Patents

Literature

301results about How to "Reduce convection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

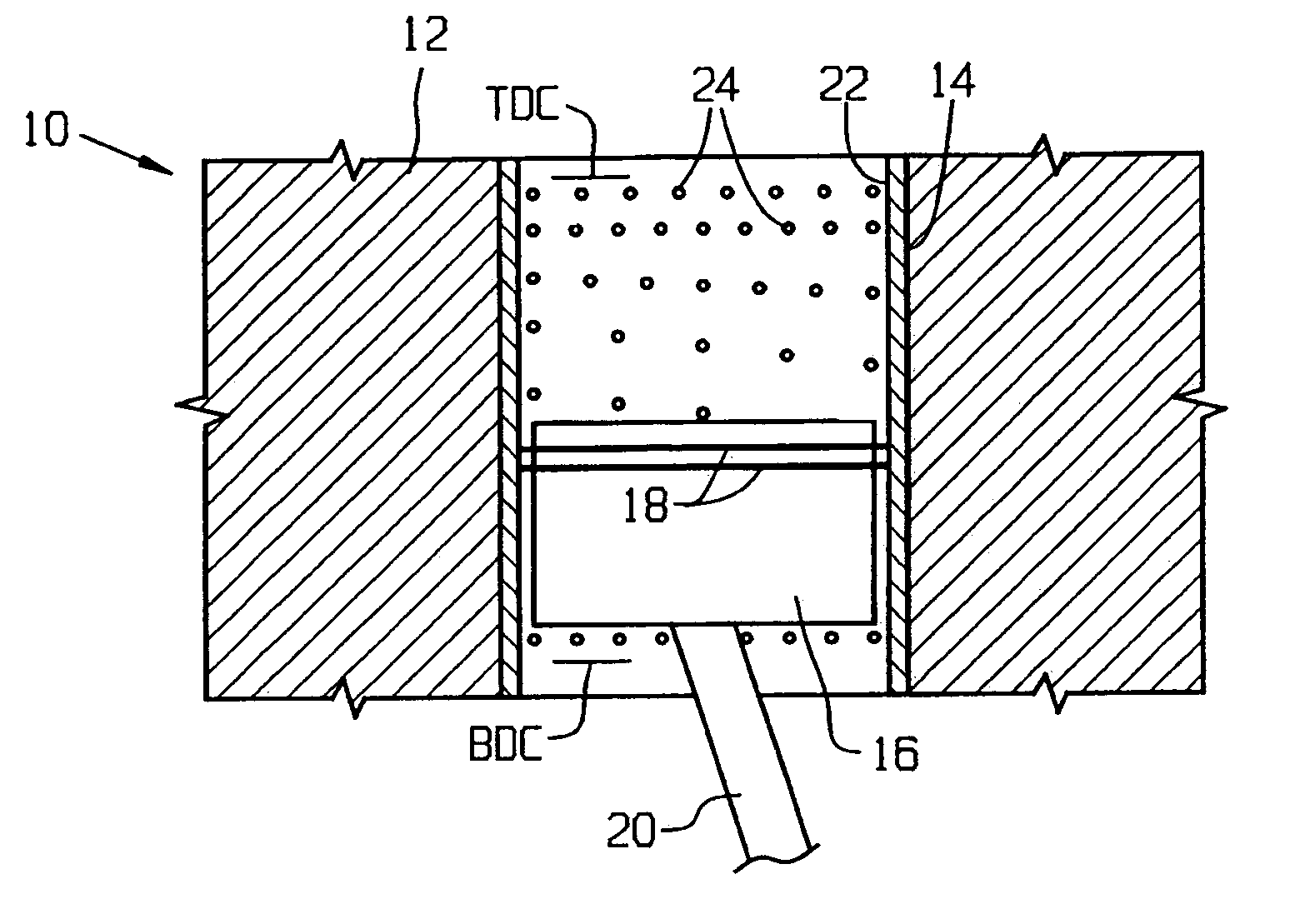

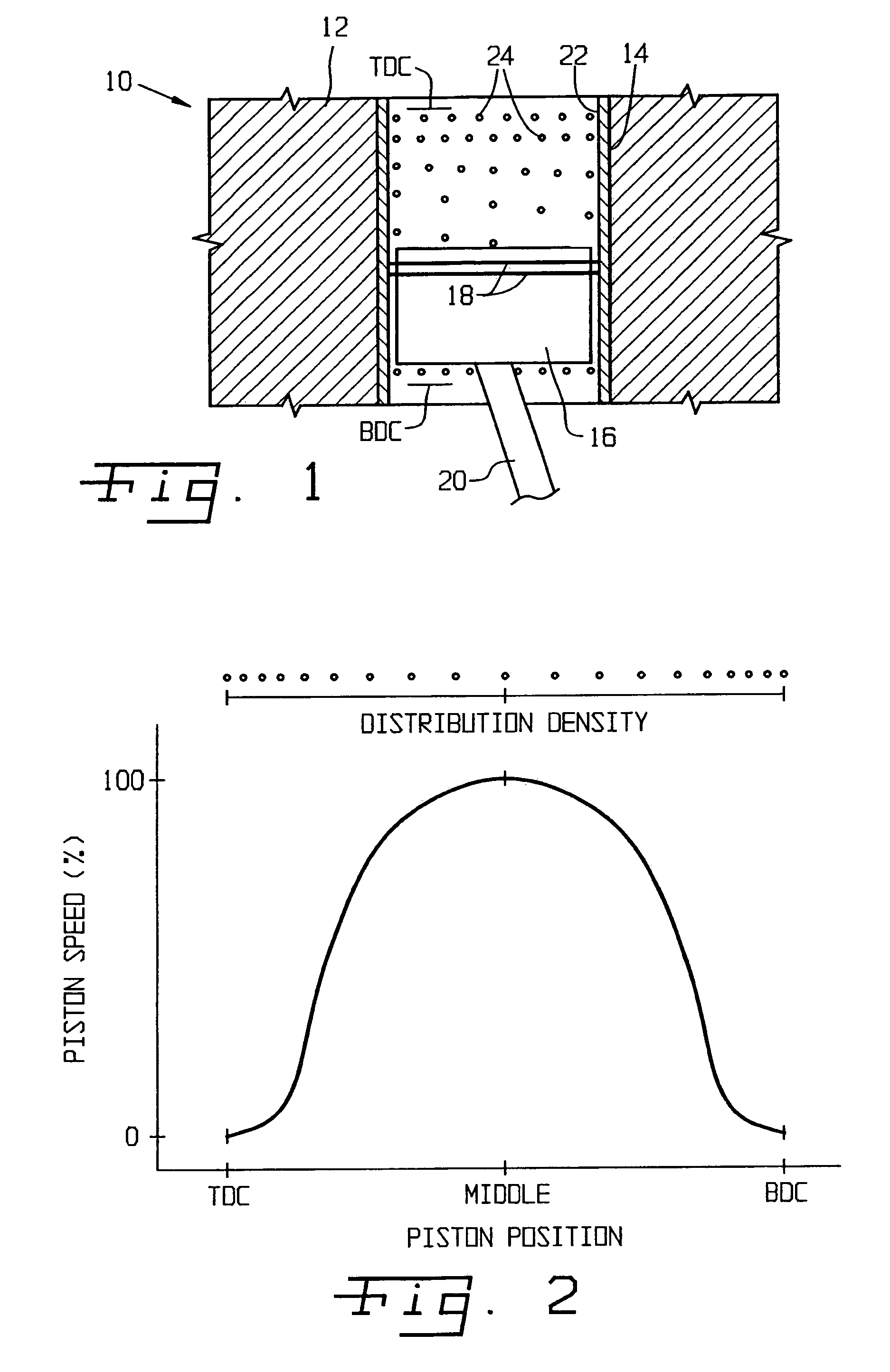

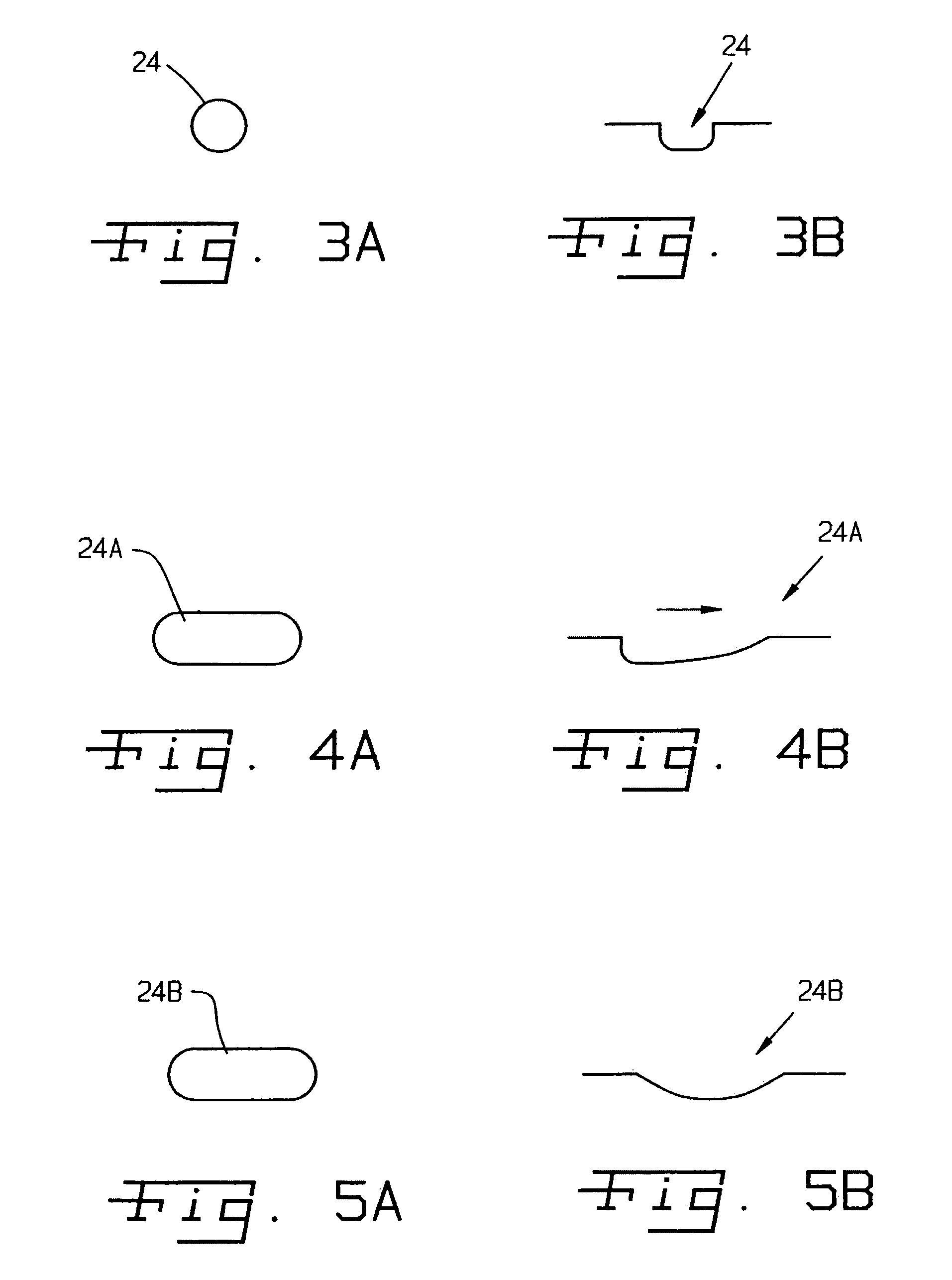

Internal combustion engine with localized lubrication control of combustion cylinders

ActiveUS7104240B1Decrease radiation and convection heat transferReduce volotization and pyrolysisCylinder headsCylindersLubricationEngineering

An internal combustion engine includes at least one cylinder block having at least one combustion cylinder. A number of cylinder liners are respectively associated with each combustion cylinder. Each cylinder liner defines a corresponding cylinder inside surface. Each cylinder liner includes a plurality of discrete oil retaining indentations in a predefined pattern on the cylinder inside surface. The plurality of oil retaining indentations are bounded in both peripheral and longitudinal directions of the corresponding cylinder liner.

Owner:DEERE & CO

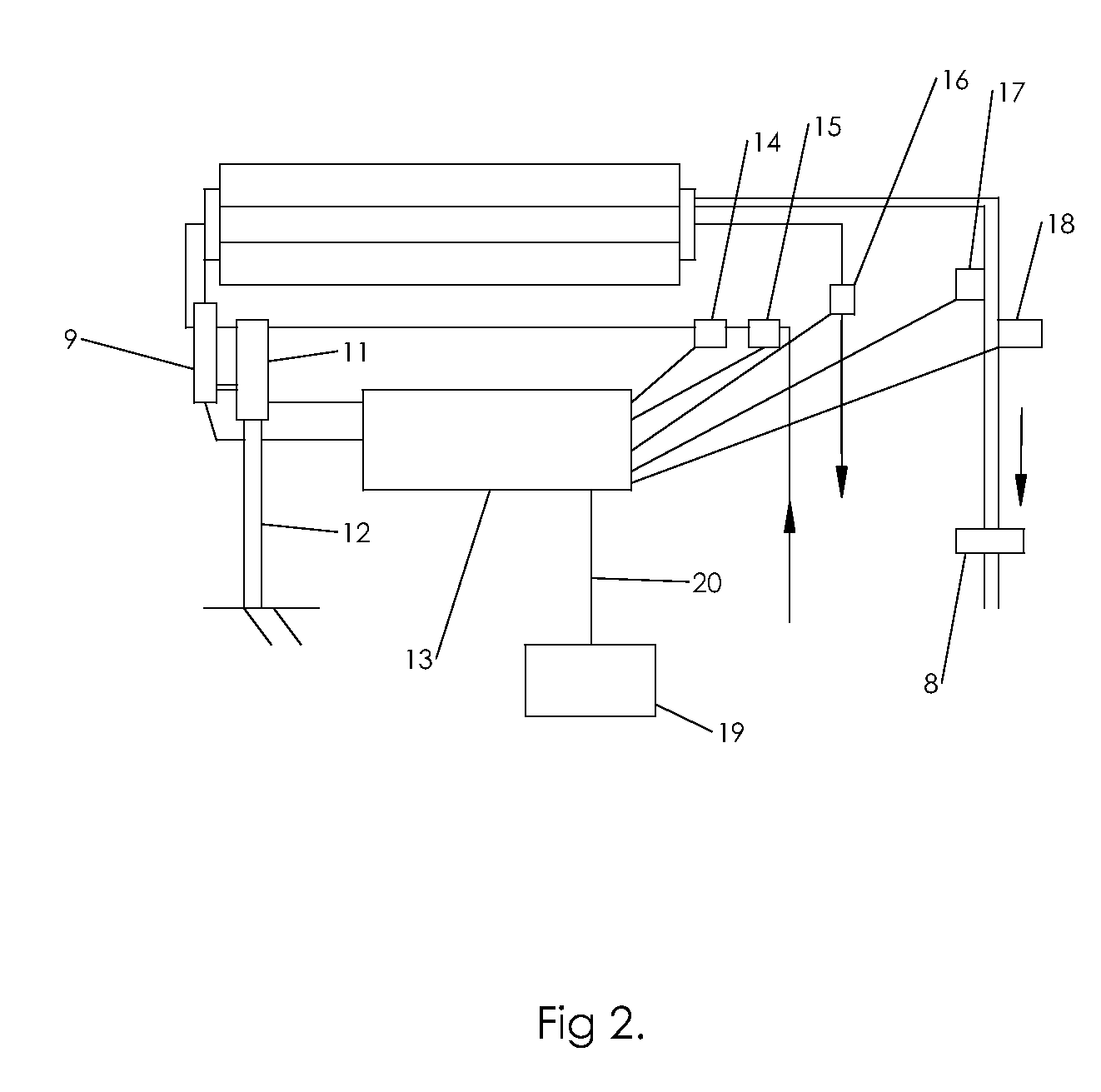

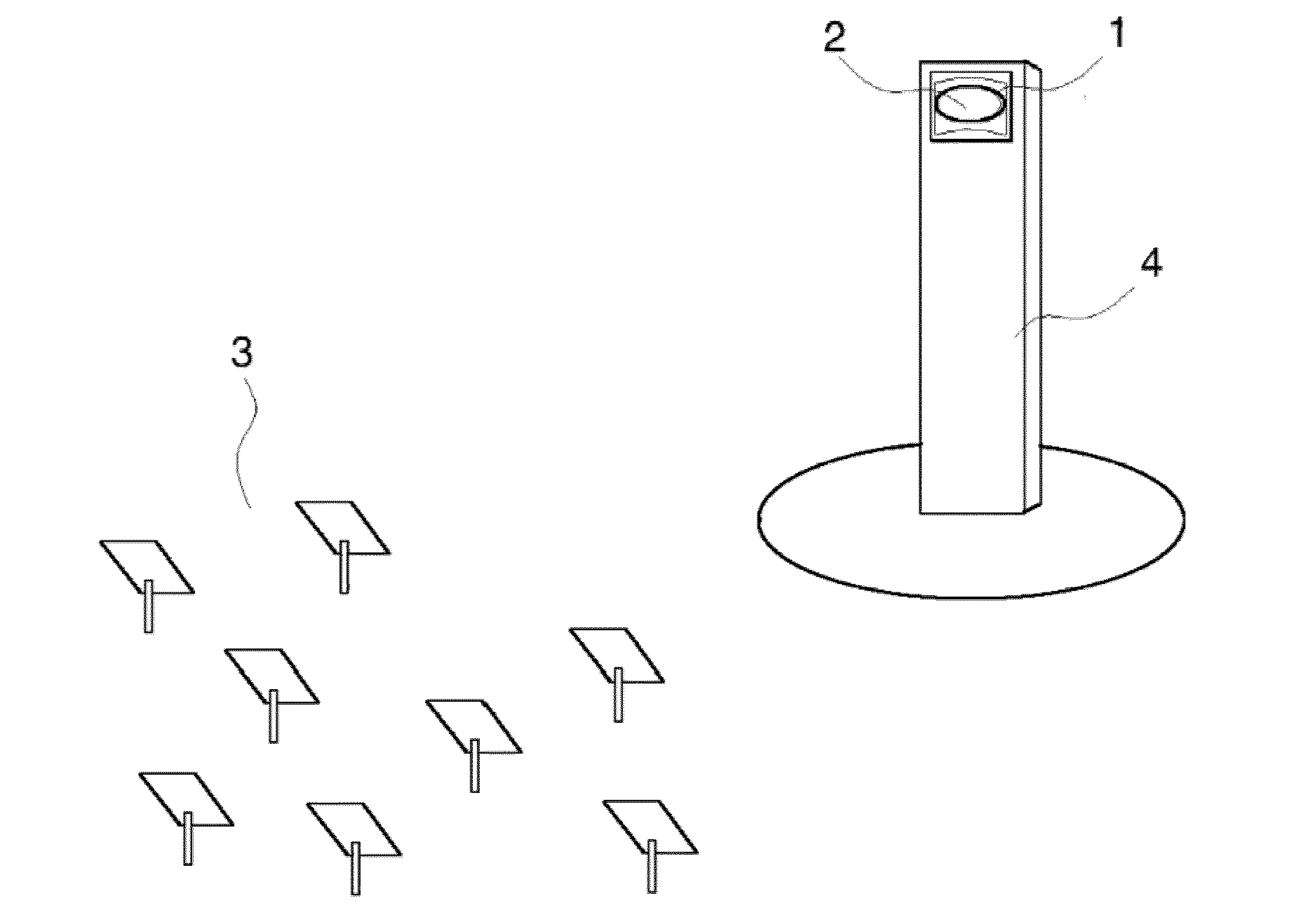

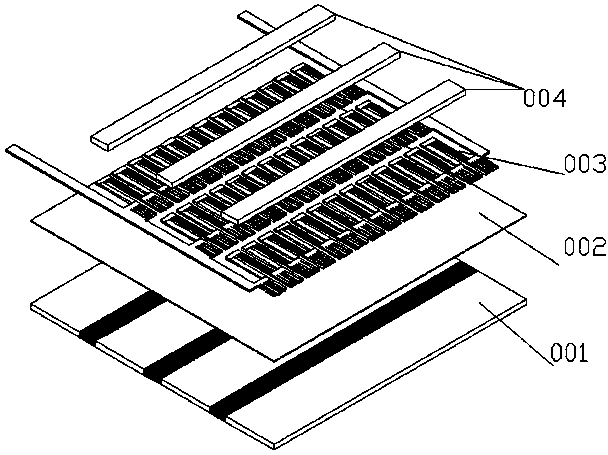

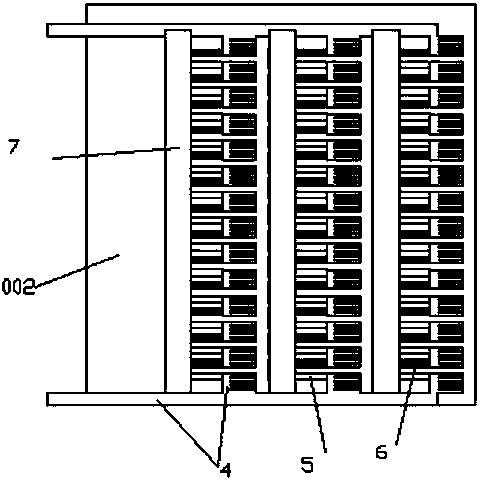

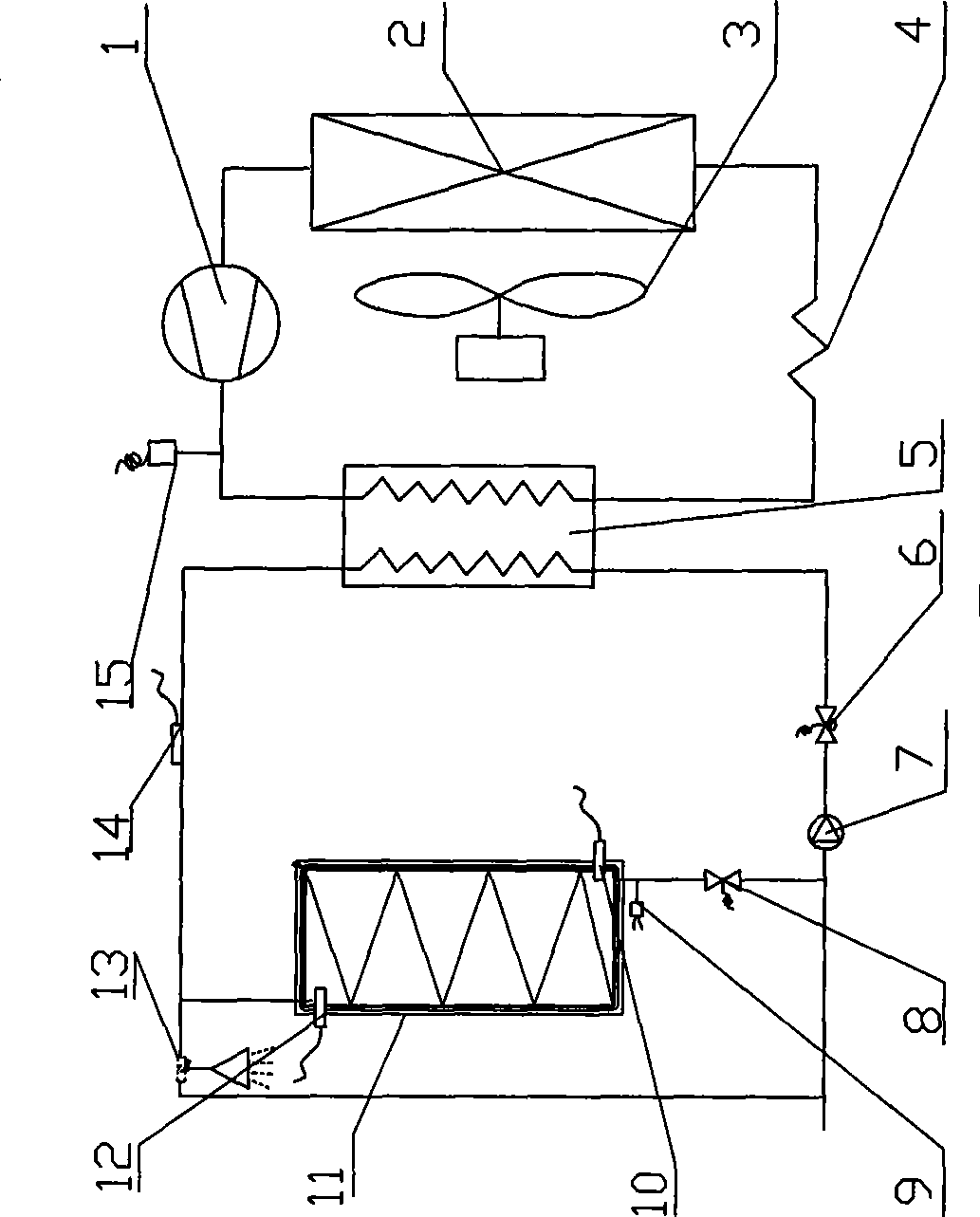

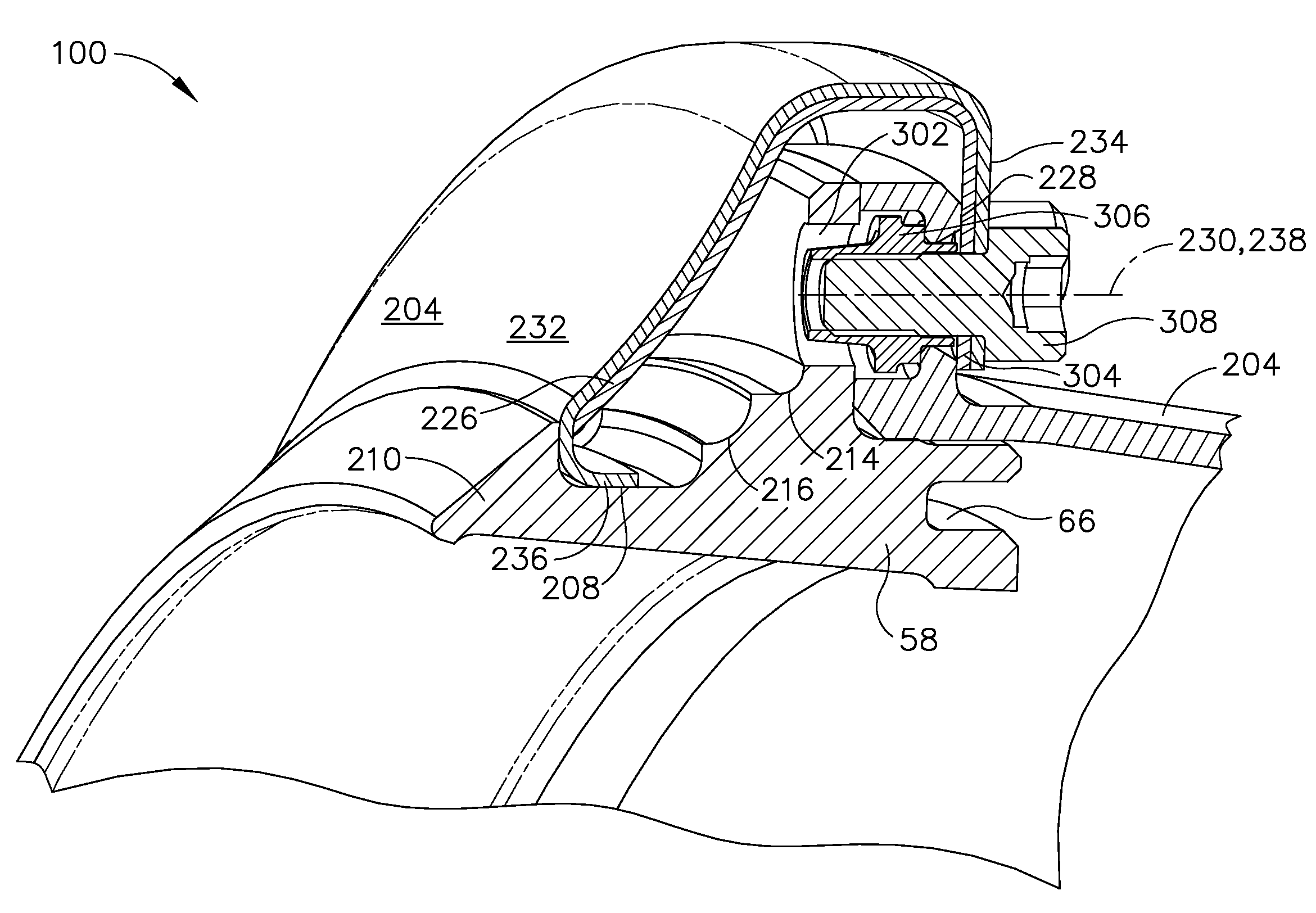

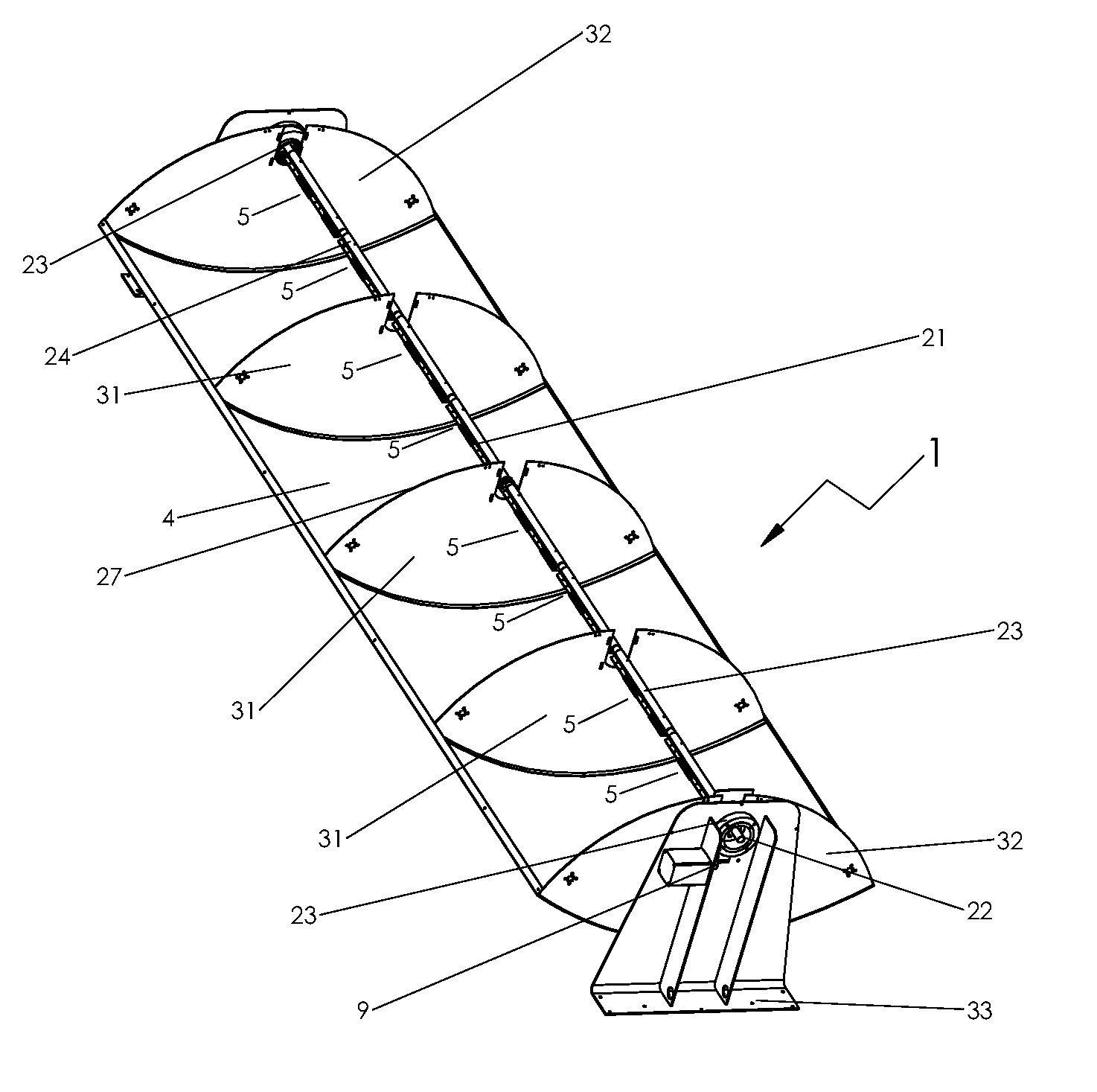

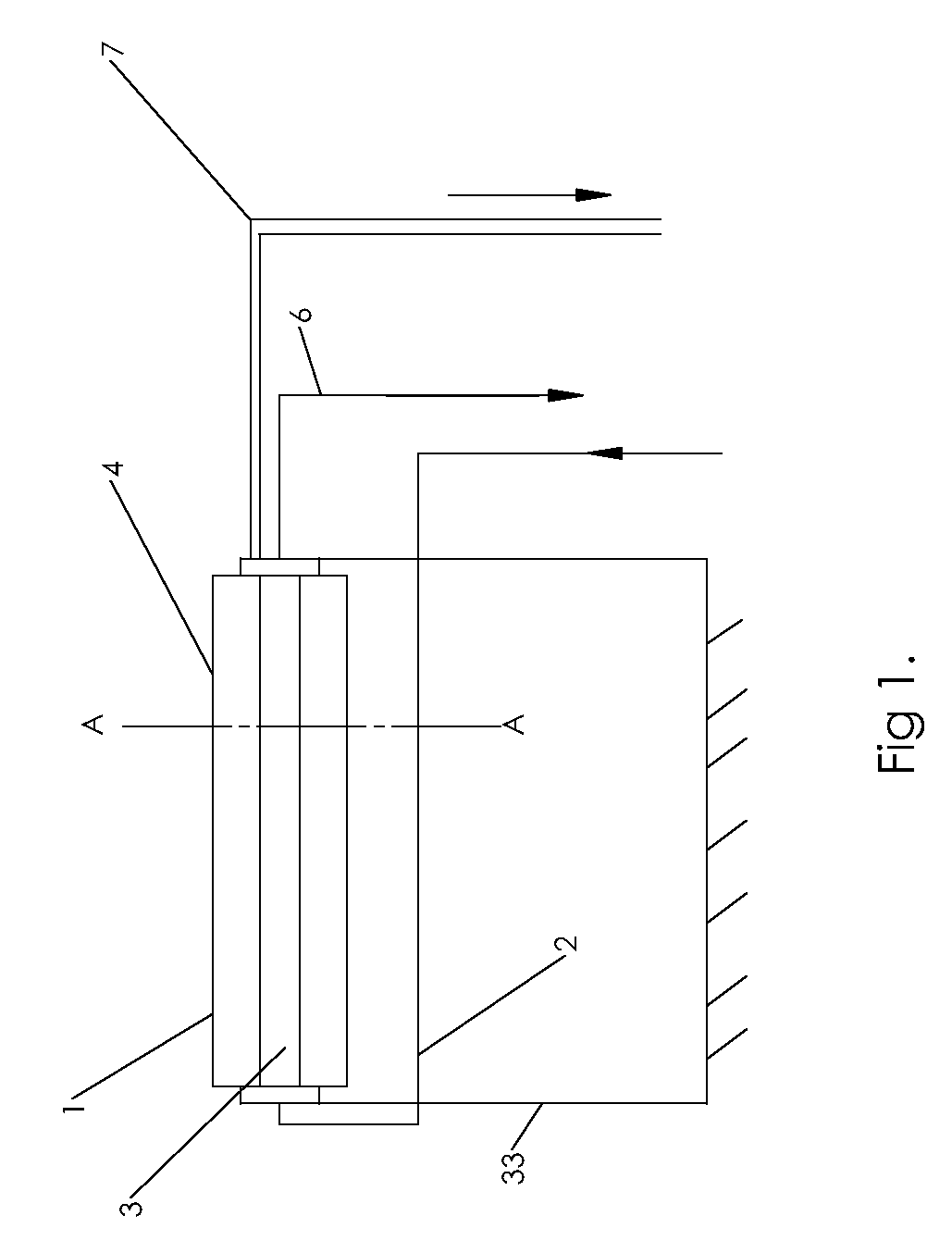

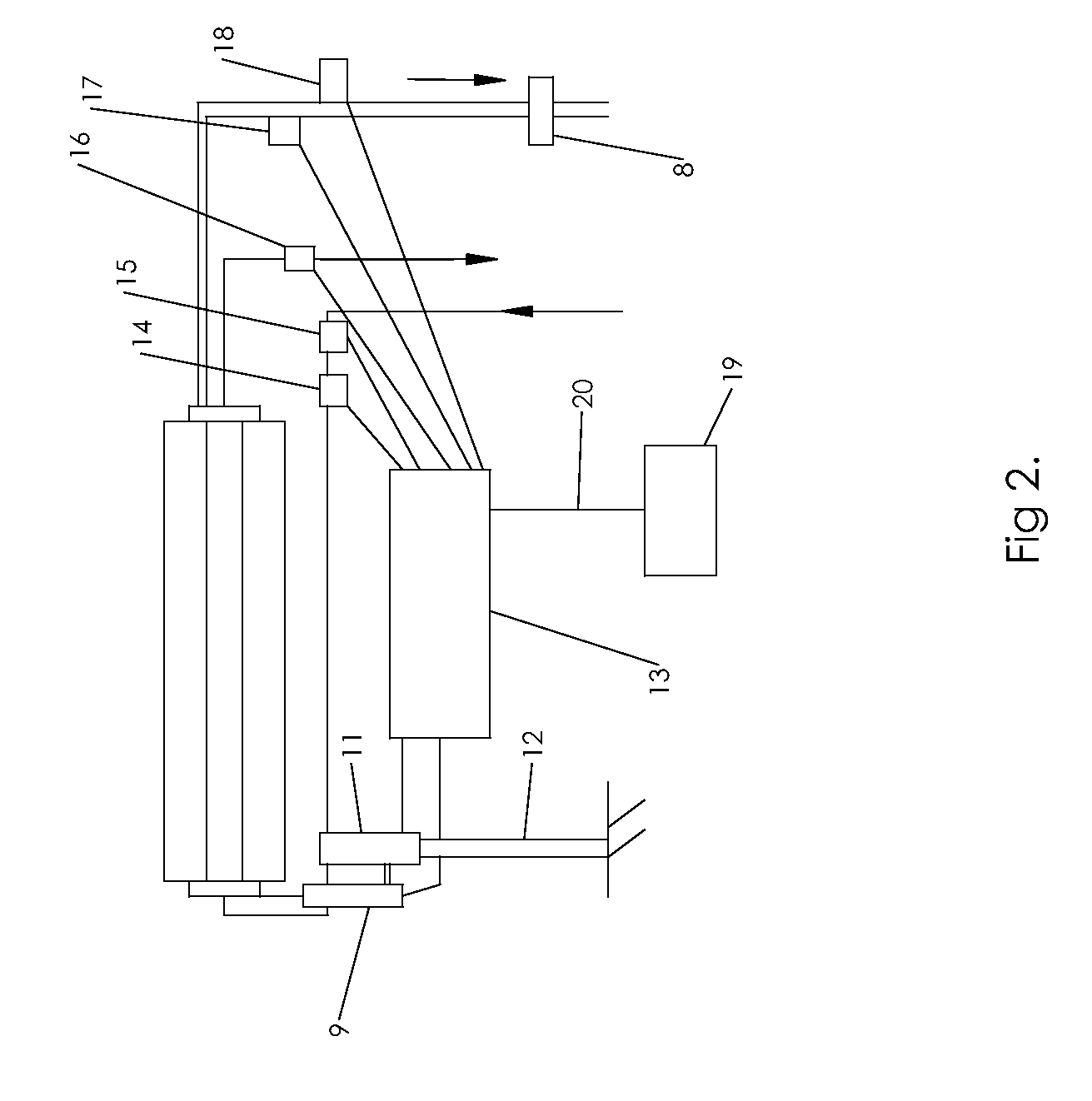

Concentrated Photovoltaic and Thermal Solar Energy Collector

ActiveUS20110132434A1Reduce material costsImprove positionSolar heating energyWave amplification devicesElectrical batteryElectric energy

This invention relates to a solar energy collector that converts solar radiation into both electrical and thermal energy. More specifically this invention relates to a concentrating solar energy collector with an integrated construction that minimizes cost, bulk, and weight, and maximizes overall efficiency. Typical non-concentrating solar collectors use photovoltaic cells over the entirety of their surface. These solar cells are the most expensive part of the collector. This invention discloses using a reflector to concentrate the incident radiation on photovoltaic cells with one-twentieth the area of the reflector, and transferring the co-generated thermal energy into a working fluid pumped through the cell support structure.

Owner:ELECTROTHERM SOLAR

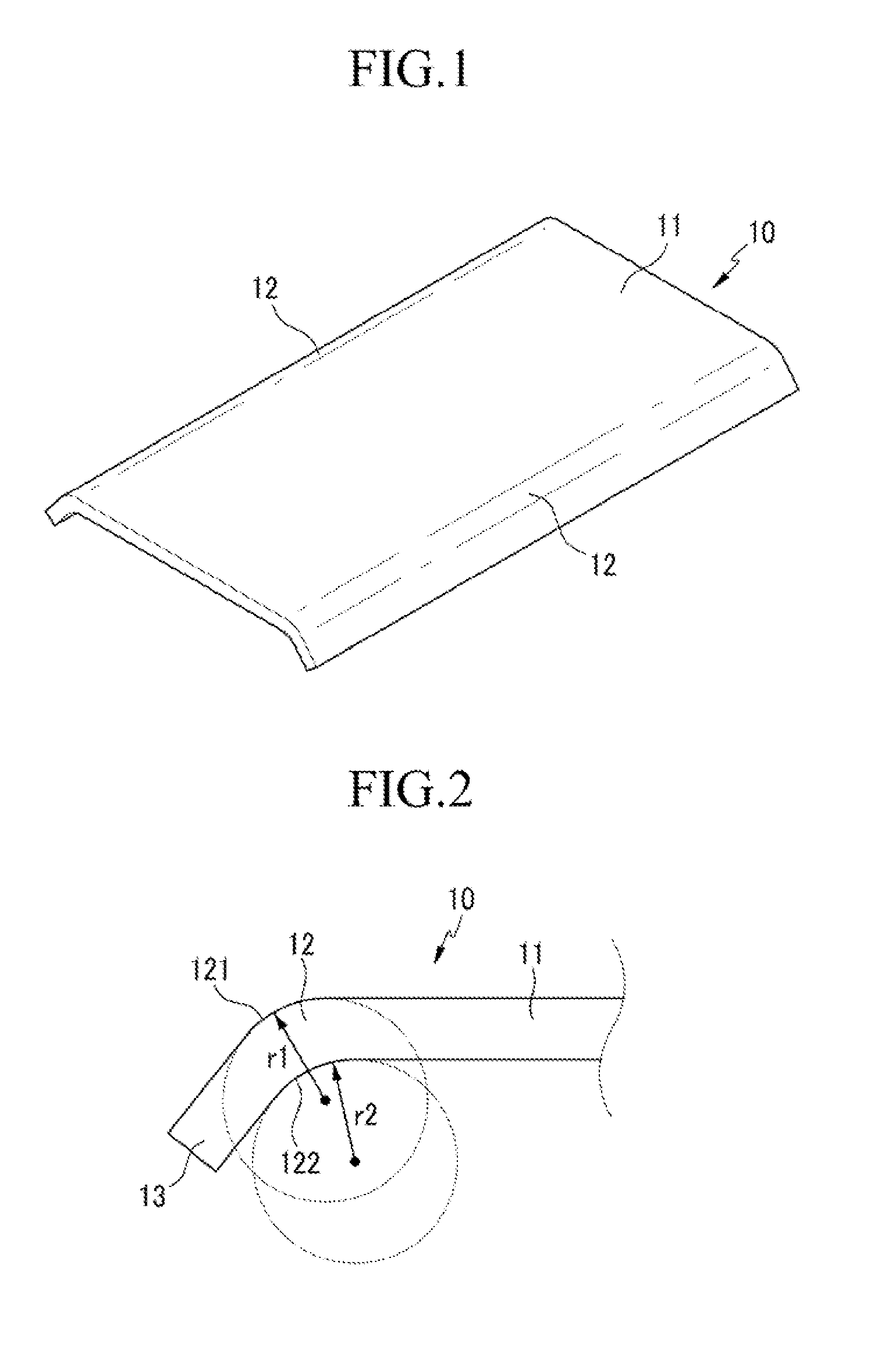

Cover window and display device with cover window

ActiveUS20140233194A1Improve liquidityImprove appearance qualityCircuit bendability/stretchabilityDigital data processing detailsVisibilityDisplay device

In a display device, a cover window is capable of increasing transparency of a curved part to improve visibility of a screen and appearance quality of a product. The cover window for the display device includes at least one curved part. In addition, the curved part includes an outer surface formed in an arc having a curvature radius of r1 and an inner surface formed in an arc having a curvature radius of r2, where r1≦r2≦2r1.

Owner:SAMSUNG DISPLAY CO LTD

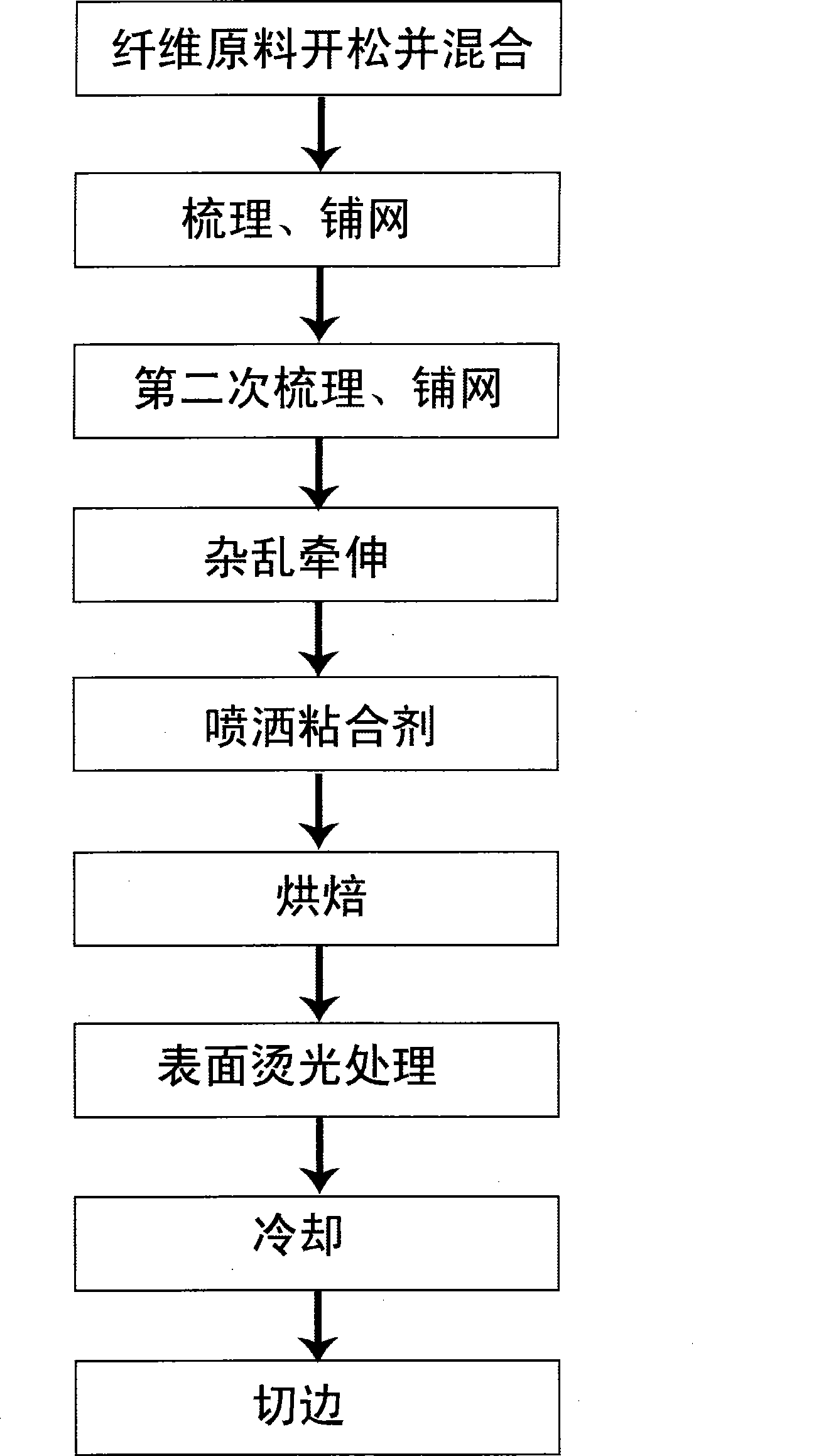

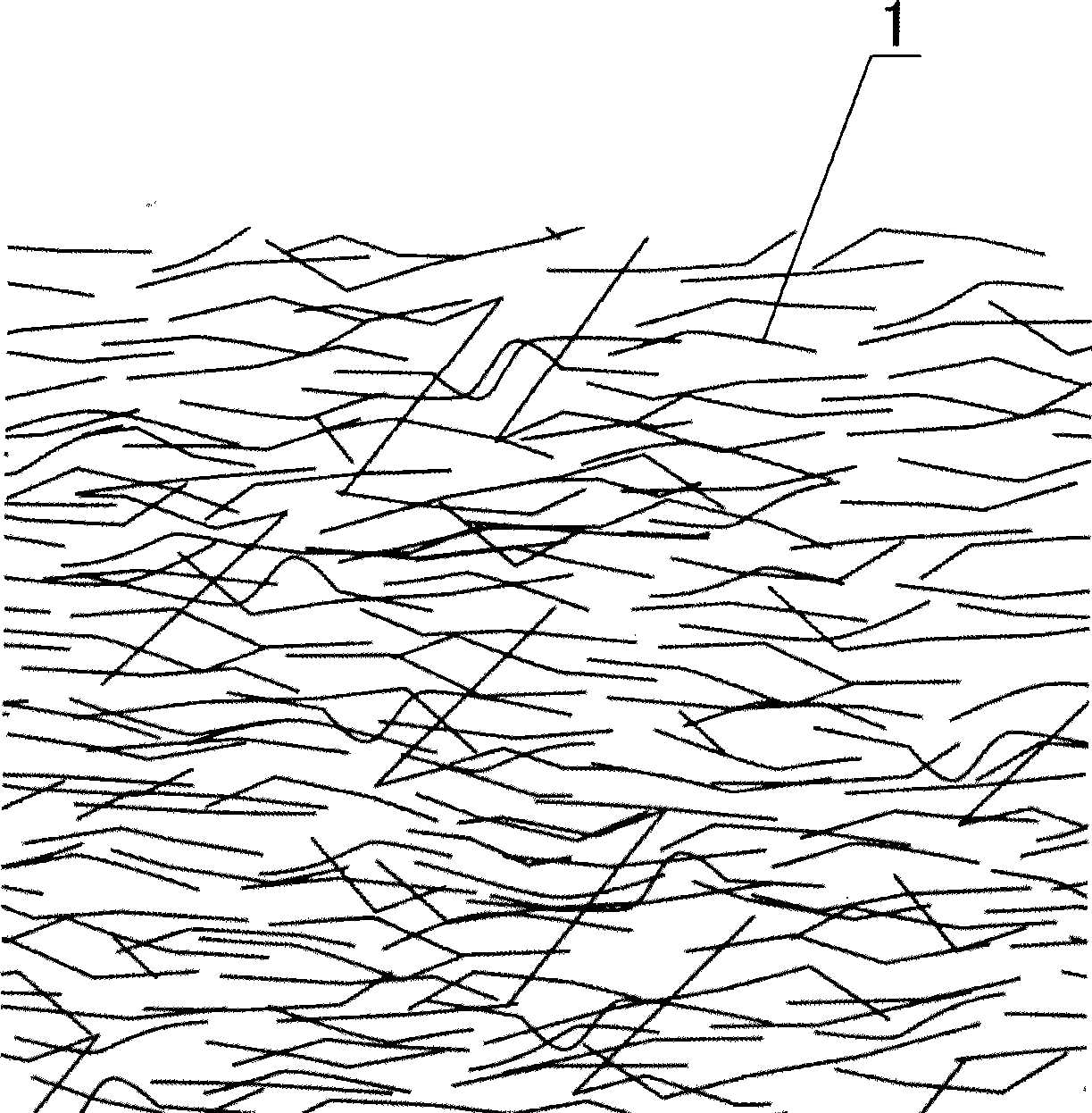

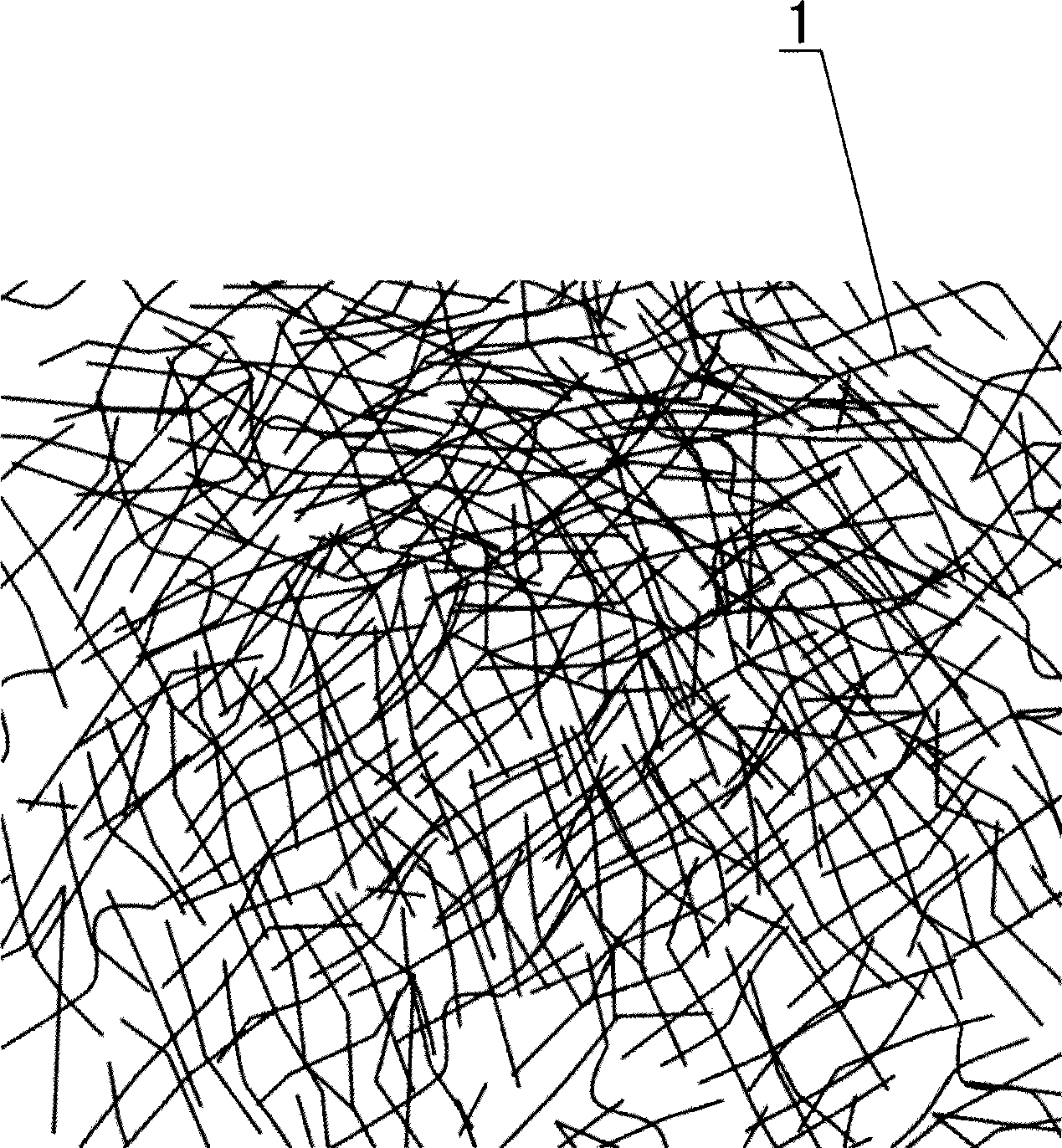

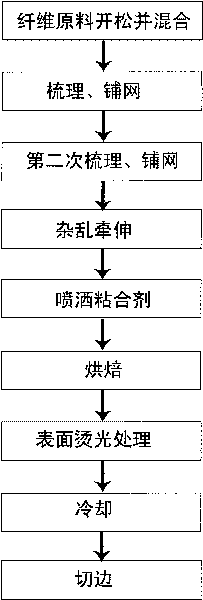

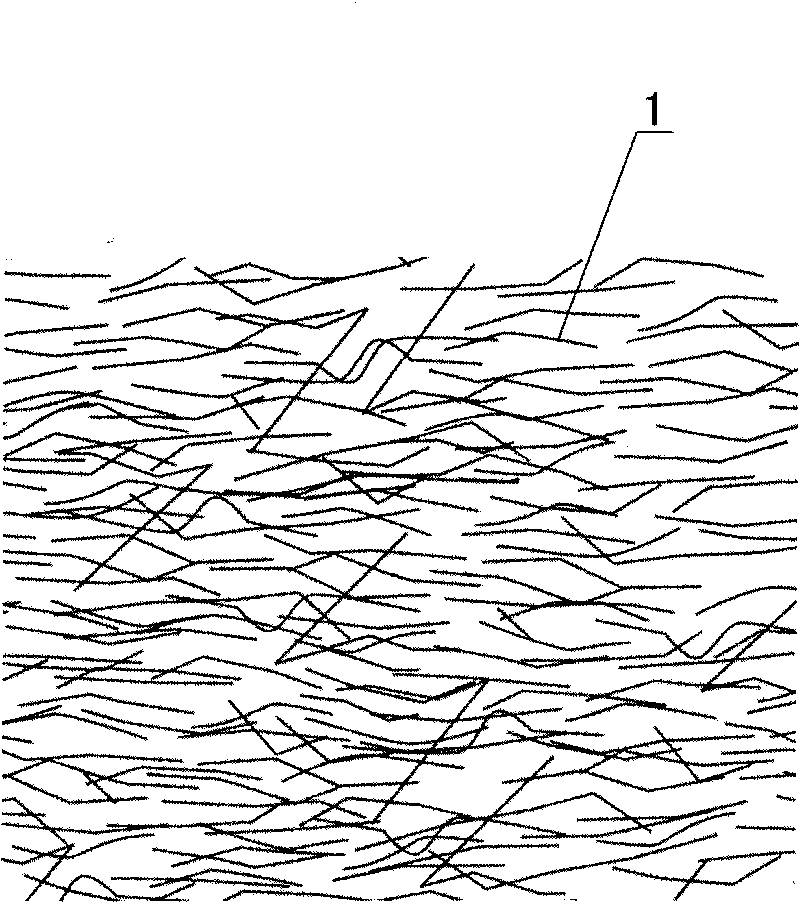

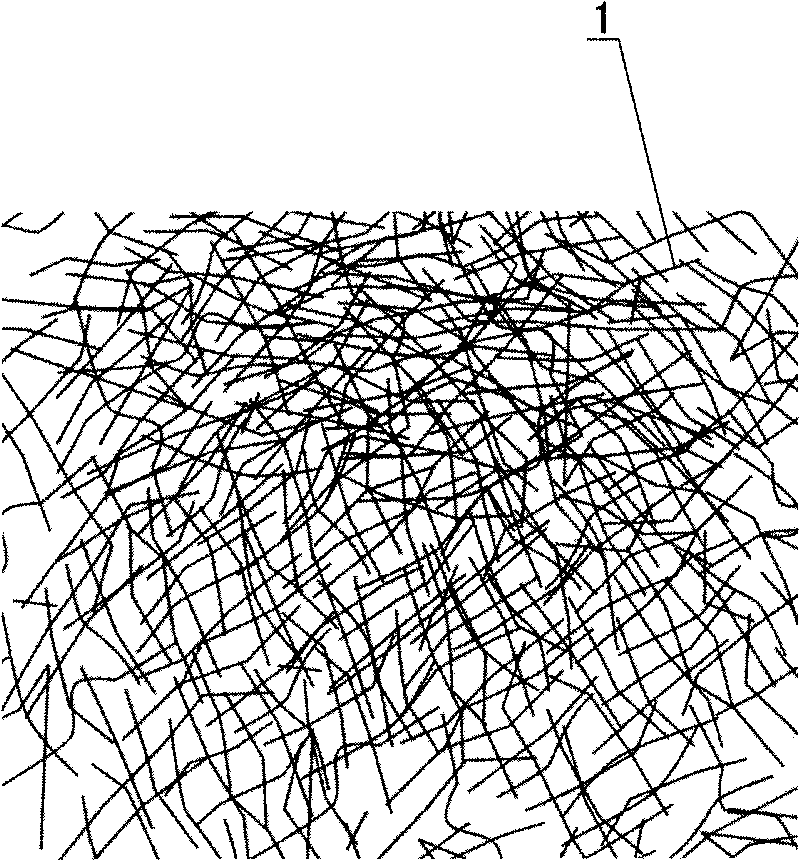

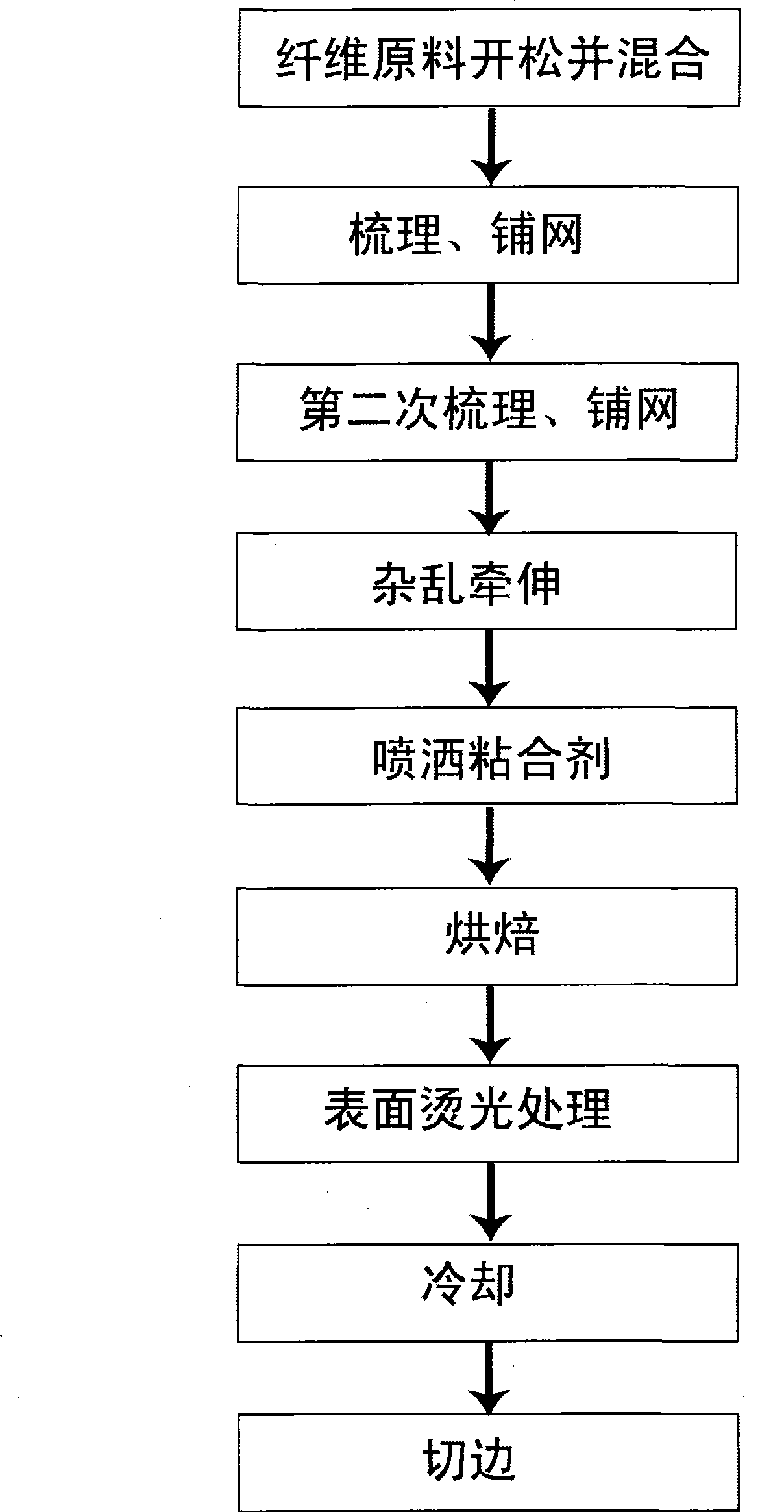

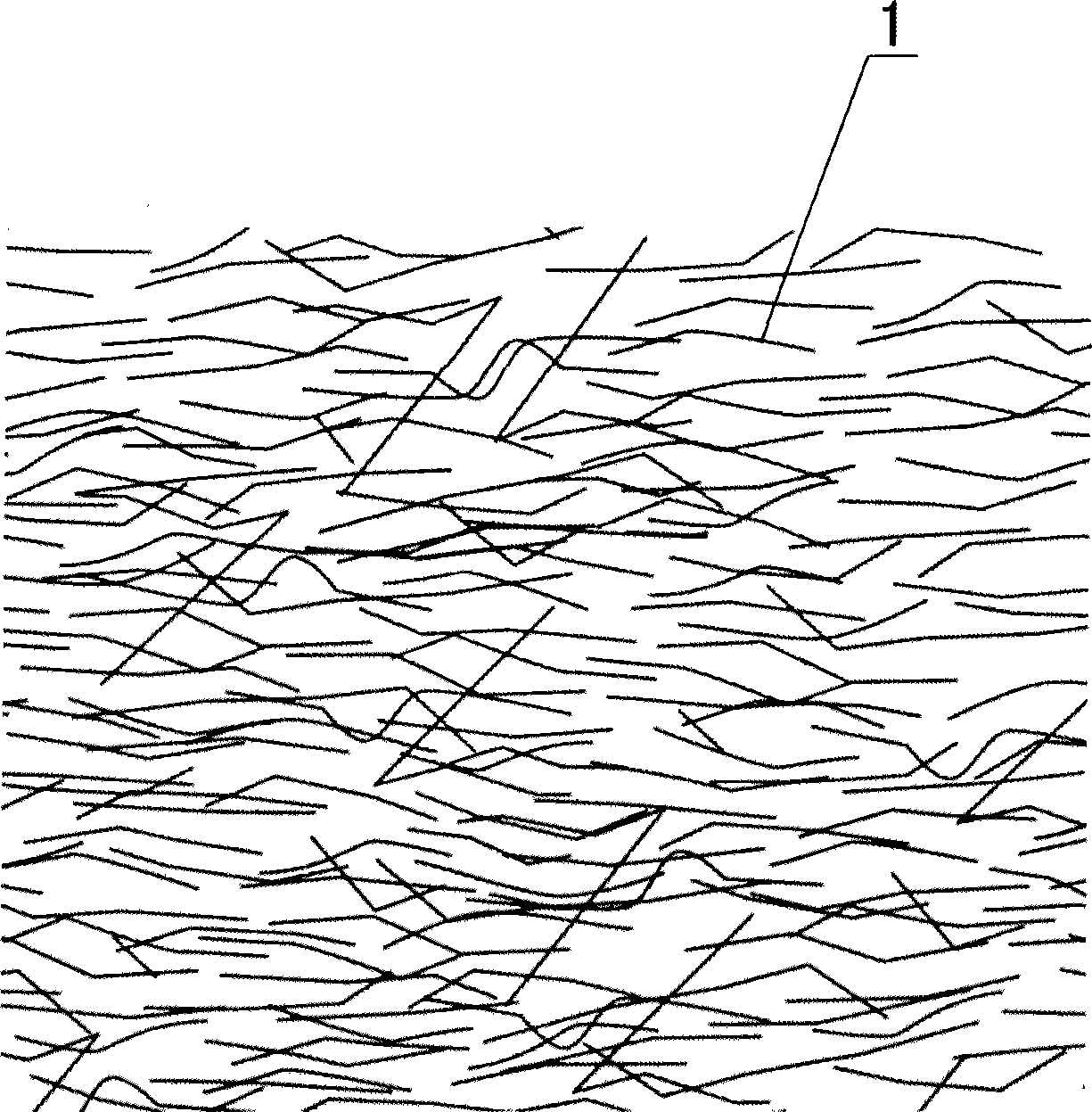

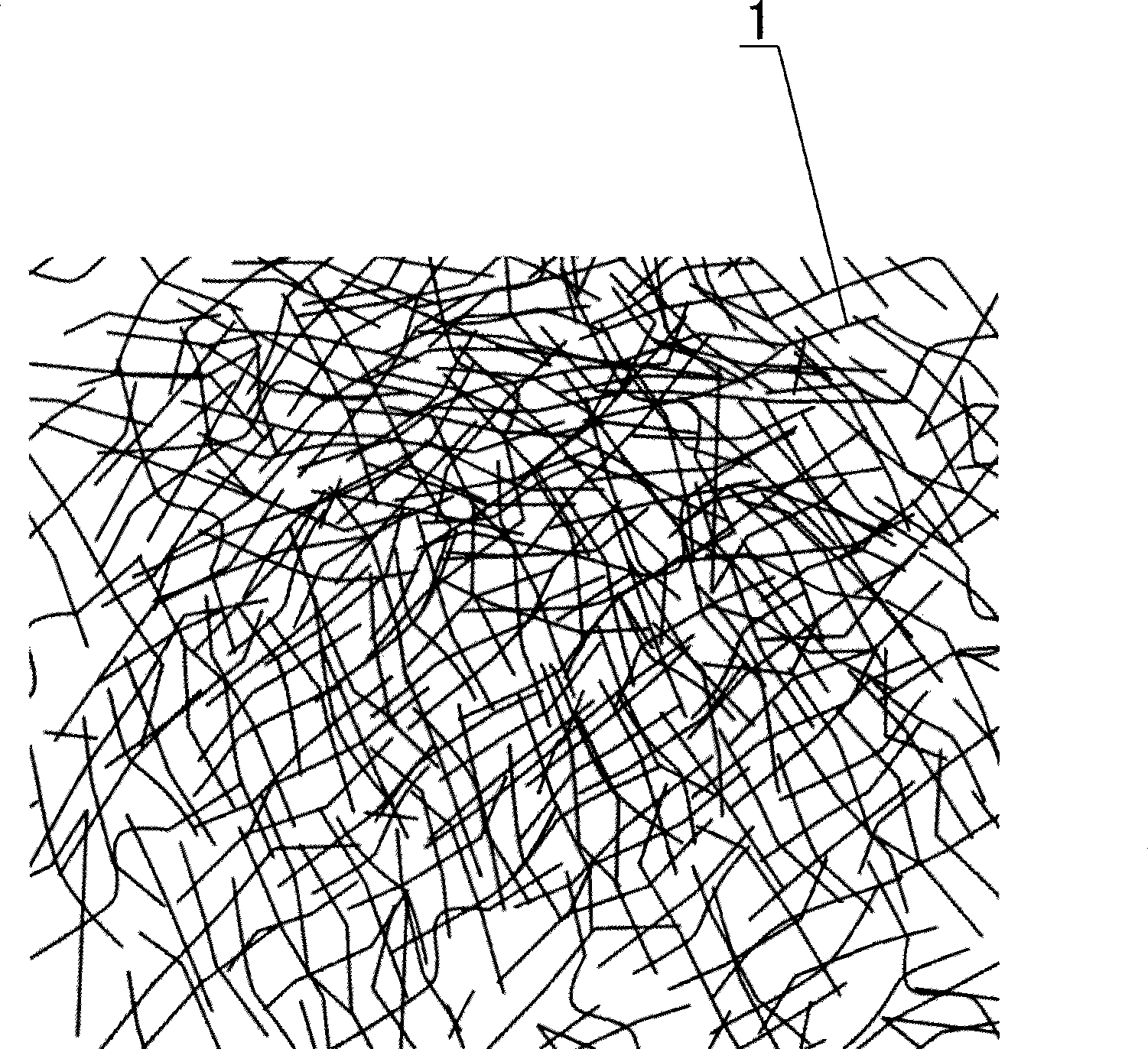

Thermal protection flocculus and manufacturing method thereof

InactiveCN101476212AReduce conductionConduction block or decreaseNon-woven fabricsAdhesivesFiberNet shape

The invention provides a keeping warm flocculus which is prepared from raw material by weight including 56%-85% fine denier fibre and / or super fine denier fibre, 0-30% hollow fibre, 5-30% felt fibre. The preparing method includes steps as follows: loosing and mixing various fibre raw material; then combing, lapping for forming fibre net; then processing disorder drafting to the felt net for forming solid net shape crossing struture; then heating and baking the felt net, at least melting surface of the felt fibre for felting surrounding fibre. The fine denier fibre can increase content of still air in the keeping warm flocculus, reduce heat quantity conduction, and can divide space in the keeping warm flocculus into smaller space for avoiding or reducing air convection, accordingly increase warm keeping property of the keeping warm flocculus; the hollow fibre can increase filling power and compress rebound property of the warm keeping flocculus; filling power and compress rebound property of the warm keeping flocculus are increased after being disorder draft.

Owner:汕头市奥山服饰有限公司

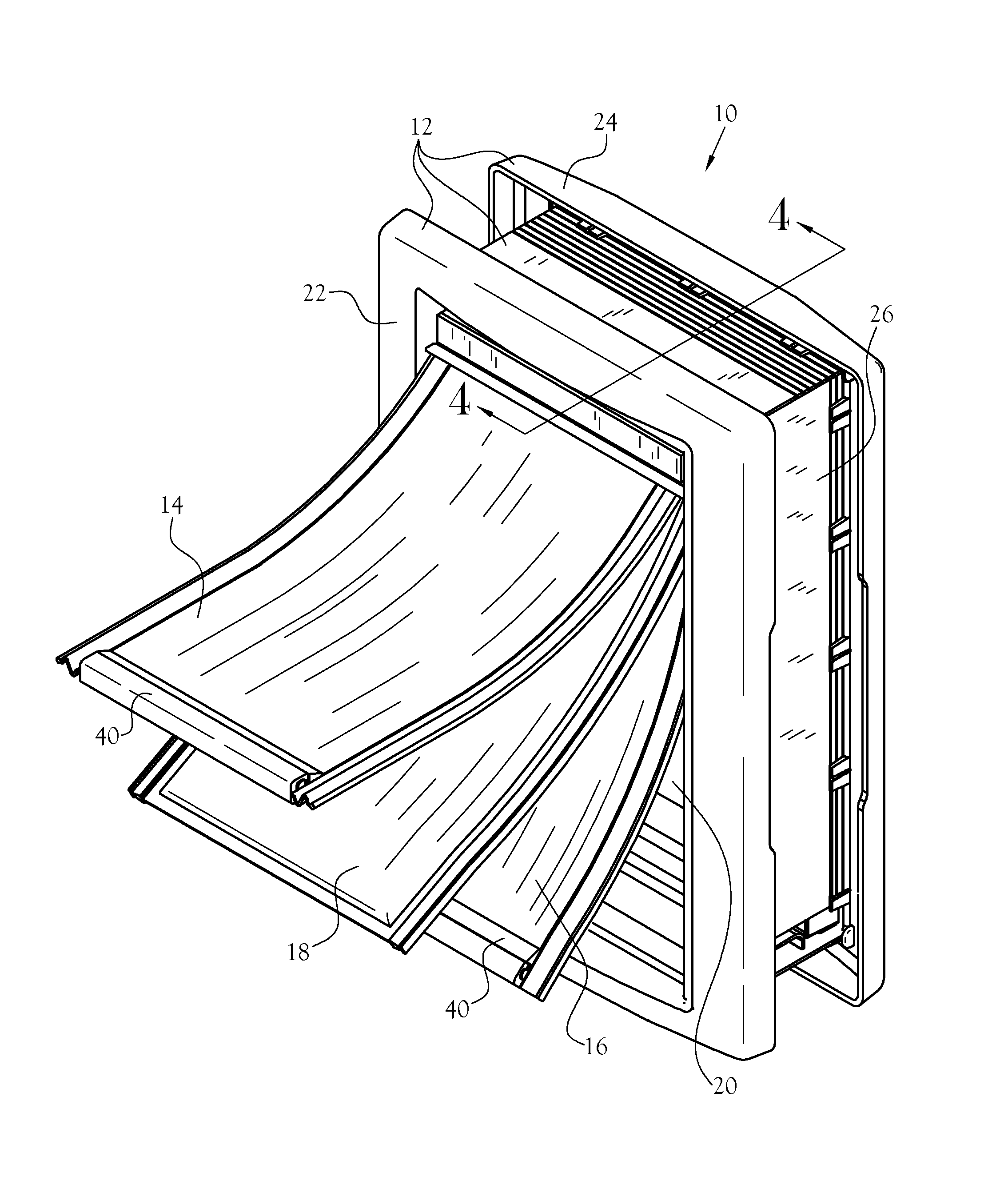

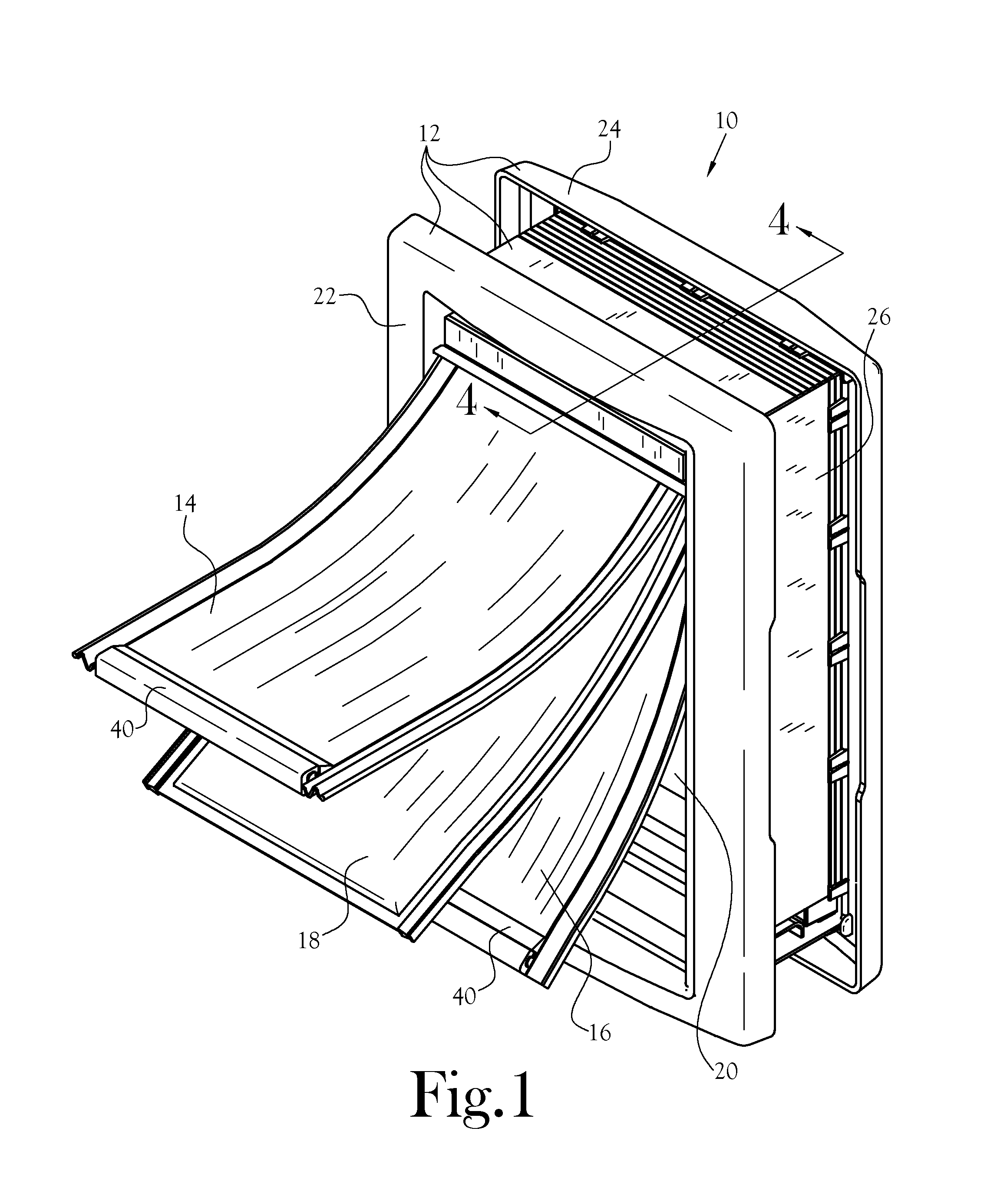

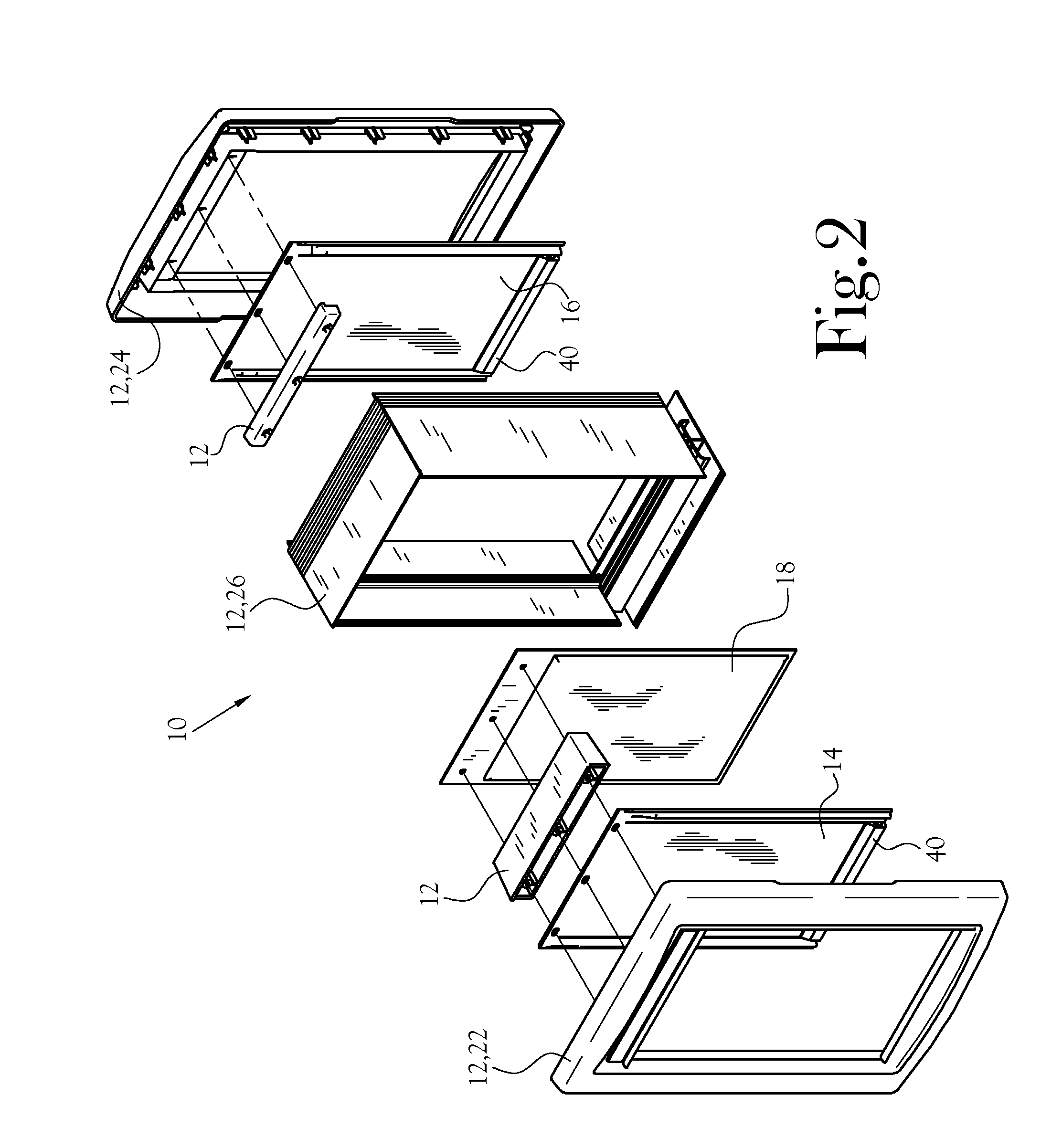

Insulated Animal Door

InactiveUS20080184625A1Reduce heat transferAvoid thermal convectionAnimal housingServing doorsEngineeringConvection

Described is an animal door for providing an animal a passageway through a structure and for reducing thermal transfer through the passageway. The animal door defines the passageway, which is sufficiently large for the animal to pass through, and is adapted to be secured to the structure such that the animal can pass through the structure by passing through the passageway. The animal door includes at least three flaps disposed at the passageway. The flaps are constructed and configured to reduce thermal transfer through the passageway by reducing both thermal convection and thermal conductivity at the passageway.

Owner:RADIO SYST CORP

Insulation flocculus and manufacture method thereof

InactiveCN101718024AReduce conductionReduce convectionNon-woven fabricsAdhesivesCross ventilationRaw material

The invention relates to insulation flocculus which is made by 20-80 percent by weight of superfine denier fiber, 10-70 percent by weight of fine denier fiber, 5-30 wt% of tacky fiber and 0-5 wt% of bond. The insulation flocculus is made by adopting the following steps of: loosening and mixing the fiber raw materials; carding and lapping to form a fiber web; carrying out disorder traction on the fiber web to enable the fiber web to form a solid meshy across structure; spraying the bond on the two faces of the fiber web; heating and baking the fiber web to enable the tacky fiber to bond the fiber around and to solidify the bond. In the invention, due to the adoption of the superfine denier fiber and the fine denier fiber, heat conduction can be effectively reduced, cross ventilation in the space can be prevented or reduced, and the insulation property of the insulation flocculus is improved. In addition, due to the adoption of the tacky fiber and the bond, the fill power and the compression resilience of the insulation flocculus can be improved, and the fill power and the compression resilience of the insulation flocculus are higher through disorder traction.

Owner:汕头市奥山服饰有限公司

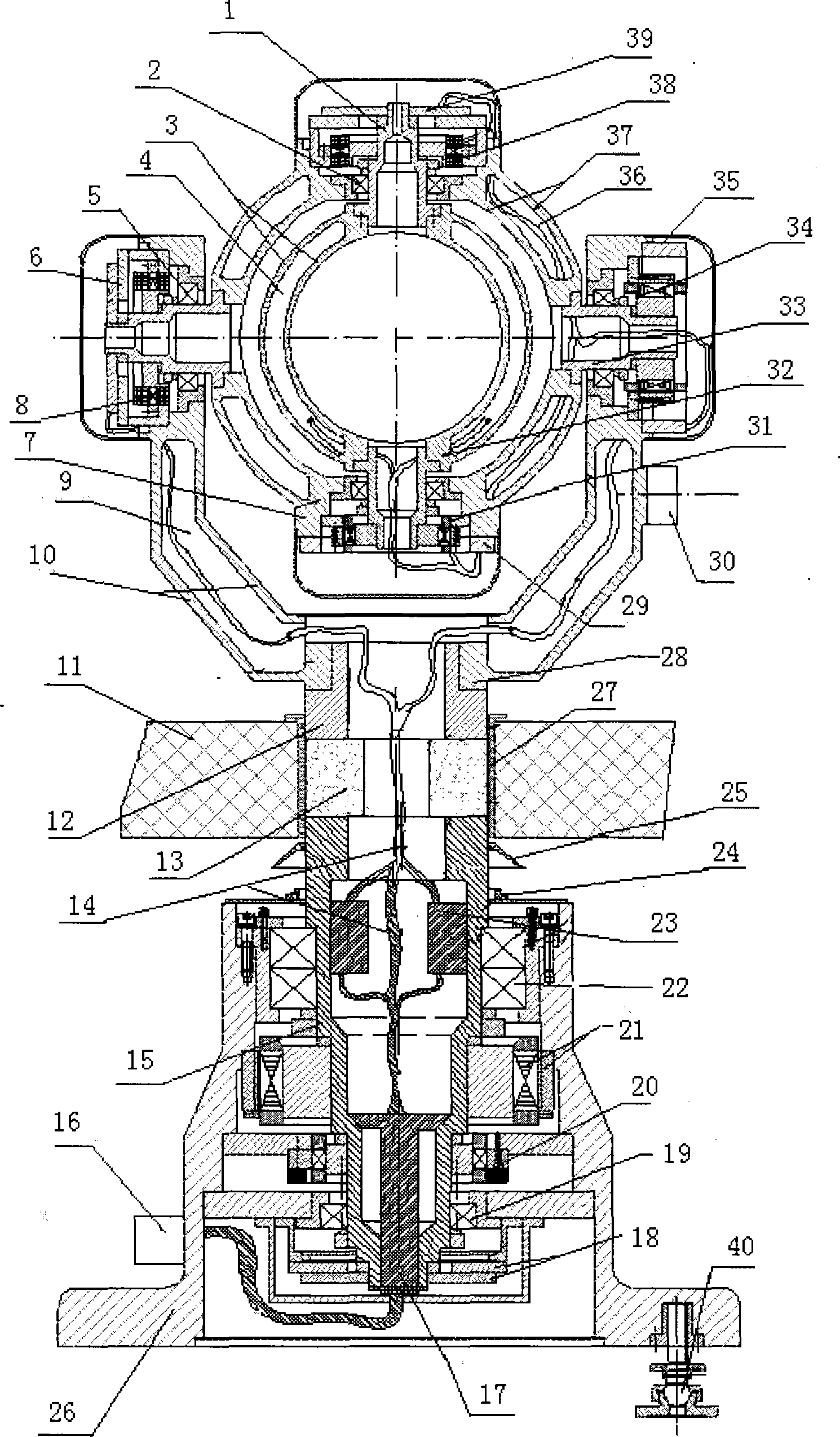

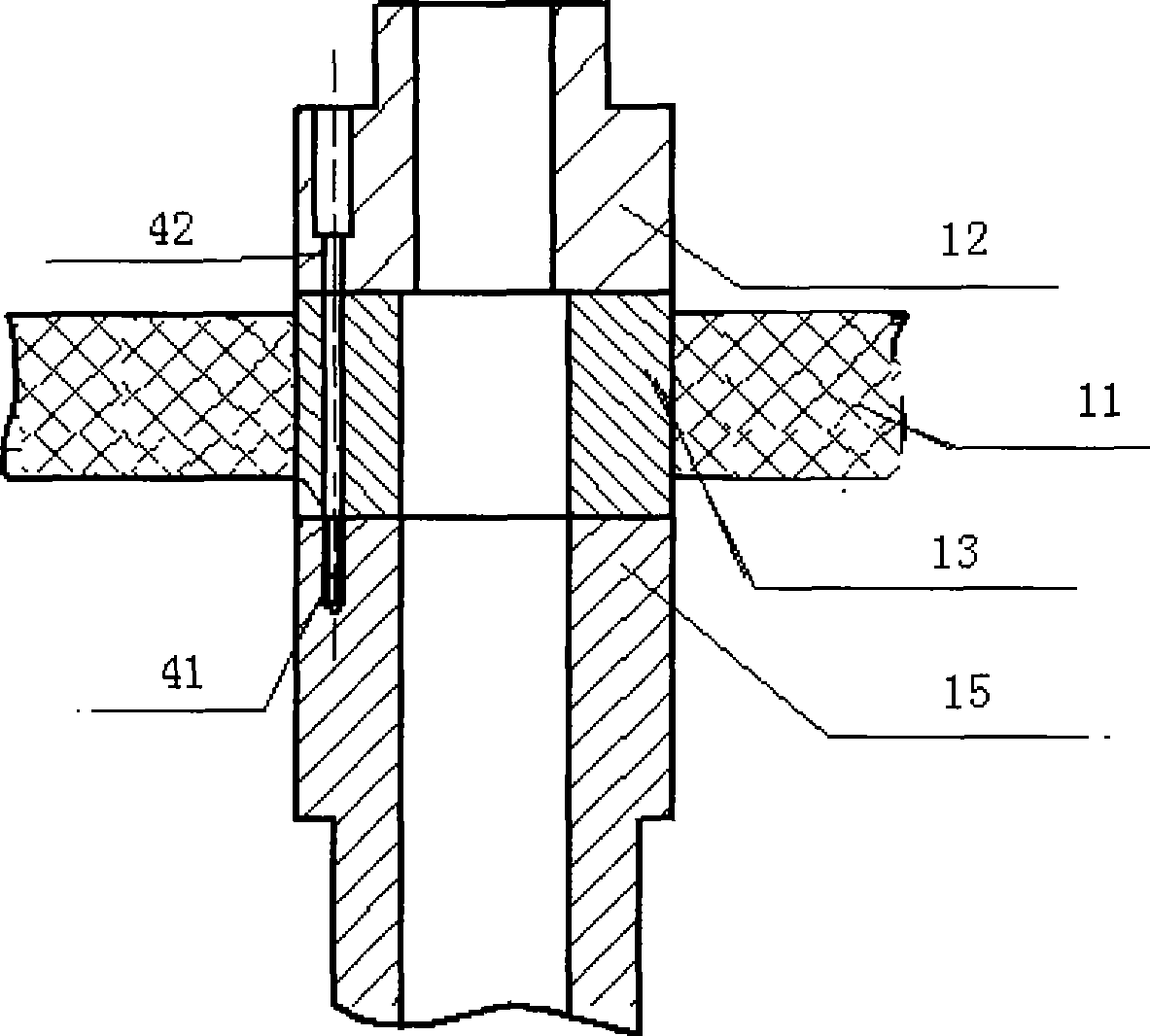

Three-shaft high-low temperature speed turntable

The invention belongs to a gyro calibrator and discloses a three-shaft high-low temperature speed turntable adaptable to high and low temperature ranges. The turntable comprises a turntable base, an outer frame, a middle frame, an inner frame, driving shafts of the outer frame, the middle frame and the inner frame, and a driving motor, wherein the outer frame has a U-shaped structure, the driving shaft of the outer frame is arranged in the turntable base; the turntable also comprises a temperature box, the outer frame, the middle frame and the inner frame are arranged in the temperature box, and a base plate of the temperature box is provided with a shaft hole which allows the driving shaft of the outer frame to pass through; the middle frame and the inner frame are standard positive circular ring shaped; and the wall of the temperature box is provided with a glass window. The three-shaft high-low temperature speed turntable has the advantages that tests on a gyro in three directions in a high temperature environment and a low temperature environment can be performed simultaneously, and the turntable has low requirement on the motor moment and has high test efficiency.

Owner:BEIJING AEROSPACE INST FOR METROLOGY & MEASUREMENT TECH

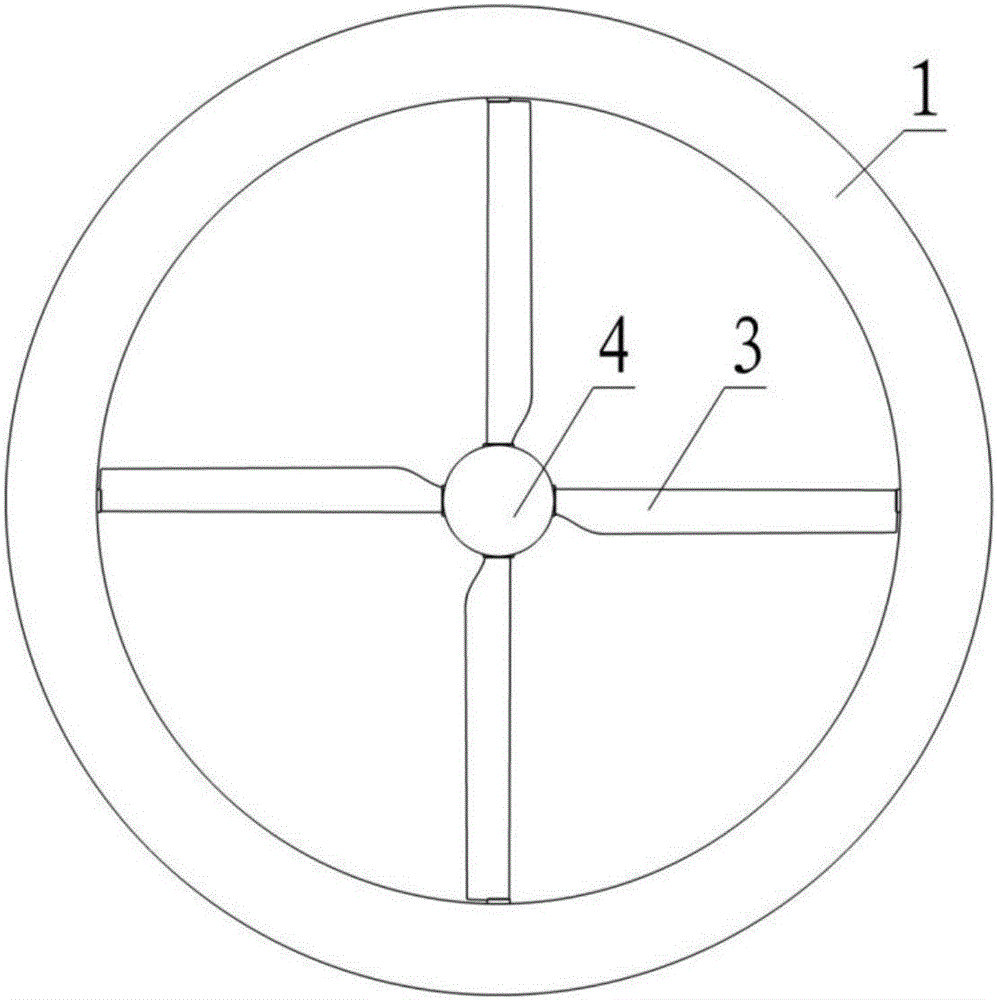

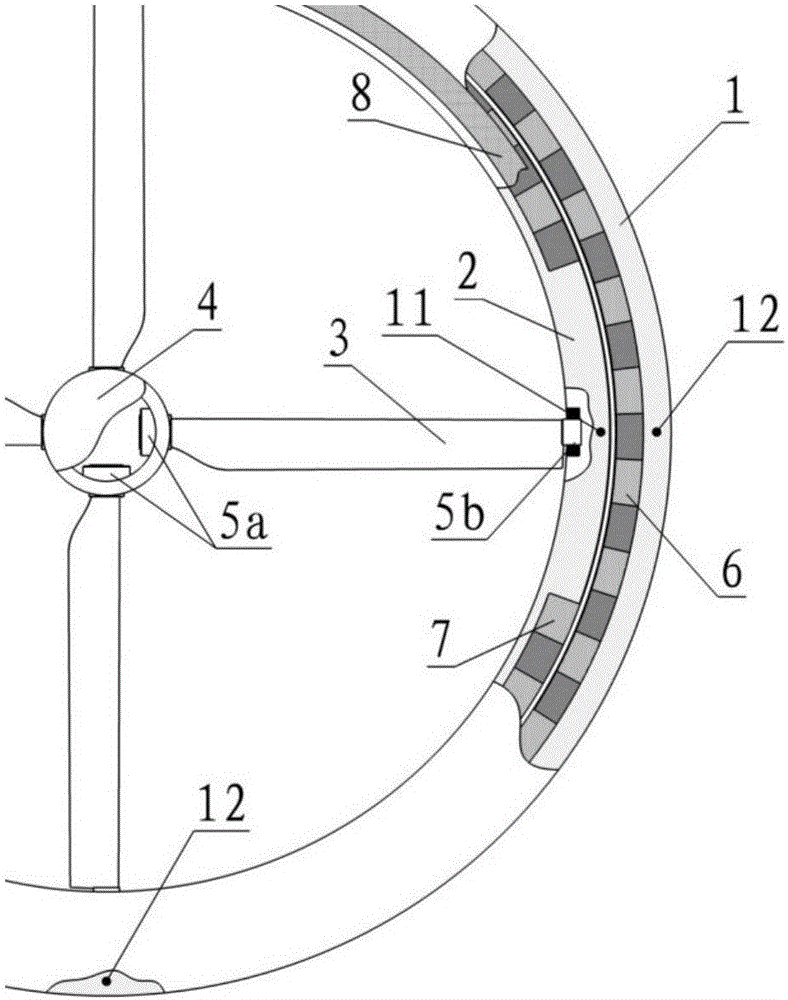

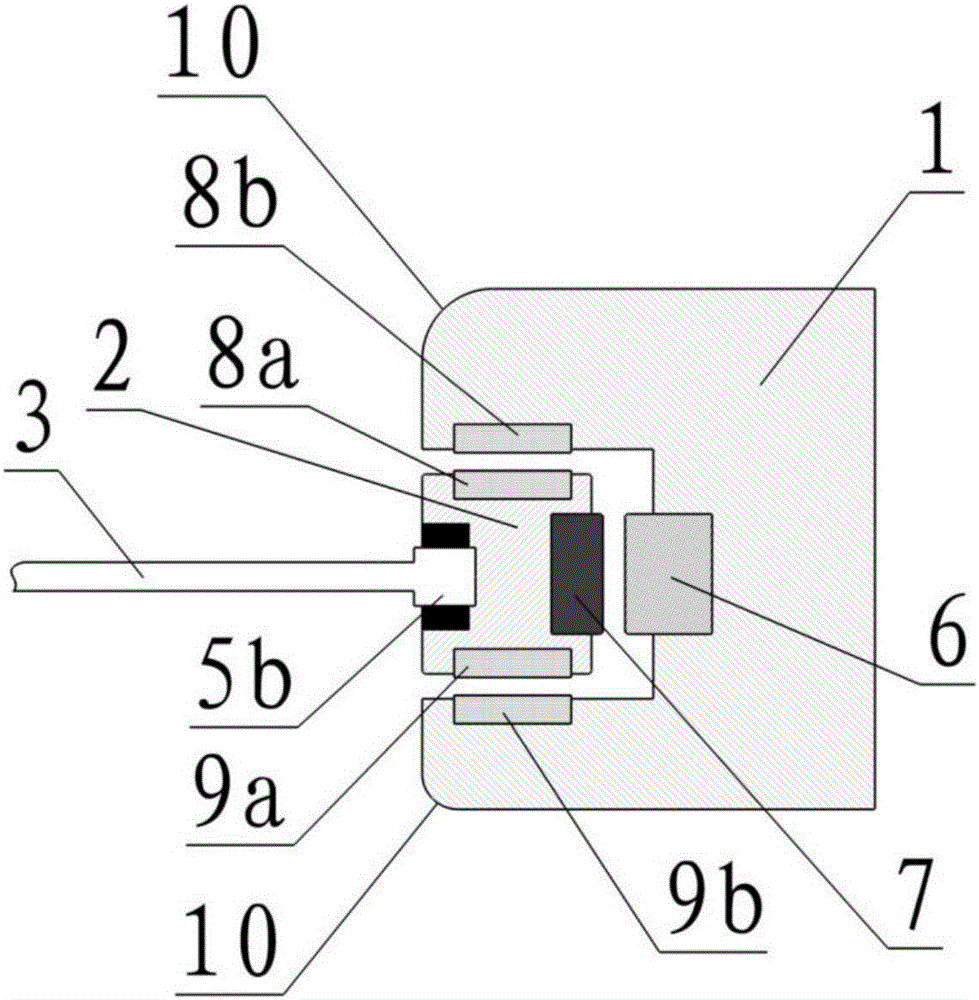

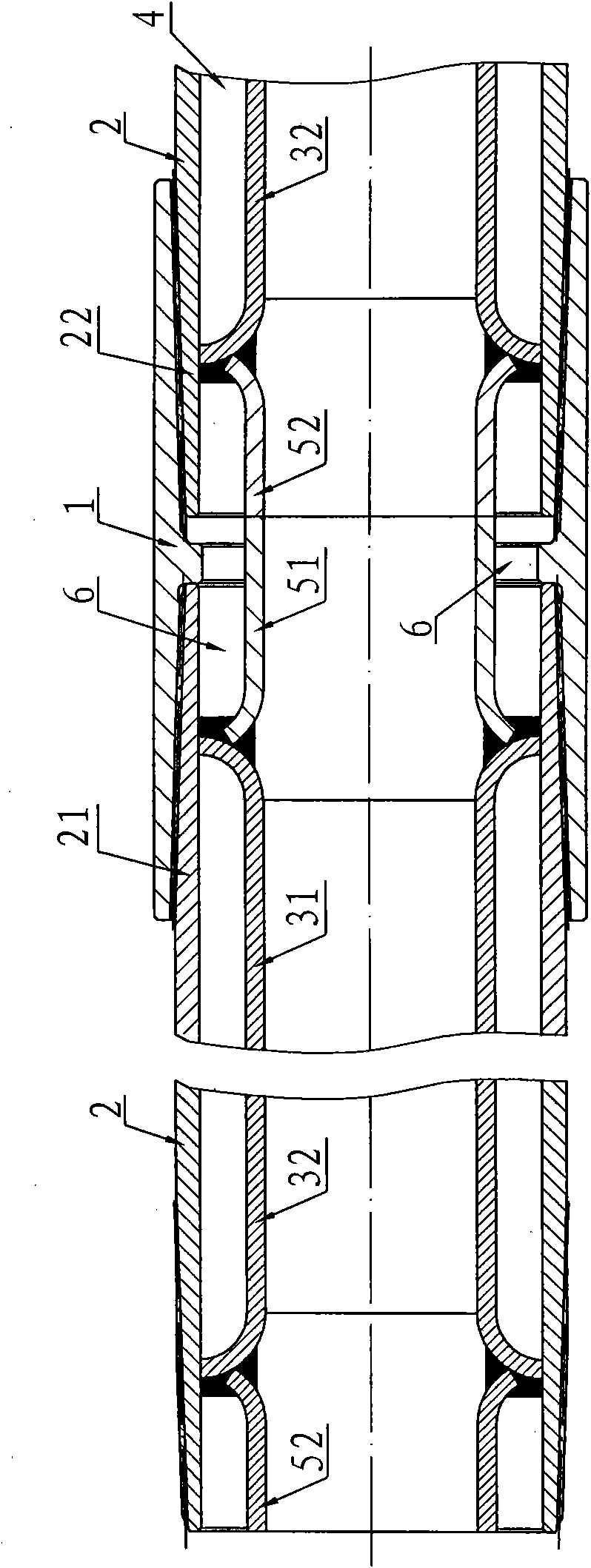

Magnetic levitation rotor wing system and helicopter with same

ActiveCN106516127AEffective consideration of strengthEffectively consider the lift effectPropellersPower plant constructionAviationPropeller

The invention relates to a magnetic levitation rotor wing system and a helicopter with the same and the field of aviation, in particular to the technical field of rotor wings. The magnetic levitation rotor wing system comprises a rotor wing ring (2) and a rail ring (1), wherein the rotor wing ring (2) is connected with a rotor wing propeller point, and the rail ring (1) provides magnetic suspension force for the rotor wing ring (2). Magnetic suspension force provided by the rail ring (1) includes a driving device capable of driving blades to rotate and a suspension device capable of enabling the propeller point to suspend. A first deflection driving mechanism is arranged on the root portions of the blades of the rotor wing so that first deflection angles of the root portions of the blades can be provided, and a second deflection driving mechanism is arranged on the rotor wing ring (2) so that second deflection angles of the points of the blades can be provided. According to the magnetic levitation rotor wing system and the helicopter with the same, only an outside rail ring is needed to drive the rotor wing ring, and the blades are connected by a central connecting component; and the requirement of independent variable pitch of the rotor wing is guaranteed, partial load of the blades is counteracted with one another through the central connecting component, integrality of the rotor wing ring is increased, and working reliability of improved.

Owner:CHINA HELICOPTER RES & DEV INST

Thermal protection flocculus and manufacturing method thereof

InactiveCN101481851AReduce conductionConduction block or decreaseNon-woven fabricsAdhesivesFiberSurface layer

The invention discloses a heat insulation flocculus which is made from the following fiber: 10-64wt / % of fine denier fiber and / or superfine denier fiber, 31-80wt / % of hollow fiber and 5-30wt / % of tacky fiber. The heat insulation flocculus is manufactured by the following method: shredding and mixing various fiber raw materials; carding and spreading webs to form a fiber web; then performing random drafting on the fiber web to cause the fiber web to form a 3D network crossed structure; heating and baking the fiber web to cause at least the surface layer of the tacky fiber to be melted, and binding the surrounding fiber of the fiber web. The use of the fine denier fiber greatly increases the content of still air in the heat insulation flocculus, reduces heat conduction, can divide the space in the heat insulation flocculus into smaller spaces, and prevents or reduces air convection, thus improving the heat insulation performance of the insulation flocculus; the hollow fiber can improve bulkiness and compression resilience of the heat insulation flocculus; and the random drafting causes the bulkiness and the compression resilience of the heat insulation flocculus to be higher.

Owner:汕头市奥山服饰有限公司

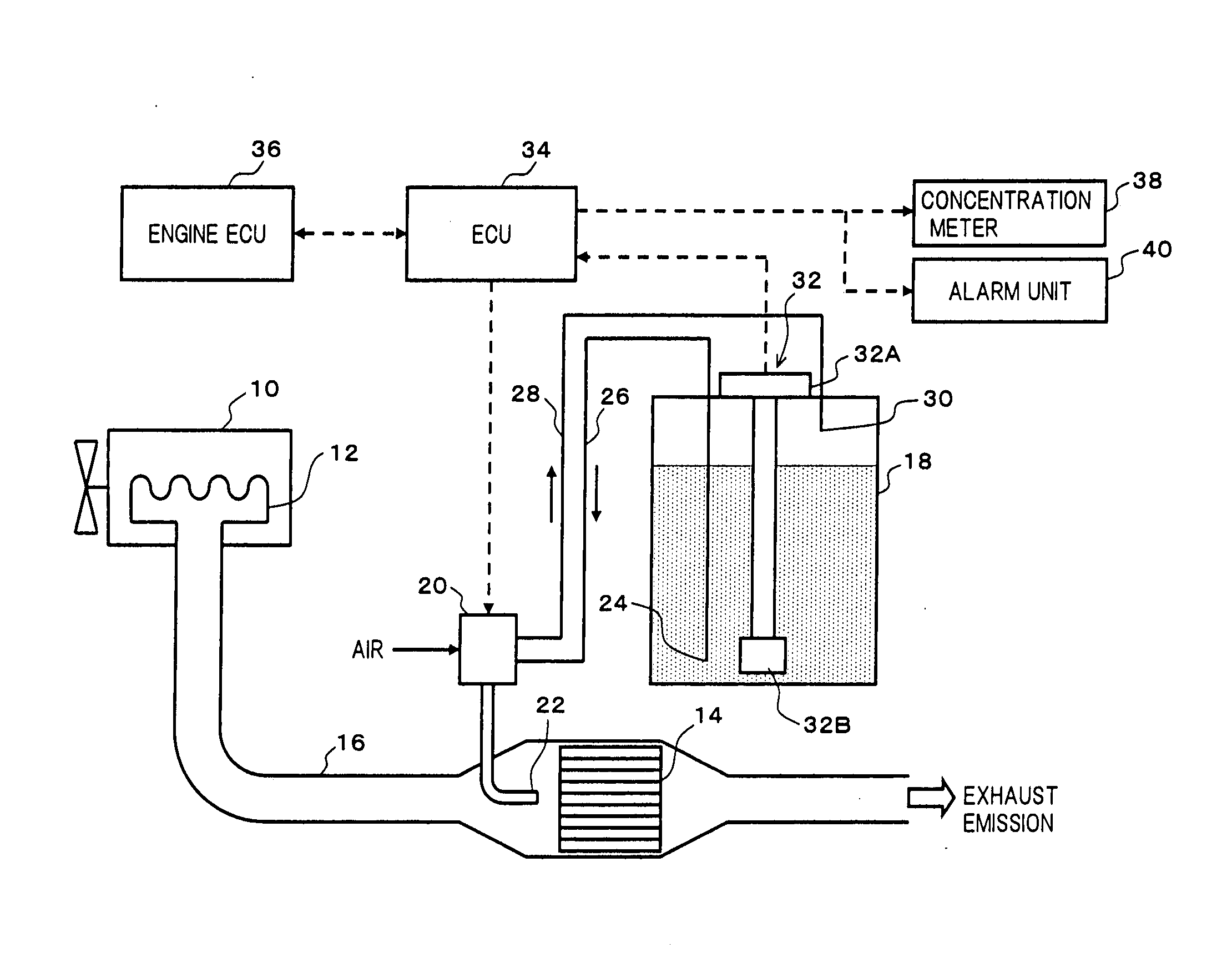

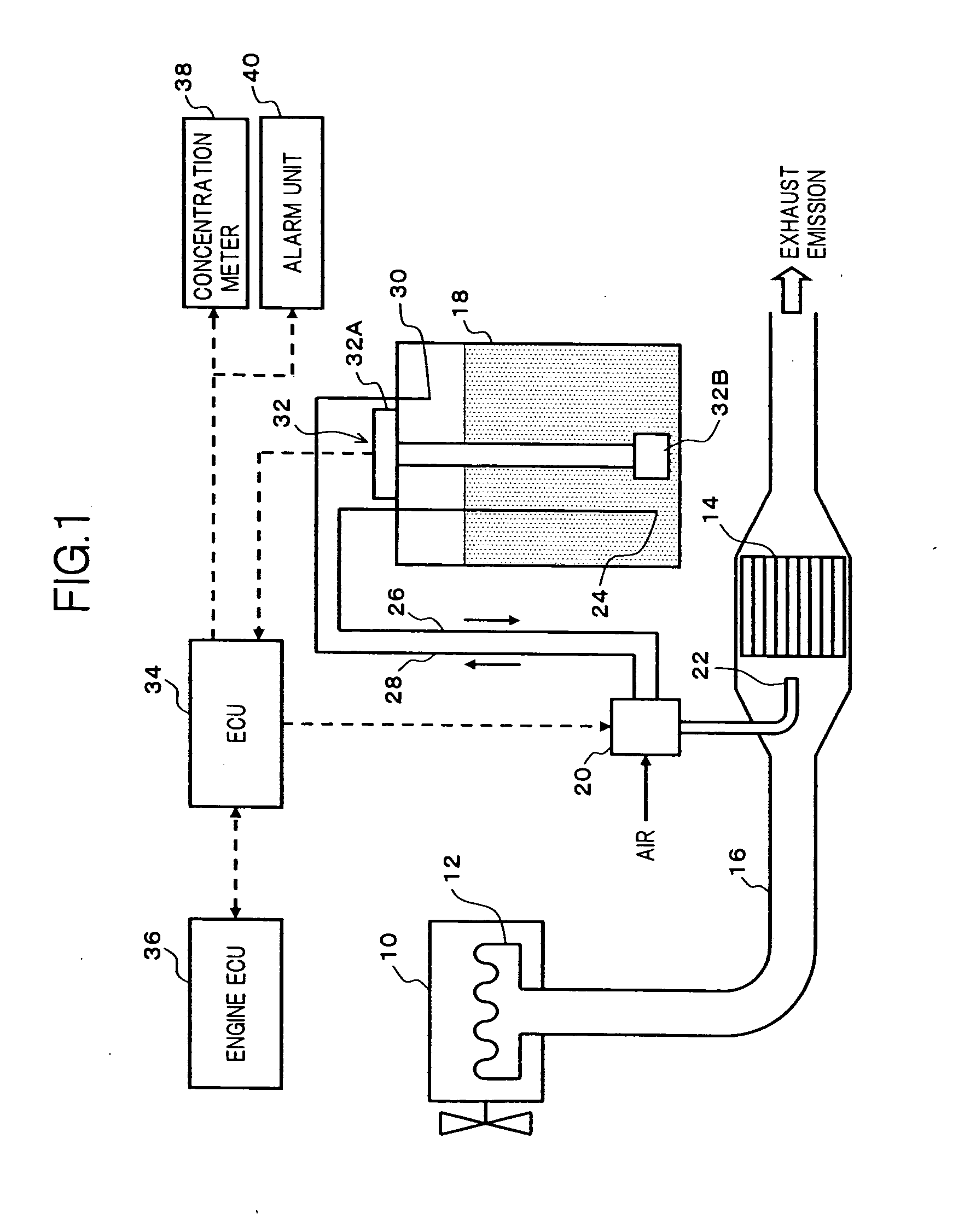

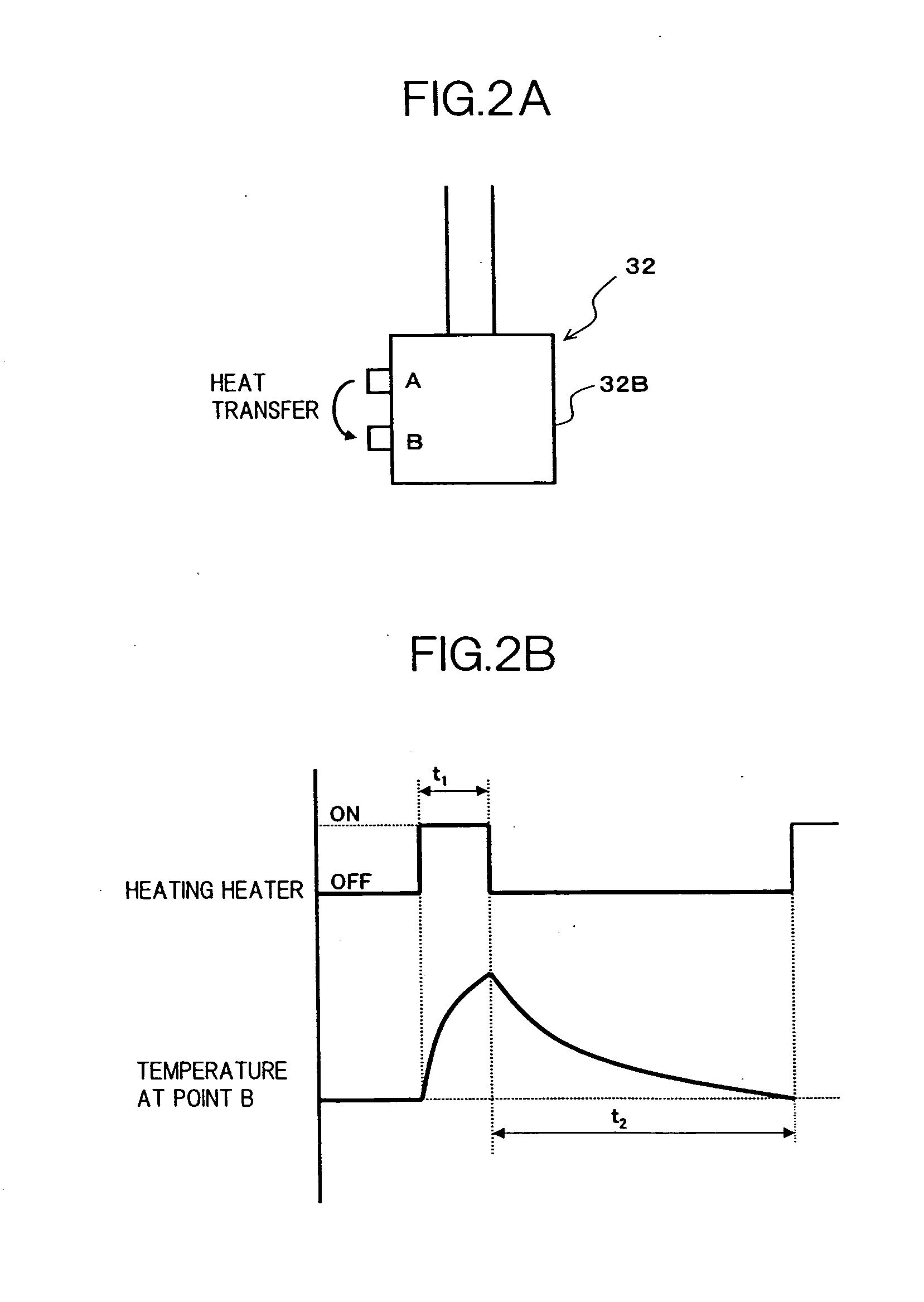

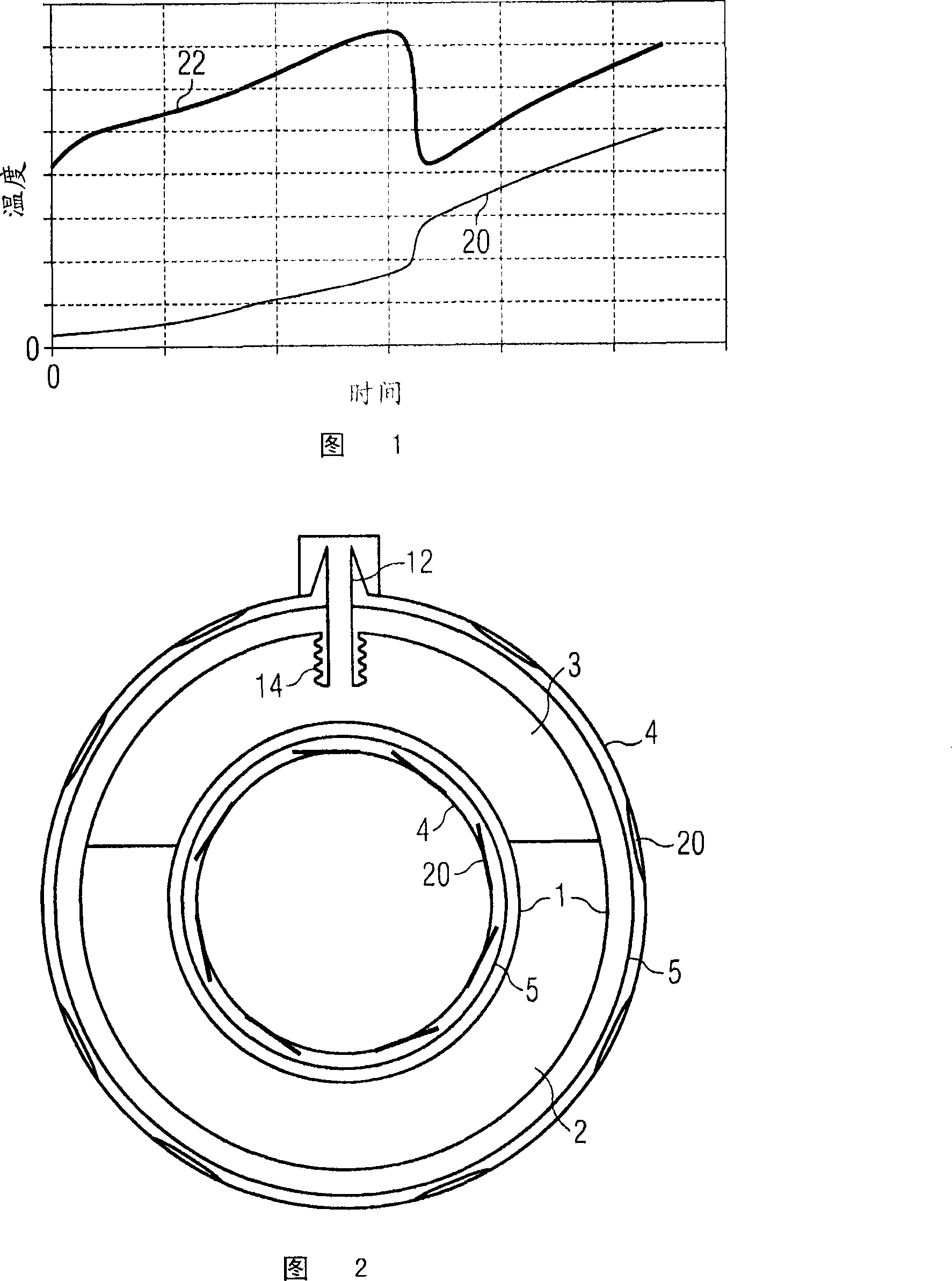

Apparatus for Detecting Concentration and Remaining Amount of Liquid Reducing Agent

InactiveUS20070204677A1Ensure in detectionImprove accuracyInternal combustion piston enginesExhaust apparatusStop timeEngineering

In a storage tank for storing a liquid reducing agent, a sensor for outputting a signal related to a concentration and a remaining amount of the liquid reducing agent based on a heat transfer characteristic between two points at a distance from each other is disposed. In a control unit which contains a built-in computer, it is determined that a vehicle state is stable when a stop time for which a vehicle is continuously in a stationary state reaches a predetermined determination time, the concentration of the liquid reducing agent is calculated based on the signal from the sensor when the vehicle state is stable, and the remaining amount of the liquid reducing agent is determined based on the signal from the sensor irrespective of the vehicle state, in response to a measurement trigger output every predetermined time after a start of an engine.

Owner:NISSAN DIESEL MOTOR CO

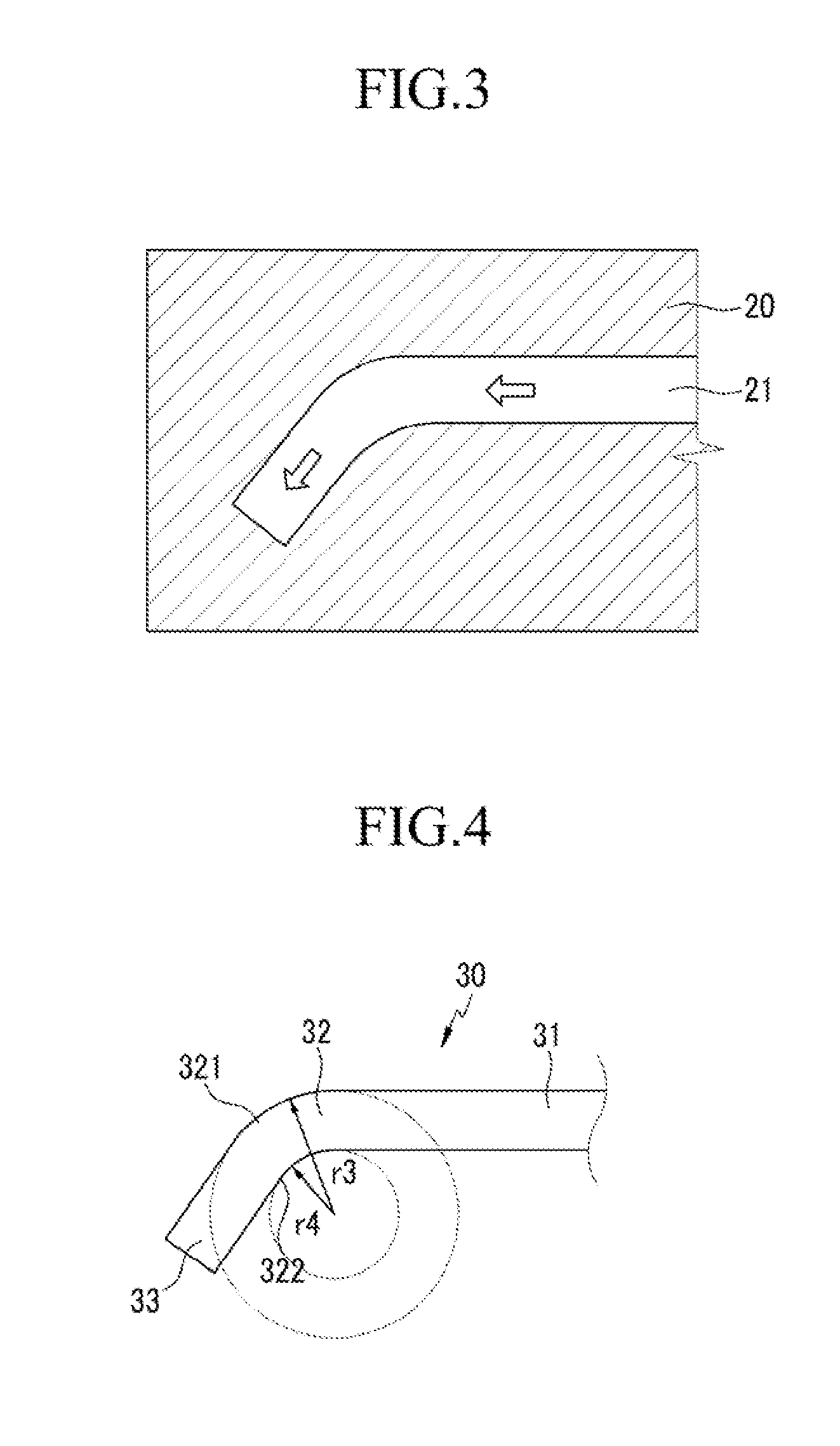

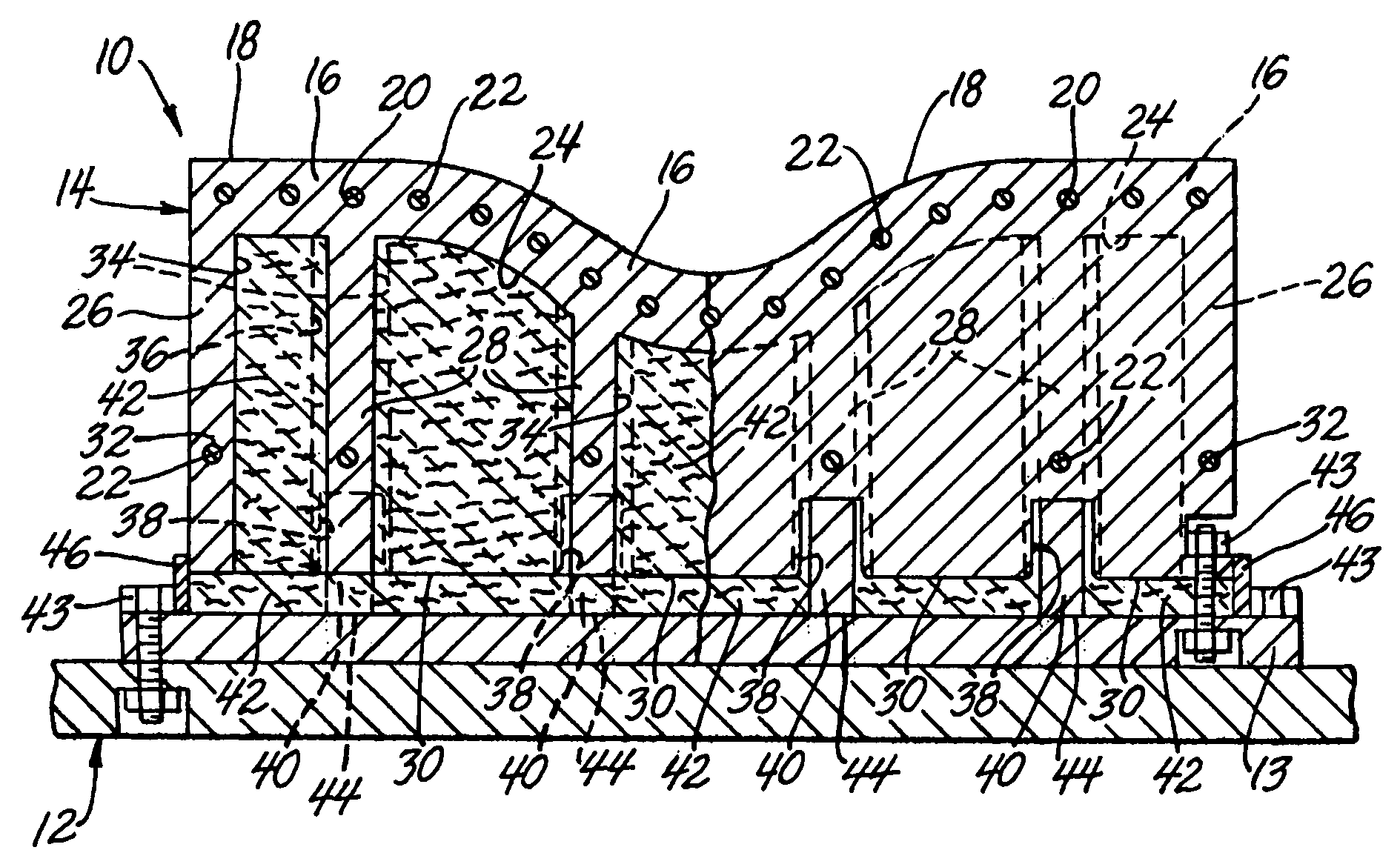

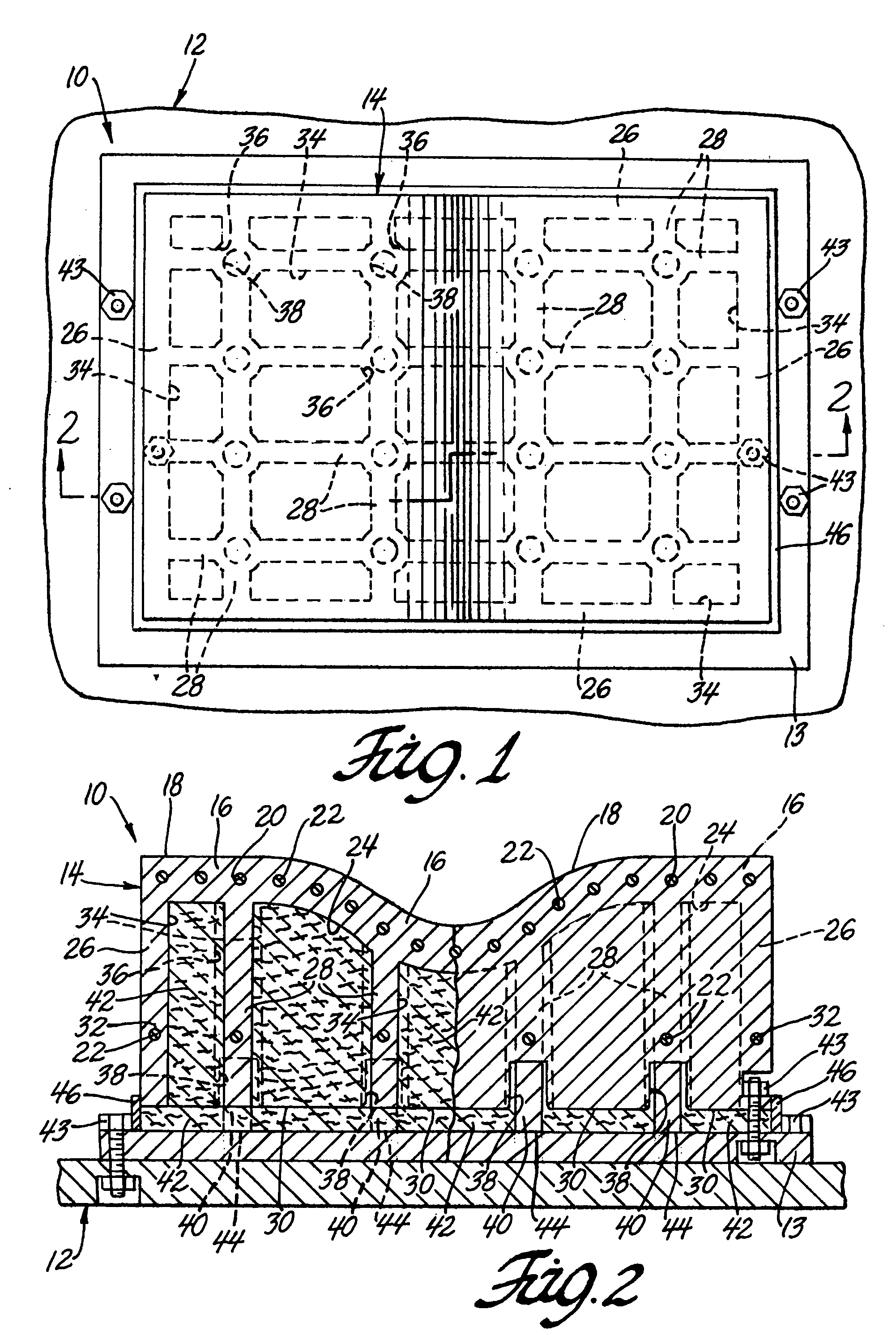

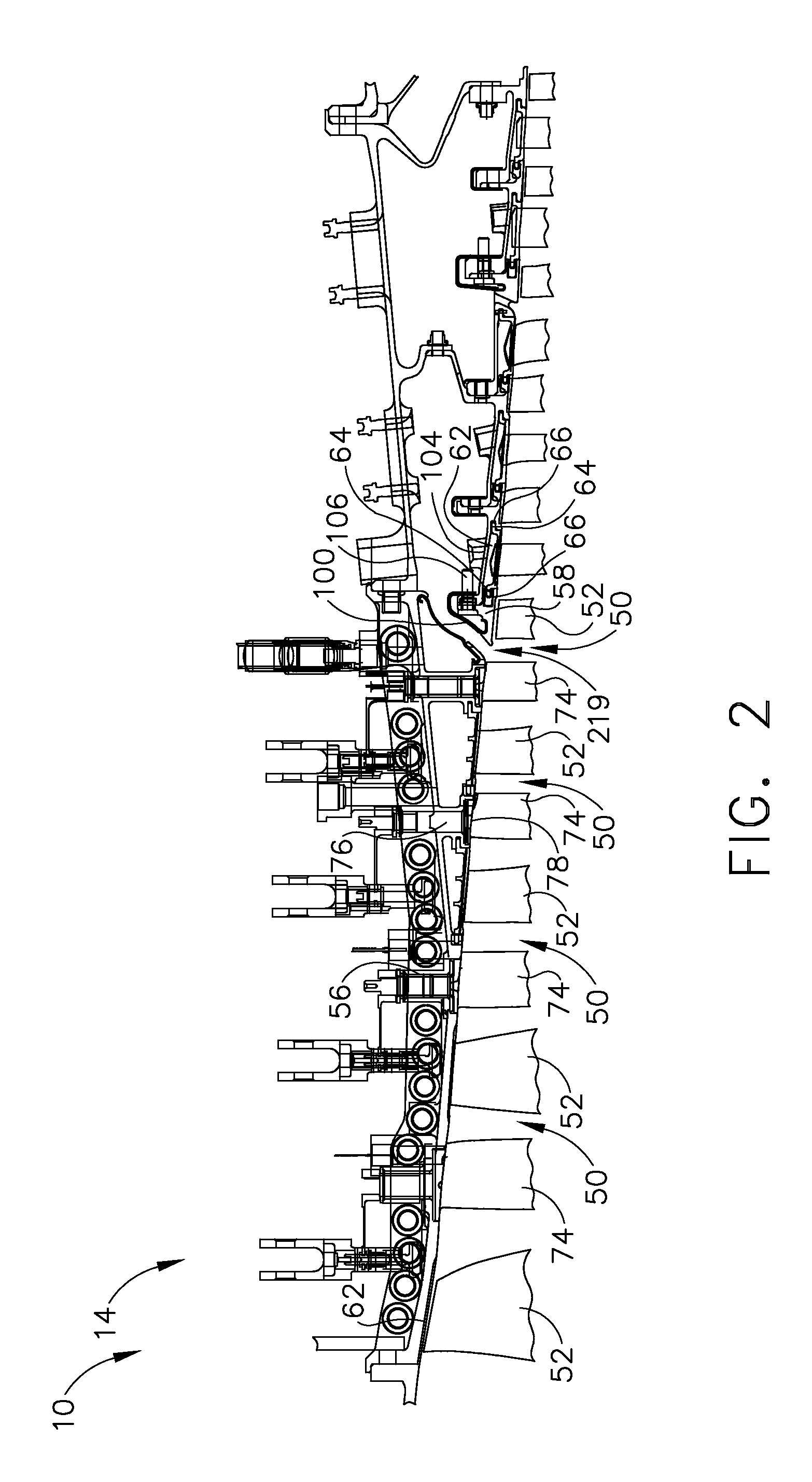

Forming tool apparatus for hot stretch-forming processes

ActiveUS20050199031A1Reduce heat lossImprove thermal efficiencyShaping toolsThermal insulationEngineering

A tooling assembly for hot stretch-forming of a sheet metal workpiece. A forming tool is attached to a plate and includes a shell having a forming surface, and support walls that extend away from the shell, that terminate in a rearward surface of the forming tool, and that define open cells between the support walls. Heating elements are embedded within the forming tool for integral and uniform heating thereof. To limit conductive thermal losses from the forming surface, through the forming tool, and to the plate and surrounding environment, the open cells are provided in the forming tool and insulative support posts are disposed between the forming tool and the plate within deep counterbores in the rearward surface of the forming tool. To limit radiative and convective thermal losses, thermal insulation is disposed within the cells and between the forming tool and plate.

Owner:GM GLOBAL TECH OPERATIONS LLC

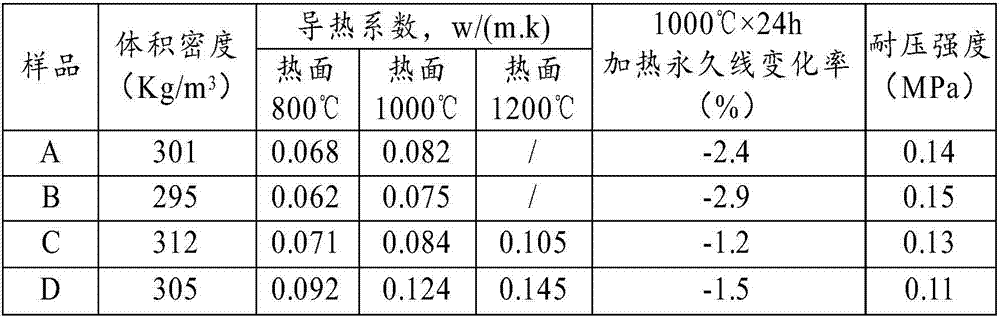

Aerogel composite heat insulation plate and preparation method thereof

The invention provides an aerogel composite heat insulation plate. The aerogel composite heat insulation plate is prepared from the following raw materials in parts by mass: 100 parts of ceramic fiber, 3 to 8 parts of an organic bonding agent, 5 to 15 parts of an inorganic bonding agent, 10 to 30 parts of aerogel powder and 0 to 15 parts of an infrared light shielding agent, wherein the aerogel powder is prepared from 5 weight percent to 15 weight percent of structural water. According to the aerogel composite heat insulation plate provided by the invention, the aerogel containing the partialstructural water is used as a filling material of a ceramic fiber plate and part of micron-pore structure in the ceramic fiber plate is changed into a nano-pore and micron-pore composite structure sothat the convection and conduction heat transfer of the ceramic fiber plate are reduced; the infrared light shielding agent is selectively added and is used as an infrared non-transparent substance inthe ceramic fiber plate, so that the radiation heat transfer of the ceramic fiber plate at high temperature is reduced.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

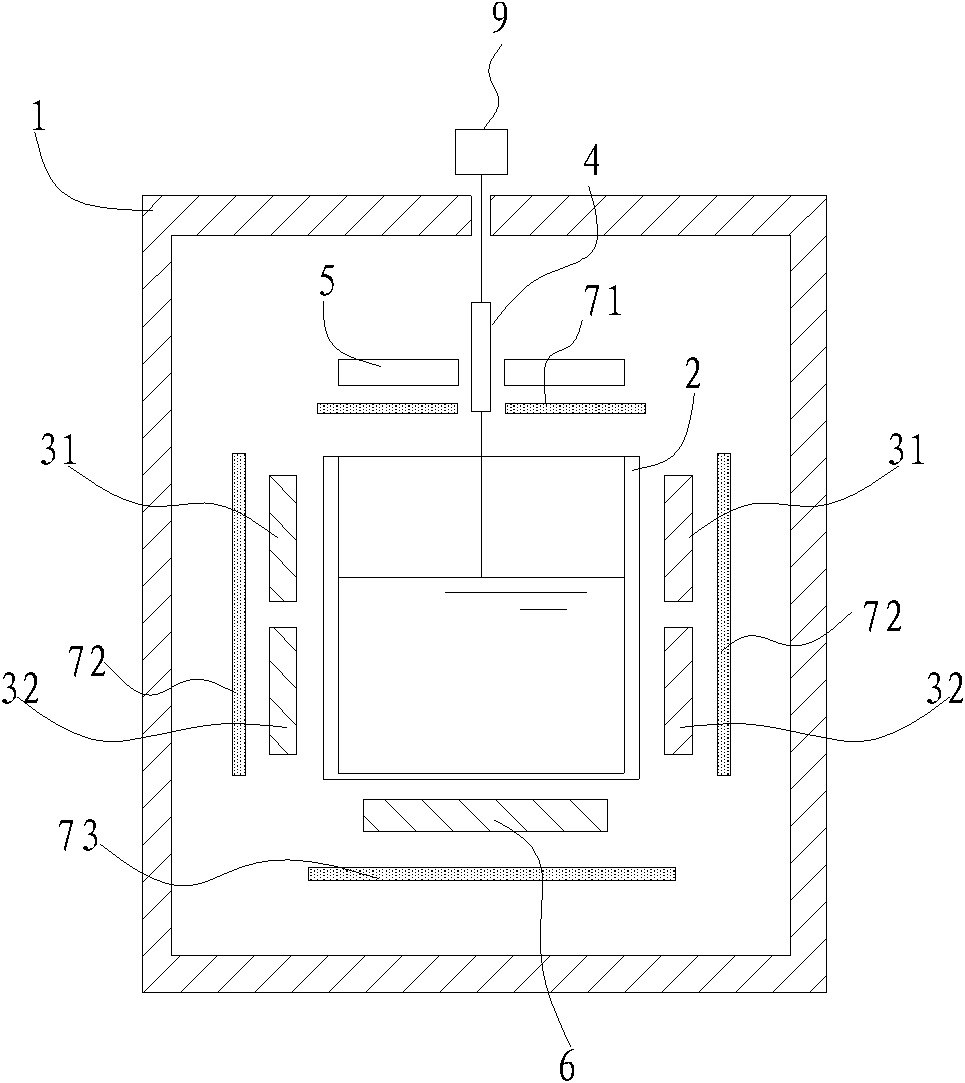

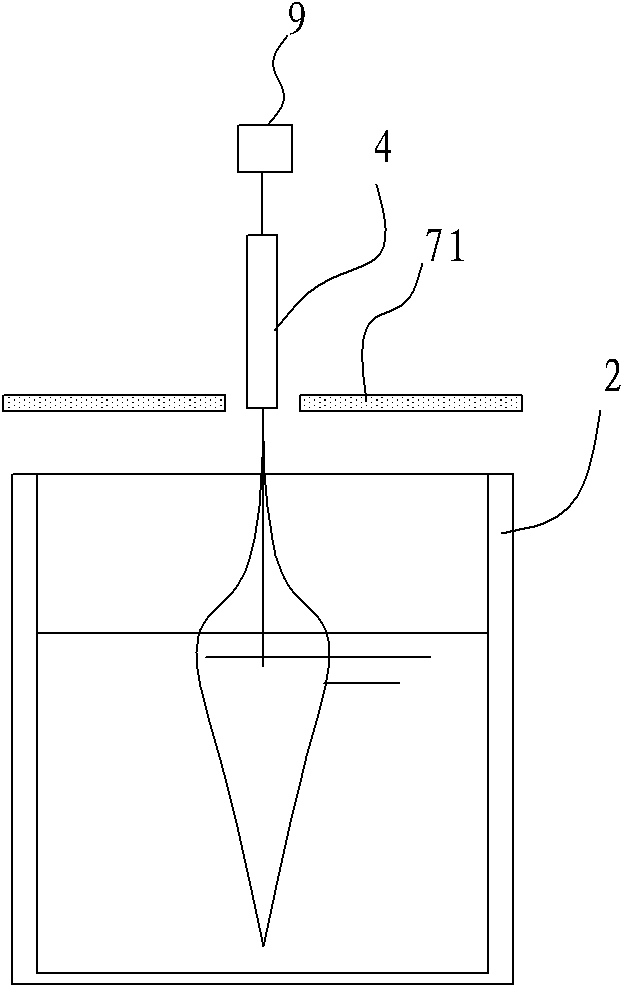

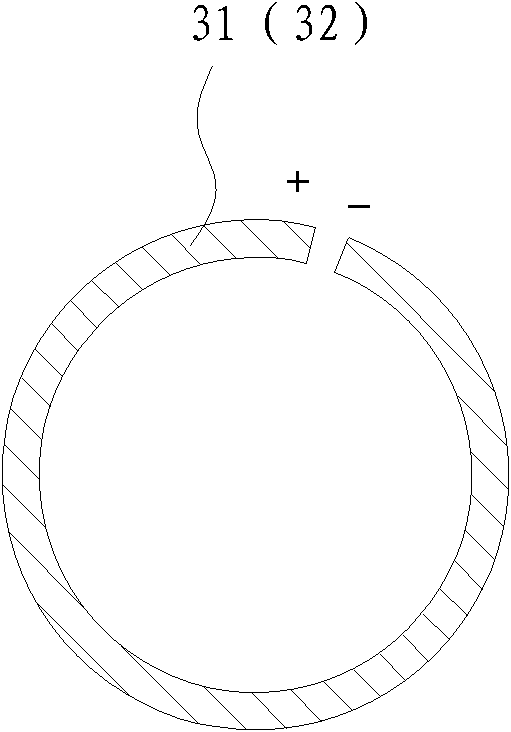

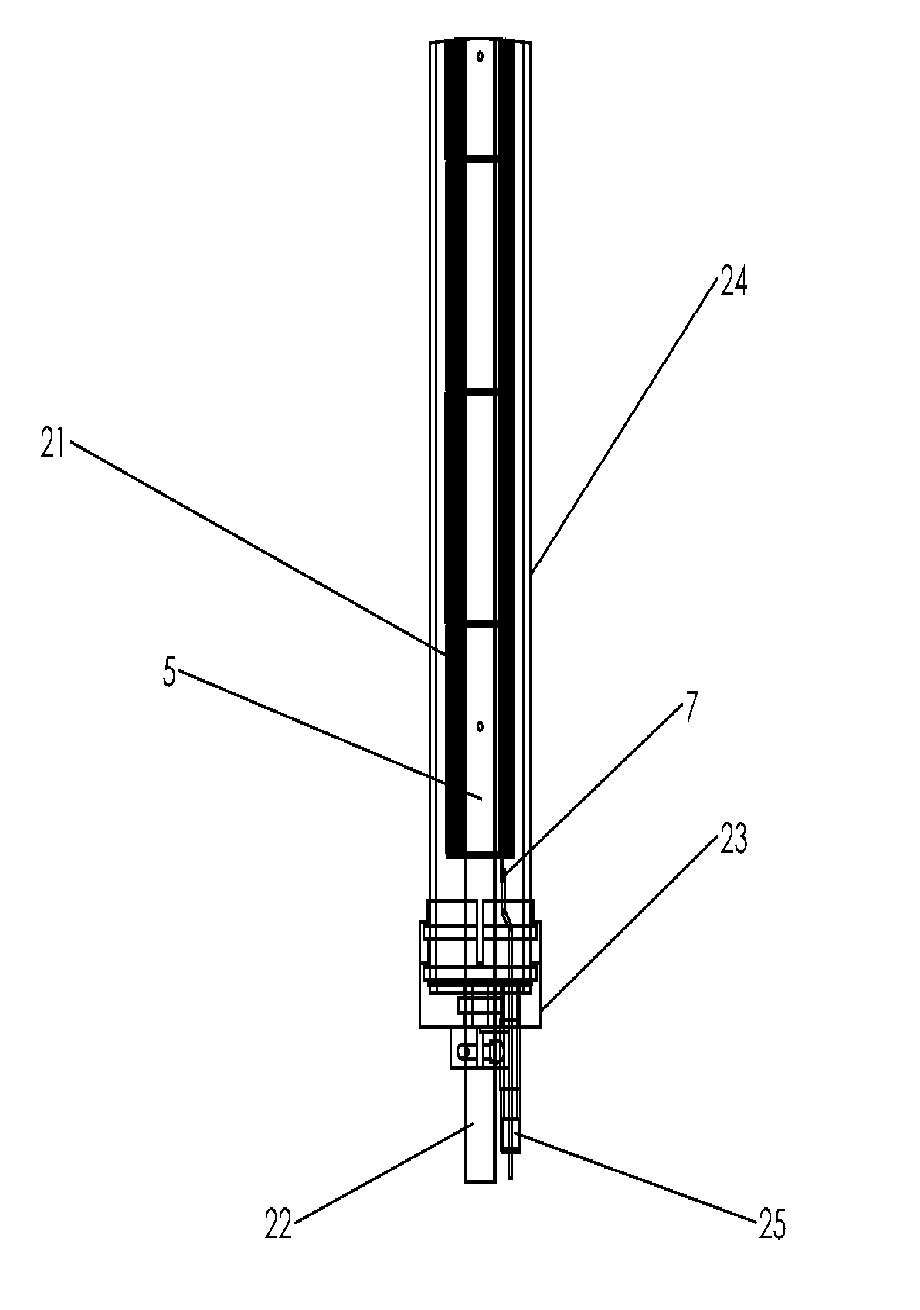

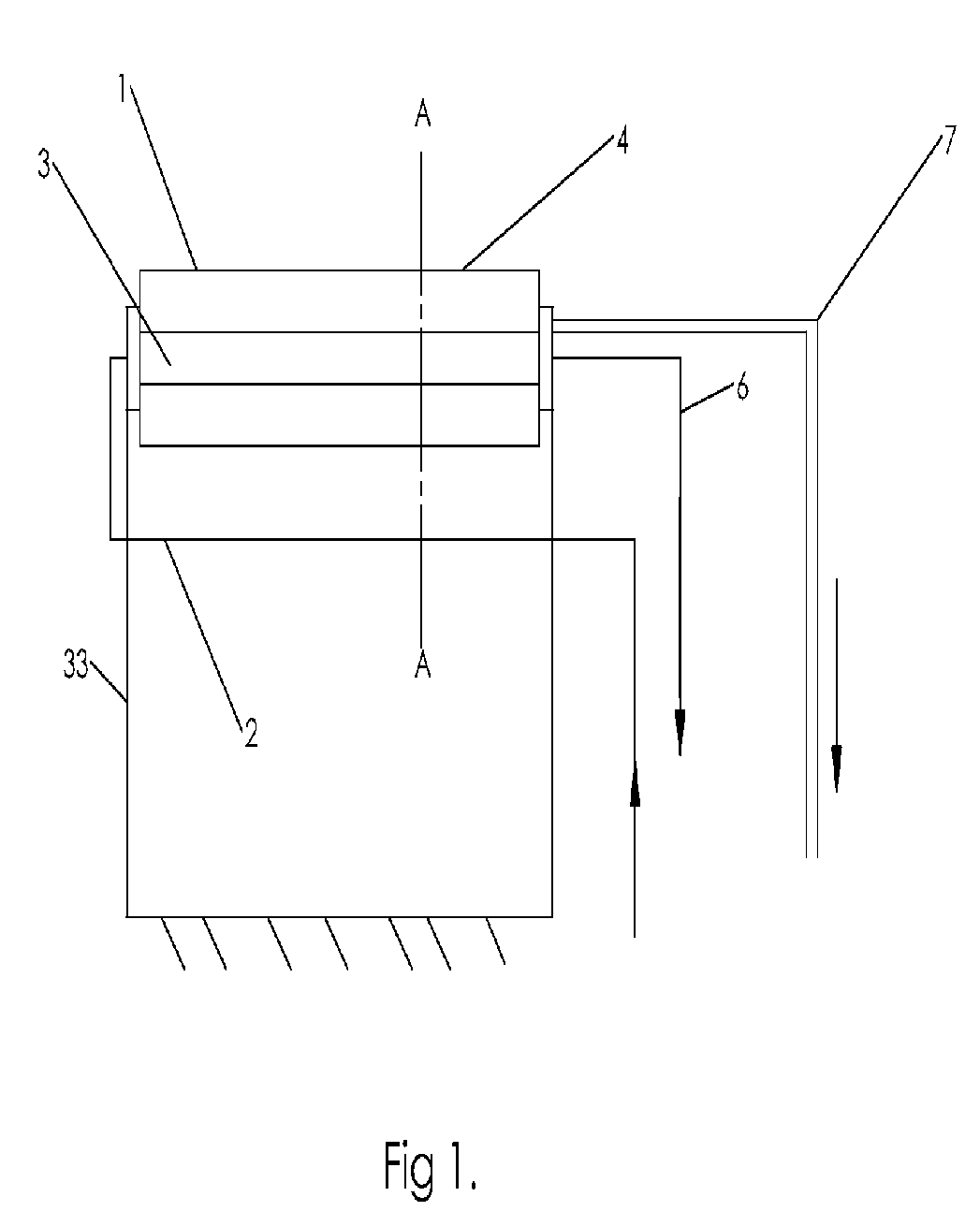

Monocrystal ingot manufacturing device

InactiveCN102051674AReduce convectionLow powerPolycrystalline material growthFrom frozen solutionsThermal insulationCrucible

The invention discloses a monocrystal ingot manufacturing device which comprises a main body, a crucible, at least two primary heaters, a crystal seed holder, a thermal insulation component and a bottom heater, wherein the crucible is arranged in the main body; the at least two primary heaters are separately arranged on the circumference of the crucible in the axial direction of the crucible, and independently control the temperature; the crystal seed holder is positioned above the crucible and used for holding seed crystals; the thermal insulation component is arranged around the crucible; and the bottom heater is arranged below the crucible. According to the monocrystal ingot manufacturing device disclosed by the embodiment of the invention, the at least two primary heaters which independently control the temperature can greatly reduce the convection in the molten mass, thereby effectively improving the crystal quality. In addition, in the later period of the crystal growth, the liquid level of the molten mass lowers, and at this time, the power of the upper heater can be greatly reduced on the premise of keeping the power of the lower primary heater unchanged to ensure that the temperature of the molten mass is not decreased, thereby effectively lowering the power consumption in the whole crystal growth process and preventing the phenomenon of pot adhesion due to the overlow temperature of the molten mass.

Owner:王楚雯

High-temperature-resisting wet-process felt and preparation method thereof

ActiveCN104534223AHigh porosityLow thermal conductivityThermal insulationPipe protection by thermal insulationPorosityFiber

The invention discloses a high-temperature-resisting wet-process felt and a preparation method thereof. The porosity of the high-temperature-resisting wet-process felt is more than 93% and the thickness of the high-temperature-resisting wet-process felt is 6mm-22mm; a nano silicon dioxide coating is arranged on the outer surface of the high-temperature-resisting wet-process felt; the diameter of fiber monofilaments of the high-temperature-resisting wet-process felt is 0.1 micron-2 microns, and closed vacuum balls with the diameter being less than 20nm are uniformly arranged on the outer surfaces of the fiber monofilaments. By the aid of the high-temperature-resisting wet-process felt, the porosity of a fiber cotton felt is greatly improved and the heat conductivity coefficient of the fiber cotton felt is reduced; any binding agent is not added into the product so that the product has the advantages of no toxin, high temperature resistance, low moisture absorption rate, soft texture and small volume density, and can be repeatedly used at high and low temperatures, and the heat insulation performance is not obviously reduced when the product is used at the high temperature; the highest utilization temperature is up to 1000 DEG C; the high-temperature-resisting wet-process felt can be widely applied to fire prevention and heat insulation of high-temperature equipment and is particularly suitable for heat preservation and heat insulation of equipment which needs to be usually converted between high temperature and low temperature.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

Concentrated Photovoltaic and Thermal Solar Energy Collector

ActiveUS20140026945A1Reduce material costsImprove positionSolar heating energyPV power plantsThermal energyWorking fluid

This invention relates to a solar energy collector that converts solar radiation into both electrical and thermal energy. More specifically this invention relates to a concentrating solar energy collector with an integrated construction that minimizes cost, bulk, and weight, and maximizes overall efficiency. Typical non-concentrating solar collectors use photovoltaic cells over the entirety of their surface. These solar cells are the most expensive part of the collector. This invention discloses using a reflector to concentrate the incident radiation on photovoltaic cells with one-twentieth the area of the reflector, and transferring the co-generated thermal energy into a working fluid pumped through the cell support structure.

Owner:ELECTROTHERM SOLAR

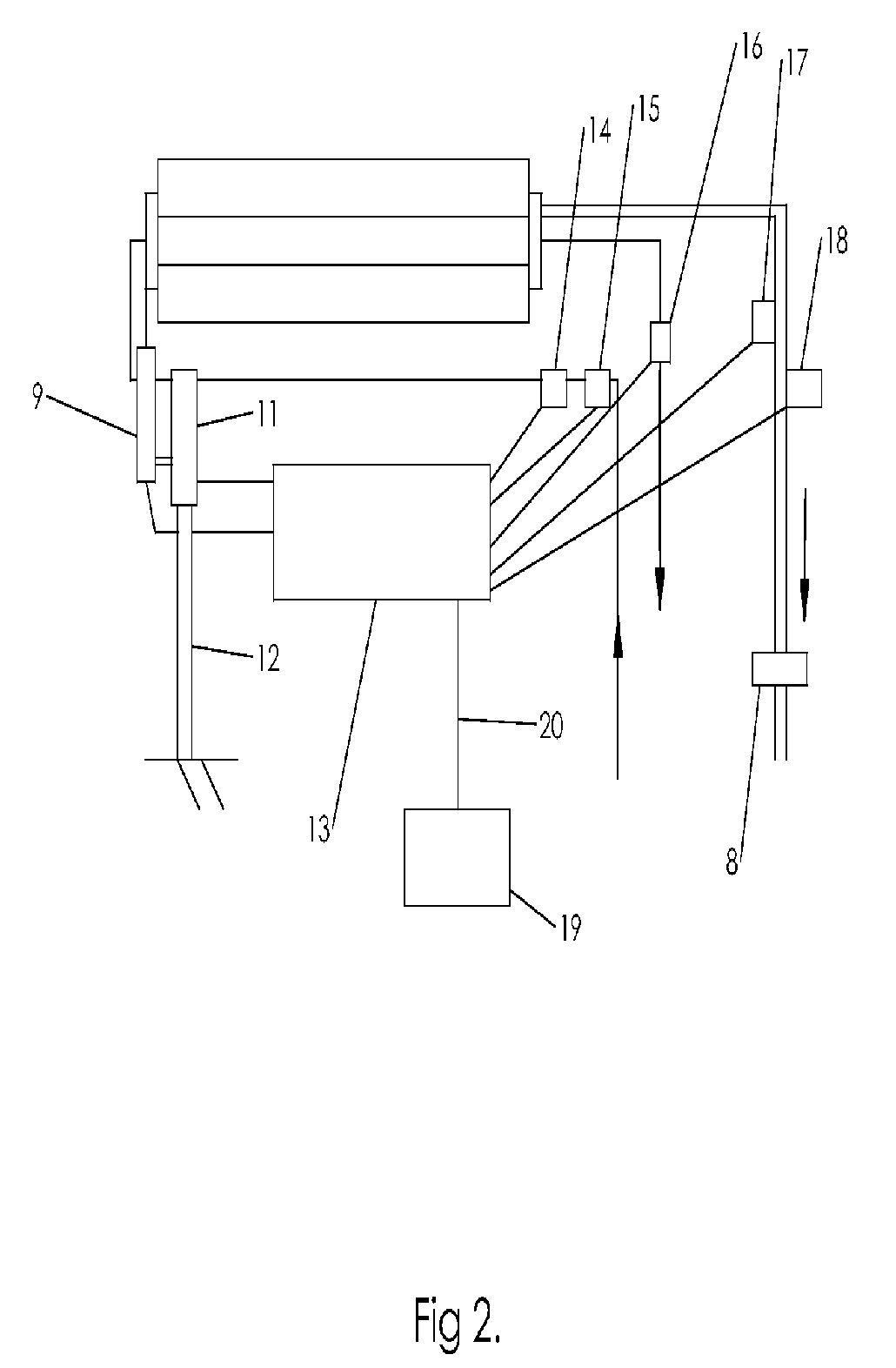

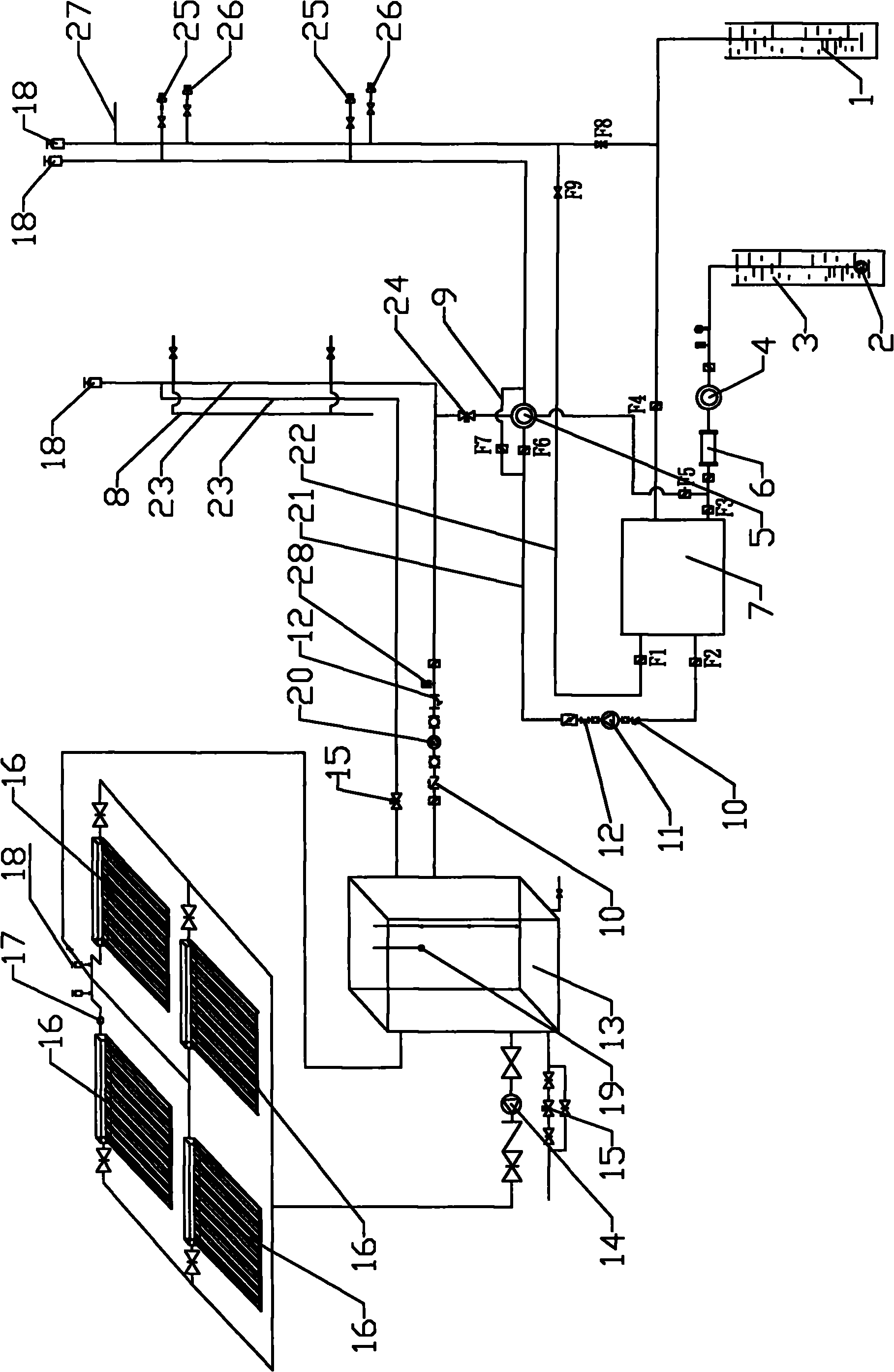

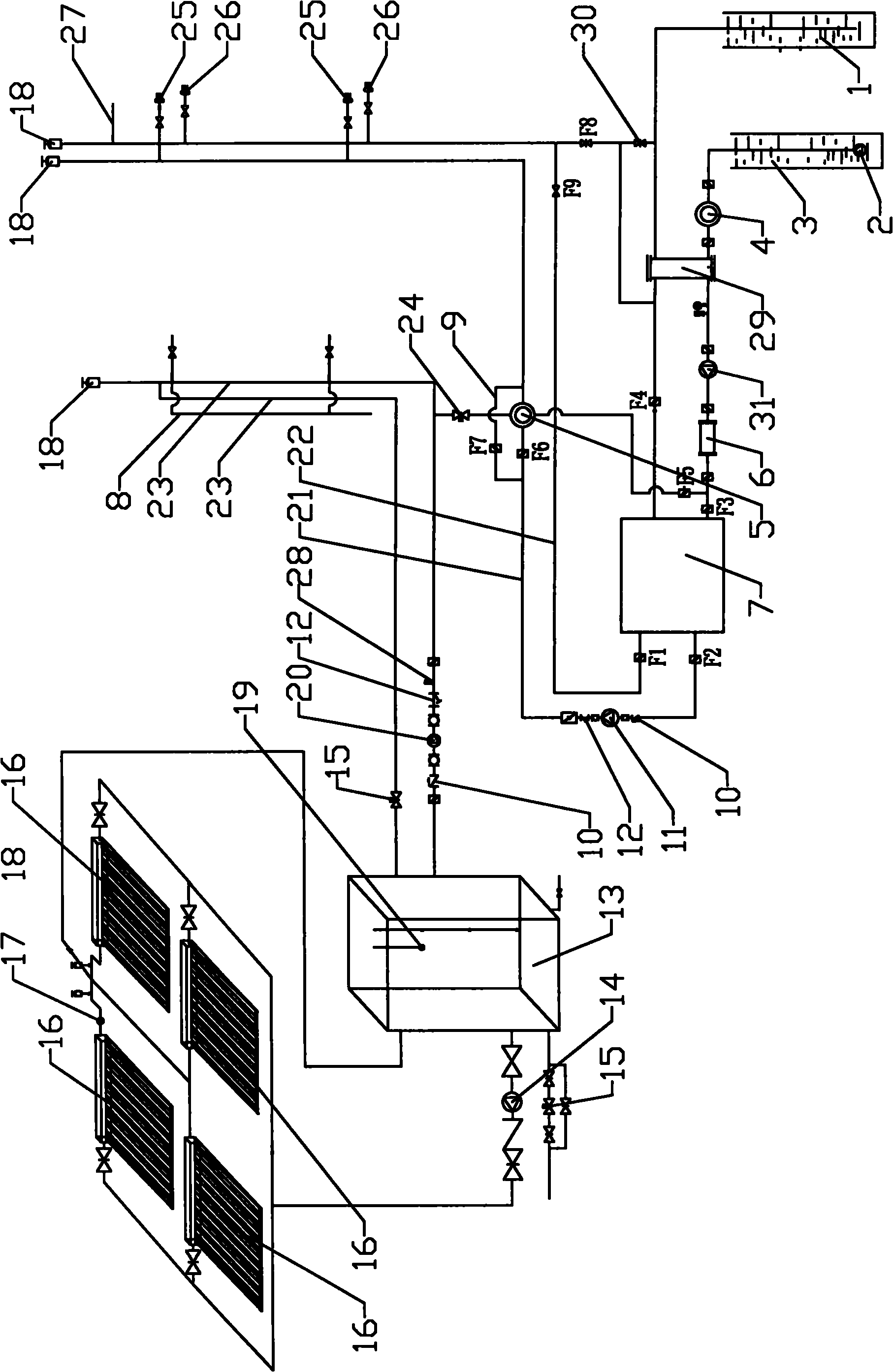

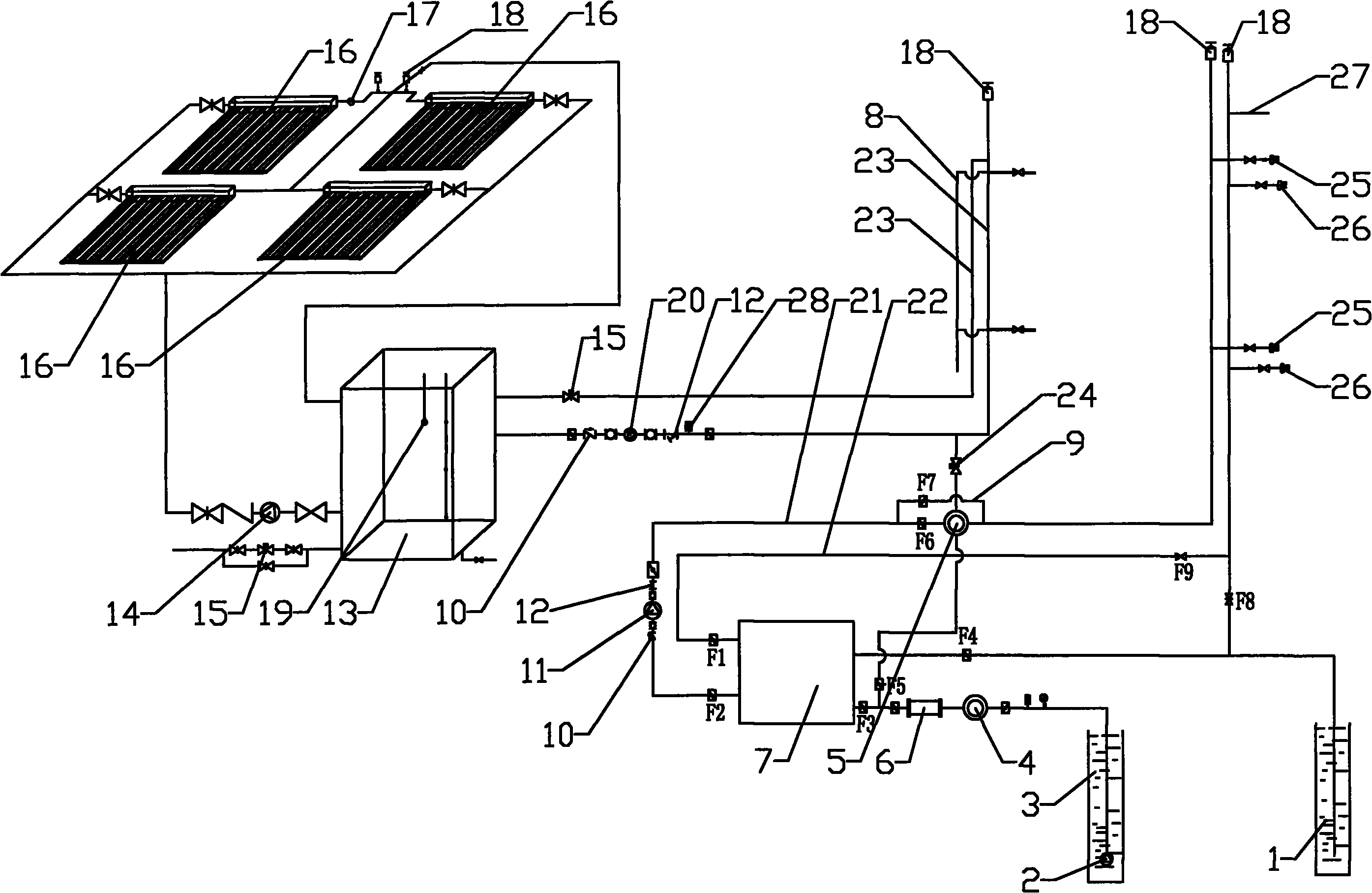

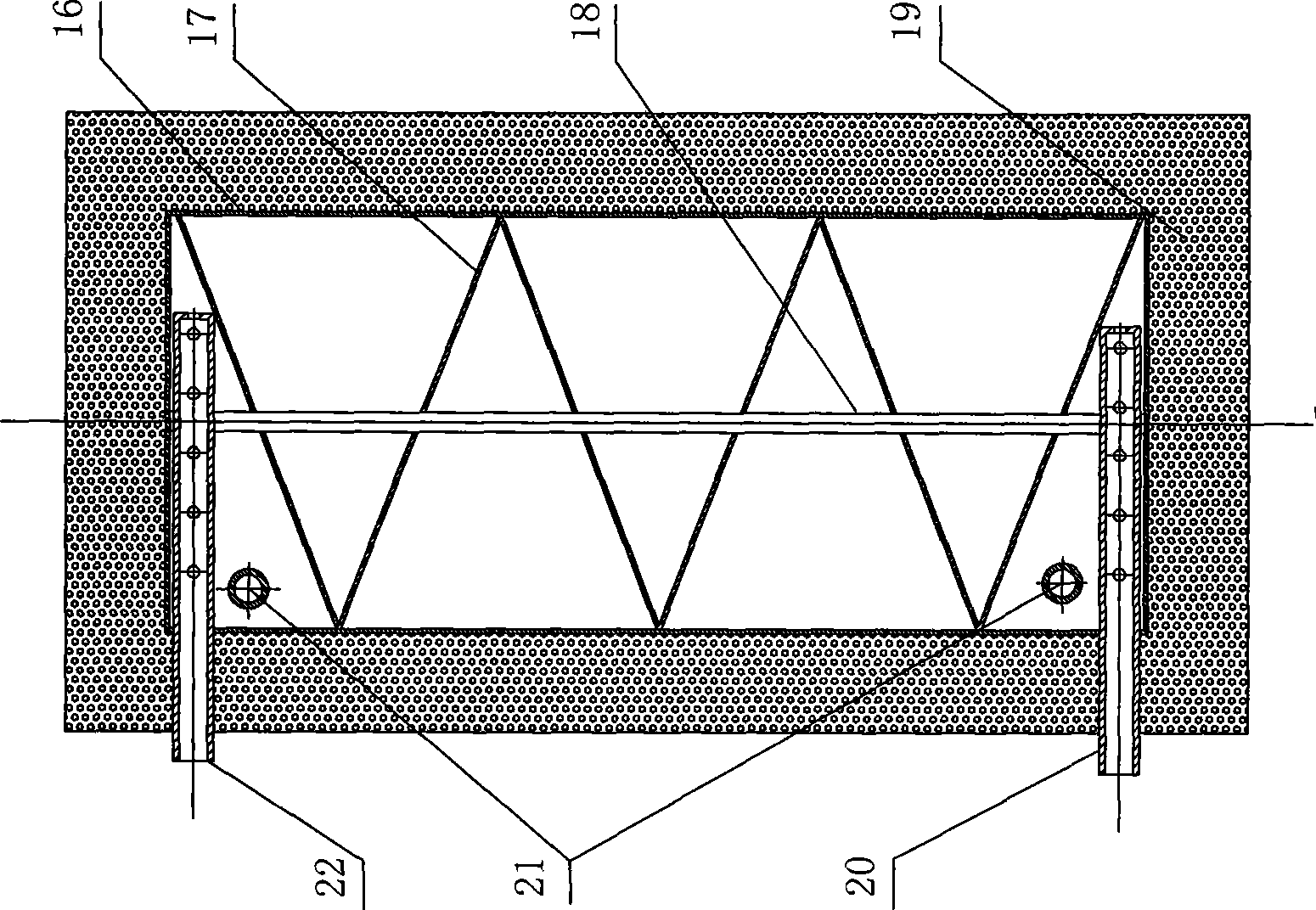

Low-temperature floor radiation heating and refrigerating system device

InactiveCN102155818ARealize heatingReach the temperature difference requirement to control the dew pointCondensate preventionHeating and refrigeration combinationsWater cyclingEngineering

The invention relates to a low-temperature floor radiation hearing and refrigerating system device, comprising a solar hot water circulating system and a heat pump circulating system, wherein the heat pump circulating system comprises a heat pump unit, an underground water circulating system, a main water supply pipe and a main water return pipe, a water inlet end of the heat pump unit is connected with the underground water circulating system and a water outlet end of the heat pump unit is connected with the main water supply pipe and the main water return pipe, the main water supply pipe isprovided with a temperature adjusting device which is connected with the solar hot water circulating system and the underground water circulating system via pipelines respectively, and the main waterreturn pipe is connected with the underground water circulating system via the pipeline; during refrigeration, hot water is fed to the main water supply pipe via the solar hot water circulating system, the temperature of the circulating water in the main water supply pipe is adjusted by the temperature adjusting device, the circulating water is adjusted to the temperature required by no condensation, the circulating water inside an indoor coil pipe is circulated on condition that the temperature of the circulating water is constantly controlled within the scope of dew point, thus the problem that condensed water can be generated by refrigeration in summer easily can be solved.

Owner:刘季林

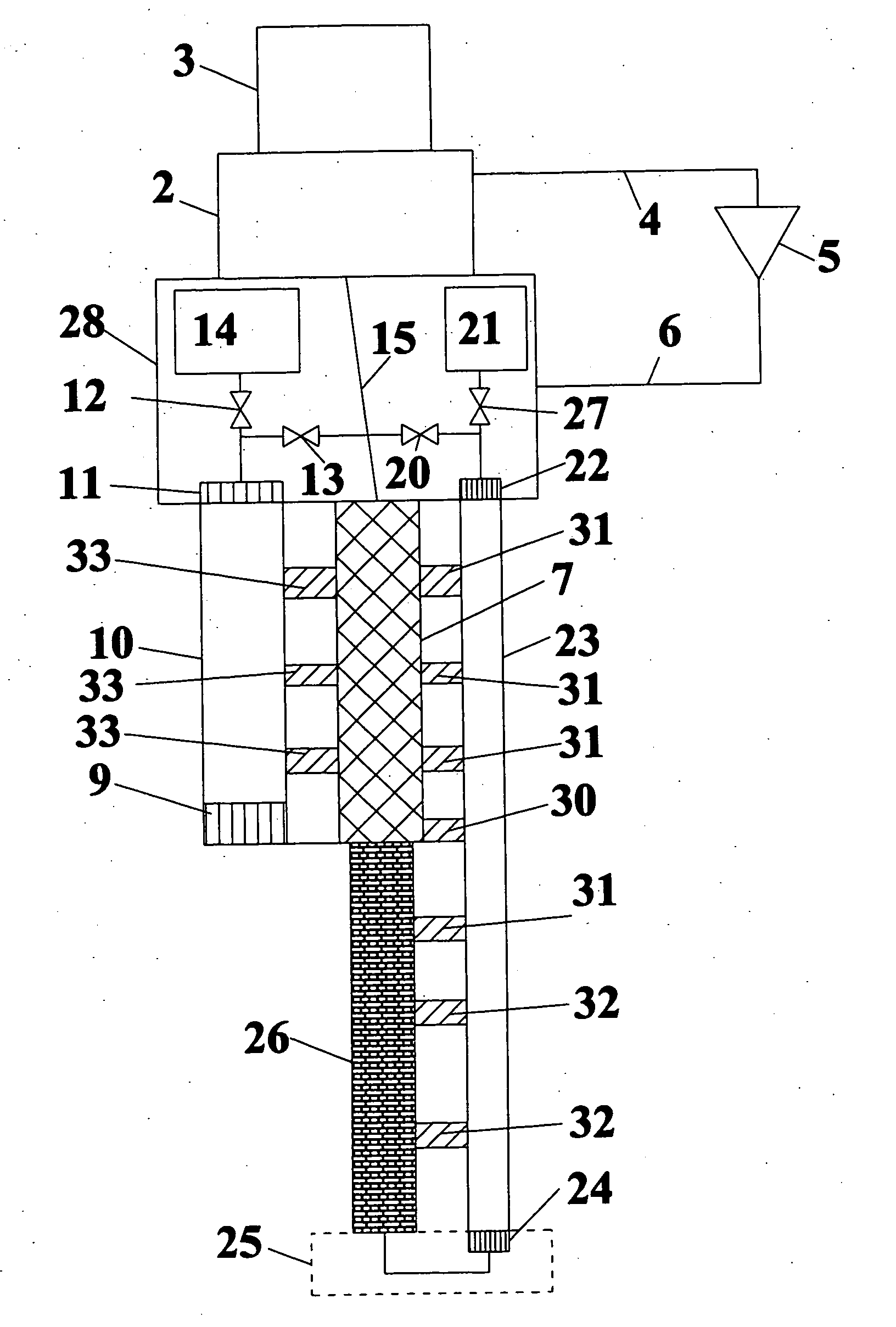

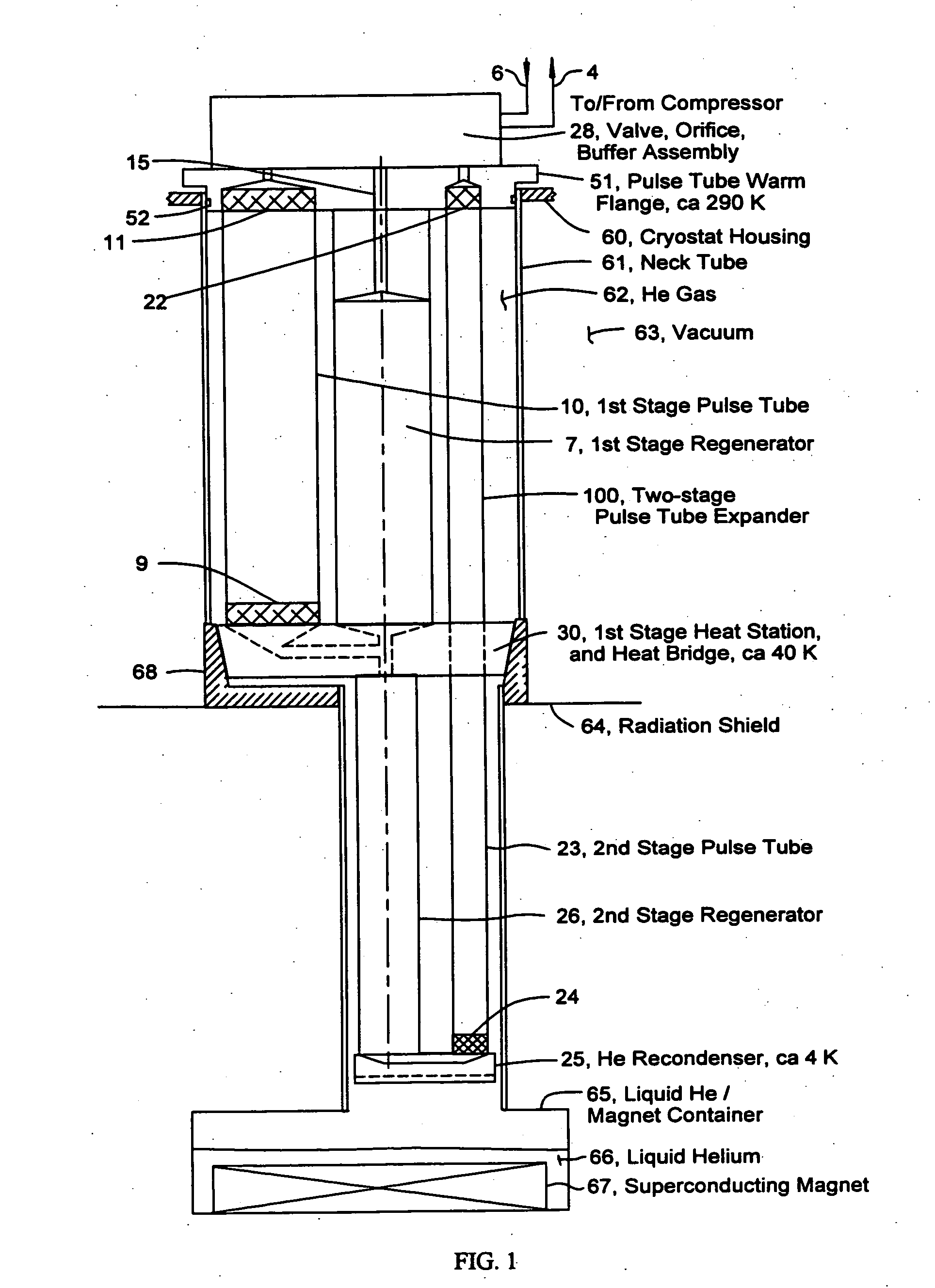

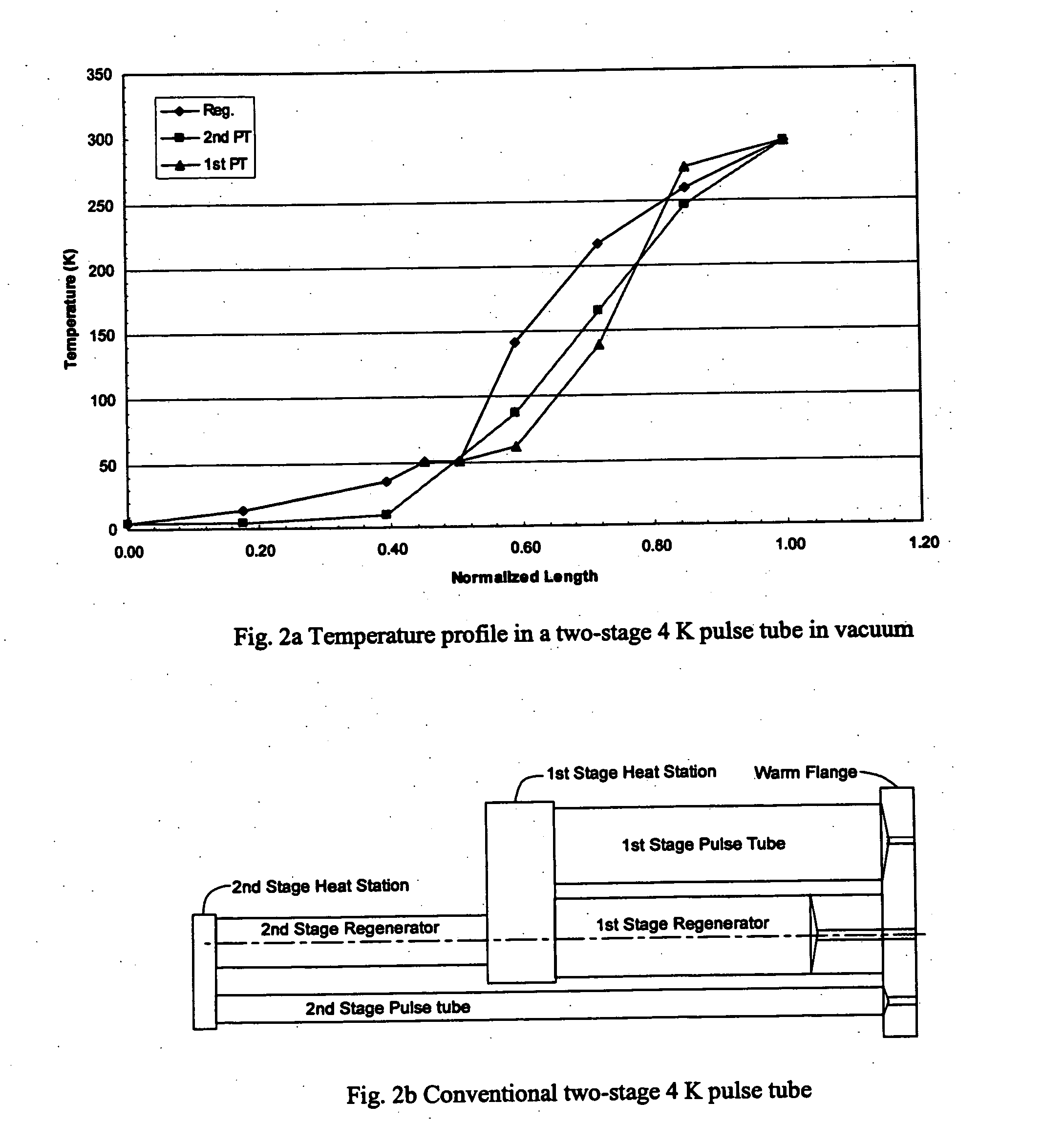

Multi-stage pulse tube with matched temperature profiles

ActiveUS20060174635A1Reduces convection lossReduce convectionCompression machinesRefrigeration devicesThermal bridgeEngineering

Convection losses associated with different temperature profiles in the pulse tubes and regenerators of multi-stage pulse tubes mounted in helium gas in the neck tube of a MRI cryostat are reduced by providing one or more of thermal bridges, and / or insulating sleeves between one or more pulse tubes and regenerators, and / or spacers, and spacer tubes, in one or more pulse tubes and regenerators.

Owner:SHI APD CRYOGENICS +1

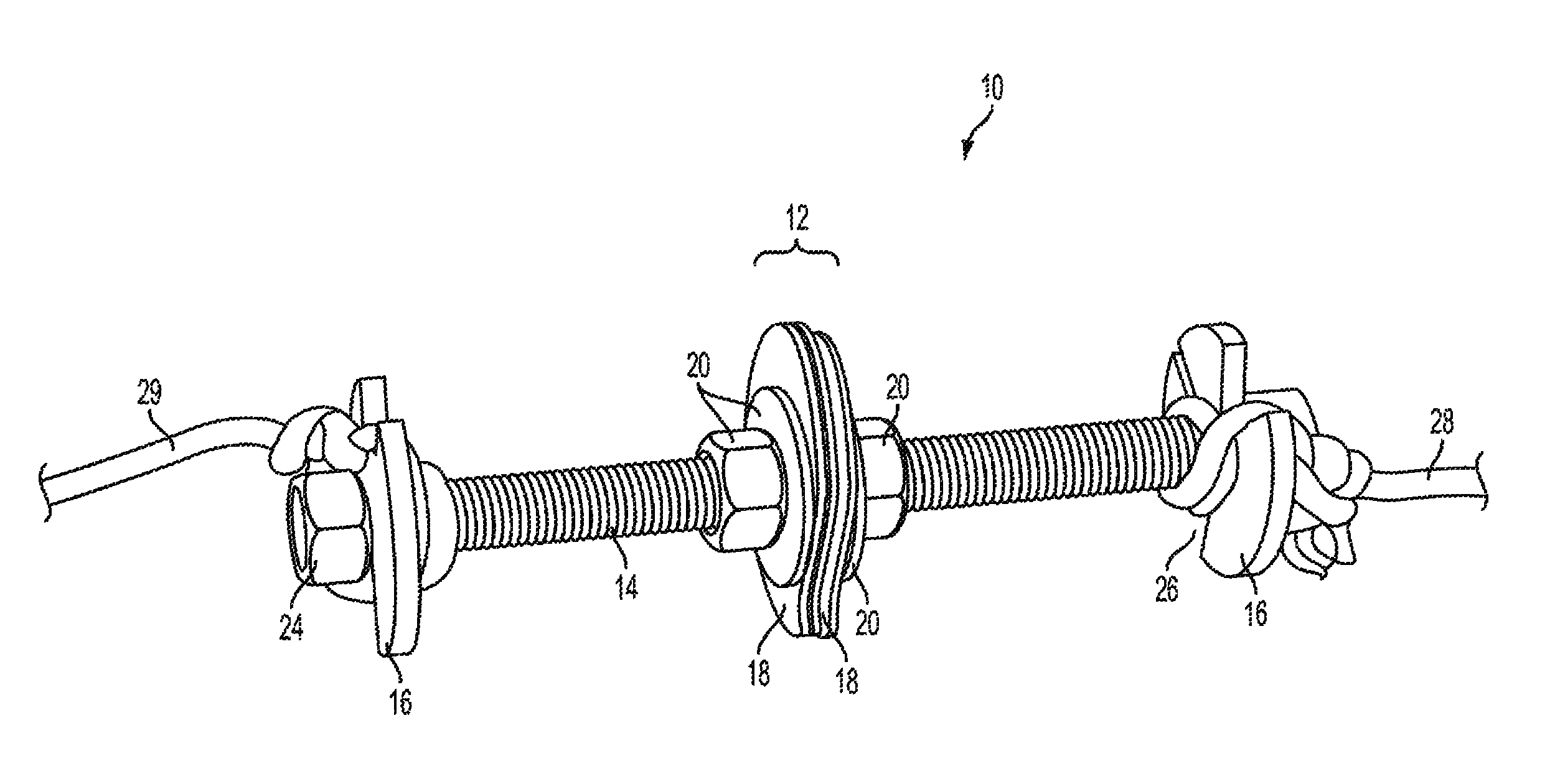

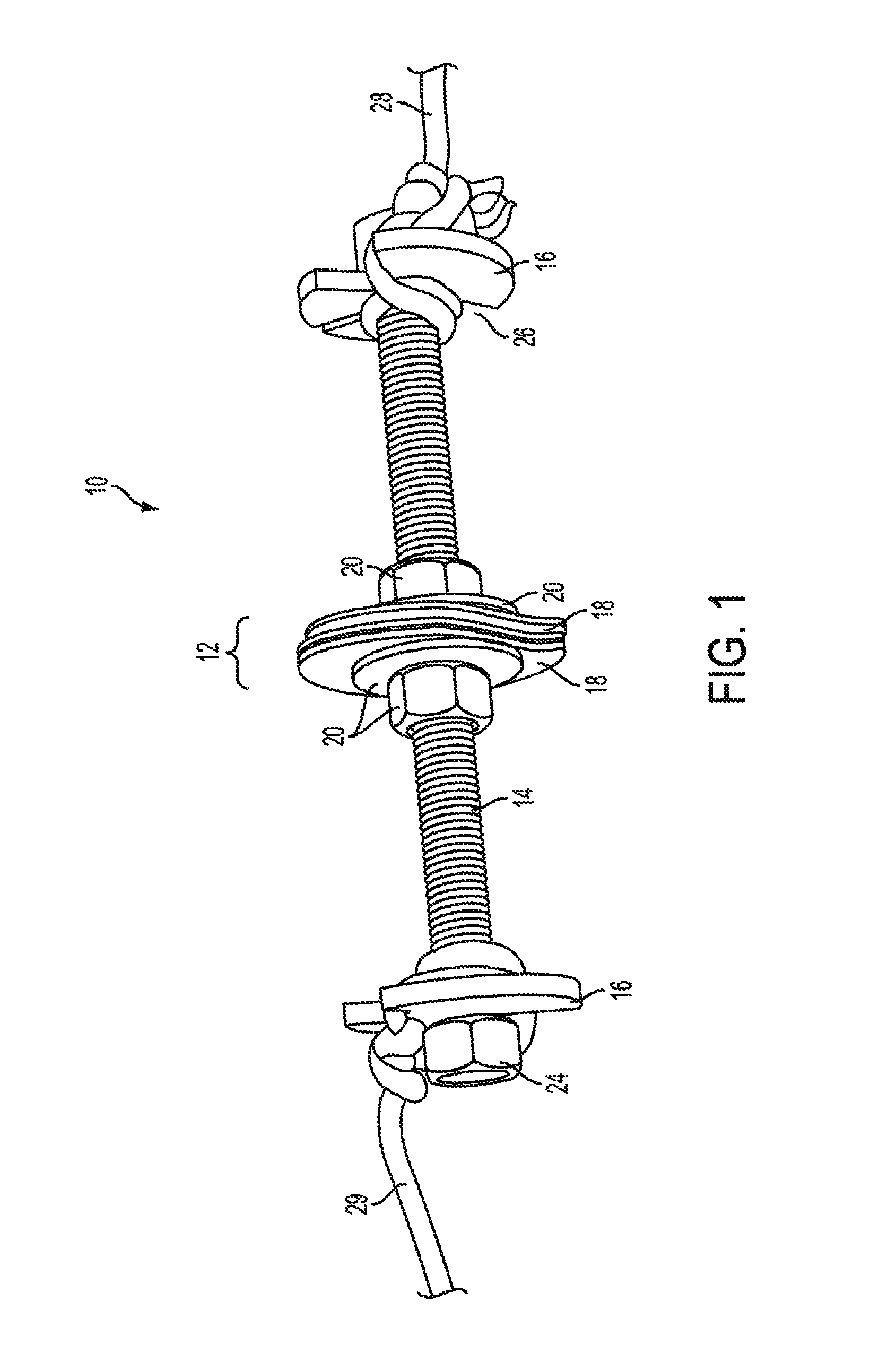

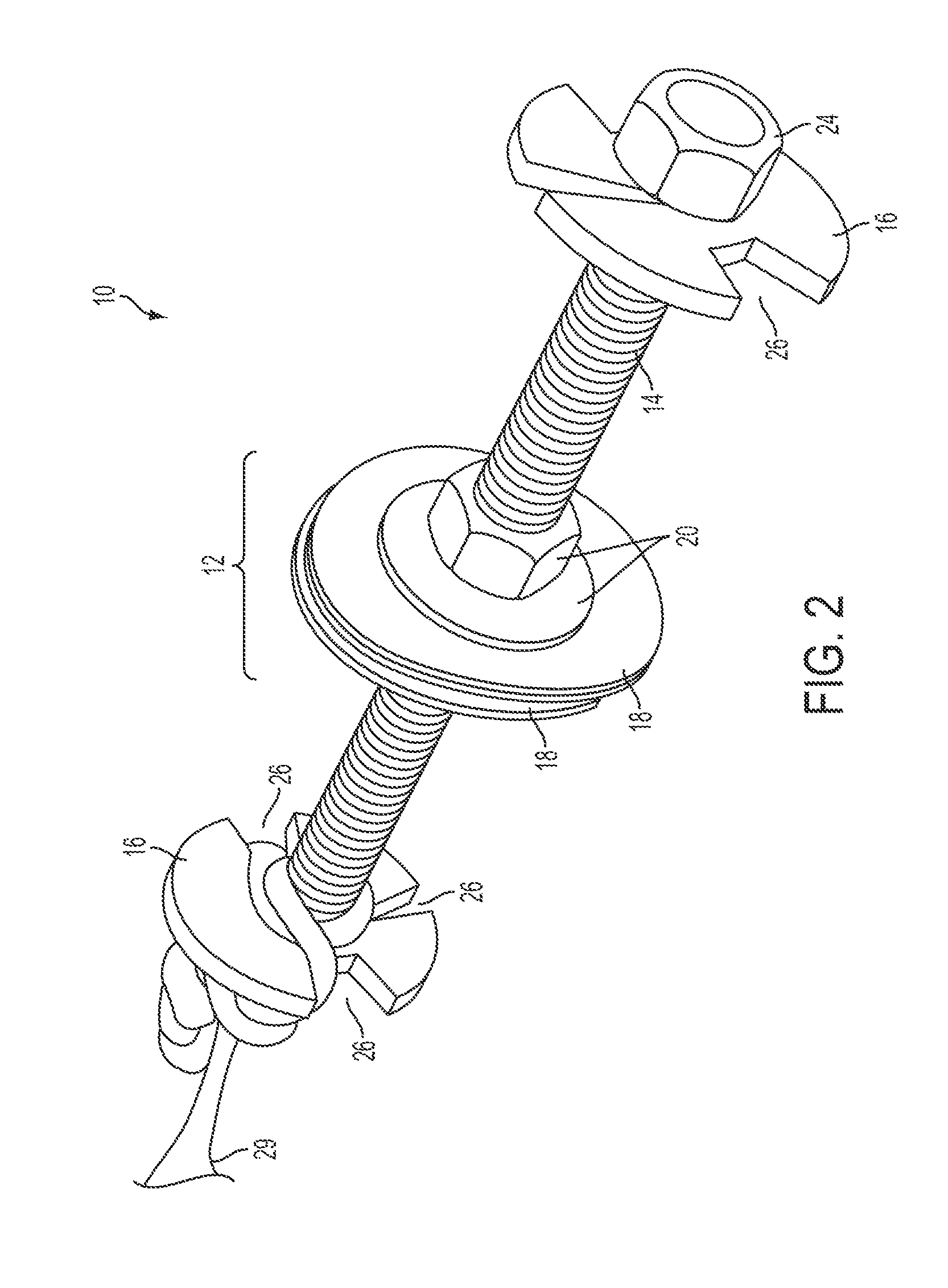

In-well baffle apparatus and method

InactiveUS7757757B1Mitigates in-well convectionReliable and reliableFluid removalWater conservationEngineeringMechanical engineering

A baffle apparatus and method for use in a well to mitigate convective in-well flow. The baffle apparatus includes a baffle member attached to a rod. The baffle member prevents vertical flow of water in the well after the baffle apparatus is deployed in the well. At least one centralizer is attached to the rod to maintain correct orientation of the baffle member within the well. The baffle member and the at least one centralizer allow well water to pass during deployment and recovery of the baffle apparatus.

Owner:U S A AS REPRESENTED BY THE SEC OF THE DEPT OF THE INTERIOR

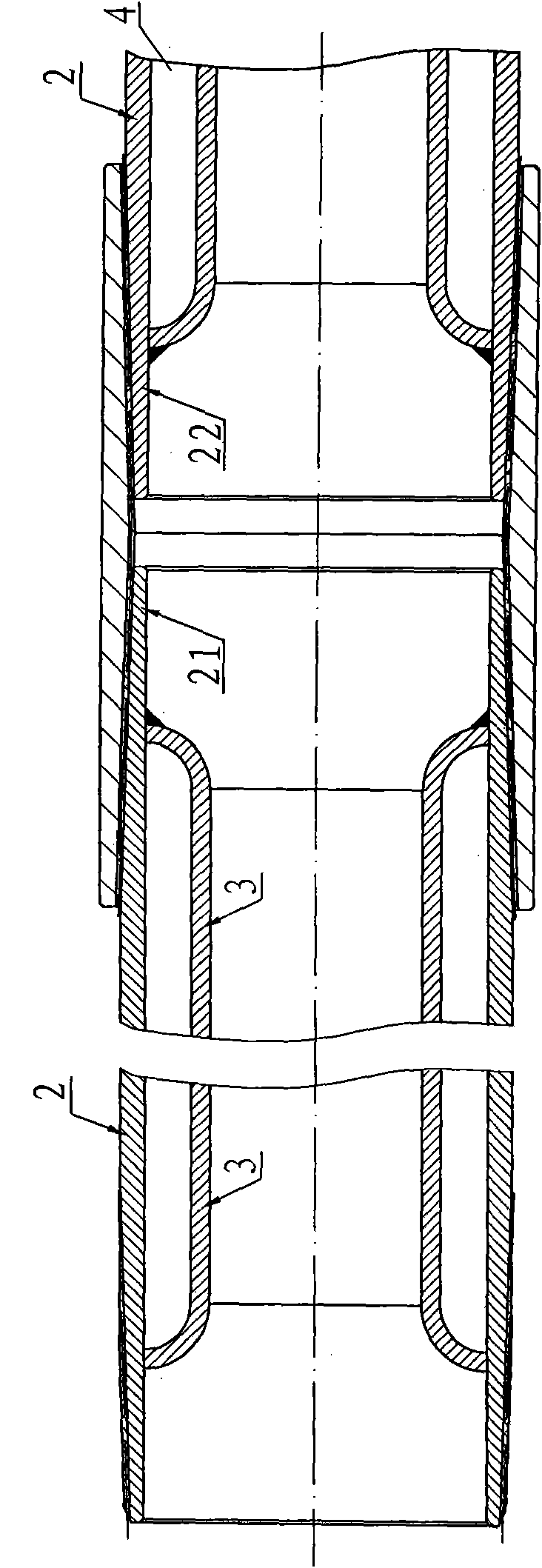

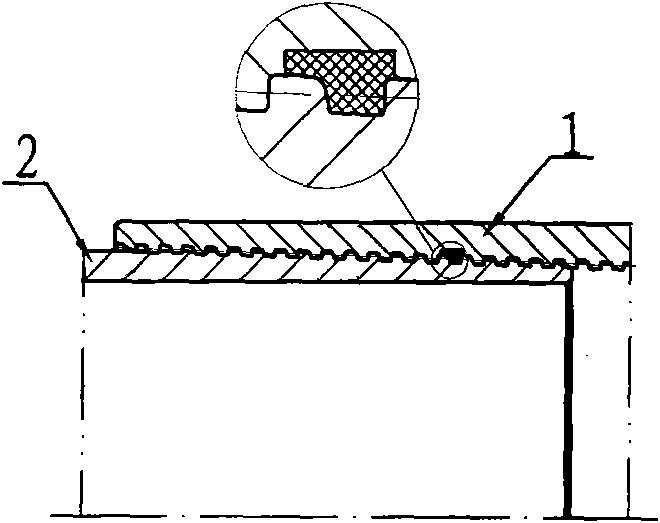

Structure for connecting heat insulation oil pipes

The invention discloses a structure for connecting heat insulation oil pipes, which comprises a coupling, an outer pipe factory end, an outer pipe user end, a pipe body inner pipe factory end, a pipe body inner pipe user end and a pipe end inner pipe, wherein the pipe end inner pipe is arranged between the pipe body inner pipe factory end and the pipe body inner pipe user end, and consists of a left pipe end inner pipe and a right pipe end inner pipe; one end of the left pipe end inner pipe is welded to the pipe body inner pipe factory end; one end of the right pipe end inner pipe is welded to the pipe body inner pipe user end; a sealed pipe end heat insulation cavity is formed between the pipe end inner pipe and the pipe body inner pipe factory end, the outer pipe factory end, the coupling, the pipe body inner pipe user end and the outer pipe user end; and a heat insulation sleeve is arranged in the pipe end heat insulation cavity. The pipe end inner pipe can reduce heat conduction, convection, radiation and heat loss at the coupling, improve the sealing performance of the heat insulation oil pipe coupling and prevent the problem that the heat insulation oil pipe coupling is easy to corrode at high temperature.

Owner:JIANGSU CHANGBAO STEELTUBE CO LTD

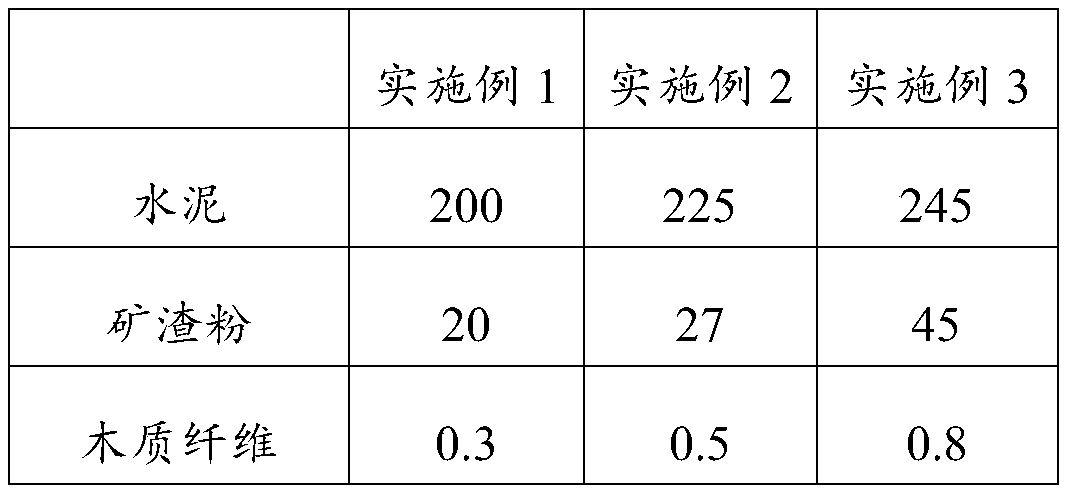

High-strength anti-cracking foam concrete and preparation method thereof

ActiveCN110105013AGuaranteed compressive strengthReduce surface tensionCeramicwareFiberFoam concrete

The invention relates to high-strength anti-cracking foam concrete and a preparation method thereof. The high-strength anti-cracking foam concrete comprises, by weight, 200-240 parts of cement, 20-45parts of slag powder, 80-120 parts of water, 1-3 parts of a waterproof agent, 1-5 parts of foaming agents, 0.2-0.5 part of a foam stabilizer, 45-70 parts of lightweight aggregate and 0.3-0.8 part of wood fiber. A double foaming method using the physical foaming agent and the chemical foaming agent is utilized, and the wood fiber is also used so that a large quantity of stable closed air holes canbe formed in the foam concrete, convection and radiation effects in the air holes can be weakened, the water absorption rate of the material is reduced, and meanwhile, the heat conductivity coefficient of the high-strength anti-cracking foam concrete is lower. Due to the double foaming method, the properties of the materials such as the cement, the slag powder and the wood fiber can be fully achieved, and the high-strength anti-cracking foam concrete with the strength and crack resistance better than those of conventional foam concrete is obtained.

Owner:CHINA FIRST METALLURGICAL GROUP

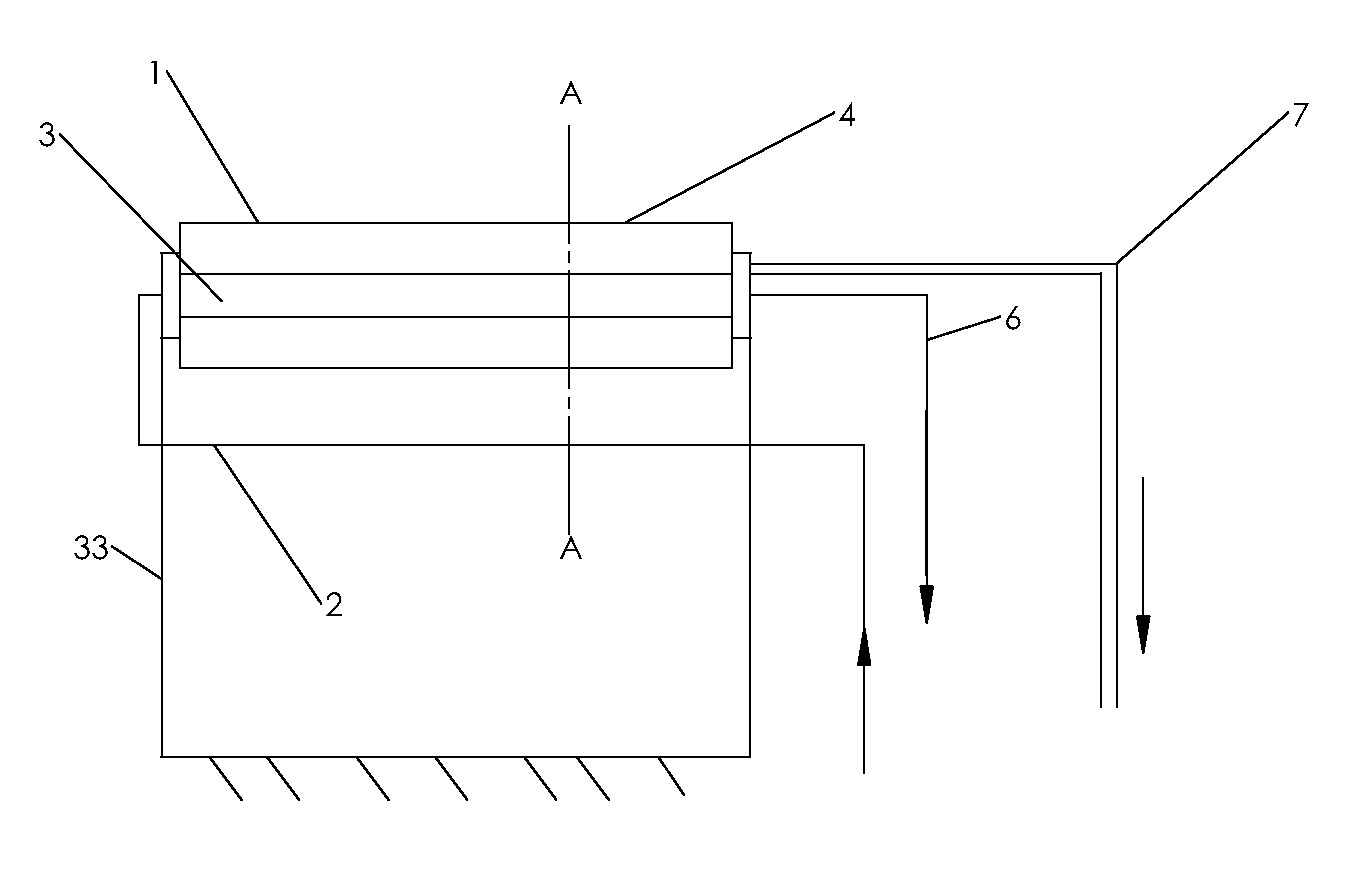

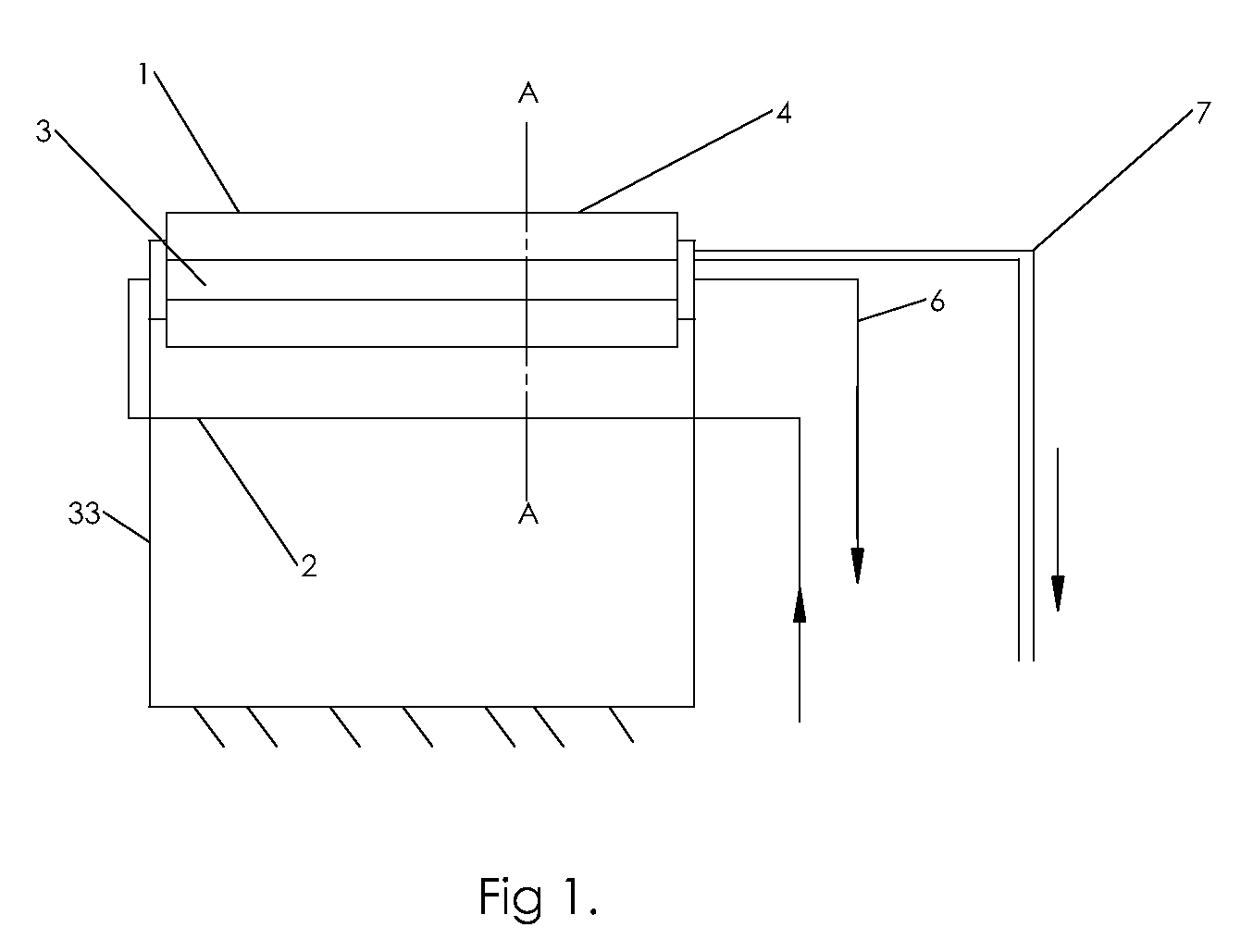

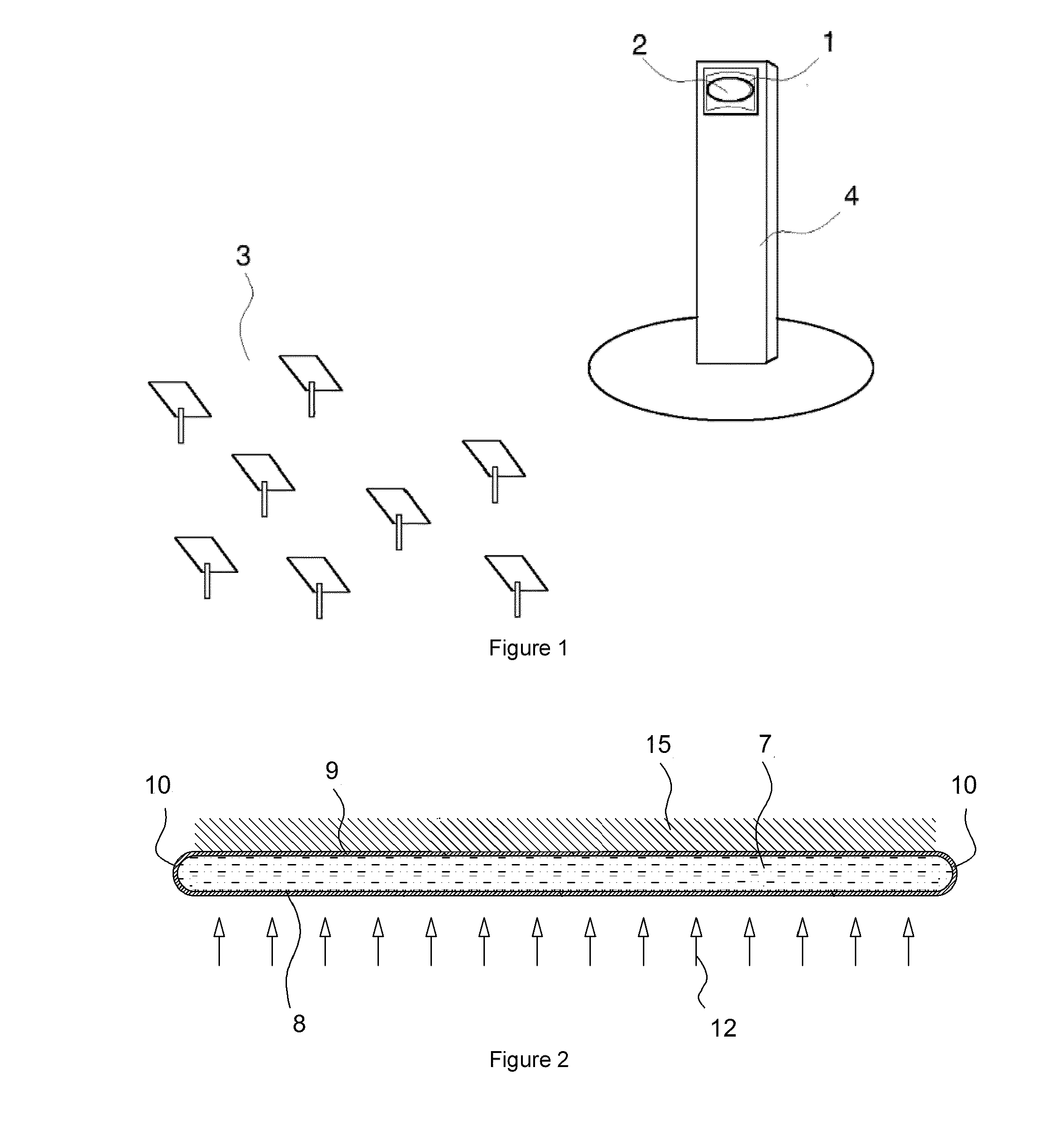

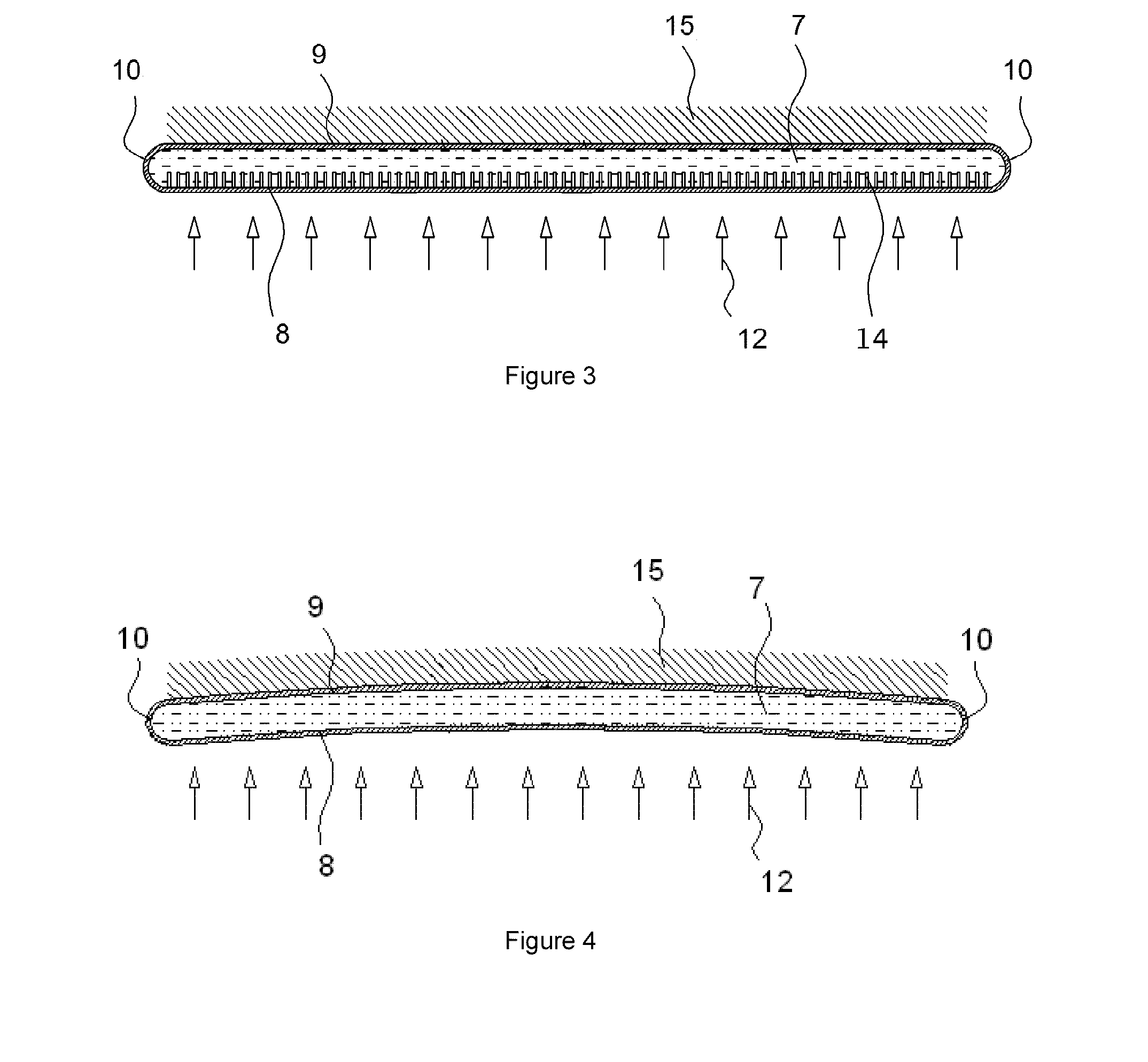

Panel-based solar receiver

InactiveUS20150020793A1Reduce convectionEasy to depositSolar heating energySolar heat collector controllersPower stationHeat transfer fluid

The invention relates to a panel-based solar receiver for a thermal solar tower power plant (4), which comprises: a front panel (8), the external surface of which receives solar radiation (2) from the field of heliostats (3), a back panel (9), sealing elements (10) between the panels (8, 9), arranged at the lateral ends of both, an intake collector (5), located in the upper part of the panels (8,9), where the heat transfer fluid enters the receiver (1) and an evacuation collector (6), located in the lower part of the panels (8, 9), where the heat transfer fluid leaves the receiver (1); wherein the front panel (8), back panel (9) and the two sealing elements (10) form the receiver body (16), which constitutes a passage for the heat transfer fluid (7) to travel through. Each solar tower can contain one or several panel-based receivers (1) and be arranged in series or in parallel, with the same or a different fluid (7) circulating there through.

Owner:ABENGOA SOLAR NEW TECH SA +1

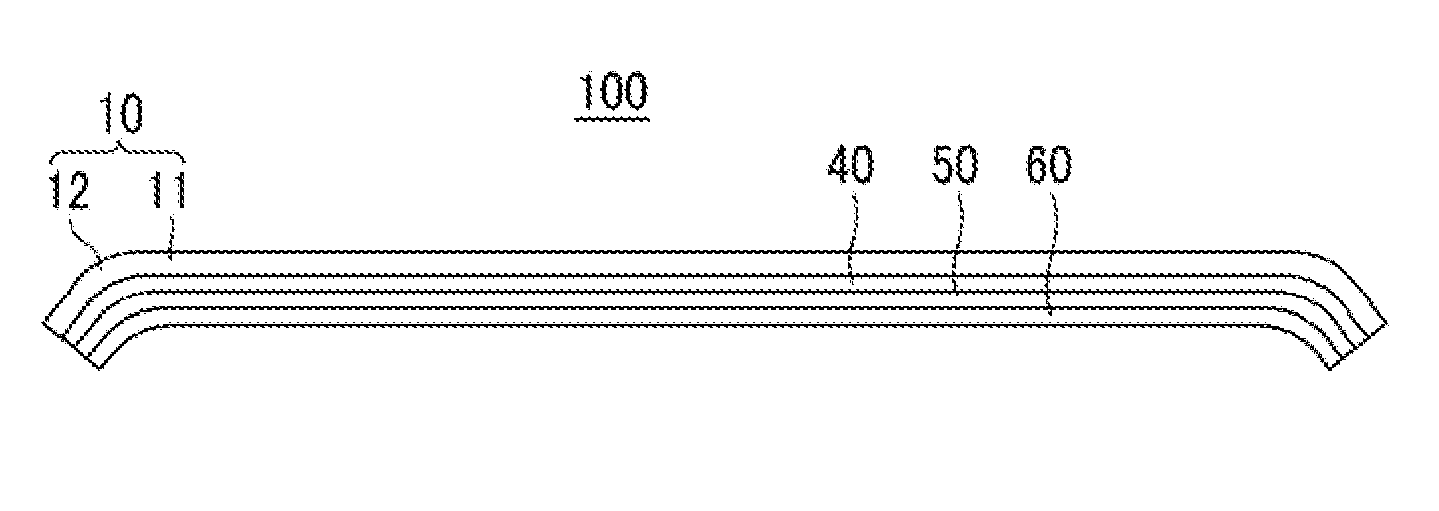

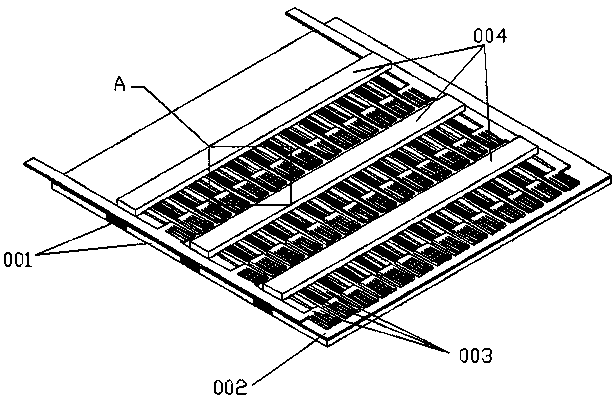

Planar flexible thermoelectric power generation structure

InactiveCN104183691AGood temperature distribution characteristicsImprove thermal conductivityThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentEngineeringProtection layer

The invention discloses a planar flexible thermoelectric power generation structure which includes a thermal conduction layer, an insulating layer, a power generation layer and a hot-end protective layer, which are sequentially arrayed and laid from bottom to top. All of the thermal conduction layer, the insulating layer, the power generation layer and the hot-end protective layer adopt flexible materials. A first flexible material and a second flexible material are closely arrayed alternatively so that the thermal conduction layer is formed. The hot-end protective layer is a flexible insulating strip. Both of the heat conduction factors of the first flexible material and the flexible insulating strip are lower than the heat conduction factor of the second flexible material. The structure increases protection of a hot end and heat radiation of a cold end, improves the temperature gradient of a thermoelectric power generator and further improves an output power and an output voltage. The thermal conduction layer provides a temperature gradient needed by the thermoelectric power generator and has a support function; the flexible materials are adopted so that compared with a rigid thermoelectric power generation device, the power generation structure is flexible, light and convenient and capable of better fitting to the plane; and the power generation structure is simple in structure and manufacturing process and capable of realizing mass production, and has an excellent application prospect.

Owner:ZHEJIANG UNIV

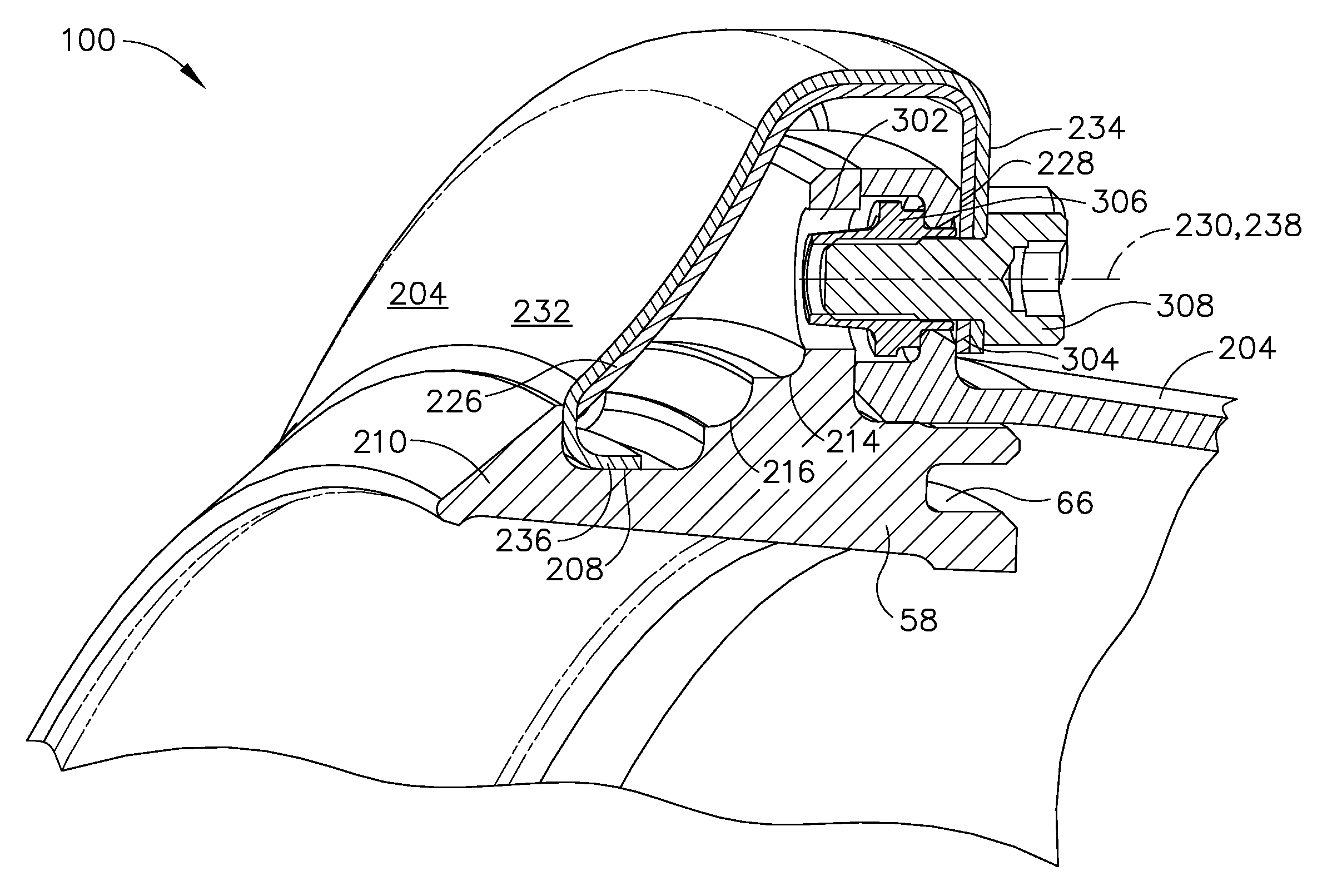

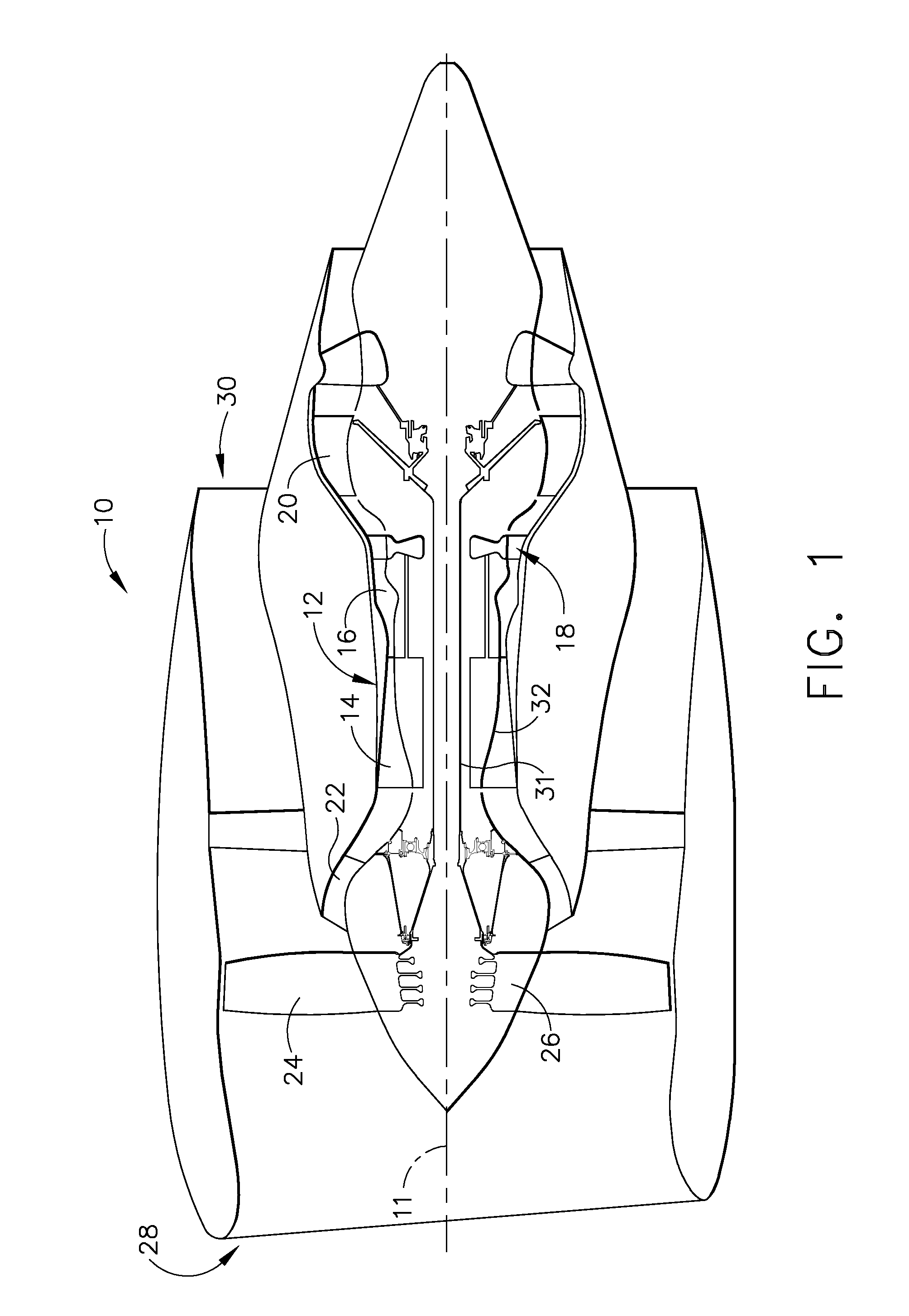

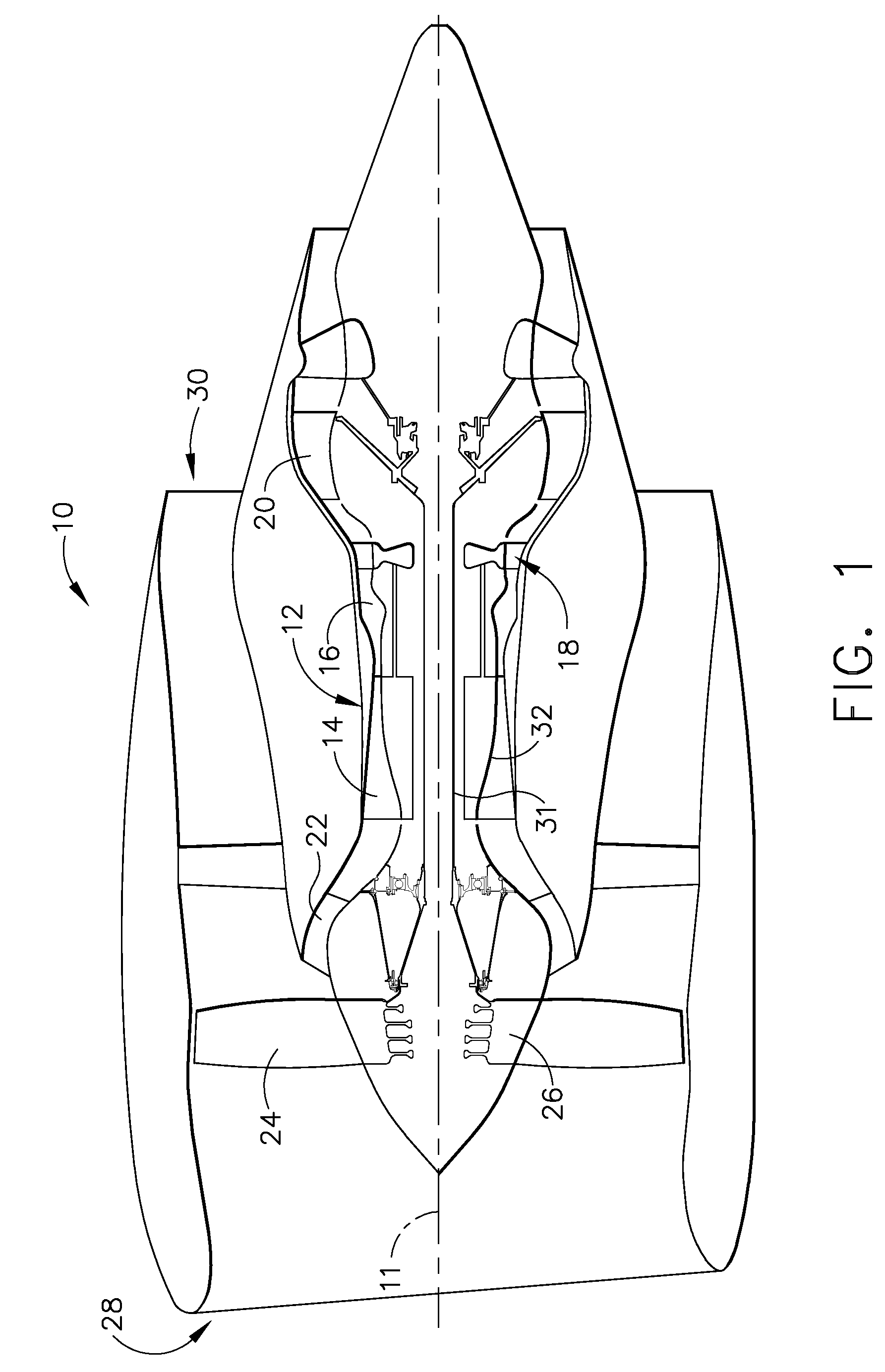

Method and apparatus to facilitate reducing losses in turbine engines

ActiveUS20080120841A1Reduce convectionReducing aerodynamicPump componentsReaction enginesTurbineConvection

A method for assembling a compressor for use with a turbine is provided. The method includes coupling at least a first stator ring to a second stator ring via at least one fastener sized to extend through at least one stator ring opening. The method further includes coupling a shield assembly to at least one of the first stator ring and the second stator ring to facilitate reducing convection and aerodynamic bleed losses of the at least one stator ring. The shield assembly includes a downstream surface, a retaining portion, and a contoured upstream surface extending from the downstream surface to the retaining portion.

Owner:GENERAL ELECTRIC CO

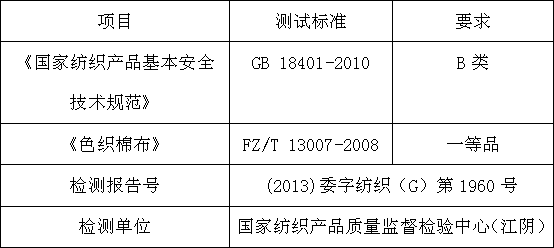

Super cotton-like cashmere double-side fabric and production process thereof

InactiveCN103276500AMaintain propertiesConvenient careFibre treatmentMulti-ply fabricsYarnPolymer science

The invention relates to super cotton-like cashmere double-side fabric. The super cotton-like cashmere double-side fabric is characterized by being made of supercool / cotton blended yarn, cotton / cashmerino blended yarn, and mercerized gassed woolen yarn. The super cotton-like cashmere double-side fabric is in double-side weave; warps are made of 7.3tex Supercool / cotton blended yarn; and accordingly the whole cover of the fabric reveals no warp but weft, the weft front side of the fabric is made of 18.2tex mercerized gassed woolen yarn, and the weft reverse side is made of 18.2tex cotton / cashmerino blended yarn. Super cotton-like fiber is high in strength, wear-resistant, highly breathable, antistatic, wrinkle-resistant, and as warm as cashmerino. With perfect combination of wefts and warps by the special double-side weave, the fabric looks and feels different on two sides.

Owner:江苏保丹服饰有限公司

Cryostat for transporting cooled equipment at a cryogenic temperature

InactiveCN101221000AReduce convectionSuperconductors/hyperconductorsThermal insulationProcess engineeringContamination

A cryostat for transporting cooled equipment at an upper cryogenic temperature, the cryostat being arranged to cool the cooled equipment by a working cryogen which boils at a lower cryogenic temperature, comprising a vacuum container surrounding the cooled equipment and defining a nominally evacuated layer between the vacuum container and the cooled equipment. Means are provided to reduce contamination of the nominally evacuated layer by a vacuum contaminant which is present in gaseous form within the evacuated layer at the upper cryogenic temperature, but which is retained in liquid or solid form at the lower cryogenic temperature.

Owner:SIEMENS MAGNET TECH

Spiral plate type bearing water tank

A spiral plate pressure water storage tank is characterized in that an inner container of a pressure water tank is set as a cylinder body, a deflector is spirally arranged by surrounding a shaft line of the cylinder body, a cold water port is formed on the side wall of the bottom part of the inner container of pressure water tank and positioned in a bottom layer of the deflector, a hot water port is formed on the side wall of the top part of the inner container of the pressure water tank and positioned in a top layer of the deflector, and a spiral water flow channel is formed along the deflector between the cold water port and the hot water port. The spiral plate pressure water storage tank can not only retain the advantages on the water supply pressure aspect of the pressure water tank, but also effectively improve the hot water efficiency, simultaneously simplify the structure, reduce the cost and miniaturize the water tank.

Owner:滁州扬子必威中央空调有限公司

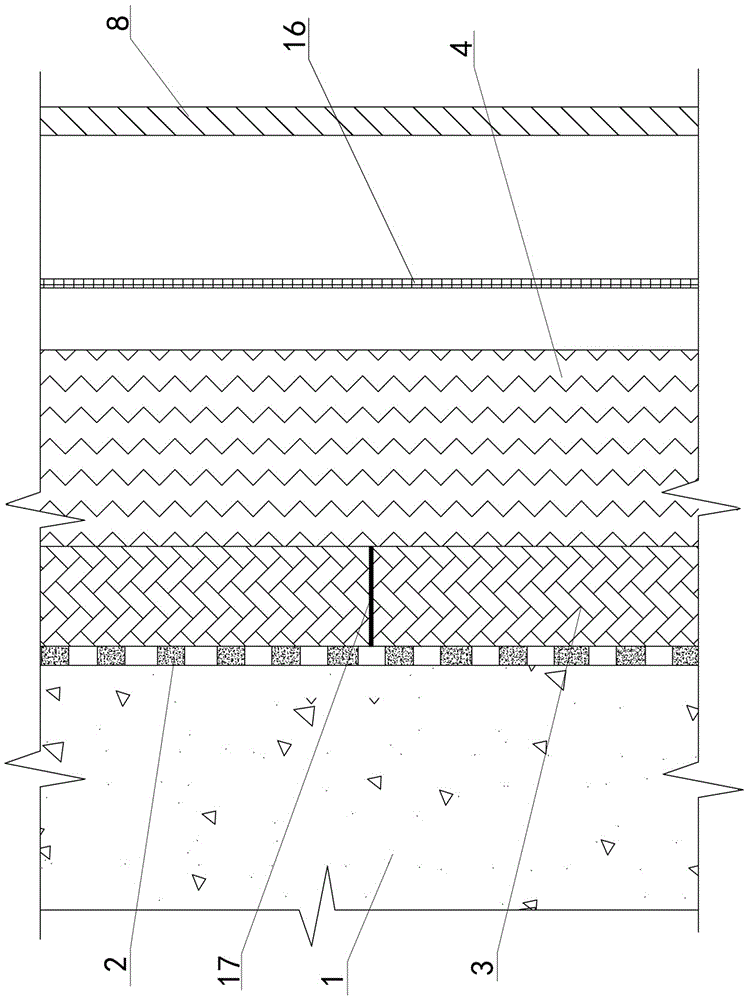

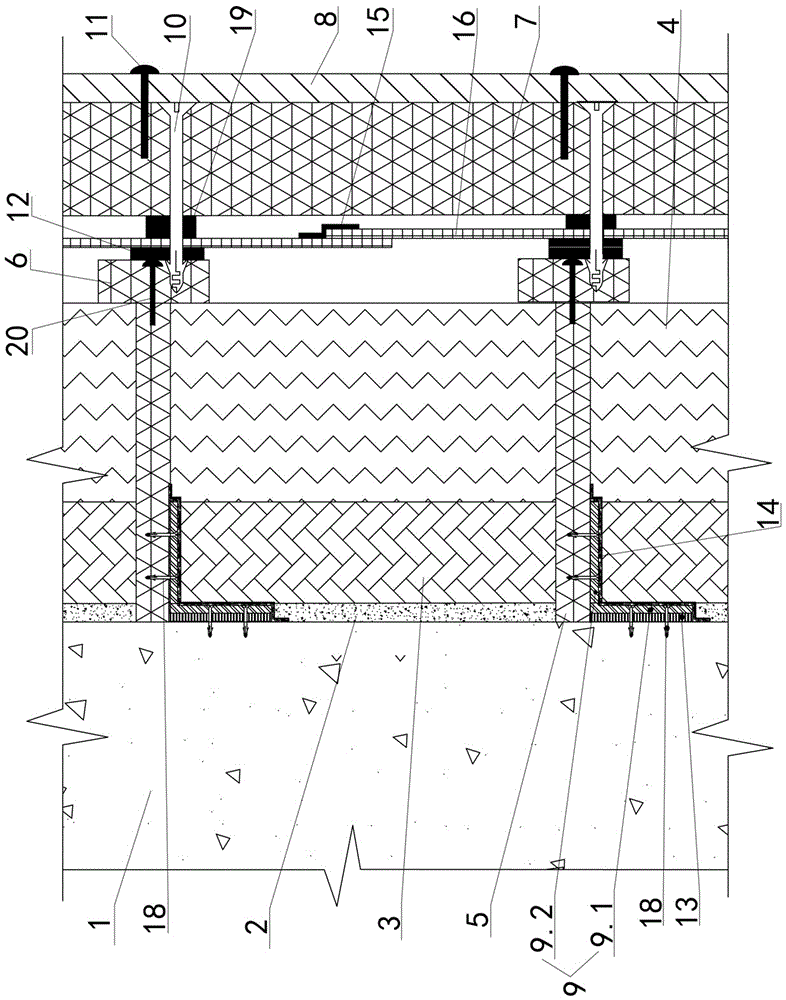

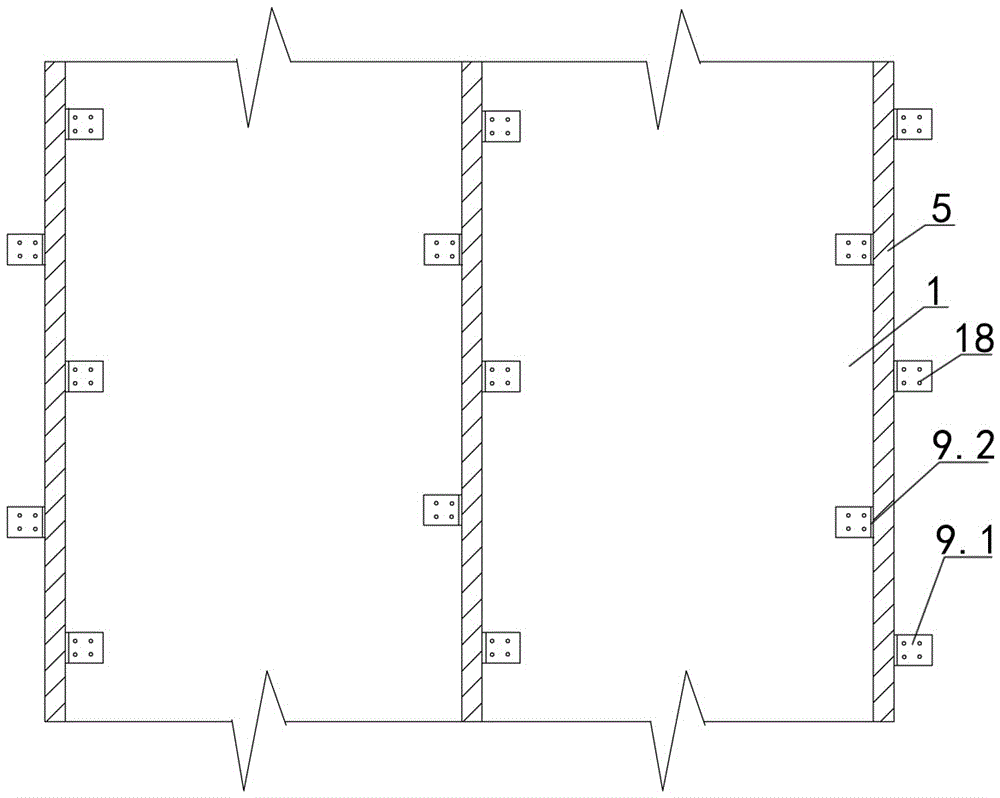

Ultralow-energy-consumption passive building vacuum insulation plate and rock wool composite wall and construction method thereof

ActiveCN106245811AReduce thicknessReduce convectionCovering/liningsWallsInsulation layerThermal insulation

Provided are an ultralow-energy-consumption passive building vacuum insulation plate and rock wool composite wall and a construction method thereof. The wall comprises bottom vertical keels, a composite insulation layer, end seal plate keels, an airtight layer, outer transverse keels, and decorative panels, the composite insulation layer comprises vacuum insulation plates and rock wool plates, the composite insulation layer fills spacing among the bottom vertical keels, the end seal plate keels are fixed to the bottom vertical keels, the airtight layer is spread on the whole wall, the outer transverse keels are arranged in transverse parallel on the surface of the airtight layer and are fixed to the end seal plate keels, and the decorative panels are fixed to the outer transverse keels. The construction method comprises the steps of layout designing, mounting of the outer transverse keels, mounting of the decorative panels and the like. The construction of the insulation system is insusceptible to external environments and is widely applicable to newly-built, extended and reconstructed civil buildings that require thermal insulation.

Owner:北京住总集团有限责任公司

Method and apparatus to facilitate reducing losses in turbine engines

A method for assembling a compressor for use with a turbine is provided. The method includes coupling at least a first stator ring to a second stator ring via at least one fastener sized to extend through at least one stator ring opening. The method further includes coupling a shield assembly to at least one of the first stator ring and the second stator ring to facilitate reducing convection and aerodynamic bleed losses of the at least one stator ring. The shield assembly includes a downstream surface, a retaining portion, and a contoured upstream surface extending from the downstream surface to the retaining portion.

Owner:GENERAL ELECTRIC CO

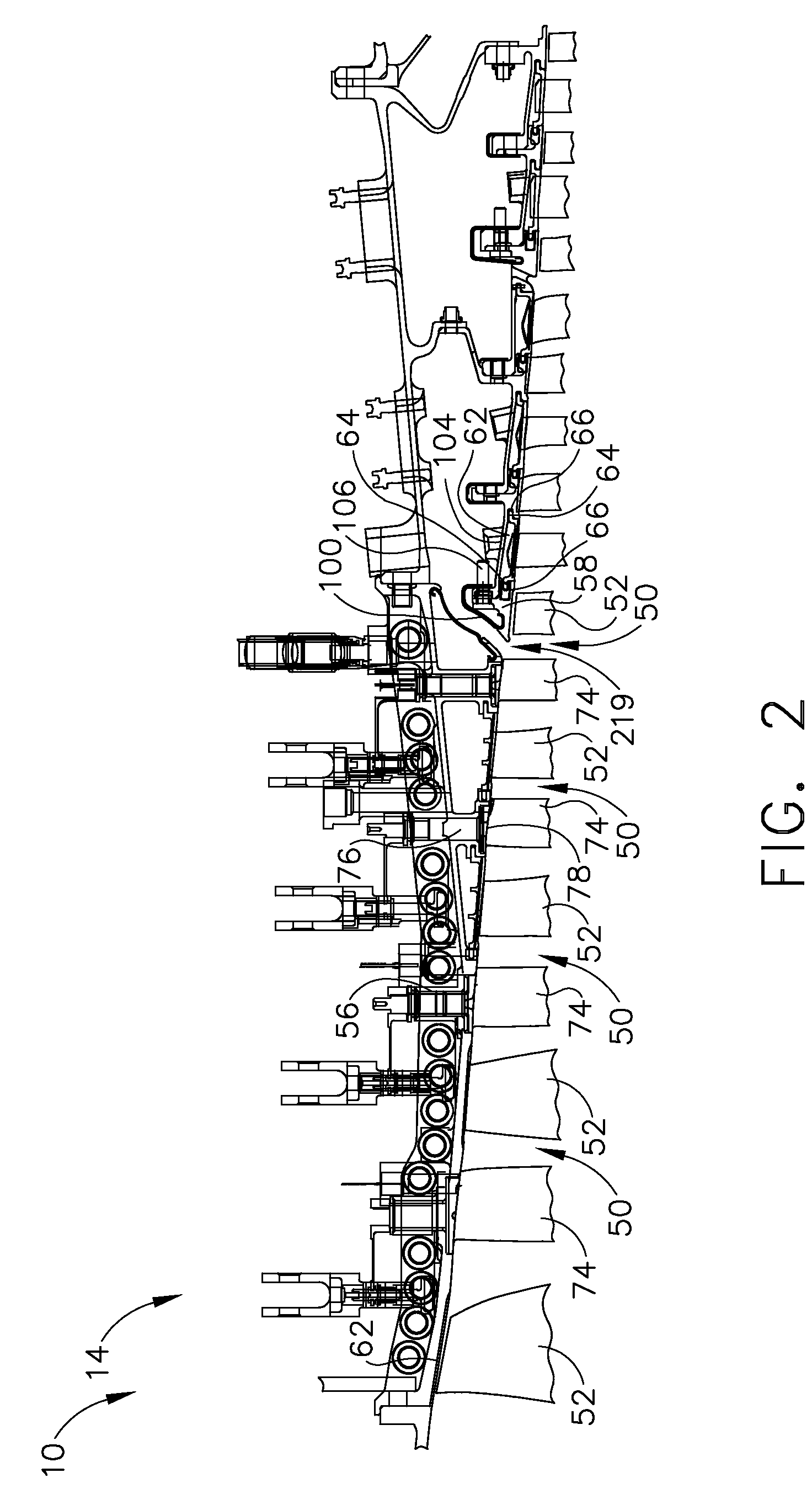

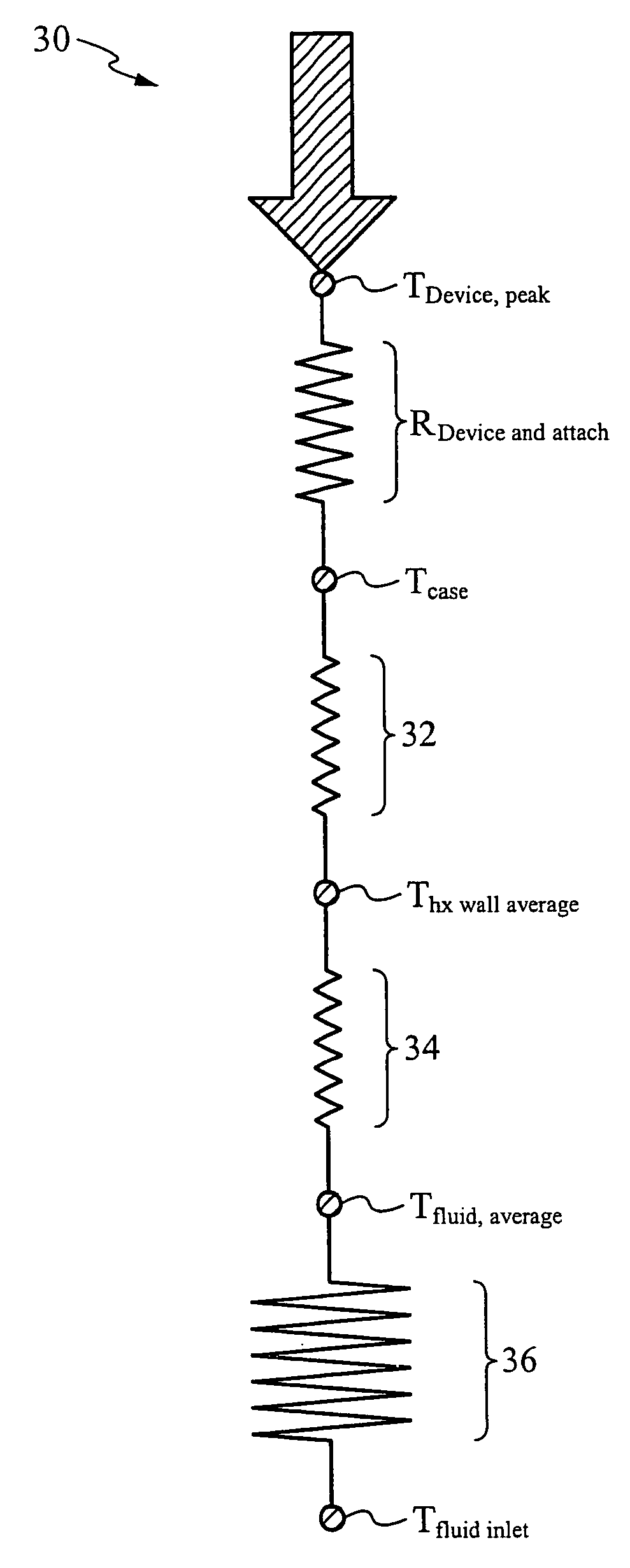

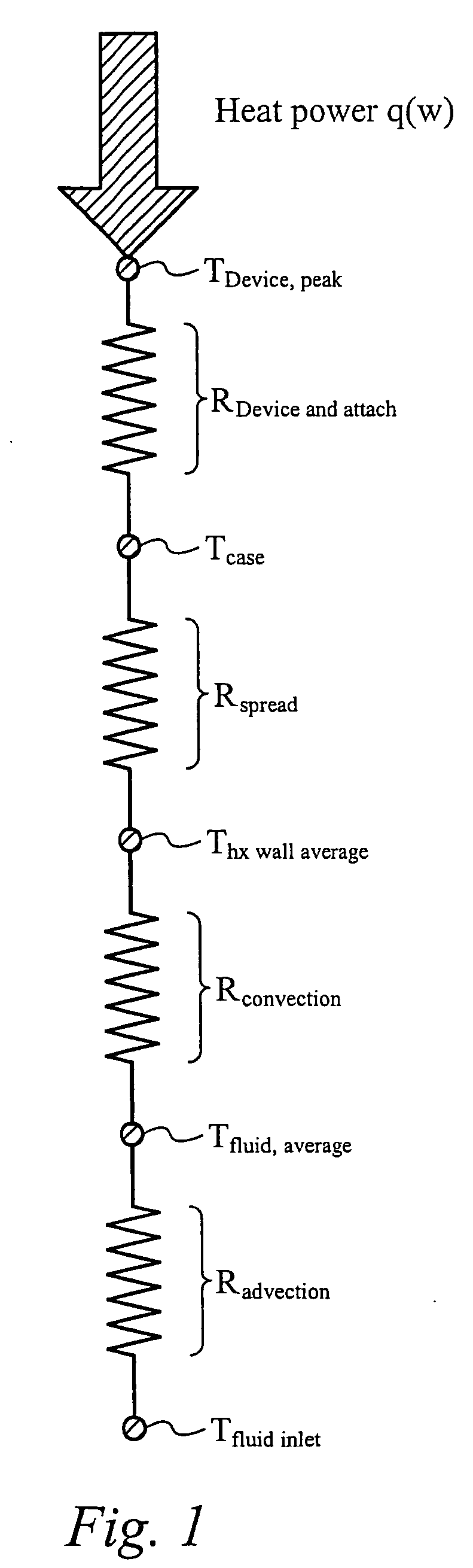

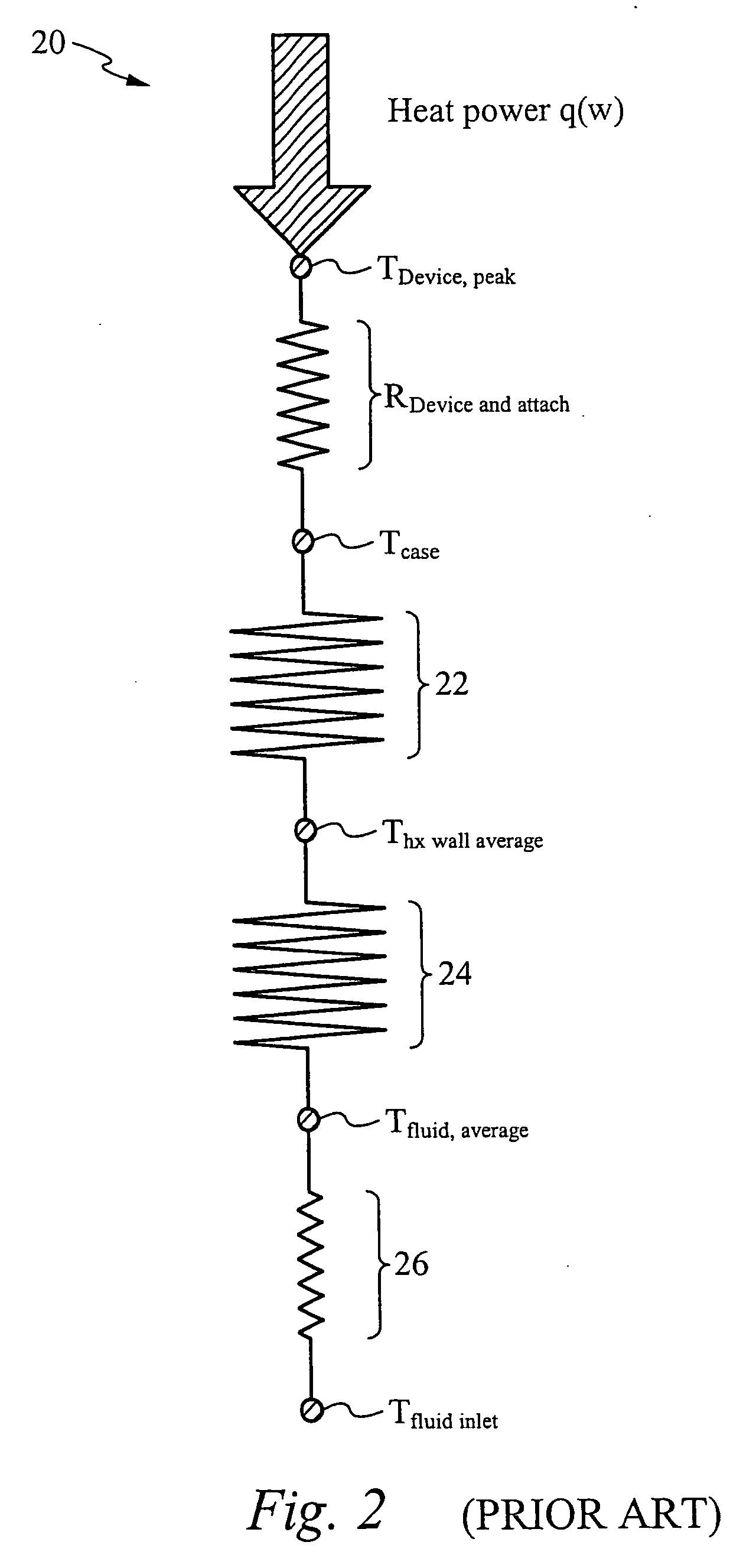

Pumped fluid cooling system and method

InactiveUS20060042785A1Reduce transmission resistanceEfficiently cooling a deviceHeat exchanger casingsLaminated elementsRelative magnitudeWorking fluid

The present invention is a pumped fluid cooling system and method. The pumped fluid cooling system and method includes new relative magnitudes of advection, convection and spreading components of the resistance for a pumped fluid system. The pumped fluid cooling system and method also includes adjusting the chemical composition of the working fluid, specifically adjusting the composition and viscosity as the sensitivity to the fluid heat capacity per unit mas increases.

Owner:COOLIGY INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com