Patents

Literature

644 results about "Suspension spring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

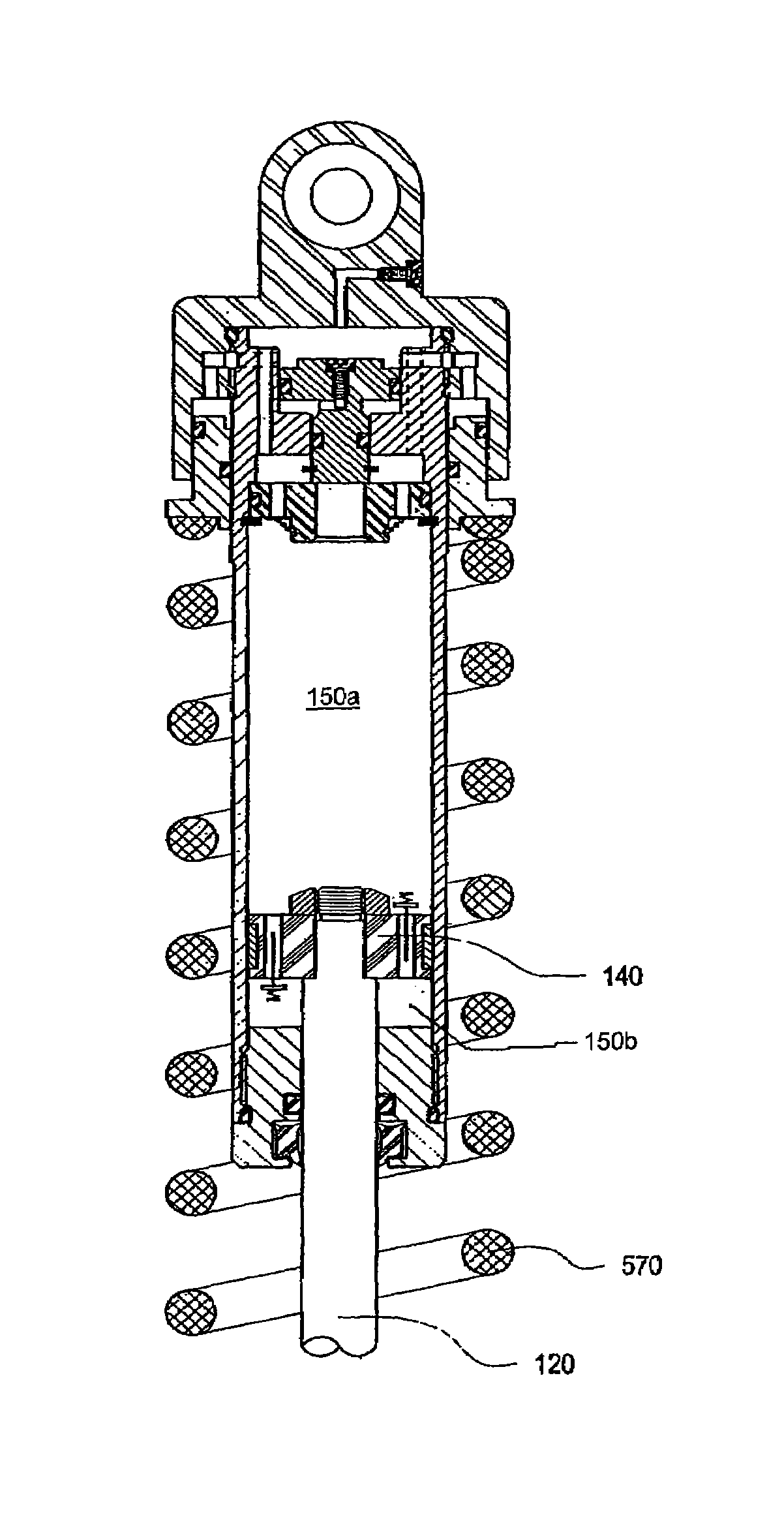

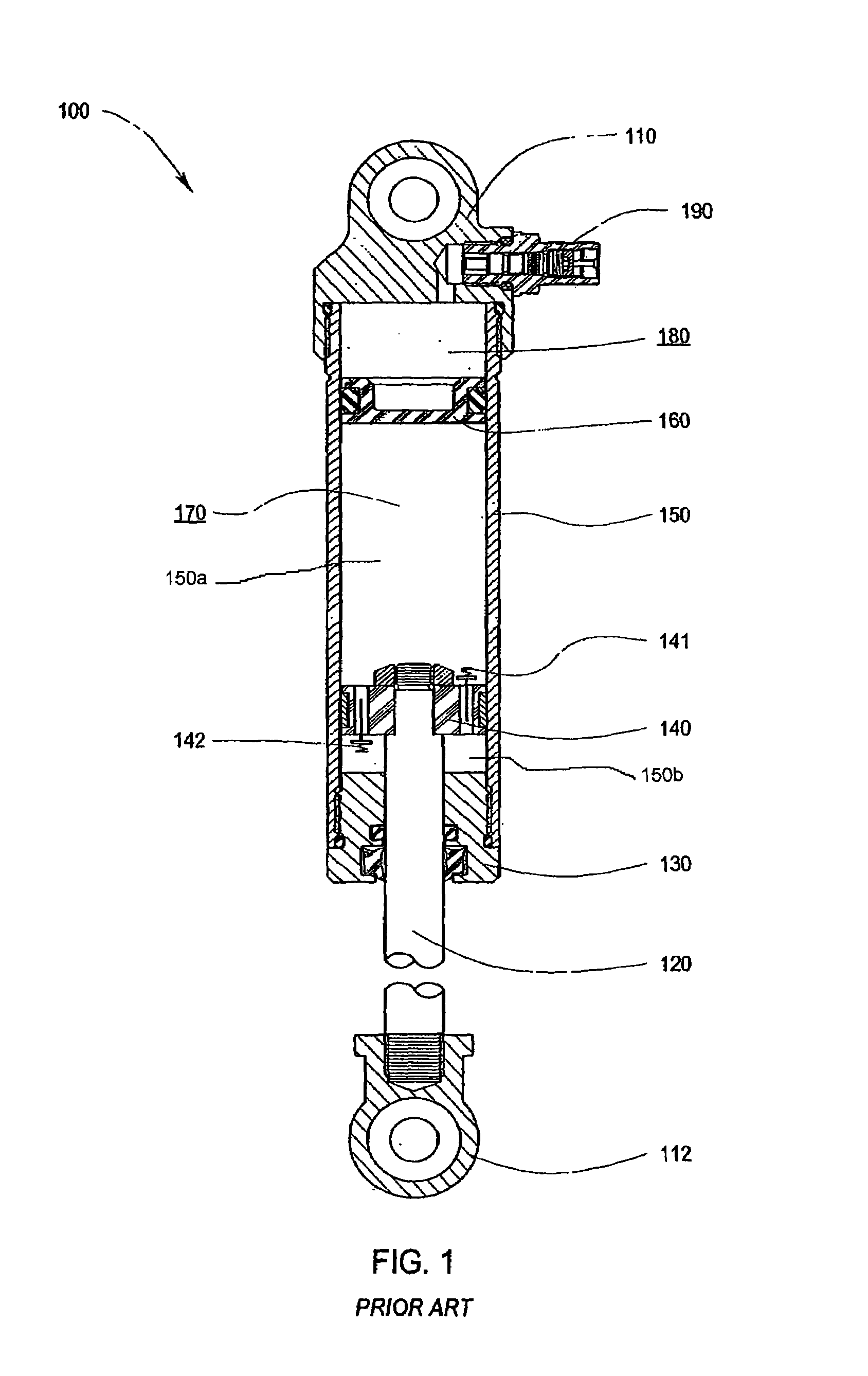

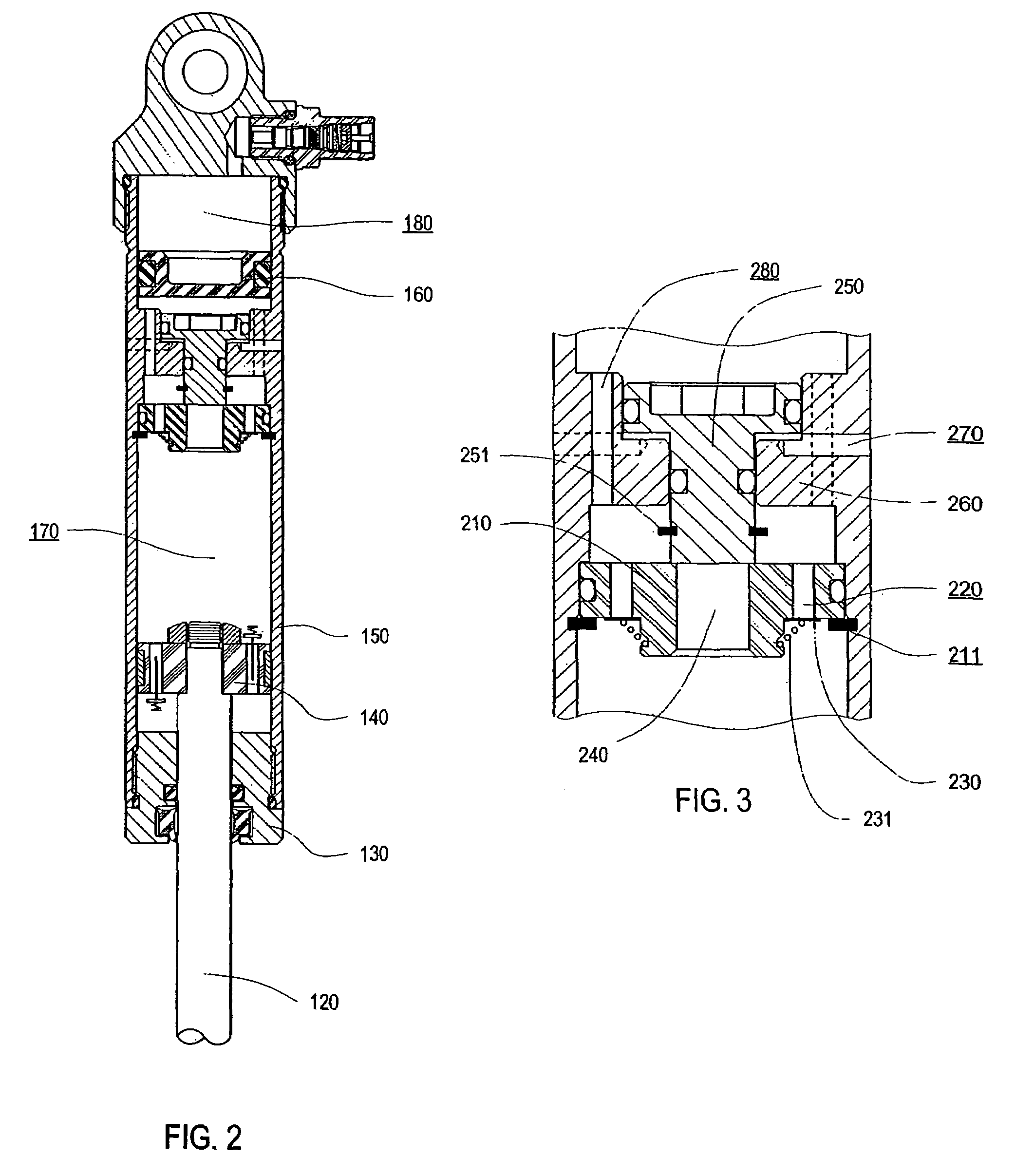

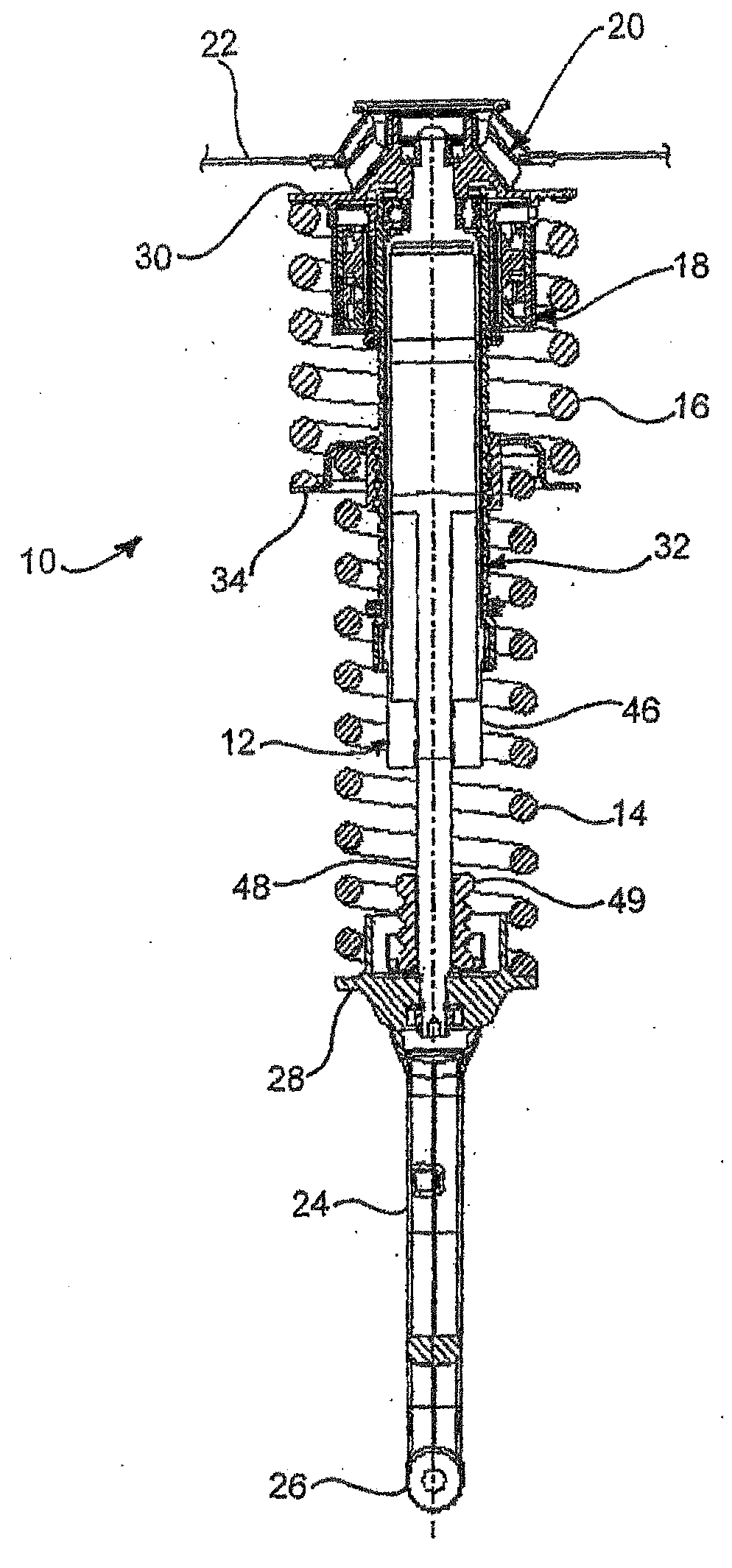

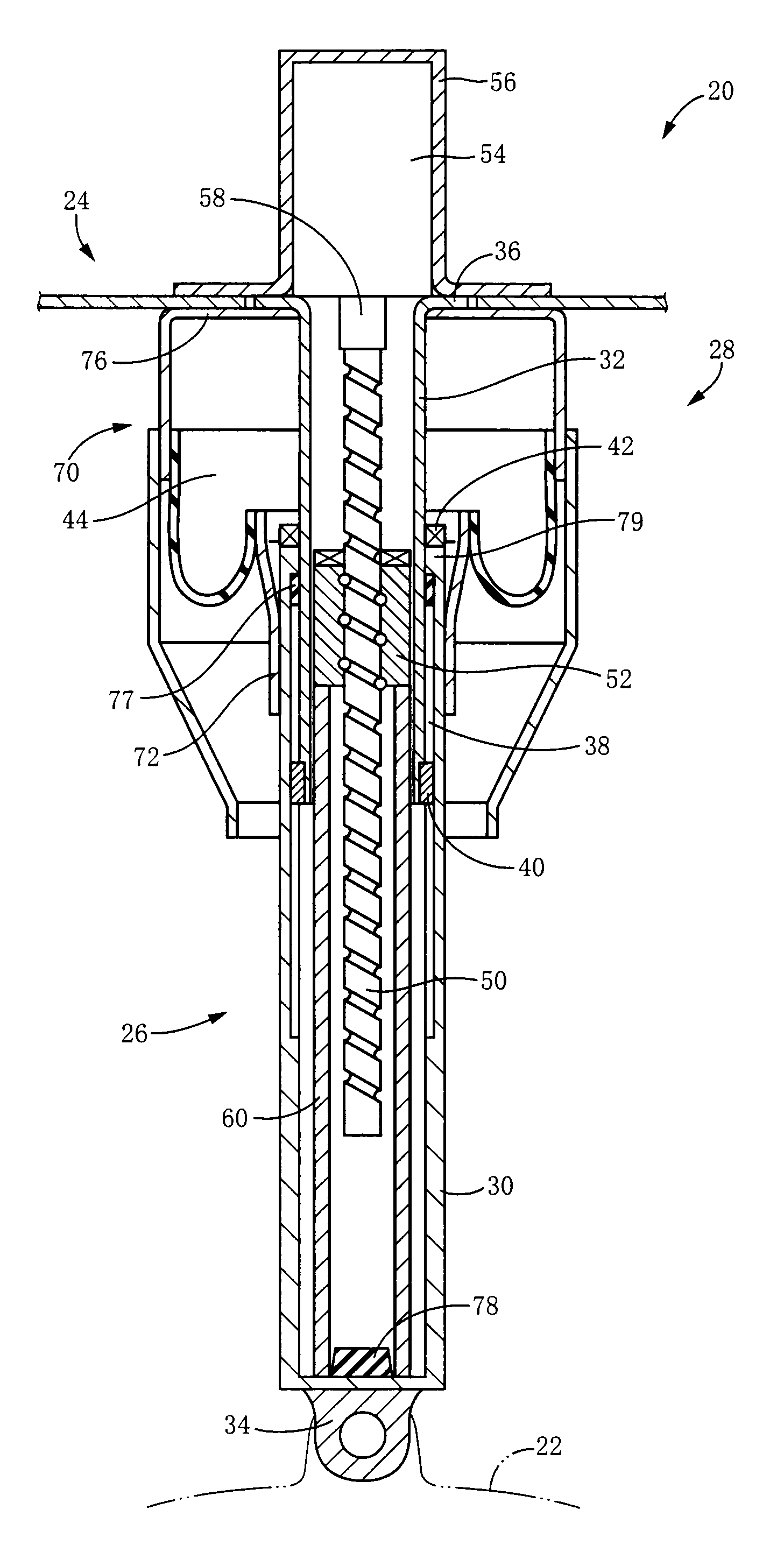

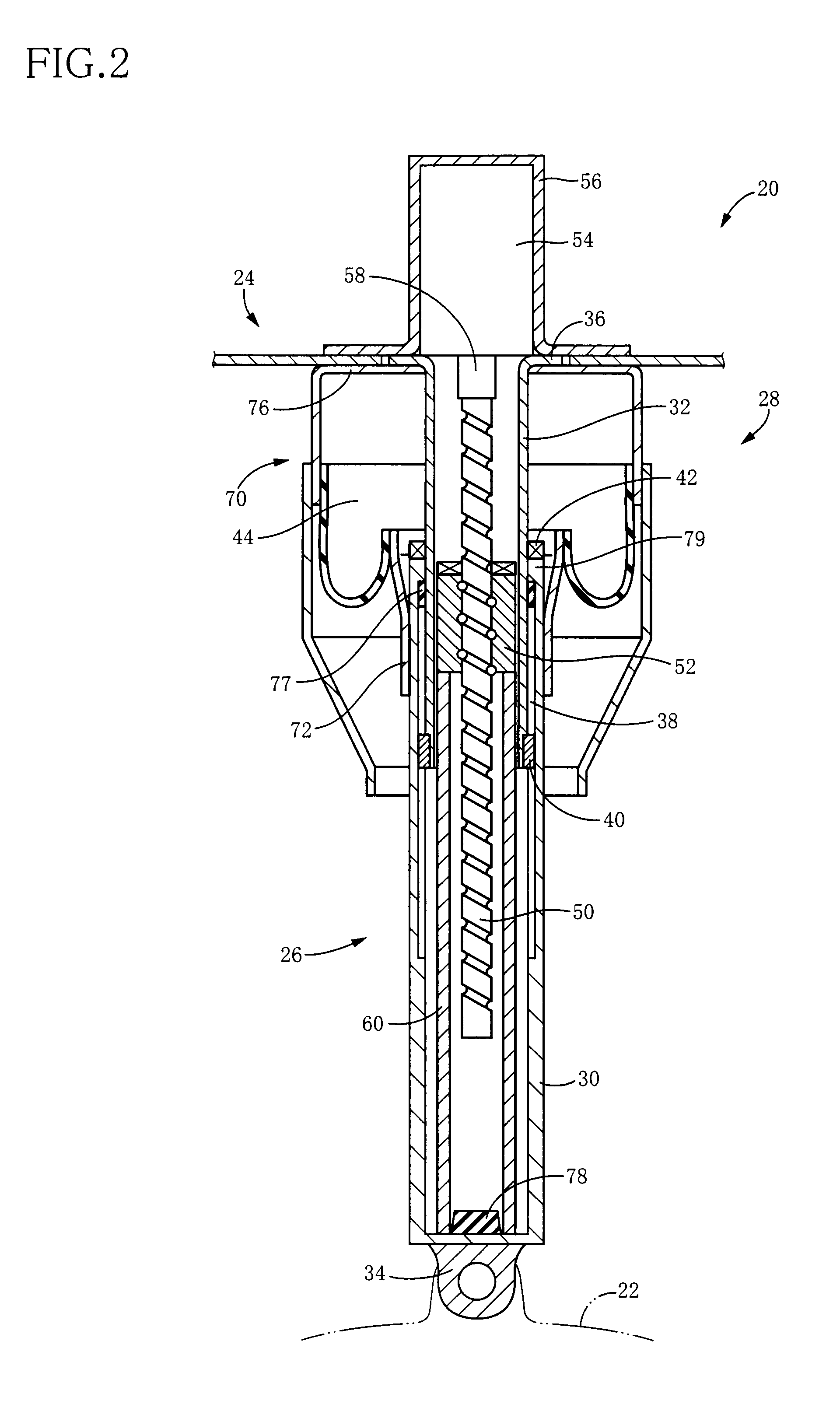

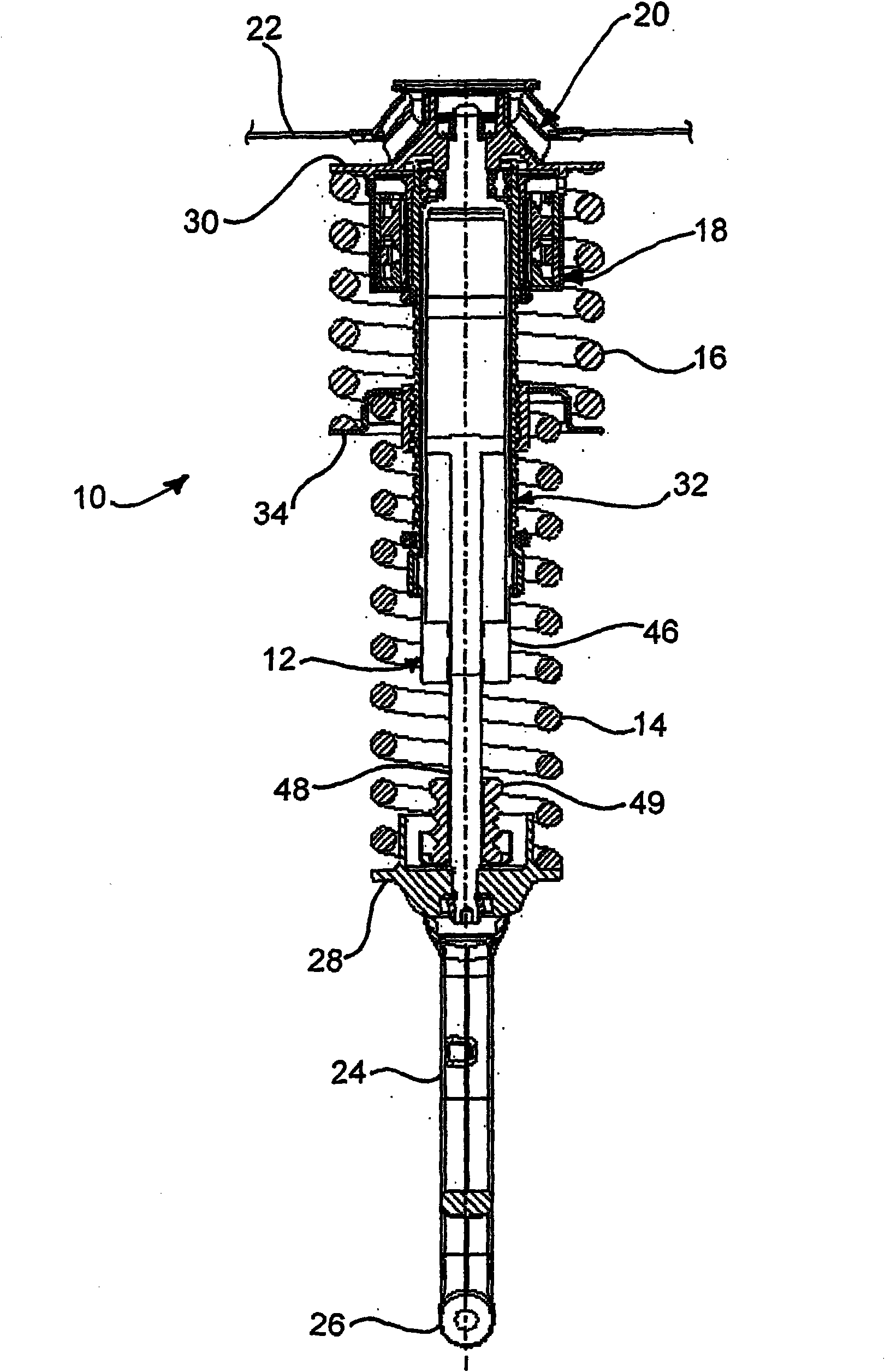

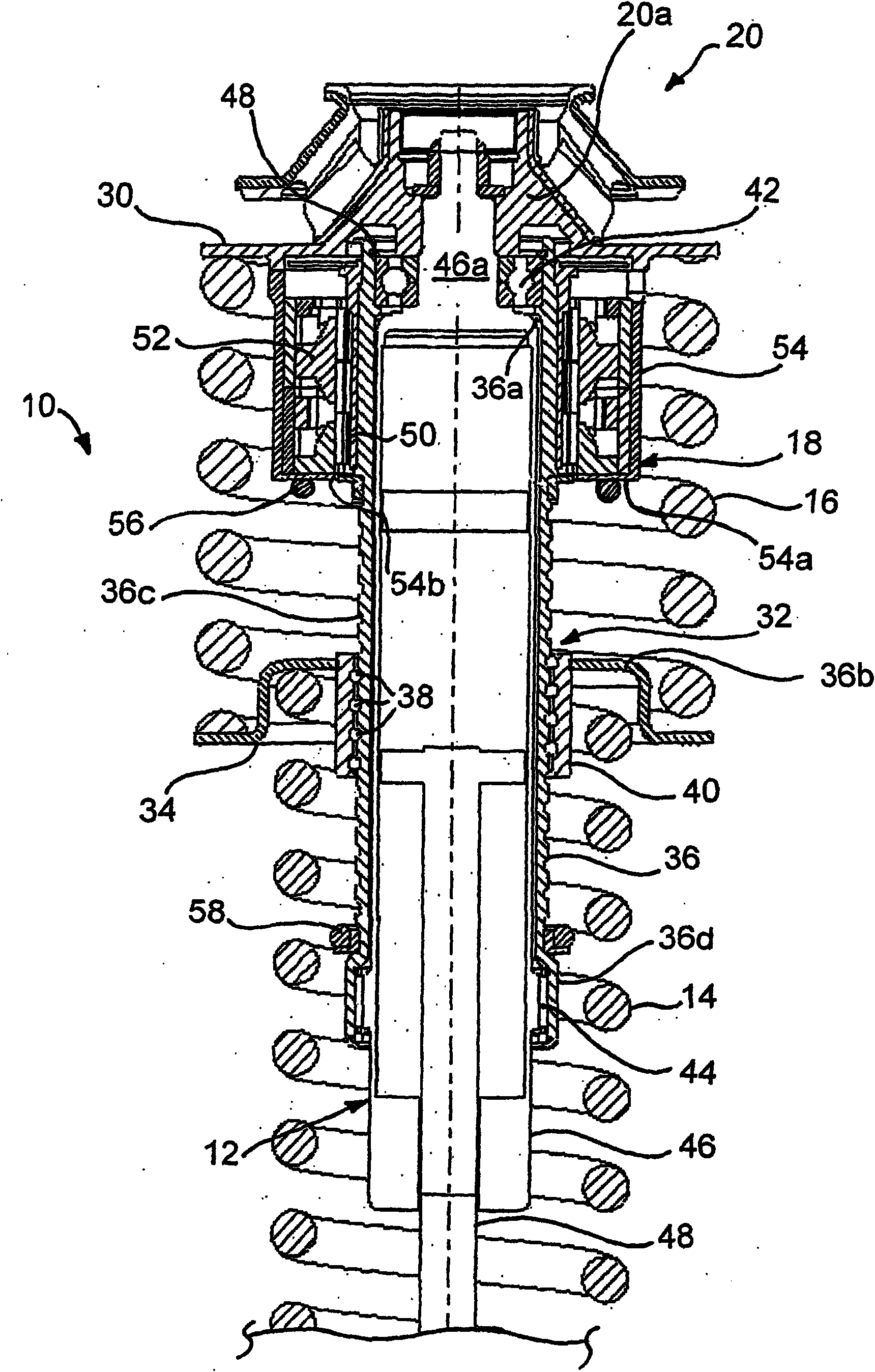

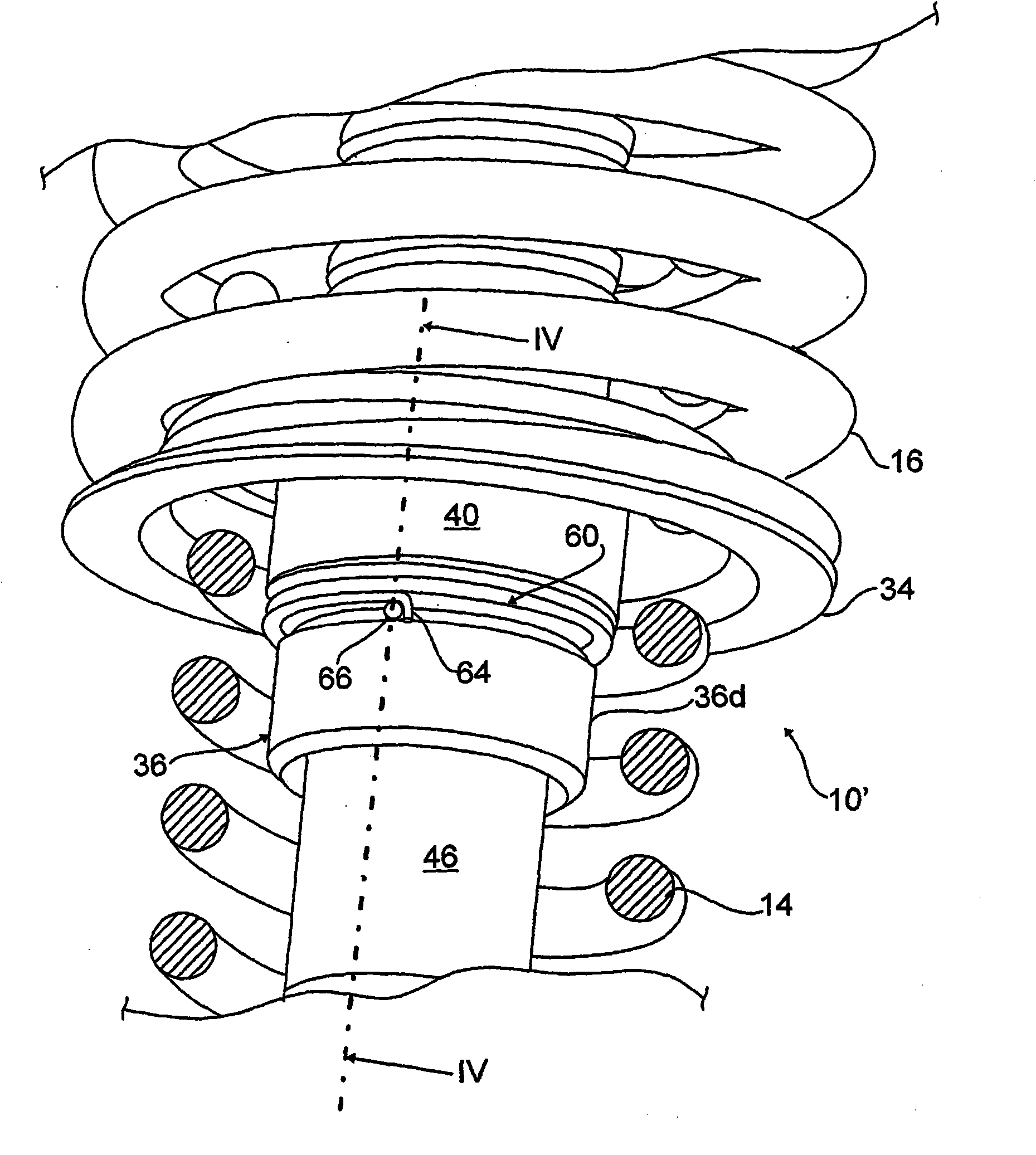

Damper with pressure-sensitive compression damping

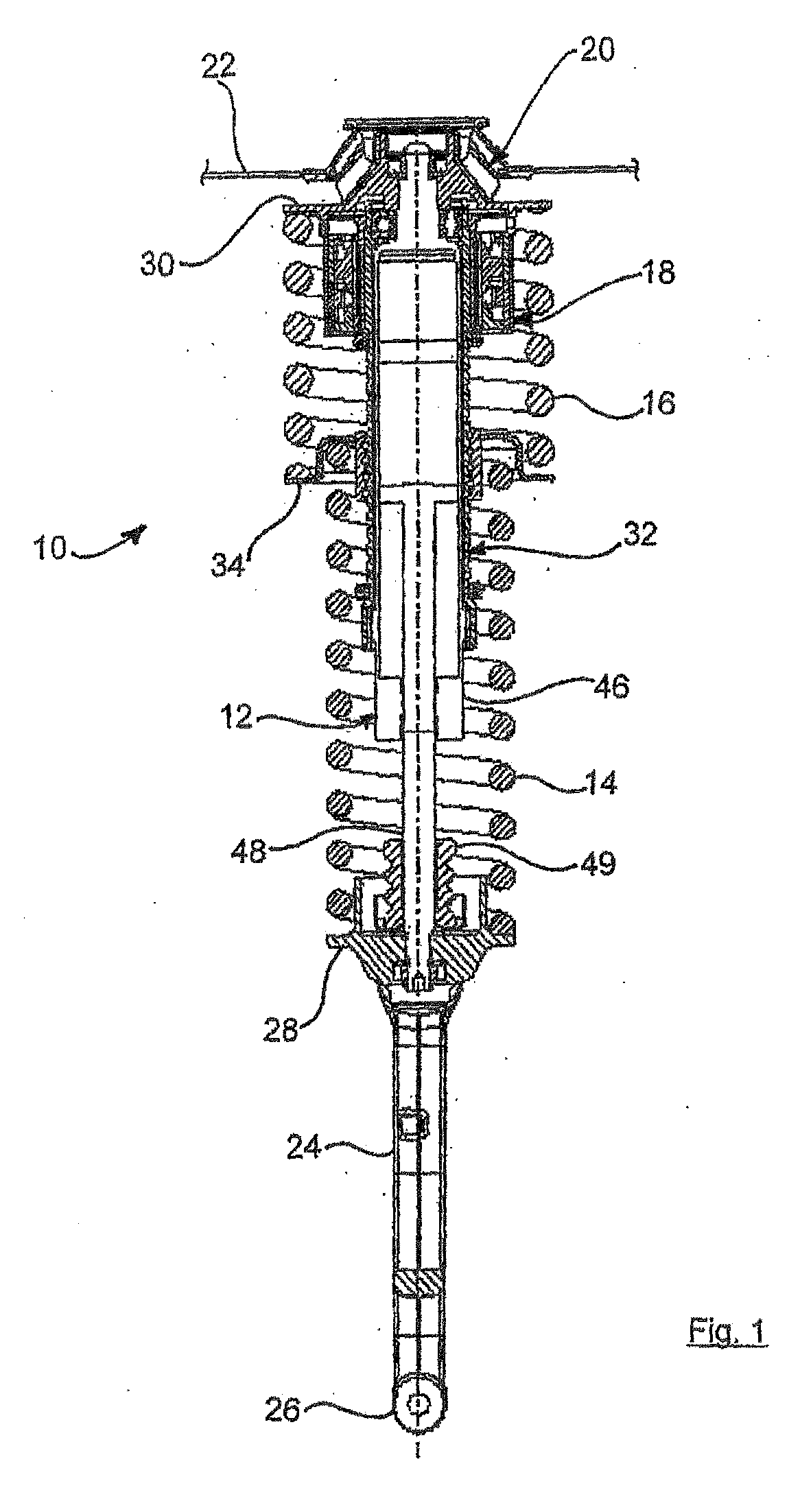

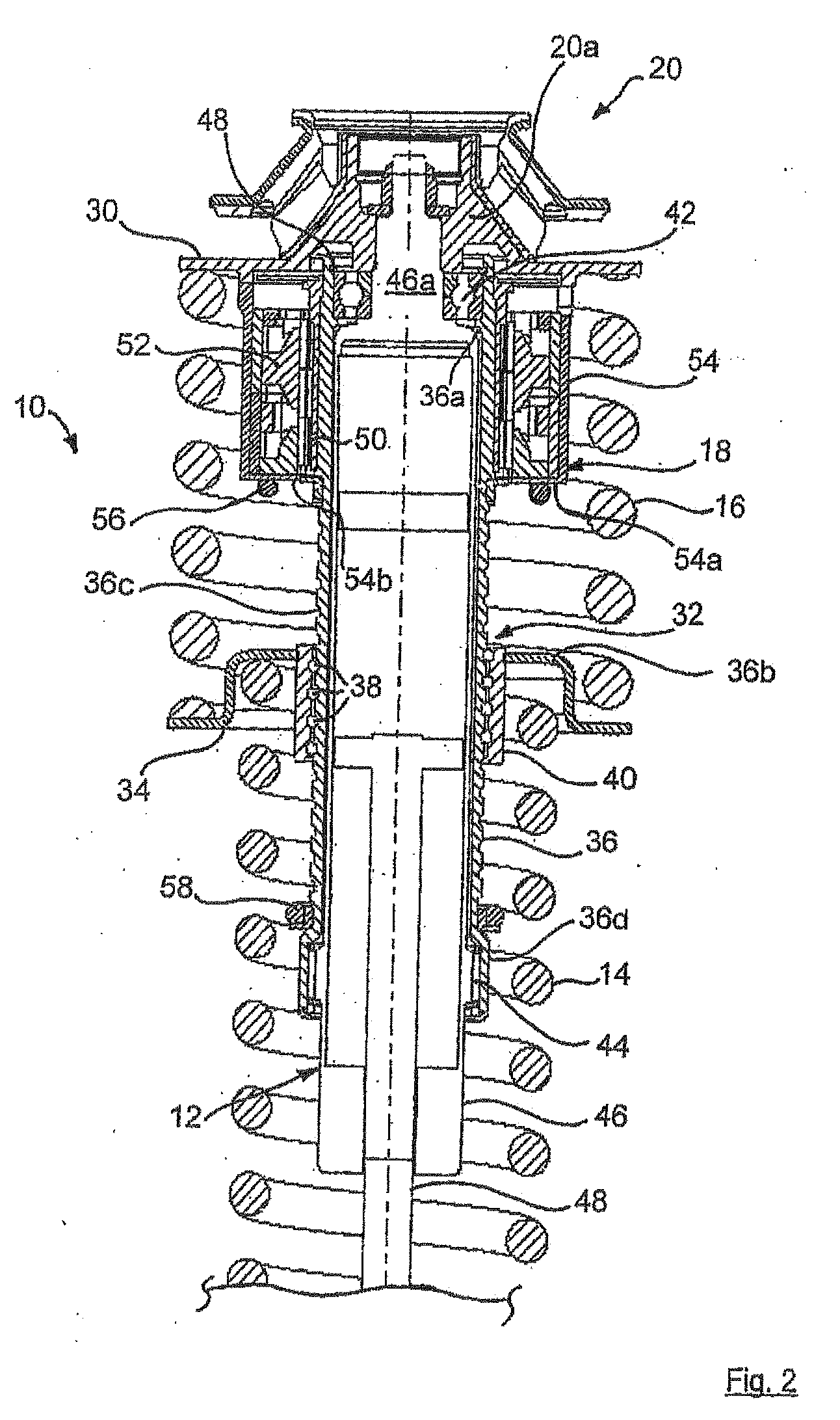

A self-pressurized damper, for example, a pressure-sensitive damper is described. At least one suspension spring is used to pressurize the damping fluid, a task typically carried out by a sealed moveable barrier, such as an internal floating piston (IFP) and a pressurized gas. Thus, stroke length may be maximized. Furthermore, the amount of compression damping force produced by the damper may be a function of the force generated by the at least one suspension spring.

Owner:FOX FACTORY

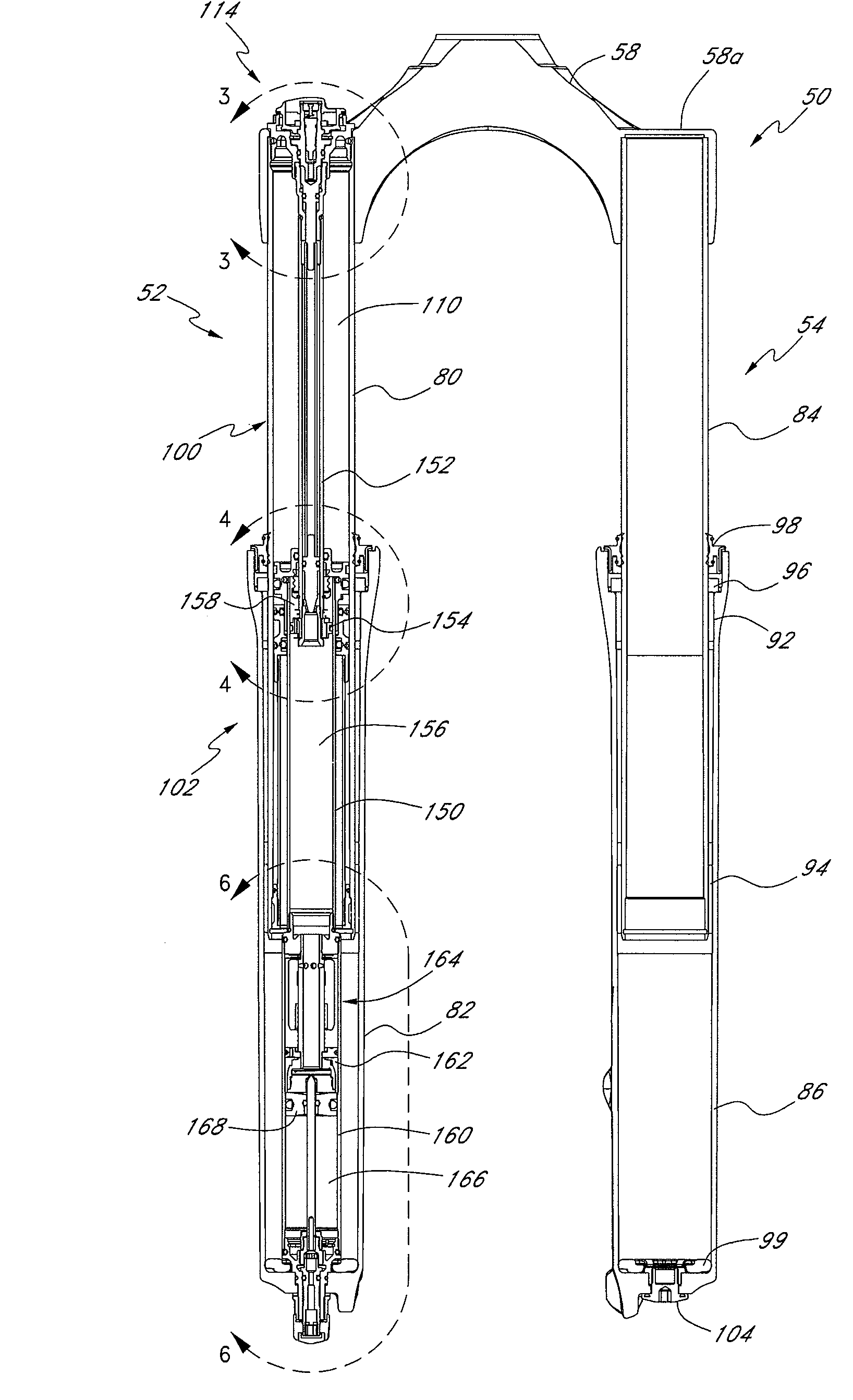

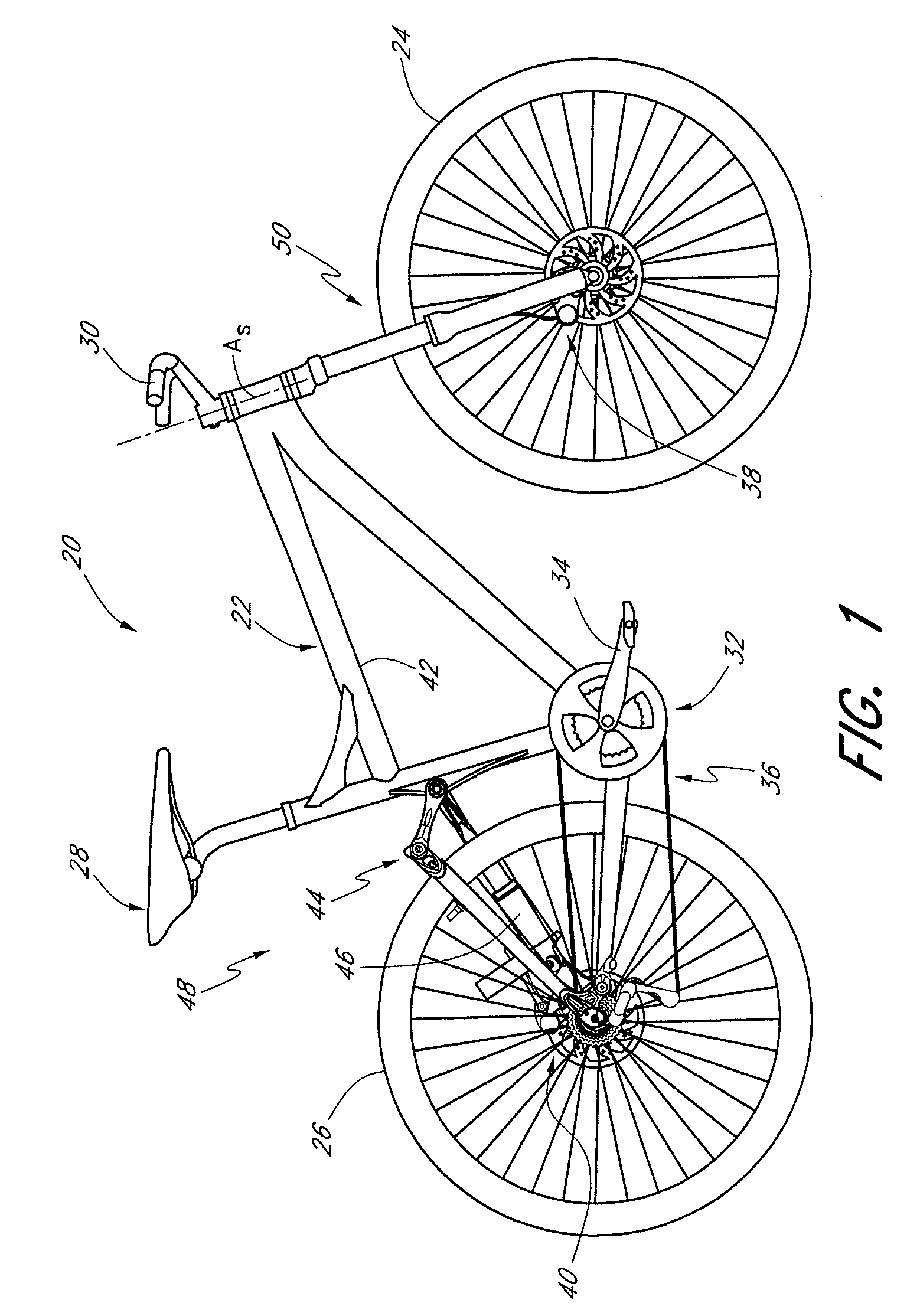

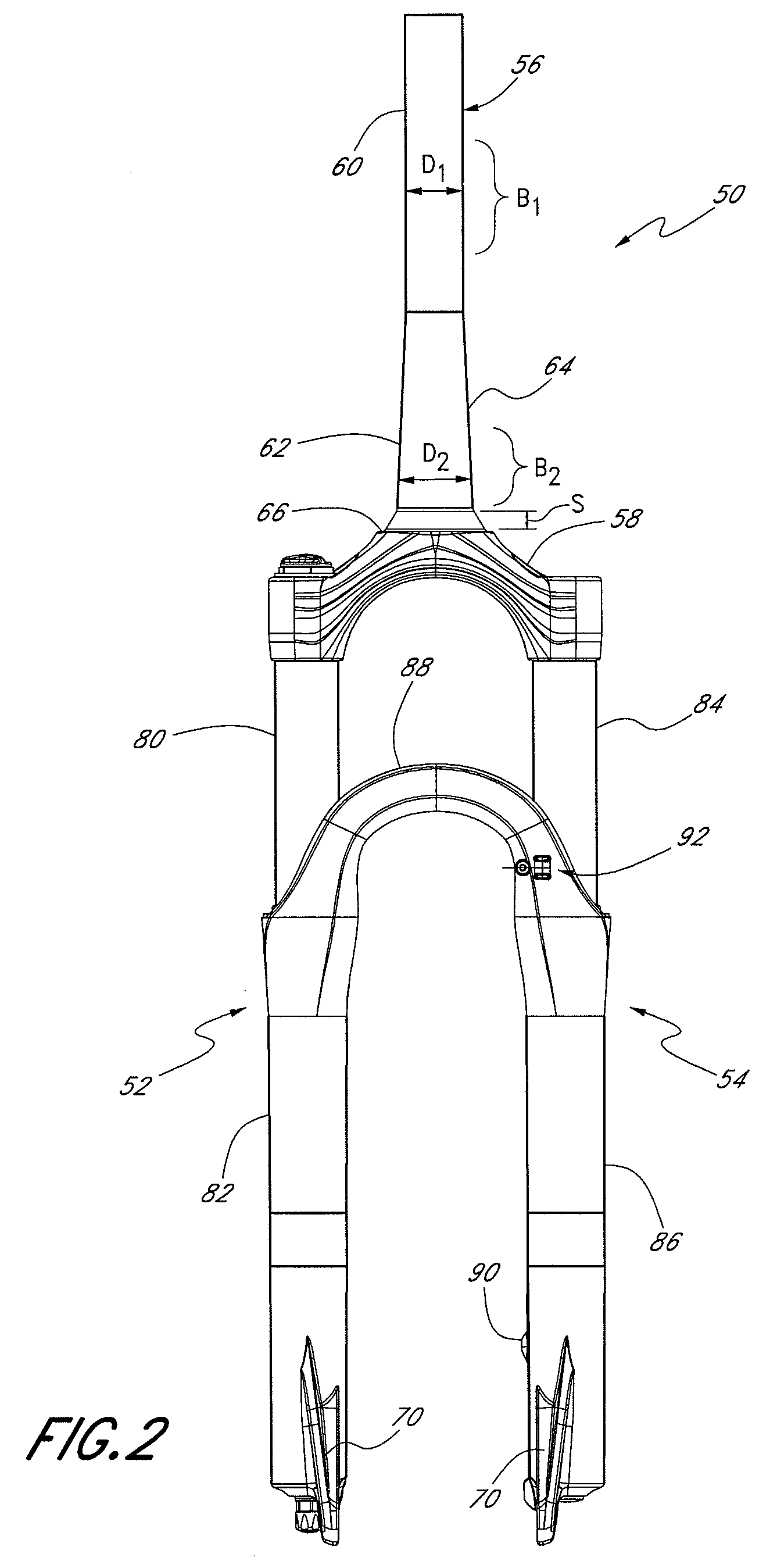

Bicycle suspension assembly

InactiveUS20090001684A1Wheel based transmissionFrictional rollers based transmissionDual stageGas spring

A bicycle suspension assembly may be in the form of a bicycle front suspension fork. The suspension fork may include a pair of telescoping fork legs. In one arrangement, a suspension spring and a damper are provided in only one of the pair of fork legs. The suspension spring assembly may include a negative spring. In one arrangement, the negative spring is a dual stage negative gas spring in which a negative spring gas chamber includes a first chamber section and a second chamber section. The first chamber section and the second chamber section are uncoupled in a first position of the suspension spring and the first chamber section and the second chamber section are coupled in a second position of the suspension spring.

Owner:SPECIALIZED BICYCLE COMPONENTS INC

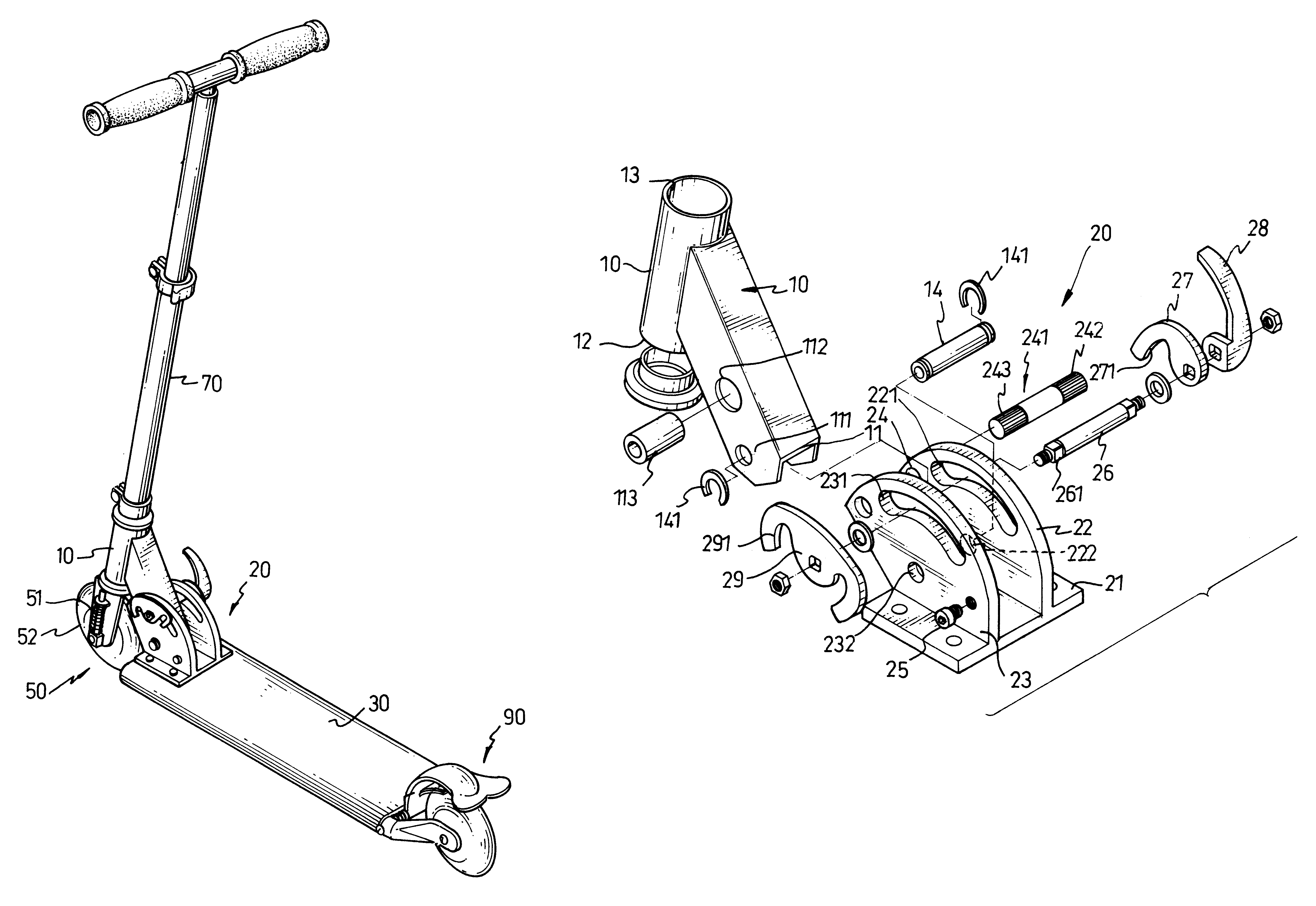

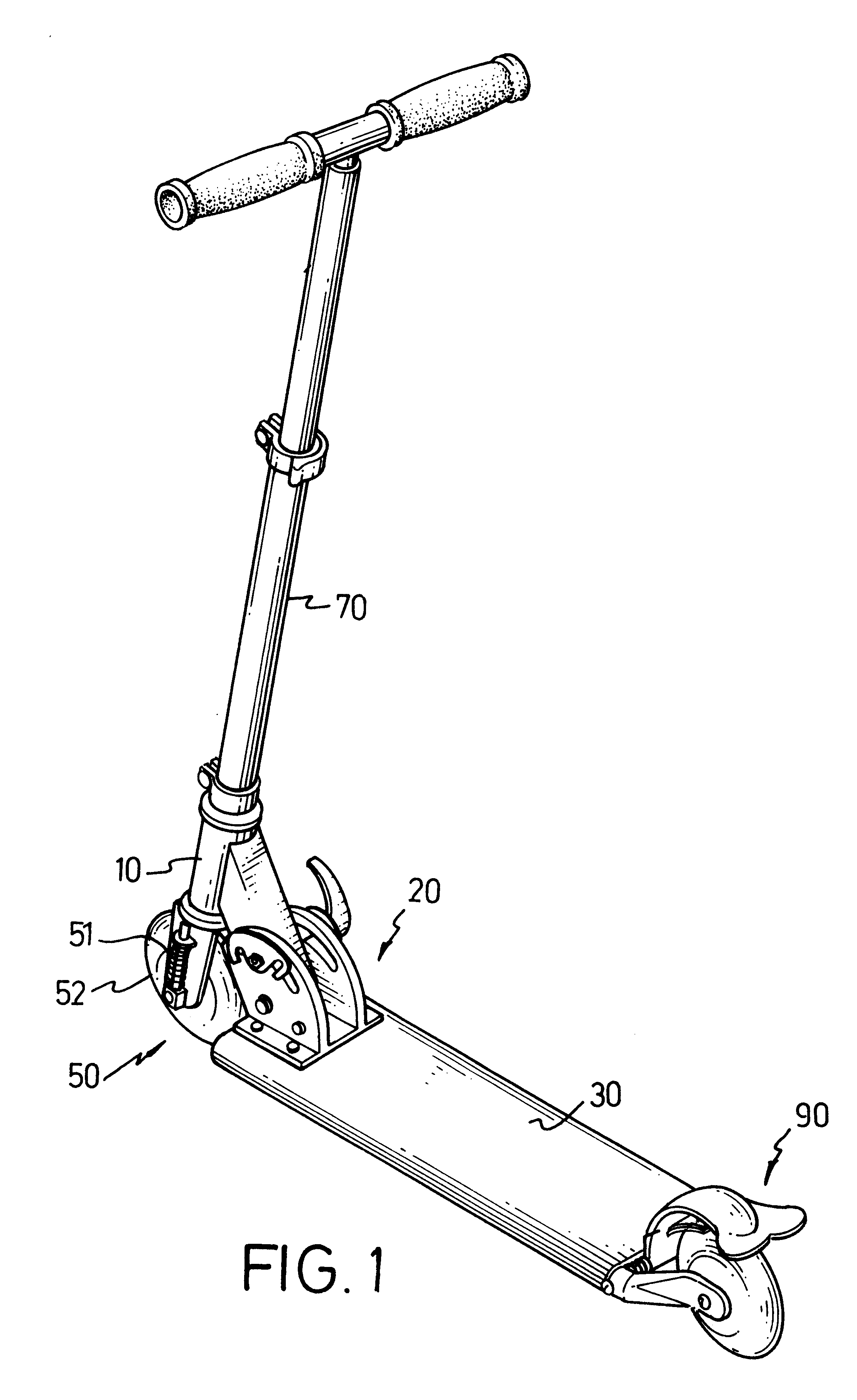

Foldable scooter with head tube assembly, brake and suspension

A foldable scooter has a head tube pivot assembly having a seat with two wings, a head tube with a push bar, a lever and a rocker. The head tube is able to be pivotally received between the wings. The lever, the push bar and the rocker are simultaneously moveable relative to the head tube, such that a hook on the push bar is able to detachably engage with one end of a limit pin to release or secure the head tube. A front wheel suspension spring is provided on both sides of the front wheel to function as a damper to smooth the ride. A brake assembly is provided on the rear wheel. The brake assembly has a fender with a brake pad securely attached thereto such that the friction between the brake pad and the rear wheel enhances the braking effect to the scooter.

Owner:CHEN CHIH LIANG

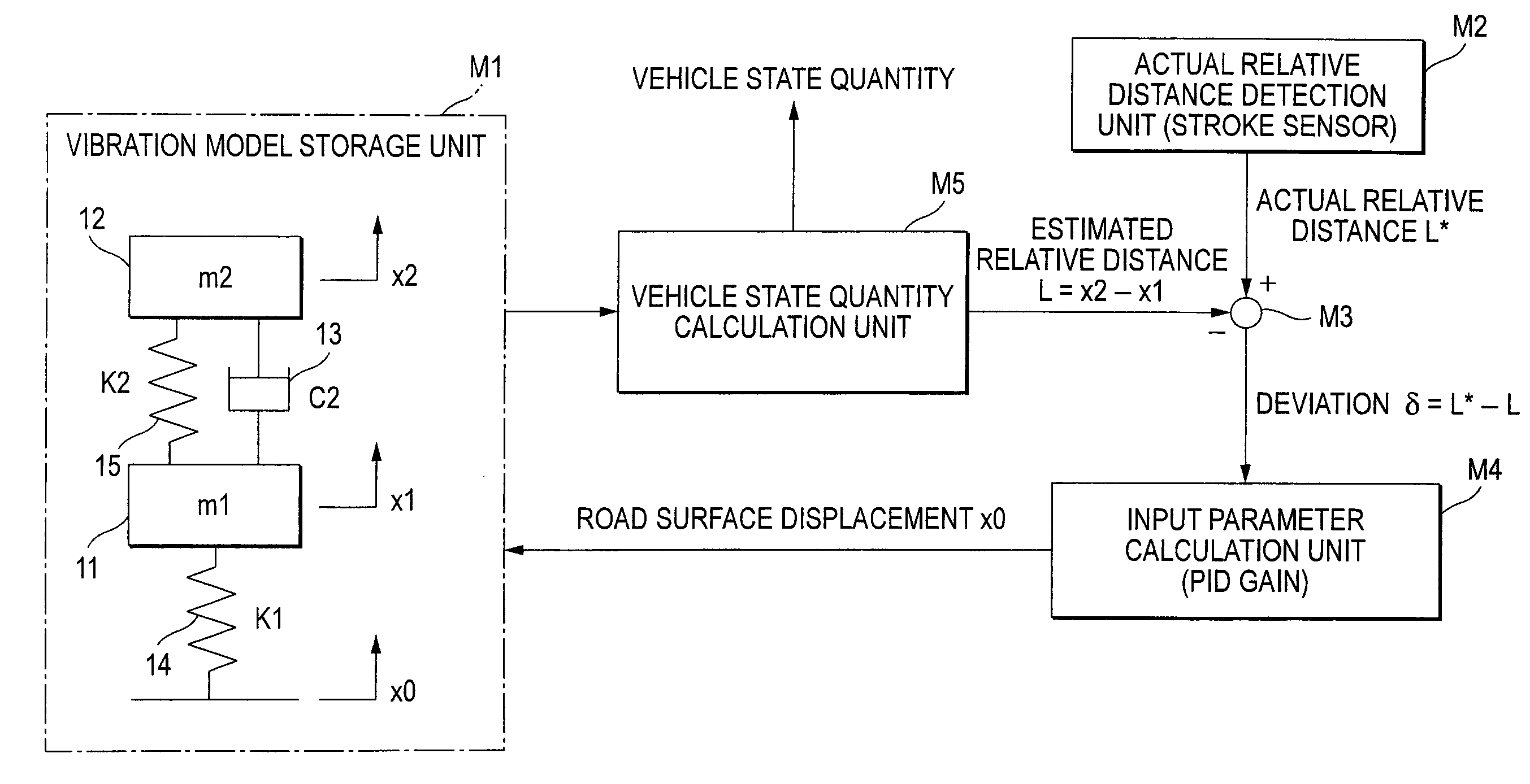

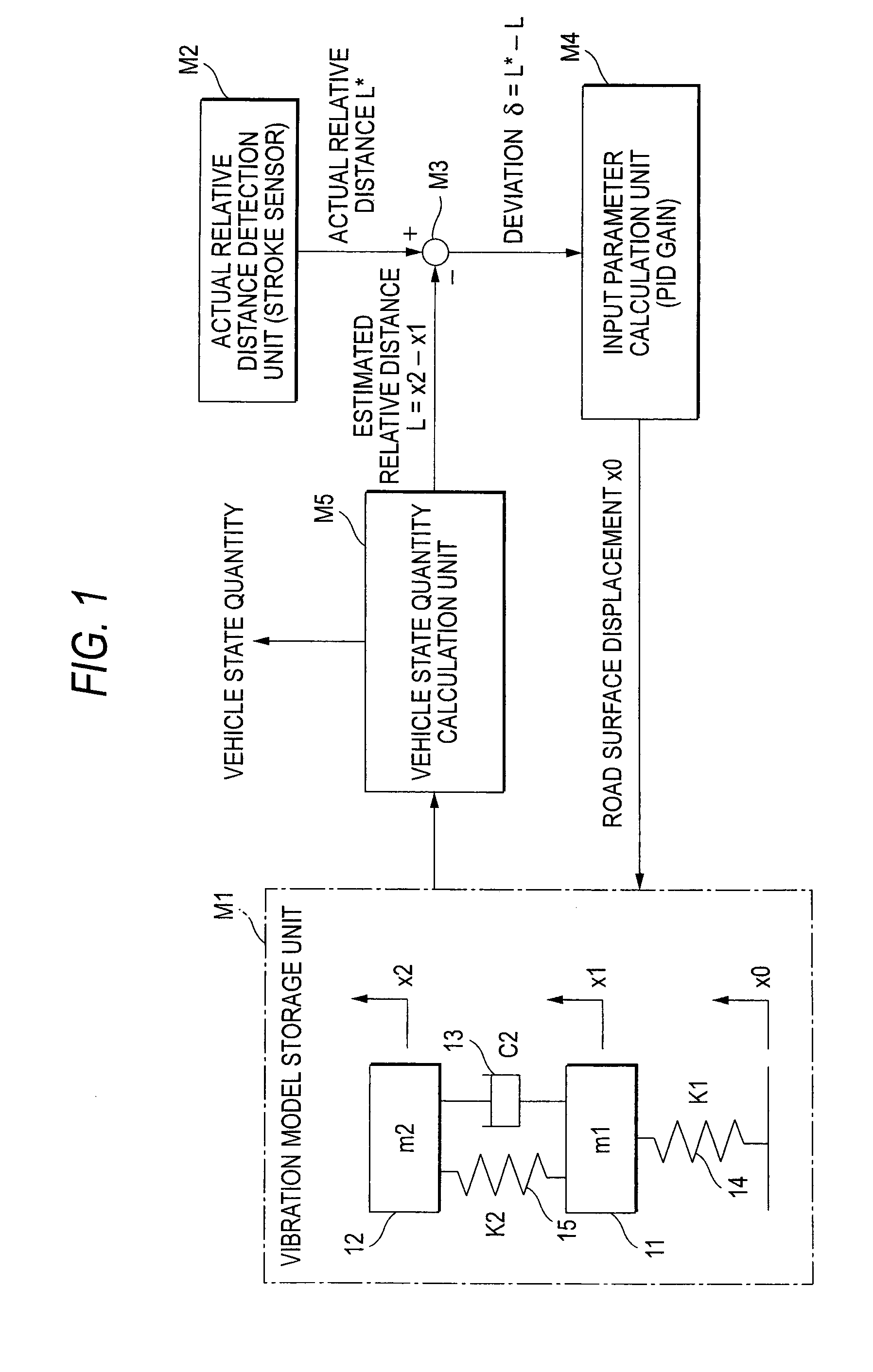

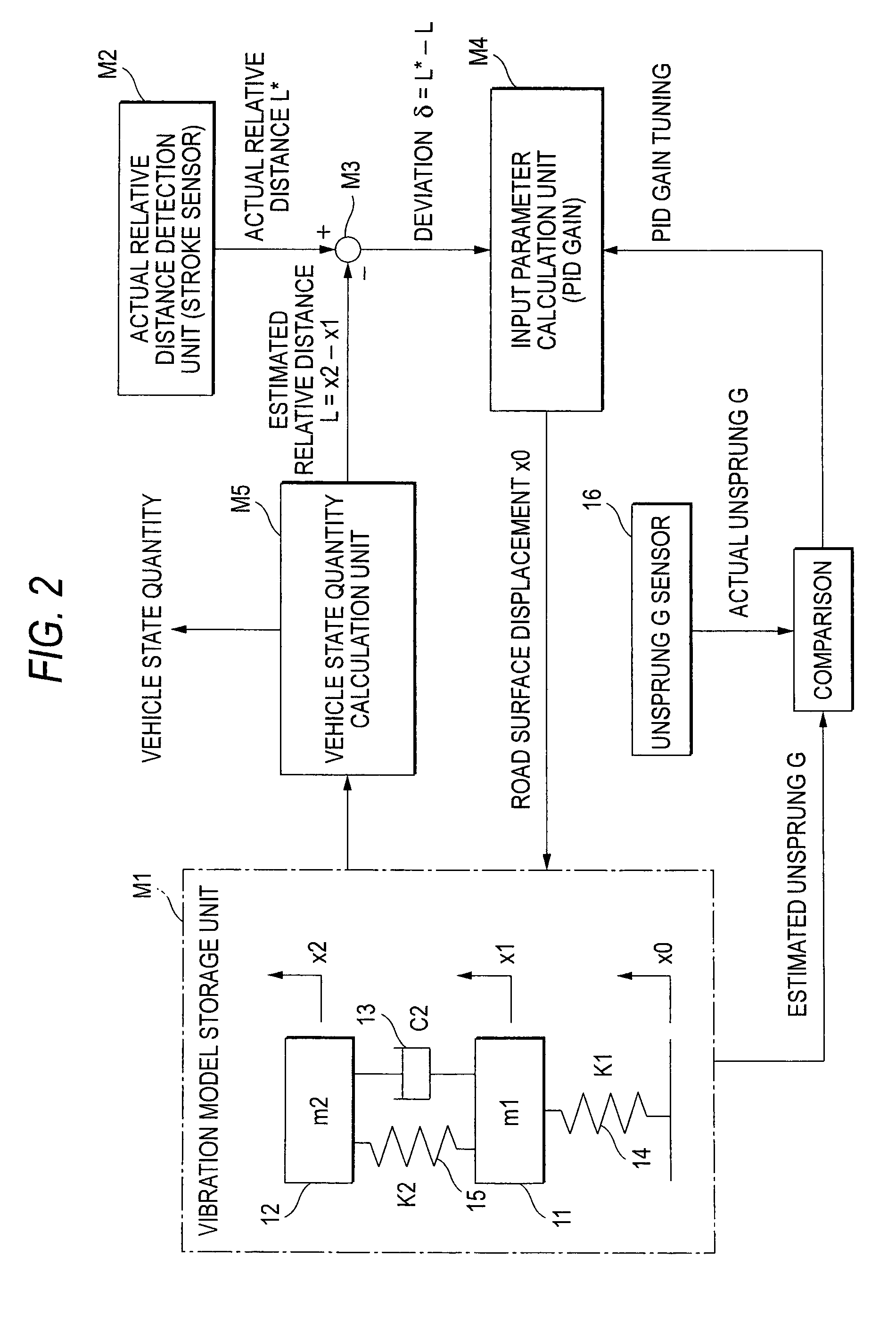

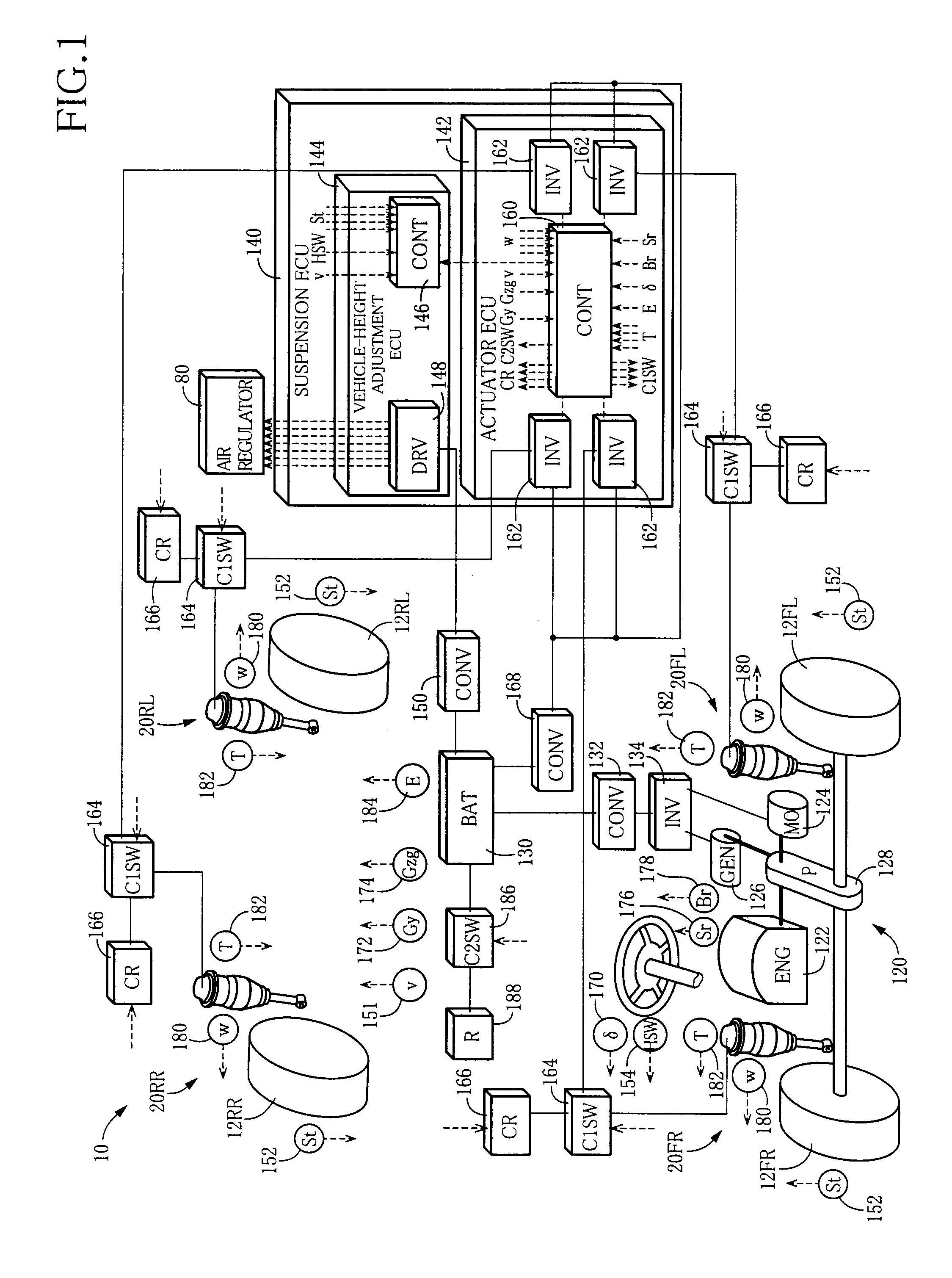

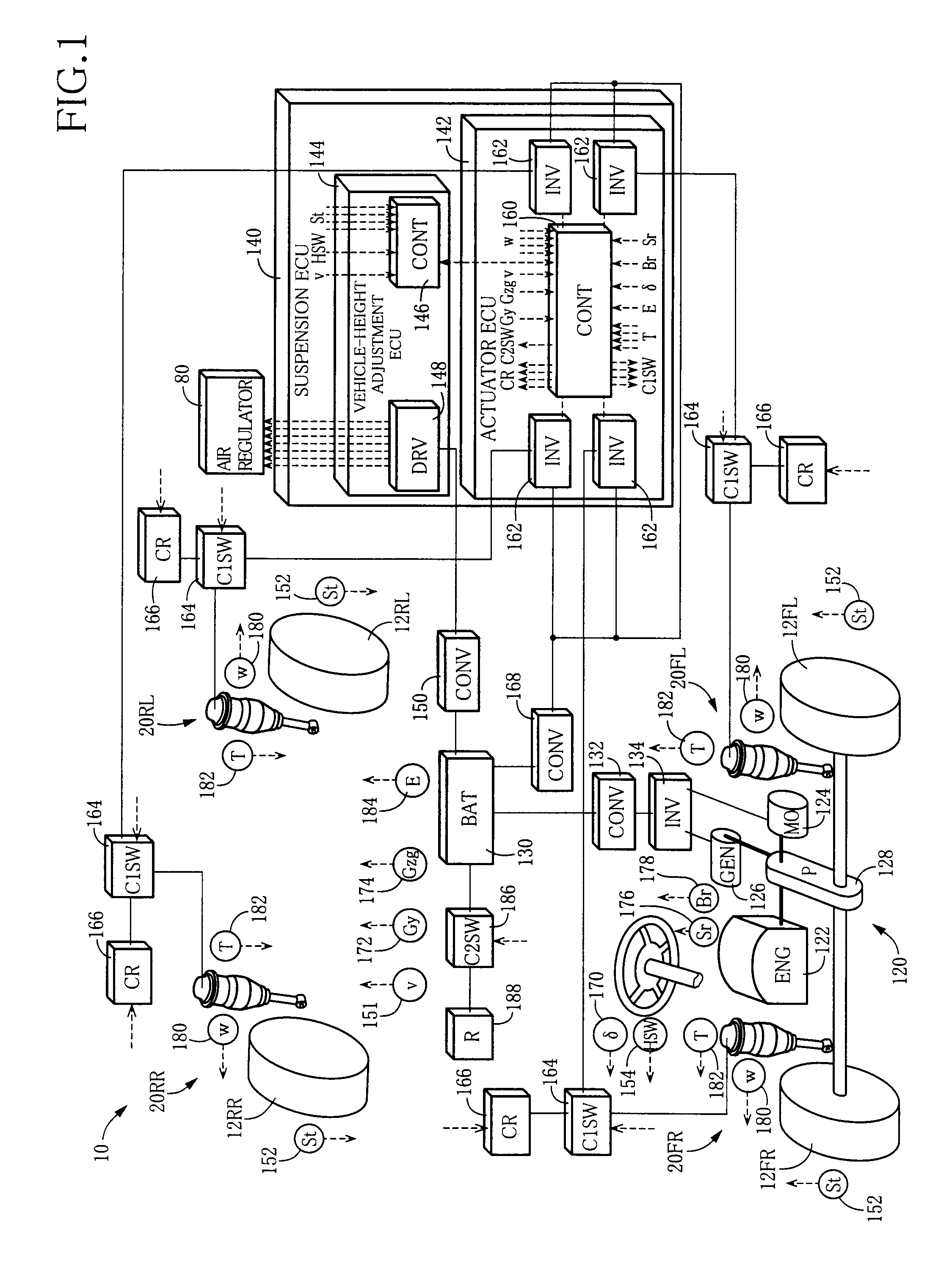

Vehicle state estimation system

InactiveUS20080059025A1Accurate calculationImprove accuracyDigital data processing detailsAnimal undercarriagesSimulationDistance detection

A vibration model storage unit stores a vibration model which is made up of an unsprung part, a sprung part, a damper, a tire and a suspension spring, an actual relative distance detection unit detects an actual relative distance of the unsprung part to the sprung part, and a deviation calculation unit calculates a deviation between an estimated relative distance of the unsprung part to the sprung part that is estimated by the vibration model and the actual relative distance. An input parameter calculation unit calculates an input parameter that is inputted into the vibration model from a road surface based on the deviation calculated by the deviation calculation unit, and a vehicle state quantity calculation unit calculates a quantity of state of a vehicle by applying the input parameter to the vibration model.

Owner:HONDA MOTOR CO LTD

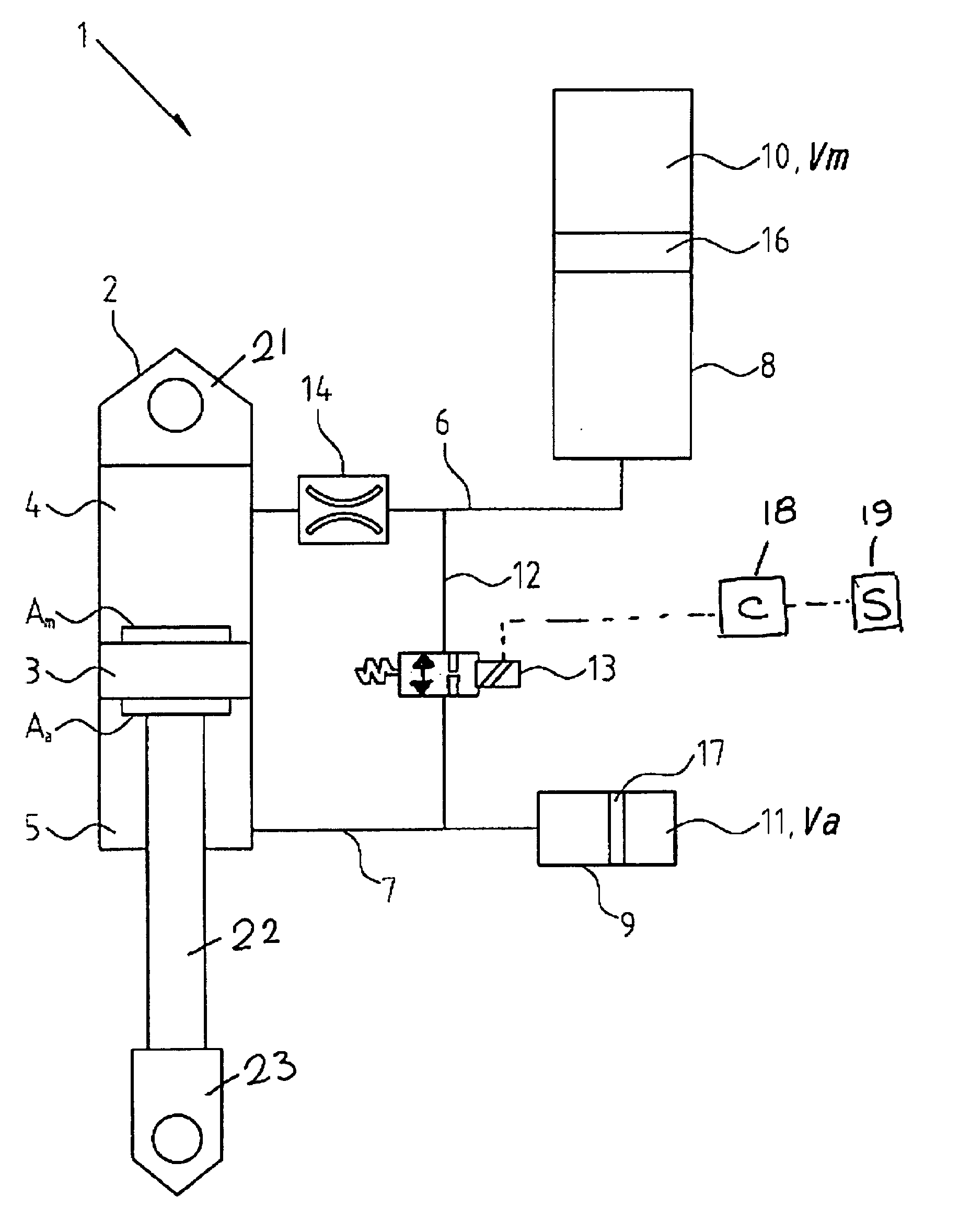

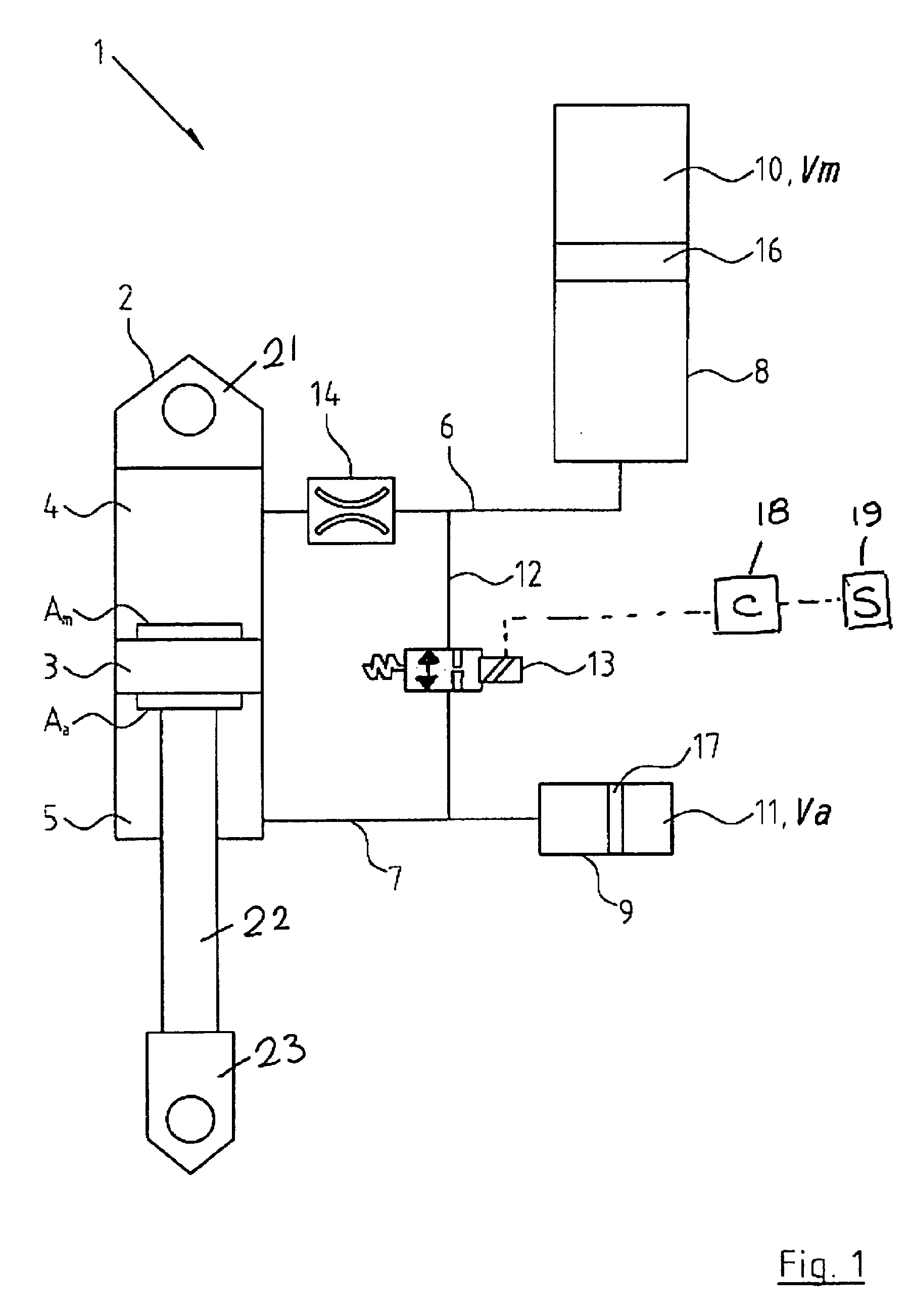

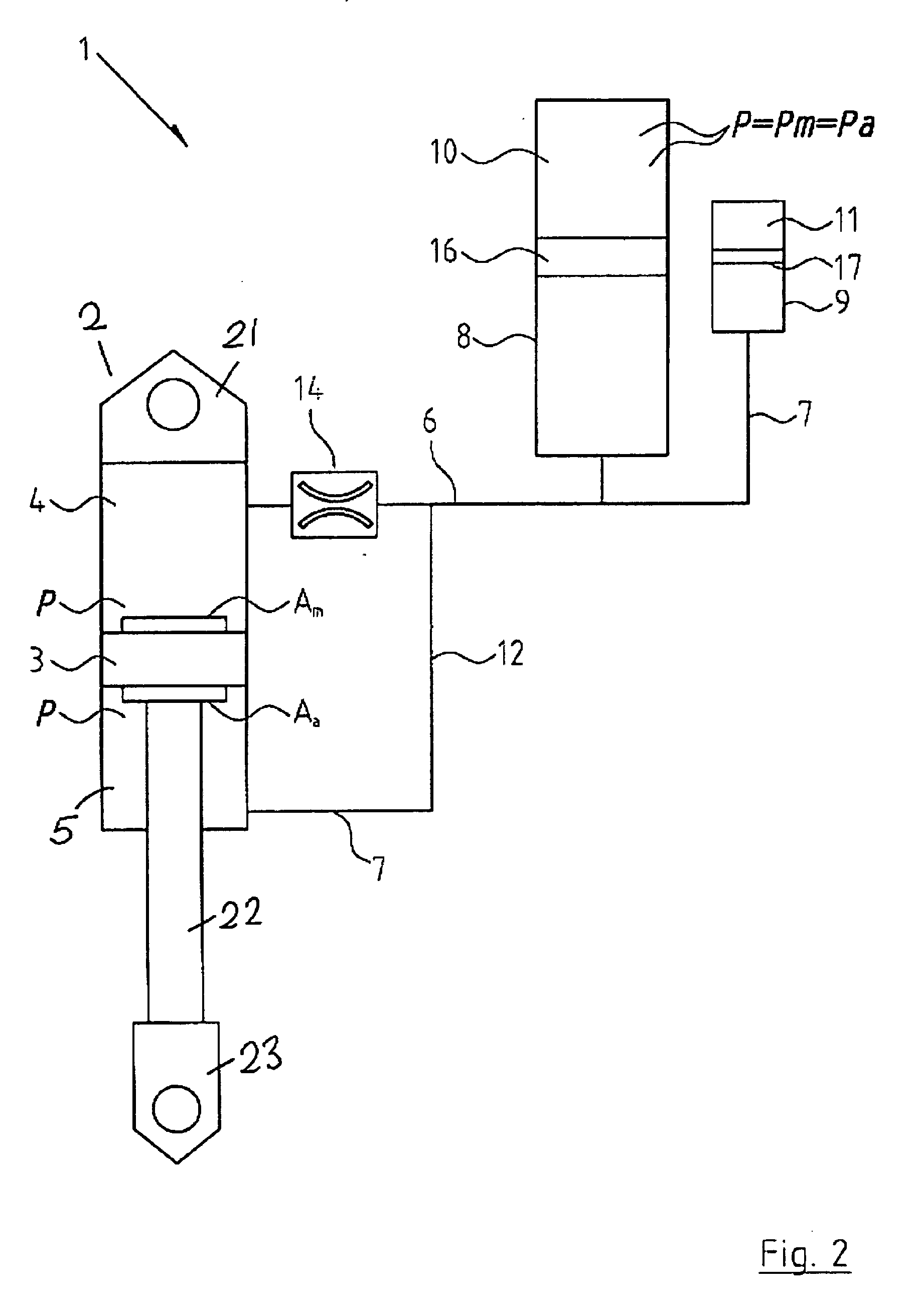

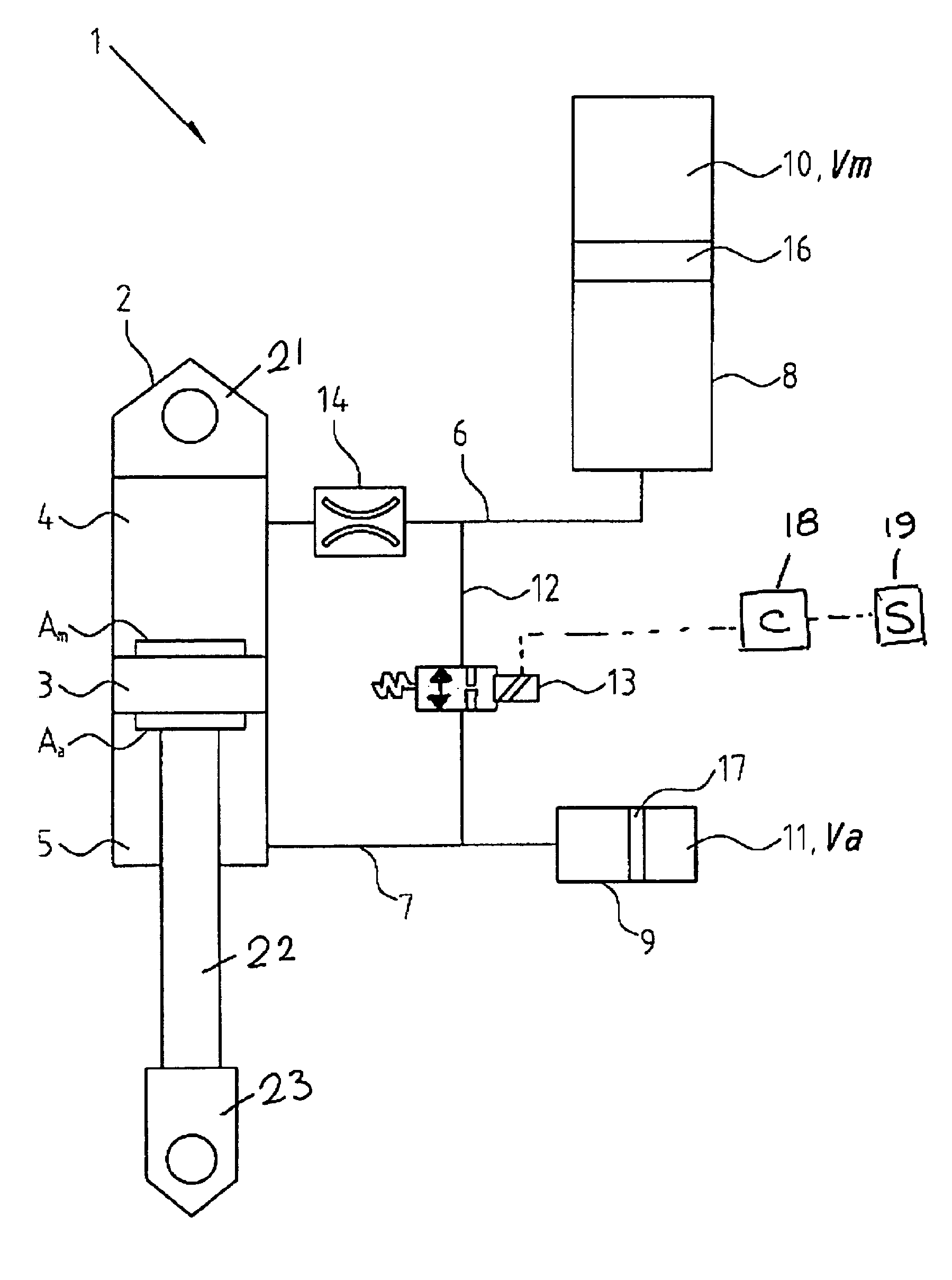

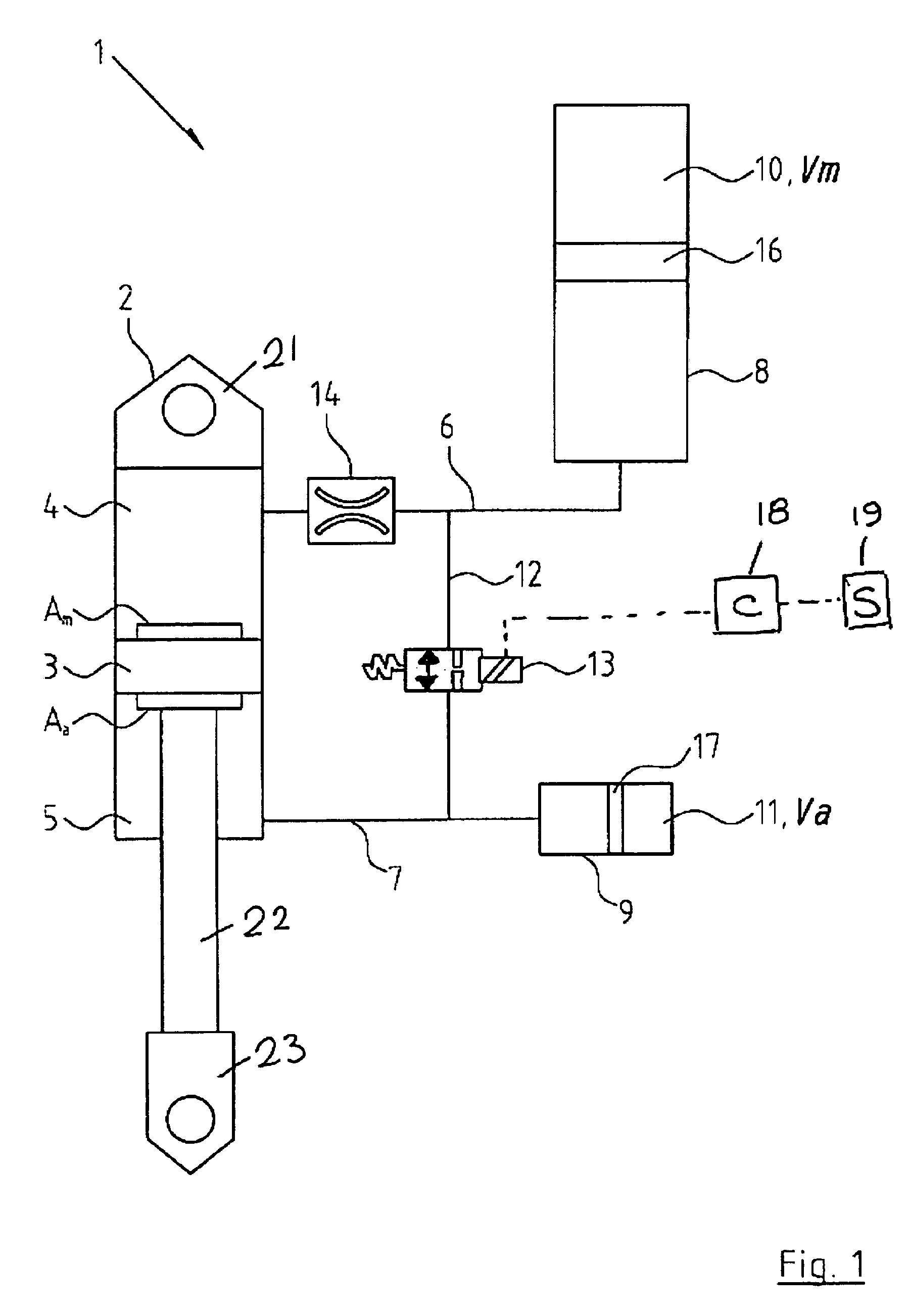

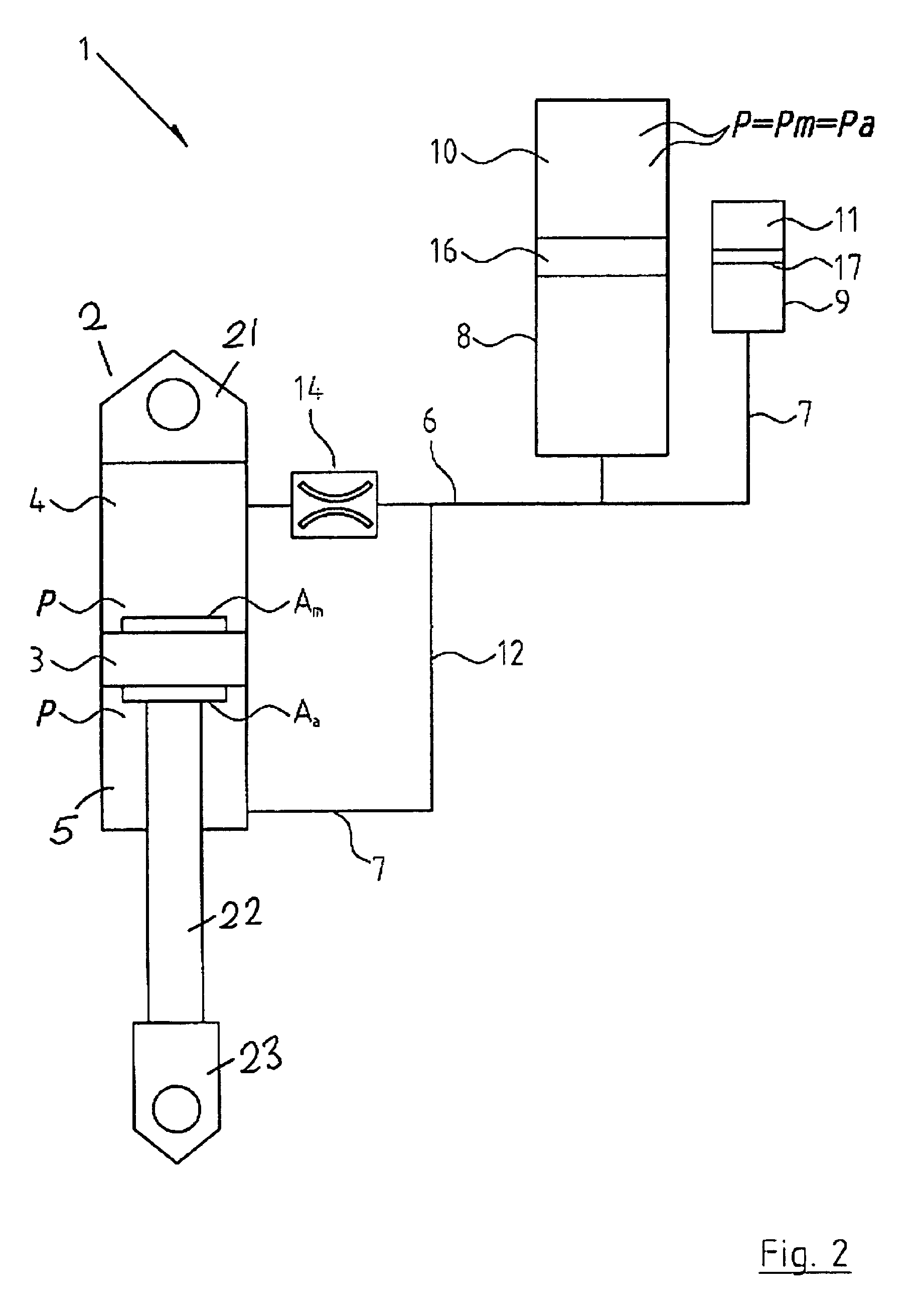

Vehicle suspension spring system

InactiveUS20070039790A1Displacement minimizationMinimising rollSpringsResilient suspensionsHydraulic cylinderIsolation valve

A vehicle suspension spring system for a vehicle wheel station includes a hydraulic cylinder or strut having a piston which divides the cylinder volume into a main oil volume and an annular oil volume. The main oil volume communicates via a first oil passage with a first accumulator having a main gas volume. The annular oil volume communicates via a second oil passage with a second accumulator having an auxiliary gas volume. The oil in each accumulator is separated from the gas by a separator piston or diaphragm. A third oil passage with an isolating valve interconnects said first and second oil passages. Operation of the isolating valve is regulated by a controller. At least one sensor for sensing a parameter associated with vehicle attitude is connected to the controller. The controller is operable for switching the isolating valve between open and closed positions for altering spring stiffness of the strut in response to said sensed vehicle attitude parameter when the vehicle is in motion.

Owner:TECH INVESTMENTS

Vehicle suspension spring system

InactiveUS7779974B2Eliminate the effects ofDisplacement minimizationSpringsResilient suspensionsHydraulic cylinderIsolation valve

A vehicle suspension spring system for a vehicle wheel station includes a hydraulic cylinder or strut having a piston which divides the cylinder volume into a main oil volume and an annular oil volume. The main oil volume communicates via a first oil passage with a first accumulator having a main gas volume. The annular oil volume communicates via a second oil passage with a second accumulator having an auxiliary gas volume. The oil in each accumulator is separated from the gas by a separator piston or diaphragm. A third oil passage with an isolating valve interconnects said first and second oil passages. Operation of the isolating valve is regulated by a controller. At least one sensor for sensing a parameter associated with vehicle attitude is connected to the controller. The controller is operable for switching the isolating valve between open and closed positions for altering spring stiffness of the strut in response to said sensed vehicle attitude parameter when the vehicle is in motion.

Owner:TECH INVESTMENTS

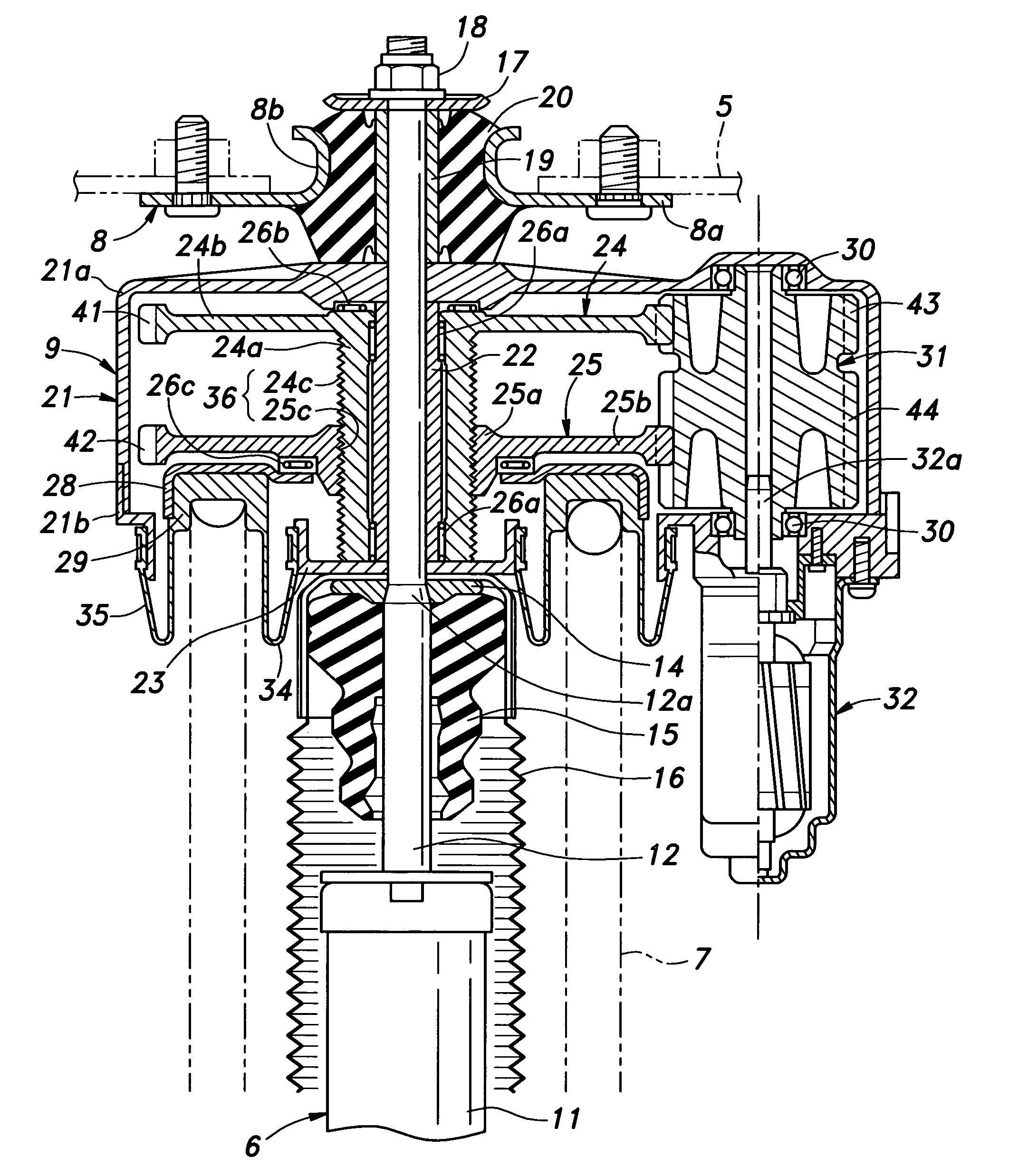

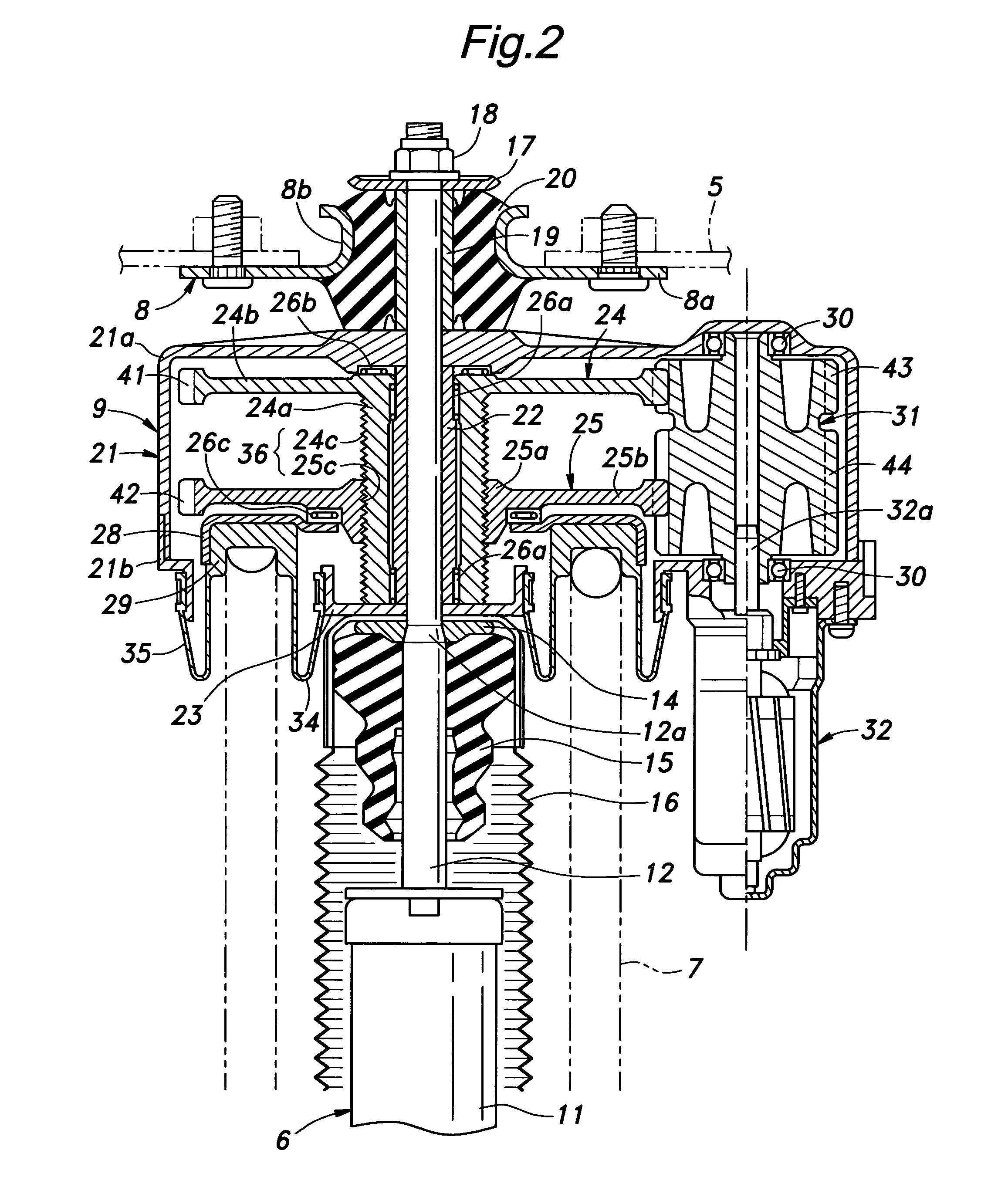

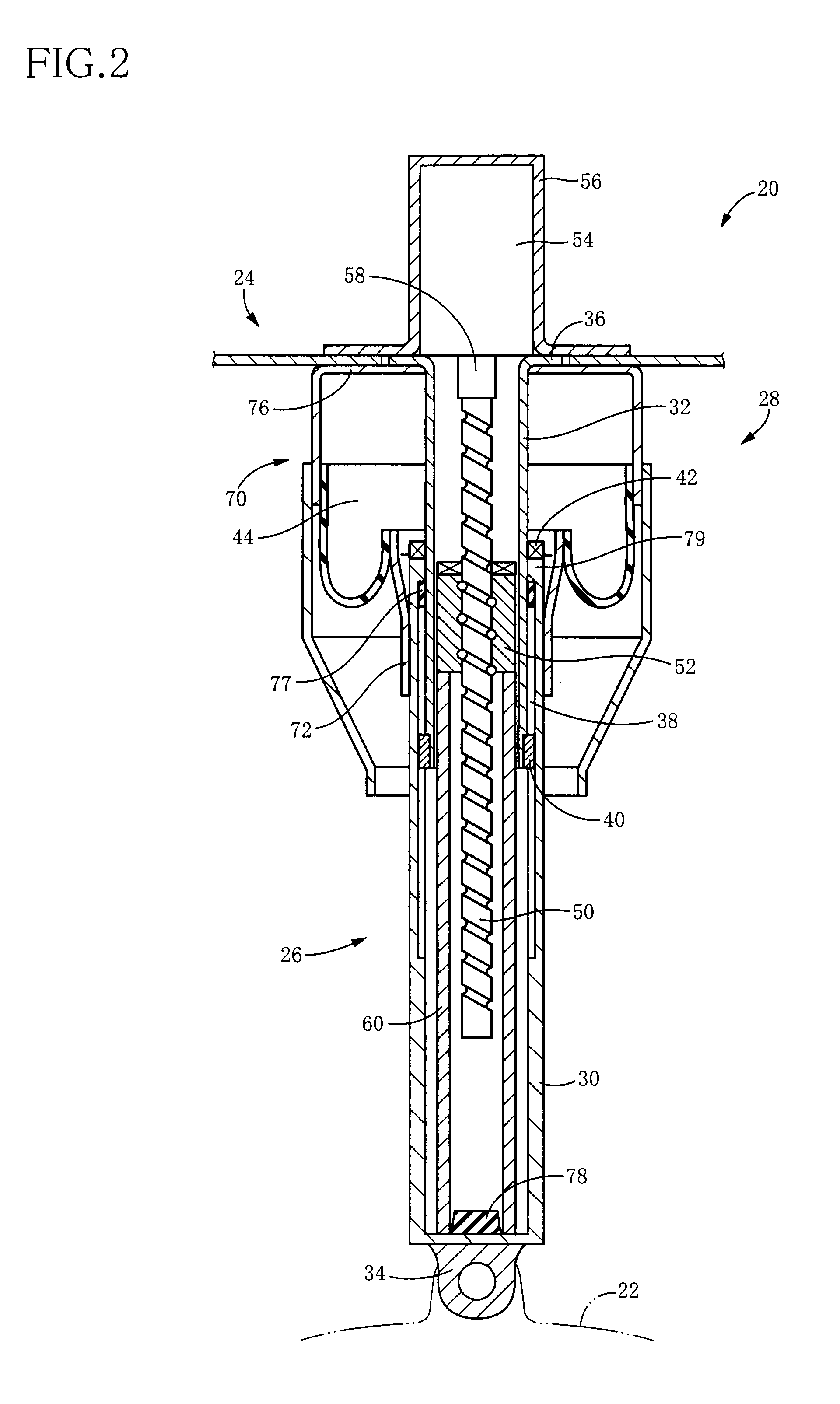

Vehicle height adjusting system

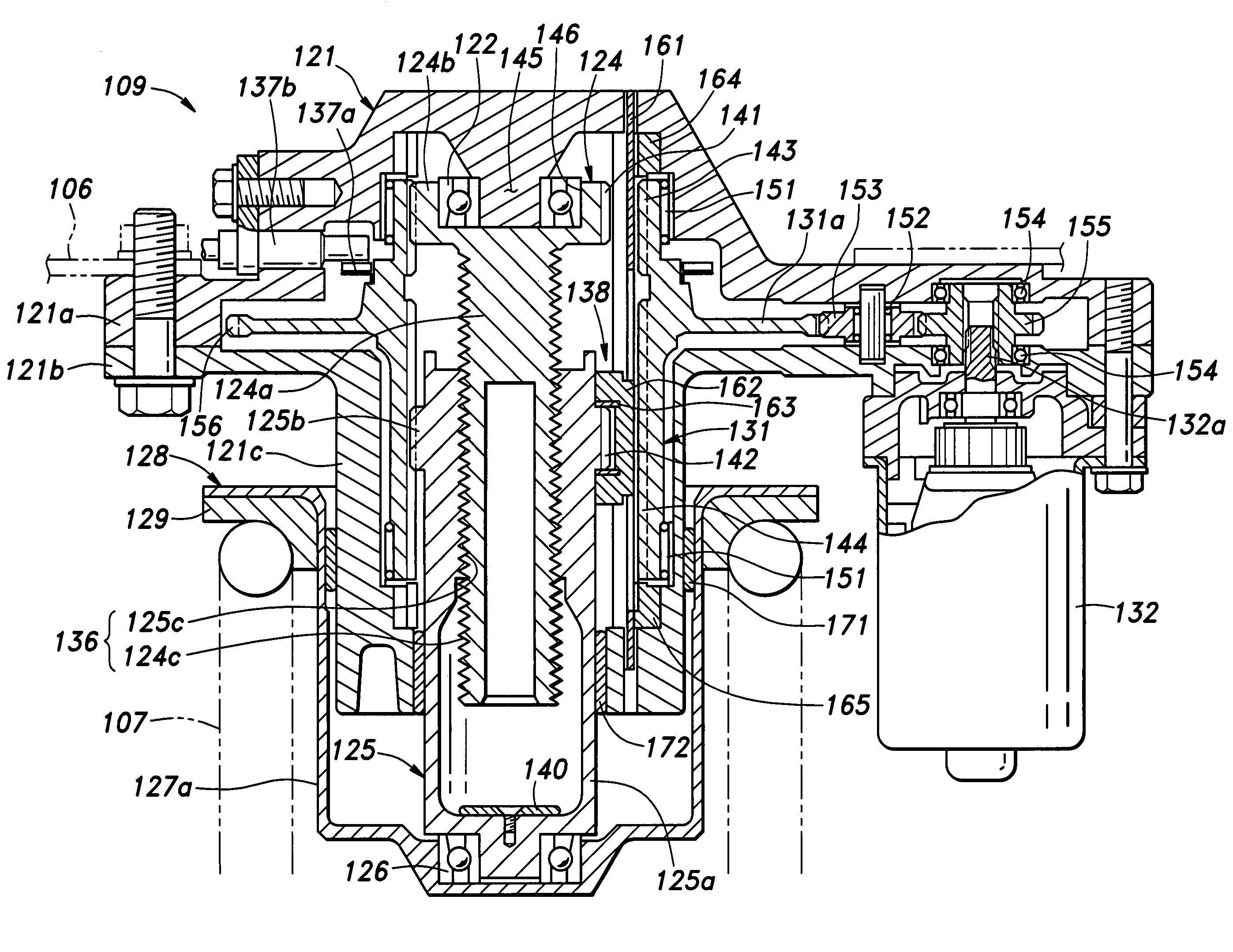

ActiveUS20070210539A1Stable supportCompact designVehicle cleaning apparatusToothed gearingsLinear motionDrive shaft

A first rotor (24; 124) and a second rotor (25; 125) are arranged in a coaxial and mutually rotatable relationship and are provided with a first driven gear (41; 141) and a second driven gear (42; 142), respectively. A drive shaft (31; 131) is also provided with a first drive gear (43; 143) and a second drive gear (44; 144) which are commonly connected to an output shaft of an electric motor (32; 132), and mesh with the first and second driven gears, respectively, at slightly different gear ratios. The first and second rotors are connected via a thread feed mechanism (36; 136) that converts a relative rotation between the first and second rotors into an axial linear movement between the first and second rotors that is used for changing a distance between a vehicle body part and a corresponding end of a suspension spring in a vehicle height adjusting system (9; 109). Owing to a differential rotation of a high gear ratio between the first and second rotors, a significant torque amplification is possible with a compact arrangement. The use of spur gears instead of a worm gear mechanism minimizes torque loss.

Owner:HONDA MOTOR CO LTD

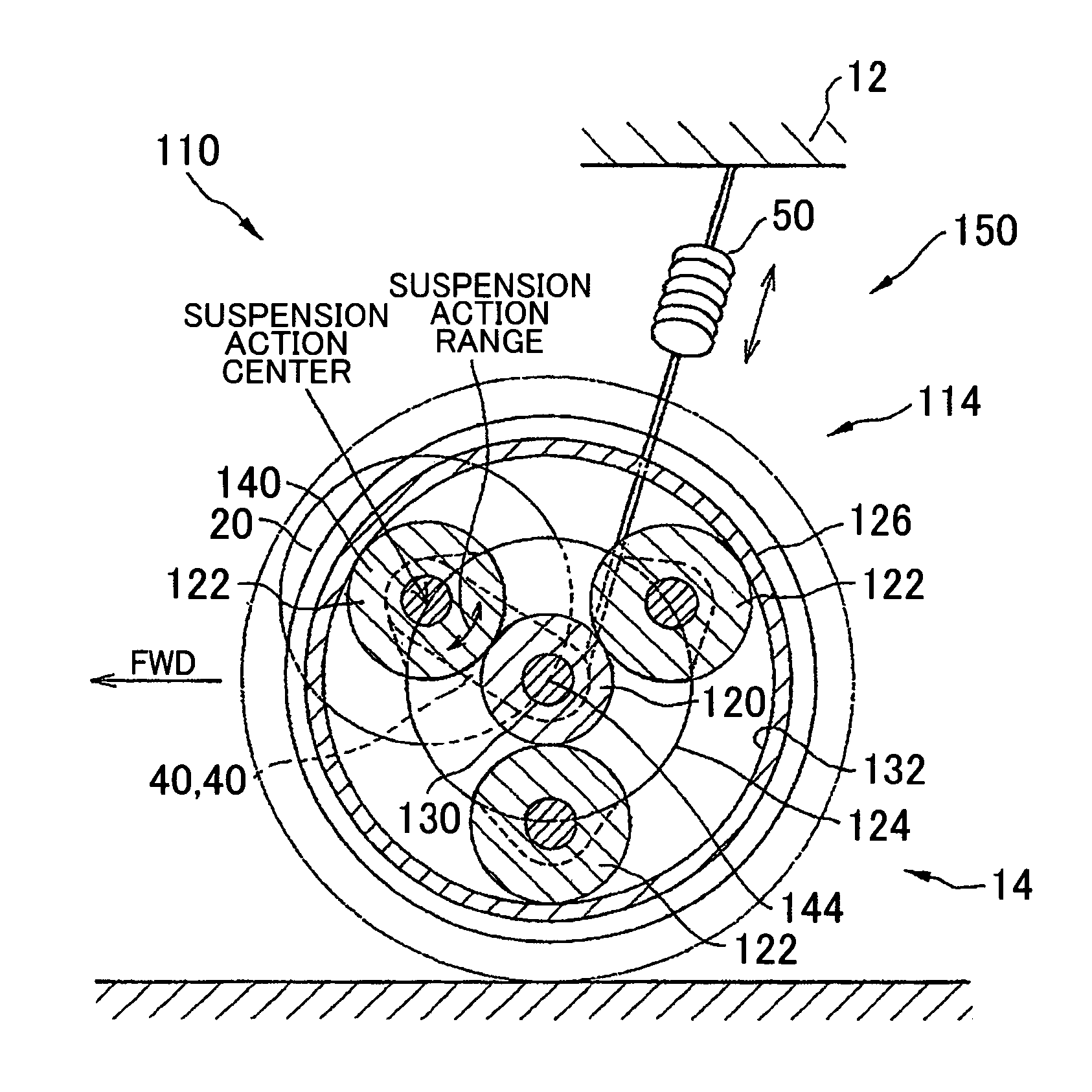

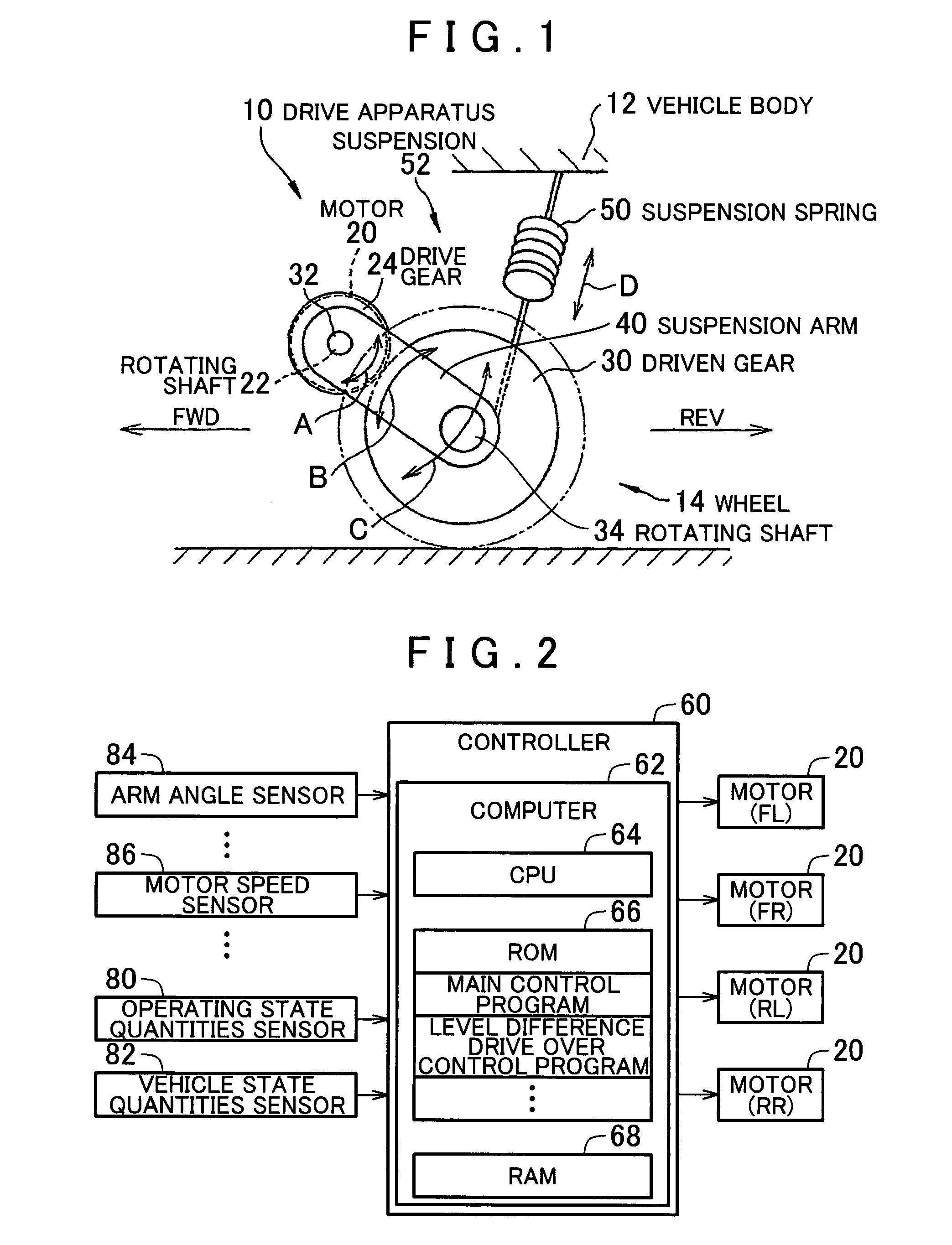

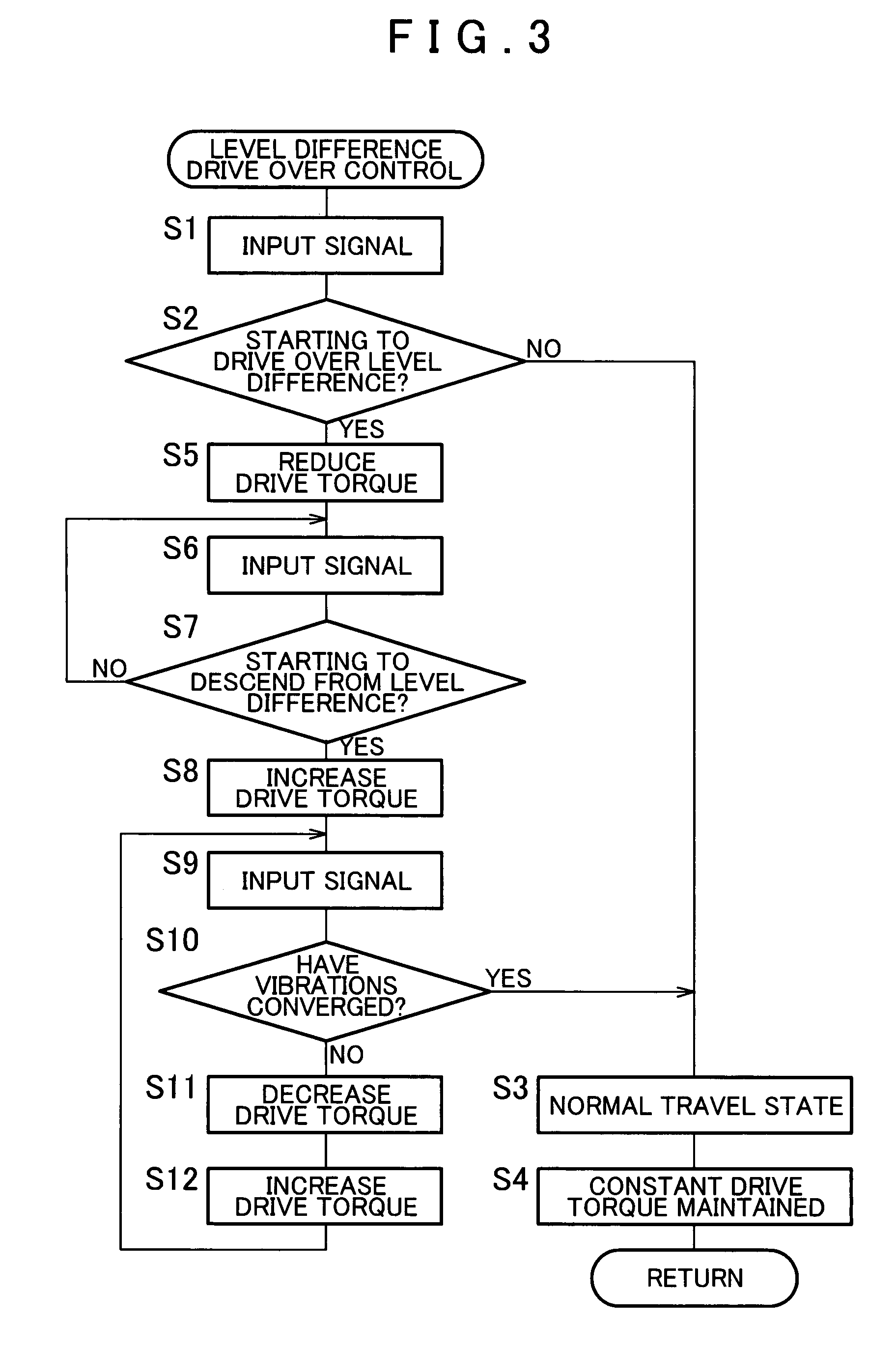

Wheel Supporting and Driving Device

InactiveUS20070272458A1Reduce vibrationImprove abilitiesSpeed controllerElectric devicesEngineeringCantilever

A wheel supporting and driving device, comprising a motor (20) fixed to a vehicle body (12), a drive gear (24) coaxially rotated by the motor (20), and a driven gear (30) coaxially and integrally rotated with a wheel (14) which are installed in a vehicle. The drive gear (24) is rotated by the motor (20) around a rotating center decentered from the rotating center of the wheel (14) in a direction crossing perpendicularly to the vertical direction. Also, the device comprises a suspension arm (40) connecting the drive gear (24) to the driven gear (30) in the state of the driven gear (30) reciprocatingly swingable around the rotating center of the drive gear (24) and a suspension spring (50) elastically connecting the wheel (14) to the vehicle body (12).

Owner:KABUSHIKIAISHA EQUOS RES

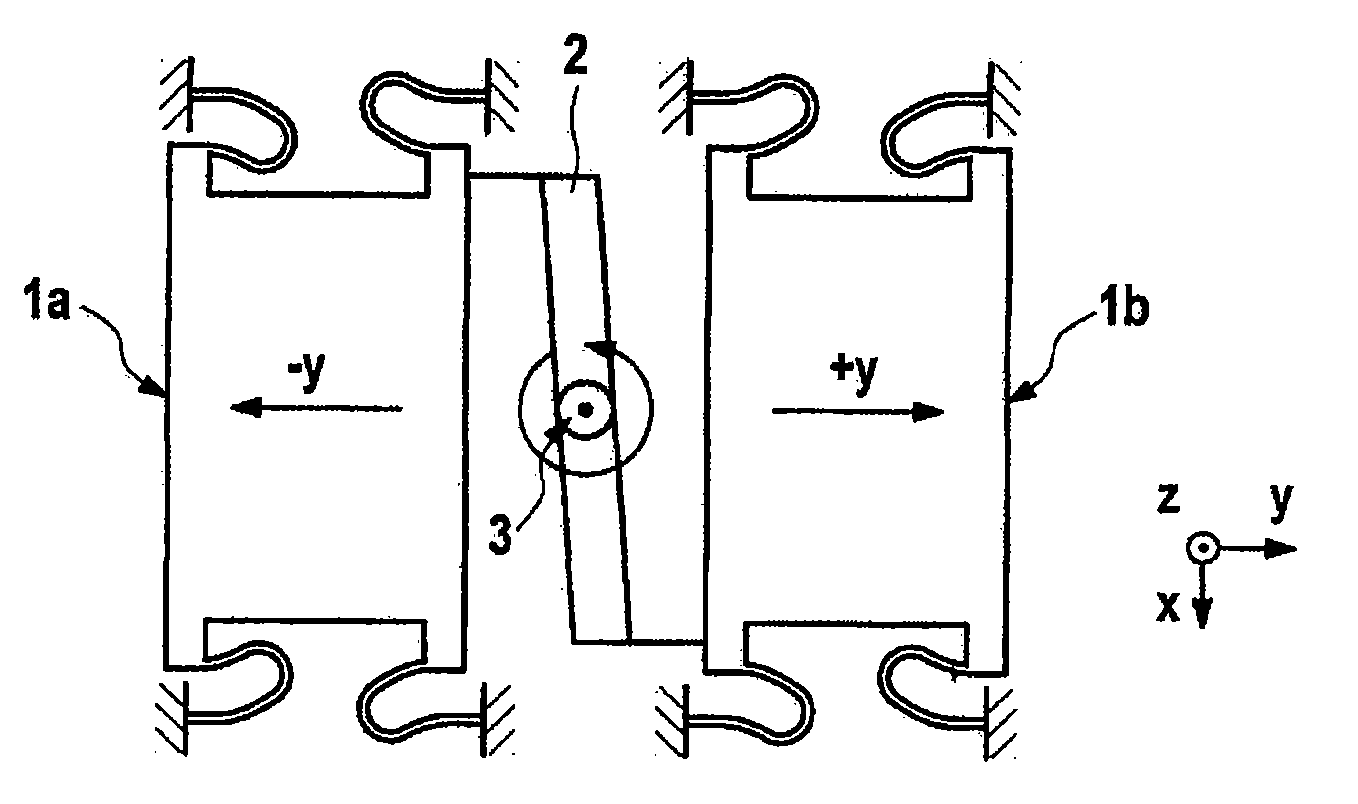

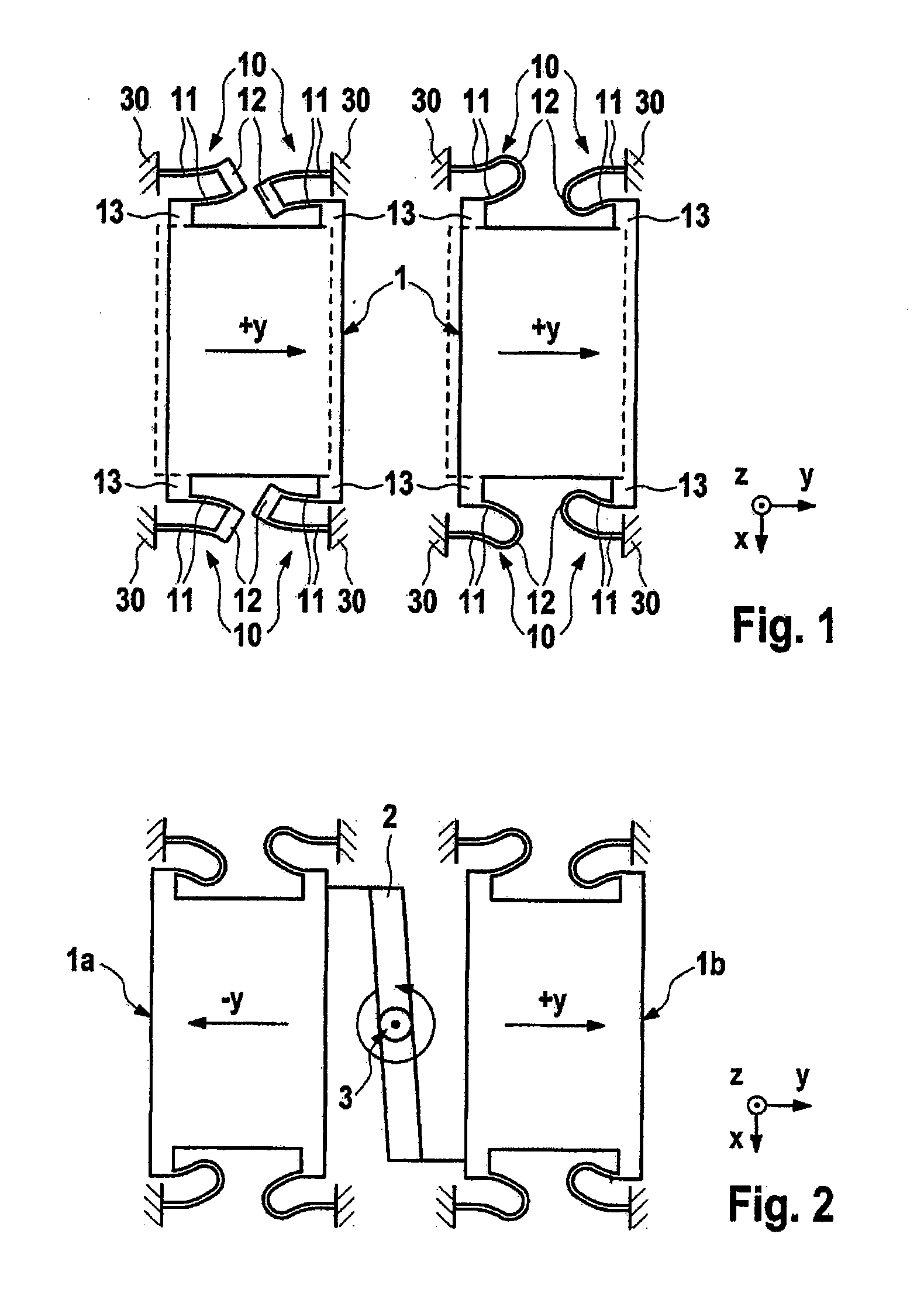

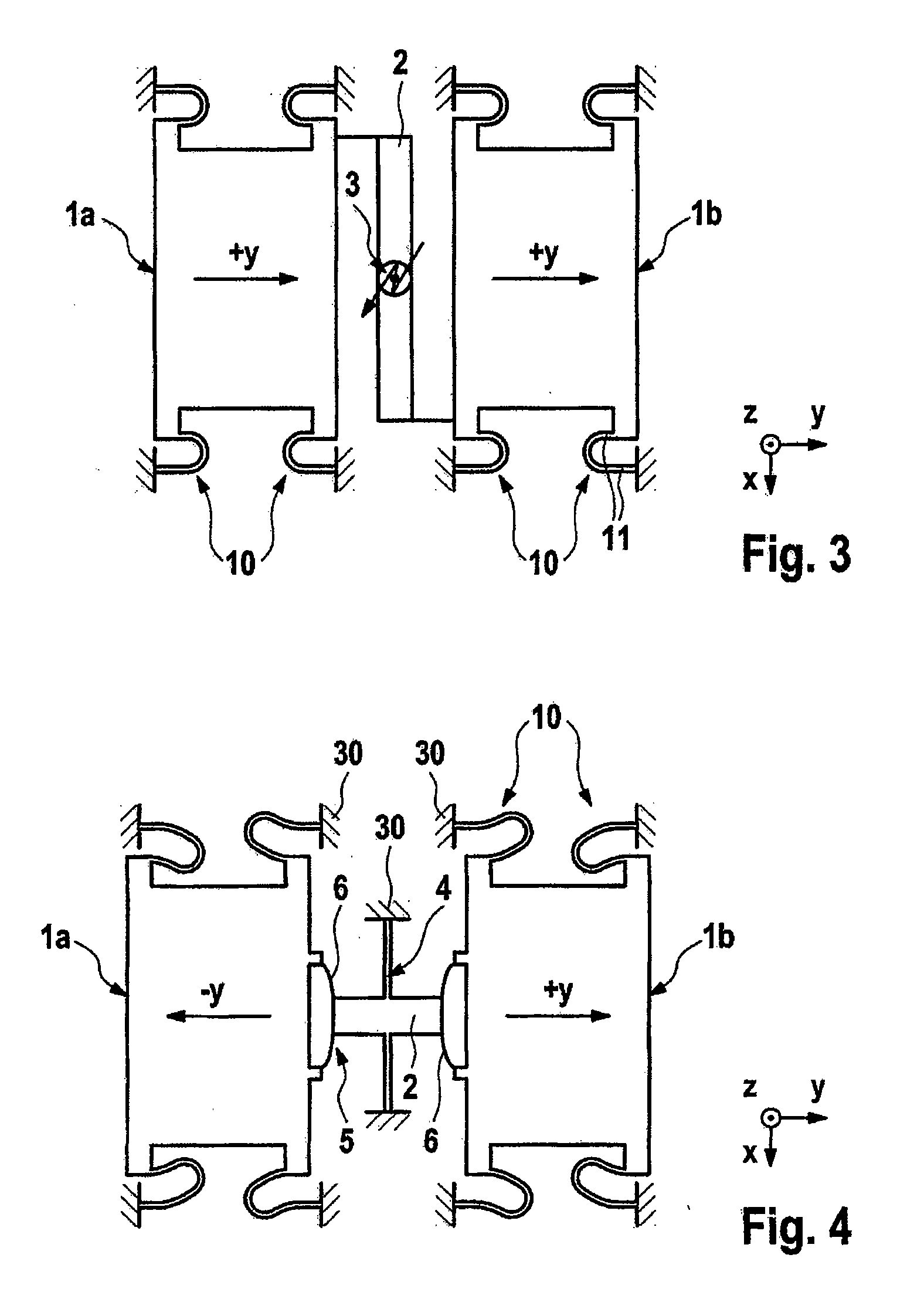

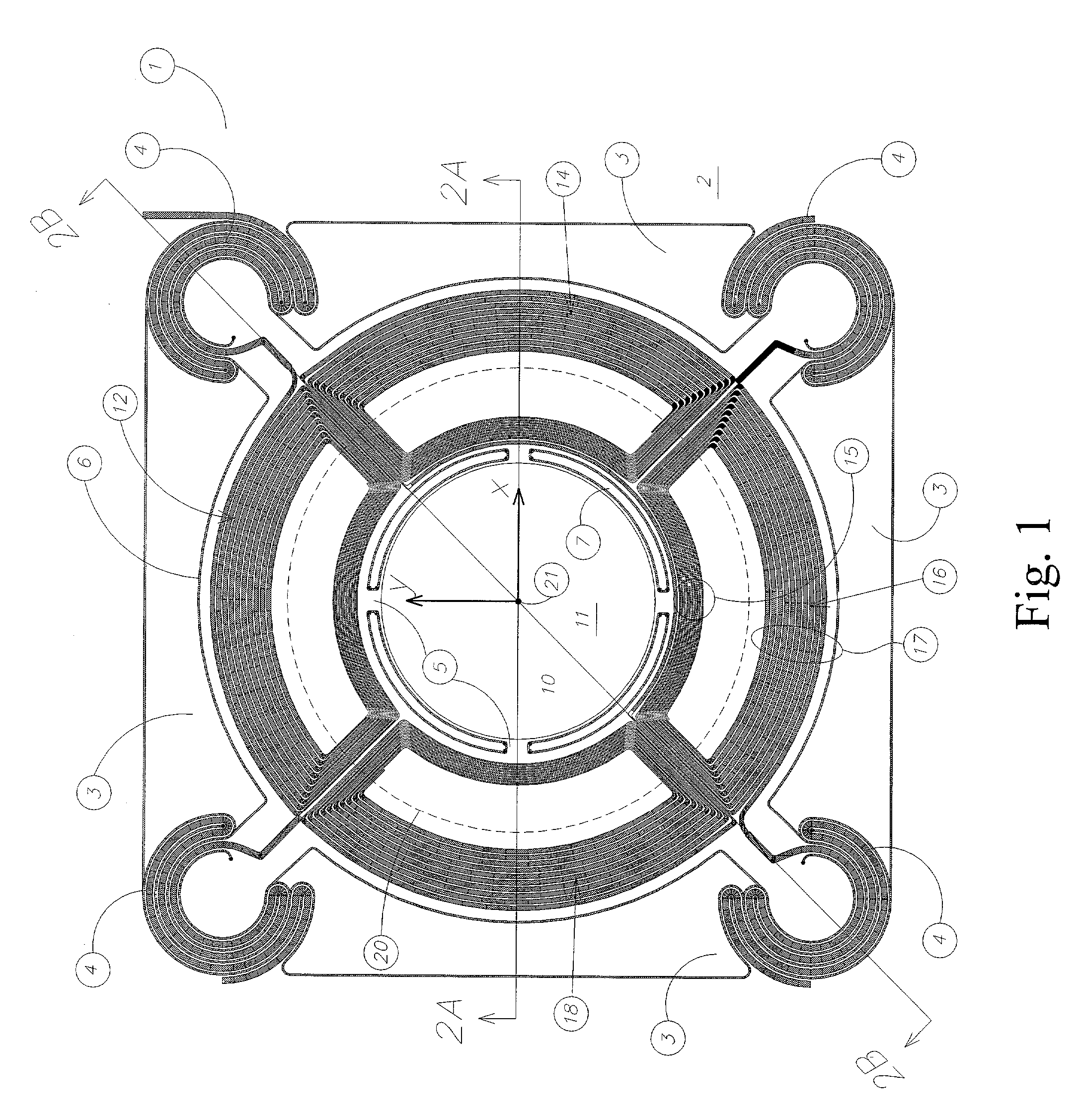

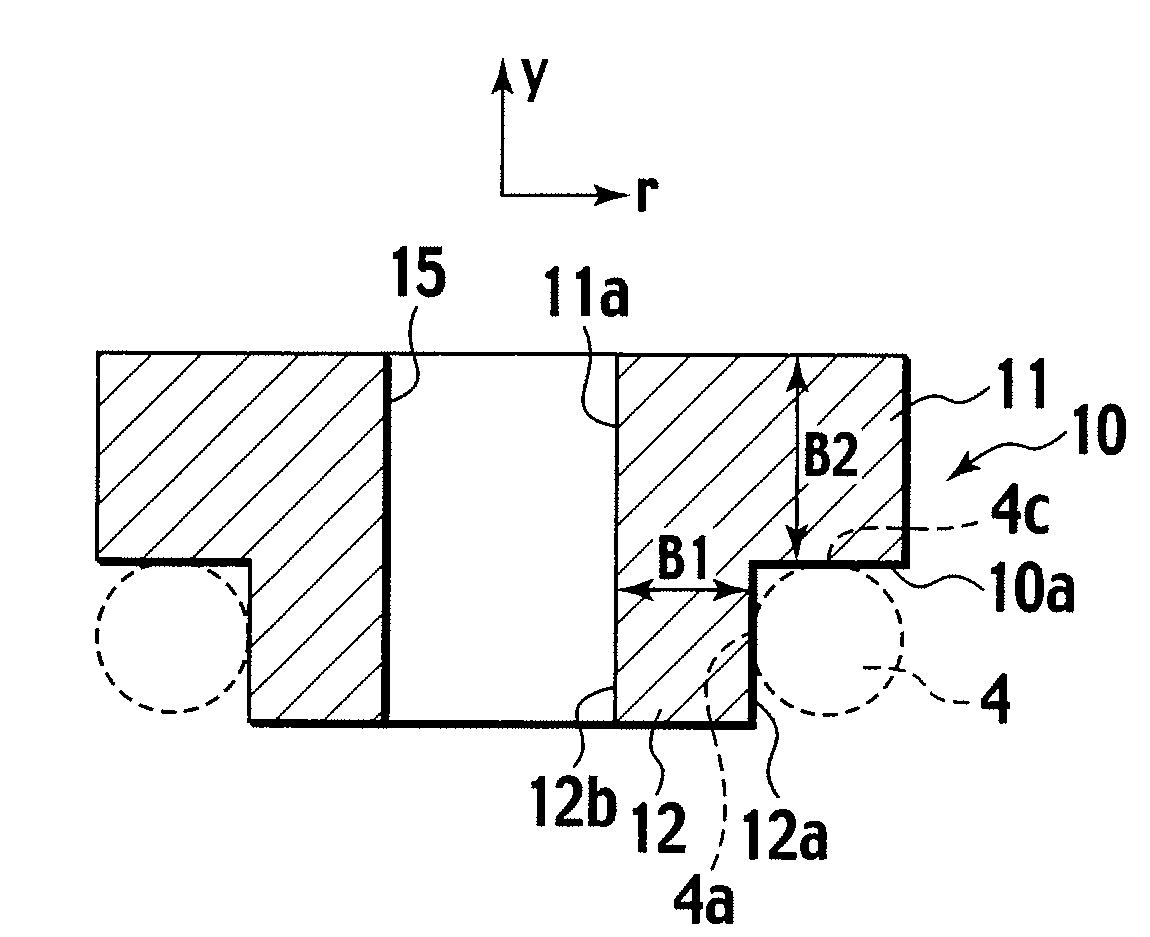

Micromechanical rotation rate sensor with a coupling bar and suspension spring elements for quadrature suppression

ActiveUS20100186507A1Reduce generationSuppresses quadratureAcceleration measurement using interia forcesSemiconductor/solid-state device manufacturingSeismic massEngineering

A micromechanical rotation rate sensor including at least one substrate, wherein the base surface of the substrate is oriented parallel to the x-y plane of a Cartesian coordinate system, at least two seismic masses and in each case at least one suspension spring element for suspending the seismic mass from the substrate, wherein the at least two seismic masses are coupled to one another by at least one coupling bar, and at least one of the suspension spring elements includes at least two bar sections, which, in the undeflected state, are oriented essentially parallel to one another or are at an angle of less than 45° with respect to one another, and one or more connecting sections, which connect the bar sections to one another, wherein the bar sections can be displaced relative to one another in their longitudinal direction.

Owner:CONTINENTAL TEVES AG & CO OHG

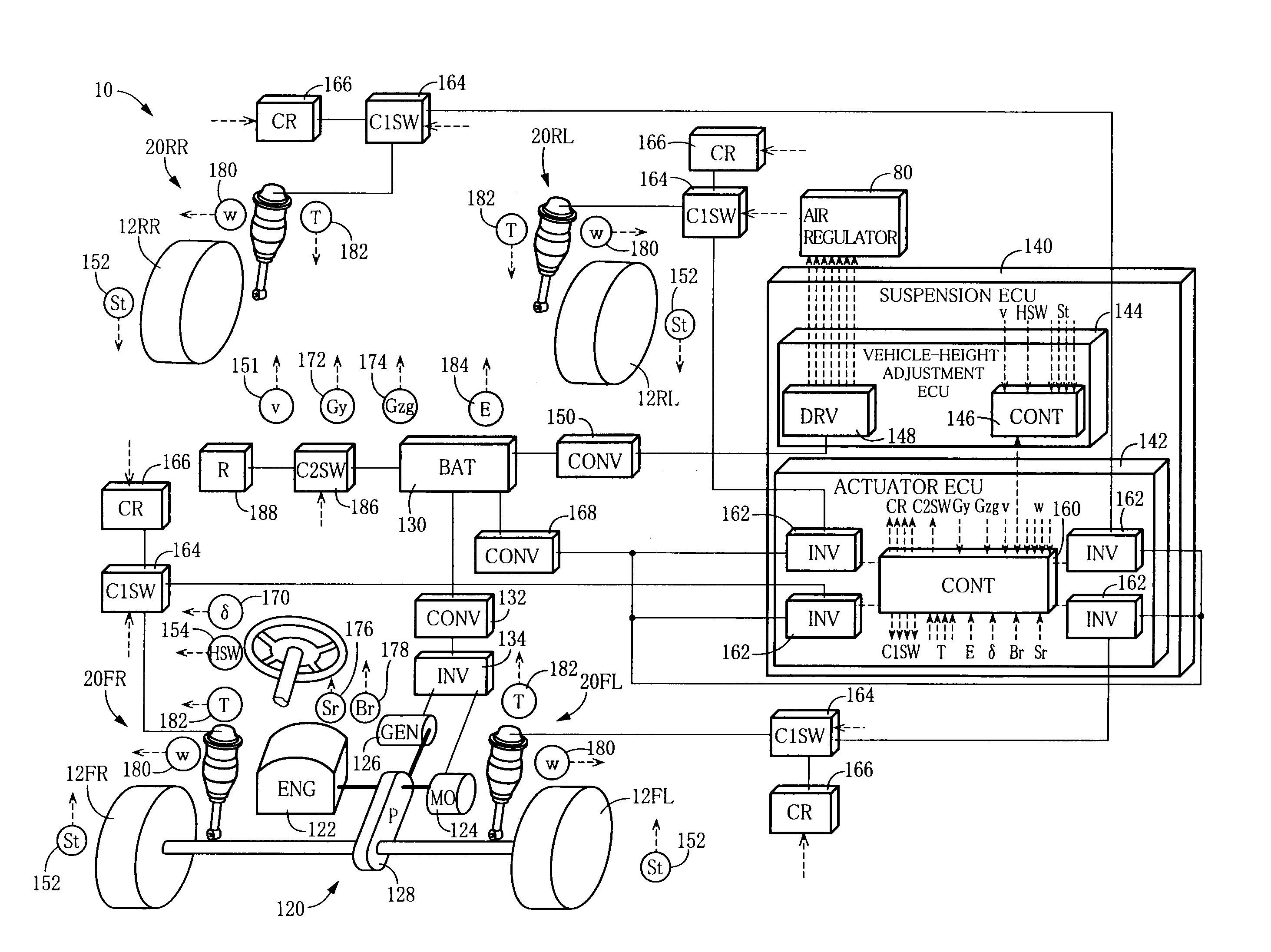

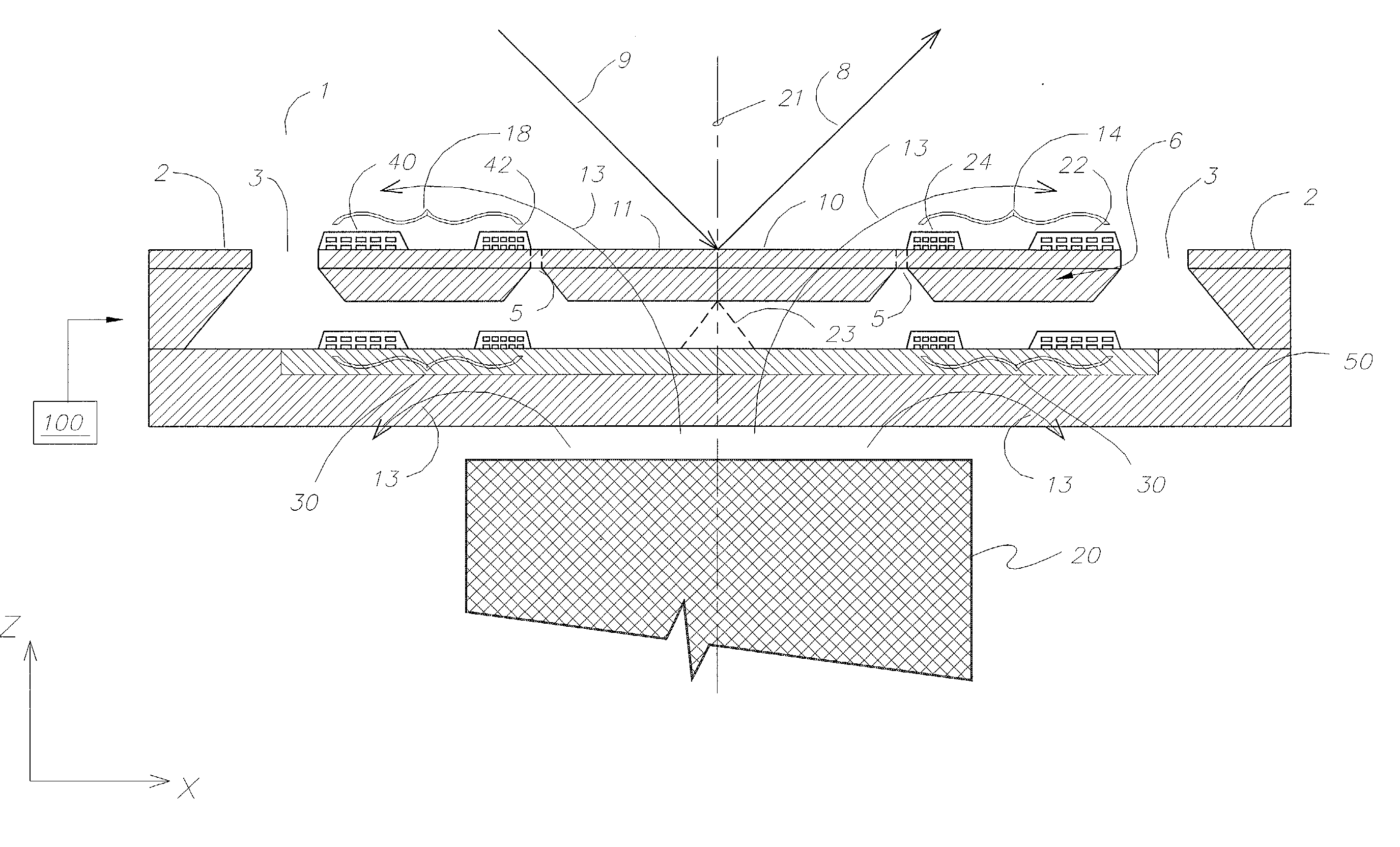

Vehicle suspension system

ActiveUS20100230876A1Effective controlImprove applicabilityMachine framesNon-rotating vibration suppressionElectrical batteryConstant force

A vehicle suspension system including: (a) a suspension spring interconnecting a vehicle body and a wheel; (b) an actuator having an electric motor, such that the actuator is capable of generating, based on a force of the electric motor, an actuator force forcing the body and the wheel toward and away from each other, and causing the generated actuator force to act as a damping force against displacement of the body and the wheel; and (c) a control device for controlling the actuator force generated by the actuator, by controlling operation of the electric motor. The control device is capable of establishing a constant-force generating state in which the actuator force is constantly generated as a constant actuator force by the actuator with supply of an electric power thereto from a battery as an electric power source of the electric motor such that the generated constant actuator force acts in a rebound direction or a bound direction. The control device controls the constant-force generating state, based on a charge state of the battery.

Owner:TOYOTA JIDOSHA KK

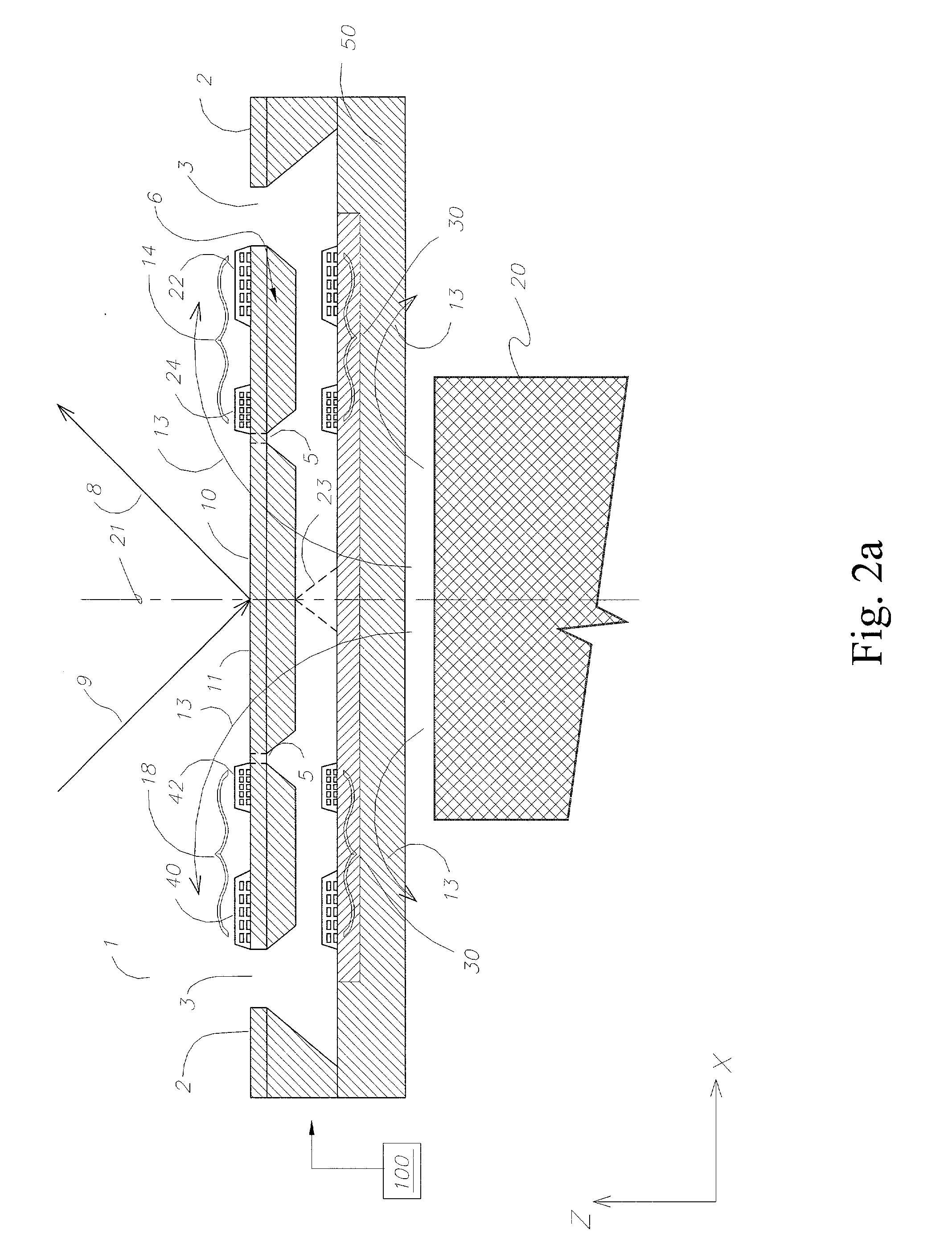

Moving coil motor and implementations in MEMS based optical switches

InactiveUS20020130561A1Expand the working areaSmall device footprintMagnetic circuitCoupling light guidesOptical cavityGalvanometer

A moving coil motor has an axisymmetric magnetic field applied to the drive coils on the movable member of the motor. The movable member is suspended by springs. The moving coil motor may be configured in a MEMS format, with the movable member and its suspension springs fabricated from a mono-crystalline substance to improve structural integrity. MEMS based moving coil motors may be configured in an array. Sensors are provided to detect the relative spatial positions of the movable member. The movable member may include several tiers. In one application, the moving coil motor may be configured to support and drive a mirror surface on the movable member to form a galvanometer, optical switch, or other optical component. Singular moving coil motors may be configured in an optical cavity to facilitate the tuning of specific wavelengths while a number of moving coil motors may be configured to form an array of optical switches to facilitate switching in a multi-channel optical network.

Owner:INTEGRATED MICROMACHINES

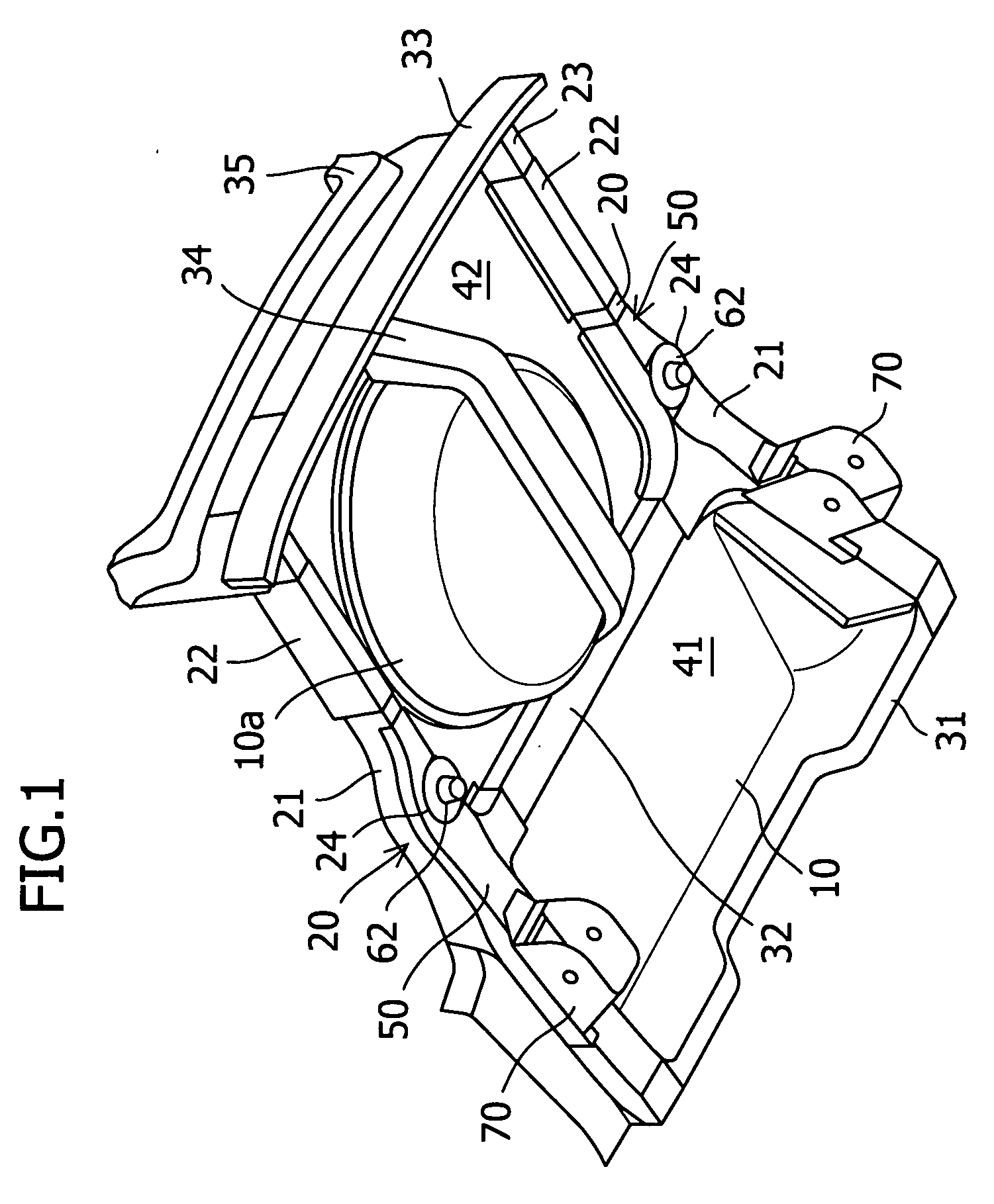

Spring Seat of Suspension

InactiveUS20090008846A1Avoid adjustmentResilient suspensionsVehicle springsCoil springSuspension spring

A spring seat for a suspension arranged between a vehicle body side member and a wheel side member, the spring seat supporting an end portion of a coil spring of the suspension, wherein rigidity of the spring seat in the orthogonal-to-axis direction of the coil spring is smaller than rigidity of the spring seat in the axial direction of the coil spring.

Owner:NISSAN MOTOR CO LTD

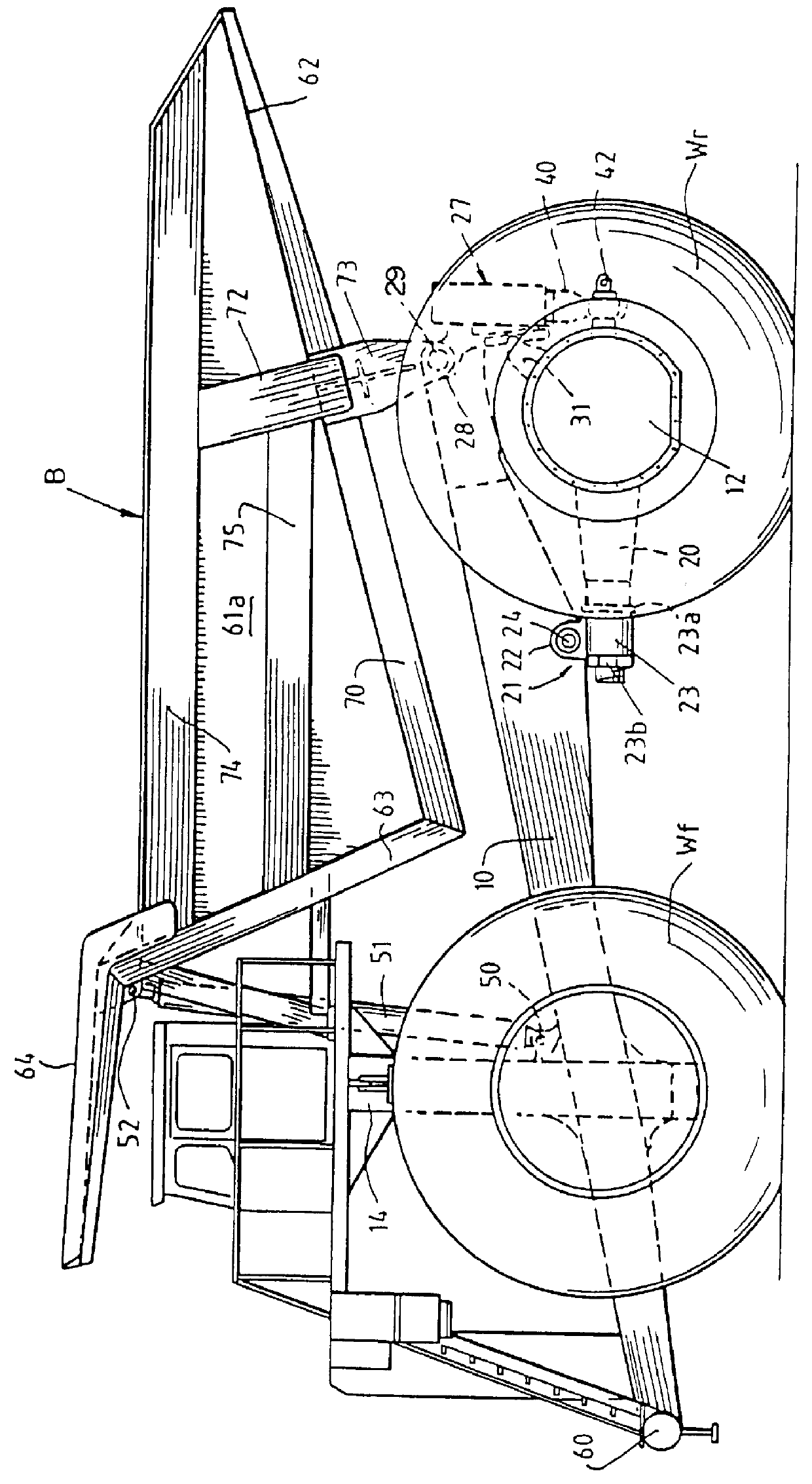

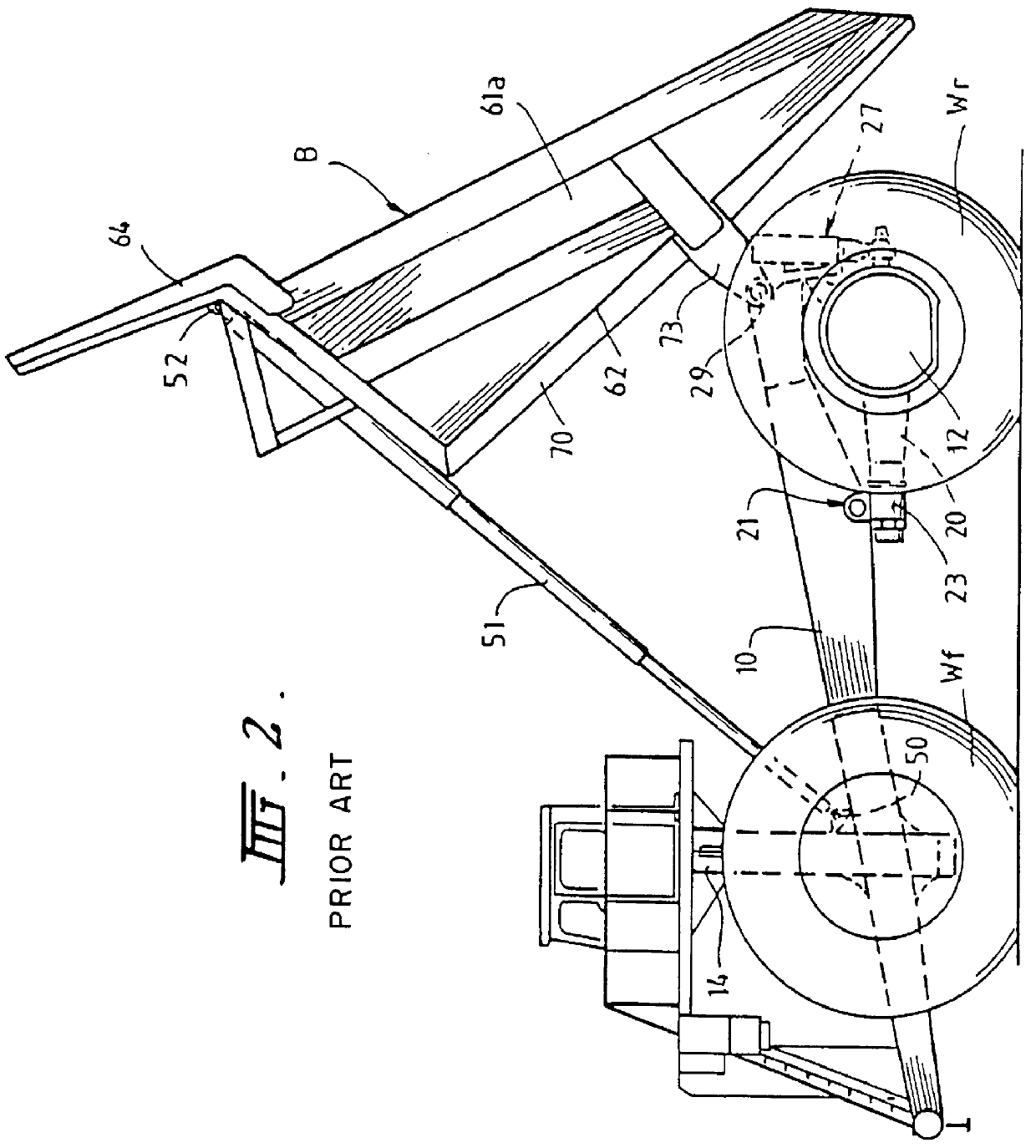

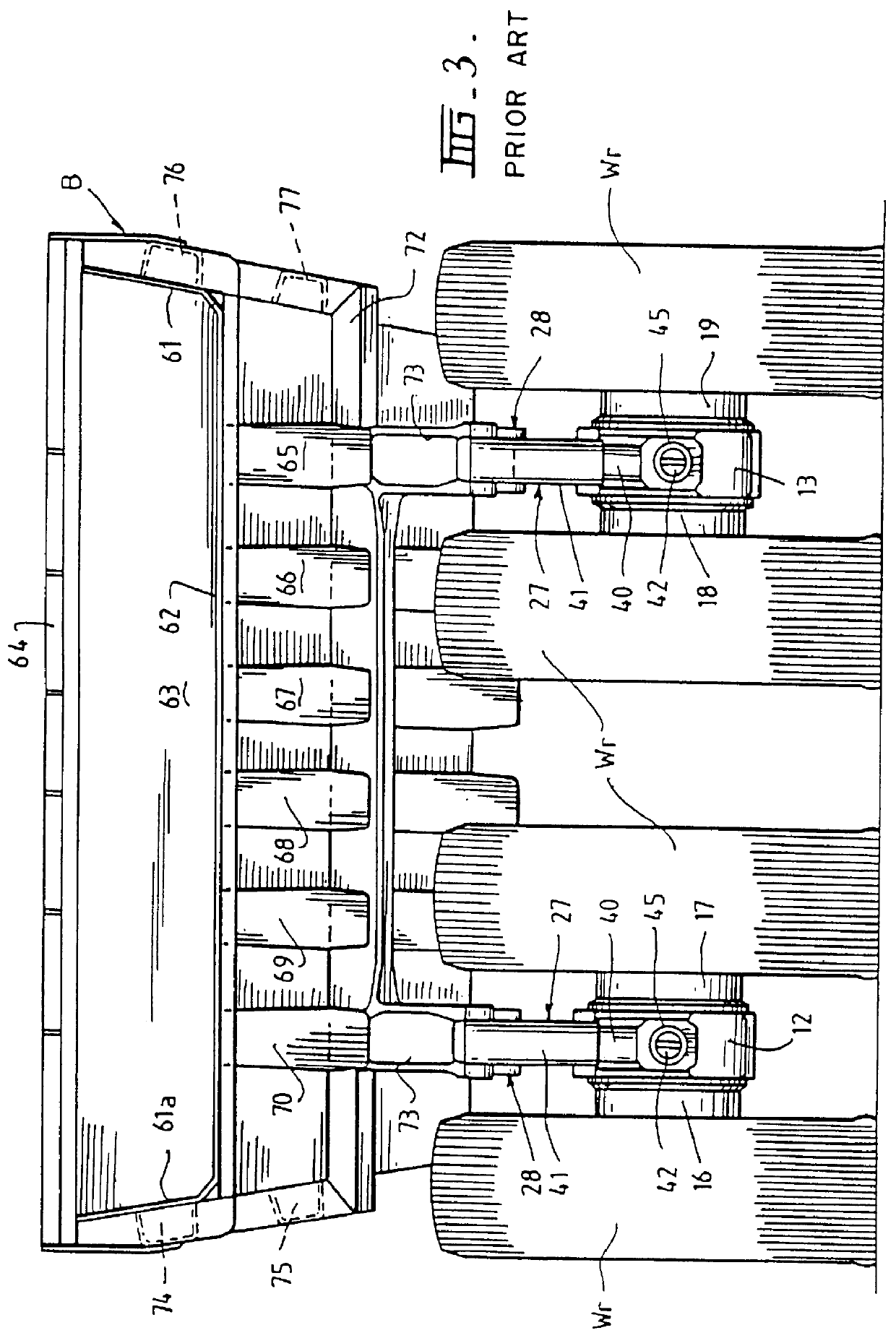

Large dump truck suspension

InactiveUS6086076APrevent rotationEliminate torsional loadsInterconnection systemsResilient suspensionsSpherical bearingEngineering

PCT No. PCT / AU96 / 00180 Sec. 371 Date Jul. 11, 1997 Sec. 102(e) Date Jul. 11, 1997 PCT Filed Mar. 29, 1996 PCT Pub. No. WO96 / 30223 PCT Pub. Date Oct. 3, 1996A suspension system for a large dump truck. The dump truck having a main frame with laterally spaced frame members each associated with a rear wheel mounting hub with a wheel on each of its sides. Each hub is attached to a respective frame member by an attachment member pivotally attached to the respective frame member by a pivotal mounting and a suspension spring pivotally attached to the hub by a spherical bearing and to the respective frame member at a pivot mounting. The connections of the hub allow for limited pivotal movement of the hub about transverse and longitudinal axes relative to the frame members. A dump body is pivotally attached to the frame members at the pivot mounting or to the rear and above a suspension pivotal connection at a body pivotal connection.

Owner:BHP AUSTRALIA COAL PTY LTD

Spring Strut Arrangement for Wheel Suspension of Motor Vehicles

InactiveUS20100308518A1Low costCompact and durableNon-rotating vibration suppressionResilient suspensionsShock absorberSuspension spring

The invention relates a spring strut arrangement for wheel suspensions of motor vehicles, which is formed from a telescoping shock absorber, a suspension spring element which is preferably made as a helical compression spring, and a preloaded spring element which is preferably made as a helical compression spring, the spring elements being supported by way of spring caps on the body of the motor vehicle and on a wheel suspension element and a third spring cap located in between being movably guided along the longitudinal axis of the shock absorber relative to the body by way of an electrically driven positioning drive which is located within the spring elements, the positioning drive having a positioning spindle which is pivoted around the shock absorber and an adjusting nut which is connected to the movable spring cap. According to the invention, the shock absorber with the shock absorber tube is located at the top on the body of the motor vehicle and the positioning spindle is pivoted on the shock absorber tube.

Owner:AUDI AG

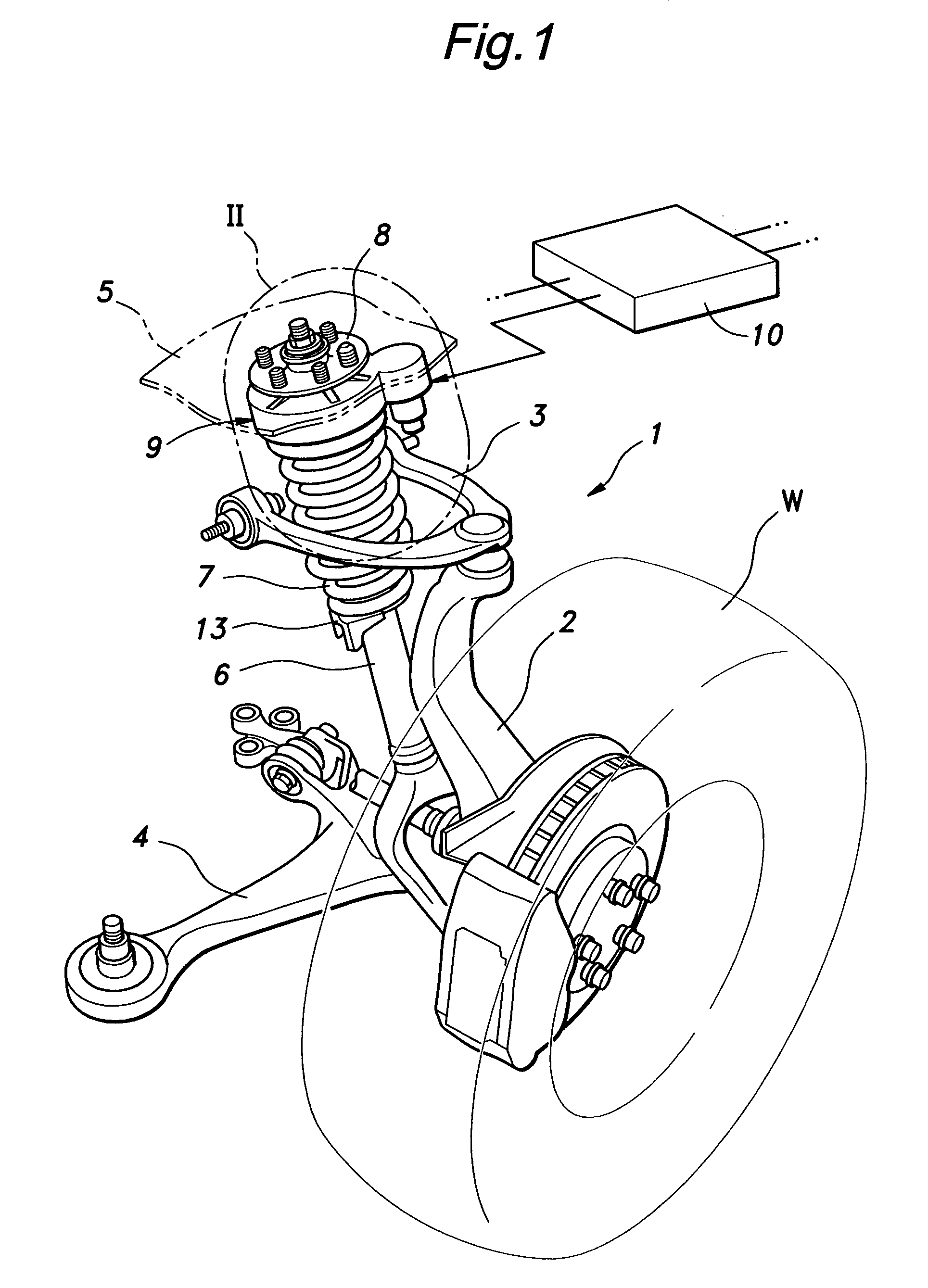

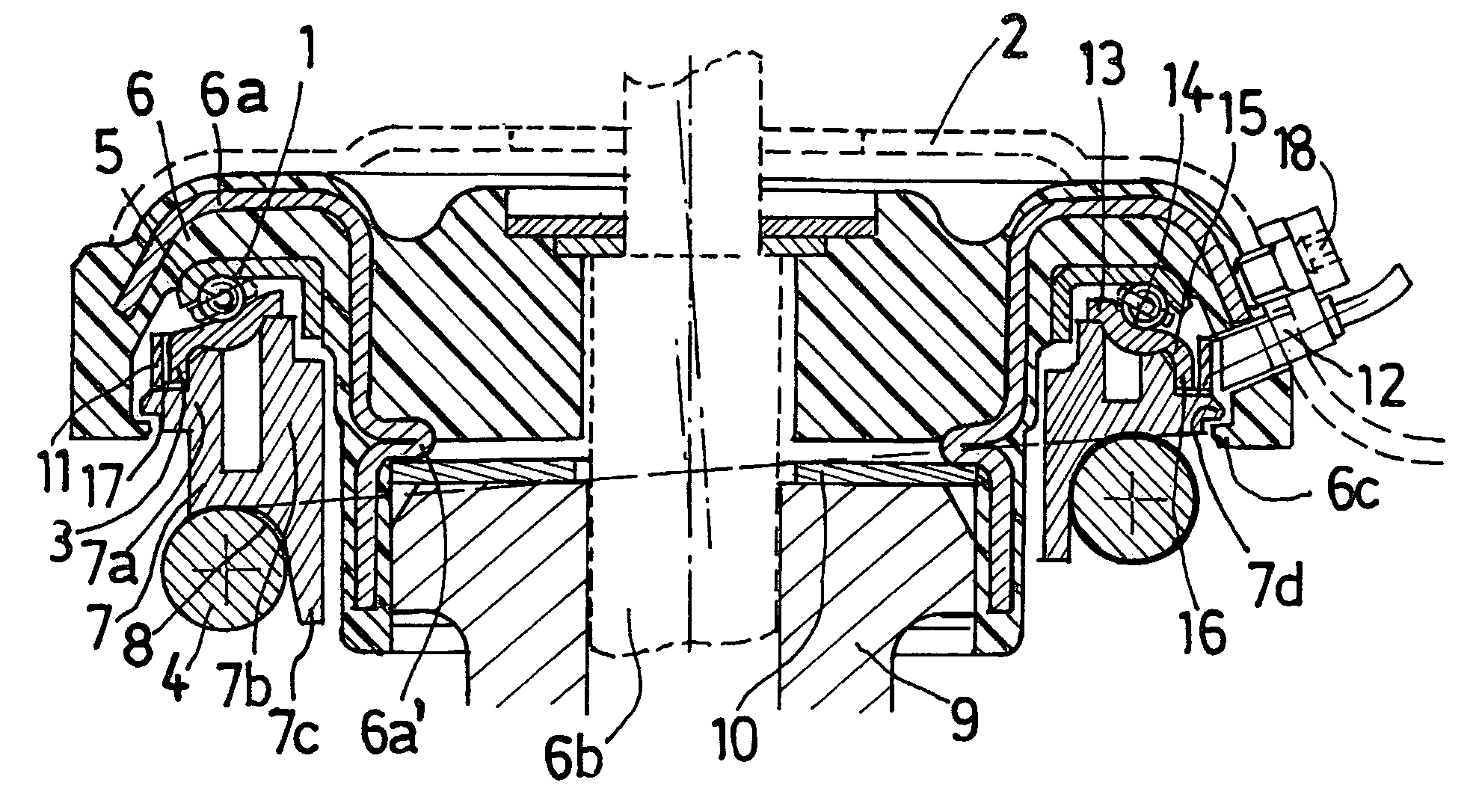

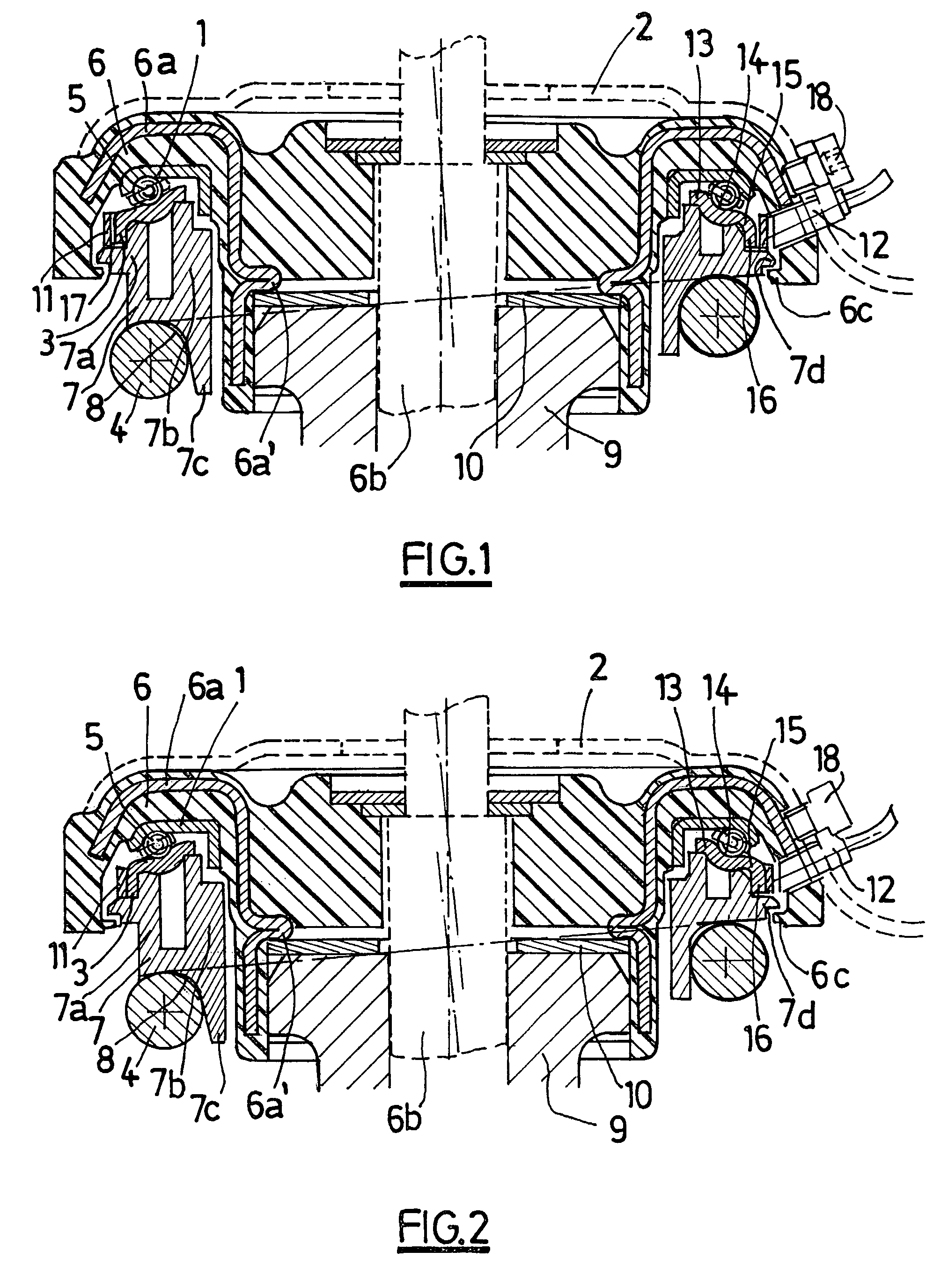

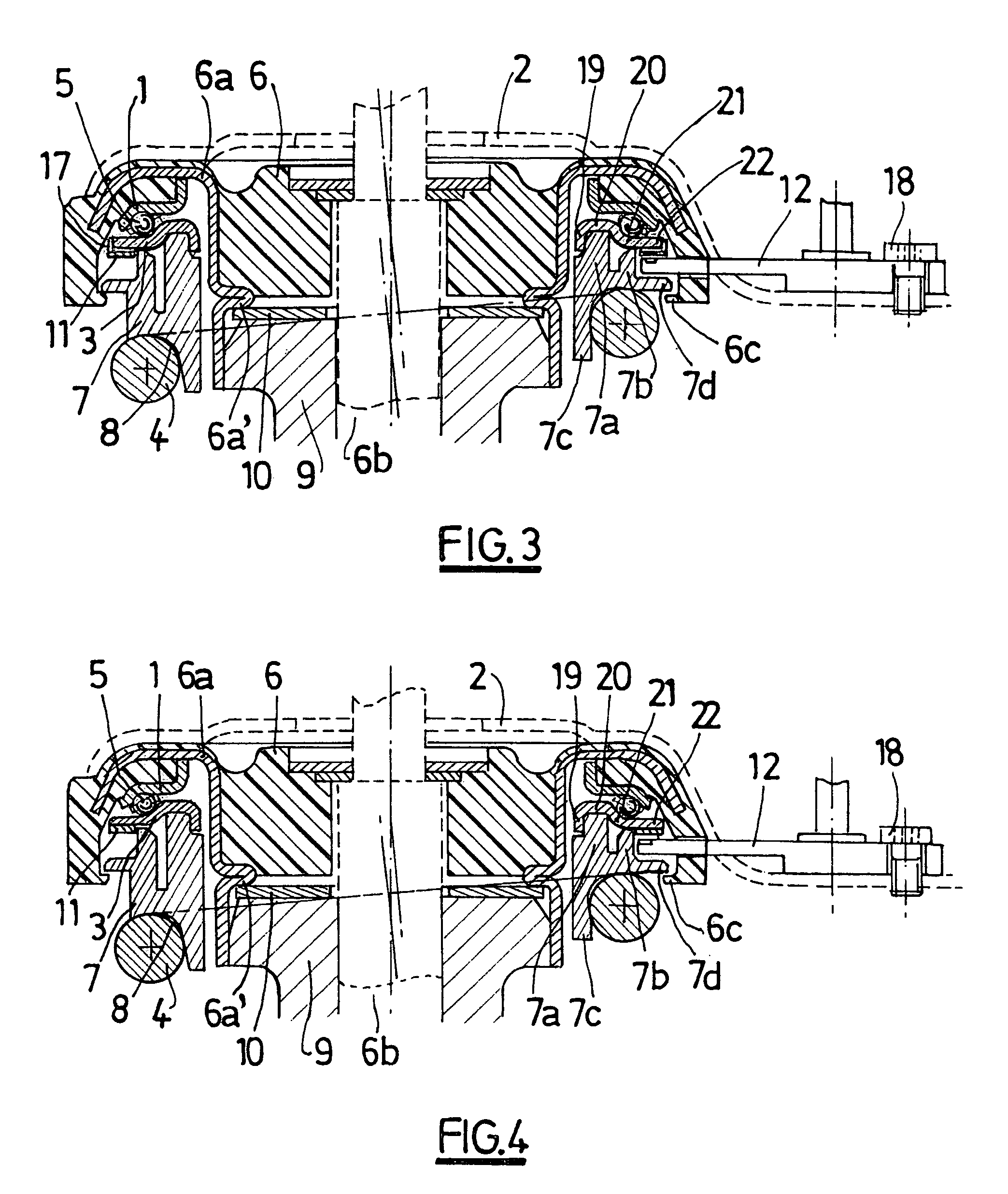

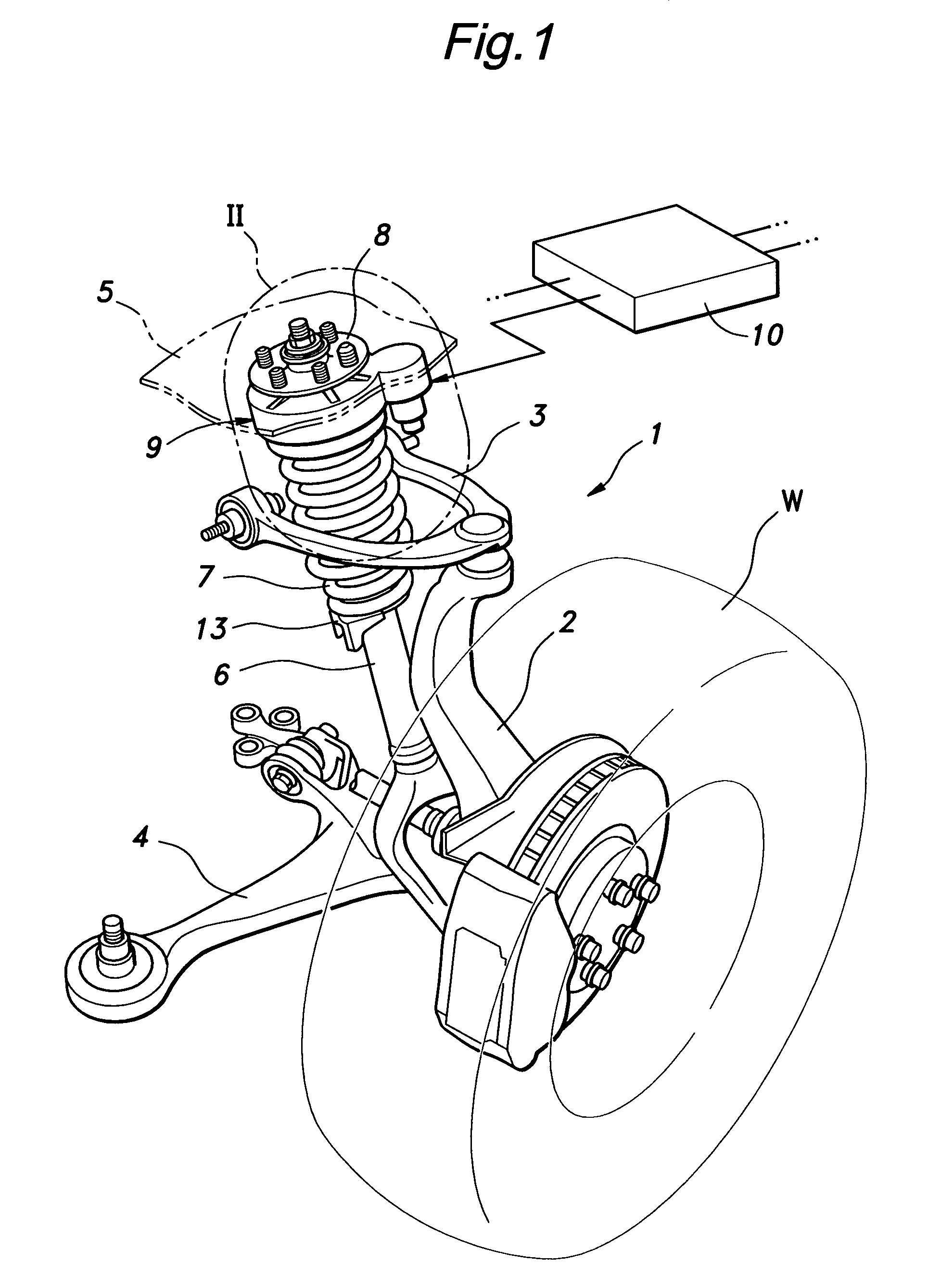

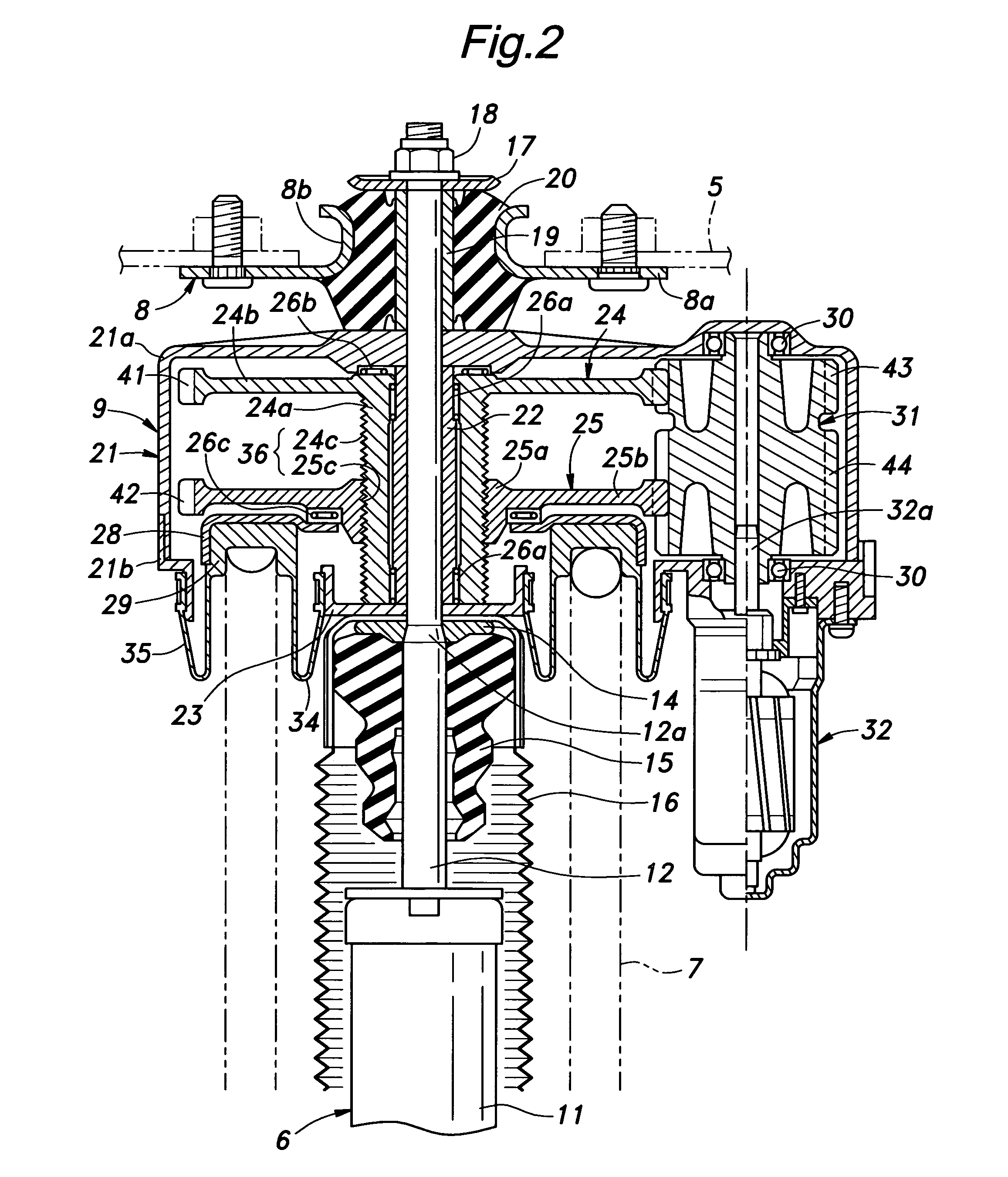

Rotating instrumented suspension stop for measuring vertical forces

A suspension stop for a motor vehicle wheel assembly comprising a fixed member adapted to be fixed to the chassis (2) of the vehicle and a rotating member adapted to be fixed to the suspension spring (4) so as to be rotationally moved under the effect of the forces exerted by the spring. The stop includes a device for measuring the vertical forces applied to the vehicle wheel. The device includes a pulse-generating coder (11) fixed to one of the members, a sensor (12) fixed to the other member which is able to detect these pulses so as to determine the angular position of the rotating member with respect to the fixed member, and a calculation device able, from this position, to calculate the corresponding vertical force applied.A method of measuring the vertical forces applied to a wheel associated with the chassis (2) of a vehicle by such a stop is also provided.

Owner:SNR ROULEMENTS SA

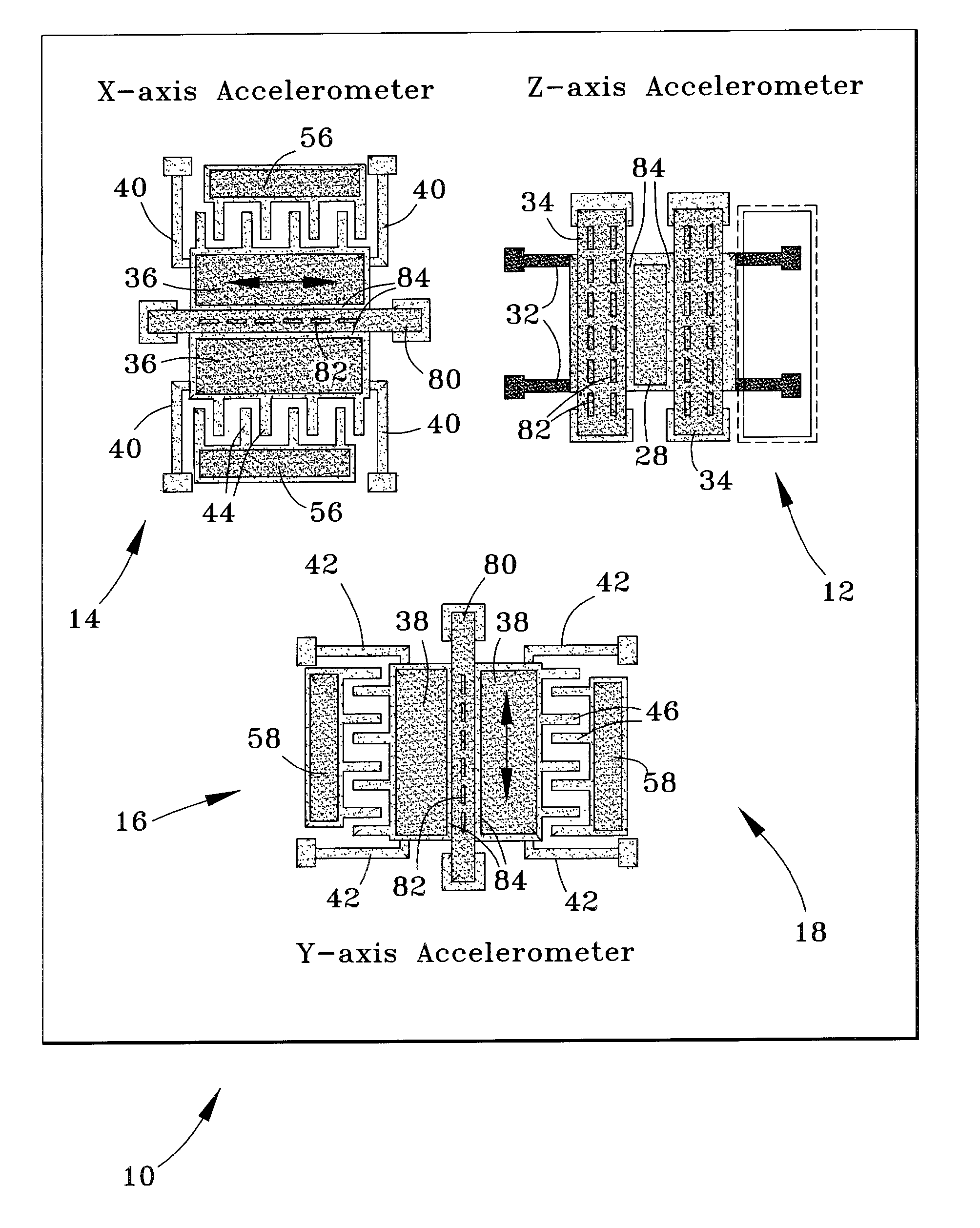

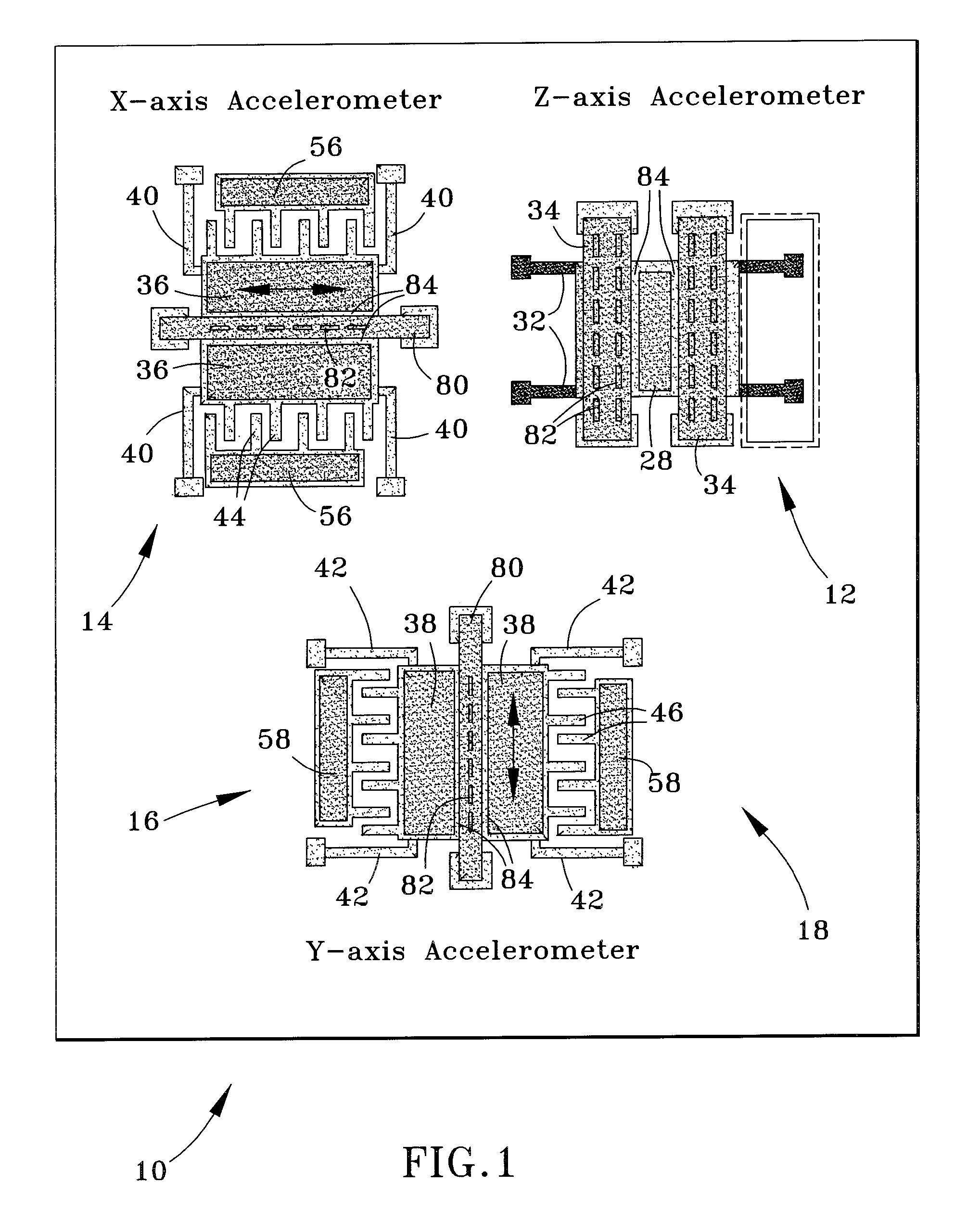

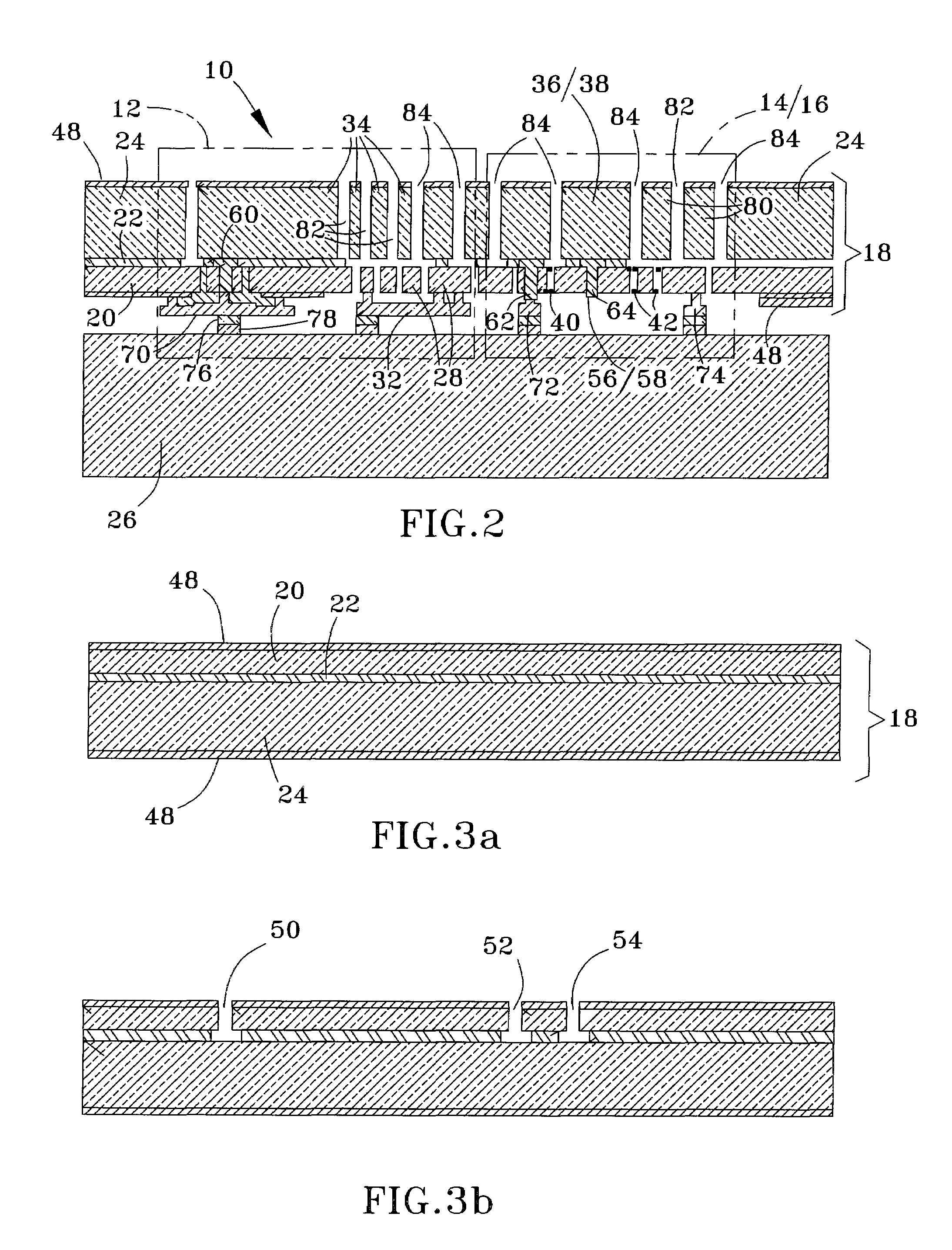

Three-axis inertial sensor and method of forming

InactiveUS7690255B2Line/current collector detailsSemiconductor/solid-state device manufacturingSiliconProof mass

A three-axis inertial sensor and a process for its fabrication using an silicon-on-oxide (SOI) wafer as a starting material. The SOI wafer has a first conductive layer separated from a second conductive layer by an insulative buried oxide (BOX) layer. The SOI wafer is fabricated to partially define in its first conductive layer at least portions of proof masses for z, x, and y-axis sensing devices of the sensor. After a conductive deposited layer is deposited and patterned to form a suspension spring for the proof mass of the z-axis sensing device, the SOI wafer is bonded to a substrate that preferably carries interface circuitry for the z, x, and y-axis devices, with the SOI wafer being oriented so that its first conductive layer faces the substrate. Portions of the BOX layer are then etched to fully release the proof masses.

Owner:EVIGIA SYST

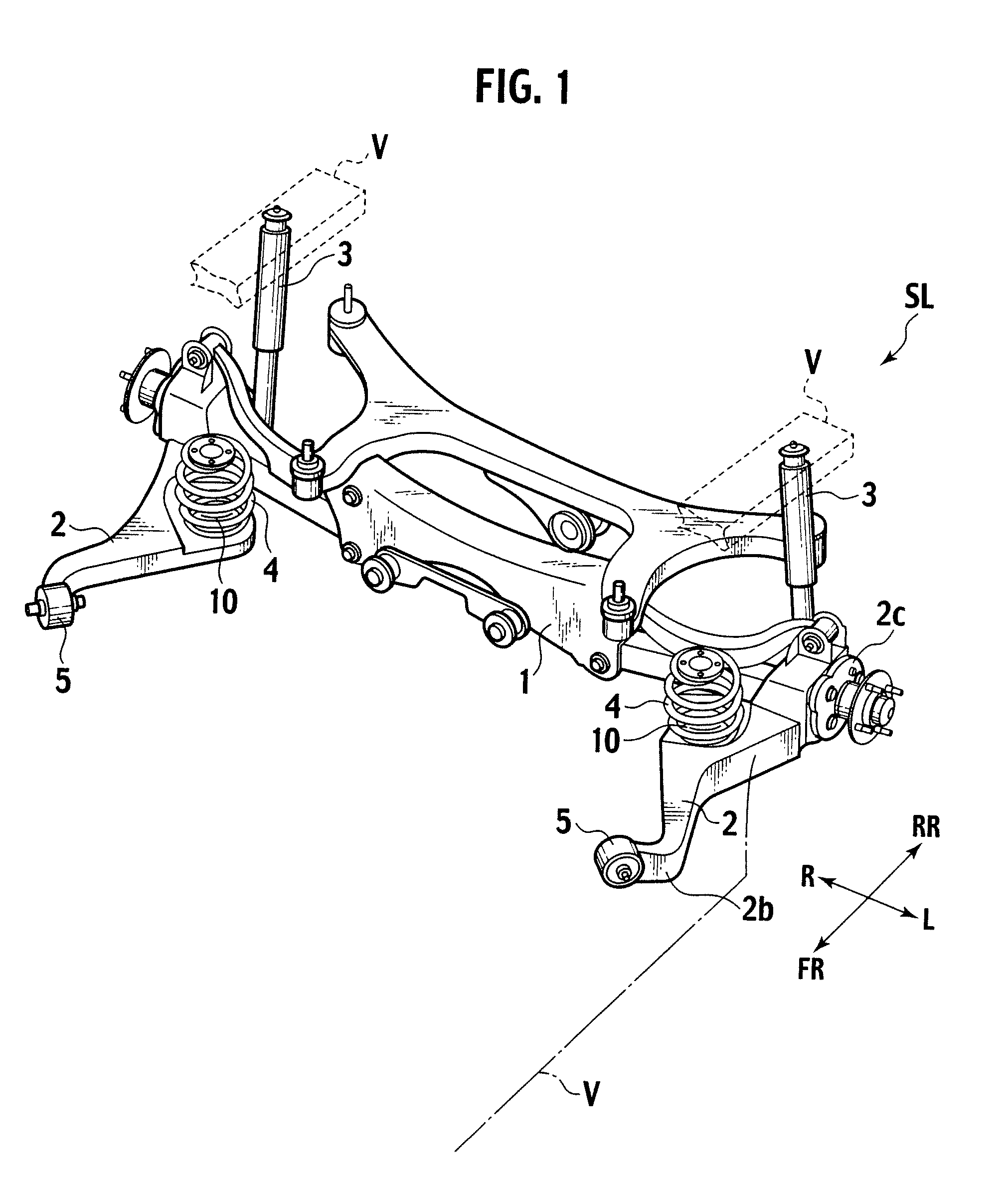

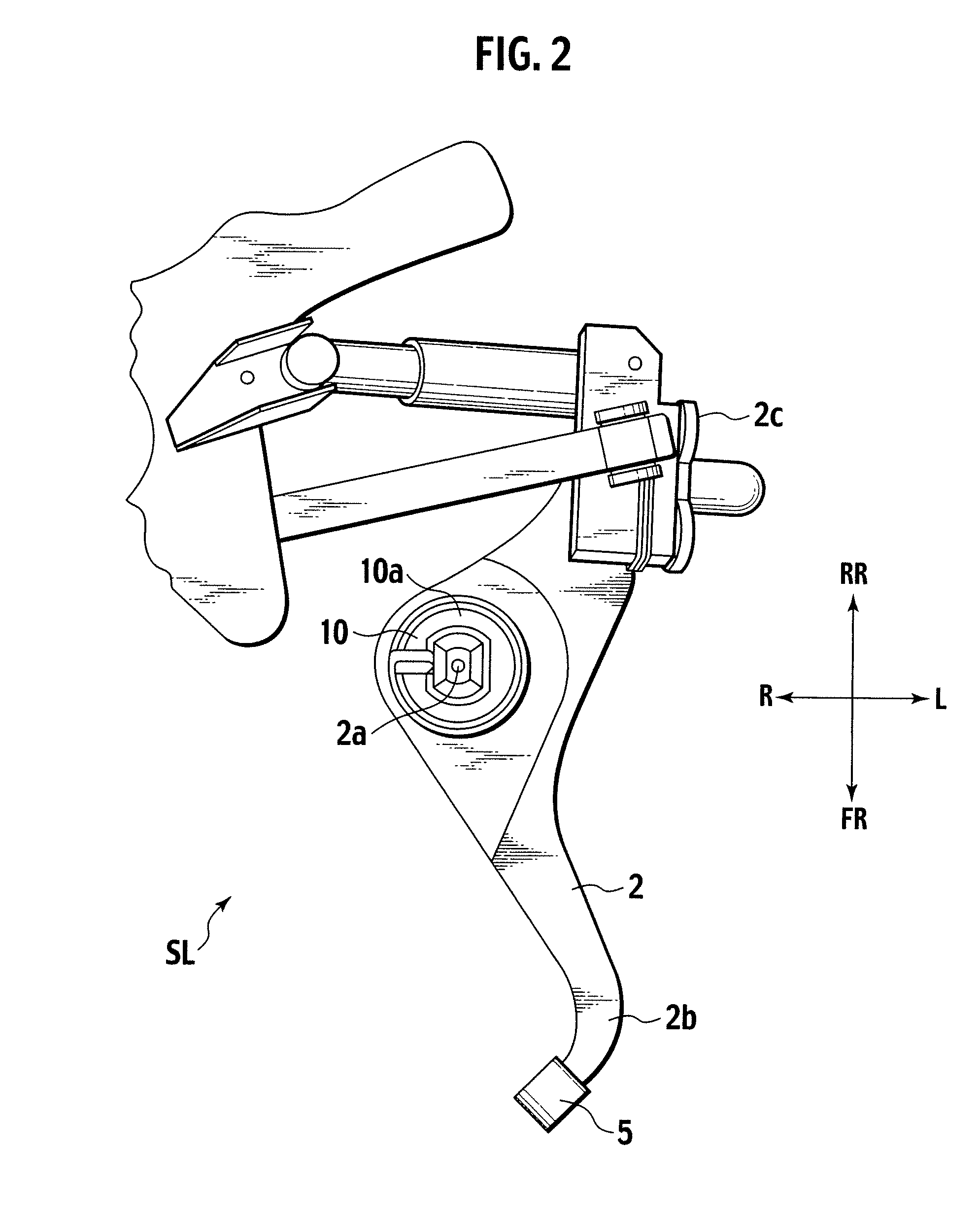

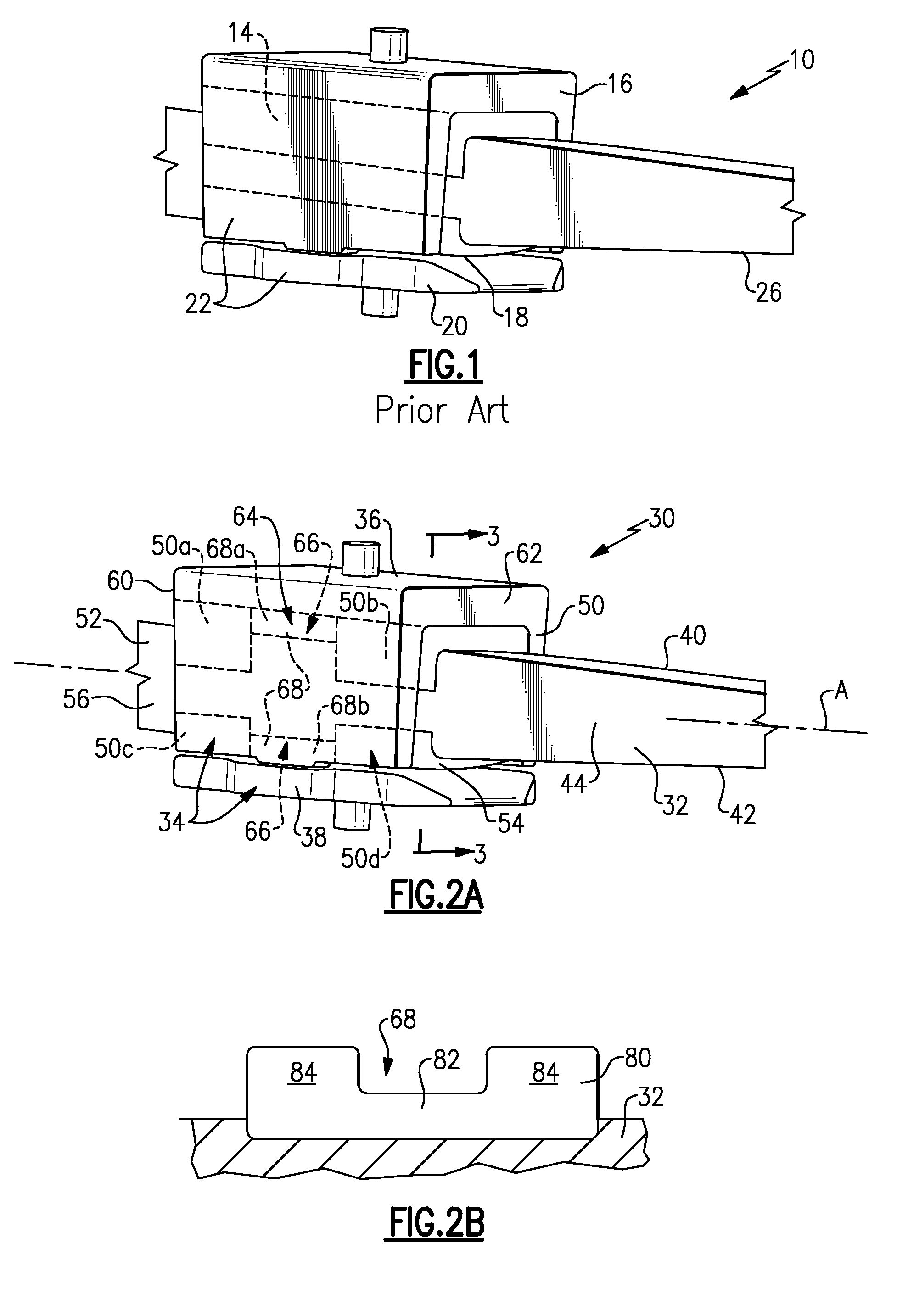

Linear suspension spring

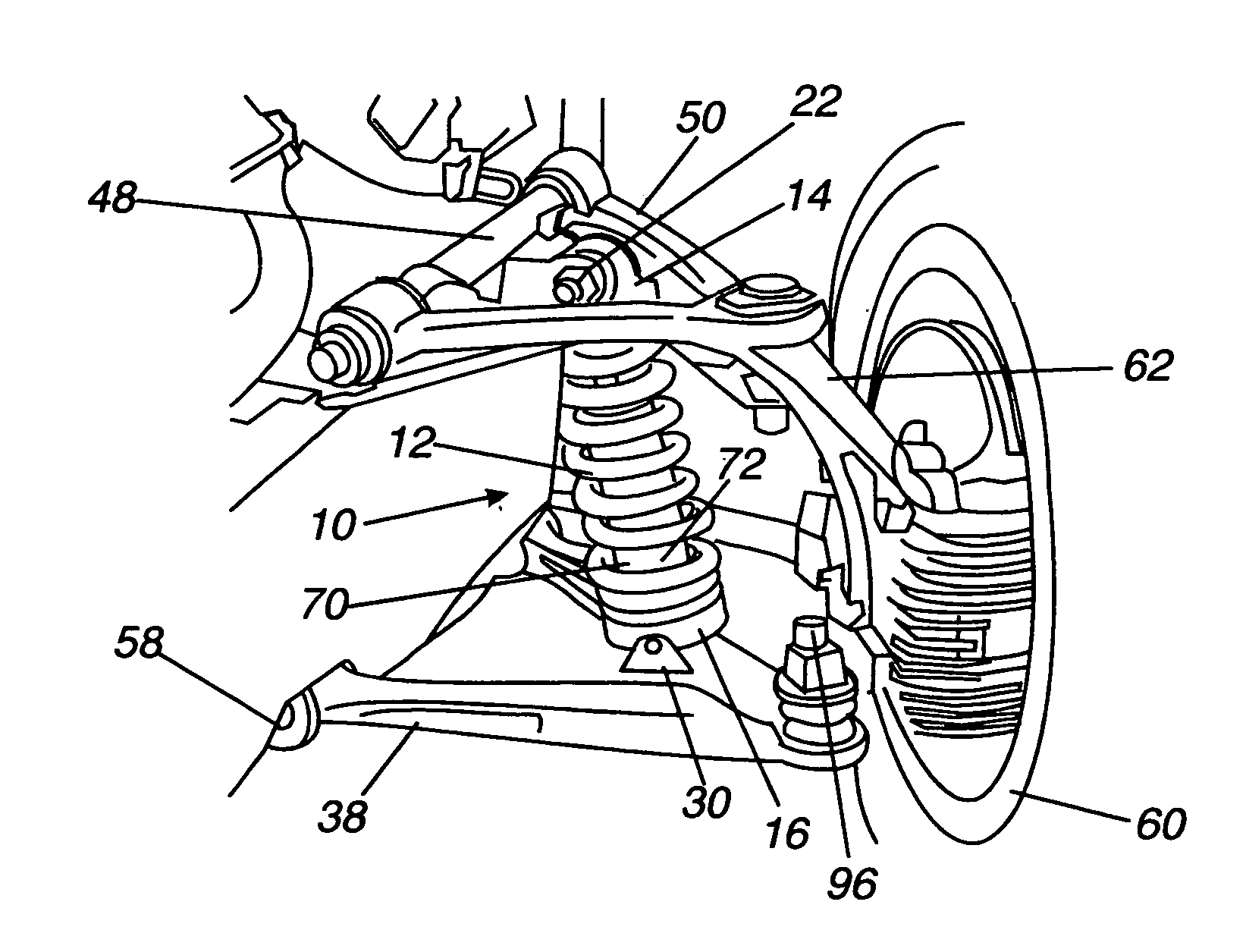

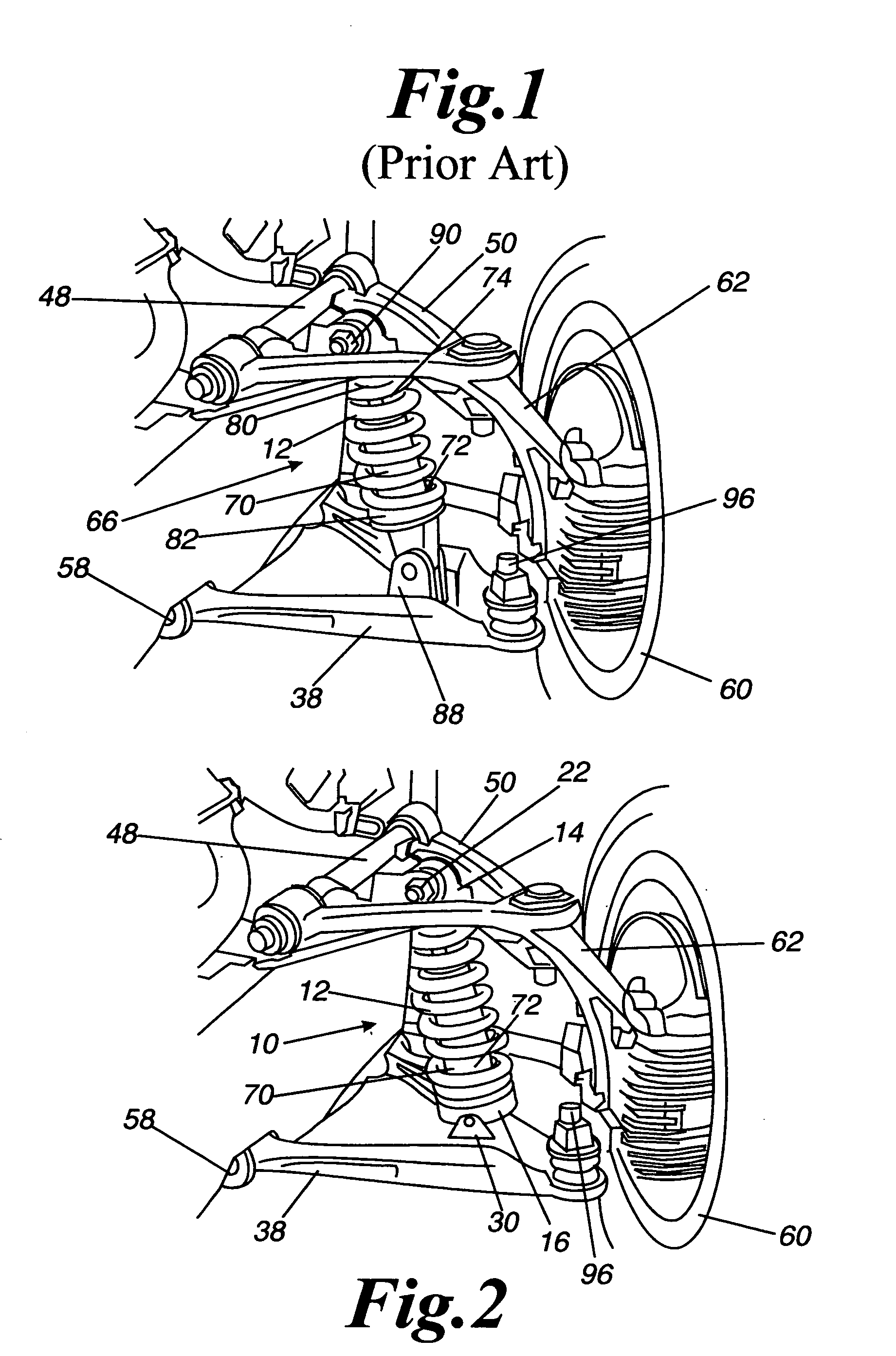

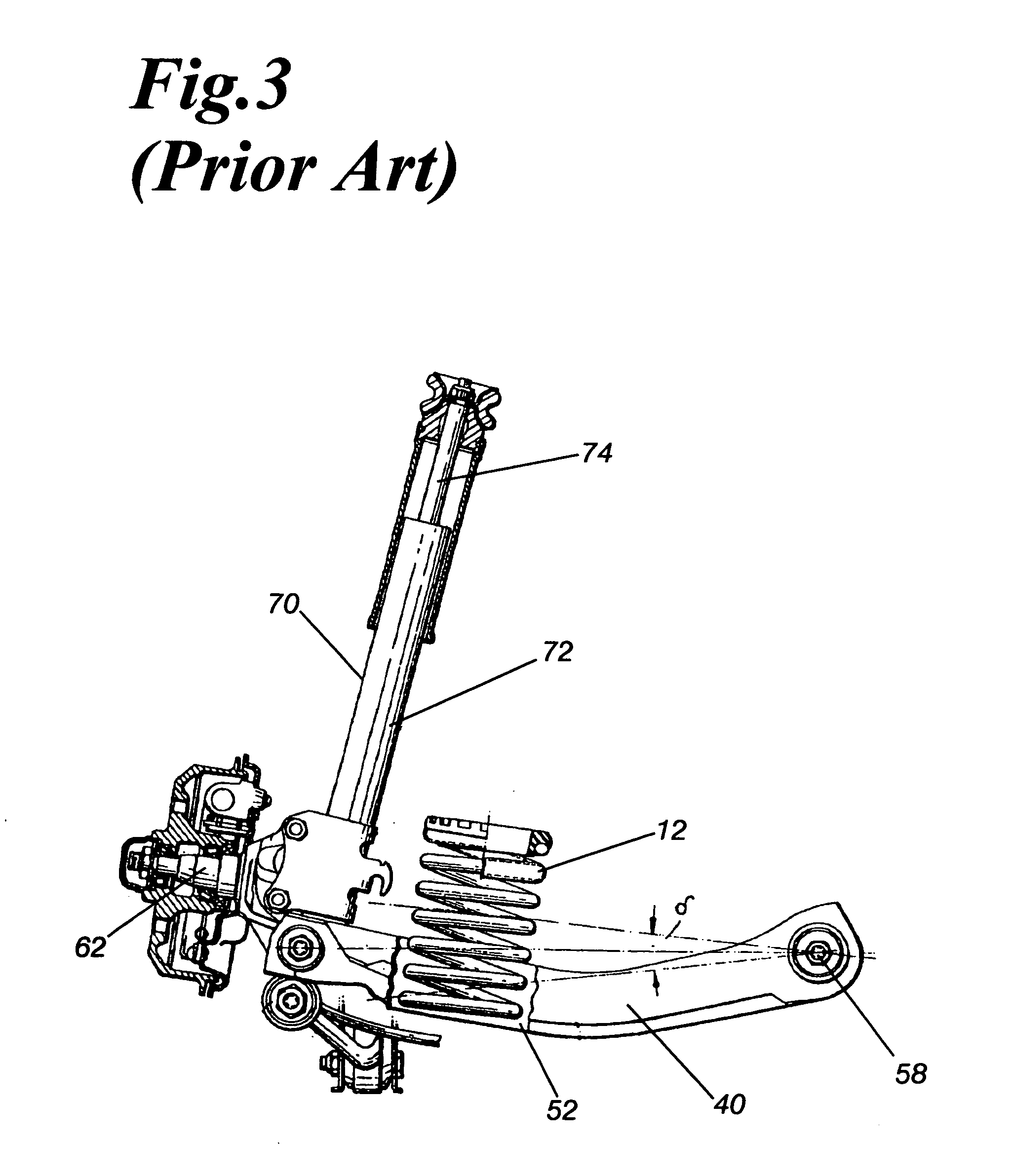

InactiveUS7185903B2Suppress noiseReduce scrapResilient suspensionsPivoted suspension armsControl armEngineering

The invention is a suspension spring apparatus for a vehicle wherein the suspension spring maintains a linear alignment irrespective of the position of the articulating strut, where the articulating strut is selected from the group consisting of: control arms, axle arms, solid axles, adjustable spring tensioning devices, and longitudinal struts. The apparatus is comprised of a compression spring mounted between a pivoting lower seat and a pivoting upper seat, where the pivoting lower seat is coupled to the articulating strut and the pivoting upper seat is coupled to a support element. The support element is static, and serves to support the suspension system, and to distribute the forces generated by the suspension system. The pivoting lower seat and the pivoting upper seat can, in combination, pivot through substantially the same plane as the articulating strut, such that when there is a change in angle of the articulating strut with respect to the support element there is a commensurate change in the pivoting lower seat and the pivoting upper seat. The compensation maintains the compression spring aligned linearly between the pivoting lower seat and the pivoting upper seat. Compression and expansion occurs along the centerline of the spring, and there is no transverse curvature, or other deformation of the spring.

Owner:DOVE JASON L

Vehicle height adjusting system

ActiveUS7922181B2Compact designDurable and reliable useVehicle cleaning apparatusToothed gearingsLinear motionDrive shaft

A first rotor (24; 124) and a second rotor (25; 125) are arranged in a coaxial and mutually rotatable relationship and are provided with a first driven gear (41; 141) and a second driven gear (42; 142), respectively. A drive shaft (31; 131) is also provided with a first drive gear (43; 143) and a second drive gear (44; 144) which are commonly connected to an output shaft of an electric motor (32; 132), and mesh with the first and second driven gears, respectively, at slightly different gear ratios. The first and second rotors are connected via a thread feed mechanism (36; 136) that converts a relative rotation between the first and second rotors into an axial linear movement between the first and second rotors that is used for changing a distance between a vehicle body part and a corresponding end of a suspension spring in a vehicle height adjusting system (9; 109). Owing to a differential rotation of a high gear ratio between the first and second rotors, a significant torque amplification is possible with a compact arrangement. The use of spur gears instead of a worm gear mechanism minimizes torque loss.

Owner:HONDA MOTOR CO LTD

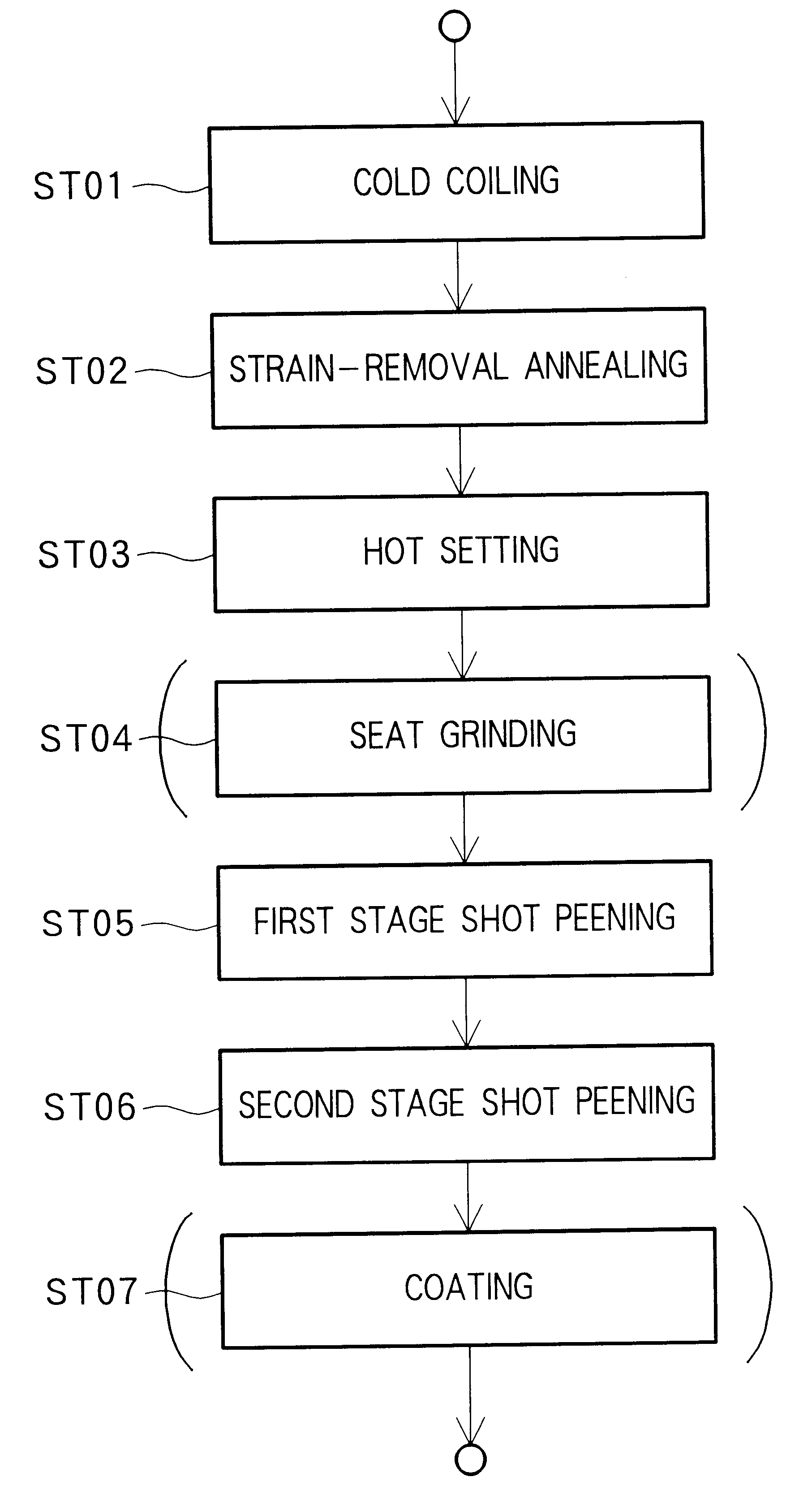

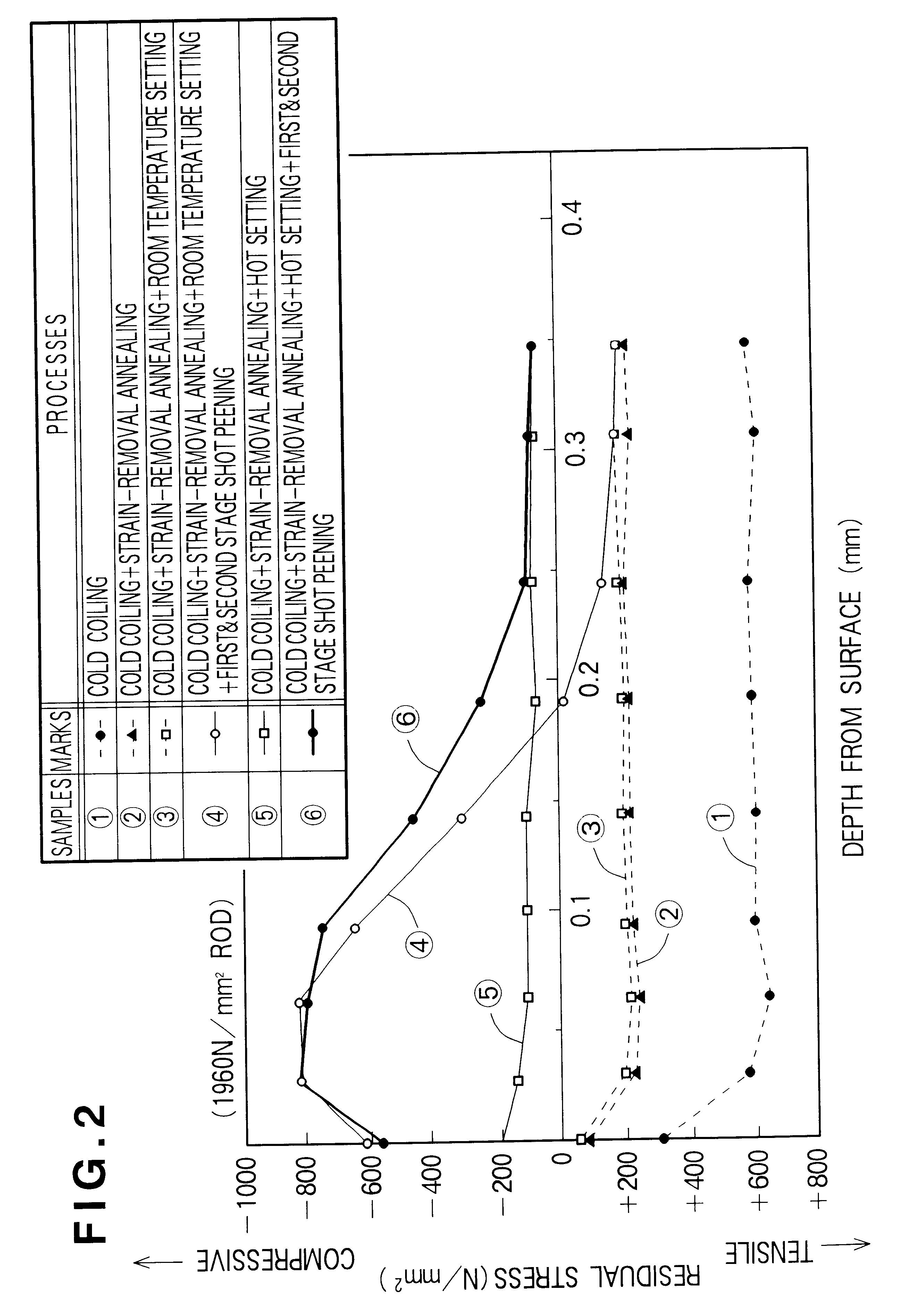

Manufacturing method of suspension spring for car

A method for manufacturing a coiled spring having a high fatigue strength to be used for example as a suspension spring of a car using a rod of tensile strength 1910 to 2020 N / mm2 and diameter 8 to 17 mm. In a cold coiling step, the rod is formed into a coil. Annealing is then carried out to remove strains having arisen inside the coil during the coiling step. A hot setting step of utilizing surplus heat from the annealing step and applying a predetermined load to the coil to compress it for a predetermined time is then carried out. After that, multi-stage shot peening is carried out on the coil.

Owner:SHOWA CORP

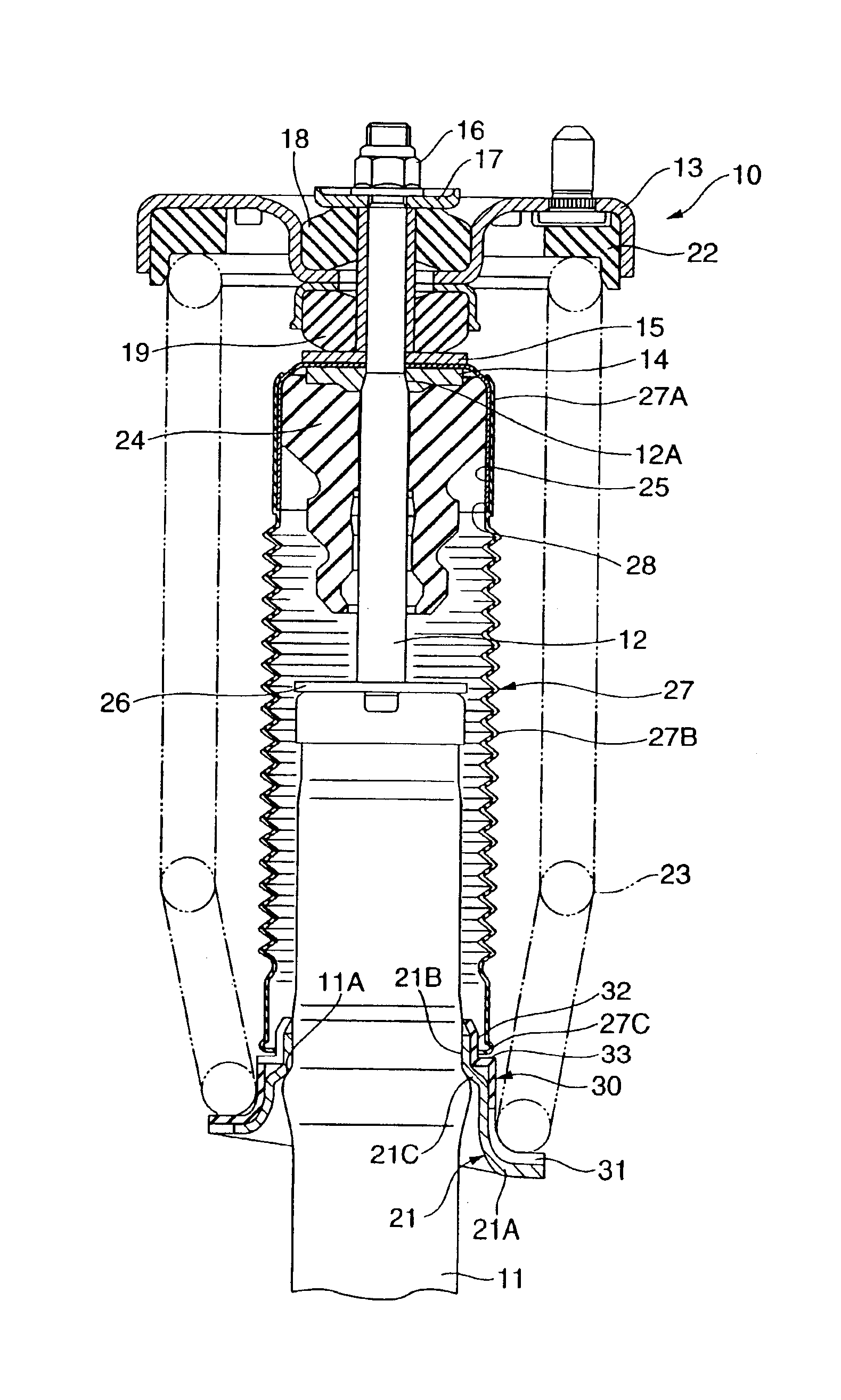

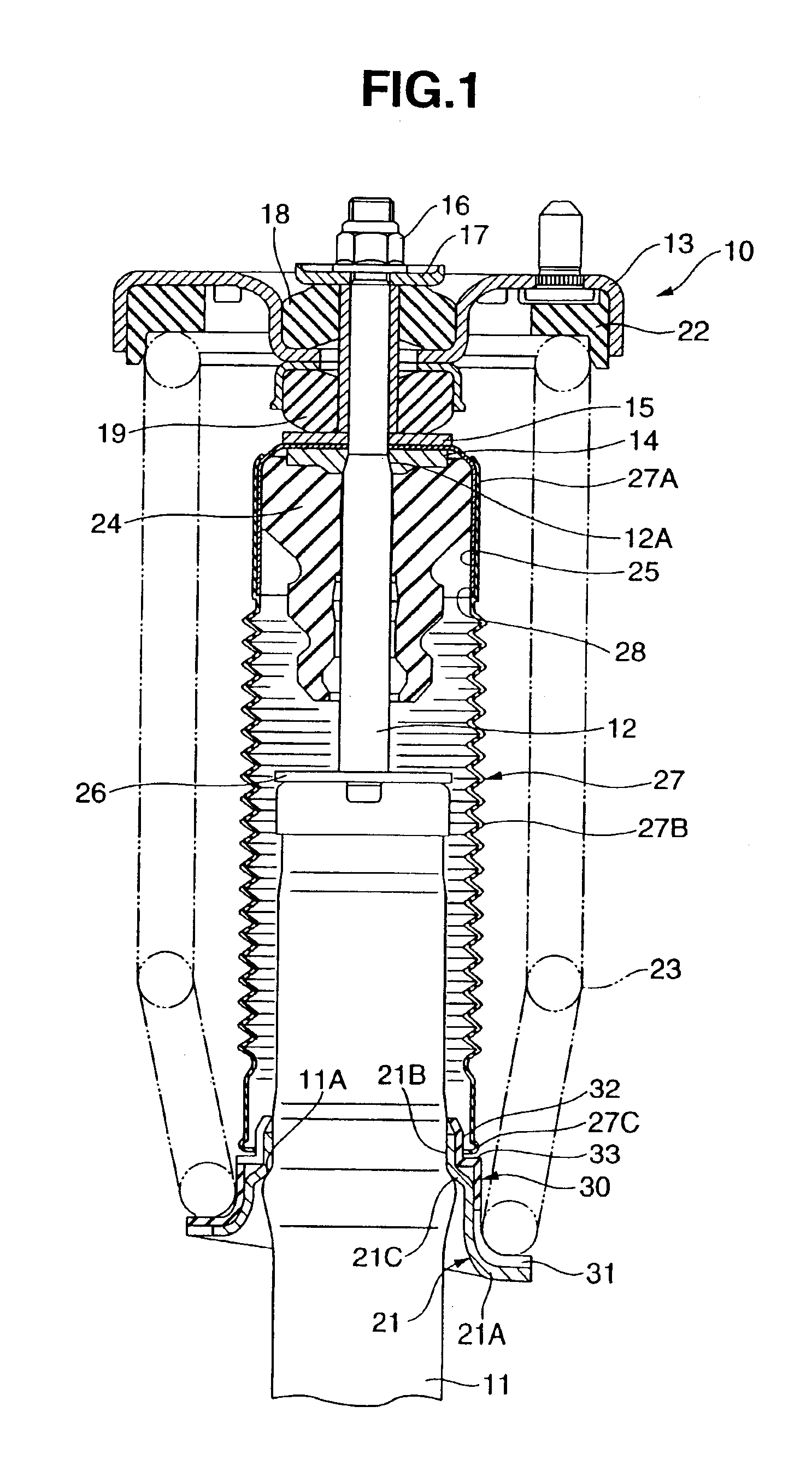

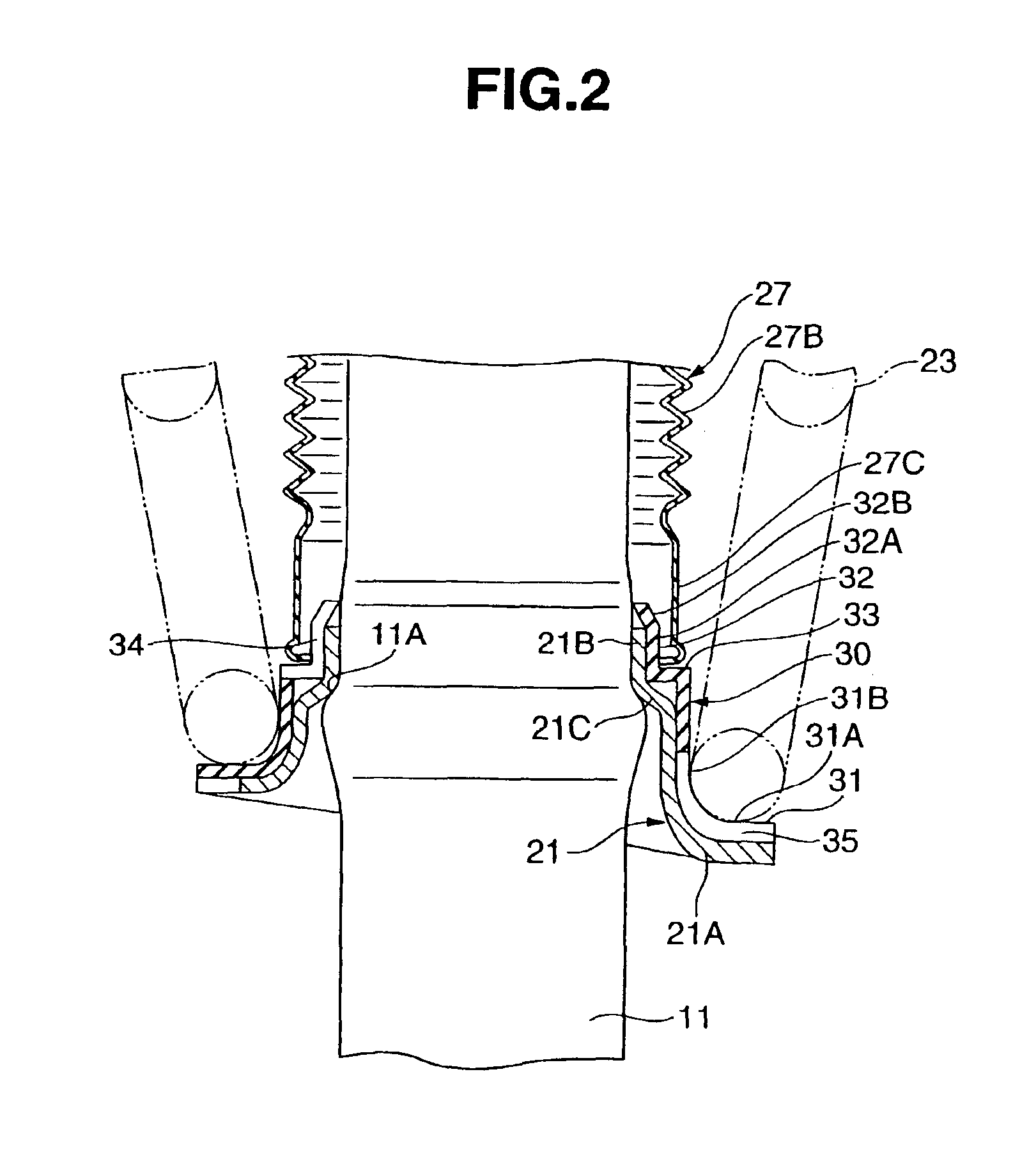

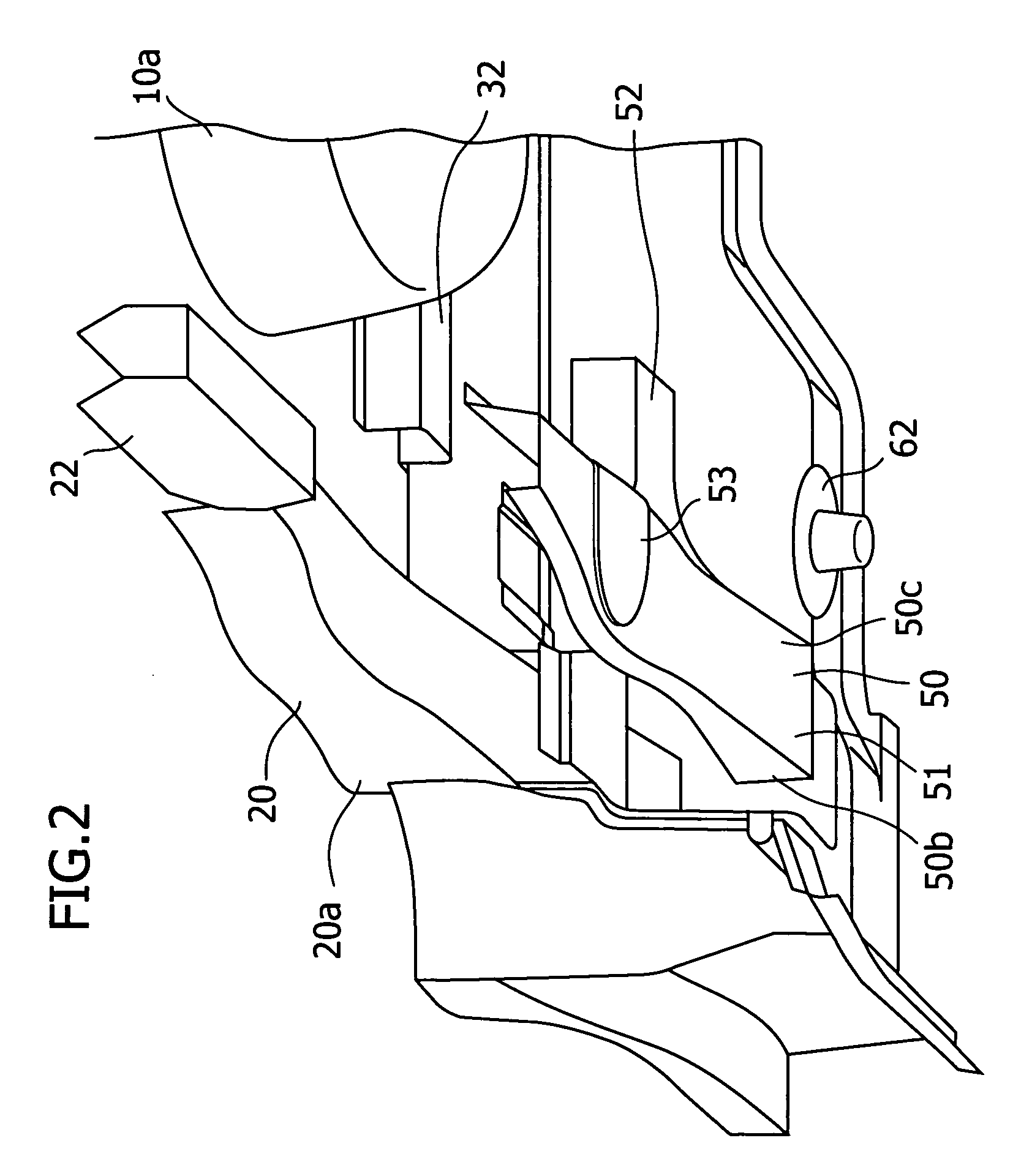

Dust cover receiving structure of hydraulic shock absorber

InactiveUS6883651B2DownsizingDownsizing of a spring seatLiquid springsResilient suspensionsEngineeringMechanical engineering

A dust cover receiving structure of a hydraulic shock absorber in which a seat rubber is interposed between a suspension spring and a spring seat. The seat rubber has a spring receiving portion which is arranged between the suspension spring and the spring seat, a centering portion which is fitted to a damper tube and guides an end portion of a dust cover in such a manner as to align the dust cover with an axial center of the damper tube, and a cover receiving portion which is provided between the spring receiving portion and the centering portion, and which receives an end surface of the dust cover.

Owner:SHOWA CORP

Suspension spring mount

Owner:ARVINMERITOR TECH

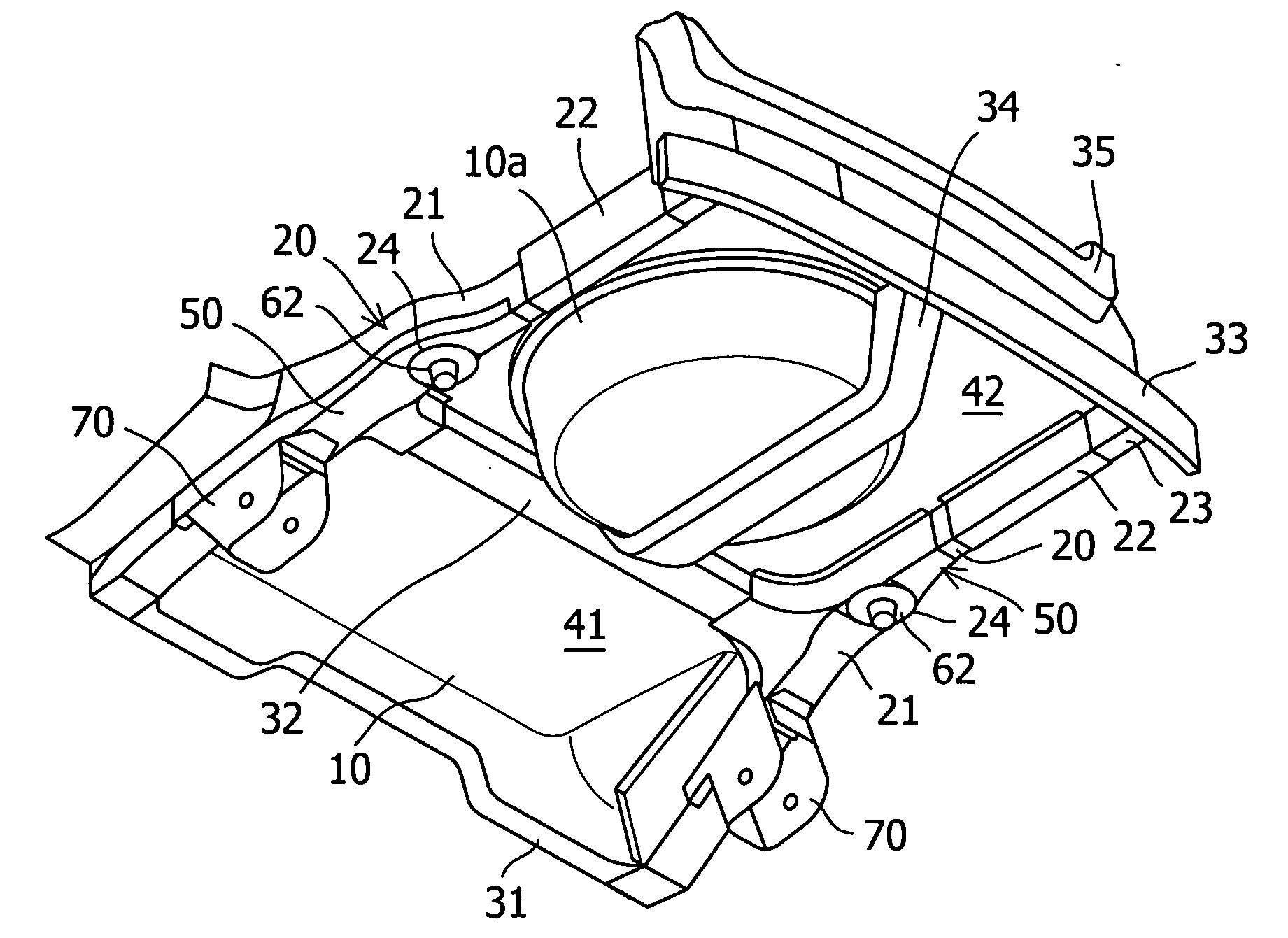

Rear vehicle body structure

InactiveUS20060061142A1Uniform loadLoad of spring is efficientlyVehicle seatsSuperstructure subunitsMechanical engineeringSuspension spring

It is an object of the present invention to increase the rigidity of a seat surface portion, to which a seat for a suspension spring is attached, of a rear side member in a vehicle body rear part. The present invention is characterized by a rear vehicle body structure in which at least intermediate portions of a pair of right and left rear side members are connected to each other by a cross member, and the seat surface portion for the suspension spring is provided on the rear side member, wherein a reinforcing panel for connecting the rear side member to the cross member is provided in a connecting portion between the rear side member and the cross member; the rear end position of the reinforcing panel is set at a substantially middle position between the connecting portion between the rear side member and the cross member and the rear end of the rear side member; and the seat surface portion for the suspension spring is set at a substantially middle position between the connecting portion between the rear side member and the cross member and the rear end of the reinforcing panel.

Owner:SUZUKI MOTOR CORP

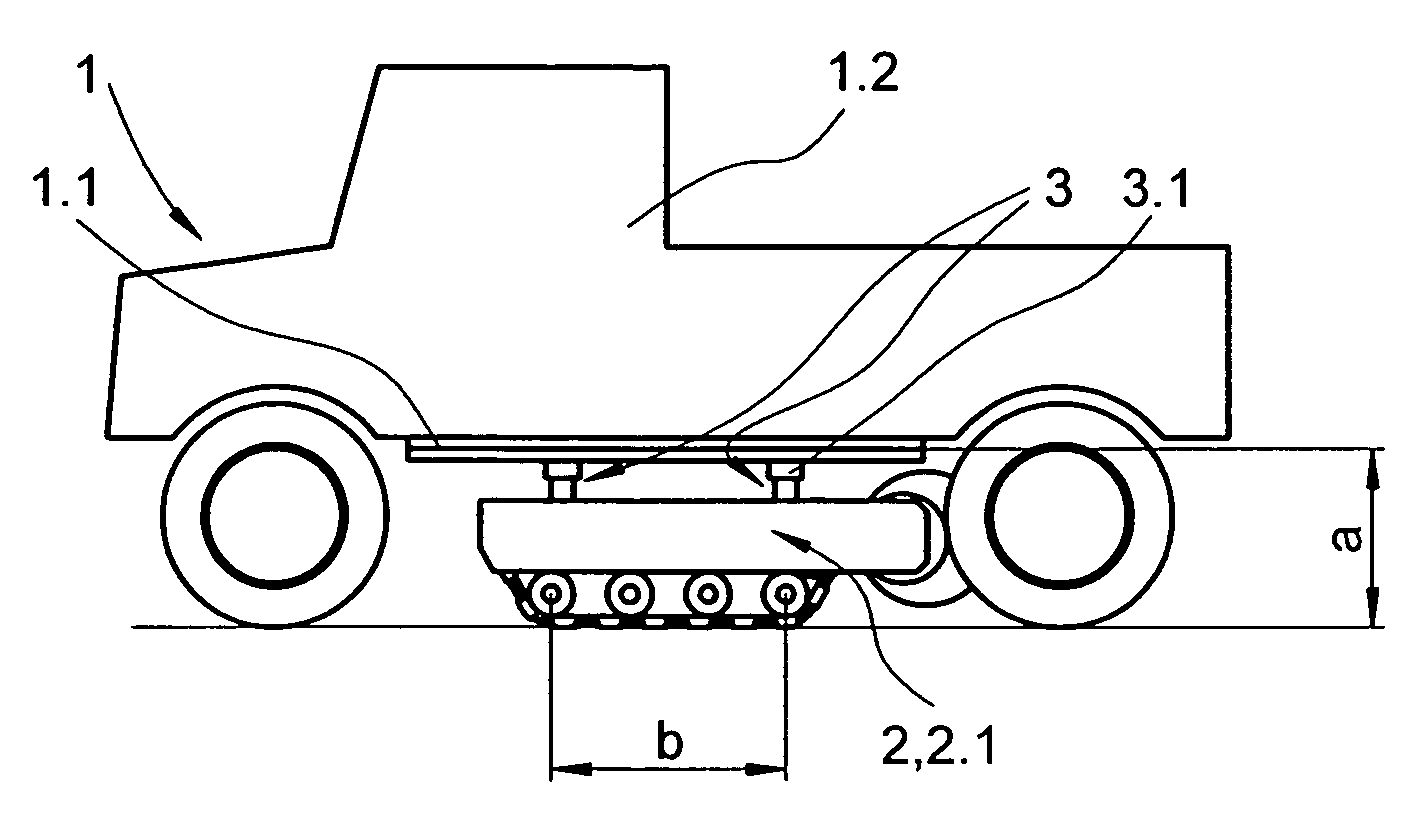

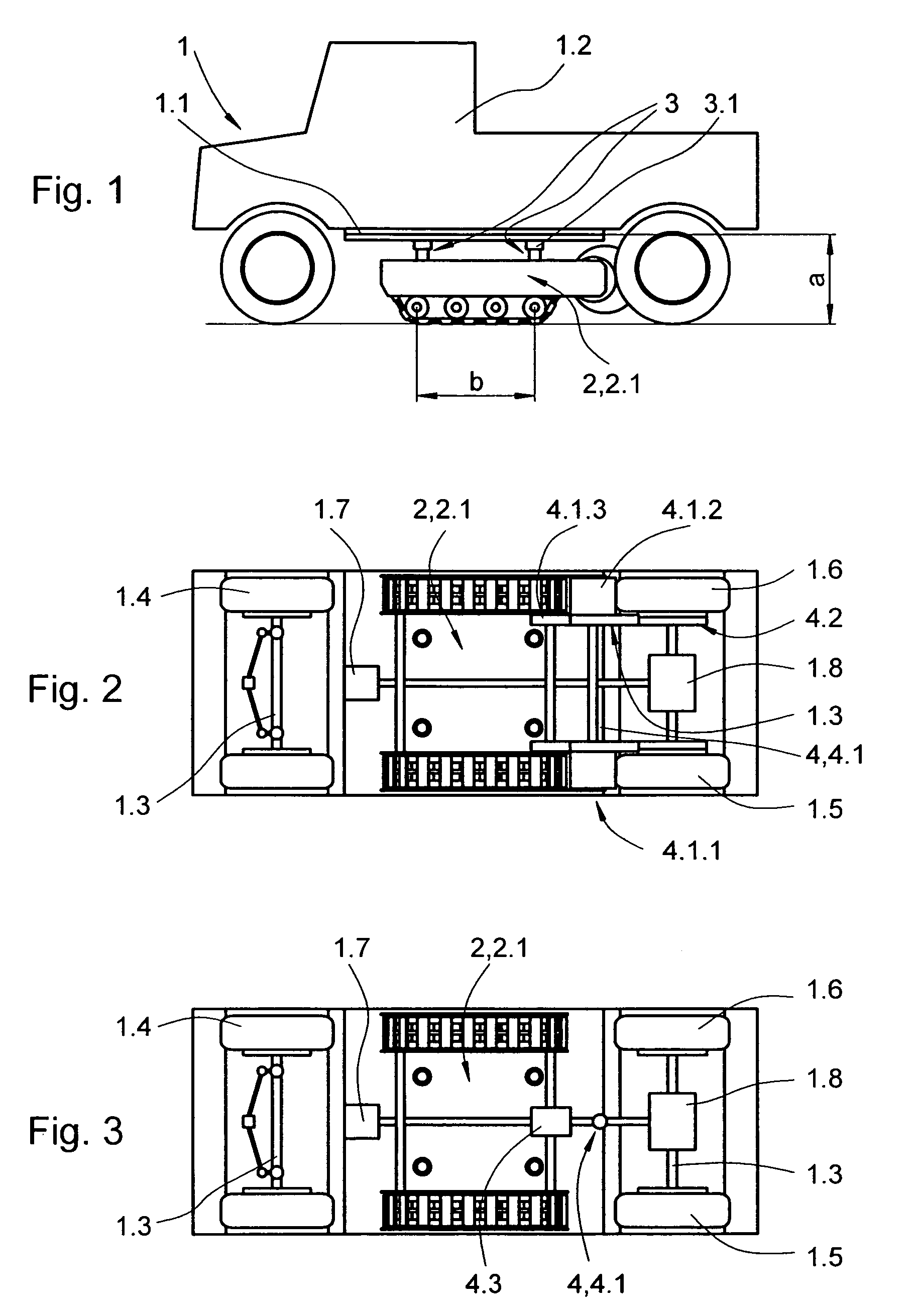

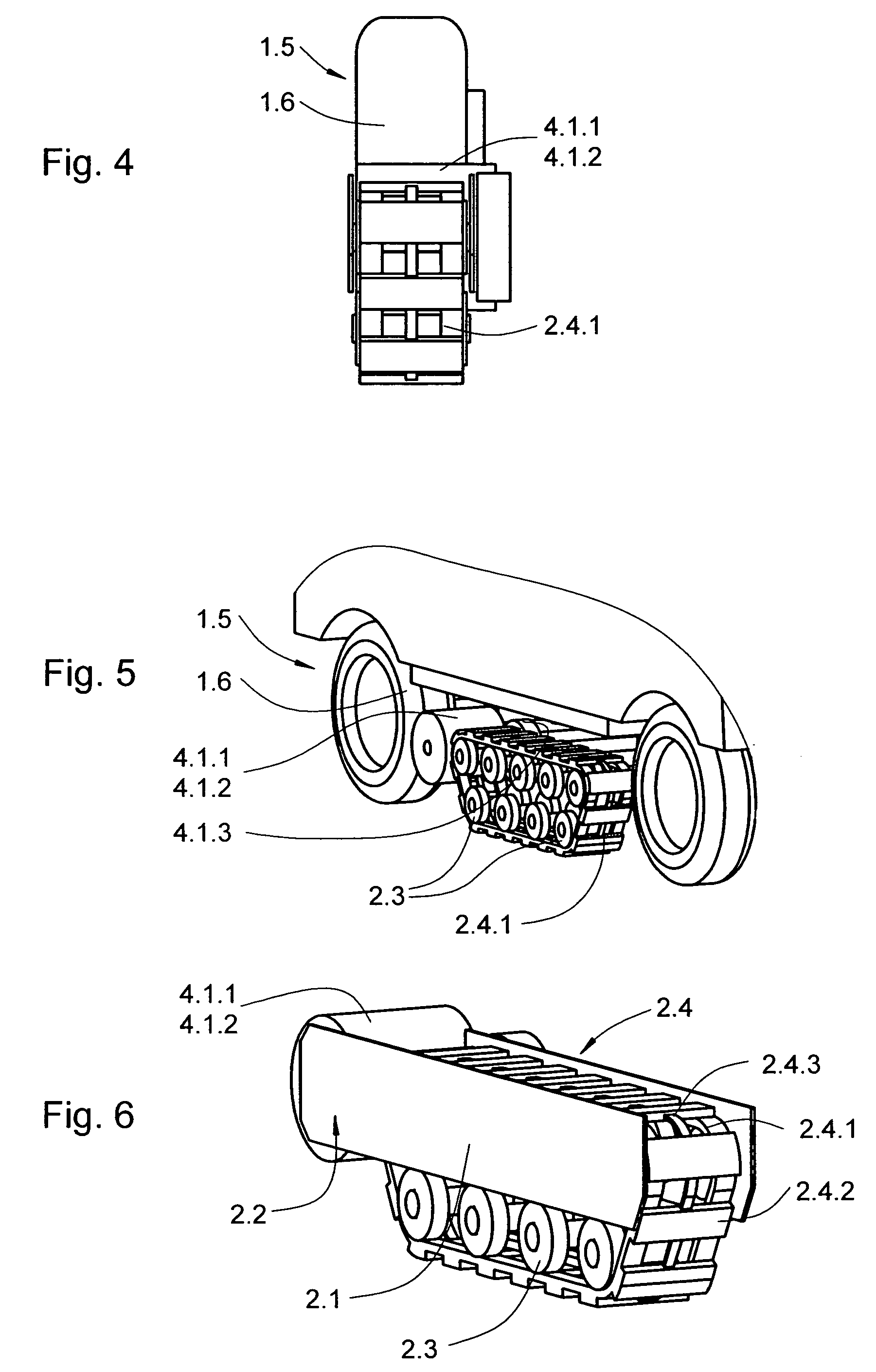

Motor vehicle with an additional crawler undercarriage

InactiveUS20060254833A1Shorten the lengthDistribute weightTractorsEndless track vehiclesTerrainDrive wheel

A motor vehicle with an additional crawler undercarriage includes assemblies to reduce the load pressure transferred to the ground and to improve off-road performance. The assemblies include components used in conventional mass-produced vehicles, with a chassis (1. 1), a body with optional cargo area (1.2), undercarriage, such as axles (1.3) with steered (1.4) and / or unsteered wheels (1.5), tires (1.6), wheel suspension, spring support, steering and brakes, and an engine-transmission unit (1.7) with drive components. An additional crawler undercarriage (2) can be mounted and / or retrofitted on the chassis (1.1) between the axles (1.3) and used for traction in any terrain. The additional crawler undercarriage (2) includes an undercarriage (2.1) with drive wheels (2.2) and carrying wheels (2.3) and revolving crawler chains / crawlers (2.4) and associated elements, first means (3) for providing an optionally extendable and retractable connection of the undercarriage (2.1) with the chassis (1.1), and second means (4) for selectively transmitting or coupling a second drive from the motor vehicle to the additional crawler undercarriage (2), as well as third means (5) for controlling the operation of the additional crawler undercarriage (2), such as steering, braking, acceleration and speed of the crawler chains / crawlers (2.4).

Owner:GROBLER HENDRIK

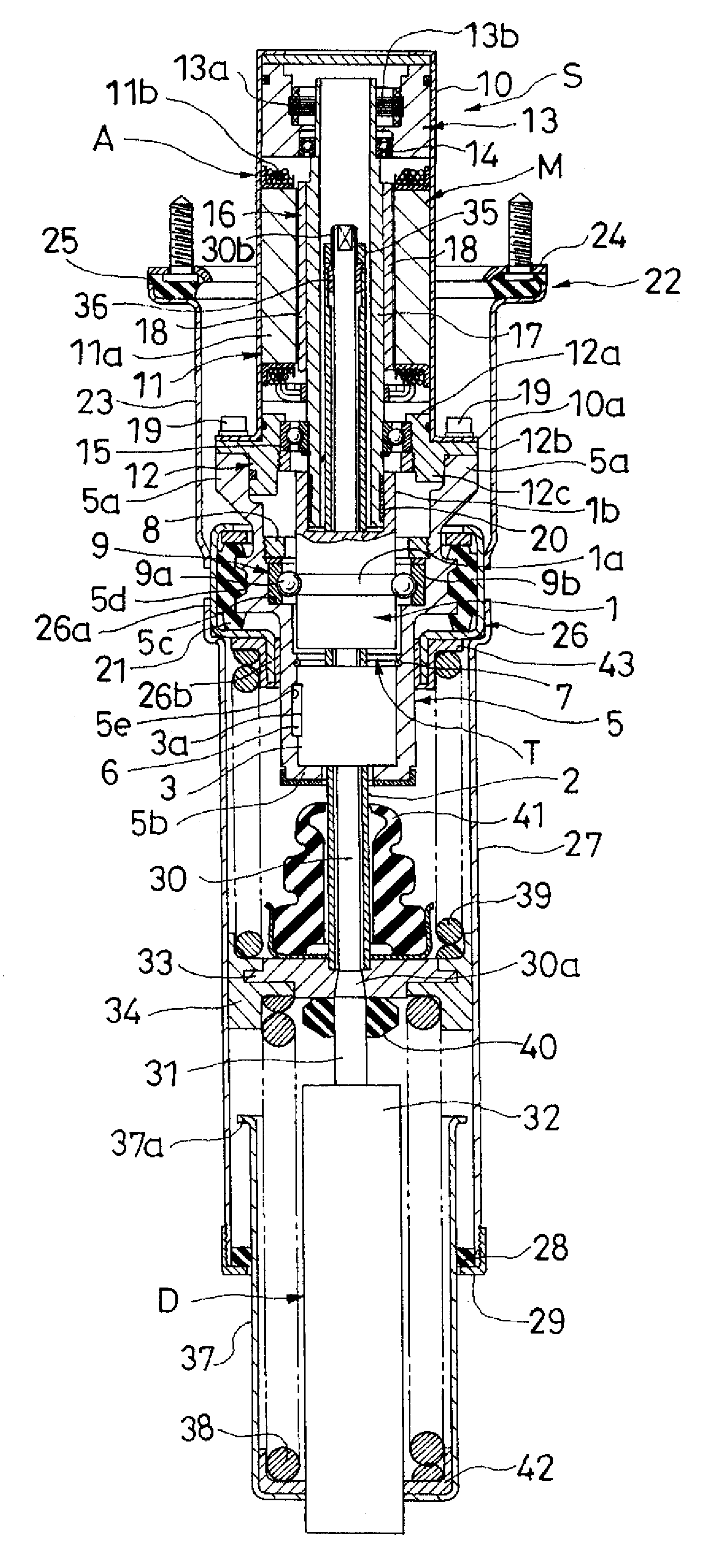

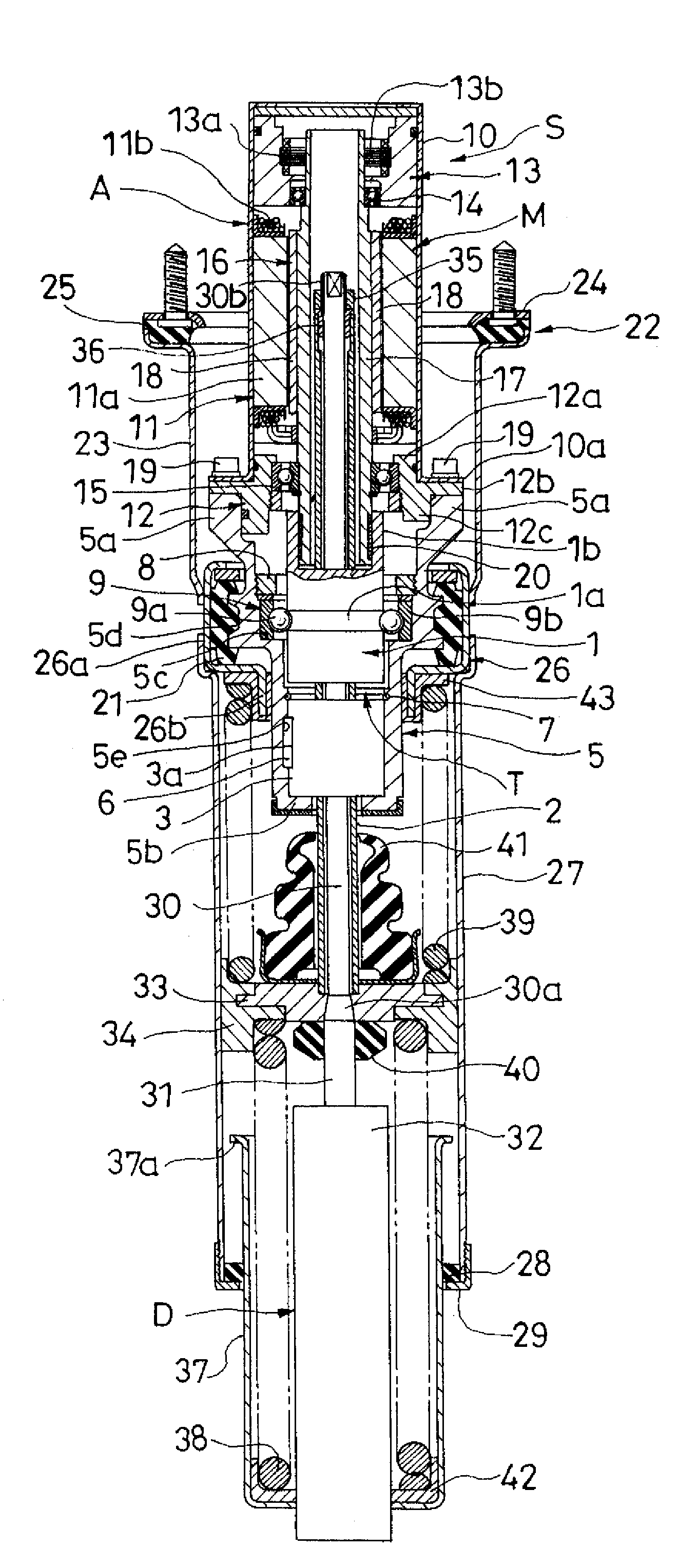

Suspension device

InactiveUS8387762B2Improving reliability and vehicle ride qualityAvoid vibrationSpringsNon-rotating vibration suppressionLinear motionEngineering

A suspension device (S) of the present invention comprises: an actuator (A) including a motion conversion mechanism (T) for converting a linear motion to a rotational motion, and a motor (M) connected to a rotational member (1) which performs the rotational motion in the motion conversion mechanism (T); a fluid pressure damper (D) connected to a linear motion member (2) which performs the linear motion in the motion conversion mechanism (T); a mount (22) connected to a sprung member of a vehicle; and suspension springs (38) and (38) interposed between the mount (22) and an unsprung member, the actuator (A) being elastically supported by the mount (22) through a rubber vibration isolator (21).

Owner:KYB CORP +1

Vehicle suspension system

ActiveUS8191874B2Effective controlImprove applicabilityNon-rotating vibration suppressionRotating bodies balancingElectric power systemElectrical battery

A vehicle suspension system including: (a) a suspension spring interconnecting a vehicle body and a wheel; (b) an actuator having an electric motor, such that the actuator is capable of generating, based on a force of the electric motor, an actuator force forcing the body and the wheel toward and away from each other, and causing the generated actuator force to act as a damping force against displacement of the body and the wheel; and (c) a control device for controlling the actuator force generated by the actuator, by controlling operation of the electric motor. The control device is capable of establishing a constant-force generating state in which the actuator force is constantly generated as a constant actuator force by the actuator with supply of an electric power thereto from a battery as an electric power source of the electric motor such that the generated constant actuator force acts in a rebound direction or a bound direction. The control device controls the constant-force generating state, based on a charge state of the battery.

Owner:TOYOTA JIDOSHA KK

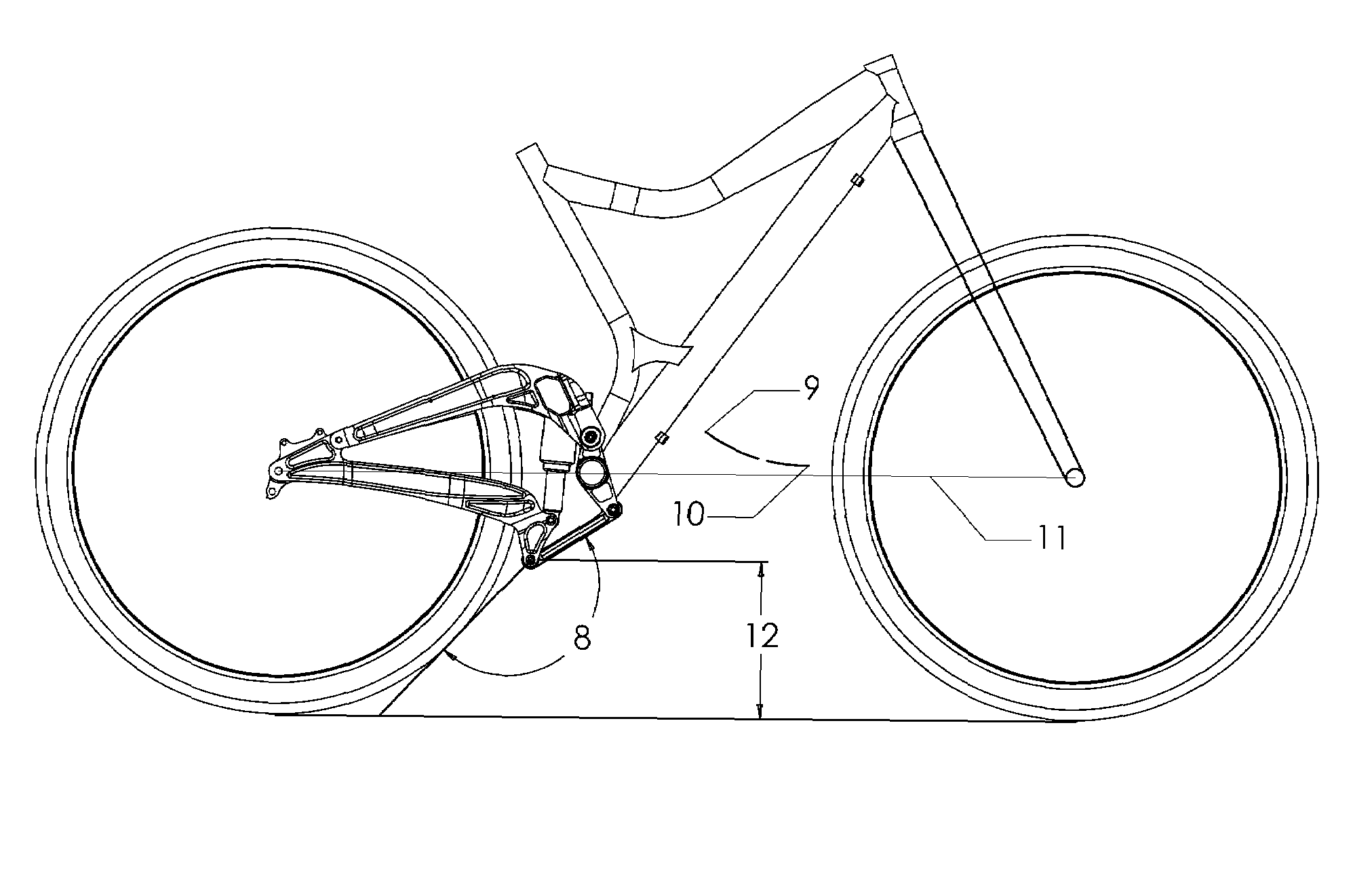

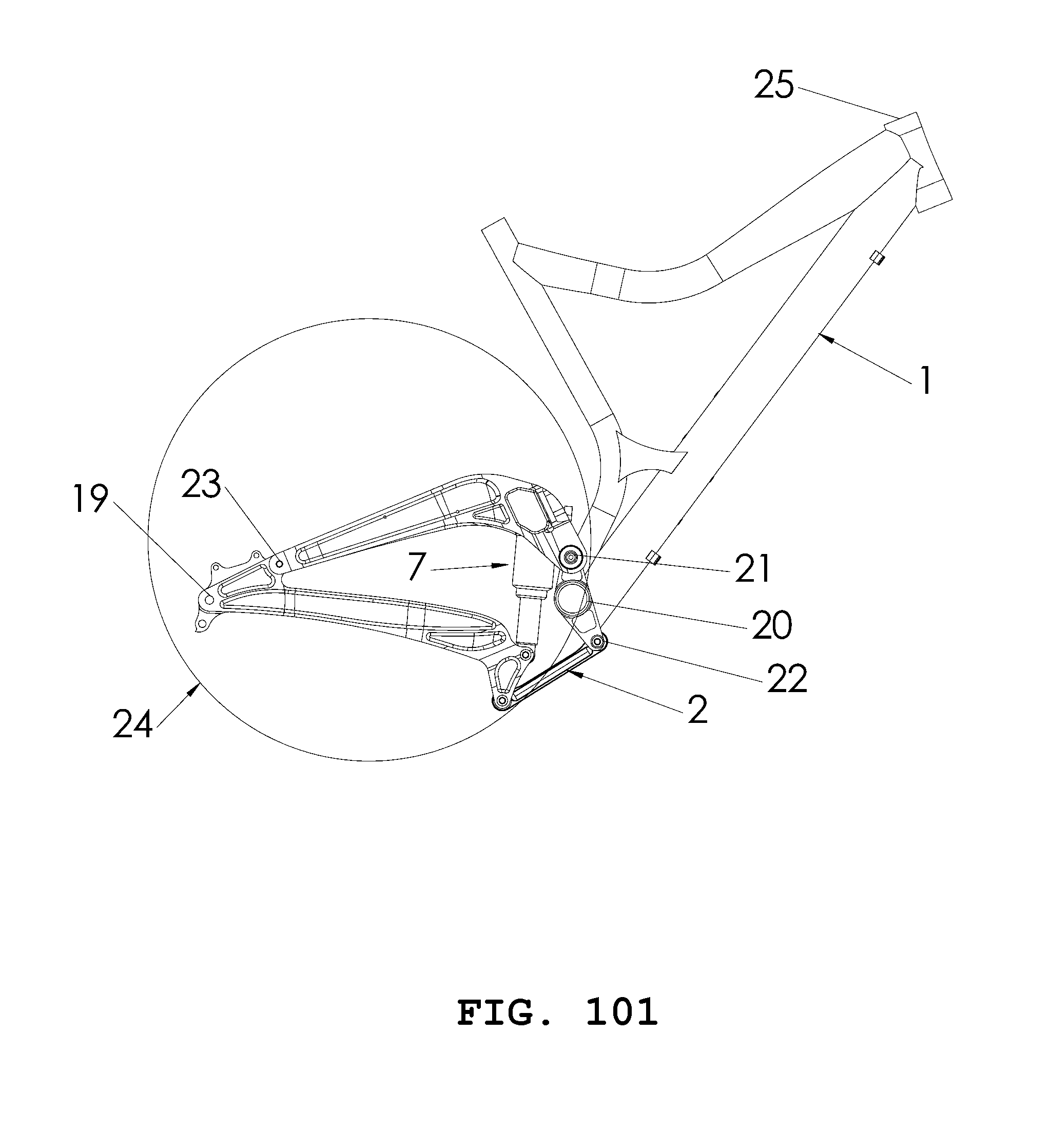

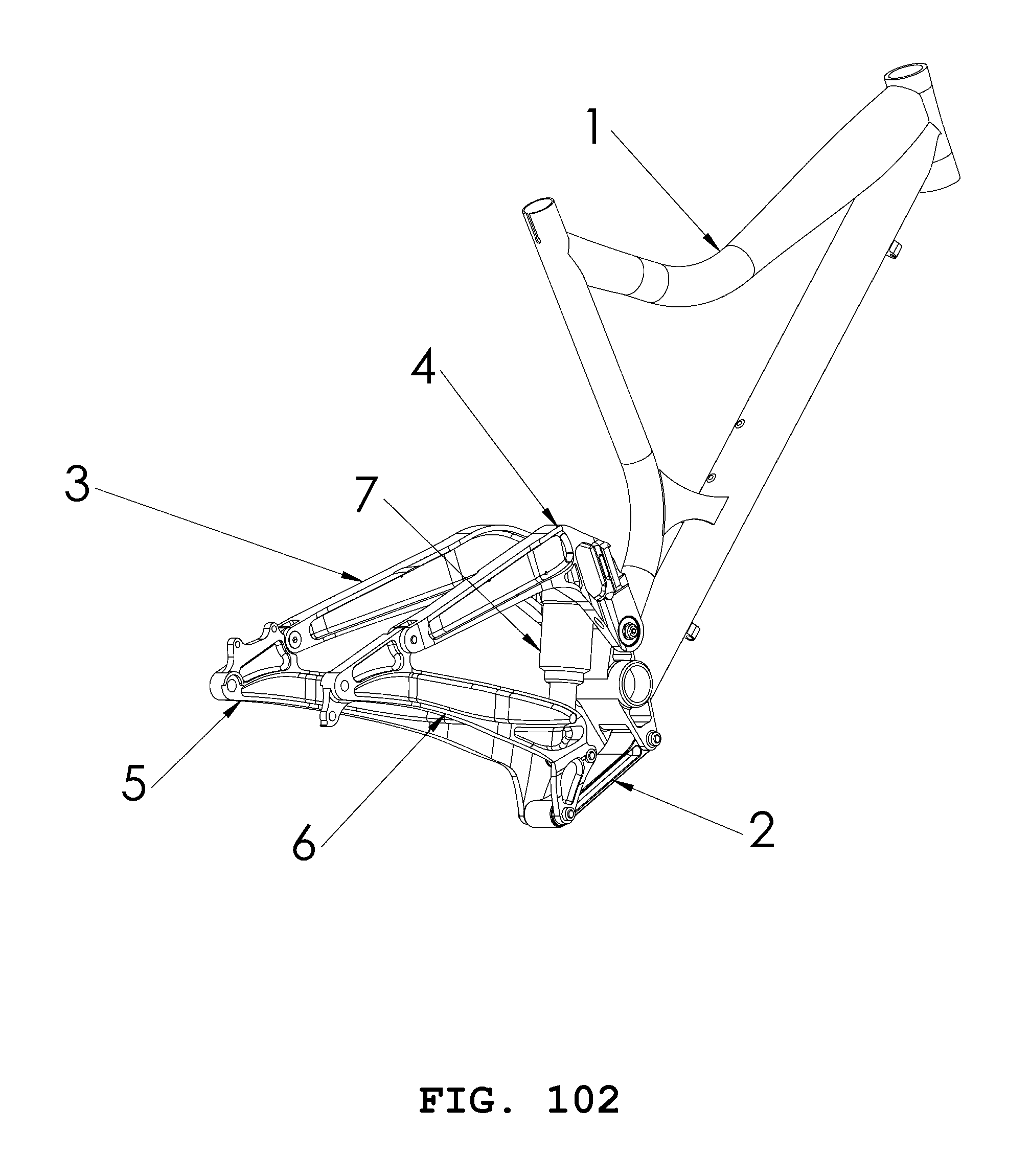

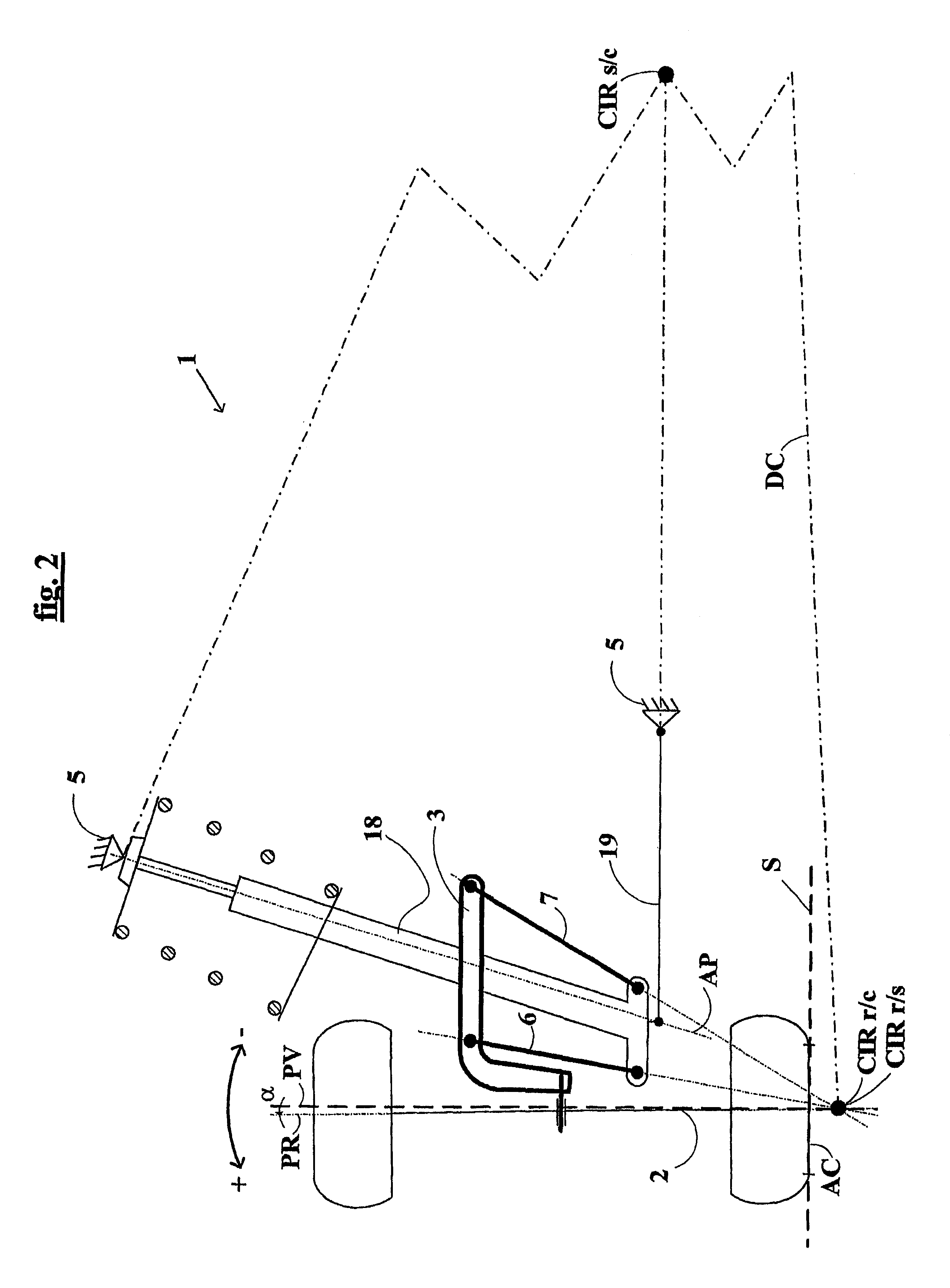

Bicycle rear wheel suspension chassis

InactiveUS7556276B1Easy to controlRaise the natural frequencyPassenger cyclesChildren cyclesEngineeringGravity center

A Bicycle Rear Wheel Suspension Chassis for a Bicycle. Improved performance, low center of gravity, and ground clearance result from a Front Triangle Frame 1 with Steering Housing 25 and Crank Shaft Housing 20, a Link 2 with forward most end pivotally attached to Lower Pivot 22, a Swingarm Chassis 24 pivotally attached to rearward most end of said Link 2, and a rear wheel pivotally attached at Rear Axle Location 19 to said Swingarm Chassis 24. The Shock Absorber 7 attached to said Swingarm Chassis 24 provides means for suspension spring rate and damping for isolating a bicycle rider from trail impacts with the rear wheel. Performance and handling advantages result from a low center of gravity system, a Link 2 at the Lower Pivot 22 that provides better control by reacting to travel over trail objects, and a moving instant center that reacts optimally to impacts of varying magnitude and frequency.

Owner:DUNLAP CHARLES E

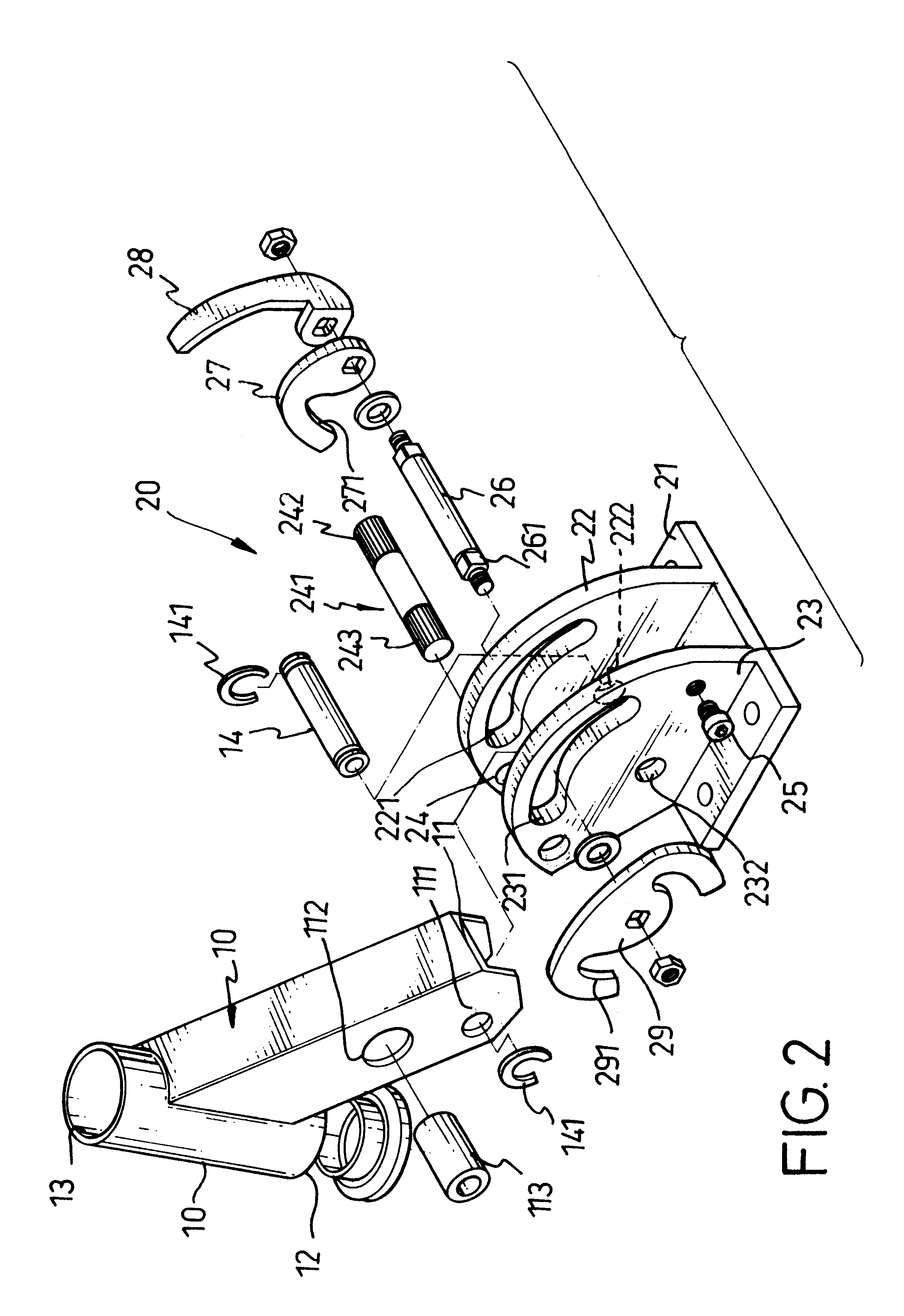

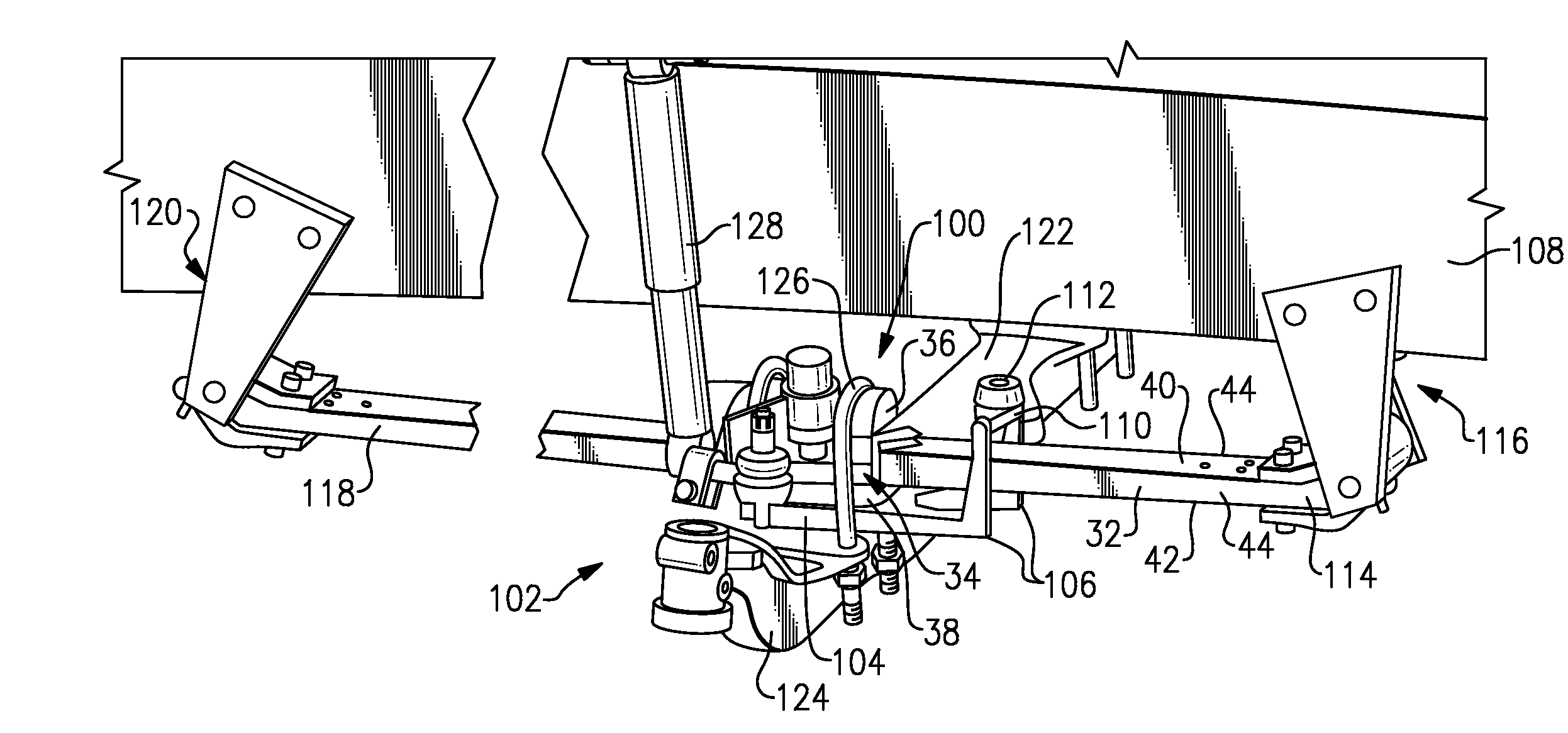

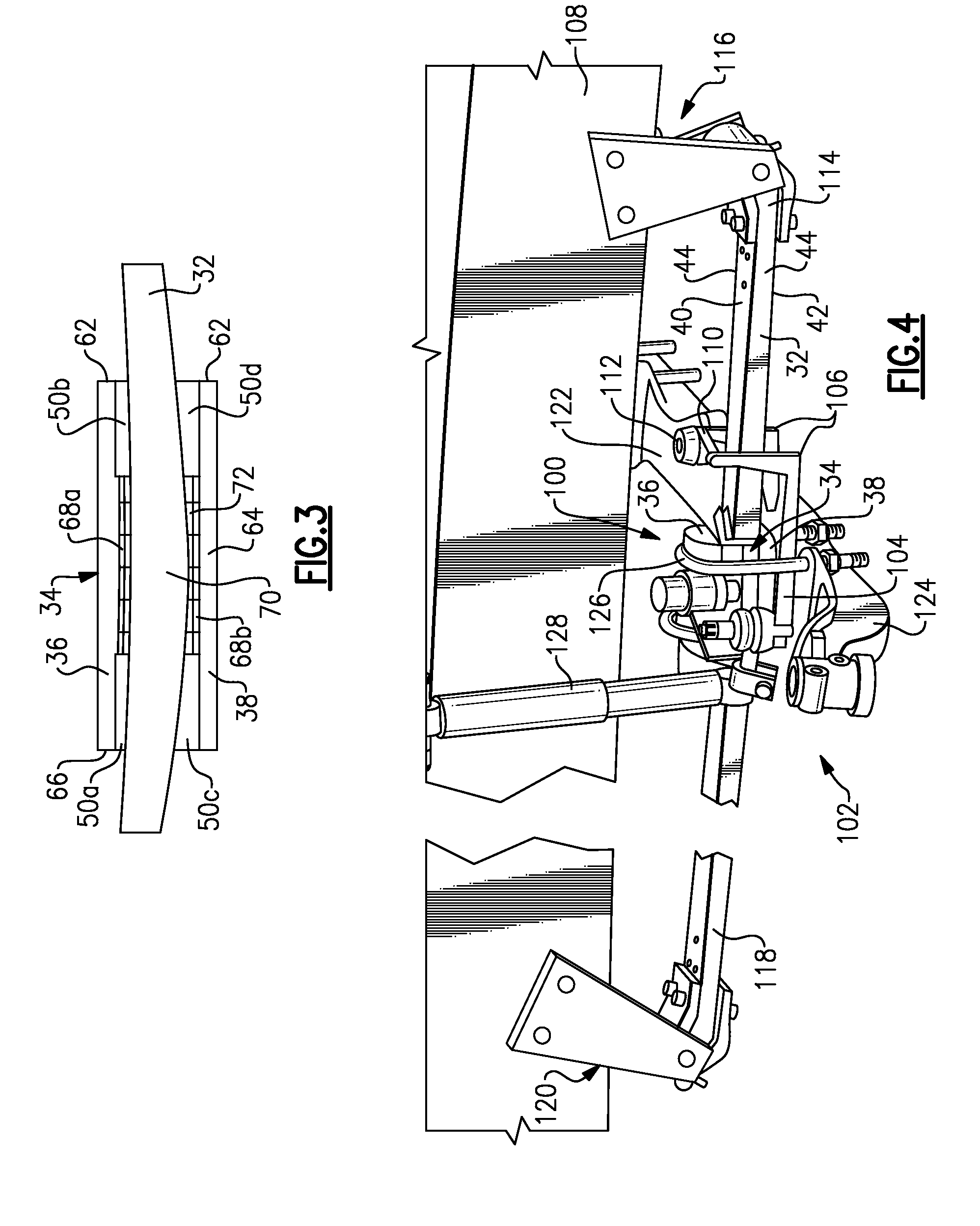

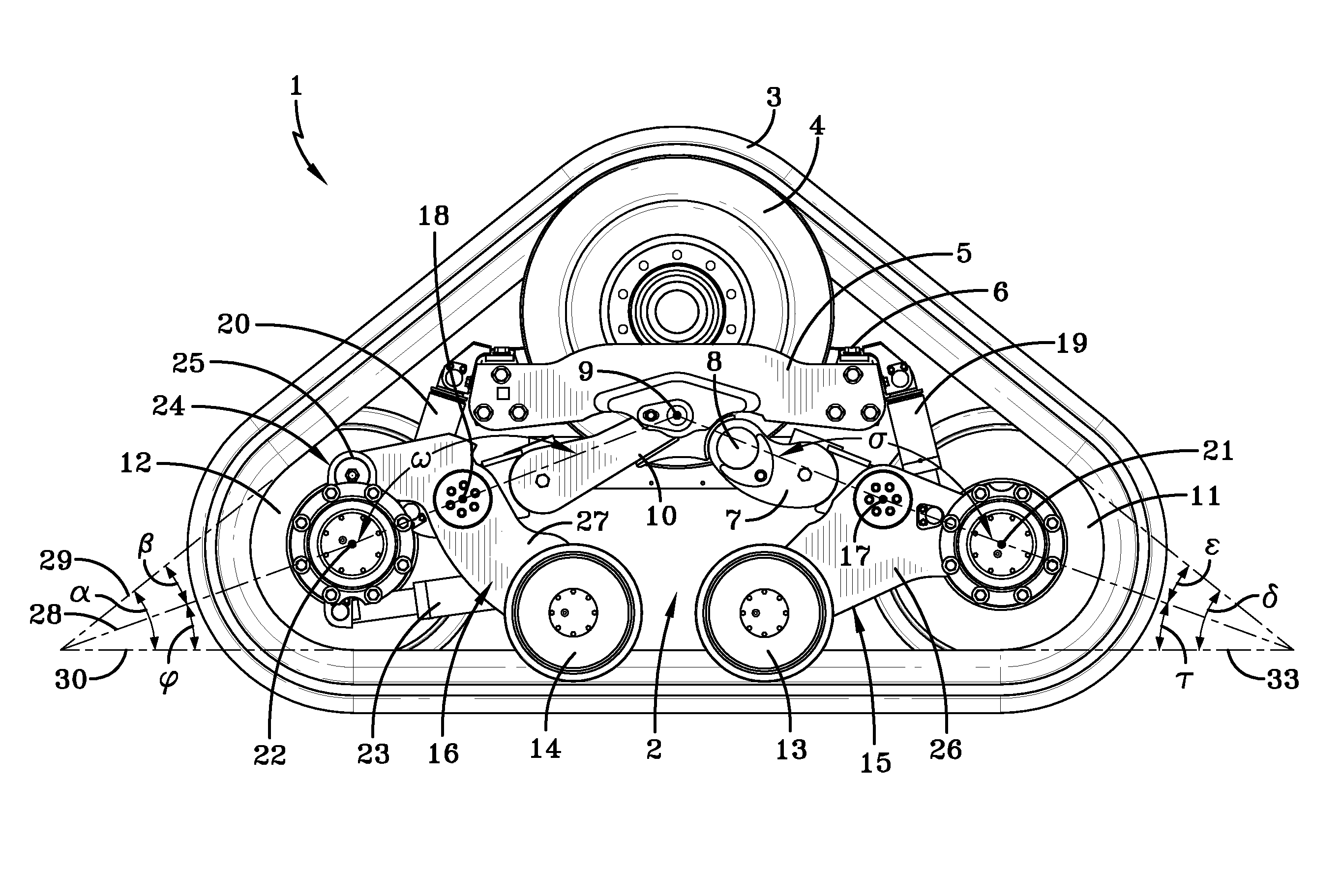

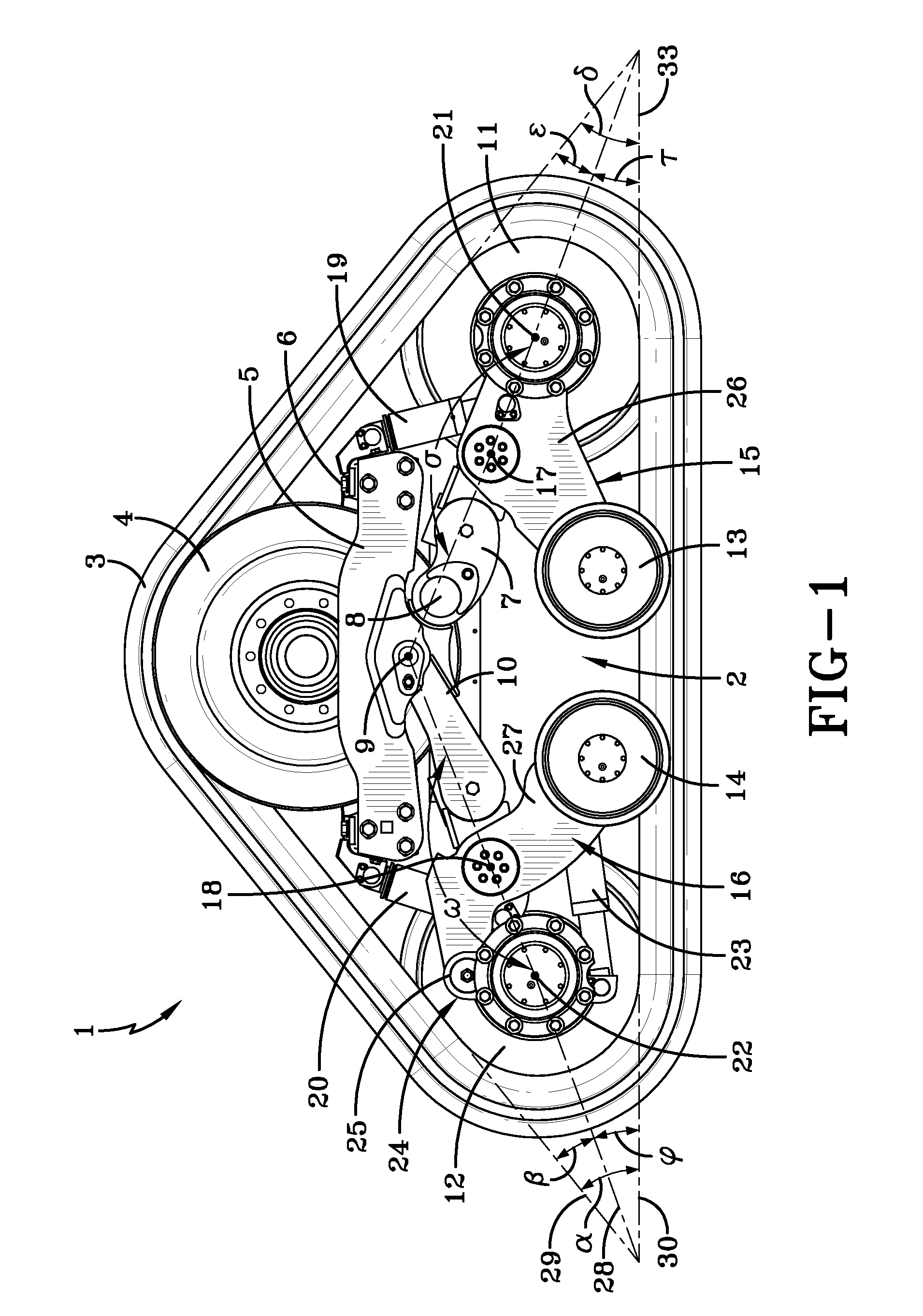

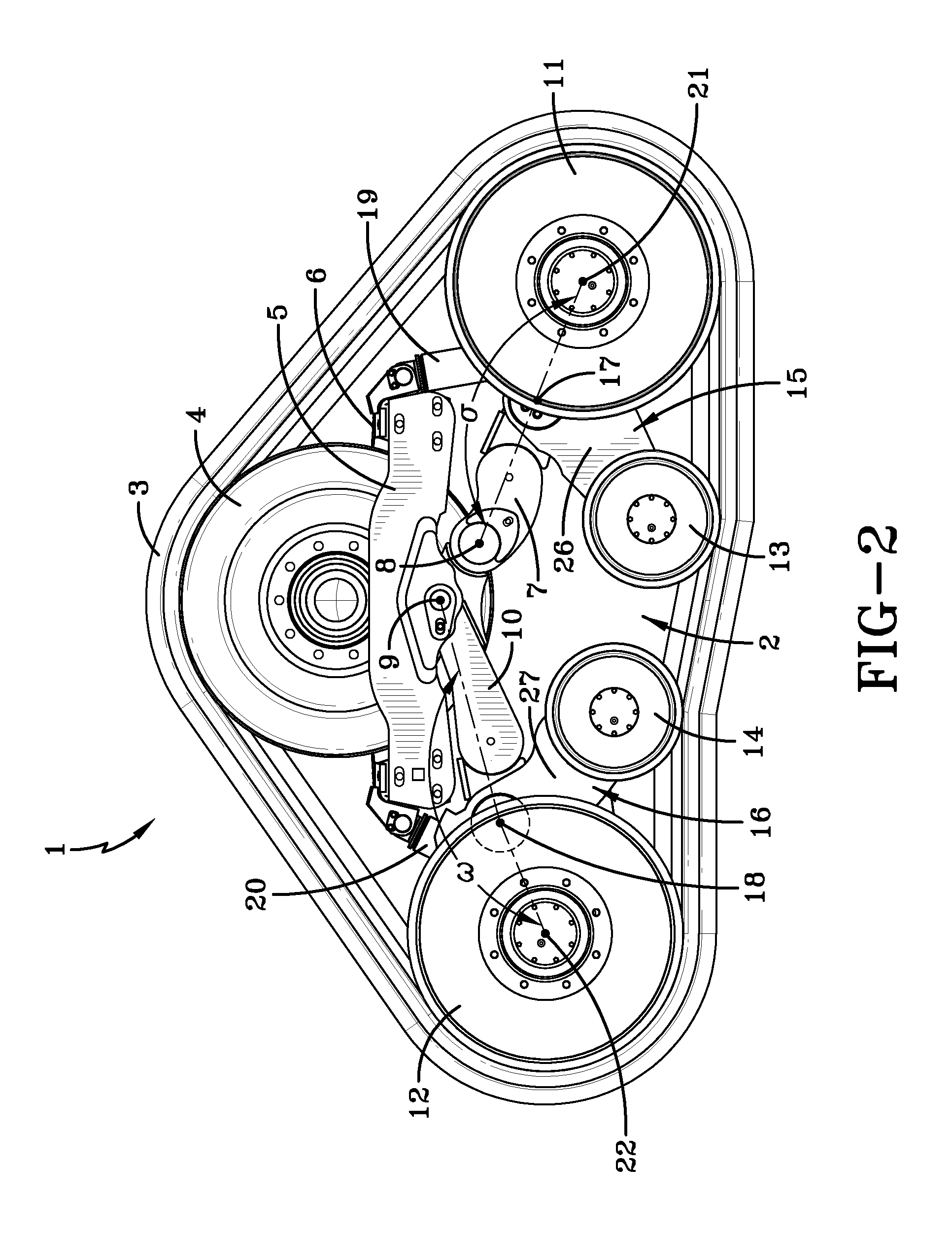

Track suspension

This invention discloses a track suspension wherein a rear wishbone member is rotatably affixed to a yoke assembly and a yoke plate carrier through a rear wishbone joint, wherein a front wishbone member is rotatably affixed to the rear wishbone member through a front wishbone joint, wherein a rear rocker assembly is comprised of a rear rocker beam, a rear roller wheel and a rear idler wheel, wherein a front rocker beam is rotatably affixed to the front wishbone through a front rocker joint, wherein the rear rocker beam is rotatably affixed to the rear wishbone member through a rear rocker joint, wherein a front suspension spring assembly is affixed between a yoke assembly and a front wishbone member, and wherein a rear suspension spring assembly is affixed between the yoke assembly and the rear wishbone member.

Owner:LOC PERFORMANCE PROD LLC

Spring strut arrangement for wheel suspensions of motor vehicles

InactiveCN101896369AWeight advantageReduce reaction forceResilient suspensionsVehicle springsHelical coilShock absorber

The invention relates to a spring strut arrangement for wheel suspensions of motor vehicles formed of a telescoping shock absorber (12), a suspension spring element (14) preferably designed as a helical compression spring, and a storage spring element (16) preferably designed as a helical coil spring, wherein the spring elements (14, 16) are supported by spring caps (28, 30) on the body (22) of the motor vehicle and on a wheel suspension element (24), and third spring cap (34) located therebetween is displaceably guided relative to the body (22) along the longitudinal axis of the shock absorber by means of an electrically driven positioning drive (32) disposed within the spring elements (14, 16), wherein the positioning drive (32) comprises a positioning spindle (36) rotatably supported about the shock absorber and a positioning nut (40) connected to the displaceable spring cap (34). According to the invention, the shock absorber (12) is disposed on the body (22) of the motor vehicle with the damping tube (46) upward, and the positioning spindle (36) is rotatably supported on the damping tube (46).

Owner:AUDI AG

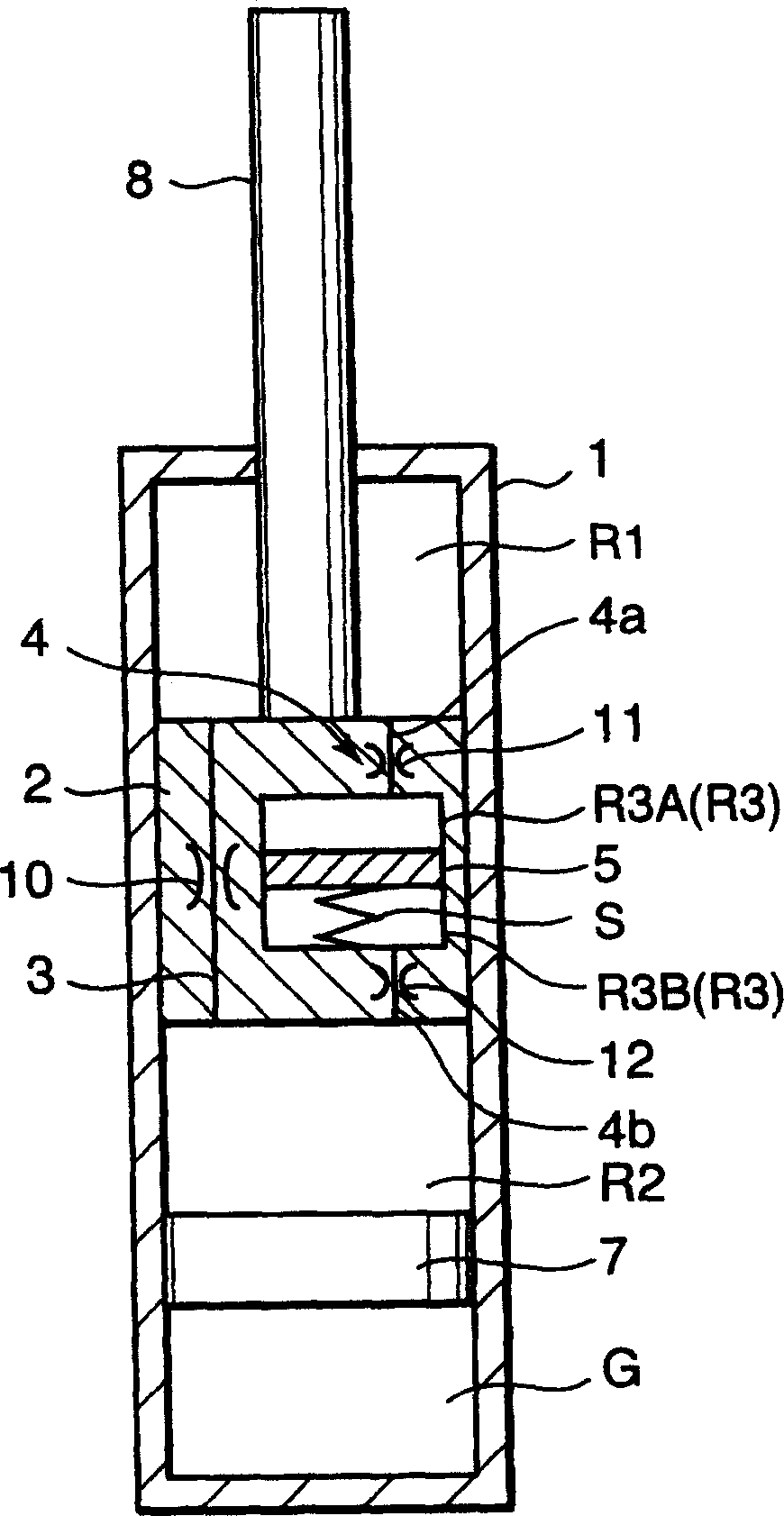

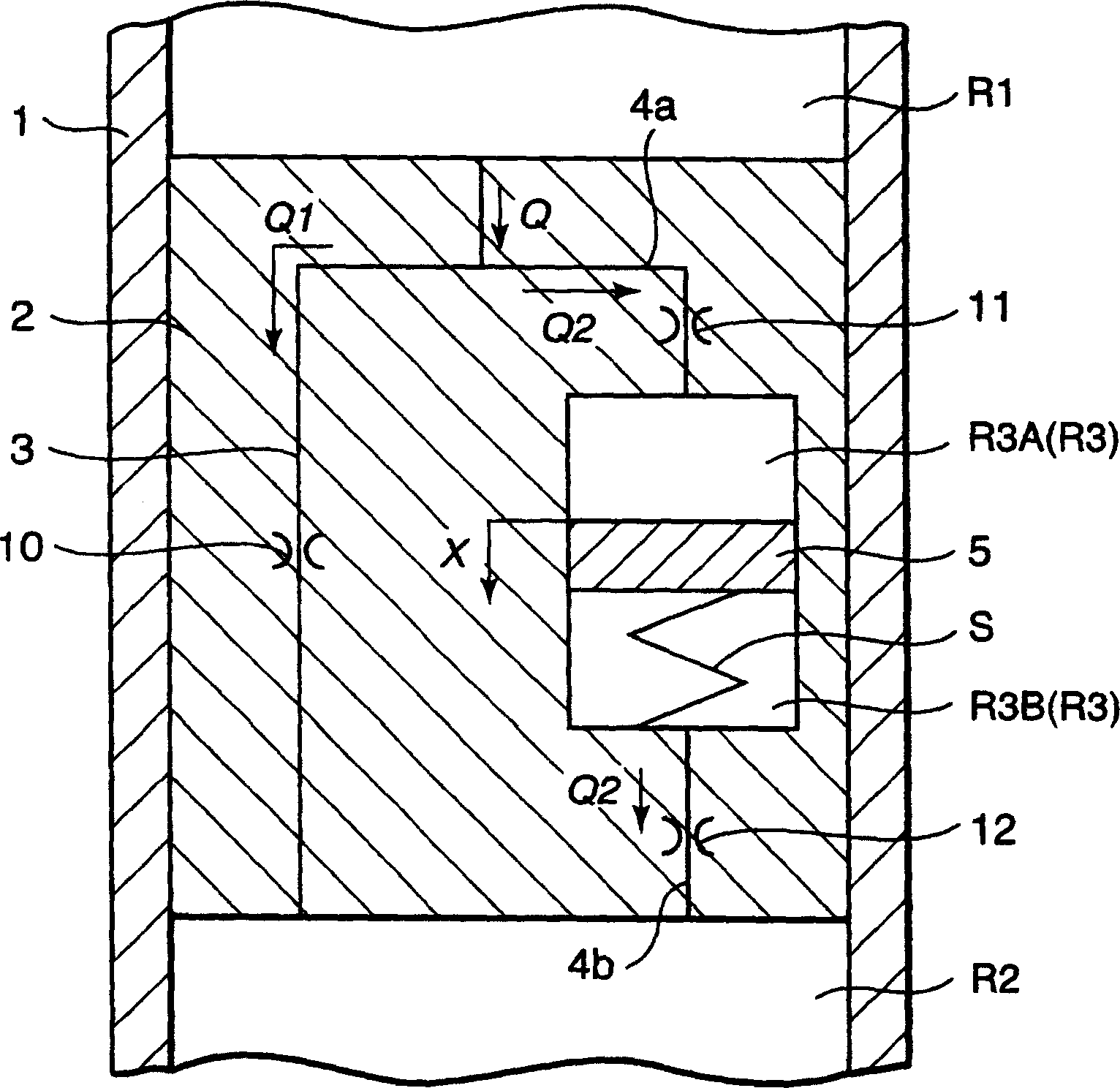

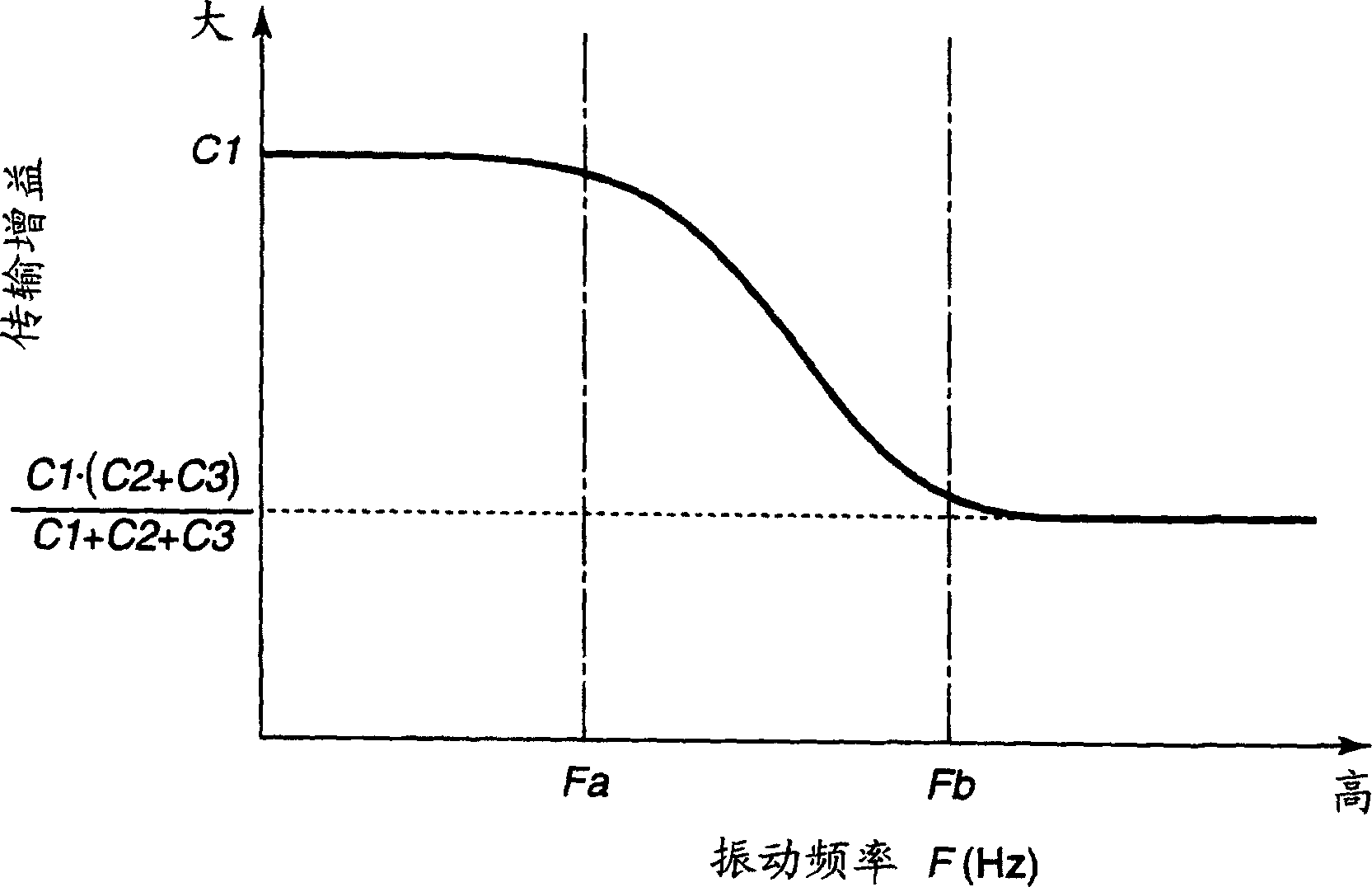

Shock absorber

ActiveCN1880792AReduce manufacturing costSuppresses sudden changes in decay forceSpringsShock absorbersEngineeringPiston rod

A shock absorber interposed in parallel with a suspension spring between a vehicle wheel and a vehicle body of a vehicle comprises a main piston (2) partitioning a cylinder (1) into a first operating chamber (R1) and a second operating chamber (R2), and connected to a piston rod (8). The first operating chamber (R1) and the second operating chamber (R2) are connected by a laminated leaf valve (V1, V2) under a first flow resistance. A passage (4a) connects one of the pressure chambers (R3A, R3B) partitioned by a free piston (5) and the first operating chamber (R1) under a second flow resistance. A passage (4b) connects the other of the pressure chambers (R3A, R3B) and the second operating chamber (R2) under a third flow resistance. The shock absorber displays stable damping force characteristics as a result of a spring (S) supporting the free piston (5) in a predetermined neutral position.

Owner:KYB CORP

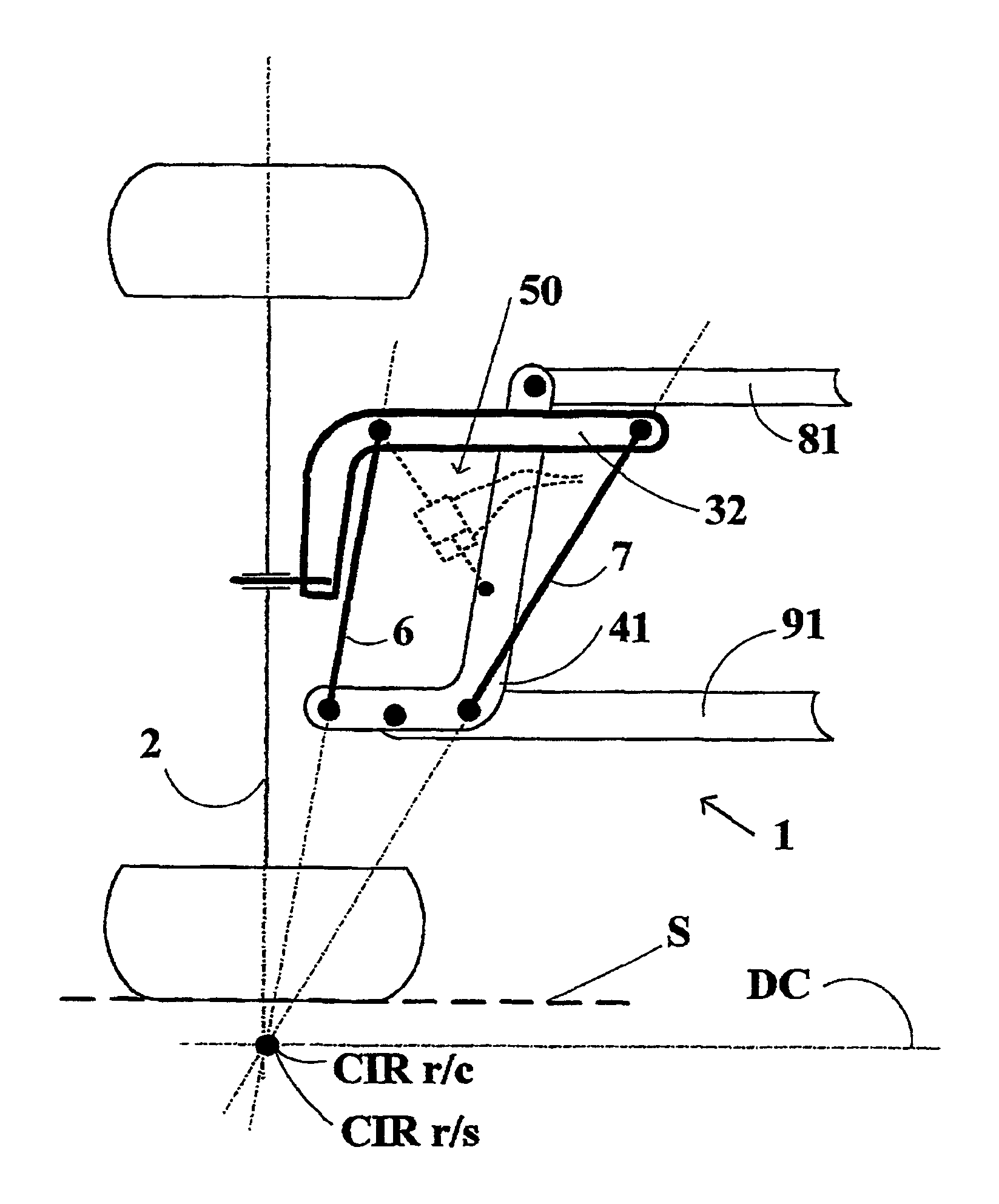

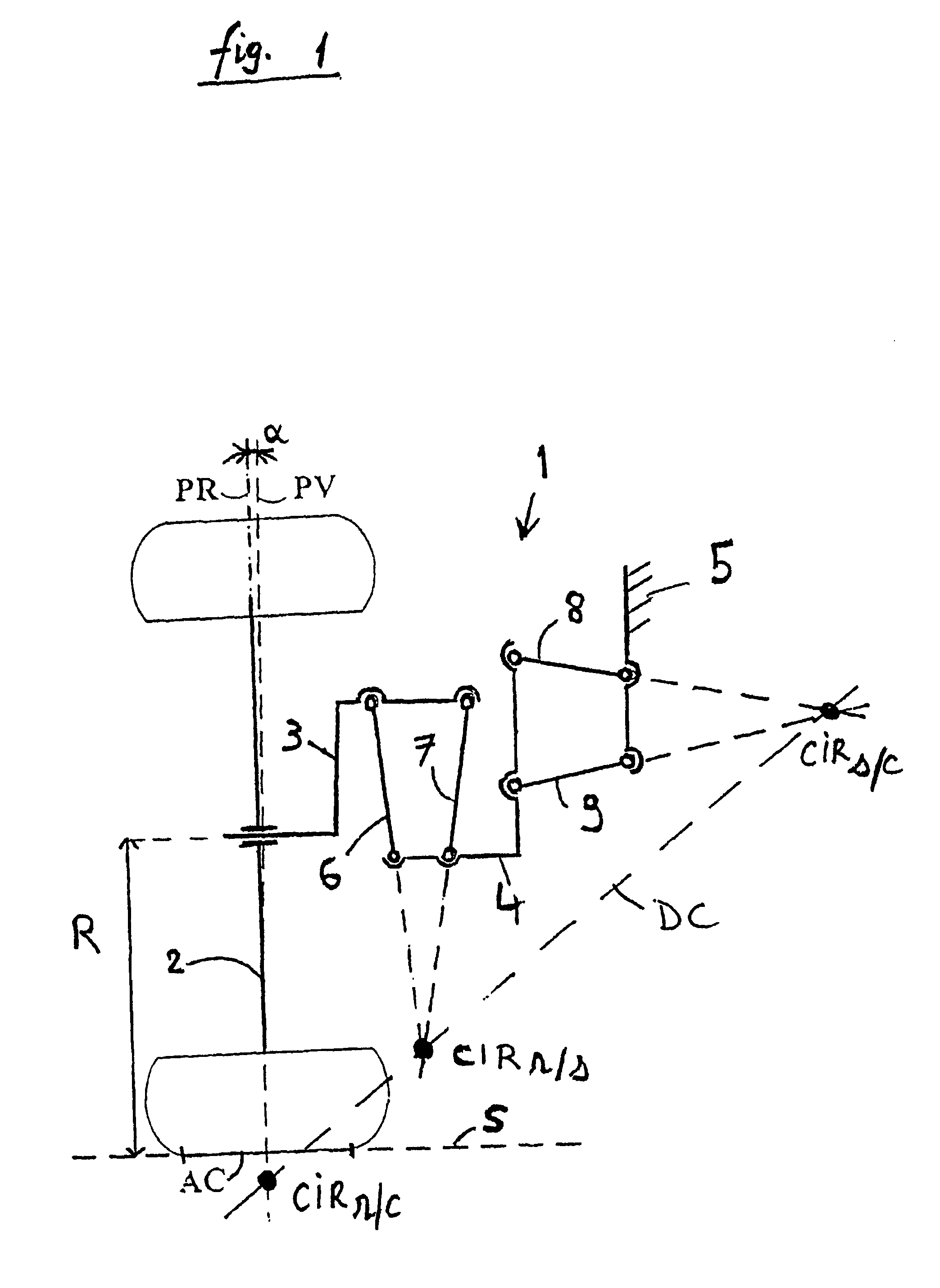

Vehicle suspension with camber control

InactiveUS6688620B2Limit track variationLimit energy necessarySteering partsResilient suspensionsGround contactCamber angle

A vehicular suspension device comprises a wheel carrier which is articulated relative to the suspension elements. This connection is provided by rigid connection rods. This additional degree of freedom permits variation of the camber angle independently of the suspension spring movement and of the deformations of its elements. The variation of the camber is preferably controlled by the forces sustained by the wheel in the ground contact area of the tire. This is obtained by a configuration in which the movements of the wheel relative to the body of the vehicle allow an instantaneous center of rotation which is situated beneath the plane of the ground.

Owner:MICHELIN RECH & TECH SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com