Dense lanthanum flint glass

A lanthanum flint glass and glass technology is applied in the field of high-refractive glass, which can solve the problems of increased manufacturing cost, insufficient anti-devitrification performance of glass, devitrification, etc., and achieves the effect of high transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

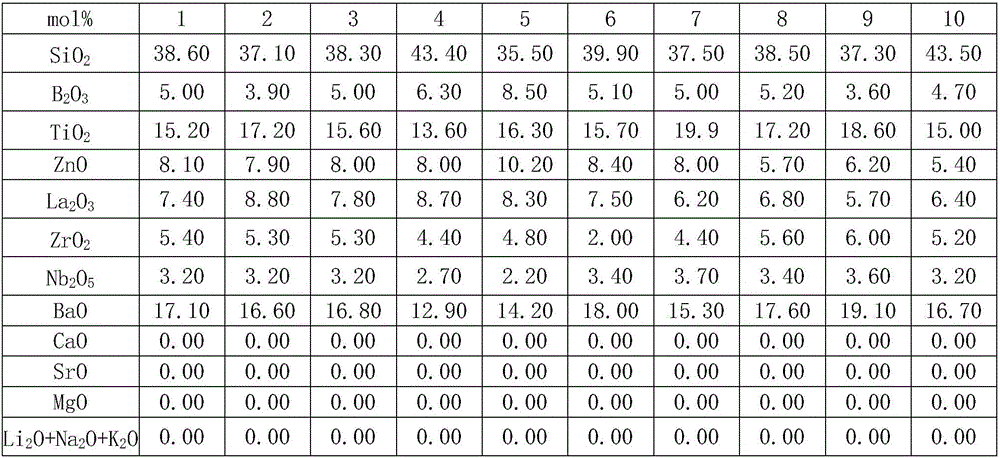

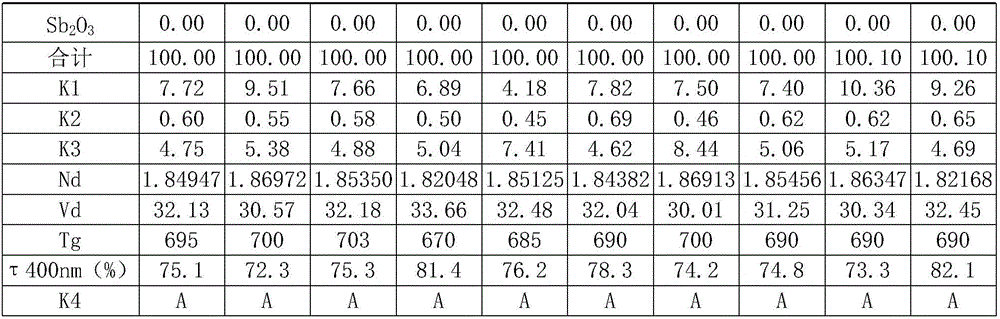

Examples

Embodiment Construction

[0024] The respective components of the glass of the present invention will be described below, and the contents of the respective components are expressed in mol % unless otherwise specified.

[0025] In the glass of the present invention, SiO 2 It is the network former of glass and the main component of glass skeleton. SiO 2 The content is closely related to the anti-devitrification performance, transmittance, refractive index and dispersion of the glass. If its content is less than 25%, the refractive index and dispersion of the glass will not meet the design expectations, and at the same time, the anti-devitrification performance and transmittance of the glass will be greatly reduced; if its content is higher than 50%, the glass's solubility, anti- The crystallization performance will decrease, and the refractive index and dispersion will not meet the design expectations. Therefore, in the present invention, SiO 2 The content is set at 25-50%, preferably 30-45%, more p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| Abbe number | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com