Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2970 results about "Plant fibre" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fibre Plants - seed, bast & hard fibres. Plant Fibre from cotton, linen, hemp & jute. A wide range of plants, including cotton, kapok, jute, flax, ramie, sisal, and hemp, may be used to produce plant fibre and many fibre plants are grown as field crops to make paper, cloth, and rope.

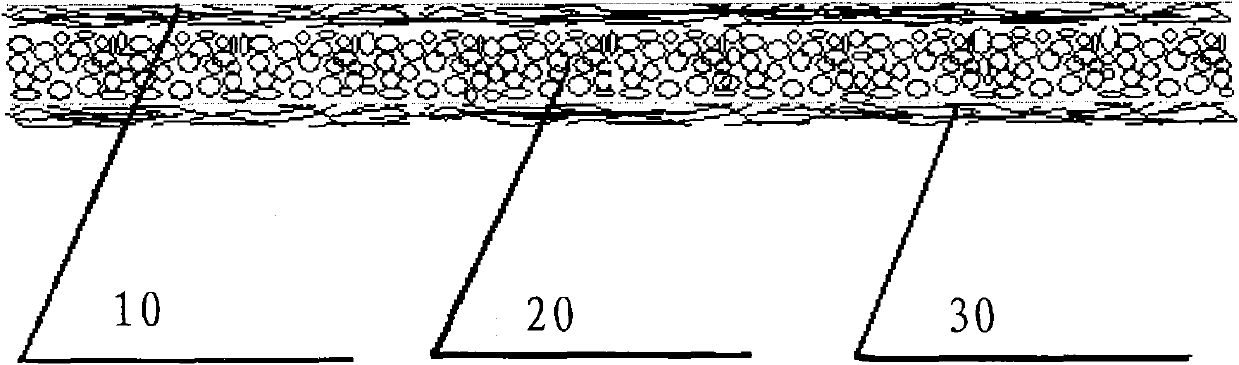

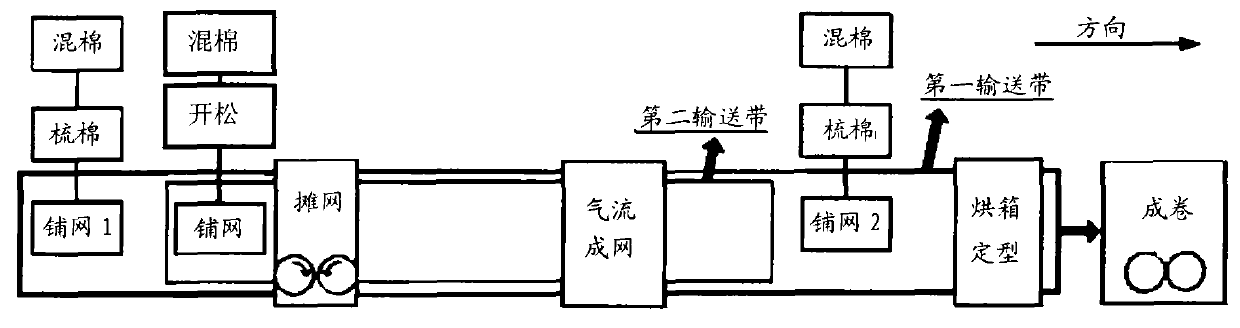

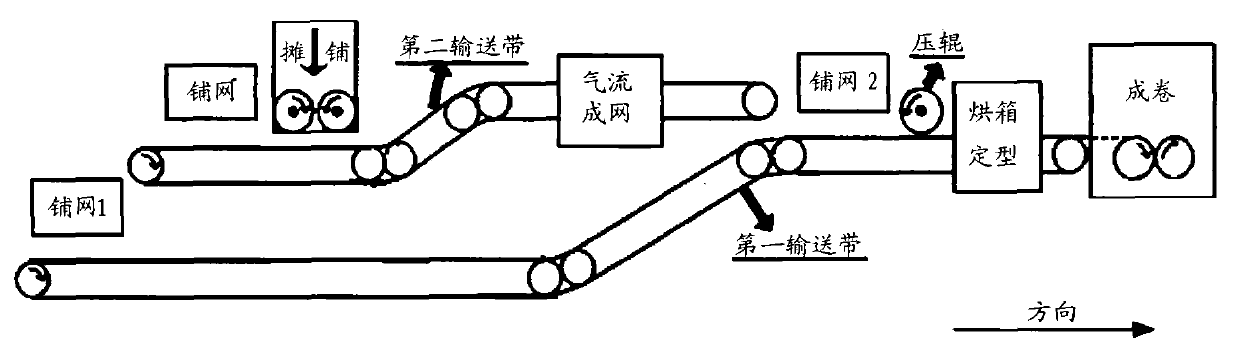

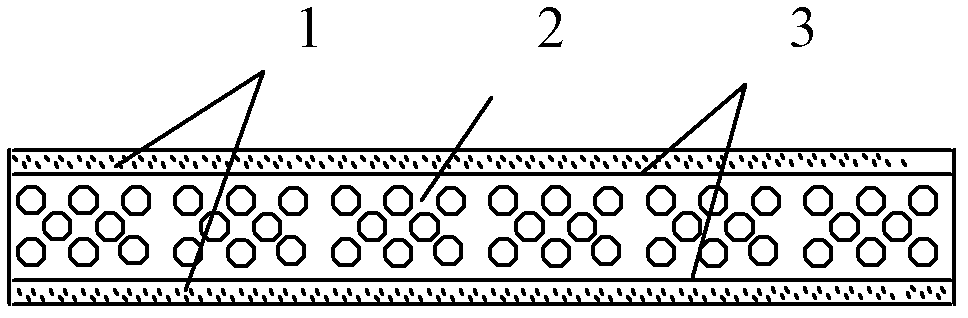

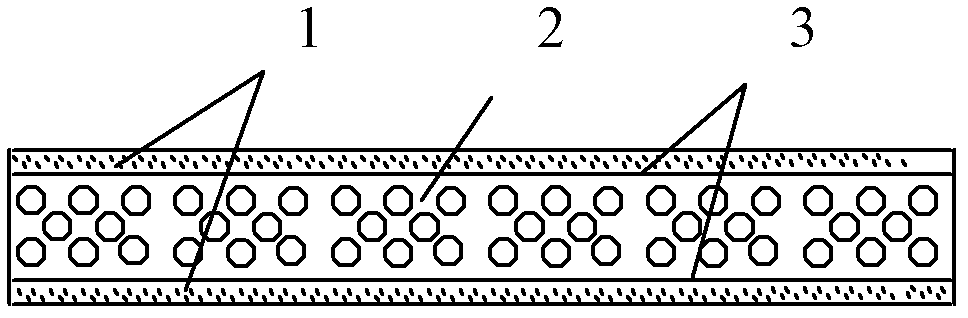

Three-layer sandwiched composite eiderdown flake and manufacturing method thereof

InactiveCN101787619AKeep the advantagesSolve the shortageNon-woven fabricsAdhesivesCardingPlant fibre

The invention relates to a three-layer sandwiched composite eiderdown flake and a manufacturing method thereof. The three-layer sandwiched composite eiderdown flake comprises a lower flake, a middle flake and an upper flake; the upper flake comprises animal and plant fibers and low-melting fibers; the middle flake comprises eiderdown fibers, animal and plant fibers and low-melting fibers; the lower flake comprises animal and plant fibers and low-melting fibers; and the upper flake, the middle flake and the lower flake are thermally fused together. The manufacturing method comprises the following steps: manufacturing the lower flake by using the animal and plant fibers and the low-melting fibers by cotton blending, cotton carding and lapping; manufacturing the middle flake by cotton blending, opening and lapping of the animal and plant fibers and the low-melting fibers, paving of the eiderdown fibers and air laying, and paving the middle flake above the lower flake; manufacturing the upper flake by using the animal and plant fibers and the low-melting fibers by cotton blending, cotton carding and lapping, and paving the lower flake above the middle flake; and thermally fusing the lower flake, the middle flake and the upper flake together.

Owner:杭州飞利弘羽绒寝具有限公司

Absorbent fibrous granules

InactiveUS6092302ALightweight productionDrying solid materials with heatOther chemical processesFiberParticulates

There is provided a cellulosic-based fiber granule with added non self-associating particulates or fibers. The resulting granule is free-flowing with a densified outer surface and is capable of removing substantially all oil or other fluids from a flat surface such as a floor. The granule is also capable of being incinerated by being formed substantially of organic materials. Cellulosic plant fibers form at least 10 percent up to 99 percent of the granule. There is also provided a method for forming the incineratable absorbent, free-flowing granules.

Owner:3M INNOVATIVE PROPERTIES CO

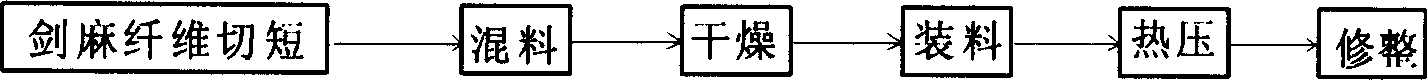

Method for polishing wheet from sisal fiber

InactiveCN1562570ARich varietyVarious ventilation structuresFlexible-parts wheelsPlant fibreSisal fiber

A polishing wheel is made up of short sisal hemp fibres, synthetic resin, plant fibres and inorganic compound through proportionally mixing, drying, hot die pressing and trimming.

Owner:黄焕仪 +1

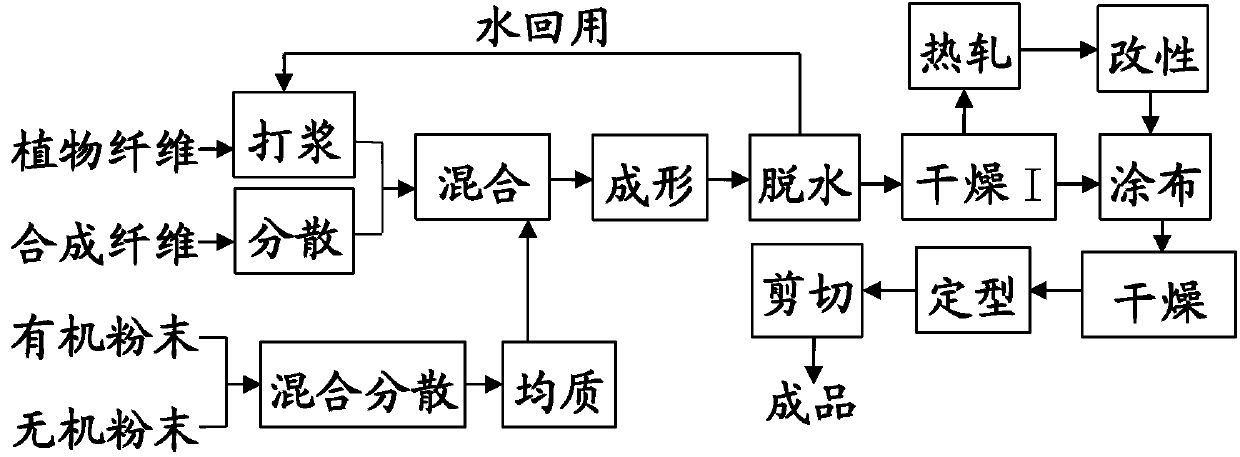

Battery and capacitor diaphragm filter material formed by wet nonwoven fabrics and preparation method of filter material

InactiveCN103100264AImprove uniformityHigh strengthCoatings with pigmentsElectrolytic capacitorsSocial benefitsHigh diaphragm

The invention discloses a battery and capacitor diaphragm filter material formed by wet nonwoven fabrics and a preparation method of the filter material. The fiber materials are as follows in percentage by weight: 0.1%-2.5% of plant fibers and 80%-99.9% of synthetic fibers, inorganic powder being 45%-1000% of the weight of the fiber, organic powder being 0-50% of the weight of the fibers, and strengthening binder being 0.5%-15% of the weight of the fibers. The preparation method of the filter material comprises the following steps of: pulping the plant fiber and the synthetic fibers, respectively; homogenizing and mixing the inorganic powder with the organic powder under high pressure, and forming the mixture into a single layer or a plurality of layers by a mixer; coating, thermally rolling and modifying the mixture, so that various physical and chemical indexes of the diagram are improved, the pore diameter size can be effectively controlled and the uniformity of the pore diameter is improved; moreover, treelike crystals can be prevented from being generated by maze type bent holes; the filtering precision and the efficiency are high; the inner resistance of the diagram is high; the liquid retaining rate and the high temperature resistance of the diagram are improved; the over-temperature closed-cell protection is improved; the dimension deformation is small; the service life is long; and the economic benefits and the social benefits are better.

Owner:吕凯

Method for manufacturing high-breathability non-woven wallpaper body paper and product

The invention discloses a method for manufacturing high-breathability non-woven wallpaper body paper and a product. The existing non-woven wallpaper has the disadvantages that the hand feel thereof is not soft enough, the principal plane stereoscopic impression is not strong and the opacity degree is low. The method of the invention comprises the following steps: beating plant fiber containing chemical wood pulp until the beating degree is 20-30OSR, and mixing with non-plant fiber containing chemical fiber; adding chemical addition agent into the mixed fiber; manufacturing the mixed fiber containing the chemical addition agent into body paper semi-finished products by utilizing a fourdrinier wire or inclined wire paper machine; mixing pigment, chemical addition agent and adhesive to form coating liquor, carrying out dip coating on the body paper semi-finished products inside or outside the machine; and drying and finishing the body paper subject to dip coating, and rolling the body paper to form finished paper of body paper, thus obtaining non-woven wallpaper which contains continuous fiber, has high breathability, and can be directly printed. The principal plane has natural lines; and the finished paper has the advantages of soft hand feel, good processability, excellent shape stability, rich color, distinct image and strong stereoscopic impression.

Owner:ZHEJIANG WINBON SPECIALTY PAPER +1

Degradable nourishing flowerpot and sprout cultivation bowl

The degradable flower pot and the seedling growing pot are produced with the material including plant fiber, adhesive, assistant and organic fertilizer; and the assistant is paraffin, animal or vet oil, stearic acid, talcum powder, calcium carbonate, lime or their mixture. The degradable flower pot and the seedling growing pot are produced through the steps of cutting plant fiber, mixing with adhesive, assistant, organic fertilizer and water via stirring, hot pressing to cure and form, and demolding. Inside the pot, the roots of plant are attached to the inside wall for well air exchange. During the degradation of the pot, nutrients are released and provided to plant gradually. The pot is ventilate and hydrophobic and has certain humidity and fertilizer maintaining effect and no environmental pollution.

Owner:SHANGHAI SAFBON WATER SERVICE CO LTD

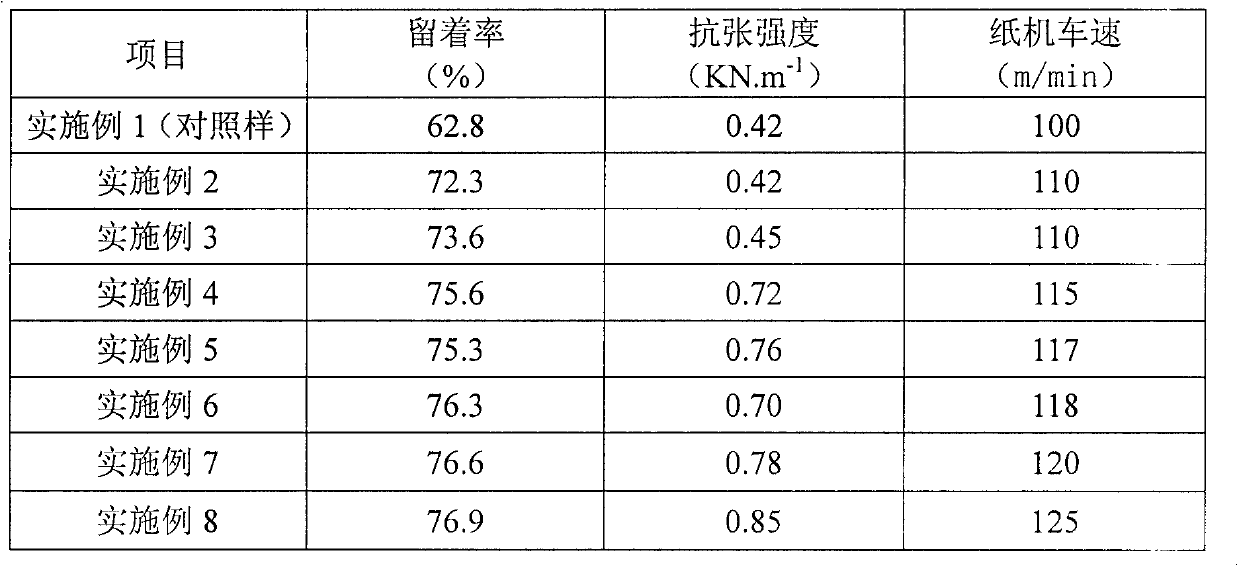

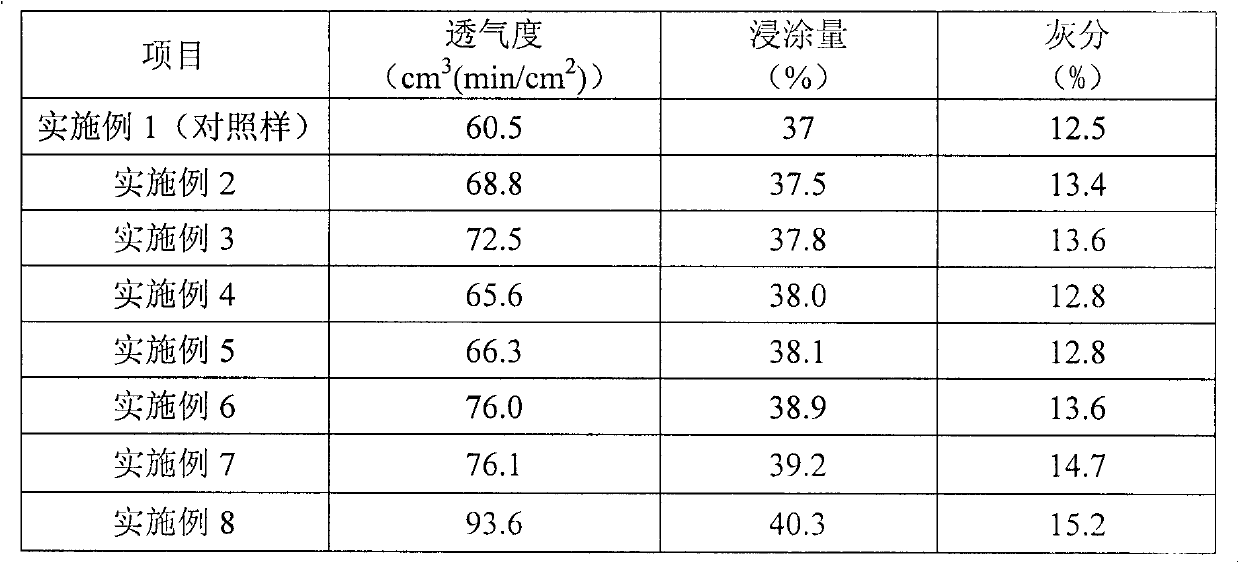

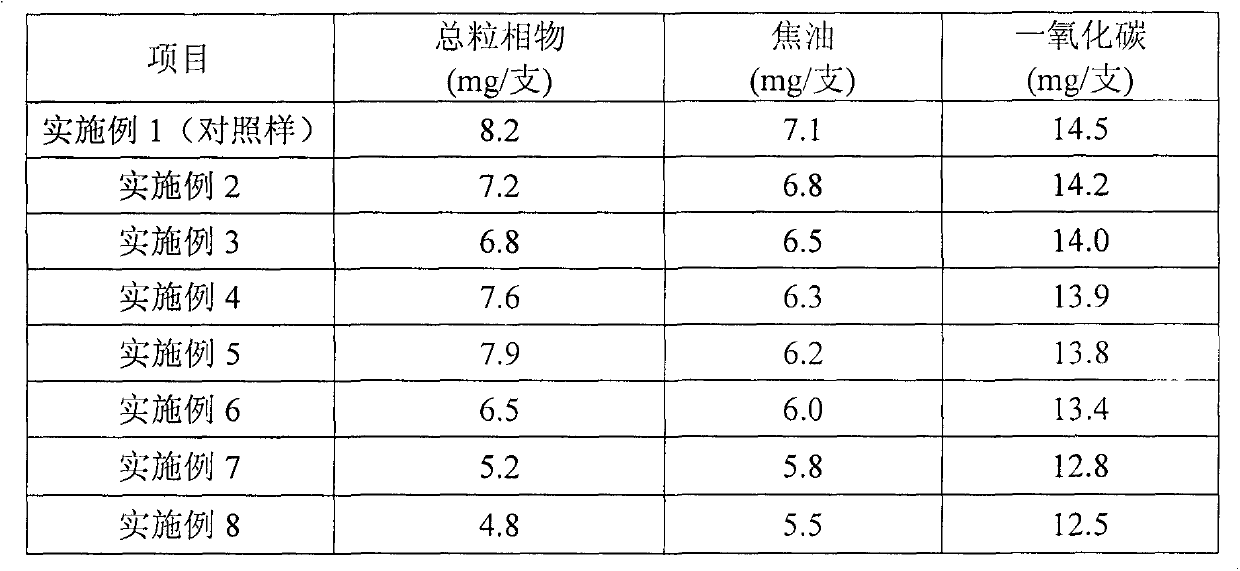

Preparation method for paper-making process tobacco sheet and finished product of paper-making process tobacco sheet

ActiveCN103141928AImprove single layer retentionImprove breathabilityTobacco preparationPlant fibrePaper based

The invention belongs to the field of tobacco industry and relates to a preparation method for a functional harm-reduction and tar-reduction paper-making process tobacco sheet and a finished product of the paper-making process tobacco sheet. The preparation method for the paper-making process tobacco sheet comprises the following steps of extracting and concentrating effective components of tobacco; mixing formulas; pulping and blending fibers; manufacturing paper with pulp; dipping, drying and tearing and shaping. The blending process comprises the following steps of: adding non-tobacco plant fiber pulp of which the beating concentration is 3-4 percent and the Schopper-Riegler (SR) beating degree is 18-28 to tobacco mixed fiber pulp, adding filling to a machine chest, regulating the pulping concentration to 2-3 percent by water, and evenly mixing. By the use or the combine use of the filling and the non-tobacco plant fiber pulp, the combustion state of the sheet can be improved while physical properties, such as the air permeability, the retention and the tensile strength of a paper base, are improved, i.e., harmful ingredients of smoke, such as tar and carbon monoxide of the paper-making process tobacco sheet, can be effectively reduced, and hazard indexes of cigarettes are reduced. Meanwhile, technical-economic indicators, such as the speed and the input- output efficiency of a paper machine, also can be improved.

Owner:杭州利群环保纸业有限公司

Method for preparing modified plant fibrous sale price biological adsorption agent

InactiveCN101239305AImprove adsorption capacitySimple processOther chemical processesChemical reactionPlant fibre

The present invention provides a method for heavy metal adsorbentusing vegetable fibre waste, including following steps : weighing fibre waste raw material, washing, drying to constant weight; crashing material, screening raw material powder; raw material after being screening mixing with the de-ionized water or aqueous slkali, plant after water washing or caustic washing by using drying net filtering mixer, and adequately cleaning several times by water, till clarification of the cleaning liquid, plant powder after being cleaning dried to constant weight; mixing the material after being water washing or caustic washing and the carboxylic acid solvent, forced air drying mixed solid-liquid mixer after being mixed, generating heat chemical reaction by improving temperature, cooling to door temperature after being heat preservation; cleaning heat reacted plant powder, dying the moisture powder to constant weight, obtaining biological adsorbent corresponding to carboxylic acid modification plant fibre after being cooled. The invention has a lower cost, wide sources and simple process.

Owner:SHANGHAI JIAO TONG UNIV

High-strength environment-friendly flame-retarding fiberboard and manufacturing method thereof

ActiveCN101905475AReduce the temperatureDelay in pyrolysis combustion reactionWood working apparatusDomestic articlesFiberSocial benefits

The invention discloses a high-strength environment-friendly flame-retarding fiberboard which comprises the following raw materials of plant fibers, flame retardants, adhesives and waterproofing agents, wherein the weight ratio of the plant fibers to the flame retardants to the adhesives to the waterproofing agents is 100:(3-30):(3-30):(0.1-4). The invention also discloses a manufacturing method of the high-strength environment-friendly flame-retarding fiberboard. Not only are the mechanical properties of the flame-retarding fiberboard obviously improved, but also the combustion property can conform to the regulations of GB8624 Class B or Class C, and the formaldehyde emission, the smoke volume produced and the smoke toxicity are also reduced. Thus, the high-strength environment-friendly flame-retarding fiberboard has good quality and low price, can be widely applied to the fields of building furnishings, flame-retarding furniture production, flame-retarding floor production, wooden fireproof door production, ship and vehicle furnishings and the like, and has good economical and social benefits.

Owner:北京盛大华源科技有限公司 +1

Magnesium oxysulfate cement board and method for preparing same by using semidry method

InactiveCN102493598AAnti-bendingLower pH valueCeramic shaping apparatusBuilding componentsPlant fibreCement board

The invention relates to a magnesium oxysulfate cement board and a method for preparing the same by using a semidry method. The magnesium oxysulfate cement board comprises a heat insulation core layer and strength structure layers respectively compounded on the two surfaces of the heat insulation core layer. The heat insulation core layer is a layer structure formed by stirring and pressing magnesium oxysulfate which is used as a gelatinizing agent and a light material which is used as a filler. Each strength structure layer is a layer structure formed by the magnesium oxysulfate which is used as the gelatinizing agent. The magnesium oxysulfate cement board disclosed by the invention has the outstanding substantive characteristics that a plate material with a multilayer composite structure is formed by mixing the magnesium oxysulfate utilized as the gelatinizing agent with the light material and / or a reinforcing fiber; the structure of the core layer has the characteristics of light weight and good heat preservation and heat insulation effects; the strength structure layers on the two surfaces of the core layer have the characteristics of bending resistance and high compression strength; and meanwhile, the magnesium oxysulfate cement board is low in PH value and has no chlorine content. Therefore, the occurrence of the moisture absorption and the halogenation are avoided; the corrosion on materials, such as plant fibers, metal pieces and the like, is avoided; and the application range is widened and the service life is prolonged.

Owner:NG TERASUN AIR DUCT

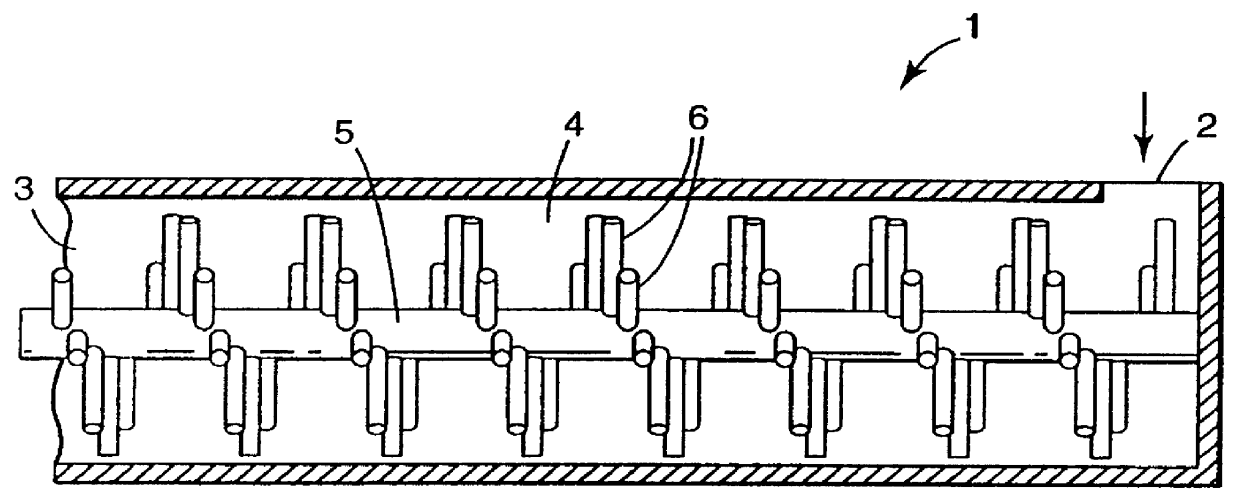

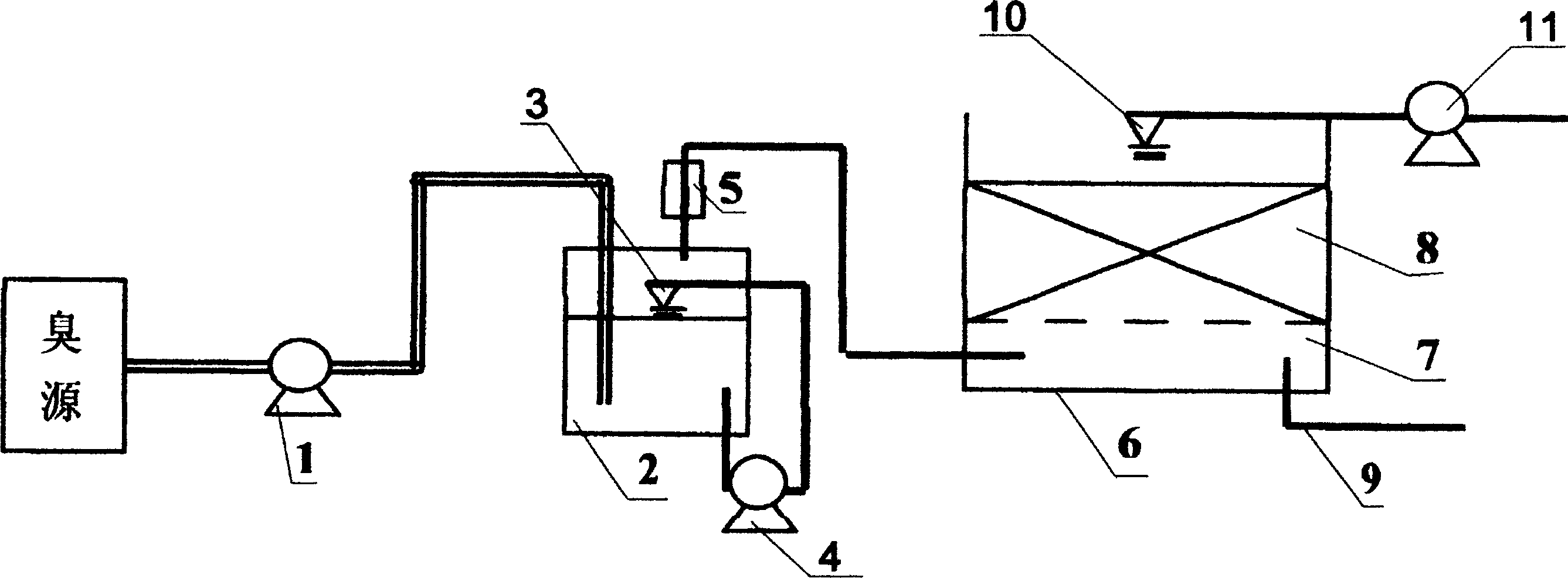

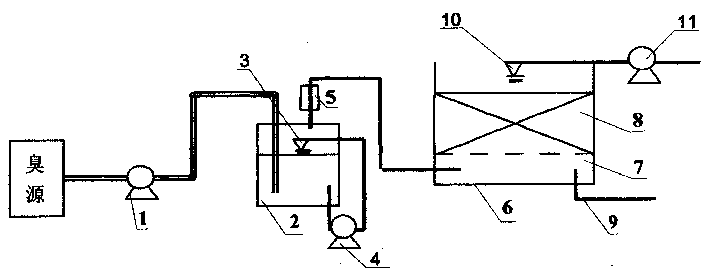

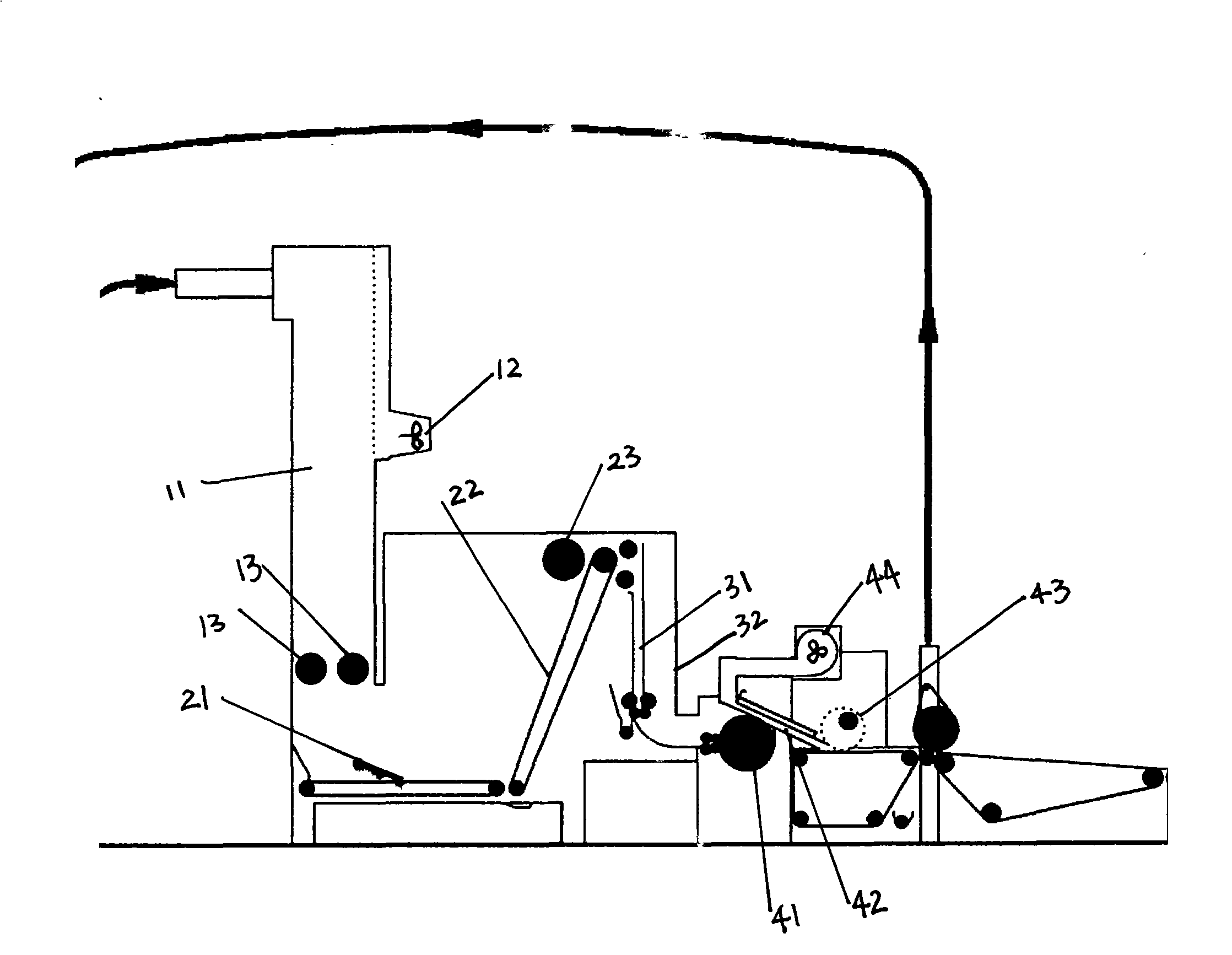

Biologic deodorization method and its device

InactiveCN1445013ALow running costEasy maintenance and managementDispersed particle separationDeodrantsPlant fibreBiological filter

A biological deodouring process for the stink gas features that the stink gas is forced to pass through the biologic filter material prepared from anticorrosion plant fibres, porous materia, or theirmixture through inoculating microns (yeast, bacteria, etc) to it. Its apparatus is composed of blower, gas washing pool and biological filter tower. Its advantages are simple apparatus, high effect, low cost, and no secondary pollution.

Owner:GUANGDONG INST OF MICROORGANISM

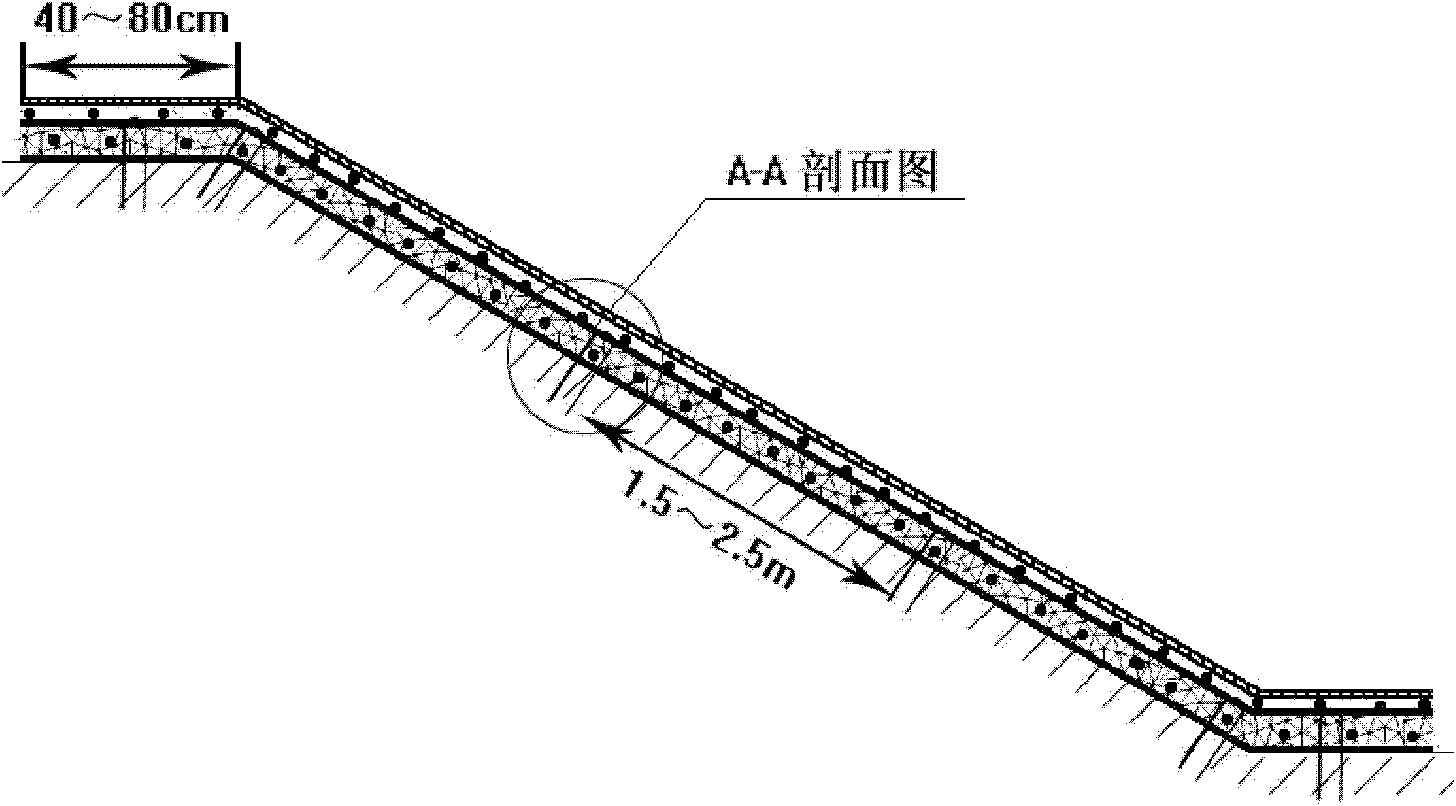

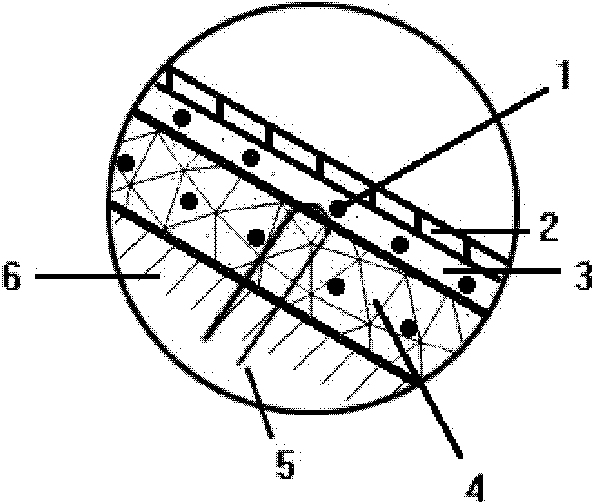

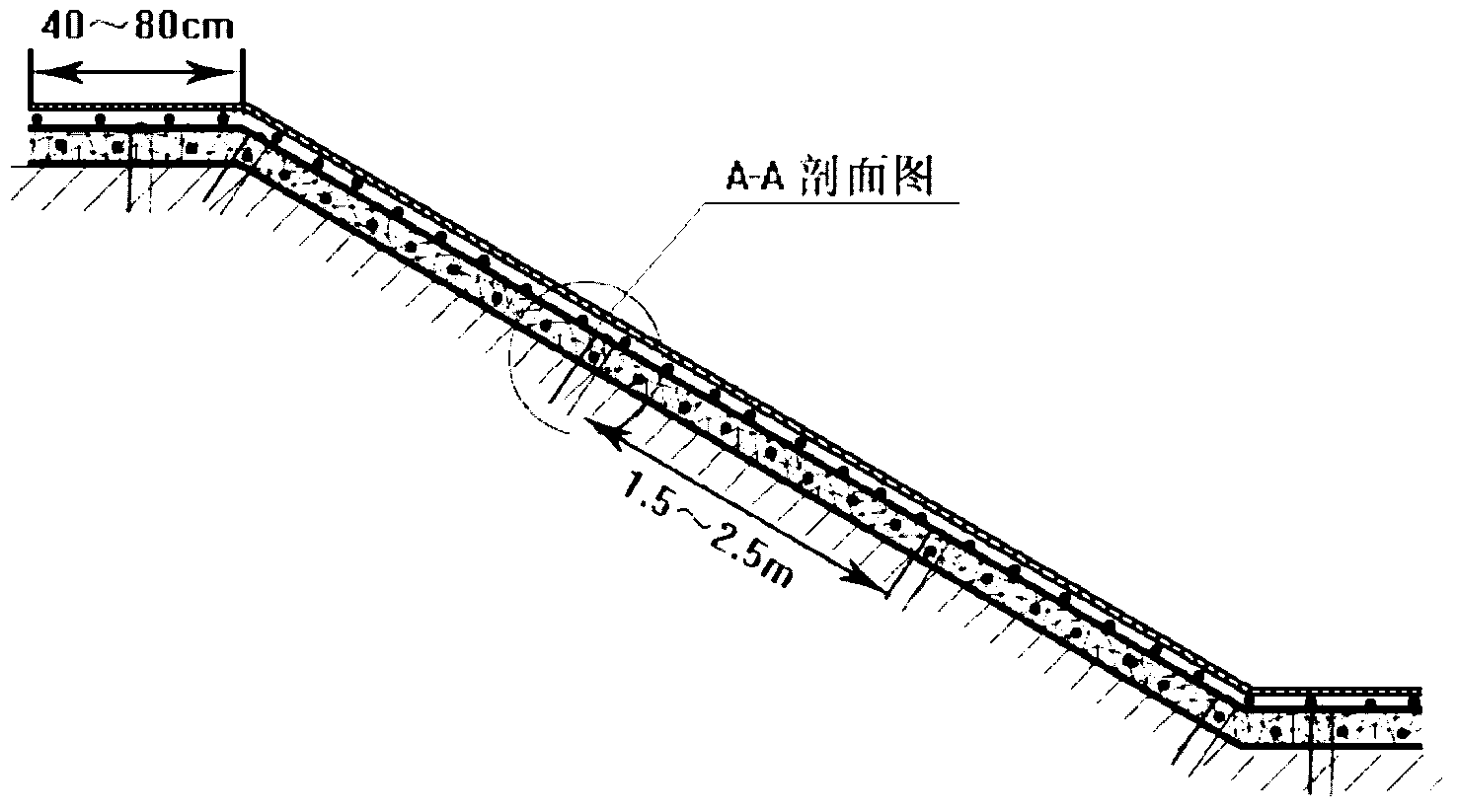

Vegetation restoration method adopting plant fiber blanket with assist of slurry spraying

InactiveCN102138428ASolve the protection problemAchieve the perfect combinationExcavationsHorticultureRevegetationPlant fibre

The invention belongs to the field of ecological engineering and relates to a construction method of spraying and covering planting in an ecological restoration project, namely, a vegetation restoration method adopting a plant fiber blanket with the assist of slurry spraying. The invention is characterized in that the method comprises the following steps: laying a slope through the plant fiber blanket firstly, spraying and covering the slope through slurry and covering the slope through the plant fiber blanket. In the invention, a three-dimensional net made of geotextile material can be replaced; chemical synthetic materials entering the natural world can be obviously reduced when the effect of improving the overall and local stability of the slope is achieved; moreover, vegetable fiber can also increase organic components of soil, is beneficial for improving the capacities of water retaining and constant-temperature keeping of the soil on the surface layer and is beneficial for the growth of vegetation on the slope; when the construction cost is reduced, the low carbon conversion and utilization of agricultural and forestal residuals are realized, agricultural and forestal chains are extended, and the industrial added value of by-products is improved; and the method has a large application value in the soil and water conservation, sand prevention and control and ecological restoration of the damaged vegetation in a project in China.

Owner:北京林丰源生态科技有限公司

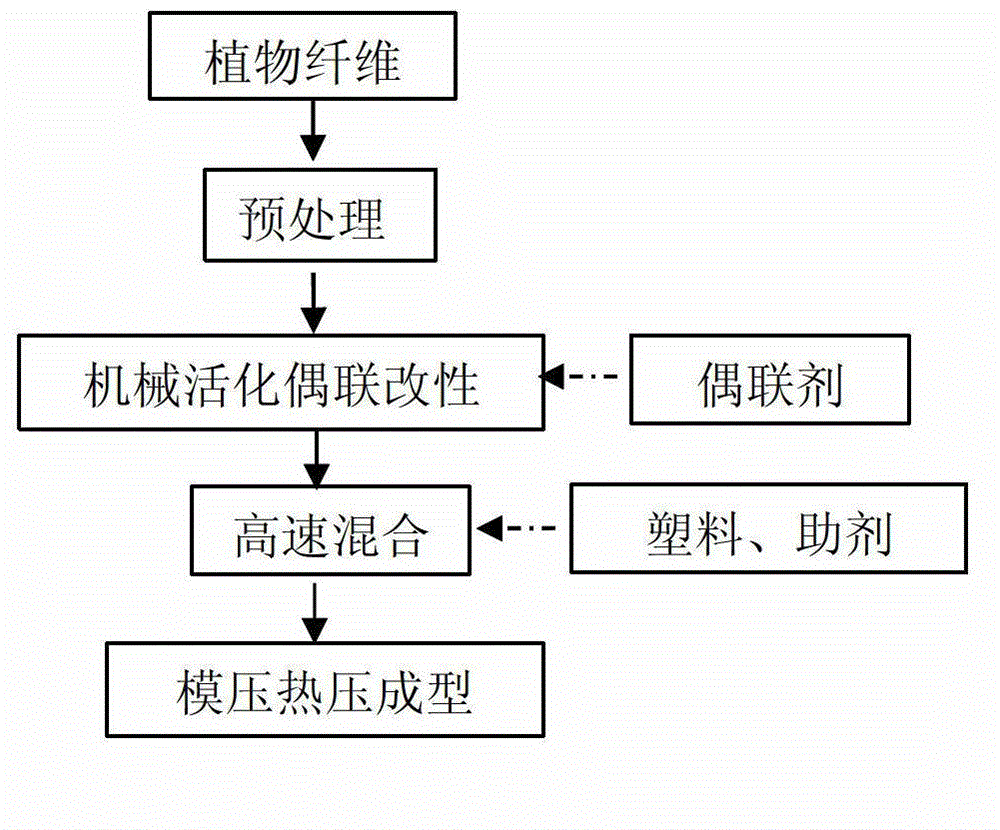

Plant fiber wood-plastic composite material and preparation method thereof

InactiveCN102942797ATake advantage ofImprove responseRaw material divisionPlant fibreCompatibilization

The invention relates to a plant fiber wood-plastic composite material and a preparation method thereof. The wood-plastic composite material includes compositions by mass: 40-60% of plant fibers, 0.6-3% of a coupling agent, and 30-55% of plastic. The additive comprises: 0.5-5% of a lubricating additive, 0.5-3% of a dispersing additive, 0.5-2% of a thermal stability additive, and 1-2% of a plasticizing additive. The modified plant fibers are obtained through synchronous activation and modification of plant fiber and a coupling agent by using the mechanical activation technology. Then the modified plant fibers, the plastic and the additive are high-speed mixed and finally molded to form the wood-plastic composite. The material utilizes the waste plant fibers in the light industry and agriculture, and has significant ecological environmental benefits. The method realizes simultaneous activation and modification for plant fibers, simplifies the preparation process, is pollution-free and has no three waste discharging in the process. The coupling agent-modified plant fibers is improved in compatibility with a thermoplastic material, and the quality of the wood-plastic composite material is enhanced.

Owner:GUANGXI UNIV +1

Composite waterproof plate, ad its manufacturing method and use

InactiveCN1640640AImprove waterproof performanceImprove corrosion resistanceWood working apparatusDomestic articlesPolymer scienceAdhesive

The present invention relates to a composite water-proof material. It is made up by using (by weight portion) 20-70 portions of plant fibre, 10-60 portions of flyash and 5-40 portions of adhesive through the processes of mixing them, die-pressing and polymerization. The described adhesive is formed from maleic anhydride, phthalic anhydride, polyalcohol, styrene or mixture of their homologous compounds, also can include trimeric cyanamide, acrylic acid or rosin and dicyclopentadiene. Its raw material composition also can include 10-40 portions of new and old plastics. Said plate material has strong strength and good water-proof property, so that it has extensive application range.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Vegetable fiber liquefied matter, and preparing method and use thereof

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

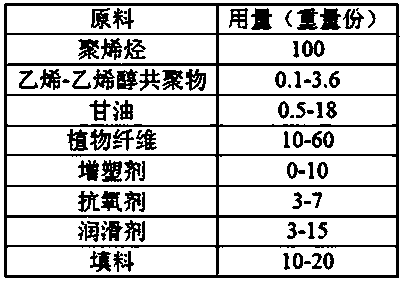

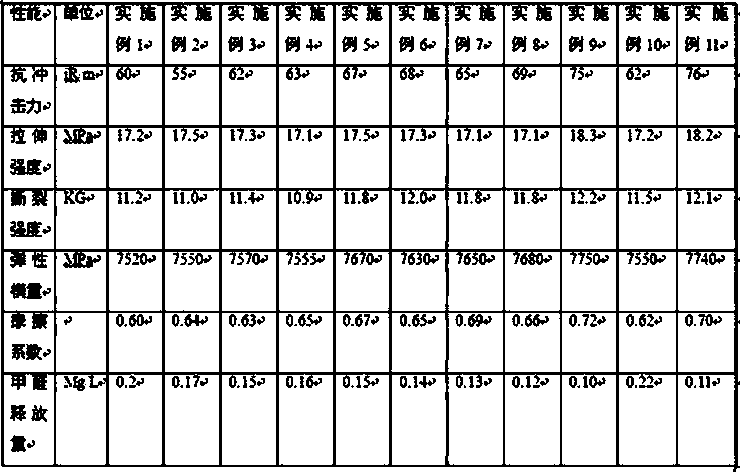

Polyolefin wood-plastic composite and preparation method thereof

The invention discloses a polyolefin wood-plastic composite and a preparation method thereof. Polyolefin and plant fiber modified by EVOH (ethylene-vinyl alcohol copolymer) are taken as main raw materials, a plasticizer, a stabilizer, a lubricating agent and the like are added, and the environment-friendly wood-plastic composite with excellent mechanical property is prepared with a melt blending method commonly used during plastic processing. The wood-plastic composite can be used in conventional fields such as building materials, decorative materials, foam materials, boards, packaging materials, toys, automobile parts and the like, and the application range of the EVOH is enlarged.

Owner:FUJIAN NORMAL UNIV

PVC (polyvinyl chloride) micro-foam floor and preparation method thereof

Owner:安徽济峰节能材料有限公司

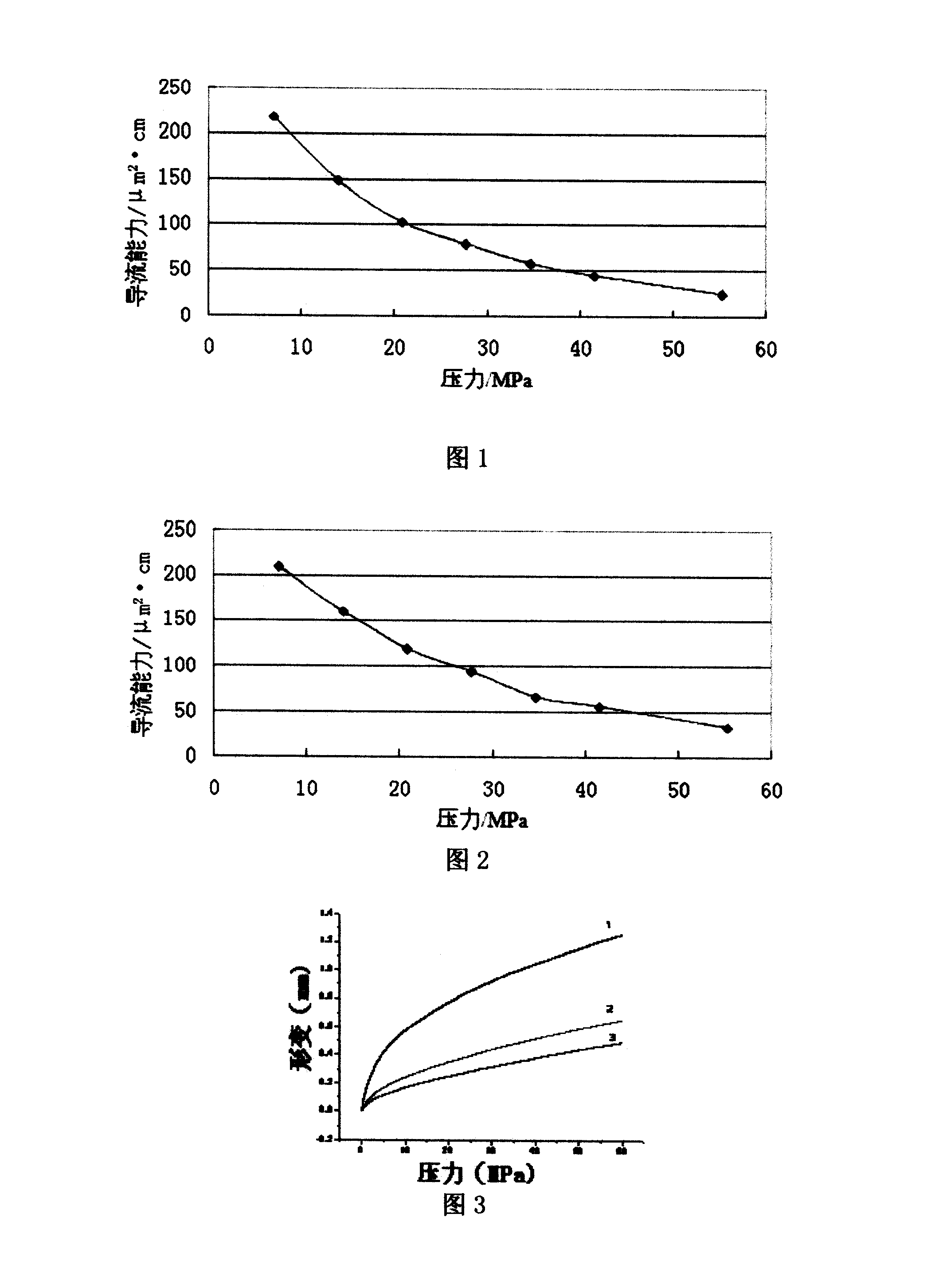

Method and technique for preparing low-density propping agent

InactiveCN101200632AImprove deformation resistanceReduced resistance to deformationFluid removalDrilling compositionPlant fibreHydraulic fracturing

The present invention relates to propping agent which is widely applied to the oil and gas well hydraulic fracturing technology, and the present invention especially relates to a manufacturing method and a preparation technology of low-consistency propping agent and is characterized in that firstly, plant fibre material is used as the raw material and is crushed and grinded as plant fibre granules; secondly, modifying agent solution dips and solidifies the plant fibre granules; thirdly, macromolecular resin is used to covering the granules which are crushed and filtered again to form the propping agent. The propping agent prepared by the technology and method can conquers that the prior propping agent has large energy consumption and high expense of the whole construction, or the propping agent of the present invention does not easily cause the phenomena of propping agent disgorging or crack emptying.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

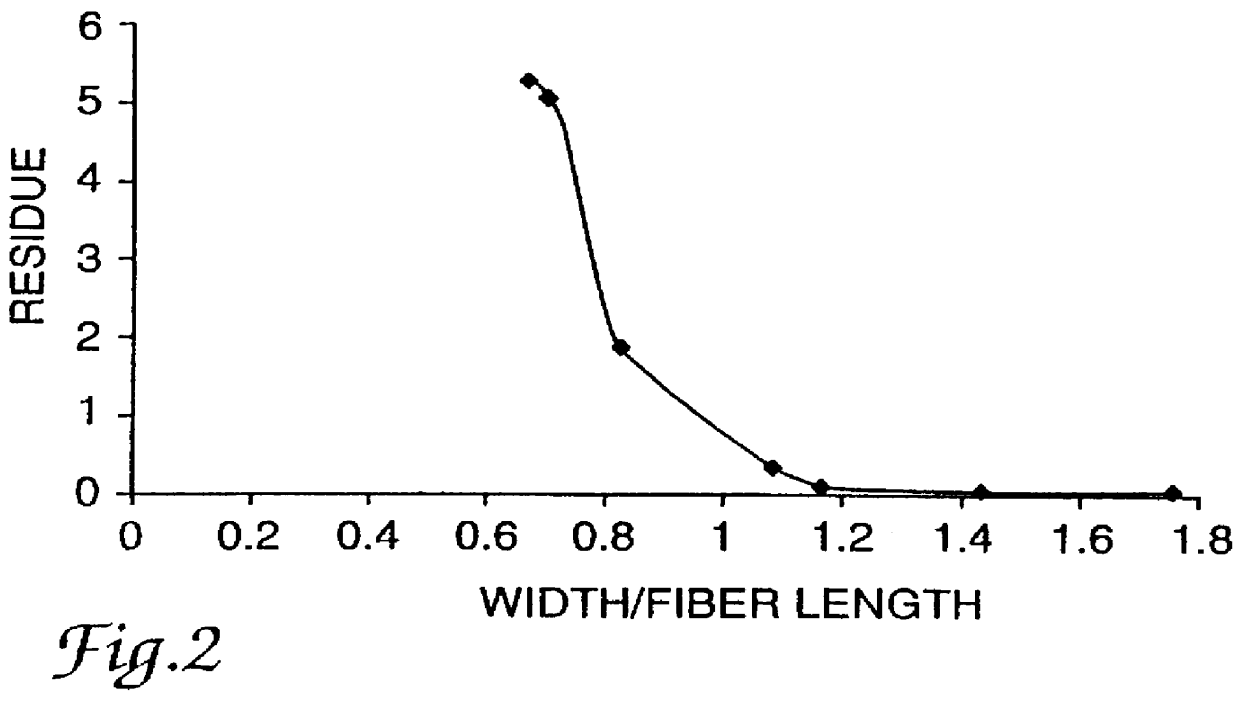

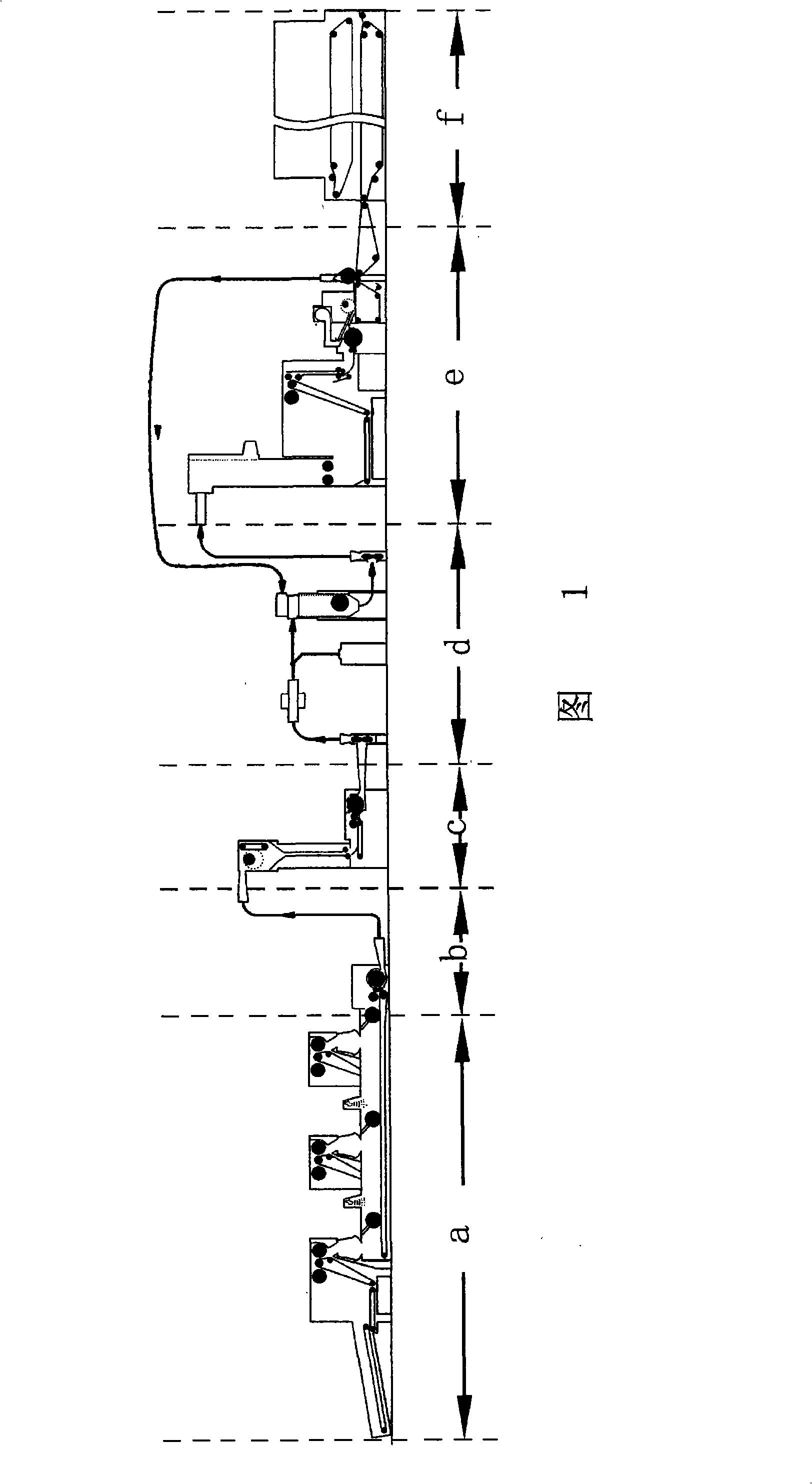

Airflow air laid fiber cotton preparing process and manufactured fibre cotton

ActiveCN101307529AWide selection of materialsImprove product qualityLap forming devicesNon-woven fabricsEngineeringWaste material

The invention discloses a method for preparing air-laying cellucotton and cellucotton produced by the method. Taking low melting point fibers and other fibers as raw material, the cellucotton is produced by rough shape cutting, coarse opening, fine opening, air laying, hot binding and parting cut packaging, wherein the air laying is as follows: the loose fibers which are distributed evenly in a cotton box after fully mixed by the fine opening are further mixed by airflow and delivered by pressurized airflow to between the net forming curtain and the net forming roller to be formed into a required retiform structure. The preparing process has wide range of material selection, is suitable for not only all the raw materials adopted in the prior process, but also the plant fiber widely existing in the natural world which are not used in the prior art such as couch grass, reed, cornstock, straw and bagasse as raw materials, and the waste materials such as wood wool, crushed sponge and wool manufacturing crushed aggregates to reuse and regenerate; in addition, the preparing process has high production efficiency and low energy consumption, and produces the cellucotton with great improvement in the performance, thereby being applied to wider fields.

Owner:广东美梦思床具有限公司

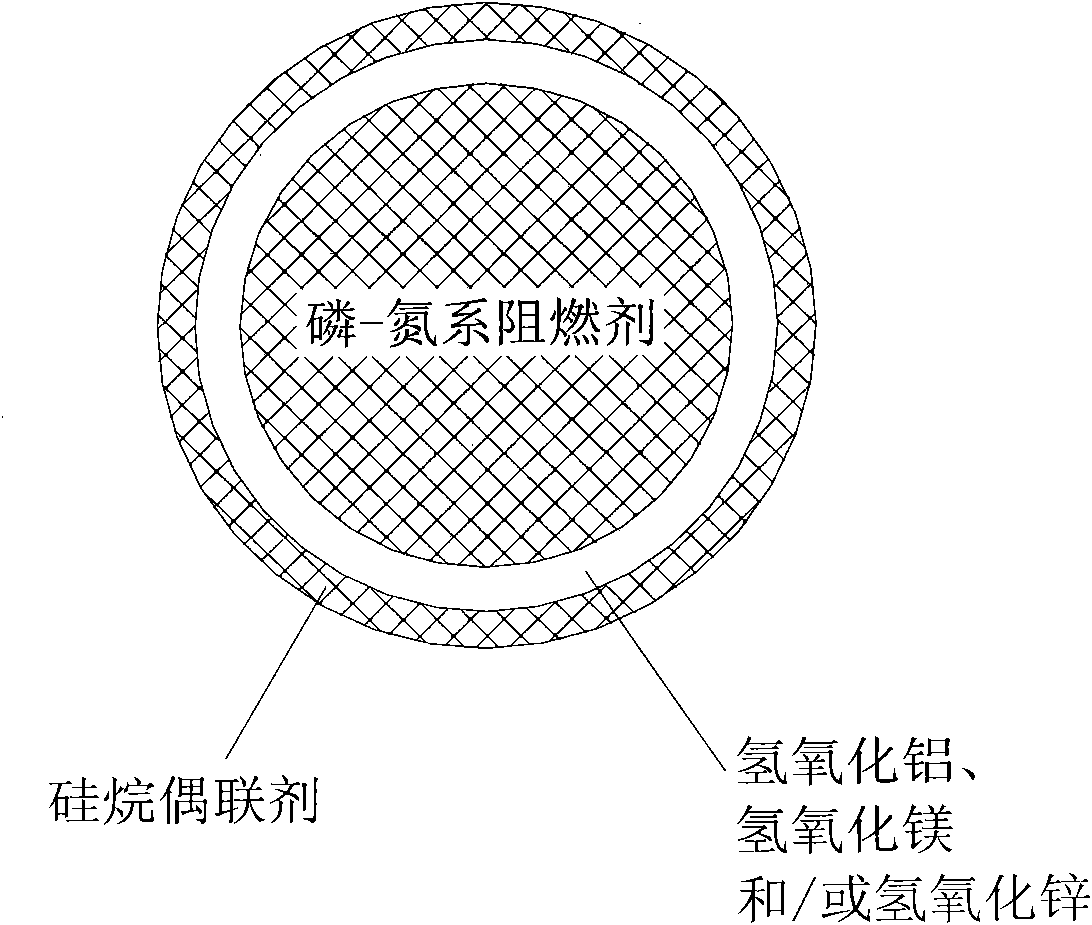

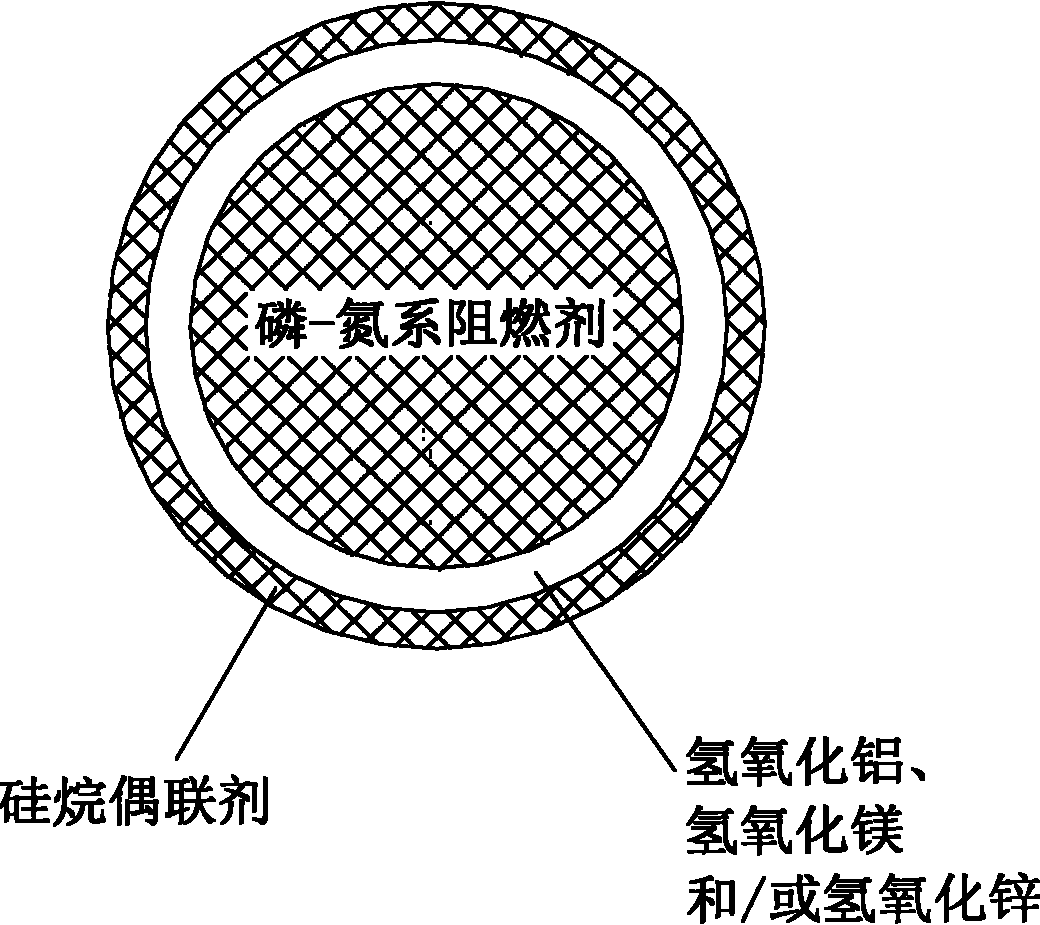

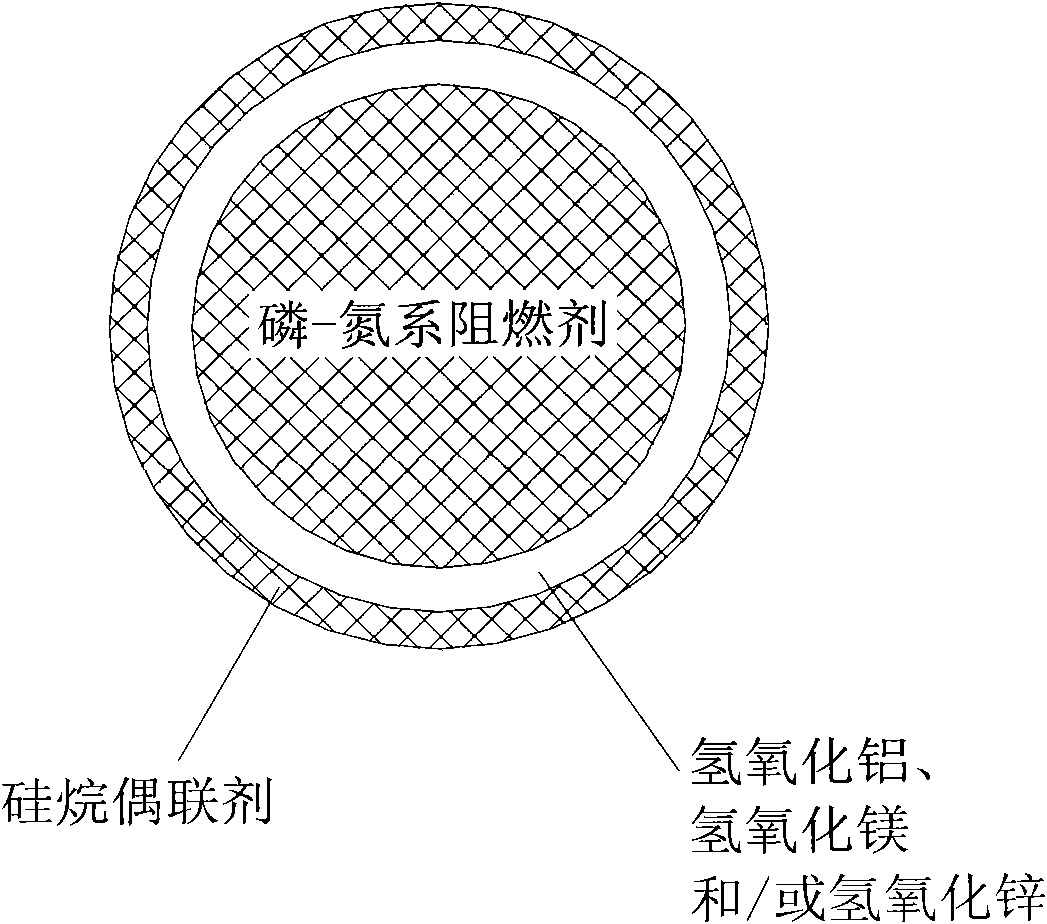

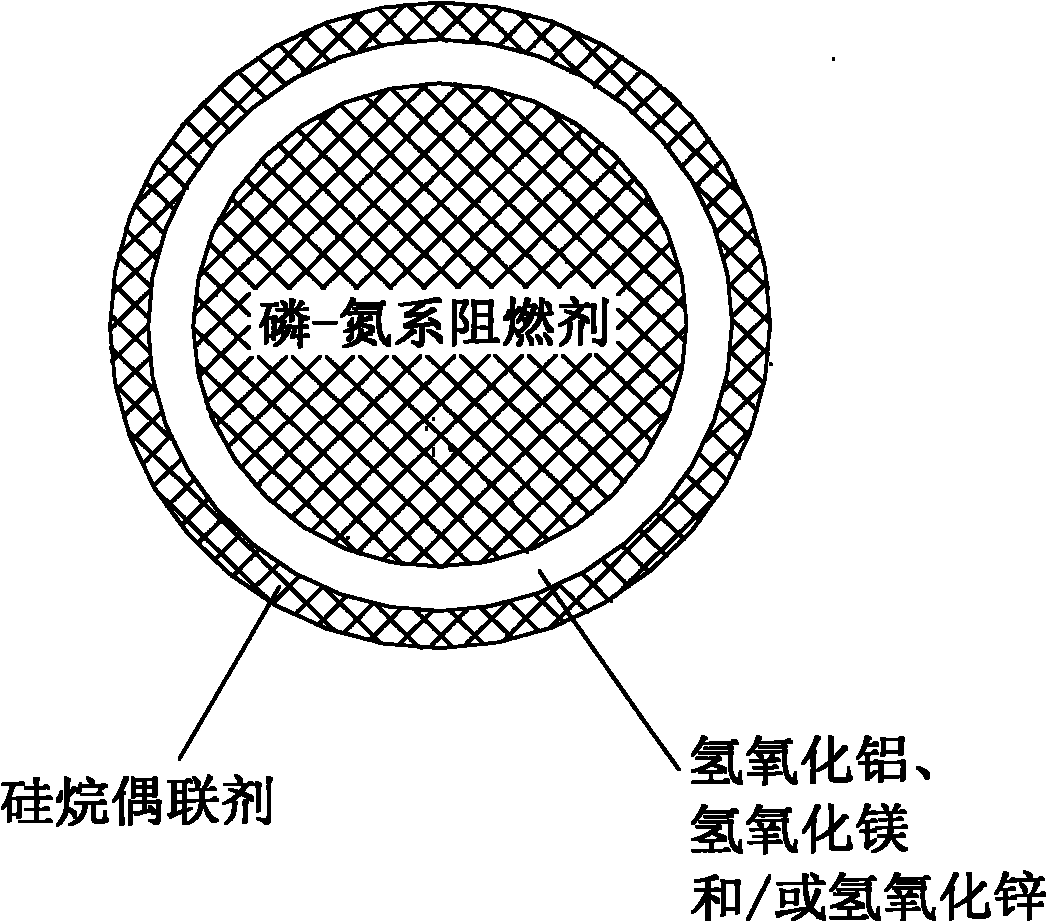

Flame retardant and preparation method thereof

ActiveCN101880408ANo harm to physical and chemical propertiesDoes not impair processabilityFiberCombustion

The invention discloses a flame retardant and a preparation method thereof. The flame retardant comprises a phosphorus-nitrogen series flame retardant, an inorganic flame retardant and a silane coupling agent, wherein the phosphorus-nitrogen series flame retardant is wrapped by the inorganic flame retardant; the inorganic flame retardant is wrapped by the silane coupling agent; and the weight ratio of the phosphorus-nitrogen series flame retardant to the inorganic flame retardant to the silane coupling agent is 100:1-100:0.01-5. By using the flame retardant, the physicochemical property, the machining performance and the service performance of a plant fiber board cannot be damaged in the flame retarding process of the plant fiber board, the chemical reaction process of the flame retardant and timber cannot be changed at a high temperature and the harm of combustion smoke gas of a flame-retardant wooden material cannot be increased.

Owner:北京盛大华源科技有限公司 +1

Heat-not-burn reconstituted tobacco with high heat transfer performance and preparation method of heat-not-burn reconstituted tobacco

InactiveCN110150722AHigh densityImprove heat transfer performanceTobacco preparationTobacco treatmentHigh densityHeat transmission

The invention belongs to the field of novel tobacco manufacturing products, and particularly relates to a heat-not-burn reconstituted tobacco with the high heat transfer performance and a preparationmethod of the heat-not-burn reconstituted tobacco. The heat-not-burn reconstituted tobacco with the high heat transfer performance comprises the following raw materials: plant fibres, cigarettes and tobacco raw materials, heat conduction materials, a smoke agent, accessories, perfume raw materials and moisture; according to the heat-not-burn reconstituted tobacco, cigarette core materials used fora heat-not-burn cigarette are prepared and obtained, due to the characteristics of high heat conduction materials and the high density core materials uniformly distributed in the core materials, thehigh heat transfer performance is provided, the problems that when the heat-not-burn reconstituted tobacco is prepared by a traditional paper-making method, nonuniform heat transmission is caused by the poor heat transfer performance of proximate materials, smoke releasing and fragrance releasing are little, the number of suction mouth is few, and the quality of suction is poor are solved, strongcigarette fragrance, sufficient smoke quantity, the excellent physical processing performance and the good suction quality are given to the heat-not-burn cigarette.

Owner:ZHONGYAN SHIWEICE (YUNNAN) RECONSTITUTED TOBACCO CO LTD

Modified calcium sulfate crystal whisker papermaking filler, preparation method and applications thereof

ActiveCN102852031AHigh whitenessHigh strengthPolycrystalline material growthInorganic compound additionPlant fibrePapermaking

The present invention discloses a modified calcium sulfate crystal whisker papermaking filler, a preparation method and applications thereof, wherein a modified calcium sulfate crystal whisker papermaking filler is prepared, and then the modified calcium sulfate crystal whisker papermaking filler is applied in papermaking industry. The application of the modified calcium sulfate crystal whisker papermaking filler in the papermaking industry comprises: 1) selection a papermaking slurry, (2) use of the modified calcium sulfate crystal whisker papermaking filler and related auxiliary materials, 3) papermaking, and 4) white water circulation. According to the present invention, the calcium sulfate crystal whisker raw material source is wide, conditions are wide, and solid waste pollution can be effectively solved; the modified calcium sulfate crystal whisker product has characteristics of high whiteness, low abrasion, effectively-controlled solubility, high papermaking retain rate, and low white water load, the problem of pipe scale is eliminated, and the product can completely replace calcium carbonate, kaolin, talc powder, and other papermaking fillers, and partial plant fiber raw materials; and the method has characteristics of low equipment investment, simple modification process, strong operability and low cost, and is applicable for large scale production.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Paper made from collagen fiber and its processing method

InactiveCN101050602ARaise the gradeImprove flame retardant performancePaper/cardboardRaw material divisionPlant fibrePapermaking

The present invention discloses a kind of paper made of collagen fiber and its processing method. The paper made of collagen fiber includes fiber component and non-fiber component; said fiber component is formed from 10-100 wt% of collagen fiber and 0-90 wt% of other fiber for making paper. Its processing method mainly includes the following steps: screening raw materials, liquid defibrination, cleaning, rinsing, and opening by using liquor, dewatering and drying, opening and removing impurity, carding, pulping and papermaking.

Owner:张立文

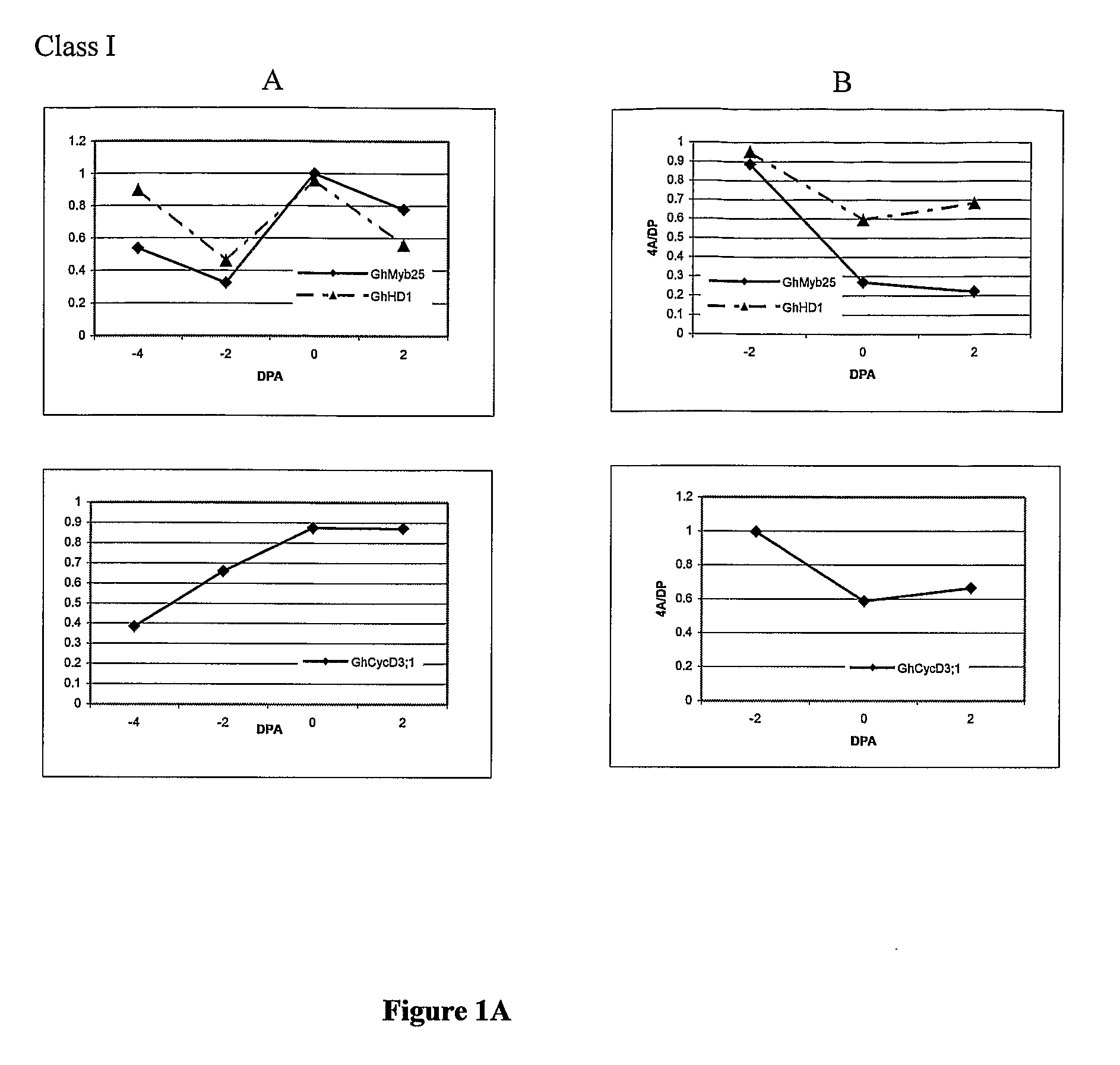

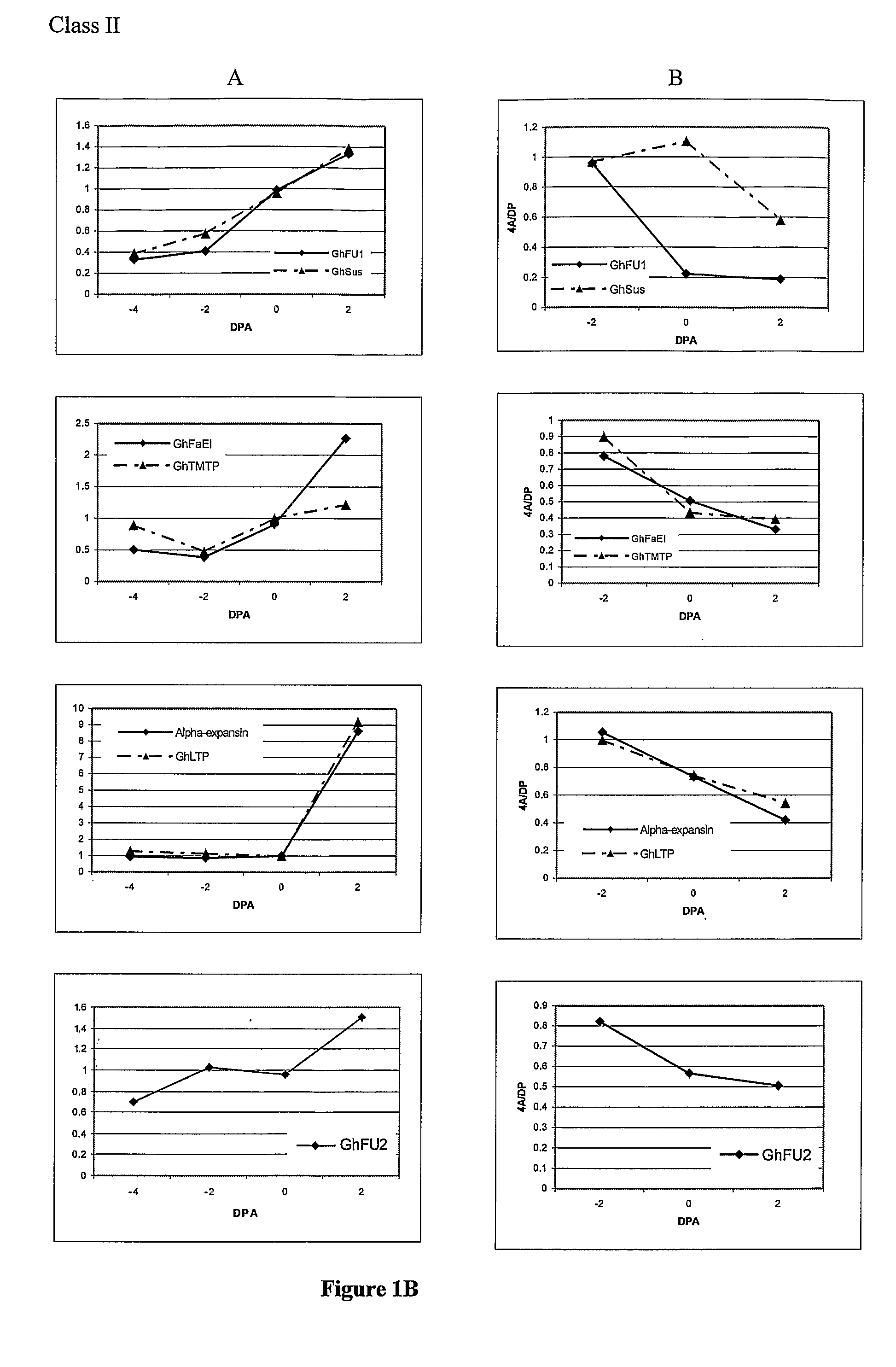

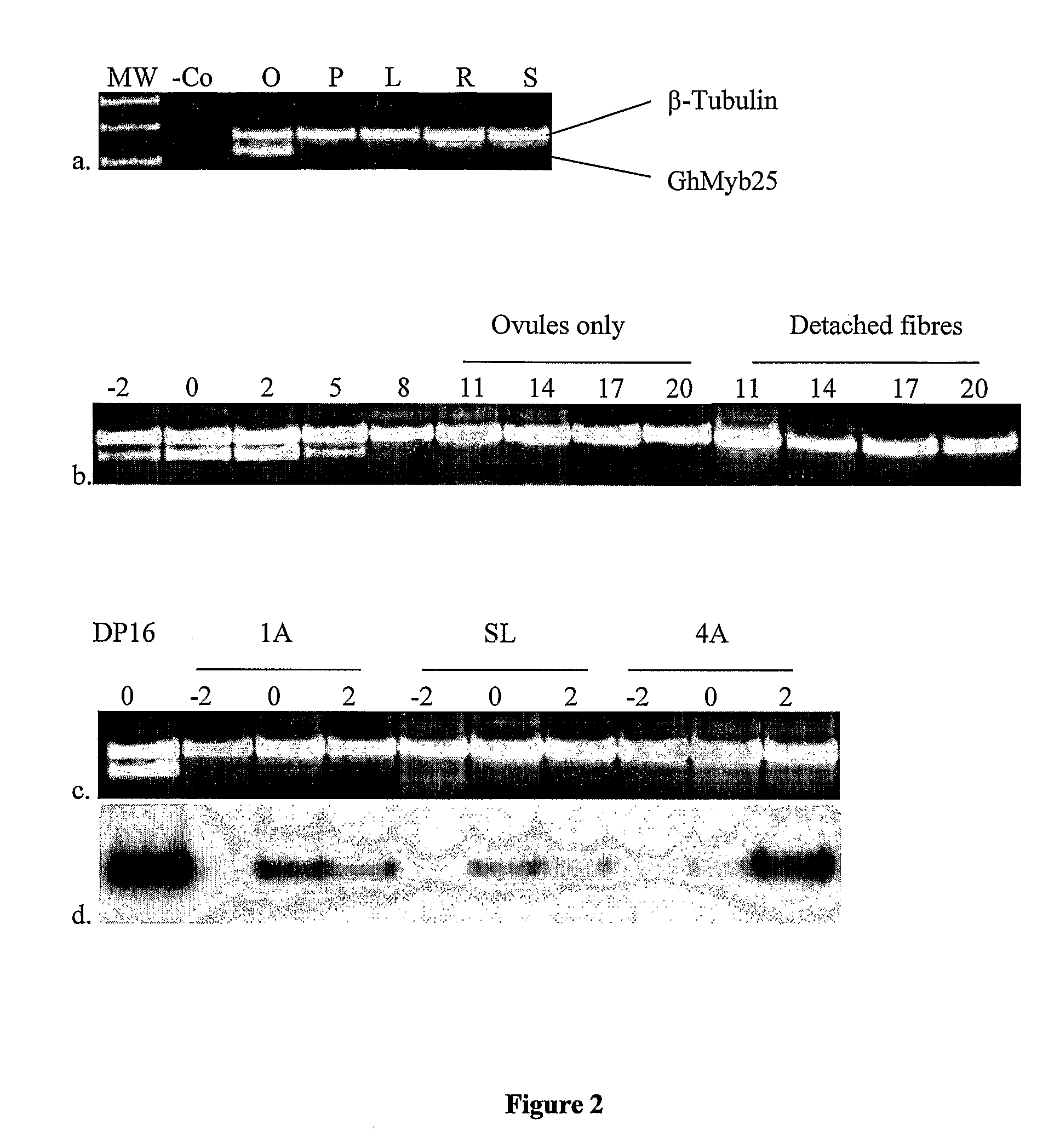

Genes involved in plant fibre development

The present invention provides polypeptides, and polynucleotides encoding therefore, involved in the regulation of fibre initiation and / or elongation in fibre producing plants. In particular, the present invention provides methods of altering fibre initiation in cotton making use of transcription factors, regulatory proteins or cell cycle proteins produced at or around anthesis. The invention also relates to the use of these as markers of fibre production in plants including cotton.

Owner:COMMONWEALTH SCI & IND RES ORG

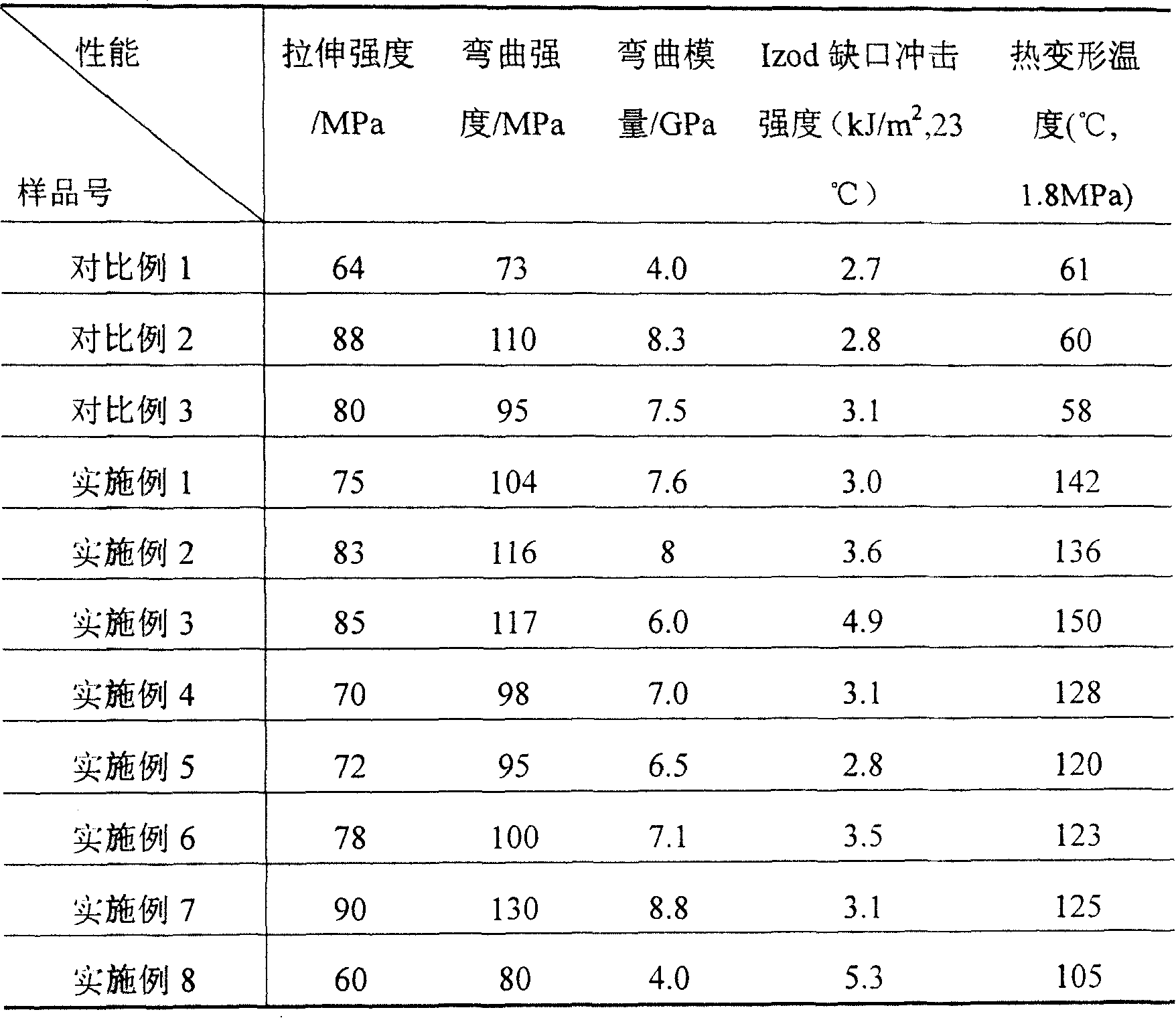

Polylactic acid and plant fiber composite material and preparation method thereof

InactiveCN101235192AImprove heat resistanceImprove mechanical propertiesHeat resistanceFibrous composites

The invention relates to composite material of polylactic acid and plant fiber, which is mainly formed by raw materials with the following parts of weight, 35-98.8 polylactic acide, 0-50 plant fiber, 0.1-5 nucleating agent and 0.1-10 nucleating-accelerant. The process of the invention has the advantages of simple operation and high production efficiency. And the composite material of polylactic acid and plant fiber which is prepared has high heat resistance, excellent mechanical property and favorable contour machining, and simultaneously keeps the biodegradability of the composite material.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

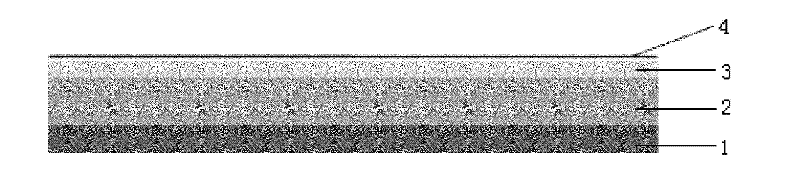

Submerged plant breeding blanket and application thereof

ActiveCN102668831AOvercoming implantation difficultiesOvercome difficultyLayered productsHorticultureVegetationFiber

The invention relates to a submerged plant breeding blanket and application thereof. The submerged plant breeding blanket disclosed by the invention is respectively composed of a carrier layer, a matrix layer and an adhesive layer from bottom to top, wherein the carrier layer is composed of palm and bamboo plant fiber; the matrix layer is composed of a growing matrix suitable for submerged plants to grow; and the adhesive layer is composed of a plant fiber net. The invention further provides a submerged vegetation transplantation technology which is characterized in that after being subjected to seedling culture, submerged plant seedling breeding embryoid bodies prepared by virtue of the breeding blanket are transplanted to the water bottom of an ecological restoration area for planting and restoring submerged vegetation of the ecological restoration area. Compared with the traditional submerged plant transplantation technology method, the submerged vegetation transplantation technology disclosed by the invention has the advantages of low transplantation cost, high speed, high survival rate, convenient technology, strong technical maneuverability, high community forming speed after transplantation, high breeding speed, good community stability and the like, and can be used for realizing the quick transplantation and the community construction and configuration of the submerged plants.

Owner:SHANGHAI INVESTIGATION DESIGN & RES INST

Natural vegetable fiber reinforced fully-degradable polymer composite material and preparation method thereof

The invention refers to a full-degradable polymer composite material strengthened by the natural plant fiber and the preparing method. It adopts India plant fiber-Hildegardia populifolia, sisal fiber, ramee, wood fibre and so on as the fiber raw material, tand the degradable plastic-the poly-methyl ethyl carbonic acid resin as the basic body, and smelts and commixes the filling and the basic body on the existent / nonexistent condition of the coupling agent to make the composite material. The weight percent content of the fiber is 5-80%, the better fiber 10-40%.

Owner:SUN YAT SEN UNIV

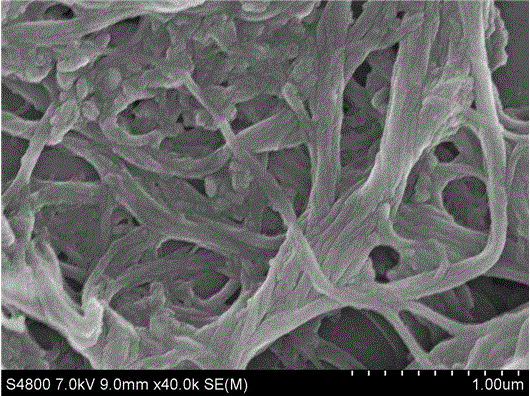

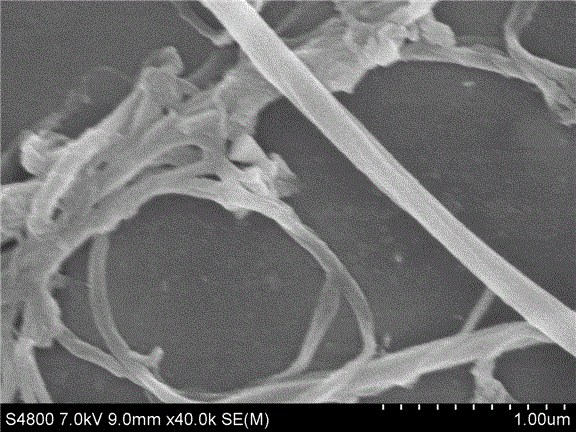

Preparation method of surface-modified ball-milling refined plant fibers

InactiveCN102978984ABall milling method is simpleBall milling method is convenientPulping with inorganic basesGrain treatmentsChemical industryCrude fibre

The invention relates to a preparation method of surface-modified ball-milling refined plant fibers. According to the preparation method, natural plant fibers are subjected to wet method ball milling after pretreatment, and the original micro-fibers can be scattered along the long-axis direction and broken along the diameter direction, so that the refined plant fibers are obtained. Compared with nano-celluloses prepared by a hydrolysis method, the refined long fibers obtained by the preparation method have the characteristics that the length is long, the length-diameter ratio is greater, and by controlling the ball milling condition, fine fibers and coarse fibers in the product are interconnected to from a net-like structure, and separated single fibers can be obtained. The fiber product does not contain acidic groups remained during preparation by the hydrolysis method. The plant fibers are subjected to appropriate surface modification, and then the surface-modified ball-milling refined plant fibers are prepared. The surface-modified ball-milling refined plant fibers have good application prospects in construction foods, medicaments, chemical industry, papermaking, spinning, new material preparation and the like.

Owner:SUN YAT SEN UNIV

Environment Protection type bioactive plant-growing container

InactiveCN1408205ANo pollution in the processGrow vigorouslyCultivating equipmentsNatural organic matterPlant fibre

The environment protection type bioactive plant-growing container for growing seedlings in planting consists of plant fiber powder 20-75 wt%, natural organic matter 10-60 wt%, bioactive nutrient 0.5-20 wt%, non-toxic adhesive 10-50 wt% and stuffing 3-10 wt%. The said plant fiber powder is husk powder, rice straw powder, corn straw powder, wheat straw powder, etc; the natural organic matter includes turf and sphagna; and the bioactive nutrient is algin. The plant-growing container is produced through mixing the said material and press molding at 80-160 deg.c.

Owner:金绿汀

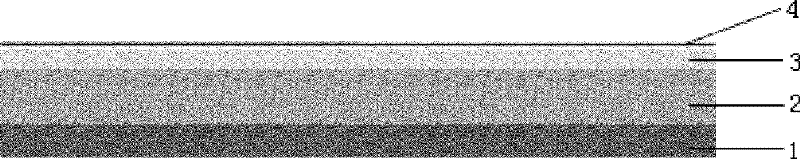

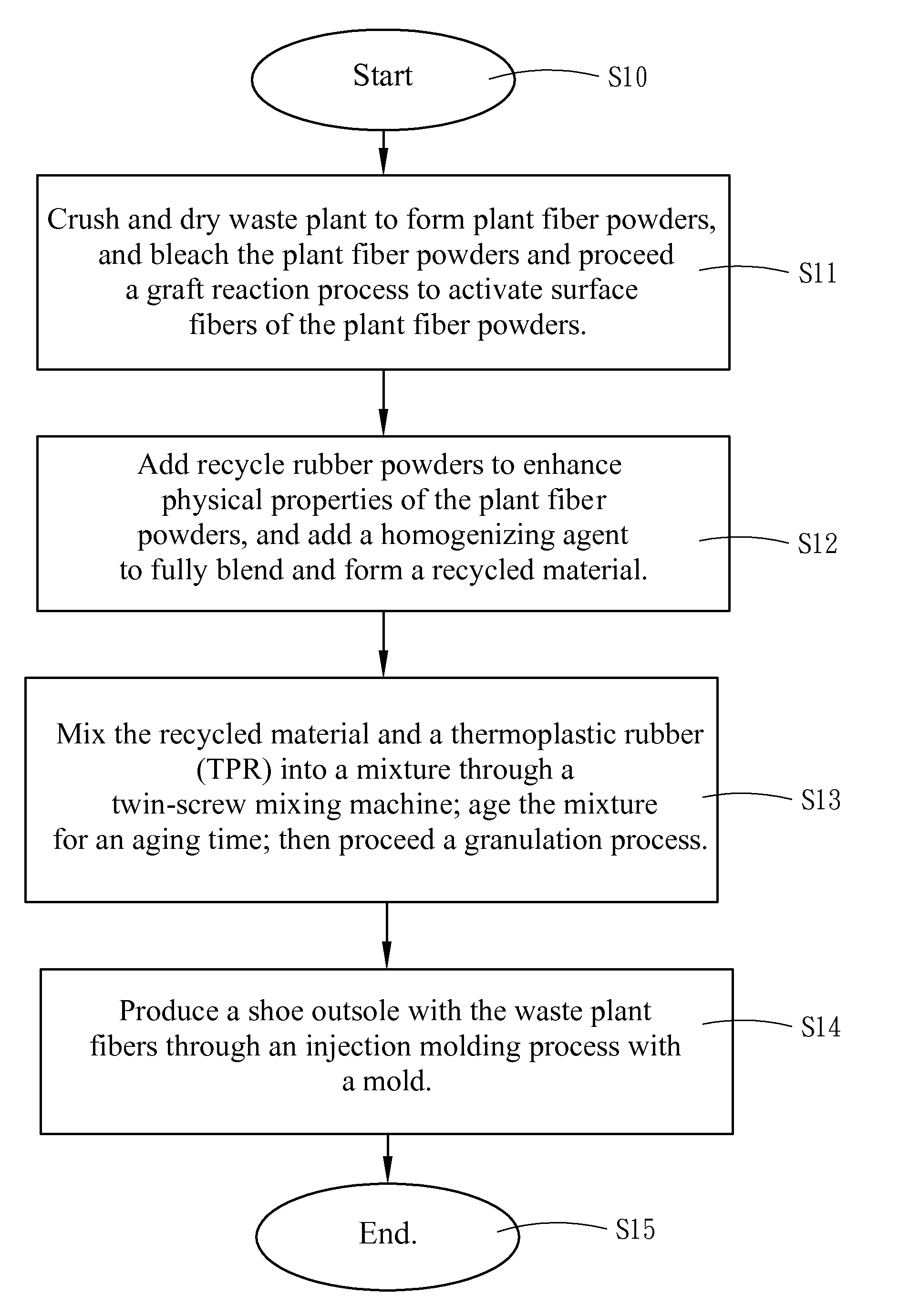

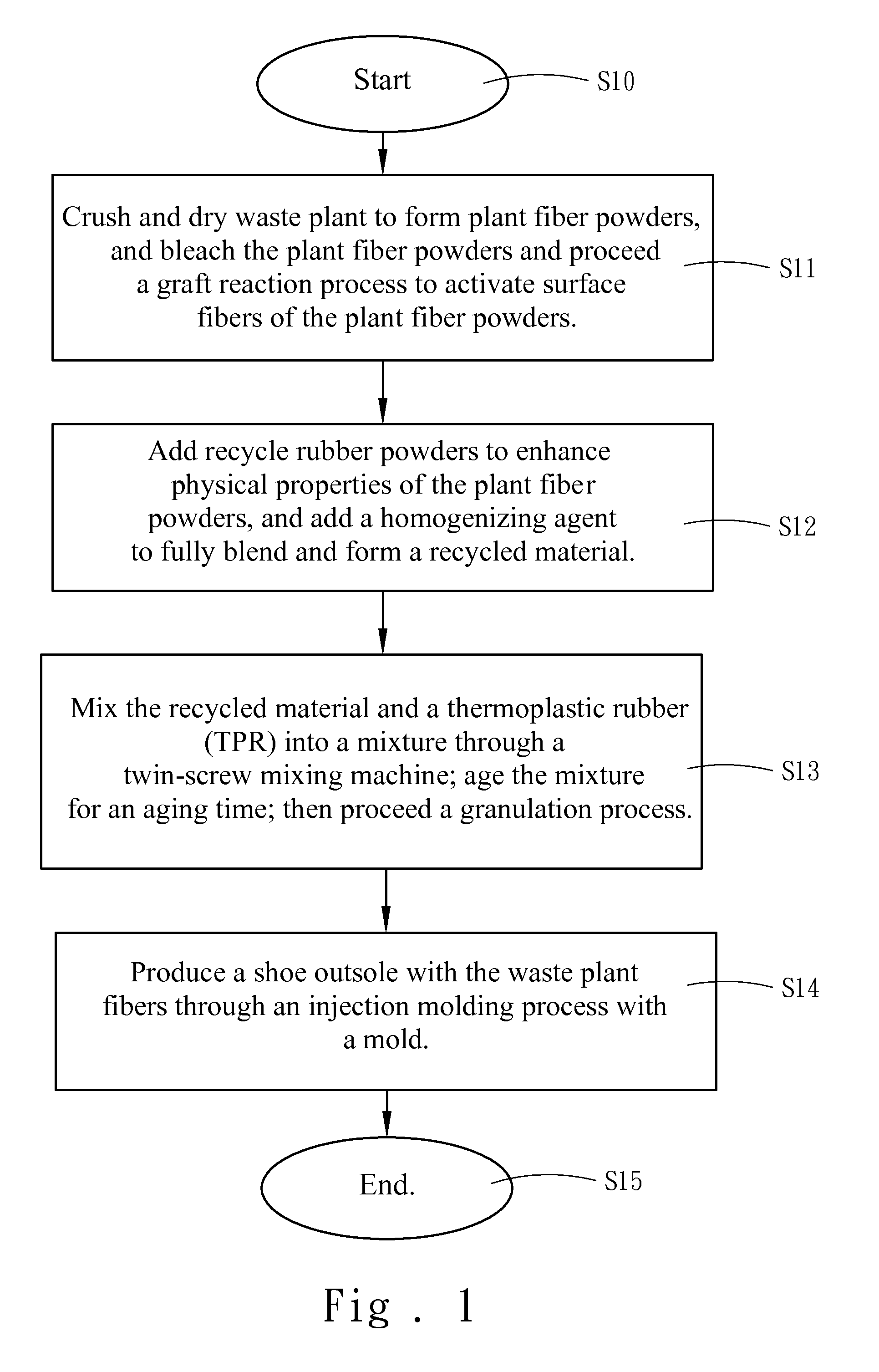

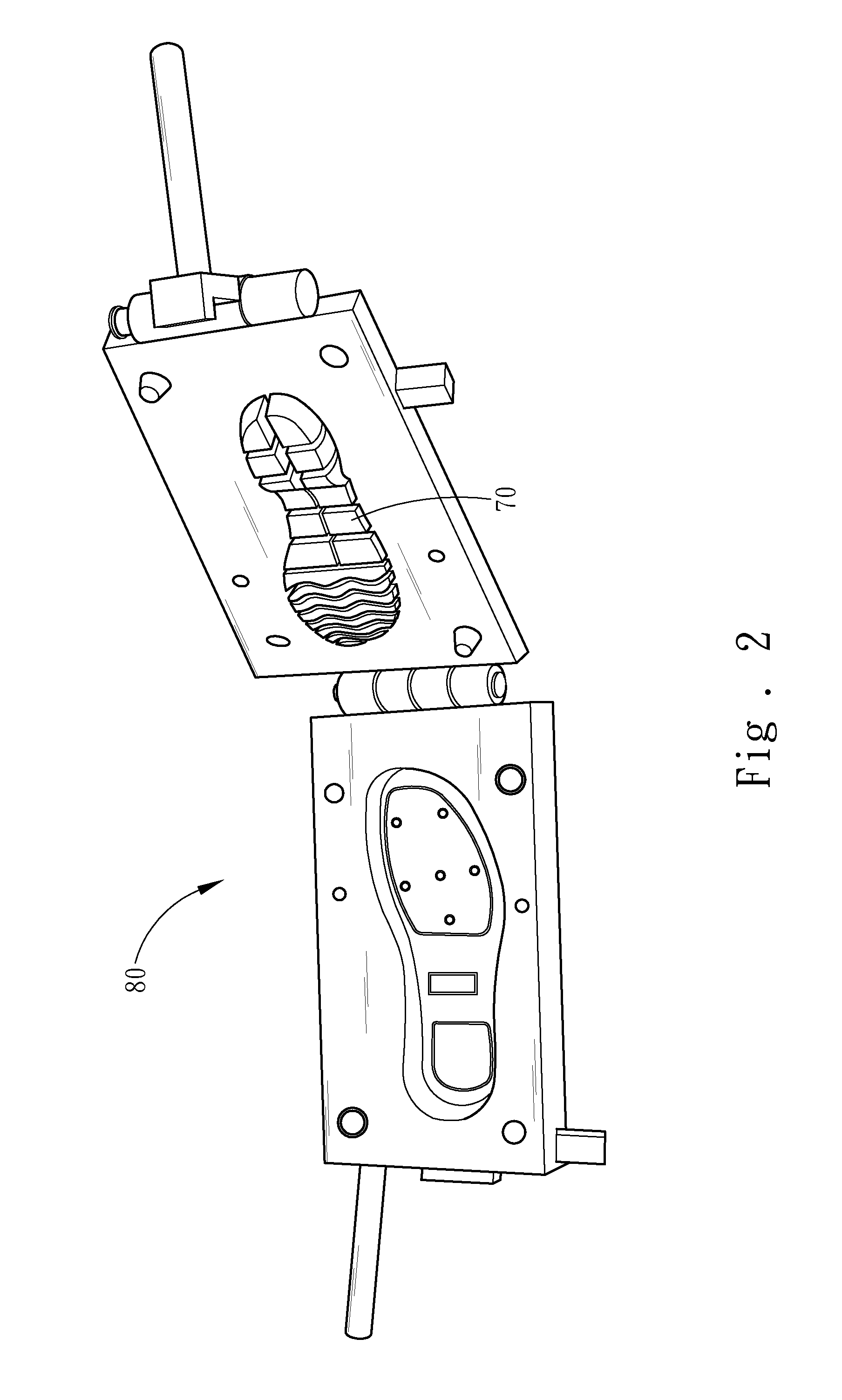

Method of manufacturing shoe outsoles from waste plant fibers

InactiveUS7785521B1Good physical propertiesUndesirable physical propertySolesPlastic recyclingGraft reactionPlant fibre

A method of manufacturing shoe outsoles from waste plant fibers includes steps of: bleaching plant fiber powders; activating the plant fiber powders through a graft reaction process; mixing the plant fiber powders and recycle rubber powders to enhance physical properties of the plant fiber powders; adding a homogenizing agent to fully blend the hydrophilic plant fiber powders and the lipophilic recycle rubber powders to form a recycled material; mixing the recycled material and thermoplastic rubber into a mixture; aging the mixture for an aging time; granulating the mixture; and producing a shoe outsole through an injection molding process. Thus a novel approach is provided to produce shoe products. Waste plants or rubber can be recycled to improve environmental conservation and protection.

Owner:CHEN SUNG HO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com