Patents

Literature

12083 results about "Pressure sensitive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

As the name "pressure-sensitive" indicates, the degree of bond is influenced by the amount of pressure which is used to apply the adhesive to the surface. Surface factors such as smoothness, surface energy, removal of contaminants, etc. are also important to proper bonding.

Electrosurgical instrument

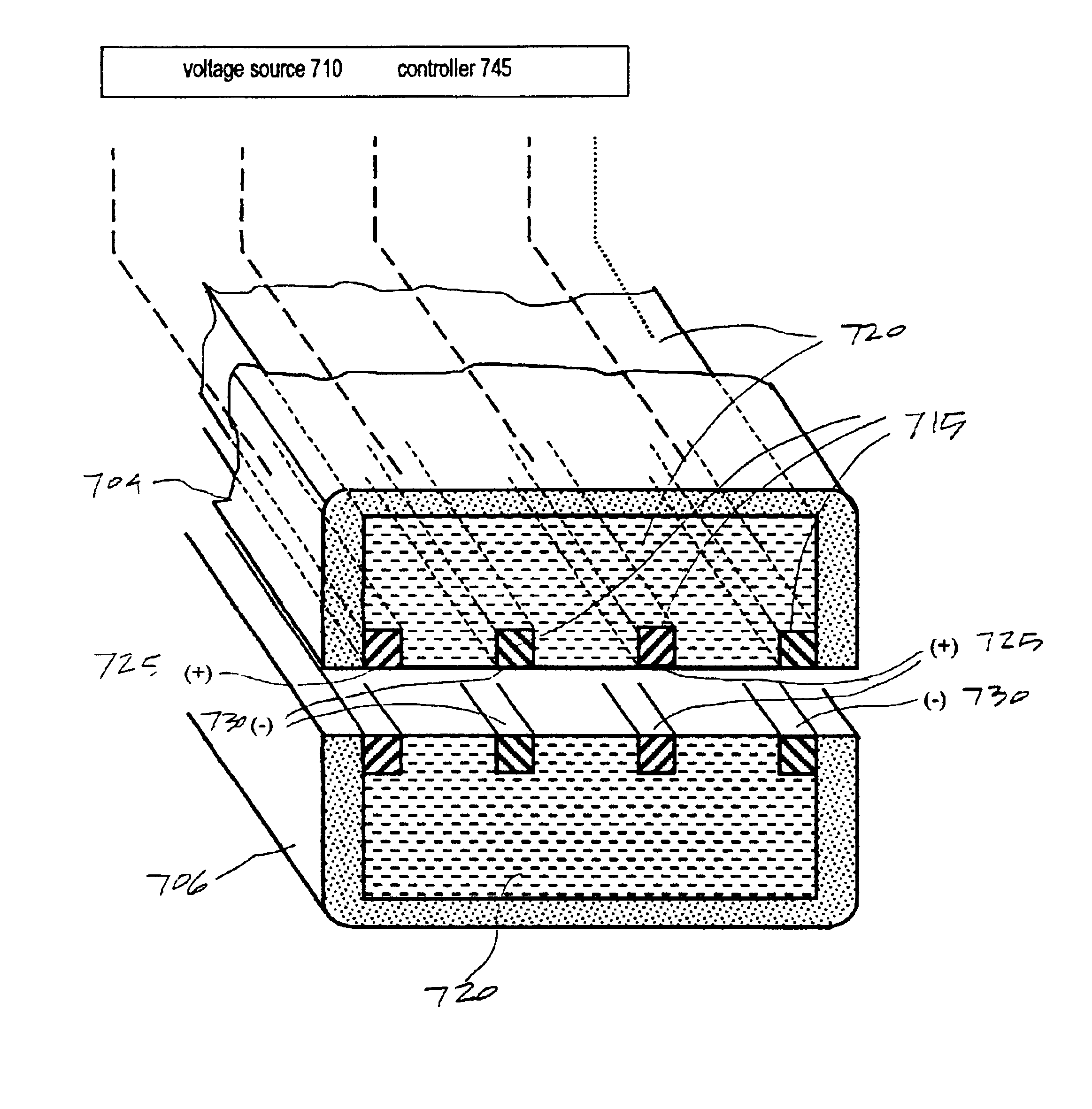

InactiveUS6926716B2Prevent any substantial dehydrationEnergy efficiencySurgical instruments for heatingSurgical forcepsElectrical resistance and conductanceVoltage source

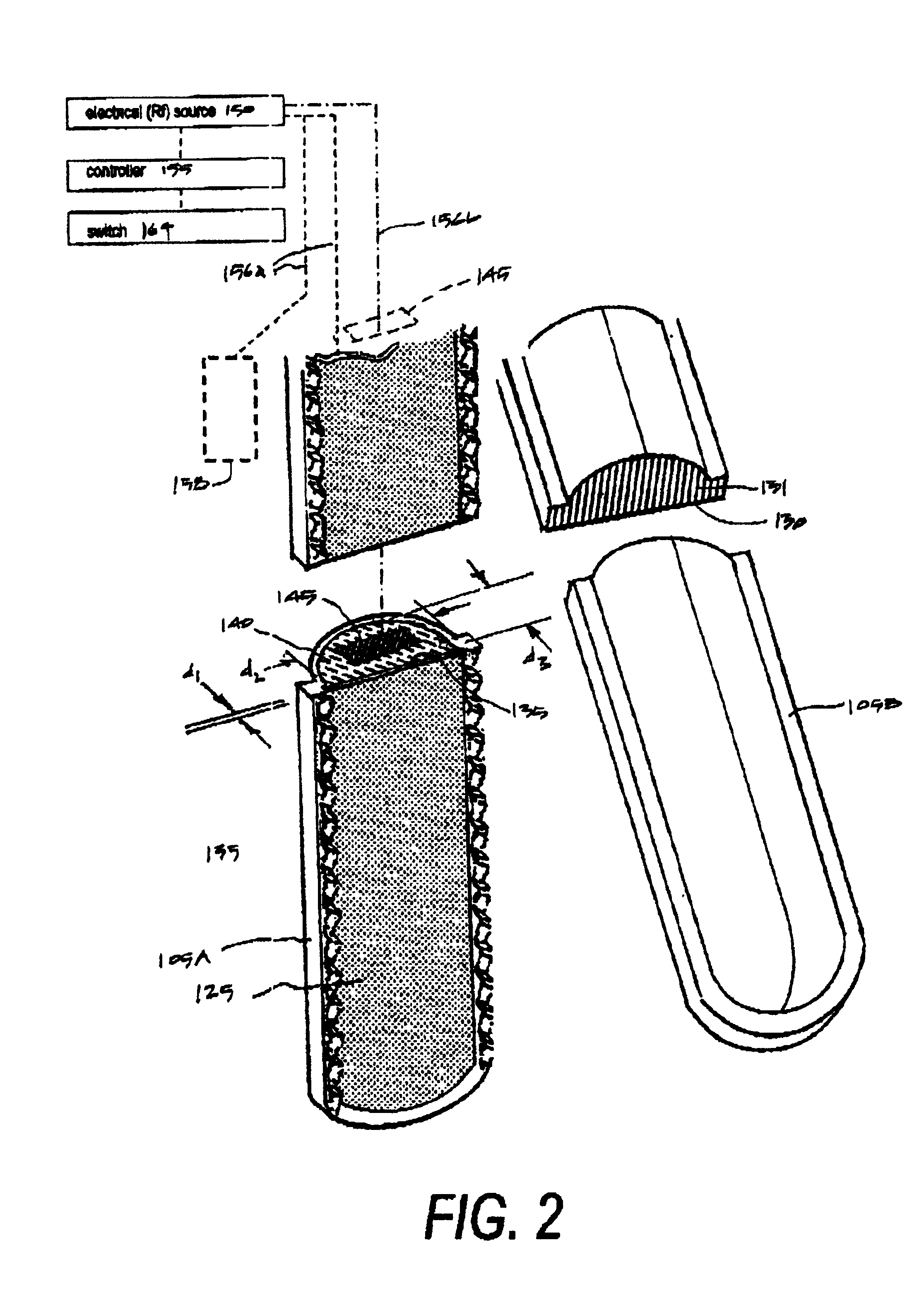

A working end of a surgical instrument that carries first and second jaws for delivering energy to tissue. In a preferred embodiment, at least one jaw of the working end defines a tissue-engagement plane that contacts the targeted tissue. The cross-section of the engagement plane reveals that it defines (i) a first surface conductive portion or a variably resistive matrix of a temperature-sensitive resistive material or a pressure-sensitive resistive material, and (ii) a second surface portion coupled to a fixed resistive material that coupled in series or parallel to a voltage source together with the first portion. In use, the engagement plane will apply active Rf energy to ohmically heat the captured tissue until the point in time that a controller senses an electrical parameter of the tissue such as impedance. Thereafter, the controller switches energy delivery to the second surface portion that is resistively heated to thereby apply energy to tissue by conductive heat transfer.

Owner:ETHICON ENDO SURGERY INC

Electrosurgical jaw structure for controlled energy delivery

InactiveUS6929644B2Prevent any substantial dehydrationEnergy efficiencySurgical instruments for heatingCoatingsThermal energyConductive materials

A working end of a surgical instrument that carries first and second jaws for delivering energy to tissue. In a preferred embodiment, at least one jaw of the working end defines a tissue-engagement plane that contacts the targeted tissue. The cross-section of the engagement plane reveals that it defines a surface conductive portion that overlies a variably resistive matrix of a temperature-sensitive resistive material or a pressure-sensitive resistive material. An interior of the jaw carries a conductive material or electrode that is coupled to an Rf source and controller. In an exemplary embodiment, the variably resistive matrix can comprise a positive temperature coefficient (PTC) material, such as a ceramic, that is engineered to exhibit a dramatically increasing resistance (i.e., several orders of magnitude) above a specific temperature of the material. In use, the engagement plane will apply active Rf energy to captured tissue until the point in time that the variably resistive matrix is heated to its selected switching range. Thereafter, current flow from the conductive electrode through the engagement surface will be terminated due to the exponential increase in the resistance of variably resistive matrix to provide instant and automatic reduction of Rf energy application. Further, the variably resistive matrix can effectively function as a resistive electrode to thereafter conduct thermal energy to the engaged tissue volume. Thus, the jaw structure can automatically modulate the application of energy to tissue between active Rf heating and passive conductive heating of captured tissue to maintain a target temperature level.

Owner:ETHICON ENDO SURGERY INC

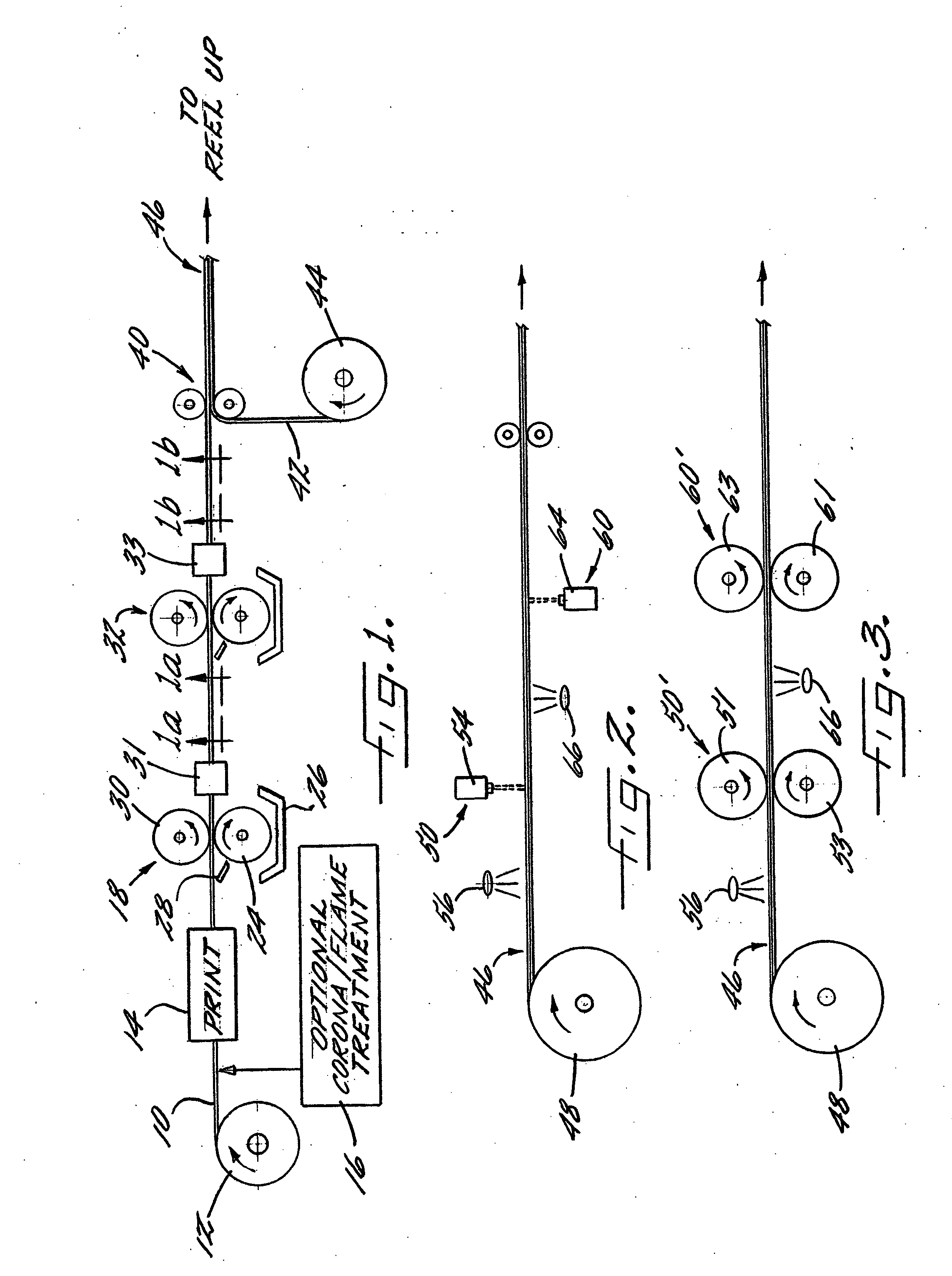

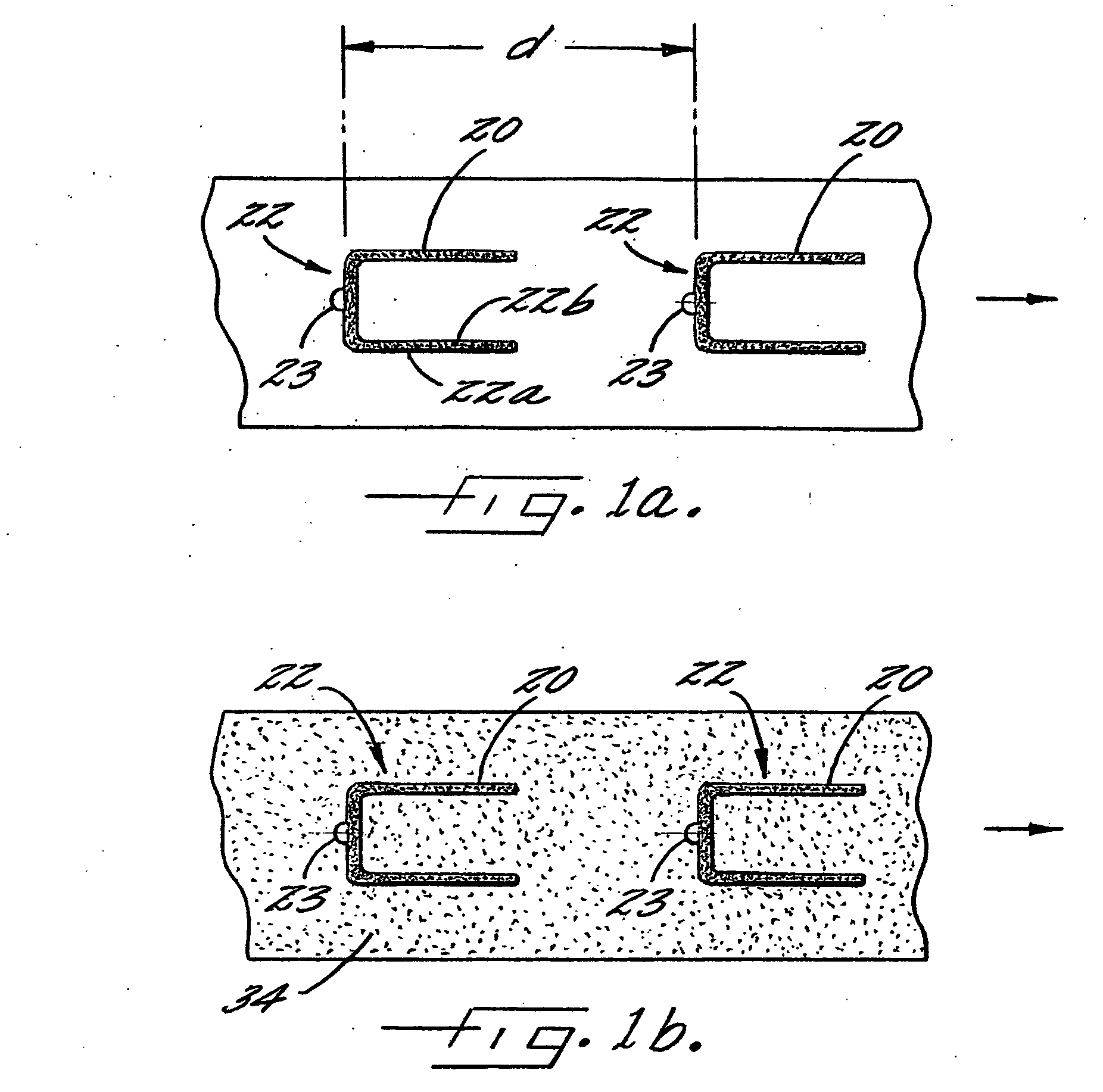

Air permeable pressure-sensitive adhesive tapes

InactiveUS20060154546A1Convenient to to manufactureEasy to useLamination ancillary operationsLayered product treatmentEngineeringPlastic film

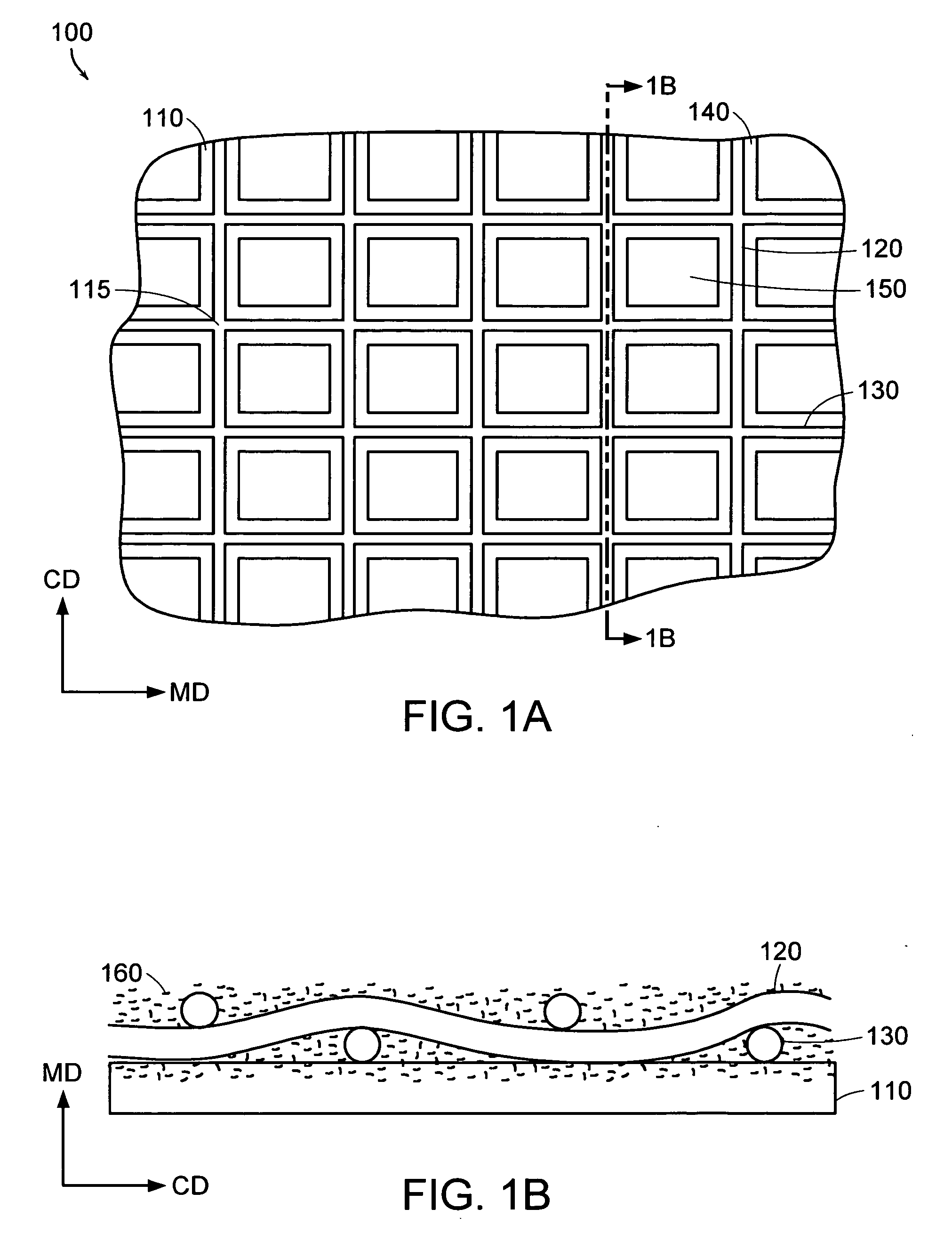

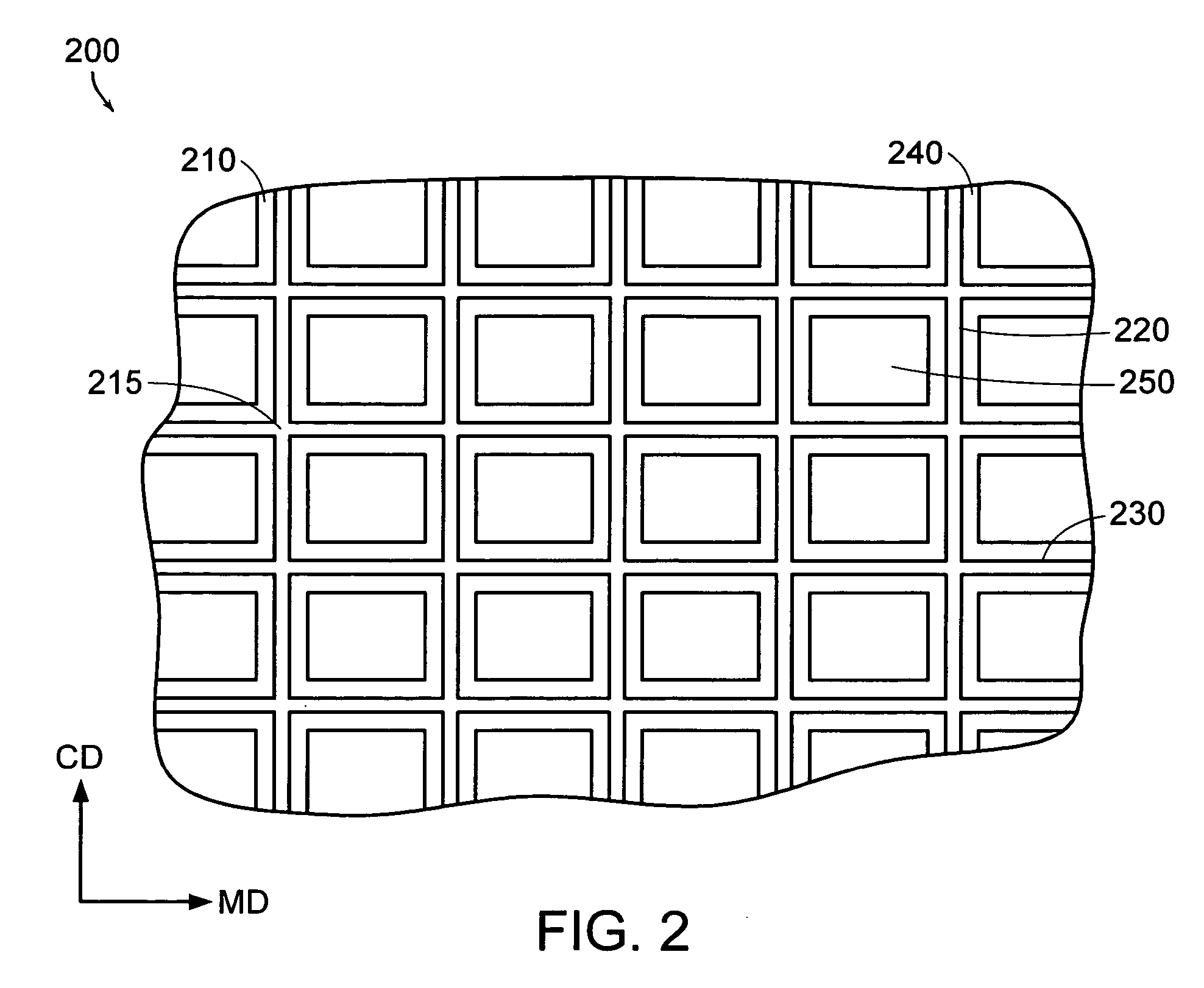

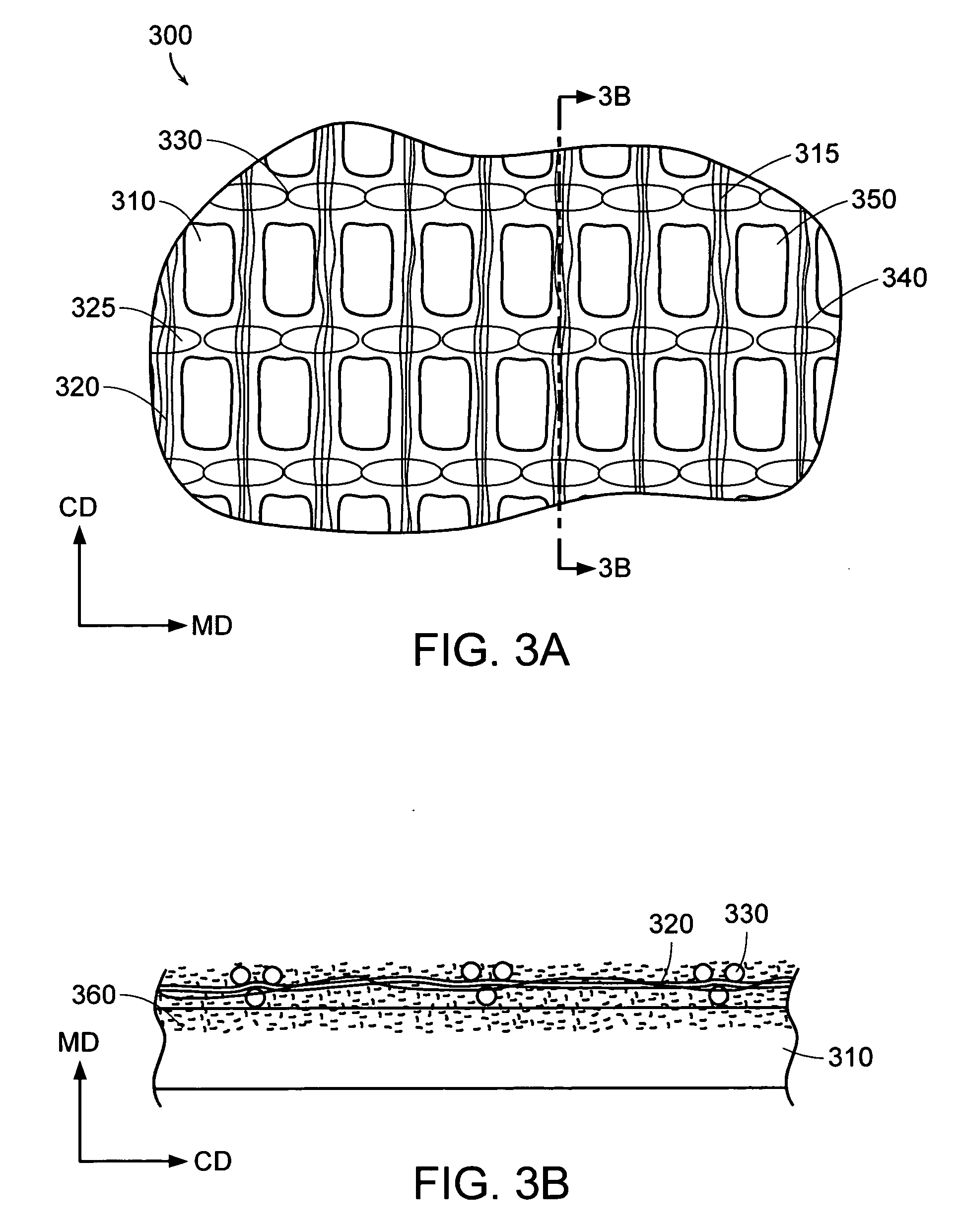

A vapor permeable article includes a porous backing substrate and an open fabric applied to one surface of the backing substrate. The open fabric has a greater porosity than that of the backing substrate. The open fabric may be a woven fabric comprising warp (MD) yarns and weft (CD) yarns, and the warp yarns may be of a lower denier than the weft yarns, so as to facilitate hand-tear of the assembled article. The open fabric is coated with an adhesive in such a manner that the open fabric remains porous and vapor permeable. The backing substrate can be a woven, knit or non-woven fabric, or a porous film, such as an apertured plastic film.

Owner:ANDOVER HEALTHCARE

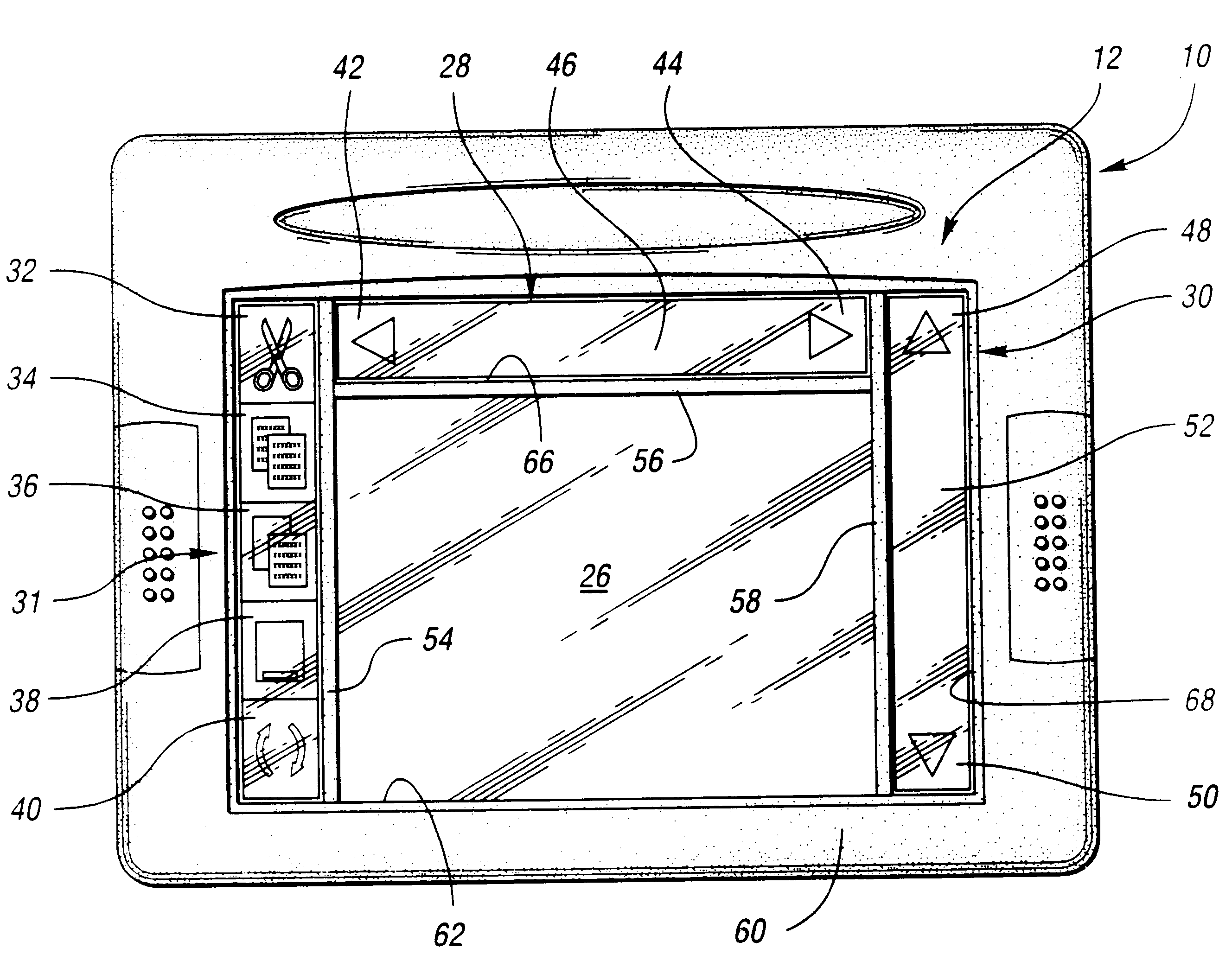

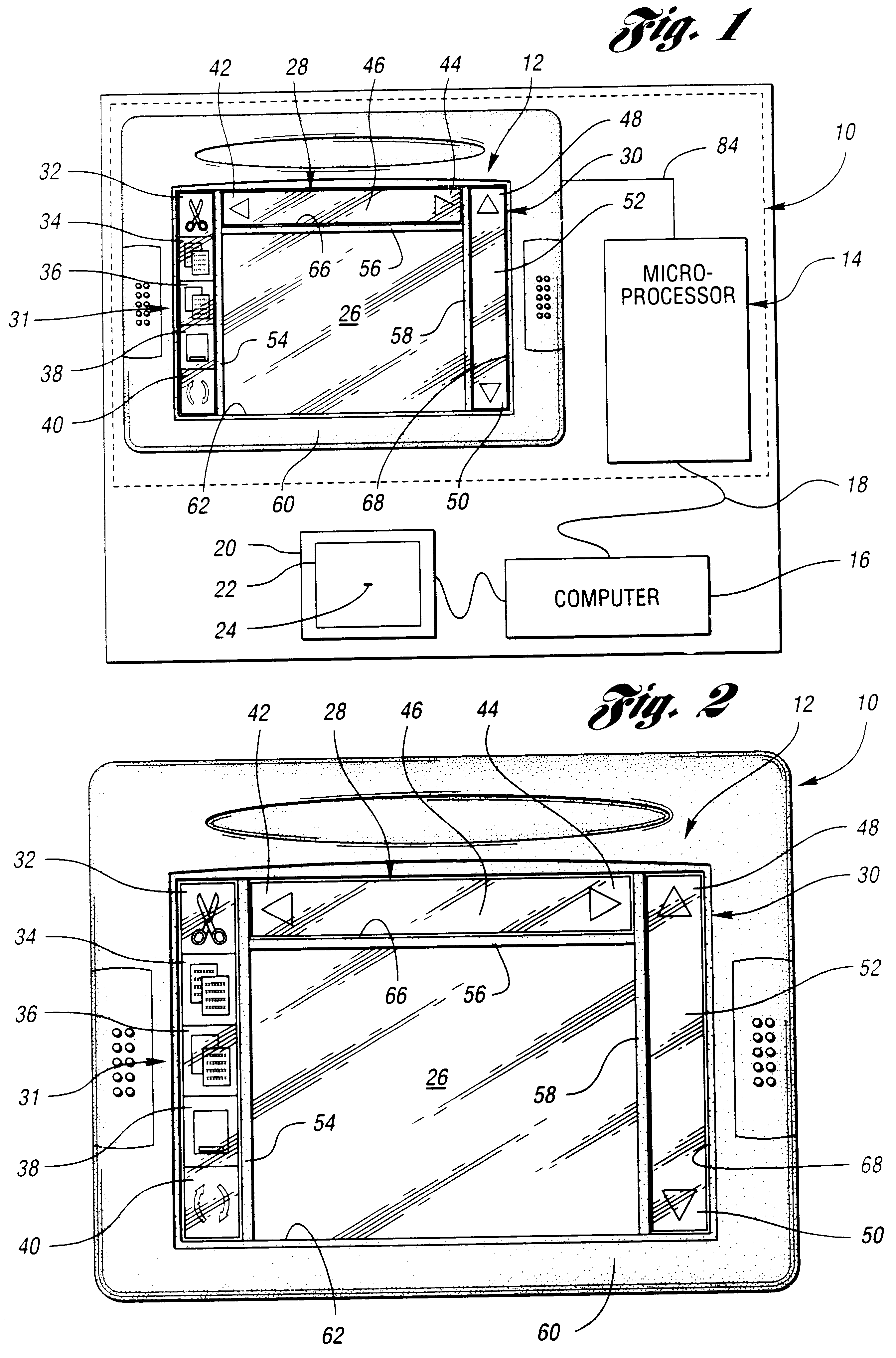

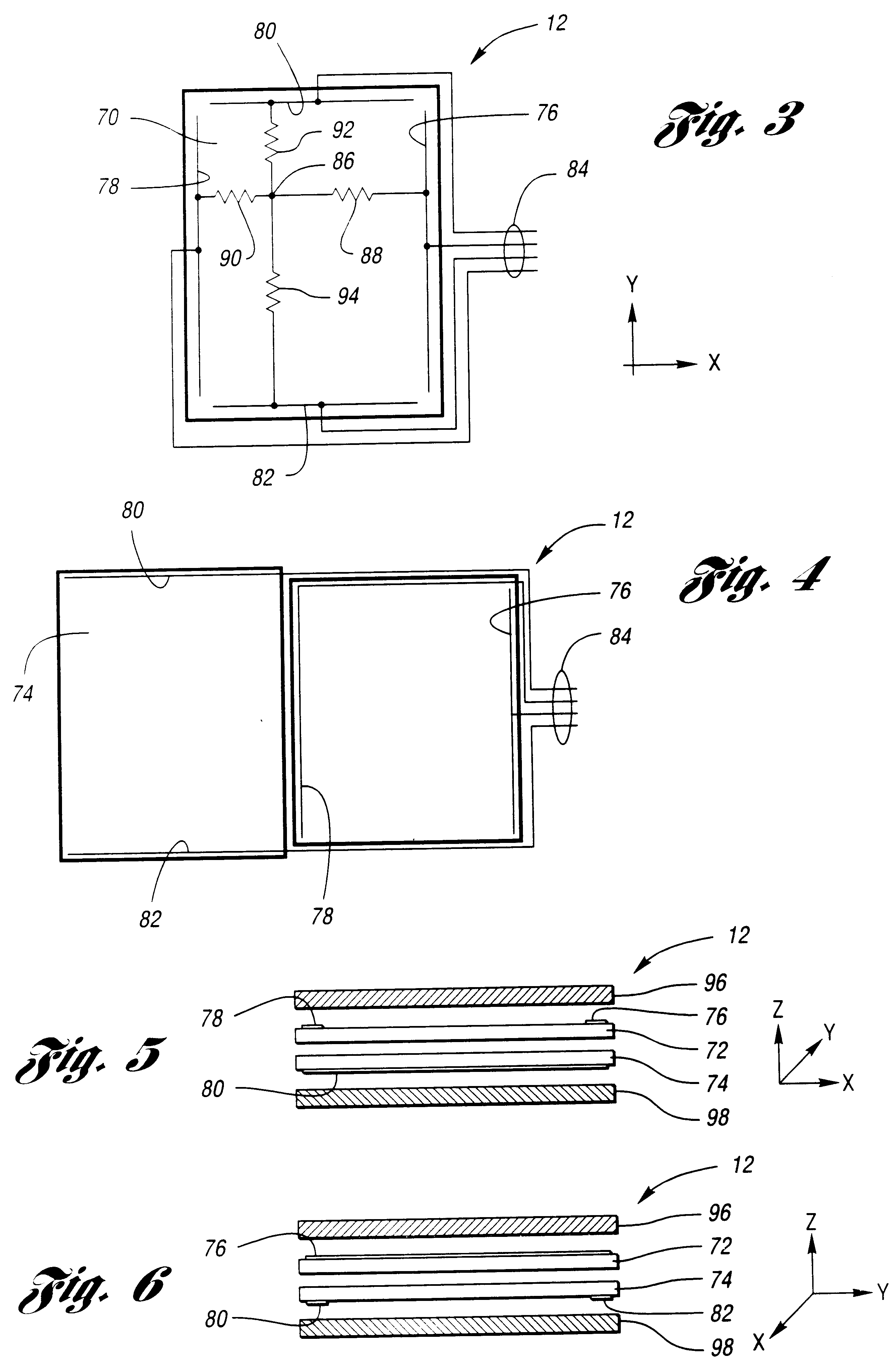

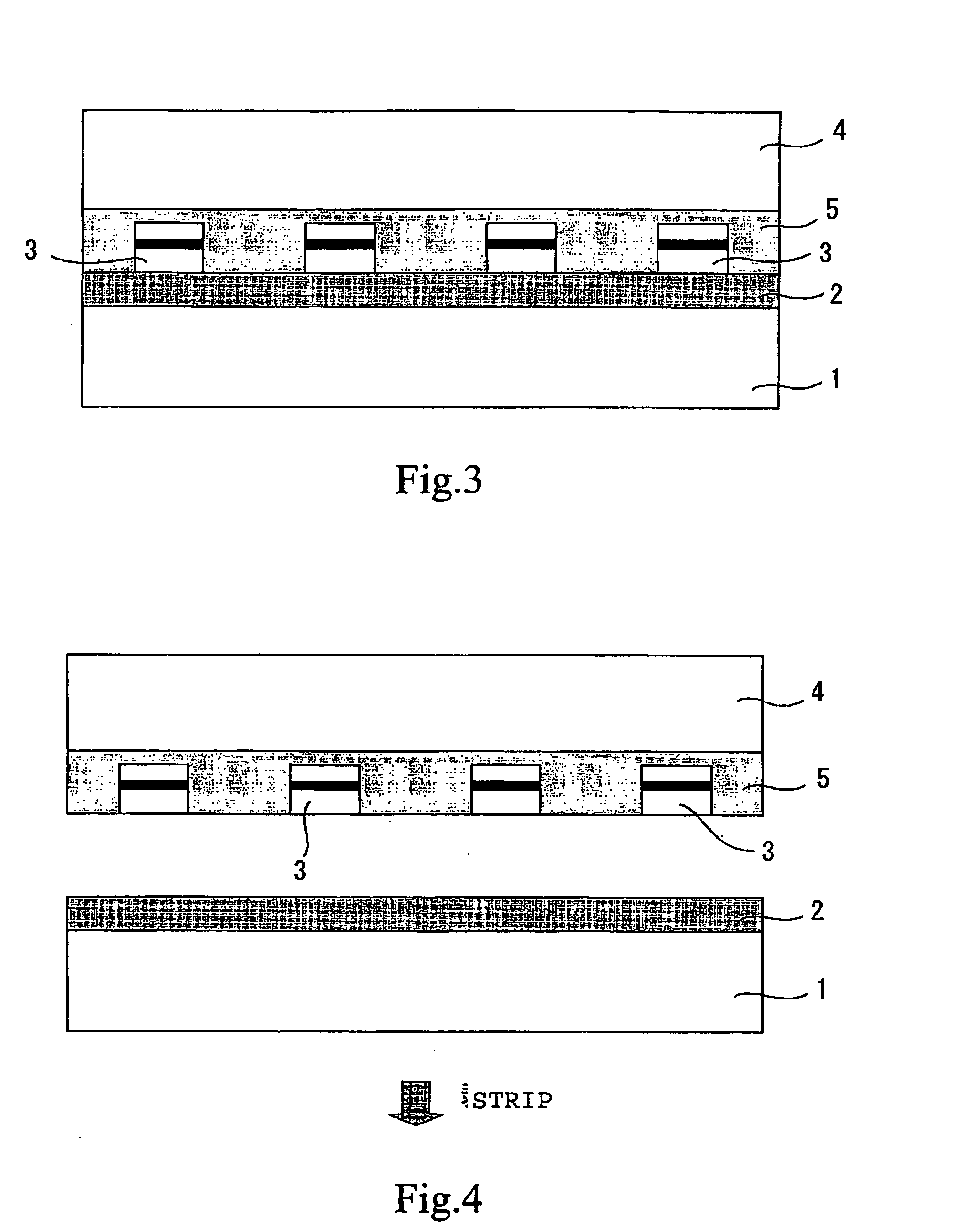

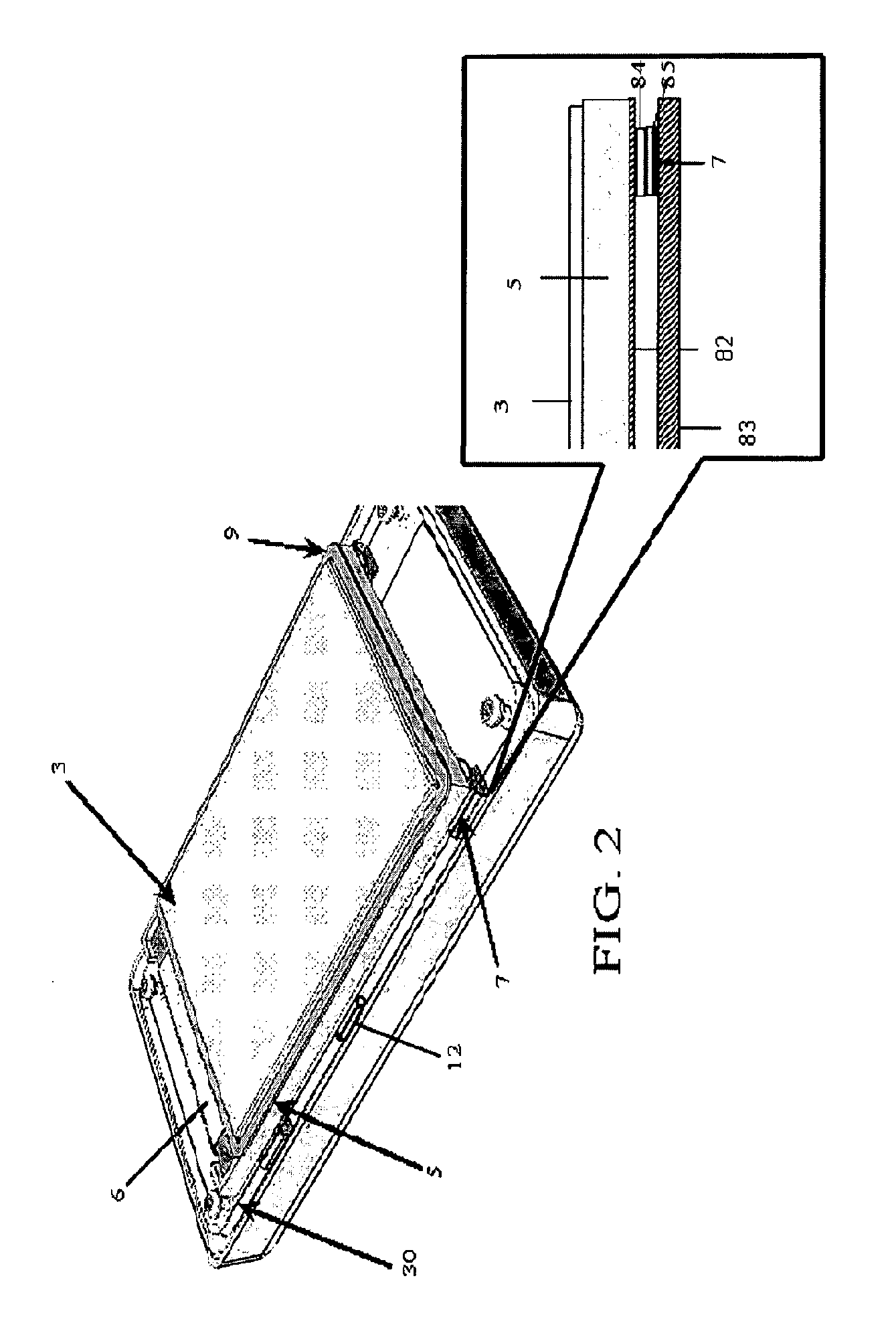

Force sensing semiconductive touchpad

InactiveUS6239790B1Minimum power consumptionLarge excursionTransmission systemsCathode-ray tube indicatorsPressure sensitiveEngineering

A touchpad assembly and method for providing a signal to a computer indicative of the location and applied pressure of an object touching the touchpad assembly is provided. The touchpad assembly includes X and Y position and pressure sensitive semiconductor resistance sensor layers. The X and Y sensors have a pair of spaced apart X and Y conductive traces running across opposite ends such that a resistance RX connects the pair of X traces and a resistance RY connects the pair of Y traces. The X and Y sensors come into contact at a contact point when an object asserts a pressure on the touchpad. The contact point is connected to each trace by a variable pressure resistance RZ associated with the X and Y sensors and variable position resistances of the X and Y resistances. First and second pair of timing capacitors are connected to respective ones of the pairs of X and Y traces. A microprocessor controls and monitors charging time of the capacitors to determine the position and asserted pressure of the object touching the touchpad.

Owner:INTERLINK ELECTRONICS

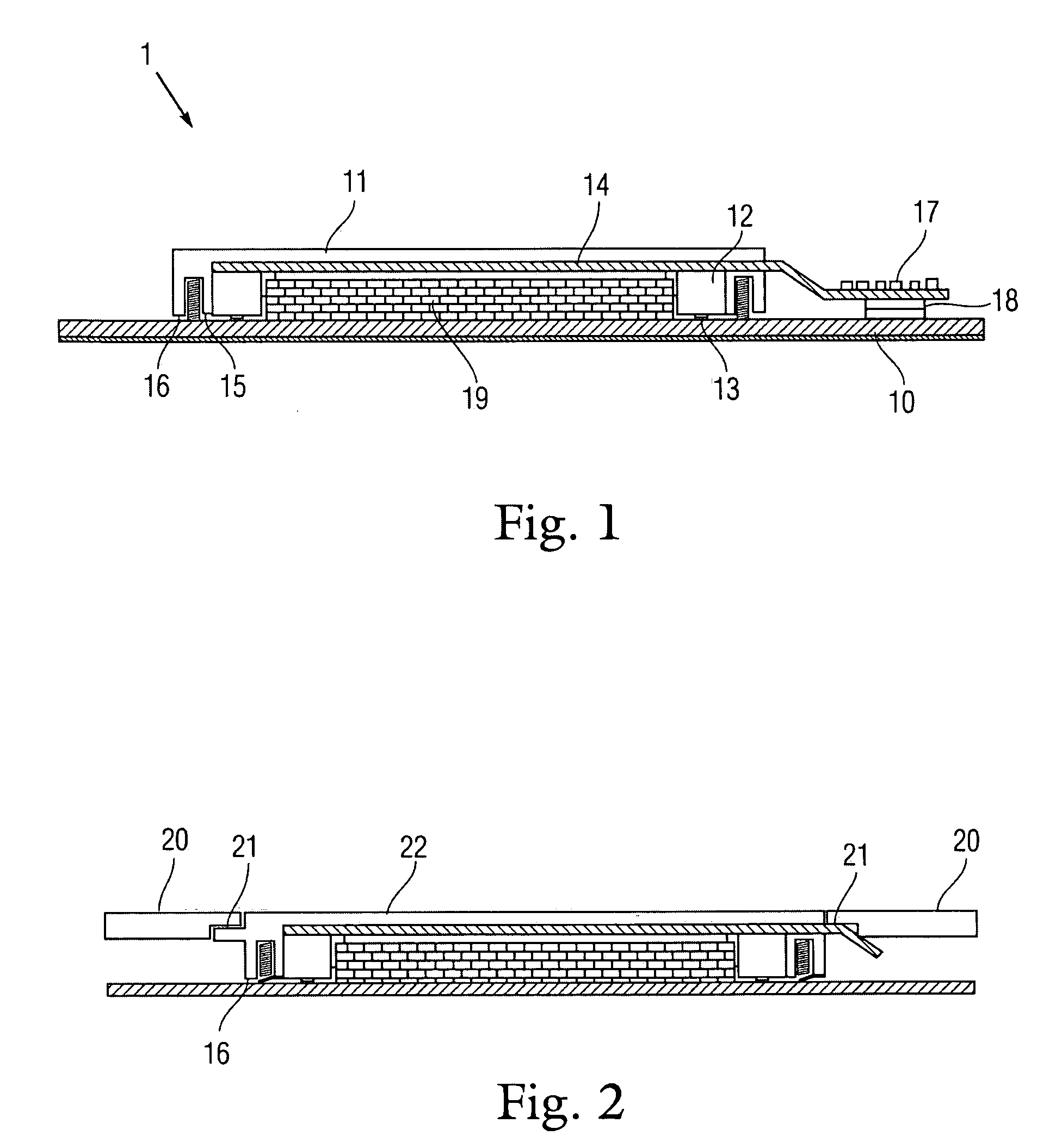

Three-Dimensional Adhesive Device Having a Microelectronic System Embedded Therein

InactiveUS20080275327A1Simple and inexpensive wayModerate viscosityWave amplification devicesLayered productsCapacitanceElectronic systems

Accordingly, the present invention relates to a three-dimensional adhesive device to be attached to the body surface of a mammal comprising a microelectronic sensing system characterized by(a) a three-dimensional adhesive body made of a pressure sensitive adhesive having an upper surface and a bottom surface;(b) a microelectronic system embedded in the body of the pressure sensitive adhesive;(c) one or more cover layer(s) attached to the upper surface; and(d) optionally a release liner releasable attached to the bottom surface of the adhesive device.Suitably the microelectronic system is a microelectronic sensing system capable of sensing physical input such as pressure, vibration, sound, electrical activity (e.g. from muscle activity), tension, blood-flow, moisture, temperature, enzyme activity, bacteria, pH, blood sugar, conductivity, resistance, capacitance, inductance or other chemical, biochemical, biological, mechanical or electrical properties.

Owner:BRAEMAR MFG +2

Compositions with Improved Adhesion to Low Surface Energy Substrates

InactiveUS20080113094A1Excellent low surface energyImprove adhesionSynthetic resin layered productsOrganic dyesOligomerEnd-group

Acrylic-based pressure sensitive adhesives are modified with a telechelic hydrocarbon oligomer. The oligomer comprises a hydrocarbon polymer chain or backbone and a functional end group, e.g., an oligomer prepared from a mono hydroxyl polybutadiene polymer and toluene diisocyanate. The oligomer attaches to the acrylic backbone of the polymer as a pendant group and in a preferred embodiment, the oligomer is mixed with the PSA shortly before the PSA is coated.

Owner:BRADY WORLDWIDE INC

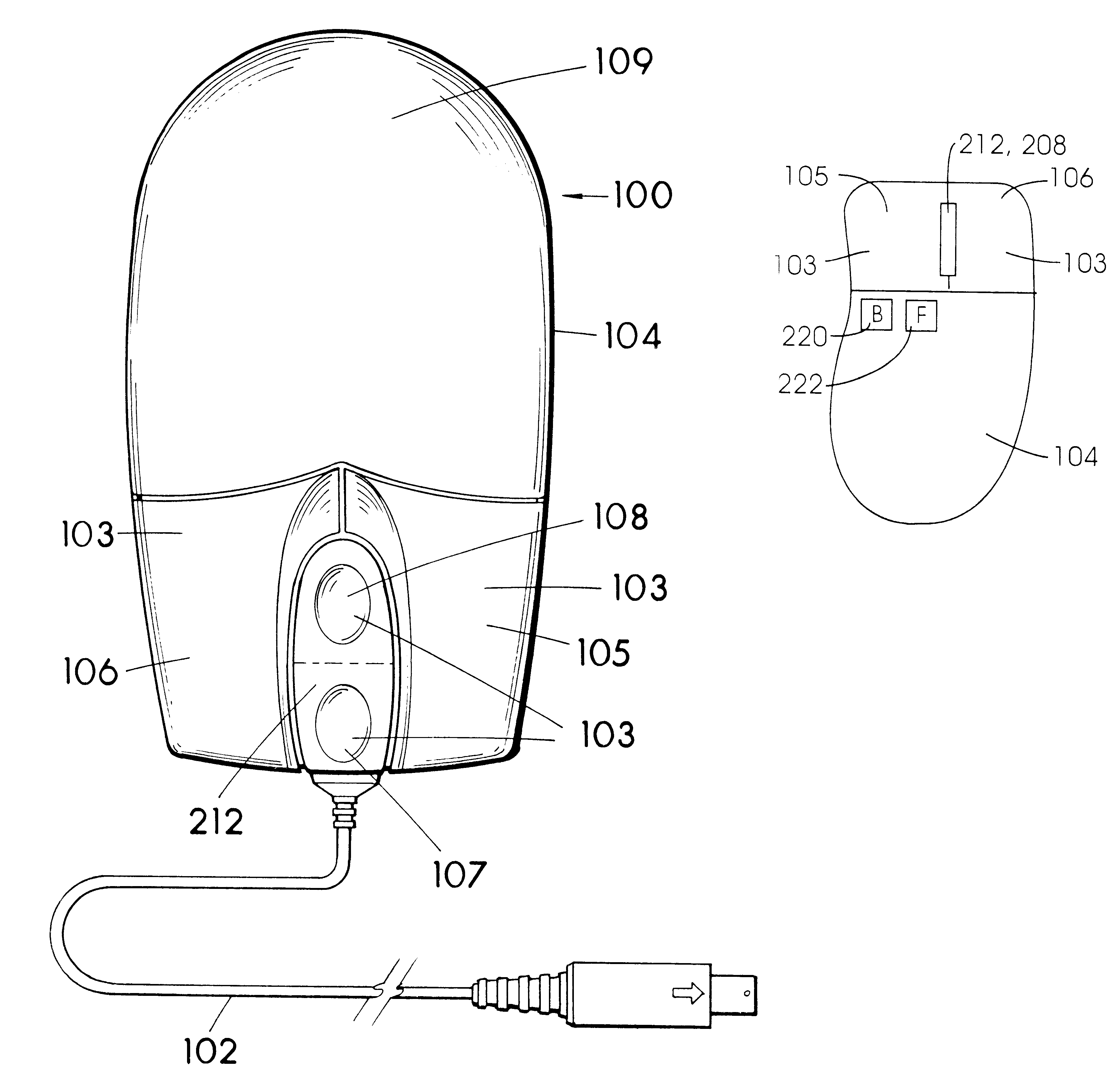

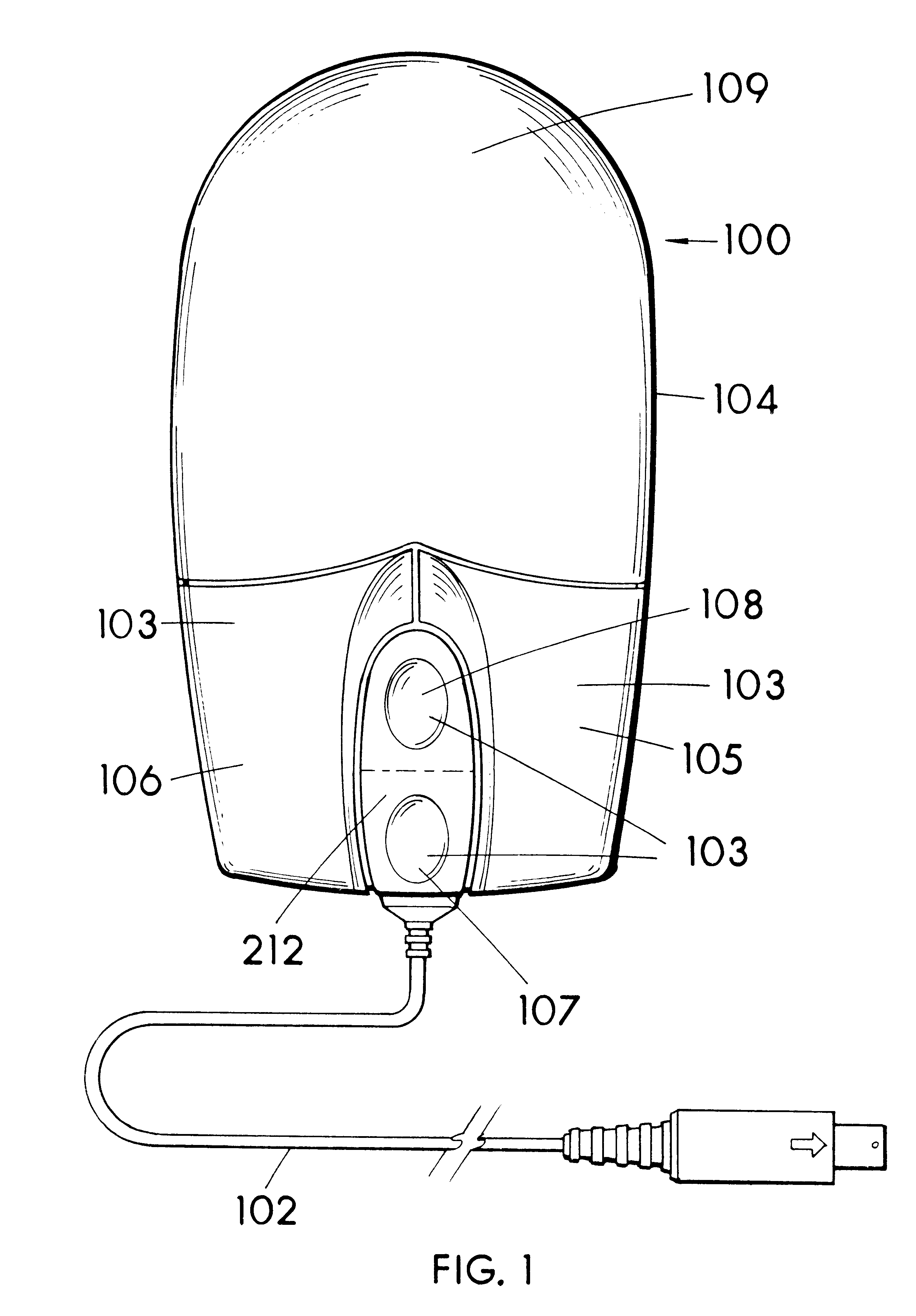

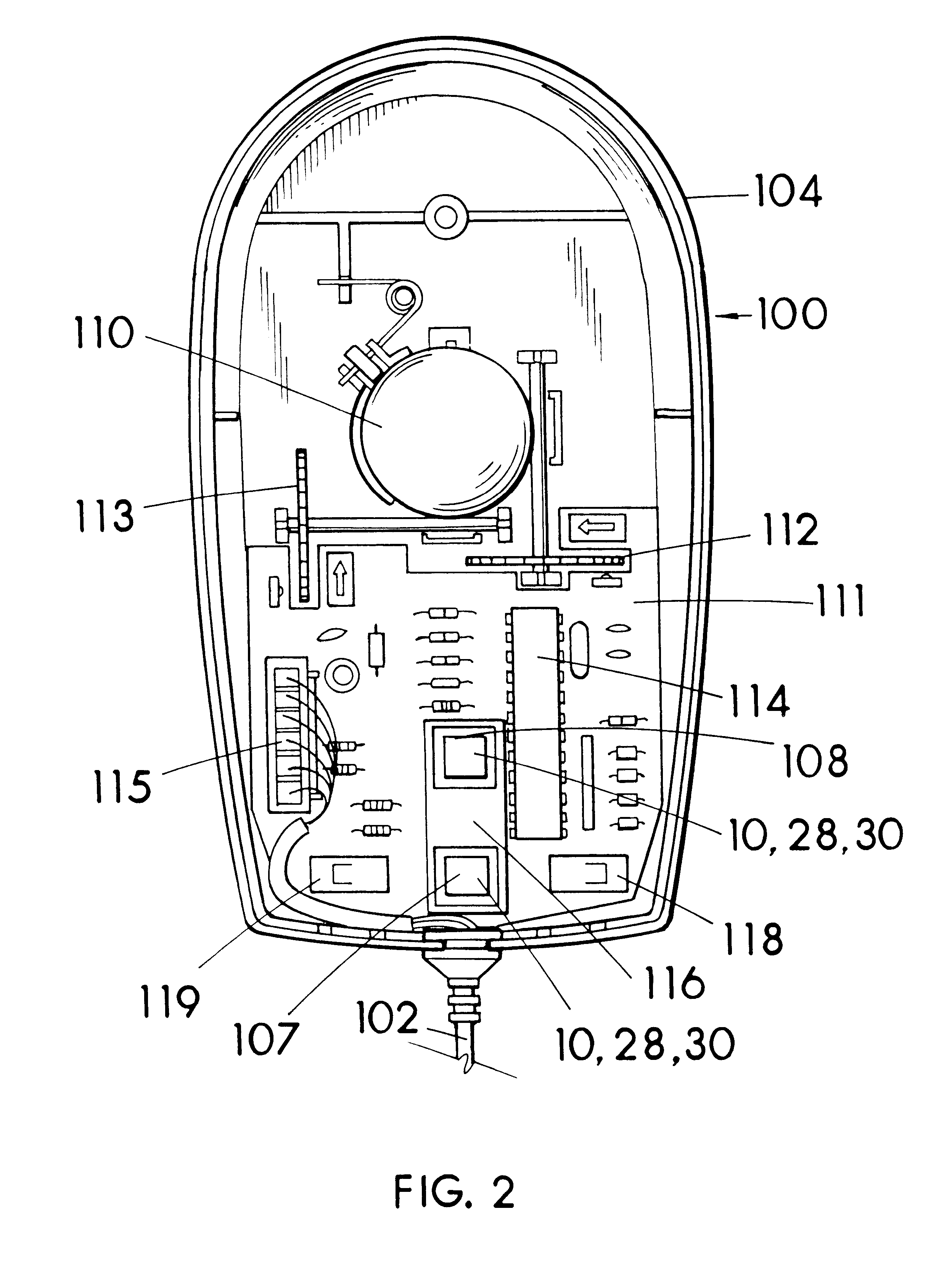

Computer mouse with enhance control button (s)

InactiveUS6198473B1Low costIncrease volumeCathode-ray tube indicatorsInput/output processes for data processingElectricityEngineering

A desktop operated computer control mouse including a housing, electronic circuitry within the housing, a user manipulable rotatable ball for pointing control, a plurality of finger depressible buttons exposed on the housing and interfacing with sensors electrically connected with the circuitry. At least some of the finger depressible buttons are for user selection of signals to be sent to the computer for window or screen scroll control, and are associated with sensor(s) which are pressure-sensitive analog sensors structured for varying electrical conductance through at least three readable states or values. The readable states are dependant upon depressive pressure applied to the sensor(s) through the finger depressible button(s). The circuitry is structured to read the at least three readable states of the pressure-sensitive analog sensor(s) and to produce signals representing the state or value of the sensor(s). In one embodiment, the analog sensor(s) are elastomeric dome-cap sensor(s) including pressure-sensitive variable-conductance material positioned over proximal circuit elements of the circuitry. In another embodiment the sensors are packaged sensors including button depressible concavo-convexed conductive disks positioned to compress pressure-sensitive variable-conductance material forming at least a portion of an electrical flow path through the packaged sensor. The analog sensors are associated with window or screen scroll control, and provide user determinable scroll rates dependant upon pressure applied by the user through ergonomically correct finger depressible buttons. Methods of use and manufacture are also disclosed.

Owner:ANASCAPE +1

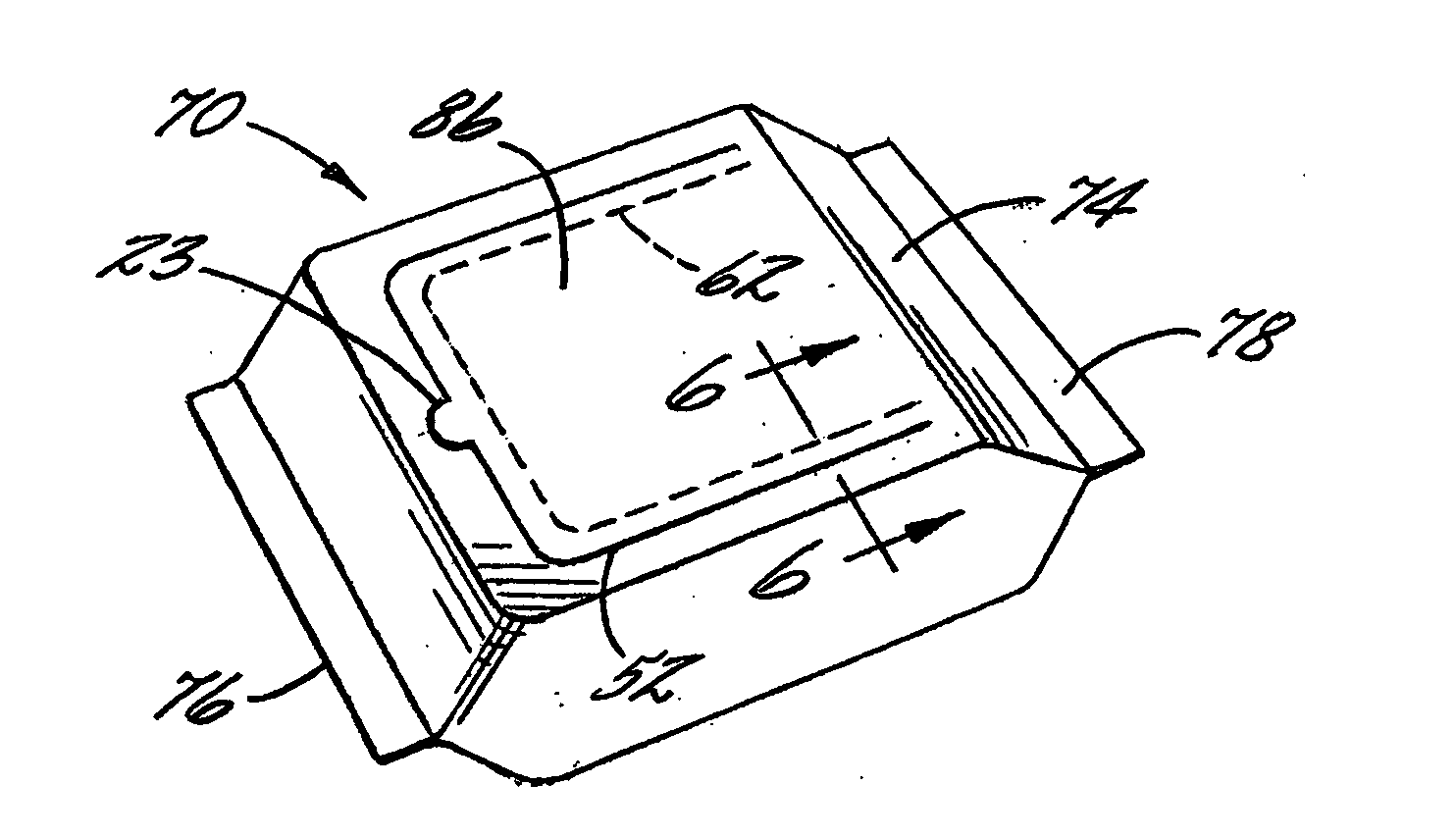

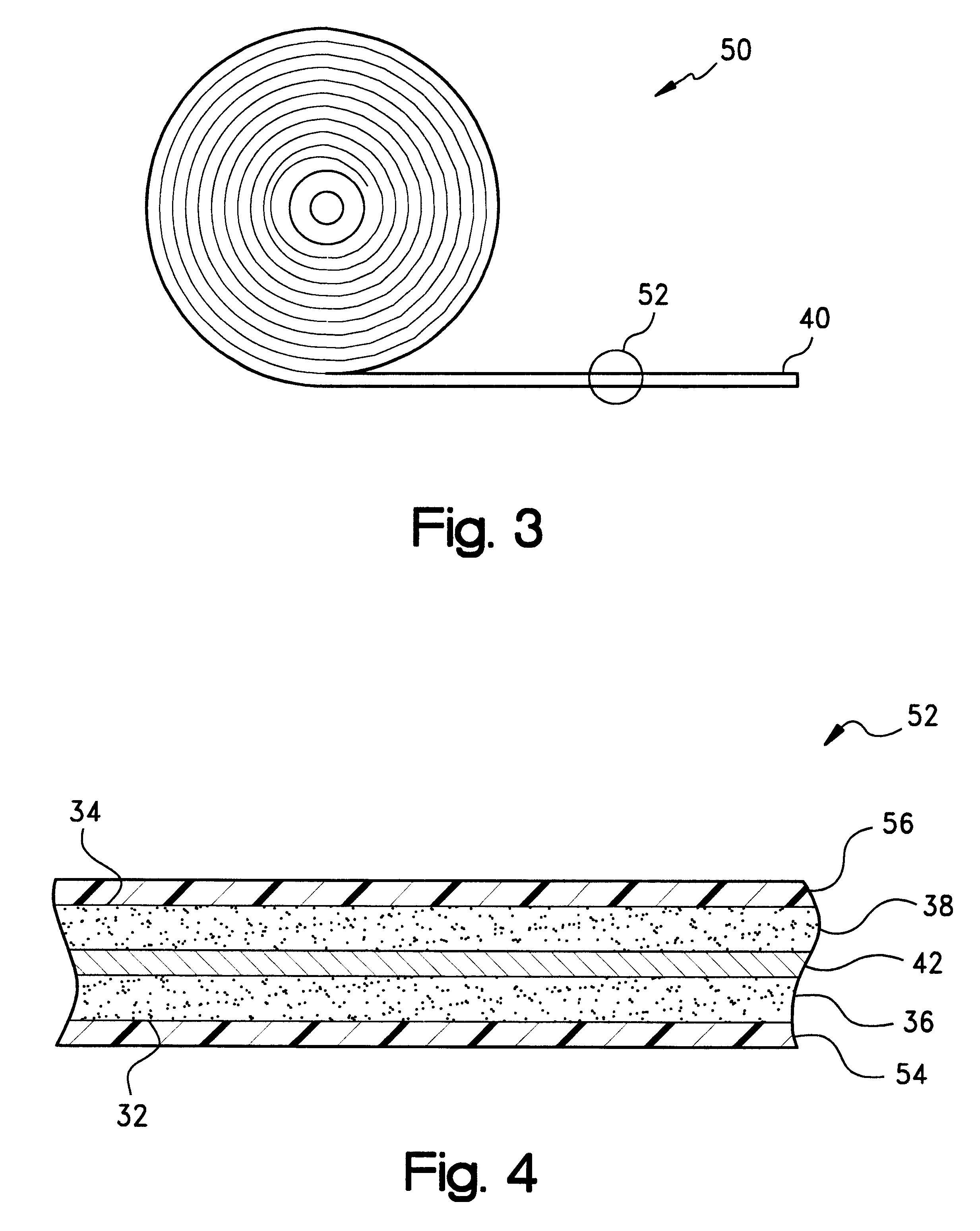

Flexible packaging structure with a built-in opening and reclose feature, and method for making same

ActiveUS20050276525A1Envelopes/bags making machineryWrappersMechanical engineeringPressure sensitive

A flexible packaging laminate is formed to have a built-in opening and reclose feature by forming the laminate as a two-part structure having an outer structure joined in face-to-face relation with an inner structure. Score lines are formed in both structures to enable an opening to be formed through the laminate by lifting an opening portion (e.g., a flap or the like) of the two structures out of the plane of the laminate. The score line through the outer structure defines a larger opening than the score line through the inner structure, such that a marginal region of the outer structure extends beyond the edge of the opening portion of the inner structure. A pressure-sensitive adhesive is used to re-adhere the marginal region to an underlying surface of the inner structure adjacent the opening through the laminate.

Owner:SONOCO DEV INC

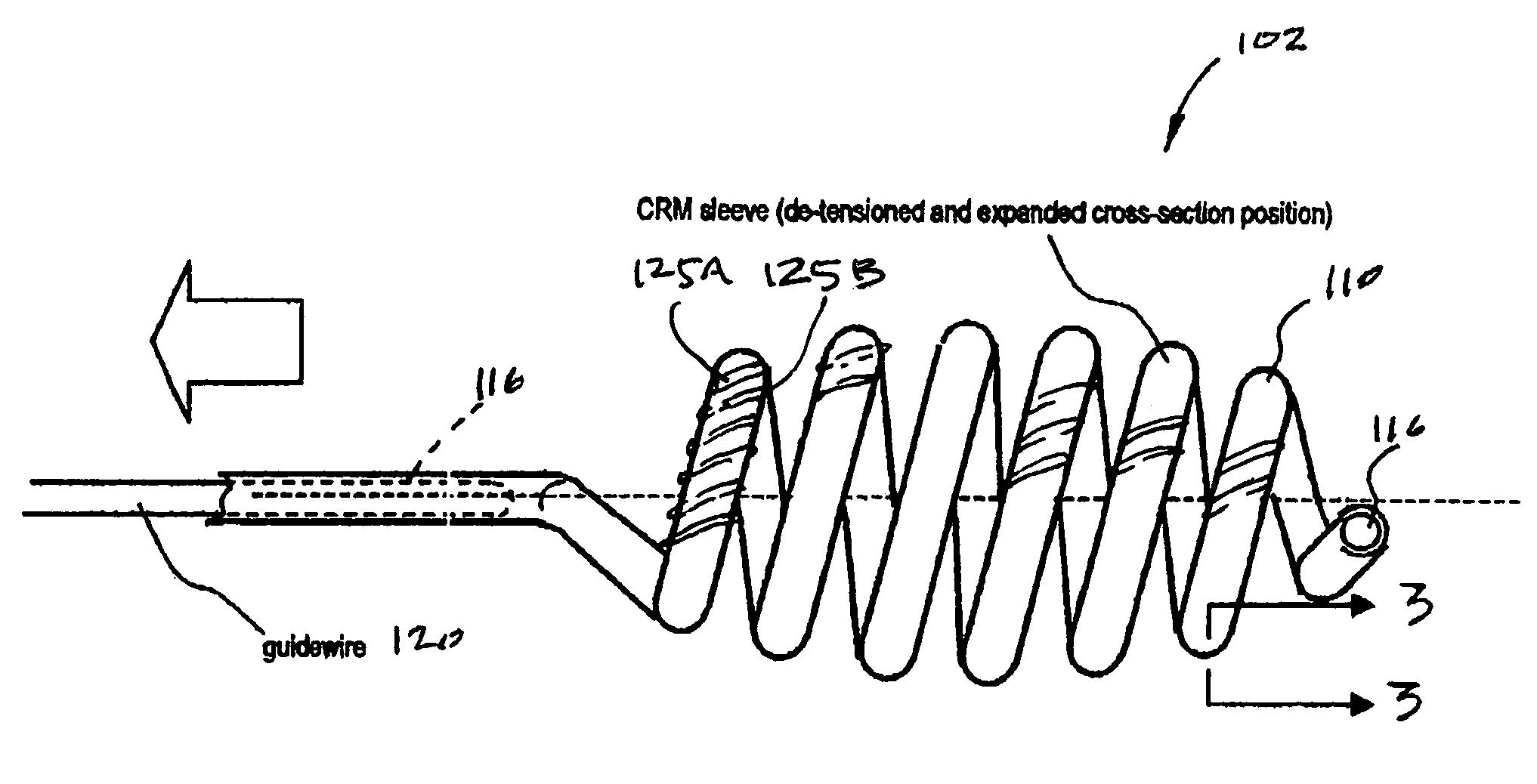

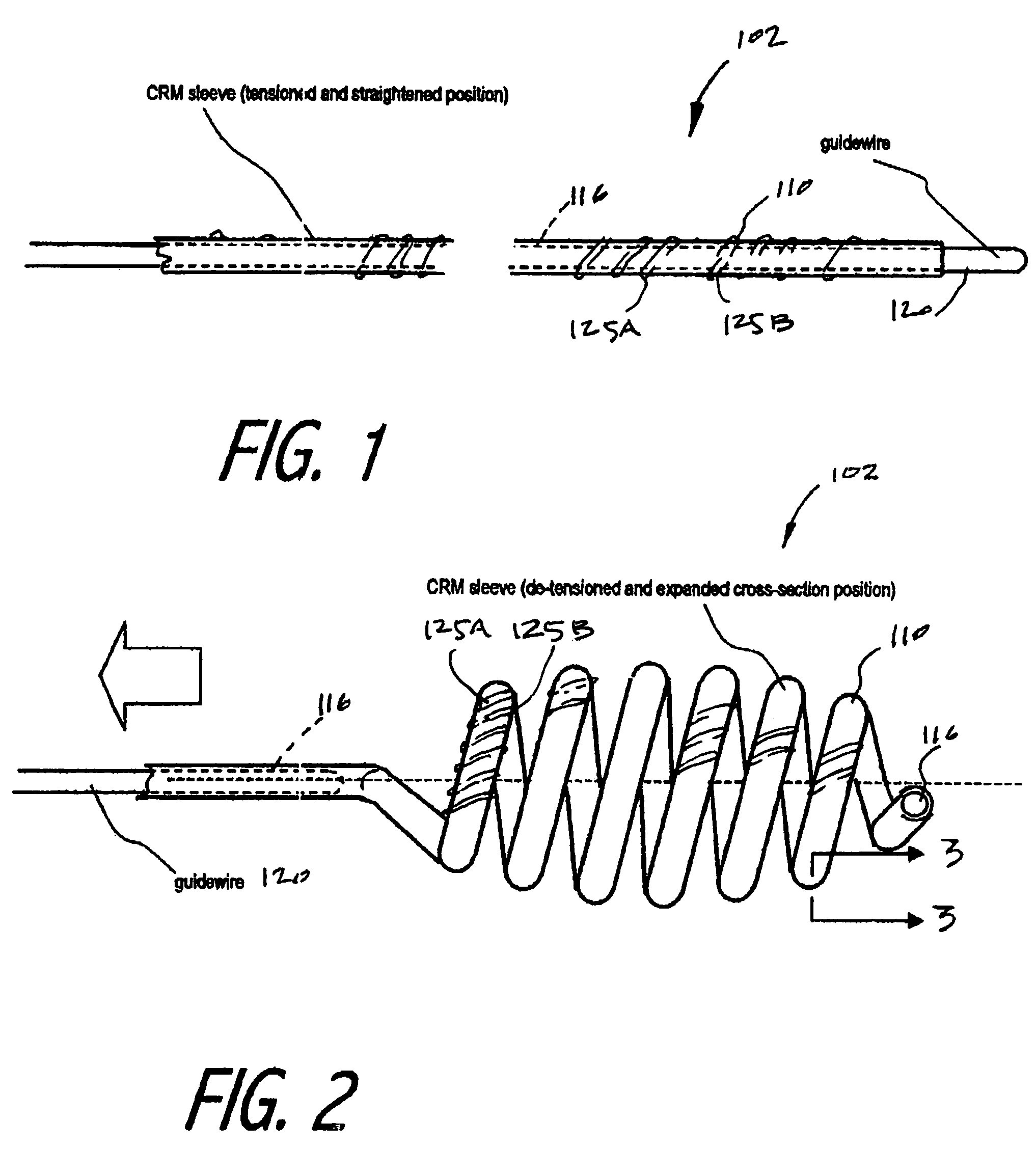

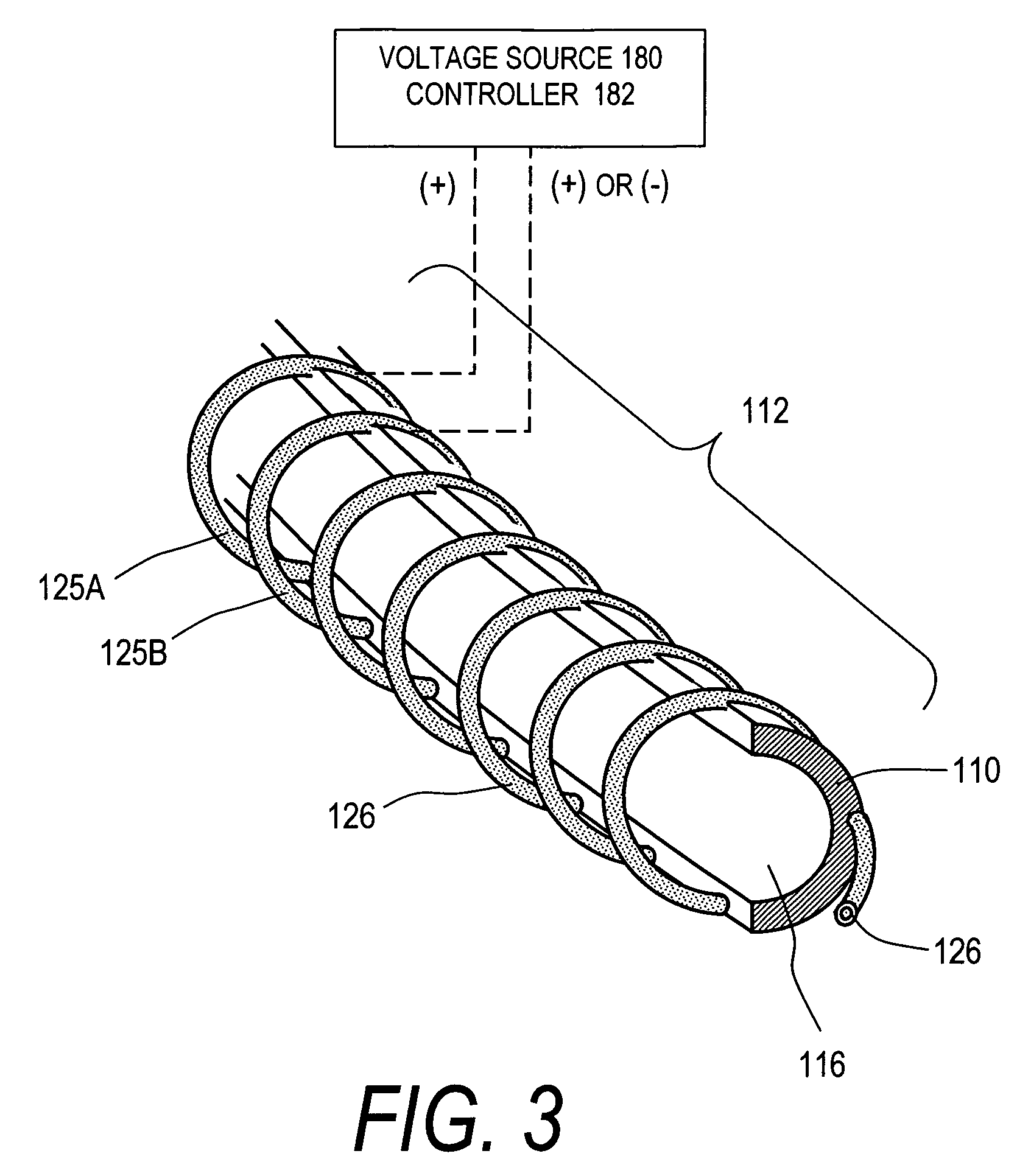

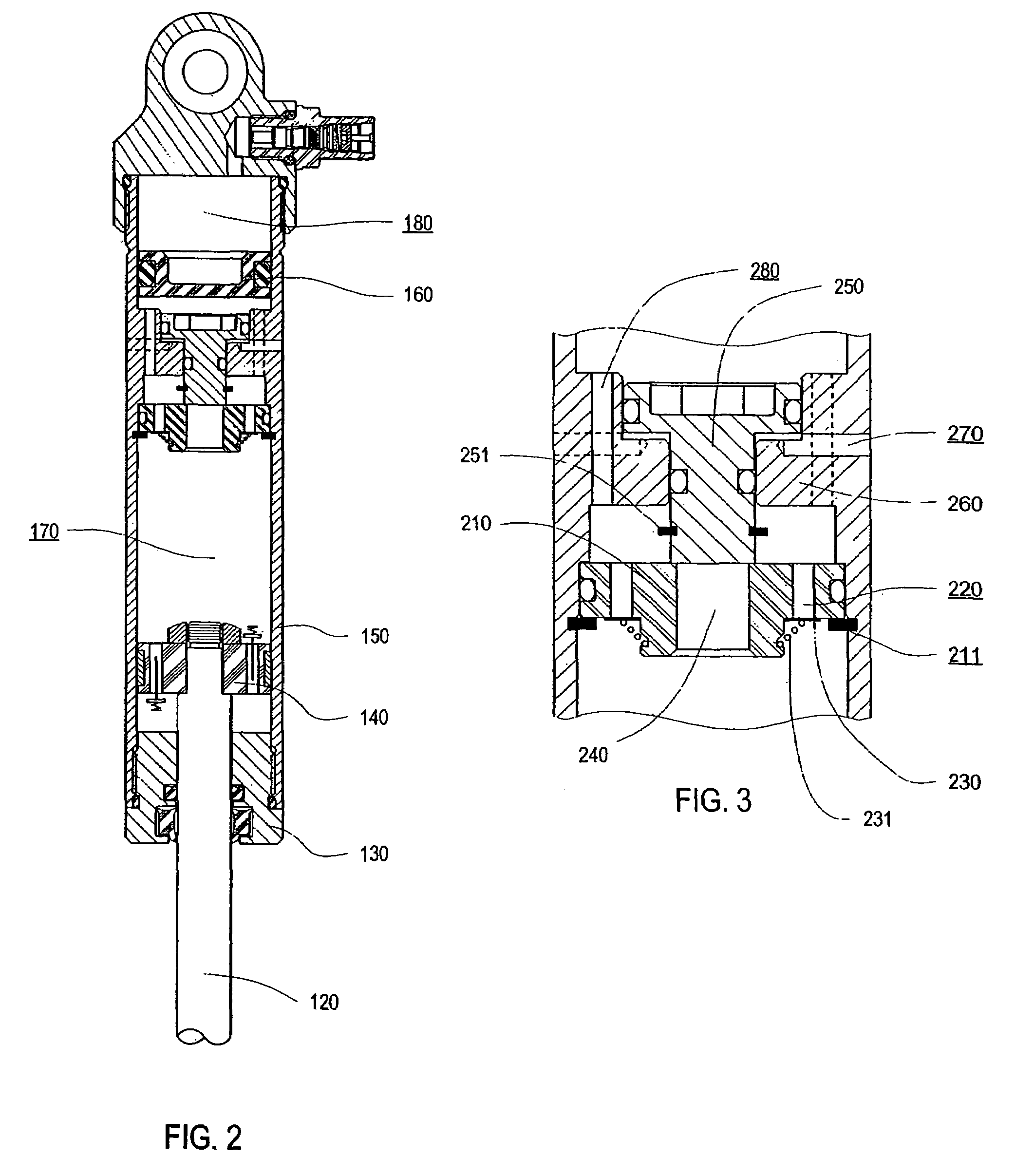

Electrosurgical instrument and method

InactiveUS7517349B2Lower base resistanceRule out the possibilityDiagnosticsSurgical instruments for heatingElectrical resistance and conductanceVaricose veins

Owner:TYCO HEALTHCARE GRP LP

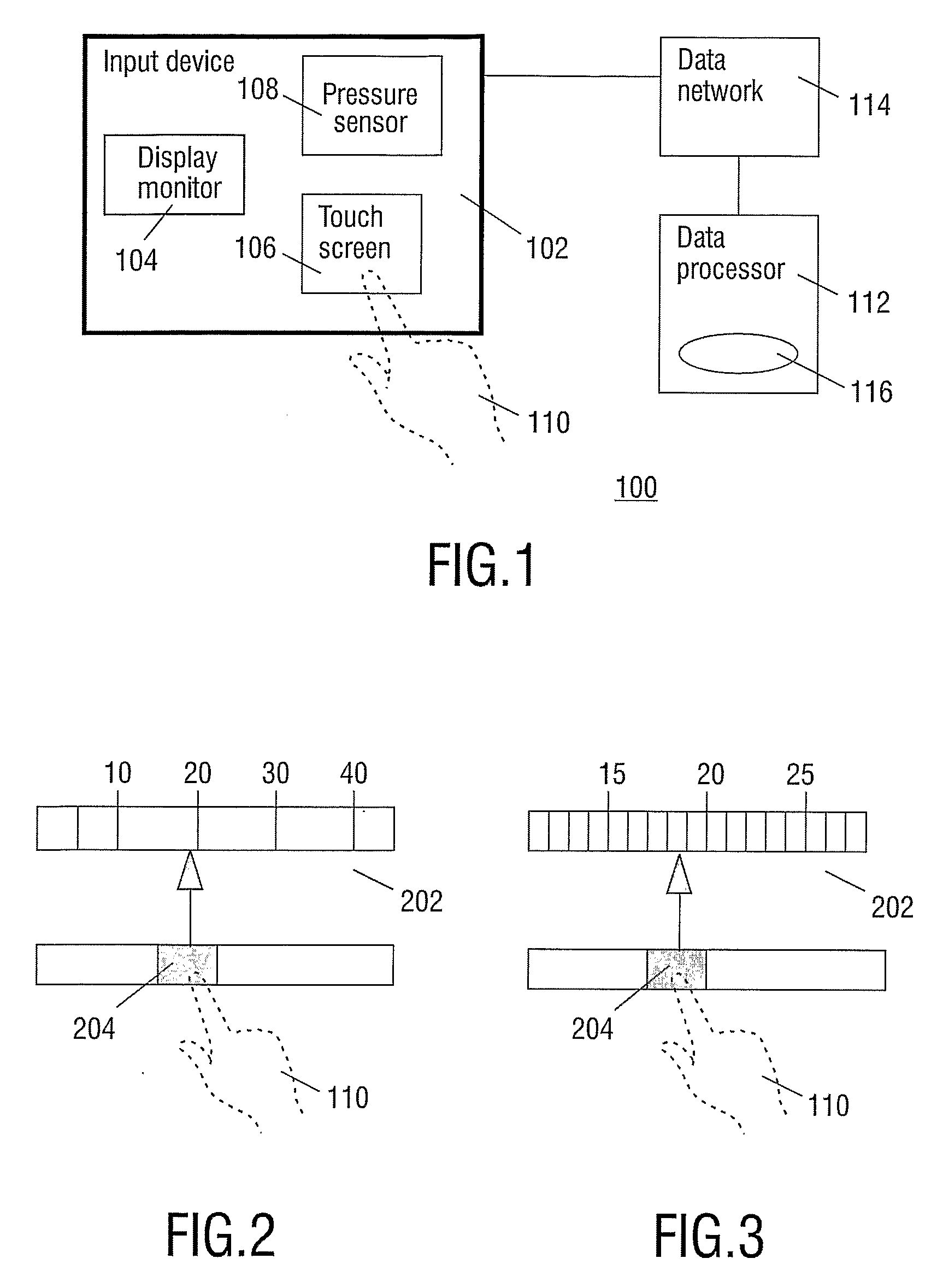

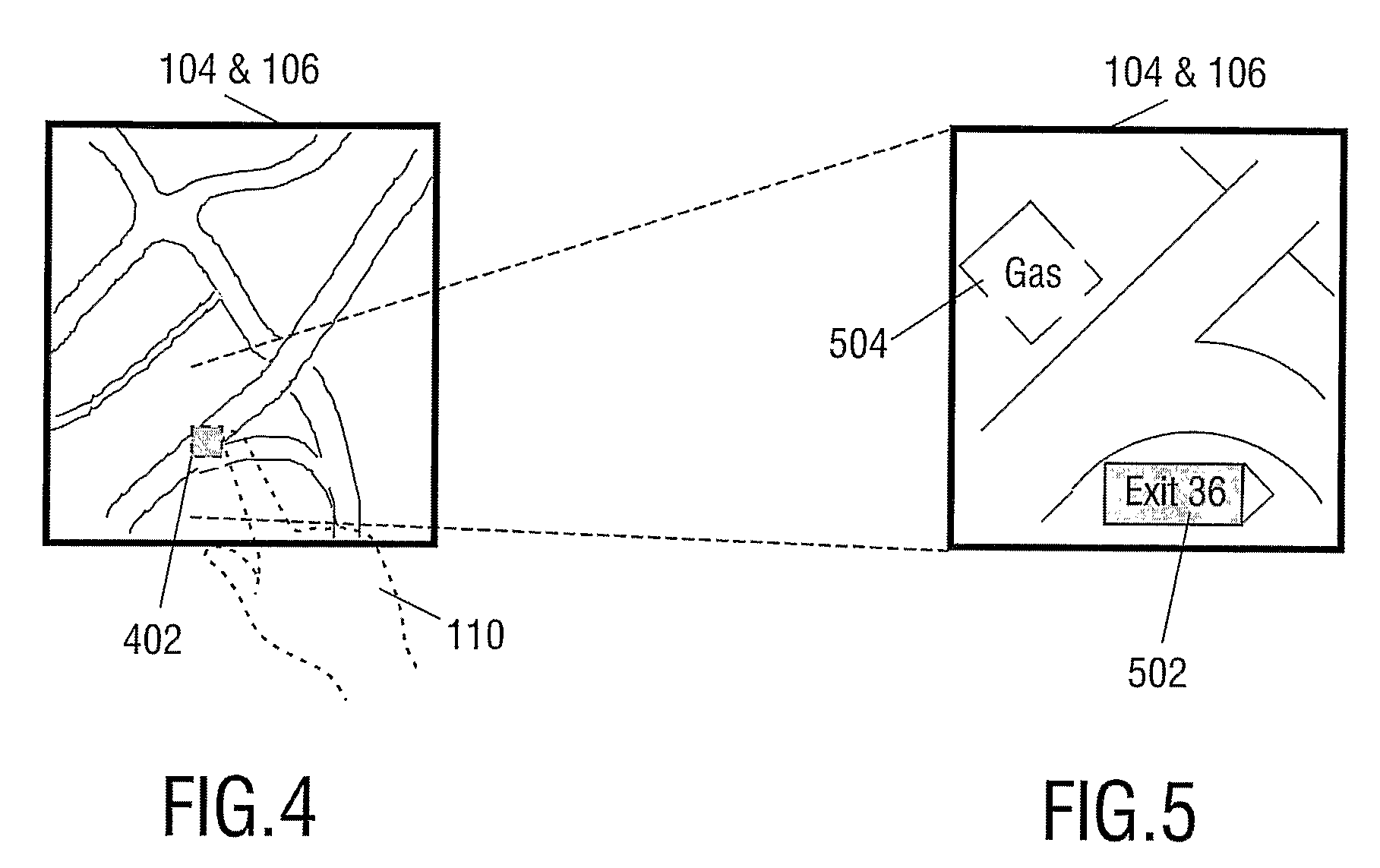

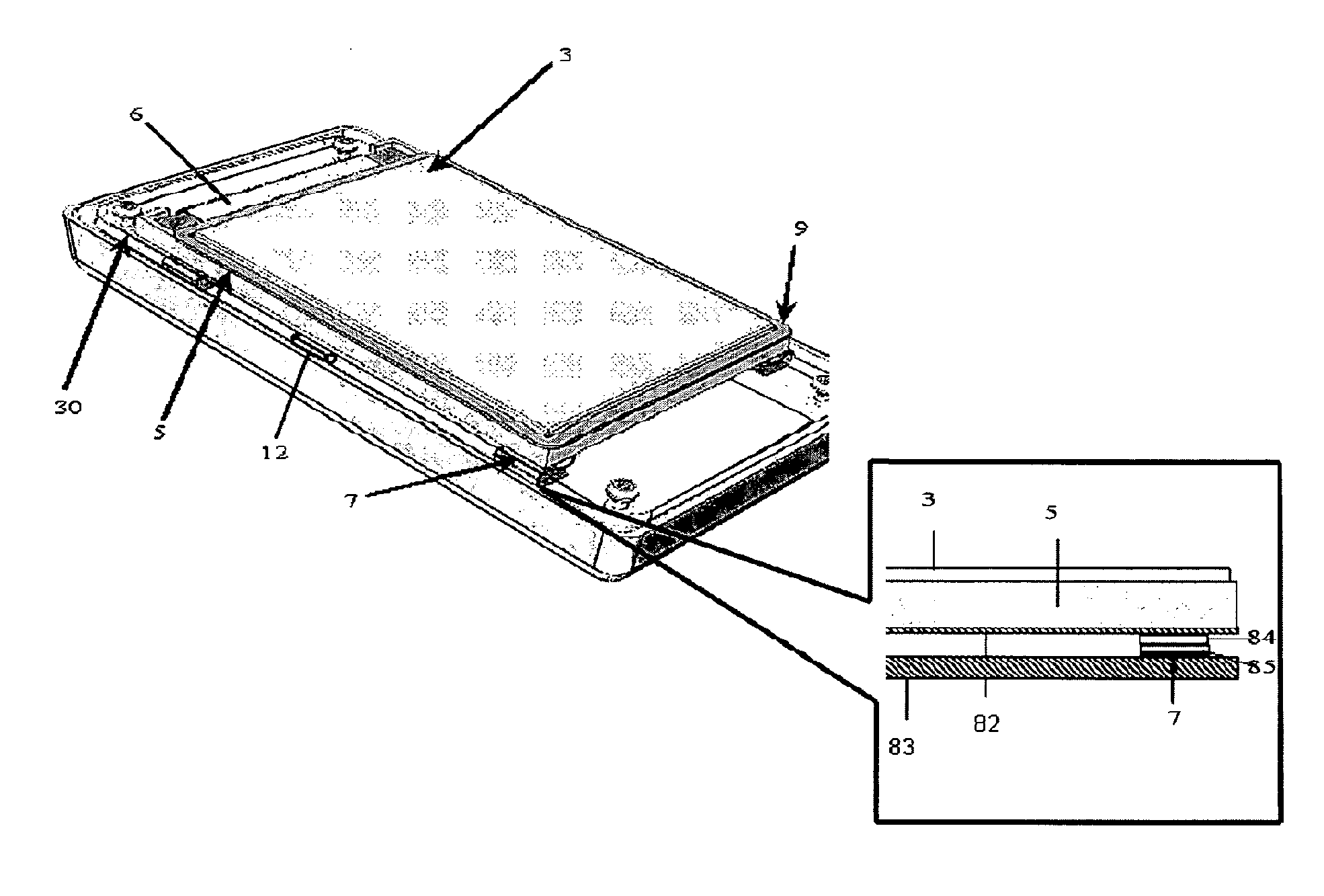

Pressure-Controlled Navigating in a Touch Screen

InactiveUS20080094367A1Improve user friendlinessUser-friendliness of the known systems can be further increasedInput/output processes for data processingRemote controlOperation mode

A remote control device has a display monitor for rendering an image and a touch screen for user interaction. The touch screen is pressure-sensitive. The device has an operational mode wherein the image is being scaled dependent on a value of the pressure registered by the touch screen.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Transformable pressure sensitive adhesive tape and use thereof in display screens

InactiveUS20060100299A1Easy and safe applicationLow level of VOC 'sNanostructure manufactureGas-filled discharge tubesDisplay deviceLight-emitting diode

A transformable pressure sensitive adhesive composition comprised of from about 15 to about 80% by weight of a polymer having a softening point greater than 60° C.; from about 20 to about 85% by weight of a polymerizable resin having a softening point less than 30° C.; a latent initiator in an amount sufficient to cause a reaction between said polymer and said resin; and optionally, a crosslinking agent. The transformable pressure sensitive adhesive has particular applicability in connection with organic light emitting diode display devices, light emitting diode display devices, medical diagnostic testing devices, flexible or rigid LCD display devices, plasma display devices, and electrochromic devices.

Owner:ADHESIVES RES

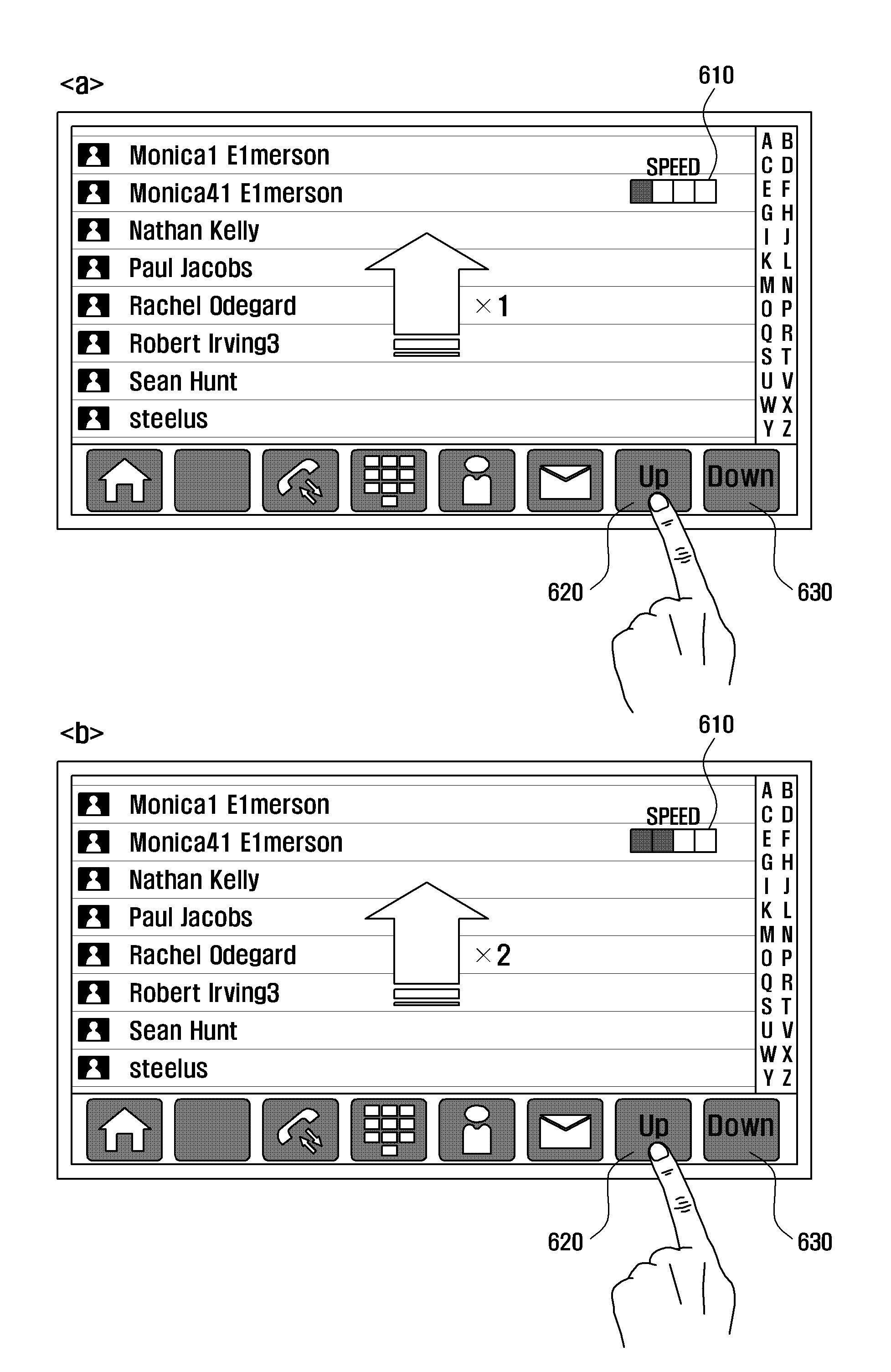

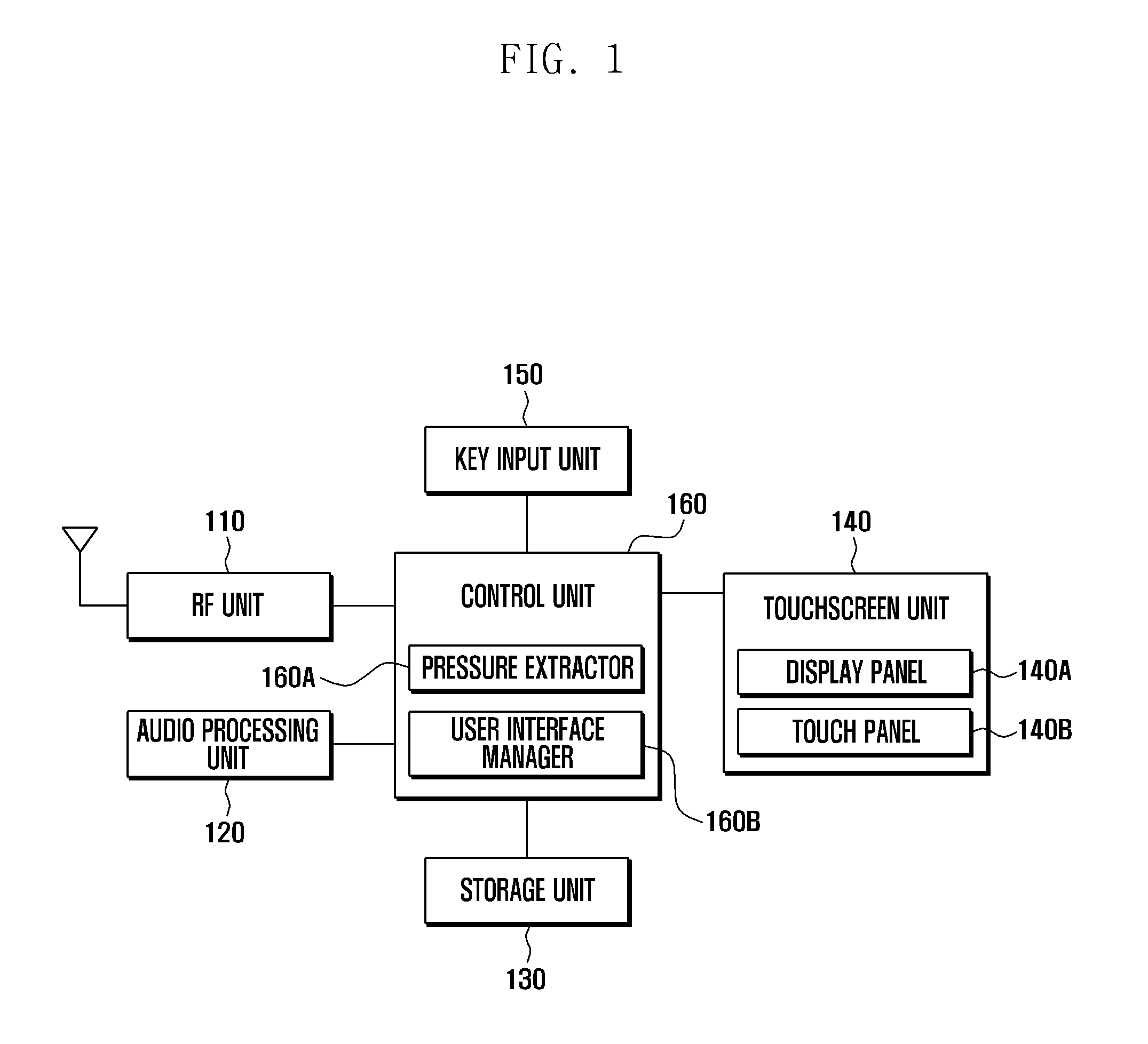

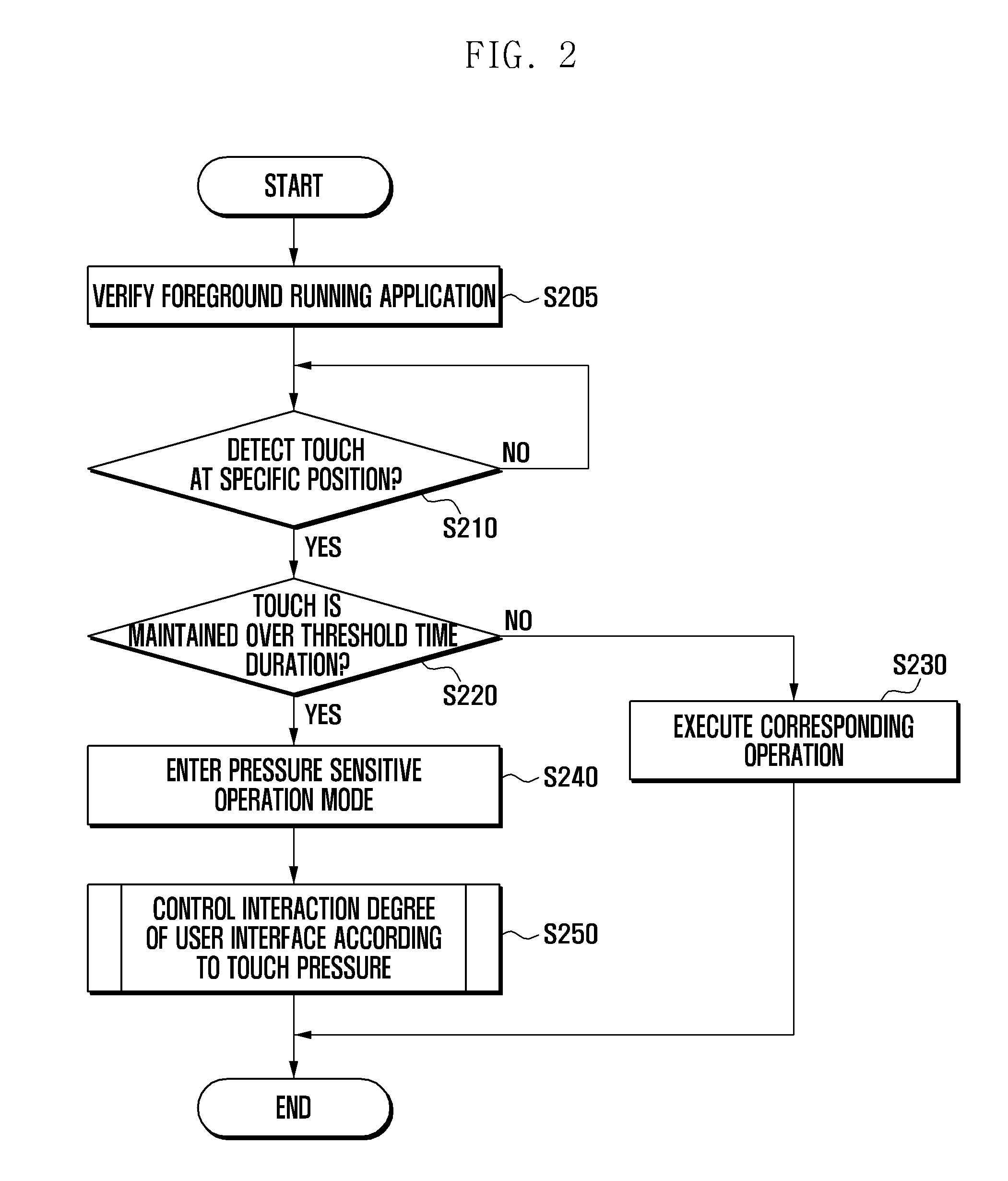

Pressure-sensitive degree control method and system for touchscreen-enabled mobile terminal

A pressure-sensitive degree control method and system of a mobile terminal including a touchscreen for controlling interaction degree of the touchscreen based on a pressure level of a touch are provided. The method includes detecting a pressure level of the touch made on the touchscreen, configuring an interaction degree of the user interface to be determined based on the pressure level, and controlling operations of the user interface according to the interaction degree.

Owner:SAMSUNG ELECTRONICS CO LTD

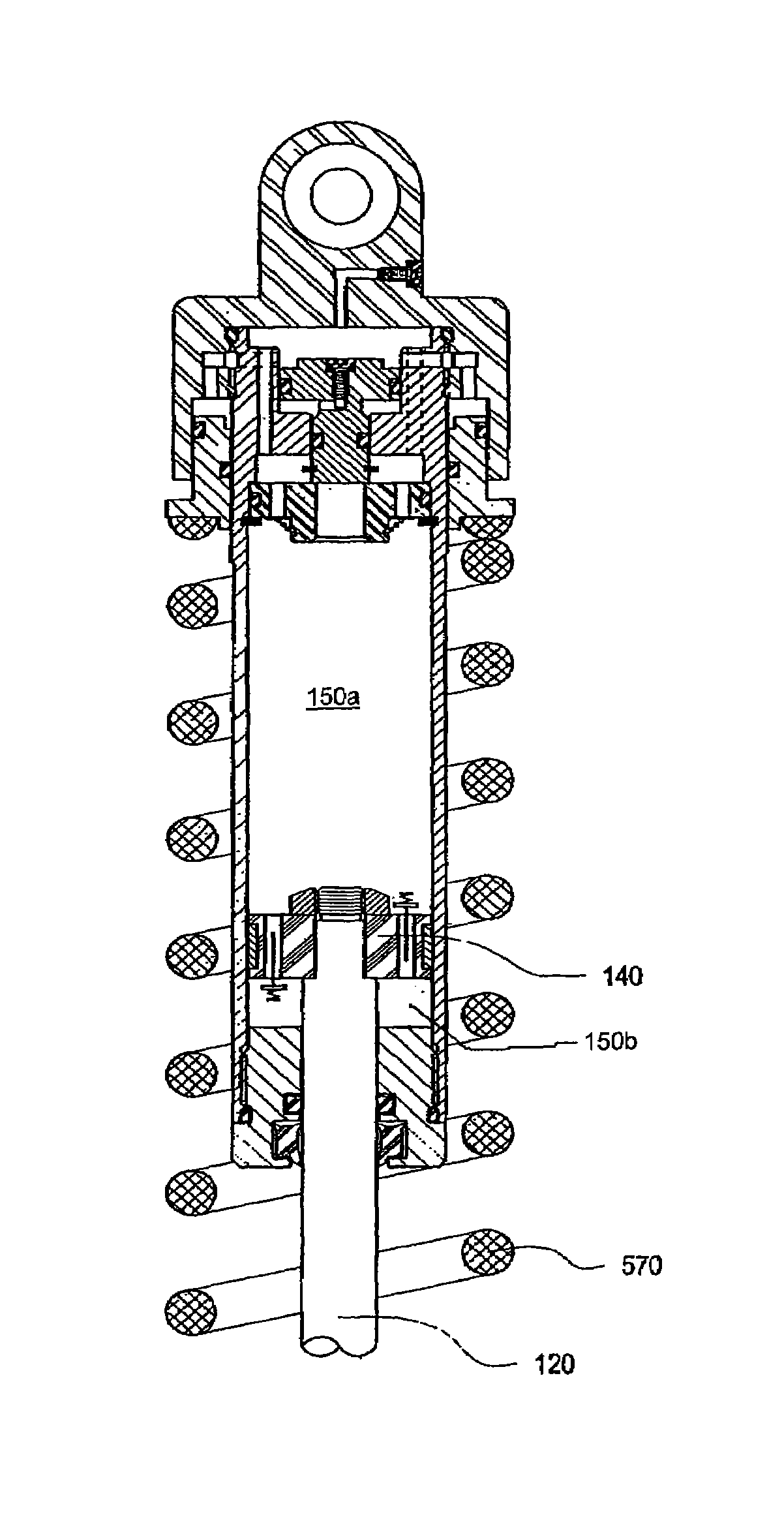

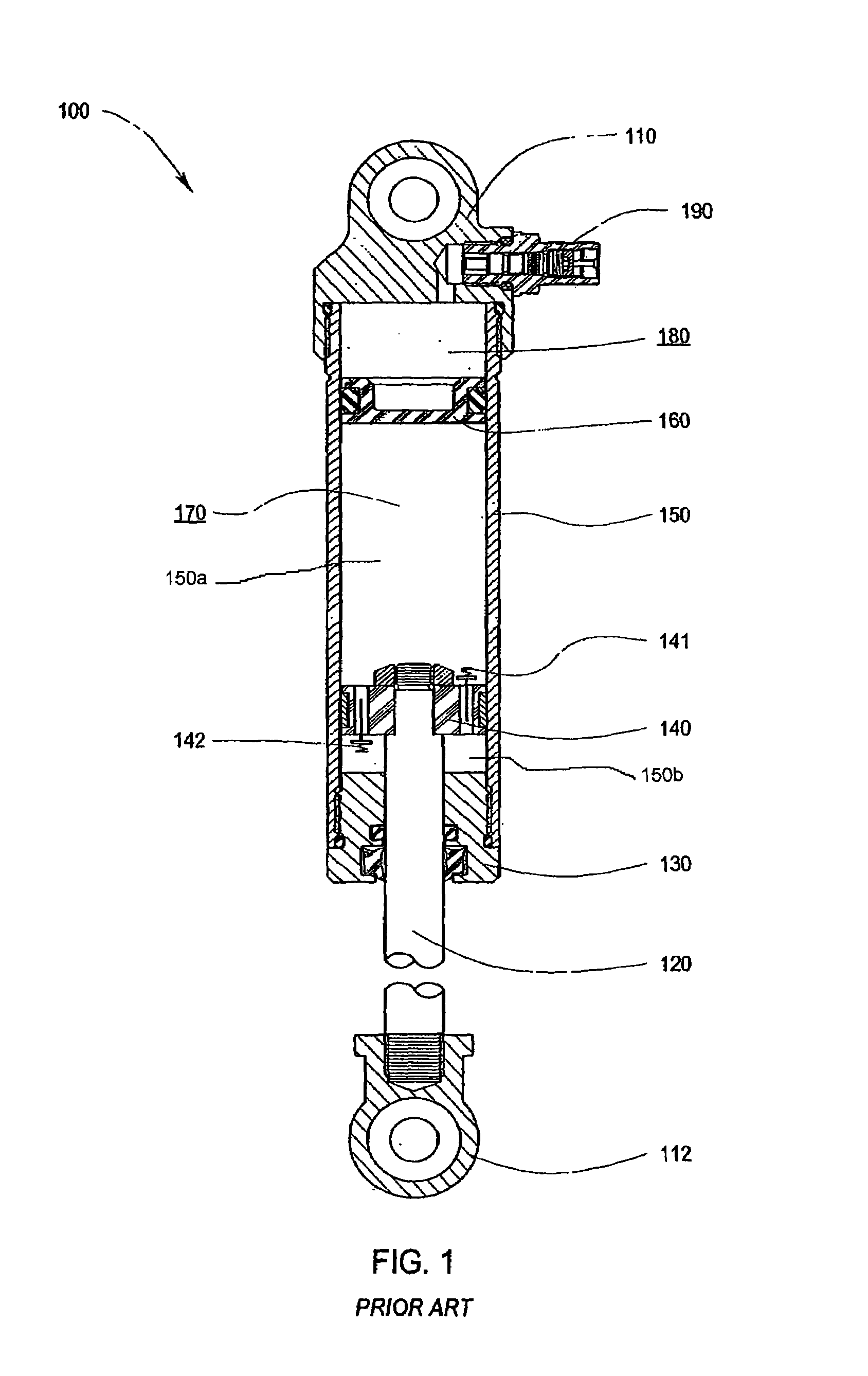

Damper with pressure-sensitive compression damping

A self-pressurized damper, for example, a pressure-sensitive damper is described. At least one suspension spring is used to pressurize the damping fluid, a task typically carried out by a sealed moveable barrier, such as an internal floating piston (IFP) and a pressurized gas. Thus, stroke length may be maximized. Furthermore, the amount of compression damping force produced by the damper may be a function of the force generated by the at least one suspension spring.

Owner:FOX FACTORY

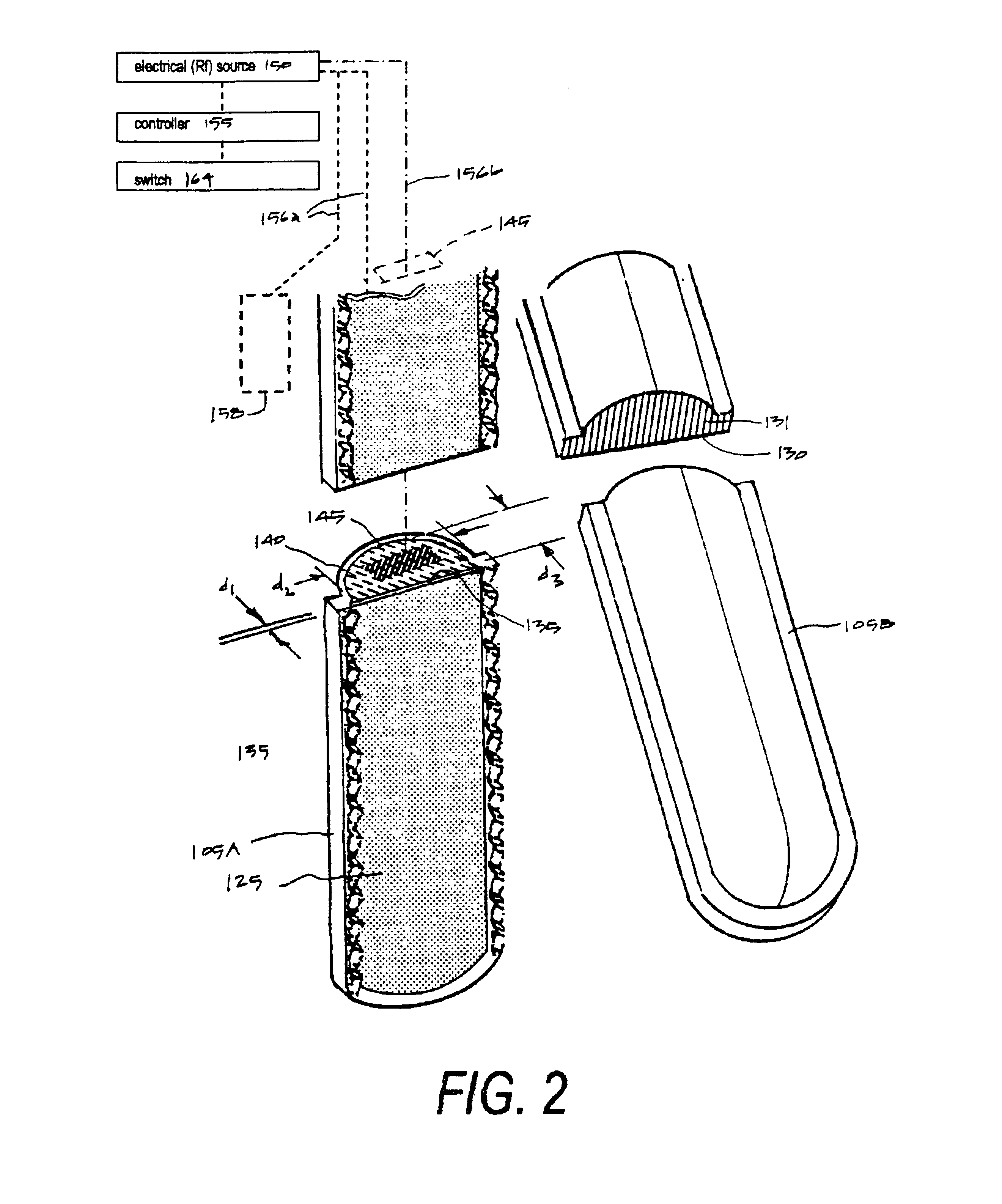

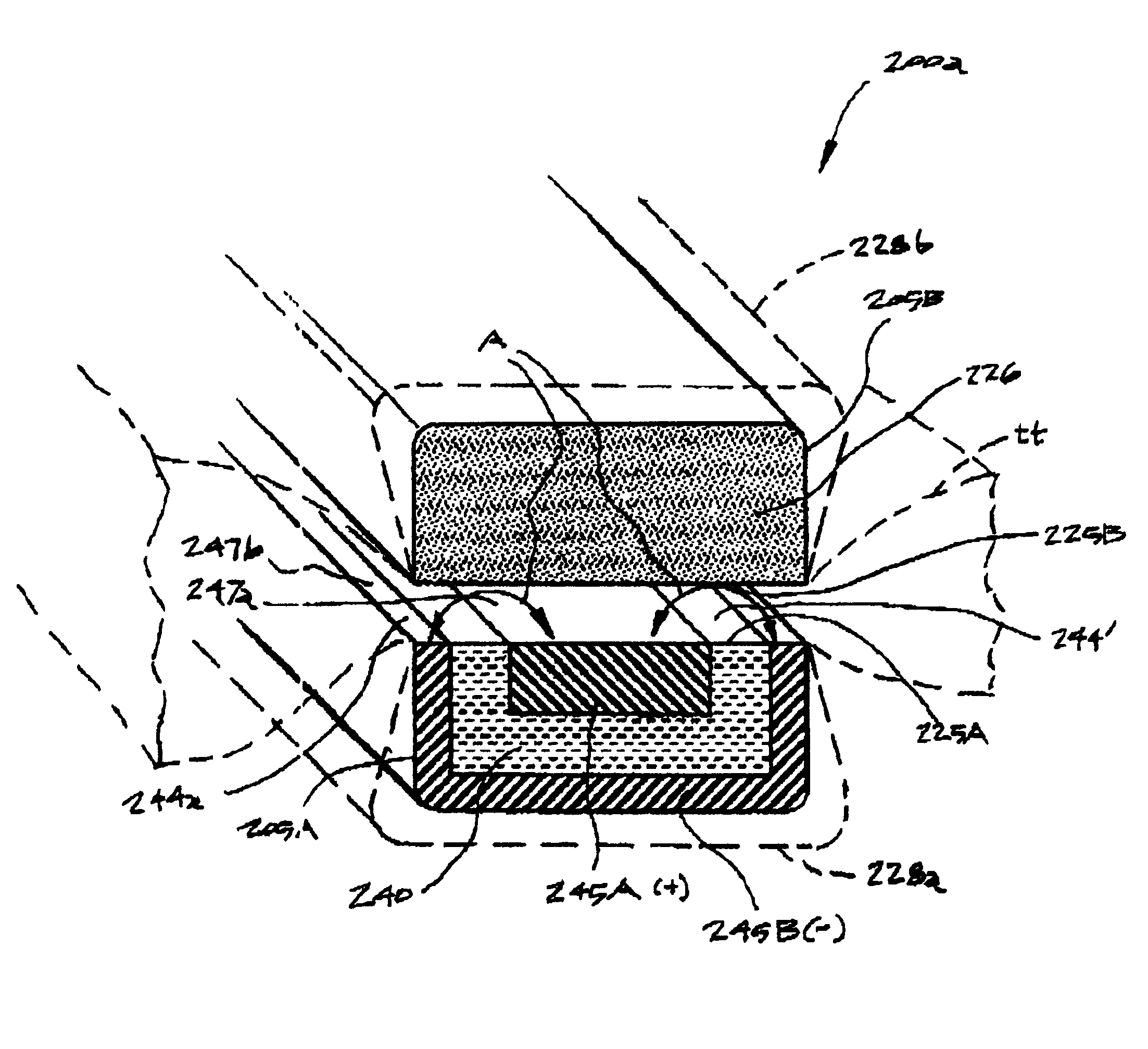

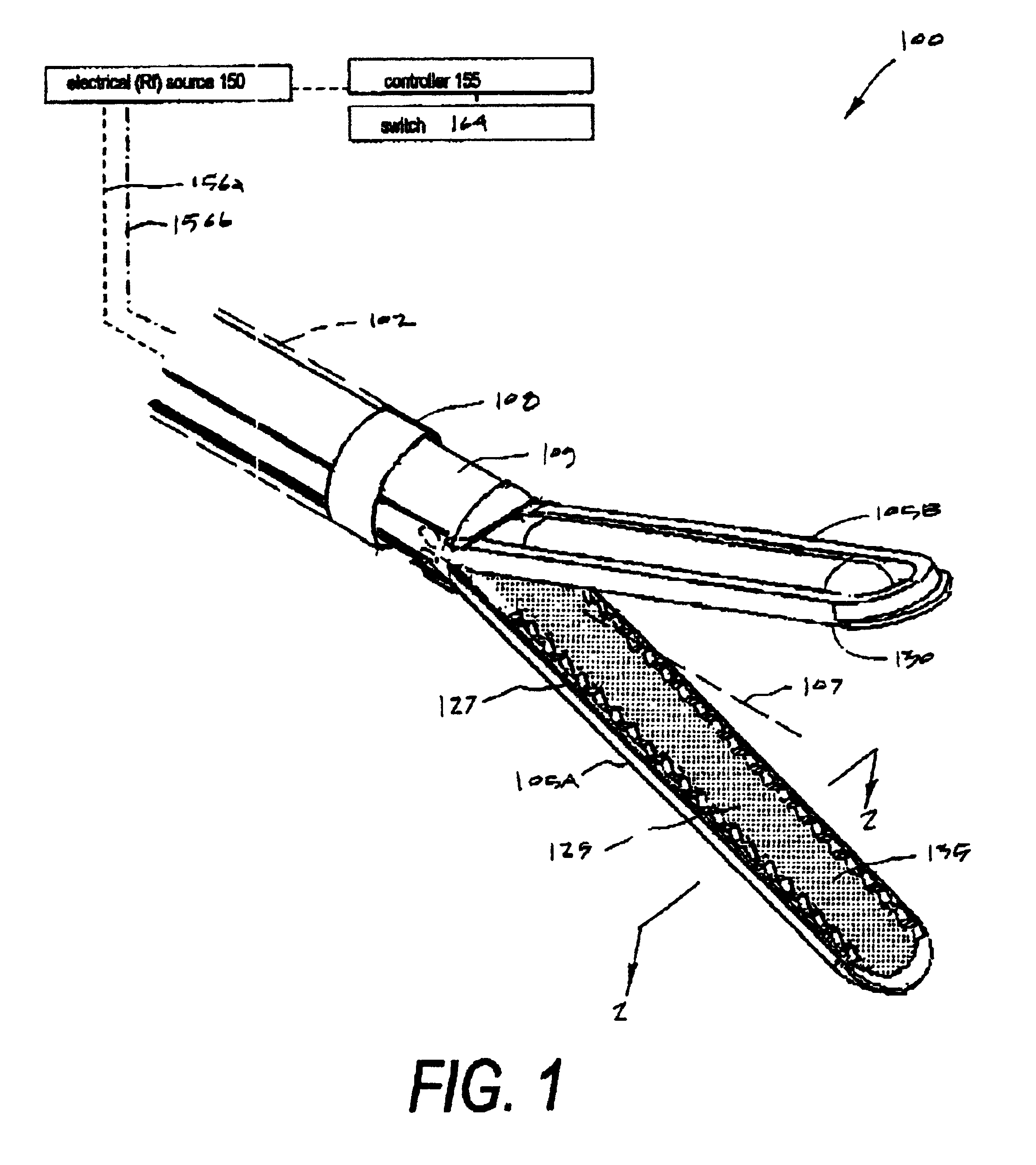

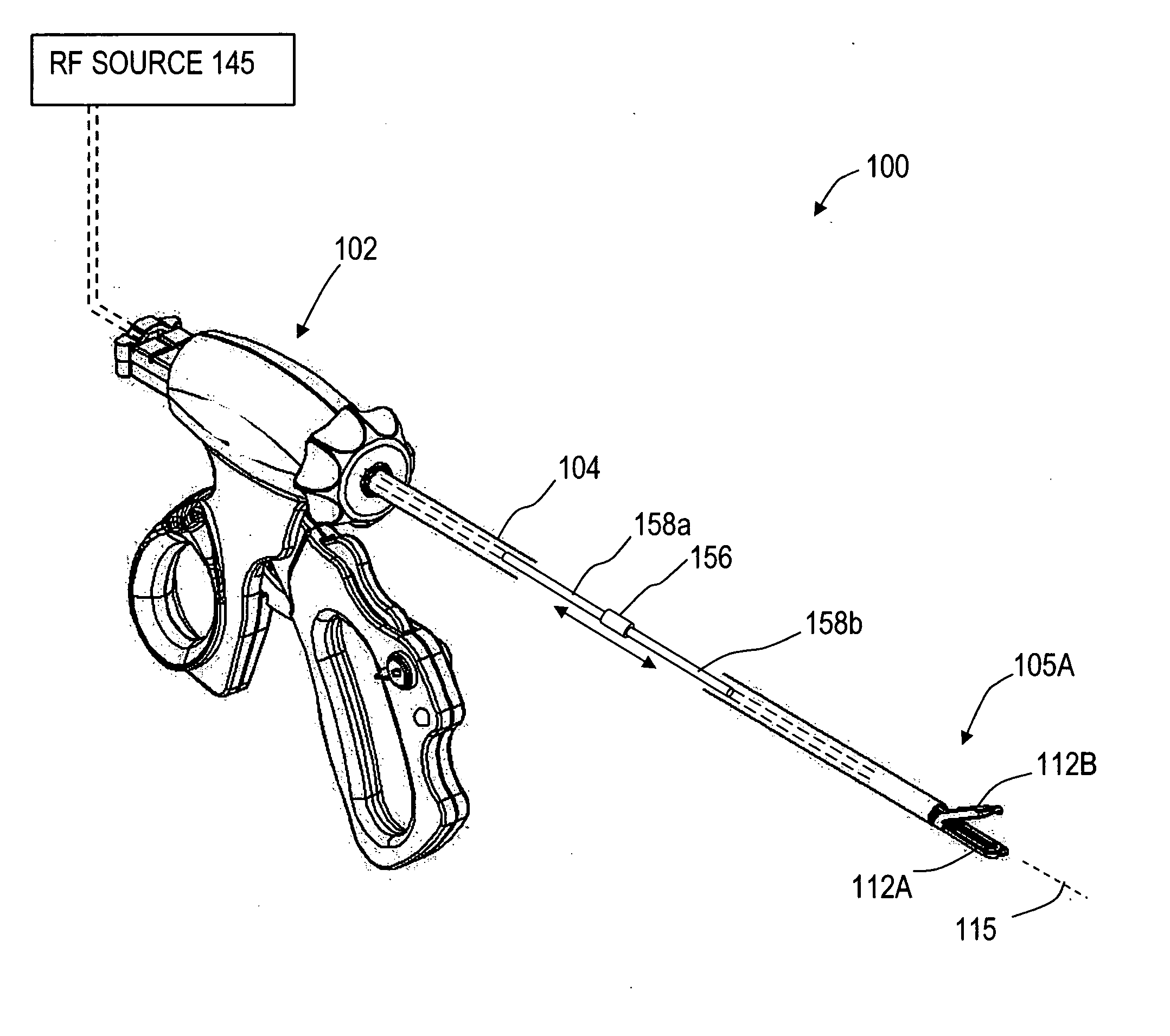

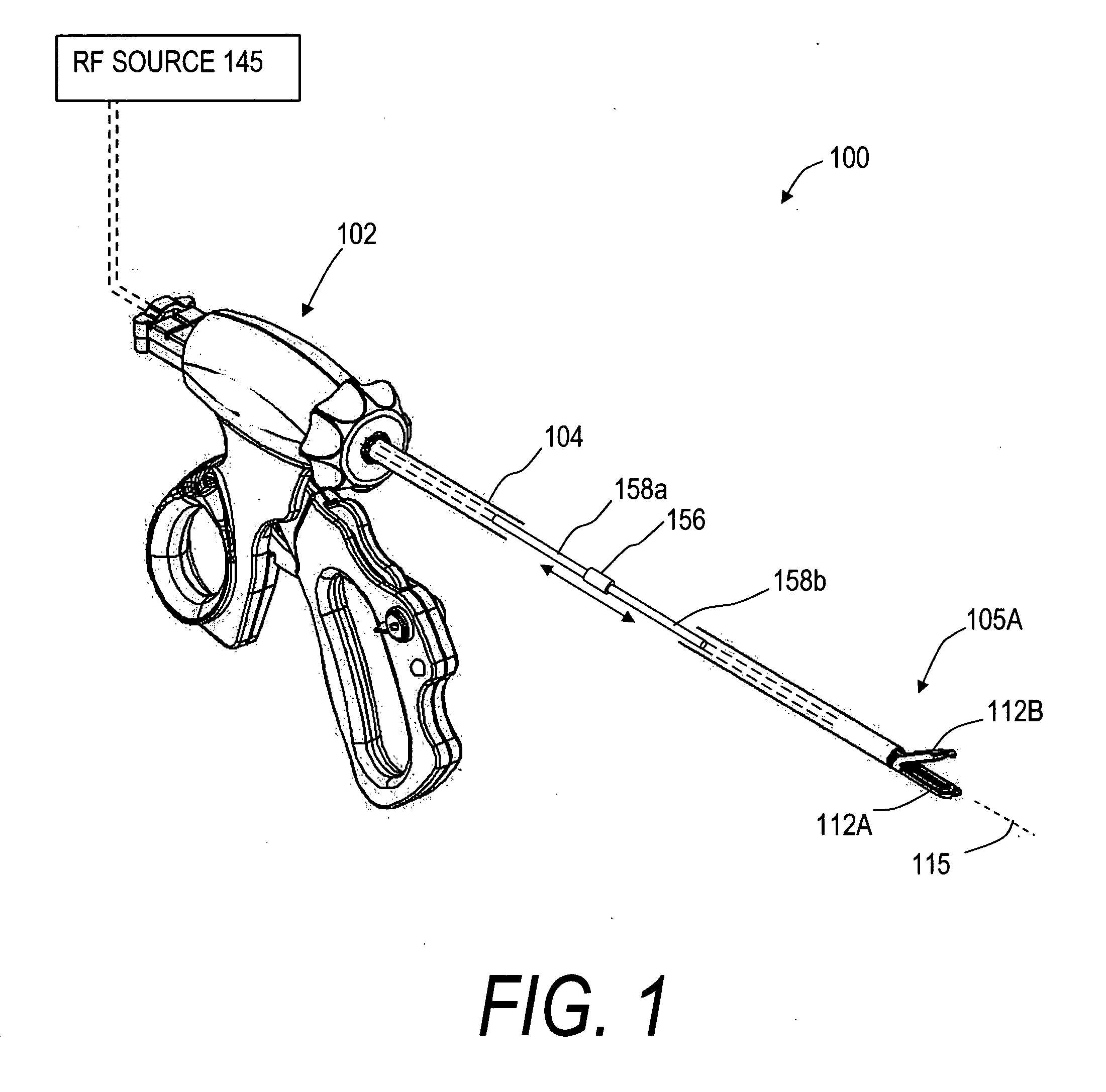

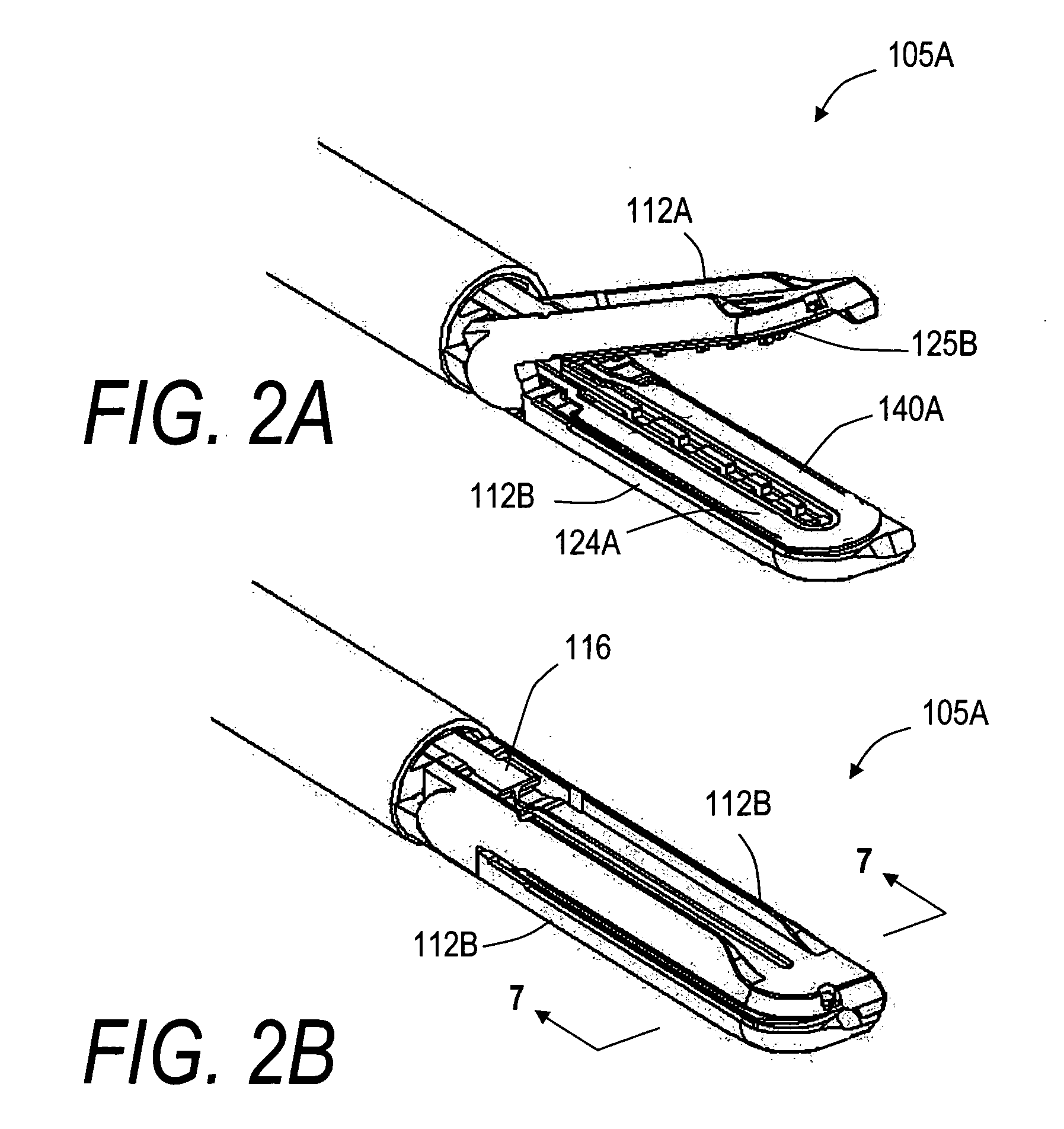

Electrosurgical instrument and method of use

InactiveUS20060293656A1High energyLimit electrosurgical energy deliveryDiagnosticsSurgical instruments for heatingElectrical resistance and conductanceBiomedical engineering

Electrosurgical jaw structures are disclosed that include pressure sensitive variable resistive materials in electrosurgical energy delivery surfaces for welding tissue. The pressure sensitive materials are configured to have megaohm impedance when not engaging tissue and can transform into highly conductive electrodes when compressed under a selected pressure. In a method of the invention, the pressure sensitive variable resistive materials prevent arcing and tissue desiccation when applying bi-polar Rf current to tissue engaged under high compression in an electrosurgical jaw structure.

Owner:SURGRX

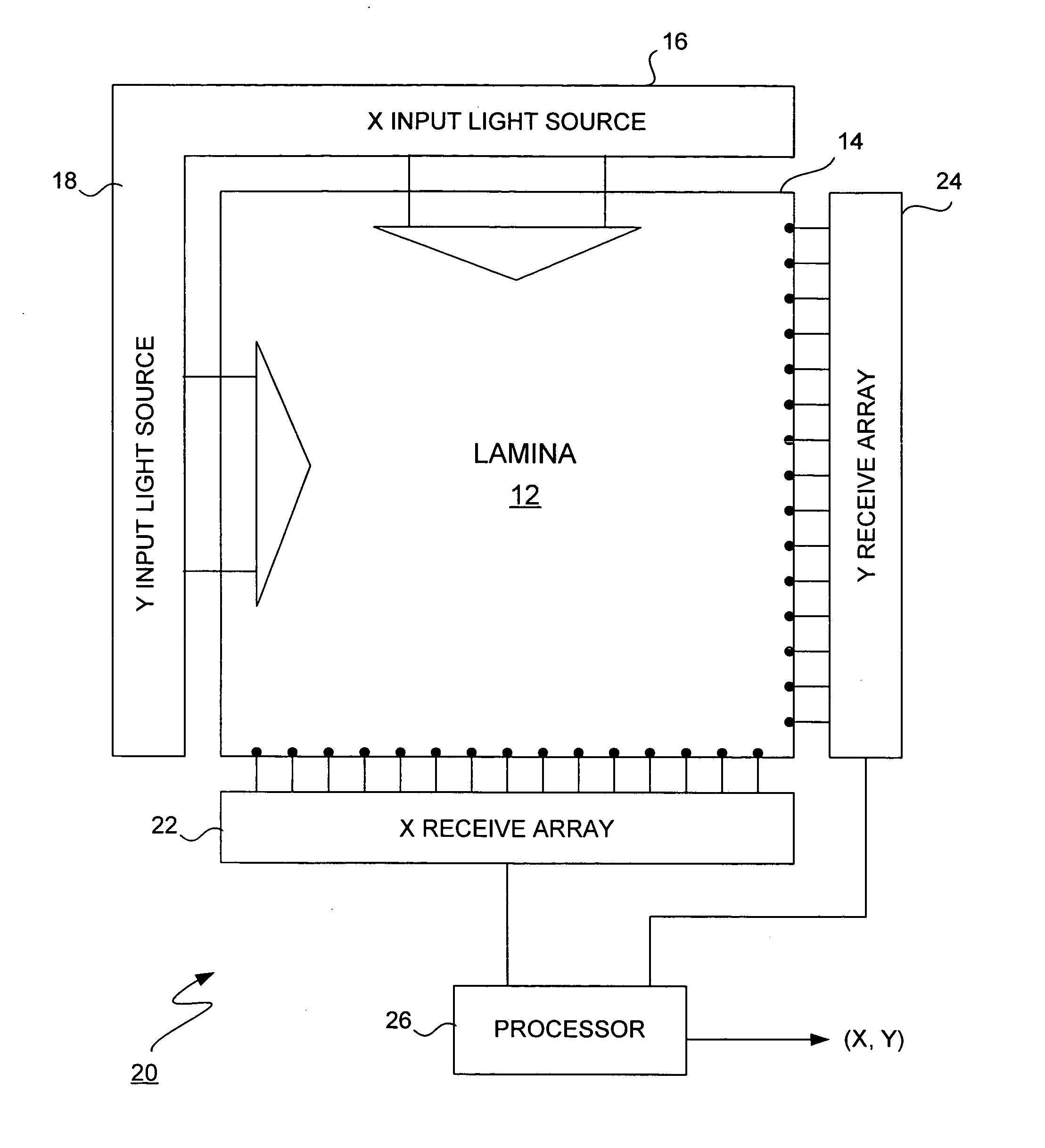

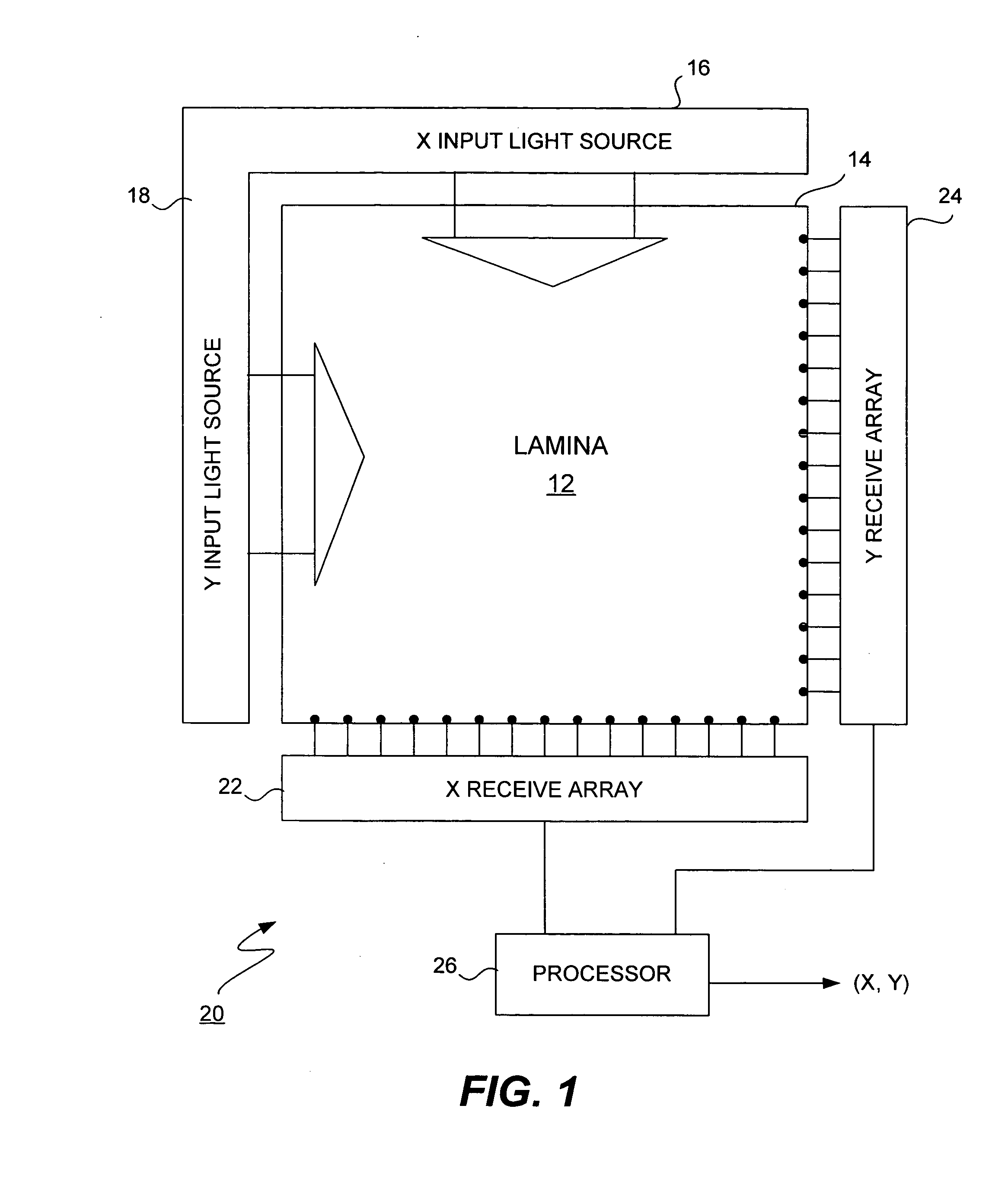

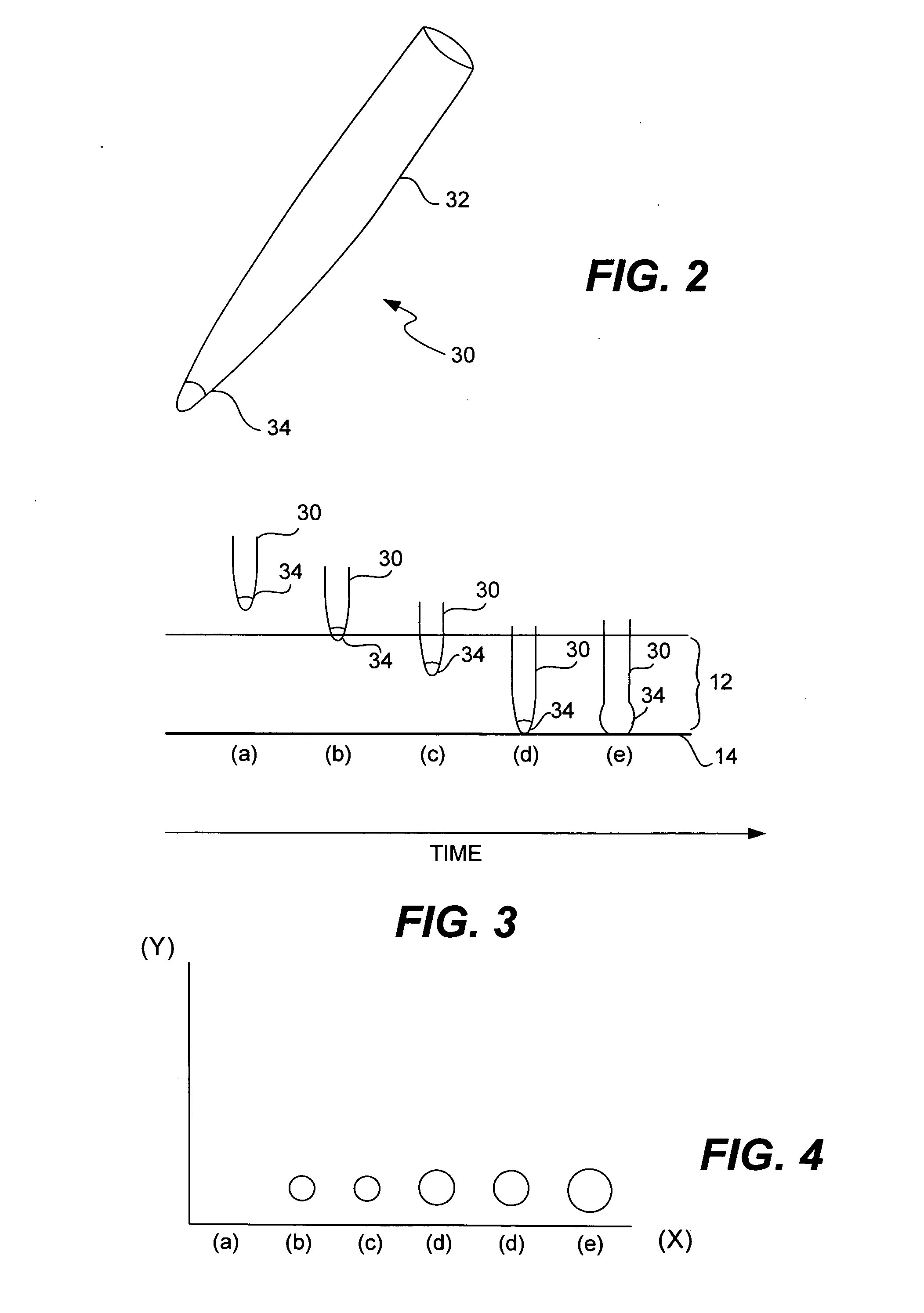

Apparatus and method for performing data entry with light based touch screen displays

InactiveUS20060001654A1Cathode-ray tube indicatorsInput/output processes for data processingDisplay deviceTouchscreen

An apparatus and method for performing data entry with light based touch screen displays and that is capable of implementing the functions of inking, pressure sensitive data entries, the rate of descent and angle of entry of the pen or stylus, the ability to rotate objects, double-clicking objects, fast clicking, etc. The apparatus and method includes a touch screen and a stylus having a tip that compresses depending on the amount of force is applied to the stylus when placed in contact with the touch screen during a data entry operation. A processor is provided to generate a display on the touch screen that traces the movements of the stylus on the touch screen. To implement the inking function, the processor is configured to extrapolate the relative thickness of the display generated on the touch screen to be commensurate with the amount of compression of the tip caused by the amount of writing force applied to the stylus. The amount of compression of the tip also enables pressure sensitive data entries.

Owner:POA SANA LIQUIDATING TRUST

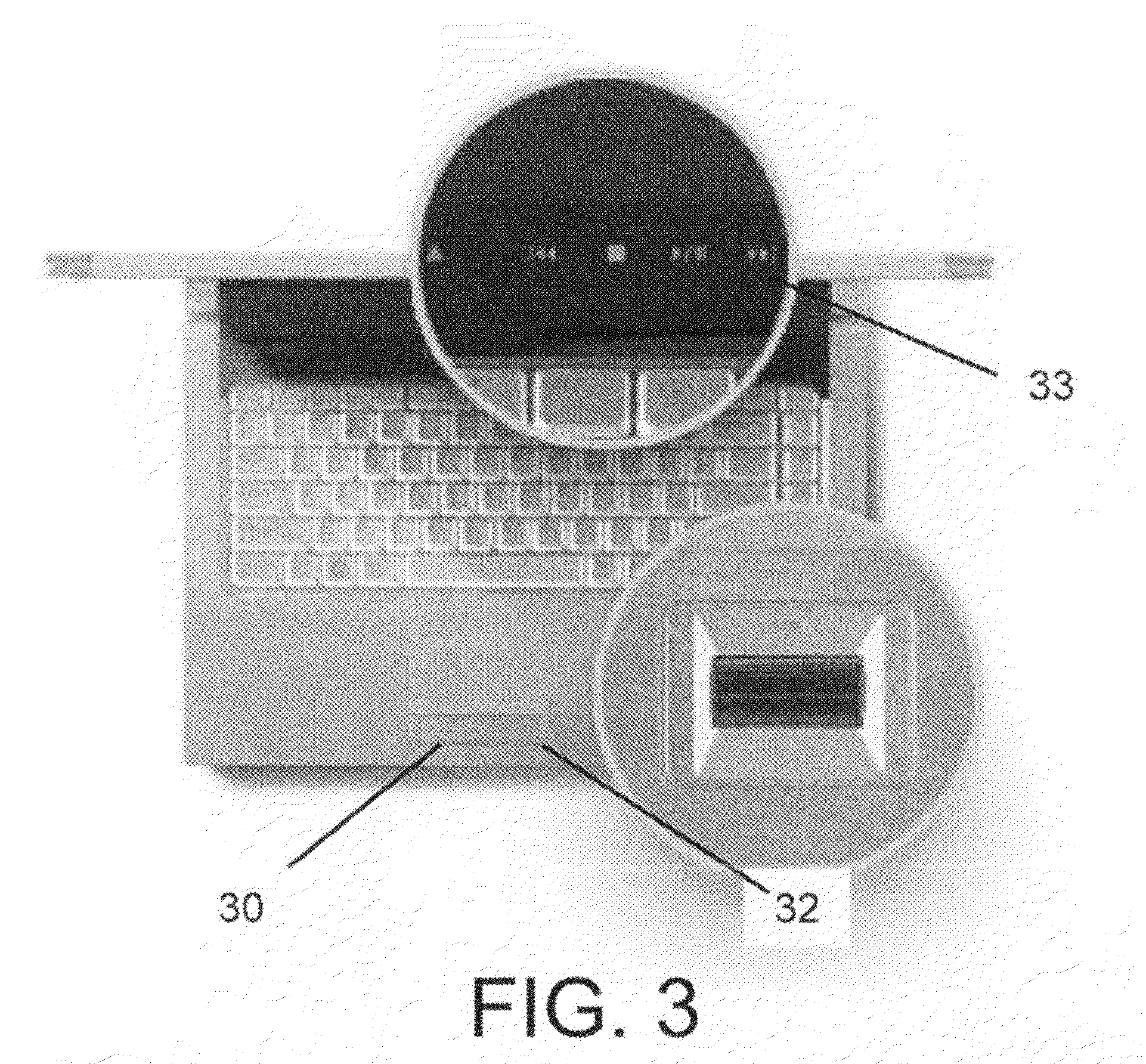

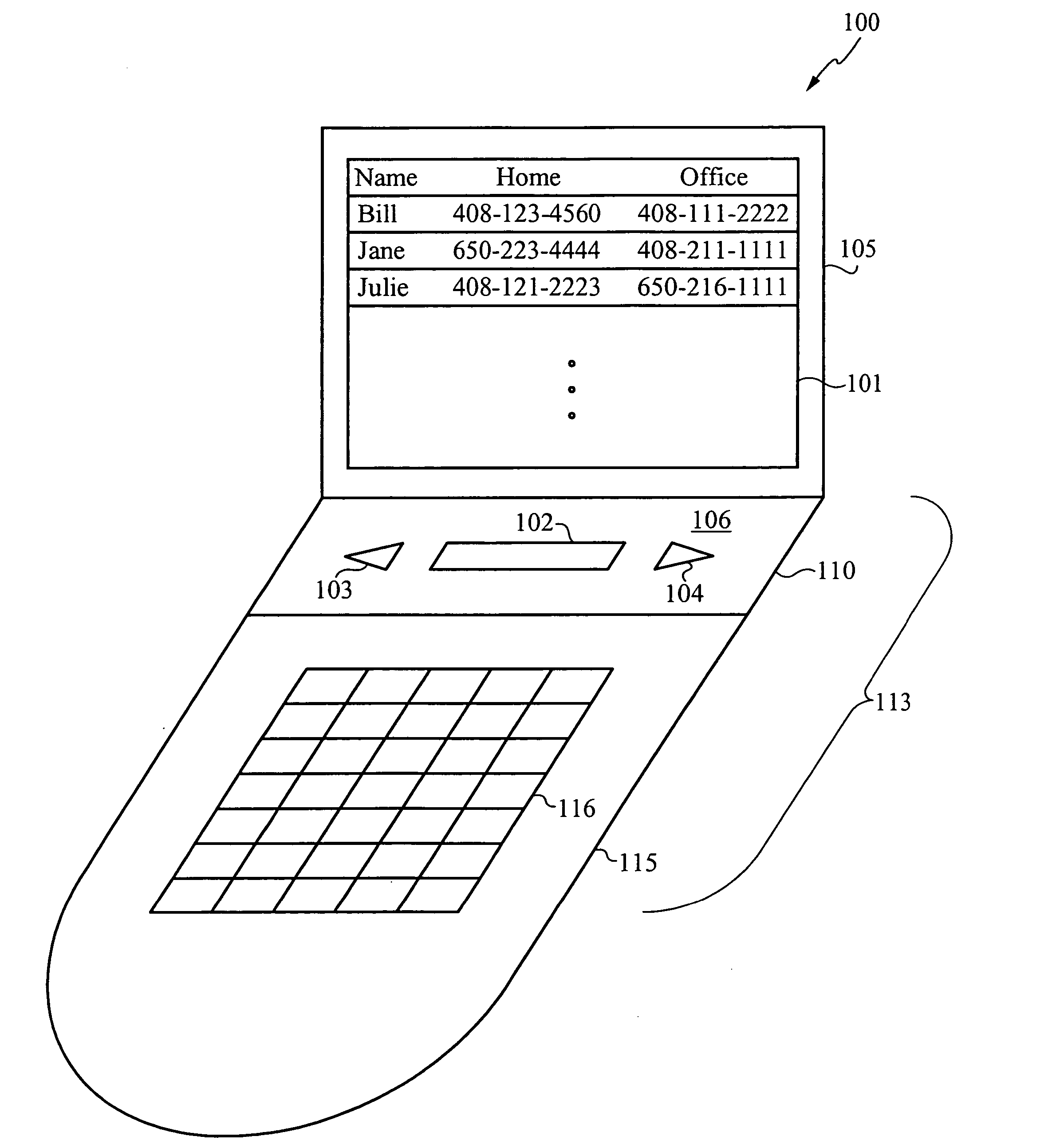

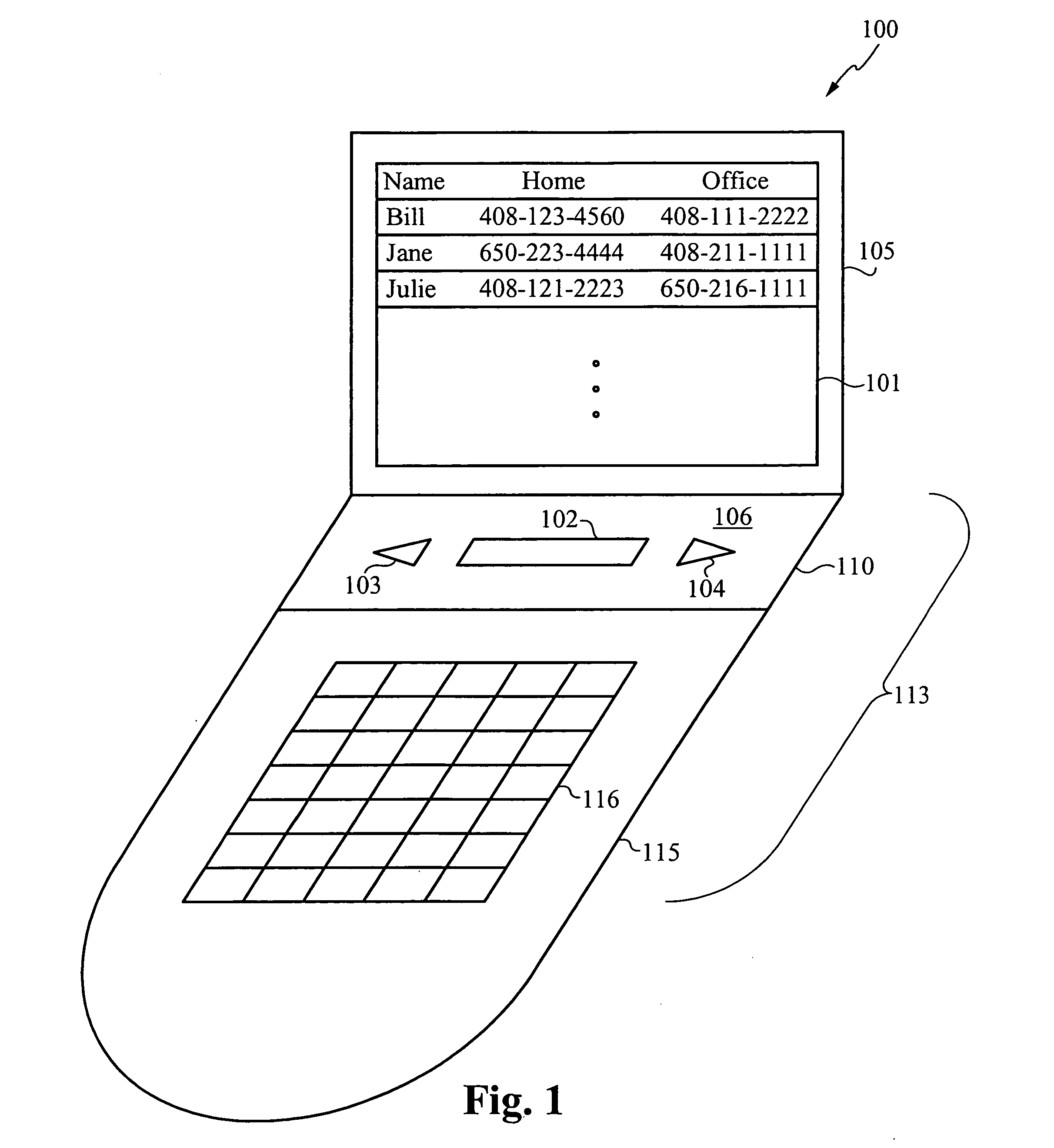

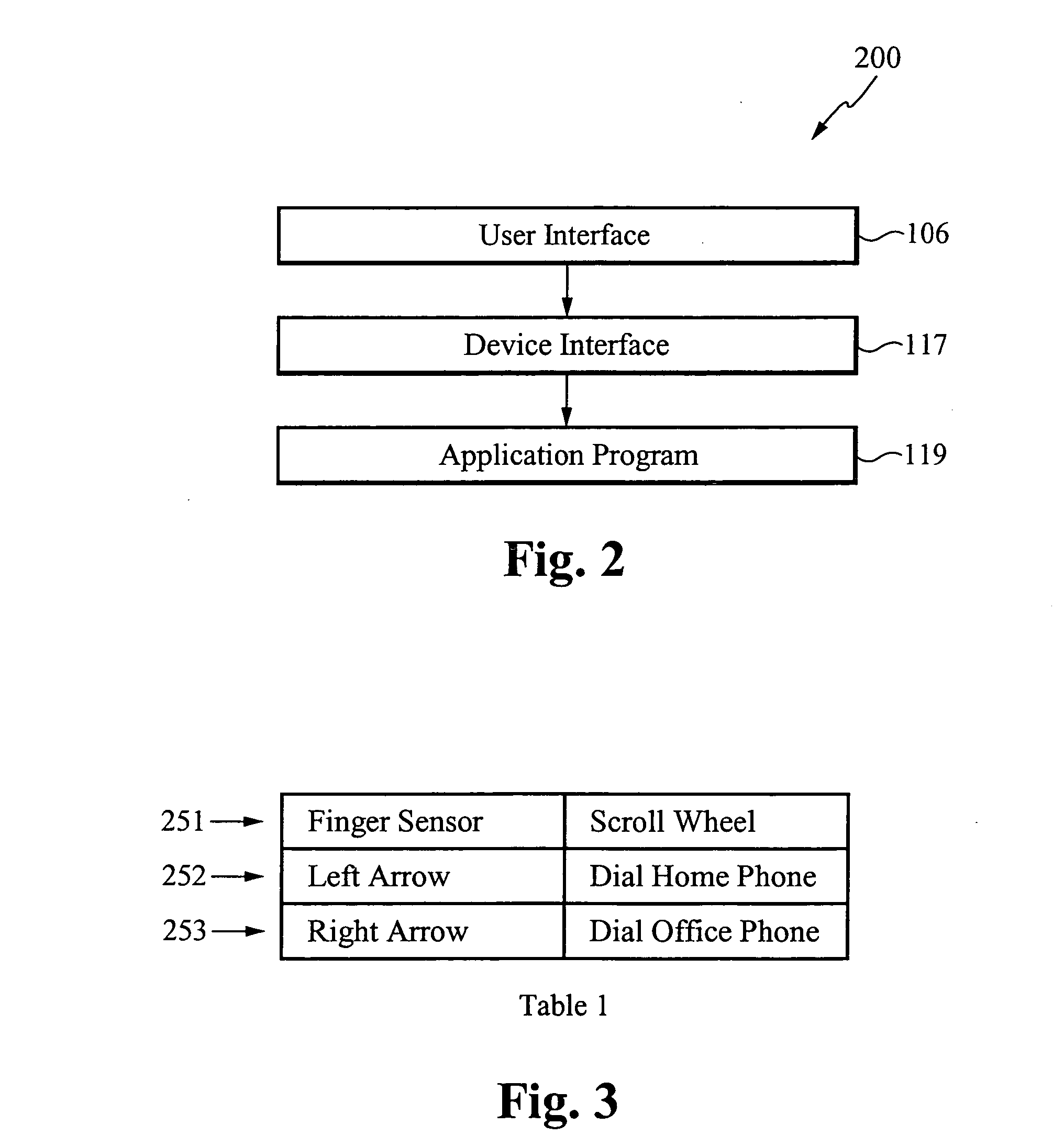

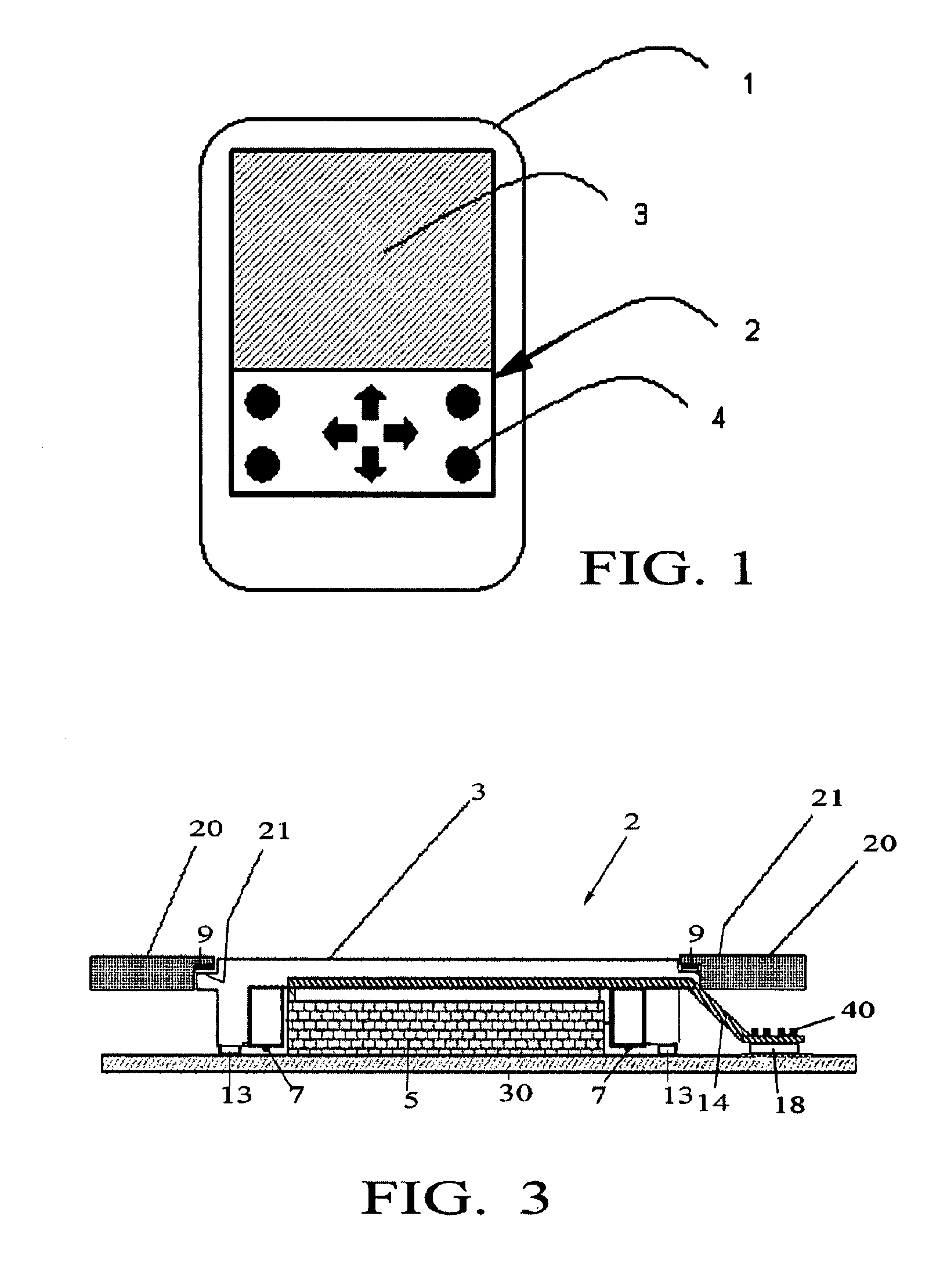

Pressure sensitive touch pad with virtual programmable buttons for launching utility applications

InactiveUS20080259046A1Reduce energy consumptionThe process is simple and convenientInput/output processes for data processingTouchpadApplication software

A pressure sensitive Display Pad having embedded dual functionality such as operating as a mouse for pointer navigation and an array of Virtual Programmable Applications Buttons for selection on the computing device and displaying applications such as a calculator, currency converter, daily event calendar, etc. The device is an improvement to existing resistive and capacitive touch pads that eliminates the need for additional dedicated mechanical buttons for launching utility applications. An exemplary embodiment is disclosed in the context of a laptop computer wherein the Display Pad performs the pointing and selection functions of existing laptop touchpads, and additionally provides for fixed or programmable pressure sensitive application functions using virtual buttons on the touchpad which can launch utility applications associated with those buttons, either on the computer screen or on the Display Pad display or both.

Owner:F-ORIGIN

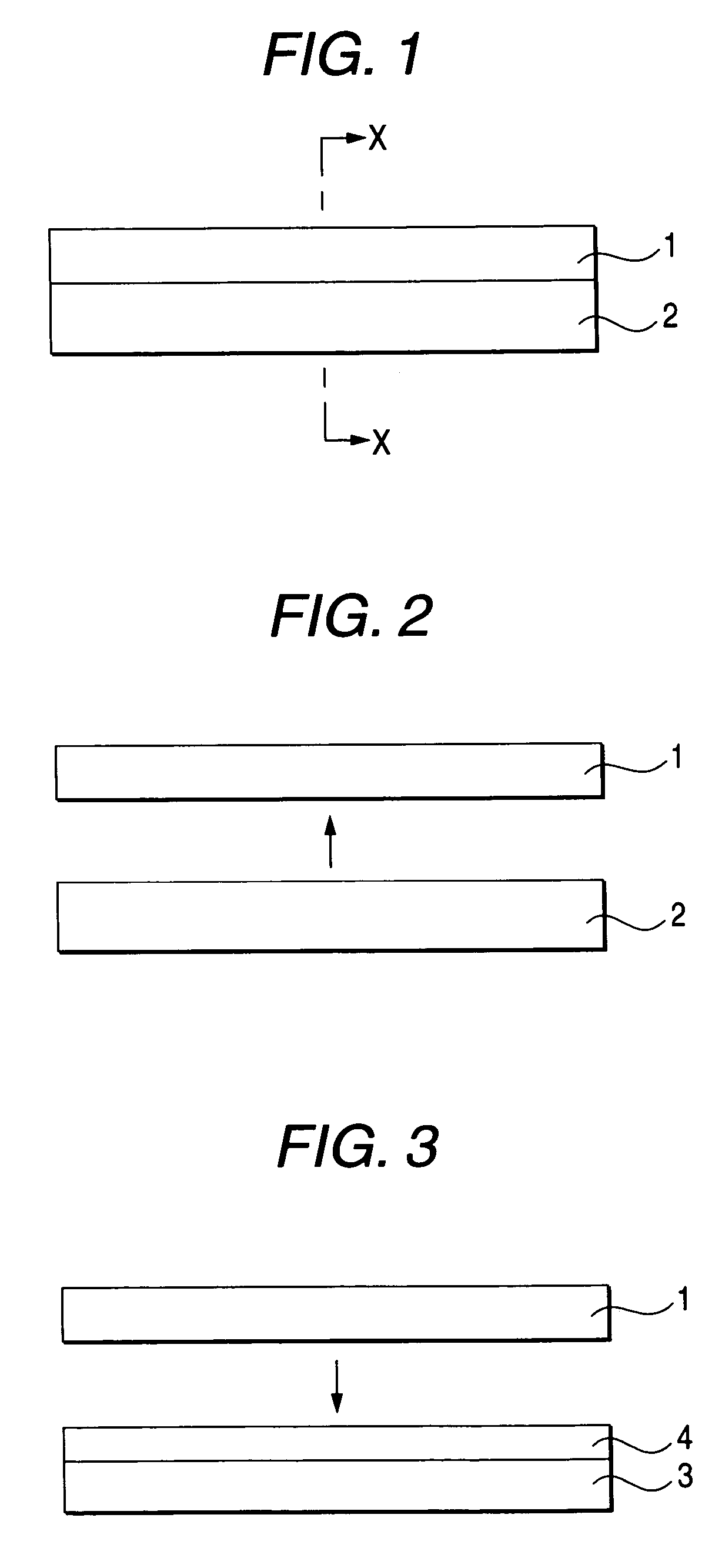

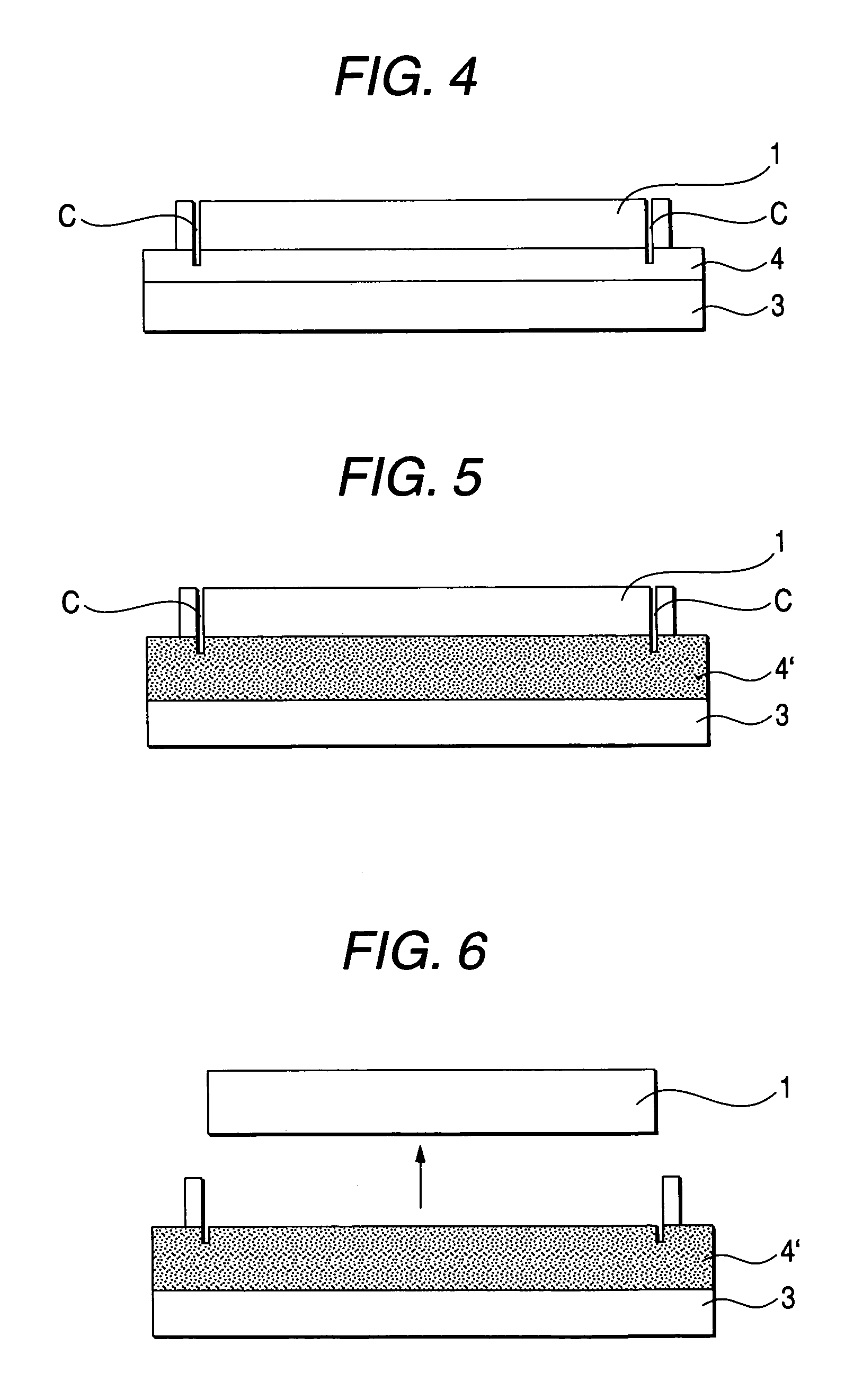

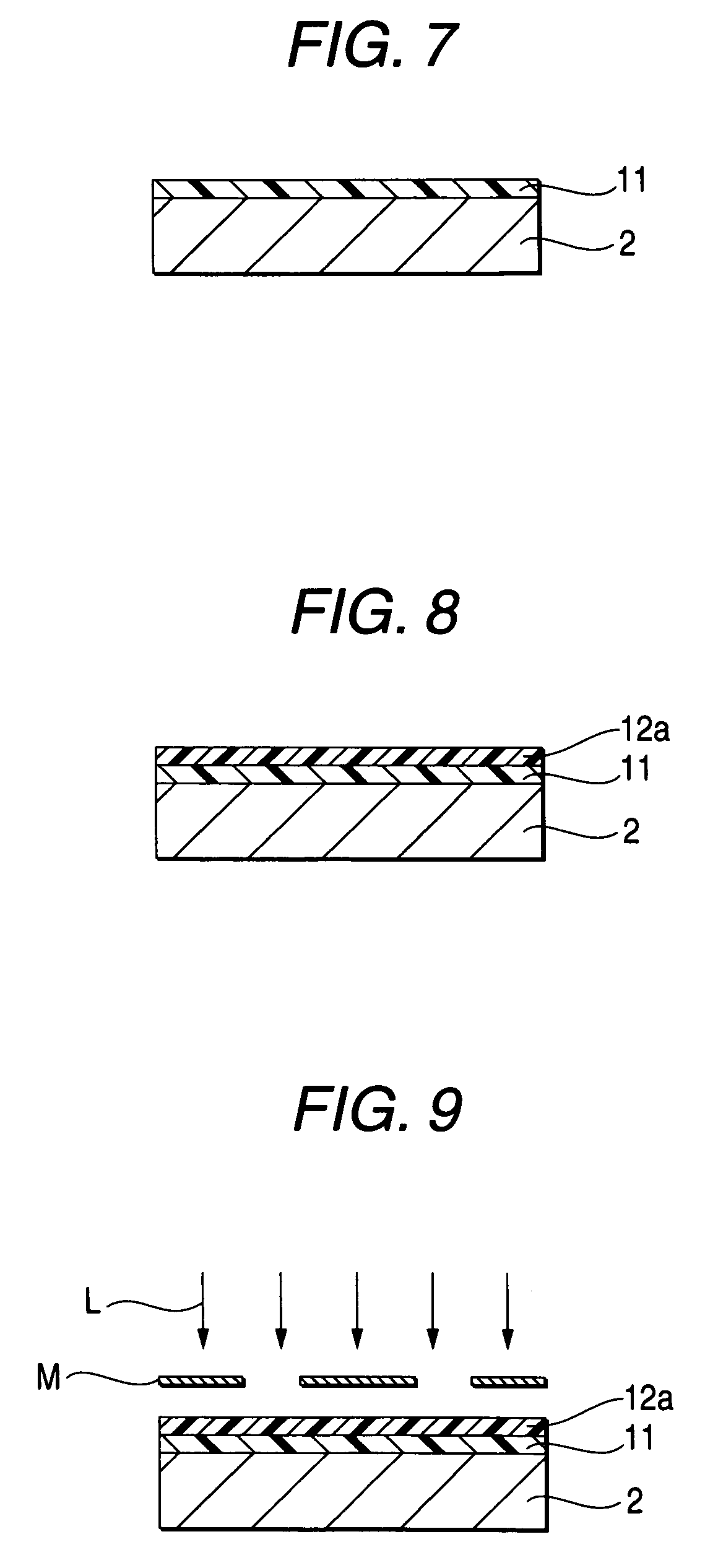

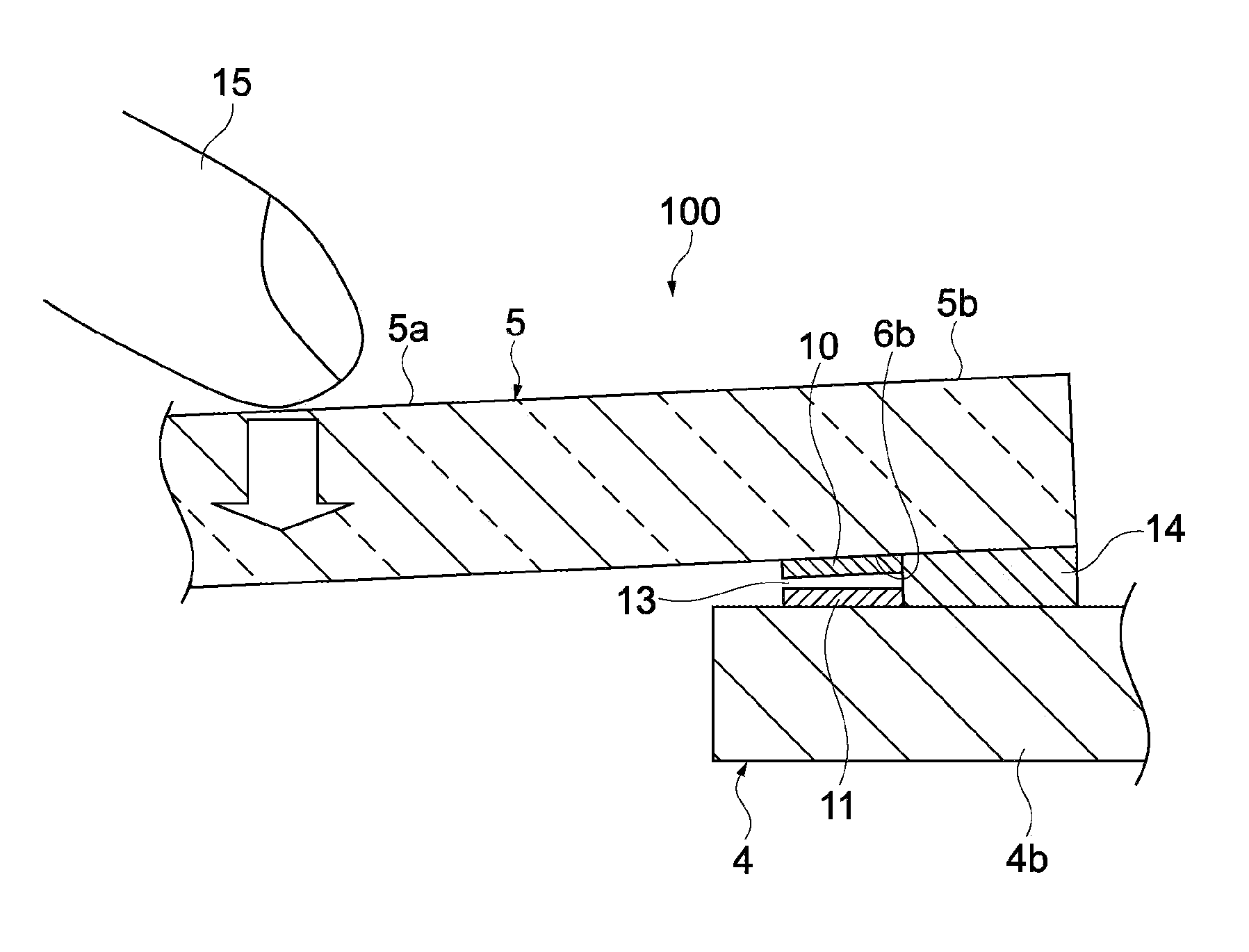

Process for producing flexible optical waveguide

InactiveUS7120345B2Peeling can be safelyReduce adhesionCoupling light guidesOptical waveguide light guideFoaming agentWaveguide

Owner:NITTO DENKO CORP

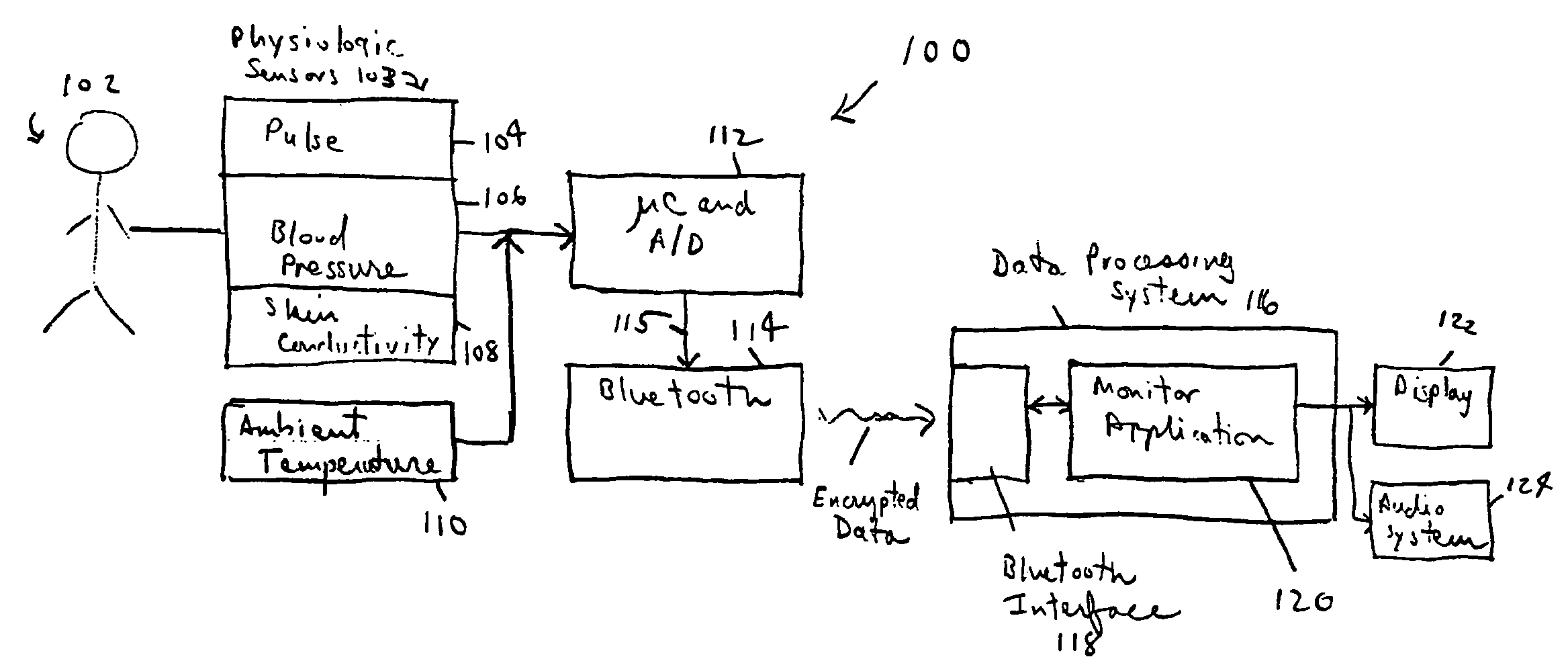

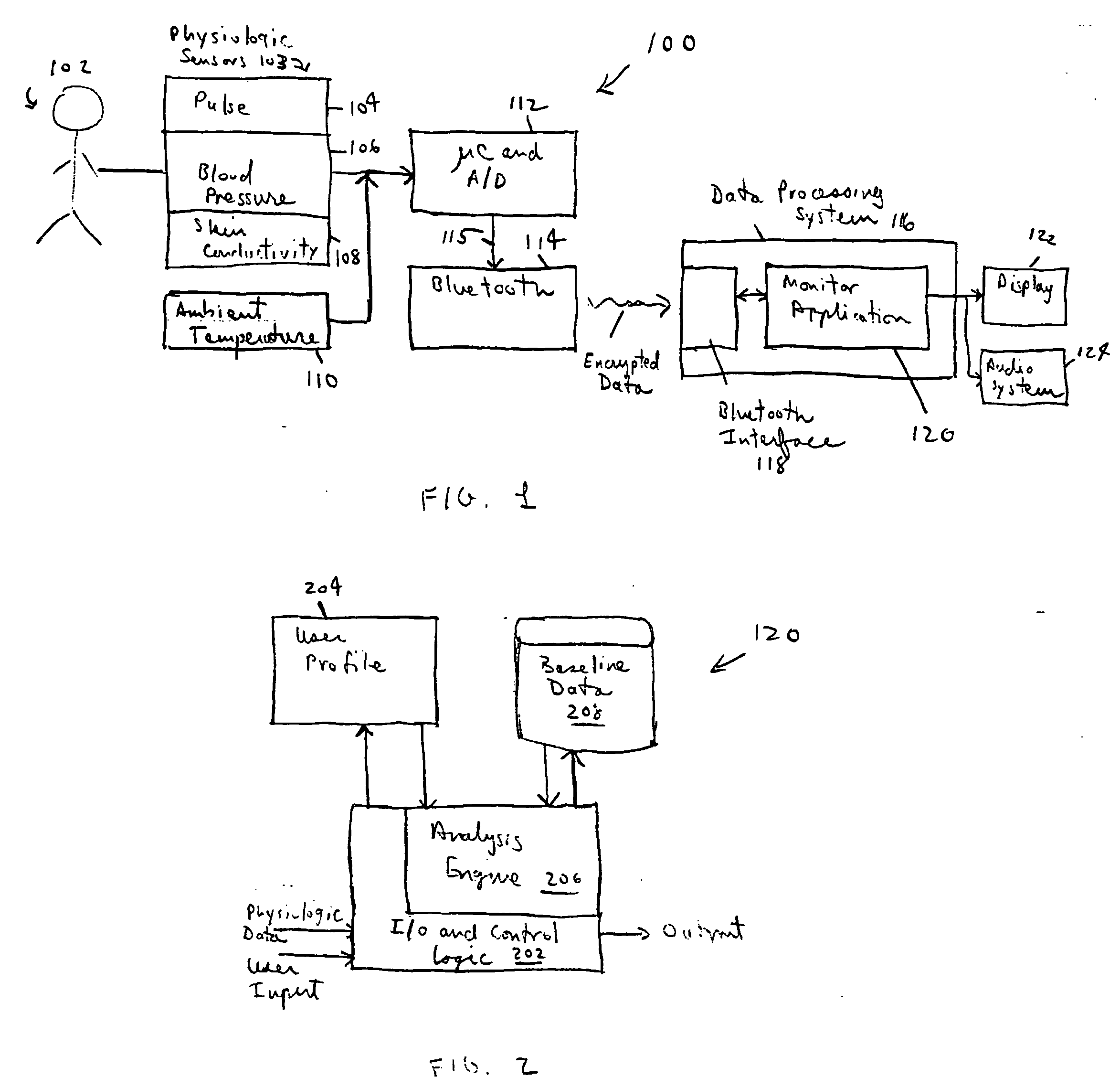

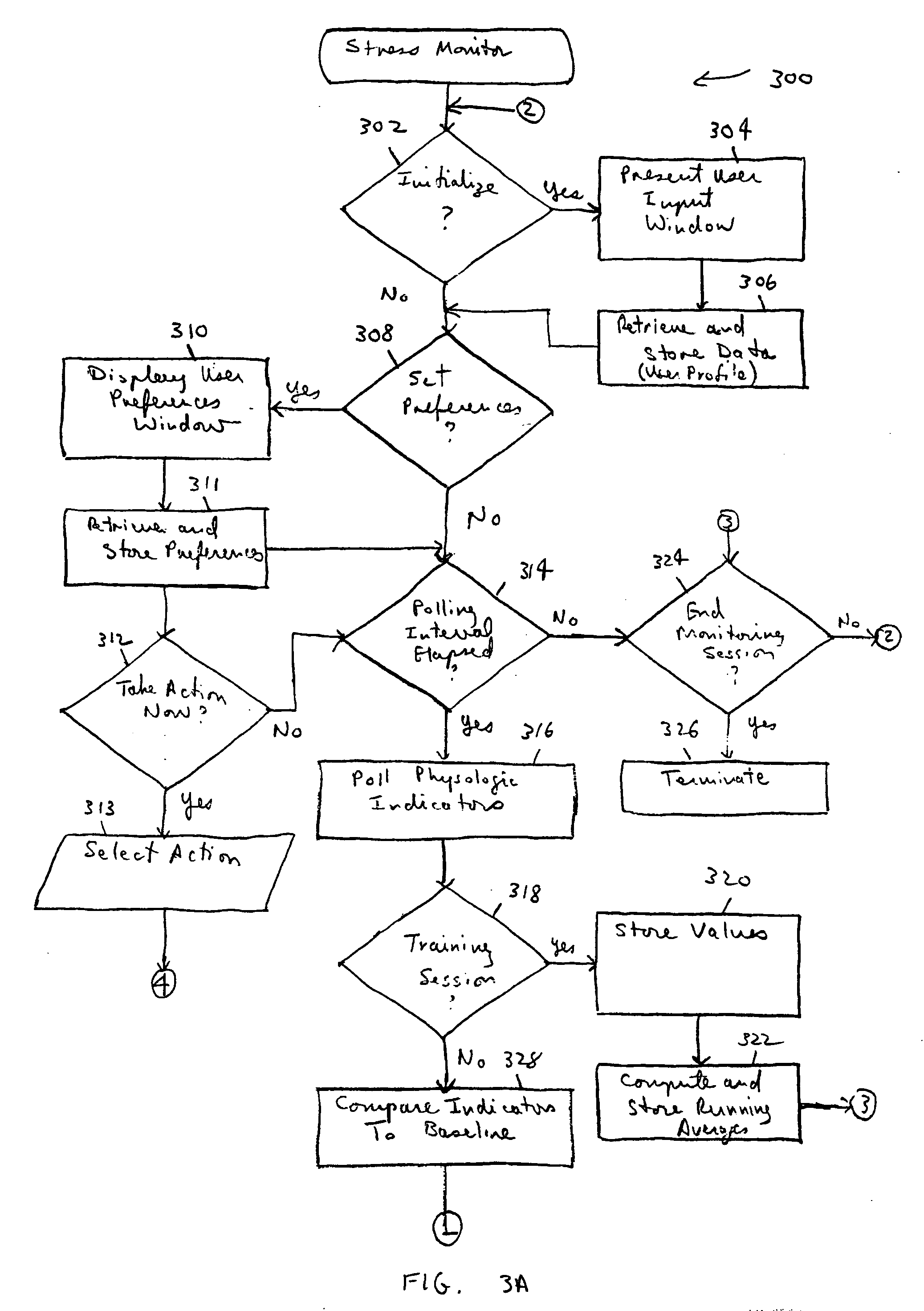

Personal stress level monitor and systems and methods for using same

A mechanism to monitor an individual's level of stress in his or her home or workplace is provided. Unobtrusive physiologic stress senses are used in combination with a wireless link and a personal computer or other intelligent device to monitor the user's stress level. Based on a user profile and the user's baseline stress indicators, one or more stress-reducing activities are presented to the user. Additionally, if a user is in a stress-sensitive population, for example, persons with a pre-existing hypertension, the user may selectively enable additional alerts.

Owner:IBM CORP

Systems for dynamically illuminating touch sensors

InactiveUS20060181521A1Precise positioningSave powerCharacter and pattern recognitionCathode-ray tube indicatorsJoystickEngineering

A system for and method of illuminating a contact (or touch) device such as a fingerprint sensor are disclosed. In an exemplary system, a touch sensor system has a surface or contact area and comprises a substantially transparent molding positioned over the contact area and a dynamic illuminator positioned to show through the molding. The dynamic illuminator is for indicating a status of the touch sensor system, such as power on, standby, error, low power, an input mode for receiving user input, or a selected operating mode. The touch sensor system includes any one of a fingerprint sensor, a miniature joystick, a touch-sensitive navigation disc, a touch-sensing navigation pad, an N-way pressure-sensitive directional control, to name a few touch sensor devices. In one embodiment, when the touch sensor comprises a fingerprint sensor, the operating mode is for emulating an input device such as a scroll wheel, a push button, a steering wheel, a joy stick, a pressure button, and a mouse. The operating mode also includes an authentication mode for authenticating an identity of a user. Preferably, the dynamic illuminator includes light sources and multiple light channels, colored or not, that are configured to be illuminated in multiple configurations, where each configuration corresponds to a status of the touch sensor system.

Owner:AUTHENTEC

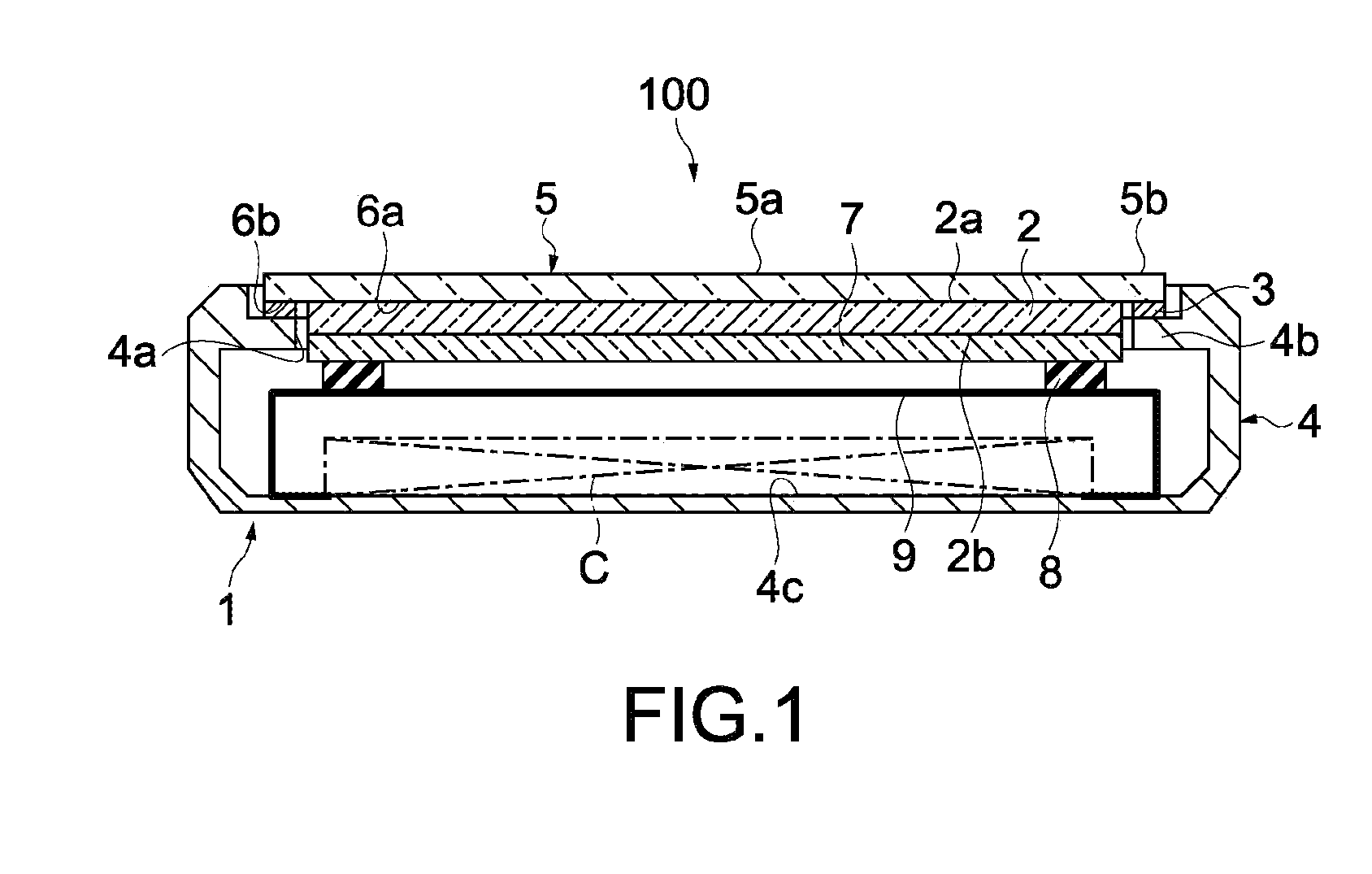

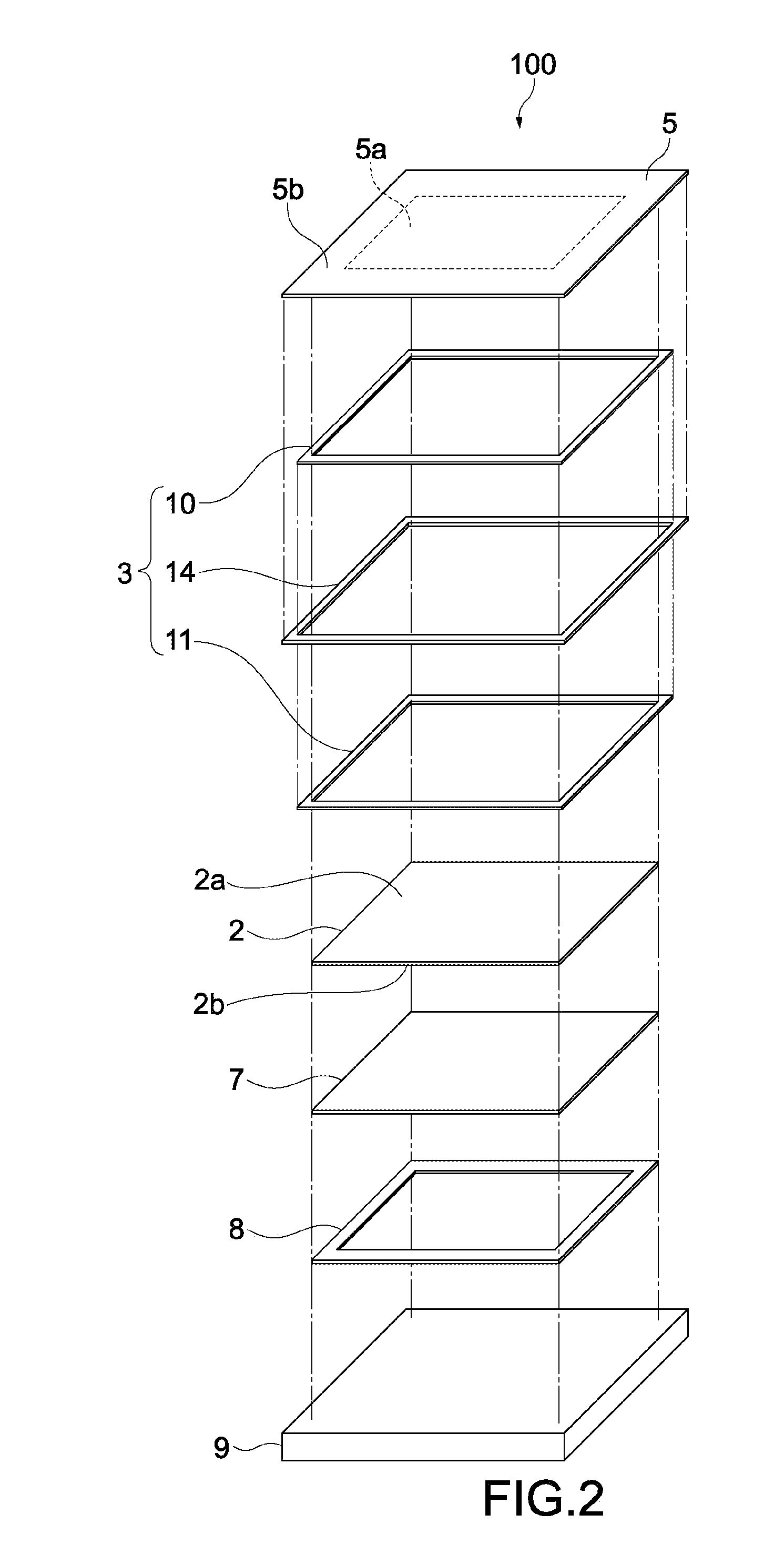

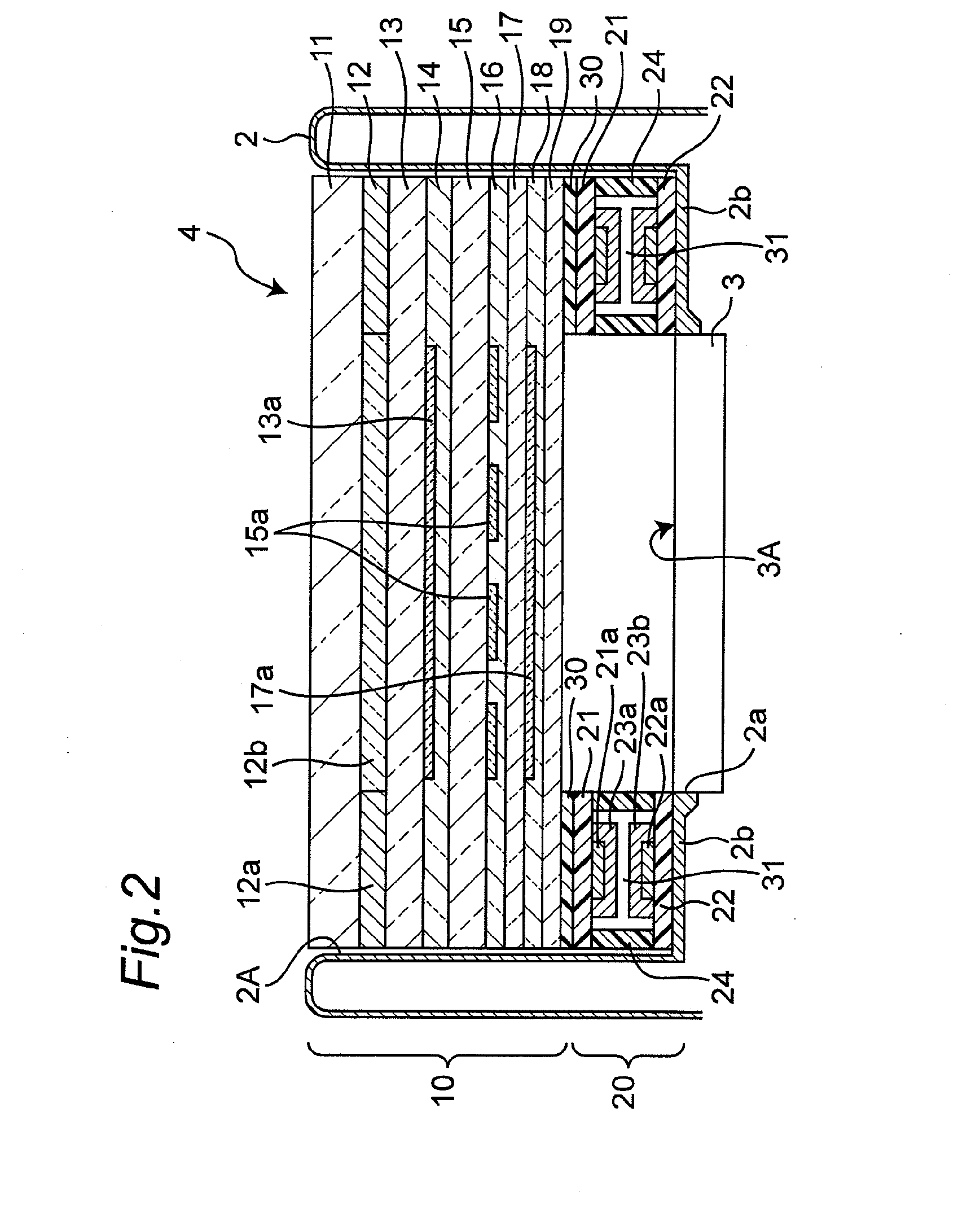

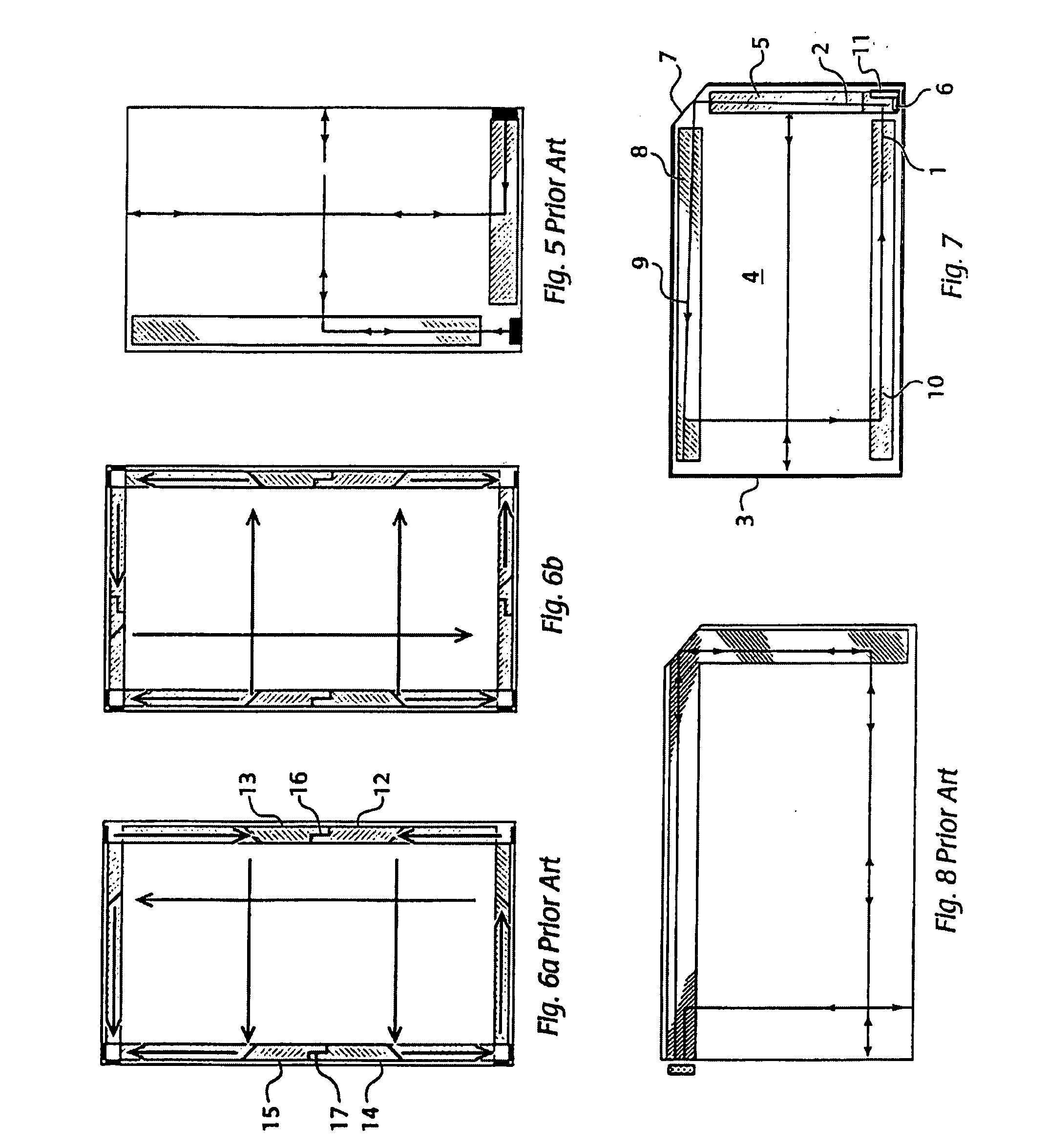

Sensor apparatus and electronic apparatus

InactiveUS20110175845A1Simple structureLow number of componentsInput/output processes for data processingCapacitanceDisplay device

A sensor apparatus includes: a display cover including an operation area that is pressed by an operator and a circumferential area located on the circumference of the operation area; a frame including an opening covered by the operation area and a fixing portion that fixes the circumferential area; a touch panel that is supported by the display cover to be positioned at the opening and detects a position at which the operator comes into contact with the operation area; and a pressure-sensitive sensor that is provided between the display cover and the frame, includes a first electrode and a second electrode opposed to the first electrode, and detects a pressing force with respect to the operation area based on a change of a capacitance between the first electrode and the second electrode that corresponds to a deflection amount of the display cover.

Owner:SONY CORP

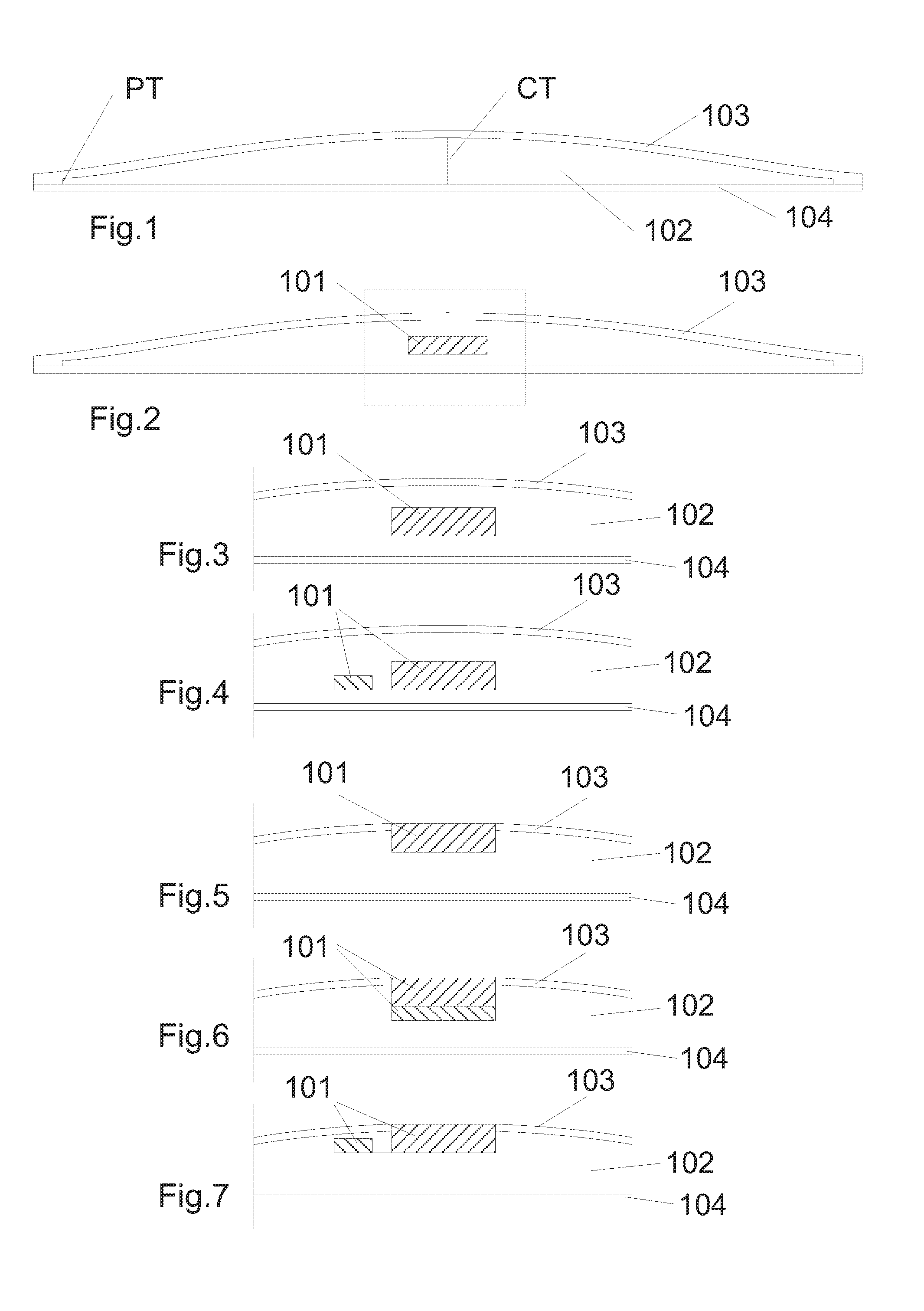

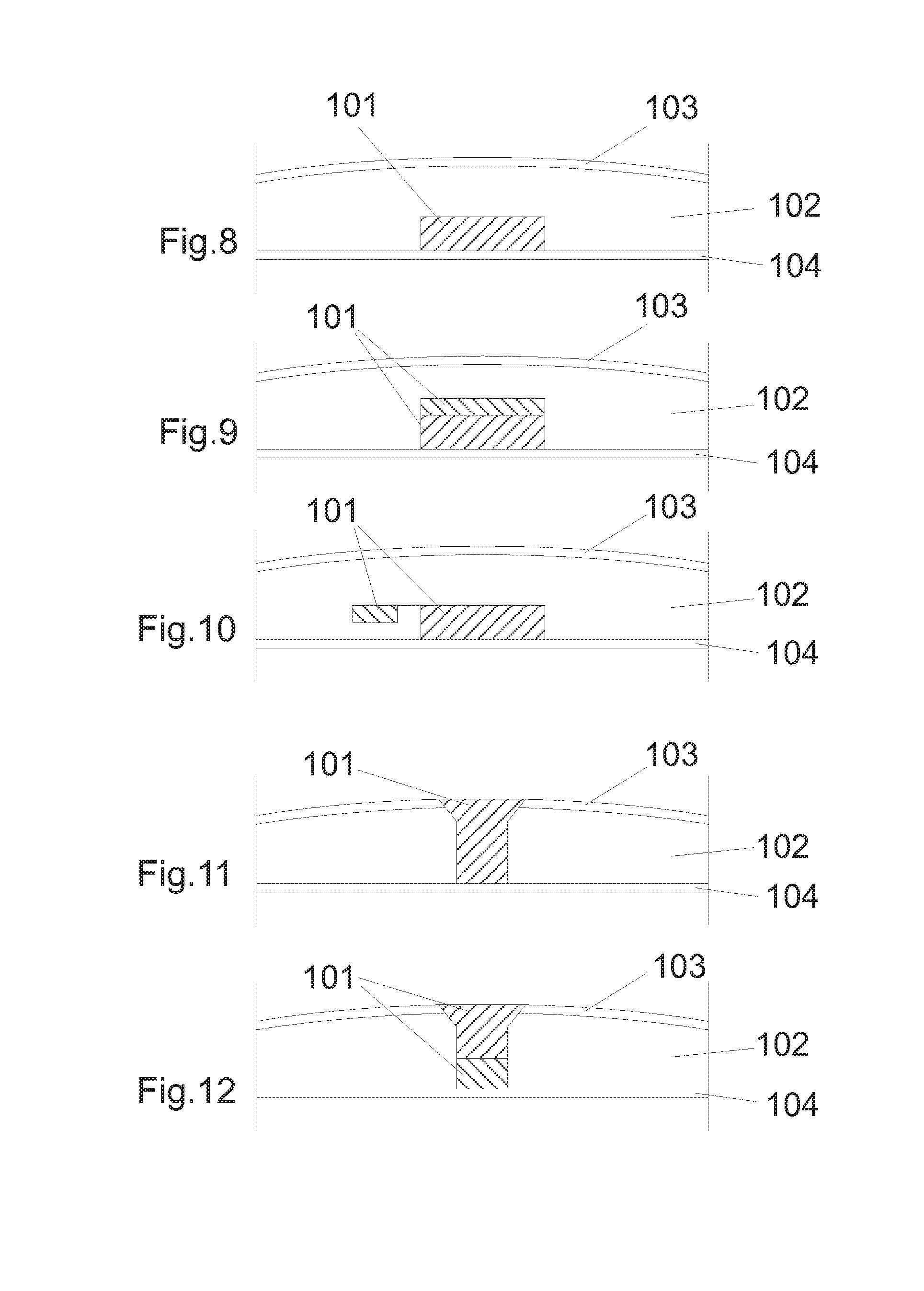

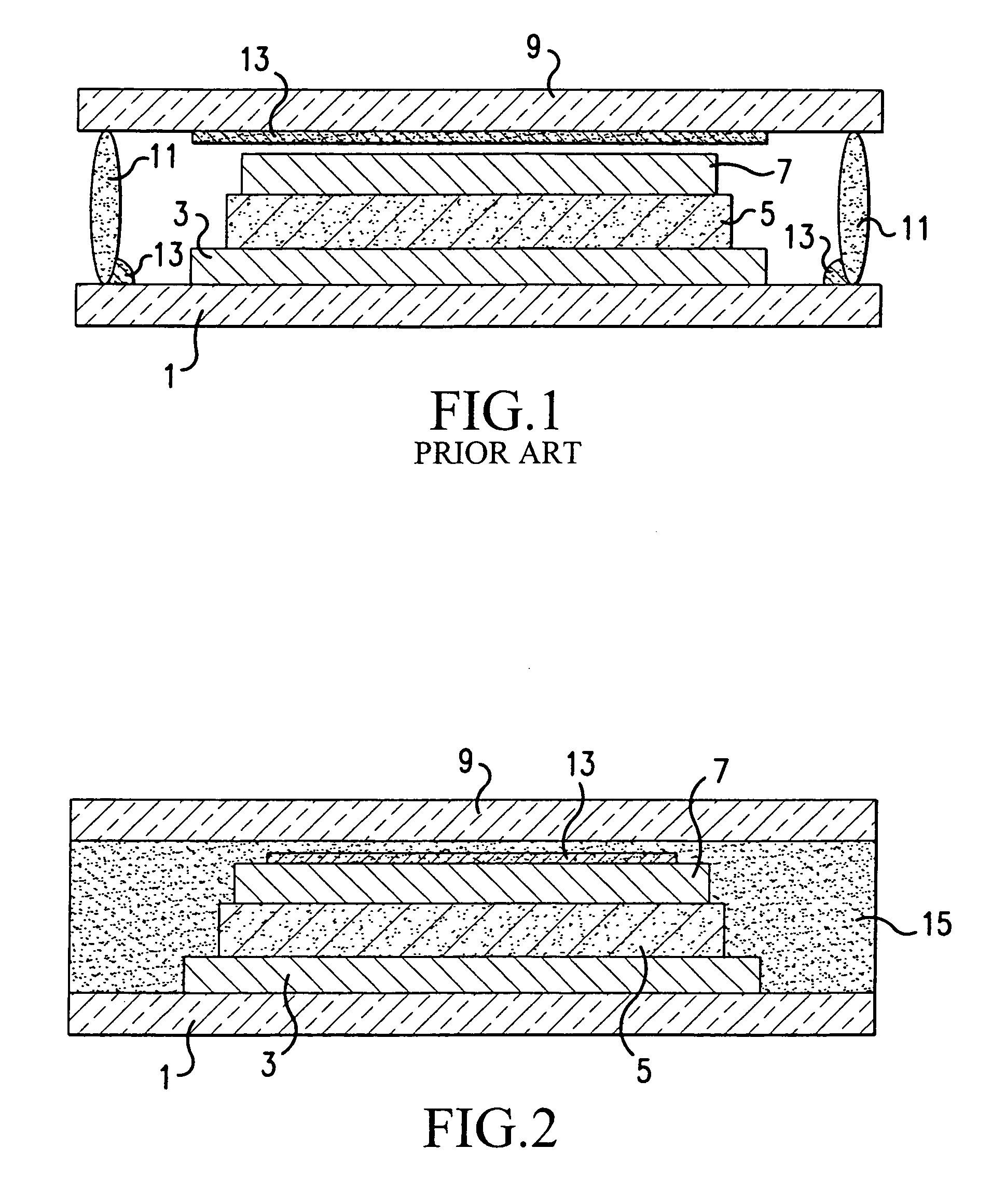

Touch panel having press detection function and pressure sensitive sensor for the touch panel

InactiveUS20110115738A1Degradation of visibility can be suppressedInhibition biasForce measurement by measuring frquency variationsApparatus for force/torque/work measurementVisibilityDisplay device

An object of the present invention is to provide a touch panel having a press detection function, which makes it possible to suppress degradation of visibility of a display unit of a display device even when mounted on an electronic device, and also to improve a pressure measuring precision. For this purpose, the touch panel of the present invention includes a first substrate, a second substrate disposed oppose to the first substrate, a pair of electrodes disposed on either one of opposed surfaces of the respective substrates or disposed separately on both of the surfaces, pressure sensitive ink members disposed with a gap from at least one of the pair of electrodes, each of the pressure sensitive ink members having an electrical characteristic varied by a pressing force applied thereto, and a gap retaining member for bonding the first and second substrates to each other and for retaining a gap between each of the pressure sensitive inks and at least one of the pair of electrodes, wherein the pair of electrodes are disposed in a frame shape along an edge portion of the first or second substrate, and the pressure sensitive ink members are scattered along the edge portion of the first or second substrate so that, when the first or second substrate is deformed upon an application of an external force, at least one of them is made in contact with both of the pair of electrodes so as to make the two electrodes conductive to each other.

Owner:NISSHA PRINTING COMPANY

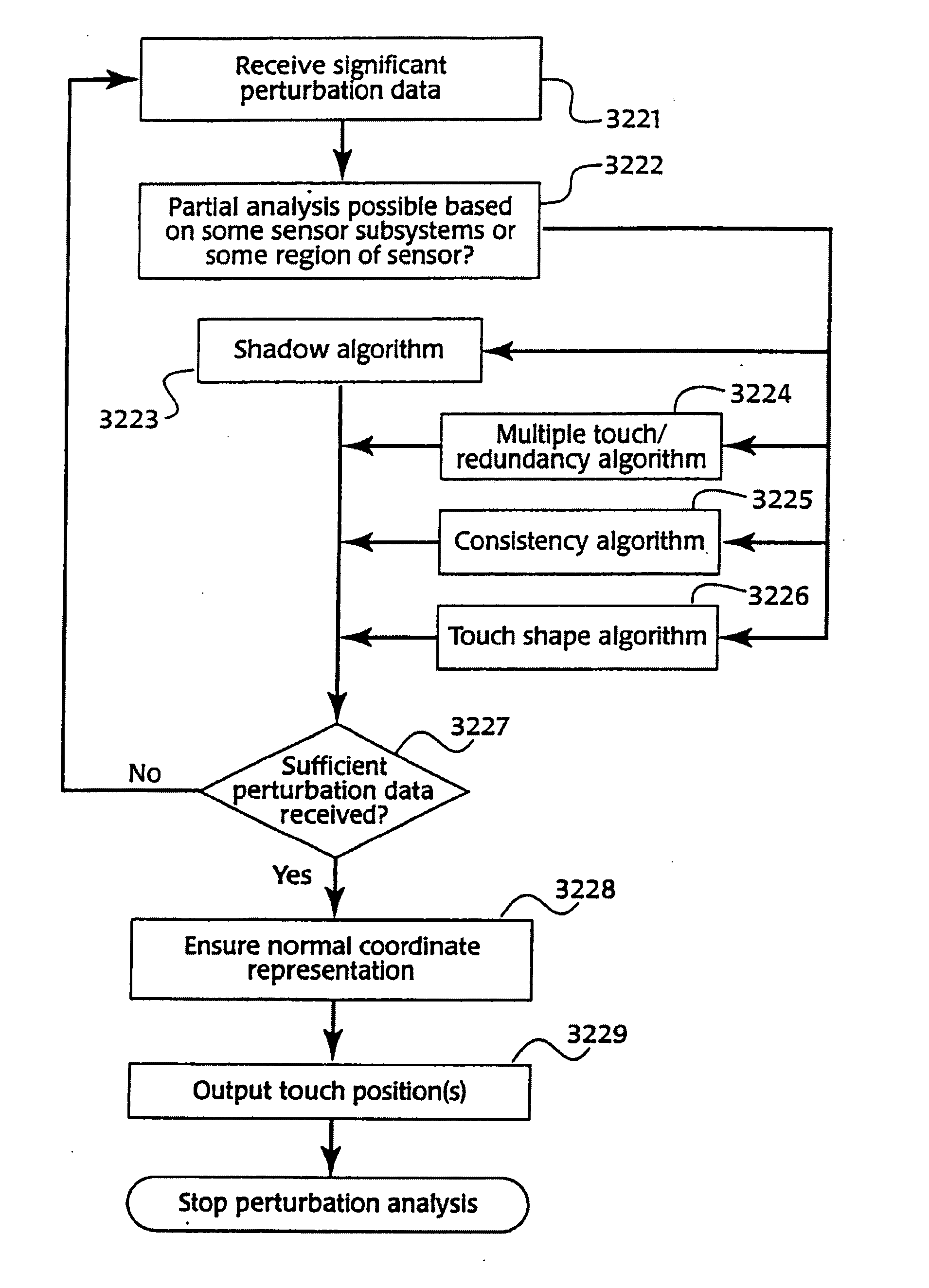

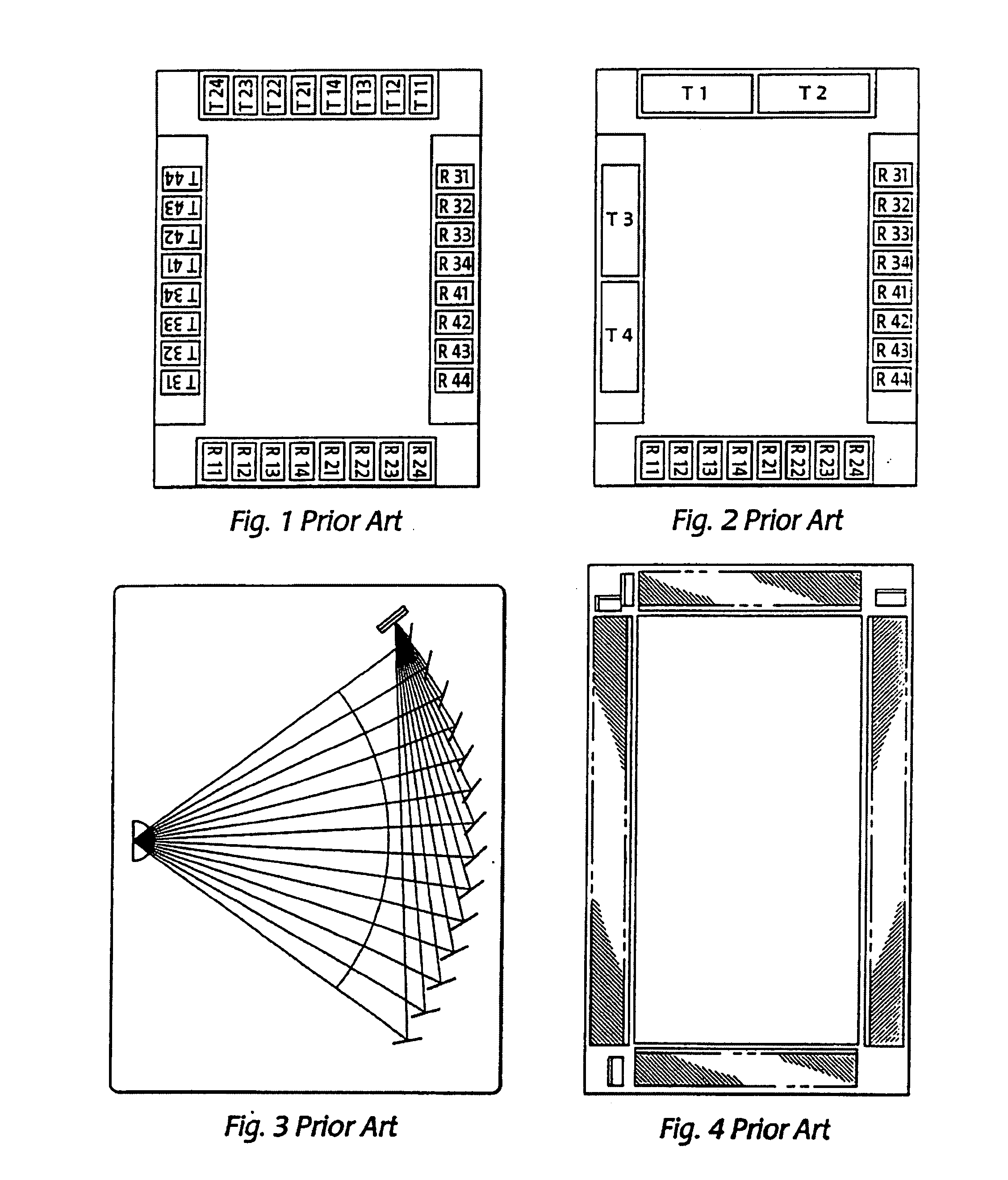

Acoustic condition sensor employing a plurality of mutually non-orthogonal waves

InactiveUS20080062151A1Reliable reconstructionImprove the level ofCathode-ray tube indicatorsInput/output processes for data processingTouchscreenNon orthogonal

A system and method for processing input from a touchscreen having a substrate and a touch surface thereof, adapted for manual interaction with a human hand, having an electronic sensor associated with said substrate adapted to detect a pressure sensitive response to at least two concurrent touches on the touch surface, having a control which receives at least one signal representing the at least two concurrent touches on the touch surface; processes the at least one signal in a manner adapted to maintain a distinction between the at least two concurrent touches; determines a respective difference of at least one coordinate between the at least two concurrent touches; and responds by selectively producing a response at least in dependence on a relationship of the coordinate of the at least two concurrent touches.

Owner:ELO TOUCH SOLUTIONS INC

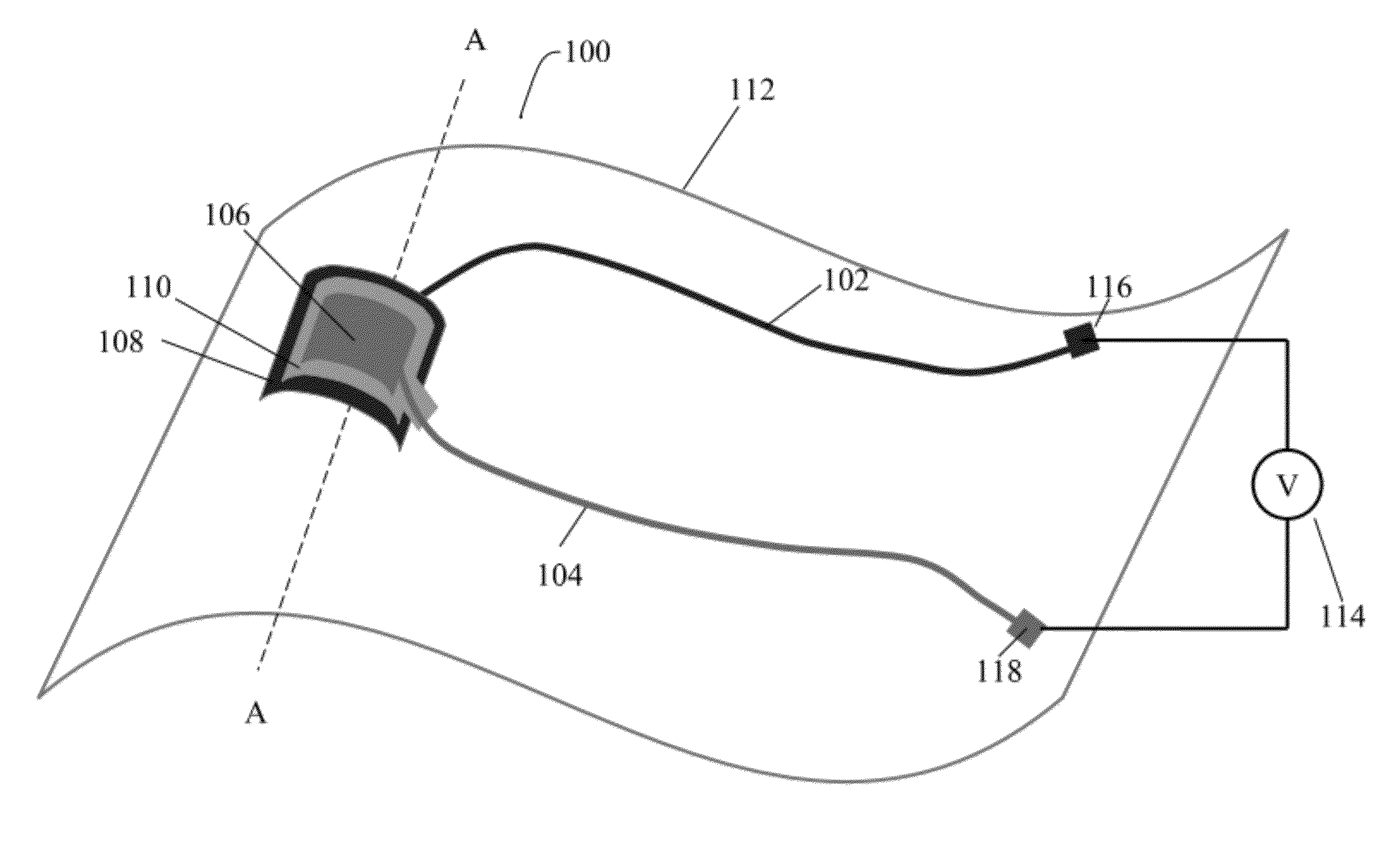

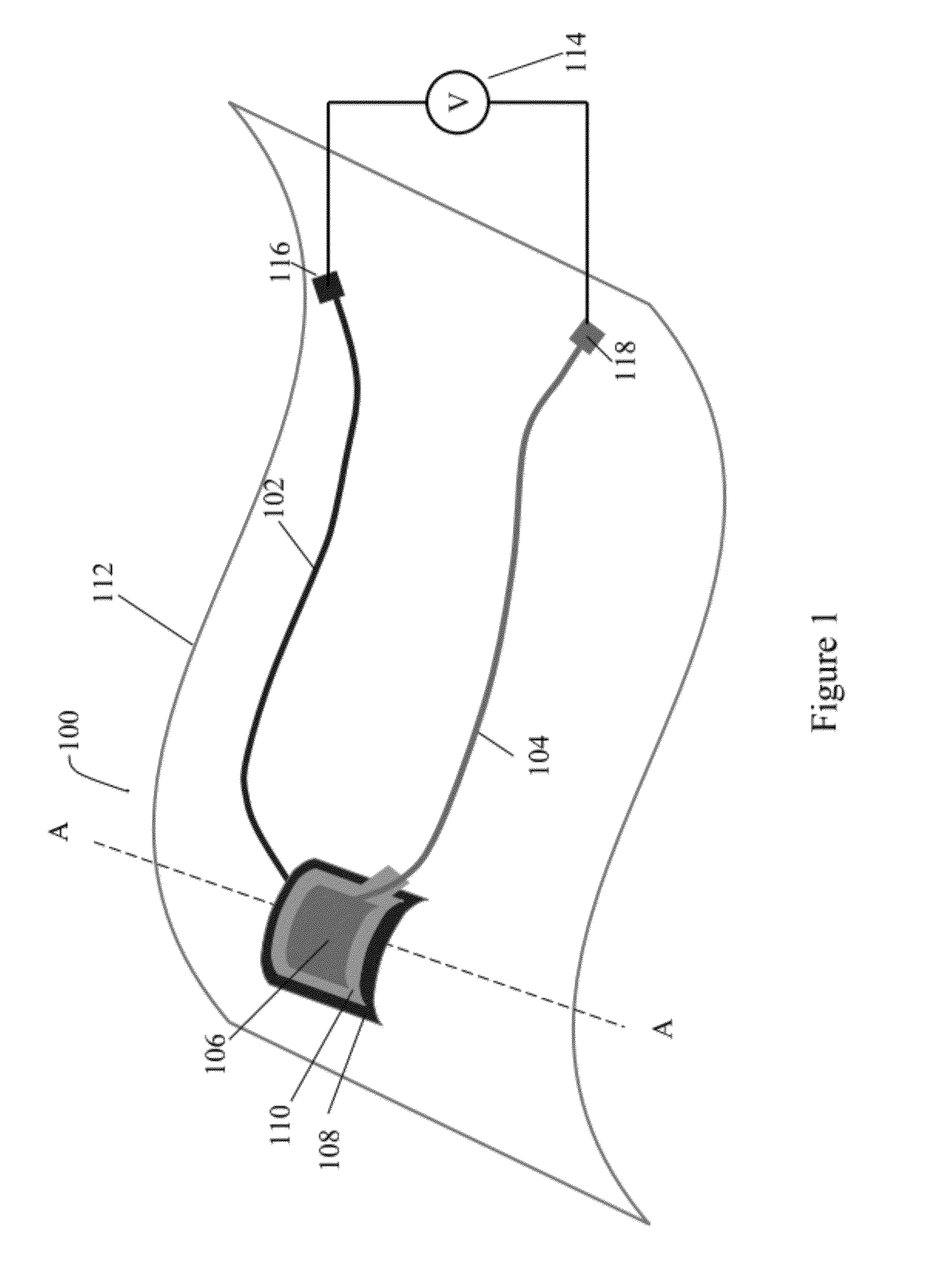

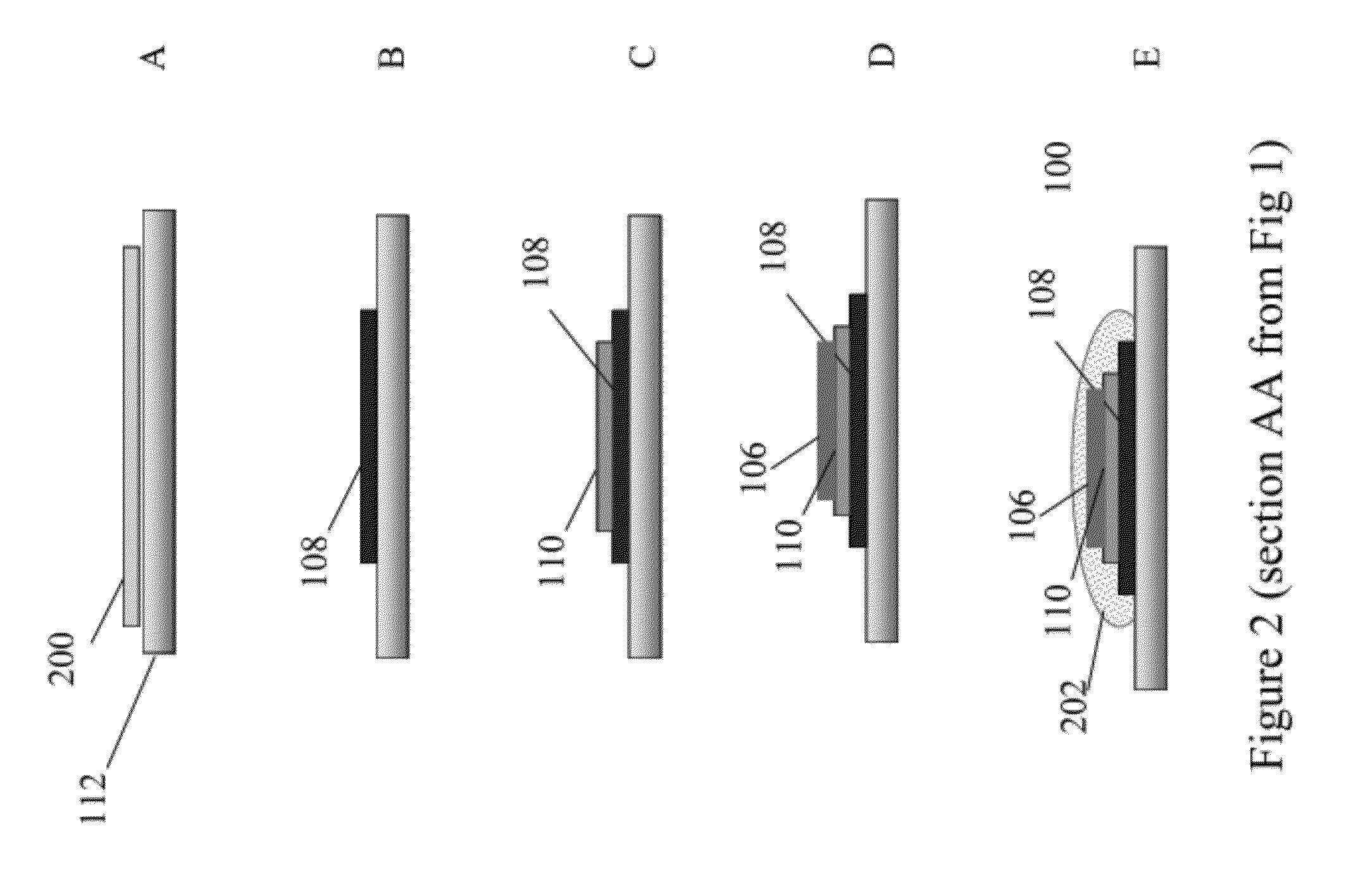

Pressure sensing or force generating device

ActiveUS20120055257A1Few contactsShorten the counting processPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesCapacitanceCapacitive effect

In one aspect, the present invention relates to a pressure sensing / force generating device comprising a non-planar substrate, a printed pressure sensitive element comprising (a) a piezoelectric material containing ink composition capable of producing a piezoelectric effect / piezoresistive effect and / or (b) a dielectric material containing ink composition capable of producing a capacitive effect. It also includes a first printed electrode comprising a conductive ink composition, and a second printed electrode comprising a conductive ink composition. The first and second electrodes are in electrical contact with the printed pressure sensitive element. The first and second printed electrodes and the printed pressure sensitive element collectively form a pressure sensitive junction, which is coupled to the non-planar substrate. The present invention further relates to medical devices comprising the pressure sensing / force generating device and methods of making such devices.

Owner:MICROPEN TECH CORP

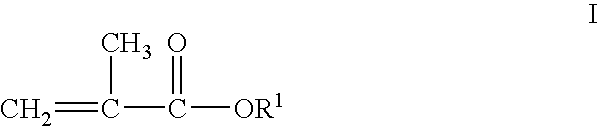

Reactive diluent and curable resin composition

InactiveUS20030199655A1Effect is not sufficientLow water resistanceFatty acid chemical modificationFatty acids production/refiningVinyl etherHydrogen atom

The present invention provides a reactive diluent composition which overcomes drawbacks of both the radical-cure and the cationic-cure reactive diluents and can be applied in a broad variety of uses such as paints, inks, adhesives, pressure sensitive adhesives, surface-modifiers, and molding materials; a curable resin composition containing the same; an activated energy ray-curable resin composition; and an activated energy ray-curable ink composition for ink-jet printing. A reactive diluent composition comprising a vinyl ether group-containing (meth)acrylic ester represented by the following general formula (1): CH2=CR<1>-COO-R<2>-O-CH=CH-R<3> (1) wherein R<1 >represents a hydrogen atom or a methyl group; R<2 >represents an organic residue of 2 to 20 carbon atoms; R<3 >represents a hydrogen atom or an organic residue of 1 to 11 carbon atoms and a hydroxyl group-containing polymerizable compound and / or divinyl ether.

Owner:NIPPON SHOKUBAI CO LTD

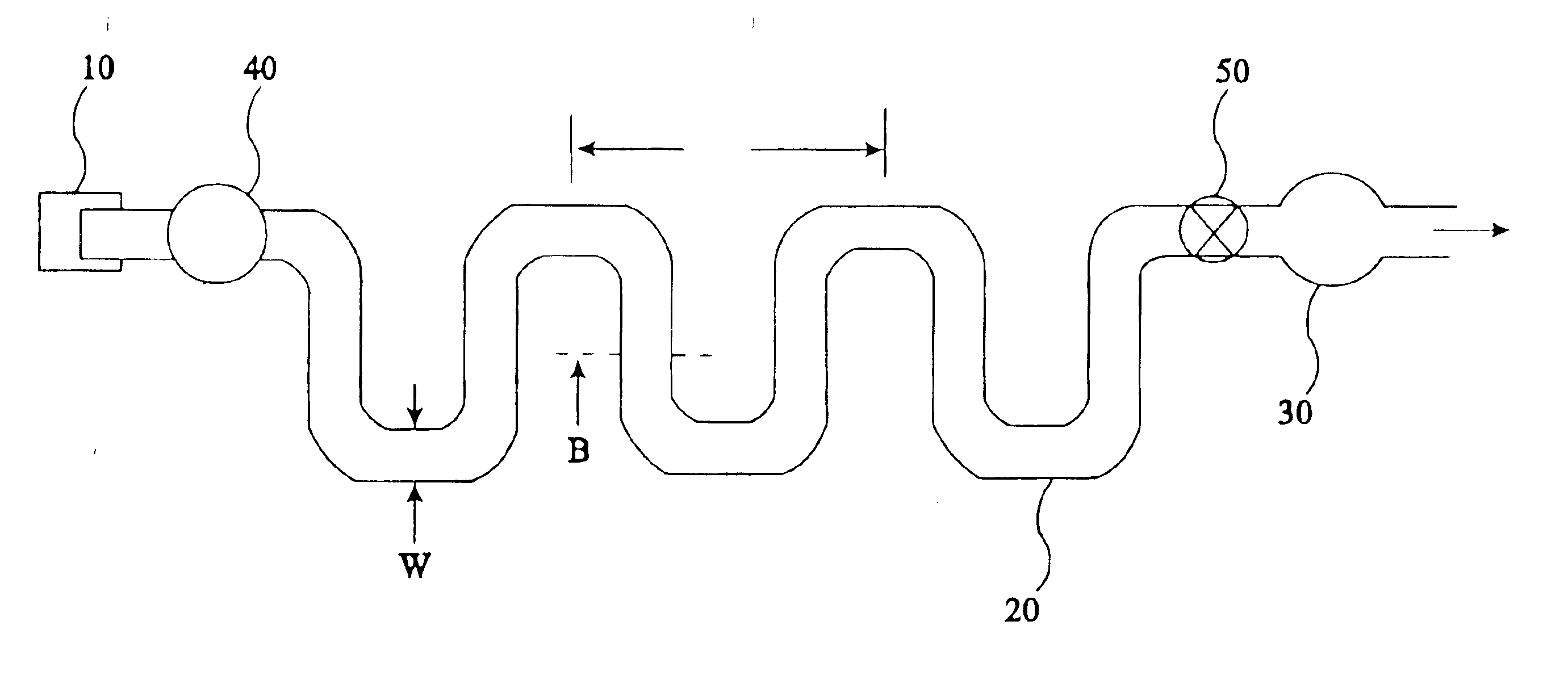

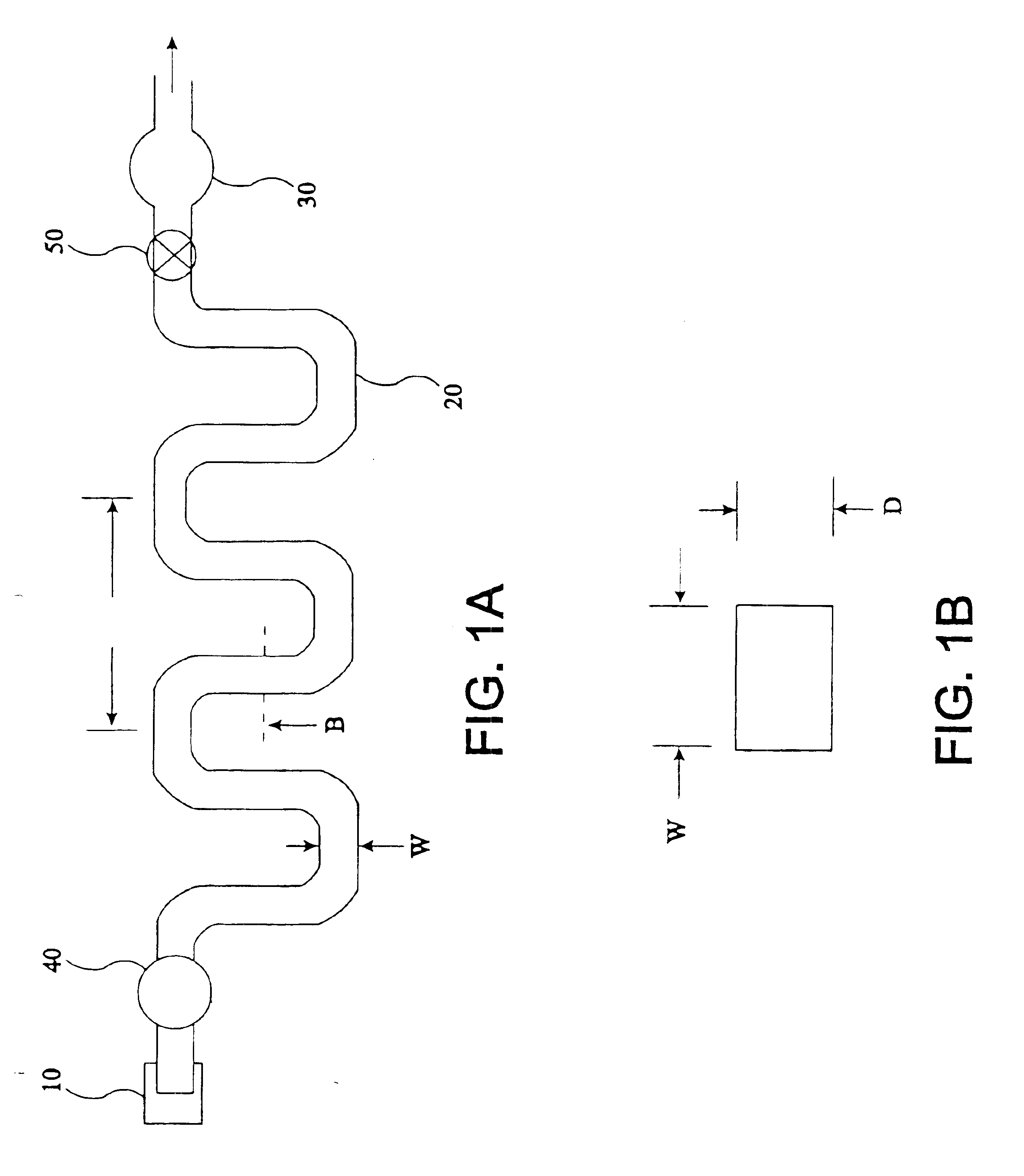

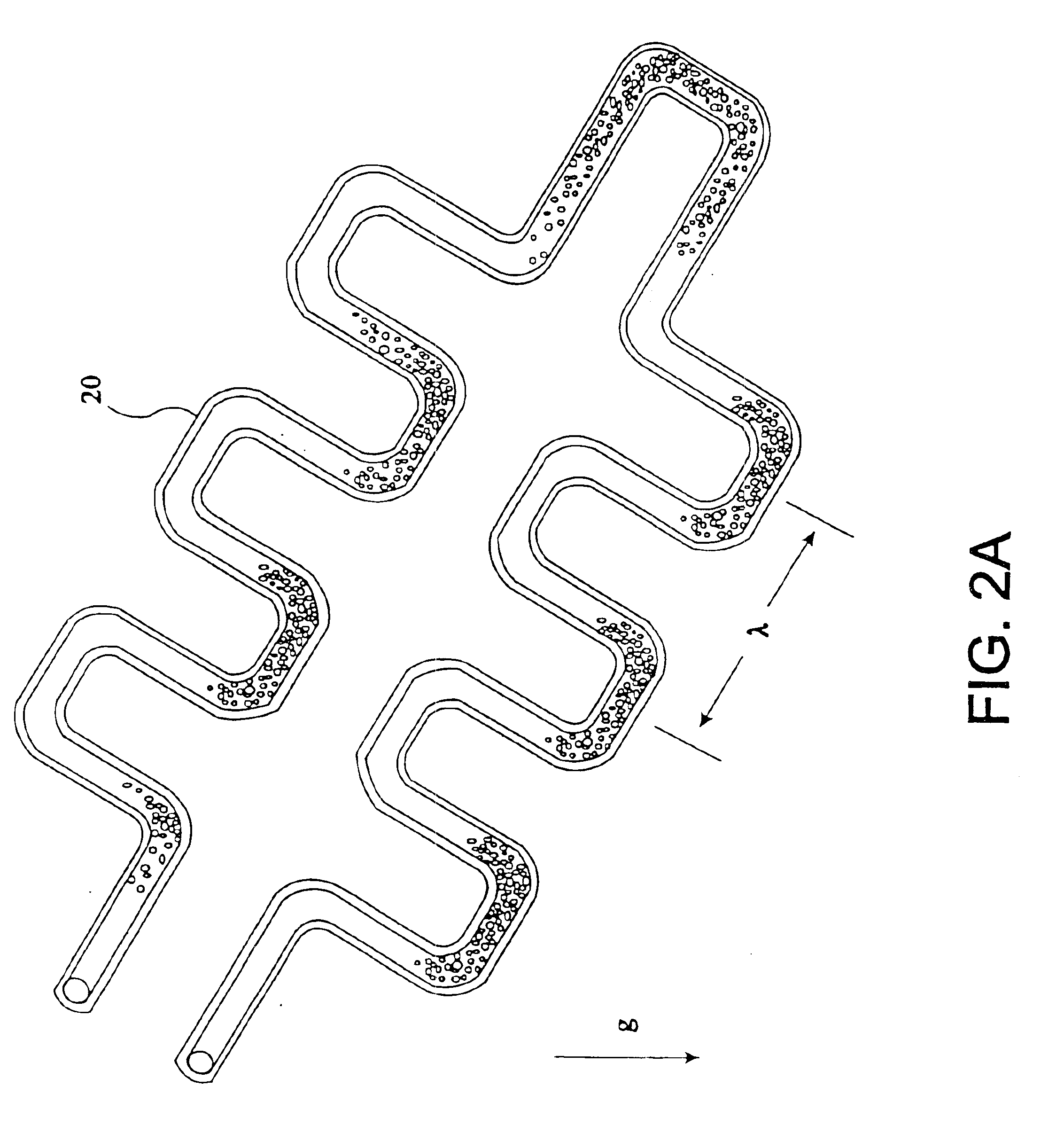

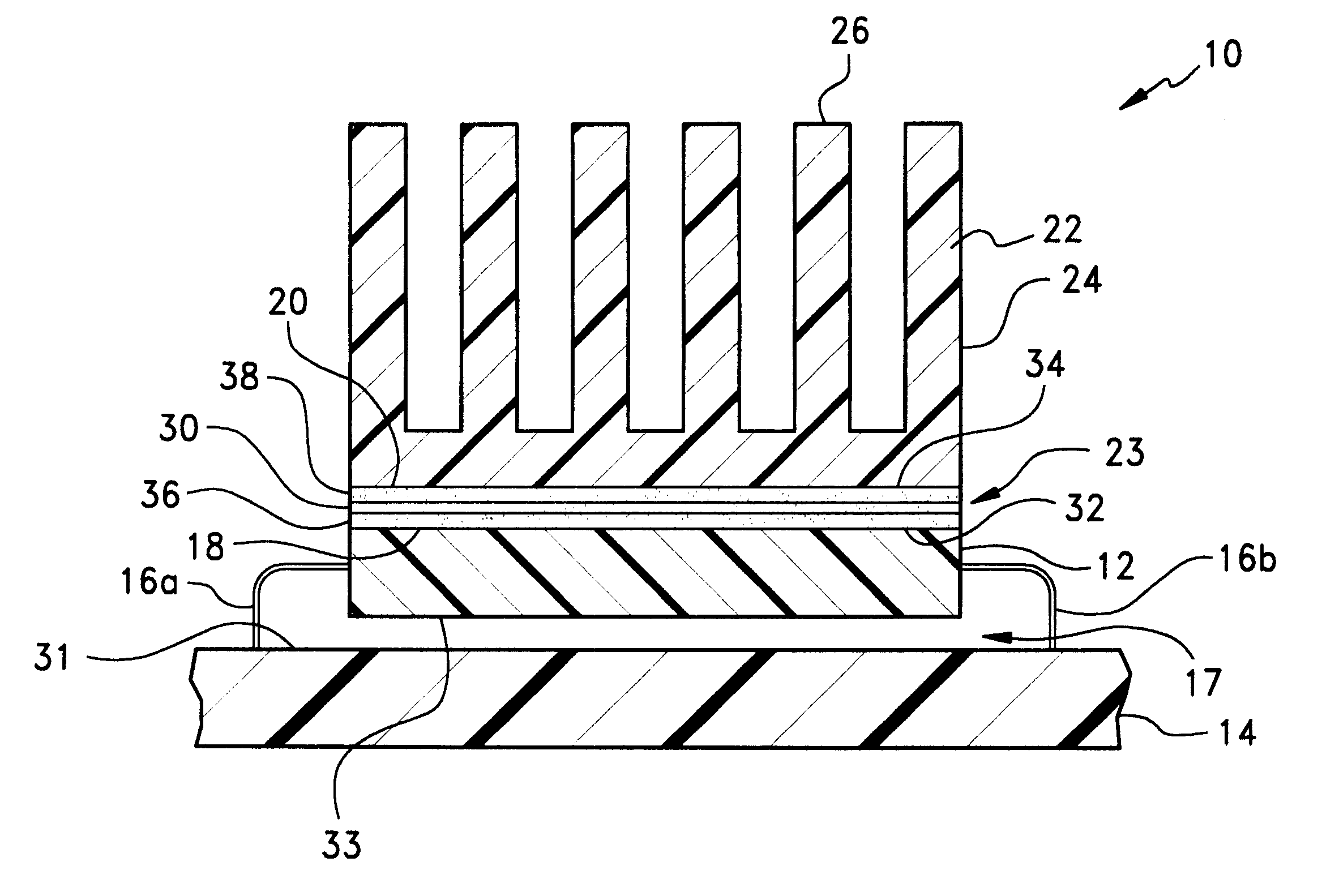

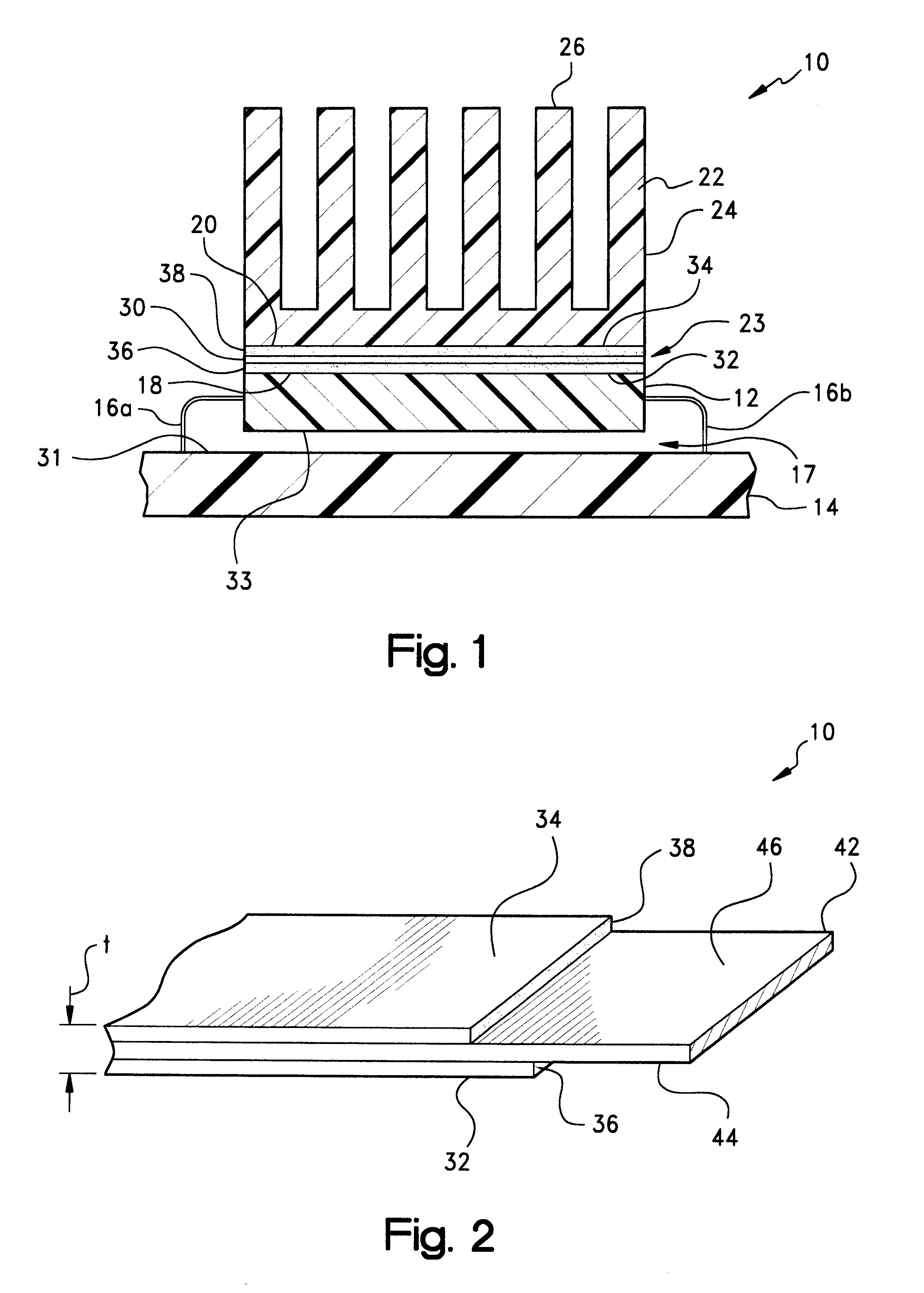

Liquid analysis cartridge

InactiveUS6852284B1Rapidly and effectively reconstituteEasy to reorganizeFlow mixersTransportation and packagingShell moldingDiluent

The present invention provides an apparatus and method for storing a particle-containing liquid. The storage apparatus comprises a microfluidic convoluted flow channel having a plurality of article capture regions. The storage channel is preferably an isotropic spatially periodic channel. Sedimented particles can be resuspended following storage. This invention further provides a microfluidic analysis cartridge having a convoluted storage channel therein. The sample analysis can use optical, electrical, pressure sensitive, or flow sensitive detection. A plurality of analysis channels can be included in a single cartridge. The analysis channels can be joined to reagent inlets for diluents, indicators or lysing agents. A mixing channel can be positioned between the reagent inlet and the analysis region to allow mixing and reaction of the reagent. The cartridge can include additional valves and pumps for flow management. The analysis cartridge can be a self-contained disposable cartridge having an integral waste storage container. This invention further provides a sheath flow assembly. The sheath flow assembly includes a sample channel and first and second sheath fluid channels positioned on either side of and converging with the sample channel. The assembly also includes upper and lower sheath fluid chambers positioned above and below and converging with the sample channel. The flow cartridges of this invention can be formed by molding, machining or etching. In a preferred embodiment they are laminated. This invention further provides a method of fabricating a laminated microfluidic flow device. In the method, flow elements are formed in rigid sheets and abutting surfaces of the sheets are bonded together.

Owner:UNIV OF WASHINGTON

Double-side thermally conductive adhesive tape for plastic-packaged electronic components

InactiveUS6432497B2Easy `` peel and stick '' installationPrecise thermal and adhesive propertiesInsulating substrate metal adhesion improvementSemiconductor/solid-state device detailsEngineeringHeat sink

A thermally conductive interface, which may be in the form of a double-sided, pressure sensitive adhesive tape, disposable intermediate a heat-generating source having a first heat transfer surface formed of a first material having a low surface energy, and a thermal dissipation member having a second heat transfer surface which is formed of a second material having a surface energy substantially higher than the surface energy of the first material, and which is disposable opposite the first heat transfer surface of the heat-generating source in a spaced-apart, heat transfer adjacency therewith. The interface includes a first pressure sensitive adhesive (PSA) surface which is bondable under pressure to at least a portion of the first heat transfer surface of the heat-generating source, and an opposing second pressure sensitive adhesive (PSA) surface bondable under pressure to at least a portion of the second heat transfer surface of the heat-generating source. The first PSA surface is presented from a layer of a thermally-conductive, first pressure sensitive adhesive composition, preferably silicone-based, having an affinity to the first heat transfer surface of the heat generating source. In turn, the second PSA surface is presented from a layer of a second pressure sensitive adhesive composition, preferably acrylic-based, different from the first composition and having an affinity to the second heat transfer surface of the thermal dissipation member. The interface is particularly adapted for bonding a plastic packaged electronic component to a metal heat sink.

Owner:PARKER INTANGIBLES LLC

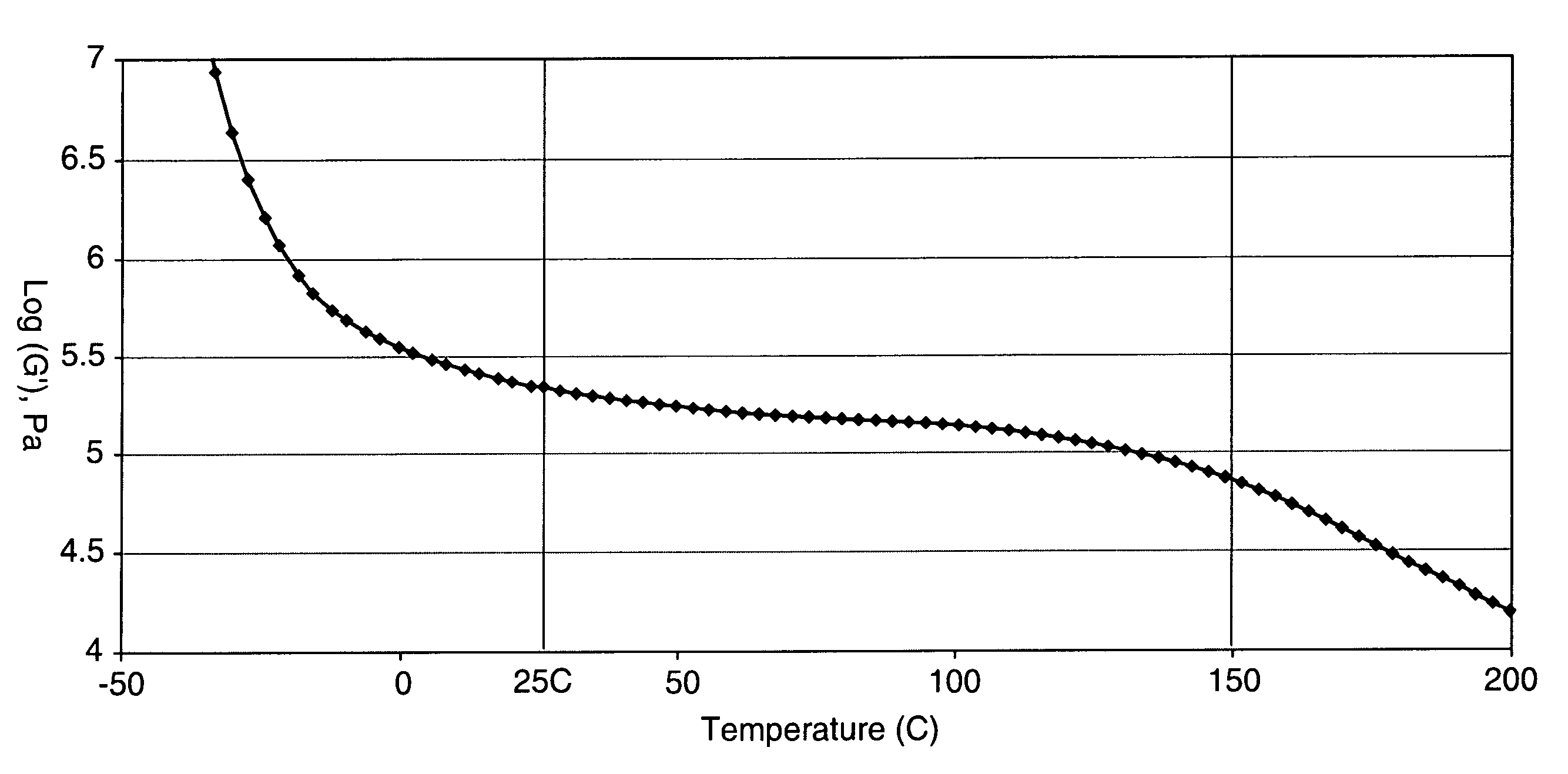

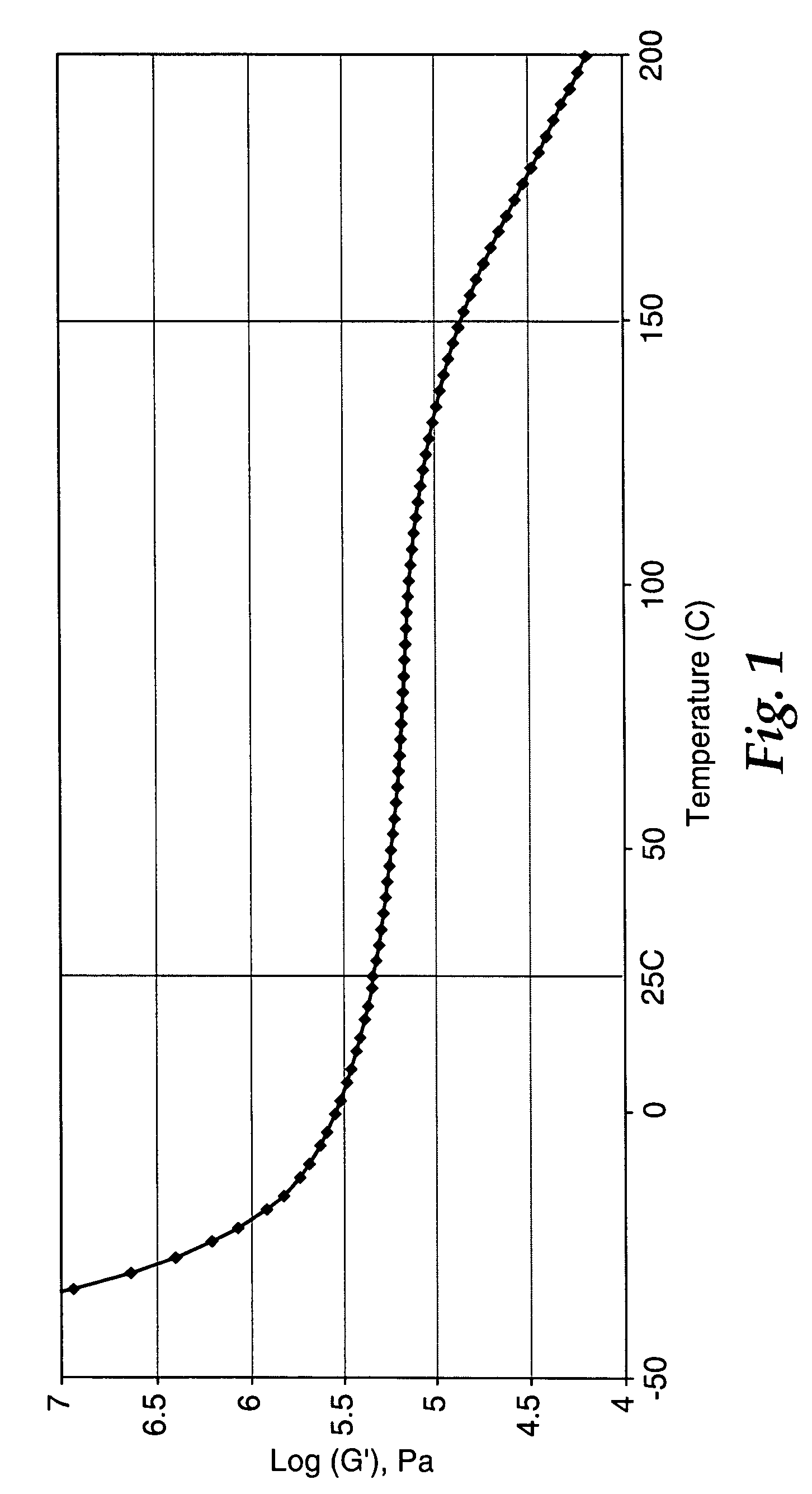

(Meth)acrylate block copolymer pressure sensitive adhesives

Articles are provided that include an optical film and an optically clear pressure sensitive adhesive layer on at least one outer surface of the optical film. Additionally, articles are provided that include a pressure sensitive adhesive layer that resists bubble formation when adhered to an outgassing substrate. The pressure sensitive adhesive layer in the various articles contain a (meth)acrylate block copolymer.

Owner:3M INNOVATIVE PROPERTIES CO

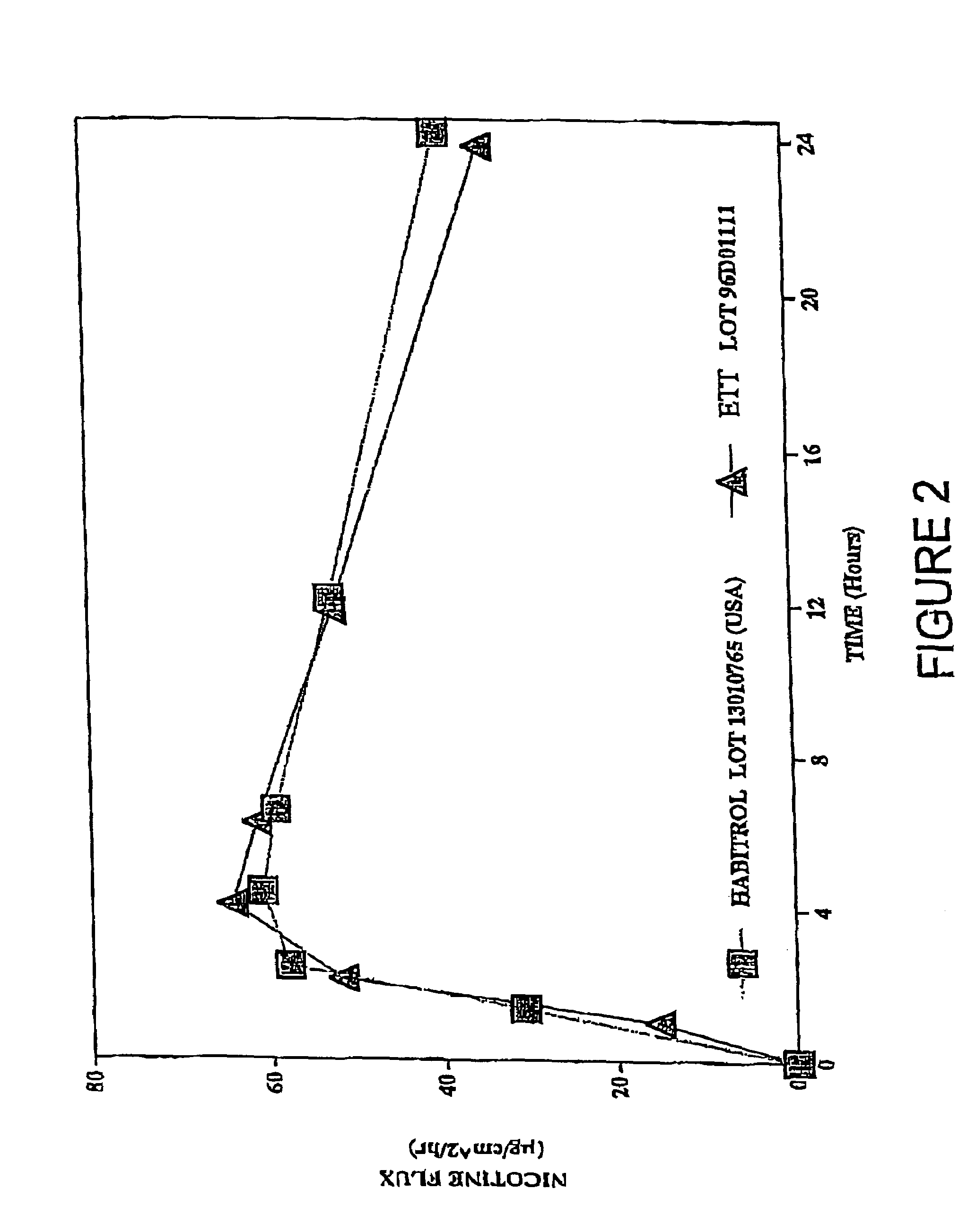

Transdermal patch for delivering volatile liquid drugs

A transdermal patch for administering a volatile liquid drug, such as nicotine, transdermally to a patient comprising a four-layer laminated composite of: a top drug impermeable backing layer; a pressure sensitive silicone adhesive layer containing the drug; a pressure sensitive acrylic adhesive layer also containing the drug; and a removable siliconized release liner layer. Also disclosed is a method for treating a person for nicotine dependence and particularly for treating a woman for nicotine dependence.

Owner:ELAN PHRMA INT LTD +1

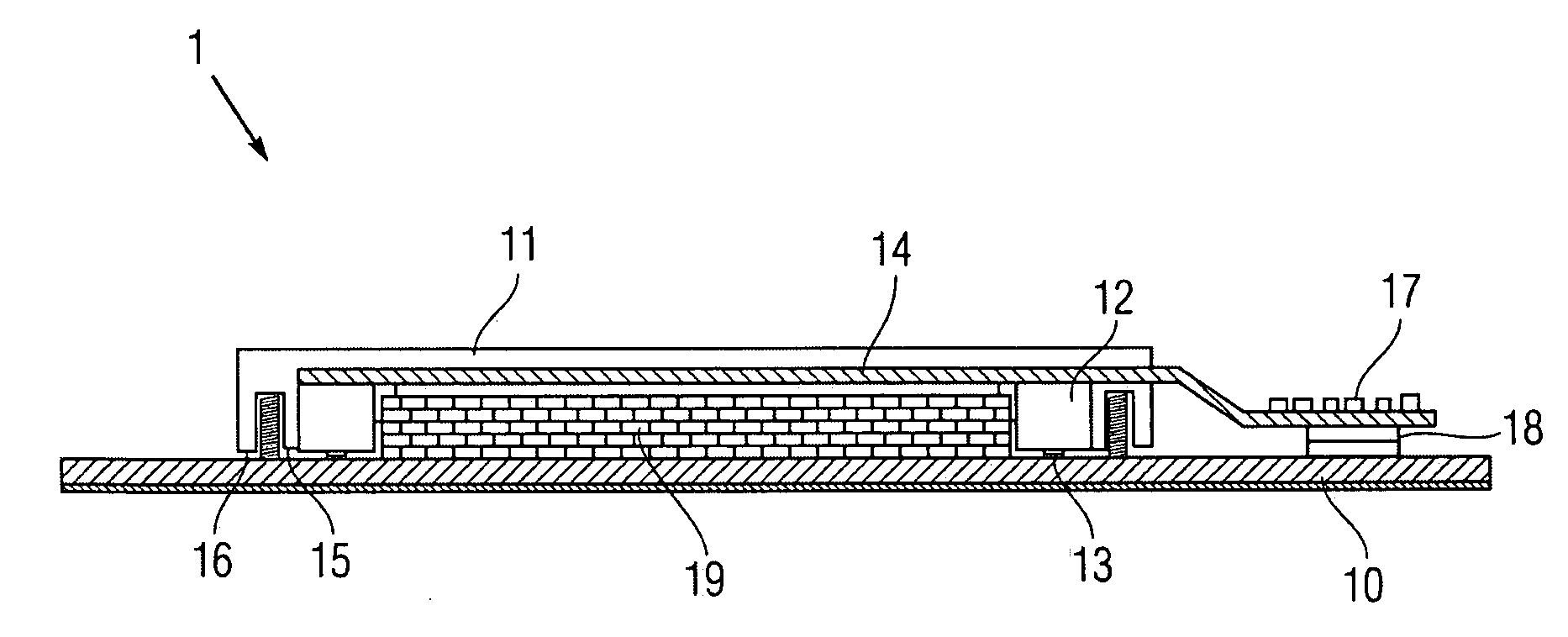

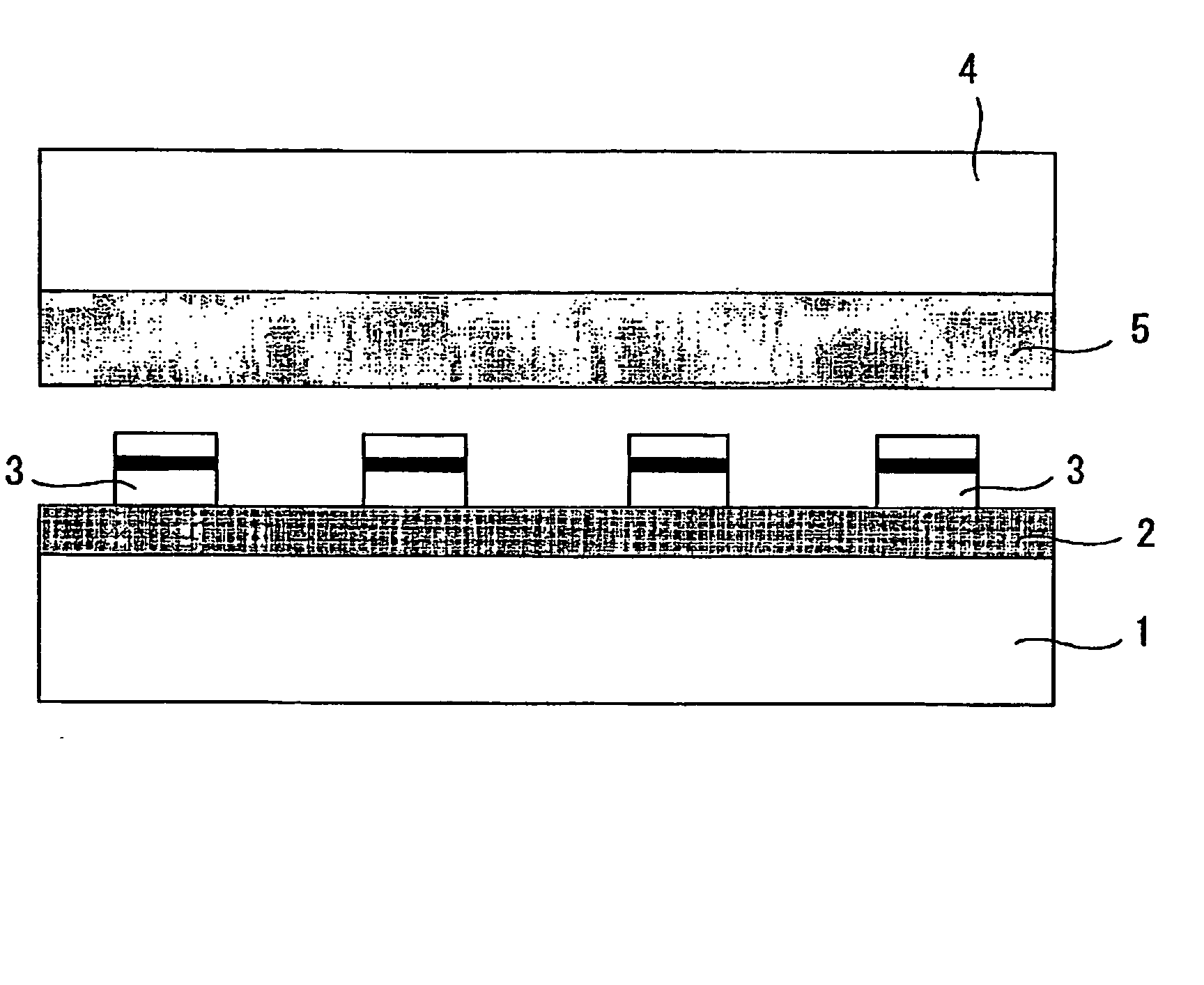

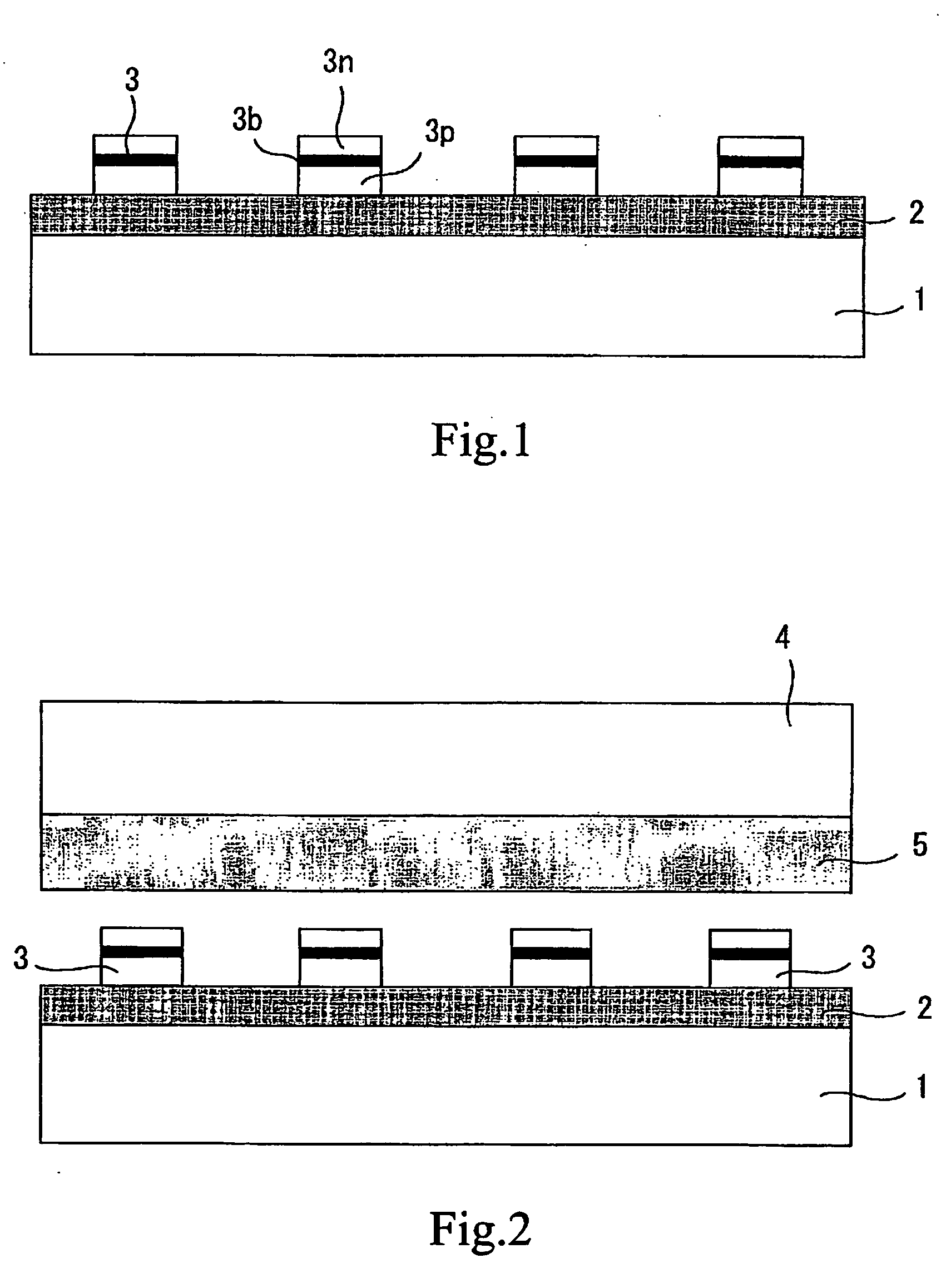

Device transfer method and display apparatus

InactiveUS20050233504A1Facilitate strippingReduce the possibilitySolid-state devicesSemiconductor/solid-state device manufacturingDisplay devicePressure sensitive

A device transfer method and a display apparatus are provided. A device transfer method and a display apparatus are provided by or in which, in transferring devices arranged on a substrate onto another substrate, it is possible to easily strip the substrate after the transfer of the devices, to lower the possibility of damaging of the substrate, and to additionally transfer devices onto the same substrate after the transfer of the devices. A plurality of devices arranged on a temporary holding substrate are embedded into and held in a pressure sensitive adhesive layer formed on a transfer substrate, and the devices are stripped from the temporary holding substrate. Other devices are further additionally embedded into the pressure sensitive adhesive layer before hardening the pressure sensitive adhesive layer, whereby the devices can be arranged on a transfer substrate having a large area. Besides, where the devices additionally embedded into the pressure sensitive adhesive layer are different in characteristics from the devices embedded in the pressure sensitive adhesive layer in advance, it is possible to easily obtain a display apparatus for multicolor display, a display apparatus having a driving circuit, and the like.

Owner:SONY CORP

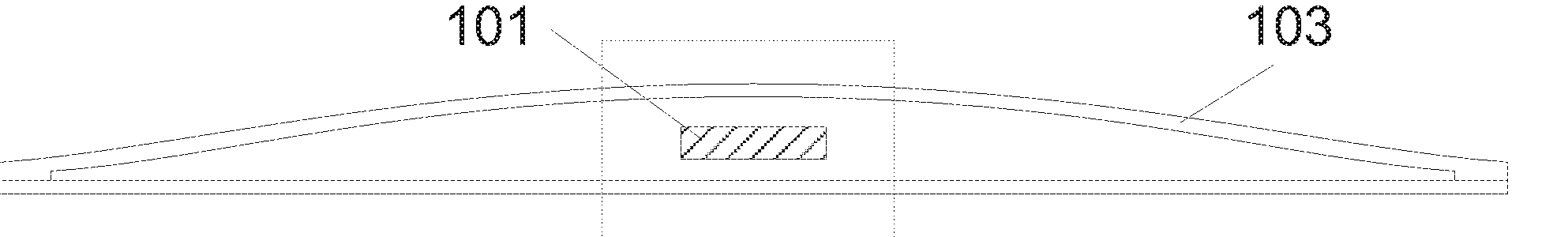

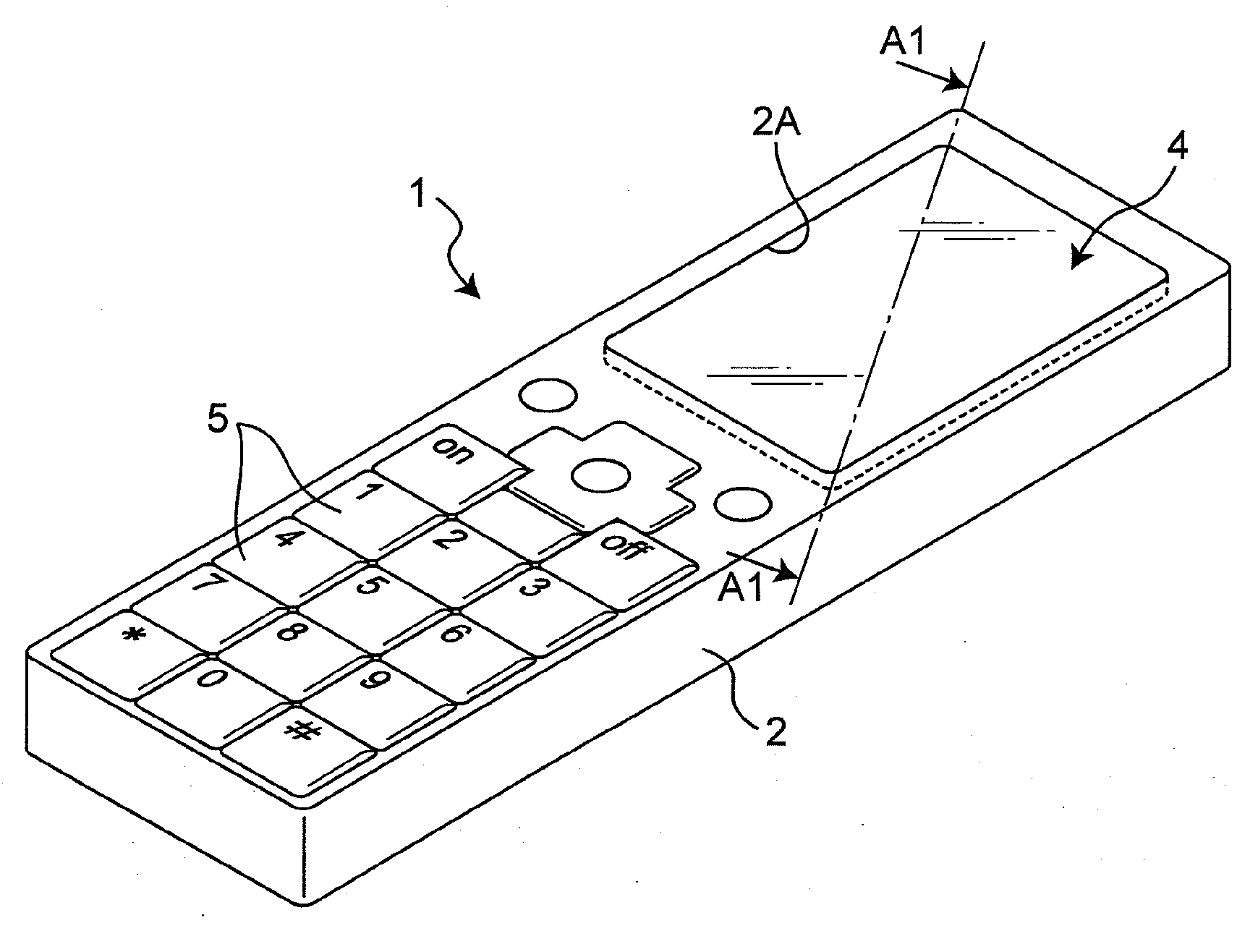

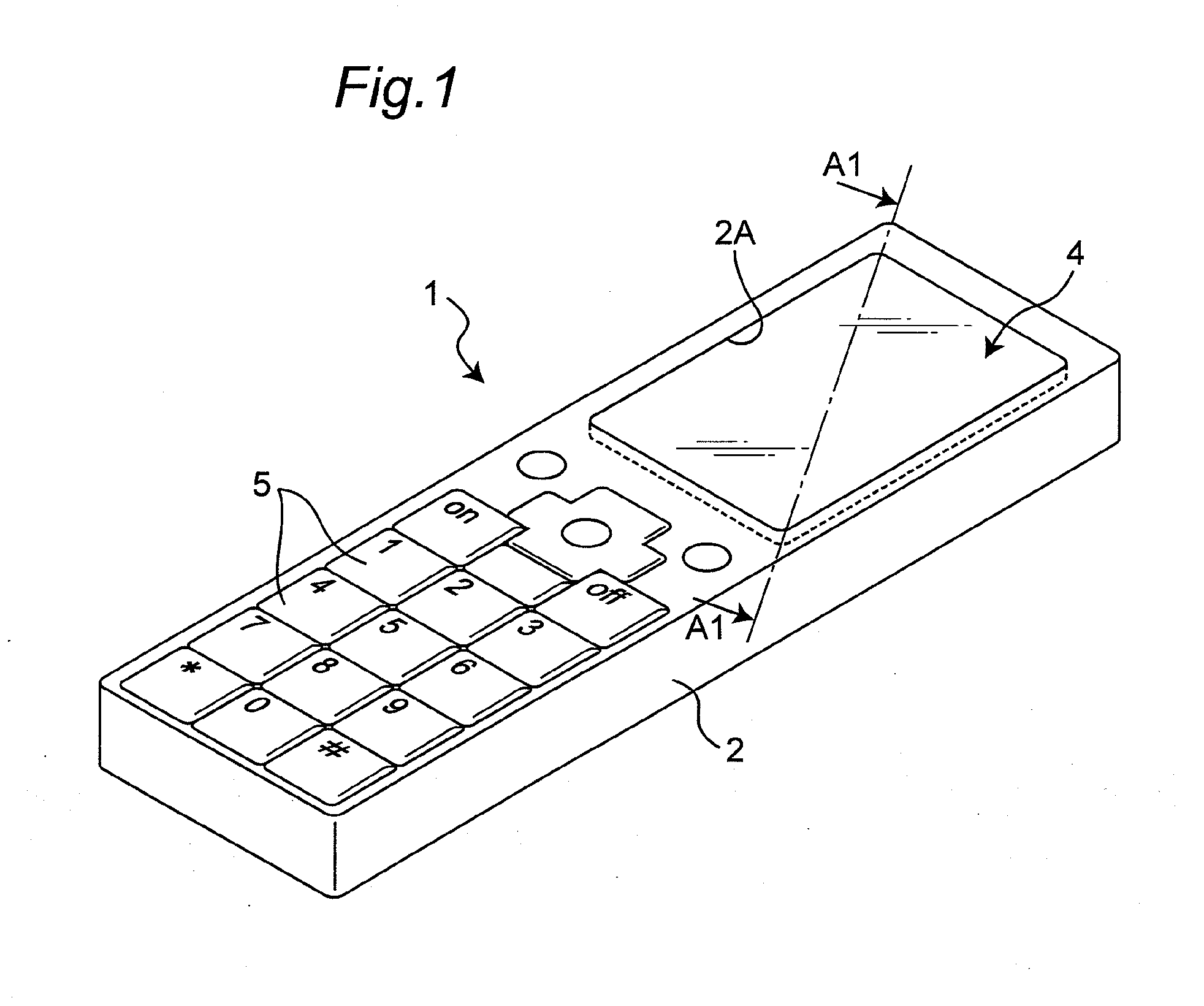

Integrated pressure sensitive lens assembly

ActiveUS20100045612A1Low costReduce cost pressureDetails for portable computersInput/output processes for data processingCamera lensData set

A touch screen assembly for an electronic device such as a cell phone or PDA. The touch screen assembly generally comprises a floating lens suspended over the display and, optionally, the keypad to allow a degree of freedom. An underlying thin connecting layer such as a flex film is attached beneath the floating lens, and a plurality (for example, four) differentially-mounted pressure sensors are mounted beneath the floating lens and are electrically connected to the electronic device via the flex film. The pressure sensors are differentially positioned along an x- and y-axis for registering a pressure z from a touch to the lens at each of the four positions, to provide four data sets (x1-4, y1-4, z1-4). Control software then interprets the exact touch-coordinate from the four data sets and generates a control signal. An optional haptic response generator and / or motion sensor are also contemplated. When used in a smaller electronics device such as a cell phone or PDA the touch screen sensor technology of the present invention is exceedingly thin and is capable of modular assembly for more-or-less “snap-in” construction.

Owner:APPLE INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com