Thermal power unit reheated steam temperature control method

A technology for reheating steam temperature and thermal power unit, which is applied in the control of overheating temperature, electric controller, temperature control using electric mode, etc., which can solve the problem of wasting energy, difficult to control the reheated steam temperature, and difficult to adjust the reheated steam temperature. and other problems to achieve the effect of improving dynamic characteristics and reducing signal errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

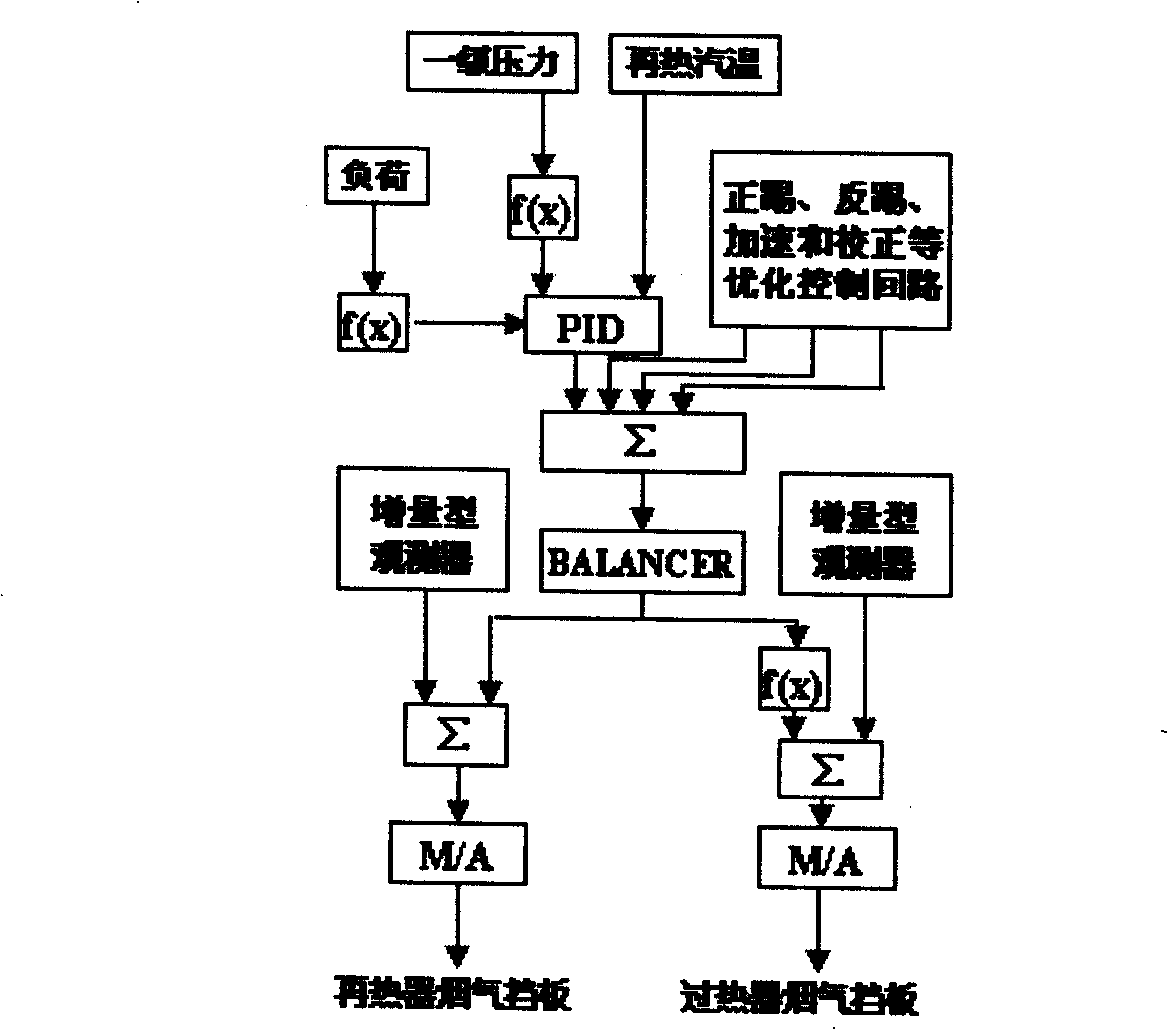

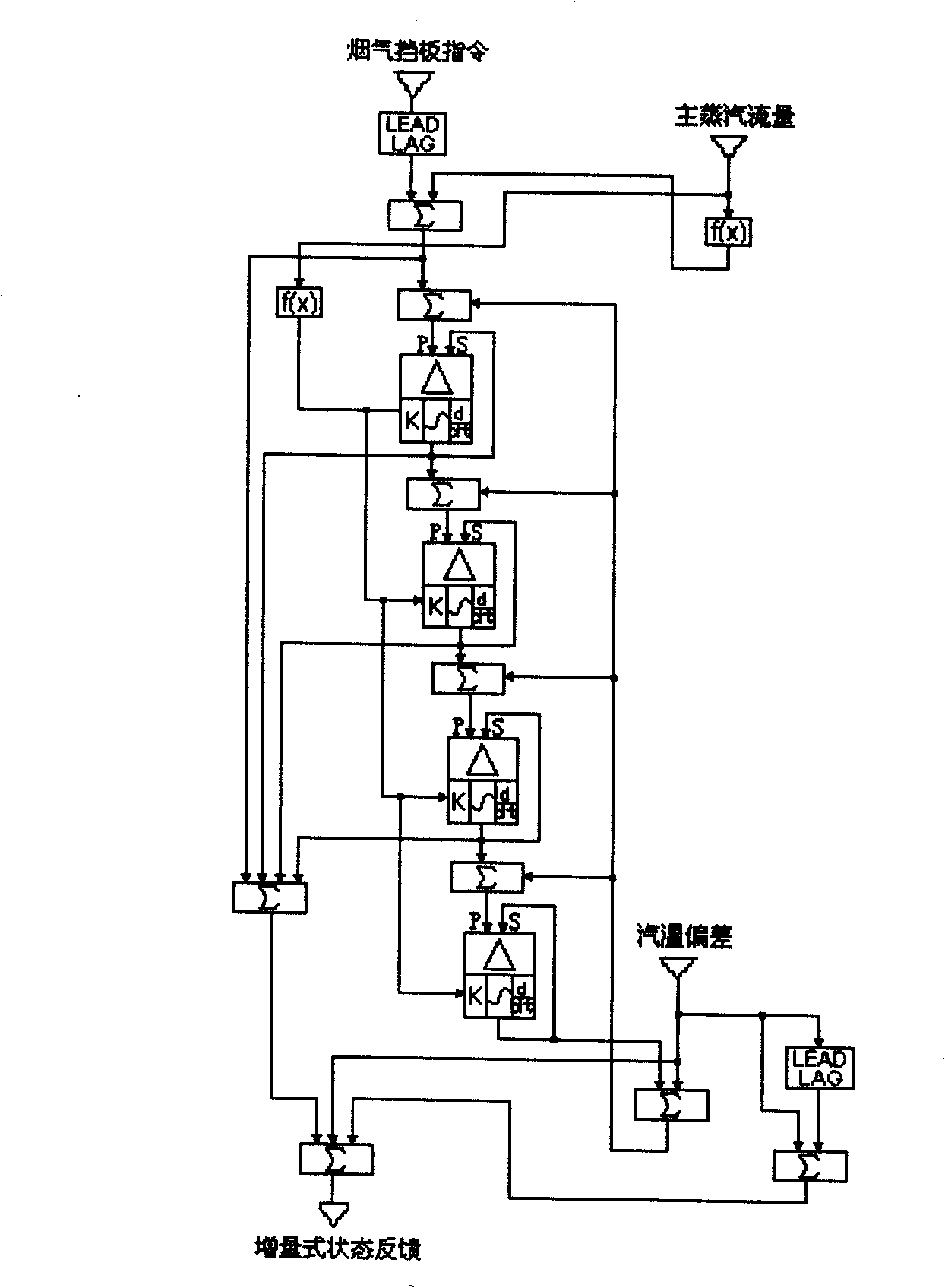

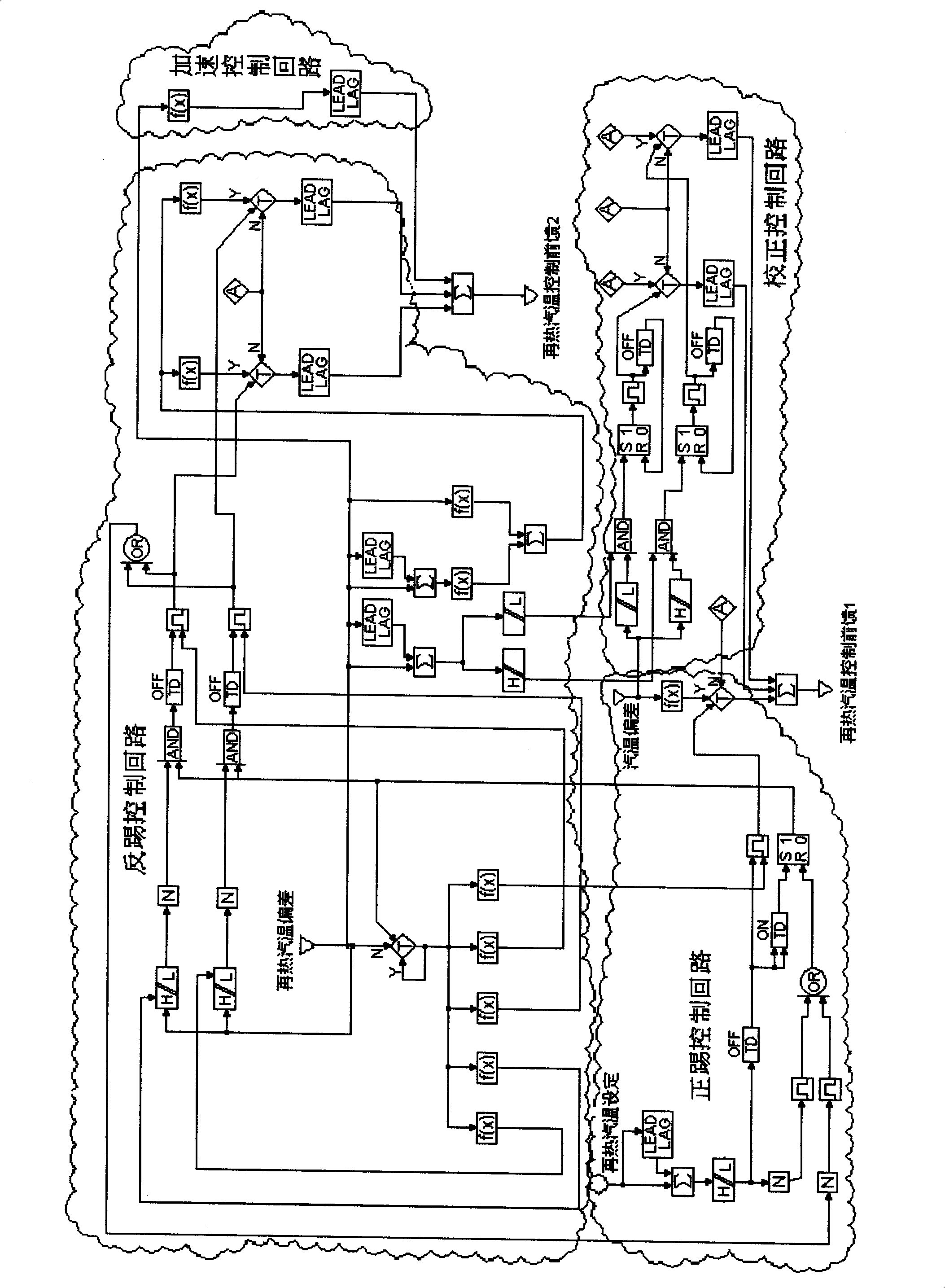

[0018] Such as figure 1 As shown, the present invention adopts the state feedback control method based on the incremental state observer according to the operation characteristics of the boiler reheater and the theoretical research on the boiler steam temperature control system, and utilizes the concept of the algebraically equivalent observer (AEO) Guide the parameter setting of the incremental state observer, and at the same time, in the steam temperature control loop, the steam temperature adjustment process is longer when the reheat steam temperature set value changes, there is nonlinearity in the steam temperature control, and the steam temperature change process is slow A special control loop is established, combined with a variable parameter PID regulator to form a comprehensive reheat steam temperature automatic adjustment system.

[0019] Su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com