Patents

Literature

68 results about "Flint glass" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flint glass is optical glass that has relatively high refractive index and low Abbe number (high dispersion). Flint glasses are arbitrarily defined as having an Abbe number of 50 to 55 or less. The currently known flint glasses have refractive indices ranging between 1.45 and 2.00. A concave lens of flint glass is commonly combined with a convex lens of crown glass to produce an achromatic doublet lens because of their compensating optical properties, which reduces chromatic aberration (colour defects).

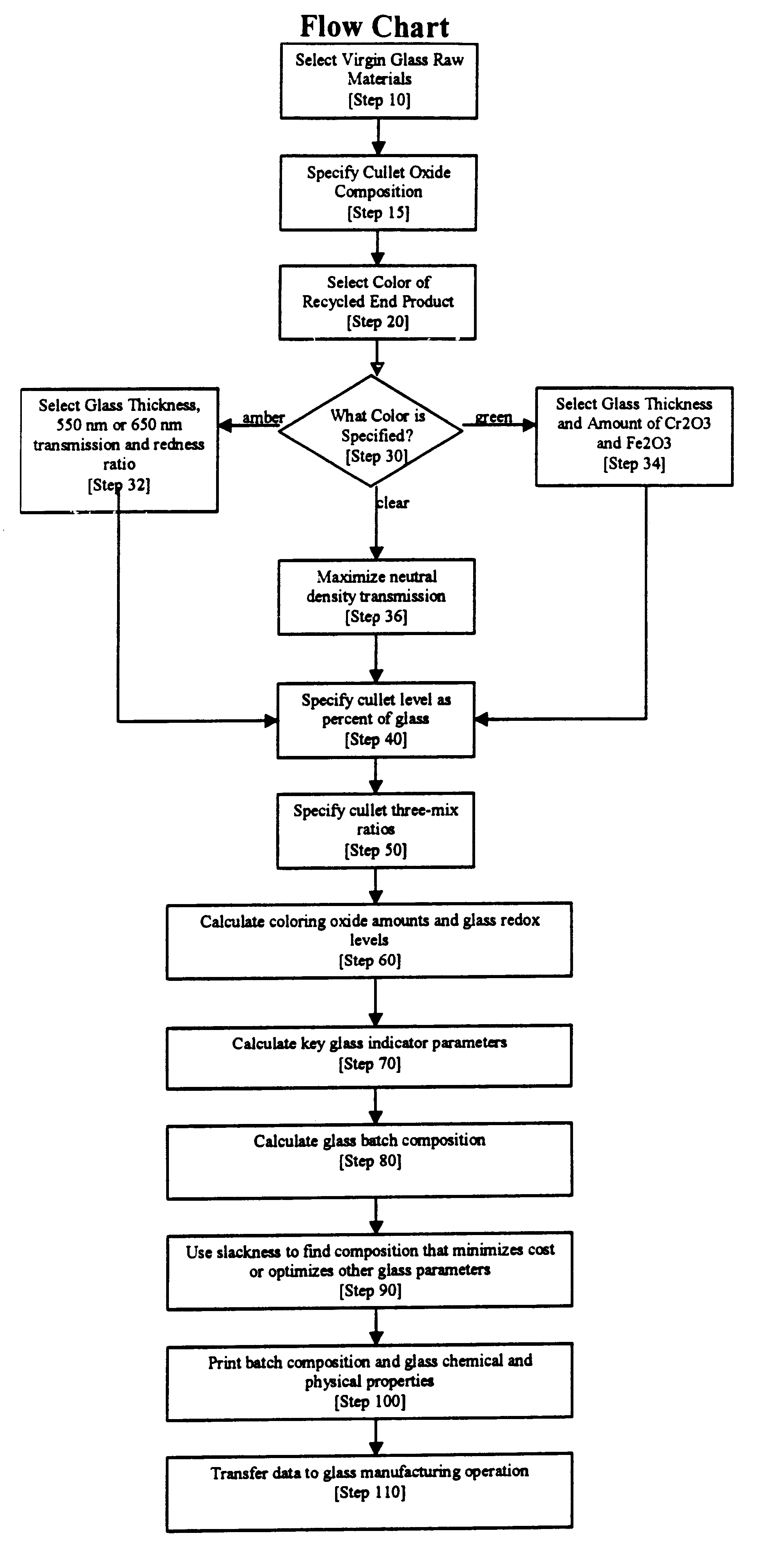

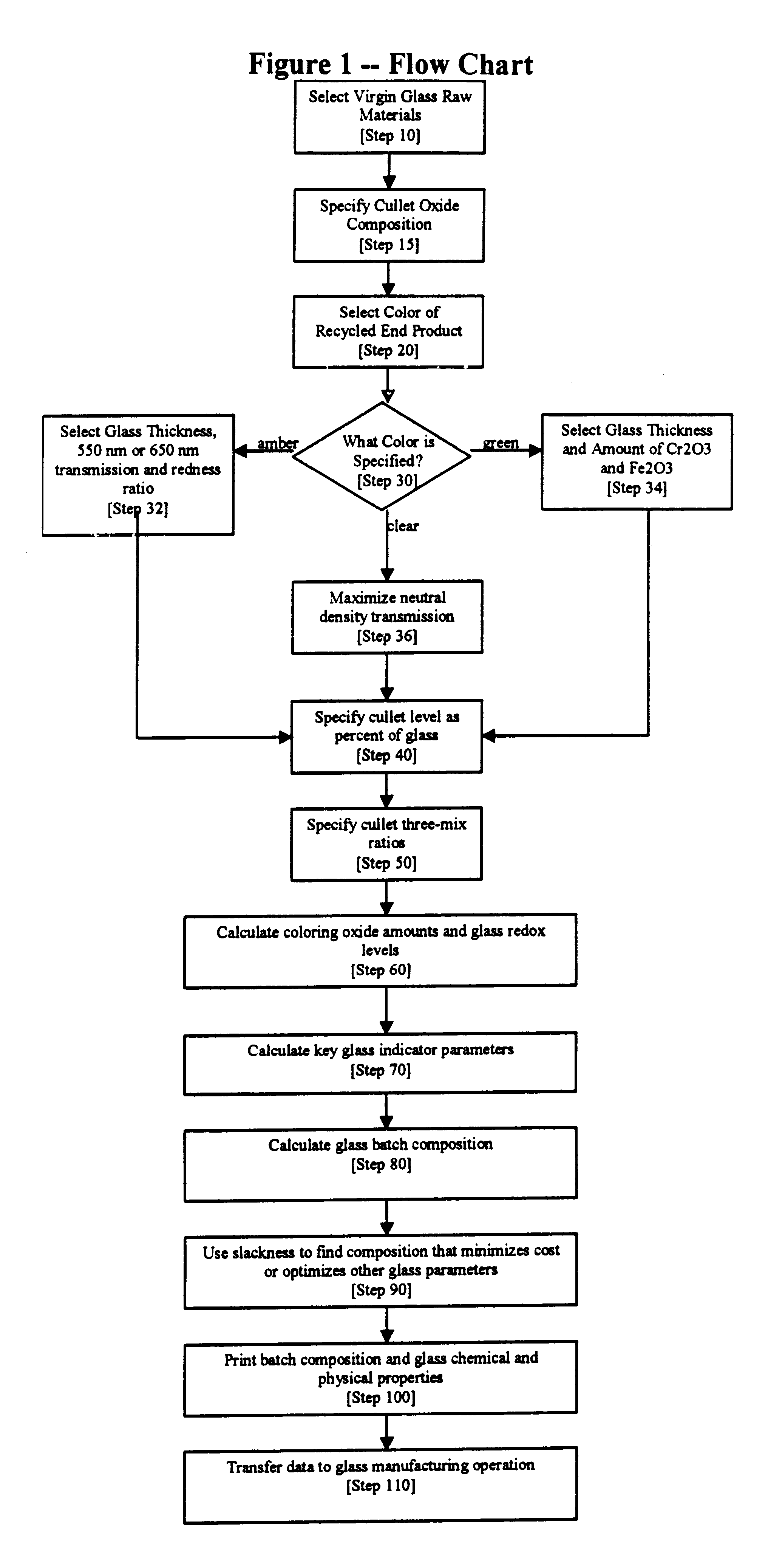

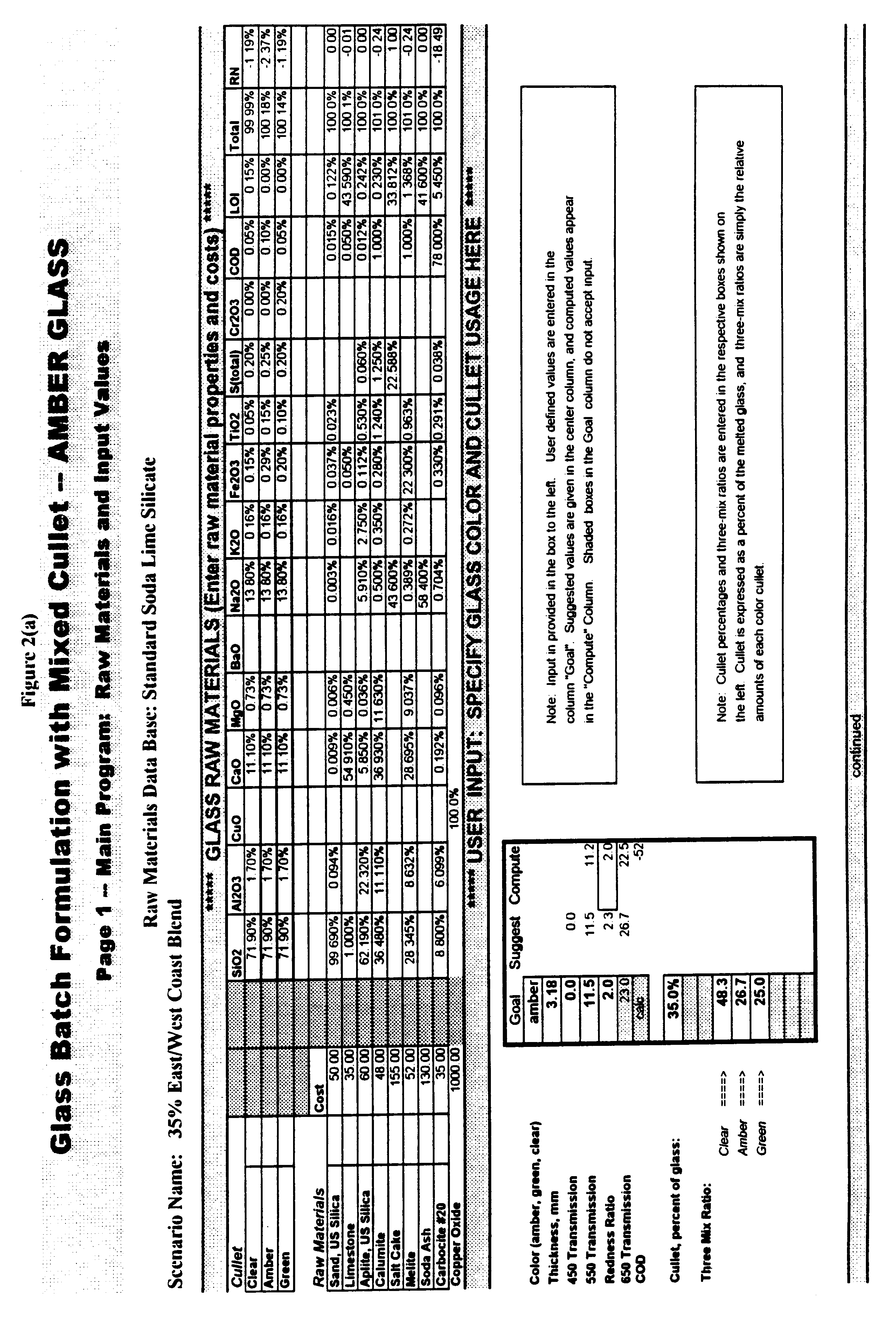

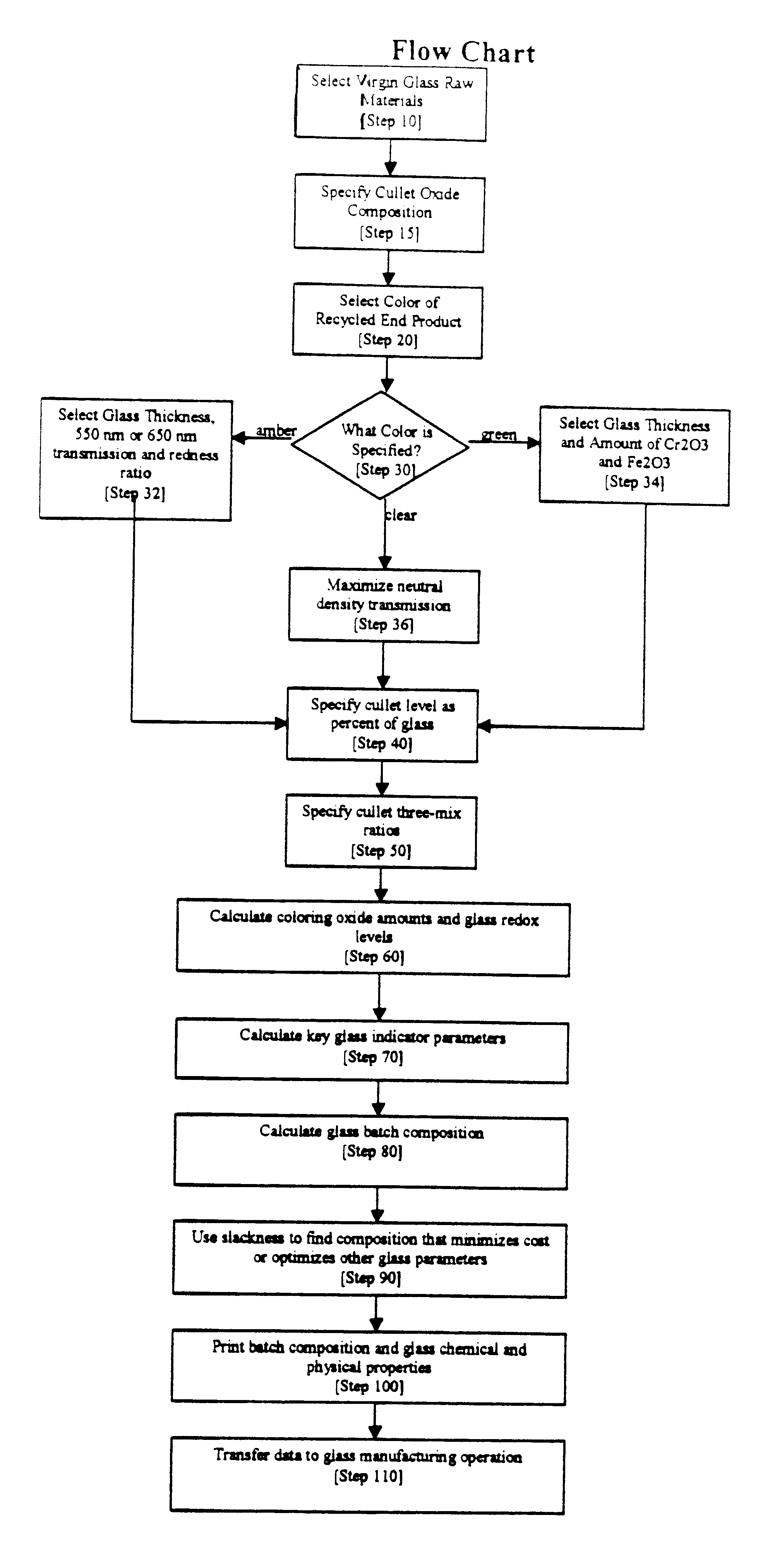

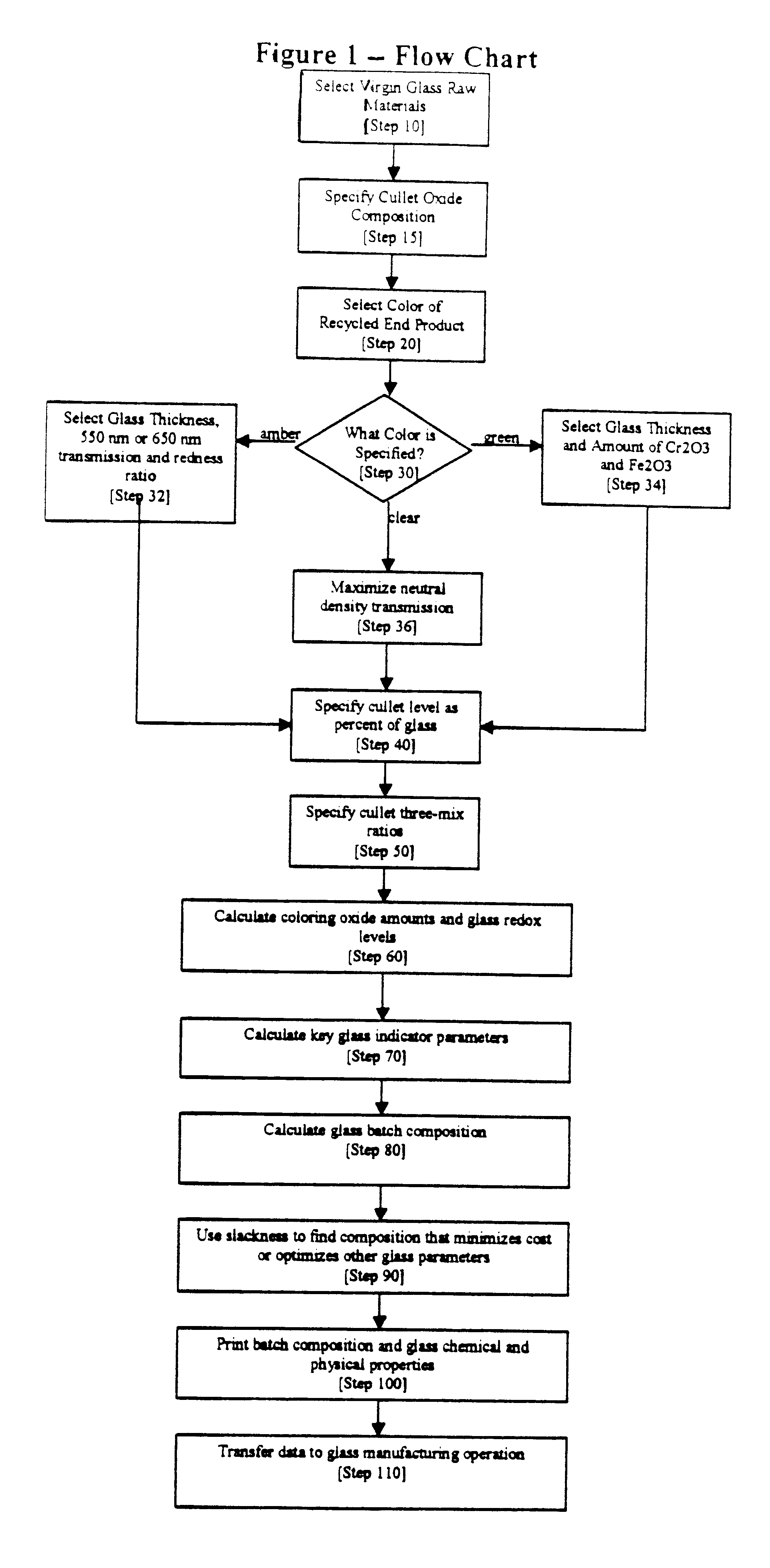

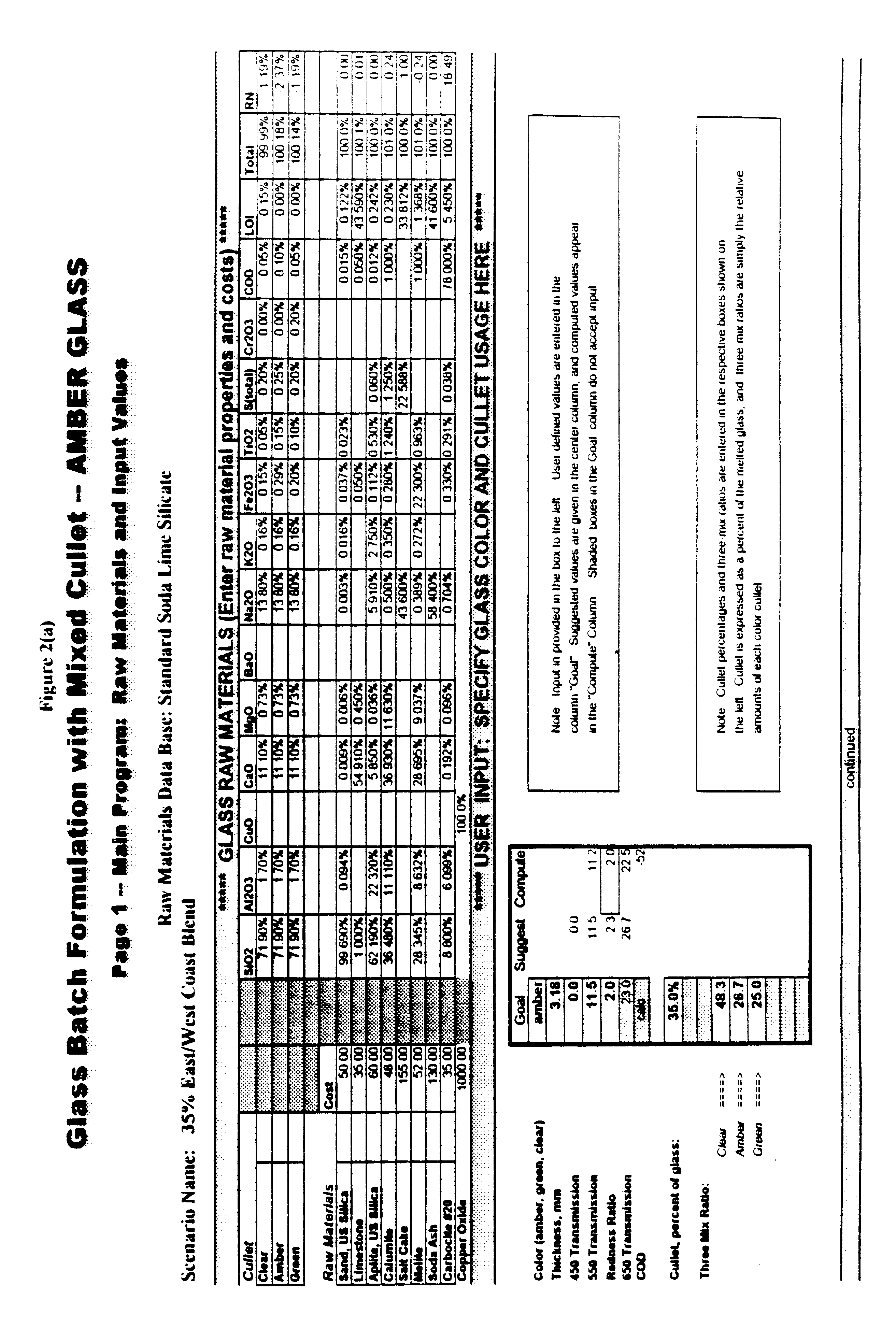

Method of recycling batches of mixed color cullet into amber, green, or flint glass with selected properties

InactiveUS6230521B1Low costMinimize iron levelCharging furnaceBlowing machine gearingsOxidation-Reduction AgentBottle

An automated method for recycling mixed colored cutlet glass (i.e., broken pieces of glass of mixed colors and types) into new glass products. A computer controlled process identifies the virgin glass raw materials, the desired target glass properties, the composition of a batch of mixed colored cullet, and the quantity of cullet to be used in the glass melt, and the computer controlled process automatically determines the proper amounts of raw materials to add to the batch of mixed colored cullet so that recycled glass is produced having the desired coloring oxides, redox agents, and glass structural oxides in the proper proportion. The recycled glass is then used to make glass products such as beer bottles.

Owner:CULCHROME LLC

Automated process for recycling batches of mixed color cullet into amber, green, or flint glass with selected properties

InactiveUS6763280B1Low costMinimize iron levelCharging furnaceBlowing machine gearingsManufactured materialRedox

An automated method for recycling mixed colored cullet glass (i.e., broken pieces of glass of mixed colors and types) into new glass products. A computer controlled process identifies the virgin glass raw materials, the desired target glass properties, the composition of a batch of mixed colored cullet, and the quantity of cullet to be used in the glass melt, and the computer controlled process automatically determines the proper amounts of raw materials to add to the batch of mixed colored cullet so that recycled glass is produced having the desired coloring oxides, redox agents, and glass structural oxides in the proper proportion. The recycled glass is then used to make glass products such as beer bottles.

Owner:CULCHROME LLC

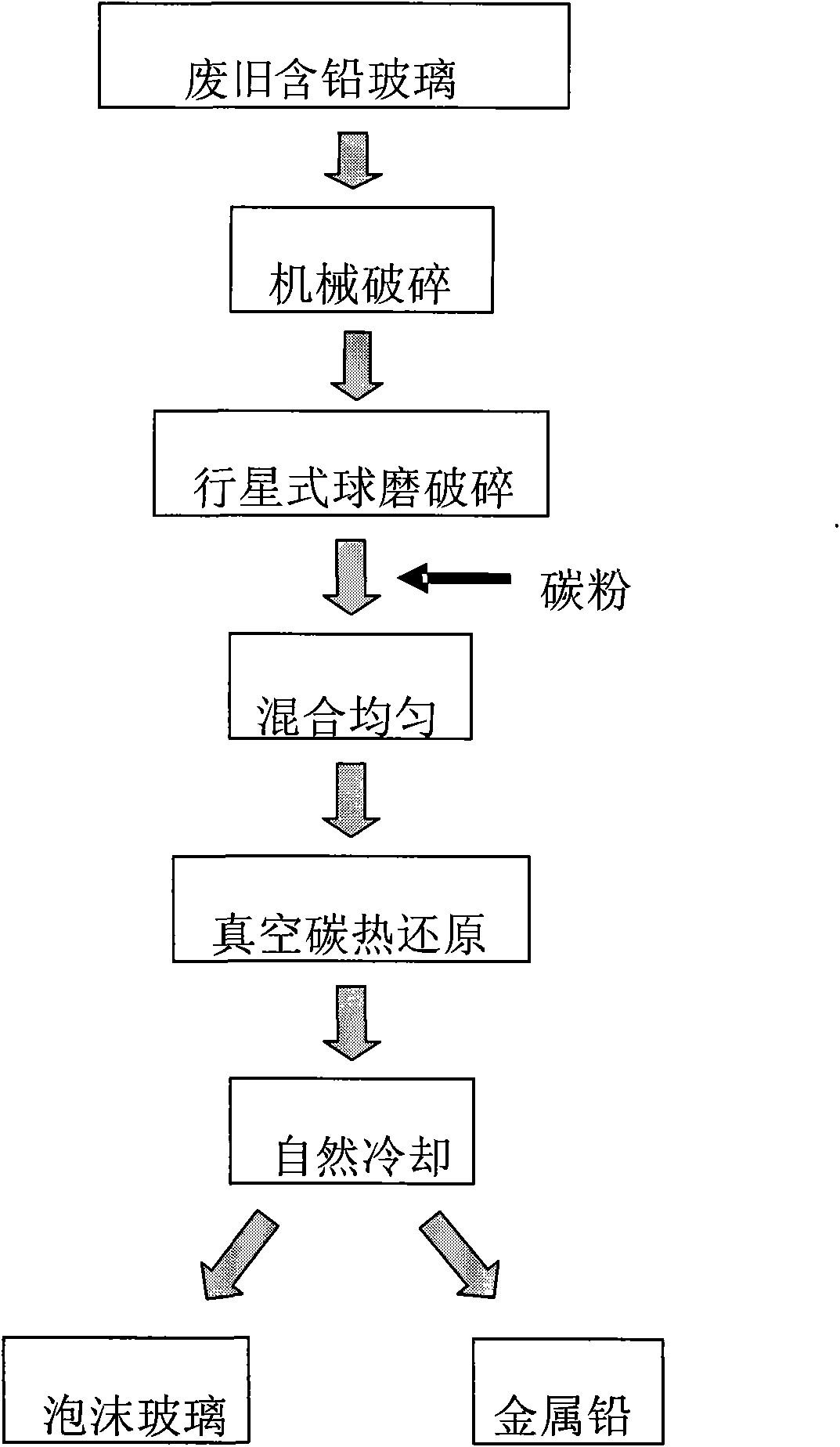

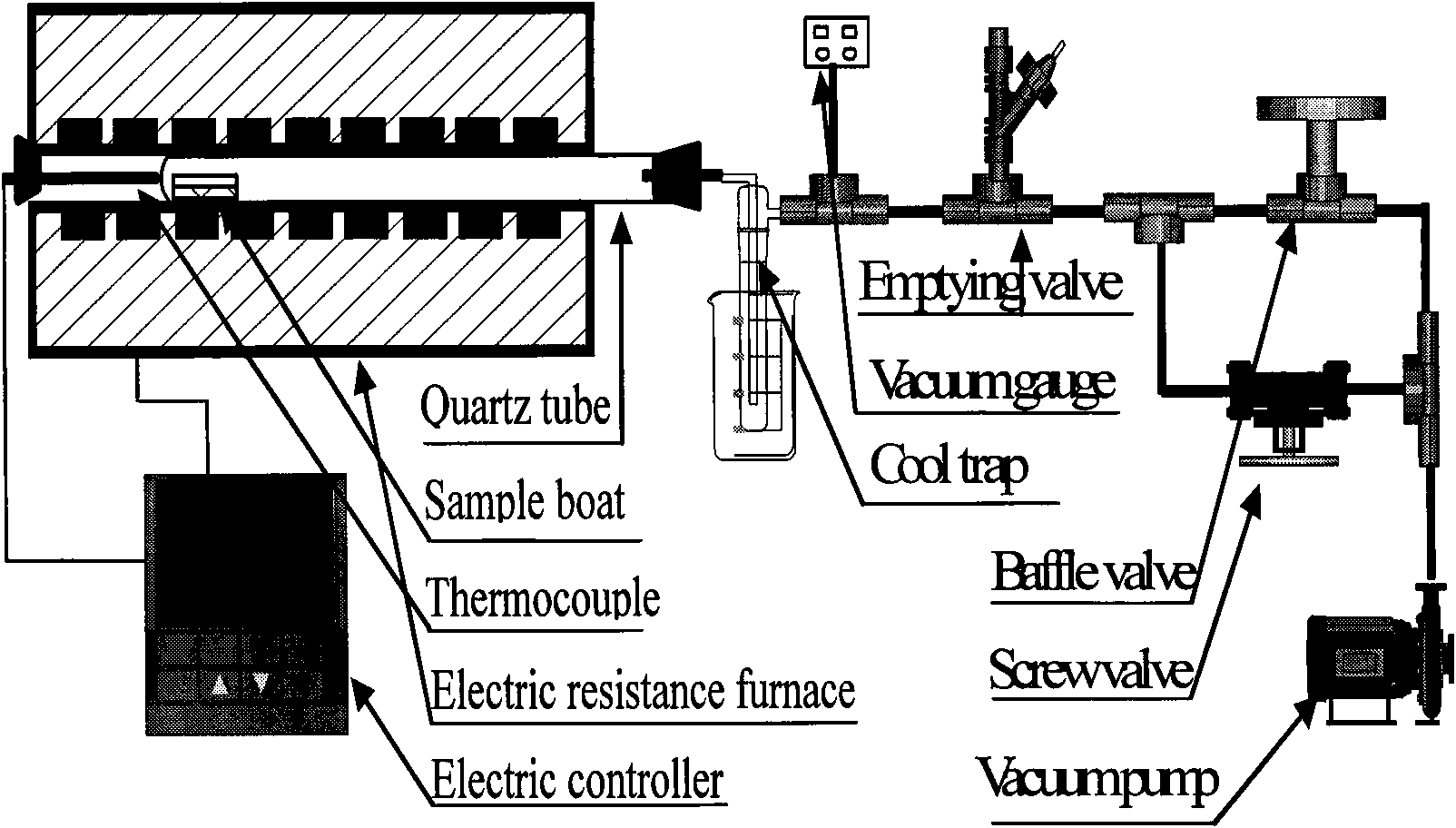

Process for reclaiming lead and producing environment-friendly building material by waste flint glass and corollary equipment thereof

InactiveCN101613802AEvaluate the environmental friendlinessBest recycling processGlass shaping apparatusProcess efficiency improvementEnvironmental engineeringPollution

The invention establishes a vacuum carbon thermal reduction process applied in high added value and resource recycling of waste flint glass, and optimizes corollary equipment, direct to the current situations of serious environment pollution and resource recycling technology of the waste flint glass. The process has the characteristic that while reclaiming lead in the waste flint glass, the rest glass residue is formed into a good-quality environment-friendly building material through controlling conditions. Results of toxicity extraction experiments prove that extraction amount of lead and other heavy metals in a product is lower than the reference value of national regulation, and can be used as a light environment-friendly building material.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

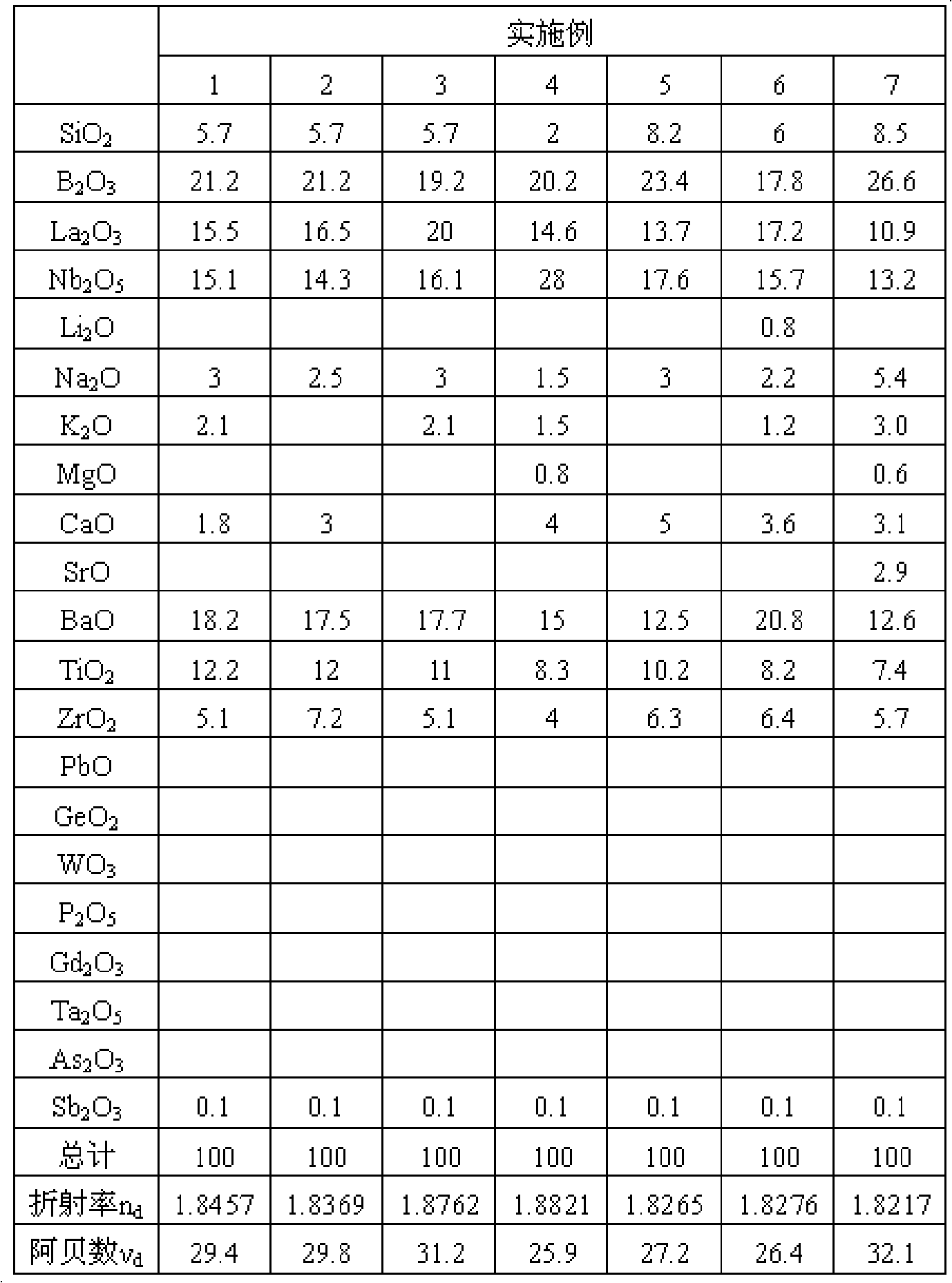

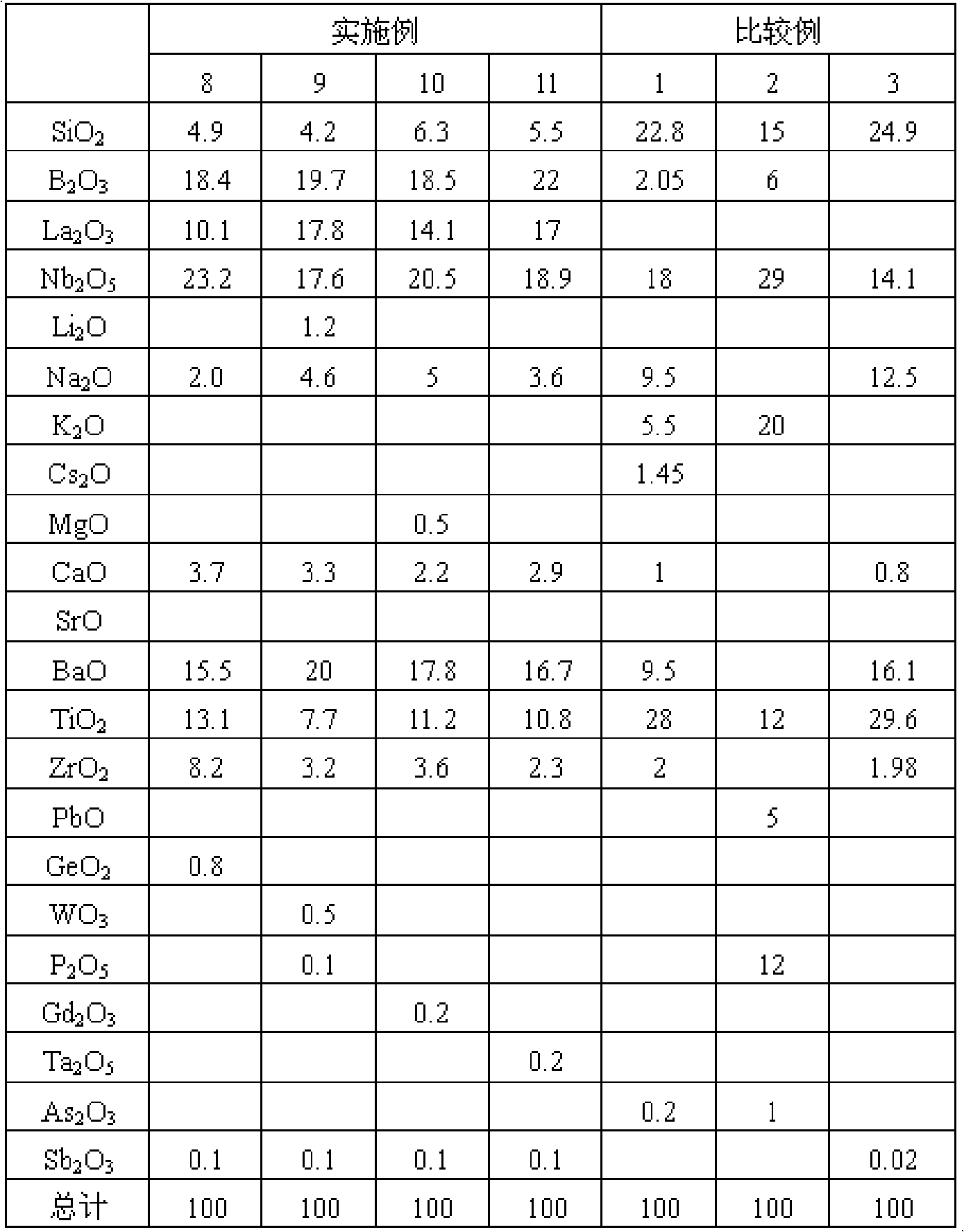

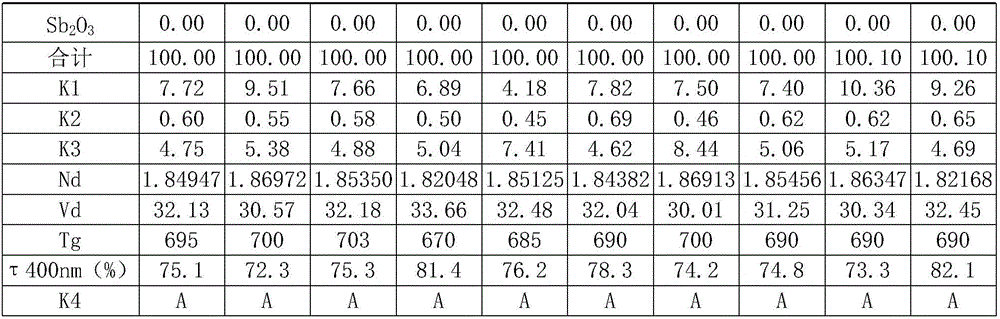

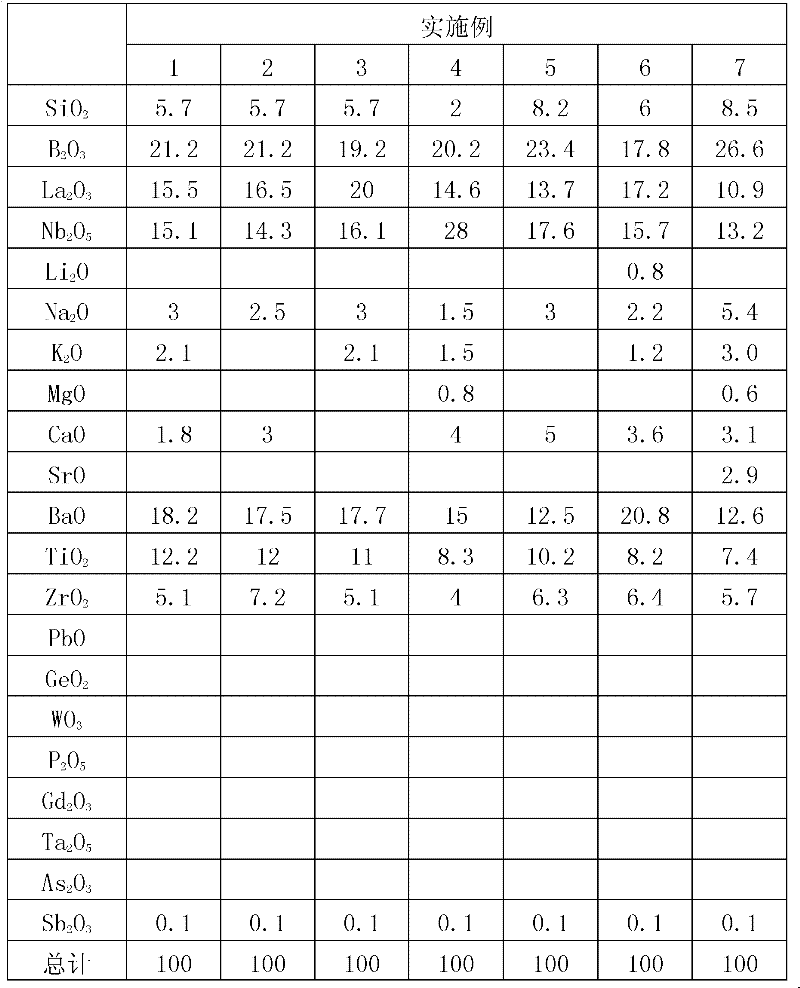

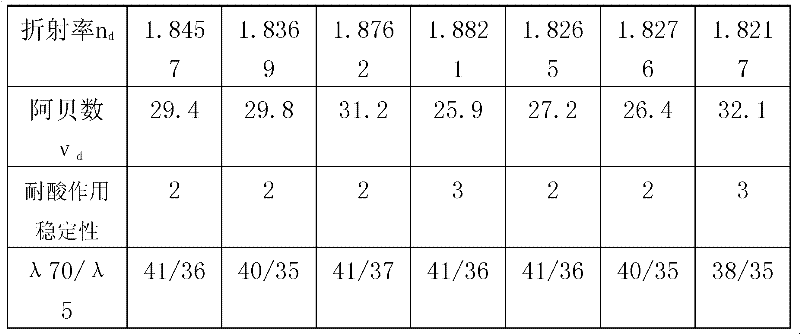

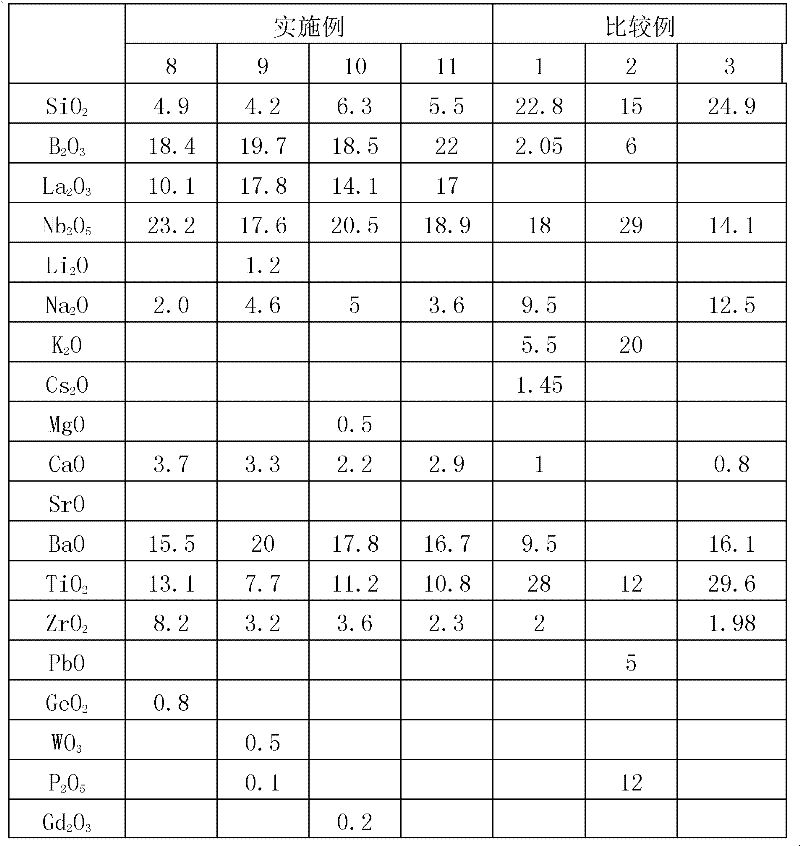

Environment friendly heavy-lanthanide flint optical glass

ActiveCN101318769AExcellent optical propertiesExcellent devitrification resistanceDevitrificationOptical property

The invention provides environmental-friendly dense-lanthanum optical flint glass, comprising the following compositions in percentage by weight: 1 to 9 percent of SiO2, 15 to 30 percent of B2O3, 10 to 25 percent of La2O3, 10 to 30 percent of Nb2O5, 0 to 3 percent of Li2O, 0 to 6 percent of Na2O, 0 to 3 percent of K2O, 0 to 3 percent of MgO, 0 to 8 percent of CaO, 0 to 3 percent of SrO, 5 to 25 percent of BaO, 0 to 15 percent of TiO2, 0 to 10 percent of ZrO2, 0 to 3 percent of GeO2, 0 to 3 percent of WO3, 0 to 3 percent of P2O5, 0 to 3 percent of Gd2O3, 0 to 3 percent of Ta2O5, and 0 to 1 percent of Sb2O3. The optical flint glass has a refractive index between 1.81 and 1.90, an Abbe number between 25 and 33, and no PbO and As2O3, and has perfect optical property and excellent devitrification resistance.

Owner:CDGM OPTICAL GLASS

Lead-free and preferably arsenic-free lanthanum heavy flint glass

ActiveUS7091145B2Good chemical resistanceSufficient crystallization resistanceOptical elementsAlkali metal oxideRefractive index

The lead-free and arsenic-free optical glass has a refractive index nd of 1.84≦nd≦1.96 and an Abbé number νd of 27≦νd≦36, with good chemical resistance, excellent crystallization resistance and the following composition (in % by weight based on oxide): SiO2, 1 to 8, B2O3, 13 to 19.5, La2O3, 34 to 50; MgO, 0 to 6, CaO, 0 to 6, BaO, 0 to 6, ZnO, 0 to 9 with ΣMO, 1 to 10; and TiO2, 4 to 15, ZrO2, 0 to 11, Nb2O5, 6 to 14.5. In addition, the glass according to the invention, as well as having a maximum alkali metal oxide content of 10% by weight, may also contain standard refining agents other than arsenic. The glass according to the invention is used in imaging, projection, telecommunications, optical communication and / or laser technology.

Owner:SCHOTT AG

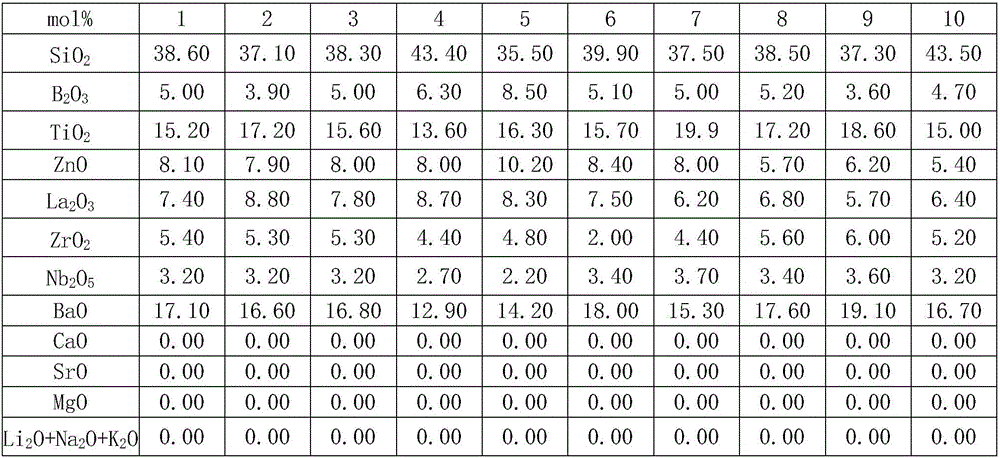

Dense lanthanum flint glass

The invention provides a dense lanthanum flint glass with a refractive index of 1.82-1.87 and an abbe number of 30-35. The glass has no apparent devitrification under the temperature of Tg+230 DEG C for over 30 minutes. The glass comprises, by mole percentage, LnO2(The LnO2 is one or more of SiO2, TiO2, ZrO2, Geo2 and CeO2), M2O3(The M2O3 is one or more of B2O3, La2O3, Y2O3, Yb2O3, Gd2O3, Ga2O3, Bi2O3, Al2O3 and Sb2O3), D2O5(The D2O5 is one or several substances of Nb2O5, Ta2O5 and P2O5) and RO. With a reasonable formula ratio design and on the precondition of guaranteeing the foreseeable optical property and performance, the flint glass is suitable for the production of high numerical aperture optical fibers and the glass elements which need heat treatment many times.

Owner:CDGM OPTICAL GLASS

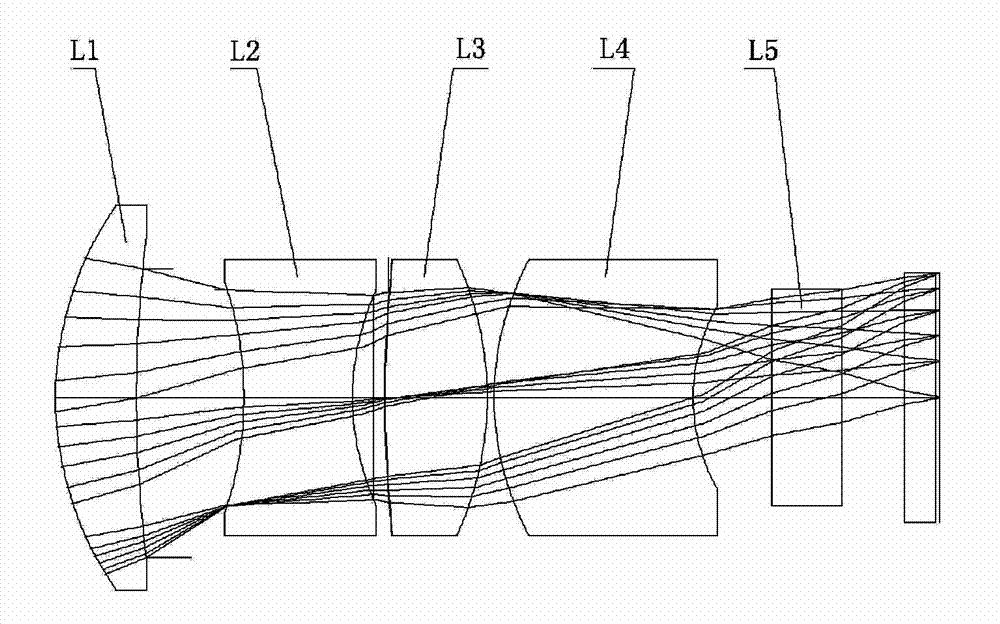

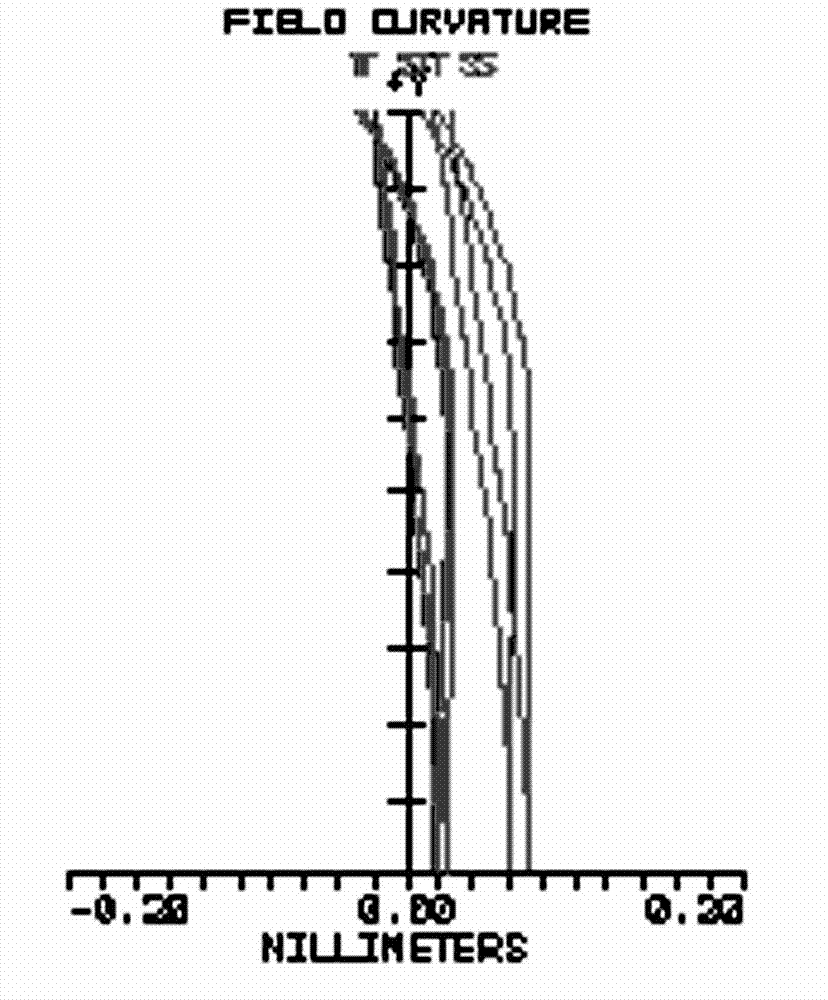

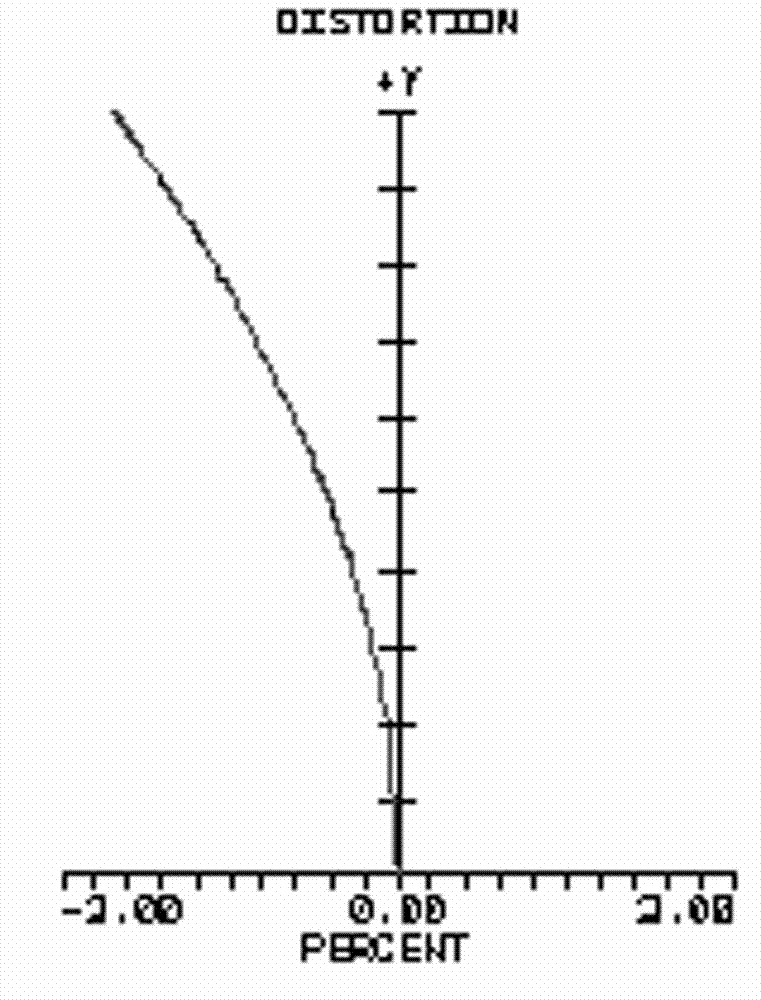

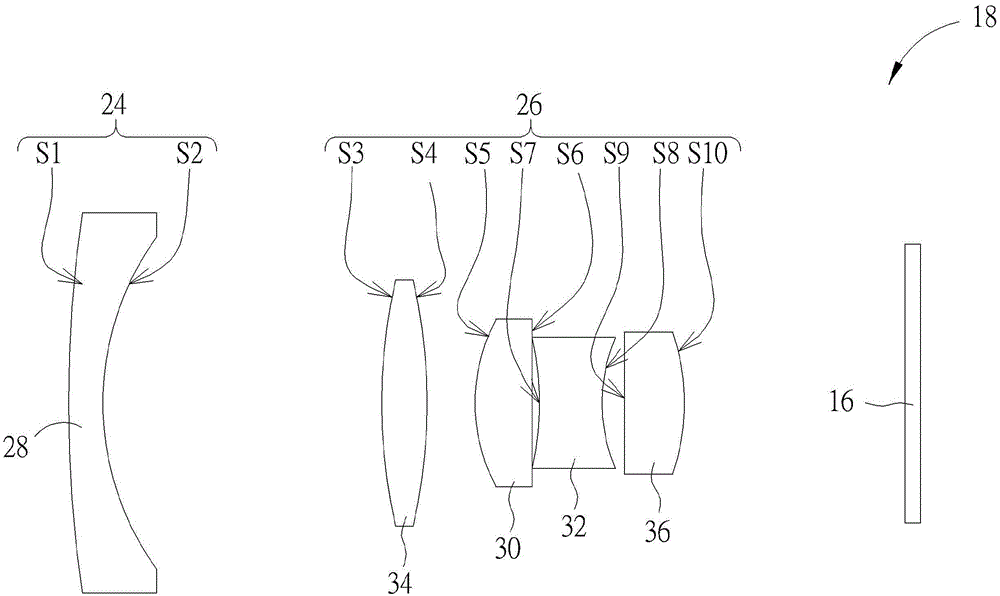

Low-cost broad-spectrum optical system of day-night confocal trigger lens

ActiveCN102778746AGuaranteed transmittanceReduce spherical aberrationOptical elementsCamera lensLow-pass filter

The invention relates to a low-cost broad-spectrum optical system of a day-night confocal trigger lens. The optical system is composed of a positive power first lens L1, a negative power second lens L2, a positive power third lens L3, a positive power fourth lens L4 and an optical low pass filter (OLPF) L5, wherein L1, L2, L3, L4 and L5 are sequentially distributed from the object to be shot to an image plane side along an optical axis, and the objects to be shot different in distance can be integrally moved through the lens to achieve clear imaging on the image plane portion. The optical system has the advantages of being capable of enabling visible wave band and near-infrared band to image clearly and simultaneously and being low in cost and suitable for batch production, and the lenses are all spherical lenses and made of common crown glass or flint glass.

Owner:NANYANG LIDA PHOTOELECTRIC

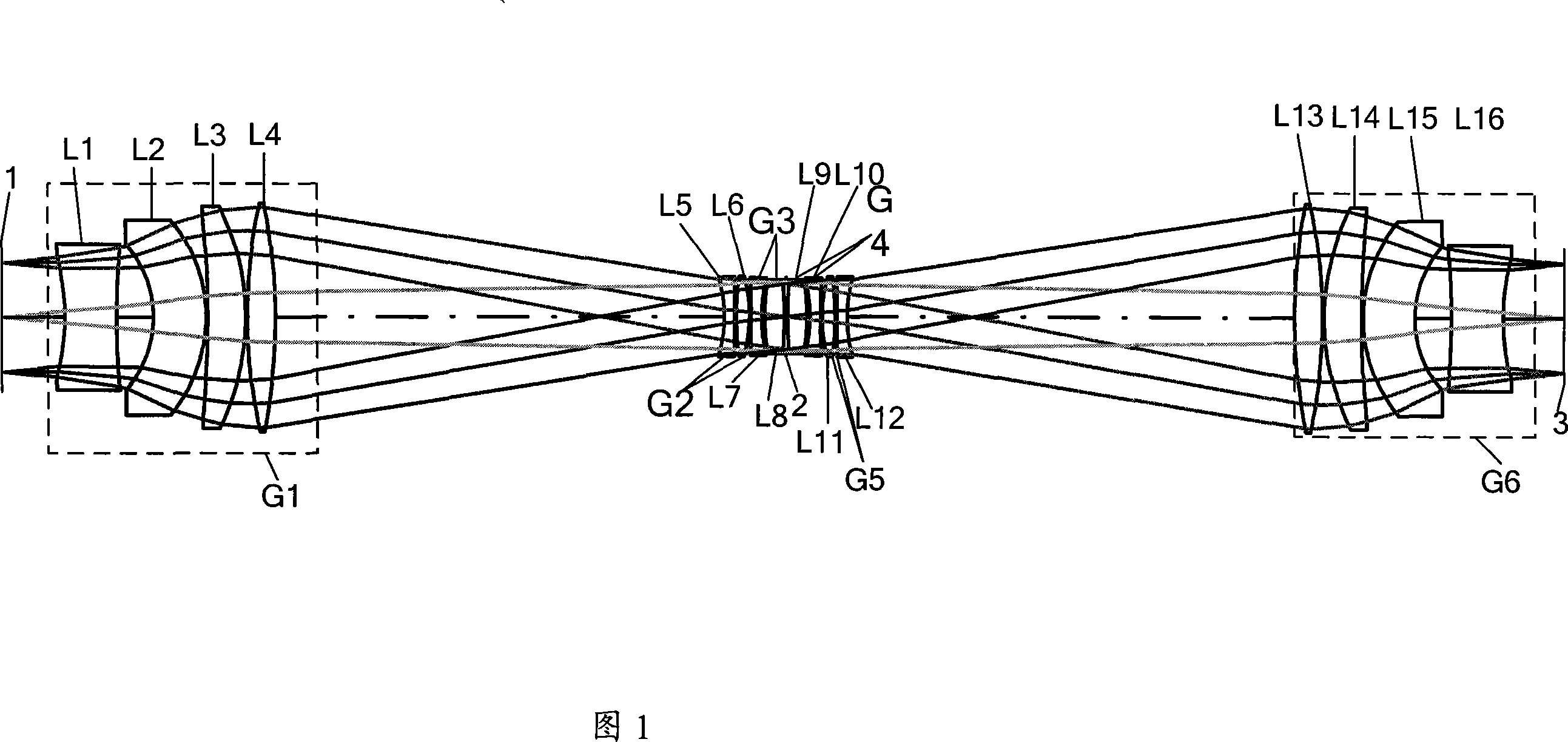

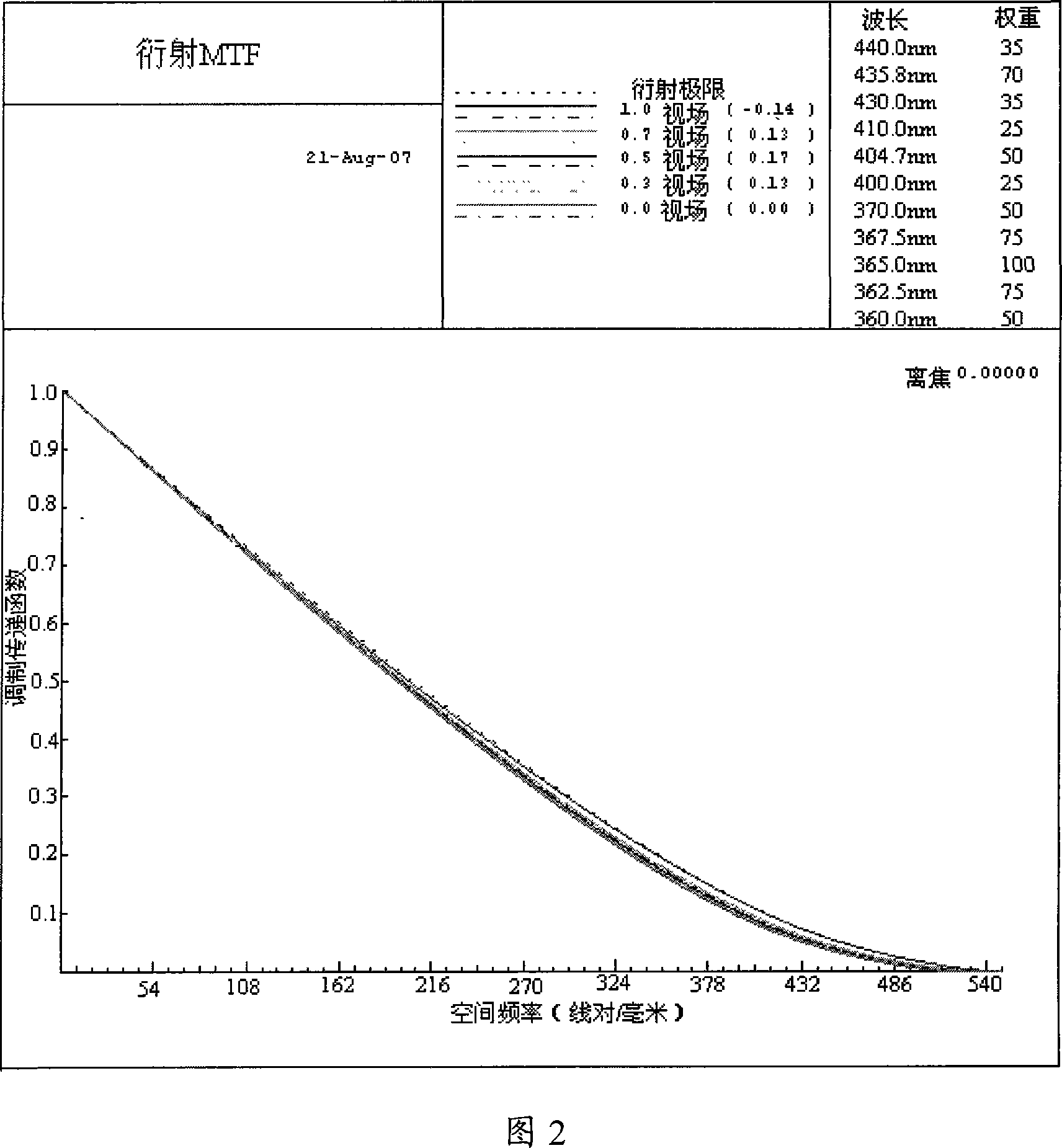

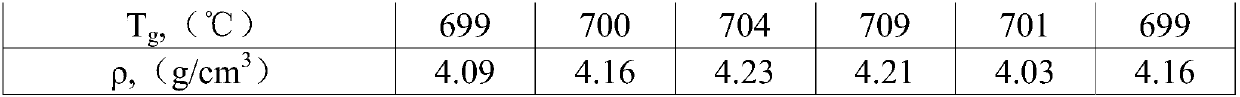

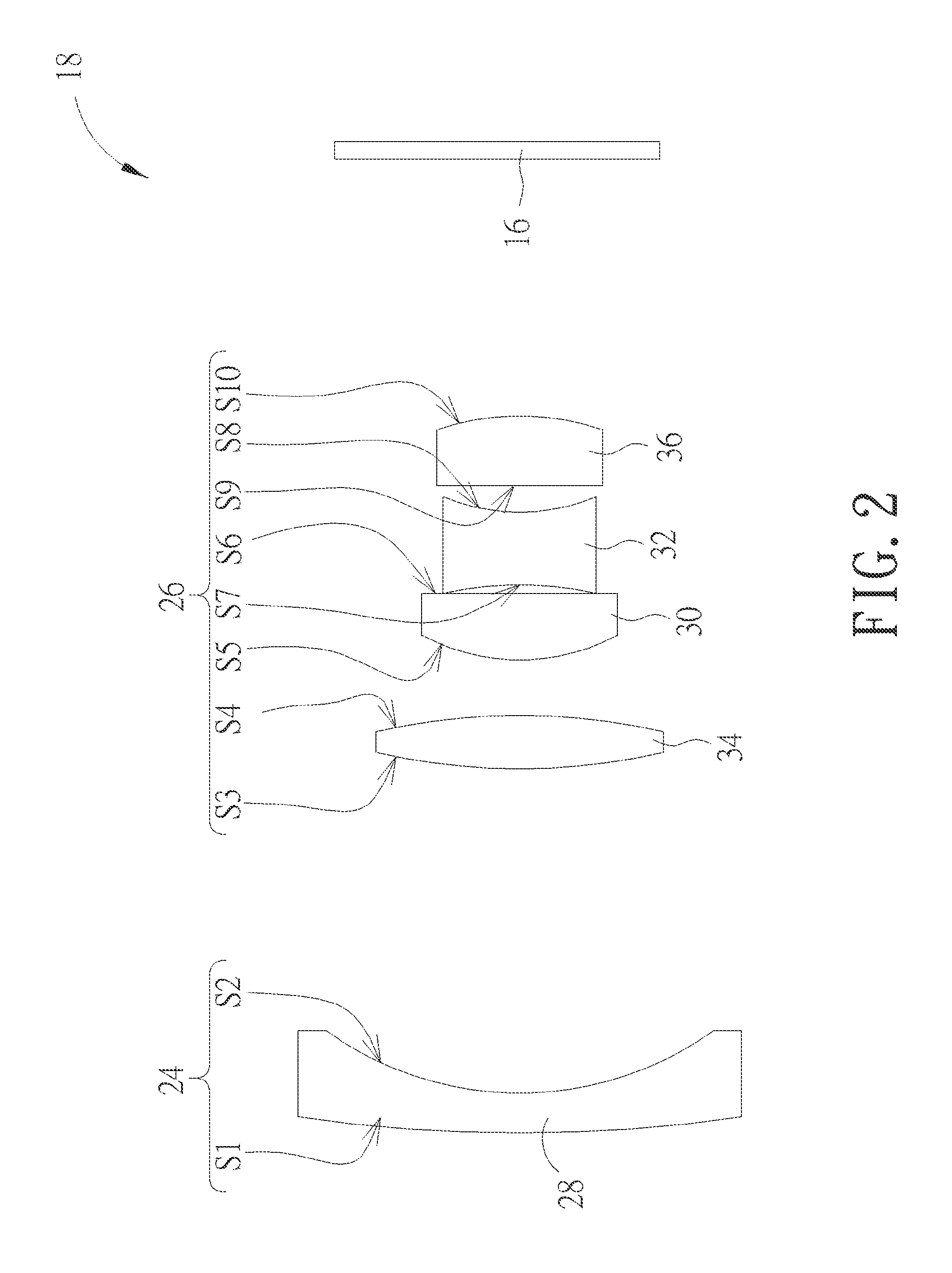

Projection optical system and projection exposure device

ActiveCN101206300AMeet the requirements of high productivityImprove transmittancePhotomechanical exposure apparatusMicrolithography exposure apparatusProjection opticsImaging quality

The invention provides a projection optical system and a projection exposure device thereof, wherein, the projection optical system is divided into a front group and a rear group and takes an aperture diaphragm as the symmetry plane; each of the front group and the rear group comprises three groups of lens groups; the three groups of lens groups of the front group and the three groups of lens groups of the rear group are respectively symmetrical relative to the aperture diaphragm; each group of lens group is a retrofocus optical structure consisting of a negative lens and a positive lens; the first lens group of the front group comprises lens L1, lens L2, lens L3 and lens L4, while the second lens group comprises lens L5 and lens L6 and the third lens group comprises lens L7 and lens L8; the fourth lens group of the rear group comprises lens L9 and lens L10, while the fifth lens group comprises lens L11 and lens L12 and the sixth lens group comprises lens L13 to L16; the lens L1 and lens L7 are made from molten quartz glass, while the lens L2 to L5 are made from flint glass, and the lens L6 and the lens L8 are made from crown glass. The operating wavelength of the projection optical system is g-line, h-line and i-line wide spectrum light, thereby having high imaging quality; moreover, lens material has small intrinsic absorption and less optical total length.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

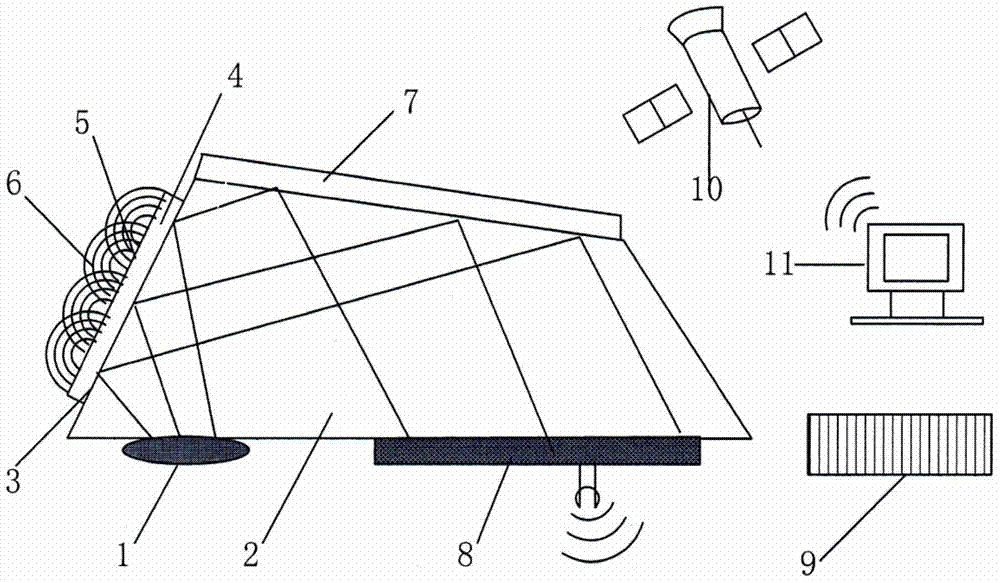

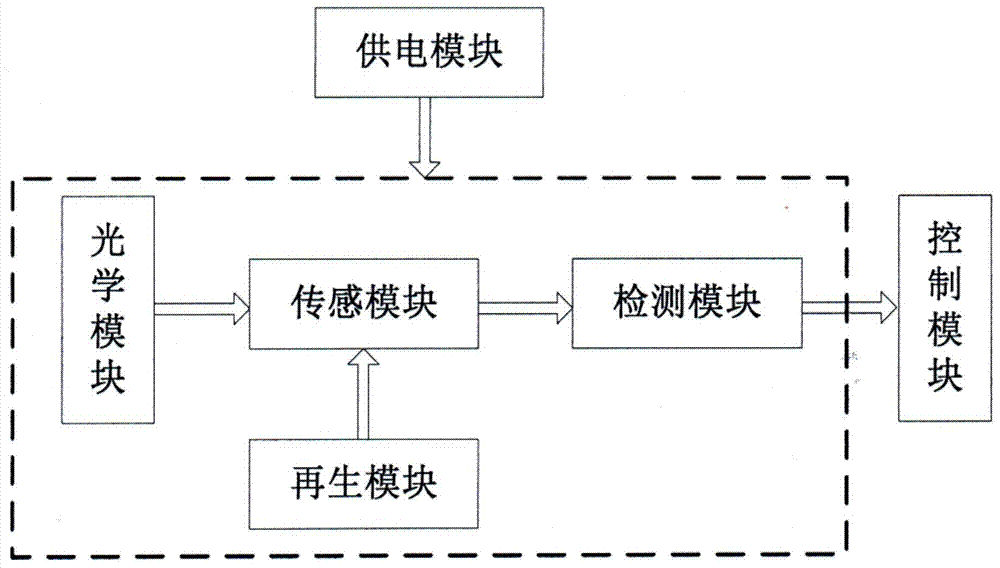

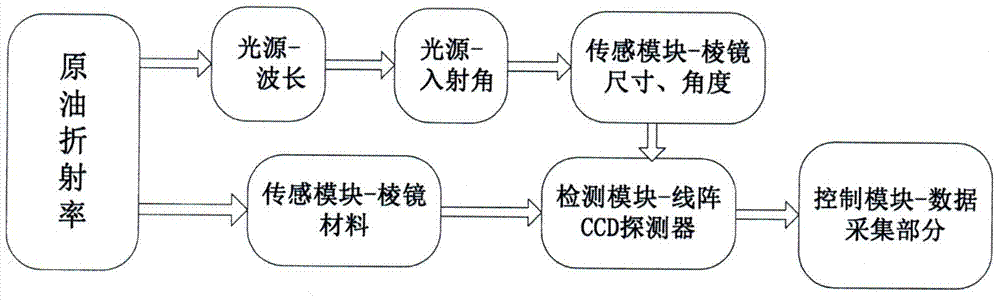

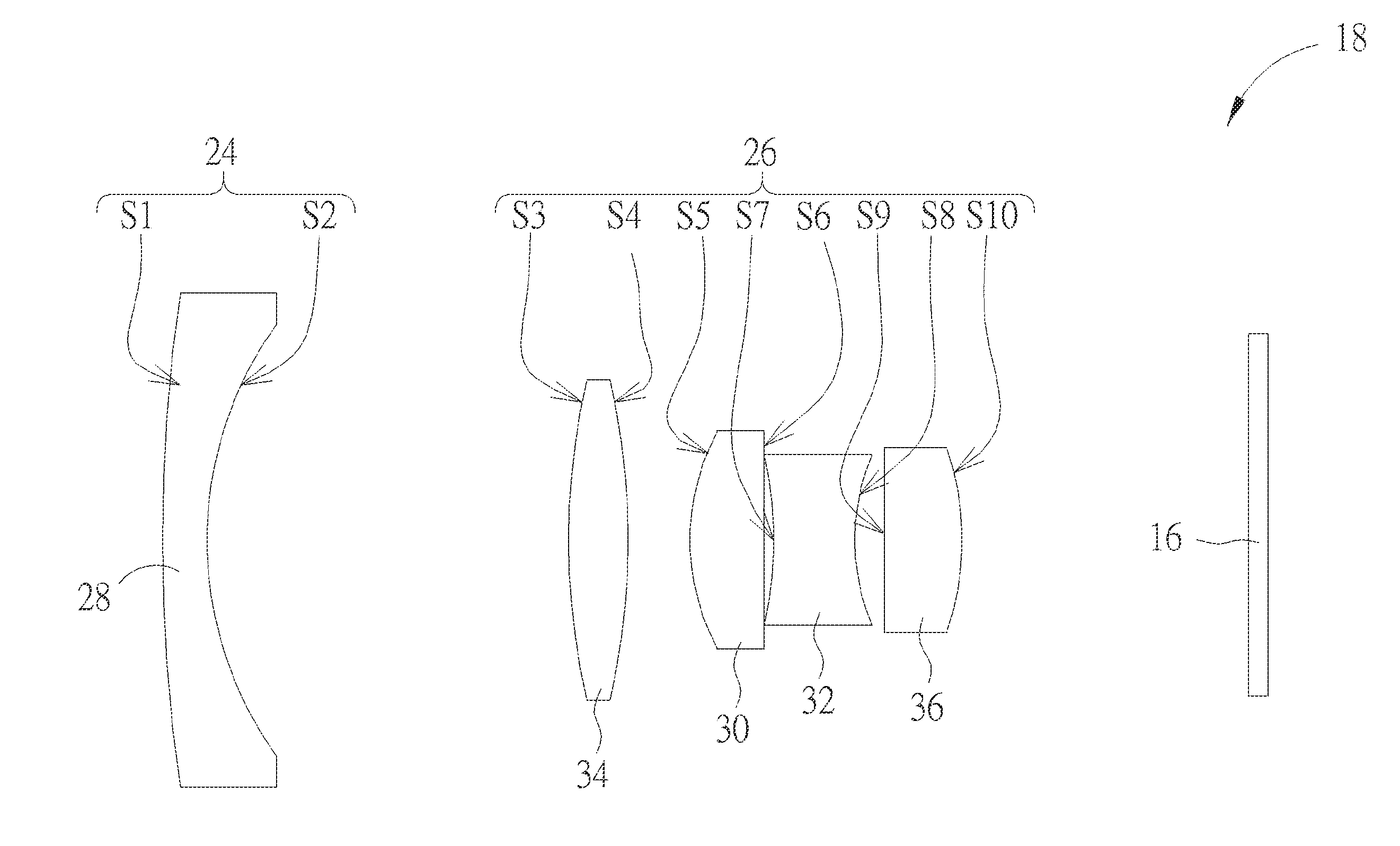

Miniature real-time on-line offshore oil spill detection system

InactiveCN104713851AExtended service lifeGuaranteed repeatabilityMaterial analysis by optical meansDivergence angleRefractive index

The invention relates to an angle-modulation type real-time on-line offshore oil spill detection system employing a miniature surface plasma resonance technique. The system comprises six parts, namely an optical module, a sensing module, a detection module, a regeneration module, a power supply module and a control module, wherein the optical module adopts a semiconductor laser module and has a relatively large divergence angle to meet the angle control on a light source; the sensing module comprises a prism which is made of a high-refractive index heavy flint glass material and a gold film sensing slide which is made of the same material with the prism; and the detection module is used for collecting an image by virtue of a wireless transmission mode linear array CCD detector and transmitting the image to a computer data collection part of the control module, and carrying out data and image processing. According to the miniature real-time on-line oil spill detection system, detection is carried out mainly aiming at small-area early offshore oil spill which cannot be easily found out; multi-sensor data fusion is realized by system encapsulation positioning and distributed network arrangement; and monitoring on real-time tracking and information display of the oil spill position, drift speed, direction and track are carried out, so that important information is provided for judgment of oil spill places.

Owner:JILIN UNIV

Method for preparing colored glaze with waste flint glass as raw material

ActiveCN103241947AOvercoming complex costsOvercoming Raw Material CostsEcological environmentMetallurgy

The invention discloses a method for preparing colored glaze with waste flint glass as a raw material. The waste flint glass not only wastes the lead resource, but also has potential threats to human health and ecological environment, but no better method for treating the water flint glass exists. The method comprises the following steps of generally smashing the waste flint glass and grinding; then regulating the chemical components of the grinded waste flint glass; melting for 2-6 hours at high temperature of 750-980 DEG C; carrying out manual forming or mechanical forming according to a designed shape; sending the formed product into an annealing furnace for annealing, wherein the annealing temperature is 450-550 DEG C and the annealing time is 2-10 hours; and cooling to normal temperature so as to obtain the colored glaze. According to the method, the waste flint glass is taken as the main raw material for preparing the colored glaze, so that the method has the advantages that technological process is simple, raw material source is wide, energy consumption is low and the like, can be used for preparing colored glaze product with good gloss, low softening point and long material property, is applicable to the existing various colored glaze product factories in north and south and is beneficial to large-scale industrial production.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

Lead- and arsenic-free optical lanthanum flint glasses

The present invention relates to lead and arsenic free optical glasses, used for the application areas imaging, digital projection, photolithography, laser technology, wafer / chip technology as well as telecommunication, optical communications engineering, optics, illumination and in the automotive sector. The glasses have a refraction power of from 1.73≦nd≦1.82 and an Abbé value of 43≦vd≦53 with good chemical consistency and excellent crystallisation stability with the following composition (in weight-%): SiO20.1-5.5B2O327-35La2O342-48BaO0-5ZnO0.5-5 Y2O3 6-12TiO20-4ZrO2 4-10Nb2O50-5WO30-5

Owner:SCHOTT AG

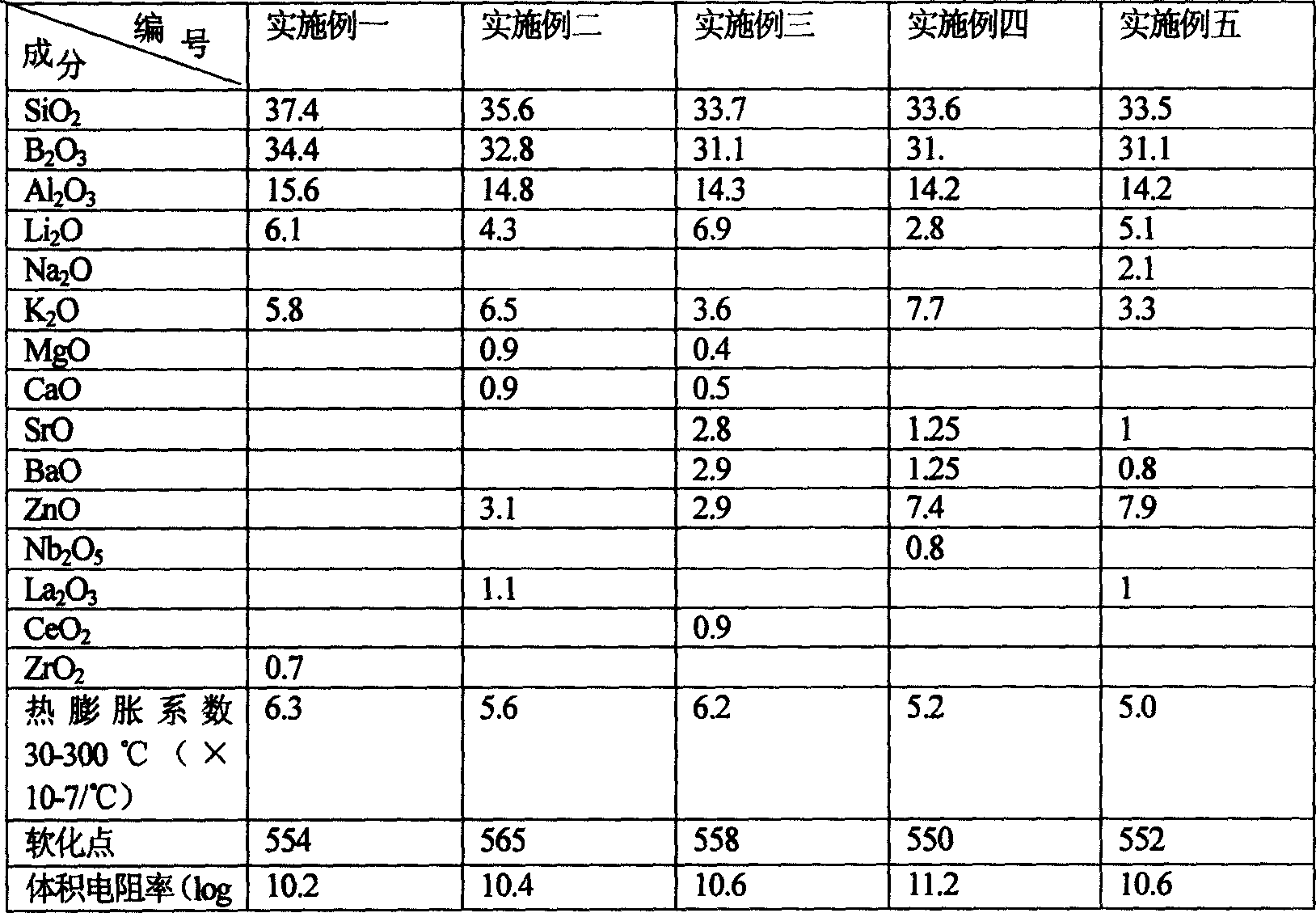

Glass material and preparing method and application thereof

The invention discloses a lead-free low-temperature glass material acting as protective layer of multiplayer sheet zinc oxide pressure sensitive resistor as well as its preparing method. It includes concrete components as follows: SiO2 30-50%, B2O3 20-35%, Al2O3 5-17 W%, RO 0-15W%, R2O 5-15%, and rare-earth oxide 0.5-1.5%. It has high transparency, good chemical stability, operating temperature not higher than 700 deg.C, primely meets the requirement for protective layer of multiplayer zinc oxide pressure sensitive resistors and solves the defects of traditional flint glass like harm to human heath, serious environmental pollution, etc.

Owner:SOUTH CHINA UNIV OF TECH +1

Lead- and arsenic-free optical lanthanum flint glasses

The present invention relates to lead and arsenic free optical glasses, used for the application areas imaging, digital projection, photolithography, laser technology, wafer / chip technology as well as telecommunication, optical communications engineering, optics, illumination and in the automotive sector. The glasses have a refraction power of from 1.73≦nd≦1.82 and an Abbé value of 43≦vd≦53 with good chemical consistency and excellent crystallisation stability with the following composition (in weight-%):SiO20.1-5.5B2O327-35La2O342-48BaO0-5ZnO0.5-5 Y2O3 6-12TiO20-4ZrO2 4-10Nb2O50-5WO3 0-5.

Owner:SCHOTT AG

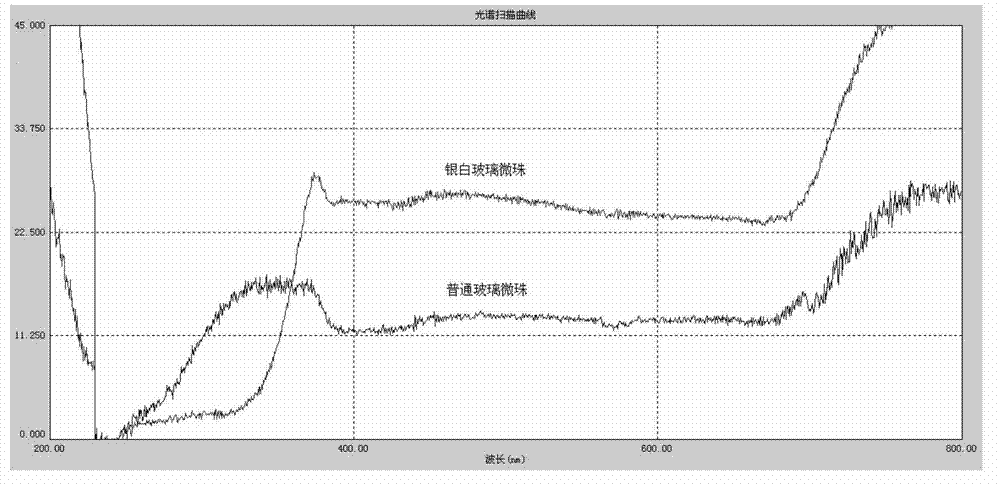

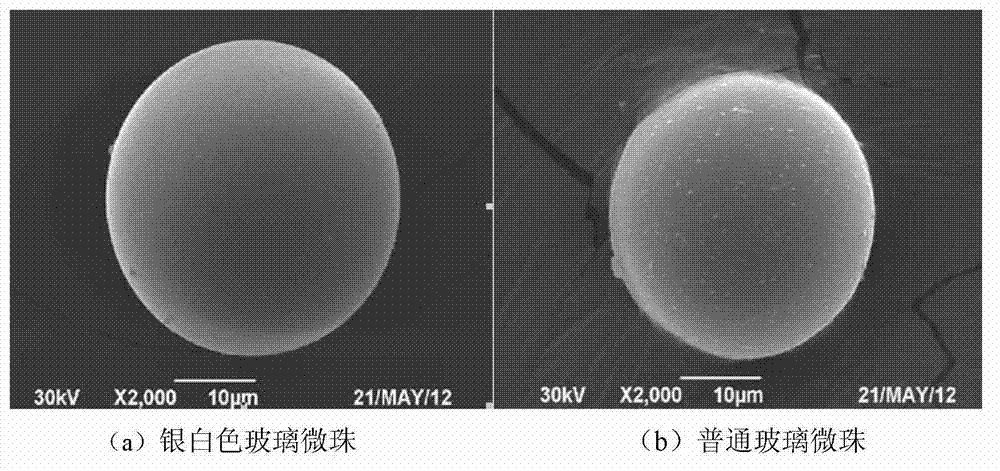

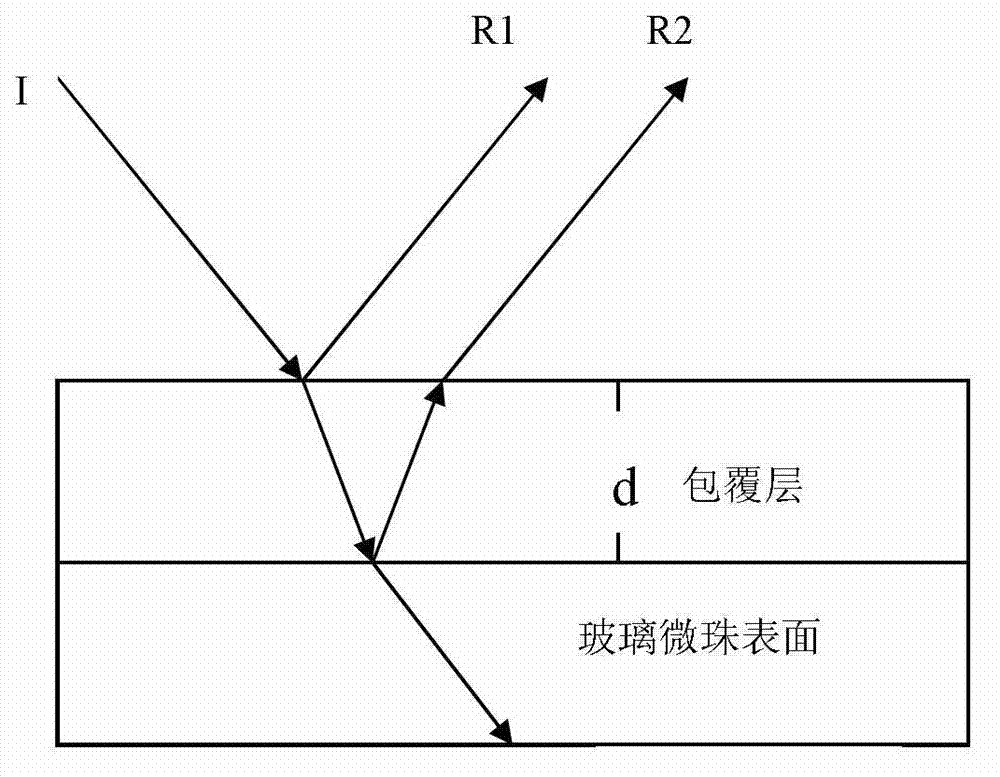

Interference color glass bead and preparation method thereof

The invention relates to an interference color glass bead and a preparation method thereof. The interference color glass bead is characterized by comprising a spherical common glass flint glass substrate and metal oxide coatings sequentially coated on the outer surface; the metal oxide coating is one layer or more; thickness of each layer of metal oxide coating meets the following formula: 2nd + 1 / 2 lambda = k lambda; n represents the index rate of metal oxide; d represents the thickness of the coating; lambda represents wavelength of interference phase light wave and values from 350 to 770nm; and K is an natural number other than 0. The metal oxide coating on the outer surface of the interference color glass bead has advantages of smoothness, compactness, good reflection performance and diversified and adjustable color; and the preparation process is simple, and convenient for popularization and application.

Owner:HUBEI UNIV OF TECH

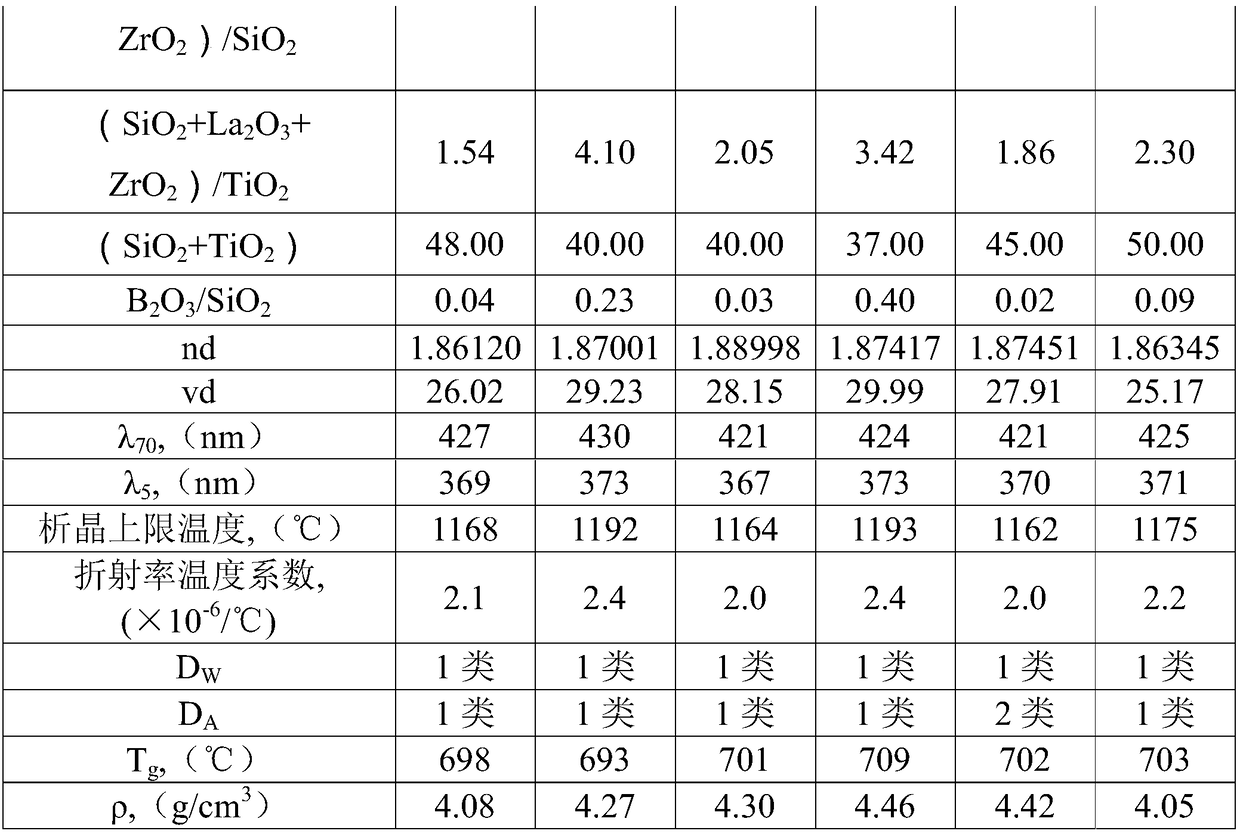

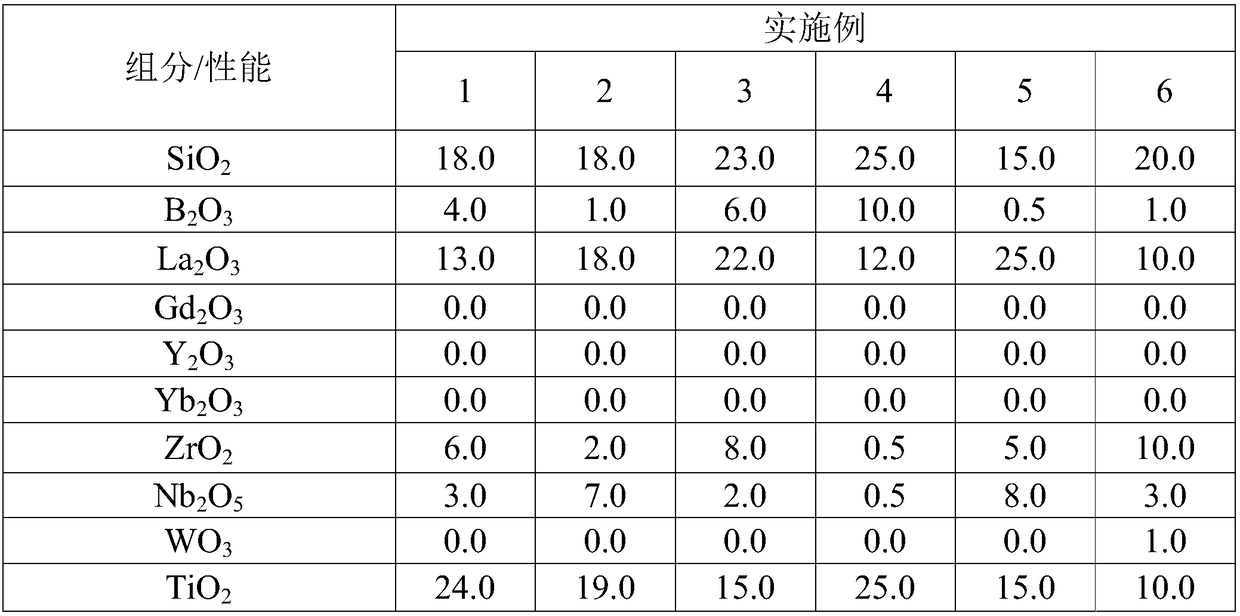

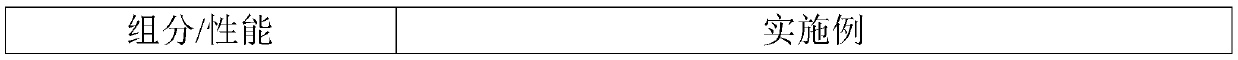

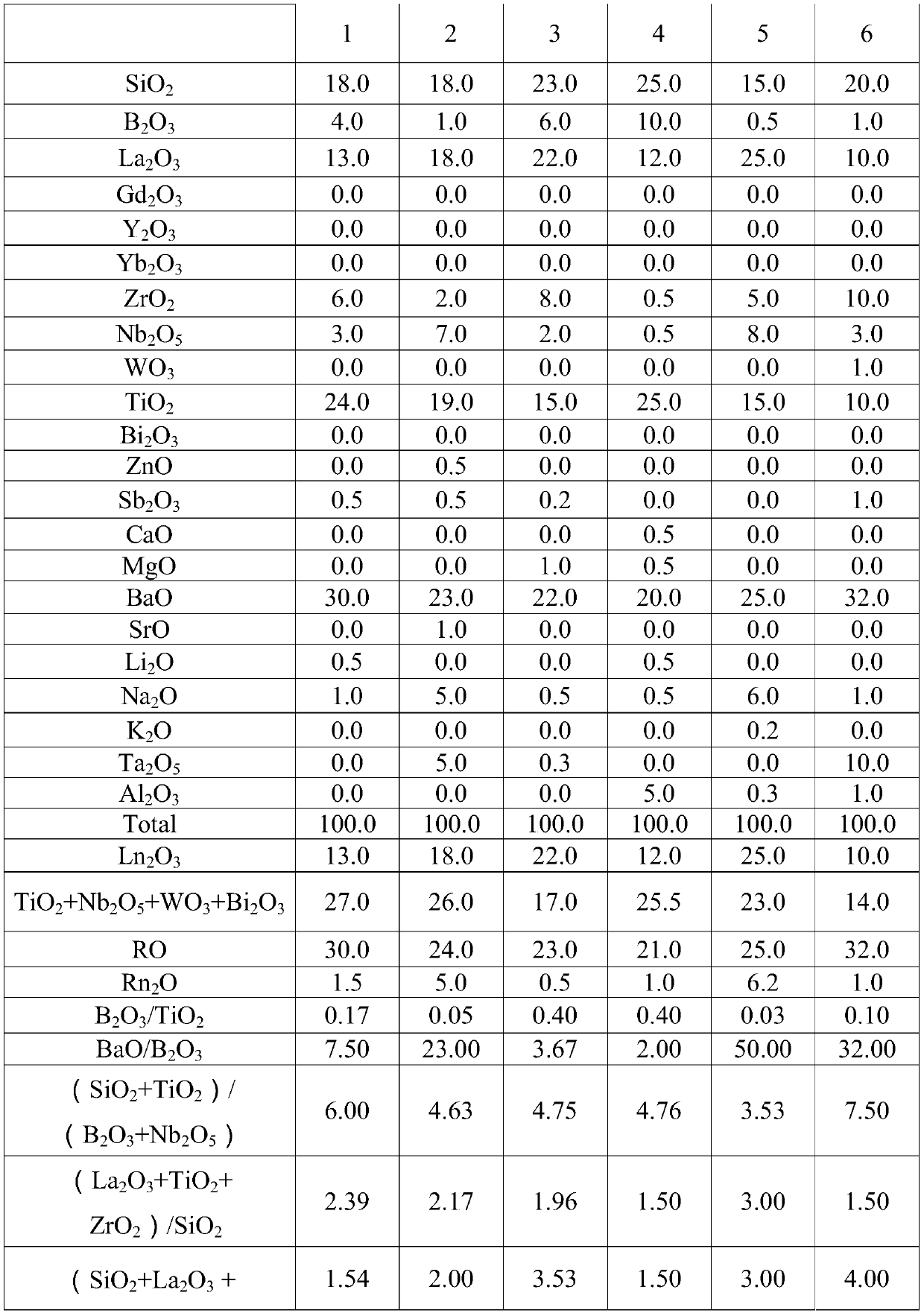

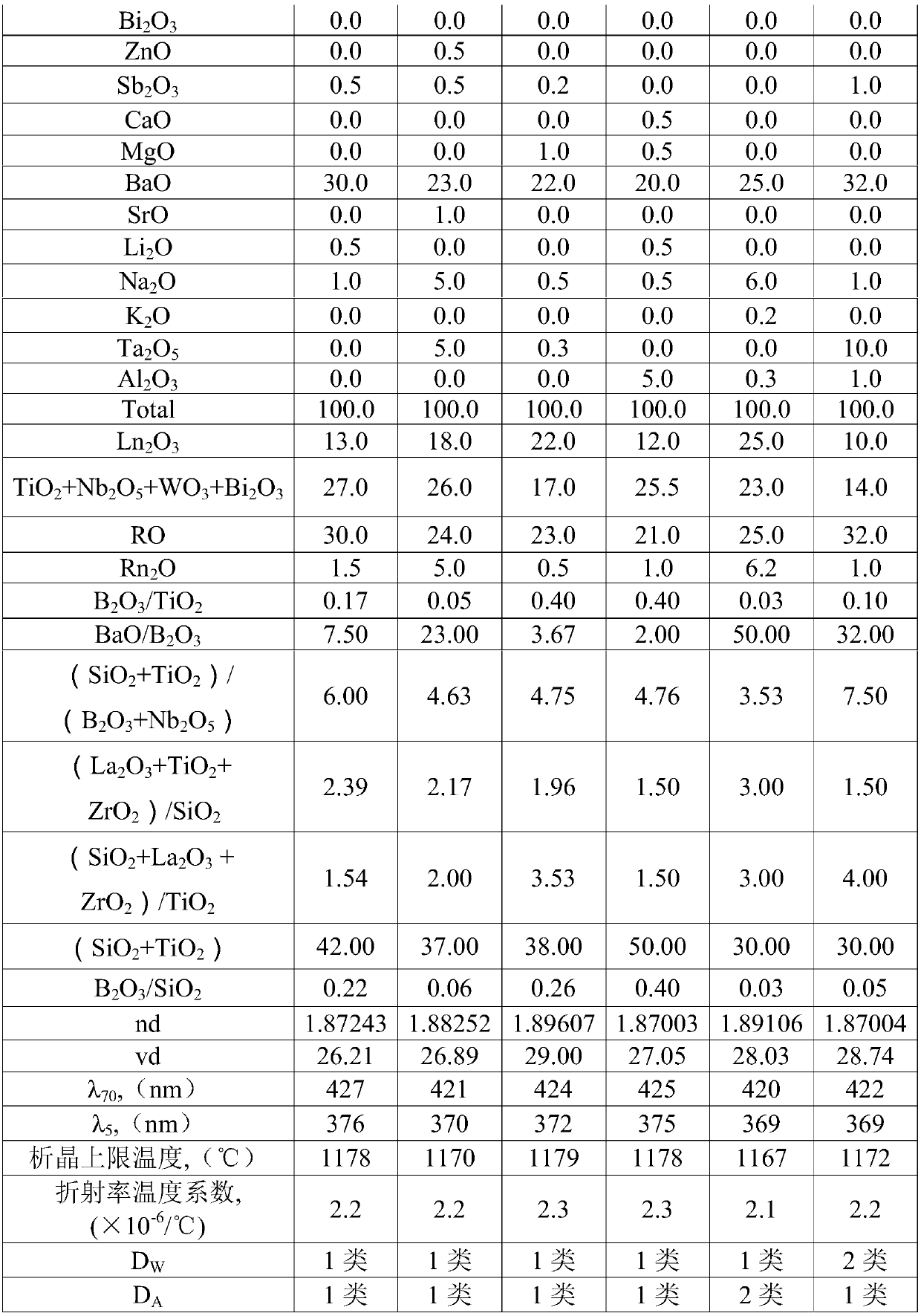

Heavy lanthanum flint glass and preform thereof, optical element and optical instrument

ActiveCN109437556AExcellent temperature coefficient of refraction indexExcellent crystallization upper limit temperatureGlass reforming apparatusOptical elementsOptical propertyRefractive index

The invention discloses a heavy lanthanum flint glass and a preform, an optical element, and an optical instrument. The heavy lanthanum flint glass is prepared from the following components in percentage by weight: 12 to 30 percent of SiO2, 10 to 25 percent of La2O3, 10.5 to 40 percent of TiO2+Nb2O5+WO3+Bi2O3 and 20 to 35 percent of RO and 0.5 to 10 percent of ZrO2, wherein the RO is one or more of BaO, CaO, MgO and SrO, and (SiO2+La2O3+ZrO2) / TiO2 is 0.75 to 6.5. The refractive index (nd) of the glass is 1.86 to 1.92 and the abbe number (vd) is 25 to 30; the heavy lanthanum flint glass can meet optical properties required by precision instruments and has the advantages of excellent anti-crystallization performance, low refractive index temperature coefficient and capability of effectivelyreducing thermal aberration caused by temperature difference.

Owner:CDGM OPTICAL GLASS

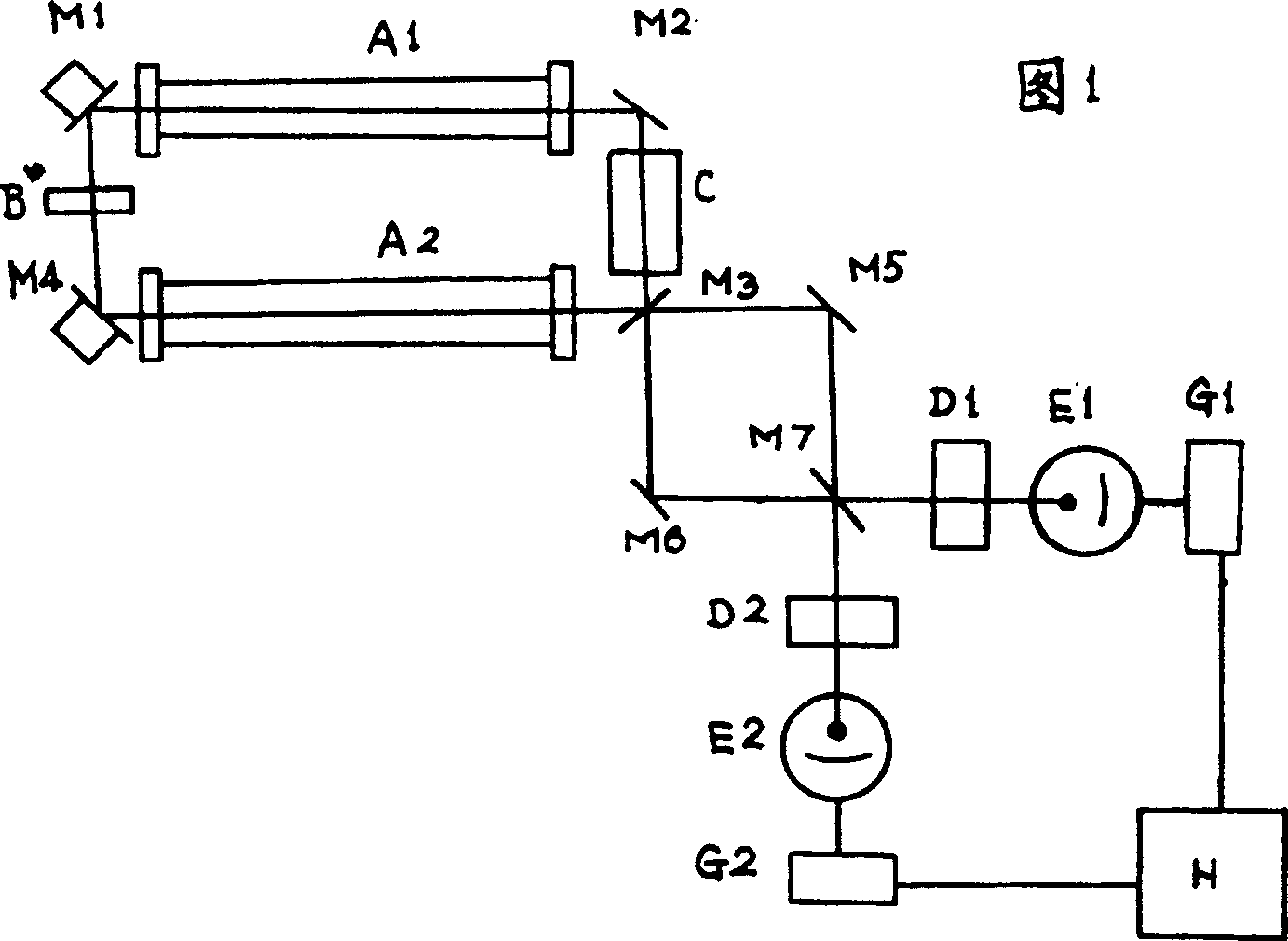

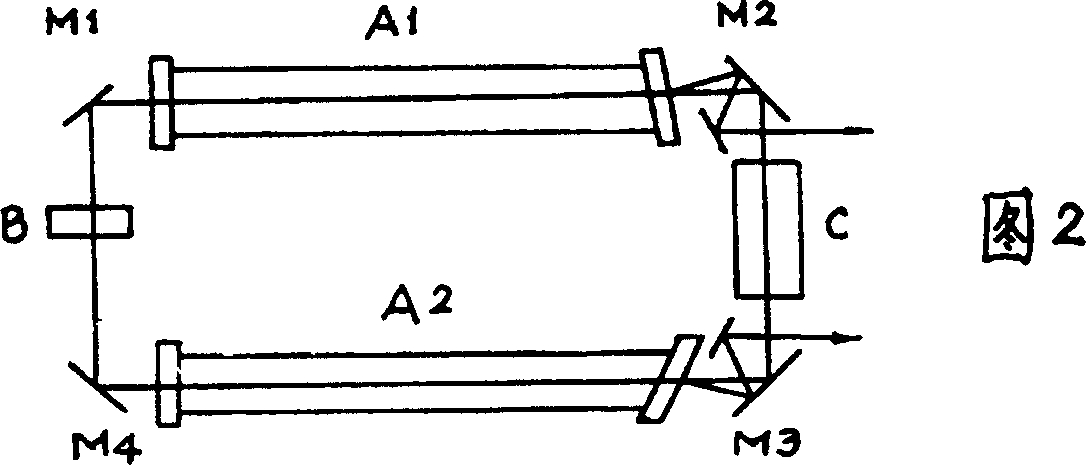

Ring-shape laser magnetometer

A laser magnetometer of ring form is prepared as setting Faraday magneto-optic material to be rectangular form, utilizing two gain tubes being set with the same parameter and being set symmetrically to provide light amplification and to overcome Zeeman effect, applying crystal quarts to generate component on internal light path of Faraday magneto-optic material in circular polarization light laser and applying flint glass in length of several mm and thickness of a dozen mm as Faraday magneto-optic material.

Owner:李贵祥

Method for preparing colorful TiN film by utilizing direct current magnetron sputtering

InactiveCN102146556ALow melting pointHigh surface finishVacuum evaporation coatingSputtering coatingNitrogen gasDirect current magnetron sputtering

The invention provides a method for preparing a colorful TiN film by utilizing direct current magnetron sputtering. The method comprises the following steps: (1) based on high-peed steel as a substrate material, grinding the substrate material by respectively using a flint glass paper and then a crocus paper, and then polishing until the surface of the substrate material is of a mirror plane; (2) immersing the processed substrate material into an ethanol solution to carry out ultrasonic excitation for 10-20 minutes, carrying out dipping bath with acetone, and drying with a blower; (3) then fixing the substrate material on a specimen holder of a vacuum precipitation chamber for film coating, pumping the vacuum at the back bottom before film coating to 3*10<-3>Pa, and carrying out ion bombarding on the surface to clean for 3-5 minutes; and (4) plating different TiN film specimens under the different nitrogen flows (precipitation pressures). The result shows that the nitrogen flow (precipitation pressure) has an important influence on the color of a decoration coating film, and the color of the TiN film layer can be effectively changed through regulating the nitrogen flow. In the method, the film layer color required in practicable production through changing the nitrogen flow.

Owner:TIANJIN NORMAL UNIVERSITY

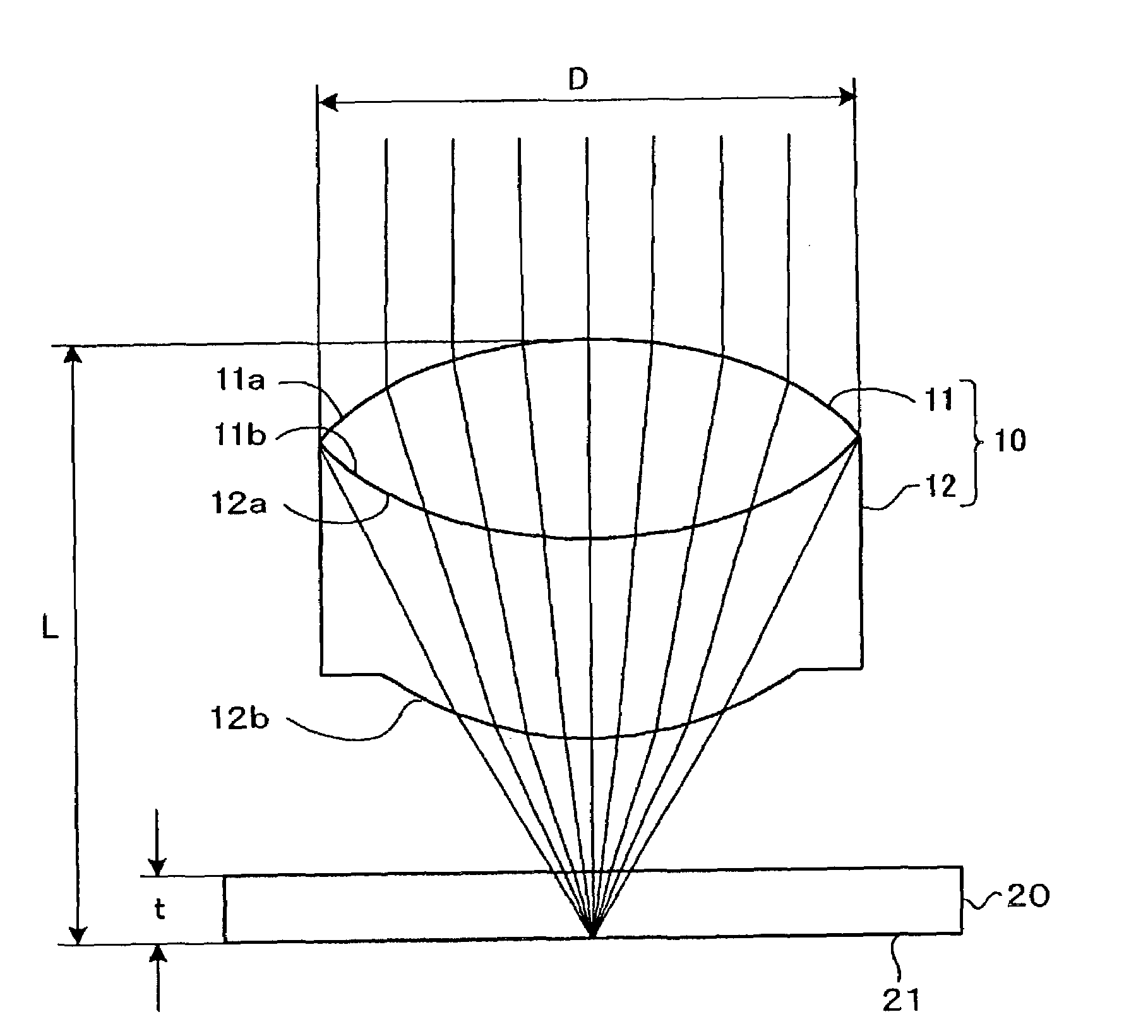

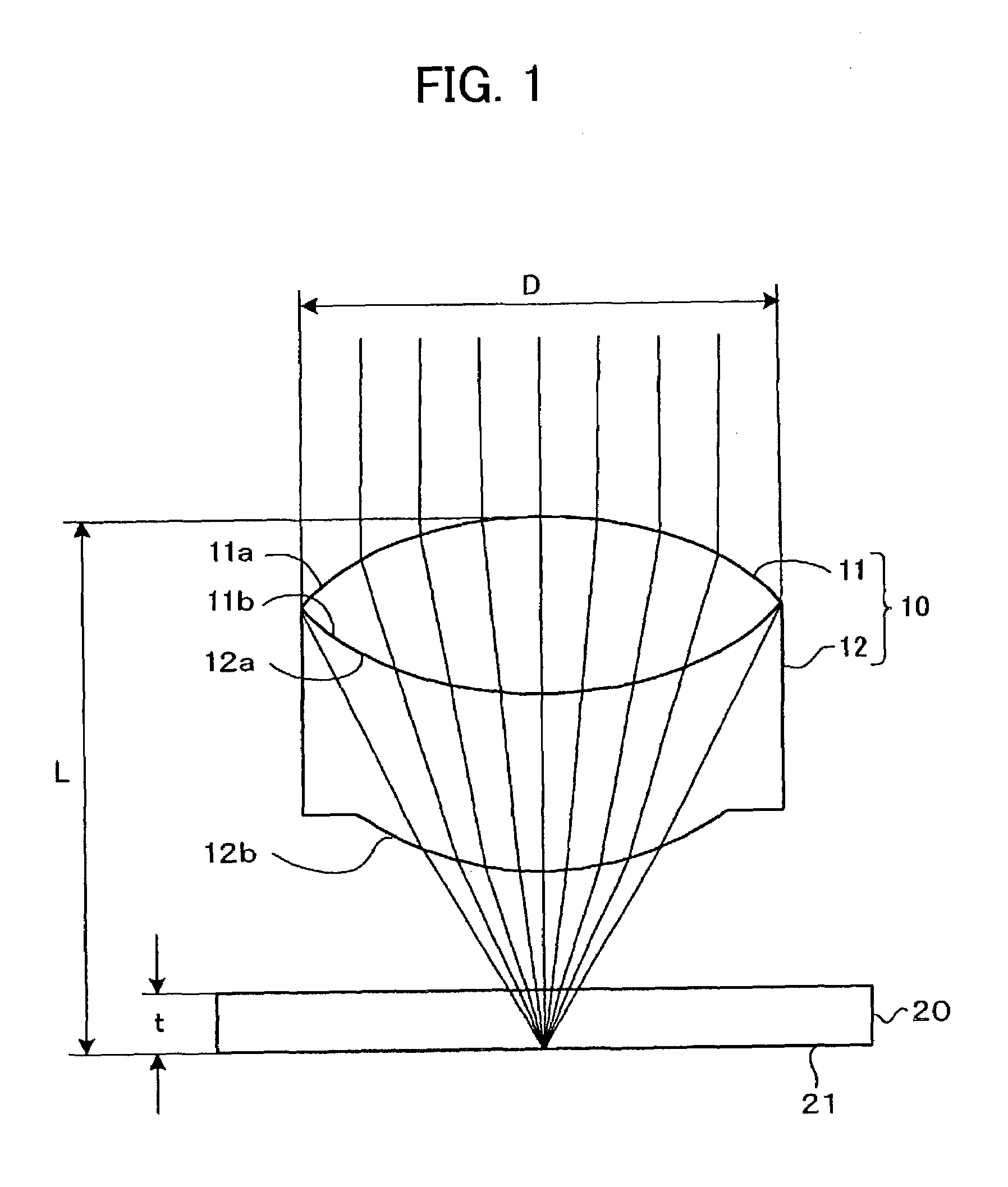

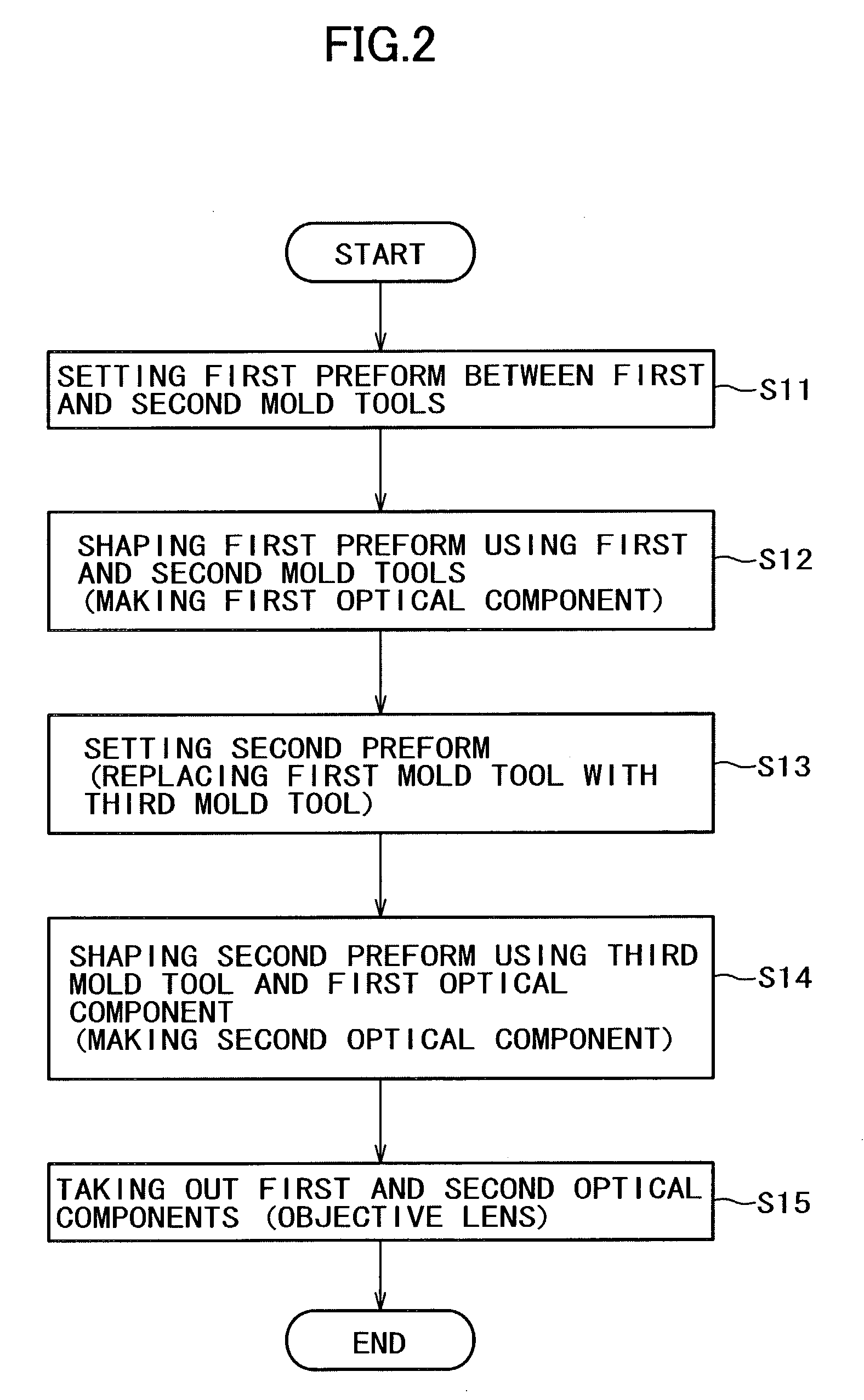

Objective lens and optical pickup apparatus, information recording/reproducing apparatus

InactiveUS7054074B2Simple configurationIdentical optical propertiesOptical beam sourcesRecord information storageOptical pickupOptical property

An objective lens is configured of a first crown-glass lens and a second flint-glass lens, whereby it can exhibit substantially identical optical properties at a plurality of recording / reproducing light source wavelengths, particularly, in both 650 nm and 405 nm wavelength bands. Also, by maximizing the difference in glass transition point between the first and second lenses, one of the first and second lenses having a higher glass transition point is molded first, to allow that first molded lens to serve as a mold tool for molding the other lens. This dispenses with the steps of aligning and adhesive bonding the two lenses, whereby this objective lens can be used at a plurality of wavelengths as a single objective lens, and thus an information recording / reproducing apparatus can be of a simple configuration.

Owner:SONY CORP

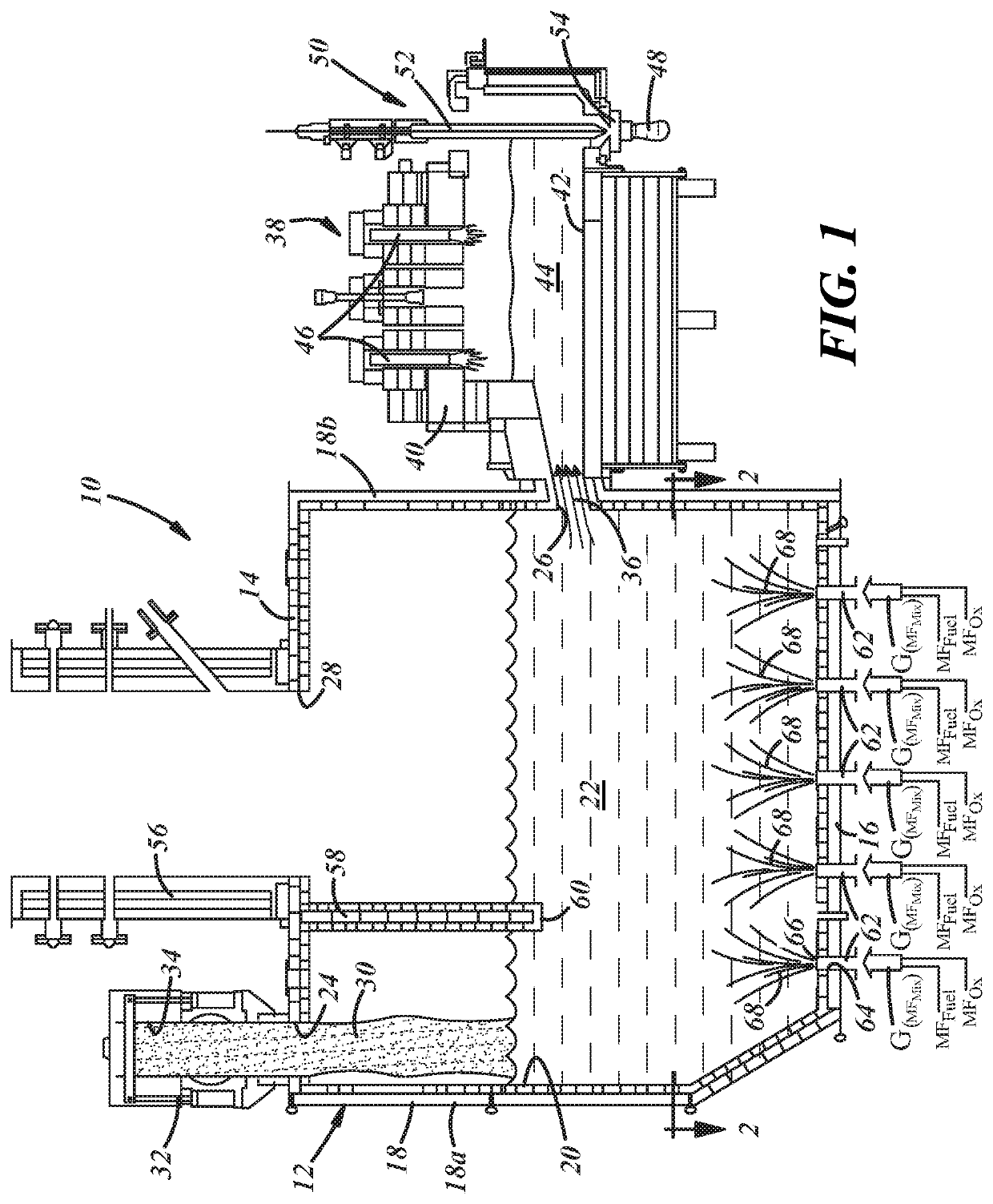

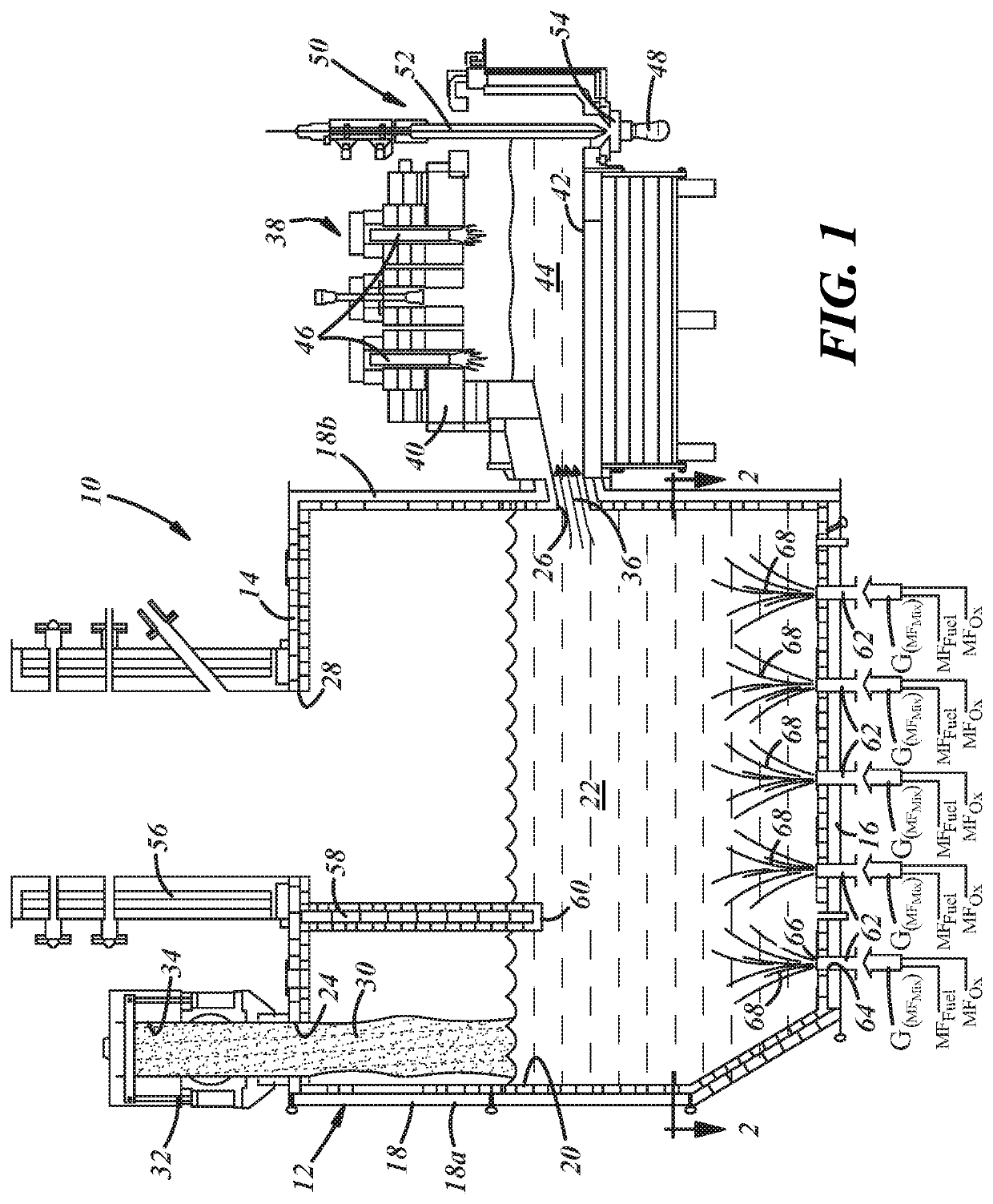

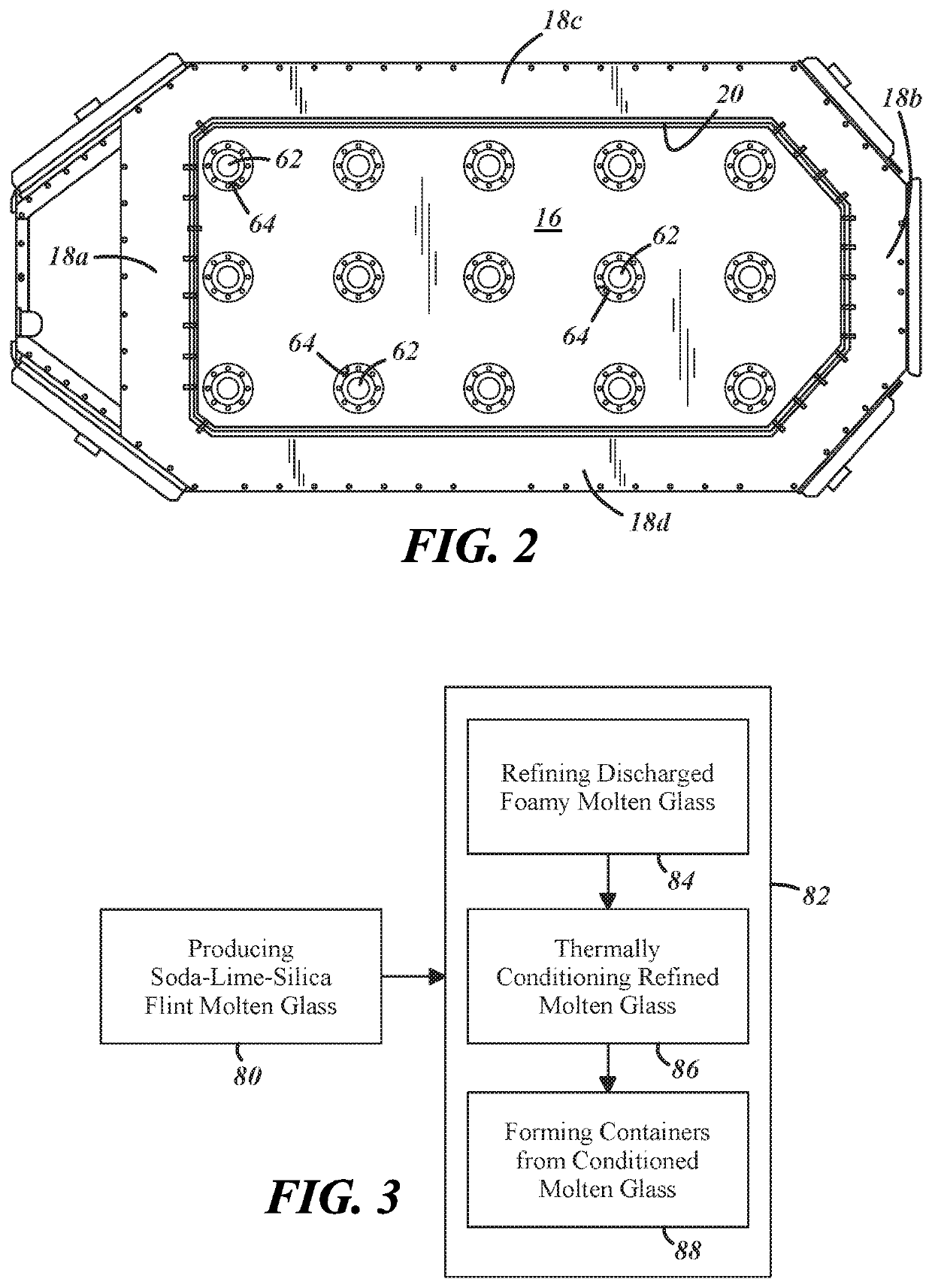

Feed Material for Producing Flint Glass using Submerged Combustion Melting

ActiveUS20210246061A1Glass furnace apparatusGlass melting apparatusVitrificationChemical composition

A method of producing flint glass using submerged combustion melting involves introducing a vitrifiable feed material into a glass melt contained within a submerged combustion melter. The vitrifiable feed material is formulated to provide the glass melt with a glass chemical composition suitable for producing flint glass articles. To that end, the glass melt comprises a total iron content expressed as Fe2O3 in an amount ranging from 0.04 wt % to 0.06 wt % and also has a redox ratio that ranges from 0.1 to 0.4, and the vitrifiable feed material further includes between 0.008 wt % and 0.016 wt % of selenium or between 0.1 wt % and 0.2 wt % of manganese oxide in order to achieve an appropriate content of selenium or manganese oxide in the glass melt.

Owner:OWENS-BROCKWAY GLASS CONTAINER INC

Projection lens and projection apparatus

The invention provides a projection lens. The projection lens comprises a first lens group and a second lens group, wherein the first lens group is provided with negative diopter, is adjacent to an object side and comprises a first lens with negative diopter; and the second lens group is provided with positive diopter, is adjacent to an image side and comprises a second lens with positive diopter and a third lens with negative diopter; the second lens is disposed between the first lens and the third lens; the third lens is made of a dense flint glass material; the thermal variation parameter of the second lens is D0, and -3.0*e<-5><=D0<=-6.0*e<-7>.

Owner:QISDA OPTRONICS (SUZHOU) CO LTD +1

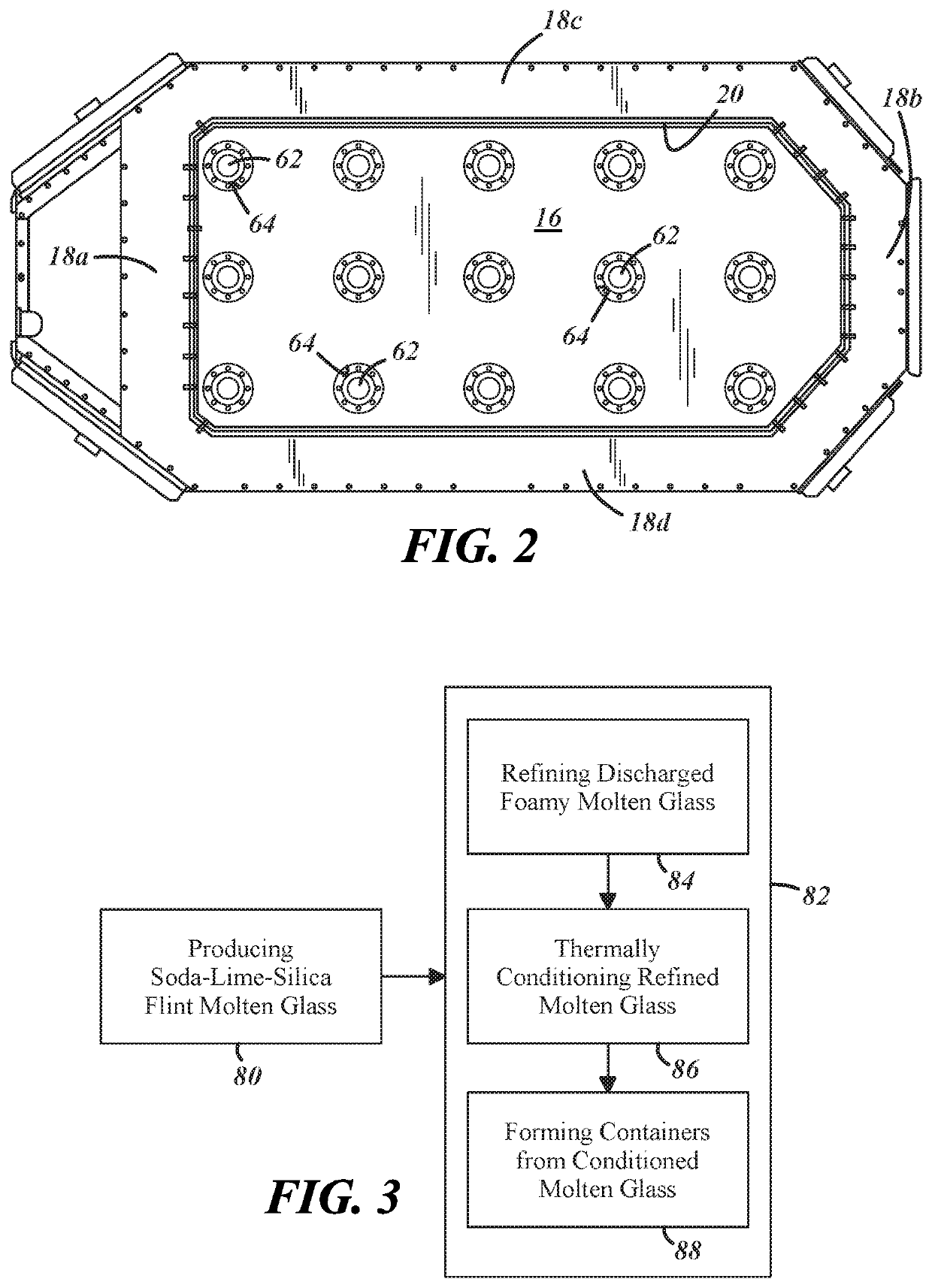

Producing Flint Glass Using Submerged Combustion Melting

PendingUS20210246060A1Maintenance timeGlass furnace apparatusGlass melting apparatusCombustorCombustible gas

A method of producing flint glass using submerged combustion melting is disclosed. The method includes operating a submerged combustion melter such that combustion products are discharged from one or more submerged burners combusting a combustible gas mixture that comprises fuel and oxygen. An oxygen-to-fuel ratio of the combustible gas mixture ranges from stoichiometry to 30% excess oxygen relative to stoichiometry, a temperature of a glass melt in the submerged combustion melter is between 1200° C. and 1500° C., a residence time of the glass melt is maintained between 1 hour and 10 hours, and a specific throughput rate of molten glass discharged from the submerged combustion melter ranges from 2 tons per day per meter squared of cross-sectional area of the submerged combustion melter [tons / day / m2] to 25 tons / day / m2. A method of forming glass containers from the molten glass discharged from the melter is also disclosed.

Owner:OWENS-BROCKWAY GLASS CONTAINER INC

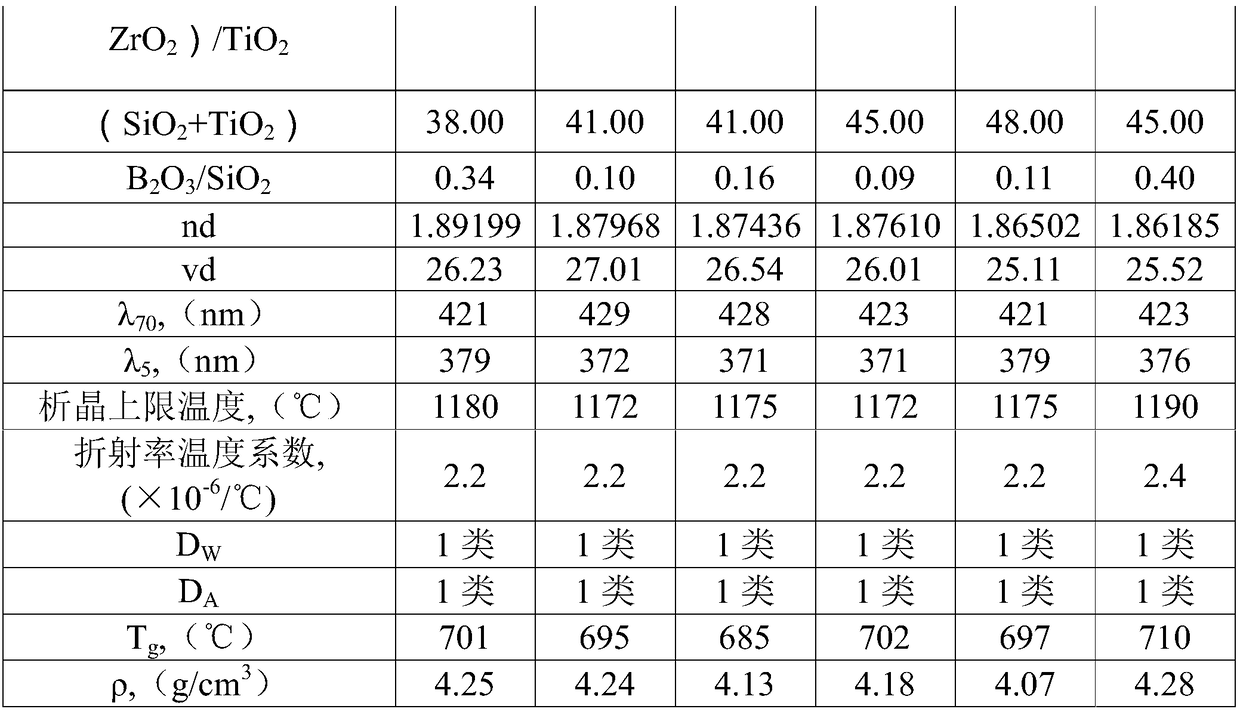

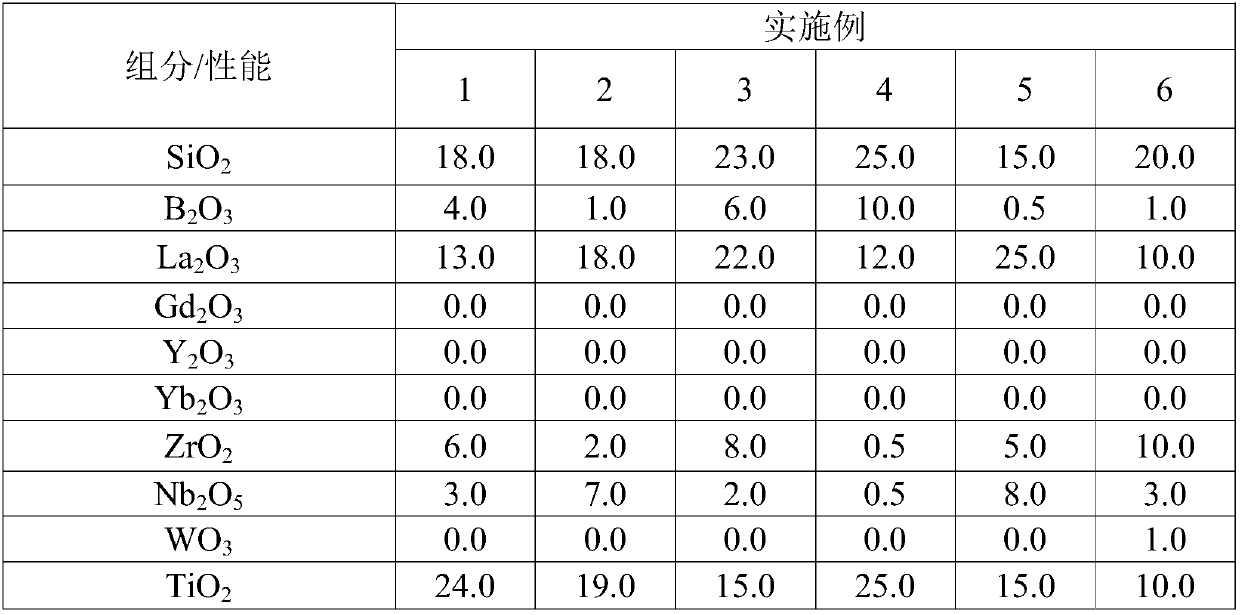

Dense-lanthanum flint glass and prefabricated part thereof, optical element and optical instrument

ActiveCN109851217AExcellent temperature coefficient of refraction indexExcellent crystallization upper limit temperatureOptical elementsRefractive indexOptical instrument

The invention discloses dense-lanthanum flint glass and a prefabricated part thereof, an optical element and an optical instrument. The dense-lanthanum flint glass contains, in percentage by weight, 12-30% of SiO2, 0-10% of B2O3, 10-25% of Ln2O3, 10.5-40% of TiO2+Nb2O5+WO3+Bi2O3, 18-40% of RO and 0.5-10% of ZrO2, wherein the percentage of the B2O3 is not 0, the content of the Ln2O3 is a sum of thecontents of La2O3, Gd2O3, Y2O3 and Yb2O3, the RO is one or more of BaO, CaO, MgO and SrO, and RO / B2O3 is larger than 0 and smaller than or equal to 70. A refraction index nd of the glass is 1.86-1.92, an abbe number is 25-30, the optical performance required for the precise instrument can be met, and the glass is excellent in thermal refractive index coefficient and good in water resistance effect stability and acid resistance effect stability.

Owner:CDGM OPTICAL GLASS

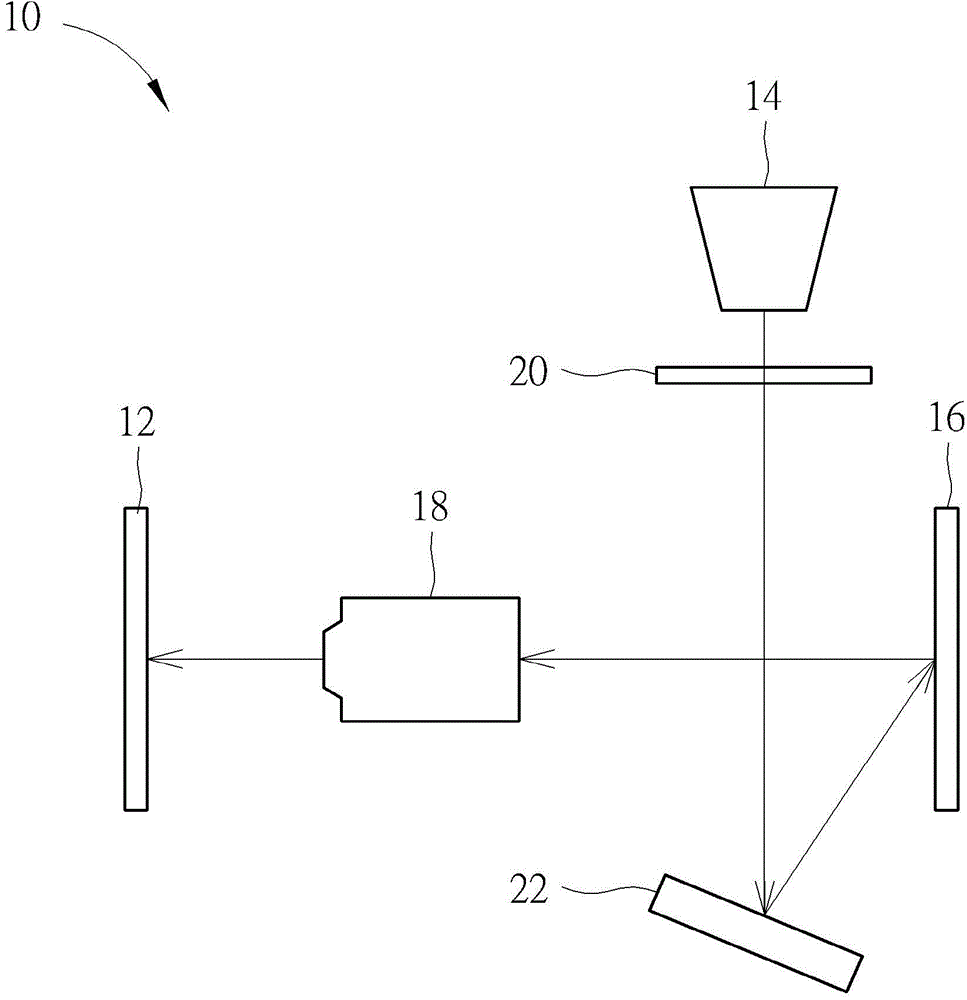

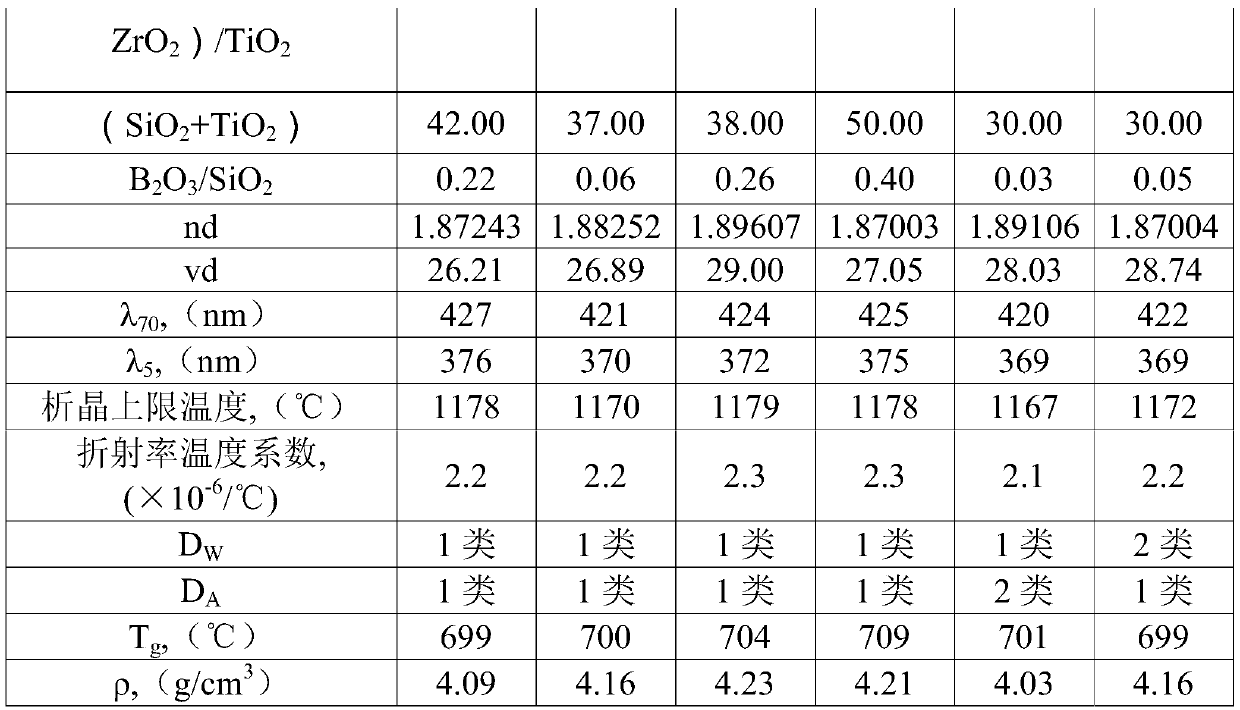

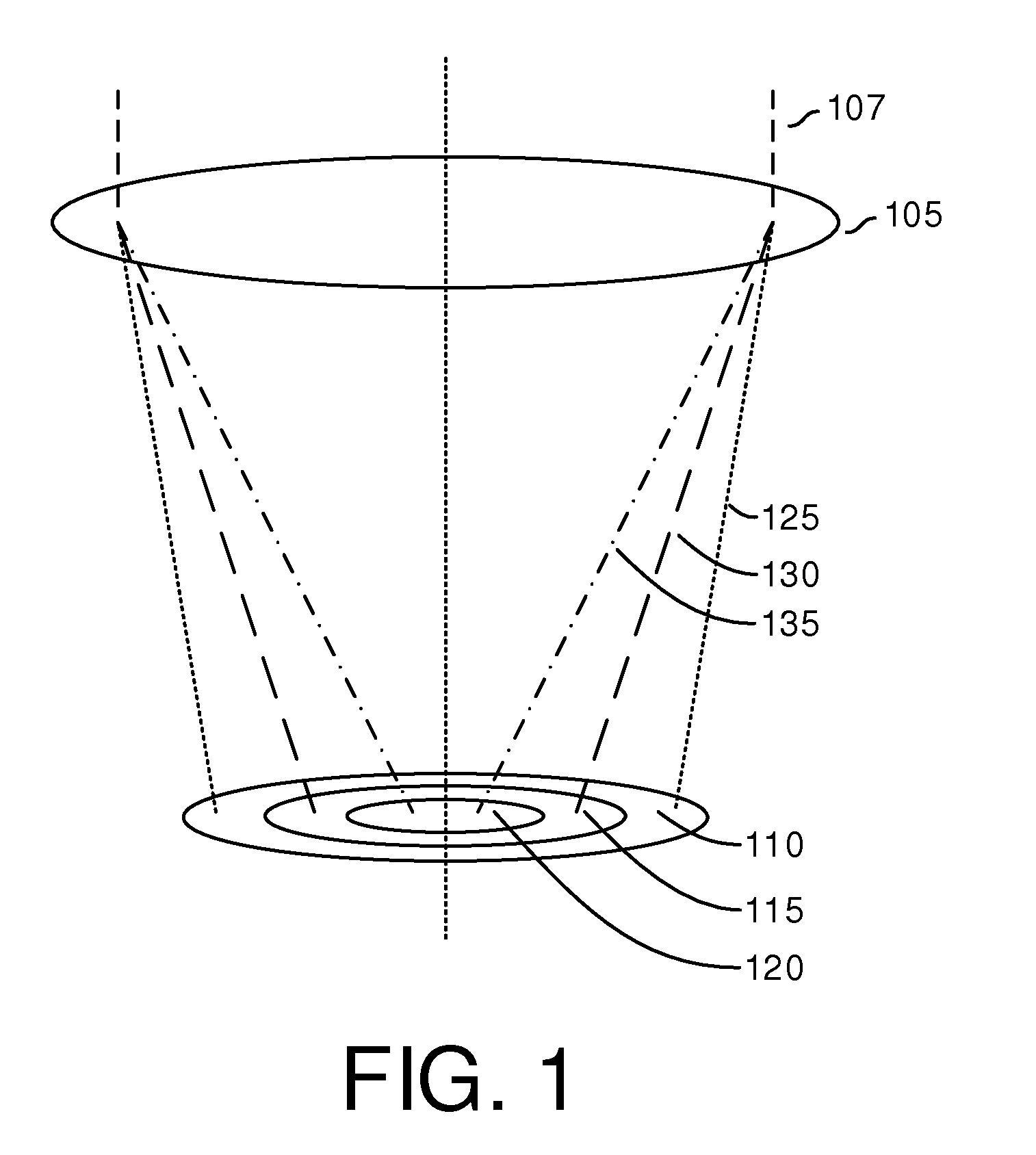

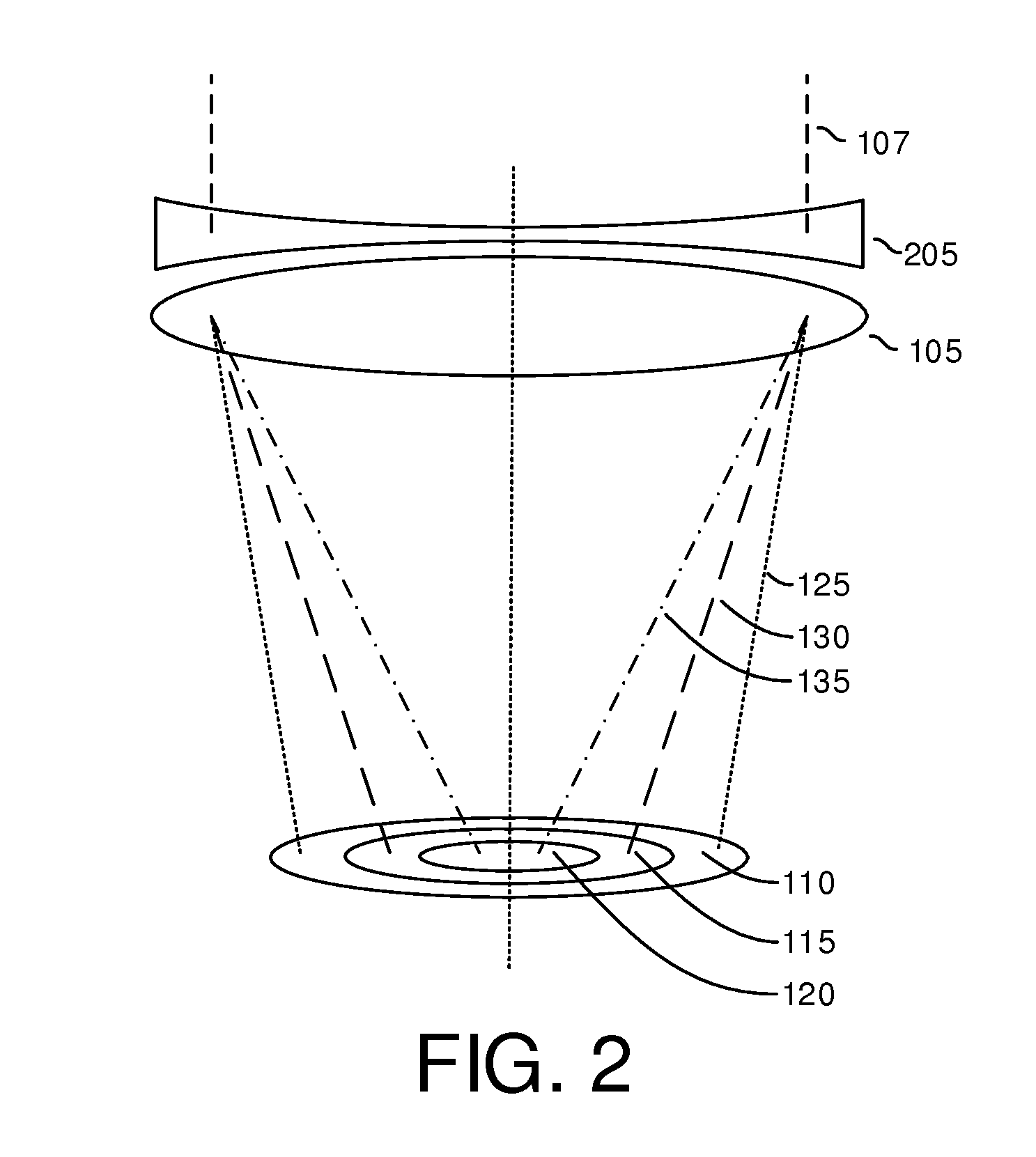

Image sensor with dispersive color separation

InactiveUS20150340396A1Reduces sensitivity of sensorImprove noisePrismsSolid-state devicesColor imagePrism

A converging composite lens with enhanced chromatic aberration comprising one or more converging lenses from flint glass, and one or more diverging lenses from crown glass. A dispersive composite prism with enhanced chromatic aberration, comprising two or more thin prisms, stacked one on atop another in alternating opposite directions, where the prisms in the first direction are produced from flint glass, and the prisms in the second direction are from crown glass. A color image sensor comprising color pixels with colors separated by such dispersive lenses or prisms. A concentric image pixel with concentric circular and ring shaped photo sensors.

Owner:BLAYVAS VLADISLAV

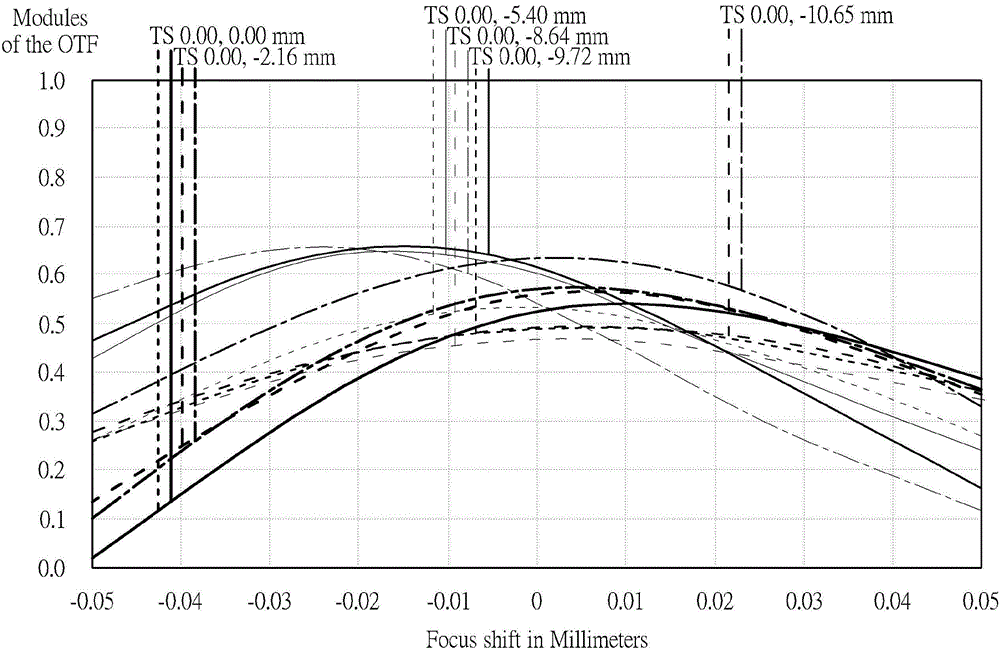

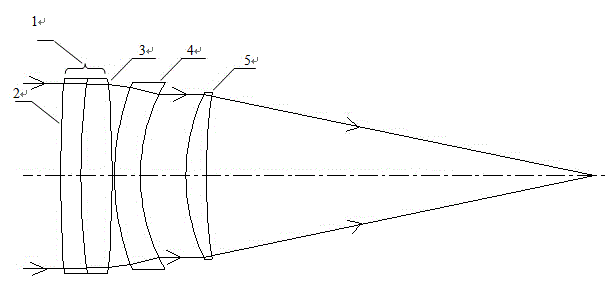

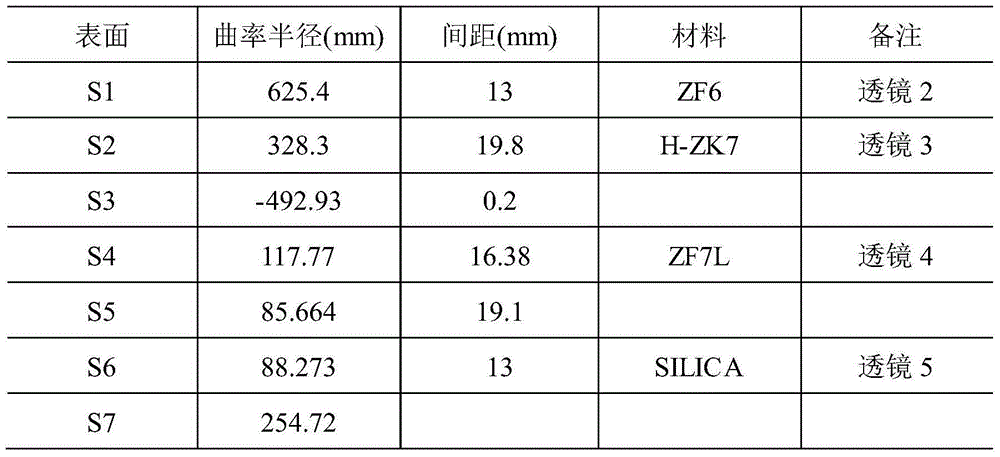

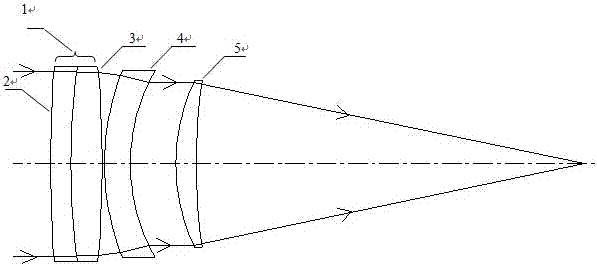

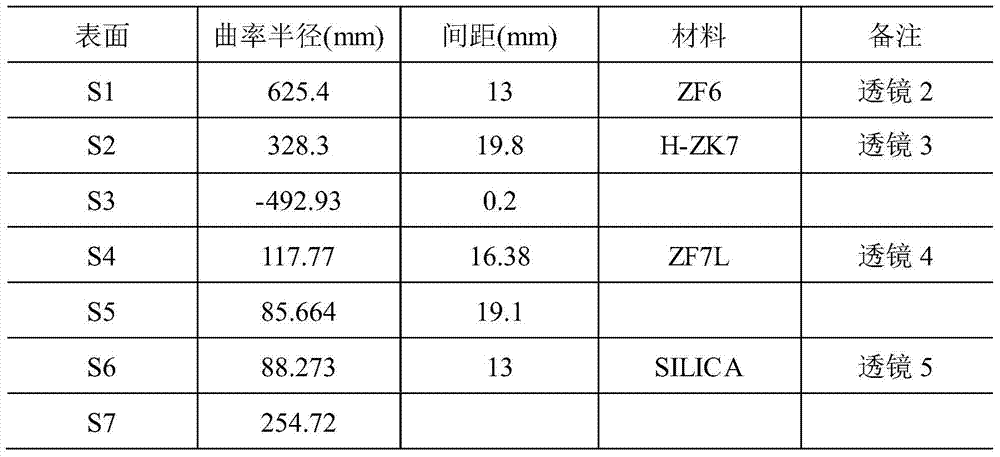

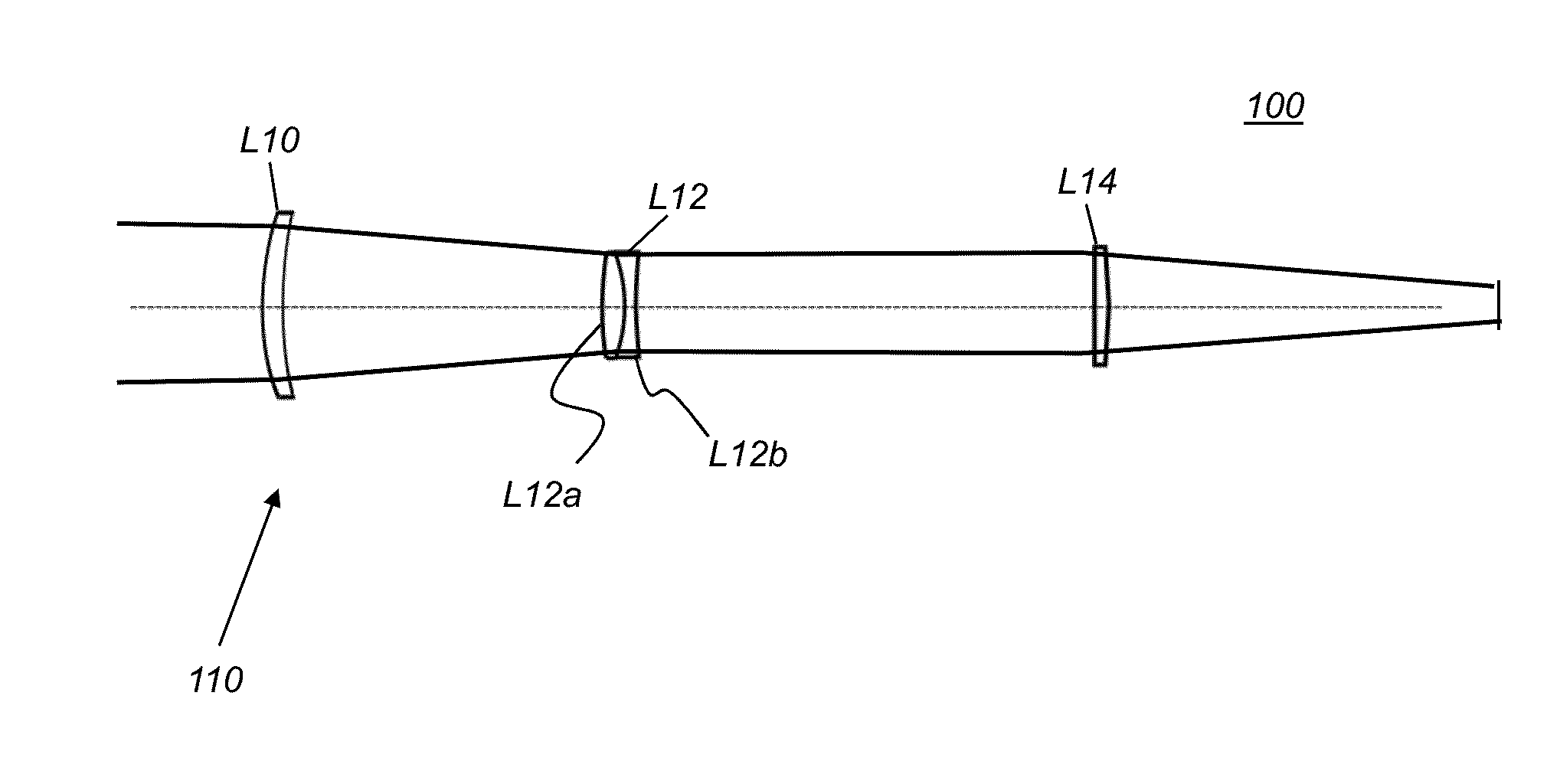

Small-F number multi-wavelength standard spherical reference lens assembly

The invention discloses a small-F number multi-wavelength standard spherical reference lens assembly. The small-F number multi-wavelength standard spherical reference lens assembly adopts the working wavelengths of 632.8 nanometers, 543.5 nanometers and 532 nanometers; achromatism of the lens assembly is achieved by using low-chromatic dispersion crown glass ZK7 and high-chromatic dispersion flint glass ZF6; the small-F number multi-wavelength standard spherical reference lens assembly adopts a three-piece lens design, and consists of a doublet positive lens, a negative lens, and a positive lens with a standard spherical surface as the last surface; the caliber, the F number and the top focal length design theoretical value of the reference lens assembly are 100mm, F / 3 and 254.7mm respectively; except for the last mirror surface of the reference lens assembly, the other mirror surfaces are plated with three-point antireflection films with the wavelengths of 632.8 nanometers, 543.5 nanometers and 532 nanometers; through combination of the doublet positive lens and the negative lens, an approximately afocal feature of an optical structure is achieved, the sensitivity of the change of a coincidence error between a focal point and the curvature center of the last surface along with the change of a mirror spacing is reduced, and installation and adjustment of the small-F number standard spherical lens assembly are facilitated.

Owner:NANJING UNIV OF SCI & TECH

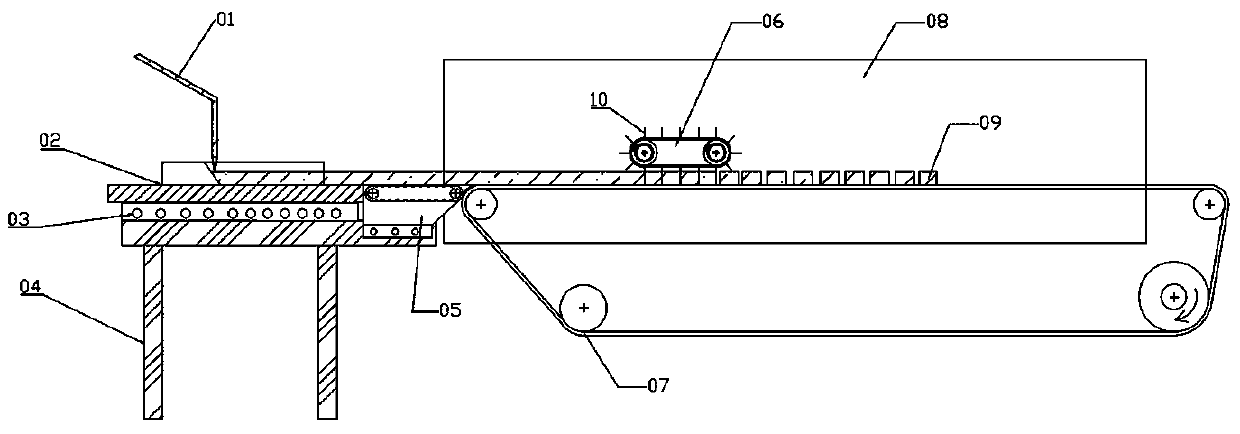

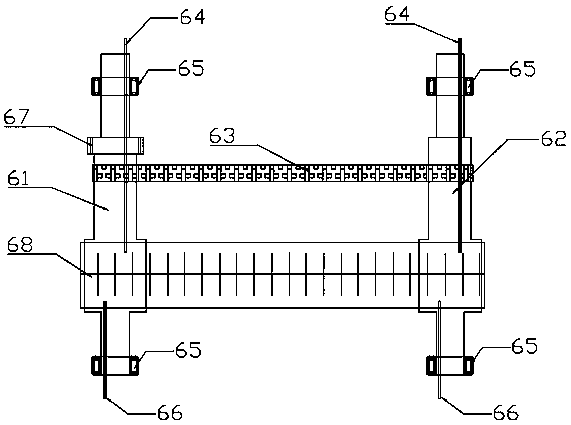

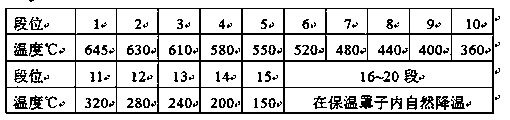

Optical glass square blank preparation device and blank preparation method

ActiveCN111559851AIncrease productivityReduce cutting wasteGlass forming apparatusGlass productionOptical glassMachining

The name of the invention is an optical glass square blank preparation device and a blank preparation method, and belongs to the technical field of optical glass smelting one-step molding. The problems that an existing optical element blank material needs to be slit from a strip material, materials are wasted, and machining efficiency is affected are mainly solved. The device is mainly characterized by comprising a forming die, a die cooler, a traction machine, a pressing and cutting machine and an annealing furnace, wherein the groove width of the forming die is integral multiples of the width of a square blank to be machined; and the pressing and cutting machine is installed in the annealing furnace and is provided with a longitudinal pressing and cutting blade and a transverse pressingand cutting blade which are used for slitting according to the width and the length of the square blank to be machined. A square blank which can be directly used for secondary profiling or cold machining can be manufactured in the optical glass production link, the large block slitting procedure is omitted, cutting material waste is greatly reduced, and the production efficiency of secondary profiling or cold machining is improved. The device and the method are suitable for one-step molding of crown glass, flint glass, dense barium flint glass and part of lanthanide glass.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

A small f-number multi-wavelength standard spherical reference lens group

The invention discloses a small F-number multi-wavelength standard spherical reference lens group, the working wavelengths are 632.8nm, 543.5nm and 532nm, and the achromatism of the lens group is realized by using crown glass ZK7 with low dispersion and flint glass ZF6 with high dispersion; It adopts 3-piece lens design, which is composed of a doublet positive lens, a negative lens and a positive lens whose last surface is a standard spherical surface; the design theoretical values of the aperture, F number and vertex focal length of the reference lens group are 100mm, F / 3 and 254.7mm respectively ;Except for the last mirror in the reference lens group, all the mirrors are coated with three-point anti-reflection coatings of 632.8nm, 543.5nm and 532nm; the combination of double-glued positive lens and negative lens is used to realize the approximate afocal of the optical path structure and reduce the The sensitivity of the coincidence error between the focal point and the center of curvature of the end surface changes with the distance between the mirrors is improved, and it is convenient for the assembly and adjustment of small F-number standard spherical lens groups.

Owner:NANJING UNIV OF SCI & TECH

Environment friendly heavy-lanthanide flint optical glass

ActiveCN101318769BExcellent optical propertiesExcellent devitrification resistanceDevitrificationOptical property

The present invention provides environmental-friendly dense-lanthanum optical flint glass, comprising the following compositions in percentage by weight: 2 to 6 percent of SiO2, 16 to 25 percent of B2O3, 10 to 20 percent of La2O3, 15 to 25 percent of Nb2O5, 0 to 3 percent of Li2O, 1.5 to 6 percent of Na2O, 0 to 3 percent of K2O, 0 to 3 percent of MgO, 1 to 5 percent of CaO, 0 to 3 percent of SrO, 8 to 22 percent of BaO, 3 to 12 percent of TiO2, 4 to 9 percent of ZrO2, 0 to 3 percent of GeO2, 0 to 3 percent of WO3, 0 to 3 percent of P2O5, 0 to 3 percent of Gb2O3, 0 to 3 percent of Ta2O5, and 0 to 1 percent of Sb2O3. The optical flint glass has a refractive index between 1.81 and 1.90, an Abbe number between 25 and 33, and no PbO and As2O3, and has perfect optical property and excellent devitrification resistance.

Owner:CDGM OPTICAL GLASS

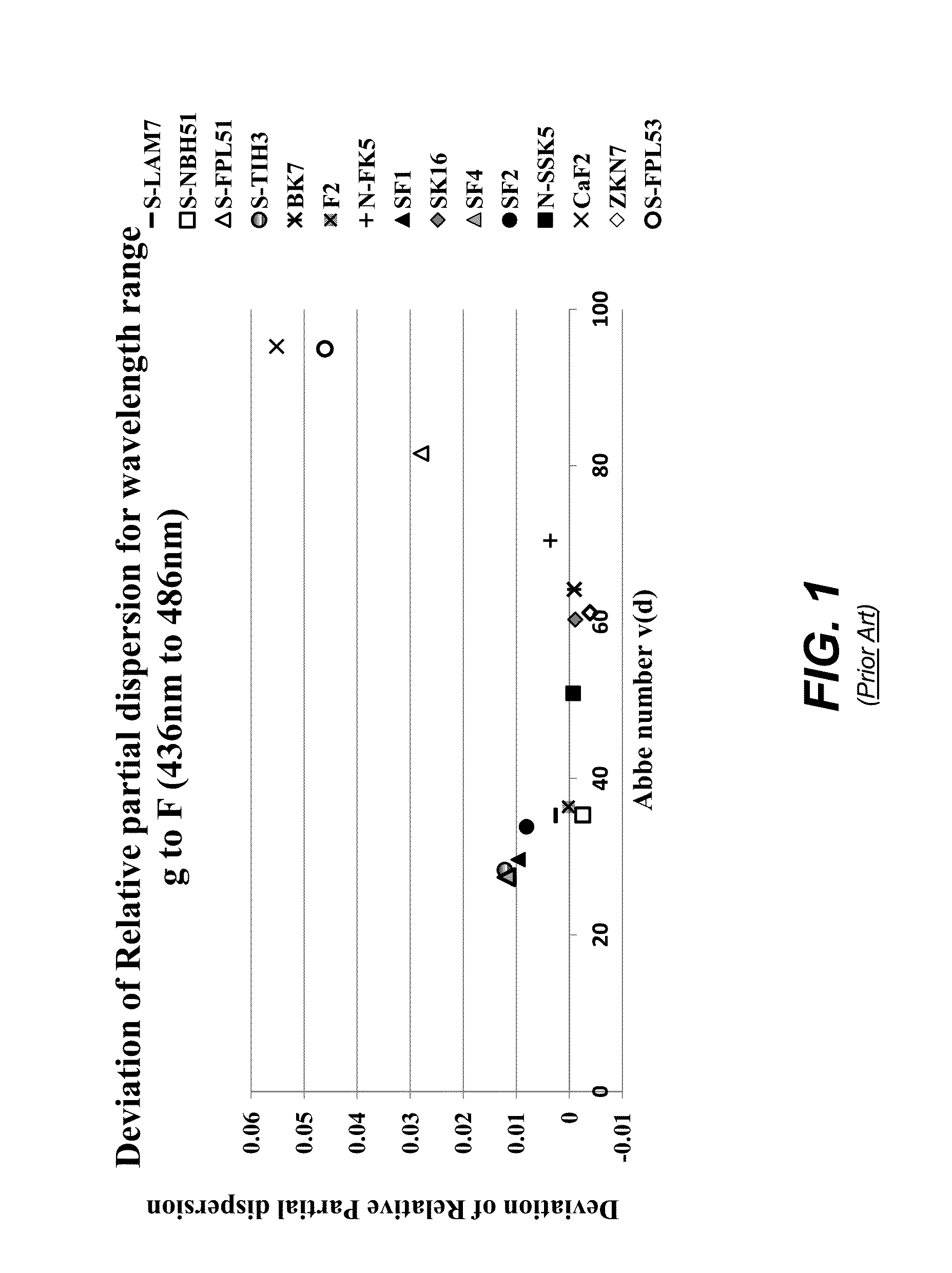

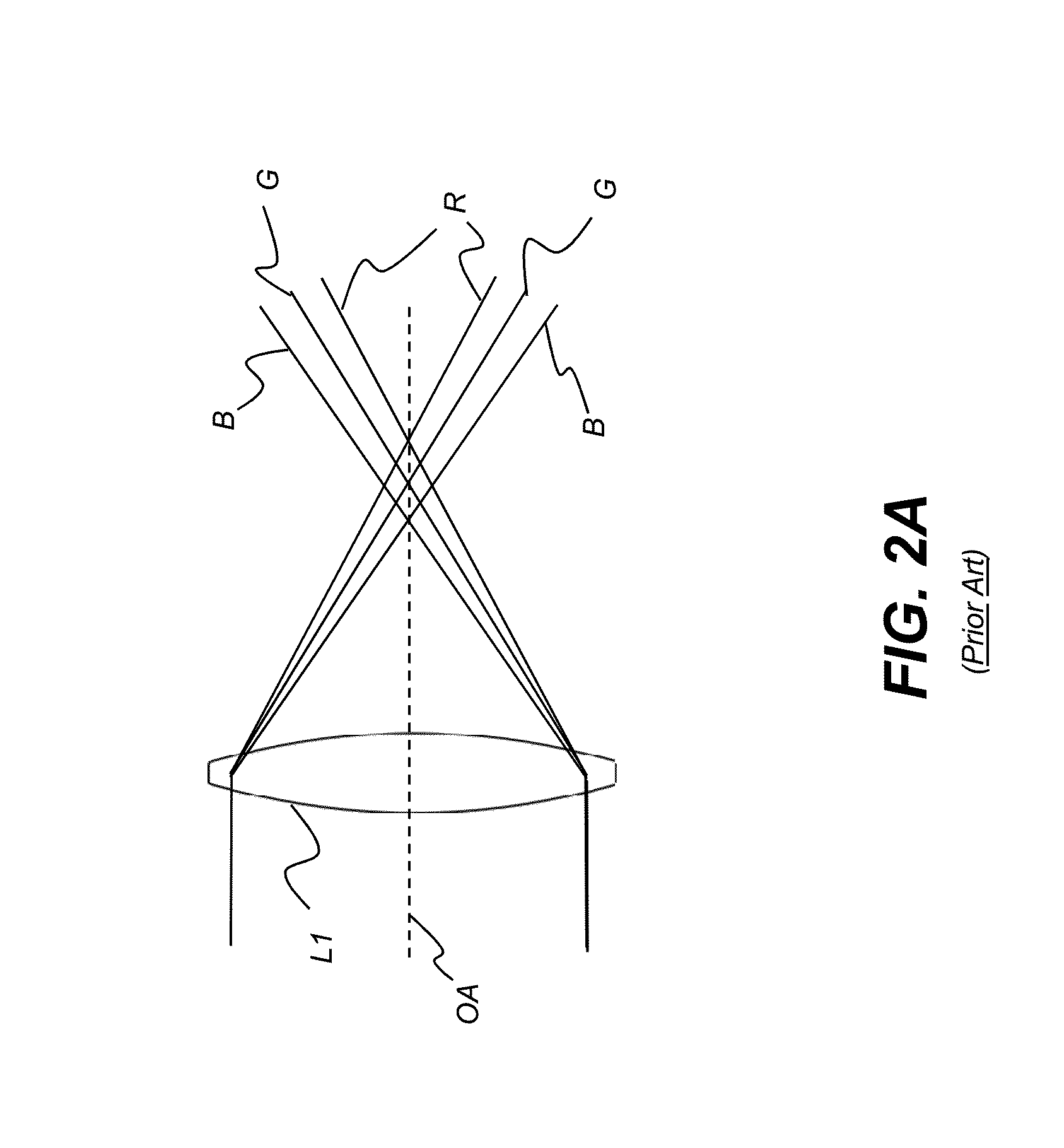

Apochromatic optical design

An apochromatic imaging system has an object-side lens group having at least an object-side lens element with positive refractive power and formed from a flint glass material with deviation of relative dispersion −0.013<ΔPg,F<+0.013 and an Abbe number less than 50. A middle lens group has at least a second lens element and a third lens element, wherein, one of the second and third lens elements has deviation of relative dispersion −0.013<ΔPg,F<0.013 and the other of the second and third lens elements has deviation of relative dispersion 0.013<ΔPg,F<0.04. An image-side lens group has at least a fourth lens element.

Owner:BIETRY JOSEPH R

Heavy lanthanum flint glass prefabricated part, optical element and optical instrument thereof

ActiveCN111285602AExcellent temperature coefficient of refraction indexExcellent crystallization upper limit temperatureOptical elementsOptical instrumentationRefractive index

The invention discloses heavy lanthanum flint glass, a prefabricated part and an optical element thereof, and an optical instrument. The heavy lanthanum flint glass comprises, by weight, 12-30% of SiO2, 10-25% of Ln2O3 (the content of Ln2O3 is the total content of La2O3, Gd2O3, Y2O3 and Yb2O3), 10.5-40% of TiO2+Nb2O5+WO3+Bi2O3, 20-35% of RO and 0.5-10% of ZrO2, wherein RO is one or more of BaO, CaO, MgO and SrO, the refractive index (nd) of the glass is 1.86-1.92, the abbe number (vd) of the glass is 25-30, and the crystallization upper limit temperature is 1200 DEG C or below. The glass can meet the optical performance required by a precise instrument, and is excellent in crystallization resistance, low in refractive index temperature coefficient, good in chemical stability and high in transmittance.

Owner:CDGM OPTICAL GLASS

Projection lens assembly and projection apparatus

InactiveUS20150260966A1Eliminate chromatic aberrationReduce manufacturing costOptical elementsCamera lensRefractive index

A projection lens assembly is provided. The projection lens assembly includes a first lens group and a second lens group. The first lens group has a negative dioptre and is disposed adjacent to an object side. The first lens group includes a first lens having a negative dioptre. The second lens group has a positive dioptre and is disposed adjacent to an image side. The second lens group includes a second lens having a positive dioptre and a third lens having a negative dioptre. The second lens is disposed between the first lens and the third lens. The third lens is made of heavy flint glass. A temperature coefficient of refractive index of the second lens is represented by D0, and −3.0×e−5≦D0≦−6.0×e−7. A projection apparatus is also provided.

Owner:QISDA OPTRONICS (SUZHOU) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com