Optical element and method for its fabrication

A technology of optical components and optical components, applied in the direction of optical components, optics, optical devices, etc., can solve the problems of expensive glass and unusable types of objective glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

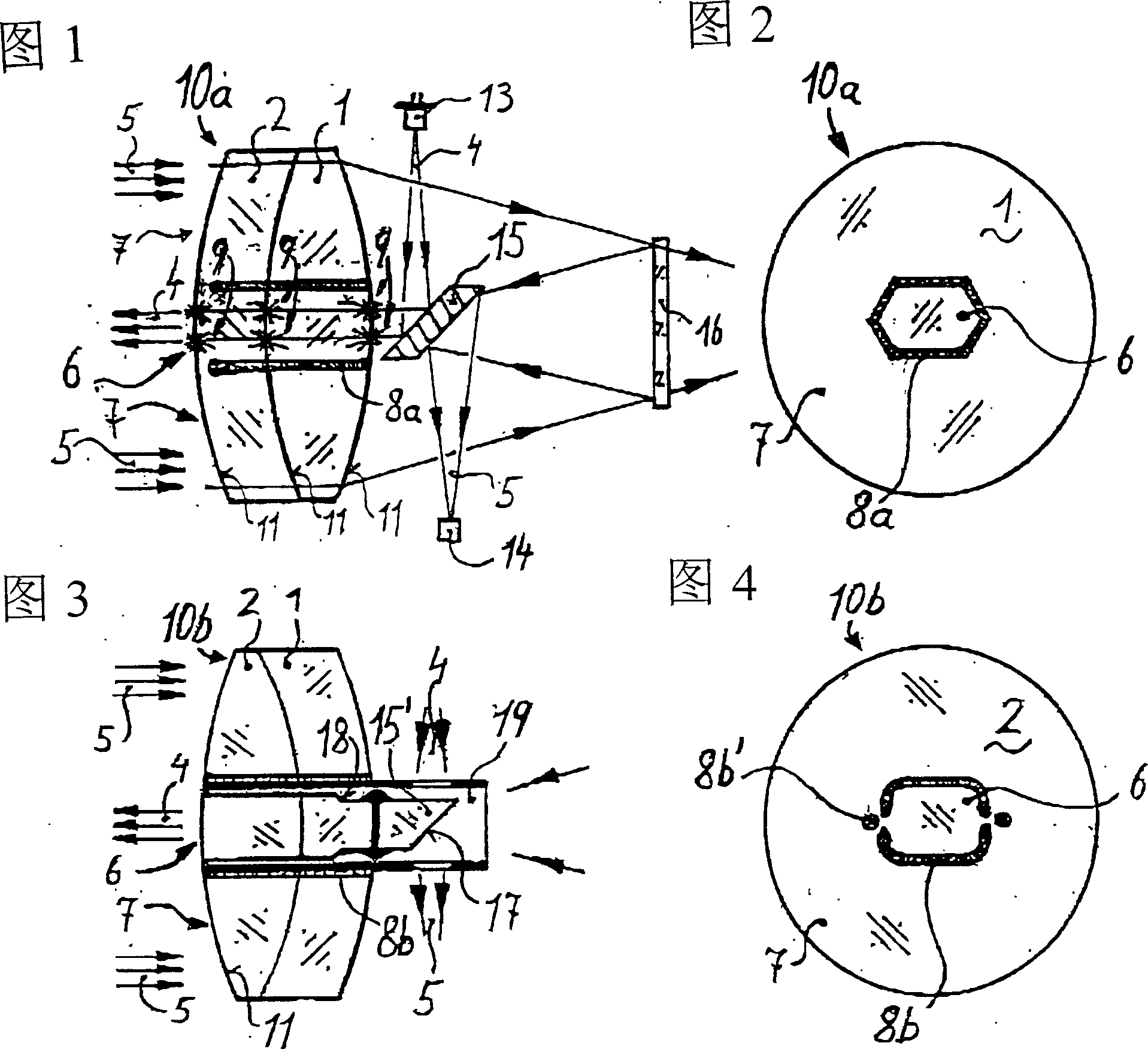

[0039] Fig. 1 shows a longitudinal sectional view of the lens barrel of the theodolite. Integrated in the lens barrel is a distance measuring device whose transmit and receive beams are coaxial with the line of sight. A first embodiment of an optical component according to the invention is a common objective 10a for both the line of sight of the lens barrel, the transmit and receive beams of the distance measuring device.

[0040] In known art, a column with such an arrangement also has an emitter 13, a receiver 14, an intermediate reflective element 15, a wavelength selective reflective element 16 and an eyepiece. The first light beam 4 as emitted light beam is generated here, for example, by a laser diode and has a hexagonal cross-section, which emerges from the emitter 13 and reaches the target not shown in FIG. 1 via the intermediate reflector element 15 . In this case, the intermediate reflector element 15 is positioned on the optical axis of the objective 10 a by means ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com