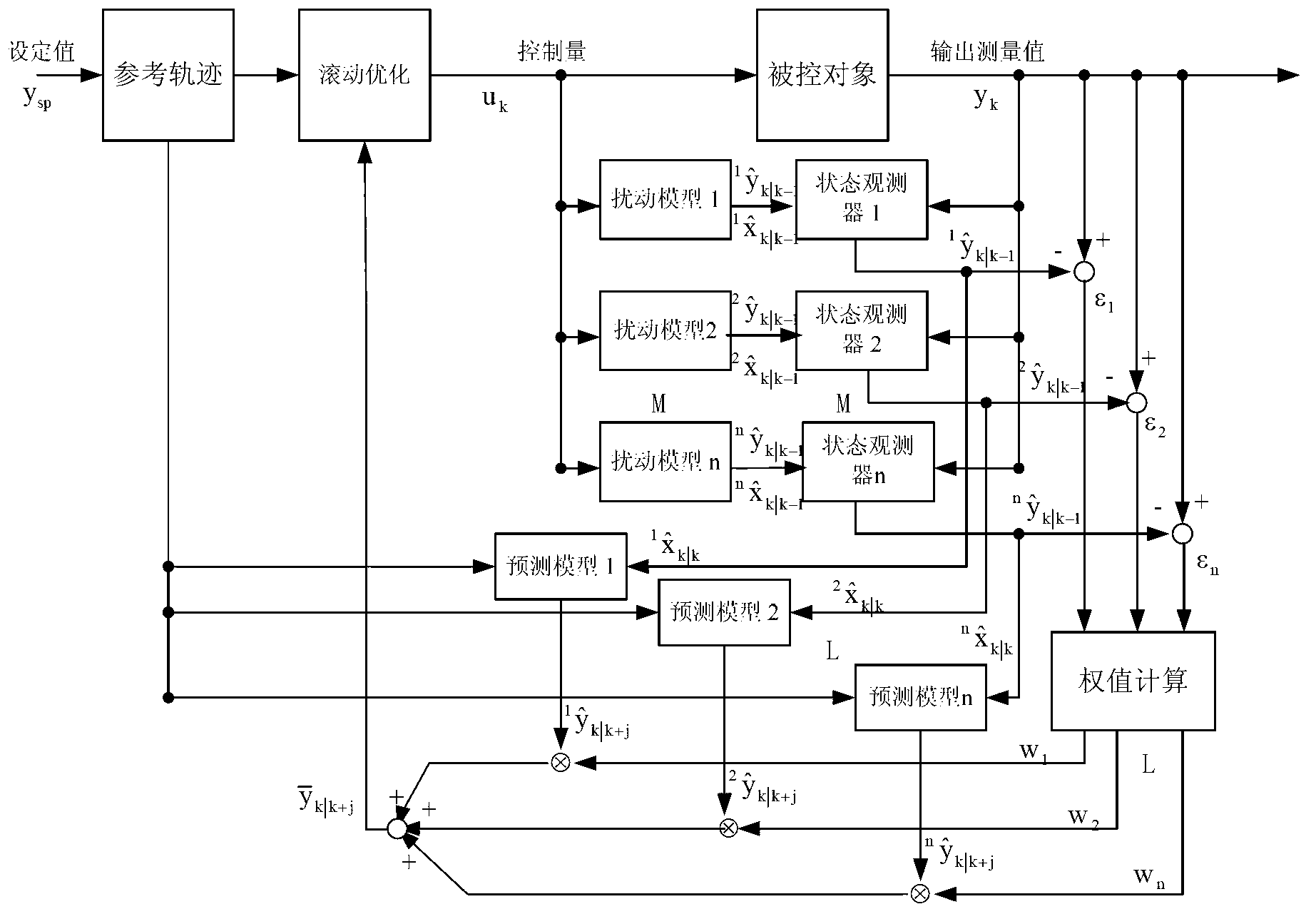

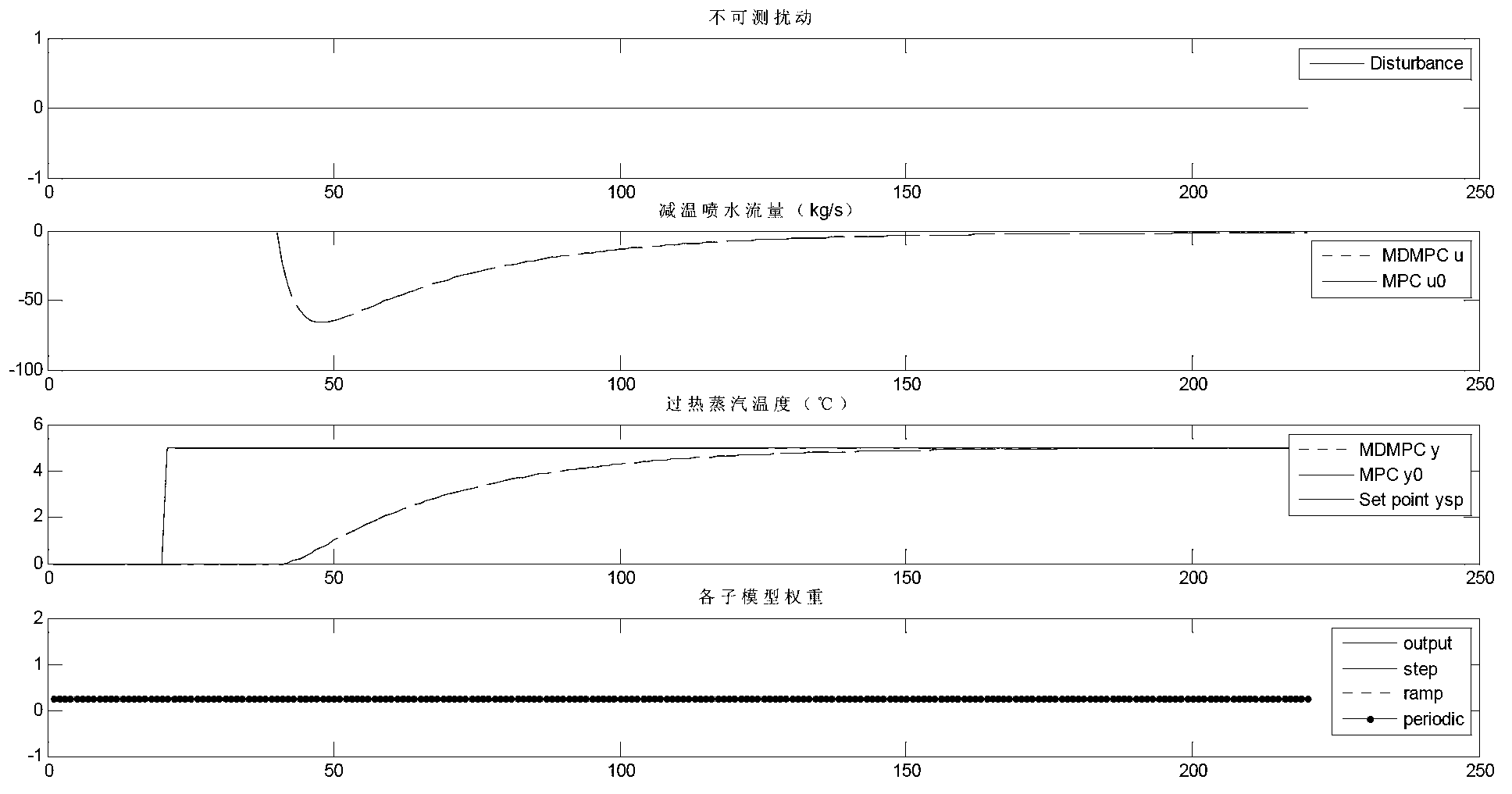

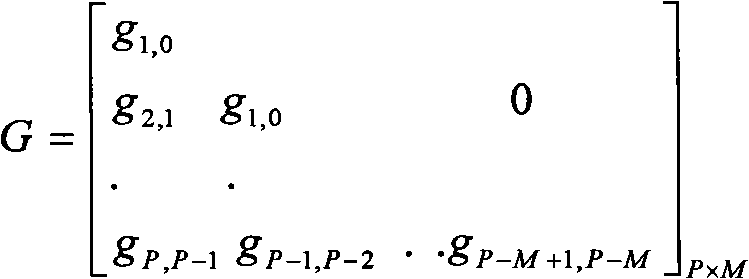

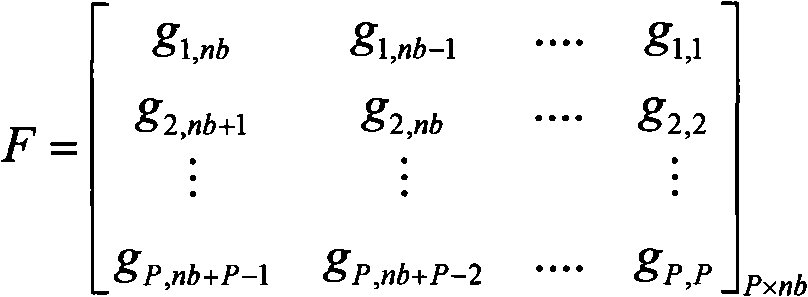

Multi-model disturbance estimation predictive-control method for superheated steam temperature of thermal power generating unit

InactiveCN103322553AEasy to set upSmall amount of calculationSuperheating controlState spaceWater flow

The invention discloses a multi-model disturbance estimation predictive-control method for superheated steam temperature of a thermal power generating unit. According to the method, a superheated steam temperature system serves a controlled object, cooling spray water flow serves as system control input, superheated steam temperature serves as system output, a plurality of disturbance models are established to respectively expand the system state on the basis of a controlled object state space model, and a disturbance model set is formed. Sub-models in the disturbance model set are subjected to weighted averaging, thus the influence of immeasurable disturbance upon the system output is fitted. According to the concept of predictive control, optimization solution is performed once for each step so that optimal system controlled input is obtained. Compared with common predictive control algorithms, the method has the advantages that immeasurable disturbance can be inhibited more effectively, and steam temperature is kept around a set value stably; when no immeasurable disturbance occurs, the method is as effective as the common predictive control algorithms, and tracking regulation performance is fine.

Owner:SOUTHEAST UNIV

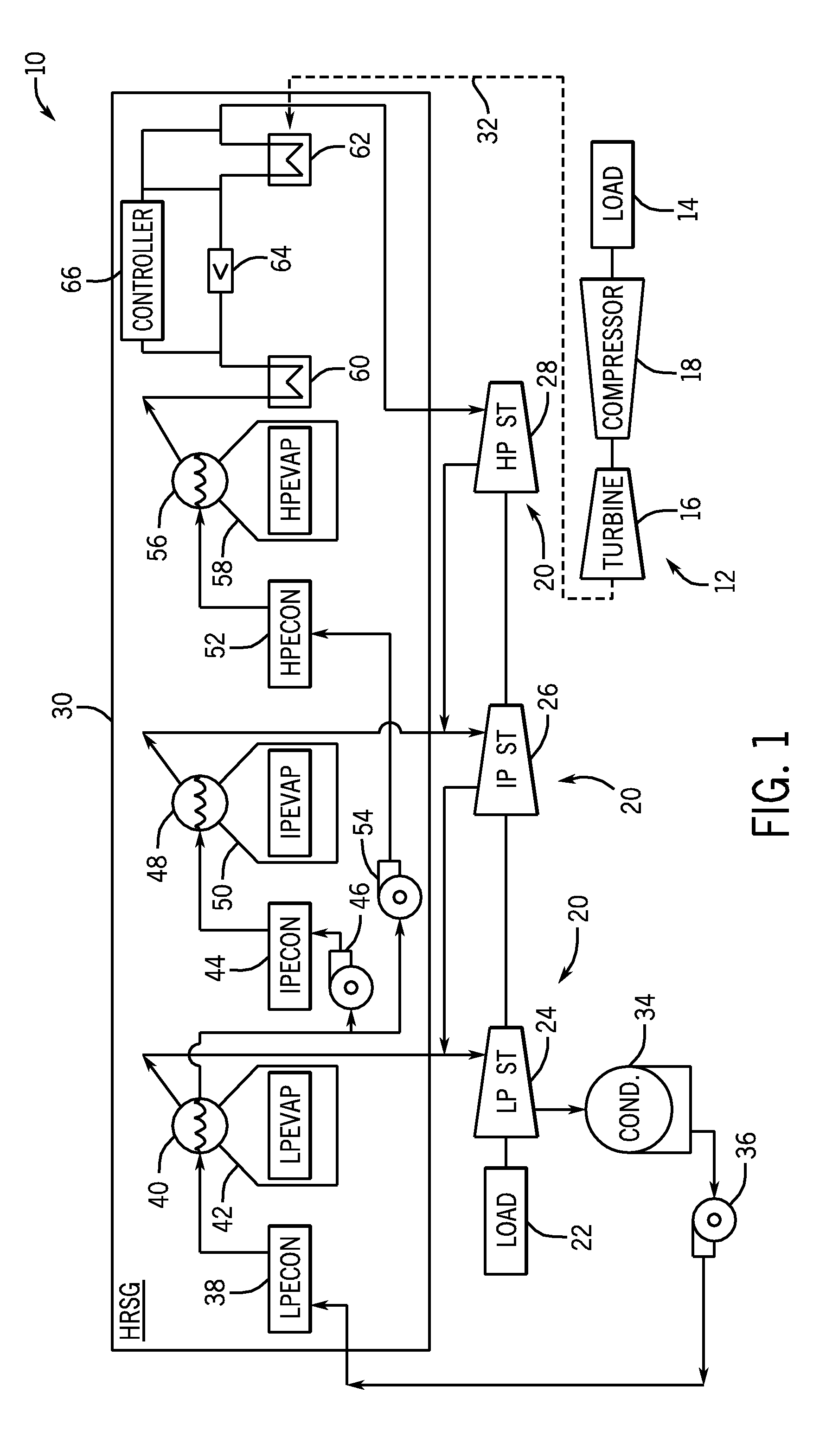

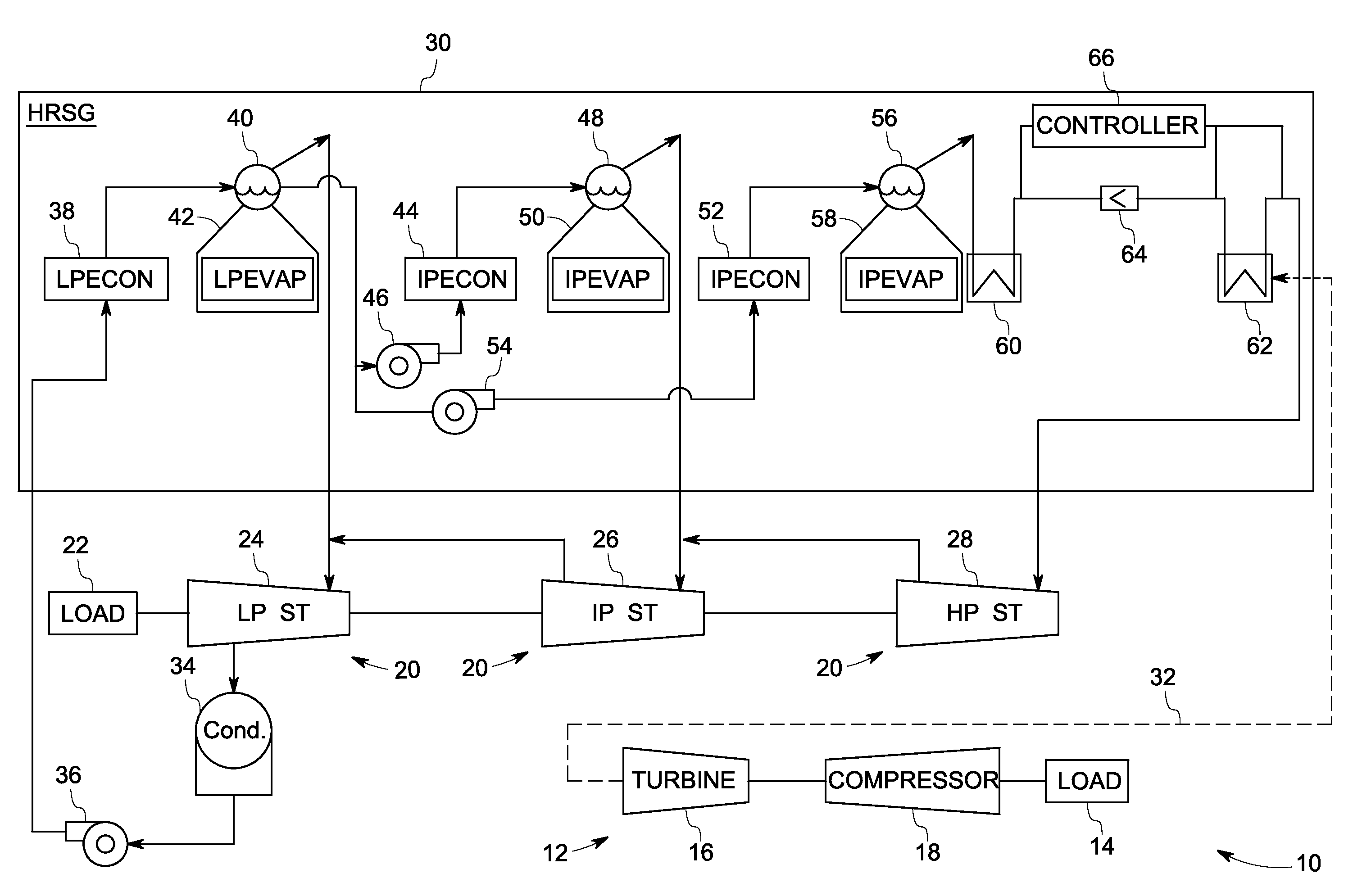

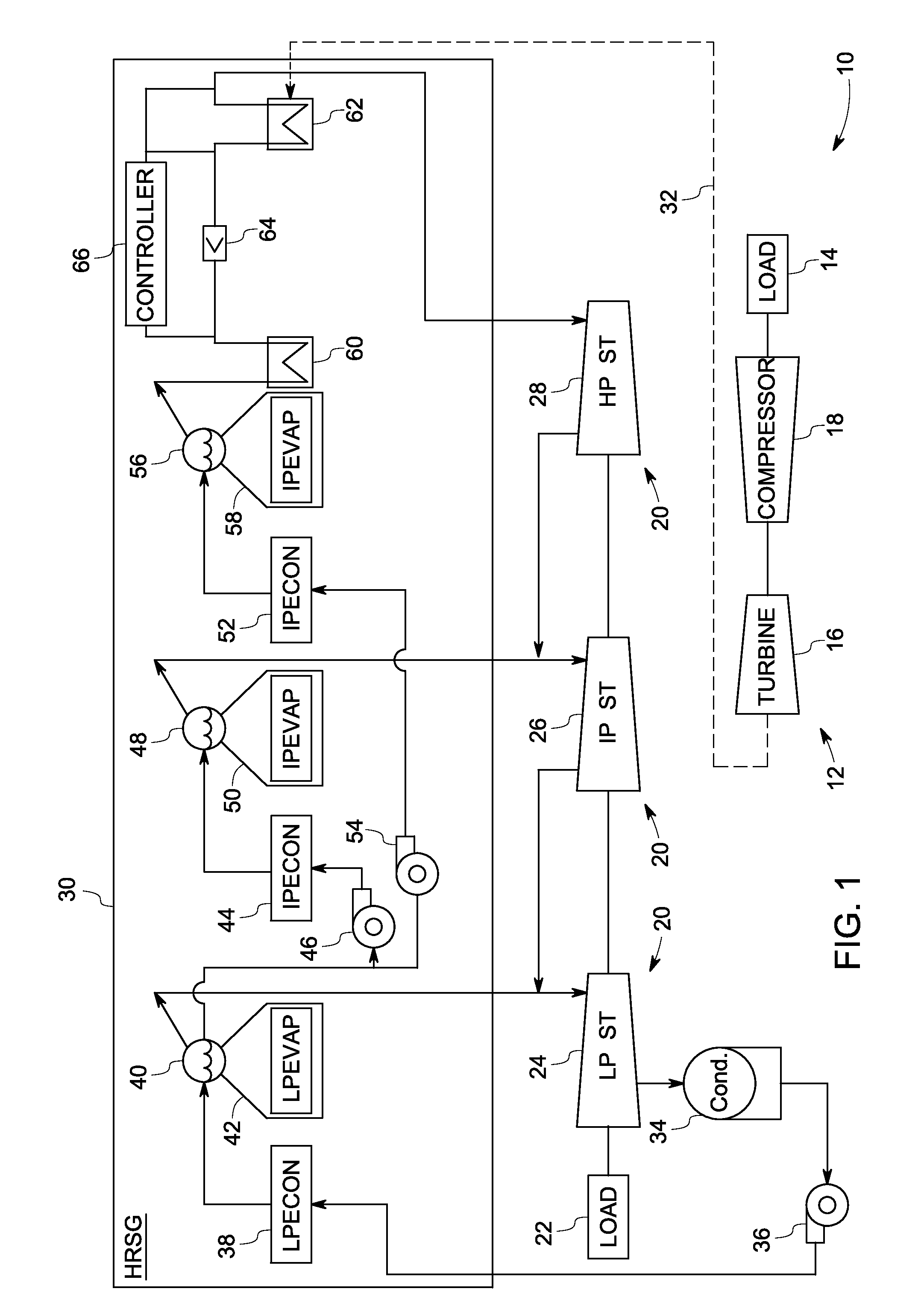

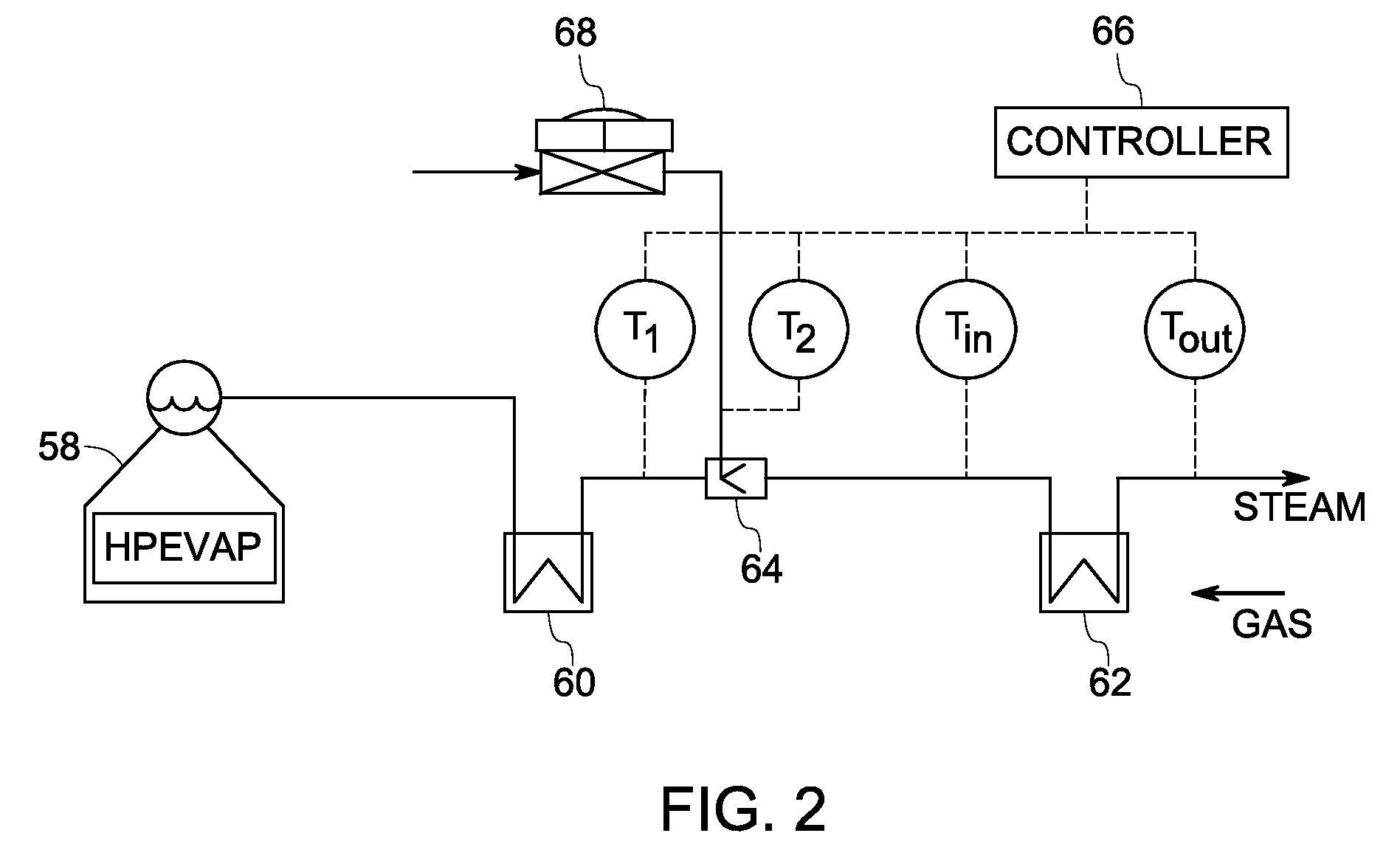

Single loop attemperation control

A heat recovery steam generation system is provided. The heat recovery steam generation system includes at least one superheater in a steam path for receiving a steam flow and configured to produce a superheated steam flow. The system also includes an inter-stage attemperator for injecting an attemperation fluid into the steam path. The system further includes a control valve coupled to the inter-stage attemperator. The control valve is configured to control flow of attemperation fluid to the inter stage attemperator. The system also includes a controller coupled to the control valve and the inter-stage attemperator. The controller further includes a feedforward controller and a trimming feedback controller. The feedforward controller is configured to determine a desired amount of flow of the attemperation fluid and the trimming feedback controller is configured to compensate for inaccuracies in the determined amount of flow of the attemperation fluid to determine a net desired amount of flow of attemperation fluid through the control valve into an inlet of the inter-stage attemperator based upon an outlet temperature of steam from the superheater. The controller also determines a control valve demand based upon the flow to valve characteristics. The controller further manipulates the control valve of the inter-stage attemperator, and injects the desired amount of attemeration flow via the inter-stage attemperator to perform attemperation upstream of an inlet into the superheater.

Owner:GENERAL ELECTRIC CO

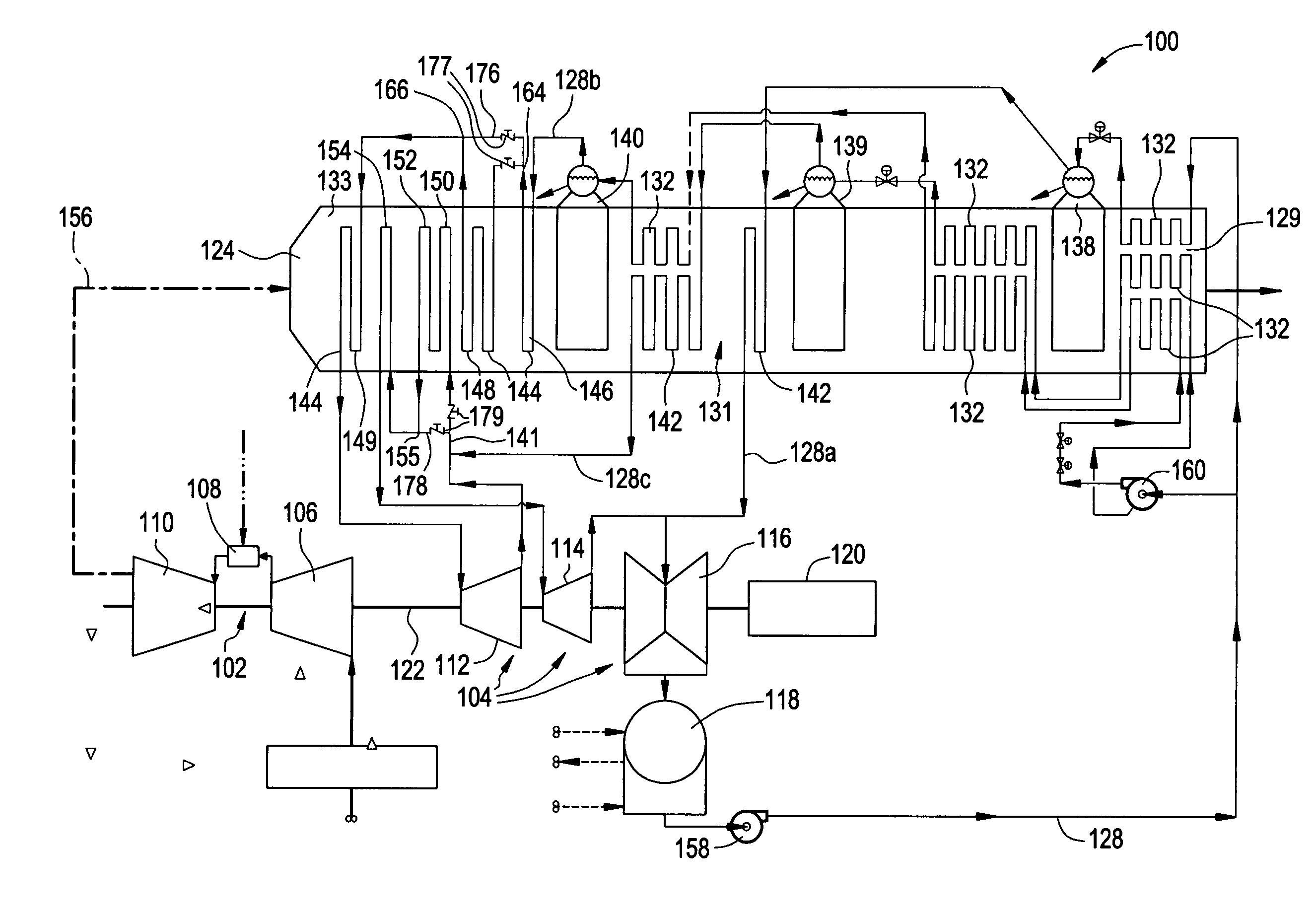

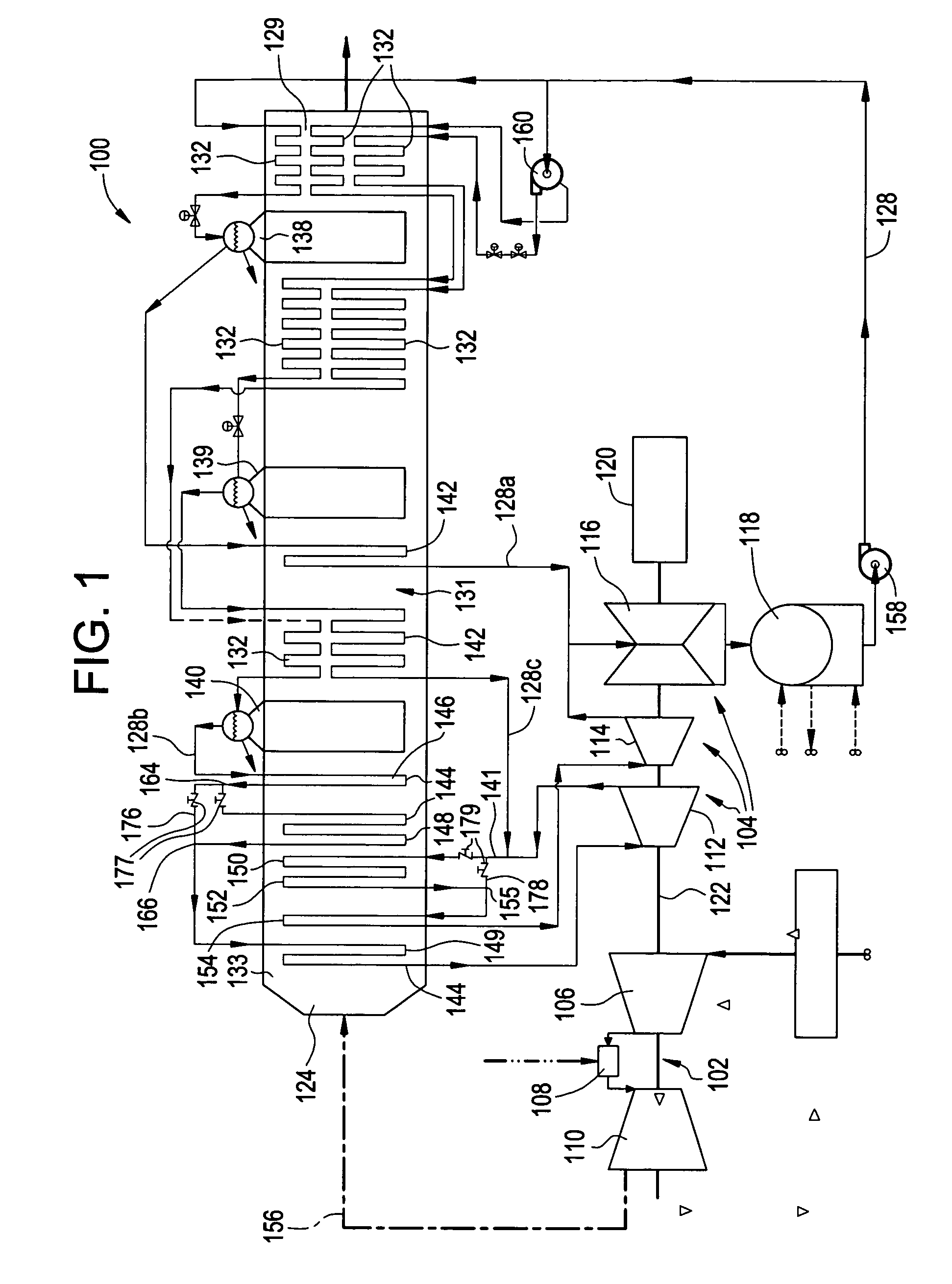

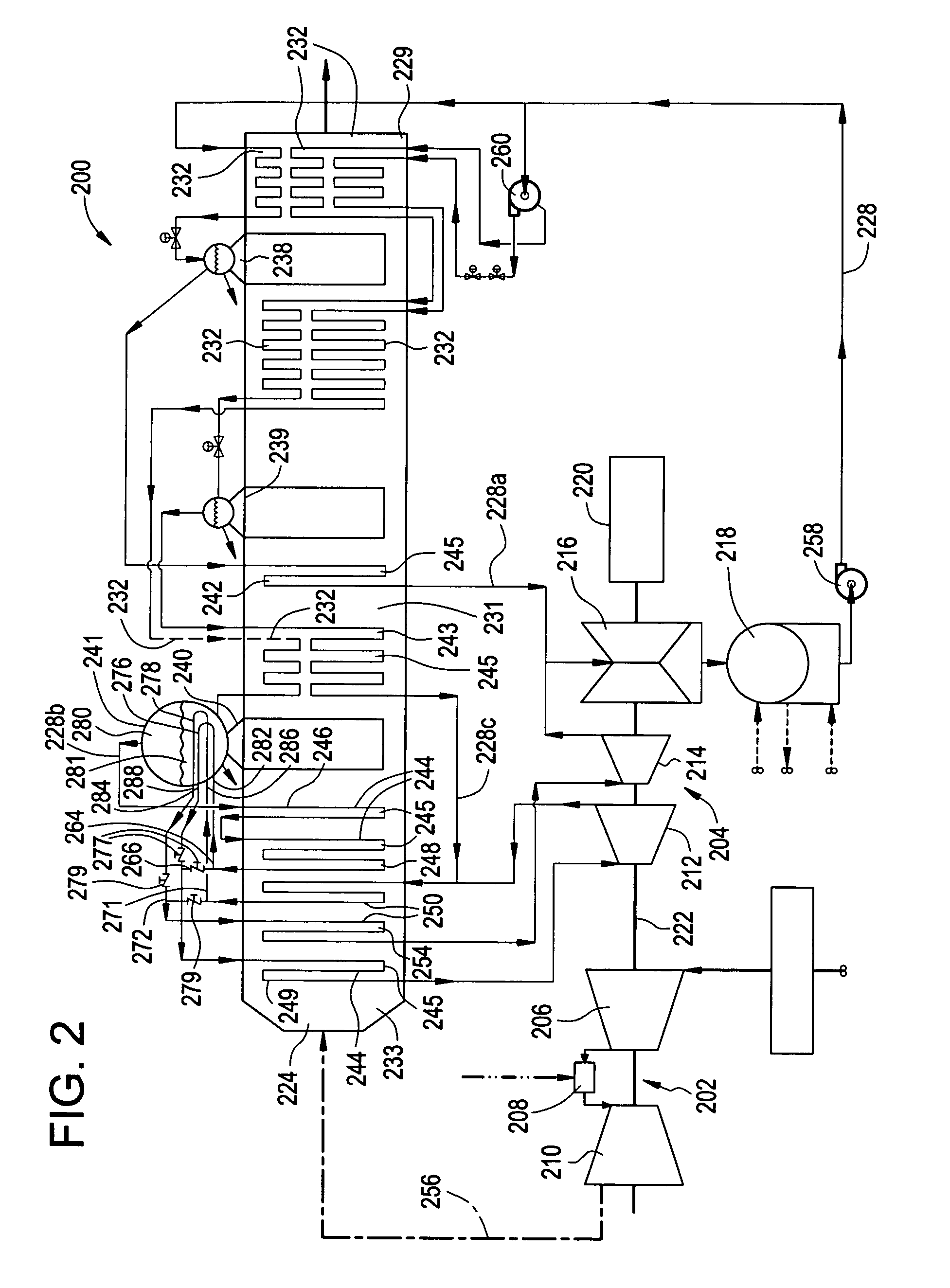

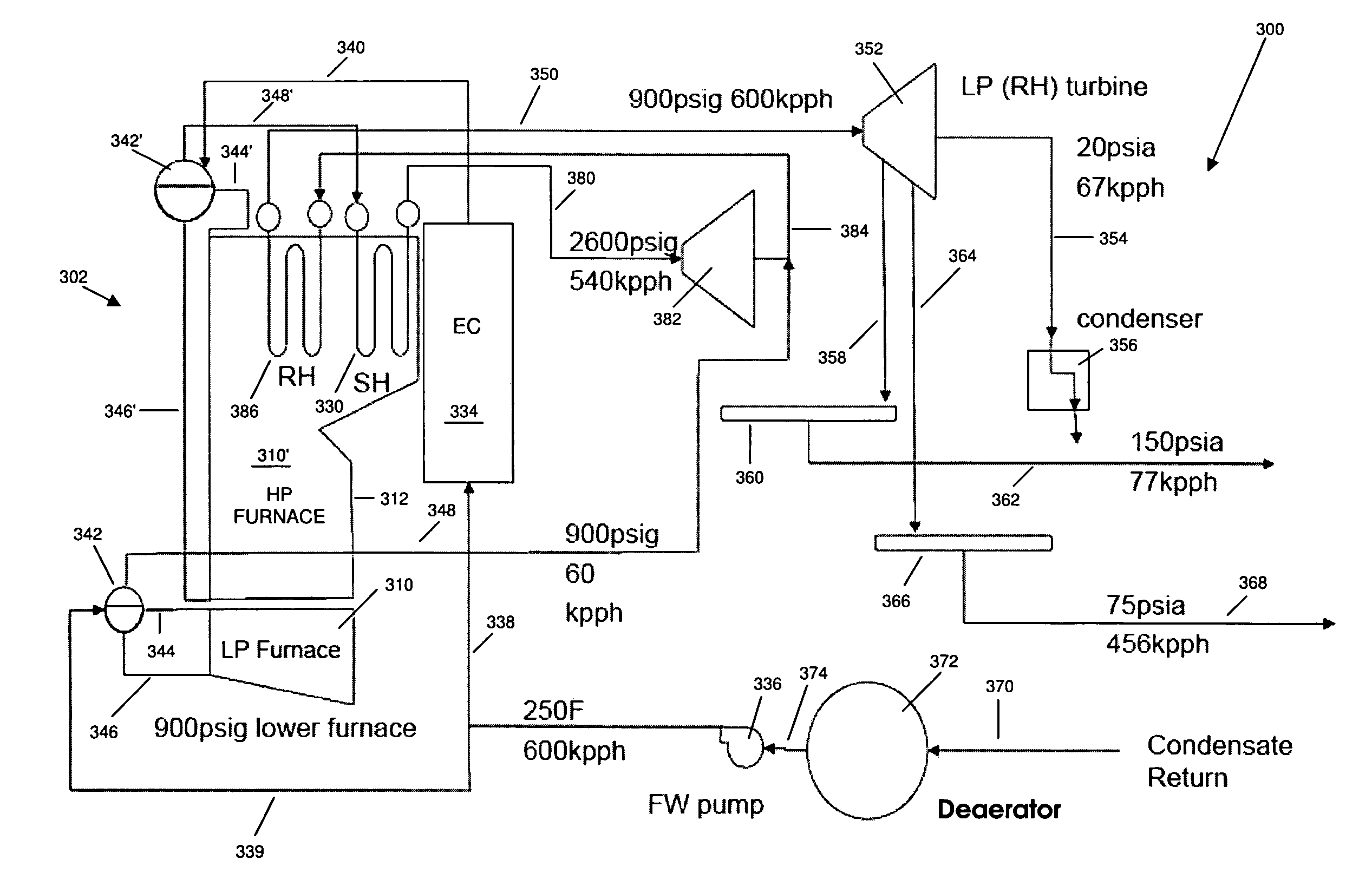

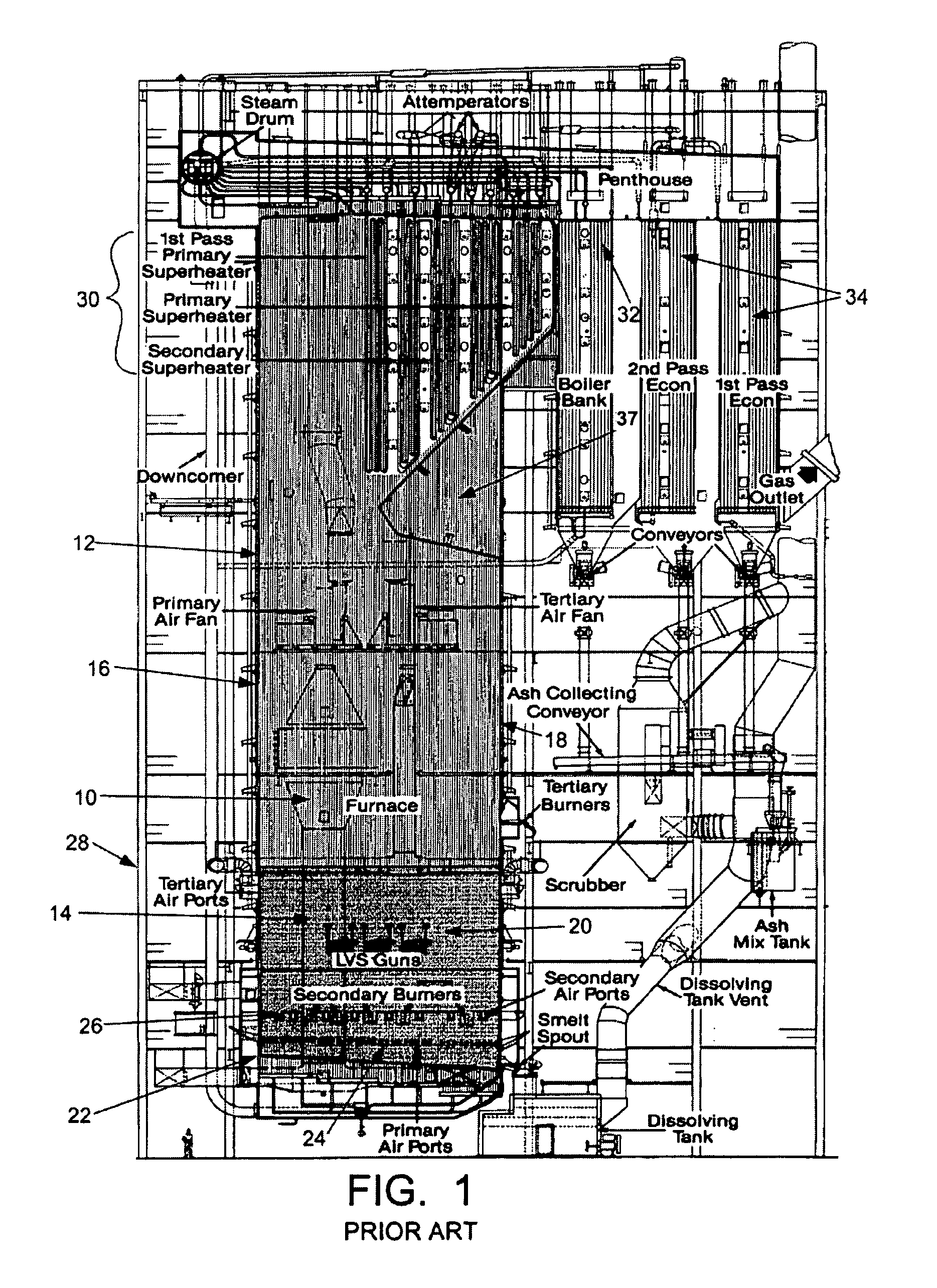

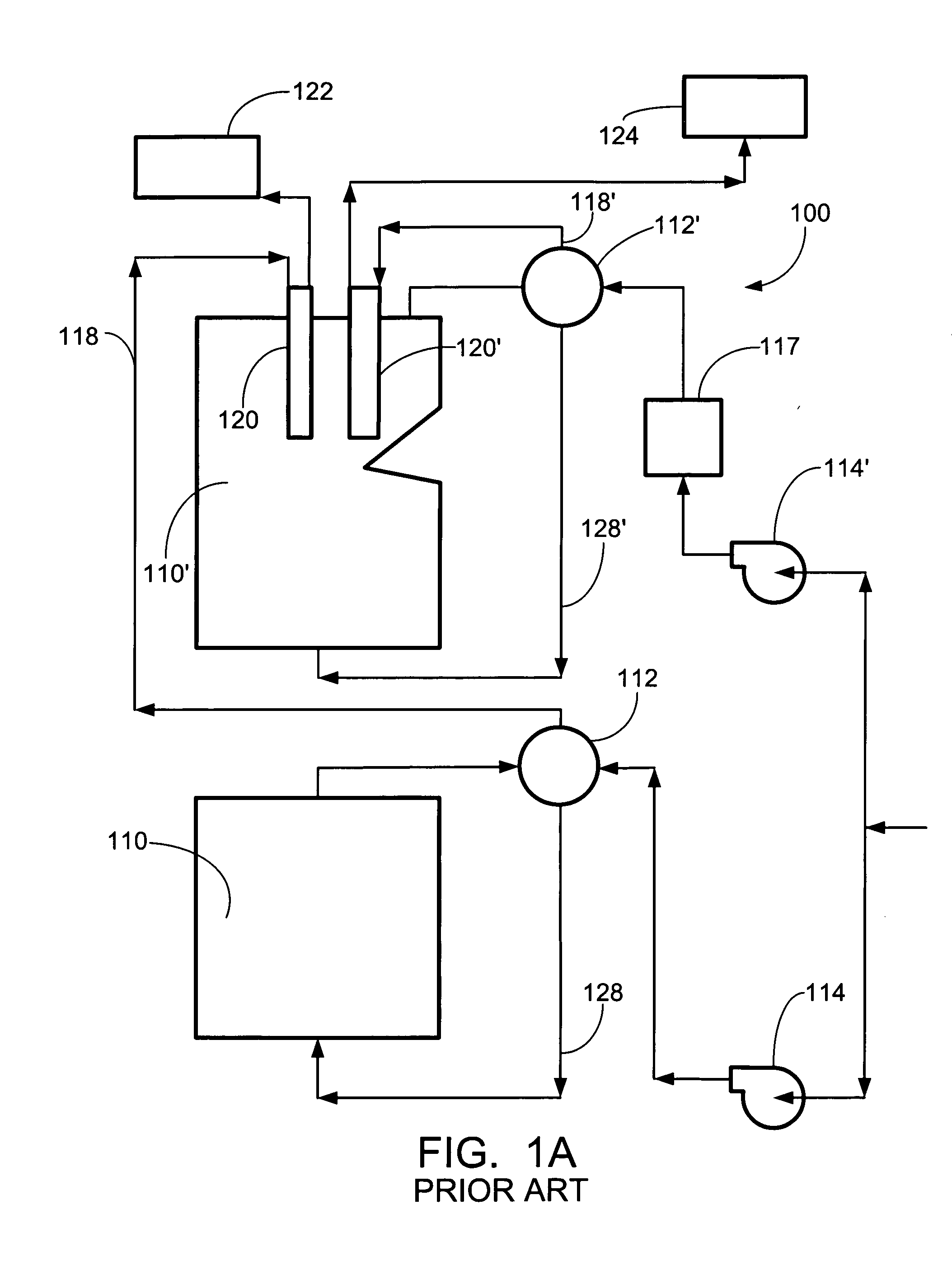

Enhanced steam cycle utilizing a dual pressure recovery boiler with reheat

InactiveUS20090241860A1Increase generationThe material is lowSuperheating controlFood processingBoiler furnaceEngineering

An enhanced steam cycle utilizing a dual pressure recovery boiler with reheat allows a large increase in electrical generation with various turbine cycles while overcoming traditional lower furnace material limitations. A dual pressure designed recovery boiler furnace is provided with a lower furnace and an upper furnace. The lower furnace is operated at a lower temperature to prevent or reduce corrosion of the lower furnace wall tubes caused by the reducing environment. The lower furnace can be either a low pressure natural circulation steam generating (drum) system or economizer. Unlike the lower furnace, the upper furnace is not exposed to a reducing environment and is therefore not as susceptible to severe corrosion rates. The upper furnace is operated at higher temperatures and pressures which permit implementation of higher efficiency reheat steam cycles. The upper furnace thus operates as a high pressure natural circulation steam generating (drum) system, or as a once-through supercritical steam generating system. The dual pressure recovery boiler can thus be coupled to a variety of condensing, non-condensing or a combination of condensing and non-condensing turbine cycles to provide a large increase in electrical generation.

Owner:THE BABCOCK & WILCOX CO

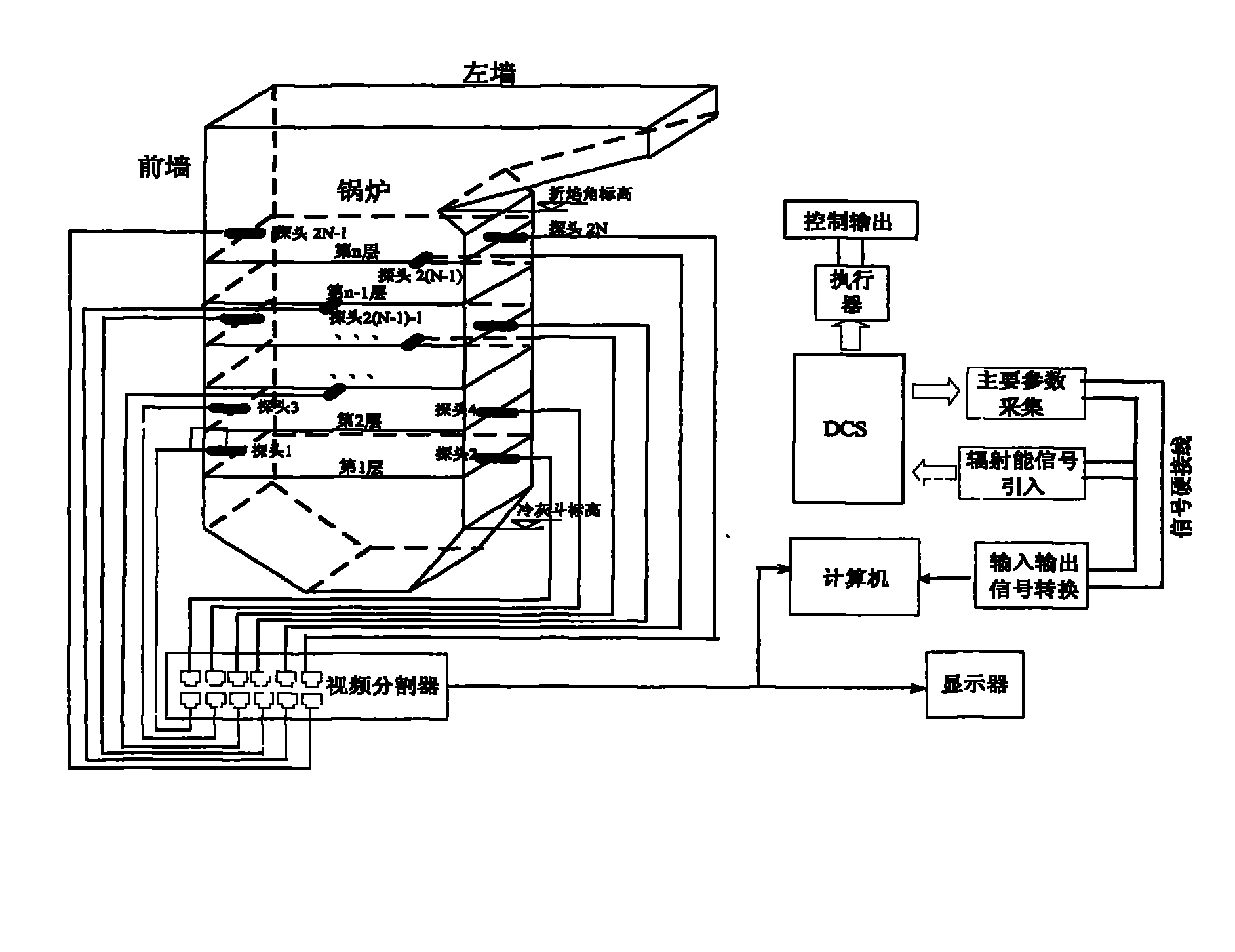

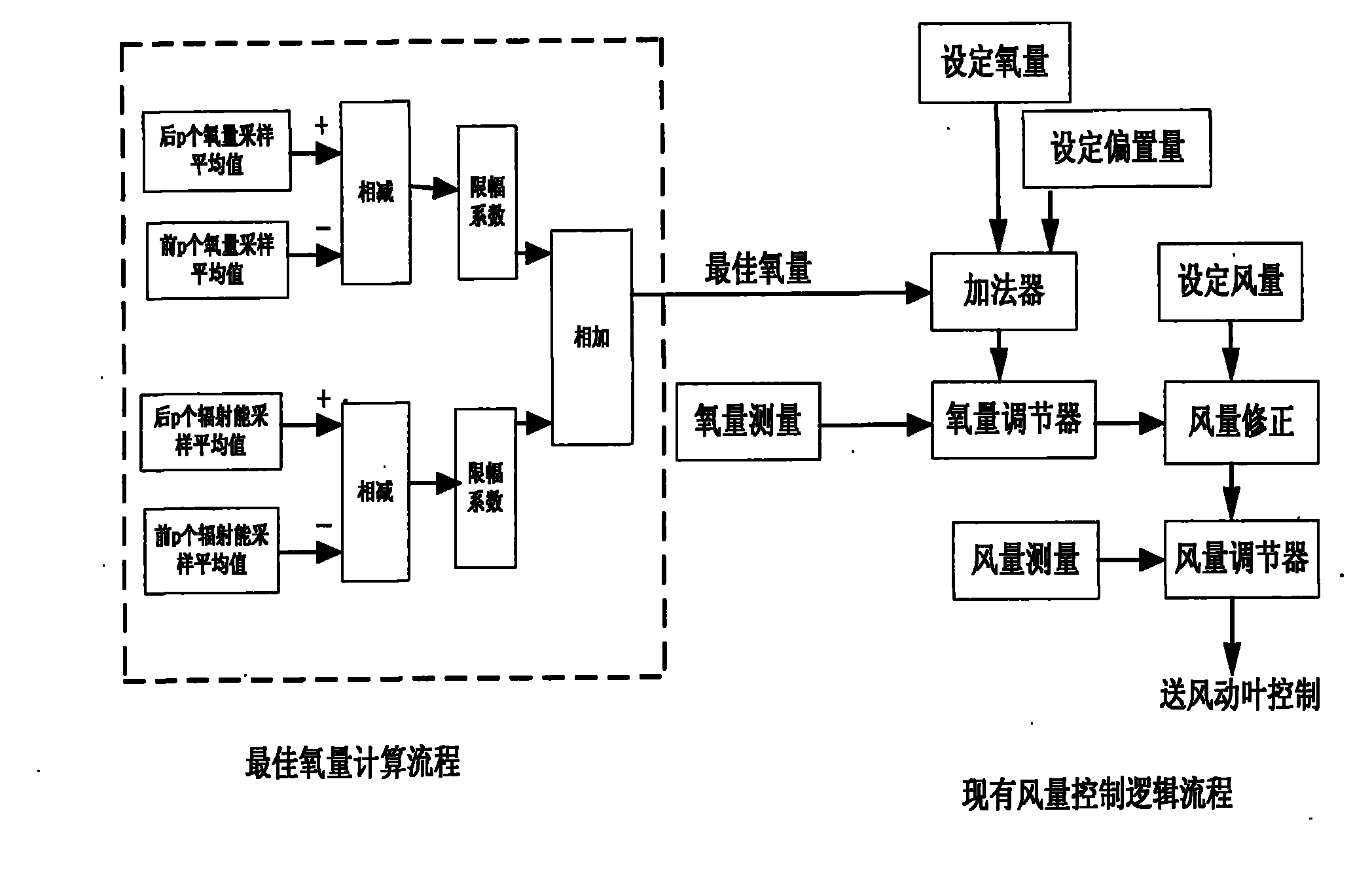

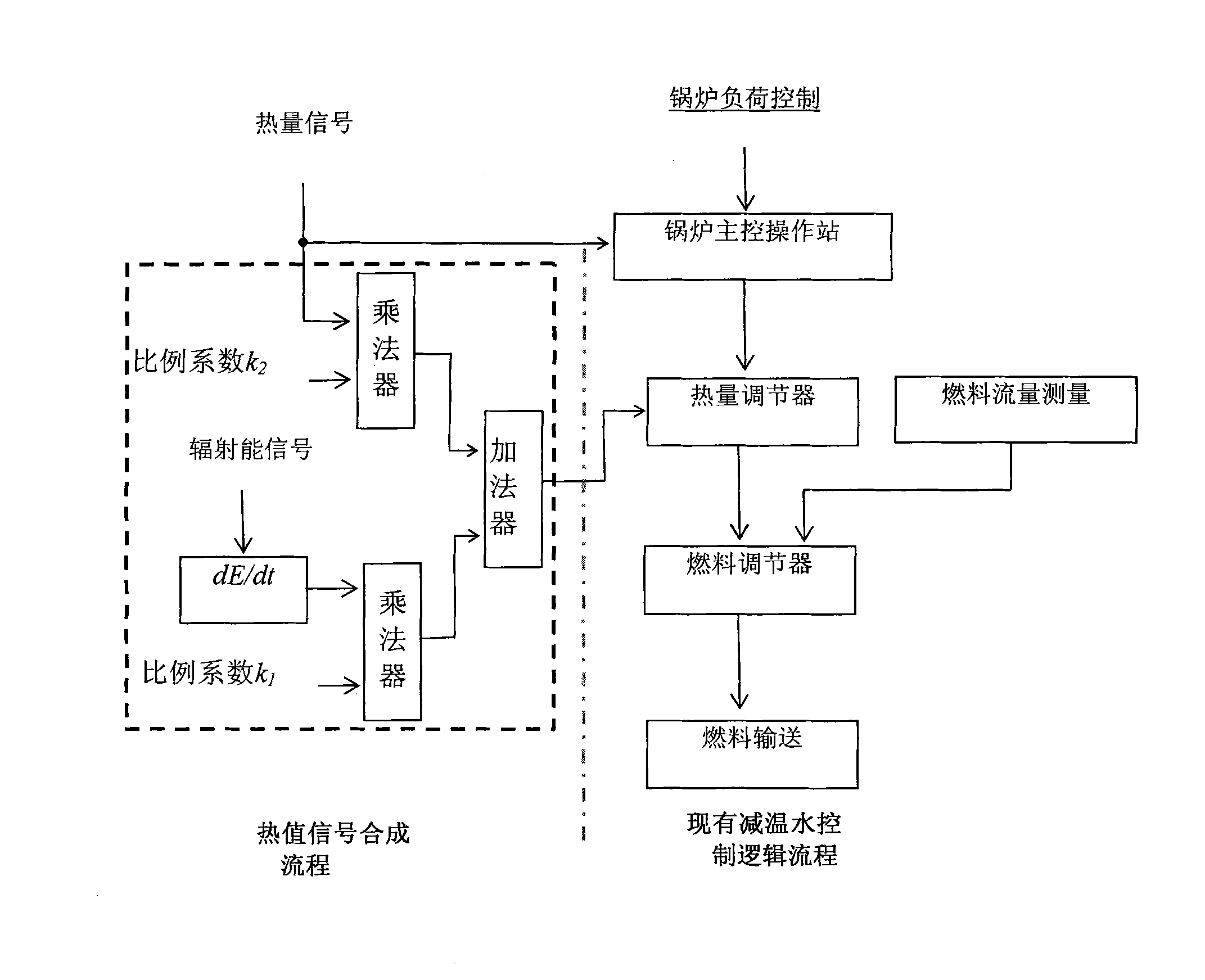

Method for detecting hearth radiation energy signal and method for controlling boiler combustion by using same

InactiveCN101788343ARealize combustion monitoringImprove temperature control qualitySuperheating controlRadiation pyrometryUnit operationSuperheater

The invention provides a method for detecting a hearth radiation energy signal and a method for controlling boiler combustion by using the same, and belongs to the field of combustion monitoring and controlling. The method for detecting the hearth radiation energy signal comprises steps of analog-to-digital conversion, color value extraction and hearth radiation energy signal calculation. In the method for controlling air quantity of hearth combustion, the optimum oxygen quantity calculated by using the hearth radiation energy signal, set oxygen quantity and set offset are added, and the sum is sent to an oxygen quantity regulator to control the air quantity of the hearth combustion. The method for controlling superheater attemperating water comprises the steps of combining the hearth radiation energy signal with a heat signal to form a heat value signal; and introducing the heat value signal to a heat regulator to control the superheater attemperating water. The radiation energy signal detected by the method has the advantages of stability, reliability, capability of accurately reflecting the combustion situation in the hearth space in real time, and strong correlation with unit operation parameters; and when the new heat value signal constructed by the radiation energy signal is introduced to air supply and attemperating water control loops of the unit, the control effect of the unit can be optimized, and the efficiency of the unit can be improved. Therefore, the method for controlling the boiler combustion is suitable for combustion optimization control of a pulverized coal fired boiler of a thermal power generating unit.

Owner:HUAZHONG UNIV OF SCI & TECH

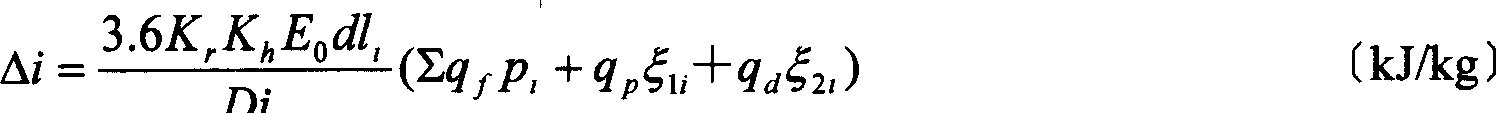

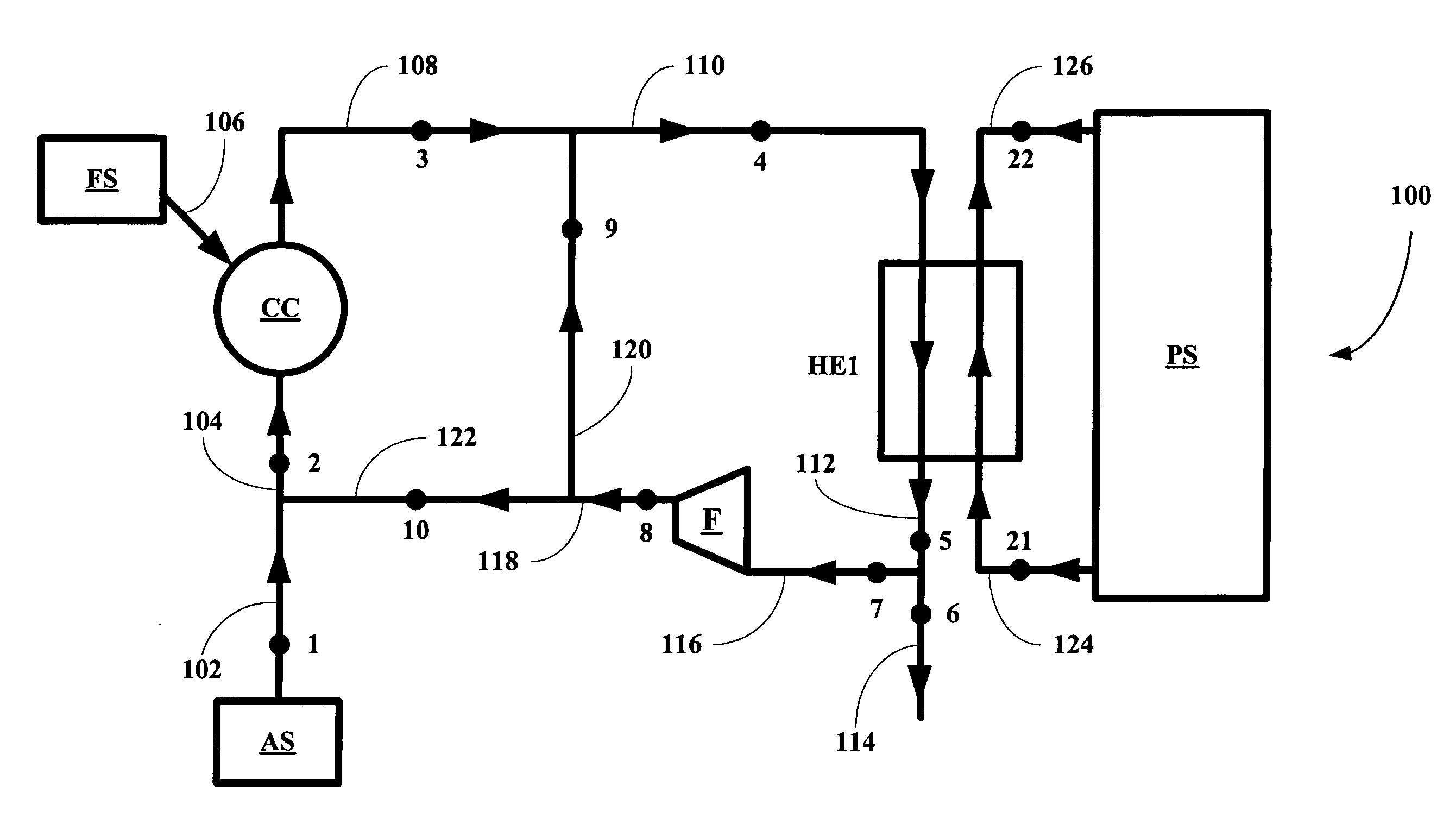

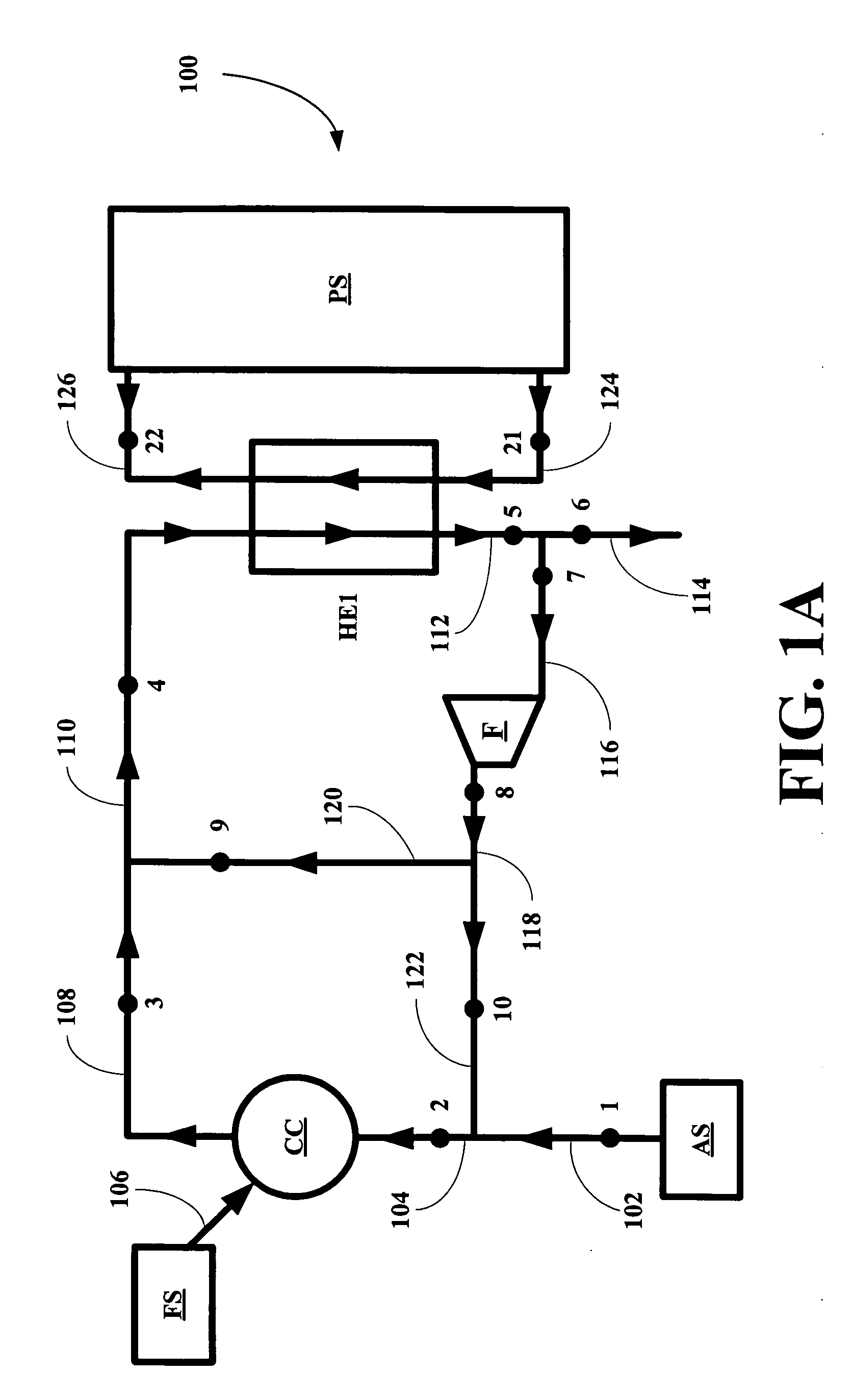

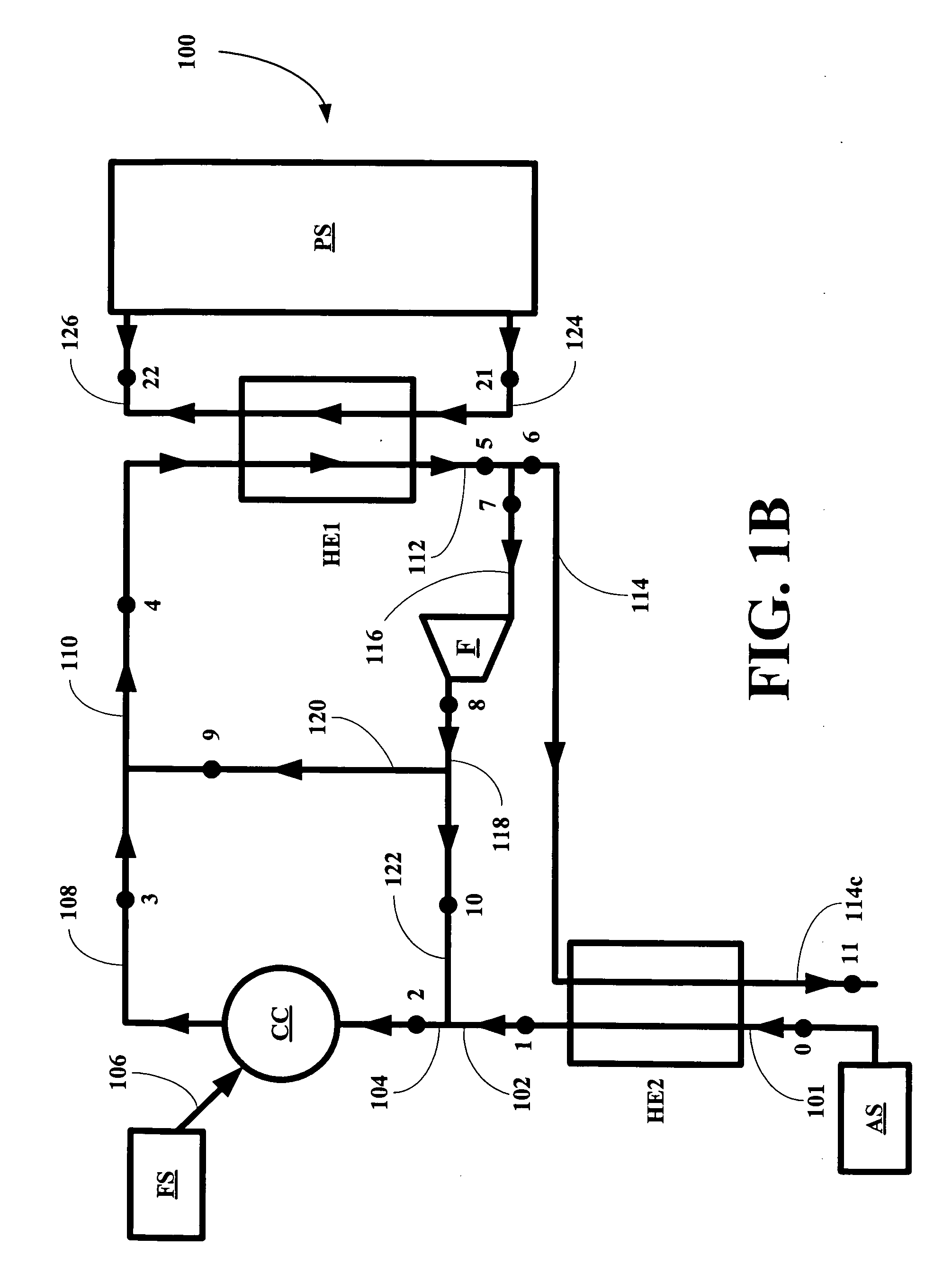

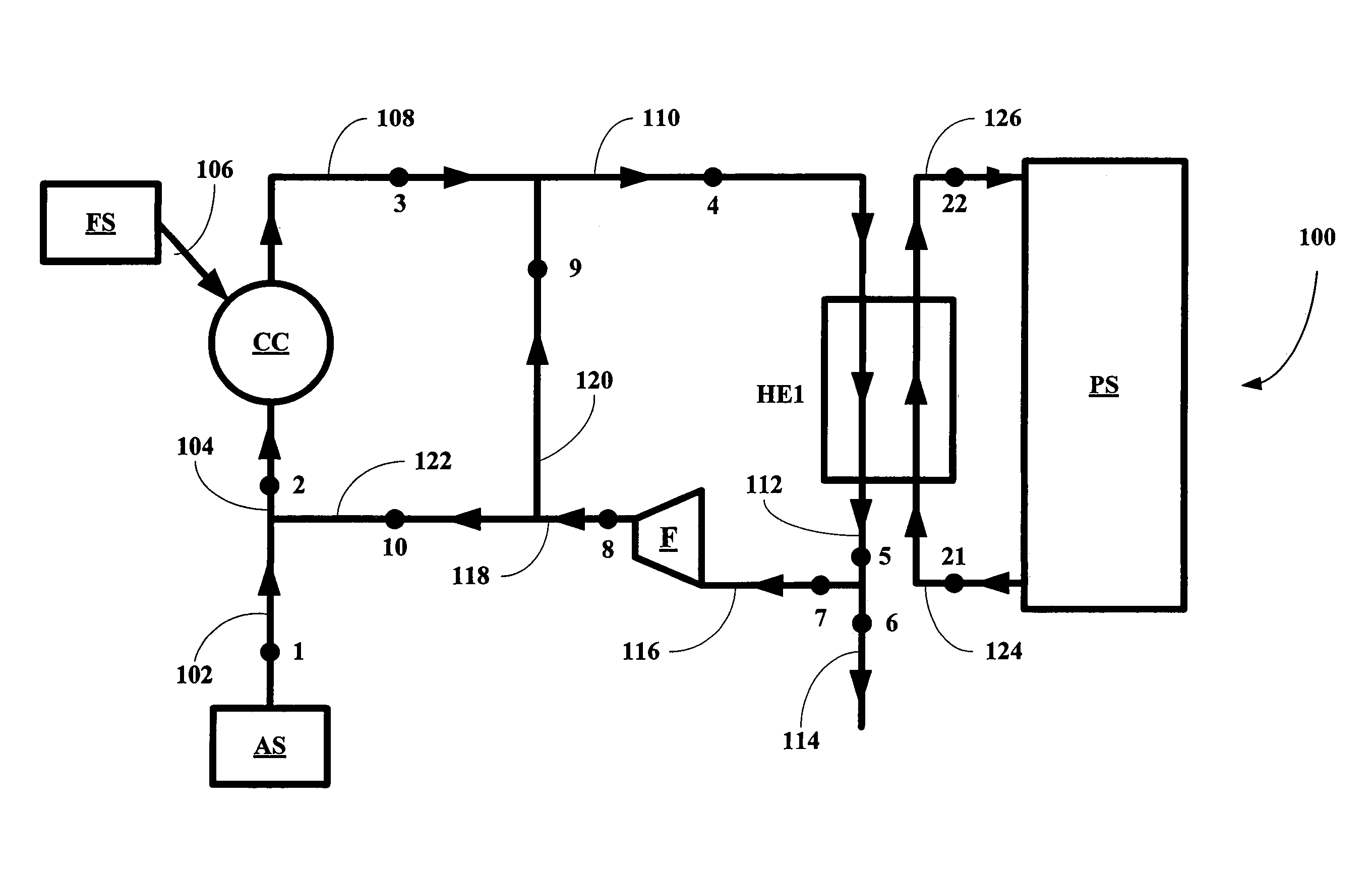

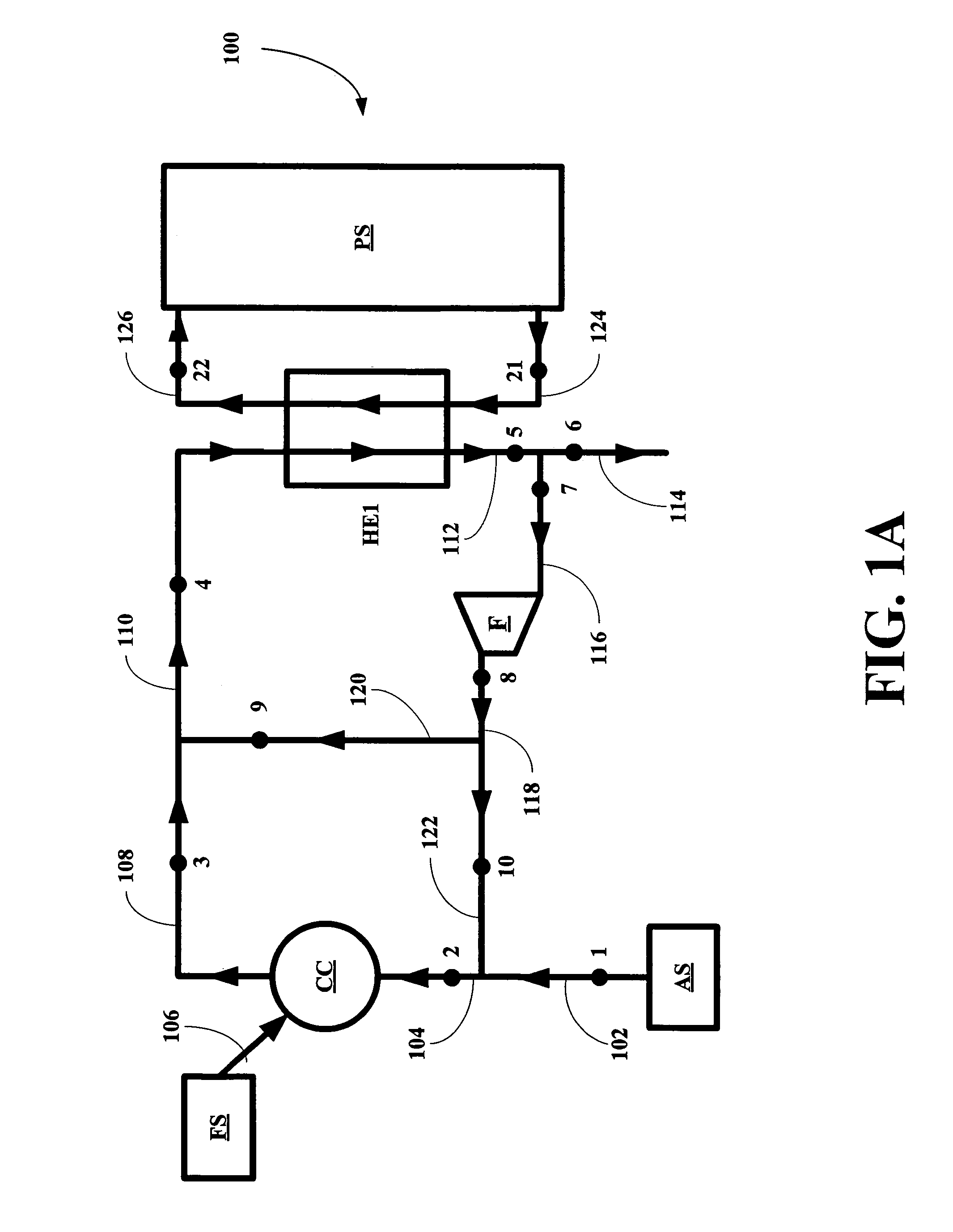

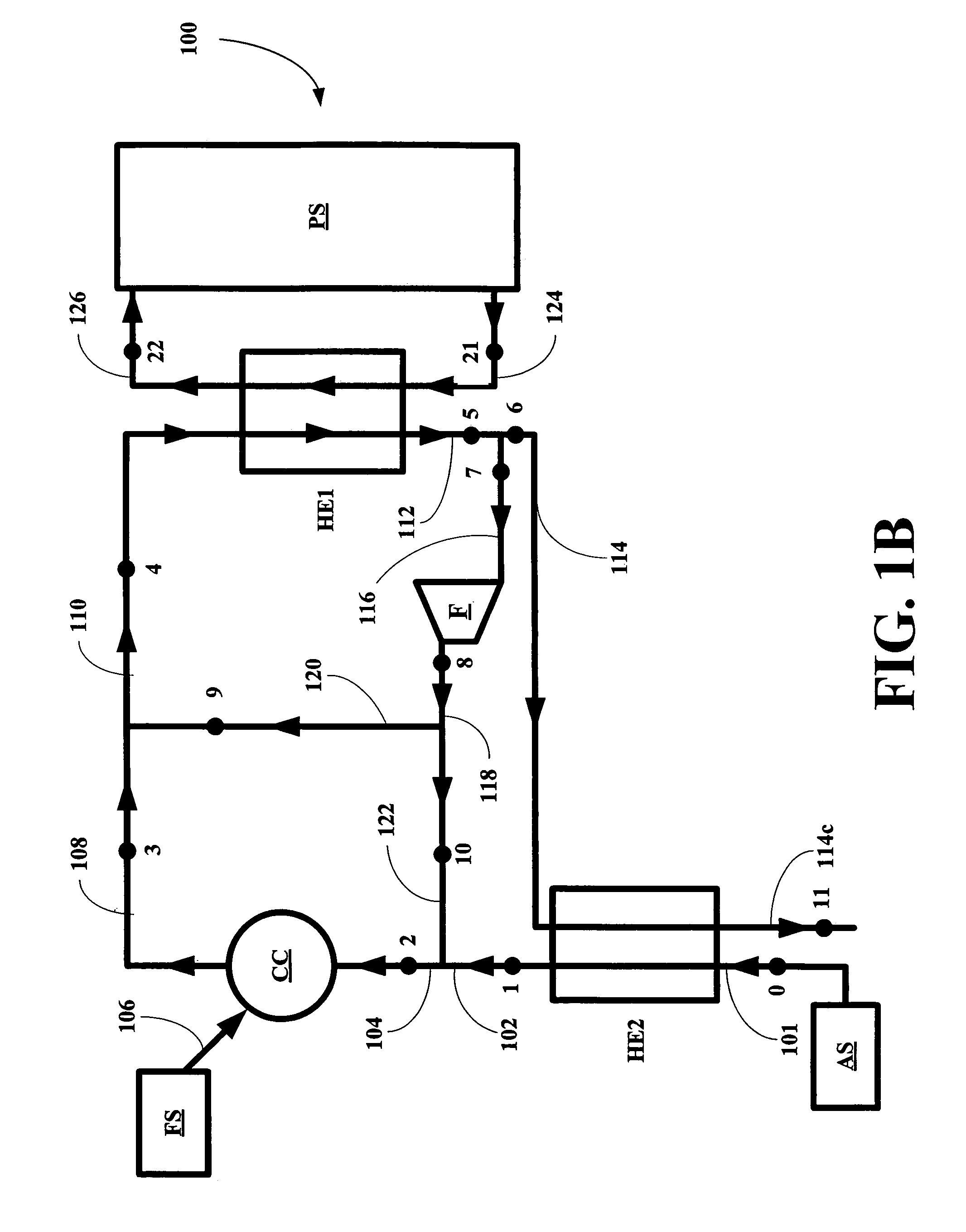

Practical method for improving the efficiency of cogeneration system

InactiveUS20060272334A1High recycling rateGenerating heat energySuperheating controlSteam generation heating methodsCogenerationProcess engineering

Systems and methods for exhaust gas recirculation in which a desired oxygen concentration is maintained for stable combustion at increased recirculation rates. Exhaust gas of an energy generation system is divided and reintroduced at different locations of the system.

Owner:PRANDA PAVOL +1

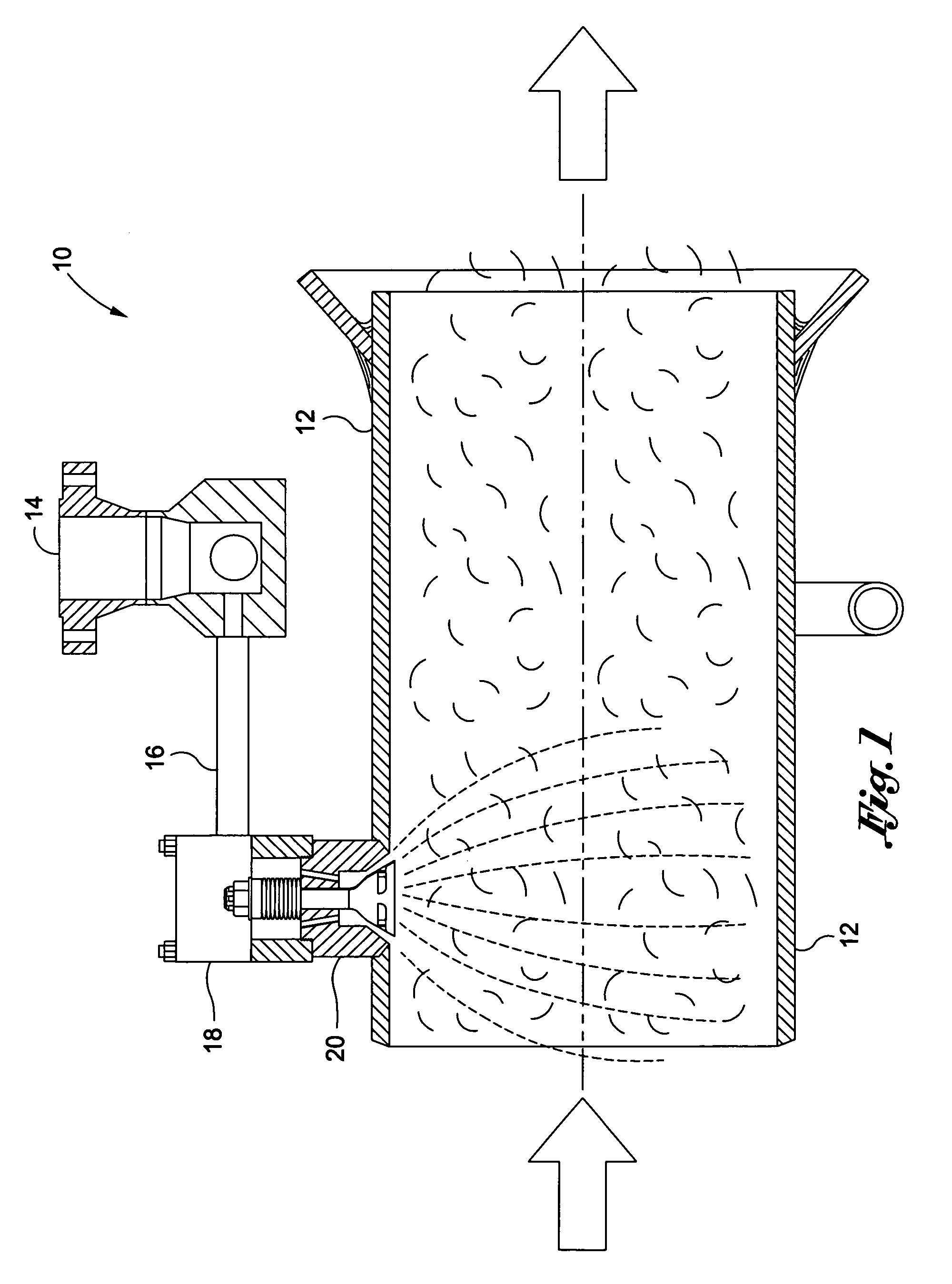

Desuperheater spray nozzle

ActiveUS7654509B2Reducing droplet sizeHigh mechanical strengthUsing liquid separation agentMixing methodsEngineeringSuperheated steam

Owner:CONTROL COMPONENTS INC

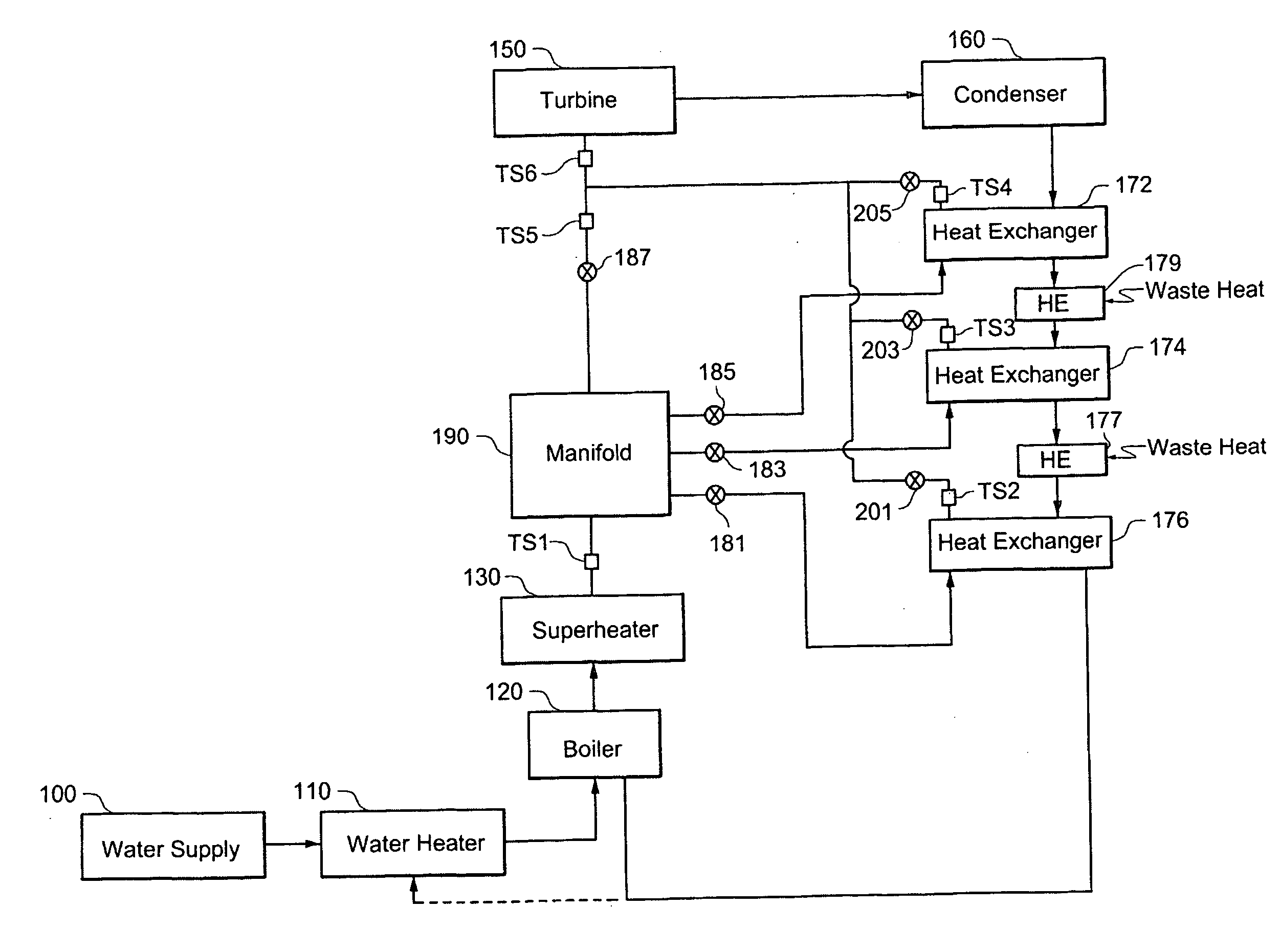

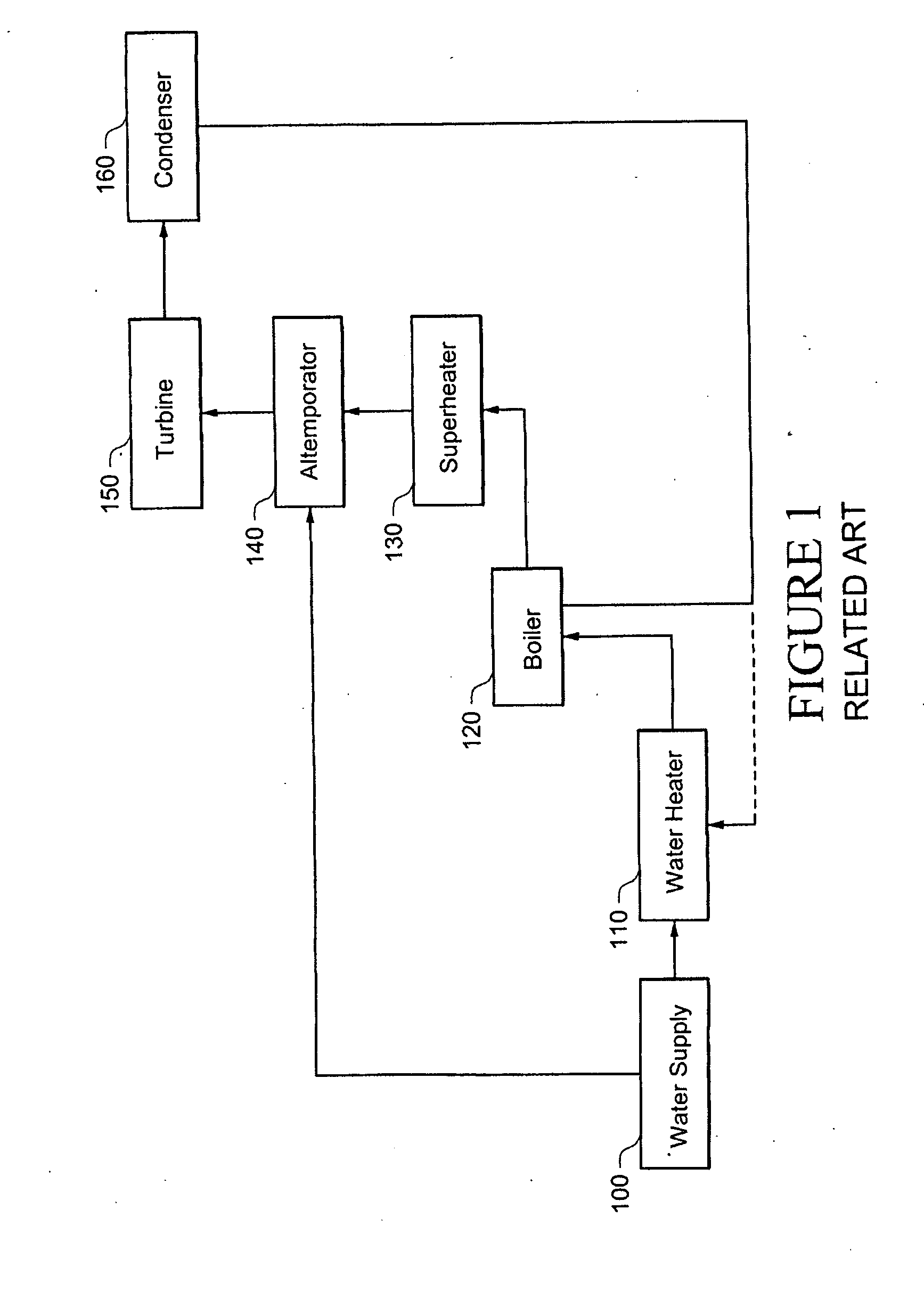

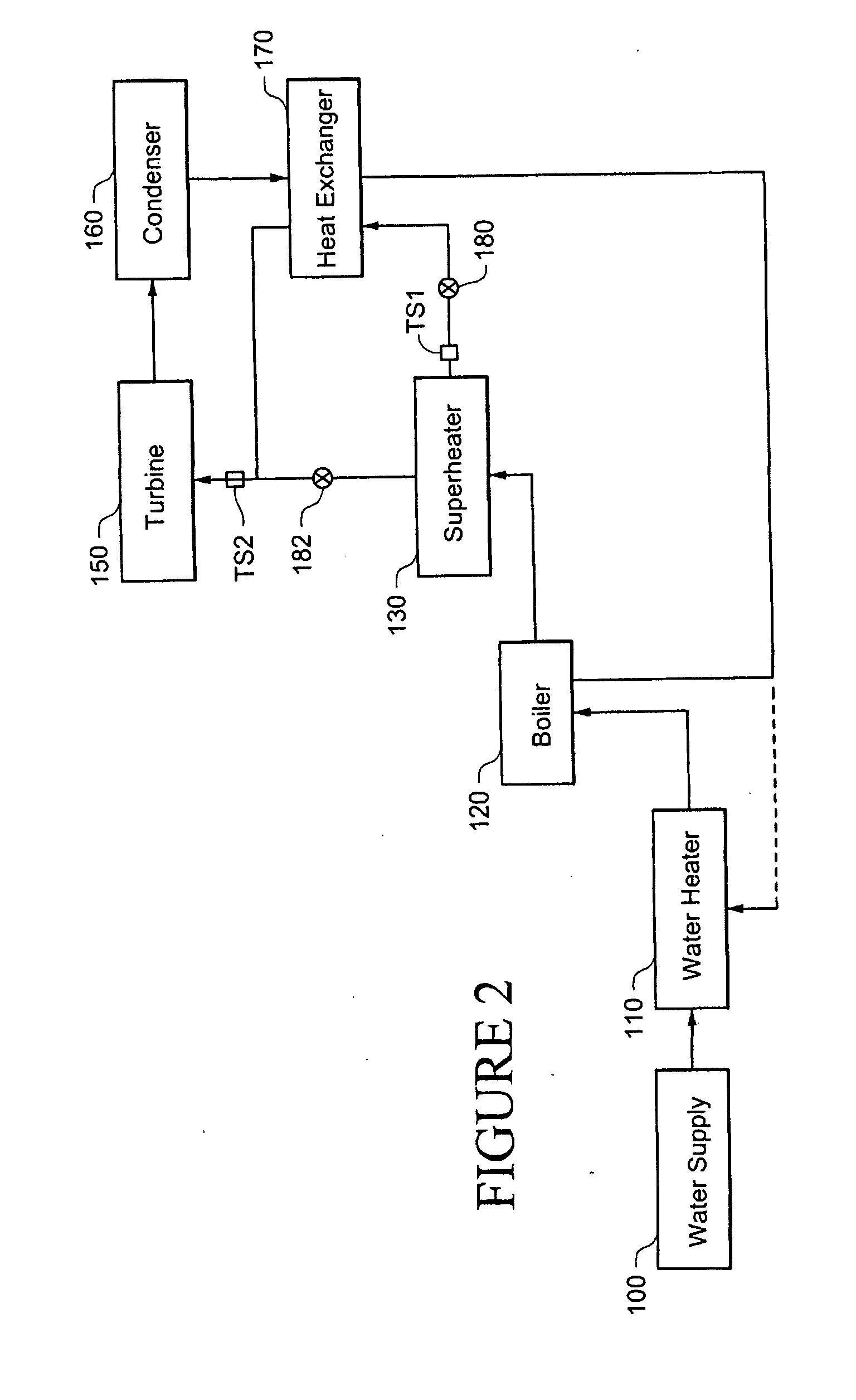

Desuperheater for a steam turbine generator

A system for generating steam for a turbine of an electric generator includes a superheater that receives steam from a boiler and that superheats the steam. All or a portion of the superheated steam from the superheater is then passed through a heat exchanger to transfer some of the heat energy in the superheated steam to a flow of water. This reduces a temperature of the superheated steam to a temperature that is suitable for the turbine. The water heated in the heat exchanger can be condensed water that has already passed through the turbine, and the water heated in the heat exchanger can be routed to the boiler, where it is re-cycled back into steam.

Owner:GENERAL ELECTRIC CO

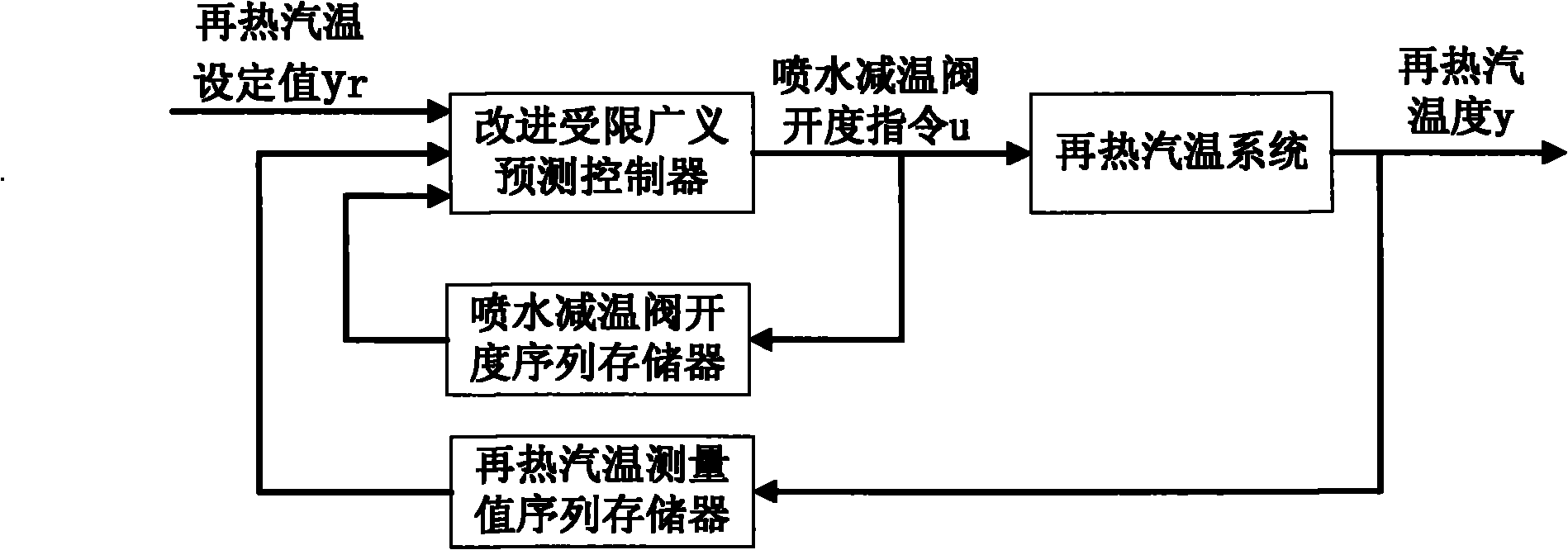

Improved method of limitation generalized predictive control for thermal power unit reheat steam temperature

InactiveCN101893232AOvercoming problems such as slow response and oscillation in the regulation processSmall amount of calculationSuperheating controlAdaptive controlTemperature controlControl system

The invention relates to an improved method of limitation generalized predictive control for thermal power unit reheat steam temperature. In the invention, an interior model for improving limitation predictive control is obtained through a reheat steam temperature set value step experience; a reheat steam temperature control system records a spray desuperheating valve opening instruction sequence and a reheat steam temperature measured value sequence in real time; and an opening increment instruction of a current spray desuperheating valve is obtained through simple calculation. The control method solves the problems that the traditional limitation generalized predictive control has complicated optimization problem and large calculated amount and the regulation of the reheat steam temperature control system is lagged and has slow response, thereby causing rapid and stable temperature control of a reheater without dynamic deviation.

Owner:SOUTHEAST UNIV

Outer drying steam triple-effect heat exchange system

InactiveCN102878547AIncrease moisture contentReduce moisture contentSuperheating controlWater bathsDry heat

The invention relates to an outer drying steam triple-effect heat exchange system. A flow divider is arranged in the liquid phase space of a water-bath-type saturated steam generator, and a steam discharge pipeline of the flow dividier is sequentially provided with a steam water separator and a steam drying heat exchanger; overheated steam enters the flow divider through a pressure control valve; wet saturated steam from the saturated steam generator is heated into dry saturated steam by overheated steam; the dry saturated steam enters a main steam heat exchanger and becomes high-temperature condensation water after materials are heated for the third time; flash steam of the high-temperature condensation water heats the materials in the flash steam heat exchanger for the second time; condensed flash steam enters the condensation water heat exchanger; the condensation water in the high-temperature condensation water continuously releases sensible heat to heat the material for the first time; the condensation water after temperature reduction enters a water collecting tank, and is pumped into the saturated steam generator by a water supplying pump; and the aperture of the pressure control valve is regulated by a PLC (programmed logic controller) according to the material outlet temperature. The system achieves cascading utilization of steam heat energy, guarantees that the steam heat energy can be used up, and improves the energy efficiency.

Owner:YIHENG ENERGY SAVING TECH JIANGSU

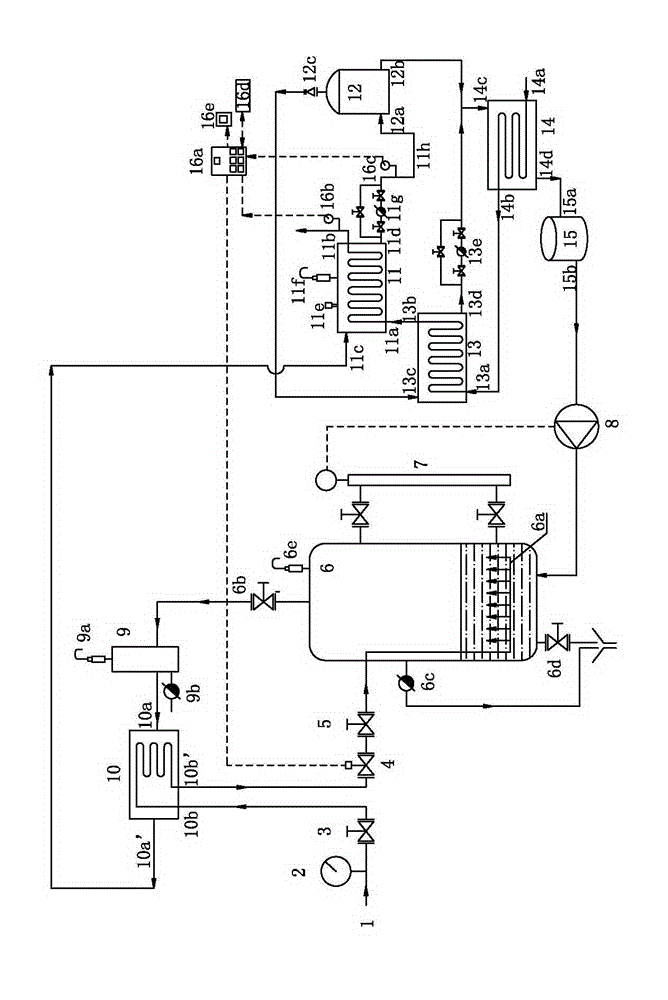

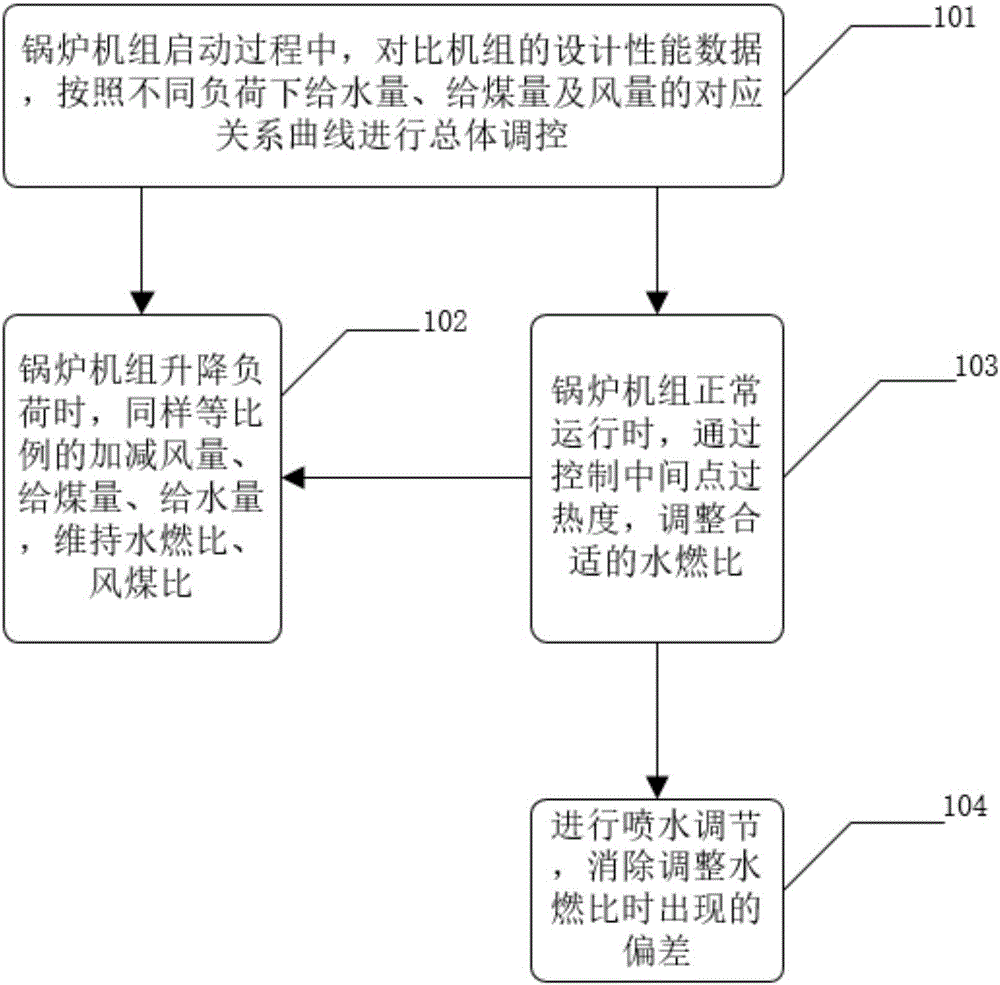

Control method for steam temperature of meager coal boiler of 1045MW ultra supercritical unit

ActiveCN106439770AGuaranteed uptimeEliminate biasSuperheating controlSteam separation arrangementsSupercritical steam generatorAir volume

The embodiment of the invention discloses a control method for the steam temperature of a meager coal boiler of a 1045MW ultra supercritical unit. The control method is used for solving the technical problems that because mature ultra supercritical steam temperature control technologies capable of being applied to actual production fields lack currently, heating surface over-temperature pipe explosion is frequently caused by unreasonable steam temperature control of a field ultra supercritical boiler, large potential safety hazards are caused to safe and stable operation of a power plant, and severe economic loss of a large thermal power plant is caused. The control method includes the steps that in the boiler unit starting process, design performance data of the unit are compared, and overall regulation and control are conducted according to the corresponding relation curve of water supply quantity, coal supply quantity and air volume under different loads; when the load of the boiler unit is increased or decreased, the air volume, coal supply quantity and water supply quantity are increased or decreased with the same ratio; when the boiler unit normally operates, the superheat degree of the intermediate point is controlled to regulate the water-fuel ratio to be proper; and water spraying adjustment is carried out, so that deviation in regulation of the water-fuel ratio is eliminated.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

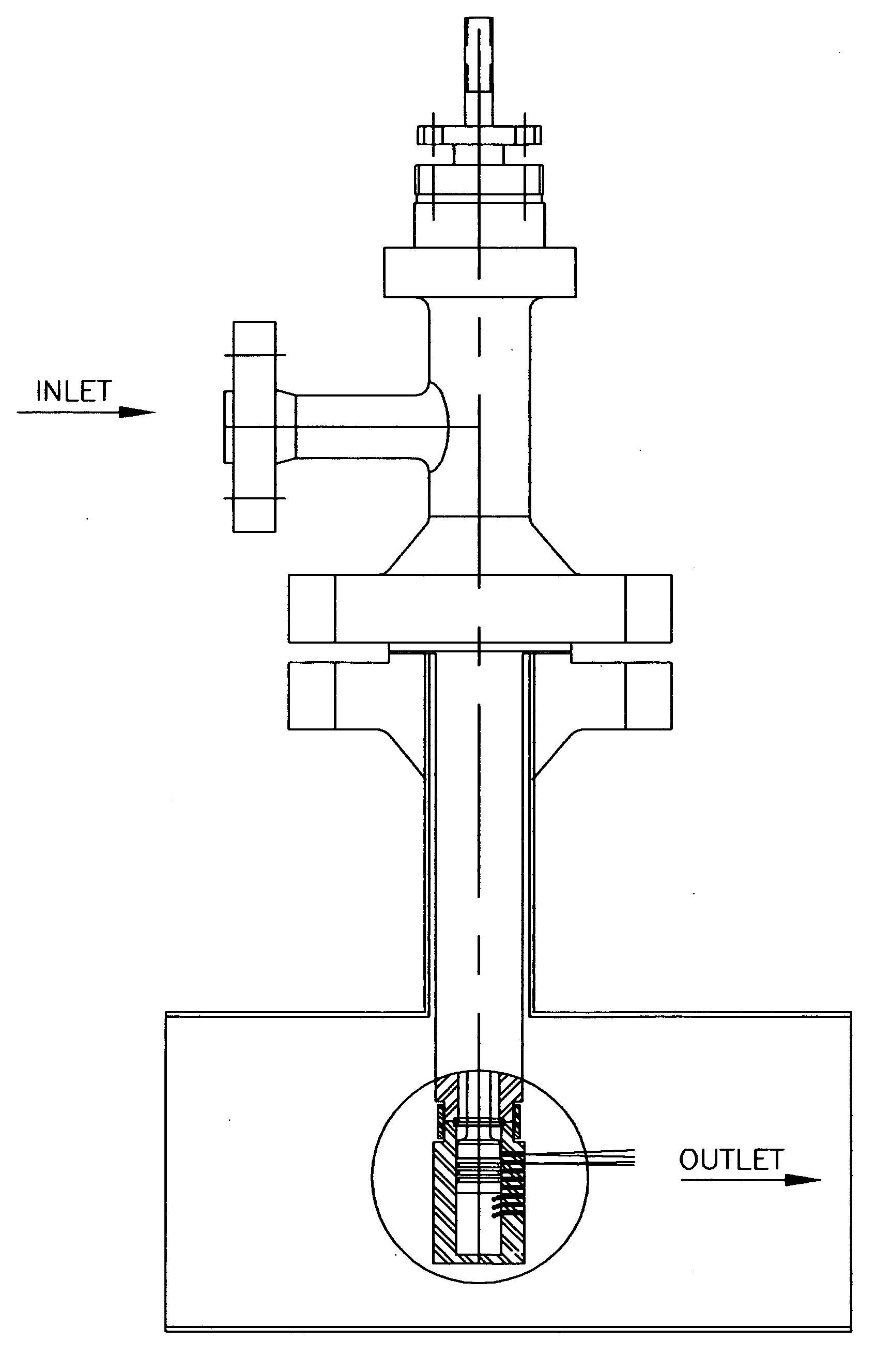

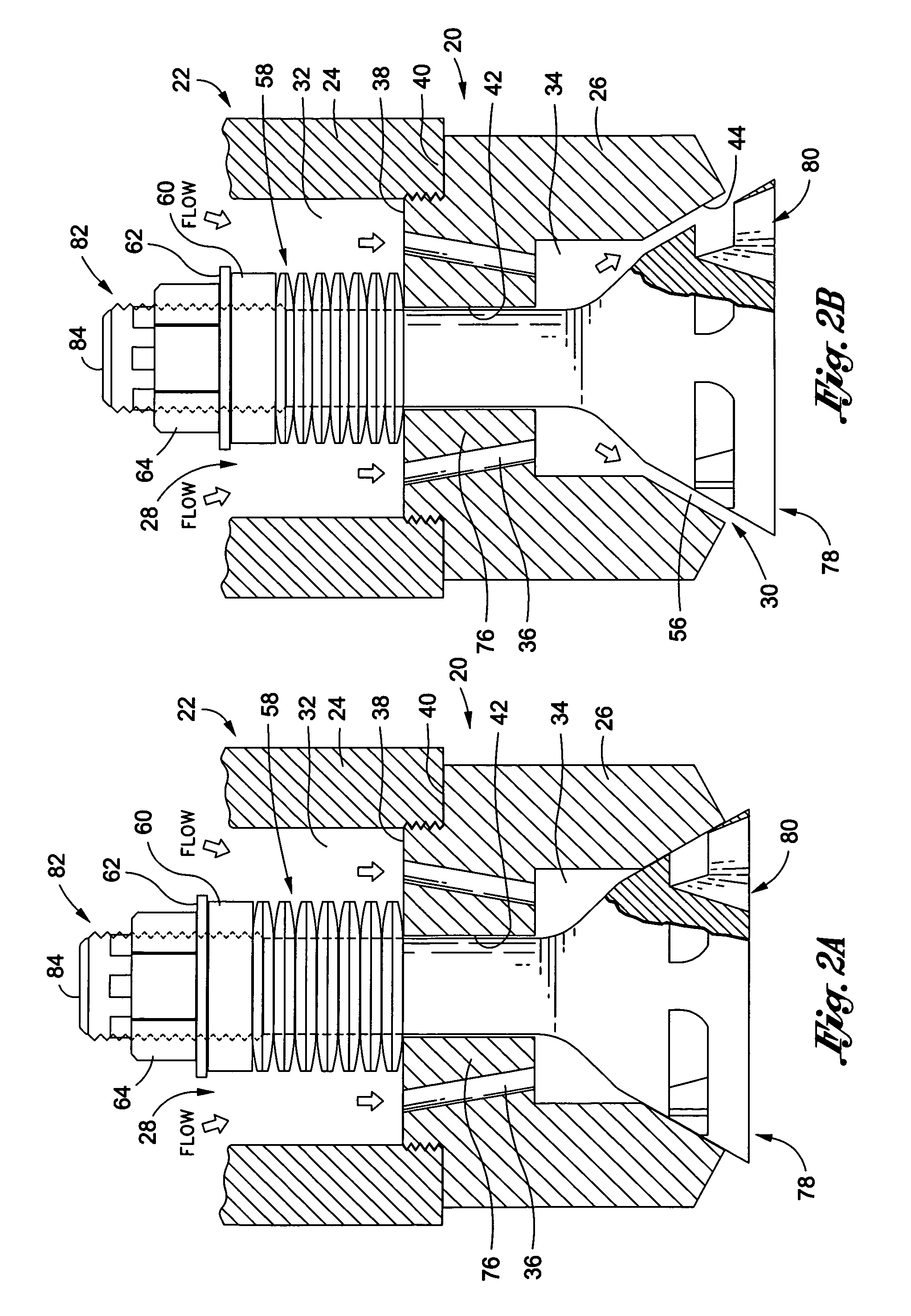

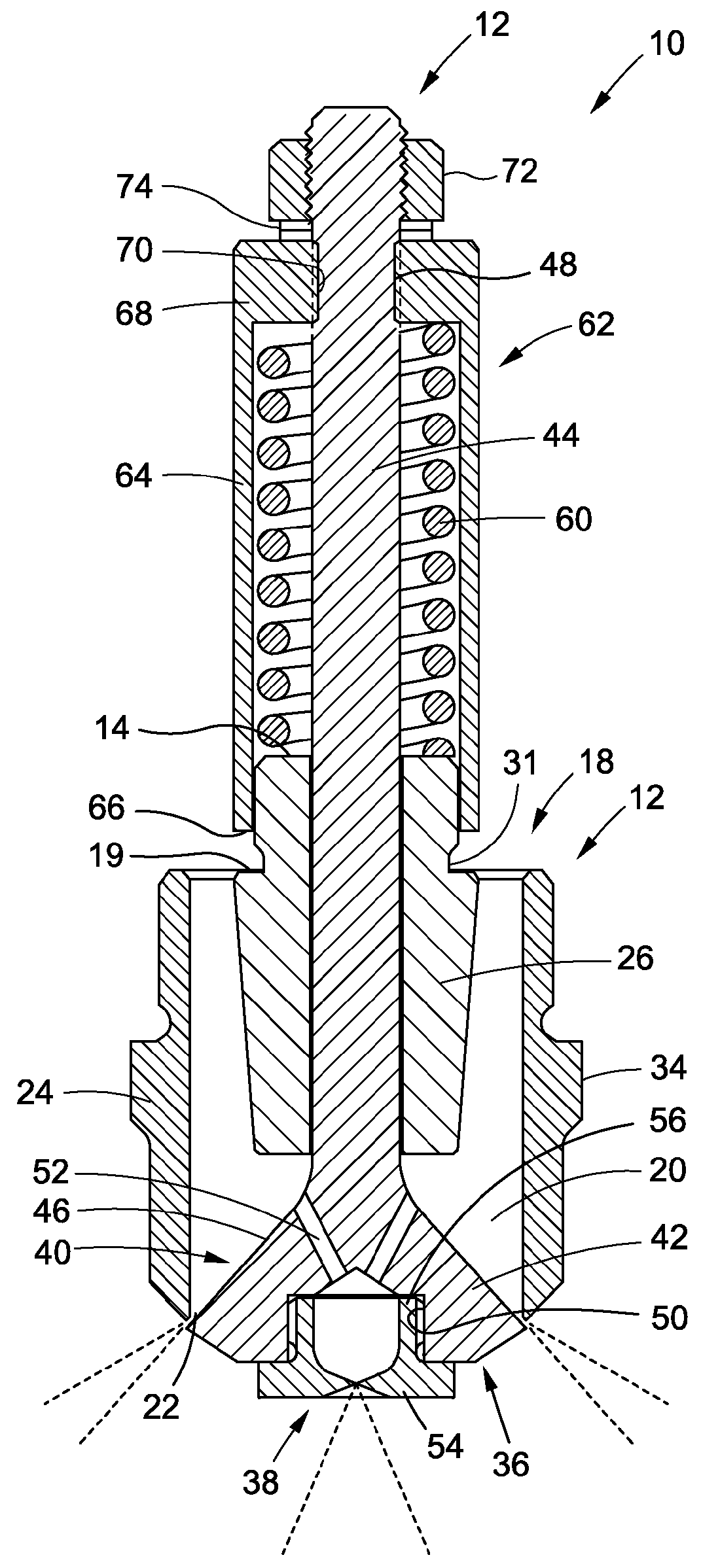

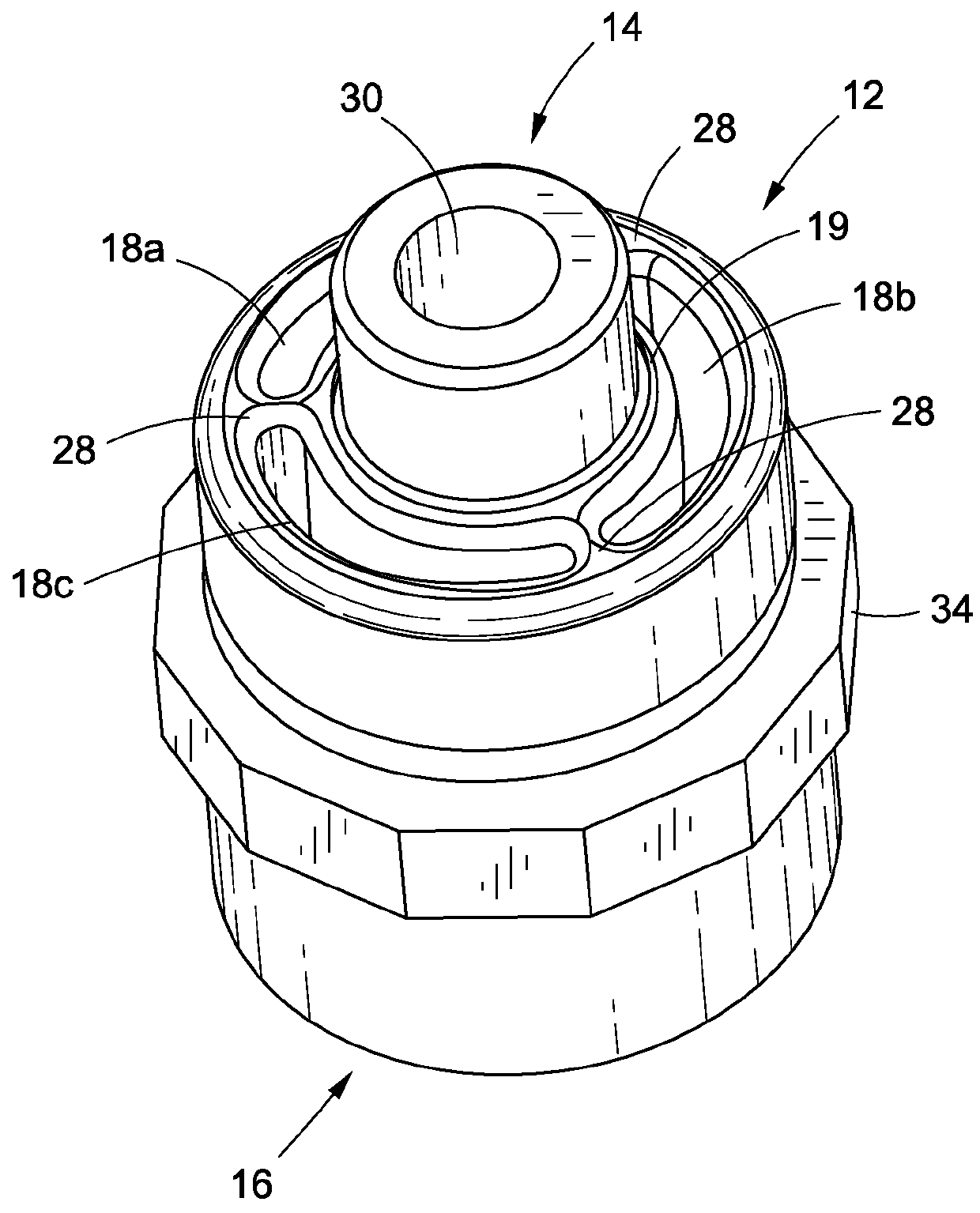

Dual cone spray nozzle assembly for high temperature attemperators

ActiveUS20160033124A1Overcome bias forceEasy to driveSuperheating controlUsing liquid separation agentFractionationSpray nozzle

A spray nozzle assembly for a steam desuperheating or attemperator device. In one embodiment, the spray nozzle sub-assembly of the spray nozzle assembly comprises a fixed nozzle element which is integrated into a spring-loaded nozzle element, and is specifically adapted to improve water droplet fractionation at higher flow rates while further providing an effectively higher spray area through the formation of two water cones (rather than a single water cone), such water cones being sprayed into a flow of superheated steam in order to reduce the temperature of the steam. In another embodiment, the spray nozzle sub-assembly of the spray nozzle assembly comprises a nested pair of spring-loaded primary and secondary nozzle elements which are also adapted to provide an effectively higher spray area through the formation of two water cones.

Owner:CCI ITAL SRL

Combustion system with recirculation of flue gas

An improved combustion method and corresponding apparatus is disclosed, where the method includes oxidizing a fuel in a combustion chamber with an oxidizing stream including an air stream and a first recycled flue gas stream and mixing a produced hot flue gas stream with a second recycled flue gas stream to form reduced temperature flue gas stream which can be used directly in a power generator or to heat a reactor. The method and apparatus allow flow rates of the streams to be adjusted so that temperatures in the combustion chamber and in the heat transfer unit or units of the power generator or reactor can be kept below temperature that would thermally damage the combustion chamber, heat transfer unit or units or the reactors.

Owner:KALINA POWER LTD

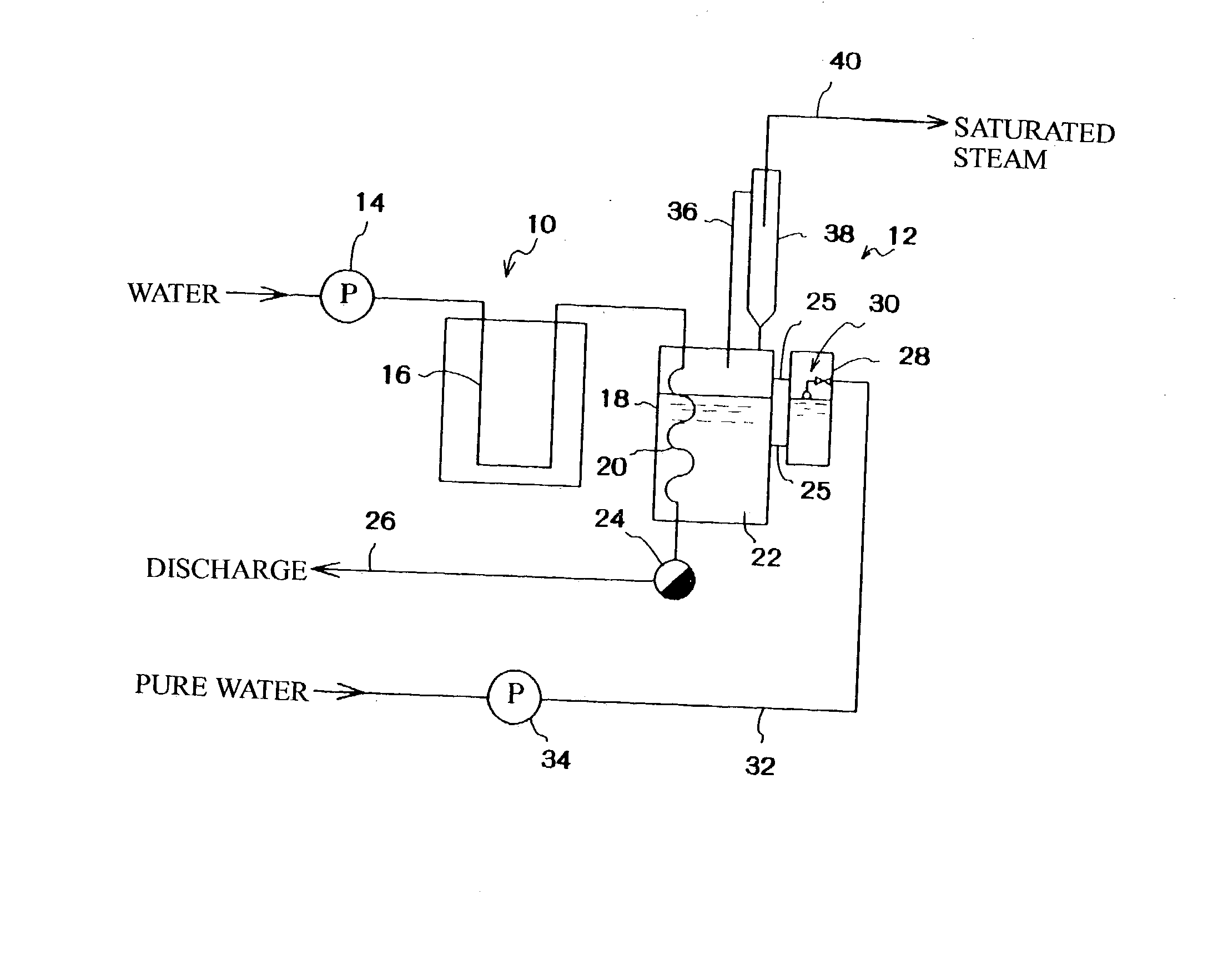

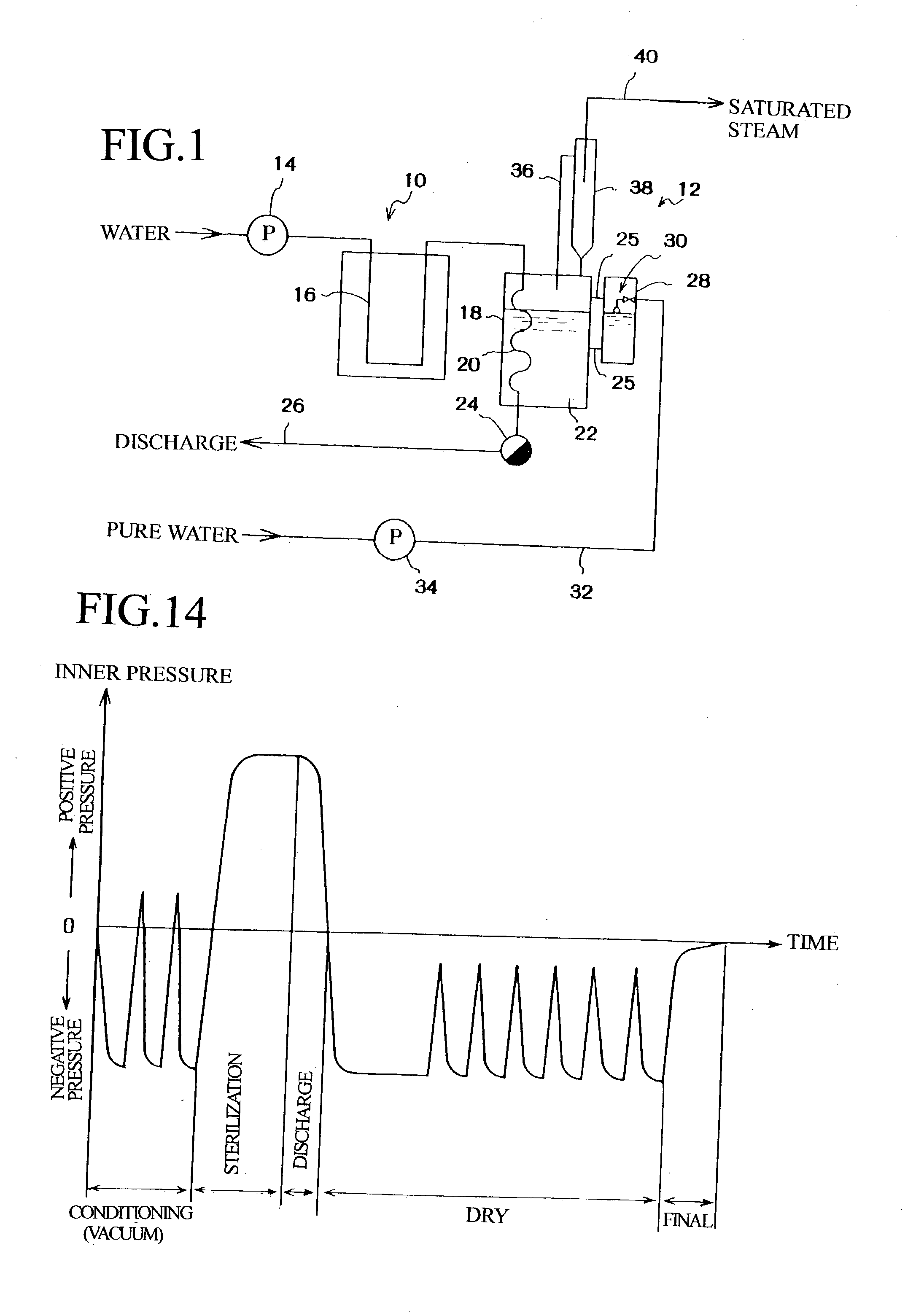

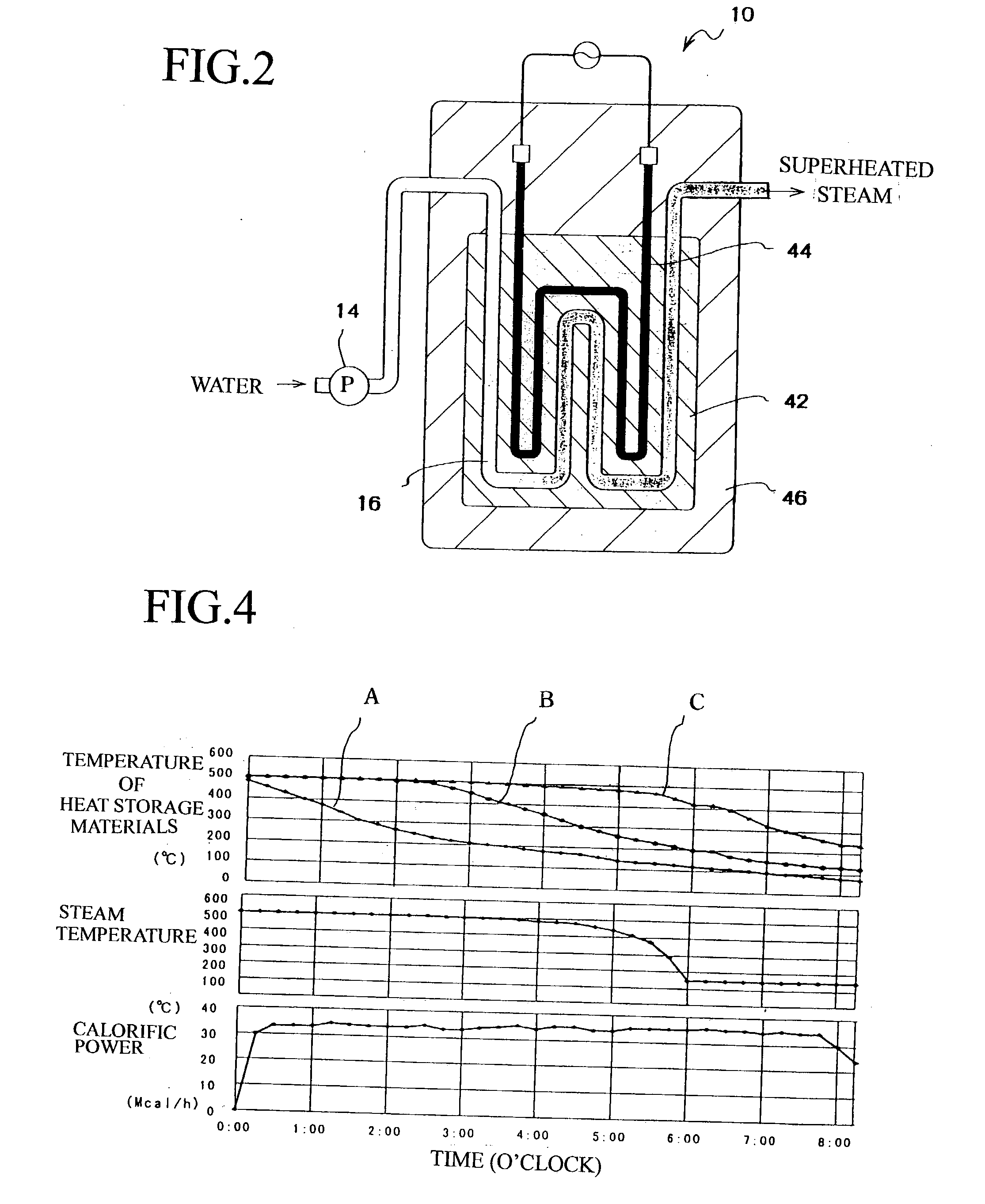

Saturated steam generator, steam sterilizer, and steam sterilization method

InactiveUS20030145806A1Liquid surface applicatorsSteam/vapor condensersHeat transmissionHeat storage material

A saturated steam generator which is provided with a heat source for heating water to generate saturated steam and which can be small-sized. A saturated steam generator for generating saturated steam by heating water with superheated steam resulting from being superheated in a heat transmission tube (16) inserted into a heat storage tank (10), characterized by the provision of a saturated steam generator tank (12), wherein in the heat storage tank (10), disposed in a heat storage section composed by having a solid heat storage material and a liquid heat storage material filled therein are a heat transmission tube (16) and a heater (44), which heats the solid heat storage material and the liquid heat storage material, it being arranged that superheated steam resulting from passing through the heat transmission tube (16) is used as a heat source to heat stored water (22) so as to generate saturated steam.

Owner:SAKURA SEIKI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com