Patents

Literature

235 results about "Seismic mass" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A proof mass or test mass is a known quantity of mass used in a measuring instrument as a reference for the measurement of an unknown quantity. A mass used to calibrate a weighing scale is sometimes called a calibration mass or calibration weight. A proof mass that deforms a spring in an accelerometer is sometimes called the seismic mass.

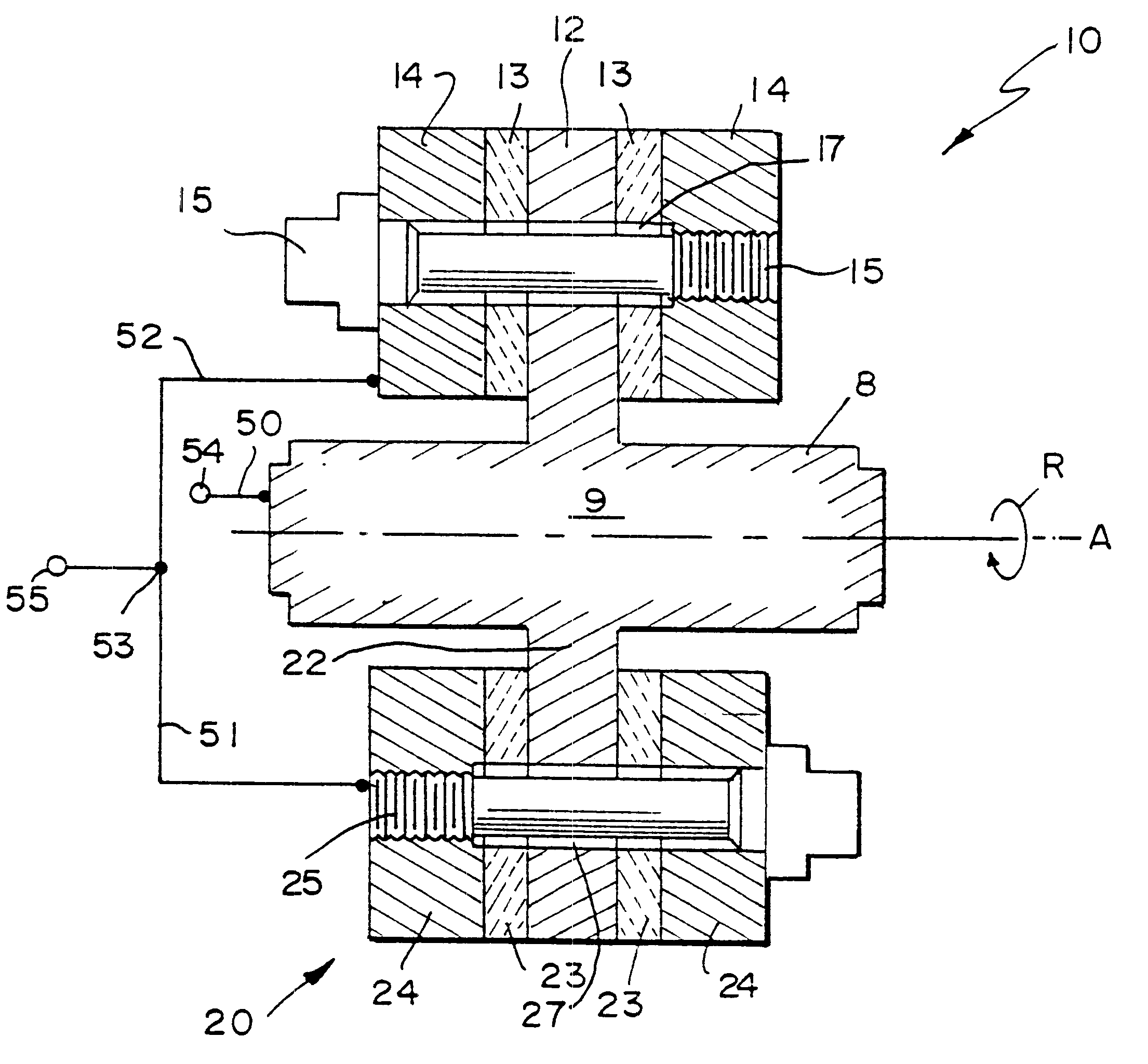

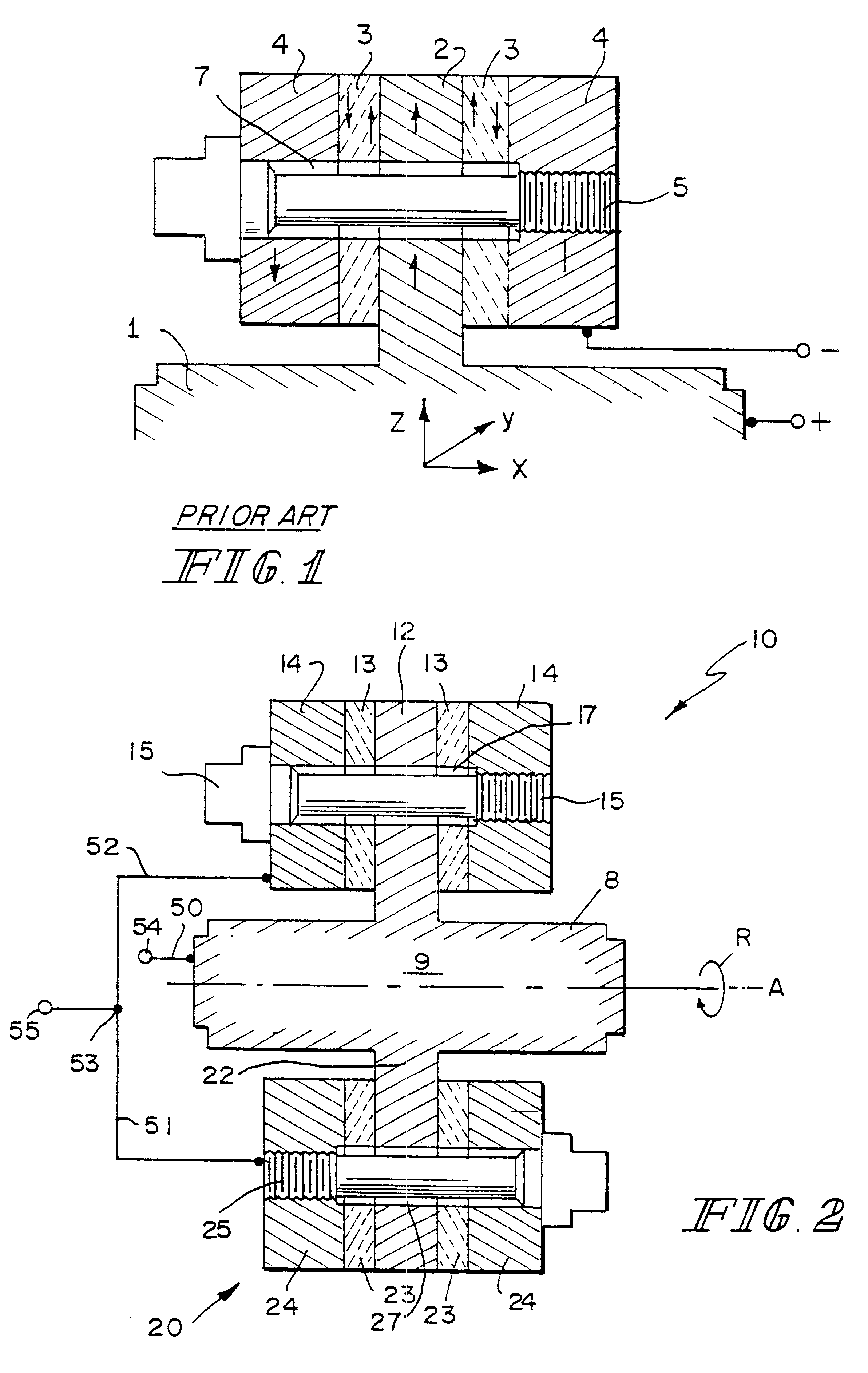

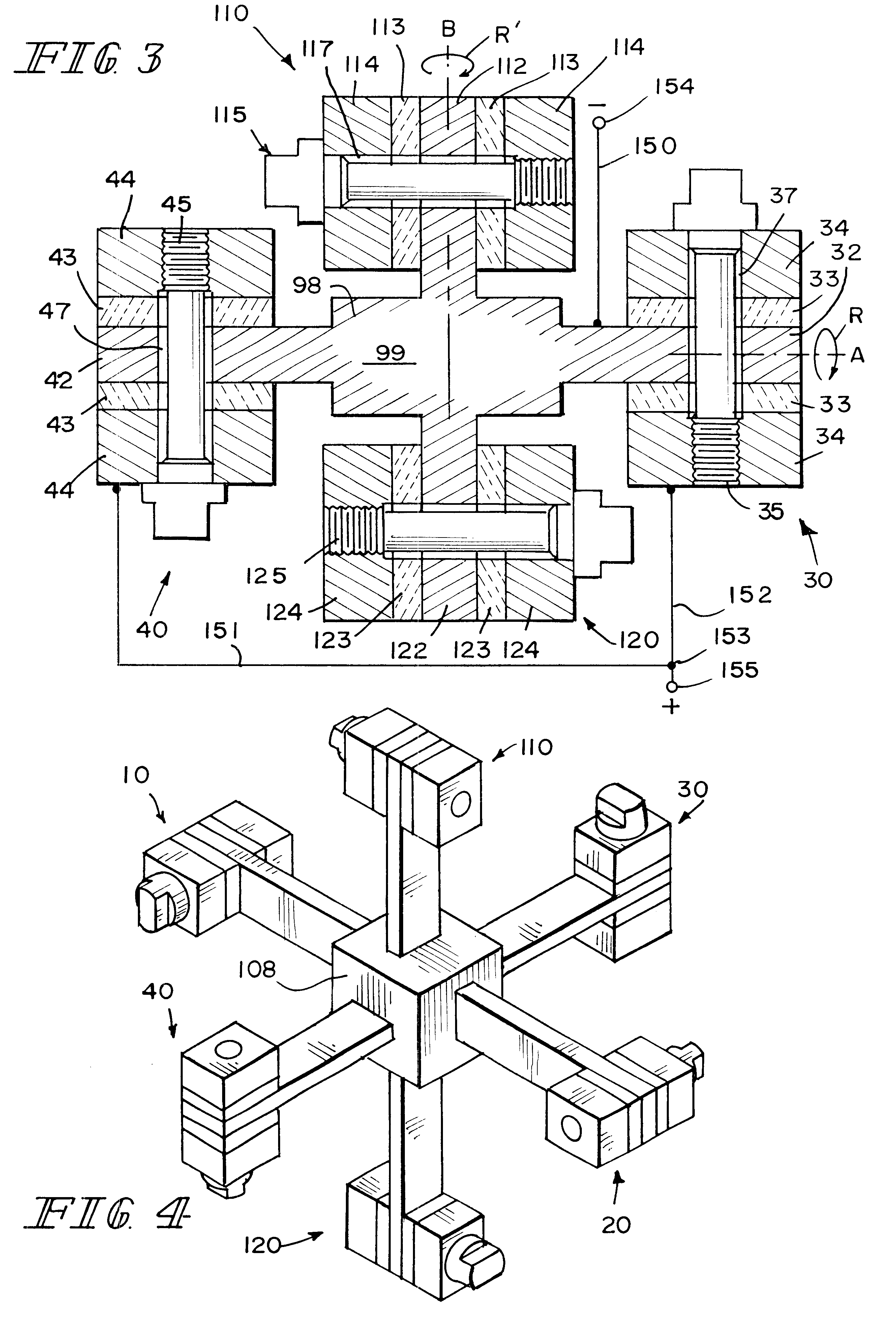

Piezoelectric rotational accelerometer

InactiveUS6397677B1Accurate detectionReduce errorsAcceleration measurement using interia forcesPiezoelectric/electrostriction/magnetostriction machinesSeismic massEngineering

A rotational accelerometer using piezoelectric material, preferably quartz, in a shear orientation. Piezoplates and conducting seismic masses, each having bores therethrough, are bolted to posts that are symmetrically mounted to a body in such a manner that the bolt passes through the piezoplates but does not make contact. The accelerometer can be assembled as a single-axis accelerometer by mounting a pair of posts symmetrically about the body along the measured axis; additionally, the accelerometer may be assembled as a double or triple axis accelerometer by symmetrically mounting additional pairs of posts to the body. The total weight of the seismic masses and the crystals of the shear-type accelerometer halves should be equal. The invention sets forth a novel rotational accelerometer that reduces or eliminates the need for signal-processing electronics.

Owner:KISTLER INSTR

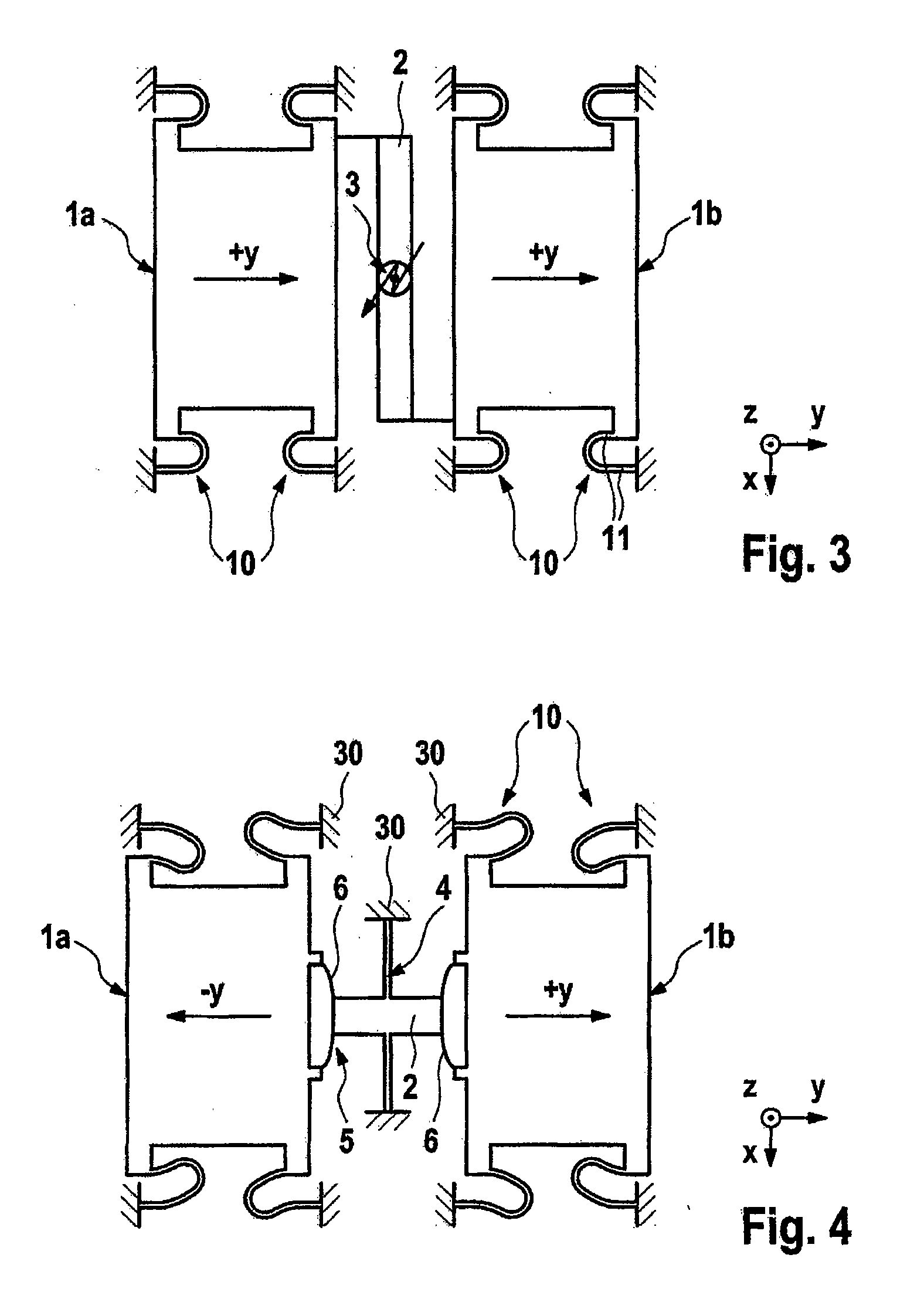

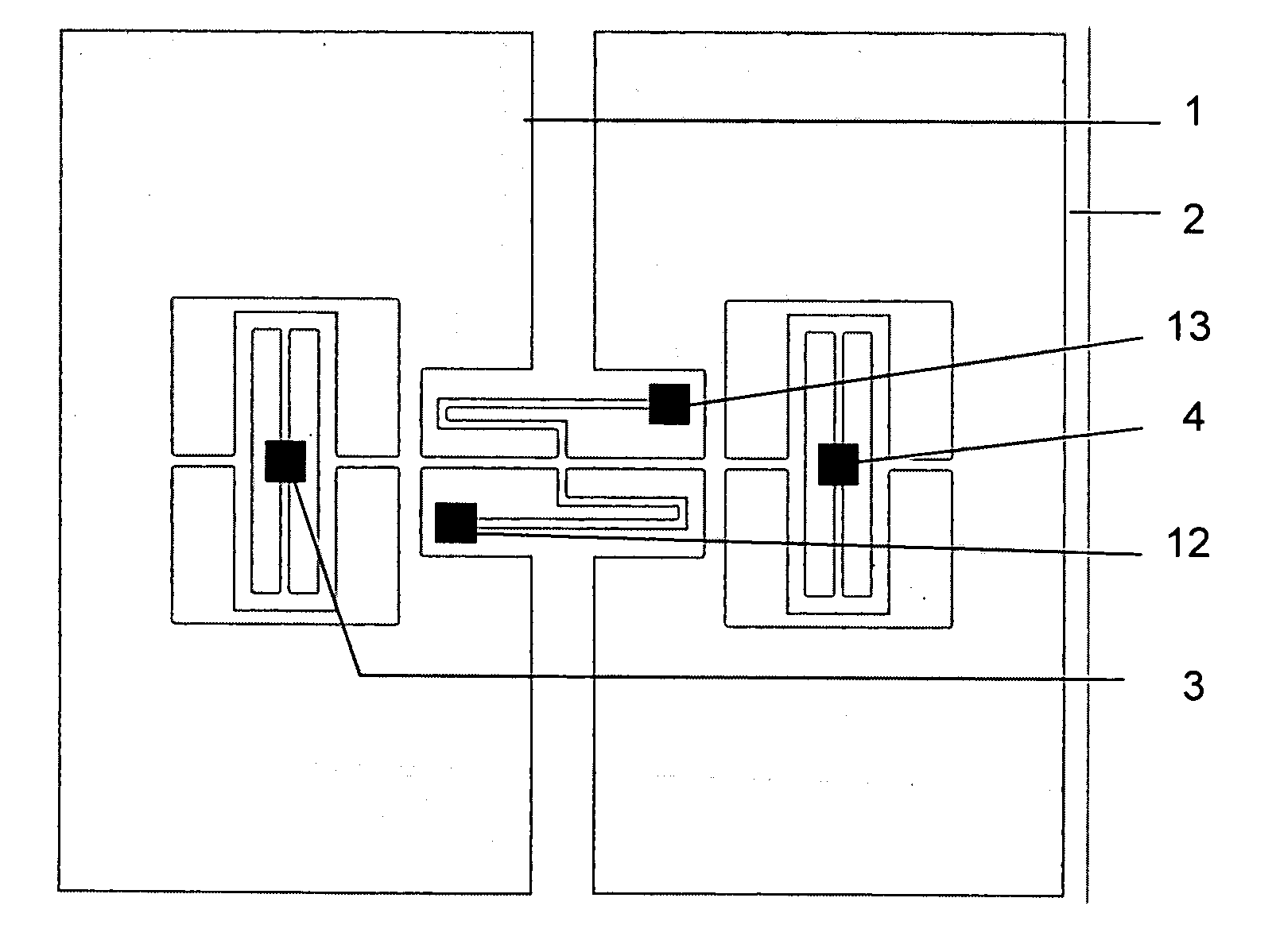

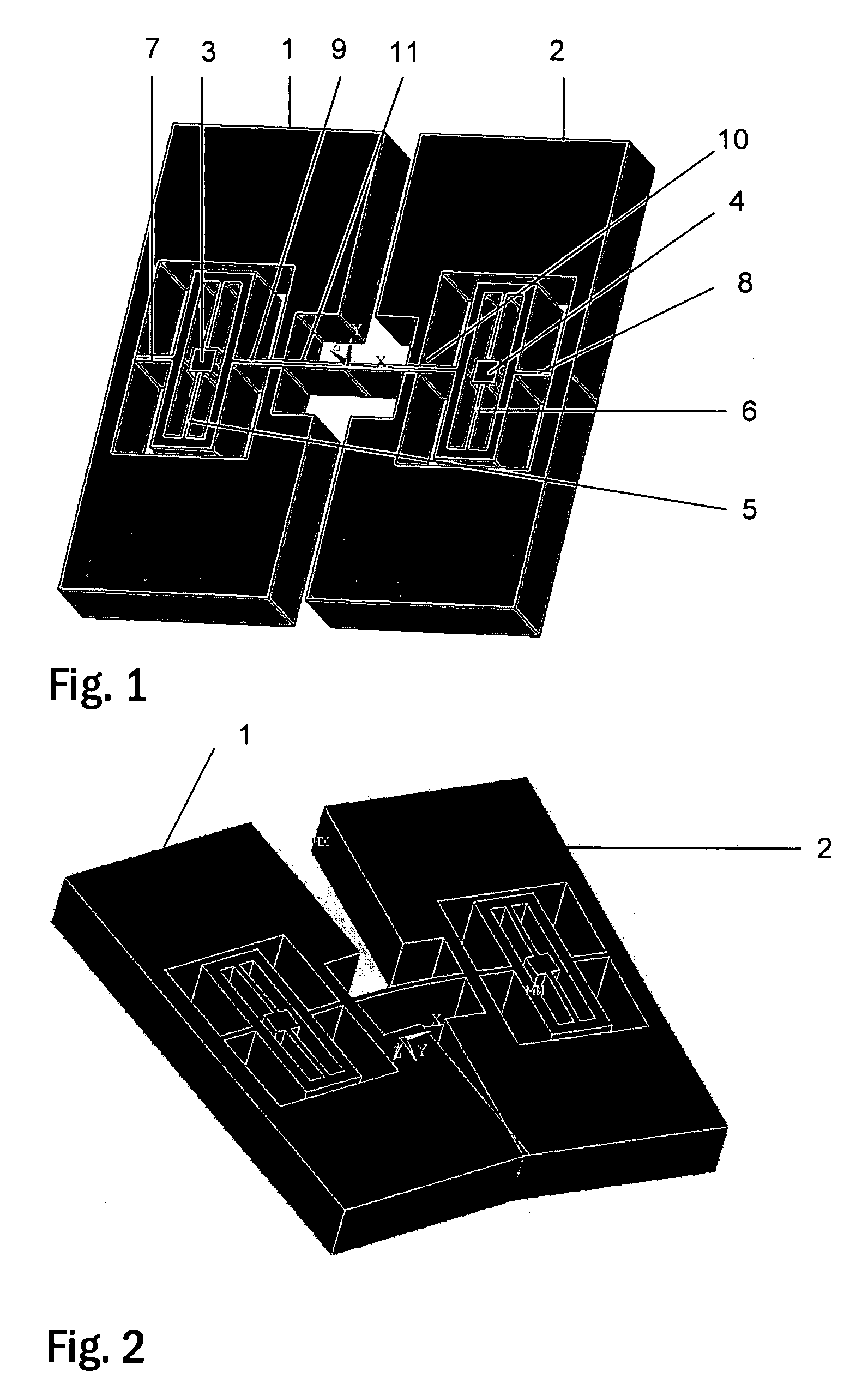

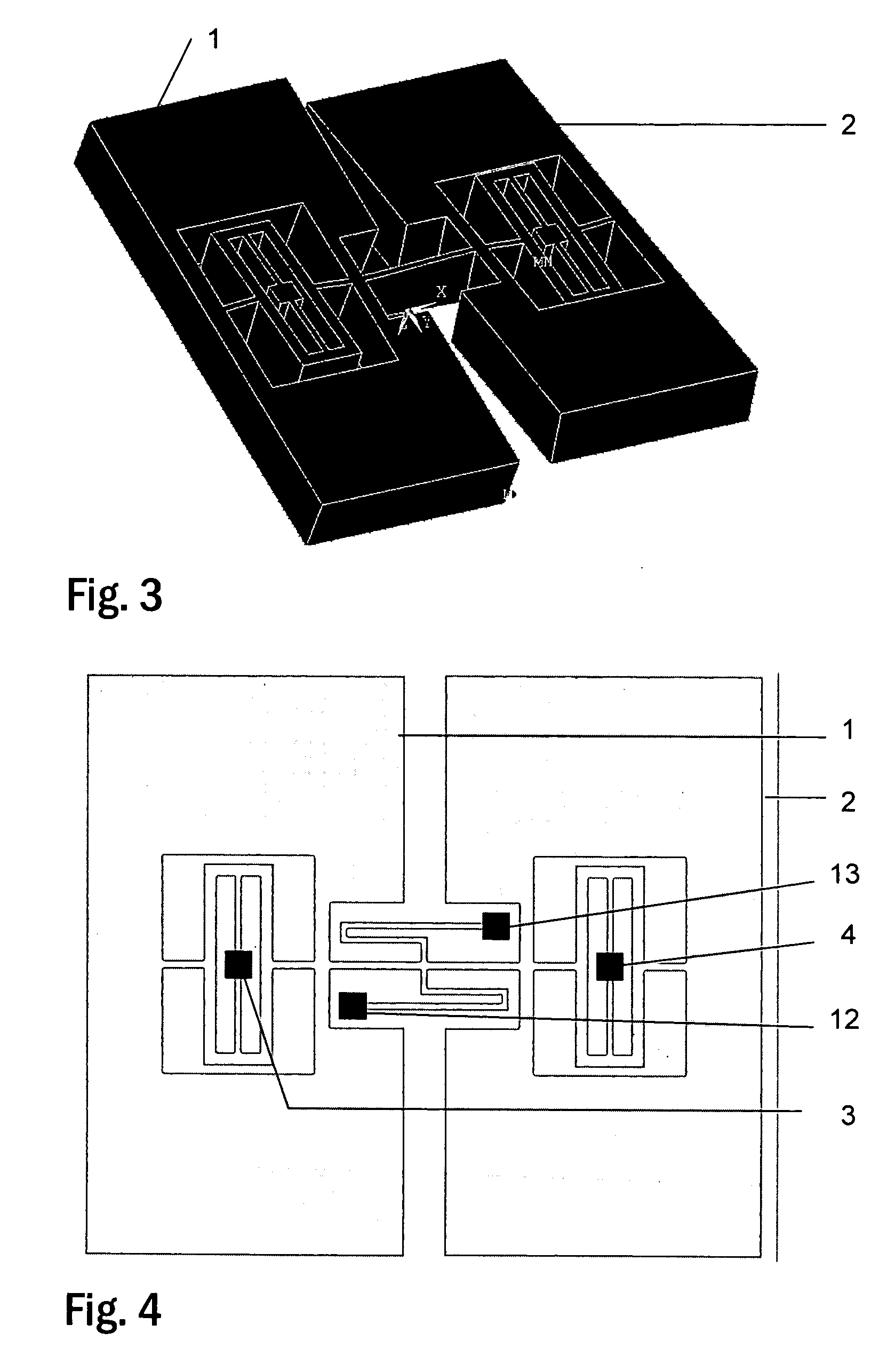

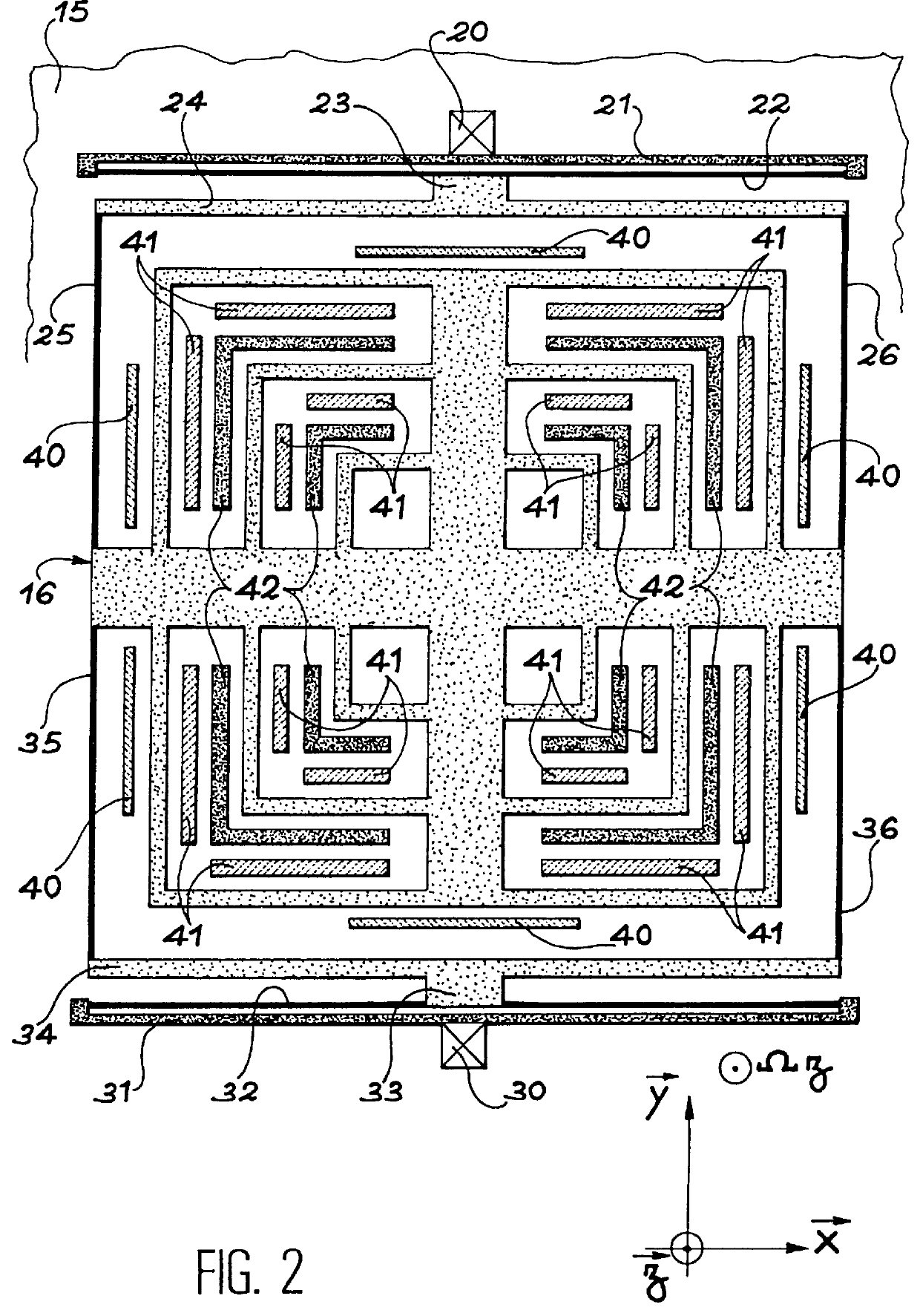

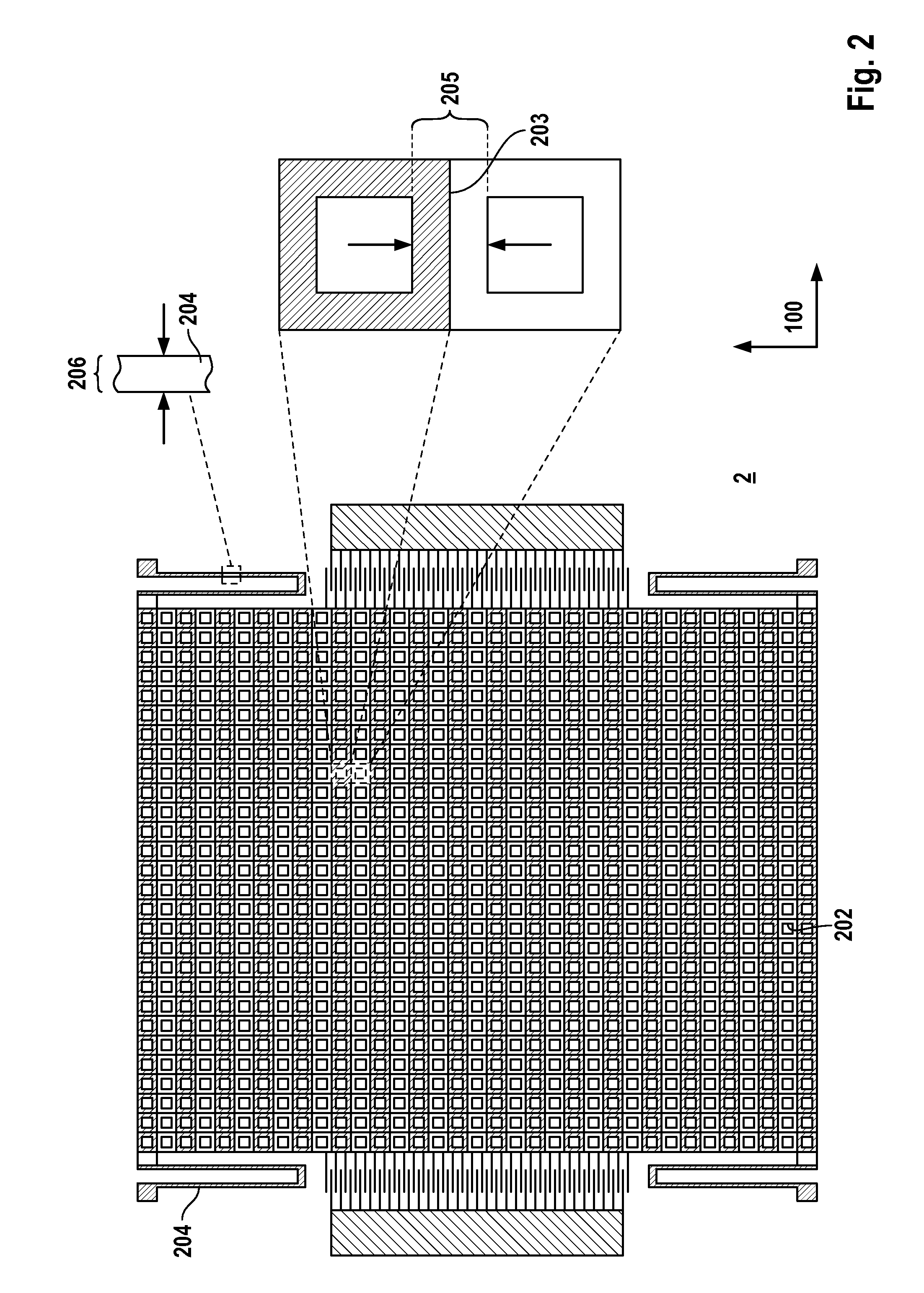

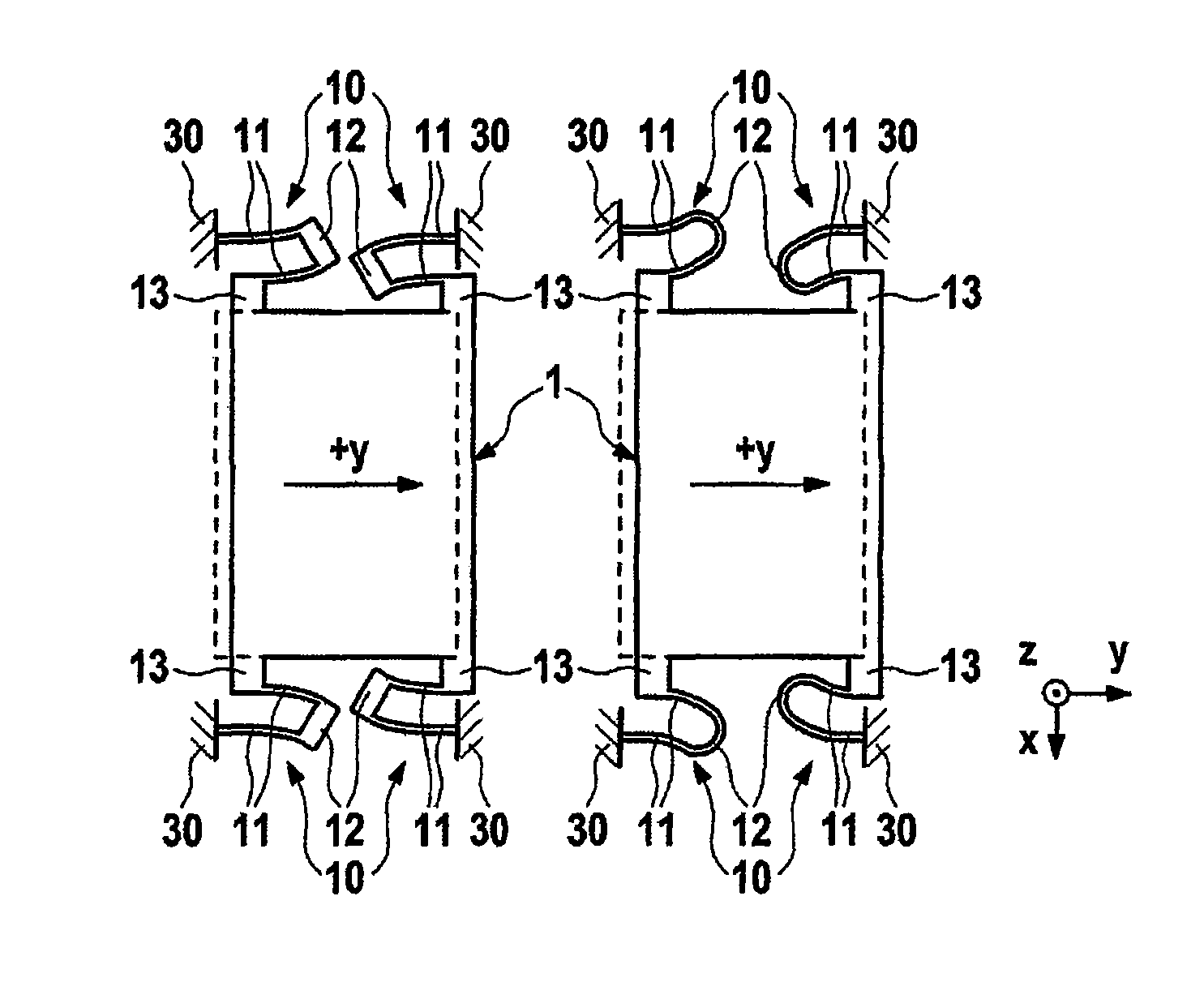

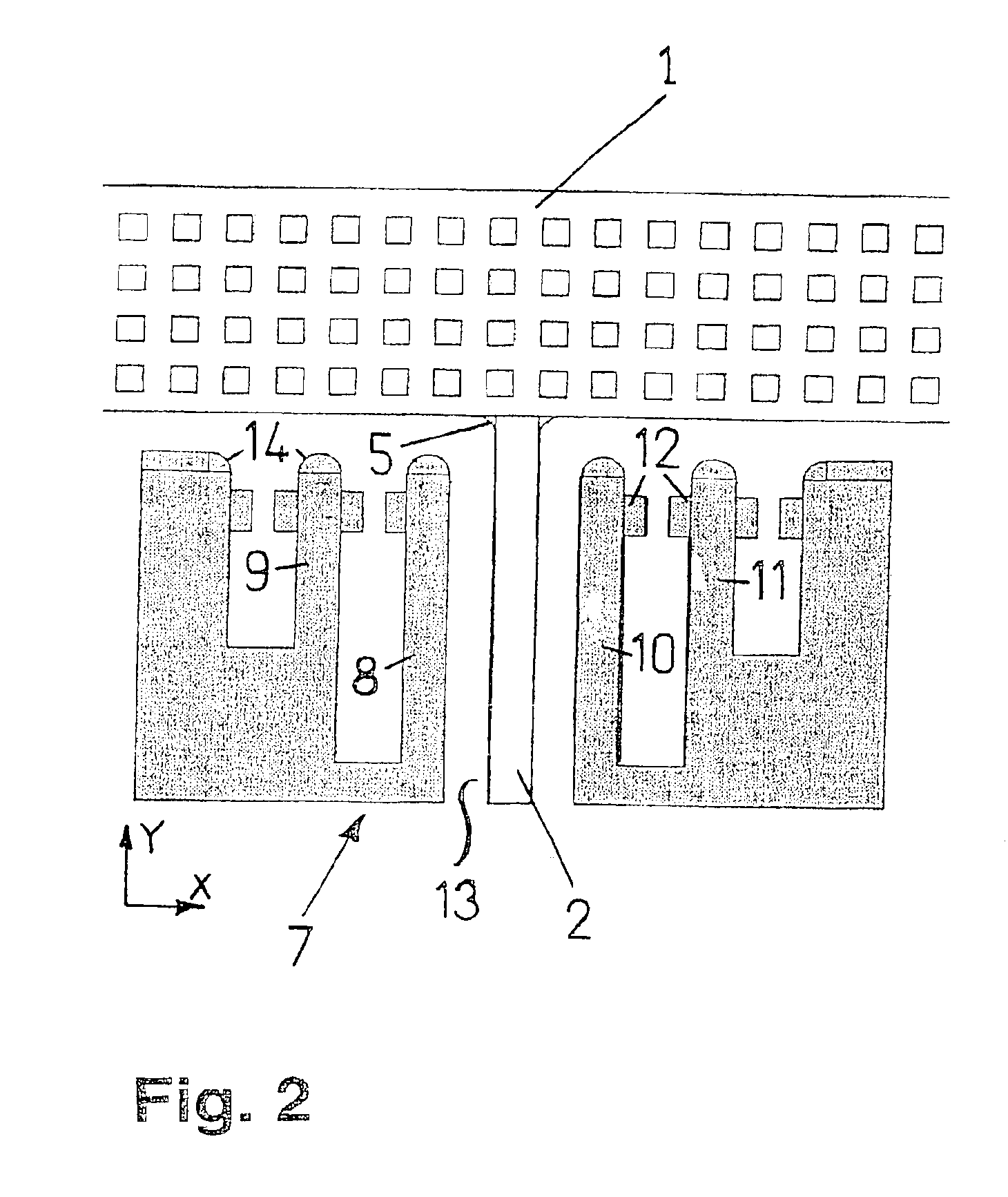

Micromechanical rotation rate sensor with a coupling bar and suspension spring elements for quadrature suppression

ActiveUS20100186507A1Reduce generationSuppresses quadratureAcceleration measurement using interia forcesSemiconductor/solid-state device manufacturingSeismic massEngineering

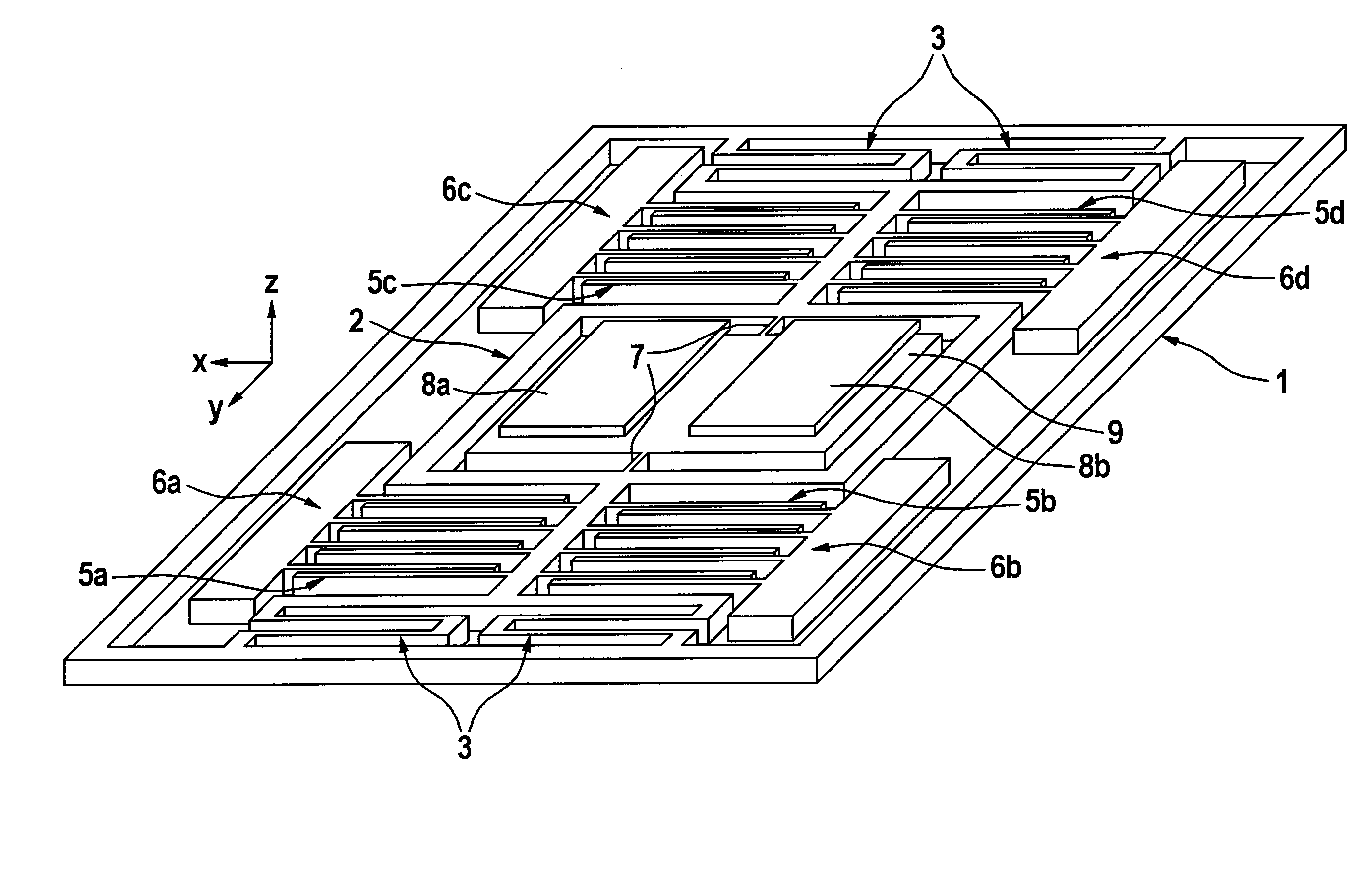

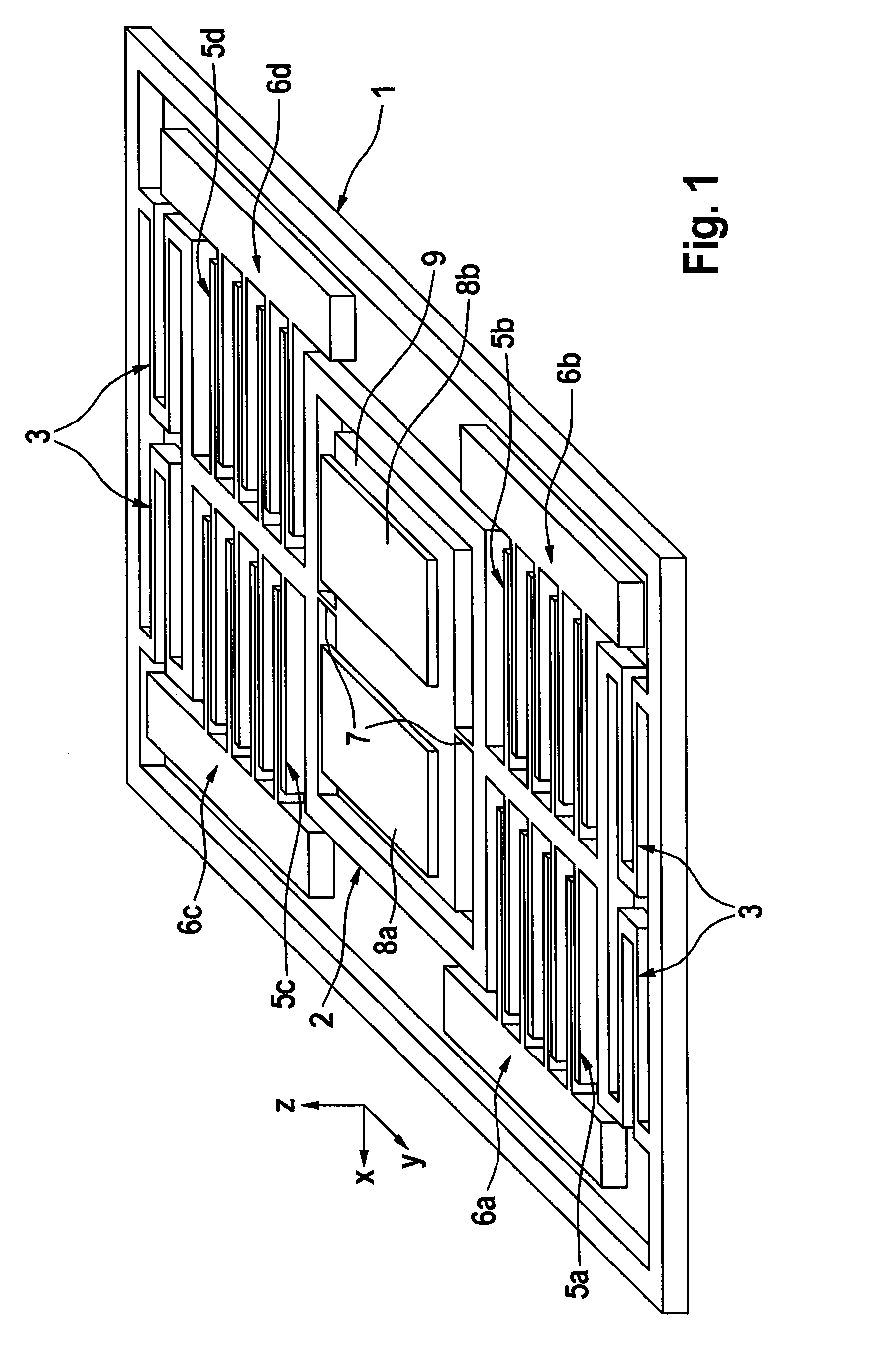

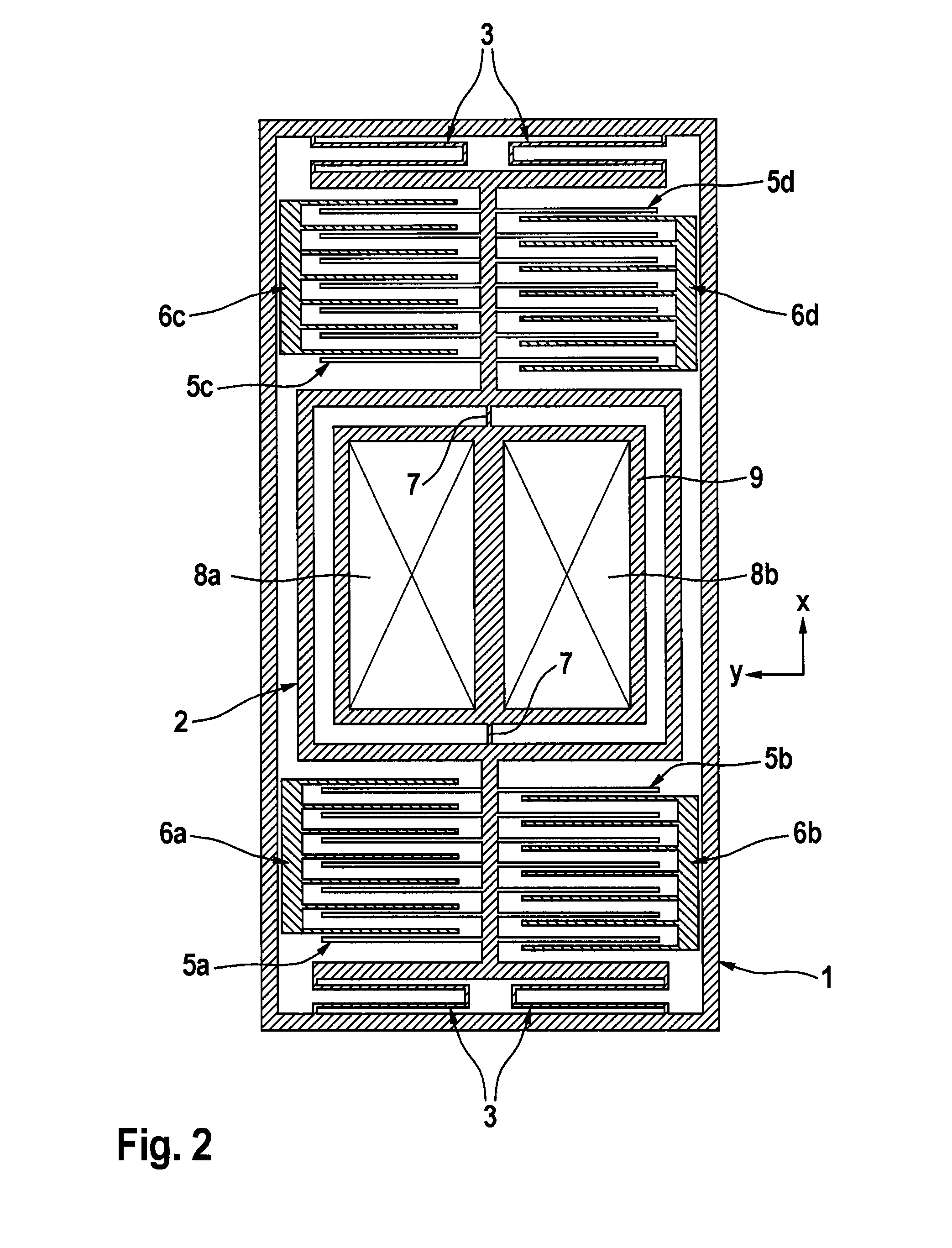

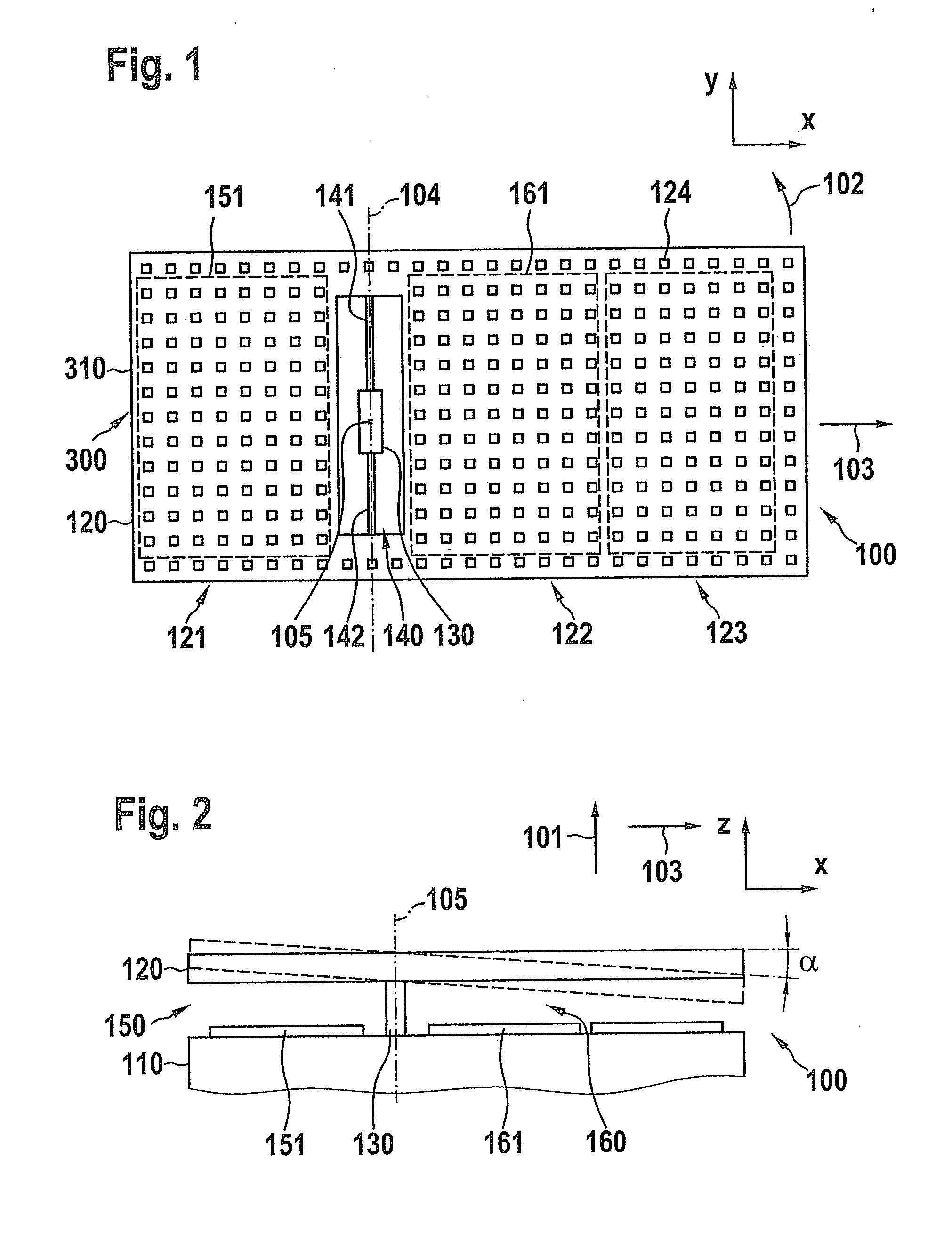

A micromechanical rotation rate sensor including at least one substrate, wherein the base surface of the substrate is oriented parallel to the x-y plane of a Cartesian coordinate system, at least two seismic masses and in each case at least one suspension spring element for suspending the seismic mass from the substrate, wherein the at least two seismic masses are coupled to one another by at least one coupling bar, and at least one of the suspension spring elements includes at least two bar sections, which, in the undeflected state, are oriented essentially parallel to one another or are at an angle of less than 45° with respect to one another, and one or more connecting sections, which connect the bar sections to one another, wherein the bar sections can be displaced relative to one another in their longitudinal direction.

Owner:CONTINENTAL TEVES AG & CO OHG

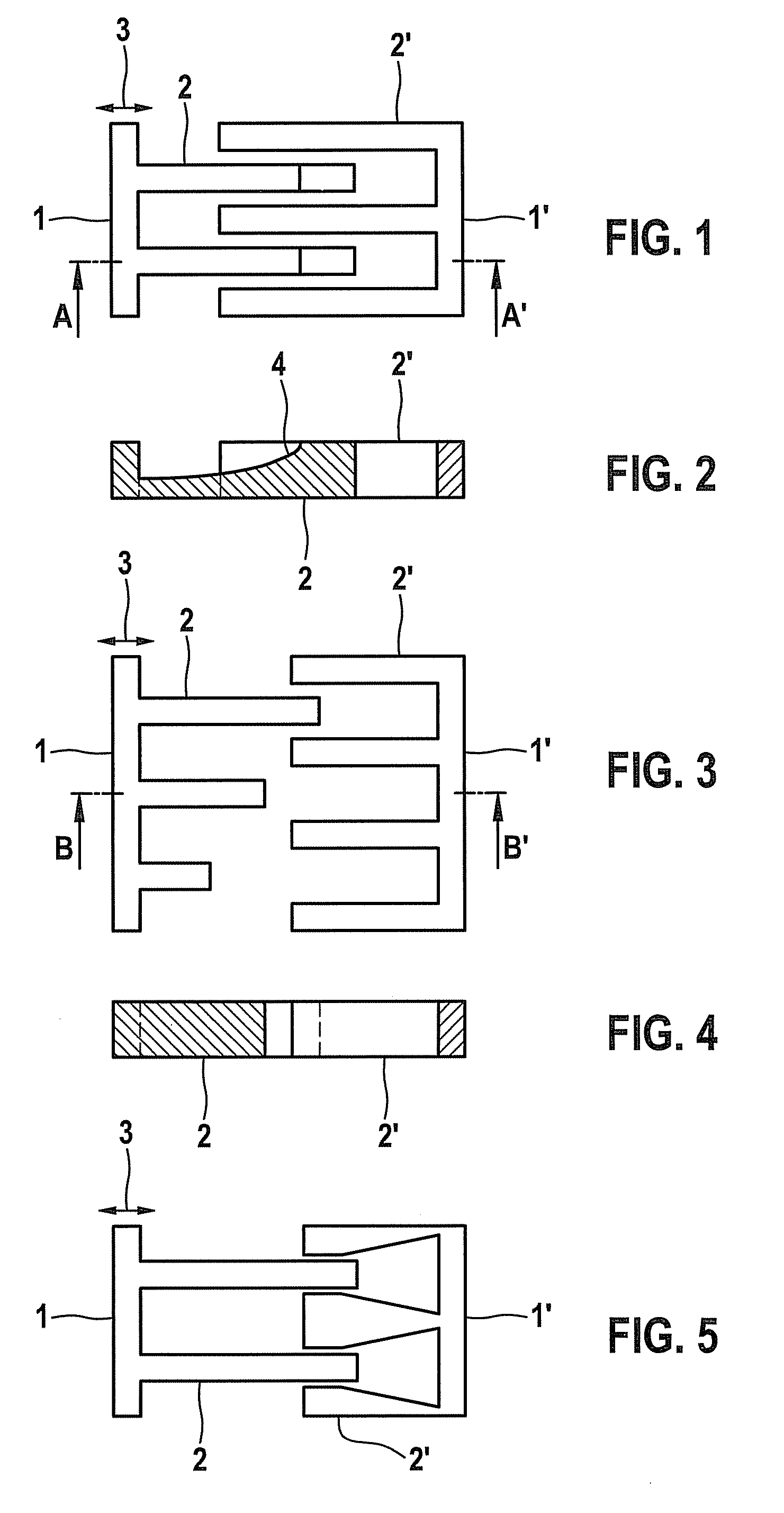

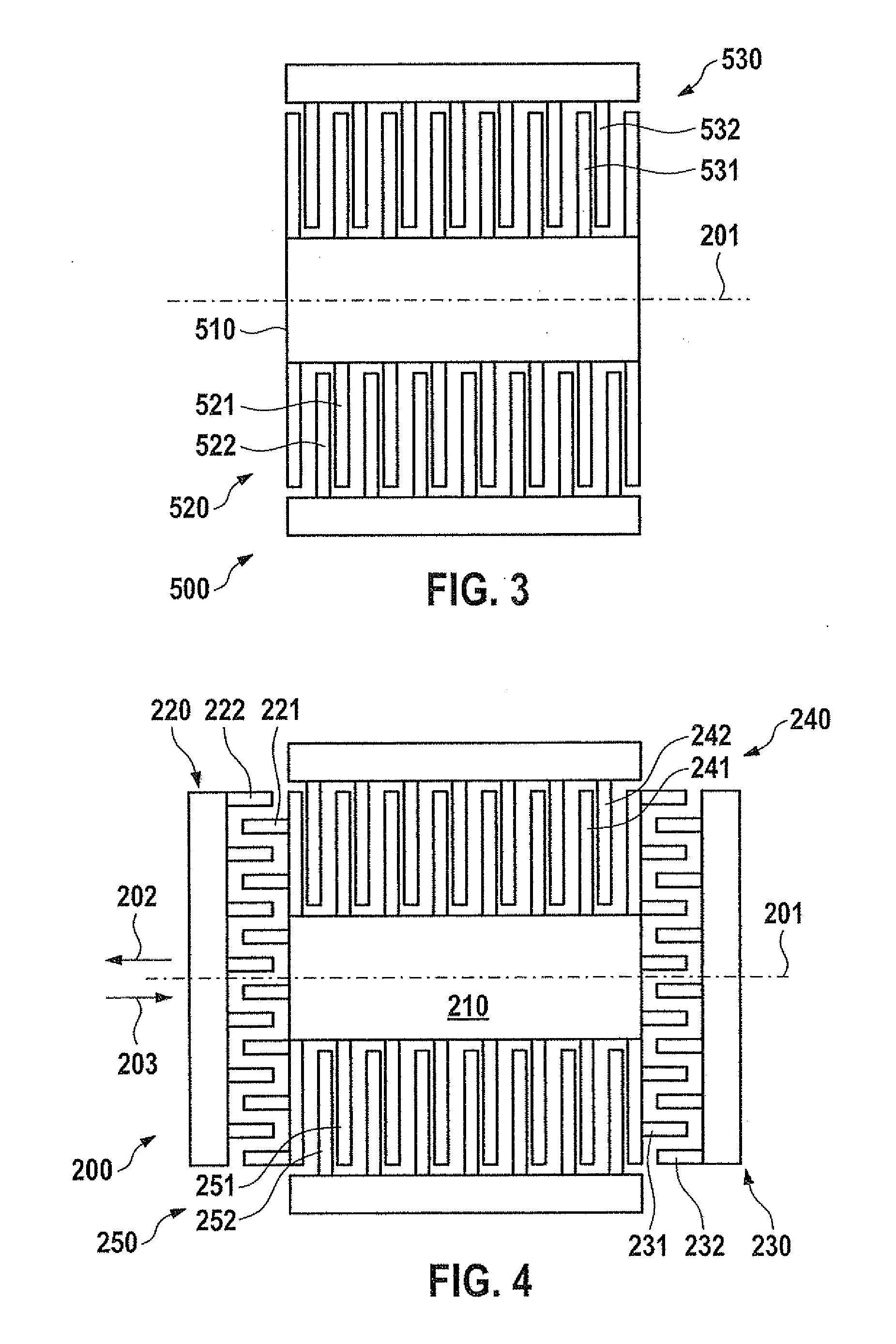

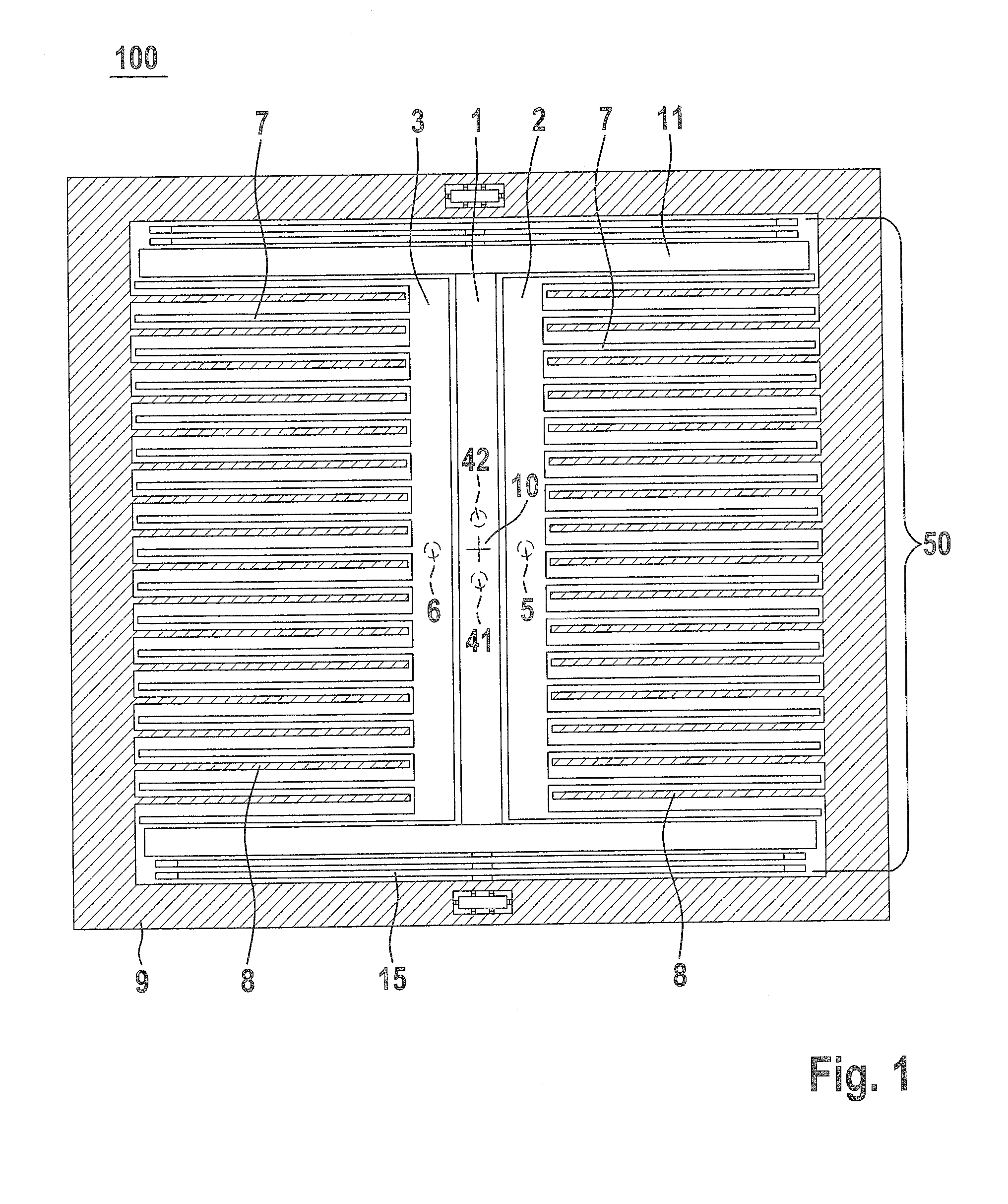

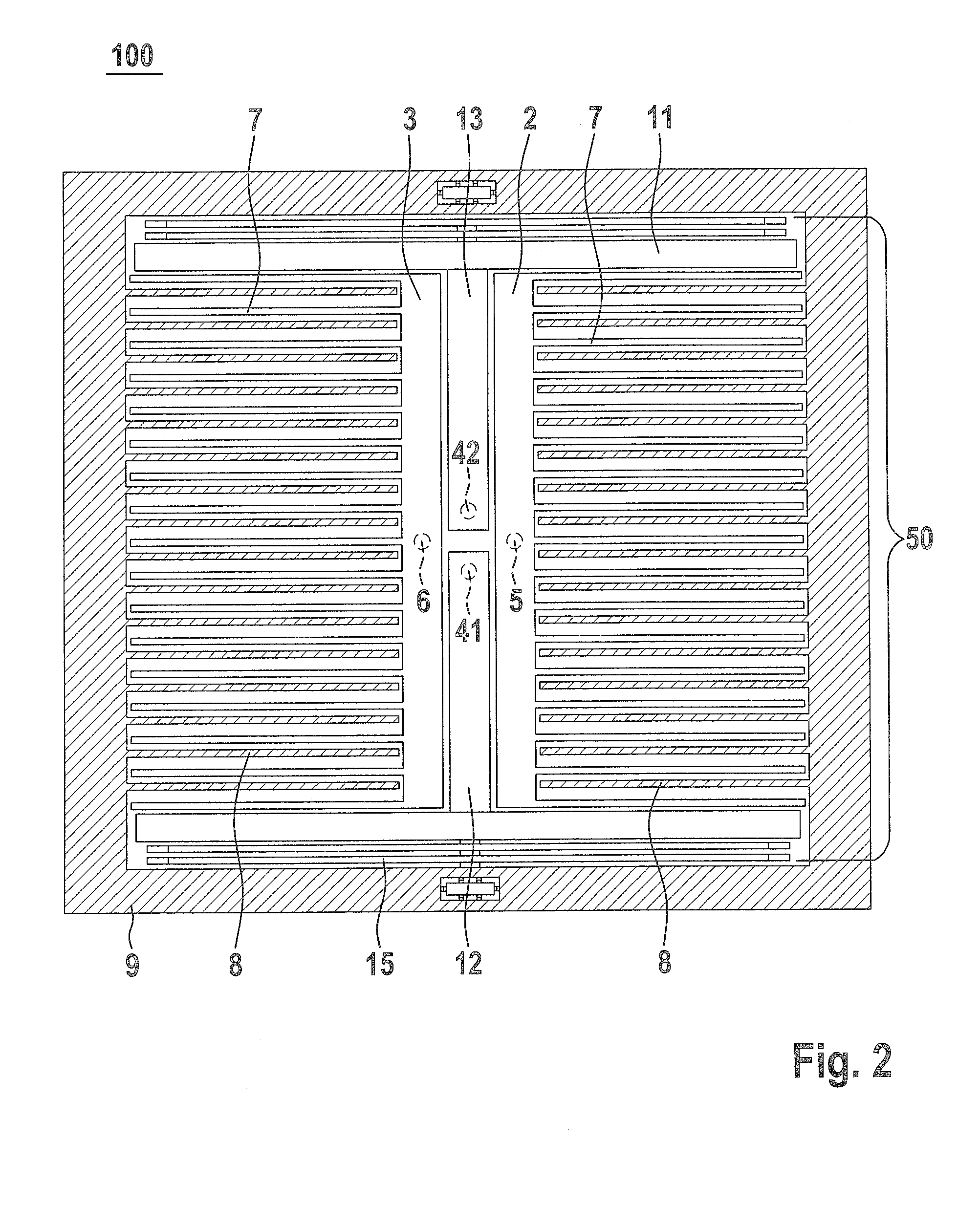

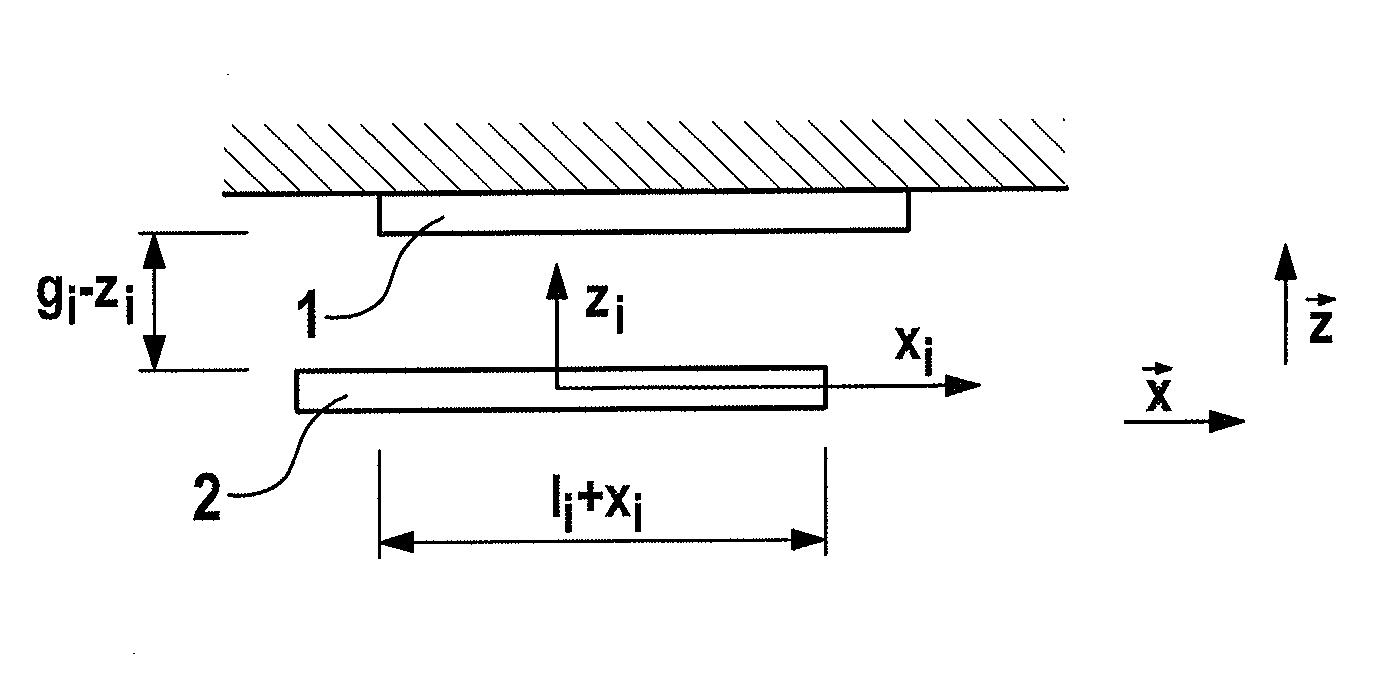

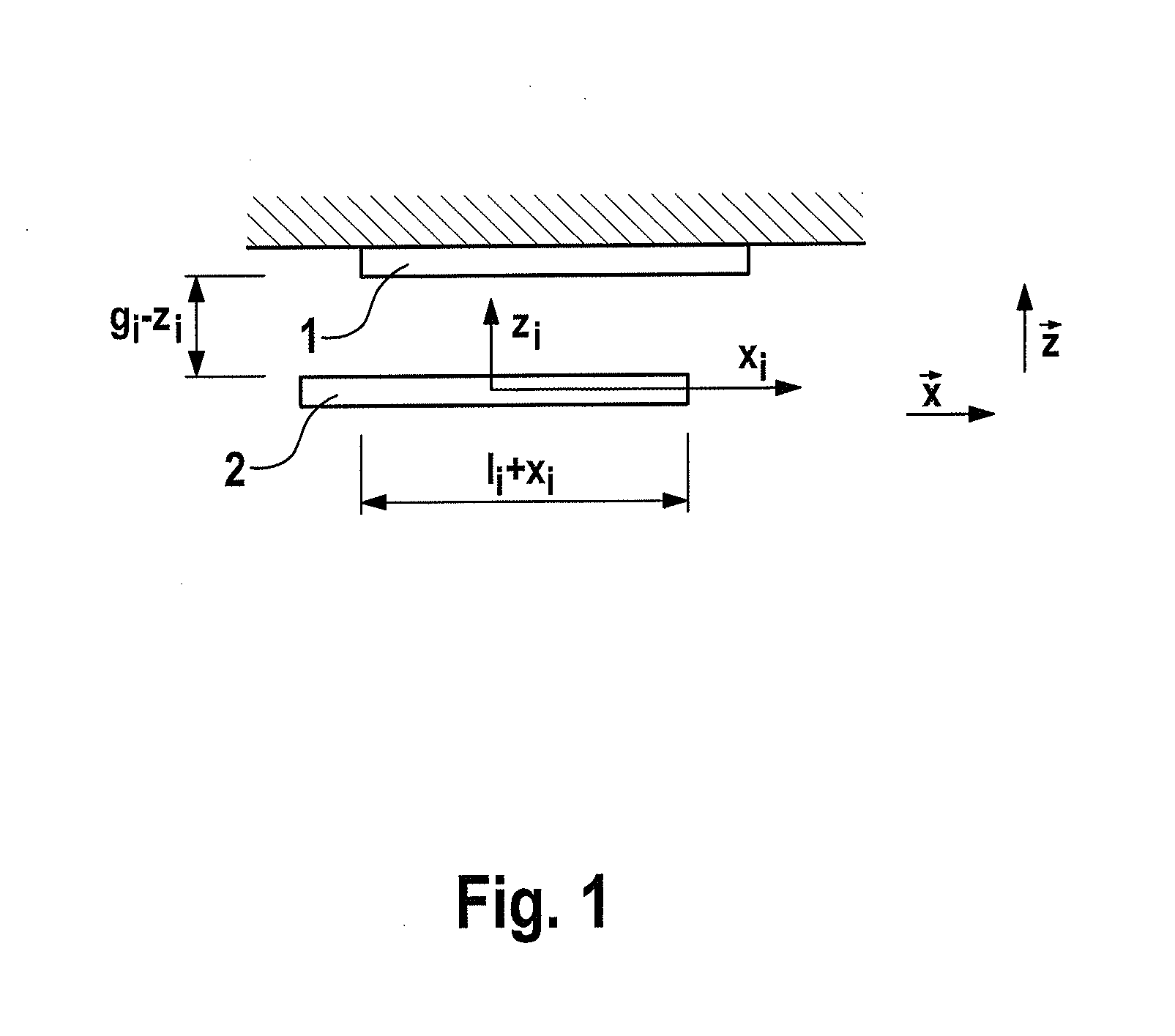

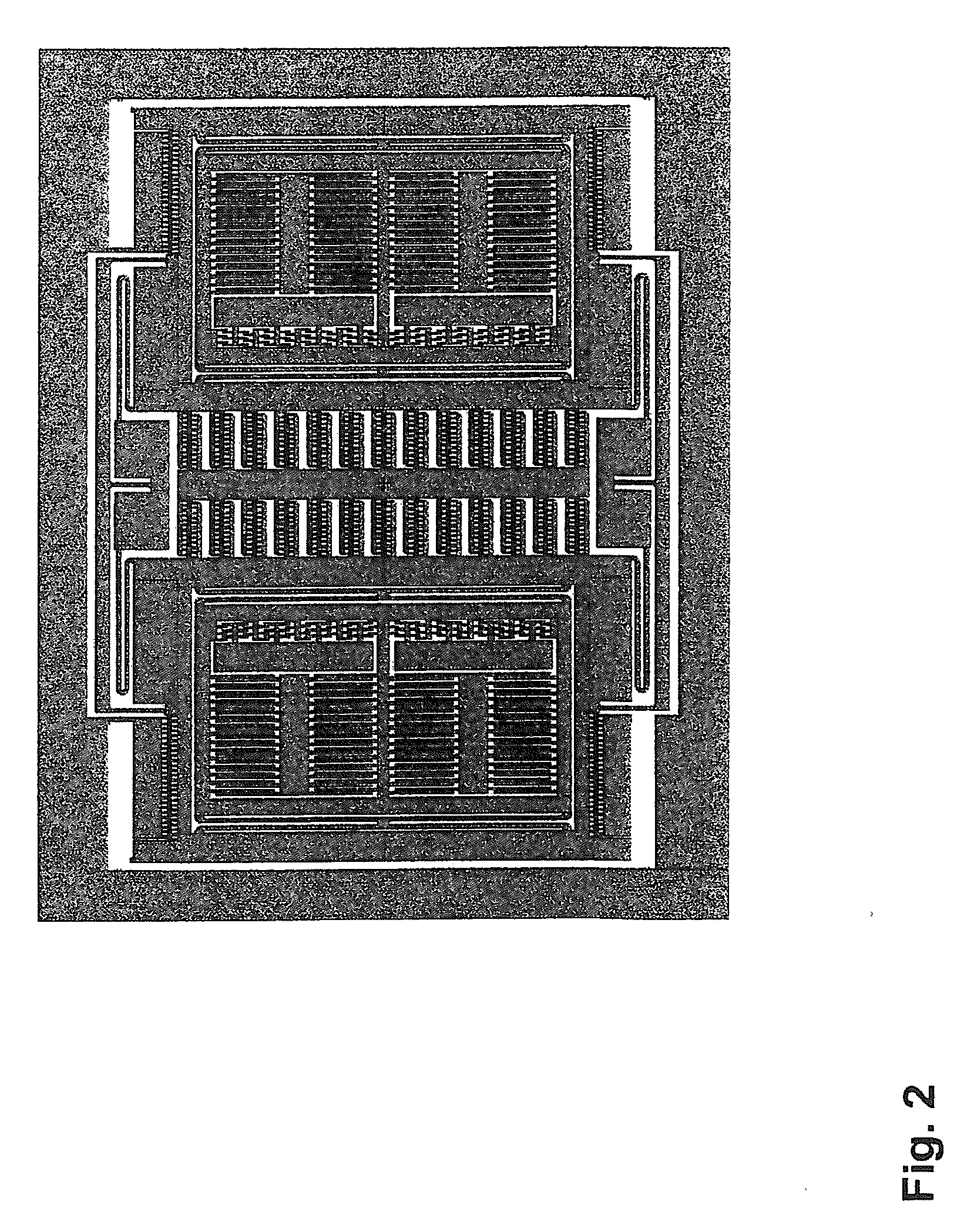

Capacitive sensor and actuator

InactiveUS20110050251A1Simple wayOptimize geometryResistance/reactance/impedenceAcceleration measurementSeismic massEngineering

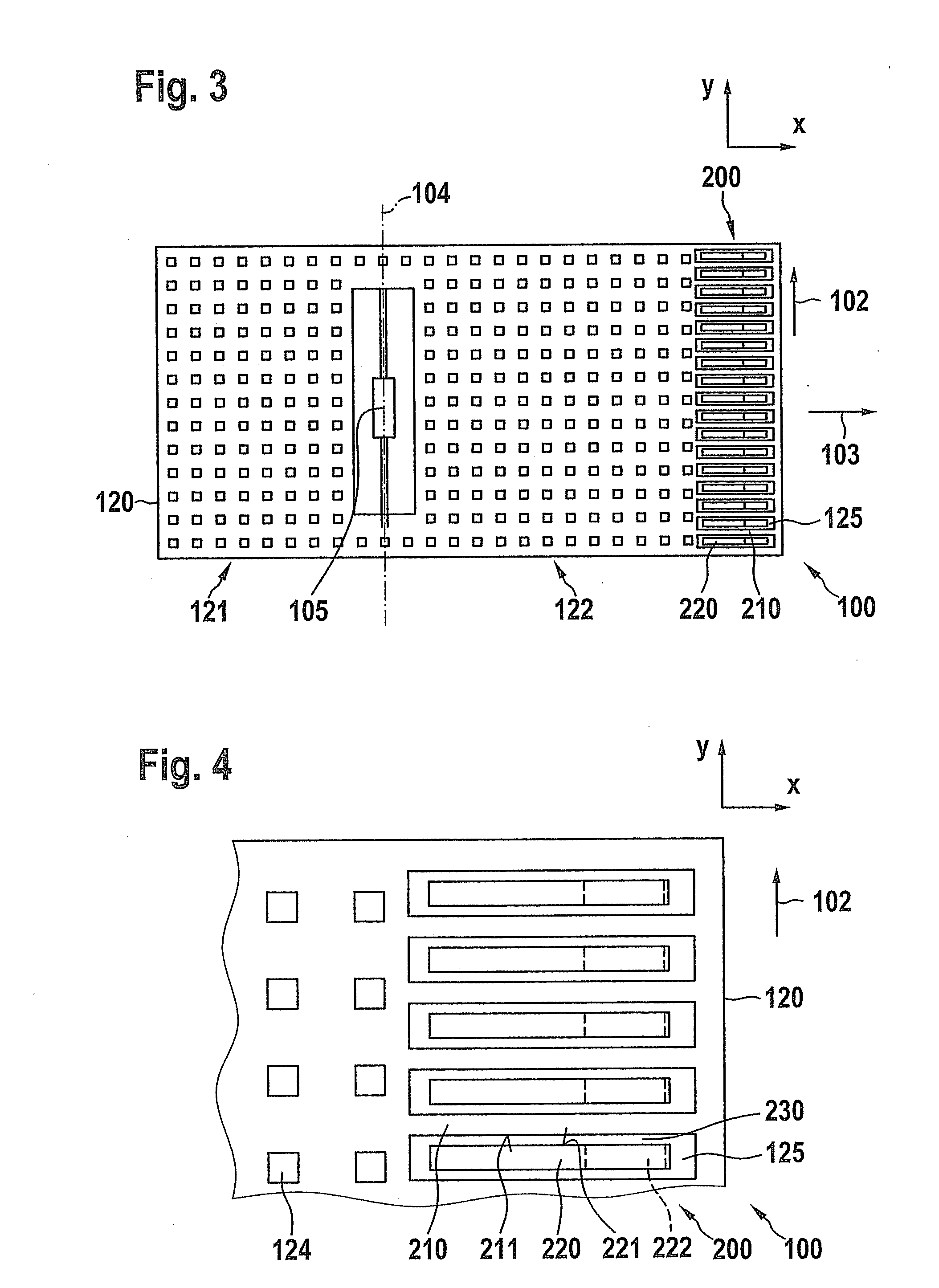

A capacitive sensor and a capacitive actuator having at least one seismic mass deflectably mounted on a substrate. A comb electrode having comb fingers is mounted on the seismic mass, and a comb electrode having comb fingers is mounted on the substrate in such a way that the comb fingers are situated parallel to a deflection direction of the seismic mass and interlock in a comb-like manner. The characteristic curve of the sensor or actuator is adjusted by optimizing the geometry of at least one comb electrode, in particular of at least one comb finger.

Owner:ROBERT BOSCH GMBH

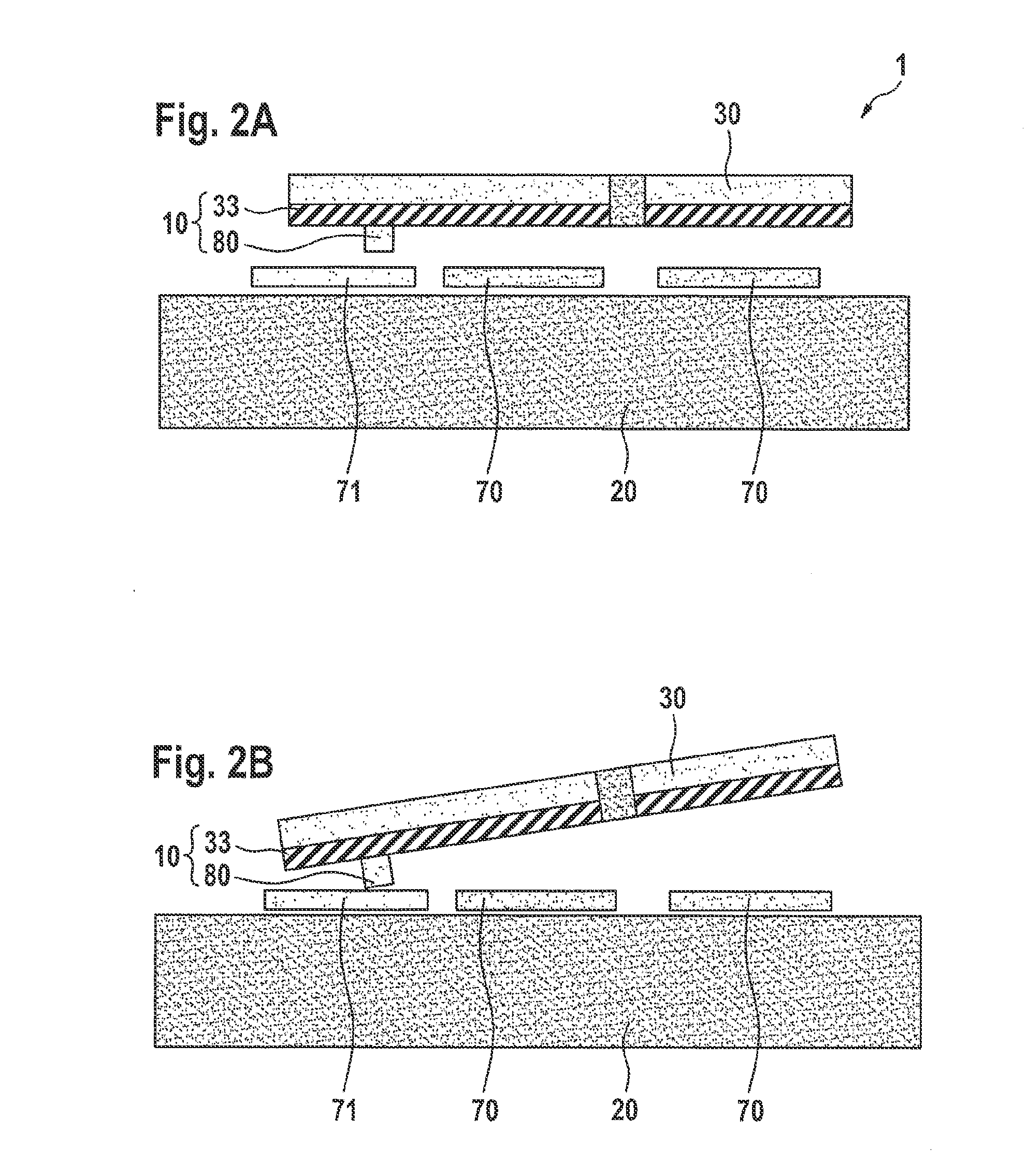

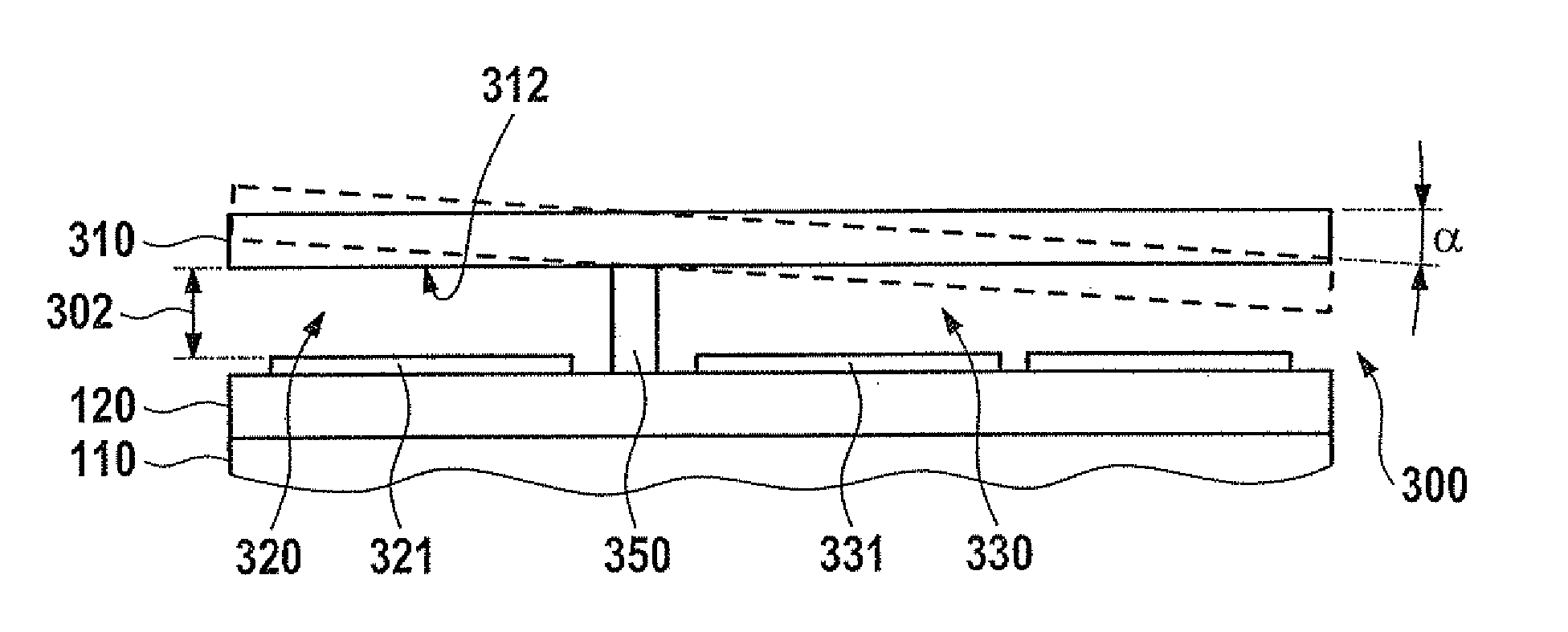

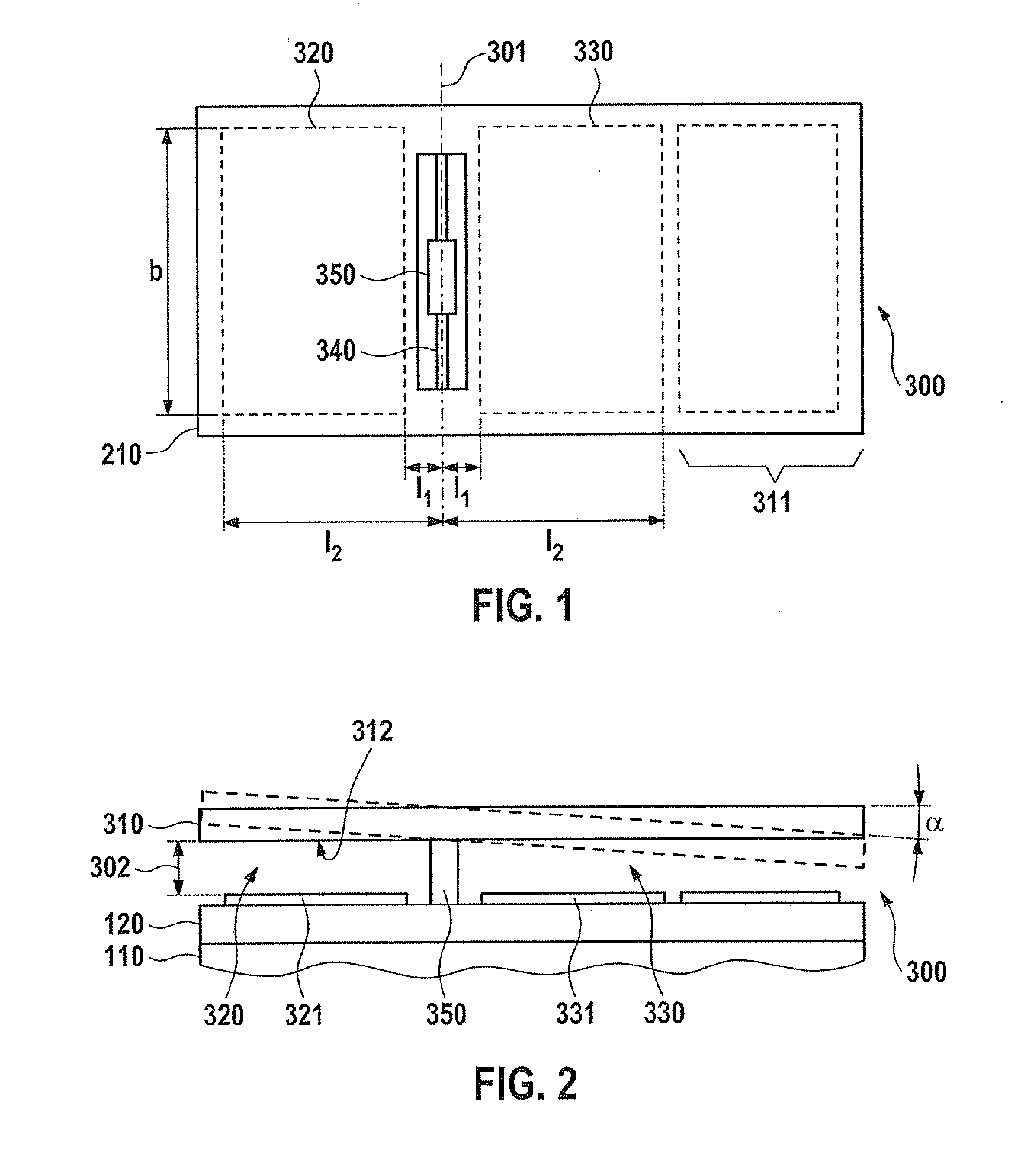

Micromechanical component

ActiveUS20110048131A1Simple methodReliable mode of operationAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsSeismic massEnvironmental geology

A micromechanical component which has a substrate, a seismic mass, which is deflectably situated on the substrate, and a stop structure for limiting a deflection of the seismic mass in a direction away from the substrate. The stop structure is situated on the substrate and has a limiting section for limiting the deflection of the seismic mass, which is in a plane with the seismic mass. Furthermore, a method for manufacturing a micromechanical component is described.

Owner:ROBERT BOSCH GMBH

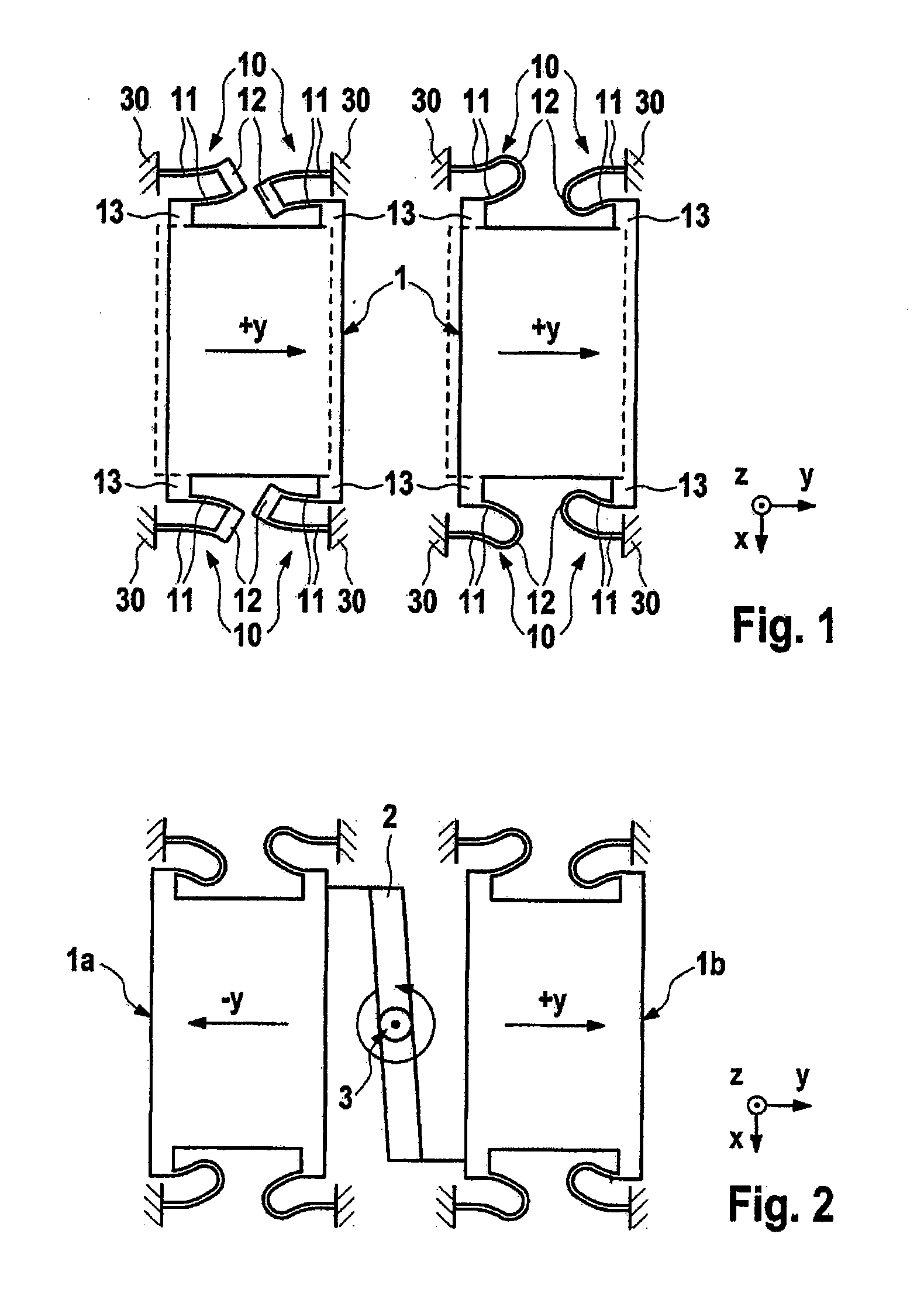

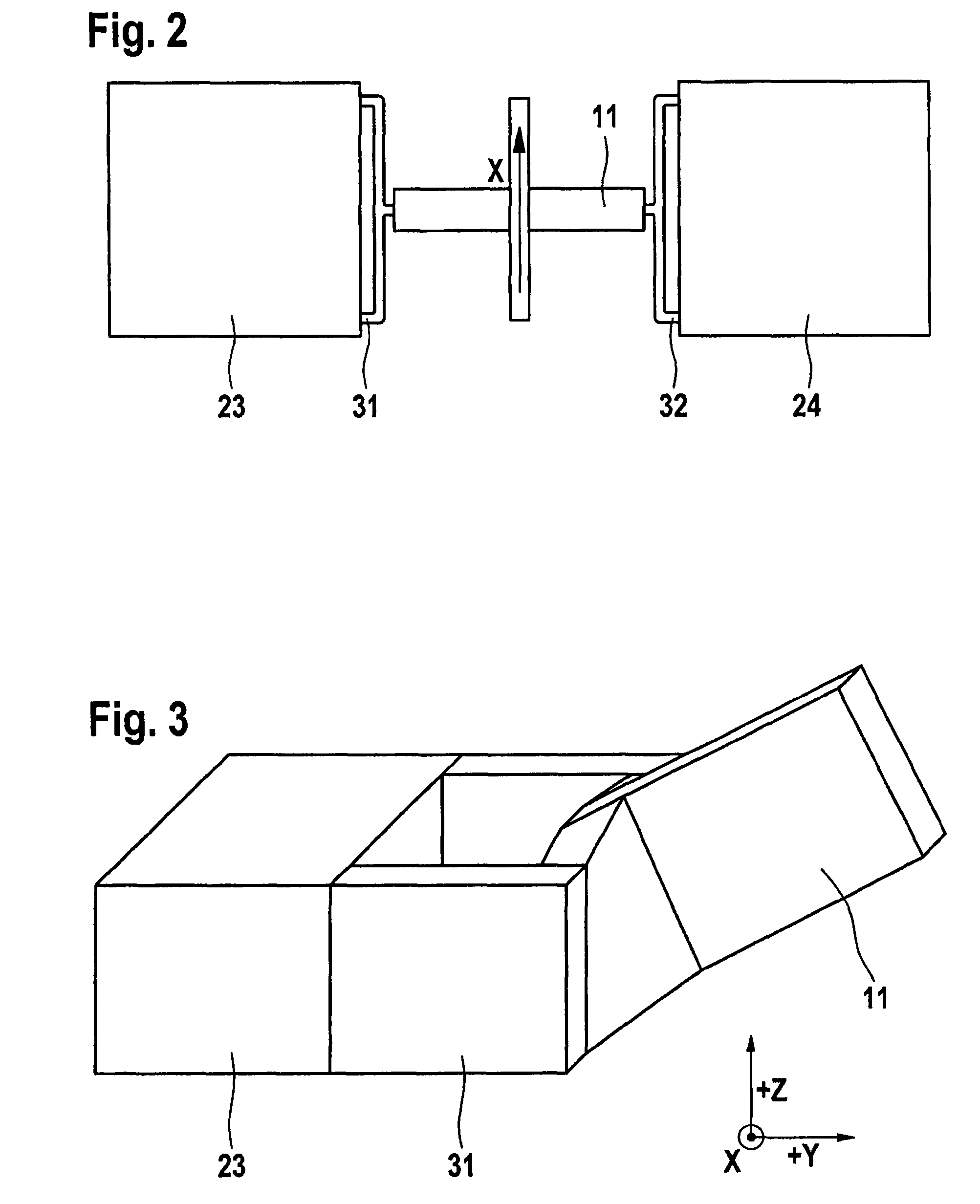

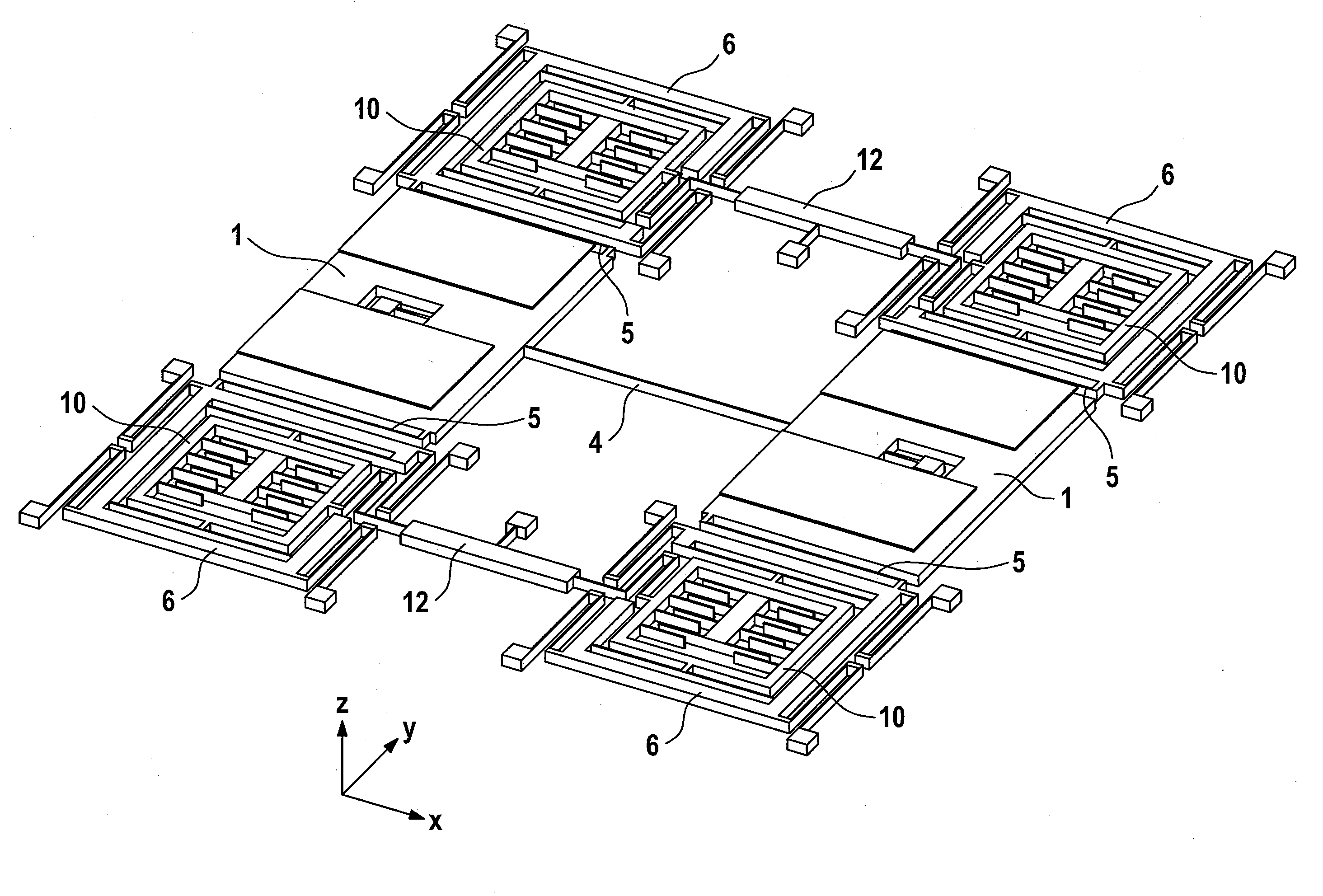

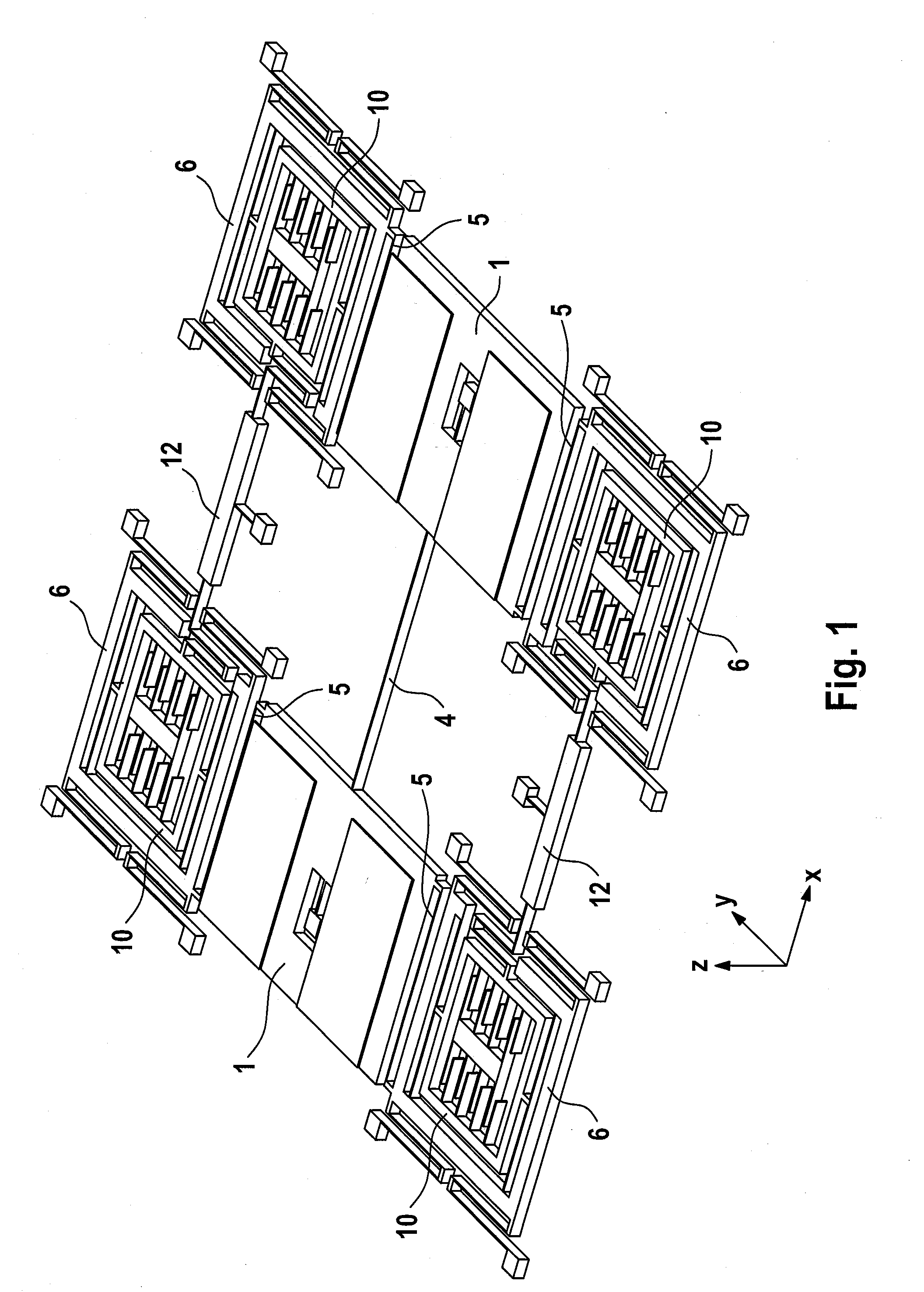

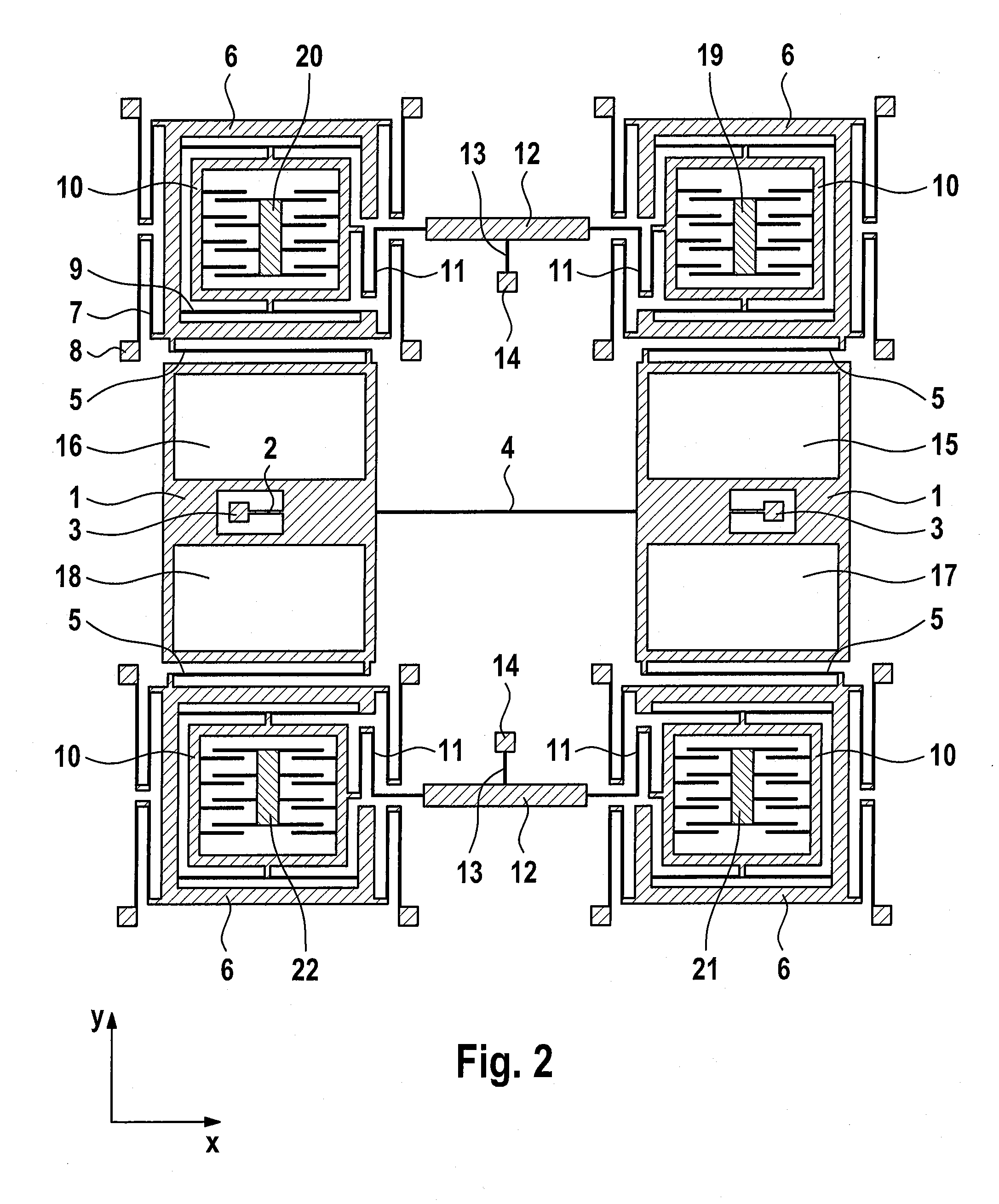

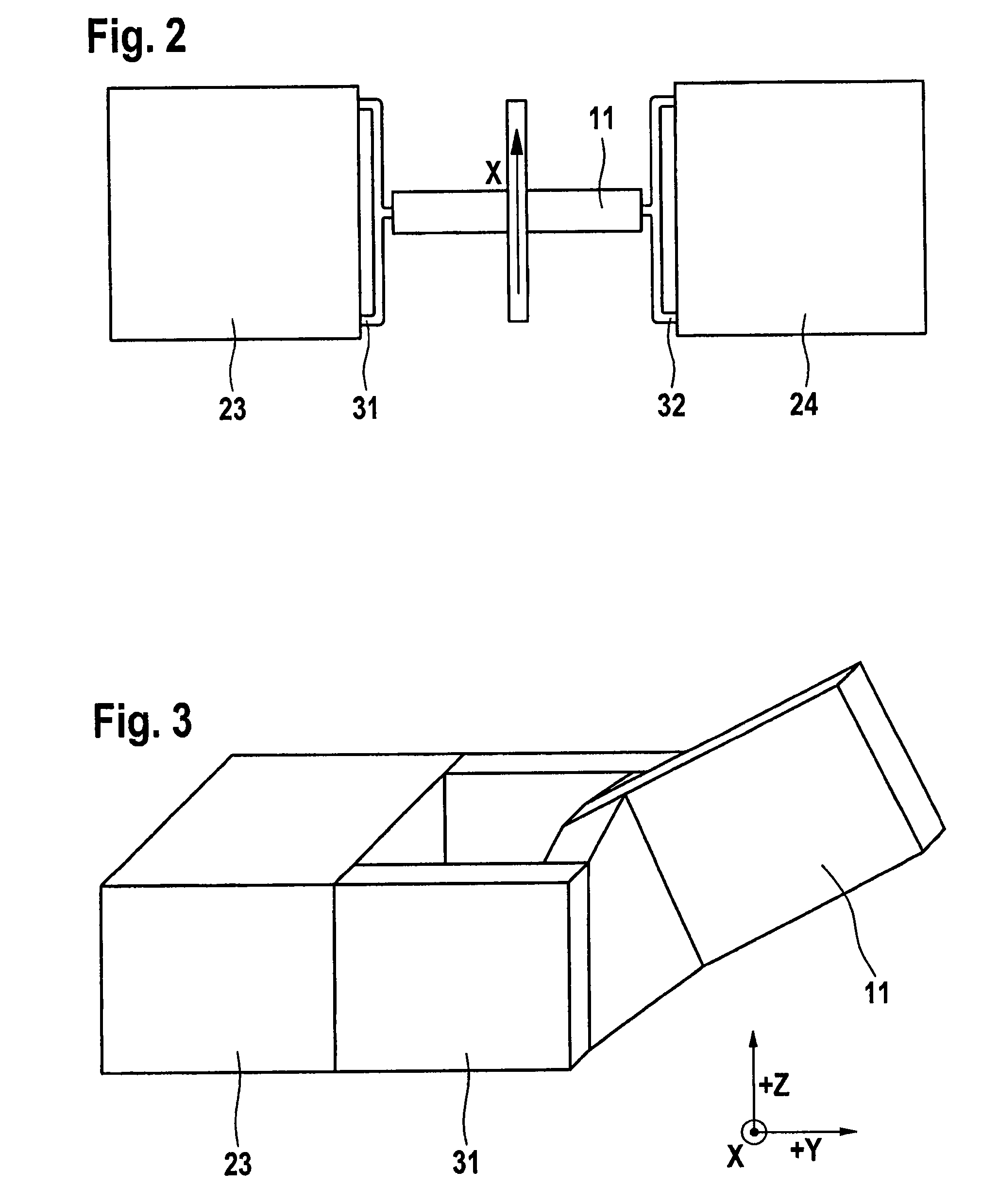

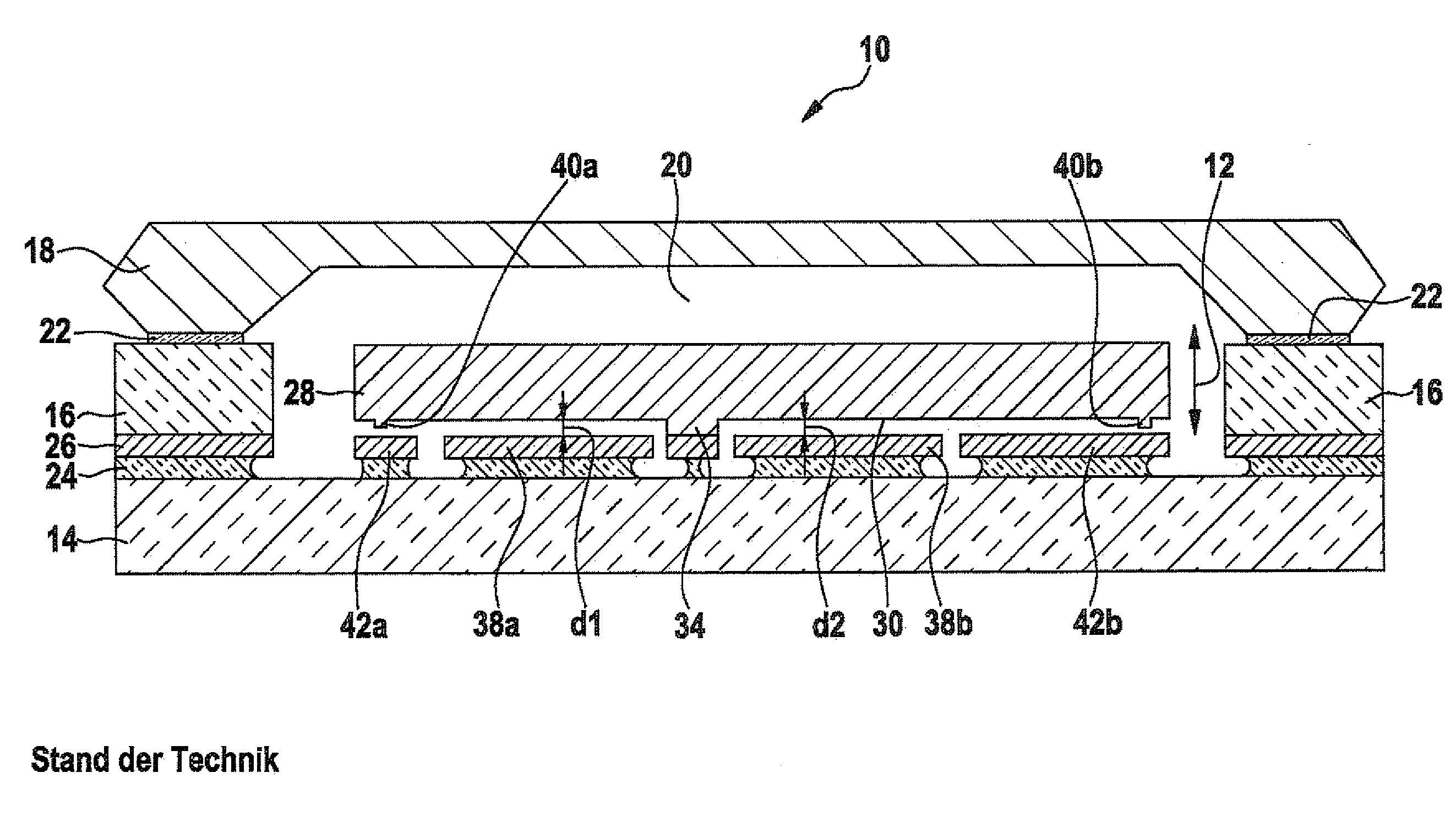

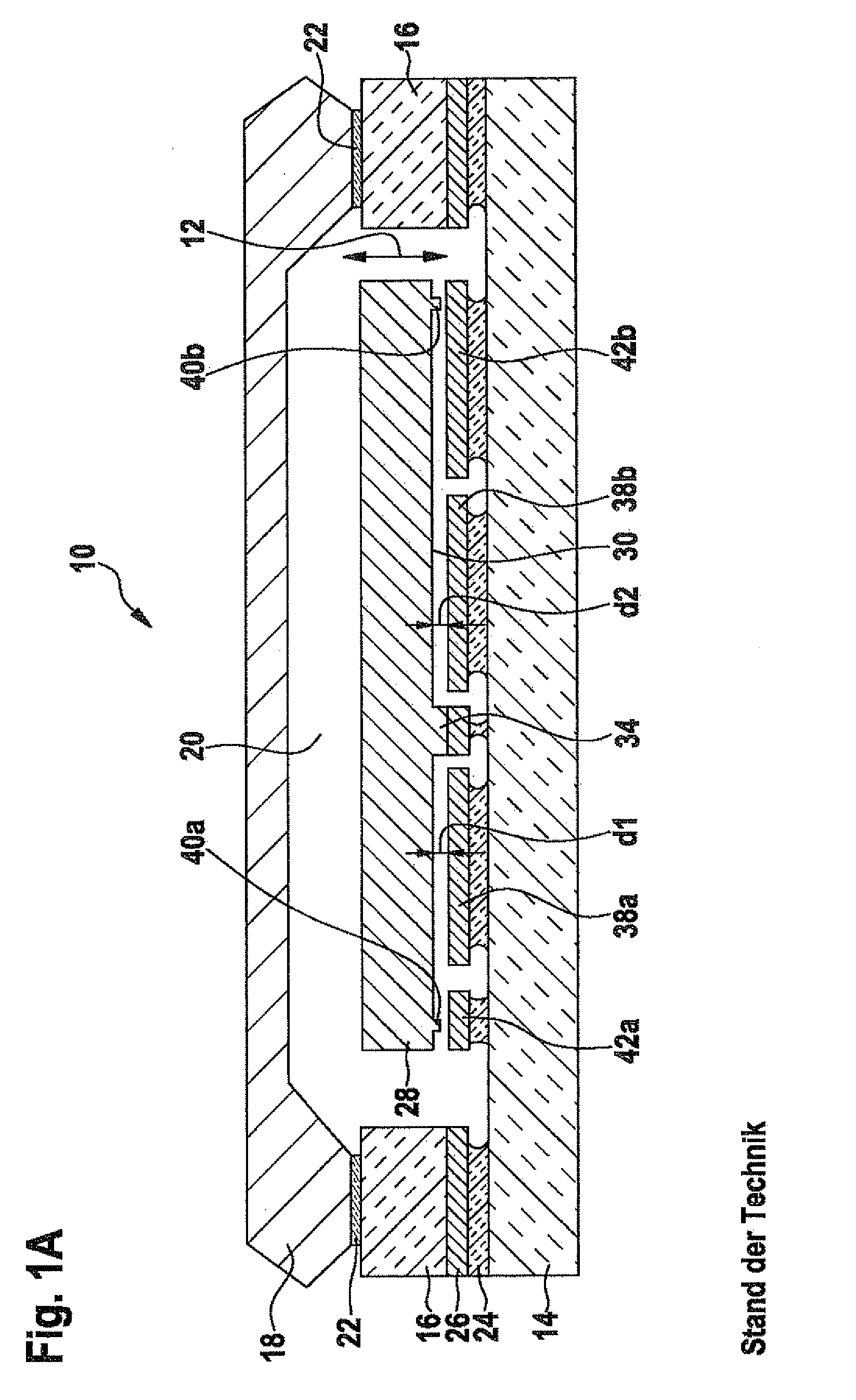

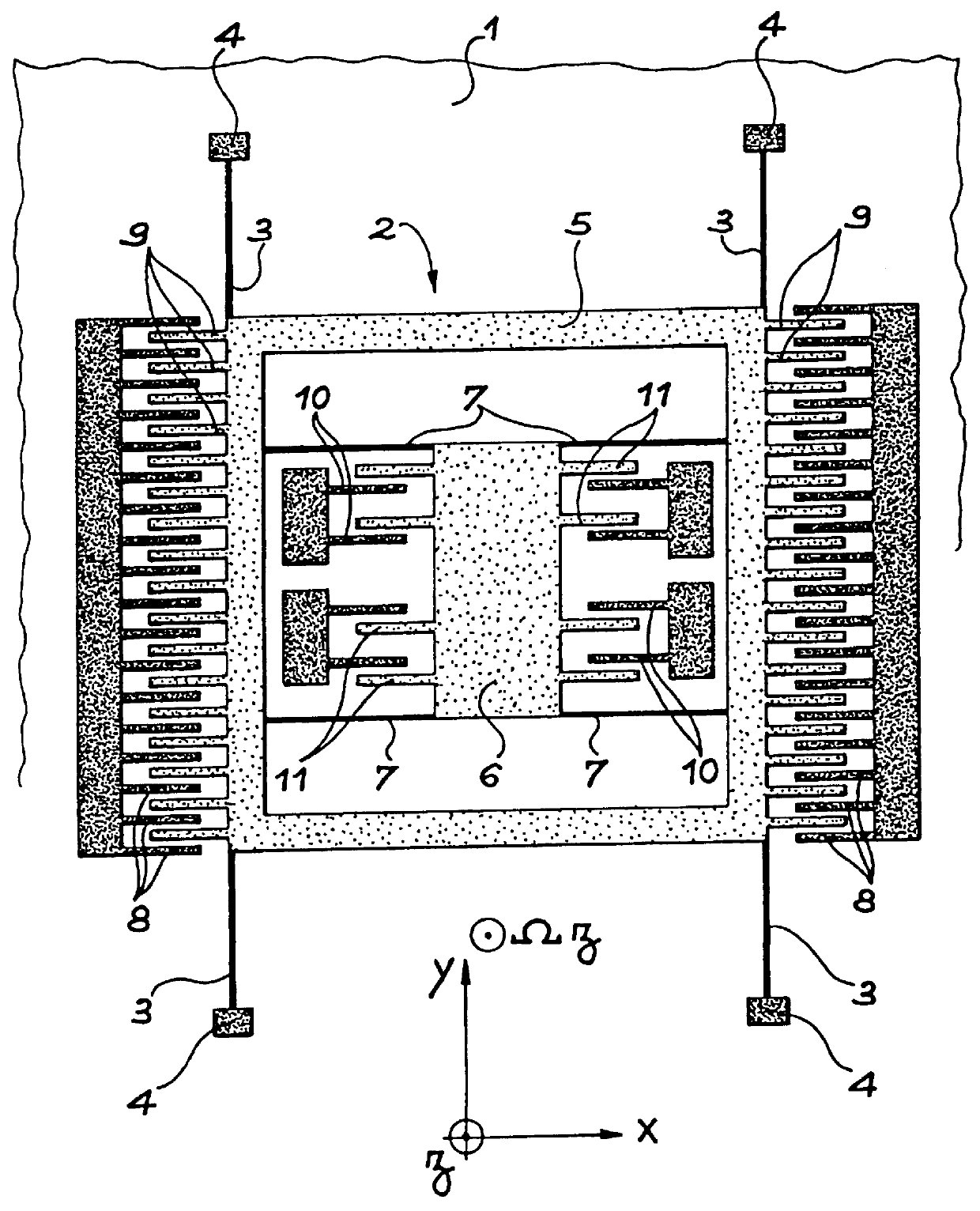

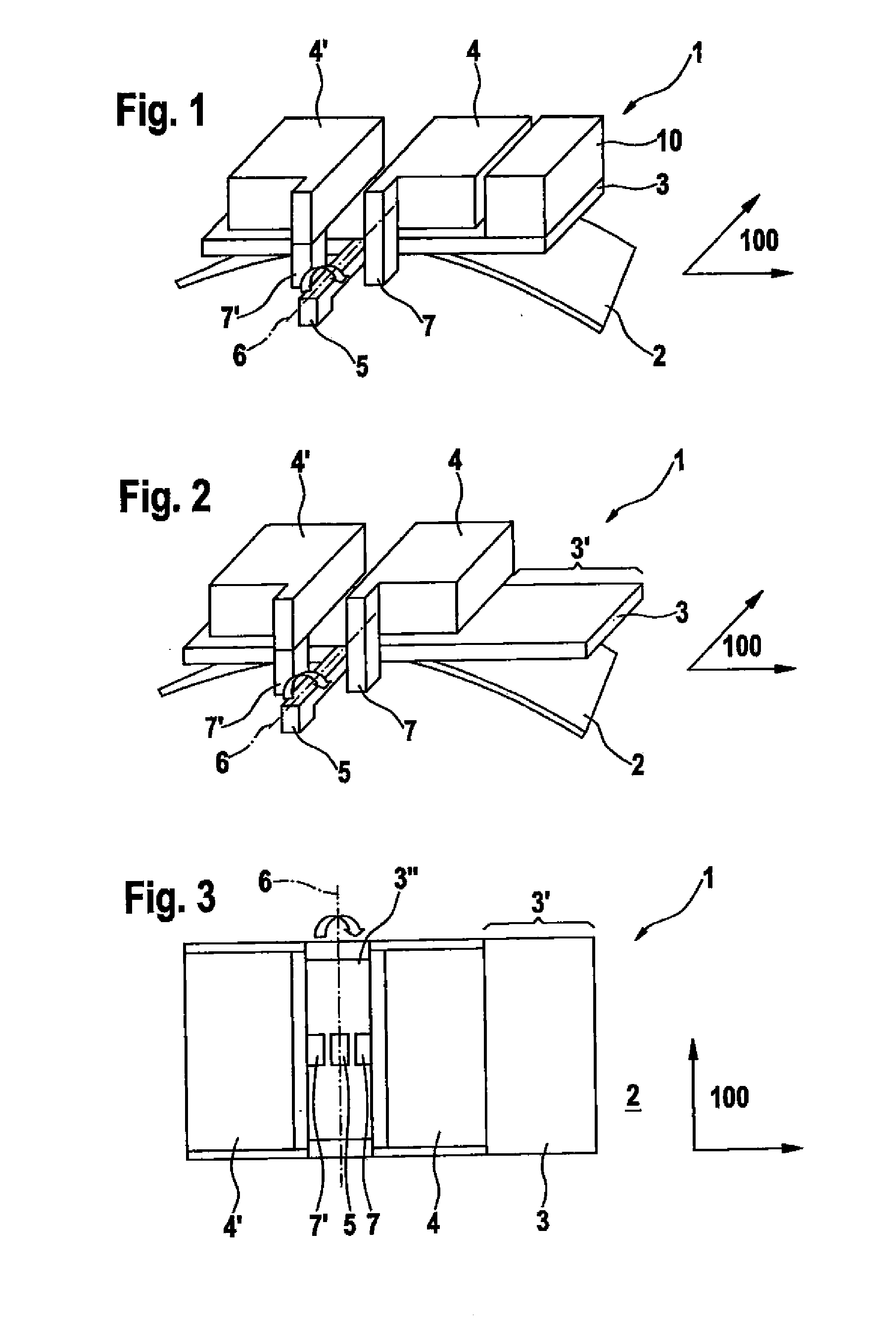

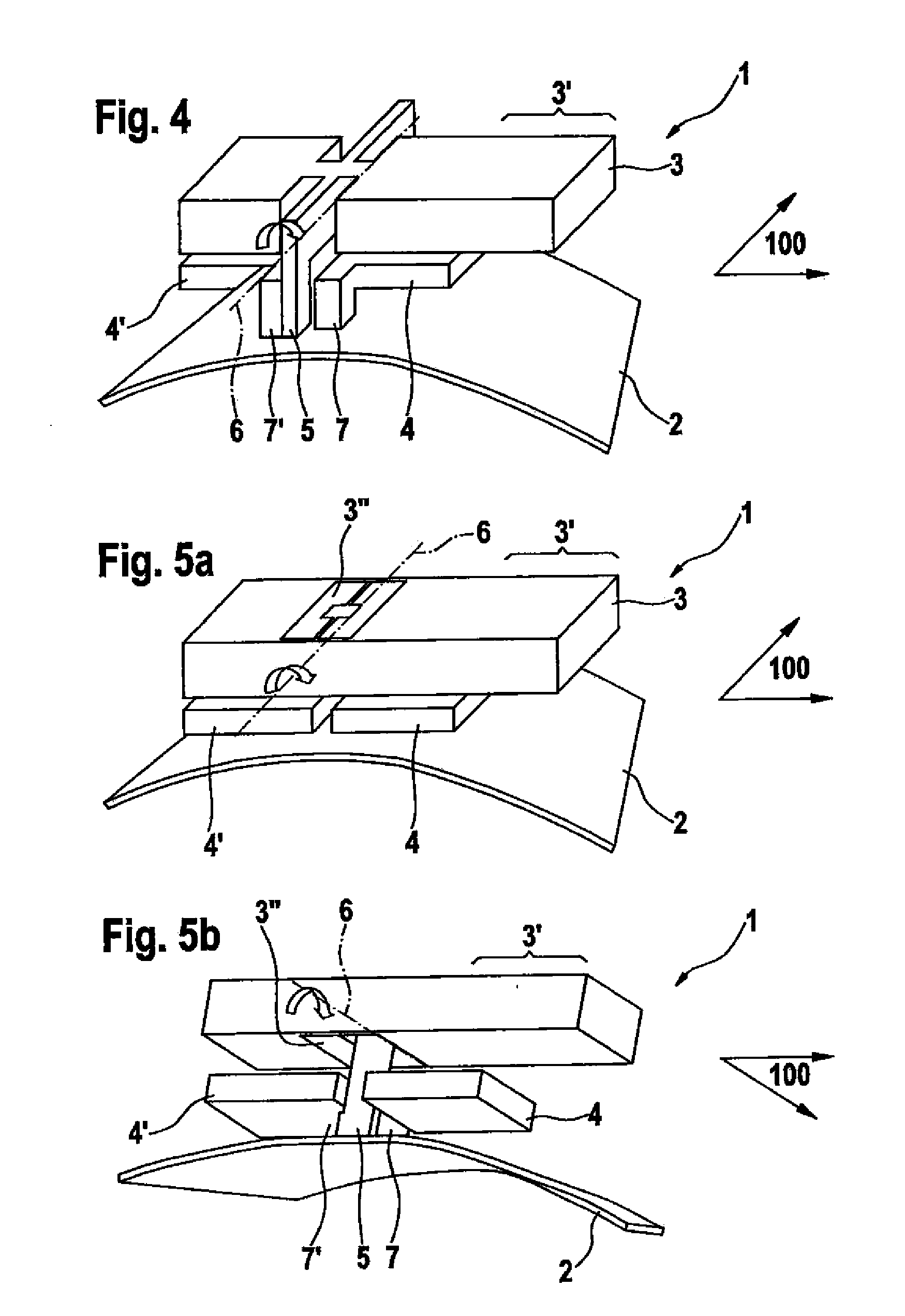

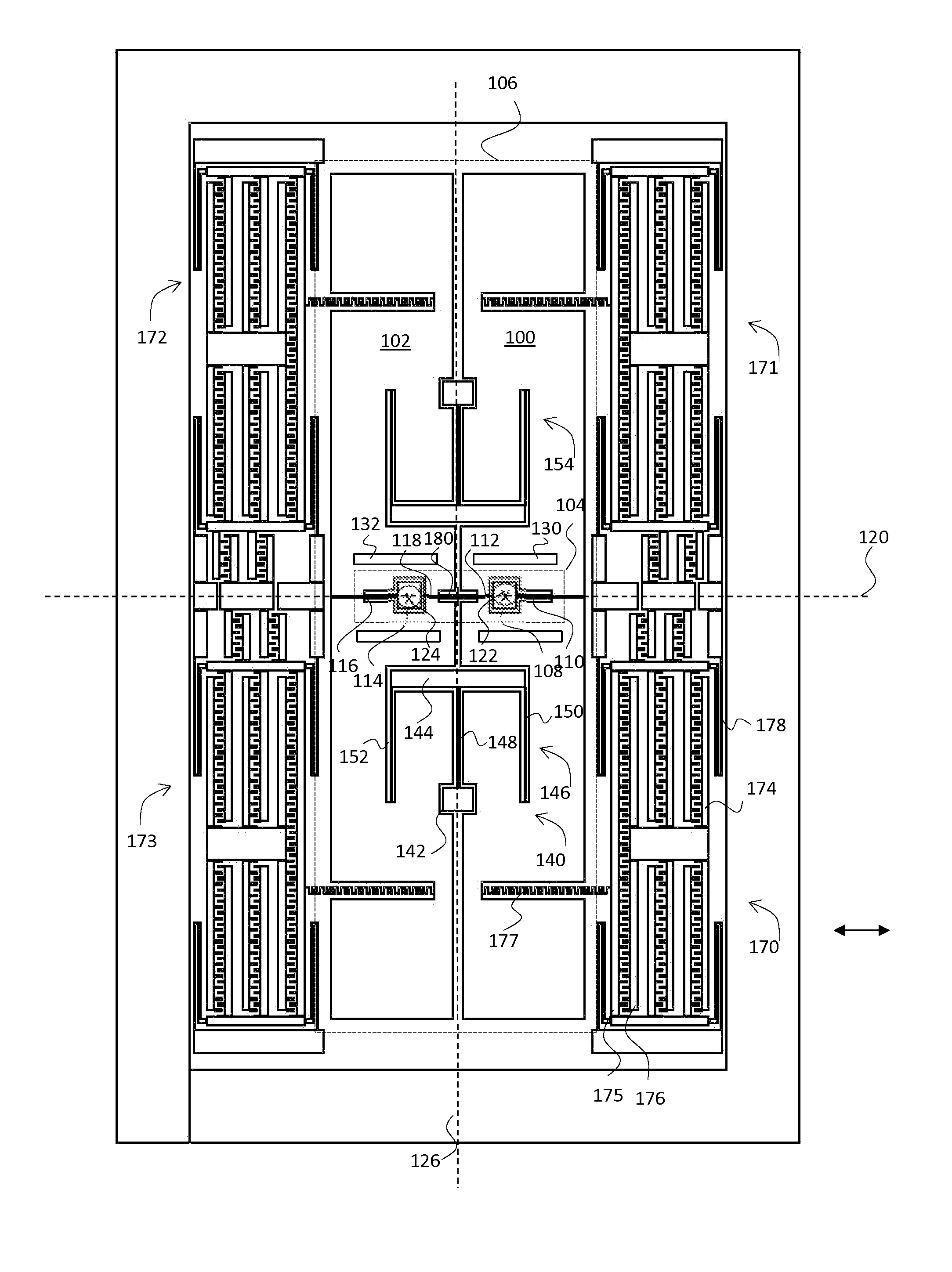

Rotational speed sensor having a coupling bar

ActiveUS8261614B2Avoid and reduce parasitic mode and interference deflectionAvoid couplingAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsSeismic massMechanical engineering

A rotational speed sensor including at least one substrate, at least two base elements which each have a frame, a means for suspending the frame from the substrate, at least one seismic mass and one means for suspending the seismic mass from the frame. One or more drive means are provided for driving one or more base elements and one or more reading devices. The at least two base elements are coupled to one another by means of at least one coupling bar.

Owner:CONTINENTAL TEVES AG & CO OHG

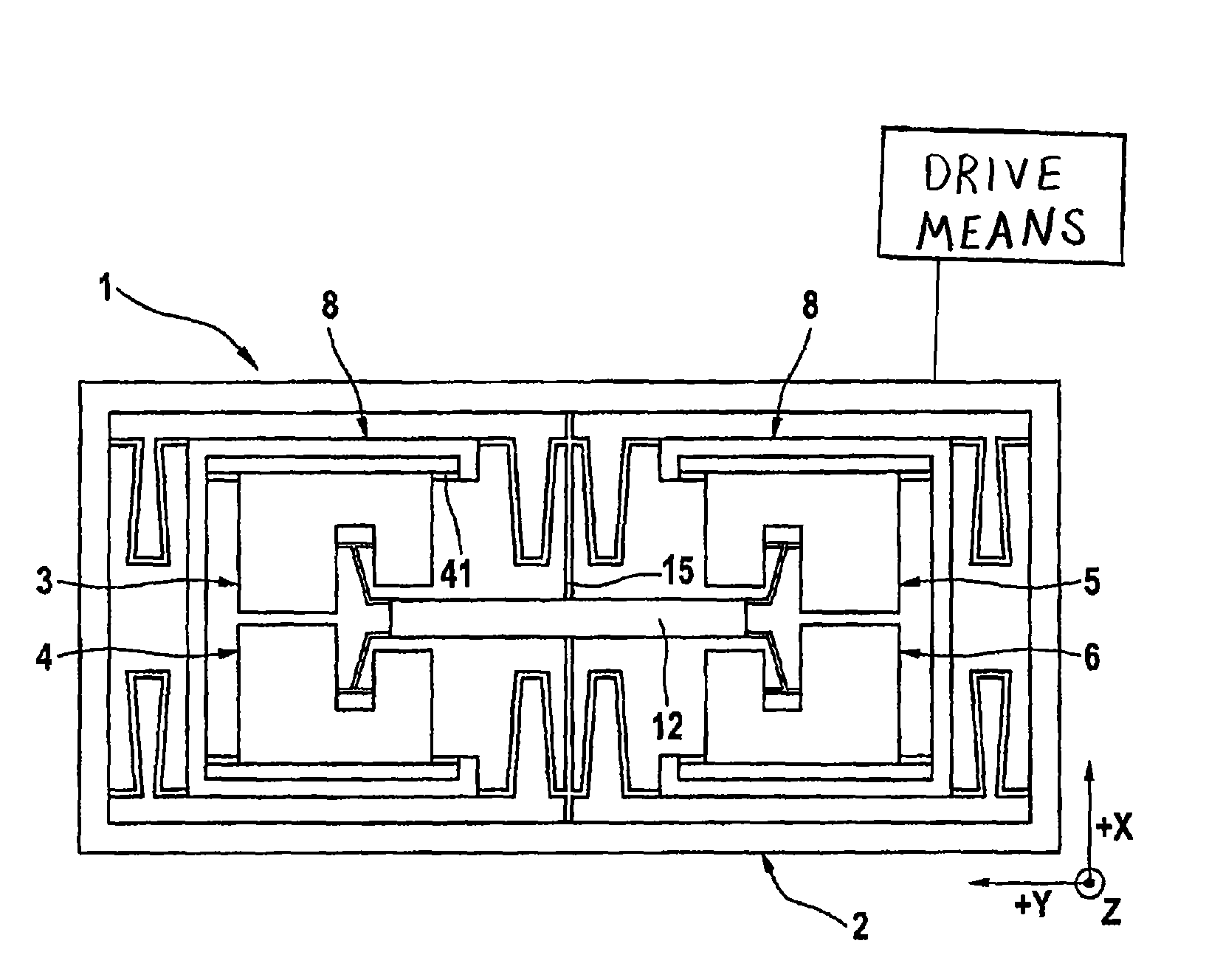

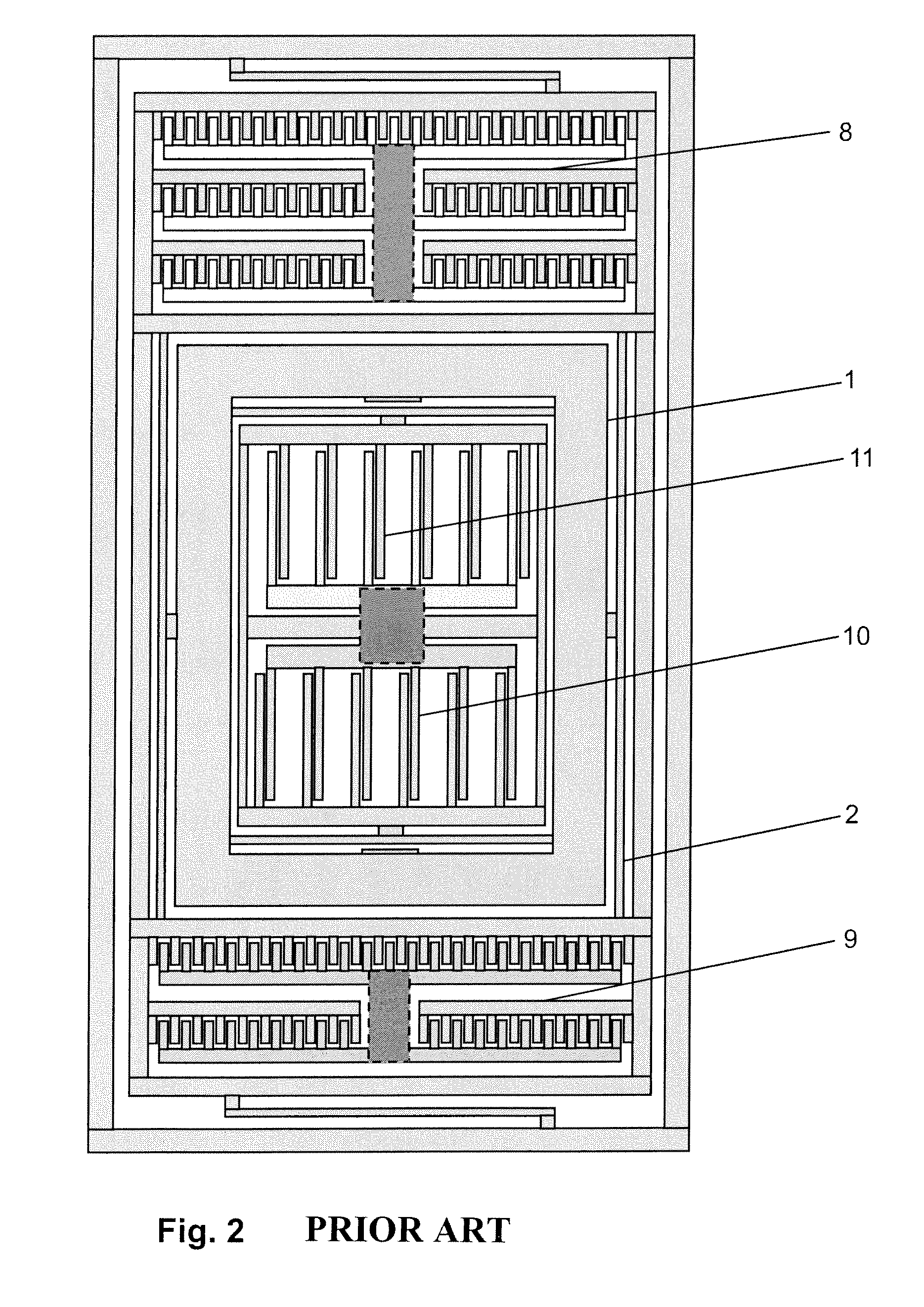

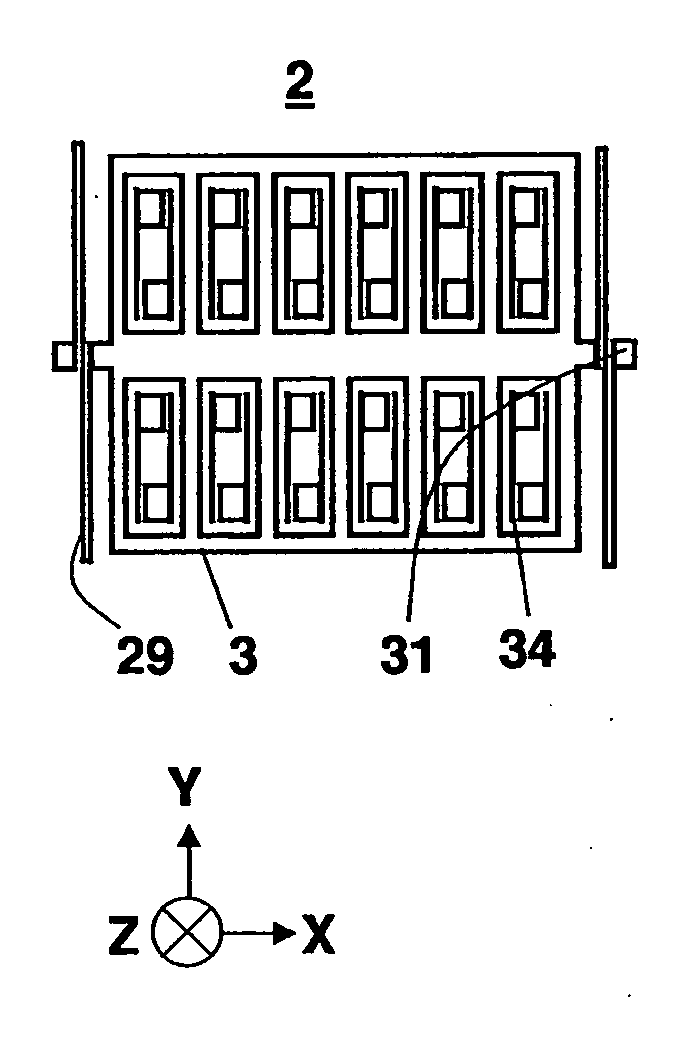

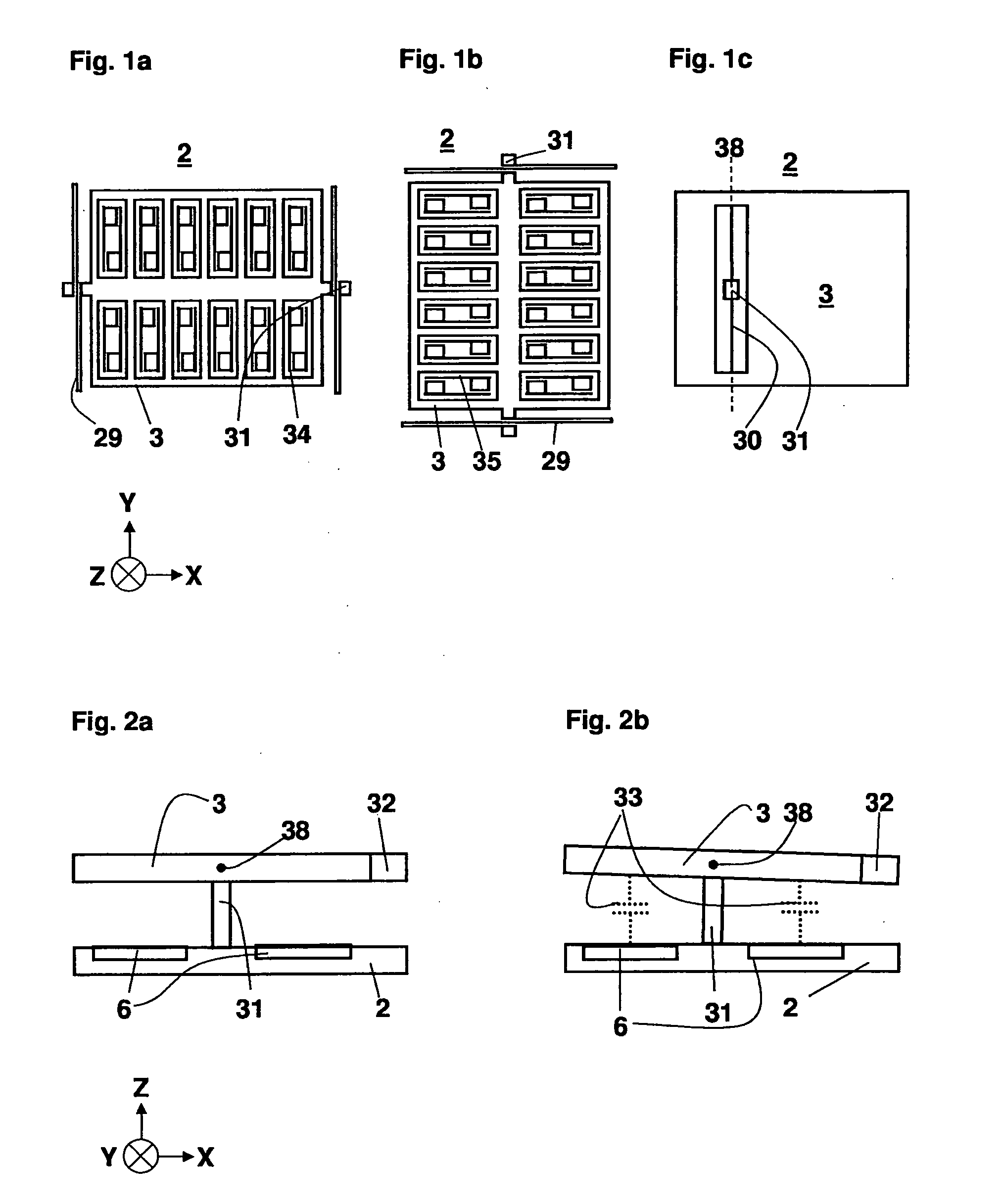

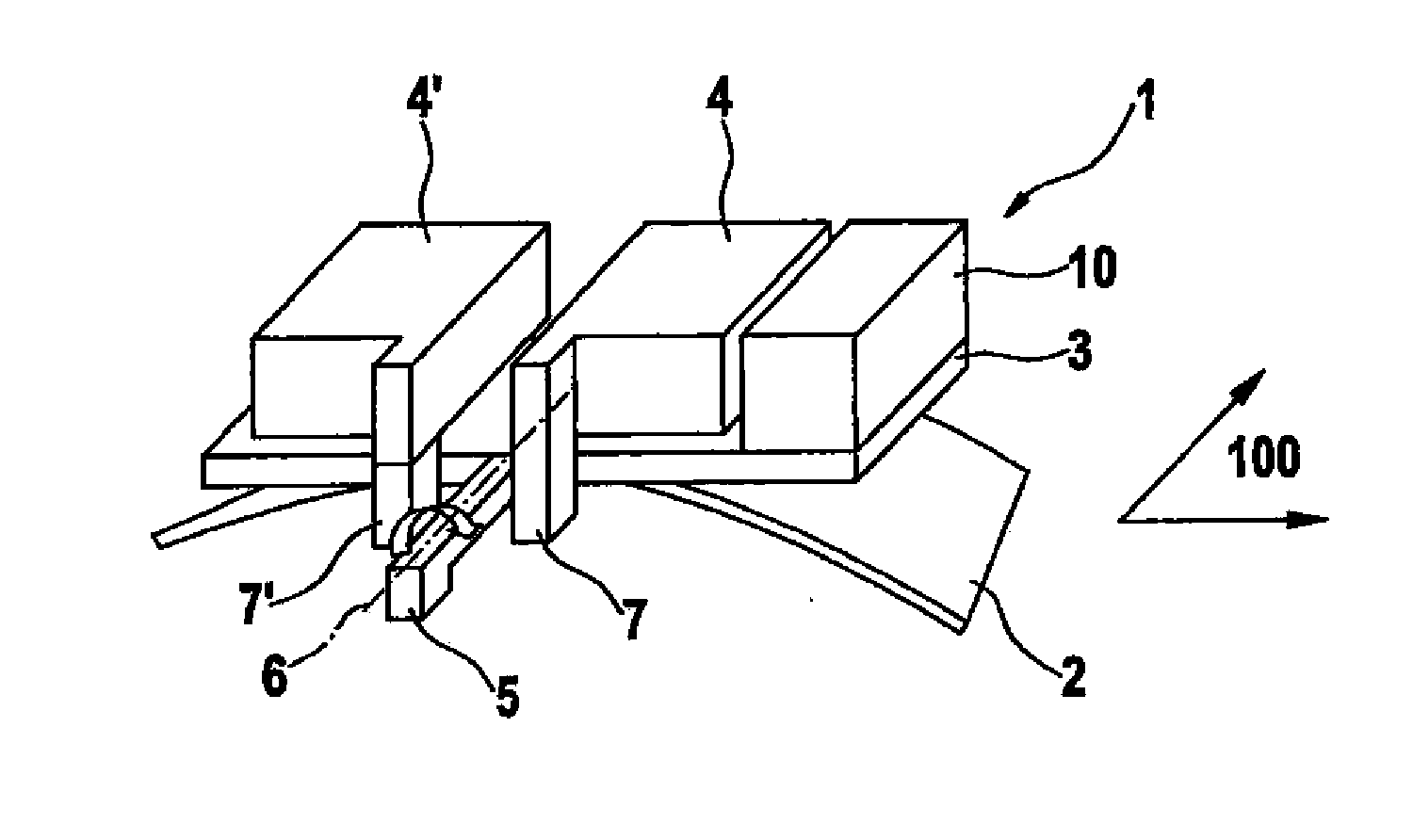

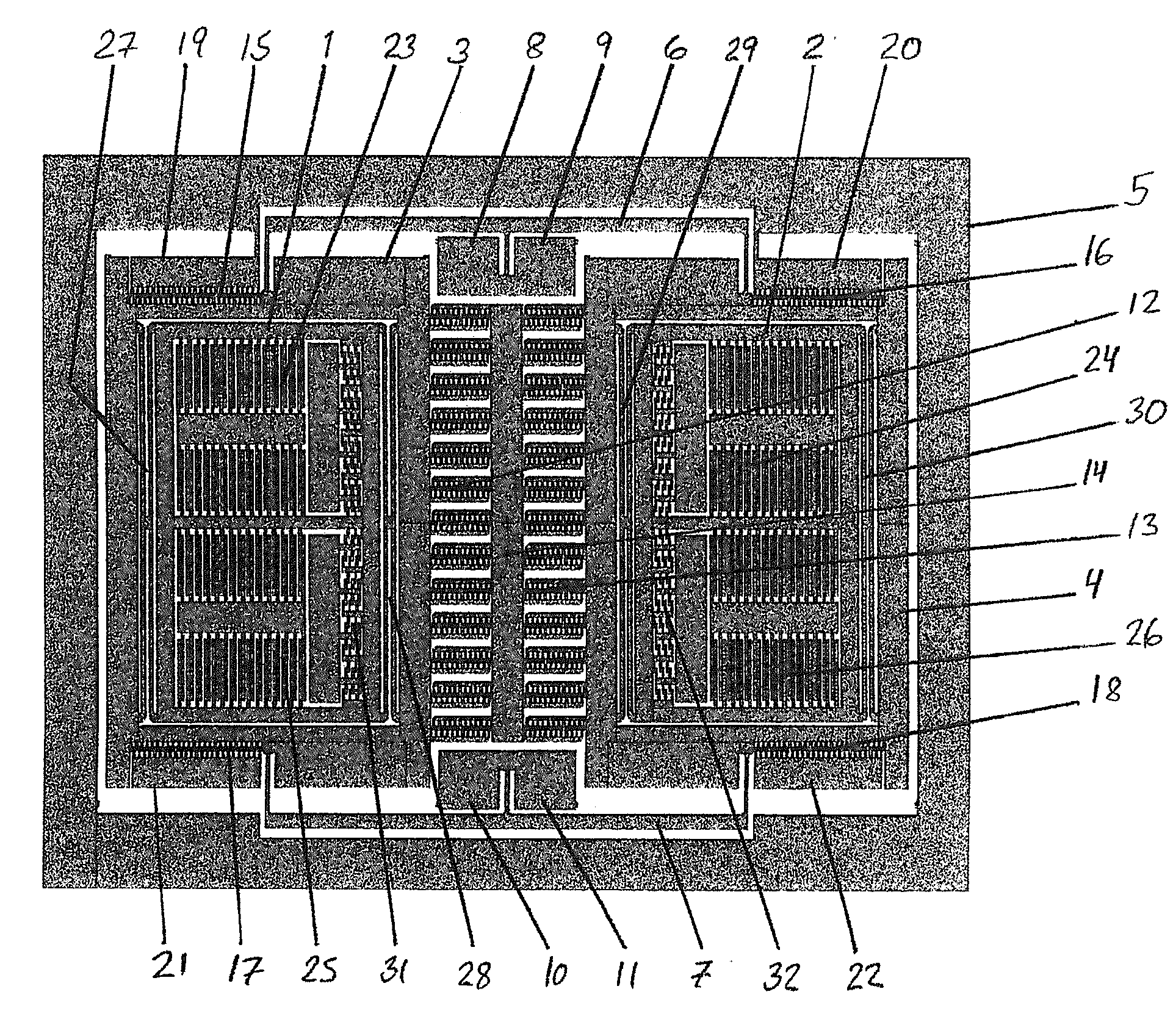

Oscillating micro-mechanical sensor of angular velocity

ActiveUS20060156814A1Reliable and efficient measuringLess sensitive to linkageAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsSeismic massMeasurement device

The invention relates to measuring devices used in measuring angular velocity, and, more specifically, to oscillating micro-mechanical sensors of angular velocity. In the sensor of angular velocity according to the present invention seismic masses (1), (2), (36), (37) are connected to support areas by means of springs or by means of springs and stiff auxiliary structures, which give the masses (1), (2), (36), (37) a degree of freedom in relation to an axis of rotation perpendicular to the plane of the wafer formed by the masses, and in relation to at least one axis of rotation parallel to the plane of the wafer. The structure of the sensor of angular velocity according to the present invention enables reliable and efficient measuring particularly in compact oscillating micro-mechanical sensors of angular velocity.

Owner:MURATA MFG CO LTD

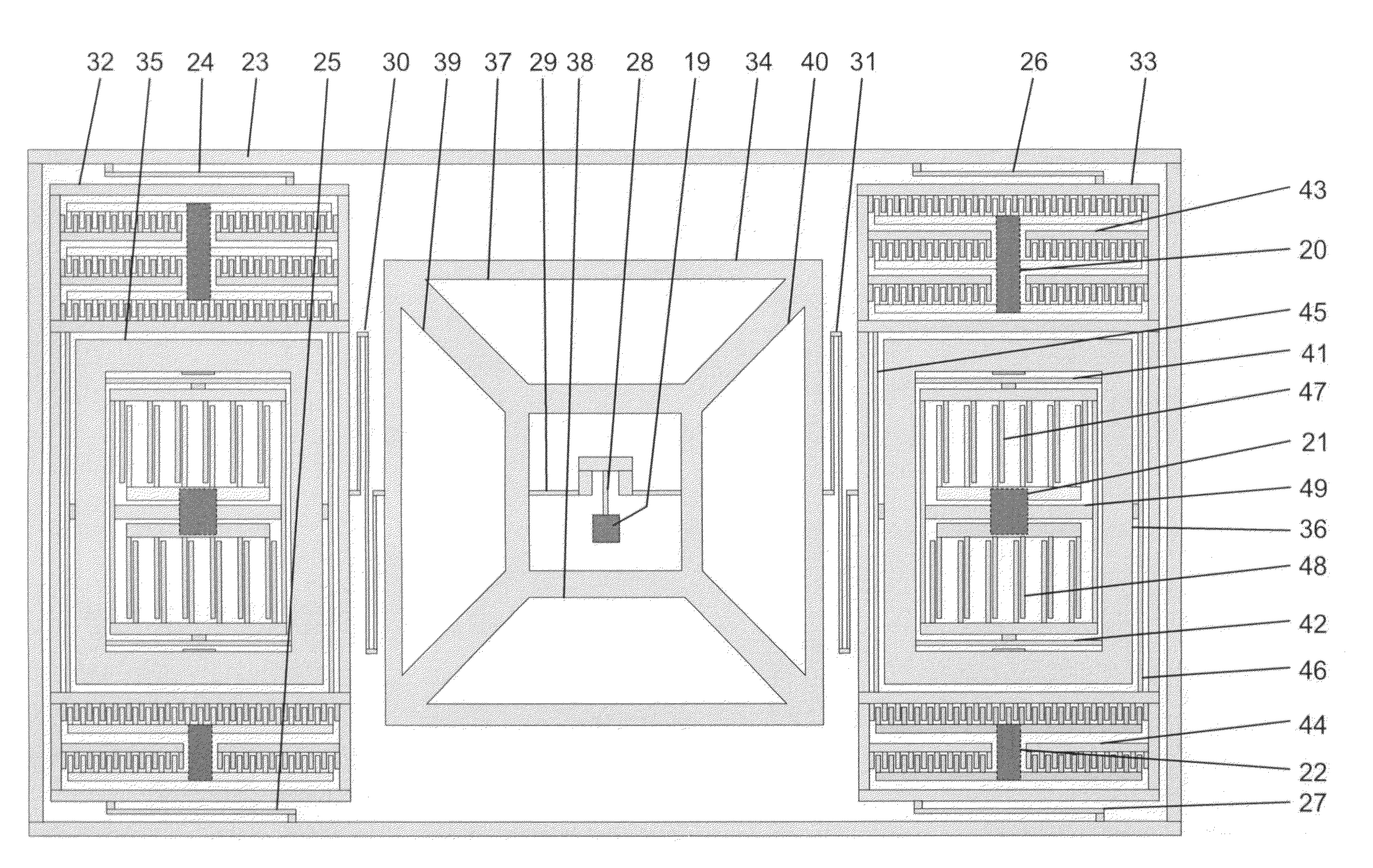

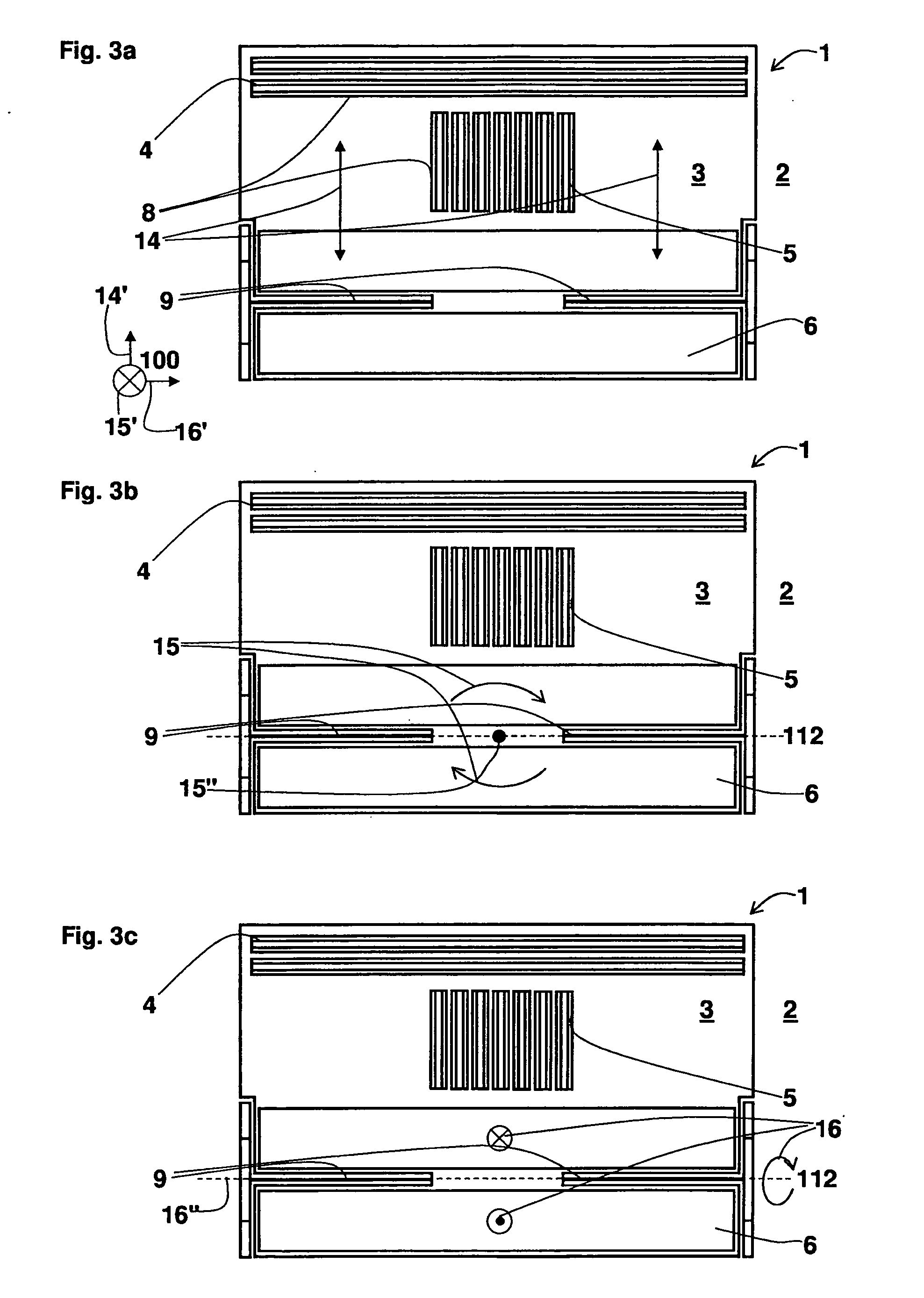

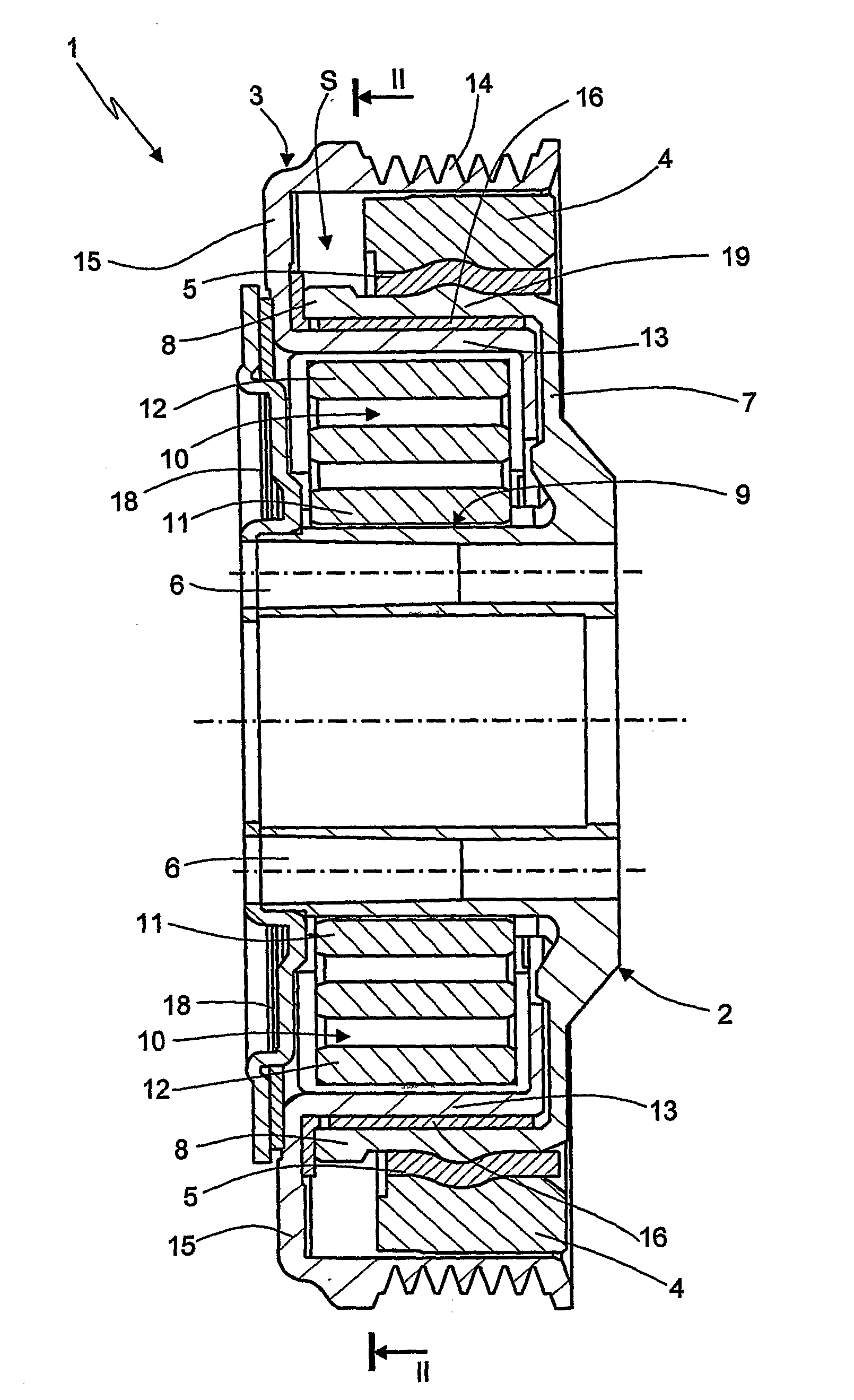

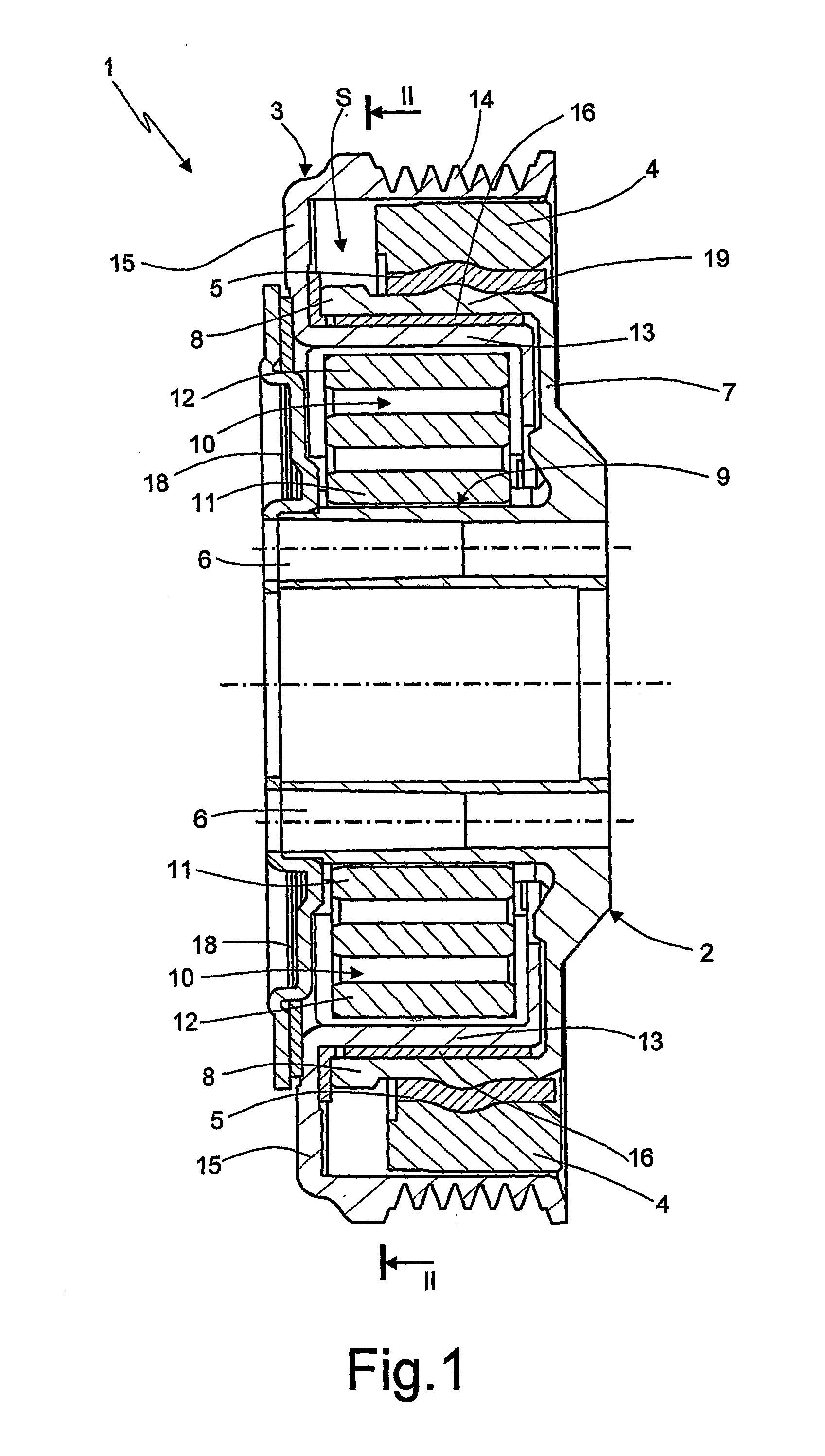

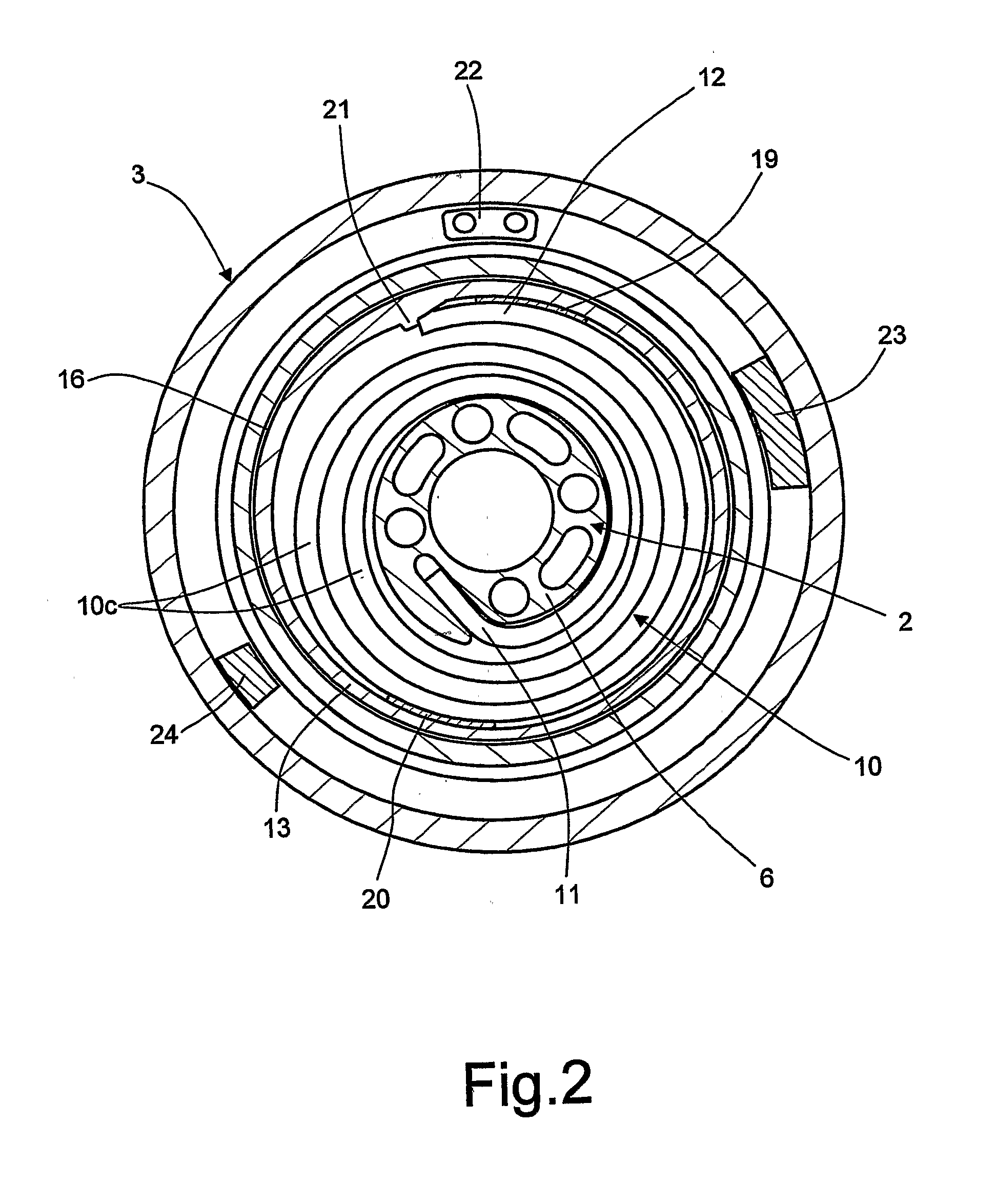

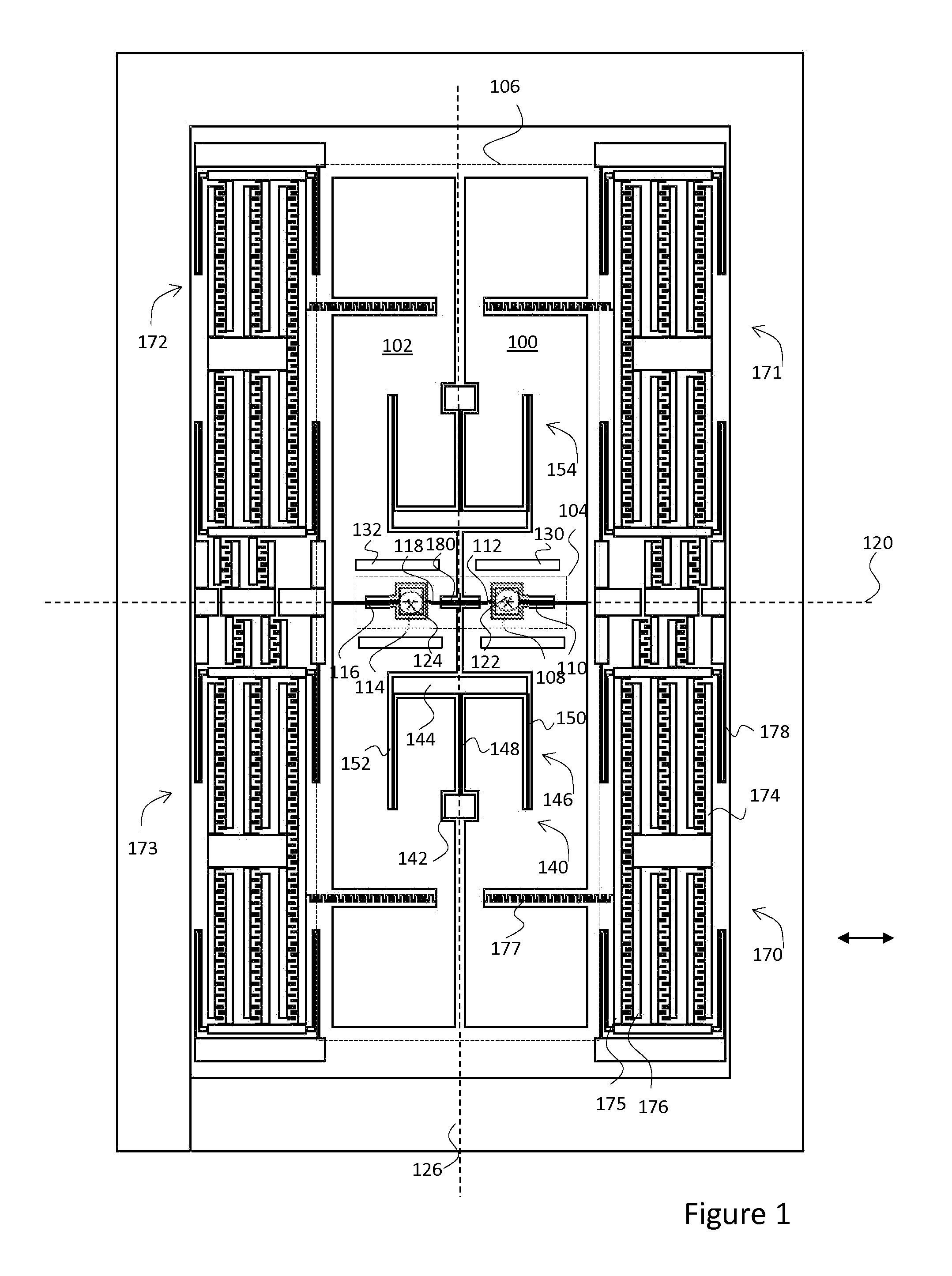

Double-axle, shock-resistant rotation rate sensor with linear and rotary seismic elements

ActiveUS20120210788A1Precise alignmentEasy to operateAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsSeismic massClassical mechanics

A micromechanical rotation rate sensor has at least one first and one second seismic mass coupled to at least one first drive device and are suspended such that the first and second seismic masses are driven such that they are deflected in antiphase in one drive mode, with the rotation rate sensor being designed such that it can detect rotation rates about at least two mutually essentially orthogonal sensitive axes, wherein at least the first and second seismic masses are designed and suspended such that they oscillate in antiphase in a first read mode when a first rotation rate about the first sensitive axis is detected, and the first and second seismic masses and / or additional seismic masses are designed and suspended such that they oscillate in antiphase in a second read mode when a second rotation rate about the second sensitive axis is detected.

Owner:CONTINENTAL TEVES AG & CO OHG

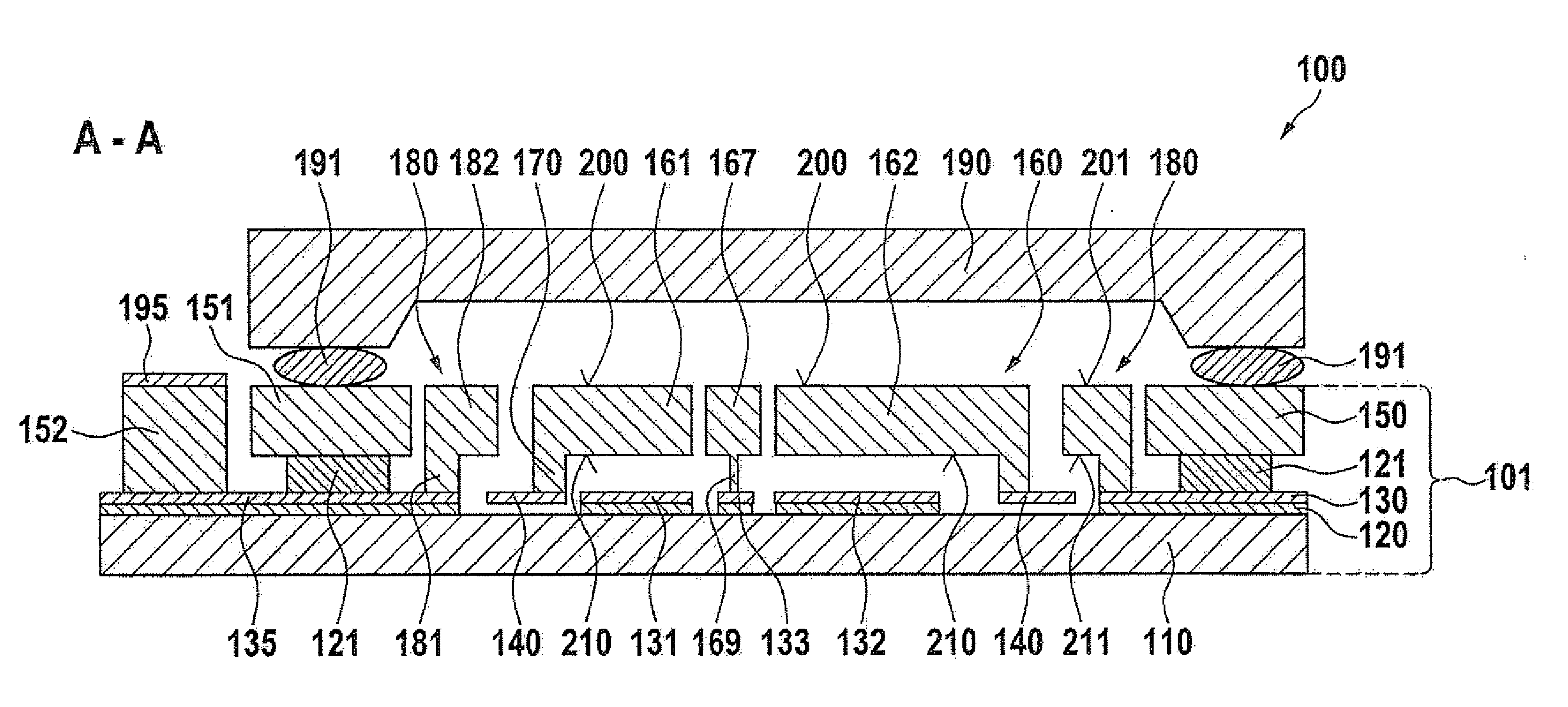

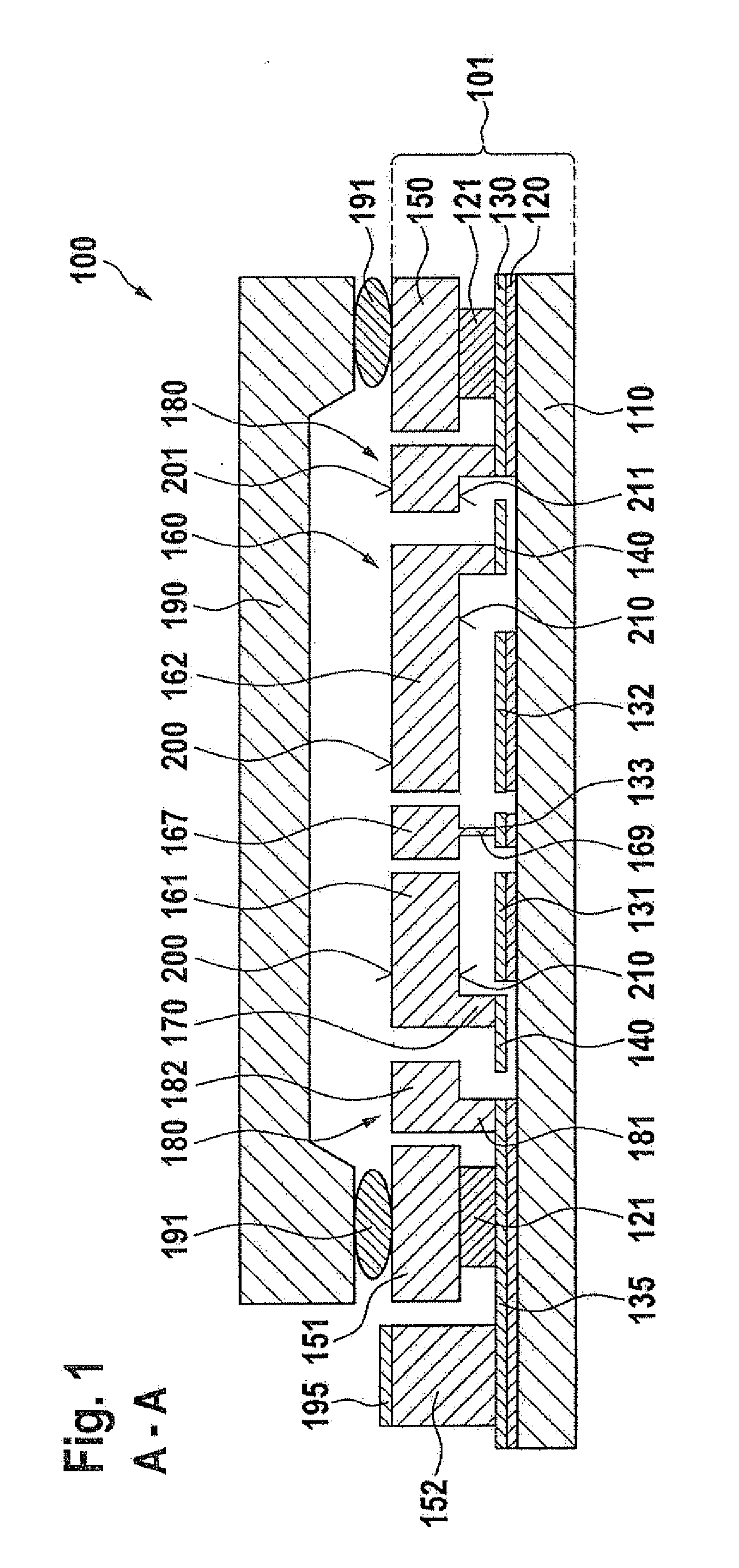

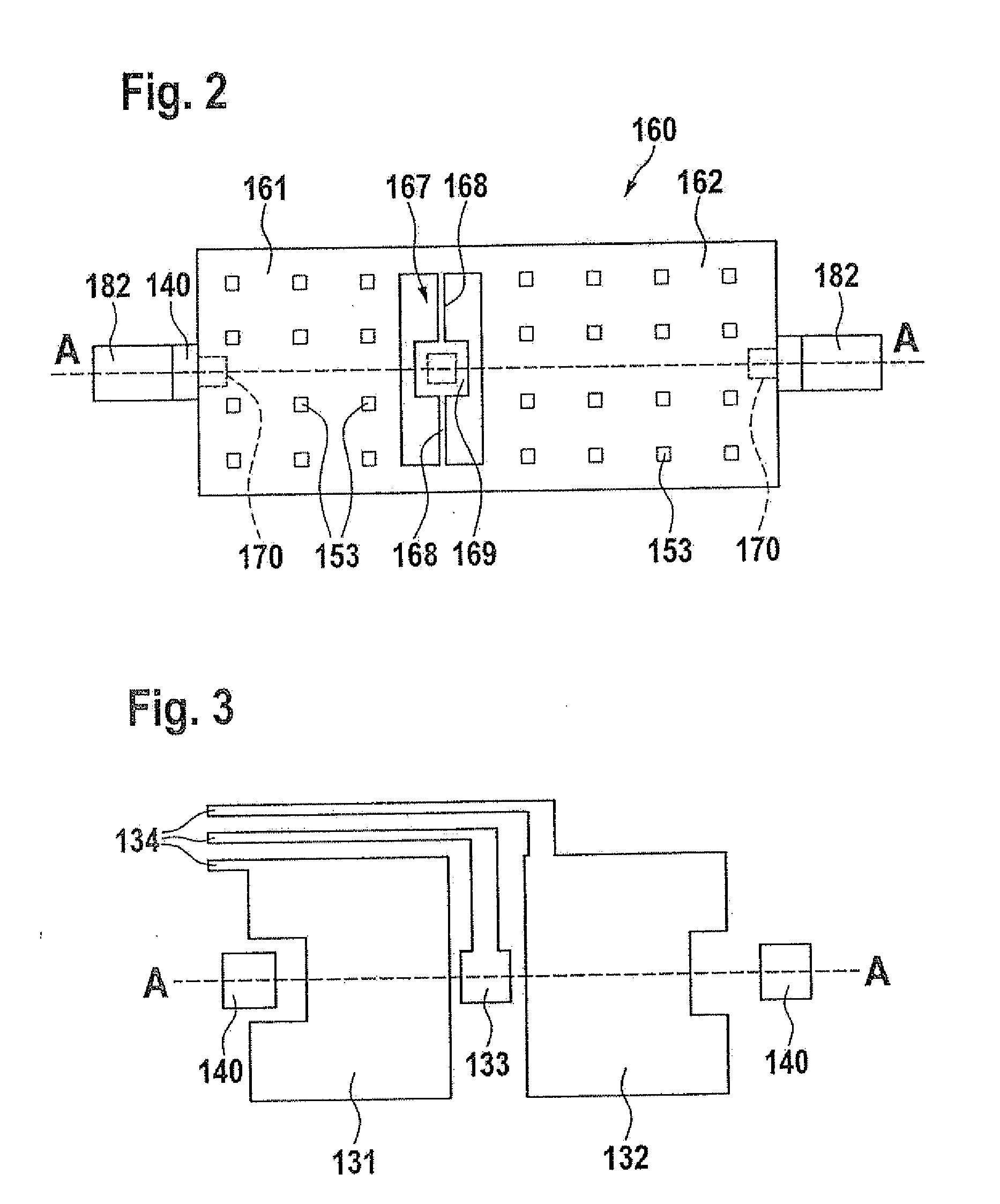

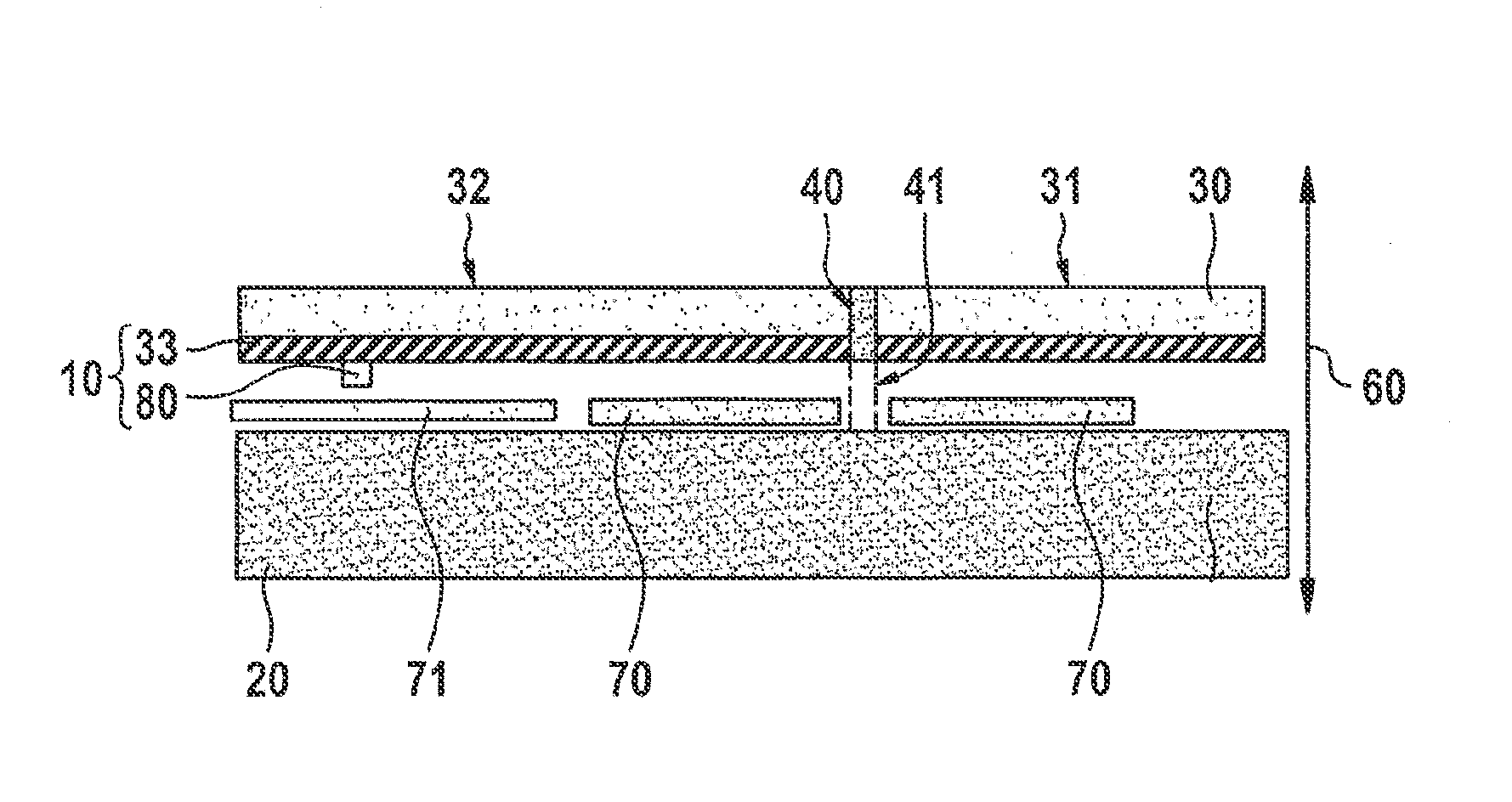

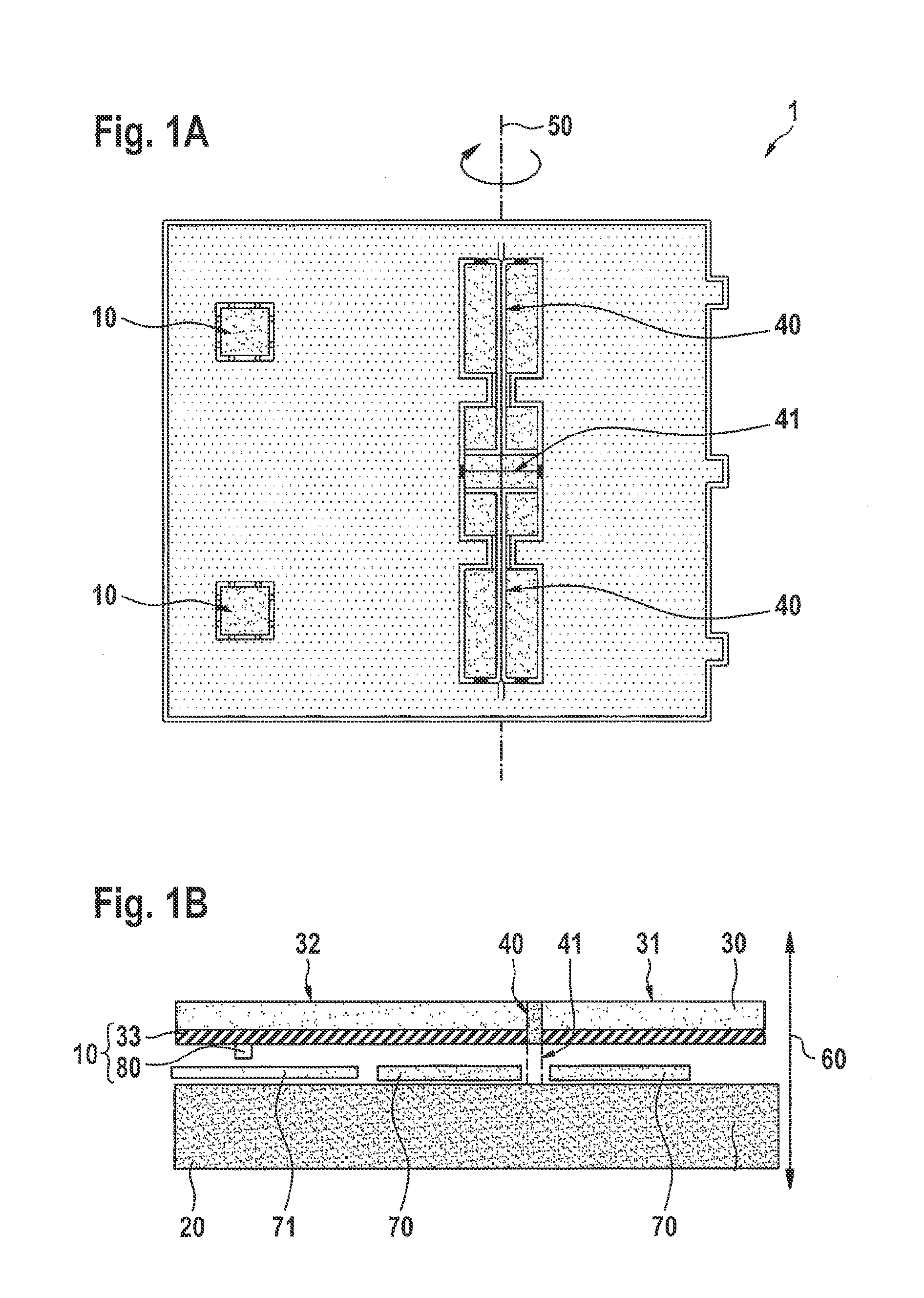

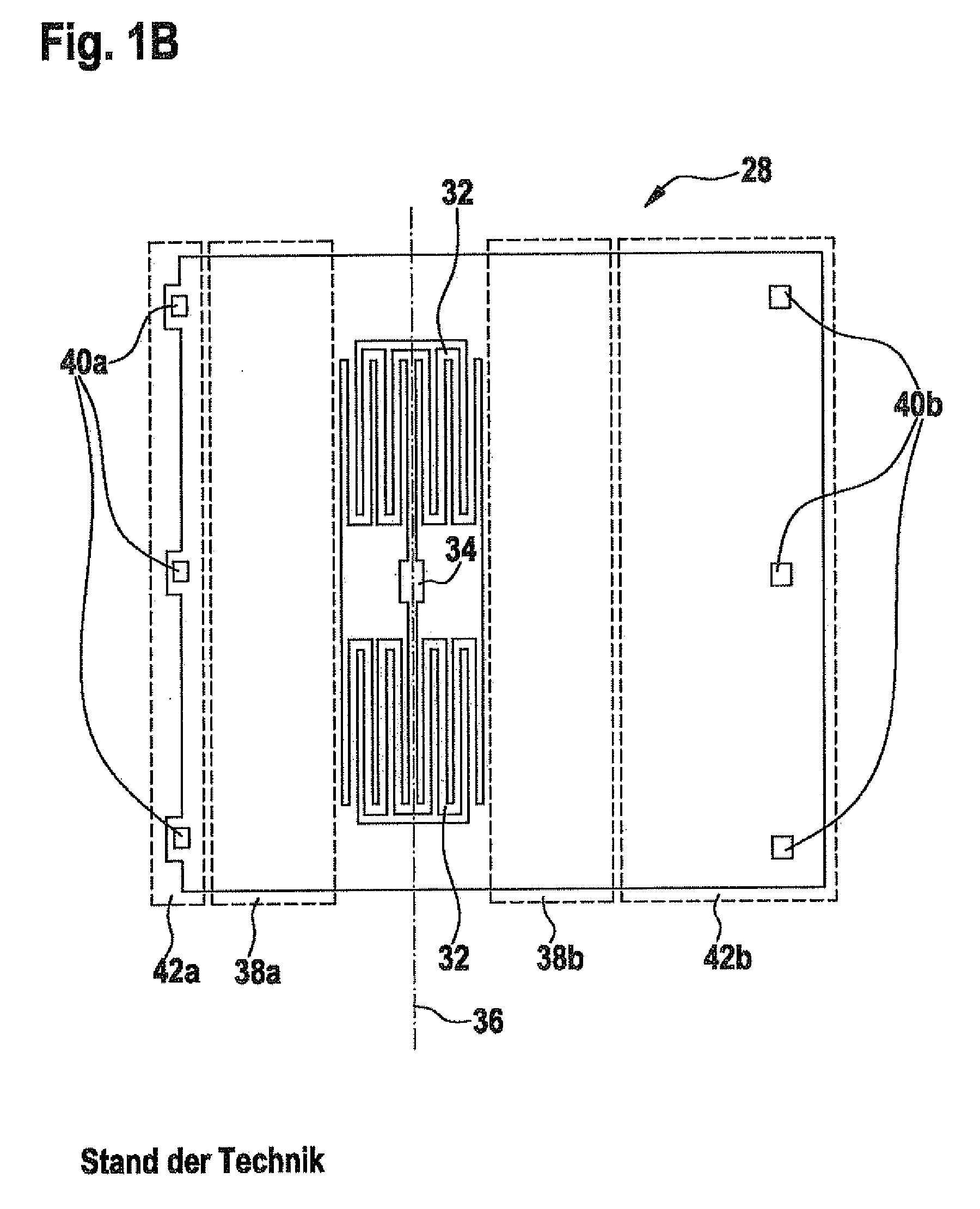

Micromechanical acceleration sensor

ActiveUS20110023606A1Accurate detectionCost-effectiveAcceleration measurement using interia forcesPrinted circuit manufactureSeismic massClassical mechanics

A micromechanical acceleration sensor, including at least one substrate, one or more frames, at least a first frame of which is suspended directly or indirectly on the substrate by at least one spring element, and is deflected with respect to the substrate when at least a first acceleration acts, and at least a first seismic mass which is suspended on the first frame or an additional frame by at least one spring element, and is deflected with respect to this frame when an acceleration acts which is, in particular, different from the first acceleration.

Owner:CONTINENTAL TEVES AG & CO OHG

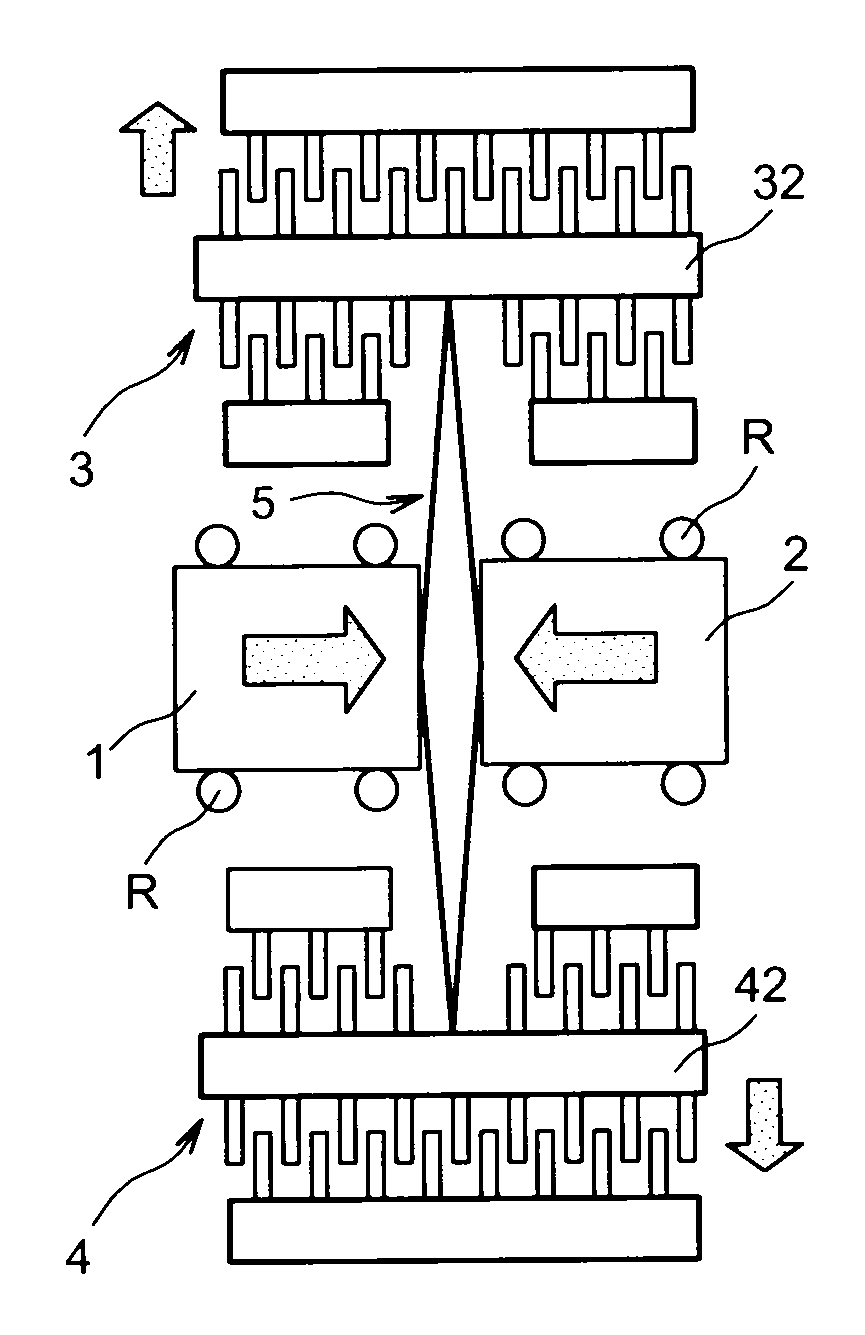

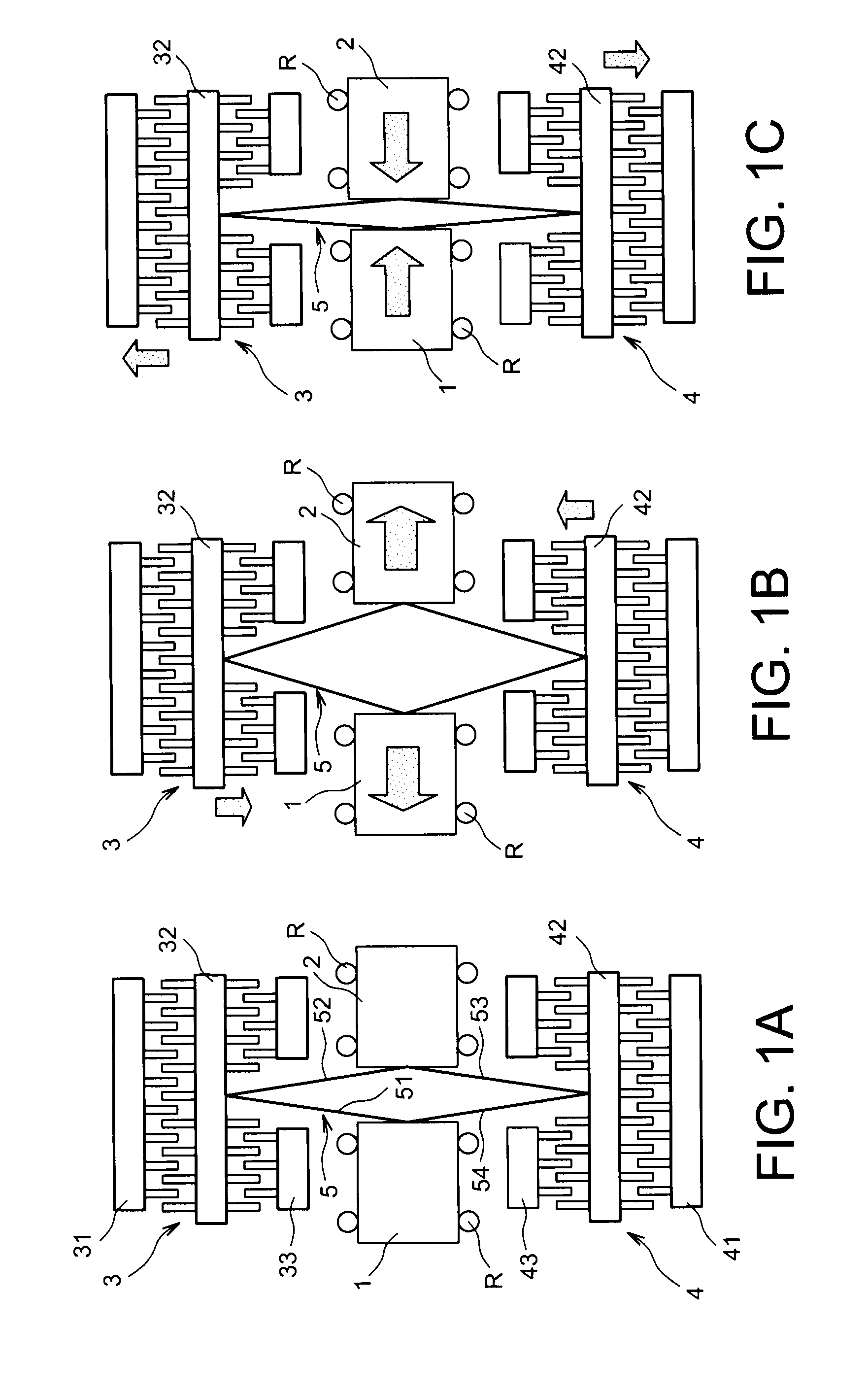

Rotational Speed Sensor Having A Coupling Bar

ActiveUS20100037690A1Avoid and reduce parasitic modeAvoid and reduce and interference deflectionAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsSeismic massEngineering

A rotational speed sensor including at least one substrate, at least two base elements which each have a frame, a means for suspending the frame from the substrate, at least one seismic mass and one means for suspending the seismic mass from the frame. One or more drive means are provided for driving one or more base elements and one or more reading devices. The at least two base elements are coupled to one another by means of at least one coupling bar.

Owner:CONTINENTAL TEVES AG & CO OHG

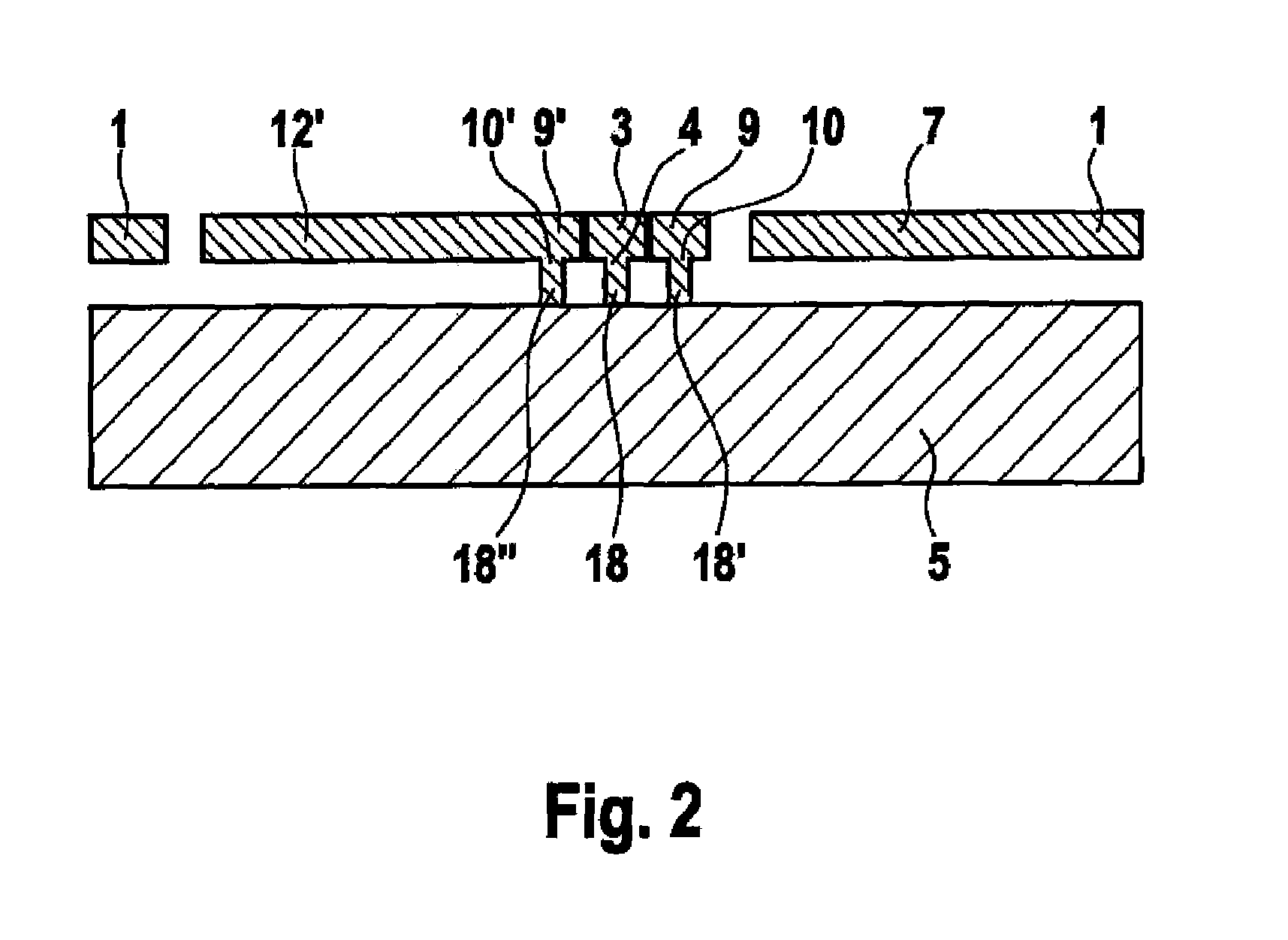

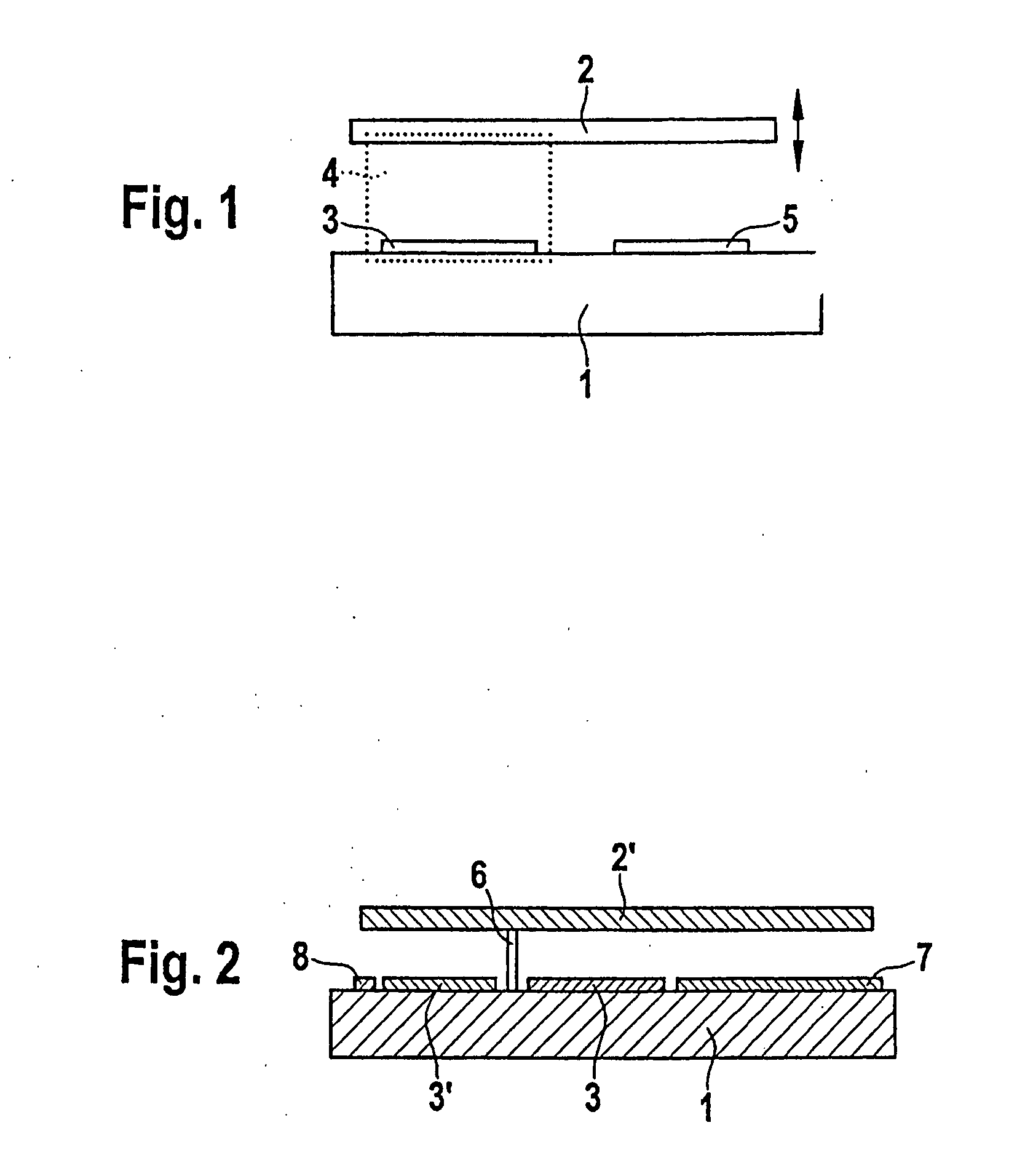

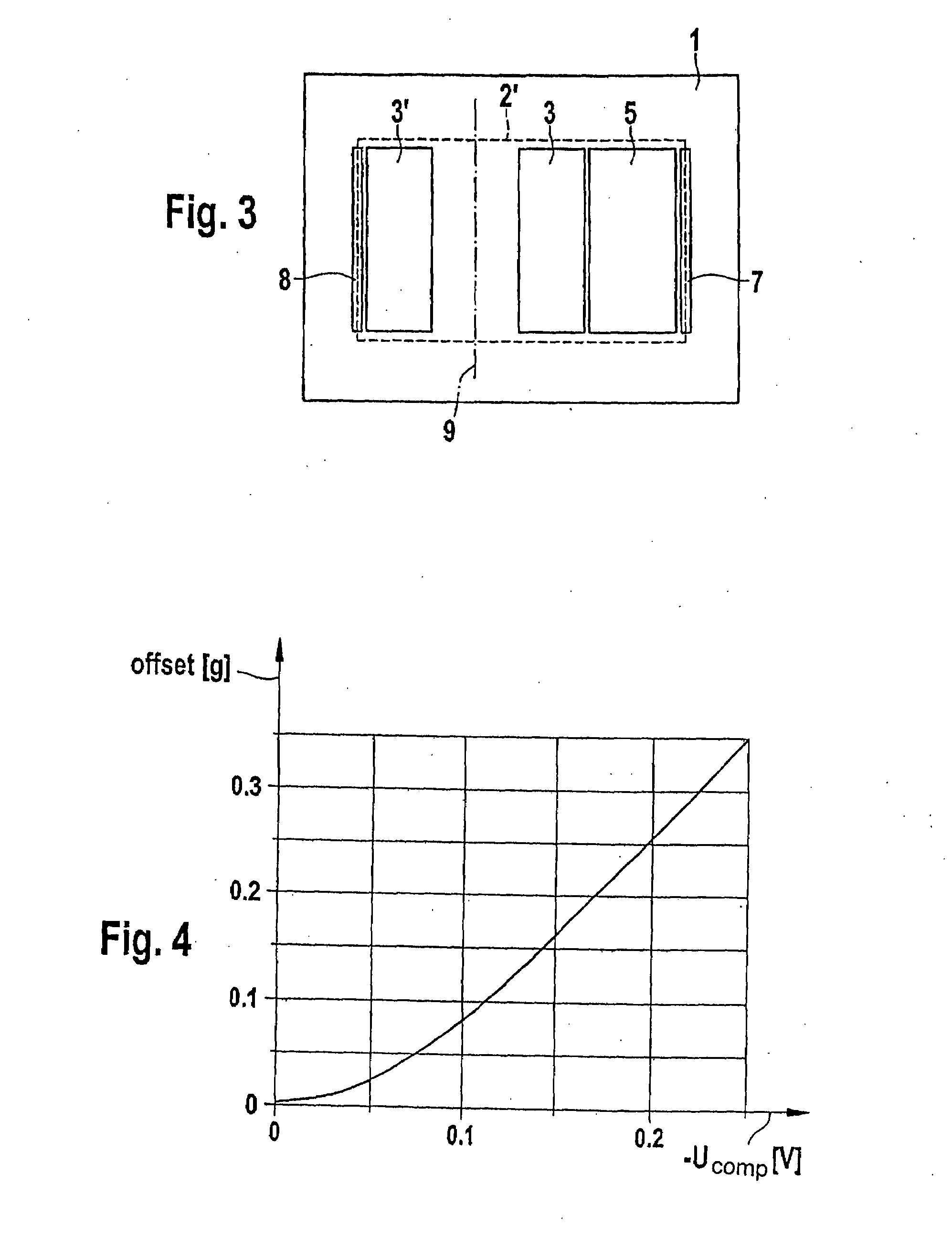

Flexible stop for an acceleration sensor

ActiveUS20130299923A1High space requirementIncrease stiffnessAcceleration measurementPiezoelectric/electrostrictive devicesSeismic massClassical mechanics

A micromechanical acceleration sensor includes a seismic mass and a substrate that has a reference electrode. The seismic mass is deflectable in a direction perpendicular to the reference electrode, and the seismic mass has a flexible stop in the deflection direction. The flexible stop of the seismic mass includes an elastic layer.

Owner:ROBERT BOSCH GMBH

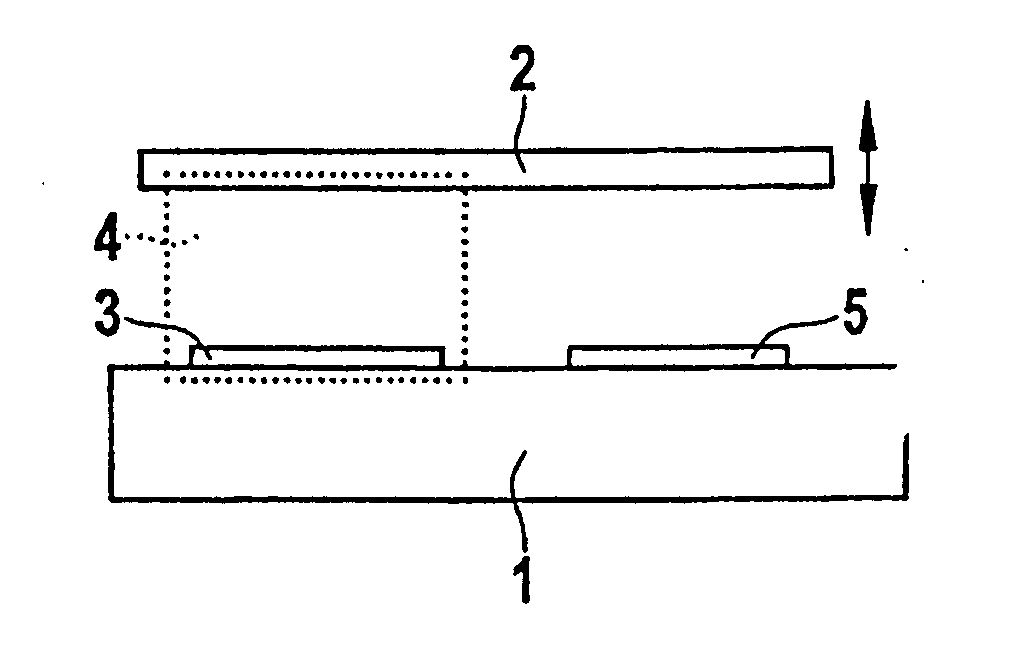

Sensor device and method for manufacturing a sensor device

ActiveUS20100186508A1Reduce kinetic energyAvoid static frictionAcceleration measurement using interia forcesWave amplification devicesSeismic massStructural engineering

A sensor device includes a base plate, a seismic mass having an upper side and a lower side that is situated such that given acceleration of the base plate the seismic mass is capable of being displaced in a direction oriented non-parallel to the upper side and / or to the lower side, at least one raised stop on the seismic mass, and a detection and evaluation device that is adapted to acquire a displacement movement of the seismic mass relative to the base plate and, taking into account the displacement movement, to determine an item of information relating to an acceleration of the sensor device and / or to a force acting on the sensor device, the seismic mass having at least one resilient area that includes the at least one stop and at least one displaceable remaining area, and the resilient area being connected to the remaining area via at least one spring. A method is for manufacturing a sensor device.

Owner:ROBERT BOSCH GMBH

Coupling structure for resonant gyroscope

ActiveUS20120061172A1Secure couplingAcceleration measurement using interia forcesSeismic energy generationGyroscopeCoupling

A coupling structure for a resonant microgyroscope produced on a substrate, wherein the coupling structure enables a vibratory movement provided by an excitation mechanism to be detected along a first axis, and enables it to be transmitted to seismic masses lying in a plane containing the first axis. The coupling structure includes a closed assembly of beams connected to the seismic masses so as to be anchored only to the seismic masses, wherein the assembly is positioned to detect the vibratory movement provided by the excitation mechanism, and to transmit it to the seismic masses along at least a second axis contained in the plane, wherein the coupling structure has no point of anchorage to the substrate.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Acceleration sensor having a damping device

ActiveUS20120031185A1Increased susceptibilityReduce susceptibility to interferenceAcceleration measurement using interia forcesSeismic massClassical mechanics

A micromechanical acceleration sensor is described which includes a substrate and a seismic mass which is movably situated with respect to the substrate in a detection direction. The micromechanical sensor includes at least one damping device for damping motions of the seismic mass perpendicular to the detection direction.

Owner:ROBERT BOSCH GMBH

Acceleration sensor with comb-shaped electrodes

InactiveUS20090320596A1Signal offsetReduce sensitivityAcceleration measurementSeismic massClassical mechanics

A micromechanical capacitive acceleration sensor having at least one seismic mass that is connected to a substrate so as to be capable of deflection, at least one electrode connected fixedly to the substrate, and at least one electrode connected to the seismic mass, the at least one electrode connected fixedly to the substrate and the at least one electrode connected to the seismic mass being realized as comb-shaped electrodes having lamellae that run parallel to the direction of deflection of the seismic mass, the lamellae of the two comb-shaped electrodes overlapping partially in the resting state.

Owner:ROBERT BOSCH GMBH

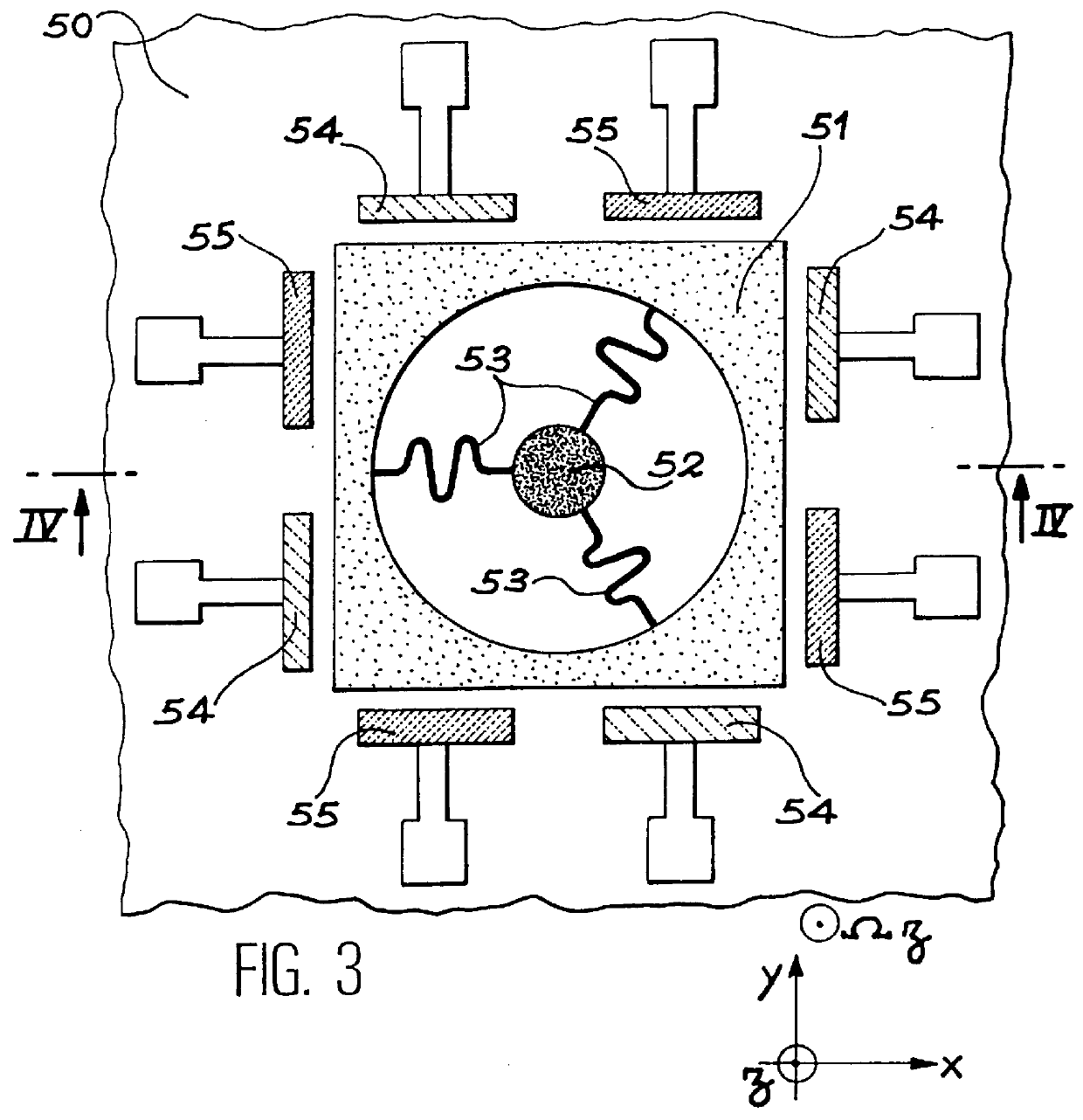

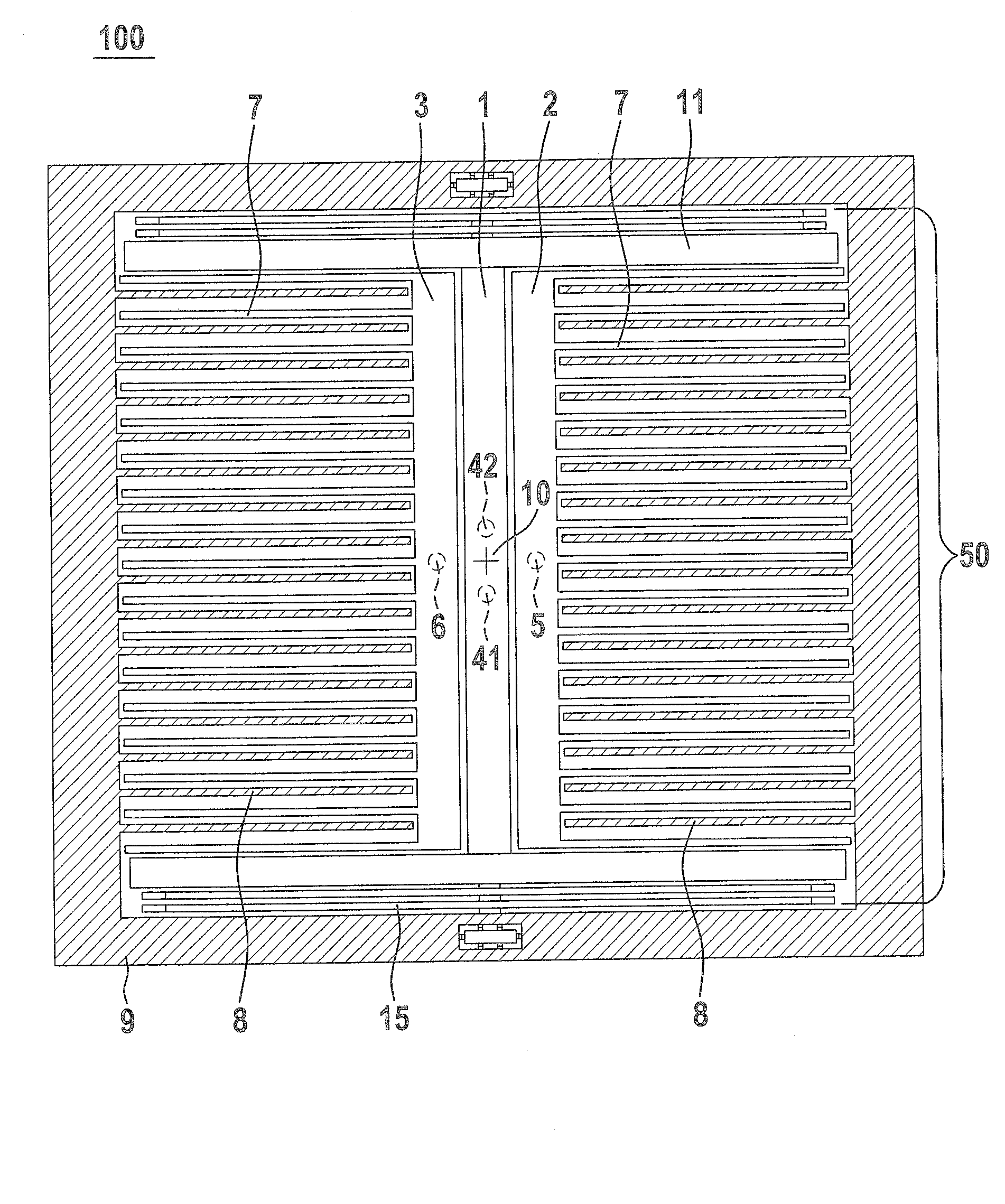

Vibrating microgyrometer

InactiveUS6089088AAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsSeismic massClassical mechanics

The invention relates to a vibrating microgyrometer incorporating a seismic mass (16) placed above a surface of a substrate (15) and attached to the surface by elastic supports arranged so as to enable the seismic mass (16) to move with respect to the substrate (15) in two directions +E,ovs x+EE , +E,ovs y+EE orthogonal to one another and orthogonal to the measurement axis of the microgyrometer. The microgyrometer also comprises excitation electrodes (40) making it possible to excite the seismic mass in the two mutually orthogonal directions and detection electrodes (41) making it possible to detect components of the Coriolis force, once again in the two mutually orthogonal directions.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Vibrating micro-mechanical sensor of angular velocity

ActiveUS8176779B2Reliable measurementImprove performanceAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsSeismic massMeasurement device

Owner:MURATA MFG CO LTD

Micromechanical inertial sensor having reduced sensitivity to the influence of drifting surface charges, and method suited for operation thereof

A micromechanical inertial sensor having at least one seismic mass which may be deflected relative to a substrate, and at least one electrode surface which in terms of circuitry, together with at least portions of the seismic mass forms at least one capacitor having a capacitance which is dependent on the deflection of the seismic mass. At least one additional auxiliary electrode is included which is located outside the region which forms the capacitor and which may be set at a potential that deviates from the potential of the seismic mass.

Owner:ROBERT BOSCH GMBH

Micromechanical structures

ActiveUS20100192690A1Width of trench structuresEasy to detectAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsSeismic massLine width

A micromechanical structure including a substrate having a main plane of extension, and including a first seismic mass, the first seismic mass including a grid structure made of intersecting first mass lines and the first seismic mass being flexibly secured with the aid of first bending-spring elements, and moreover, a first line width of the first mass lines parallel to the main plane of extension being between 20 and 50 percent of a further first line width of the first bending-spring elements parallel to the main plane of extension.

Owner:ROBERT BOSCH GMBH

Micromechanical component and method for operating a micromechanical component

ActiveUS20110154899A1Consumes less powerMore compactAcceleration measurement using interia forcesAcceleration measurement in multiple dimensionsSeismic massClassical mechanics

A micromechanical component comprising a substrate, a seismic mass, and first and second detection means, the substrate having a main extension plane and the first detection means being provided for detection of a substantially translational first deflection of the seismic mass along a first direction substantially parallel to the main extension plane, and the second detection means further being provided for detection of a substantially rotational second deflection of the seismic mass about a first rotation axis parallel to a second direction substantially perpendicular to the main extension plane. The seismic mass can be embodied as an asymmetrical rocker, with the result that accelerations can be sensed as rotations. Detection can be accomplished via capacitive sensors.

Owner:ROBERT BOSCH GMBH

Micromechanical component having a test structure for determining the layer thickness of a spacer layer and method for manufacturing such a test structure

ActiveUS20110296917A1Reduce manufacturing costSimplified determinationResistance/reactance/impedenceAcceleration measurementSeismic massSlice thickness

A micromechanical component is described including a substrate having a spacer layer and a test structure for ascertaining the thickness of the spacer layer. The test structure includes a seismic mass, which is elastically deflectable along a measuring axis parallel to the substrate, a first electrode system and a second electrode system for deflecting the seismic mass along the measuring axis, having a mass electrode, which is produced by a part of the seismic mass, and a substrate electrode, which is situated on the substrate in each case, the first electrode system being designed to be thicker than the second electrode system by the layer thickness of the spacer layer.

Owner:ROBERT BOSCH GMBH

Sensor system

InactiveUS20100175473A1Simple and cost-effective to implementReduces sensitivity of sensorAcceleration measurement using interia forcesSeismic massClassical mechanics

A sensor system having a substrate, that has a main plane of extension, and a seismic mass, the seismic mass being developed movably about a torsional axis that is parallel to the main plane of extension; and the seismic mass having an asymmetrical mass distribution with respect to the torsional axis; and furthermore an area of the seismic mass facing the substrate is developed symmetrically with respect to the torsional axis.

Owner:ROBERT BOSCH GMBH

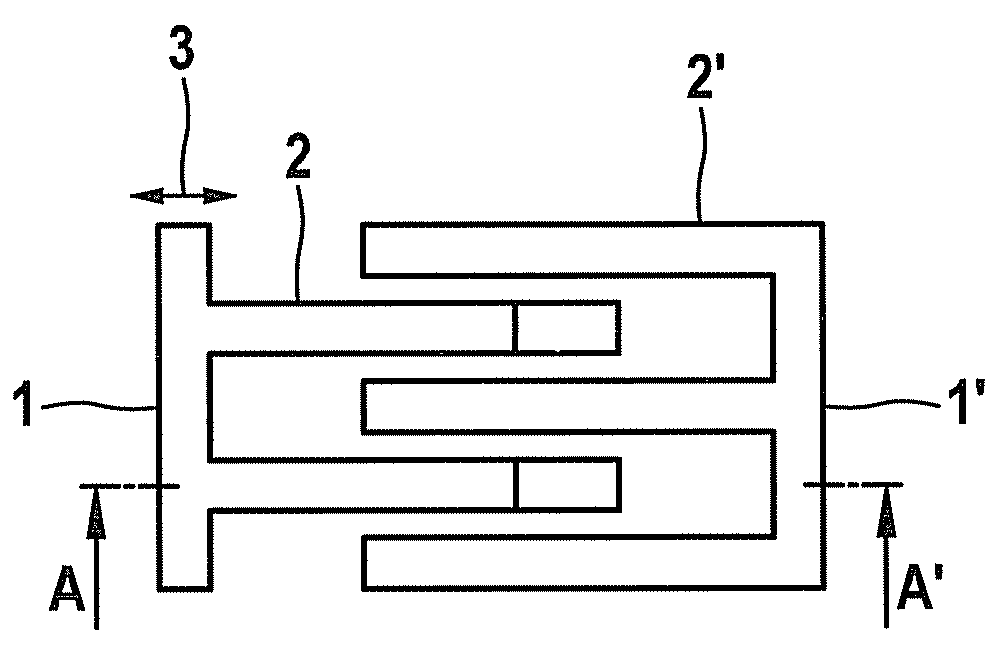

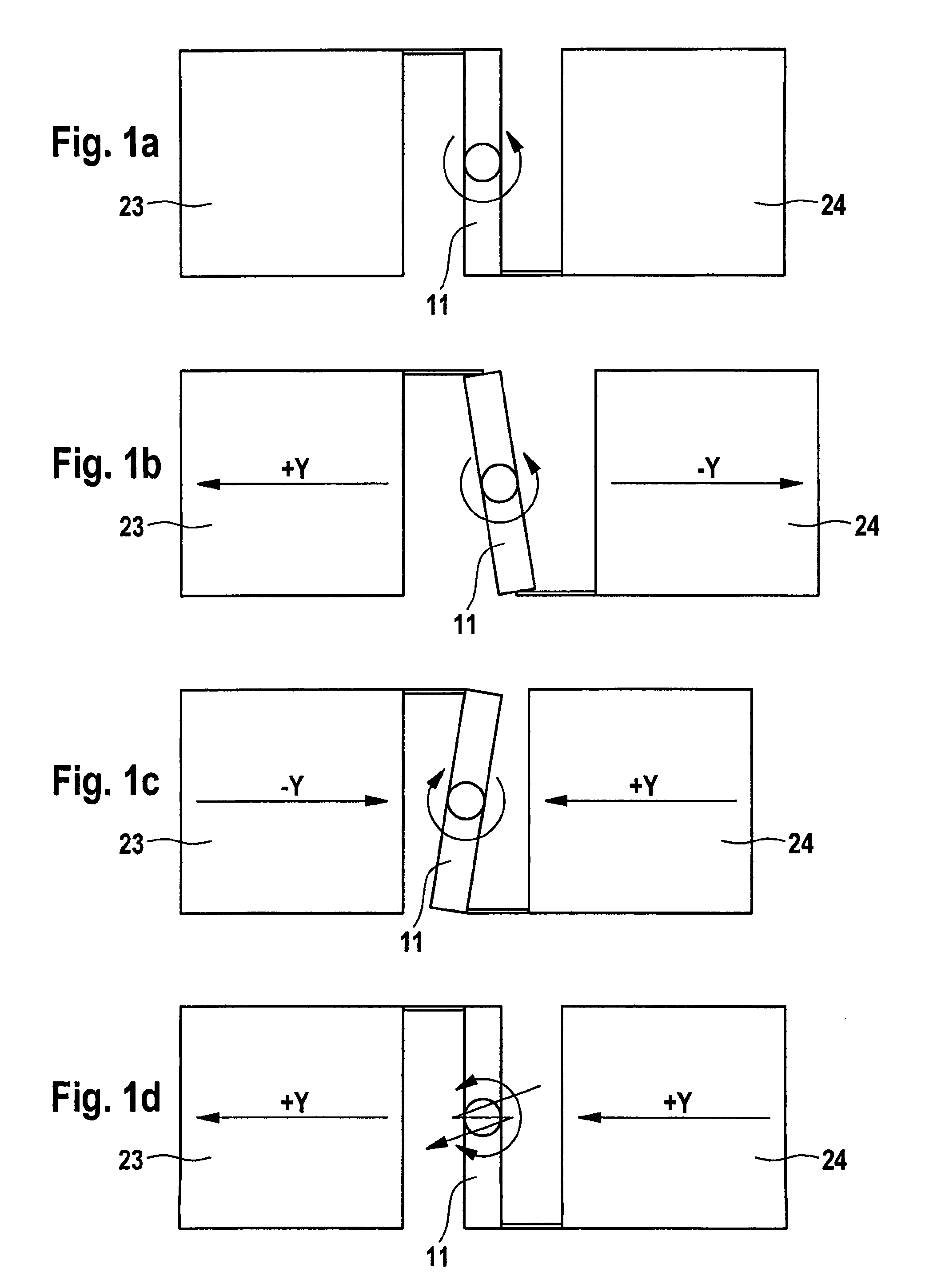

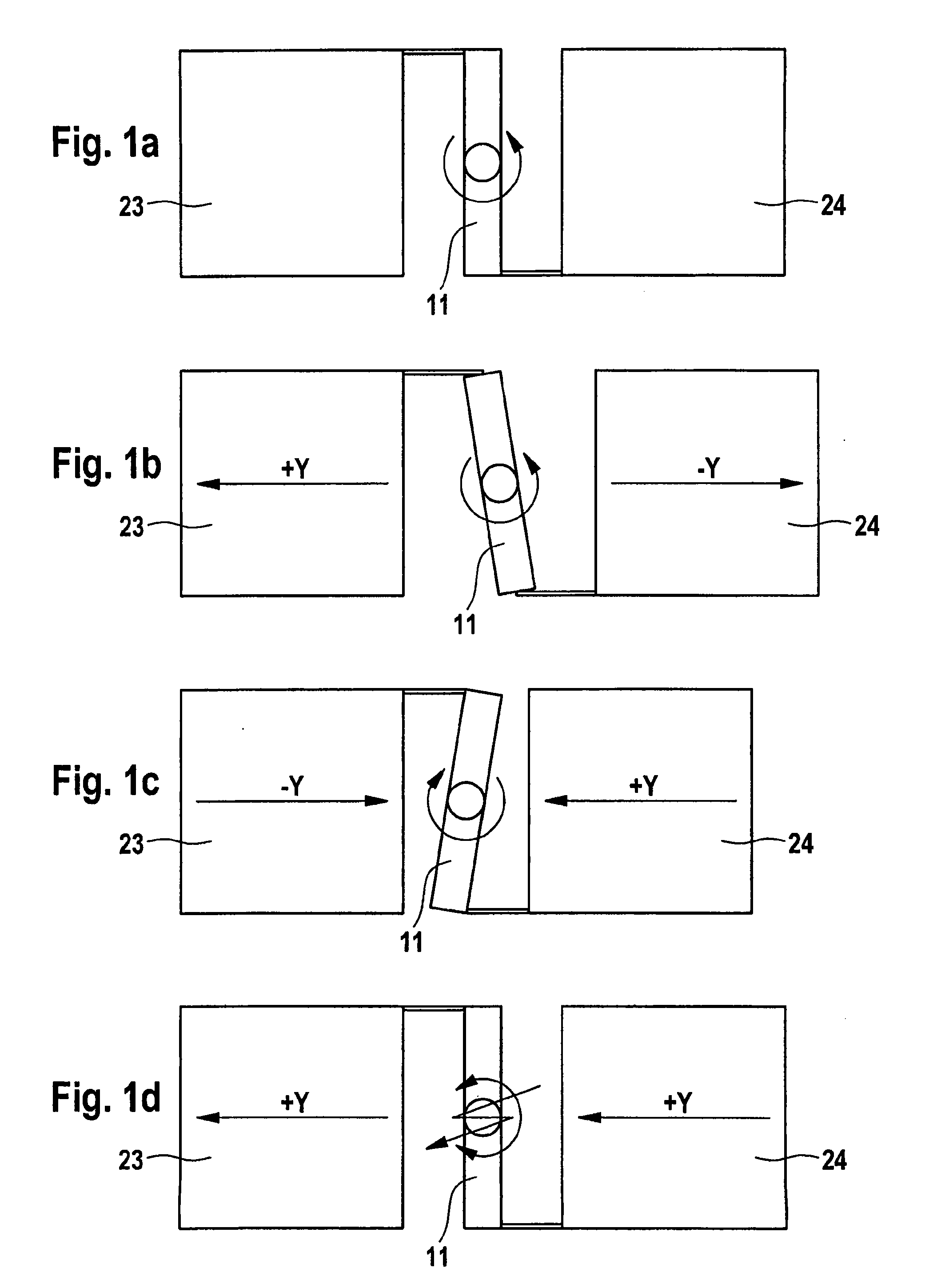

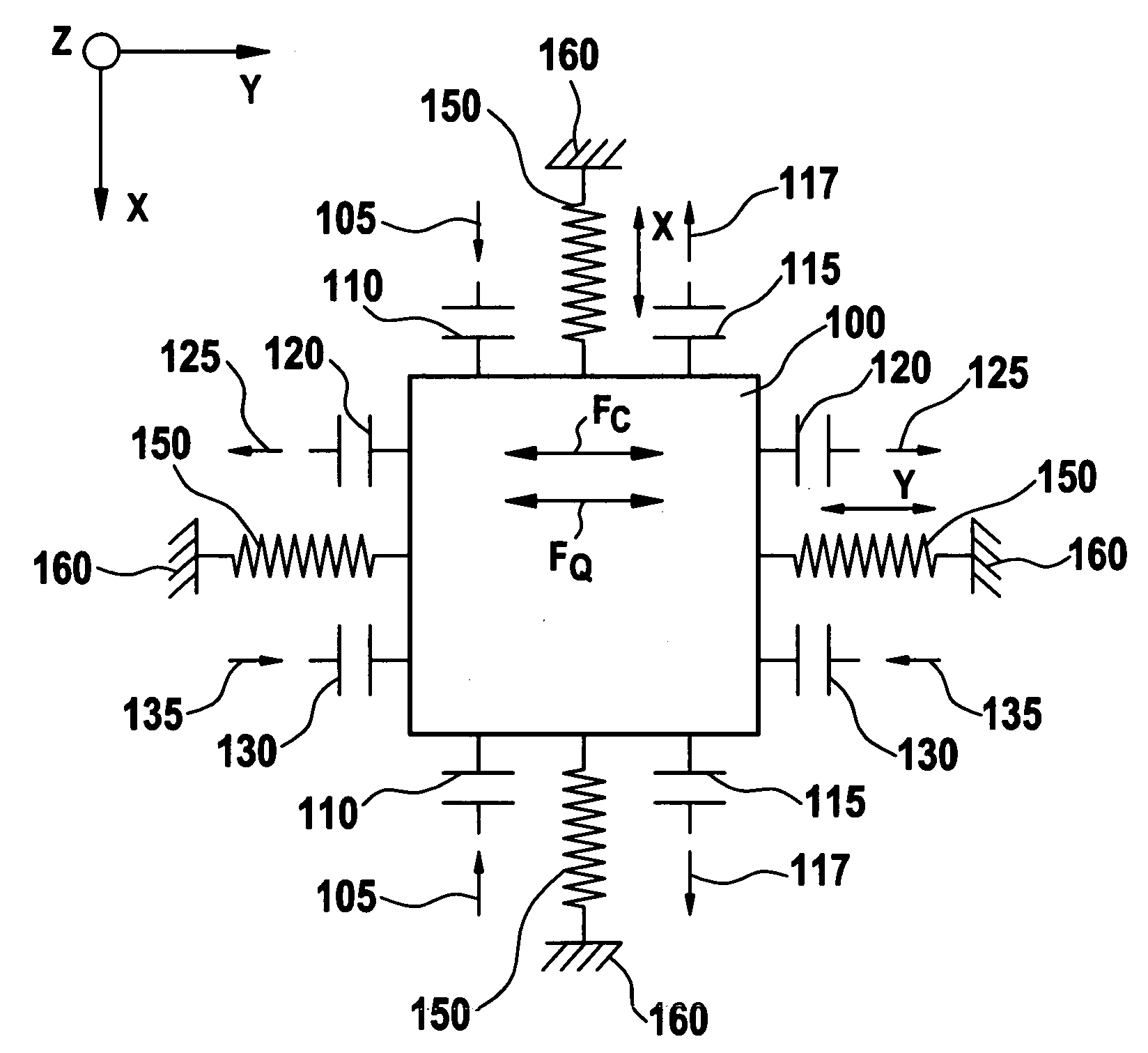

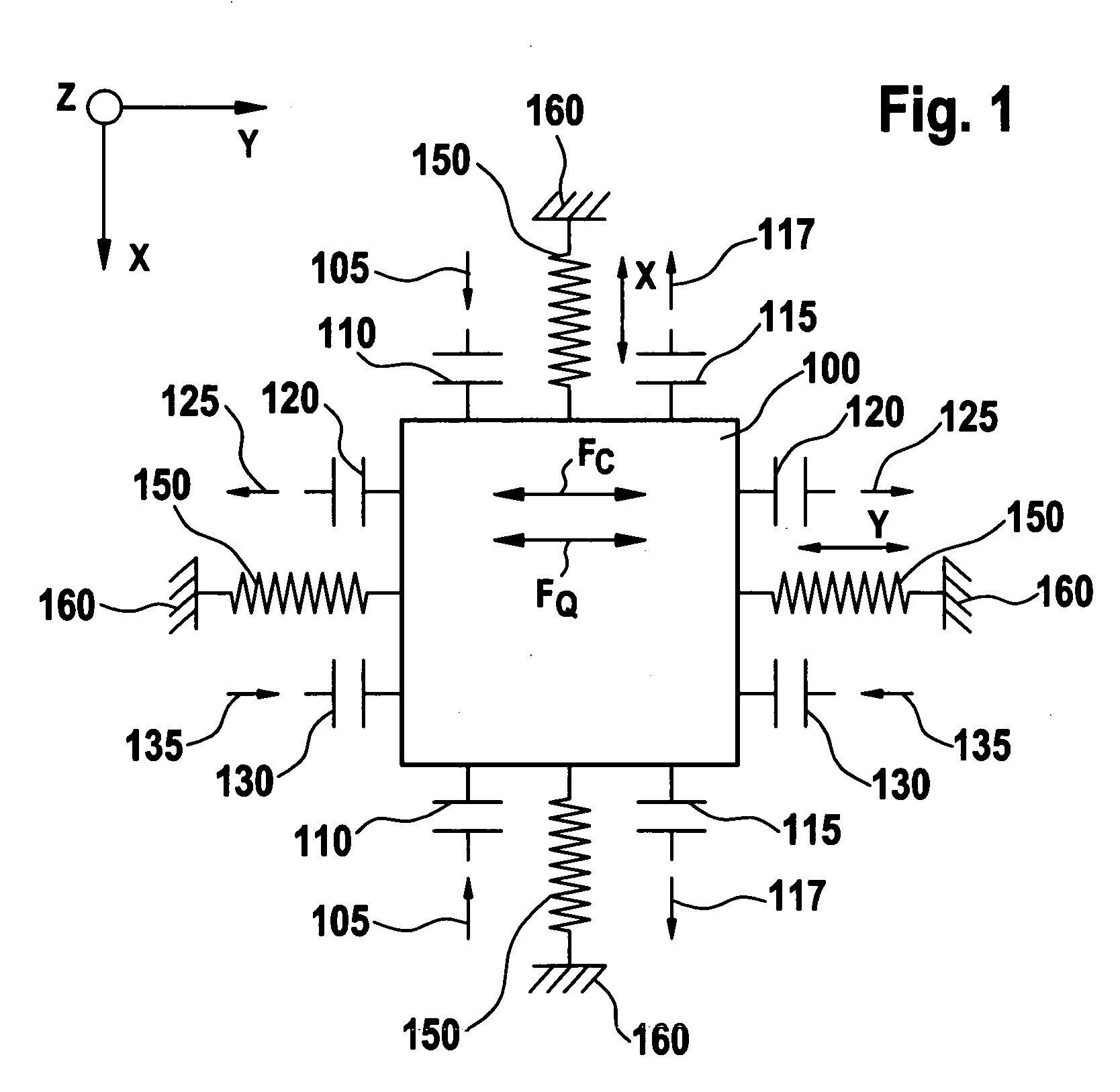

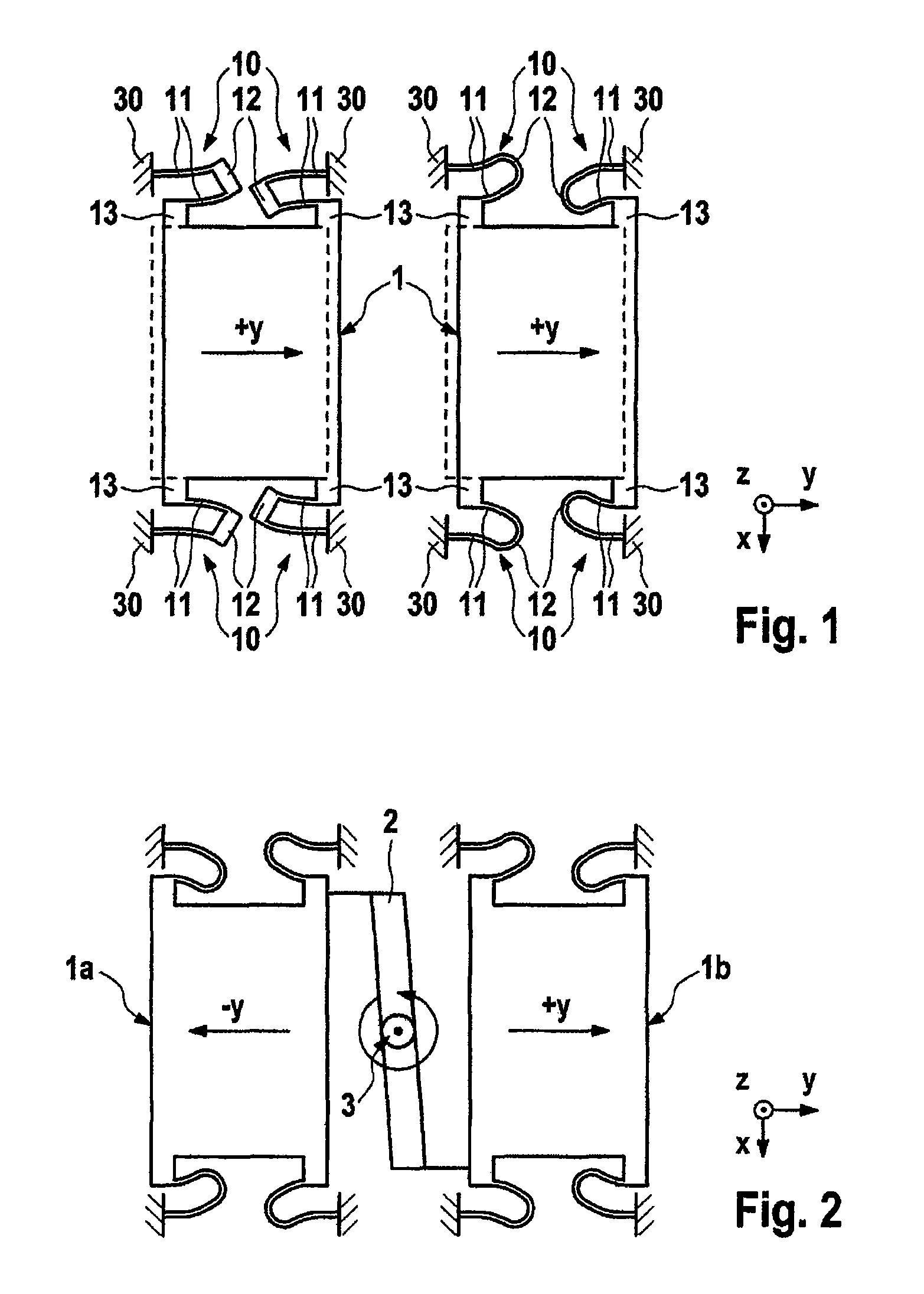

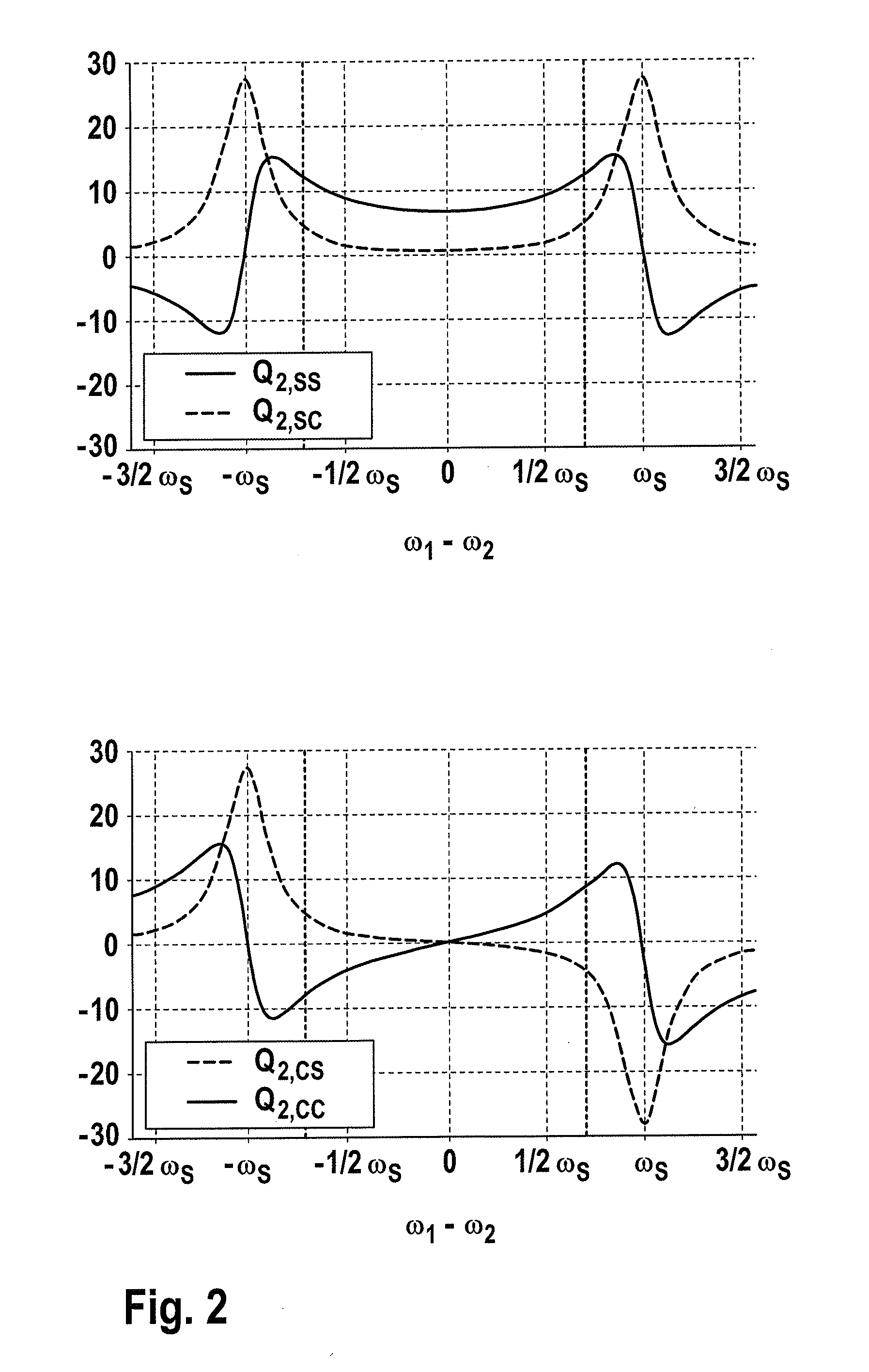

Micromechanical rotation rate sensor having error suppression

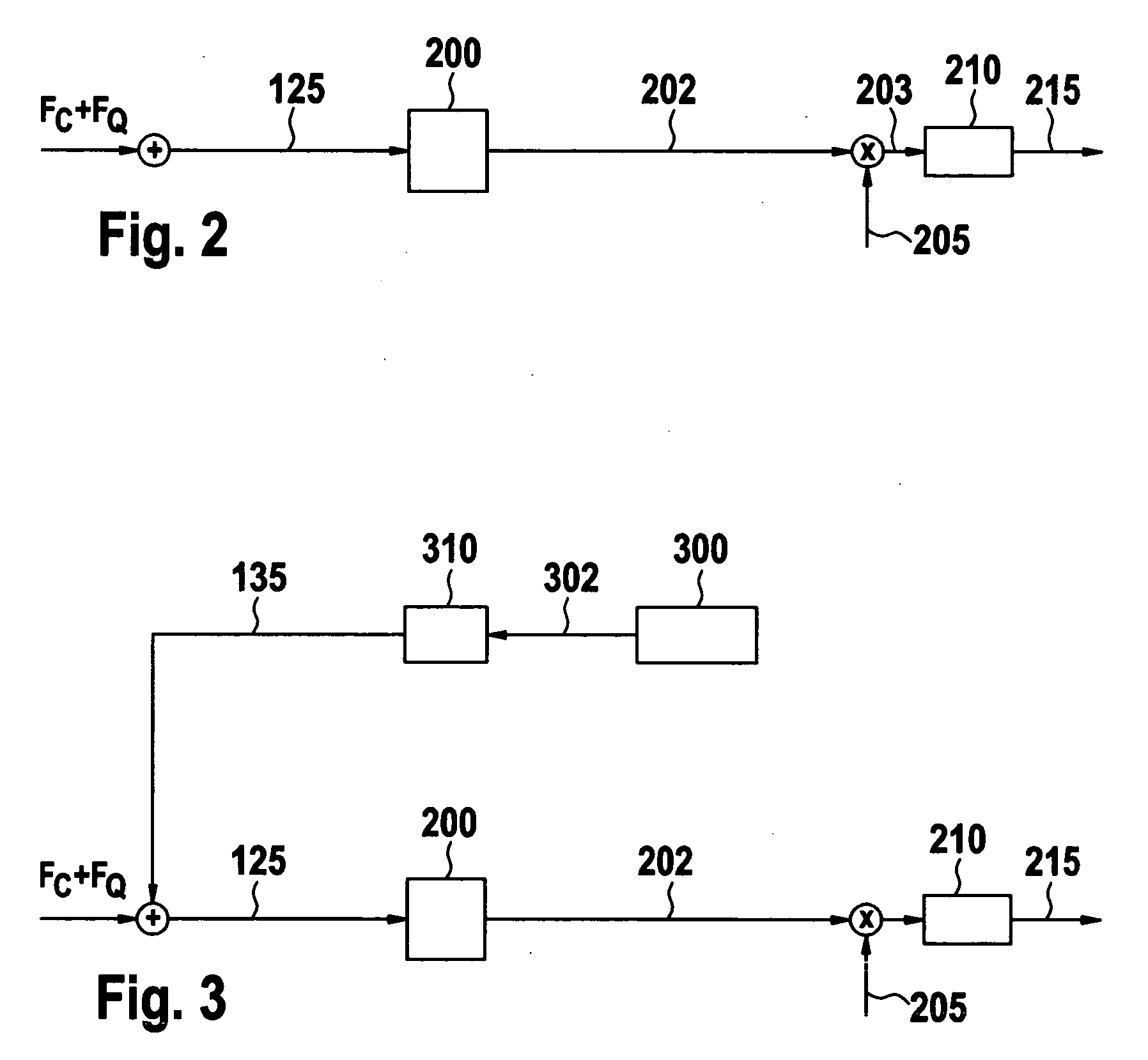

ActiveUS20060191338A1Capture range can be decreasedHigh resolutionAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsSeismic massPhase shifted

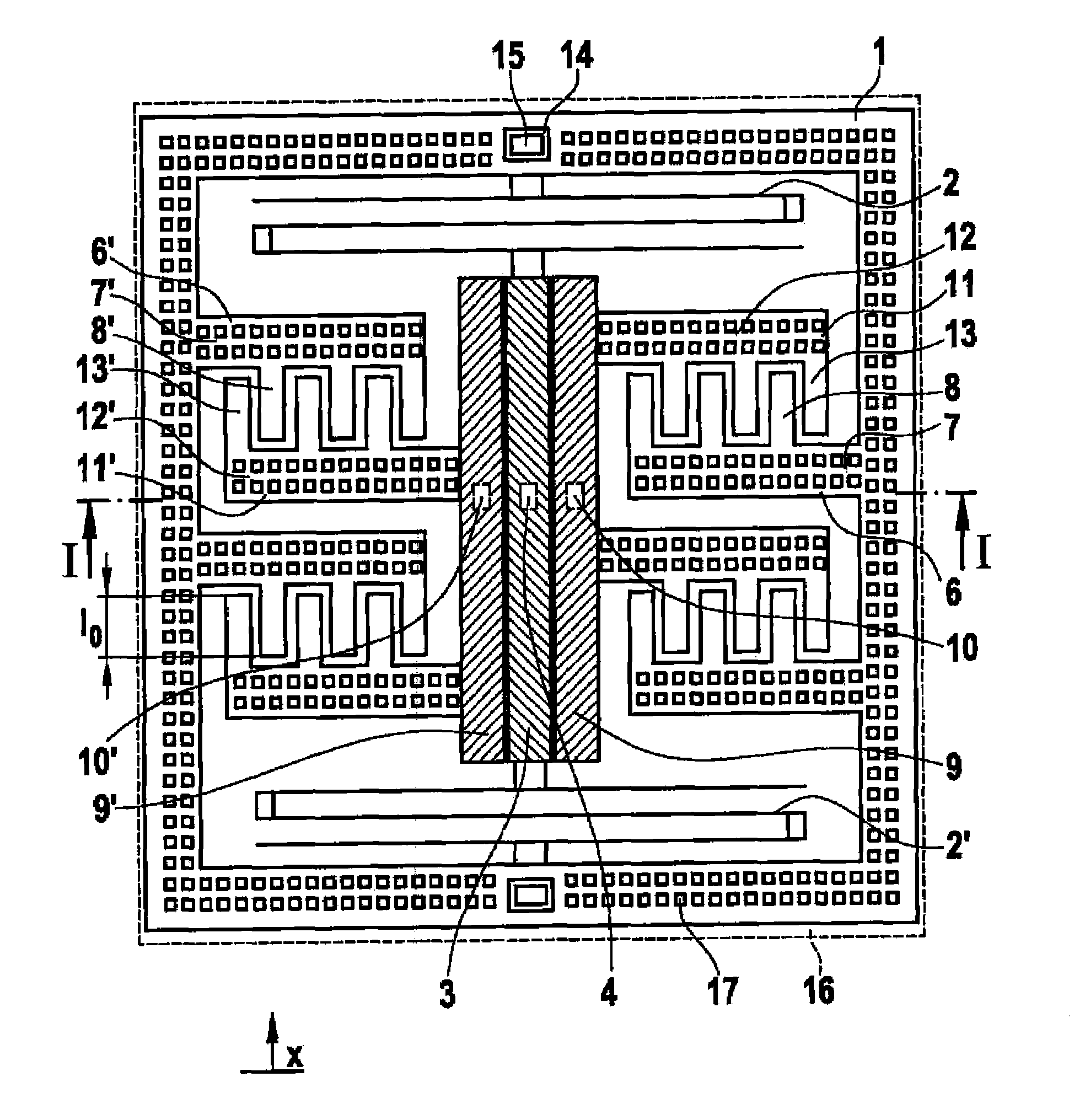

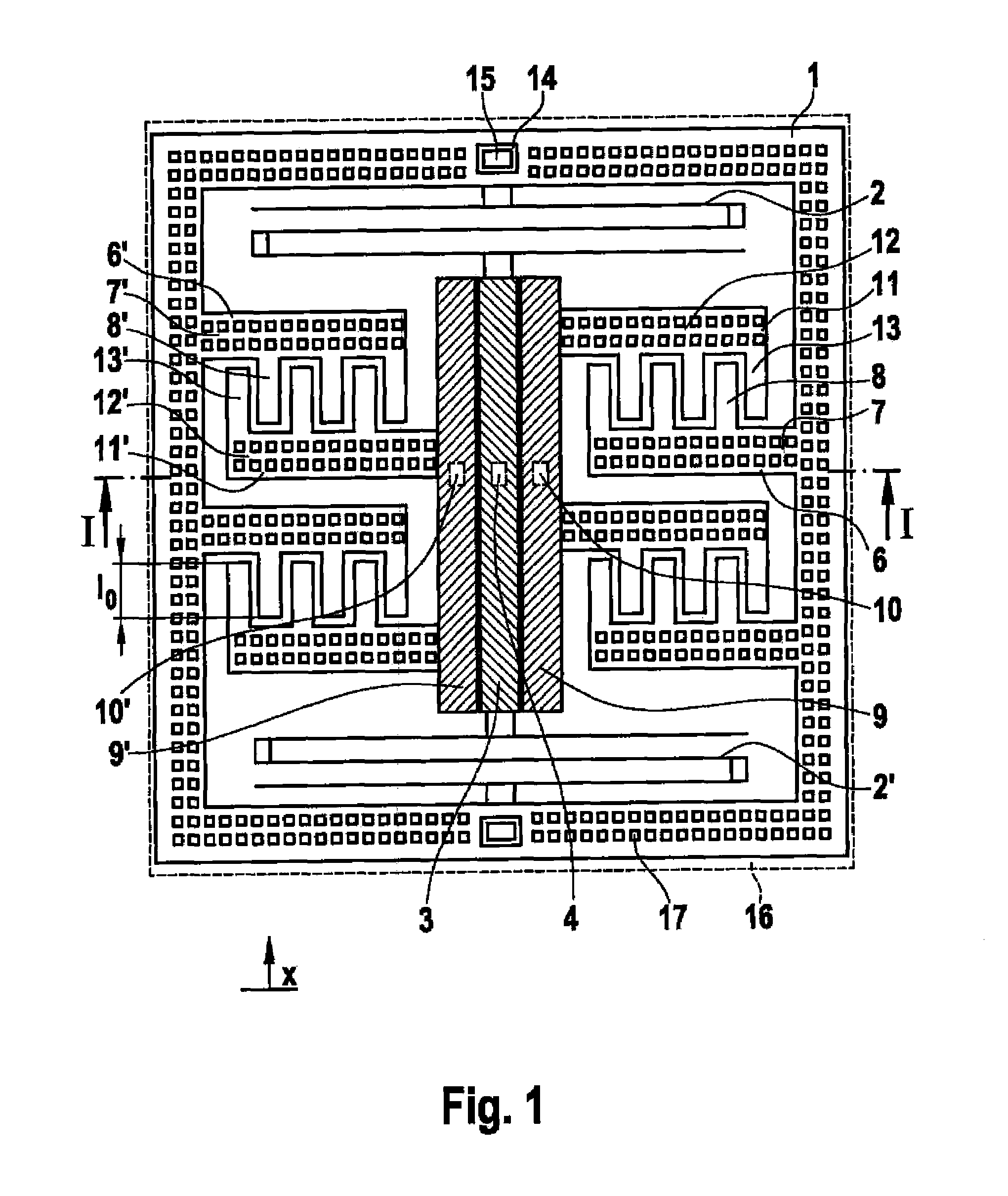

A micromechanical rotation rate sensor has a seismic mass and driving devices which cause a driving vibration of the seismic mass in a first direction x. The rotation rate sensor has measuring devices which measure a deflection of the seismic mass in a second direction y, and generate a deflection signal. The deflection includes a measurement deflection caused by a Coriolis force and an interference deflection, the interference deflection being phase-shifted with respect to the measurement deflection by 90°. Compensation devices are provided at the seismic mass to reduce the interference deflection. Regulation devices are provided, to which the deflection signal is supplied as an input variable, which demodulate an interference deflection signal from the deflection signal, and which generate a compensation signal from the interference deflection signal, which is supplied to the compensation devices.

Owner:ROBERT BOSCH GMBH

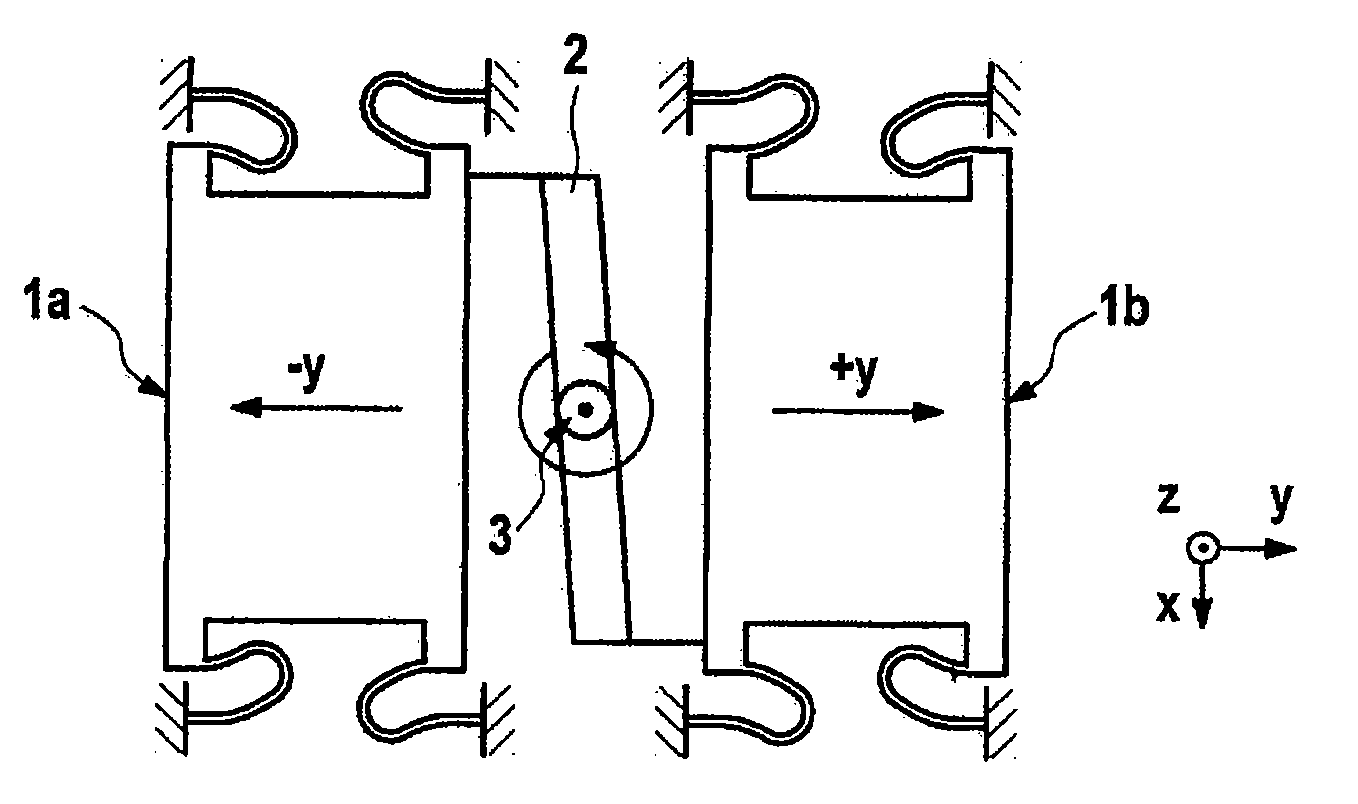

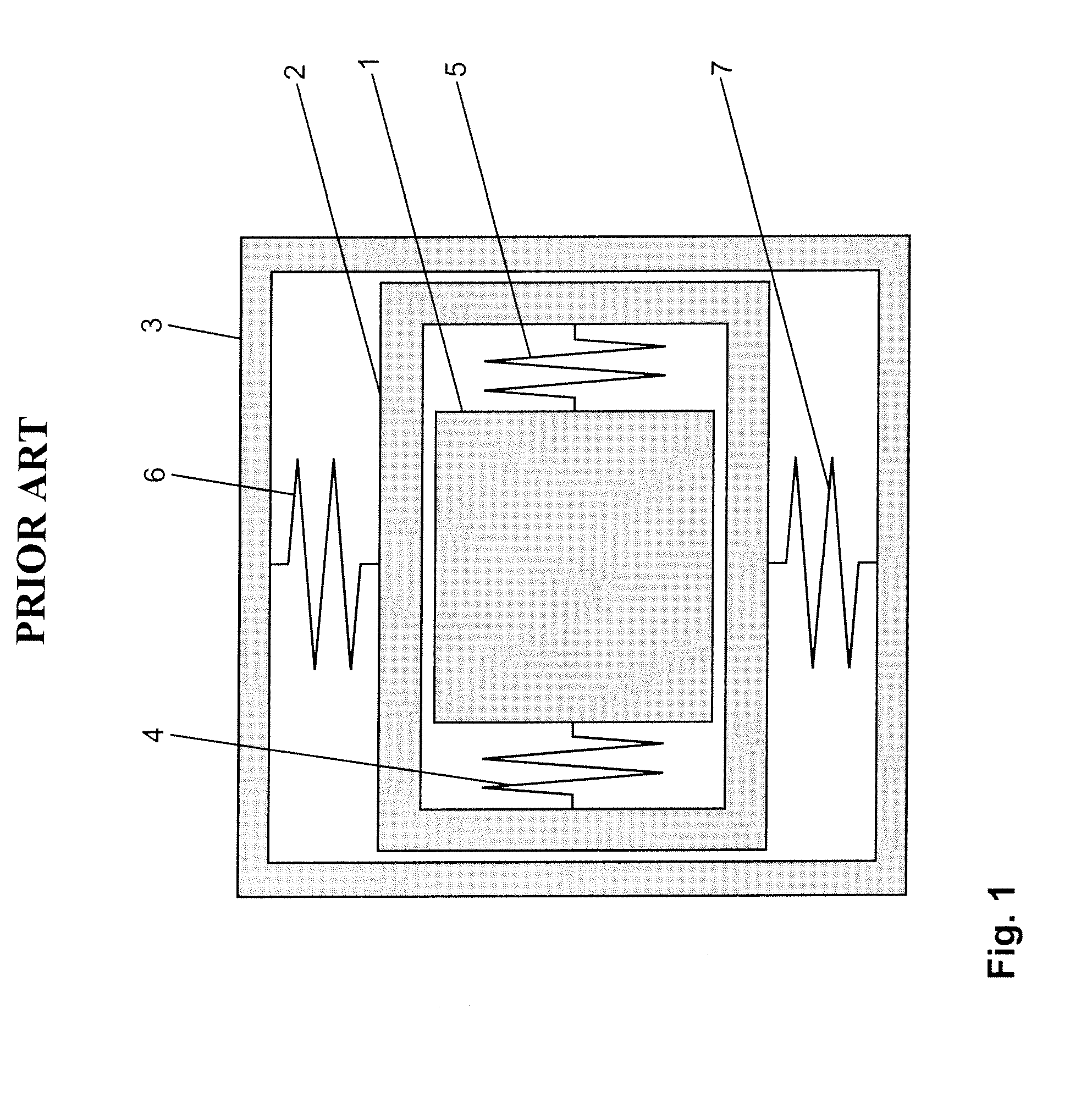

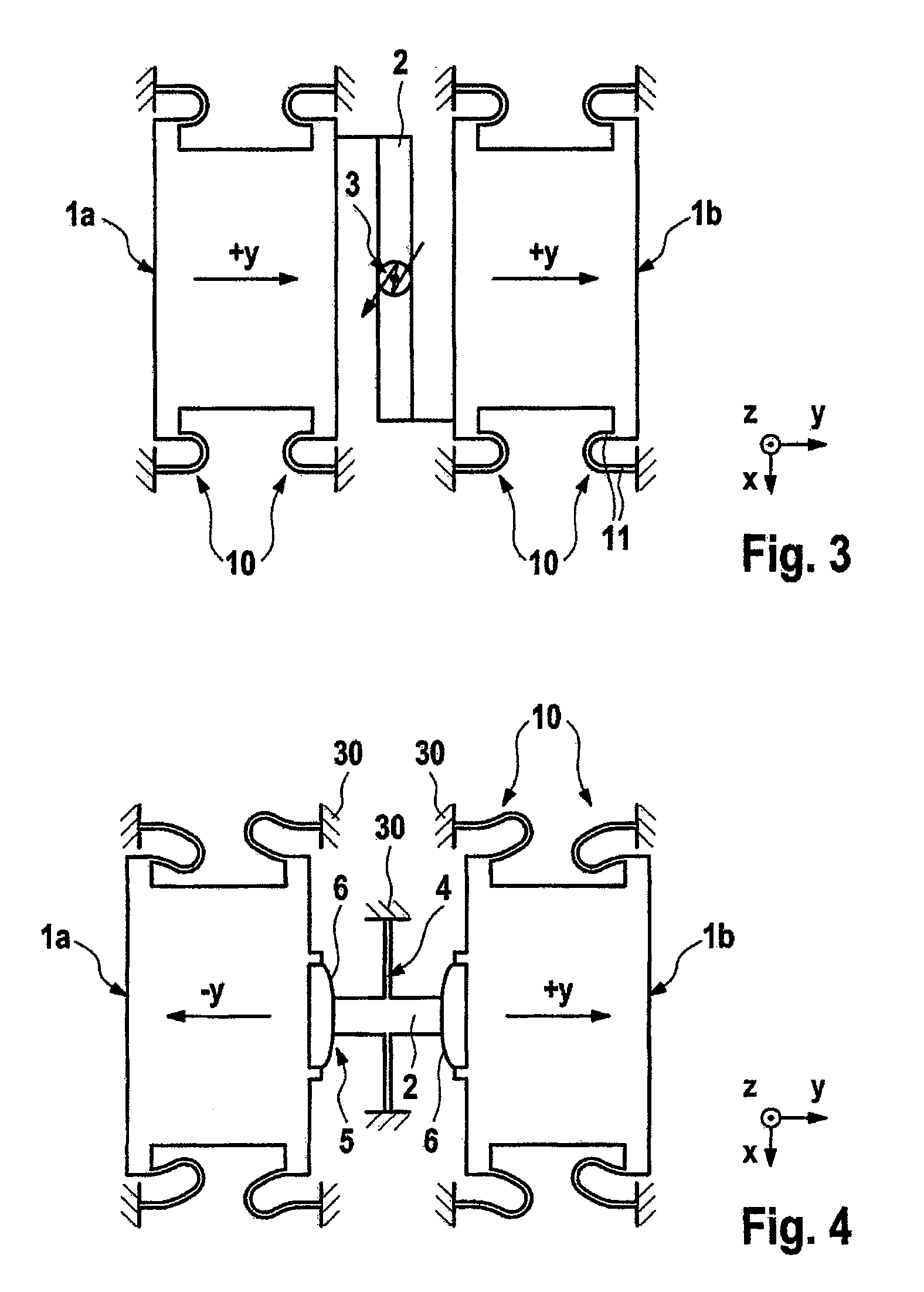

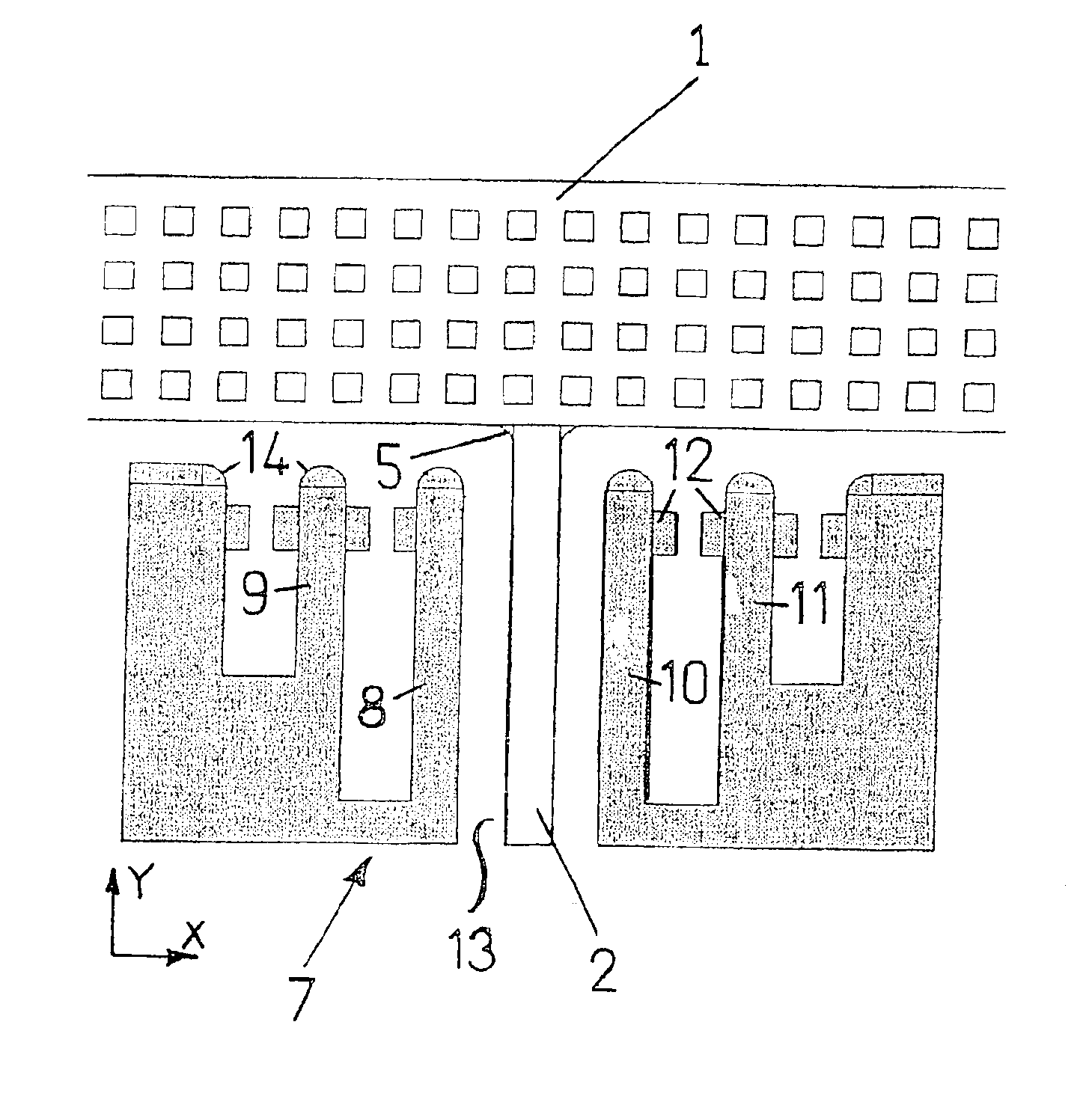

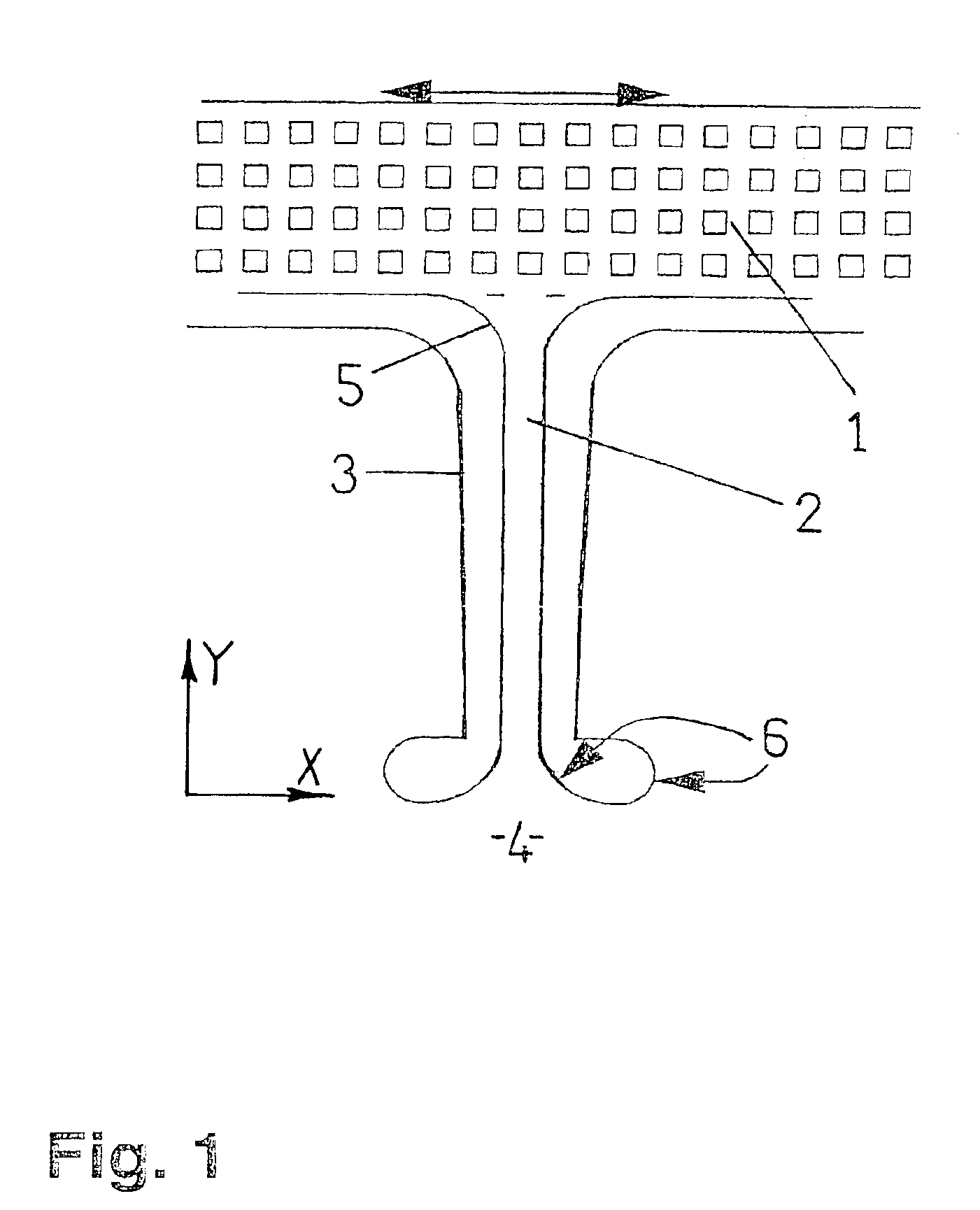

Sensor

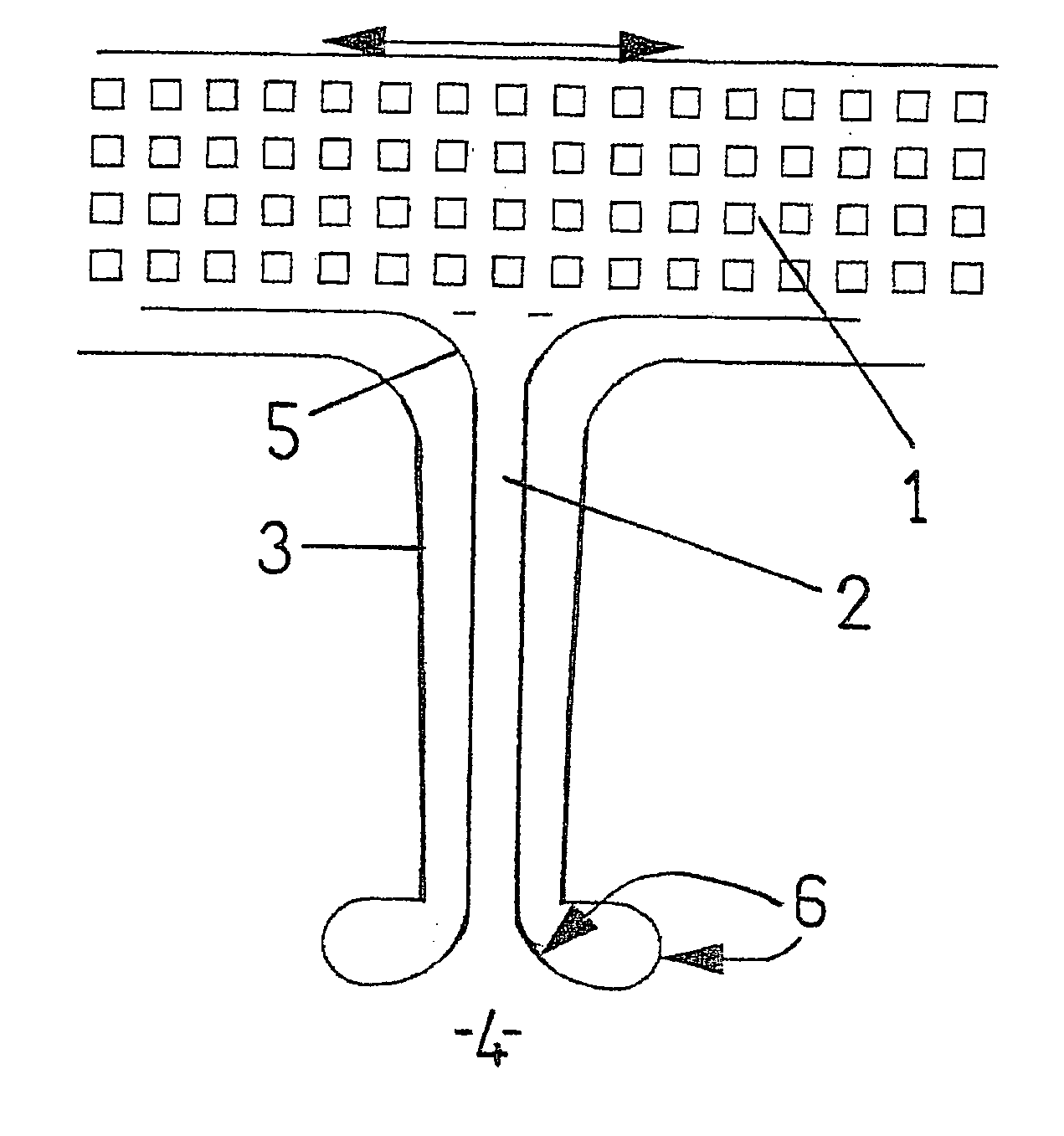

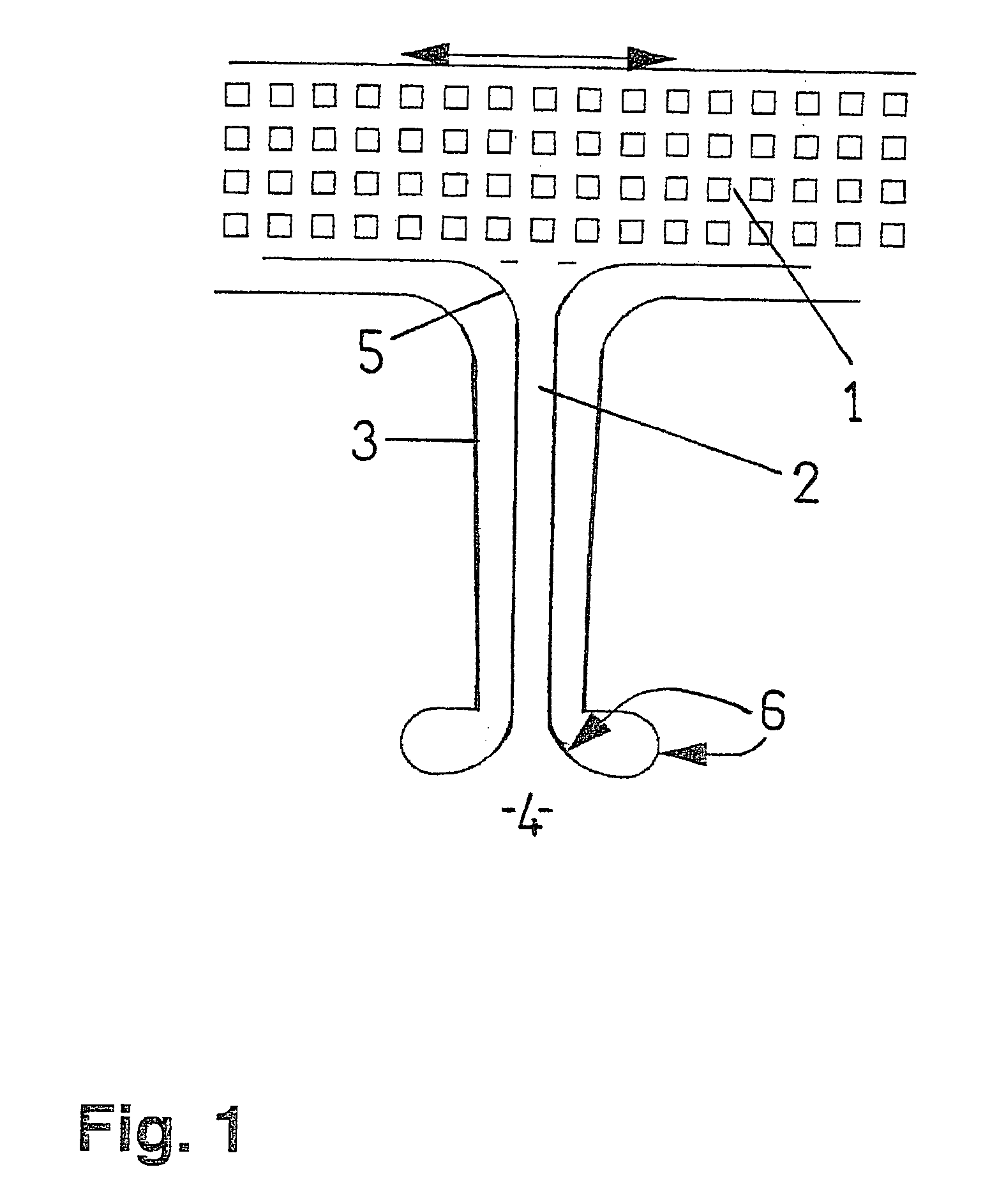

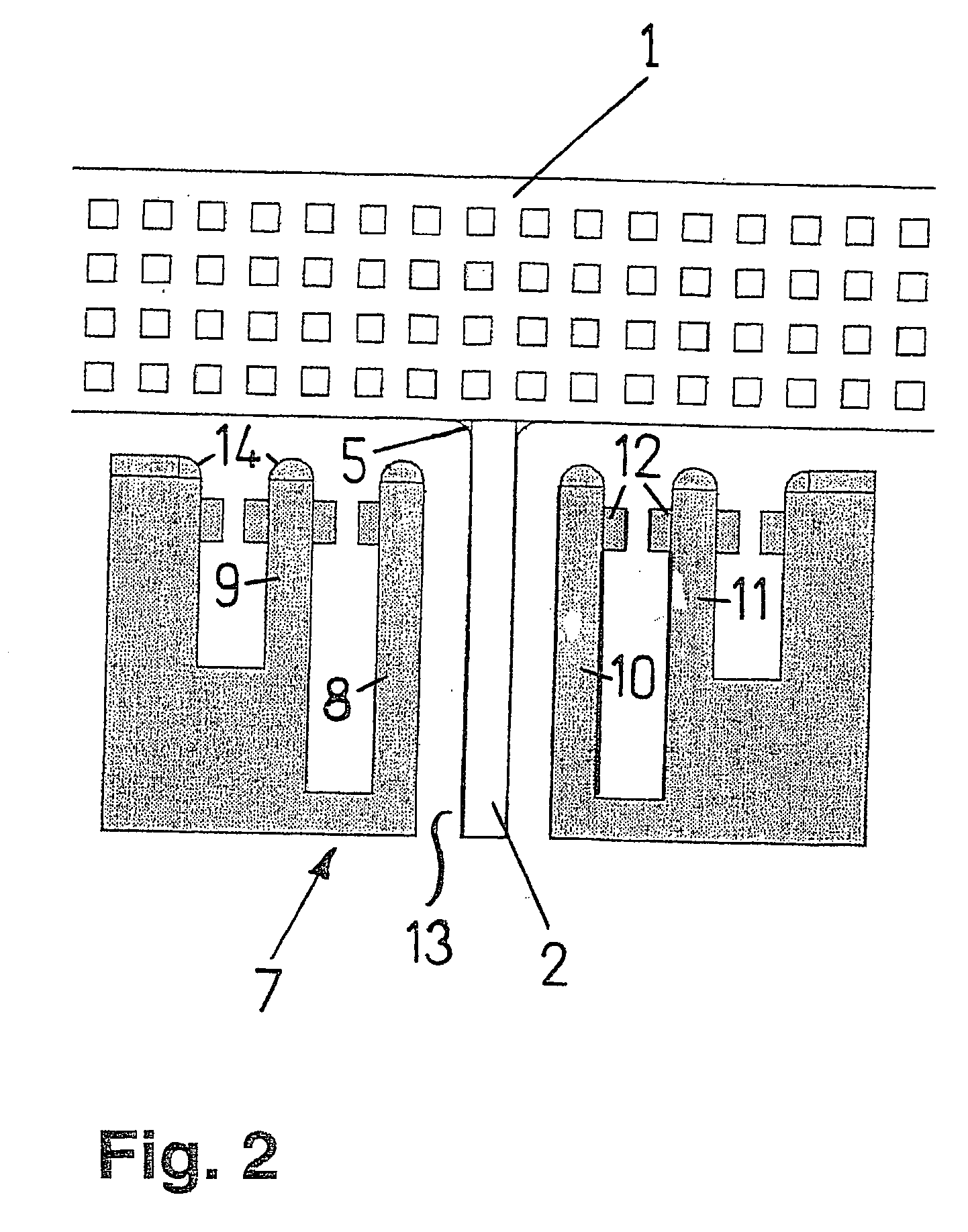

InactiveUS20040129077A1Vibration measurement in solidsAcceleration measurement using interia forcesSeismic massEngineering

For a sensor whose sensor structure is implemented in a micromechanical structural component and which has parts which are movable in relation to the stationary substrate of the structural component, and which also includes an unsupported seismic mass (1), a spring system having at least one spring (2), the seismic mass (1) being connected to the substrate through the spring system, an overload protection to limit the deflection of the spring system and the seismic mass (1) in at least one direction, and means for detecting the deflections of the spring system and the seismic mass (1), design measures are proposed whereby the impact forces may be reduced to prevent conchoidal breaks and resulting incipient damage to the sensor structure, as well as formation of particles. To that end, at least one two-dimensional stop (3) for at least one moving part of the sensor structure is provided as overload protection. Alternatively or in addition thereto, at least one spring stop (7) for at least one moving part of the sensor structure is provided according to the present invention as overload protection.

Owner:ROBERT BOSCH GMBH

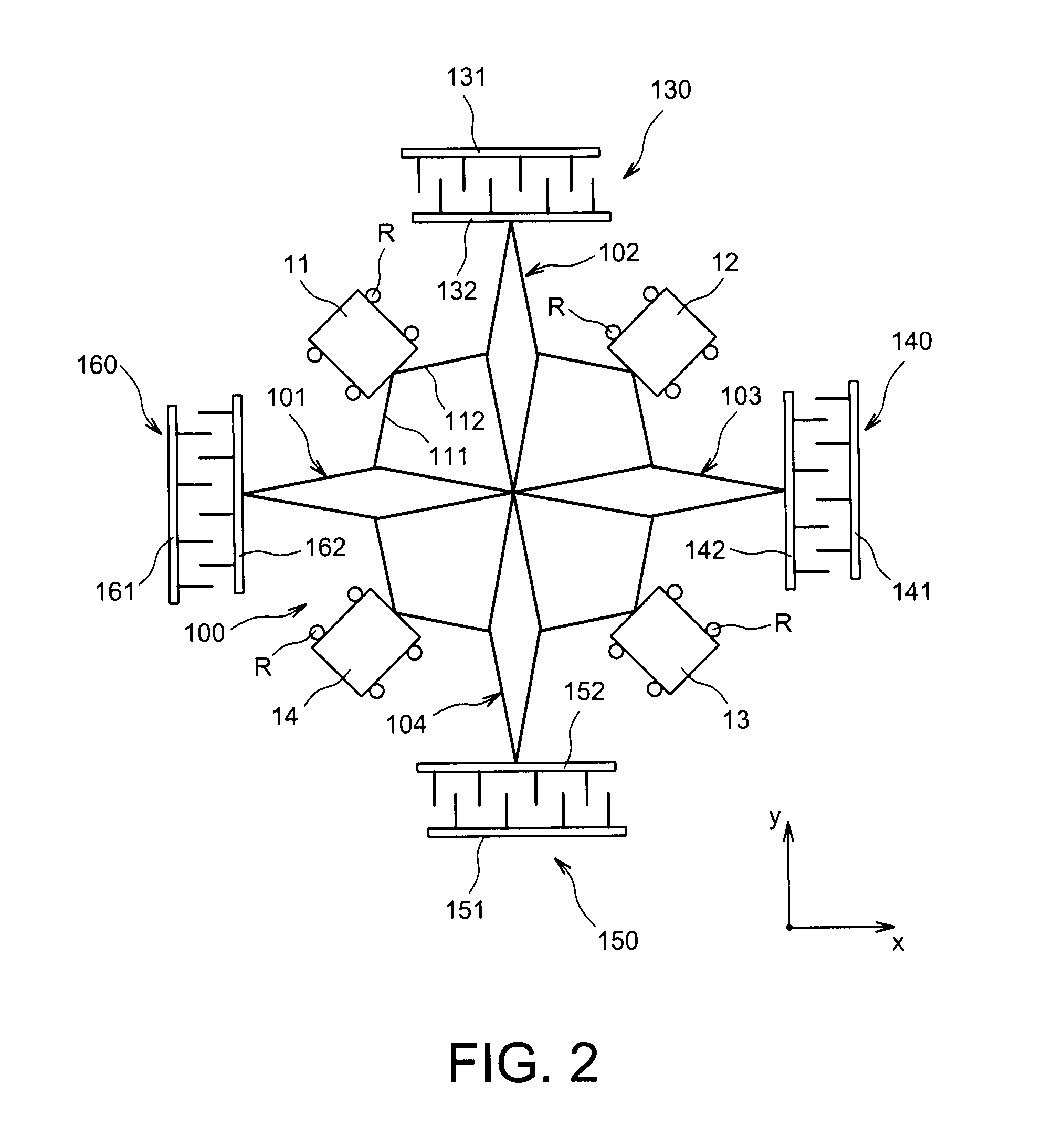

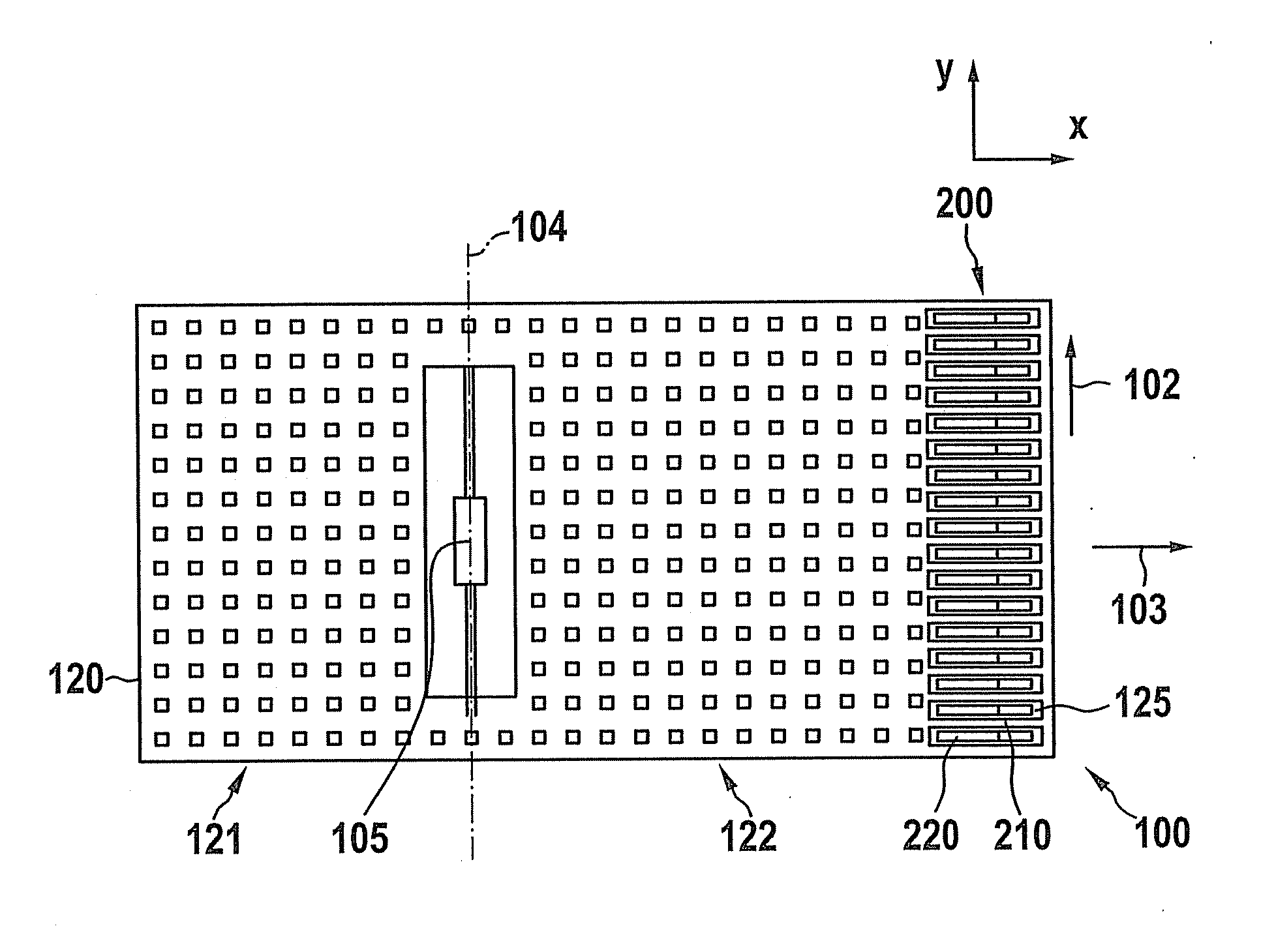

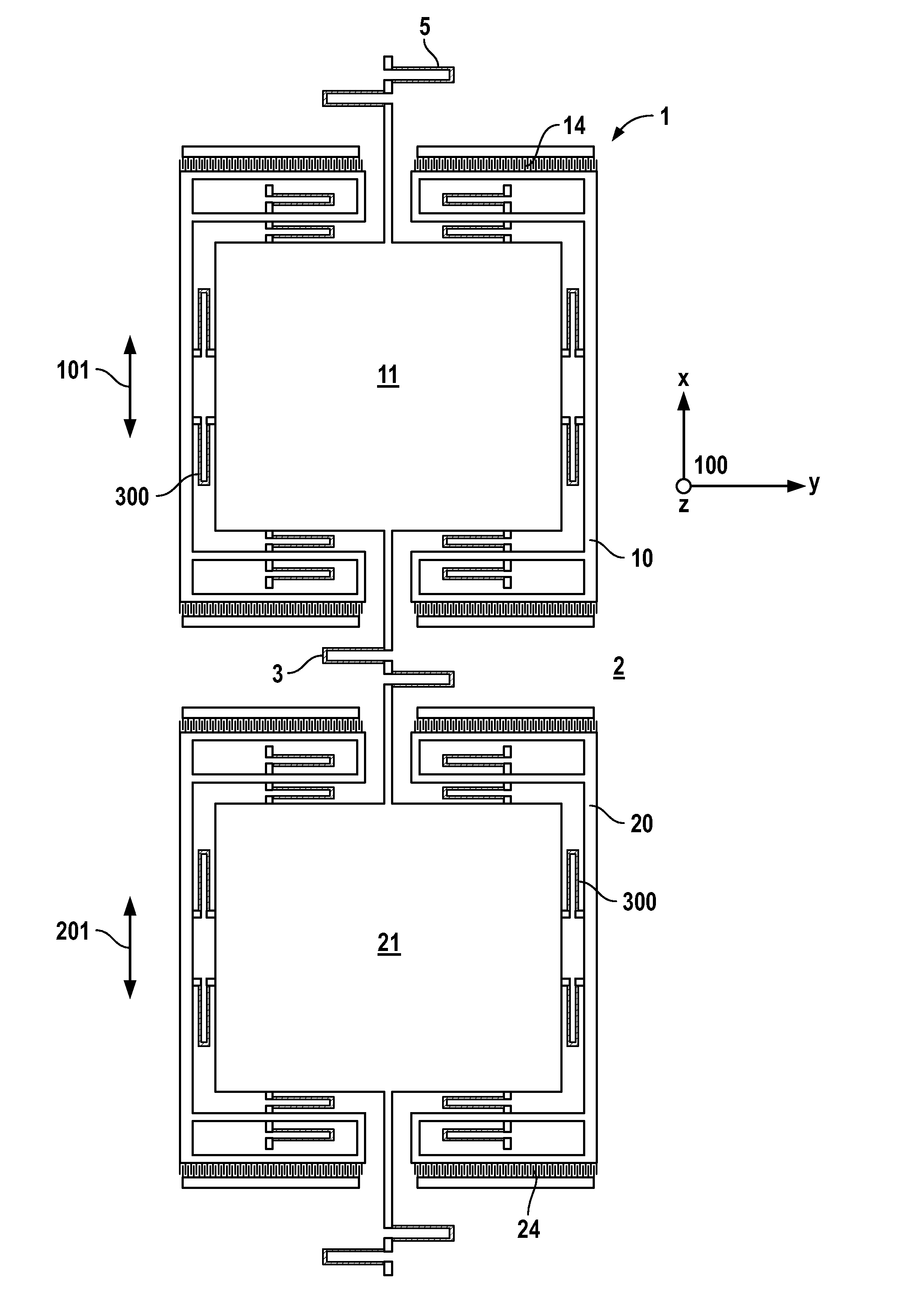

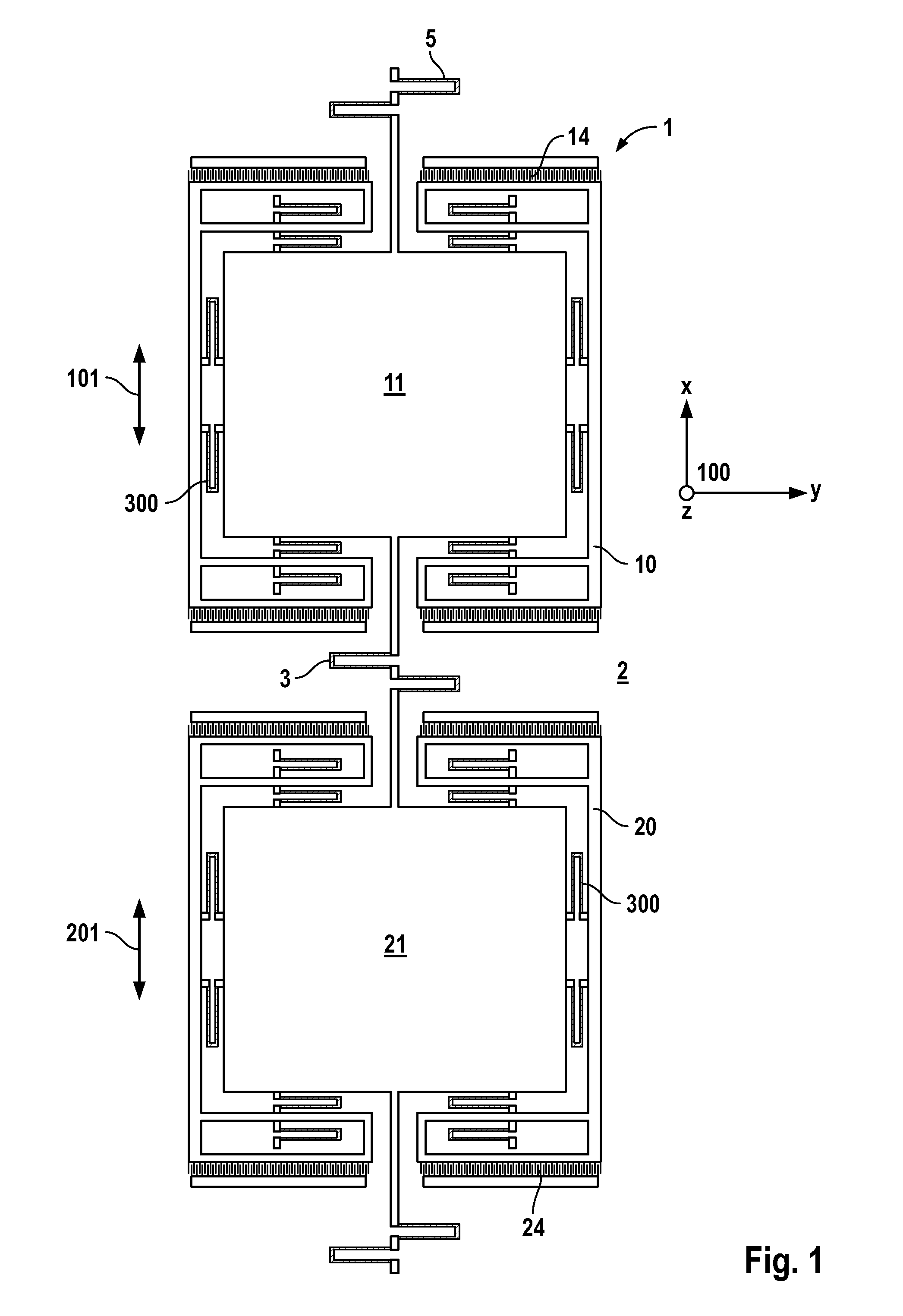

Micromechanical rotation rate sensor with a coupling bar and suspension spring elements for quadrature suppression

ActiveUS8549919B2Reduce generationSuppresses quadratureAcceleration measurement using interia forcesSemiconductor/solid-state device manufacturingSeismic massEngineering

A micromechanical rotation rate sensor including at least one substrate, wherein the base surface of the substrate is oriented parallel to the x-y plane of a Cartesian coordinate system, at least two seismic masses and in each case at least one suspension spring element for suspending the seismic mass from the substrate, wherein the at least two seismic masses are coupled to one another by at least one coupling bar, and at least one of the suspension spring elements includes at least two bar sections, which, in the undeflected state, are oriented essentially parallel to one another or are at an angle of less than 45° with respect to one another, and one or more connecting sections, which connect the bar sections to one another, wherein the bar sections can be displaced relative to one another in their longitudinal direction.

Owner:CONTINENTAL TEVES AG & CO OHG

Acceleration sensor having a surrounding seismic mass

InactiveUS20090282914A1Sturdy against deformationMore recessionAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsSeismic massGravitation

A micromechanical acceleration sensor has a substrate, a suspension, a seismic mass, and stationary capacitive electrodes, which seismic mass is suspended over the substrate with the aid of the suspension. The seismic mass has a mass center of gravity, and the suspension has at least two anchors on the substrate, the at least two anchors being situated next to the mass center of gravity at a distance which is small compared to a horizontal extension of the seismic mass. The stationary capacitive electrodes are provided in recesses of the seismic mass. The seismic mass directly surrounds the suspension.

Owner:ROBERT BOSCH GMBH

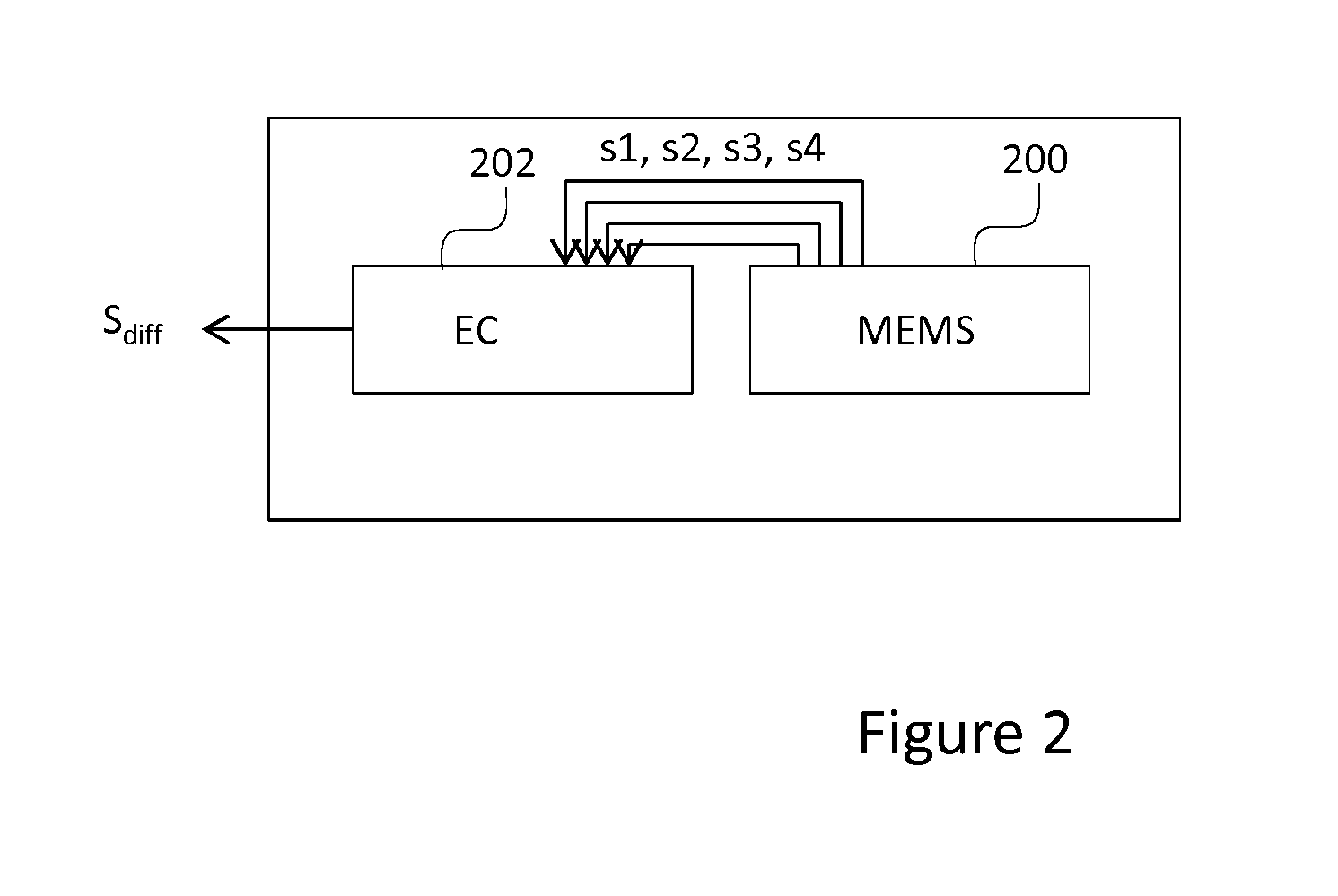

Method for the decoupled control of the quadrature and the resonance frequency of a micro-mechanical gyroscope

A method for the precise measuring operation of a micro-mechanical rotation rate sensor, including at least one seismic mass, at least one drive device for driving the seismic mass in the primary mode (qi) and at least three trimming electrode elements which are jointly associated directly or indirectly with the seismic mass. An electric trimming voltage (u1, u2, u3, u4) is set respectively between said trimming electrode elements and the seismic mass. Each of the electric trimming voltages (u1, u2, u3, u4) are adjusted in accordance with a resonance frequency variable (ũT, ŨT,0), a quadrature variable (ũT, ŨT,0) and a restoring variable (ũS).

Owner:CONTINENTAL TEVES AG & CO OHG

Sensor

InactiveUS6923062B2Prevent conchoidal breaksReduce impactAcceleration measurement using interia forcesSamplingSeismic massEngineering

For a sensor whose sensor structure is implemented in a micromechanical structural component and which has parts which are movable in relation to the stationary substrate of the structural component, and which also includes an unsupported a seismic mass, a spring system having at least one spring, the seismic mass being connected to the substrate through the spring system, and an overload protection to limit the deflection of the spring system and the seismic mass in at least one direction, and an arrangement for detecting the deflections of the spring system and the seismic mass, whereby the impact forces may be reduced to prevent conchoidal breaks and resulting incipient damage to the sensor structure, as well as formation of particles. To that end, at least one two-dimensional stop for at least one moving part of the sensor structure is provided as overload protection. Alternatively or in addition thereto, at least one spring or resilient stop for at least one moving part of the sensor structure is provided as overload protection.

Owner:ROBERT BOSCH GMBH

Damper pulley assembly having a safety device

Owner:DAYCO EURO

Gyroscope structure and gyroscope

ActiveUS20150068308A1Increase signal levelEasy to implementAcceleration measurement using interia forcesSolid-state devicesGyroscopeSeismic mass

A microelectromechanical gyroscope that comprises two seismic masses suspended to form a plane of masses. The seismic masses are excited into rotary oscillation about a common primary axis that is in the plane of masses. Detected angular motion causes a rotary oscillation of the first seismic mass about a first detection axis, and of the second seismic mass about a second detection axis. The detection axes are perpendicular to the plane of masses and separated by a non-zero distance.

Owner:MURATA MFG CO LTD

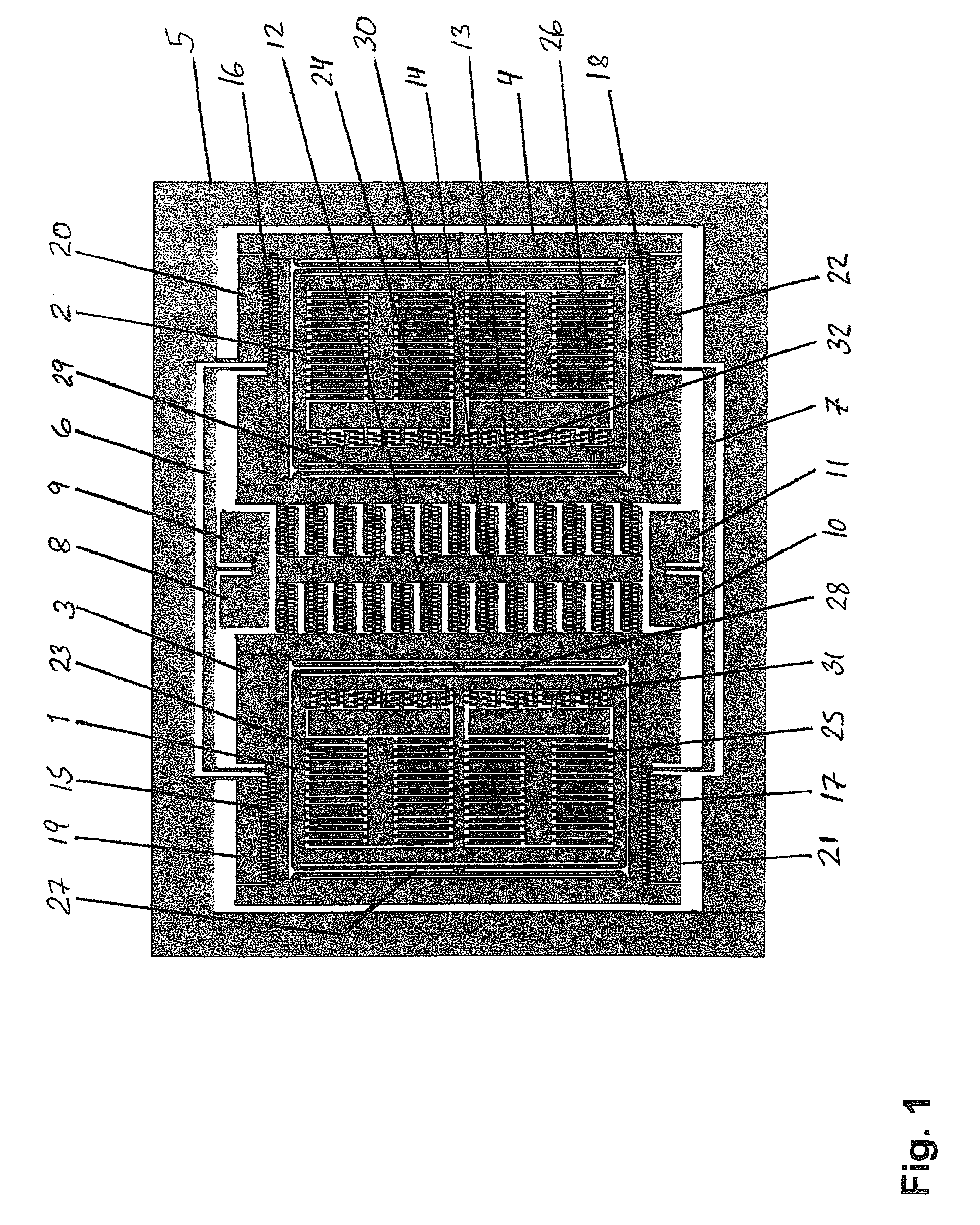

Vibrating micro-mechanical sensor of angular velocity

ActiveUS20100218605A1Reliable measurementImprove performanceAcceleration measurement using interia forcesNavigation by speed/acceleration measurementsSeismic massMeasurement device

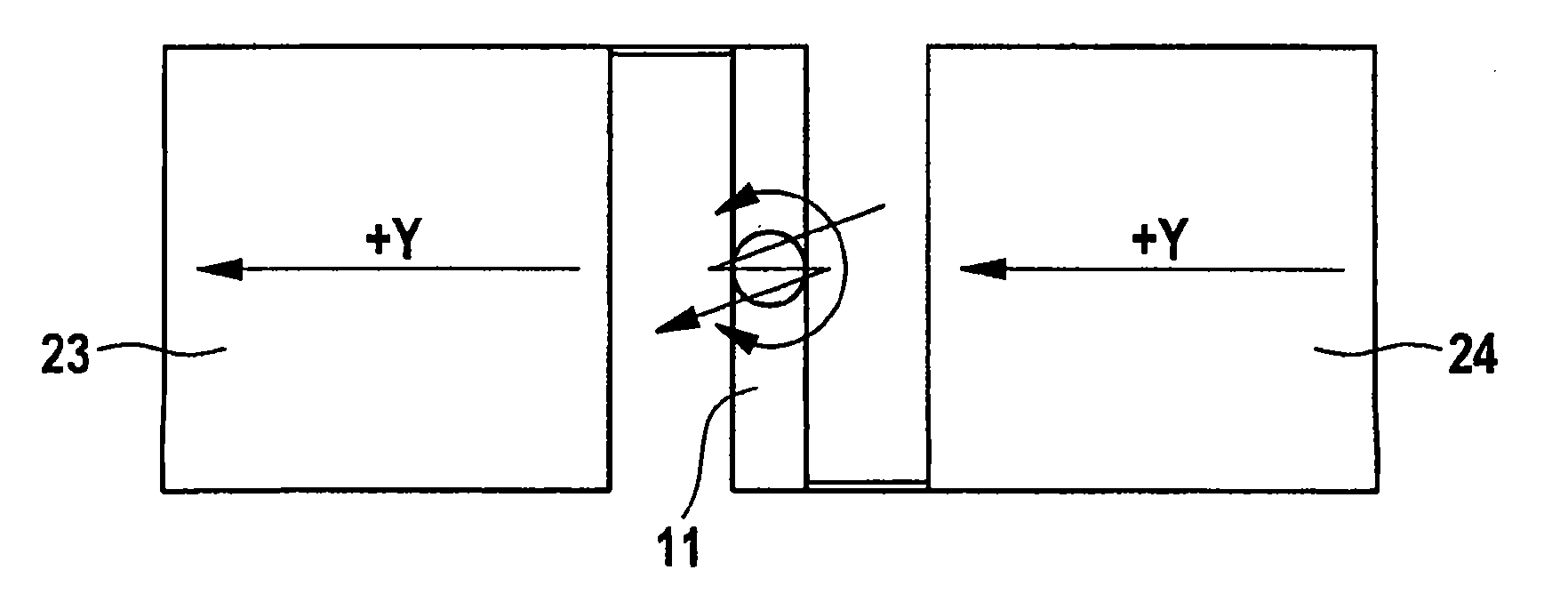

The invention relates to measuring devices used for measuring angular velocity, and more precisely, to vibrating micro-mechanical sensors of angular velocity. The sensor of angular velocity according to the invention comprises at least two seismic mass structures (1), (2), excitation structures (3), (4) and coupling seesaw type springs (6), (7). The objective of the invention is to provide an improved sensor structure, which enables reliable measuring with good efficiency particularly in small vibrating micro-mechanical angular velocity sensor solutions.

Owner:MURATA MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com