Patents

Literature

110 results about "Solar tower" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

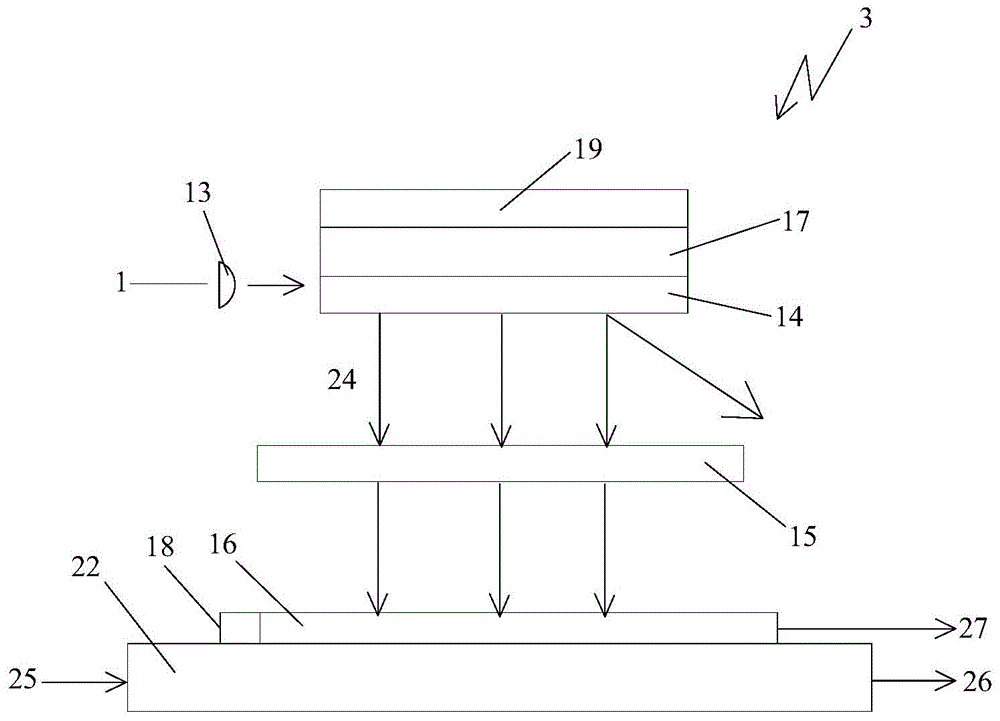

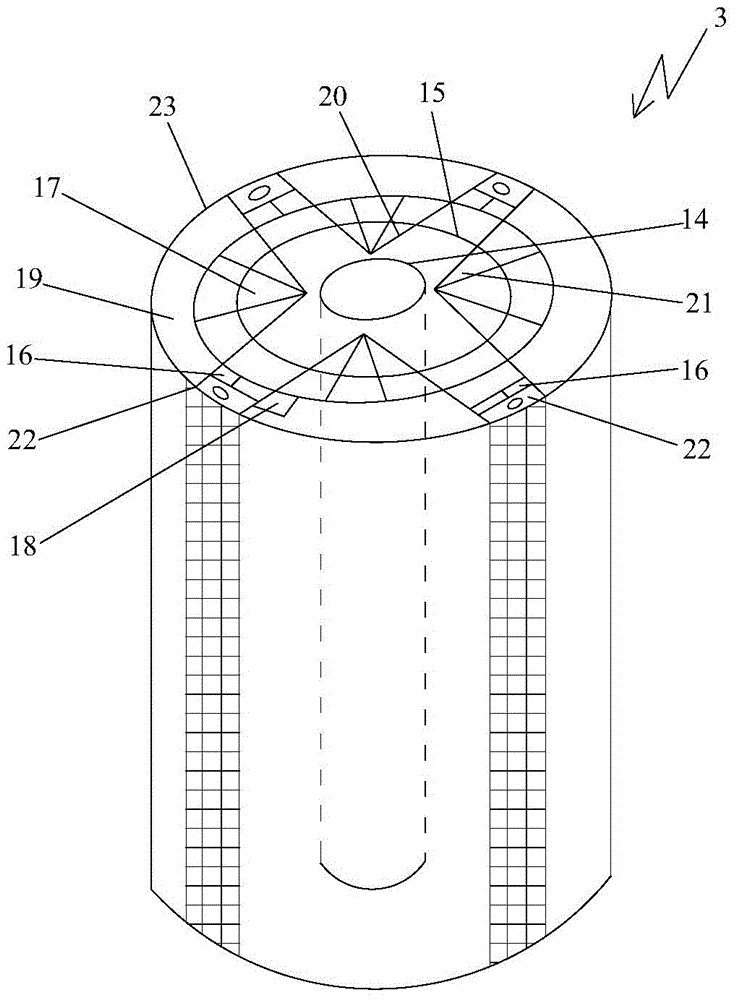

Solar blackbody waveguide for efficient and effective conversion of solar flux to heat energy

A solar blackbody waveguide that captures and uses sunlight to heat a thermal working or heat transfer fluid. Solar cell arrays capture the sunlight. The arrays are movably mounted on solar towers to track the daily movement of the sun and to maintain the proper angle with the horizon throughout the year. The arrays direct the light into a series of light pipes to deliver the light into a solar coil located within an underground insulated pipeline. Energy from the light rays is absorbed by the solar coil and transferred to the thermal working fluid or heat transfer fluid flowing between the solar coil and the insulated pipeline. The energy laden thermal working or heat transfer fluid is removed from the downstream end of the insulated pipeline so that it can be used with existing technologies, such as with a combined cycle gas turbine, boiler, or steam generator.

Owner:MECHAM TRAVIS W

All-weather clean energy comprehensive electricity generating and energy saving method and facility manufacturing method thereof

InactiveCN104295448AHigh light transmittanceImprove efficiencyWind motor with solar radiationGeneral water supply conservationNew energyTransmitted power

The invention discloses an all-weather clean energy comprehensive electricity generating and energy saving method and a facility manufacturing method. In ten inventions, having at least one identical or corresponding specific technical characteristic and related to the total inventive concept, of solar gallery buildings, through graphene series facilities under solar gallery buildings, in a land field, a zero-carbon environment-friendly safe type raft-shaped basic-framed-tube-structured huge building group of a universal wind energy tower shape is established and new energy automobiles and trains are manufactured, wherein cheap wind power solids are established, photoelectric benzene expansion optical fibers are manufactured, lightning is utilized firstly for supplying power externally, various spaces are shared through building three-dimensional afforesting, and three-dimensional energy collection is achieved; in a water field, deep water self-floating buildings of a super steel concrete frame-tube structure (preferably, complete steel plates are adopted) are built, the deep water self-floating buildings are connected in series to form a global ocean water and electricity and agriculture and forestry extraction traffic network and a large lake and reservoir water and electricity and agriculture and forestry dredging dam water level traffic network, wherein the deep water automatic floating buildings are free of influences of earthquakes, tsunamis and wars, the Red Cross can rescue people in all-weather conditions; in a space field, multiple receiving and transmitting solar towers are first established on the equator of the earth and the equator of the moon, the receiving and transmitting solar towers are connected in series to operate in a timed mode in the specific direction and transmit power to the whole world through graphene cables which are all packaged with colored insulating films.

Owner:熊凌云 +6

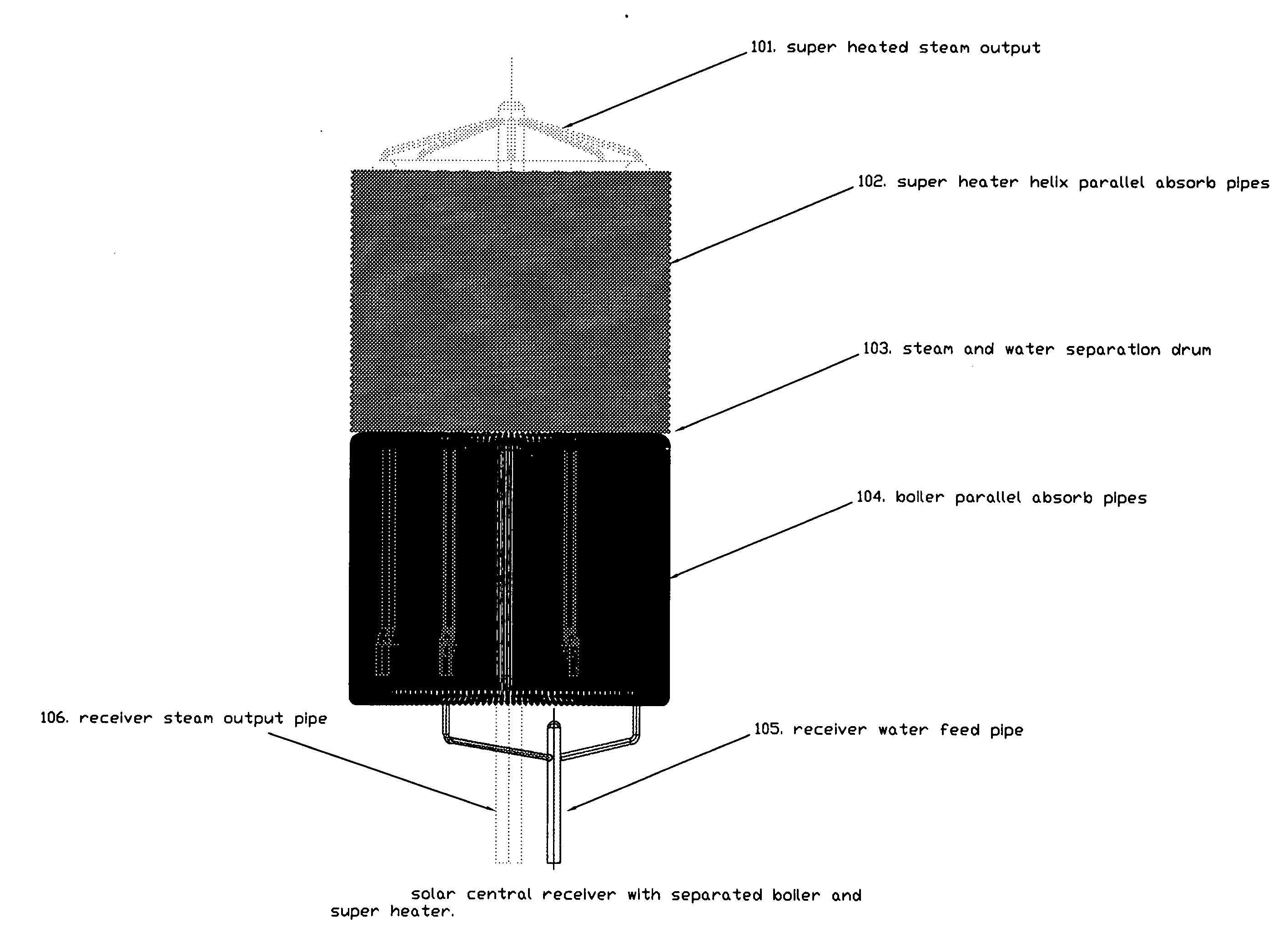

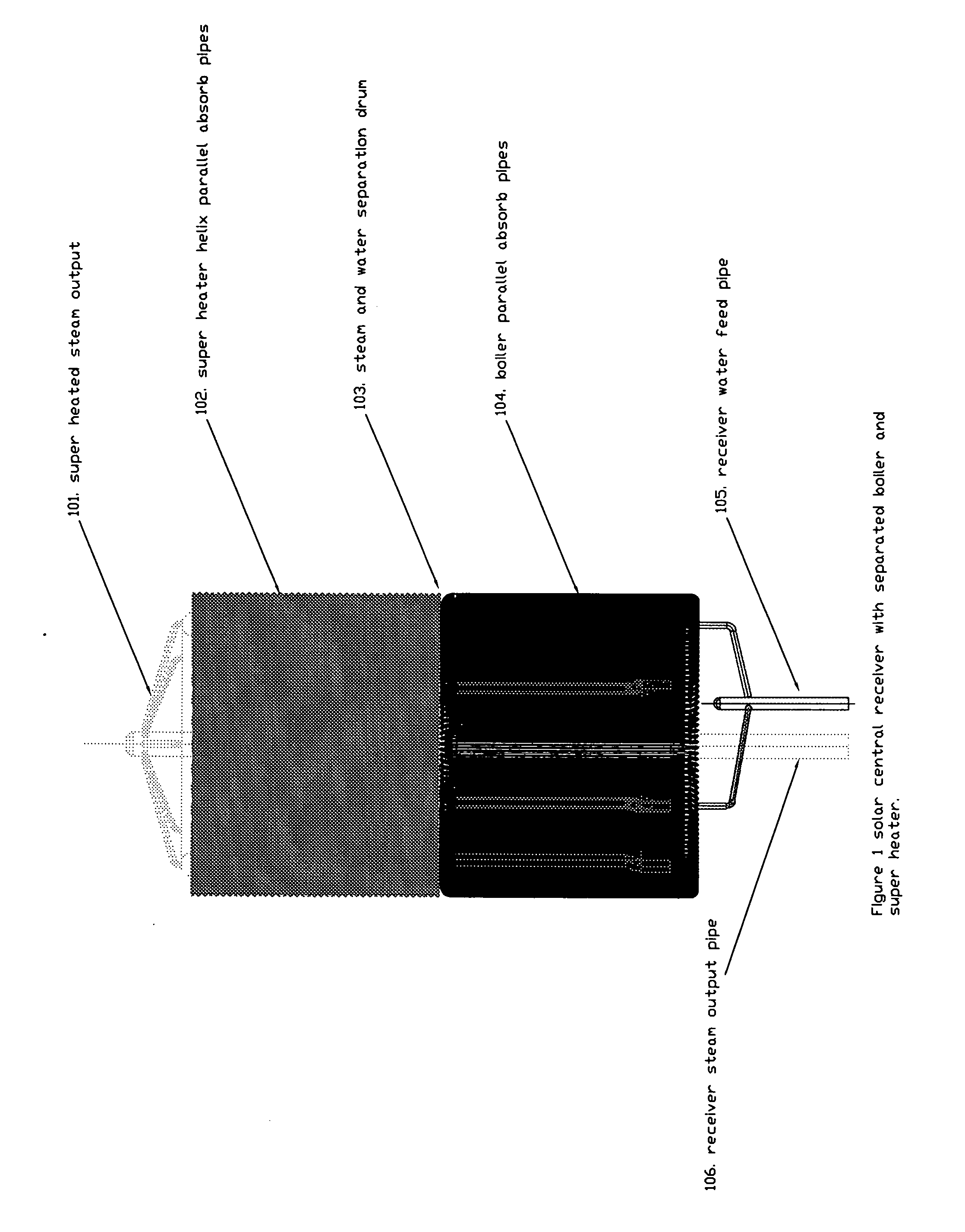

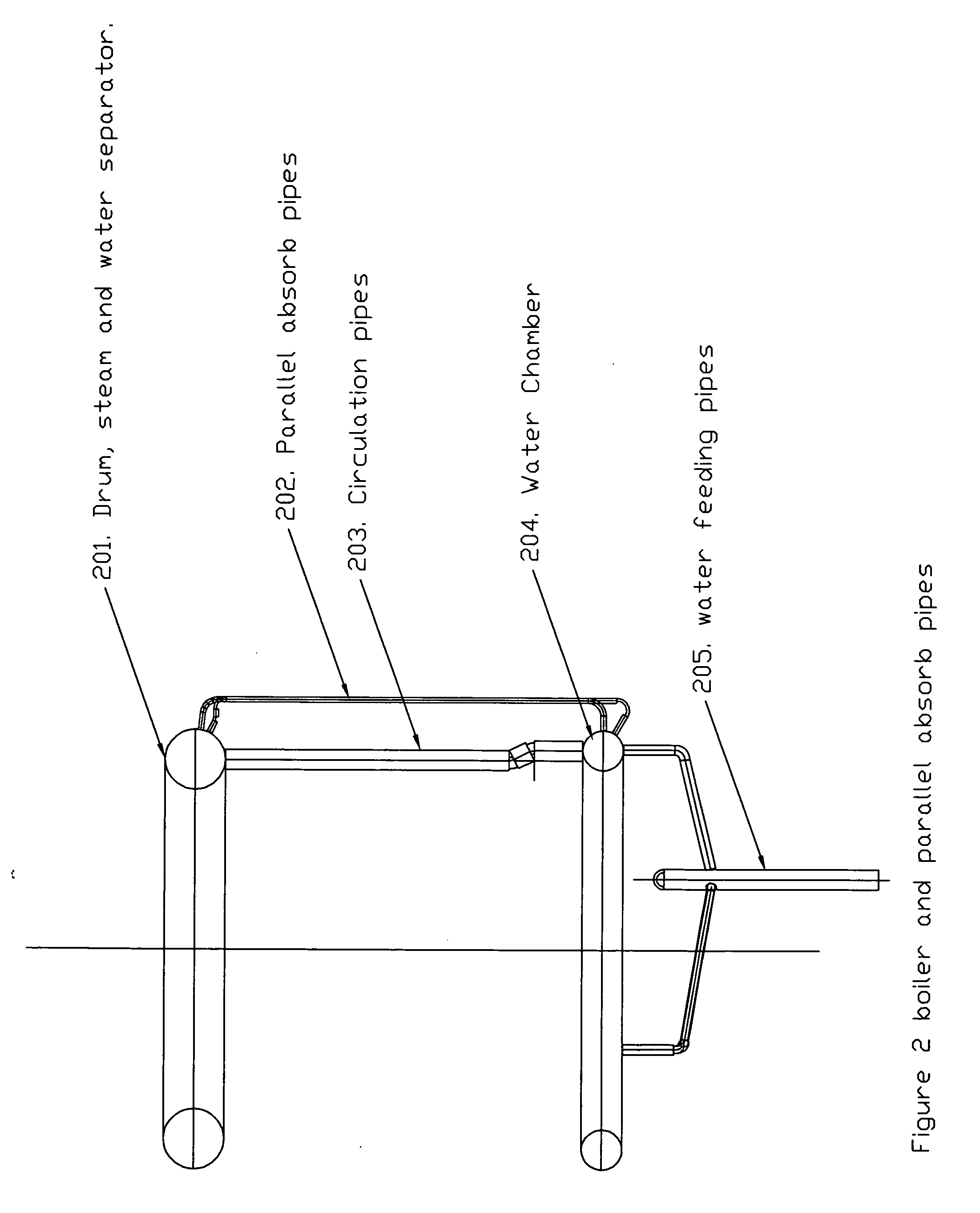

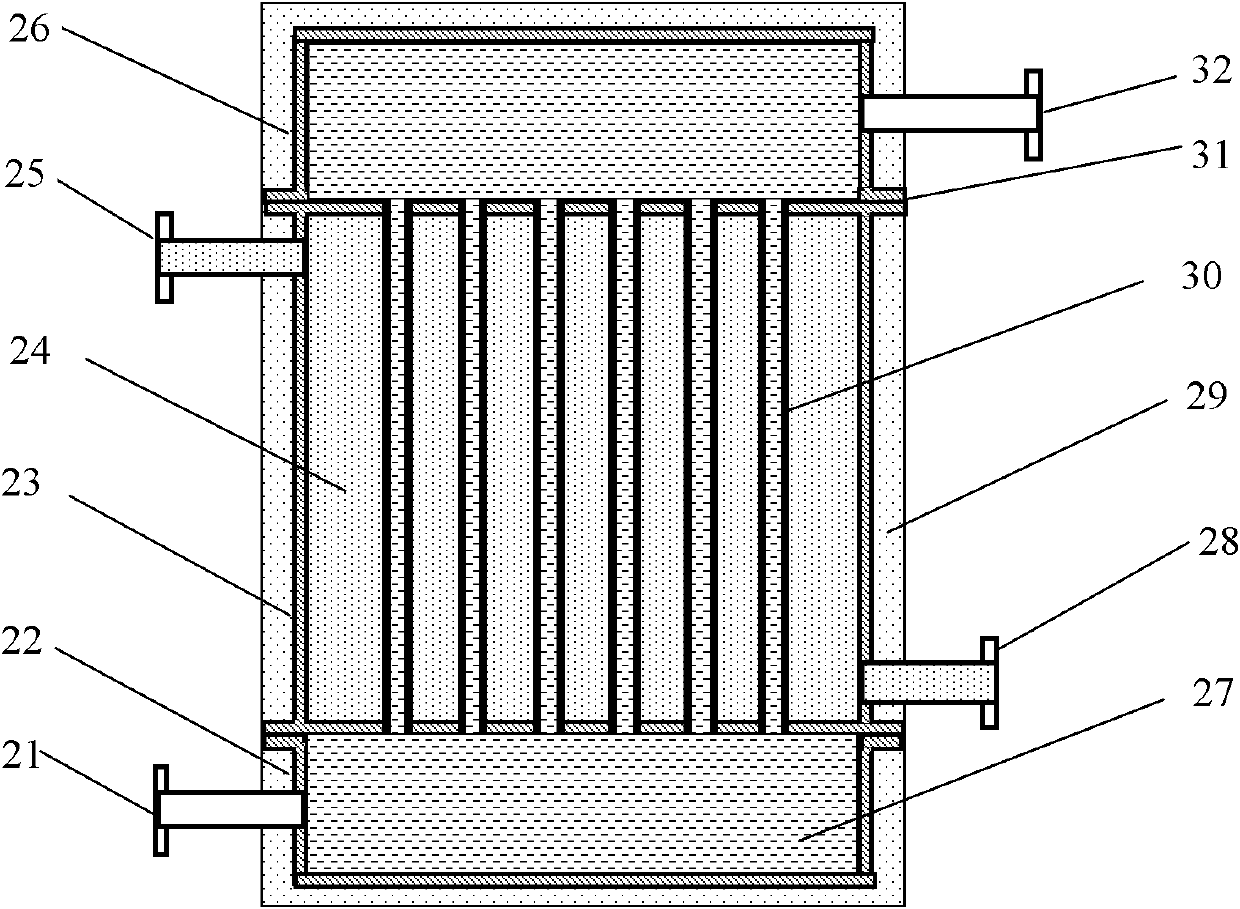

Method and apparatus of solar central receiver with boiler and super-heater

InactiveUS20080078378A1High solar flux densityInhibit thermal stressSolar heating energySolar heat devicesEngineeringSuperheater

A solar tower central receiver with separated boiler and Super-Heater allows better control on the output steam's temperature. The boiler takes higher solar flux density and works at lower temperature while the Super-Heater takes lower solar flux and works at high temperature to optimize the cost to performance ratio. The solar fluxes of the boiler and super-heater are adjustable through the pointing of the heliostats. The boiler consists of parallel pipes as solar absorber and the Super-Heater consists of helix parallel pipes as solar absorber. The steam drum chamber interconnects boiler and Super-Heater. The absorb pipes and circulation pipes are connected to water chamber, steam drum chamber, and Super-Heater chambers. The water level sensor and temperature sensors provide information regarding the operating status of the receiver.

Owner:ZHU YANONG

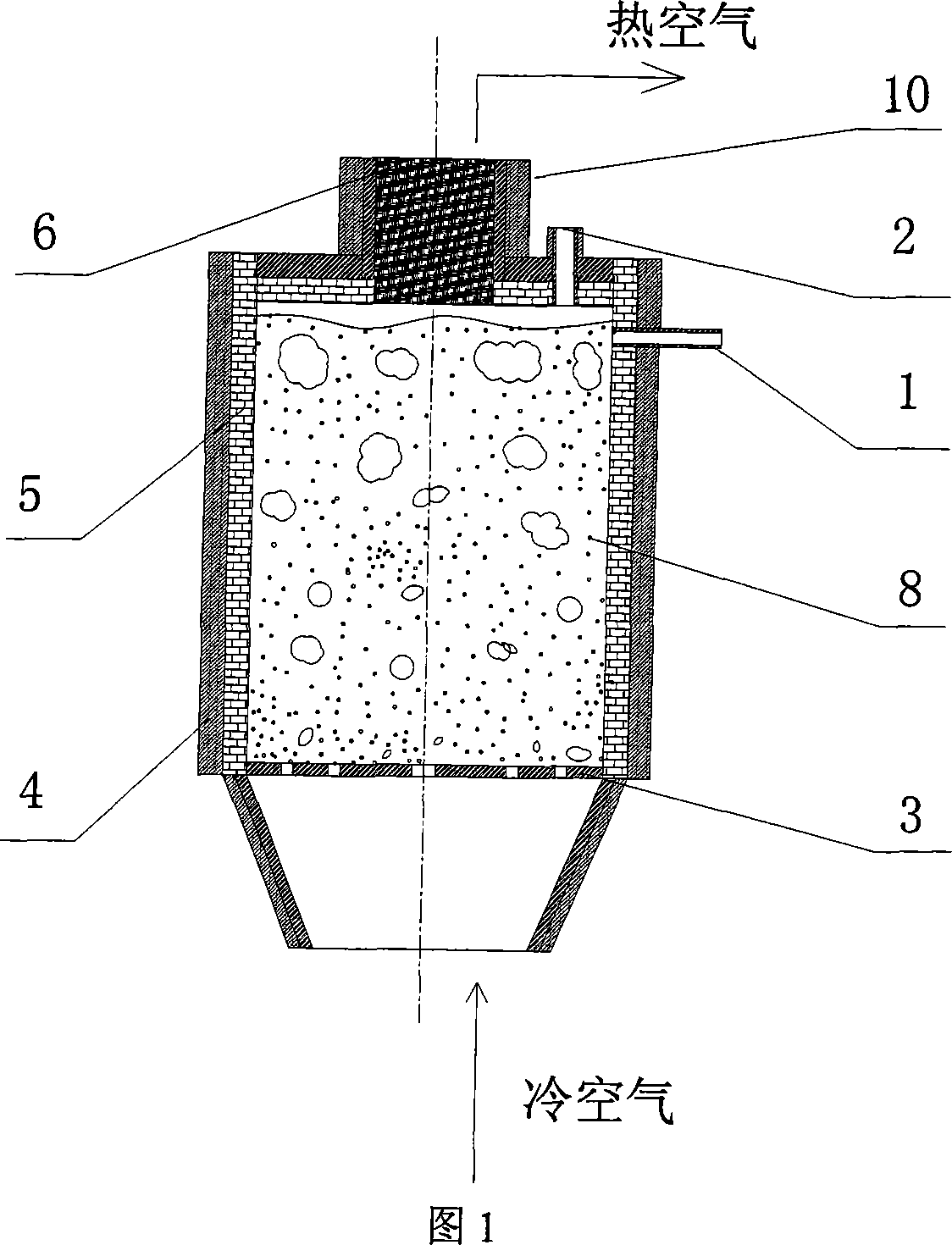

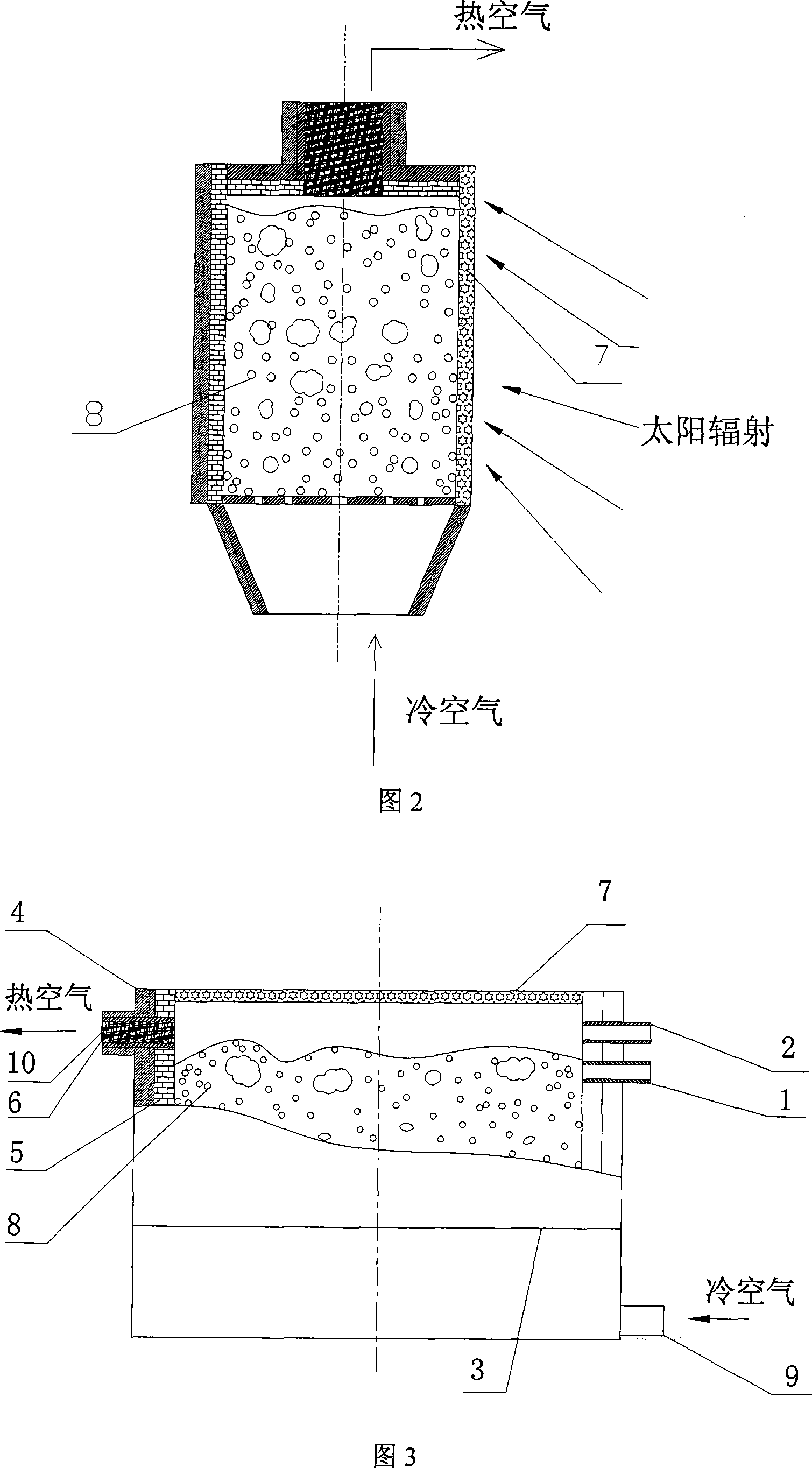

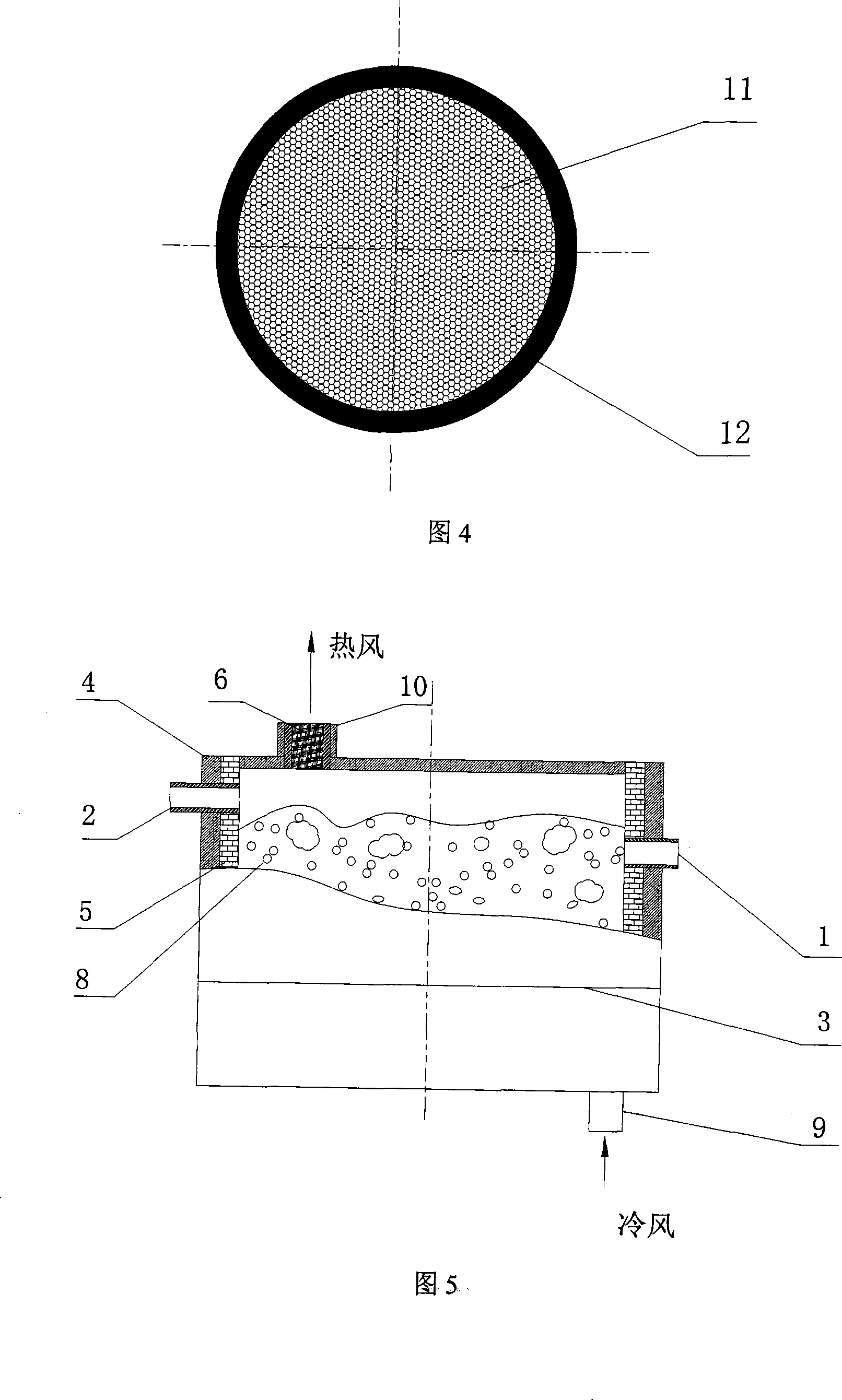

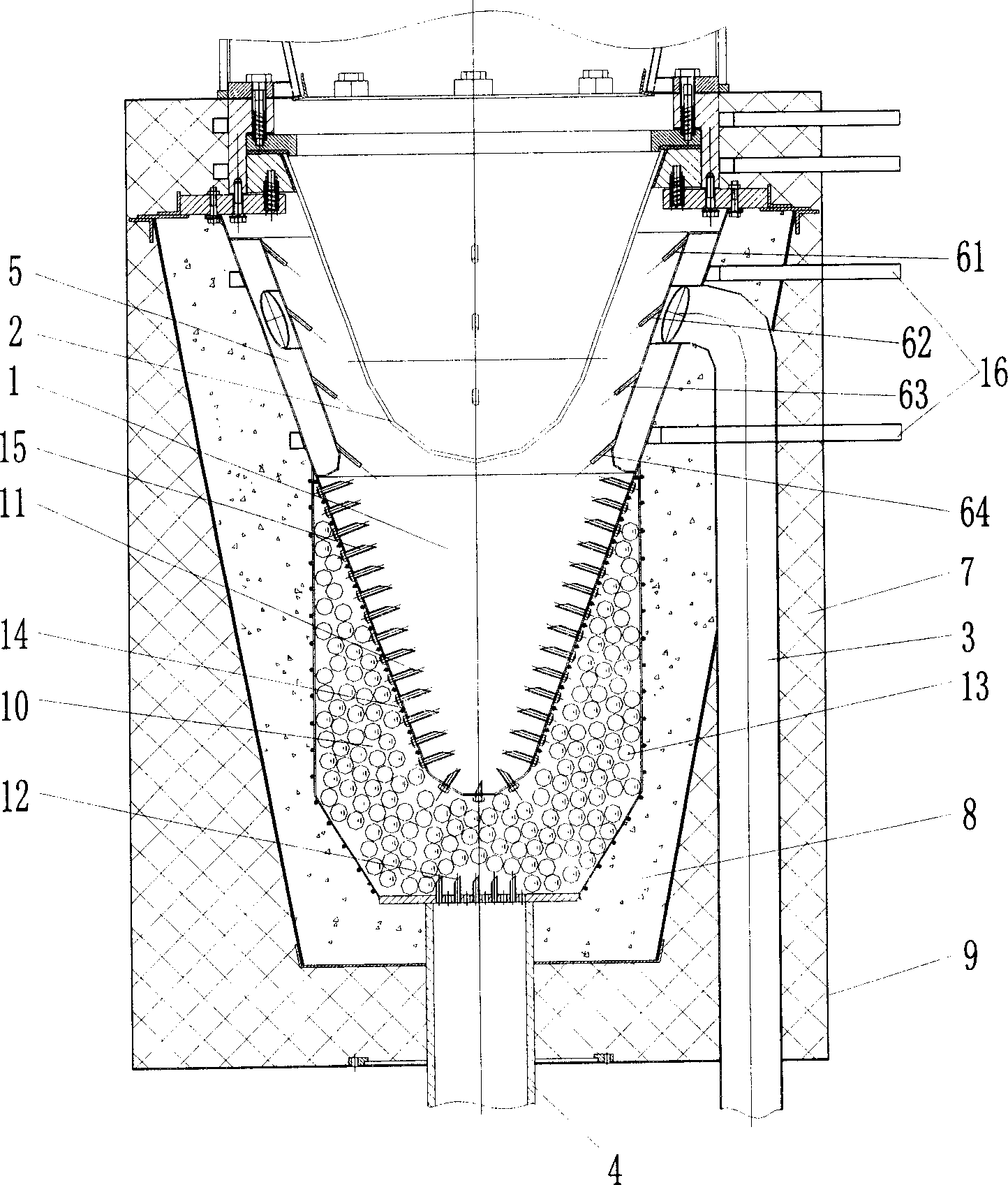

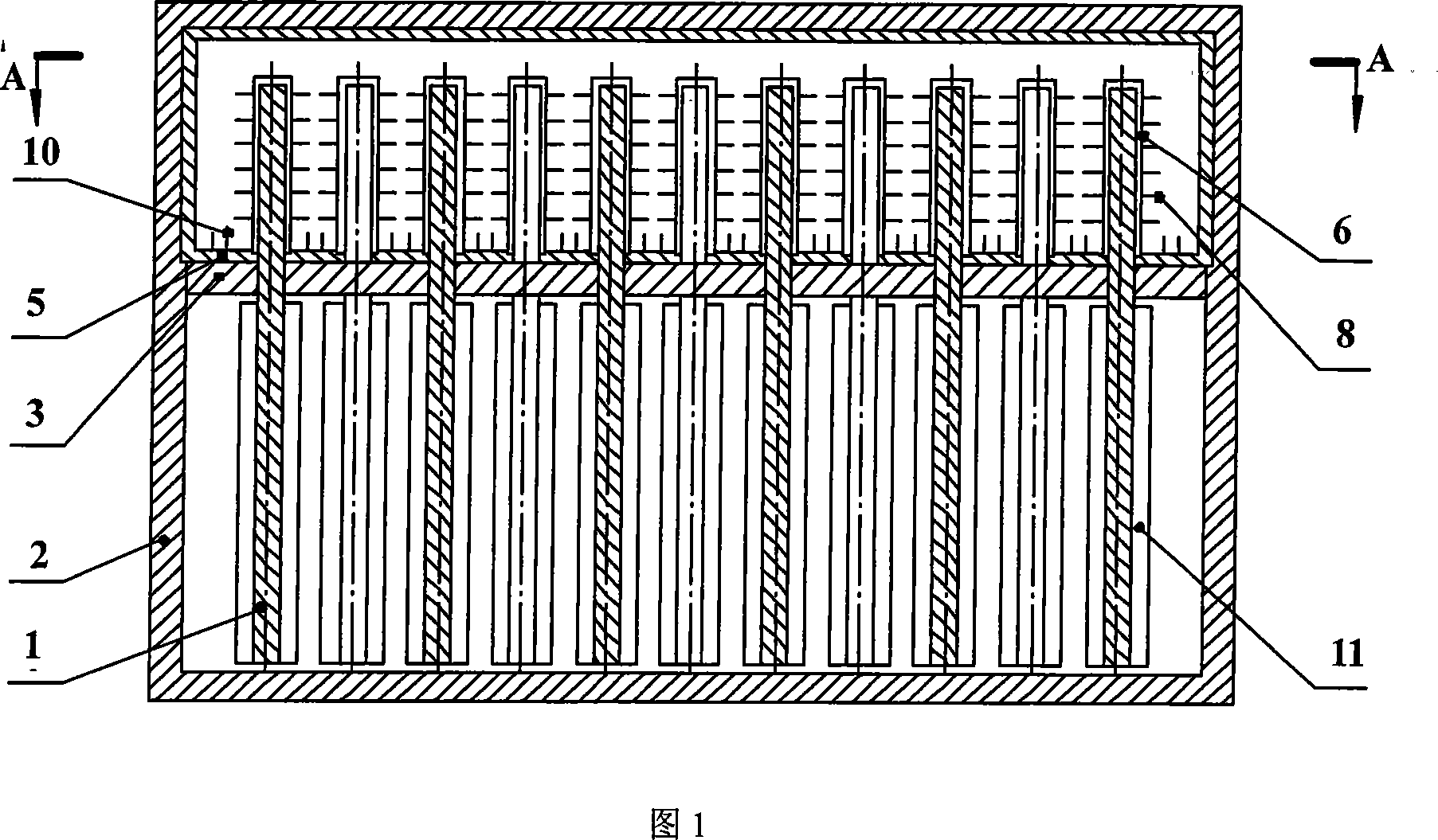

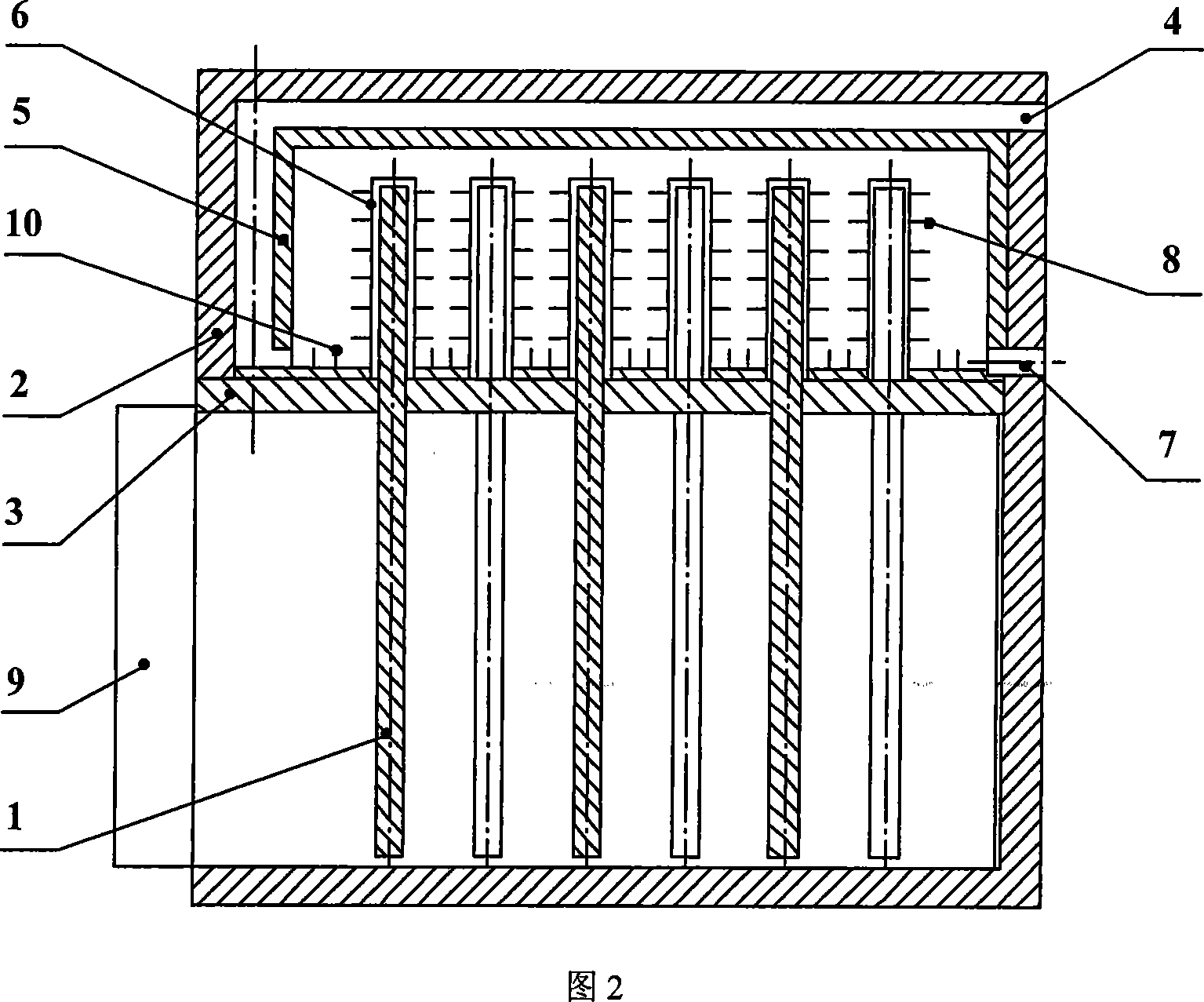

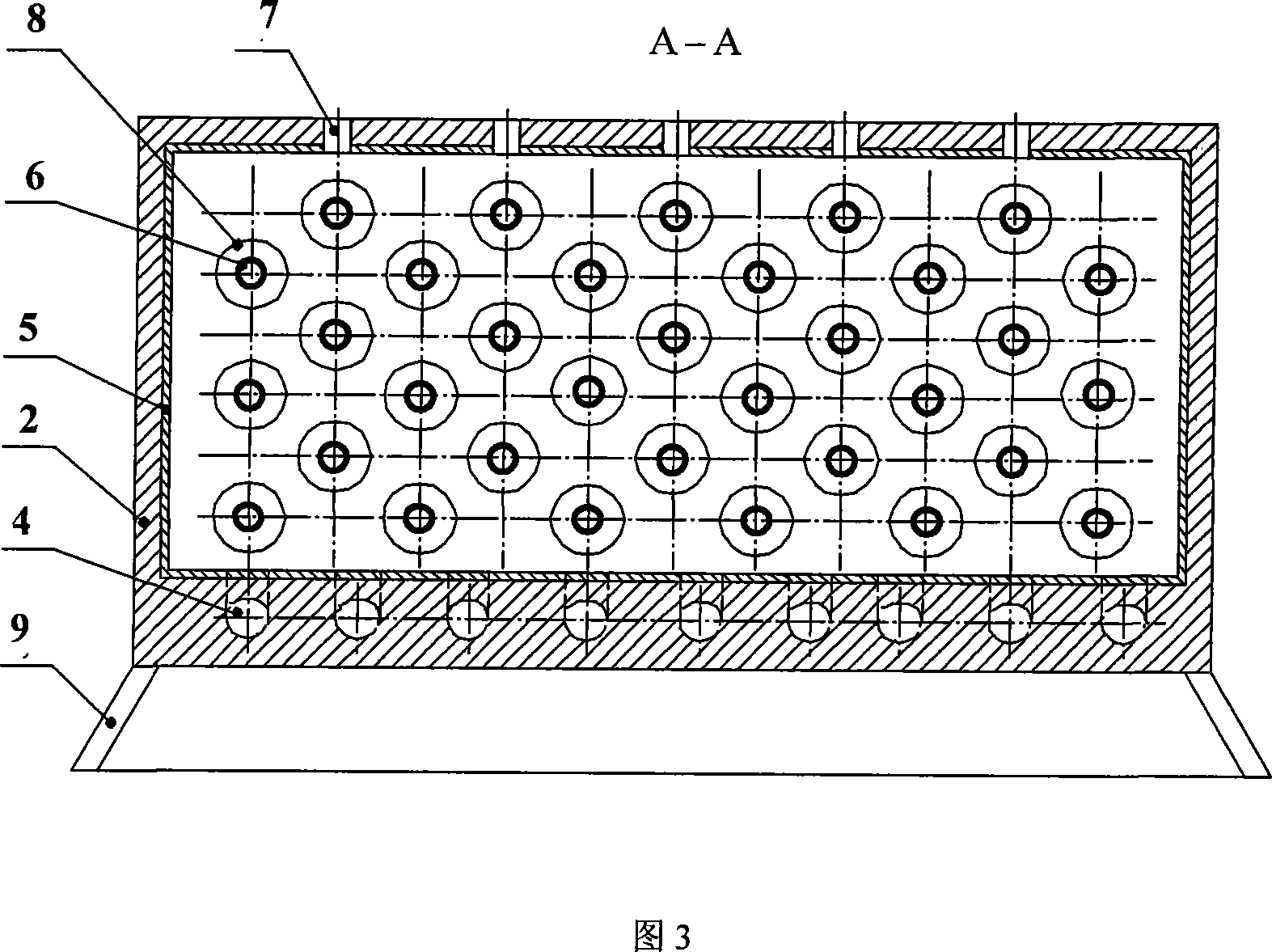

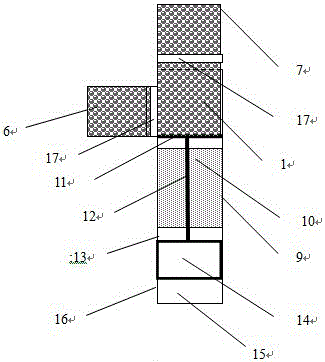

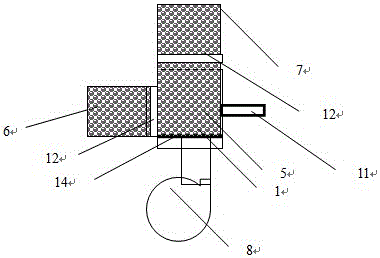

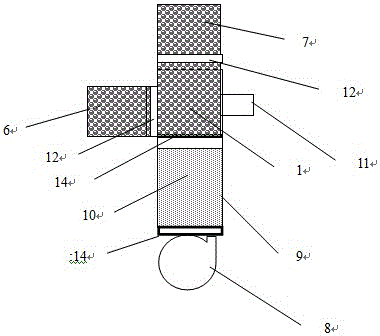

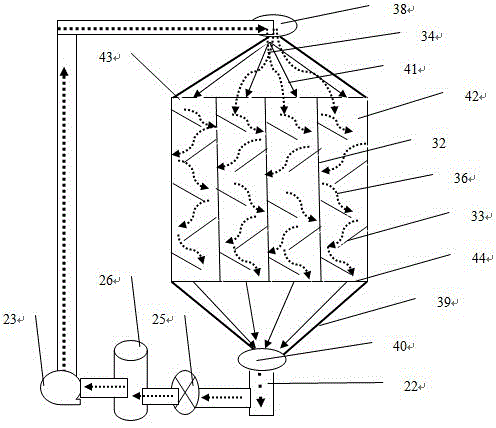

Fluid bed high temperature heat absorber for solar energy tower type thermal generation and its heat absorbing-heat storage double fluid bed system

InactiveCN101122422AOvercoming heat-absorbing surface ablationOvercome stressSolar heating energySolar heat devicesFluidized bedEngineering

A fluidized bed high temperature endothermic device used for solar tower thermal power generation and heat absorbing-accumulating double fluidized bed system is provided. The double fluidized bed system consists of a fluidized bed heat absorber (15) and a fluidized bed heat accumulator (14). A regenerative ball (8) flows between the fluidized bed heat absorber (15) and the fluidized bed heat accumulator (14). The regenerative ball is both a heat absorbing media and a heat accumulating media, which makes heat absorbing-accumulating integration realized. The invention can adjust the absorbed heat and the accumulated heat according to the conditions of sunlight. The fluidized bed heat absorber (15) makes full use of the flow characteristics of the fluidized bed to overcome the heat exchange problem caused by the uneven distributed radiation after the aggregation of the sunlight. With the heat capacity of the regenerative ball (8), thermal shock influences on the heat absorber under the conditions such as cloudy can be eliminated. The invention has the advantages of safety, reliability and low cost.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Hollow chamber type solar energy receiver

InactiveCN1821679AReasonable structureReasonable flow pathSolar heat devicesSolar thermal energy generationElectricityWorking fluid

The present invention relates to cavity type solar energy receiver for tower type solar energy electricity generator, and belongs to the field of solar energy utilizing technology. The solar energy receiver includes concave heat absorbing cavity, inwards notched glass window for receiving sunlight, work fluid inlet pipe and work fluid outlet pipe connected to the heat absorbing cavity, ring cavity around the glass window and connected to the work fluid inlet pipe, and needle tubes arranged regularly onto the surface of the glass surface and connected to the ring cavity and the heat absorbing cavity. When the work fluid flows through the heat absorbing cavity, it is heated while cooling the glass window.

Owner:张耀明 +1

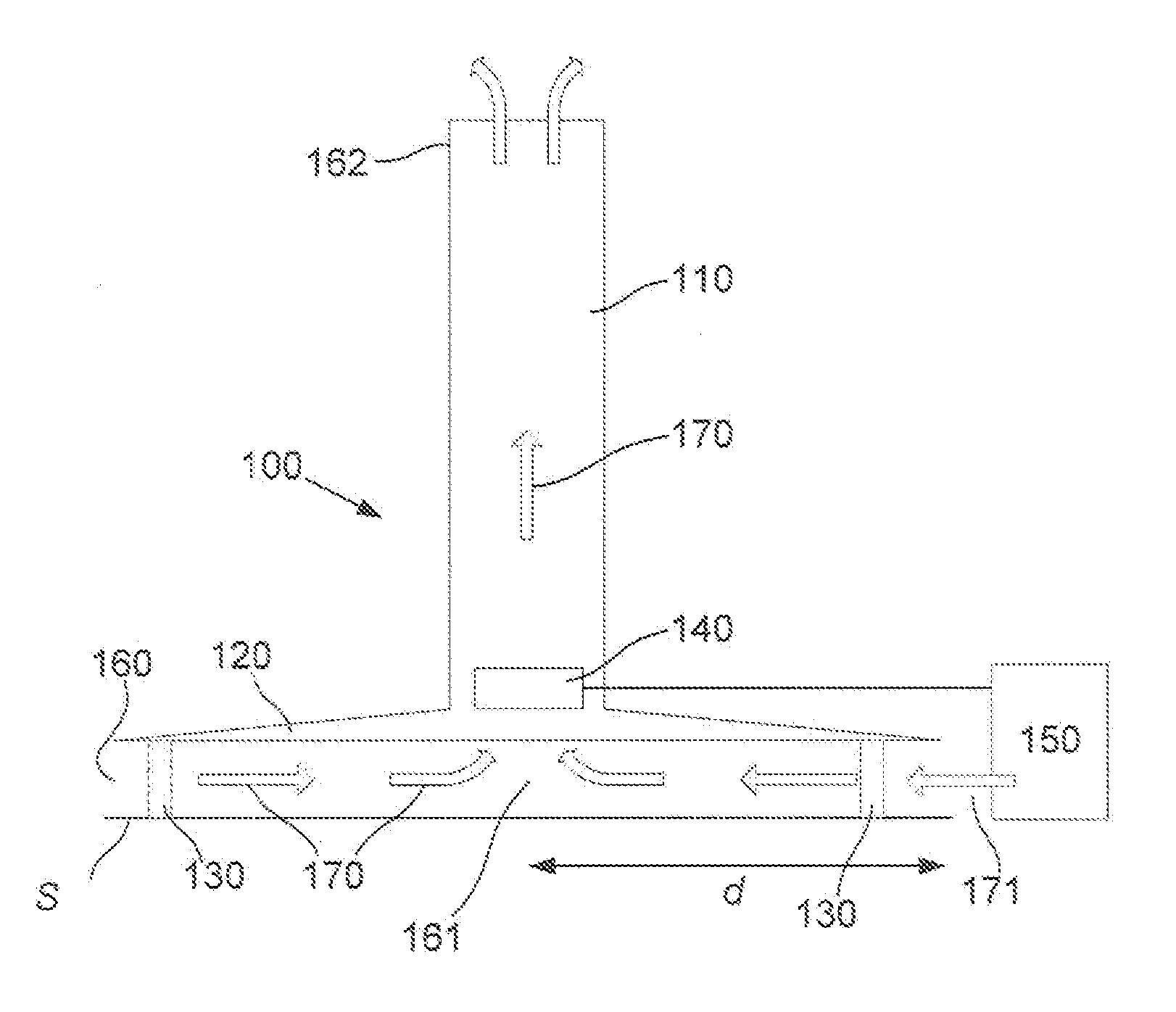

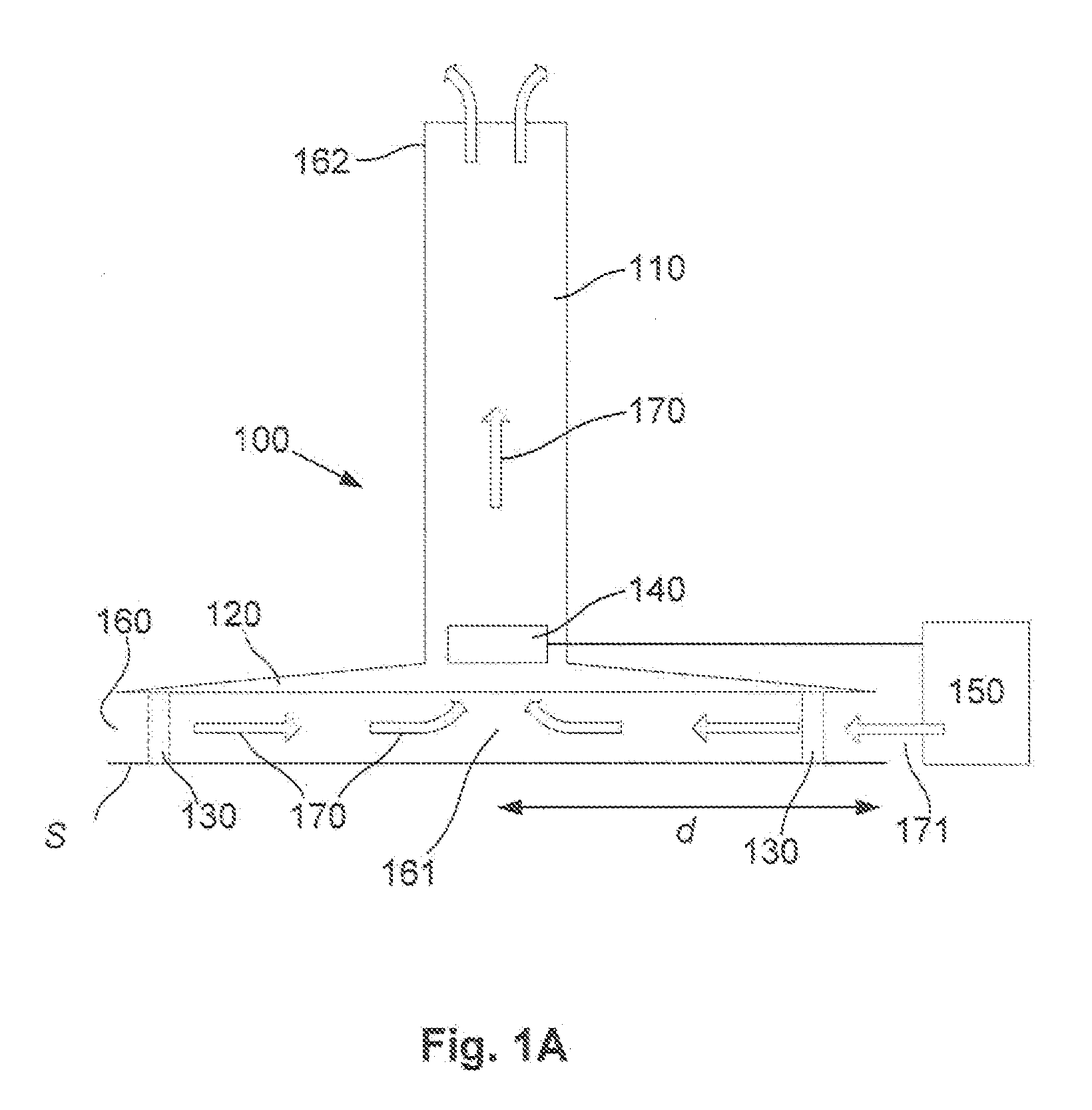

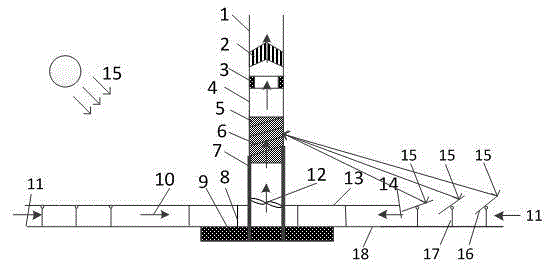

Cooling system

Apparatus for cooling, the apparatus including a solar tower having a collector extending radially outwardly from a base of a chimney, the collector being for heating air at least in part using solar radiation to thereby induce air flow radially inwardly from a perimeter of the collector and up the chimney and at least one cooling air pipe, the cooling air pipe extending at least partially along a length of the chimney to allow cool air to be drawn through the pipe at least partially using the air flow, the cool air being used to provide cooling.

Owner:CAVE DAVIES COLLISON

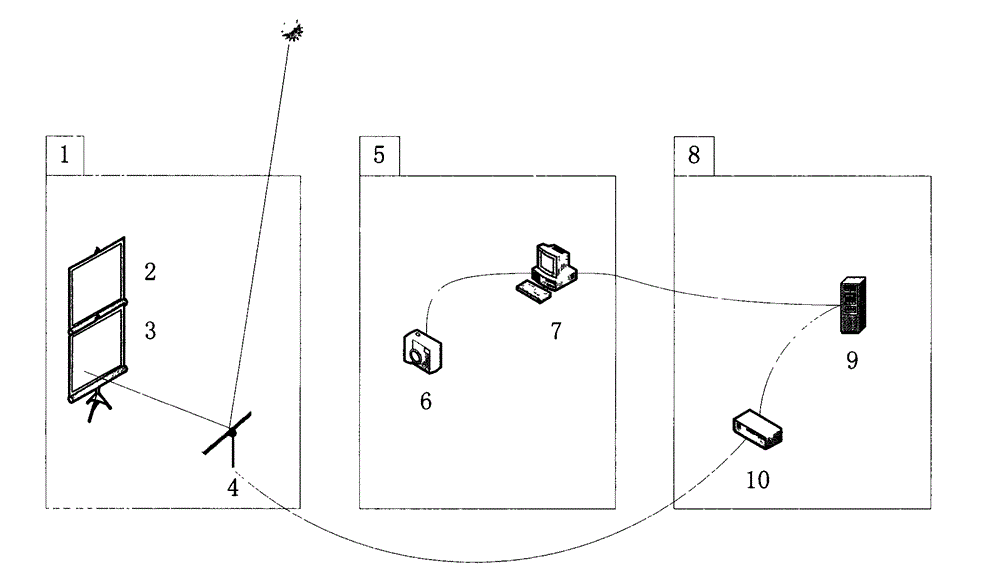

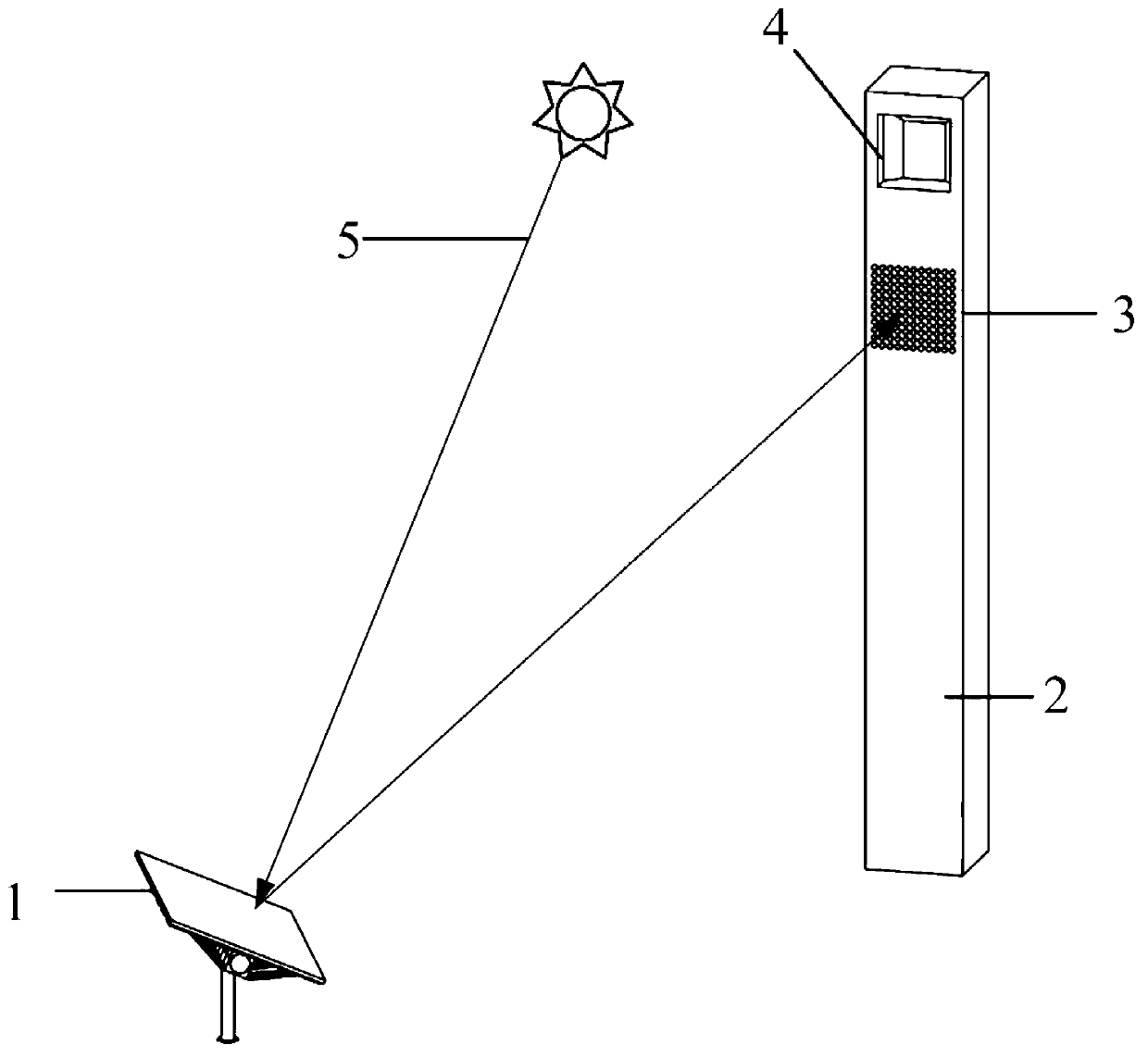

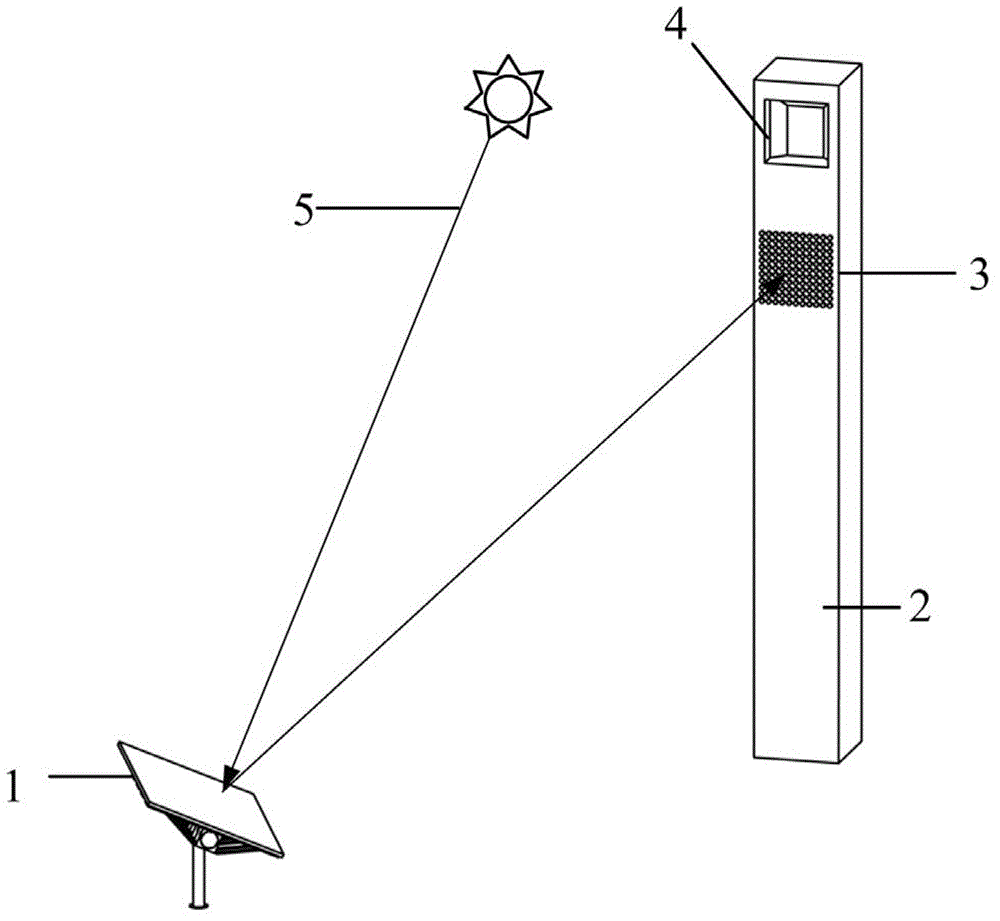

Heliostat error correction system and method for solar tower optical-thermal power station

InactiveCN102980313AImprove maintainabilityRealize fully automatic unattended operationSolar heating energySolar heat collector controllersImaging processingControl theory

The invention discloses a heliostat error correction system for a solar tower optical-thermal power station, which comprises a heliostat field sub system, an image collecting and processing sub system and a heliostat control sub system. The heliostat field sub system comprises a collector, a correcting plate and heliostat devices. The correcting plate for a target as the tracking error of the heliostat is installed near the collector. The image collecting and processing sub system comprises a camera and an image processing unit. The heliostat control sub system comprises a master control unit and a heliostat control unit. One heliostat device is provided with a heliostat control unit, and one master control unit controls at least one heliostat control unit.

Owner:SHOUHANG ENERGY SAVING SOLAR THERMAL TECH CO LTD

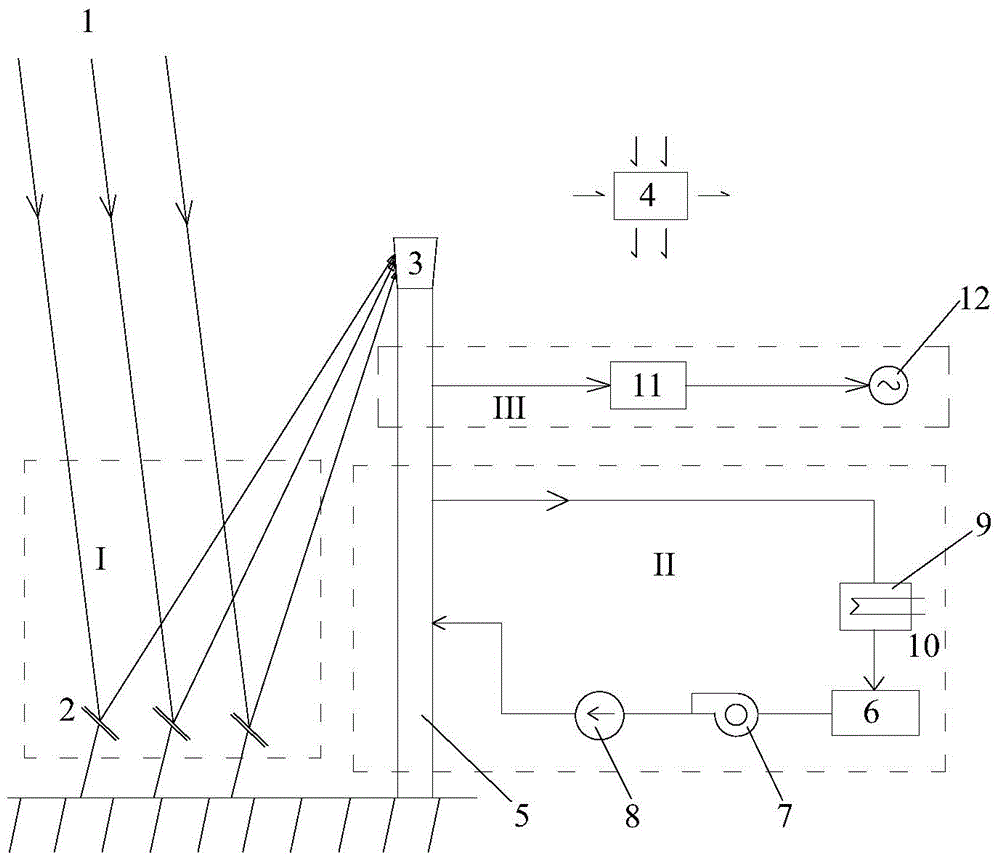

Solar energy tower type optical-condensation heat-storage thermophotovoltaic power generation system

InactiveCN104993776ASolving Dispersion ProblemsReduce dosageSolar heating energySolar heat collector controllersThermal insulationEngineering

The invention relates to a solar energy tower type optical-condensation heat-storage thermophotovoltaic power generation system. The system comprises a tower type solar heat collector field, an optical-condensation heat-storage thermophotovoltaic generator, a working medium circulating system, a generation output system and an intelligent central controller. The optical-condensation heat-storage thermophotovoltaic generator comprises a central reflector, a heat radiator, an optical filter, a thermophotovoltaic cell, a latticed phase change heat-storage box, a temperature sensor, a thermal insulation layer, an upper reflecting plate, a lower reflecting plate, a radiator and a housing. The tower type solar heat collector field comprises a tower and heliostats for collecting solar energy and reflecting the solar energy to the central reflector. The central reflector further reflects the solar condensation energy to the heat radiator. Heat radiation spectrums are then generated. Parts of the heat radiation spectrums pass through the optical filter and irradiate the thermophotovoltaic cell in an optically condensing way. The thermophotovoltaic cell further generates power. The disperse solar energy use problem is solved. The heat radiator can be kept in a high temperature state. The photoelectric conversion efficiency of the thermophotovoltaic system is improved.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

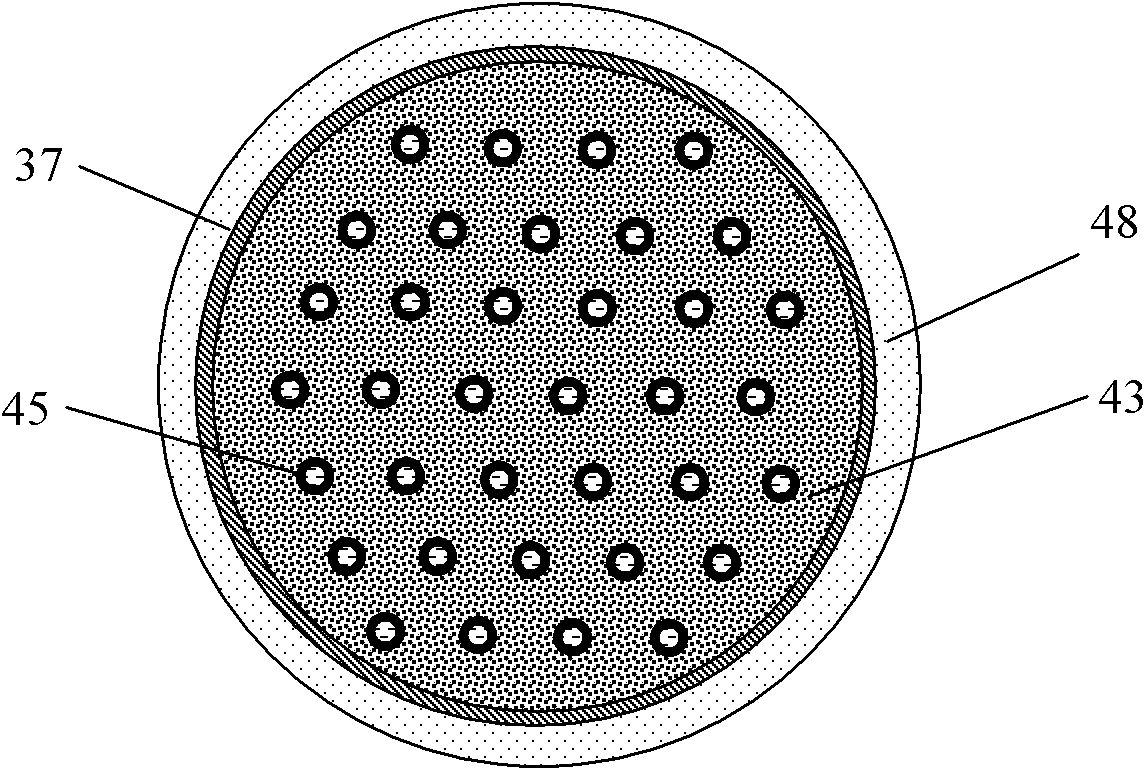

High temperature heat absorber used in solar tower-type thermal power station

InactiveCN101033892AHigh working reliabilityImprove thermal efficiencySolar heating energySolar heat devicesIncident energyEvaporation

A high temperature heat sink used in the solar energy tower thermal generating station. It includes hot pipe, the heat-resisting insulating layer, the thermal baffle, the cooling channel and the second predocus mouth. The hot pipe is installed in the heat absorbing hollow and the lower of the cooling channel. The heat absorbing hollow faces to the lens field. Except the mouth, the other sides of the hollow are close which the out surface is covered with the heat-resisting insulating layer. The evaporation zone of the hot pipe is the heat absorbing face of the heat absorber and the cooling zone is inserted into the liner tube of the cooling channel. The evaporation zone is the free end and the out face is installed with the fin which is the straight fin faced to the incident energy flow. The hot pipe is arrayed crossly and working separately. The cooling channel is the heat exchanger of thick-wall square hollow made by the stainless steel which is installed on the top of the heat absorbing hollow and the rib pole is installed in the inner surface. It can select the hot pipes of different material according to the different outlet temperature. The invention is safe and simple to operate; also it has the wide using temperature and is easy to maintenance.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

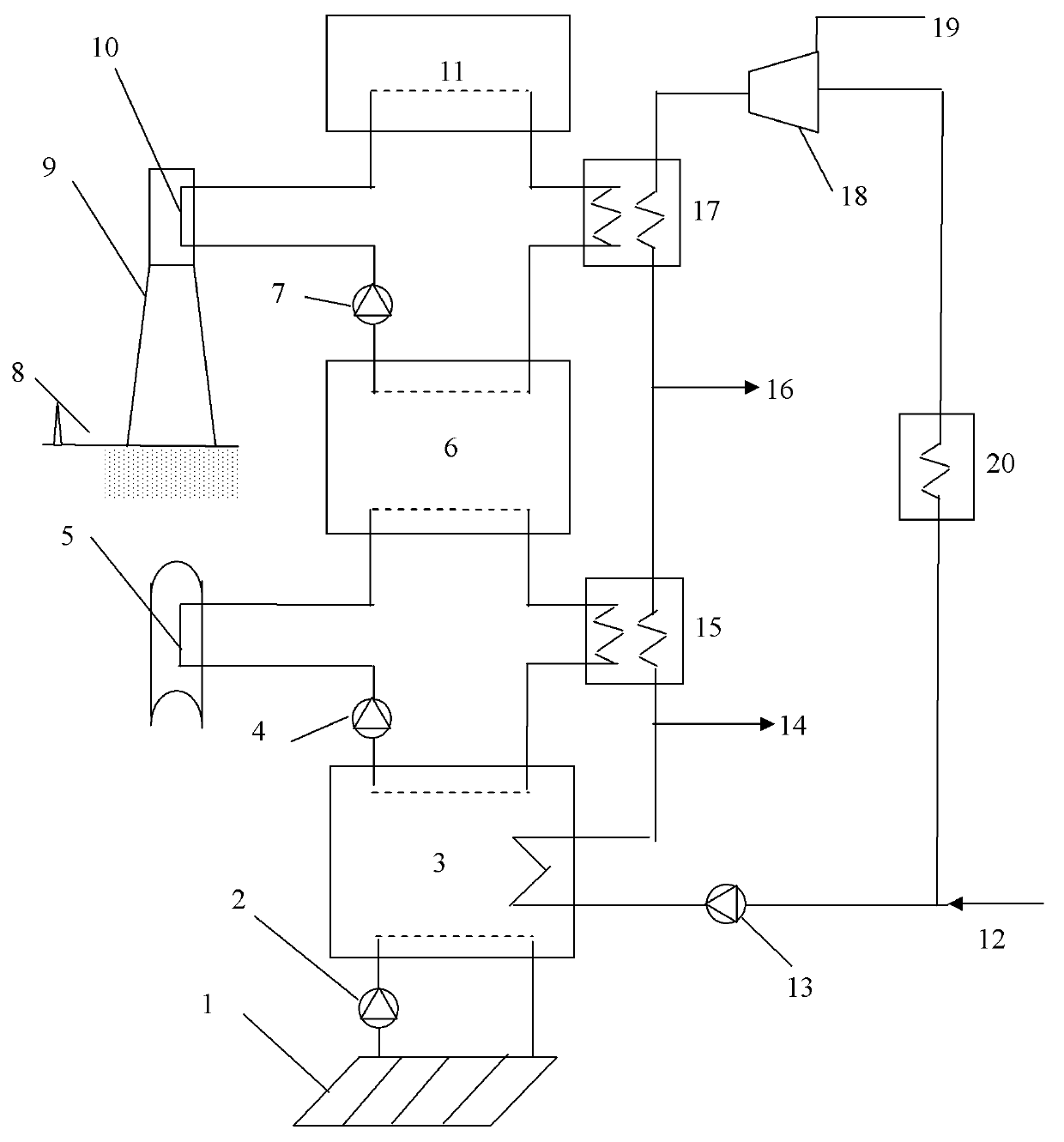

Multistage coupling heat accumulating type solar heat-power cogeneration system

InactiveCN101907075AEasy to useConducive to cascading utilizationFrom solar energySolar heat devicesThree stageCogeneration

The invention provides a multistage heat accumulating type solar heat-power cogeneration system which comprises a tower type heat absorption-accumulation-transfer subsystem, a tank type heat absorption-accumulation-transfer subsystem, a flat plate type heat absorption-accumulation-transfer subsystem and a heat-power cogeneration subsystem, wherein the tower type heat absorption-accumulation-transfer subsystem, the tank type heat absorption-accumulation-transfer subsystem and the flat plate type heat absorption-accumulation-transfer subsystem are coupled through a moderate temperature coupling heat accumulator and a low temperature coupling heat accumulator; and the heat-power cogeneration system comprises a power supply mode, a heat supply mode and a heat-power cogeneration mode, and operates together with the three heat absorption-accumulation-transfer subsystems. The invention organically combines the solar tower type, tank type and flat plate type heat collecting systems to form high temperature, moderate temperature and low temperature three-stage heat accumulators; and thus, the invention can meet the requirements for industrial large-scale solar moderate temperature and high temperature heat utilization, and is beneficial to the comprehensive cascading utilization of energies.

Owner:SUN YAT SEN UNIV +1

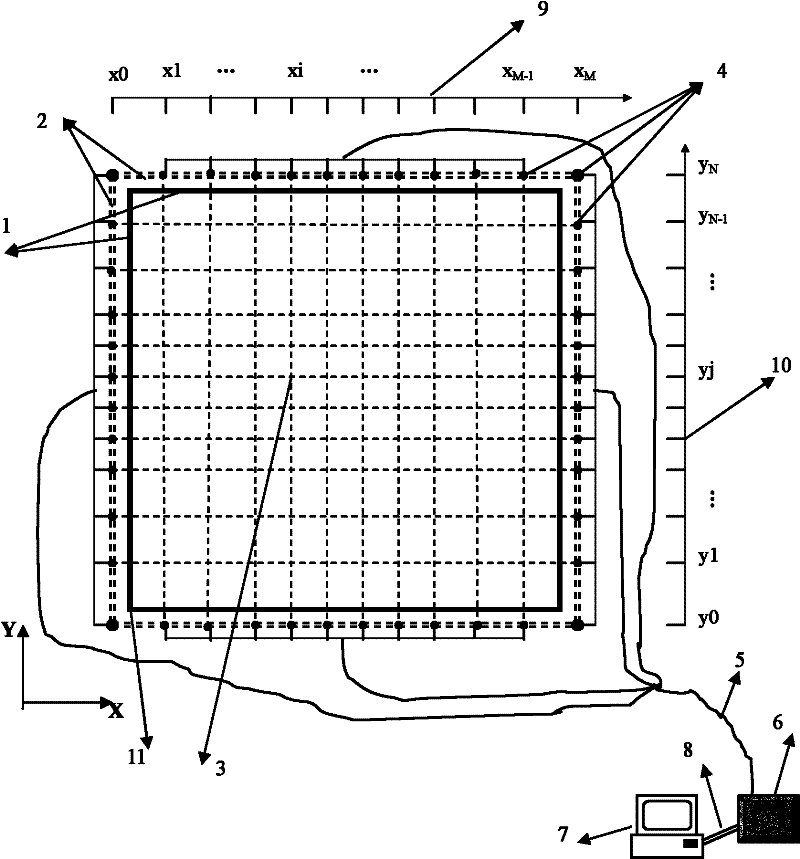

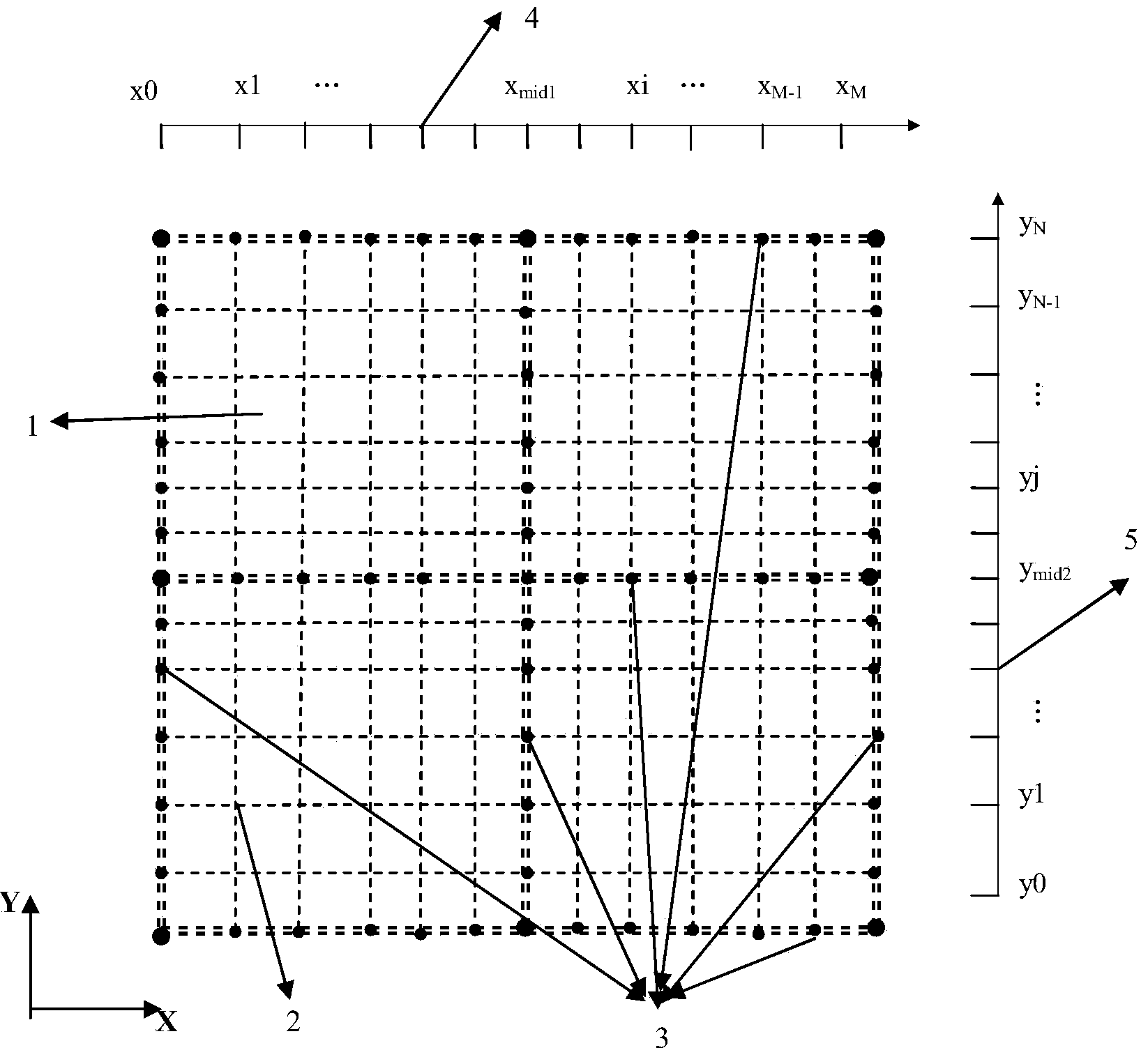

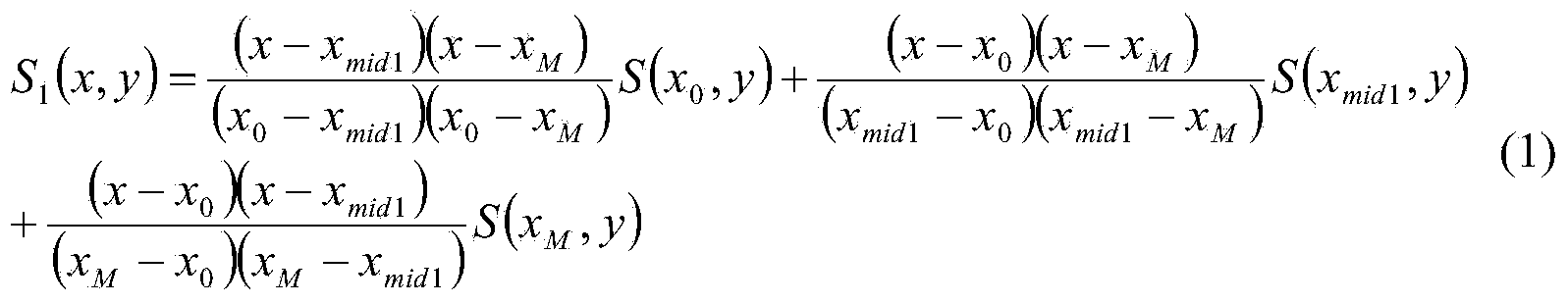

Method for measuring heat flow distribution on opening plane of tower-type solar heat absorber

InactiveCN102175349AReal-time evaluation of heat absorption efficiencyEvaluate spotlight effects in real timeTesting optical propertiesCalorimeterHeat flowData acquisition

The invention provides a method for measuring heat flow distribution on an opening plane of a tower-type solar heat absorber, which is characterized by comprising the following steps of: choosing a rectangular region boundary on the opening plane of the heat absorber, wherein the rectangular region boundary comprises a physical boundary of the opening plane of the heat absorber; dividing a rectangular region of the opening plane of the heat absorber into rectangular grids, taking a direction of a horizontal grid line as an X-axis direction, taking a direction from an upper grid line to a lower grid line as a Y-axis direction, and arranging heat-flow meters at grid points on the rectangular region boundary; synchronously measuring and acquiring heat-flow density values of the rectangular region boundary by the heat-flow meters through a data acquisition instrument, and rebuilding the heat flow distribution on the opening plane of the heat absorber by interpolation.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

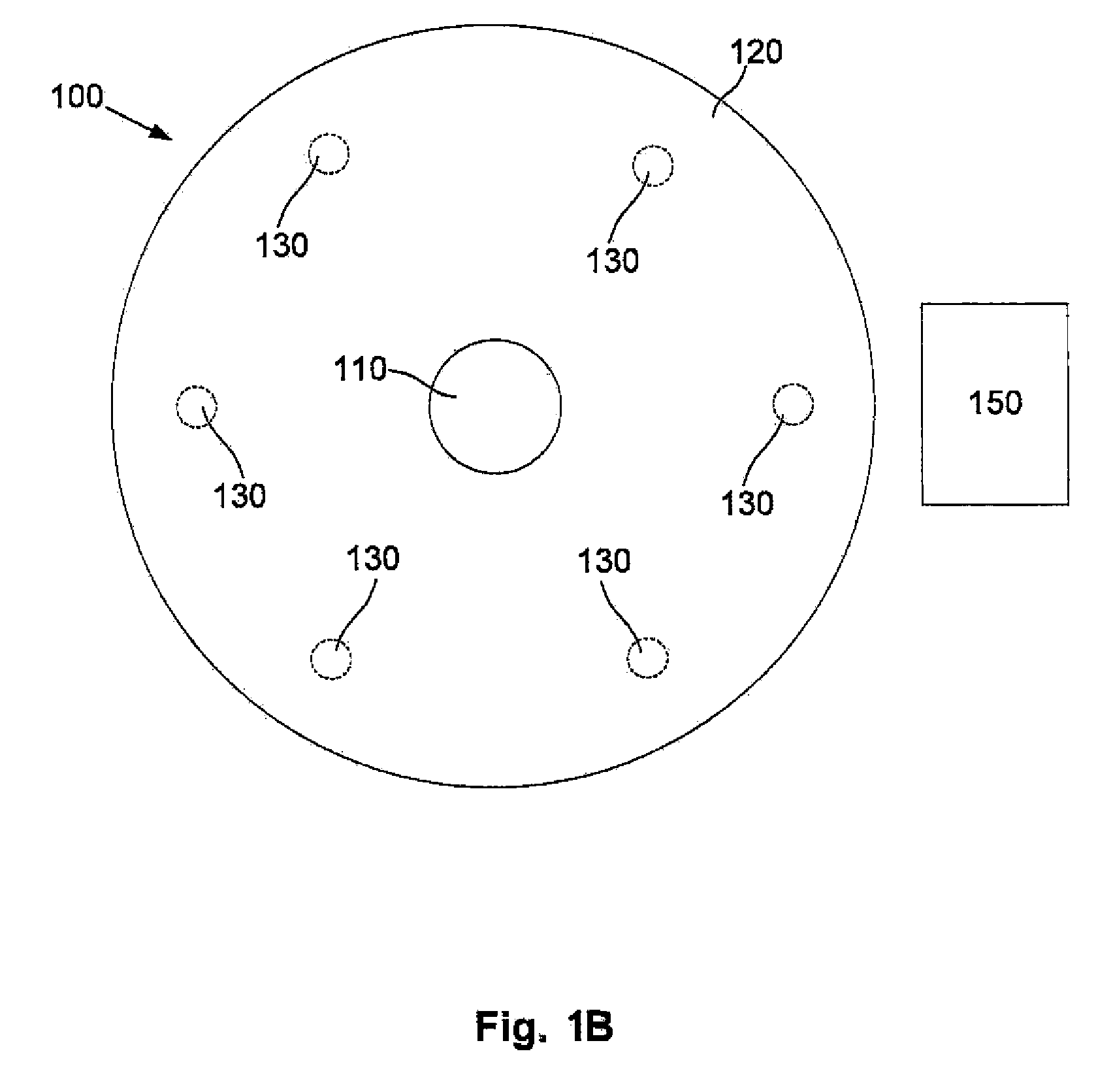

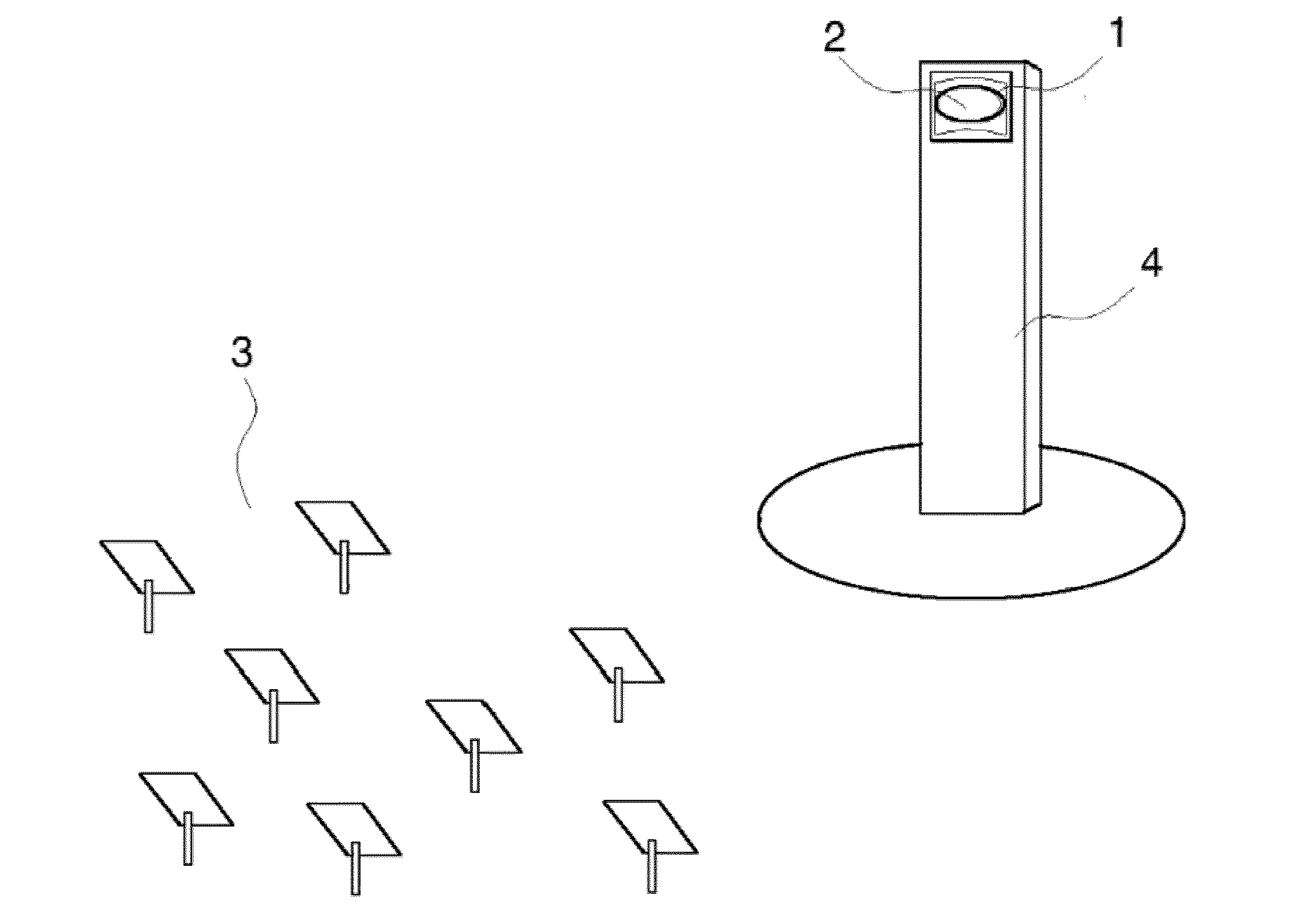

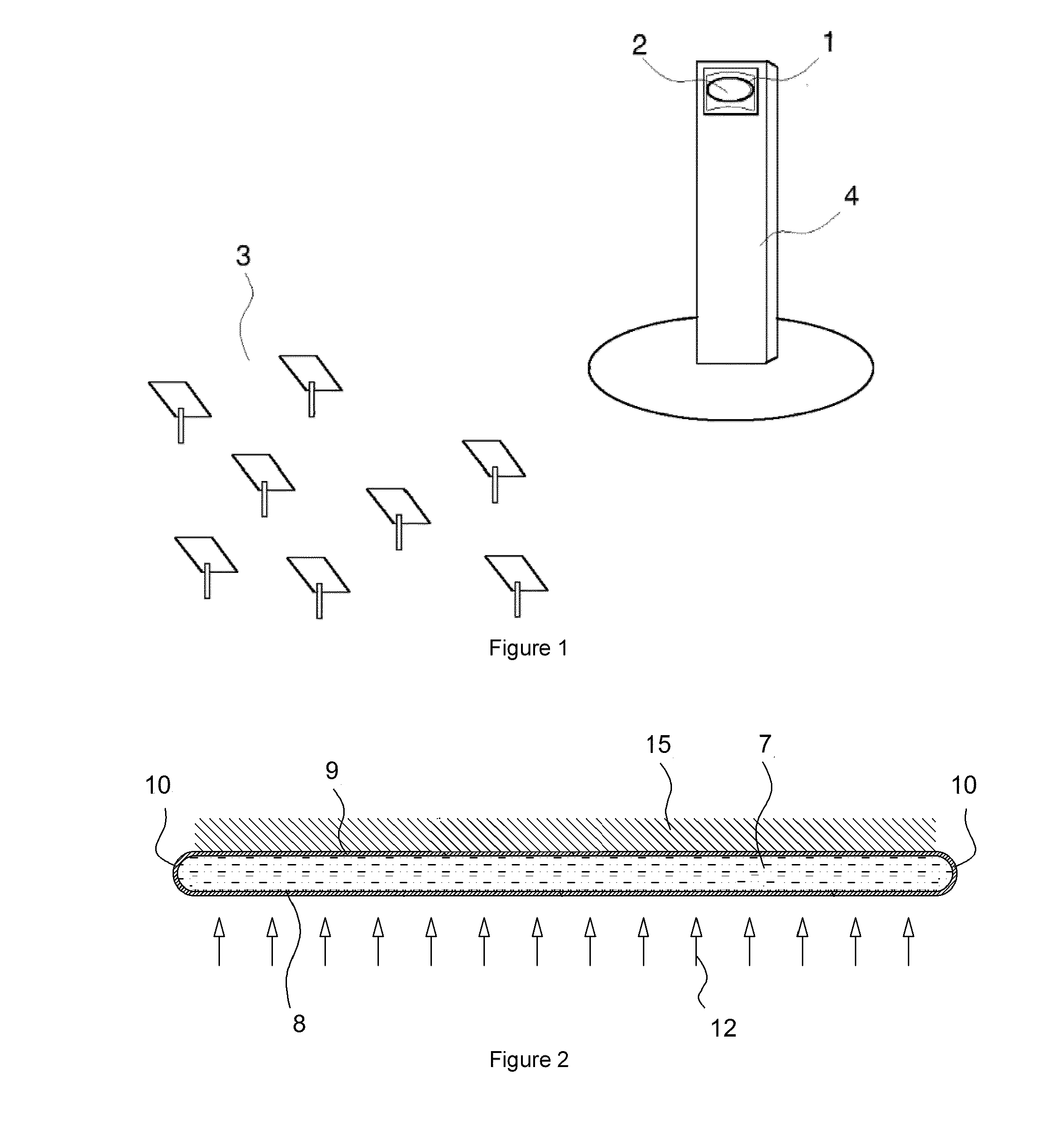

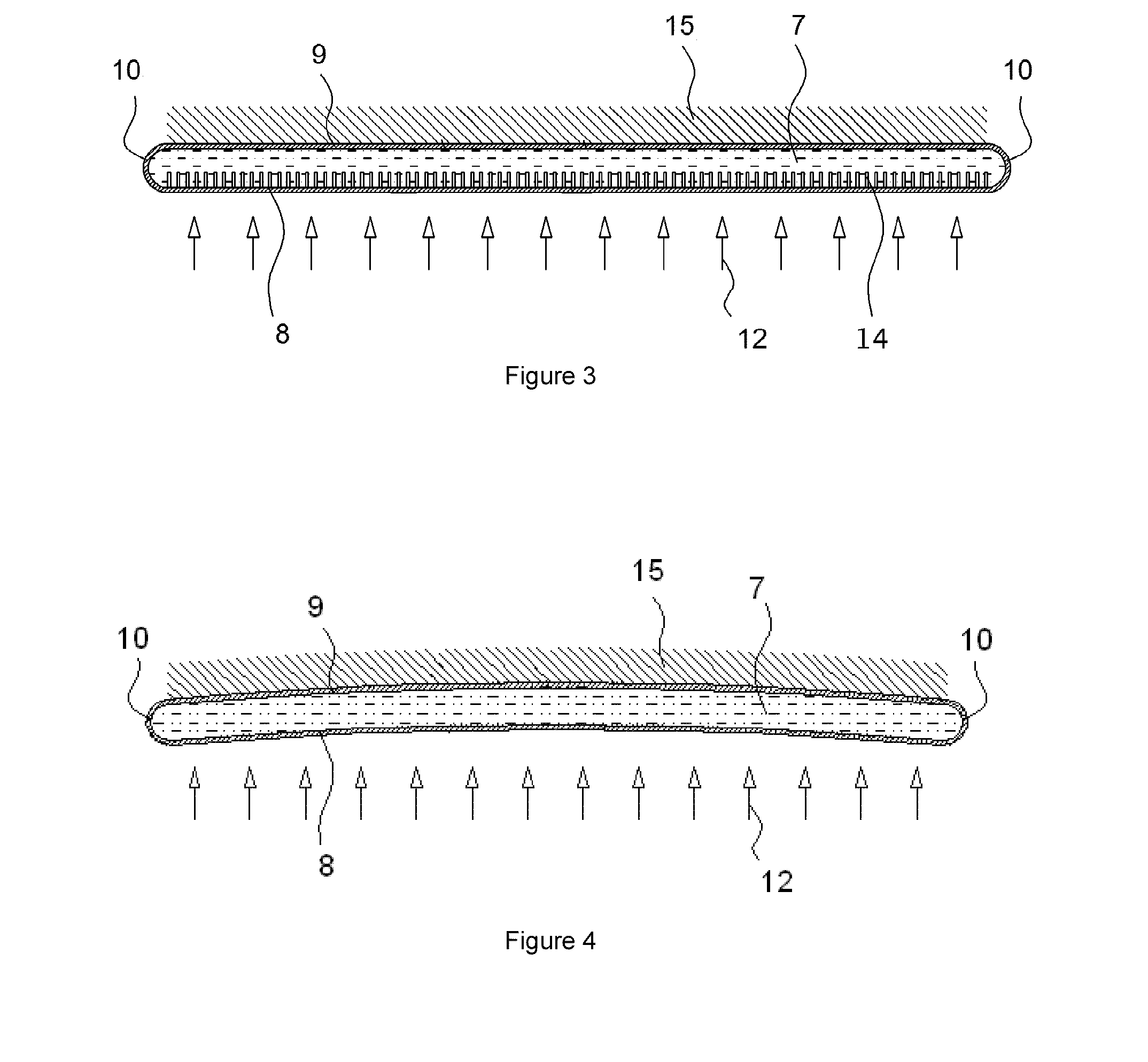

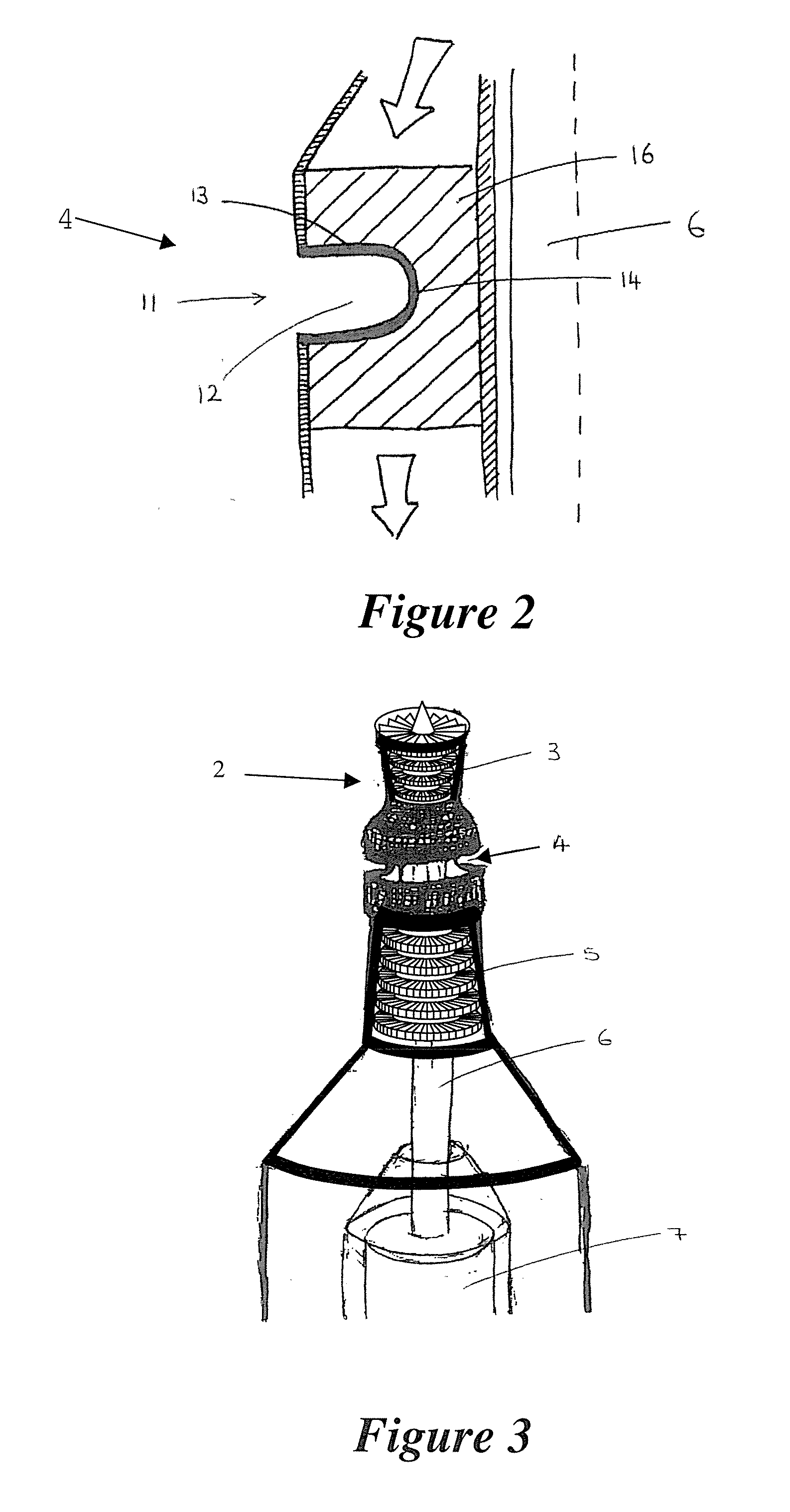

Panel-based solar receiver

InactiveUS20150020793A1Reduce convectionEasy to depositSolar heating energySolar heat collector controllersPower stationHeat transfer fluid

The invention relates to a panel-based solar receiver for a thermal solar tower power plant (4), which comprises: a front panel (8), the external surface of which receives solar radiation (2) from the field of heliostats (3), a back panel (9), sealing elements (10) between the panels (8, 9), arranged at the lateral ends of both, an intake collector (5), located in the upper part of the panels (8,9), where the heat transfer fluid enters the receiver (1) and an evacuation collector (6), located in the lower part of the panels (8, 9), where the heat transfer fluid leaves the receiver (1); wherein the front panel (8), back panel (9) and the two sealing elements (10) form the receiver body (16), which constitutes a passage for the heat transfer fluid (7) to travel through. Each solar tower can contain one or several panel-based receivers (1) and be arranged in series or in parallel, with the same or a different fluid (7) circulating there through.

Owner:ABENGOA SOLAR NEW TECH SA +1

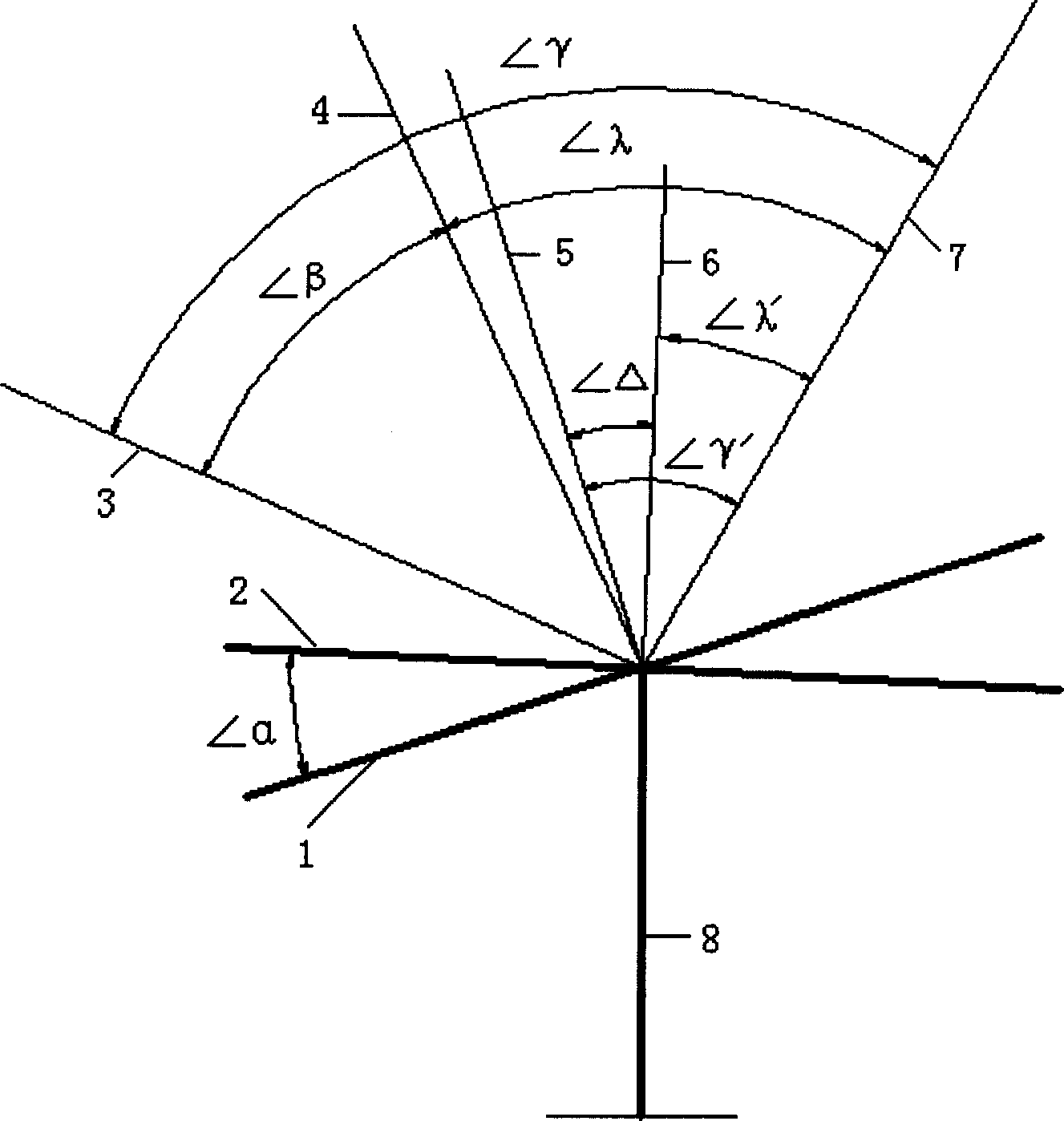

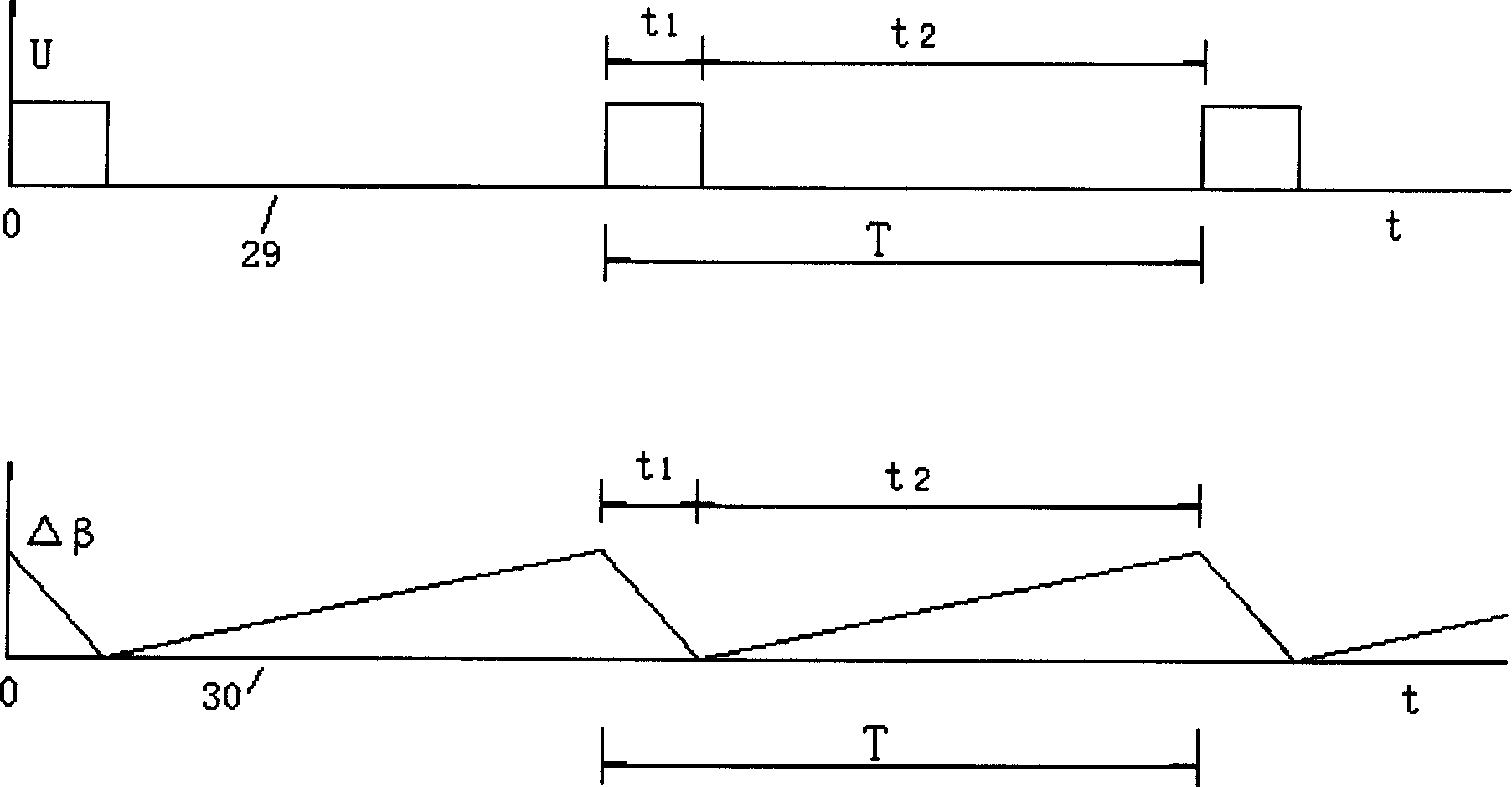

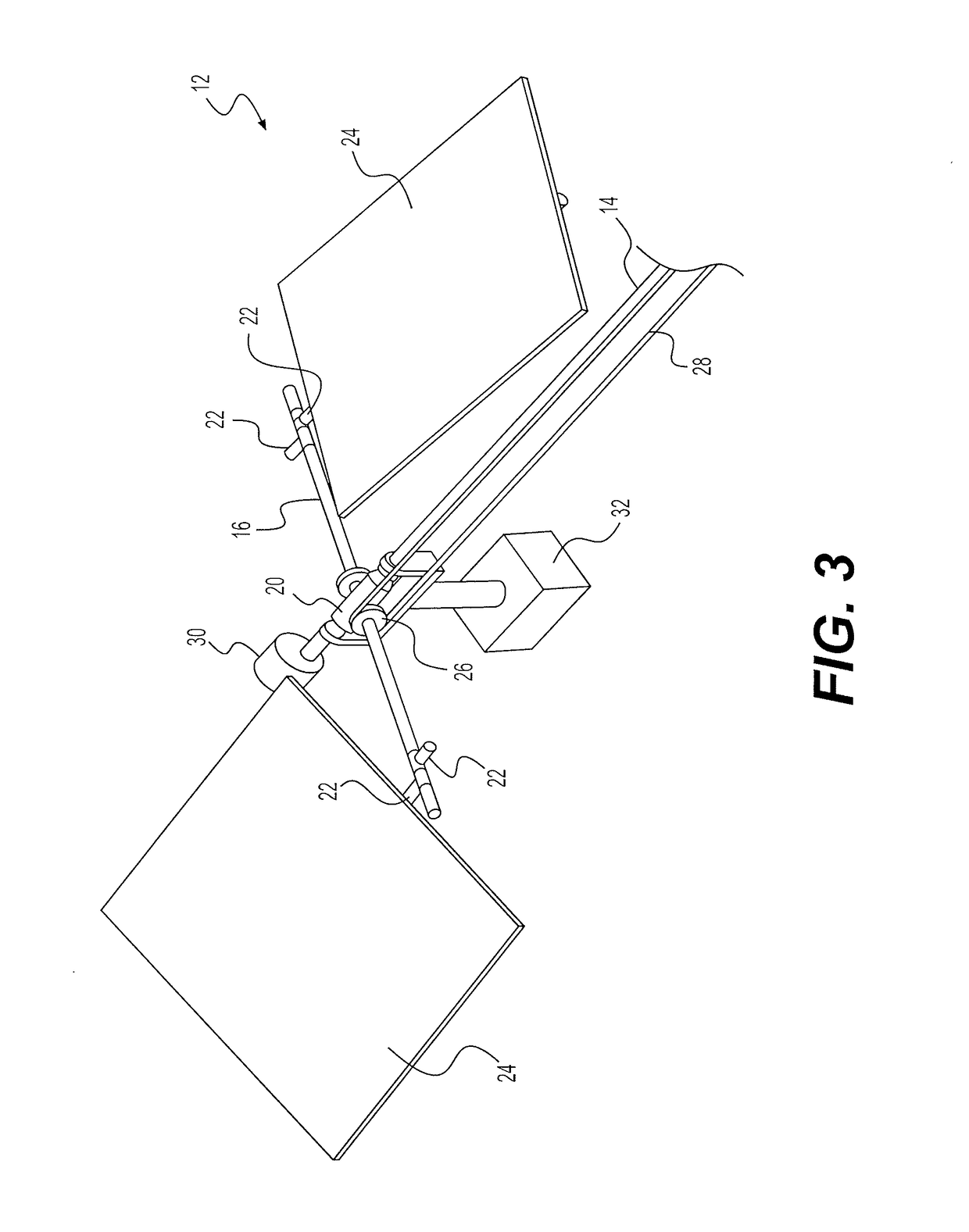

Method for adjusting heliostat array synchronous traction

InactiveCN1854639ALow costSimple structureSolar heating energySolar heat collector controllersFollow-the-sunReduction rate

In the invention, employing a sun tracker follows the sun. The drive motor of the sun tracker and a heliostat uses the same synchronous micromotor driven by a common-frequency power supply and the synchronous micromotor can run and stop at the same time. The reduction rate of the speed reducer of the sun tracker is 1:N and the reduction rate of the speed reducer of the heliostat is 1:2N. Provided that the sun tracker follows the sun, the whole heliostat in the array offset following the tracked sun to make the reflected light point to the fixed target.

Owner:孙迎光

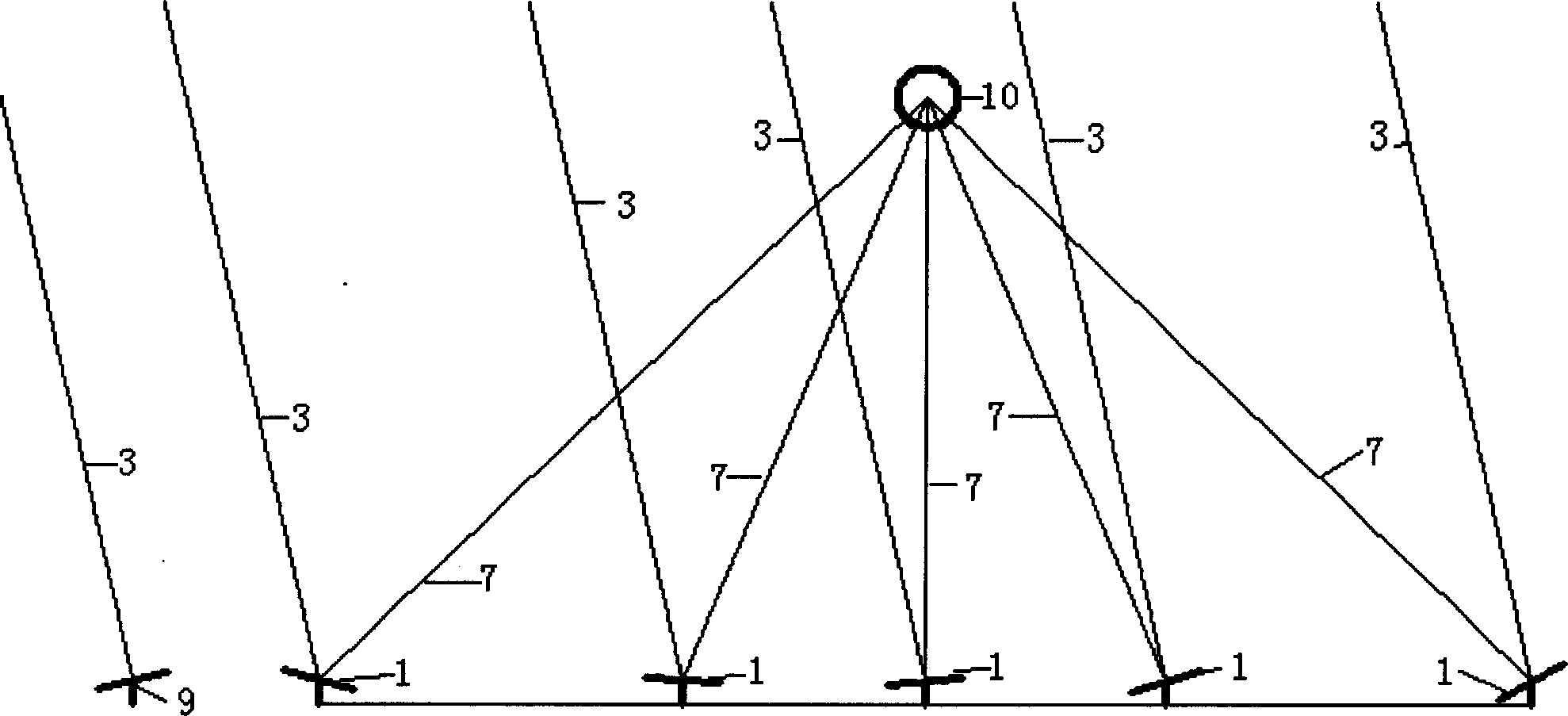

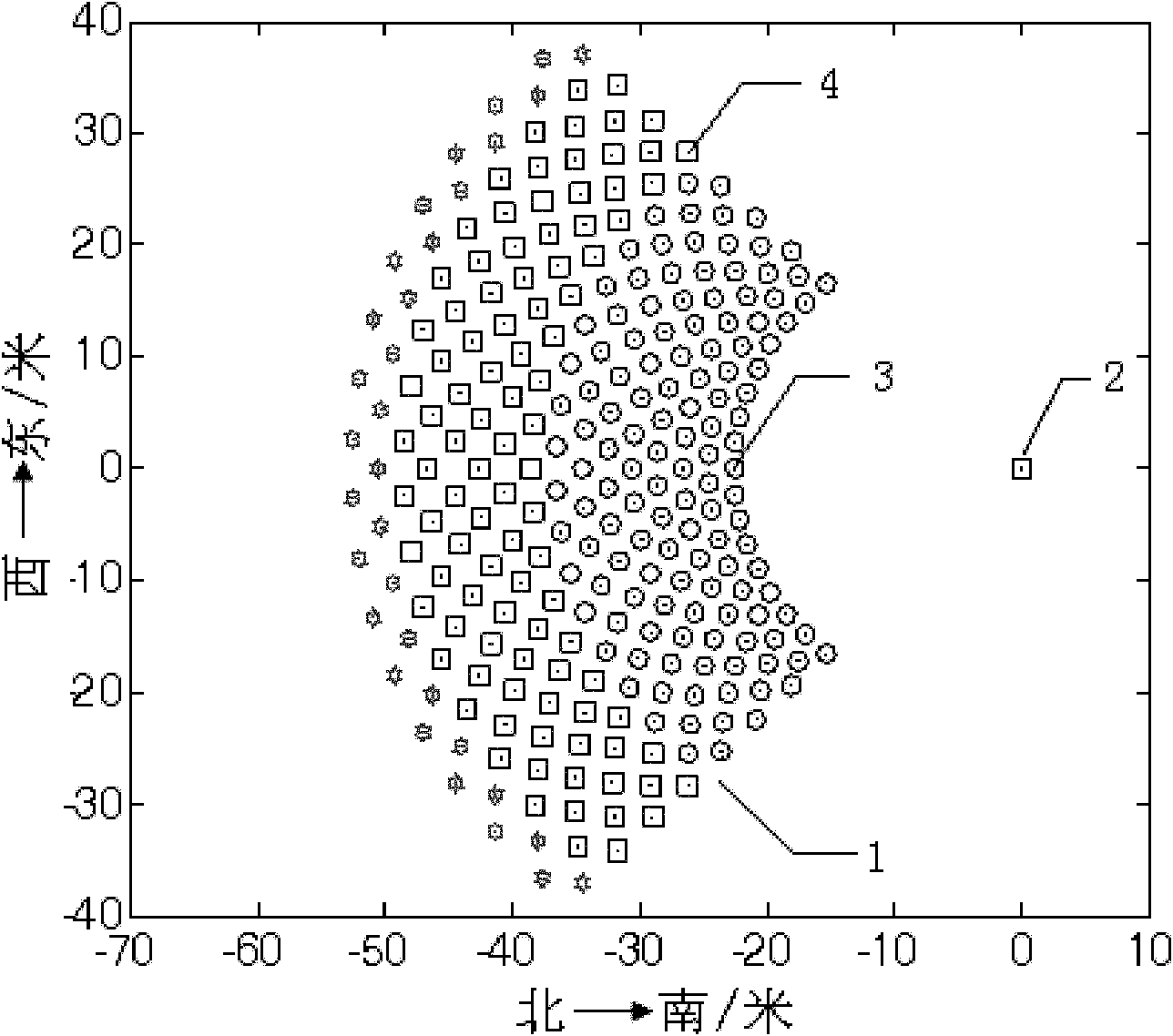

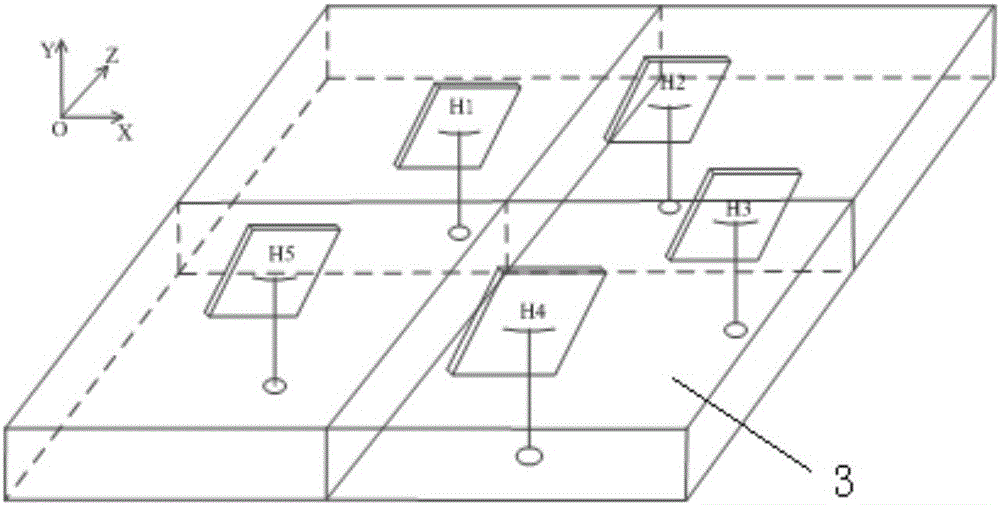

Heliostat grouping control device in heliostat field of solar tower power plant

InactiveCN102081407ALight in massImprove optical efficiencyControl using feedbackPush pullEngineering

The invention relates to a heliostat grouping control device in a heliostat field of a solar tower power plant, wherein an azimuth control driving mechanism of the device provided by the invention is installed at the upper end of a bracket; the bracket is vertically fixed on the ground; the peaks of heliostats are flexibly connected with the azimuth control driving mechanism through a pitching axis; the azimuth control driving mechanism drives the heliostats to synchronously track the azimuth angle of the sun to operate through the pitching axis; the pitching motors of pitching control driving mechanisms drive transmission wheels to rotate, thereby driving transmission rods to make a push-pull reciprocating movement; and power is transferred to the heliostats through the pitching transmission mechanism of each heliostat, thereby driving each heliostat to finish a pitching movement. The heliostat grouping control device provided by the invention adopts a single pitching control driving mechanism to control a group of heliostats which are longitudinally arranged, thereby realizing the pitching tracking of the sun, and the number of the pitching control driving mechanisms is reduced by N-1 (N shows the number of heliostats in the same line), thereby reducing the control cost of the heliostat field.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

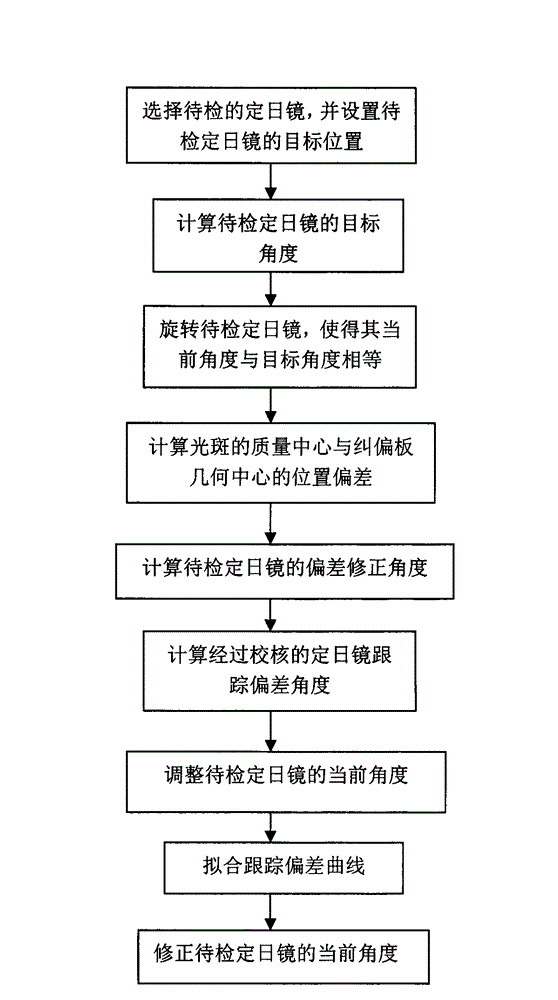

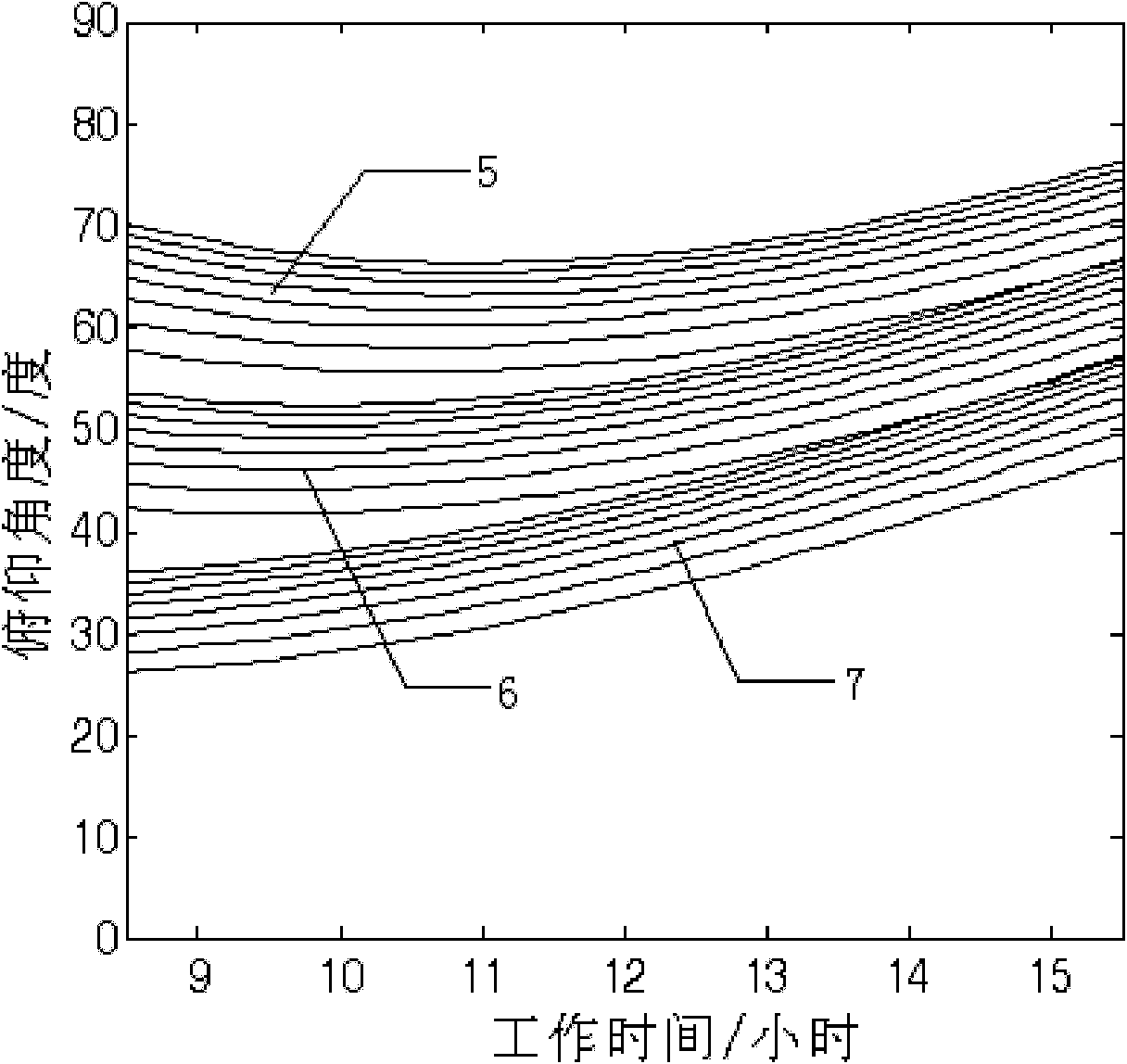

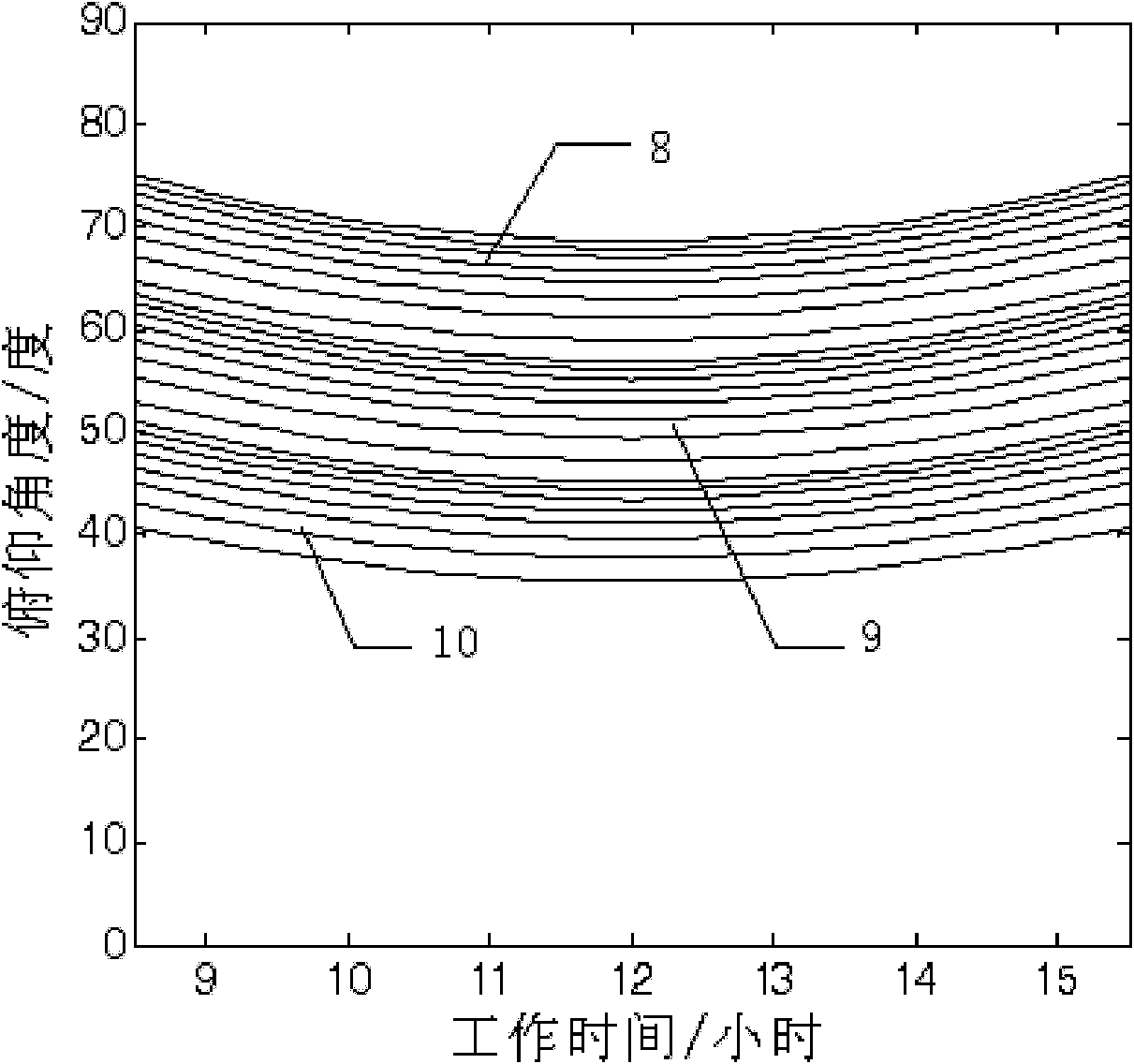

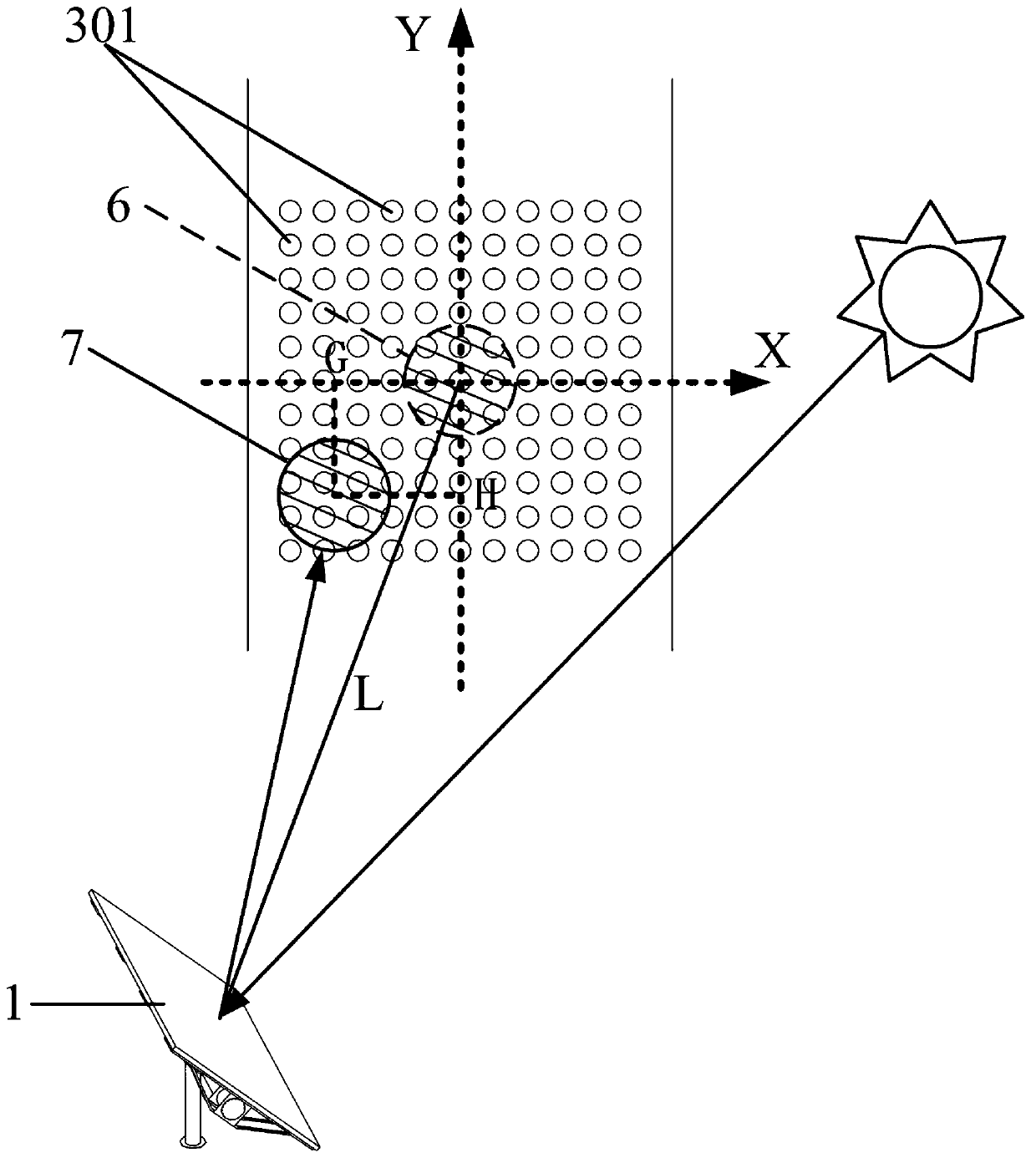

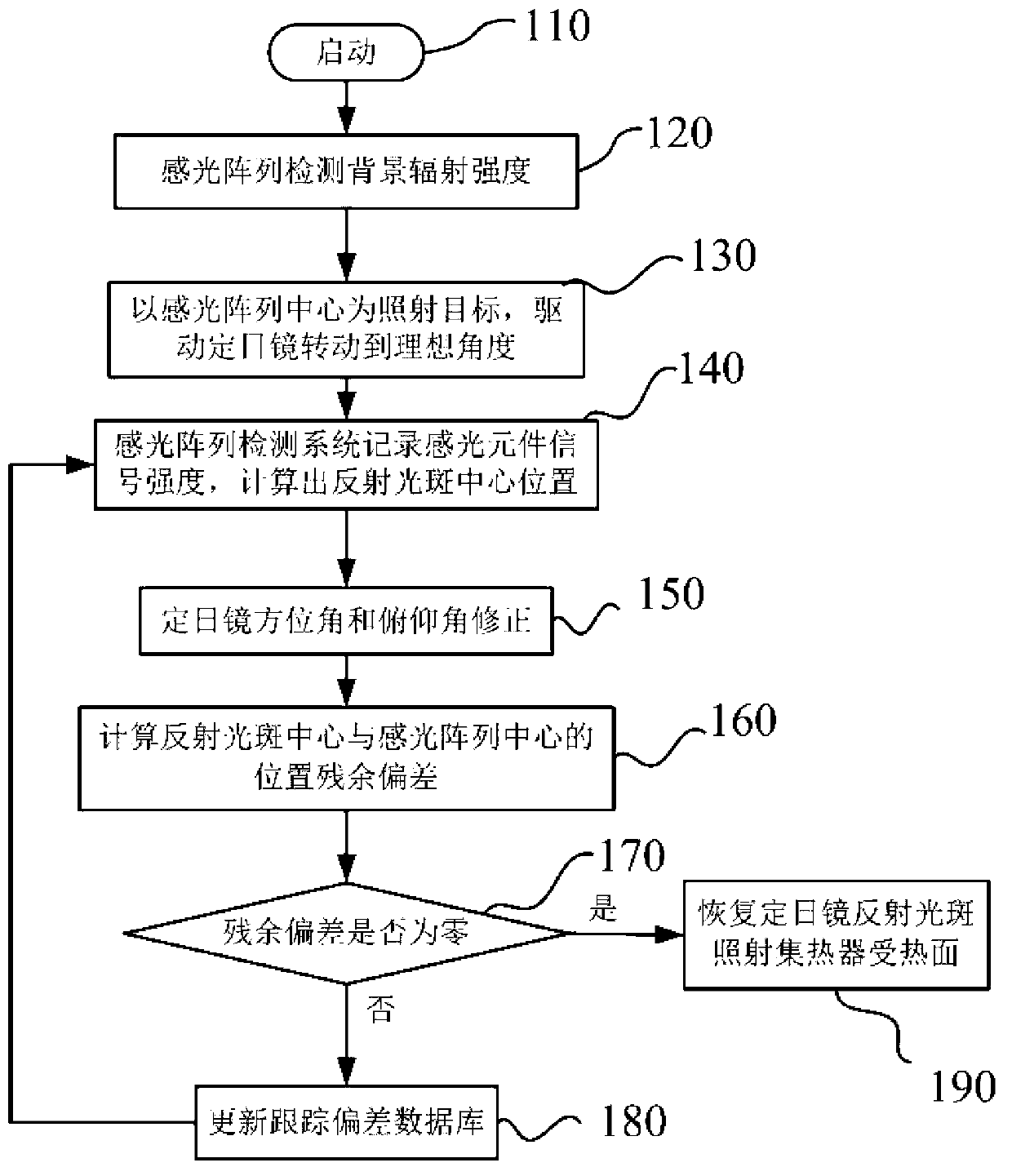

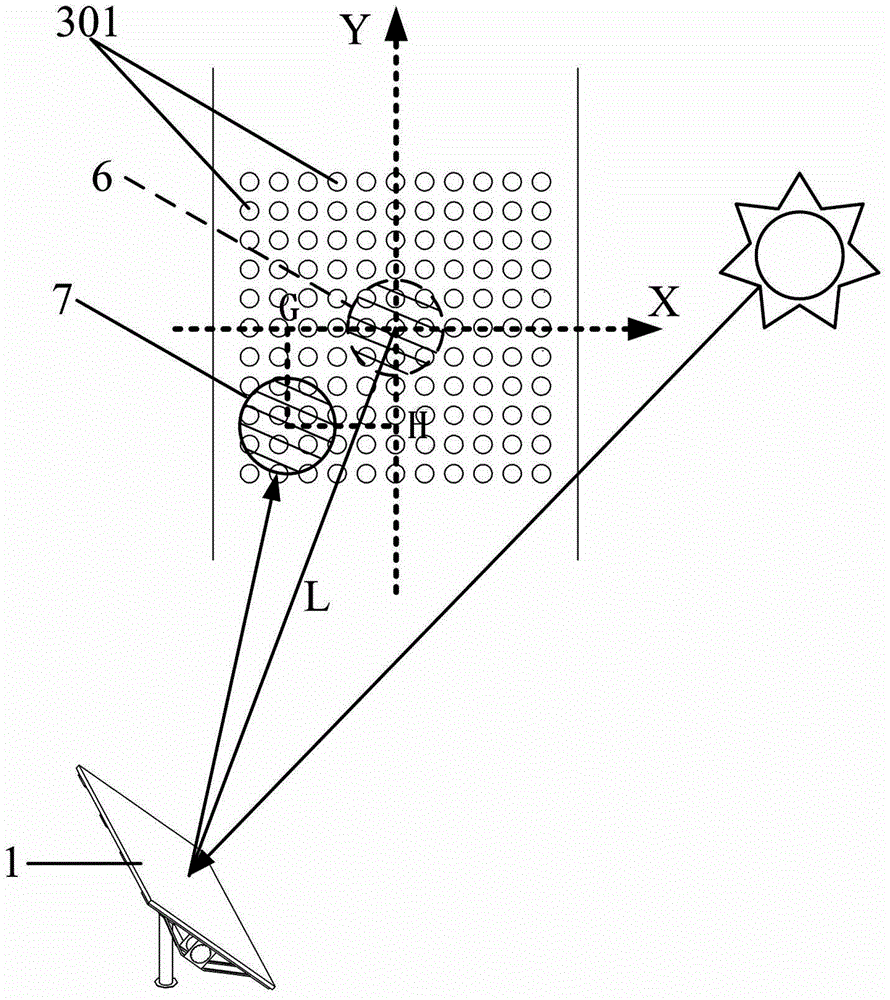

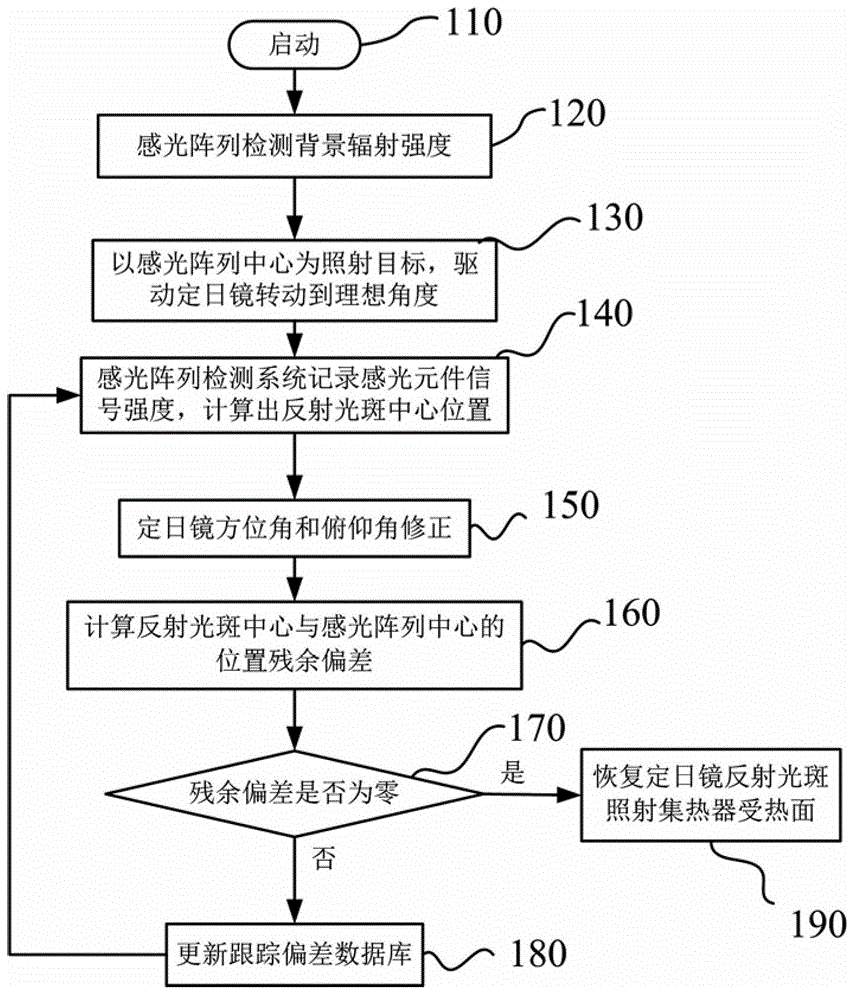

Heliostat reflecting facula offset correction method

InactiveCN103345261AStrong ability to resist environmental interferenceInterference resistantPosition/direction controlClassical mechanicsCorrection method

The invention discloses a heliostat reflecting facula offset correction method and belongs to the technical field of solar tower type thermal generating. According to the heliostat reflecting facula offset correction method, a heliostat reflecting facula offset correction device and a heliostat tracking offset database of the heliostat reflecting facula offset correction device are used for carrying out heliostat reflecting facula offset correction. The azimuth angle and the angle of pitch of a heliostat are adjusted and corrected by means of data on the ideal azimuth angle, the ideal angle of pitch, azimuth angle correction and angle of pitch correction of the heliostat in a heliostat tracking offset database based on relevant characteristics of tracking offset of the heliostat and the angle of pitch and the azimuth angle of the heliostat so as to achieve heliostat reflecting facula offset correction. The correction device and the heliostat tracking offset database of the correction device are low in cost and capable of resisting interference by ambient light and procedures of correcting heliostat reflecting facula offset are simple. The requirement for industrial on-spot application can be met. The heliostat reflecting facula offset correction method is suitable for heliostat reflecting facula offset correction of a heliostat tracking system of a tower type solar thermal generating station.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

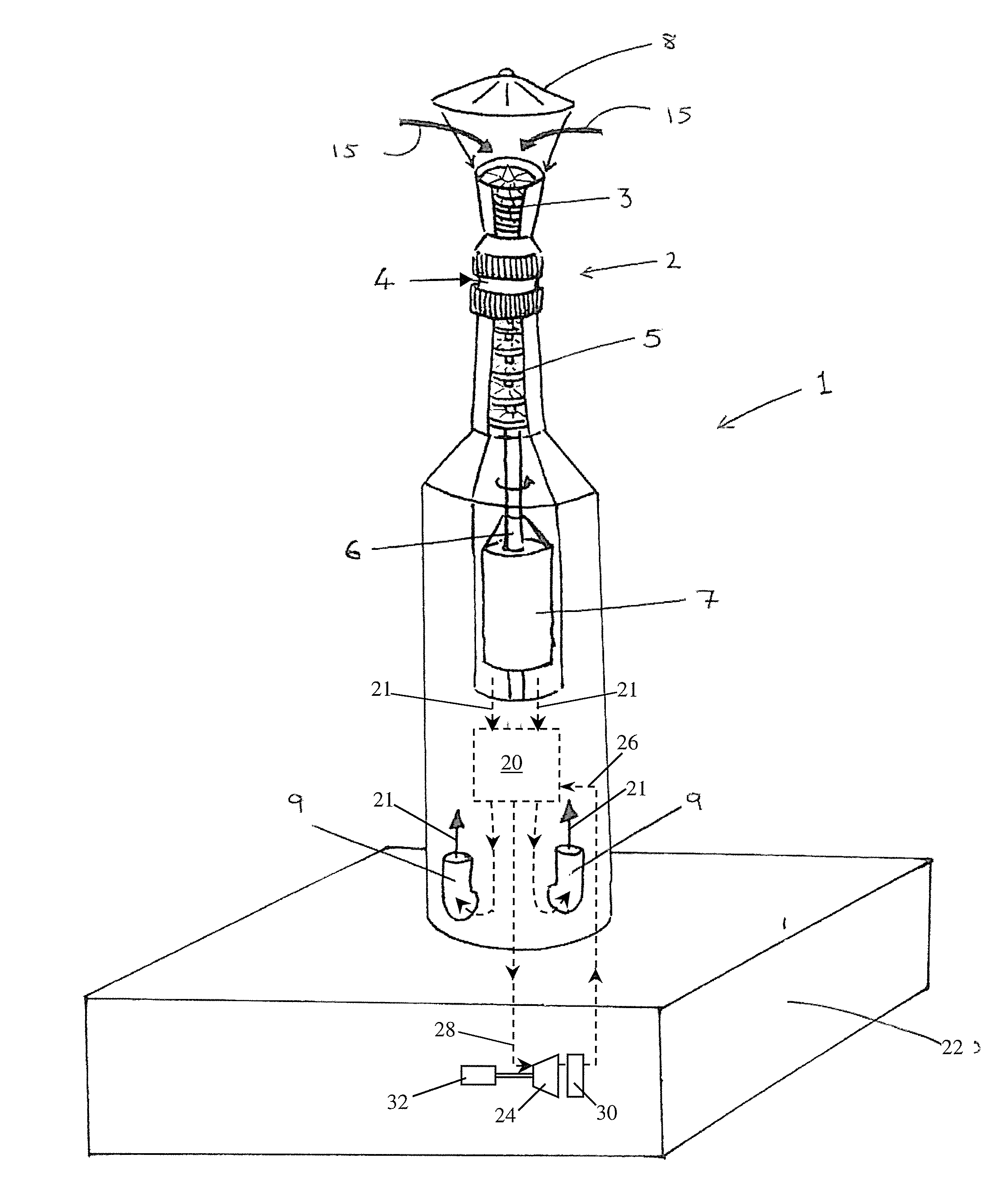

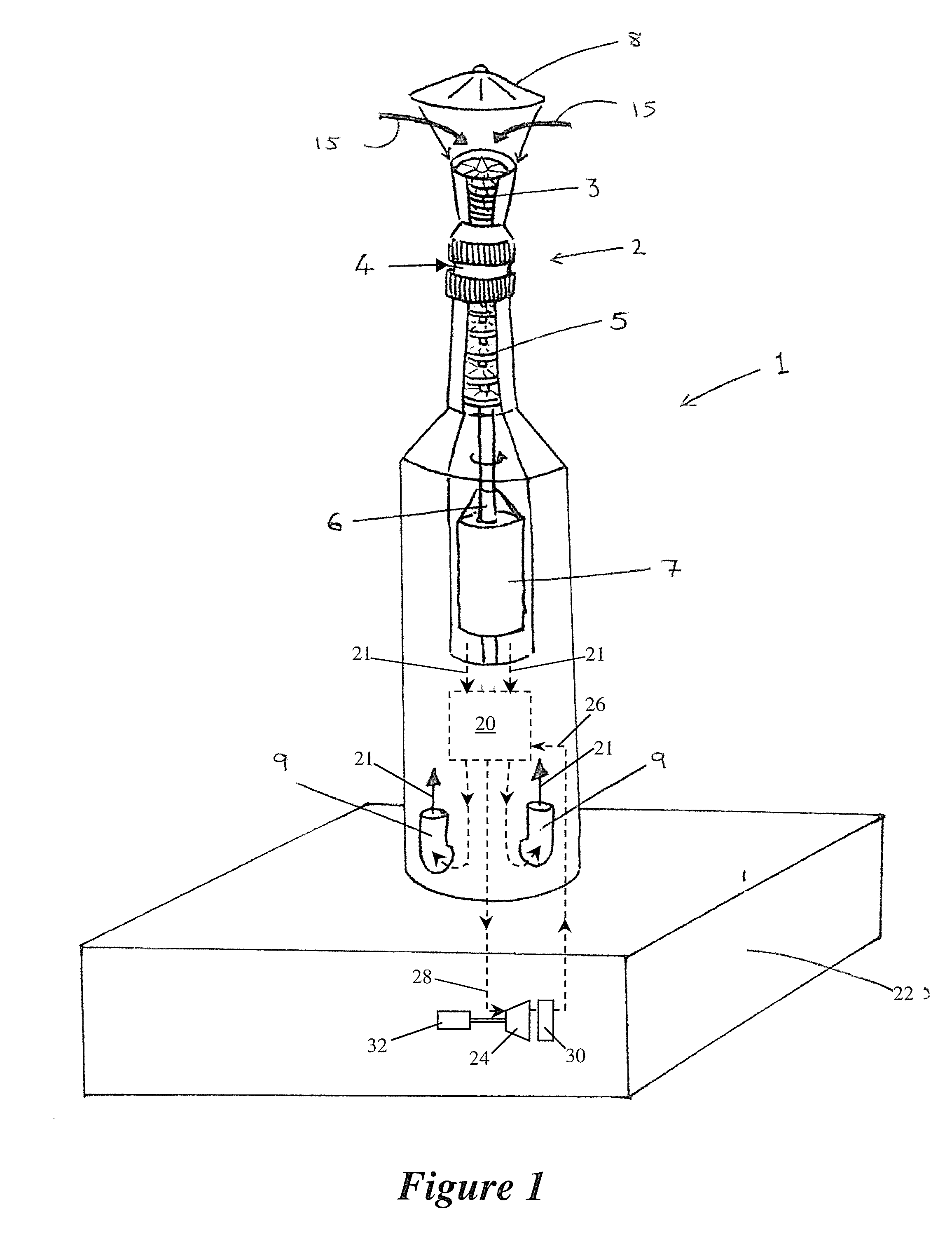

Solar Tower With Integrated Gas Turbine

InactiveUS20130147196A1Reduce energy lossCompact mountingSolar heating energyFrom solar energyTowerGas heating

A solar tower (1) has a solar radiation receiver (4) and a gas turbine engine (2). The gas turbine engine (2) is vertically arranged within the tower and includes, in downward flow series:a compressor (3) for compressing ambient air (15) drawn through at least one air inlet at an upper end of the tower,a heating arrangement (4) for heating compressed air from the compressor, the solar radiation receiver includes at least part of the heating arrangement, anda turbine (5) for extracting work from the heated compressed air.The gas turbine engine (2) is integrally formed with the solar tower (1) and the gas heating arrangement of the gas turbine engine (2) is integrally formed with the solar radiation receiver (4).

Owner:ALSTOM TECH LTD

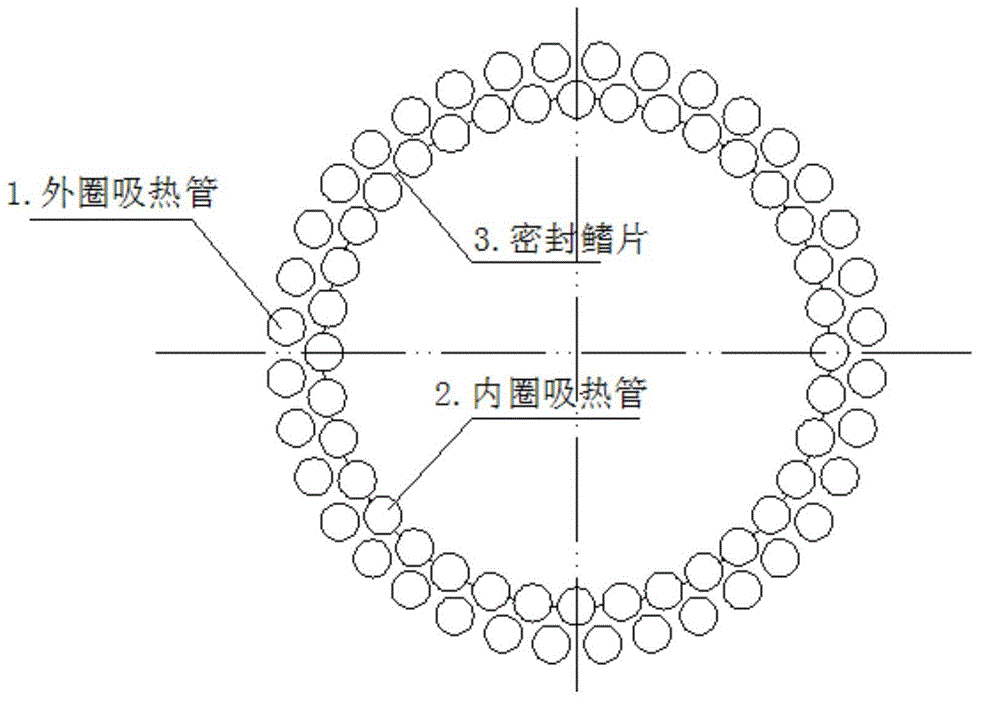

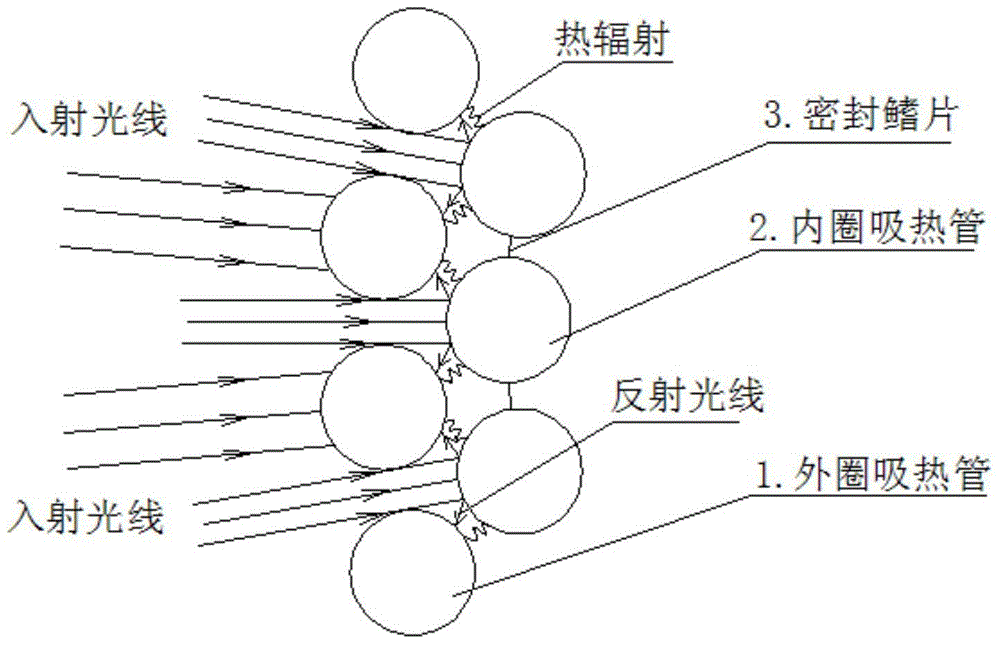

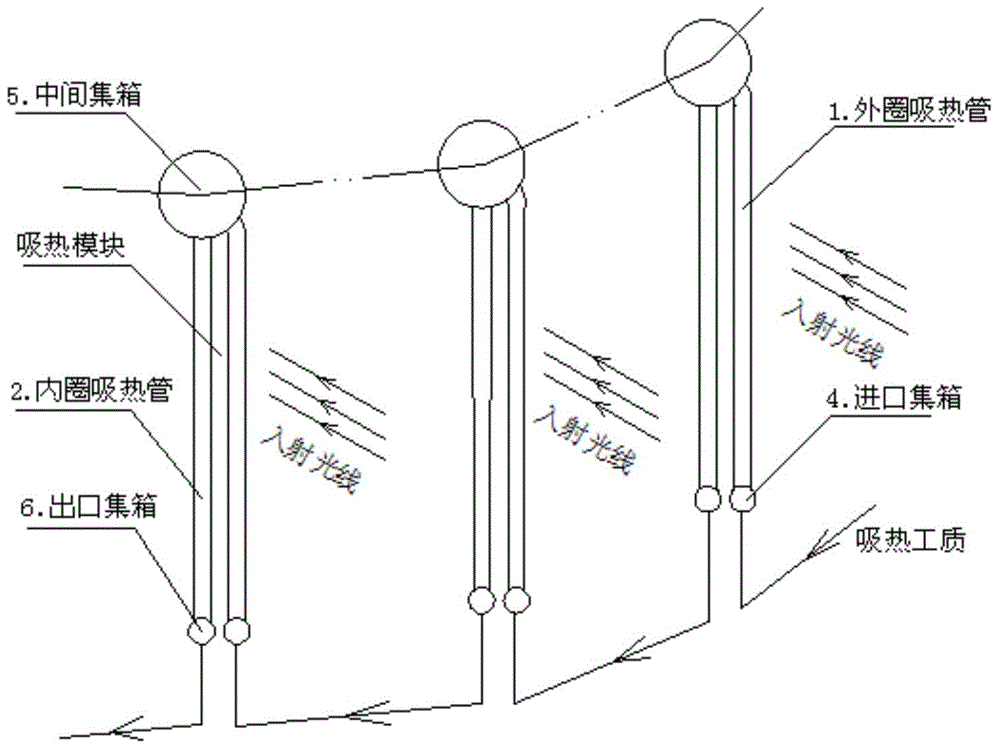

Solar tower type heat absorber with double-tube structure and design method for solar tower type heat absorber

ActiveCN104676919AReduce wall temperature differenceReduce stressSolar heating energySolar heat devicesDouble tubeHeat flux

The invention discloses a solar tower type heat absorber with a double-tube structure and a design method for the solar tower type heat absorber. The solar tower type heat absorber comprises necessary parts of outer ring heat absorbing tubes, inner ring heat absorbing tubes, a sealing fin and the like. According to the design requirements of the heat absorber, a certain gap is formed between two adjacent outer ring heat absorbing tubes or between the outer ring heat absorbing tubes and the inner ring heat absorbing tubes; the inner ring heat absorbing tubes are connected into a group through a closely-packed structure or a fin structure, so that sealing and heat transfer effects are achieved on sunlight received by the heat absorber. According to the solar tower type heat absorber disclosed by the invention, the wall temperature difference of phototropic surfaces and backlight surfaces of heat absorbing tubes is effectively reduced, the stress borne by the heat absorbing tubes can be reduced, the safety of the heat absorber is improved, and the service life of the heat absorber is prolonged; selection requirements on a heat absorber tube sub material can be reduced by reducing the front-rear wall temperature difference, so that the initial investment cost of the heat absorber can be greatly reduced. The heat absorber can improve heat flux density and average heat flux density allowed by the surface, so that the appearance dimension of the heat absorber can be reduced, and the efficiency of the heat absorber is improved.

Owner:HANGZHOU BOILER GRP CO LTD

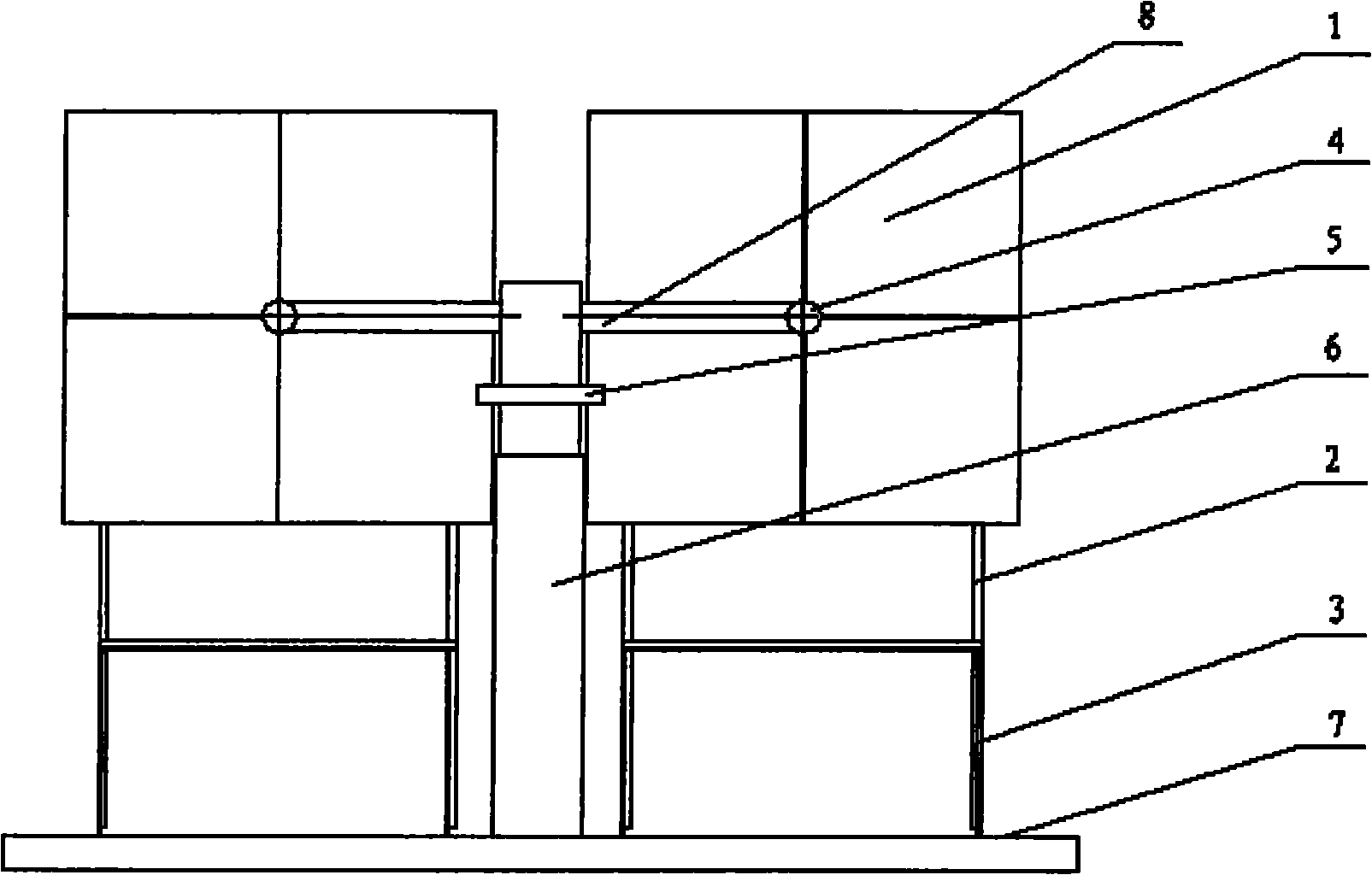

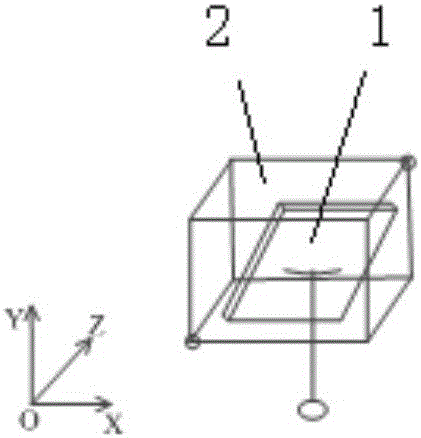

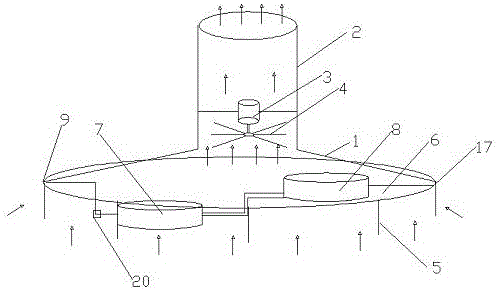

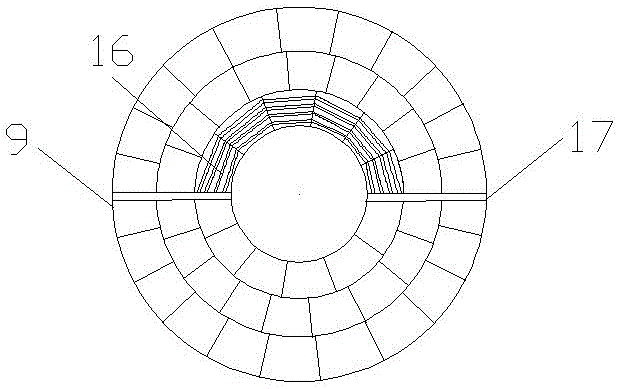

Single-tower multi-disc type solar power generating system

InactiveCN102400868AShorten the lengthSettle the lossSolar heating energyFrom solar energyEngineeringSolar power

The invention discloses a single-tower multi-disc type solar concentrating power generating system. The single-tower multi-disc type solar concentrating power generating system comprises a solar tower and a solar condenser lens component, wherein the solar condenser lens component comprises a solar condenser lens, a solar condenser lens pitch angle support rail and an azimuth angle rotating rail; the azimuth angle rotating rail is circular, horizontally arranged and rotatable; two solar condenser lens pitching and rotating support rails are fixed on the azimuth angle rotating rail in an inclined way; the solar condenser lens is arranged along a solar condenser lens pitching support rail and dose a circumferential movement around a pitch and rotation central line of heat collectors on the top of the tower; the solar tower is vertically arranged at a circular center of the azimuth angle rotating rail; a heat-transferring heat-preserving pipe is horizontally arranged at the top end of the solar tower through a rotating device on the solar tower; and the solar heat collectors are arranged at two outer ends of the heat-transferring heat-preserving pipe symmetrically through the center of the tower.

Owner:钜光太阳能科技(北京)股份有限公司

Petroleum-alternative power plant

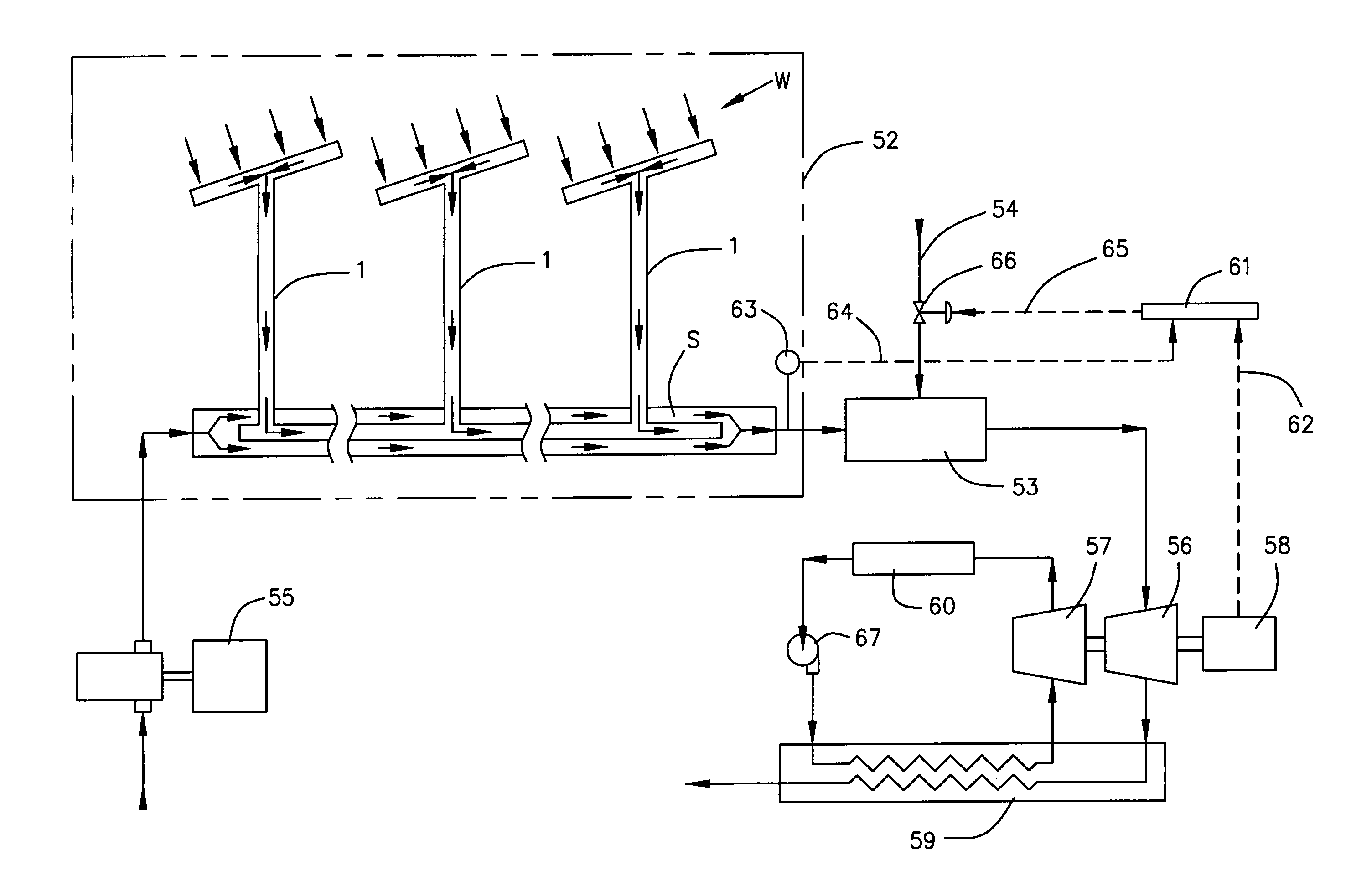

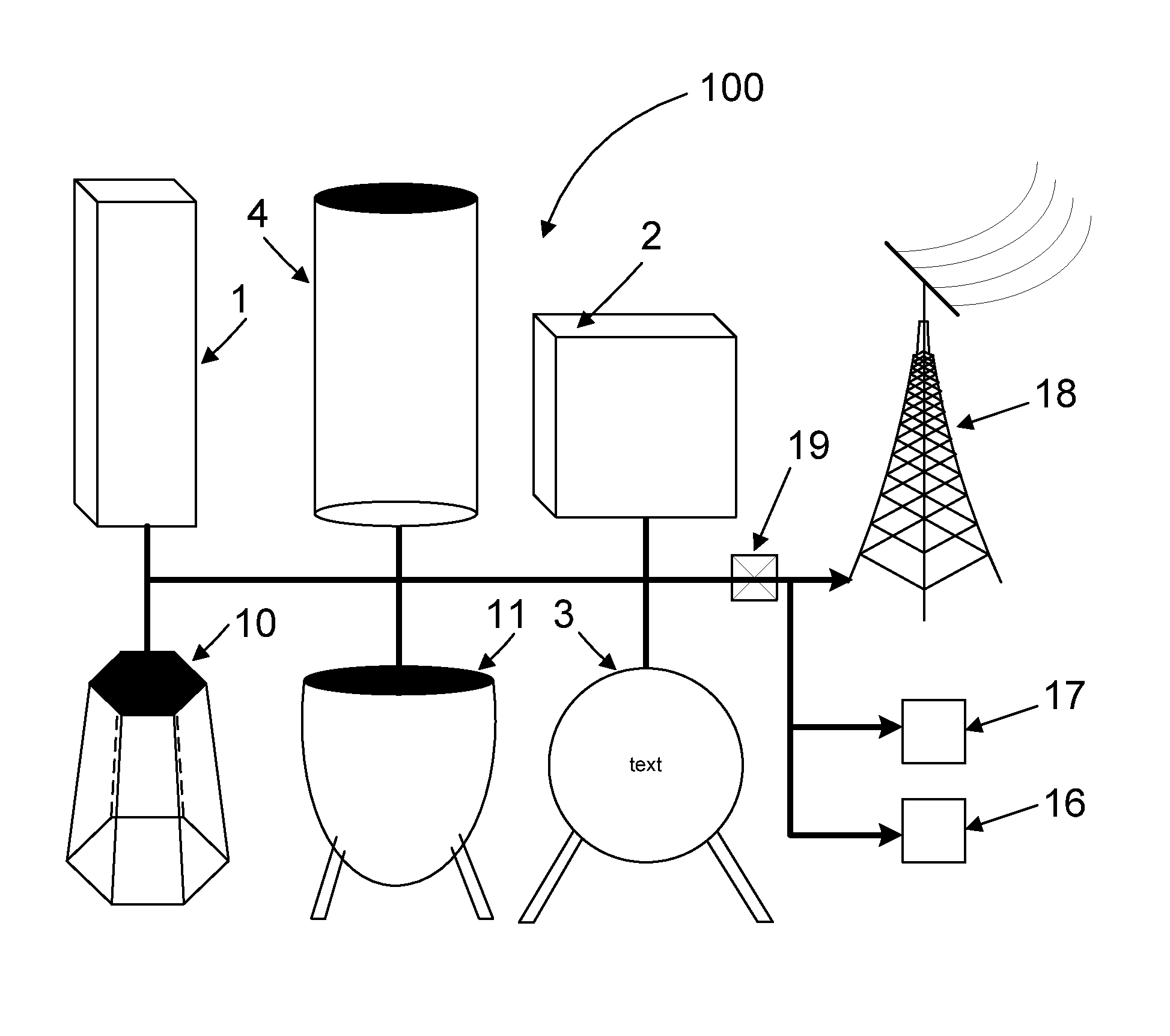

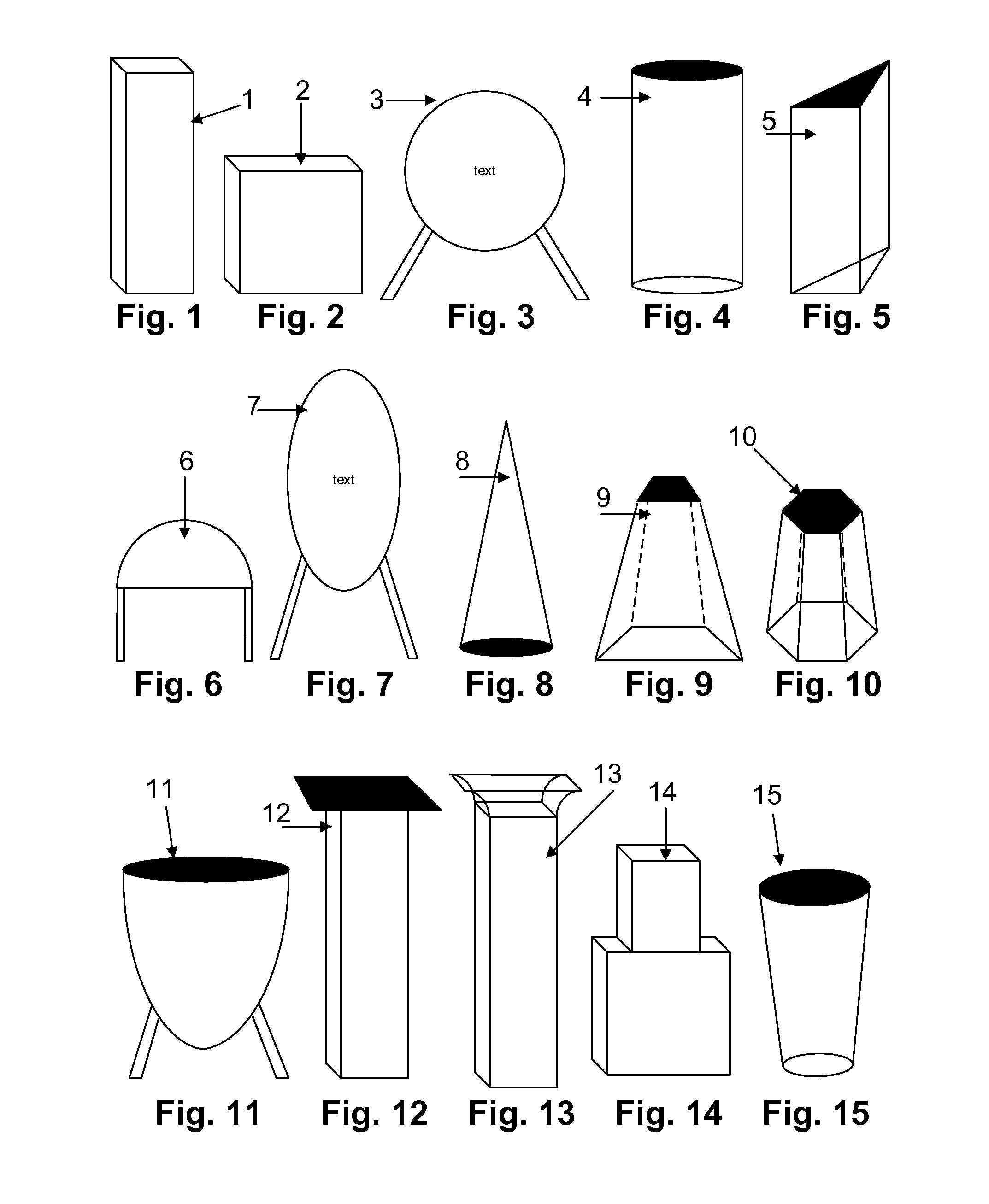

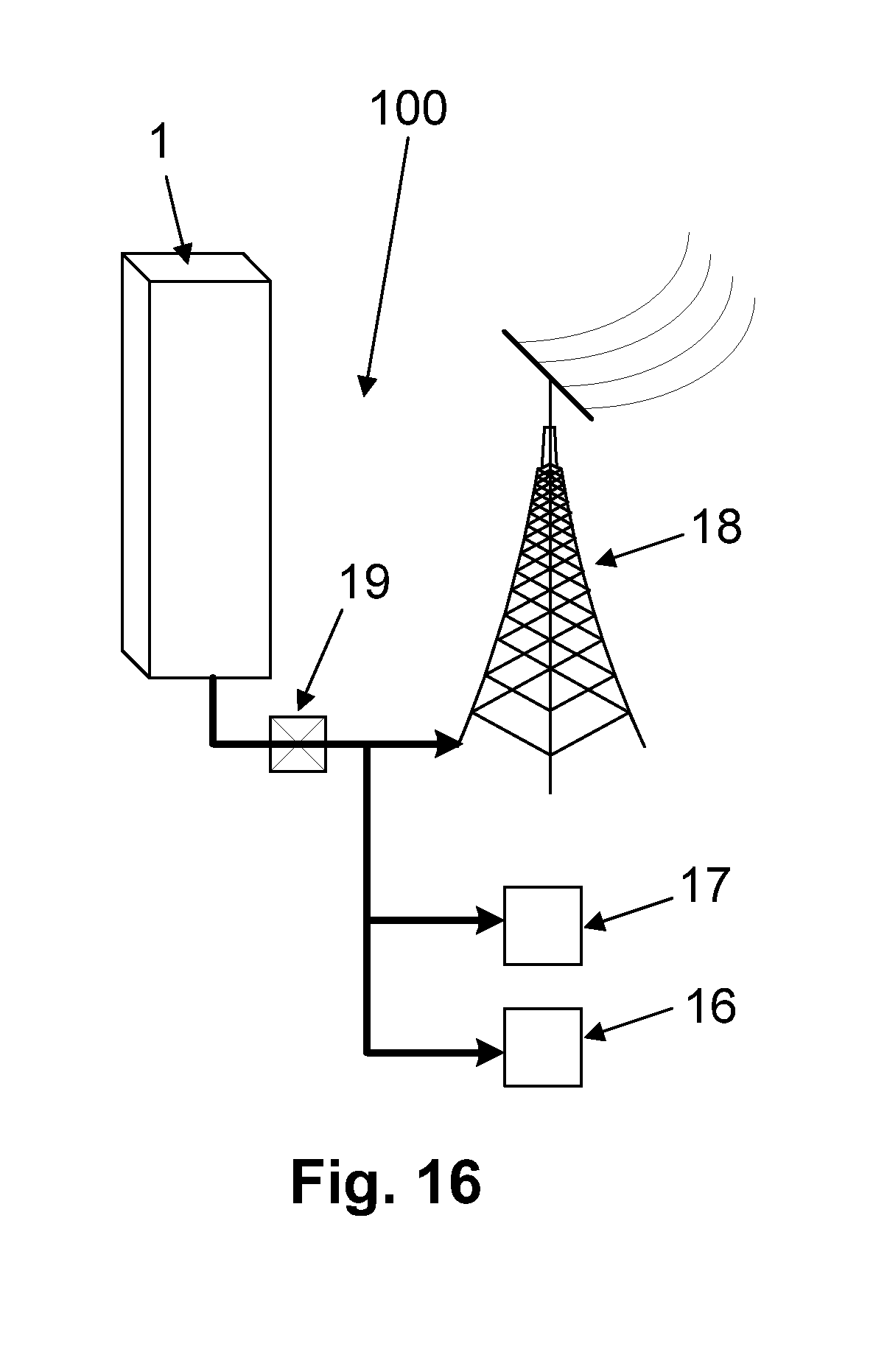

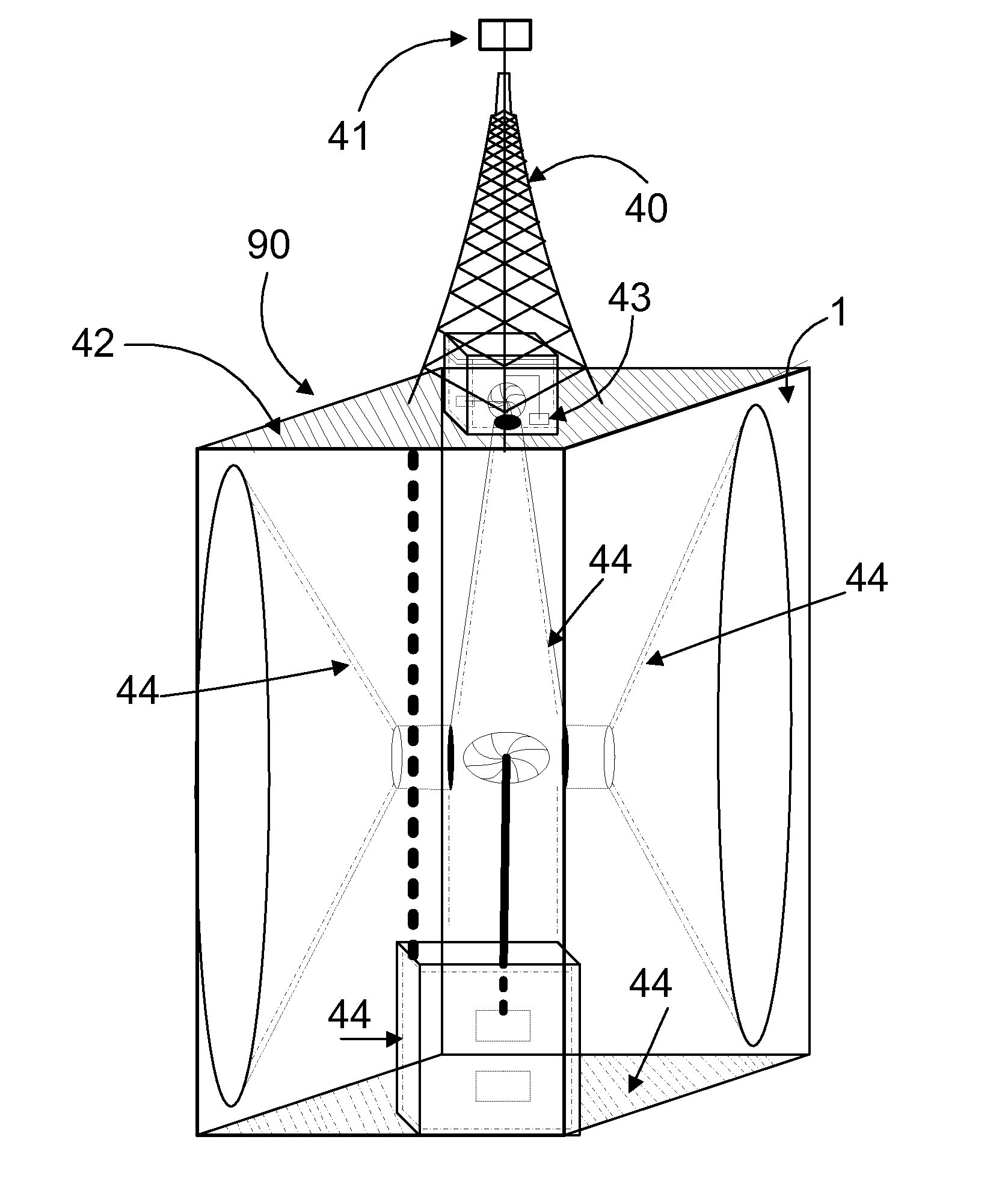

InactiveUS8729726B2Improve system efficiencyIncrease speedWind motor with solar radiationPV power plantsThermal energyEngineering

The present disclosure includes a petroleum-alternative power plant system harvesting wind, solar, and thermal energies. The system may include at least one two-wind-turbine power tower building where the outside surface of the building is divided into a number of sections. Each section forms a funnel- shaped duct to guide and accelerate the wind streams toward the vanes of the first wind turbine; then wind streams accelerated further and guided toward the vanes of a second wind turbine. The system may also include solar receptors, solar tower, and thermal receptors to harvest more energy. A management control subsystem is provided to combine electricity, and selectively delivering electricity to any electric load, a non-fossil fuel production subsystem, and the power grid.

Owner:HASSAN M HASSAN

Petroleum-Alternative Power Plant

InactiveUS20140103663A1Improve system efficiencyIncrease speedPV power plantsMachines/enginesThermal energyEngineering

The present disclosure includes a petroleum-alternative power plant system harvesting wind, solar, and thermal energies. The system may include at least one two-wind-turbine power tower building where the outside surface of the building is divided into a number of sections. Each section forms a funnel- shaped duct to guide and accelerate the wind streams toward the vanes of the first wind turbine; then wind streams accelerated further and guided toward the vanes of a second wind turbine. The system may also include solar receptors, solar tower, and thermal receptors to harvest more energy. A management control subsystem is provided to combine electricity, and selectively delivering electricity to any electric load, a non-fossil fuel production subsystem, and the power grid.

Owner:HASSAN M HASSAN

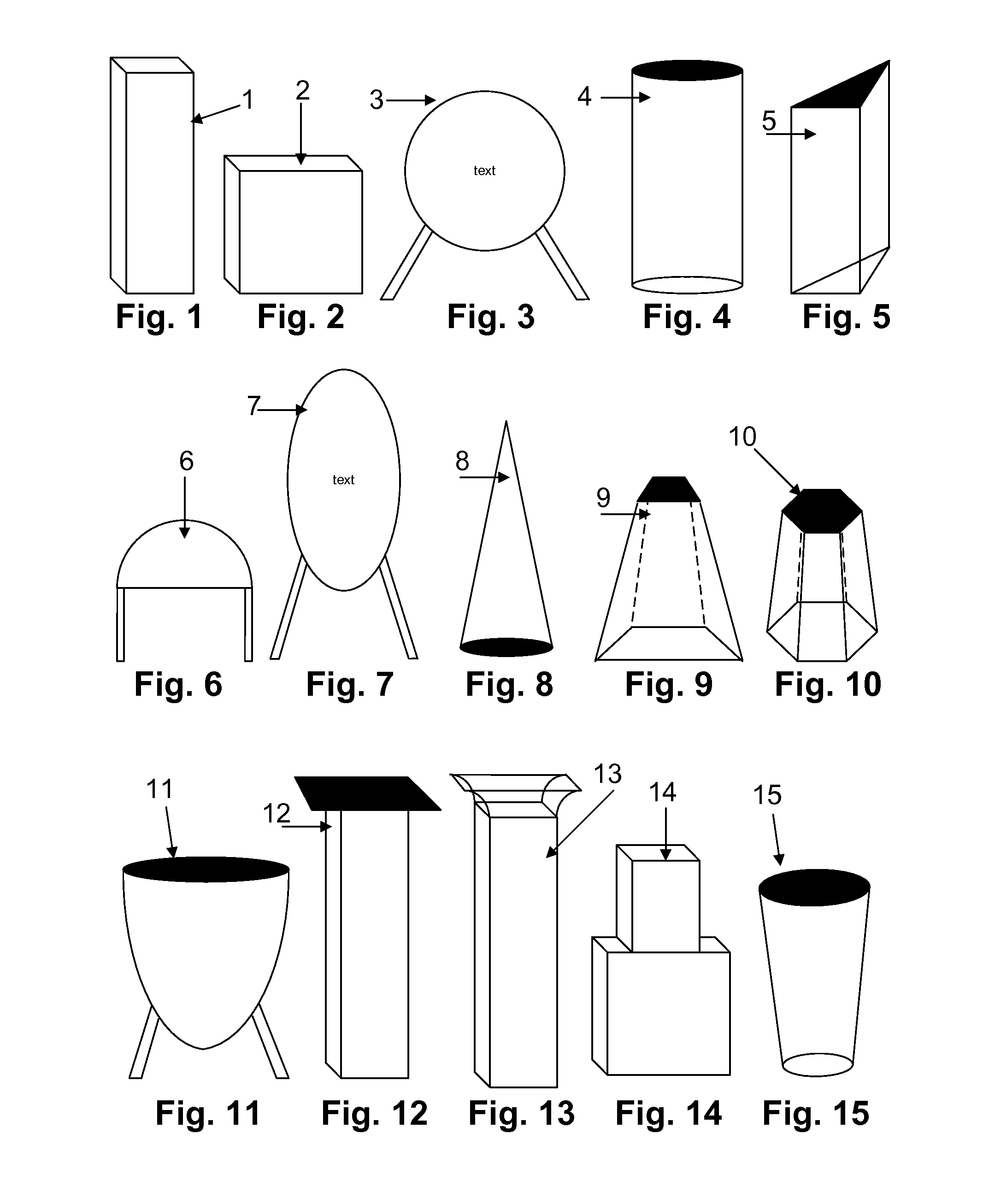

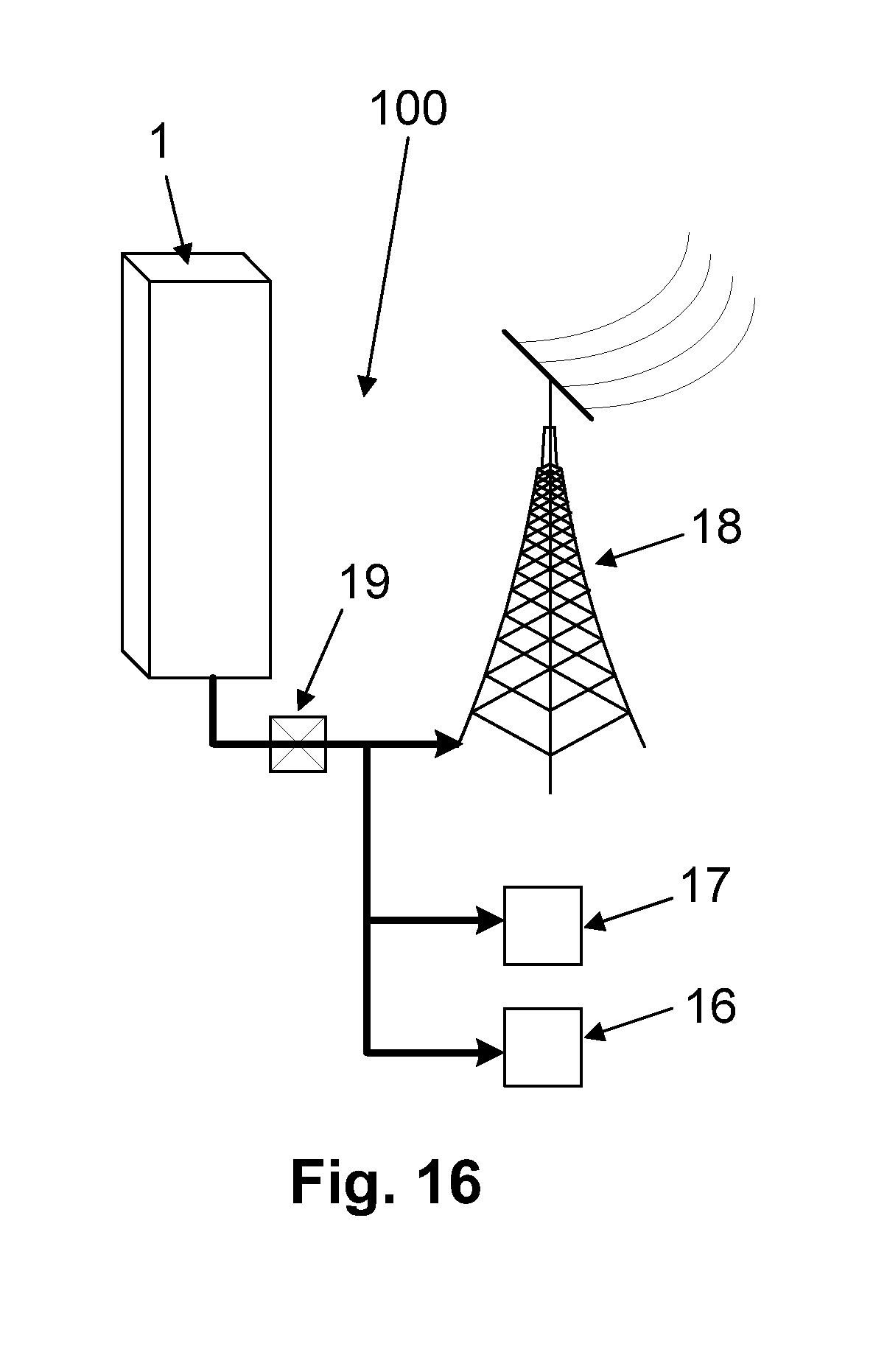

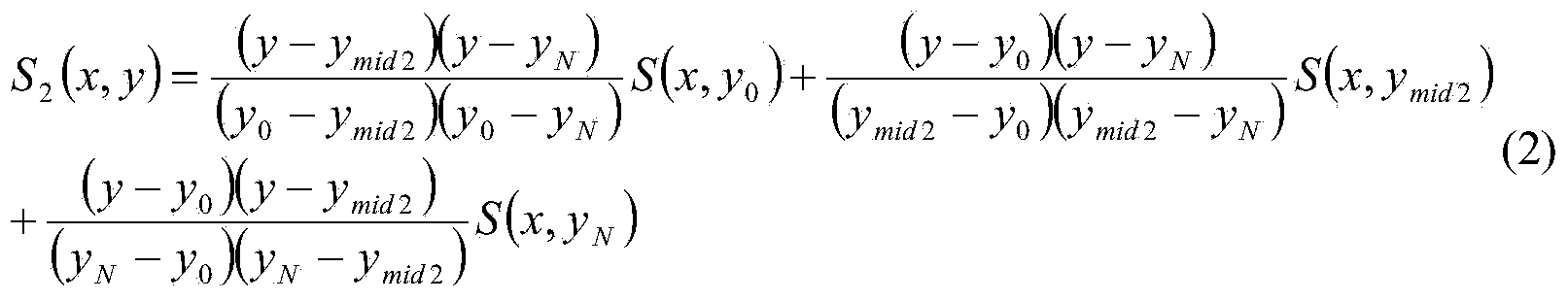

Computing method of lighting surface light condensation energy flux density distribution of solar tower type electric generation thermal absorber

ActiveCN103530518ASmall amount of calculationImprove computing efficiencySpecial data processing applicationsChinese charactersDensity distribution

Provided is a computing method of lighting surface light condensation energy flux density distribution of a solar tower type electric generation thermal absorber. According to the thermal absorber corresponding to an unilateral heliostat field, the lighting surface of the thermal absorber is divided into rectangular grids to form rectangular planar grids or cylindrical surface grids, and meanwhile borders of a grid in a shape of Chinese character 'tian' of the lighting surface are determined. The reverse light tracing method is used, a light condensation energy flux density value of the heliostat field on the borders of the 'tian'-shaped grid of the lighting surface of the thermal absorber is computed, the lighting surface grid of the thermal absorber is unfolded into an X-Y planar grid, according to the light condensation energy flux density value of the heliostat field on the borders of the 'tian'-shaped grid of the lighting surface of the thermal absorber, energy flux density values of all grid points of the lighting surface of the thermal absorber are reset in an interpolation mode. In reference to a circumferential heliostat field, for all cylindrical surface lighting surface sub areas, the energy flux density value of the borders of the 'tian'-shaped grid is computed first, and then light condensation energy flux density values of corresponding lighting surface sub areas are reset in an interpolation mode.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

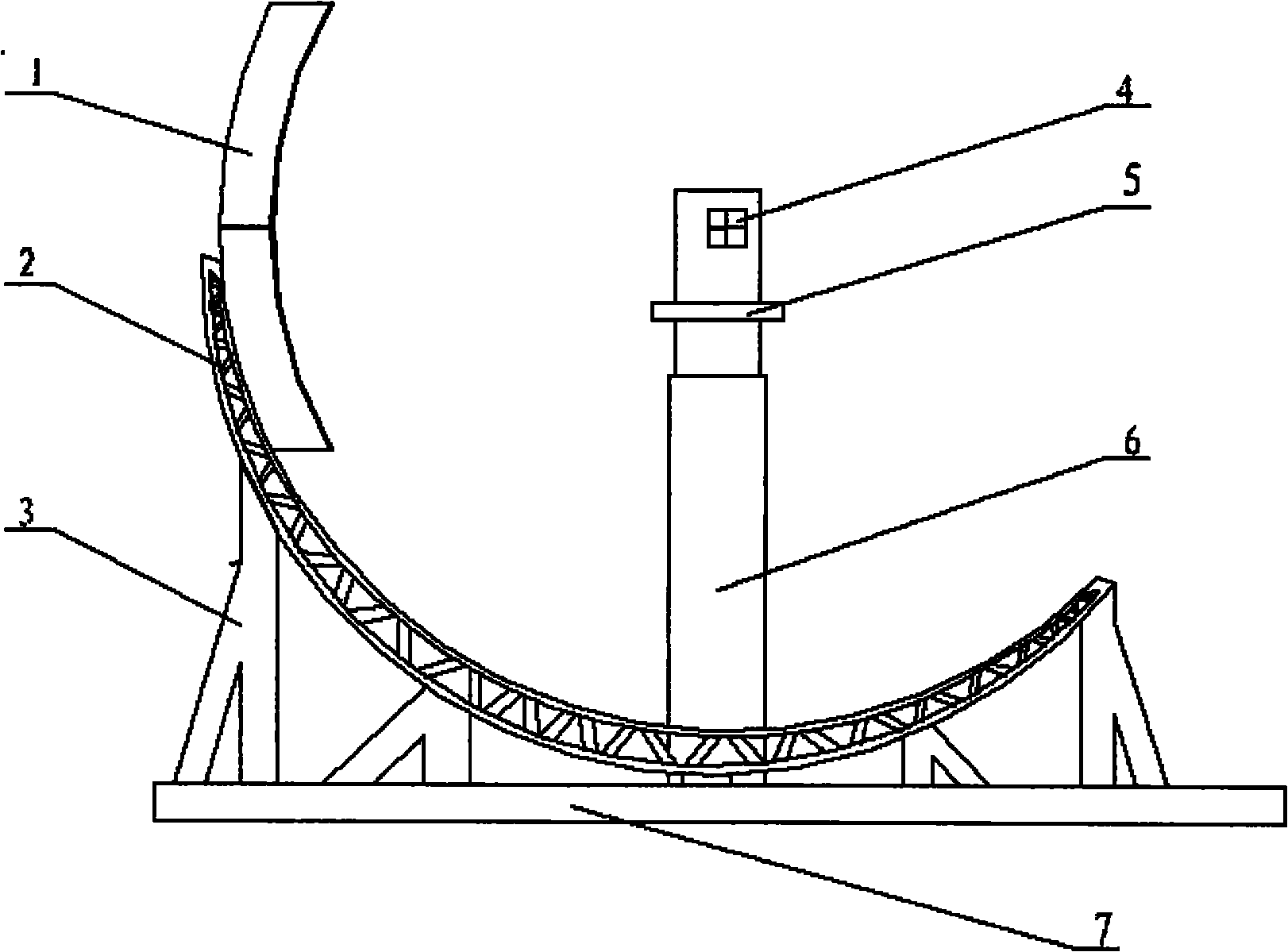

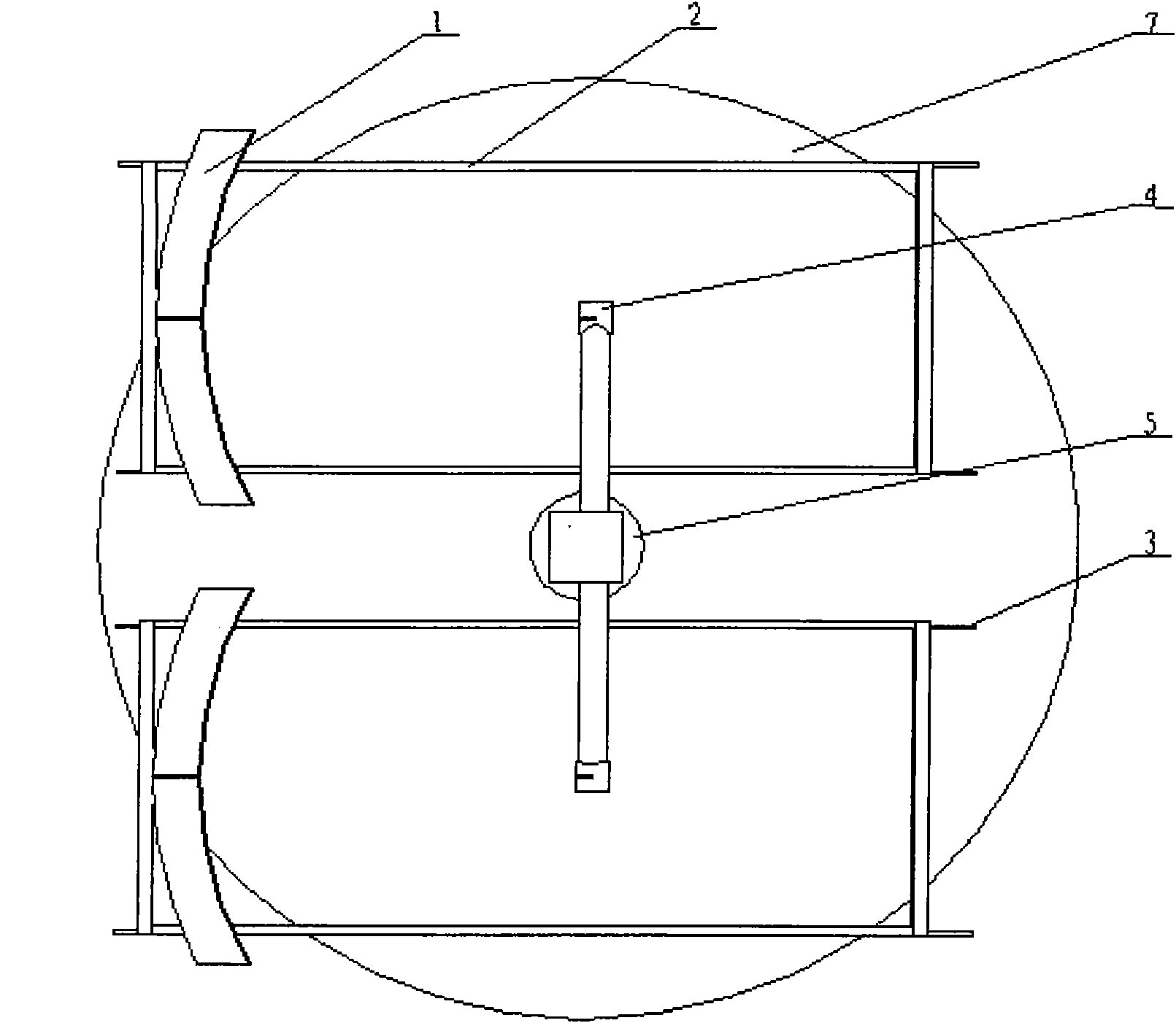

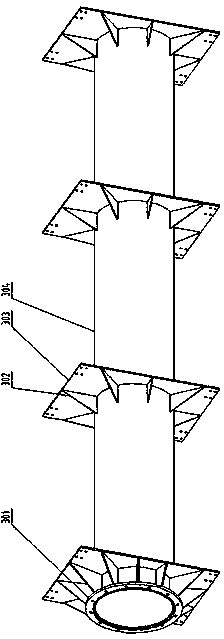

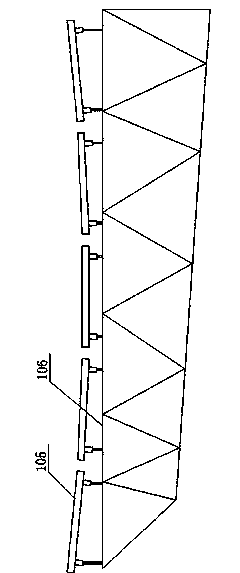

Large tower-type heliostat solar heat collecting support

The invention discloses a large tower-type heliostat solar heat collecting support. The support comprises heat collecting glass (106), a glass supporting plate (105), a middle rotary shaft supporting frame (104), a middle rotary shaft (102), a middle rotating mechanism (103), a stand column (101) and the like. The large tower-type heliostat solar heat collecting support has a large heat collecting area, the face, receiving sunlight, of a reflection mirror cannot be shielded by any element, and the solar heat collecting support is low in cost, easy to control, convenient to install and debug and convenient and quick to maintain.

Owner:成都博昱新能源有限公司

Salt-water-electricity cogeneration system of sun-tracking solar chimney and operation method of salt-water-electricity cogeneration system

InactiveCN104944488AReduce areaIncrease heightSolar heating energyGeneral water supply conservationElectricityCoupling

The invention discloses a salt-water-electricity cogeneration system of a sun-tracking solar chimney and an operation method of the salt-water-electricity cogeneration system. The salt-water-electricity cogeneration system is characterized by comprising a heat collecting shed, the solar chimney arranged in the center of the heat collecting shed, and a wind driven generator arranged in the junction between the heat collecting shed and the solar chimney; a plurality of heliostats are arranged on the edge of the heat collecting shed. The salt-water-electricity cogeneration system and the operation method have the benefits that double advantages of the solar chimney and a solar tower are integrated, solar energy can be utilized through condensing coupling or non-concentrating coupling, the area of the heat collecting shed and the height of the solar chimney can be effectively reduced, various types of energy can be sufficiently recovered, and the heat efficiency of the salt-water-electricity cogeneration system is improved.

Owner:HOHAI UNIV CHANGZHOU

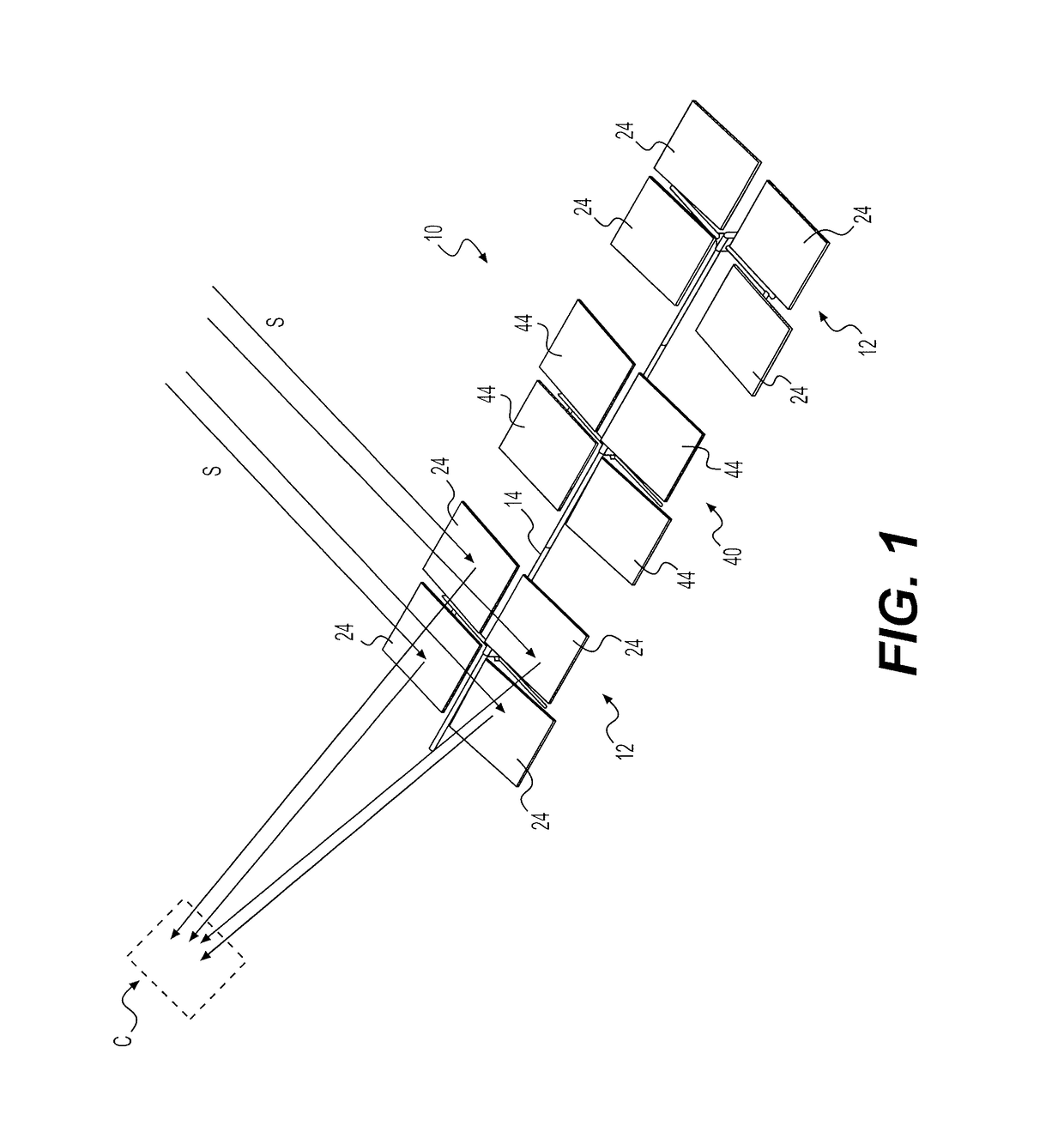

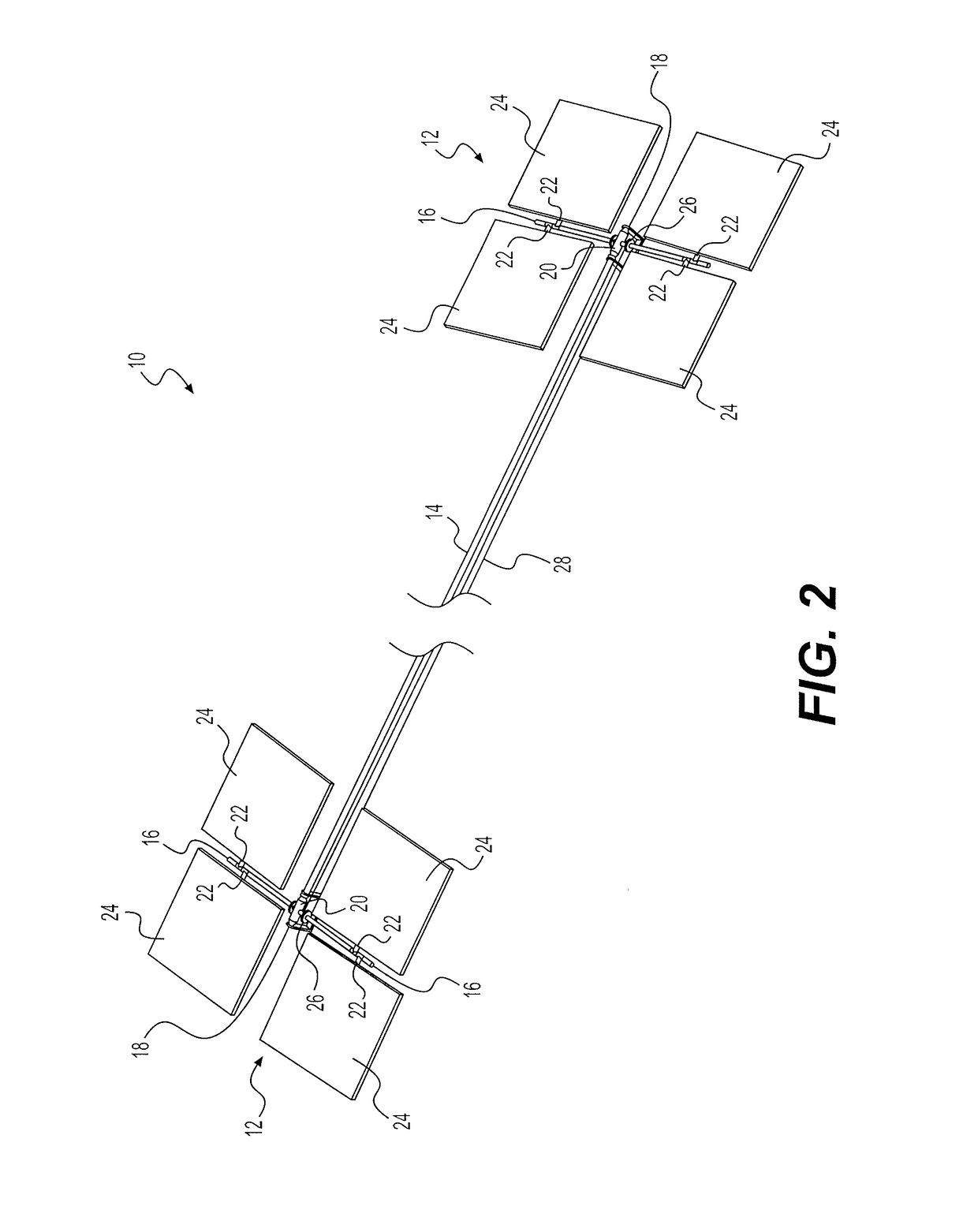

Solar heating apparatus

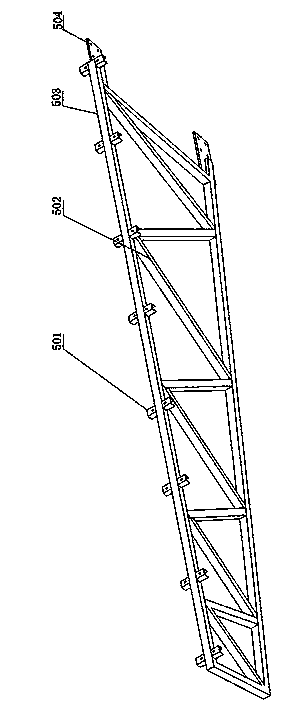

ActiveUS10190801B1Readily apparentSolar heating energySolar heat collector controllersEngineeringSolar tower

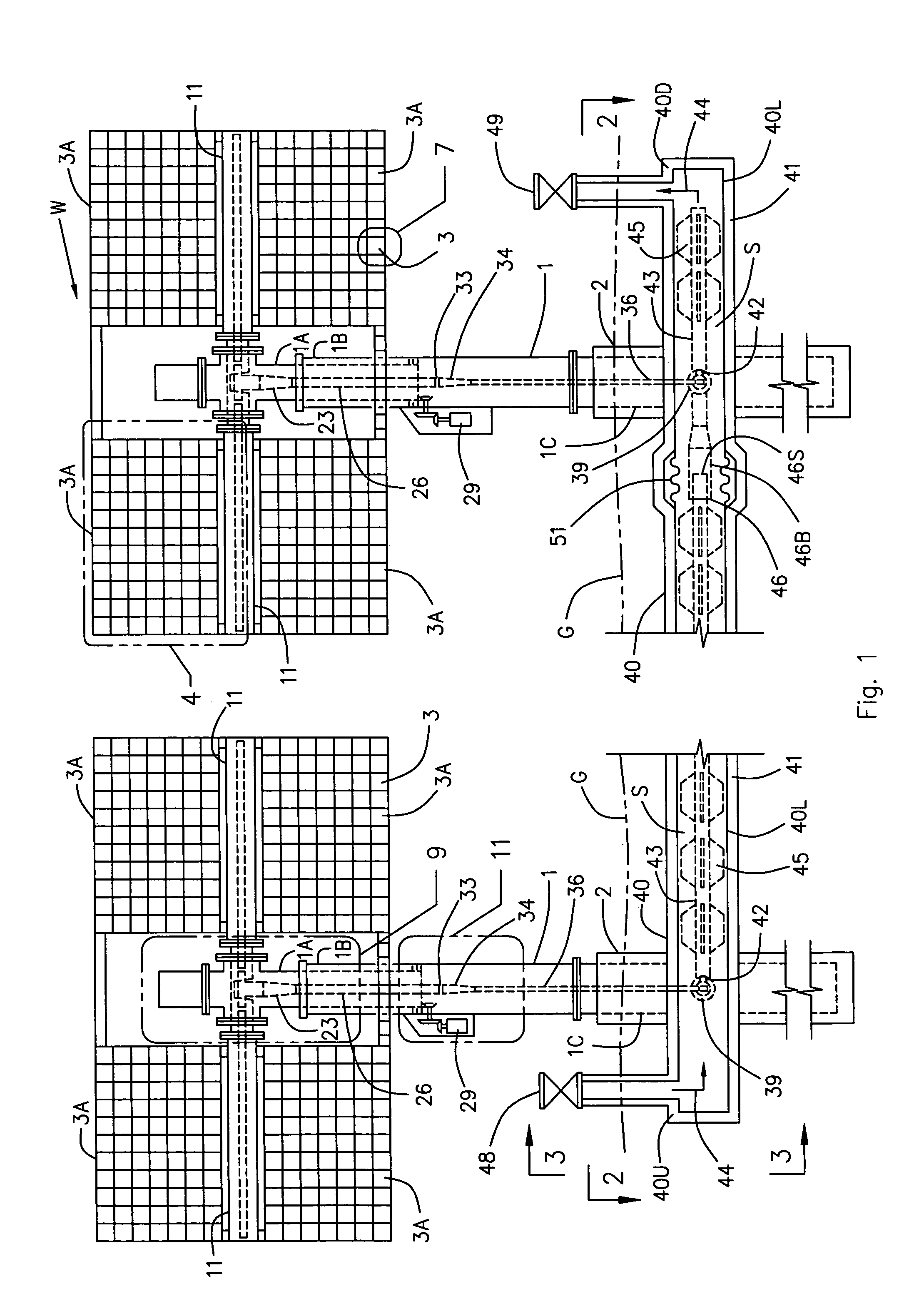

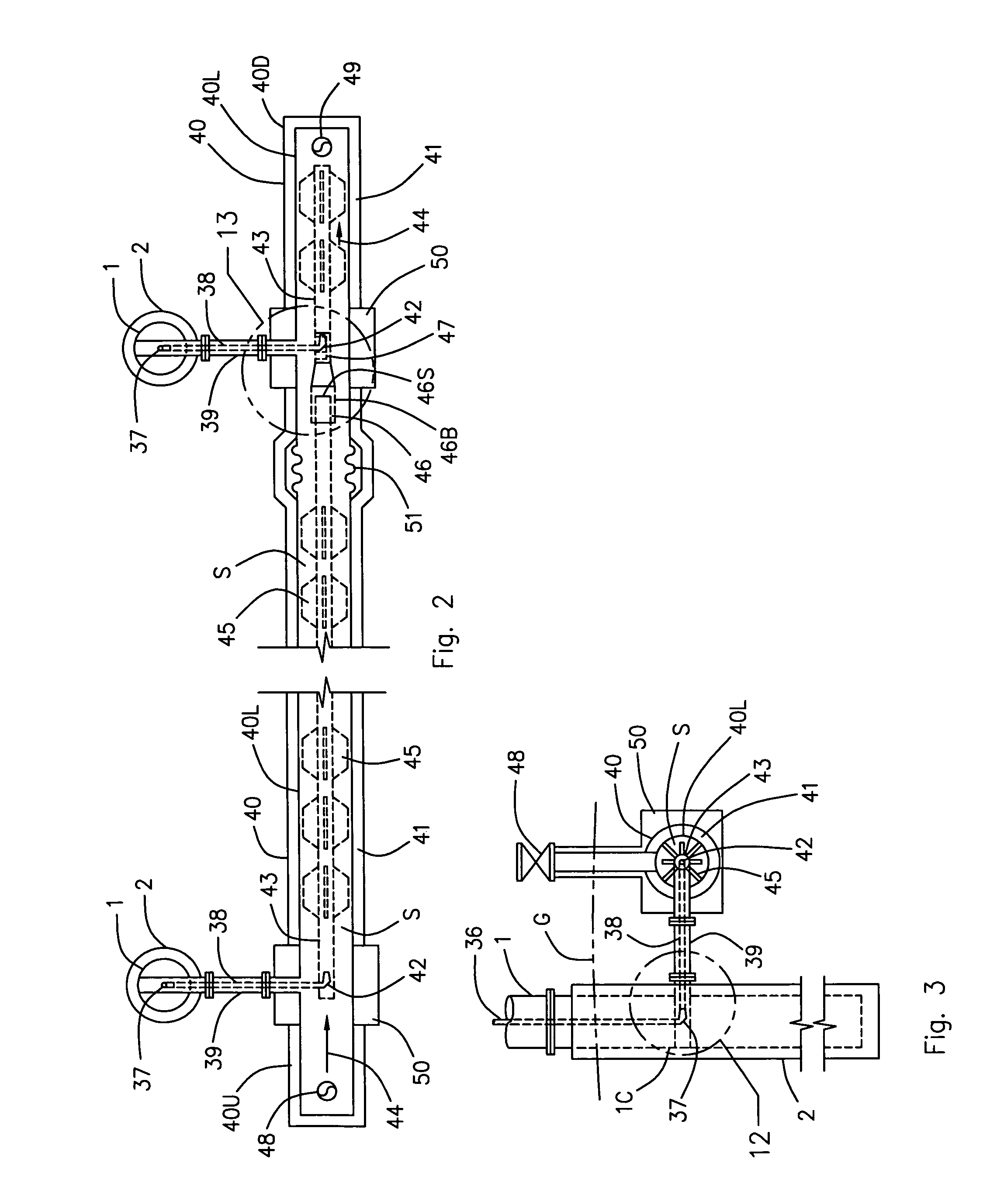

The solar heating apparatus includes driven and controllable reflectors for concentrating solar radiation on a solar tower or the like. Each of the reflectors provided in an array of reflectors is selectively driven to rotate about multiple axes of rotation. A plurality of groupings of optical reflectors, such as mirrors or the like, are mounted about a single, common longitudinally extending shaft, providing simultaneous rotation of the optical reflectors about a longitudinal axis. Through a two-axis bearing associated with each grouping of optical reflectors, the optical reflectors are also mounted on a laterally extending shaft associated with each individual reflector grouping. The laterally extending shafts are linked, each to the other, by a continuous belt or the like, providing selective simultaneous rotation of the optical reflectors about the lateral axis in addition to the simultaneous rotation about the longitudinal axis.

Owner:KING SAUD UNIVERSITY +1

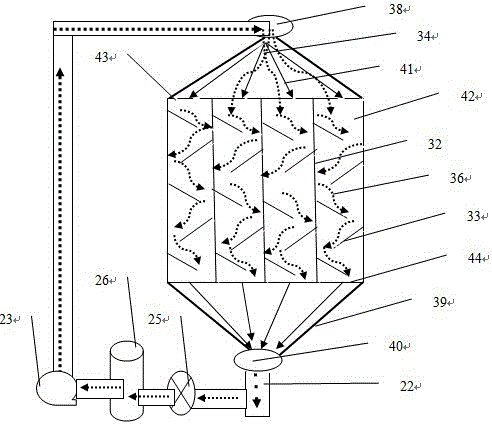

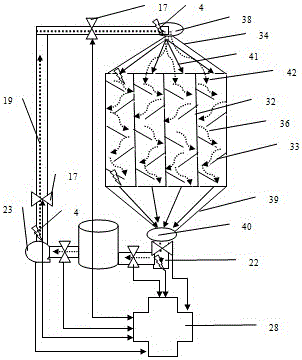

Solid particle block tower-type solar pulse driven heat-exchange and heat-transmission system

PendingCN105318579ALow costHigh Efficiency AcquisitionSolar heat devicesSolar thermal energy generationSolar lightCollection system

The invention aims to provide a solid particle block tower-type solar heating and heat-transmission system. The solid particle block tower-type solar heating and heat-transmission system comprises a solid particle block pulse driven pump and a solar tower-type collection system. The solid particle block pulse driven pump drives solid particle blocks to enter a solar light-heat converter arranged in the focal position of the tower-type collection system along an ascending pipeline of the solid particle blocks. The hot solid particle blocks converted through the solar light-heat converter enable the temperature of the solid particle blocks to reach 600 DEG C-1200 DEG C, then the solid particle blocks enter a regenerative heat exchanger along a descending pipeline, and heat exchange is conducted between the regenerative heat exchanger and a working medium used for generating power, so that the temperature of the solid particle blocks is lowered to be 100 DEG C-400 DEG C. The low temperature solid particle blocks enter a loading box along a connecting pipeline and then are driven by the solid particle block pulse driven pump to enter the solar light-heat converter, so that circulation of the solid particle blocks in a sealed circulating pipeline through driving of the solid particle block pulse driven pump is achieved, and high temperature collection, heat transmission, heat exchange and heat storage are achieved.

Owner:CHENGDU AONENGPU TECH

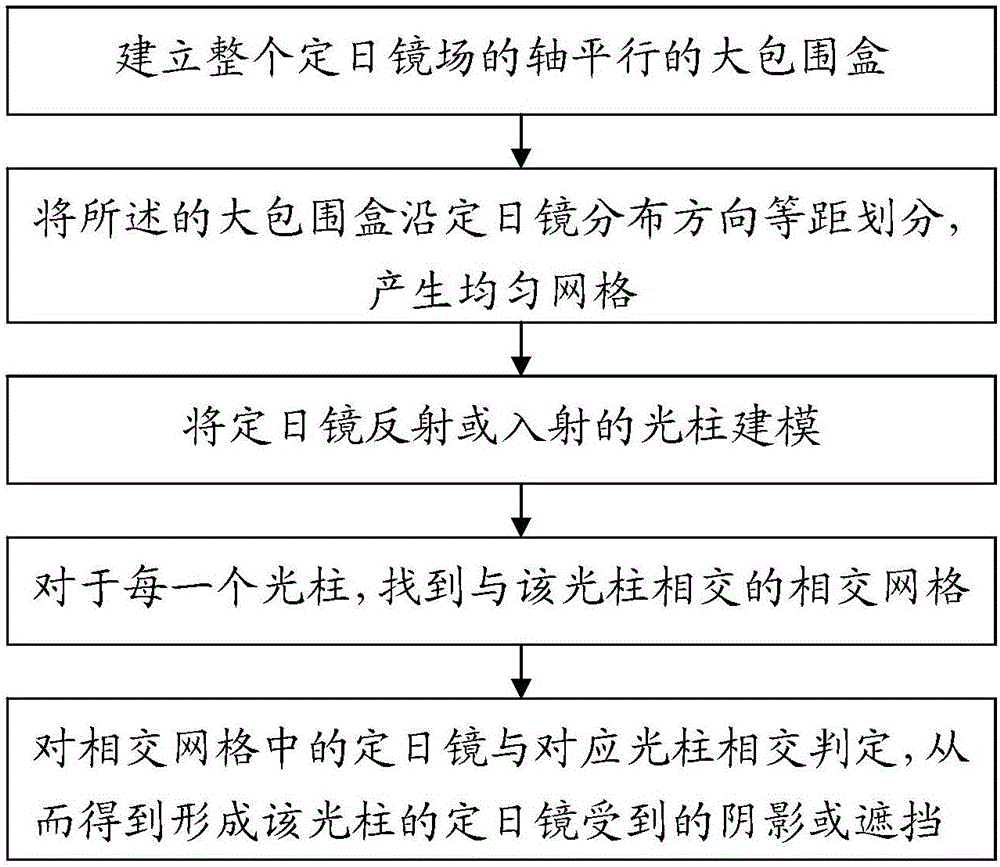

Method for rapidly judging shade and shielding in solar tower thermal power generating system

ActiveCN105956331AEfficient organizationImprove accuracyData processing applicationsDesign optimisation/simulationGraphicsRegular distribution

The invention discloses a method for rapidly judging shade and shielding in a solar tower thermal power generating system. The method comprises the following steps of: (1) establishing a big bounding box with parallel axes of the whole heliostat field; (2) equidistantly dividing the big bounding box along the distribution direction of heliostats to generate uniform grids; (3) modeling light pillars reflected by or entering the heliostats; (4) finding out an intersection grid which intersects with each light pillar; (5) judging intersection of the heliostats in the intersection grids and the corresponding light pillars so as to obtain the shade or shielding of the heliostats which form the light pillars. According to the judging method disclosed by the invention, a classic uniform grid data structure in graphics is introduced, the characteristics of regular distribution of the heliostats on the heliostat field are reasonably utilized, the data information in a simulation environment is efficiently organized and the calculation accuracy and the calculation efficiency are effectively improved.

Owner:ZHEJIANG UNIV

Solid particle block tower-type solar fluidization driven heat-exchange and heat-transmission system

InactiveCN105318577AEnables heat harvestingAchieve deliverySolar heating energySolar heat devicesSolar lightHeat transmission

Owner:CHENGDU AONENGPU TECH

Correction Method of Heliostat Reflection Facula Deviation

InactiveCN103345261BStrong ability to resist environmental interferenceInterference resistantPosition/direction controlClassical mechanicsFlare

The invention discloses a heliostat reflecting facula offset correction method and belongs to the technical field of solar tower type thermal generating. According to the heliostat reflecting facula offset correction method, a heliostat reflecting facula offset correction device and a heliostat tracking offset database of the heliostat reflecting facula offset correction device are used for carrying out heliostat reflecting facula offset correction. The azimuth angle and the angle of pitch of a heliostat are adjusted and corrected by means of data on the ideal azimuth angle, the ideal angle of pitch, azimuth angle correction and angle of pitch correction of the heliostat in a heliostat tracking offset database based on relevant characteristics of tracking offset of the heliostat and the angle of pitch and the azimuth angle of the heliostat so as to achieve heliostat reflecting facula offset correction. The correction device and the heliostat tracking offset database of the correction device are low in cost and capable of resisting interference by ambient light and procedures of correcting heliostat reflecting facula offset are simple. The requirement for industrial on-spot application can be met. The heliostat reflecting facula offset correction method is suitable for heliostat reflecting facula offset correction of a heliostat tracking system of a tower type solar thermal generating station.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

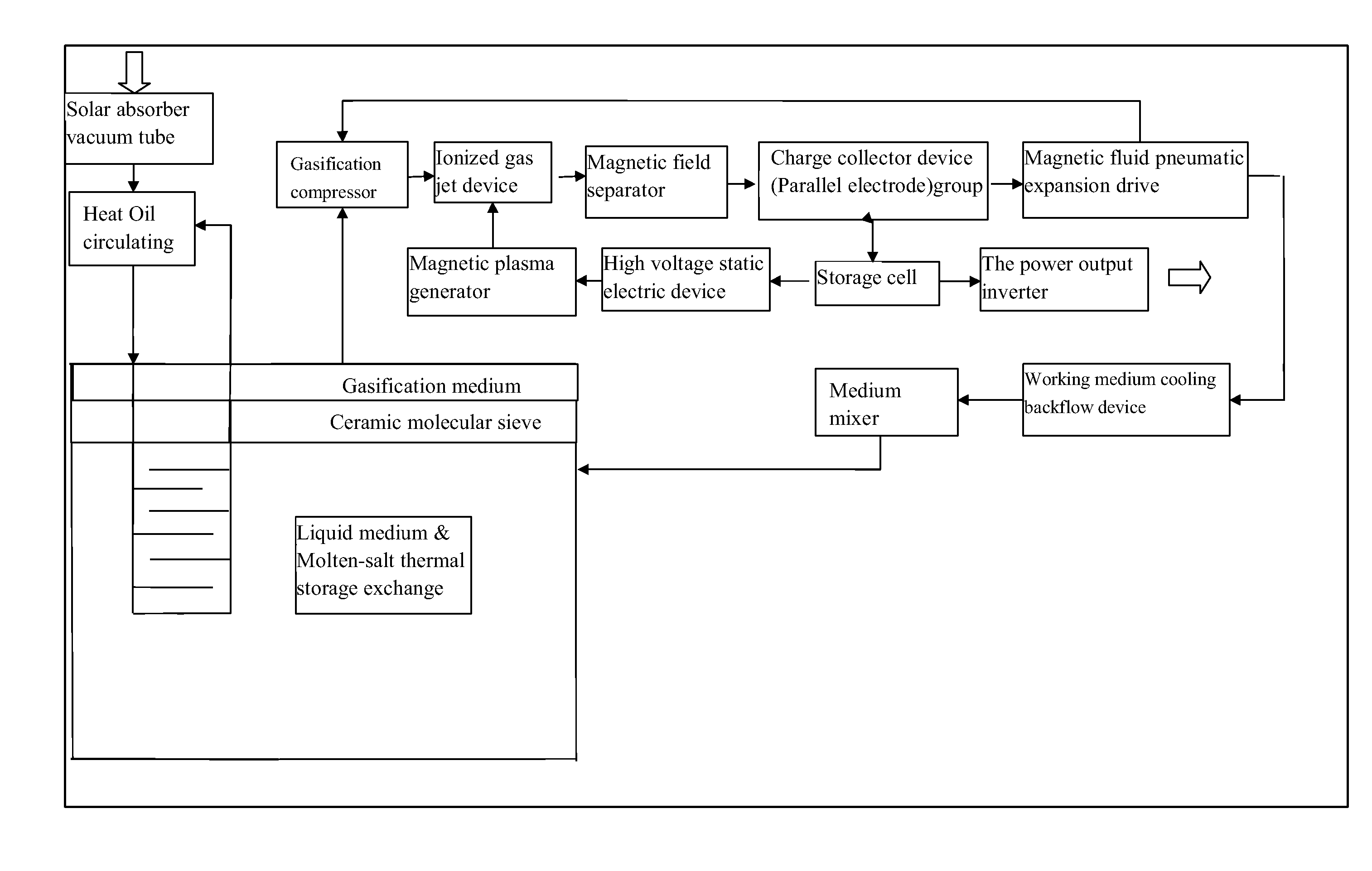

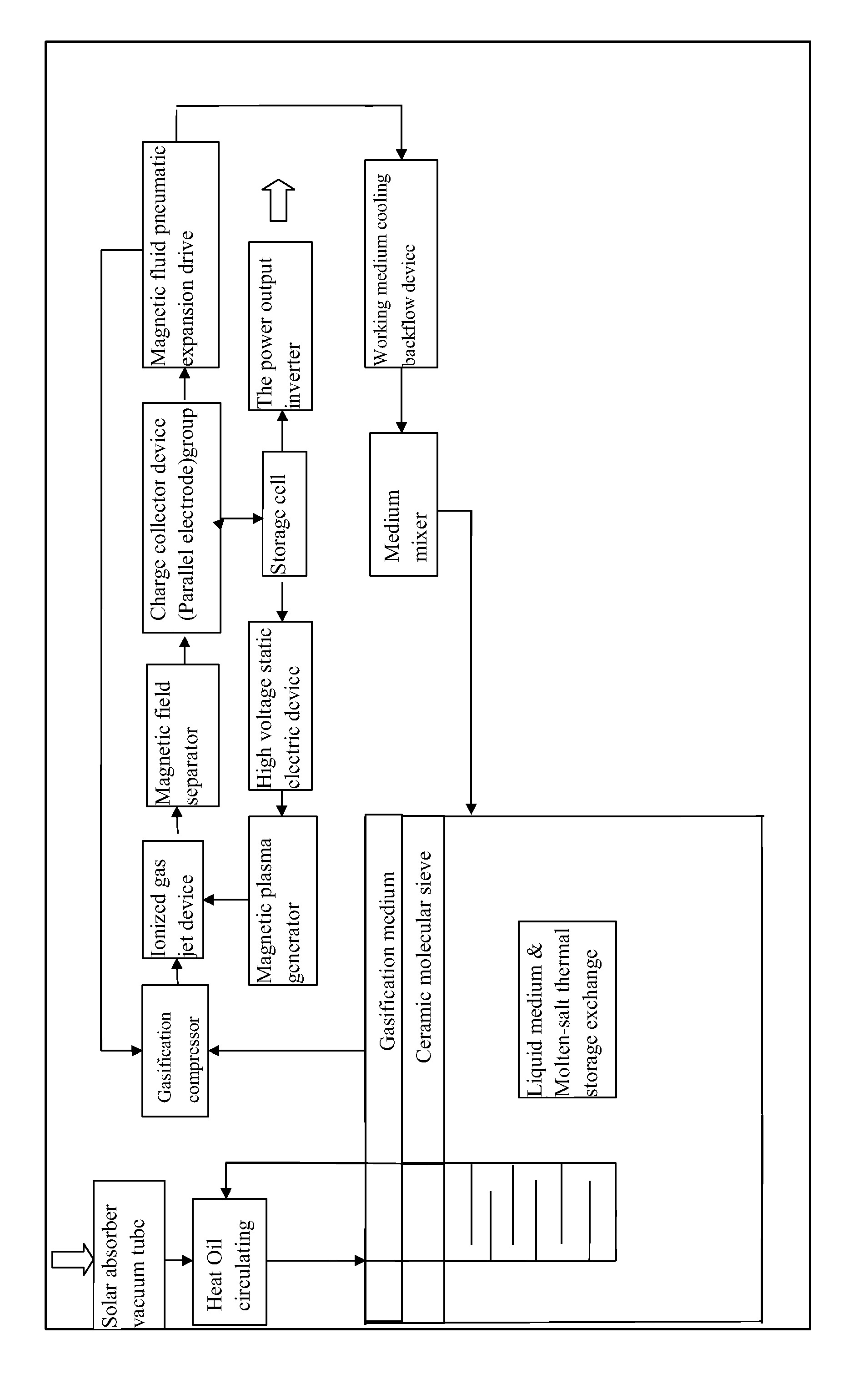

Solar thermodynamic machine power generation technology

InactiveUS20140026570A1Improve thermal efficiencyIncrease pressureAuxillary drivesFrom solar energyEnvironmental resistanceEngineering

A solar thermodynamic machine power generation method can use the radiant energy of the solar concentrator, and directly convert the internal energy of the working medium molecule with cyclic phase transformation at low boiling point into electric energy for achieving the fuel-free large-scale electric power production. It has the characteristics of long-term continuous operation, green environmental protection, safety and reliability and low cost, and has a great application and social economic value. It makes use of the internal energy exchanging of the working medium molecule. It working process is thermal cycling balance. The present invention can be long-term continuously operated without the external power and does not consume any fuel and water. It is especially suitably applied to the solar tower-type and other light-gathering and thermal storage power generation systems.

Owner:WANG HAIBIAO +3

Photovoltaic-thermal integrated solar tower

ActiveCN106452292AEnsure power generation efficiencyEfficiency impactPV power plantsPhotovoltaic energy generationEngineeringTower

The invention discloses a photovoltaic-thermal integrated solar tower. The photovoltaic-thermal integrated solar tower comprises a heat-collecting shed, a tower drum, a power generator and a turbo machine, wherein the tower drum is arranged at the center of the heat-collecting shed and upwards extends; the power generator and the turbo machine are arranged in a lower area in the tower drum; the turbo machine is arranged below the power generator; the heat-collecting shed is of a flat top conical structure and is formed by mutually splicing transparent photovoltaic modules; the lower part of the heat-collecting shed is supported by support pillars, so that the heat-collecting shed is away from the ground by a certain height so as to form a heat collecting area; a cold water pool and a hot water pool are arranged in the heat collecting area below the heat-collecting shed. According to the photovoltaic-thermal integrated solar tower provided by the invention, photovoltaic power generation and solar thermal electric power generation can be utilized, and the utilization rate of solar energy is improved on the basis of not increasing the occupied area.

Owner:ZHONGTIAN PHOTOVOLTAIC MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com