Solid particle block tower-type solar fluidization driven heat-exchange and heat-transmission system

A tower-type solar energy and solid block technology, which is applied in the field of solar thermal energy utilization, can solve the problems of inability to realize thermal energy storage, use limitation of molten salt thermal storage, and small air heat capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

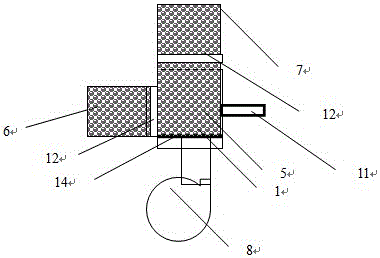

[0045] Embodiment 1. Fluidization-driven pump of solid particles for high-temperature heat transfer

[0046] figure 1 Shown is composed of a power unit 13, a fluidization chamber 5, a fluid inlet 11, a solid particle inlet 6, a solid particle outlet 7, an electronic control device, a fluidized bed, and a housing. In order to make the solid particles reach a fluid state Add a fluid 11 from the outside, the fluid enters the fluidization chamber from the fluid inlet, and the solid particles and fluid entering the fluidization chamber are mixed to achieve a fluidization state. If the fluid is air, high-pressure air enters the After the fluidization chamber, the solid particles are mixed to achieve fluidization, so as to realize the fluidized transmission of solid particles and air; or the mixing of solid particles and fluid (such as inert gas can be used) is provided by the high-pressure turbo fan of the power unit Driven by power to make it reach a fluidized state, solid particl...

Embodiment 2

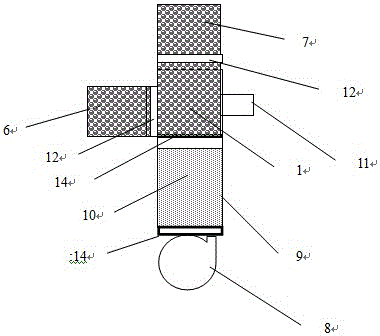

[0048] Embodiment 2: A Solid Particle Fluidization-Driven Pump Equipped with an Insulation Chamber

[0049] figure 2 As shown, it consists of a power unit 13, a fluidization chamber 5, a fluid inlet 11, a solid particle inlet 6, a solid particle outlet 7, an electronic control device, and a housing. In order to make the solid particles fluidize, add A fluid 11, the fluid enters the fluidization chamber from the fluid inlet, and the solid particles and fluid entering the fluidization chamber are mixed to achieve a fluidization state. If the fluid is air, high-pressure air enters the fluidization chamber Finally, the solid particles are mixed to achieve fluidization, so as to realize the transmission of solid particles and air fluidization; or the solid particles and fluid (such as inert gas can be used) are mixed and driven by the high-pressure turbine fan of the power device to achieve In the fluidized state, solid particles and fluid flow out from the outlet of the solid pa...

Embodiment 3

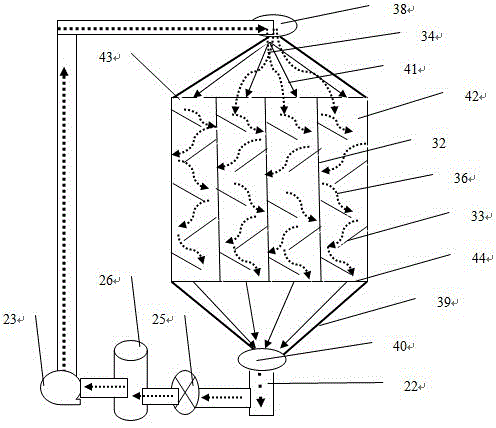

[0051] Embodiment 3. Solid block tower type solar heating transmission system

[0052] image 3 The solid block tower type solar heating heat transfer system shown is composed of a tower type solid block light-to-heat converter 22, a loading box 26, a fluidized driving pump 23, a solid block 1, a heat storage heat exchanger 5, and a valve Or switch 17, ascending pipe 19, descending pipe 20, heat storage heat exchanger 25, loading box 26, connecting pipe 27 and other components. The light-to-heat converter 22 is at the focal point of the solar energy irradiation of the tower solar mirror, the upstream pipe 19 is connected to the inlet of the light-to-heat converter 22, and the down-going pipe 20 is connected to the outlet of the light-to-heat converter 22, and is arranged on the outside of the pipe. There is an insulating pipe 24, and the fluidized driving pump is connected to the loading box 26 arranged on the ground after being connected with the uplink pipeline 19, the soli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com