Thermal protection flocculus and manufacturing method thereof

A manufacturing method and technology of wadding, applied in non-woven fabrics, textiles, papermaking, fabric surface trimming, etc., can solve problems such as uneven carding of thermal insulation wadding, fiber clustering, low fiber strength and rigidity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] First, by weight, the following fiber raw materials are equipped: 25% of fine denier fibers (all are fine denier polyester fibers, the fiber fineness is 0.78dtex, and the length is 51mm), 60% of hollow fibers (all are hollow three-dimensional crimped poly Ester fiber, its fiber fineness is 3.3dtex, length is 64mm), bonding fiber 15% (all is bonding fiber 4080, i.e. skin core structure low-melting point polyester fiber, its fiber fineness is 4.4dtex, length is 51mm ).

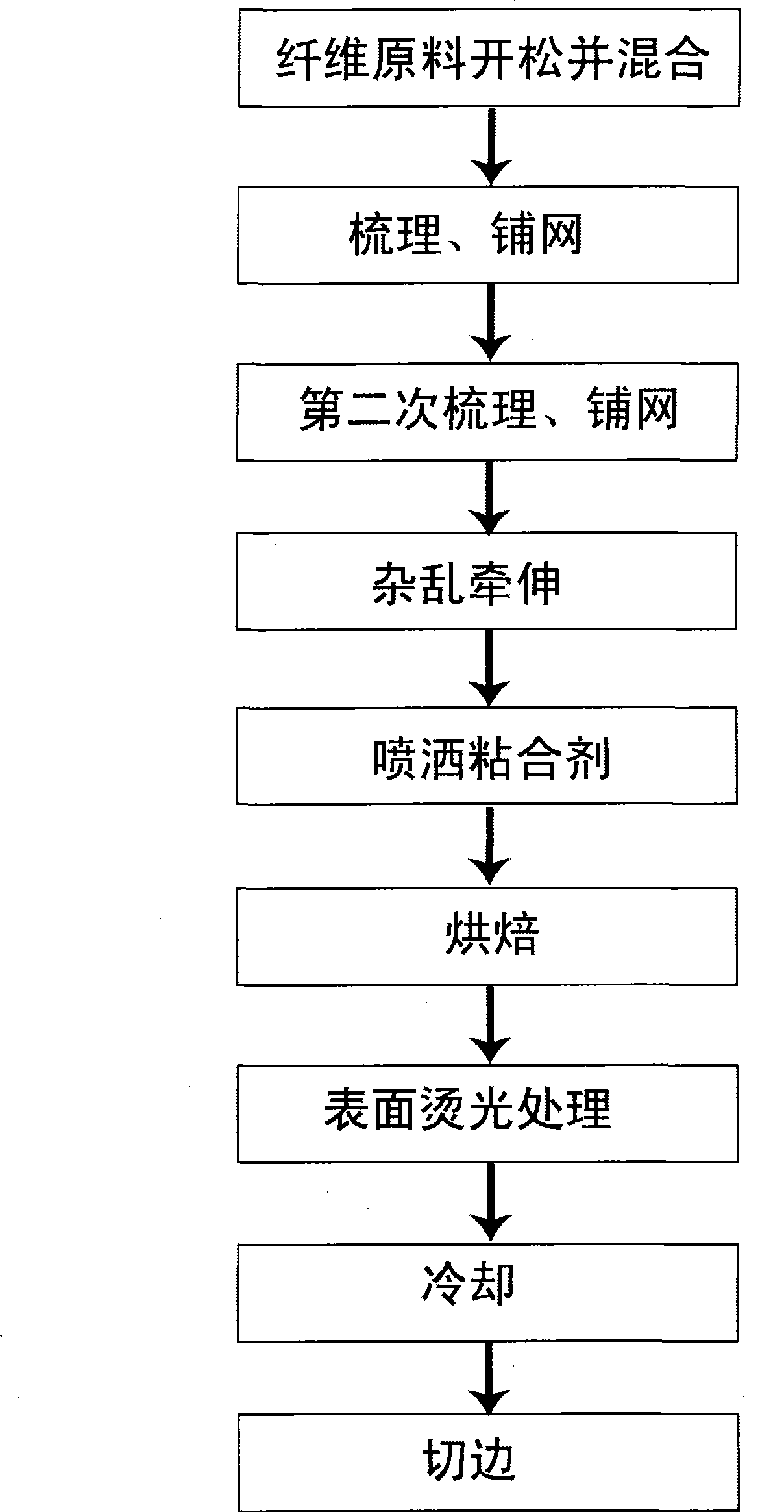

[0035] Then, follow the steps below to make thermal insulation batting successively (refer to figure 1 ):

[0036] (1) Opening and mixing fiber raw materials such as fine denier fibers, hollow fibers and bonding fibers;

[0037] (2) Combing and laying the mixed fiber raw materials to form a fiber web; the carding equipment used uses single cylinder and double doffers, and the card clothing adopts an ultra-fine tooth structure (the tooth spacing of the card clothing is 1.8mm) ;

[0038] (3) Carry out c...

Embodiment 2

[0045] First, by weight, the following fiber raw materials are equipped: 40% of fine-denier fibers (all are fine-denier polyester fibers, the fiber fineness is 1.32dtex, and the length is 51mm), 40% of hollow fibers (all are hollow three-dimensional curled far Infrared fiber, whose fiber fineness is 6.7dtex, and length is 64mm), bonding fiber 20% (all are polypropylene fibers, and its fiber fineness is 2.2dtex, and length is 51mm).

[0046] The manufacture method of this warm-keeping batting is identical with embodiment 1.

Embodiment 3

[0048] At first, by weight, be equipped with following fiber raw material: fine denier fiber 38% (wherein 28% is the fine denier polyester fiber that fiber fineness is 0.5dtex, length is 64mm; Other 10% is that fiber fineness is 1.5dtex, Fine denier polyester fiber with a length of 32mm), ultra-fine denier fiber 20% (all are ultra-fine denier polyester fiber, wherein 10% of the fiber fineness is 0.012dtex, the length is 38mm, and the other 10% of the fiber fineness is 0.33dtex, length 64mm), hollow fiber 34% (all hollow polyester fiber, the fiber fineness is 5.5dtex, length 64mm), binder fiber 8% (all polypropylene polyester composite fiber, its fiber The fineness is 3.2dtex and the length is 36mm).

[0049] The manufacture method of this warm-keeping batting is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com