Patents

Literature

2157 results about "Polyethylene terephtalate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

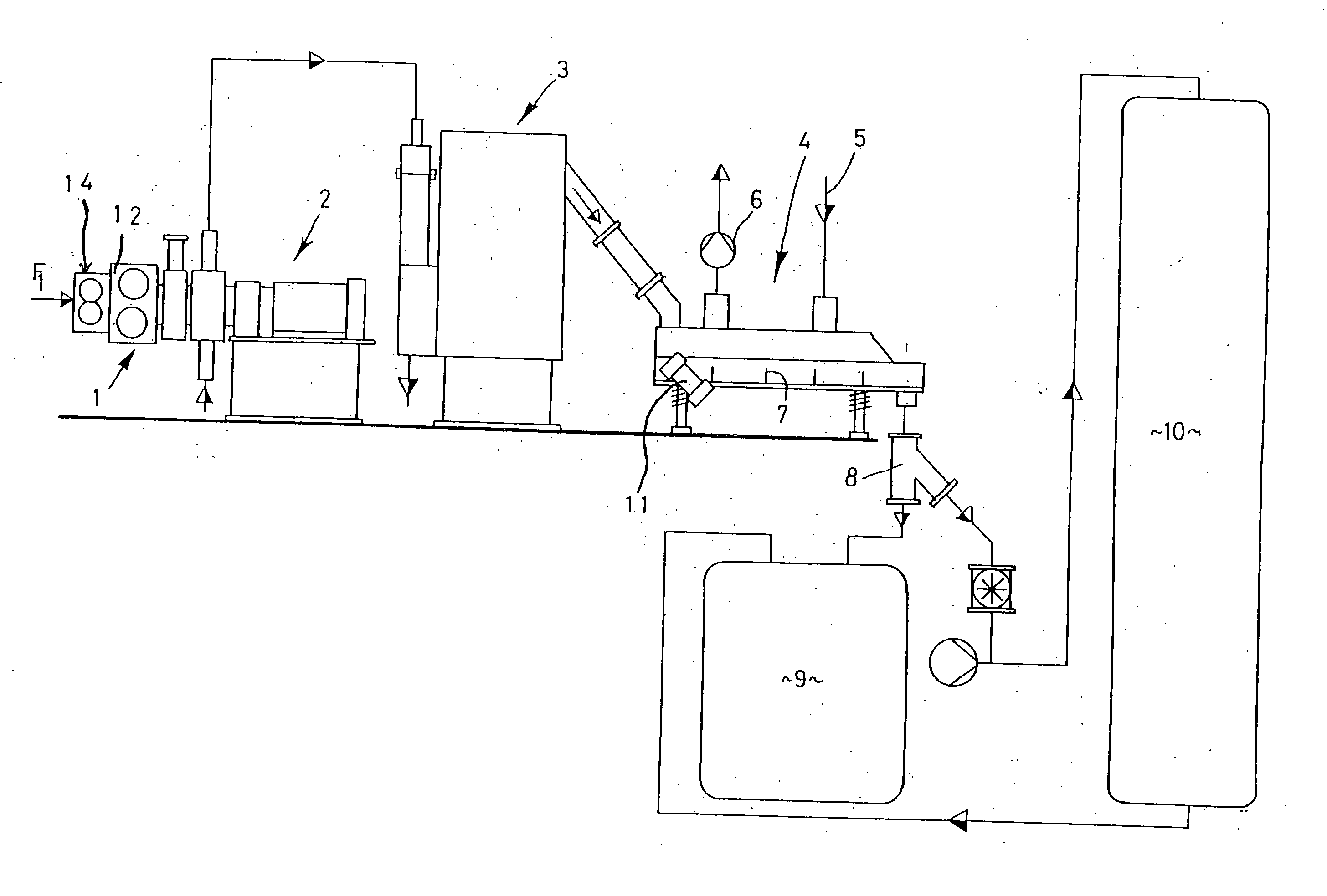

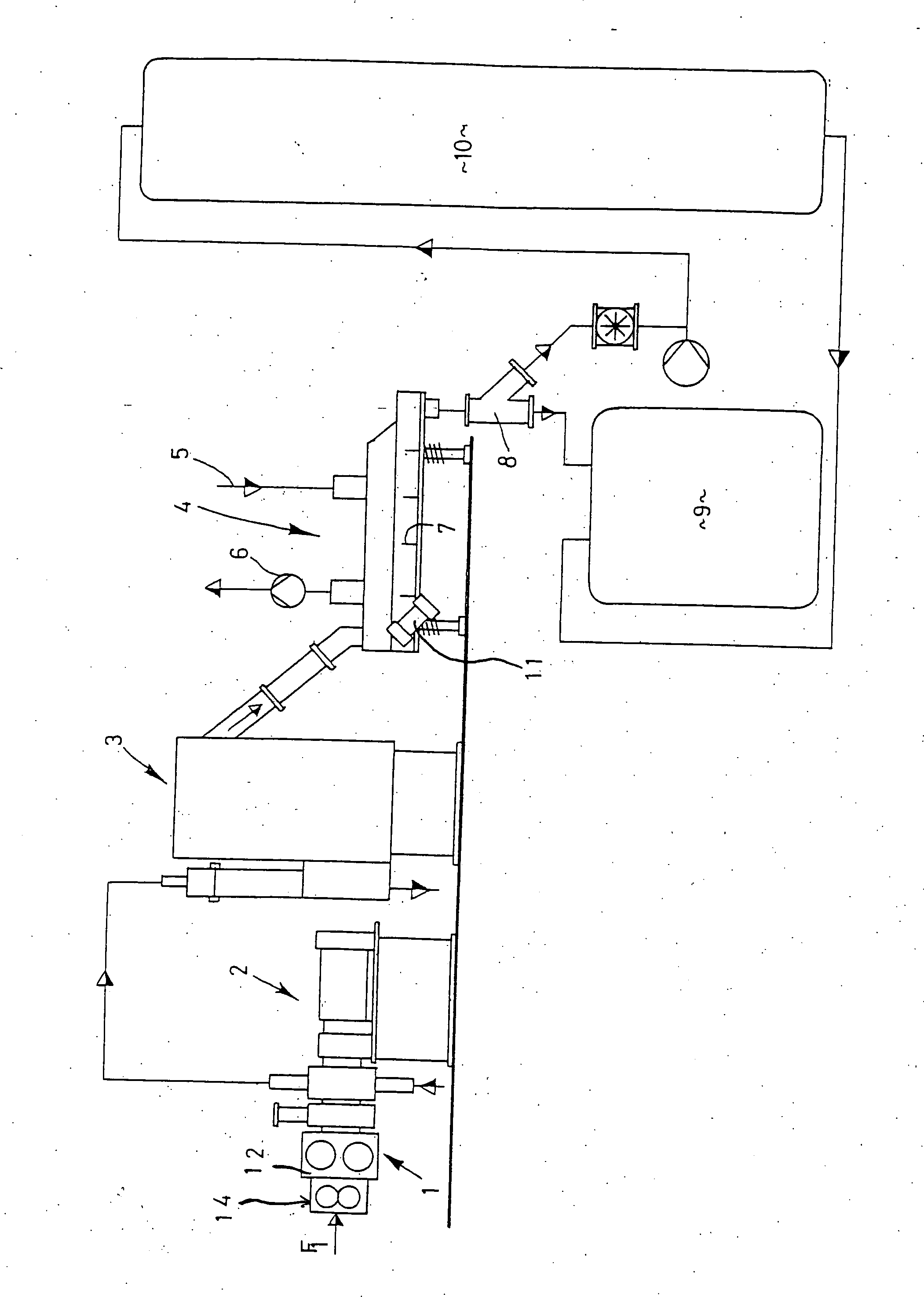

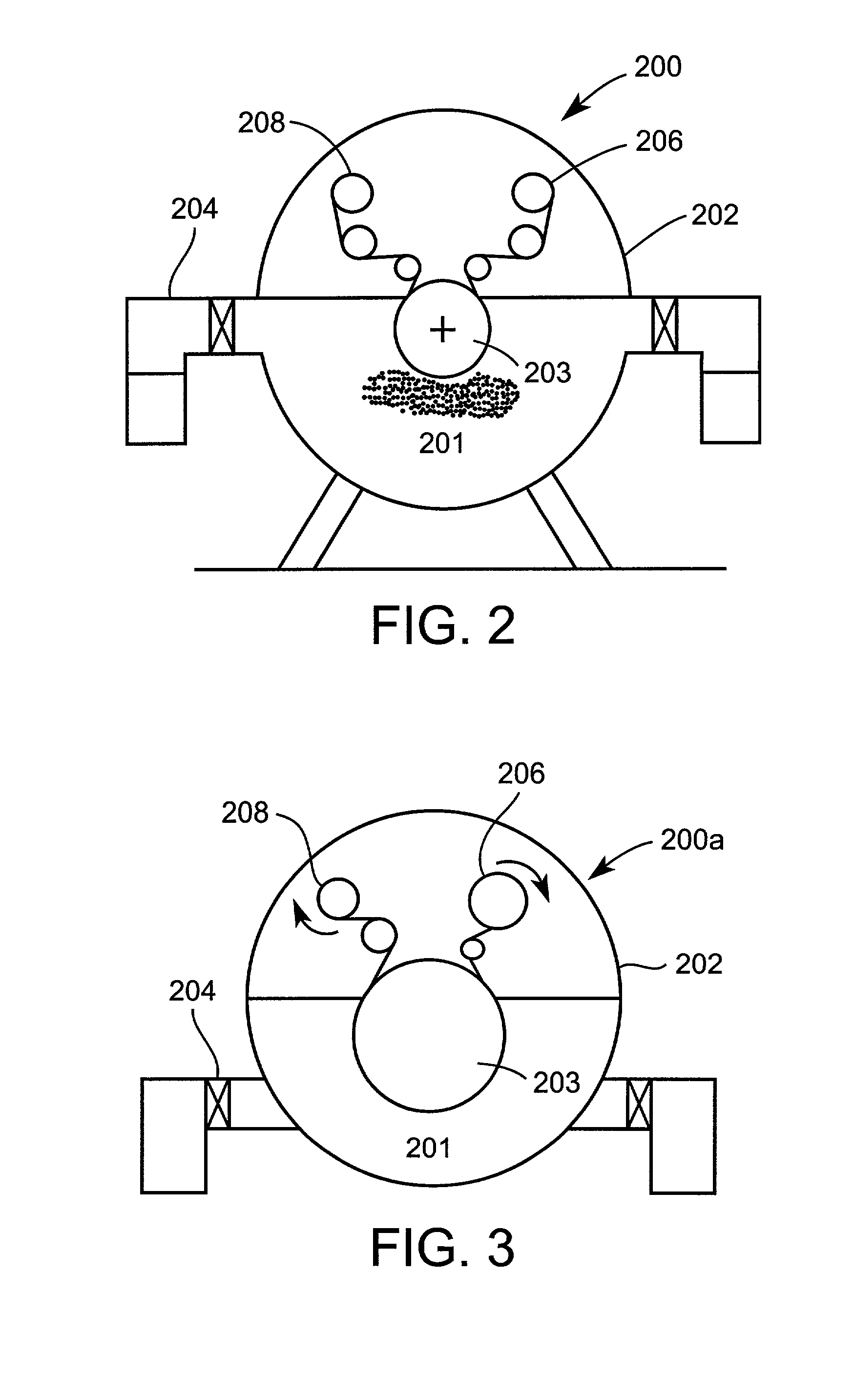

Method and apparatus for thermally processing polyester pellets

InactiveUS20050085620A1Long dwell timeSmall contact surfaceMouldsConfectioneryPolyesterPolyethylene terephthalate

Method and apparatus for thermally processing polyester pellets, e.g., polyethylene terephthalate pellets, in order to achieve a partial crystallization, whereby the polyester melt is fed to an underwater pelletizer and pelletized, the pellets obtained are fed to a water / solids separating device and the dried pellets are fed at a pellet temperature of greater than 100° C. to an agitation device that the pellets leave at a pellet temperature of over 100° C.

Owner:NORDSON CORP

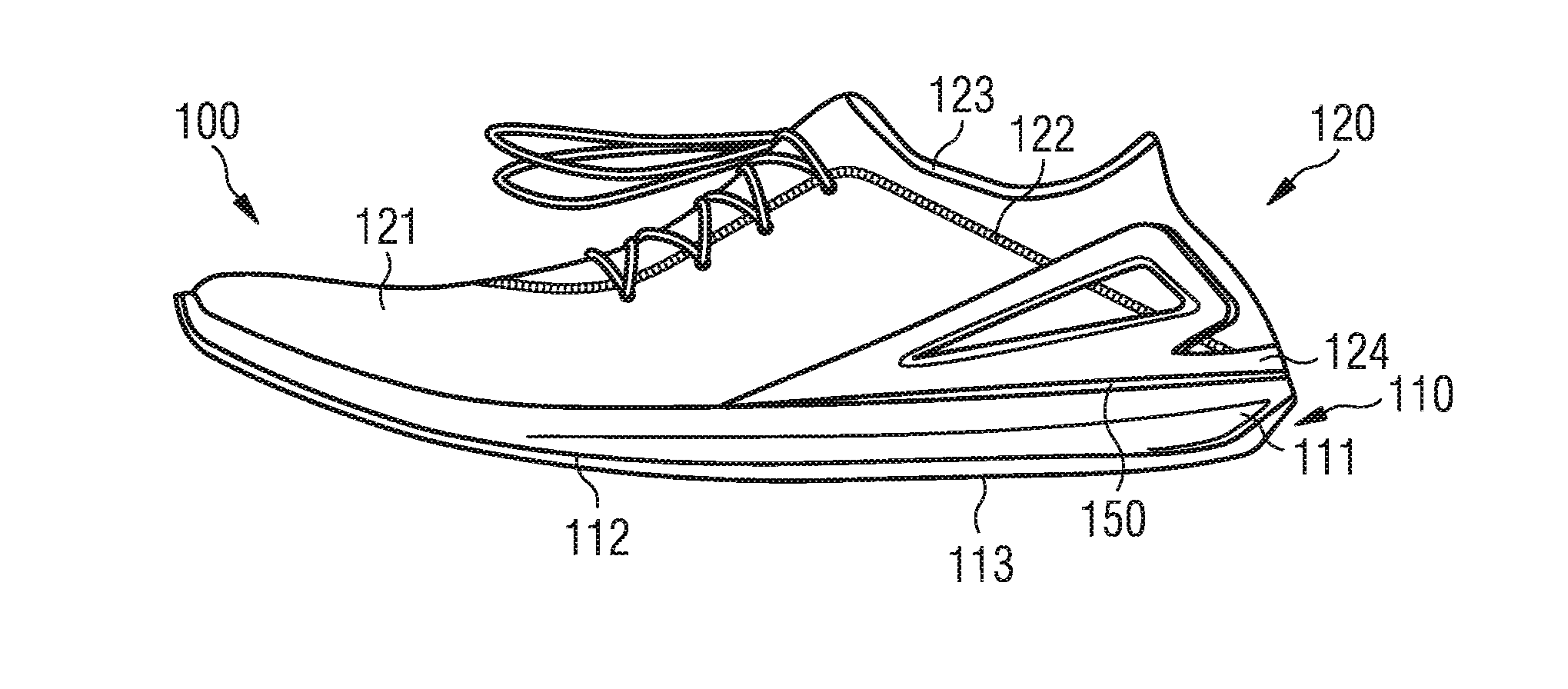

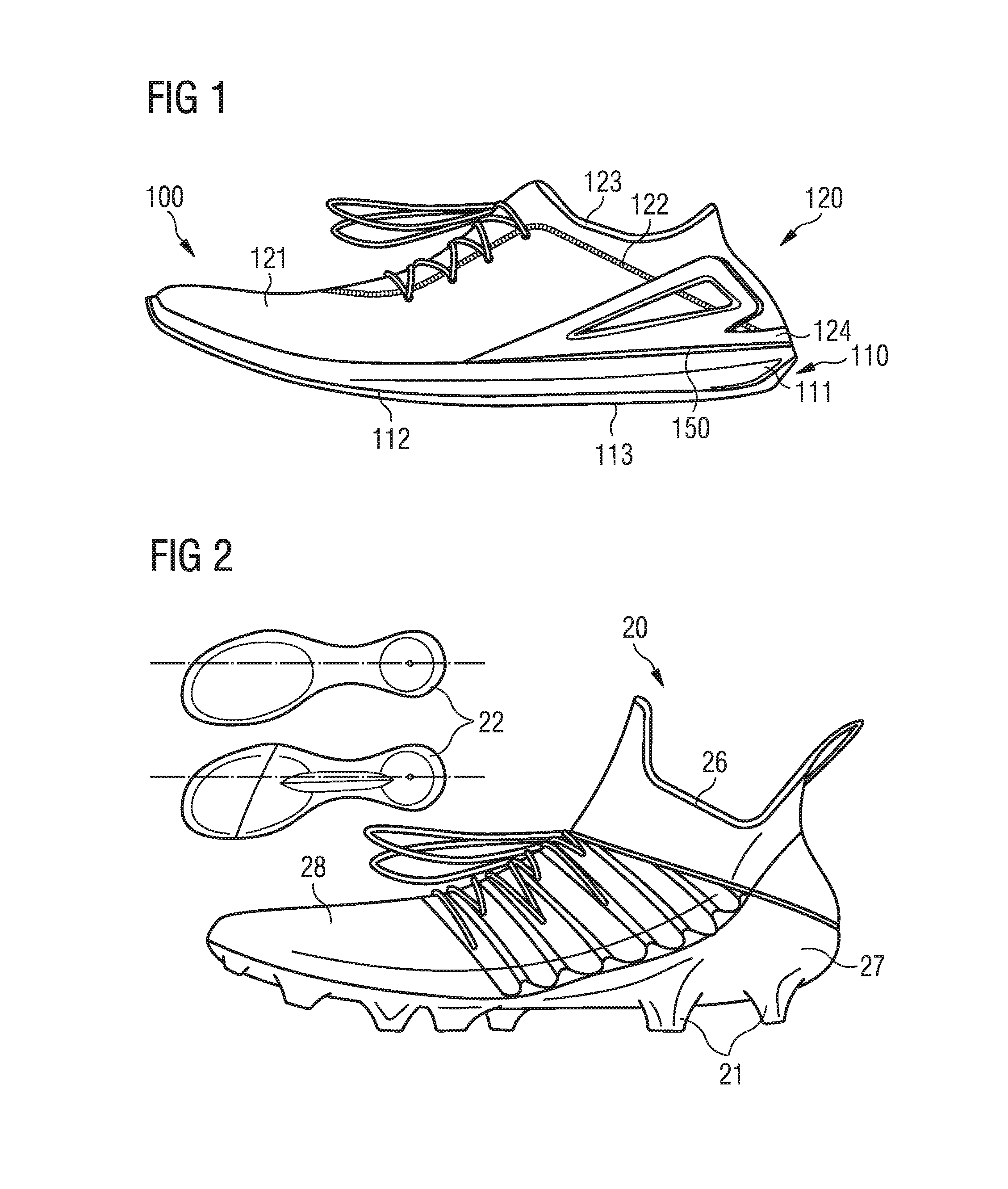

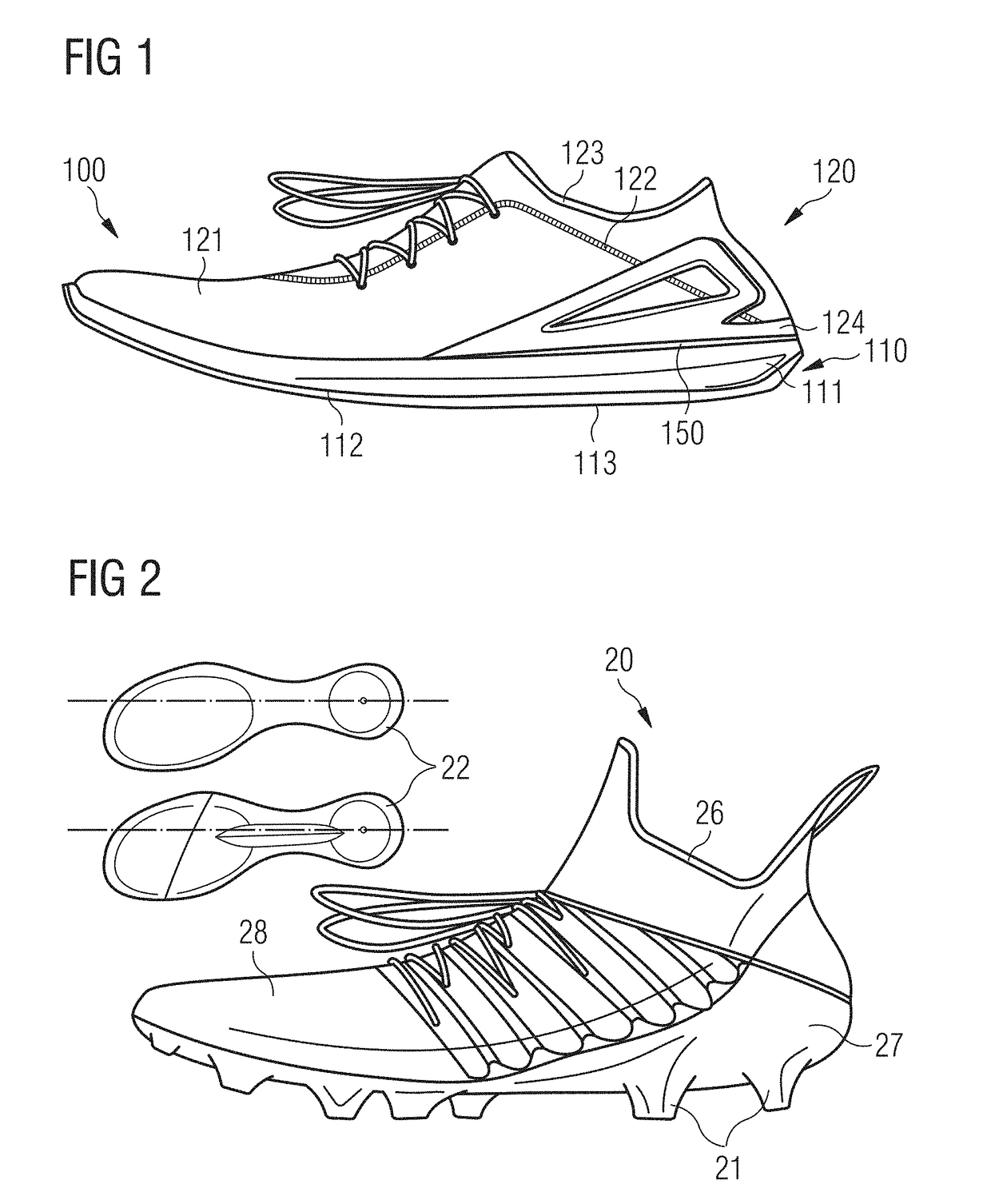

Sports Shoes and Methods for Manufacturing and Recycling of Sports Shoes

InactiveUS20160302508A1Easy to identifySolesInsolesPolyethylene terephthalatePolyethylene terephthalate glycol

A sports shoe includes an upper wherein a majority by weight of the upper is made from a thermoplastic base material and a sole wherein a majority by weight of the sole is made from the same thermoplastic base material. The sole and the upper are individually fabricated and joined to each other. The thermoplastic base material includes at least one of the following materials: thermoplastic polyurethane TPU, polyamide PA, polyethylene terephthalate PET, or polybutylene terephthalate PBT.

Owner:ADIDAS

Impact-modified polycarbonate blends

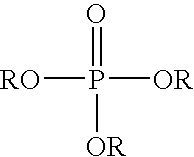

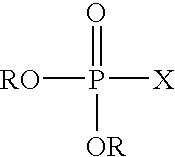

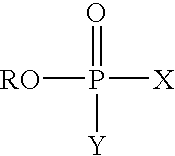

ActiveUS7067567B2High impact strengthEasy to processCoatingsPhosphorus organic compoundsPhosphoric Acid EstersPolyolefin

A thermoplastic molding composition having improved flammability rating and mechanical properties is disclosed. The composition contains aromatic polycarbonate having a weight-average molecular weight Mw≧25,000 g / mol., polyalkylene terephthalate, graft (co)polymer characterized in that its grafted phase includes structural units derived from acrylate monomers, an oligomeric organic phosphoric acid ester, and an optional fluorinated polyolefin. In a preferred embodiment the graft (co)polymer is characterized in its core-shell morphology.

Owner:COVESTRO DEUTSCHLAND AG

Process of preparing PDT copolyester fiber

InactiveCN101046007ASpinning high speedHigh speed spinning equipmentMonocomponent copolyesters artificial filamentFiberAlcohol

The process of preparing PDT copolyester fiber includes the following steps: 1. saccharifying and catalytically hydrogenating corn starch to prepare sorbitol, catalytically hydrogenating to prepare multicomponent mixed alcohol, and fractionating in a fractionating tower at 182-212 deg.c to obtain corn-base ethylene glycol product of 89-99 % content and with ethylene glycol as main component and other diols; 2. detecting the contents of component diols in the ethylene glycol product and adding insufficient components for content fluctuation controlled within 10-30 %; and 3. adding nanometer titania in 0.05-1 wt% into the corn-base ethylene glycol product, and copolymerizing together with terephthalic acid at 280-288 deg.c for 5-7 hr to prepare PDT copolyester. The process is suitable for industrial production.

Owner:DONGHUA UNIV

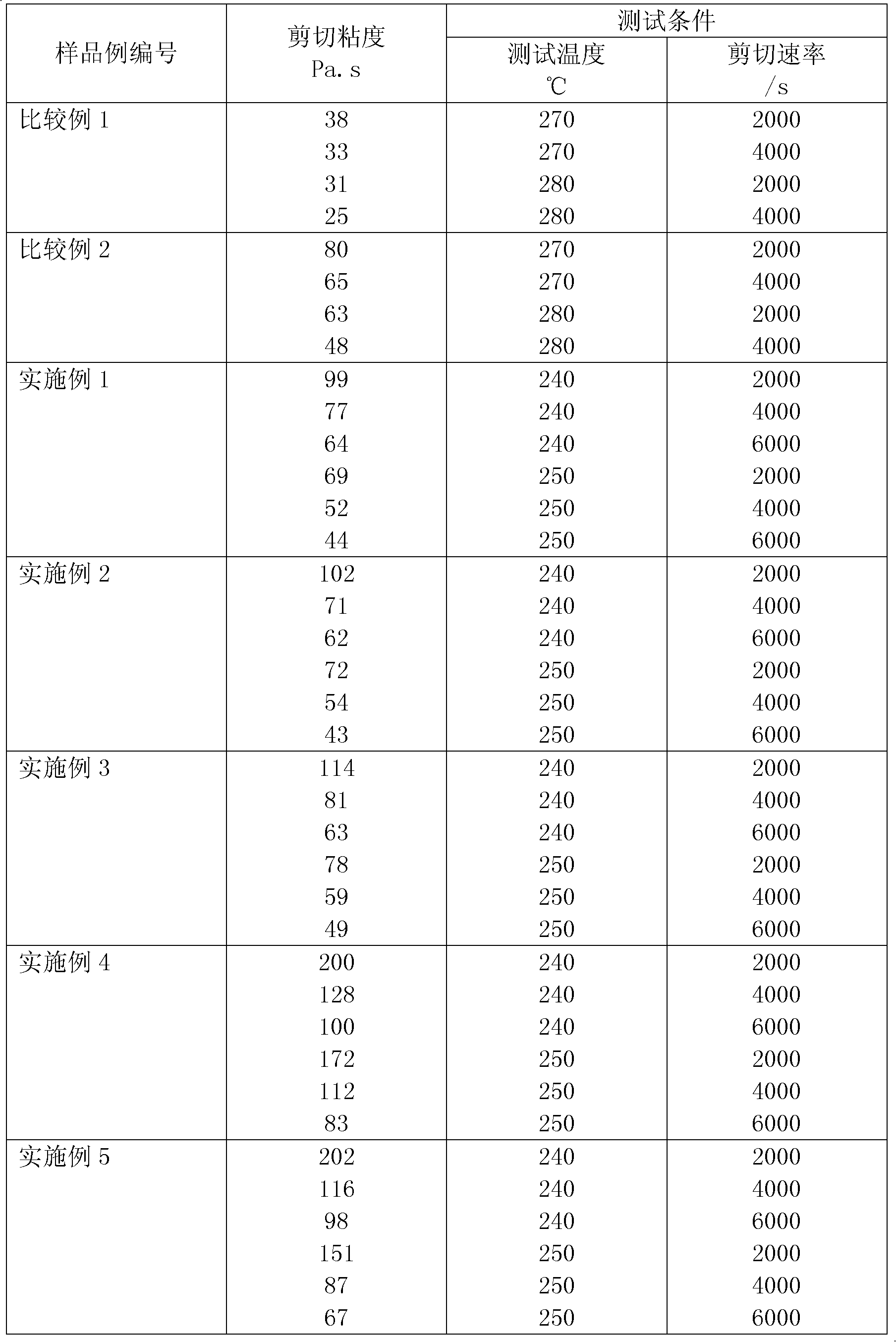

Low warping high surface gloss glass fiber reinforced polyester composite material and preparation method thereof

The invention relates to a low warping high surface gloss glass fiber reinforced polyester composite material and preparation method thereof. The composite material comprises the following components (wt%): 10-35% of polycarbonate, 20-45% of polybutylece terephthalate, 1-10% of flexibilizer, 3-10% of kaolin and 15-38% of glass fiber; 0.1-1% of antioxidant, 0.1-0.5% of ester exchange inhibiting agent and 0.1-3% of processing agent are prepared, silane coupling agent is utilized to process kaolin, then raw materials are placed into a mixing machine to be mixed for 2-5min, then mixture is placed into a screw machine for extrusion granulation, and meanwhile side charging is carried out on the glass fiber, the rotating speed of screw machine is 180-600rpm, and temperature is 240-280 DEG C, thus obtaining the product. The invention can obtain products with high surface gloss, excellent comprehensive mechanical properties and dimensional stability and especially ensures low warping property of product when being produced into injection moulding product.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

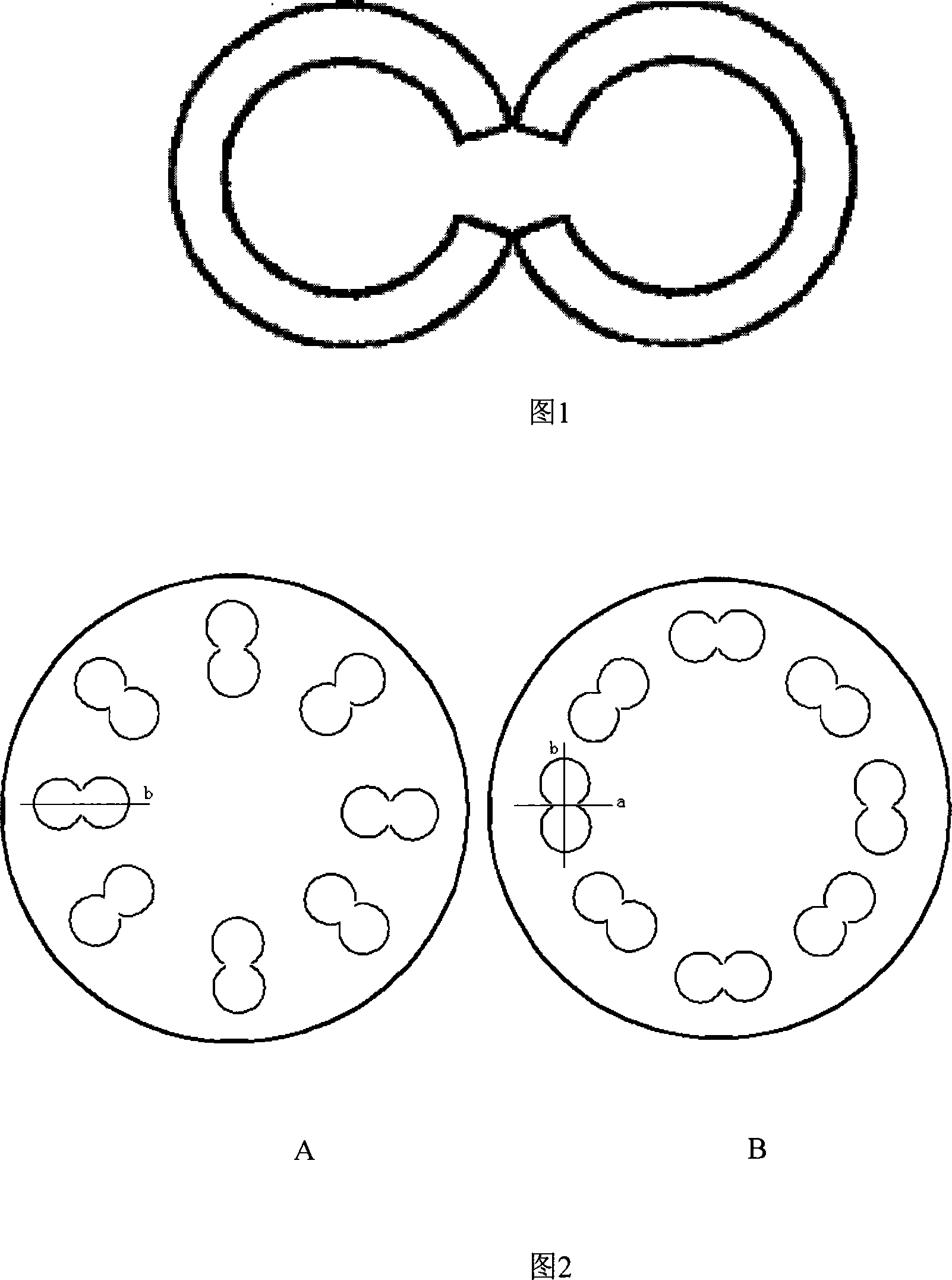

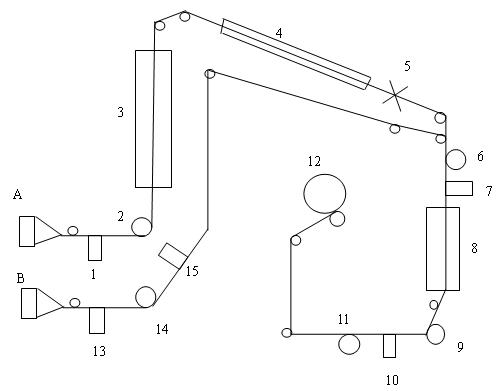

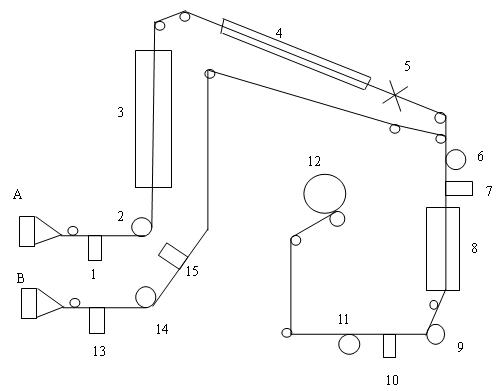

Elastic polyester fibre and preparation method thereof

InactiveCN101126180AIncrease elasticityConvenient careFilament/thread formingMonocomponent polyesters artificial filamentFiberPolymer science

The invention relates to a springy polyester fiber and the preparing method. The technical problem of the invention to be solved is that the invention provides a springy fiber and the preparing method to make up the disadvantages of the capability of the spandex and the applying arrange. The springy fiber of the invention adopts the method of the compound filature and uses two screw extrusion machines to respectively melt the two components, and the product is obtained through the extrusion of the compound filature component. The invention is characterized in that the components of the springy fiber comprise two of the following high polymers which have heat shrinking capability difference: the high fasculation PETP, the PET, the PBT, the PTT with the weight proportion of 30-70:50.

Owner:ZHEJIANG HENGYI GRP CO LTD

Fully biodegradable material with polylactic acid/polyterephthalic dibutyl adipate used as base materials and preparation method thereof

The invention discloses a fully biodegradable material with polylactic acid / polyterephthalic dibutyl adipate used as base materials and a preparation method thereof. The material provided by the invention is composed of polylactic acid, polyterephthalic dibutyl adipate, a bio-based filler, an inorganic filler and a few amount of auxiliaries. The material has been certified by American ASTMD6400, European EN13432 and Australian AS4736 and is a fully biodegradable material. The fully biodegradable material contains the following ingredients, by weight, 5-60 parts of polylactic acid (PLA), 5-60 parts of polyterephthalic dibutyl adipate, 5-40 parts of the bio-based filler, 5-45 parts of the inorganic filler and 0.3-10 parts of the auxiliaries. The above ingredients are fully mixed, and the mixture undergoes melt plastification by a screw and then is directly extruded to obtain a board of 0.2-2mm thick. The board can undergo embossed work to obtain fruit trays, vegetable trays, disposable knives and forks and the like.

Owner:江苏天仁生物材料有限公司

Screen protector film

InactiveUS20130045371A1Increase resistanceQuick installationFilm/foil adhesivesSynthetic resin layered productsPolyethylene terephthalatePolystyrene

A multi-layer screen protector for digital display screens, such as LCD's, cell phones, tablets, laptops, and pad computer devices, that may be readily applied without the need for special tools and in dusty environments, the screen protector being designed and die-cut to match the shape of the digital display screen, including cut-outs for cameras, microphones and device buttons, where the top surface is a layer of polycaprolactone aliphatic urethane that is connected to a bottom layer made from plastic such as polystyrene, acrylic and / or polyethylene terephthalate, and a self-wetting adhesive layer provided on the bottom surface of the bottom polystyrene, acrylic and / or polyethylene terephthalate layer. The screen protector provides an optically clear view of the device and is constructed with the abrasion resistant layer being provided and supported on a plastic layer and may be removed and reinstalled.

Owner:CURIO HLDG CO

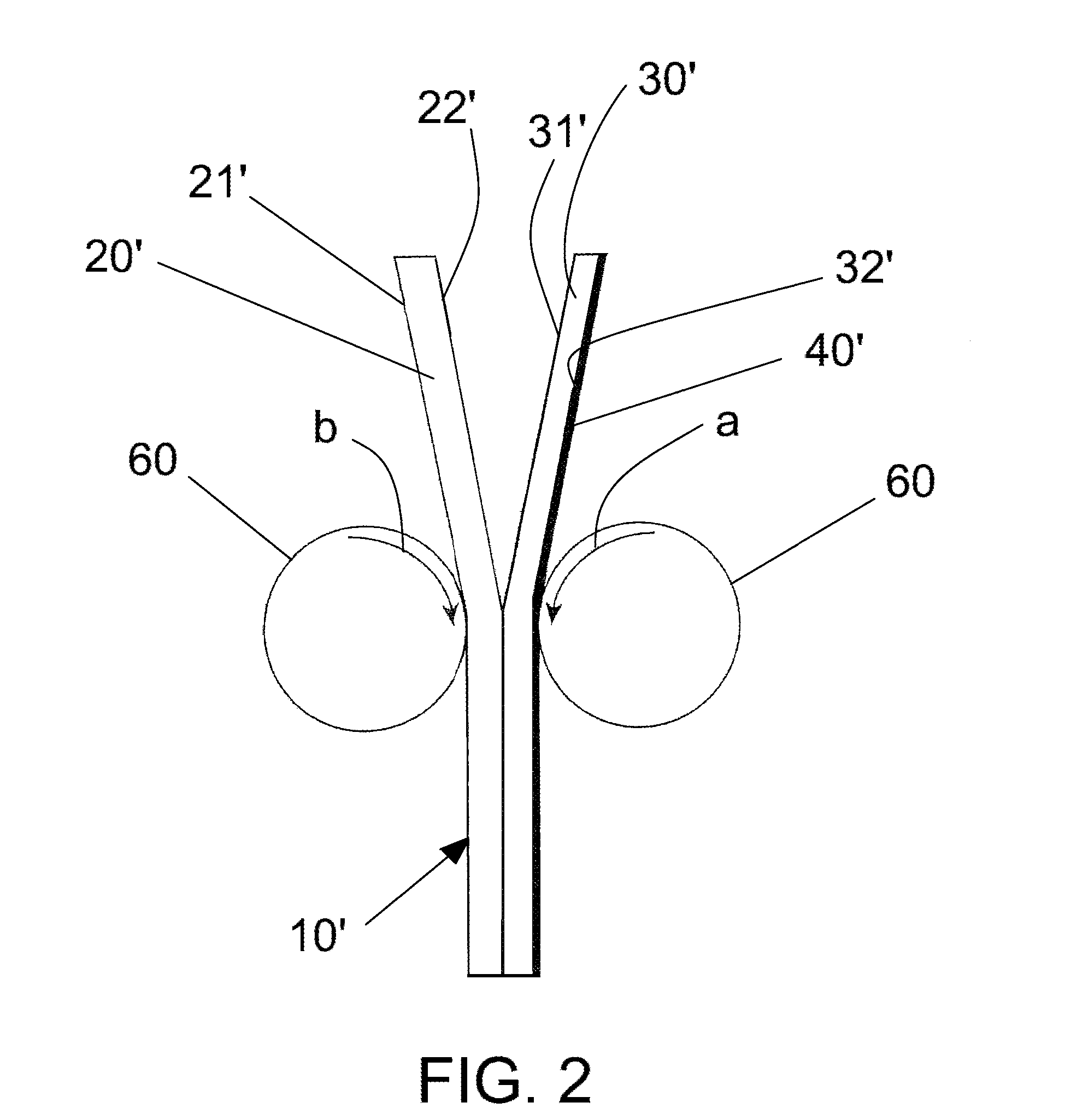

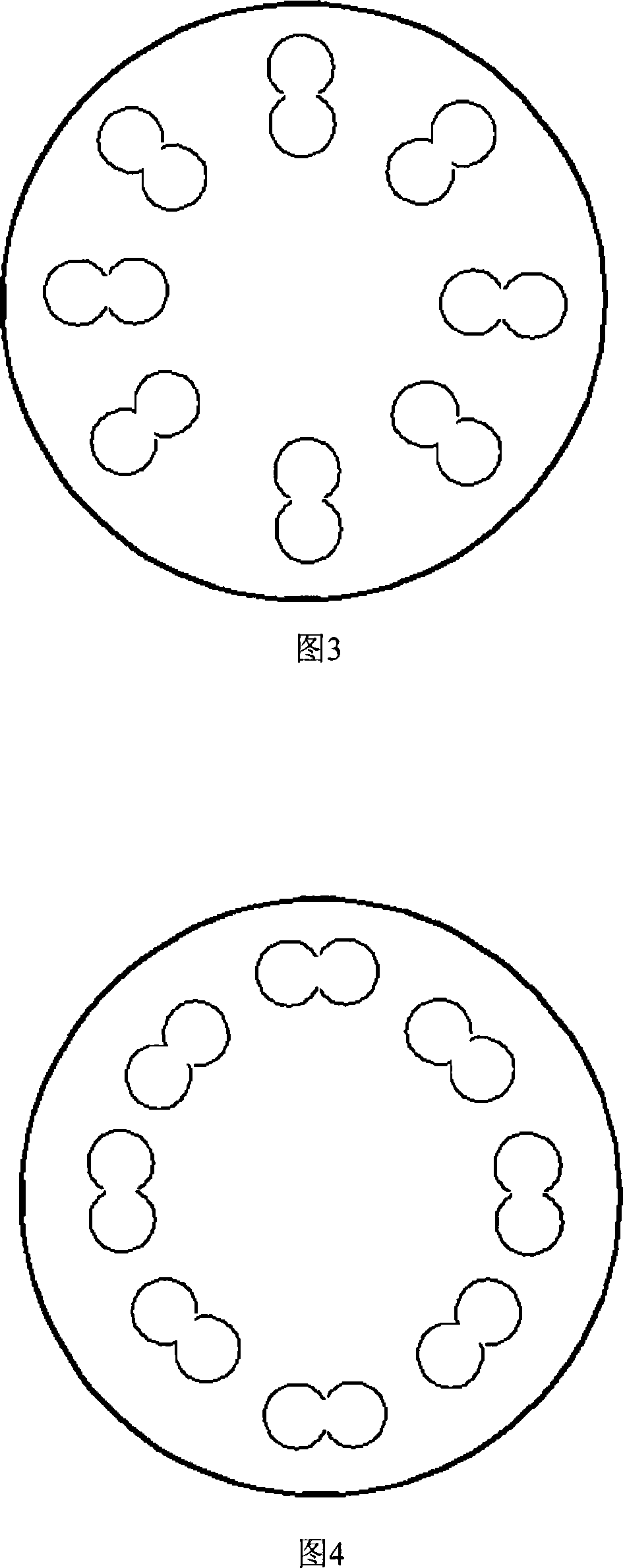

8-shaped pet/PTT hollow fibre and preparing method thereof

InactiveCN101215723ACurly giftMeet needsHollow filament manufactureFilament manufacturePolyesterPolymer science

The invention relates to '8'-shaped PET / PTT hollow fiber and a process for preparation. The fiber is prepared by composite spinning which is obtained through melting polyethylene glycol terephthalate PET and polyytrimethylene terephthalate PTT slice. The process for preparation comprises drying PET and PTT polyester slice, entering into a composite spinning assembly through a twin-screw extruder in parallel, carrying out melt spinning, cooling through cross air blow, oiling on an oil tanker, drafting by two channels, coiling, finally obtaining '8'-shaped PET / PTT hollow fiber. The fiber fully exerts the excellent property of PTT and PET fiber, which is thermal insulating, highly moisture absorbable and breathable, soft and touching, since PTT and PET fiber have different shrinkage ratio and have the potential function of coiling property, the product has greatly wide application prospect in the field of clothing face fabric and various filling material.

Owner:DONGHUA UNIV

Controllable bio-based full-degradable mulching film

InactiveCN104559087ASolve the interface compatibility problemSolve the problem of the controllability of the degradation film cyclePlant protective coveringsAntioxidantPolyethylene terephtalate

The invention discloses a controllable bio-based full-degradable mulching film which is prepared from the following raw materials in parts by weight: 15-60 parts of polylactic acid (PLA), 40-85 parts of polyterephthalic acid-butanediol adipate, 0.1-0.5 part of reactive assistant, 0.1-0.5 part of antioxidant, 0.1-0.5 part of lubricant, 0.1-0.5 part of ultraviolet absorbent and 0.1-0.5 part of light stabilizer. The novel reactive assistant is adopted to solve the problem of interface compatibility between PLA and PBAT; by adjusting the PLA / PBAT proportion and adding other ultraviolet absorbents and light stabilizers, the problem of controllability on mulching film degradation period is solved; and by utilizing the characteristic of high mechanical strength of the PLA in combination with favorable flexibility of the PBAT, the controllable-degradation-period full-biodegradable low-cost agricultural mulching film based on PLA multielement composite modification technique, of which the thickness is down to 6 mu m and the maximum bio-base content is up to 60%, is developed. The controllable bio-based full-degradable mulching film has favorable quality, and has wide popularization application prospects in promoting national soil pollution treatment and developing ecological agriculture.

Owner:JIANGSU UNIV OF SCI & TECH

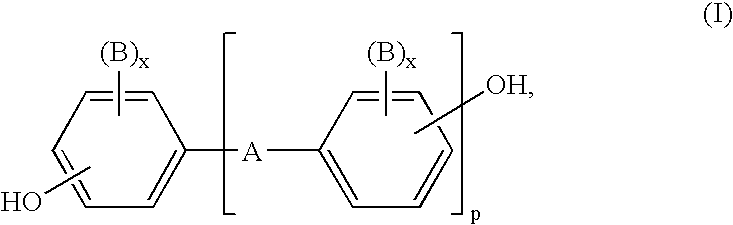

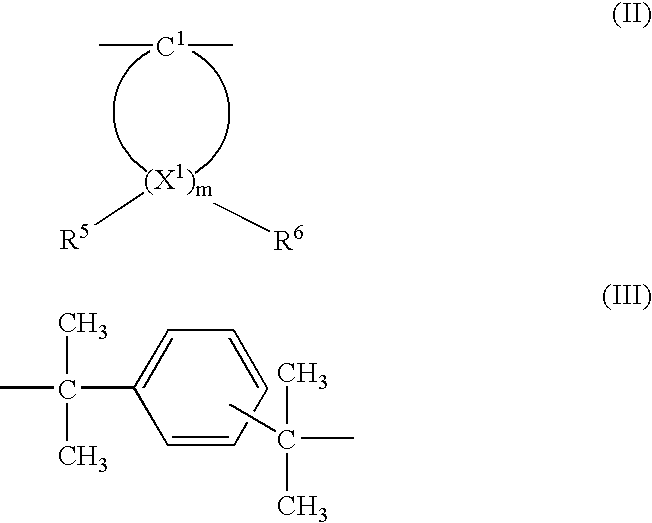

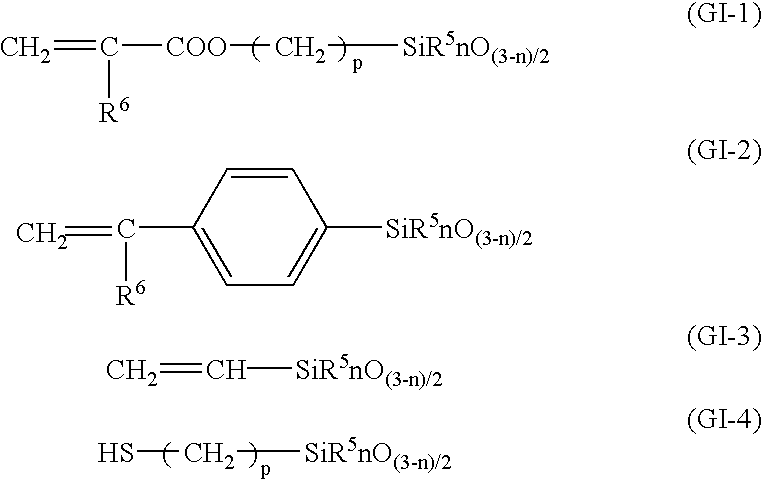

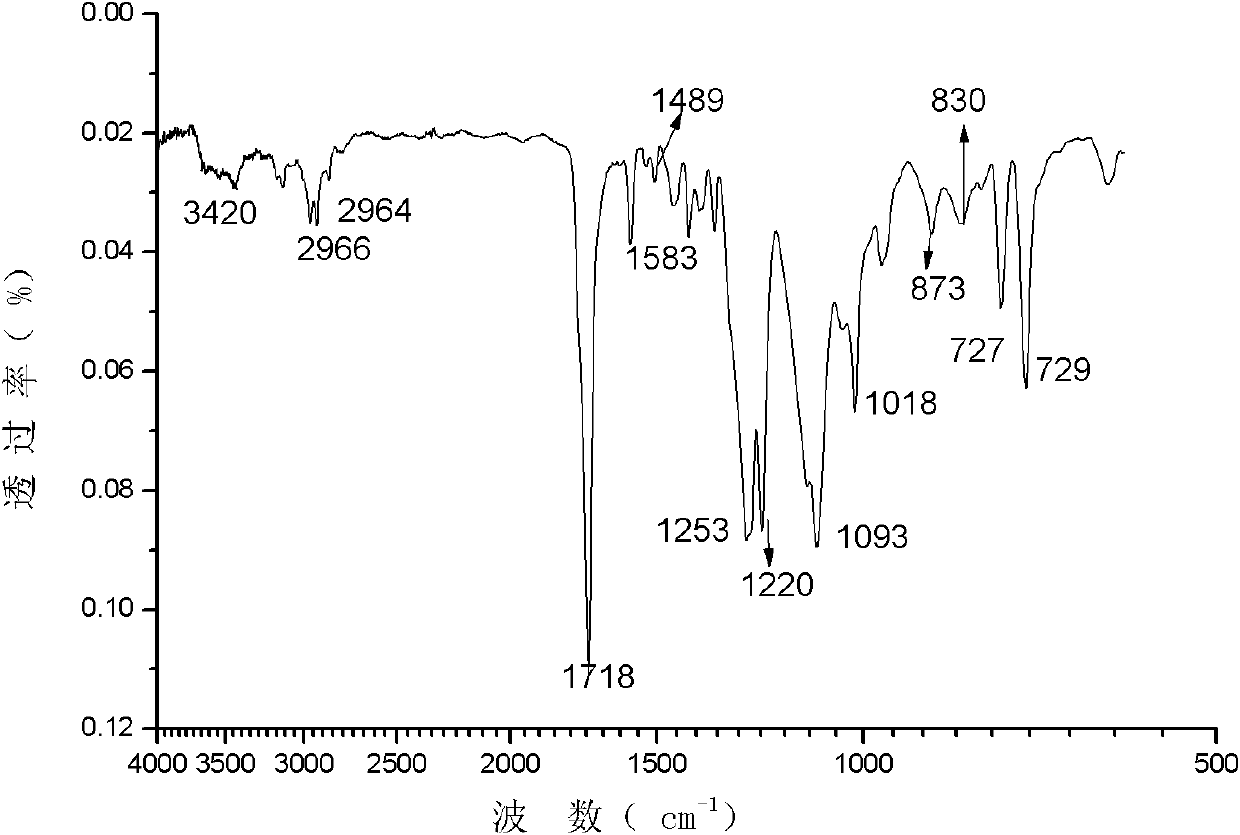

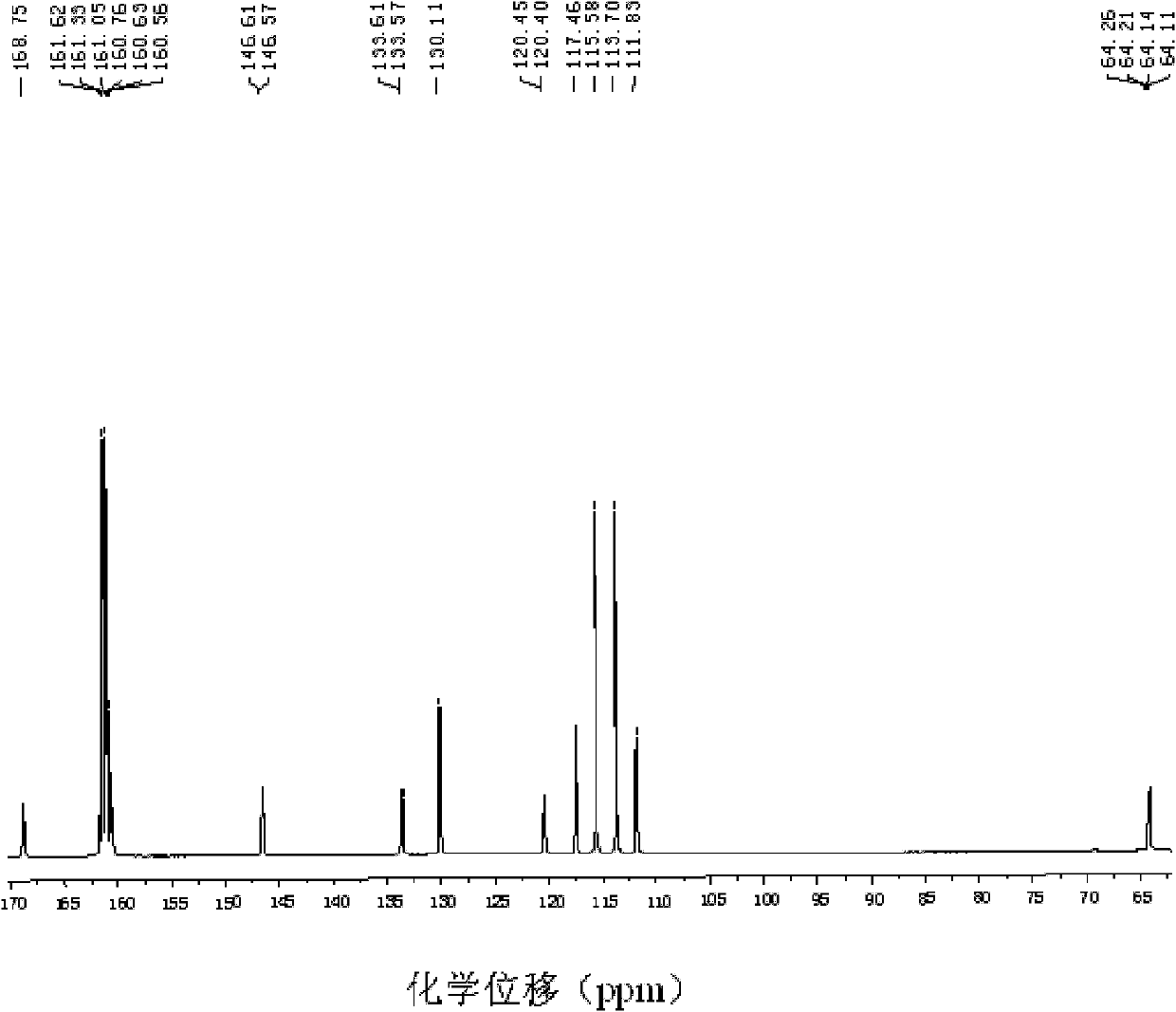

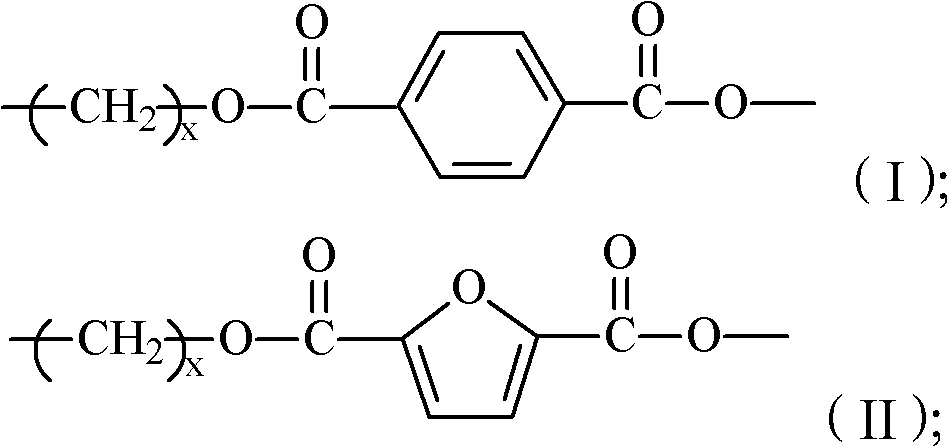

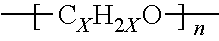

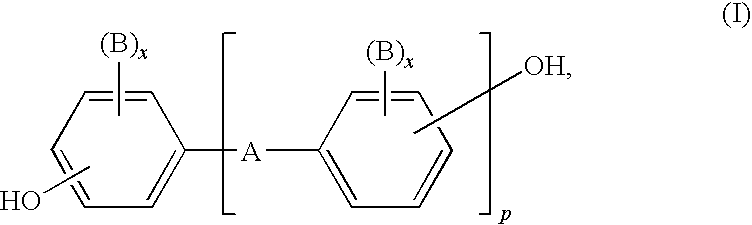

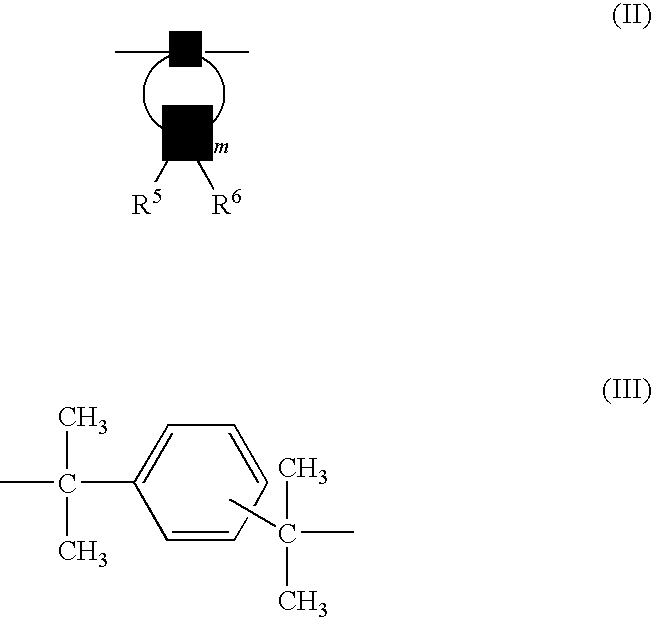

2,5-furandicarboxylic-terephthalic-aliphatic copolyester and preparation method thereof

ActiveCN102432847ANot affected by resource depletionImprove performancePolymer scienceEngineering plastic

The invention provides 2,5-furandicarboxylic-terephthalic-aliphatic copolyester and a preparation method thereof. 2,5-furandicarboxylic-terephthalic-aliphatic copolyester has a first repetitive unit represented by a formula (I) and a second repetitive unit represented by a formula (II), wherein x=2 to 8. The molar ratio of the first repetitive unit to the second repetitive unit is 1:1000-1000:1. 2,5-furandicarboxylic-terephthalic-aliphatic copolyester provided by the invention has a structure and even a good performance similar to that of diol polyterephthalate. 2,5-furandicarboxylic-terephthalic-aliphatic copolyester can be used for preparing materials such as engineering plastics and membranes. As one of the raw materials, 2,5-furandicarboxylic acid can be obtained based on renewable resources, such that the resource is wide, and is not influenced by increasingly exhausted petroleum resources. The invention also provides a preparation method of 2,5-furandicarboxylic-terephthalic-aliphatic copolyester.

Owner:芜湖万隆新材料有限公司

Molding compositions containing polyalkylene terephthalates and modified polybutylene terephthalate (PBT) random copolymers derived from pet

A molding composition comprising (a) from 5 to 90 wt % of a modified polybutylene terephthalate random copolymer that (1) is derived from polyethylene terephthalate component selected from the group consisting of polyethylene terephthalate and polyethylene terephthalate copolymers and (2) at least one residue derived from the polyethylene terephthalate component, and (b) from 5 to 40 wt % of a polyalkylene terephthalate component; wherein the modified polybutylene terephthalate random copolymer, the polyalkylene terephthalate component, and optionally, at least one additive, have a combined weight % of 100 wt %. Methods for making the composition and articles made from the composition.

Owner:SHPP GLOBAL TECH BV

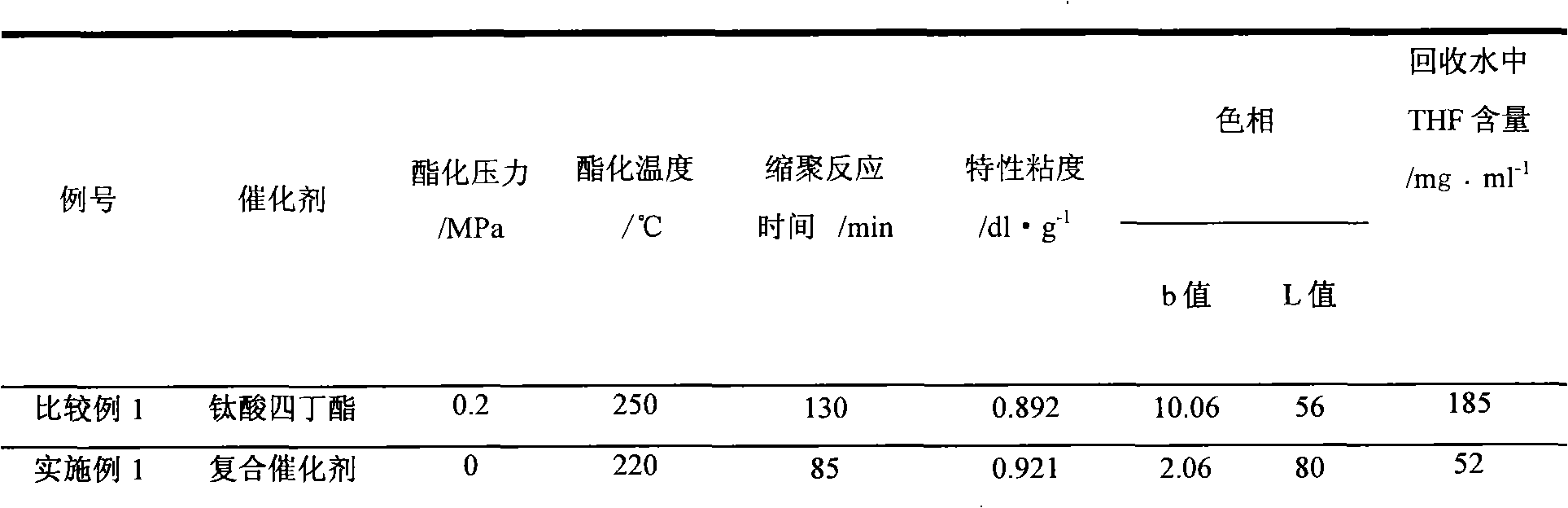

Preparation method of polybutylene terephthalate/adipate butanediol copolyester

The invention relates to a preparation method of polybutylene terephthalate / adipate butanediol copolyester, which utilizes a titanium compound and an antimony compound as the composite catalyst, the mole ratio of terephthalic acid to adipate is 3:7-8:2, the ratio of the total mole of the terephthalic acid and the adipate to the mole of 1,4-butanediol is 1:1.0-1.8, esterification is carried out at normal pressure and the temperature of 150-220 DEG C, the pressure is reduced to high vacuum 10-150 Pa for the reaction, the final temperature for the reaction is 265-280 DEG C, and inert gas is utilized to recover the pressure to be normal to obtain the copolyester. The reaction time is shortened, the production amount of tetrahydrofuran is small, the intrinsic viscosity of copolyester chips is 0.90-1.32 dL / g, the hue b value of the product is between 0 and 8, the L value is between 68 and 85, and the product of the polybutylene terephthalate / adipate butanediol copolyester can be used in the fields of various soft package plastic products.

Owner:PETROCHINA CO LTD

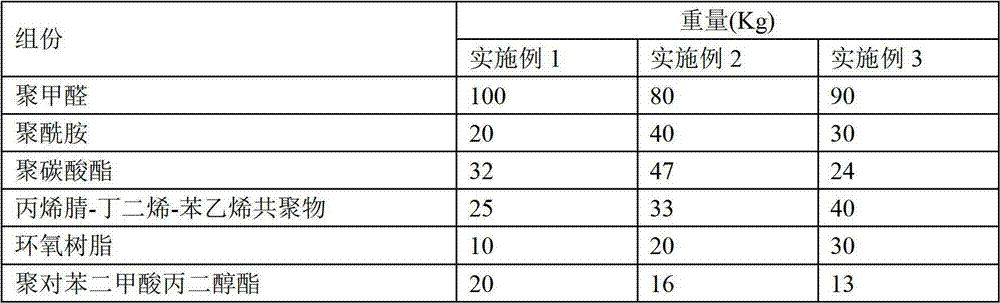

Engineering plastic with high wearing resistance

InactiveCN102875956AGood mechanical propertiesReduce wear ratePolyethylene glycolPolymethyl methacrylate

The invention provides an engineering plastic with high wearing resistance. The engineering plastic is made from the following raw materials by weight: 80-100 parts of polyformaldehyde, 20-40 parts of polyamide, 20-50 parts of polycarbonate, 25-40 parts of acrylonitrile-butadiene-styrene copolymer, 10-30 parts of epoxy resin, 12-20 parts of polytrimethylene terephthalate, 1-5 parts of diphenylmethane bismaleimide, 10-15 parts of polyphenyl ether, 20-40 parts of polyether-ether-ketone, 10-20 parts of polytetrafluoroethylene, 5-10 parts of melamine, 4-12 parts of boric acid alkanolamide, 2-6 parts of polyethylene glycol, 4-12 parts of phenolic ether phosphomonoester, 5-15 parts of polymethyl methacrylate, 10-20 parts of organic silicone oil, 5-10 parts of silane coupling agent, 3-5 parts of zinc stearate, 10-20 parts of glass fibre, 12-20 parts of graphite, 5-10 parts of silicon carbide whisker, 5-8 parts of nanometre titanium oxide, 4-6 parts of diphenyl ketone, 3-8 parts of butylated hydroxyanisole and 15-30 parts of filler. The engineering plastic provided by the invention has a good wear-resisting property.

Owner:SUZHOU YUNYUAN NETWORK TECH

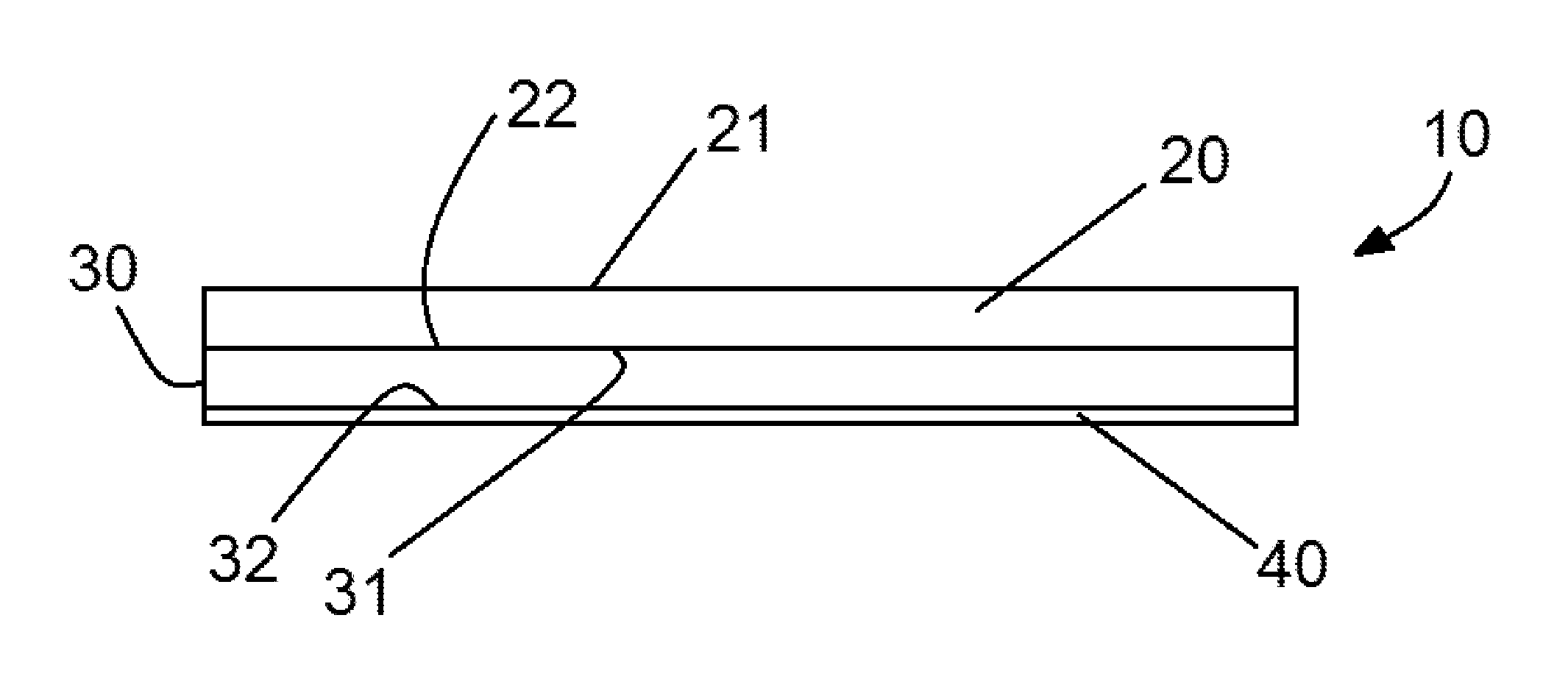

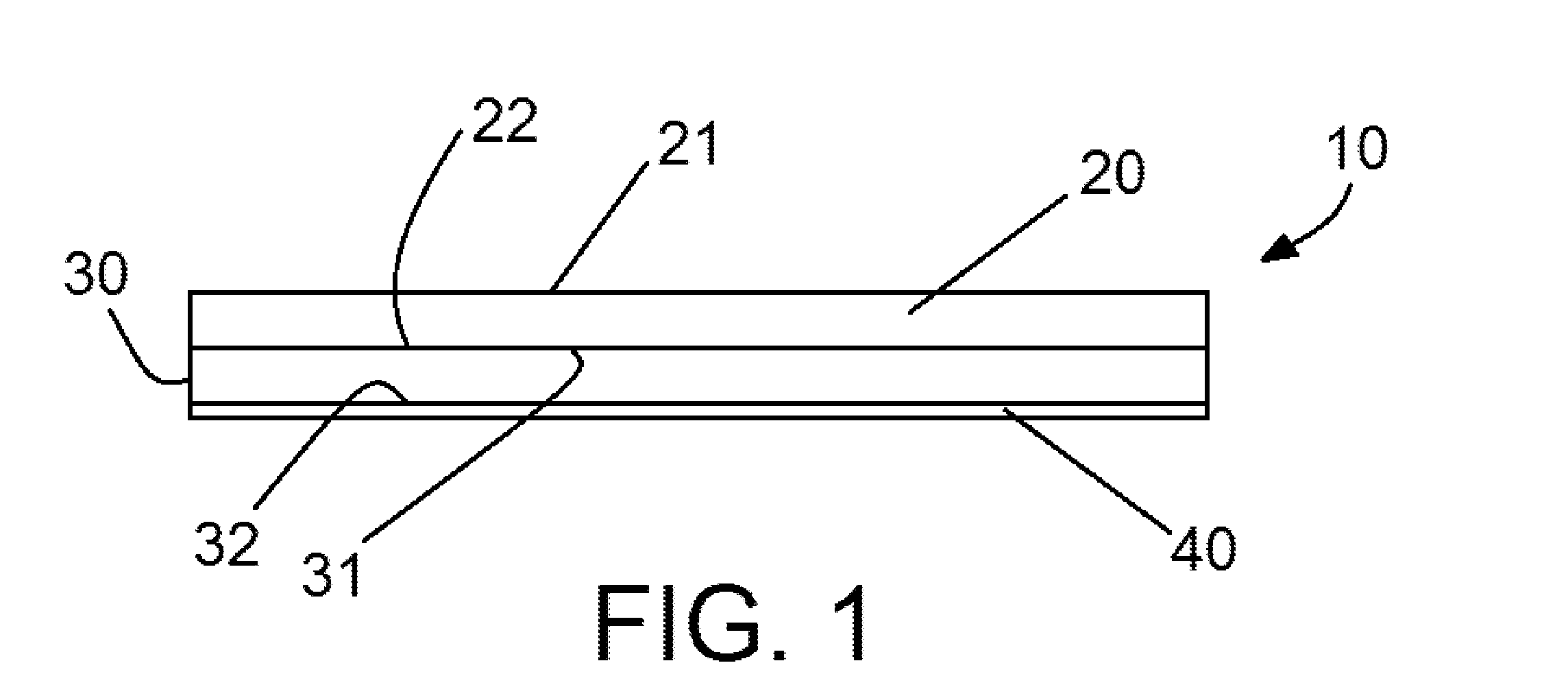

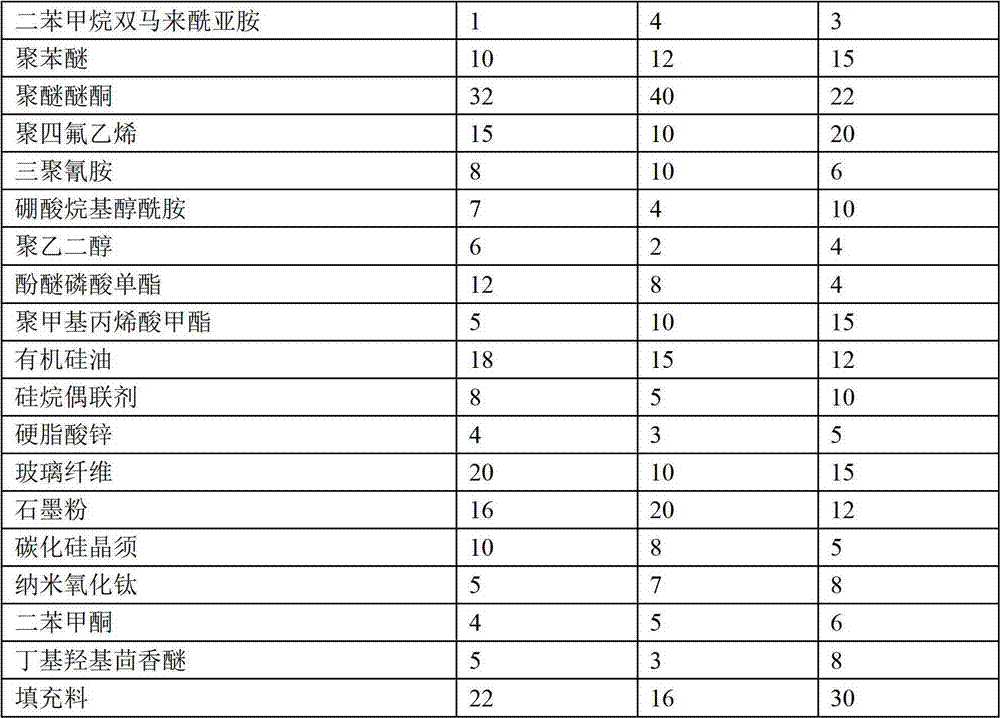

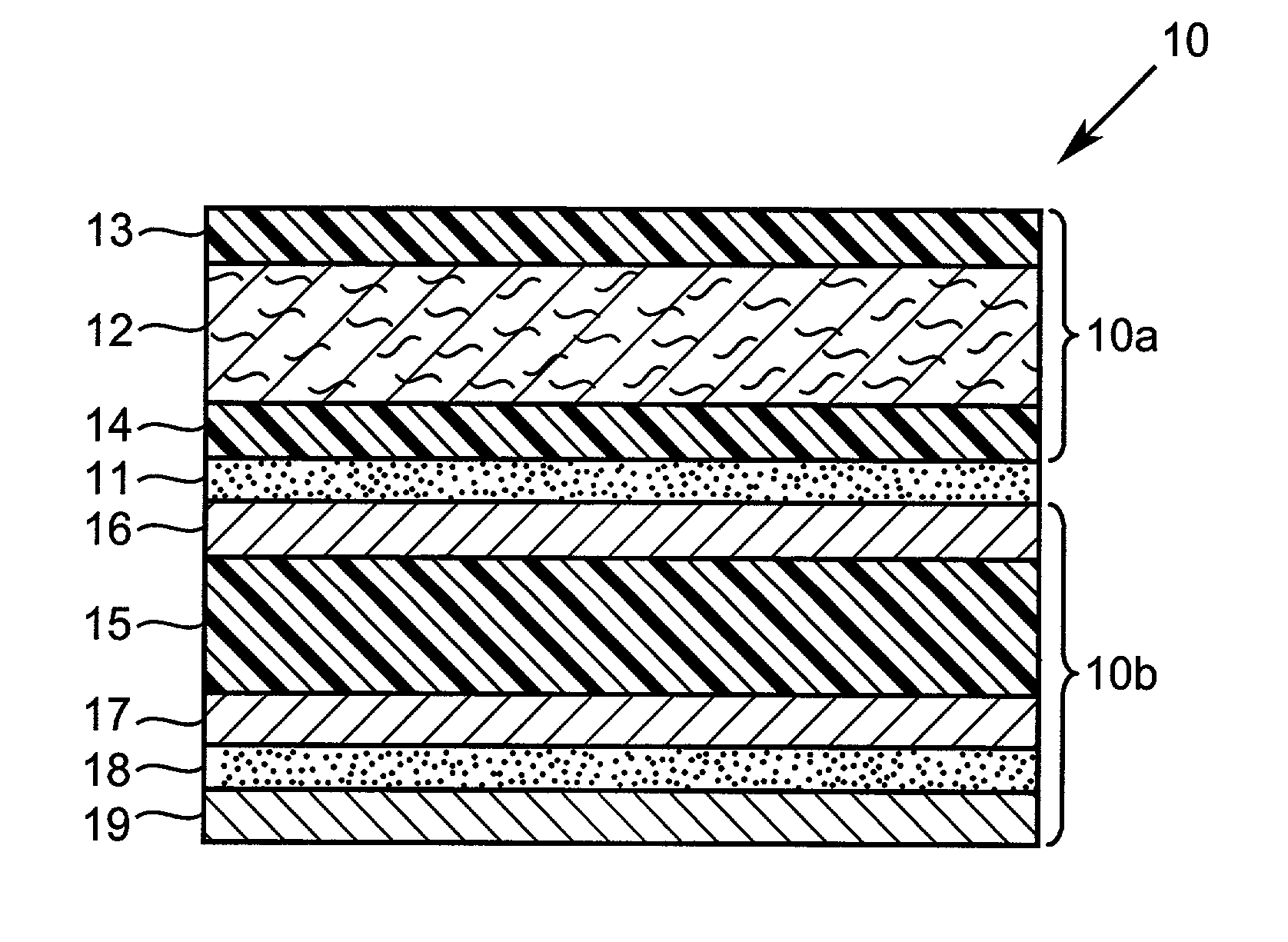

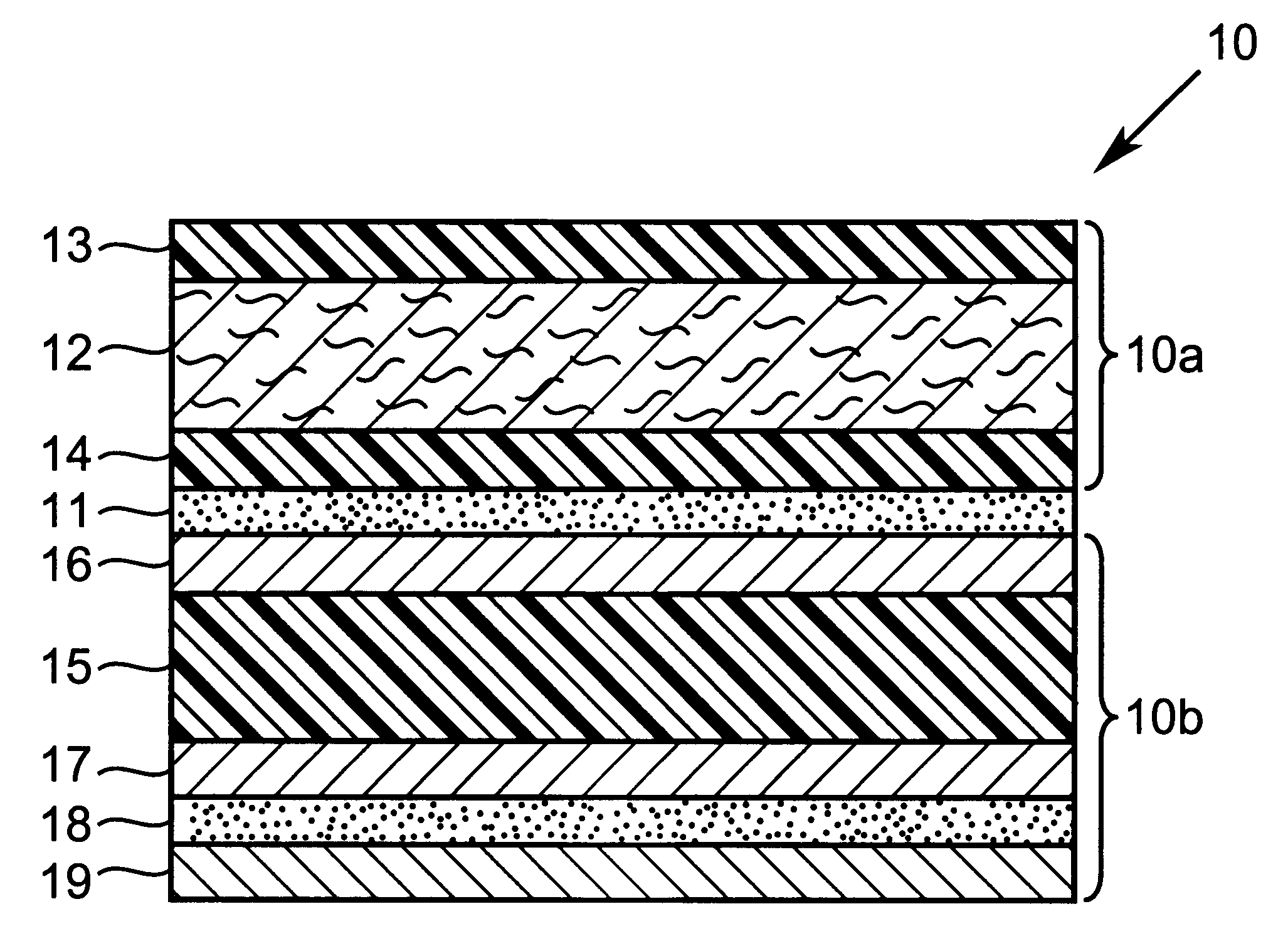

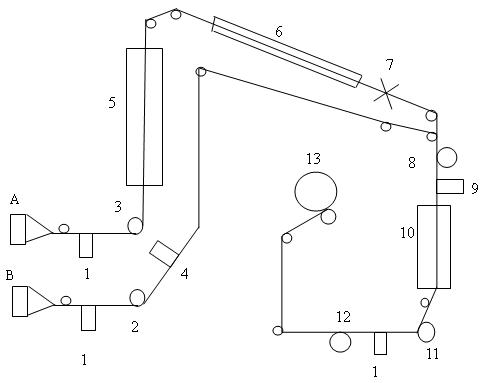

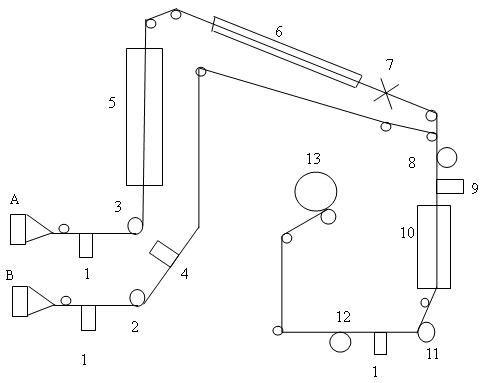

Packaging laminate with gas and aroma barrier properties

InactiveUS20020028336A1Improved barrier and durability propertyCapable being formedLiquid surface applicatorsFlexible coversThin oxidePaperboard

A packaging laminate (10) including a substrate film (15) coated with a carbon containing silicon oxide layer (16, 17) on both surfaces is disclosed herein. A method for producing the laminate (10), and blanks and packages fabricated from the laminate are also disclosed herein. The PECVD process of the present invention strains the substrate film (15) during deposition thereby creating a very thin oxide layer with superior durability, oxygen and aroma barrier properties. The carbon-containing silicon oxide coating (16, 17) has a stoichiometry of SiOxCy in which x is within the range of 1.5-2.2 and y is within the range of 0.15-0.80. The substrate film (15) may include a core layer (12) of a material selected from the group consisting of paper, paperboard, a foamed core, polyethylene terephtalate, polyamide, polyethylene and polypropylene.

Owner:JACCOUD BERTRAND

Method for preparing functional composite woolly elastic fiber

The invention relates to a method for preparing functional composite woolly elastic fiber, comprising the following steps: (1) preparing uvioresistant fine-denier polyester pre-oriented yarn (a) with the method of adding uvioresistant masterbatch; (2) carrying out composite spinning with low viscosity polyester (PET) or modified PET and polyethylene terephthalate (PTT) to prepare fully-drawn self-winding composite elastic fiber (b); and (3) stretching and false twisting the uvioresistant fine-denier polyester pre-oriented yarn (a) on a false-twisting texturing machine, converging the uvioresistant fine-denier polyester pre-oriented yarn (a) and the fully-drawn self-winding composite elastic fiber (b) in the position of a second roller, combining the uvioresistant the fine-denier polyesterpre-oriented yarn (a) and the fully-drawn self-winding composite elastic fiber (b) through an interlacing machine, shaping the uvioresistant the fine-denier polyester pre-oriented yarn (a) and the fully-drawn self-winding composite elastic fiber (b) through a second heating box, and winding the uvioresistant the fine-denier polyester pre-oriented yarn (a) and the fully-drawn self-winding composite elastic fiber (b) into a composite yarn, contracting the PET / PTT self-winding composite elastic fiber with the elasticity and the contractibility in the core layer of the composite woolly elastic fiber to show the elasticity of the composite yarn, and making the uvioresistant fine-denier polyester pre-oriented yarn to float on the surface layer of the composite yarn to show the uvioresistant performance of the composite yarn. Therefore, the uvioresistant composite woolly elastic fiber is prepared.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

Packaging laminate with gas and aroma barrier properties

InactiveUS6338870B1Improved barrier and durability propertyWrappersMolten spray coatingThin oxidePaperboard

A packaging laminate (10) including a substrate film (15) coated with a carbon containing silicon oxide layer (16, 17) on both surfaces is disclosed herein. A method for producing the laminate (10), and blanks and packages fabricated from the laminate are also disclosed herein. The PECVD process of the present invention strains the substrate film (15) during deposition thereby creating a very thin oxide layer with superior durability, oxygen and aroma barrier properties. The carbon-containing silicon oxide coating (16, 17) has a stoichiometry of SiOxCy in which x is witin the range of 1.5-2.2 and y is within the range of 0.15-0.80. The substrate film (15) may include a core layer (12) of a material selected from the group consisting of paper, paperboard, a foamed core, polyethylene terephtalate, polyamide, polyethylene and polypropylene.

Owner:TETRA LAVAL HLDG & FINANCE SA

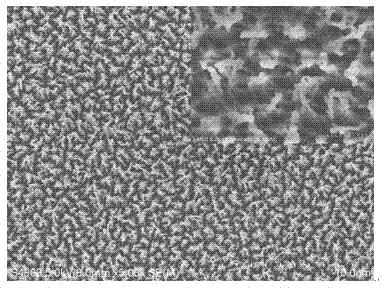

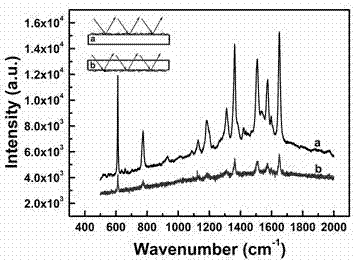

Transparent flexible surface enhanced Raman active substrate and preparation method thereof

The invention discloses a transparent flexible surface enhanced Raman active substrate and a preparation method thereof. The preparation method of the substrate comprises the following steps: taking a transparent flexible material such as polybutylene terephthalate (PET) plastics as a substrate, performing O2 plasma etching to form a nano wire array, loading gold, silver and other precious metal nanoparticles on the nano wire surface by virtue of a coating technology, and forming a three-dimensional nanometer structure array. The transparent flexible surface enhanced Raman active substrate provided by the invention is uniform in morphology and controllable in structure and has high-density electromagnetic hot spots in three-dimensional distribution. Therefore, the substrate has high sensitivity and reproducibility. The PET plastic film is high in flexibility and high in transparency, and incident laser and Raman scattered light easily penetrate through the substrate at low loss, so that the substrate can be used for in-situ detection of to-be-detected objects. The preparation method provided by the invention is simple in process, large-area preparation is easily realized, even roll-to-roll production process is permitted, and the cost is low.

Owner:ANHUI NORMAL UNIV

Sports Shoes and Methods for Manufacturing and Recycling of Sports Shoes

ActiveUS20190021435A1Easy to identifySolesInsolesPolyethylene terephthalateThermoplastic polyurethane

A sports shoe includes an upper wherein a majority by weight of the upper is made from a thermoplastic base material and a sole wherein a majority by weight of the sole is made from the same thermoplastic base material. The sole and the upper are individually fabricated and joined to each other. The thermoplastic base material includes at least one of the following materials: thermoplastic polyurethane TPU, polyamide PA, polyethylene terephthalate PET, or polybutylene terephthalate PBT.

Owner:ADIDAS

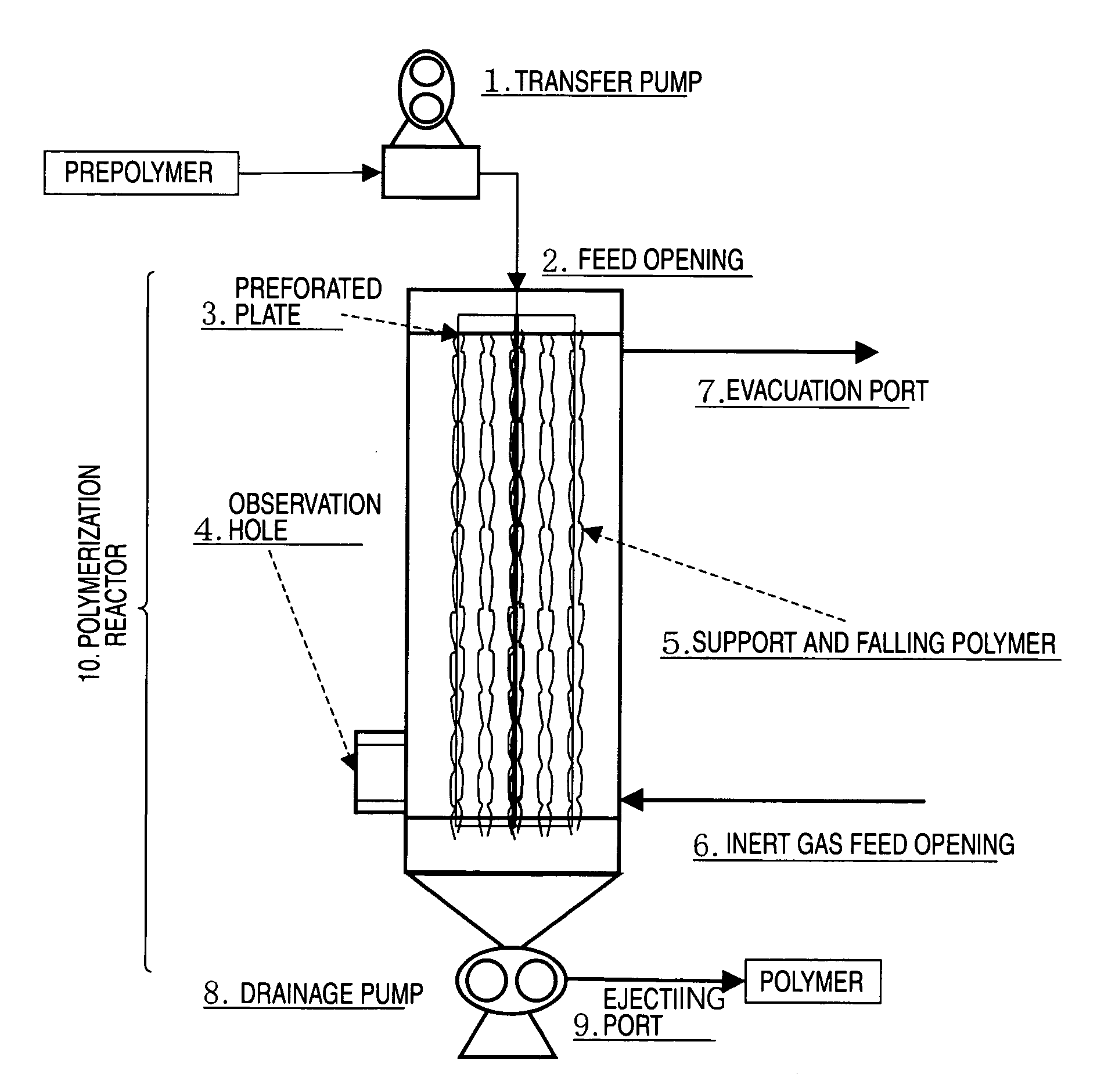

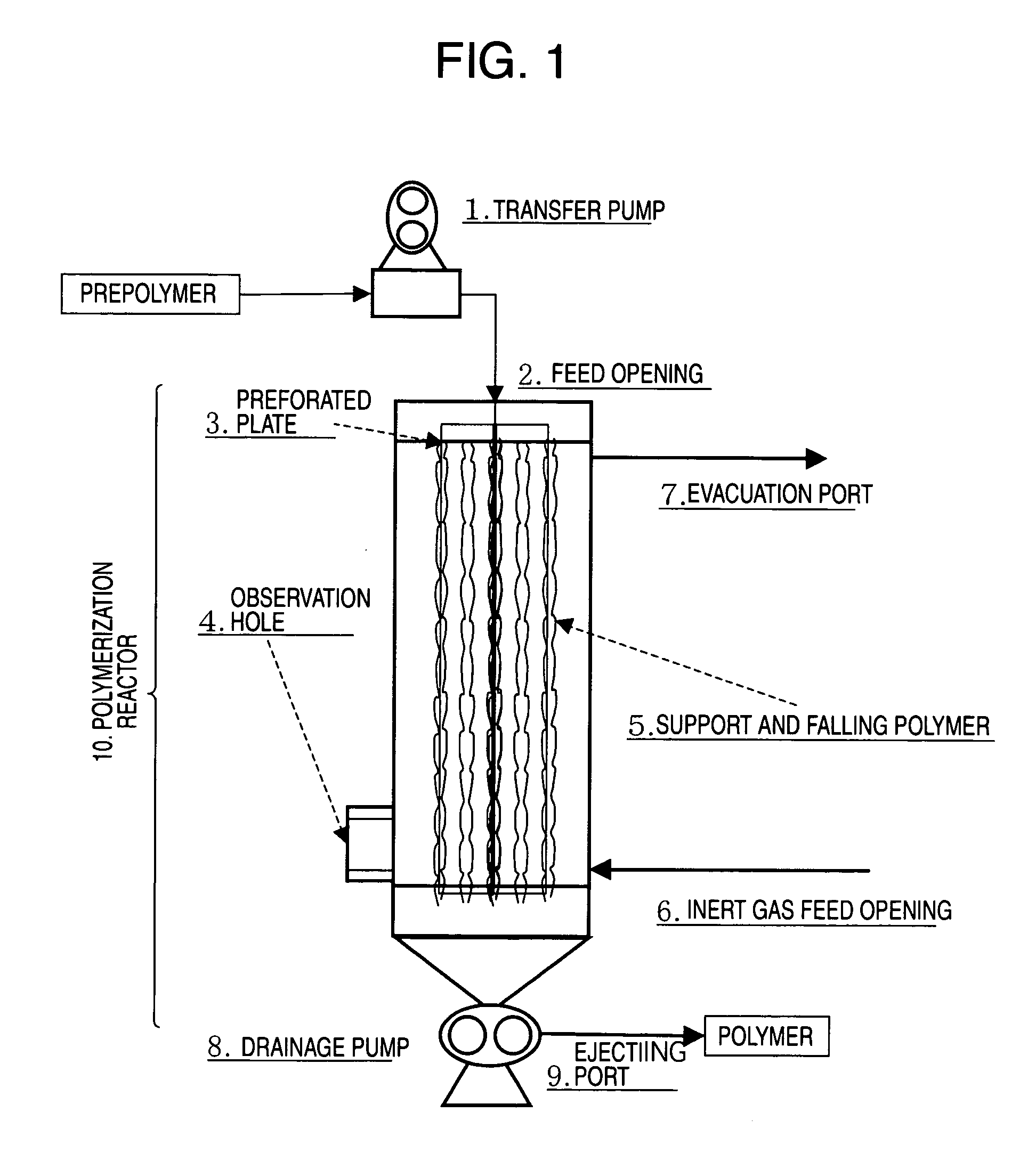

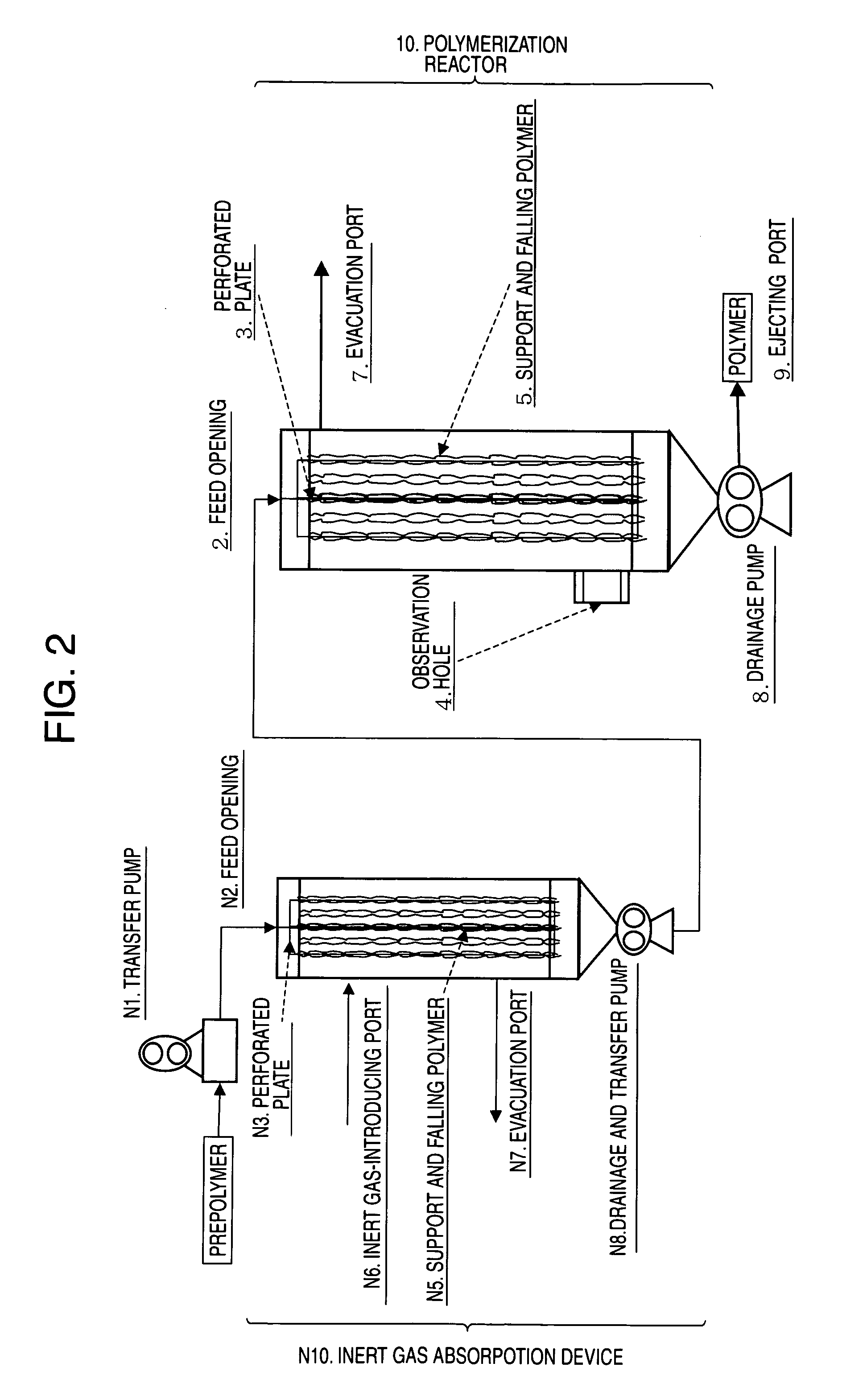

Process for Producing Polyalkylene Terephthalate, Process for Producing Polyalkylene Terephthalate Molding and Polyalkylene Terephthalate Molding

ActiveUS20080274320A1Low costIncrease production capacitySuture equipmentsLayered productsMolten statePolymer science

The present invention provides a method of producing polyalkylene terephthalate, which comprises: introducing a prepolymer of polyalkylene terephthalate that is in a molten state comprising 70 mol % or more of ethylene terephthalate or 1,4-butylene terephthalate repeating units and having an intrinsic viscosity [η] between 0.2 and 2 dl / g through a feed opening to a polymerization reactor; discharging the introduced prepolymer from holes of a perforated plate; and polymerizing the prepolymer under reduced pressure, while allowing the prepolymer to fall along the surface of a support that is open towards the outside at a temperature between the [crystalline melting point−10° C.] of the prepolymer or higher and the [crystalline melting point+30° C.] of the prepolymer or lower under the conditions represented by a formula S1 / S2>1, wherein S1 is the surface area of falling polyalkylene terephthalate, and S2 is the area where the support is in contact with polyalkylene terephthalate.

Owner:ASAHI KASEI CHEM CORP

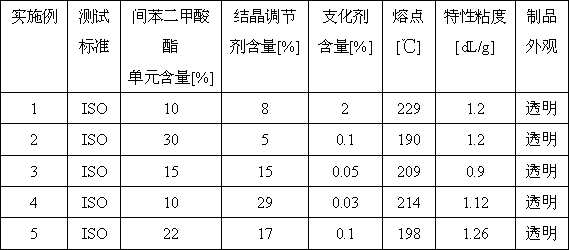

Low-melting point and transparent PET copolyester, its preparation method and application

ActiveCN103102473ASolve problems such as whiteningHigh transparencyMolten statePolyethylene terephthalate glycol

The invention discloses a low-melting point and transparent PET (polyethylene terephthalate) copolyester, its preparation method and application. The PET copolyester comprises, by mass: 60-84% of PET, 10%-30% of a unit derived from isophthalic acid, 5%-29% of a crystallization adjusting agent, and 0.03-2% of a branching agent. According to the preparation method, in a synthesis process of PET, based on p-phthalic acid (PTA) and ethylene glycol (EG), the unit derived from isophthalic acid, the crystallization adjusting agent and the branching agent are added to undergo a chemical reaction together, thus obtaining the low-melting point and transparent PET copolyester. The PET copolyester provided by the invention has an intrinsic viscosity greater than 0.9dL / g and a melting point lower than 230DEG C, can be solidified into an amorphous state from a molten state during injection molding, and has good transparency as well as further improved processing performance.

Owner:KINGFA SCI & TECH CO LTD +2

Scratch-resistant polybutylene terephthalate composition and preparation method thereof

The invention belongs to the field of high molecular materials and forming and processing thereof and relates to a scratch-resistant polybutylene terephthalate composition and a preparation method thereof. The composition comprises the following components in parts by weight: 40-84 parts of polybutylene terephthalate, 10-45 parts of glass fiber, 5-40 parts of crystal whiskers, 2-10 parts of elastomer, 0.01-2 parts of nucleating agent, 0.01-2 parts of lubricant and 0.01-2 parts of other assistants. Compared with the prior art, the composition provided by the invention has the advantages of smooth product surface, no exposed and warped glass fiber and excellent scratch resistance after being formed.

Owner:HEFEI GENIUS NEW MATERIALS

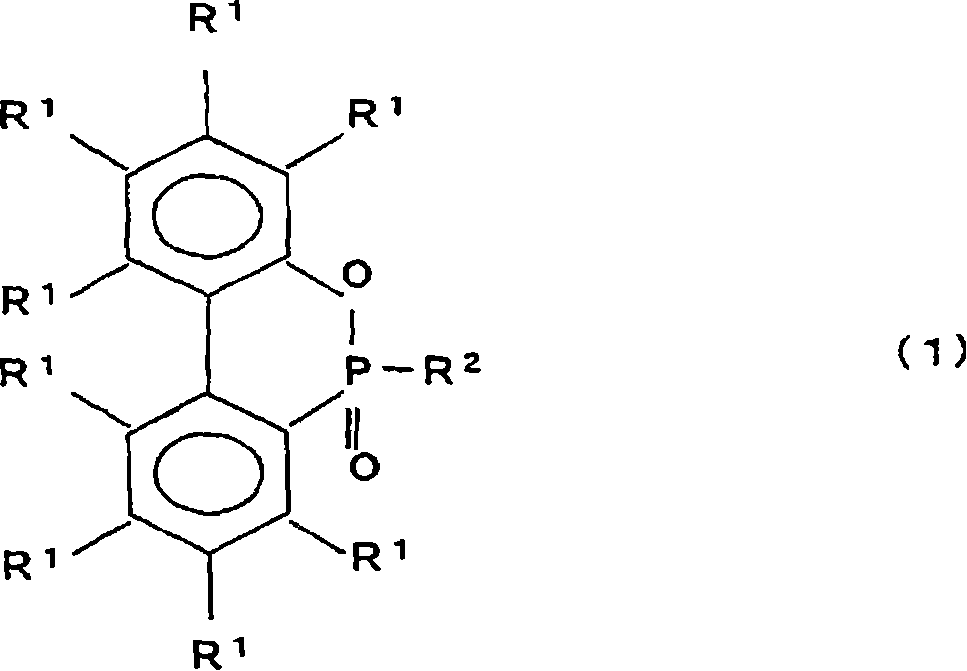

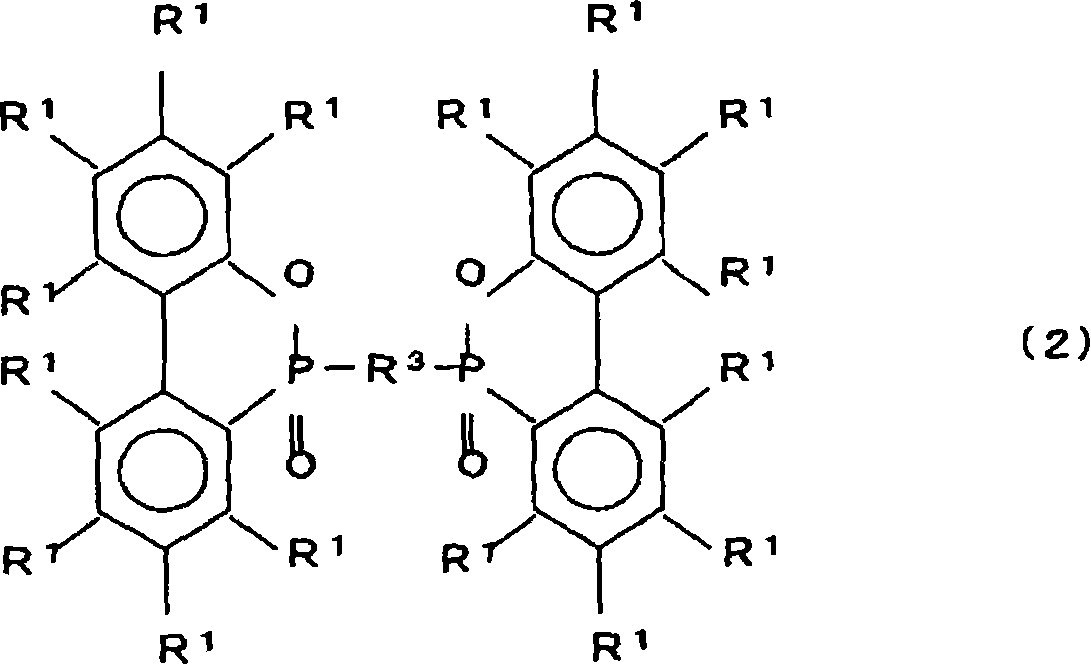

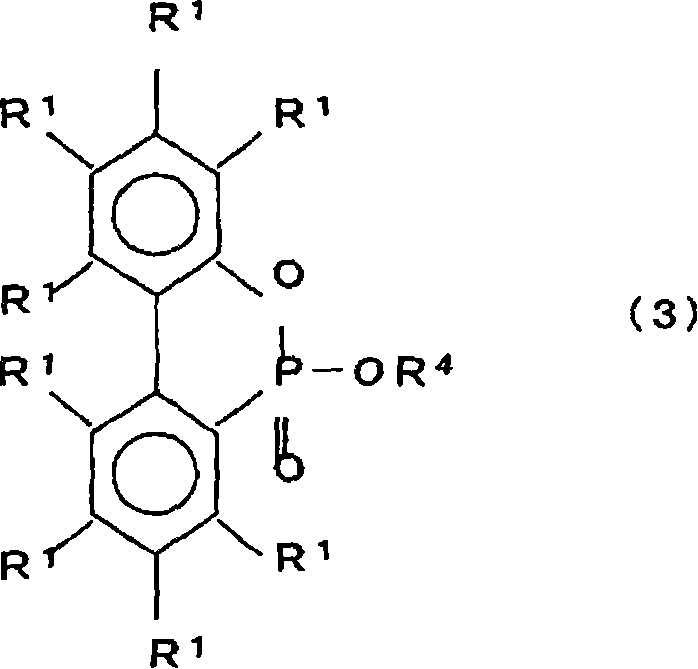

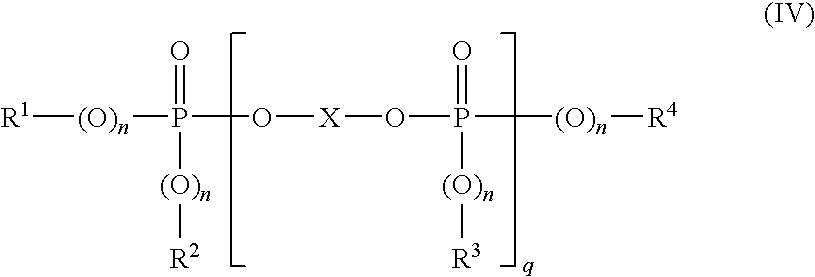

Halogen-free stibium-free antiflaming polydiethylene terephthalate engineering plastics and method for preparing same

The invention discloses halogen-free stibium-free antiflaming polydiethylene terephthalate engineering plastics and a method for preparing the same. The plastics consist of the following components in percentage by weight: 39 to 65 percent of polydiethylene terephthalate, 15 to 40 percent of reinforcing agent, 0 to 8 percent of toughening agent, 5 to 8 percent of phosphorus flame retardant, 0 to 8 percent of nitrogen flame retardant, 0 to 4 percent of synergetic flame retardant, 0 to 0.5 percent of nucleating agent and 0 to 0.5 percent of antioxidant. In the preparation method, the phosphorus-nitrogen antiflaming system is combined with the nanometer clay, so that while the halogen-free stibium-free flame retardation of the compound material is realized, the higher CTI value of the antiflaming material is ensured; the plastics are applicable in the field of electric appliances; and the method for preparing the material is simple and avoids adopting mould temperature forming processing, and the compound material possesses excellent thermal stability and therefore can be recycled.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

Flame-retardant polyester-based fiber for artificial hair

InactiveCN1846019AUsually heat resistanceUsual strengthFlame-proof filament manufactureWigsPolyesterFiber

The present invention provides a common polyester fiber which maintains fiber physical properties such as heat resistance and elongation, and is excellent in flame retardancy, fixation, drip resistance, transparency, and devitrification resistance, and the fiber beauty is controlled Polyester fiber and its artificial hair. It consists of 100 parts by weight of polyester (A) composed of one or more of polyalkylene terephthalate polyesters and copolyesters mainly composed of polyalkylene terephthalate polyesters, and organic cyclic phosphorus compounds and / or a composition obtained by melt-kneading 2 to 20 parts by weight of a phosphate ester amide compound (B), and a composition in which organic microparticles (C) and / or inorganic microparticles (D) are mixed in the composition, by By melt spinning, a flame-retardant polyester-based artificial hair fiber having solved the above-mentioned problems was obtained.

Owner:KANEKA CORP

Physically cross-linked gel electrolyte

ActiveUS9350046B2Promote formationHigh affinitySecondary cellsVehicular energy storageCross-linkPolyamide

An electrochemical battery cell of a lithium ion battery has a physically cross-linked gel electrolyte situated between a negative electrode and a positive electrode. The gel electrolyte includes a block co-polymer host and a liquid electrolyte, which can transport lithium ions, absorbed into the block co-polymer host. The block co-polymer host includes poly(alkylene oxide) block units and physically cross-linkable block units. A few preferred physically cross-linkable block units that may be employed include polyamide block units and poly(terephthalate)ester block units.

Owner:GM GLOBAL TECH OPERATIONS LLC

Waterproof rubber material

InactiveCN105384989AImprove thermal conductivityImprove conductivityPolyethylene glycolMaterials science

The invention discloses a waterproof rubber material. The waterproof rubber material is prepared from the following raw materials by weight: 7 to 8 parts of polyethylene glycol terephthalate, 3 to 4 parts of trioctyl citrate, 1 to 2 parts of rosin, 24 to 27 parts of polyacrylonitrile, 1 to 2 parts of sodium diacetate, 12 to 13 parts of graphite, 3 to 4 parts of fly ash bead, 0.7 to 1 part of sodium dodecyl sulfate, 42 to 55 parts of liquid acrylonitrile-butadiene rubber, 0.6 to 1 part of methacrylic acid, 52 to 60 parts of acrylonitrile-butadiene rubber, 20 to 255 parts of butadiene styrene rubber, 5 to 6 parts of nanometer silica sol, 3 to 4 parts of tetramethyl-thiuram disulfide, 2 to 3 parts of diglycol, 6 to 8 parts of VAE emulsion, 14 to 16 parts of activated clay, 5 to 7 parts of barium titanate, 7 to 9 parts of magnesium hydroxide and 0.2 to 0.3 part of calcium propionate. The waterproof rubber material prepared in the invention has good waterproof performance and acid resistance, oil resistance and flame retardation performance, can perfectly meet requirements of production and is worth popularization.

Owner:安徽创奇乐智能游乐设备有限公司

Impact-modified polycarbonate compositions having a good combination of natural color, hydrolytic stability and melt stability

The present invention relates to polycarbonate compositions comprisingA) from 10 to 99 parts by weight, in each ease based on the sum of components A+B+C, of aromatic polycarbonate and / or aromatic polyester carbonate,B) from 1 to 35 parts by weight, in each case based on the sum of components A+B+C, of rubber-modified graft polymer ofB.1 from 5 to 95 wt. % of at least one vinyl monomer onB.2 from 95 to 5 wt. % of one or more graft bases having a glass transition temperature <10° C.,C) from 0 to 40 parts by weight, in each case based on the sum of components A+B+C, of vinyl (co)polymer and / or polyalkylene terephthalate,D) from 0 to 50 parts by weight, in each case based on the sum of components A+B+C, of phosphorus-containing flameproofing agent,E) from 0 to 1.0 part by weight, in each case based on the sum of components A+B+C, of acidic additives, andF) from 0 to 50 parts by weight, in each case based on the sum of components A+B+C, of additives,wherein component B is obtainable by reacting component B.1 with the graft base B.2 by means of emulsion polymerization, with the proviso that in those compositions that are free of components D) and E), the graft polymer dispersion in the spray drying or in the precipitation has a pH value of less than 7,characterized in that there are used in the graft reaction from 0.1 to 5 parts by weight (based on the sum of the parts by weight of the monomers B.1 and of the graft base B.2 that are used=100 parts by weight) of at least one emulsifier selected from the group consisting of alkali, alkaline earth, ammonium and phosphonium salts of a saturated fatty acid having from 10 to 50 carbon atoms, wherein the emulsifier or emulsifiers remains or remain in component B,and also to a process for the preparation of these polycarbonate compositions and to the use of the polycarbonate compositions in the production of molded bodies, and to the molded bodies themselves.

Owner:BAYER MATERIALSCIENCE AG

Preparation method of foamable polyethylene terephthalate copolyester

ActiveCN102993421AHigh molecular weightImprove melt strengthPolymer sciencePolyethylene terephthalate glycol

The invention discloses a preparation method of a foamable polyethylene terephthalate copolyester. The preparation method comprises the following steps: carrying out an esterifying reaction of terephthalic acid and glycol, and carrying out a condensation polymerization reaction, wherein diacids except terephthalic acid, polyprotic acid containing more than two functional groups, and polybasic acid anhydride or polyol are added in the esterifying reaction. A resin prepared through the method has the advantages of high melt strength, high mechanical performances, high heat resistance, direct extrusion foaming, low temperature of the foaming processing technology, and production energy consumption reduction.

Owner:CHINA PETROLEUM & CHEM CORP +1

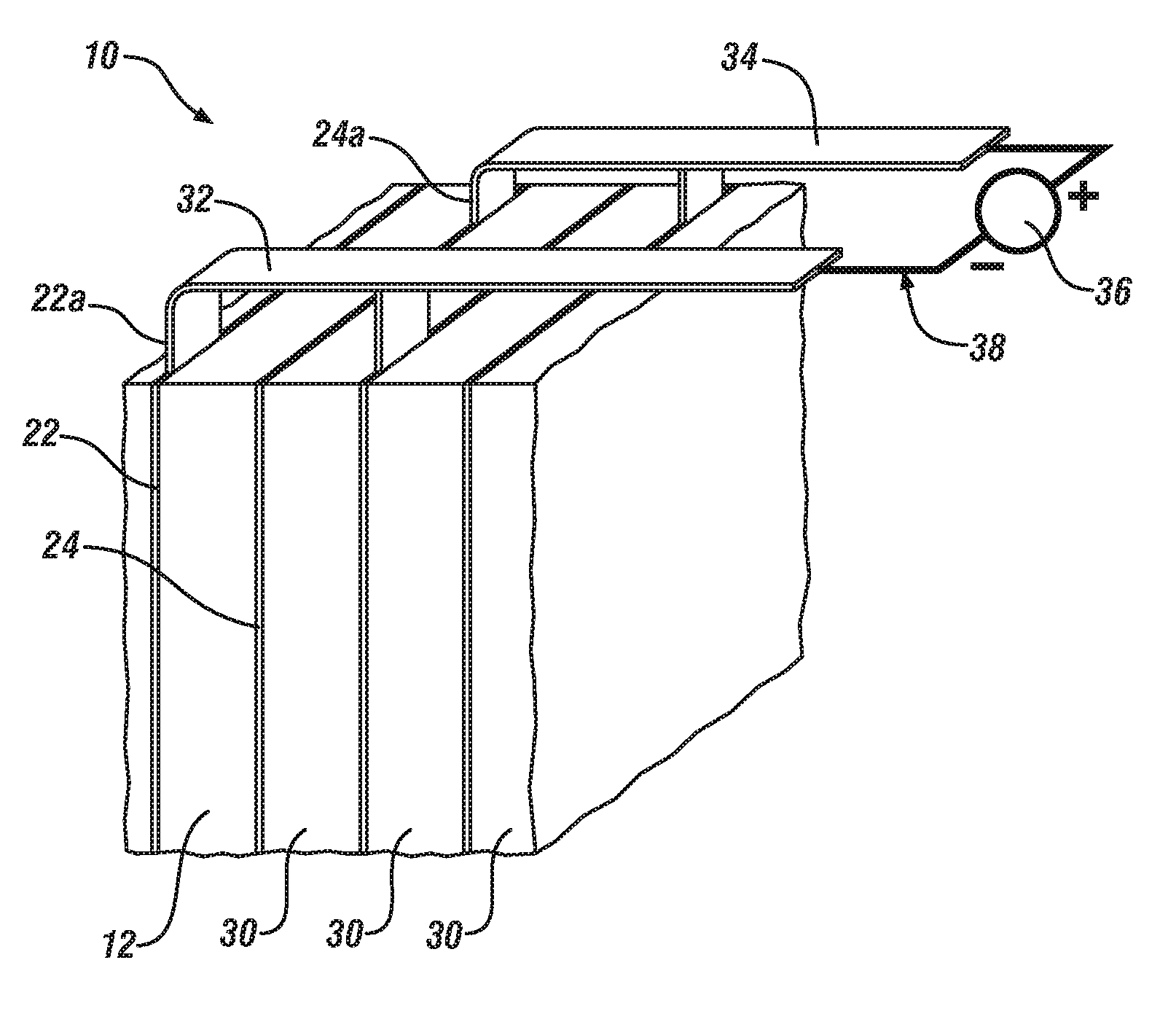

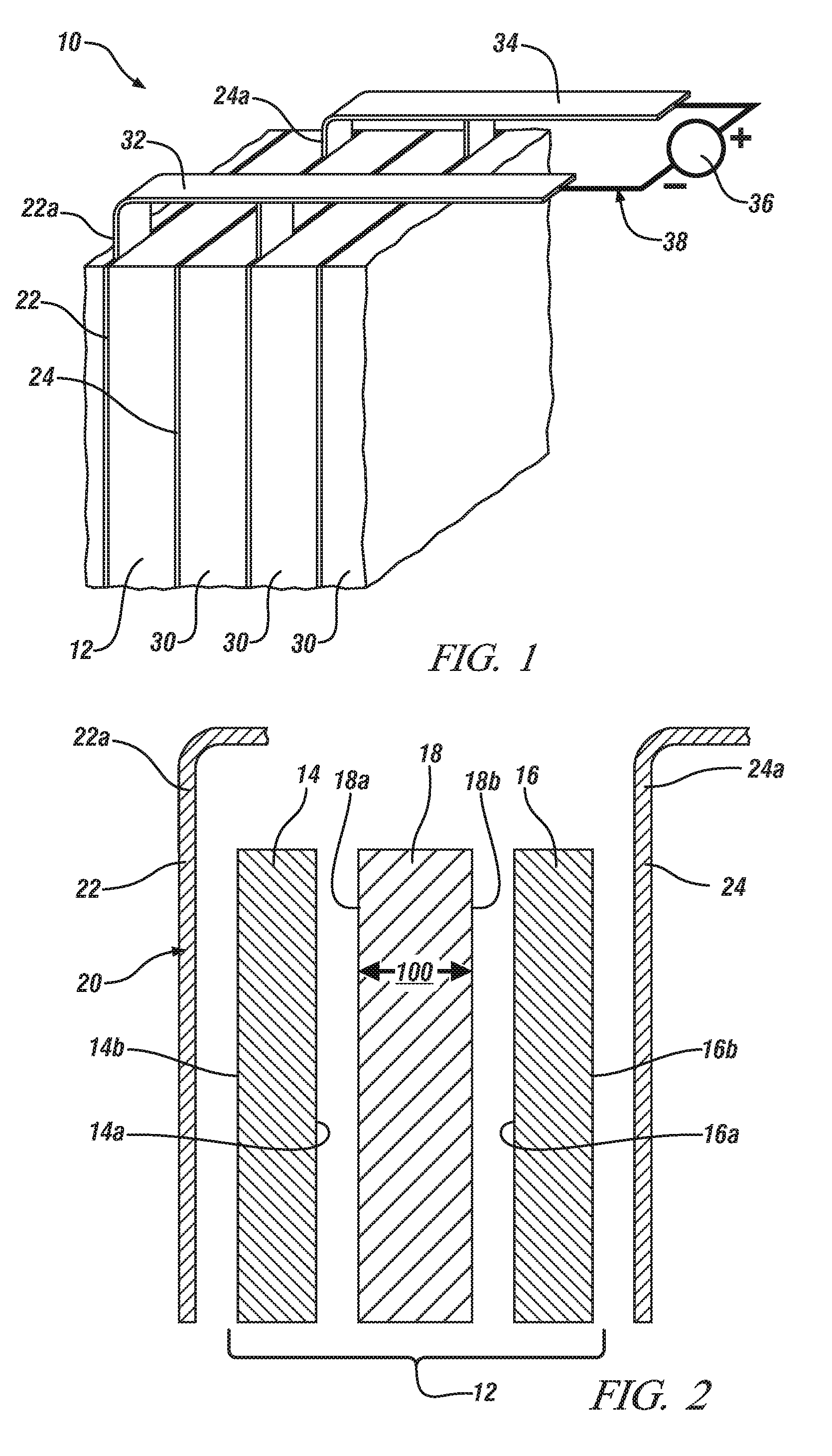

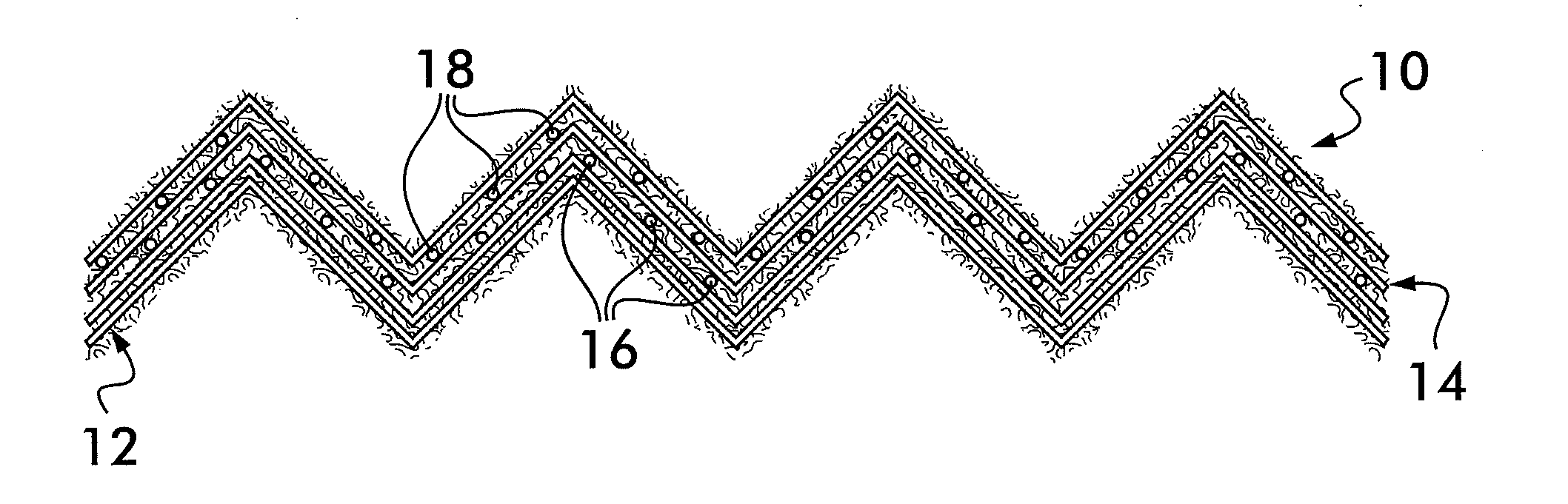

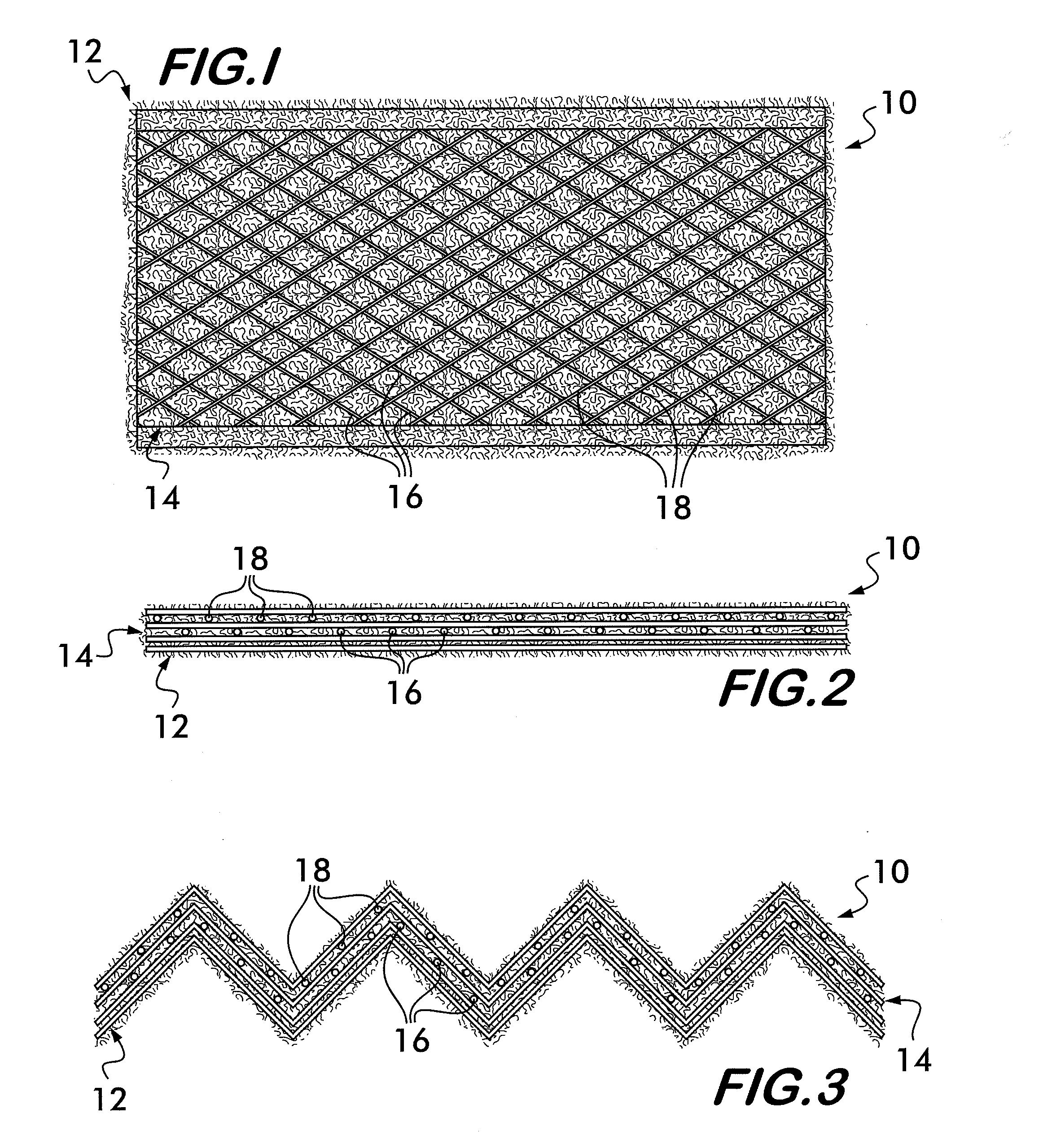

Reinforced, pleated filter structure

InactiveUS20110084017A1Reduce crystallinityIncrease stiffnessLaminationLamination apparatusPolyethylene terephthalateEngineering

A pleated filter structure includes a pleated filtering substrate and a pleated, polymer, mesh reinforcing sheet or netting for assisting in maintaining the pleated configuration of the filtering substrate. The pleated, polymer, mesh reinforcing sheet or netting includes a mechanically degraded polyalkylene terephthalate as the primary polymer therein. A method of making the pleated filter structure includes the steps of obtaining commercial articles having been made from a high crystallinity, flexible polyalkylene terephthalate; and mechanically degrading said articles to decrease the crystallinity and increase the stiffness of the polyalkylene terephthalate and extruding the mechanically degraded articles into an extruded structure stiffer and more amorphous than the polyalkylene terephthalate in the commercial articles.

Owner:DELSTAR TECH

Preparation method of novel wool-like differential fibers

The invention discloses a preparation method of novel wool-like differential fibers, which is characterized by comprising the following steps of: 1) adopting polytrimethylene terephthalate (PTT) as a raw material to prepare a pre-oriented yarn (a); 2) adopting modified high-shrinkage polyester as a raw material to prepare fully-drawn high boiling water shrinkage fibers (b); and 3) on a DTY machine, passing the pre-oriented yarn (a) through a roller, a hot box and a cooling plate, performing drawing false twisting on the pre-oriented yarn on a false twister, converging the pre-oriented yarn with the high boiling water shrinkage fibers (b) in front of two rollers, and performing network compounding on the pre-oriented yarn and the high boiling water shrinkage fibers, and then passing the pre-oriented yarn and the high boiling water shrinkage fibers through two hot boxes to obtain a composite yarn product. The preparation method develops the novel wool-like differential fibers, the PTT fibers floating on the surface layer are much closer to wool fibers in performance and are superior to common wool-like products in the performance of elastic recovery, handfeel, antistatic property, dyeing and the like, and simultaneously, the treatment of forming different sections of the two raw materials ensures that the products have significant improvements on luster and fibrillation resistance.

Owner:嘉兴逸鹏化纤有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com