Patents

Literature

9617 results about "Filter material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

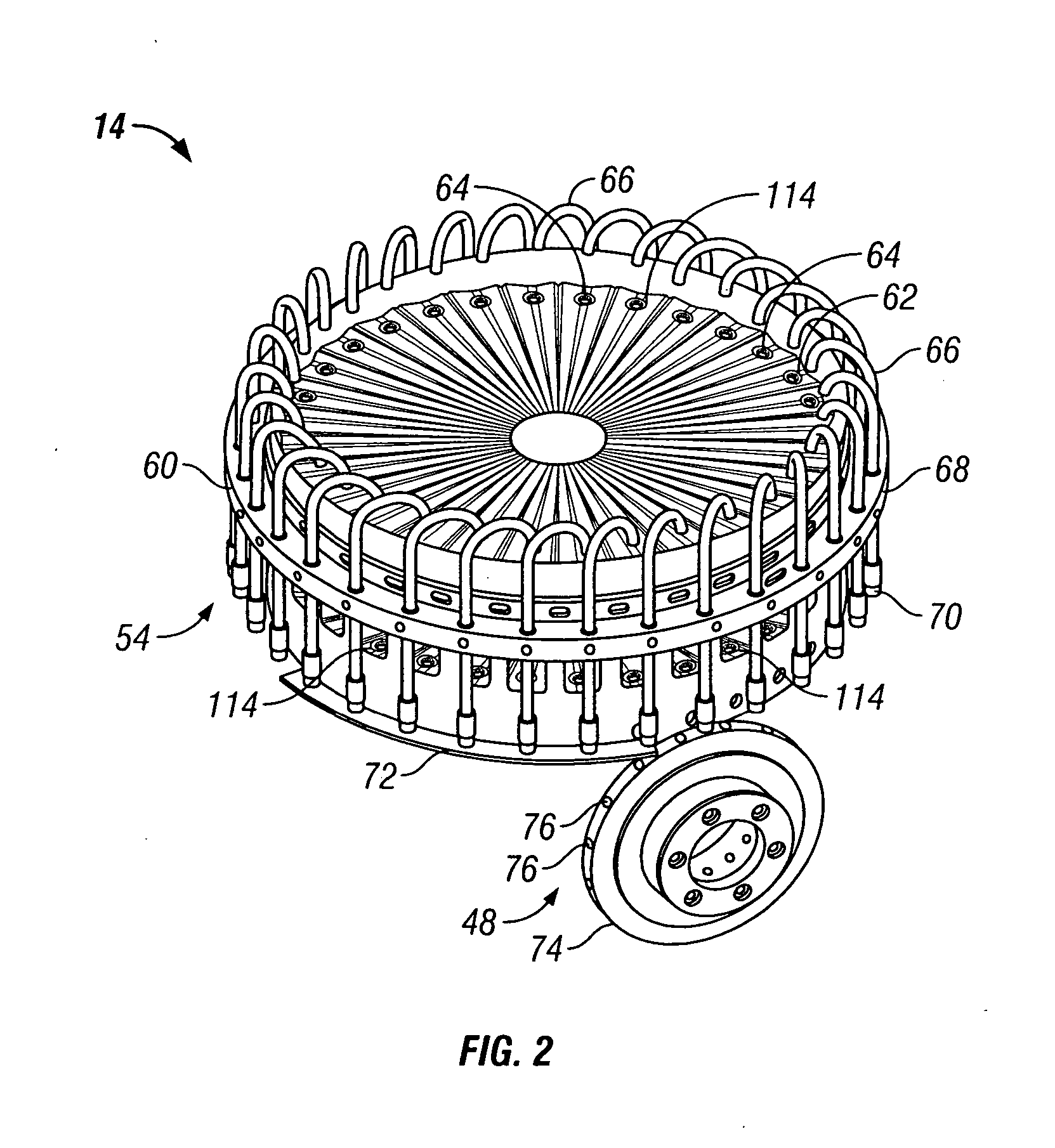

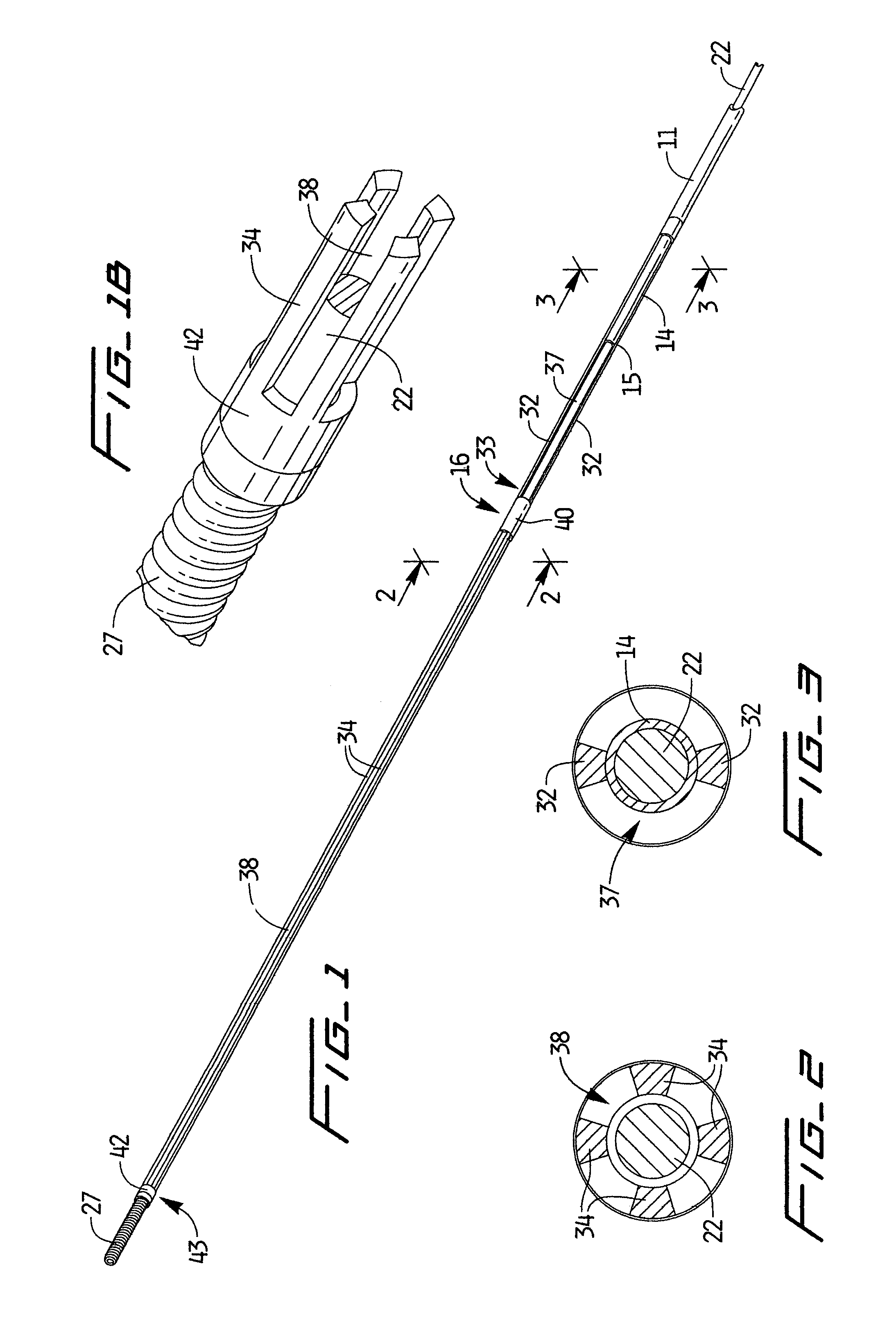

Filter for embolic material mounted on expandable frame

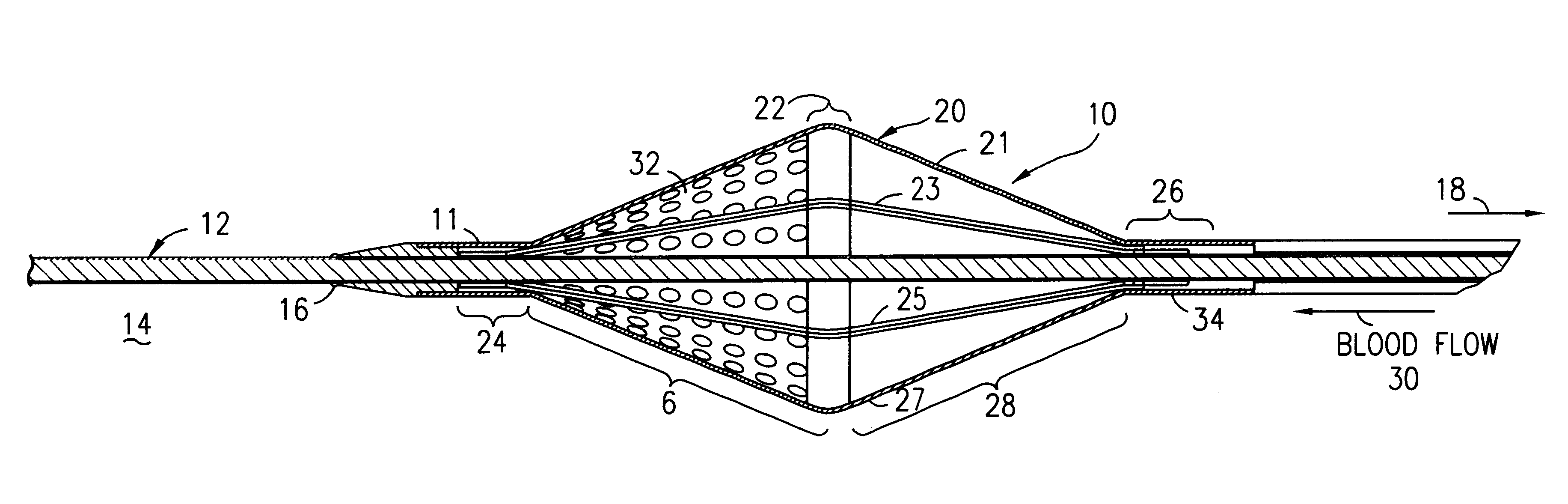

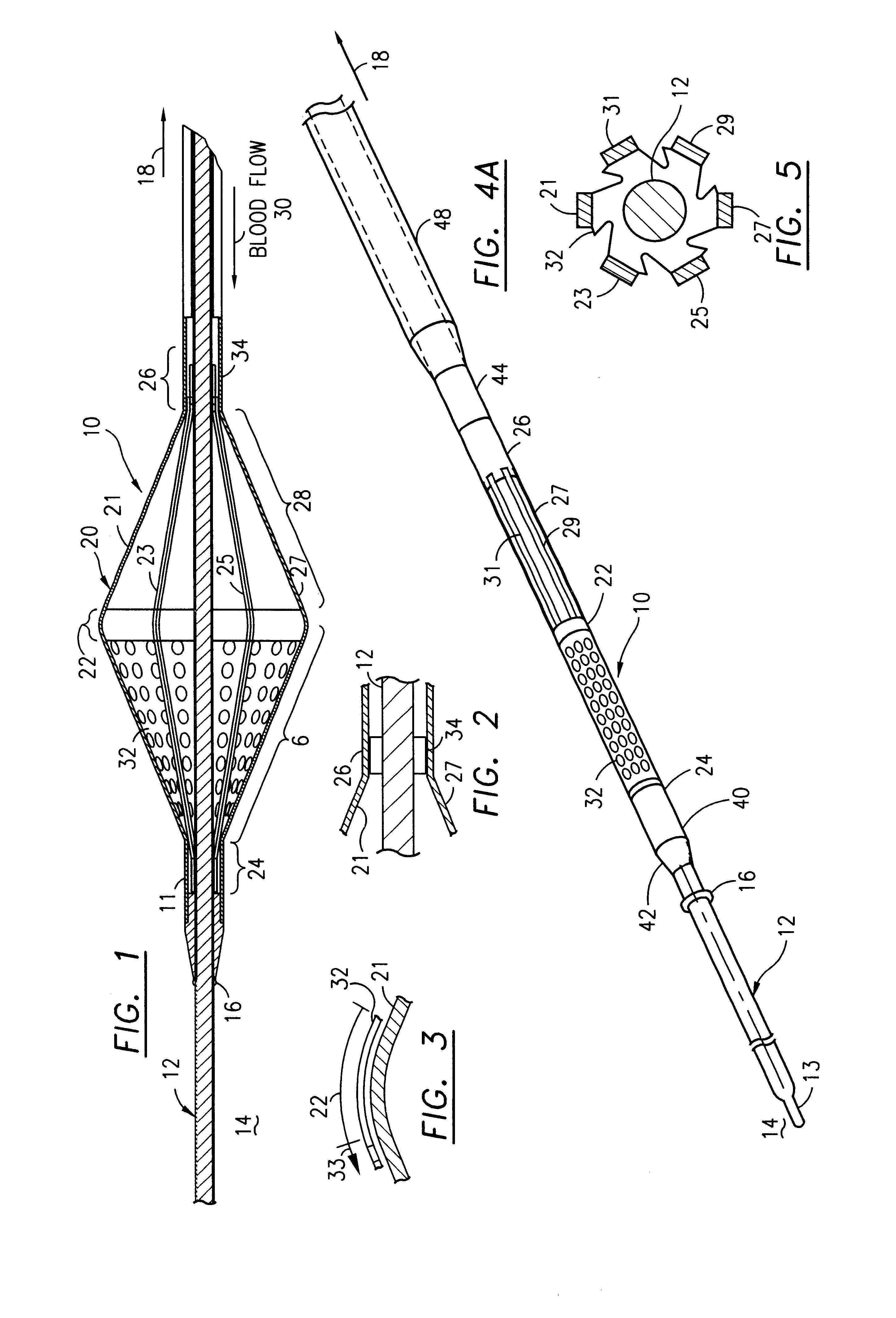

The filter device captures embolic material in a blood vessel and is placed in the blood vessel via a guide wire. The guide wire has a proximal end, a distal end and a stop near its distal end. The filter device includes an expandable frame of frame struts having a closed, radially compact form and an open, radially expanded form. The frame, in the radially expanded form, has frame struts forming a pair of facing frustoconical frame structures. Filter material is attached to one of the pair of frustoconical frame structures. In one embodiment, the filter material is a perforated membrane. The guide wire extends through the expandable frame and the expandable frame is freely movable over the guide wire (likewise, the guide wire is freely movable within the frame), both rotatably and longitudinally, except distally beyond the stop near the distal end of the guide wire. This mobility of the guide wire with respect to the expandable frame enables to guide wire to be guided by the operator through the blood vessel.

Owner:SCION CARDIO VASCULAR

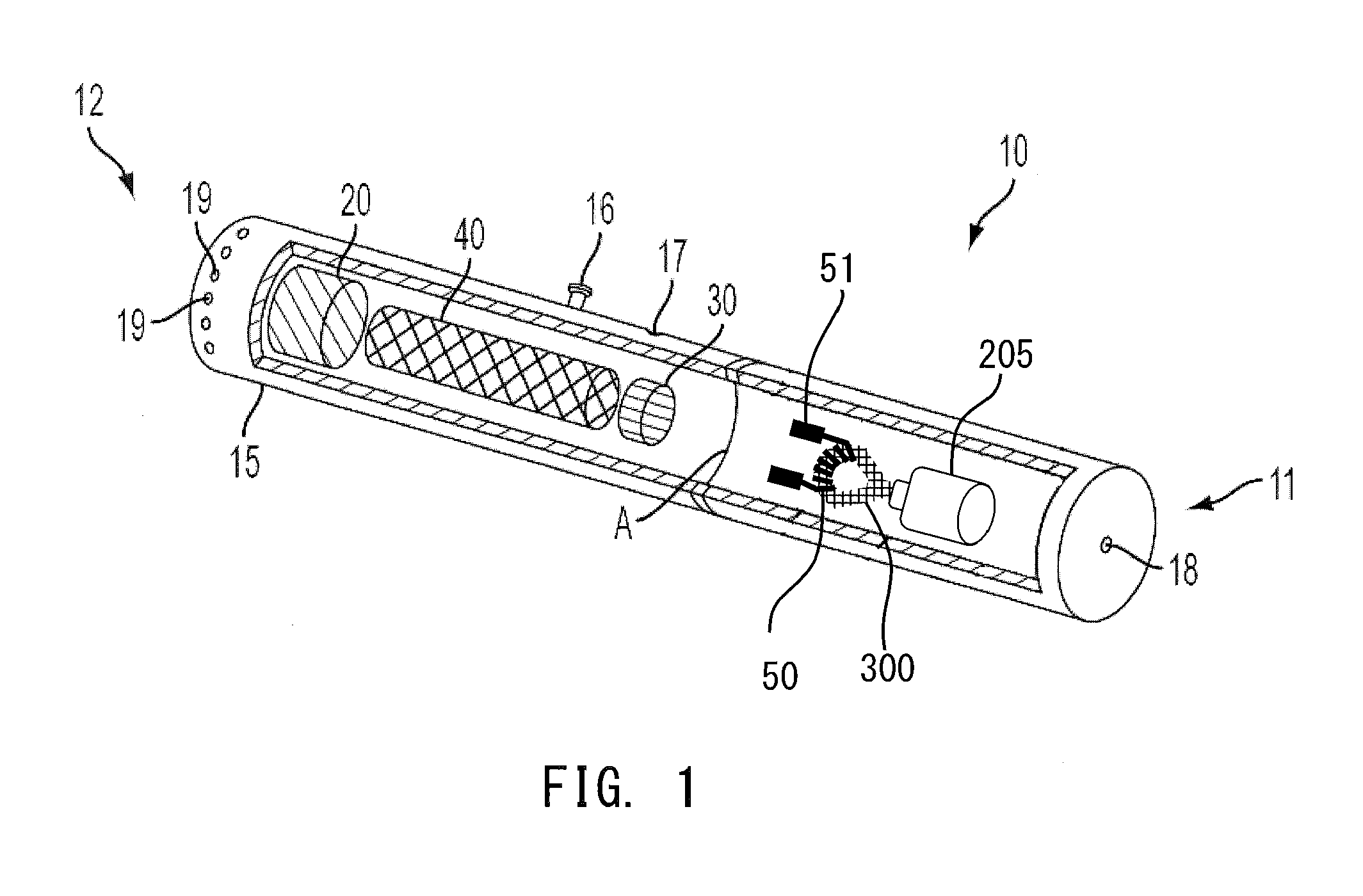

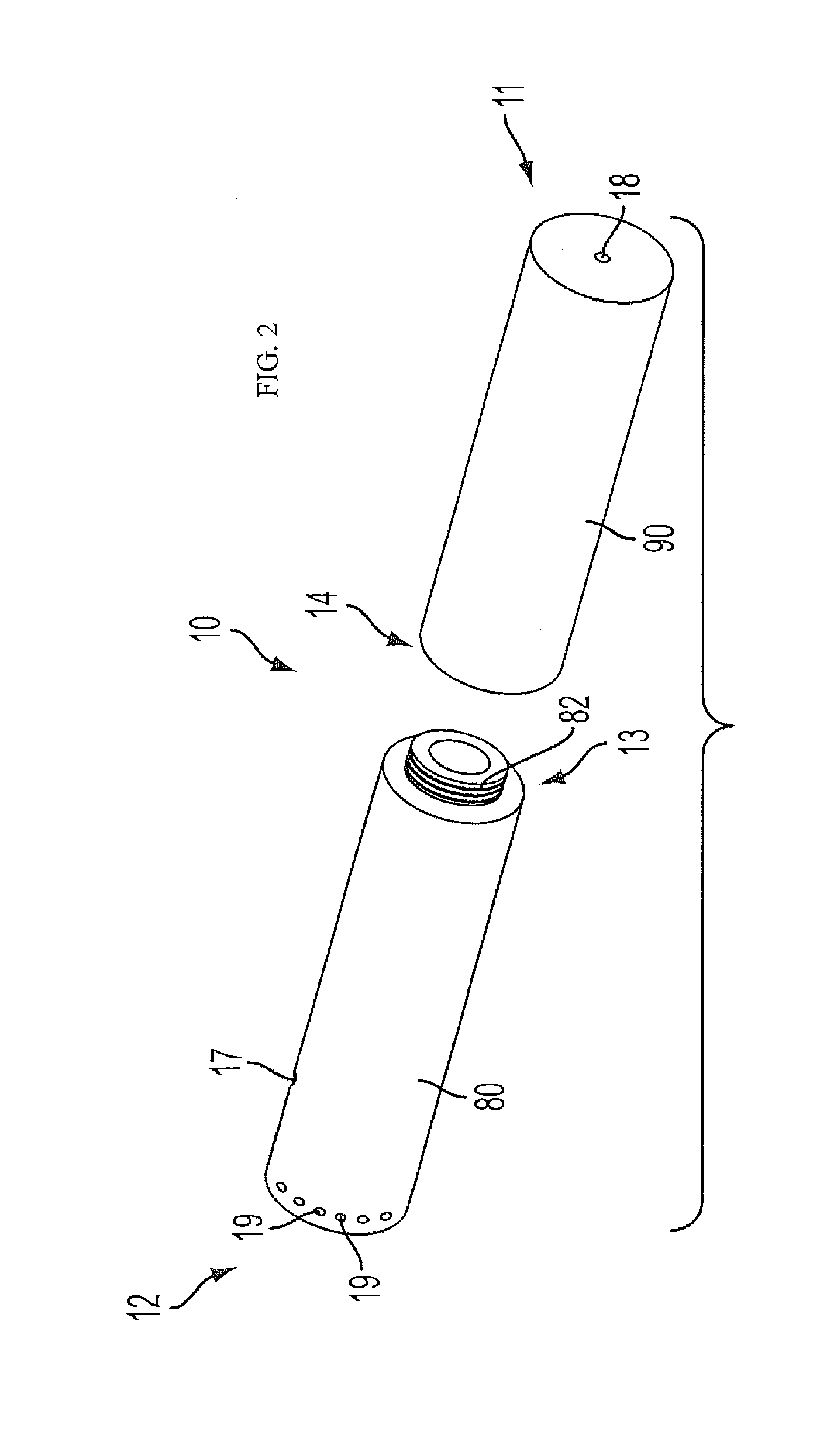

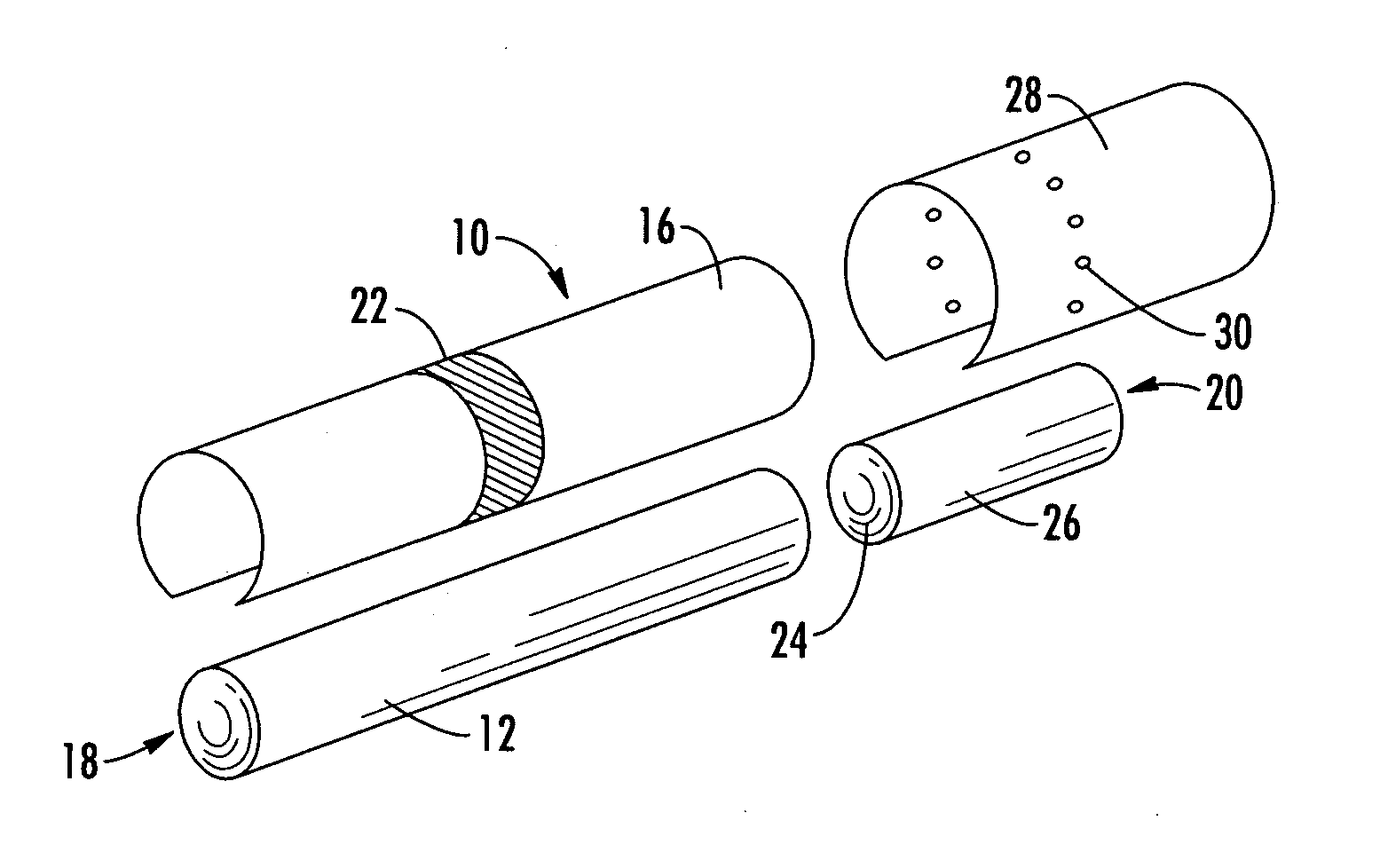

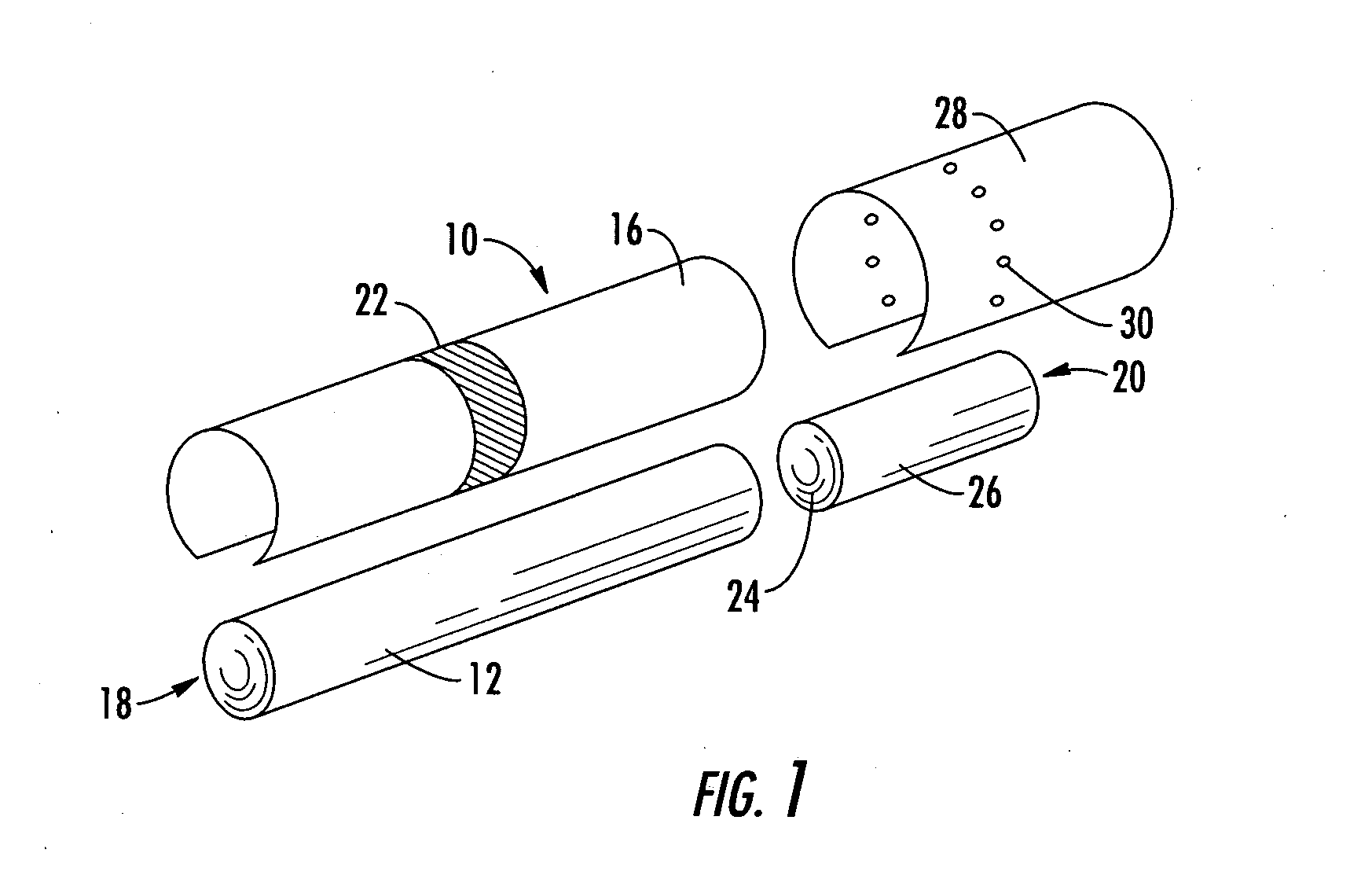

Electronic smoking article having a vapor-enhancing apparatus and associated method

A vapor-enhancing apparatus is provided for an electronic vapor smoking article. Such an apparatus includes a filter material and a tubular housing defining a lumen. The lumen has a mouth-engaging end and a longitudinally-opposed component-engaging end, and is configured to receive the filter material therein. The component-engaging end is adapted to operably engage a control body portion associated with the electronic vapor smoking article and to receive a vapor therethrough. A vapor-enhancing element is operably engaged with the filter material and is configured to enhance the vapor drawn through the filter material within the lumen, and through the mouth-engaging end, by application of suction to the mouth-engaging end of the housing. An associated method is also provided.

Owner:RAI STRATEGIC HLDG INC

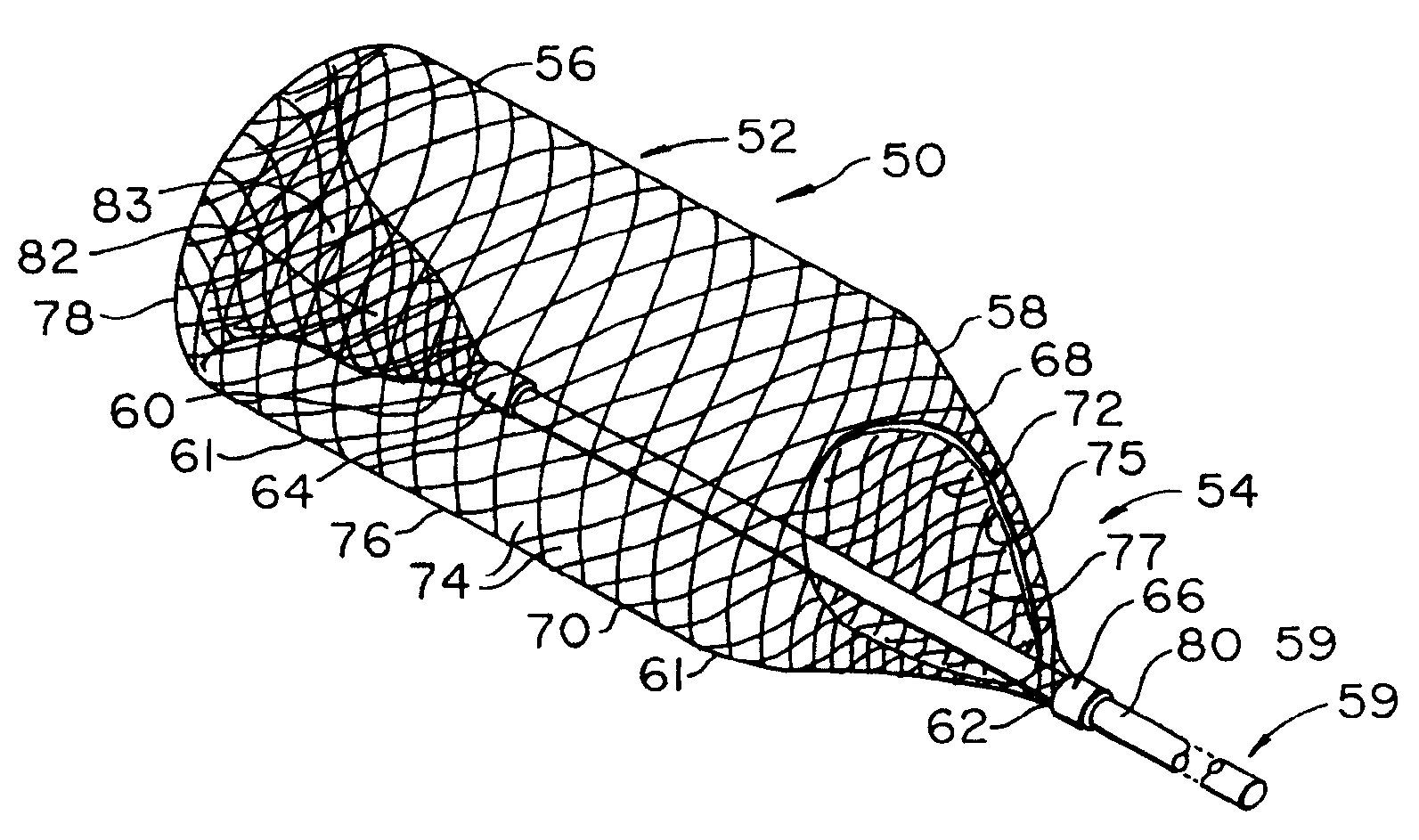

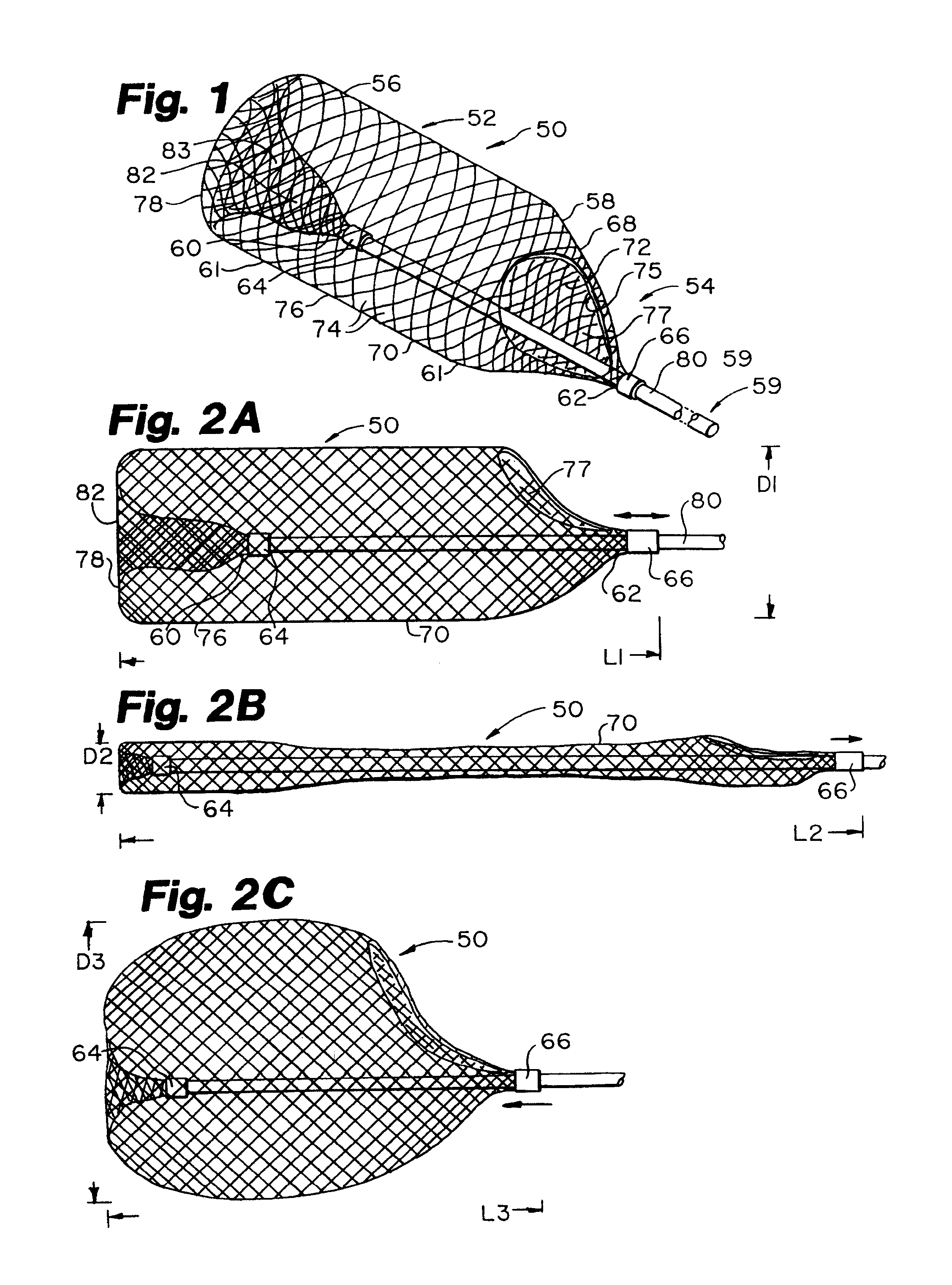

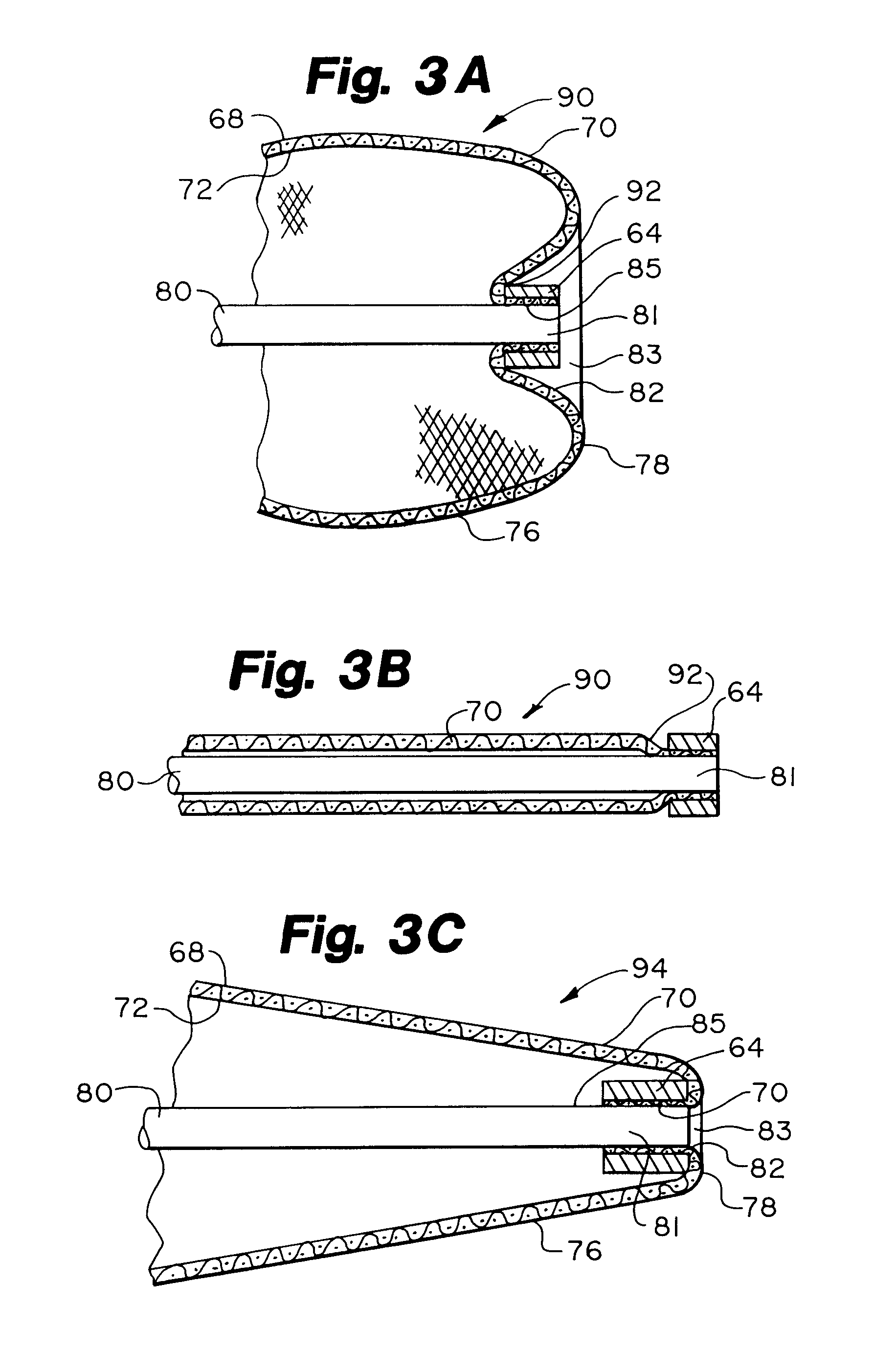

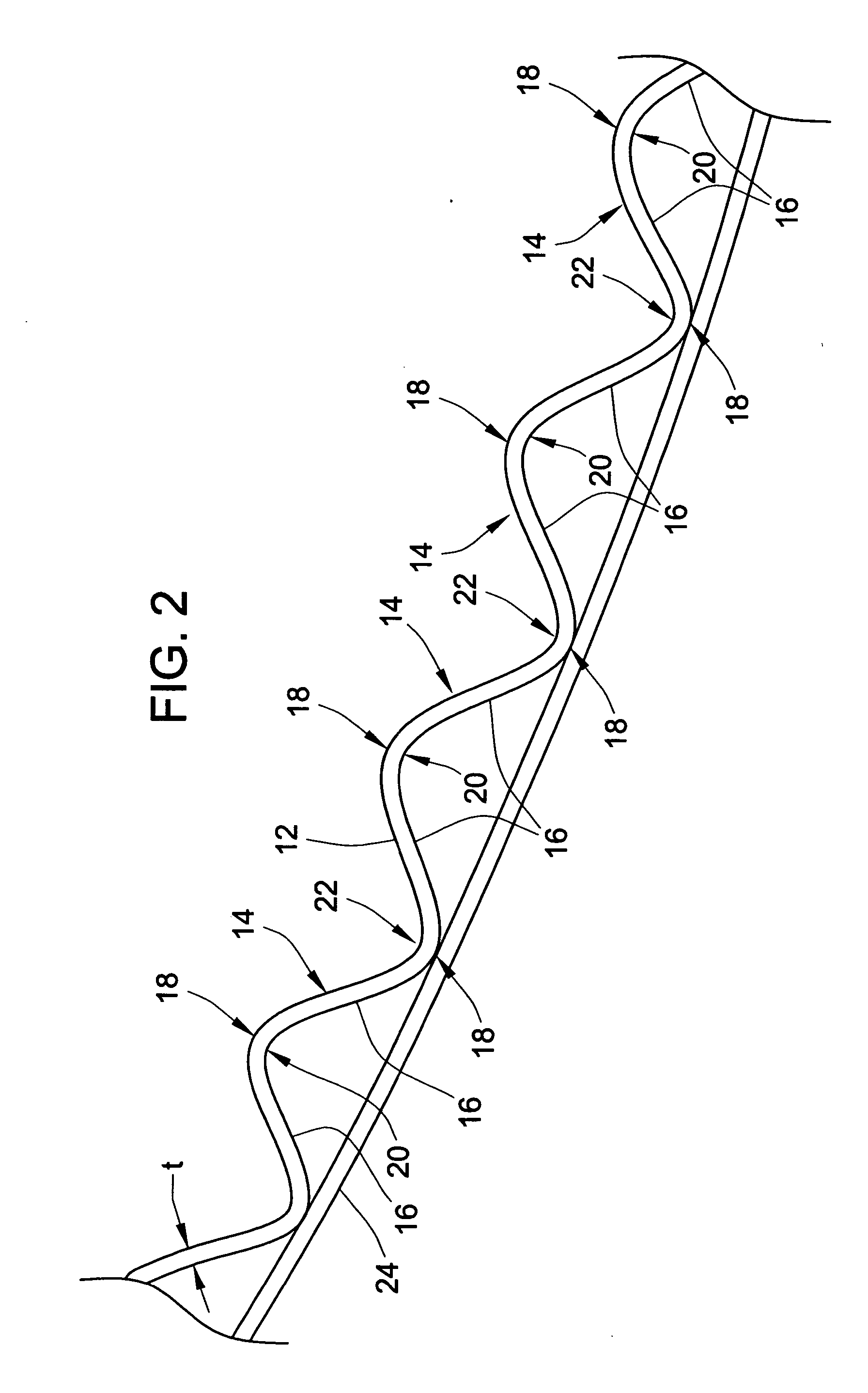

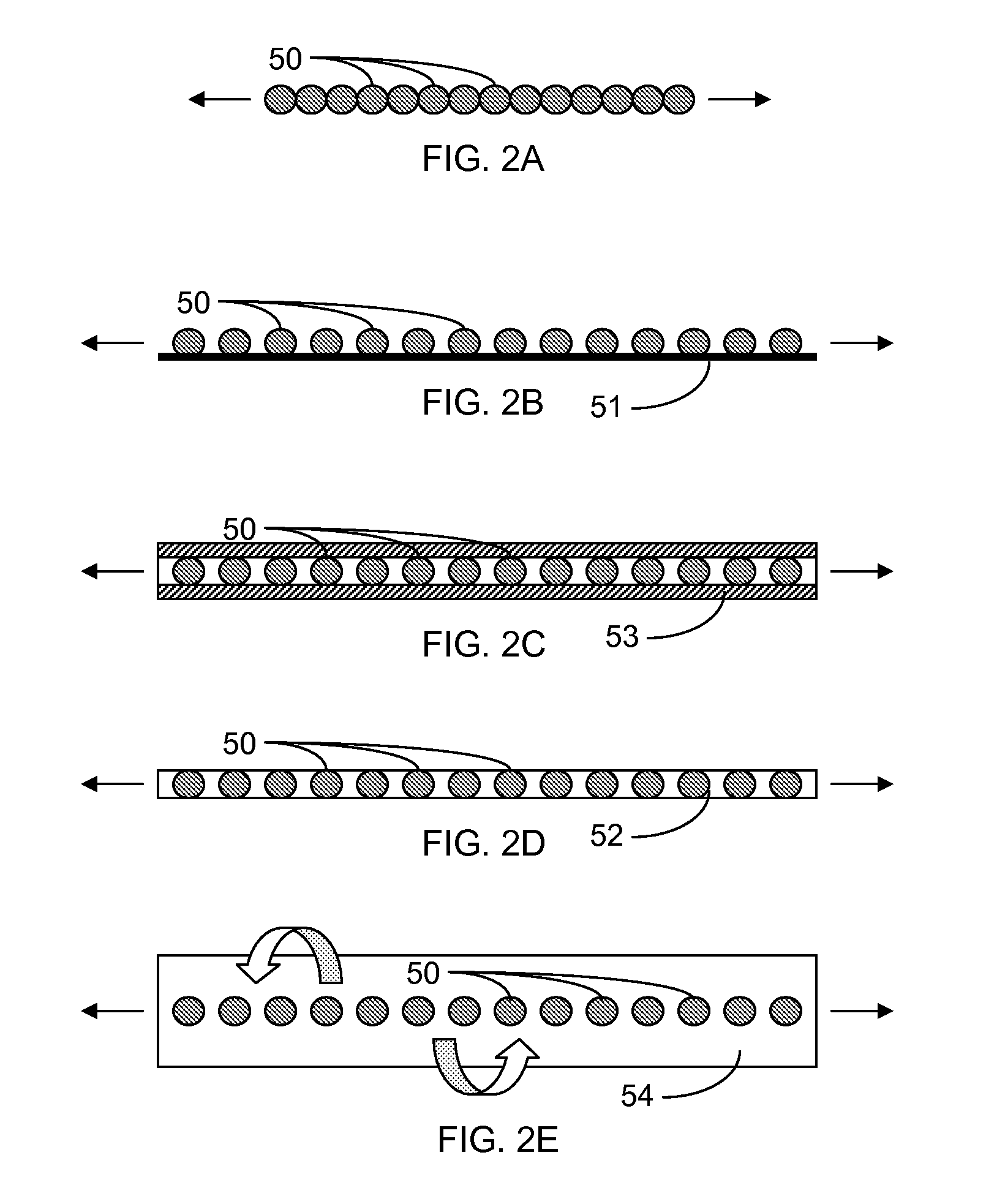

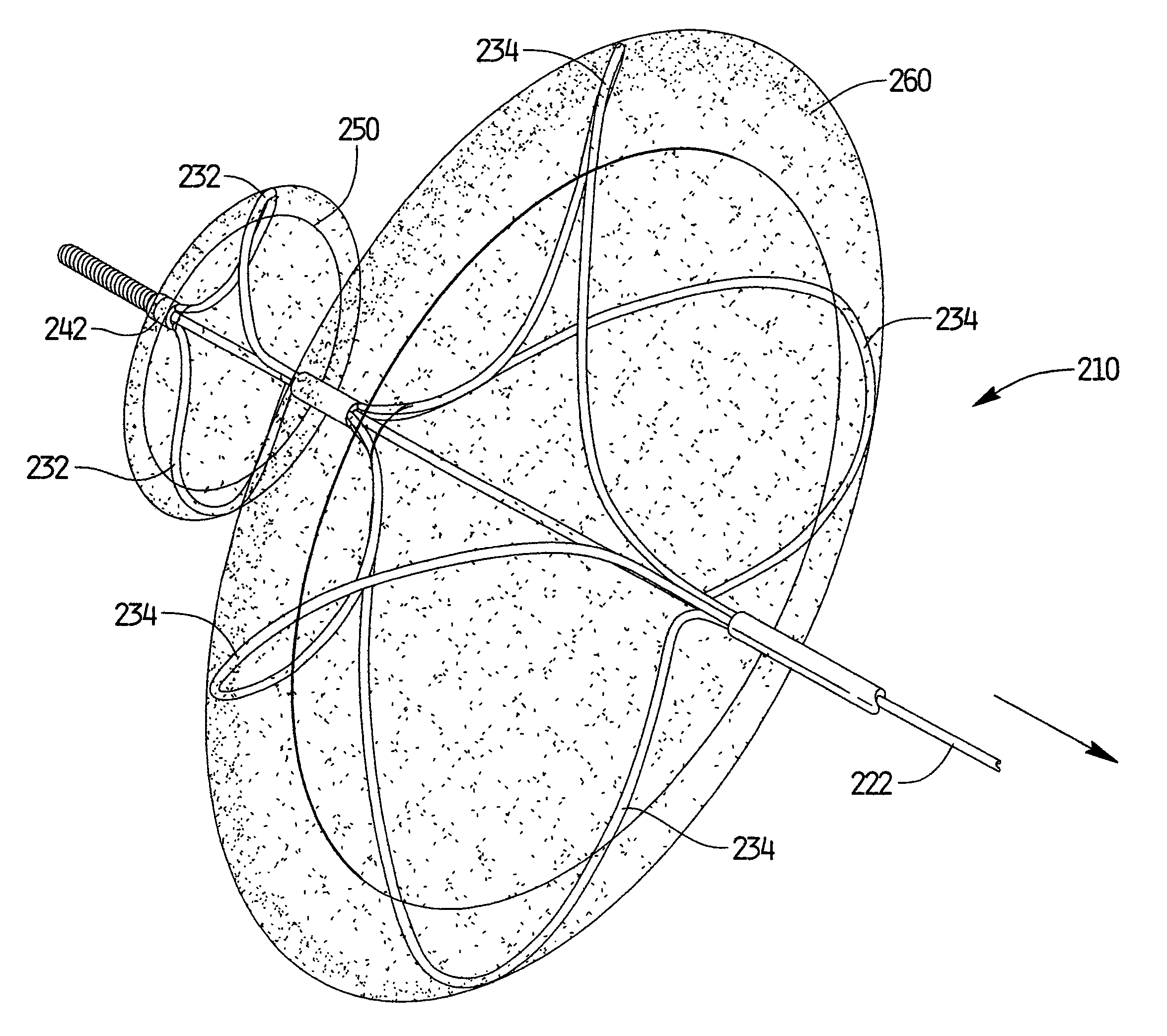

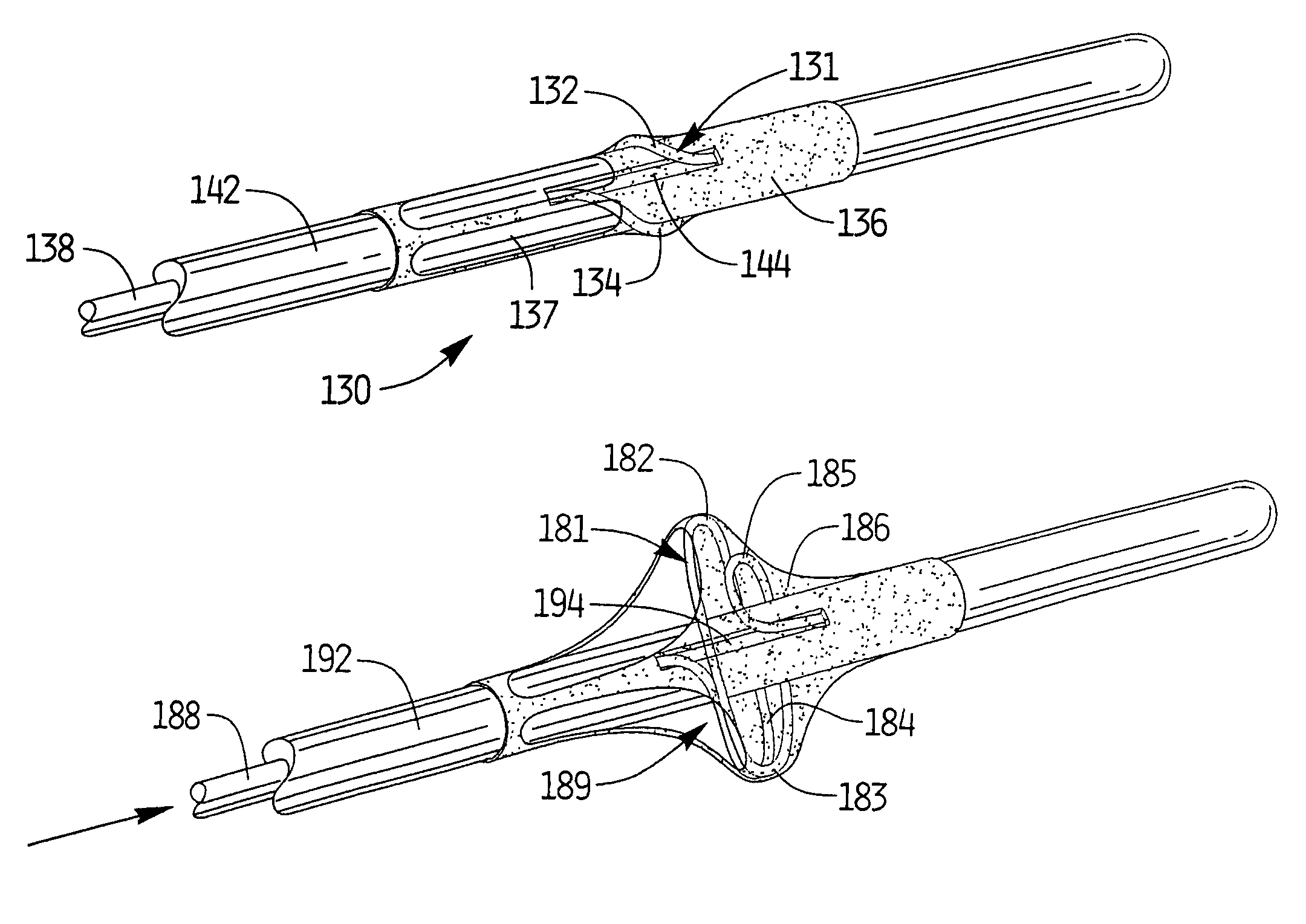

Everted filter device

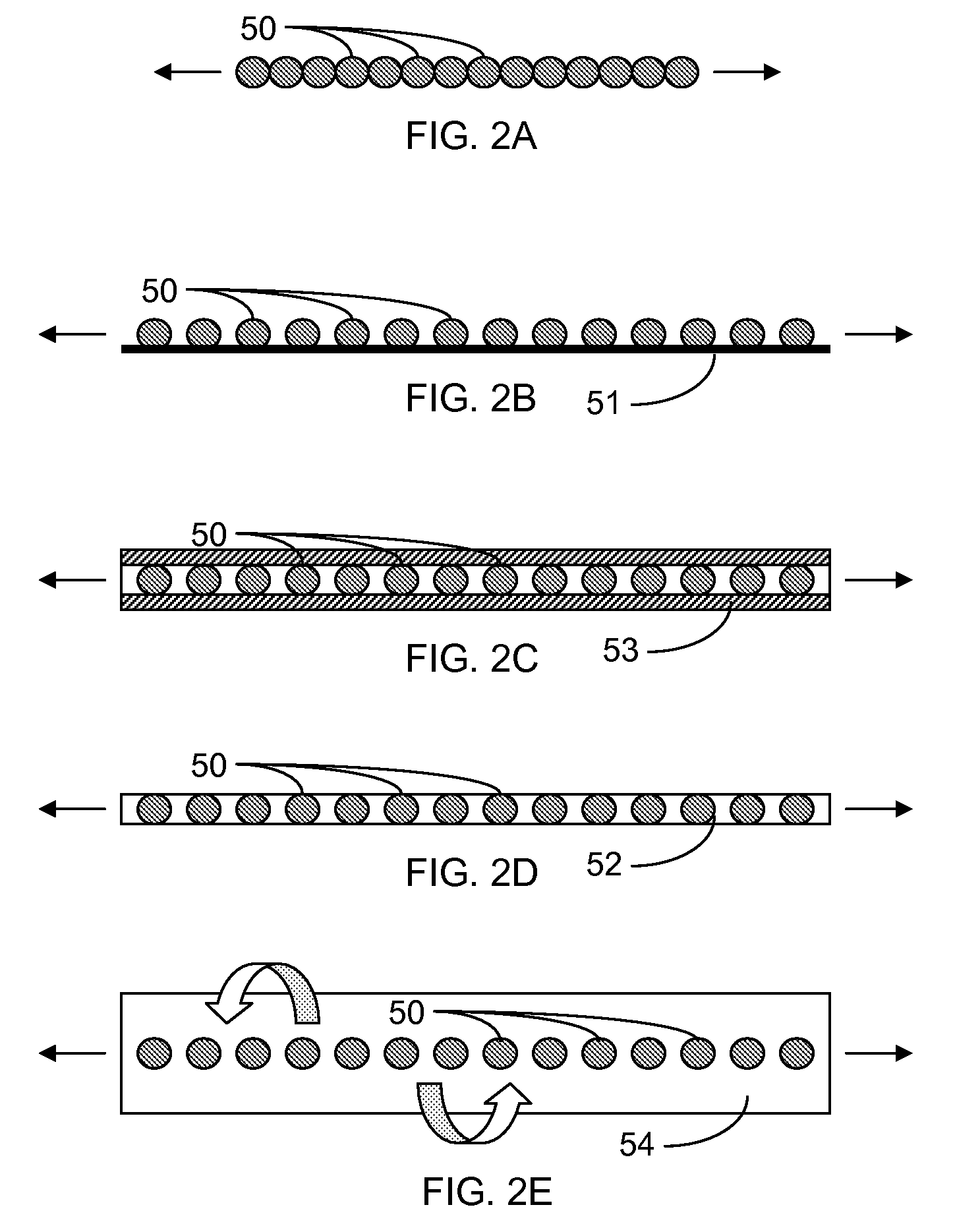

ActiveUS20050283186A1Effective coverageProvide protectionBronchoscopesLaryngoscopesVascular filterThrombus

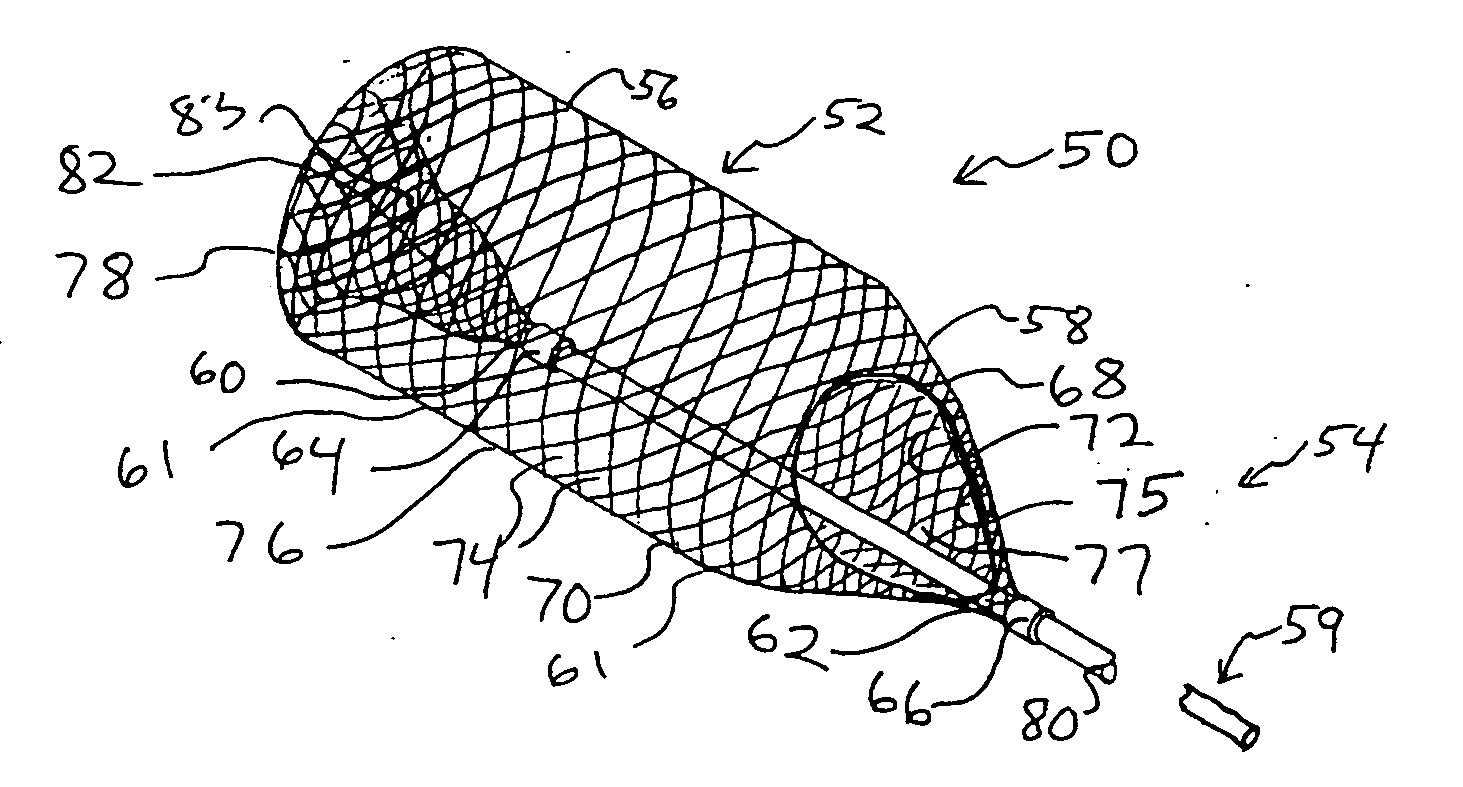

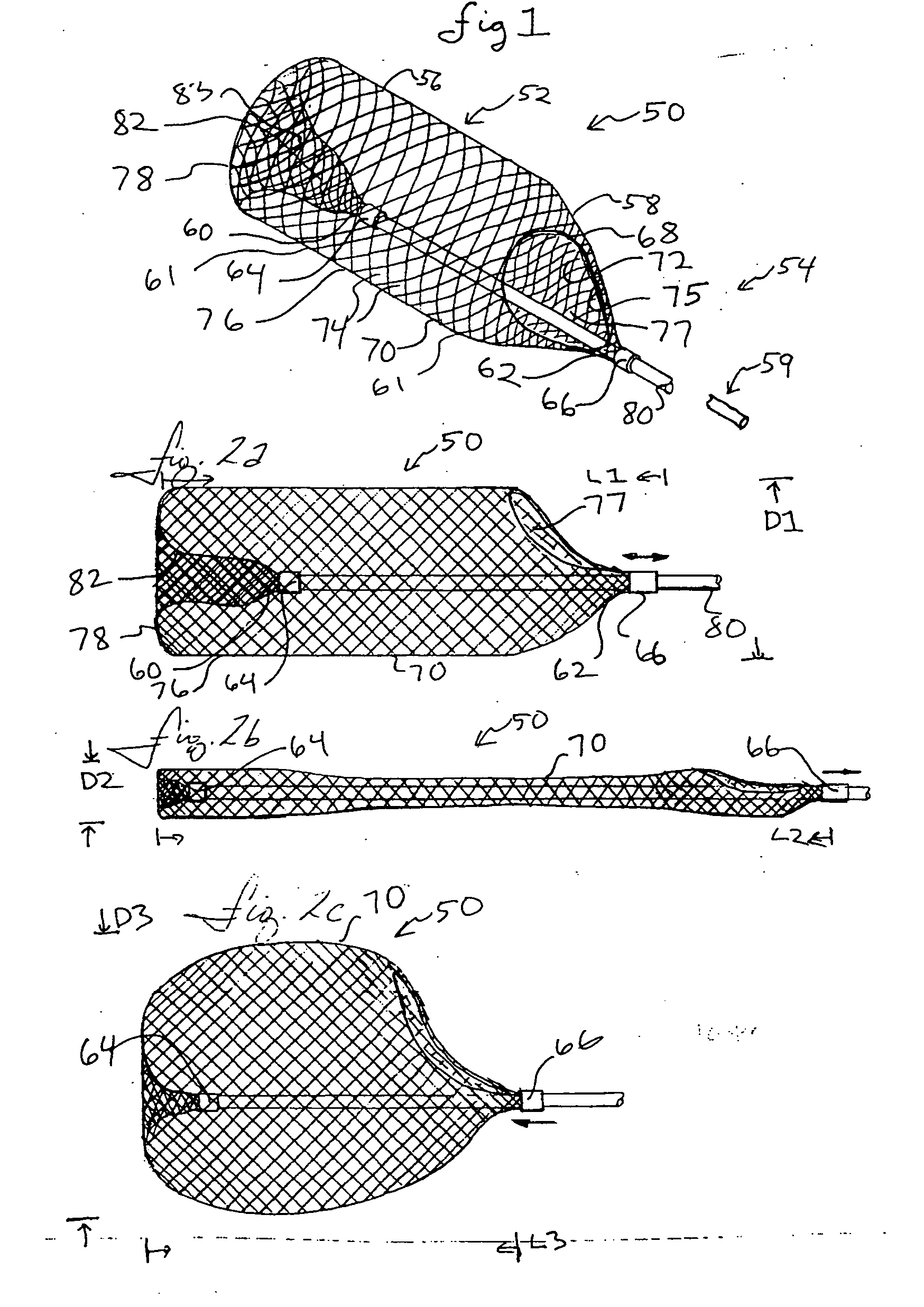

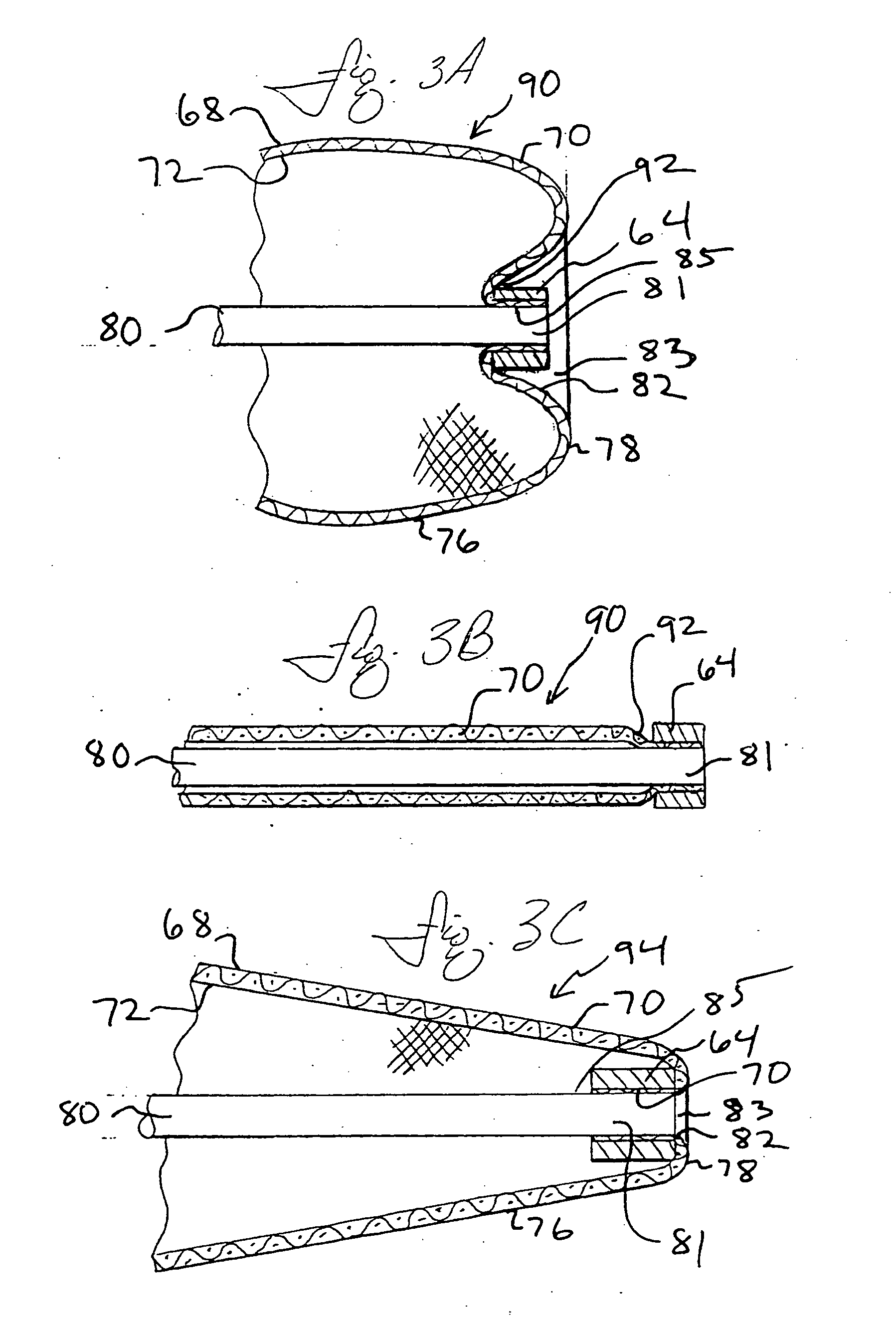

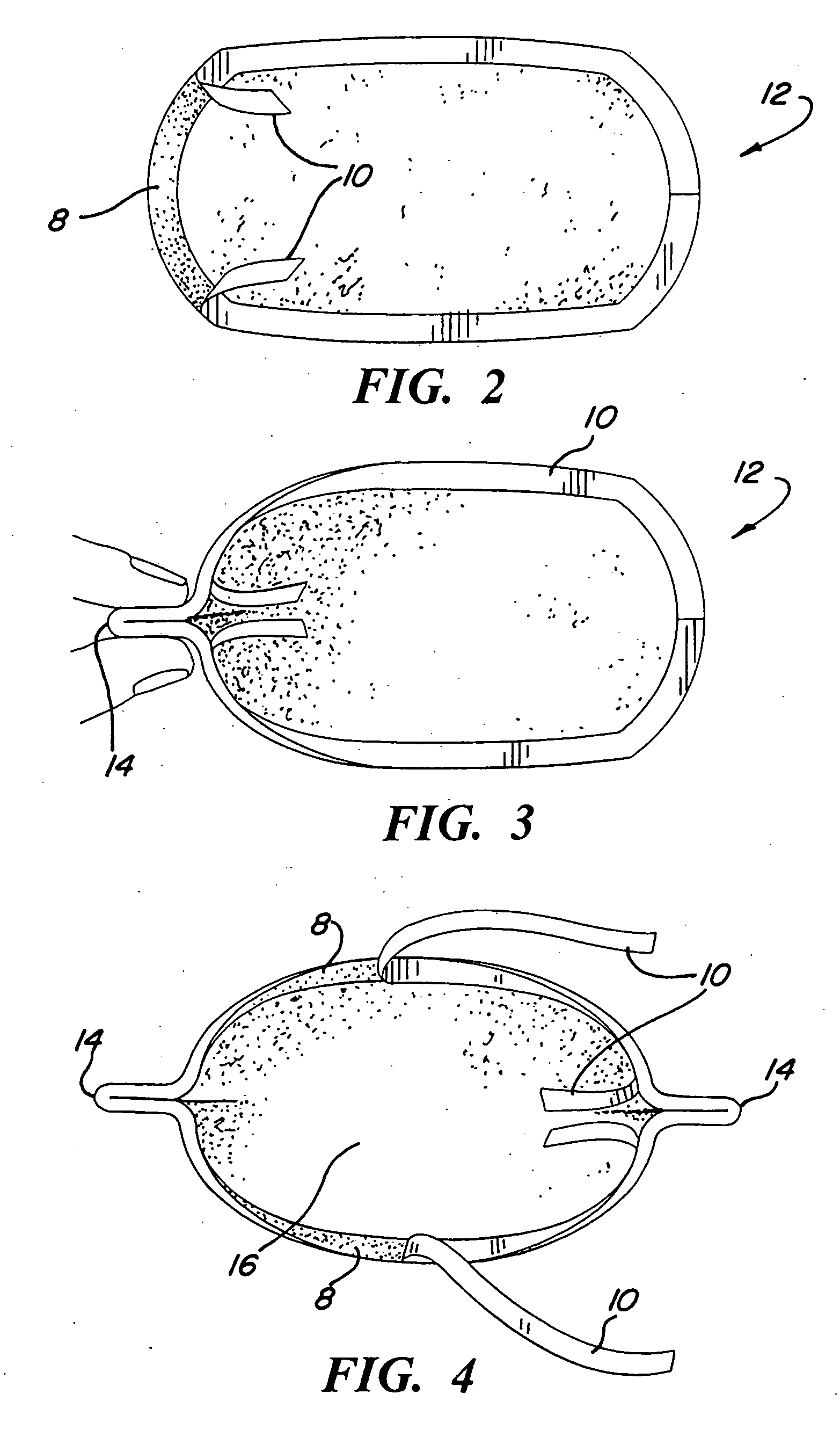

Everting filter devices and methods for using the devices, including using the devices as intra-vascular filters to filter thrombus, emboli, and plaque fragments from blood vessels. The filter devices include a filter body nominally tubular in shape and having a large proximal opening. The filter body can extend from a proximal first end region distally over the non-everted exterior surface of the filter, further extending distally to a distal-most region, then converging inwardly and extending proximally toward the filter second end region, forming a distal everted cavity. The degree of eversion of the filter can be controlled by varying the distance between the filter first end region near the proximal opening and the closed second end region. Bringing the filter first and second end regions closer together can bring filter material previously on the non-everted filter exterior to occupy the distal-most region. The everting process can also bring filter material previously in the distal-most position further into the distal everted cavity. The filter devices can be used to remove filtrate from body vessels, with the filtrate eventually occluding the distal-most region. The filter can then be further everted, bringing fresh, unoccluded filter material into place to provide additional filter capacity. Some everting filters have the capability of switching between occluding and filtering modes of operation, thereby allowing a treating physician to postpone the decision to use filtering or occluding devices until well after insertion of the device into the patient's body.

Owner:TYCO HEALTHCARE GRP LP

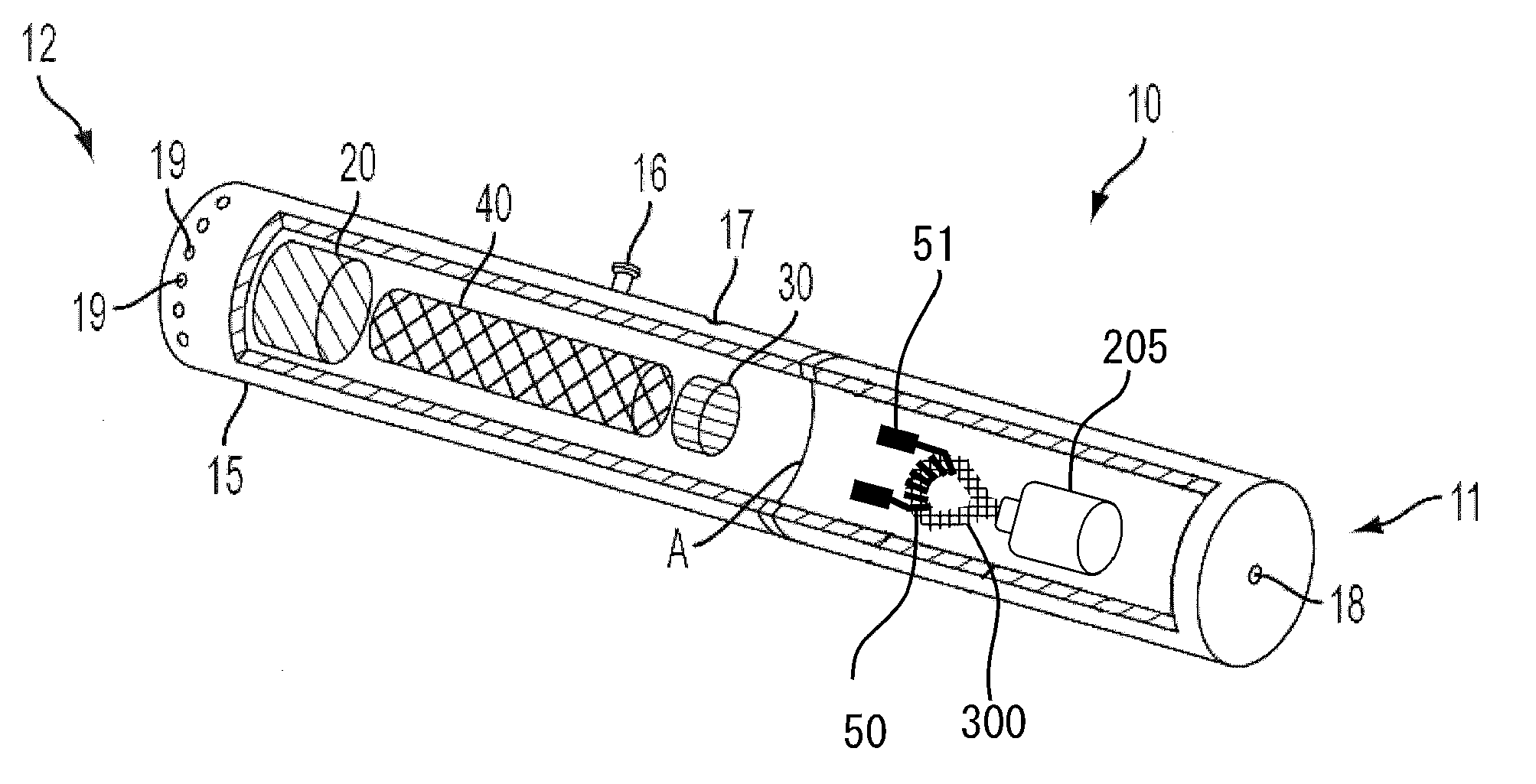

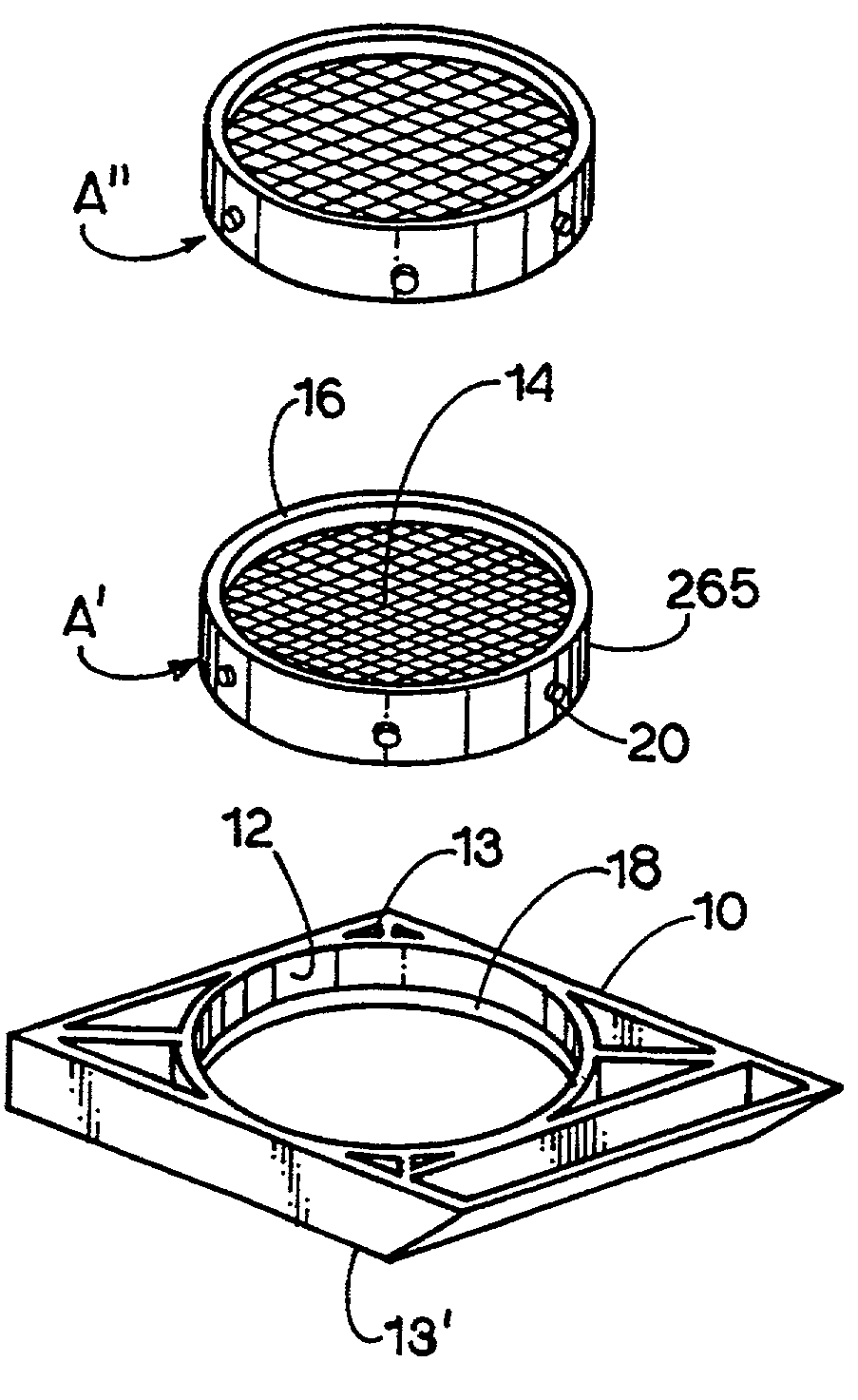

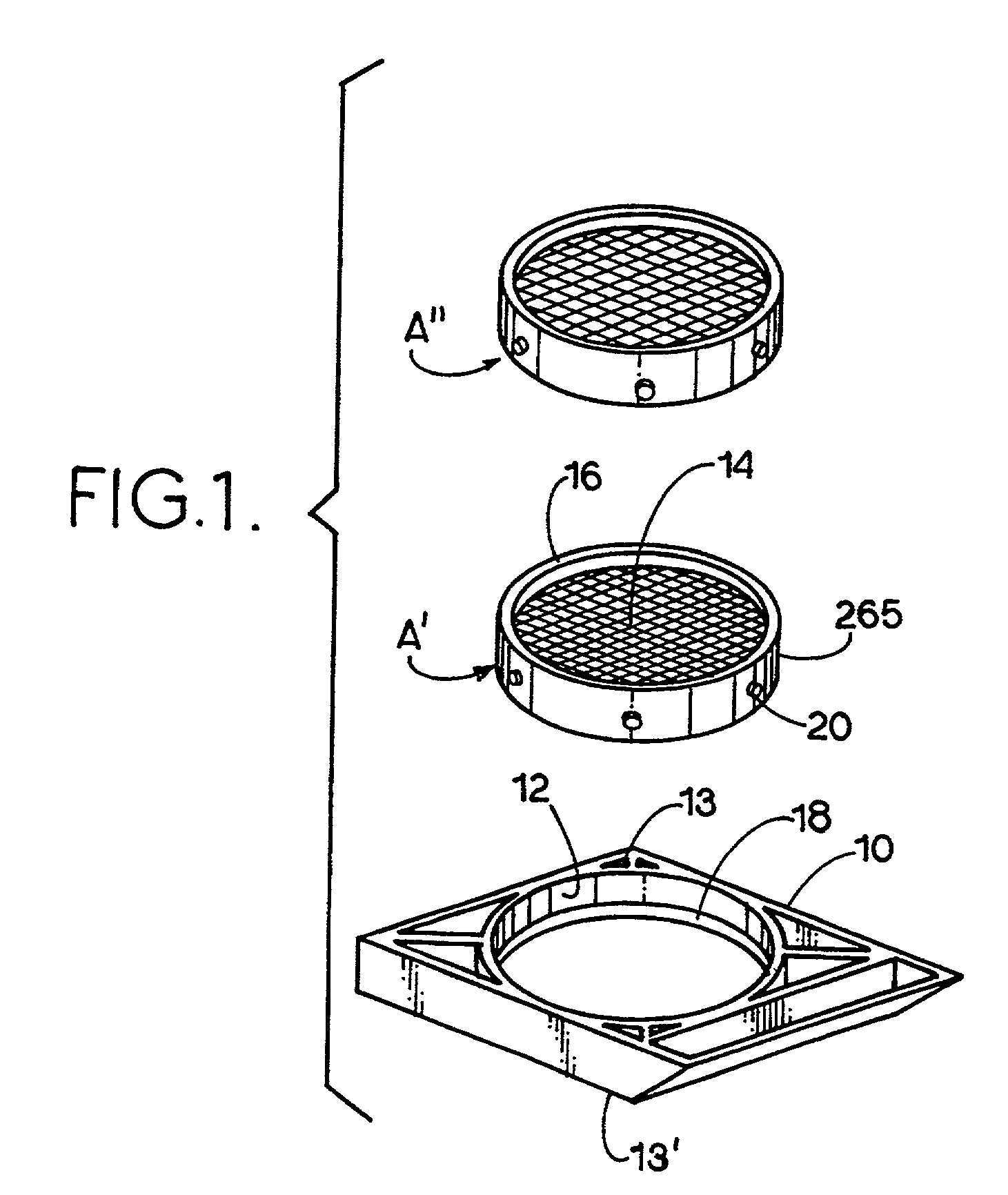

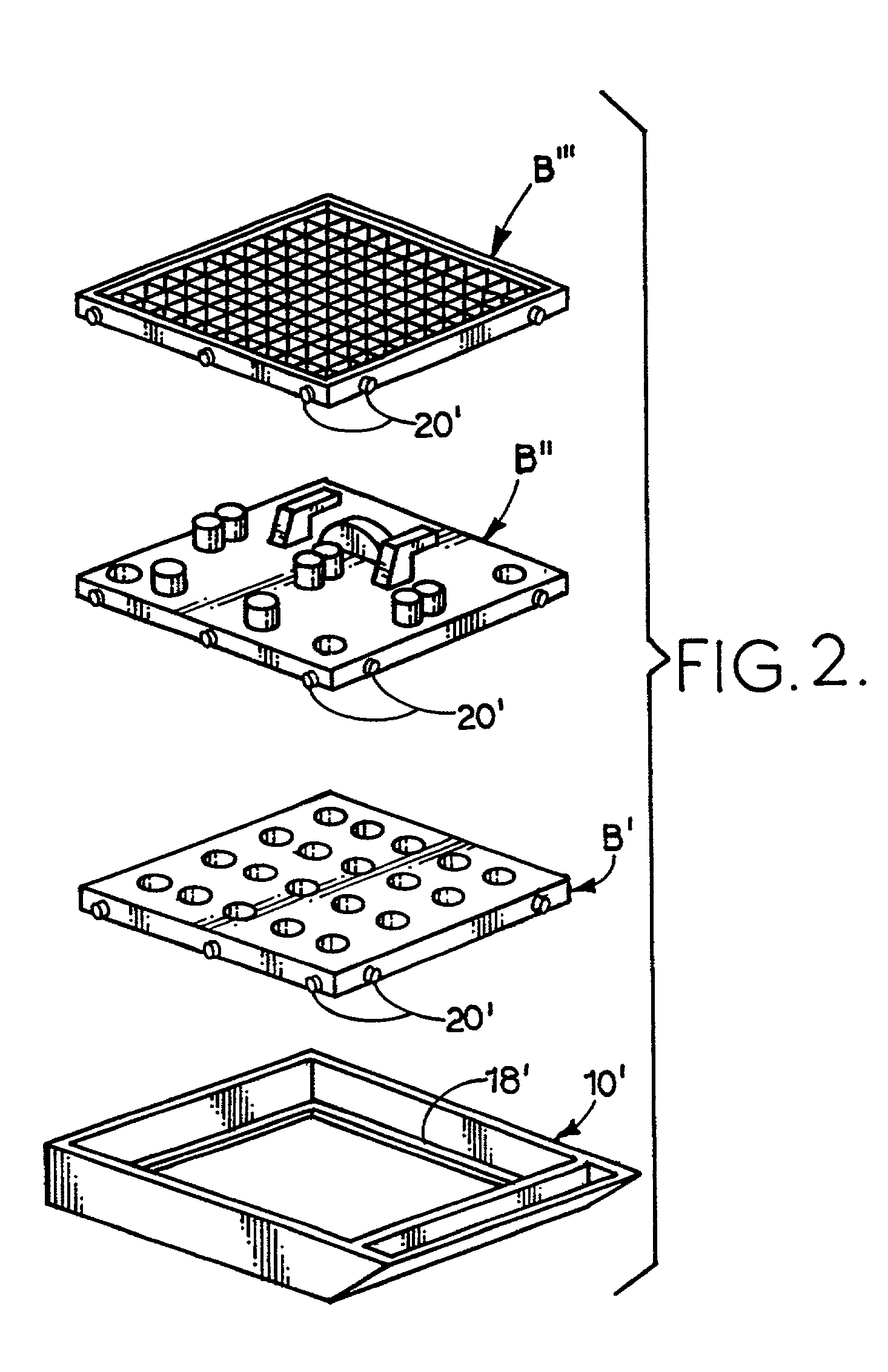

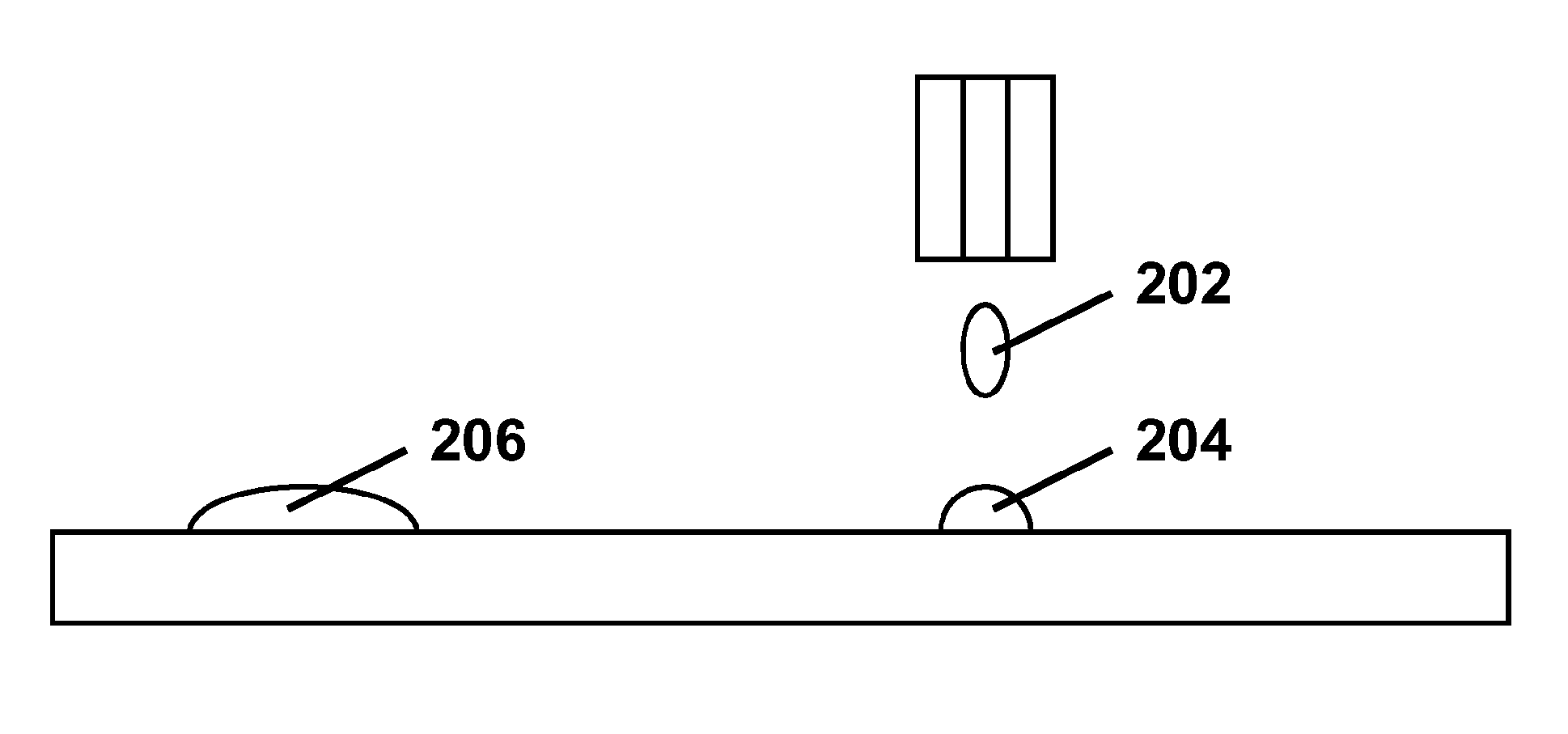

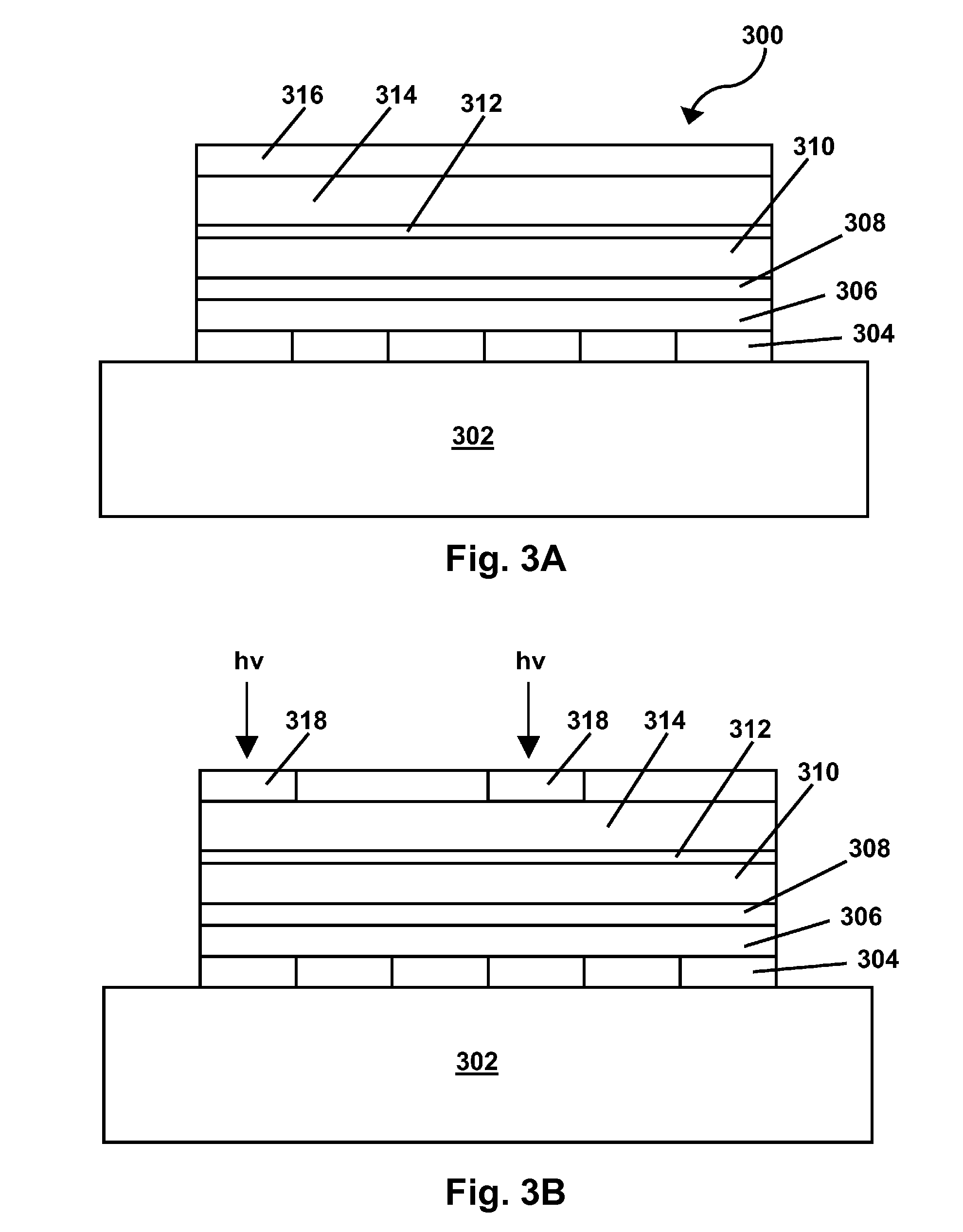

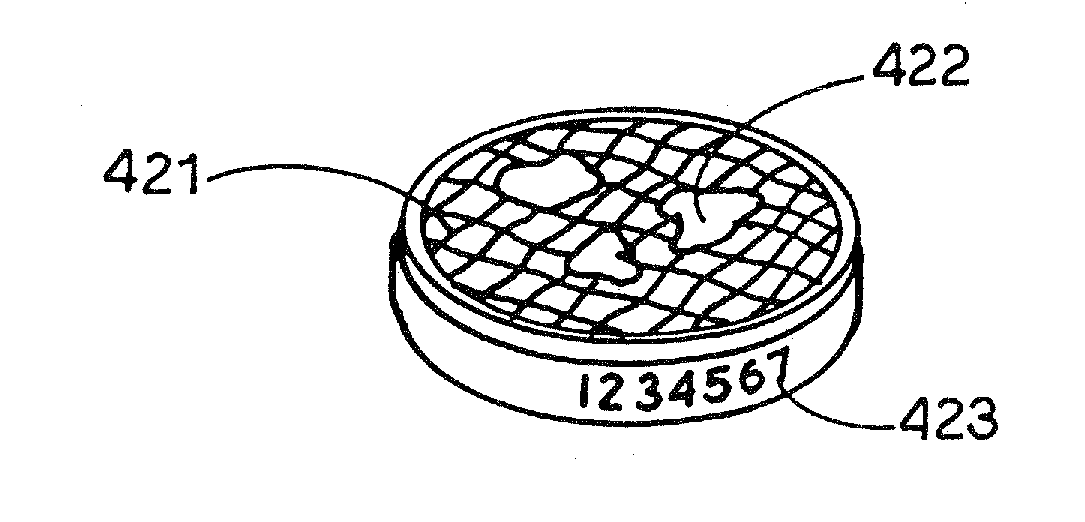

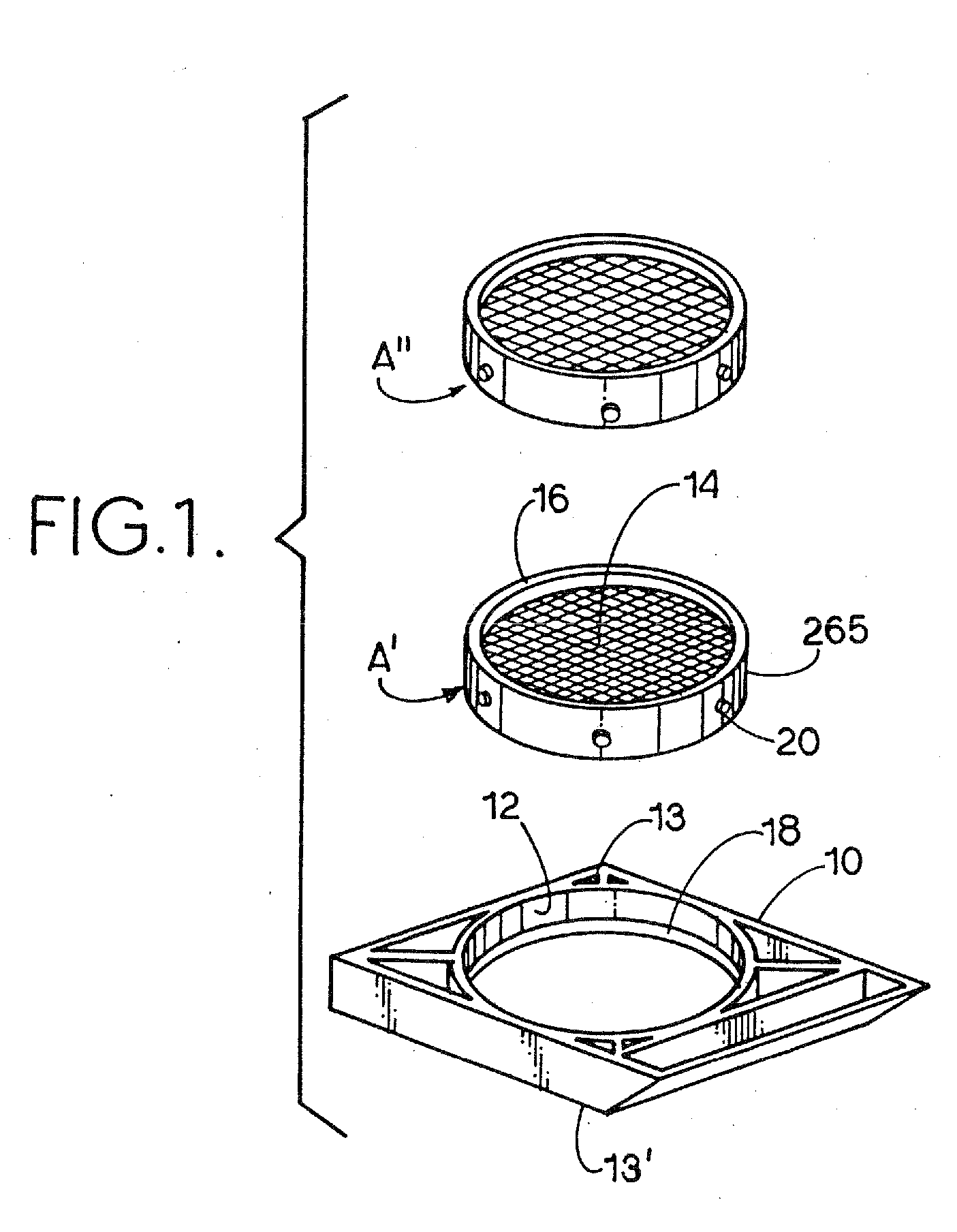

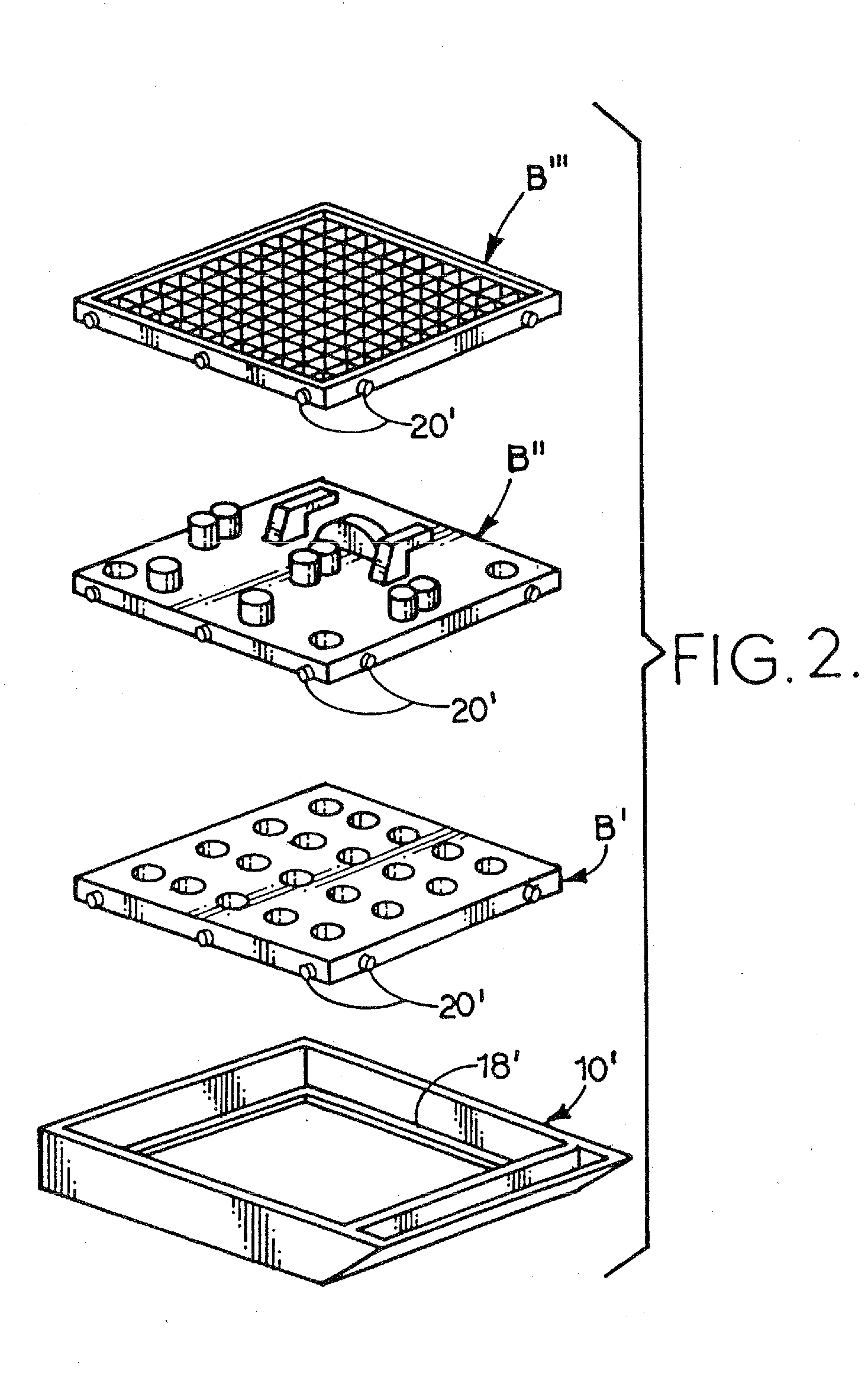

Apparatus and method for harvesting and handling tissue samples for biopsy analysis

InactiveUS7156814B1Exemption stepsReduce the numberBioreactor/fermenter combinationsBiological substance pretreatmentsTissue biopsyTissue fluid

A sectional cassette (10) for use in a process for harvesting and handling tissue samples for biopsy analysis is disclosed. In the procedure, a tissue biopsy sample is placed on a tissue trapping supporting material (A′) that can withstand tissue preparation procedures, and which can be cut with a microtome. The tissue is immobilized on the material, and the material and the tissue are held in the cassette (10) subjected to a process for replacing tissue fluids with wax. The tissue and supporting material are sliced for mounting on slides using a microtome. Harvesting devices and containers (200) using the filter material (202) are disclosed. An automated process is also disclosed.

Owner:BIOPATH AUTOMATION

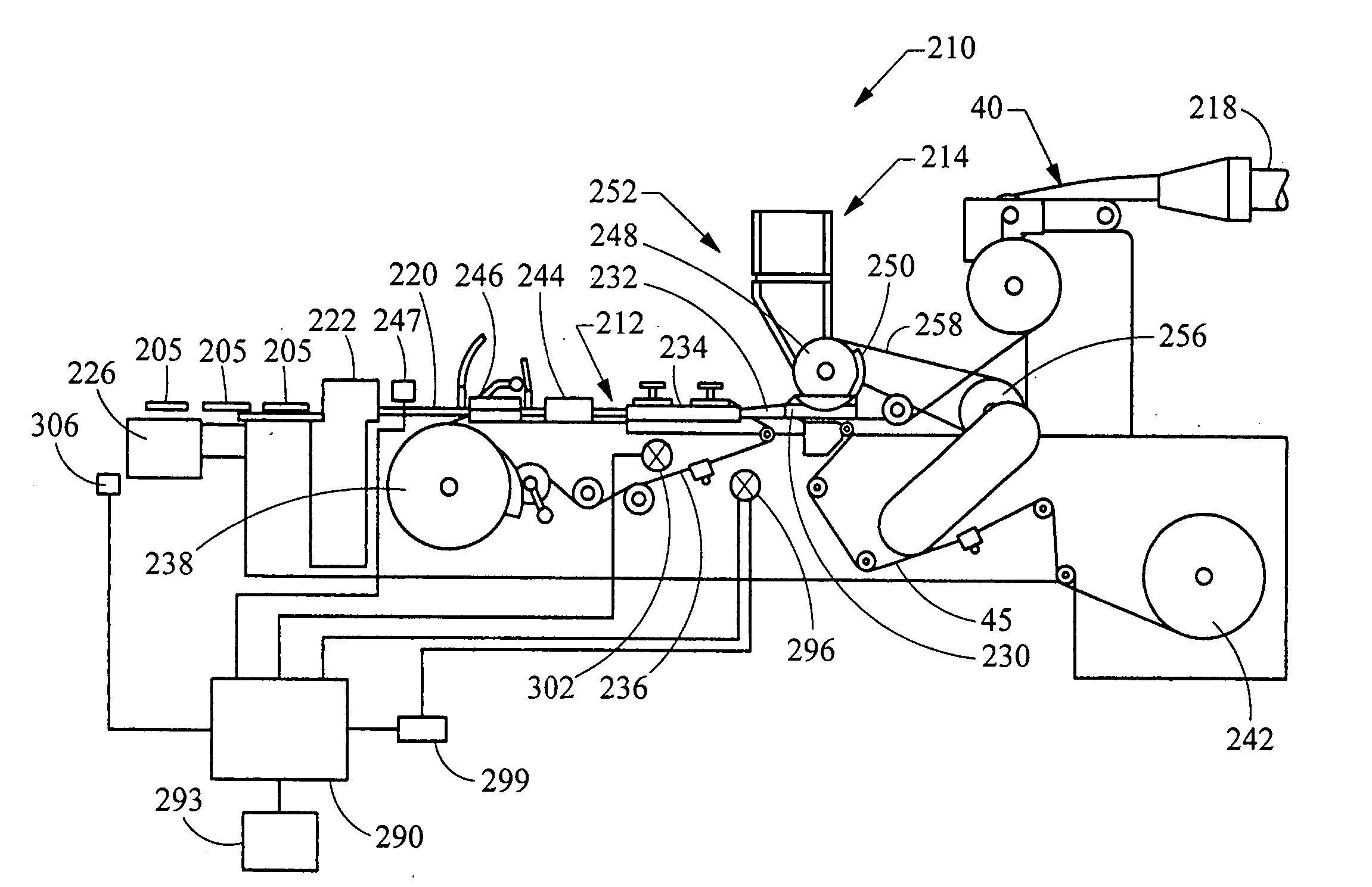

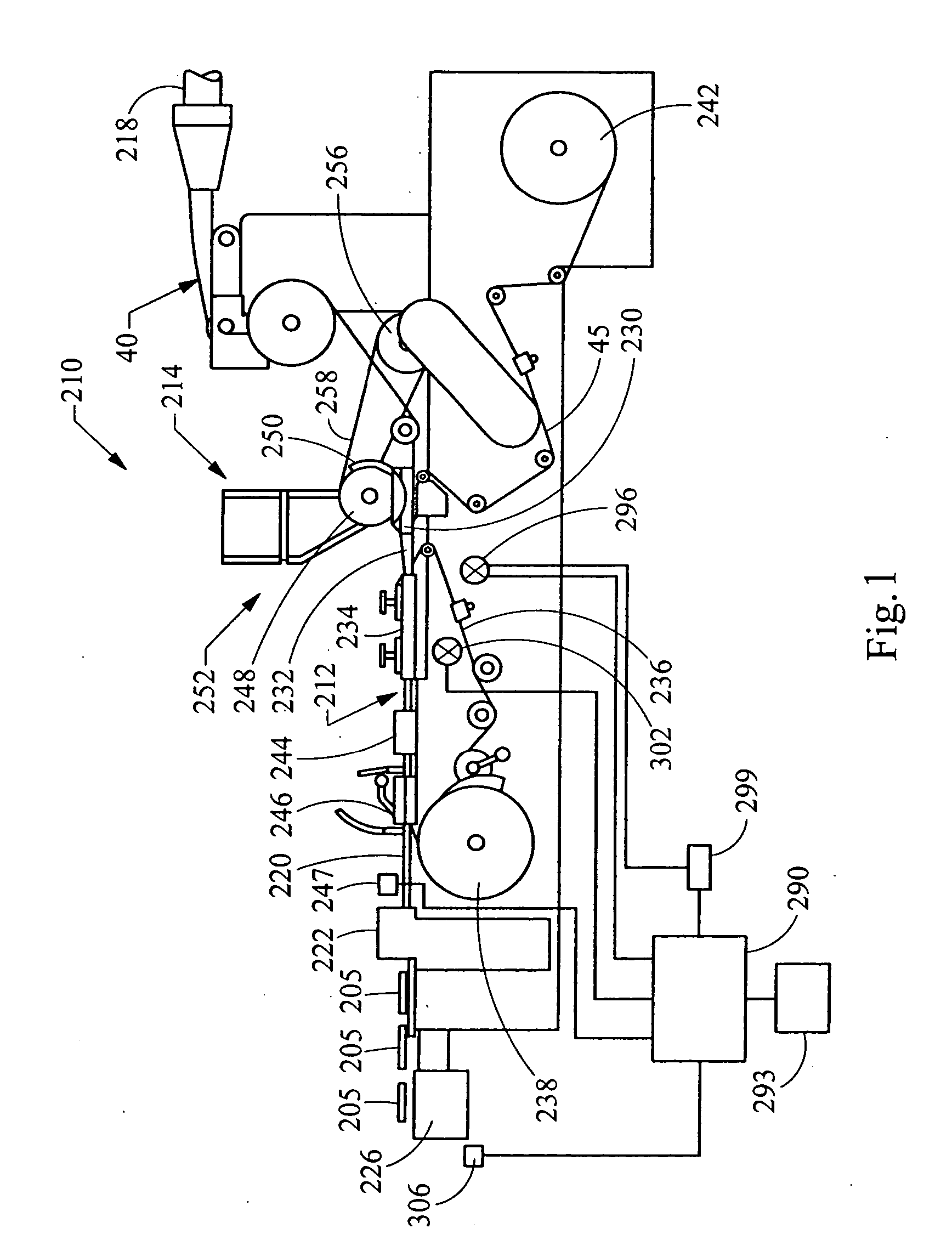

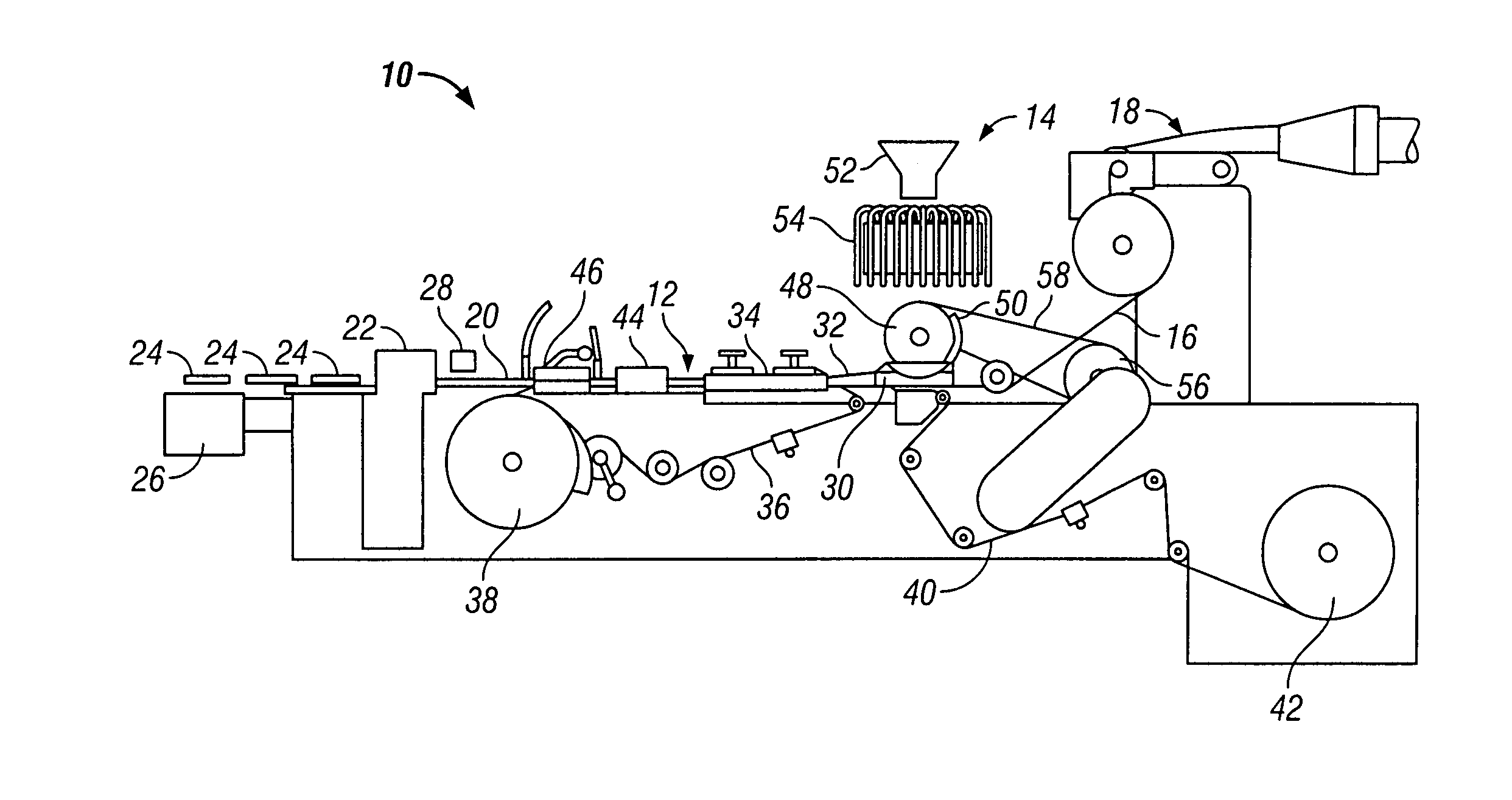

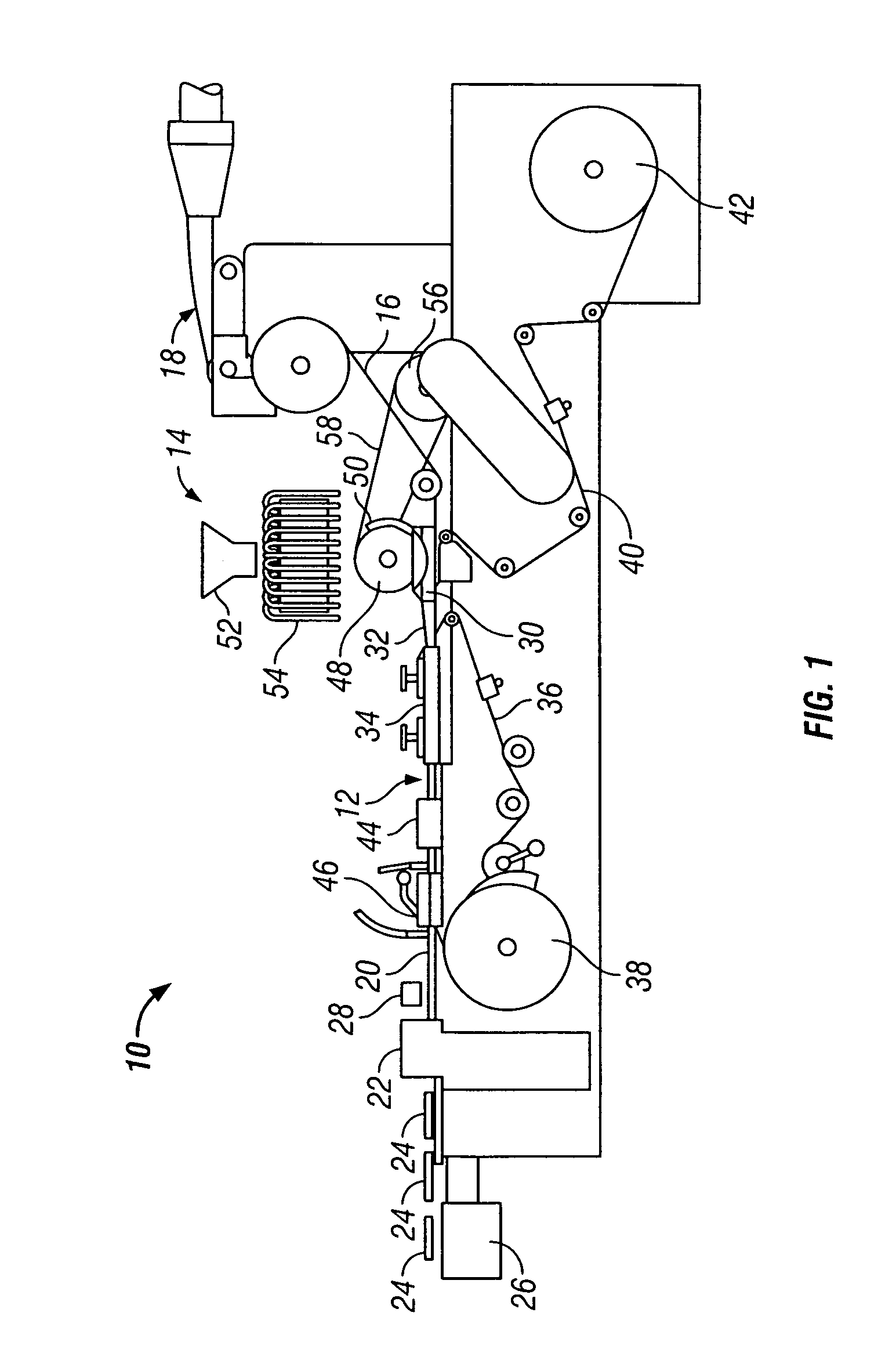

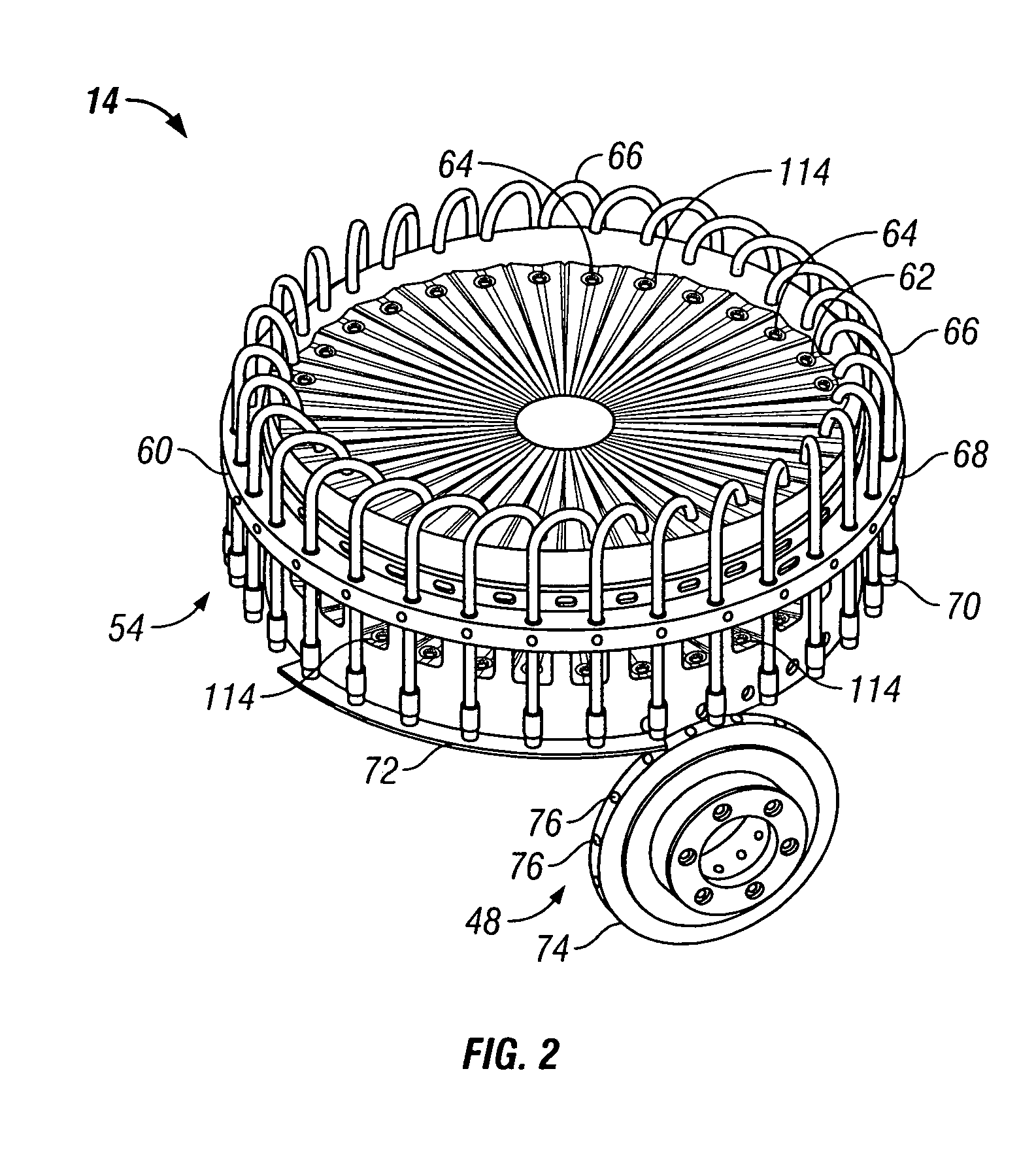

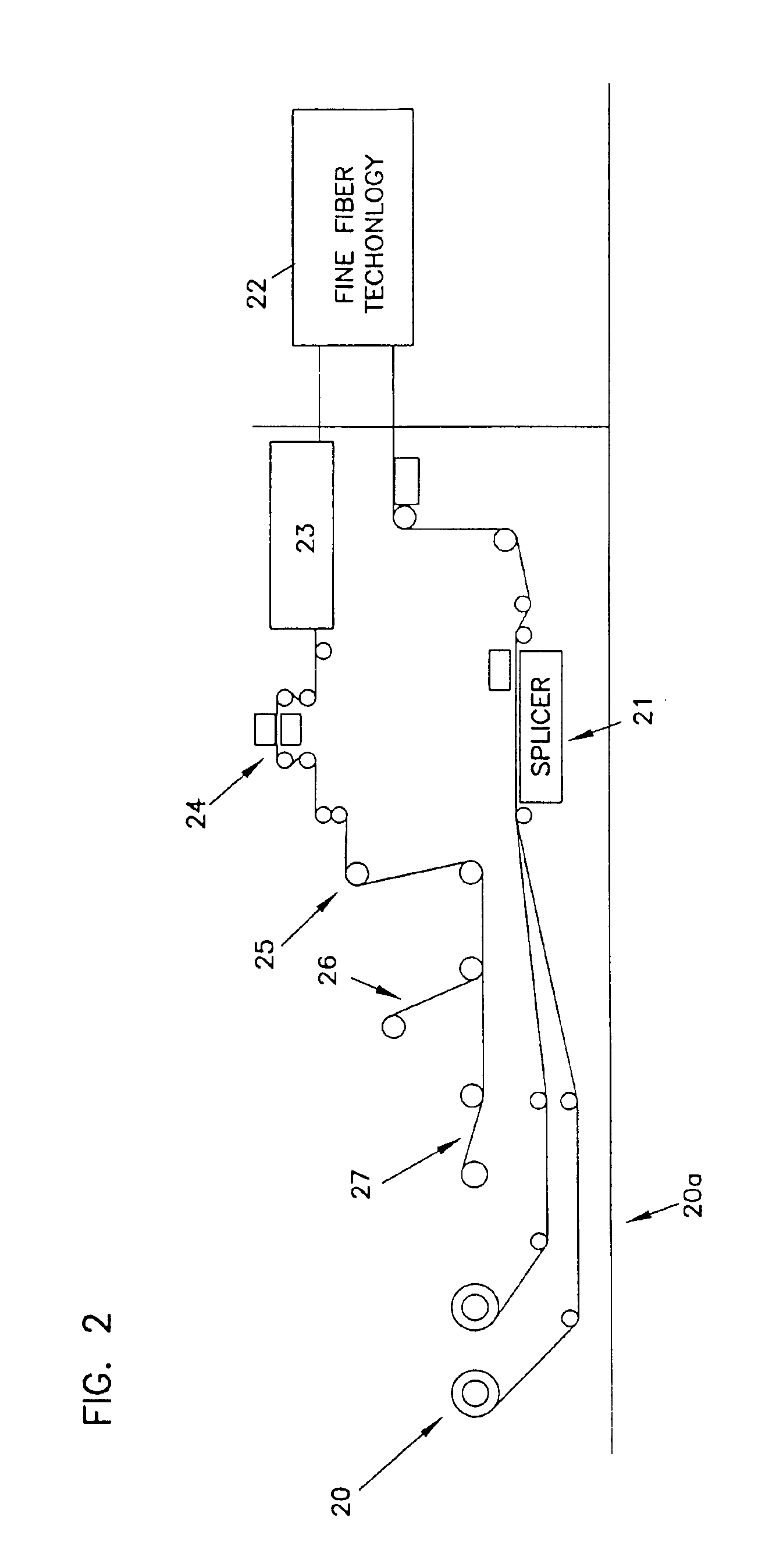

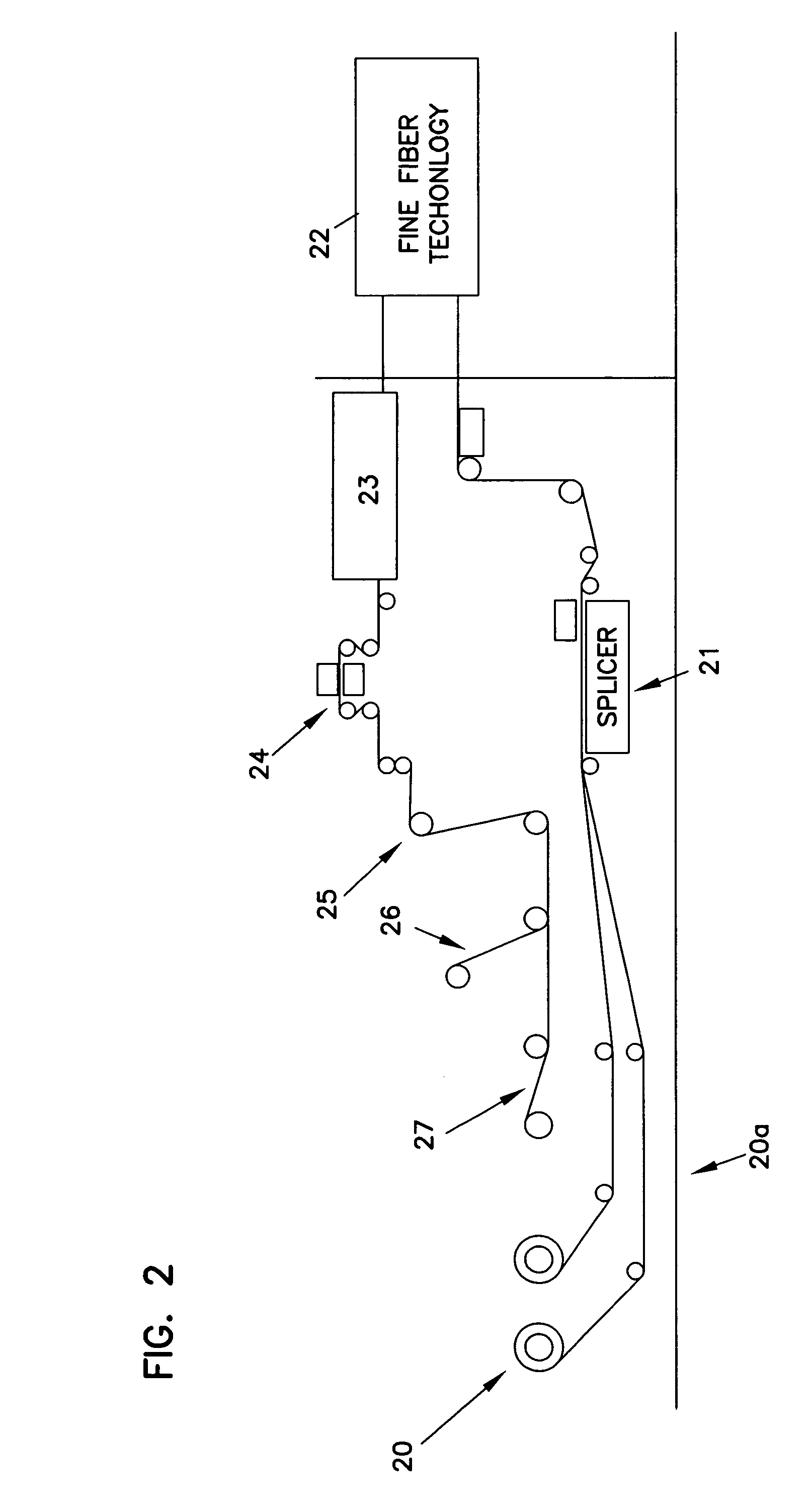

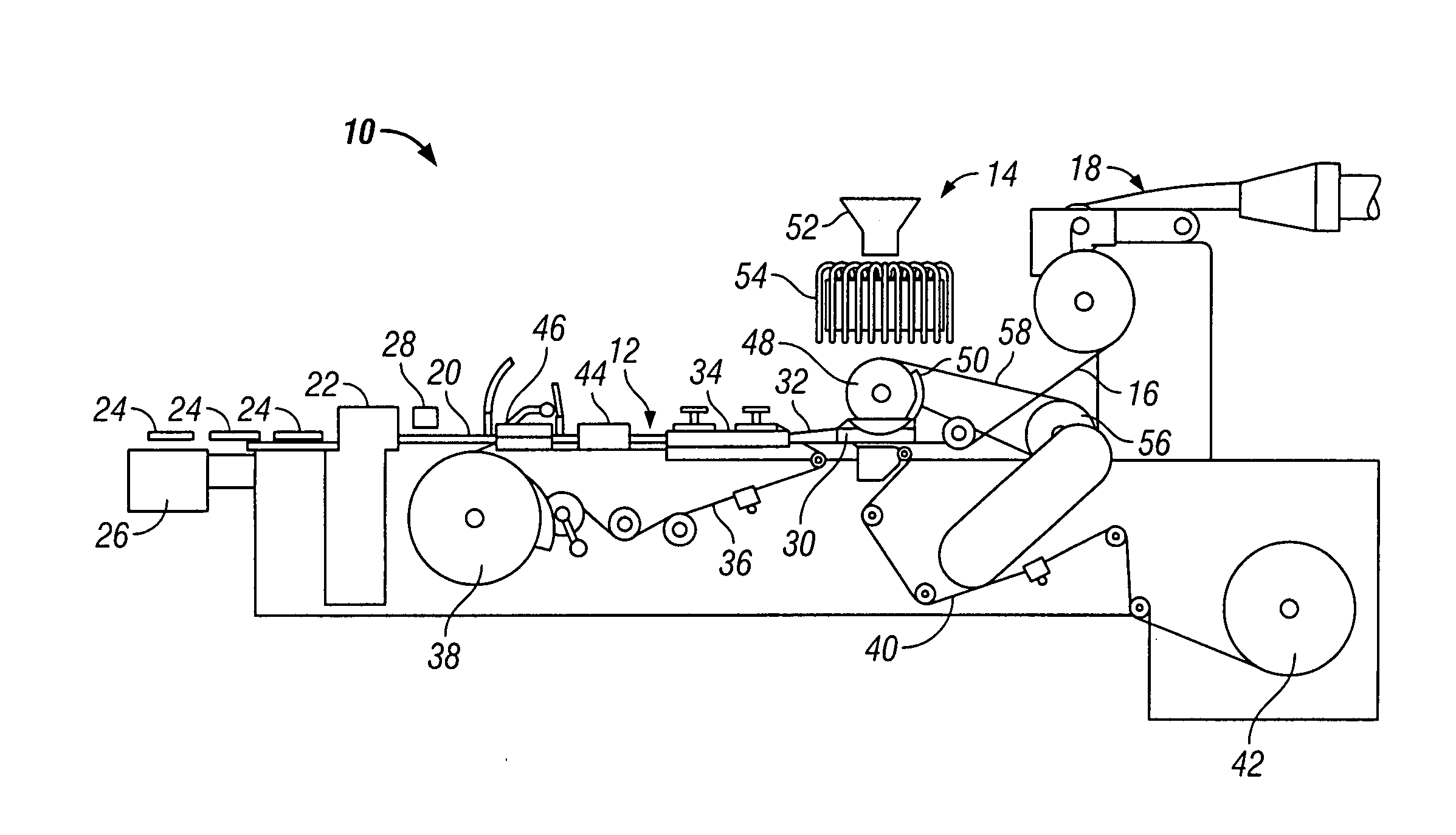

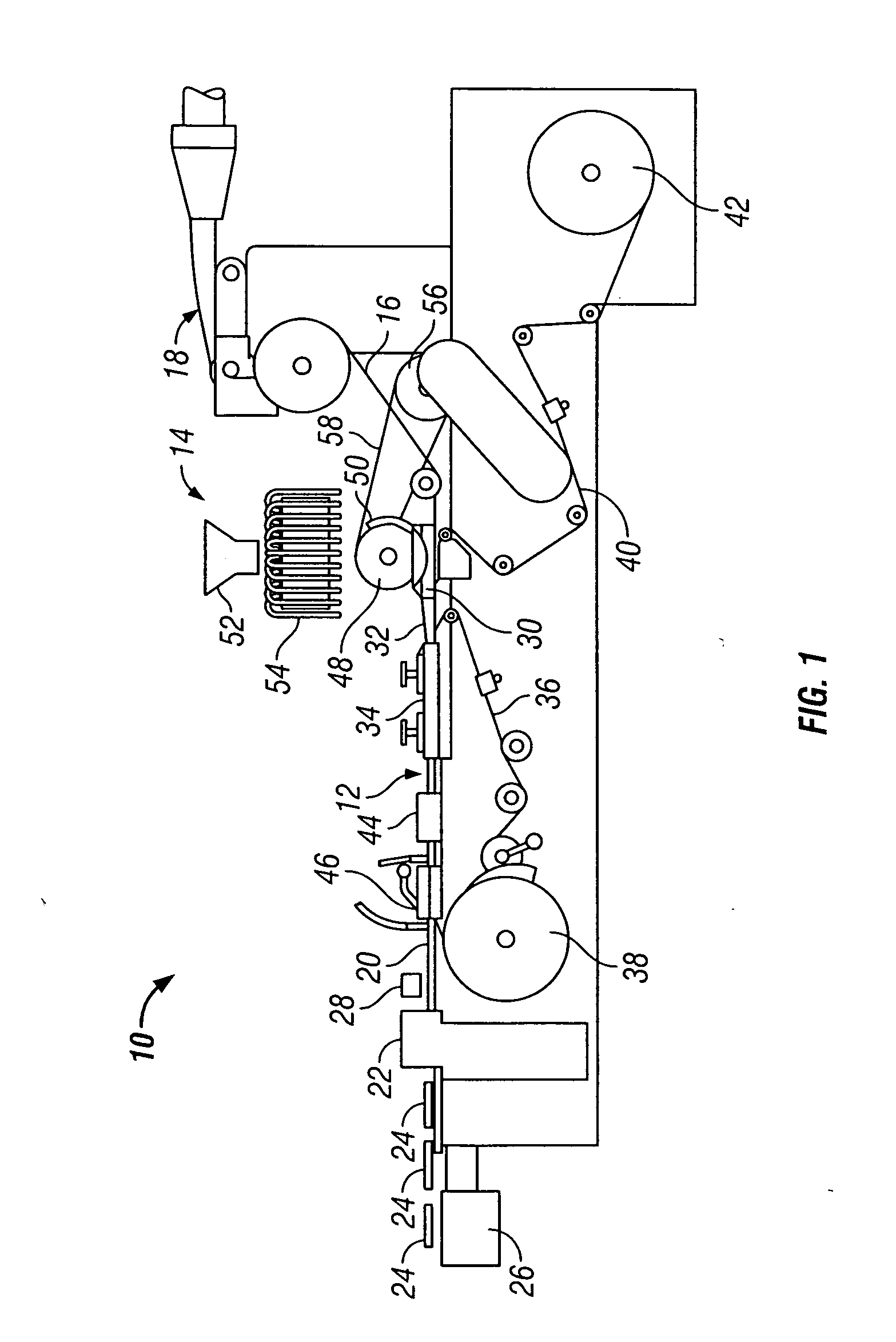

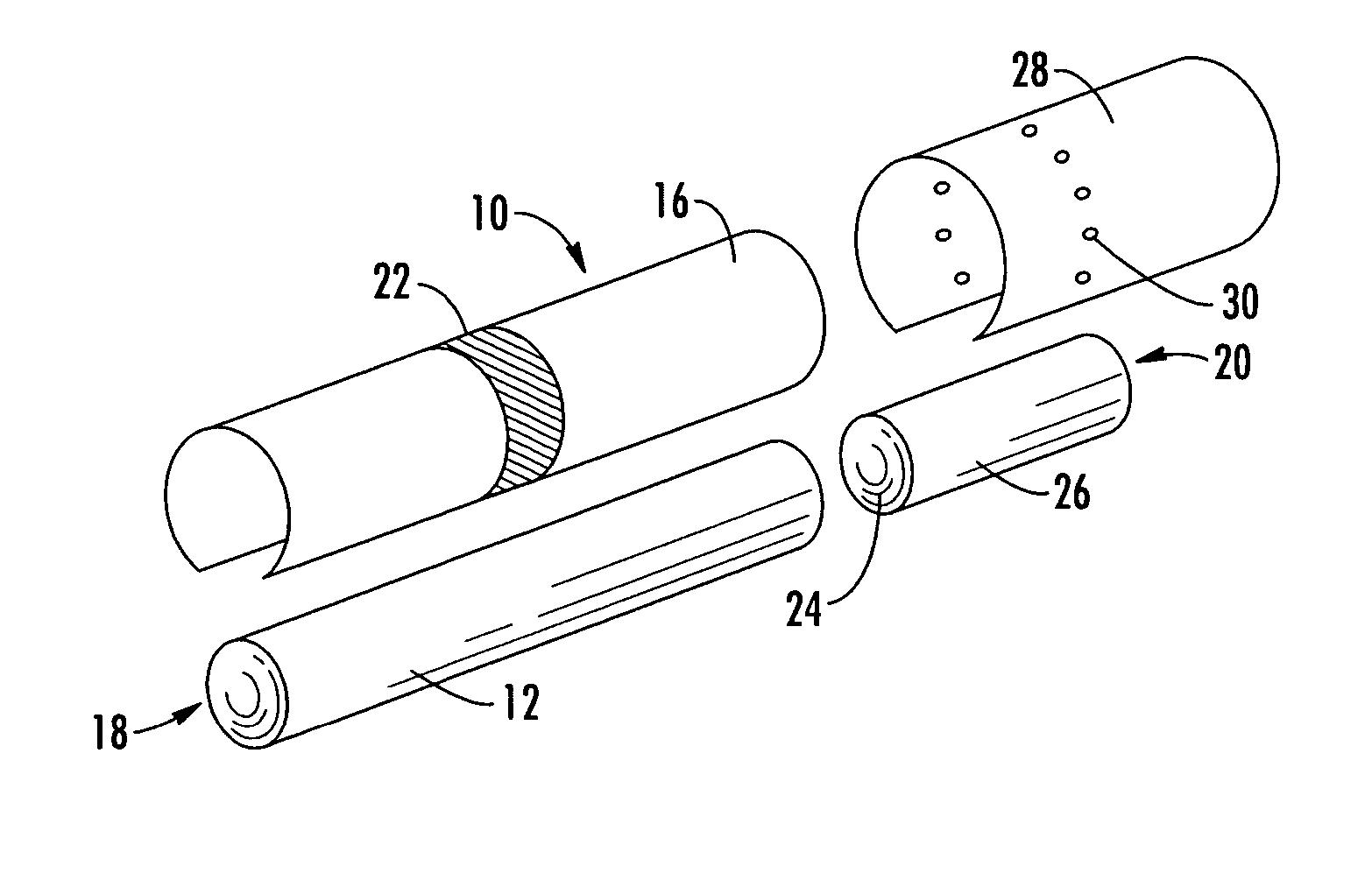

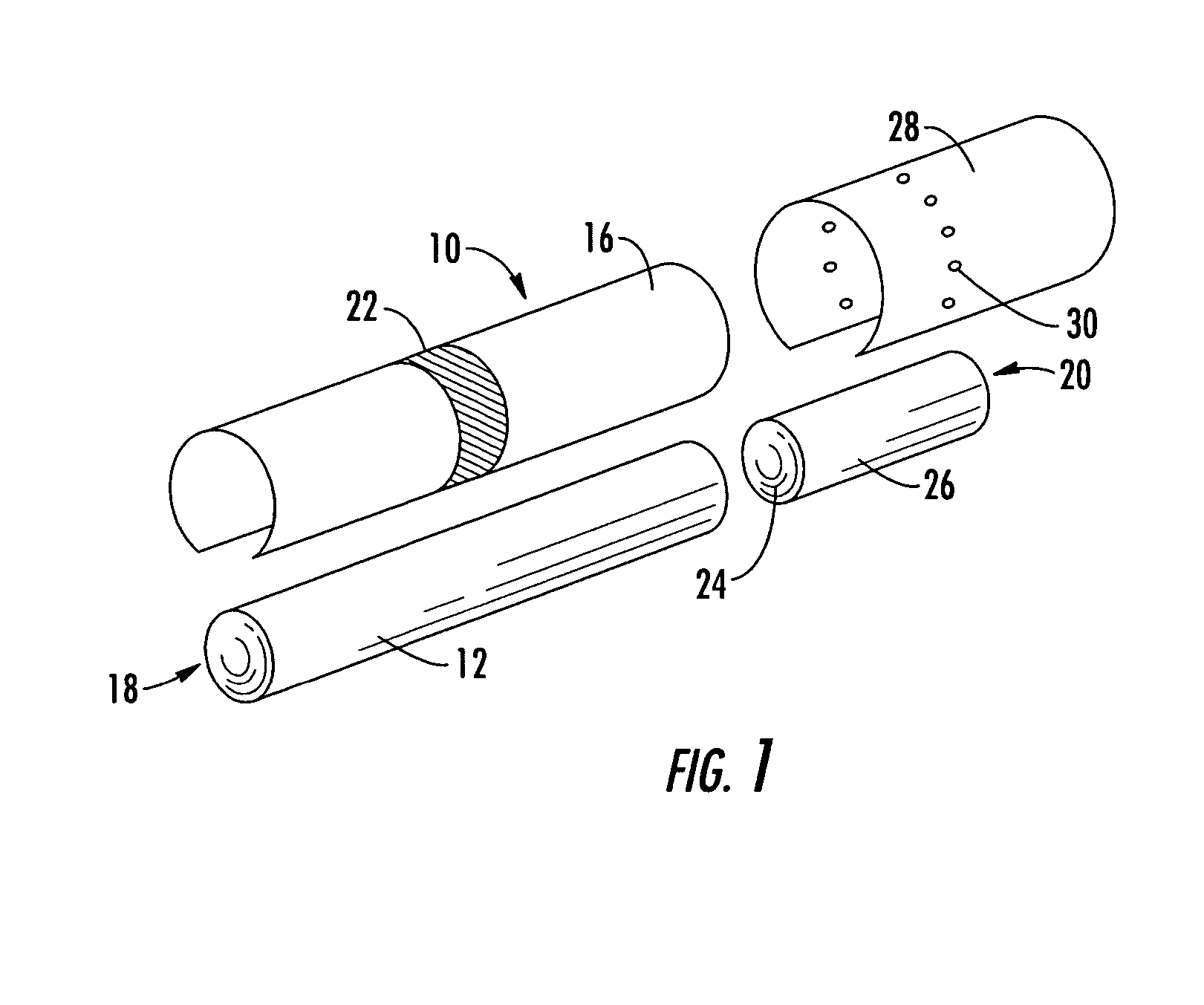

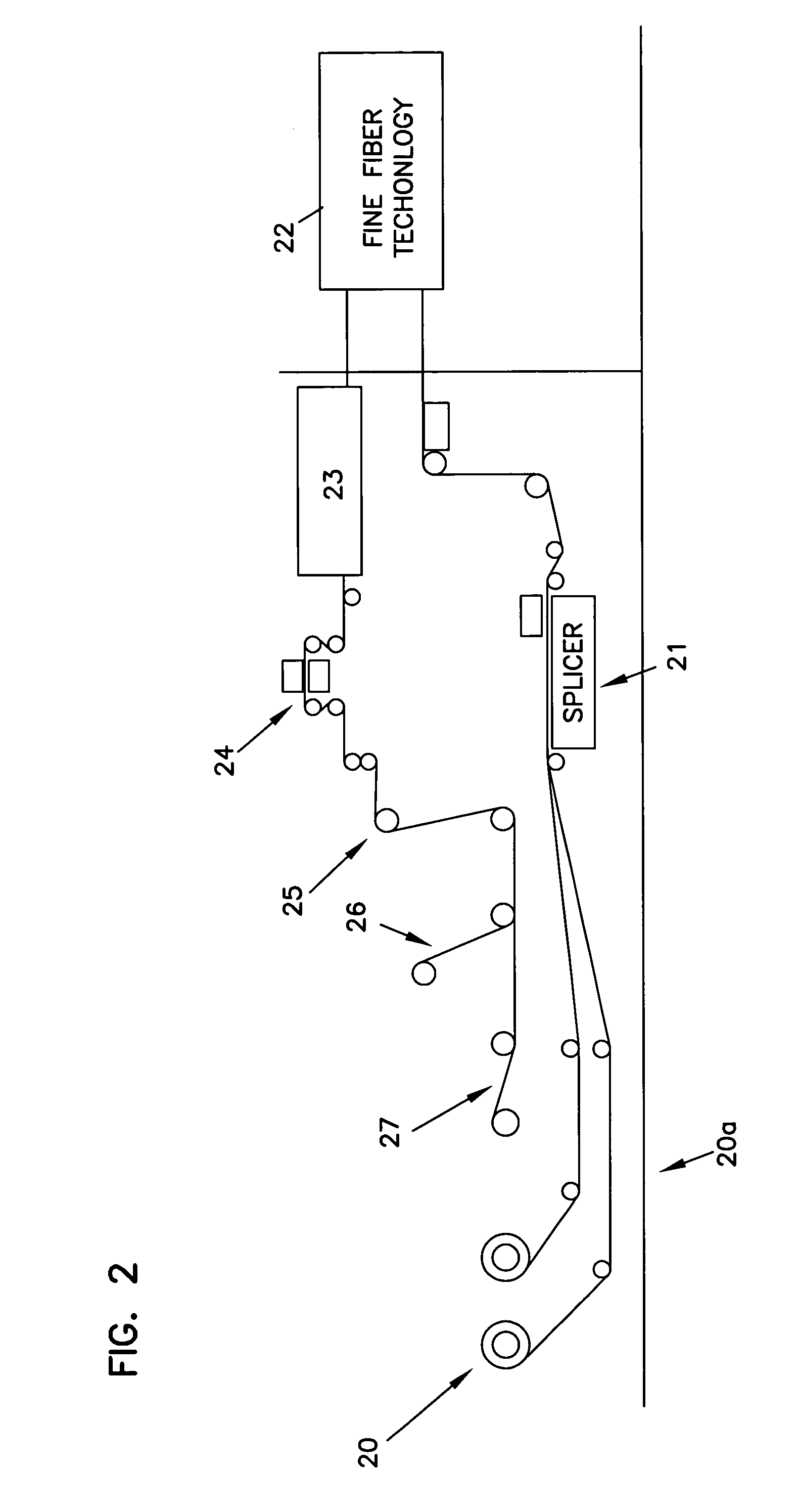

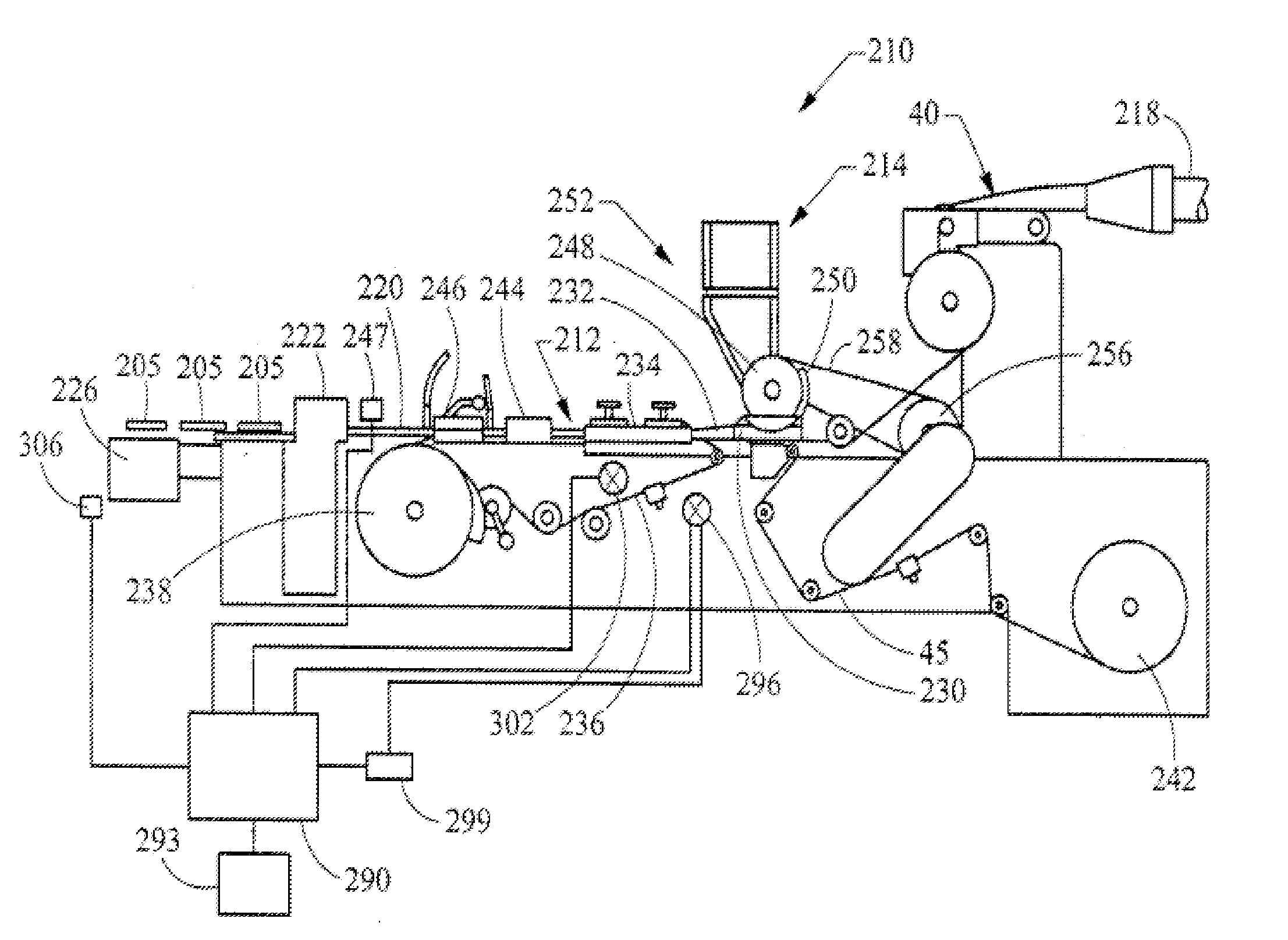

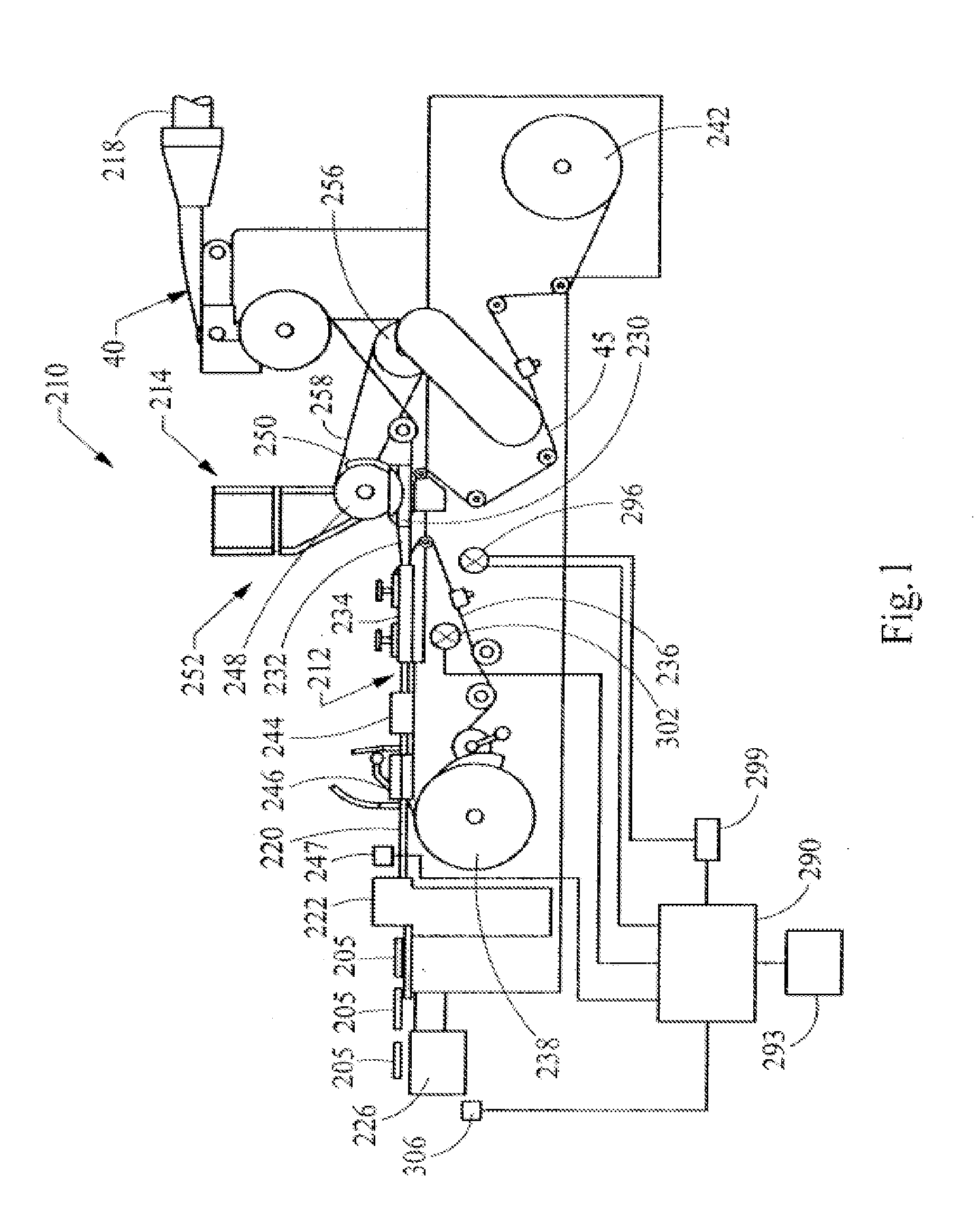

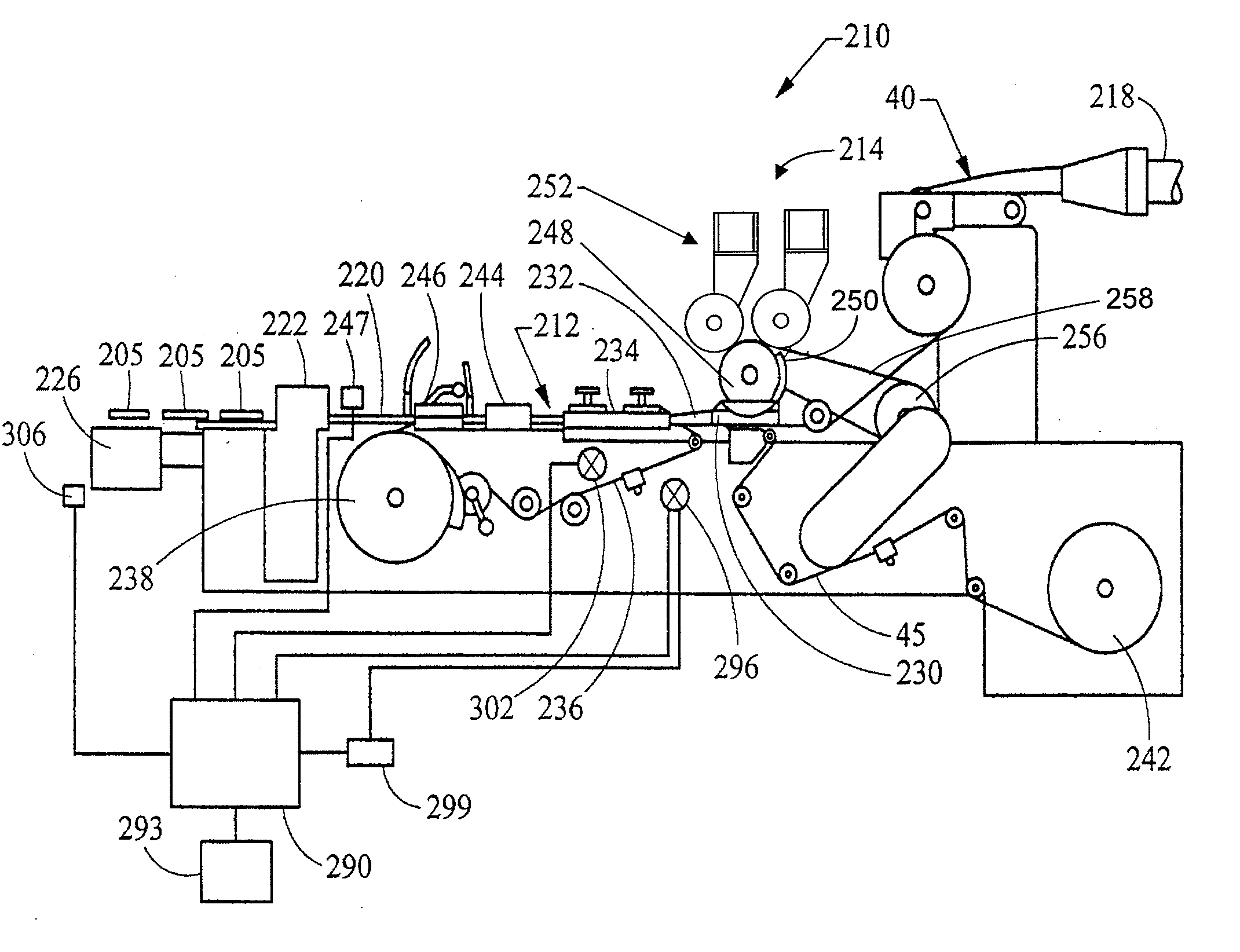

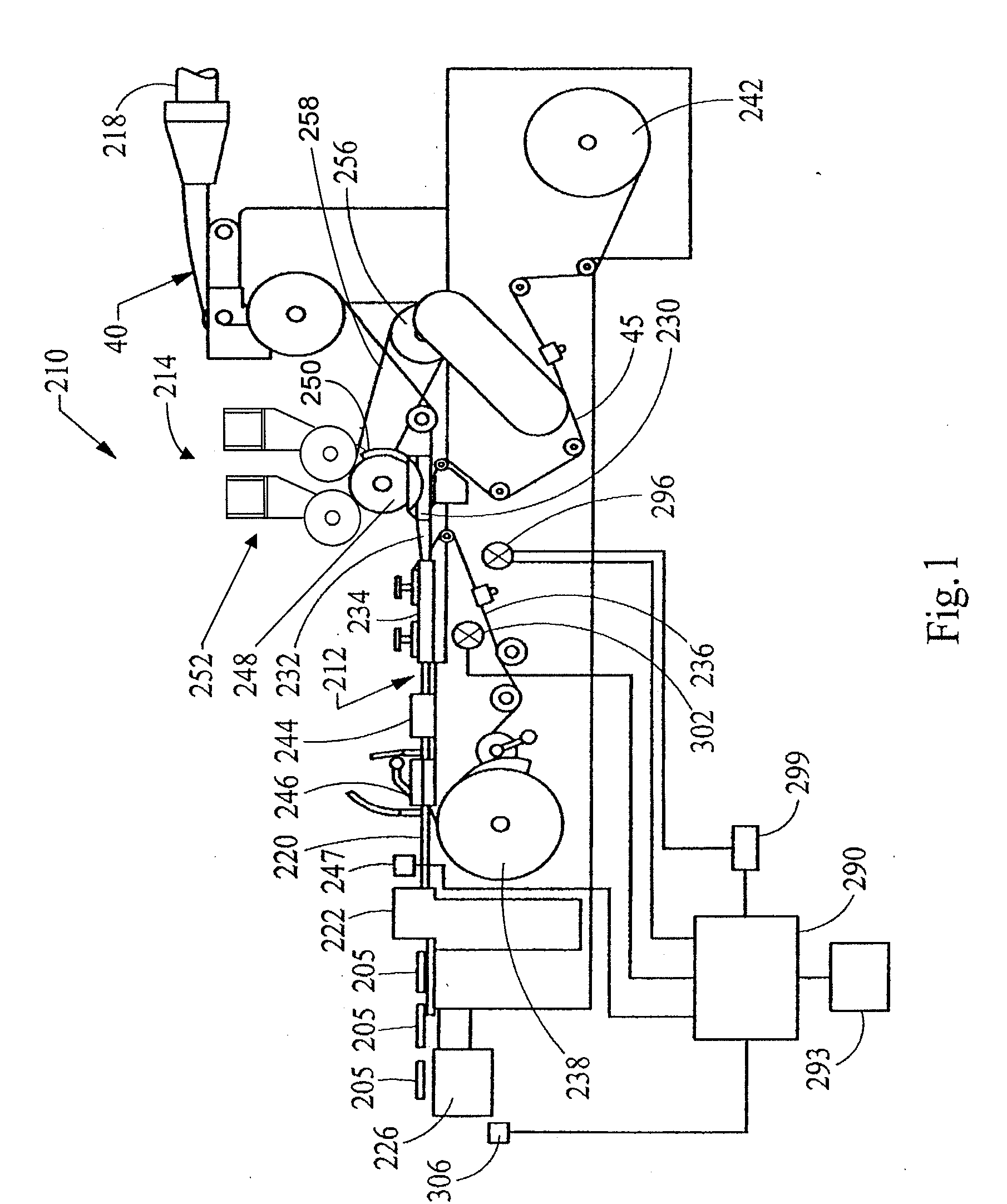

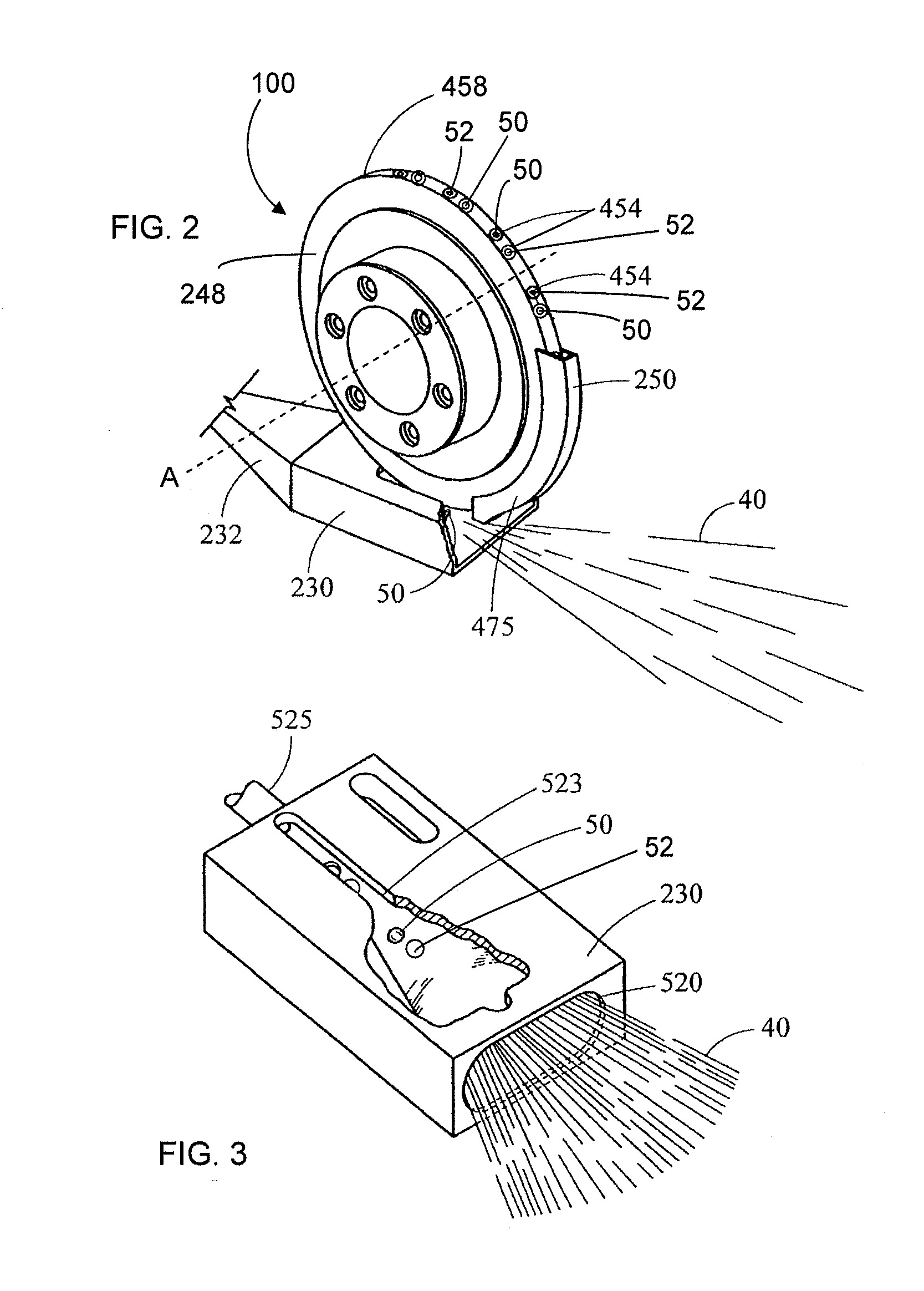

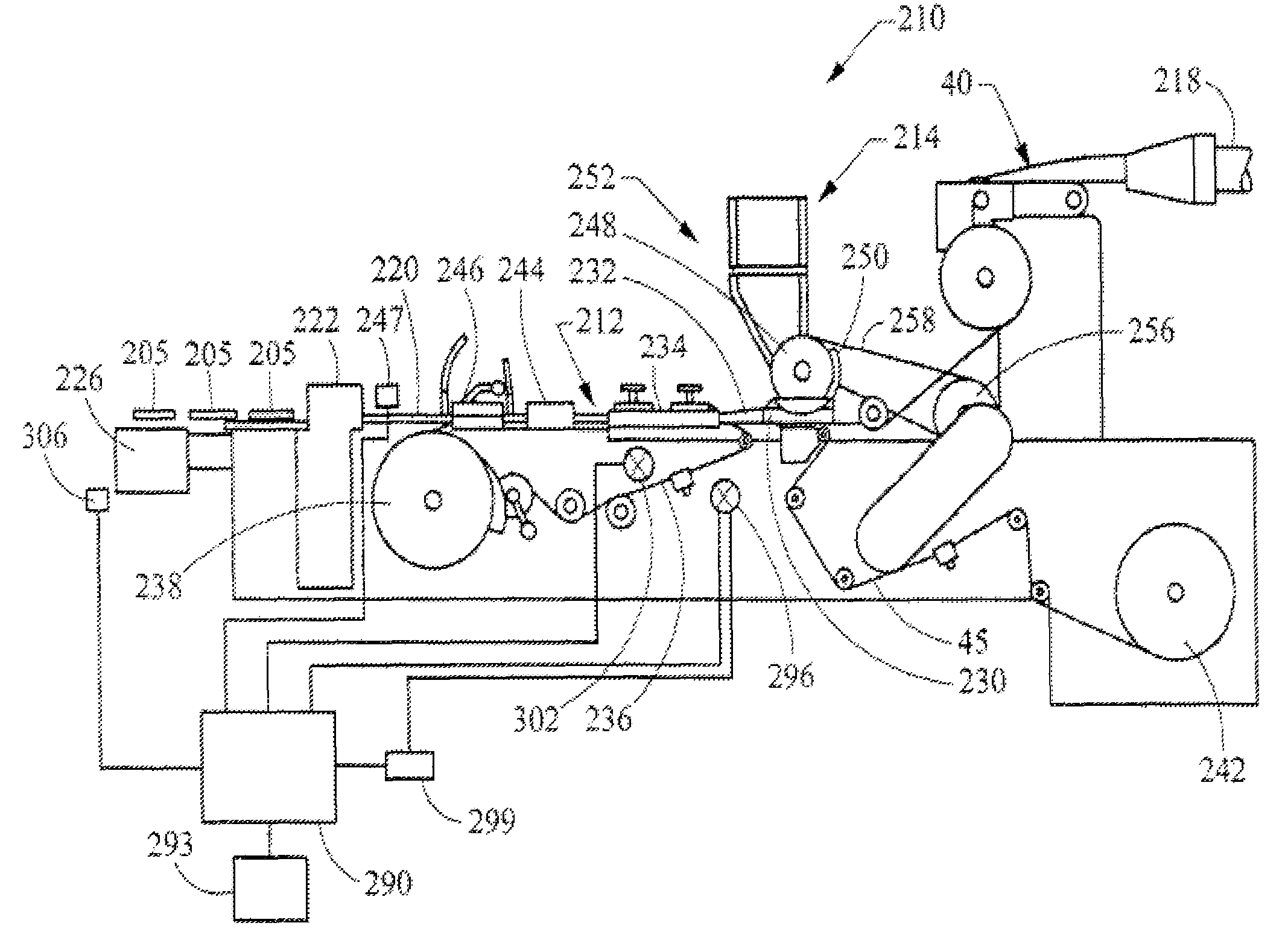

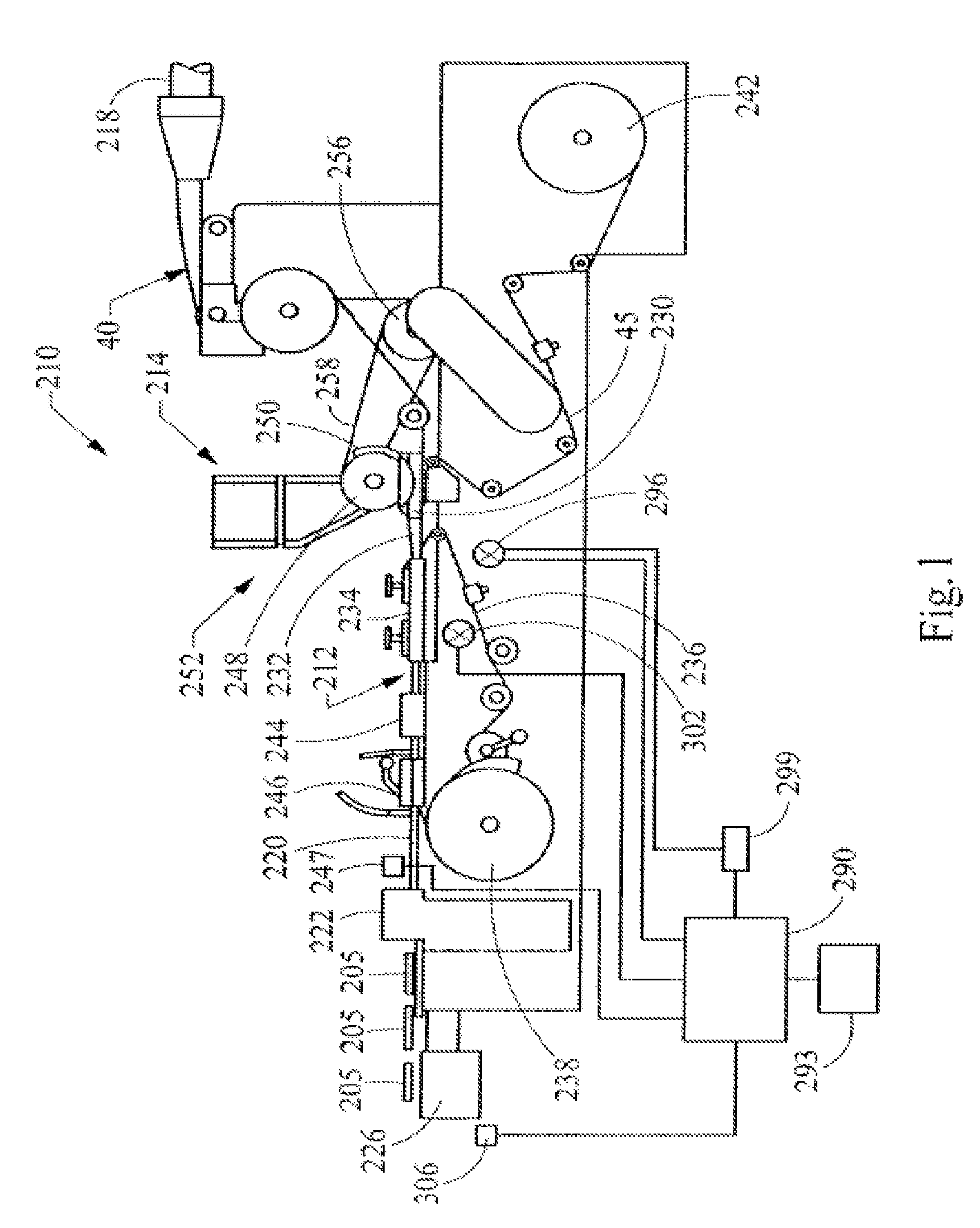

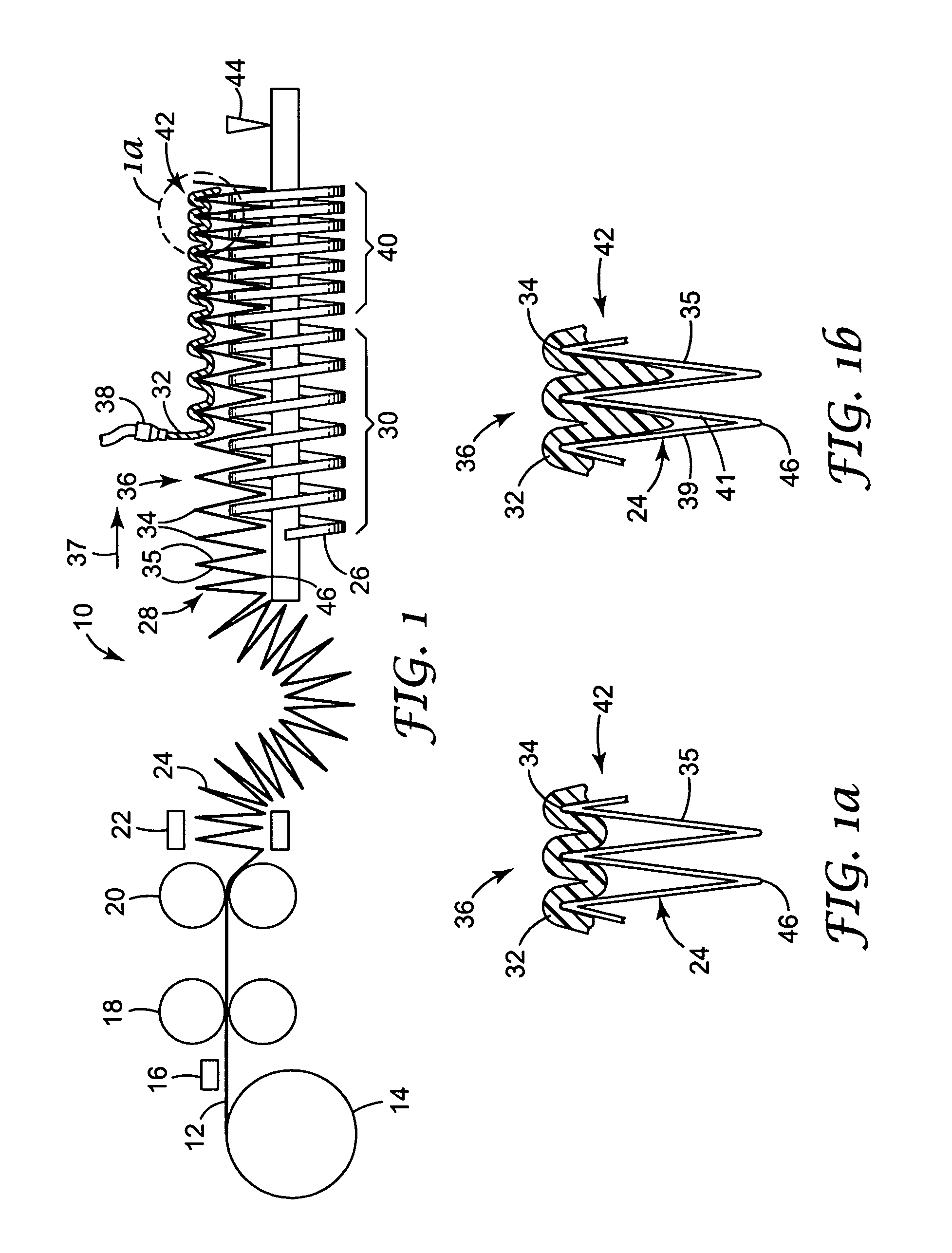

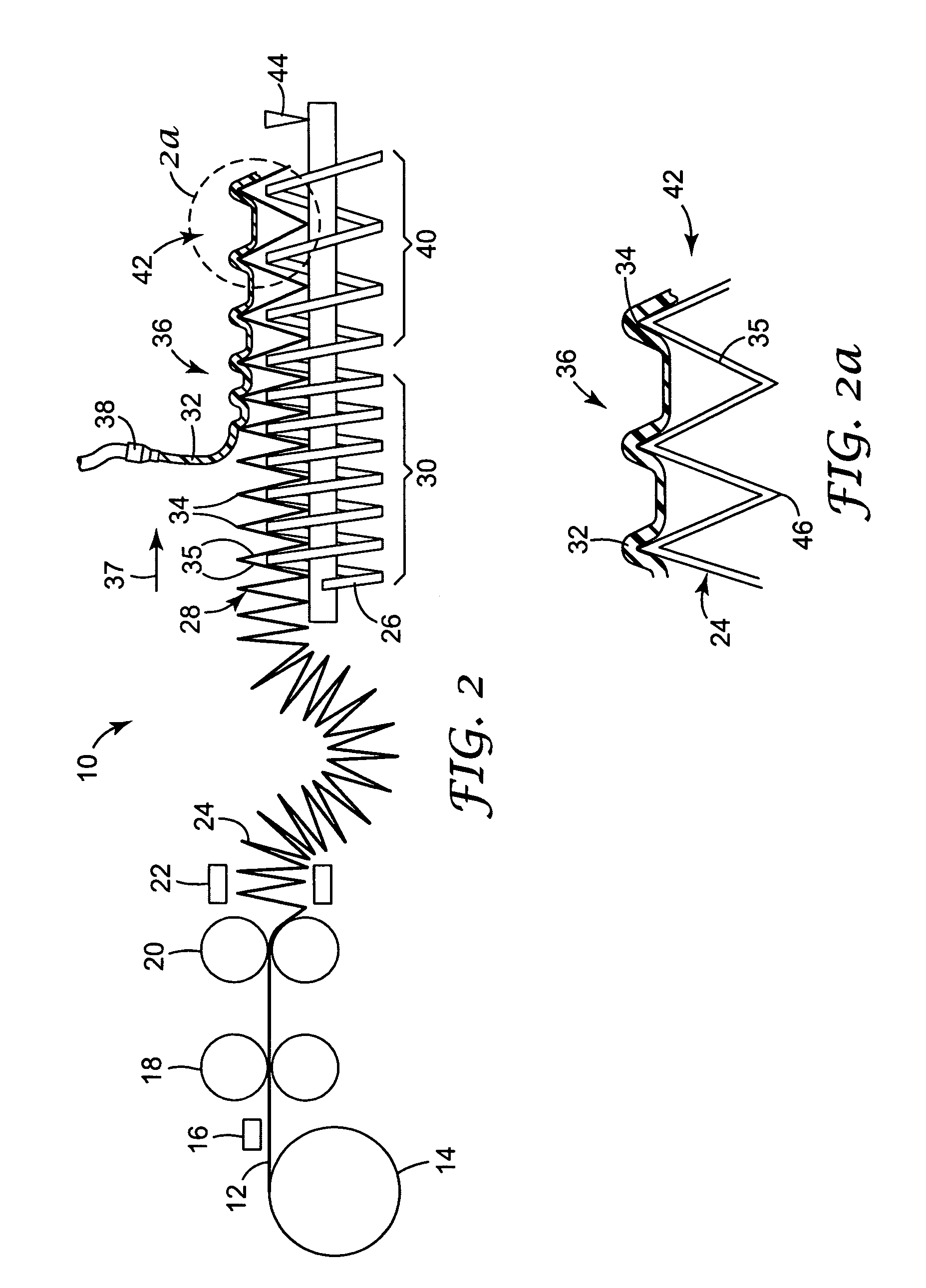

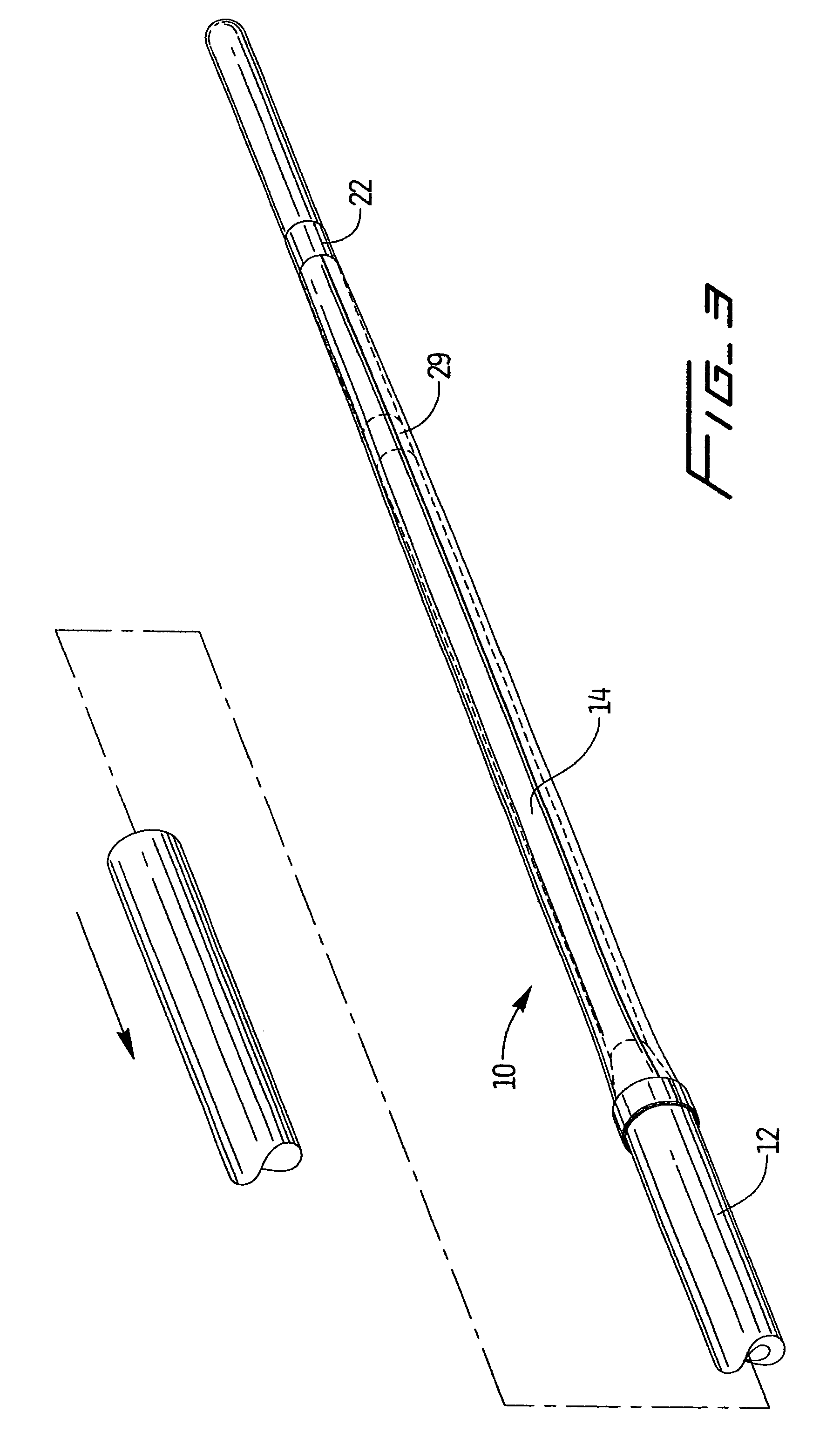

Equipment for insertion of objects into smoking articles

ActiveUS20070068540A1Sufficient shapeSufficient sizeMechanical working/deformationPaper/cardboard articlesEngineeringSpace object

Apparatus incorporating a filter tow processing unit adapted to supply filter tow to a continuous rod forming unit includes an object insertion unit that positions objects within the filter tow to manufacture a filter rod containing objects positioned at predetermined intervals. The apparatus also includes an upper hopper that acts as a reservoir for a plurality of objects, and provides for supply of objects to a lower hopper. The lower hopper is shaped so that objects are stacked therein. The bottom of the lower hopper is shaped so as to cooperate with a portion of upper region of a rotating wheel. The peripheral face of the rotating wheel incorporates a plurality of spaced pockets, each pocket being of sufficient shape and size to accommodate one object. Objects within the lower hopper are aligned in a single line along a portion of the peripheral face in the upper region of the rotating wheel. Each object then is positioned at predetermined intervals within a continuous supply of filter material. Then, the filter material is formed into a continuous rod having individual objects positioned at predetermined spaced intervals within that rod. The continuous rod then is subdivided at predetermined intervals so as to form a plurality of filter rods (e.g., four-up filter rods containing four spaced objects).

Owner:R J REYNOLDS TOBACCO COMPANY

Method and apparatus for incorporating objects into cigarette filters

Owner:R J REYNOLDS TOBACCO COMPANY

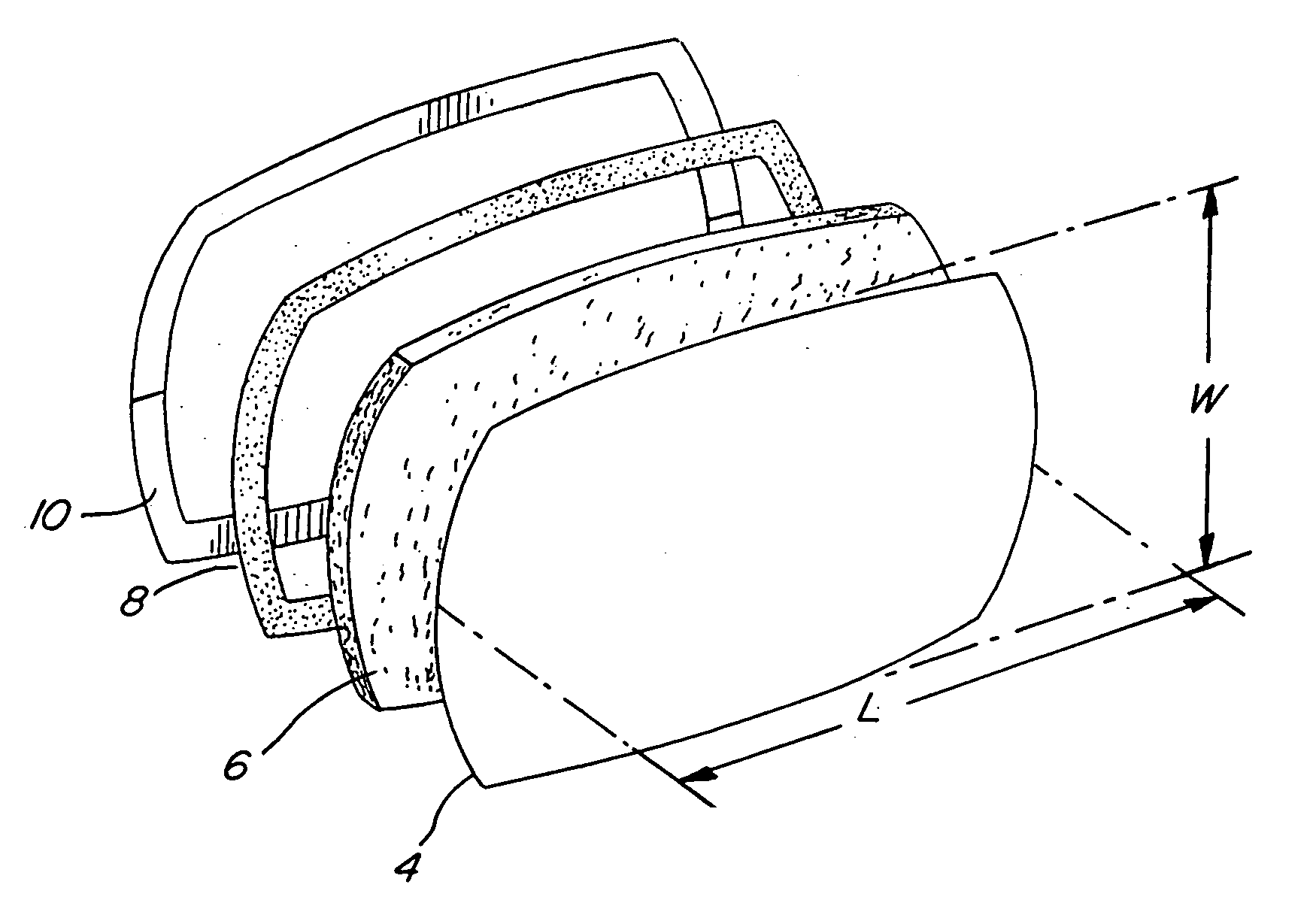

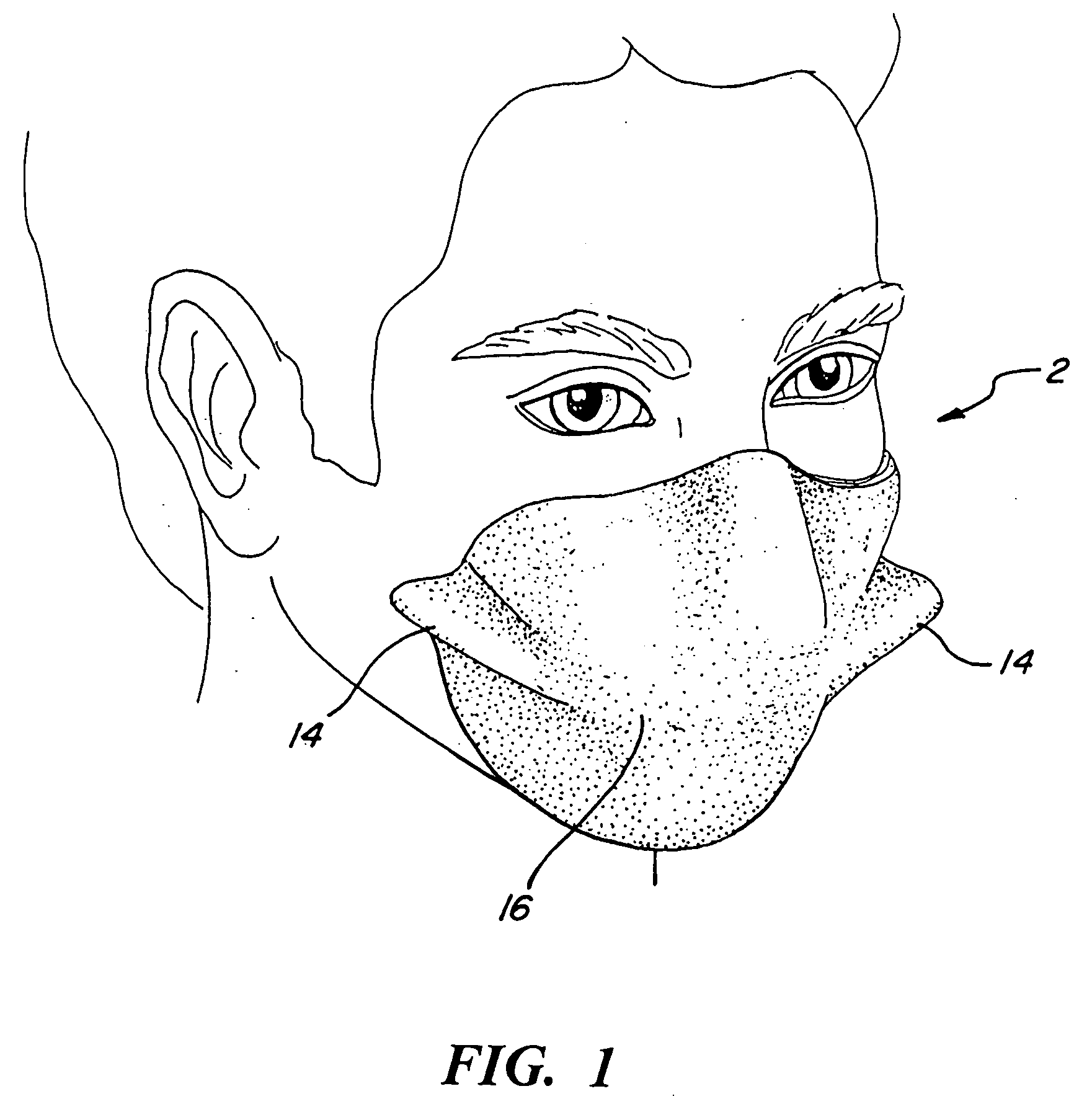

Strapless flexible tribo-charged respiratory facial mask and method

A facial mask for filtering ambient air is formed from a pre-form of a multilayer flexible flat filter member of a size to extend over the mouth and nostrils of the user. The flat pre-form filter member can have an ovoid perimeter with an endless band of a hypoallergenic adhesive tape encircling a perimeter of the filter member and operable for sealing with the user's skin to prevent leakage over extended use. Portions of the adhesive tape can self-seal during a sizing step to form structural paths for maintaining a central concavity to ensure a large filtration area offset from the nostrils and mouth of the user. The flexible filter material can further include an activated carbon layer.

Owner:WEINBERG STANLEY

Polymer, polymer microfiber, polymer nanofiber and applications including filter structures

InactiveUS6924028B2Simple materialSubstantial surface loadingCombination devicesMaterial nanotechnologyPolymer scienceNanofiber

Disclosed are improved polymer materials. Also disclosed are fine fiber materials that can be made from the improved polymeric materials in the form of microfiber and nanofiber structures. The microfiber and nanofiber structures can be used in a variety of useful applications including the formation of filter materials.

Owner:DONALDSON CO INC

Air filter with fine fiber and spun bonded media

Disclosed are improved polymer materials. Also disclosed are fine fiber materials that can be made from the improved polymeric materials in the form of microfiber and nanofiber structures. The microfiber and nanofiber structures can be used in a variety of useful applications including the formation of filter materials.

Owner:DONALDSON CO INC

Everted filter device

Everting filter devices and methods for using the devices, including using the devices as intra-vascular filters to filter thrombus, emboli, and plaque fragments from blood vessels. The filter devices include a filter body nominally tubular in shape and having a large proximal opening. The filter body can extend from a proximal first end region distally over the non-everted exterior surface of the filter, further extending distally to a distal-most region, then converging inwardly and extending proximally toward the filter second end region, forming a distal everted cavity. The degree of eversion of the filter can be controlled by varying the distance between the filter first end region near the proximal opening and the closed second end region. Bringing the filter first and second end regions closer together can bring filter material previously on the non-everted filter exterior to occupy the distal-most region. The everting process can also bring filter material previously in the distal-most position further into the distal everted cavity. The filter devices can be used to remove filtrate from body vessels, with the filtrate eventually occluding the distal-most region. The filter can then be further everted, bringing fresh, unoccluded filter material into place to provide additional filter capacity. Some everting filters have the capability of switching between occluding and filtering modes of operation, thereby allowing a treating physician to postpone the decision to use filtering or occluding devices until well after insertion of the device into the patient's body.

Owner:TYCO HEALTHCARE GRP LP

Dust filter bag including a highly porous backing material ply

InactiveUS6706086B2Simple and cost-effective productionCleaning filter meansCombination devicesBursting strengthCellulose fiber

A dust filter bag having a highly porous backing material ply and a method for producing the dust filter bag. The dust filter bag includes at least one filter material ply and at least one backing material ply, the backing material ply possessing an air permeability of at least 900 l / m<2 >x s, a burst strength of at least 70 kPa, a rupture strength longitudinally better than 10 and transversely better than 3 N, a flexural rigidity longitudinally better than 0.5 cN cm<2 >and transversely better than 0.25 cN cm<2>, a basis weight of 30-80 g / m<2 >and a droplet sink-in time of less than 10 minimum. The dust filter bag can be produced by the following steps: mixing fibers including cellulose fibers and fusible fibers into a homogenous fiber mix, processing the fiber mix into a fiber web by wet laying, drying the fiber web, curing the dried fiber web by thermofusion into a backing material ply, processing the backing material ply with a filter material ply into a raw bag, and finishing the raw bag into a dust filter bag.

Owner:NEENAH GESSNER GMBH

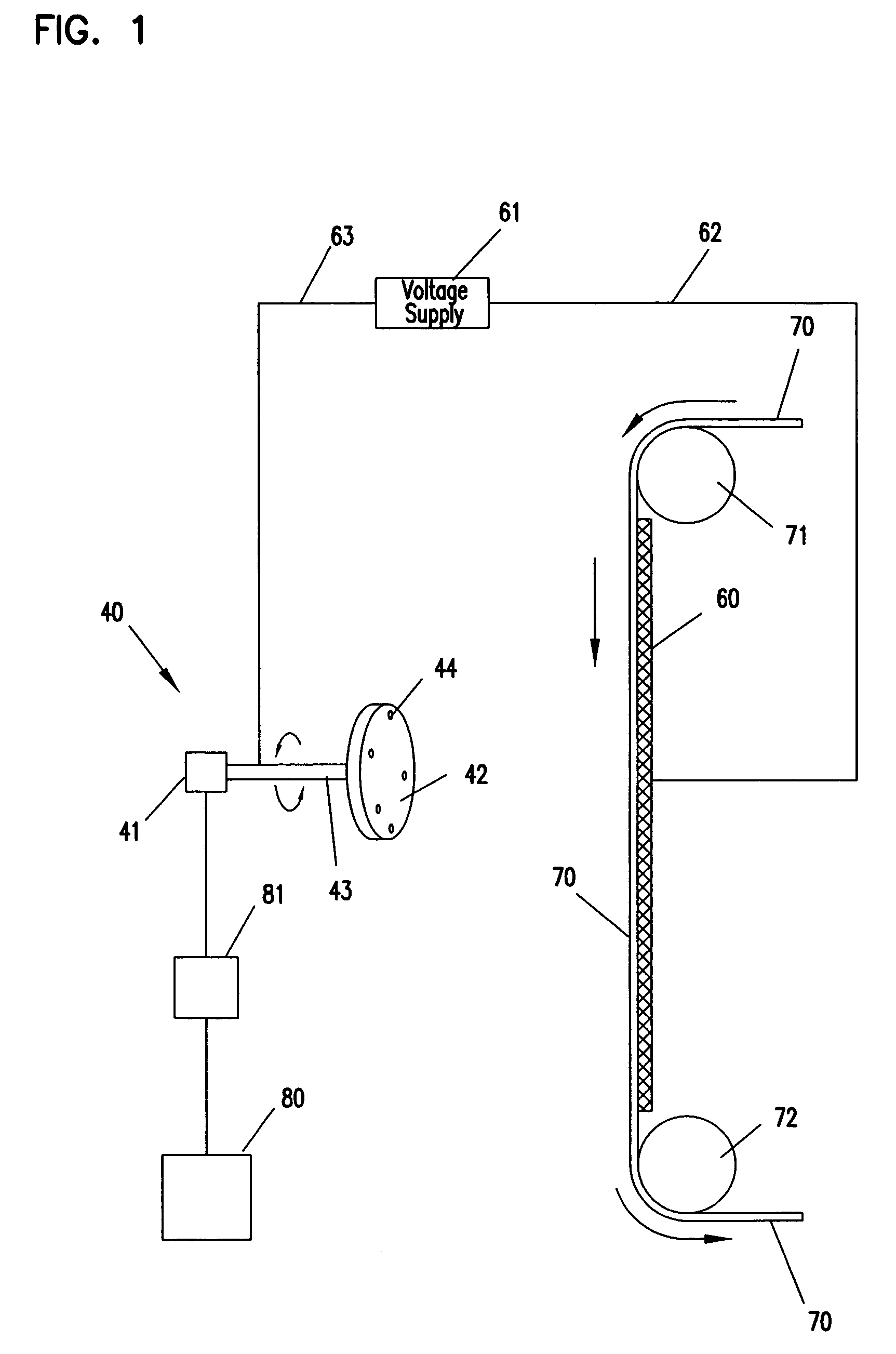

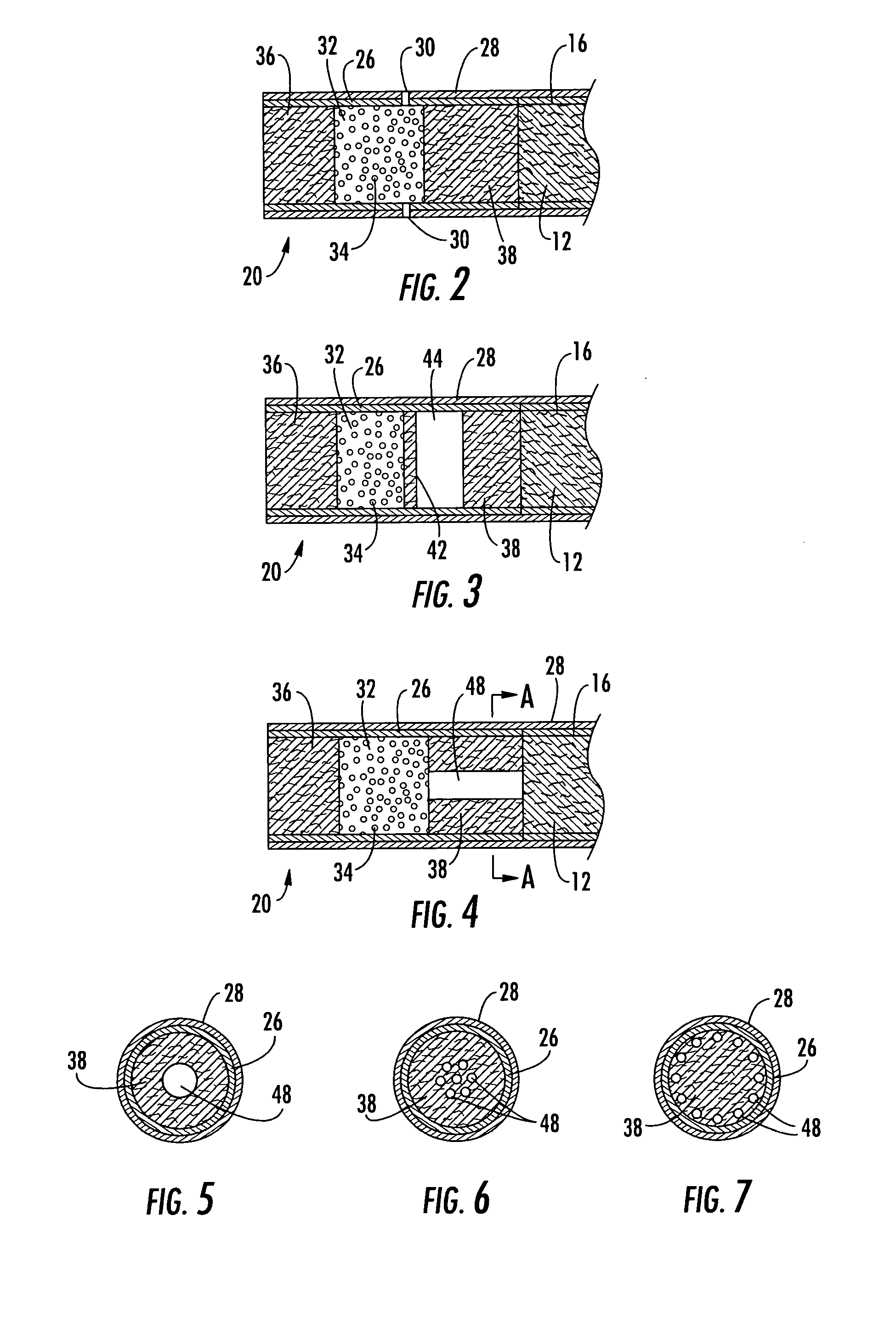

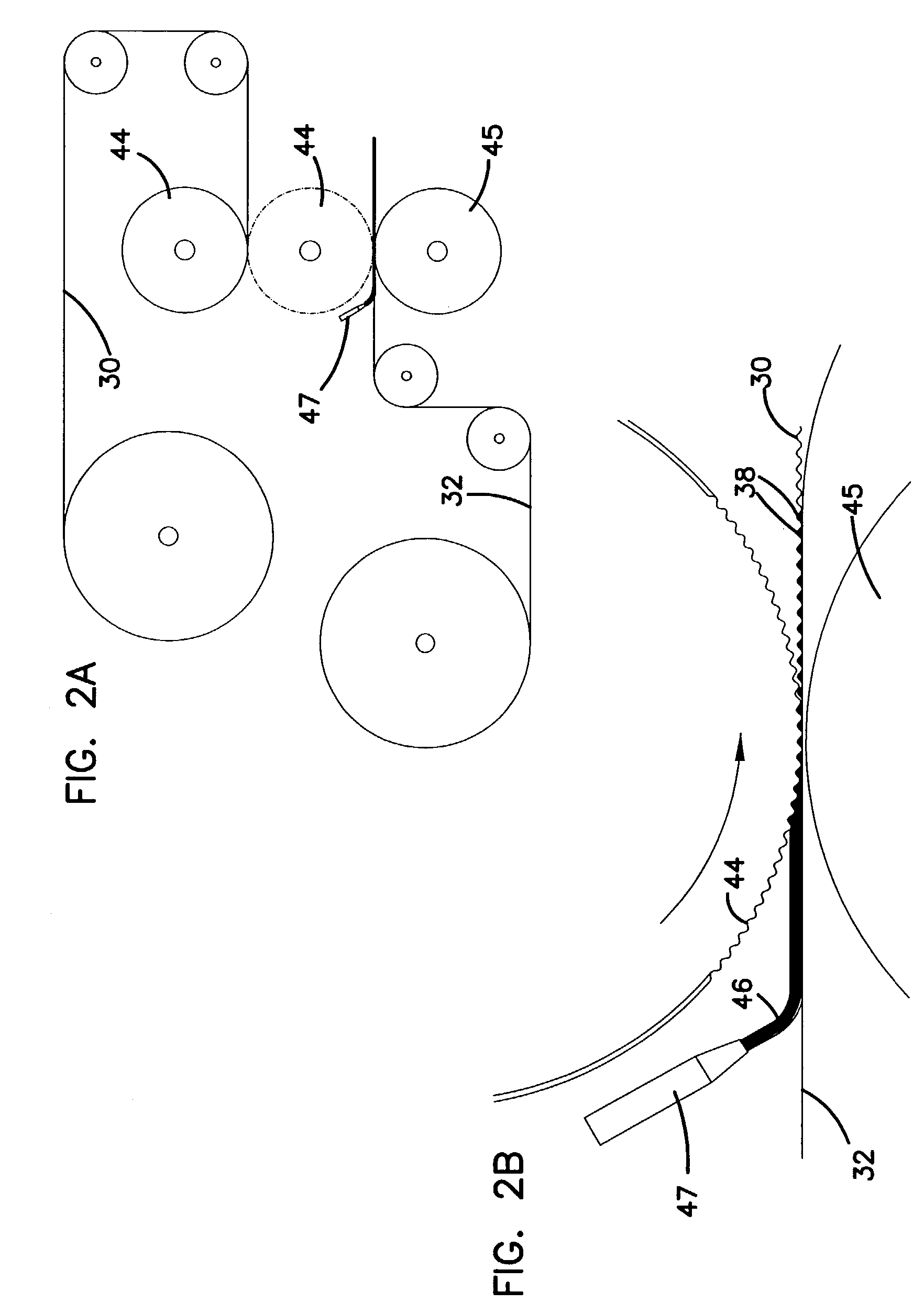

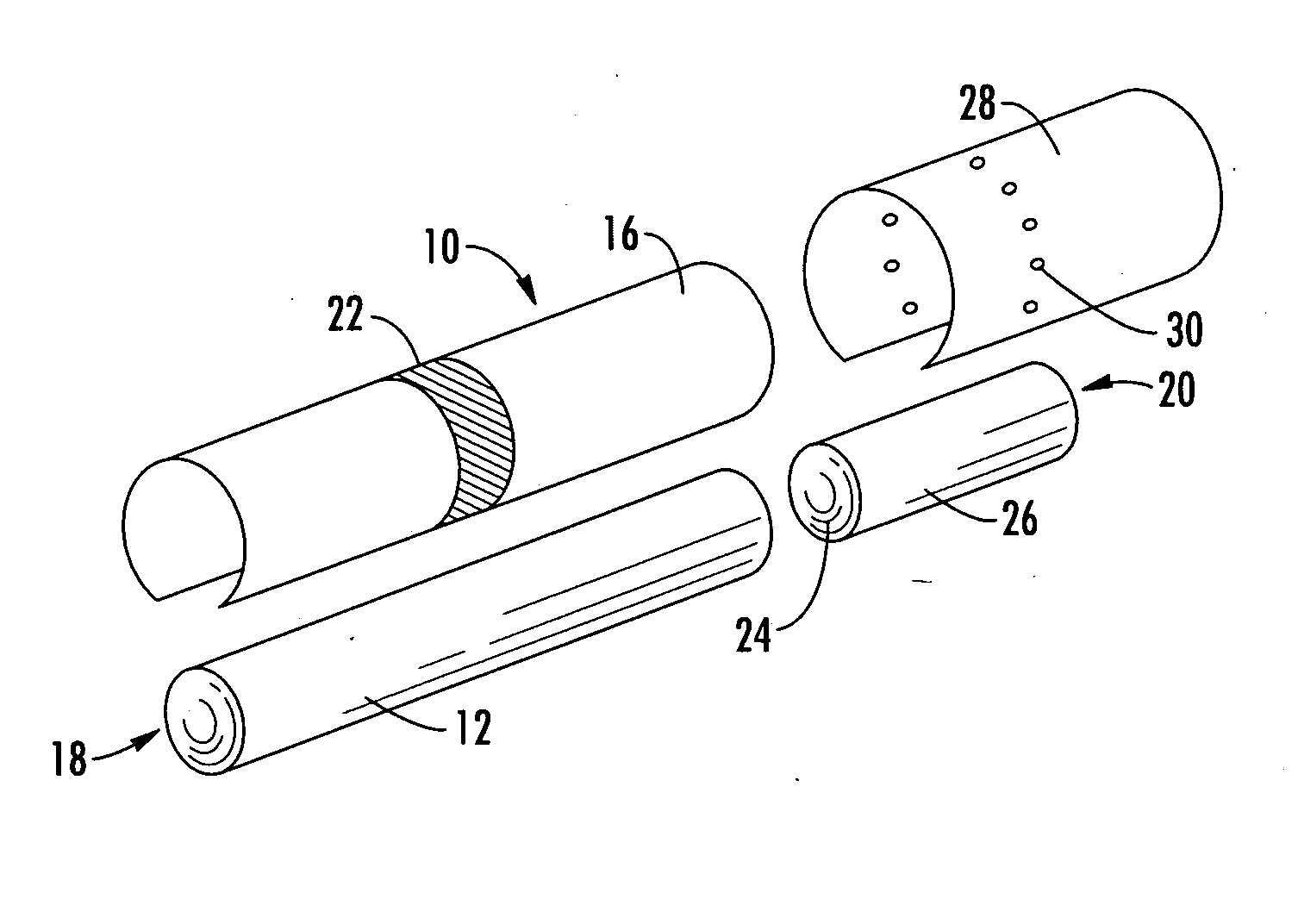

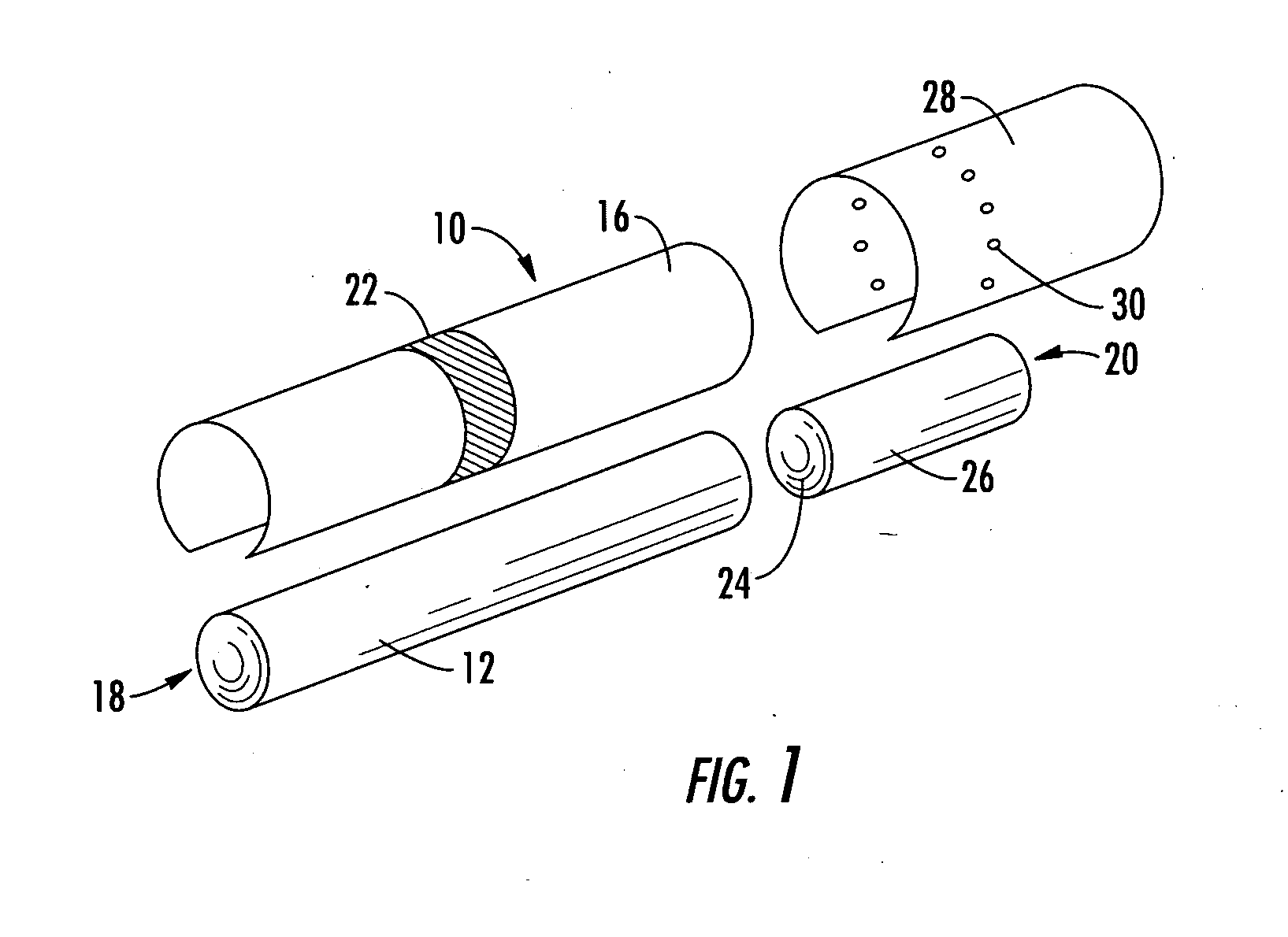

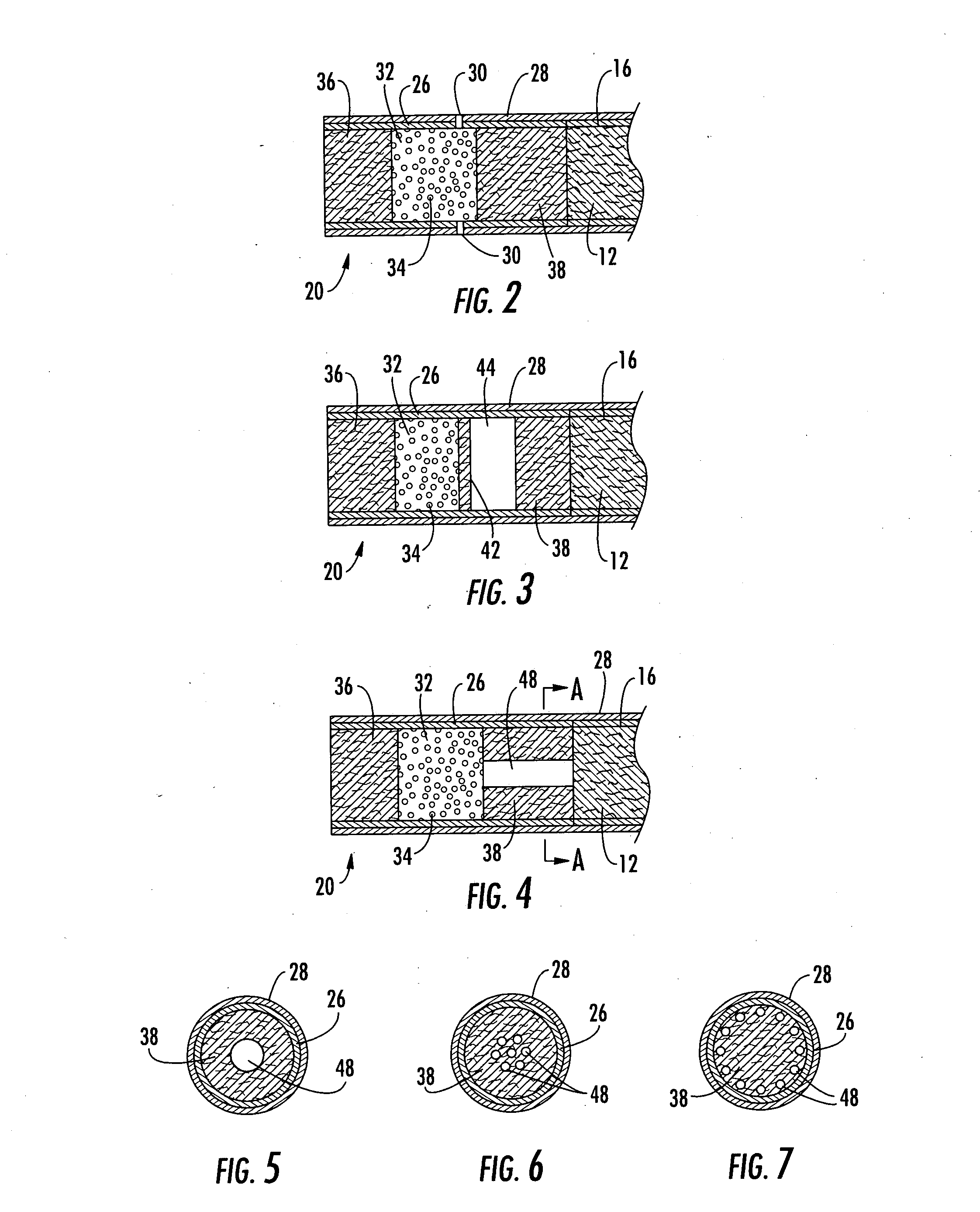

Method and apparatus for incorporating objects into cigarette filters

ActiveUS20050070409A1Tobacco treatmentPaper/cardboard wound articlesFilter materialMechanical engineering

Cigarette filter rods having individual objects positioned at predetermined intervals therein are prepared by transferring the individual objects from a rotating horizontal pan to a rotating vertical wheel and then depositing the object into a web of filter tow. Each object is positioned within the moving web of tow. The web filter material and the objects positioned within the web are introduced into a rod-forming unit wherein the rod is formed. The rate of feed of the filter tow, the rate of rotation of the horizontal pan and the vertical wheel are controlled relative to one another such that objects are positioned at predetermined intervals along the rod. Cigarette filter elements having well controlled amounts of flavorant contained therein can be made from the rods.

Owner:R J REYNOLDS TOBACCO COMPANY

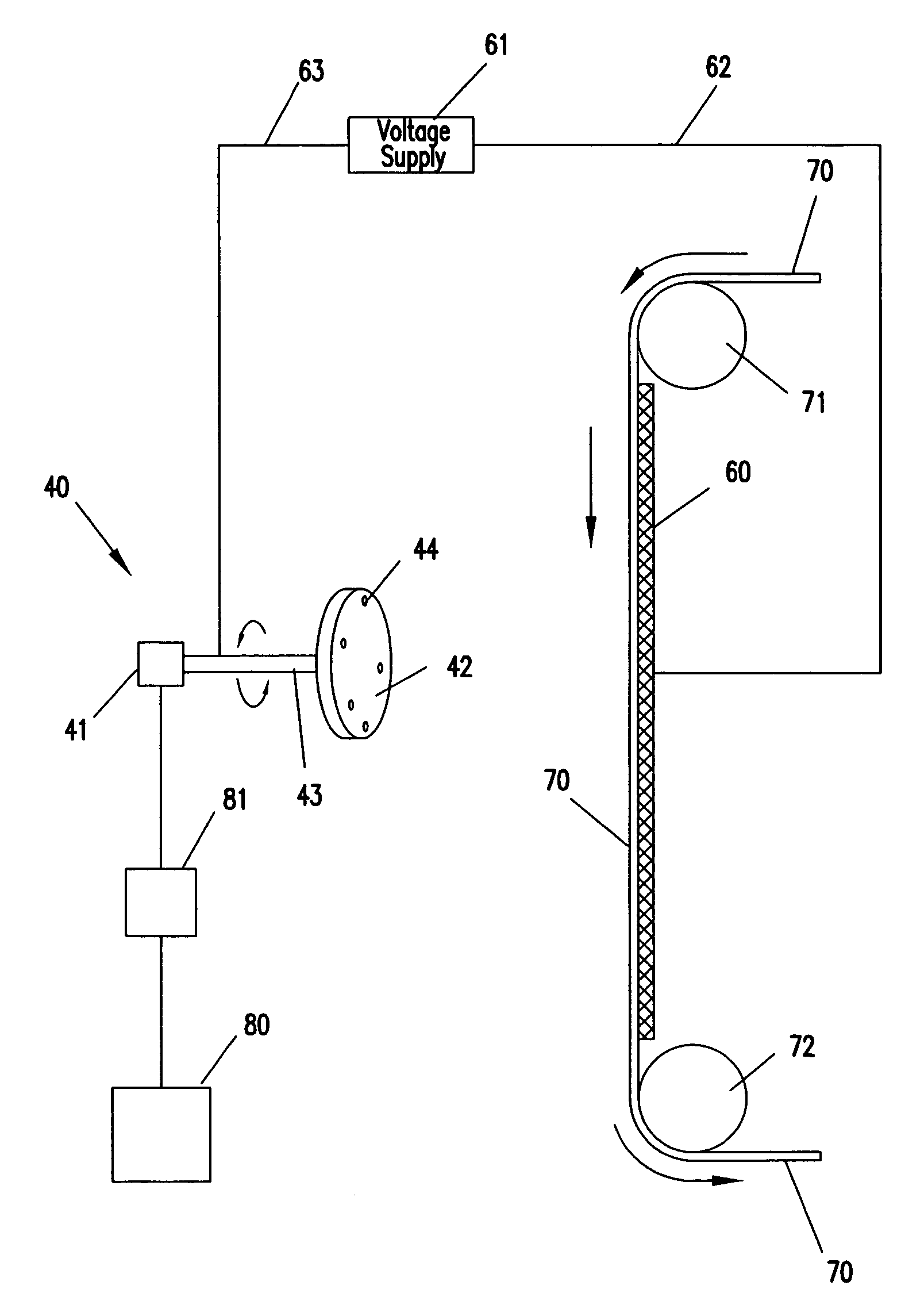

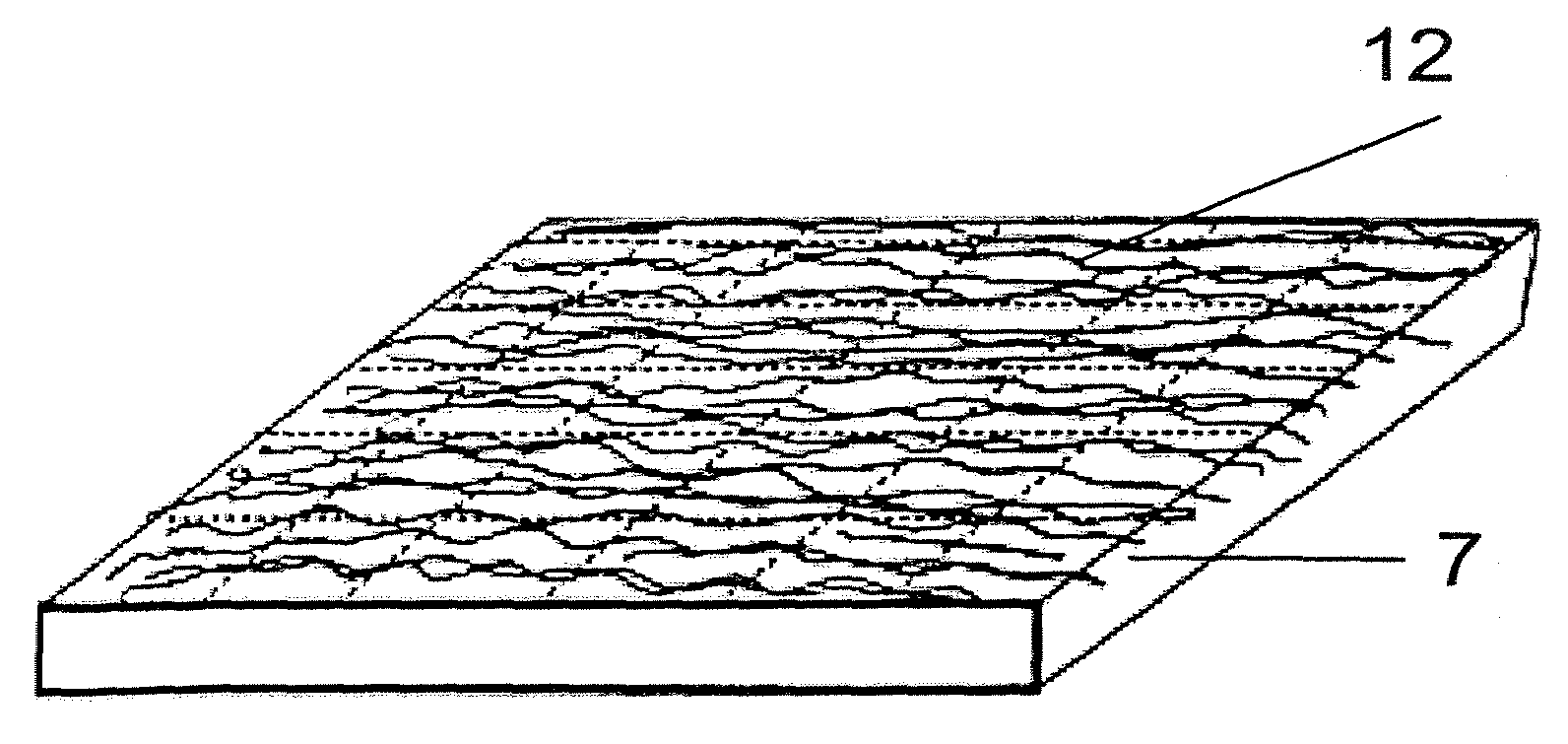

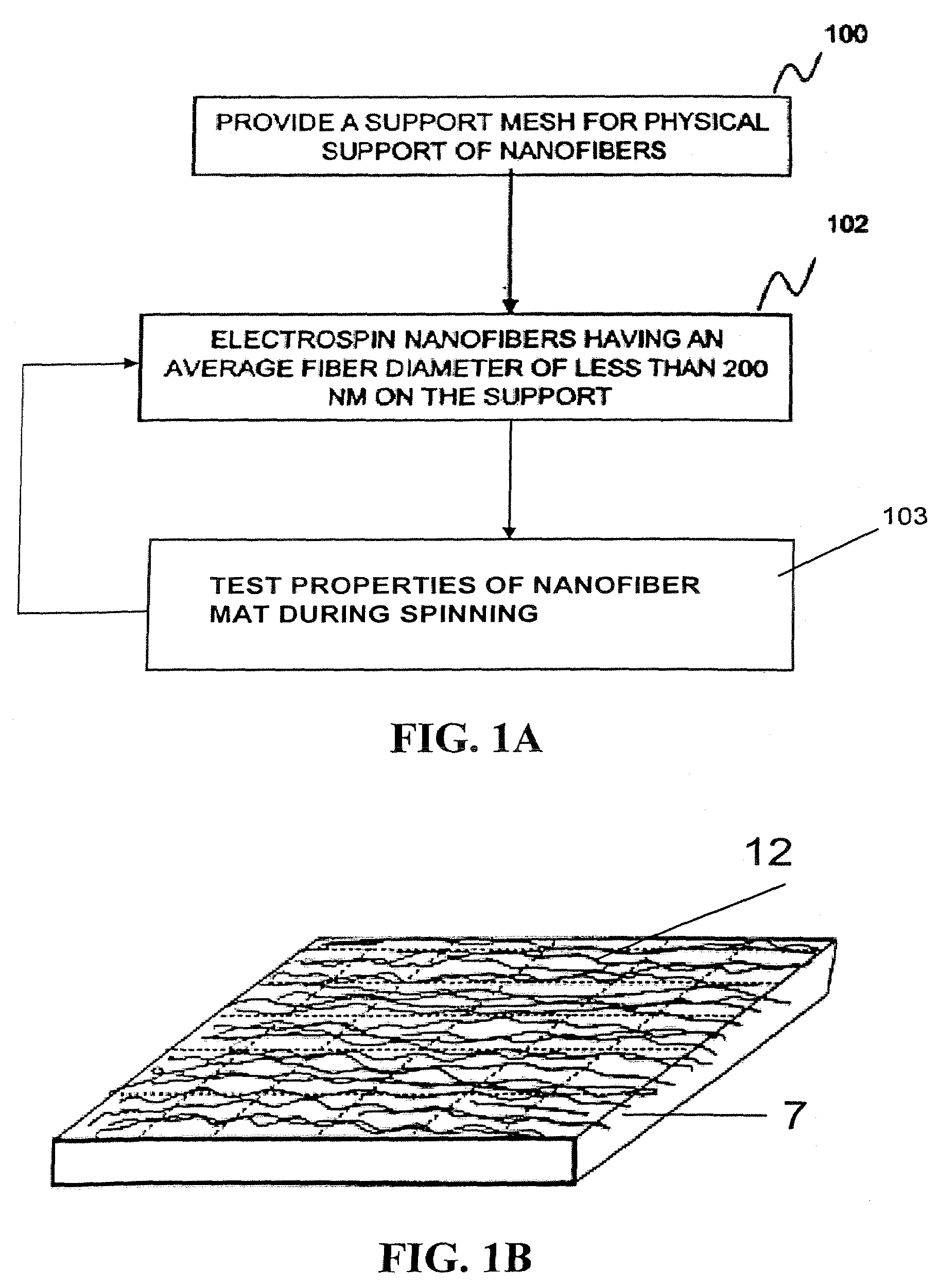

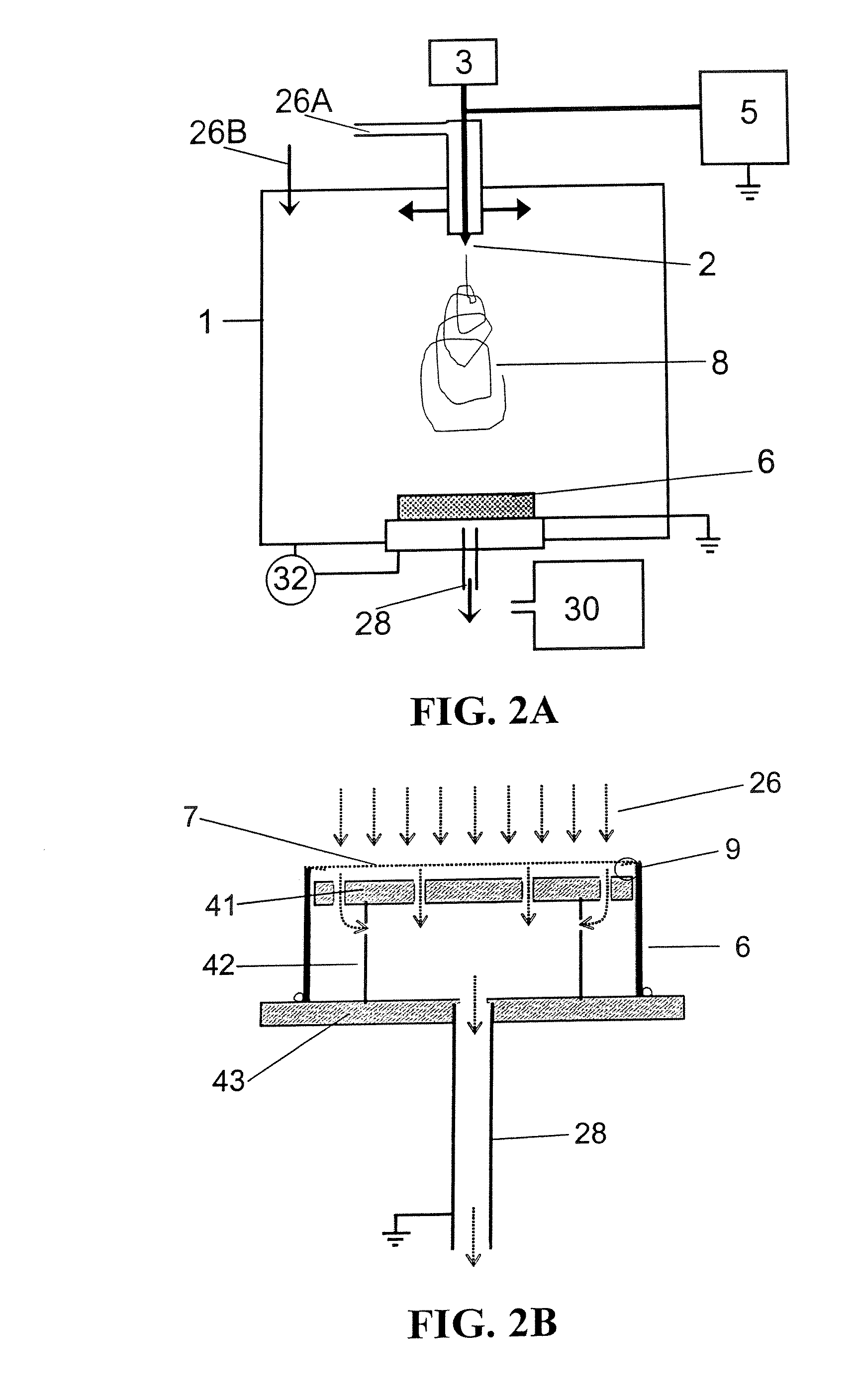

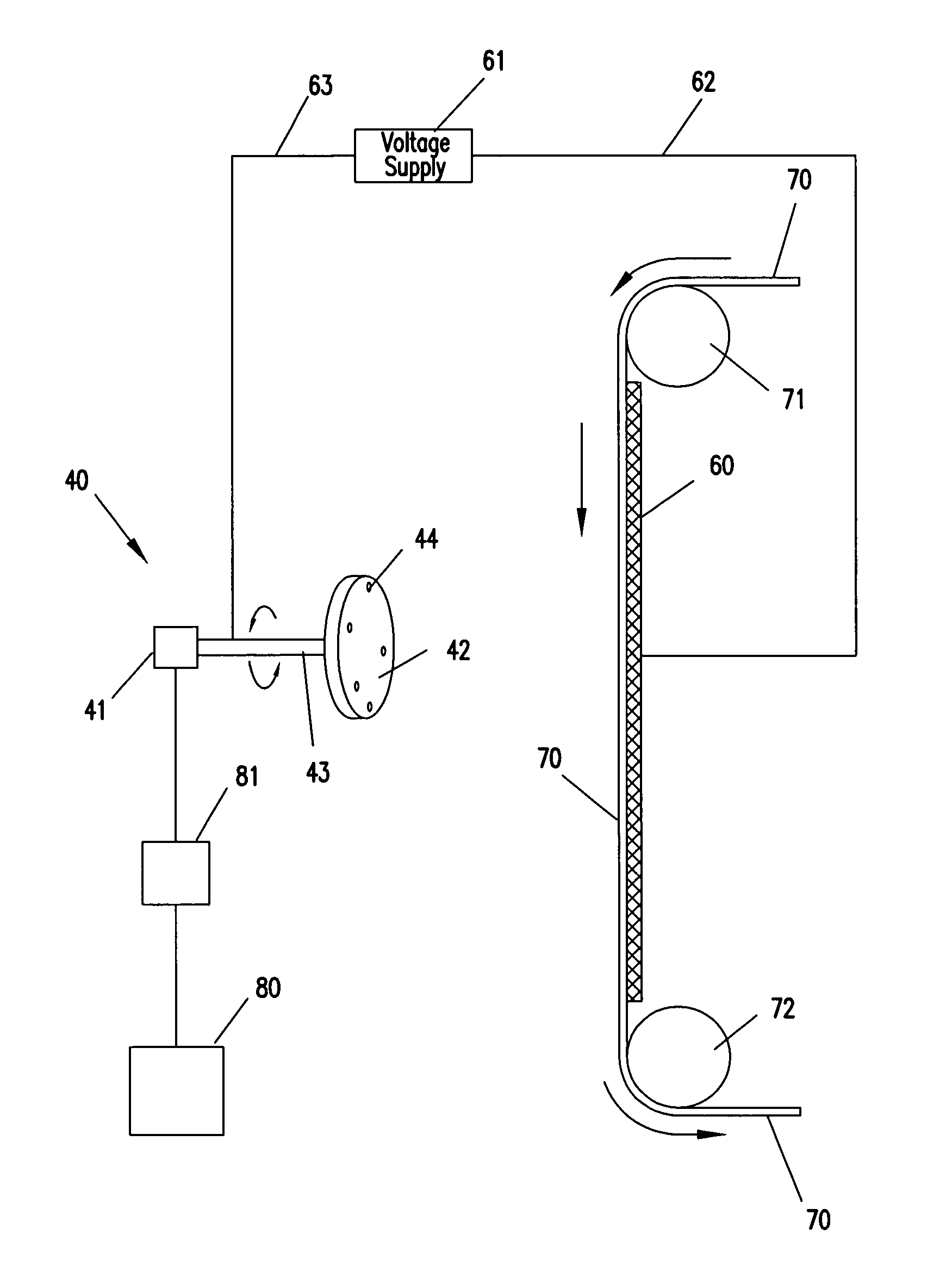

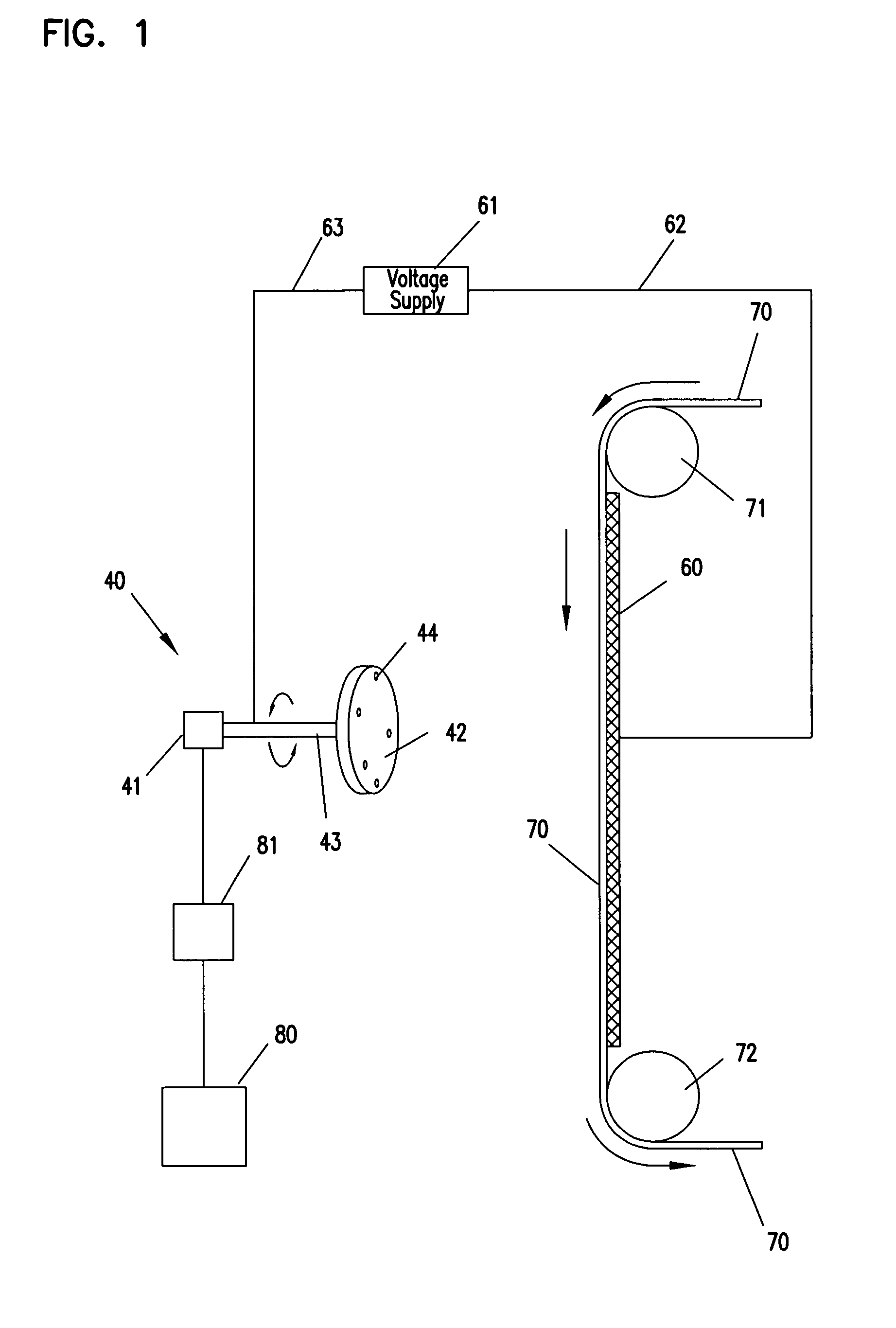

Particle filter system incorporating nanofibers

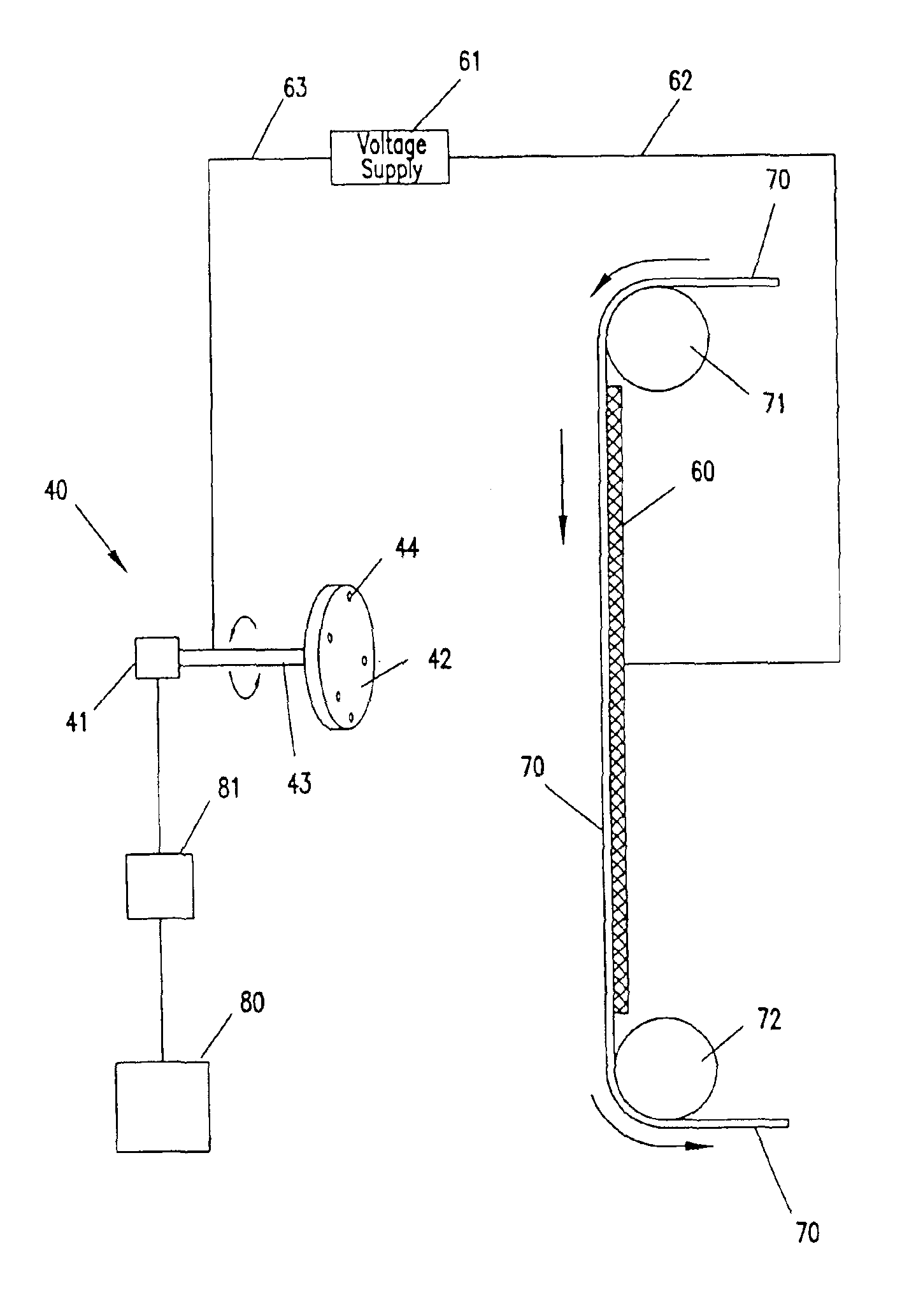

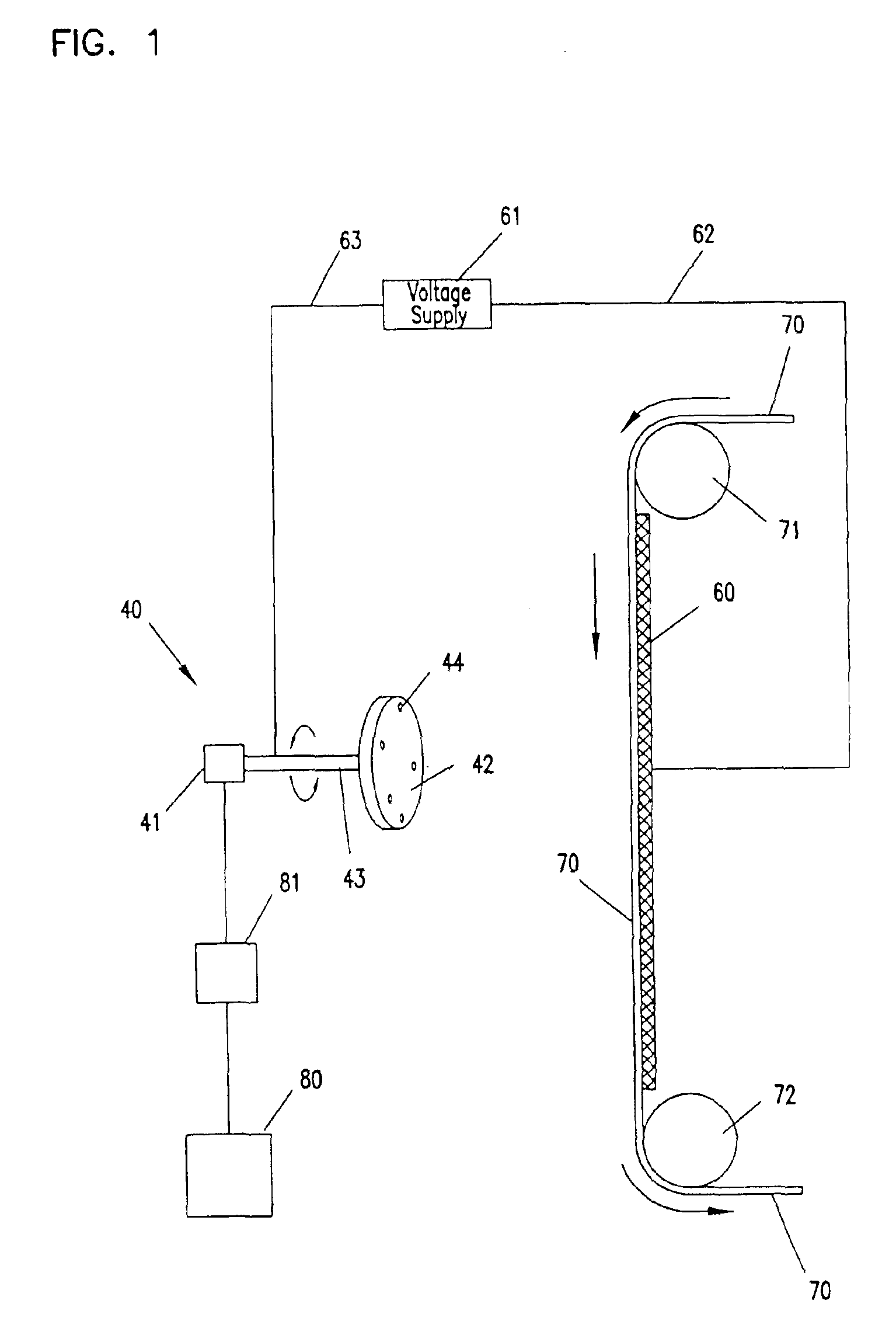

ActiveUS20080110342A1Electric discharge heatingFilament/thread formingElectric field modulationFiber

A filtration device including a filtration medium having a plurality of nanofibers of diameters less than 1 micron formed into a fiber mat in the presence of an abruptly varying electric field. The filtration device includes a support attached to the filtration medium and having openings for fluid flow therethrough. A device for making a filter material. The device includes an electrospinning element configured to electrospin a plurality of fibers from a tip of the electrospinning element, a collector opposed to the electrospinning element configured to collect electrospun fibers on a surface of the collector, and an electric field modulation device configured to abruptly vary an electric field at the collector at least once during electrospinning of the fibers. A method for making a filter material. The method provides a support having openings for fluid flow therethrough, electrospins nanofibers across an entirety of the openings, and abruptly varies an electric field at the collector at least once during electrospinning of the fibers.

Owner:RES TRIANGLE INST

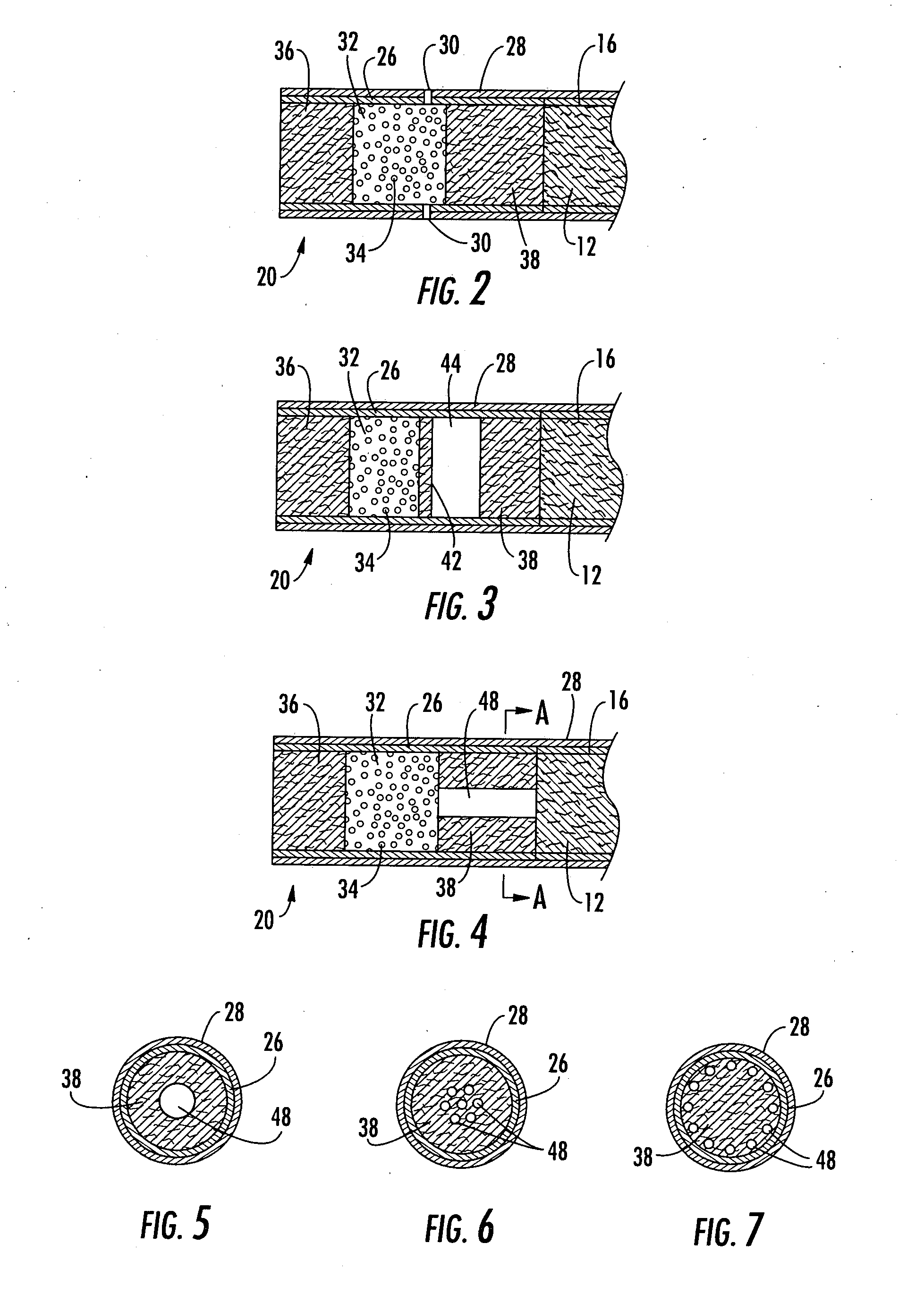

Filtered cigarette incorporating an adsorbent material

ActiveUS20050066984A1Enhanced mixing processTobacco treatmentTobacco smoke filtersFilter materialIon-exchange resin

A filter element incorporating an adsorbent material is provided. The filter element may comprise a first section of filter material and a second section of filter material spaced apart to form a compartment therebetween. The compartment may be filled with one or more adsorbents or the compartment may be divided into two regions, wherein one compartment region is filled with an adsorbent and the other compartment region is either filled with an ion-exchange resin or remains empty. The section of filter material adjacent to the tobacco rod may include one or more channels therethrough for passaging smoke directly from the tobacco rod into the adsorbent-filled compartment. The mouth end section of filter material may contain a breakable capsule, wherein the breakable capsule is filled with a flavoring agent capable of altering the taste characteristics of mainstream smoke.

Owner:R J REYNOLDS TOBACCO COMPANY

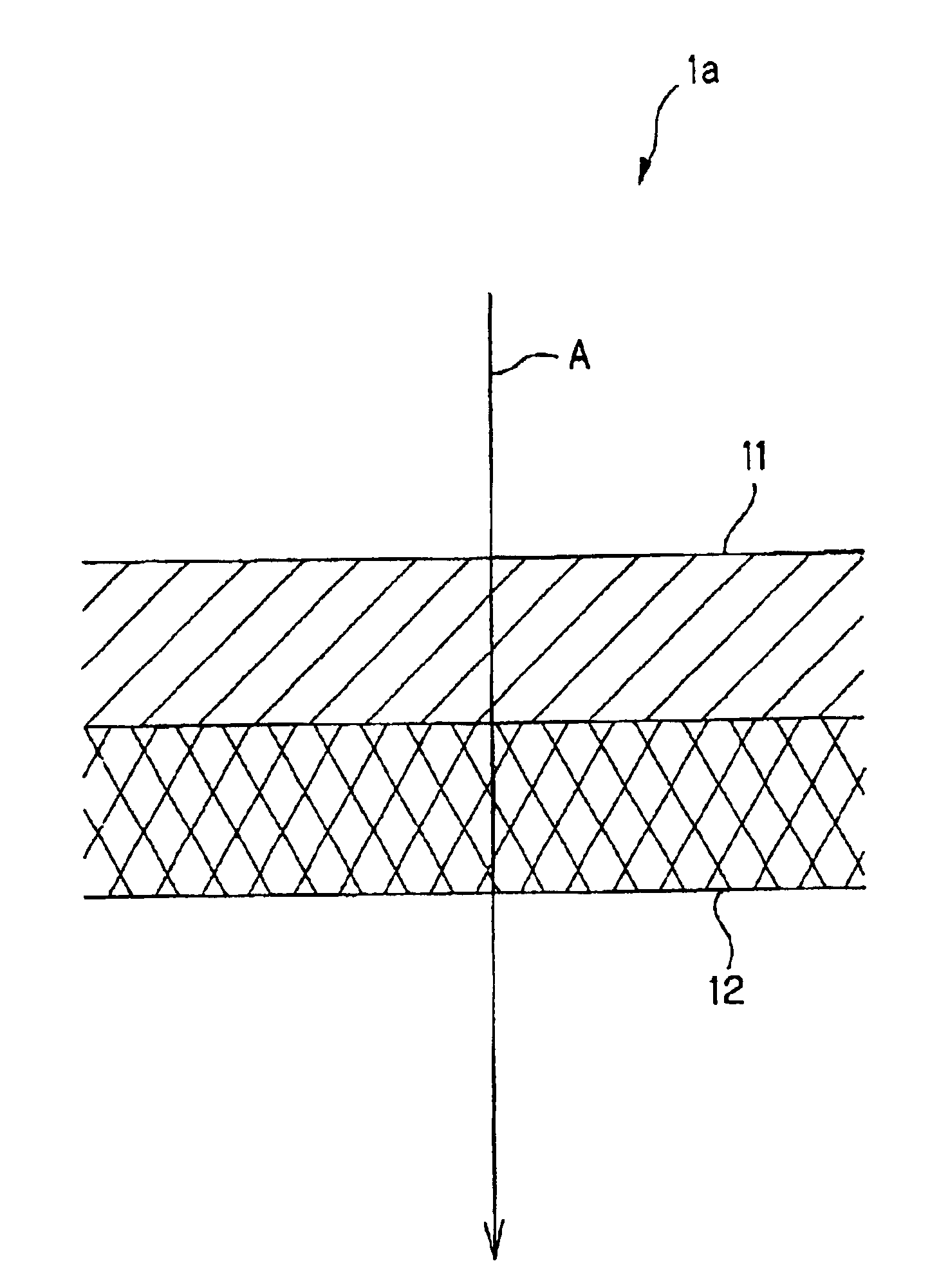

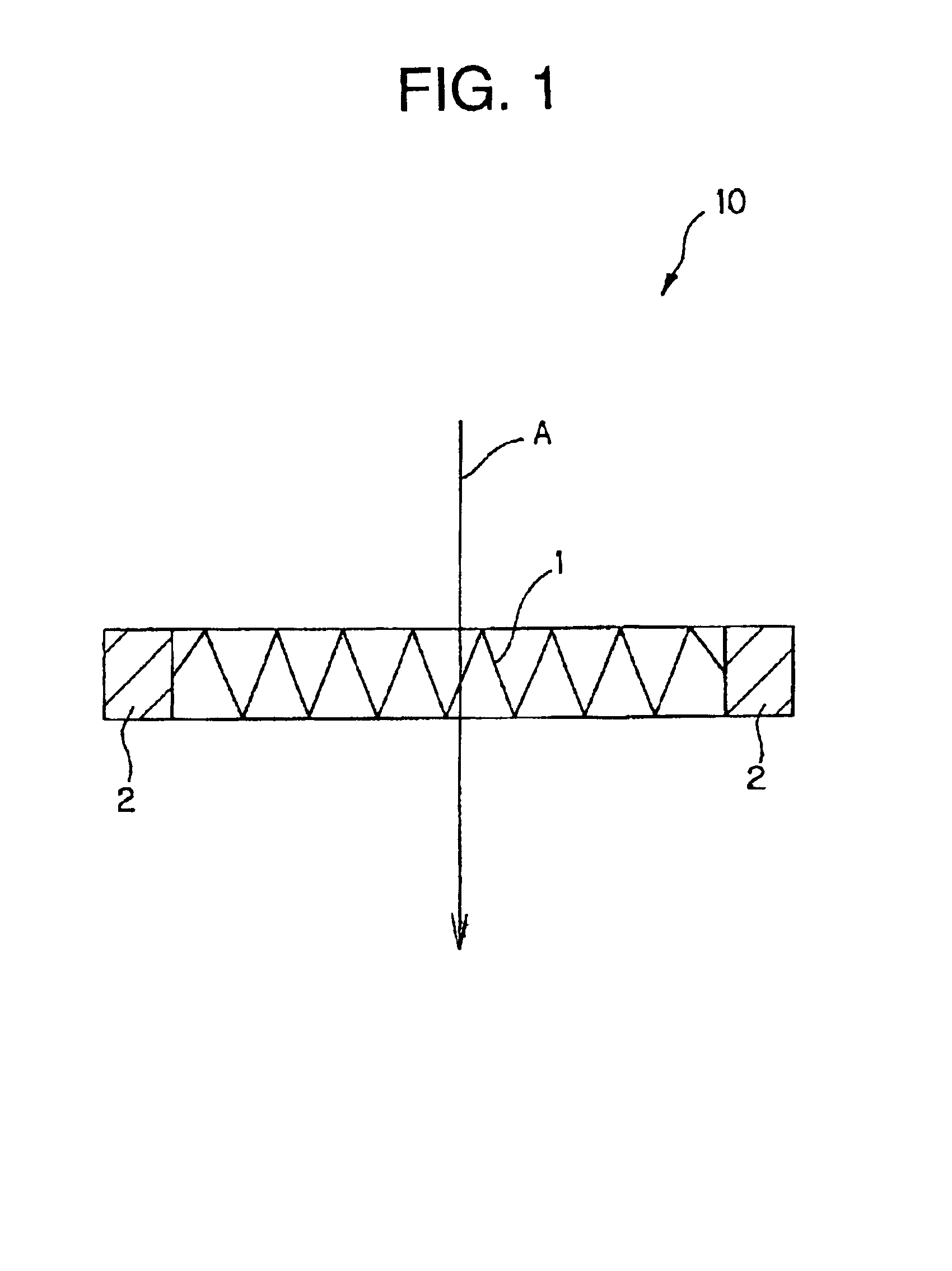

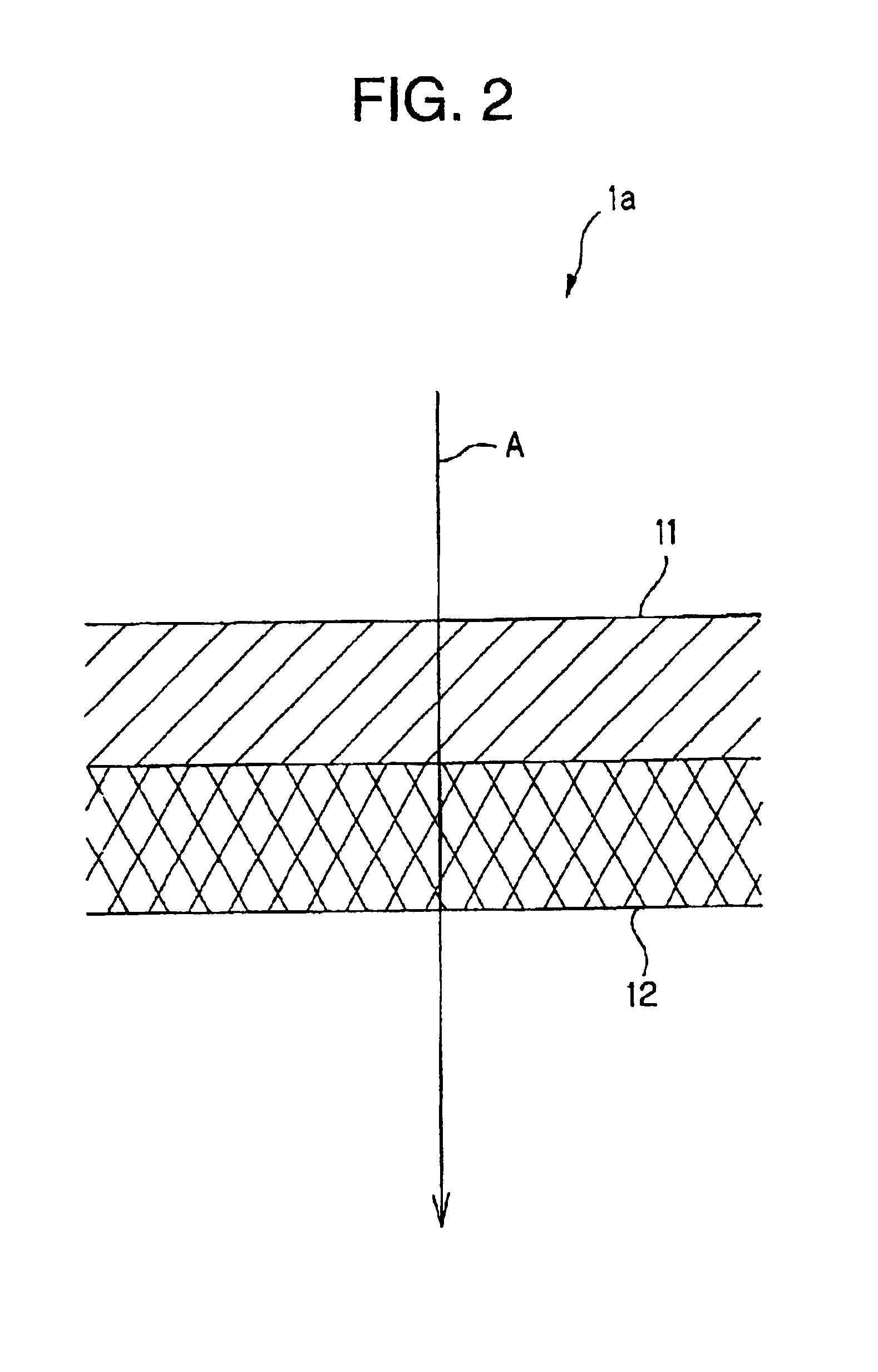

Air filter

InactiveUS6843819B2Low costEfficient captureCombination devicesDispersed particle filtrationHigh densityAir filter

There is provided an air filter, which has a long lifetime and permits to capture effectively carbon particles and reduce costs. The air filter has the first filter layer 11 impregnated with oil and the second filter layer 12, which is provided on the downstream side of the first filter layer 11 and serves as a lipophobic layer having an oil-repellent property. The filter material of the first filter layer 11 has a higher density than the filter material of the second filter material 12.

Owner:TOYO ROKI MFG CO LTD +1

Polymer, polymer microfiber, polymer nanofiber and applications including filter structures

Disclosed are improved polymer materials. Also disclosed are fine fiber materials that can be made from the improved polymeric materials in the form of microfiber and nanofiber structures. The microfiber and nanofiber structures can be used in a variety of useful applications including the formation of filter materials.

Owner:DONALDSON CO INC

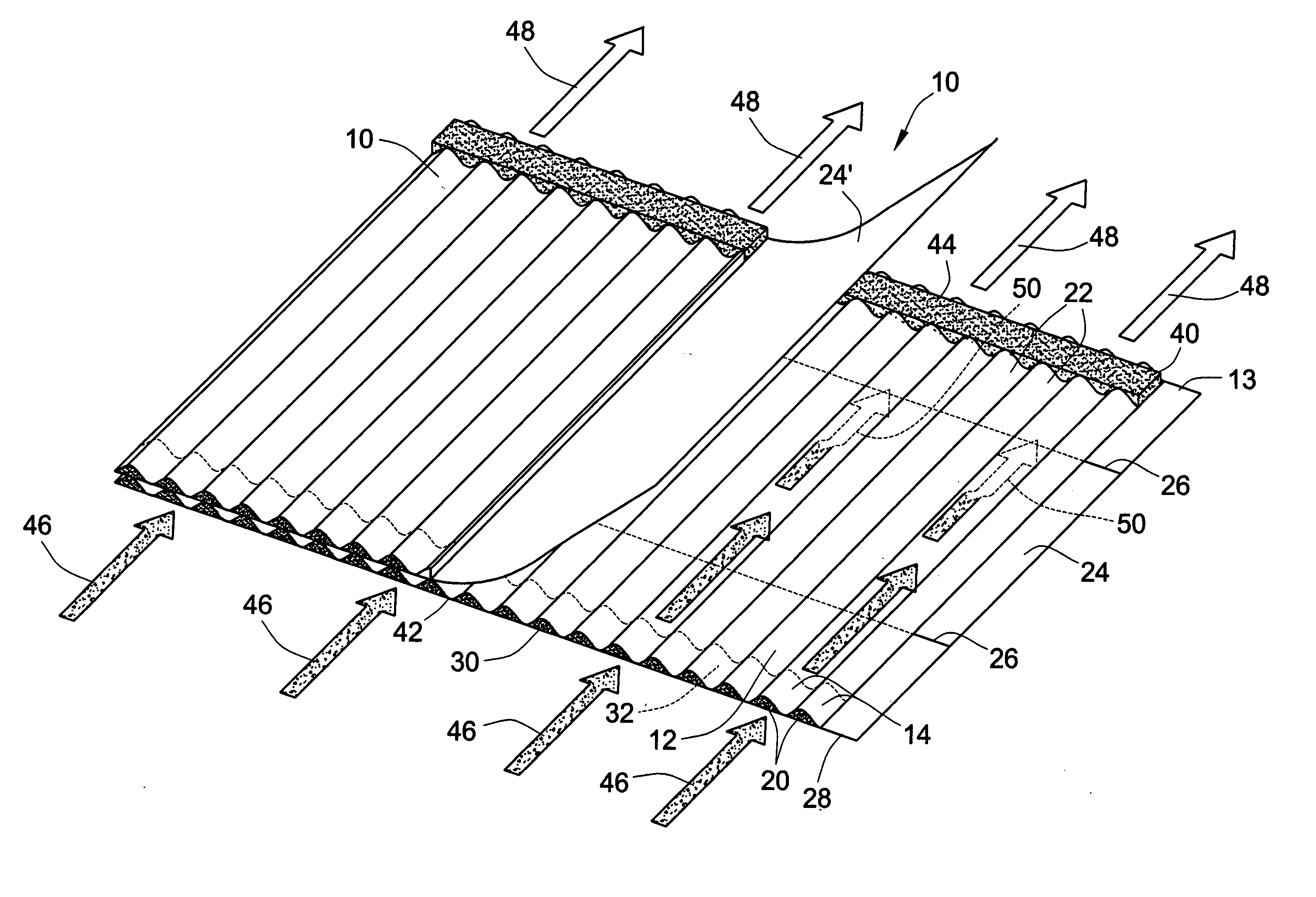

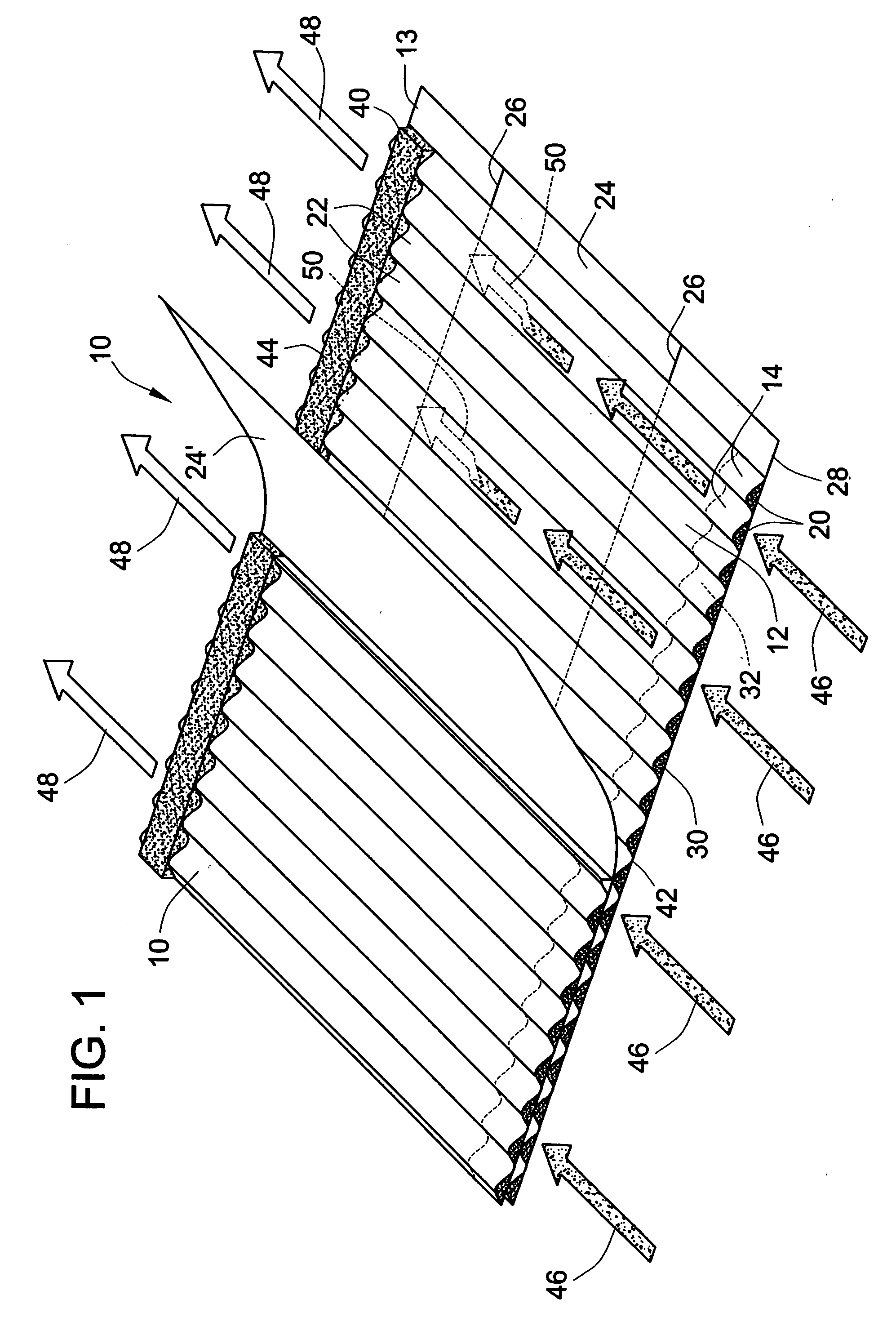

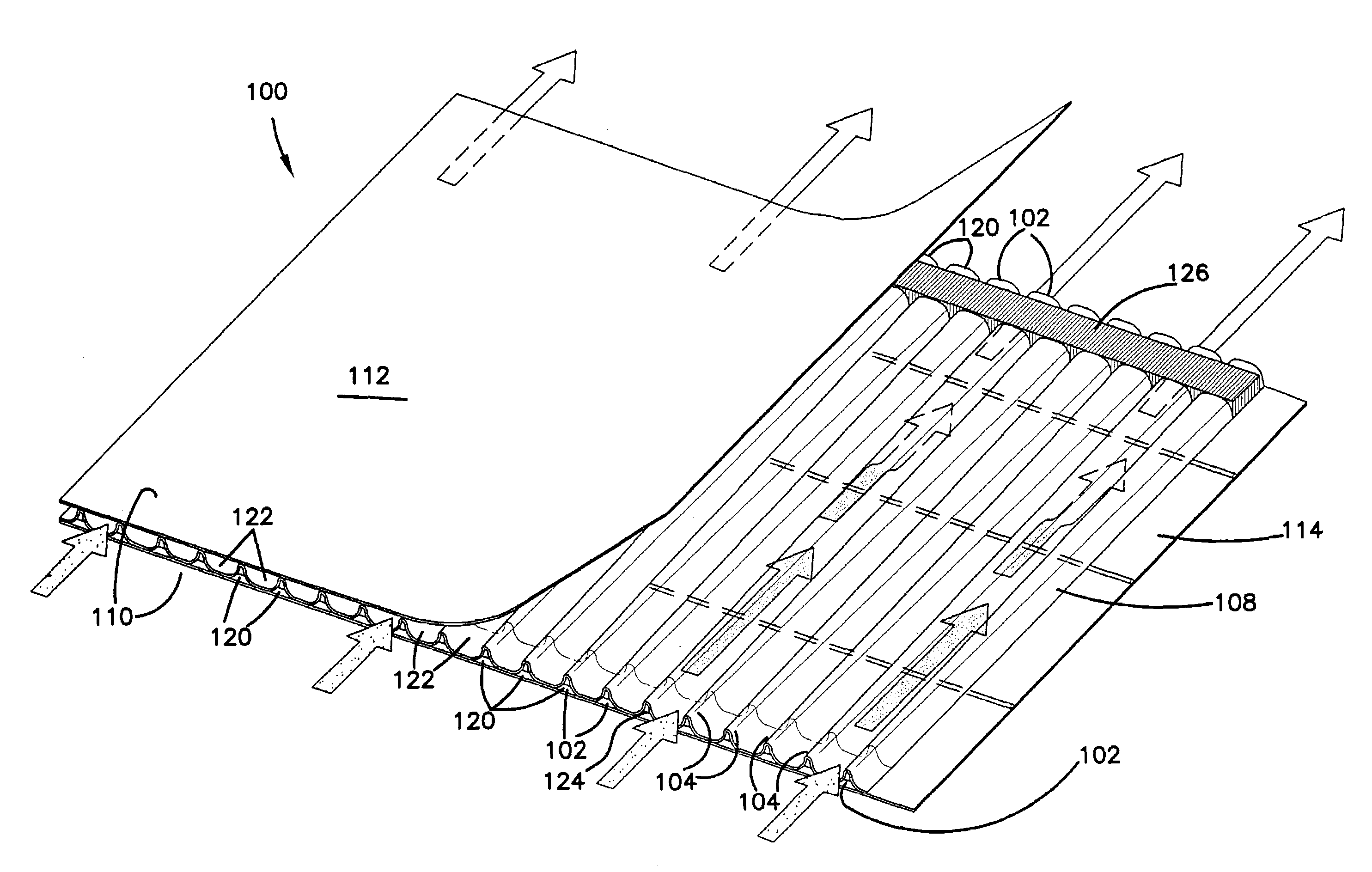

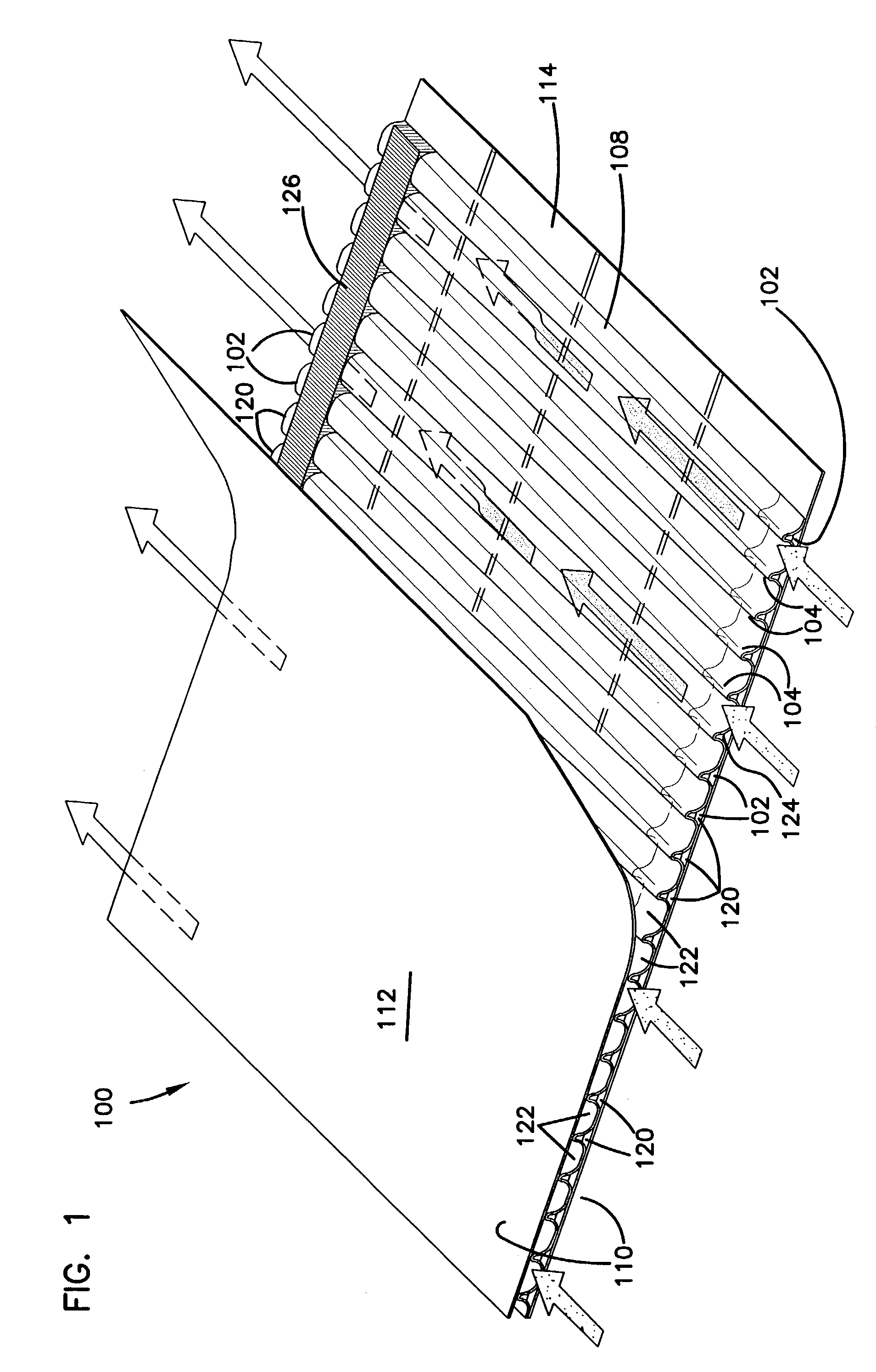

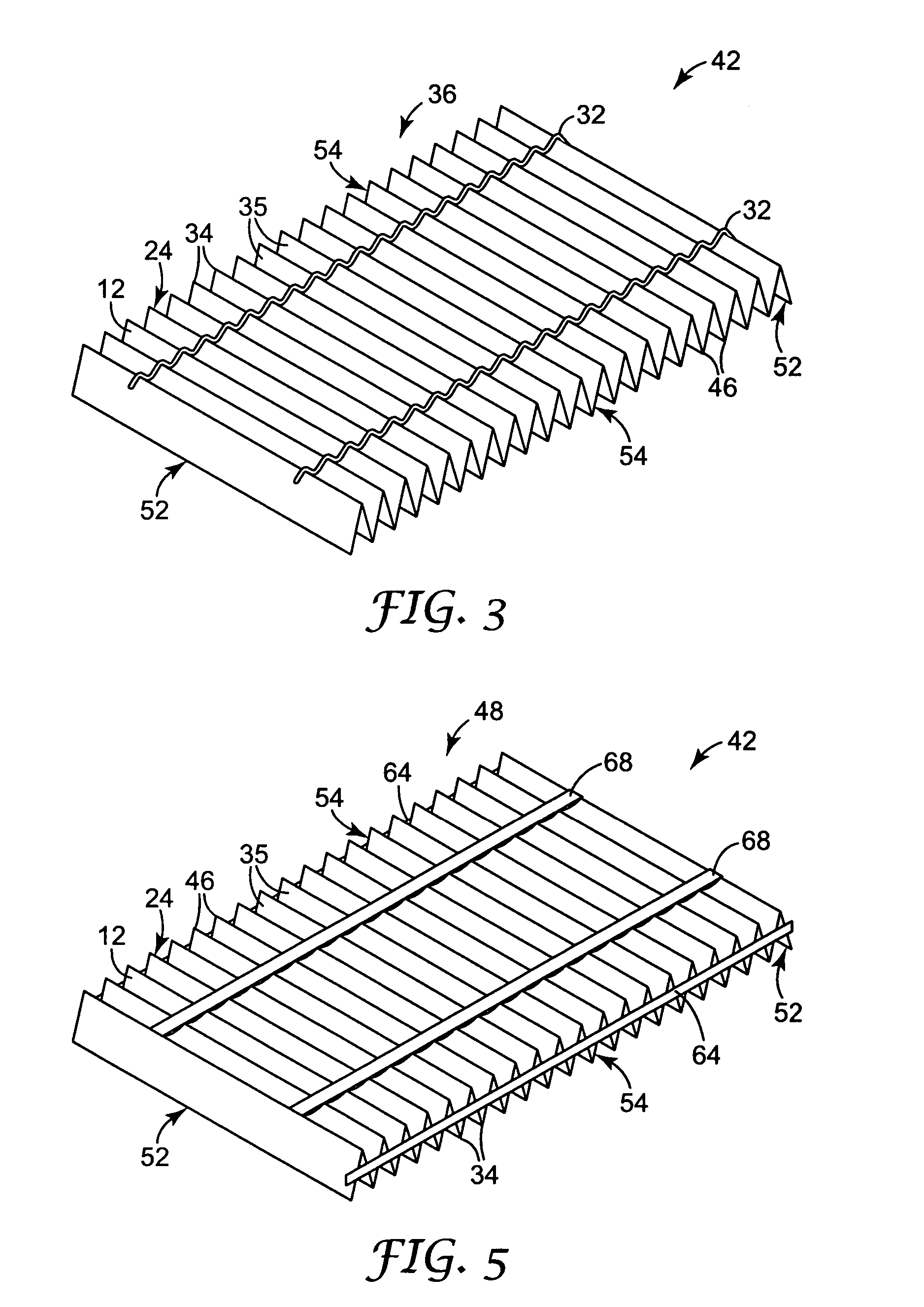

Gathered filter media for an air filter and method of making same

ActiveUS20060091066A1Reduce complexityReduce manufacturing costGas treatmentMechanical working/deformationAir filterFilter media

A filter media including a gathered sheet of porous filter material, is provided, together with an apparatus and method for fabricating such a gathered sheet of porous filter material. An improved filter apparatus incorporating such gathered porous filter material is also provided. By gathering the porous filter material, rather than forming convolutions through corrugating or pleating, as was done in the past, a desirable convoluted shape is achieved with little or no compression of the filter media.

Owner:BALDWIN FILTERS

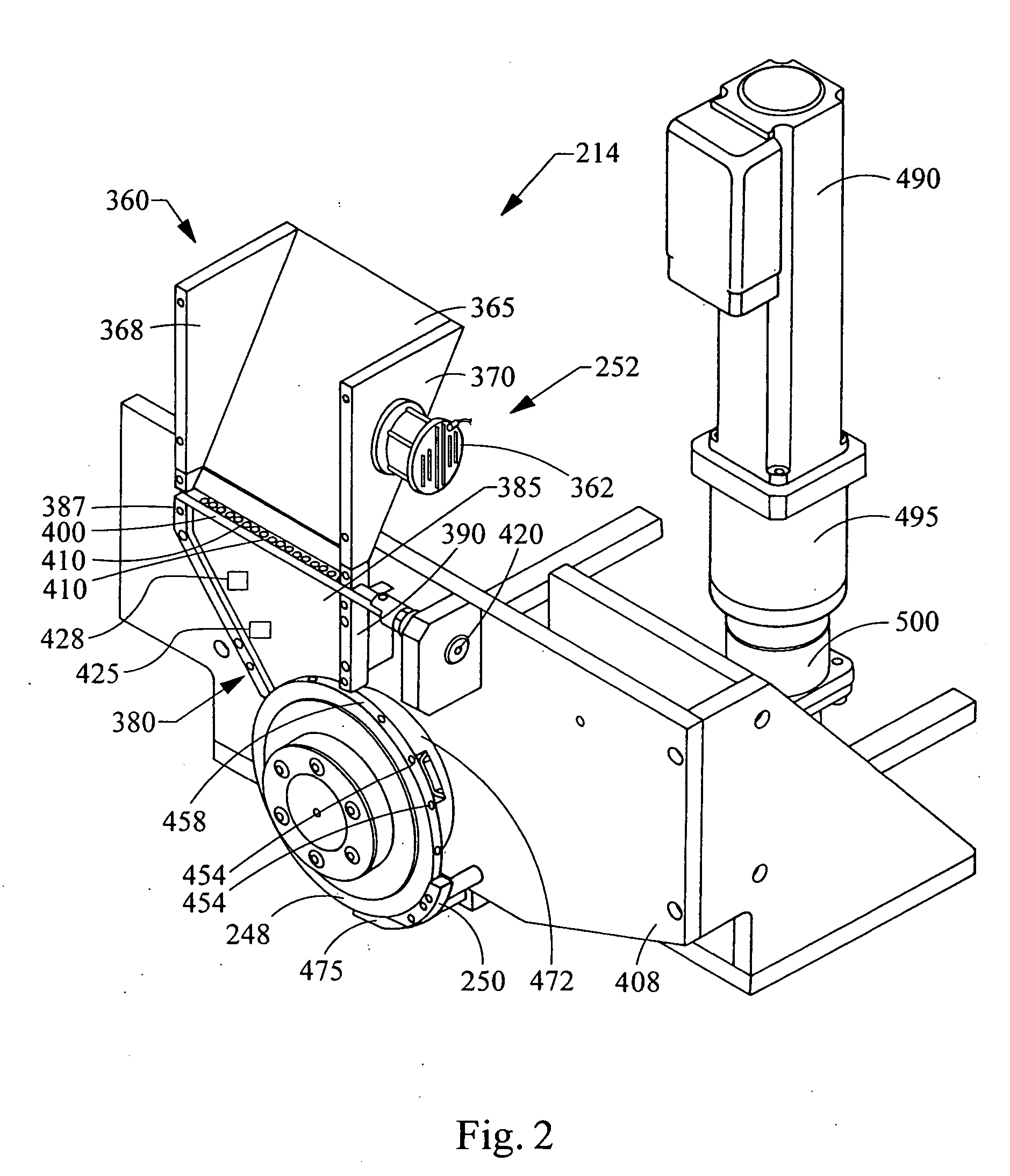

Apparatus for Inserting Objects into a Filter Component of a Smoking Article, and Associated Method

ActiveUS20080302373A1Paper/cardboard wound articlesCigarette manufactureFilter materialBiomedical engineering

An apparatus for manufacturing a rod member for a cigarette filter element, is provided. Each rod member defines a longitudinal axis and includes a generally longitudinally-extending filter material and a plurality of objects disposed therein along the longitudinal axis. Such an apparatus comprises a rod-forming unit configured to form a continuous supply of a filter material into a continuous cylindrical rod member. An object insertion unit is configured to introduce a plurality of objects into engagement with the rod member. A rod-dividing unit is configured to divide the rod member into a plurality of rod portions such that each rod portion includes a plurality of the objects. Associated method are also provided.

Owner:R J REYNOLDS TOBACCO COMPANY

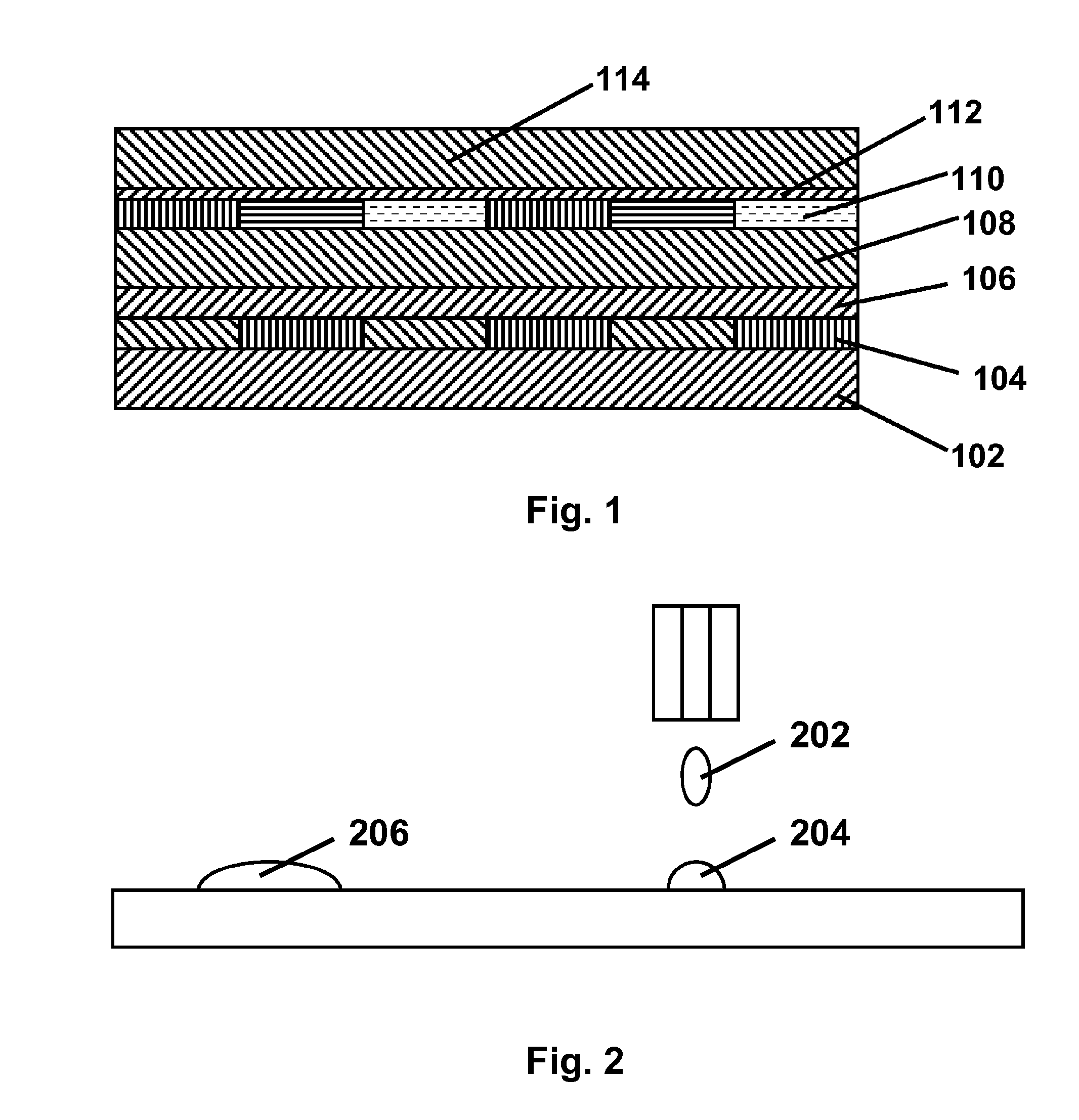

Processes for the production of electro-optic displays, and color filters for use therein

ActiveUS20090004442A1Decorative surface effectsPhotomechanical apparatusRadiative transferEngineering

Processes are provided for depositing multiple color filter materials on a substrate to form color filters. In a first process, the surface characteristic of a substrate is modified by radiation so that a flowable form of a first color filter material will be deposited on a first area, and converted to a non-flowable form. A second color filter material can then be deposited on a second area of the substrate. In a second process, first and second color filter materials are deposited on separate donor sheets and transferred by radiation to separate areas of the substrate. A third process uses flexographic printing to transfer the first and second color filter materials to the substrate.

Owner:E INK CORPORATION

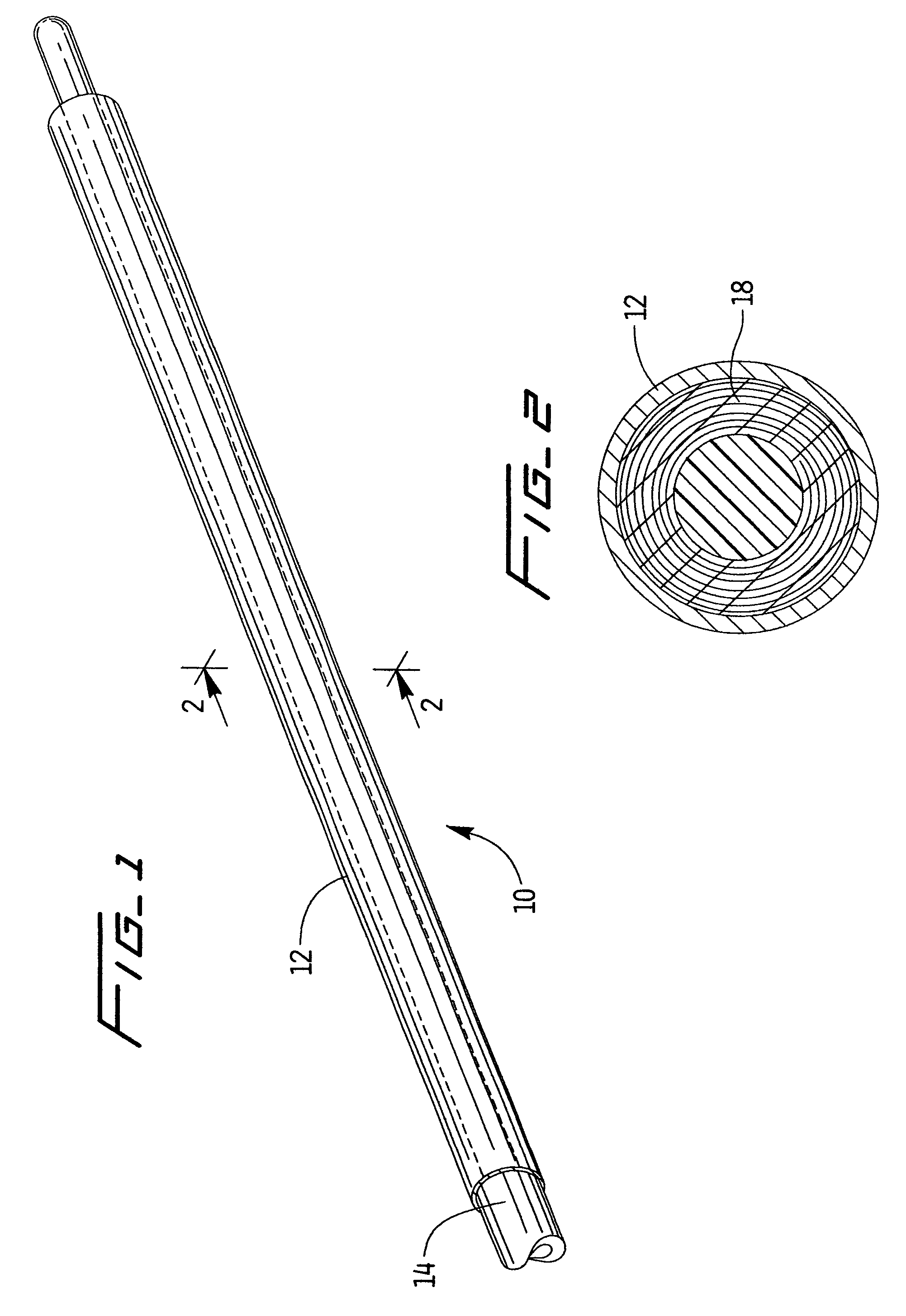

Distal protection device

A distal protection device comprising a catheter having a first strut movable from a collapsed configuration to an expanded configuration having a first dimension and a second strut movable from a collapsed configuration to an expanded configuration having a second dimension larger than the first dimension. Movement of the first strut deploys filter material to a first position having a first deployed dimension and movement of the second strut to a first position deploys filter material to a second deployed dimension larger than the first expanded dimension.

Owner:REX MEDICAL LP

Filtered cigarette incorporating an adsorbent material

ActiveUS20050066981A1Enhanced mixing processCigar manufactureTobacco smoke filtersFilter materialIon-exchange resin

A filter element incorporating an adsorbent material is provided. The filter element may comprise a first section of filter material and a second section of filter material spaced apart to form a compartment therebetween. The compartment may be filled with one or more adsorbents or the compartment may be divided into two regions, wherein one compartment region is filled with an adsorbent and the other compartment region is either filled with an ion-exchange resin or remains empty. The section of filter material adjacent to the tobacco rod may include one or more channels therethrough for passaging smoke directly from the tobacco rod into the adsorbent-filled compartment. The mouth end section of filter material may contain a breakable capsule, wherein the breakable capsule is filled with a flavoring agent capable of altering the taste characteristics of mainstream smoke.

Owner:R J REYNOLDS TOBACCO COMPANY

Method of making a fluted filter media for air filter

InactiveUS7329326B2Improve flow characteristicsReduce restrictionsMechanical working/deformationLamination ancillary operationsFluteAir filter

Fluted filter media includes filter material having a plurality of flutes formed therein having alternating ends of adjacent flutes closed to force fluid through filter material. A first embodiment of the filter media includes tapered flutes which have the open ends of the flutes larger in cross-section than the closed flutes, wherein the upstream open flutes converge toward the downstream end and the upstream closed end flutes diverge toward the downstream end. A second embodiment includes filter media which is asymmetric formed with dissimilar upstream and downstream flute cross-sections with larger flute openings to the upstream side of the filter. A third embodiment includes filter media with an upstream edge crushed to improve flow at the upstream edge. A fourth embodiment includes filter media with the upstream sealing material recessed from the upstream edge for reducing effects from blockages at the upstream edge of the filter.

Owner:DONALDSON CO INC

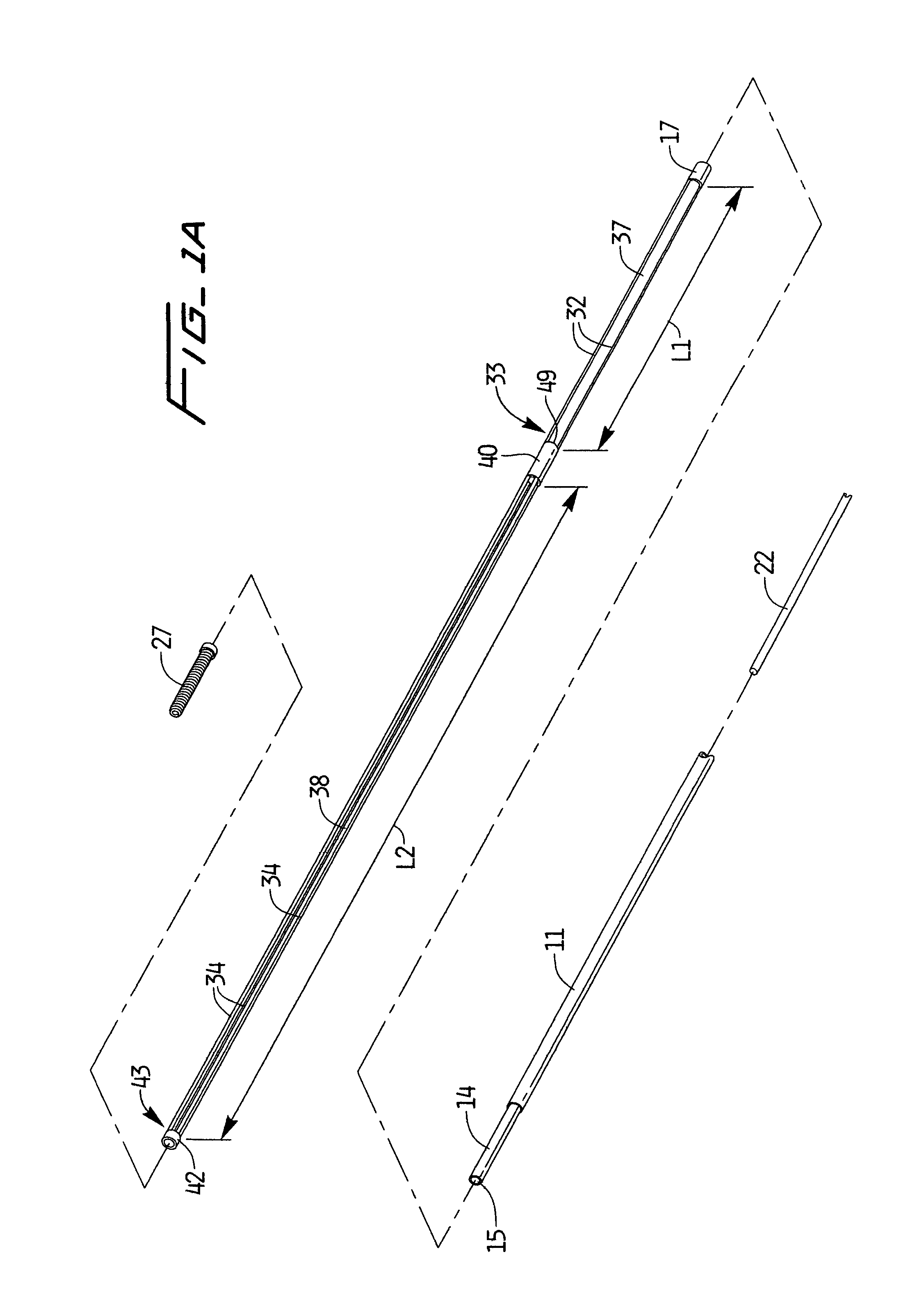

Apparatus for inserting objects into a filter component of a smoking article, and associated method

An apparatus and associated method is provided for forming a rod for use in the manufacture of cigarette filter elements. A continuous supply of a filter material is formed into a continuous filter rod by a rod-forming unit. An object insertion unit is configured to insert a plurality of first objects and a plurality of second objects into the continuous filter rod. A rod-dividing unit is configured to subdivide the continuous filter rod, at predetermined intervals along the longitudinal axis thereof, into a plurality of filter rod portions such that each filter rod portion includes at least one first object and at least one second object disposed therein, with the first objects being different from the second objects.

Owner:R J REYNOLDS TOBACCO COMPANY

Melt-blown nonwoven fabric, process for producing same and the uses thereof

InactiveUS6207601B1Avoid undesirable oxidative processEliminate useLayered productsTobacco smoke filtersMean diameterPolymer science

The disclosure relates to a melt-blown non-woven fabric based on cellulose esters, with fibers of mean diameter less than about 10 microns. The fabric contains 0-10 wt. % extractable softener, has a reflection factor determined according to DIN 53 145 Part I (1992) of more than 60% and the cellulose ester has a degree of substitution DS of about 1.5-3.0. The softener is preferably water-extractable. A melt-blown non-woven fabric is produced with the cellulose ester as follows: a cellulose ester, cellulose acetate, with a DS of about 1.5-3.0, in particular 1.7-2.7, is mixed with softener in a weight ratio of about 2:1 to 1:4 and simultaneously heated and melted. The mixture of softener and cellulose ester has a melting index MFI (210 / 2.16) according to DIN 53 735 of about 400 to 5 g / 10 min., in particular 300 to 50 g / 10 min. The melt is worked in a melt-blown spinning device into a melt-blown non-woven fabric and the softener is then extracted with a softener solvent to leave a proportion of 0-10 wt. %. The melt-blown non-woven fabric is especially suitable as a filter material.

Owner:RHODIA ACETOW AG

Apparatus for inserting objects into a filter component of a smoking article, and associated method

ActiveUS7972254B2Paper/cardboard wound articlesCigarette manufactureFilter materialBiomedical engineering

Owner:R J REYNOLDS TOBACCO COMPANY

Apparatus and method for harvesting and handling tissue samples for biopsy analysis

InactiveUS20070166834A1Exemption stepsReduce the numberPreparing sample for investigationBiological testingWaxTissue biopsy

A sectionable cassette for use in a process for harvesting and handling tissue samples for biopsy analysis is disclosed. In the procedure, a tissue biopsy sample is placed on a tissue trapping and supporting material that can withstand tissue preparation procedures and which can be cut with a microtome. The tissue is immobilized on the material and the material and the tissue are held in the cassette and are subjected to a process for replacing tissue fluids with wax, and then the tissue and the supporting material are sliced for mounting on slides using a microtome. Harvesting devices and containers using the filter material are disclosed. An automated process is also disclosed. One embodiment has the tissue trapping and supporting material porous and another embodiment includes a tissue supporting material that is not easily microtomed.

Owner:BIOPATH AUTOMATION

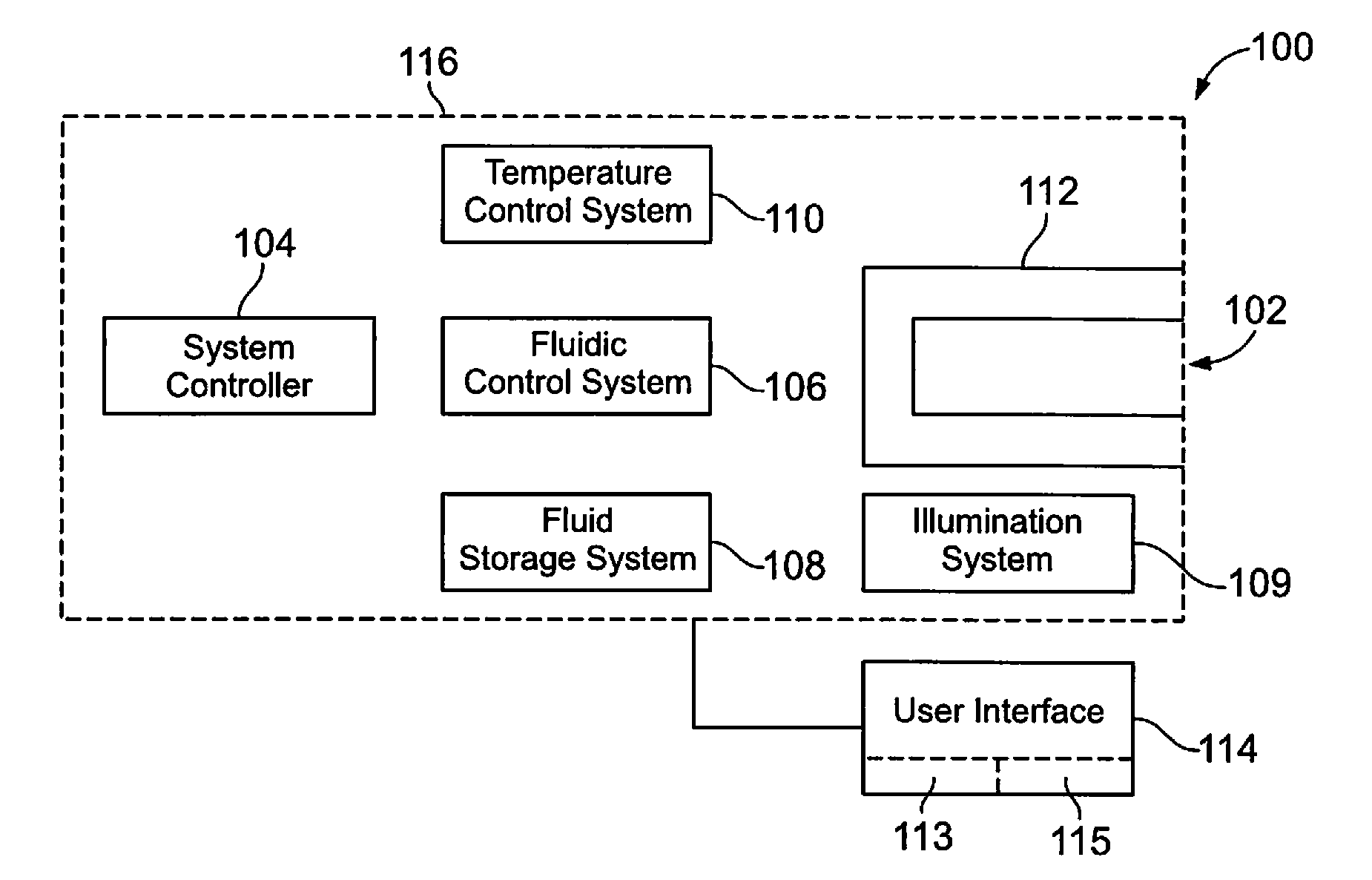

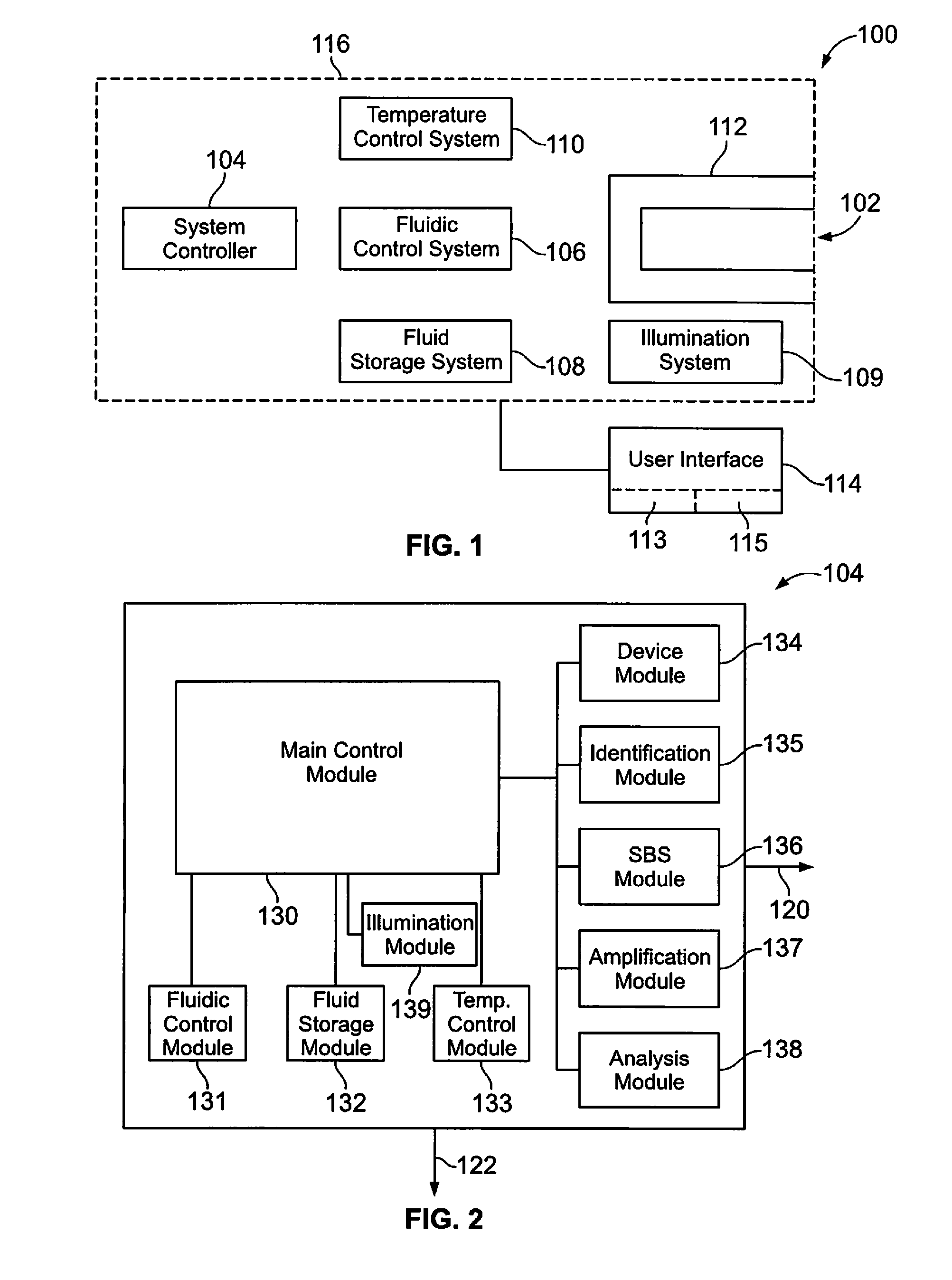

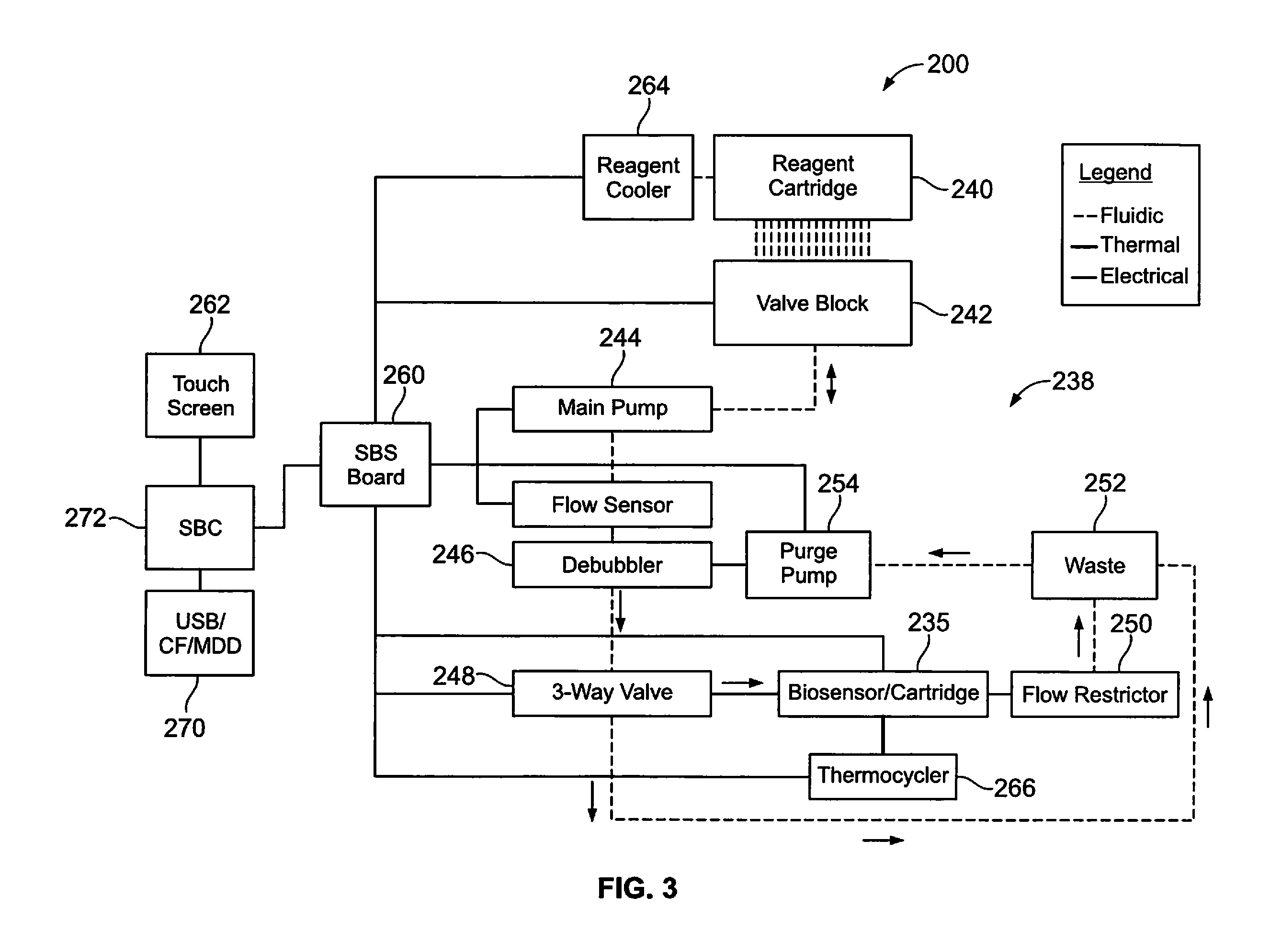

Biosensors for biological or chemical analysis and methods of manufacturing the same

ActiveUS20160356715A1Reduce optical crosstalkTransistorMicrobiological testing/measurementSensor arrayElectricity

Biosensor including a device base having a sensor array of light sensors and a guide array of light guides. The light guides have input regions that are configured to receive excitation light and light emissions generated by biological or chemical substances. The light guides extend into the device base toward corresponding light sensors and have a filter material. The device base includes device circuitry electrically coupled to the light sensors and configured to transmit data signals. The biosensor also includes a shield layer having apertures that are positioned relative to the input regions of corresponding light guides such that the light emissions propagate through the apertures into the corresponding input regions. The shield layer extends between adjacent apertures and is configured to block the excitation light and the light emissions incident on the shield layer between the adjacent apertures.

Owner:ILLUMINA INC

Method of forming self-supporting pleated filter media

The method of forming pleated filter media includes providing a generally planar web of filter material, folding the web to form a pleated web having a plurality of fold lines, arranging the plurality of pleats in a first spaced configuration defined by a first distance between adjacent pleat tips, applying a continuous strand of adhesive to the web, and adjusting the arrangement of the plurality of pleats into a second spaced configuration defined by a second distance between adjacent pleat tips. The web has a front face and a rear face. Each fold line is intermediate oppositely sloping first and second wall surfaces. The plurality of fold lines form a plurality of pleats having a first plurality of pleat tips and a second plurality of pleat valleys. The second distance is different from the first distance.

Owner:3M INNOVATIVE PROPERTIES CO

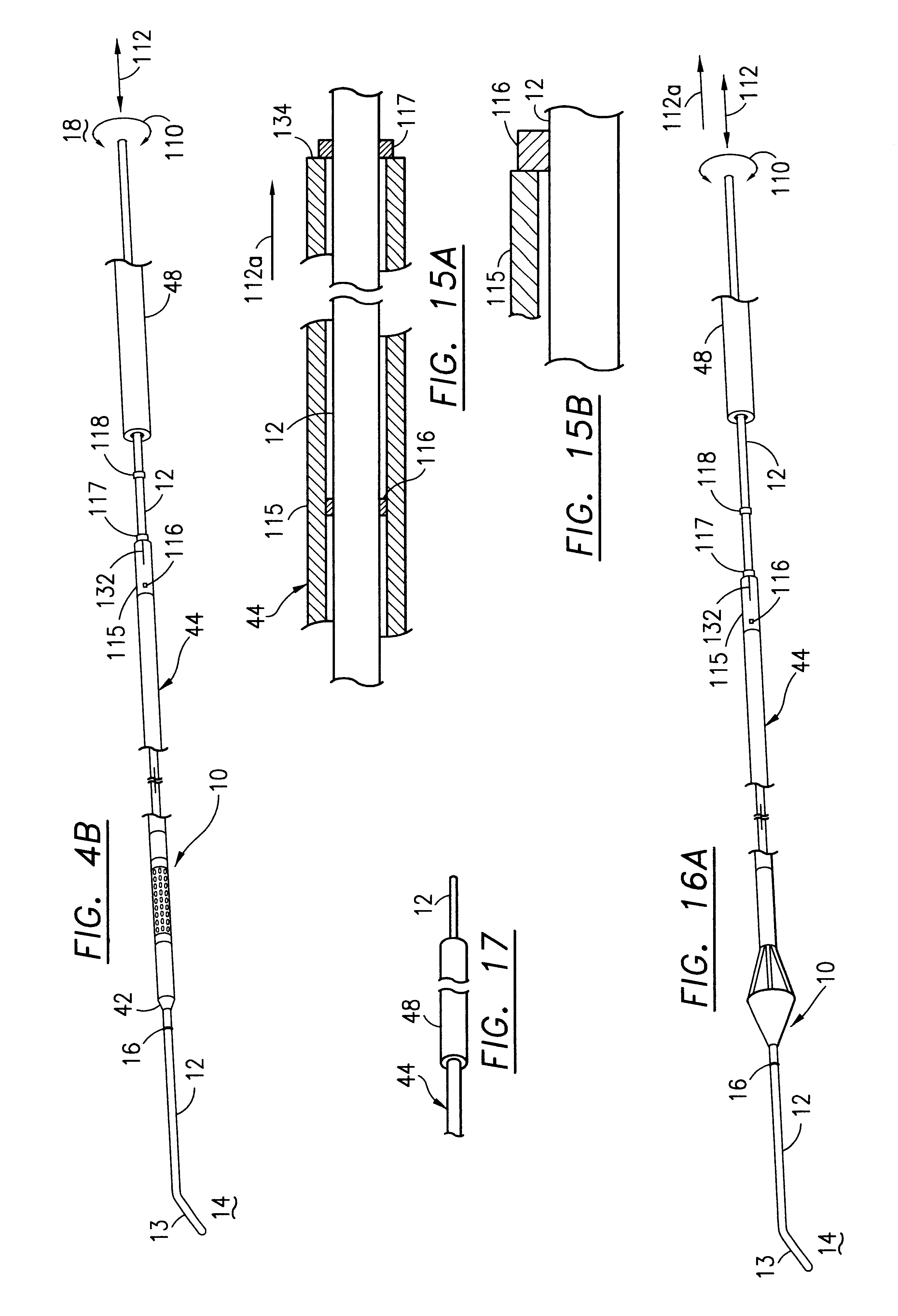

Distal protection device

A distal protection device comprising a catheter, a flexible member movable from a first position to a second looped position extending laterally with respect to the catheter, such that a first loop opening extends substantially in a direction of blood flow as the first loop opening extends in a plane substantially parallel to a transverse axis of the catheter, and filtering material movable from a collapsed position to an expanded position in response to movement of the flexible member.

Owner:REX MEDICAL LP

Filtered cigarette incorporating an adsorbent material

ActiveUS20050066982A1Enhanced mixing processTobacco treatmentTobacco smoke filtersEngineeringFilter material

A filter element incorporating an adsorbent material is provided. The filter element may comprise a first section of filter material and a second section of filter material spaced apart to form a compartment therebetween. The compartment may be filled with one or more adsorbents or the compartment may be divided into two regions, wherein one compartment region is filled with an adsorbent and the other compartment region is either filled with an ion-exchange resin or remains empty. The section of filter material adjacent to the tobacco rod may include one or more channels therethrough for passaging smoke directly from the tobacco rod into the adsorbent-filled compartment. The mouth end section of filter material may contain a breakable capsule, wherein the breakable capsule is filled with a flavoring agent capable of altering the taste characteristics of mainstream smoke.

Owner:R J REYNOLDS TOBACCO COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com