Patents

Literature

2860 results about "Superheater" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

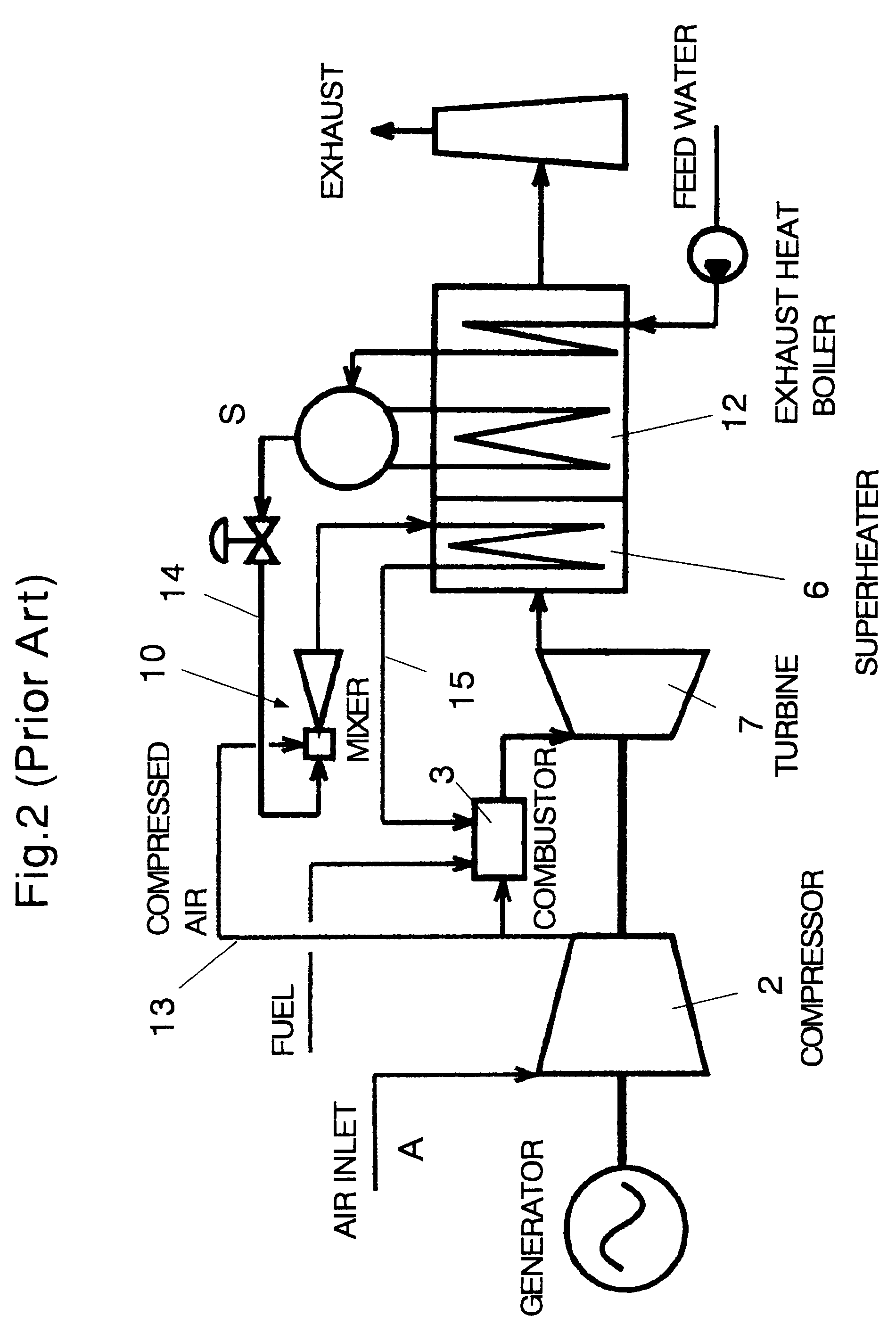

A superheater is a device used to convert saturated steam or wet steam into superheated steam or dry steam. Superheated steam is used in steam turbines for electricity generation, steam engines, and in processes such as steam reforming. There are three types of superheaters: radiant, convection, and separately fired. A superheater can vary in size from a few tens of feet to several hundred feet (a few metres to some hundred metres).

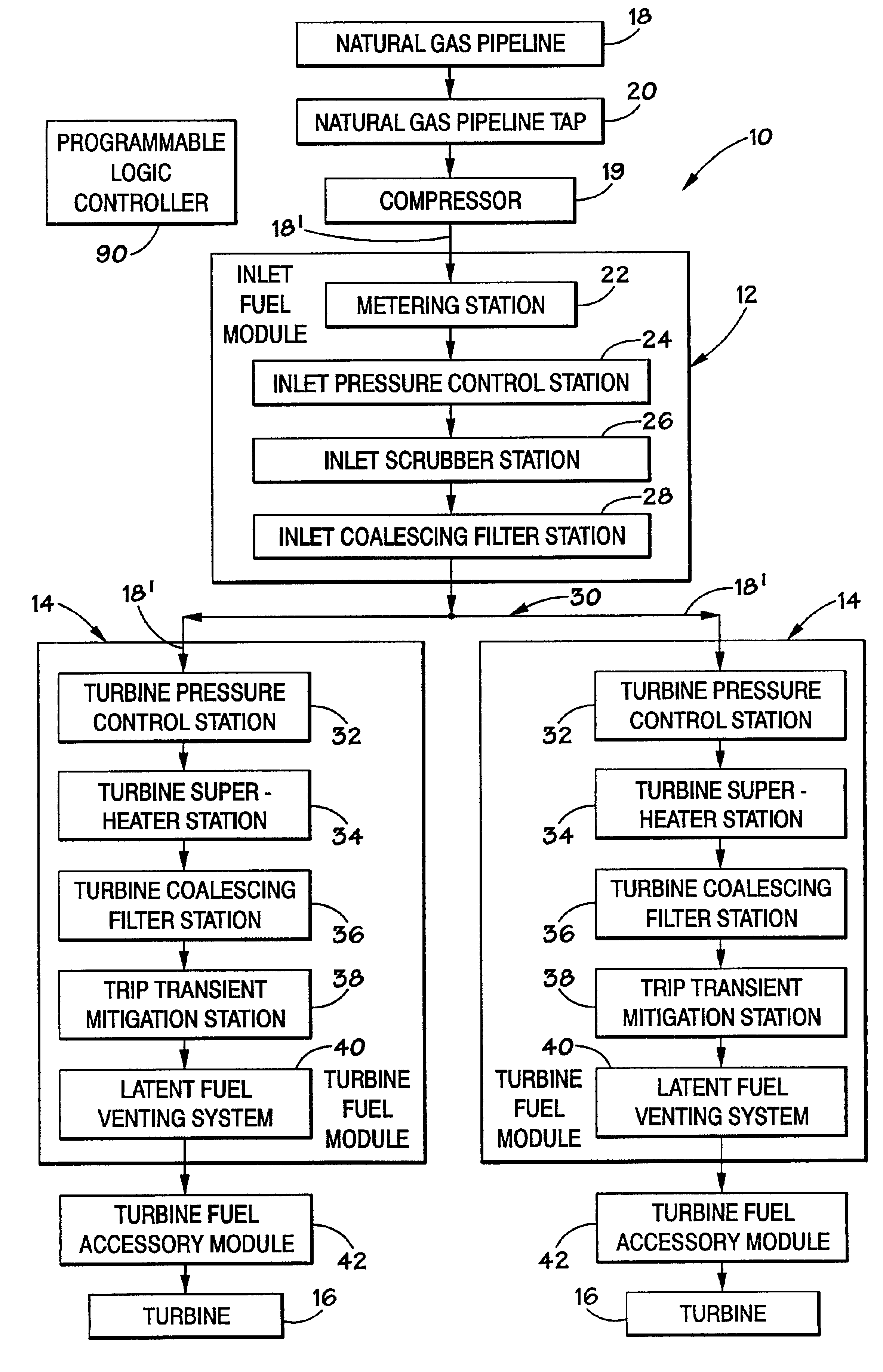

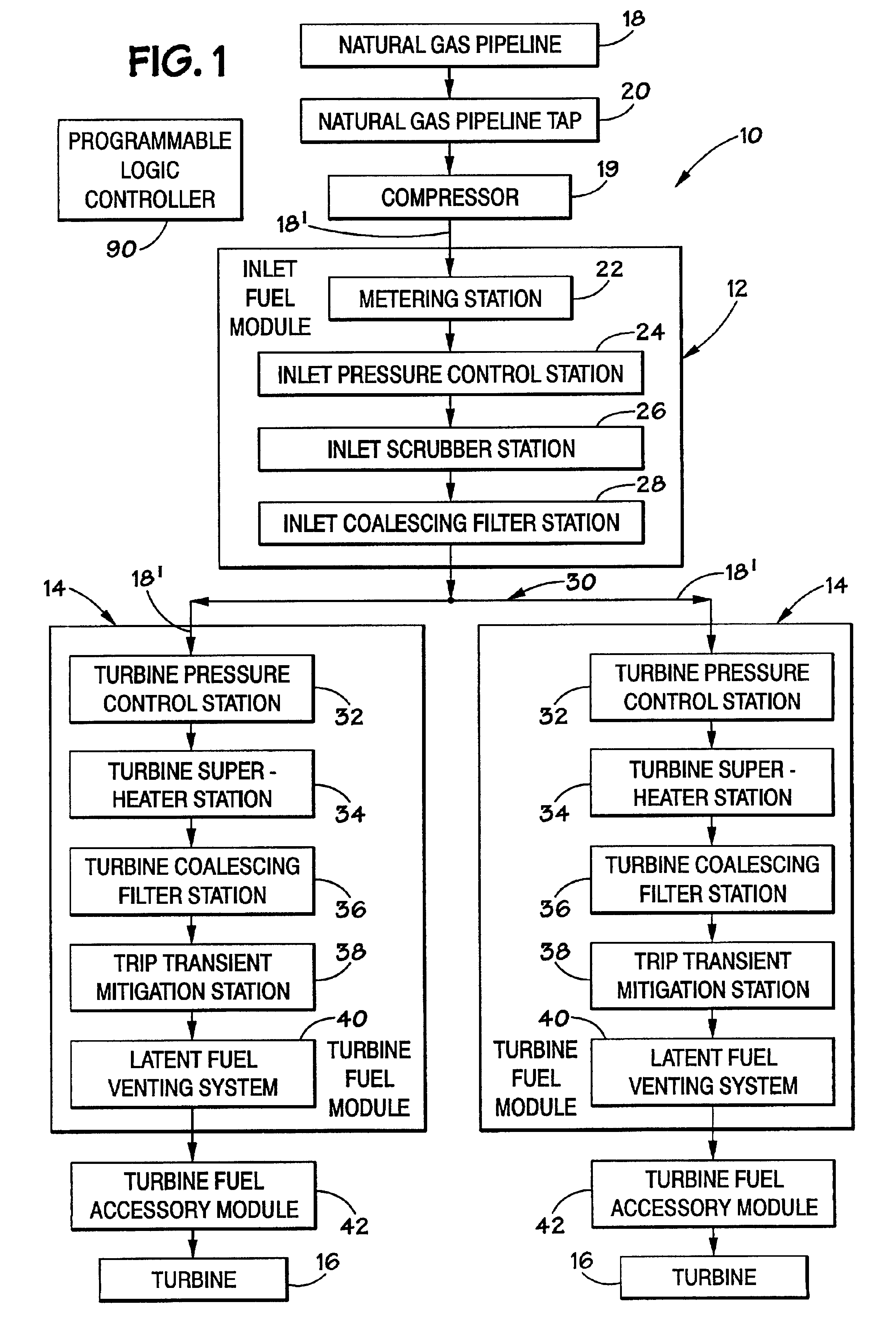

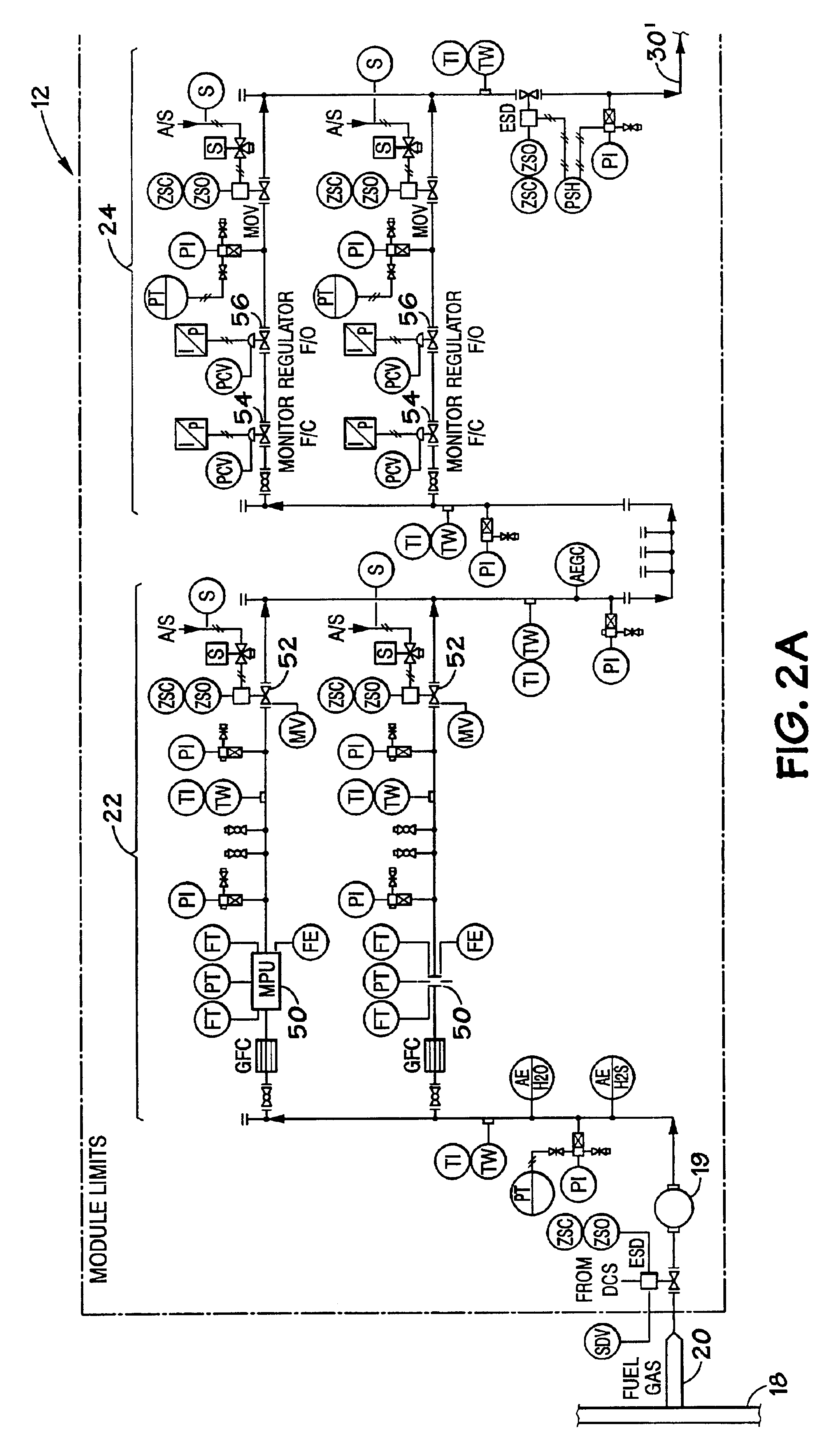

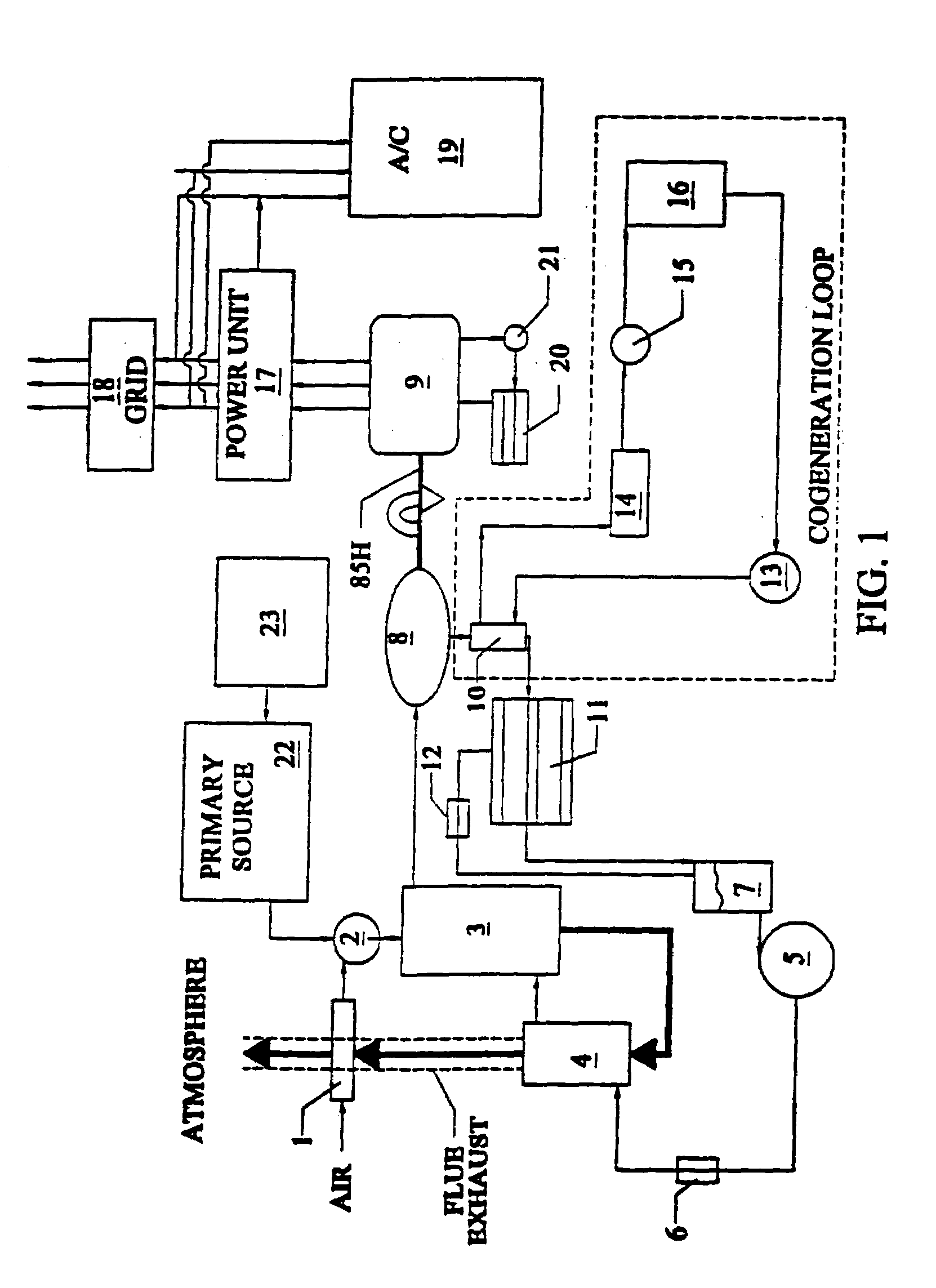

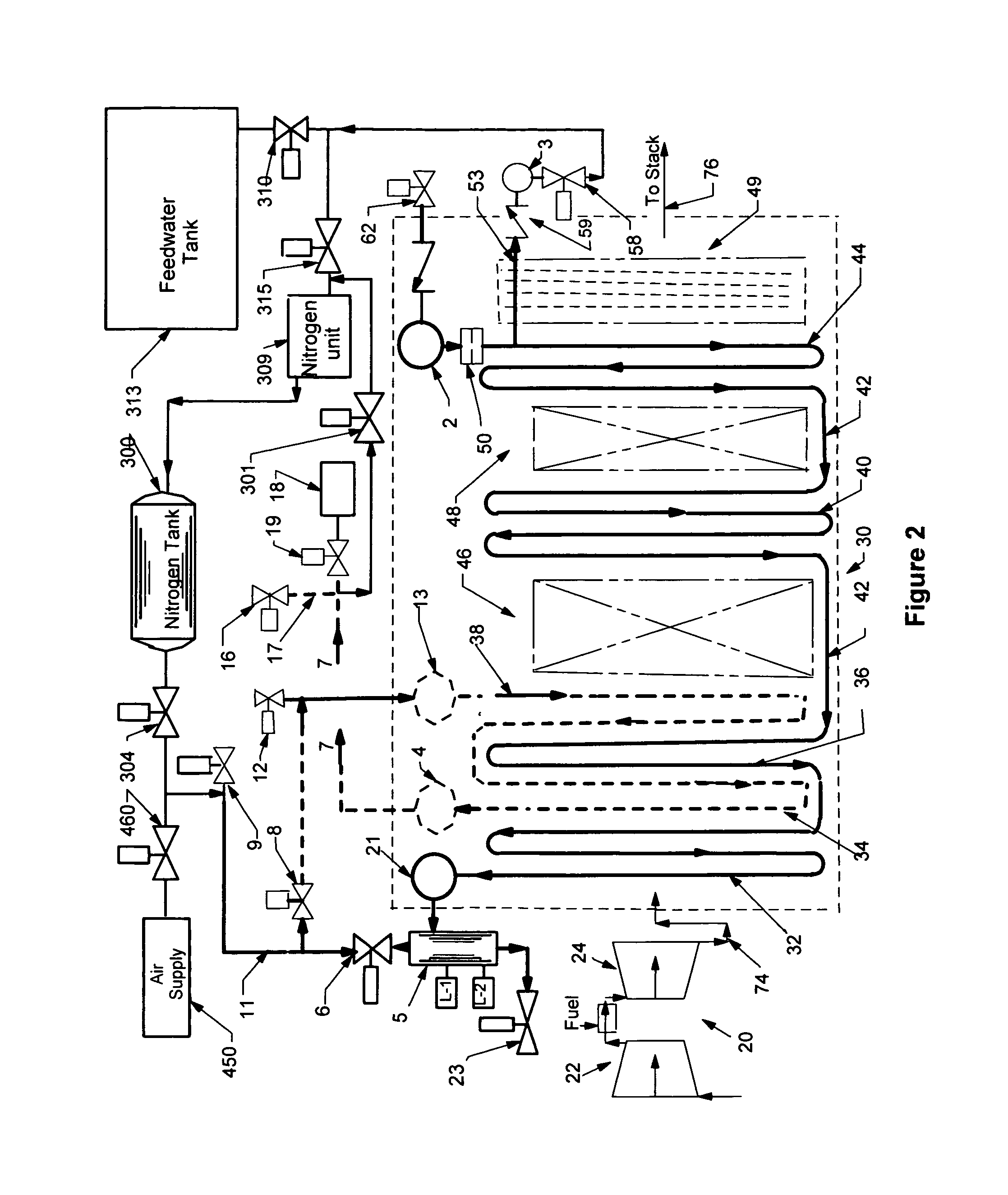

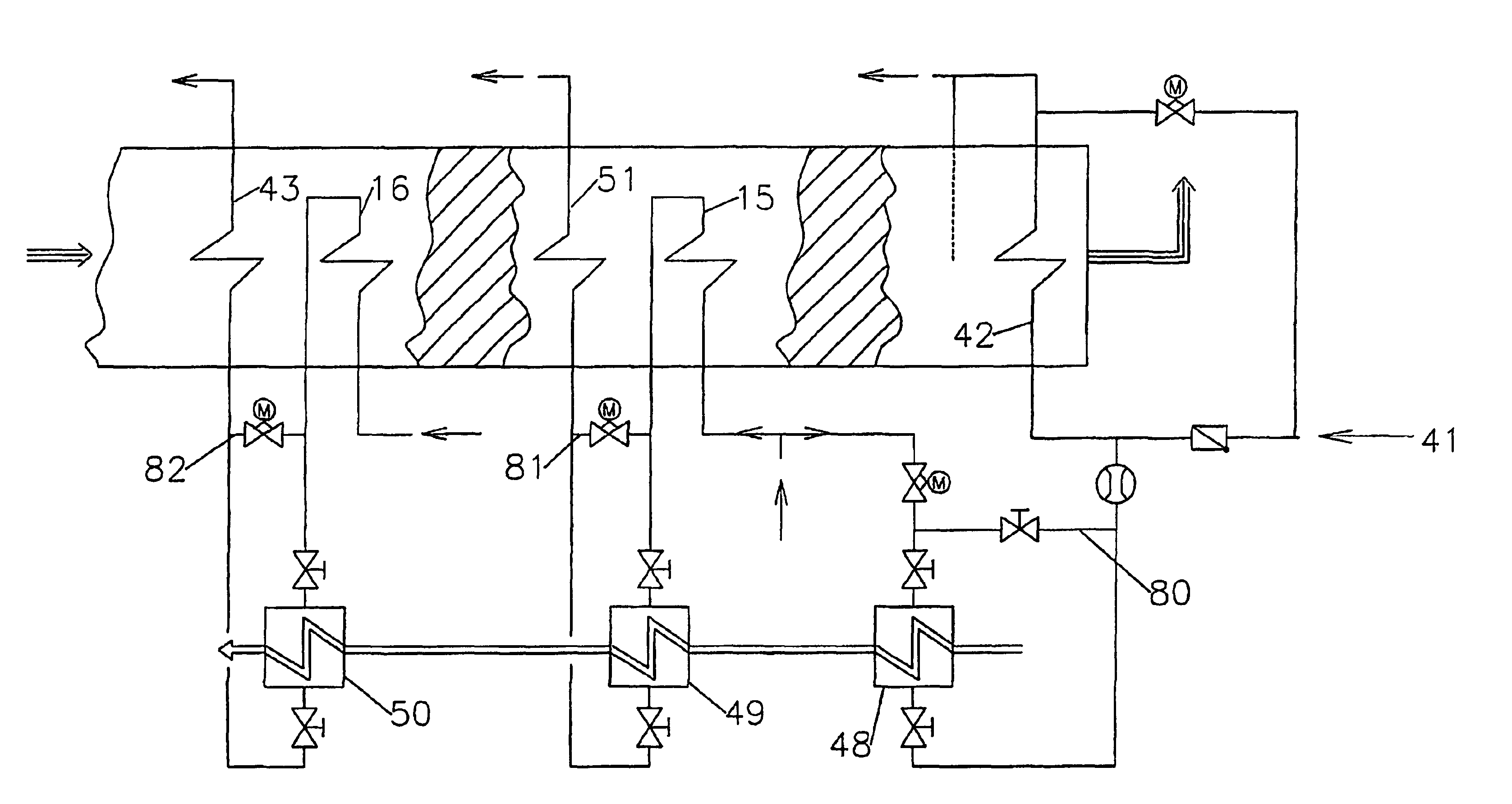

Modular fuel conditioning system

InactiveUS6901735B2Reduce pressureControl moreGas turbine plantsTurbine/propulsion fuel heatingProgrammable logic controllerModularity

A fuel conditioning system for a turbine plant may include an inlet fuel module followed by a turbine fuel module for each turbine, the modules being monitored and controlled by a programmable logic controller. The inlet fuel module may include a metering station, an inlet pressure control station, an inlet scrubber station, and an inlet coalescing filter station. Each turbine fuel module has a turbine pressure control station, a turbine super-heater station, and a turbine coalescing filter station. The fuel conditioning system may also include a trip transient mitigation system and a latent fuel venting system. The programmable logic controller collects data from all of the stations and systems as well as the turbine and then uses self-correcting algorithms to control the stations and systems. The programmable logic controller also stores the data collected and transmits the data to an off-site storage and verification center.

Owner:PIPELINE CONTROLS

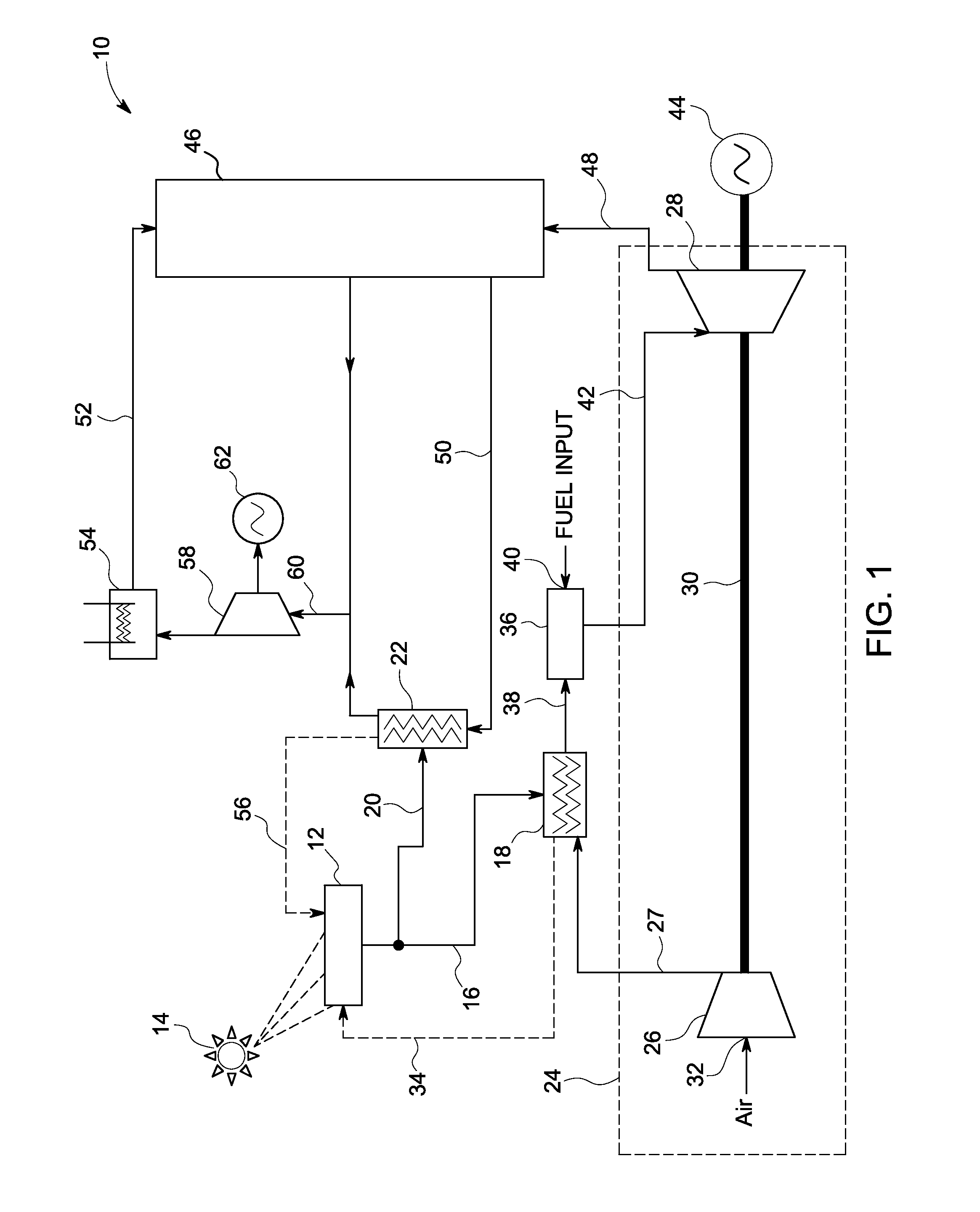

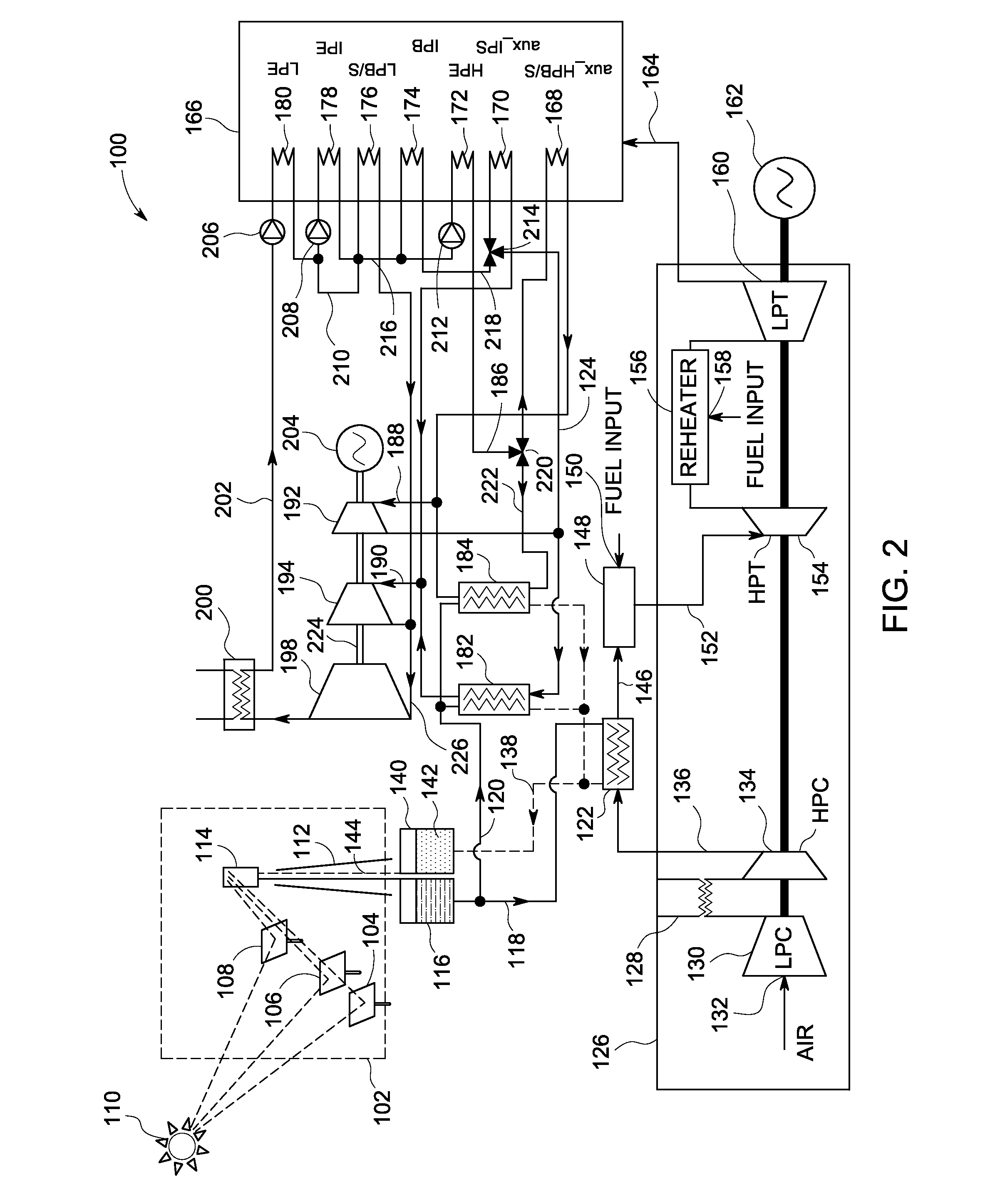

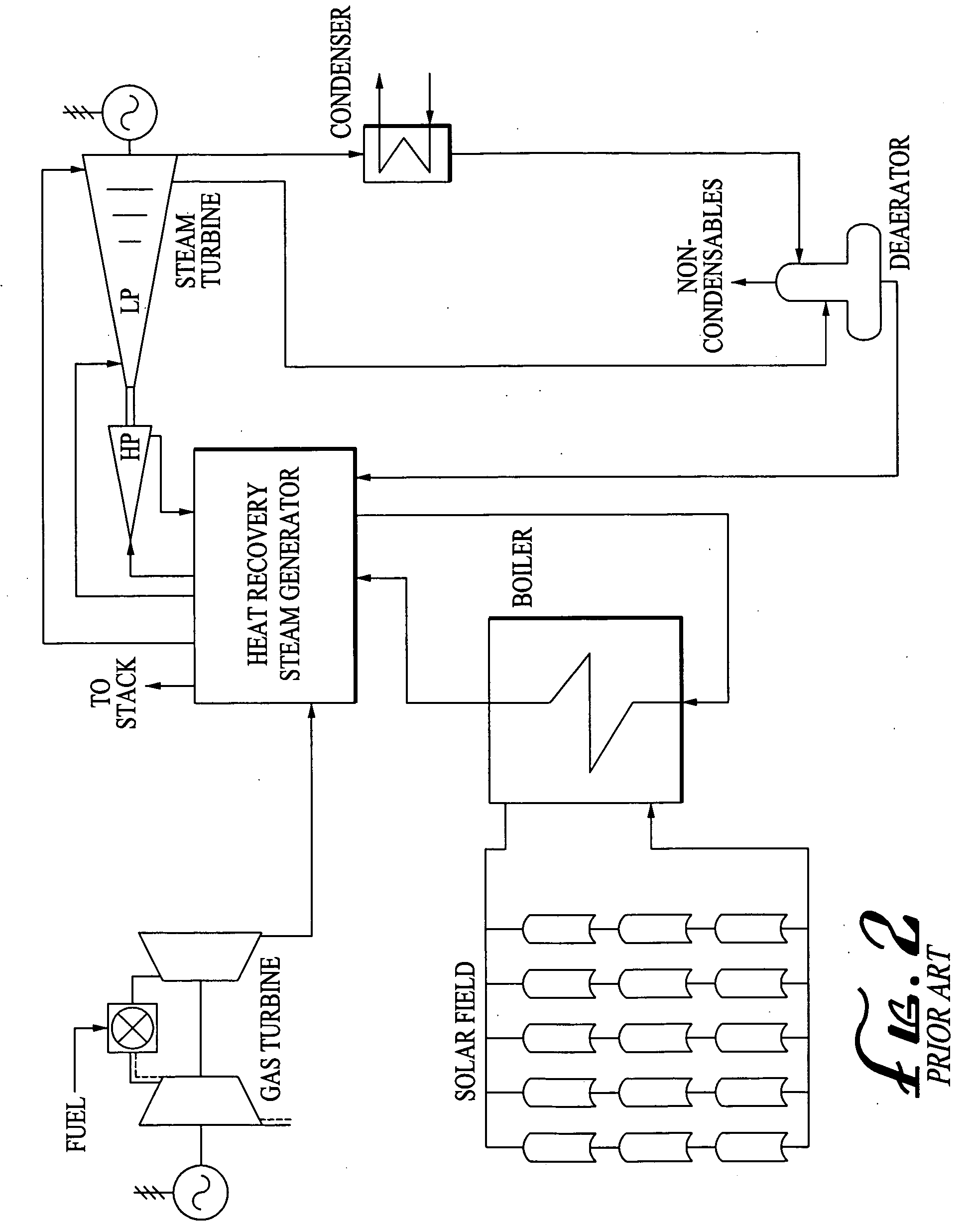

System for generation of power using solar energy

An electricity generation system is presented. The electricity generation system includes a solar preheater for preheating compressed discharge air, a combustor to receive the heated compressed air from the solar preheater, burn a fuel using the heated compressed air to generate hot burned gas, a first turbine to receive the hot burned gas from the combustor, expand the hot burned gas to generate exhaust gas, a heat recovery steam generator to receive the exhaust gas from the first turbine, generate vapor by heating a condensed fluid using the exhaust gas, a solar evaporator / superheater to receive a heated working fluid from the heat recovery steam generator, generate solar vapor by heating the heated working fluid, and a second turbine to drive a second generator using vapor and the solar vapor.

Owner:GENERAL ELECTRIC CO

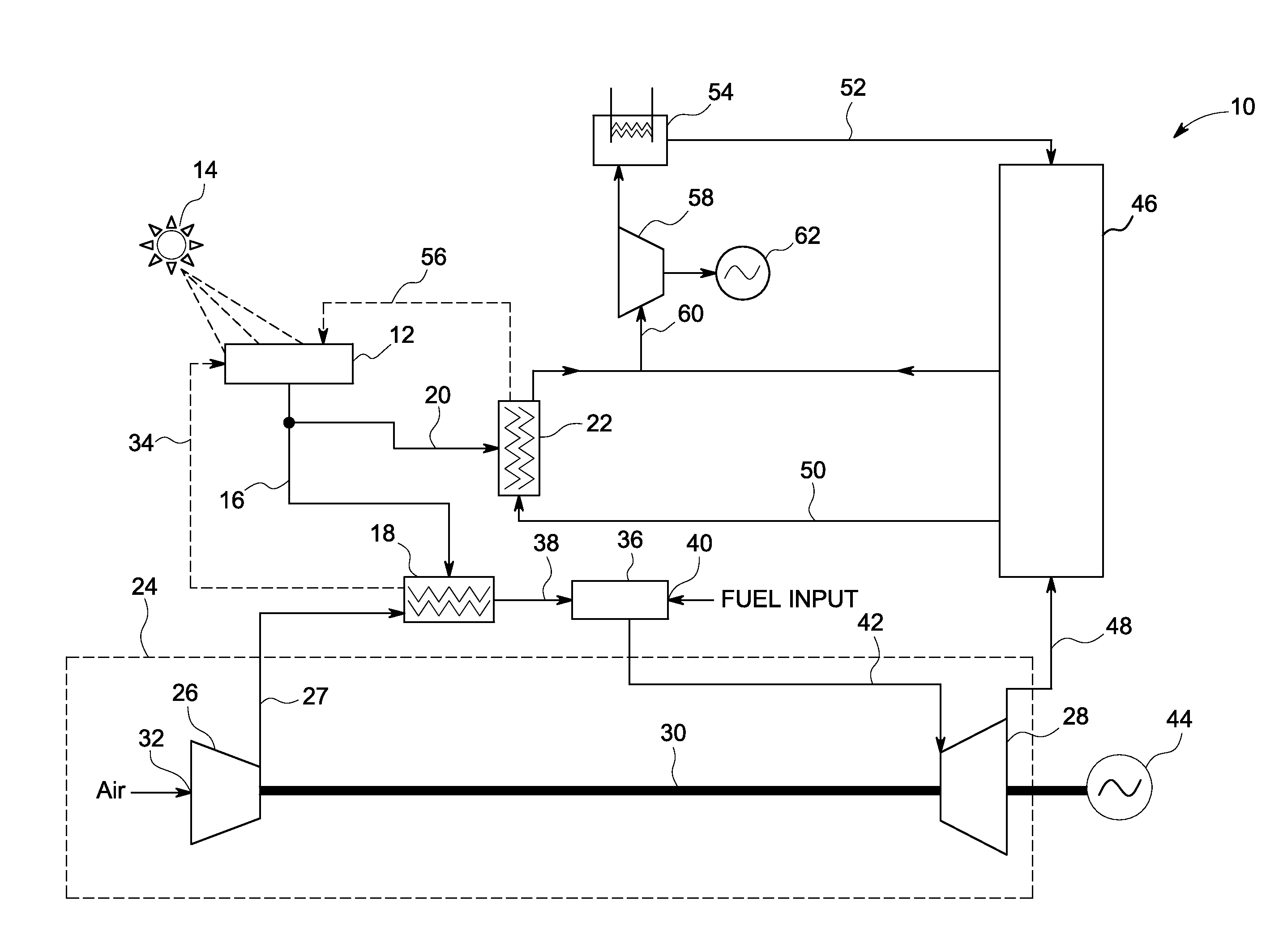

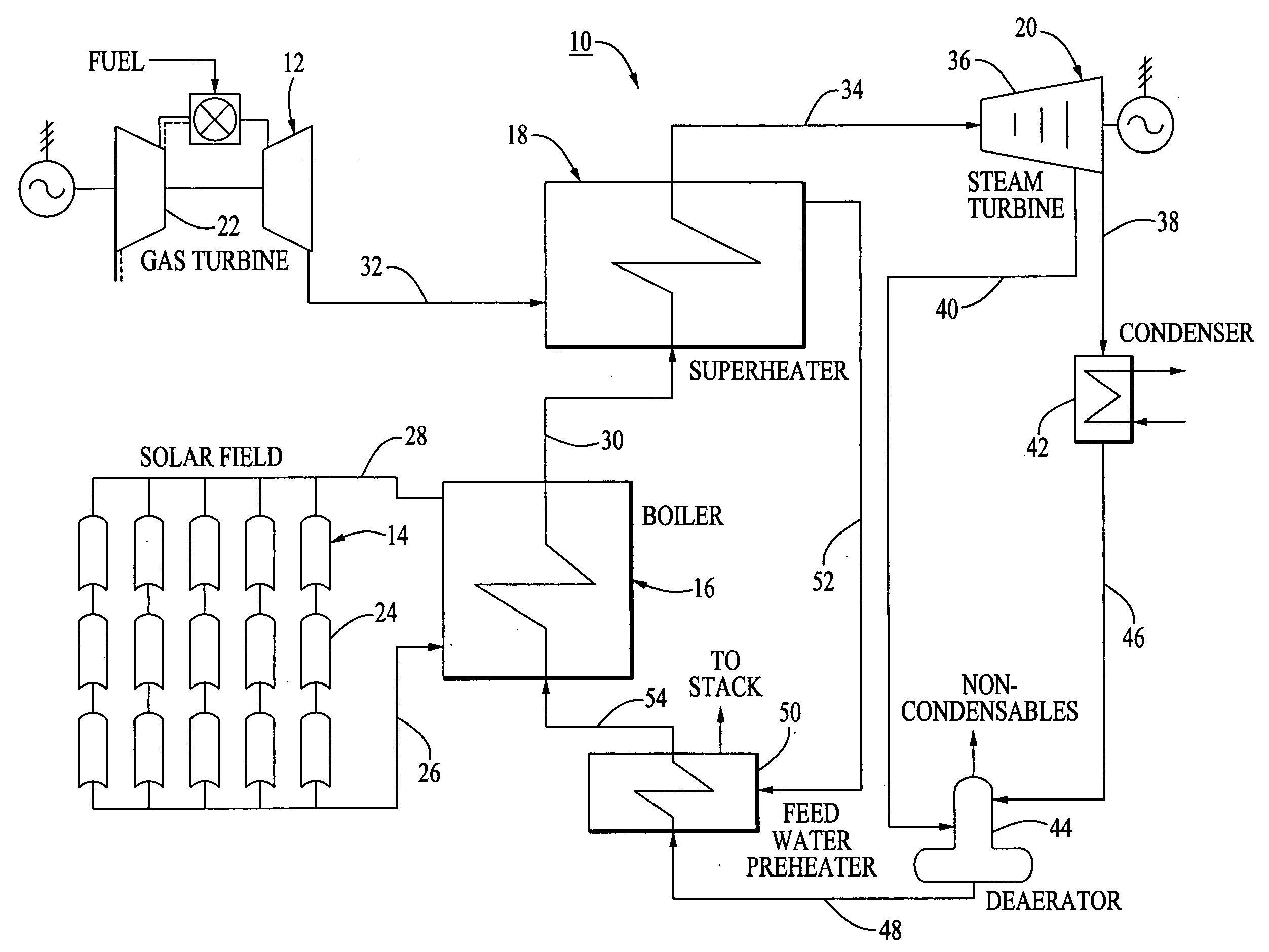

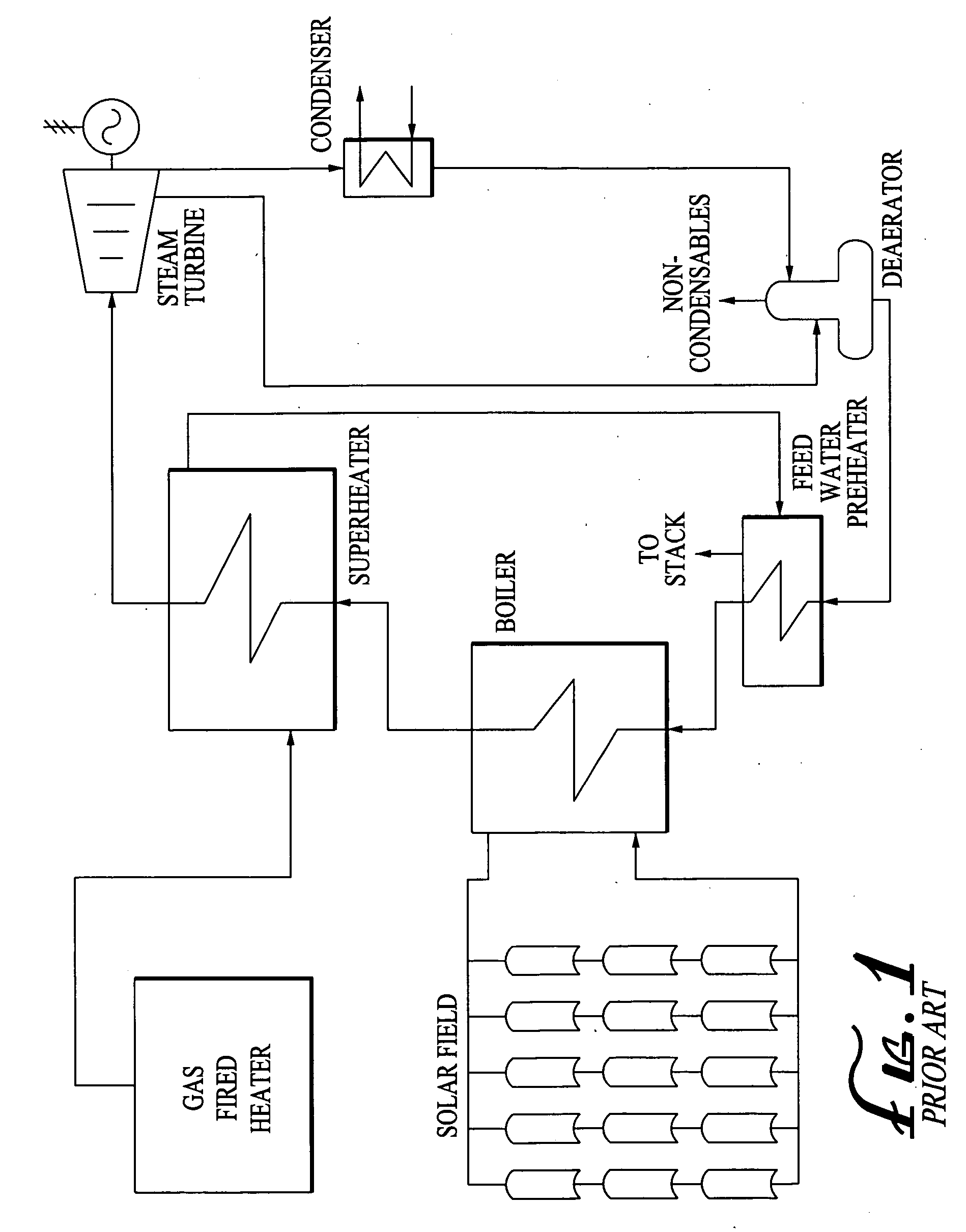

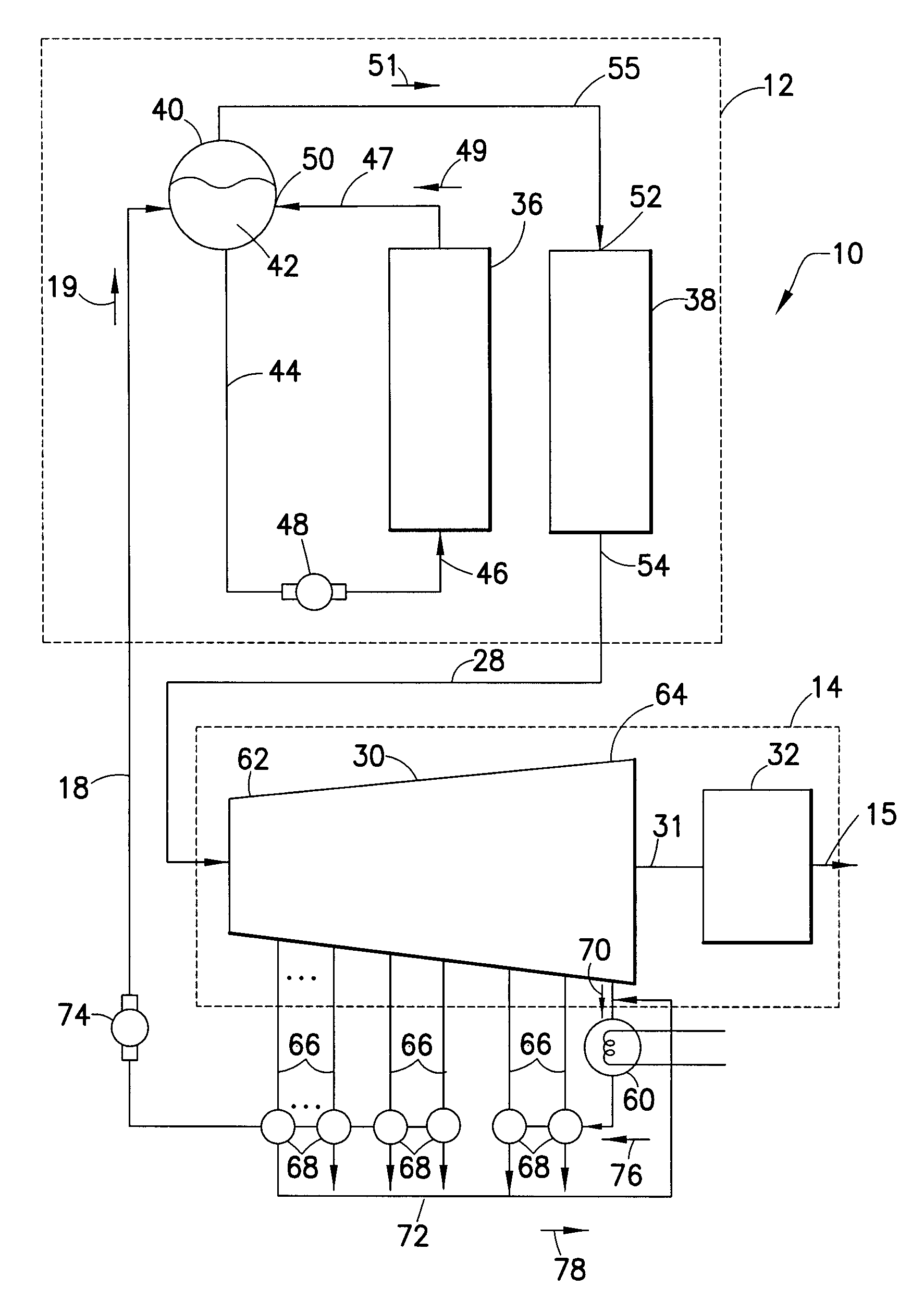

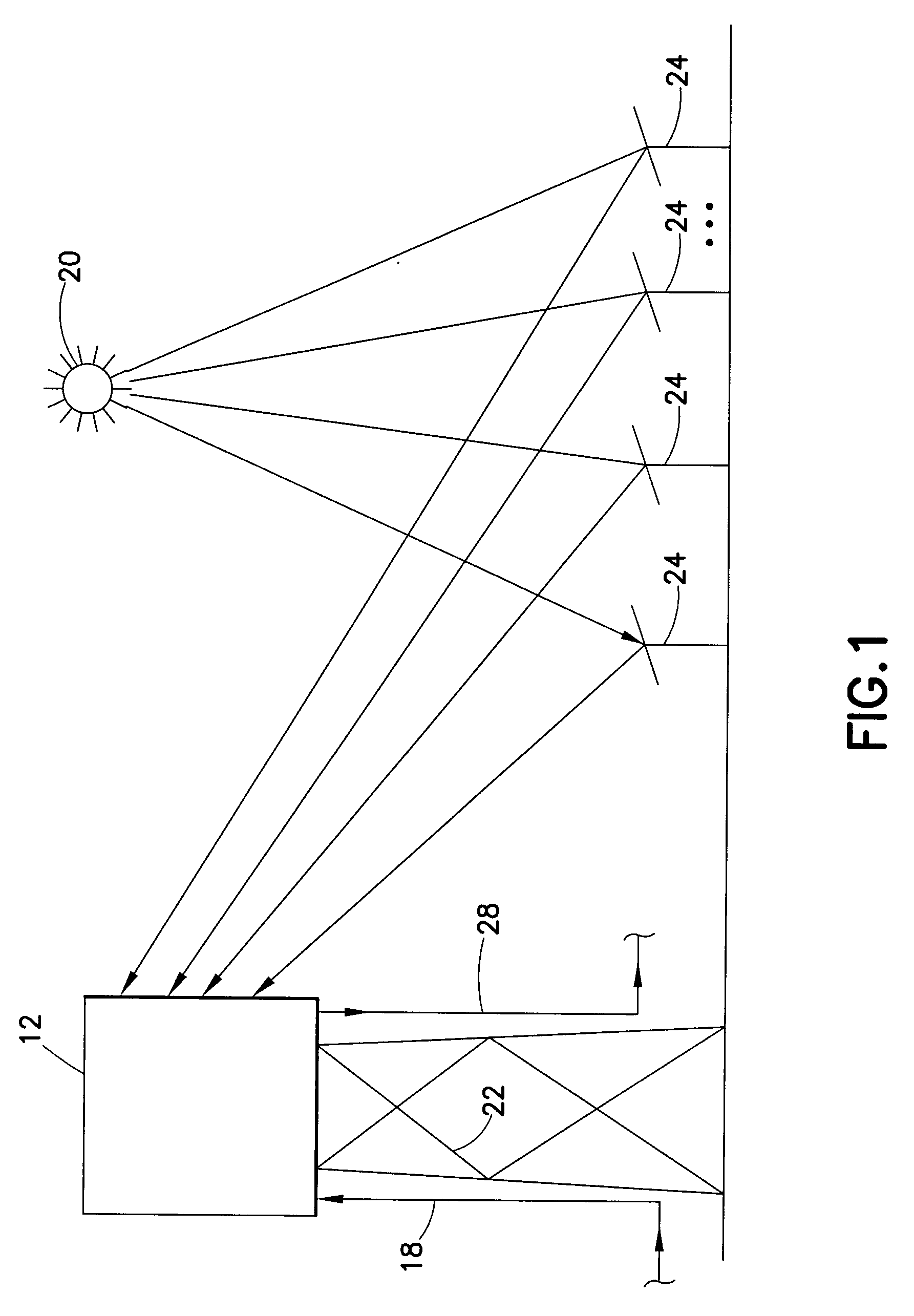

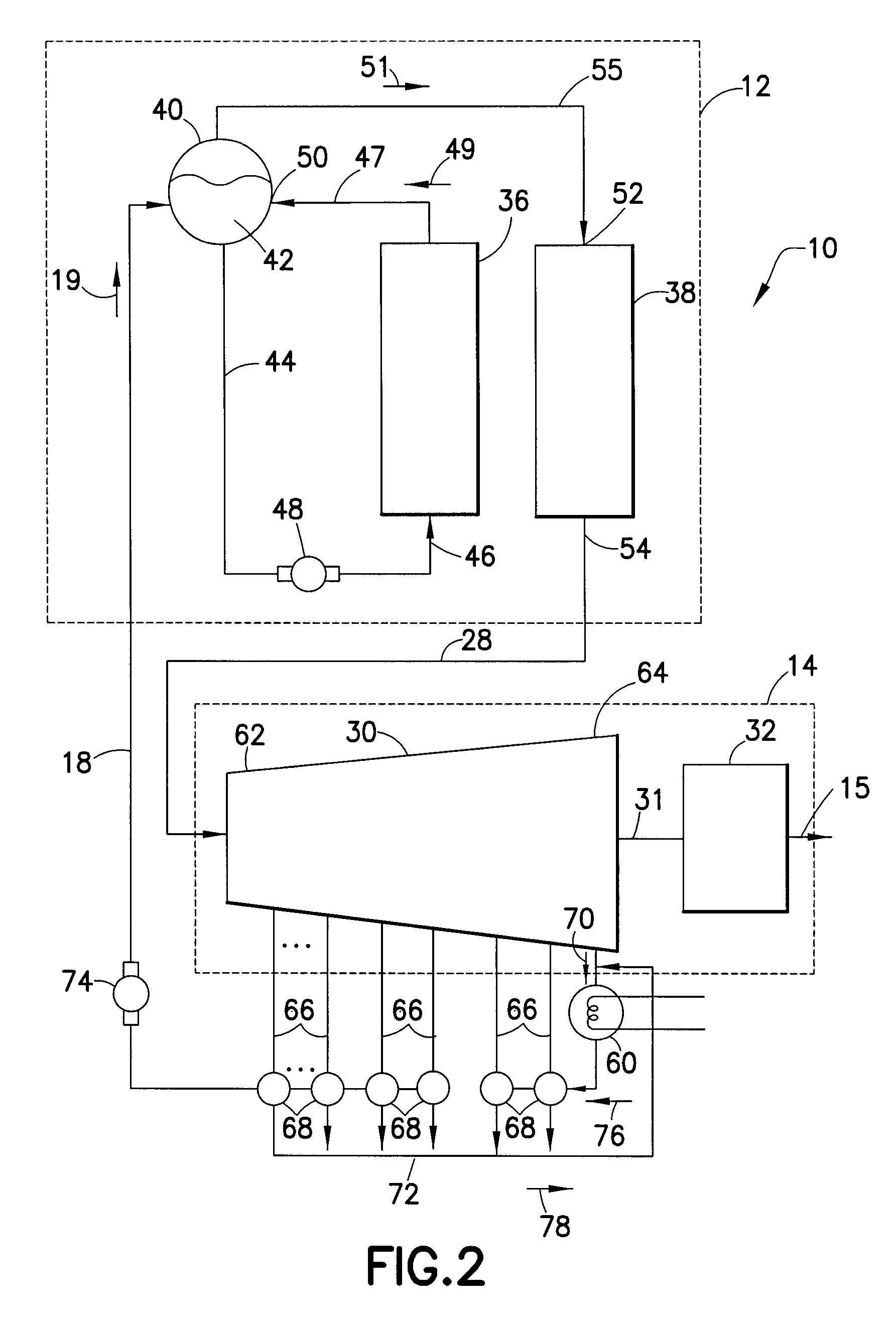

Electrical generating system using solar energy and gas turbine

An apparatus for generating electricity using both solar energy and a gas turbine includes (a) a gas turbine electric generator; (b) a solar energy collector array; (c) a vaporizer for vaporizing a working fluid liquid, such as water, using thermal energy derived from the solar energy collector array; (d) one or more superheaters for superheating working fluid vapor produced in the vaporizer; and (e) a working fluid vapor turbine electric generator, such as a steam turbine electric generator, the working fluid vapor turbine electric generator being driven by the superheated working fluid vapor. The apparatus is configured such that all of the working fluid vapor exiting the one or more superheaters is that which is produced in the vaporizer.

Owner:SKOWRONSKI MARK

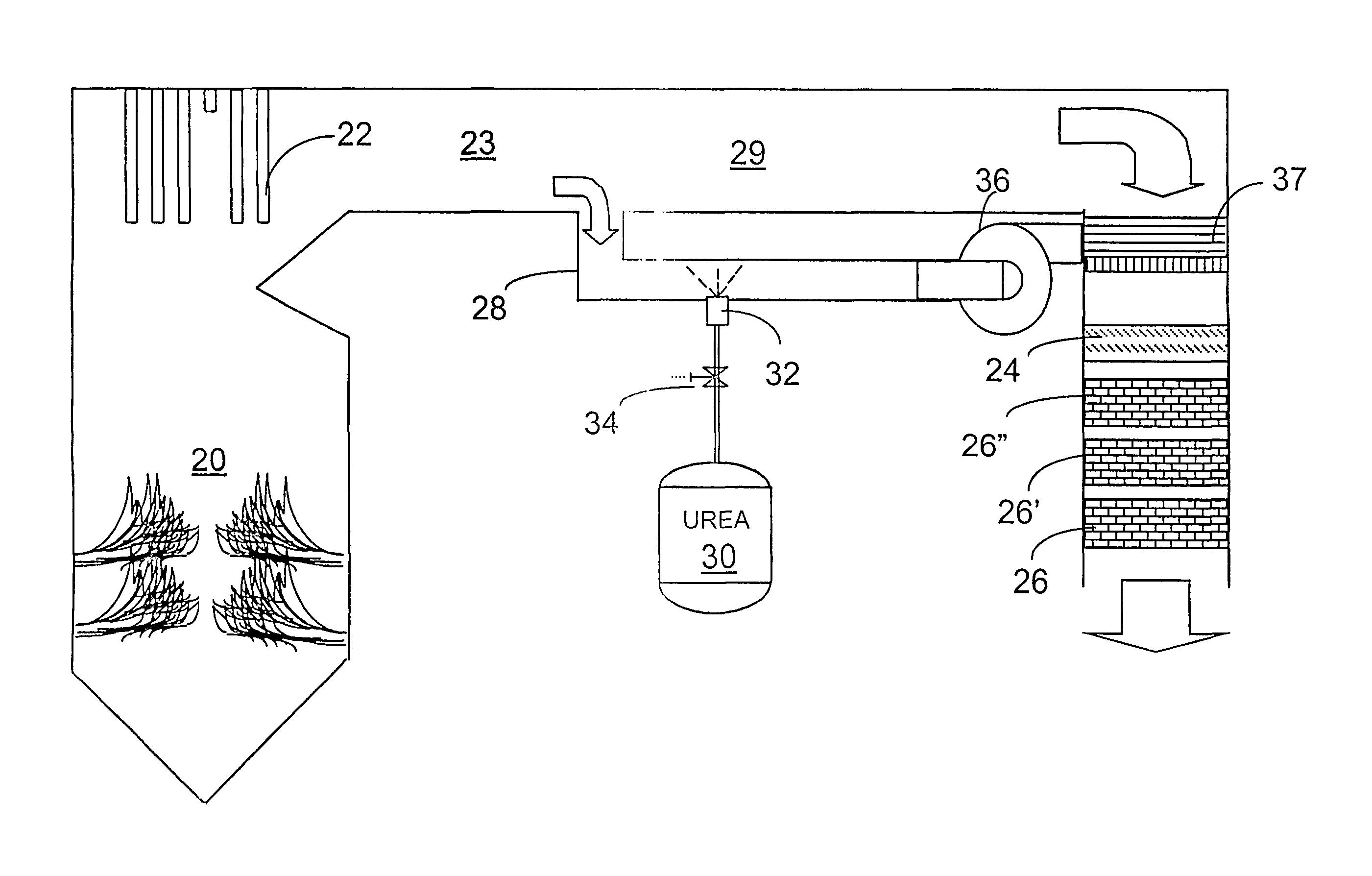

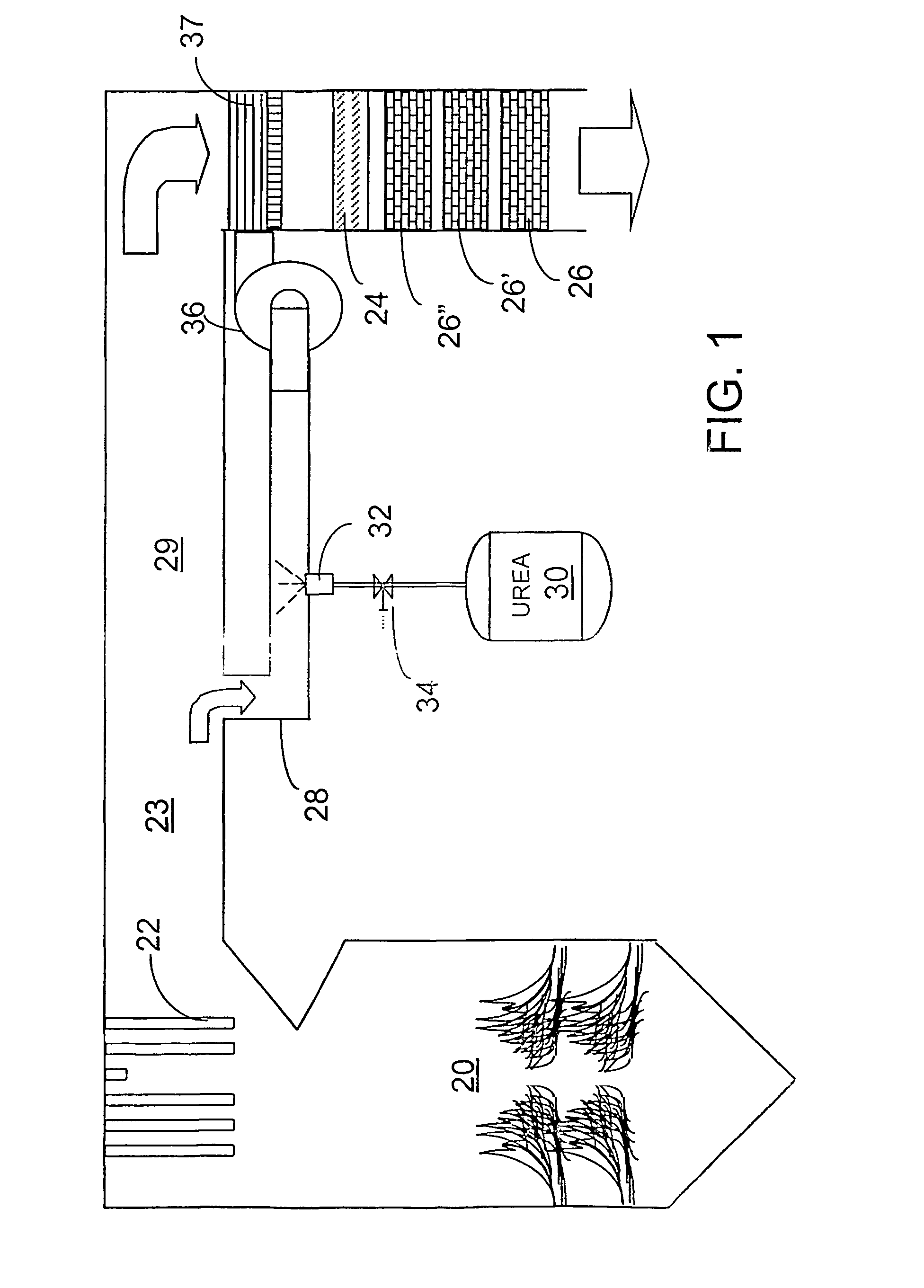

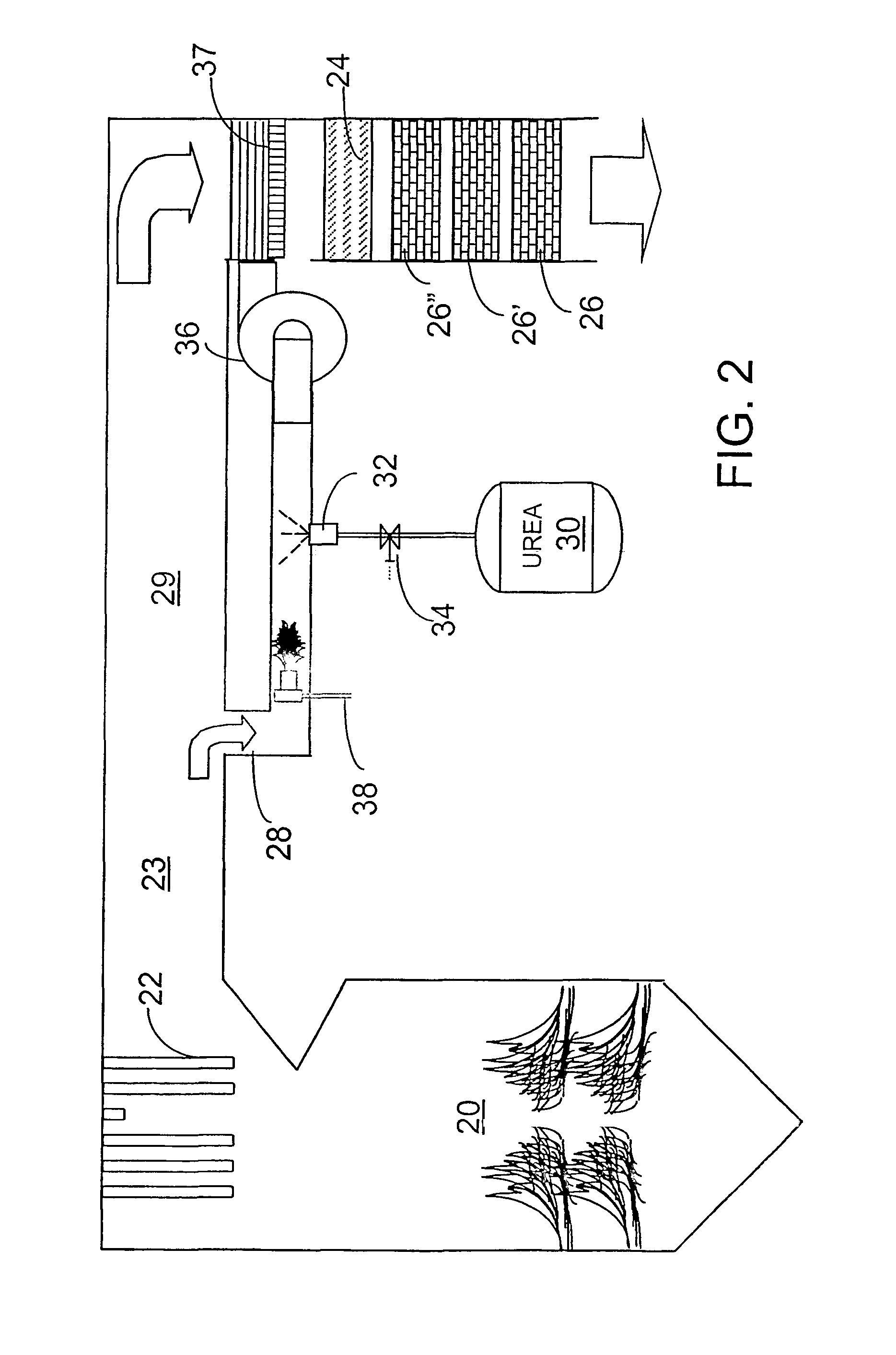

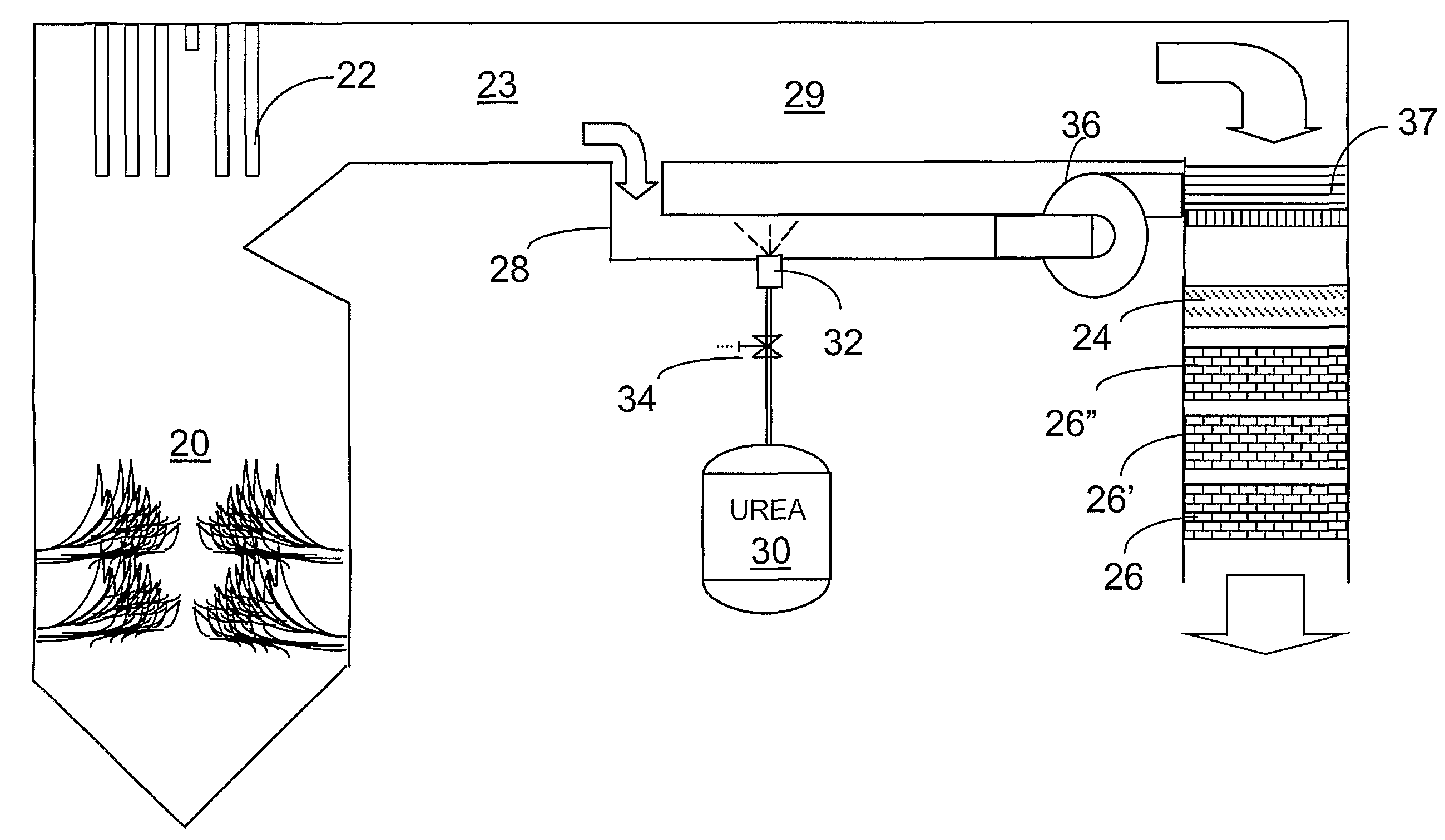

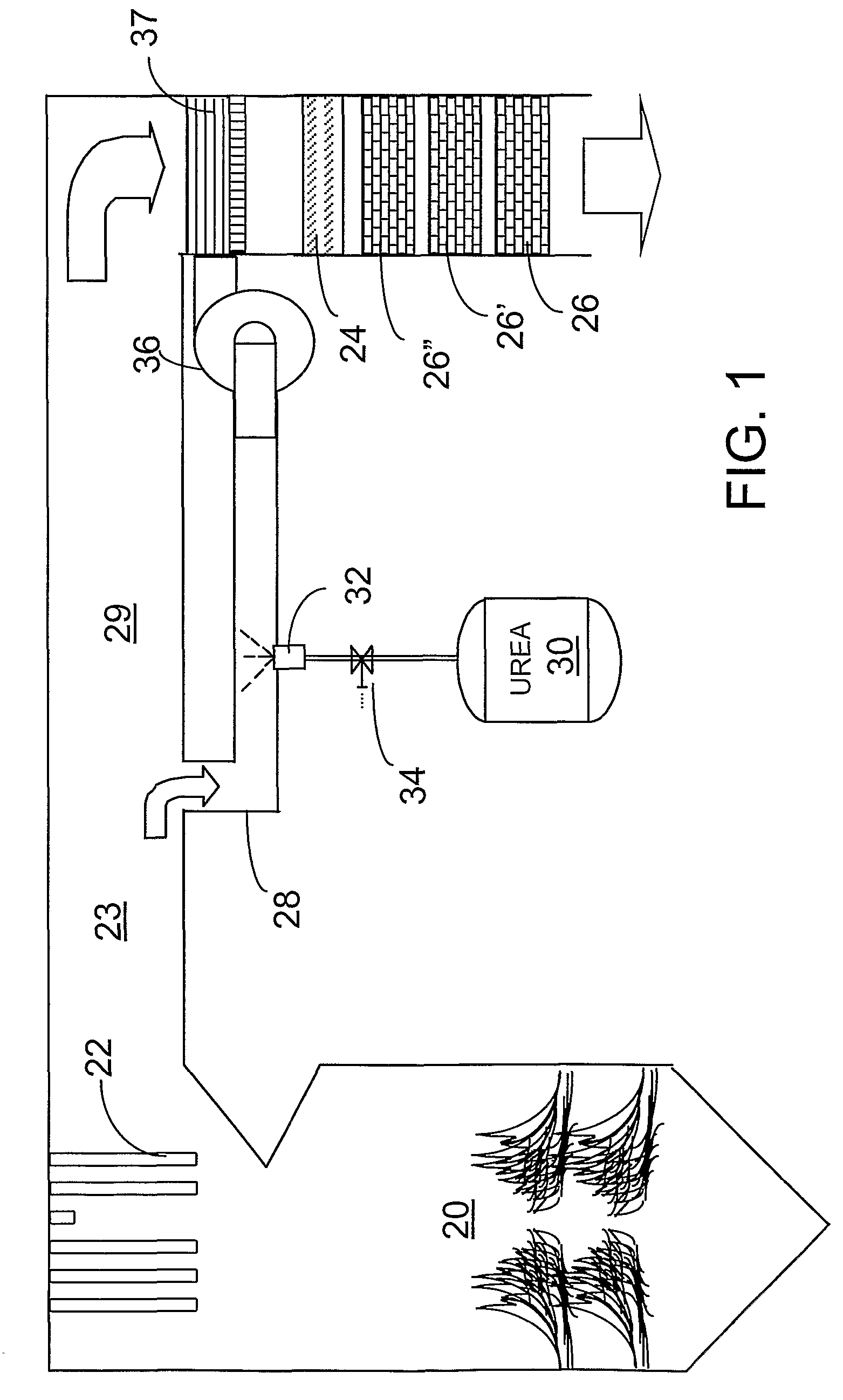

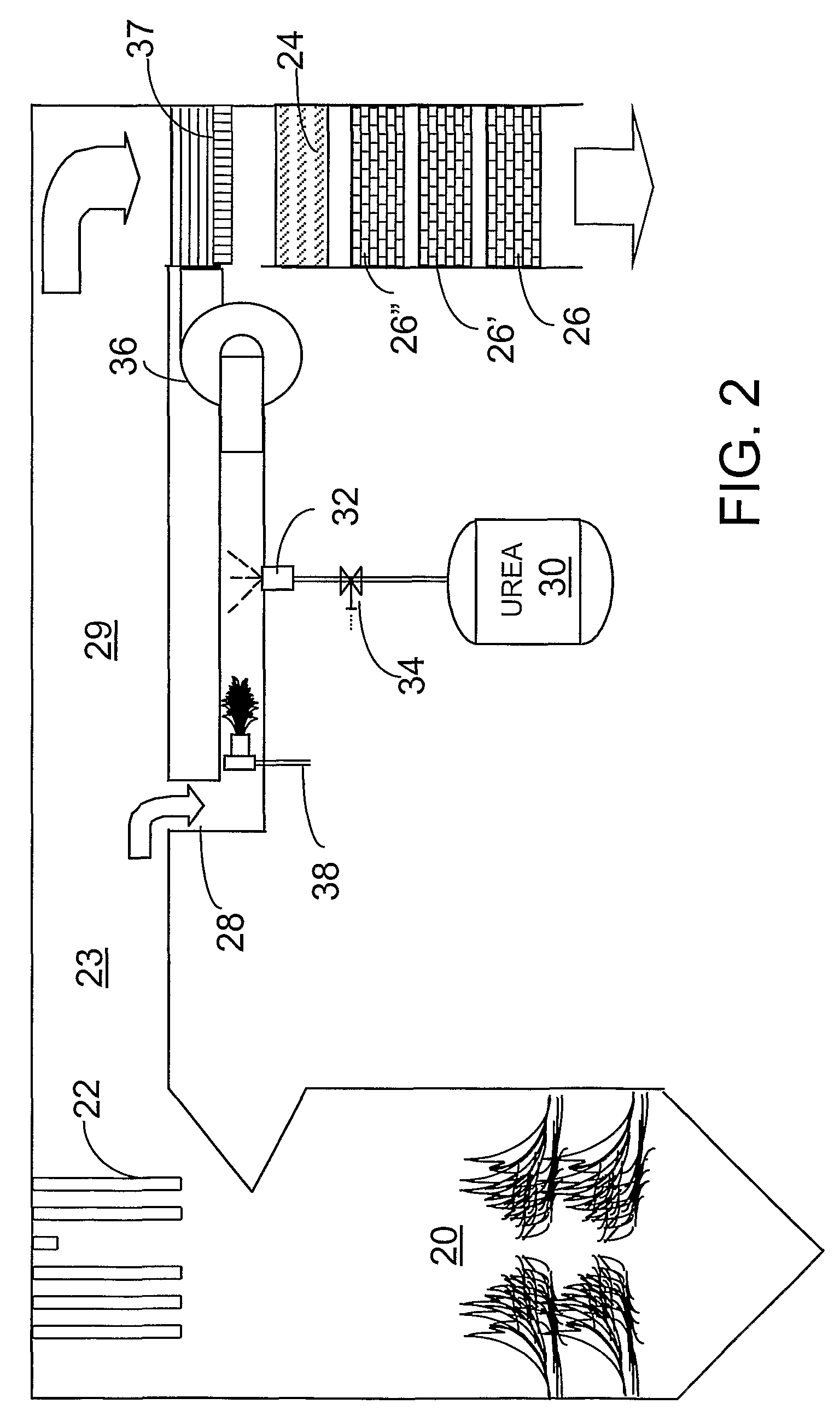

Selective catalytic reduction of nox enabled by sidestream urea decomposition

InactiveUS7090810B2Well mixedAccurate temperatureNitrogen compoundsInternal combustion piston enginesParticulatesSuperheater

A preferred process arrangement utilizes the enthalpy of the flue gas, which can be supplemented if need be, to convert urea (30) into ammonia for SCR. Urea (30), which decomposes at temperatures above 140 ° C., is injected (32) into a flue gas stream split off (28) after a heat exchanger (22), such as a primary superheater or an economizer. Ideally, the side stream would gasify the urea without need for further heating; but, when heat is required it is far less than would be needed to heat either the entire effluent (23) or the urea (30). This side stream, typically less than 3% of the flue gas, provides the required temperature and residence time for complete decomposition of urea (30). A cyclonic separator can be used to remove particulates and completely mix the reagent and flue gas. This stream can then be directed to an injection grid (37) ahead of SCR using a blower (36). The mixing with the flue gas is facilitated due to an order of magnitude higher mass of side stream compared to that injected through the AIG in a traditional ammonia-SCR process.

Owner:FUEL TECH

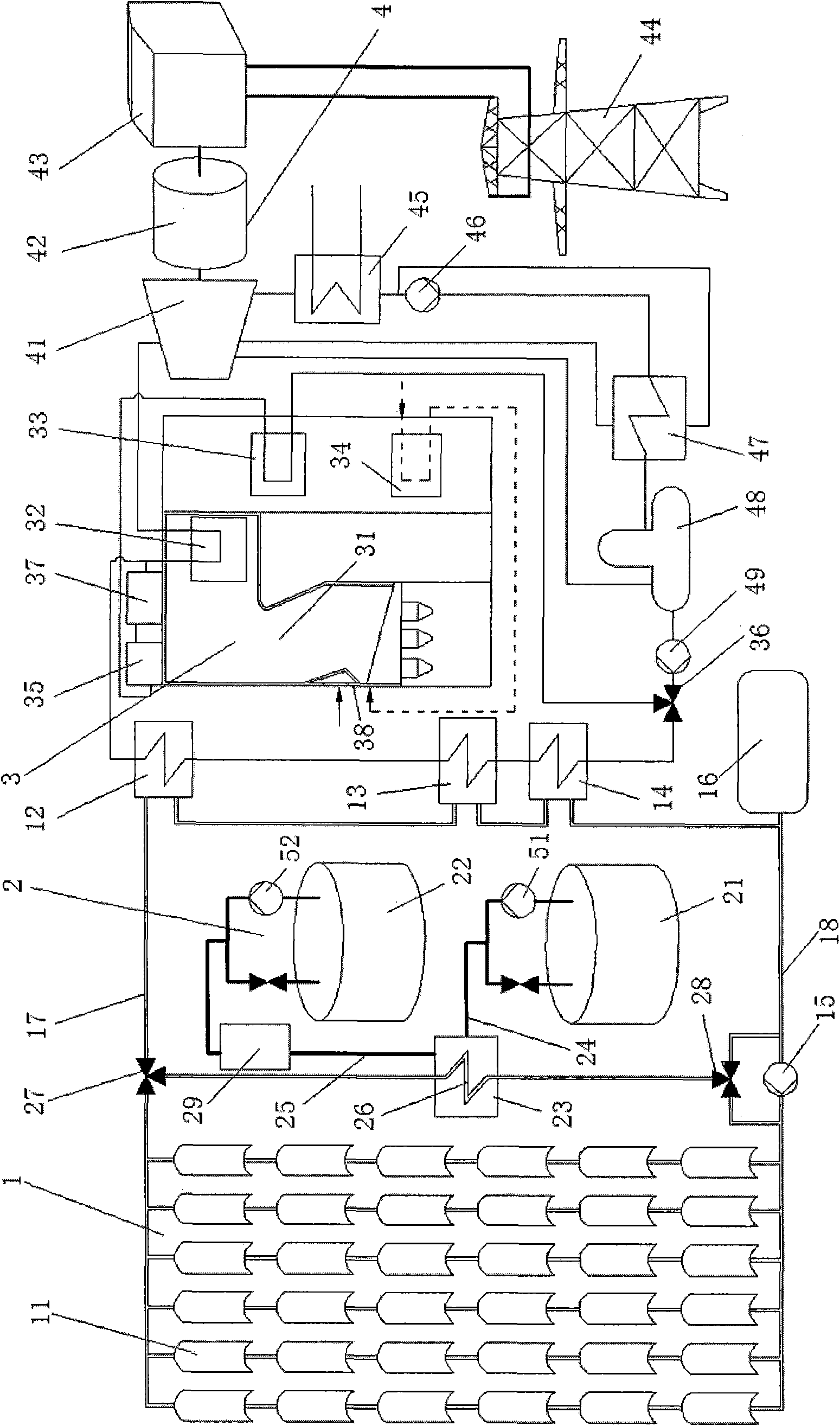

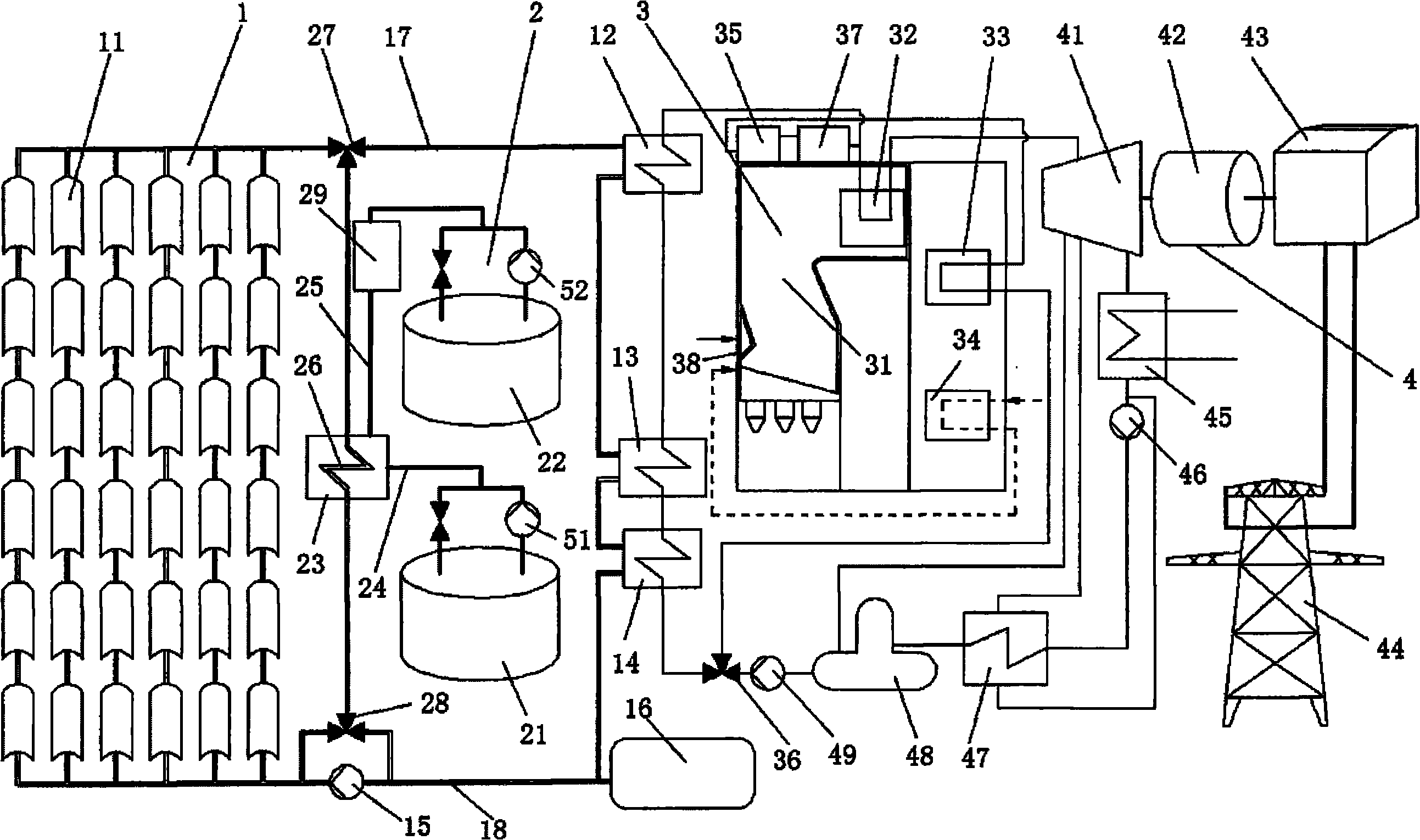

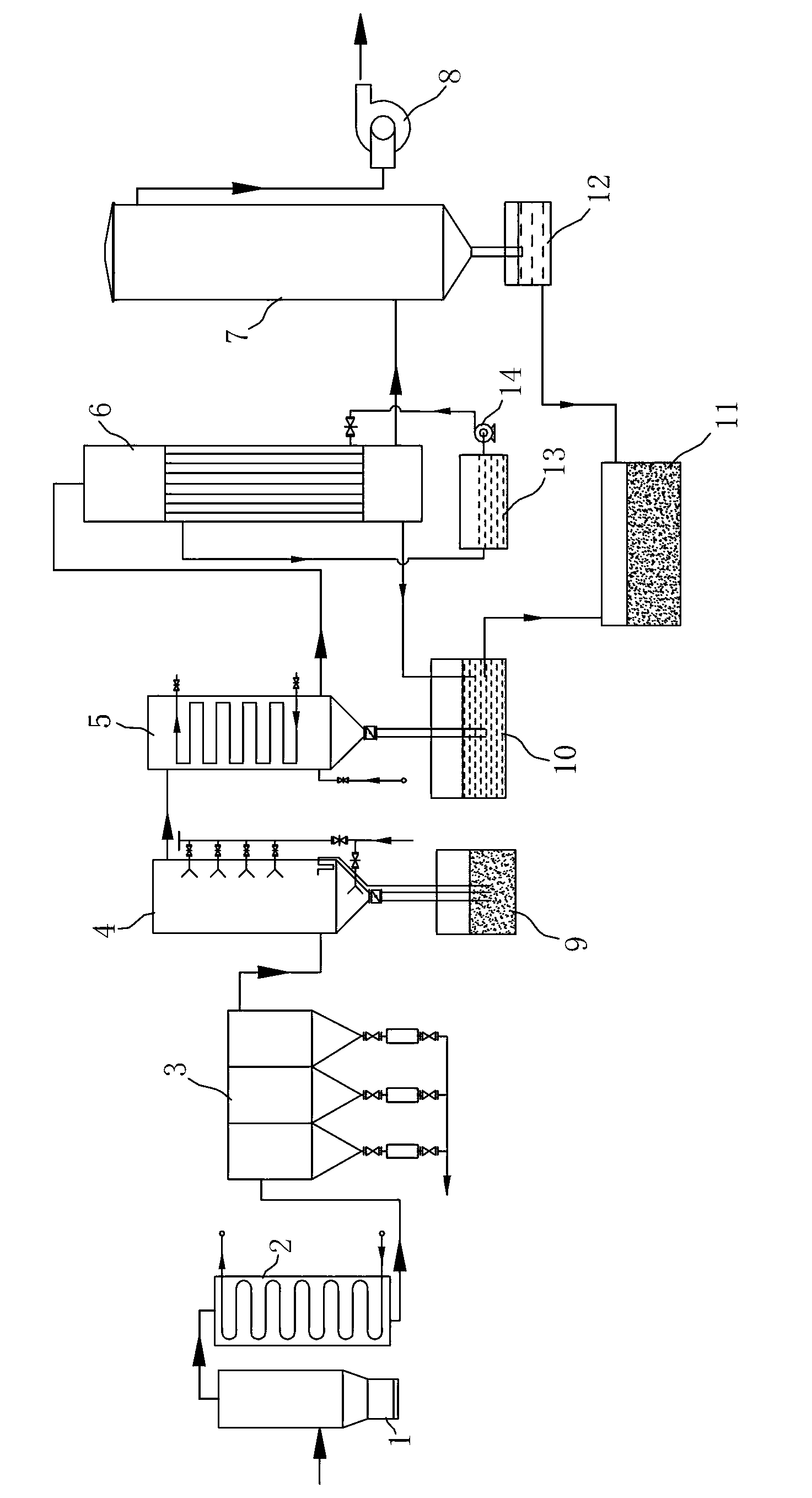

Method and system for combing solar energy thermal power generation with biomass power generation

ActiveCN101876299AReduce dosageReduce procurement costsSteam generation heating methodsFrom solar energyThermal energyCounter flow

The invention relates to a method and a system for combining solar energy thermal power generation with biomass power generation. When the method is used for generating electricity in the daytime (a fine day), one path of heat transfer oil heated in a heat collection field passes through a heat exchanger to ensure that counter-flow water is heated up into superheated steam at the temperature of between 360 and 380 DEG C; and the other path of the heat transfer oil heated in the heat collection field passes through the heat exchanger to heat up a fused salt so as to perform energy storage. The water heated in a water cooled wall of a biomass boiler is changed into steam which enters a steam header and a steam-water separator, then is heated to the temperature of between 535 and 545 DDEG C after being sent into a super-heater of the boiler together with the steam at the temperature of between 360 and 380 DEG C, and then is supplied to a steam turbine to drive a generator to finish the power generation process. During receiving electric valley adjustment, the biomass boiler maintains the minimum stable combustion state. The self power generation of the method and the system can be used for supplying electricity to an electric heater in a fused salt heat storage system to heat the fused salt and perform secondary energy storage for a fused salt heat tank. During the night, or when a solar energy condition is not good, the heat energy stored in the fused salt is released by the heat exchanger to generate electricity.

Owner:北京京仪集团有限公司

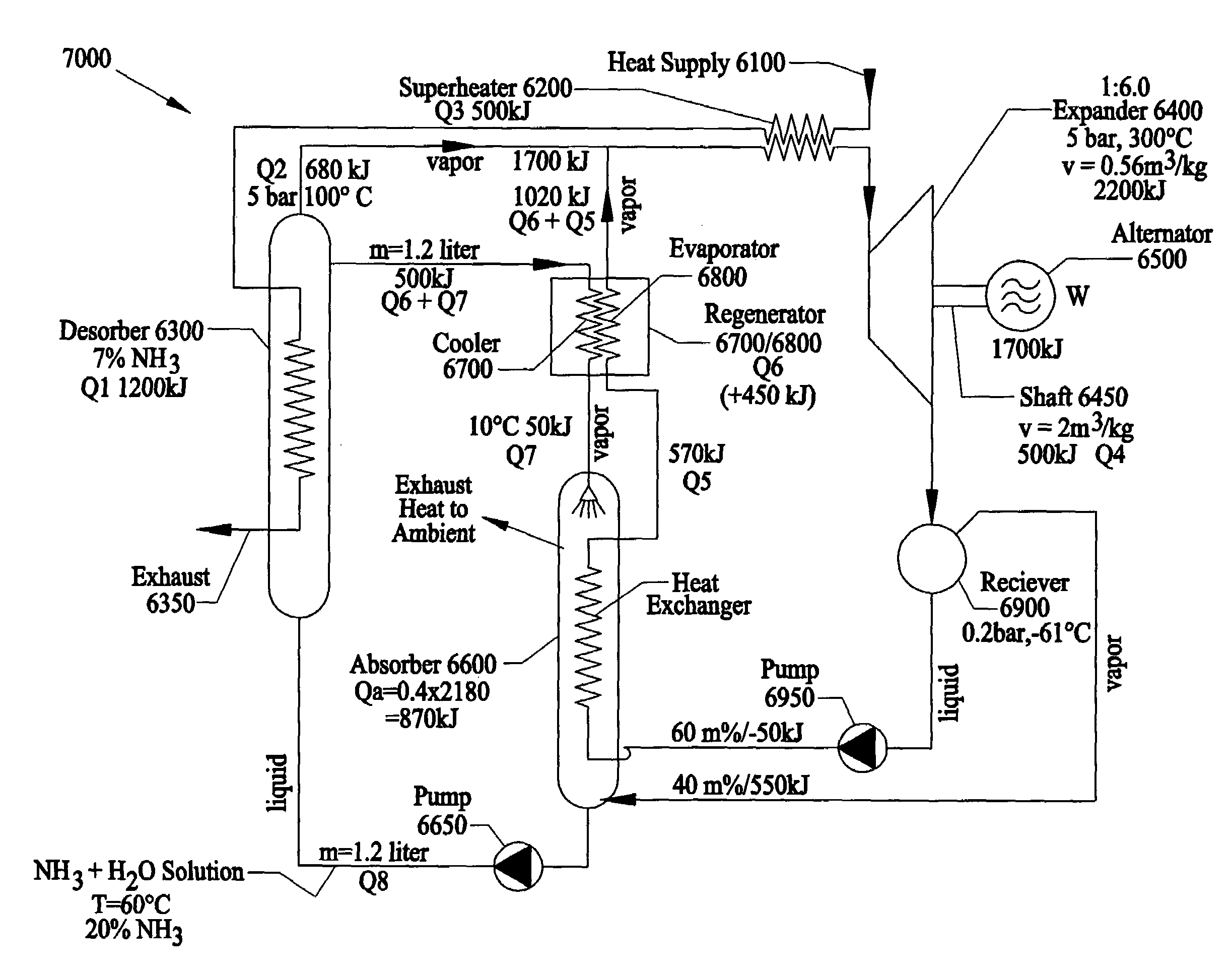

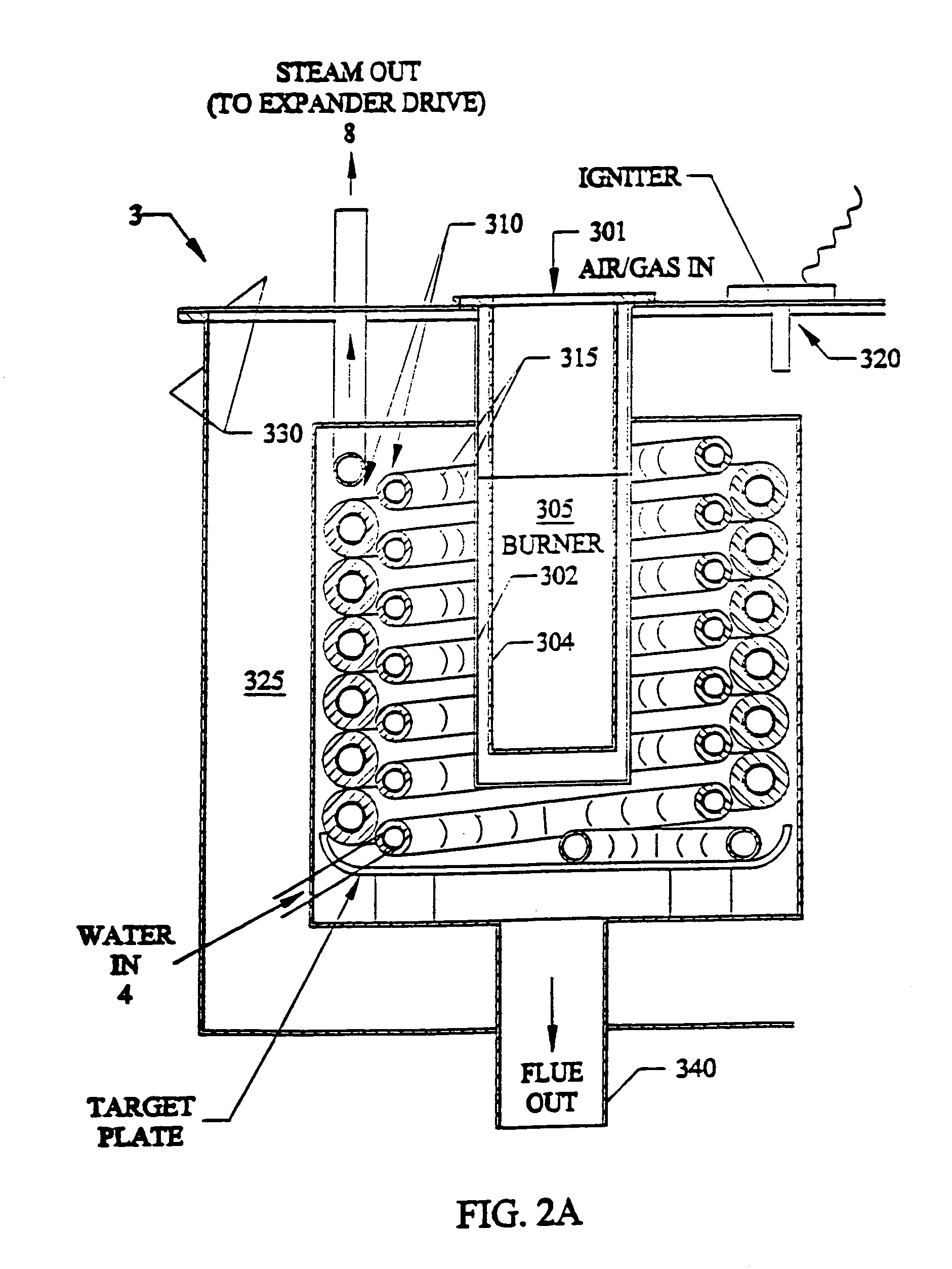

Power generation methods and systems

A closed loop system for generating mechanical energy at high efficiencies from hydrogen, fossil fuels, bio-fuels, solar or other renewable and recoverable energy sources. The system can have a heating source, a superheater, an expander, a receiver, a condenser, vacuum pump, or absorber, a desorber, and regenerator with pumps and controls. The heating source and superheater are used to heat a working fluid (including ammonia, other refrigerants, a combination of refrigerants, or steam). A positive displacement liquid / vapor expander expands the heated working fluid to the near saturated or saturated state utilizing a reduced pressure, low-pressure, or sub-atmospheric exhaust sink. A condenser, vacuum pump, or absorber is used to generate the reduced pressure, low pressure, or sub-atmospheric sink. The desorber is used to reconstitute inlet vapor (for reuse) and the regenerator recovers heat generated by the process. The system can generate mechanical energy (or power) which can be used to drive a wide range of mechanical systems (including pumps, compressors, vehicles, conveyances, or other similar mechanical devices); or used to drive an electrical generator to meet electrical power needs-for residences, businesses or office buildings, or commercial and industrial applications. The system can supply electrical energy to power grids, and can be an alternative to power generation plants.

Owner:RES SCI

Solar thermal power plant

A solar thermal power plant 10 includes a steam generation portion 12 and a turbine 30. The steam generation portion 12 includes a steam drum 50 that separates water and steam, and an evaporator 36 and super heater 38 in fluid communication with the steam drum. The evaporator 36 receives and heats a portion of a flow of water from the steam drum 50 to provide the steam using solar energy provided thereto. The super heater 38 heats the steam from the evaporator 36 to provide super heated steam. A turbine 30 receives the super heated steam from the steam generation portion 12 to rotate the turbine. A plurality of extraction stages 66 extracts steam from the turbine 30 and provides the steam to a plurality of feedwater heaters 68. The feedwater heaters 68 heat the feedwater provided by the turbine 30, wherein the heated feedwater is provided to the steam generation portion 12.

Owner:ALSTOM TECH LTD

Coal-based supercritical carbon dioxide Brayton cycle double-split-flow efficient power generation system

ActiveCN105526576AReduce flue gas temperatureLower exhaust gas temperatureSteam engine plantsSteam boilersSuperheaterHigh pressure

The invention discloses a coal-based supercritical carbon dioxide Brayton cycle double-split-flow efficient power generation system which comprises a low-temperature regenerator, a precooler, a main compressor, a re-compressor, a high-temperature regenerator, a boiler, a high-pressure turbine, a low-pressure turbine and an electric generator. The boiler is composed of a combustion channel, a main heat exchange channel and a tail flue in the smoke flowing direction, wherein the combustion channel, the main heat exchange channel and the tail flue are communicated in sequence; a water-cooled wall and a reheating water-cooled wall are sequentially arranged in the combustion channel in the smoke flowing direction; a high-temperature superheater and a high-temperature reheater are sequentially arranged in the main heat exchange channel in the smoke flowing direction; a baffle, a coal economizer and a low-temperature coal economizer are sequentially arranged in the tail flue in the smoke flowing direction, and a low-temperature reheater and a lower-temperature superheater are arranged on the two sides of the baffle. According to the coal-based supercritical carbon dioxide Brayton cycle double-split-flow efficient power generation system, optimal combining of the coal-fired boiler and the supercritical carbon dioxide Brayton cycle can be achieved, and the heat exchange efficiency of the high-temperature regenerator, the thermal efficiency of the boiler and the efficiency of the power generation system are high.

Owner:XIAN THERMAL POWER RES INST CO LTD

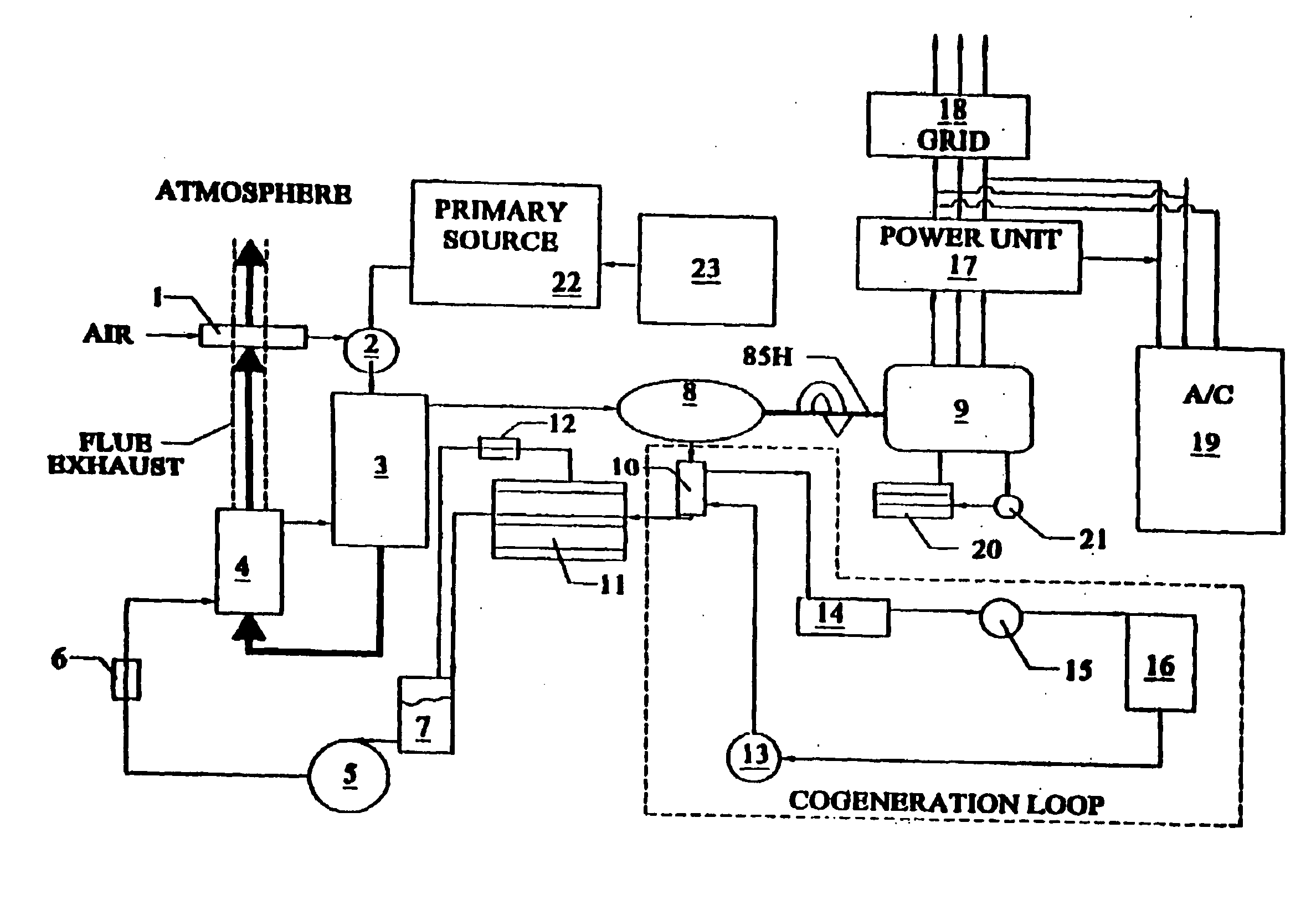

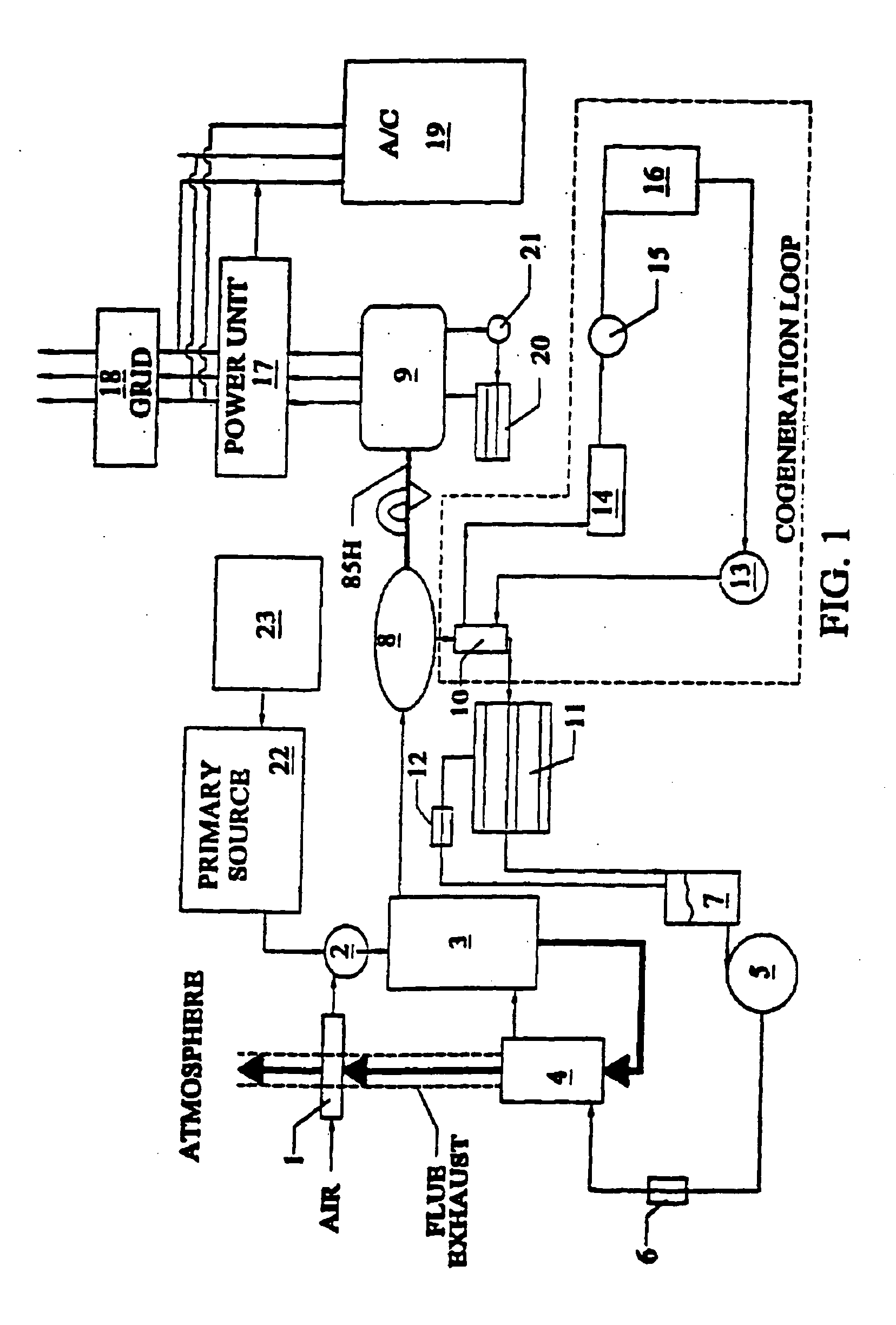

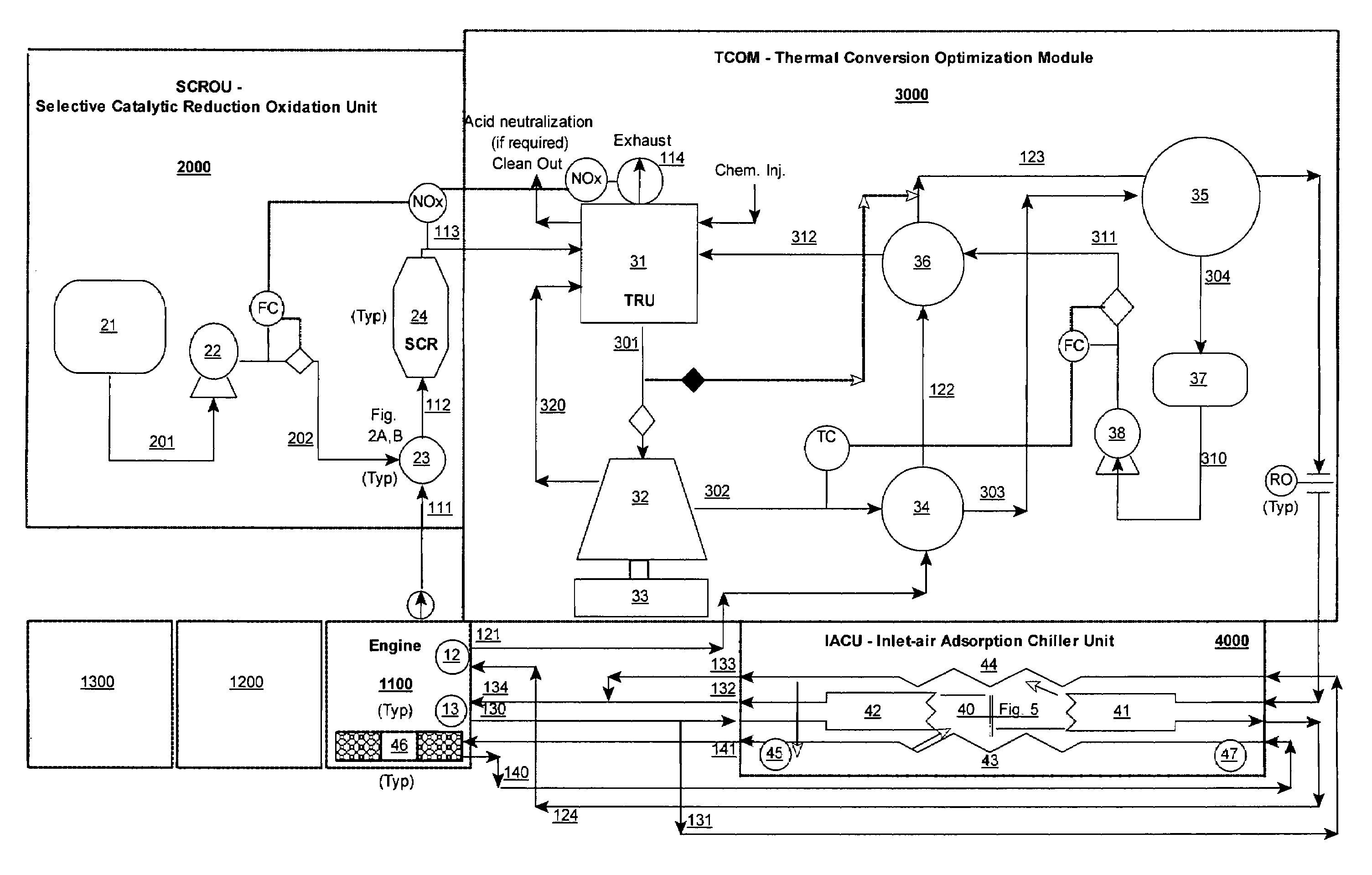

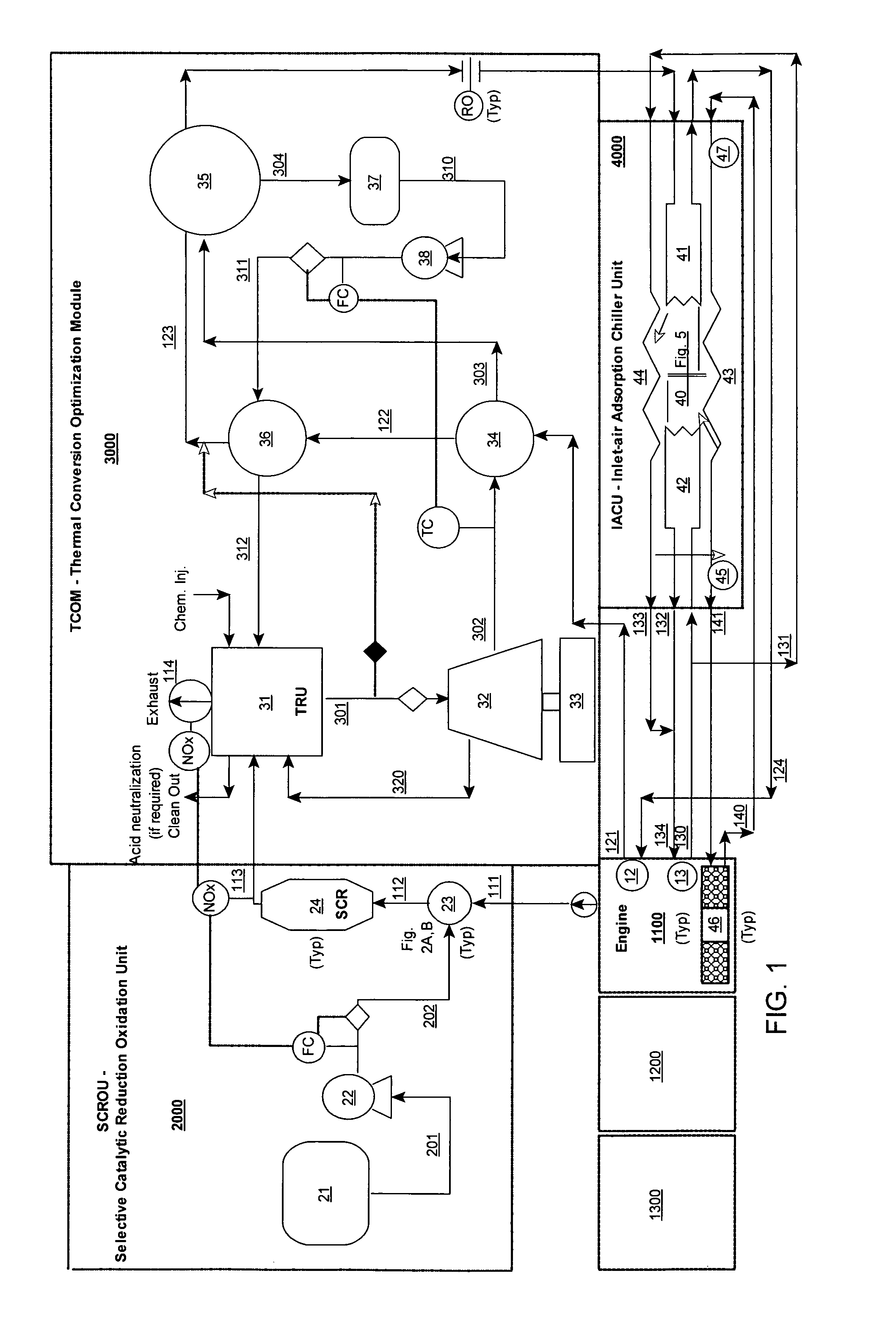

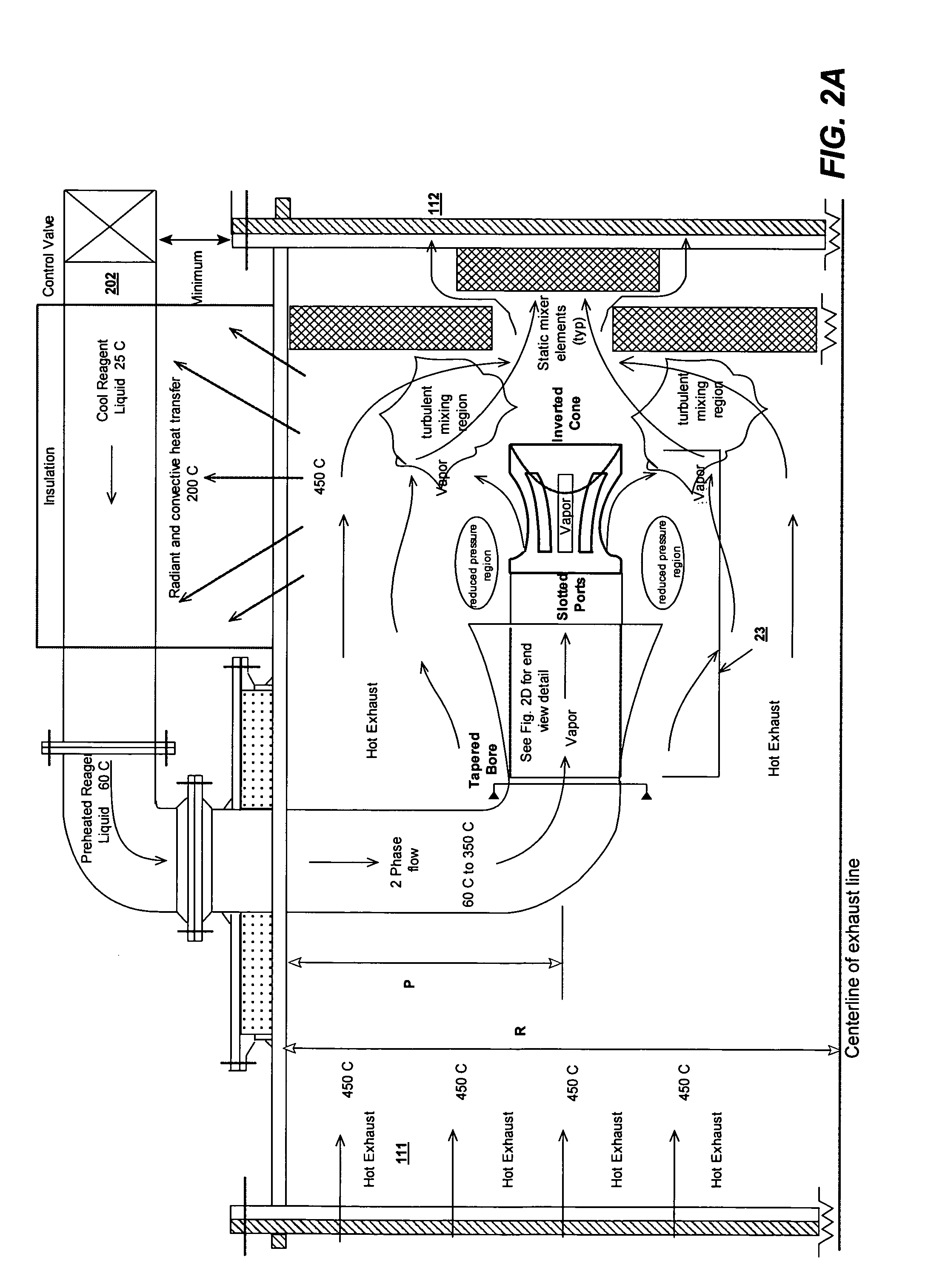

Energy recovery from waste heat sources

InactiveUS7469540B1Emission reductionResist acidic corrosionInternal combustion piston enginesExhaust apparatusThermal energyEngineering

In some embodiments, three integrated phases may be used to reduce emissions, convert thermal energy into electricity, and cool inlet combustion air. An ammonia injection system may be designed to eliminate extraneous equipment and hazardous re-circulation lines by directly vaporizing, injecting, and mixing ammonia using a specially designed nozzle. The second phase may include using a preheat / vaporizer / superheater exchanger to convert ammonia liquid into a superheated vapor that is then passed through a turbo-expander / generator to produce power. In some embodiments, the third phase may include inlet combustion air chilling.

Owner:KNAPTON BRENT WILLIAM +1

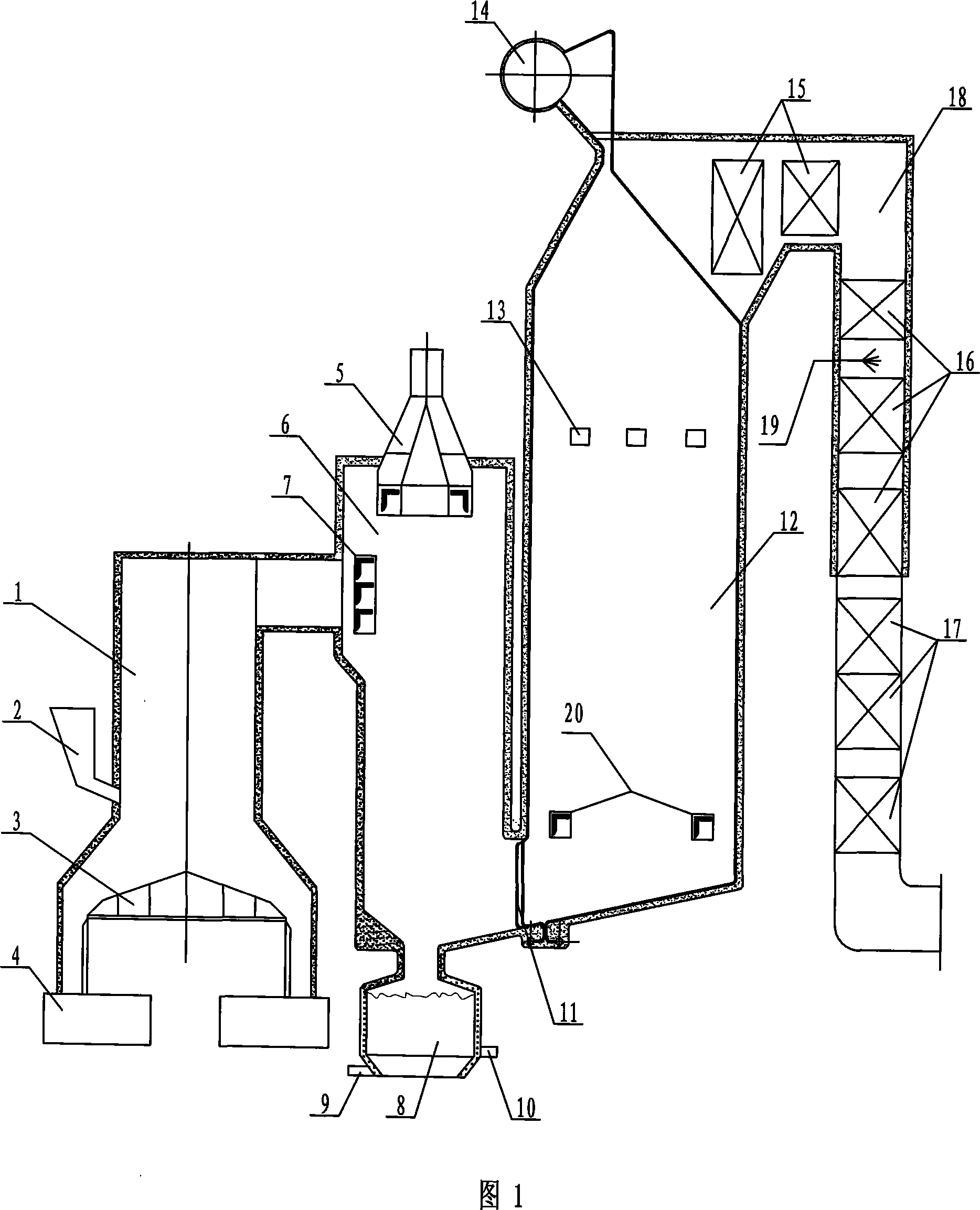

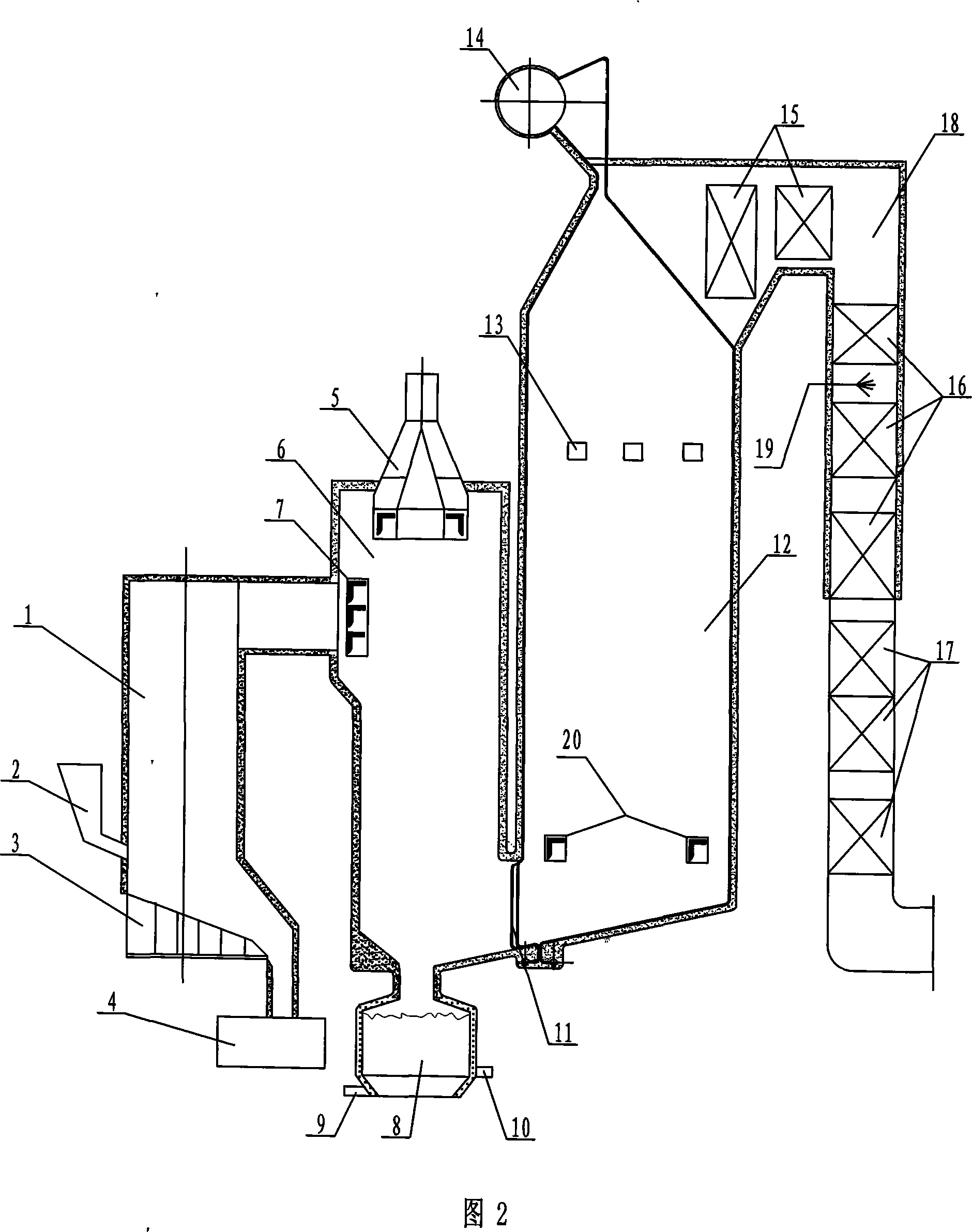

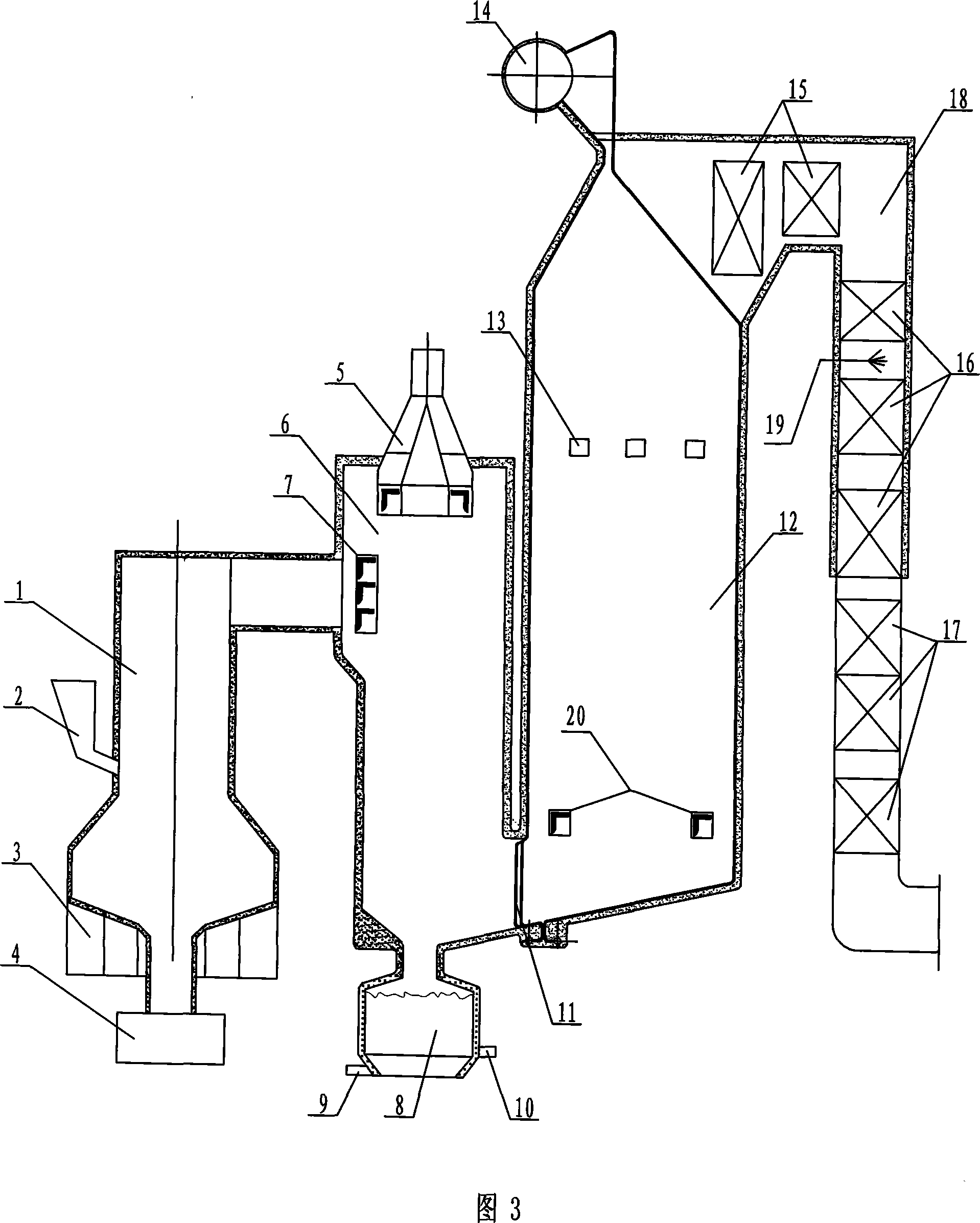

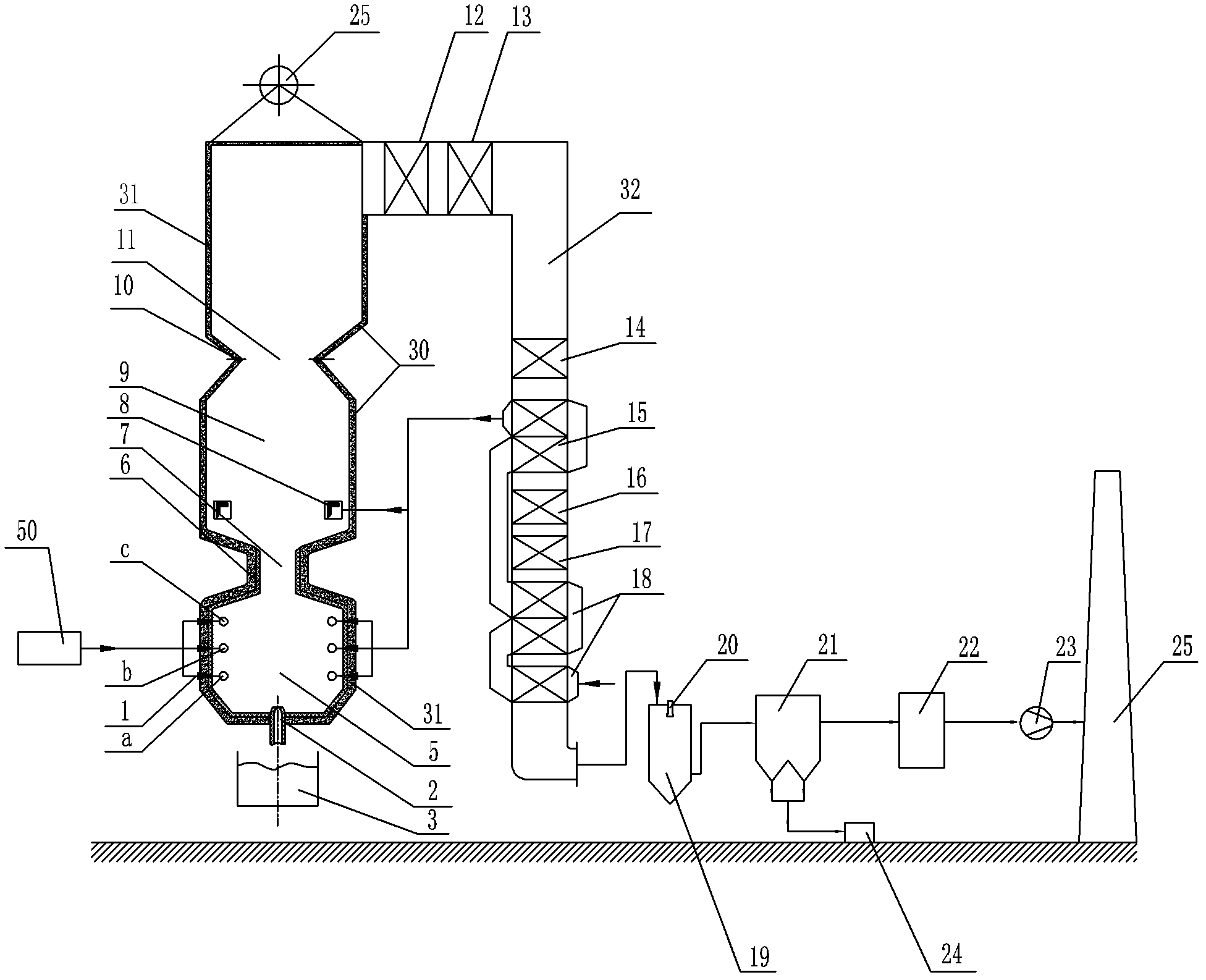

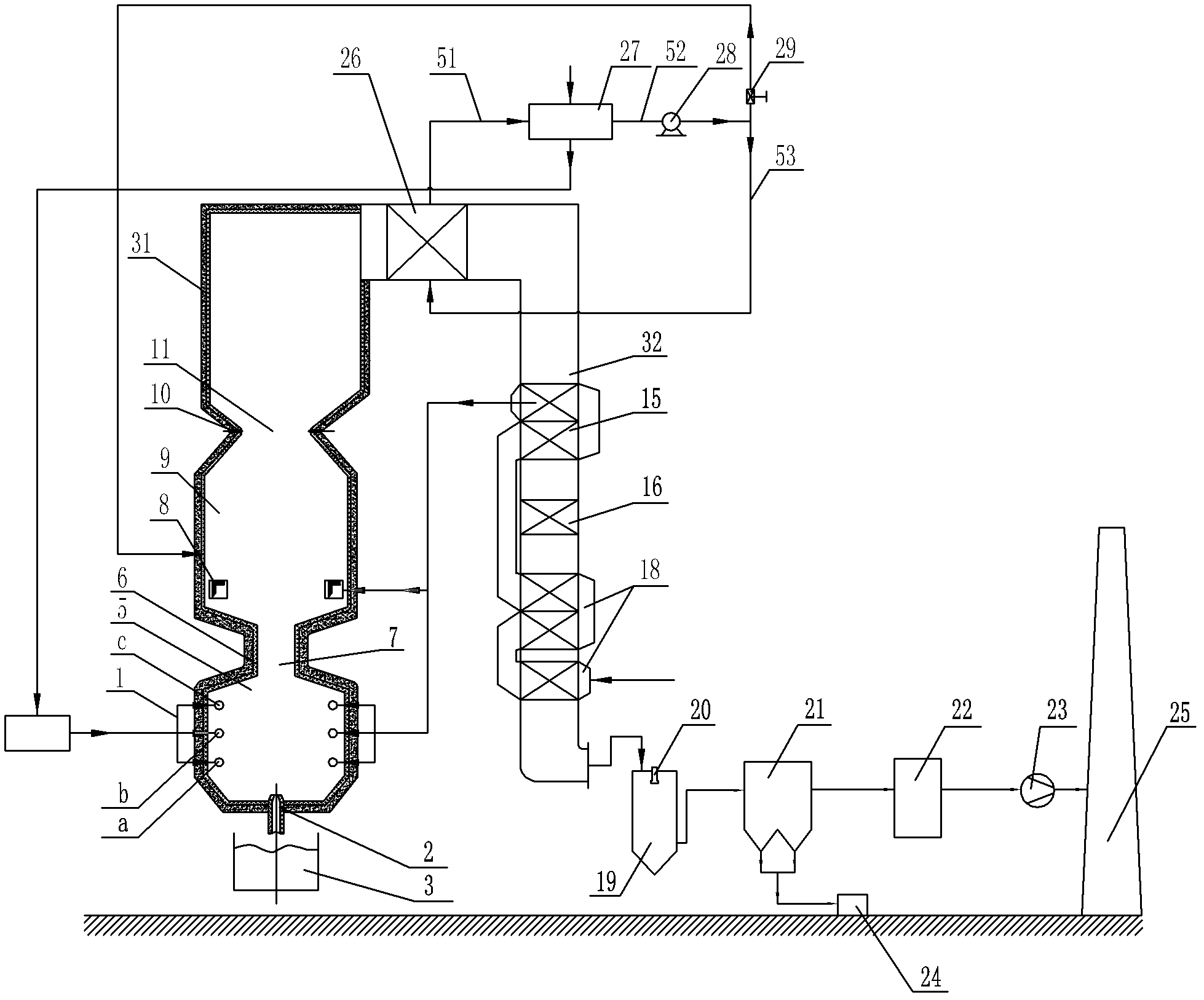

Apparatus and method for gasification of refuse and hyperthermia melt processing of flying ash

ActiveCN101201167AWith waste heat utilizationHigh heat intensity of combustionDamper arrangementIndirect carbon-dioxide mitigationAir preheaterEngineering

A device and method for garbage gasification and flying ash high temperature melting treatment relates to an integrated technology for garbage gasification and flying ash high temperature melting. The invention aims at solving the problem that the heavy metals and dioxins in the ash collected by a hop-pocket in an incinerator for garbage gasification exceeds the standard limits greatly. The device is formed in the way that a fluidized bed gasifier is communicated with a cyclone furnace; the cyclone furnace is communicated with a burnt chamber and the burnt chamber is communicated with a flue. The method includes that the smoke and gas generated by the gasification of the garbage in the fluidized bed gasifier enters the cyclone furnace and burns with the help of coal powder; the heavy metals in the flying ash are reduced to metals and recycled; the dioxins in the flying ash are decomposed; the exhaust smoke and gas enters a tail gas treatment device after entering the burnt chamber, a superheater, a coal saving device and an air preheater. The invention leads the smoke and gas generated by the gasification and burning of the garbage in the fluidized bed gasifier to enter the cyclone furnace for high temperature melting treatment so as to lead the dioxins in the tail gas collecting ash and in the tail gas to be respectively lower than 50ng-TEQ / kg, 0.1ng-TEQ / m{3}.

Owner:HARBIN INST OF TECH

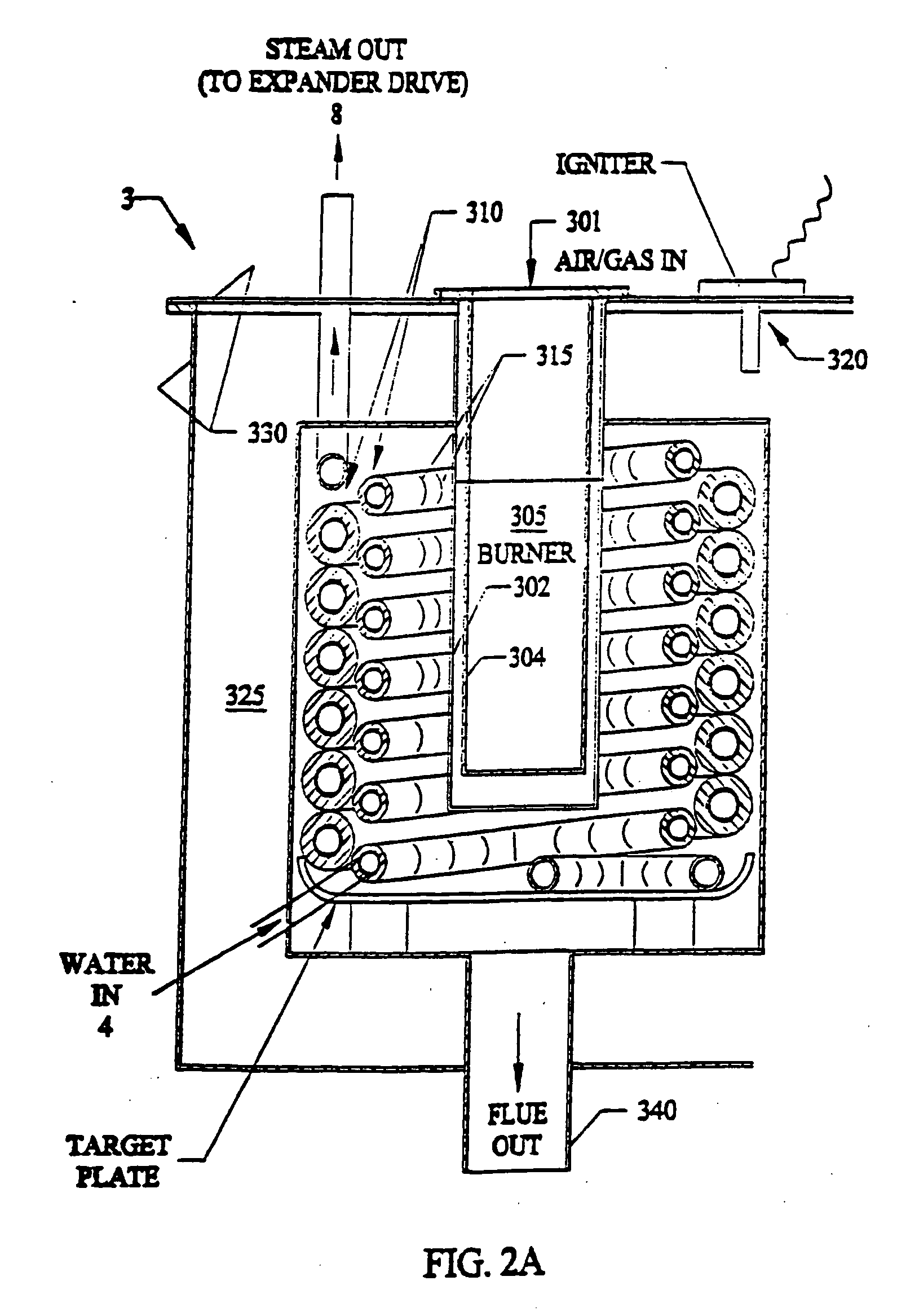

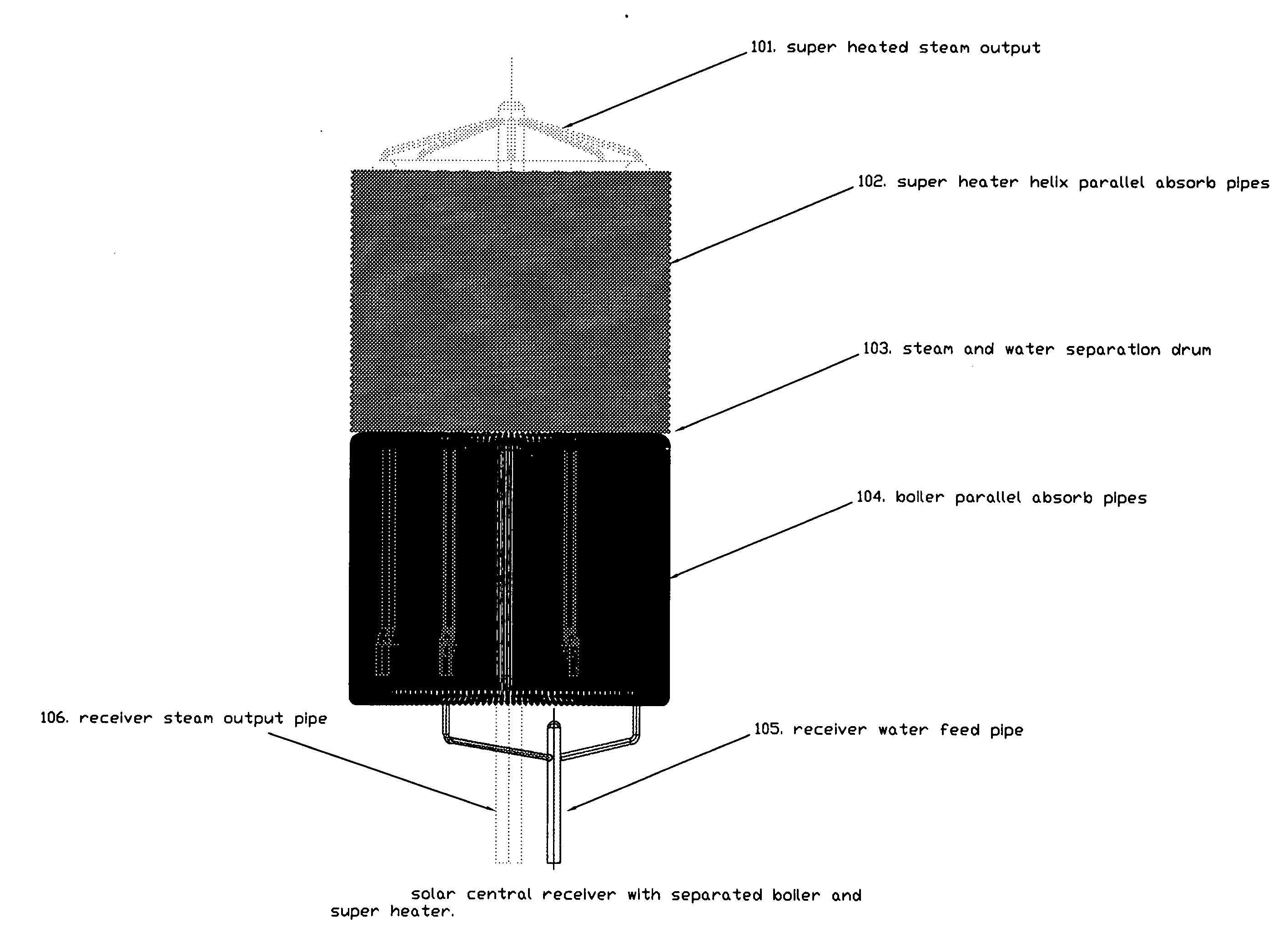

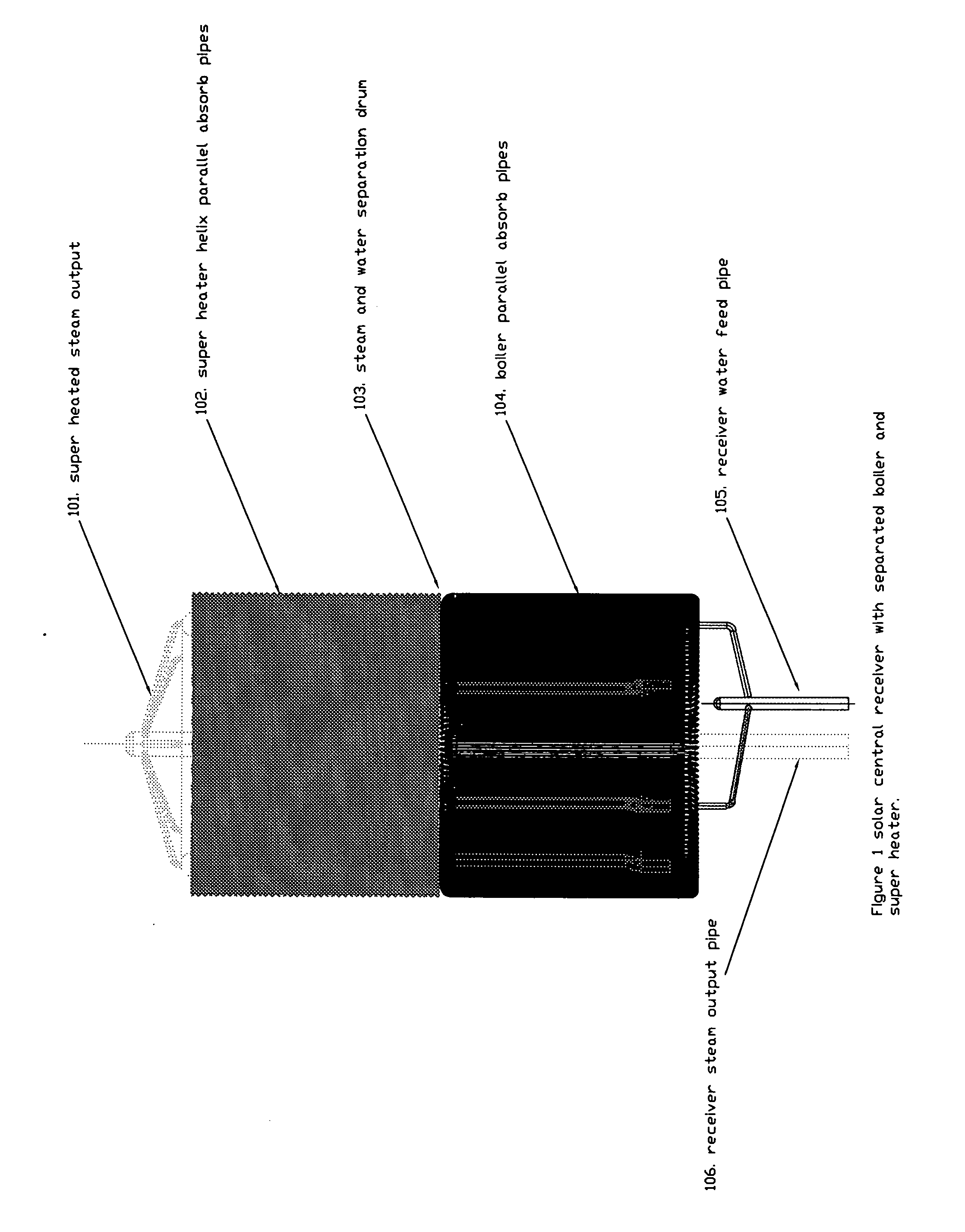

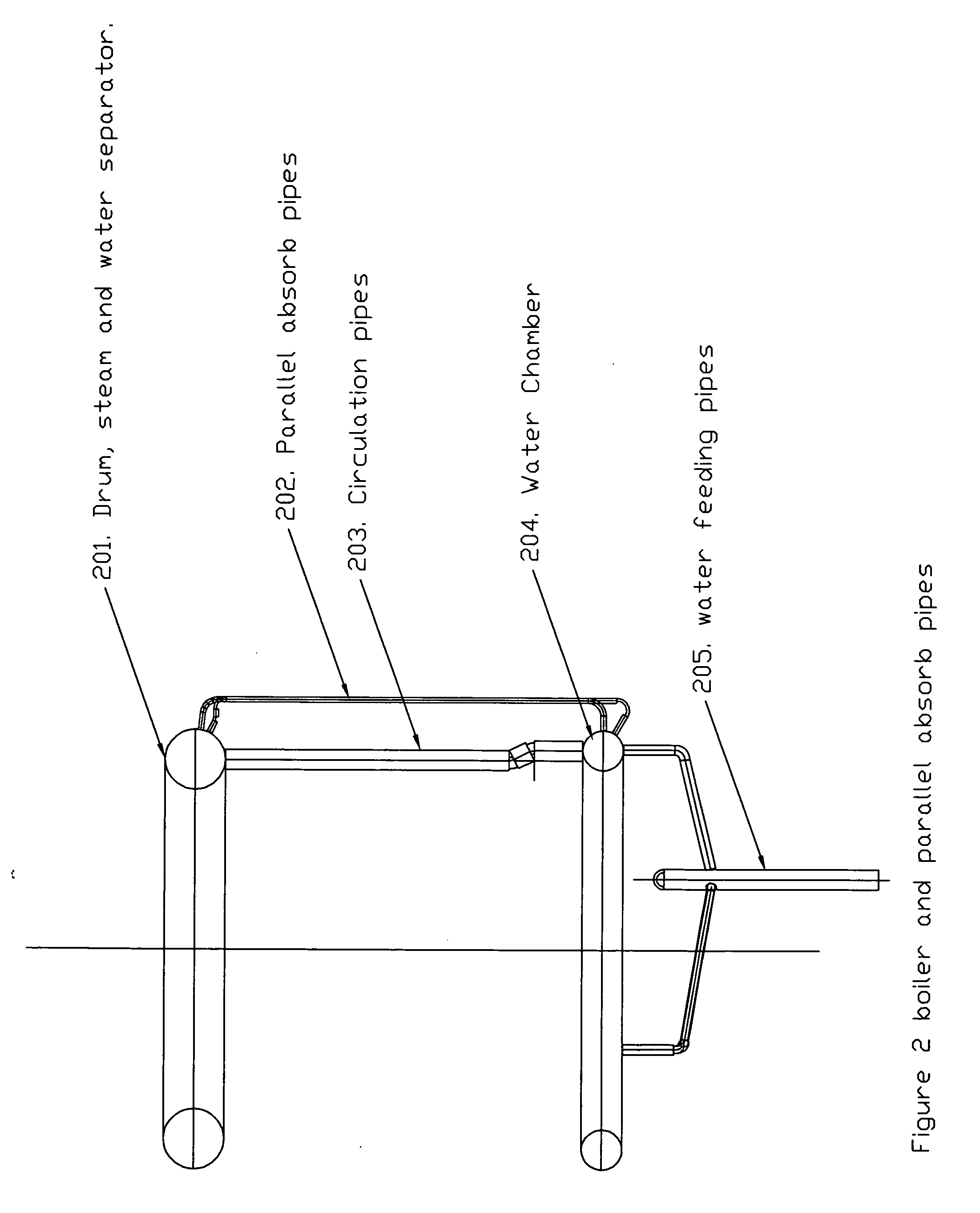

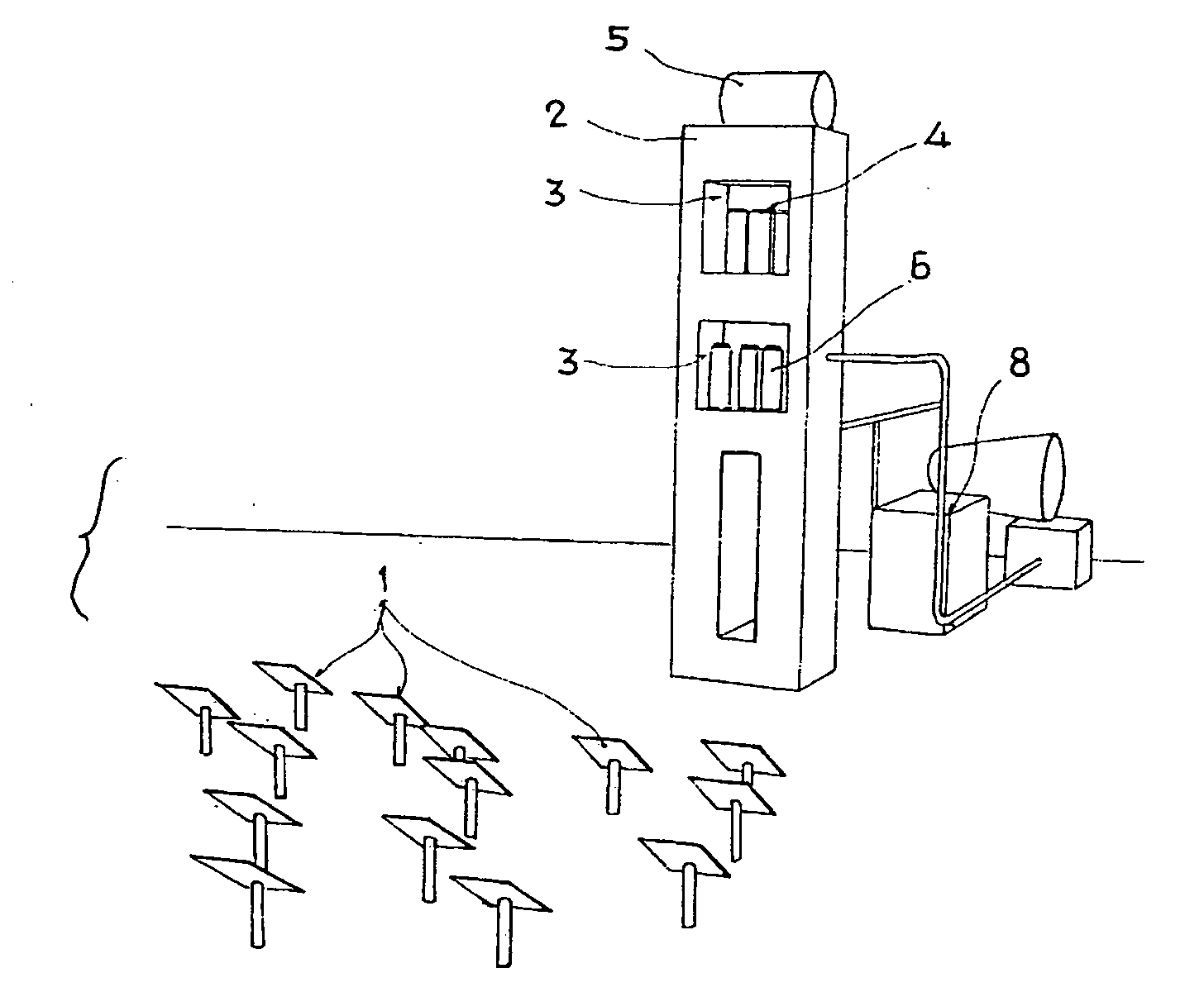

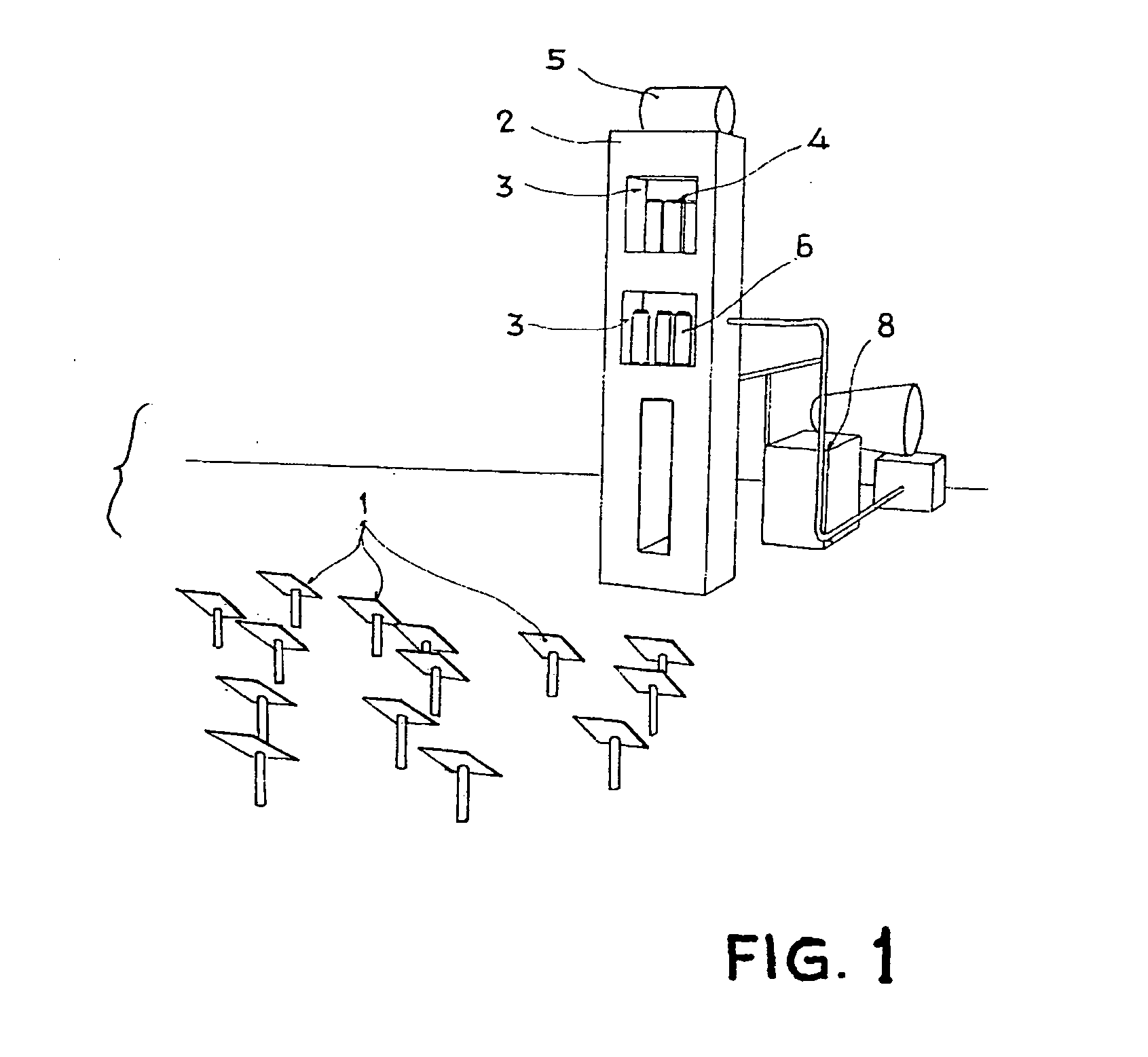

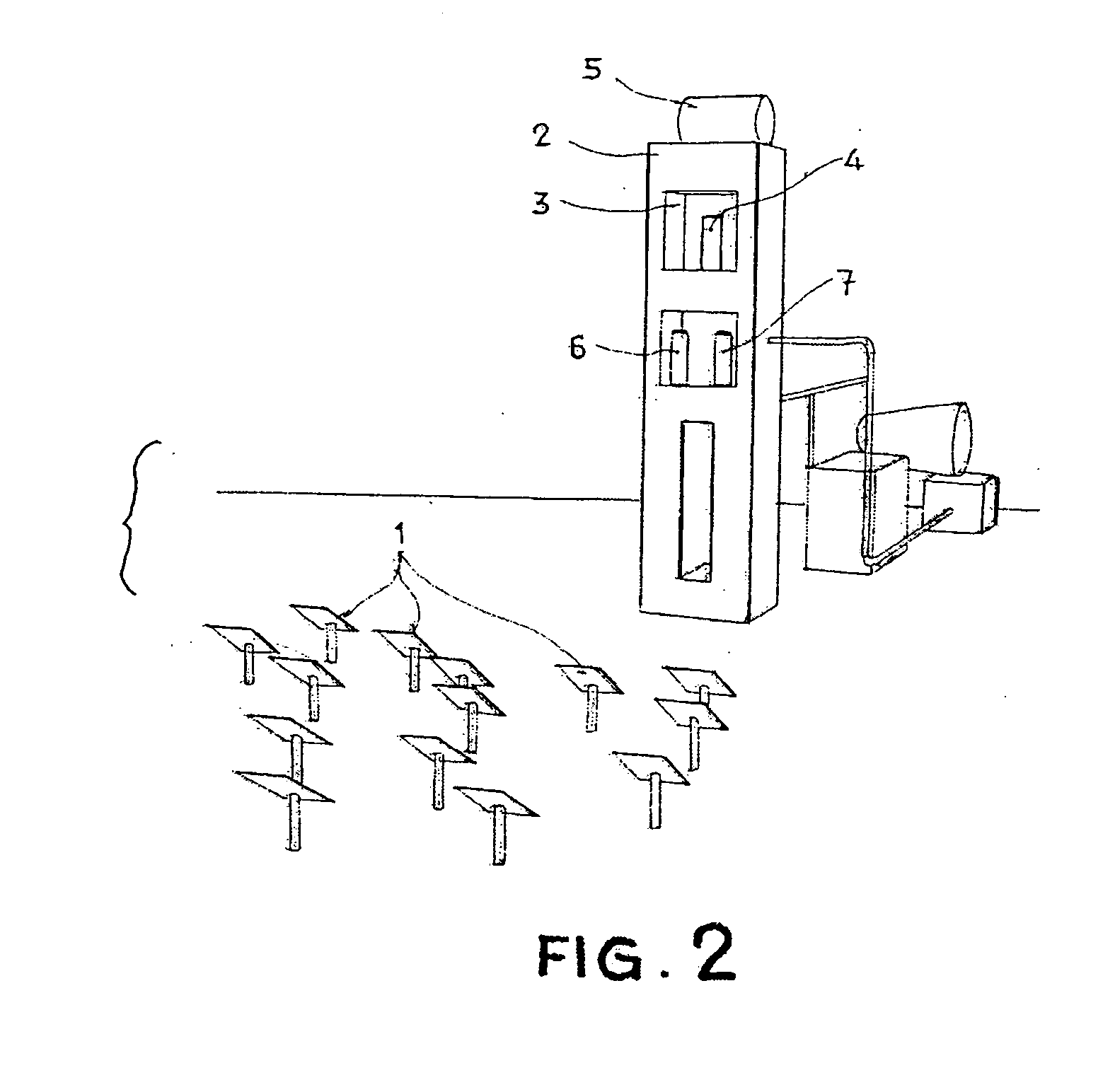

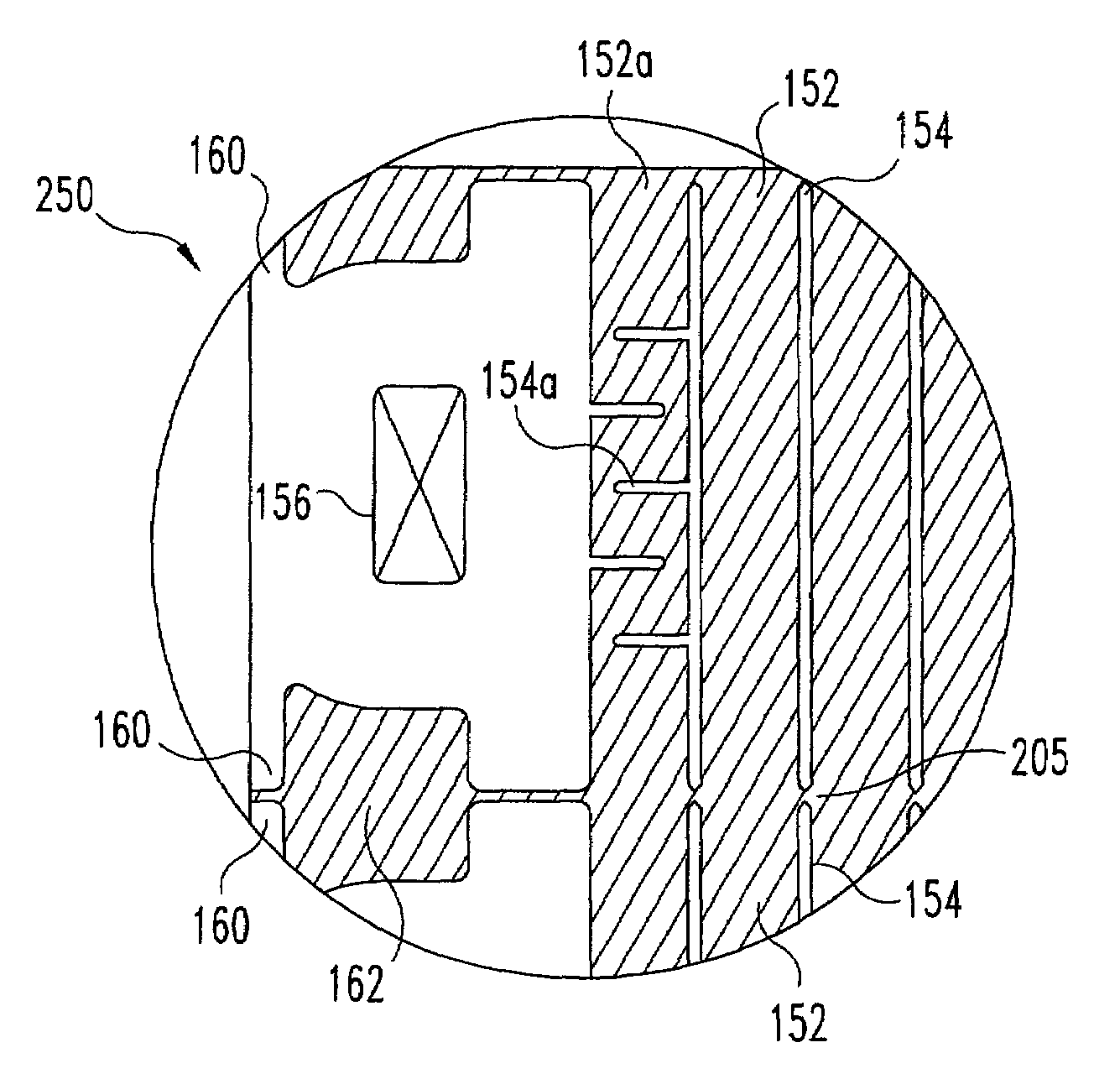

Method and apparatus of solar central receiver with boiler and super-heater

InactiveUS20080078378A1High solar flux densityInhibit thermal stressSolar heating energySolar heat devicesEngineeringSuperheater

A solar tower central receiver with separated boiler and Super-Heater allows better control on the output steam's temperature. The boiler takes higher solar flux density and works at lower temperature while the Super-Heater takes lower solar flux and works at high temperature to optimize the cost to performance ratio. The solar fluxes of the boiler and super-heater are adjustable through the pointing of the heliostats. The boiler consists of parallel pipes as solar absorber and the Super-Heater consists of helix parallel pipes as solar absorber. The steam drum chamber interconnects boiler and Super-Heater. The absorb pipes and circulation pipes are connected to water chamber, steam drum chamber, and Super-Heater chambers. The water level sensor and temperature sensors provide information regarding the operating status of the receiver.

Owner:ZHU YANONG

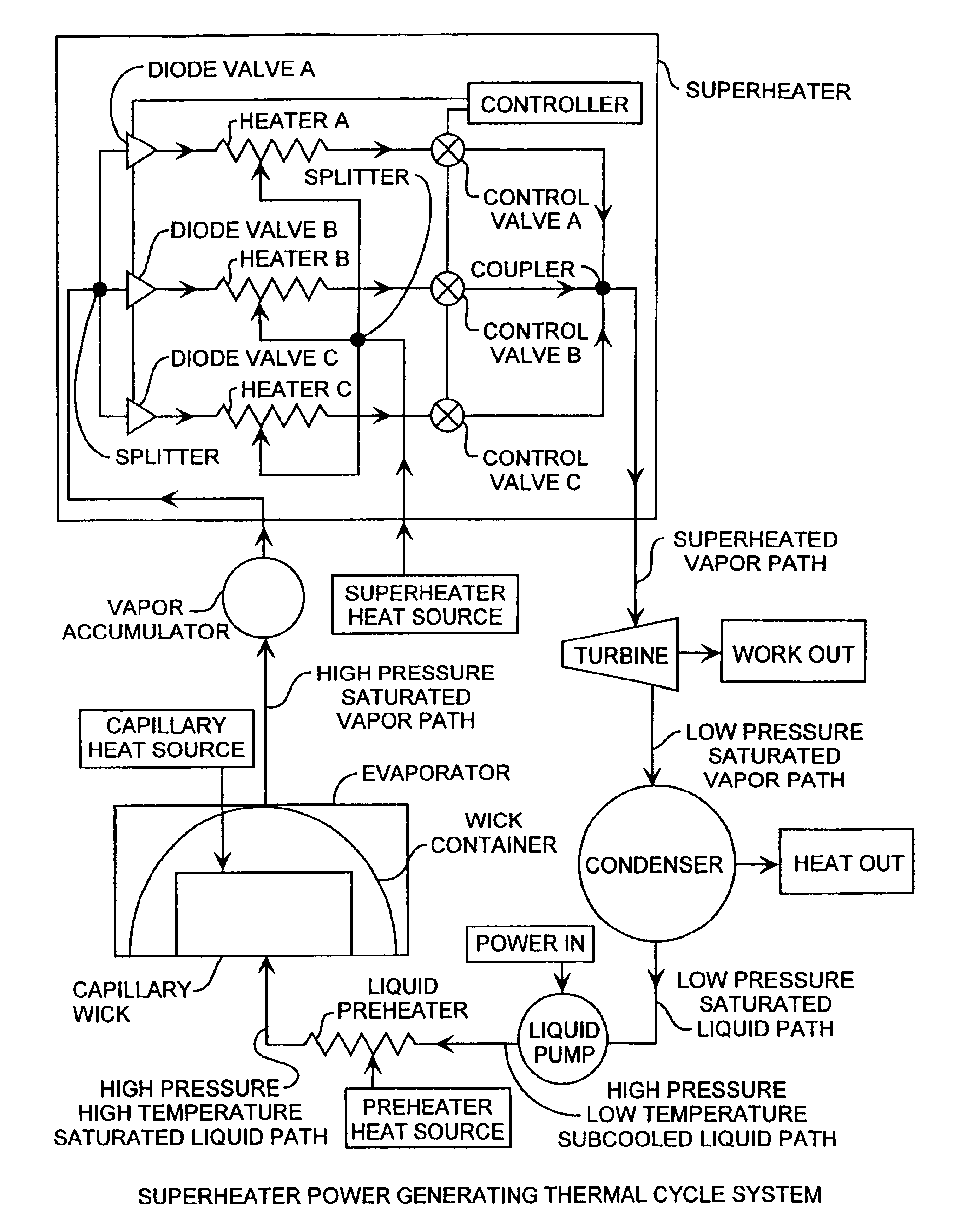

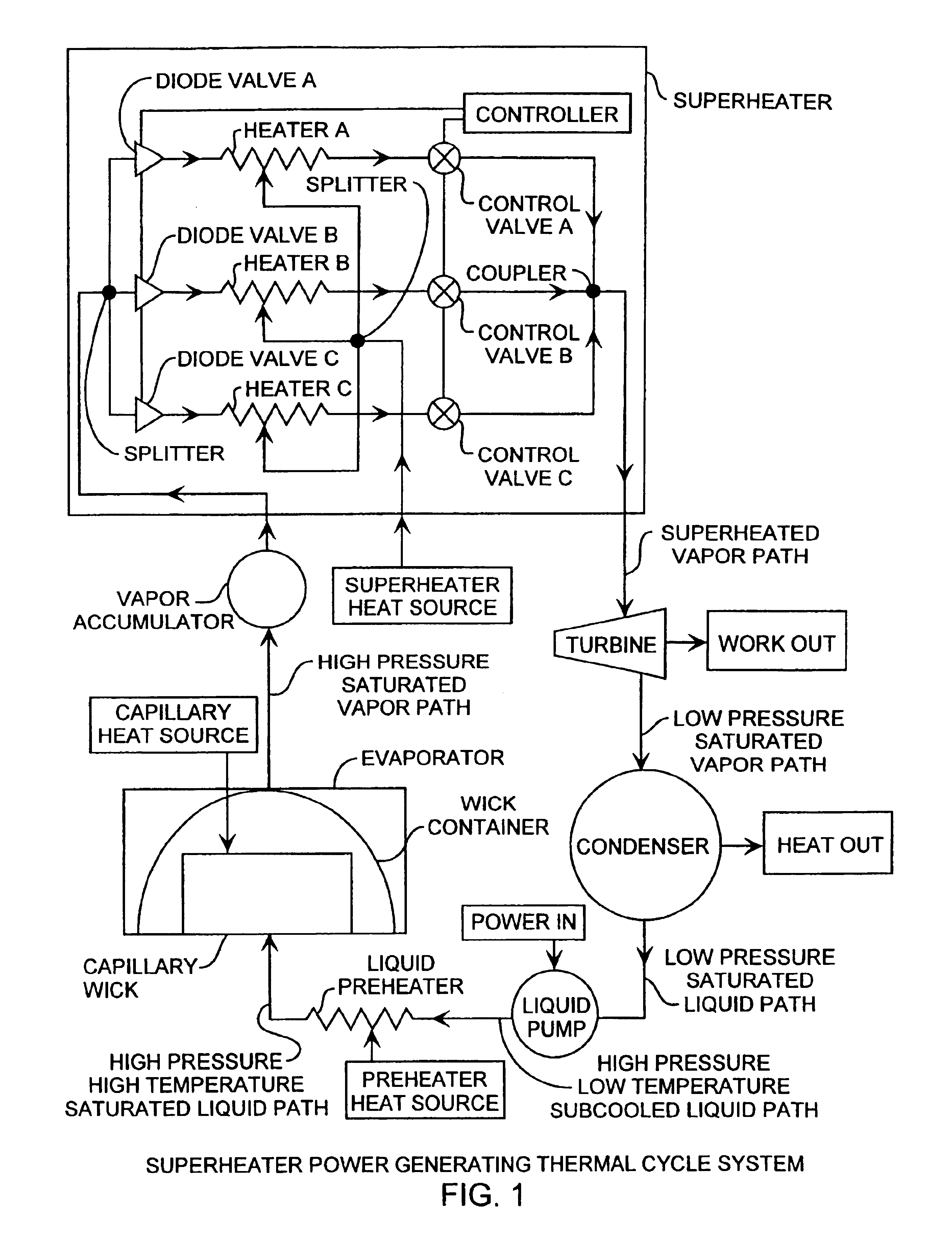

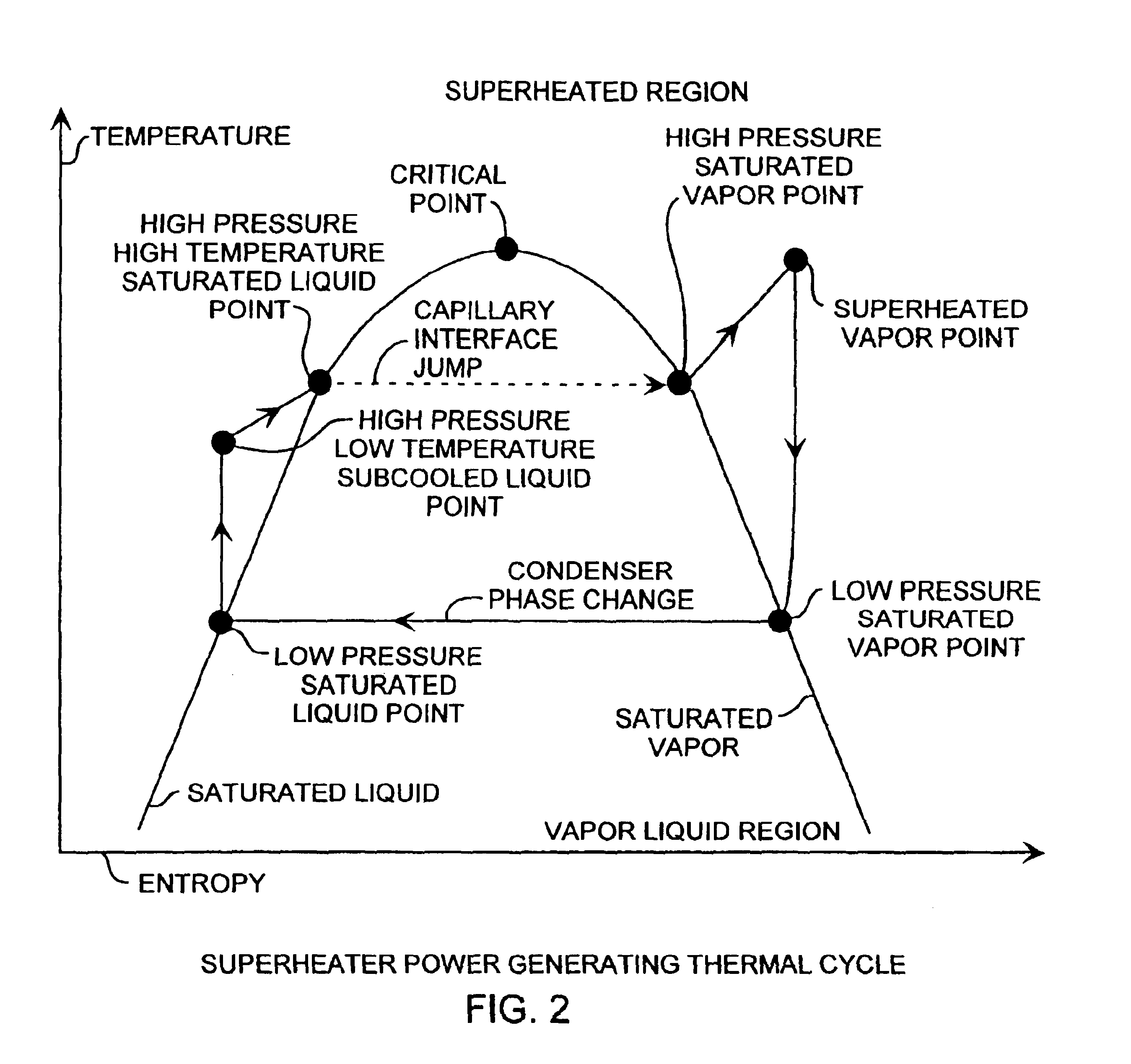

Superheater capillary two-phase thermodynamic power conversion cycle system

InactiveUS6918254B2Power generationImprove efficiencyIndirect heat exchangersSteam engine plantsThermal energyThermal energy storage

A two-phase thermodynamic power system includes a capillary device, vapor accumulator, superheater, an inline turbine, a condenser, a liquid pump and a liquid preheater for generating output power as a generator. The capillary device, such as a loop heat pipe or a capillary pumped loop, is coupled to a vapor accumulator, superheater, the inline turbine for generating output power for power generation, liquid pump and liquid preheater. The capillary device receives input heat that is used to change phase of liquid received from the liquid preheater, liquid pump and condenser into vapor for extra heating in the superheater used to then drive the turbine. The power system is well suited for space applications using a radioisotope, active nuclear or solar heat source. The system can use waste heat from various dynamic or static power systems as a heat source and waste heat from spacecraft components such as electronics as a heat source. These heat sources can be used separately or in any combination. The power system can be combined with thermal energy storage devices when operated with heat sources that are not steady state. Heat sources are useful for driving the capillary wick, superheater and liquid preheater for increased power efficiency and long lifetime operation. The power system is well suited for space receiving heat from a heat source to produce useful mechanical energy. A superheater in combination with a liquid pump and preheater are implemented for use with the evaporator for improved thermal efficiency while operating at maximum cycle temperatures well below other available power conversion cycles.

Owner:THE AEROSPACE CORPORATION

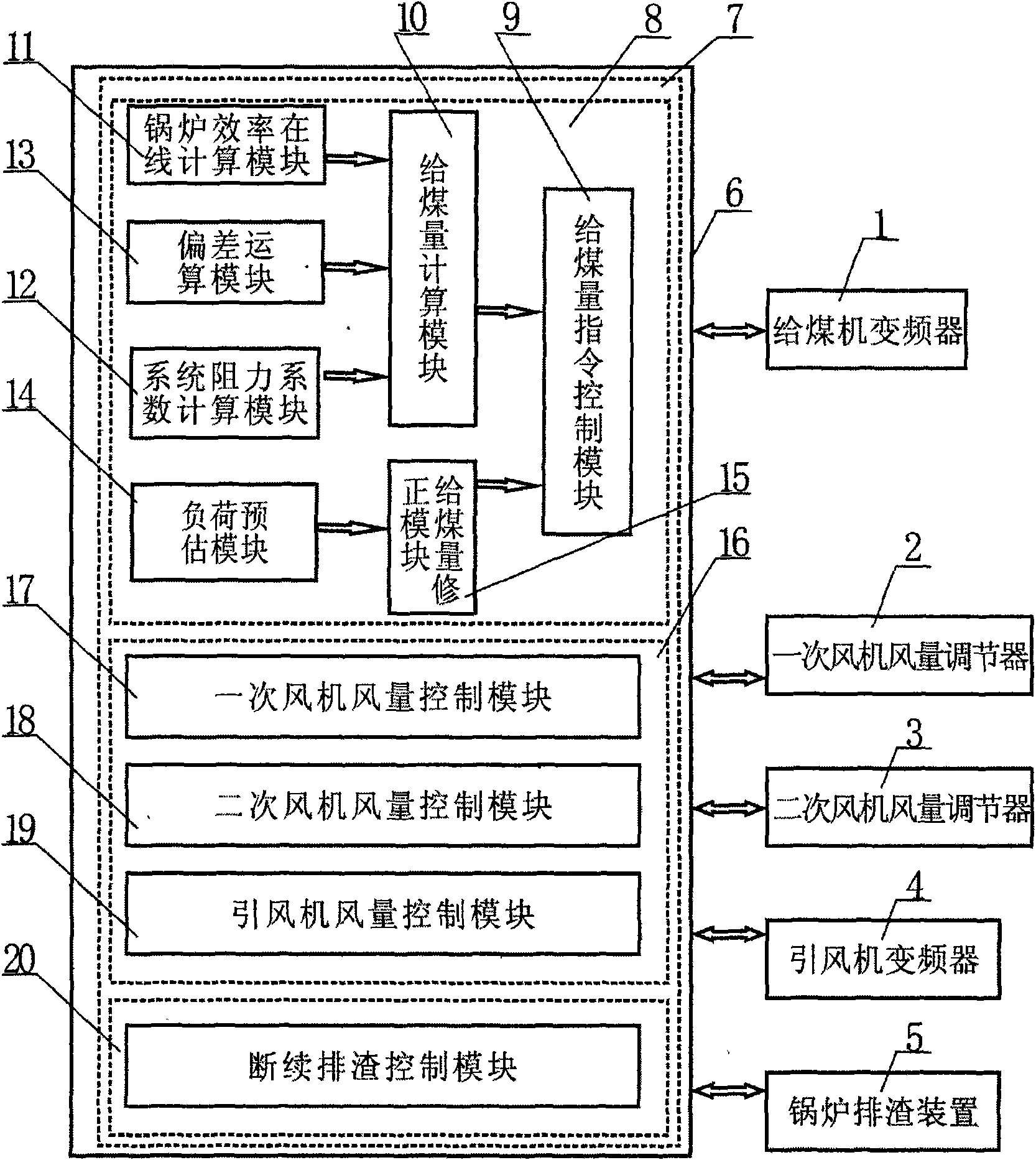

Automatic boiler combustion control system of circulating fluid bed

ActiveCN101551103AAdvanced and reasonable designImprove combustion efficiencyFluidized bed combustionProgramme control in sequence/logic controllersSteam pressureAir volume

The invention discloses an automatic boiler combustion control system of a circulating fluid bed, which is applied to machine sets for coal-fired power generation, heat supply or combined heat and power generation. The system comprises hardware and control program software, wherein the control program software comprises a fuel control part, an air volume control part and a deslagging control part, and the control program software can automatically and timely control the input quantity of boiler fuel, the oxygen content in the boiler and the boiler deslagging device. The combustion control system is applicable to all sorts of complicated operating conditions, has consistently correct and reliable reaction, advanced and reasonable algorithm design as well as good control effect, is safe and effective, has the capabilities of improving boiler combustion condition, increasing boiler combustion efficiency and reducing unburned carbon in flue dust, leads main steam pressure control to be stable, enhances the capability of tracking the change in load of the boiler and greatly improves the running safety performance, leads main steam temperature control precision to be effectively improved, avoids temperature excursion of an overheater, reduces the danger of steam turbine water slug caused by low-temperature steam, and improves the thermal efficiency and automation control degree of the steam turbine.

Owner:DONGGUAN TEXWINCA HLDG

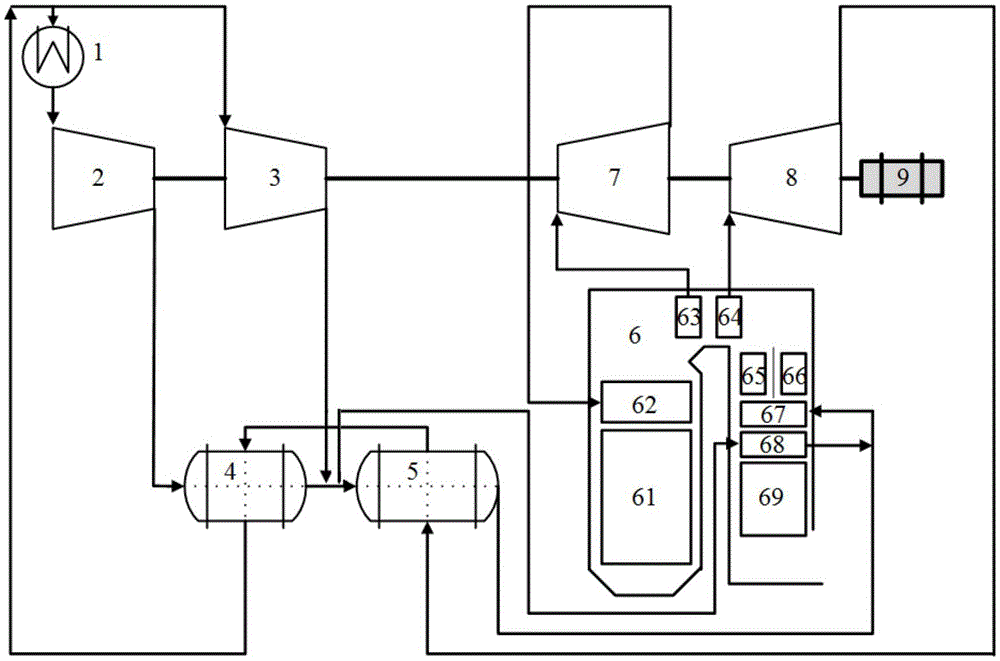

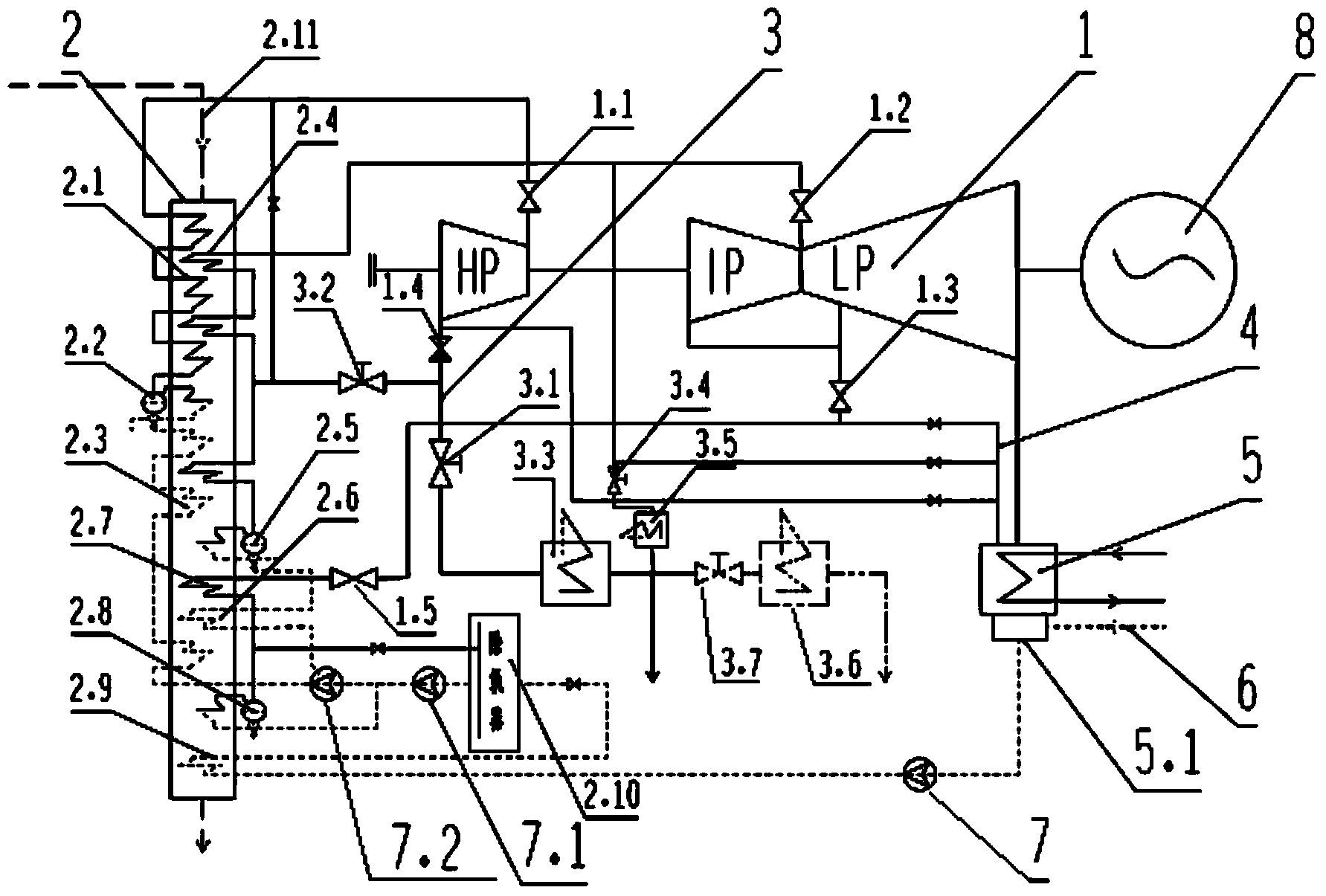

Combined-cycle combined heat and power system

ActiveCN103452611AHigh in-flow efficiencyIncrease wasteSteam useEnergy industrySuperheaterElectric generator

The invention provides a combined-cycle combined heat and power system, which comprises a steam turbine, an afterheat boiler and a heat network steam extraction system, wherein the steam turbine comprises a high-pressure cylinder, an intermediate-pressure cylinder and a low-pressure cylinder, the afterheat boiler comprises a high-pressure steam drum, an intermediate-pressure steam drum and a low-pressure steam drum, the three steam drums respectively generate three flows of steam, high-pressure steam, intermediate-pressure steam and low-pressure steam are respectively injected into the high-pressure cylinder, the intermediate-pressure cylinder and the low-pressure cylinder to apply work through expansion, and a generator is driven to output electric energy. A high-discharge check valve is arranged on a steam discharge pipeline of the high-pressure cylinder, and the heat network steam extraction system designed for heating is arranged at the downstream part of the high-discharge check valve and comprises two regulating valves in parallel connection, wherein the first regulating valve is connected with a first-stage temperature and pressure reduction device used for realizing the primary steam extraction regulation of the steam turbine, and the second regulation valve is connected with a pipeline arranged between an intermediate-pressure steam generator and an intermediate-pressure superheater through a cold reheating pipeline. Compared with a traditional combined cycle combined heat and power system, the combined-cycle combined heat and power system provided by the invention has the advantages that the operation efficiency is high, the generating efficiency is high, and high-quality energy source waste is little.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

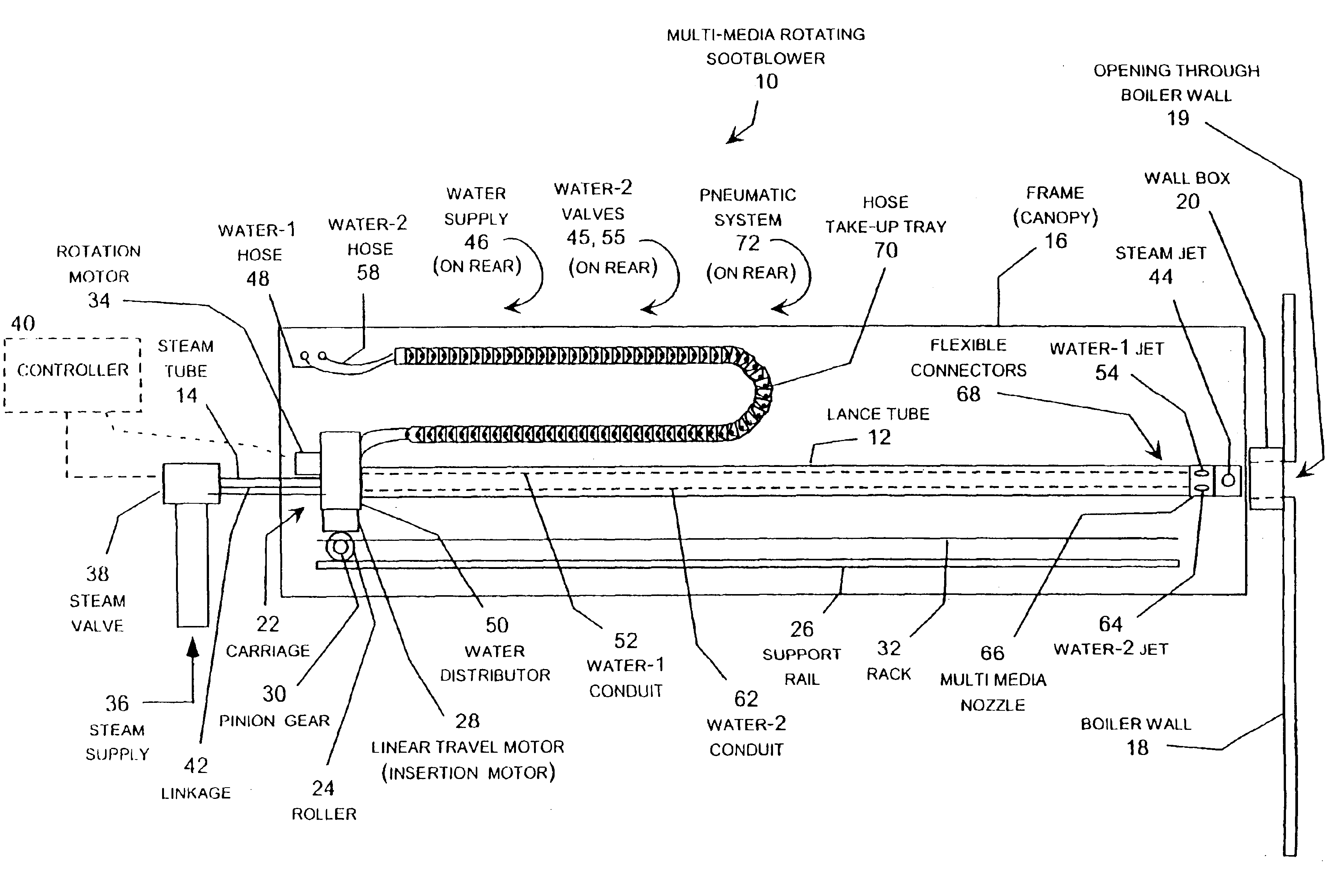

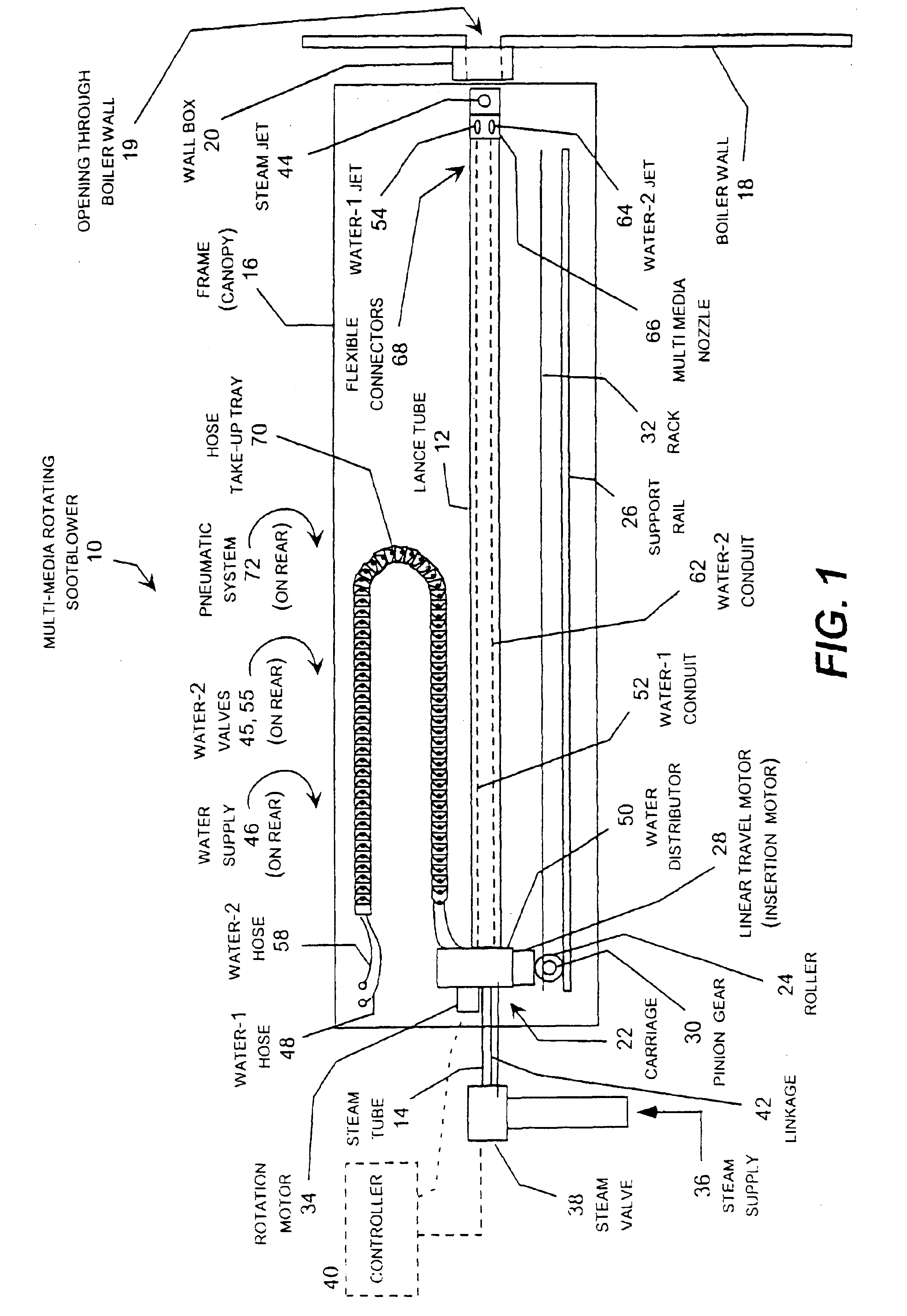

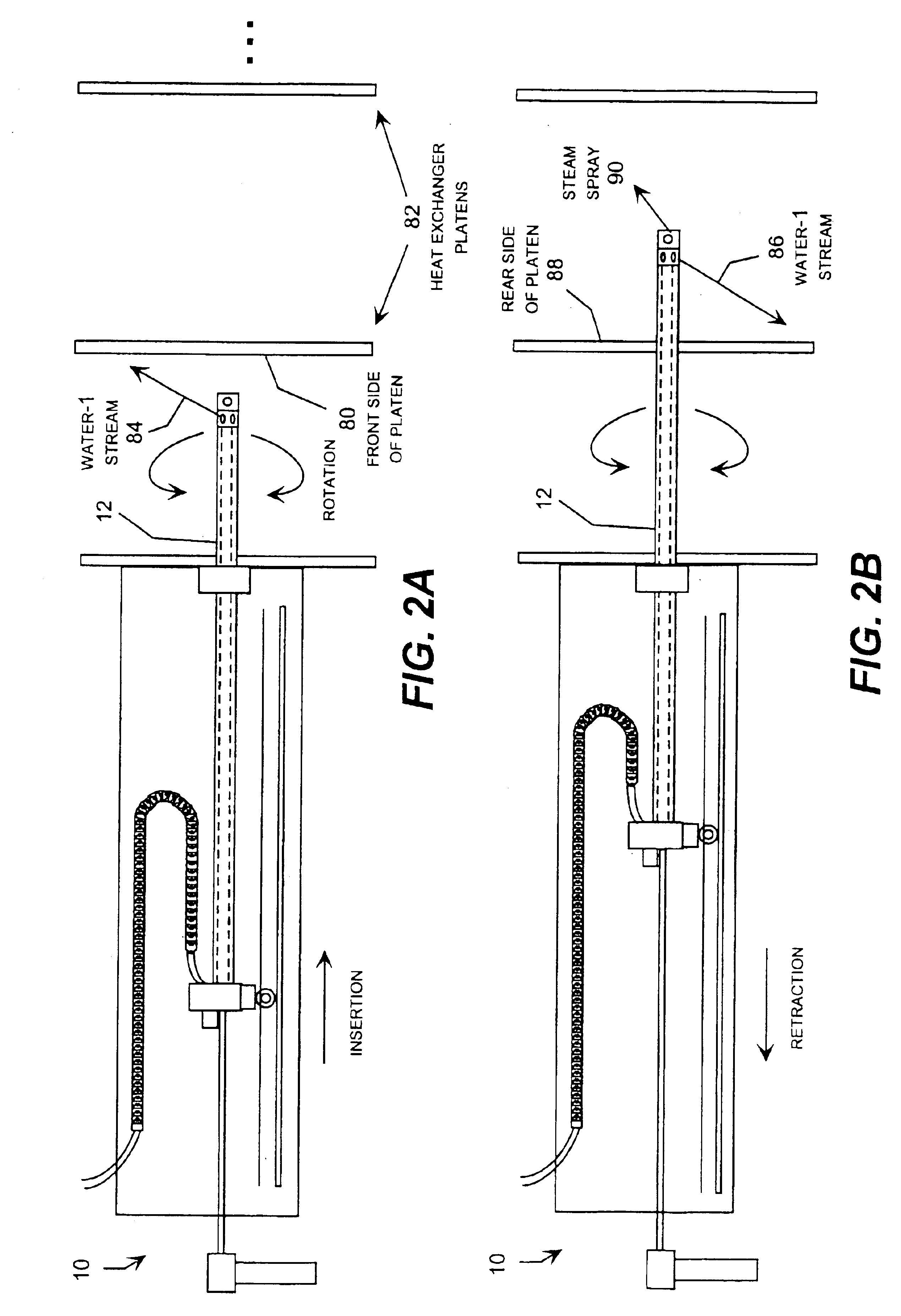

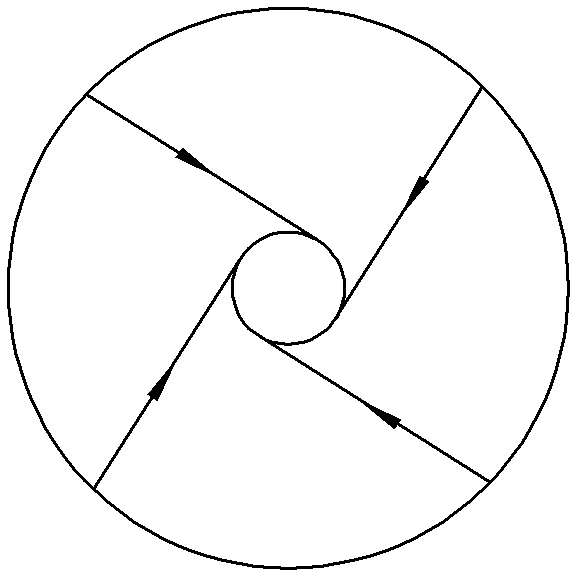

Multi-media rotating sootblower and automatic industrial boiler cleaning system

ActiveUS6892679B2Avoiding unnecessary thermal stressUnnecessary thermal stressMechanical cleaningPressure cleaningRegimenControl system

A multi-media rotating sootblower that includes multiple rotating and individually controlled cleaning fluid applicators, such a set of steam nozzles and two sets of water nozzles, and an automatic boiler cleaning system using these sootblowers. The boiler superheater typically includes a system of these sootblowers to clean a number of large platens that are arranged in rows. The boiler may also include additional boiler cleaning equipment, including water cannons to clean the furnace, and conventional steam sootblowers to clean other heat exchangers of the boiler. A number of sensors, including heat transfer gauges that measure the heat transfer at the furnace wall, strain gauges that measure the weight of slag deposits on platens, and boiler cameras are used to monitor slag accumulations within the boiler. A control system uses this sensor data to automatically operate the boiler cleaning system to implement an automatic boiler cleaning regimen.

Owner:CLYDE IND

Power generation methods and systems

A closed loop system for generating mechanical energy at high efficiencies. The system can have a heating source, a superheater, an expander, a receiver, an absorber, a desorber, and regenerator with pumps and controls. The superheater heats a working fluid (a refrigerant or steam). A positive liquid / vapor expander expands a low temperature refrigerant, or steam vapor to the saturated state (having both liquid and vapor parts) utilizing a low-pressure sub-atmospheric exhaust sink. An absorber, generates a low-pressure sub-atmospheric sink using chemosorption which involves the exothermic reaction / absorption of ammonia refrigerant in water. The desorber is used to reconstitute inlet vapor (for reuse) and the regenerator recovers heat generated by chemosorption. The system can meet electrical power needs for residences, businesses or office buildings. The system can supply electrical energy to power grids, and can be an alternative power generation plants.

Owner:RES SCI

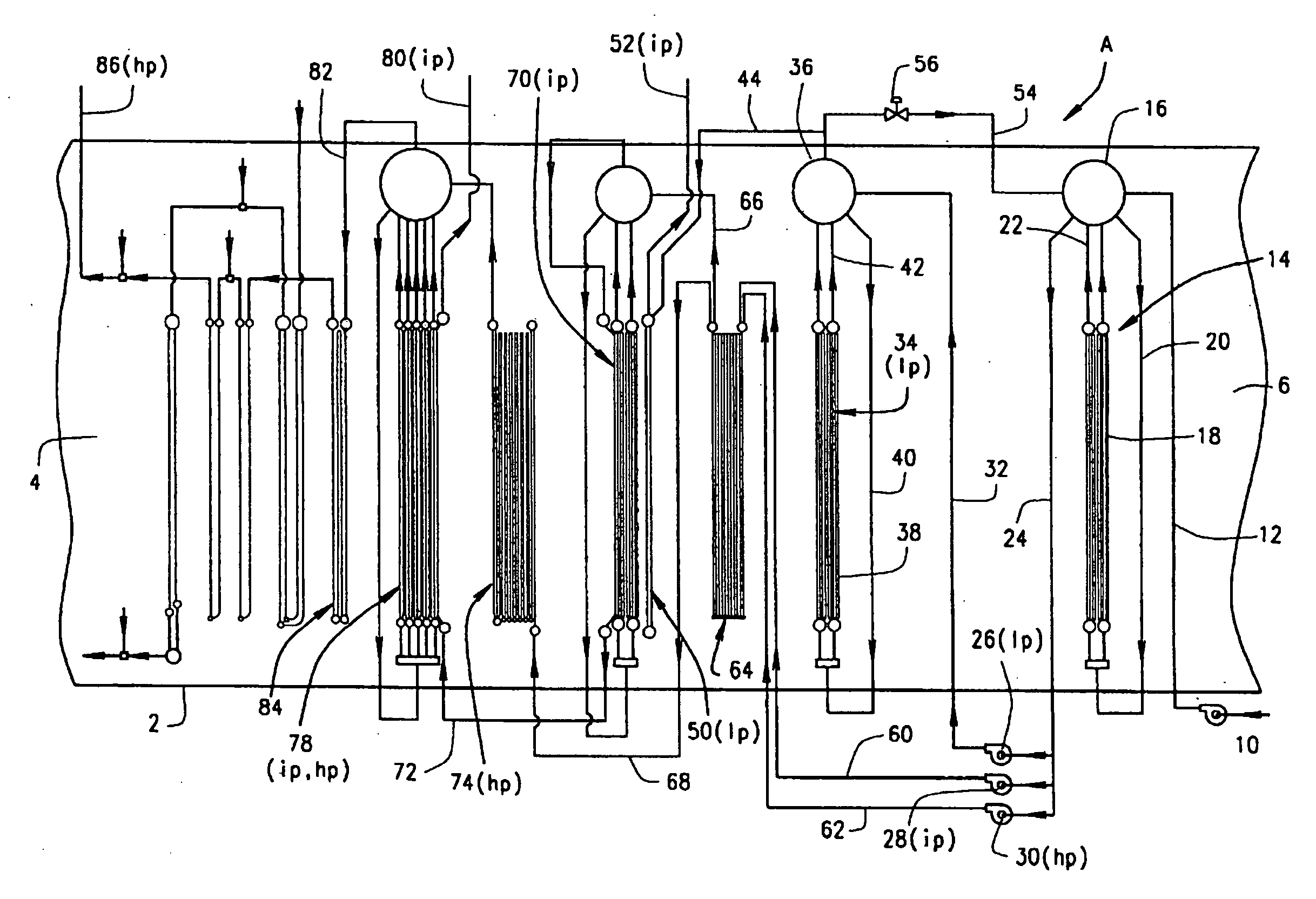

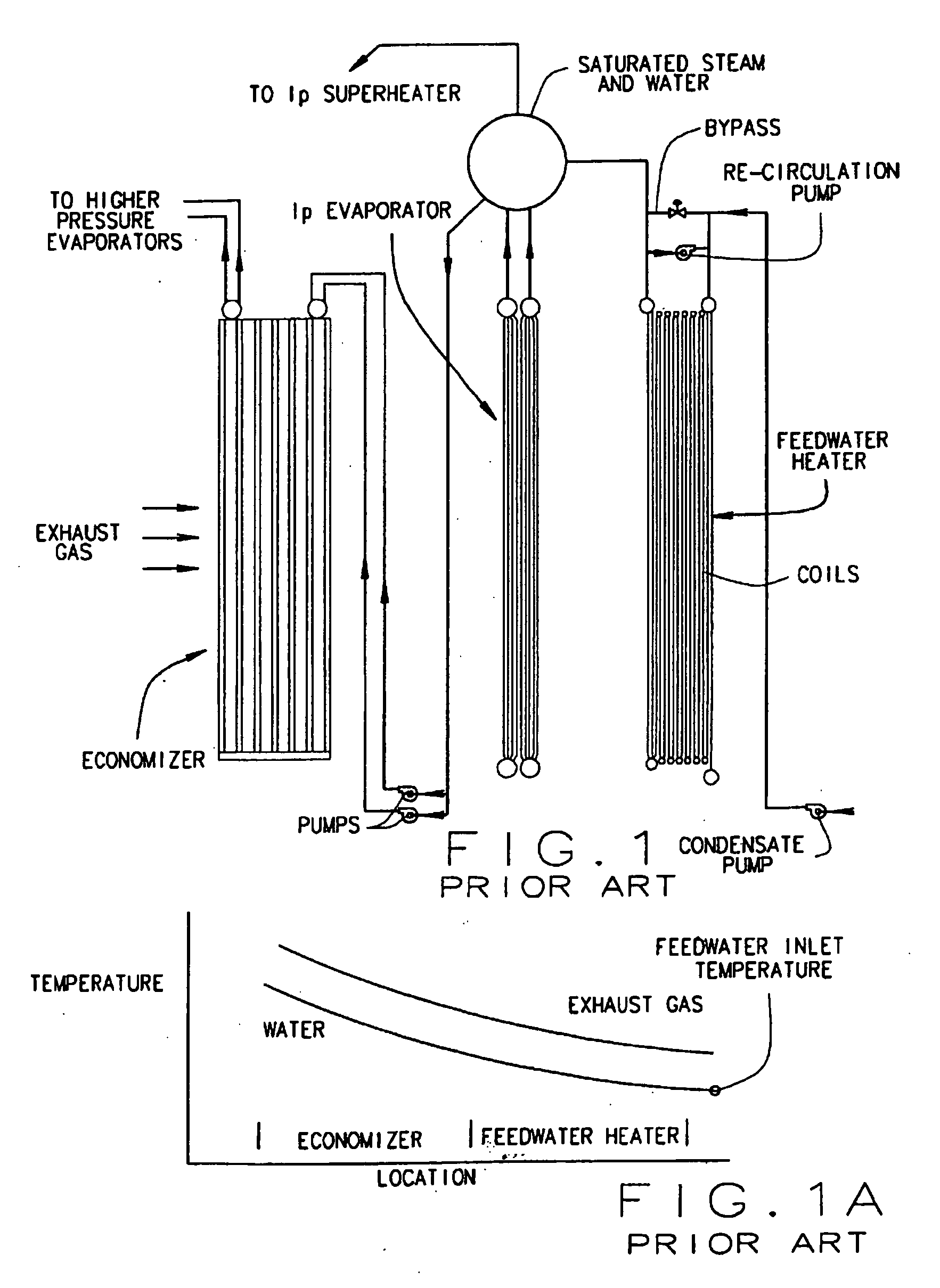

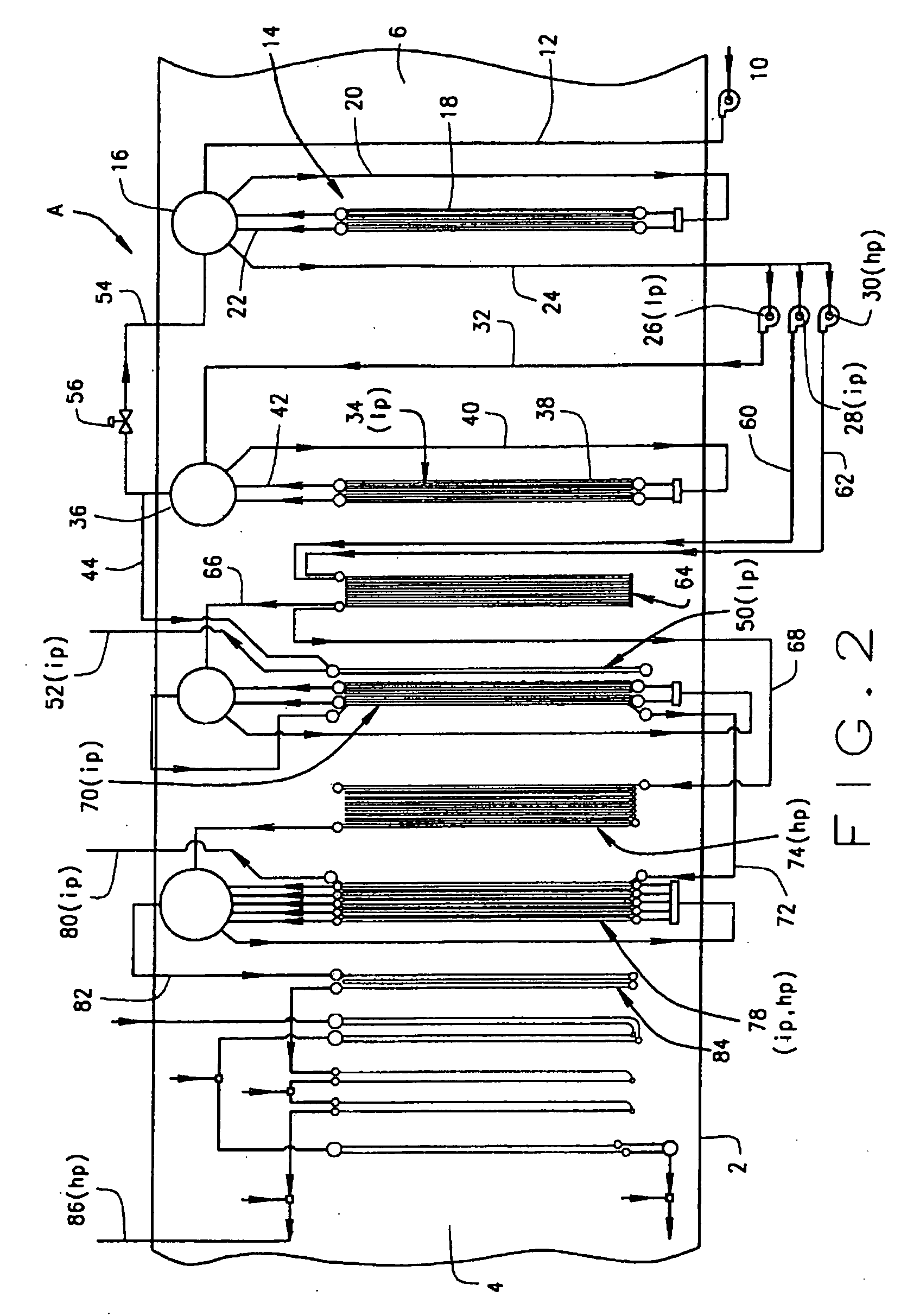

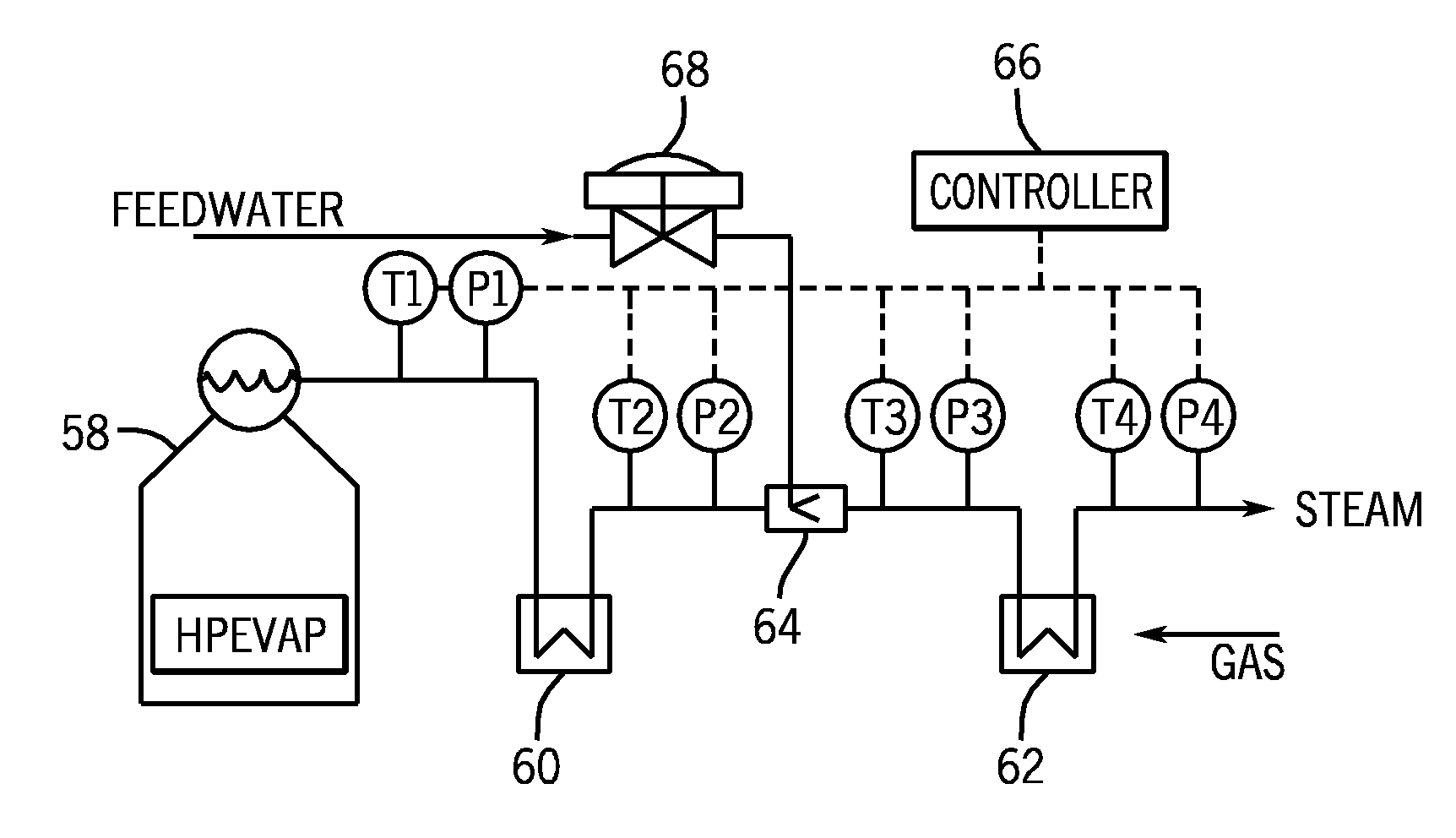

Process and apparatus for heating feedwater in a heat recovery steam generator

InactiveUS20120312019A1Steam generation heating methodsSteam accumulatorsCorrosive acidExhaust fumes

A feedwater heater (14) in a heat recovery steam generator (A,B) lies within a flow of hot exhaust gas. The feedwater heater (14) converts subcooled feedwater into saturated feedwater water, the temperature of which is only lightly above the acid dew point temperature of the exhaust gas so that corrosive acids do not condense on coils (18) of the feedwater heater (14). Yet the temperature of the saturated feedwater lies significantly below the temperature of the exhaust gas at the coils (18), so that the coils (18) operate efficiently and require minimal surface area. Pumps (26, 28, 30) elevate the pressure of the saturated feedwater and direct it into an economizer (64, 90) where, owing to the increase in pressure, the water is again subcooled. The economizer (64, 90) elevates the temperature still further and delivers the higher pressure feedwater to evaporators (34, 70, 78) that convert it into saturated steam that flows on to the superheaters (50, 78, 84). Higher pressure pegging stem admitted to the feedwater heater (14) controls the pressure—and temperature—of saturated steam and water in the feedwater heater (14).

Owner:NOOTER ERIKSEN INC

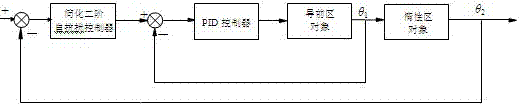

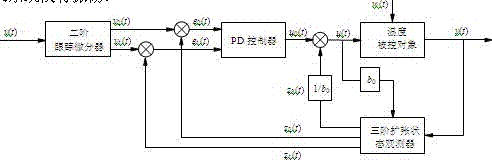

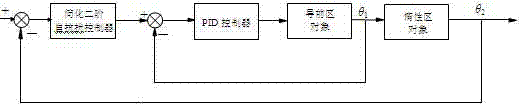

Method for controlling main steam temperature in power plant based on simplified second-order auto disturbance rejection controller

InactiveCN102360176AEasy to adjustRealize decoupling controlControllers with particular characteristicsCompensation effectControl manner

The invention discloses a method for controlling a main steam temperature in a power plant based on a second-order simplified auto disturbance rejection controller. In the method, a cascade control mode is used for forming a cascade steam temperature mediation and control system; in an inner ring, proportion integration differentiation (PID) adjustment is used for eliminating the deviation of an advance timing steam temperature to achieve a coarse tuning effect on an overheating steam temperature; in an outer ring, the simplified second-order auto disturbance rejection controller is used for controlling the outlet temperature of an overheater, so that the defects of large inertia and large delay of a temperature object in an inertia area are fully overcome; and by a disturbance compensation effect of the simplified second-order auto disturbance rejection controller, the disturbance of factors such as loads, flue gas and the like is eliminated, so that the stability of the main steam temperature is ensured. In the method, an algorithm is simple, a parameter is easy to adjust, and a higher response speed, higher steady state accuracy, higher disturbance resistance and higher robustness can be well acquired without dependence on a mathematical model with an accurate main steam temperature in the power plant.

Owner:SHANDONG ELECTRIC POWER SCHOOL

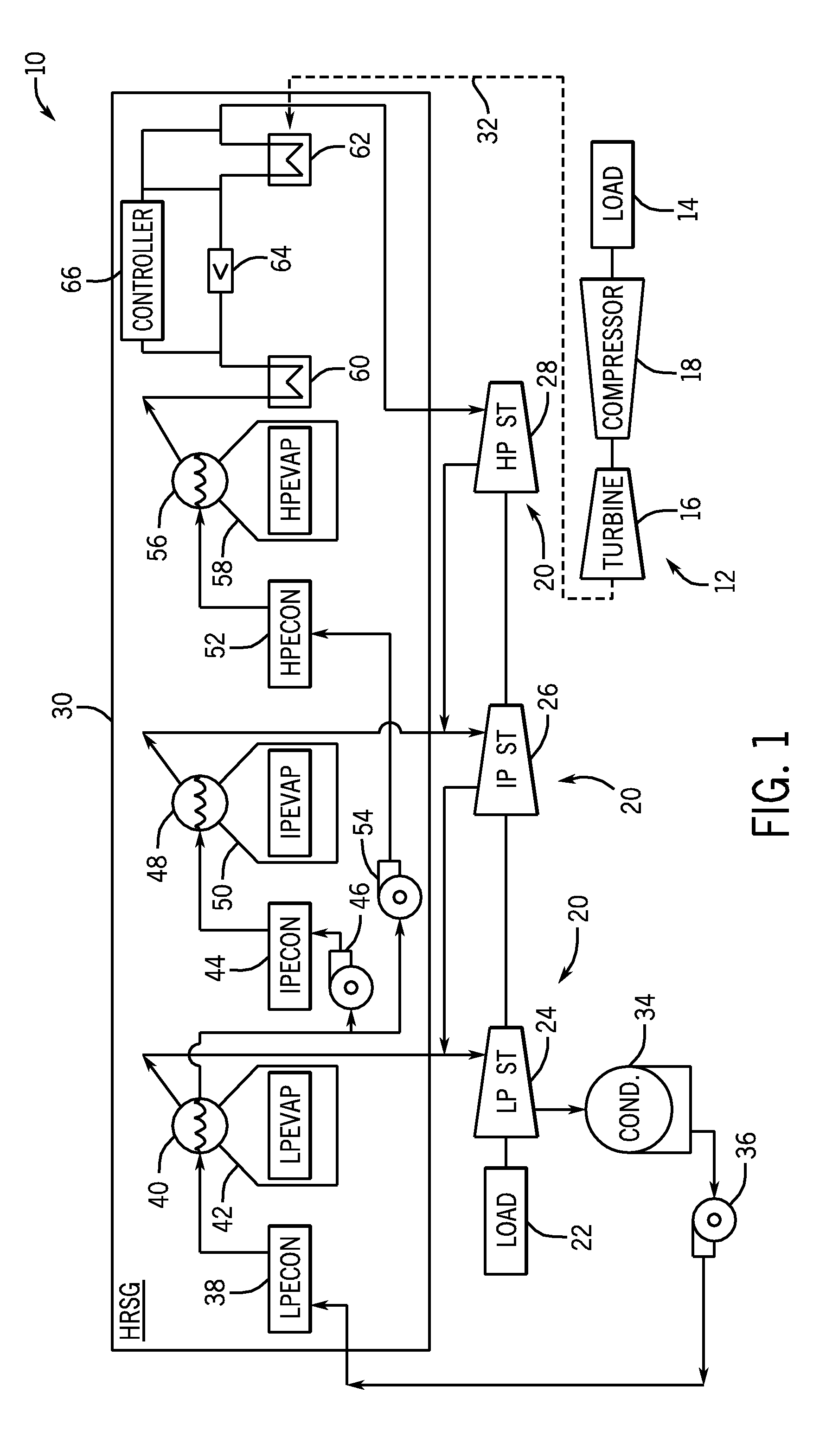

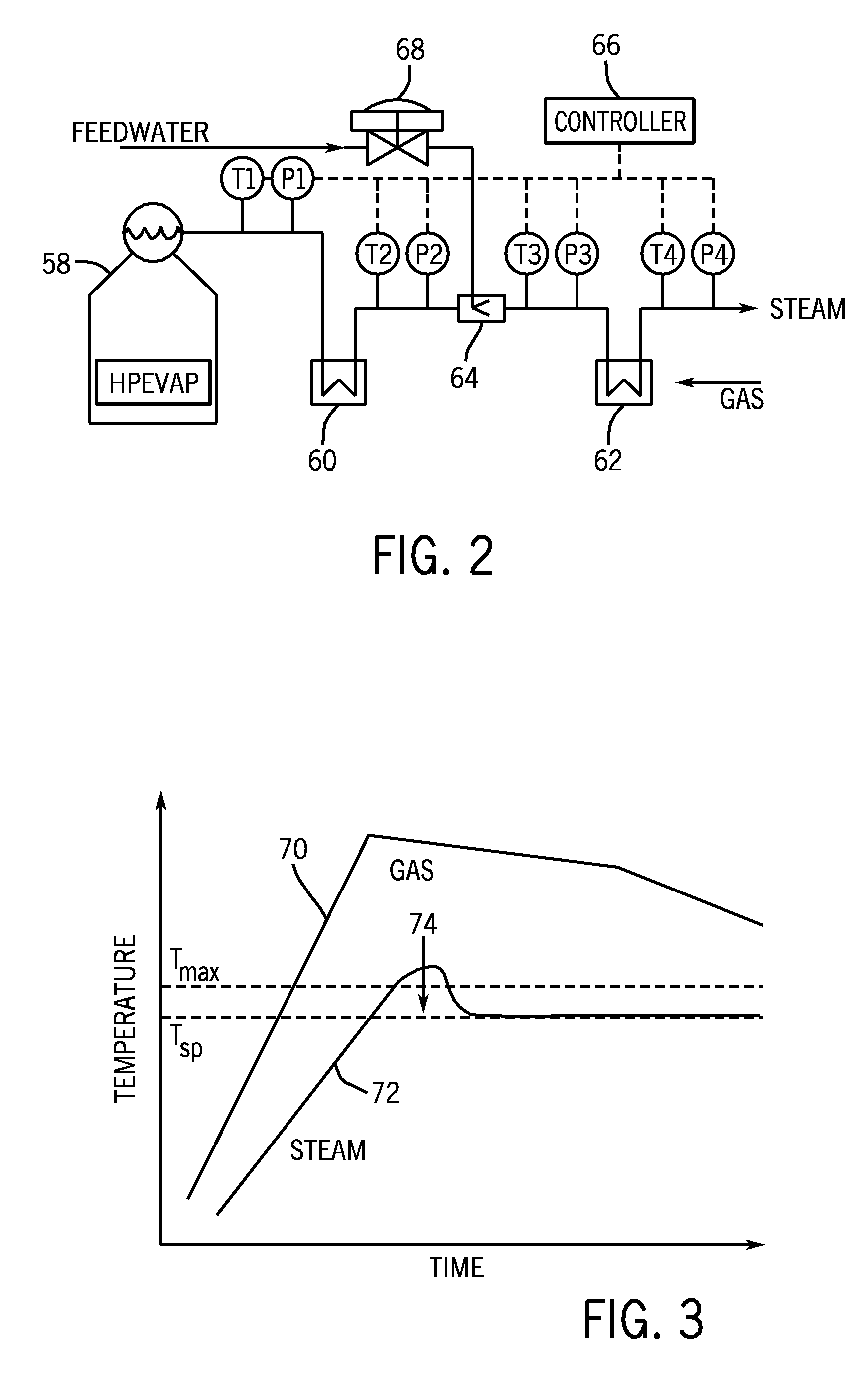

Inter-stage attemperation system and method

Systems and methods for controlling exhaust steam temperatures from a finishing superheater are provided. In certain embodiments, the system includes a controller which includes control logic for predicting an exhaust temperature of steam from the finishing superheater using model-based predictive techniques (e.g., based on empirical data or thermodynamic calculations). Based on the predicted exhaust temperature of steam, the control logic may use feed-forward control techniques to control the operation of an inter-stage attemperation system upstream of the finishing superheater. The control logic may determine if attemperation is required based on whether the predicted exhaust temperature of steam from the finishing superheater exceeds a set point temperature as well as whether the inlet temperature of steam into the finishing superheater drops below a set point temperature of steam. The attemperation system may include a characterizing function to linearize the valve operation controlled by the control logic to inject cooled, high-pressure feedwater into the steam upstream of the finishing superheater, which may, in turn, control the exhaust temperature of steam from the finishing superheater. The disclosed embodiments may also be applied to any systems where an outlet temperature of a fluid from a heat transfer device may be controlled.

Owner:GENERAL ELECTRIC CO

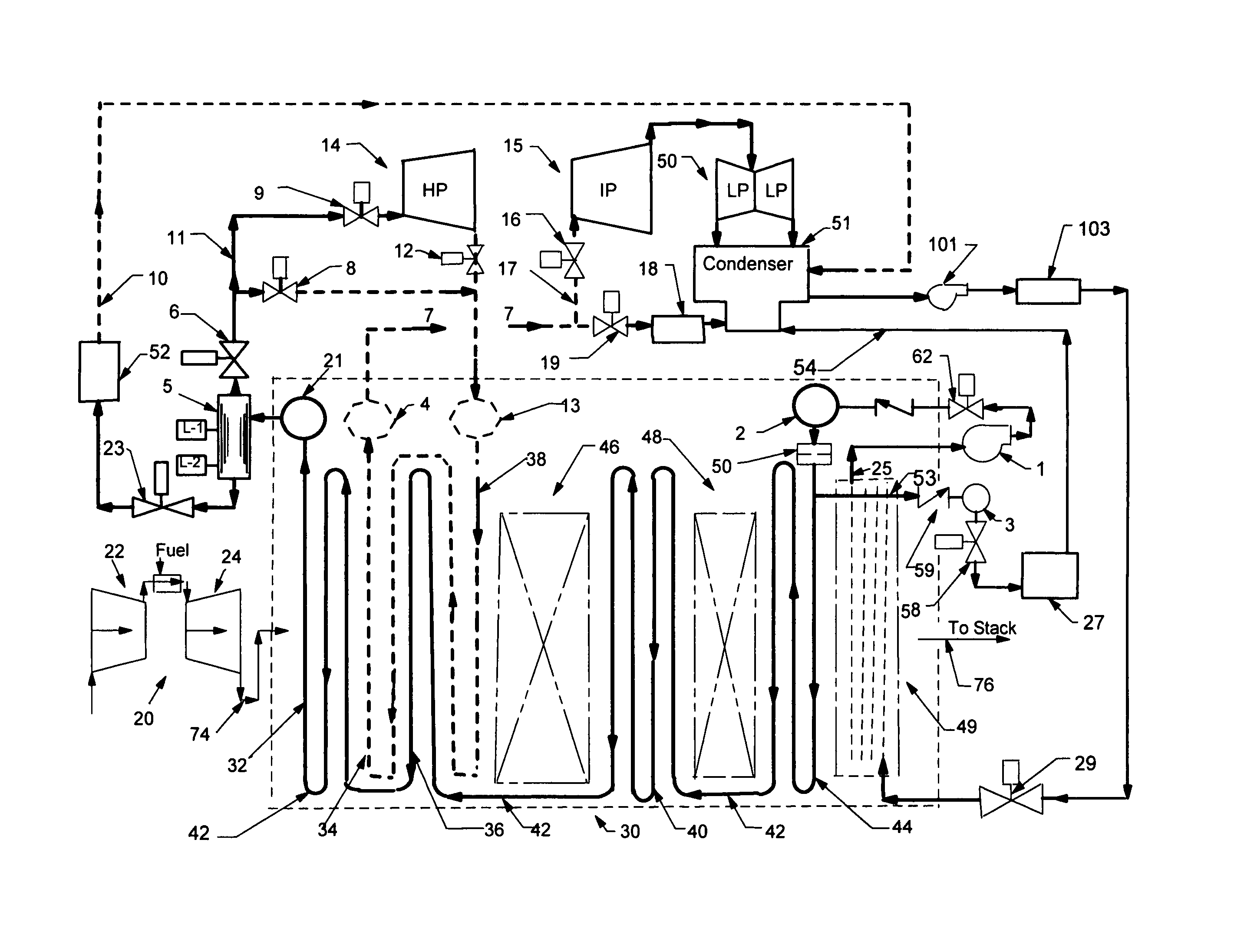

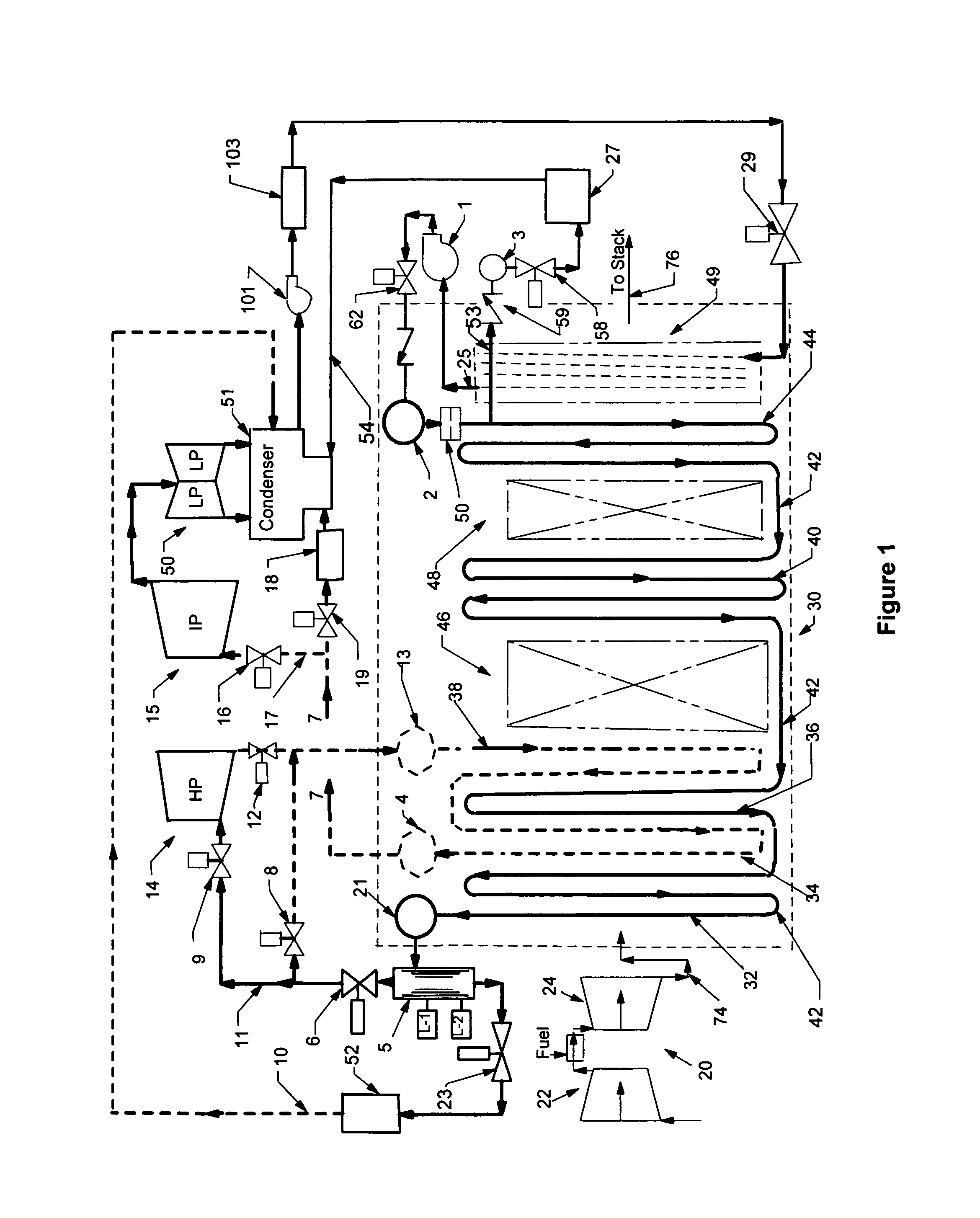

Heat recovery steam generator and method for fast starting combined cycles

ActiveUS8820078B1Control moisture contentPossible leakageLiquid degasificationSteam generation heating methodsEngineeringSuperheater

A once-through high pressure steam generator and reheater configured to eliminate the majority of components limiting cyclical life of fast start conventional HRSGs. Two remaining problematic components in conventional designs the final superheater and reheater tubes overheat while their headers remain colder in fast starts. In this inventive HRSG the critical components are arranged and started by a method that limits these damaging temperature differentials. At ignition when exhaust gas surges into a wet superheater steam flow starts minutes before conventional systems. This early steam flow cools the tubes while heating the headers, thereby reducing life damaging stresses. Steam temperature is controlled through the start and warms the rest of the plant earlier without attemperators with their problematic thermal stress history. Faster starts than conventional result without damaging fatigue life depletion with this low cost innovation.

Owner:DUFFY THOMAS EDWARD

High-temperature melting treatment system and method for sludge

ActiveCN102537980ALow running costEmission reductionCombination devicesSludge treatment by pyrolysisAir preheaterCooling tower

The invention discloses a high-temperature melting treatment system and a method for sludge, and relates to a sludge treatment system and a sludge treatment method. The system and the method solve the problem that dioxine exists in sludge incineration methods in prior arts. A first device comprises a melting chamber with a furnace body integrally manufactured from a lower side to an upper side, a shrinking section smoke outlet and a secondary combustor, high temperature and low temperature superheaters arranged in a smoke duct, high temperature and low temperature coal economizers, high temperature and low temperature air preheaters, and an SCR (selective catalytic reduction) denitration system, wherein the smoke duct is communicated with a smoke fast cooling tower, the smoke fast cooling tower is communicated with a bag-type dust collector, and the bag-type dust collector is communicated with a chimney by a smoke wet desulphurization system and a draught fan. The first method comprises the steps of feeding dry sludge powder into the melting chamber for burning to a high-temperature melting state, recycling liquid-state slag and reusing, treating high-temperature smoke after entering the smoke duct, and discharging. The differences between a system in a second scheme and the first device are as follows: the high temperature and low temperature superheaters and the high temperature and low temperature coal economizers are not arranged, and a steam heat exchanger is additionally arranged. A difference between a system in the third scheme and the second scheme is as follows: a multistage sludge dryer is additionally arranged. The high-temperature melting treatment system and method for the sludge are used for high-temperature melting treatment of the sludge.

Owner:HARBIN INST OF TECH

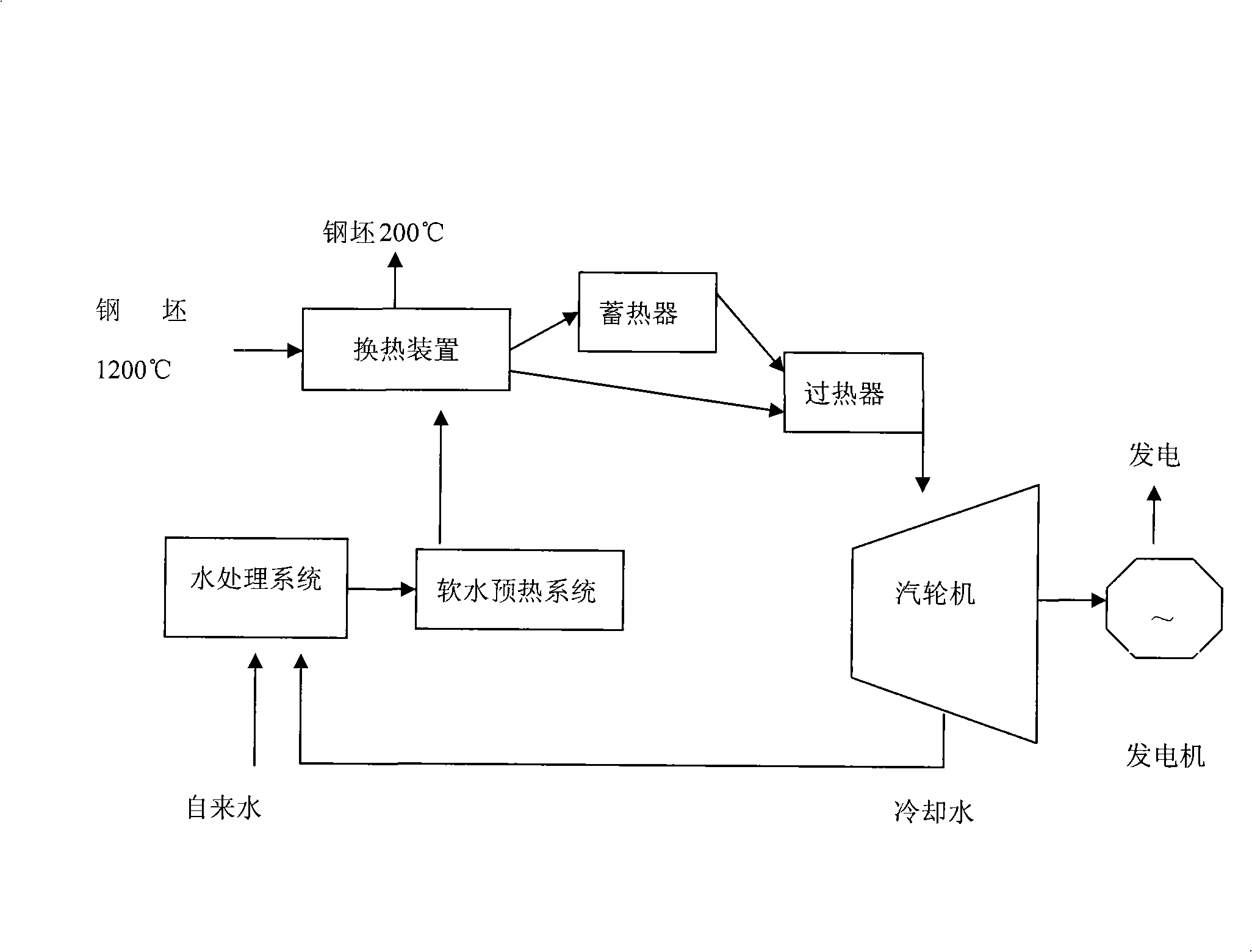

Method and device for reclaiming and utilizing billet residual heat

InactiveCN101260816AGuaranteed uptimeSave electricitySteam engine plantsThermal energyWater storage tank

The invention discloses a method for recycling billet residual heat and a device thereof; water is treated by softening; superheated water is obtained through a steel making cooling system, then the superheated water and discharged billet exchange heat to obtain water vapour; the method comprises the following specific steps: A. superheated water obtained by softening tap water or cooling water is stored in a water storage tank; B. the superheated water in the water storage tank referred in the step A is conveyed to steel tubes of a heat exchange device by a high-pressure water pump through a pipeline; billet is pushed into the heat exchange device surrounded by the steel tubes; heat energy of the billet is dispersed out in order that water in the heat exchange device becomes high-temperature and high-pressure water vapour; C. the high-temperature and high-pressure water vapour passes through a superheater and impels a steam turbine to drive a dynamo to generate power; D. the water vapour after being utilized by the steam turbine is condensed into condensed water; the condensed water enters a water treating system by the pipeline, is treated by the water treating system and conveyed to a cooling water softening system of the step A by the pipeline; through the method, the device recycles cooling water, can dramatically recycle the billet residual heat in high efficiency and is stable and reliable.

Owner:朱学仪

Solar concentration plant for the production of superheated steam

InactiveUS20080302314A1Easy to controlReduce riskSolar heating energySuperheating controlHeliostatEvaporation

A solar concentration plant which uses water / steam as a heat-carrying fluid, in any thermodynamic cycle or system for the exploitation of process heat, which is comprised of an evaporation subsystem, where saturated steam is produced under the conditions of pressure of the system, and a superheater subsystem through which the steam reaches the required conditions of pressure and temperature at the turbine inlet, and in which an attemperation system (10) may be incorporated, these being physically separated and interconnected by means of a drum (5) in which the separation of water and steam takes place, and in which a strategic control of the pointing of the field of heliostats (1) towards either of the subsystems (evaporator or superheater) may be carried out, with individual or group pointing of the heliostats, in such a way that they jointly control both the pressure within the drum (5) and the outlet temperature of the superheated steam (11).

Owner:ABENGOA SOLAR NEW TECH SA

A membrane-type water-cooled wall four-flue biomass circulating fluidized bed boiler

InactiveCN102297423AIncrease profitGuaranteed uptimeFluidized bed combustionCombustion technology mitigationSuperheaterHeat energy

A membrane water-cooled wall four-flue biomass circulating fluidized bed boiler, including a drum, a furnace, a cyclone separator, a return device, a second flue, a third flue, a fourth flue, an economizer, and a dust collector appliance, induced draft fan, chimney. The furnace, the second flue and the third flue are surrounded by membrane water-cooled walls; in the lower part of the furnace and the inner surface of the flue gas outlet, the cyclone separator and the inner surface of the flue gas outlet, the second flue and the third flue Refractory castables are laid around the connecting parts of the flue; a medium-temperature screen superheater is arranged at the upper end of the second flue; high-temperature and low-temperature convection superheaters are spaced in the third flue; the middle wall adopts a tapered wall structure; low-temperature convection superheater The first water spray desuperheater and the second water spray desuperheater are respectively arranged between the high temperature convection superheater and the medium temperature screen convection superheater. The invention improves the combustion heat energy utilization rate of the biomass fluidized bed boiler, reduces the wear and alkali metal corrosion of the inner wall of the flue by high-speed and high-temperature flue gas, and enhances the wear resistance of the wall surface.

Owner:JIANGSU SIFANG BOILER +1

SELECTIVE CATALYTIC REDUCTION OF NOx ENABLED BY SIDESTREAM UREA DECOMPOSITION

ActiveUS20060115402A1Well mixedAccurate temperatureCombination devicesNitrogen compoundsParticulatesSuperheater

A preferred apparatus arrangement utilizes the enthalpy of the flue gas, which can be supplemented if need be, to convert urea (30) into ammonia for SCR. Urea (30), which decomposes at temperatures above 140.degree. C., is injected (32) into a flue gas stream split off (28) after a heat exchanger (22), such as a primary superheater or an economizer. Ideally, the side stream would gasify the urea without need for further heating; but, when heat is required it is far less than would be needed to heat either the entire effluent (23) or the urea (30). This side stream, typically less than 3% of the flue gas, provides the required temperature and residence time for complete decomposition of urea (30). A cyclonic separator can be used to remove particulates and completely mix the reagent and flue gas. This stream can then be directed to an injection grid (37) ahead of SCR using a blower (36). The mixing with the flue gas is facilitated due to an order of magnitude higher mass of side stream compared to that injected through the AIG in a traditional ammonia-SCR process.

Owner:FUEL TECH

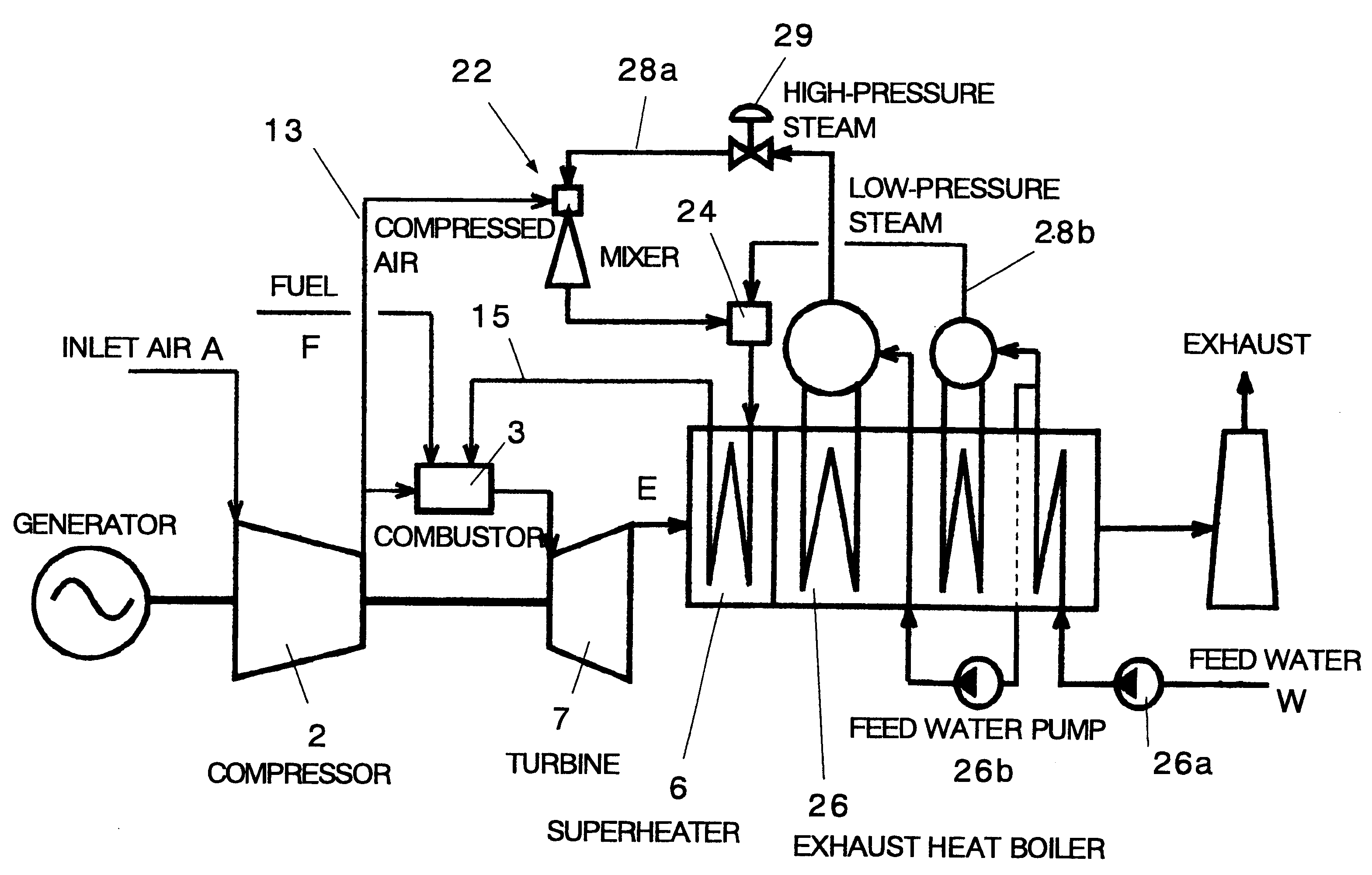

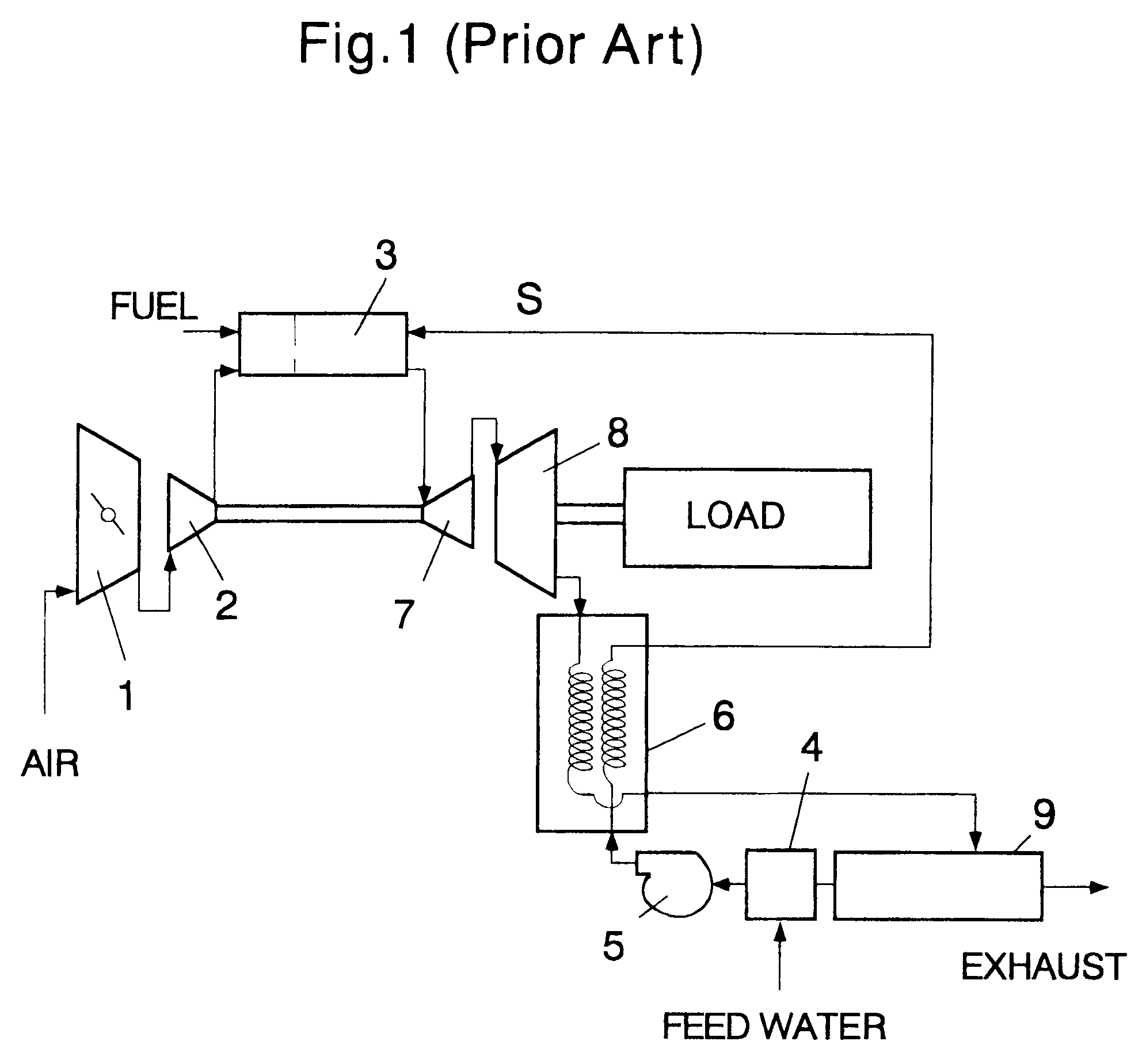

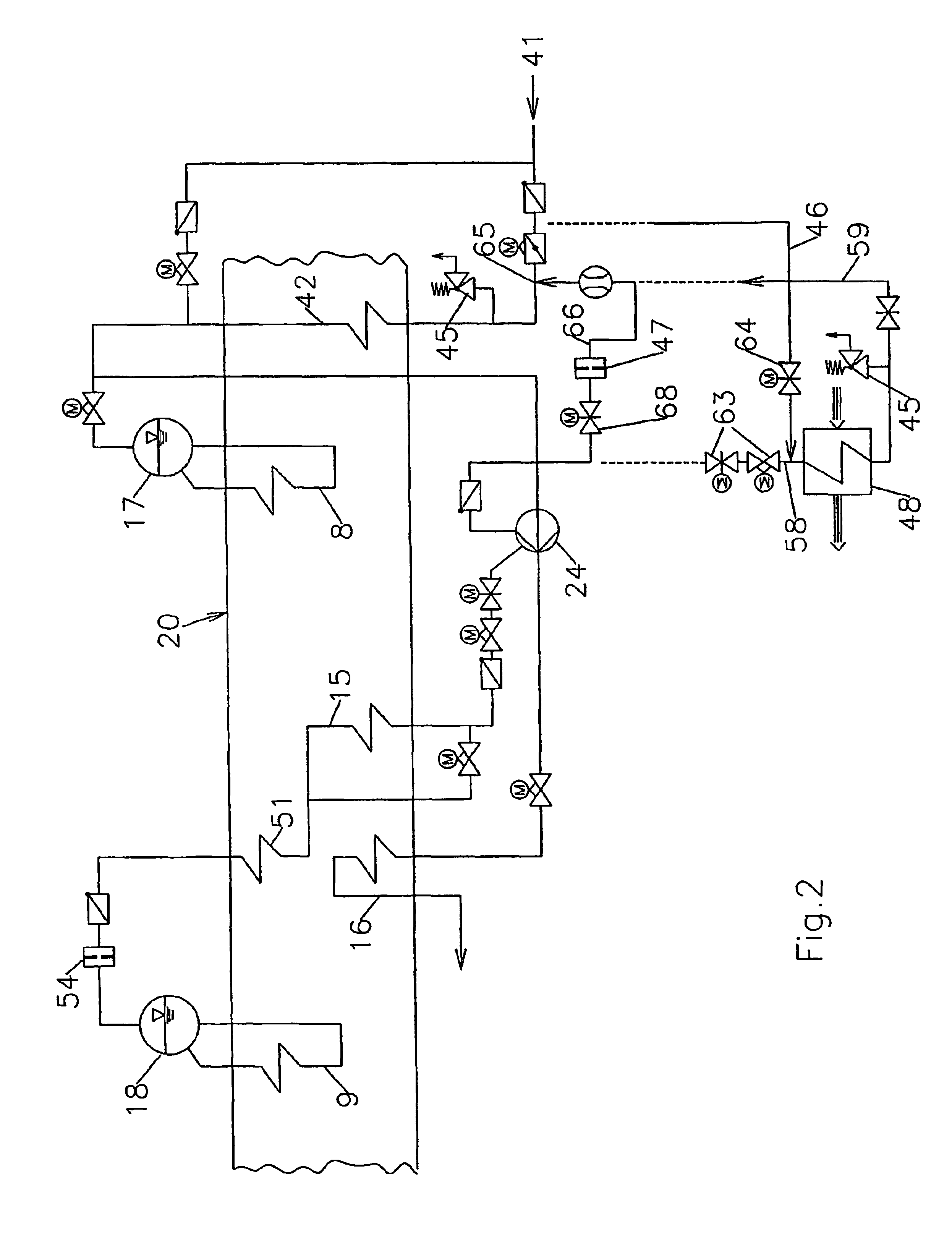

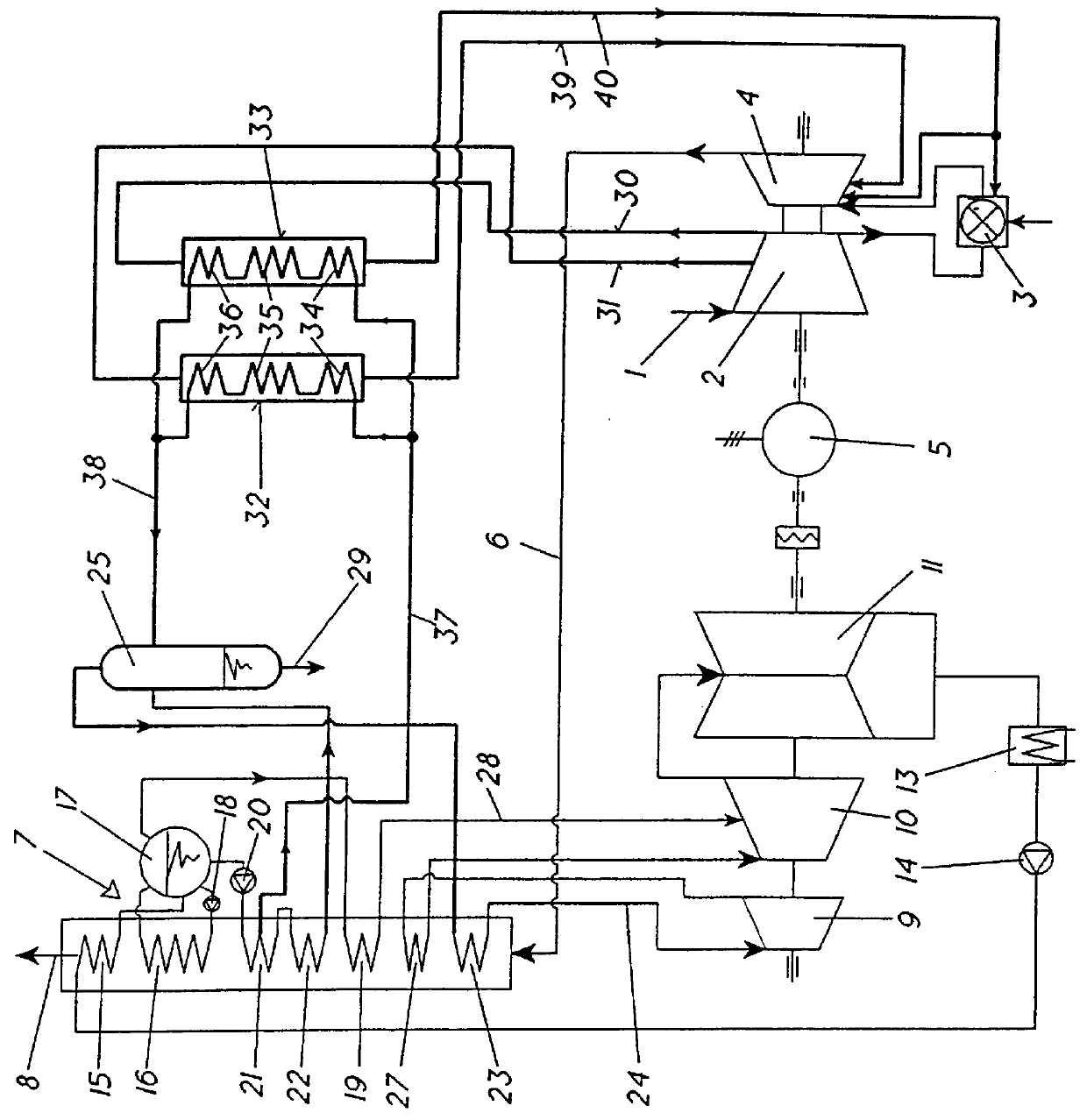

Dual-pressure steam injection partial-regeneration-cycle gas turbine system

In the partial-regeneration cycle gas turbine system wherein part of the air compressed by a compressor 2 is extracted before a combustor 3, mixed with steam, and after the mixed gas is superheated by exhaust heat of a turbine, and the mixed gas is injected into the combustor, high-pressure steam is used as a fluid for driving a first mixer 22 that compresses extracted air, to increase the ratio of extracted air to steam, and then this mixed gas of extracted air and steam is further mixed with low-pressure steam from a low-pressure exhaust heat boiler, in a second mixer, and the mixture of gas is superheated in a superheater 6 by exhaust heat of the turbine, and injected into the combustor. Thus, the pressure of the driving steam can be raised, an exergy loss in an exhaust heat recovery portion can be reduced, and the efficiency of power generation can be increased without reducing the flow of generated steam.

Owner:IHI POWER SYST CO LTD

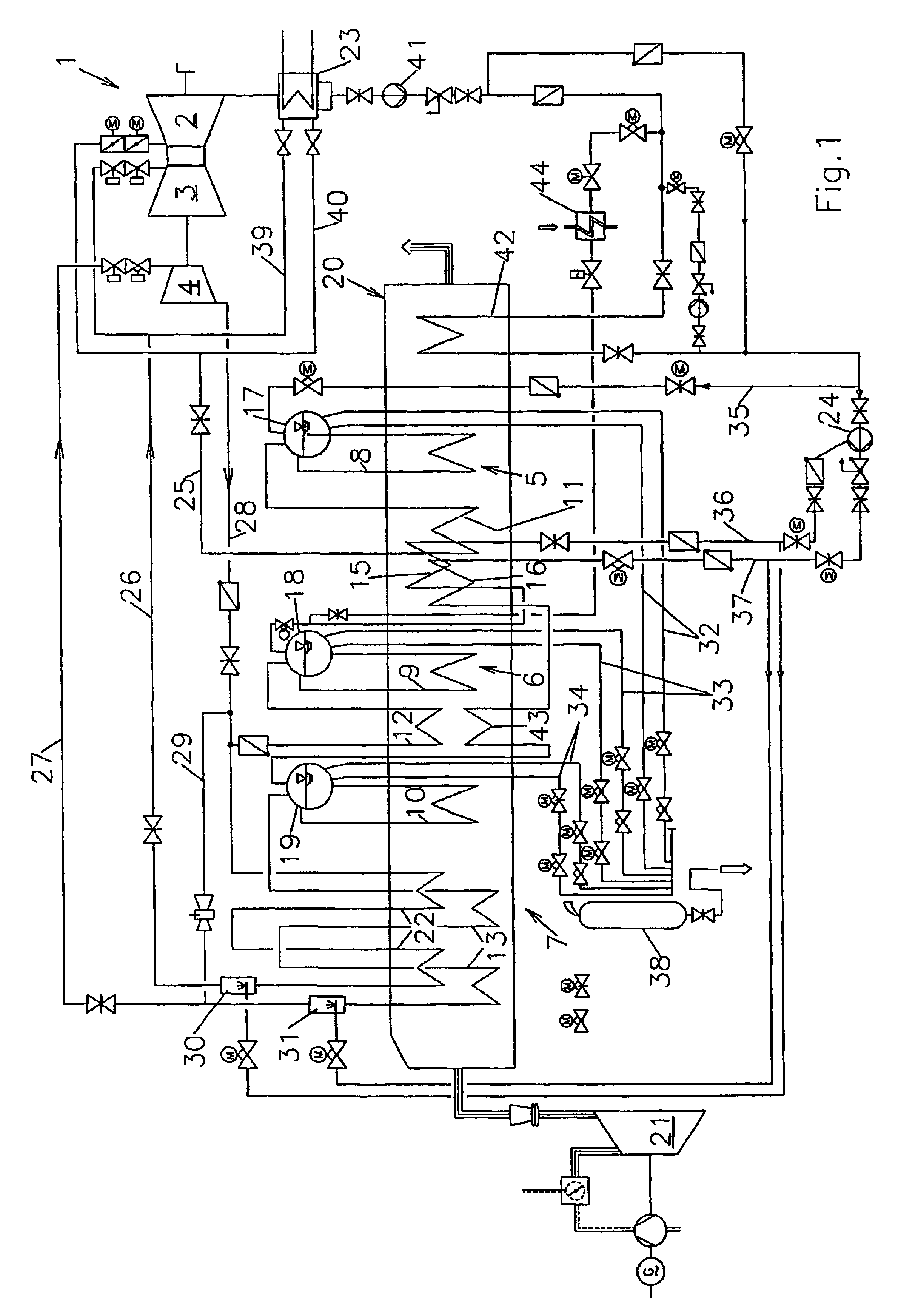

Device and method for preheating combustibles in combined gas and steam turbine installations

InactiveUS6920760B2Low costAdapted quickly and cost-effectivelyGas turbine plantsTurbine/propulsion fuel heatingSuperheaterProcess engineering

A device is for preheating combustibles in combined gas and steam turbine installations. The device includes at least one steam generator for heating, evaporating and superheating feed water, which has a feed water preheater, an evaporator and a superheater. At least part of the heated feed water is used for preheating combustibles in a combustible preheater, which can be supplied with feed water of a predetermined temperature by a feed water supply line. Once the combustible has been heated, the cooled feed water can be drained using a feed water drain line. The device is configured so that it can be used in different gas turbine installations and its heating capacity can be rapidly and cost-effectively adapted to predetermined combustible preheating requirements. To achieve this, the combustible is preheated in stages, which can be activated individually as required and through which the combustible can successively pass.

Owner:SIEMENS AG

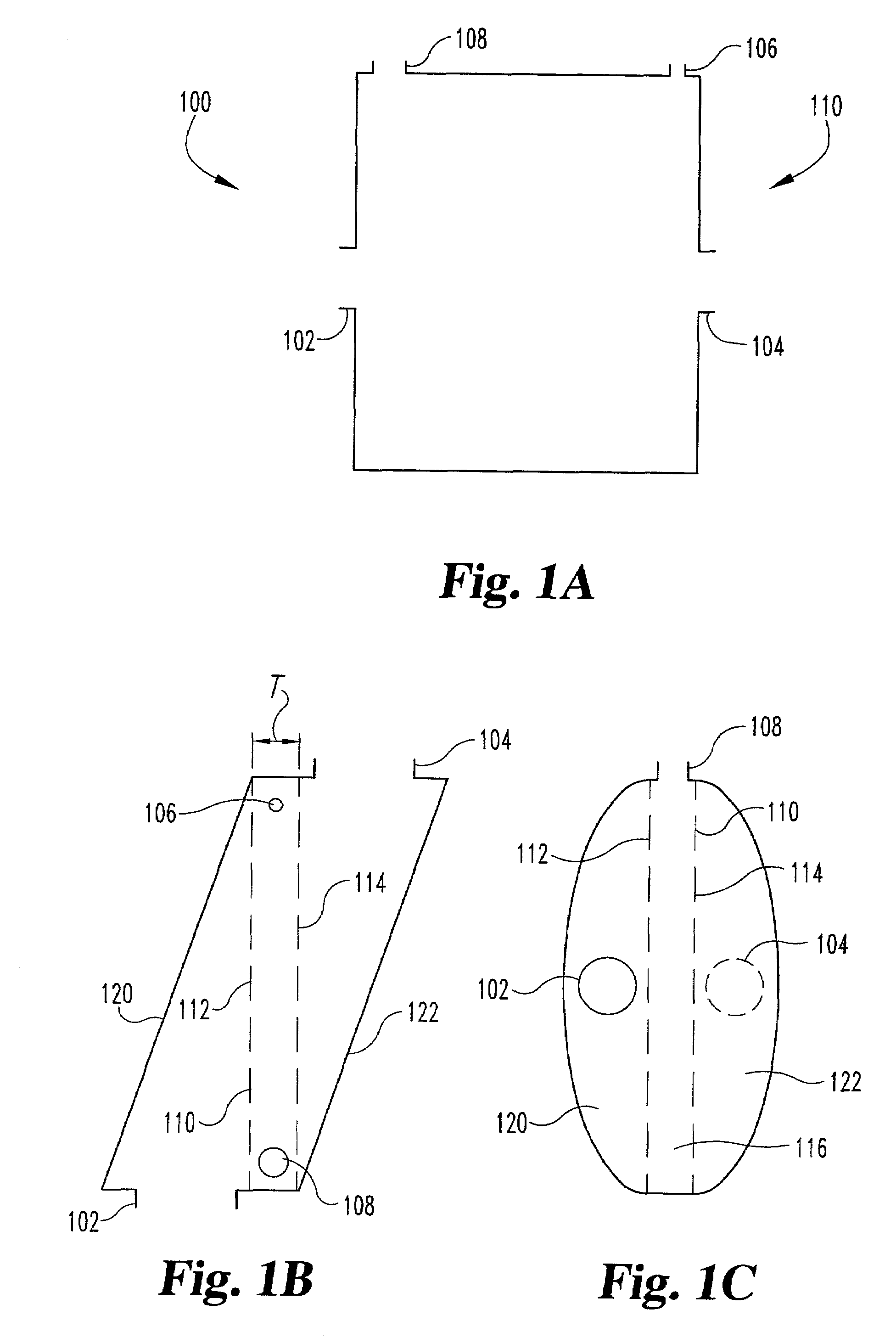

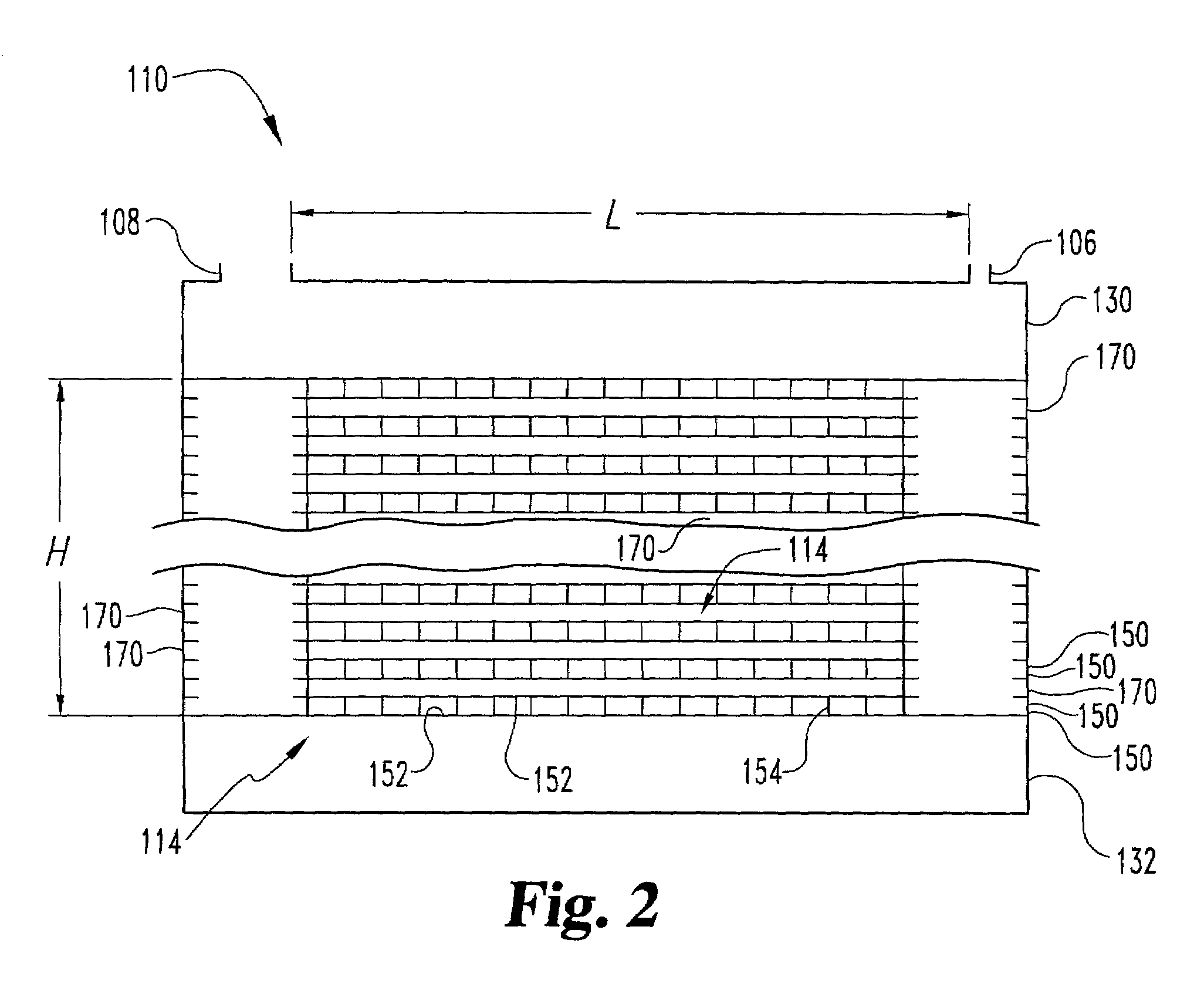

Fluid processing device and method

A fluid processing unit having first and second interleaved flow paths in a cross flow configuration is disclosed. The first flow paths are substantially longer than the second flow paths such that the pressure drop in the second flow paths can be maintained at a relatively low level and temperature variations across the second flow paths are reduced. One or more of the flow paths can be microchannels. When used as a vaporizer and / or superheater, the longer first flow paths include an upstream liquid flow portion and a downstream vapor flow portion of enlarged cross sectional area. A substantial pressure drop is maintained through the upstream liquid flow portion for which one or more tortuous flow channels can be utilized. The unit is a thin panel, having a width substantially less its length or height, and is manufactured together with other thin units in a bonded stack of thin metal sheets. The individual units are then separated from the stack after bonding.

Owner:BATTELLE MEMORIAL INST

Process for dust removing, cooling and tar oil recovering of pyrolysis coal gas

The invention discloses a process for dust removing, cooling and tar oil recovering of pyrolysis coal gas. The process adopts an overheater, a high-temperature dust remover, an accident quench tower, a waste heat recovering boiler, an indirect cooling device and an electrical tar precipitator which are connected in sequence, and comprises the following steps: pyrolysis coal gas is fed into the overheater to be cooled to 400-700 DEG C, fed into the high-temperature dust remover to be subjected to dust removing, fed into the waste heat recovering boiler to be cooled to 50-100 DEG C and condensed to separate out water and tar oil, fed into the indirect cooling device to be cooled to 10-30 DEG C and further condensed to separate out water and tar oil, and finally fed into the electrical tar precipitator, so that the carried tar oil mist and water mist are recovered. According to the process, dust particles in the coal gas are removed by high-performance dust removing equipment before condensing of tar oil, so as to prevent tar oil and dust separated out through condensation in the coal gas cooling process from being mixed together, improve the quality of tar oil and avoid the problems of equipment blockage and high dust content of tar oil.

Owner:ZHEJIANG UNIV

Combined cycle power station with gas turbine cooling air cooler

InactiveUS6018942AHigh-quality heatTurbine/propulsion engine coolingSteam usePower stationExhaust fumes

Owner:GENERAL ELECTRIC TECH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com