Patents

Literature

247results about How to "Secure coupling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

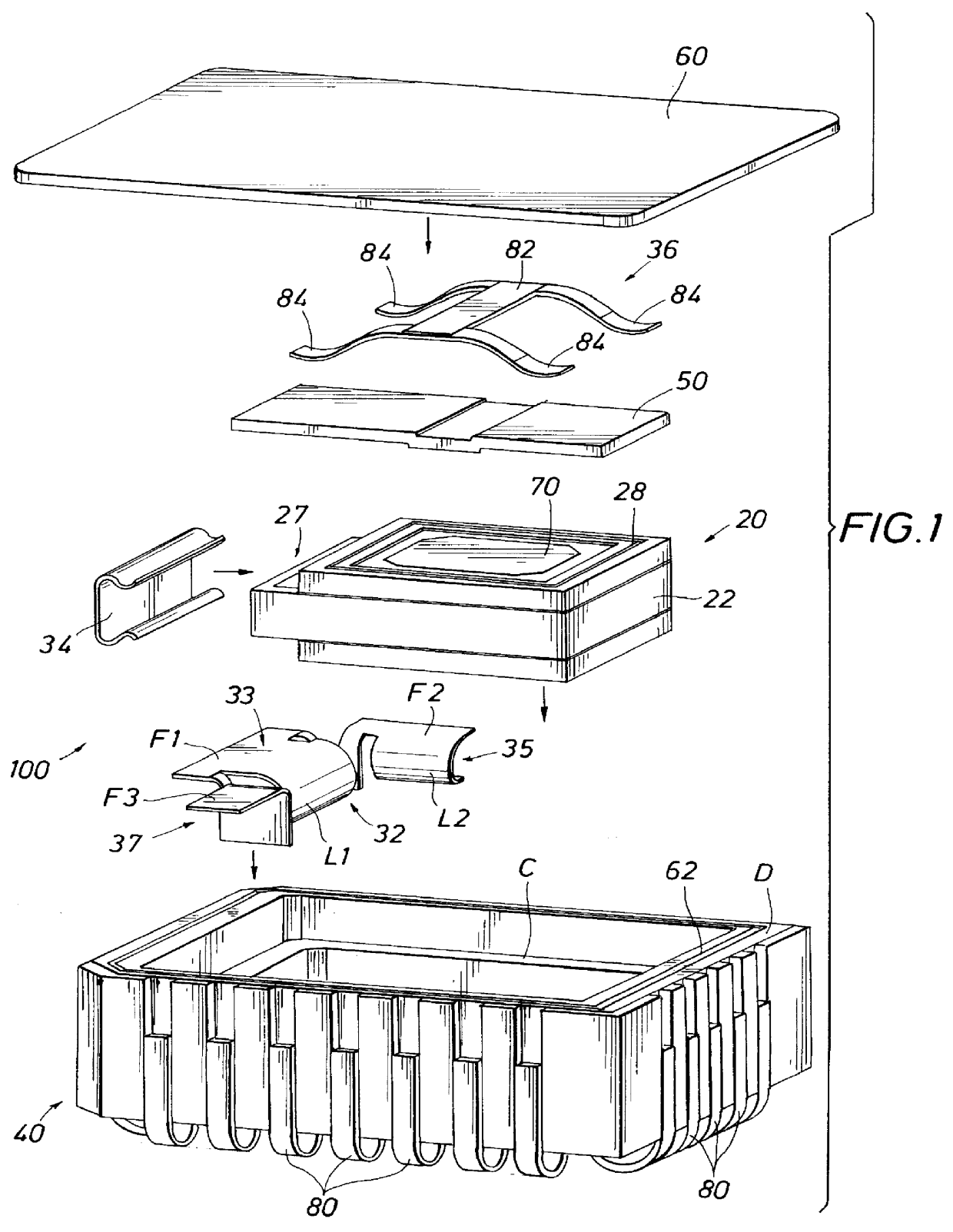

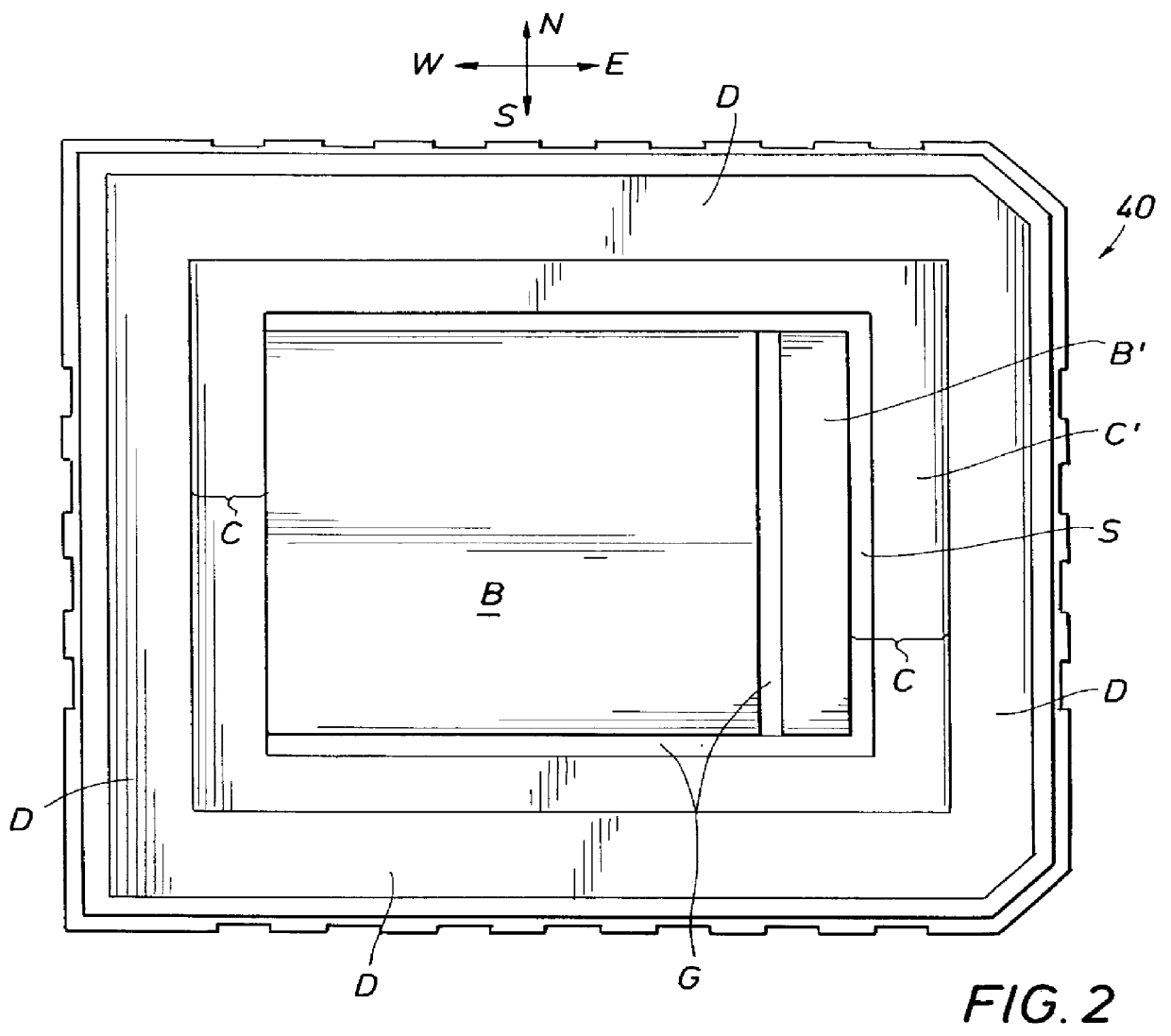

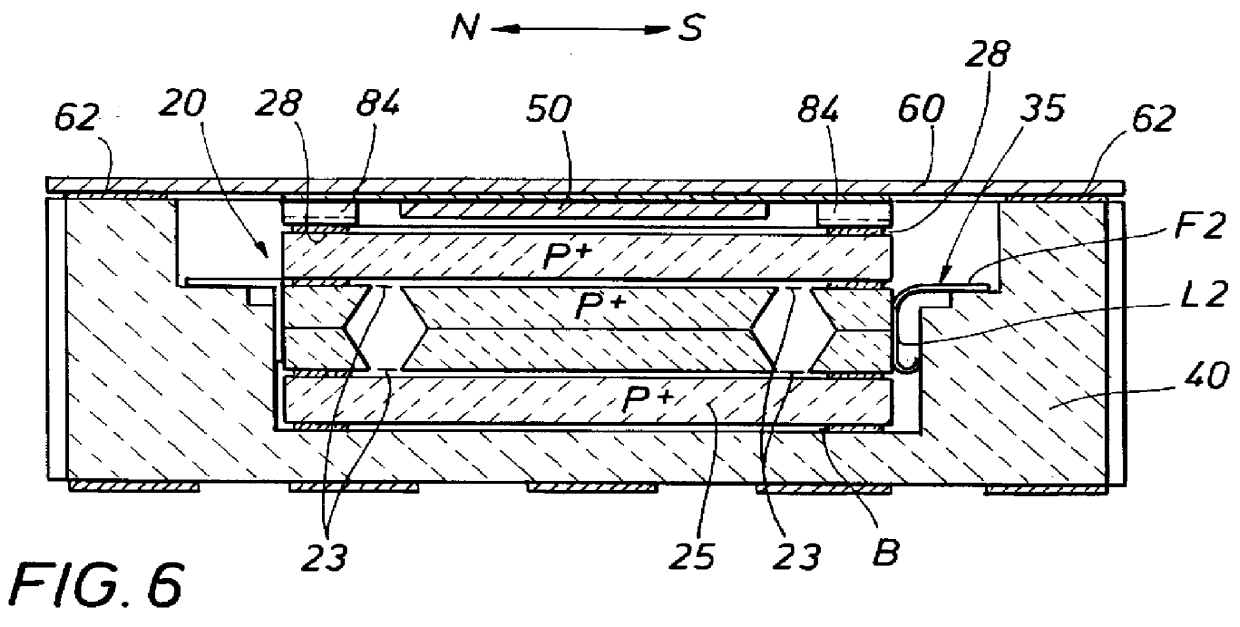

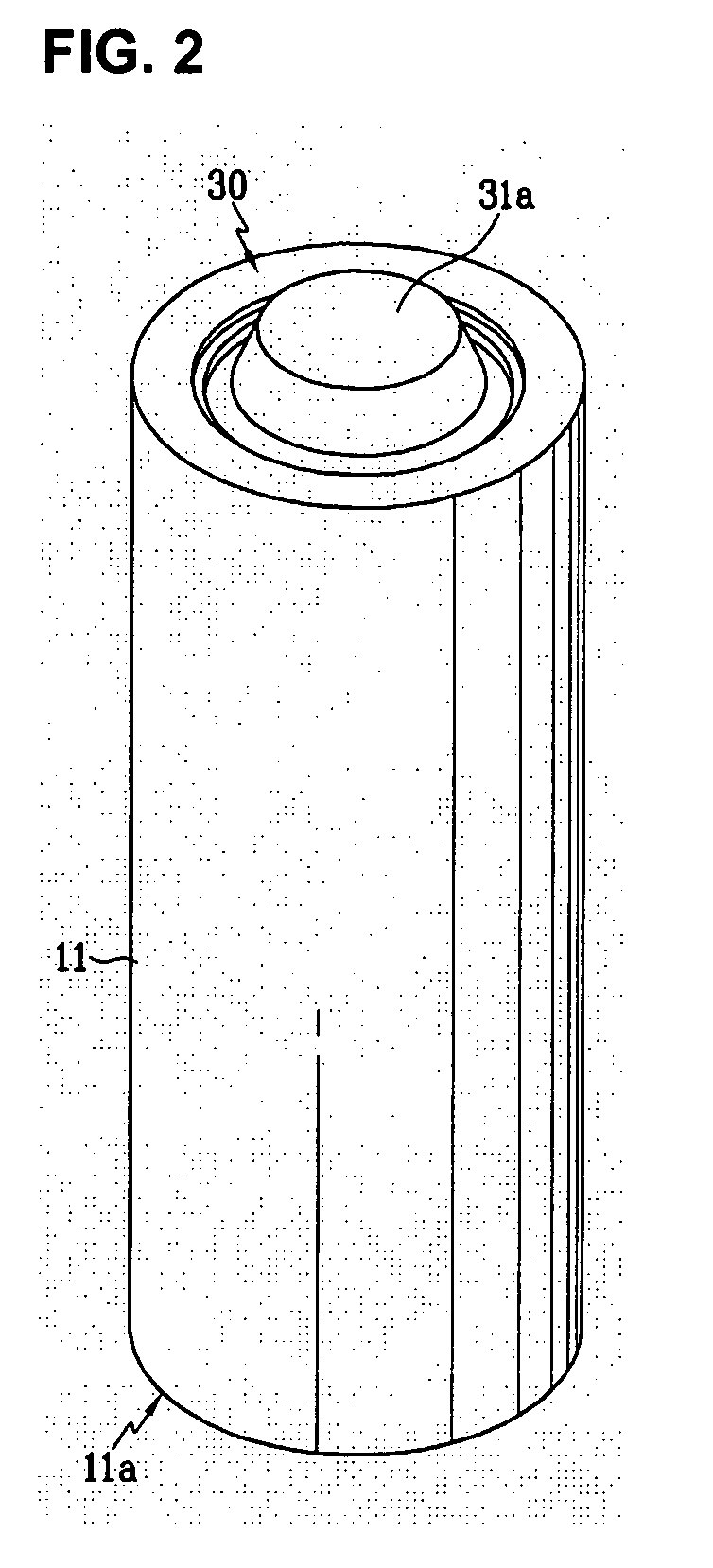

Sensor package arrangement

InactiveUS6040625AEasy to installMinimizing chance for outgassingSemiconductor/solid-state device detailsSolid-state devicesCapacitanceElectrical connection

A highly sensitive silicon micro-machined sensor package is provided for use in a micro-g environment that can also resist high shock in excess of 5000 g. The sensor is provided to measure acceleration in cooperation with associated electronics which are required to have electrical contact with sensor elements. The sensor is sealed in a high vacuum environment, and is arranged and designed to be free of temperature induced stress to the sensor. The sensor die package assembly comprises a silicon micro-machined sensor die, a ceramic package, two contact springs, a shorting clip, solder preform, a metal lid and a getter foil for ensuring a good vacuum for an extended period. The sensor die comprises a moving mass with eight supporting flexures on both sides of the proof mass. The proof mass's movement is protected on both sides by a top and a bottom cap. Acceleration applied to the package and the die causes the proof mass to move vertically in relation with the adjacent caps. The changes in distance between the proof mass and the caps in turn generate a change in an electrical signal which corresponds to the capacitance changes between the gaps. The sensor die package arrangement provides that the sensor die be secured within an evacuated ceramic case. Electrical connections made between external contacts of the case and contacts of the sensor die within the case are made through conductive springs, thereby minimizing materials in the interior of the case which would outgass in the vacuum environment.

Owner:I O SENSORS

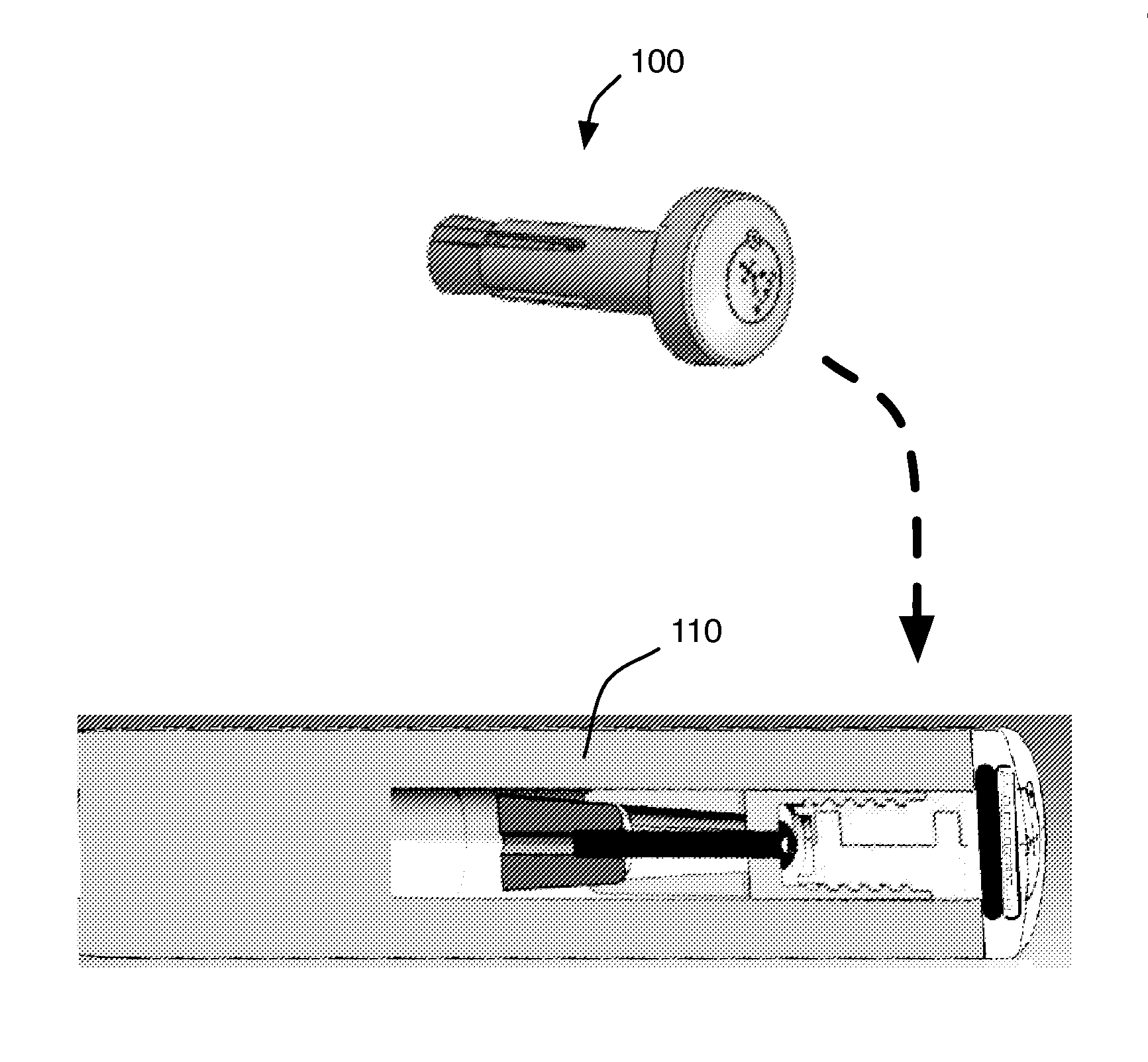

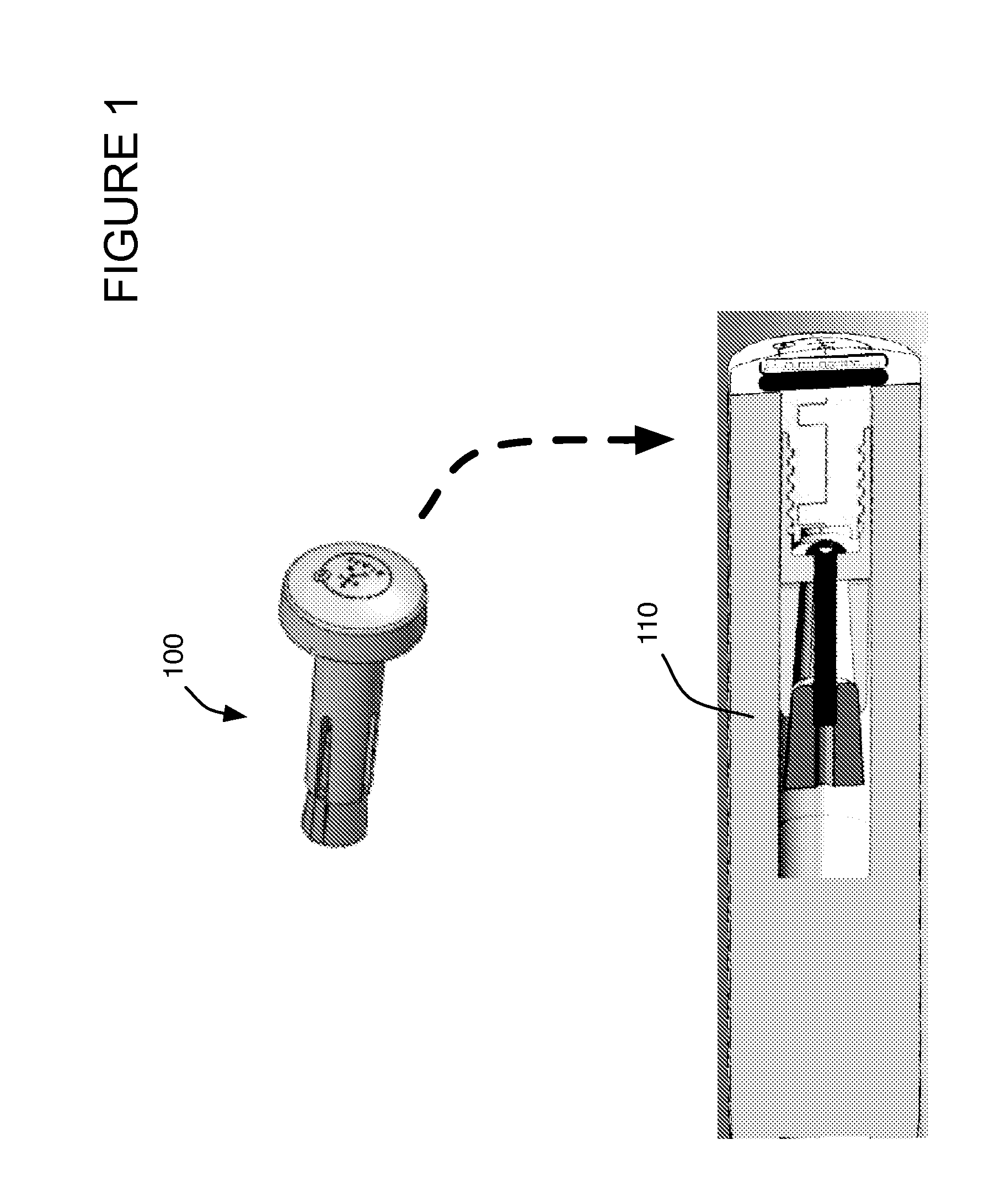

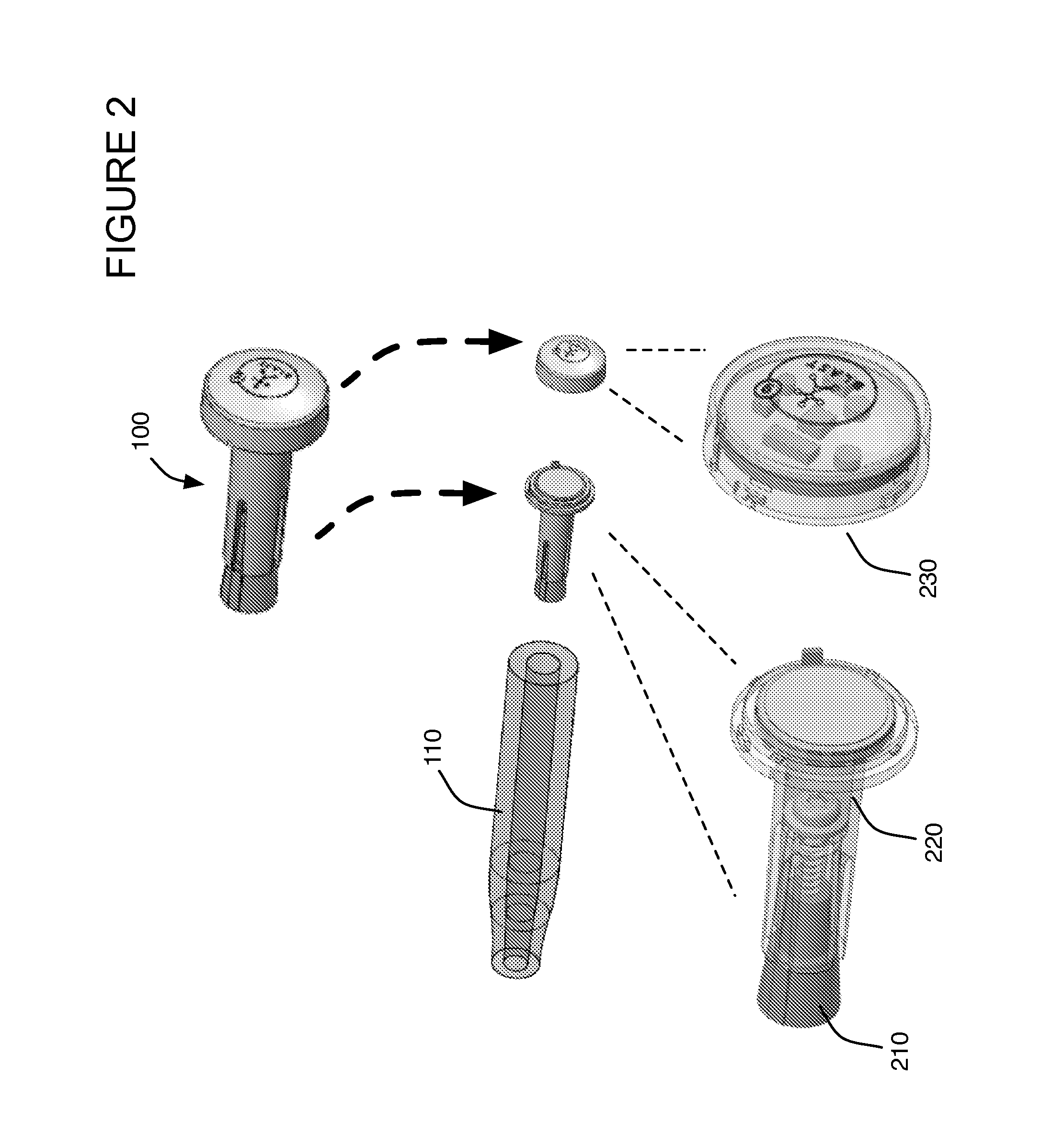

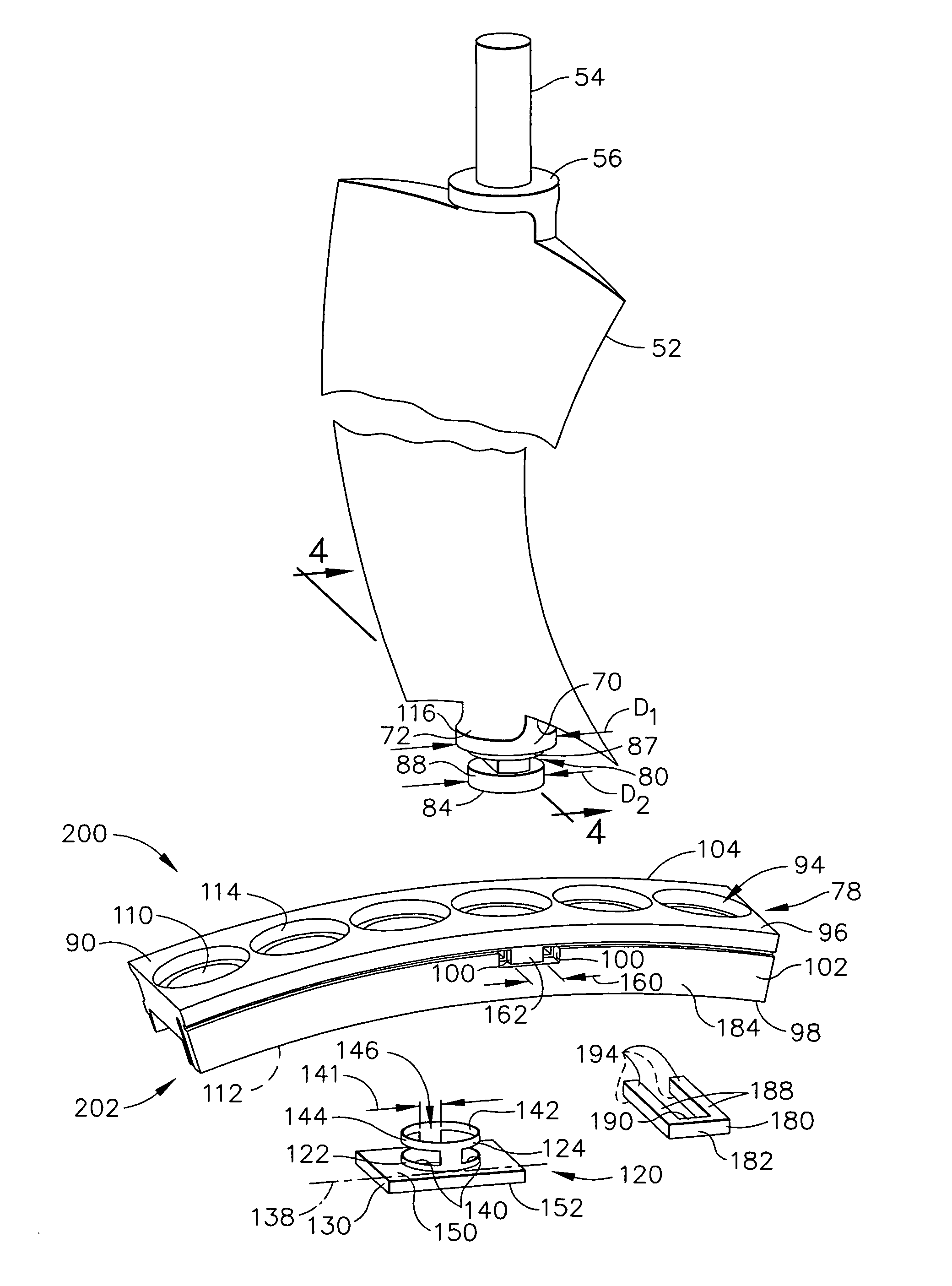

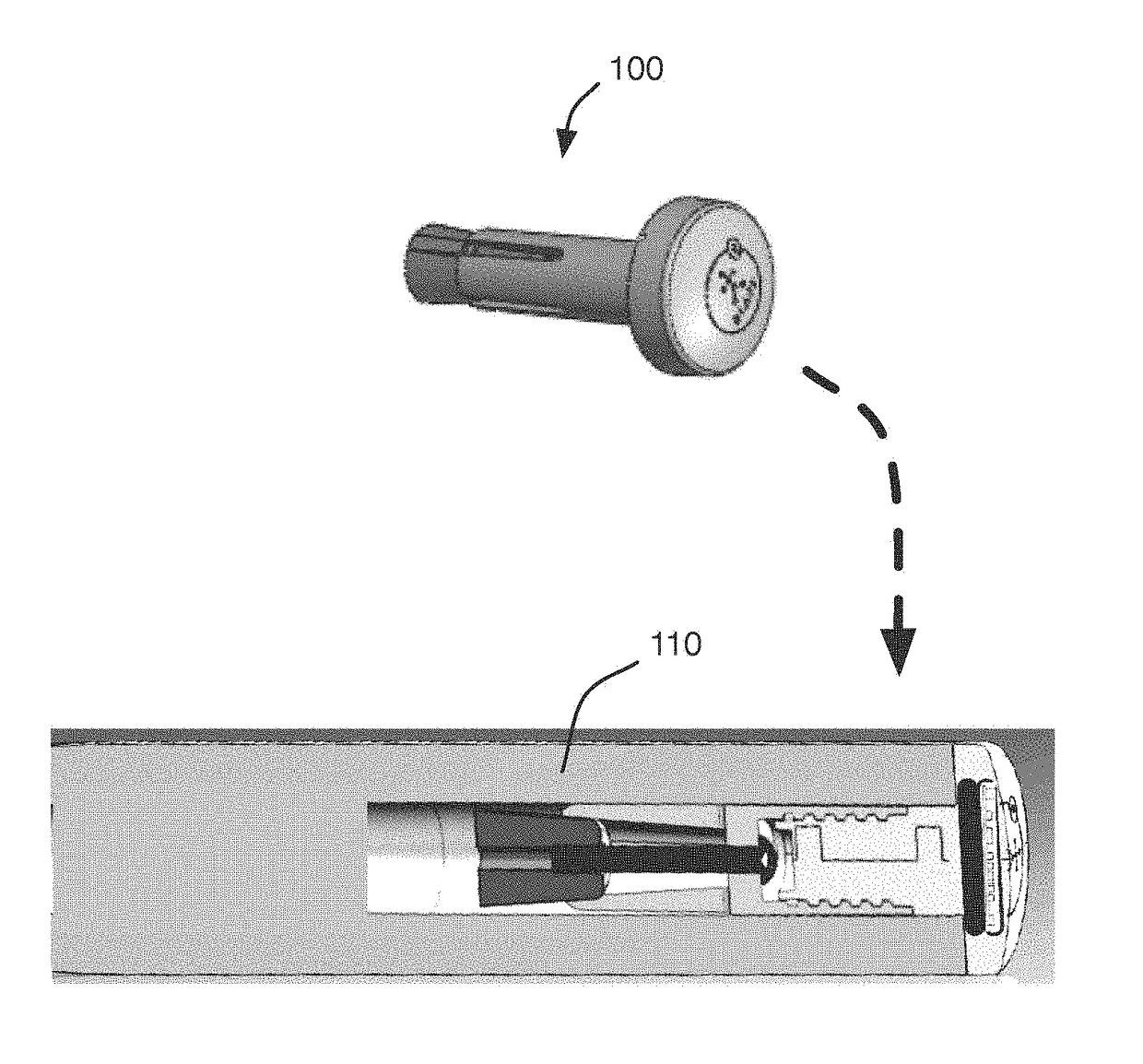

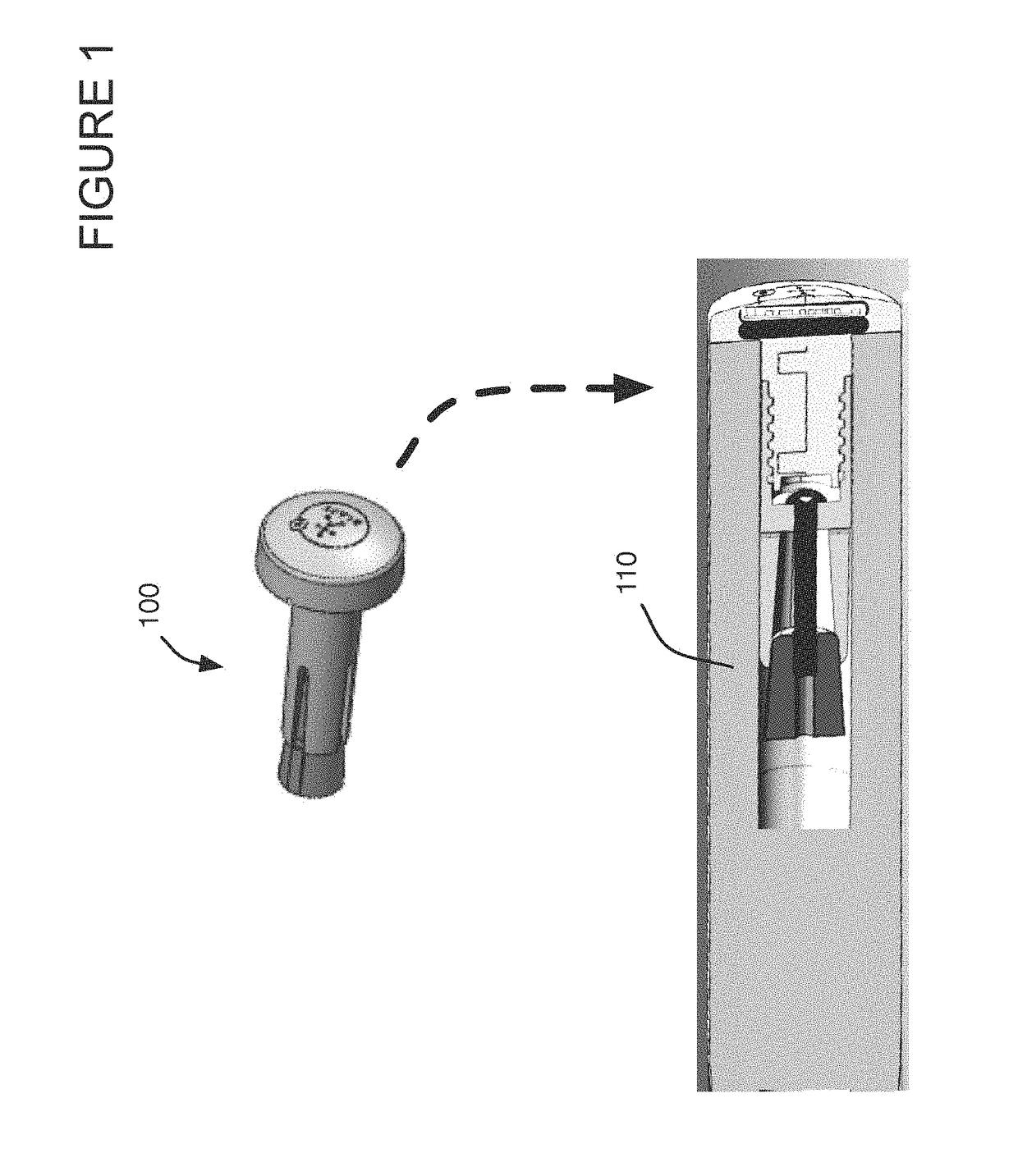

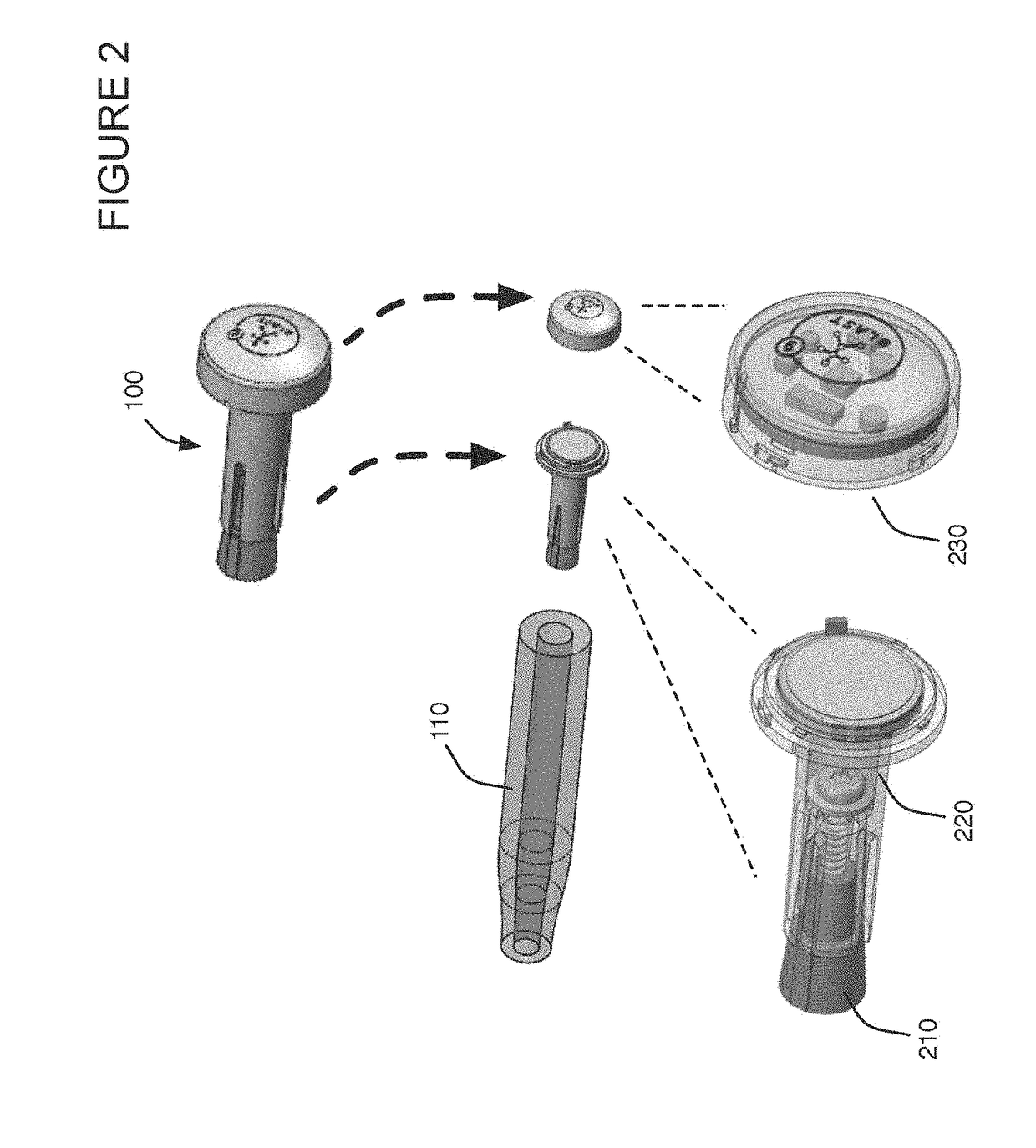

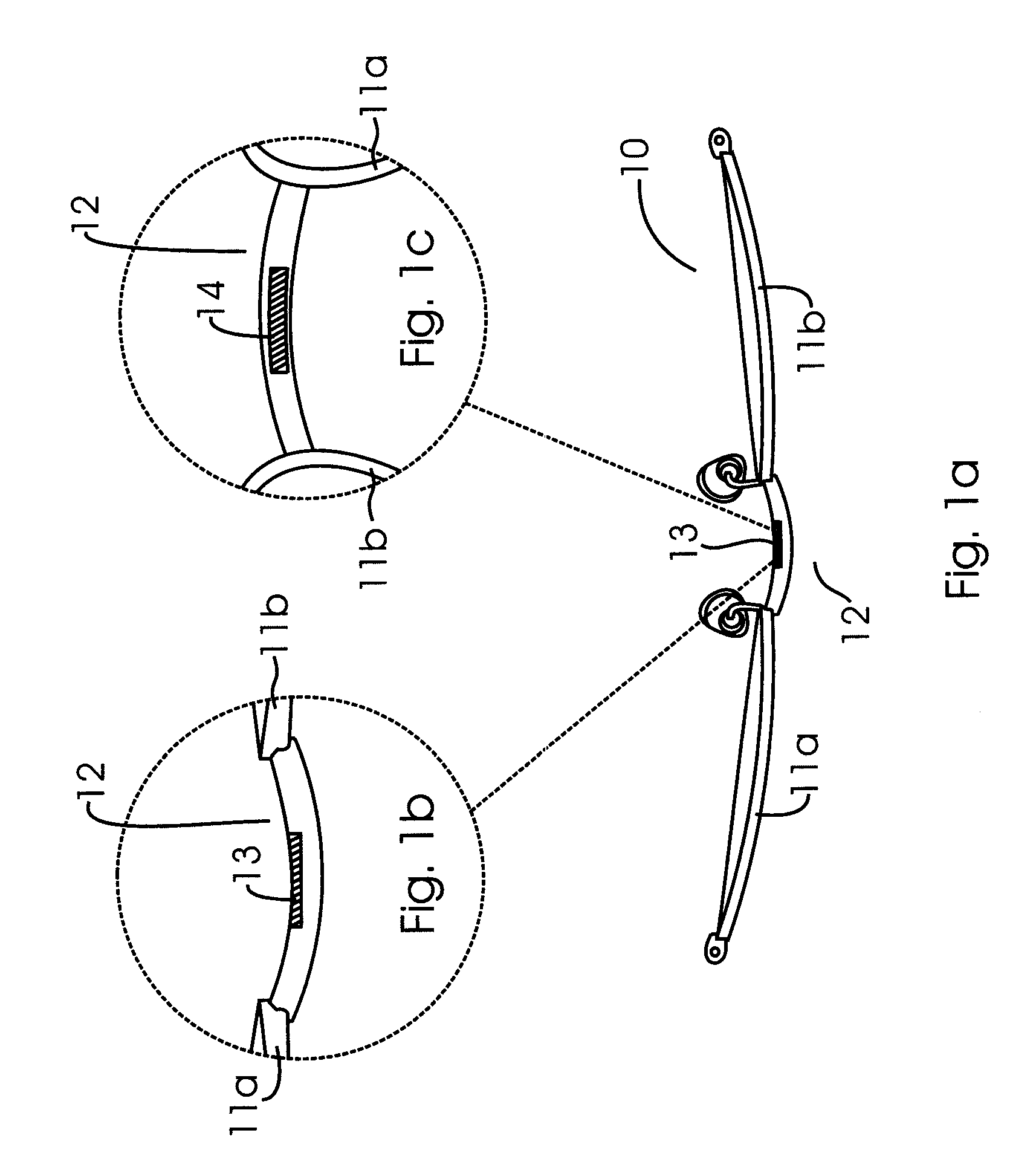

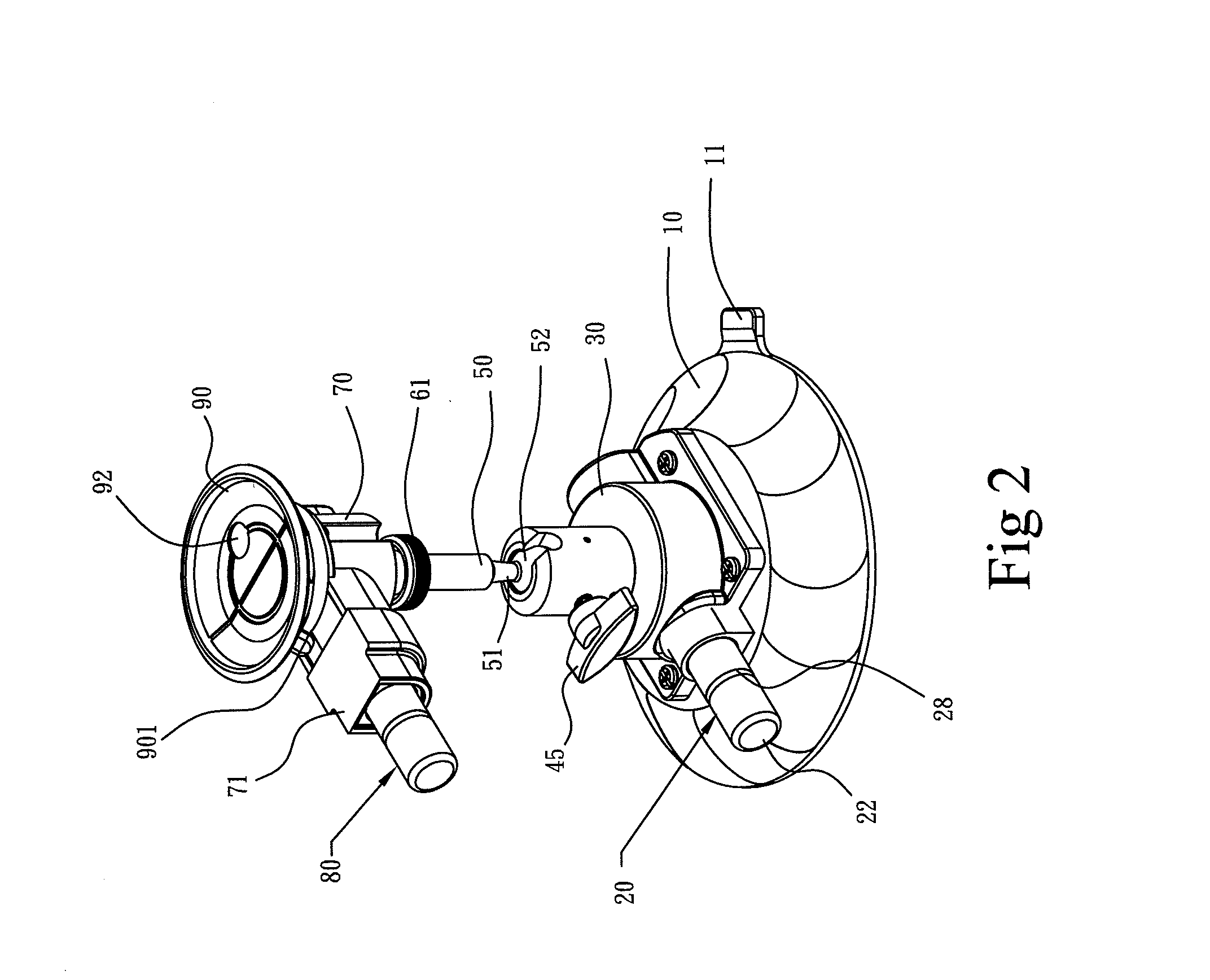

Enclosure and mount for motion capture element

ActiveUS20130095941A1Easy to removeEasy to replaceCharacter and pattern recognitionFurniture partsEngineeringGolf Ball

Enables coupling or retrofitting a golf club with active motion capture electronics that are battery powered, passive or active shot count components, for example a passive RFID, and / or a visual marker on the cap for use with visual motion capture cameras. Does not require modifying the golf club. Electronics package and battery can be easily removed and replaced, for example without any tools. May utilize a weight that is removed when inserting the electronic package in the mount, wherein the weight element may have the same weight as an electronics package, for no net change or minimal change in club weight. May be implemented with a shaft enclosure and expander that may be coupled with a screw aligned along an axis parallel to the axis of the shaft. May utilize non-permanently and / or friction coupling between the mount and shaft. Cap may include a visual marker and / or logo.

Owner:NEWLIGHT CAPITAL LLC

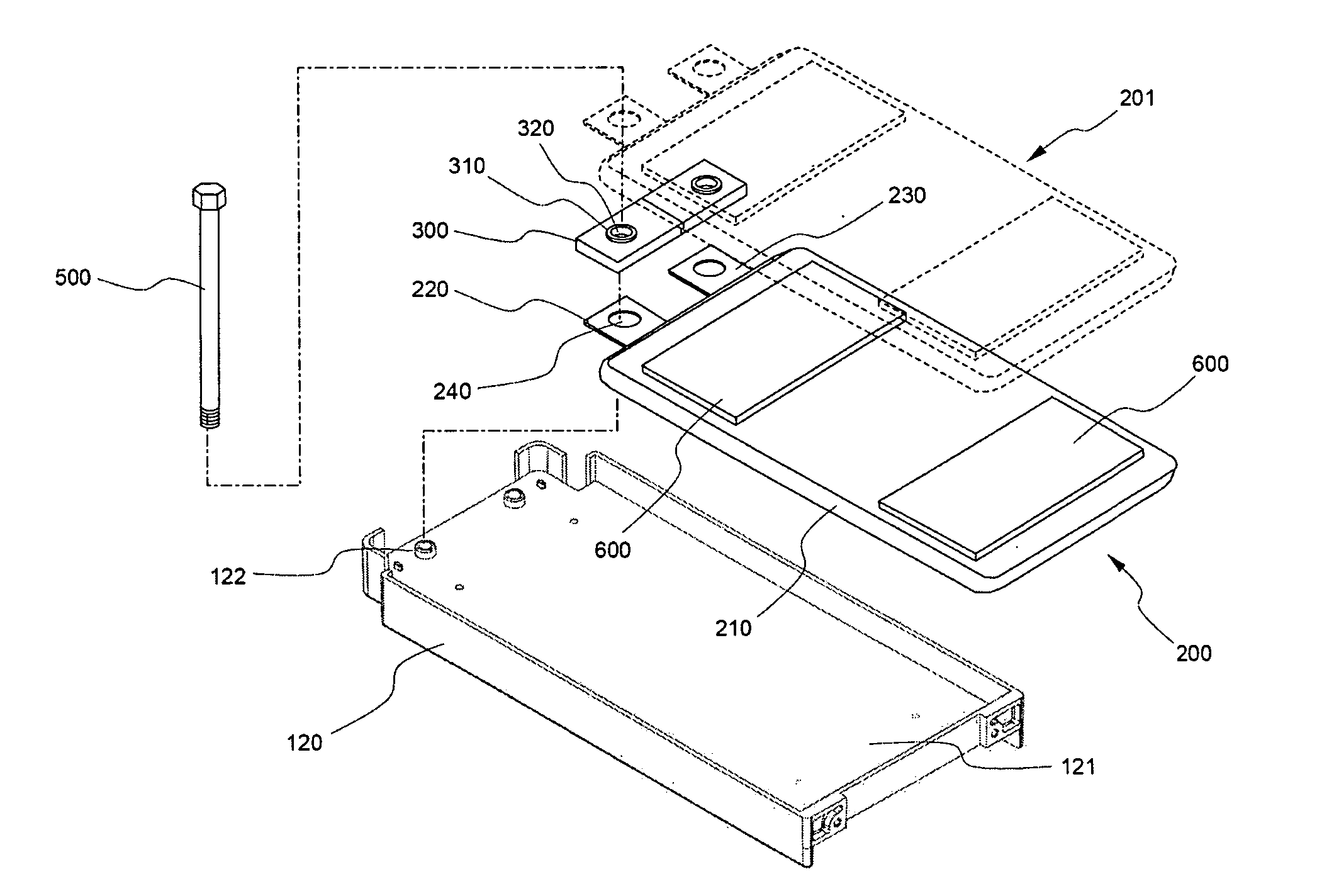

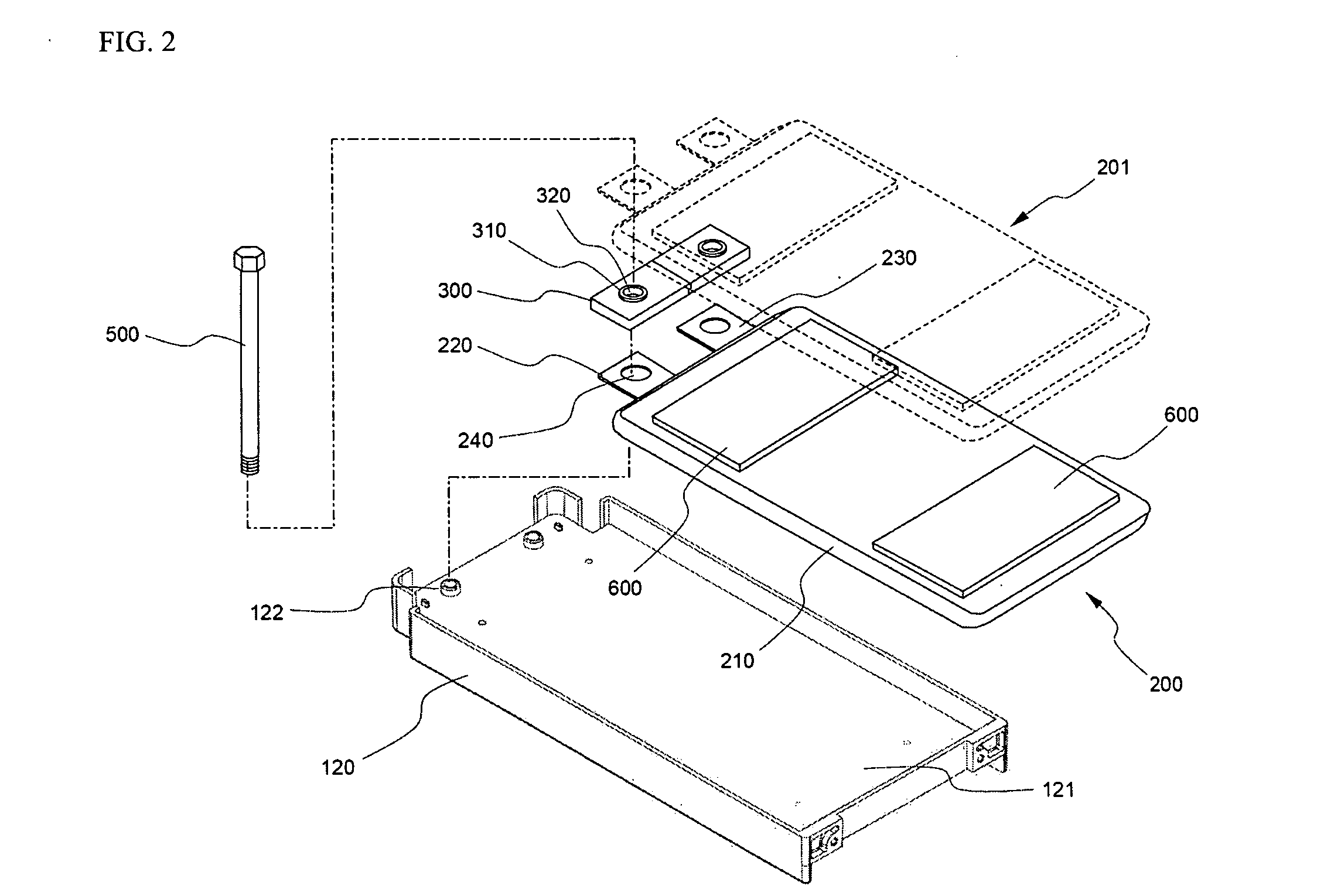

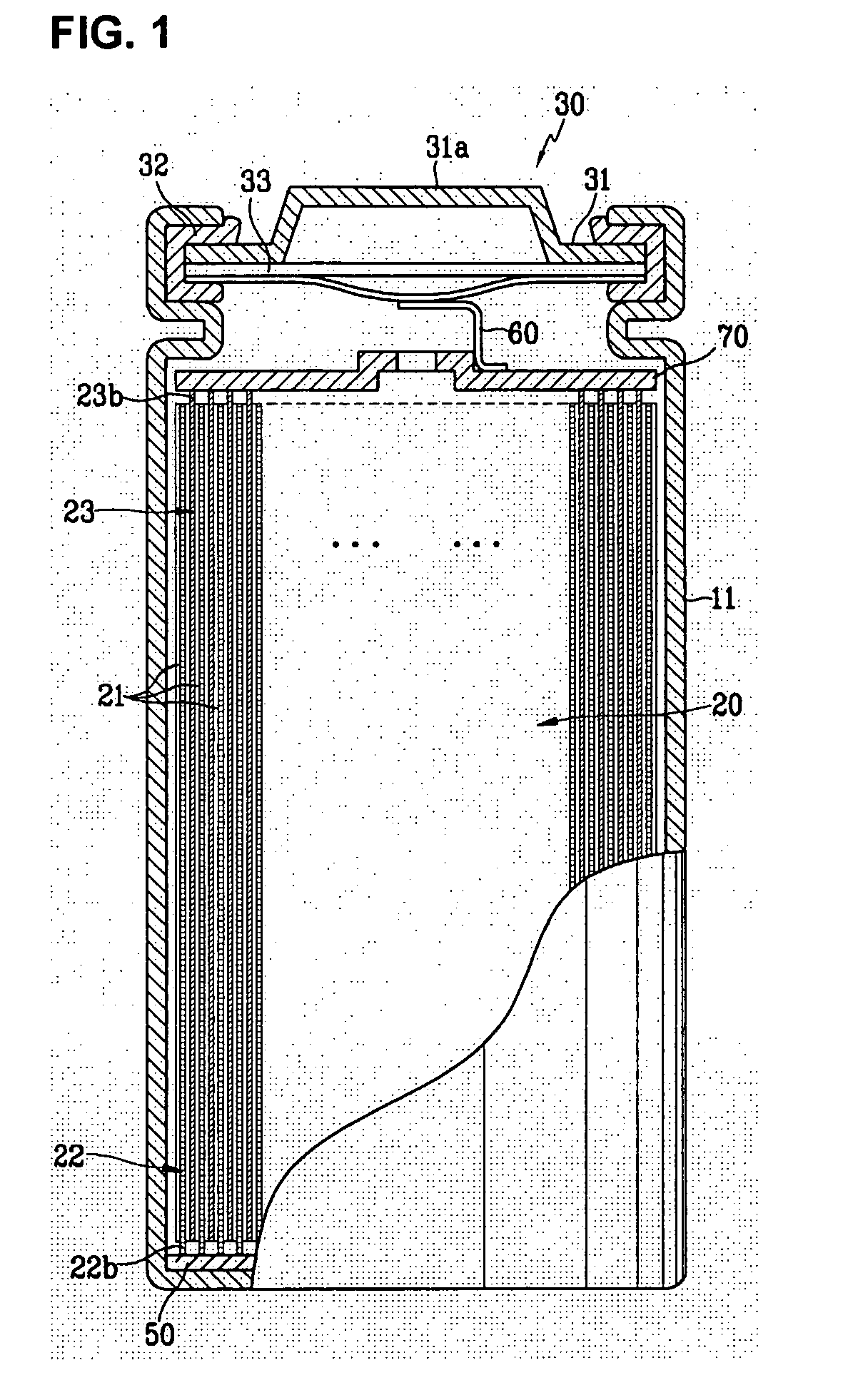

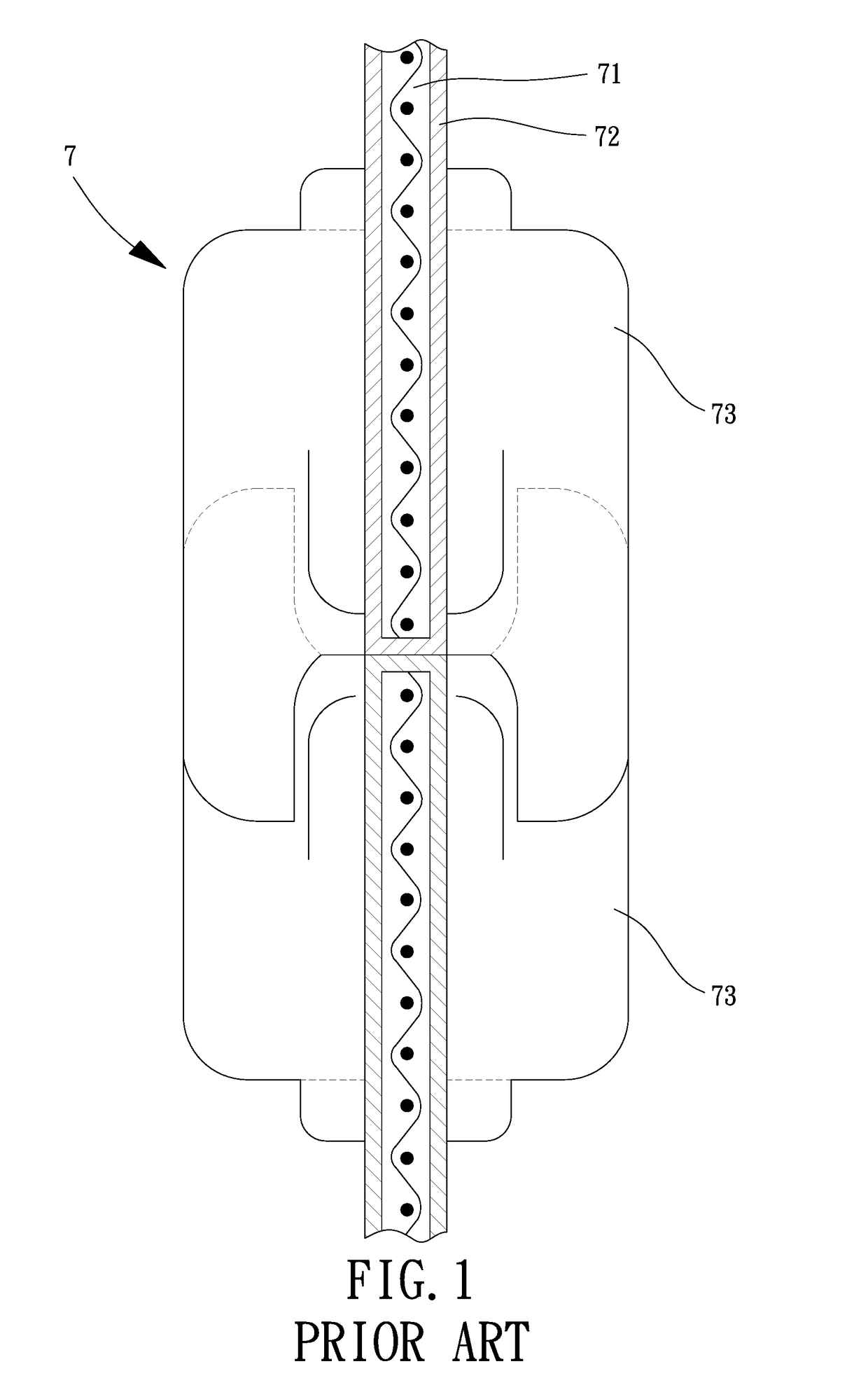

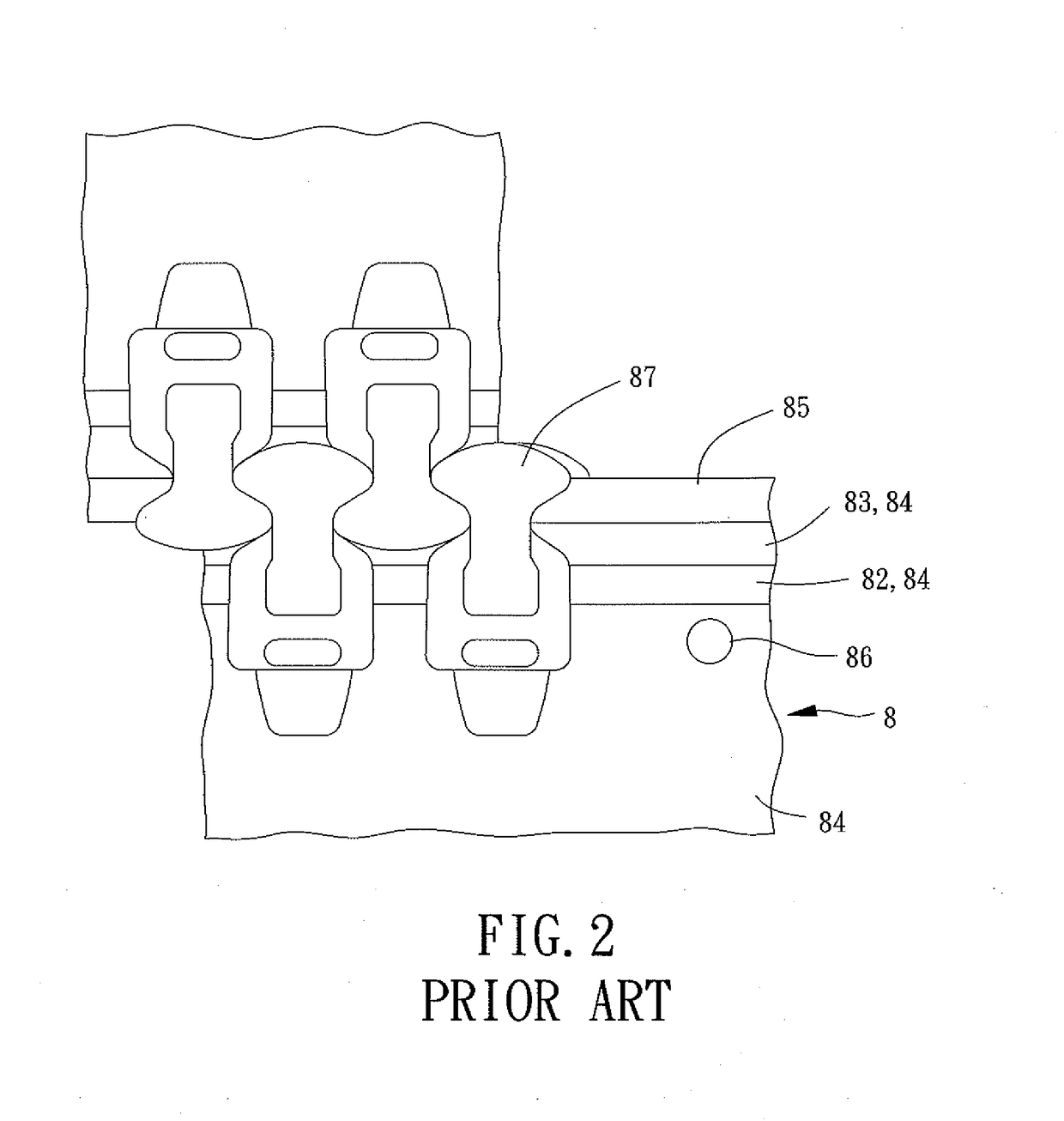

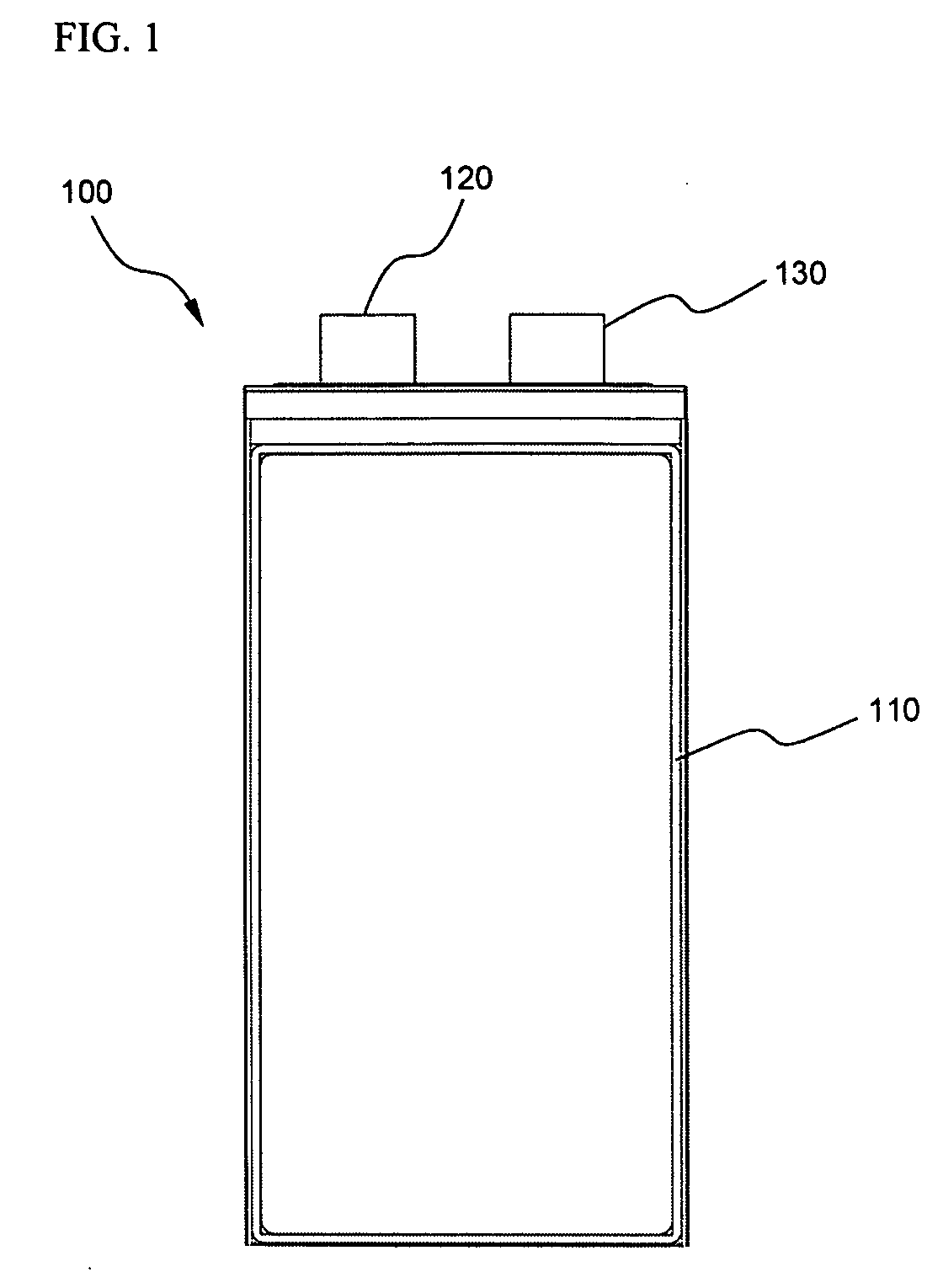

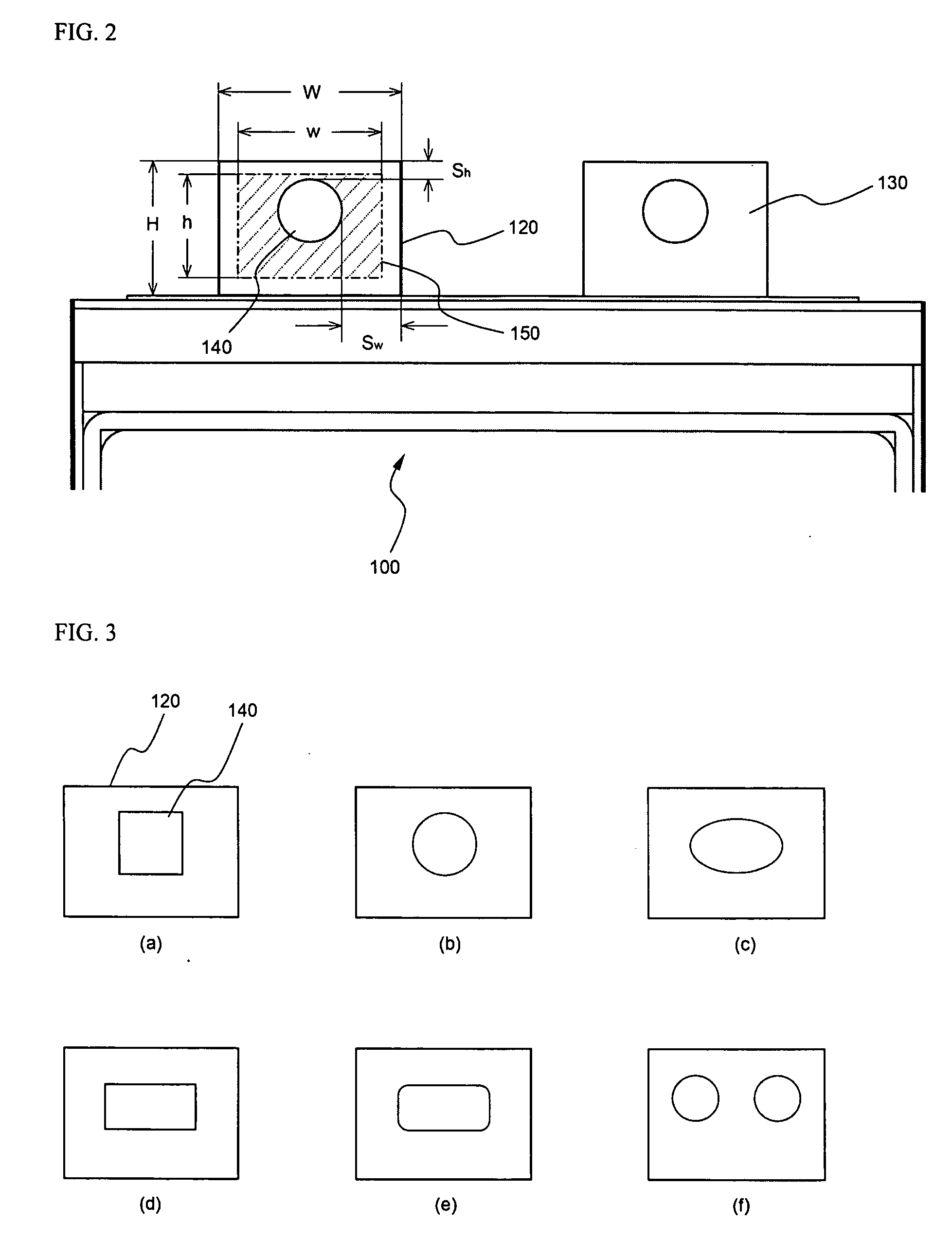

Terminal-linking member of secondary battery module

ActiveUS20060194101A1Secure couplingSimple processElectric discharge tubesLarge-sized flat cells/batteriesEngineeringBattery cell

Disclosed herein is a terminal-linking member of a high-output, large-capacity secondary battery module or pack having a plurality of unit cells stacked one on another and electrically connected with each other. The terminal-linking member includes an insulating member mounted between electrode terminals of the neighboring unit cells for accomplishing the electrical insulation between the electrode terminals, the insulating member being coupled to the electrode terminals, and a connecting member coupled to the insulating member for electrically connecting the electrode terminals of the unit cells coupled to the insulating member in series or in parallel with each other.

Owner:LG ENERGY SOLUTION LTD

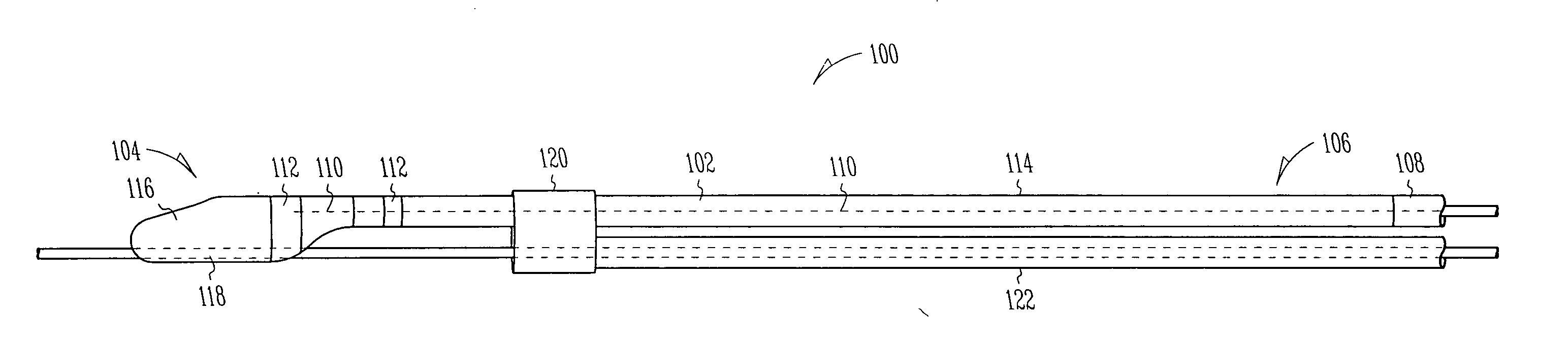

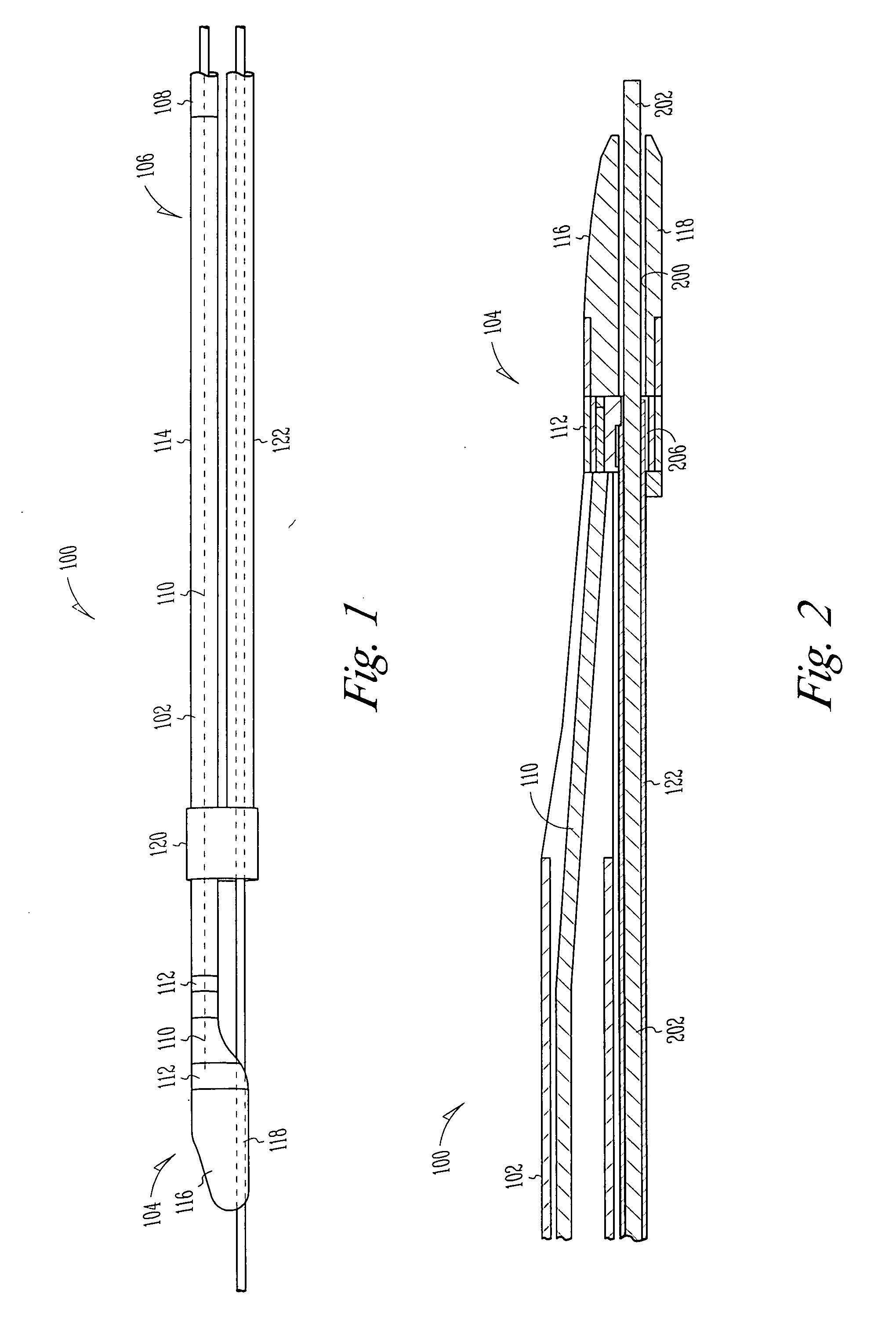

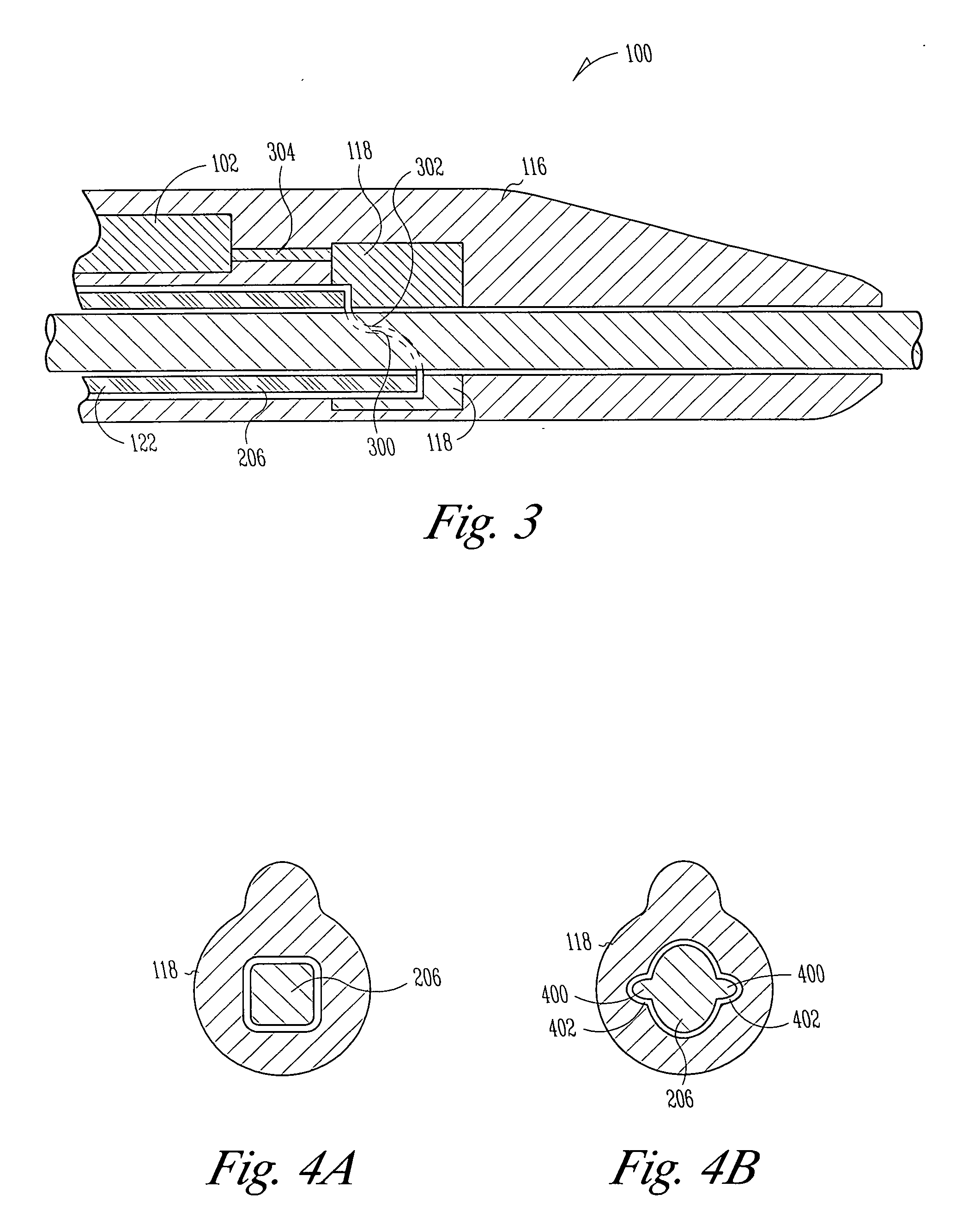

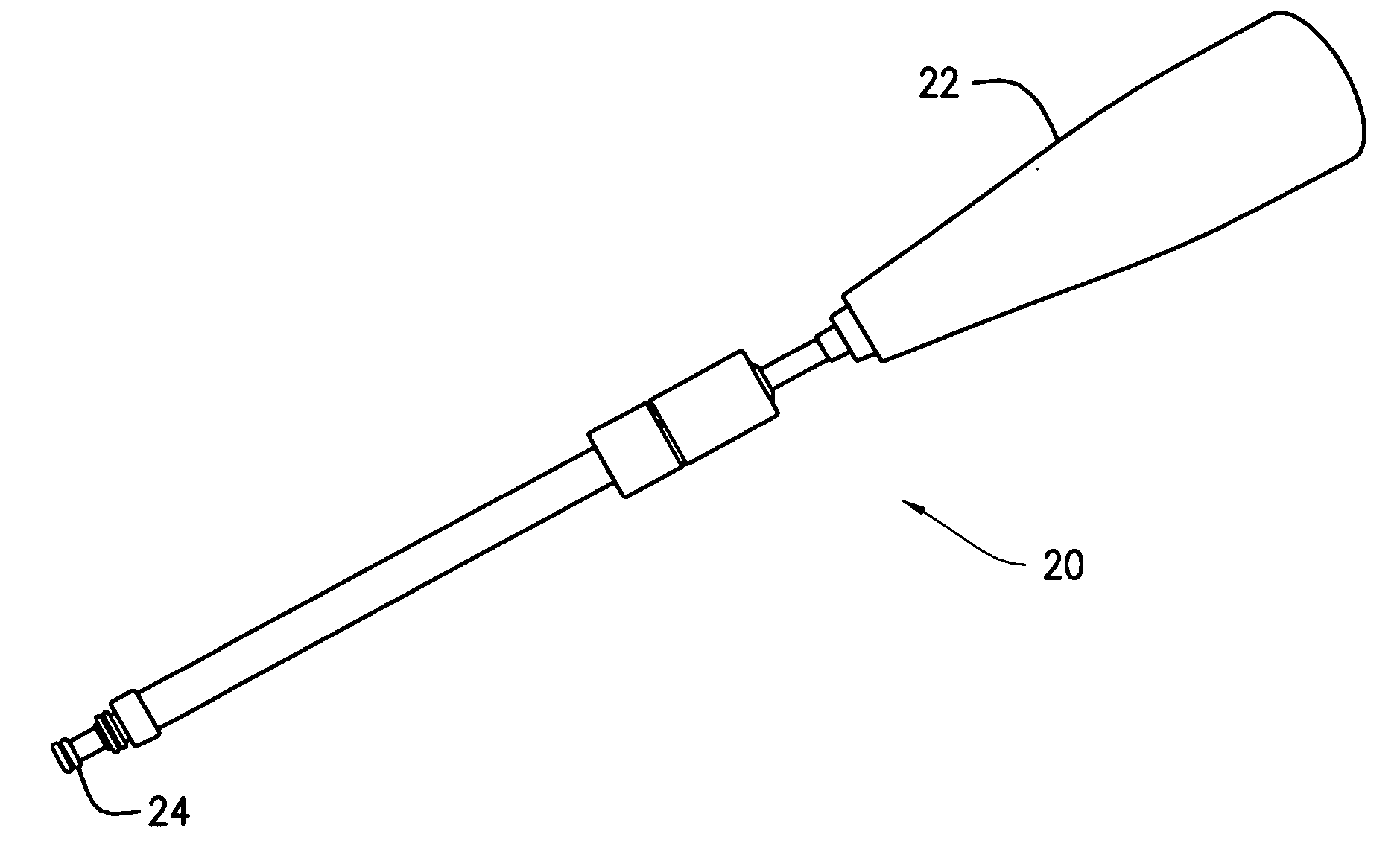

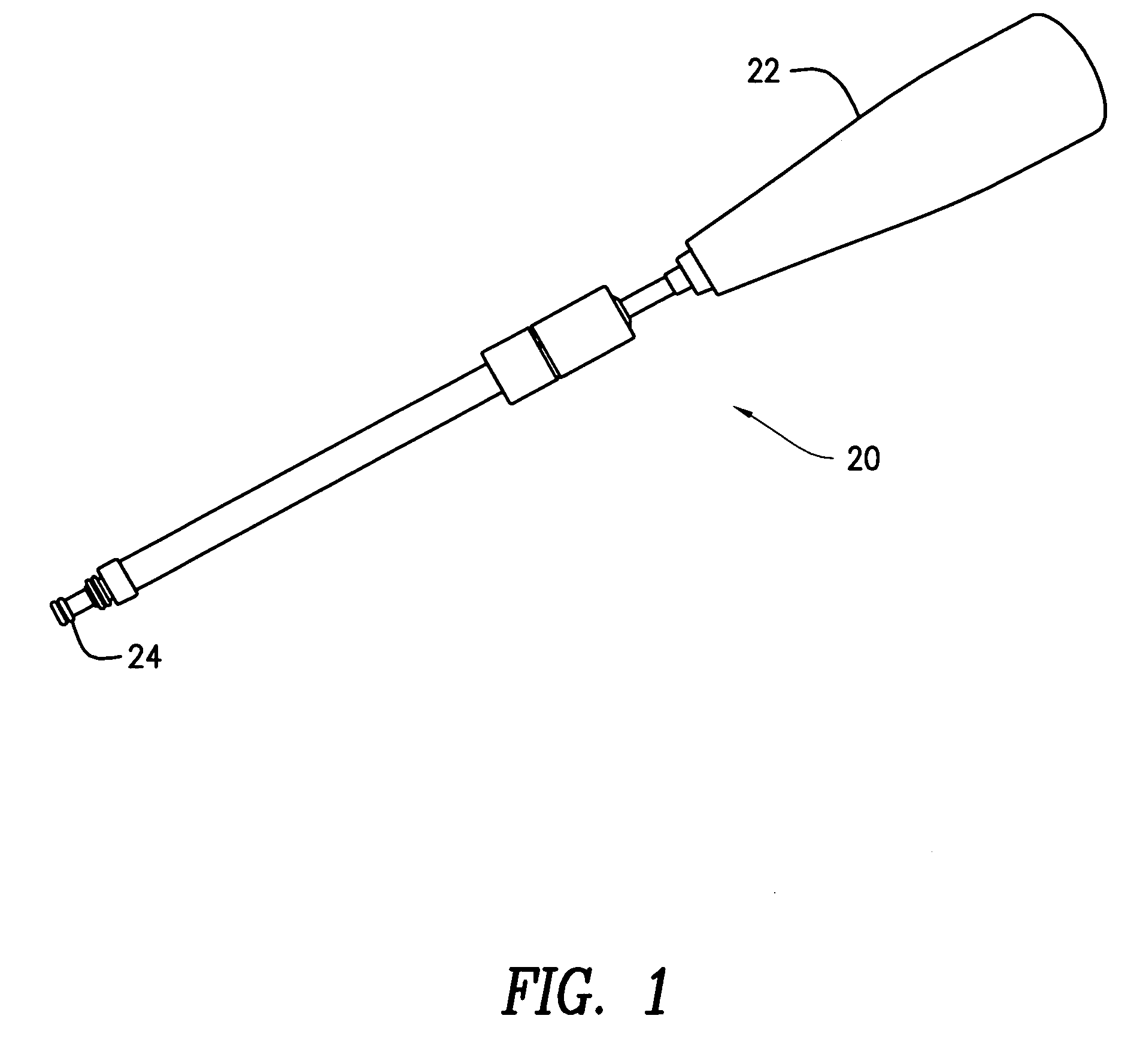

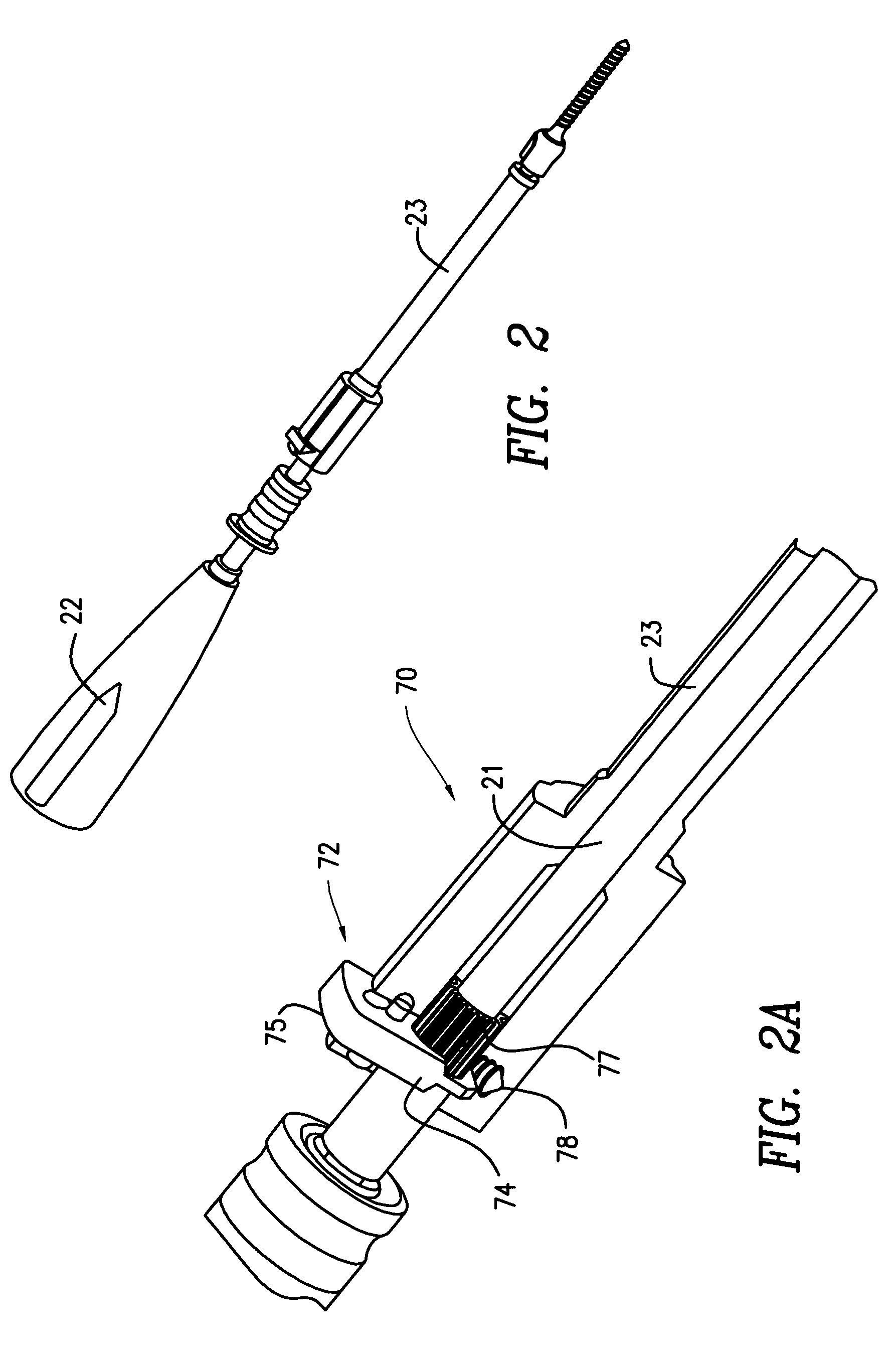

Lead assembly and methods including a push tube

InactiveUS20060036307A1Easy to browseSmall sectionTransvascular endocardial electrodesExternal electrodesElectrical conductorEngineering

A lead assembly includes an elongate body having a conductor electrically coupled with an electrode coupled to the elongate body. The lead assembly includes a push tube extending along at least a portion of the elongate body. A distal tip is coupled to the elongate body substantially adjacent to the distal end of the elongate body. The distal tip is sized and shaped to couple with a push tube distal end. In one option, the distal tip includes a seat to receive the push tube distal end. In another option, the seat is a side rail seat and a guide wire extends along the elongate body and is slidably coupled with the side rail seat. The lead assembly includes, optionally, an active fixation device slidably coupled with a portion of the elongate body, and the active fixation device is sized and shaped to couple with the push tube.

Owner:CARDIAC PACEMAKERS INC

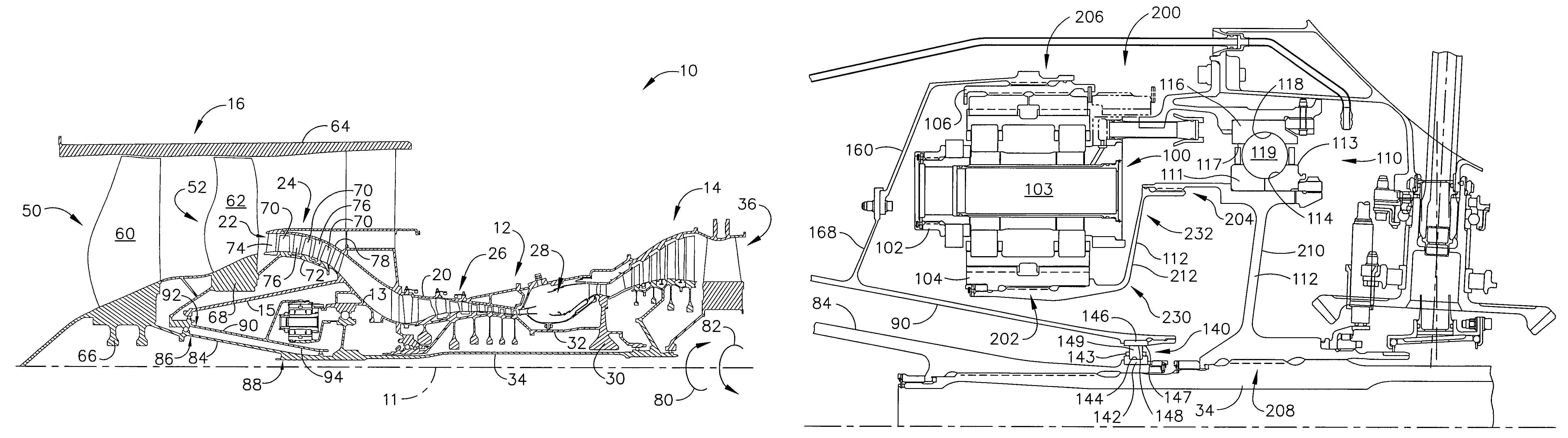

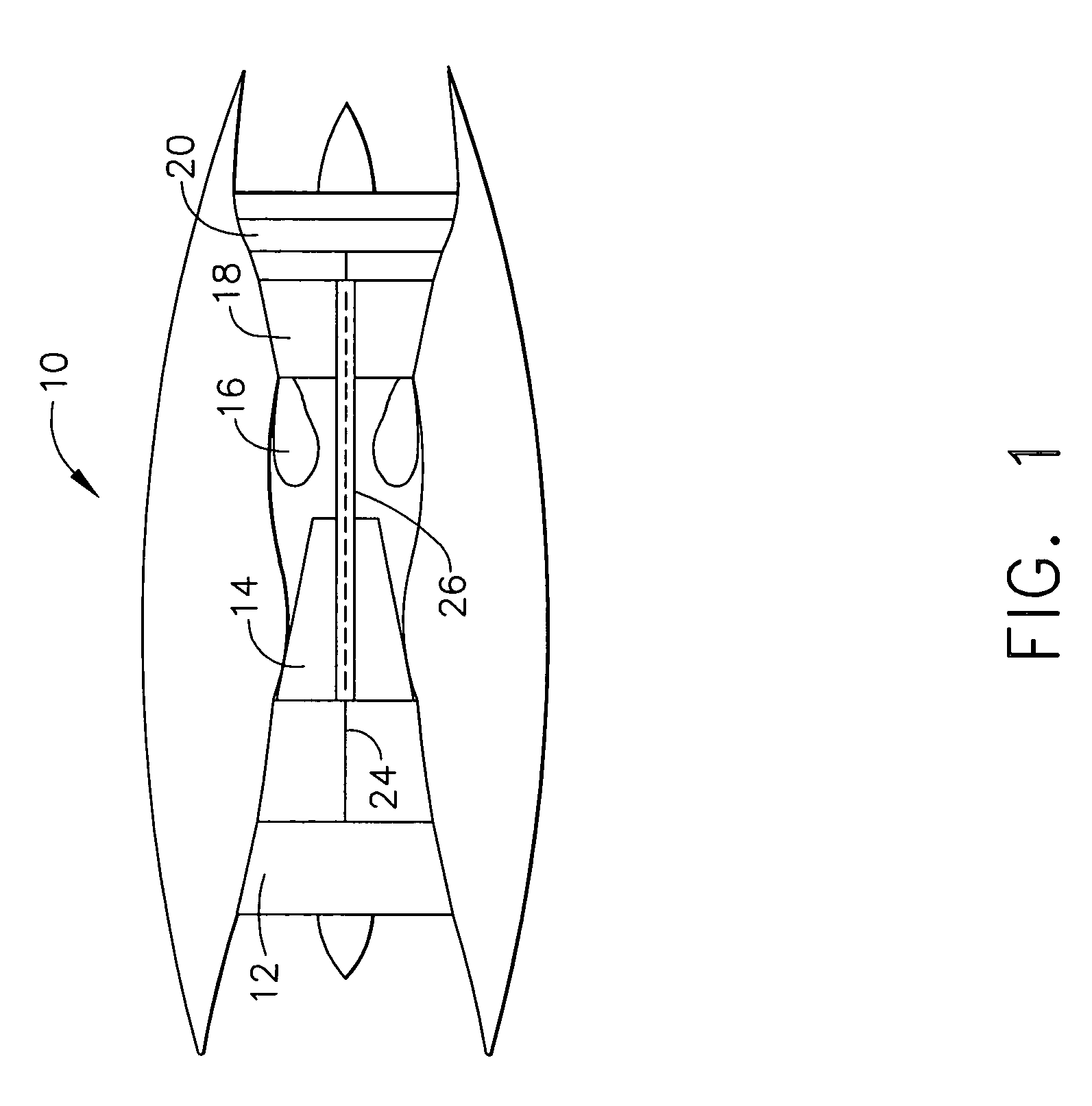

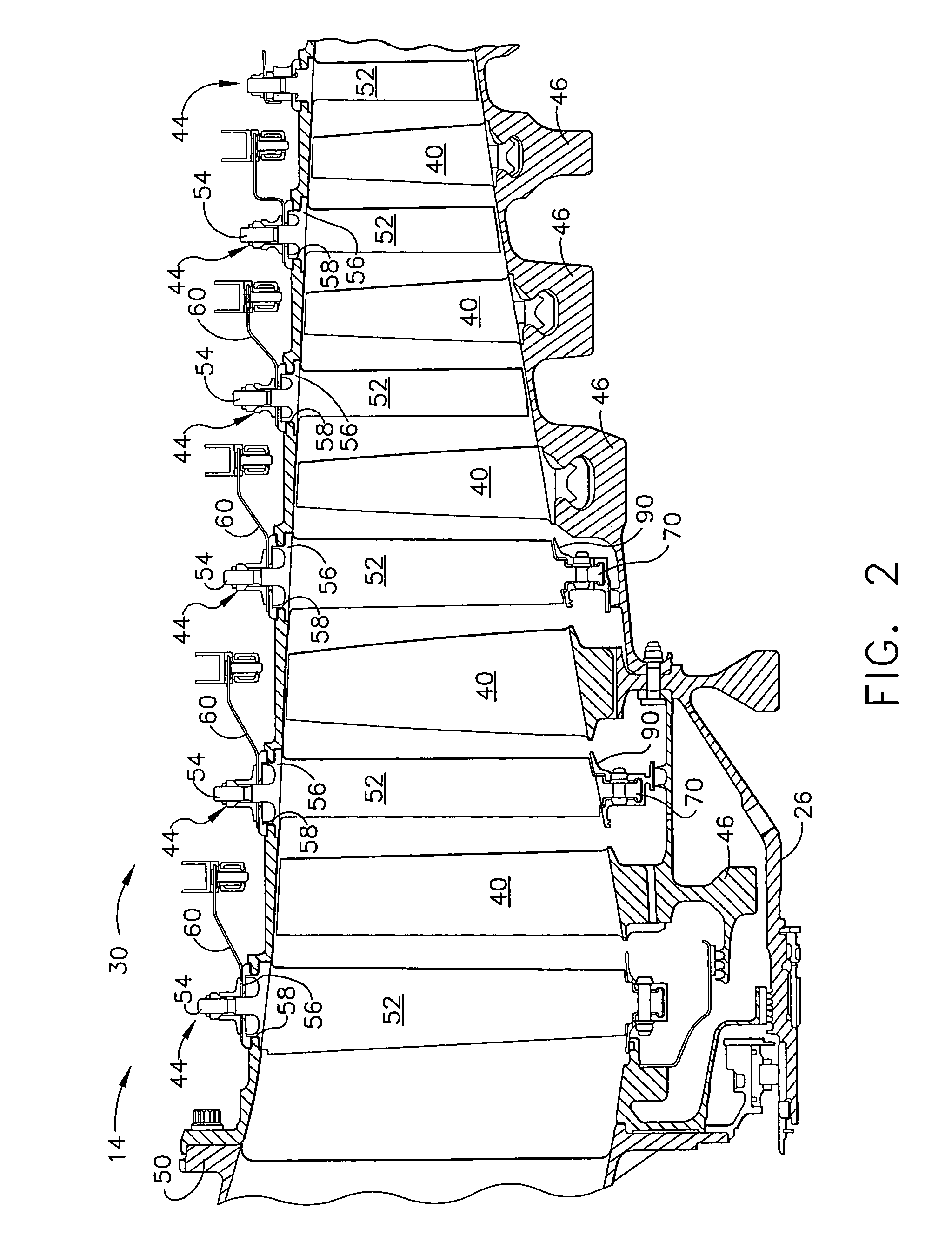

Gas turbine engine assembly and methods of assembling same

A method for assembling a gas turbine engine including providing a core gas turbine engine at least partially defined by a frame and having a drive shaft rotatable about a longitudinal axis of the core gas turbine engine. A low-pressure turbine is coupled to a core turbine engine. A counter-rotating fan assembly is coupled to the low-pressure turbine. The counter-rotating fan assembly includes a first fan assembly and a second fan assembly. A booster compressor is coupled to the second fan assembly. A gearbox is securely coupled to the frame so that the gearbox is circumferentially positioned about the drive shaft. The first fan assembly is rotatably coupled to an input of the gearbox such that the first fan assembly rotates in a first direction. The second fan assembly is rotatably coupled to an output of the gearbox such that the second fan assembly rotates in a second direction opposite the first direction.

Owner:GENERAL ELECTRIC CO

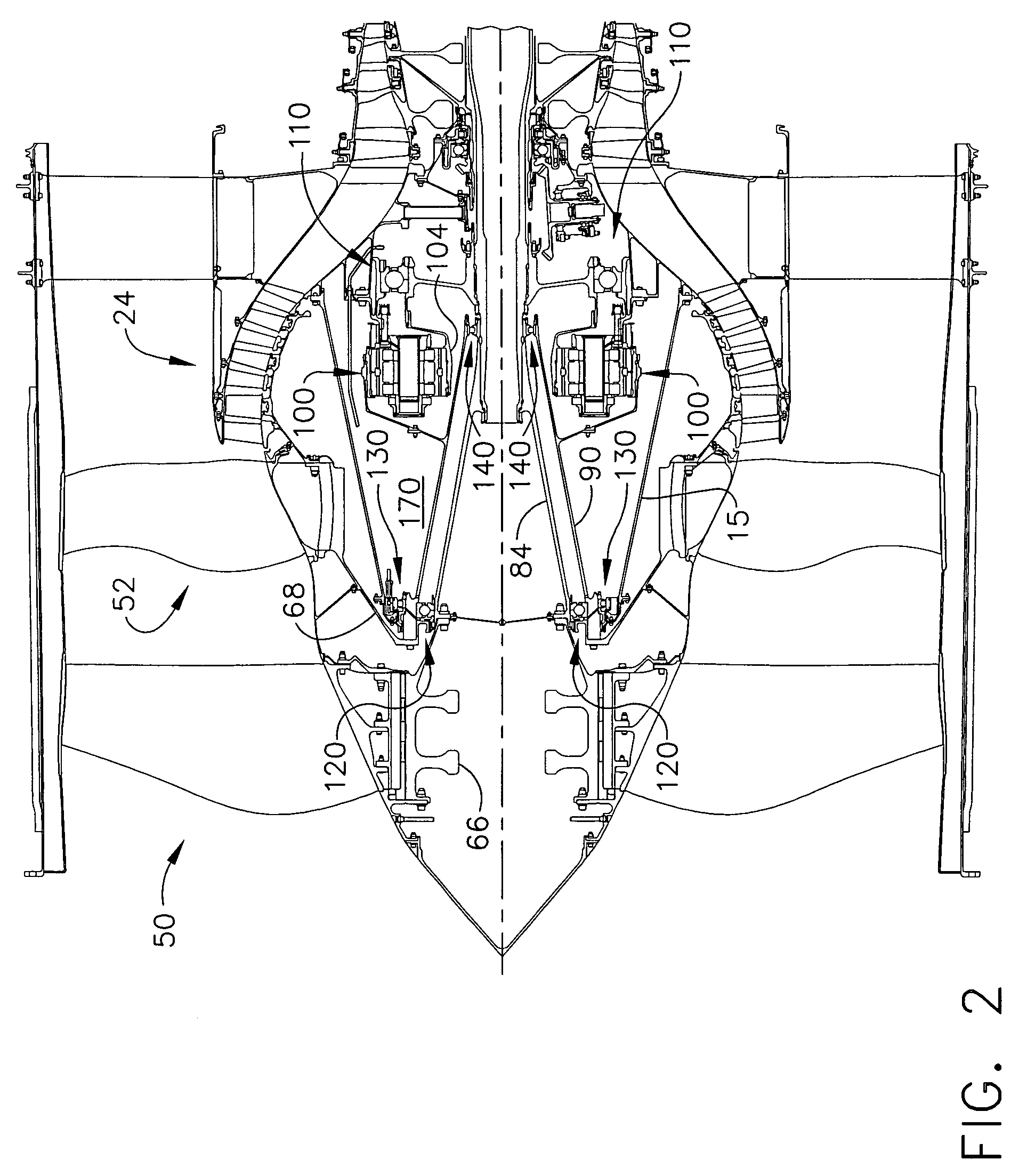

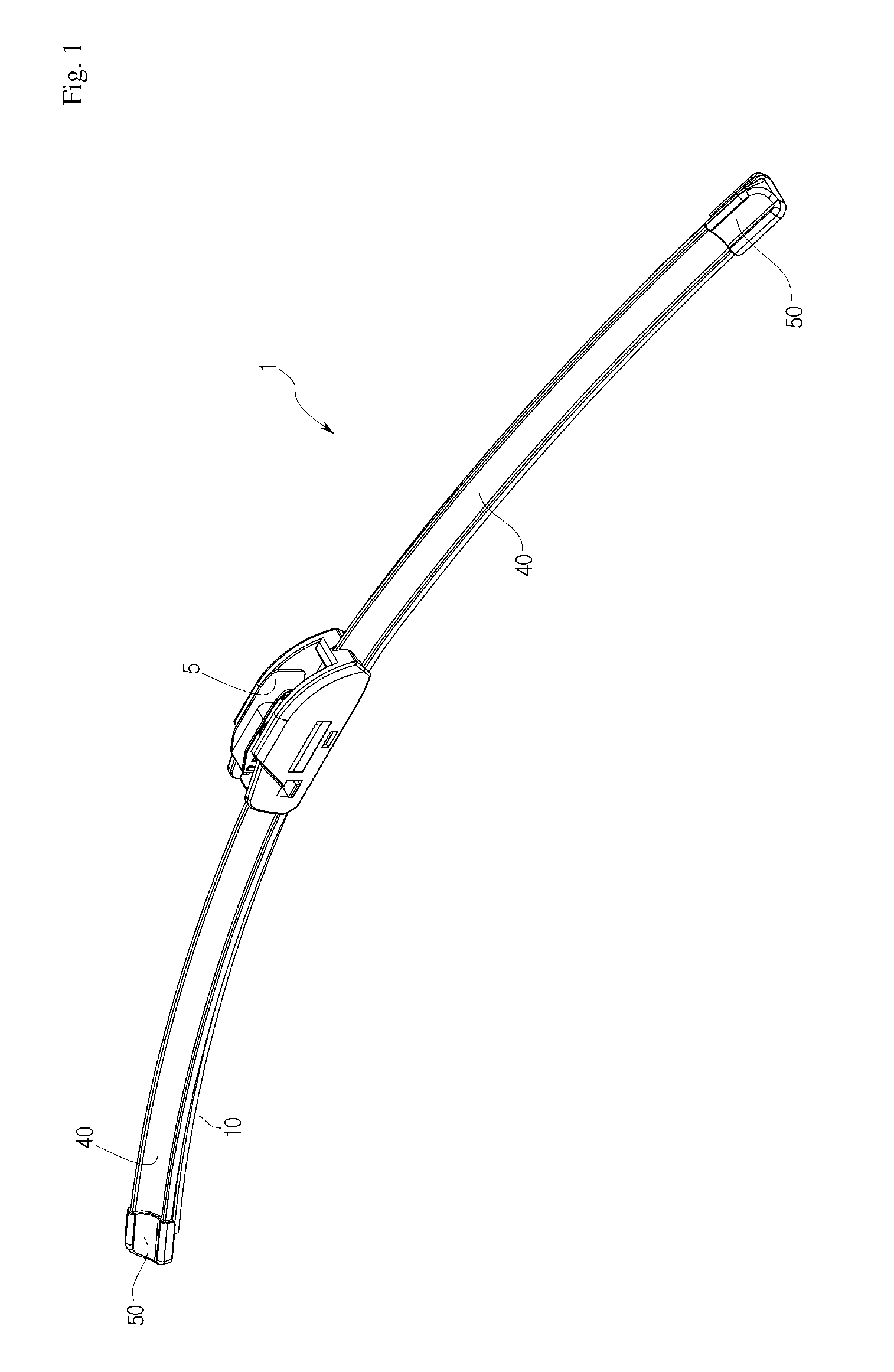

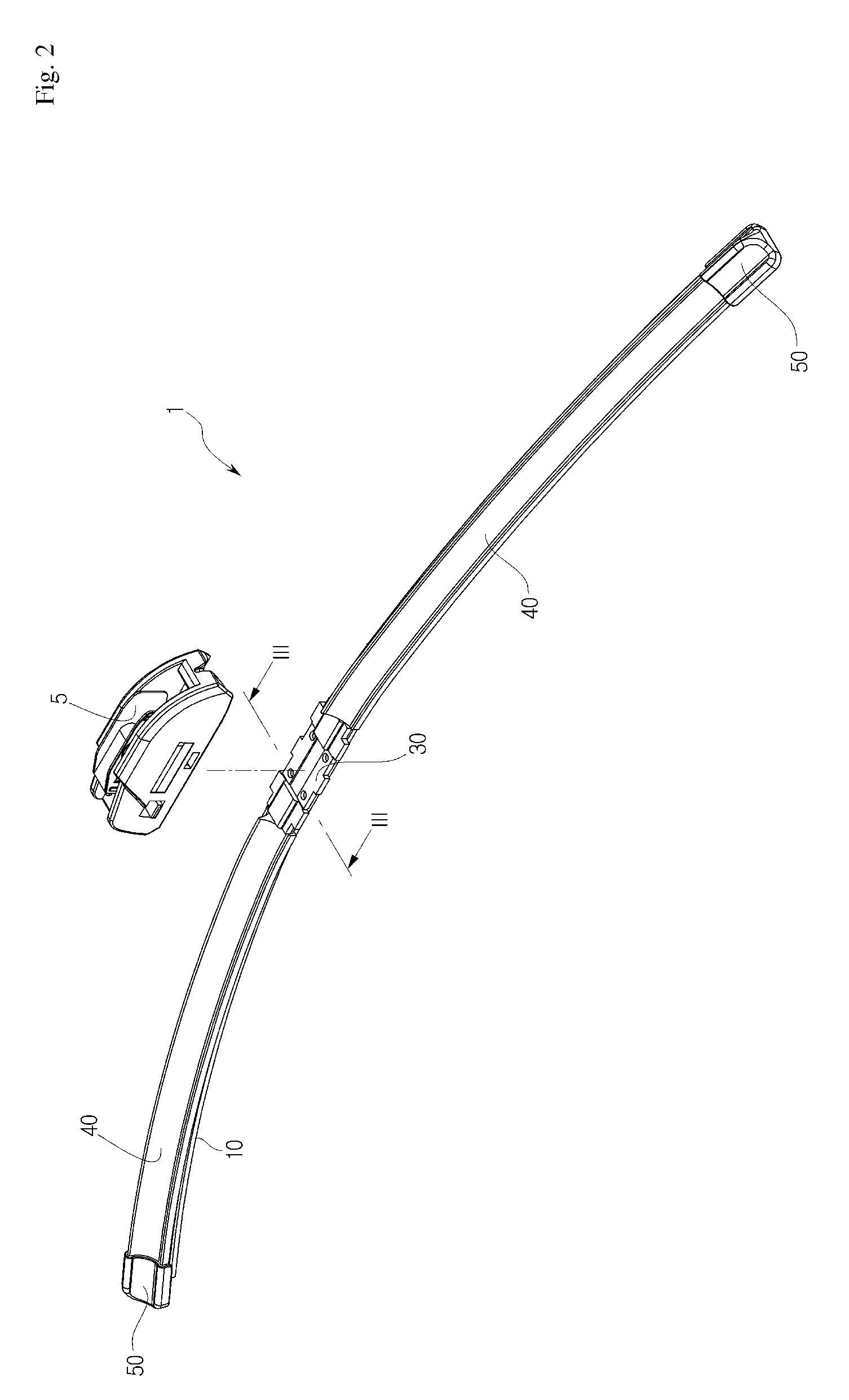

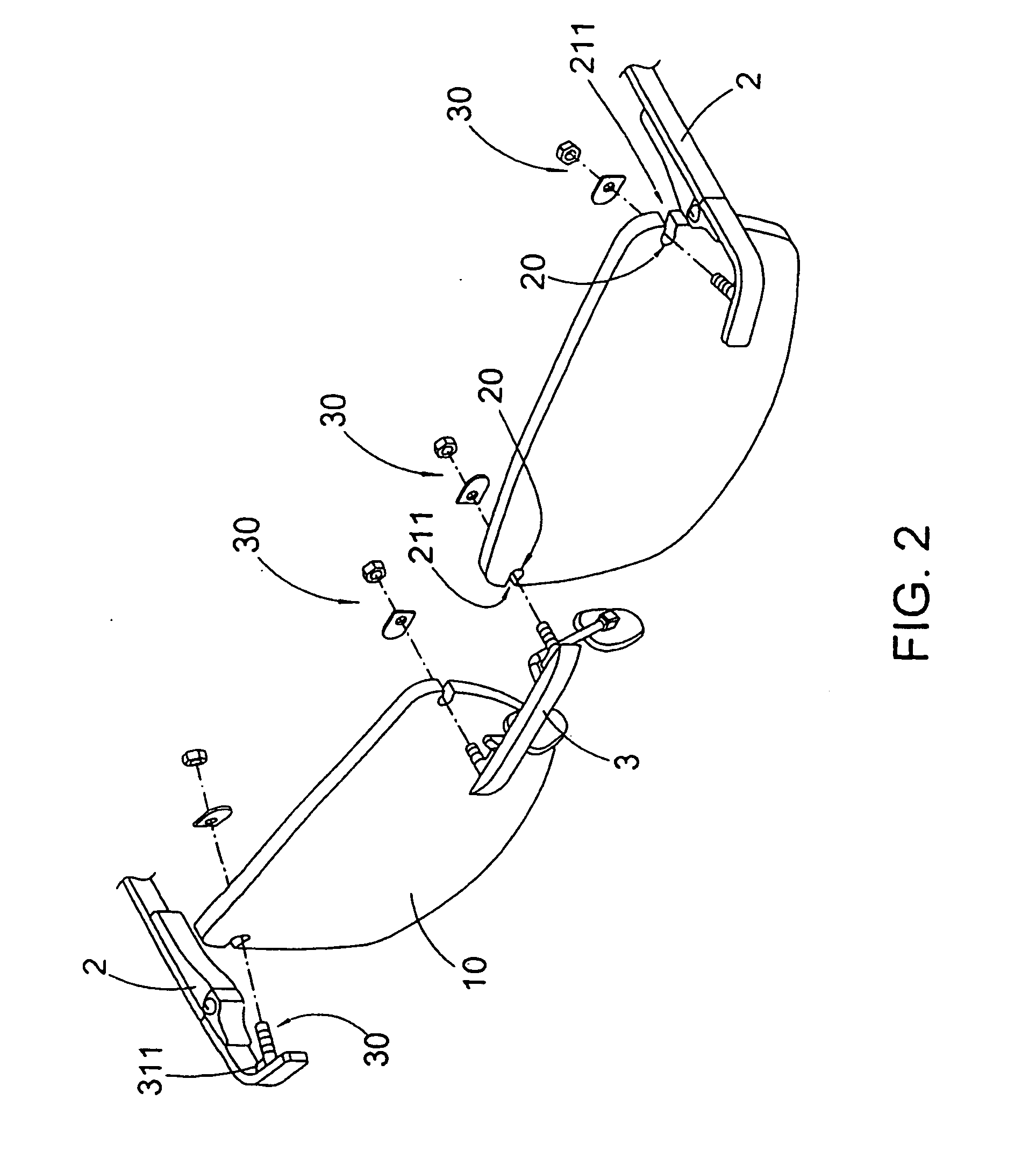

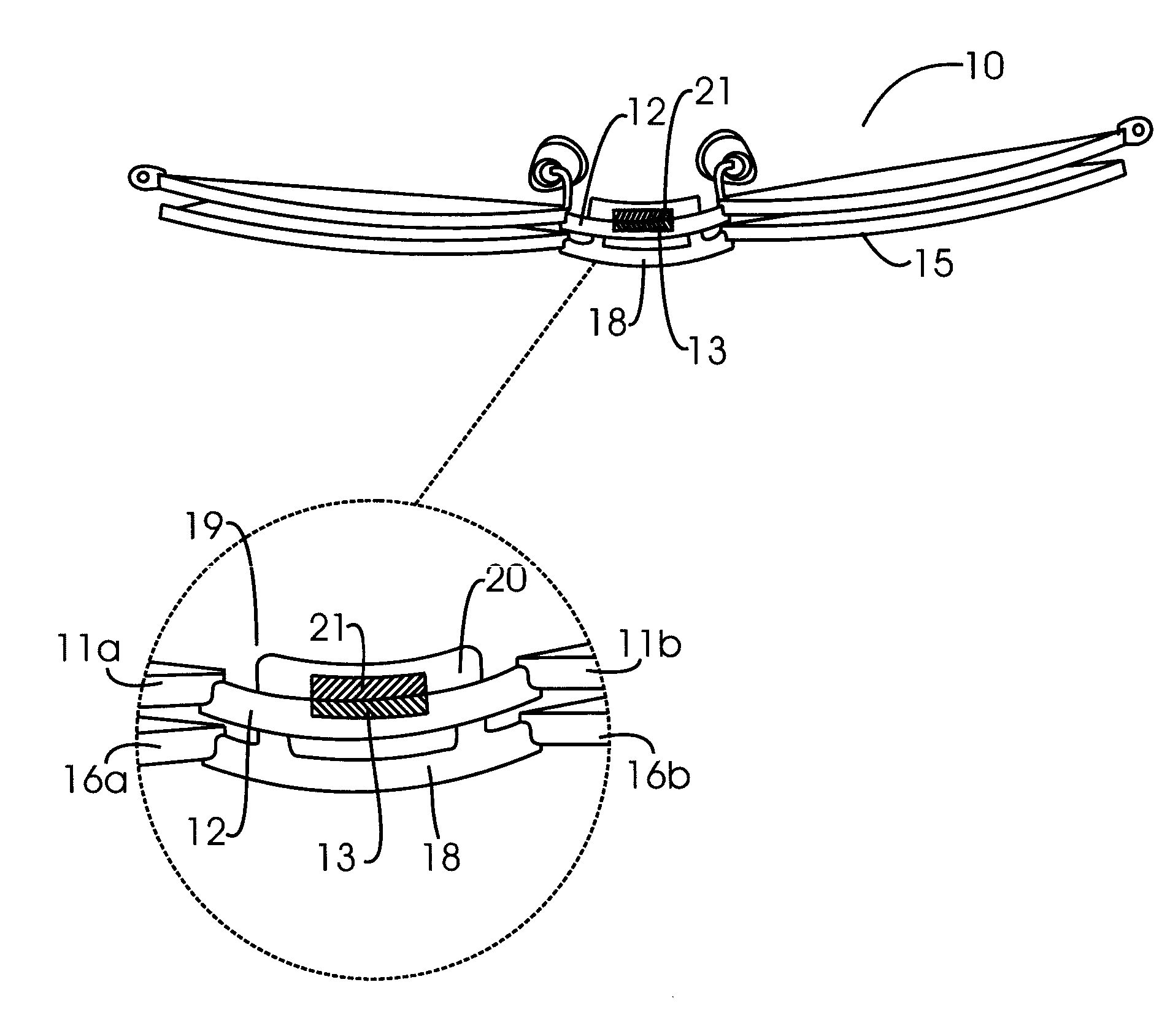

Method of assembling metal clamp and body springs of wiper blade for vehicle and assembly

ActiveUS20110041280A1Reduce distortionEasy to useWindow cleanersVehicle cleaningBiomedical engineeringMetal

Disclosed is a method of assembling a metal clamp and body springs of a wiper blade for vehicles, and an assembly. The method includes forming a plurality of through holes at major sides of the body springs, forming a plurality of protrusions corresponding to the through holes at a major side of the clamp such that the protrusions extend outward from the major side of the clamp, inserting the protrusions of the clamp into the respective through holes of the body springs, fixing the protrusions, which are located in the respective through holes, in the respective through holes by pressure welding or riveting such that the clamp is mounted to the body springs.

Owner:CAP CORP

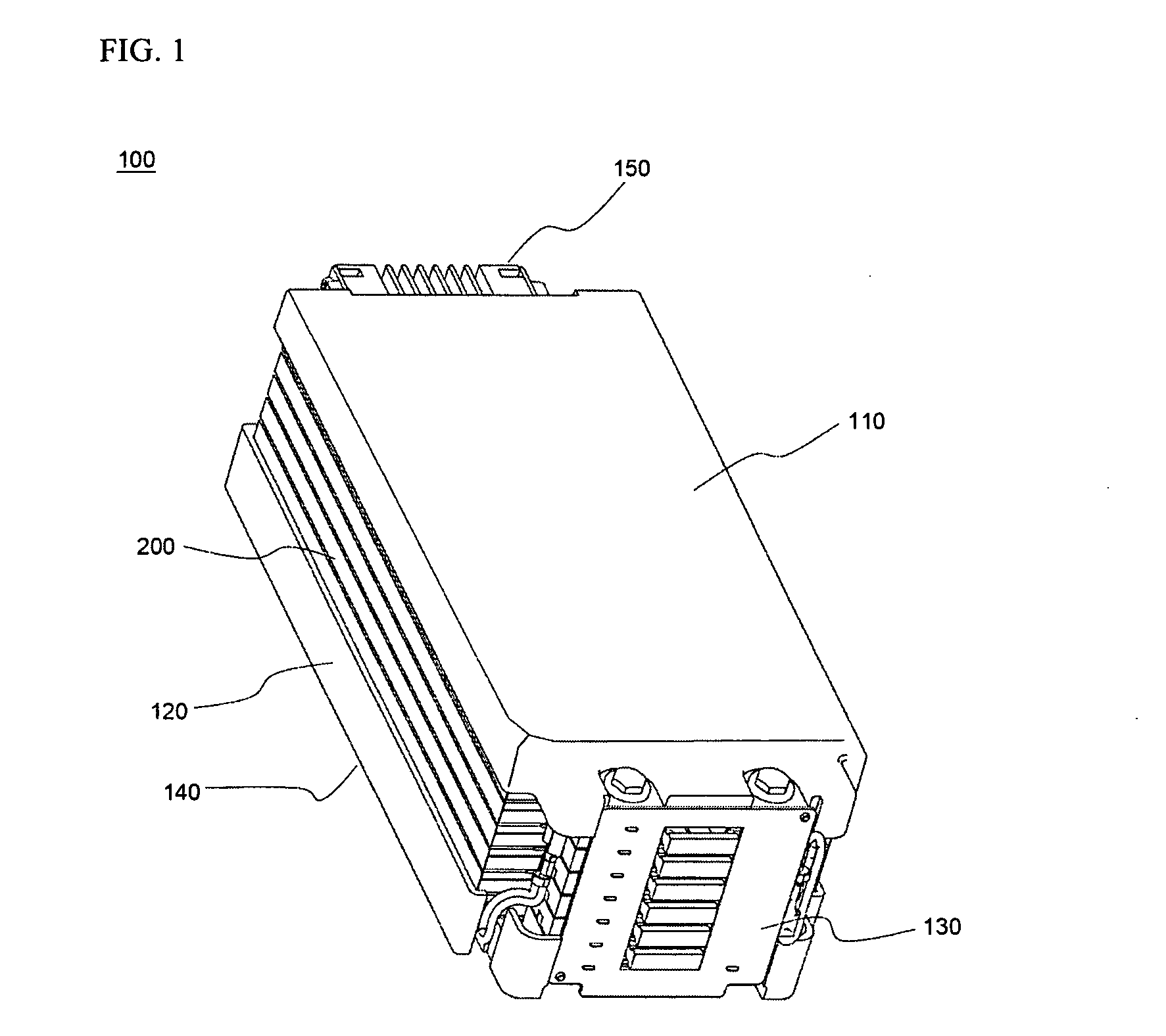

Battery module

InactiveUS20050287427A1Secure couplingPrimary cell to battery groupingCurrent conducting connectionsElectrical and Electronics engineeringElectrode

Owner:SAMSUNG SDI CO LTD

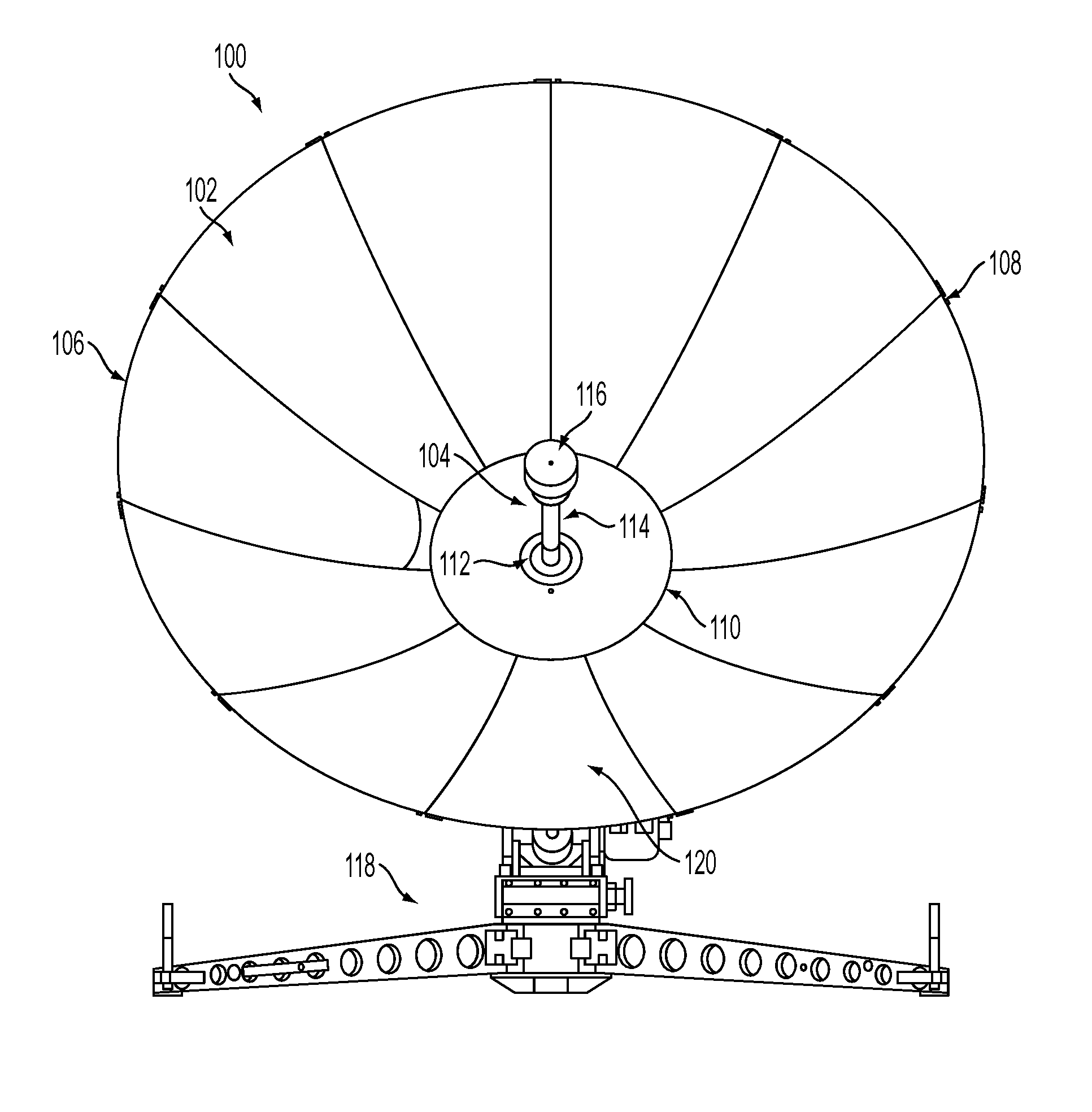

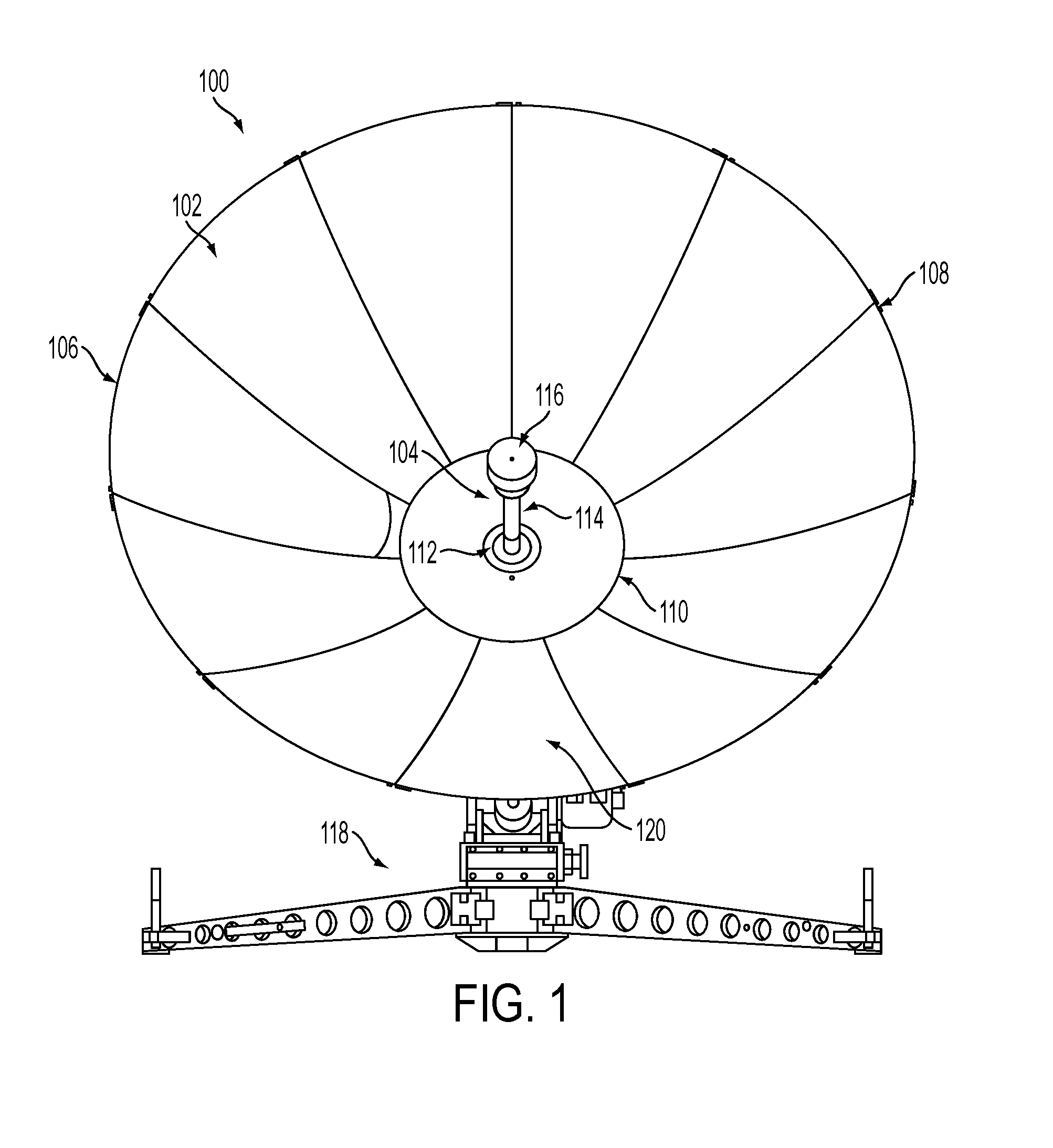

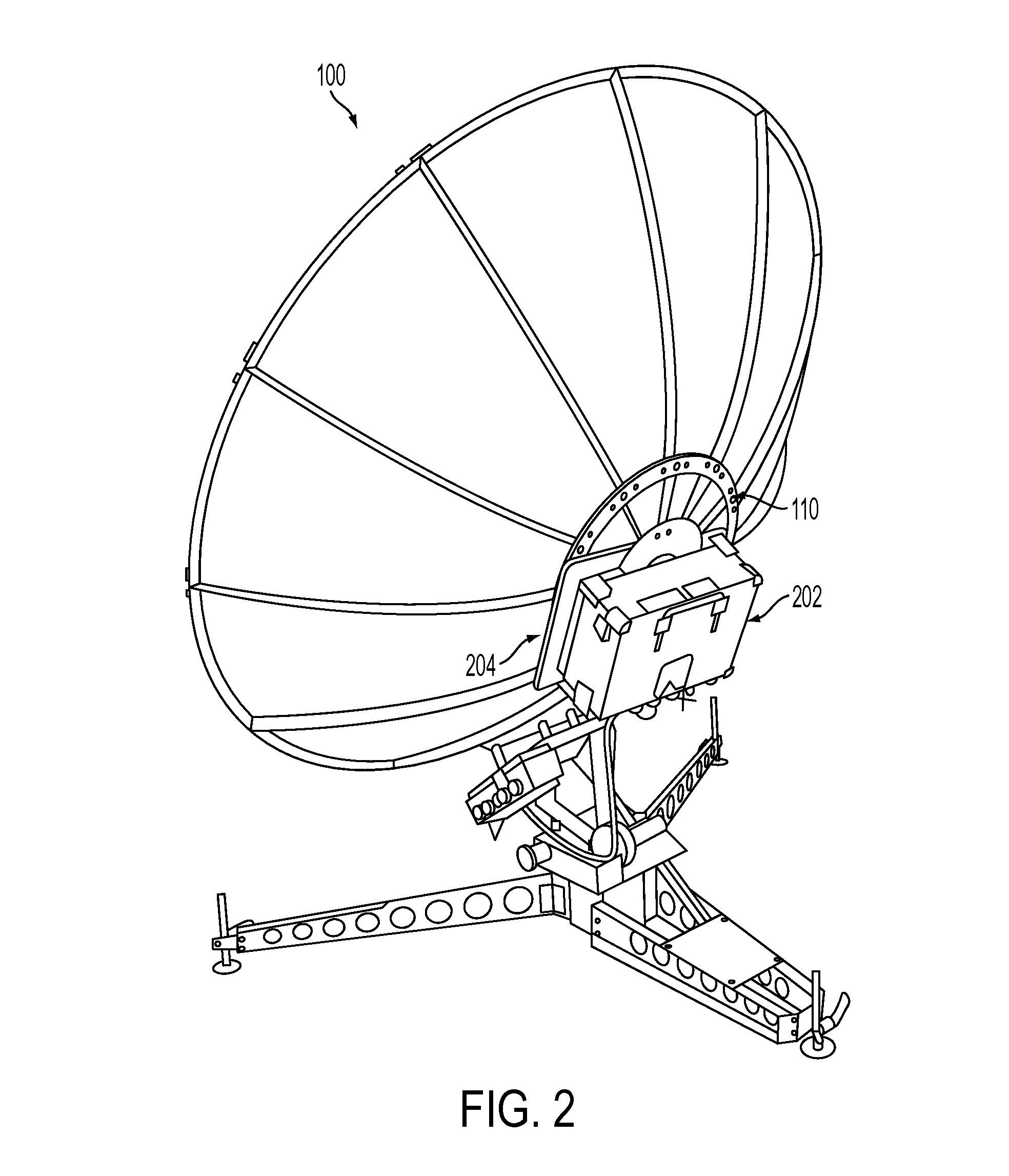

Portable satellite communication system

ActiveUS20140152492A1Increase contact forceSecure couplingCollapsable antennas meansBeacon systems using radio wavesTransceiverConvex side

Systems and methods for providing a Portable Satellite Communication (“PSC”) antenna. The PSC antenna (100) comprises: a Parabolic Segmented Antenna (“PSA”) reflector (102) with a plurality of identical and interchangeable panels (106) that can be stowed in a nested stacked arrangement; a plurality of interchangeable feedhorn assemblies (104) that can be coupled to a center hub (110) via a quick-connect mechanism (112); an adjustment mechanism (2512, 2602, 2604) for adjusting an angular orientation of the feedhorn assemblies relative to the center hub; a transceiver (202) that can be coupled to a convex side of the PSA reflector; a base panel (120) which is coupled to a tripod positioning structure (118) such that reflector wind moment loads can be transferred through a base panel to the tripod positioning structure; and a tripod positioning structure with folding legs (3102, 3104) and hard stops (3306) against which the folding legs can be preloaded.

Owner:HARRIS CORP

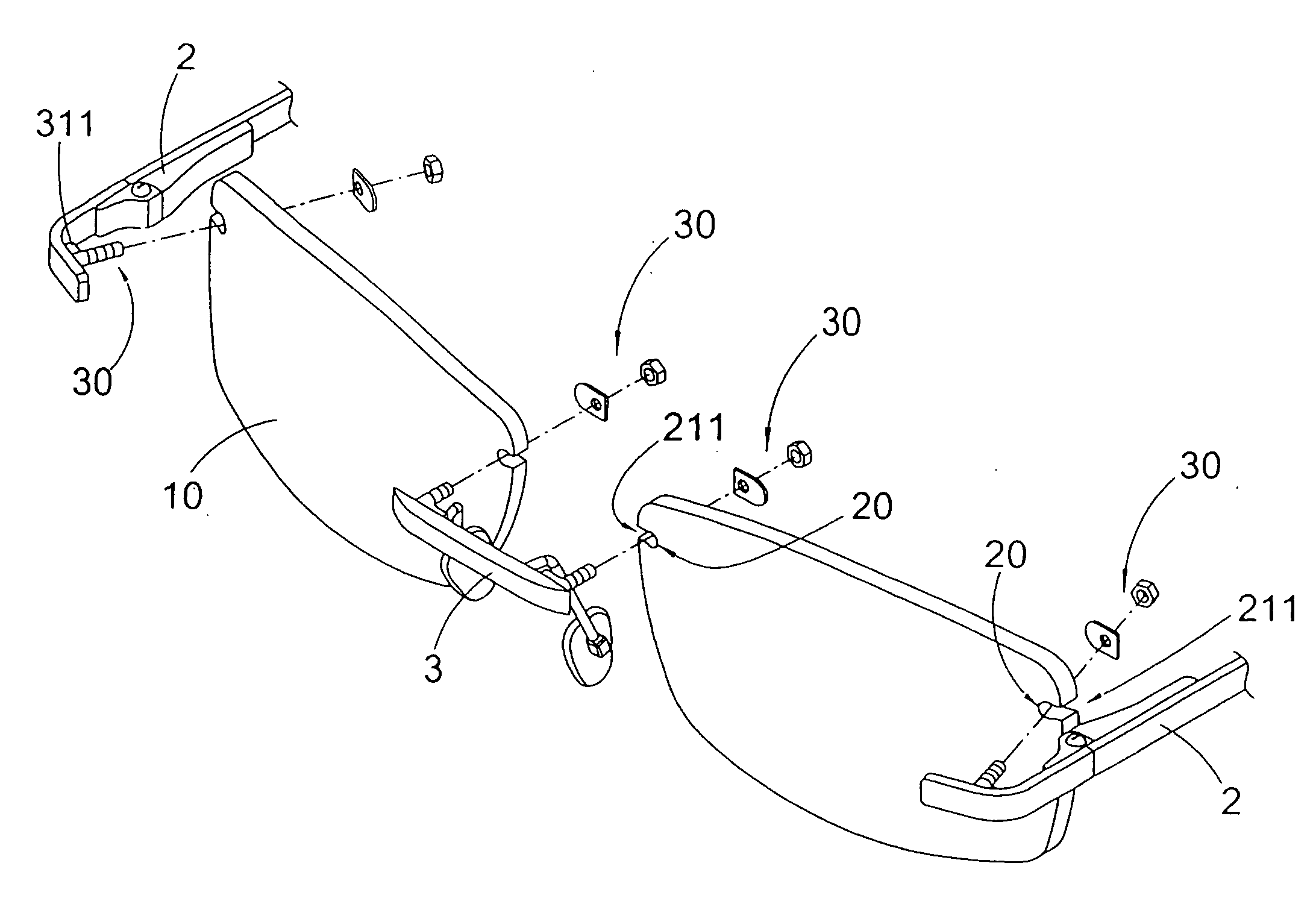

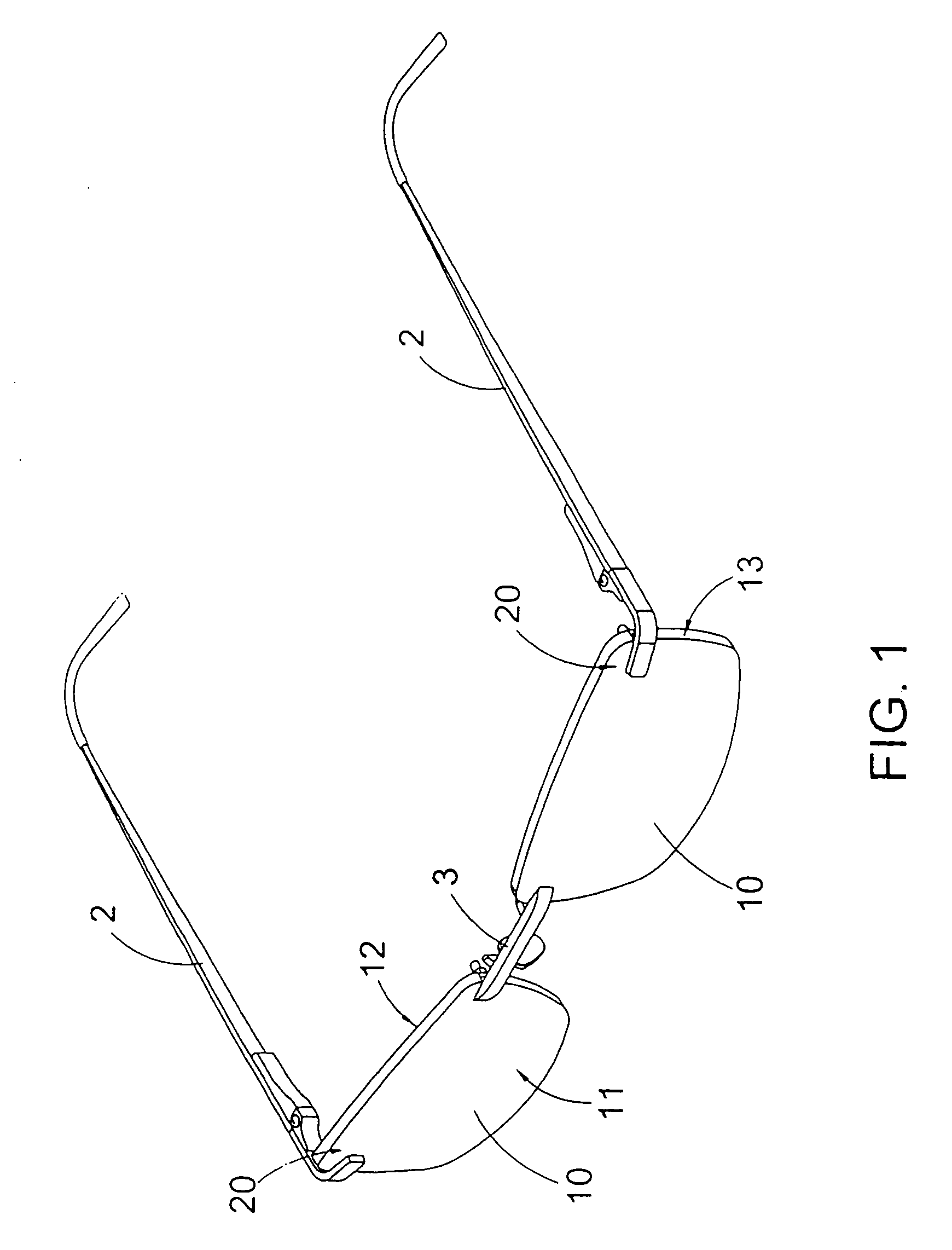

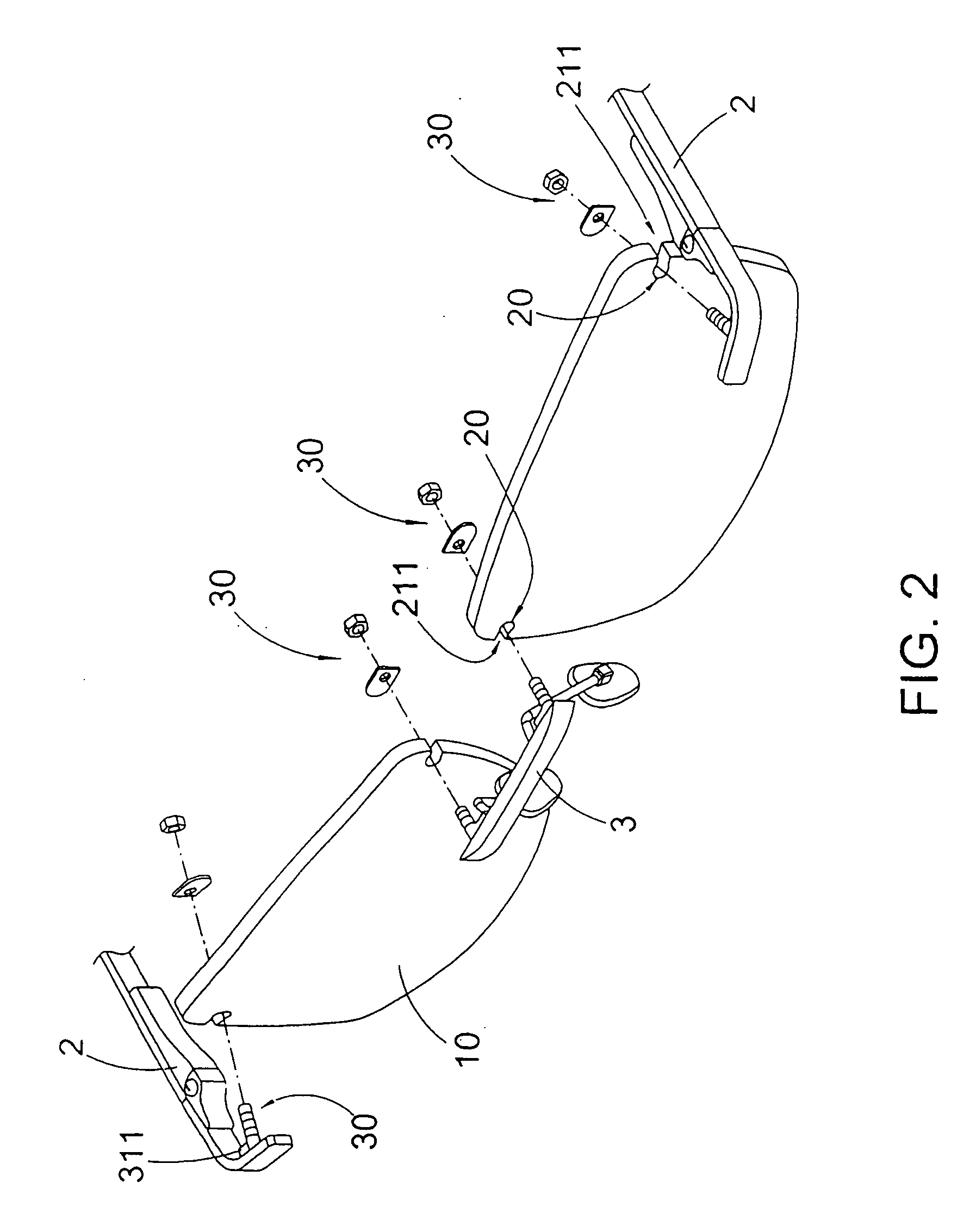

Spectacles

InactiveUS20110013134A1Difficult to manufactureImprove production efficiencySpectales/gogglesLens assembliesEngineeringElectrical and Electronics engineering

Owner:SIU YU +1

Waterproof Fastener Tape and Watertight Slide Fastener Including the Same

A waterproof fastener tape of a watertight slide fastener includes a fabric tape and a waterproof layer. The fabric tape includes a first surface, a second surface, a first edge, a second edge, a first cord portion, and an extension portion. The first cord portion protrudes from the first surface. The first and second edges are connected between the first and second surfaces. The first cord portion is spaced from the first edge at a smaller distance than from the second edge. The extension portion extends between the first edge and the first cord portion. The second surface is planar. The waterproof layer covers the first surface, the second surface, the first cord portion, the first edge and the second edge.

Owner:UNITECH ZIPPER & MACHINERY

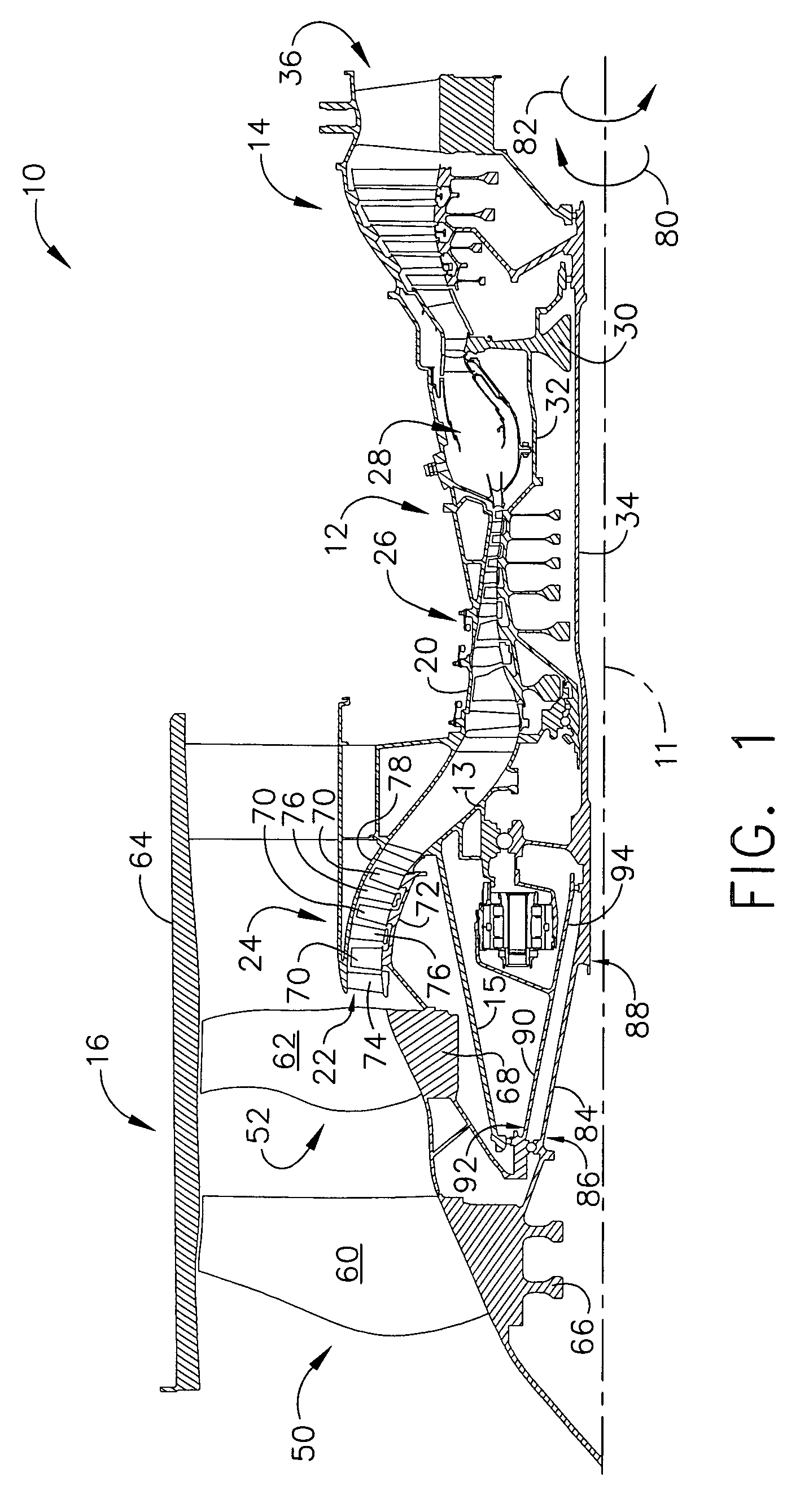

Gas turbine engine variable vane assembly

A method facilitates assembling a variable vane assembly for a gas turbine engine including a casing and an inner shroud. The method comprises providing at least one variable vane including a radially inner spindle that includes a groove defined therein that has at least one machined face, and coupling the variable vane radially between the casing and the inner shroud such that at least a portion of the radially inner spindle is inserted at least partially through an opening extending radially through the inner shroud. The method also comprises securing the variable vane to the inner shroud by engaging the spindle machined face with a retainer coupled to the inner shroud.

Owner:GENERAL ELECTRIC CO

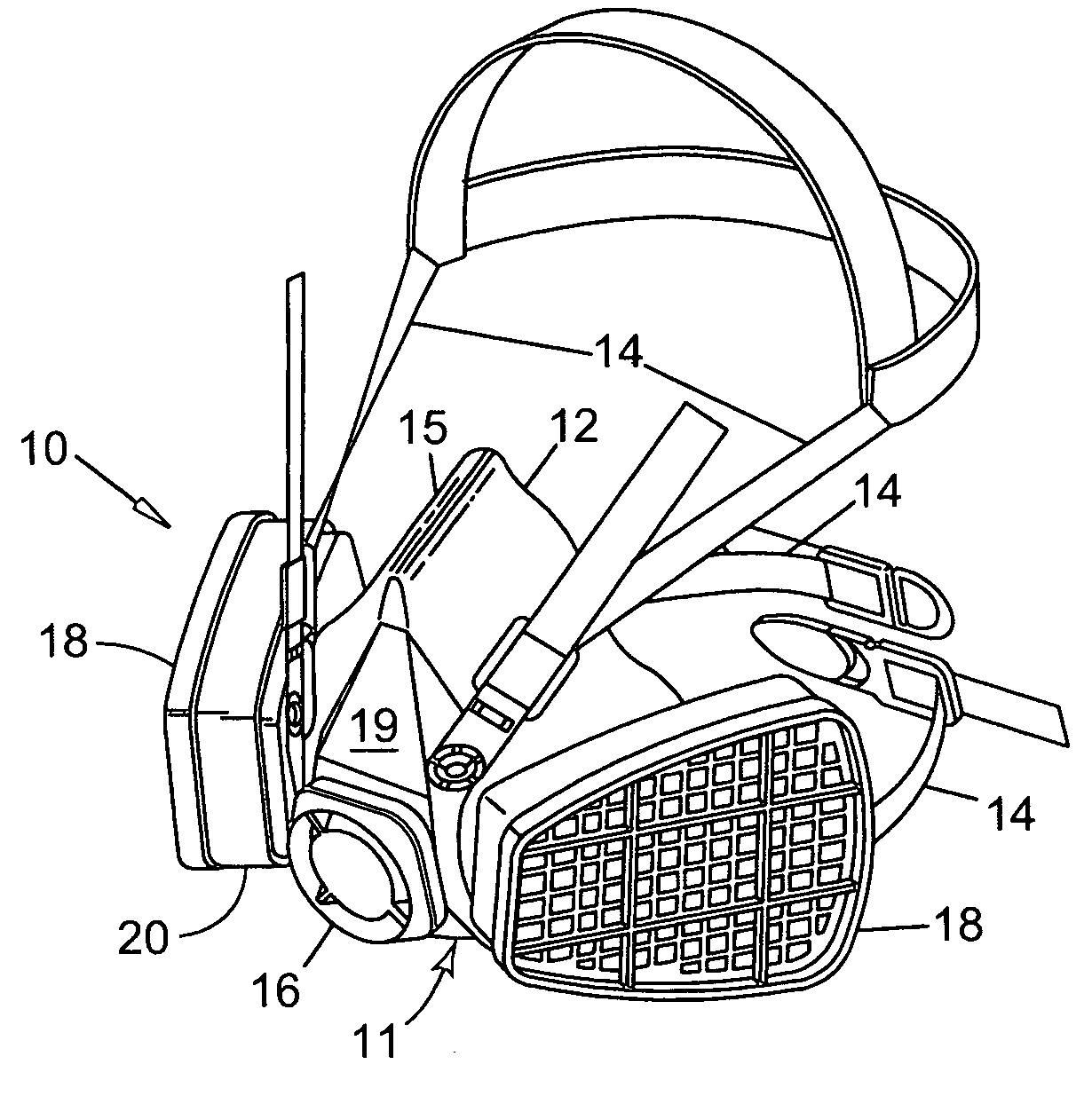

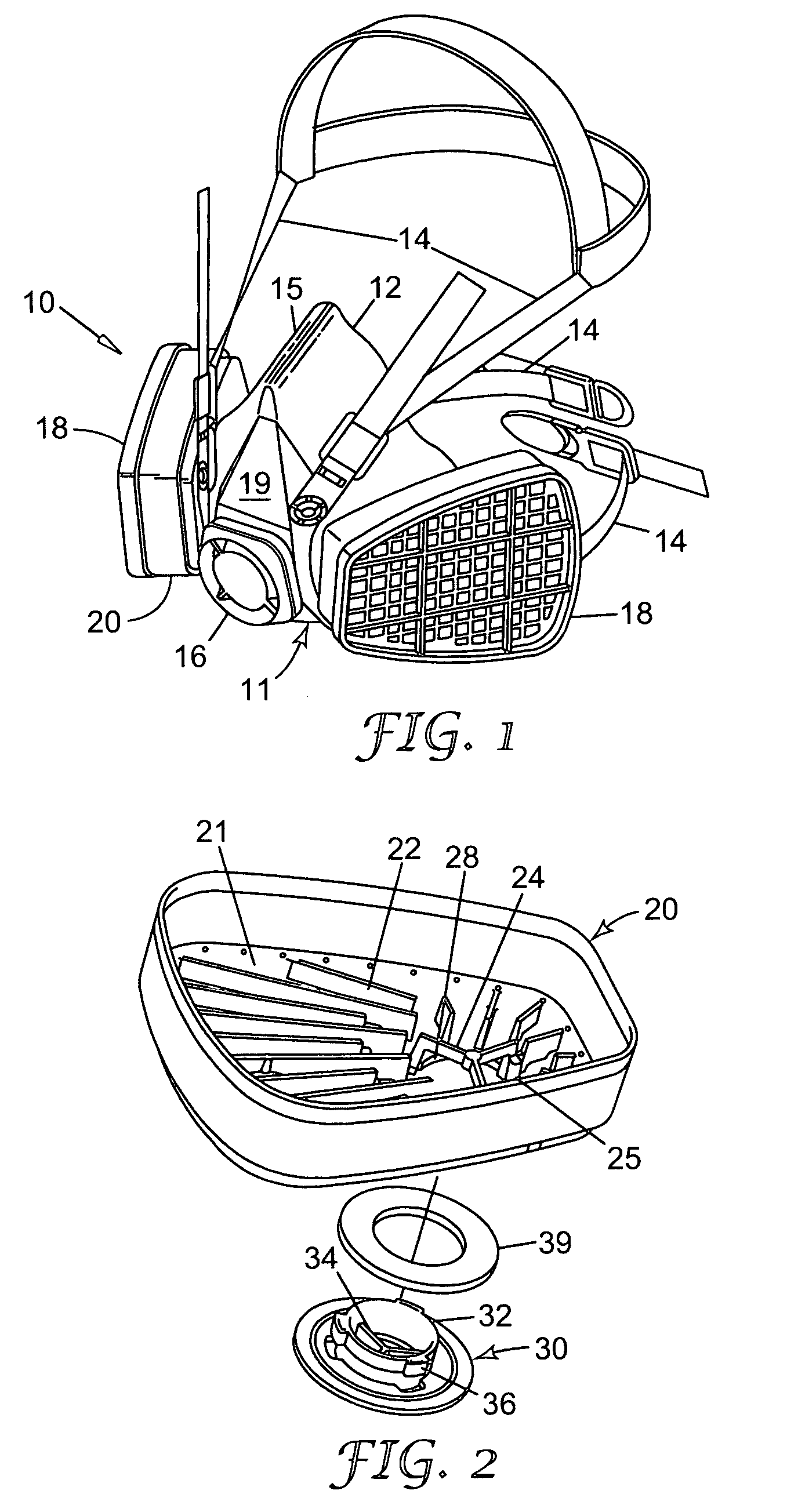

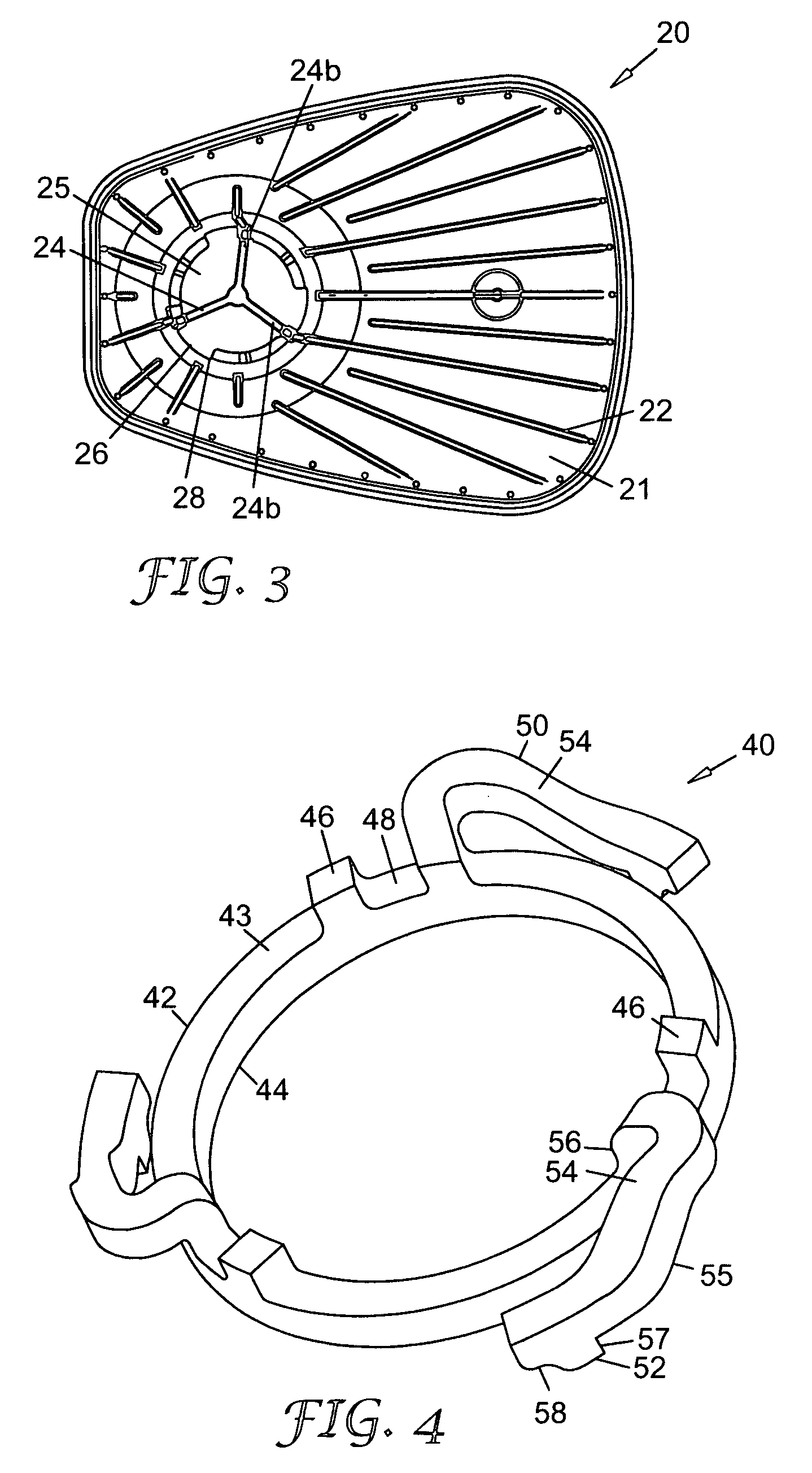

Personal respiratory protection device that has a permanent or semi-permanent bayonet connection

InactiveUS20050145249A1Inhibits accidental disengagementEliminate disengagementBreathing filtersBreathing masksEngineeringElectrical and Electronics engineering

A personal respiratory protection device that has a bayonet attachment system. The bayonet attachment system comprising a first portion and a second portion, wherein the first portion comprises a tab receptacle and a tab void area, and the second portion comprises a tab extending therefrom. The tab has a size no greater than the tab void area and no greater than the tab receptacle. When the first portion is attached to the second portion to cause the tab to seat within the tab receptacle, a connection is formed that is incapable of being inadvertently removed.

Owner:3M INNOVATIVE PROPERTIES CO

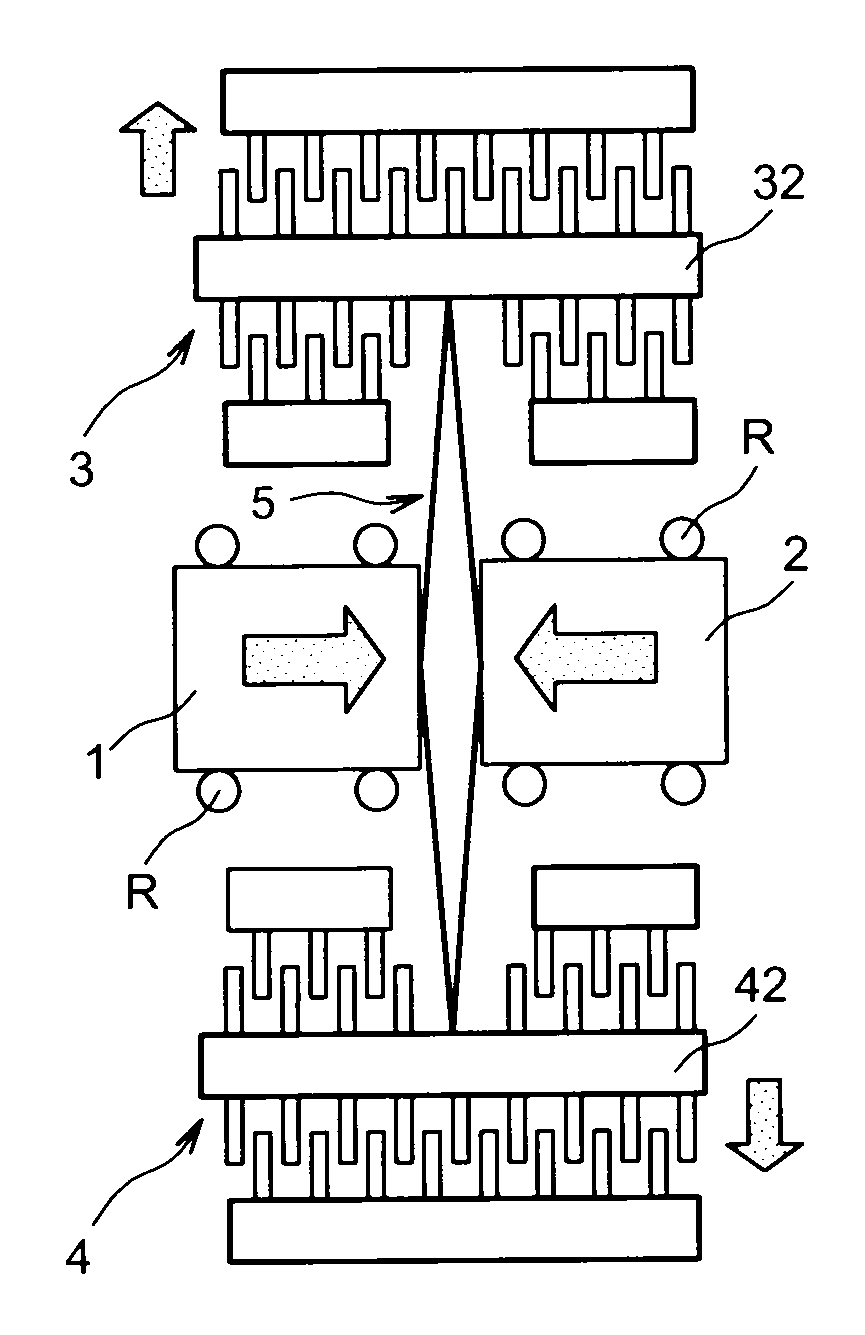

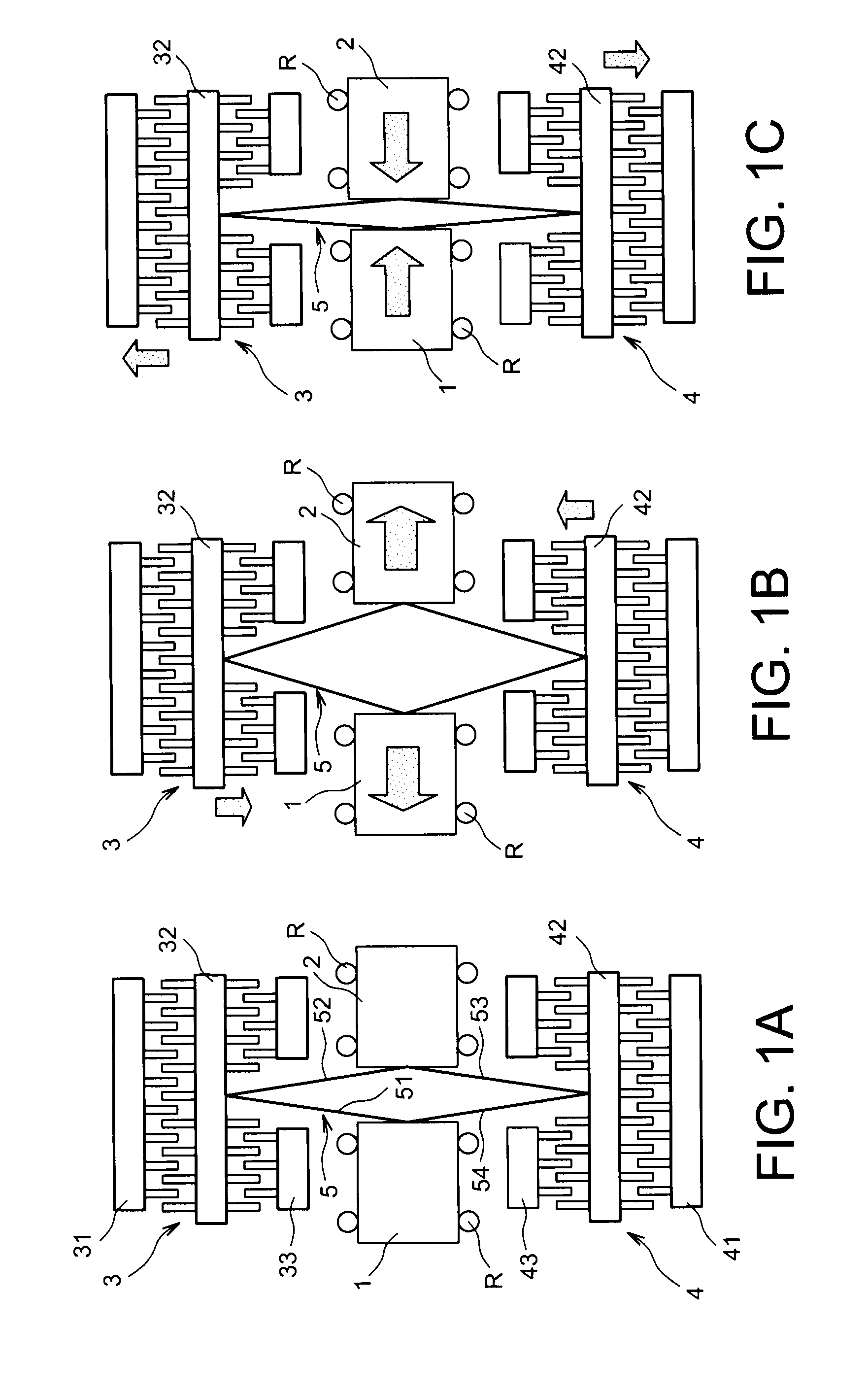

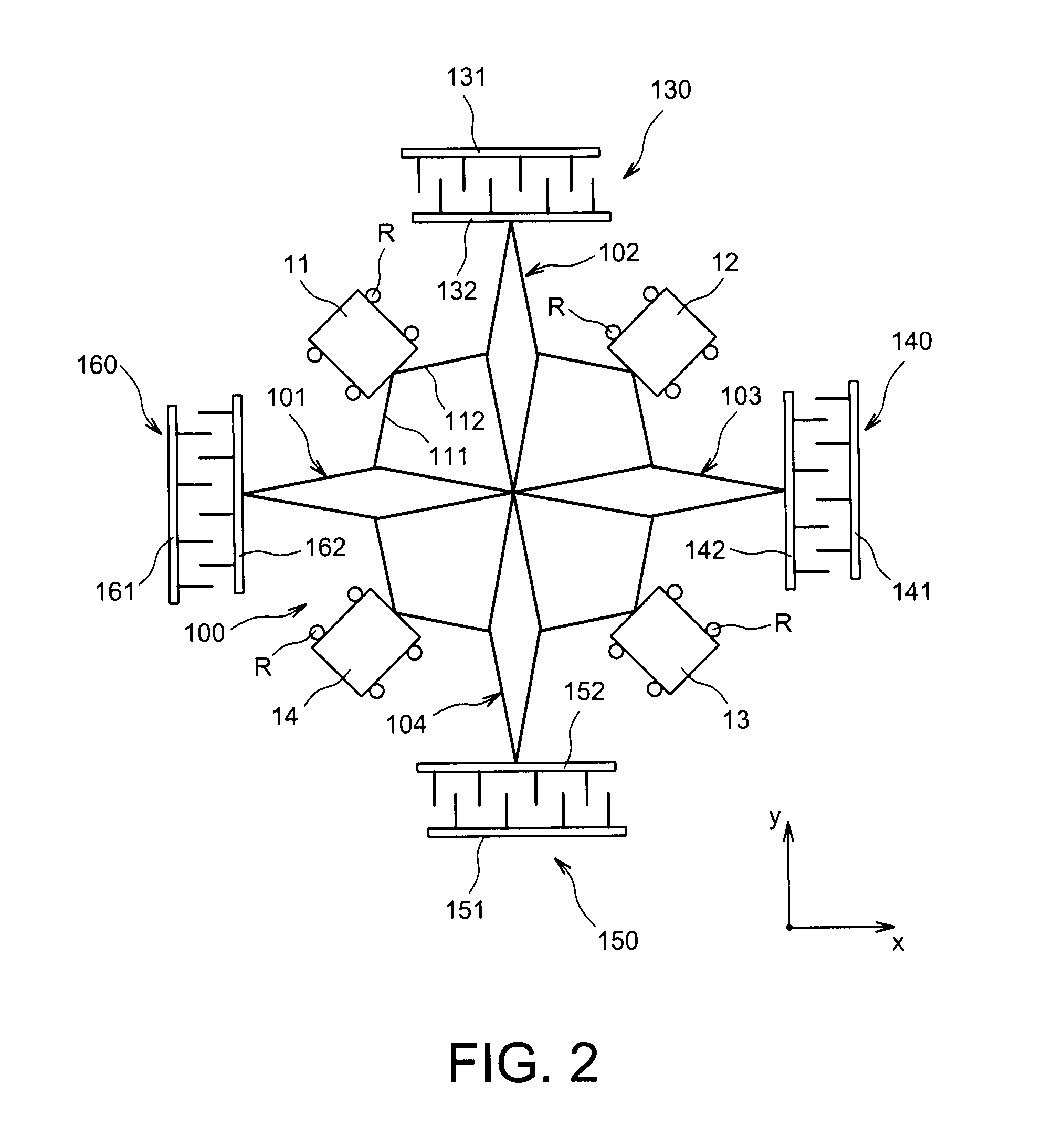

Coupling structure for resonant gyroscope

ActiveUS20120061172A1Secure couplingAcceleration measurement using interia forcesSeismic energy generationGyroscopeCoupling

A coupling structure for a resonant microgyroscope produced on a substrate, wherein the coupling structure enables a vibratory movement provided by an excitation mechanism to be detected along a first axis, and enables it to be transmitted to seismic masses lying in a plane containing the first axis. The coupling structure includes a closed assembly of beams connected to the seismic masses so as to be anchored only to the seismic masses, wherein the assembly is positioned to detect the vibratory movement provided by the excitation mechanism, and to transmit it to the seismic masses along at least a second axis contained in the plane, wherein the coupling structure has no point of anchorage to the substrate.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Polyaxial screwdriver for a pedicle screw system

ActiveUS20080221583A1Secure couplingSecure attachmentInternal osteosythesisSpannersVertebraPedicle screw

A polyaxial screwdriver for inserting a bone screw in a vertebra. A polyaxial bone screw assembly includes a coupling element. When a screw engaging end of the polyaxial screwdriver is lowered on the head of the bone screw, the complimentary surfaces of the screw engaging end of the screwdriver and the head of the screw self-align. A ratchet mechanism formed in the screwdriver provides progressive and automatic locking of the polyaxial screwdriver to the coupling element and prevents the accidental unthreading from the coupling element. In another embodiment of the polyaxial screwdriver, a collet slides over the outside surface of the upper end of the coupling element and locks on to the coupling element. In yet another embodiment of a polyaxial screwdriver, the outer sleeve of the polyaxial screwdriver has a split end that securely engages the coupling element.

Owner:STRYKER EURO OPERATIONS HLDG LLC

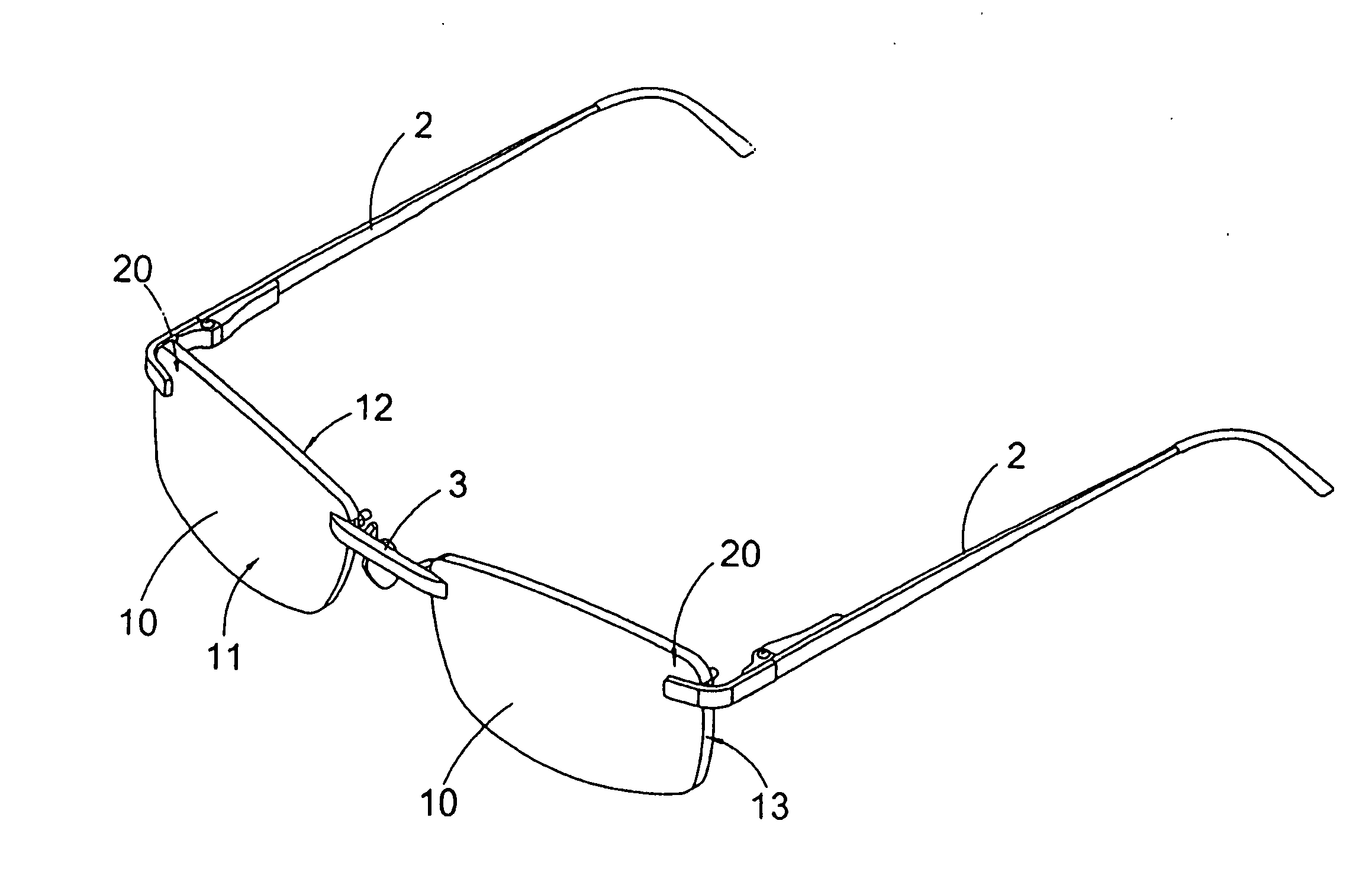

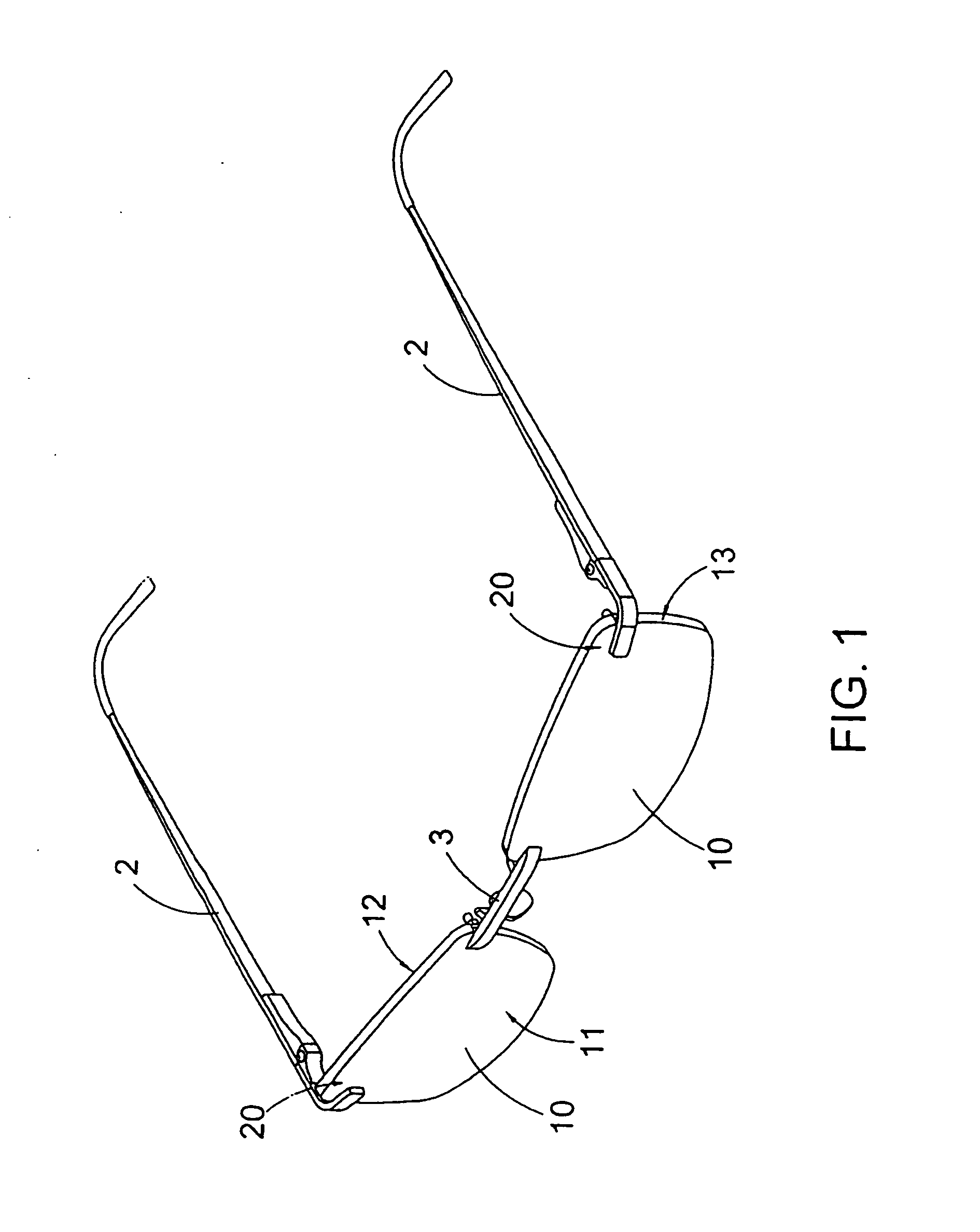

Spectacles

InactiveUS20140333887A1Difficult to manufactureImprove production efficiencyLens assembliesEngineeringElectrical and Electronics engineering

Owner:SIU YU +1

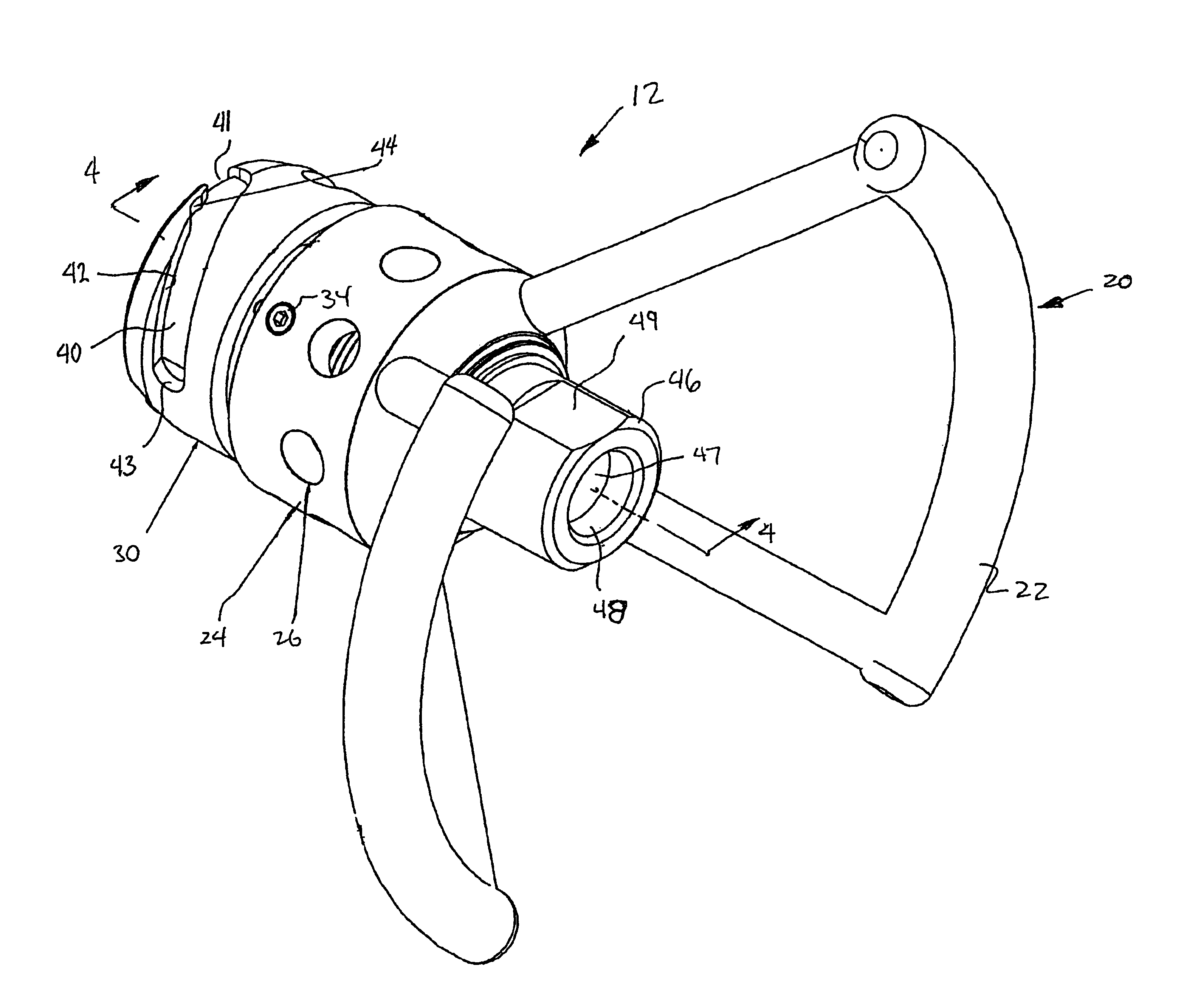

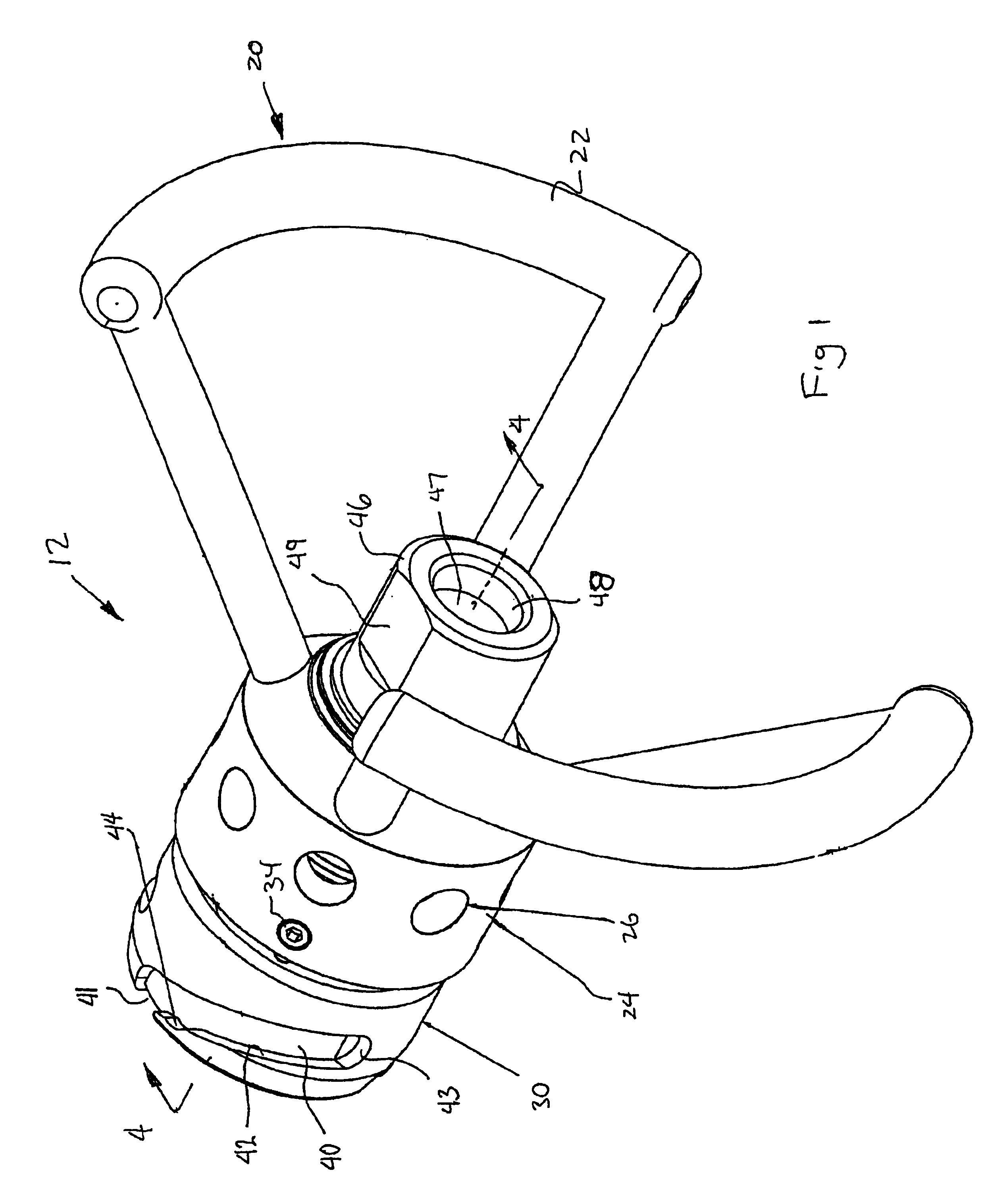

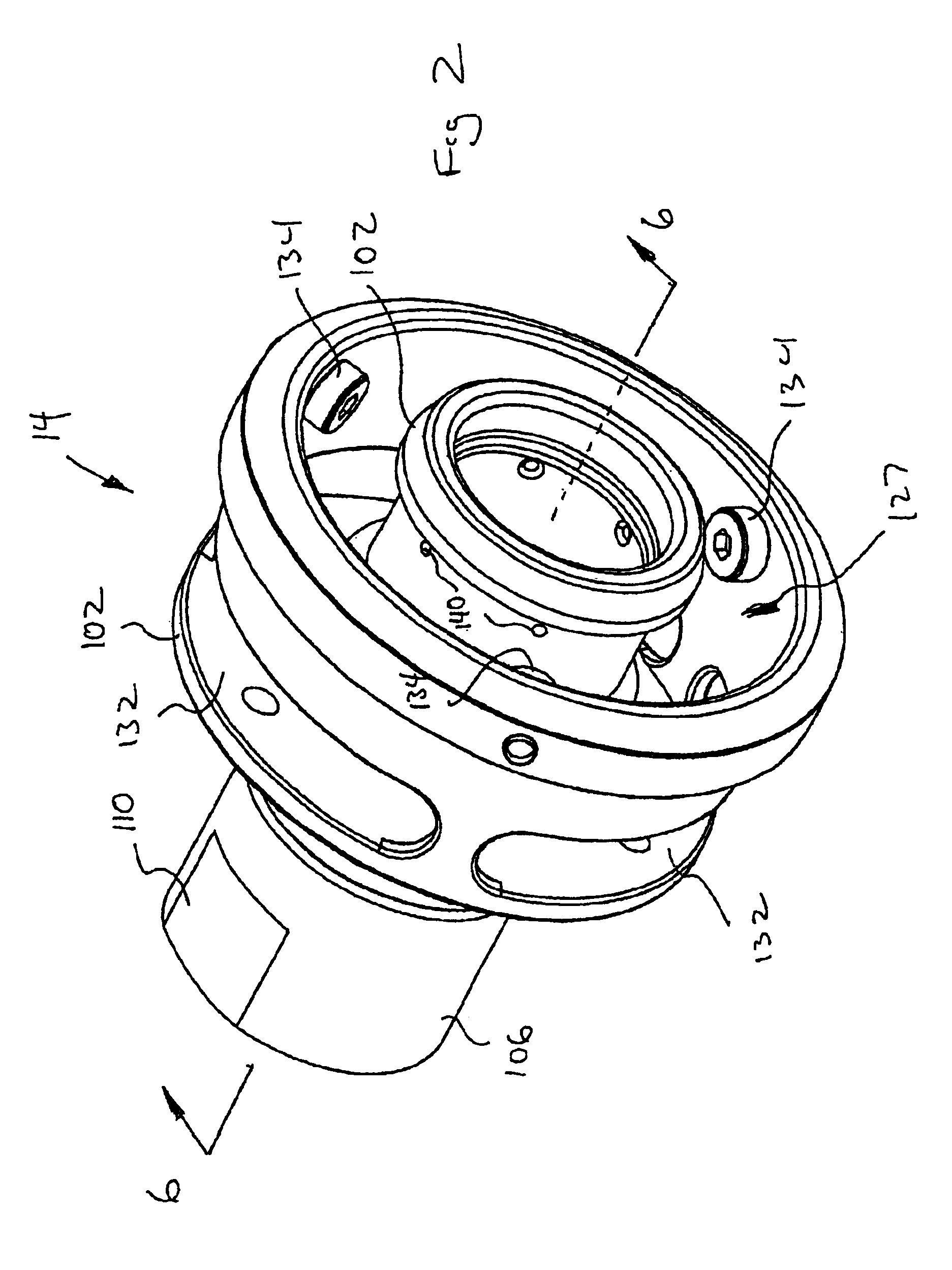

Cryogenic coupling device

ActiveUS6945477B2Prevent overflowSmall sizeVessel mounting detailsSpray nozzlesThermal breakCoupling

A cryogenic coupling device includes a valved receptacle and a valved nozzle. Rollers in an outer collar of the receptacle are received in helical channels along a collar of the nozzle. A notch or detent in each of the channels provides a vent position to vent fluid before the nozzle is fully disconnected from the receptacle. Interface seals on the nozzle include first and second annular seals that function as ice and containment scrapers, as well as fluid seals. The nozzle has a rotatable handle assembly, isolated from the fluid path, which provides easy connect and disconnect of the nozzle from the receptacle. The handle assembly includes a thermal break, and is easily removable from the nozzle, along with other parts of the nozzle and receptacle, for service and maintenance.

Owner:PARKER INTANGIBLES LLC

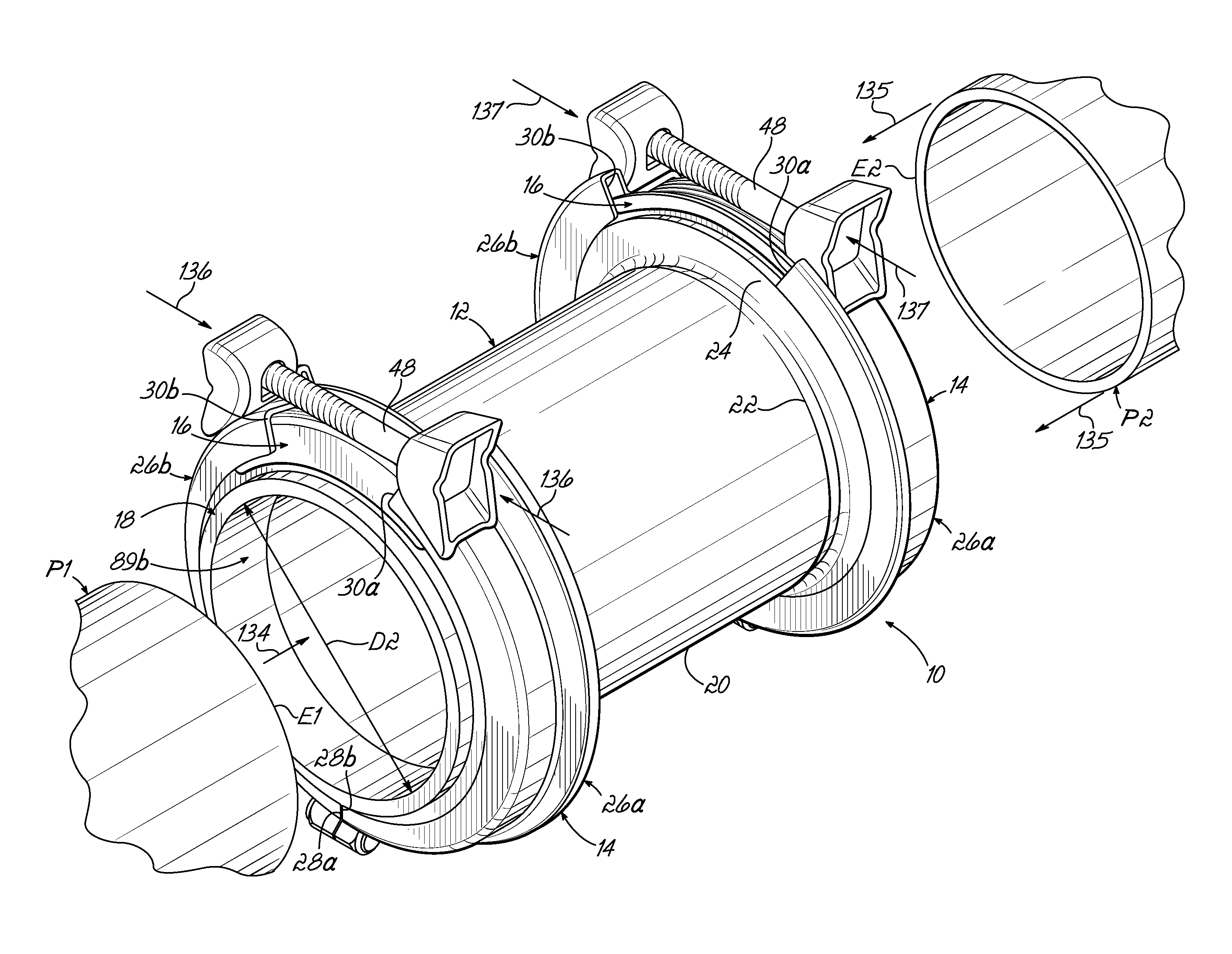

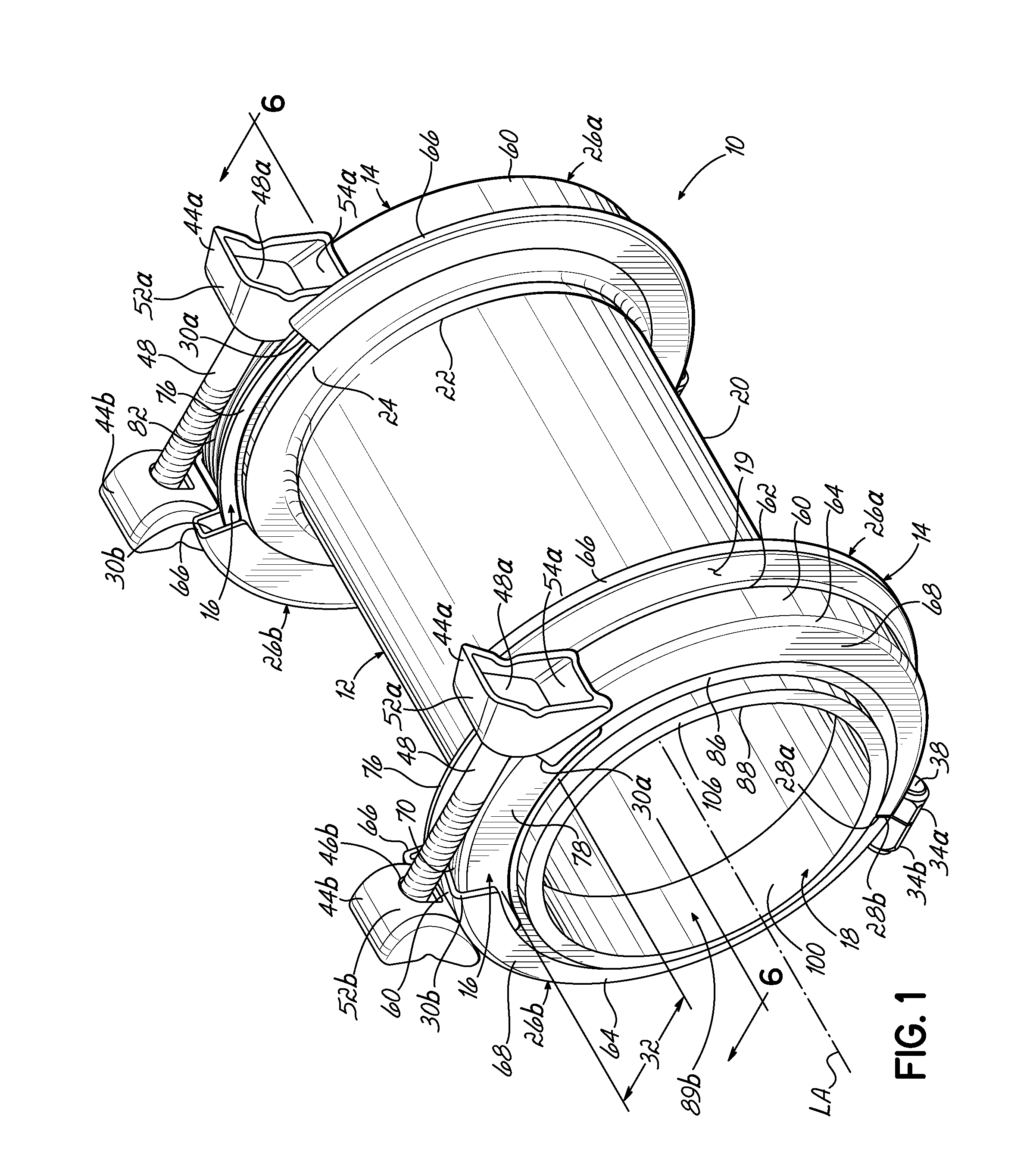

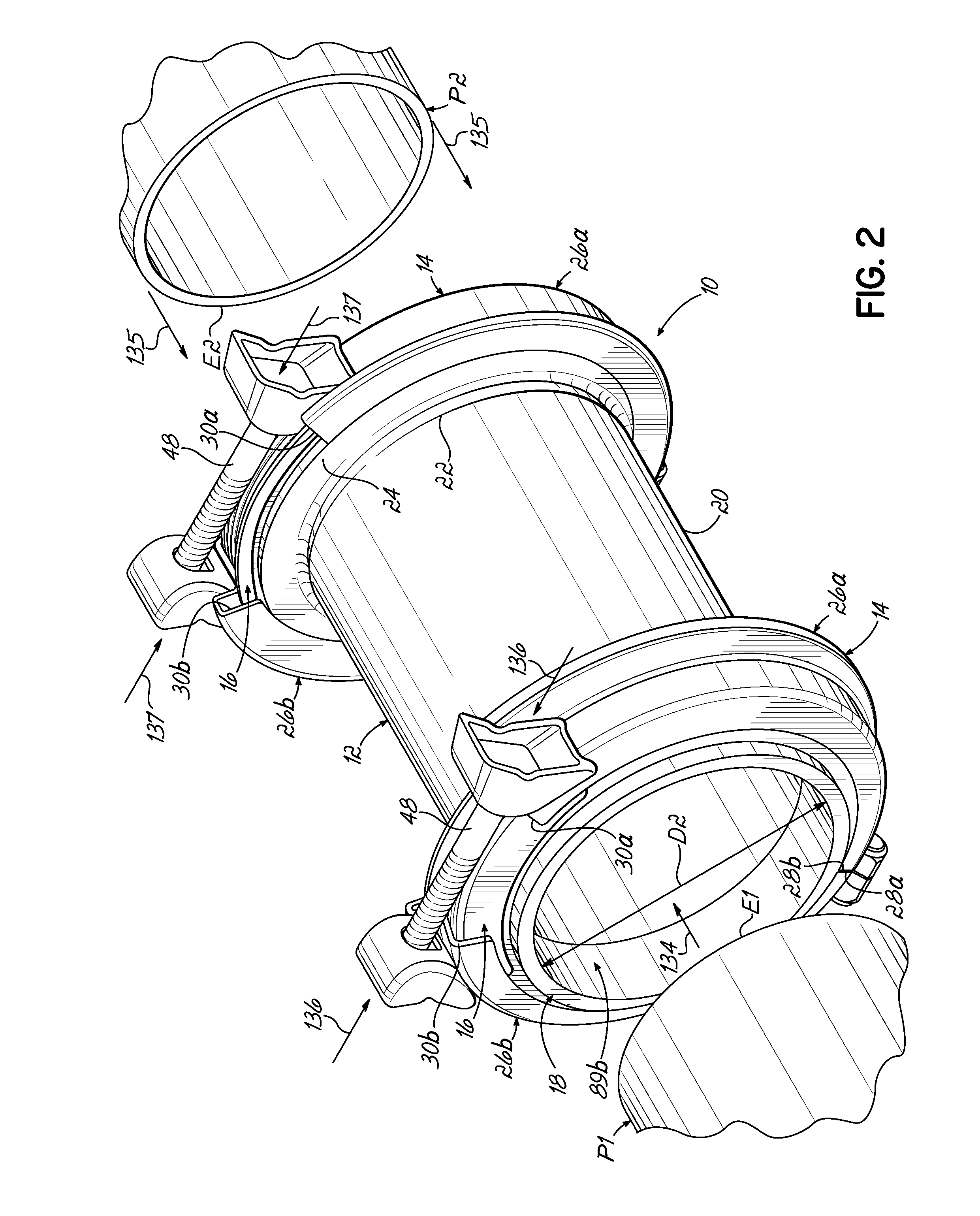

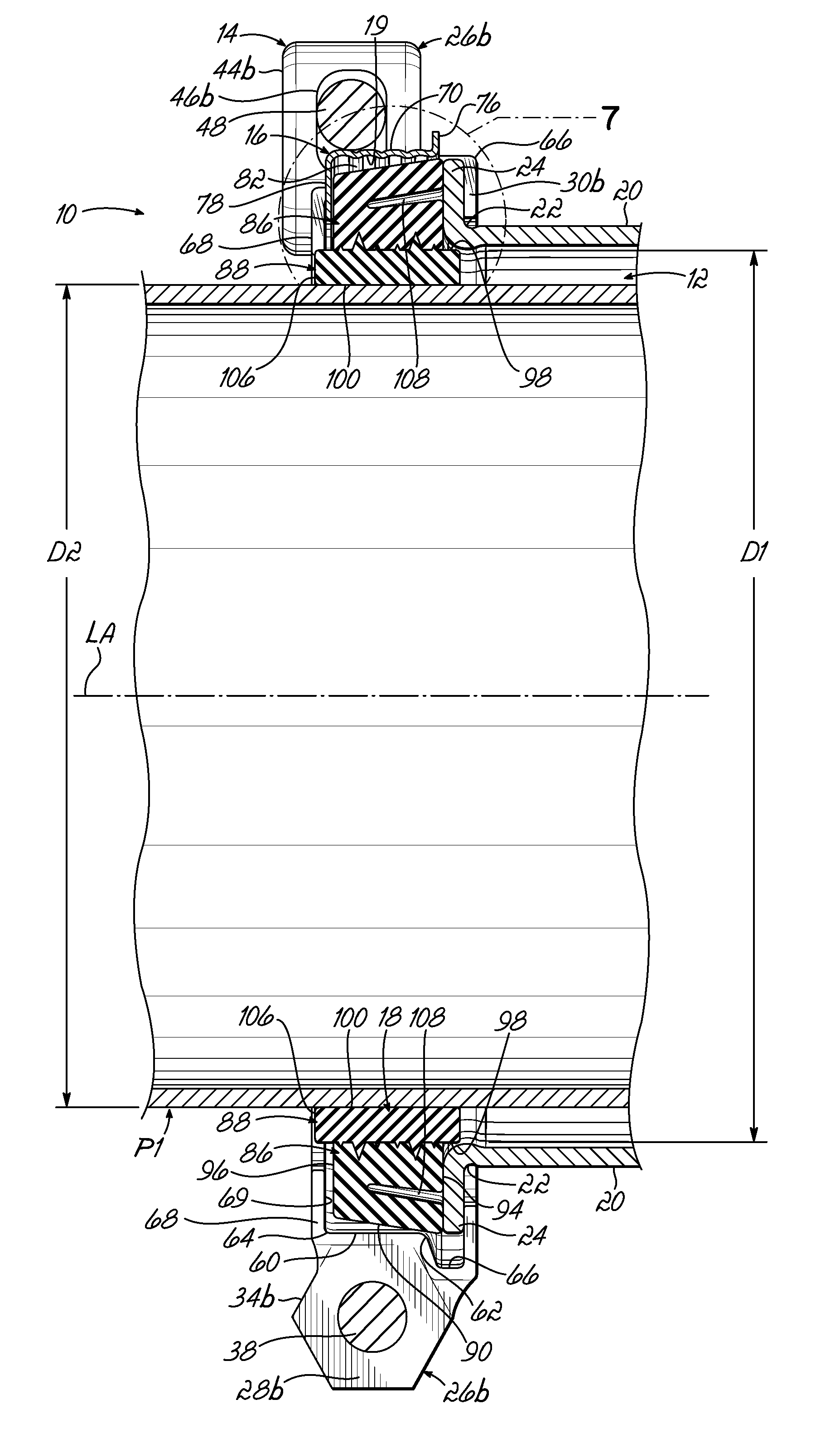

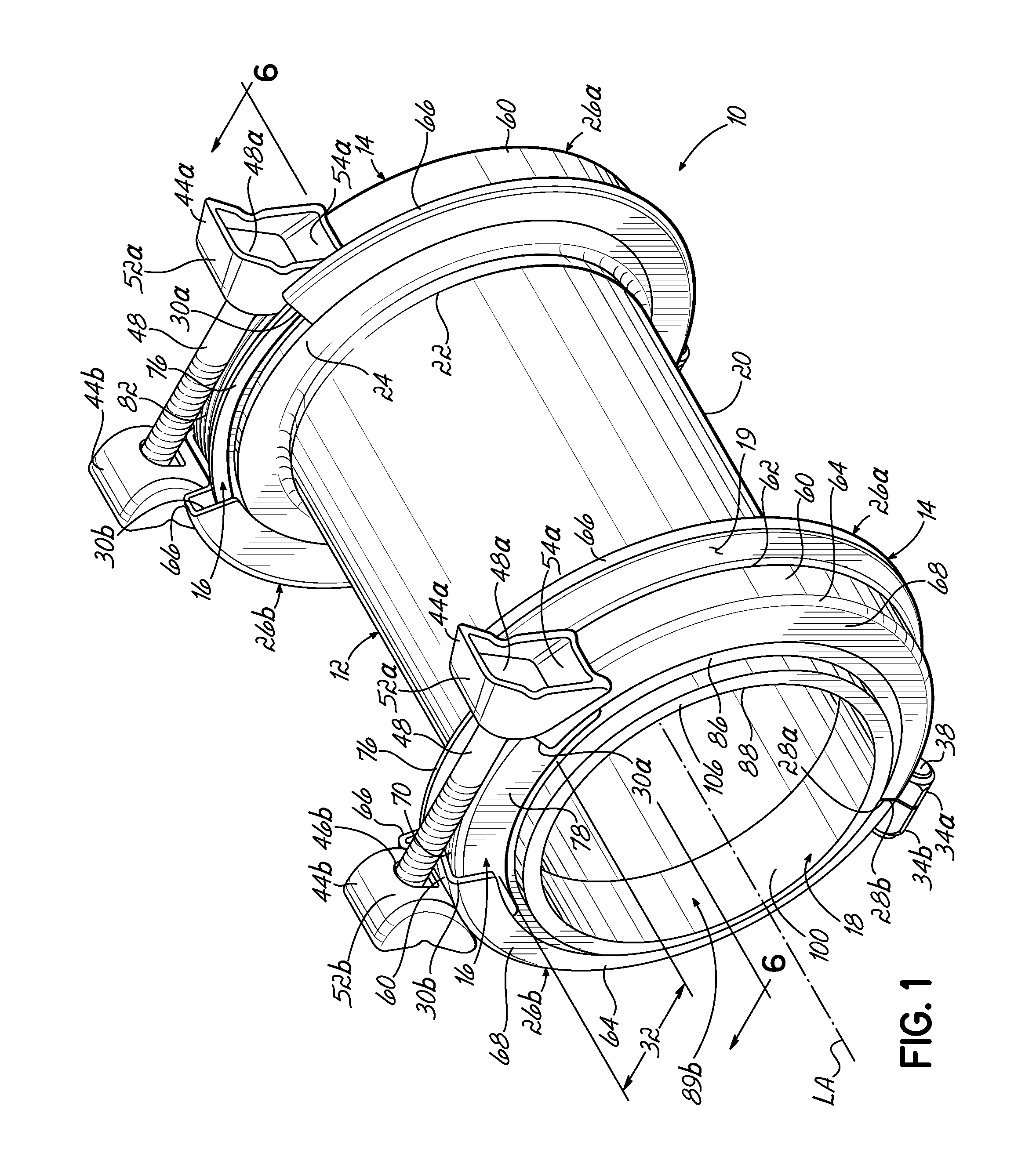

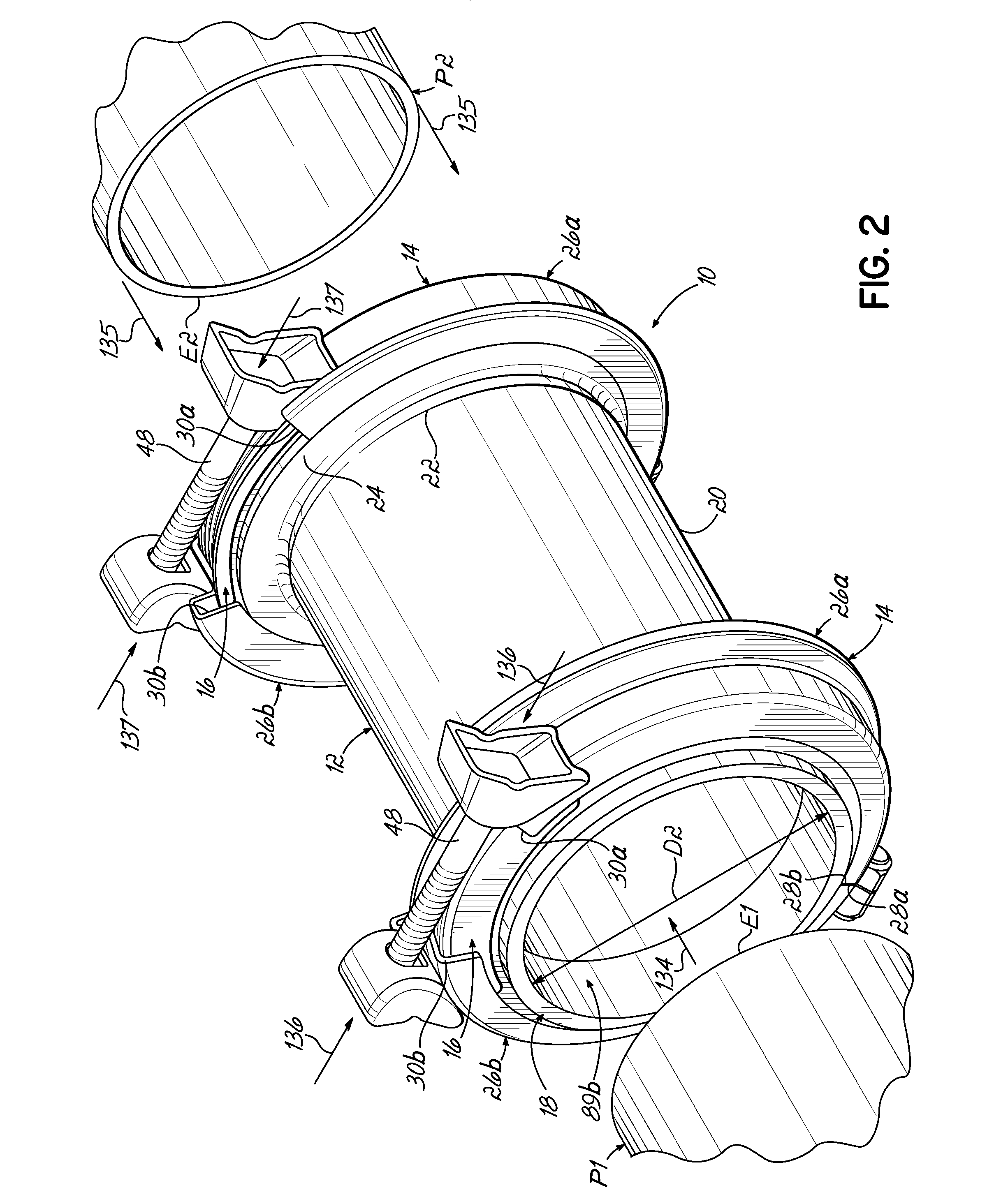

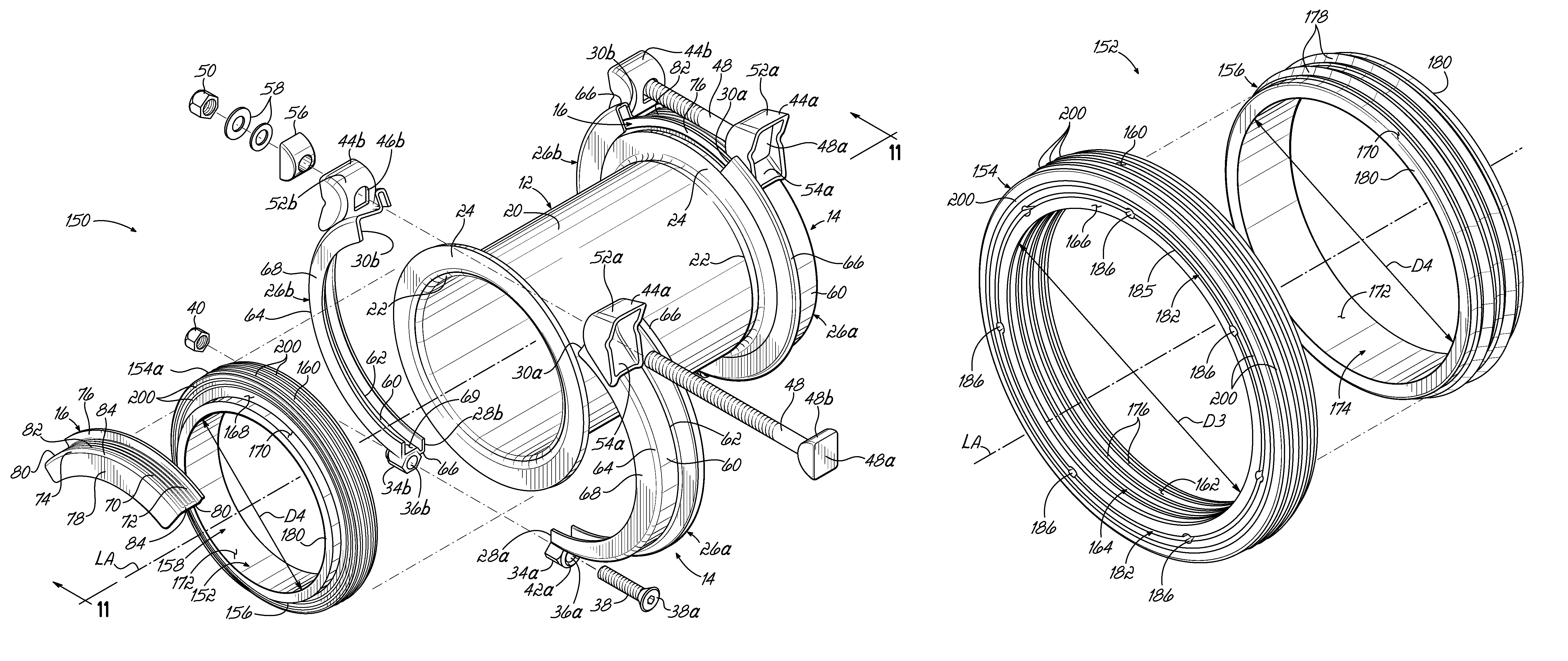

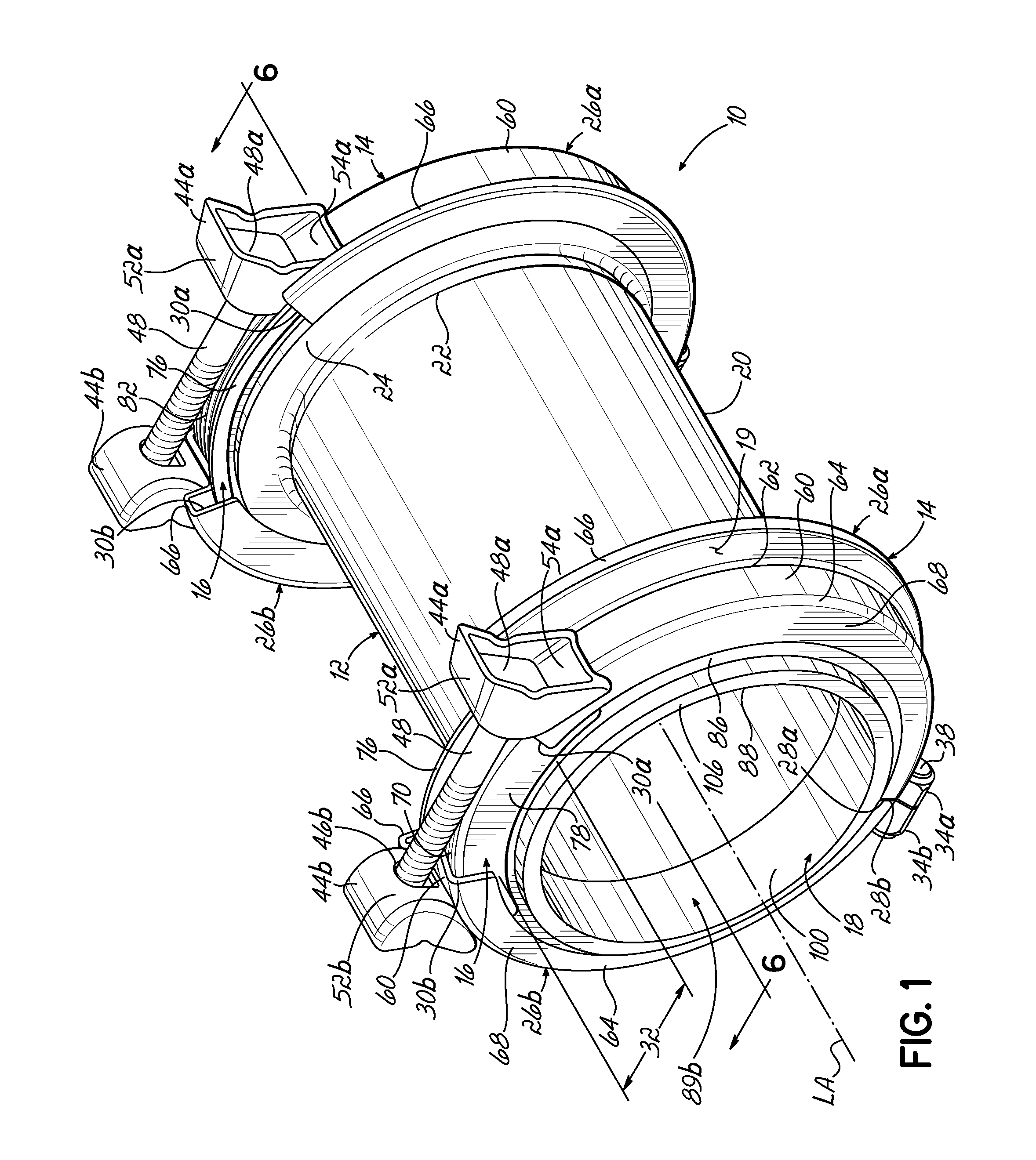

Split-Ring Gland Pipe Coupling with Corrugated Armor

ActiveUS20120205909A1Improve performanceEnhance assemblySleeve/socket jointsEngine sealsEngineeringSplit ring

A pipe coupling for coupling adjacent ends of a pair of pipes includes a sleeve, a split-ring gland positioned around one of the ends of the sleeve, and at least one annular gasket positioned within the split-ring gland and configured to be compressed by the split-ring gland for sealing one pipe end to the sleeve. The split-ring gland includes two partially circular gland members with spaced ends defining a gap. The pipe coupling includes an armor positioned to span the gap between the spaced ends to provide a generally closed annular periphery about the gasket. The armor includes a corrugated portion having a plurality of corrugations engaging the split-ring gland and the gasket during compression of the gasket. The armor is cold formed to improve structural strength and durability.

Owner:SENSUS SPECTRUM LLC

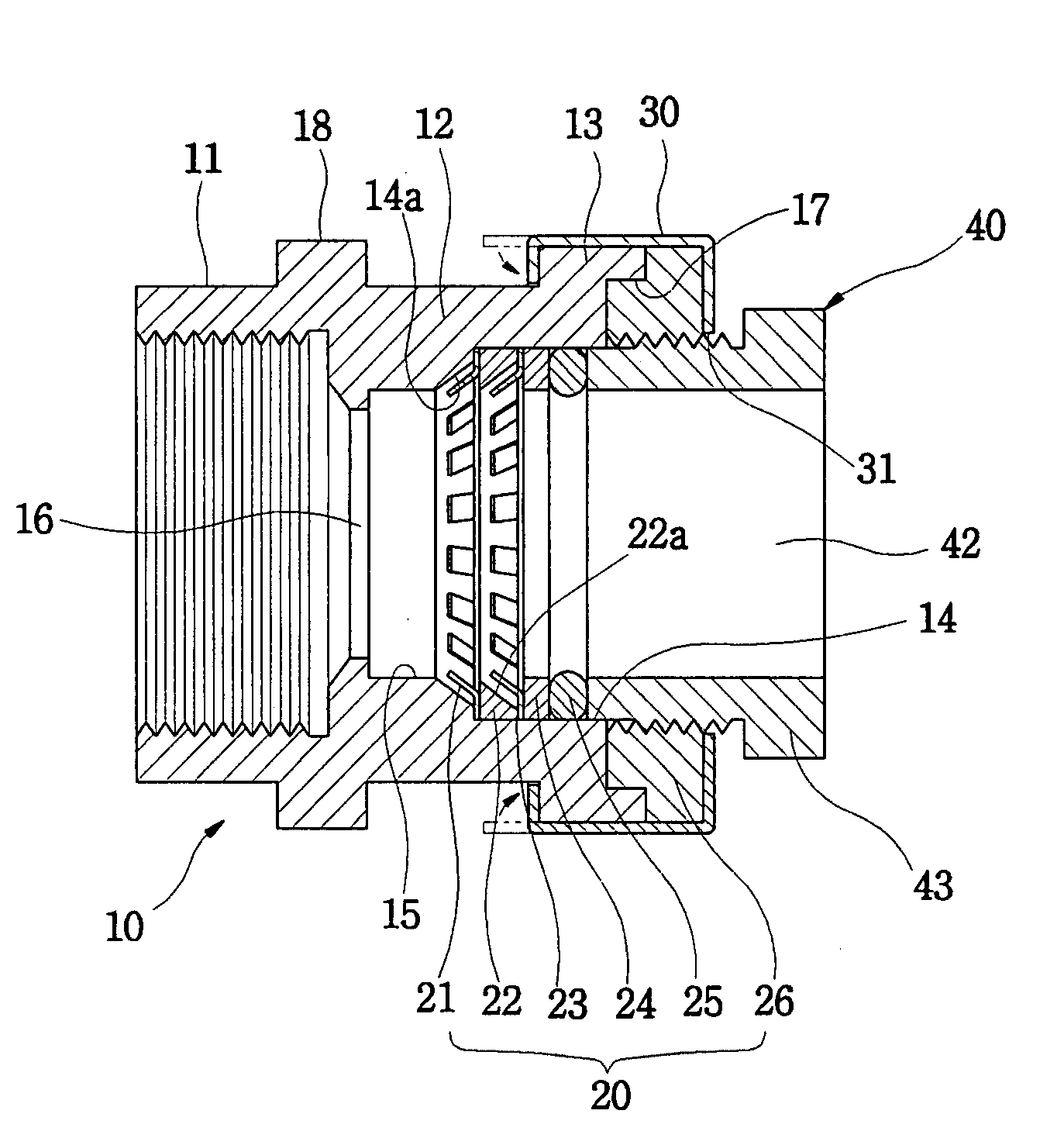

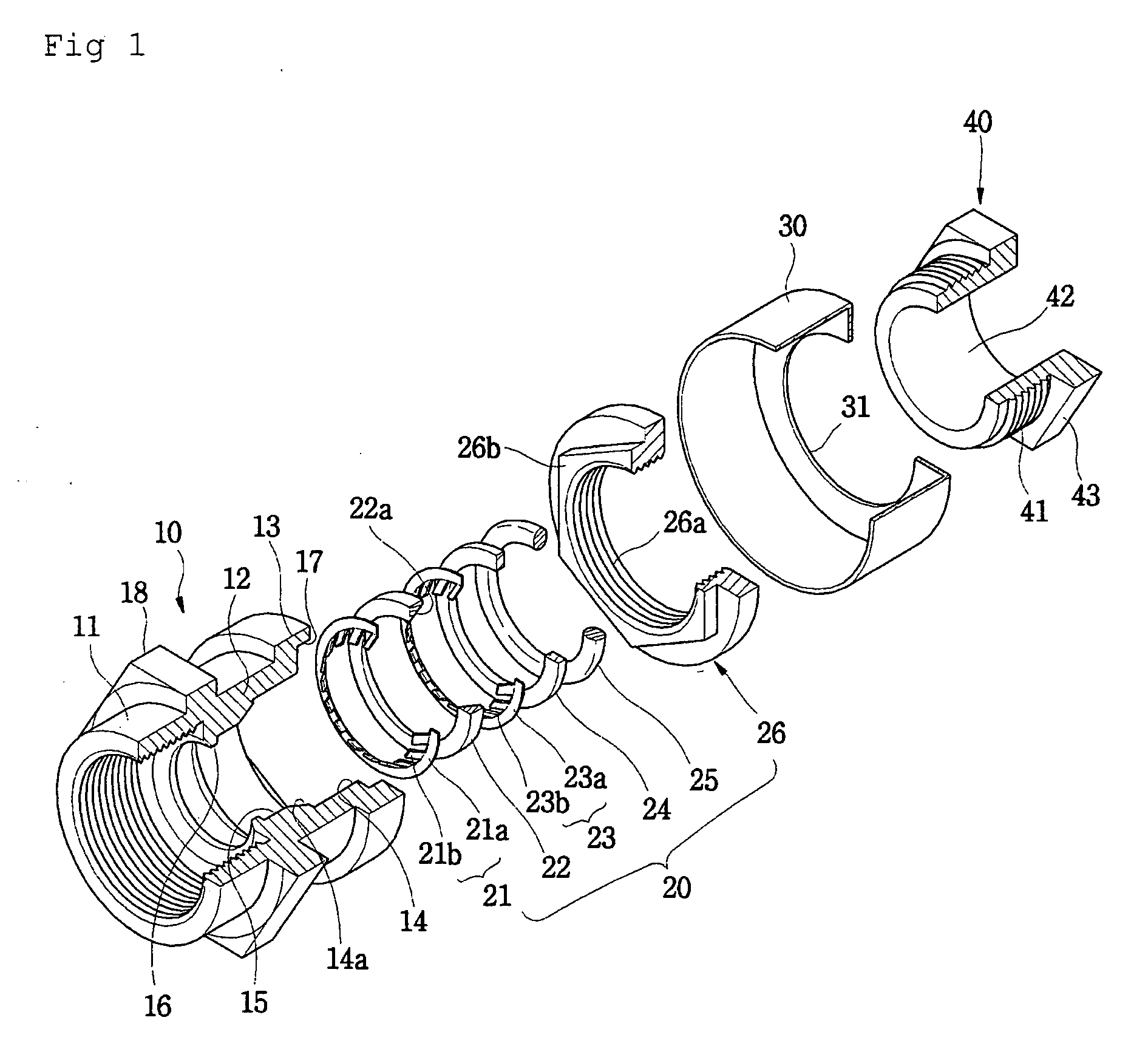

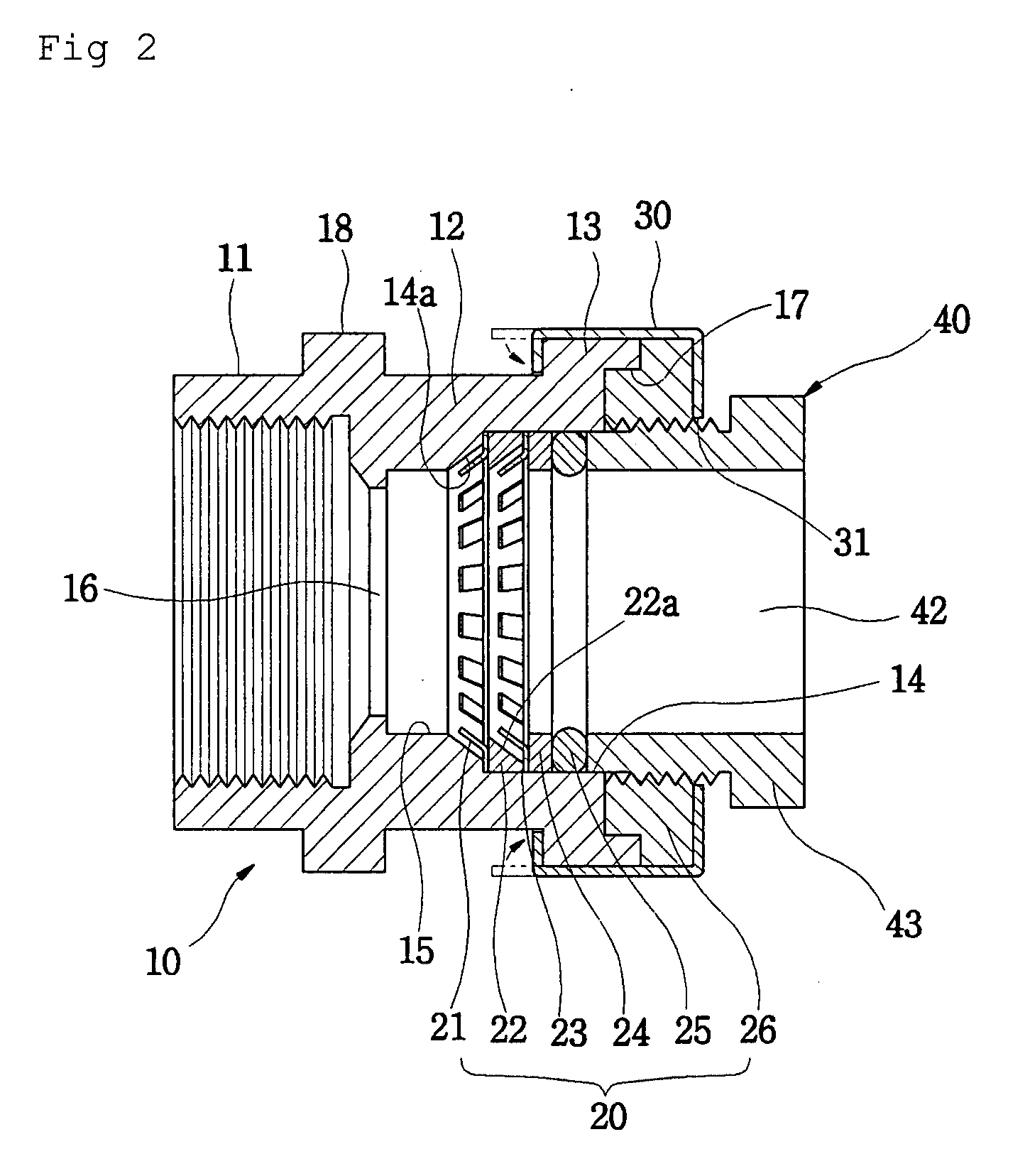

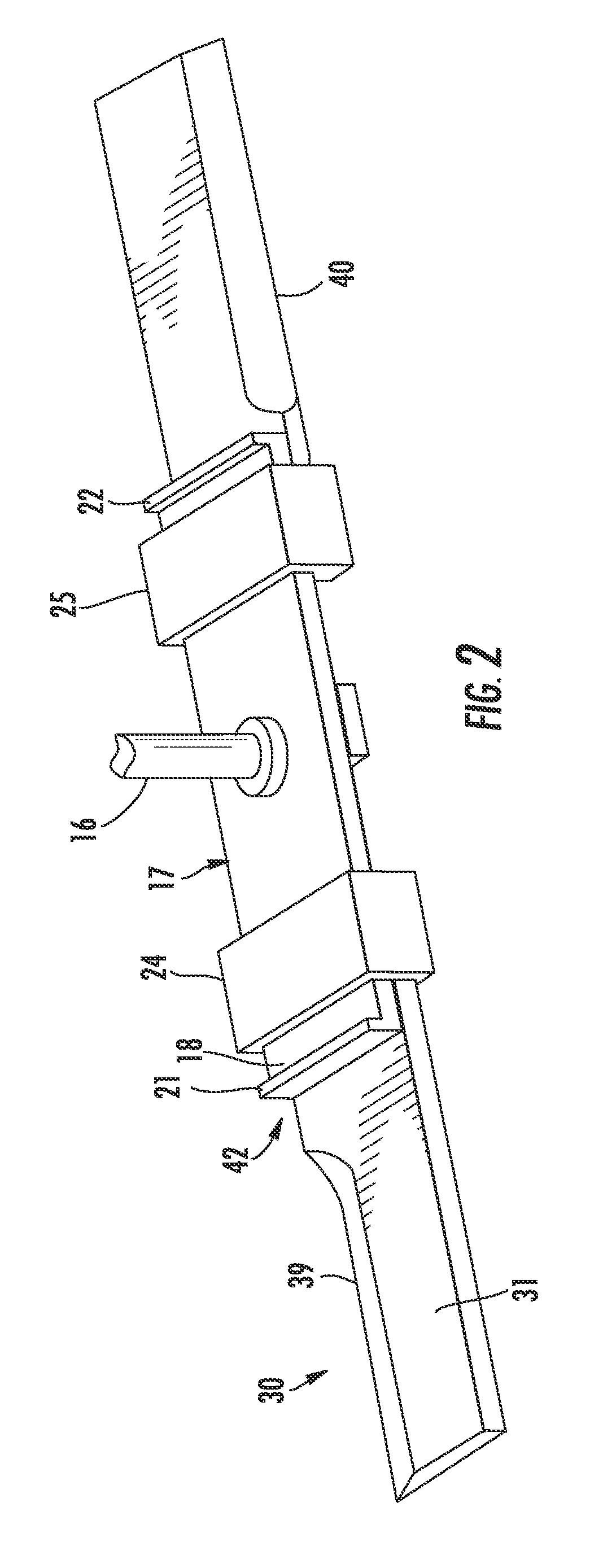

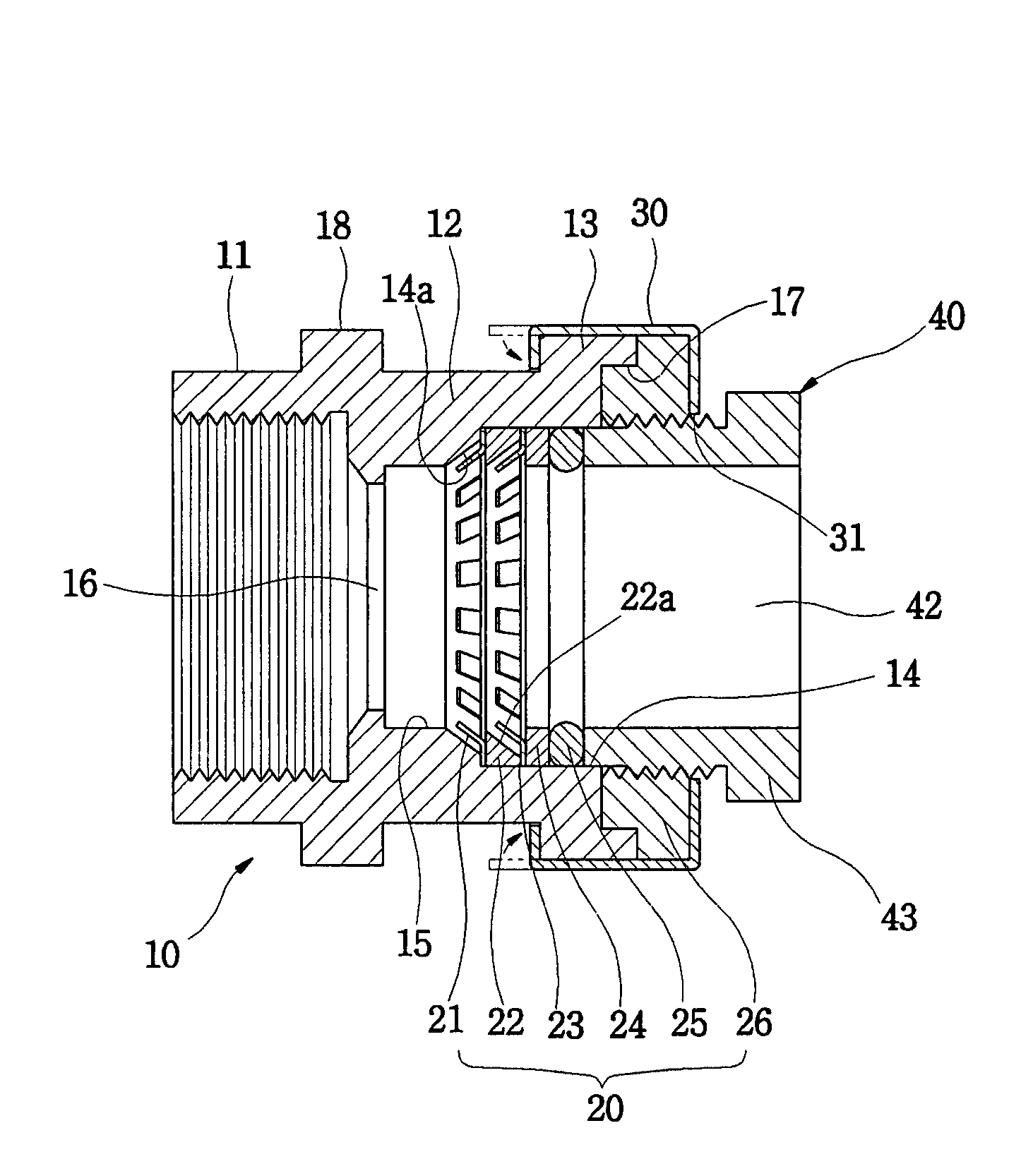

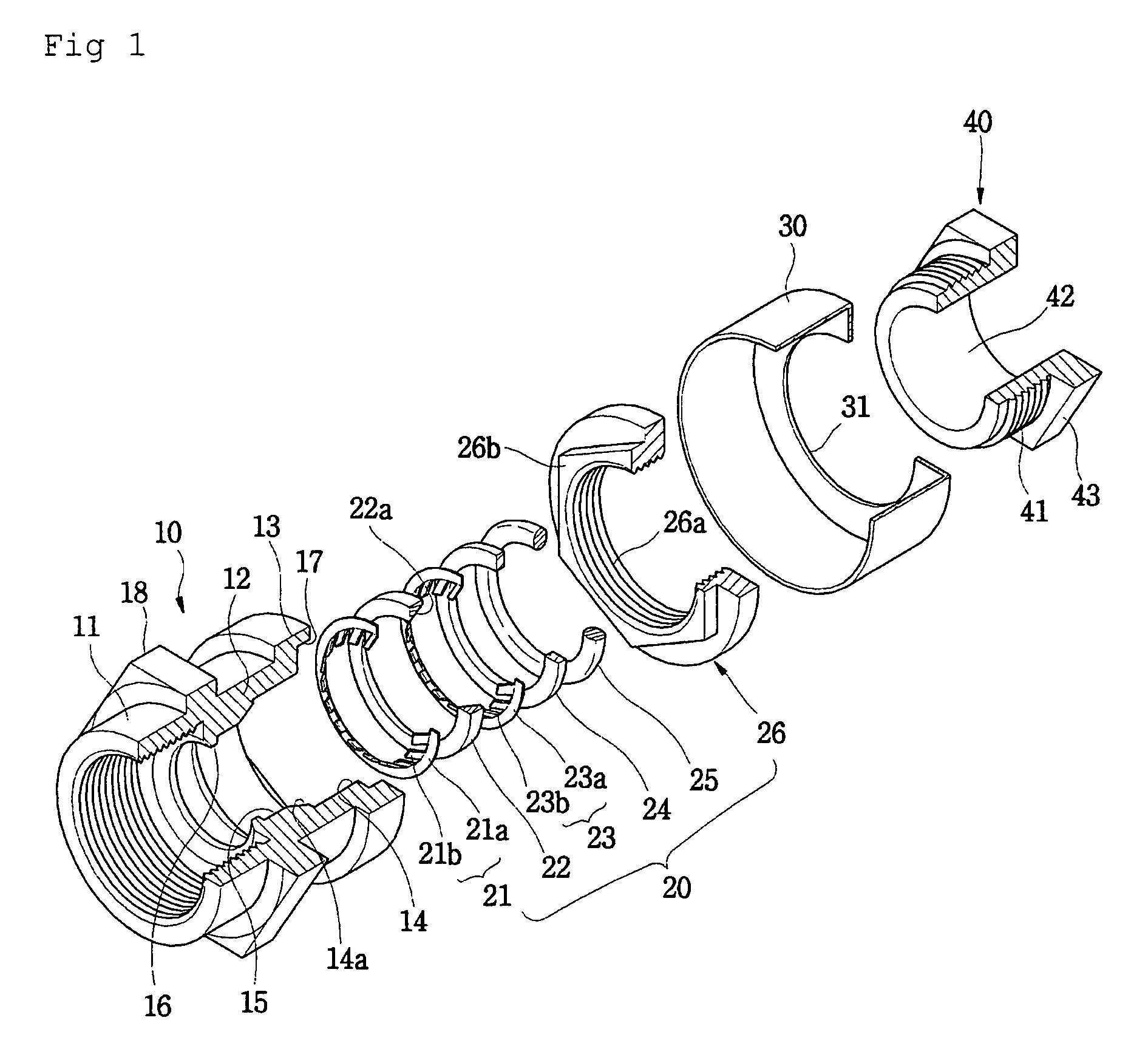

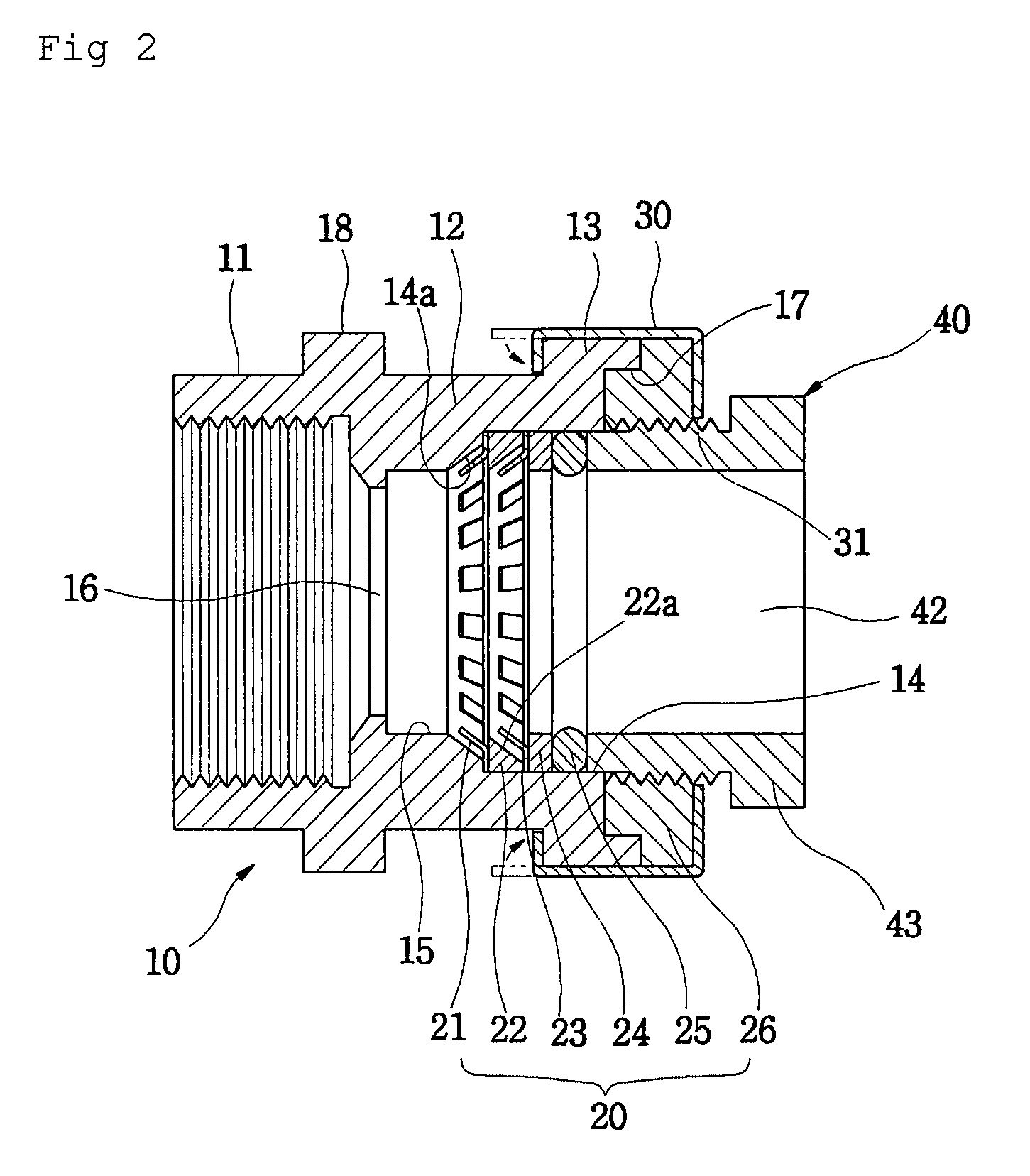

Coupling device for circular pipes

ActiveUS20090021001A1Maintained satisfactorilySecure couplingSleeve/socket jointsFluid pressure sealed jointsEngineeringCoupling

A coupling device for circular pipes, in which locking rings, inserted into a body to clamp a circular pipe, are arranged in a pair so that the central line of a circular pipe can be aligned when the circular pipe is inserted. Furthermore, the degree to which the body presses the seal packing can be adjusted so that a reliable seal can be maintained and the circular pipe can be securely coupled no matter who uses the coupling device. A coupling device for corrugated and circular pipes is provided for the case where it is more effective to replace one of the circular pipes with a corrugated pipe. The first coupling section and a connecting means, which can engage with a corrugated pipe, are provided opposite the second coupling section, which is coupled with the circular pipe.

Owner:KOFULSO

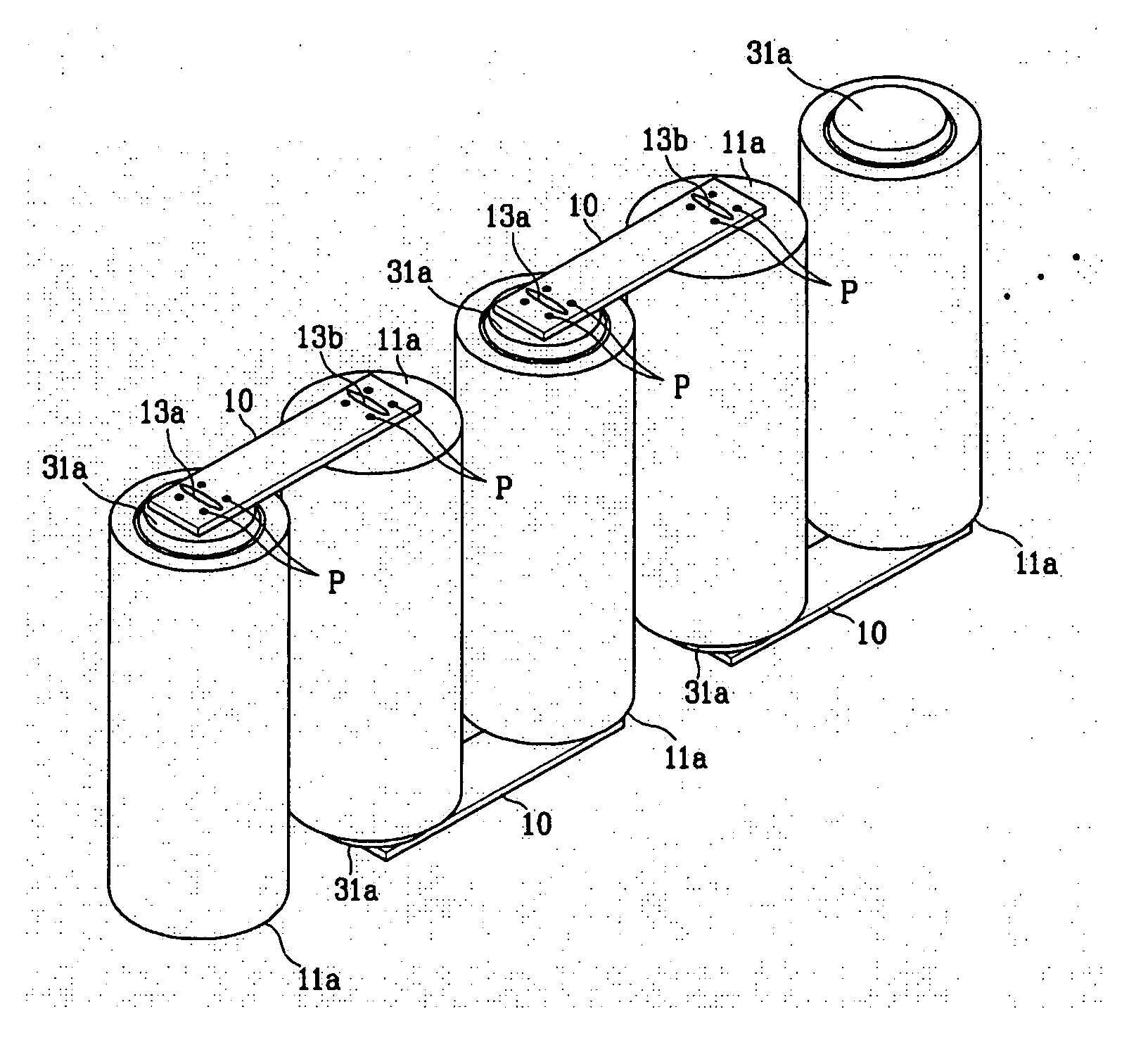

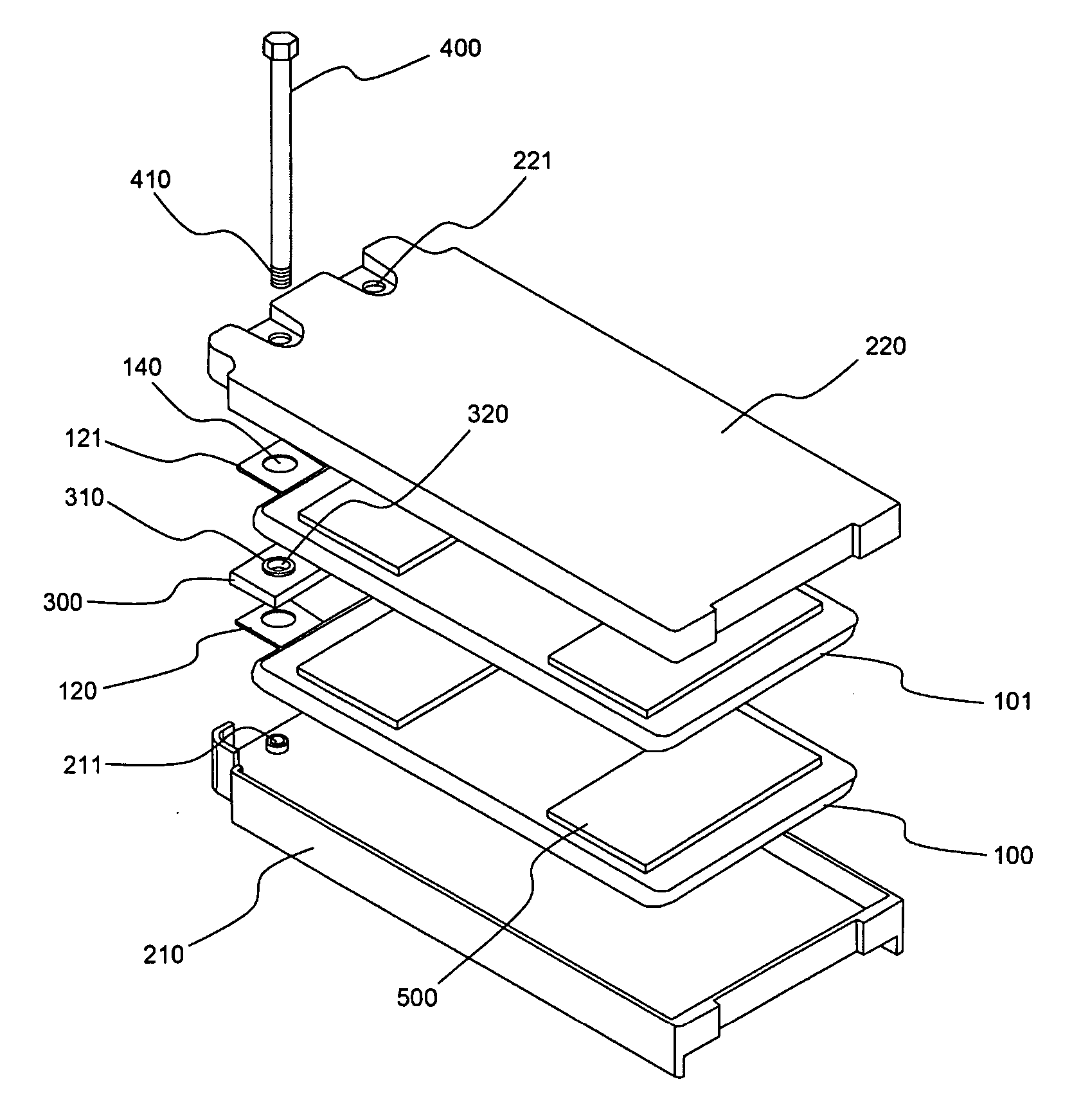

Process for preparation of secondary battery module

ActiveUS20060162149A1Compact structureConnection securitySeveral cell simultaneous arrangementsCell seperators/membranes/diaphragms/spacersCouplingElectrical connection

Disclosed herein is a process for preparation of a secondary battery module. The process includes forming coupling through-holes having specific shapes at plate-shaped electrode terminals of a plurality of unit cells, stacking the unit cells one on another, and inserting coupling members through the coupling through-holes to couple the unit cells with each other. Consequently, the secure coupling and the electrical connection between the unit cells is accomplished without using additional members, such as cartridges, and therefore, a compact battery module having high coupling force is prepared.

Owner:LG ENERGY SOLUTION LTD

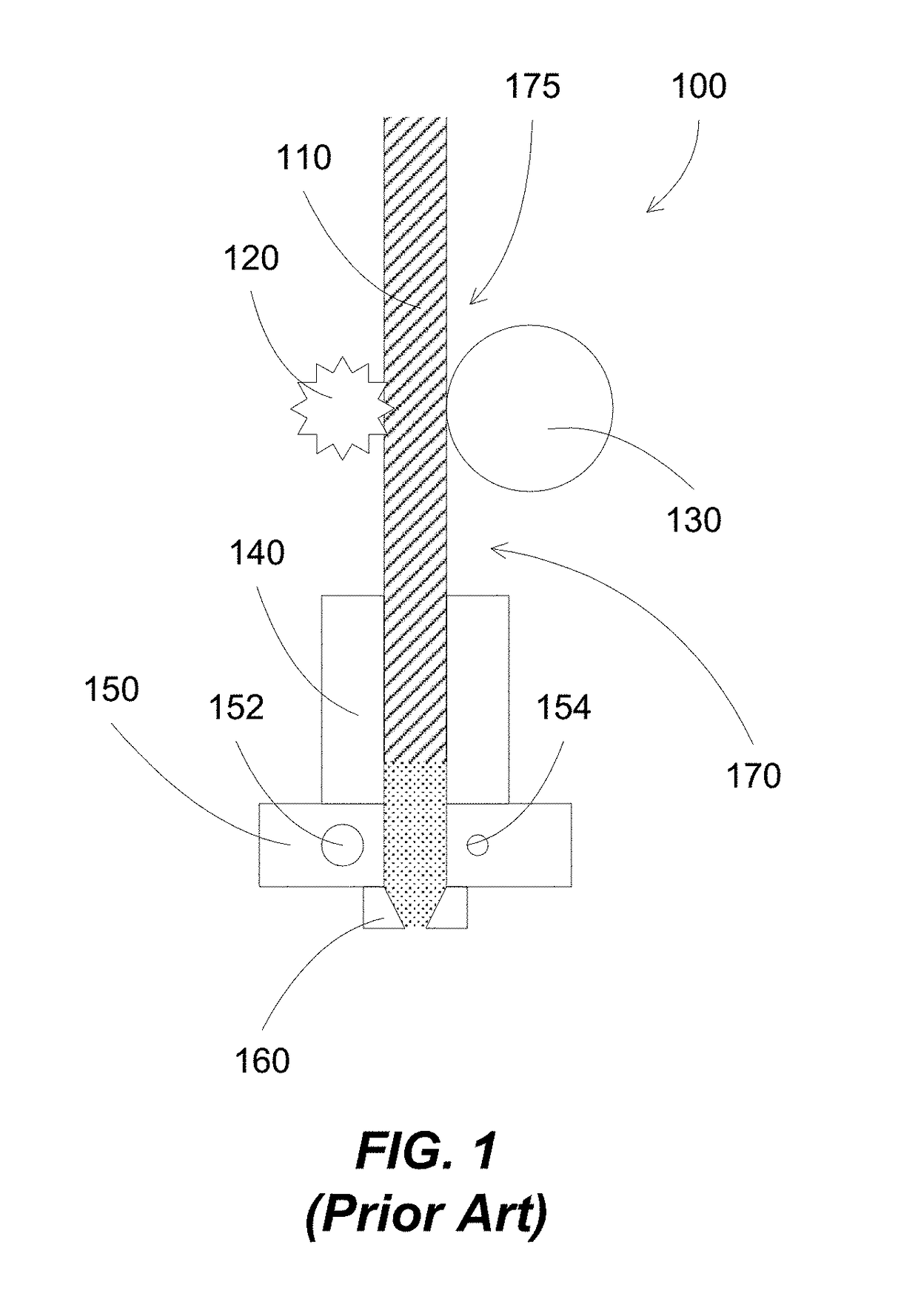

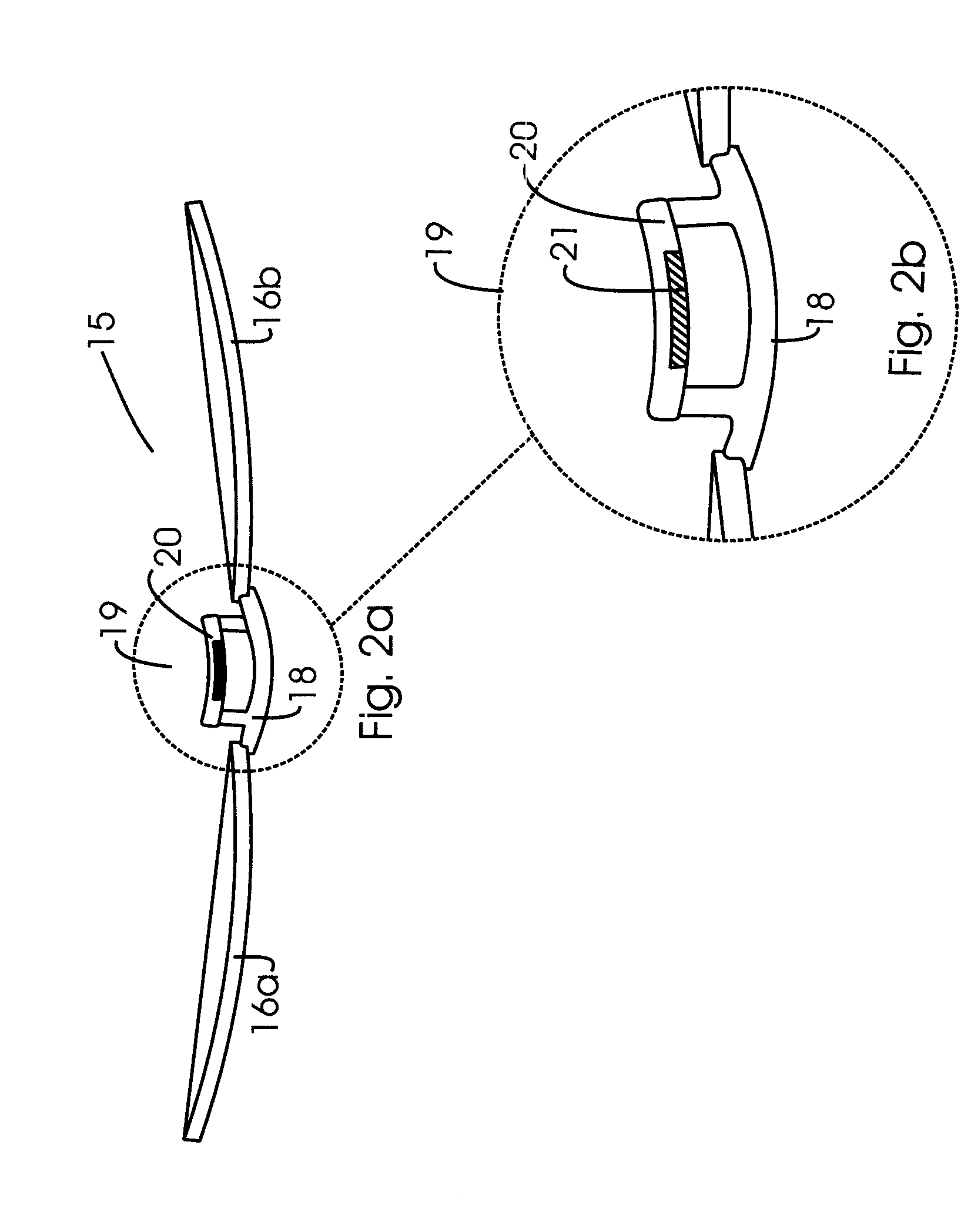

Method of coupling a motion sensor to a piece of equipment

ActiveUS20170234706A1Easy to removeEasy to replaceInertial sensorsNavigation instrumentsDegrees of freedomEngineering

Method for coupling a sensor to a piece of equipment, such as a golf club, baseball bat, or tennis racket, that ensures that the sensor is in a known position and orientation relative to the equipment. Compensates and calibrates for degrees of freedom introduced in manufacturing and installation. The method may include manufacturing a sensor receiver that aligns with equipment in a fixed orientation, and that holds a sensor housing in a fixed orientation relative to the receiver. Remaining uncertainties in sensor position and orientation may be addressed using post-installation calibration. Calibration may include performing specific calibration movements with the equipment and analyzing the sensor data collected during these calibration movements.

Owner:NEWLIGHT CAPITAL LLC

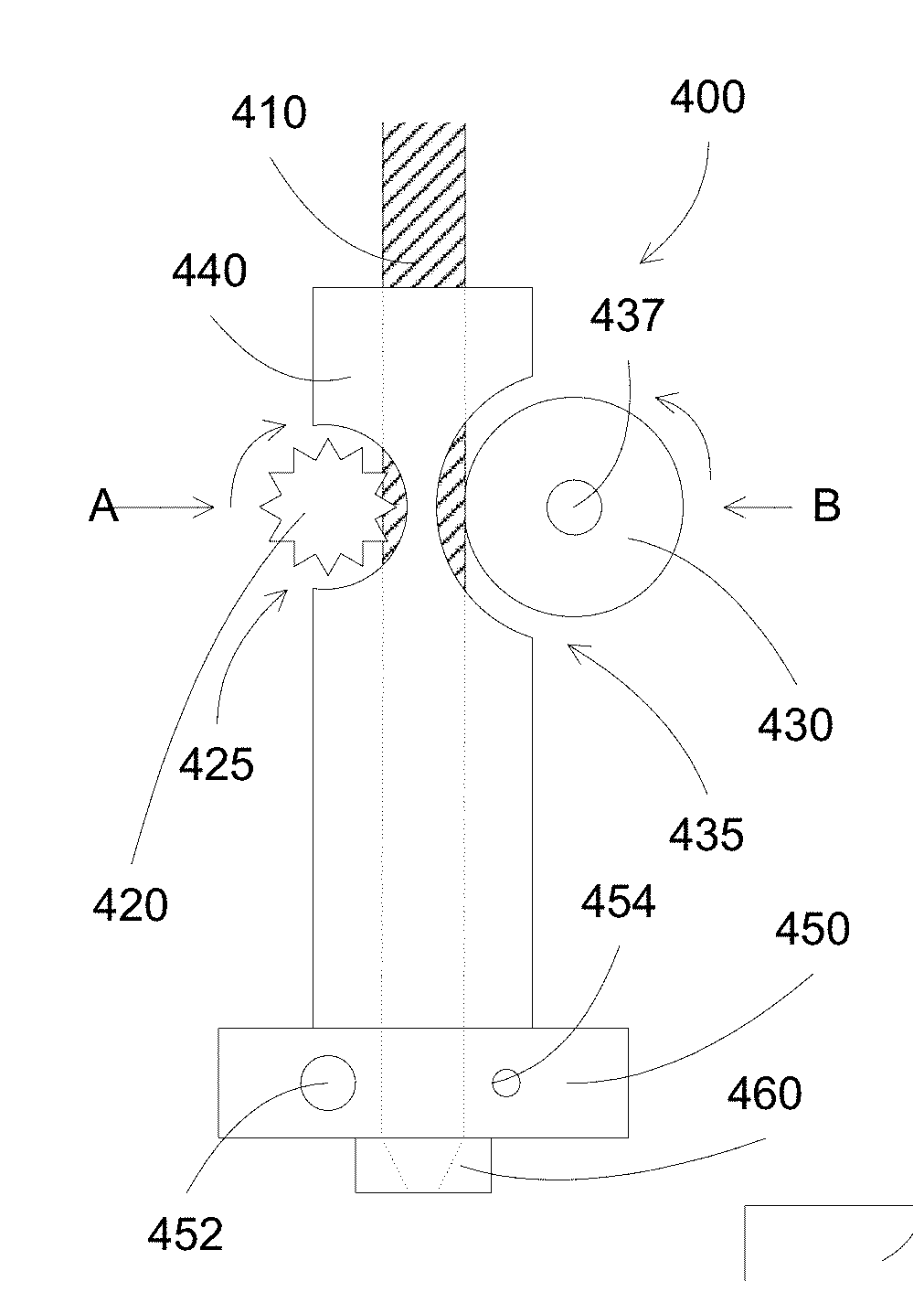

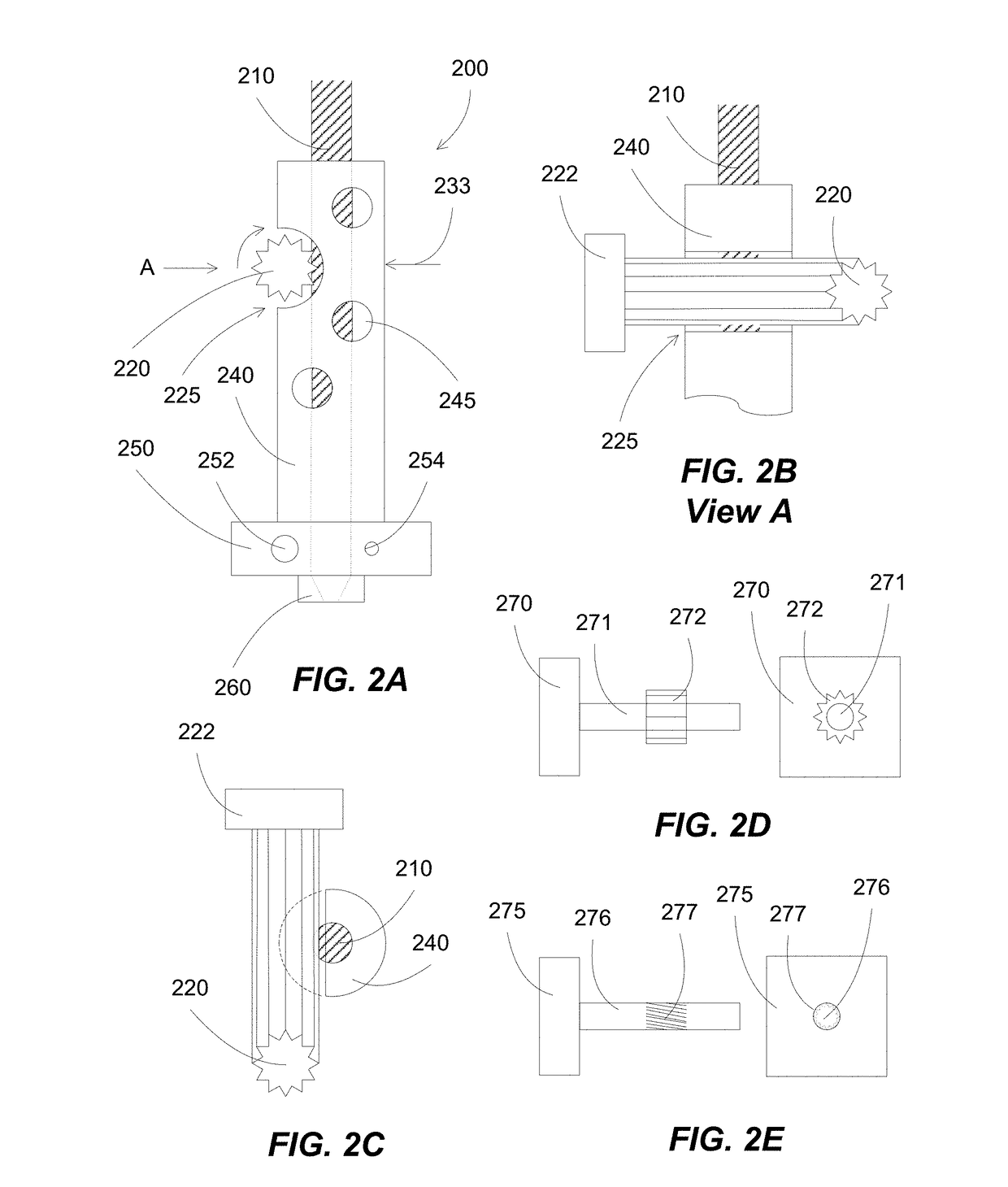

3D printer systems and methods

ActiveUS20170266885A1Secure couplingEasy to move3D object support structuresApplying layer means3d printerElectric motor

A print head comprising two shafts disposed in opposite sides of a filament to drive the filament to a heated chamber for delivering a molten material. The shafts are actively driven, for example, by two independent motors. The two shaft configuration of the print head can improve a control of the filament movement rate, especially for soft filament materials.

Owner:GIFFORD KARL JOSEPH DODDS +2

Eyeglasses having magnetically coupled primary lens frame and auxiliary lens frame

InactiveUS7328999B2Minimize the numberSecure couplingSpectales/gogglesAuxillary optical partsCamera lensCoupling

Eyeglasses comprising a primary lens frame having a first pair of lens holders separated by a bridge portion having a major magnetic member disposed on a rear side thereof and facing rearward. The eyeglasses further include an auxiliary frame having a second pair of lens holders separated by a bridge portion and having pivoting arms attached to each lens. The arms are connected by a grip extension having minor magnetic members disposed on a side facing the major magnetic members. The auxiliary frame is coupled to the primary lens frame from the bottom such that the grip extension extends under the bridge portion in the primary lens frame and allows the major and minor magnetic members to form a magnetic attraction. The pivoting arms permit the auxiliary frame to be moved in and out of the line of sight of the user without disrupting the magnetic coupling of the primary and the auxiliary frames.

Owner:THE WALMAN OPTICAL

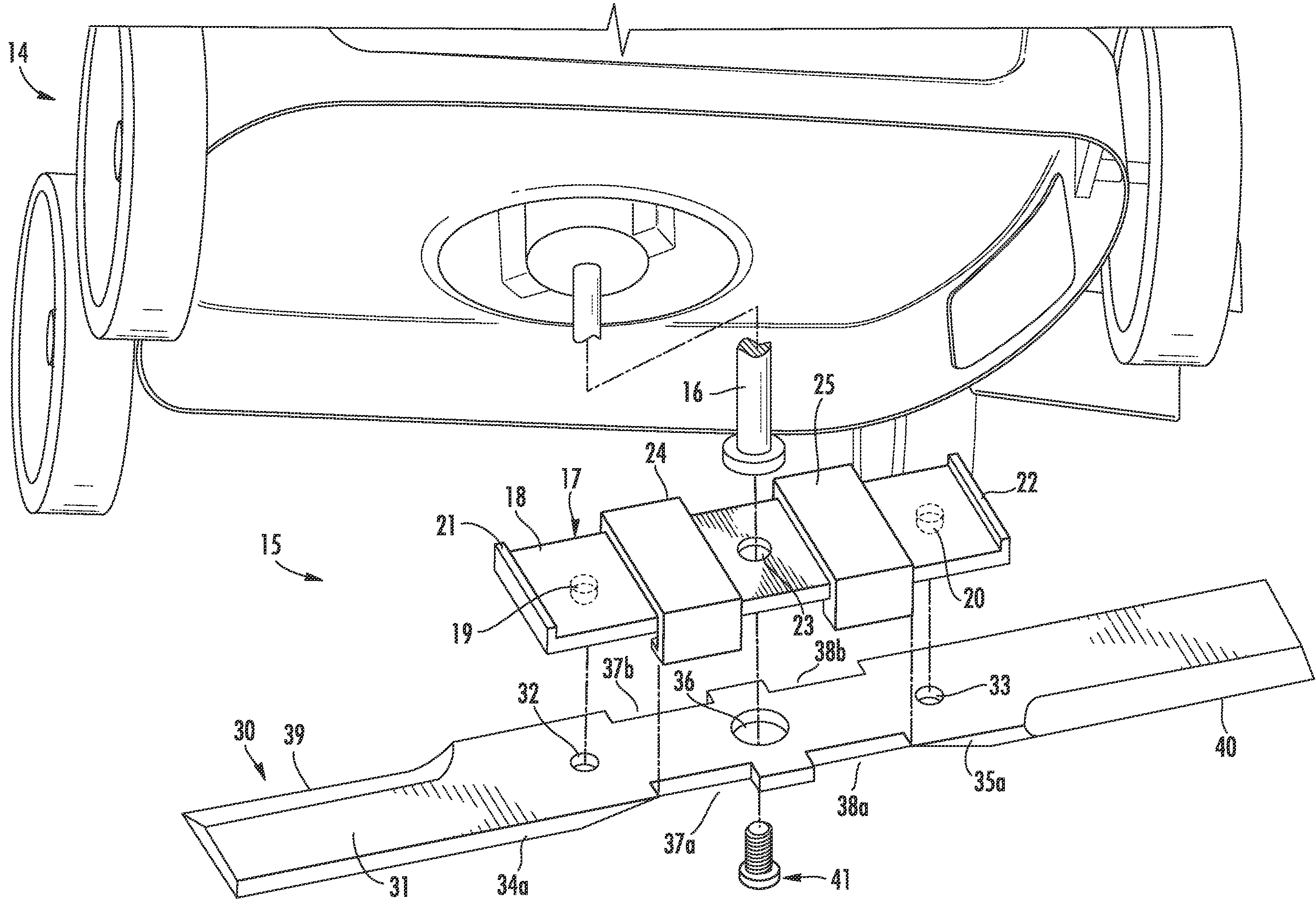

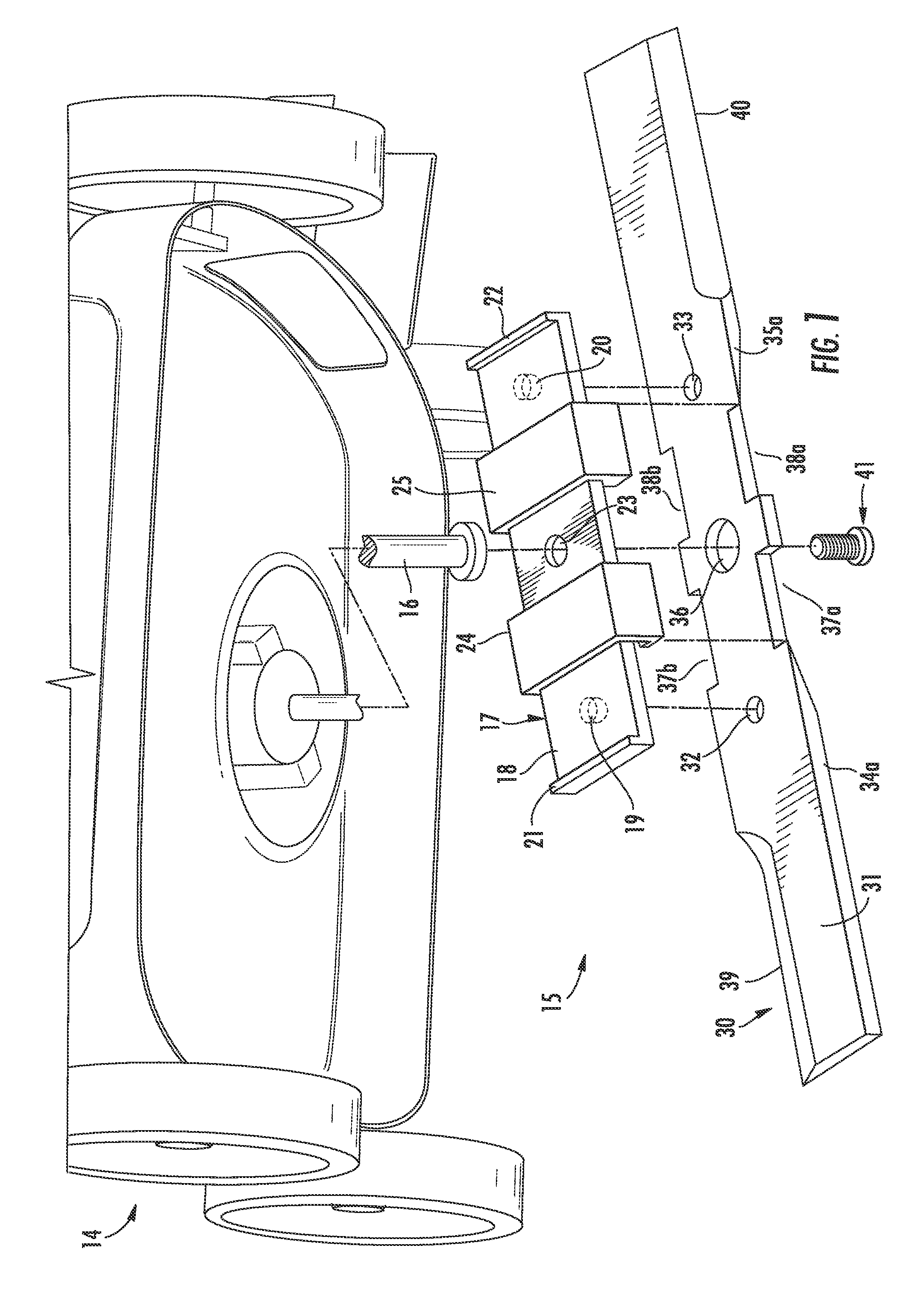

Lawn mower blade assembly having blade mount for quick blade replacement and associated methods

A lawn mower blade assembly for a rotatable driveshaft includes a blade mount to be secured to the rotatable driveshaft and having at least one wedge surface thereon. A cutting blade is removably coupled to the blade mount. At least one sliding retainer removably couples the cutting blade to the blade mount and is slidably movable between a locked position and a released position. The at least one sliding retainer has at least one wedge surface thereon cooperating with the at least one wedge surface of the blade mount to securely couple the cutting blade to the blade mount when in the locked position.

Owner:BEVER CHRISTOPHER

Coupling device for circular pipes

ActiveUS7878555B2Maintained satisfactorilySecure couplingSleeve/socket jointsFluid pressure sealed jointsCoupling

A coupling device for circular pipes, in which locking rings, inserted into a body to clamp a circular pipe, are arranged in a pair so that the central line of a circular pipe can be aligned when the circular pipe is inserted. Furthermore, the degree to which the body presses the seal packing can be adjusted so that a reliable seal can be maintained and the circular pipe can be securely coupled no matter who uses the coupling device. A coupling device for corrugated and circular pipes is provided for the case where it is more effective to replace one of the circular pipes with a corrugated pipe. The first coupling section and a connecting means, which can engage with a corrugated pipe, are provided opposite the second coupling section, which is coupled with the circular pipe.

Owner:KOFULSO

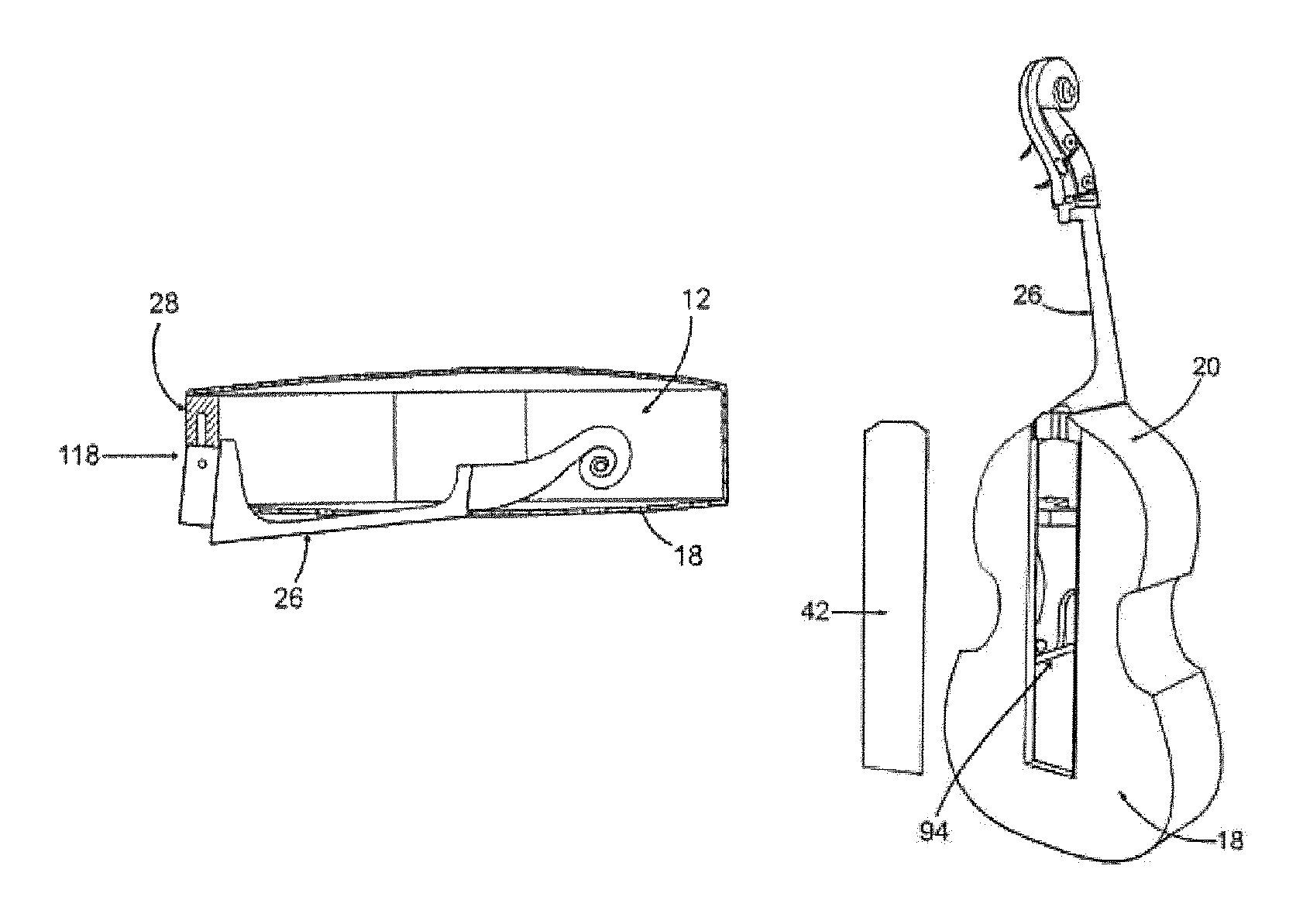

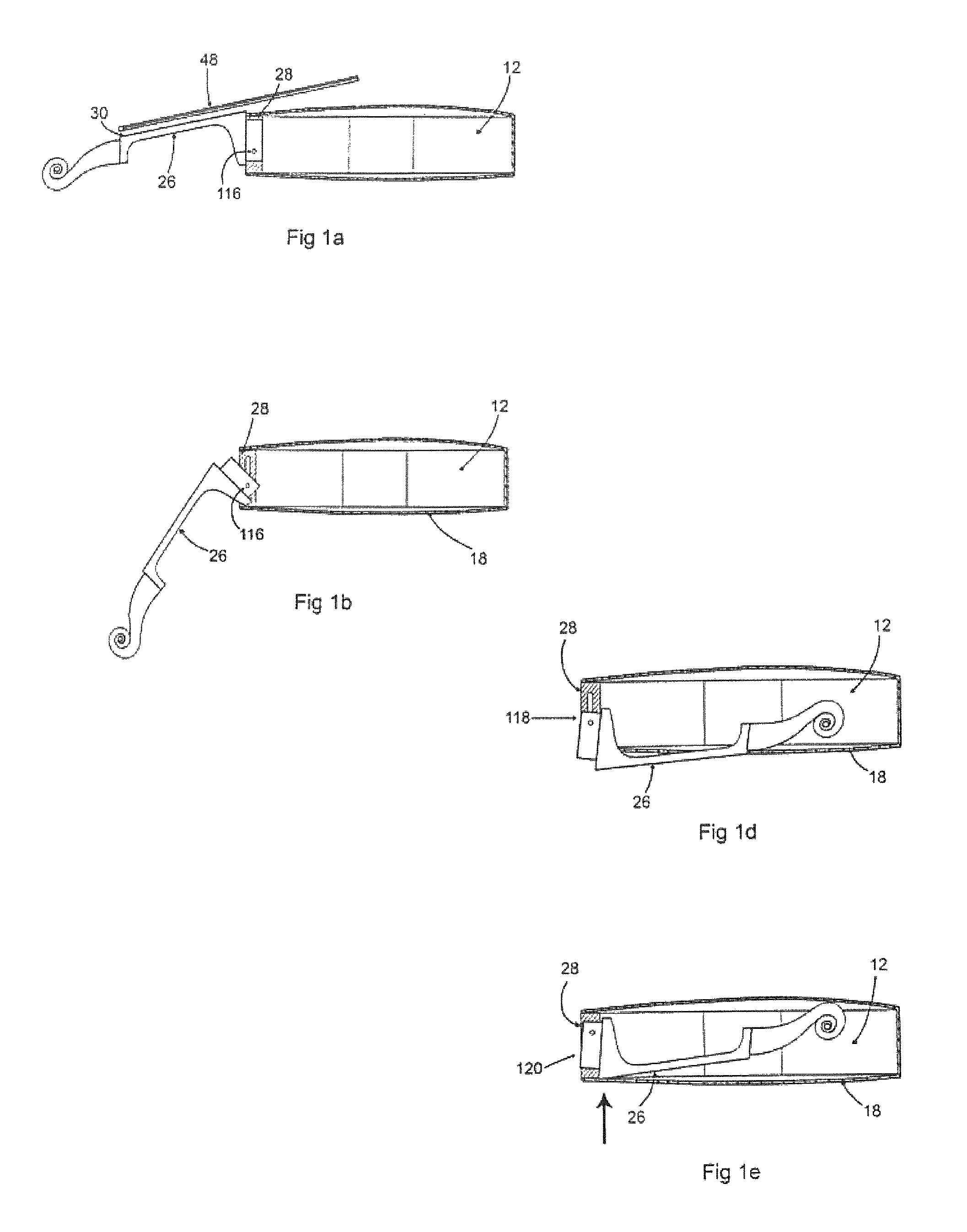

Collapsible stringed musical instrument

A collapsible acoustic stringed instrument is disclosed having a hollow body with a soundboard, a back face and a spacer defining a sound chamber. A sound post is secured within the hollow body and engaging the soundboard and the back face. The sound post has a securement pin on each end with a sharpened portion to engage the soundboard and the back face and maintain proper positioning when the instrument strings are loosened. A neck is pivotally and laterally coupled to the body, which further has a door slidably received by specially formed channels in the back face. The neck is able to pivot and slide through the door and into the sound chamber from a playing position to a stored position, without disturbing the sound post or otherwise compromising the appearance or performance of the instrument with respect to a standard non-collapsible instrument.

Owner:CHADWICK RICHARD W

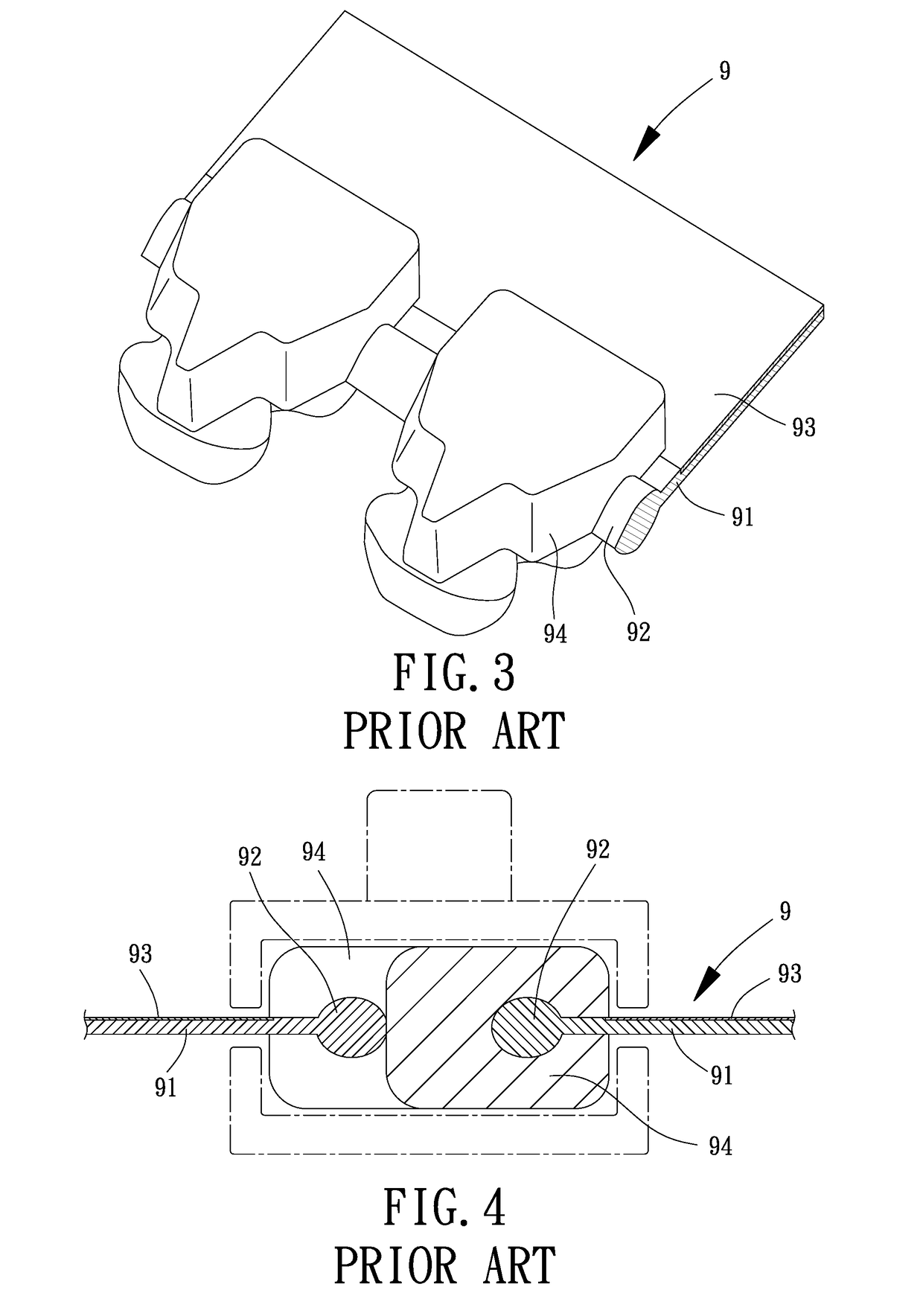

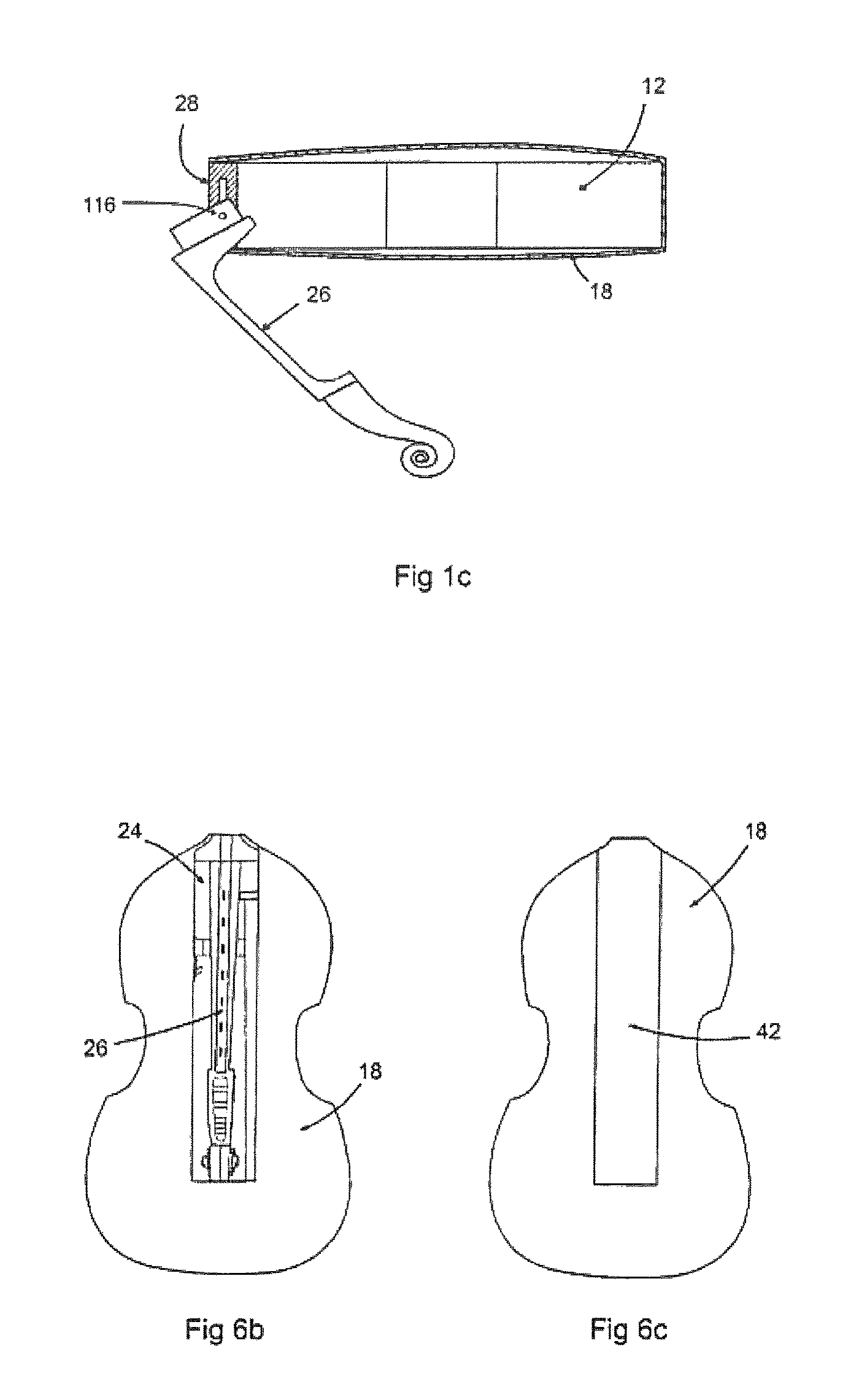

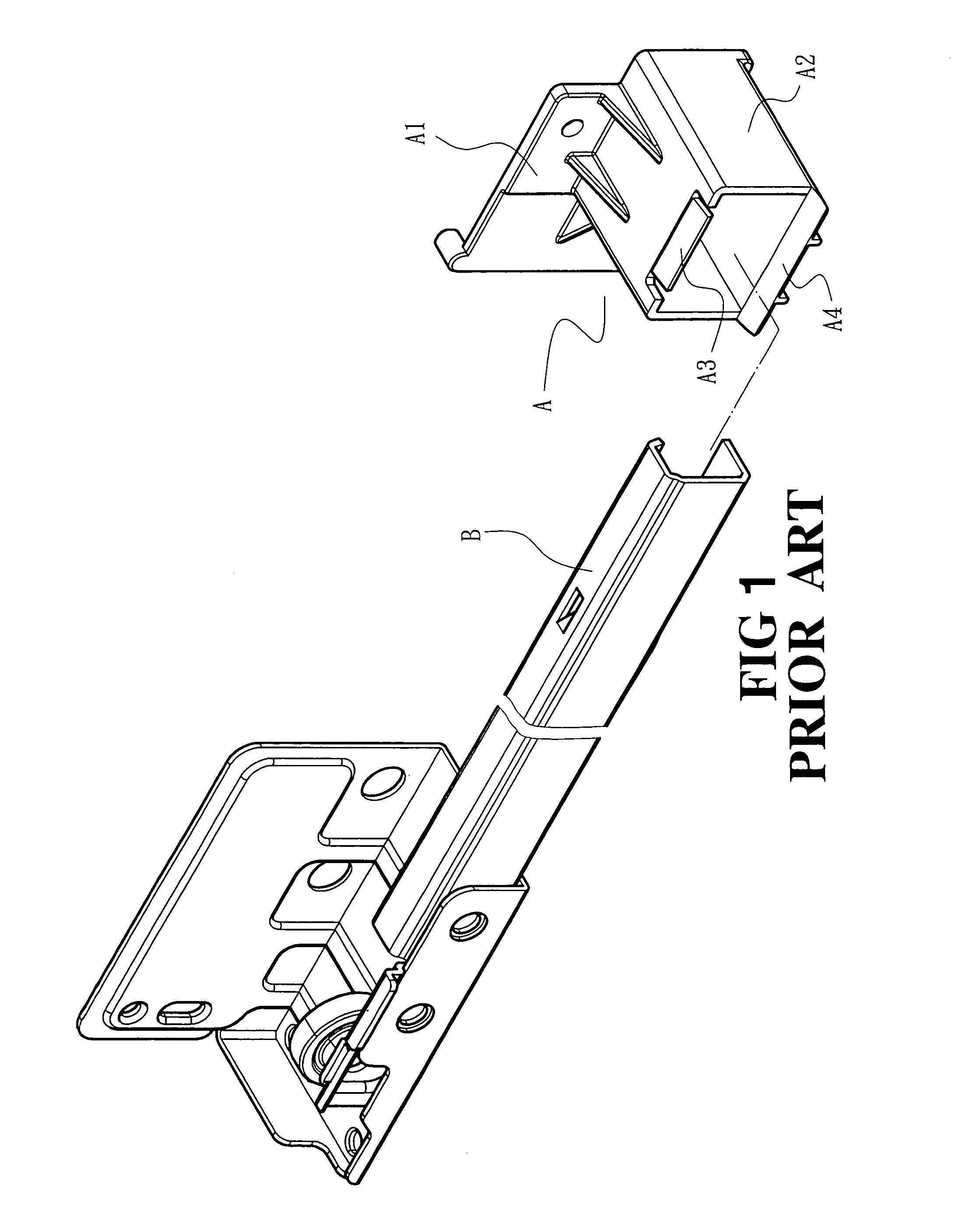

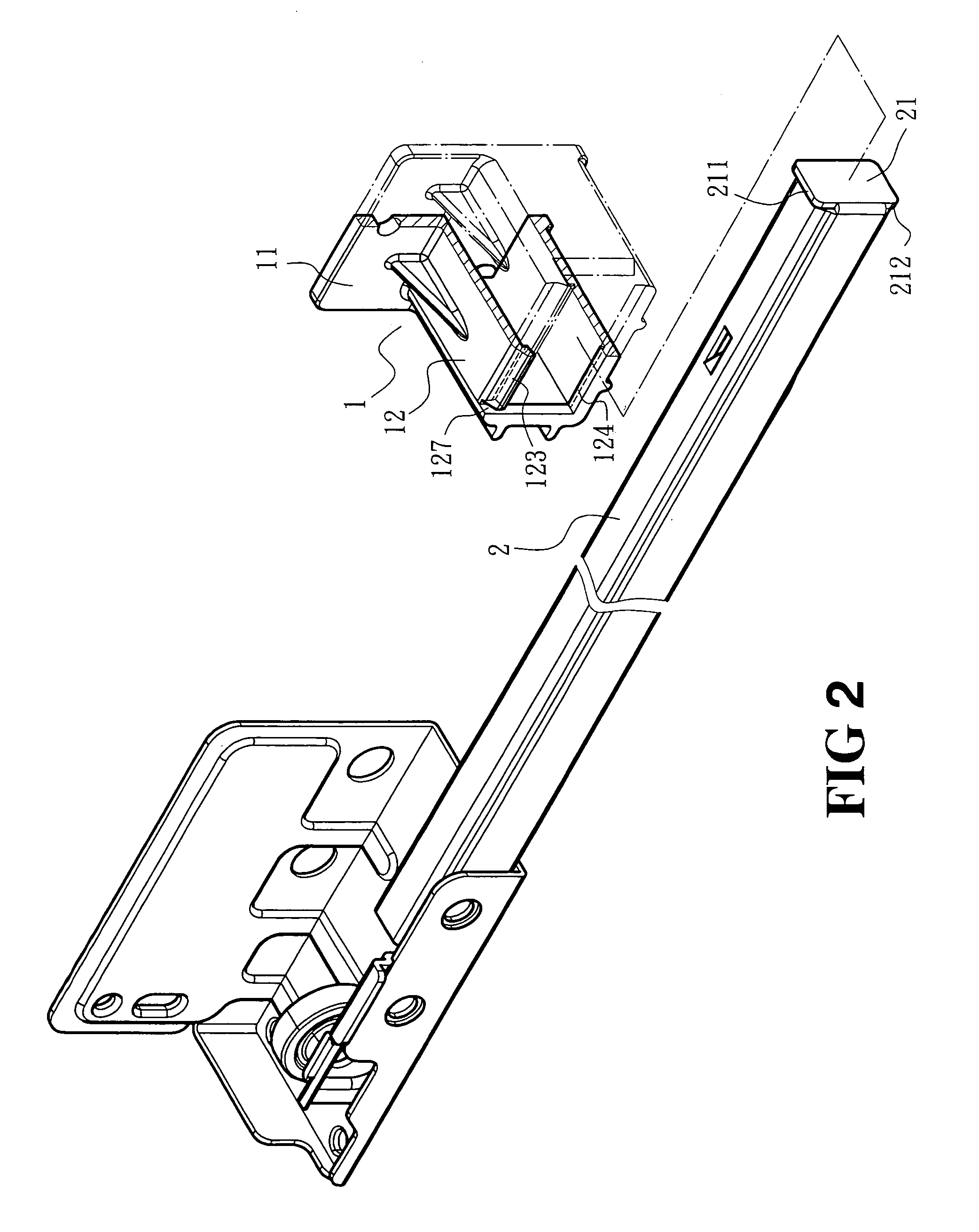

Coupling structure for a sliding track and a mounting bracket

A coupling structure for a sliding track and a mounting bracket includes a rear mounting plate and a frame shell. The frame shell has a front opening end which has one side forming a guiding notch. The front opening end further has an upper and a lower retaining flange on the upper edge and a lower edge, which form respectively a ramp at one end adjacent to the guiding notch. The upper retaining flange has a slit formed at another end so that the upper retaining flange becomes flexible and elastic to facilitate pressing of the sliding track. The sliding track has a retaining plate on the rear end to form an upper flange and a lower flange extending outside the sliding track. The flanges may slide transversely through the guiding notch to allow the sliding track to enter the frame shell and be moved longitudinally inwards for positioning.

Owner:KING SLIDE WORKS CO LTD

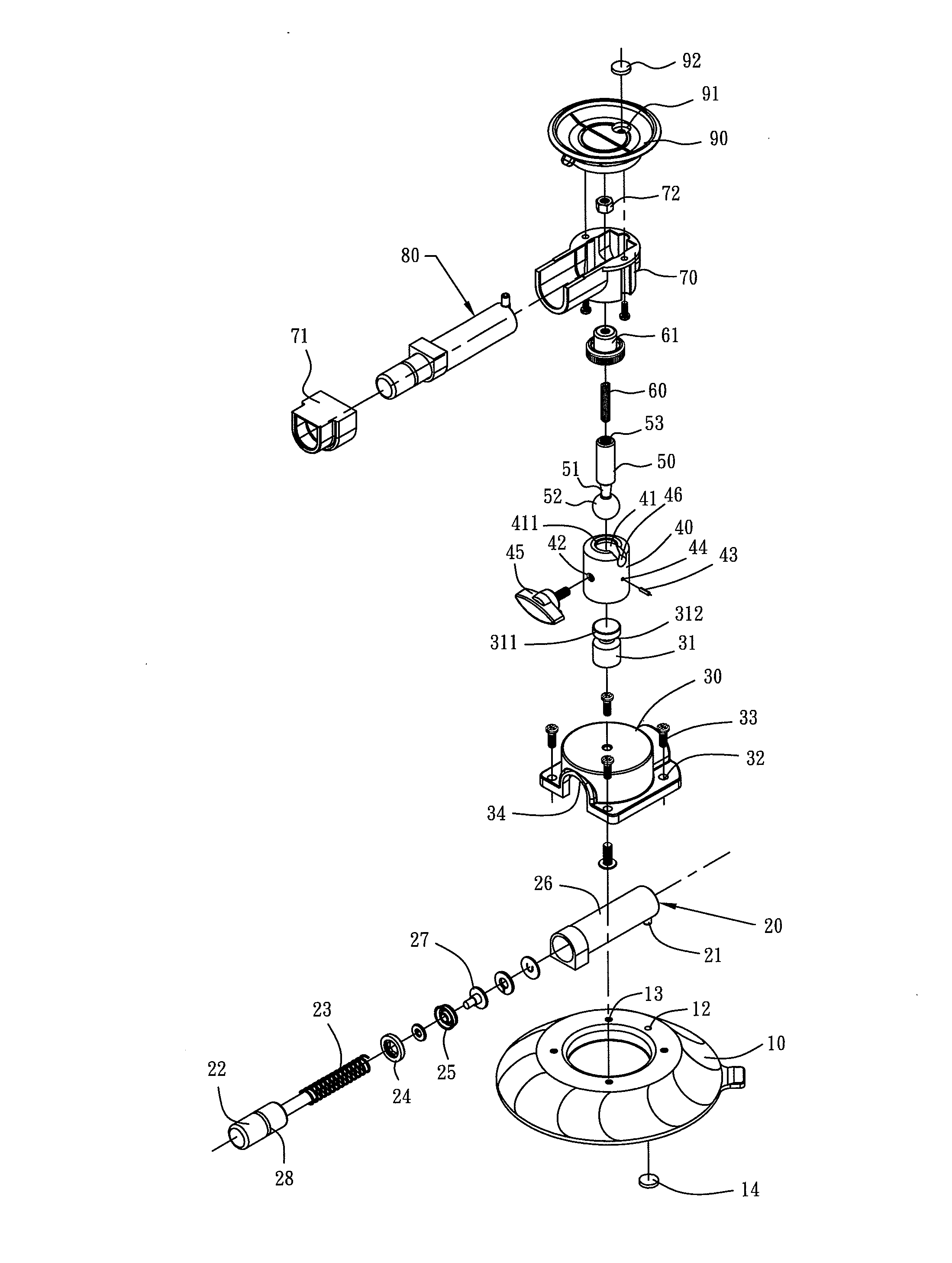

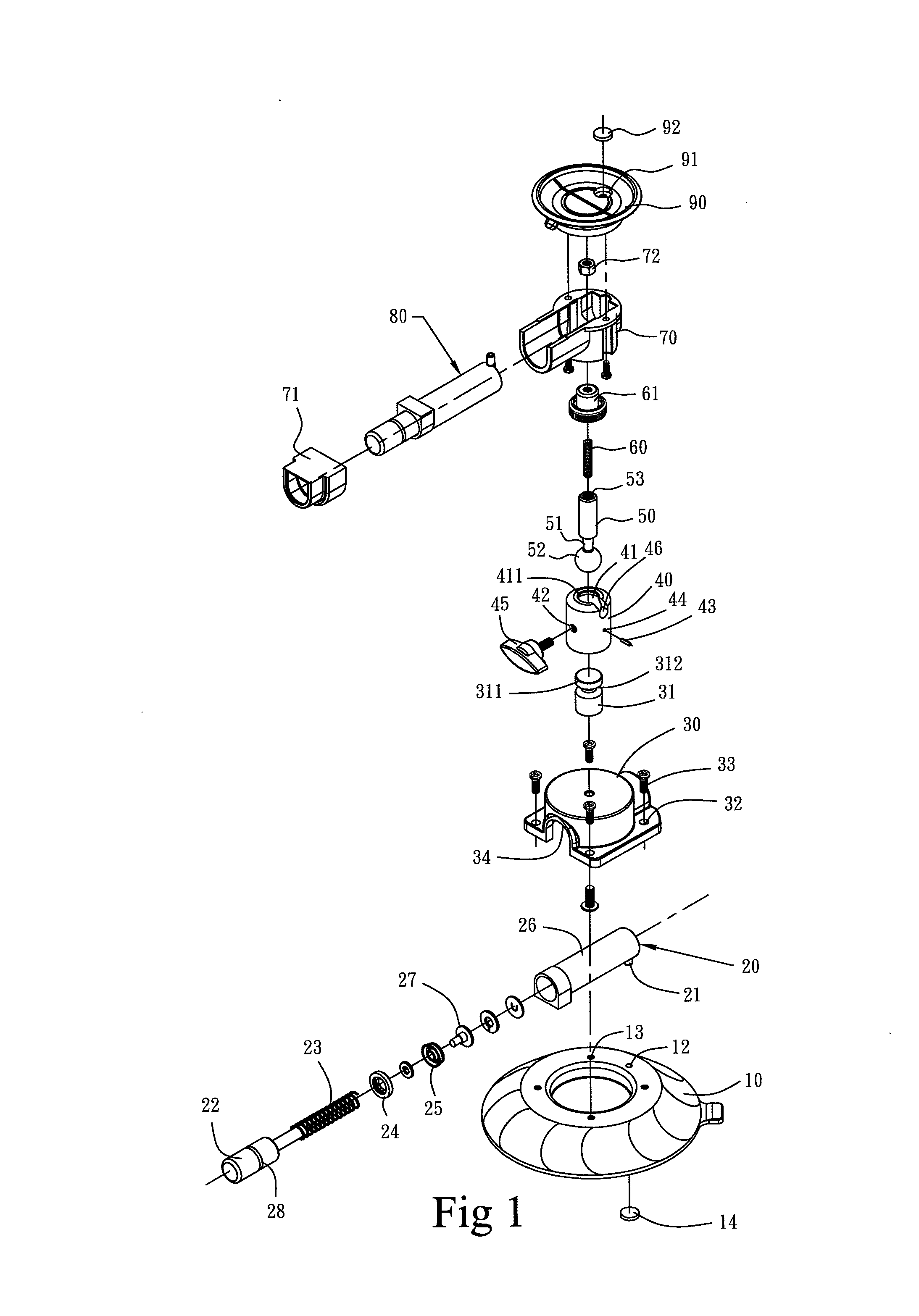

Omni-direction rotatable dual-cup suction device

ActiveUS20120043439A1Improve practicalityMultiple efficacyWork holdersStands/trestlesSuction forceEngineering

An omni-direction rotatable dual-cup suction device includes two suction cups, which are respectively combined with and in communication with two evacuation structures, so that the two evacuation structures can evacuate air from the suction cups to induce vacuum suction forces. The two suction cups are respectively provided with a mounting seat and an attaching seat for securely coupling the two evacuation structures. The mounting seat includes a pillar fixed thereto. A collar receives a ball end of a bar therein and is attached to the pillar. The ball-ended bar is coupled to a threaded rod, which extends through an internally-threaded locking knob and received into the attaching seat to be secured by a nut. With such an arrangement, one of the suction cups can be attached to a planar fixture surface, while the other suction cup can be used to hold an article and is orientation adjustable in any direction.

Owner:LIH YANN INDAL

Split-ring gland pipe coupling with corrugated armor and annular gasket having pressure assist slot

ActiveUS20130193685A1Simple and reliable processLess costlySleeve/socket jointsFluid pressure sealed jointsSplit ringMechanical engineering

A pipe coupling for coupling adjacent ends of a pair of pipes includes a sleeve, a split-ring gland positioned around one of the ends of the sleeve, and an annular gasket positioned within the split-ring gland and configured to be compressed by the split-ring gland for sealing one pipe end to the sleeve. The split-ring gland includes two partially circular gland members with spaced ends defining a gap, which is spanned by an armor positioned in the gap to provide a generally closed annular periphery about the gasket. The armor includes a corrugated portion engaging the gasket during compression. The gasket includes a pressure assist slot configured to receive pressurized fluid leaking from the pipes and a plurality of cross grooves ensuring continued fluid communication with the pressure assist slot. The gasket also includes ribs engaging the split-ring gland and the armor to reduce or eliminate added lubrication necessary.

Owner:SENSUS SPECTRUM LLC

Split-ring gland pipe coupling with corrugated armor and annular gasket having pressure assist slot

ActiveUS8528945B2Simple and reliable processLess costlySleeve/socket jointsFluid pressure sealed jointsSplit ringEngineering

A pipe coupling for coupling adjacent ends of a pair of pipes includes a sleeve, a split-ring gland positioned around one of the ends of the sleeve, and an annular gasket positioned within the split-ring gland and configured to be compressed by the split-ring gland for sealing one pipe end to the sleeve. The split-ring gland includes two partially circular gland members with spaced ends defining a gap, which is spanned by an armor positioned in the gap to provide a generally closed annular periphery about the gasket. The armor includes a corrugated portion engaging the gasket during compression. The gasket includes a pressure assist slot configured to receive pressurized fluid leaking from the pipes and a plurality of cross grooves ensuring continued fluid communication with the pressure assist slot. The gasket also includes ribs engaging the split-ring gland and the armor to reduce or eliminate added lubrication necessary.

Owner:SENSUS SPECTRUM LLC

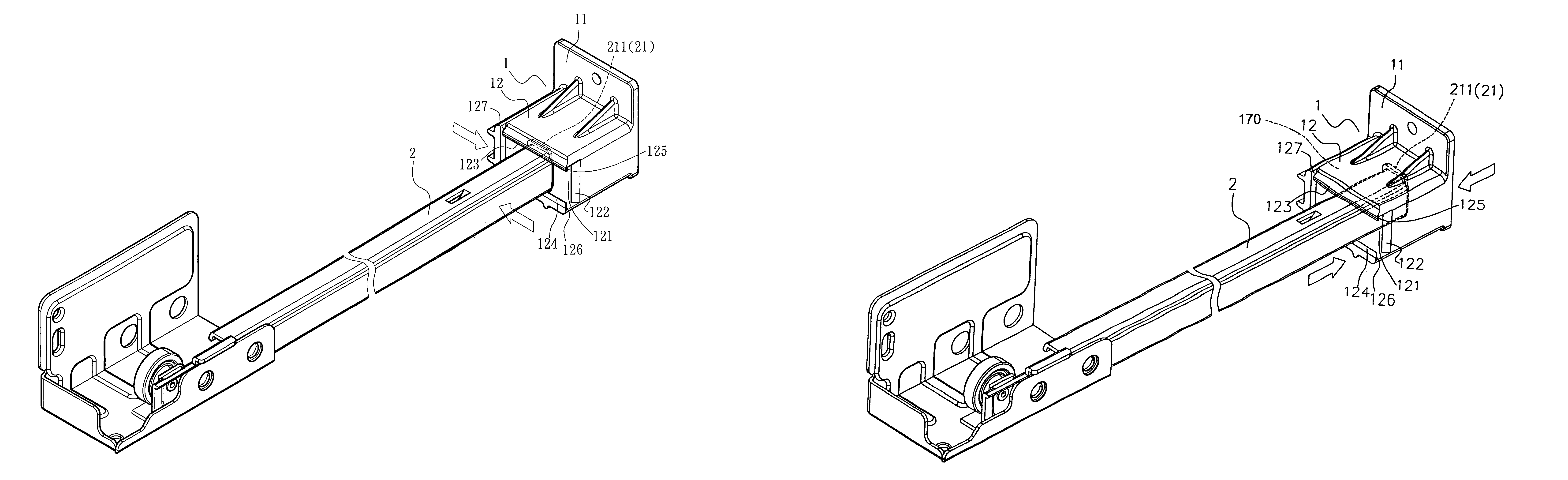

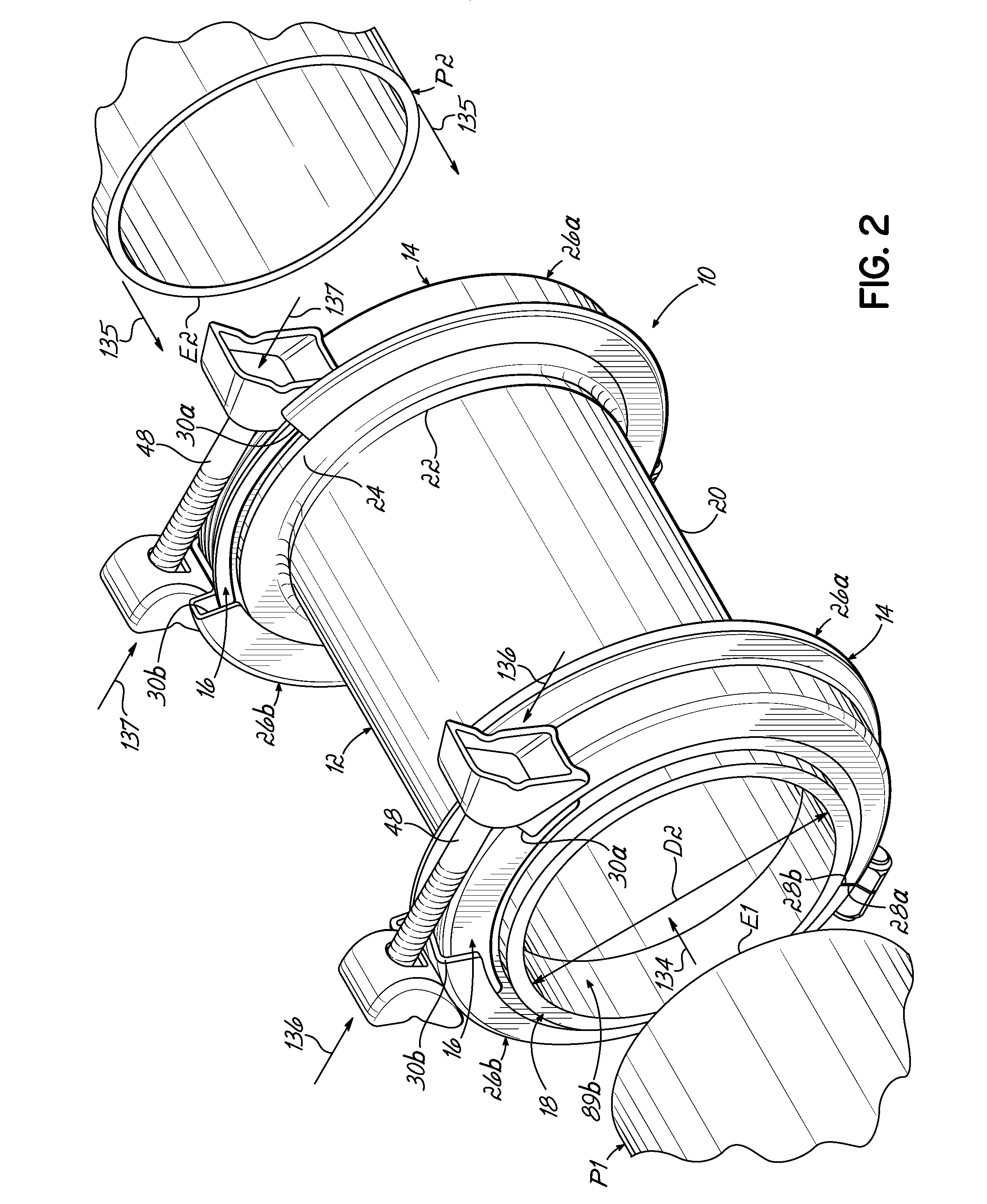

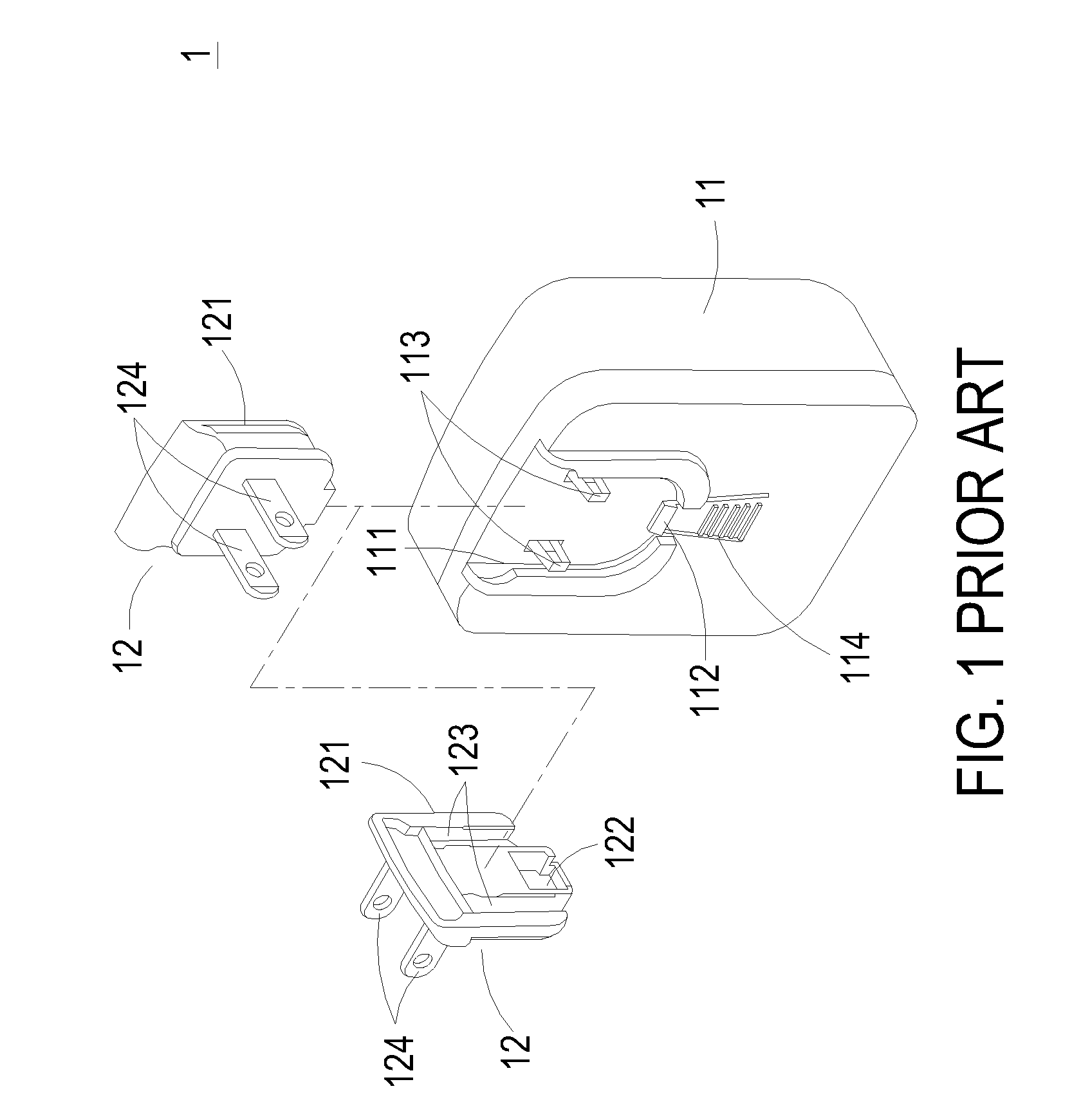

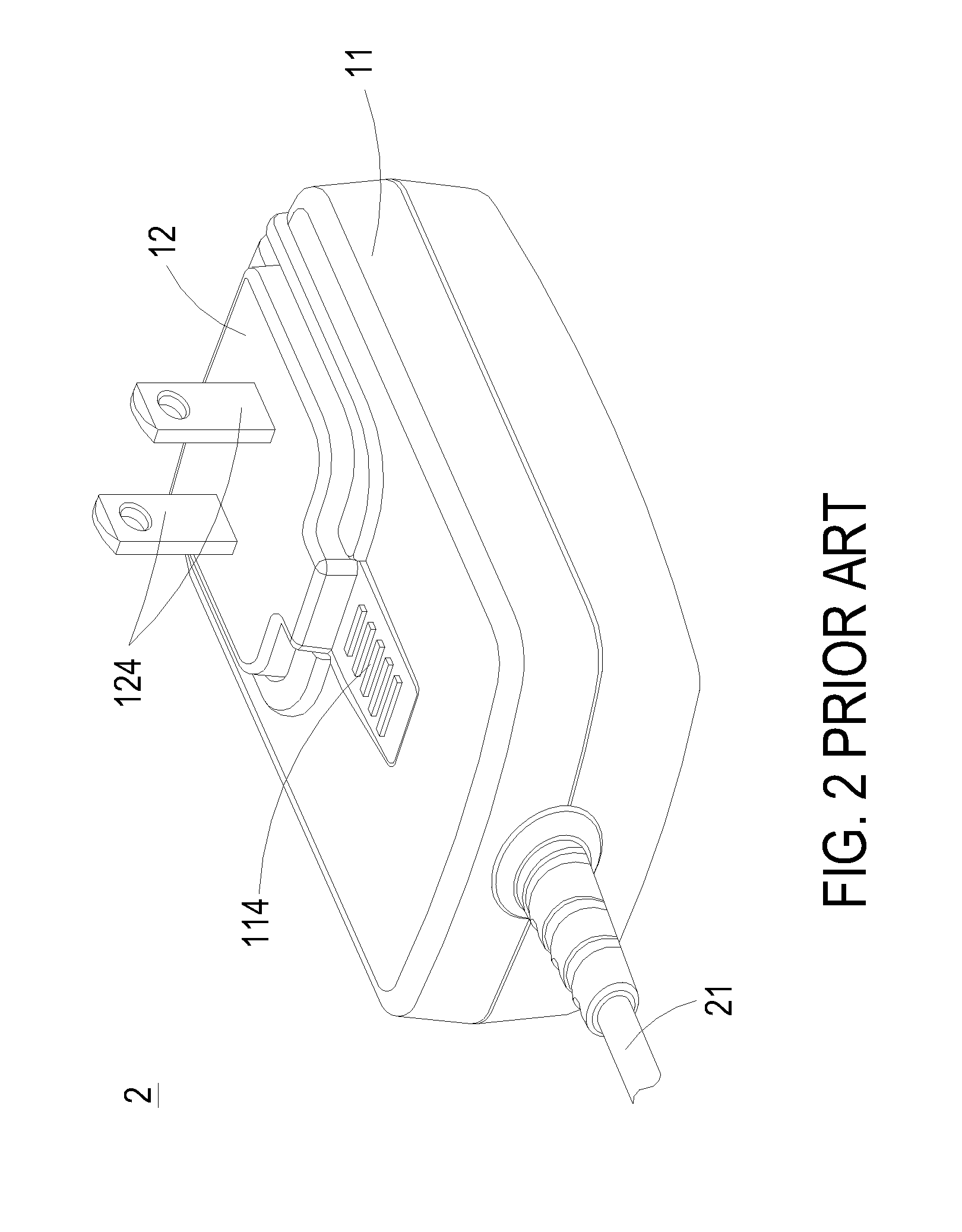

Power adapter with interchangeable connectors and power supply having the same

ActiveUS8382526B2Improve securitySecure couplingElectric discharge tubesCoupling device detailsElectrical connectionSlide plate

There is disclosed a power adapter which comprises an adapter body and a modular connector. The adapter body has a cavity forming a first opening and a second opening respectively disposed on two adjacent lateral walls of the adapter body, a first connecting member disposed on one of the lateral walls and adjacent to the first opening, and a sliding plate member having a sliding plate embedded in a slide and protrusible in said second opening. The connector is interchangeably coupled to the cavity and blocked by the sliding plate to form an electrical connection with the adapter body, and comprises a second connecting member engaged with the first connecting member.

Owner:DELTA ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com