Patents

Literature

697 results about "Polyester composite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

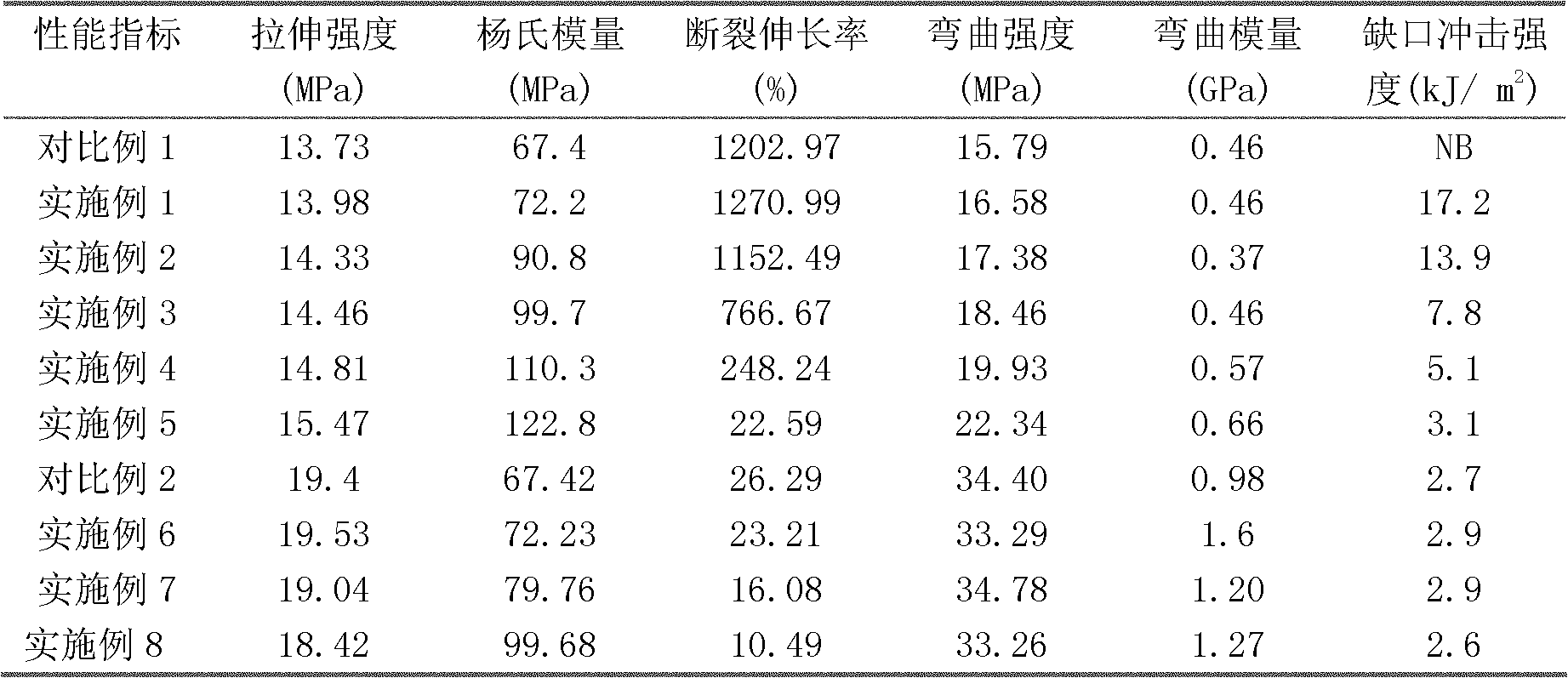

Low warping high surface gloss glass fiber reinforced polyester composite material and preparation method thereof

The invention relates to a low warping high surface gloss glass fiber reinforced polyester composite material and preparation method thereof. The composite material comprises the following components (wt%): 10-35% of polycarbonate, 20-45% of polybutylece terephthalate, 1-10% of flexibilizer, 3-10% of kaolin and 15-38% of glass fiber; 0.1-1% of antioxidant, 0.1-0.5% of ester exchange inhibiting agent and 0.1-3% of processing agent are prepared, silane coupling agent is utilized to process kaolin, then raw materials are placed into a mixing machine to be mixed for 2-5min, then mixture is placed into a screw machine for extrusion granulation, and meanwhile side charging is carried out on the glass fiber, the rotating speed of screw machine is 180-600rpm, and temperature is 240-280 DEG C, thus obtaining the product. The invention can obtain products with high surface gloss, excellent comprehensive mechanical properties and dimensional stability and especially ensures low warping property of product when being produced into injection moulding product.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

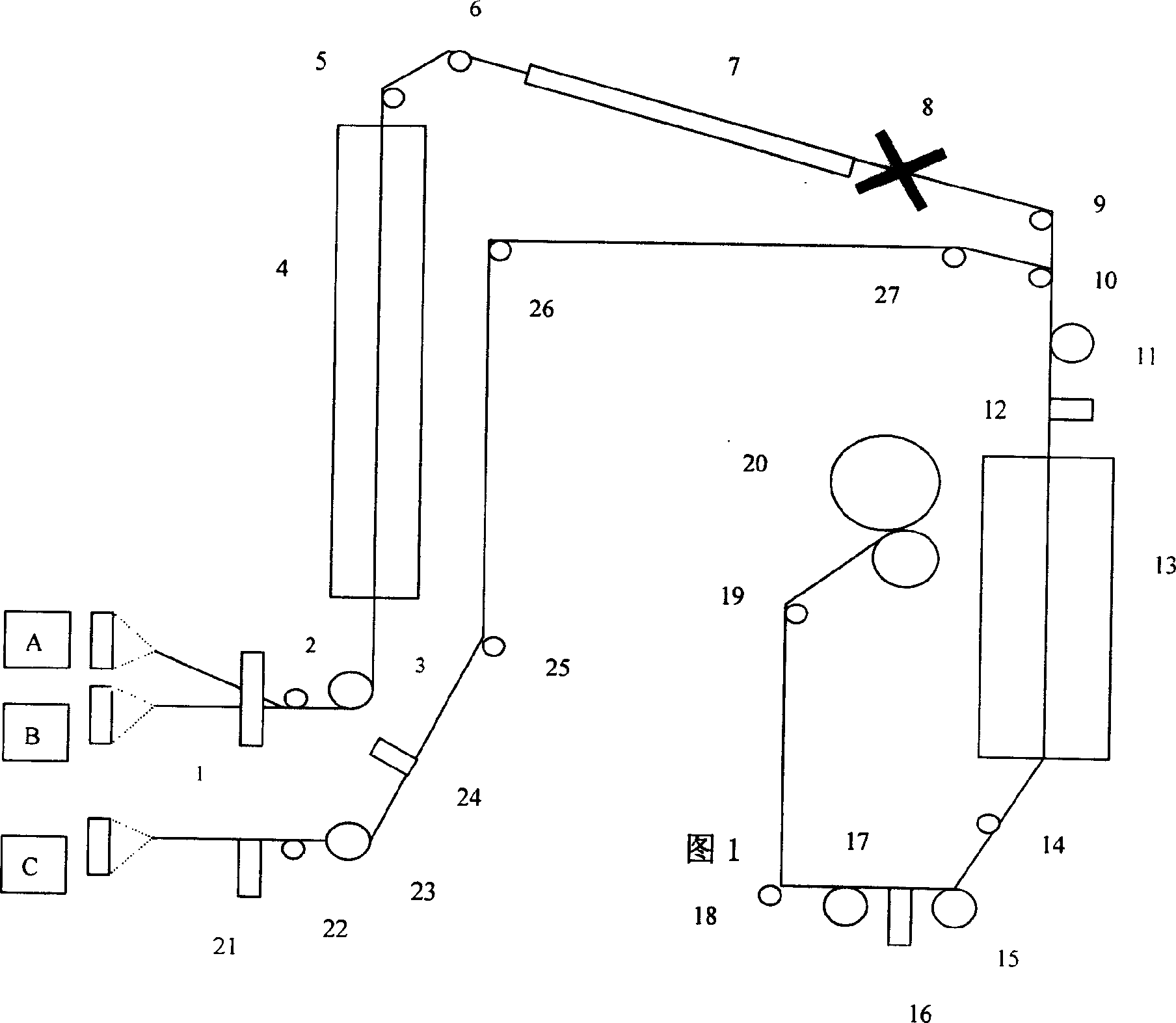

Process for producing wool-like polyester composite filament yarn

The present invention discloses the production process of composite wool-like polyester filament yarn. Very fine sea island polyester fiber and conventional polyester fiber are stretched, false twisted and combined to form composite fiber filament, and the composite fiber filament is then combined with high shrinkage polyester fiber with boiling water shrinkage over 20 % via air spray twisting to form the composite wool-like polyester filament yarn. The composite filament yarn is woven, and processed through fiber opening, post finishing and light roughing to form soft and fine wool-like fabric with excellent rebound resilience.

Owner:厦门翔鹭化纤股份有限公司

Room temperature curable water-based mold release agent for composite materials

InactiveUS20060074159A1Effective regulationGroup 4/14 element organic compoundsOther chemical processesEpoxyWater based

A room temperature curable water-based mold release agent that is useful for demolding composite parts, such as epoxy and polyester based polymer materials. The mold release agent is curable at low temperatures, such as room temperature, but is thermally stable up to conventional epoxy based composite molding temperatures, e.g., greater than 200 or 280° C. The mold release agent is useful for demolding large composite parts that are cured in large ovens at high temperature when the molds themselves are prepped at room temperature before placing in the oven. The mold release agent is also useful for demolding polyester composite parts that are prepared and cured at low temperature such as room temperature.

Owner:HENKEL IP & HOLDING GMBH

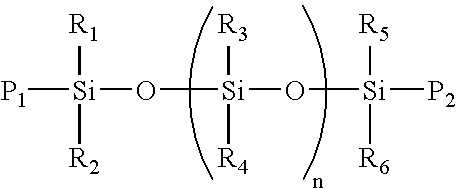

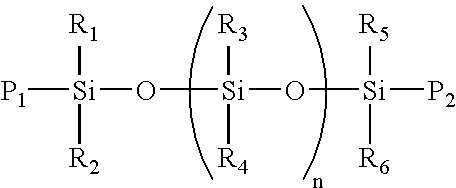

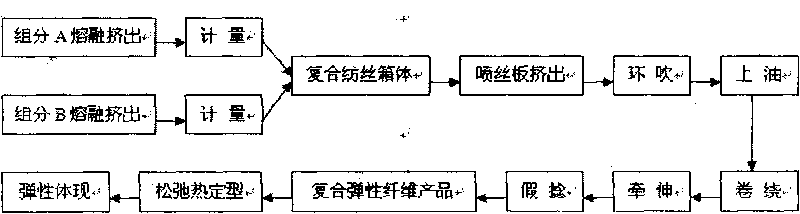

High-performance polyester composite elastic fiber and manufacturing method thereof

InactiveCN101718008AGood dyeabilityGood wrinkle resistance and shape retentionMelt spinning methodsConjugated synthetic polymer artificial filamentsCopolyesterViscosity

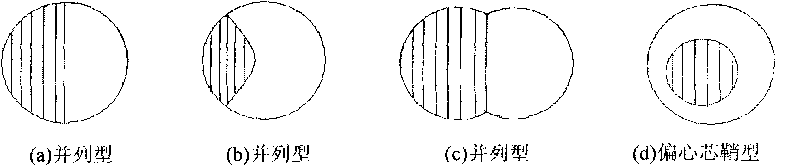

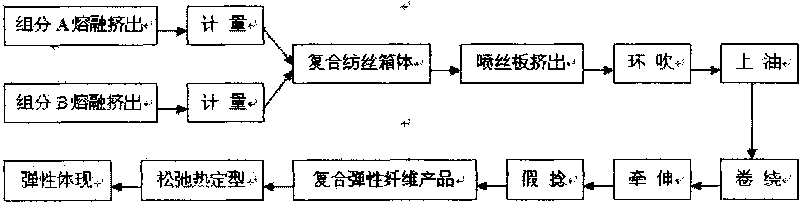

The invention provides a high-performance polyester composite elastic fiber with good dyeability. The composite fiber is prepared from two polyester or copolyester components with viscosity differences through a composite spinning process, wherein the high-viscosity component accounts for 30 to 70 percent by weight, and the low-viscosity component accounts for 70 to 30 percent by weight. The composite fiber has a parallel or eccentric core sheath type structure, and has good curling property, natural resilience and dyeability; meanwhile, the manufacturing process is simple and convenient and easy to operate; the low-temperature dyeing property of the composite fiber has the functions of environmental protection and energy conservation; and the composite fiber of the invention can be widely applied to various woven and knitted elastic fabrics.

Owner:SHANGHAI VITA SCI & TECH

Nonwoven fabric of polyester composite fiber

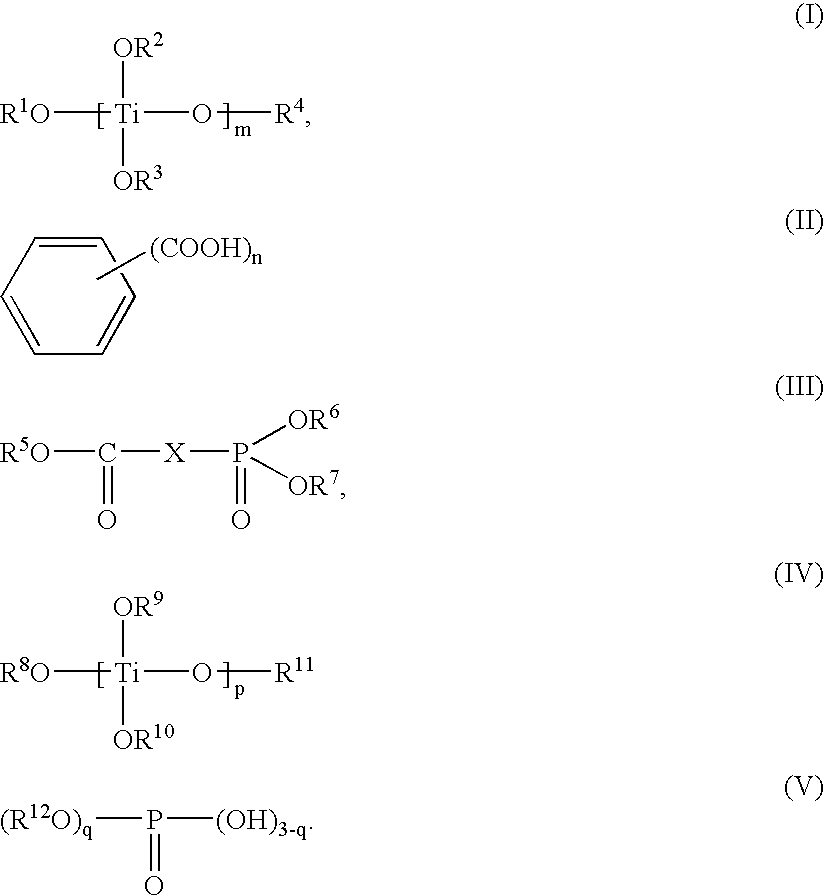

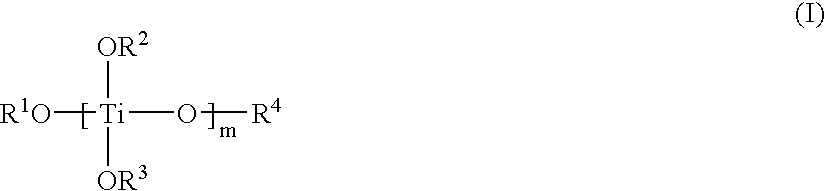

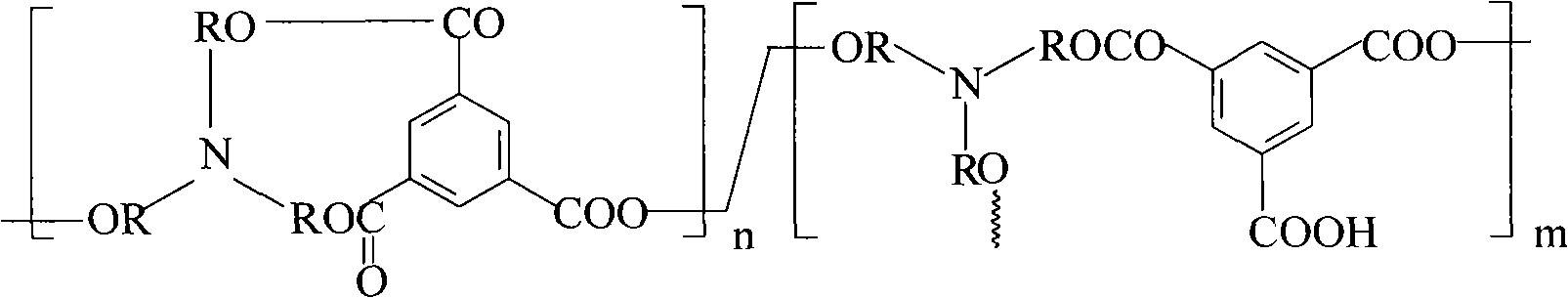

ActiveUS7371701B2Quality improvementExcellent tonePaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperCarboxylic acidTitanium

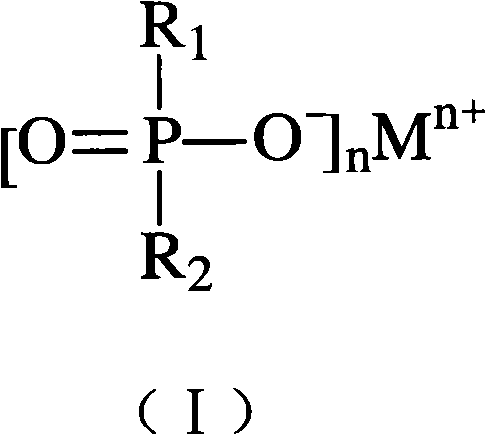

A nonwoven fabric of polyester composite fibers which has a satisfactory color tone (low value of b*). It is formed from short composite fibers obtained from a polyester polymer obtained with the following catalyst and a fusion-bondable polymer. The catalyst comprises: (1) a mixture of a phosphorus compound ingredient comprising a phosphorus compound represented by the formula (III) with a titanium compound ingredient comprising a titanium alkoxide represented by the following formula (I) and / or a product of the reaction of the titanium alkoxide with a carboxylic acid represented by the formula (II) or anhydride thereof; and / or (2) a product of the reaction of a phosphorus compound ingredient comprising a phosphorus compound represented by the formula (V) with a titanium compound ingredient comprising a titanium alkoxide (IV) represented by the formula (IV) and / or a product of the reaction of the titanium alkoxide with a carboxylic acid represented by the formula (III) or anhydride thereof

Owner:TEIJIN FRONTIER CO LTD

Graphene oxide/unsaturated polyester composite material and preparation method thereof

The invention discloses a graphene oxide / unsaturated polyester composite material and a preparation method of the composite material. The composite material comprises the raw materials: dihydric alcohol, graphene oxide, saturated binary acid or acid anhydride, unsaturated binary acid or acid anhydride, vinyl monomer, and normal polymerization inhibitor, initiator and accelerant, wherein the content of the graphene oxide is 0.06-0.5wt%. The preparation method of the graphene oxide / unsaturated polyester composite material comprises the following steps of: adding the graphene oxide into the dihydric alcohol to directly and ultrasonically disperse, or adding the dihydric alcohol into graphene oxide water solution to ultrasonically disperse and remove water in a fractional distillation way so as to obtain graphene oxide / dihydric alcohol solution which is evenly dispersed; performing polycondensation between the obtained graphene oxide / dihydric alcohol solution and the saturated binary acidor acid anhydride, unsaturated binary acid or acid anhydride and polymerization inhibitor with metering ratio, and diluting by adding the vinyl monomer after the polymerization so as to prepare graphene oxide / unsaturated polyester resin; and adding the initiator and the accelerant, and curing and crosslinking to prepare the graphene oxide / unsaturated polyester composite material.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

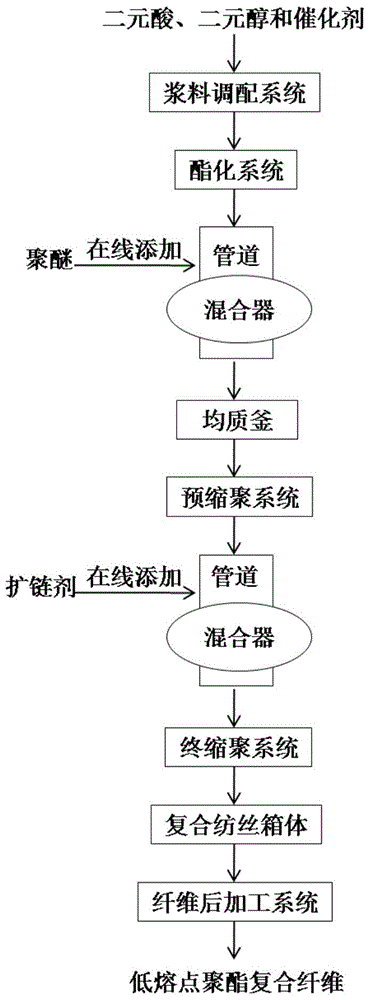

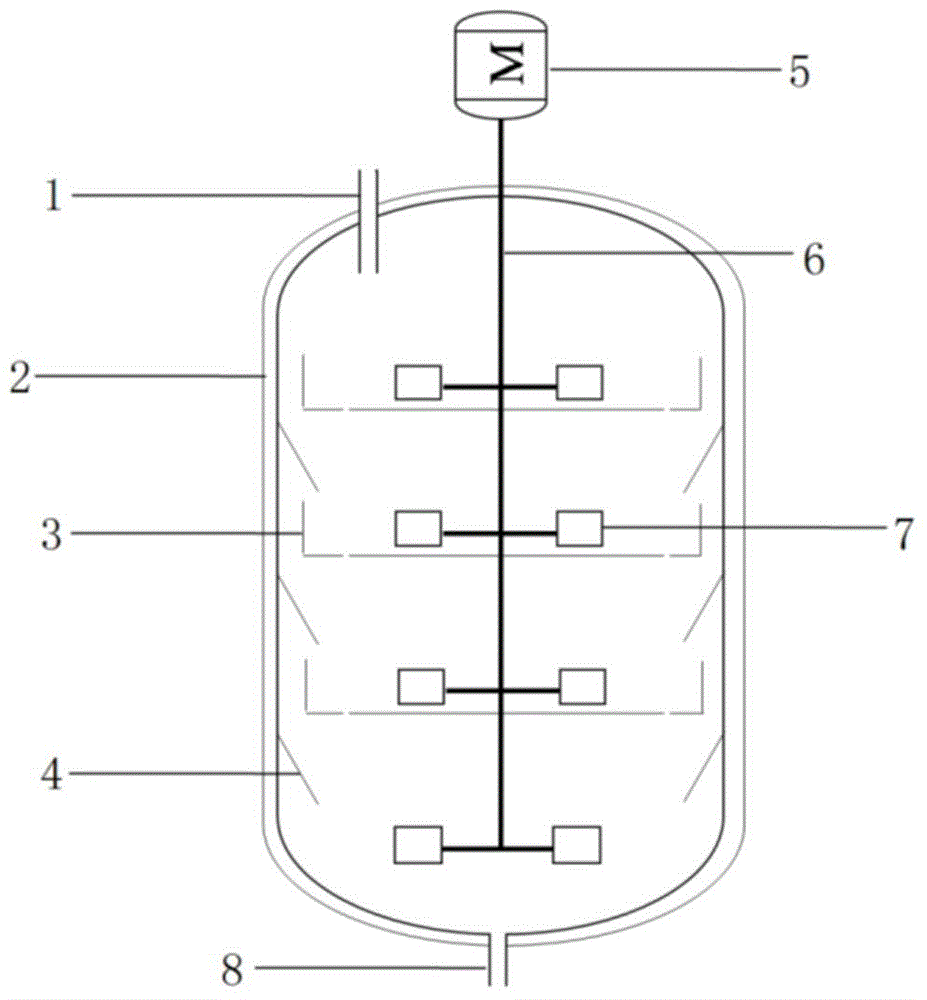

Method for preparing low-melting-point polyester composite fiber by adopting continuous polymerization and melt direct-spinning

ActiveCN105063797AImprove thermal stabilitySuppress thermal degradation side reactionsArtificial filament heat treatmentConjugated synthetic polymer artificial filamentsOligomerTransesterification

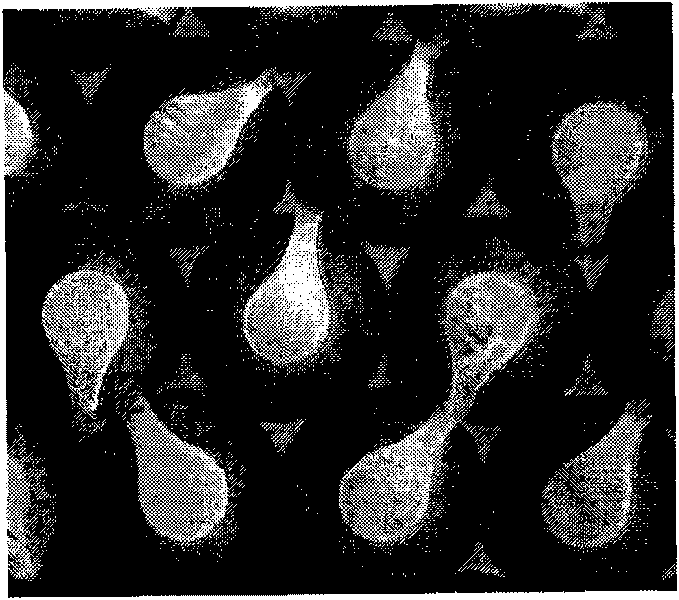

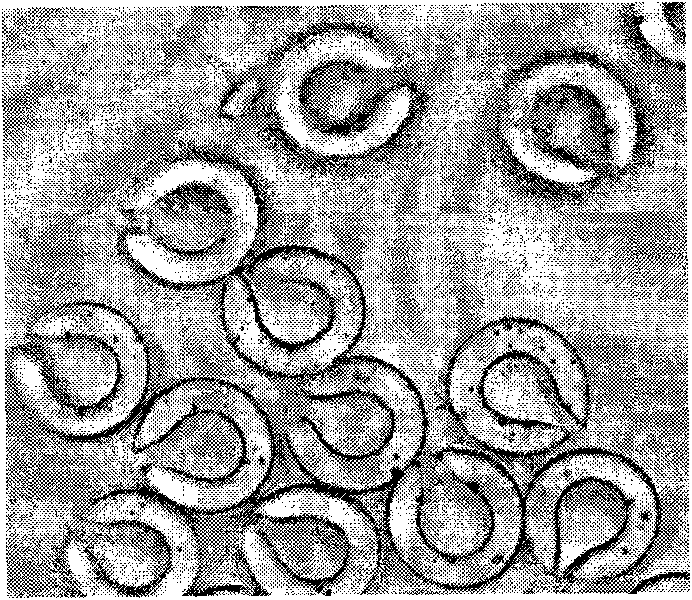

The invention relates to a method for preparing a modified copolyester composite fiber, in particular to a method for preparing a low-melting-point polyester composite fiber by adopting continuous polymerization and melt direct-spinning. The method comprises the following steps: slurry is prepared from raw materials in proportion and added continuously into an esterification system for an esterification reaction, an obtained oligomer is uniformly mixed with polyether, the mixture enters a homogenizing kettle for transesterification and pre-polycondensation, a product is uniformly mixed with a chain extender for final polycondensation, and an obtained low-melting-point polyester melt and a common polyester melt enter a composite spinning assembly to prepare the low-melting-point polyester composite fiber which comprises a common polyester core layer and a low-melting-point polyester cortex layer. The method has the advantages as follows: a side reaction of thermal degradation of polyether components is inhibited effectively, and the color and spinnability of the low-melting-point polyester melt are improved; the problem of poor performance of composite spinning of the low-melting-point polyester on the cortex layer and the common polyester on the core layer due to large dynamic viscosity difference of the melt is solved, and the composite fiber is well formed; the production efficiency of the low-melting-point polyester composite fiber is improved.

Owner:CHINESE TEXTILE ACAD

Method for manufacturing biologically degradable polyester composite material with capacity increasing function

The invention belongs to the technical field of polymer materials, which more particularly relates to a preparation method of a biological decomposable polyester composite material with compatibilization function. The specific steps are that: a method of small molecular diol hydroxyl end capping is adopted for preparing polylactic acid and biological decomposable polyester diol, a diisocyanate series chain extender is used for preparing the block copolymer of the polylactic acid and the decomposable polyester by a method of fusion chain extension, and the block copolymer is used in a blend system of the polylactic acid and the corresponding polyester to play the role of compatibilization function. The preparation method of the biological decomposable polyester composite material is simple in method and technique, easy in industrial production and the prepared block copolymer can increase the compatibility of the polylactic acid and the biological decomposable polyester blend system effectively and play the role of a compatibilizer.

Owner:TONGJI UNIV

Polyester composite fiber and method for producing same

InactiveCN101748512AFilament/thread formingConjugated synthetic polymer artificial filamentsCopolyesterUltimate tensile strength

The invention discloses polyester composite fiber and a method for producing the same. The polyester composite fiber adopts the skin-core composite structure, wherein the ratio of weight percent of the skin to the weight percent of the core is 50:50 to 90:10. The polymer in the core is alkali soluble copolyester. The length of the arc of the exposed part of the core on the cross section of the polyester composite fiber is 5-20 percent of the outer circumference of the polyester composite fiber. The thickness of the wall of the skin is 5-20 micron. The method for producing the polyester composite fiber comprises the steps of preparing original filament, preparing deformed filament or preparing extended filament. The fiber of the invention is prepared to fabric after post processing and is subjected to deweighting in the sodium hydroxide solution, the processed polyester composite fiber can keep the strength of more than 95 percent and the complete C-section so that the fabric has light weight, good heat preservation performance and good moisture adsorption and perspiration elimination performance.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Method for preparing uvioresistant polyester by nanometer titania in situ

InactiveCN1552764AUniform dispersionInhibition of photocatalytic activityNanoparticleEngineering plastic

A process for in-situ preparing UV-resistant polyester by use of TiO2 nanoparticles includes such steps as modifying the surface of TiO2 nanoparticle as UV shielding agent, dispersing them in diol, high-speed stirring, cyclic sand grinding, and polymerizing (or copolymerizing) with polyester and other monomer. Its advantage is high UV shielding effect.

Owner:SHANGHAI JIAO TONG UNIV

Polyethylene toughening thermoplastic polyester composite material and preparation method thereof

The invention relates to the field of modification of high molecular materials, and in particular relates to a polyethylene toughening thermoplastic polyester composite material and a preparation method of the polyethylene toughening thermoplastic polyester composite material, aiming at overcoming the shortcoming of comparatively poor comprehensive performance of the existing polyethylene, polyester or other composite materials, wherein the composite material consists of 5-60% of thermoplastic polyester resin, 5-60% of glass fiber, 5-60% of polyethylene resin and 2-10% of aid according to weight proportion. The polyethylene toughening thermoplastic polyester composite material disclosed by the invention is comparatively low in cost; by enhancing the toughness through the glass fiber and by finely selecting various component materials and proportions of the component materials, the composite material is excellent in physical performance, capable of overcoming the shortcomings of difficult forming and processing of the thermoplastic polyester, insufficient toughness of the material and the like, and effectively improving the mechanical performance and thermical performance; and the preparation method is simple in process and easy to operate.

Owner:NINGBO CHANGYANG TECH

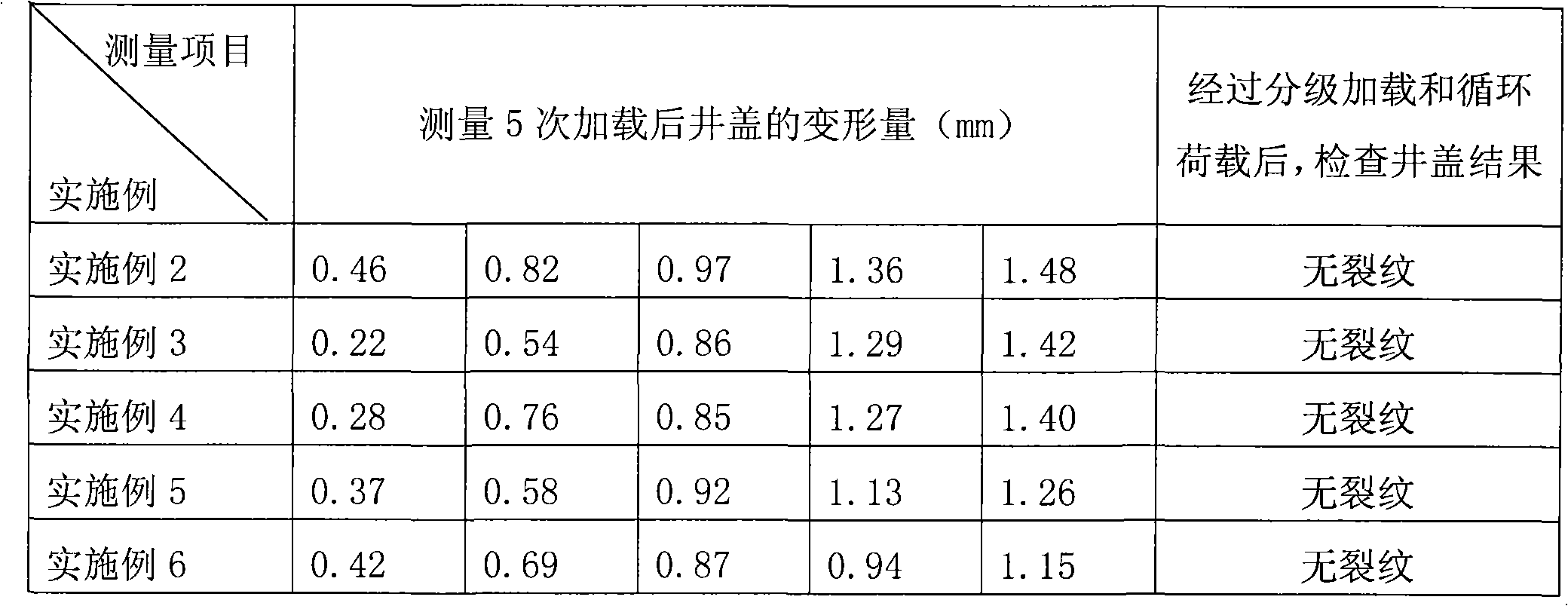

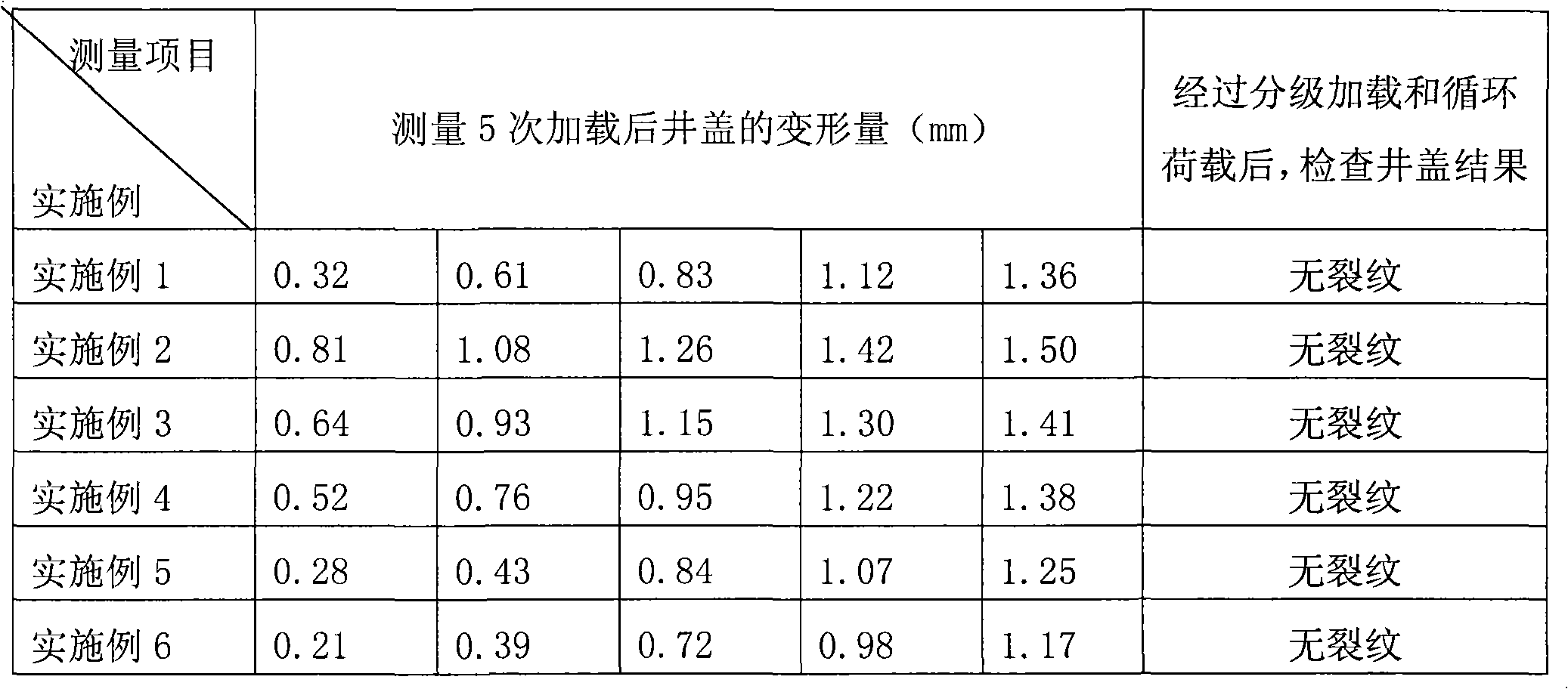

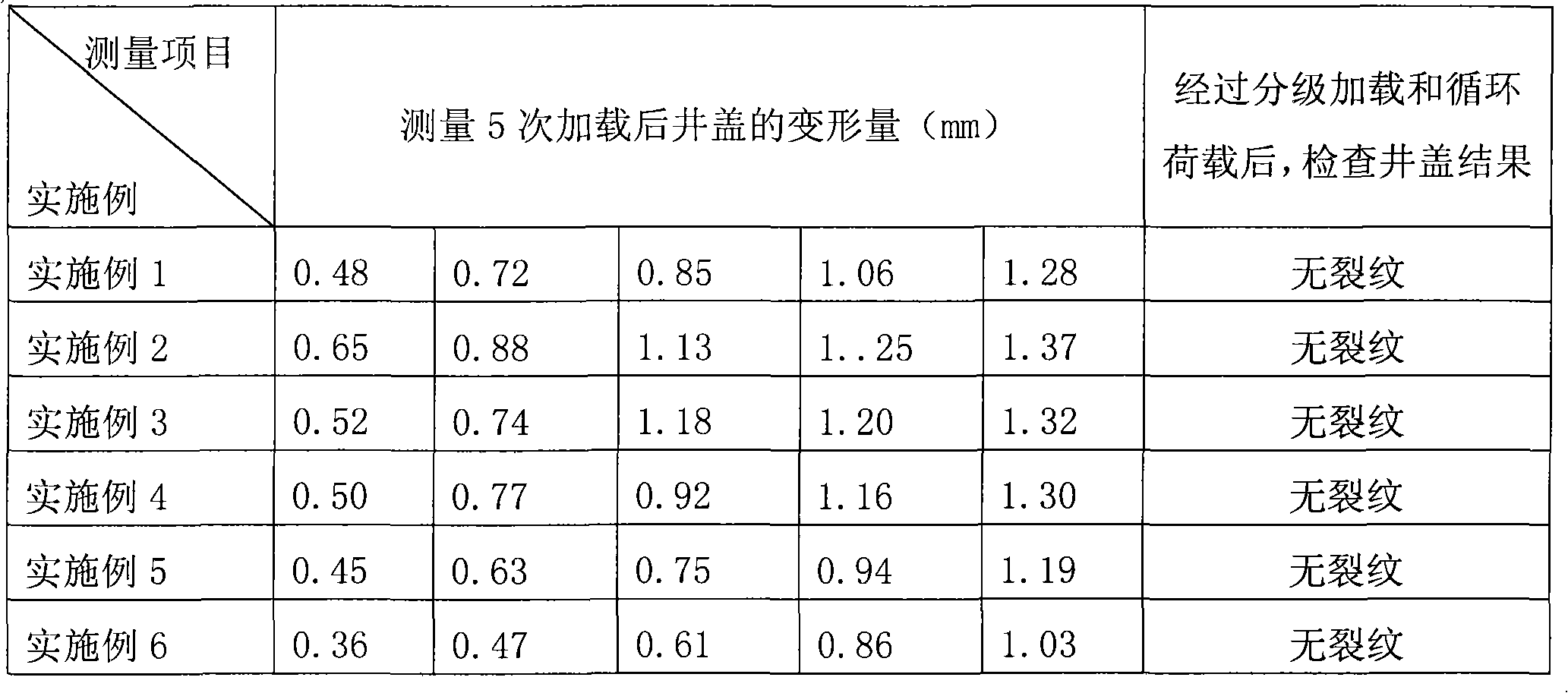

High-strength polyester composite well cover as well as formula and preparation method thereof

InactiveCN101871219AImprove carrying capacityImpact resistantArtificial islandsUnderwater structuresEnvironmental resistanceAlkali free

The invention discloses a formula of a high-strength polyester composite well cover, which comprises the following raw materials in parts by weight: 21-22 parts of unsaturated polyester resin, 8-9 parts of low shrink additive, 40-50 parts of heavy calcium carbonate, 1-1.5 parts of zinc stearate, 0.2-0.8 part of active magnesia, 0.12-0.28 part of curing agent, 0.2-0.8 part of carbon black, 10-20 parts of alkali-free glass fiber roving and 10-20 parts of glass fiber woven roving. A production method of the well cover of the invention comprises the following steps of: firstly preparing resin paste, preparing sheets by utilizing the resin paste, and then, forming the sheets by die pressing. The well cover of the invention has the characteristics of strong carrying capacity, shock resistance, ageing resistance, wear resistance, corrosion resistance, novel and attractive appearance, simple structure, environmental protection and the like, and basically solves the problem of well cover pilfering.

Owner:北京泛亚电通工贸有限责任公司

Flame-resistant and uvioresistant polyester composite material and method for preparing same

ActiveCN101735578AFlame retardant hasHas anti-ultraviolet effectFlame-proof filament manufactureMonocomponent polyesters artificial filamentLow vacuumEsterification reaction

The invention relates to a flame-resistant and uvioresistant polyester composite material and a method for preparing the same. The composite material is prepared by performing an esterification reaction on ethylene glycol, terephthalic acid, uvioresistant agent pulp and a flame retardant and then performing low-vacuum condensation polymerization and high-vacuum condensation polymerization, wherein the added amounts of the uvioresistant agent pulp and the flame retardant are between 0.1 and 20 weight percent and between 0.1 and 20 weight percent respectively; the esterification reaction is performed at the temperature of between 200 and 290 DEG C and under a pressure of between 0.1 and 0.6 MPa for 1 to 4 hours; the low-vacuum condensation polymerization is performed at the temperature of between 200 and 290 DEG C and under the pressure of between 100,000 and 500 Pa for 10 to 90 minutes; the high-vacuum condensation polymerization is performed at the temperature of between 250 and 300 DEG C and under the pressure of between 500 and 50 Pa for 1 to 4 hours; and the uvioresistant agent pulp consists of 5 to 30 weight percent of inorganic nano-oxide and the ethylene glycol. Flame-resistant and uvioresistant polyester fiber fabrics prepared from the material have flame resistance and uvioresistant effect.

Owner:PETROCHINA CO LTD

Halogen-free antiflaming polyester molding compound composite and preparation method thereof

The invention discloses a halogen-free antiflaming polyester molding compound composite and a preparation method thereof. The halogen-free antiflaming polyester molding compound composite is composed of the following components in weight percent: 10-60% of polyester, 10-50% of filling intensifier, 5-35% of complex flame retardant and 0.1-8.0% of other auxiliary agents. The antiflaming reinforced polyester composite prepared by the invention greatly improves the antiflaming performance of the PET molding compound composite, in particular to the antiflaming performance of thin-wall products. The molding compound composite can be processed by traditional methods, such as injection molding and extrusion molding. In addition, the antiflaming reinforced polyester composite of the invention does not contain halogen, thus protecting environment.

Owner:GUANGZHOU KINGSKY MATERIAL

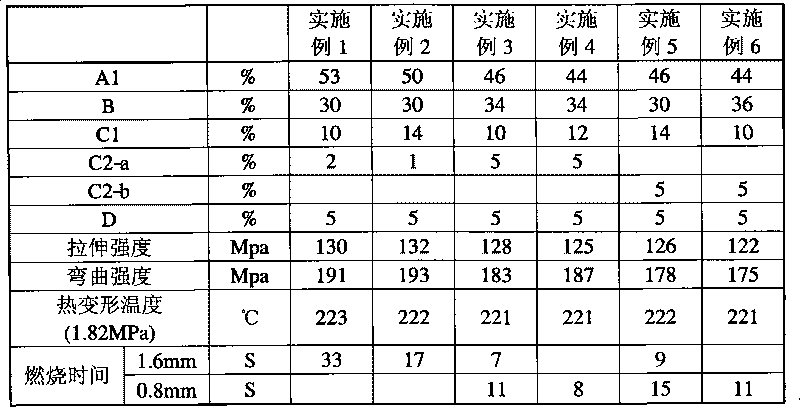

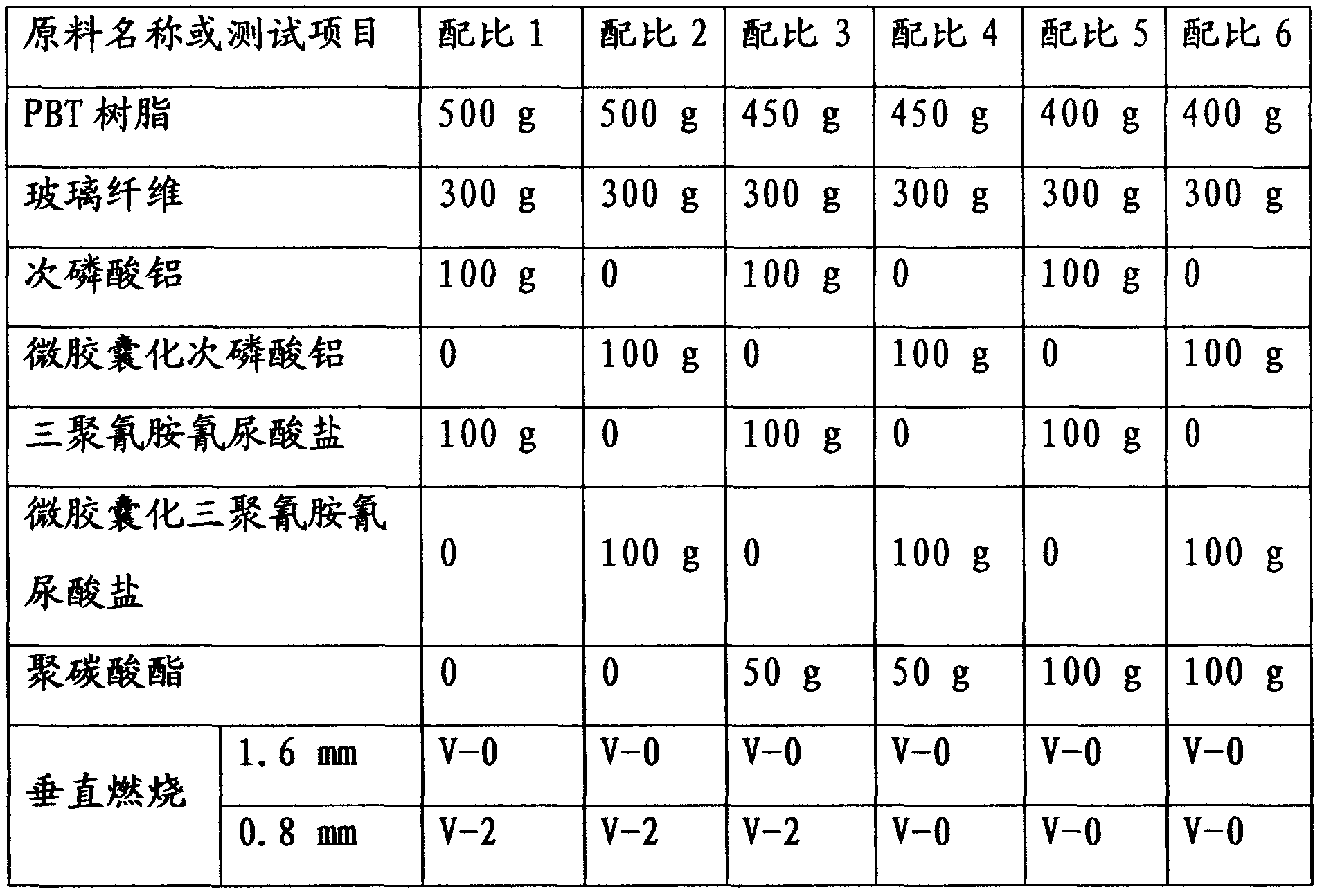

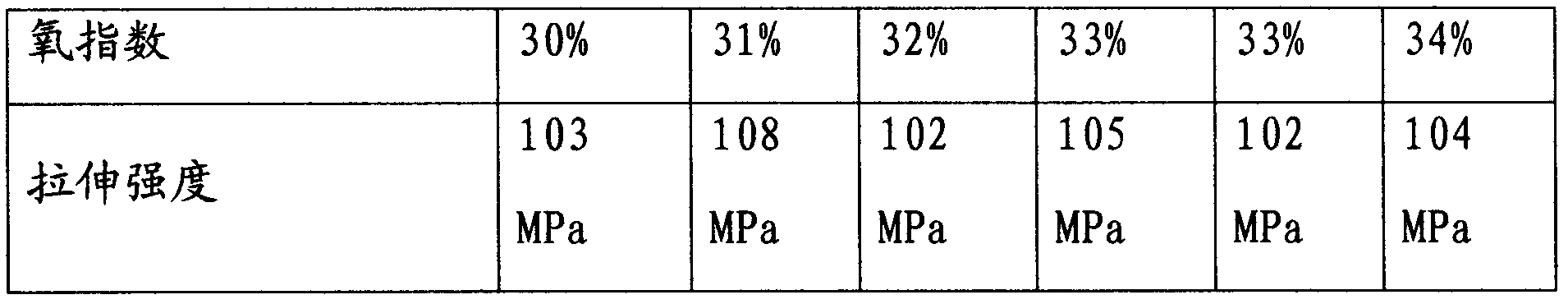

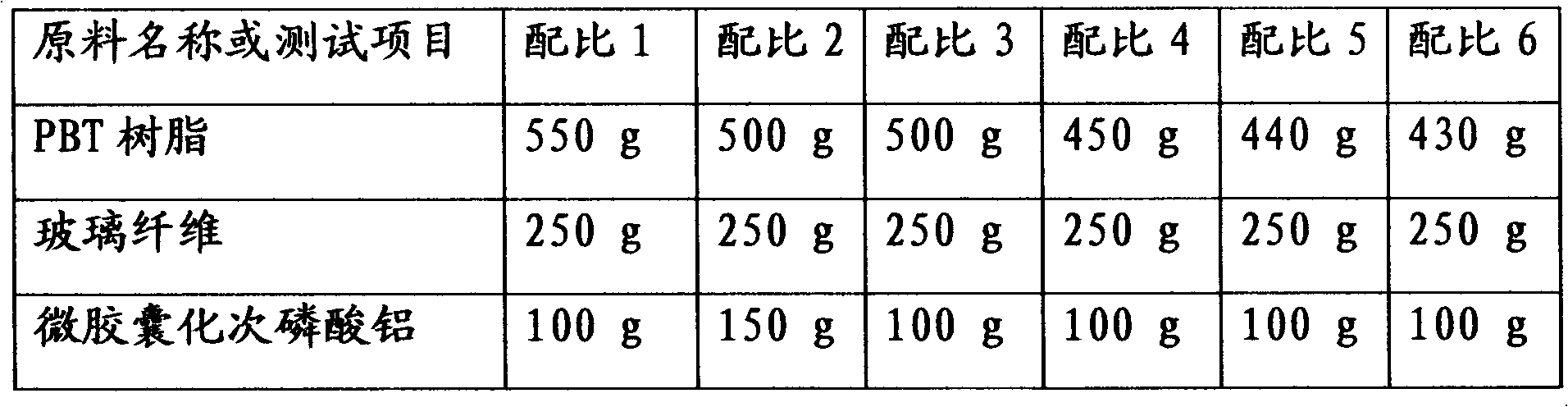

Halogen-free flame retardant glass fiber reinforced polyester composite and preparation method thereof

The invention discloses a halogen-free flame retardant glass fiber reinforced polyester composite and a preparation method thereof. The invention is characterized in that the preparation method of the composite comprises the following steps: mixing polyester, glass fiber, microencapsulated metal hypophosphite and microencapsulated nitrogen-containing flame retardant evenly, heating to 230-275 DEG C, and performing melt blending; and extruding, pulling, cooling, granulating and drying to obtain the composite, wherein the weight percentages of the polyester, glass fiber, microencapsulated metal hypophosphite and microencapsulated nitrogen-containing flame retardant to the total weight of the composite are 40-60%, 25-30%, 10-20% and 5-10% respectively. The halogen-free flame retardant glass fiber reinforced polyester composite has both good flame resistance and physical properties; the defects of the existing reinforced polyester material modification technology that the halogen-containing flame retardant inflicts great damage on the environment, the additional amount of the inorganic flame retardant is great and the material has poor physical properties and weather resistance can be overcome; and the composite has wide application prospect.

Owner:SUZHOU INST FOR ADVANCED STUDY USTC

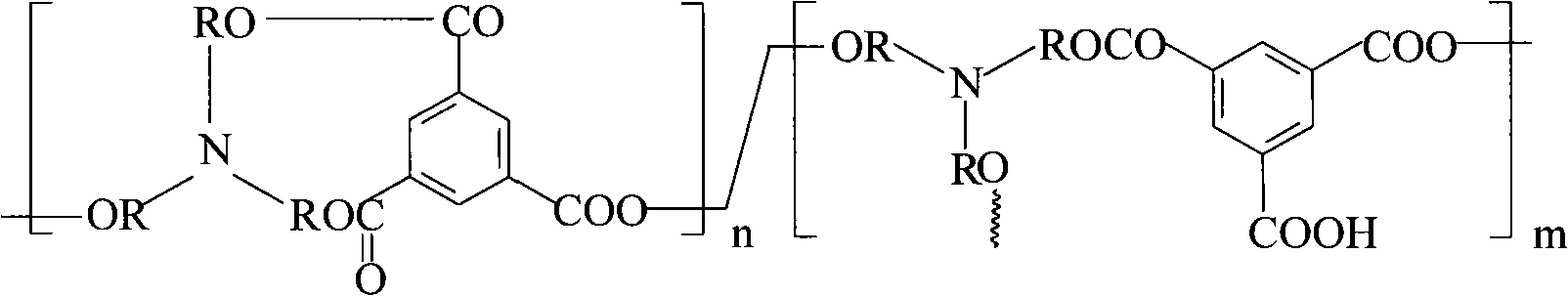

Crosslinked hyperbranched polyalcohol composite nano filter membrance and method of preparing the same

InactiveCN101254419ALow operating pressureReduce manufacturing costSemi-permeable membranesAlcoholMembrane technology

The invention belongs to the membrane technology field, in particular to a polyester composite nanofiltration membrane as well as the manufacturing method thereof. The composite membrane is characterized in that a layer of aromatic polyester functional cortex is compounded on a porous supporting membrane through multivariate alcohol amine and multivariate acyl chloride interfacial polymerization. The novel polyester composite nanofiltration membrane of the invention has low operating pressure, and the adopted multivariate alcohol amine has the advantages of innocuity, low price, easy availability, etc. Besides, as the functional cortex contains tertiary amine and carboxylic groups, the membrane surface can present different charge properties through adjusting the pH value of separated feed liquid, thereby being applicable to more industrial requirements. Furthermore, the production cost is low, the industrial production basis is good, and the application prospect is wide.

Owner:FUDAN UNIV

Process for in-situ quiclely preparing crystalline polyester using nano silicon dioxide

The present invention relates to composite material preparing technology. The production process of nano composite silica / polyester material includes the following steps: coating nano silica as crystallizing nucleartor with organic matter for surface modification to make it capable of distribute well in ethylene glycol as one monomer for polyester; high temperature pre-treating compounded nano silica / ethylene glycol slurry to make nano silica possess average size smaller than 100 nm; and polymerization or copolymerization between nano silica / ethylene glycol slurry and other monomer for polyester inside reactor to obtain in-situ nano composite silica / polyester material. The composite material with 1 wt% of nanometer silica contained has non-isothermal crystallization melting peak temperature raised to 213.4 deg.c and 4-8 times raised isothermal crystallization rate at 185-200 deg.c.

Owner:SHANGHAI JIAO TONG UNIV

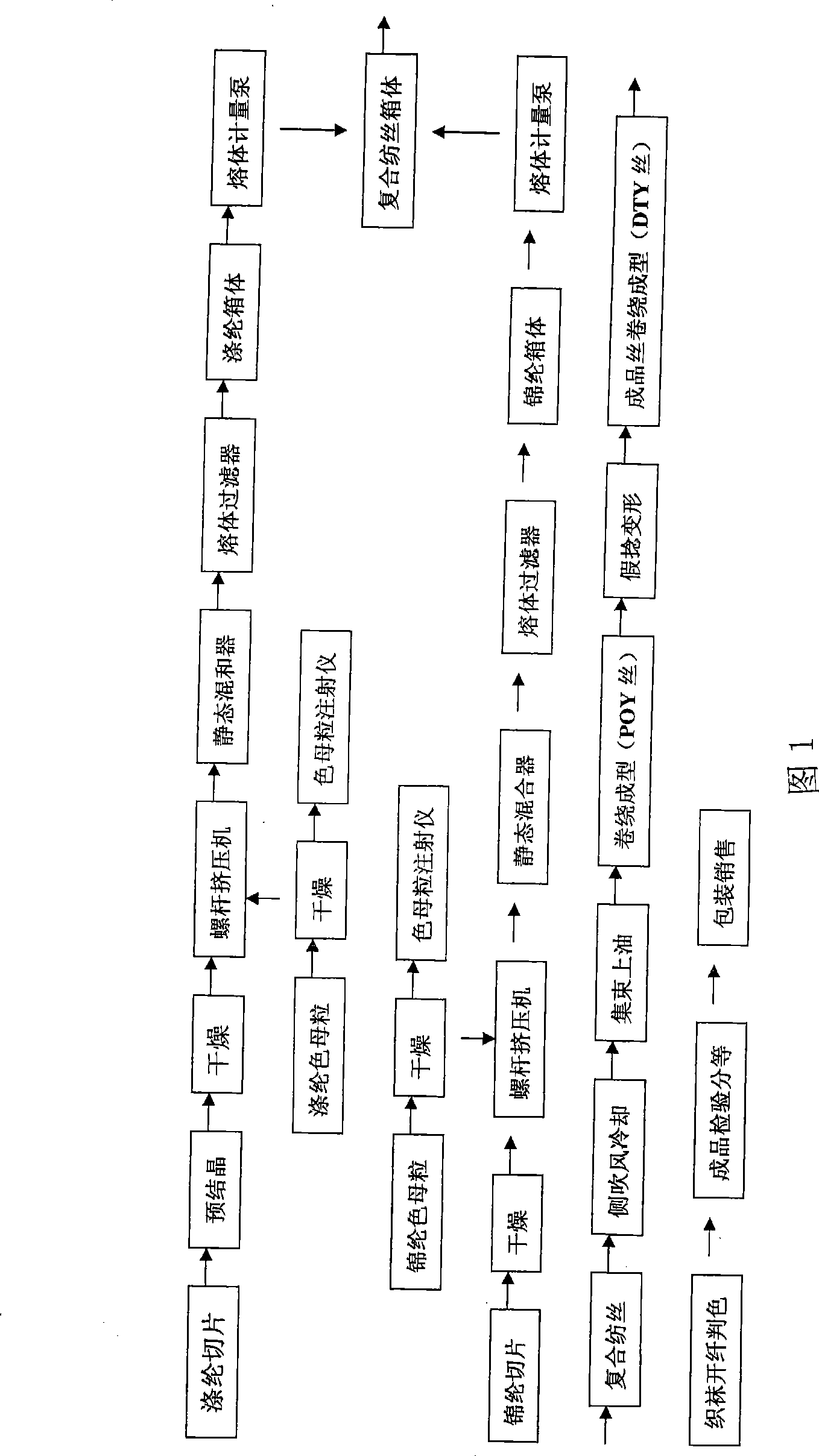

Colour superfine polyester-nylon complex fiber and its processing method

InactiveCN101397698AHigh color fastnessEvenly and fully connectedFibre mixingMelt spinning methodsColour fastnessDark color

The invention relates to a colored ultra-fine polyester / nylon composite fiber and a processing method thereof. The colored ultra-fine nylon / polyester composite fiber is formed by the following materials according to weight part: 62 portions to 82 portions of polyester chips, 15 portions to 35 portions of nylon chips, 1 portion to 3.5 portions of polyester colored master batches and 0.5 portion to 2 portions of nylon colored master batches. The invention has the advantages that: as the polyester colored master batches and the nylon colored master batches are added into the raw material of the polyester chips and the nylon chips, coloring requirement before spinning is met, thus causing spun products not to require dyeing; textile products produced by using the colored ultra-fine polyester / nylon composite fiber has the color fastness much better than that of textile products by dyeing; in addition, the processing method makes up the defect that the textile products of the ultra-fine polyester / nylon composite fiber can not be dyed into dark colors, widens the application scope of the ultra-fine polyester / nylon composite fiber in the field of the textile products; does not need dyeing processing, thus avoiding environmental pollution caused by the textile products due to dyeing; has reasonable processing conditions, and can carry out production with the assistance of the traditional double-component equipment; the colored ultra-fine polyester / nylon composite fiber has all the properties and styles of the ultra-fine polyester / nylon composite fibers with true colors.

Owner:常熟市海欣复合材料有限公司

Polyester composite filled with lignin and preparation method thereof

InactiveCN102070891AReduce manufacturing costDoes not affect goodnessEconomic benefitsMixed materials

The invention discloses a polyester composite filled with lignin and a preparation method thereof. The preparation method comprises the following steps: mixing polyester and lignin evenly, wherein the weight percentages of polyester and lignin are separately 60-95% and 5-40%; and performing melt extrusion granulation to the mixed material with a twin screw extruder to obtain the polyester composite filled with lignin. The preparation method of the invention uses rich, cheap and renewable biological resource lignin to fill biodegradable polyester material, thus the production cost of the material can be reduced extremely without affecting the good performances of the polyester matrix; and the preparation process is simple and has a certain social and economic benefits.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Preparation method of antibacterial polyester material

The invention discloses a preparation method of an antibacterial polyester material. The preparation method of the antibacterial polyester material comprises the following concrete steps: 1) preparing a disperse system composed of nano cuprous oxide particles and polyalcohol; 2) adding polyacid into the disperse system prepared in the step (1), so as to prepare a polyester composite melt containing the nano cuprous oxide particles; 3) carrying out extruding, bracing, water cooling and pelletizing on the polyester composite melt containing the cuprous oxide particles, thus an antibacterial polyester material is obtained. The prepared antibacterial polyester material has the advantage of good, lasting and stable antibacterial effect.

Owner:ZHEJIANG YINYU NEW MATERIAL CO LTD

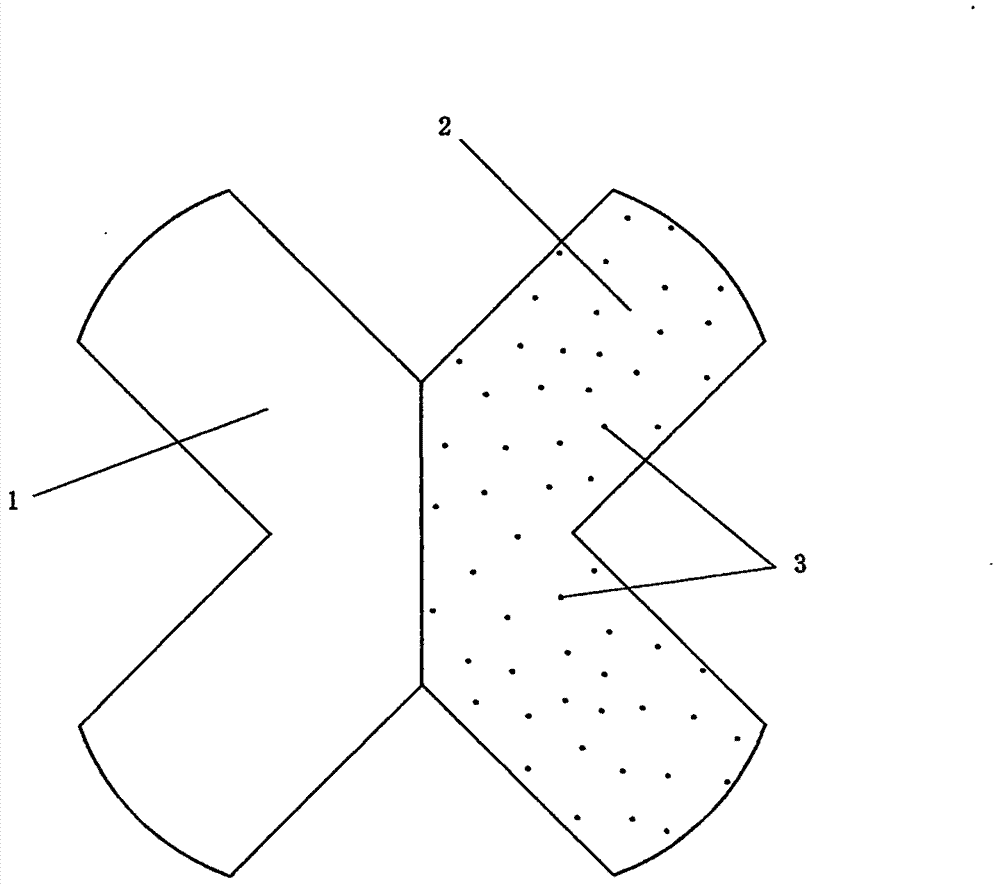

Antibacterial, moisture absorption and sweat releasing polyester composite elastic fiber

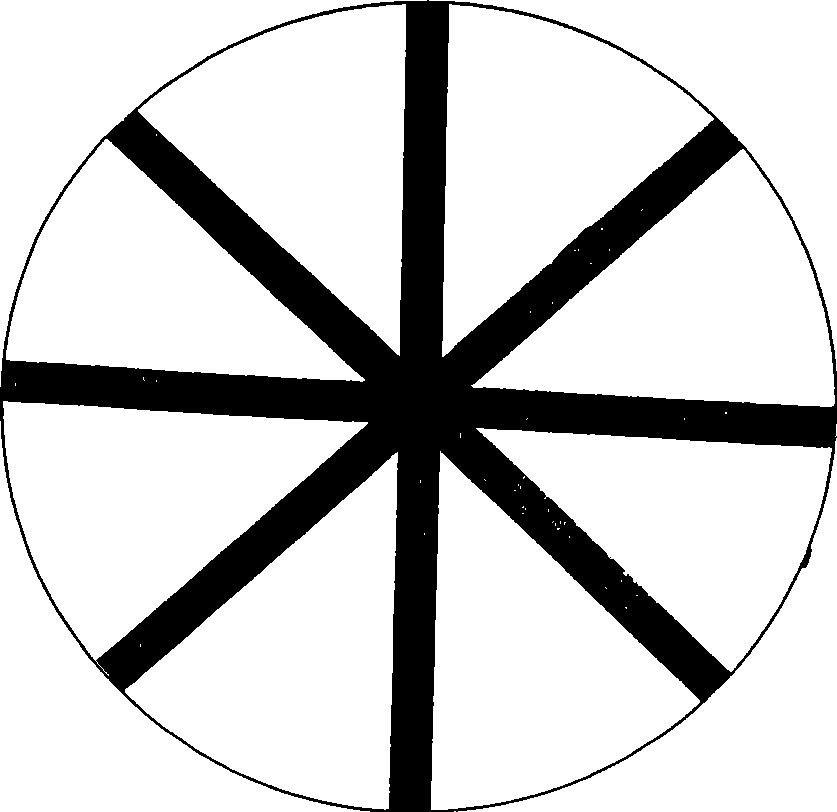

InactiveCN104726947AMultiple choiceSimple weaving processFilament/thread formingConjugated synthetic polymer artificial filamentsMoisture absorptionCompanion animal

The invention discloses a polyester composite elastic fiber with antibacterial, moisture absorption and sweat releasing function. The polyester composite elastic fiber has dual-component parallel composite structure and has cross-shaped cross section. Two components of the parallel composite fiber are respectively selected from one of PET, PBT, PTT and CO-PET and are different one another; antibacterial silver ions are added in at least one component. The fiber has natural curly spiral structure due to different shrinking percentage of the two components and has permanent elasticity; the elastic fiber has moisture absorption, sweat releasing and anti-bacterial function due to the fact that the cross-shaped cross section structure is adopted and the antibacterial agent is added. The fiber is widely applicable to the high-grade underwear, sportswear and swimwear and has the characteristics of being elastic, comfortable, breathable, fresh, bacteriostatic and healthy.

Owner:SHANGHAI VITA SCI & TECH

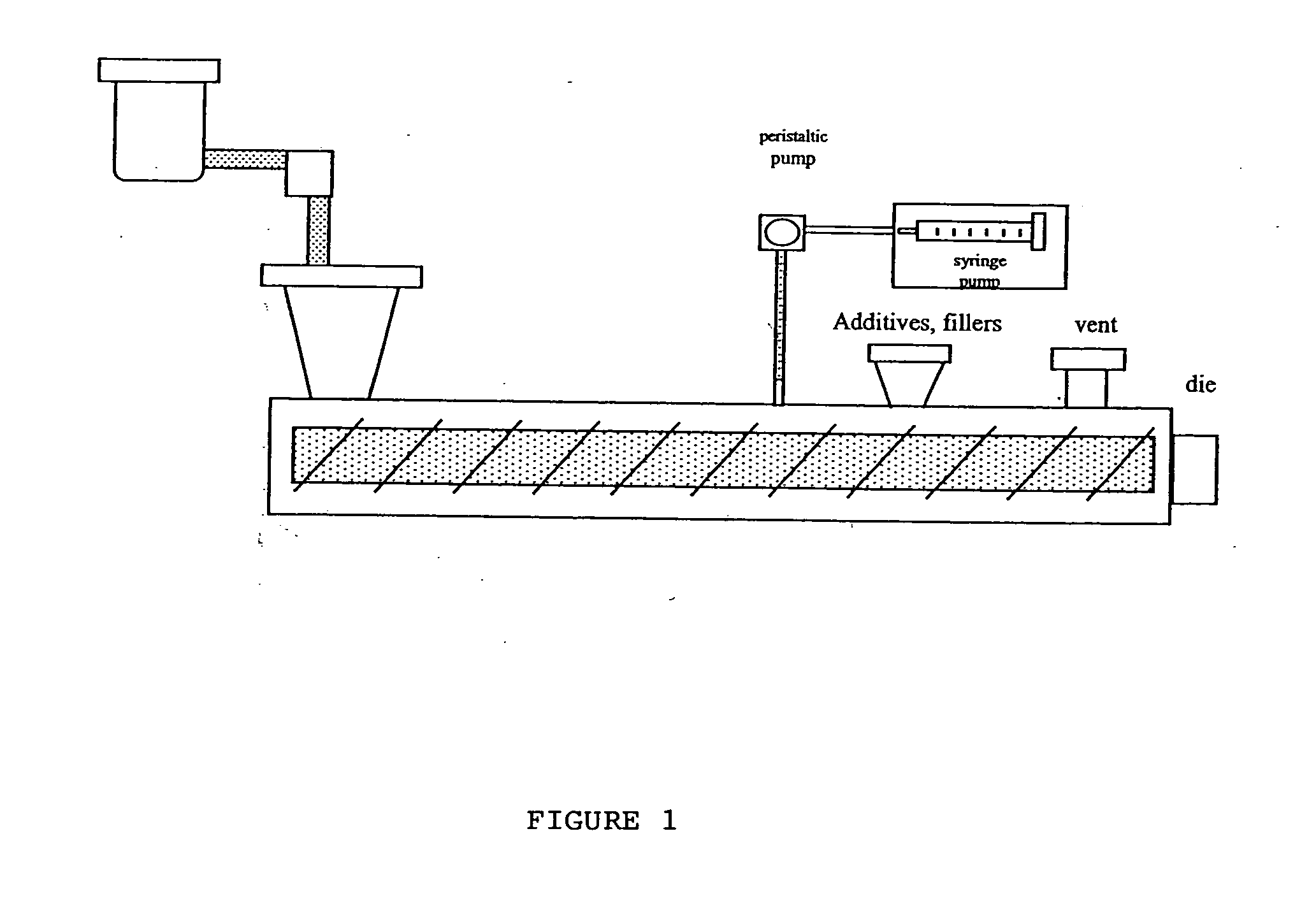

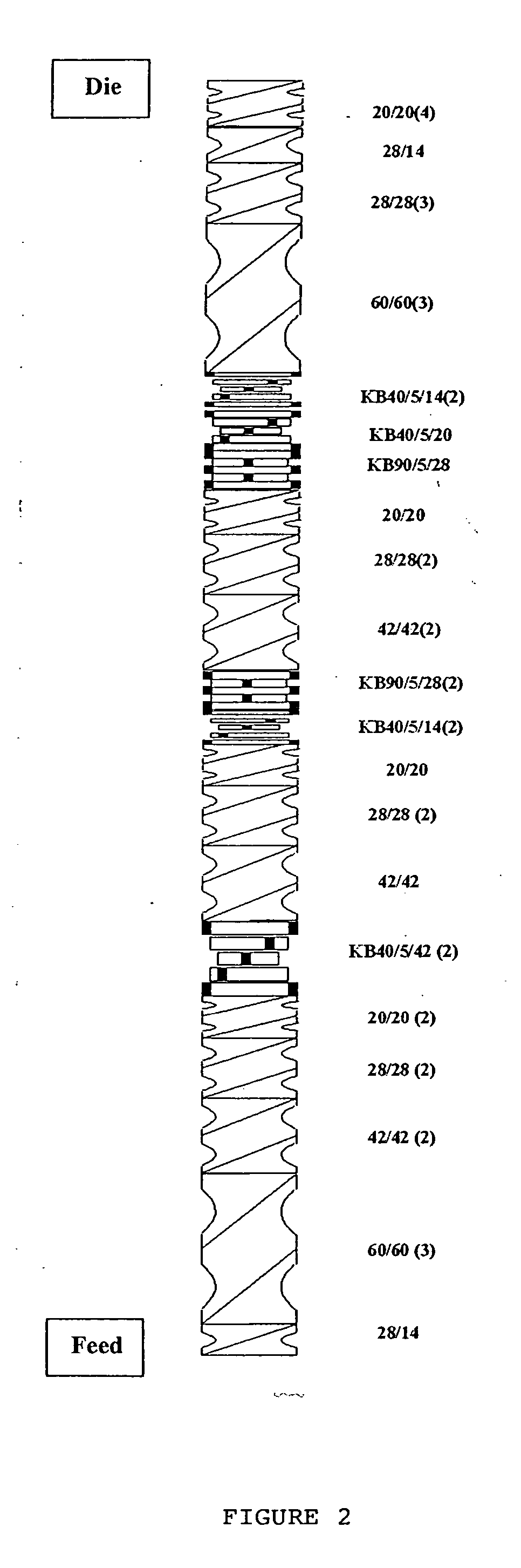

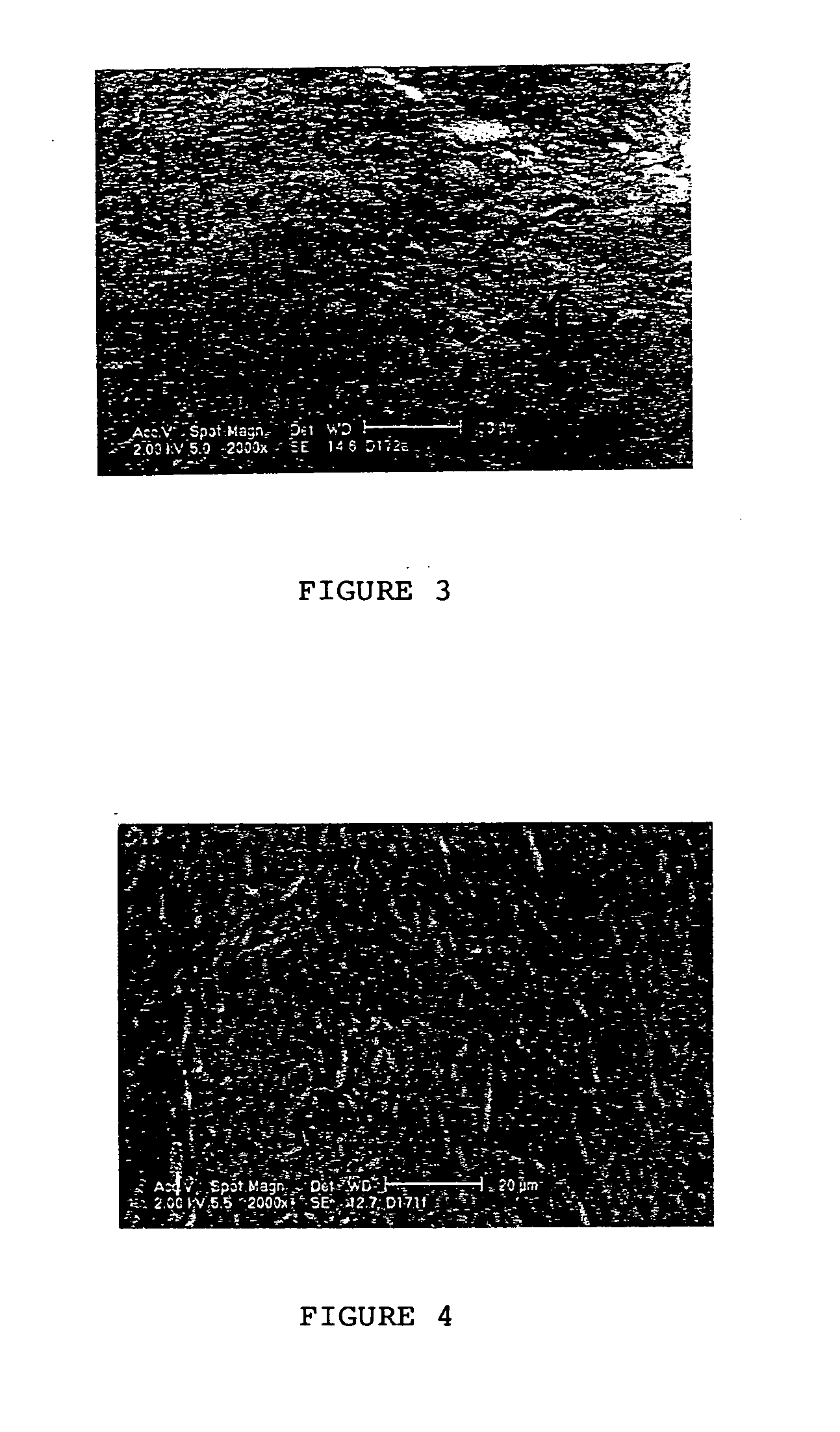

Reactively blended polyester and filler composite compositions and process

InactiveUS20070203261A1Improve interfacial adhesionFacilitates chemical bondingPolyester compositeReactive extrusion

High-performance inorganic filled thermoplastic polyester composites are provided, and the process for preparing thereof. Biodegradable inorganic filled thermoplastic polyester composites are provided by reactive melt-blending of biodegradable thermoplastic polyesters with inorganic fillers using a reactive extrusion processing.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

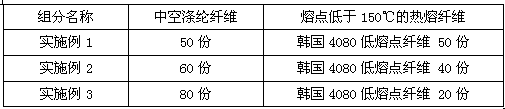

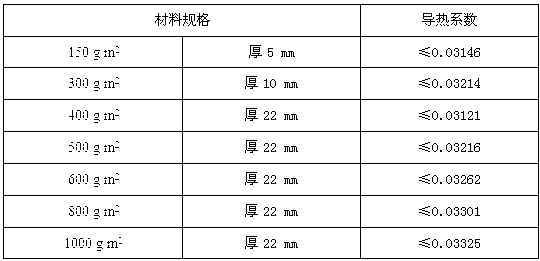

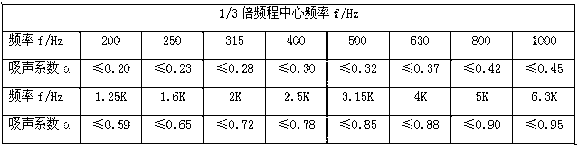

Sound absorption and vibration reduction polyester composite cotton and preparation method of sound absorption and vibration reduction polyester composite cotton

InactiveCN103074736ATo achieve the purpose of noise reductionExtended propagation pathNon-woven fabricsMetallurgyPolyester composite

The invention discloses sound absorption and vibration reduction polyester composite cotton, which is formed by mixing 50 percent to 80 percent of hollow polyester fibers with 20 percent to 50 percent of meldable fibers with the melting point lower than 150 DEG C through being metered by the mass percent. The sound absorption and vibration reduction polyester composite cotton disclosed by the invention has the advantages that the weight is light, the environment is protected, the composite cotton is nonflammable, the heat conductivity coefficient is small, sound absorption, sound isolation, vibration reduction and water resistance are realized, the maintenance is convenient, the secondary recovery can be realized, the production quality is stable, and the likes. Meanwhile, the invention also discloses a preparation method of the sound absorption and vibration reduction polyester composite cotton.

Owner:WUHU HUANRUI AUTO INTERIOR DECORATION

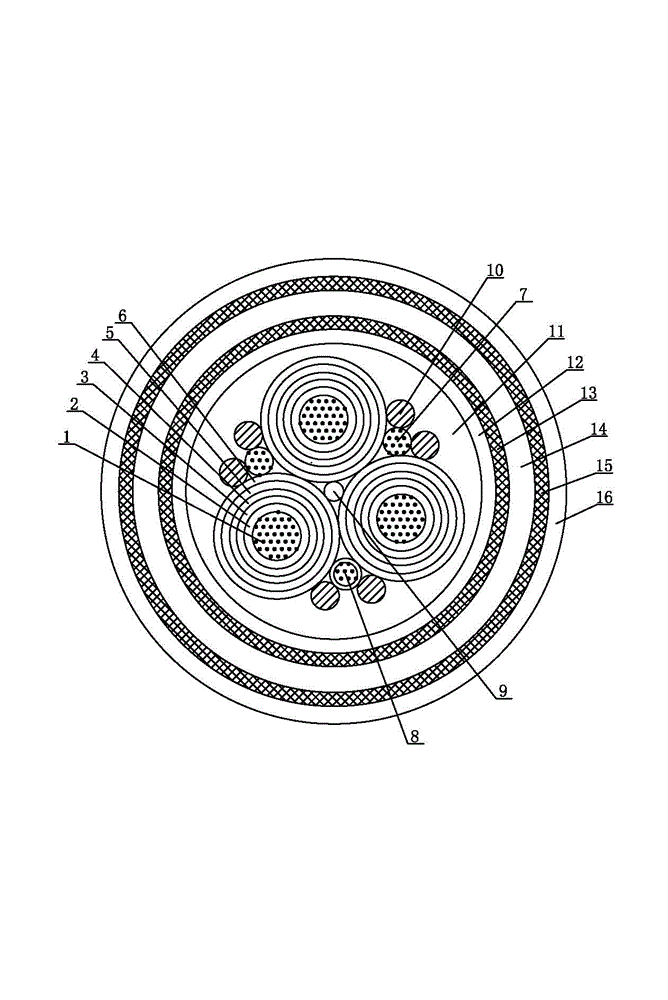

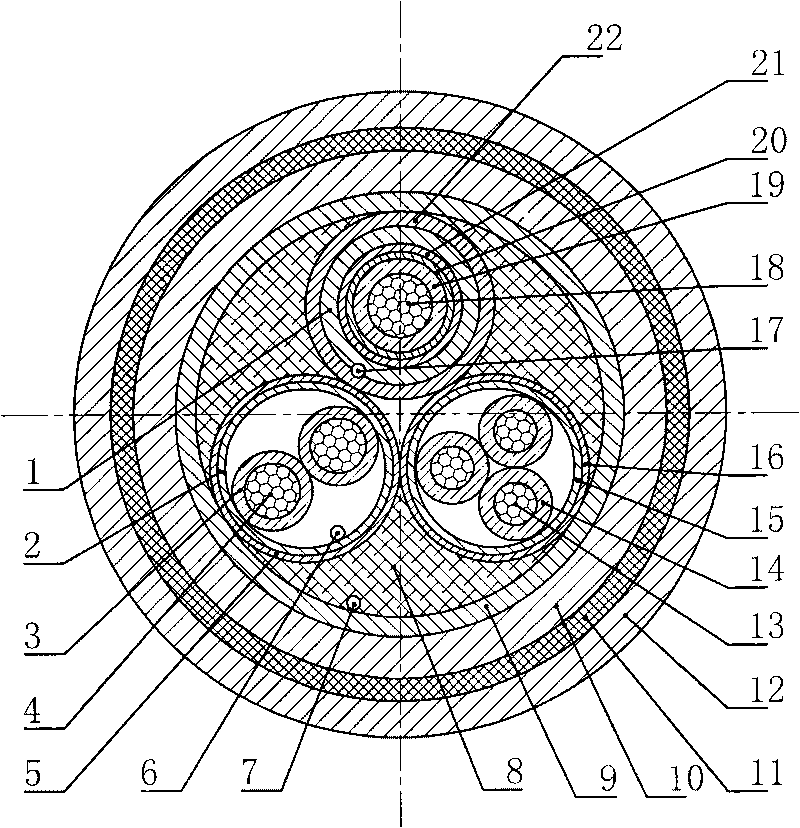

Medium and high-voltage cable for moving petrochemical device and manufacturing method thereof

ActiveCN102751013AHigh mechanical strengthMeet the use requirementsNon-insulated conductorsFlexible cablesCopper conductorCopper wire

The invention discloses a medium and high-voltage cable for moving a petrochemical device and a manufacturing method thereof. A semiconducting conductor shielding belt, a semiconducting conductor shielding extruding and wrapping layer, an oil-resistant rubber insulating layer, a semiconducting insulating shielding extruding and wrapping layer and an insulating shielding braiding reinforcing layer are sequentially arranged outside a stranded copper conductor; three insulating shielding phase wire cores are provided with central tensile components; three grounding wires and a plurality of tensile filling cores are integrally stranded into a cable core; and an oil-resistant rubber inner lining layer, an aluminum foil polyester composite belt shielding layer, a tin-coated copper wire braided shielding layer, an oil-resistant rubber inner sheath, an armored braided layer and an oil-resistant rubber outer sheath are sequentially arranged at the periphery of the cable core. A multiple shielding effect is achieved by the cable, and the oil-resistant rubber insulating layer, the oil-resistant rubber inner sheath and the oil-resistant rubber outer sheath achieve a triplex protection effect, so that the oil resistance of the cable is better. The central tensile components are arranged in the center of the three insulating shielding phase wire cores, and the tensile filling cores are arranged at the peripheries of the three insulating shielding phase wire cores, so that the cable can bear high tensile force.

Owner:嘉兴顾翔制冷设备有限公司

Method for preparing bioceramic and biodegradable aliphatic polyester composite materials

InactiveCN1631973AHigh strengthToughness adjustablePigment treatment with macromolecular organic compoundsLactideOxygen

The invention has supplied a method to prepare aliphatic polyester compound material of biological ceramic and biological degradation. Biological ceramic nm / mm particle reacts with glycolic acid in the dehydrating condition of boiling with toluene, or with biological ceramic and glycolic acid in inorganic solvent. By graft on the surface of the biological ceramic particle, acquire the chemical strycture of -biological ceramic, then without water and oxygen, with stannous octoate as initiator, initiate hydroxyl group of glycolic acid loaded with caprolactone, lactide, diglycolide and cyclic ester, acquiring the product of them and nm / mm compound material of copolymer. The biological ceramic modified by glycolic acid and loaded with polyester of surface graft can be used for polyester material directly.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Method for preparing nano-calcium carbonate/polyester composite material

The invention discloses a new method for preparing a nano-calcium carbonate / polyester composite material. The nano-calcium carbonate / polyester composite material is successfully prepared by the adoption of the technology of nano-calcium carbonate in situ synthesis and modification and the technology of even dispersion in monomers and in situ esterification and condensation polymerization. Due to the stable suspension and even dispersion of the nano-calcium carbonate particles in the monomers, the modification agent is linked to the surface of the nano-calcium carbonate and participates in esterification reaction to combine the nano-calcium carbonate particles with polyester chemical bonds, thus finally realizing the even dispersion of the nano-calcium carbonate in the polyester without agglomeration, and effectively improving the mechanical property of the polyester. The new method does not change the original production technology and equipment of polyester, thus being easy to realize commercial process.

Owner:JILIN UNIV

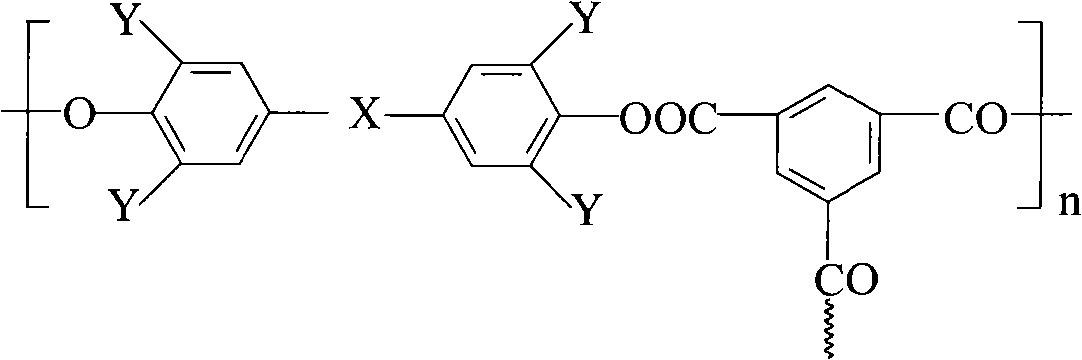

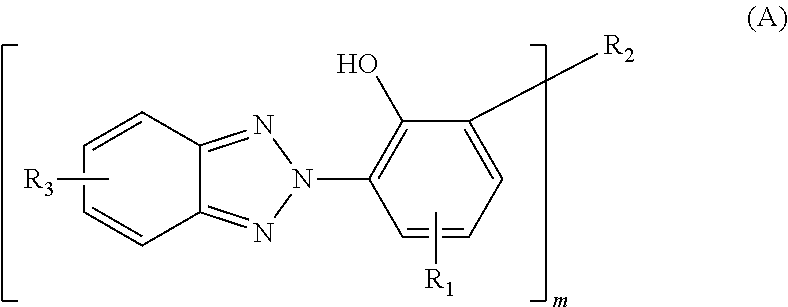

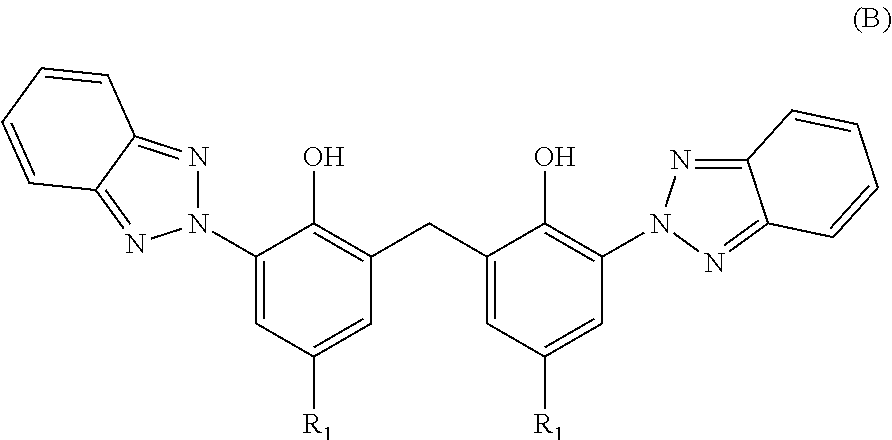

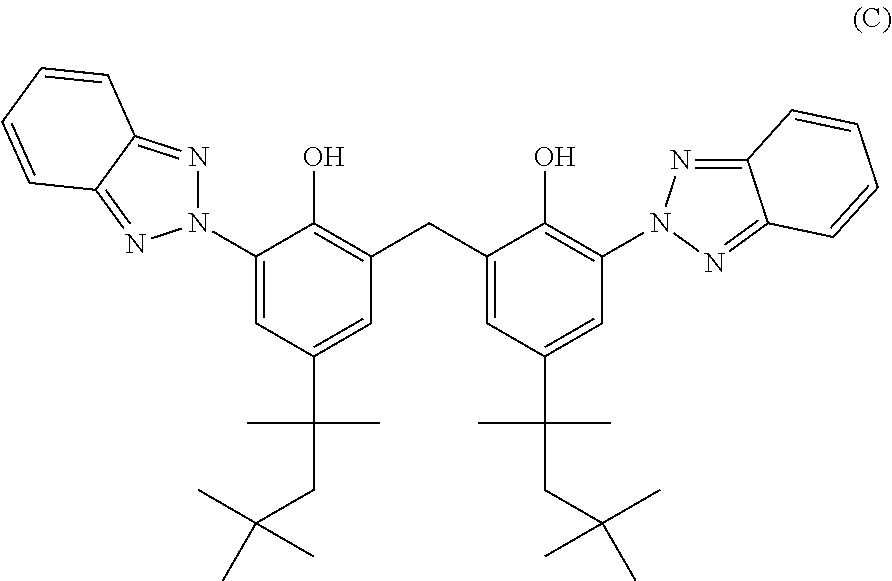

Long-term outdoor exposure resistant overmolded polyester composite structures and processes for their preparation

InactiveUS20110306262A1Effective protectionSynthetic resin layered productsAnimal housingUltraviolet lightsPolyester resin

Disclosed herein is an ultraviolet light stabilized overmolded composite structures comprising polyester compositions comprising i) a first component having a least a portion of its surface made of a surface resin composition and comprising a fibrous material being impregnated with a matrix resin composition, and ii) a second component comprising an overmolding resin composition, adhered to the first component over at least a portion of the surface of the first component, wherein the surface resin composition is selected from polyester compositions comprising a) one or more polyester resins, and b) at least three UV stabilizers.

Owner:EI DU PONT DE NEMOURS & CO

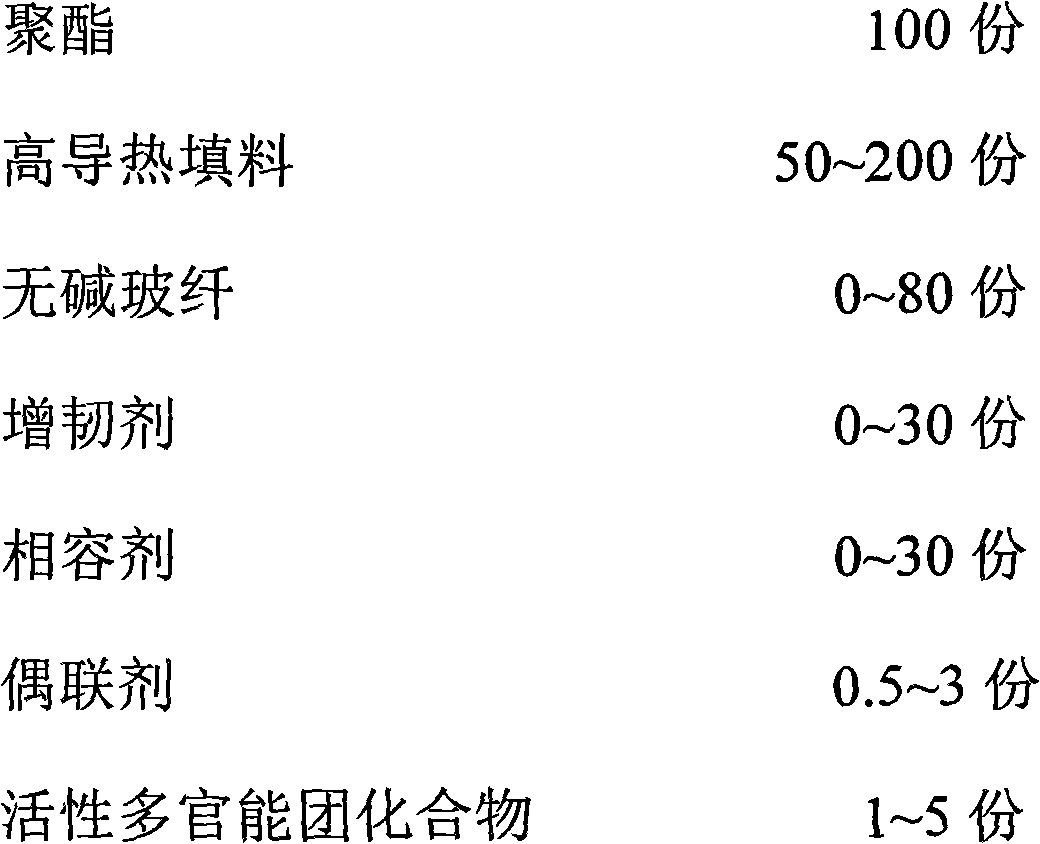

High-thermal-conductivity insulation polyester composite material and preparation method thereof

The invention relates to a formula and a preparation method of an injection-molded high-thermal-conductivity insulation polyester composite material. The heat conduction coefficient is higher than 0.78W / m.K. The material is composed of the components of, by weight: 100 parts of polyester, 50-200 parts of a high-thermal-conductivity filling material, 50-200 parts of metal oxide, 0-30 parts of alkali-free glass fiber, 0-20 parts of a toughening agent, 0-10 parts of a compatilizer, 0.5-3 parts of a coupling agent, and 1-5 parts of an active multi-functional-group compound. The characteristics of the preparation method are that: metal oxide pre-coating treatment and active multi-functional-group compound adding methods cooperates, such that a polyester degradation problem during a processing process is solved. Also, belt conveying, air-cooling, and hot cutting technologies are adopted, such that the steps are simplified, and time is saved.

Owner:BEIJING UNIV OF CHEM TECH

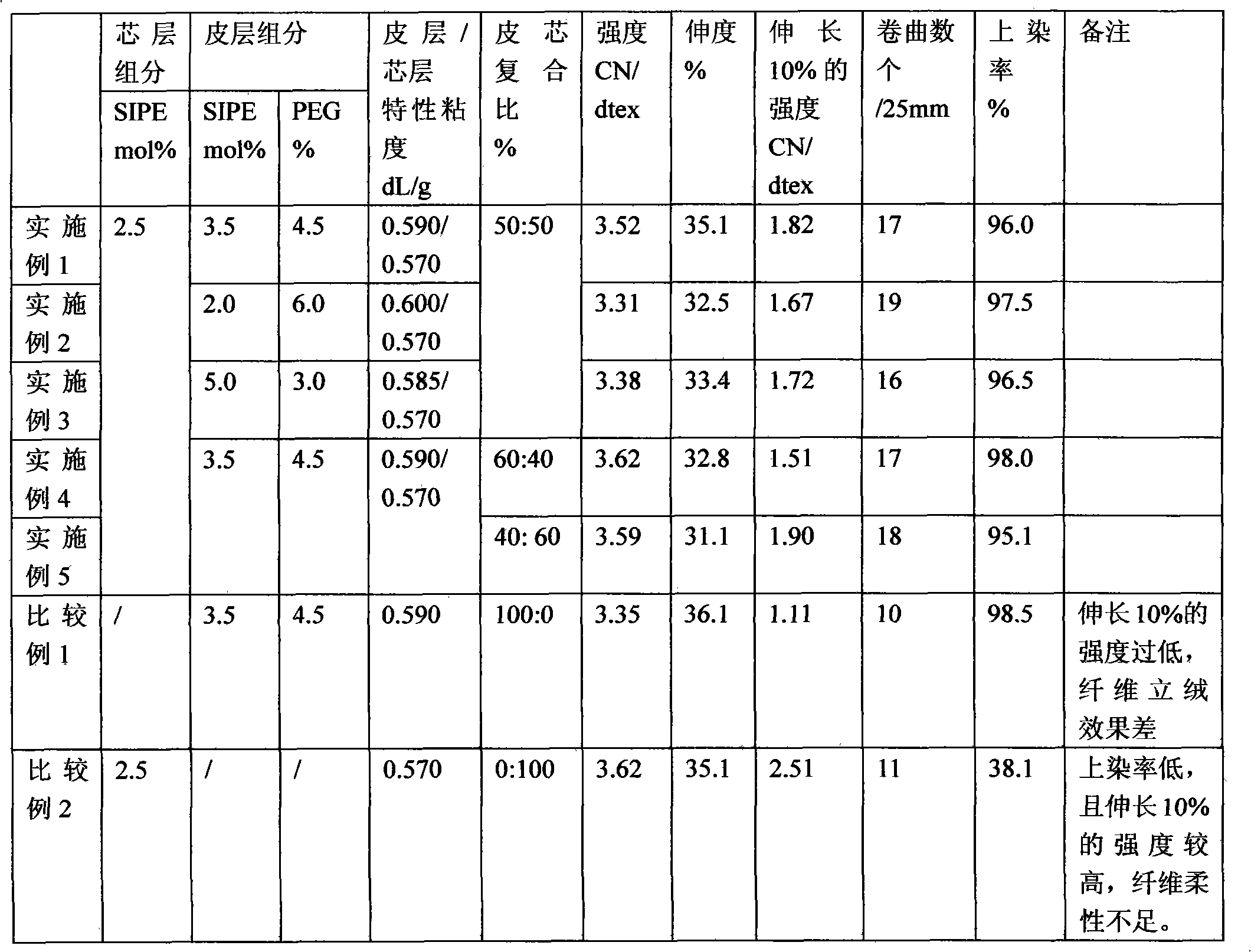

Preparation method of dyeable polyester composite fiber of cationic dye

InactiveCN101613894ALow modulusTo overcome the disadvantage of low initial modulusFilament/thread formingConjugated synthetic polymer artificial filamentsColour differenceHeat setting

The invention discloses a preparation method of dyeable polyester composite fiber of cationic dye. The preparation method comprises the following steps of: (1) preparation of modified polyester materials: including the preparation of core layer components and skin layer components; (2) preparation of polyester composite fiber: using the above method to prepare two types of dyeable modified polyester chips of cationic dyes, respectively carrying out crystallizing, drying, screw melting and extruding, metering, entering a skin-core eccentric composite spinning component according to the weight composite ratio of the skin layer and the core layer, completely wrapping the core layer by the skin layer, and preparing the three-dimensional curly dyeable polyester composite fiber of cationic dye by the follow-up technique. The invention has higher fiber initial modulus, can overcome the defects of lower fiber initial modulus of normal-pressure single component of the cationic dye, and form spiral three-dimensional curl after drawing and heat-setting, the curl number is higher than that of the fiber obtained by two-dimensional mechanical curl obviously; the cationic dye can carry out normal-pressure dyeing; and when being made into short fiber, the fiber section of the dyeable polyester composite fiber has no colour difference and is characterized by bright color and various styles.

Owner:ZHEJIANG SCI-TECH UNIV

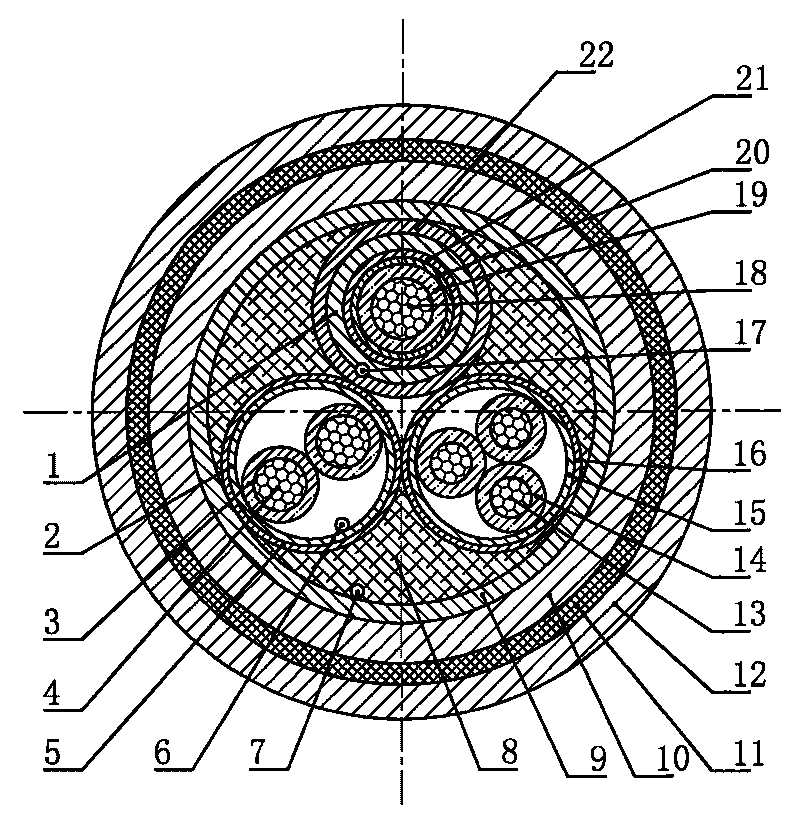

Low-smoke halogen-free flame-retardant multifunctional armored cable for ship and marine engineering

InactiveCN101707067AHigh strengthEasy to manufactureInsulated cablesInsulated conductorsPower cableFilling materials

The invention discloses a low-smoke halogen-free flame-retardant multifunctional armored cable for ship and marine engineering in the technical field of cables, comprising an electric power cable, an instrument cable and a coaxial signal cable which are distributed like three stacked cube blocks, a double-layer shielding layer lapped by an aluminum foil polyester composite strip is respectively arranged outside the electric power cable, the instrument cable and the coaxial signal cable, wherein polyester strip lapping layers are arranged outside the double-layer shielding layers of the electric power cable and the instrument cable, a filling material with sector-shaped cross section is respectively arranged in clearances among the peripheries of all cables, the electric power cable, the instrument cable, the coaxial signal cable and the filling material are twisted into a cable bundle, an external drainage wire is arranged outside the cable bundle, a total shielding layer is wholly lapped at the periphery of the cable bundle, an internal sheath is arranged outside the total shielding layer, a weaved armored layer is arranged outside the internal sheath, and an external sheath is arranged outside the weaved armored layer. The cable has a plurality of functions of transmitting an electric power signal, an instrument signal and a video signal, small laying space and compact structure, and can be used in ship or marine engineering.

Owner:JIANGSU YUANYANG DONGZE CABLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com