Optical glass square blank preparation device and blank preparation method

A technology for optical glass and preparation equipment, which is applied in glass manufacturing equipment, glass production, glass molding, etc., which can solve the problems of difficulty in ensuring the appearance size and internal stripe quality, and difficulty in solidification and fixing, so as to avoid large pieces of cutting process, reduce cutting material waste, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A method for preparing an optical glass square blank, characterized in that it comprises the following steps:

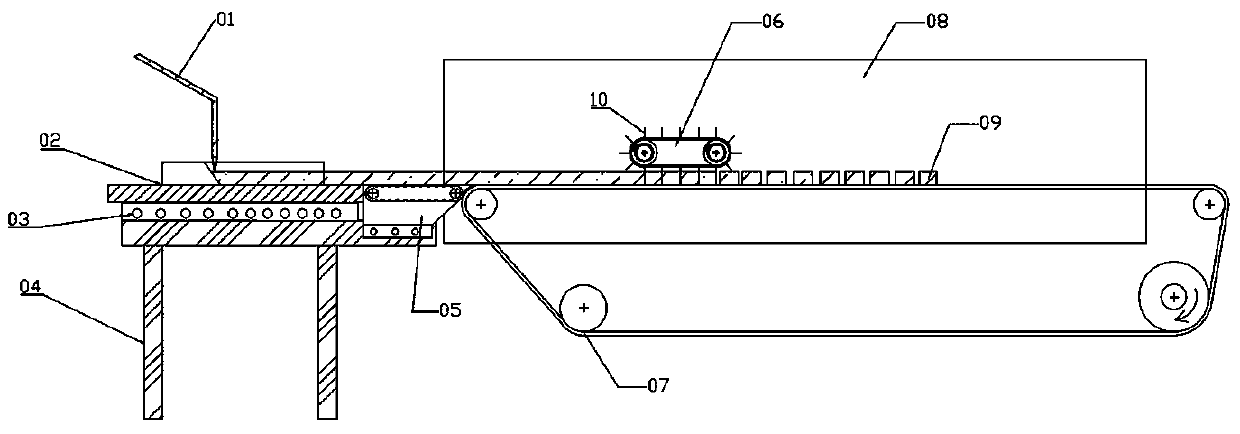

[0024] a. The molten glass melted and homogenized in the kiln is diverted into the forming mold 02 through the leakage pipe 01; the groove width of the forming mold 02 is an integer multiple of the width of the square blank to be processed;

[0025] b. The mold cooling device 03 assists the forming mold 02 to conduct conduction cooling on the bottom and both sides of the molten glass, and gradually solidifies the molten glass by absorbing the heat on the surface of the molten glass, forming the molten glass to make glass strips of required thickness;

[0026] c. The glass strip is driven by the tractor 05 to run towards the entrance of the annealing furnace, and at the same time blows and cools, and the glass strip is drawn to the conveyor belt 07 in the annealing furnace 08;

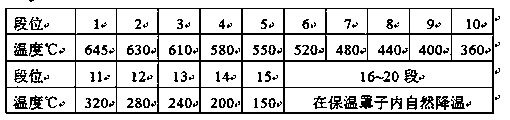

[0027] d. After the glass strip enters the annealing furnace 08 with a certain temp...

Embodiment

[0031] Example: A certain grade of optical glass, the specific gravity is 3.66 grams per cubic centimeter, the glass softening temperature is 655°C, and the output of the kiln is 135 liters per day. Use the device and method of this invention to prepare the process of optical glass square blank as follows:

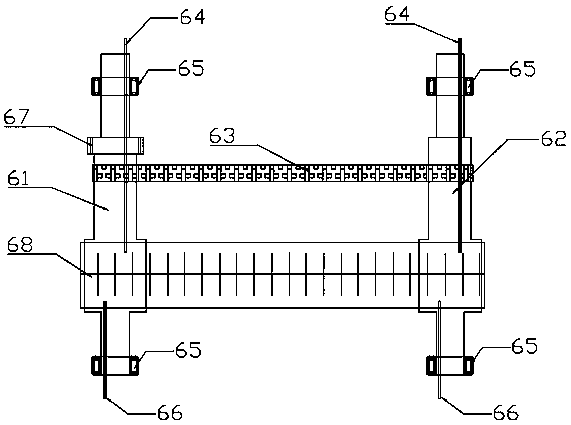

[0032] The homogenized molten glass flows into the forming mold 02 through the leakage pipe 01, and the forming mold 02 limits the width of the glass molten to 32mm; the tractor 05 pulls the glass strip at a speed of 346mm per minute, and the glass The thickness of the liquid is controlled to about 8.5mm. The mold cooling device 03 assists the forming mold 02 to conduct conduction cooling on the bottom and both sides of the molten glass to promote the solidification of the glass into strips. The glass strip is drawn onto the annealing furnace 08, and advances synchronously with the conveyor belt 07 of the annealing furnace 08. The press-cutting machine 06 is installed at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com