Method for preparing functional composite woolly elastic fiber

An elastic fiber and functional technology, which is applied in the field of preparation of functional composite wool-like elastic fibers, can solve the problems of poor fluffiness, long elongation, and no function of composite yarns, and achieves good elasticity and high strength. , the effect of good dyeing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

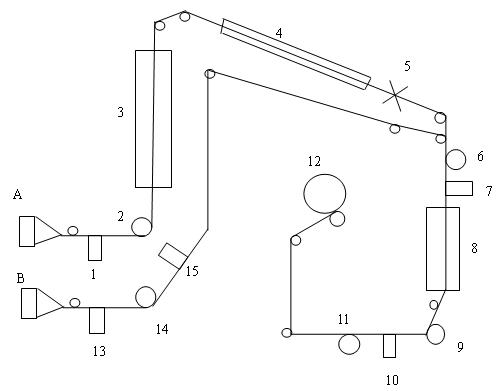

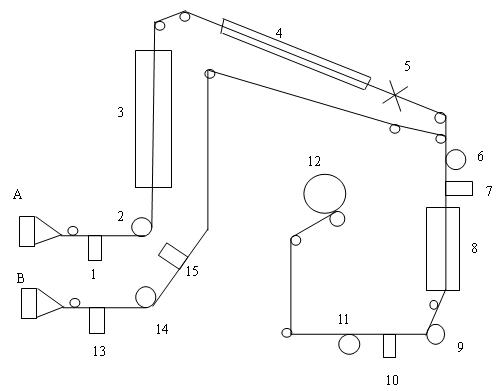

Image

Examples

Embodiment 1

[0020] Embodiment 1: produce with nanometer TiO 2 Fine-denier polyester pre-oriented yarn 265D / 288f as anti-ultraviolet additive, TiO 2 The mass content is 3.5%, and the elongation at break is 122%. After the pre-oriented yarn is stretched and twisted, the single-filament fineness is 0.5dpf, and the shrinkage in boiling water is 3.2%. PET with an intrinsic viscosity (η) of 0.5dl / g and 1.30dl / g g of PTT, composite mass ratio 1:1, using polyester FDY drawing equipment to produce 150D / 36f, monofilament fineness 4.2dpf, PET / PTT composite self-crimping elastic fiber (b), boiling water shrinkage 20%, crimp shrinkage The ratio is 25%, the section is inverted 8, compounded on the 33H Murata false twist texturing machine, the pre-oriented yarn (a) passes through a roller, a hot box, a cooling plate, and a false twister in sequence, and is stretched and false twisted. The rollers are combined with the fully drawn self-crimping composite elastic fiber (b) passing through the zero roller...

Embodiment 2

[0021] Embodiment 2: produce with nanometer TiO 2 Fine denier polyester pre-oriented yarn 265D / 288f as anti-ultraviolet additive, TiO 2 The mass content is 3.5%, and the elongation at break is 122%. After the pre-oriented yarn is stretched and twisted, the single-filament fineness is 0.5dpf, and the shrinkage in boiling water is 3.2%. PET with an intrinsic viscosity (η) of 0.5dl / g and 1.30dl / g g of PTT, composite mass ratio 1:1, using polyester FDY drawing equipment to produce 75D / 24f, monofilament fineness 3.1dpf, PET / PTT composite self-crimping elastic fiber (b), boiling water shrinkage rate 25%, crimp shrinkage The rate is 32%, and the section is inverted 8. Compounding is carried out on the 33H Murata false twist texturing machine. The pre-oriented yarn (a) passes through one roller, one hot box, cooling plate and false twister in turn for stretching and false twisting. The self-crimping composite elastic fibers (b) are merged, then composited by the network device, and ...

Embodiment 3

[0022] Embodiment 3: produce with nanometer TiO 2 Fine denier polyester pre-oriented yarn 125D / 144f as anti-ultraviolet additive, TiO 2 The mass content is 3.5%, and the elongation at break is 128%. After the pre-oriented yarn is stretched and twisted, the single-filament fineness is 0.5dpf, and the shrinkage in boiling water is 3.5%. PET with an intrinsic viscosity (η) of 0.5 and PTT with 1.30 are used, and the composite quality Ratio 1:1, using polyester FDY drawing equipment to produce 100D / 24f, monofilament fineness 5dpf, PET / PTT composite self-crimping elastic fiber (b), boiling water shrinkage 28%, crimp shrinkage 37%, cross-section inverted 8 font. Compounding is carried out on the 33H Murata false twist texturing machine. The pre-oriented yarn (a) passes through one roller, one hot box, cooling plate and false twister in turn for stretching and false twisting. The self-crimping composite elastic fibers (b) are merged, then composited by the network device, and heat-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com