Glass material and preparing method and application thereof

A technology of glass material and weight percentage is applied in the preparation of the glass material, in the field of lead-free low-temperature glass materials, and can solve the problems of high alkali metal content, large difference in expansion coefficient, mismatch of expansion coefficient between glass and ZnO ceramics, etc. Achieve high transparency, good chemical stability, and solve the effects of human harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

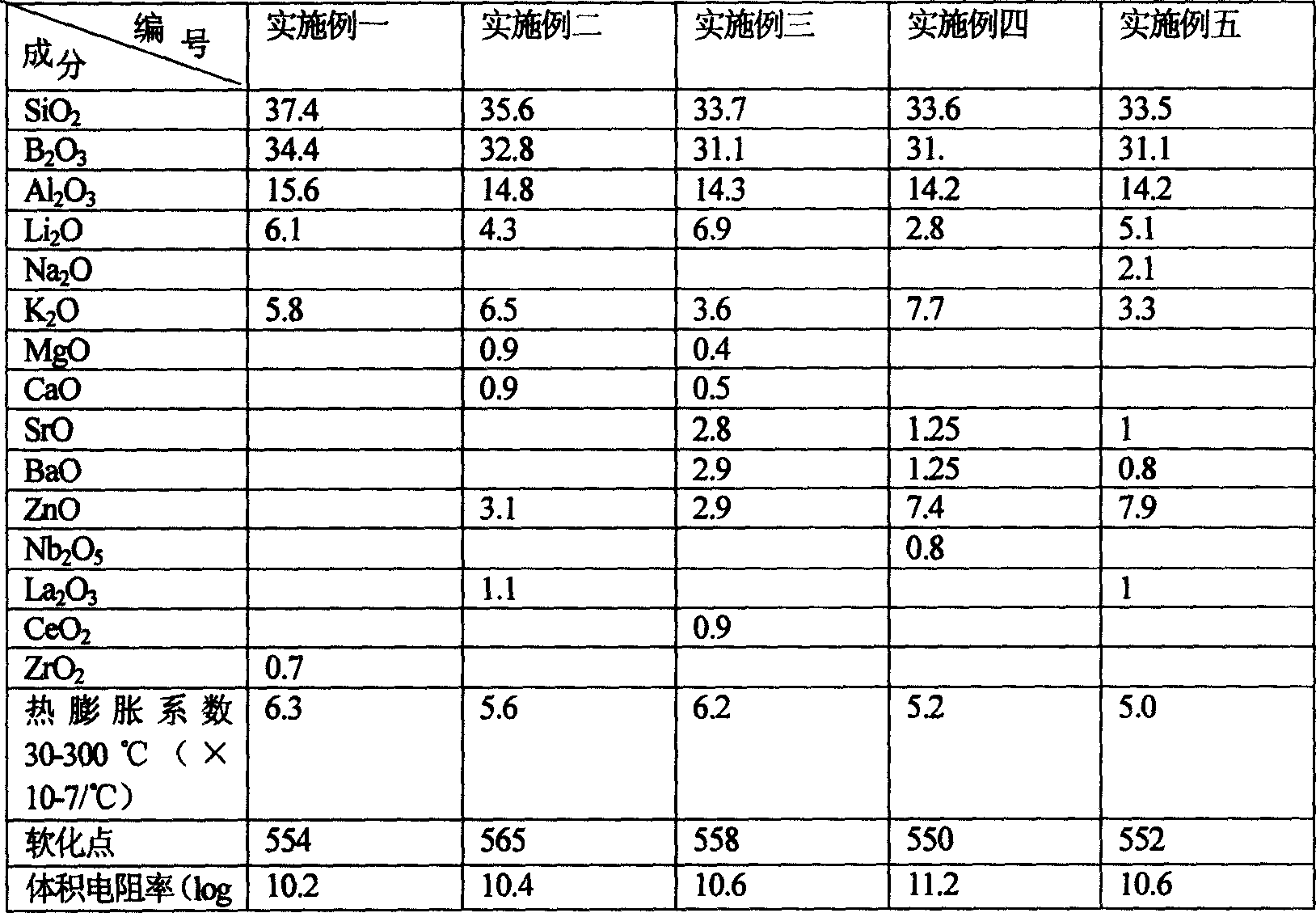

[0019] Table I

[0020]

[0021] ρ, Ω·m)

[0022] In order to evaluate the properties of the glass, the individual samples shown in the above table were prepared by the following method:

Embodiment 1

[0023] Embodiment one, accurately weigh the analytically pure chemically pure chemical raw material according to the ratio in the table: SiO 2 、H 3 BO 3 、Al 2 o 3 , Li 2 CO 3 、K 2 CO 3 , and rare earth oxide ZrO 2 , fully mixed, can be stirred with a stirrer for 4 hours, put into a platinum crucible, put it into a high-temperature furnace, melt normally at a temperature of 1150°C for 2 hours, pour the melt into a mold at 200°C, and anneal at an annealing temperature of 460°C for 12 hours Hour. The manufactured glass is used for testing various performance indexes of the glass after processing.

Embodiment 2

[0024] Embodiment two, accurately weigh analytically pure chemical pure chemical raw material according to the ratio in the table: SiO 2 、H 3 BO 3 、Al 2 o 3 , Li 2 CO 3 、K 2 CO 3 , CaCO 3 , (MgCO 3 ) 4 ·Mg(OH) 2 ·5H 2 O, ZnO and La 2 o 3 , fully mixed, can be stirred with a stirrer for 4 hours, put into a platinum crucible, put into a high temperature furnace, melt normally at a temperature of 1150°C for 3 hours, pour the melt into a mold at 200°C, and anneal at an annealing temperature of 460°C for 15 Hour. The manufactured glass is used for testing various performance indexes of the glass after processing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com