Patents

Literature

78results about How to "Reduce optical crosstalk" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and apparatus defining a color filter array for an image sensor

InactiveUS20070238035A1Precise definitionReducing optical crosstalkOptical filtersSolid-state devicesColor filter arrayImage sensor

An apparatus and method to provide an imager having an array of color filter elements, each color filter element being separated from each other by spacers. The spacers can optically isolate filter elements from each other.

Owner:APTINA IMAGING CORP

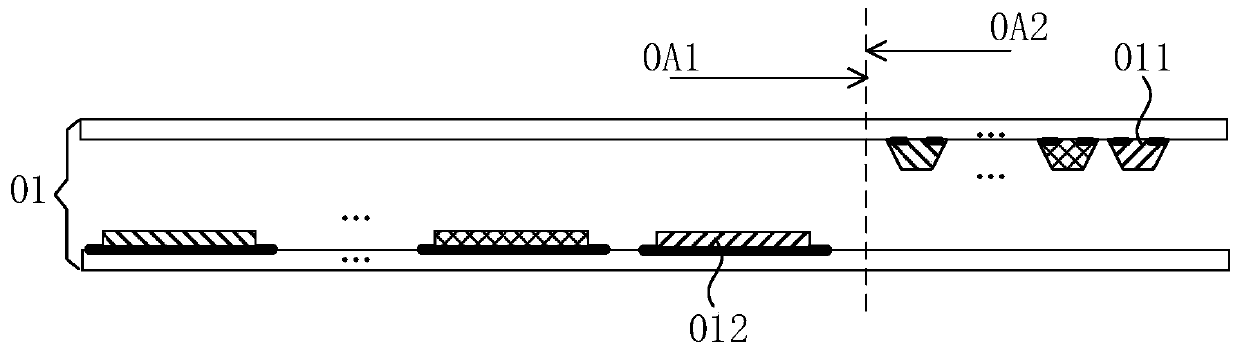

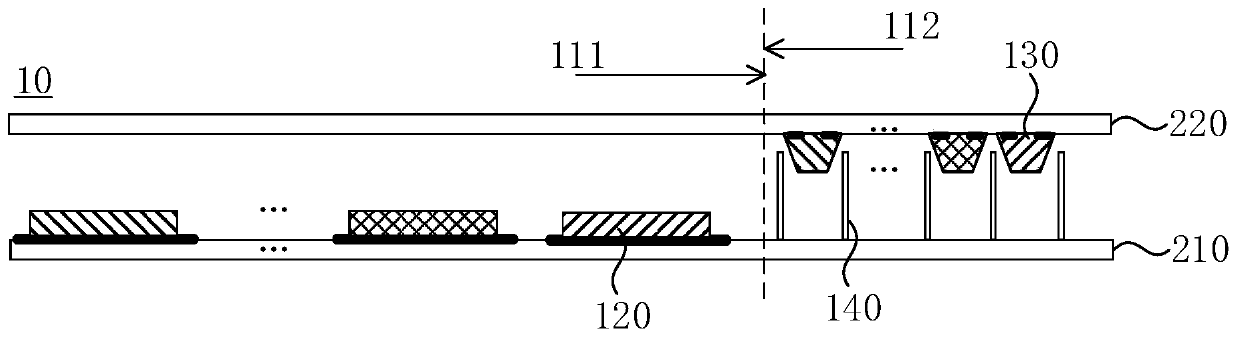

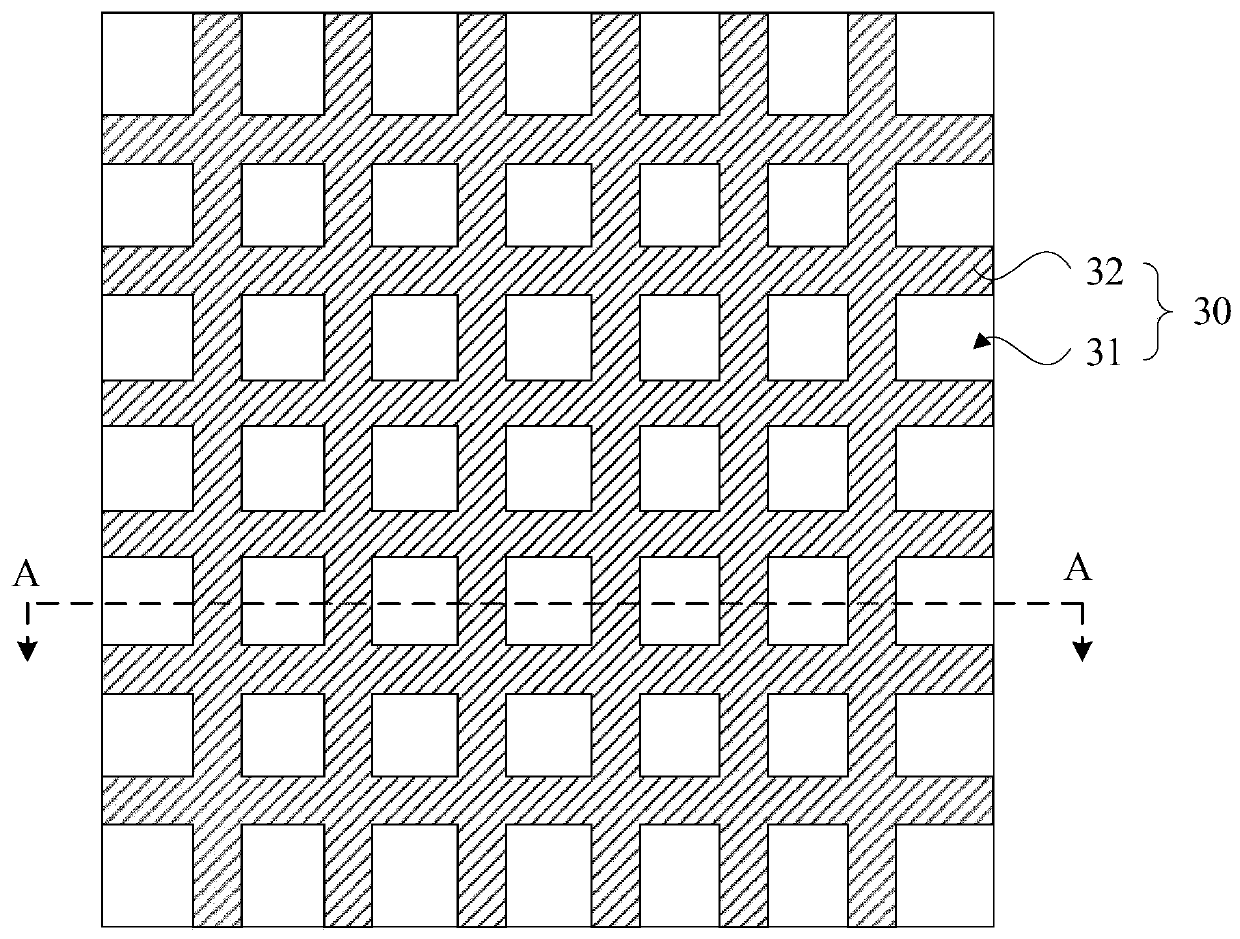

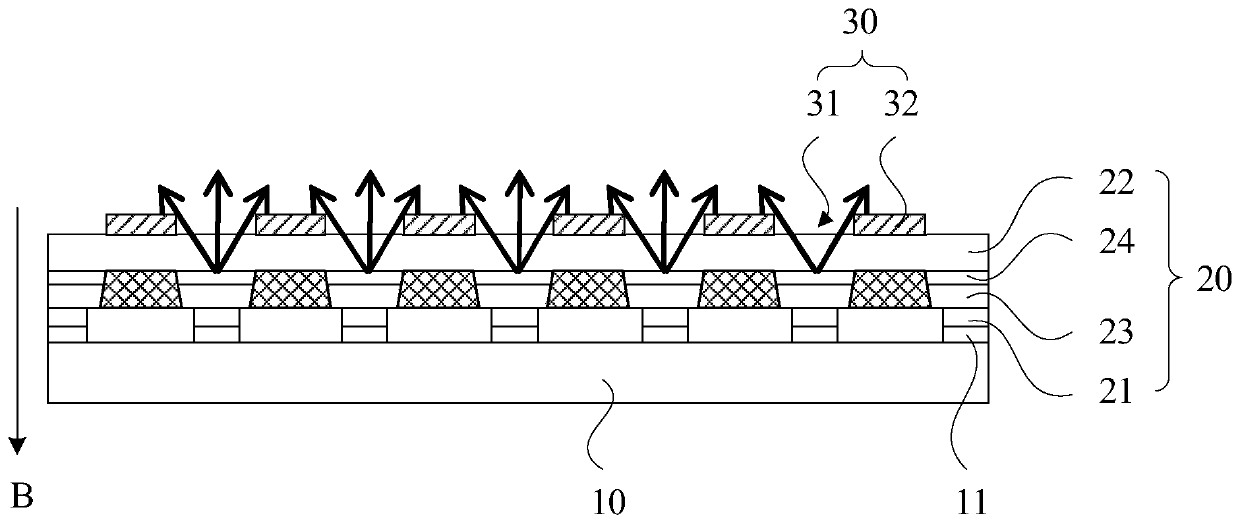

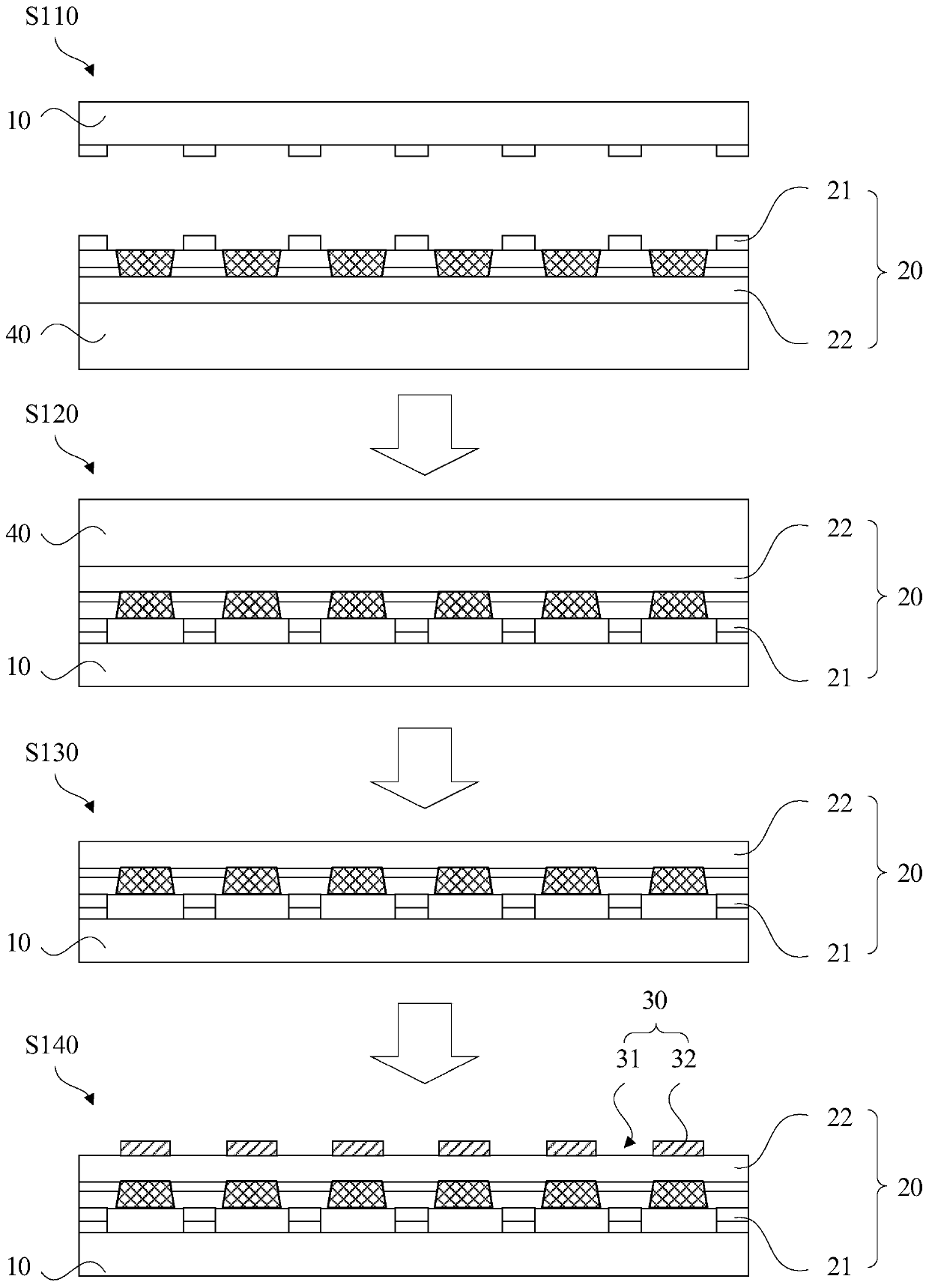

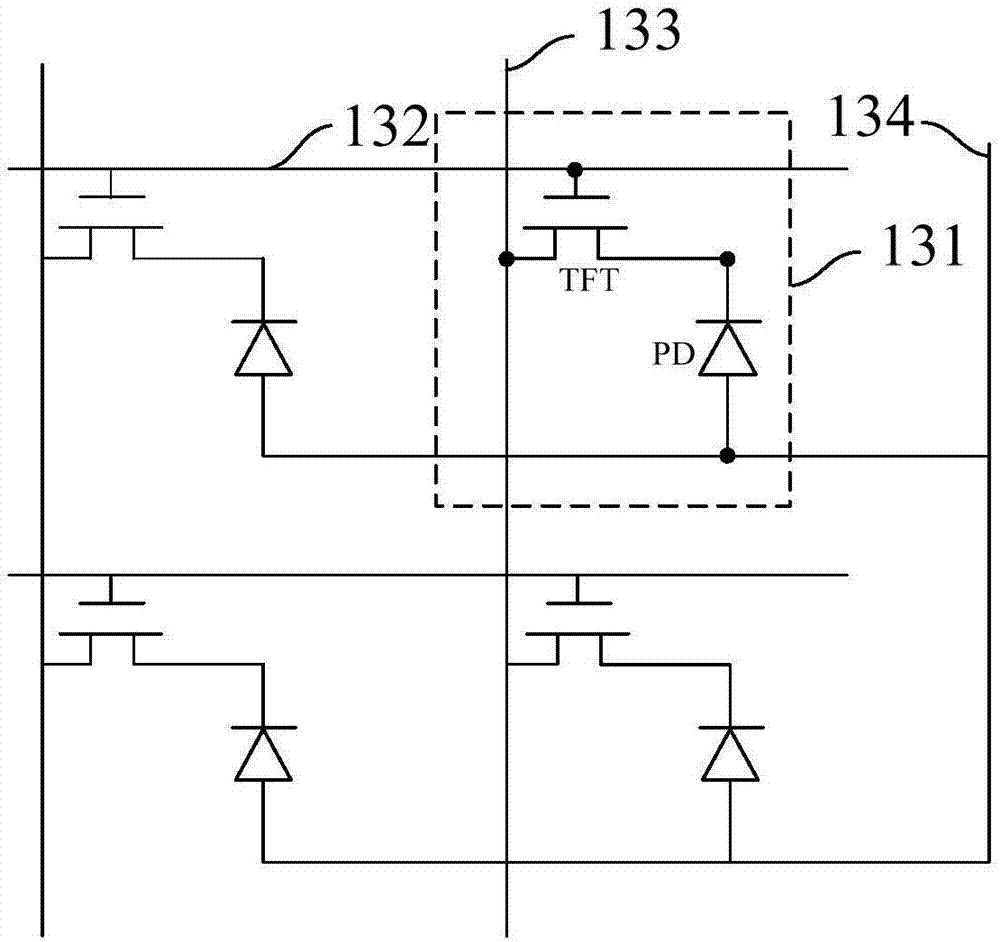

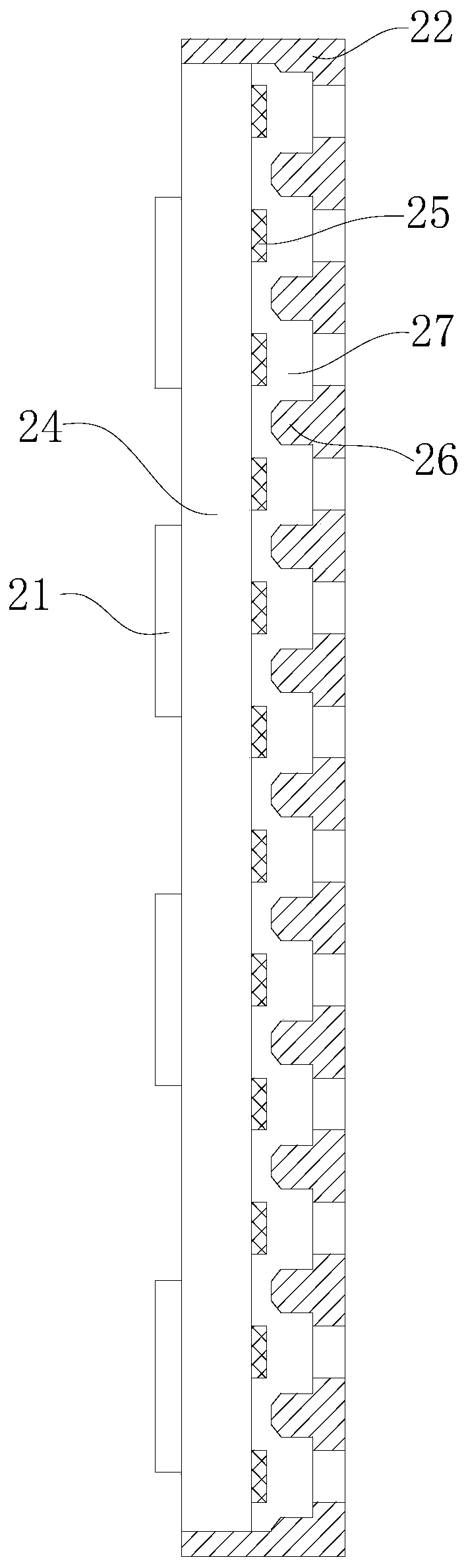

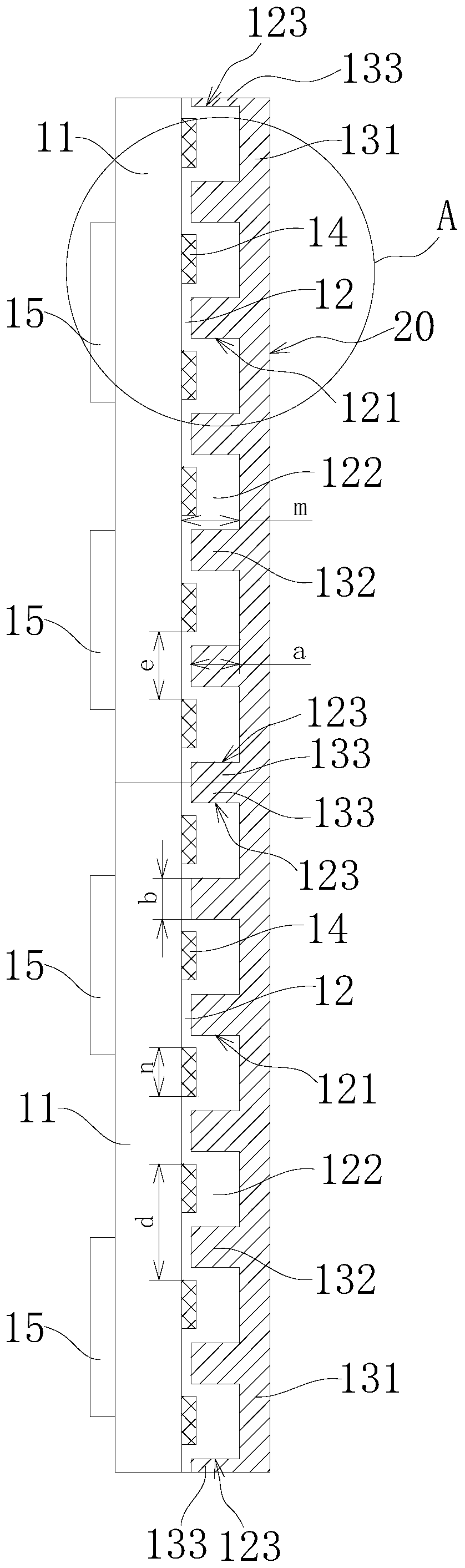

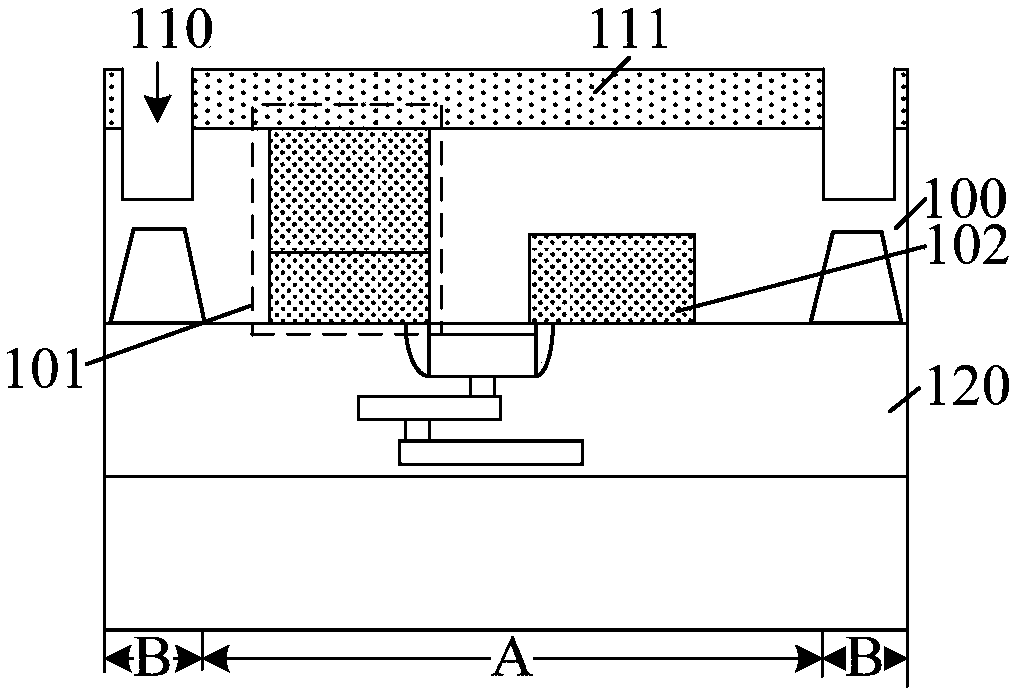

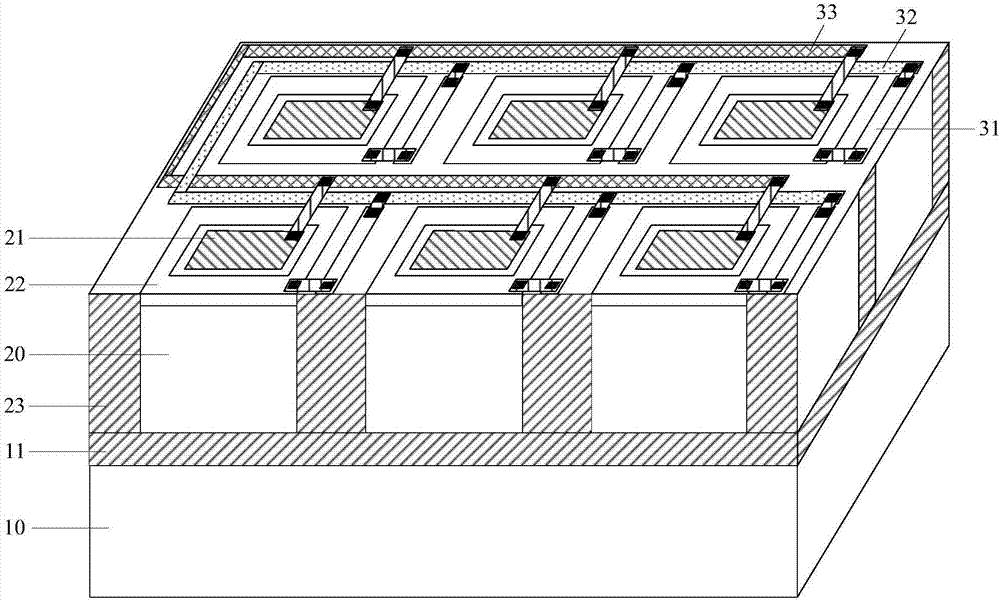

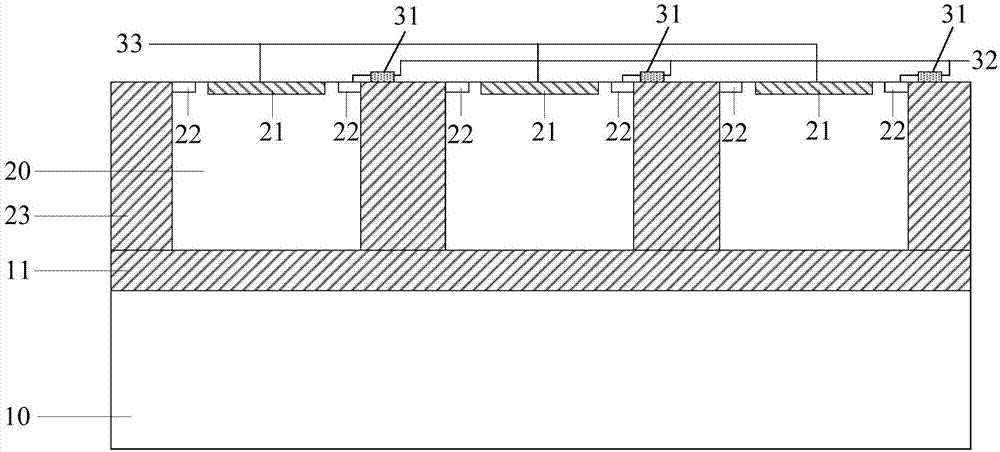

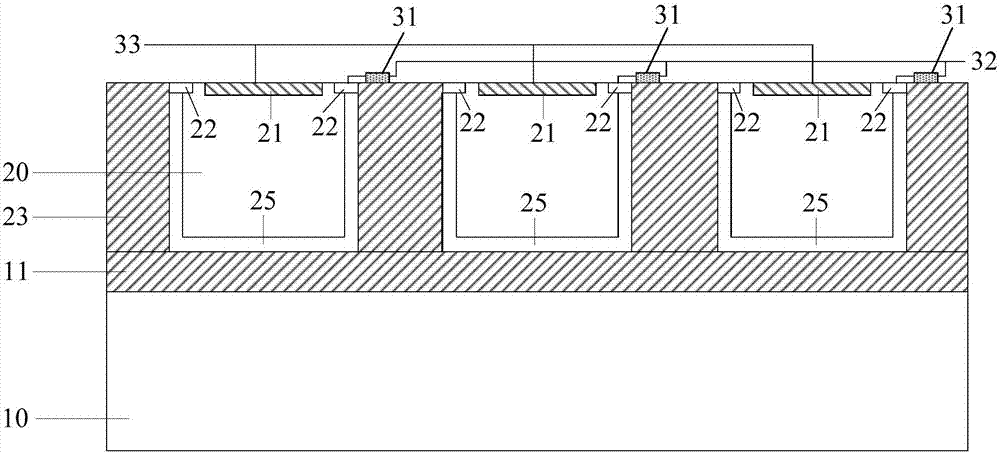

Display panel, display device and display panel manufacturing method

ActiveCN109935599AImprove the display effectReduce optical crosstalkSolid-state devicesSemiconductor devicesDisplay deviceComputer science

The embodiment of the invention discloses a display panel, a display device and a display panel manufacturing method. The display panel comprises a display region; the display region comprises a firstdisplay region and a second display region; the second display region is multiplexed to a sensor reservation region; the second display region comprises a light transmission region and a light emitting region; the first display region is provided with a plurality of organic light emitting units; the light emitting region of the second display region is provided with a plurality of Micro LEDs; andthe second display region is further provided with baffle wall structures located in gaps between the Micro LEDs and the organic light emitting units and in a gap between adjacent Micro LEDs. According to the display panel provided by the embodiment of the invention, the light crosstalk of lateral light of the Micro LEDs to the peripheral display units can be weakened, and the display effects ofthe display panel are enhanced.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

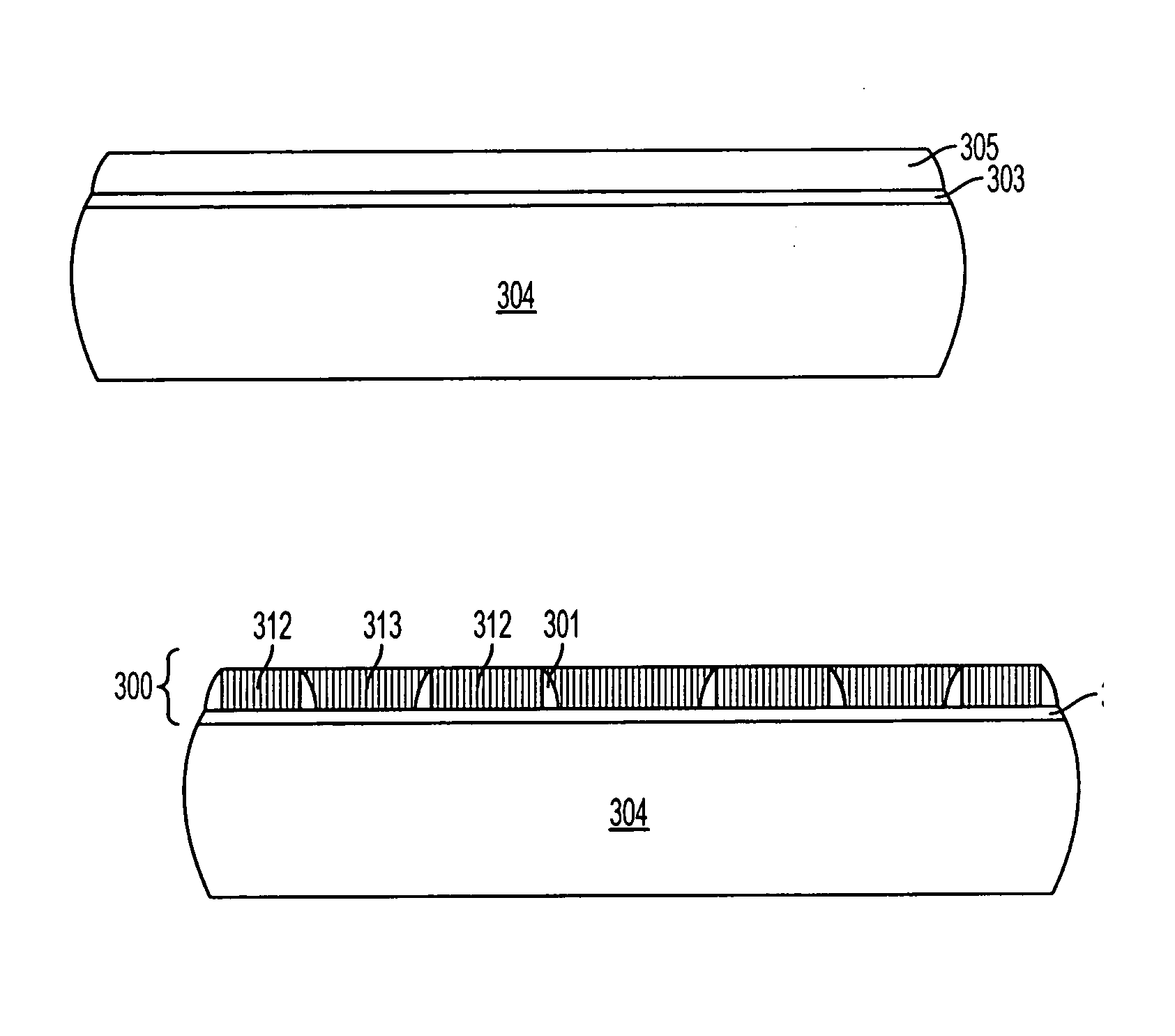

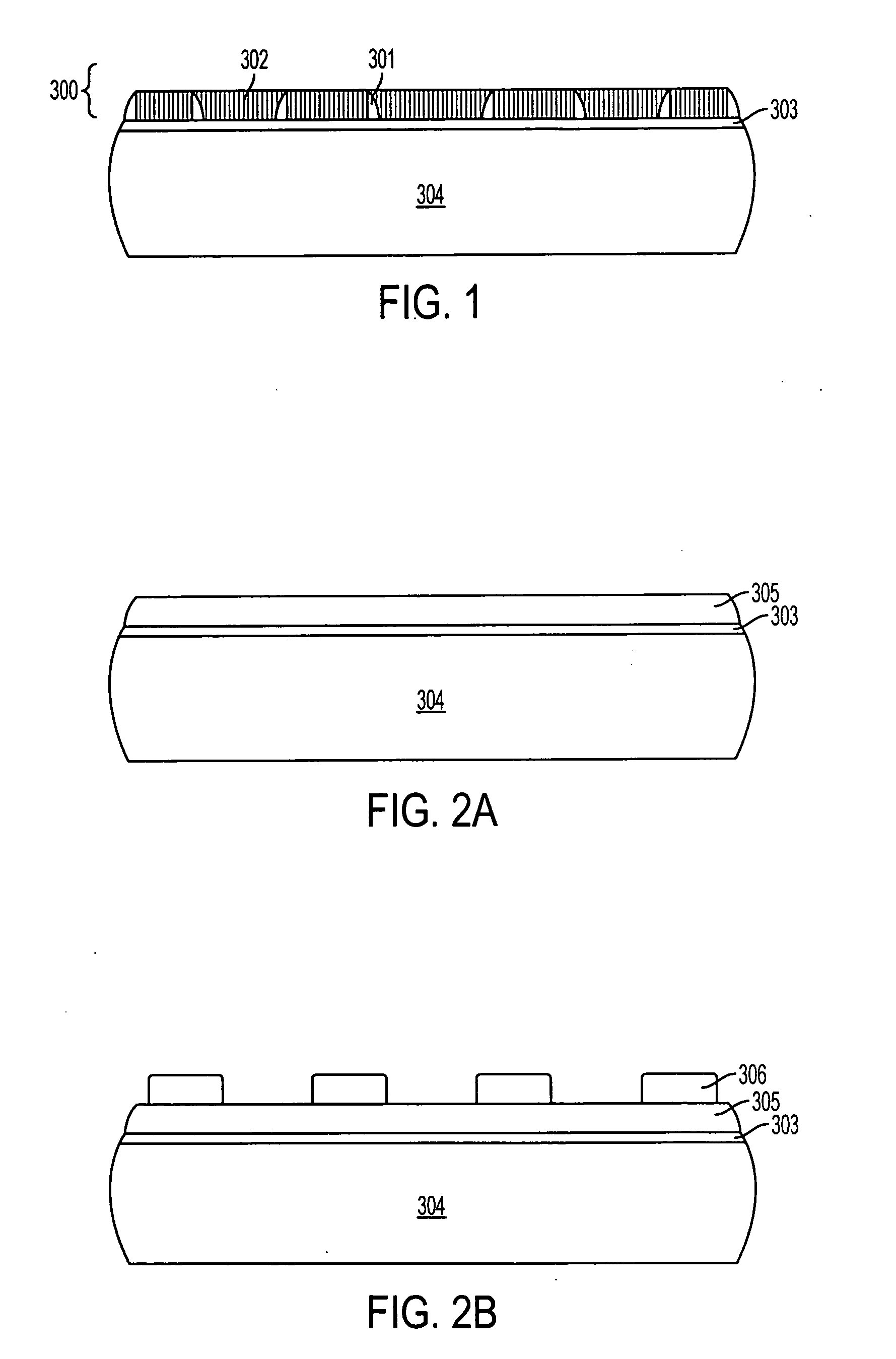

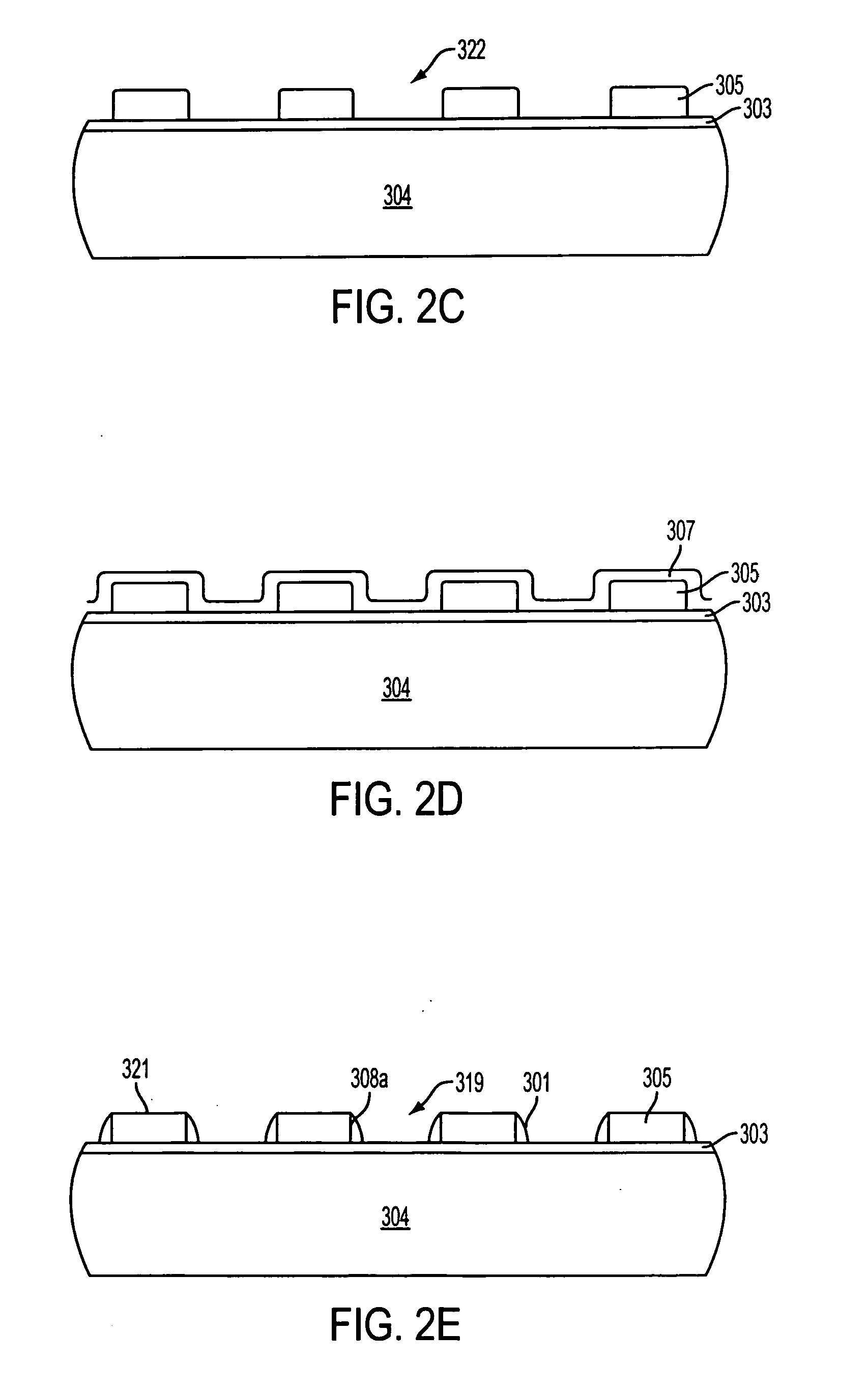

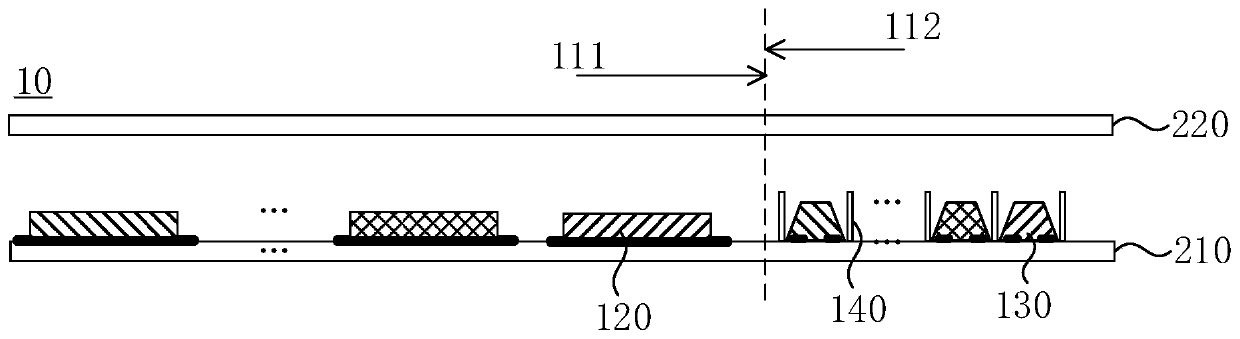

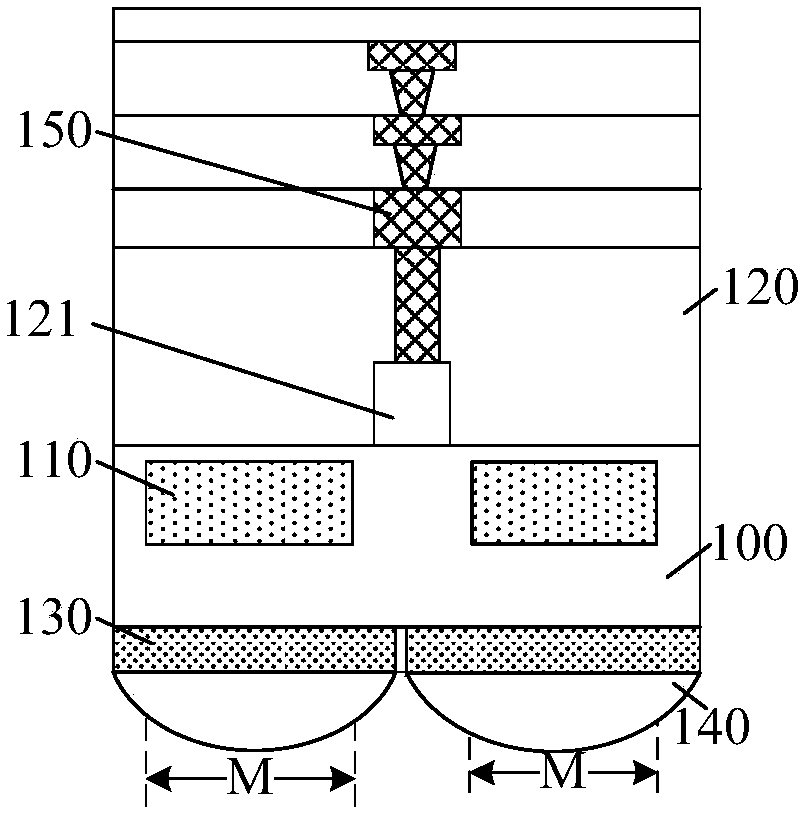

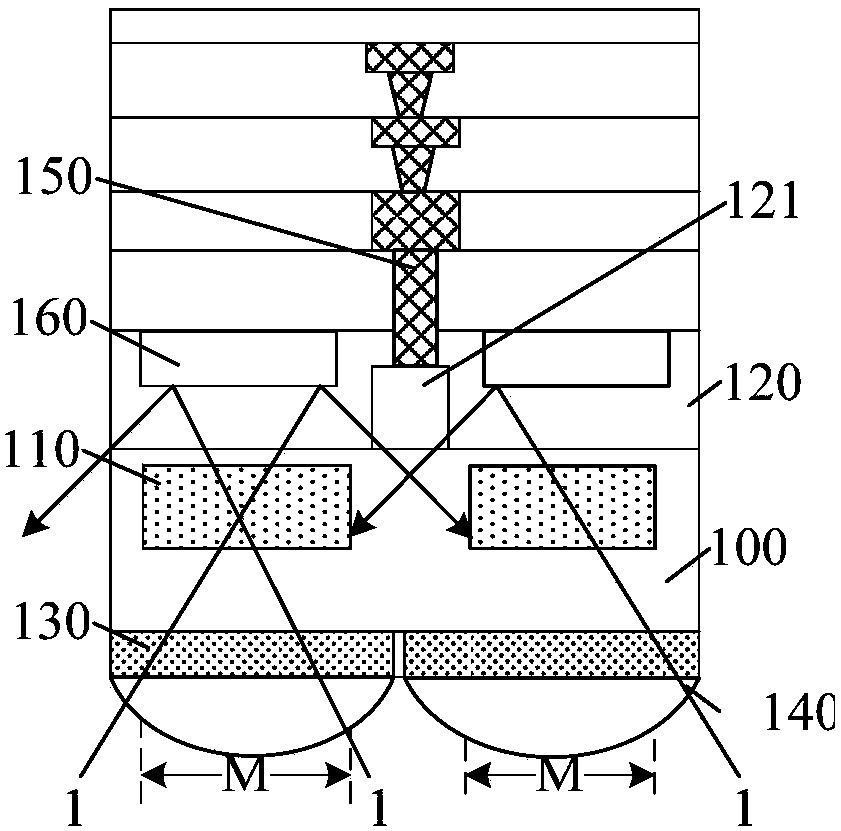

Image sensor and method of fabricating same

ActiveCN101853812AReduce Optical CrosstalkImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringCrosstalk

Provided is a method of fabricating an image sensor device. The method includes providing a device substrate having a front side and a back side. The method includes forming first and second radiation-sensing regions in the device substrate, the first and second radiation-sensing regions being separated by an isolation structure. The method also includes forming a transparent layer over the back side of the device substrate. The method further includes forming an opening in the transparent layer, the opening being aligned with the isolation structure. The method also includes filling the opening with an opaque material. The invention can reduce the optical crosstalk in the image sensor device and can improve the performance of the image sensor device.

Owner:TAIWAN SEMICON MFG CO LTD

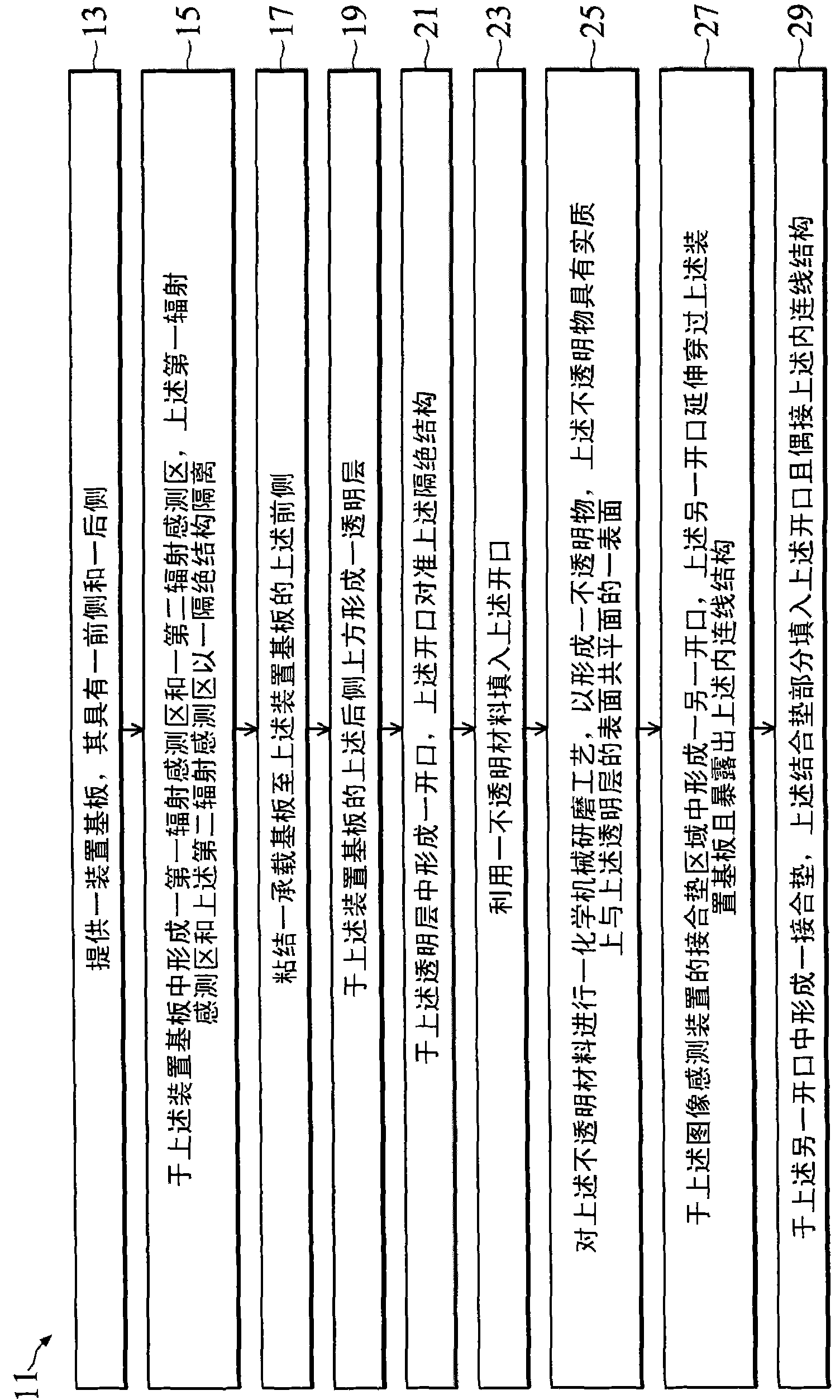

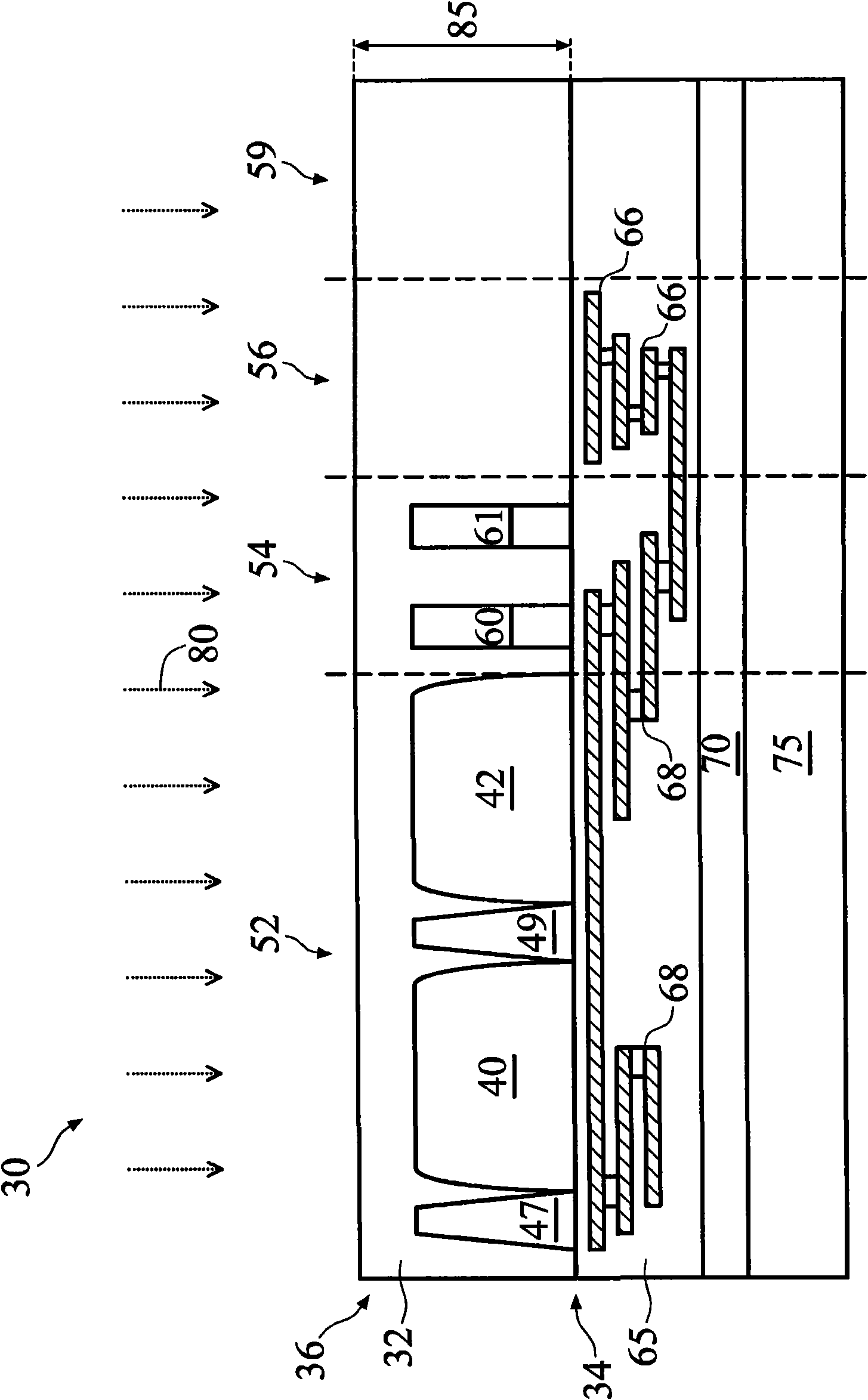

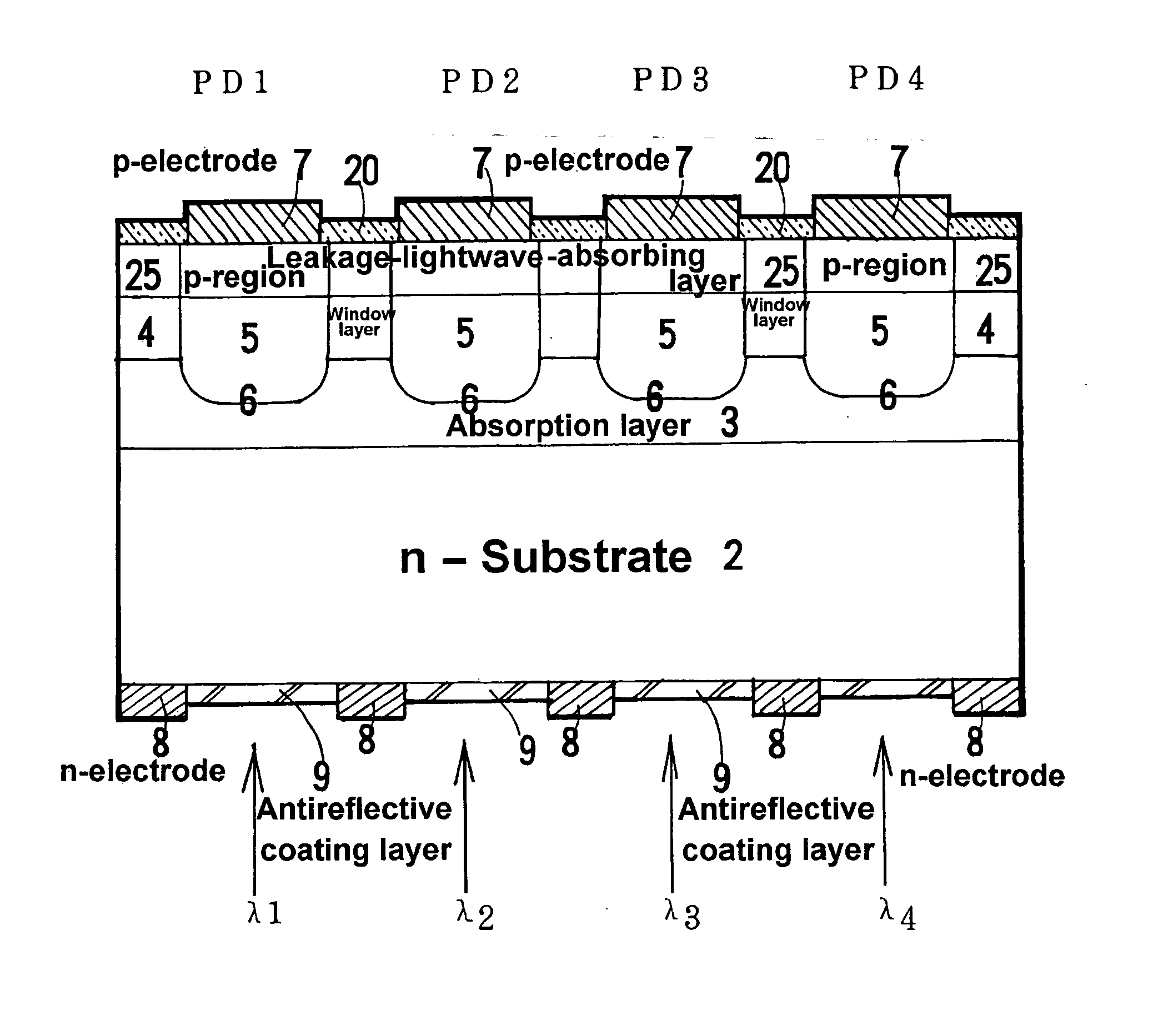

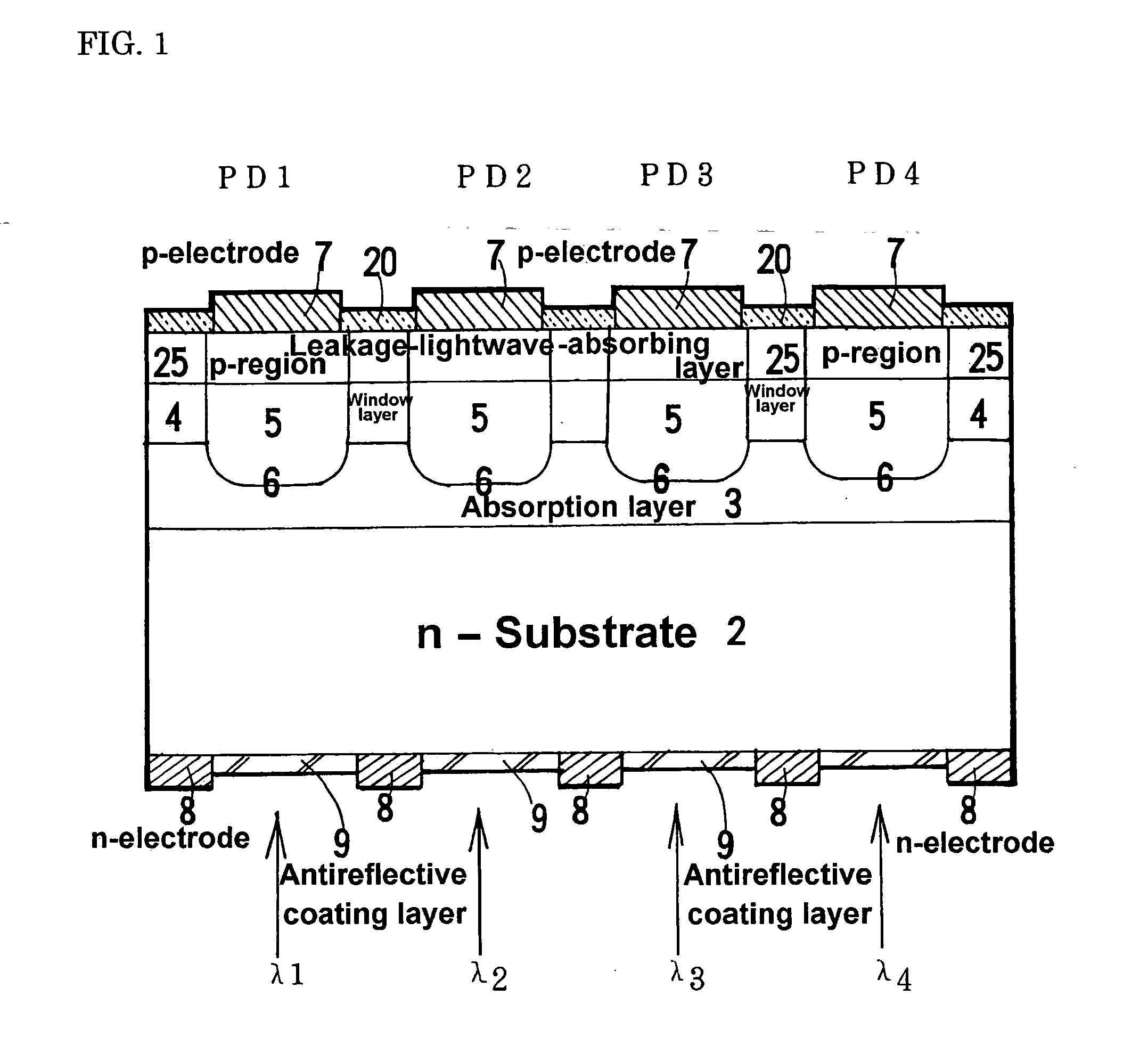

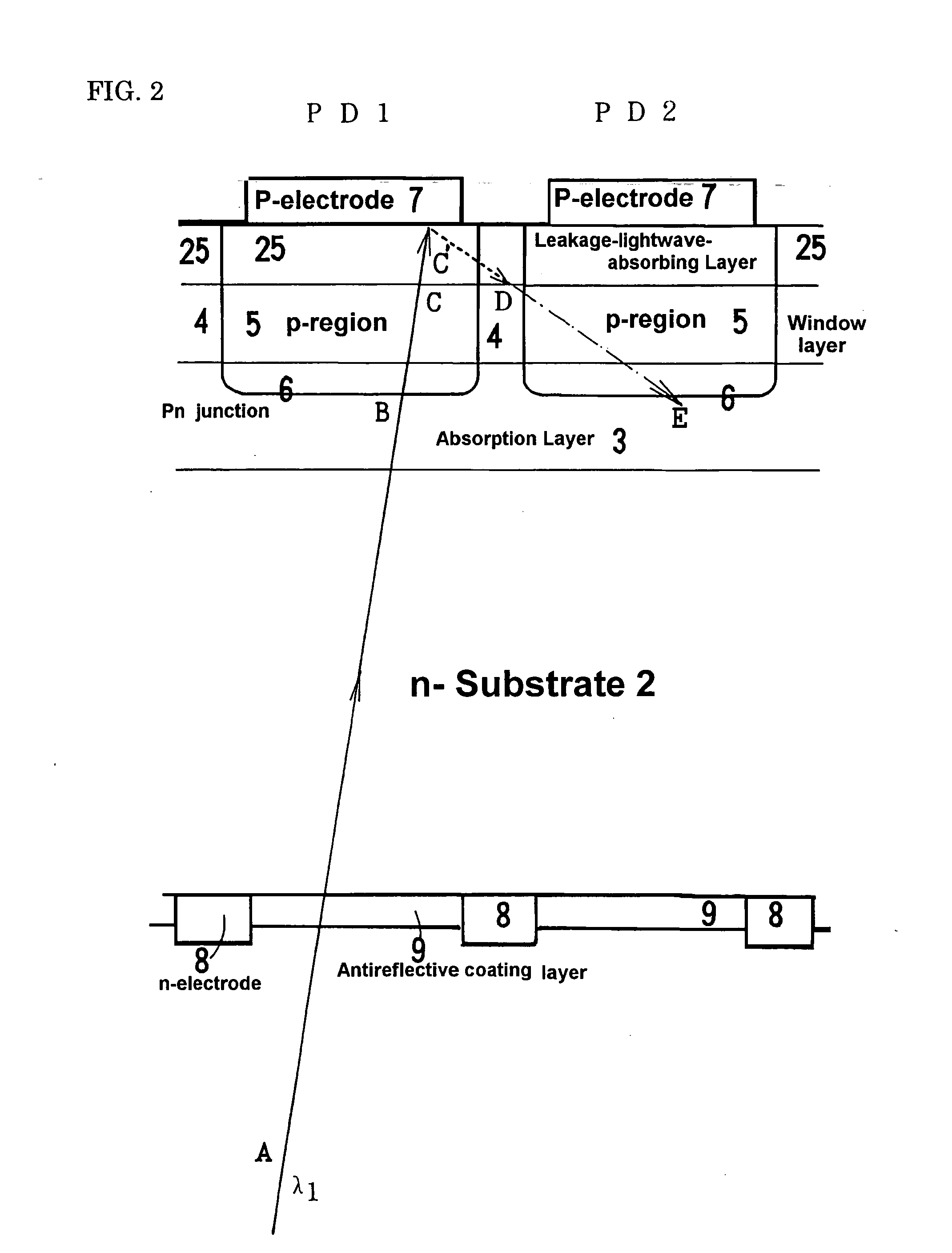

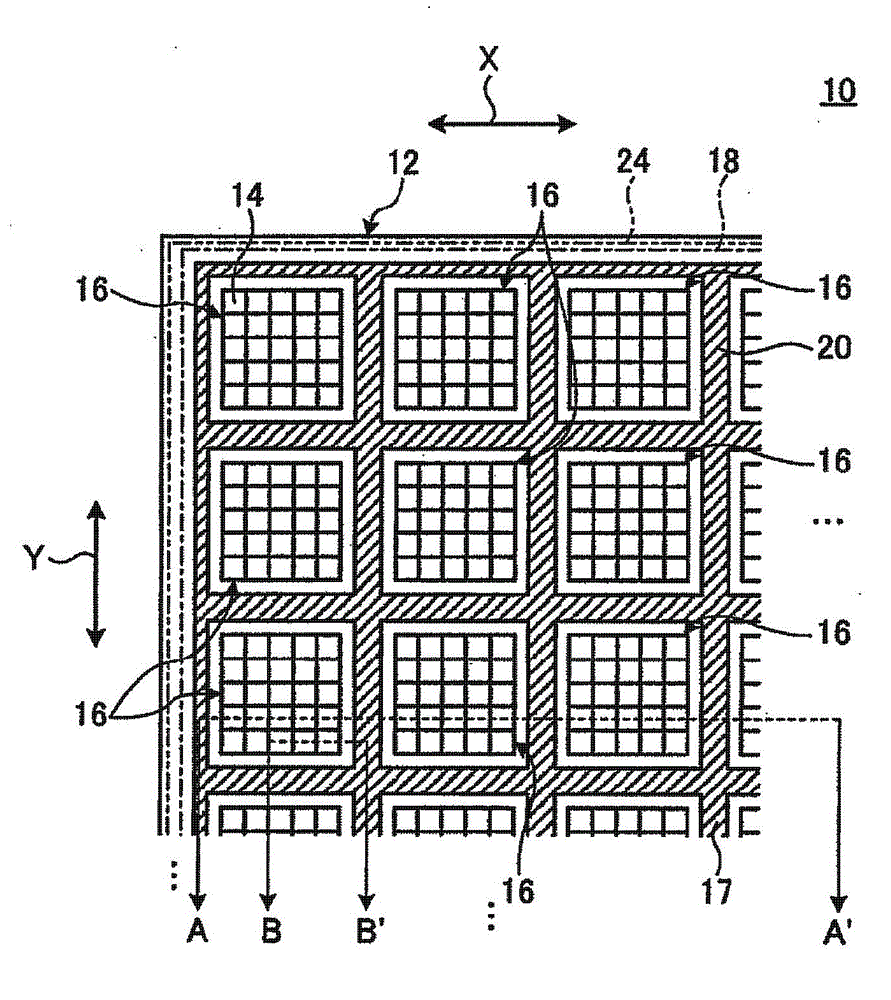

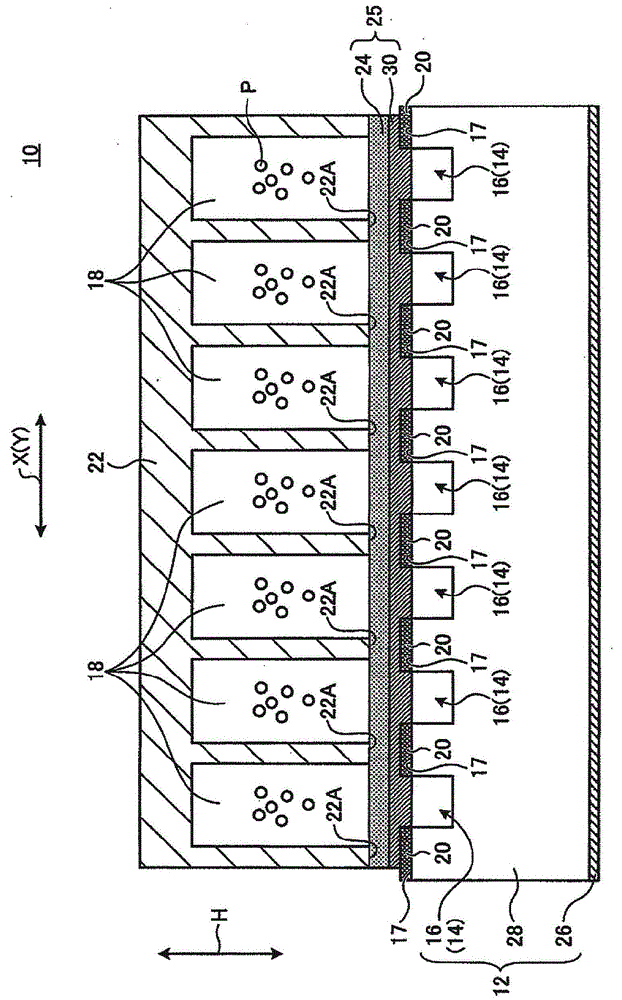

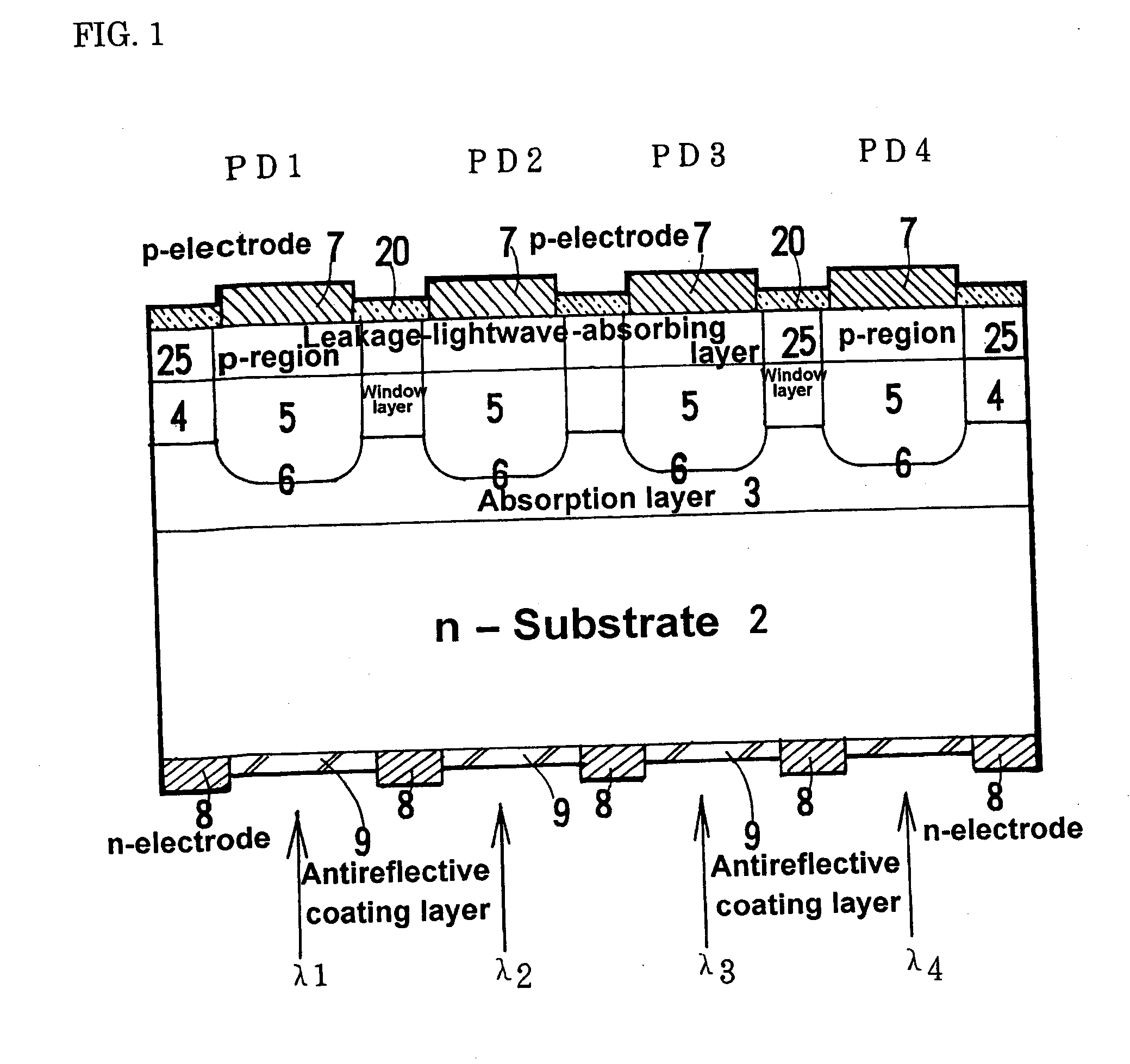

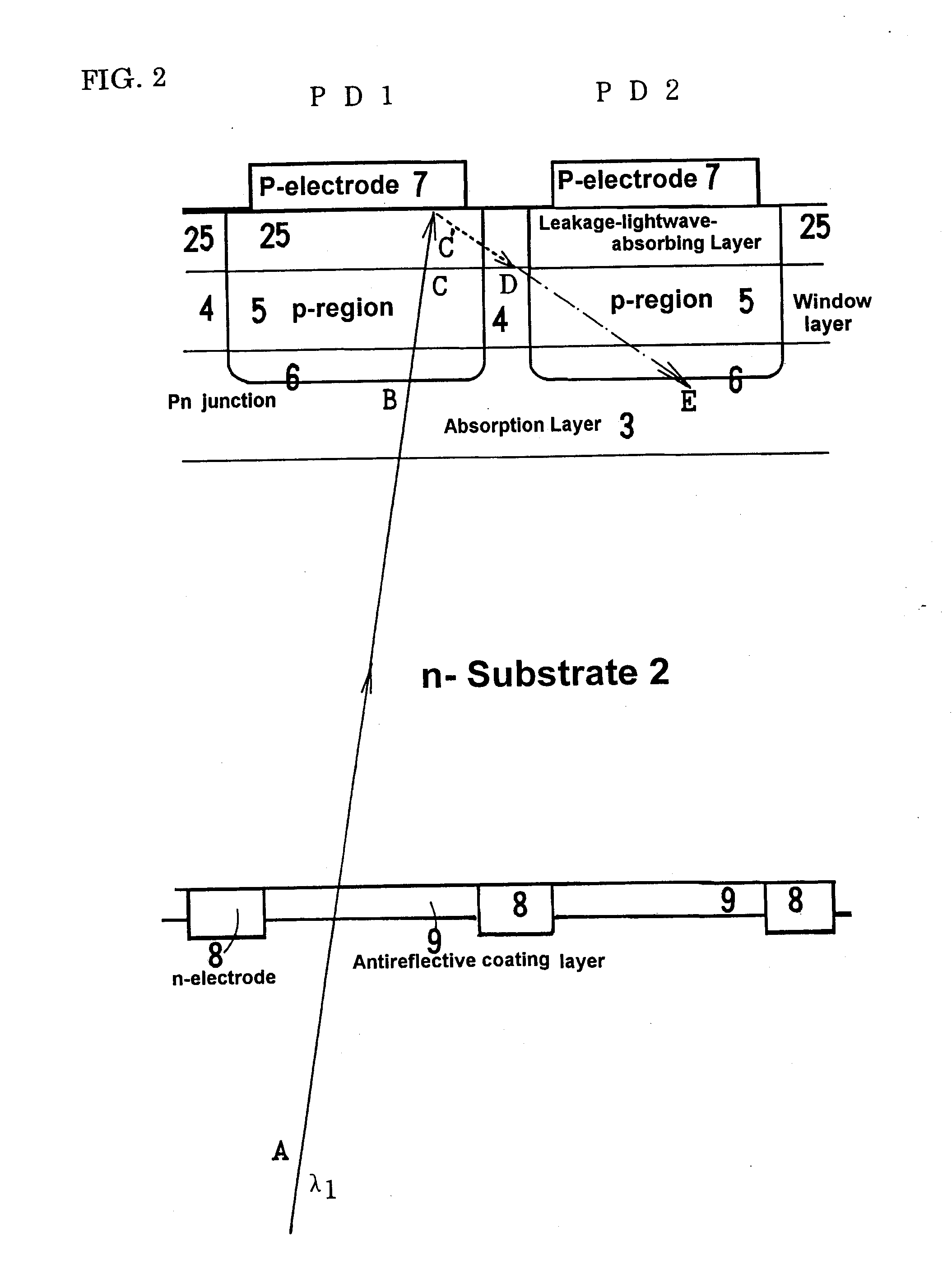

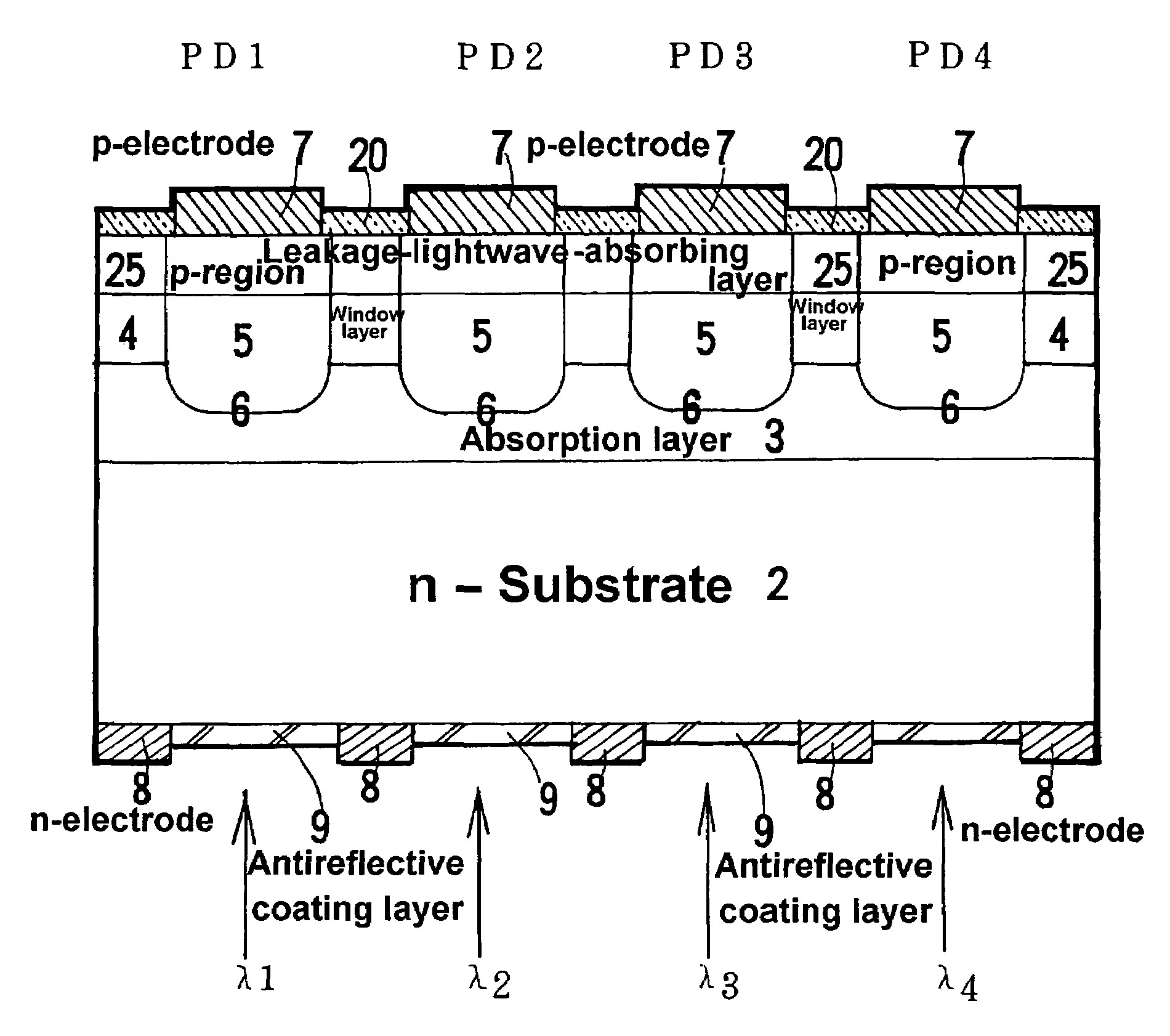

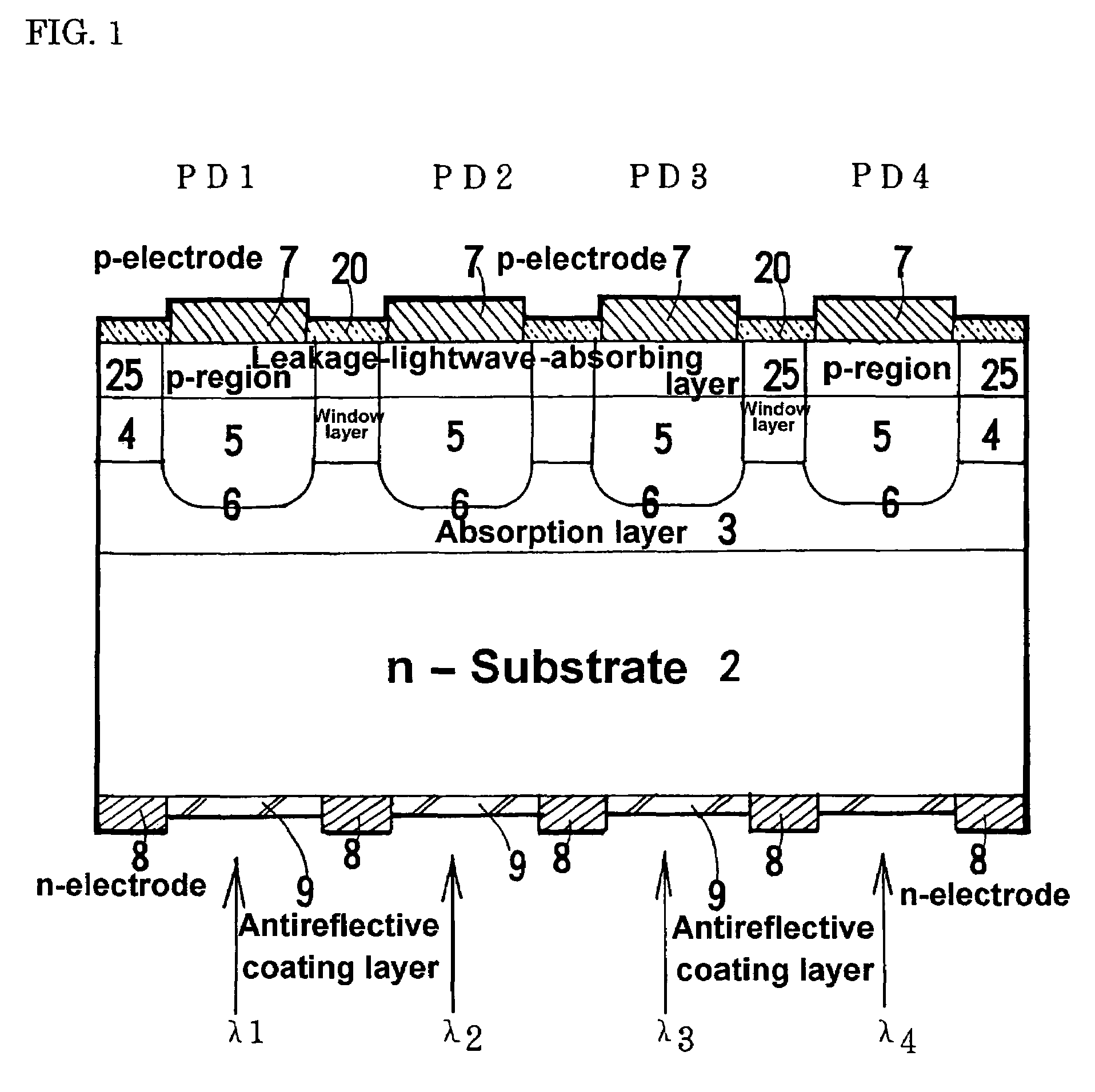

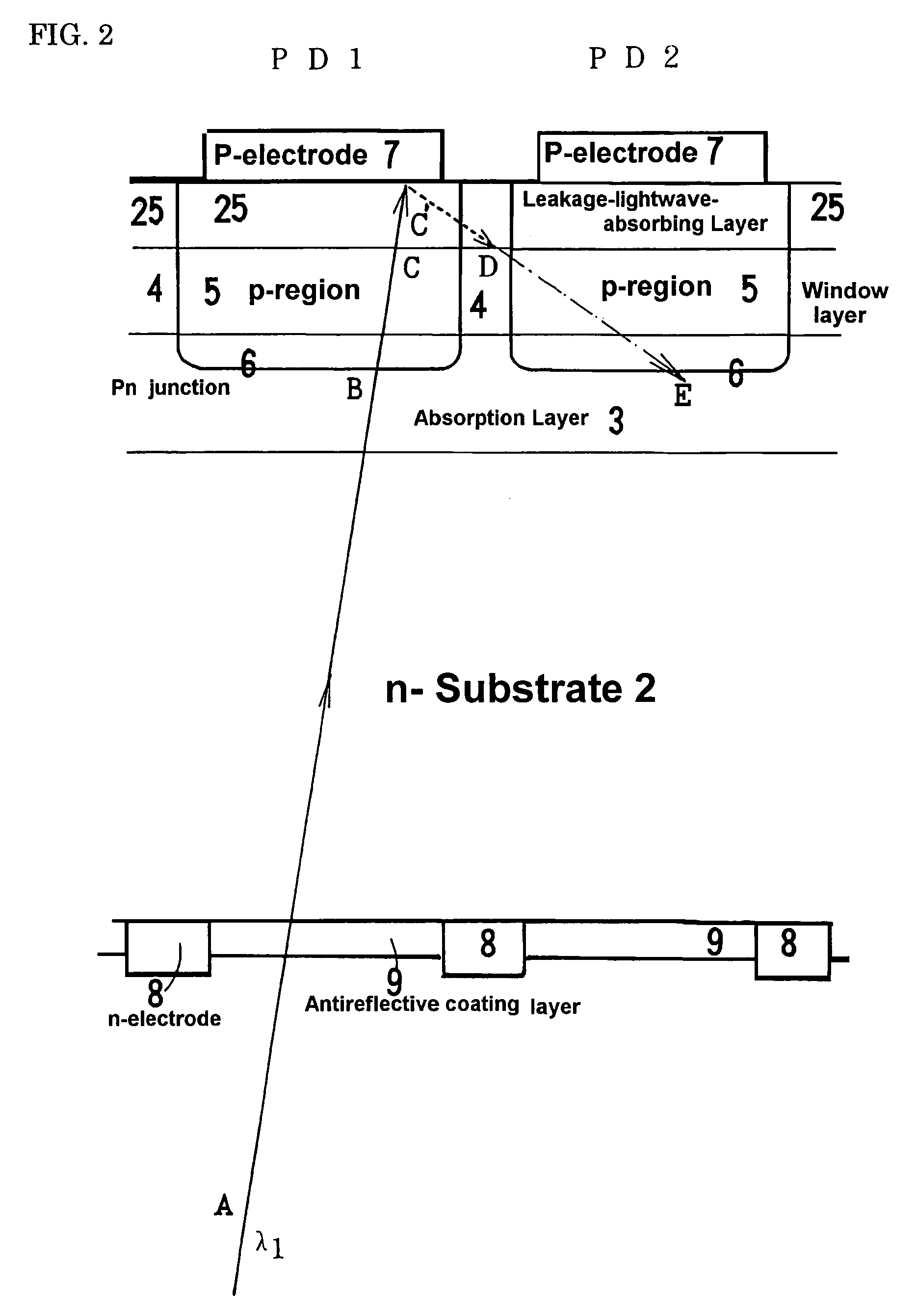

Rear-illuminated-type photodiode array

ActiveUS20050199976A1Prevent optical crosstalkOptical obstructionSolid-state devicesSemiconductor devicesAnti-reflective coatingSemiconductor

A rear-illuminated-type photodiode array has (a) a first-electroconductive-type semiconductor substrate, (b) a first-electroconductive-type electrode that is placed at the rear side of the semiconductor substrate and has openings arranged one- or two-dimensionally, (c) an antireflective coating provided at each of the openings of the first-electroconductive-type electrode, (d) a first-electroconductive-type absorption layer formed at the front-face side of the substrate, (e) a leakage-lightwave-absorbing layer that is provided on the absorption layer and has an absorption edge wavelength longer than that of the absorption layer, (f) a plurality of second-electroconductive-type regions that are formed so as to penetrate through the leakage-lightwave-absorbing layer from the top surface and extend into the absorption layer to a certain extent and are arranged one- or two-dimensionally at the positions coinciding with those of the antireflective coatings at the opposite side, and (g) a second-electroconductive-type electrode provided on the top surface of each of the second-electroconductive-type regions.

Owner:SUMITOMO ELECTRIC IND LTD

Display panel, display device and manufacturing method of display panel

ActiveCN110416245ALower resistanceIncrease resistanceSolid-state devicesSemiconductor devicesPower flowDisplay device

The embodiment of the invention discloses a display panel, a display device and a manufacturing method of the display panel. The display panel comprises at least one light emitting diode chip and a conducting layer, wherein the light emitting diode chip comprises a first electrode and a first semiconductor layer which are arranged in a laminated manner; the conducing layer is positioned at one side, which is away from a first electrode, of the light emitting diode chip; the conducting layer is in contact with the first semiconductor layer; and the conducting layer comprises a hollowed-out part, and the projection of the hollowed-out part on the conducting layer is overlapped with the projection of the first electrode on the conducting layer in the thickness direction of the first semiconductor layer. The embodiment of the invention achieves the effect of reducing the resistance of the current conducting layer with low process difficulty on the basis of ensuring the light emitting rateof the display panel.

Owner:CHENGDU VISTAR OPTEOLECTRONICS CO LTD

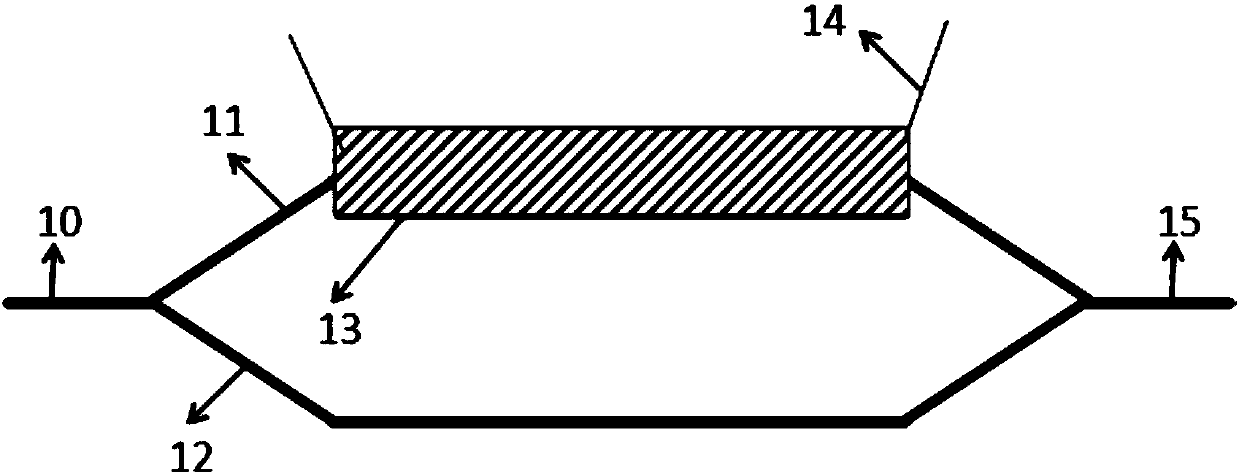

Array-adjustable optical attenuator, attenuation method implemented by same and method for manufacturing array-adjustable optical attenuator

InactiveCN107608029AImprove performanceReduce optical crosstalkCoupling light guidesNon-linear opticsUltrasound attenuationOptical attenuator

The invention relates to an attenuator, an attenuation method implemented by the same and a method for manufacturing the attenuator, belongs to the field of optical communication, and particularly relates to an array-adjustable optical attenuator, an attenuation method implemented by the same and a method for manufacturing the array-adjustable optical attenuator. The array-adjustable optical attenuator, the attenuation method and the method have the advantages that the array-adjustable optical attenuator is in bent optical waveguide structural designs, and accordingly optical crosstalk on adjacent channels due to stray light formed by light leakage at input ends can be reduced; deeply etched heat-insulation grooves are formed in positions between the channels and are filled with Polymer materials with low heat conduction and low expansion properties, and accordingly cross heat conduction between the various channels can be effectively isolated.

Owner:GUANGXUN SCI & TECH WUHAN

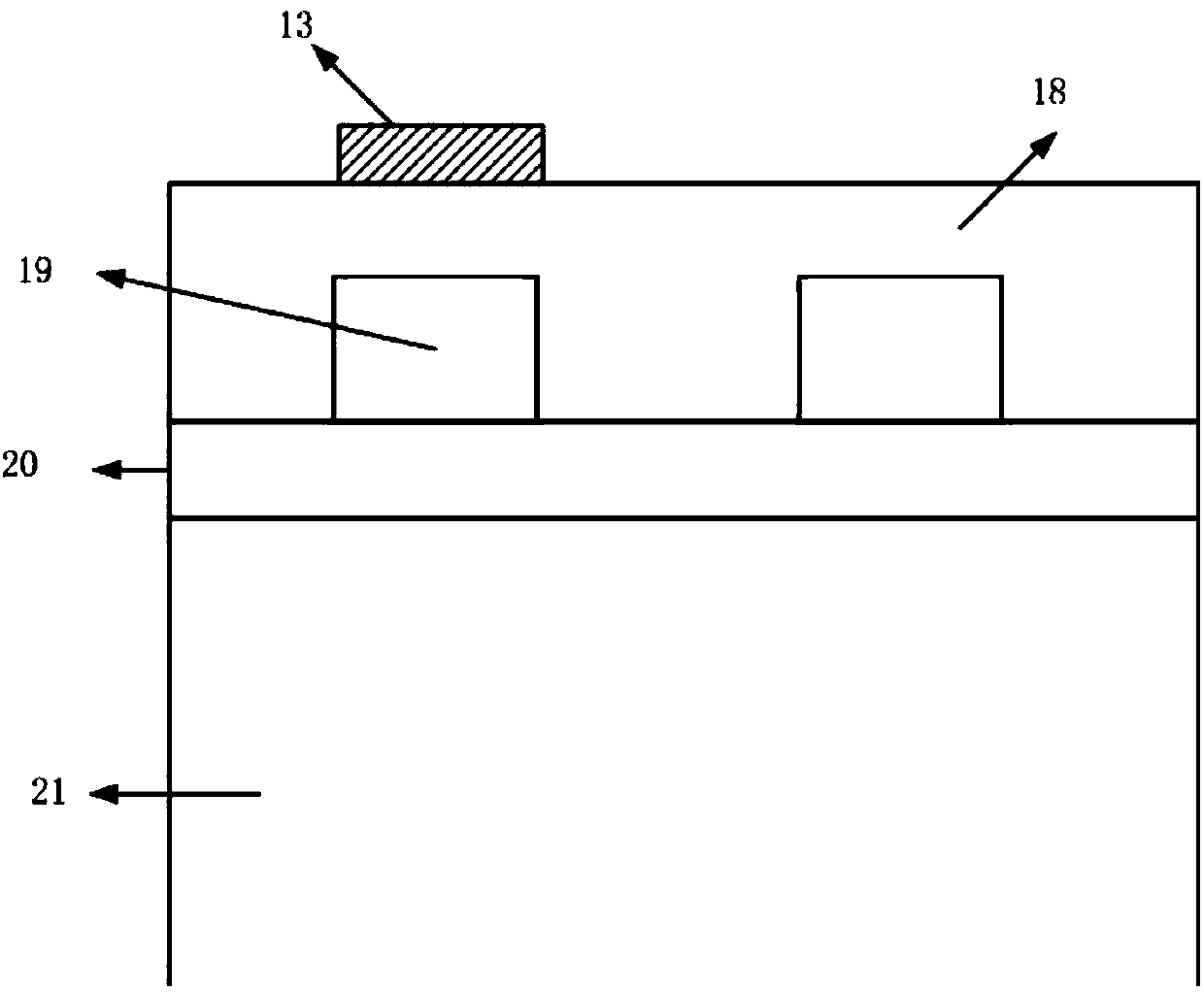

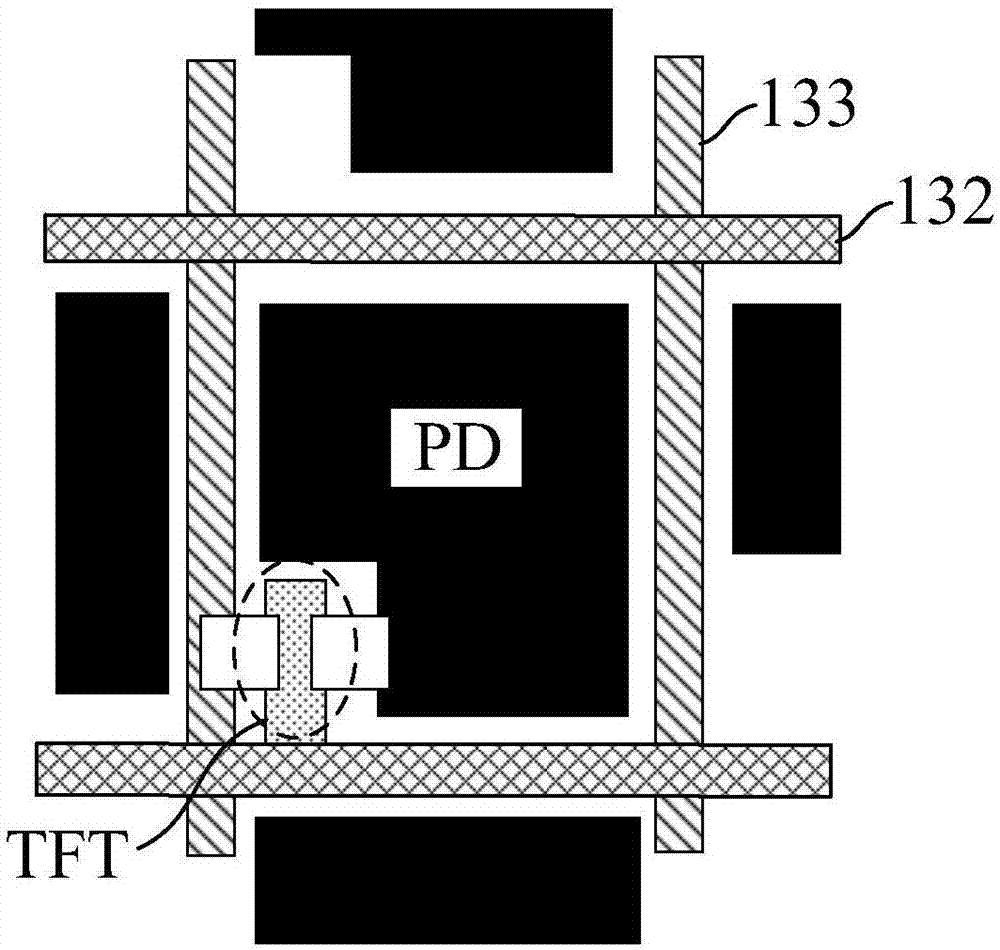

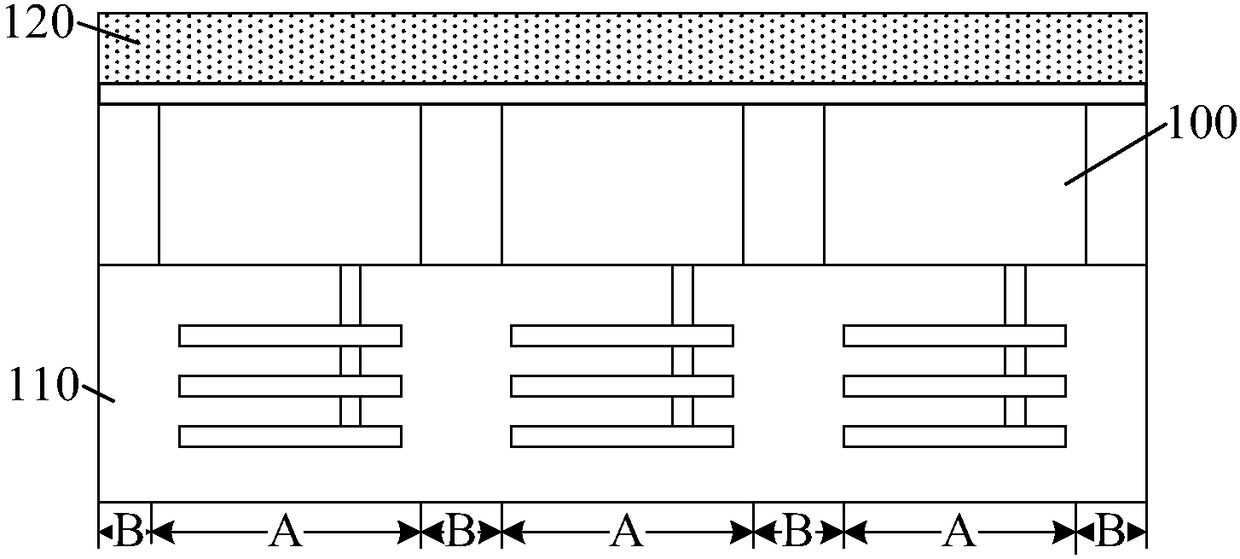

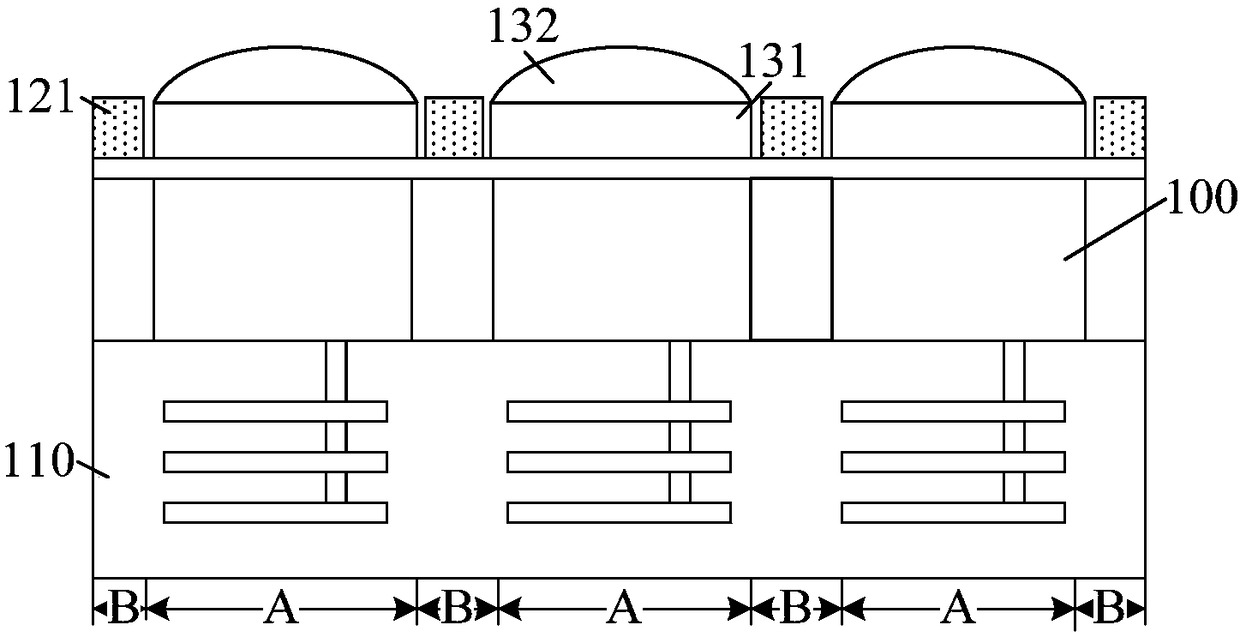

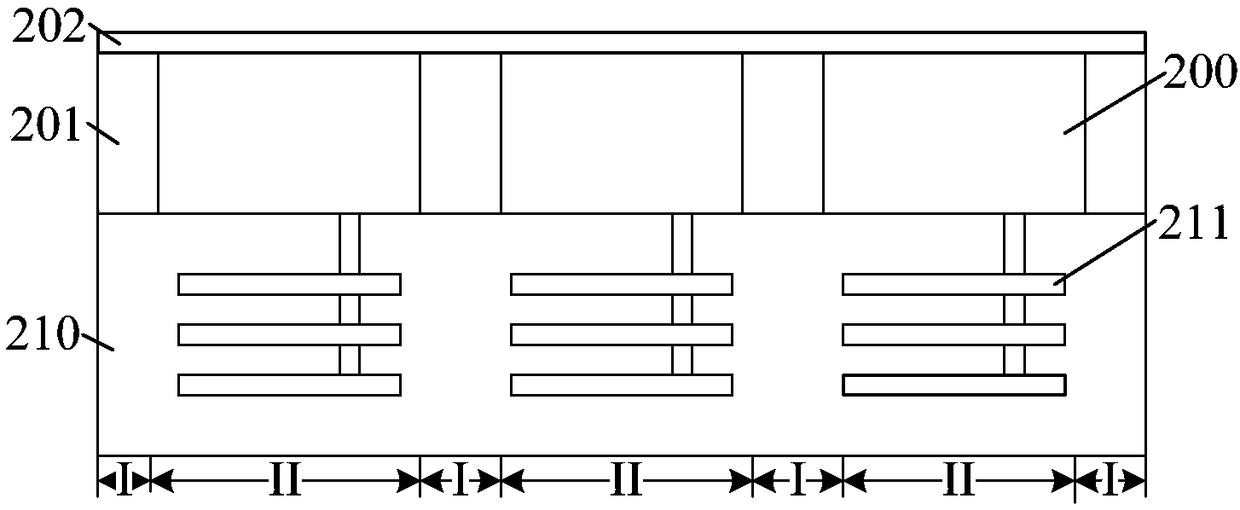

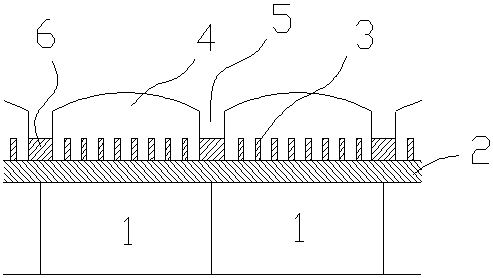

Amorphous silicon flat-panel detector and preparation method thereof

InactiveCN107195647AHigh sensitivityImprove spatial resolutionSolid-state devicesRadiation controlled devicesSensor arrayFlat panel detector

The invention provides an amorphous silicon flat-panel detector and a preparation method thereof. The method comprises the following steps: preparing an image sensor array on a substrate, and forming a planar focusing microlens material layer on the image sensor array; forming a photoresist layer on the focusing microlens material layer; carrying out exposure and development on the photoresist layer and forming a photoresist array, photoresist units in the photoresist array being in one-to-one correspondence with pixel units in the image sensor array; enabling each photoresist unit to be in a spherical crown shape through hot melting; enabling the spherical crown shape to be transferred to the focusing microlens material layer through etching, and forming a focusing microlens array; and forming a scintillation layer on the focusing microlens array. Through light condensation effect, more light beams are allowed to enter a light sensitive area of an image sensor, so that light collecting efficiency of the image sensor array is improved, and sensitivity of the amorphous silicon flat-panel detector is improved; and meanwhile, through convergence effect, optical crosstalk between adjacent pixels is reduced, and spatial resolution of the amorphous silicon flat-panel detector is improved.

Owner:SHANGHAI IRAY TECH

LED display module and LED display screen

InactiveCN111179774AImprove thermal stabilityReduced chance of stress crackingIdentification meansThermal dilatationLED display

The invention belongs to the technical field of LED display screens, in particular to an LED display module and an LED display screen. The LED display module comprises a circuit board, a packaging assembly, a plurality of LED chips and a plurality of driving ICs. The packaging assembly comprises a transparent packaging layer, a blocking part and an optical layer, the transparent packaging layer ispackaged on the circuit board, grooves are formed in the surface, opposite to the circuit board, of the transparent packaging layer at intervals, the grooves divide the surface of the transparent packaging layer into a plurality of light transmitting parts, and the light transmitting parts are packaged on the LED chips in a one-to-one correspondence mode; the grooves are filled with the blockingparts in a one-to-one correspondence mode, the optical layer is packaged on the surface, back on to the circuit board, of the transparent packaging layer, and the blocking parts are connected with theoptical layer. Due to the fact that the matrix resin of the blocking part, the matrix resin of the optical layer and the matrix resin of the transparent packaging layer are the same in thermal expansion coefficient, thermal stress in the LED display module can be reduced, and therefore the thermal stability and reliability of the LED display module are improved.

Owner:SHENZHEN ABSEN OPTOELECTRONIC CO LTD +1

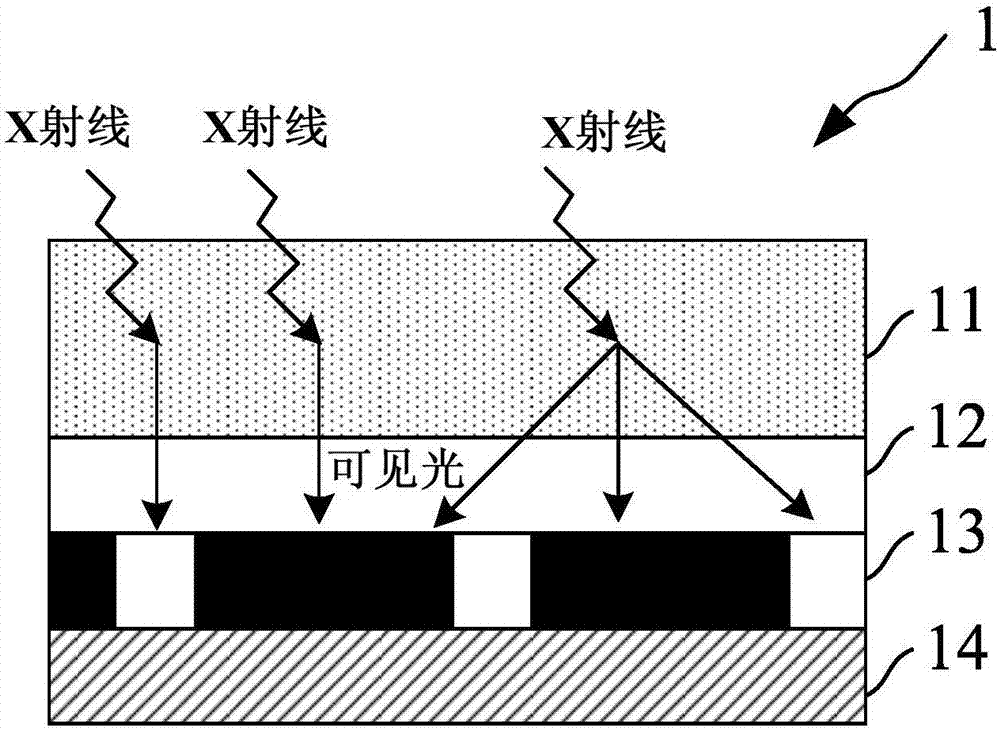

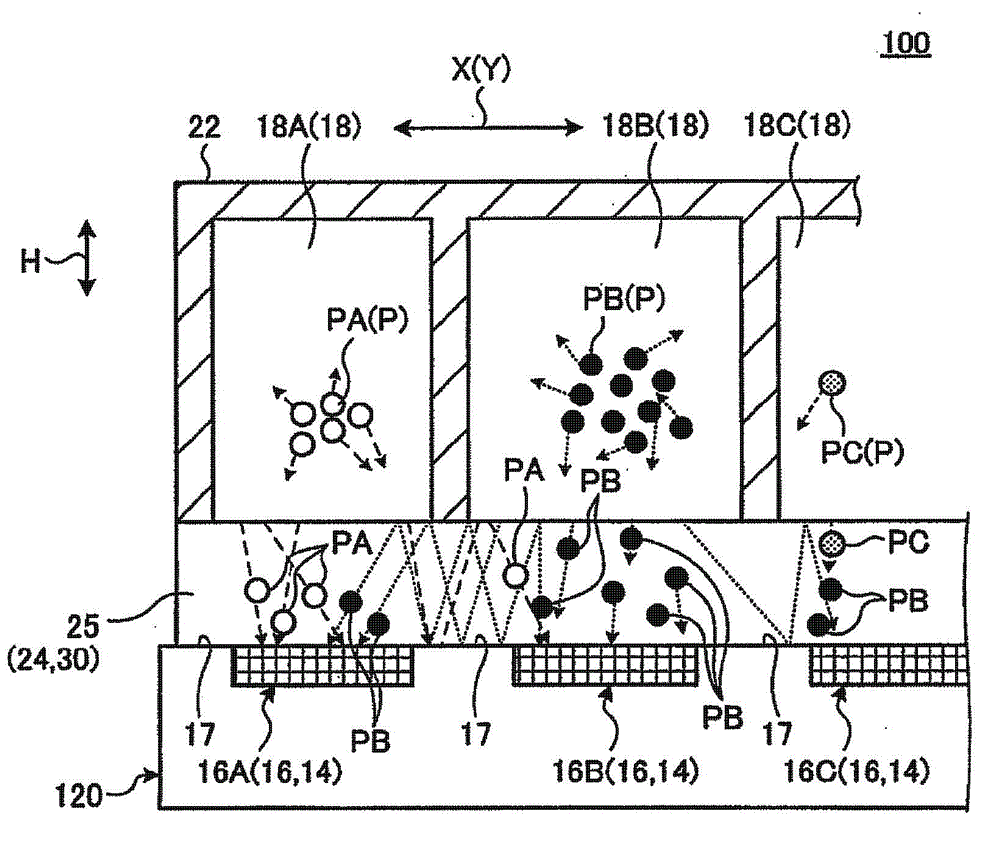

Photodetector

InactiveCN104570041AReduce Optical CrosstalkSolid-state devicesRadiation intensity measurementScintillatorPhotodetection

According to an embodiment, a photodetector includes a scintillator layer (18), a photodetection layer (12), an antireflective member (20), and an intermediate layer (25). The scintillator layer (18) is configured to convert radiation into light. The photodetection layer has a first surface facing the scintillator layer. The photodetection layer includes a pixel region (16) including multiple photodetection devices (14) configured to detect light, and a peripheral region (17) that surrounds the pixel region. The pixel and peripheral regions are provided on the first surface. The antireflective member is provided between the scintillator layer and the photodetection layer and opposed to at least part of the peripheral region. The antireflective member is configured to prevent reflection of at least part of light in a sensitive wavelength range of the photodetection devices. The intermediate layer is provided in a region other than the antireflective member between the scintillator and photodetection layers.

Owner:KK TOSHIBA

Image sensor and forming method thereof

InactiveCN108231814AInhibition of charge recombinationReduce dark currentSolid-state devicesRadiation controlled devicesLight sensingElectric current

The invention provides an image sensor and a forming method thereof. The forming method of the image sensor comprises the steps that a substrate is provided, wherein the substrate comprises a first surface and a second surface which are opposite to each other, the substrate also comprises a plurality of separated light sensing regions and isolation regions between the adjacent light sensing regions, a light sensing element is arranged in the position, in each light sensing region, in the substrate, and the second surface is exposed out of the light sensing elements; grooves are formed in the positions, in the isolation regions, in the substrate; the first surface is exposed out of the grooves; doping treatment is conducted on the bottoms and the side walls of the grooves, and doping regions are formed in the positions, at the bottoms and side walls of the grooves, in the substrate; after the doping regions are formed, isolation structures are formed in the grooves. The dark current ofthe image sensor formed through the method is small.

Owner:HUAIAN IMAGING DEVICE MFGR CORP

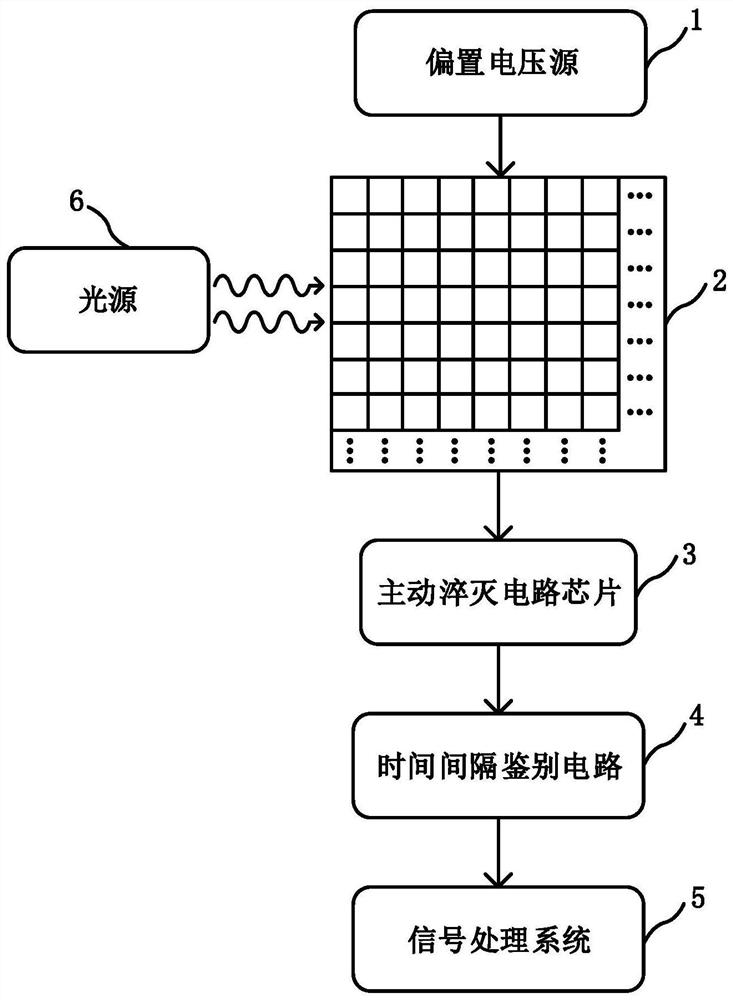

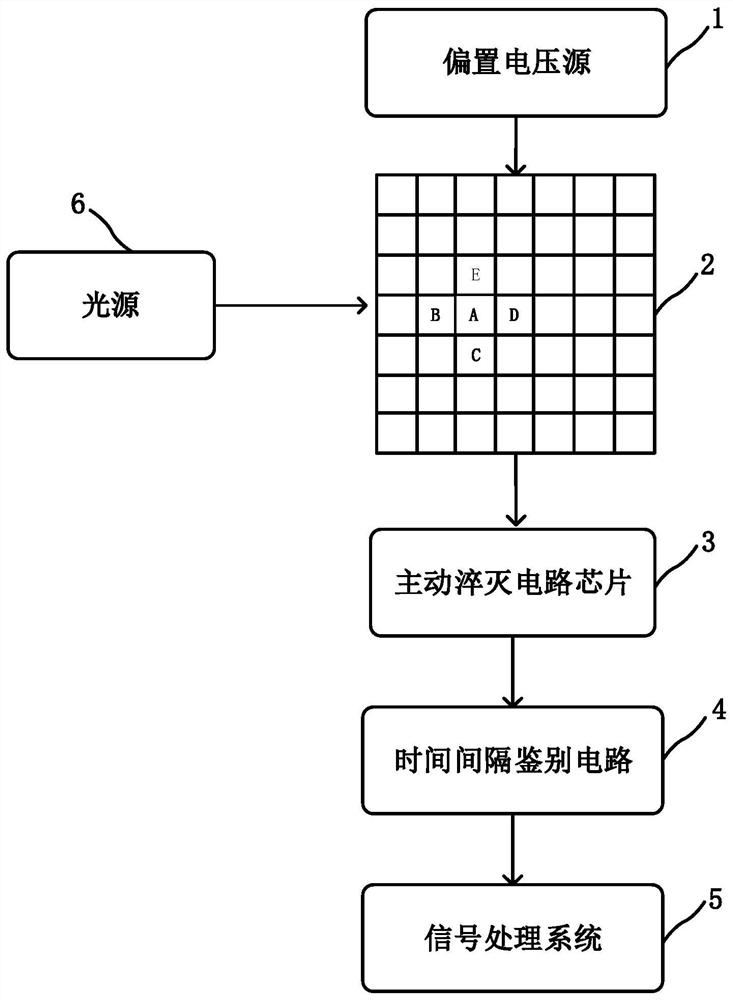

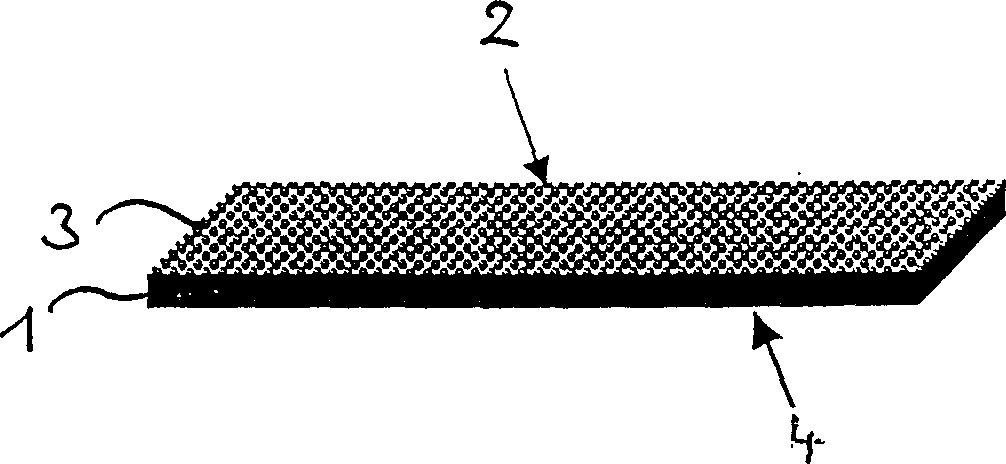

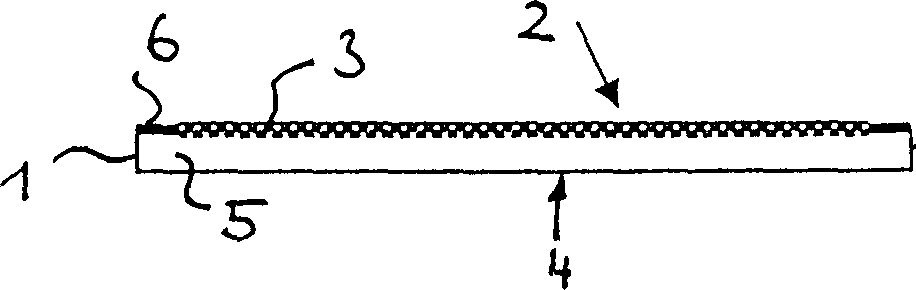

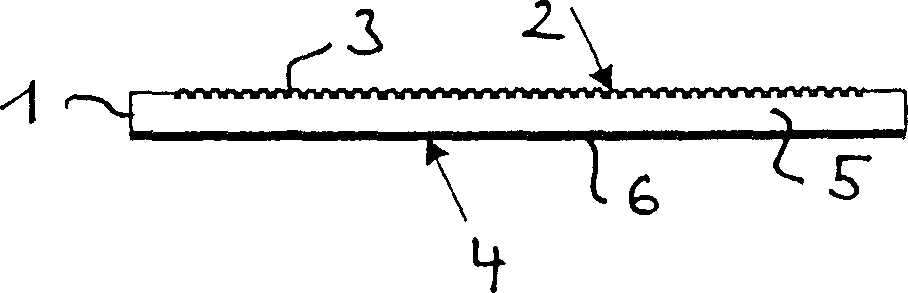

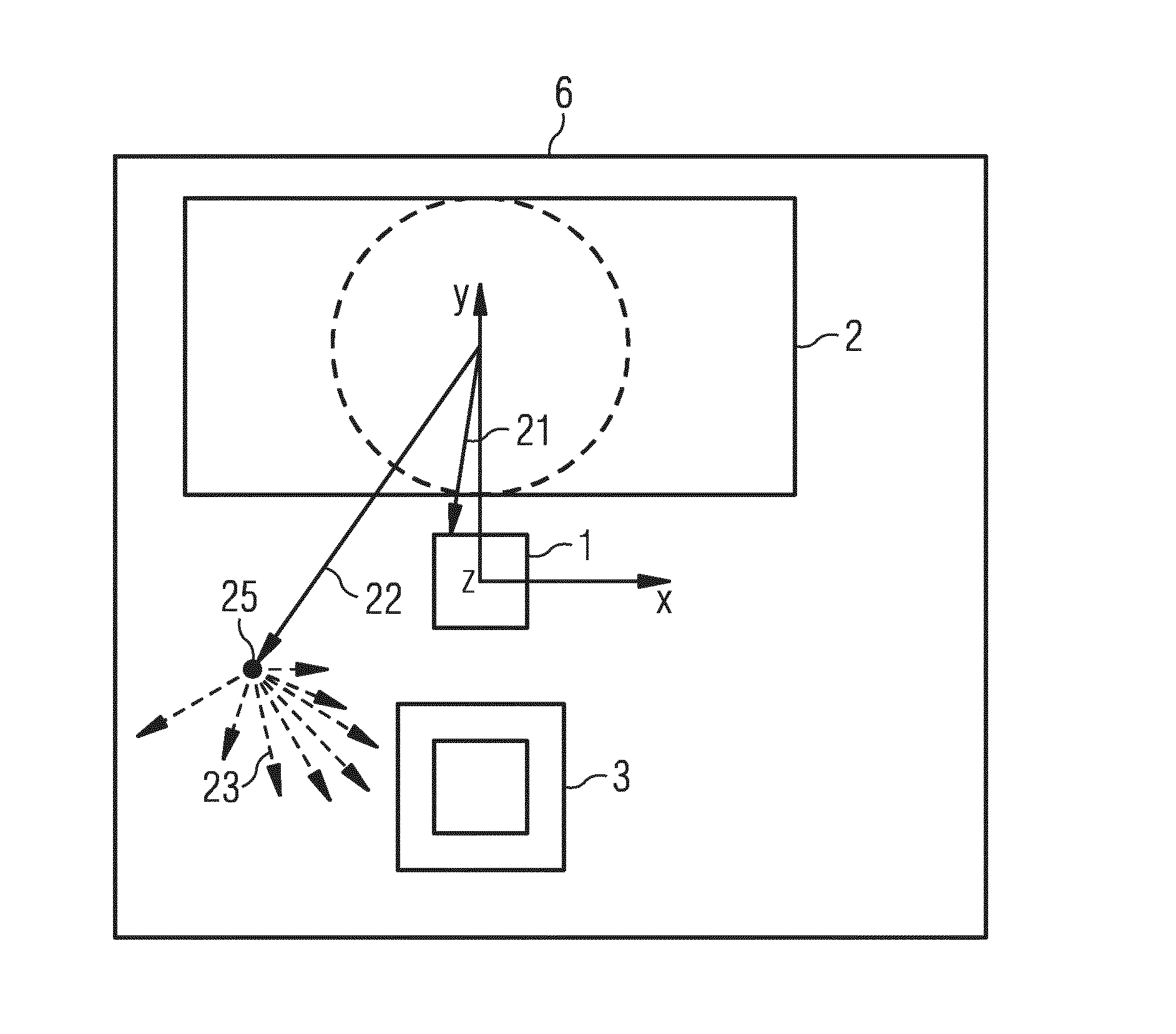

High-detection-efficiency single-photon detection array with crosstalk suppression function and system

ActiveCN112129406AImprove fill factorReduce optical crosstalkPhotometry electrical circuitsPhoton detectionPositron emission tomography

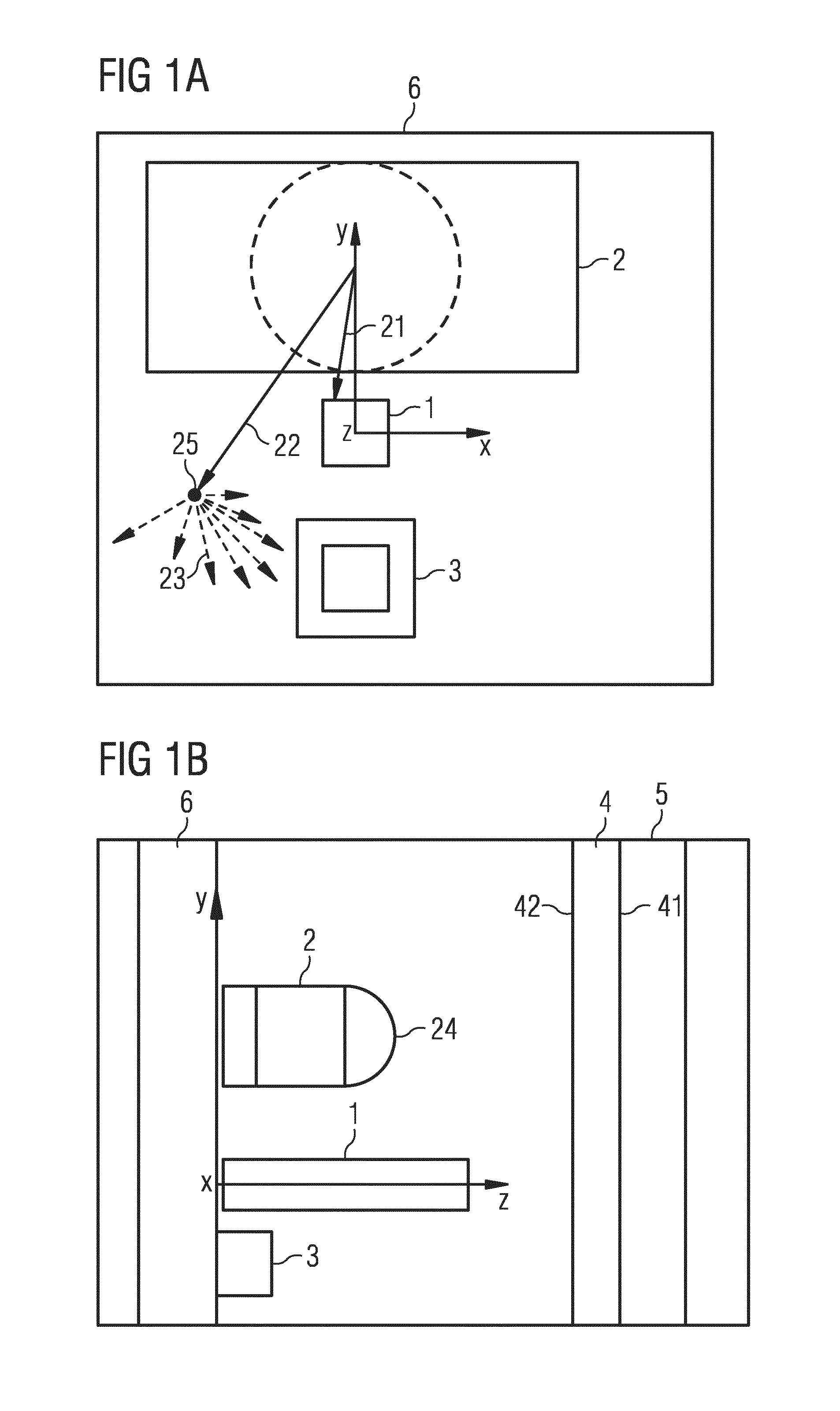

The invention provides a high-detection-efficiency single-photon detection array with a crosstalk suppression function and a system. The high-detection-efficiency single-photon detection array is composed of a bias voltage source 1, a single-photon detector array 2, an active quenching circuit chip 3, a crosstalk identification and suppression circuit 4, a signal processing system 5 and a light source 6. The high-detection-efficiency single-photon detection array can be used for realizing high fill factor and low crosstalk of the single-photon detector array, and can be widely applied to the field of ultra-weak light detection such as laser radar, fluorescence lifetime imaging, positron emission tomography and medical imaging.

Owner:GUILIN UNIV OF ELECTRONIC TECH

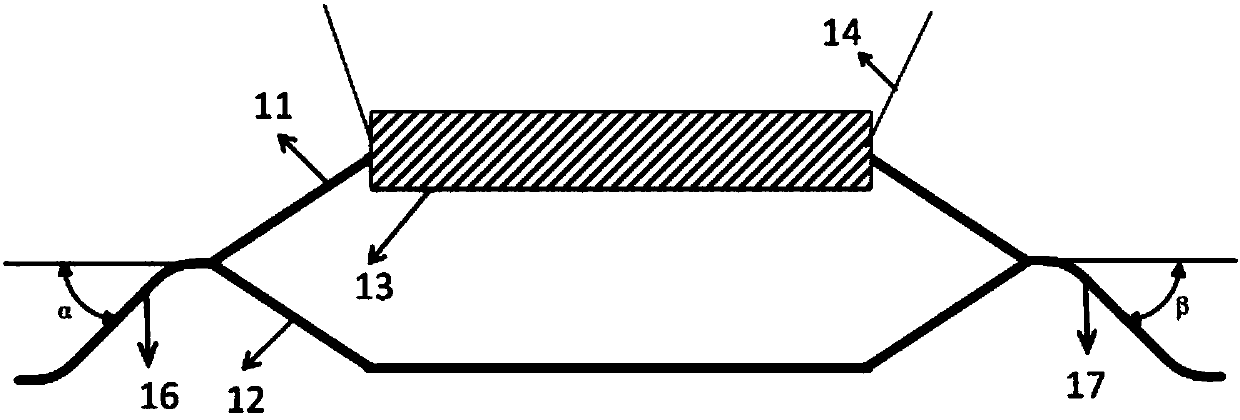

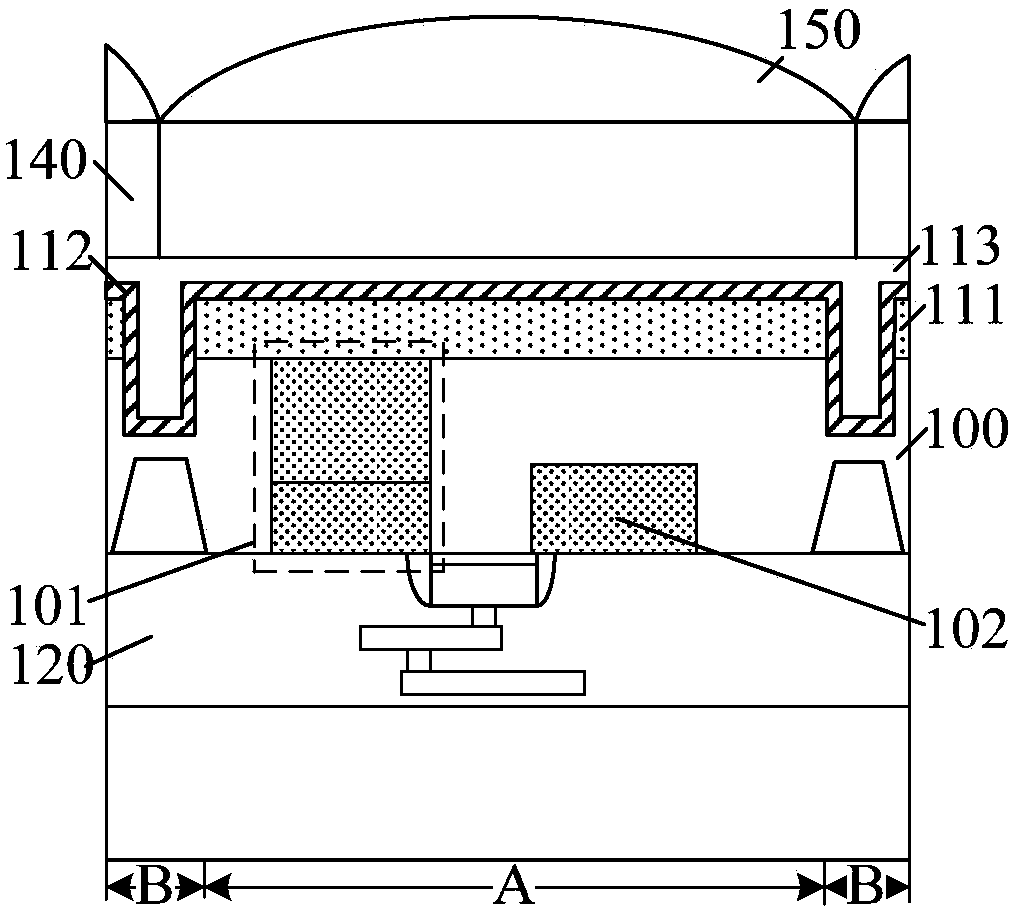

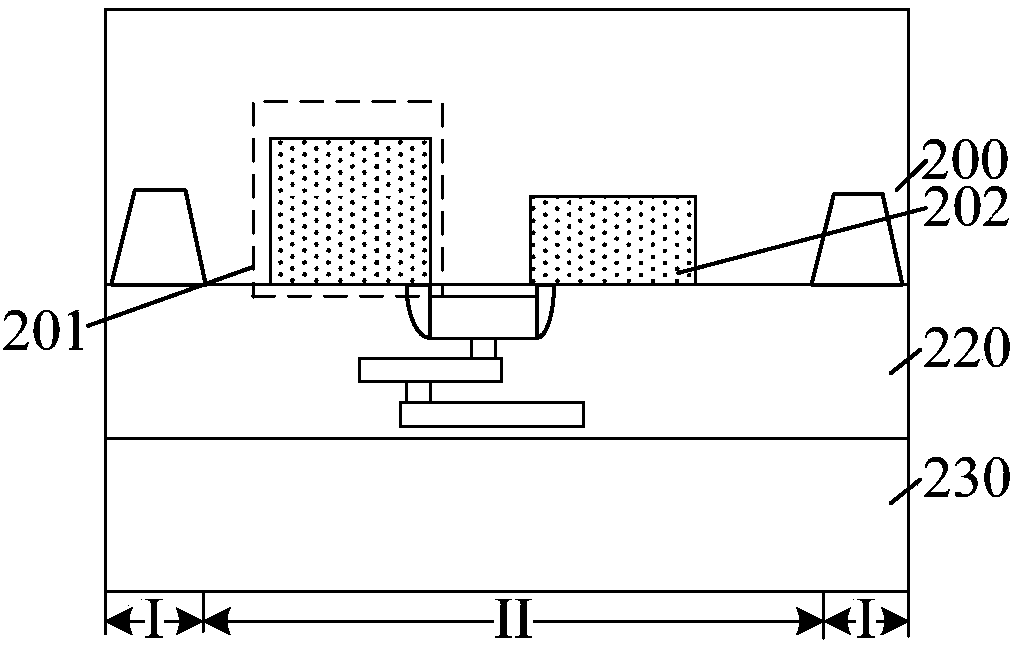

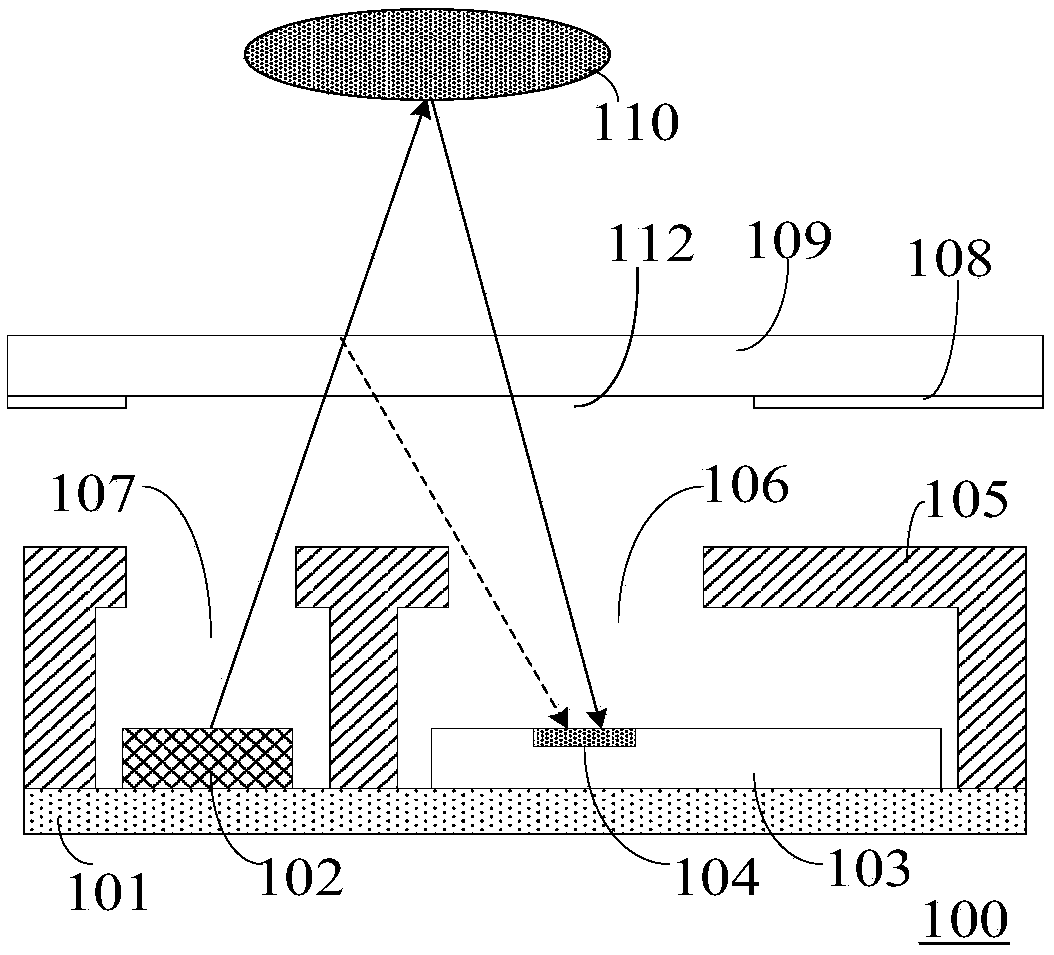

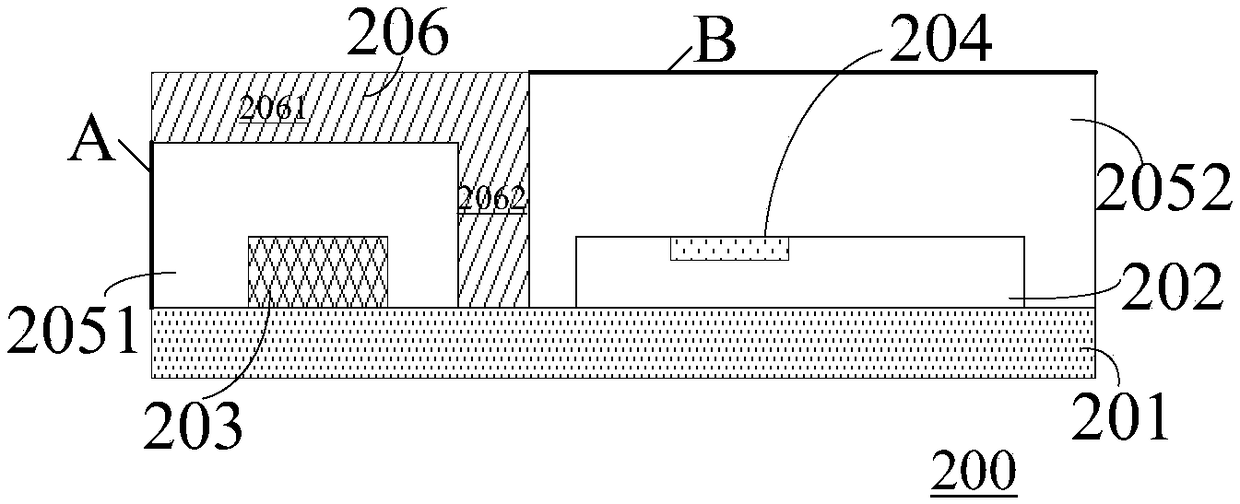

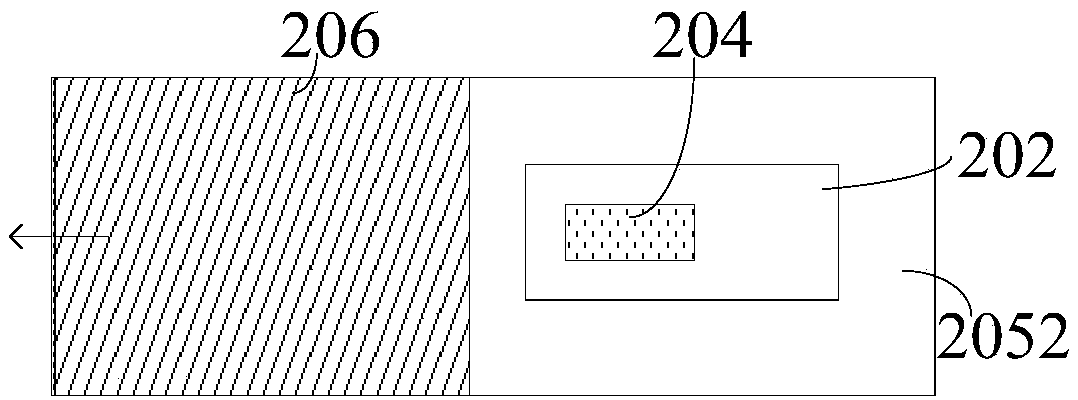

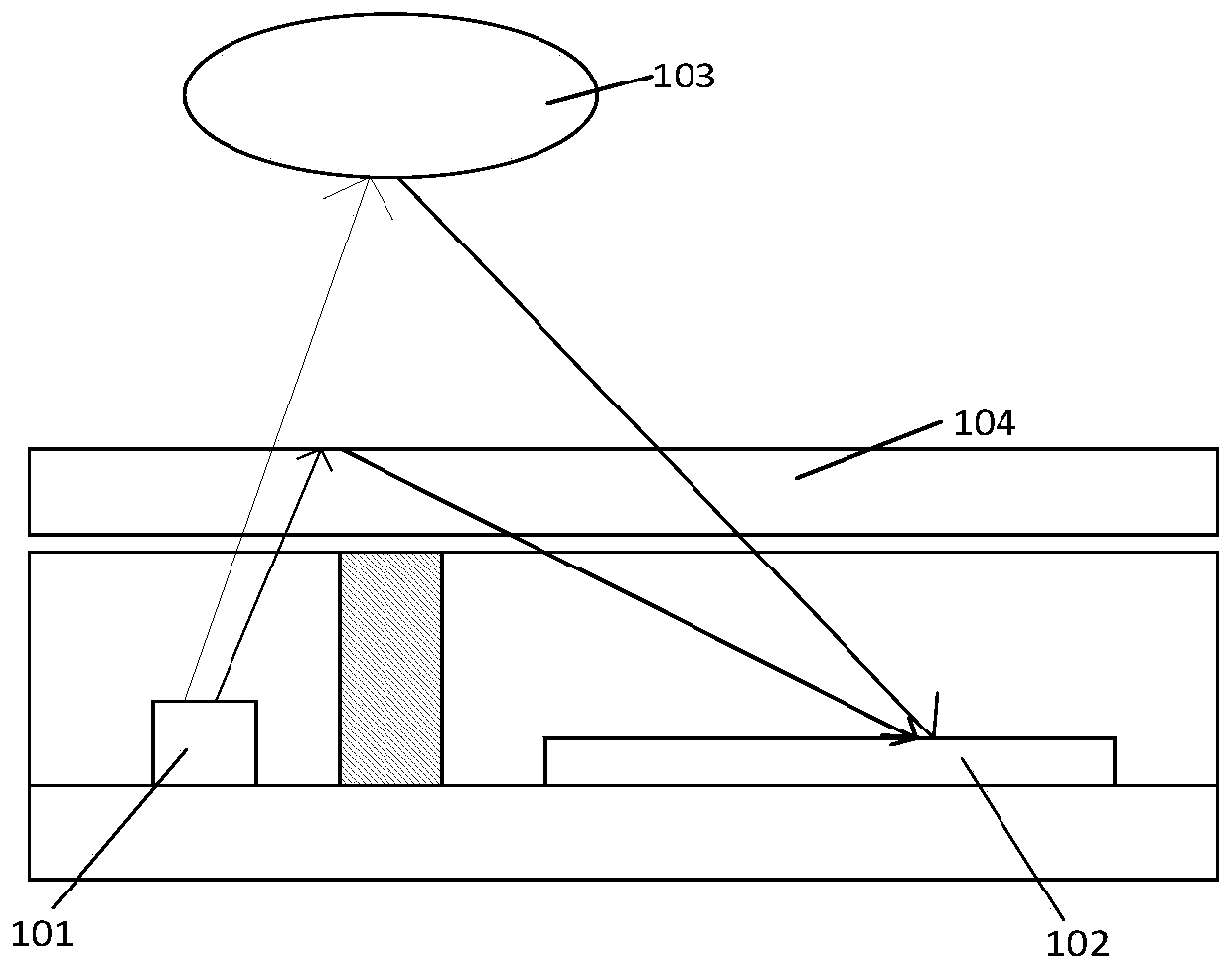

Optical sensing system, optical sensing component and manufacturing method thereof

PendingCN108711566AIncrease distanceReduce Optical CrosstalkSolid-state devicesElectromagnetic wave reradiationLight sensingDistance detection

The invention discloses an optical sensing system, an optical sensing component and a manufacturing method thereof. The optical sensing component comprises a light-emitting element; a first structuralbody packaging the light-emitting element, wherein the surface of the first structural body is provided with a light emergent surface; a light sensing element; and a second structural body packagingthe light sensing element, wherein the surface of the second structural body is provided with a light receiving surface. The light emitted by the light-emitting element is emitted outside the opticalsensing component through the light emergent surface and then reflected by the object to be measured. The reflected light reflected by the object to be measured reaches the light sensing element through the light receiving surface. The light sensing element senses the distance of the object to be measured according to the received reflected light, wherein the light emergent surface is not parallelto the light receiving surface. The light emergent surface and the light receiving surface of the optical sensing component are arranged on different planes so that the optical crosstalk can be reduced and the accuracy of distance detection can be enhanced.

Owner:NANJING SILERGY SEMICON TECH CO LTD

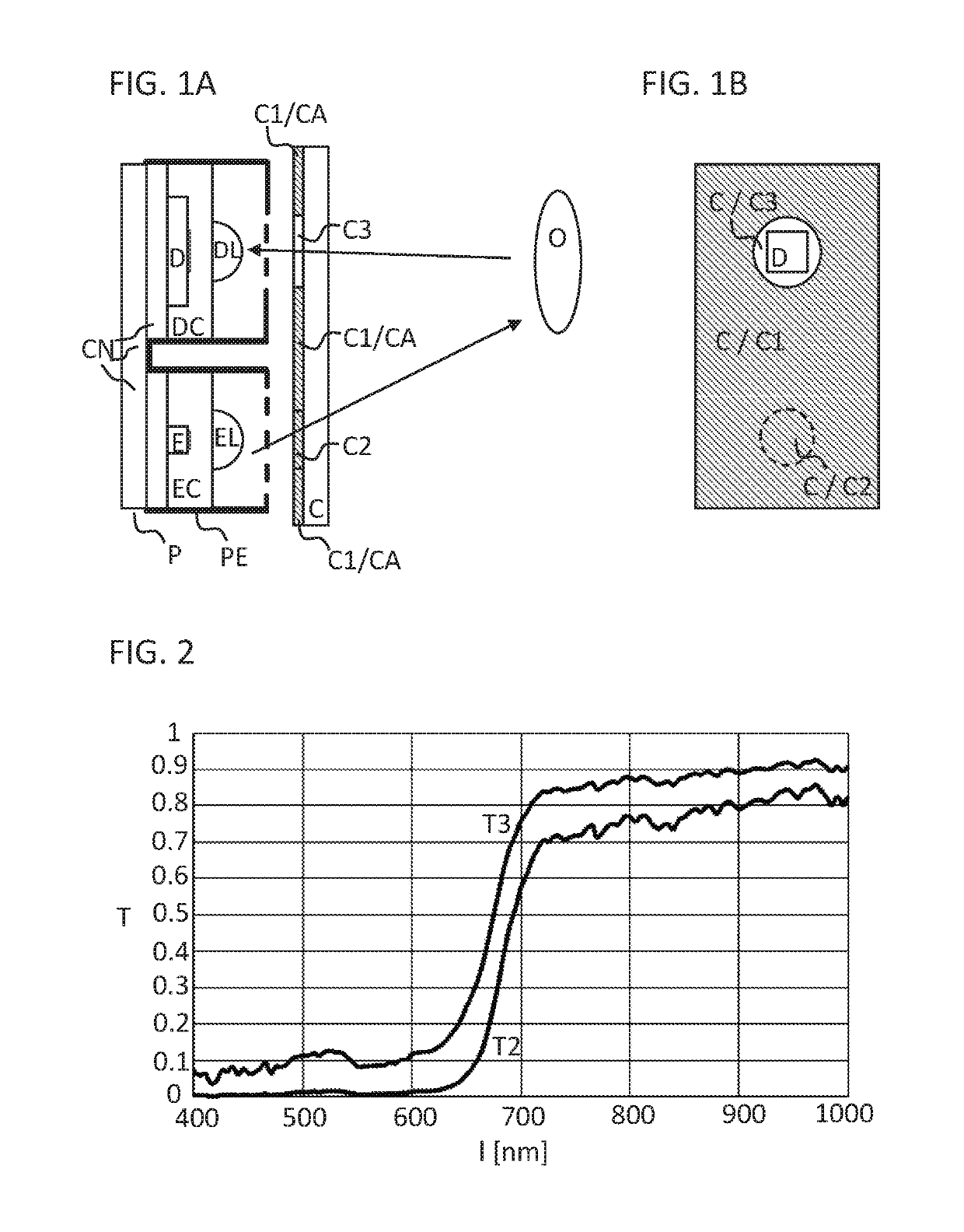

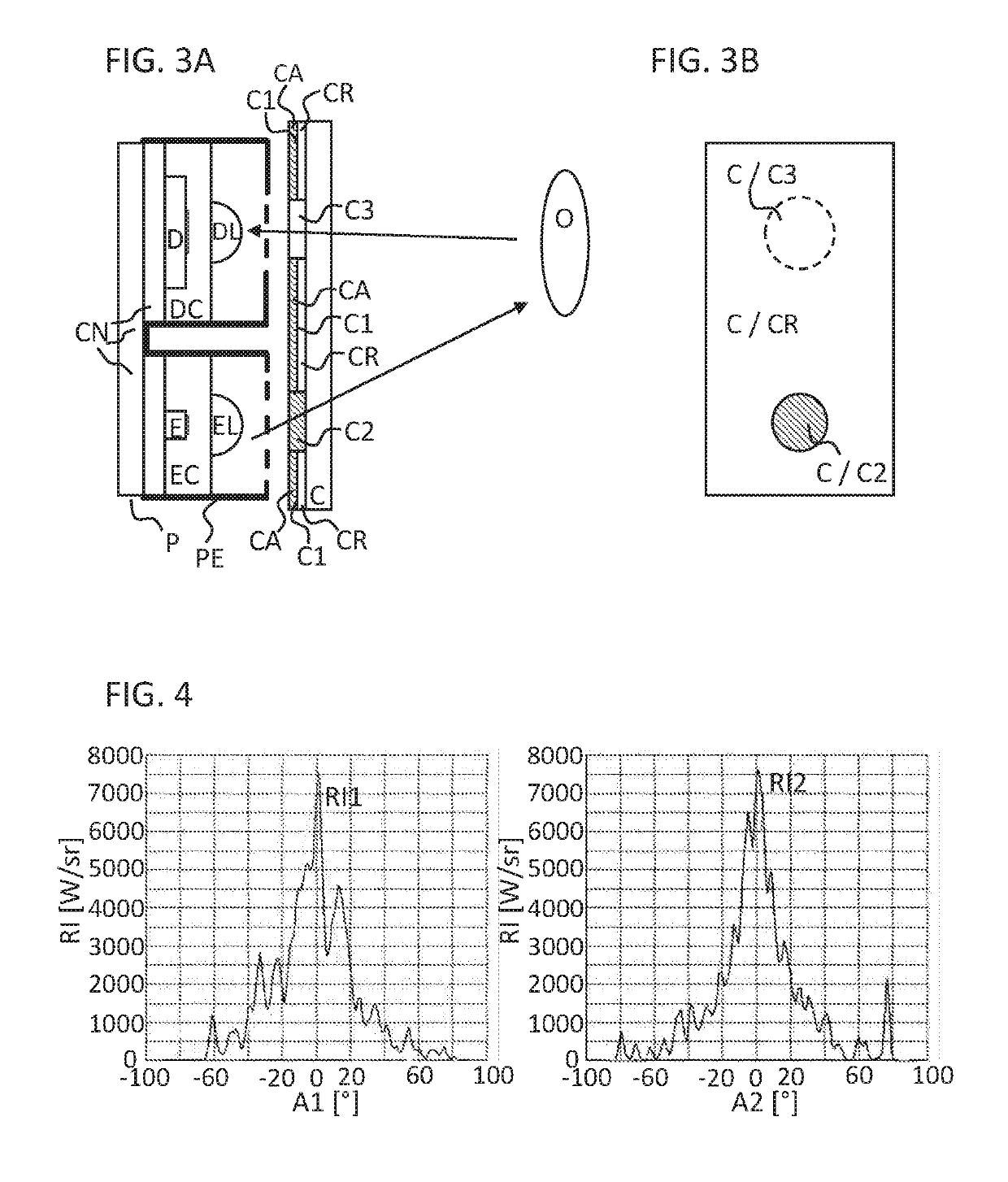

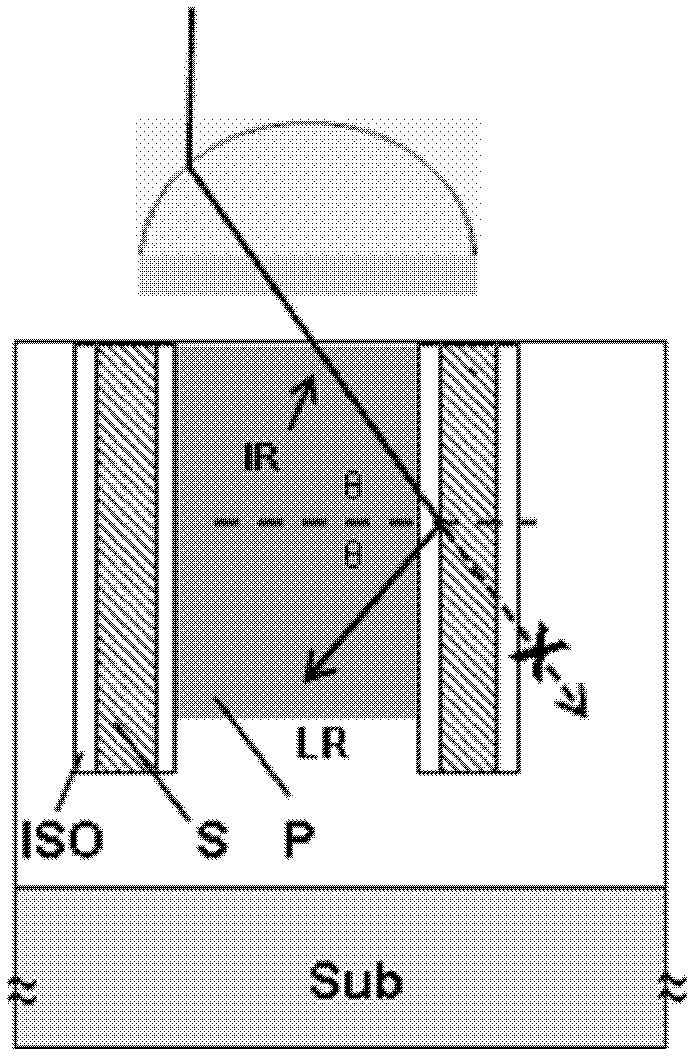

Optical sensor arrangement

ActiveUS10422876B2Improve visibilityReduce optical crosstalkInput/output for user-computer interactionPhotometryEngineeringElectromagnetic radiation

An optical sensor arrangement comprises an emitting device (E) and a detection device (D) configured to emit and detect, respectively, electromagnetic radiation and a cover (C) arranged to cover the emitting and the detection device (E, D). The sensor arrangement comprises a first cover layer (C1) partially covering an inner surface of the cover (C) and having a first and a second opening located above the emitting and the detection device (E, D), respectively. The sensor arrangement comprises a second and a third cover layer (C2, C3) covering the inner surface at areas of the first and the second opening. A reflection and / or an absorption characteristics of at least one of the second and third cover layer (C2, C3) is adapted to a reflection and / or an absorption characteristics of the first cover layer (C1) for incident light within the specified spectrum.

Owner:AMS AG

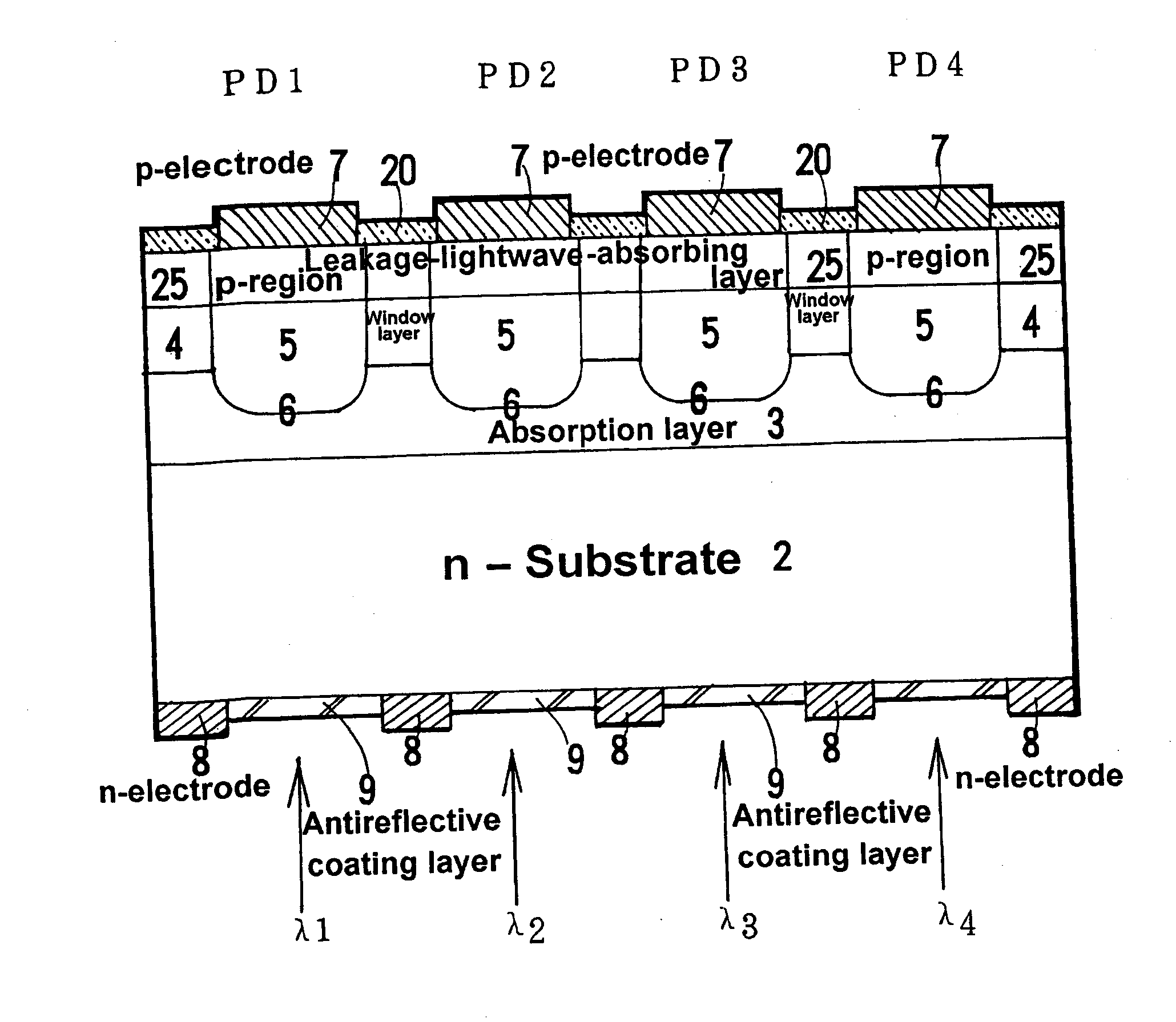

Rear-Illuminated -Type Photodiode Array

InactiveUS20070096178A1Optical obstructionReduce optical crosstalkSolid-state devicesSemiconductor devicesAnti-reflective coatingLength wave

A rear-illuminated-type photodiode array has (a) a first-electroconductive-type semiconductor substrate, (b) a first-electroconductive-type electrode that is placed at the rear side of the semiconductor substrate and has openings arranged one- or two-dimensionally, (c) an antireflective coating provided at each of the openings of the first-electroconductive-type electrode, (d) a first-electroconductive-type absorption layer formed at the front-face side of the substrate, (e) a leakage-lightwave-absorbing layer that is provided on the absorption layer and has an absorption edge wavelength longer than that of the absorption layer, (f) a plurality of second-electroconductive-type regions that are formed so as to penetrate through the leakage-lightwave-absorbing layer from the top surface and extend into the absorption layer to a certain extent and are arranged one- or two-dimensionally at the positions coinciding with those of the antireflective coatings at the opposite side, and (g) a second-electroconductive-type electrode provided on the top surface of each of the second-electroconductive-type regions.

Owner:SUMITOMO ELECTRIC IND LTD

Image sensor and formation method thereof

InactiveCN108364965AReduce thicknessReduce processing difficultySolid-state devicesRadiation controlled devicesCrosstalkLight sensitive

The invention provides an image sensor and a formation method thereof. The formation method of the image sensor comprises the steps of providing a substrate, wherein the substrate comprises a first surface; the substrate comprises multiple separated light sensitive regions and isolation regions positioned between the adjacent light sensitive regions; forming a supporting layer on the surface of the first surface of the substrate in the isolation regions; and forming an anti-crosstalk layer on the surface of the side wall of the supporting layer. By virtue of the method, the technological difficulty is relatively low, and the formed image sensor is relatively low in optical crosstalk.

Owner:HUAIAN IMAGING DEVICE MFGR CORP

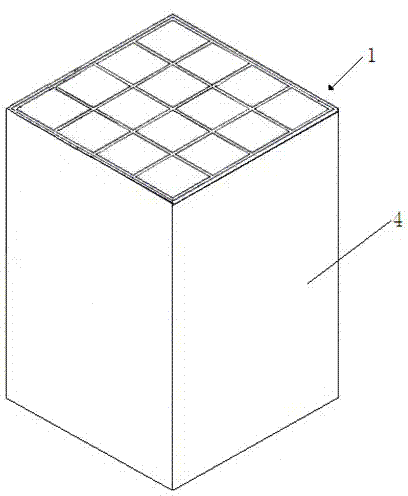

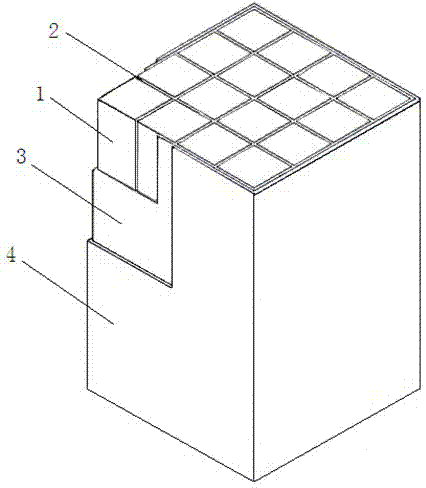

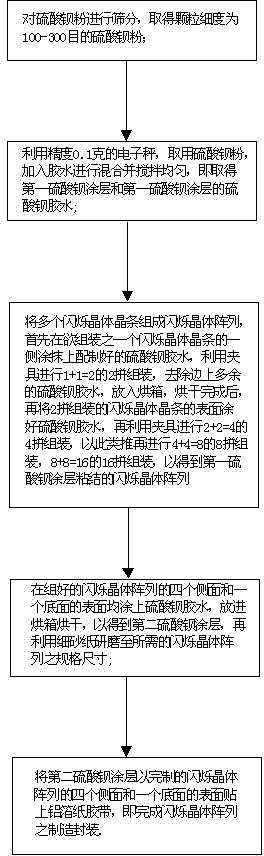

Radiography imaging detector scintillation crystal array and manufacture method thereof

ActiveCN103777225AImprove light outputReduce optical crosstalkX/gamma/cosmic radiation measurmentIsolation effectPaper tape

The invention discloses a radiography imaging detector scintillation crystal array which comprises scintillation crystal bars, a first barium sulfate coating, a second barium sulfate coating and an aluminum foil paper tape. A number of scintillation crystal bars form the scintillation crystal array through the first barium sulfate coating. The second barium sulfate coating and the aluminum foil paper tape respectively coat the outer surface of the scintillation crystal array. According to the radiography imaging detector scintillation crystal array and a manufacture method thereof, which are provided by the invention, the manufactured scintillation crystal array can acquire high light output, low light crosstalk, great position resolution and a great light isolation effect; and the radiography imaging detector scintillation crystal array and the manufacture method thereof have the advantages of assembly repeatability, low cost and good light collection and imaging effects.

Owner:江苏晶特晶体科技有限公司

Rear-illuminated-type photodiode array

ActiveUS7332751B2Optical obstructionReduce optical crosstalkSolid-state devicesSemiconductor devicesLength wavePhotodiode

Owner:SUMITOMO ELECTRIC IND LTD

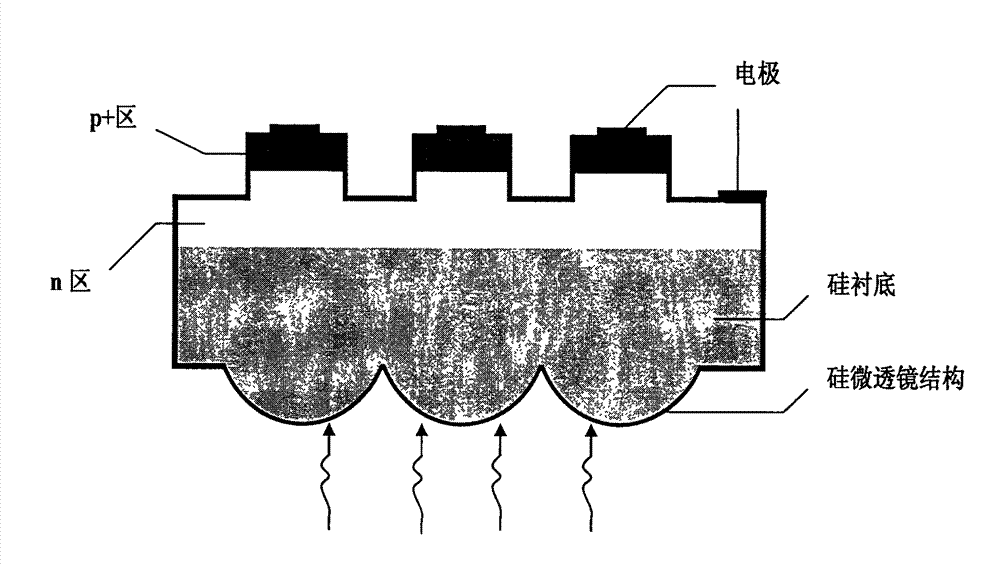

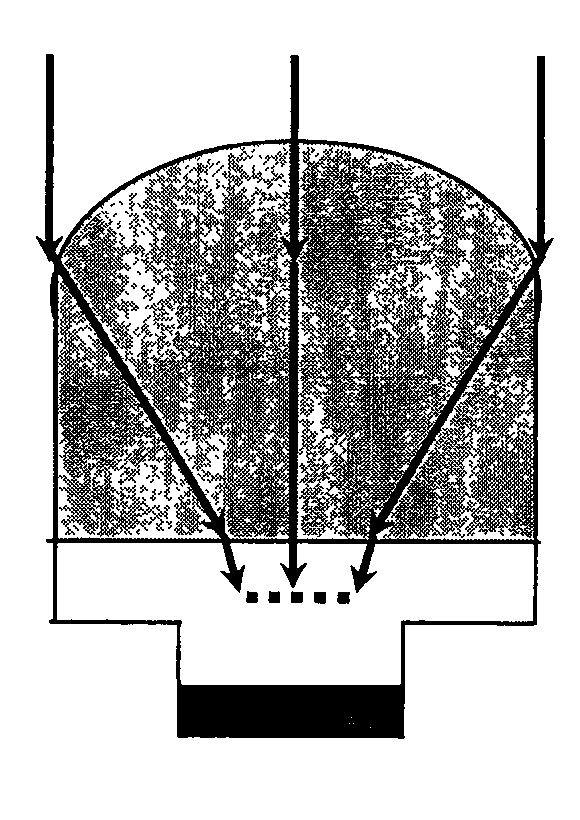

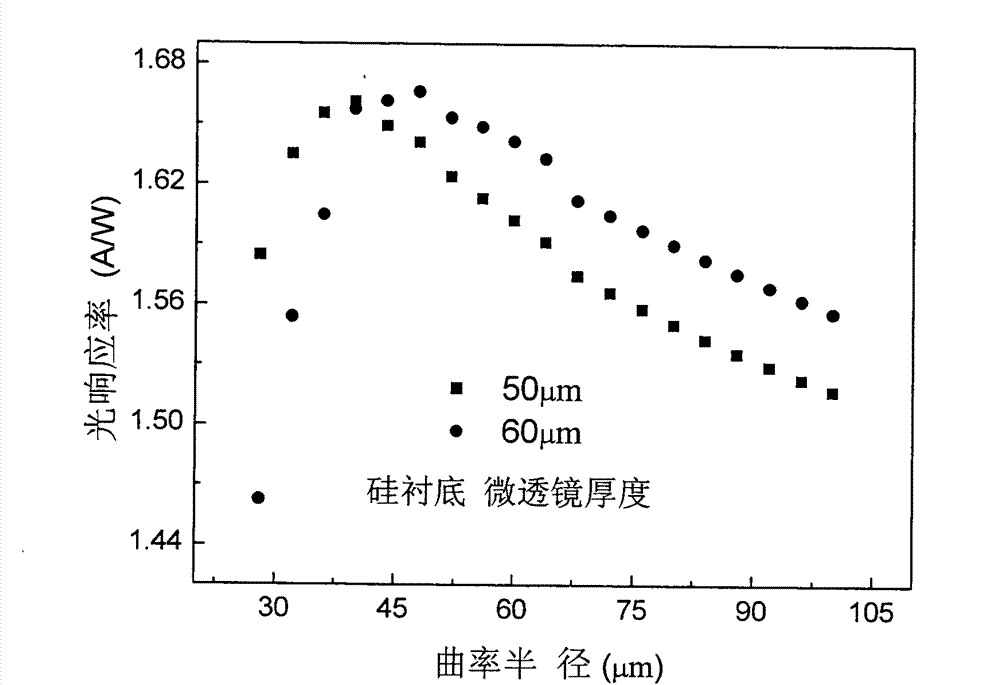

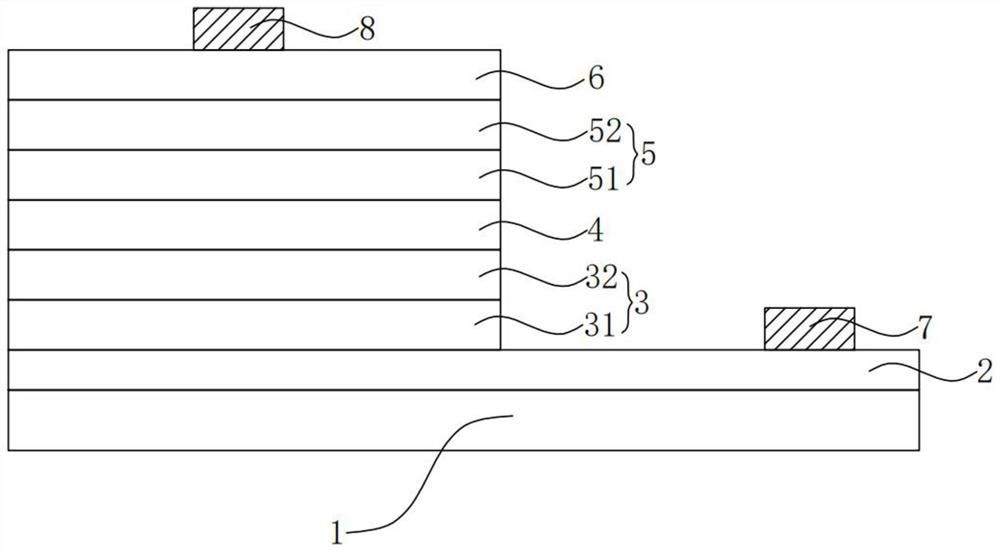

Method for optimizing light gathering ability of micro-lens array of back-illuminated infrared detector

InactiveCN102201487BHighly integratedImprove reliabilityFinal product manufactureLensDevice simulationMicro lens array

The invention discloses a method for optimizing the light gathering capability of a back-integrated micro-lens array of an InSb infrared focal plane detector. Through device simulation and theoretical calculation, the method finds that the device performance can be well improved by focusing light on a position 2.75 times of absorption distance away from an InSb-Si interface, and a micro-lens can be directly etched on a back substrate of the InSb infrared focal plane detector according to the result, thereby providing the basis for optimizing the light gathering ability of the back-integrated micro-lens array of the InSb IR focal plane detector. The method provided by the invention has important meanings for improving the device performance and optimizing the device design.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

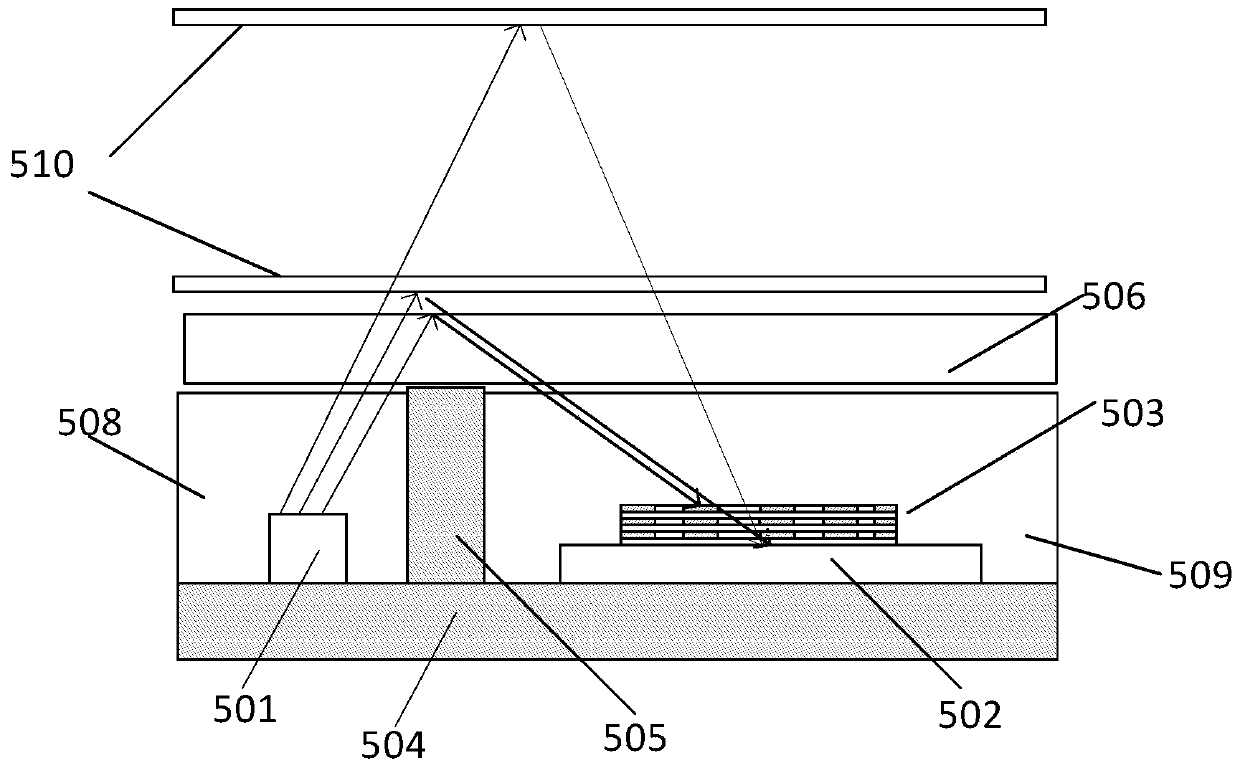

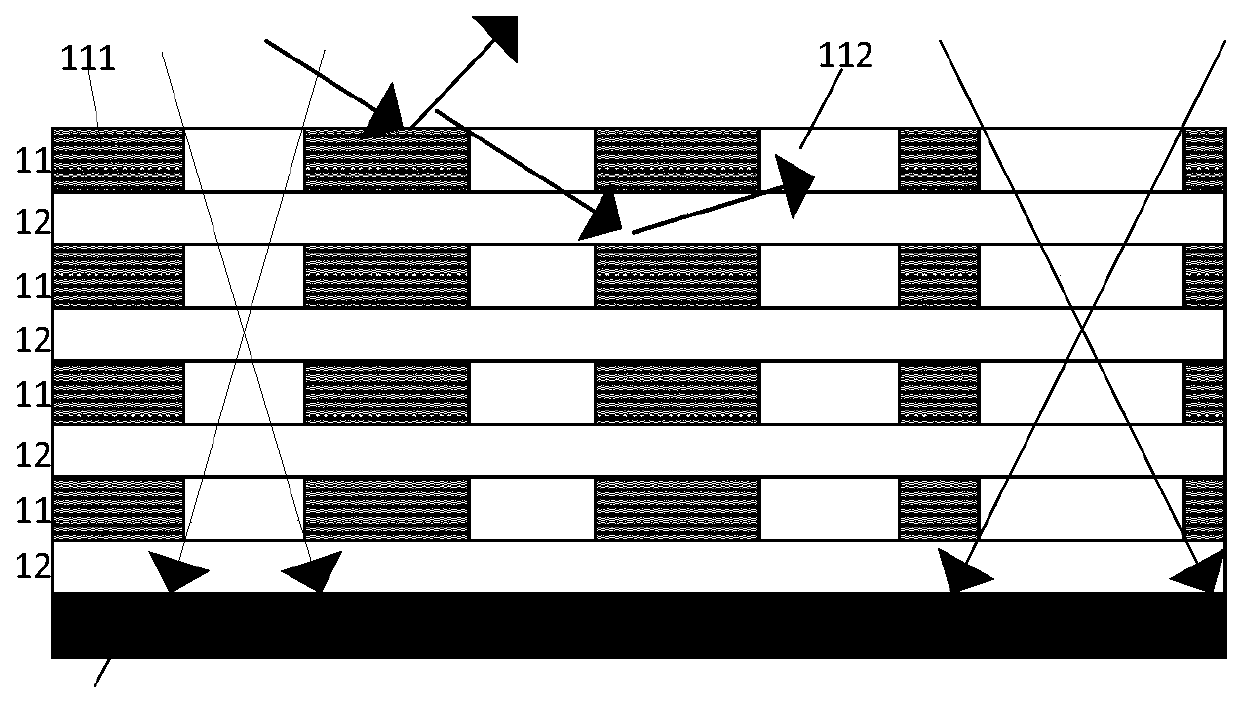

Optical sensing device

PendingCN111446310ASmall sizeReduce Optical CrosstalkElectromagnetic wave reradiationSemiconductor devicesOptical sensingLight filter

The invention provides an optical sensing device. The device comprises at least one semiconductor with a photosensitive area and an optical structure. The optical structure is positioned above the photosensitive area; and the optical structure comprises a light filtering layer and a light transmitting layer which are alternately stacked so as to prevent large-angle incident light from entering thephotosensitive area and reduce optical crosstalk.

Owner:SILERGY SEMICON TECH (HANGZHOU) CO LTD

Fabrication process for photoresist die

InactiveCN105045050AReduce Optical CrosstalkImprove transmission efficiencyPhotosensitive material processingPhotoresistMaterials science

The invention discloses a fabrication process for a photoresist die. A photoresist spin coating method comprises the following steps of: adding photoresist to the center of an optical fiber panel dropwise; accelerating the optical fiber panel to 600 rpm / min from a standstill; accelerating the optical fiber panel to 1,800 rpm / min; accelerating the optical fiber panel to 2,000 rpm / min; accelerating the optical fiber panel to 2,200 rpm / min; decelerating the optical fiber panel to 800 rpm / min; and gradually decelerating the optical fiber panel and ending spinning. The fabrication method for the photoresist die comprises photoresist spin coating, pre-baking, exposing, post-baking, cooling, developing and hardening. By the photoresist die fabricated according to the method, the optical crosstalk between adjacent micro reaction pool arrays is reduced, and the problem of signal misreading caused by sequencing reaction is effectively solved.

Owner:BEIJING ZHONGKEZIXIN TECH

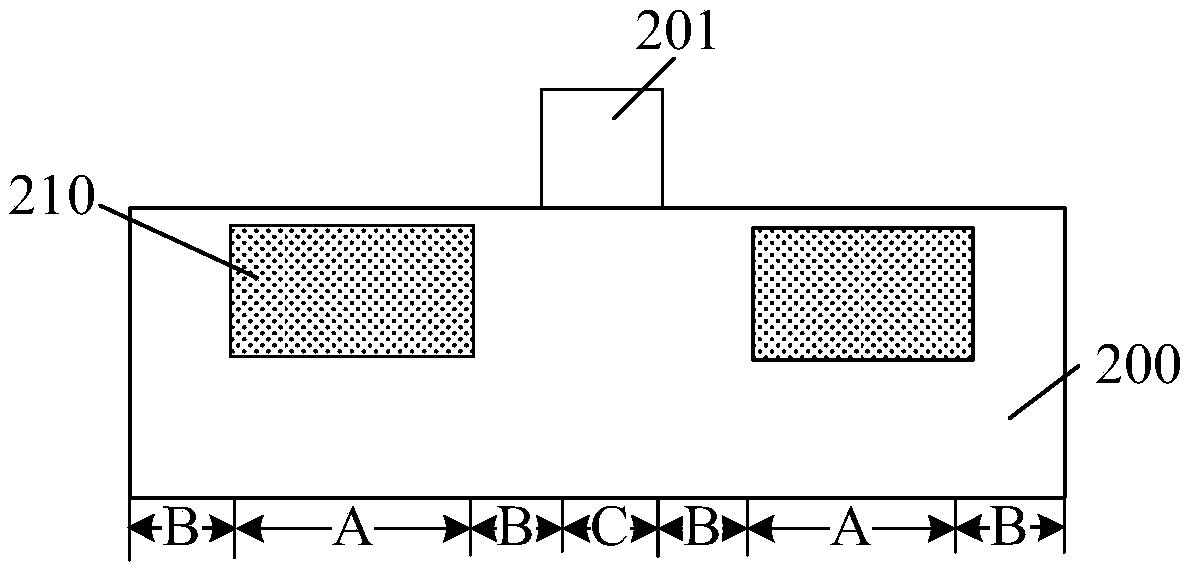

Micro-lens array capable of reducing optical crosstalk between pixels of polarization imaging device

InactiveCN108231811AReduce optical crosstalkSolid-state devicesDiffraction gratingsPixel arrayPolarization imaging

The invention provides a micro-lens array capable of reducing optical crosstalk between pixels of a polarization imaging device. The micro-lens array comprises a pixel array, a planarization layer, agrating array and a micro-lens array body; the pixel array is composed of the pixels distributed in an array; the grating array is composed of a plurality of sub-wavelength gratings which are distributed in an array; the micro-lens array body is composed of a plurality of micro-lenses which are distributed in an array. The micro-lens array is characterized in that the diameter of the micro-lensesis equal to the length of the diagonal lines of the pixels; isolation grooves are formed between every two adjacent micro-lenses, and the depth of the isolation grooves reaches the surface of the grating array. The micro-lens array has the advantages that the micro-lens array for the polarization imaging device is provided and can effectively reduce the optical crosstalk between the pixels.

Owner:THE 44TH INST OF CHINA ELECTRONICS TECH GROUP CORP

Novel semiconductor photomultiplier device

ActiveCN107275433AReduce Optical CrosstalkReduce the noise floorSolid-state devicesSemiconductor/solid-state device manufacturingHigh resistanceSemiconductor

A novel semiconductor photomultiplier device includes an epitaxial photodiode array over an SOI substrate, a deep trench dielectric layer that completely isolates each photodiode, a high resistance resistor in series connection with each of the photodiodes, and metal interconnection lines for the interconnection of the high resistance resistor and the photodiodes. The benefit effect is that the deep trench dielectric layer and the SOI substrate completely isolate each of the photodiodes from the other adjacent photodiodes, prevent direct optical crosstalk and delay optical crosstalk, and reduce the influence of secondary photons on the adjacent photodiodes, so as to significantly reduce the overall optical crosstalk of the device, and significantly enhance the single-photon resolution.

Owner:湖北京邦科技有限公司

Slide for fluorescent microscope

InactiveCN1434318APrevention is cheapEasy maintenanceMicroscopesImage resolutionFluorescent radiation

To improve spatial resolution or sensitivity in measuring fluorescent layers, a specimen slide is provided which is not fluorescent by itself, is plate-shaped and has at least one plate side provided with fluorescent light absorbing properties, or with an antireflection-coating for fluorescent radiation.

Owner:CARL ZEISS JENA GMBH

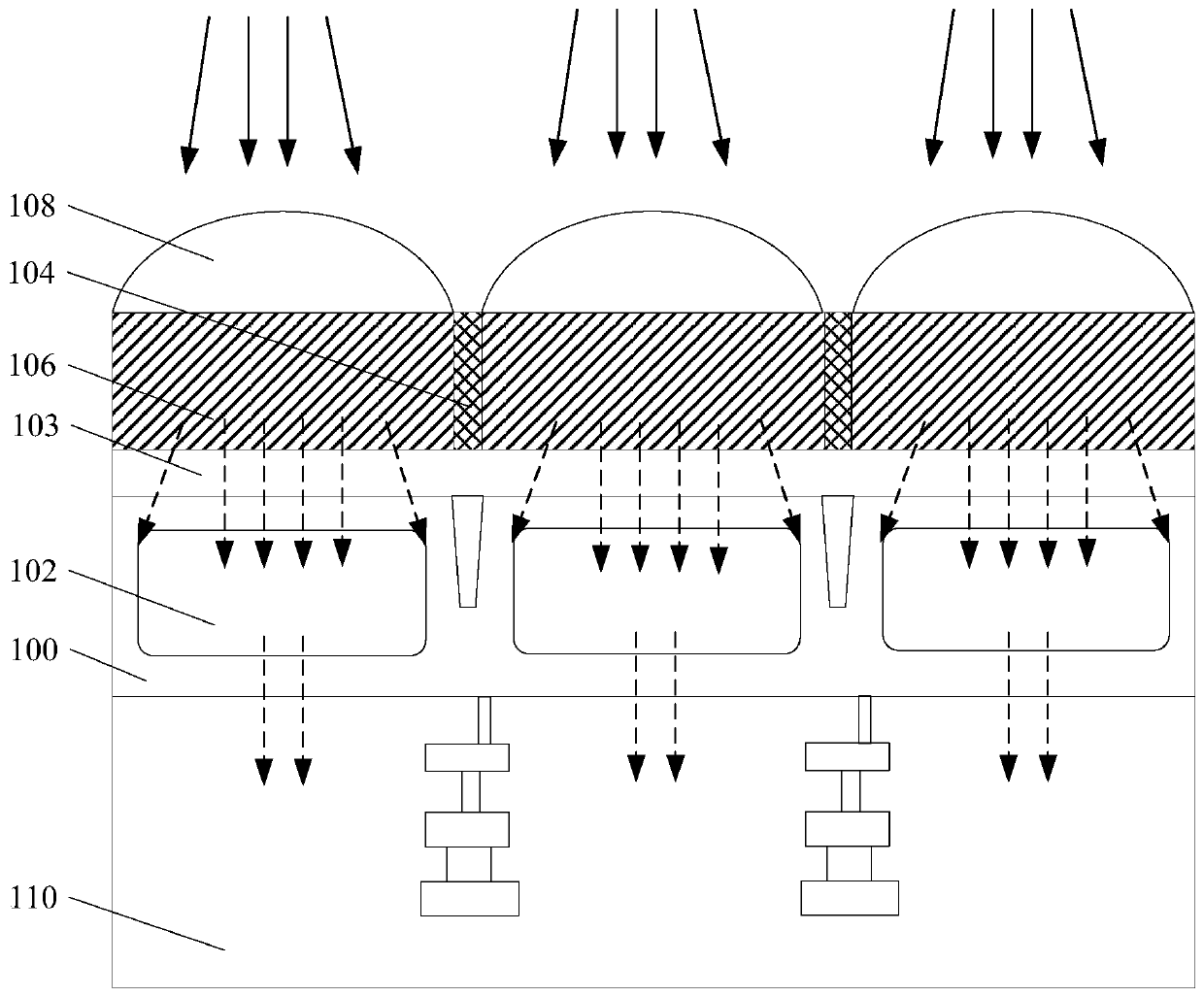

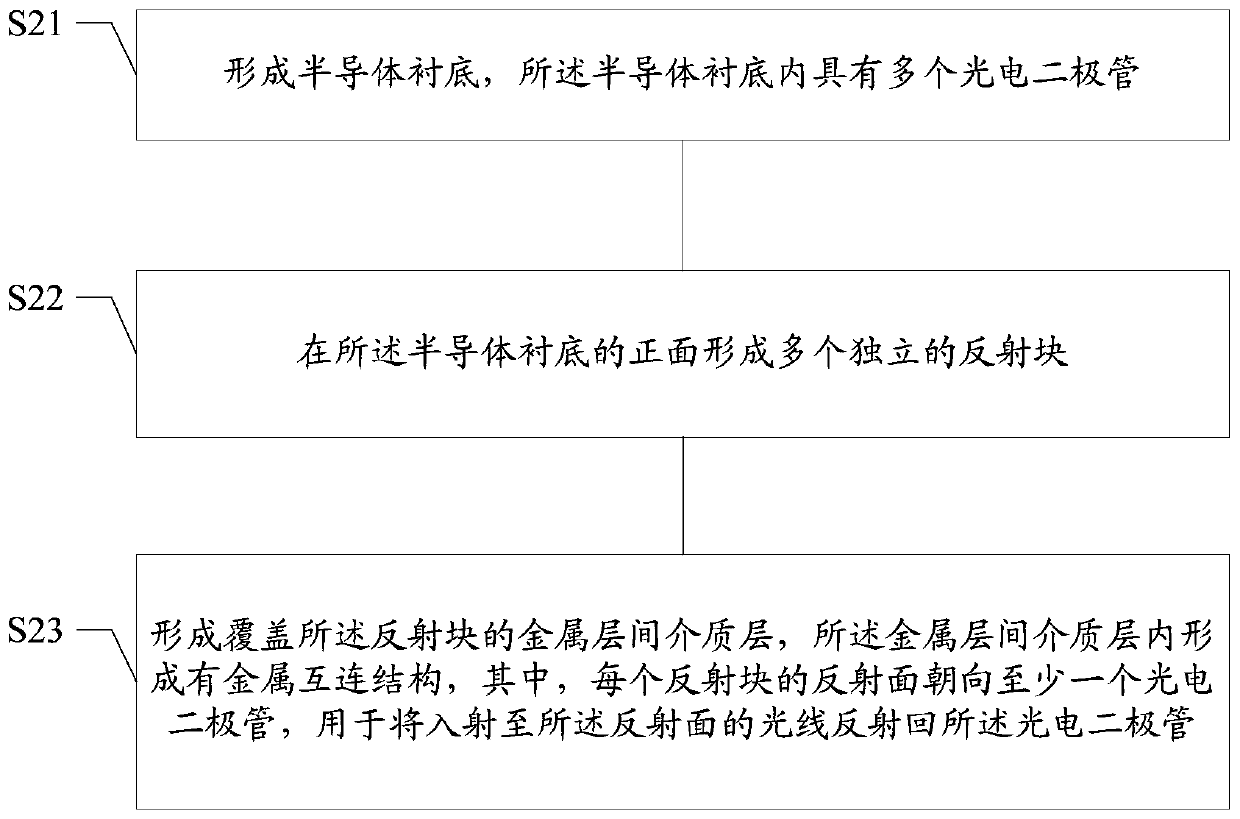

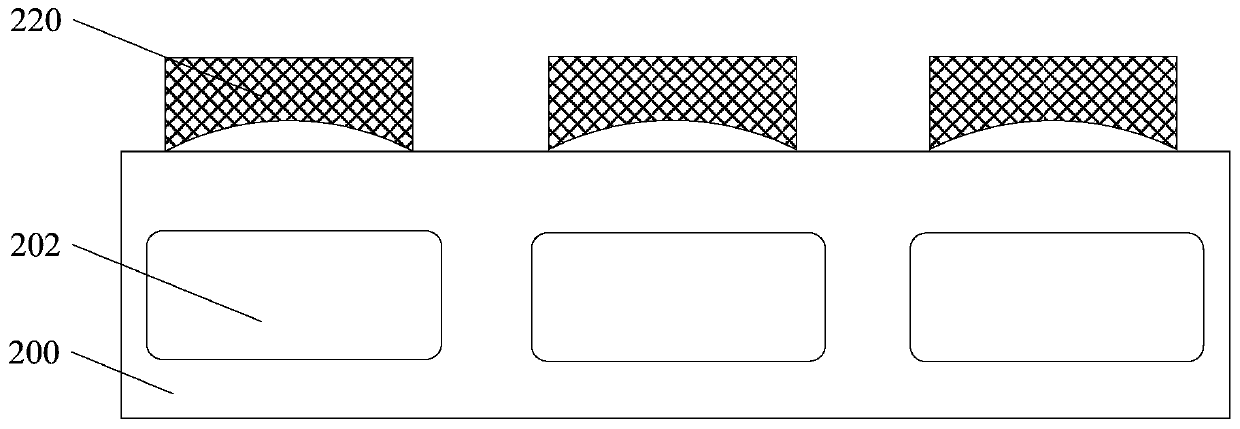

Image sensor and formation method thereof

InactiveCN109786414AImprove consistencyLongitudinal Leakage Current ReductionRadiation controlled devicesInterconnectionMedia layer

The invention discloses an image sensor and a formation method thereof. The image sensor can comprise a semiconductor substrate, a plurality of reflection blocks and a metal interlayer medium layer, wherein a plurality of photodiodes are arranged in the semiconductor substrate; the plurality of reflection blocks are positioned on the front side of the semiconductor substrate, and a gap is formed between adjacent reflection blocks; the metal interlayer medium layer covers the reflection blocks, and a metal interconnection structure is formed in the metal interlayer medium layer; and the reflection surface of each reflection block faces at least one photodiode for reflecting rays which enter the reflection surface back to the photodiode. By use of the scheme, a ray adsorption amount can be improved, optical crosstalk is reduced, and the sensitivity of the image sensor is improved.

Owner:HUAIAN IMAGING DEVICE MFGR CORP

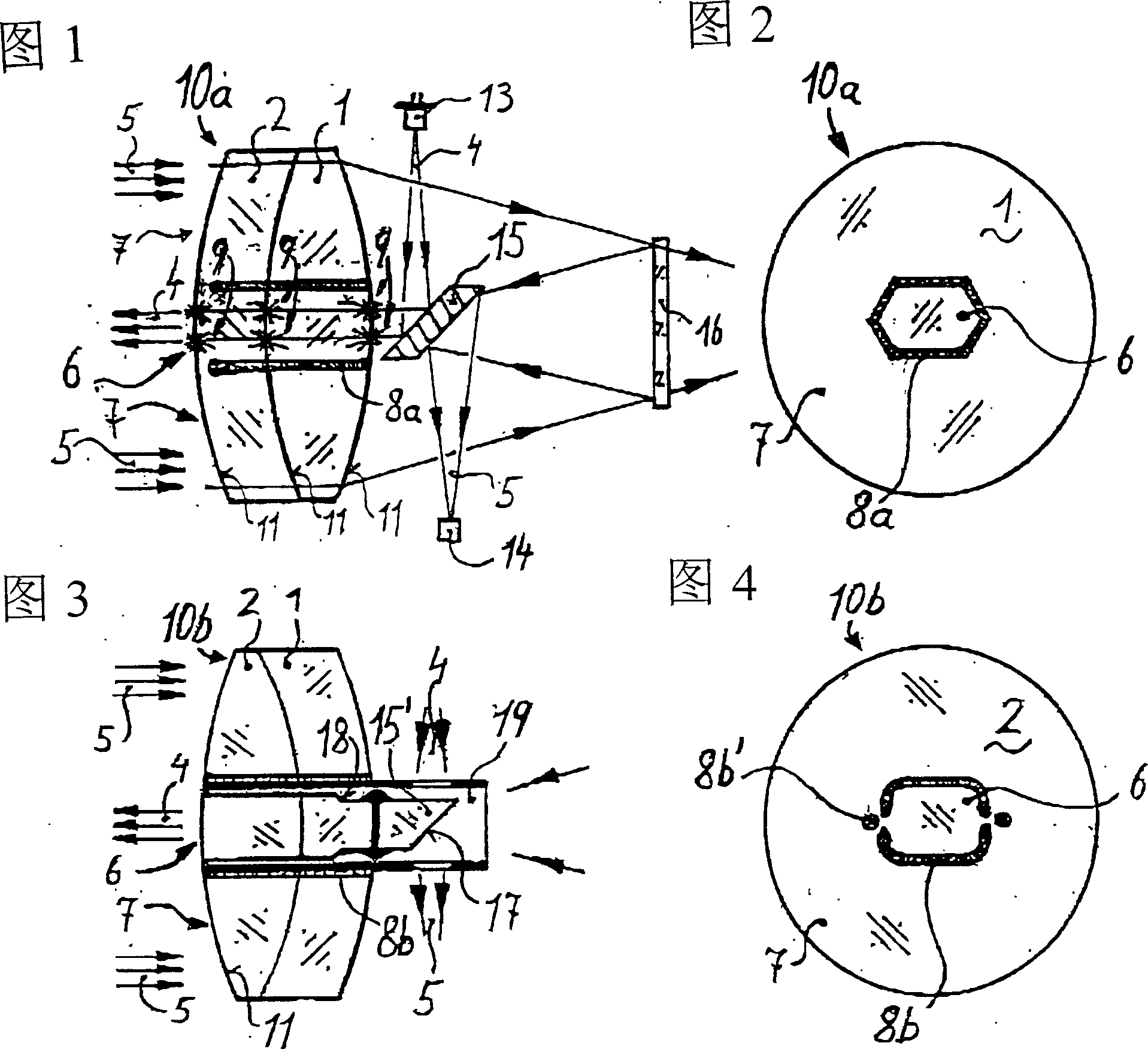

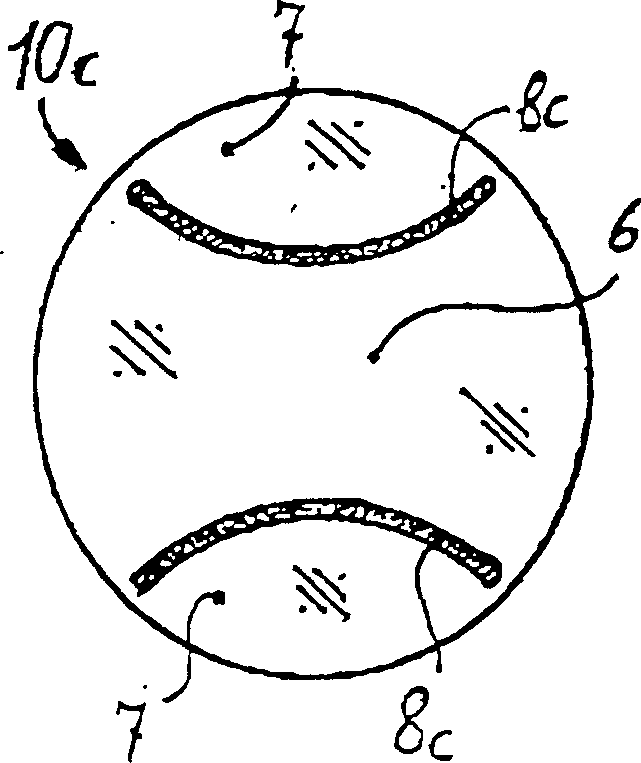

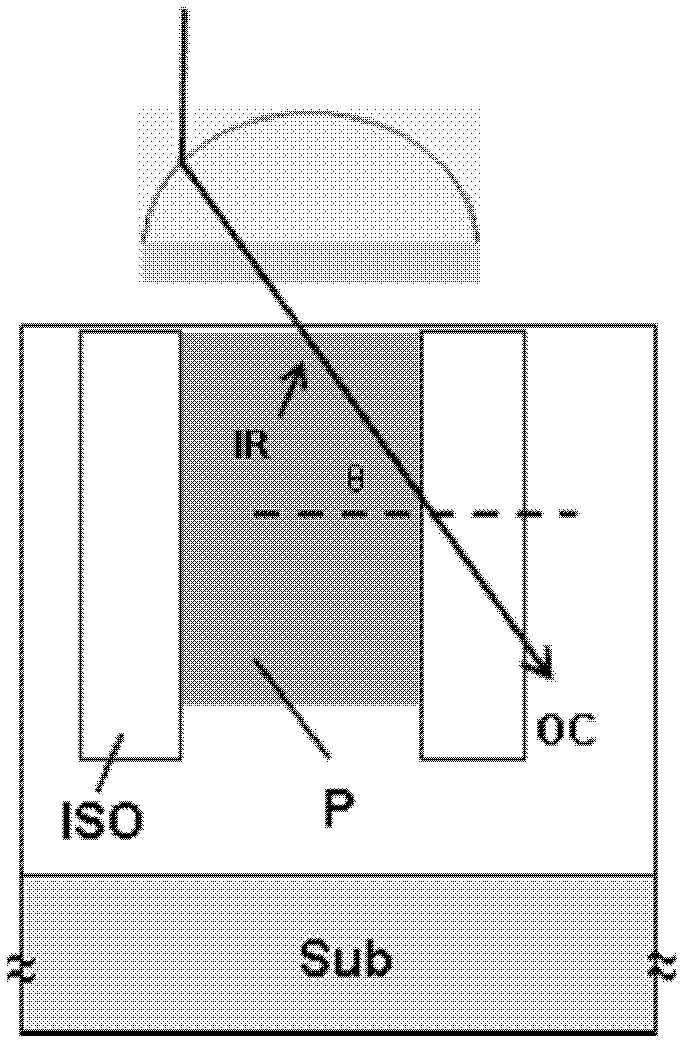

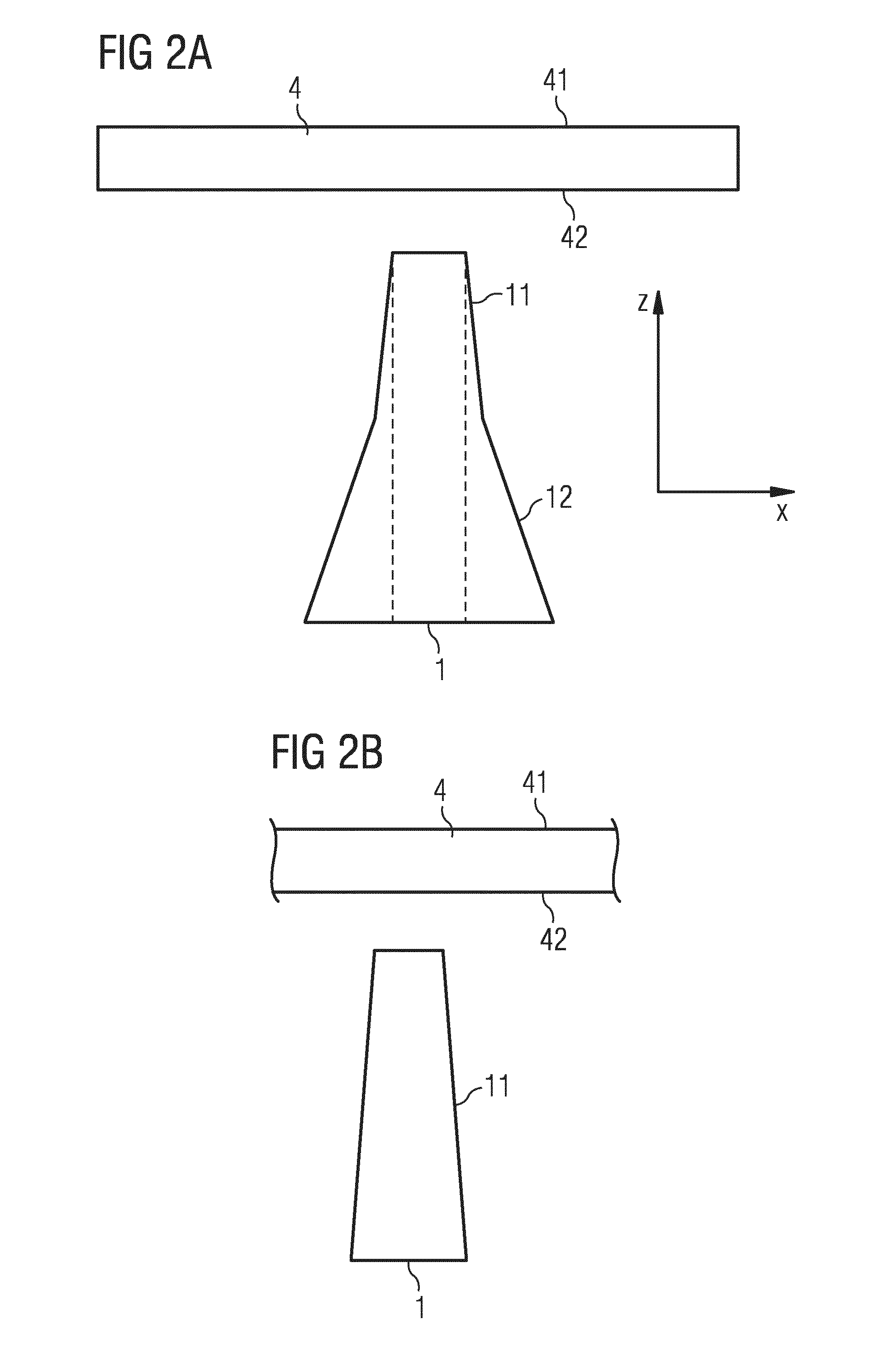

Optical element and method for its fabrication

ActiveCN1611962AReduce optical crosstalkImproved shape stabilityOptical rangefindersSurveying instrumentsMeasuring instrumentLight beam

Optical component (10a) for a device for emitting a first beam cluster (4) and for receiving at least one second beam cluster (5) comprises a one-part element (1, 2) made of glass, quartz or another inorganic optical material with a first segment (6) refracting the first beam cluster and at least one second segment (7) refracting the second beam cluster. The first segment is surrounded by the second segment. A hollow (8a) is provided which surrounds the first segment and is designed so that, within the device, optical disturbances of scattered beams (9) of the first beam cluster with the second beam cluster are directly or indirectly prevented. Independent claims are also included for: (1) Device for distance measurement comprising the above optical component and a receiving beam cluster arranged coaxially to an emitting beam cluster; (2) Measuring instrument comprising the above distance-measuring device; (3) Alternative optical components; and (4) Processes for producing an optical component.

Owner:LEICA GEOSYSTEMS AG

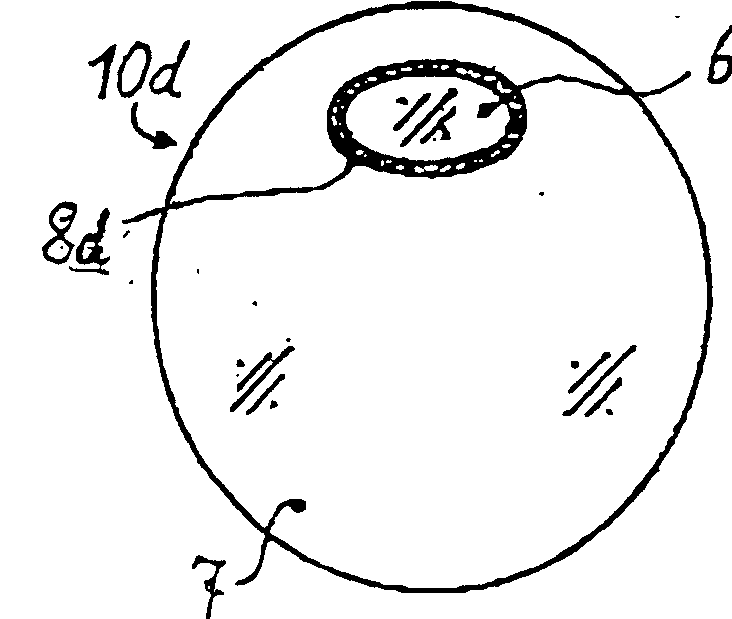

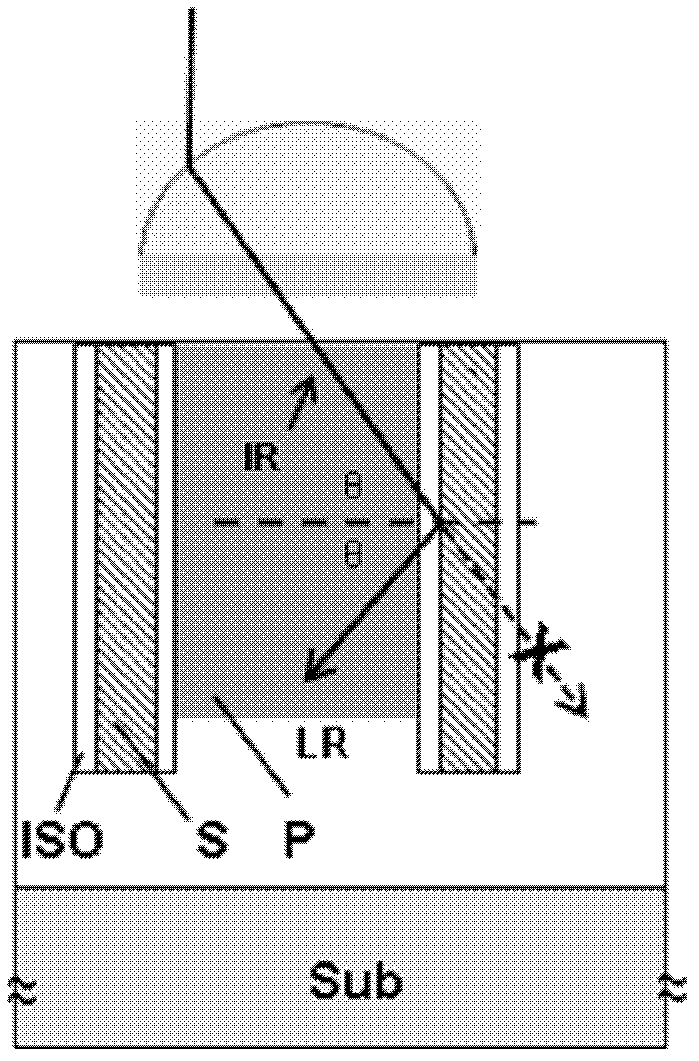

Pixel isolation structure and manufacturing method of pixel isolation structure

InactiveCN102280464AMinimize impact on normal functionReduce Optical CrosstalkSemiconductor/solid-state device manufacturingRadiation controlled devicesAngle of incidenceEngineering

The invention provides a pixel isolation structure and a manufacturing method of the pixel isolation structure. The pixel isolation structure according to the present invention includes: a substrate, a pixel structure, and an isolation structure, wherein the pixel structure is arranged on the substrate, and the isolation structure is arranged around the pixel structure; and, the isolation structure An oxide layer is arranged in it. Using the pixel isolation structure, when the incident light reaches the isolation structure after a certain distance in the pixel structure, the incident light will enter the isolation structure and reach the interface between the isolation structure and the oxide layer; at this time, as an optically dense medium The refractive index of the isolation structure is different from that of the oxide layer as the optical thinning medium, so that the light reaching the boundary between the isolation structure and the oxide layer is partially reflected back into the pixel structure. If the incident angle θ satisfies certain conditions, the light that reaches the boundary between the isolation structure and the oxide layer is completely reflected back into the pixel structure. Thus, the occurrence of optical crosstalk is reduced, thereby reducing the optical crosstalk from affecting the normal function of the pixel structure.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

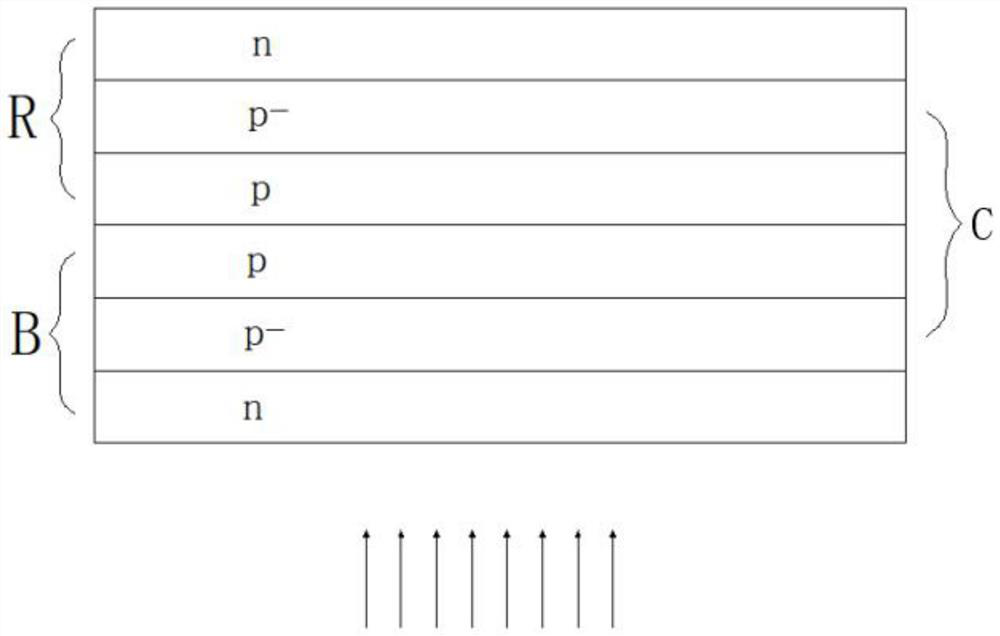

Double-color infrared detector and manufacturing method thereof

ActiveCN111799350ASuppresses electrical crosstalkGuaranteed normal transportationFinal product manufacturePyrometry using electric radation detectorsContact layerElectrode pair

The invention discloses a double-color infrared detector. The double-color infrared detector comprises an n-type substrate, and a first n-type contact layer, an n-type blue channel layer, a p-type connecting layer, an n-type red channel layer and a second n-type contact layer which are sequentially stacked on the n-type substrate. The first n-type contact layer is further provided with a first electrode, and the second n-type contact layer is provided with a second electrode corresponding to the first electrode. The invention further discloses a manufacturing method of the double-color infrared detector. According to the double-color infrared detector, the problem that in the double-color infrared detector, when one channel works, minority carriers generated by the other channel are easilydiffused to the working channel, and therefore large crosstalk is generated is solved.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Image sensor and method of forming same

InactiveCN107845651AImprove quantum conversion efficiencyReduce Optical CrosstalkSolid-state devicesRadiation controlled devicesOptoelectronicsReflective layer

The invention provides an image sensor and a method of forming the same. The image sensor includes a substrate having first and second surfaces opposite to each other; and a dielectric structure on the first side of the substrate. The substrate includes a plurality of discrete photosensitive regions and isolation regions surrounding the respective photosensitive regions, and each photosensitive region including a central region and a peripheral region surrounding the central region. The dielectric structure has reflective structures therein. The reflective structures are not in contact with the substrate. The reflective structures include reflective layers in the dielectric structure at the central regions and reflective frames located in the dielectric structure. The distance between eachreflective layer and the first surface is a first interval. The reflective frames are located in the isolation regions and the peripheral regions, or extend from the isolation regions to the peripheral regions. The distance between each reflective frame and the first surface is a second interval, and the second interval is smaller than the second interval. The image sensor can improve the quantumconversion efficiency and reduce the optical crosstalk.

Owner:HUAIAN IMAGING DEVICE MFGR CORP

Proximity sensor arrangement

ActiveUS20150323653A1Improve mechanical stabilityReduce optical crosstalkRadiation pyrometryOptical detectionProximity sensorSpecular reflection

A proximity sensor arrangement comprises an optical barrier being placed between a light emitting device and a photo-detector. The light emitting device, the photo-detector and the optical barrier are covered by a cover. The optical barrier is being designed to block light emitted from the light emitting device to the photo-detector and reflected by the cover by means of specular reflection. Furthermore, the optical barrier is being designed to pass the light emitted from the light emitting device to the photo-detector via the cover and scattered on or above a first surface of the cover facing away from the light emitting device and the photo-detector.

Owner:AMS AG

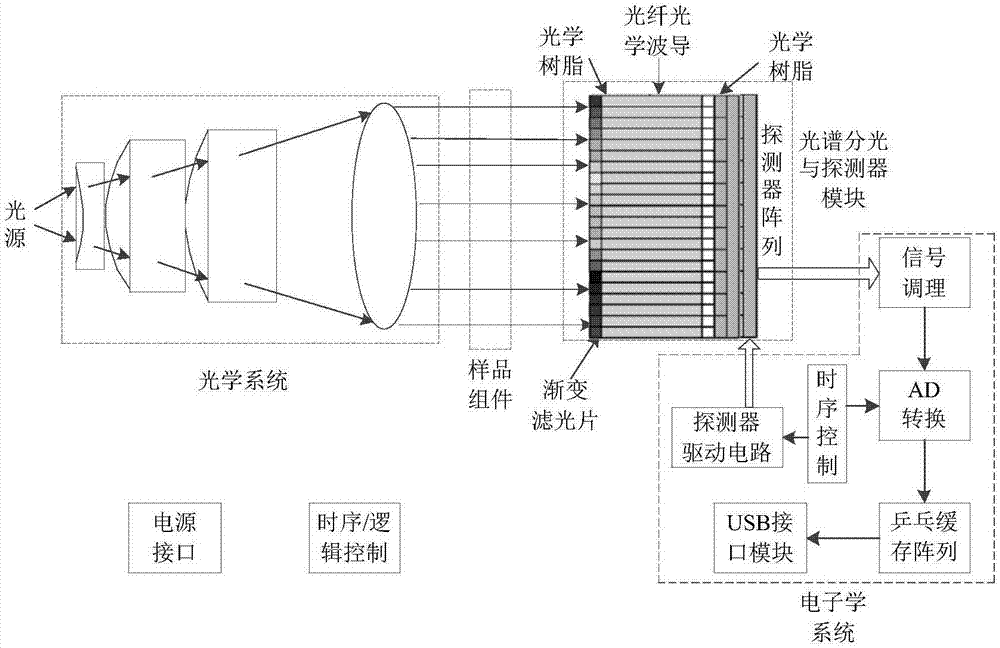

Gradual-filter-based super-portable near infrared spectroscopic analysis system

ActiveCN106940295ACompact and ultra-smallUltra-portableMaterial analysis by optical meansBeam splittingSpectrum analyzer

The invention relates to a gradual-filter-based super-portable near infrared spectroscopic analysis system. The system includes a light source, an optical system, a sample assembly, a beam-splitting and detector module and an electronic system. The light source emits a near infrared beam, and the optical system collects the near infrared beam, projects the near infrared beam to the sample assembly, and radiates the beam-splitting and detector module with the near infrared beam. The beam-splitting and detector module includes a gradual filter and a detector array, is used for converting split incident light to an electrical signal and sends the electrical signal to the electronic system. The electronic system is used for obtaining, sampling, buffer memory, and transmission of the electrical signal, communicates with a host computer, and drives and controls the beam-splitting and detector module. Without any mobile component, beam splitting is achieved through the gradual filter, the packaging size of a spectrum analyzer is effectively reduced, and the problem of spectrum crosstalk in a conventional filter-type spectrometer is overcome.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com