Biologic deodorization method and its device

A biological deodorization and microbial technology, applied in deodorization, separation methods, chemical instruments and methods, etc., can solve the problems of failing to meet the requirements of industrial practical application, high investment cost, low deodorization efficiency, etc., and the possibility of achieving it is low. , The effect of low equipment operating cost and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

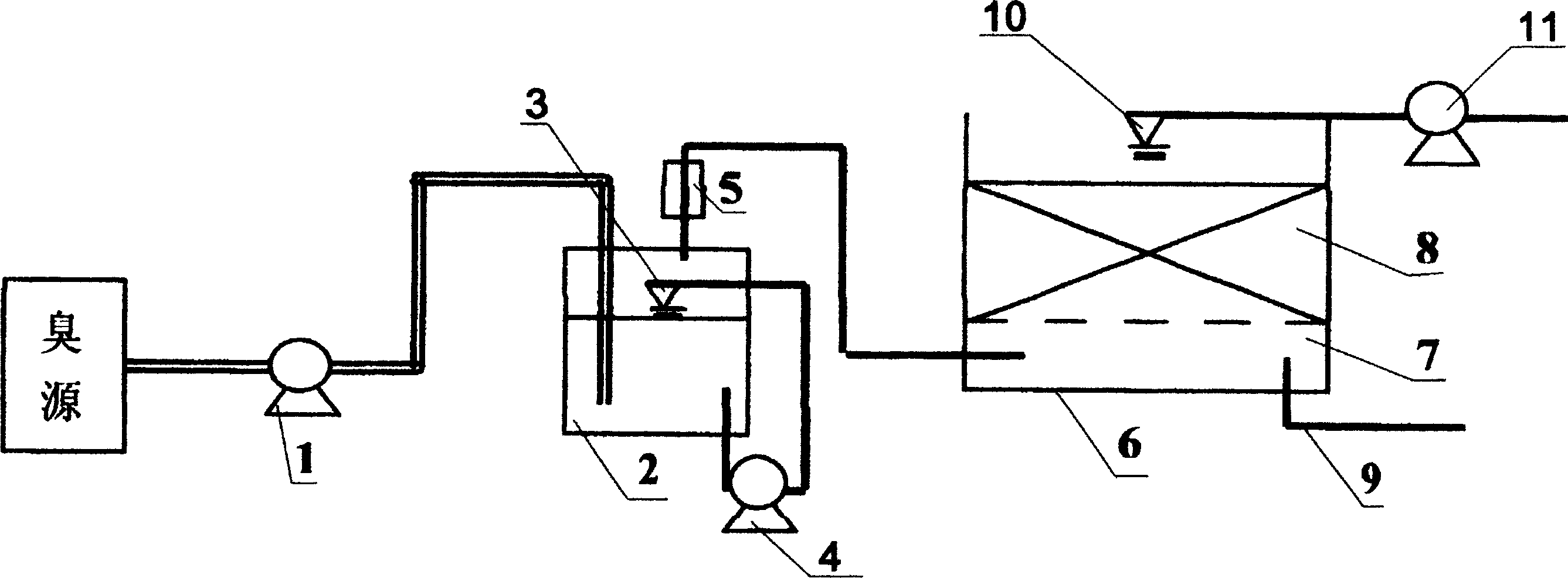

[0030] The structural details of the embodiment of the biological deodorization device are illustrated below by accompanying drawings. The device mainly includes a blower 1, a scrubber 2 and a biological filter tower 6. The malodorous gas in the odor source is blown into the scrubber 2 by the blower 1, and is washed The gas outlet of the gas pool 2 is connected to the air inlet at the bottom of the biological filter tower through a pipeline. The lower part of the biological filter tower 6 has a gas distributor 7, and the upper part of the gas distributor is filled with a biological filter material layer 8. The gas from the scrubber is passed through The gas distributor 7 flows into the biological filter material layer 8, is deodorized and purified after being contacted with the biological filter material and filtered, and then discharged from the top of the tower. The top of the tower is provided with a spraying device consisting of a spraying device nozzle 10 and a water pump ...

Embodiment 2

[0037] Inoculate yeasts with an inoculum of 1:10: Schizosaccharomyces pombe, Hansenula anomala, Candida utilis, Saceharomyces cerevisiae; Bacillus megaterium, Bacillus pumilus, Bacillus subtilis, and streptomyces microflavus were added to 500ml of liquid medium, shaken overnight and mixed thoroughly.

[0038] The filler ingredients are mixed according to the following ratio (volume ratio), coconut palm: straw mushroom mud: sawdust = 50:4:46

[0039] After inoculating the above culture solution, put it into the biofiltration tower.

[0040] at 20m 3 h -1 The gas flow is passed into the organic malodorous gas.

[0041] After passing through the scrubber, the odorous gas of garbage enters the biological filter tower from the bottom of the tower, and is purified by contacting with the biological filter material inoculated with microorganisms, and the purified gas is discharged from the top of the tower. Regularly spray tap water to the filter material to keep the water content...

Embodiment 3

[0044] Inoculate yeasts with an inoculum of 1:10: Schizosaccharomyces pombe, Hansenula anomala, Candida utilis, Saceharomyces cerevisiae; Bacillus megaterium, Bacillus pumilus, Bacillus subtilis, and streptomyces microflavus were added to 300ml of liquid culture medium, and mixed thoroughly after shaking the flask overnight.

[0045] The filler components are mixed in the following ratio (volume ratio), perlite: ceramsite = 30:70

[0046] After inoculating the above culture solution, put it into the filter tower.

[0047] at 20m 3 h -1 The gas flow rate is passed into the malodorous gas.

[0048] After passing through the scrubber, the odorous gas of garbage enters the biological filter tower from the bottom of the tower, and is purified by contacting with the biological filter material inoculated with microorganisms, and the purified gas is discharged from the top of the tower. Spray the microbial culture to the filter material regularly, keep the water content of the fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com